Patents

Literature

748 results about "IGNITOR" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

IGNITOR is the Italian name for a nuclear research project of magnetic confinement fusion, developed by ENEA Laboratories in Frascati. Construction (in Russia) is not complete. The project theory is based on ignited plasma in tokamak. Started in 1977 by Prof. Bruno Coppi of MIT, IGNITOR is based on the 1970s Alcator machine at MIT which pioneered the high magnetic field approach to plasma magnetic confinement, continued with the Alcator C/C-Mod at MIT and the FT/FTU series of experiments.

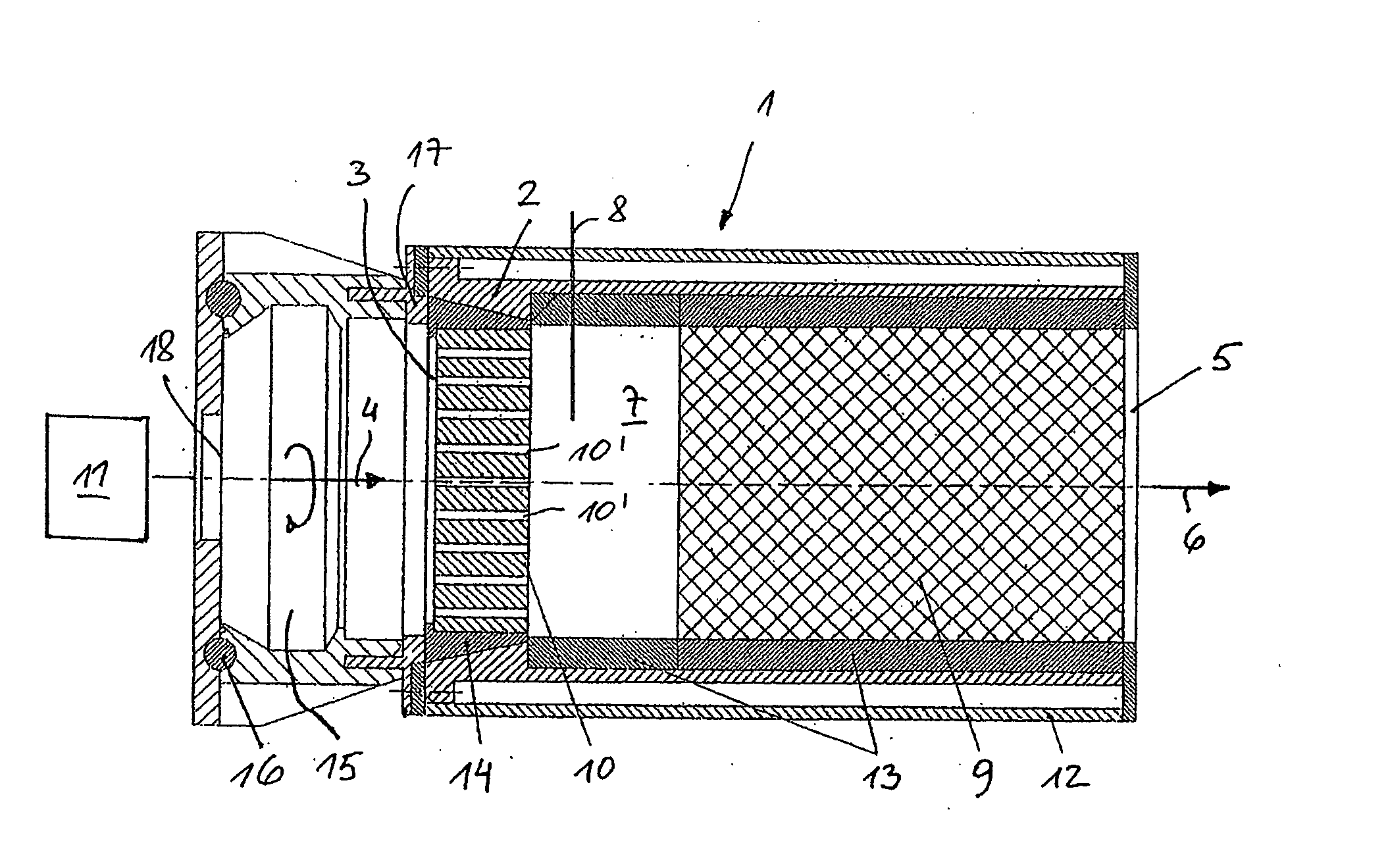

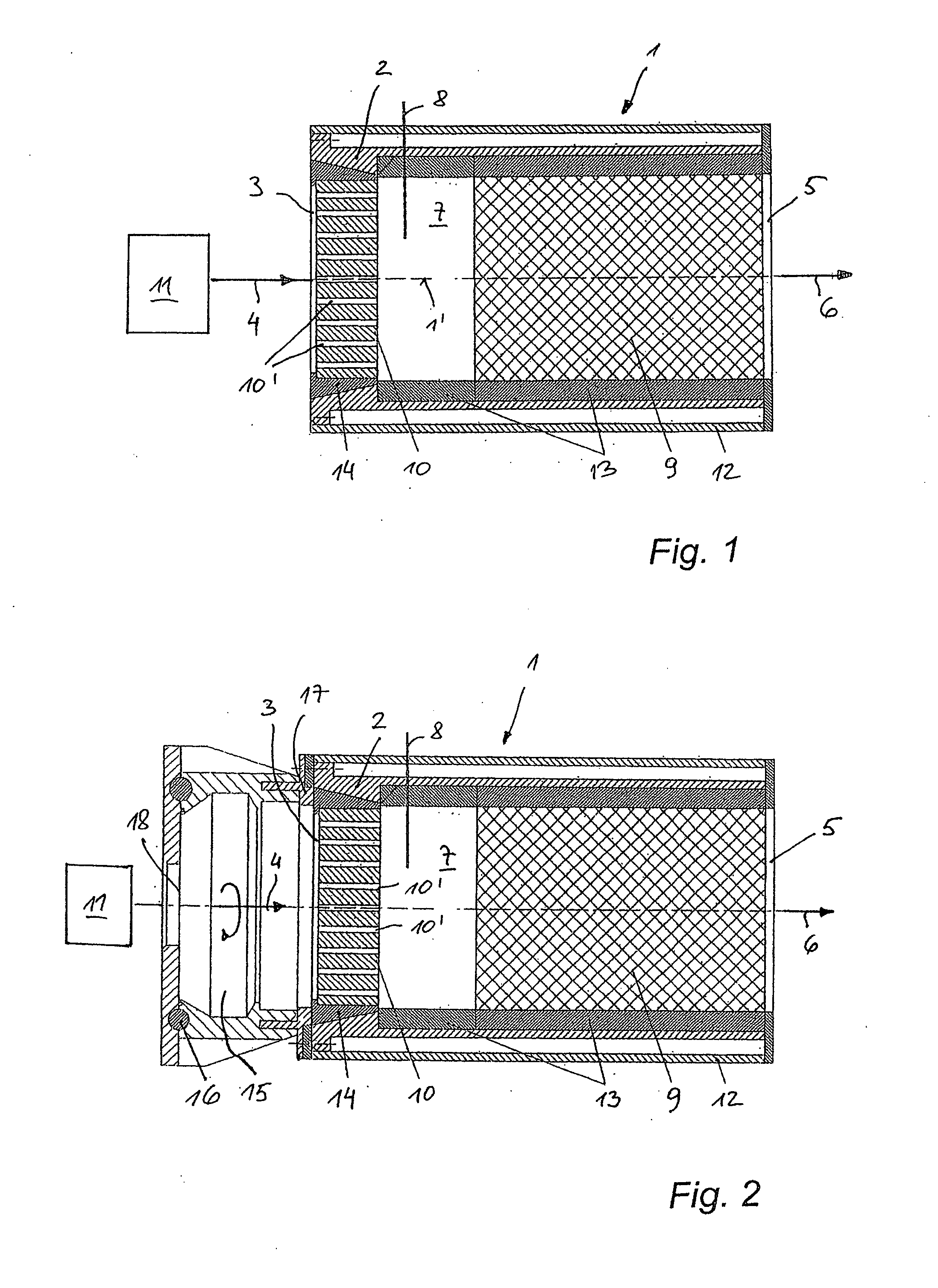

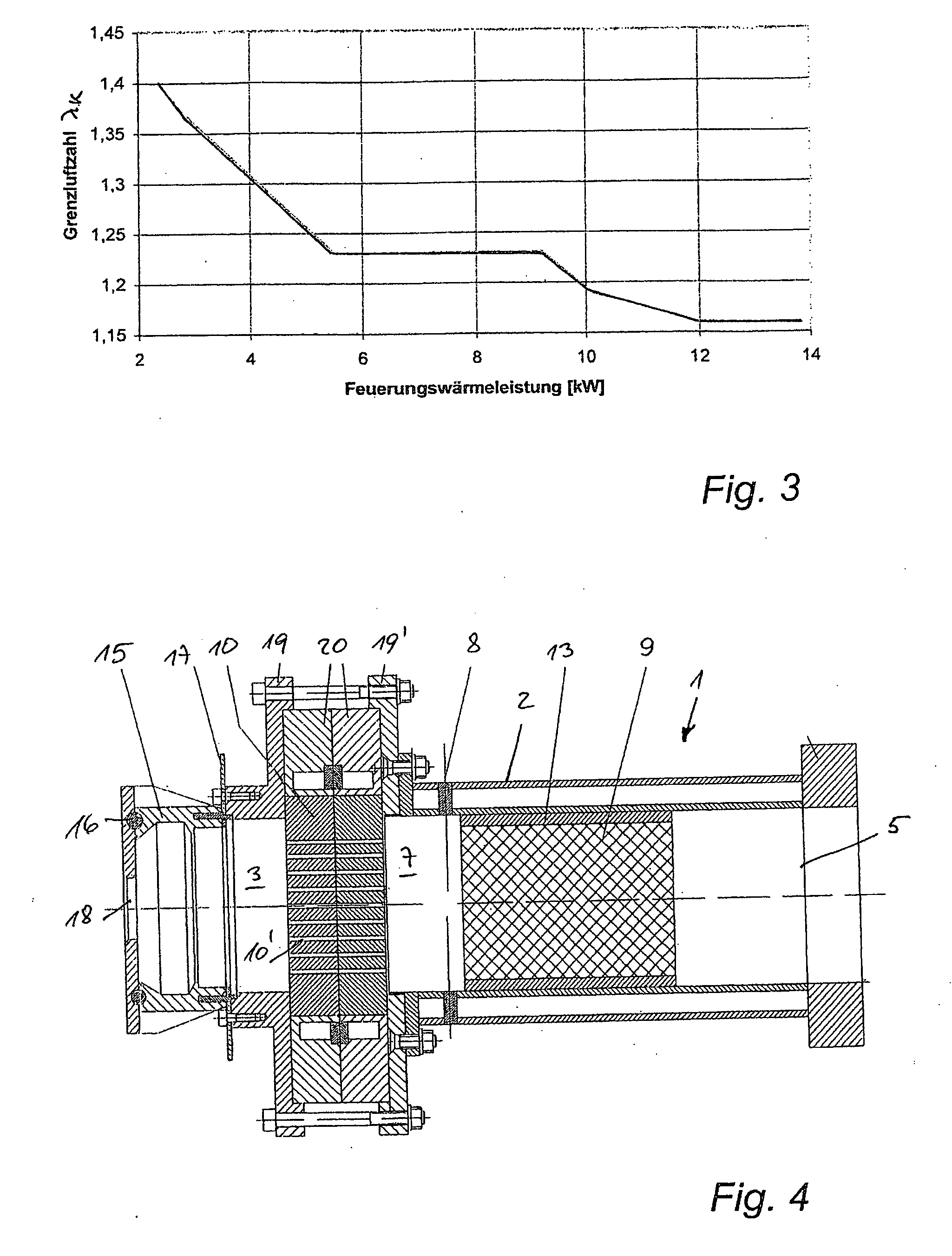

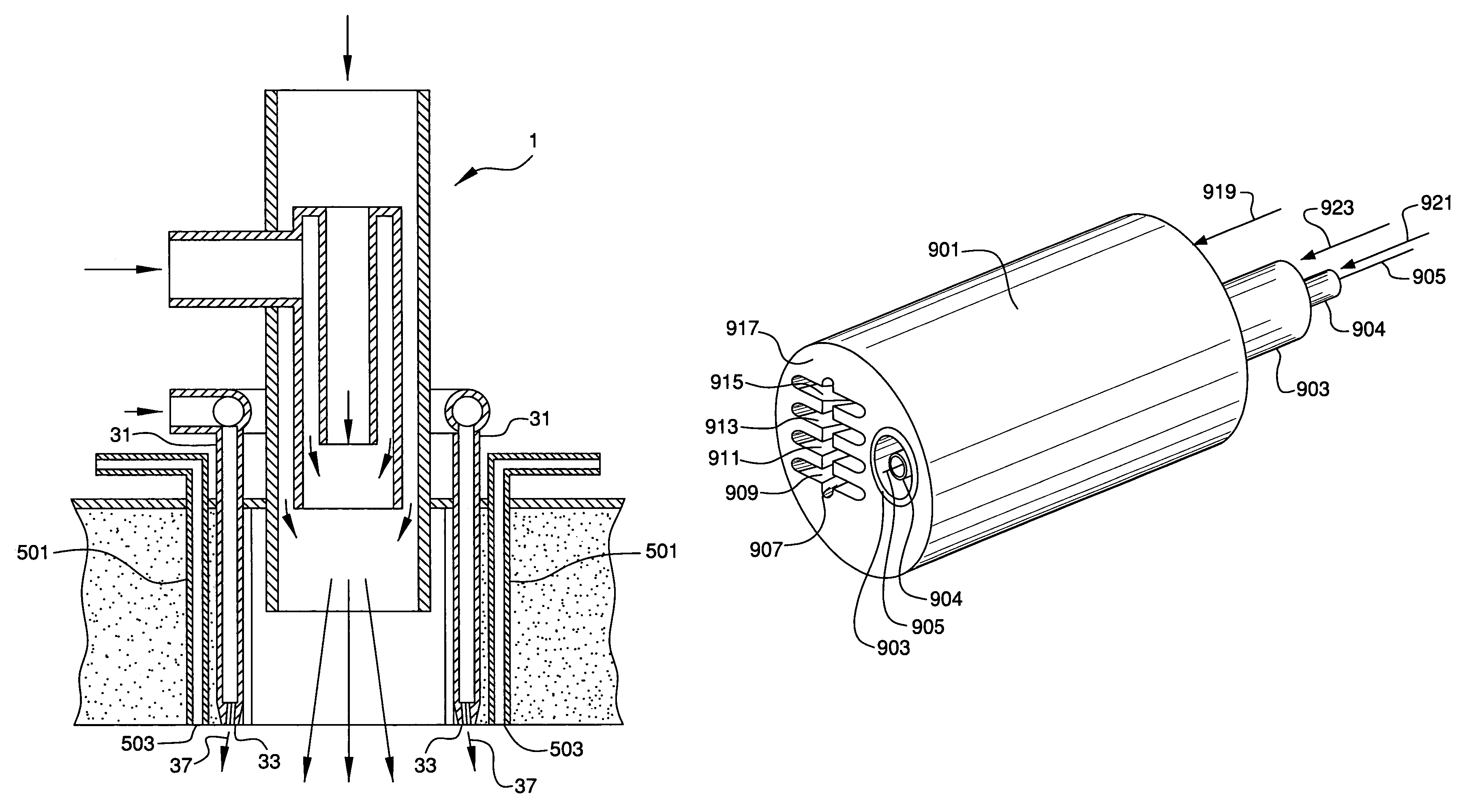

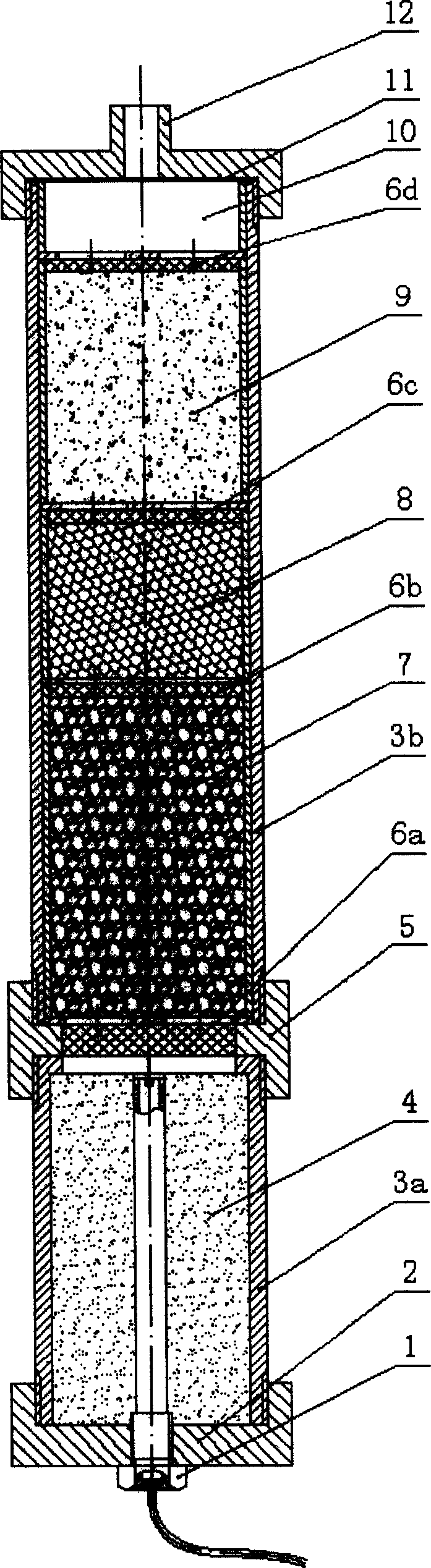

Porous burner as well as a method for operating a porous burner

The invention relates to a porous burner with a housing, which has an inlet for a fuel-air mixture and an outlet for the exhaust gas mixture generated in the burner, where in flow-direction of the fuel-air mixture the housing contains an ignition space with an ignition device and adjacent to this space a porous burner medium. On the inlet side the ignition space is provided with a stabilizing element, which reduces the inlet cross-section and directs the flow of the fuel-air mixture essentially perpendicular to the inlet cross-section of the porous medium. The porous burner is provided with a device for controlling the mass flow of the fuel-air mixture, which serves to shift the combustion zone from the ignition space into the porous medium.

Owner:WINDHAGER ZENTRALHEIZUNG TECHN

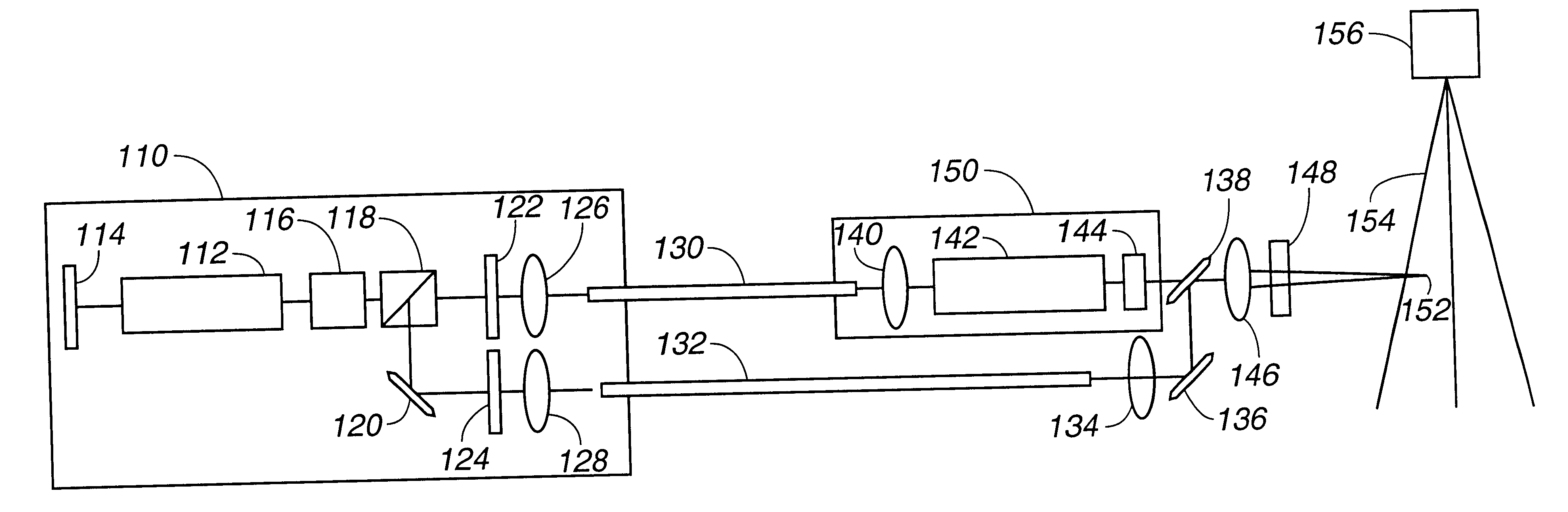

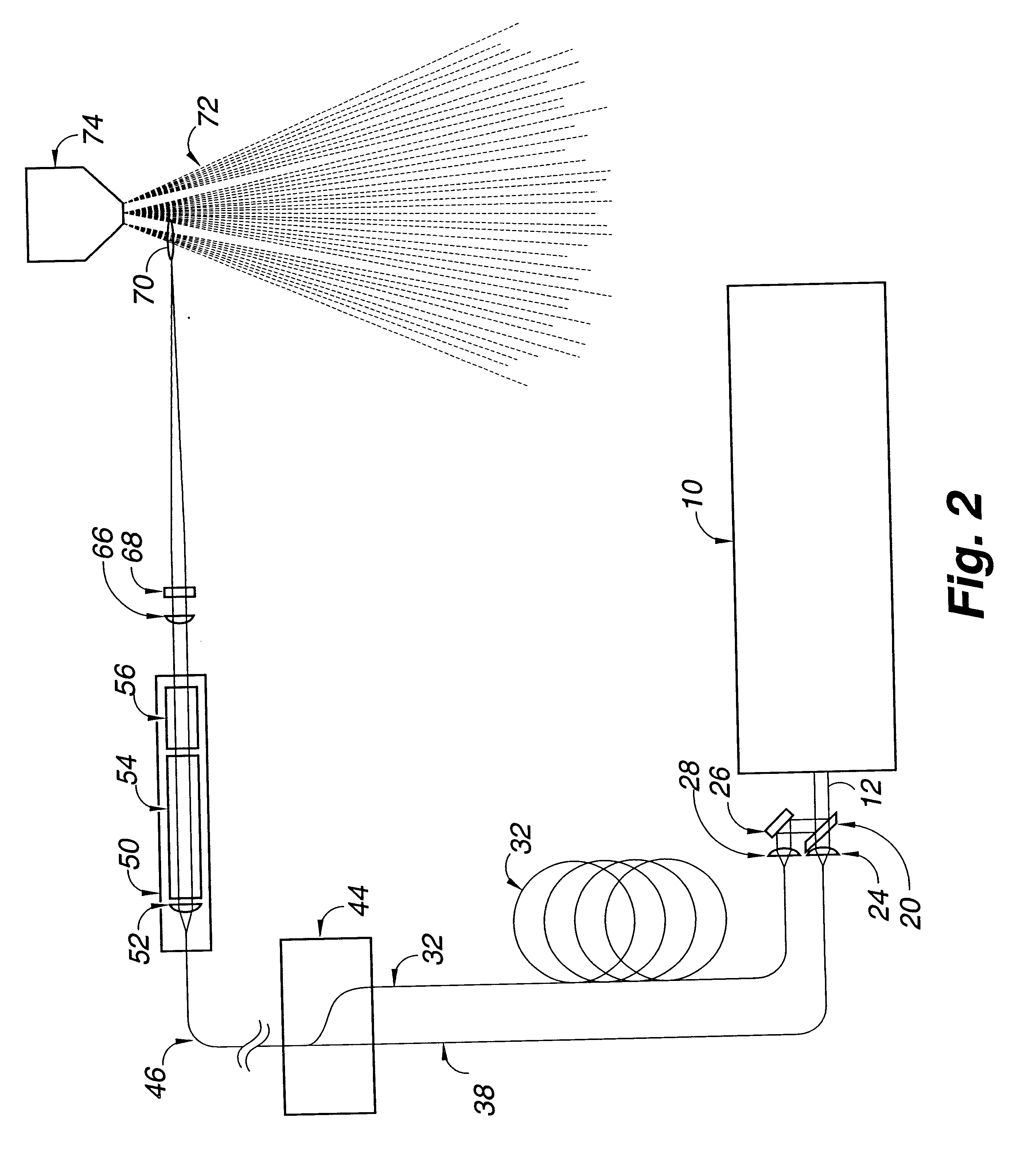

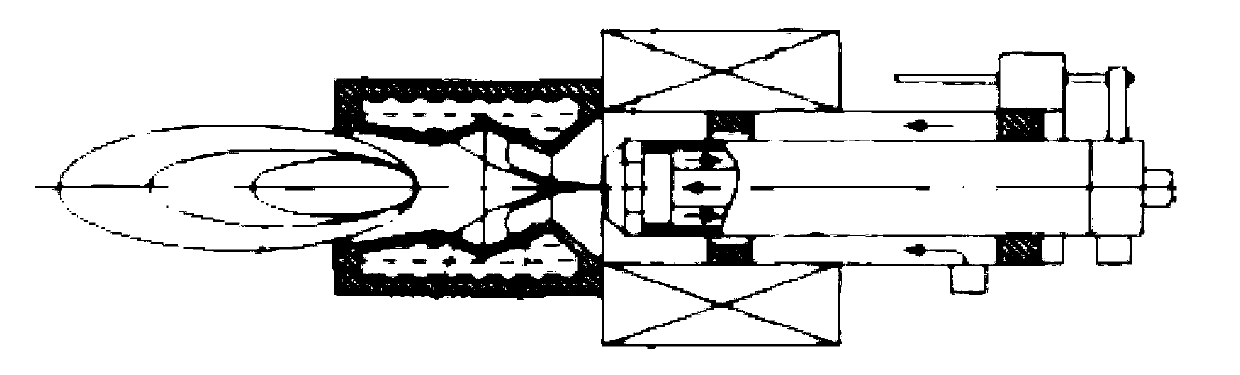

Laser ignition

InactiveUS6676402B1Durable and reliable and economical ignitionEliminate needLaser detailsPulsating combustionResonant cavityLight beam

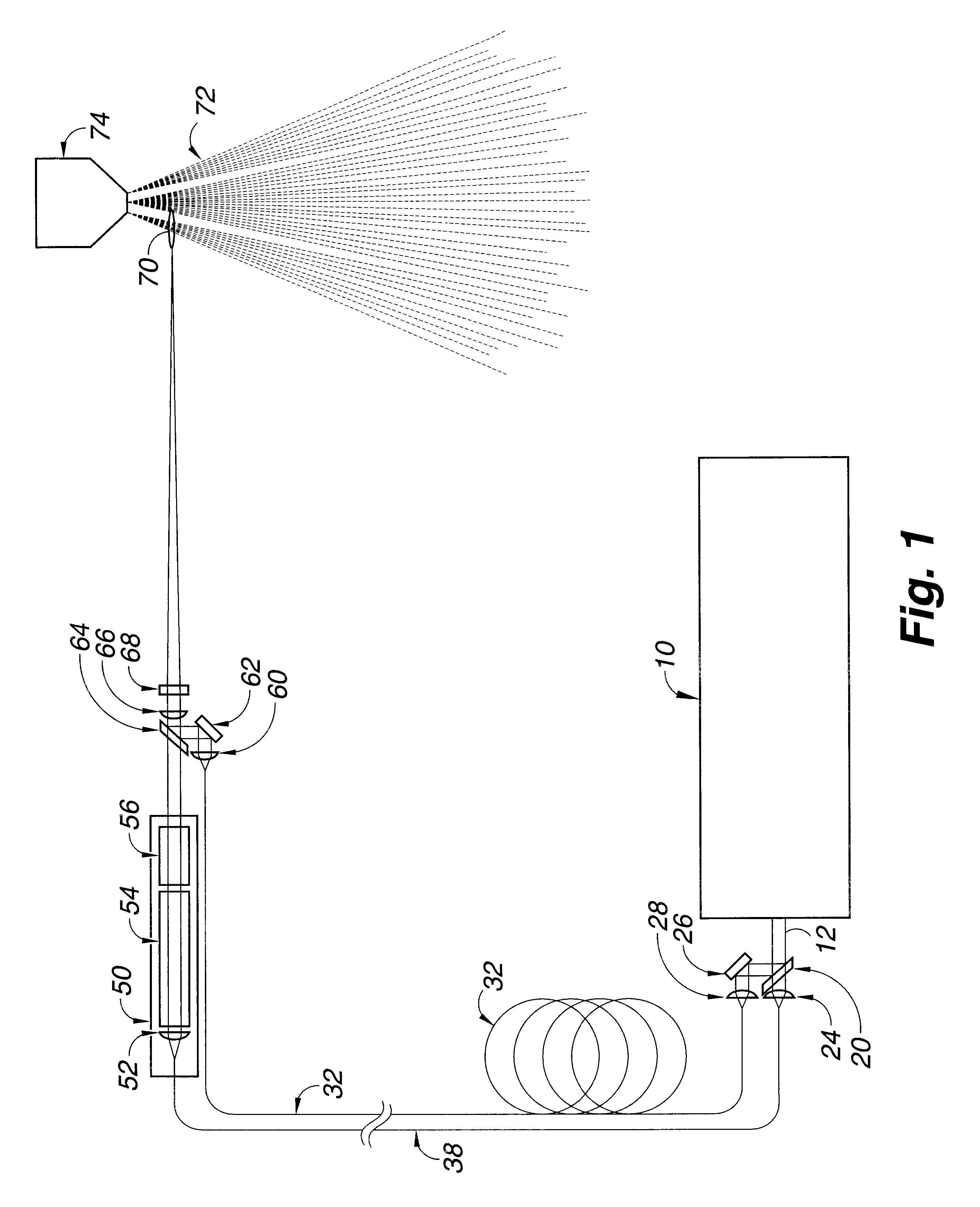

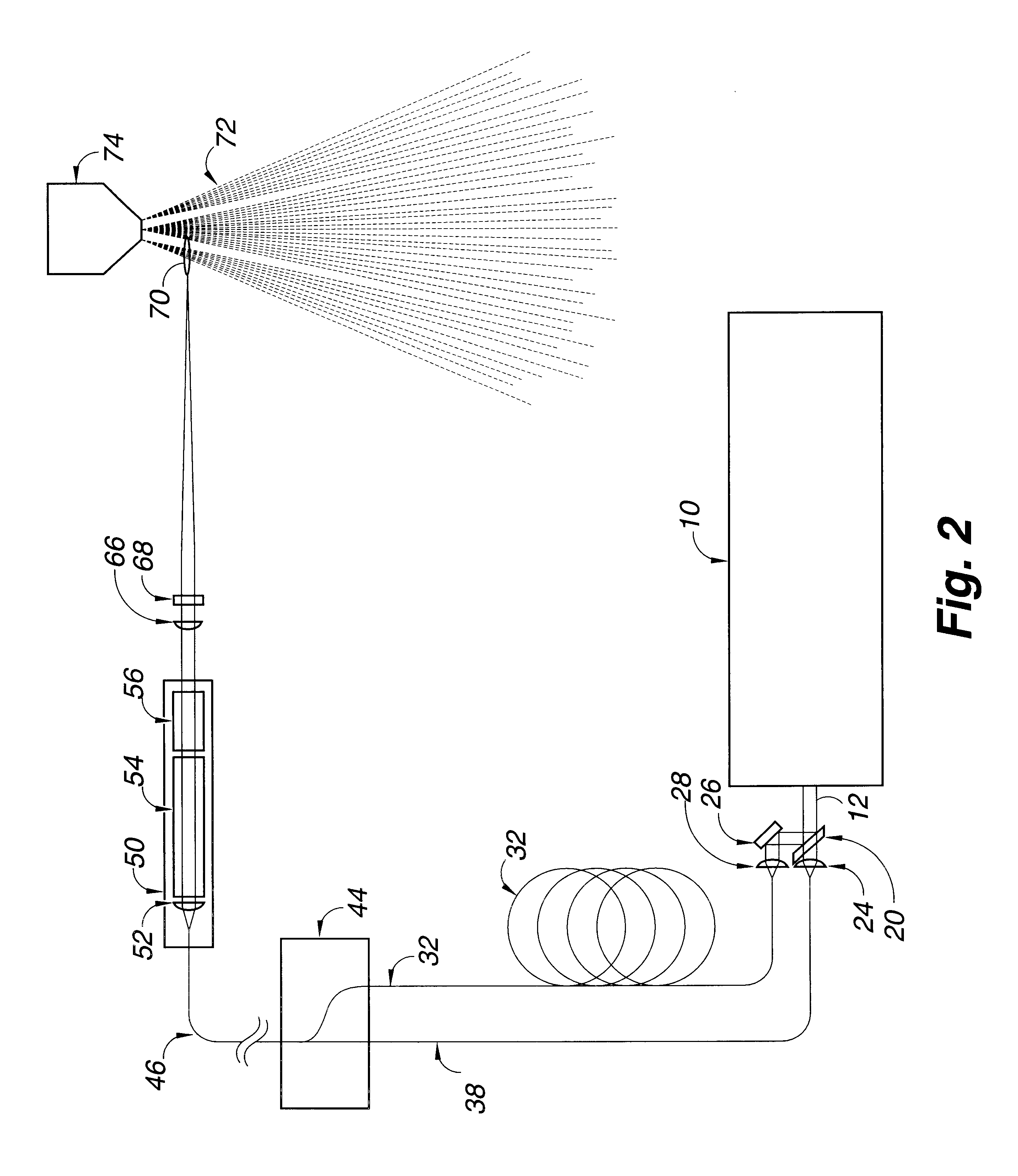

Sequenced pulses of light from an excitation laser with at least two resonator cavities with separate output couplers are directed through a light modulator and a first polarzing analyzer. A portion of the light not rejected by the first polarizing analyzer is transported through a first optical fiber into a first ignitor laser rod in an ignitor laser. Another portion of the light is rejected by the first polarizing analyzer and directed through a halfwave plate into a second polarization analyzer. A first portion of the output of the second polarization analyzer passes through the second polarization analyzer to a second, oscillator, laser rod in the ignitor laser. A second portion of the output of the second polarization analyzer is redirected by the second polarization analyzer to a second optical fiber which delays the beam before the beam is combined with output of the first ignitor laser rod. Output of the second laser rod in the ignitor laser is directed into the first ignitor laser rod which was energized by light passing through the first polarizing analyzer. Combined output of the first ignitor laser rod and output of the second optical fiber is focused into a combustible fuel where the first short duration, high peak power pulse from the ignitor laser ignites the fuel and the second long duration, low peak power pulse directly from the excitation laser sustains the combustion.

Owner:LOS ALAMOS NATIONAL SECURITY

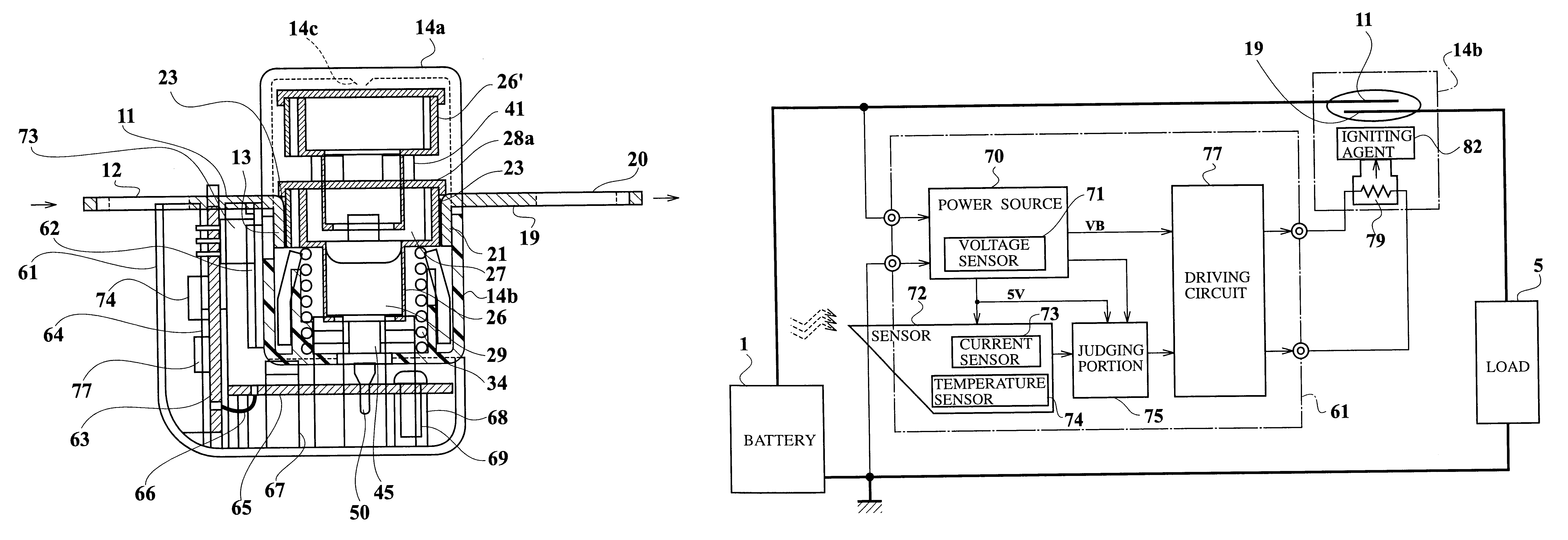

Circuit breaker

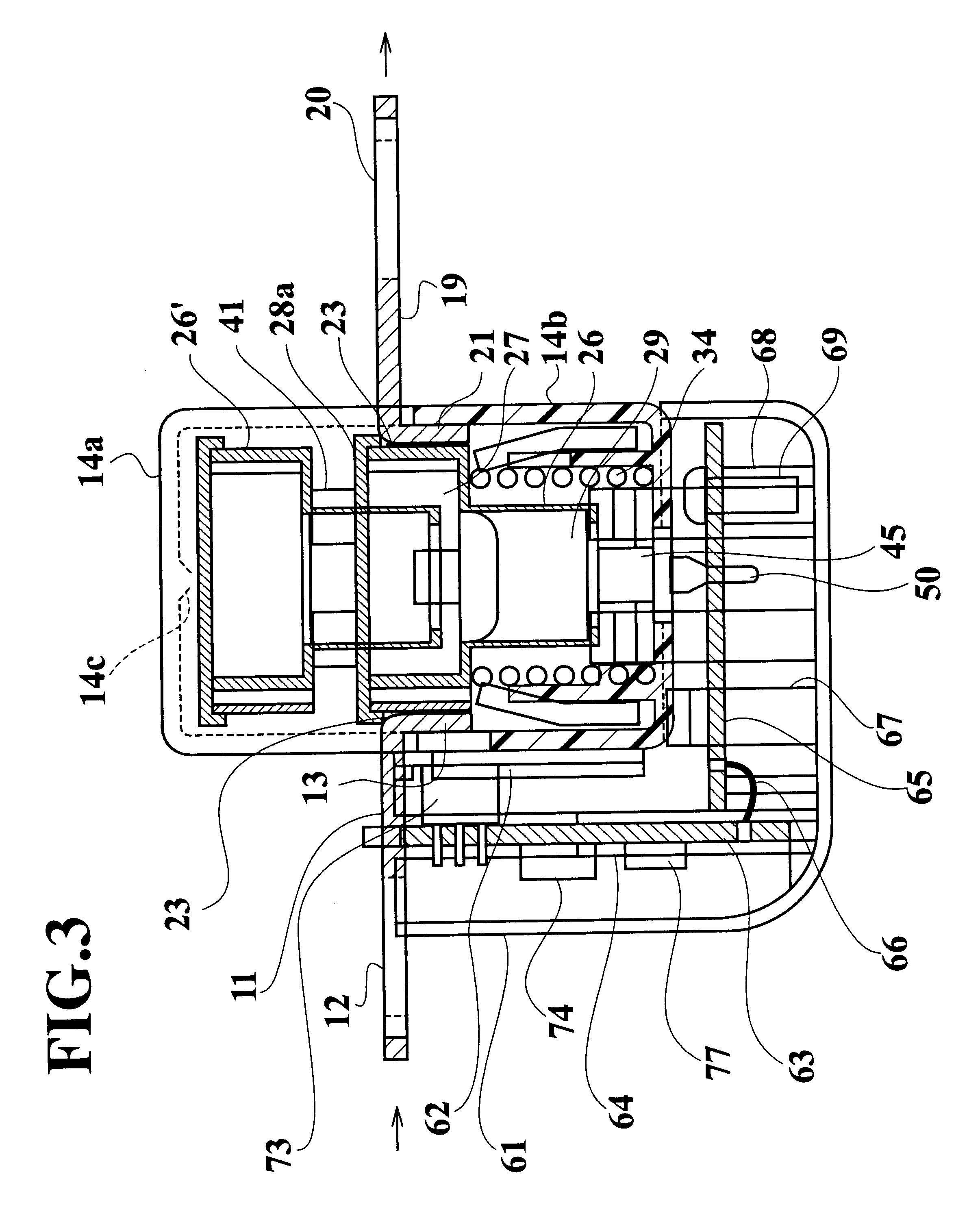

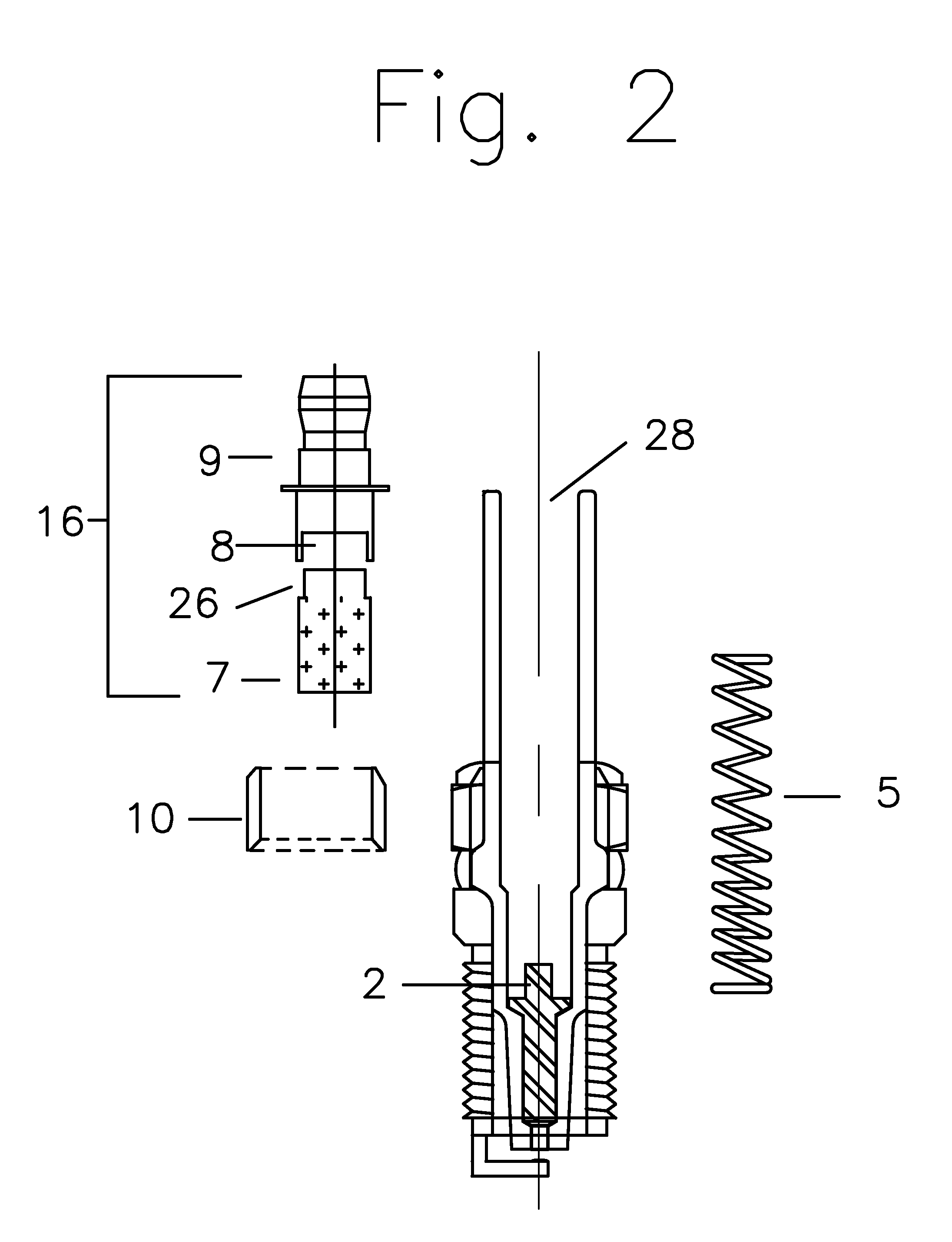

A current sensor 73 detects a current flowing through a first buss bar 11. When a current value detected by the current sensor 73 became equal to or greater than a threshold current value, a CPU 74 outputs a driving control signal to a driving circuit 77, and the driving circuit 77 operates an, ignitor 29 through a second substrate 65 and a terminal 50. Therefore, the ignitor 29 ignites, a second projection 41 is melted by heat of a heating agent 27, a compression spring 34 is expanded and a thermite case 26 jumps up. Thus, electrical connection between the thermite case 26 and the first and second buss bars 11, 19 is interrupted. Further, since an outer container 61 in which the current sensor 73, the CPU and the driving circuit 77 are accommodated is integrally assembled with the cap 14a and the resin case 14b in which the thermite case 26, the ignitor 29, the compression spring 34 and the second projection 41 are accommodated, non-operational state of the ignitor 29 due to disconnection of electric wire is not generated.

Owner:YAZAKI CORP

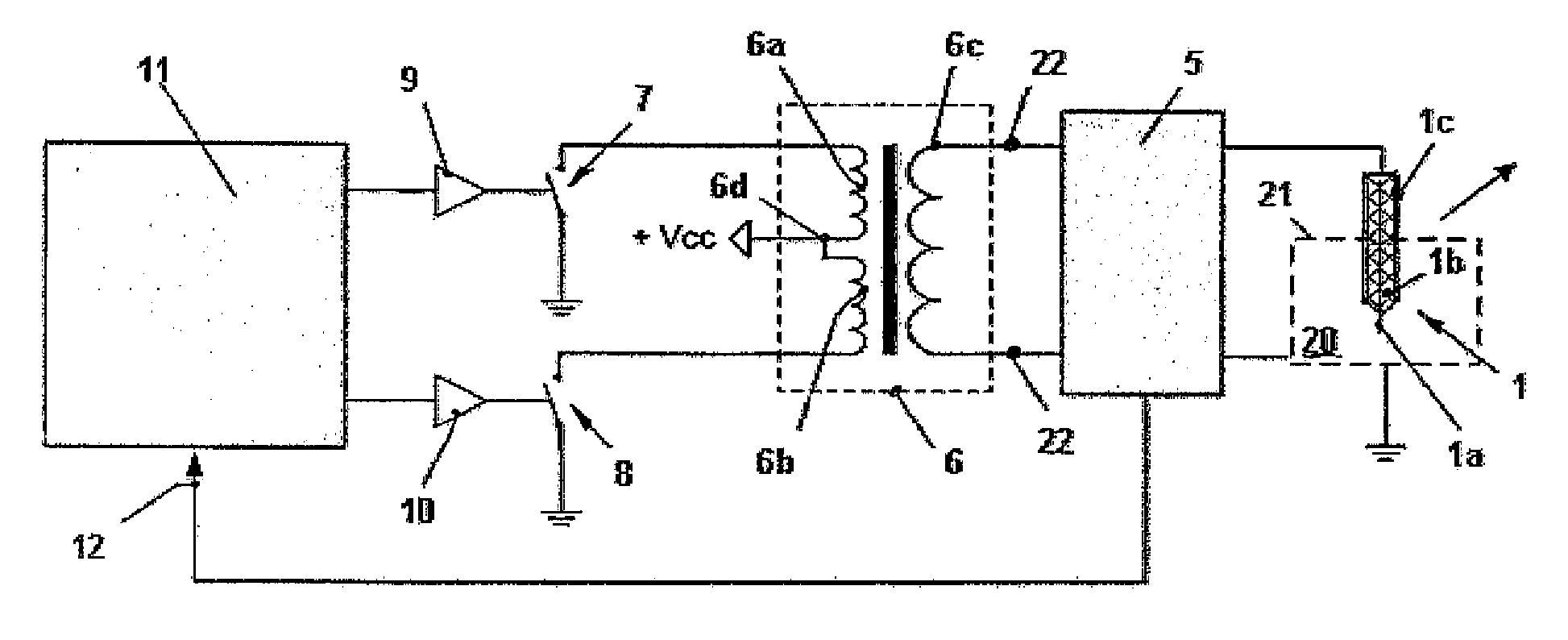

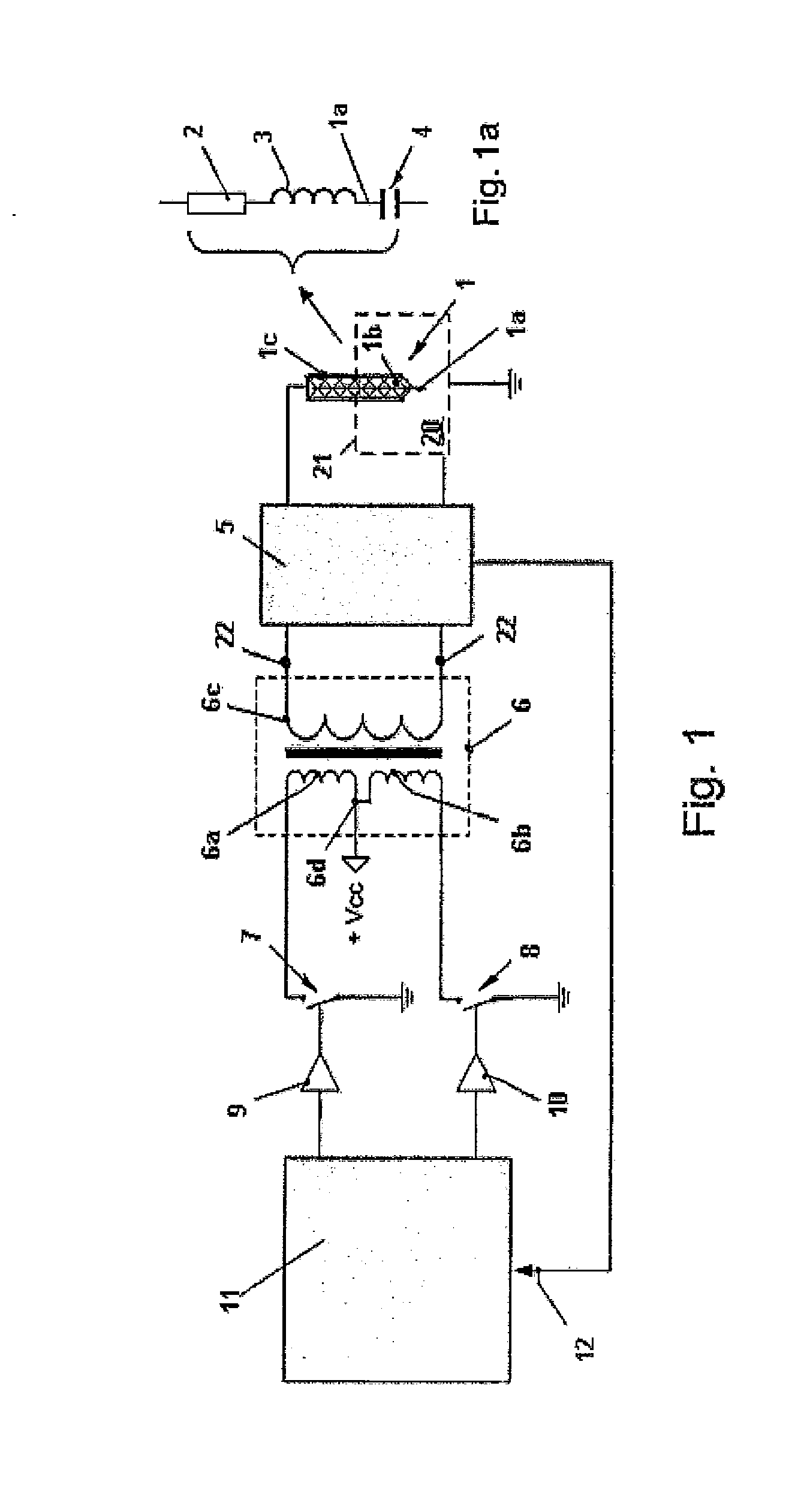

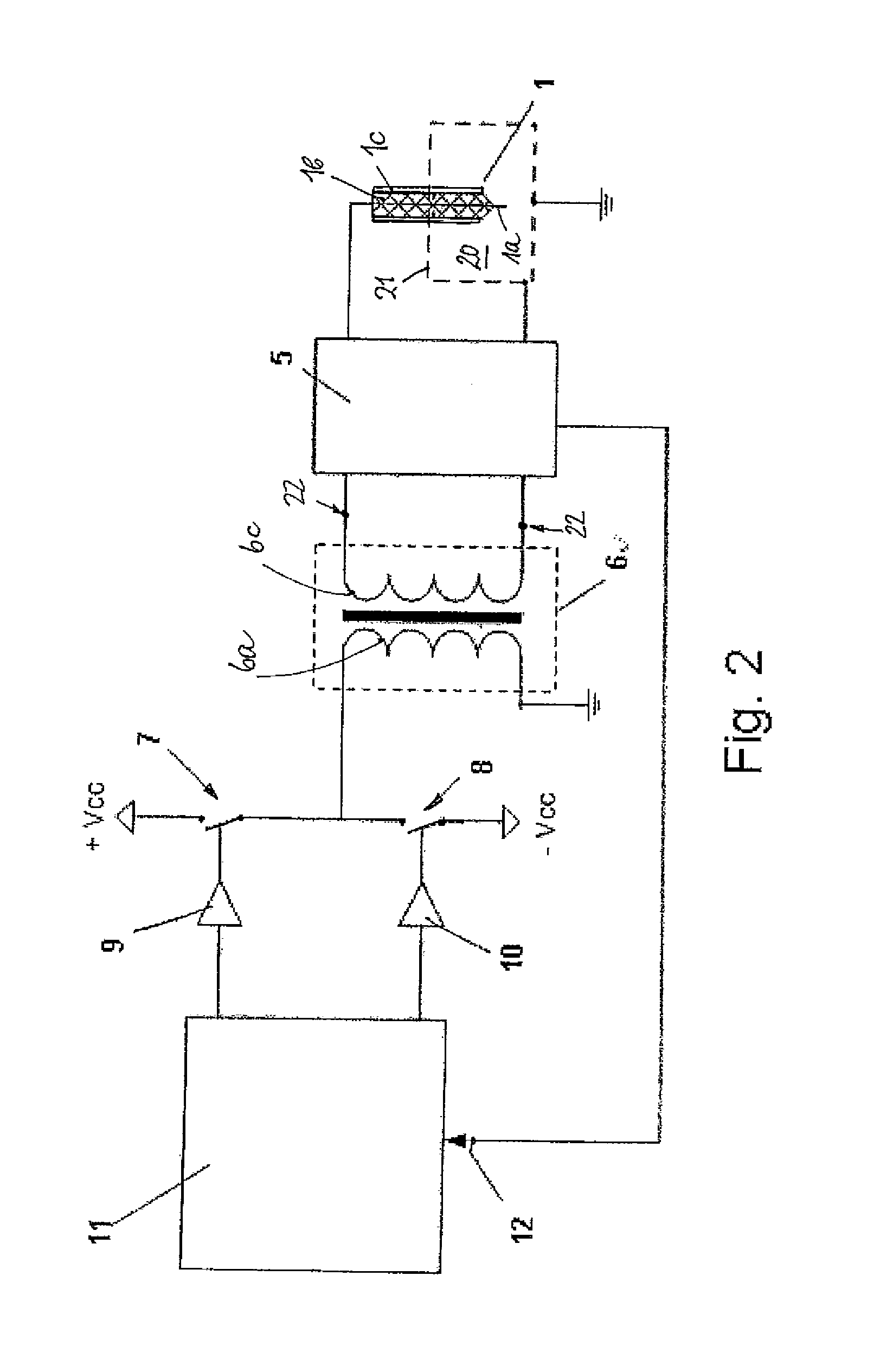

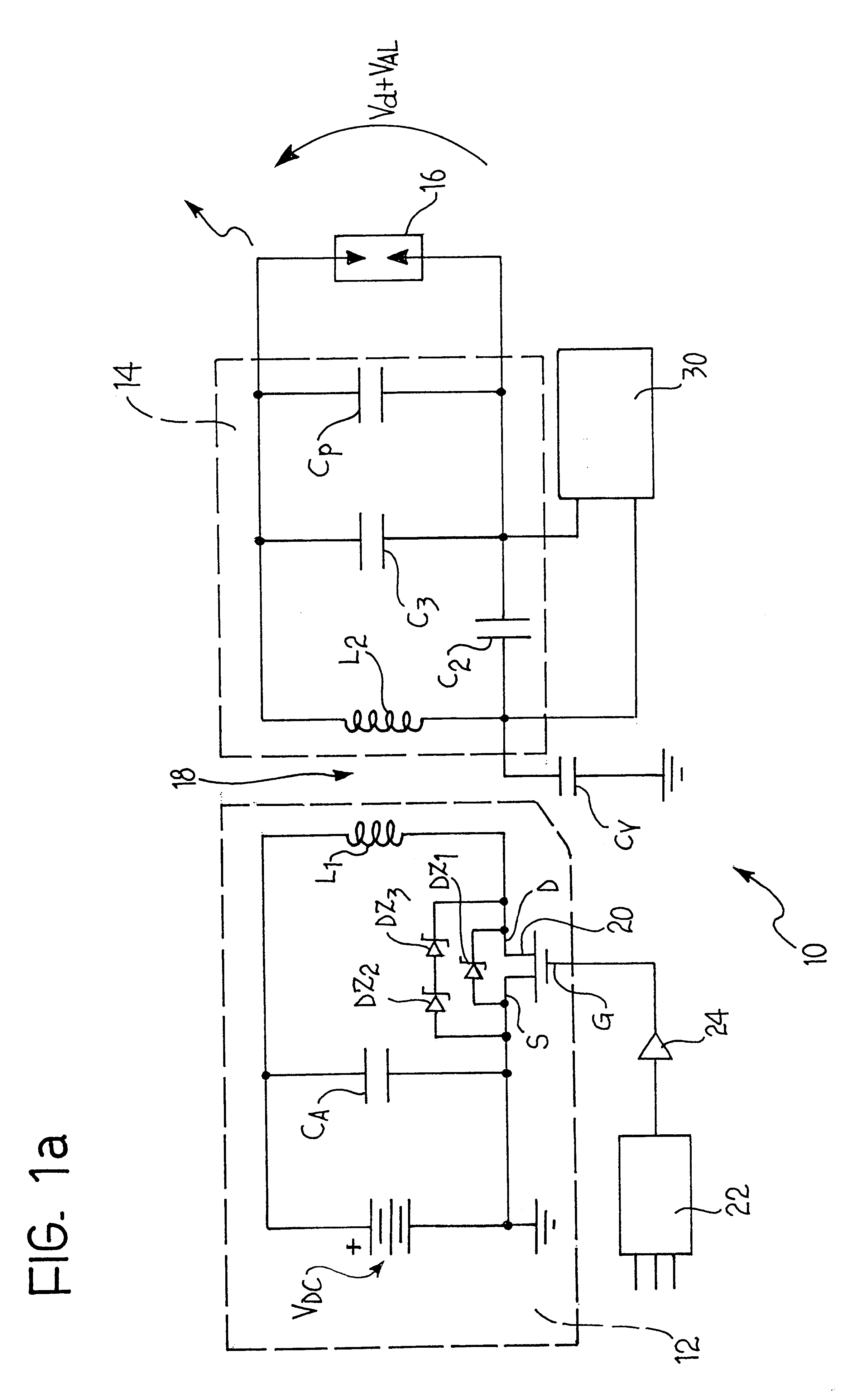

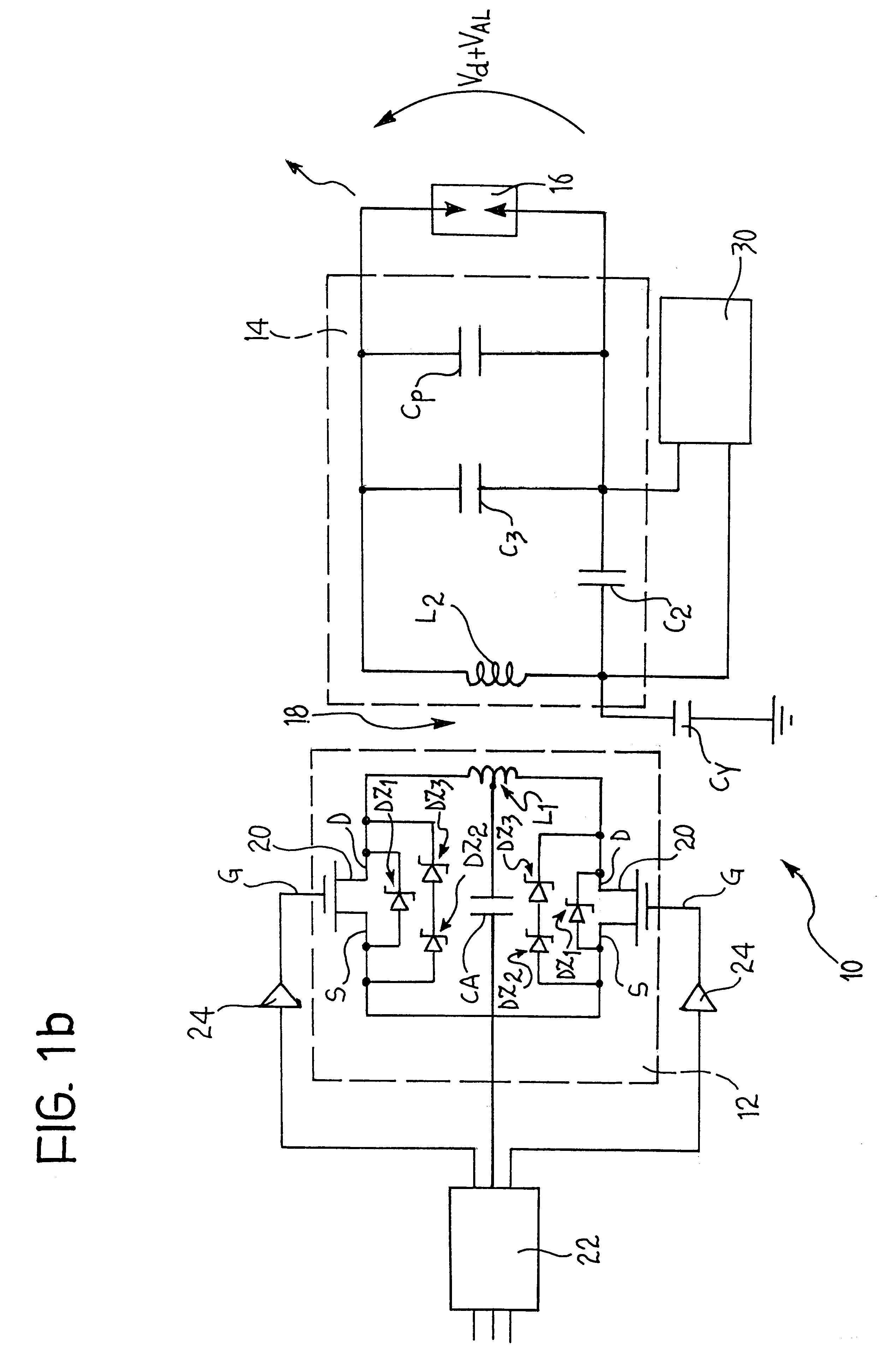

Method for energizing an HF resonant circuit which has an igniter as a component for igniting a fuel-air mixture in a combustion chamber

ActiveUS20120055455A1React more quicklyEasy to exciteMachines/enginesElectric spark ignition installationsCombustion chamberCorona discharge

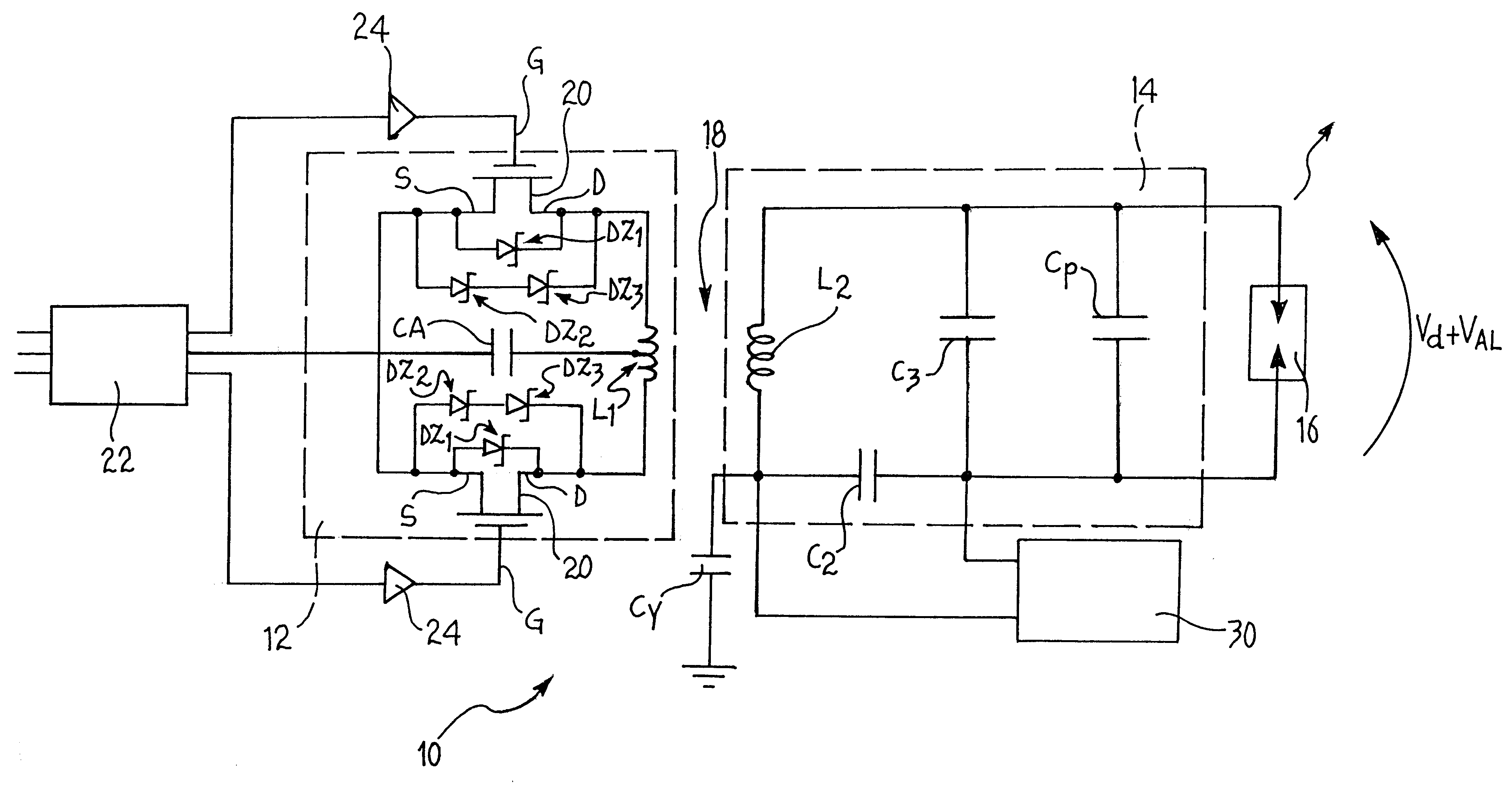

The invention relates to a method for energizing an HF resonant circuit which contains an igniter as a component for igniting a fuel-air mixture in a combustion chamber of an internal combustion engine by means of a corona discharge, wherein the igniter comprises an ignition electrode and an insulator surrounding the ignition electrode, by means of a DC-AC inverter which is excited by successive current pulses which each last while a switch controlled by a control circuit is in its conducting switching state. It is provided according to the invention that the switch is actuated when an instantaneous value of an alternating current or an alternating current voltage excited in the HF resonant circuit falls below a first switching threshold (A−, B−, C−) and the switch s actuated when the instantaneous value of the alternating current or the alternating current voltage excited in the HF resonant circuit exceeds a second switching threshold (A+, B+, C+).

Owner:BORGWARNER BERU SYST

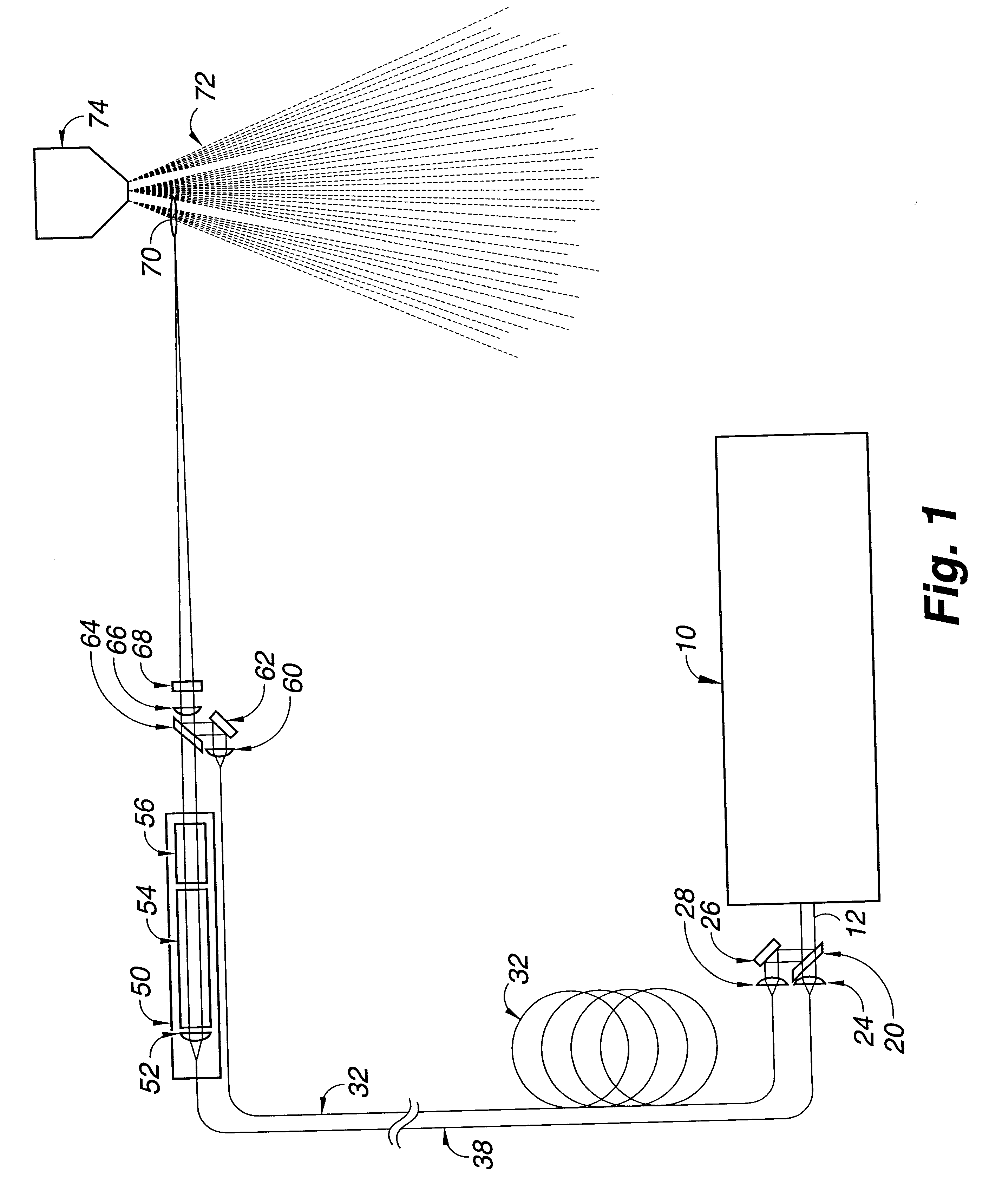

Laser ignition

InactiveUS6382957B1Durable and reliable and economical ignitionEliminate needLaser detailsPulsating combustionLight beamEngineering

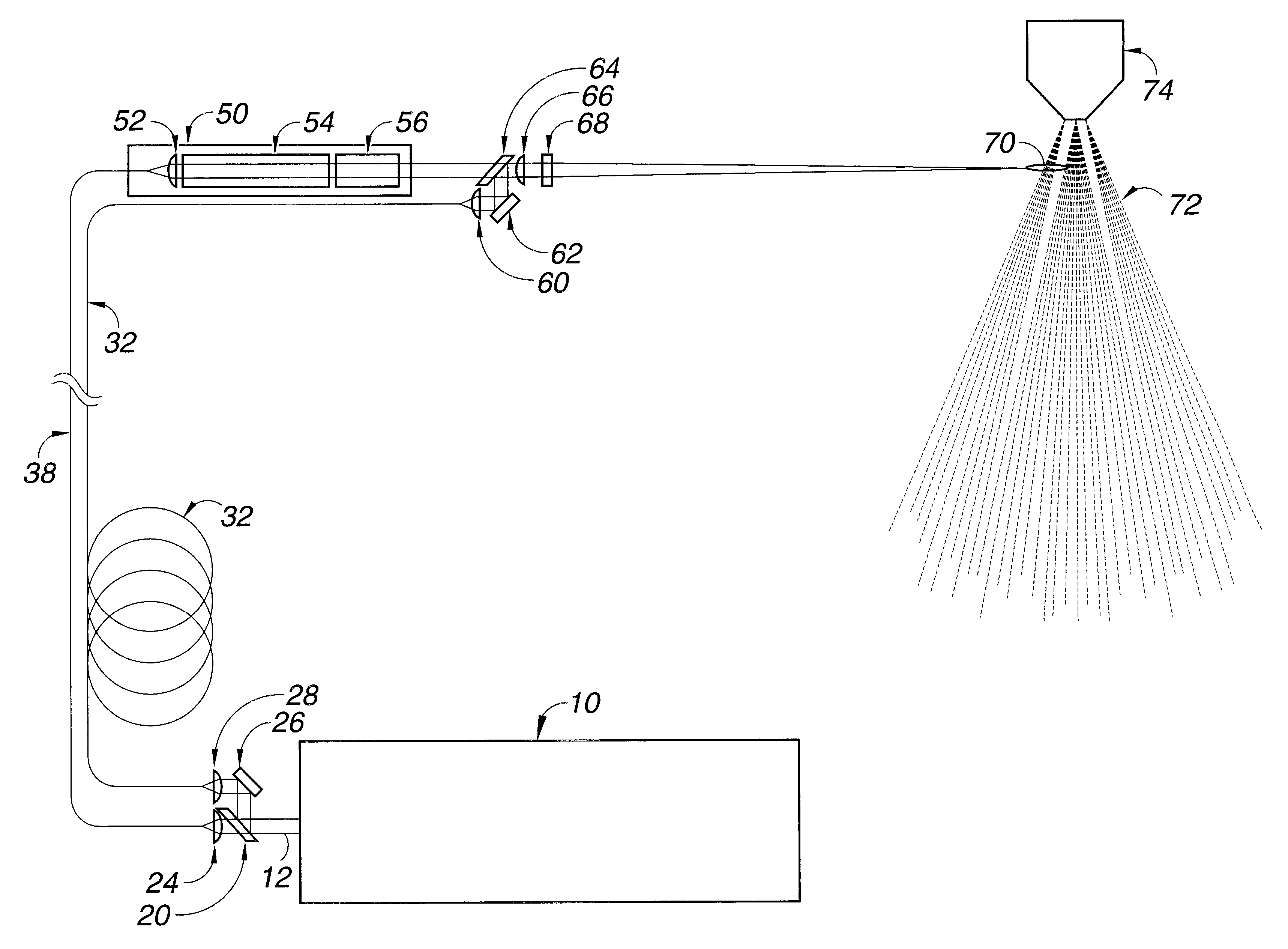

In the apparatus of the invention, a first excitation laser or other excitation light source is used in tandem with an ignitor laser to provide a compact, durable, engine deployable fuel ignition laser system. Reliable fuel ignition is provided over a wide range of fuel conditions by using a single remote excitation light source for one or more small lasers located proximate to one or more fuel combustion zones.In the embodiment of the invention claimed herein, the beam from the excitation light source is split with a portion of it going to the ignitor laser and a second portion of it being combined with either the first portion after a delay before injection into the ignitor laser.

Owner:LOS ALAMOS NATIONAL SECURITY

Solid state resonance igniter for control of the number of high voltage pulses for hot restrike of discharge lamps

InactiveUS6191537B1Keep for a long timeElectrical apparatusElectric light circuit arrangementEngineeringHigh pressure

A solid state igniter device for hot restrike of discharge lamps with an associated supply circuit. The ignitor device comprises a primary circuit with at least one solid state switch element controlled to switch to induce in the primary circuit a controlled oscillation phenomenon at a frequency greater than a megahertz and a secondary circuit including a resonant circuit with a high quality factor Q (at least 100), capable of resonating and producing a pulse signal for striking the discharge of the lamp, controlled through the controlled oscillation phenomenon produced in the primary circuit. A control unit acting on the switch element controls the oscillation phenomenon in a pulse mode as a function of the characteristics of the lamp and the power supply, wherein the control unit induces the controlled oscillation phenomenon for a predetermined time duration a programmable number of times in a predetermined time interval.

Owner:IREM

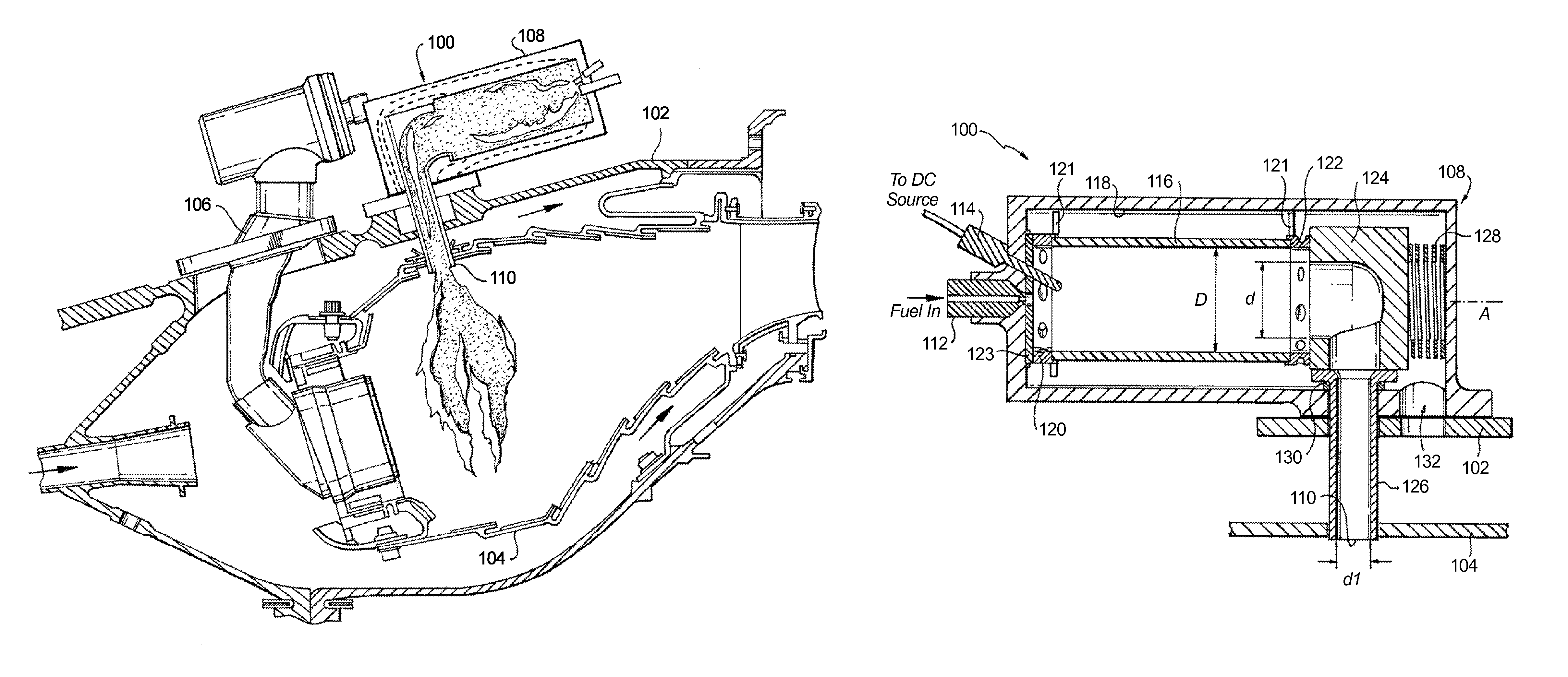

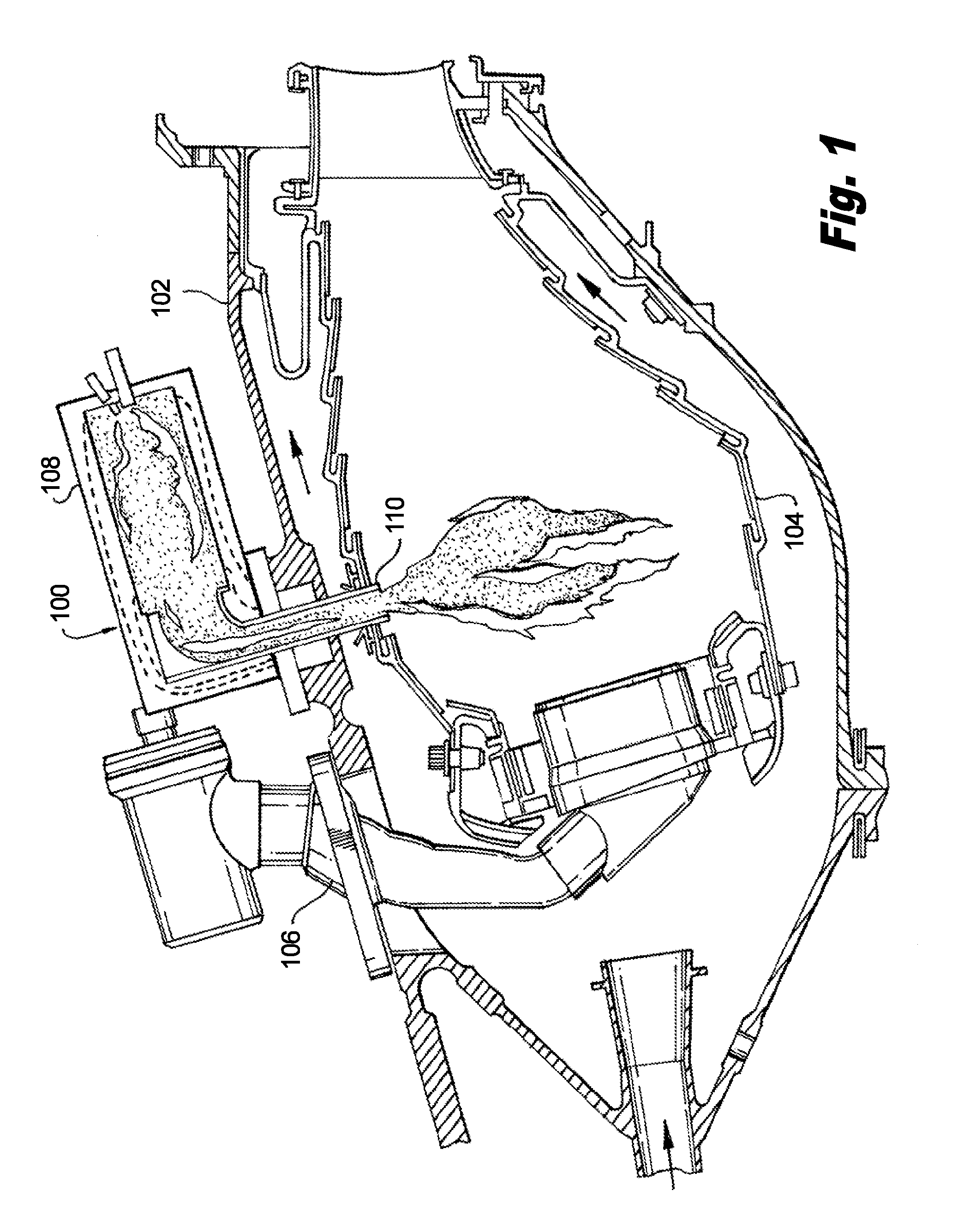

Continuous ignition

ActiveUS20140366551A1High flame intensityDecreasing flame strengthBurnersContinuous combustion chamberCombustorIgnition point

An ignition system includes a housing defining an interior and an exhaust outlet. The housing is configured and adapted to be mounted to a combustor to issue flame from the exhaust outlet into the combustor for ignition and flame stabilization within the combustor. A fuel injector is mounted to the housing with an outlet of the fuel injector directed to issue a spray of fuel into the interior of the housing. An igniter is mounted to the housing with an ignition point of the igniter proximate the outlet of the fuel injector for ignition within the interior of the housing.

Owner:COLLINS ENGINE NOZZLES INC

Double-cavity excitation enhanced microwave plasma torch generation device

PendingCN107087339AIncrease maximum powerStanding wave enhancementPlasma techniqueSurface modificationMicrowave plasma torch

The invention relates to a double-cavity excitation enhanced microwave plasma torch generation device, and belongs to the technical field of microwave plasma. The device comprises a microwave magnetron, a circulator, a directional coupler, a microwave plasma coupling waveguide, a cylindrical waveguide, an igniter and a discharge tube. After the microwave magnetron, the circulator and the directional coupler are sequentially connected in series, the directional coupler is connected with the microwave plasma coupling waveguide. The cylindrical waveguide chamber is additionally arranged in the axial direction of the discharge tube perpendicular to a compression rectangular waveguide; a thermal resistance waveguide in the microwave plasma coupling waveguide effectively isolates the influence of thermal release of plasma discharge on a whole system; the igniter makes the whole system operated by a single person to complete a series of processes of ignition, excitation and maintenance, and the ignition success rate is close to 100% under the condition that the no-load output of a microwave source is low. Plasma torch afterglow with a larger volume action area can be obtained by increasing the maximum power of a plasma torch, so that the device can operate stably and reliably for a long time, and can be used in various relevant fields such as combustion assistance, nano material synthesis, waste gas treatment and high-temperature-resistant material surface modification.

Owner:李容毅

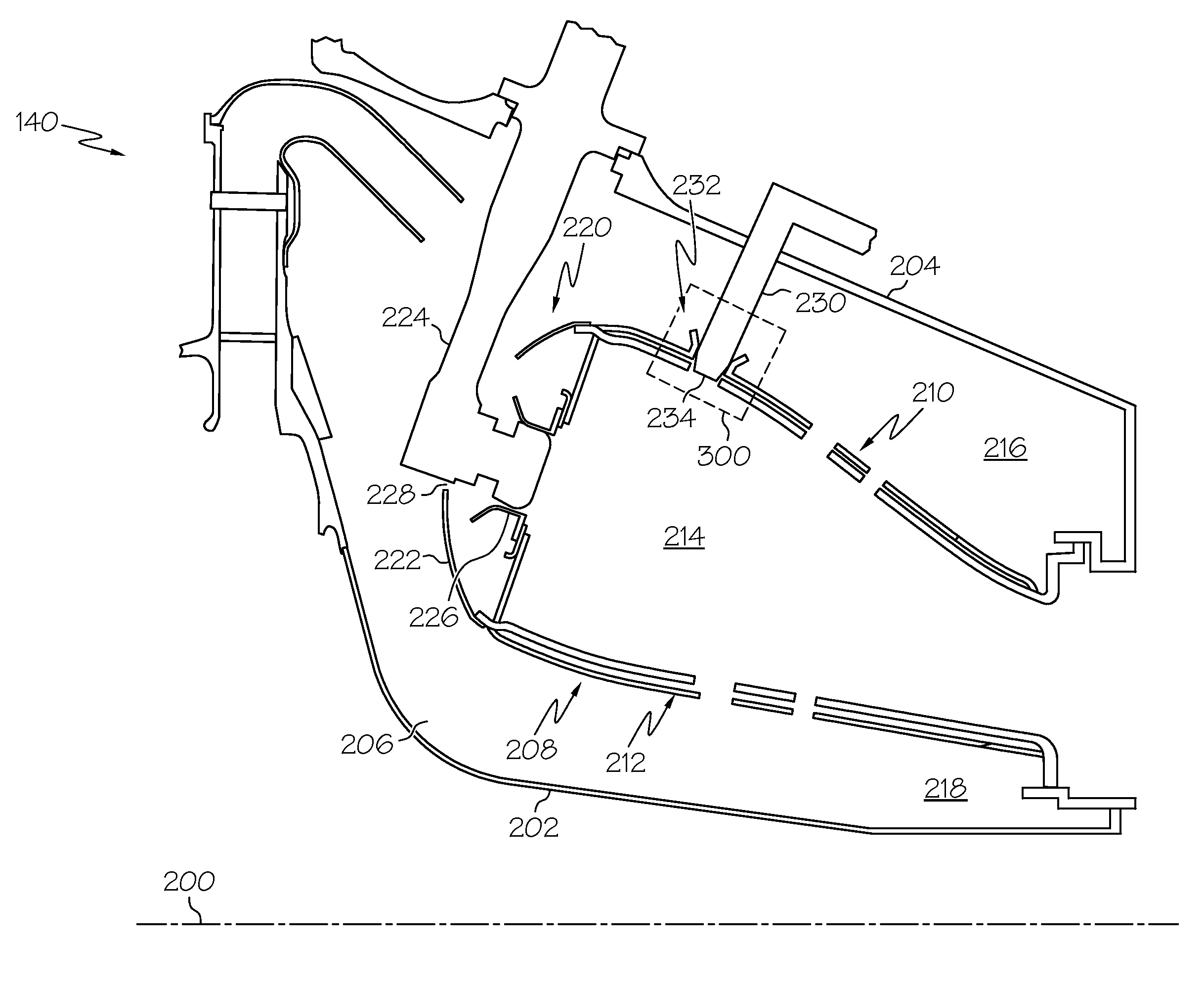

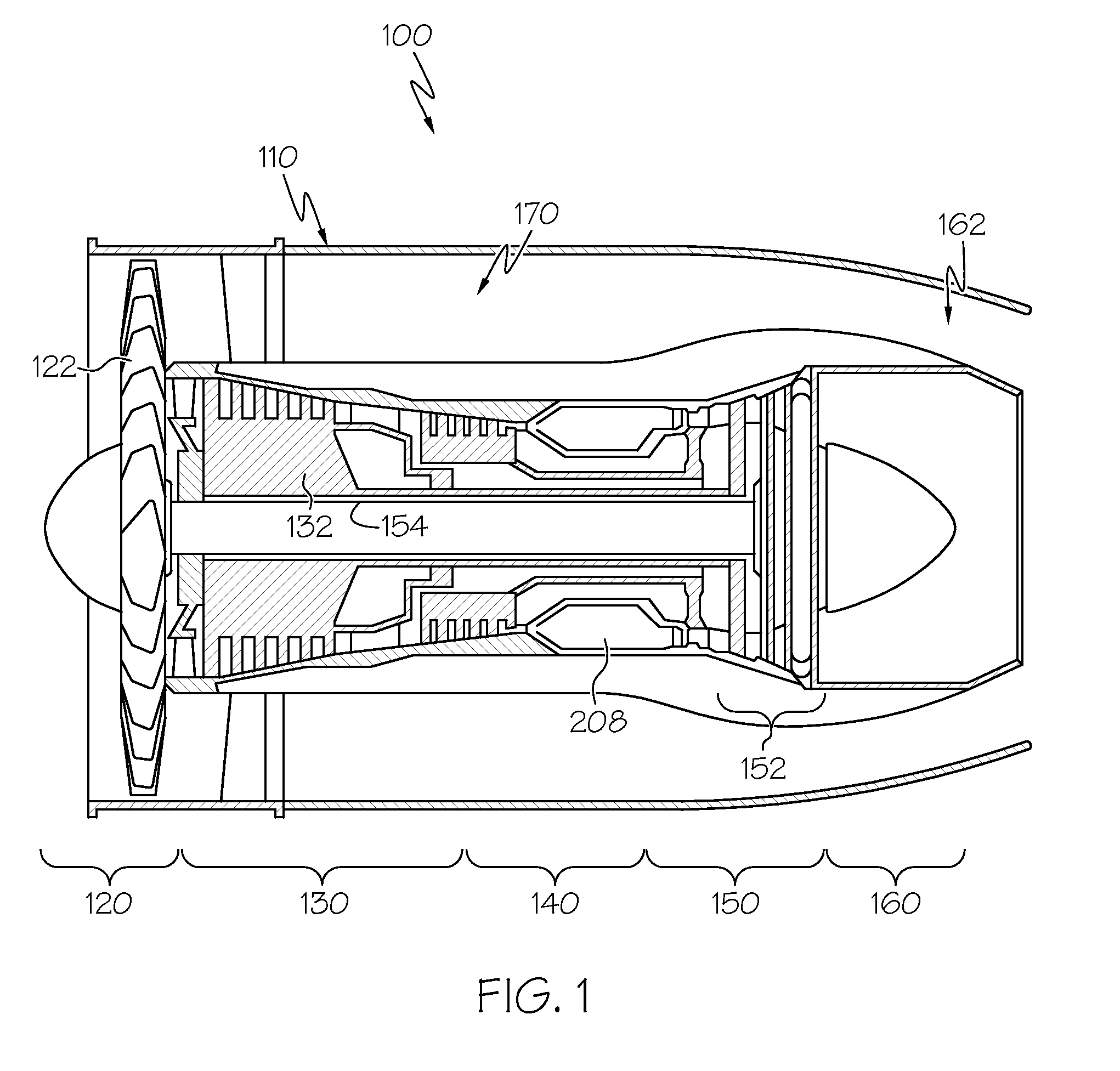

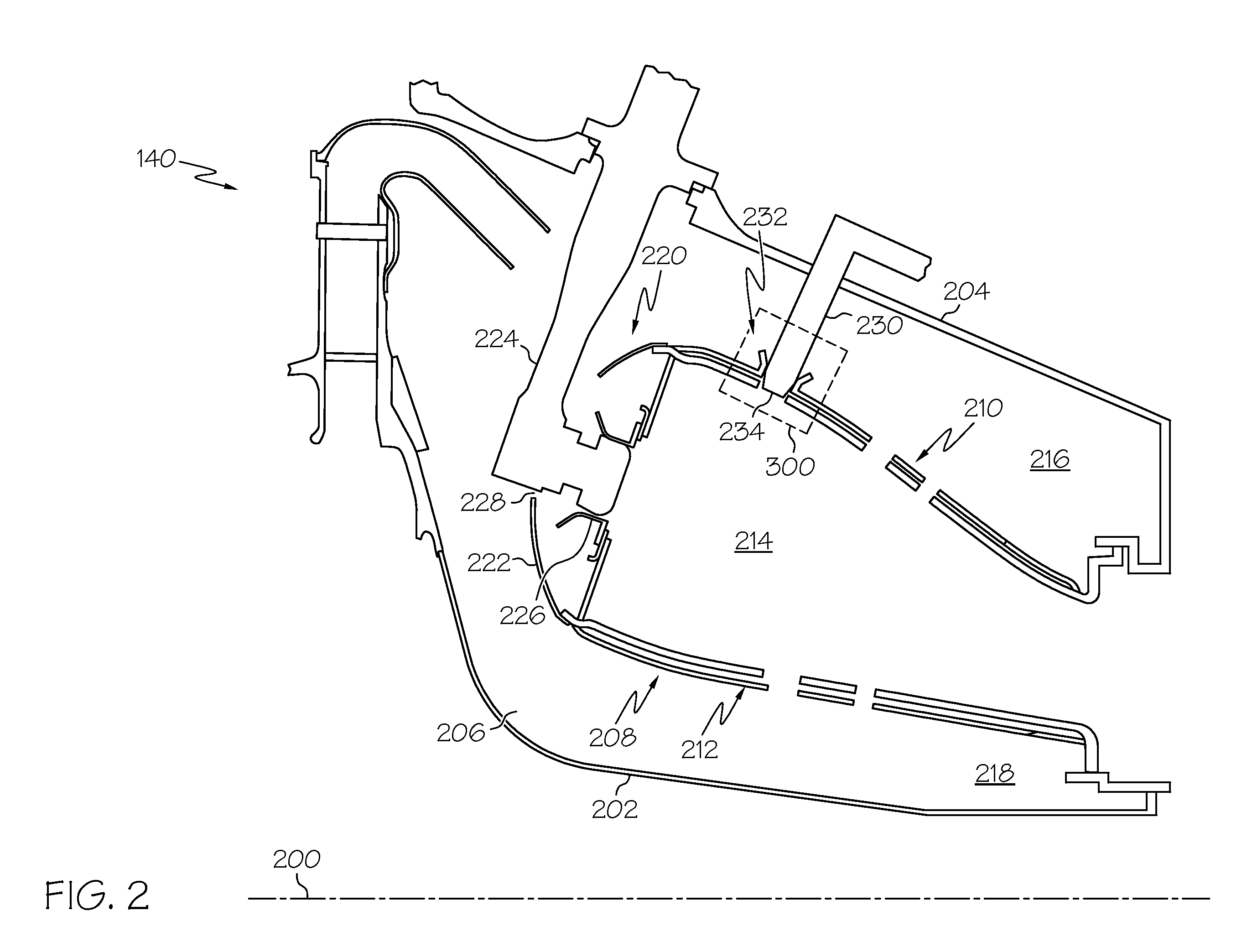

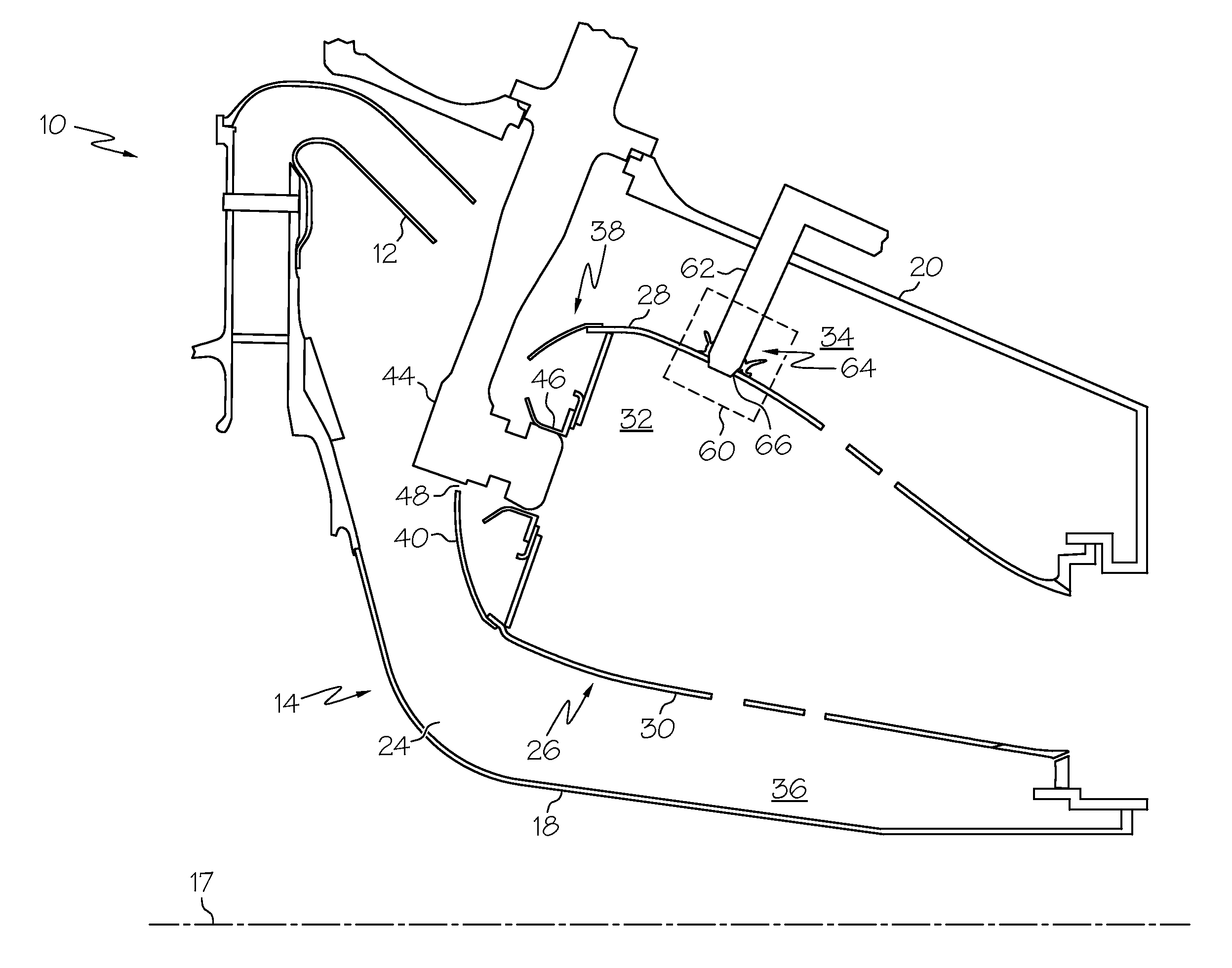

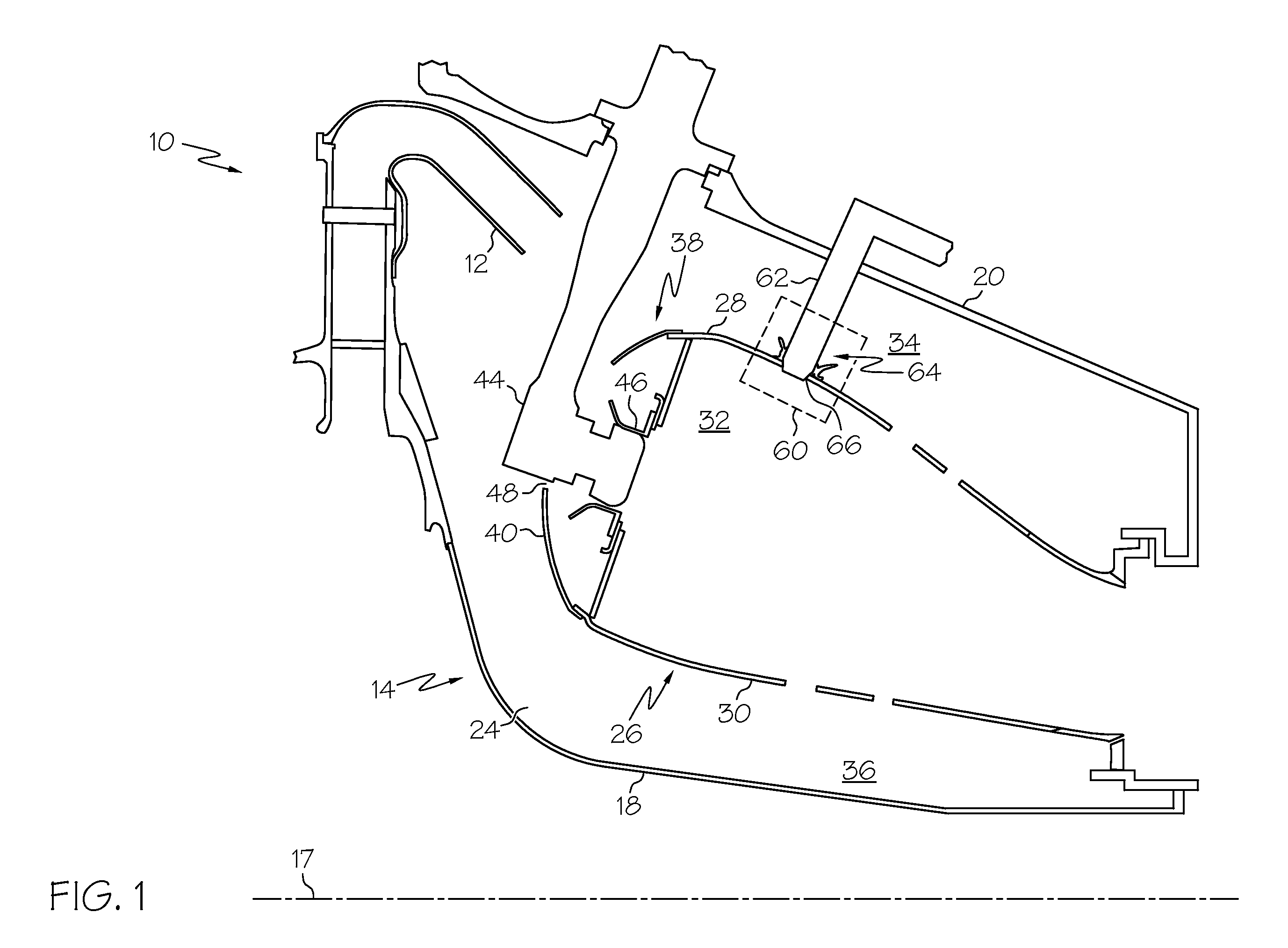

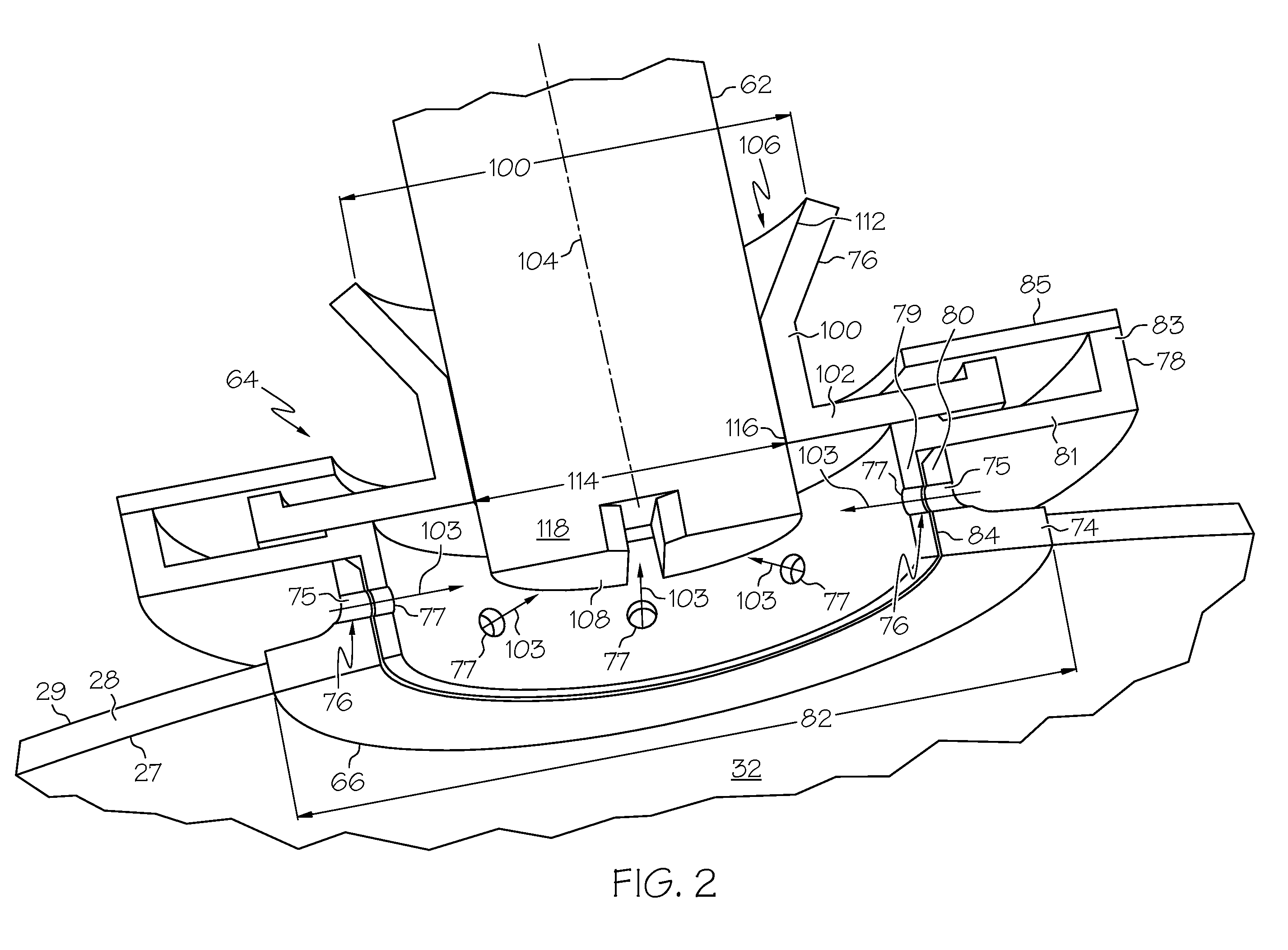

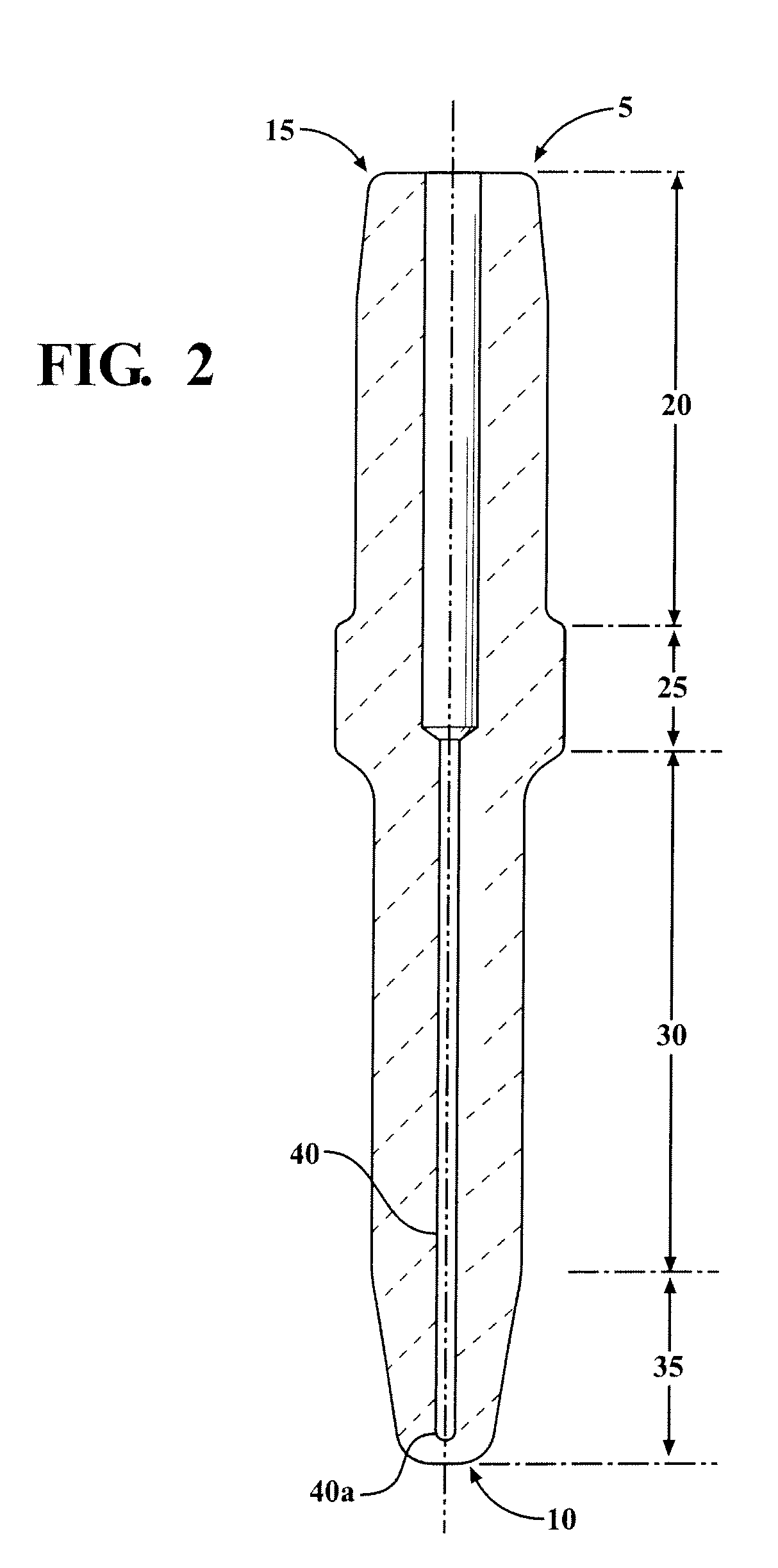

Dual walled combustors with impingement cooled igniters

A combustor for a gas turbine engine includes an inner liner and an outer liner circumscribing the inner liner and forming a combustion chamber therewith. The outer liner is a dual walled liner with a first wall and a second wall. A fuel igniter includes a tip portion configured to ignite an air and fuel mixture in the combustion chamber. An igniter support assembly positions the fuel igniter relative to the combustion chamber. The igniter support assembly defines a plurality of holes configured to direct cooling air toward the tip portion of the fuel igniter. The igniter support assembly includes first and second floating seals that are configured to accommodate radial and axial relative movements.

Owner:HONEYWELL INT INC

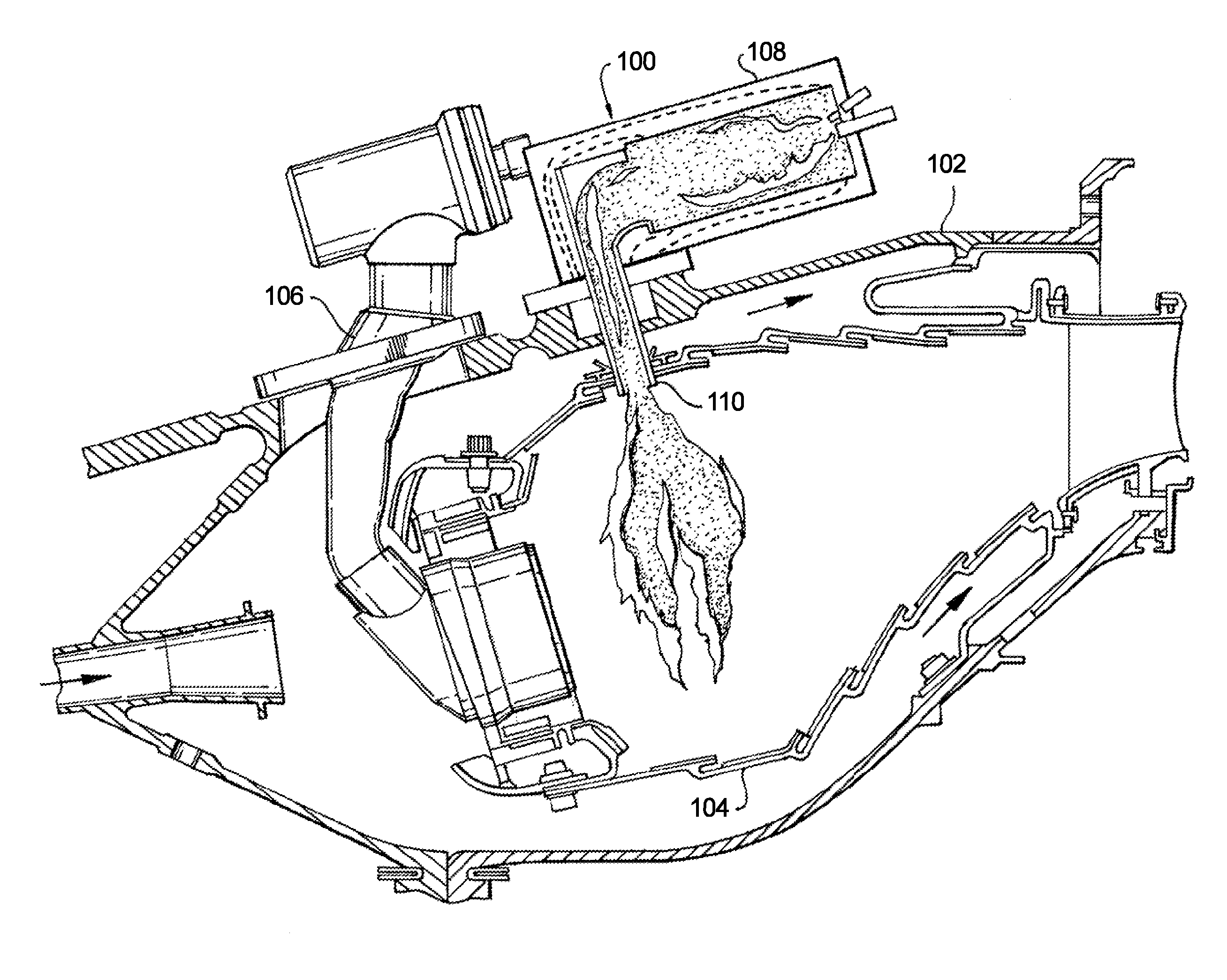

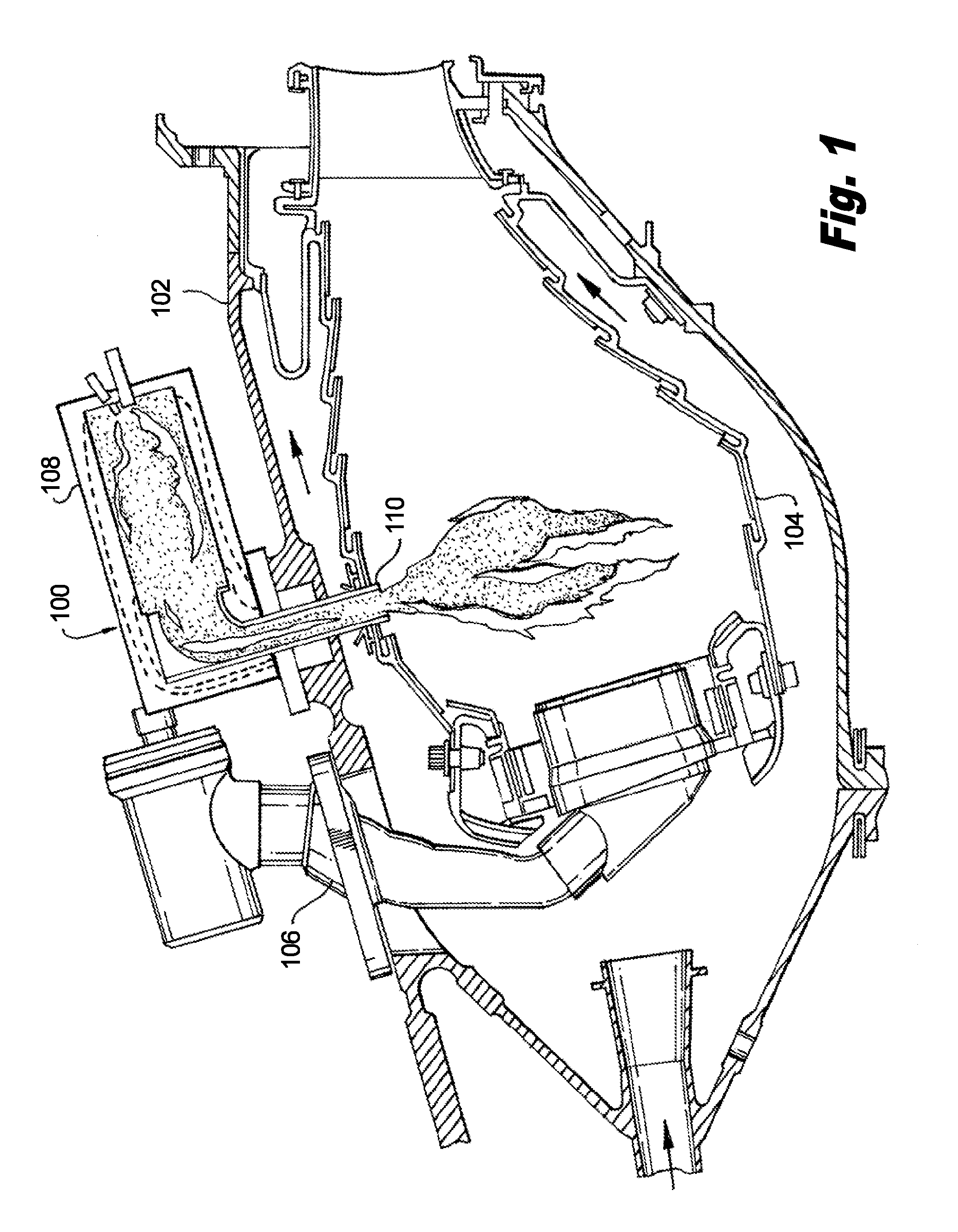

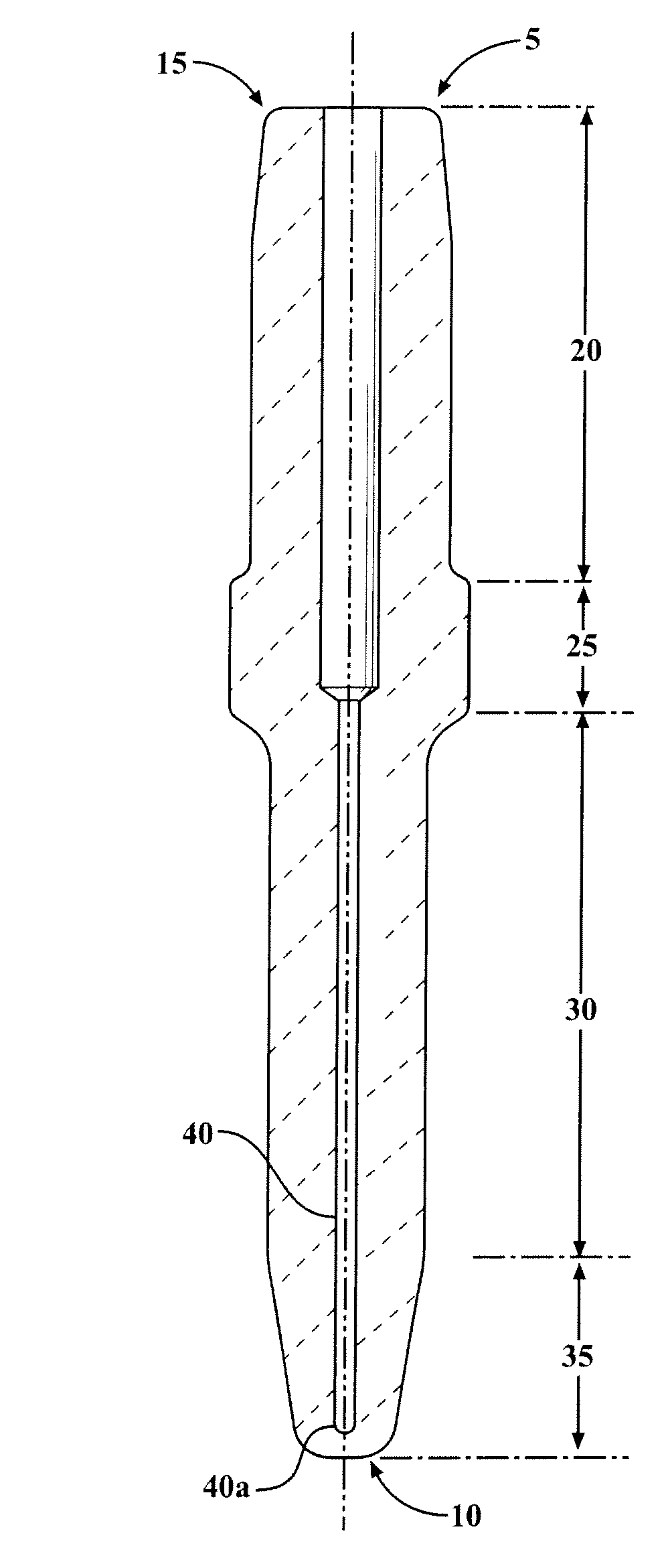

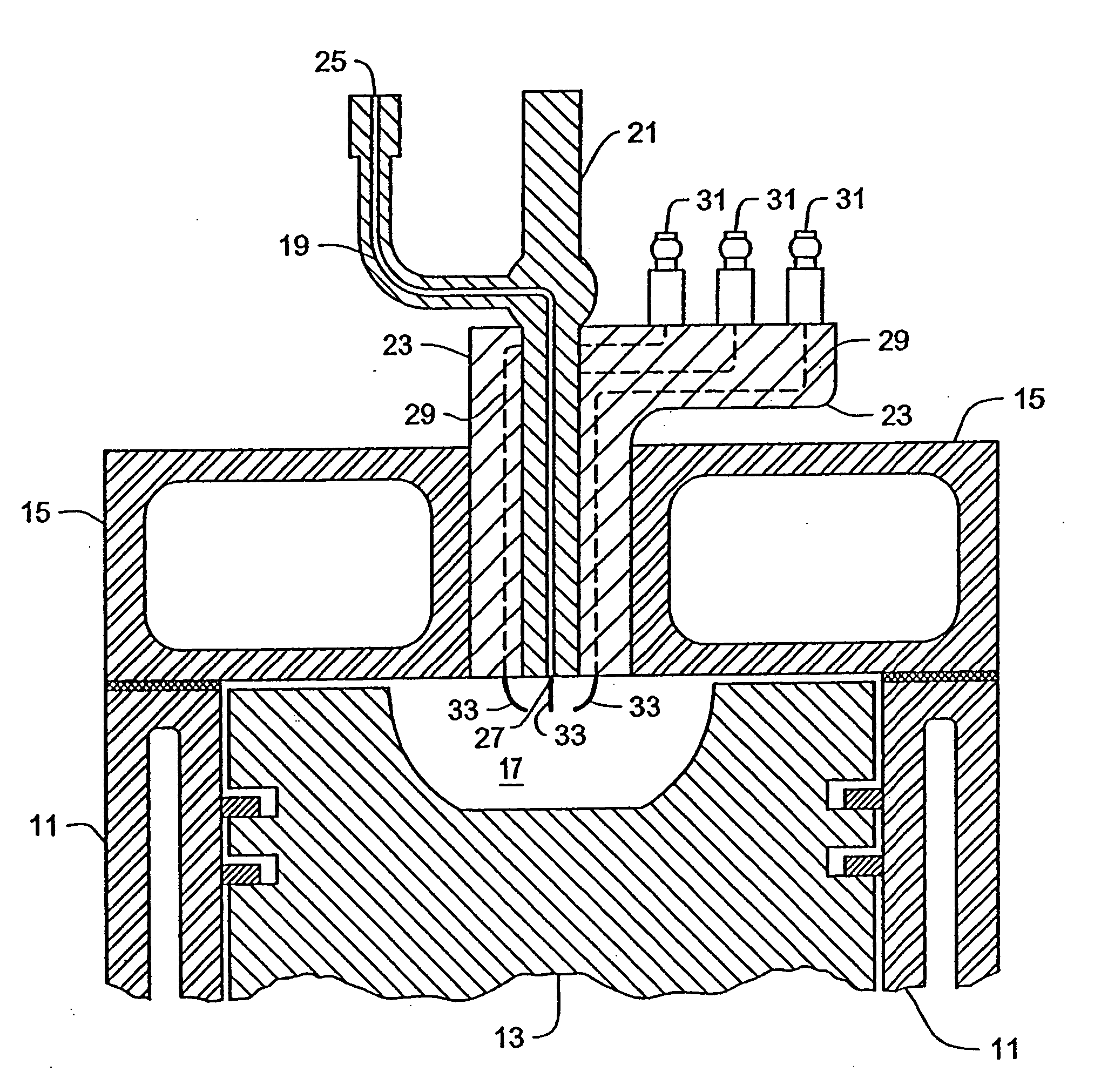

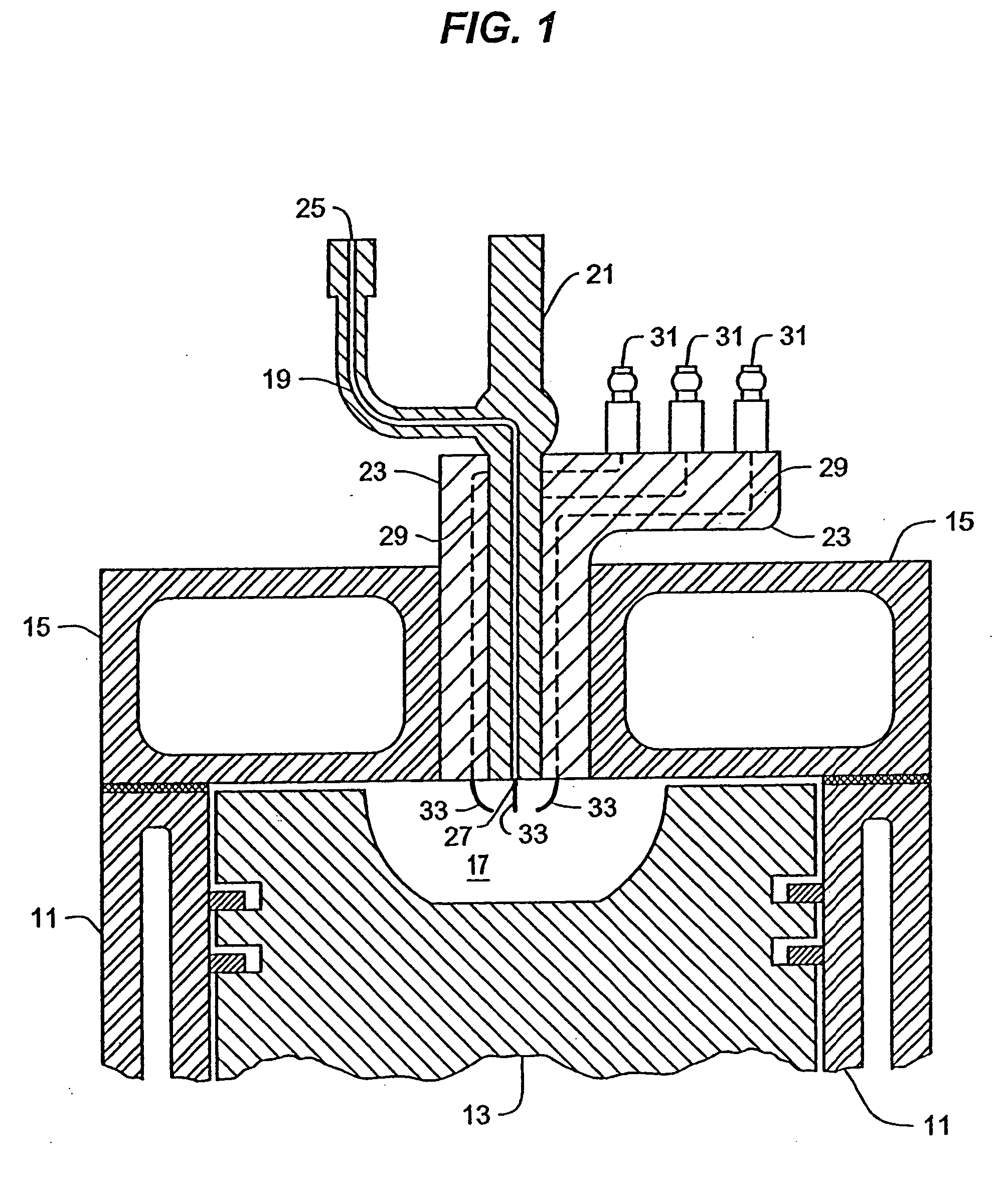

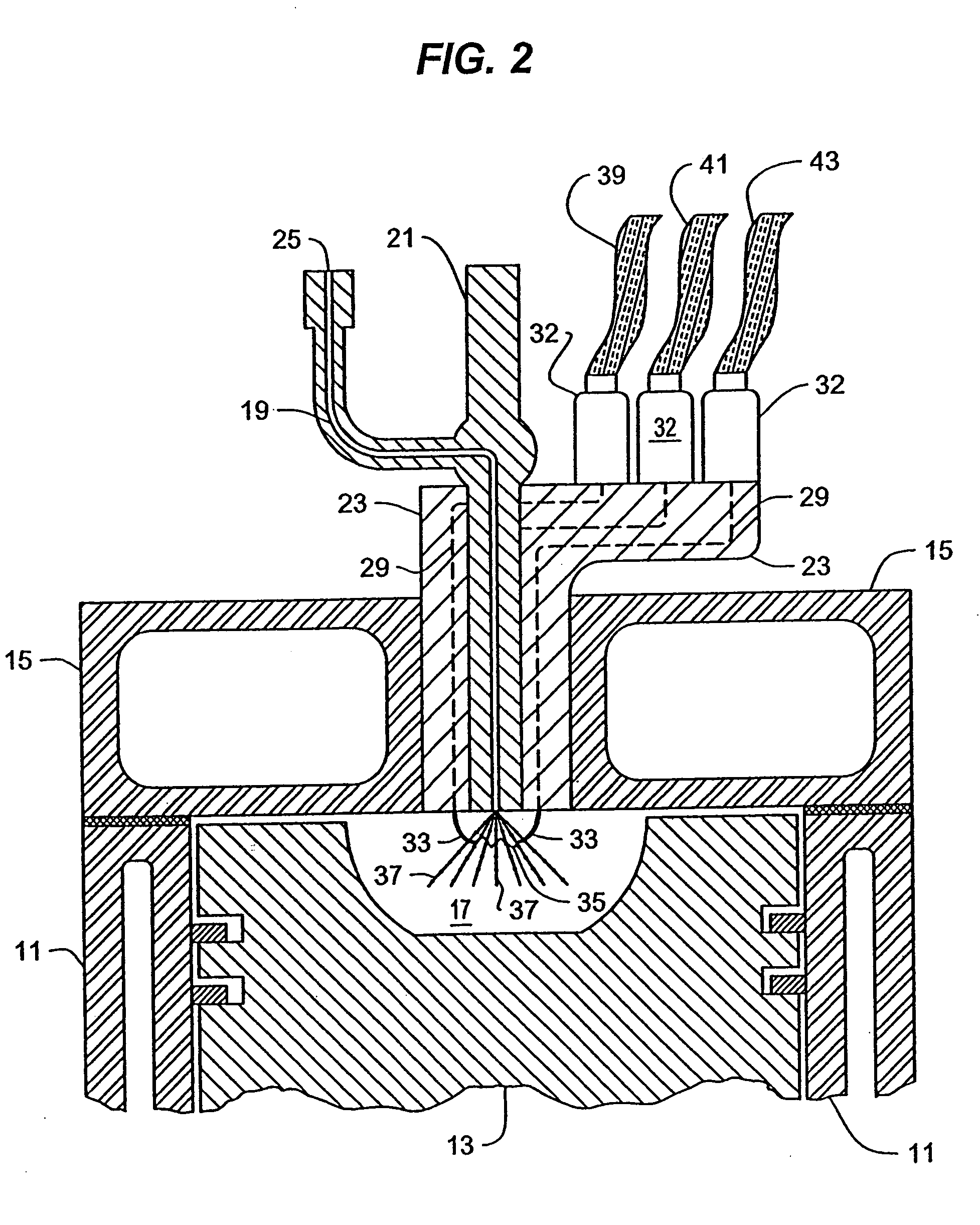

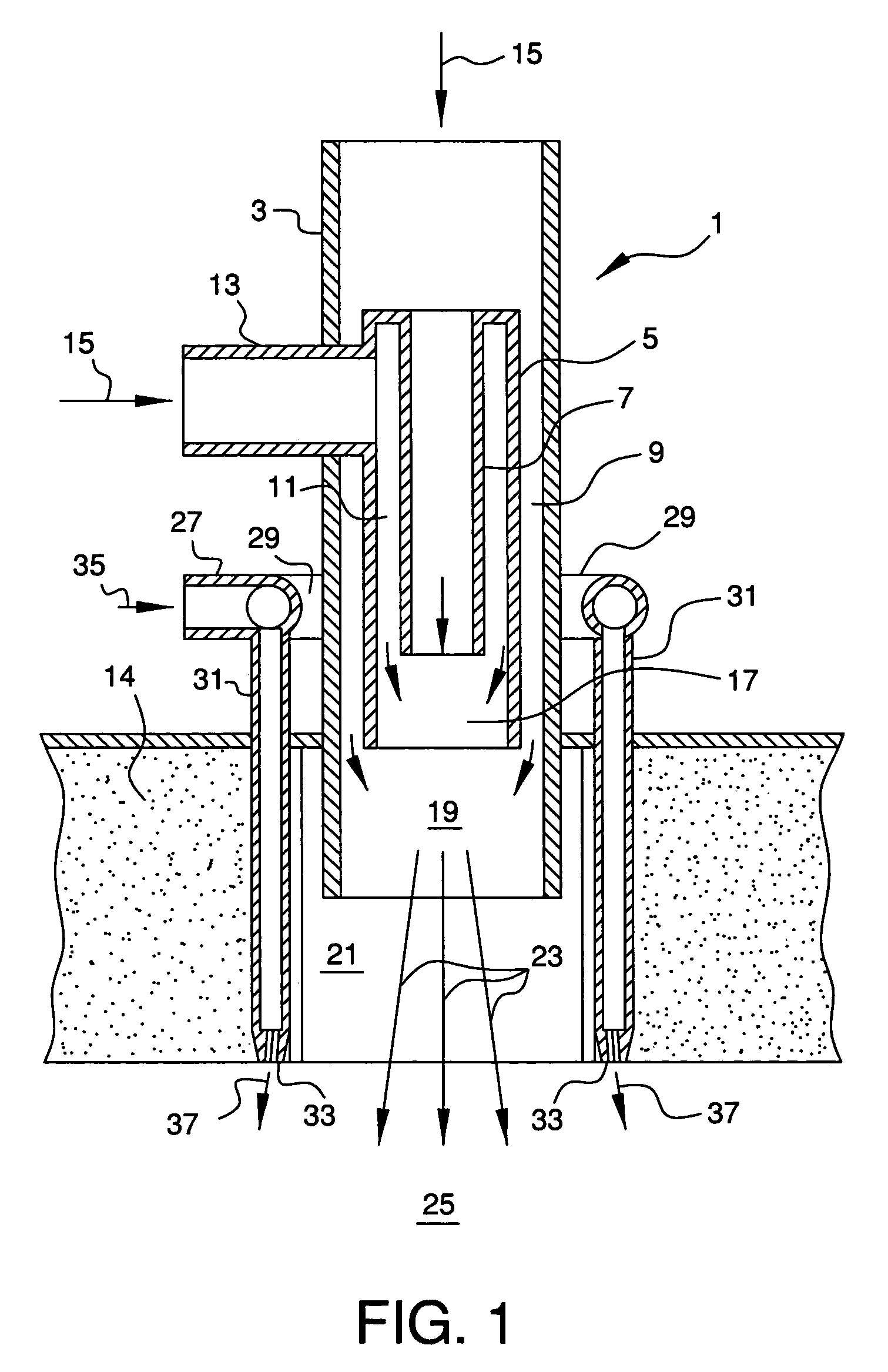

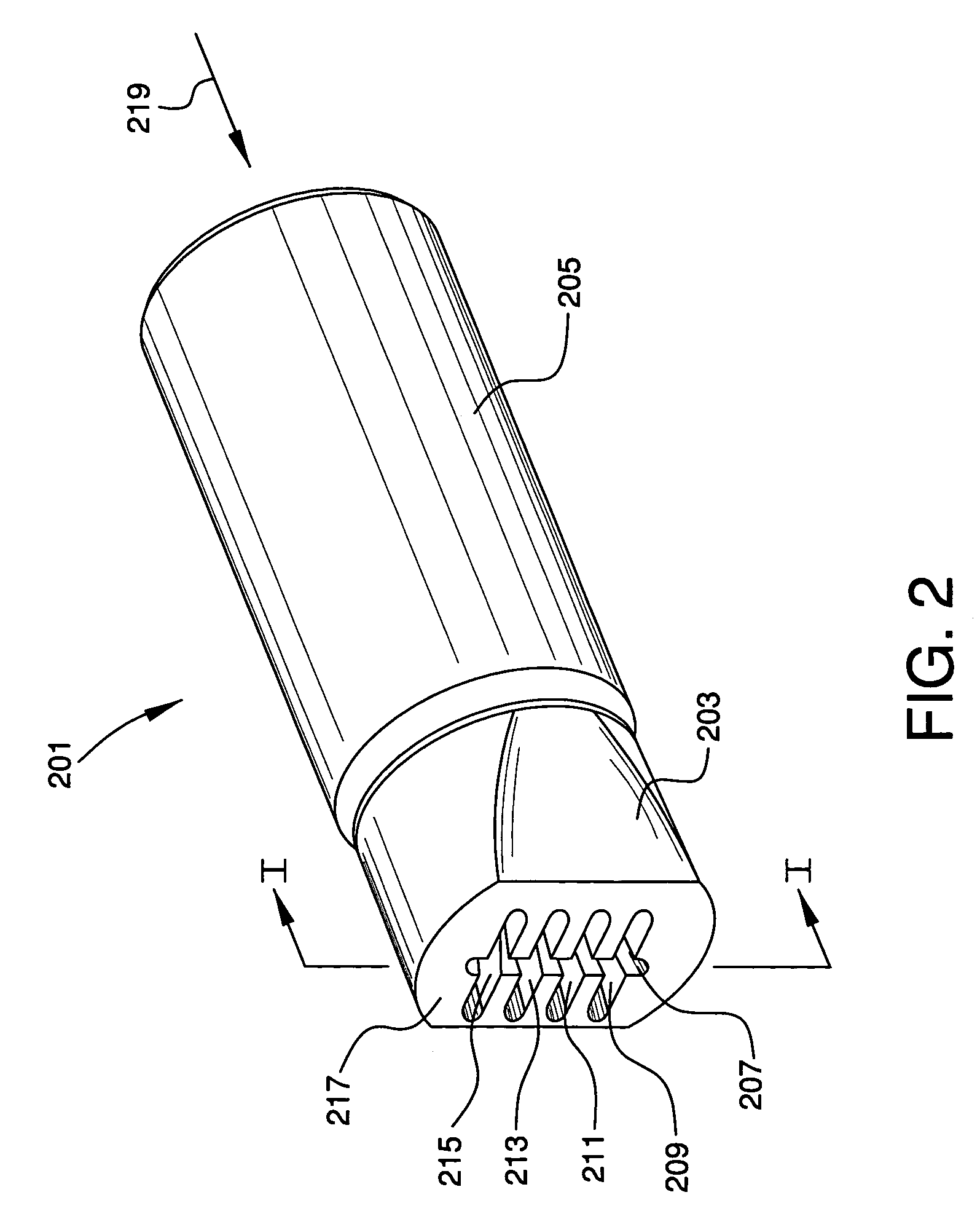

Combustors with impingement cooled igniters and igniter tubes for improved cooling of igniters

ActiveUS20090064657A1Continuous combustion chamberTurbine/propulsion engine coolingCombustorCombustion chamber

A combustor for a gas turbine engine is provided, and includes an inner liner; an outer liner circumscribing the inner liner and forming a combustion chamber with the inner liner; a fuel igniter comprising a tip portion configured to ignite an air and fuel mixture in the combustion chamber; and an igniter tube positioning the fuel igniter relative to the combustion chamber, the igniter tube having a plurality of channels configured to direct cooling air toward the tip portion of the fuel igniter.

Owner:HONEYWELL INT INC

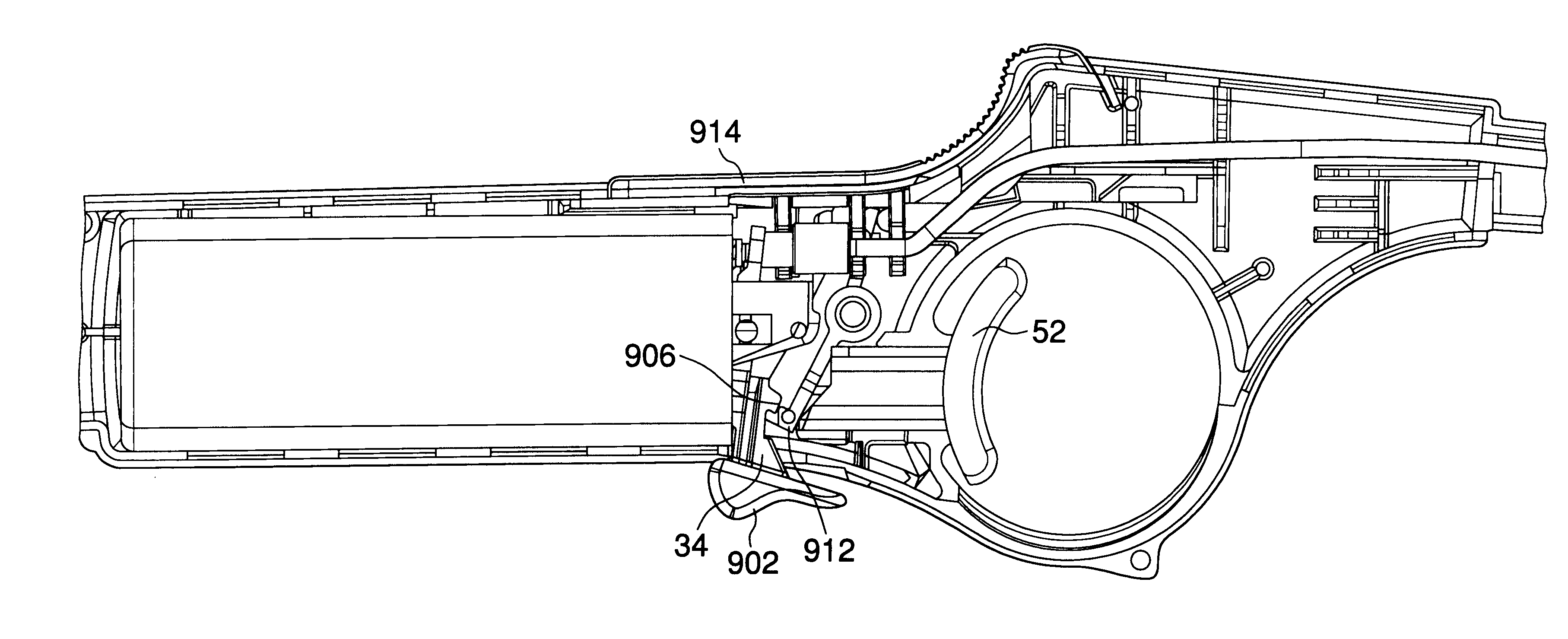

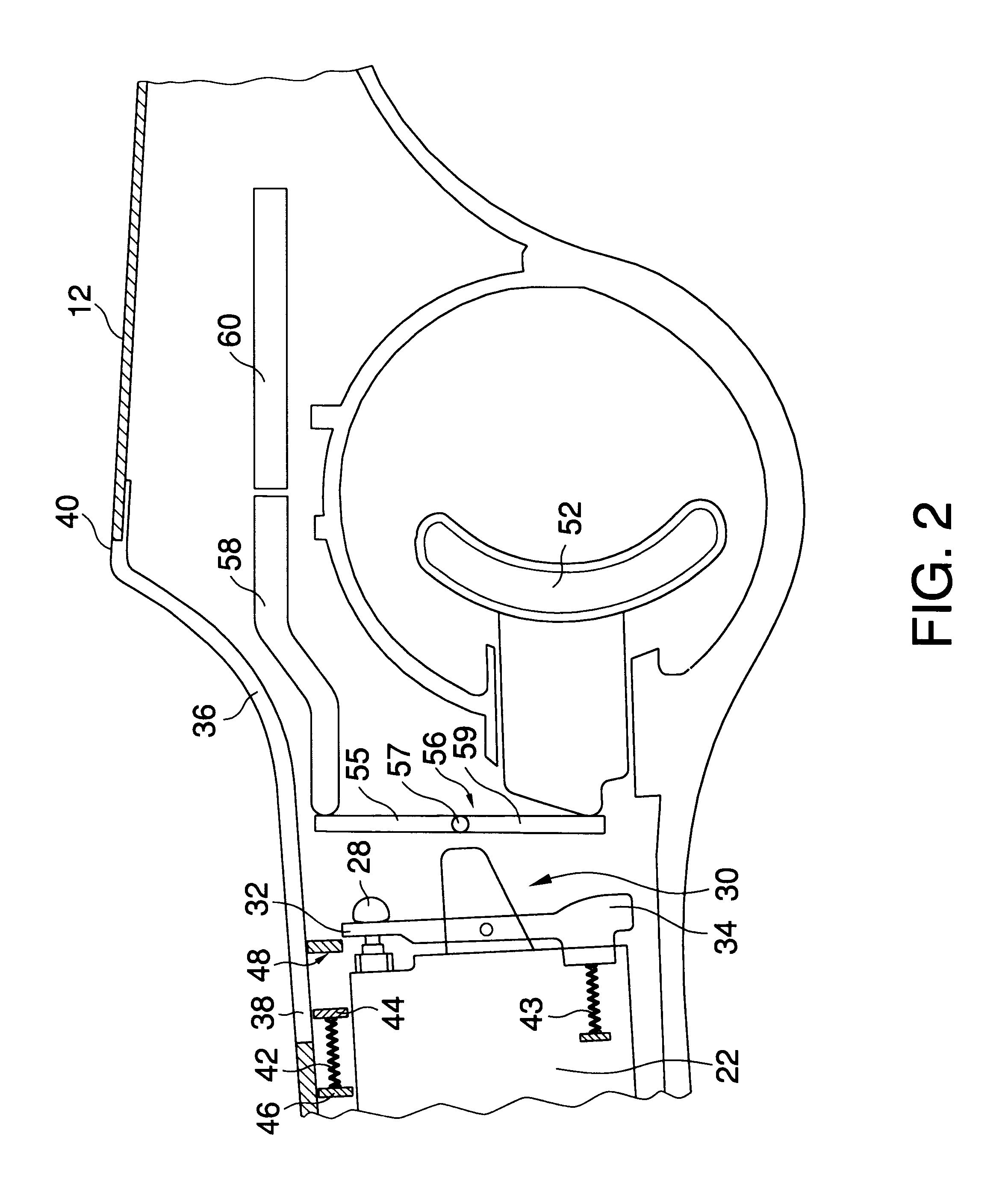

Utility lighter

The present invention relates to a lighter including a housing having a handle at one end and a nozzle at another end and including a fuel supply connected for selective fluid communication with the nozzle. A release member is cooperatively connected to the housing to initiate the flow of fuel from the fuel supply to the nozzle. An ignitor, such as a piezoelectric mechanism, is provided for generating a spark proximate the nozzle. A trigger spaced from the release member is operatively connected to the housing for actuating the ignitor for the generation of a spark igniting the fuel present at the nozzle.

Owner:SOC DITE SOC BIC

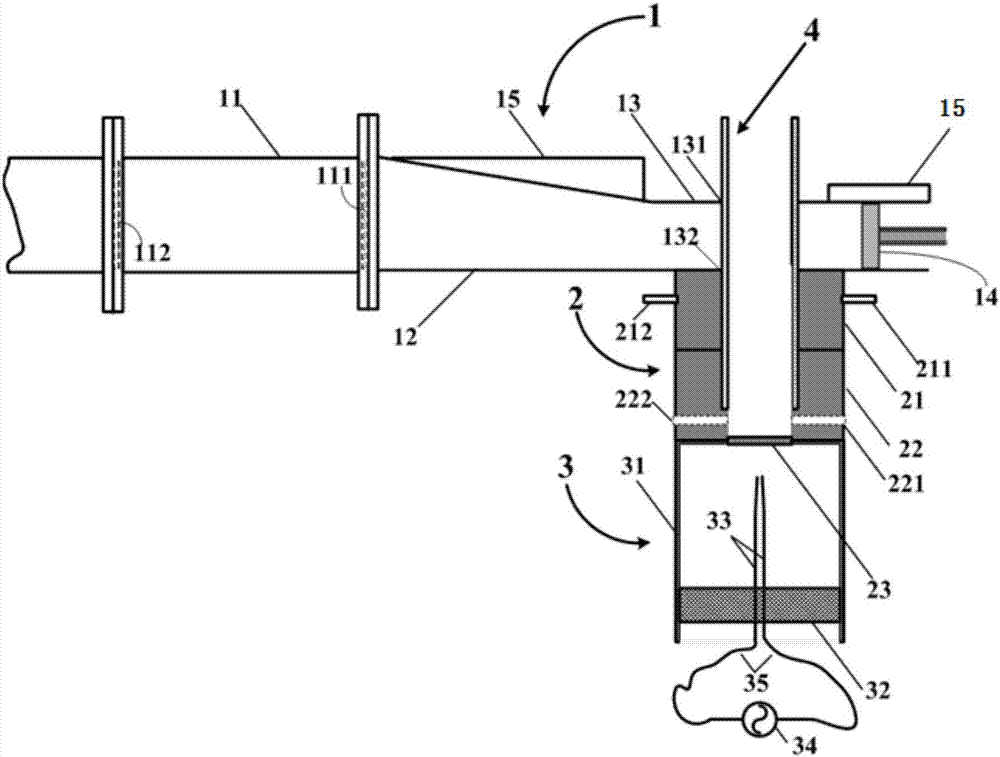

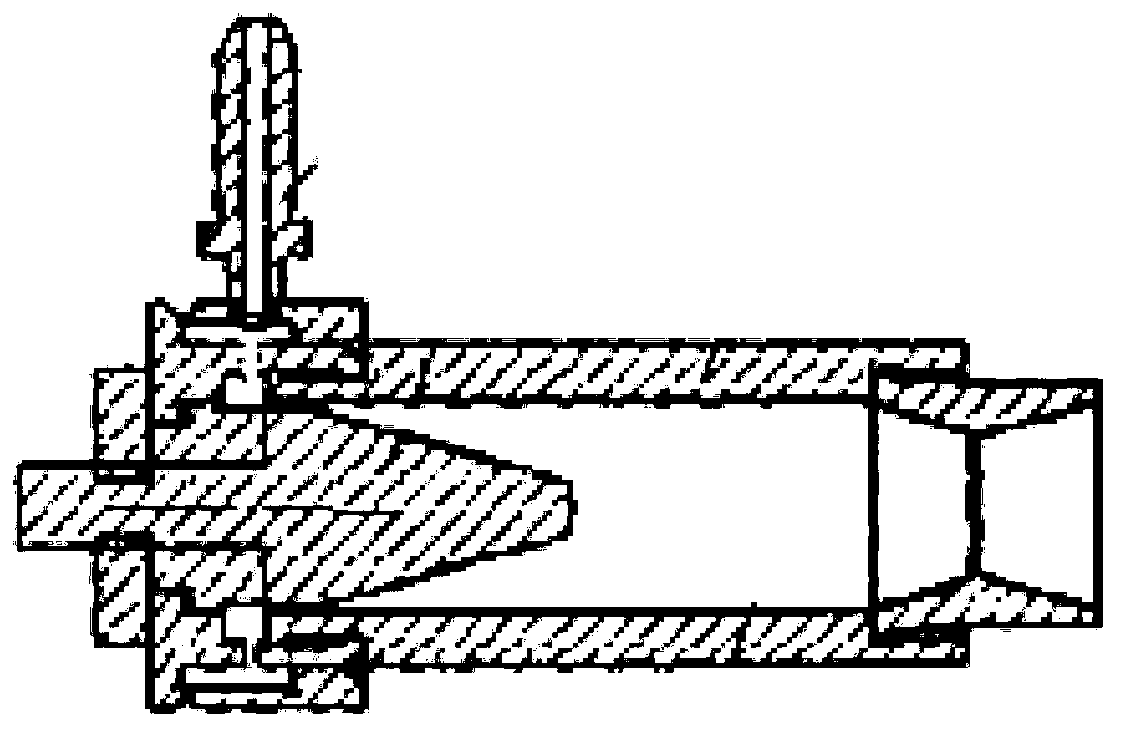

Aero-engine air rotational flow plasma igniter

InactiveCN103277231AHelps coolingGood for breakdownEngine ignitionMachines/enginesAviationCombustion chamber

Provided is an aero-engine air rotational flow plasma igniter. An insulating sleeve and a supporting sleeve are installed inside a shell, the insulating sleeve is arranged on one side of a separating plate inside the shell, the supporting sleeve is arranged inside the shell, and an air chamber is formed between the outer surface of the supporting sleeve and the inner surface of the shell. An anode sleeve is sleeved at one end, provided with the supporting sleeve, of the shell. A swirler is arranged inside the anode sleeve, and the end surface of the swirler makes contact with the end surface of the supporting sleeve. A cathode installation base is arranged inside the insulating sleeve, and the end surface of the cathode installation base makes contact with a cathode binding post in a coaxial cable. The external thread end of a cathode is fixed inside the cathode installation base and sequentially penetrates through the supporting sleeve and the swirler from top to bottom, and the arc end of the cathode extends out of the lower end surface of the swirler. The aero-engine air rotational flow plasma igniter does not change the structure and the position of an electric spark igniter originally installed in an engine combustor, penetrates through the outer duct of an engine, is installed on the outer wall of the combustor vertically, improves reliability of products, and has the advantages of being small in size, light in weight, simple in structure, and convenient to use and maintain.

Owner:AIR FORCE UNIV PLA

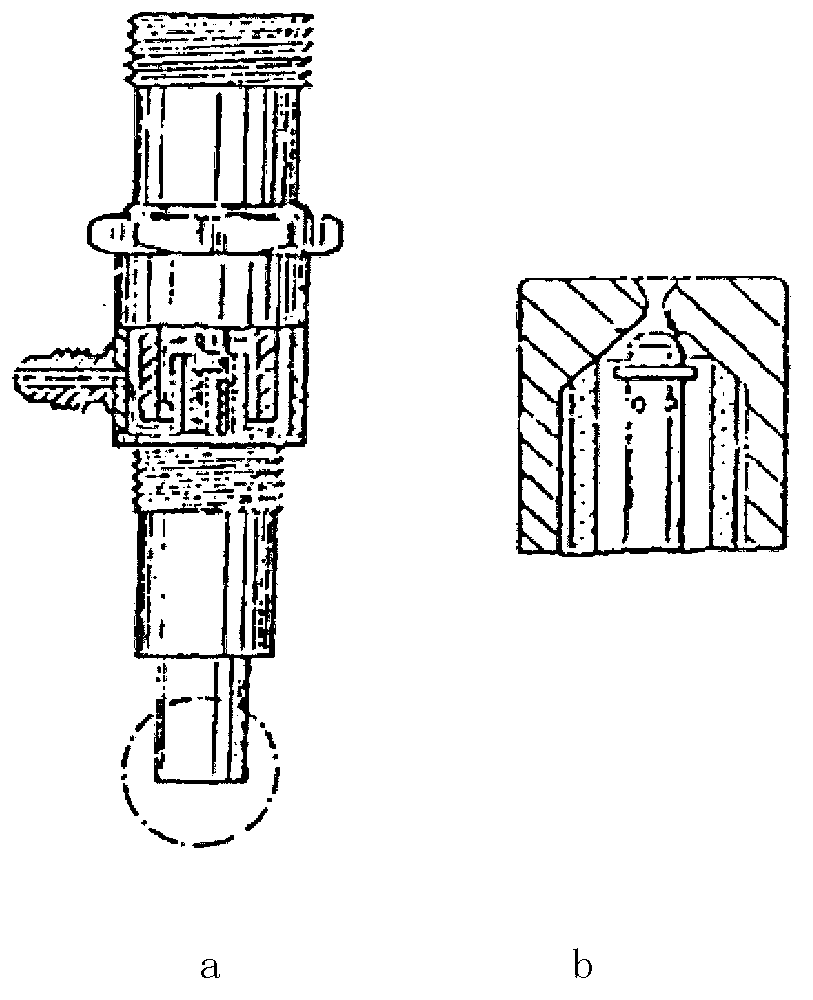

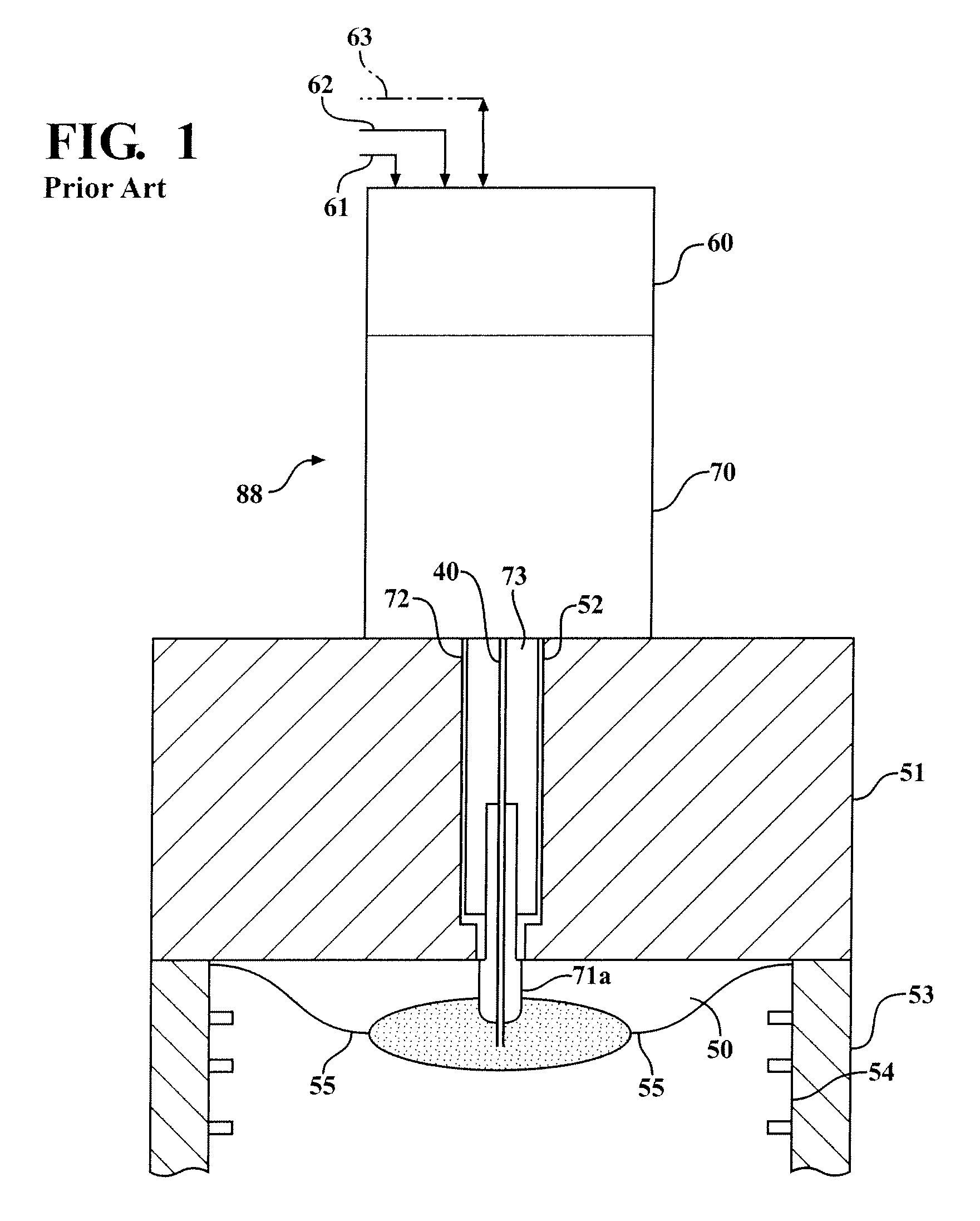

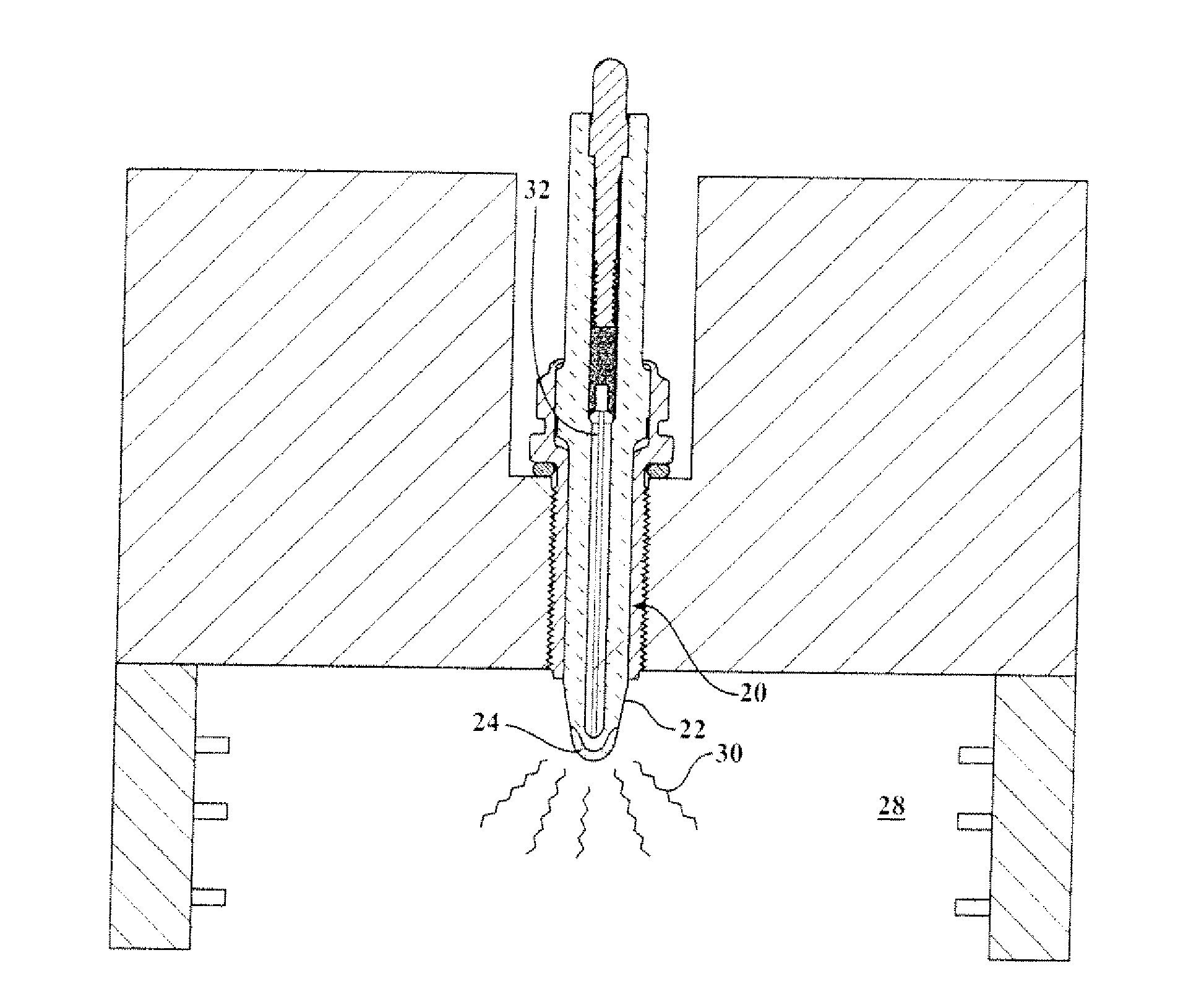

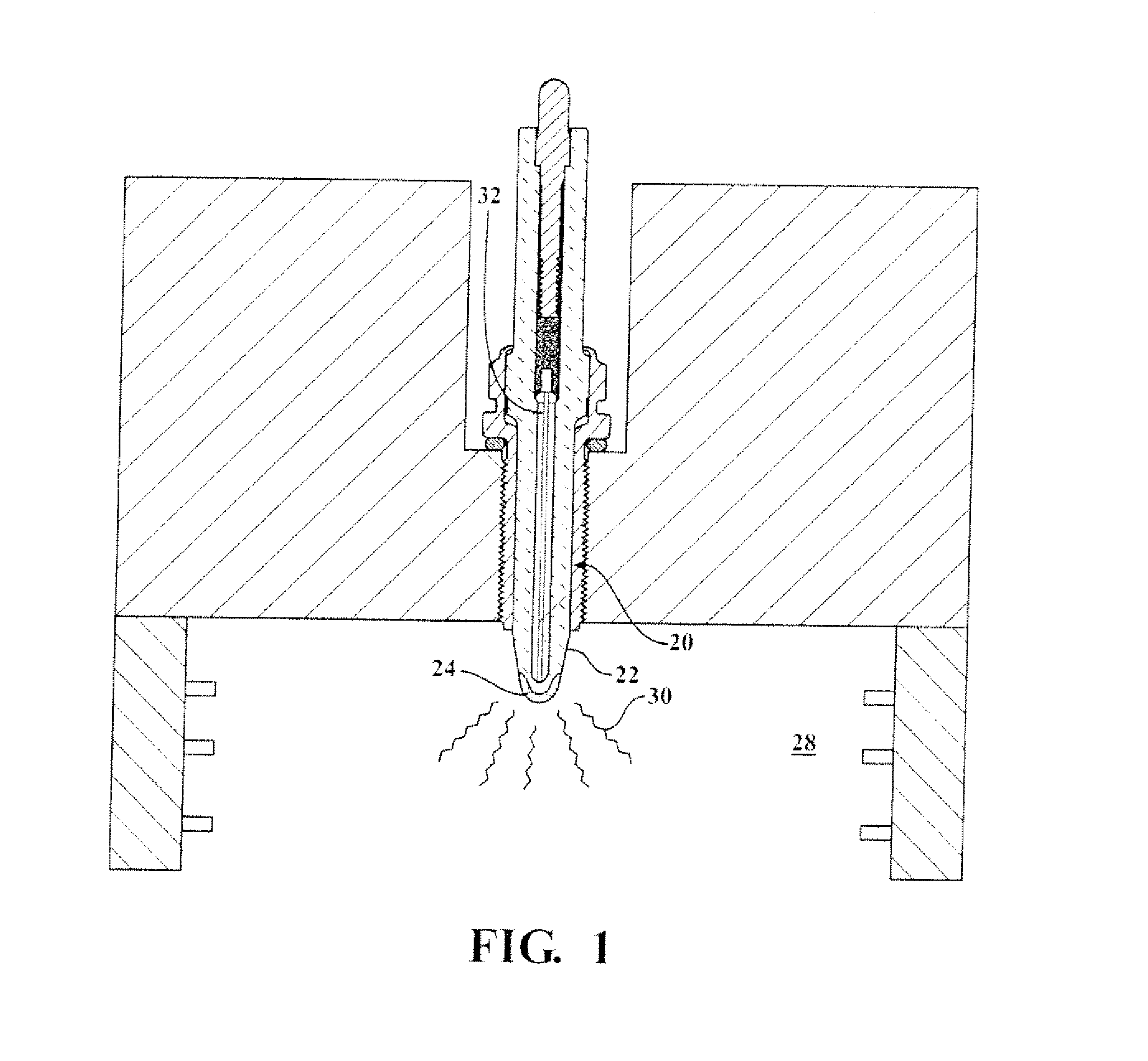

Exothermic welding

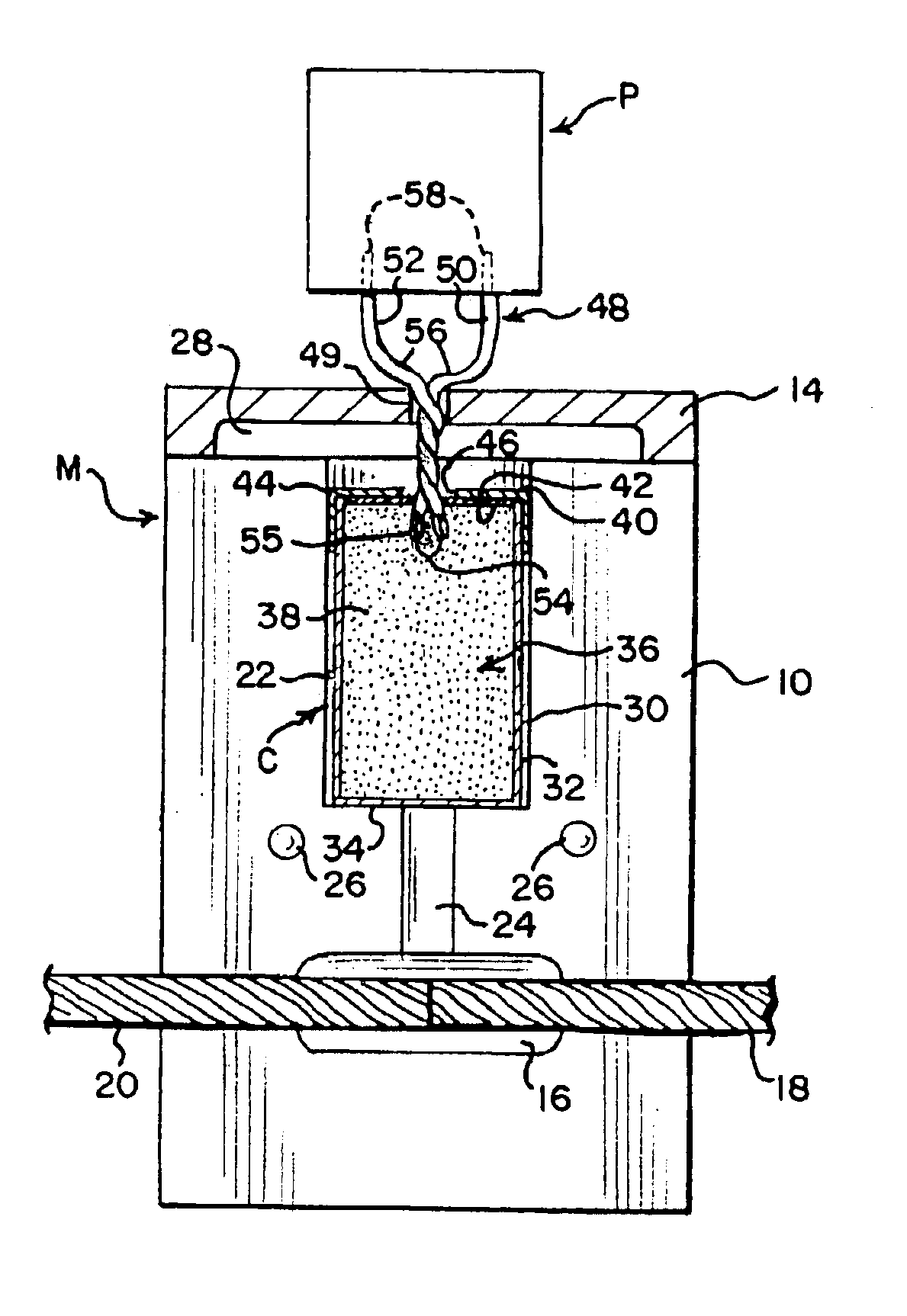

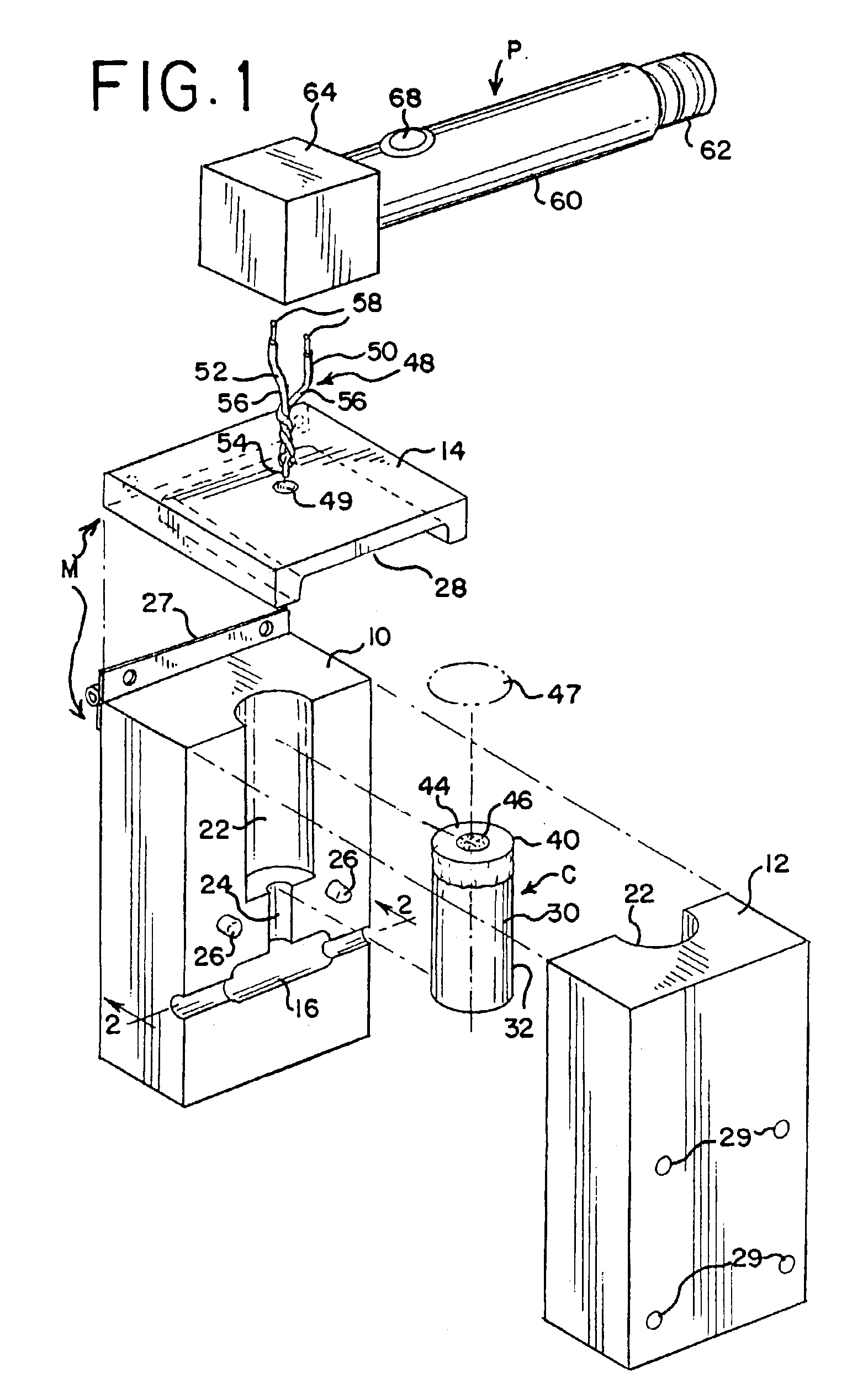

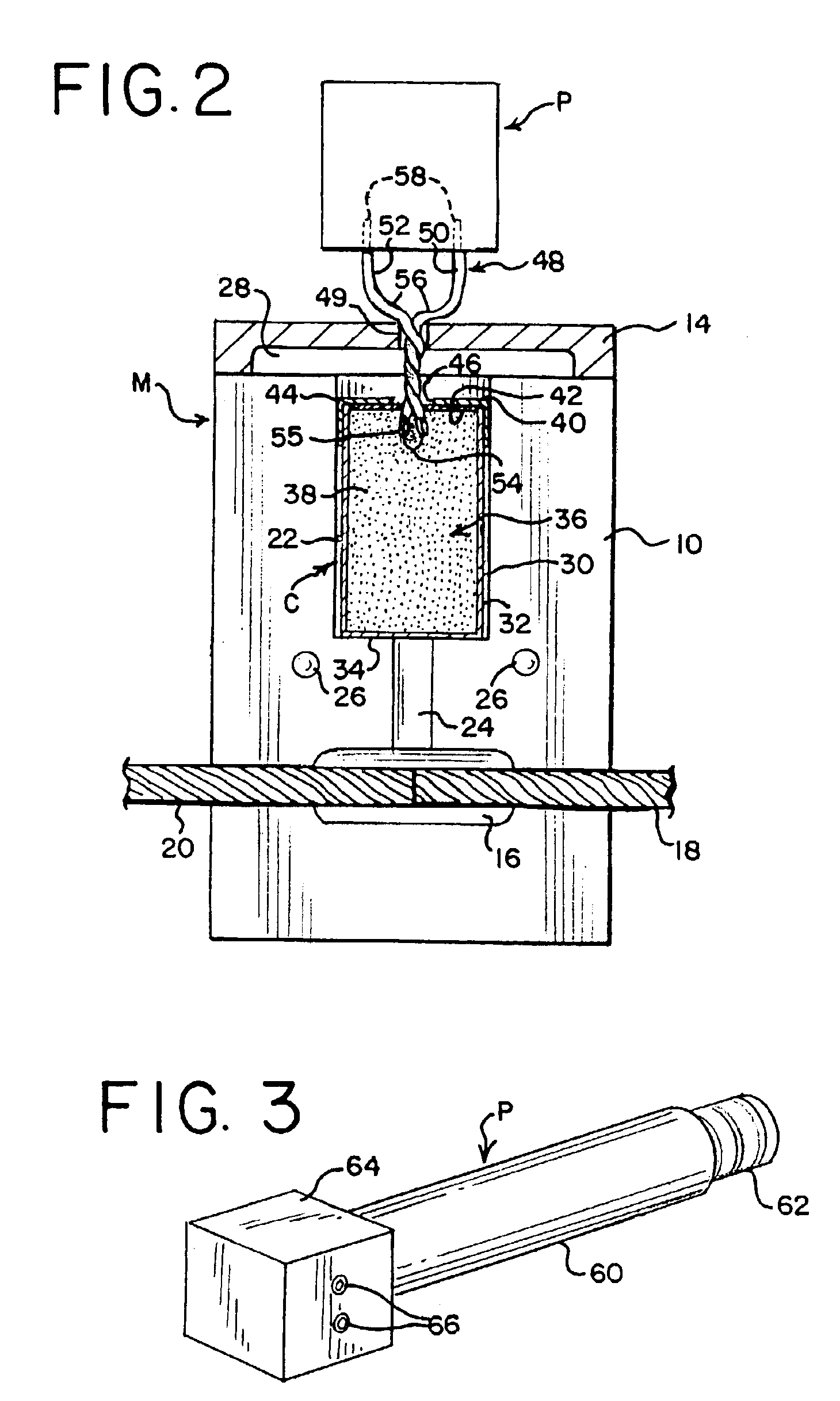

ActiveUS6994244B2Eliminate needImprove the immunityWelding/soldering/cutting articlesMetal working apparatusExothermic weldingEngineering

An assembly and method are disclosed for exothermic welding including a mold which is formed of a material which withstands exothermic welding temperatures, and includes a weld cavity therein for positioning at least two members which are to be exothermically welded together adjacent to each other, and an ignition cavity communicating with the first cavity. The members which are to be exothermically welded together are positioned adjacent to each other using the weld cavity, and a weld metal cartridge is positioned in the ignition cavity. The cartridge comprises a container having copper walls which define a chamber therein, and a particulate weld metal in the chamber. The tip of an electrical igniter is positioned into the chamber of the container and particulate weld material therein, the igniter is electrically fired while the container is in the ignition cavity of the mold to melt the particulate weld material, and the contents of the ignition cavity are passed after melting the particulate weld metal to the weld cavity to weld the members together.

Owner:HARGER

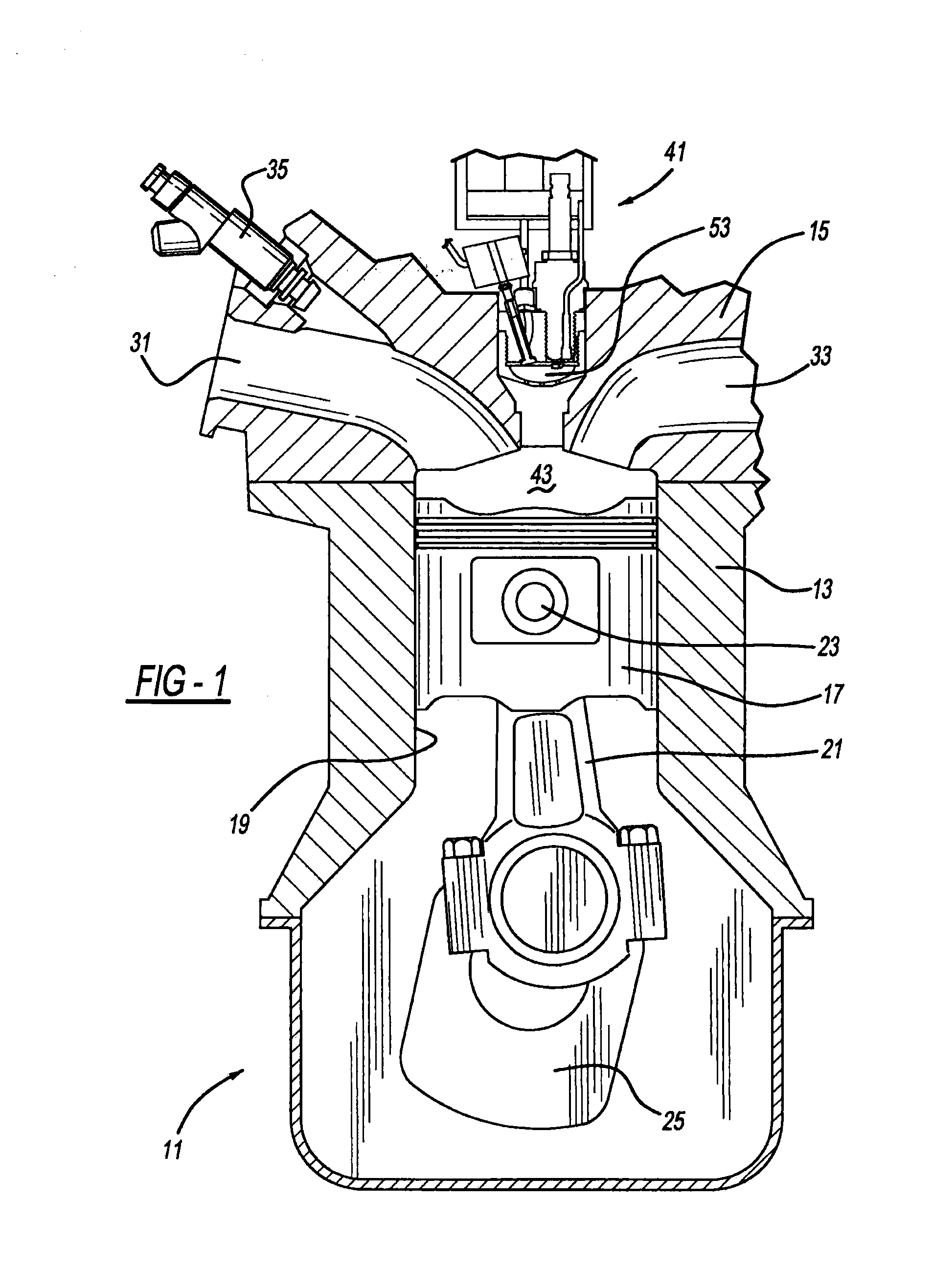

Internal combustion engine

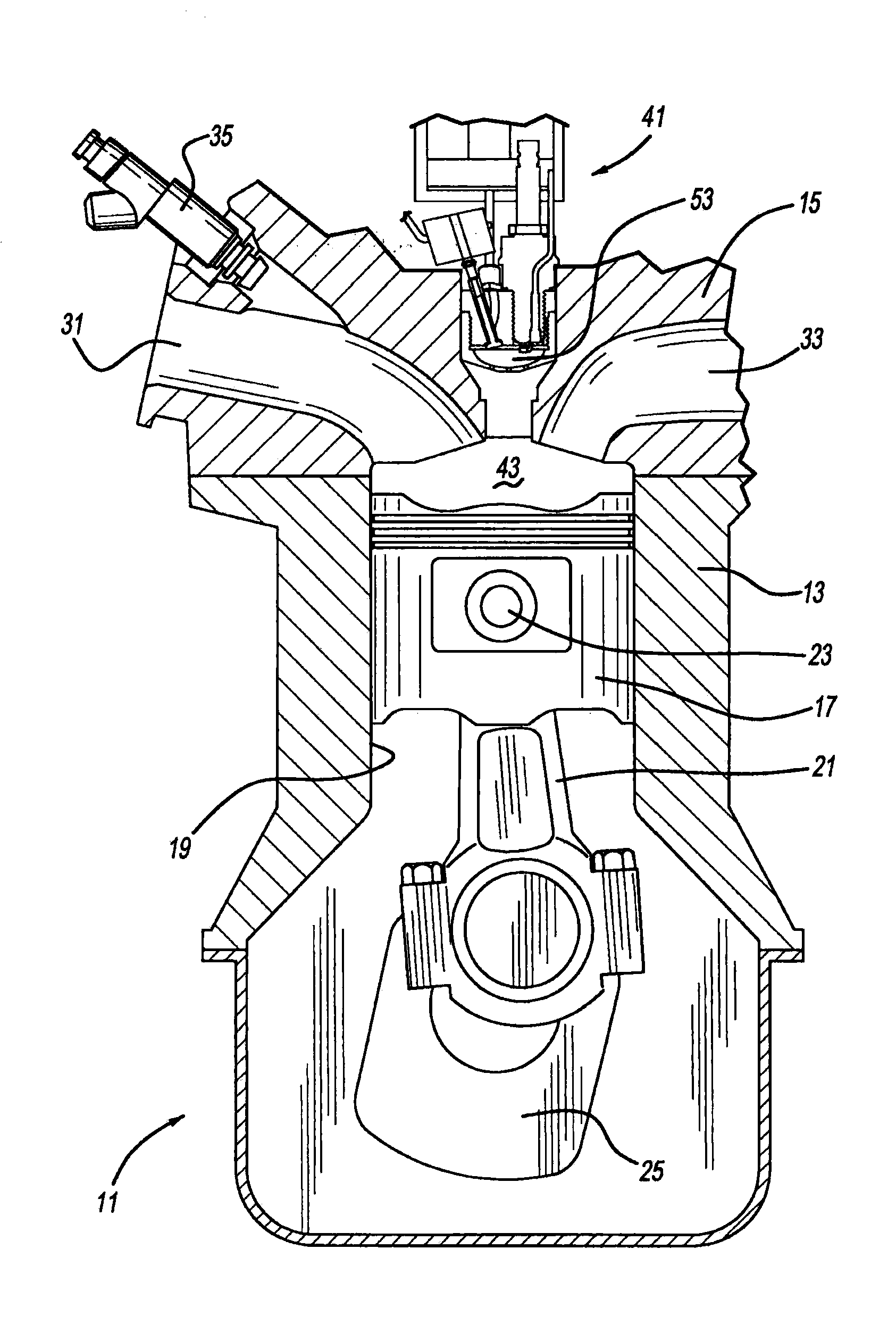

InactiveUS20140144406A1Reduce nitrogen oxide emissionsImprove fuel efficiencyInternal combustion piston enginesCombustion chamberValve actuator

An internal combustion engine includes a pre-chamber. In another aspect, pressure within a pre-chamber is equal to or greater than pressure within a main combustion chamber at least prior to ignition in the main combustion chamber. A further aspect provides a supplemental piston creating pressure and supplying a fuel-air mixture into a pre-chamber, and a spark or glow plug has an end located within the pre-chamber for ignition of the mixture therein. In yet another aspect, internal combustion engine control software automatically controls pressure within a turbulent jet ignition pre-chamber, controls a valve-actuator to admit a fuel-air charge into the pre-chamber, and causes an ignitor to initiate combustion in the pressurized pre-chamber.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

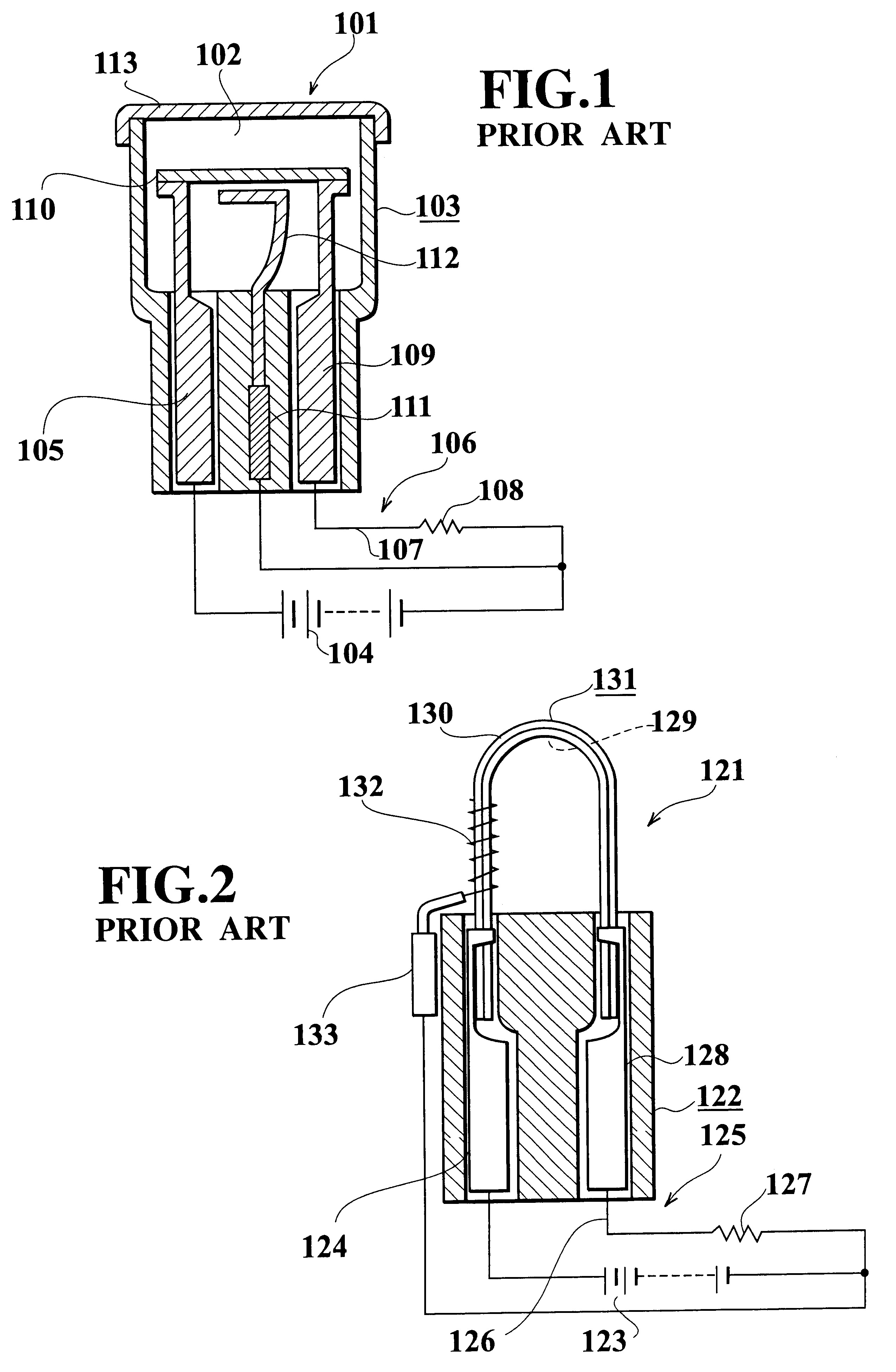

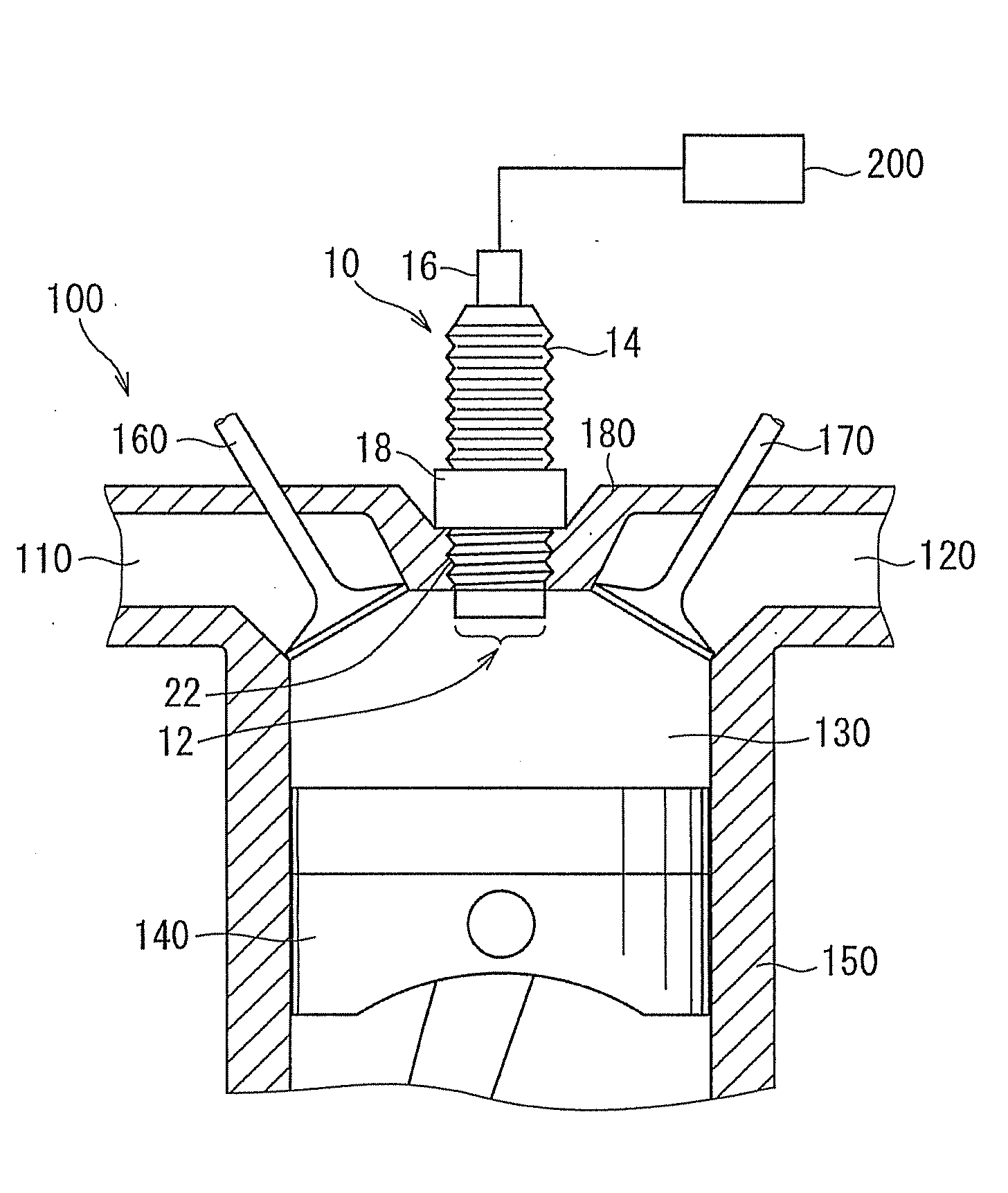

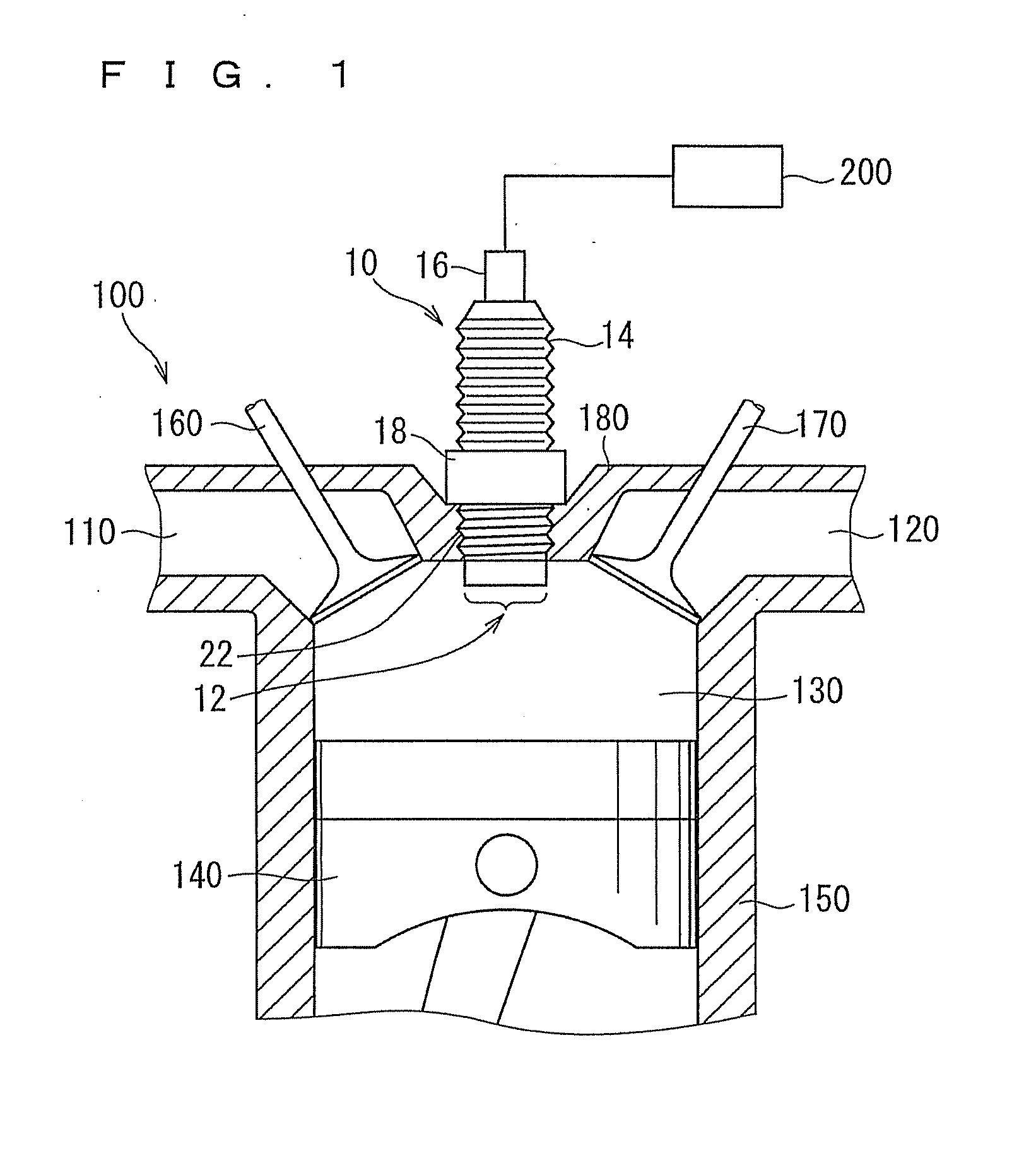

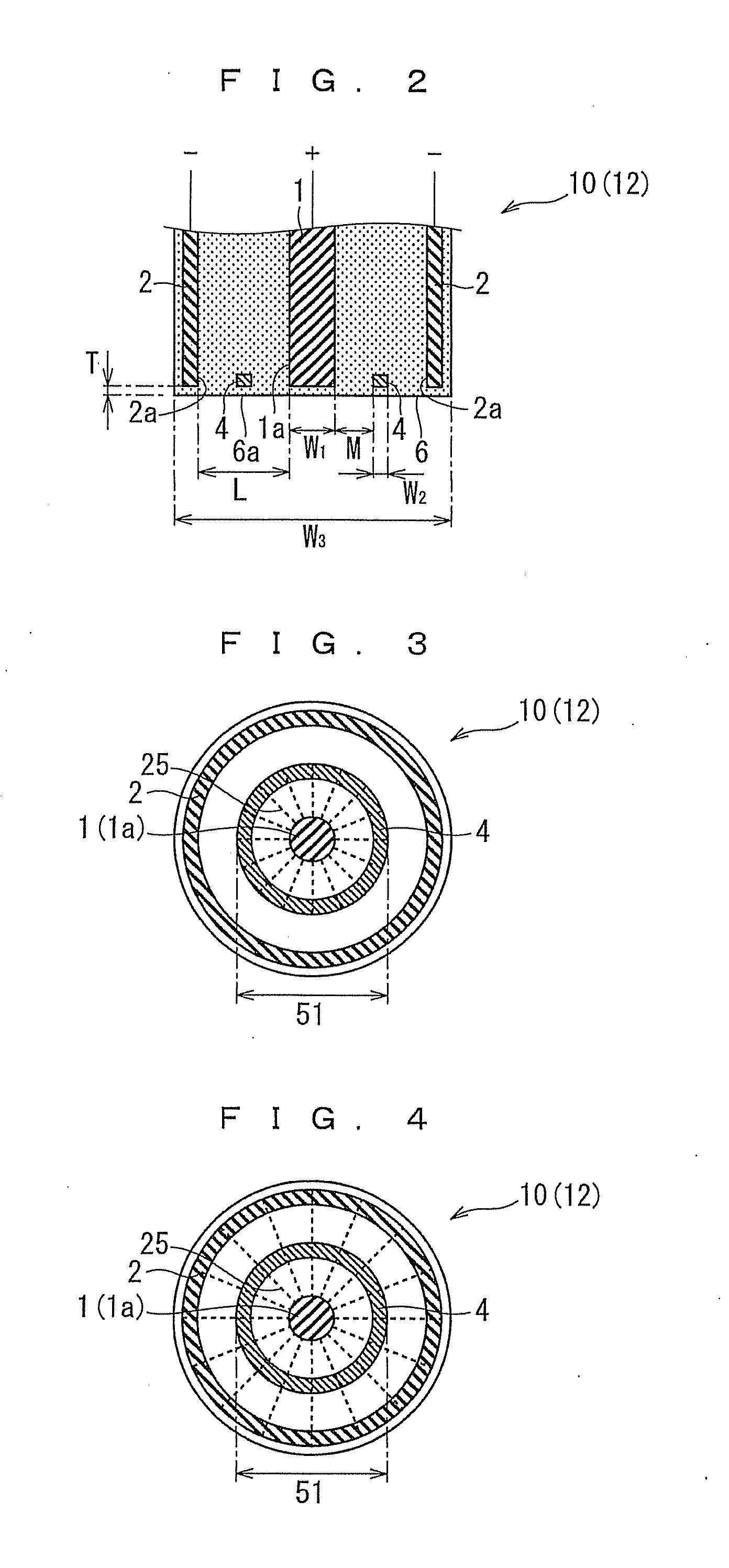

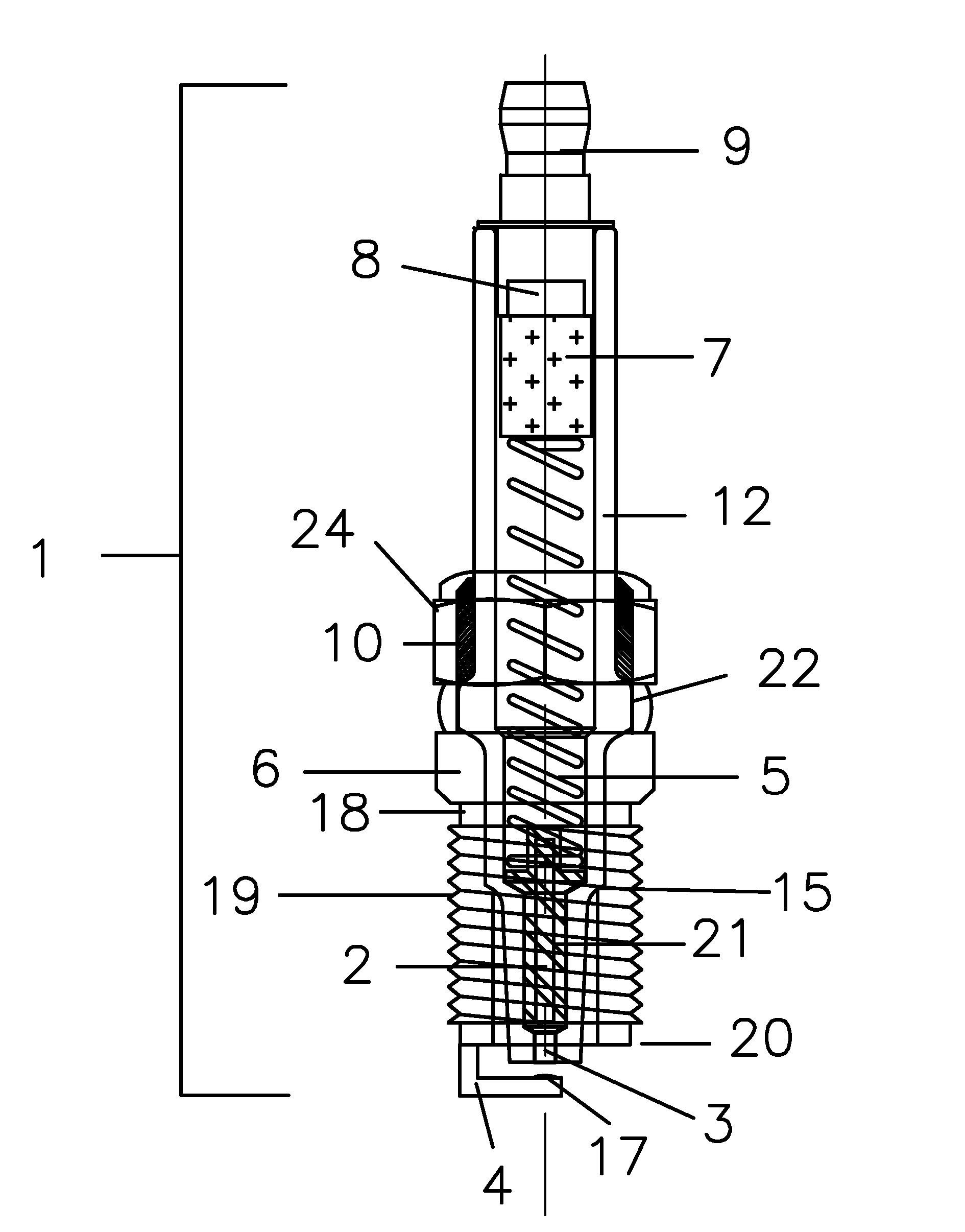

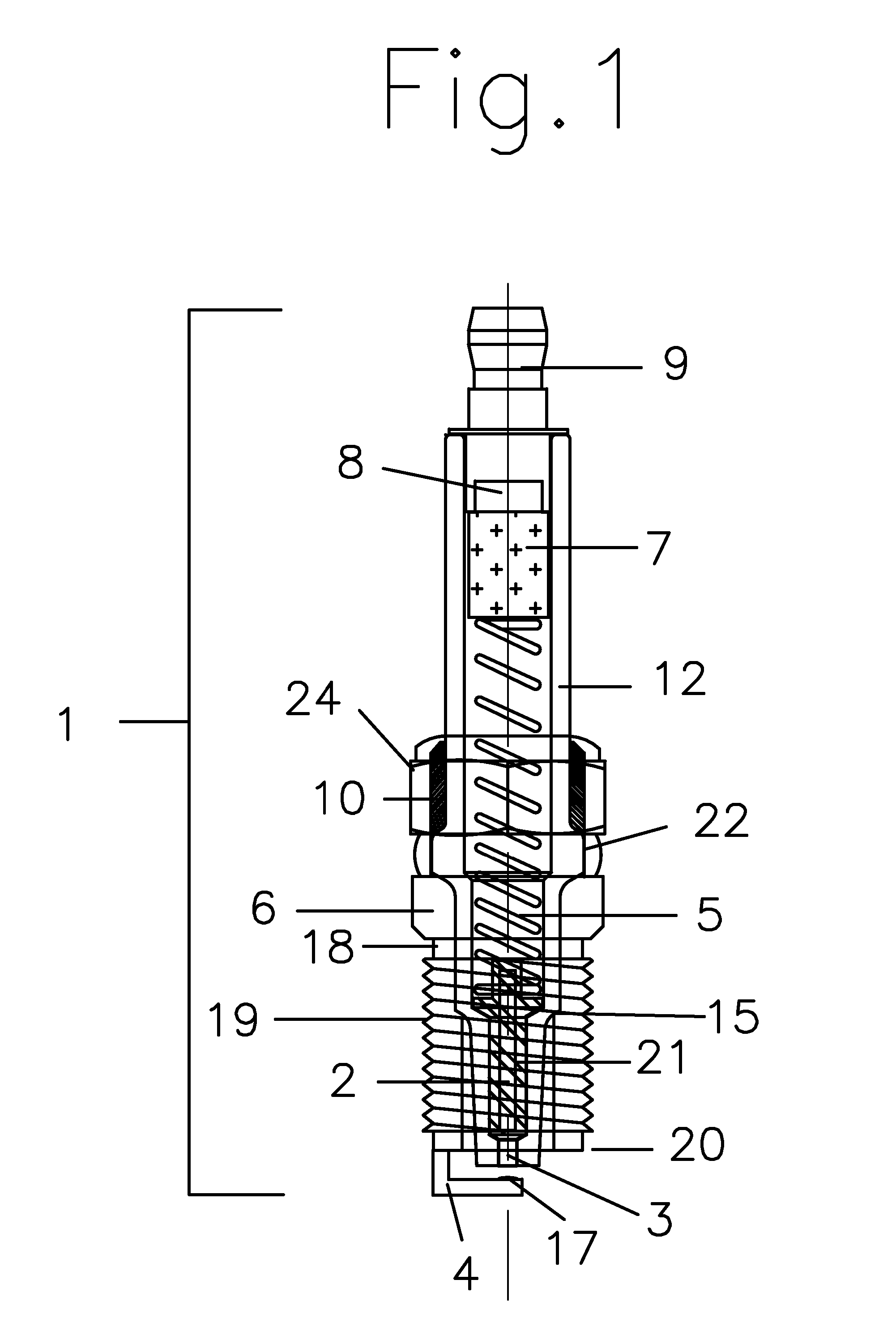

Plasma igniter and ignition device for internal combustion engine

InactiveUS20100212620A1Reduced areaLow degreeSparking plugsCombustion enginesCombustion chamberLow voltage

To provide a plasma igniter capable of generating a discharge such as a pulse streamer discharge in a large region even by application of a low voltage, implementing powerful ignition by pulse voltage application in two or more stages, improving an air-fuel ratio (A / F), and reducing a CO2 emission amount.A plasma igniter includes an igniter part having a combustion chamber, and a discharge part arranged in such a manner that its discharge tip end is exposed to the combustion chamber. The discharge tip end has a column-shaped anode, an annular cathode arranged to be a predetermined interval away from an anode tip end part, and an annular floating electrode arranged between the anode tip end part and the cathode.

Owner:NGK INSULATORS LTD

Corona tip insulator

This invention relates to a corona discharge ignitor used to ignite air / fuel mixtures in automotive applications and the like. To suppress an arc from forming when a voltage is applied to the ignitor, the corona discharge ignitor has various shapes and configurations, such as angular depressions or grooves, at the tip of the insulator. The shape and configuration of the tip provides a smaller radius which creates a more intensified electric field and provides better combustion.

Owner:TENNECO INC

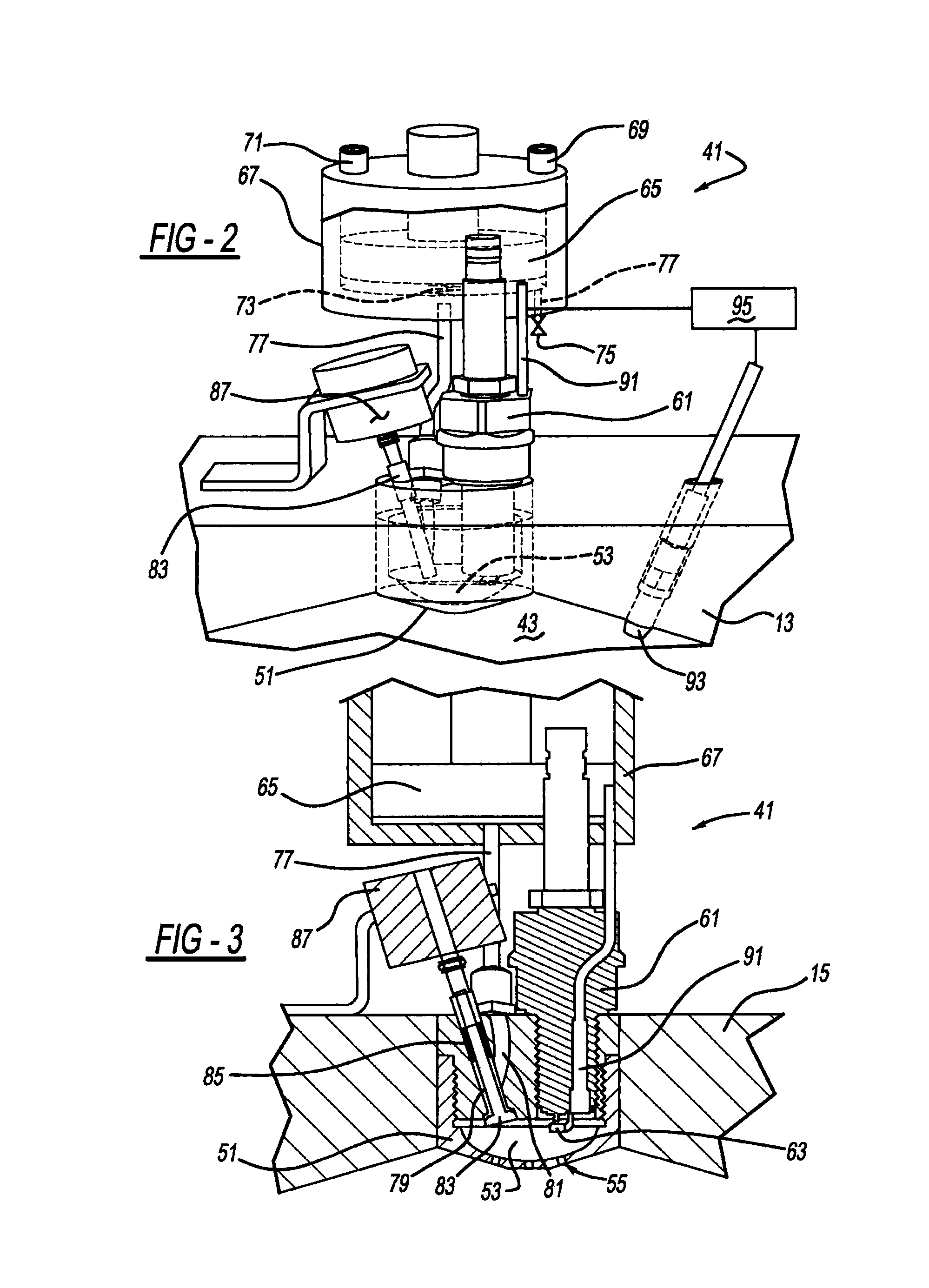

Integral spark detector in fitting which supports igniter in gas turbine engine

InactiveUS20050175491A1Positive displacement pump componentsElectric ignition installationGas turbinesCurrent pulse

A system for detecting spark in an igniter for a gas turbine engine. An igniter generates a plasma, or spark, somewhat similar to an automotive spark plug. In the invention, an inductive pick-up is positioned adjacent the igniter, to detect current pulses in the igniter, to thereby infer the presence of spark. The pick-up can take the form of a coil embedded in a mounting bracket which is used to fasten the igniter to the engine.

Owner:GENERAL ELECTRIC CO

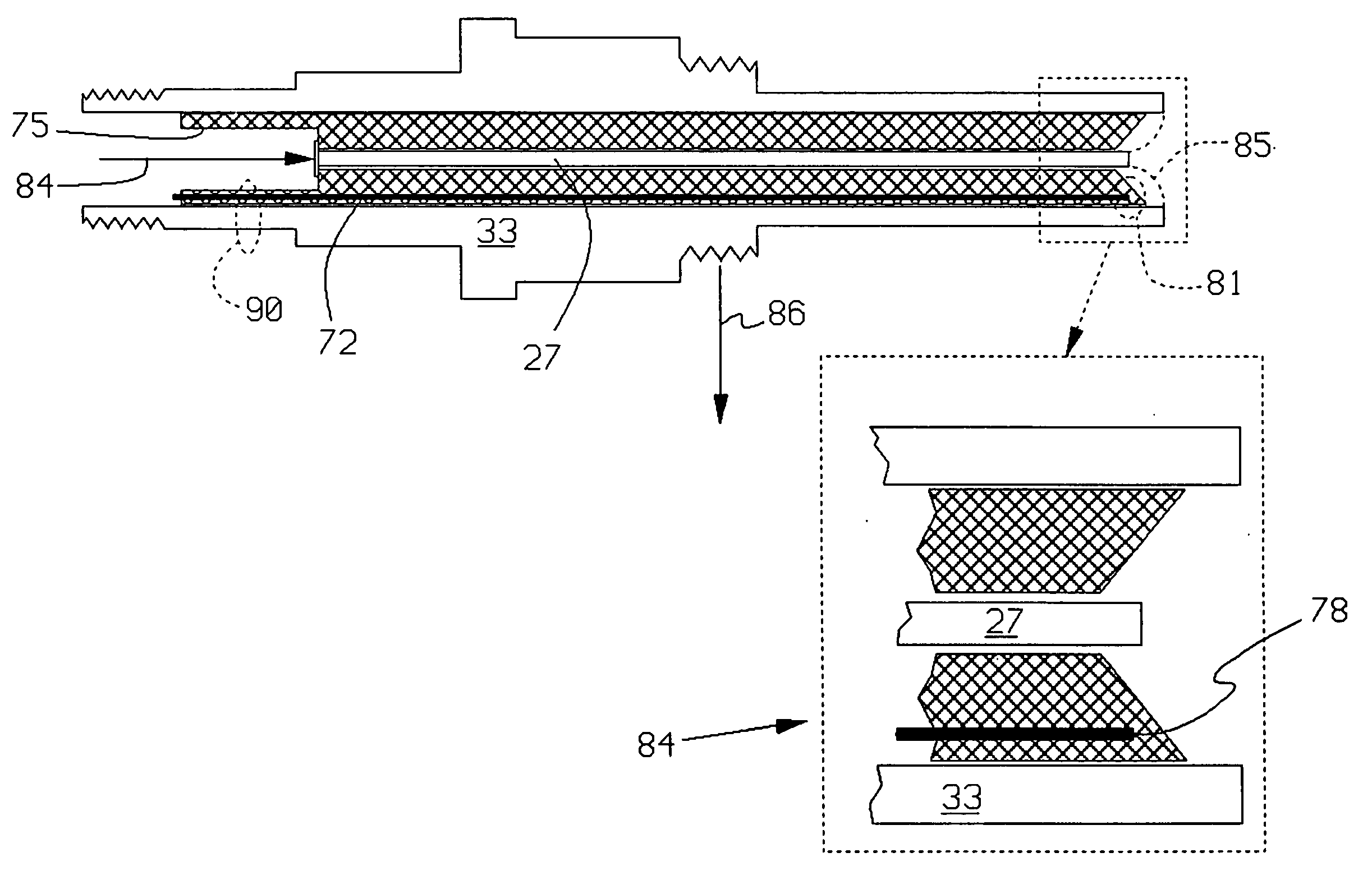

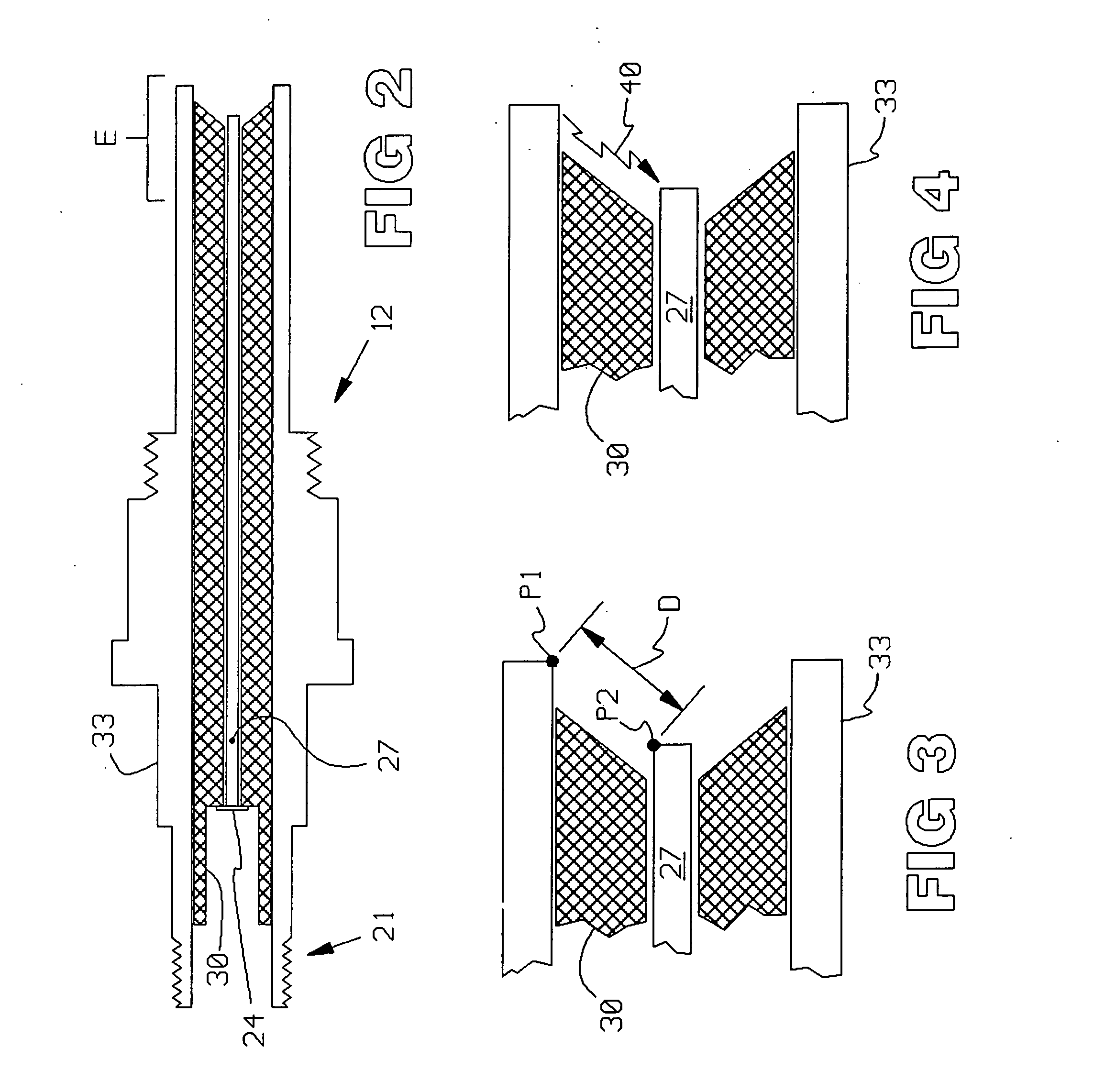

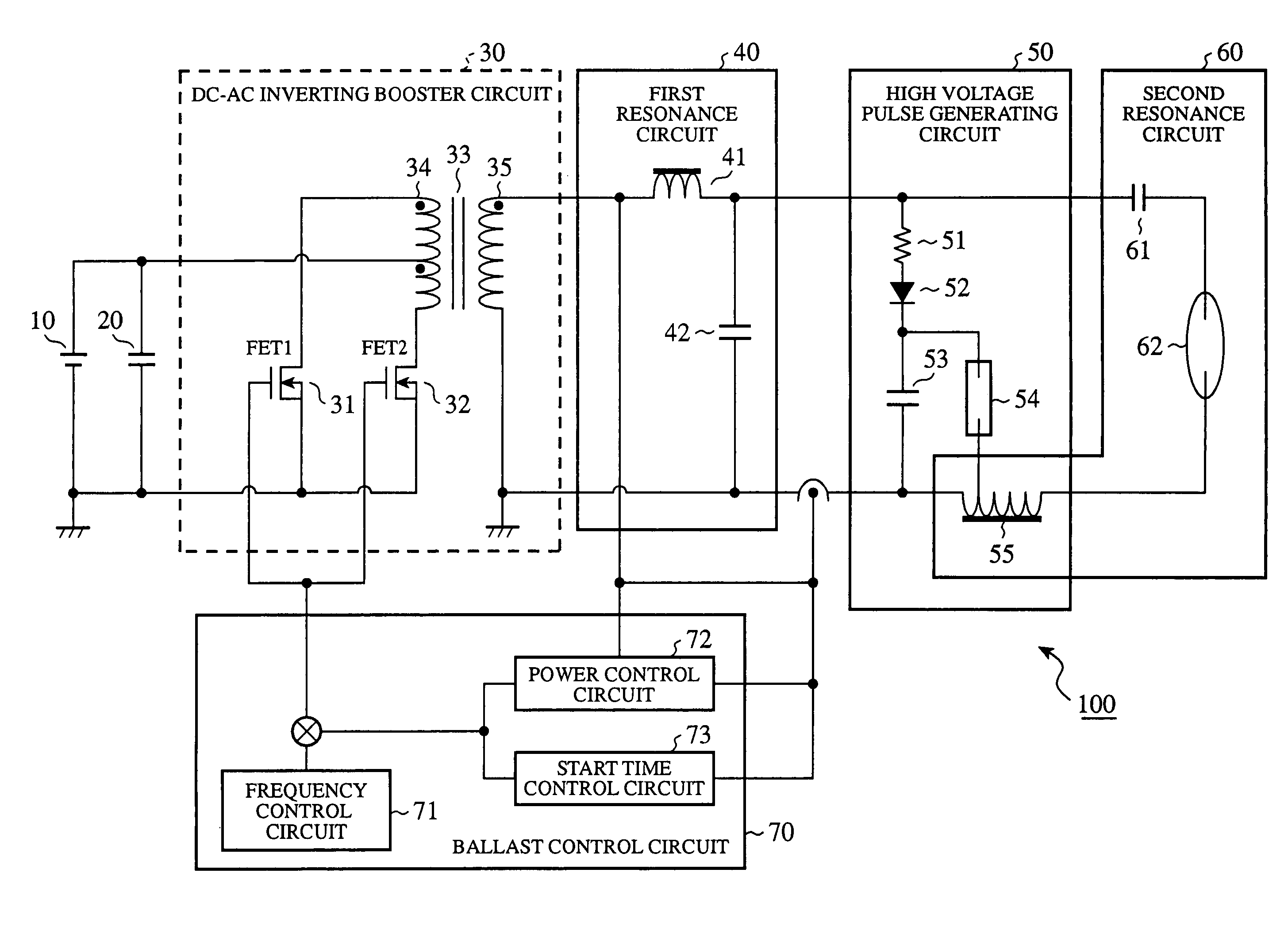

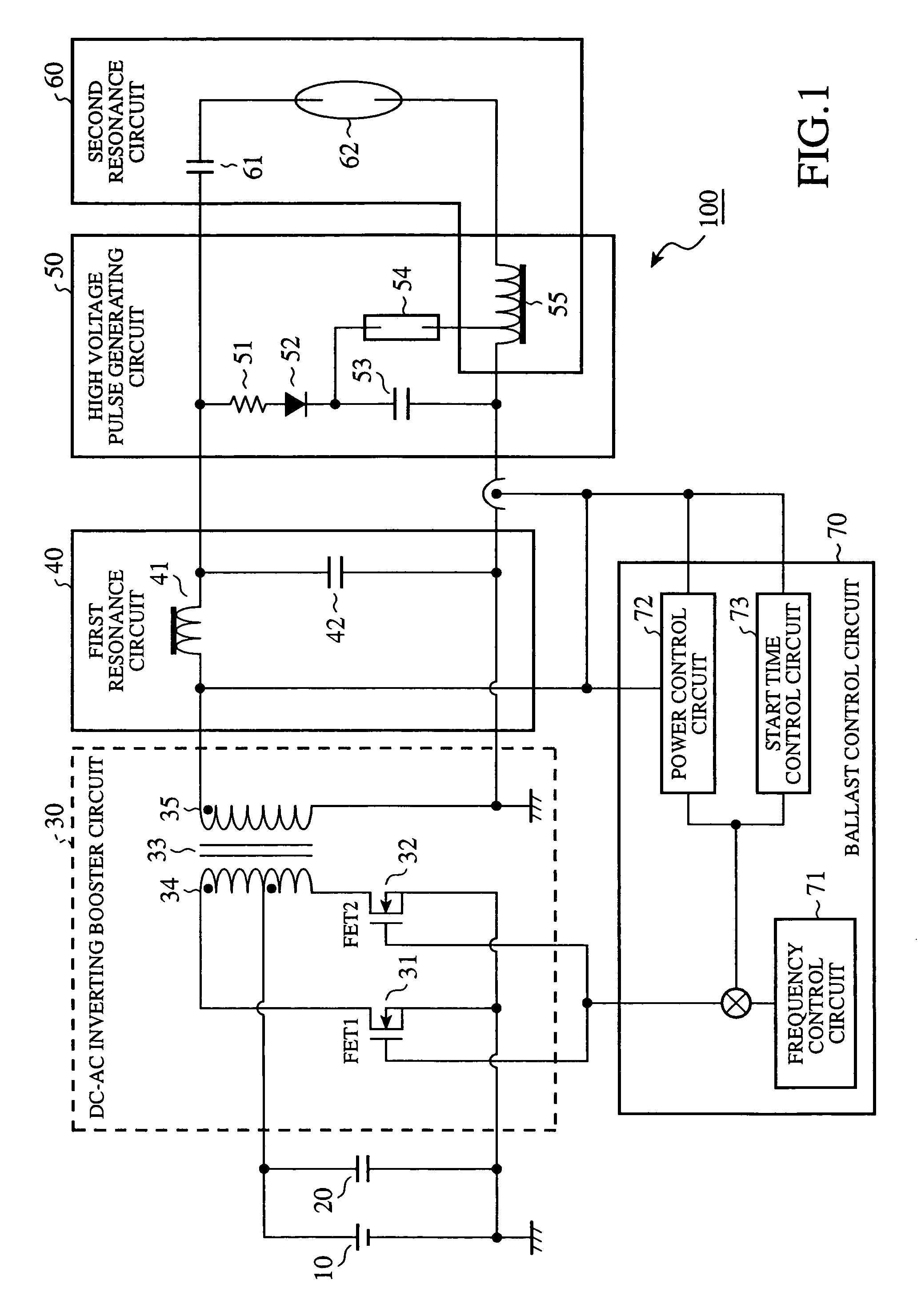

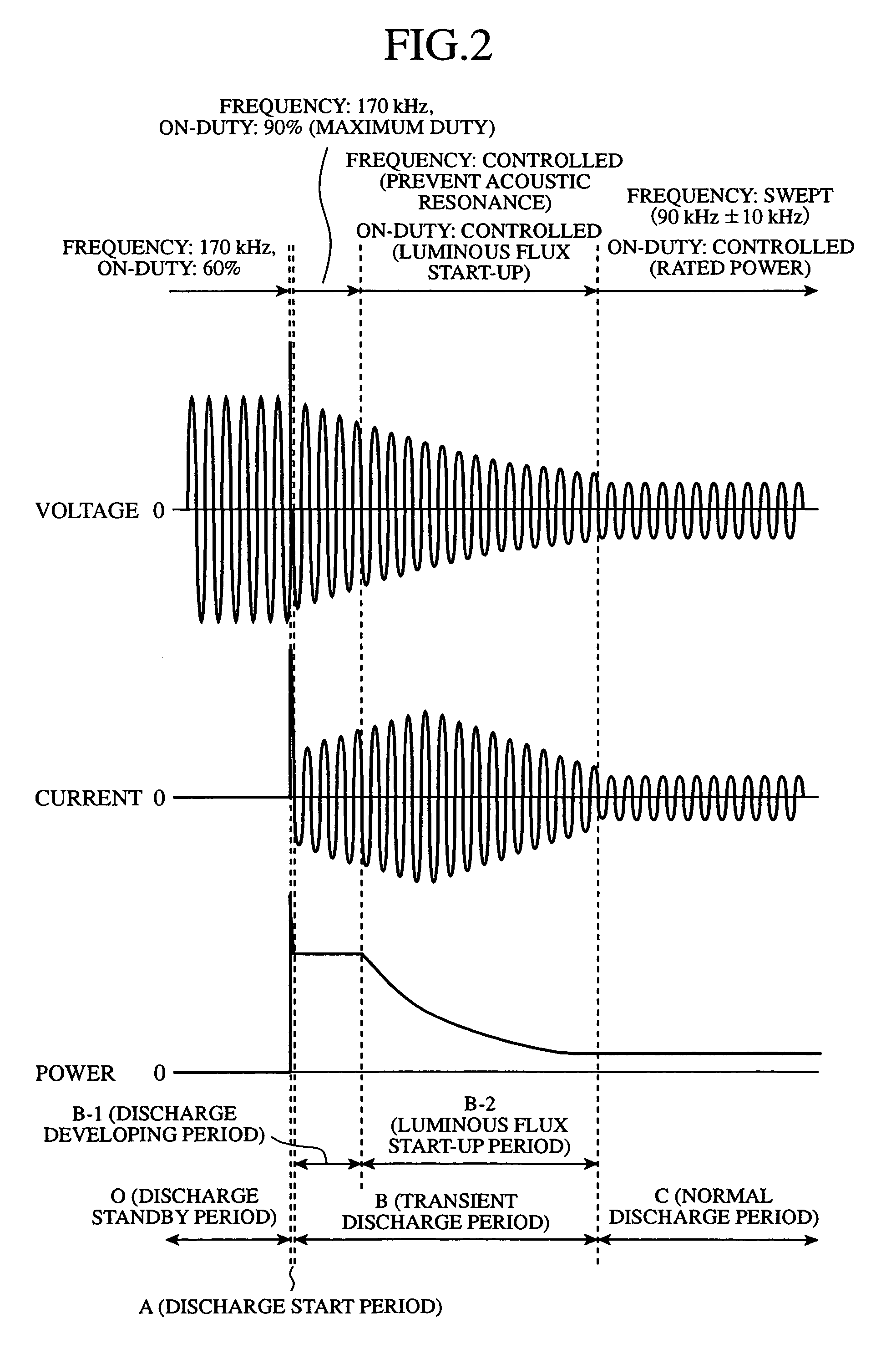

High intensity discharge lamp ballast apparatus

InactiveUS6975077B2Sufficient energySmall sizeElectric light circuit arrangementGas discharge lamp usageEngineeringDc ac converter

A compact, low cost high intensity discharge lamp ballast apparatus which can carry out normal ballasting without extinction at discharge start includes a DC-AC inverting booster circuit, a first resonance circuit, and a second resonance circuit. The DC-AC inverting booster circuit includes a DC-AC converter transformer for converting a DC voltage fed from a DC power supply to an AC voltage in response to switching on and off of FETs, boosting the voltage. The first resonance circuit includes a leakage inductance connected in series with the secondary winding of the DC-AC converter transformer, and a first resonant capacitor connected in parallel with the secondary winding. The second resonance circuit includes a metal halide lamp, an ignitor transformer for producing a voltage to start lighting of the metal halide lamp, and a second resonant capacitor.

Owner:MITSUBISHI ELECTRIC CORP

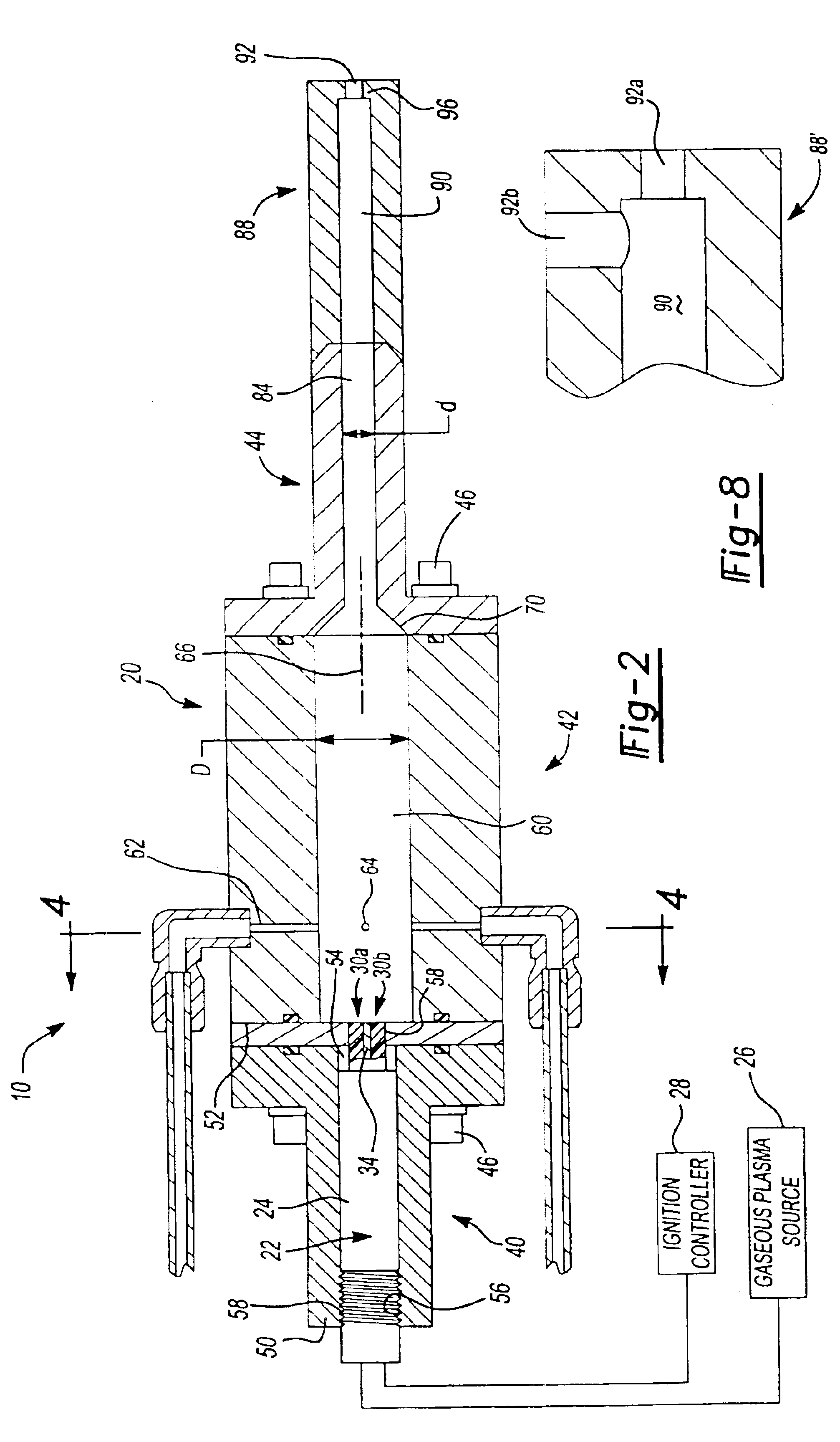

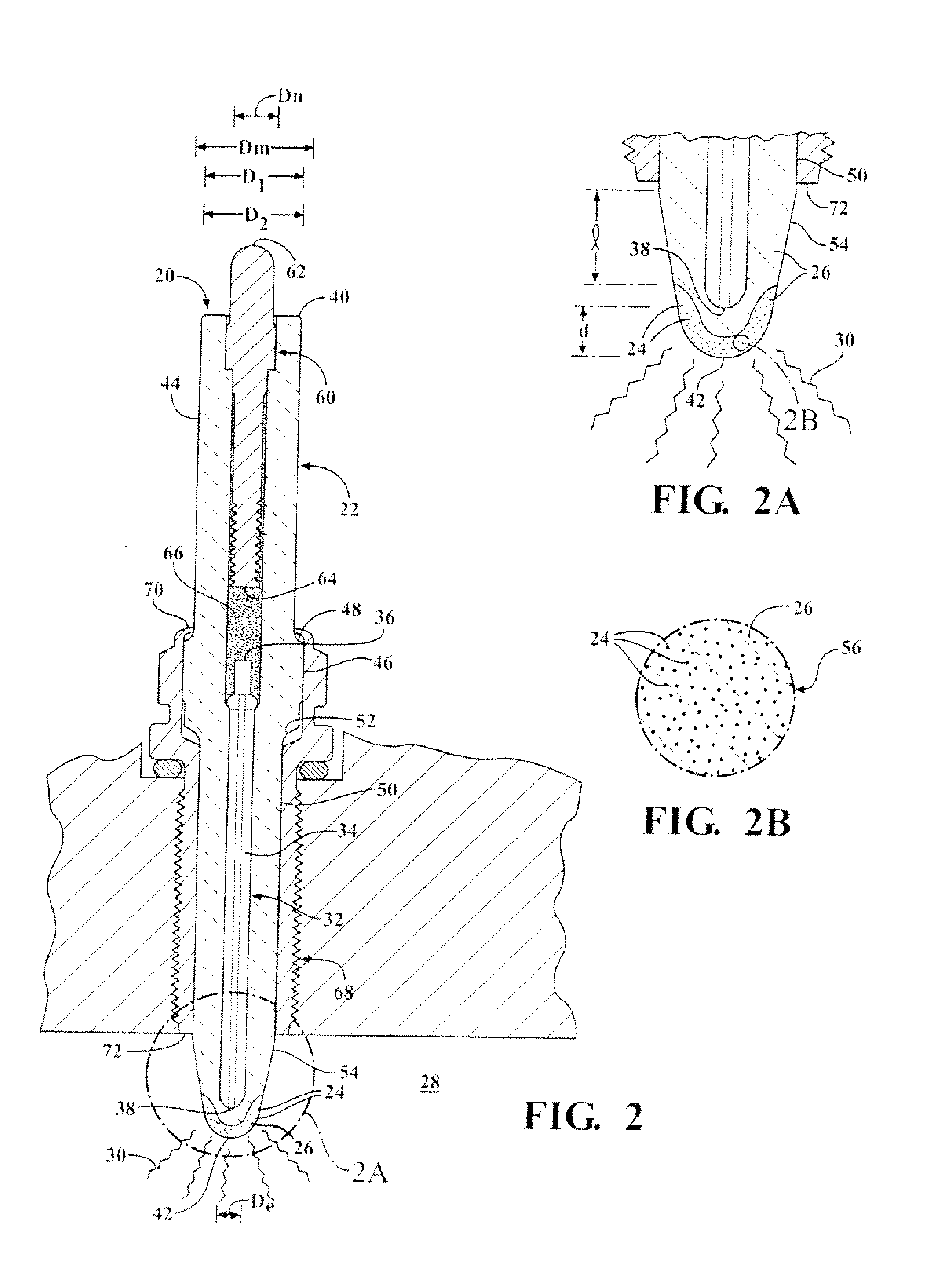

High power discharge fuel ignitor

ActiveUS20080018216A1Reduce erosionGreat cross sectionSpark gapsMachines/enginesElectricityCombustion

A spark-ignited, internal combustion engine ignition device to increase electrical transfer efficiency of the ignition by peaking the electrical power of the spark during the streamer phase of spark creation and improving combustion quality, incorporating an electrode design and materials to reduce electrode erosion due to high power discharge, an insulator provided with capacitive plates to peak the electrical current of the spark discharge, and concomitant methods.

Owner:PASSAIC RIVER CO INC

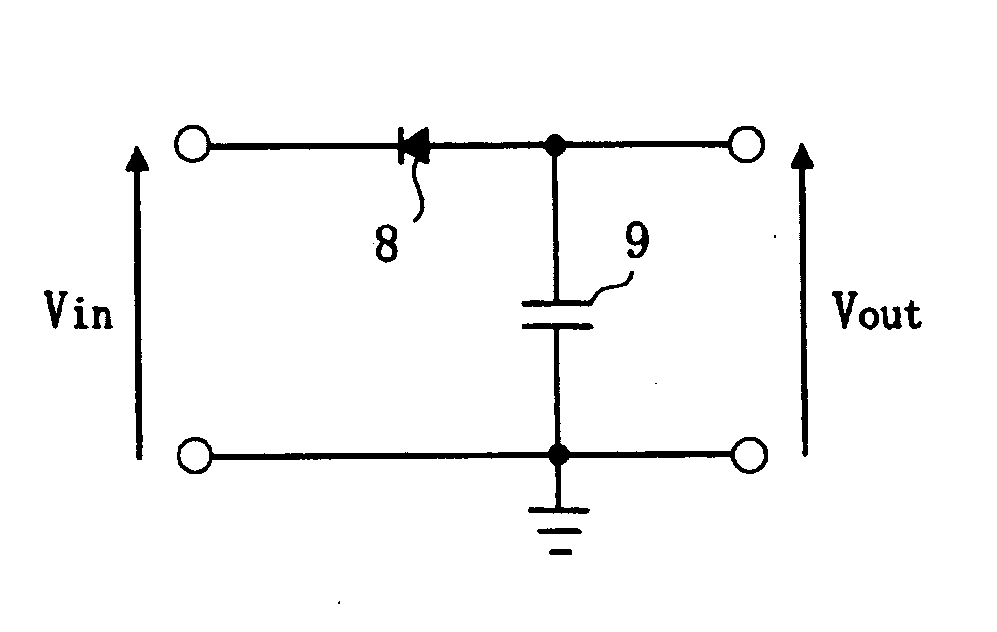

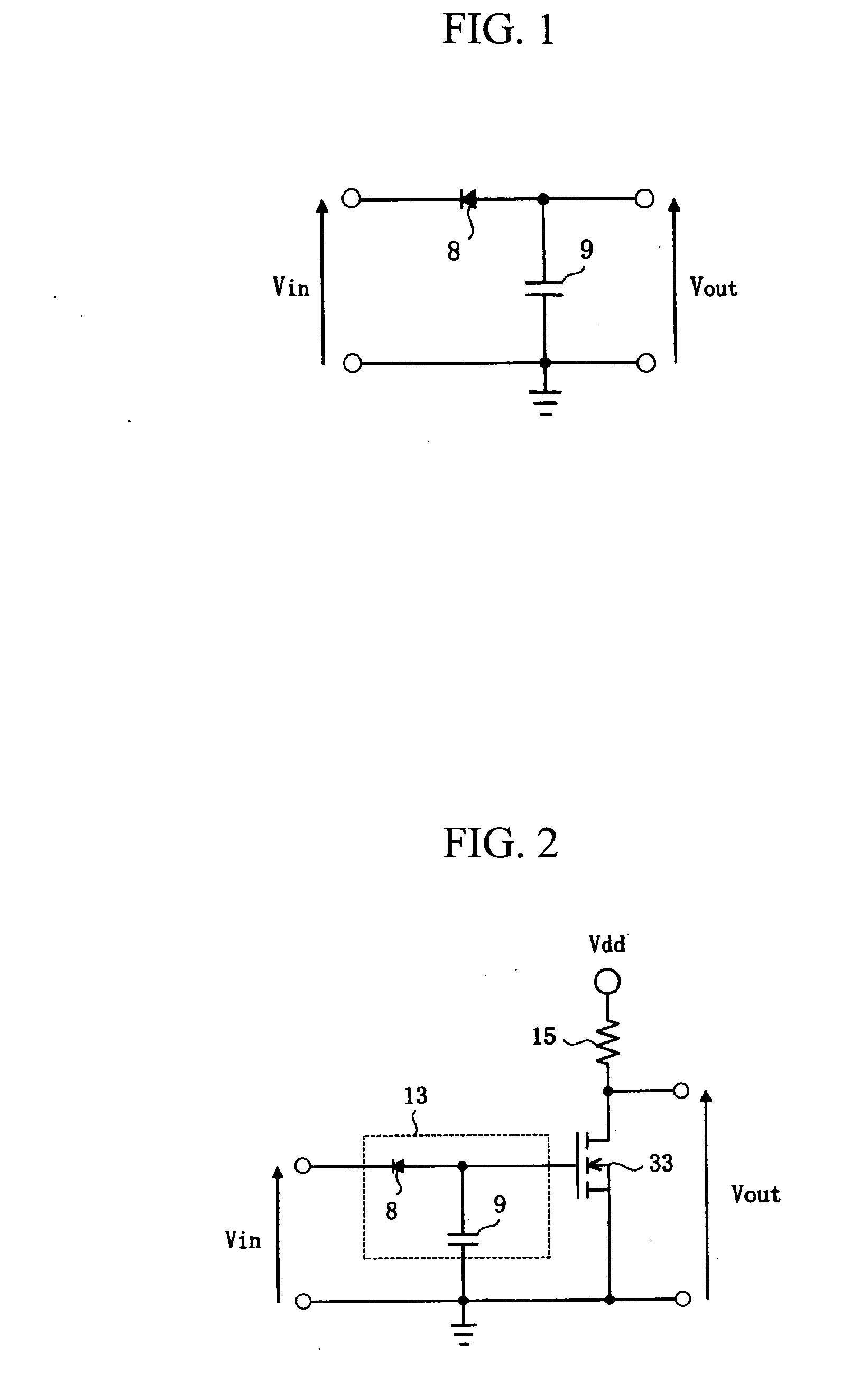

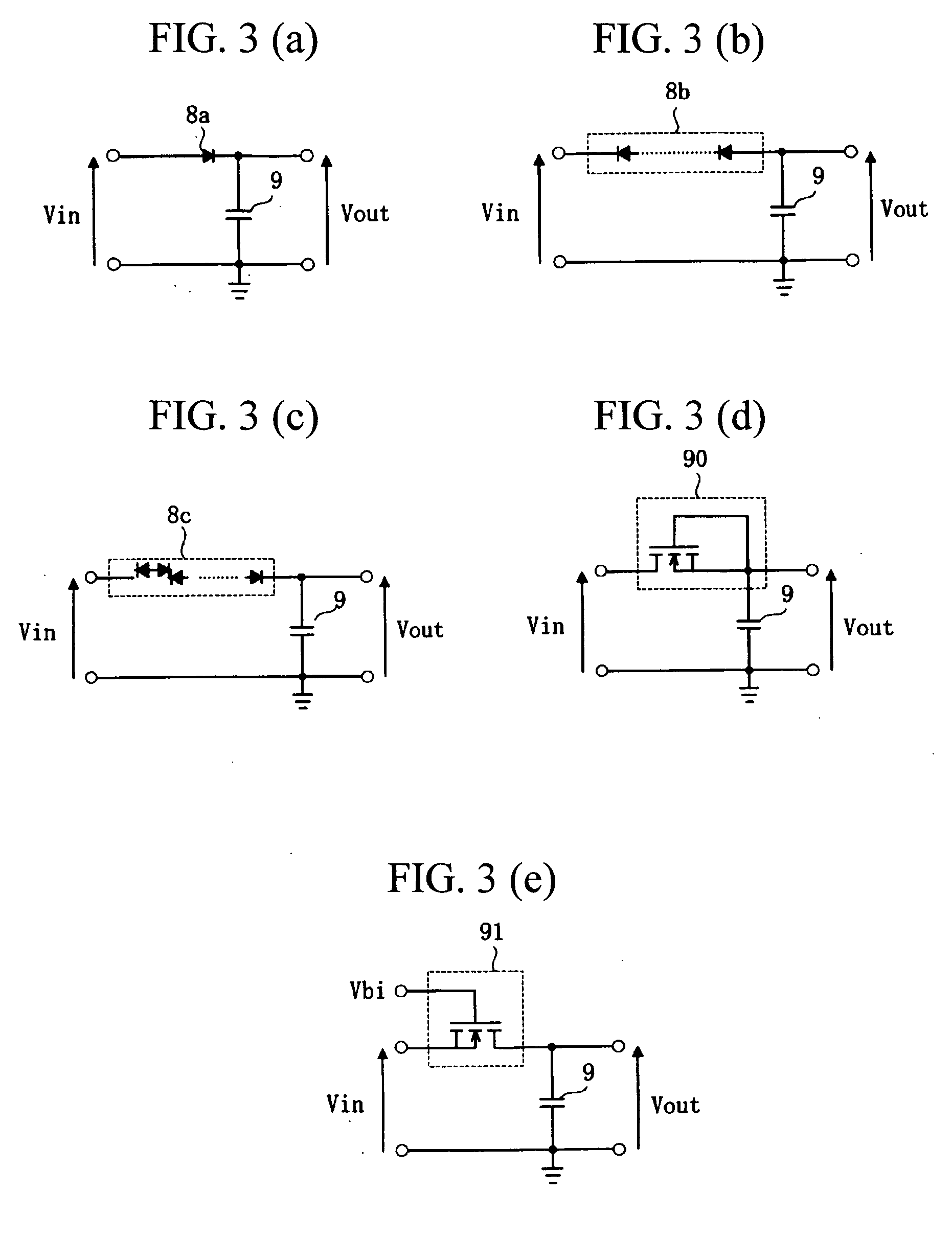

Integration circuit, decrement circuit, and semiconductor devices

InactiveUS20060022609A1Reduce areaSmall sizeComputing operations for integral formationComputing operations for integration/differentiationMOSFETPower flow

Owner:RENESAS ELECTRONICS CORP

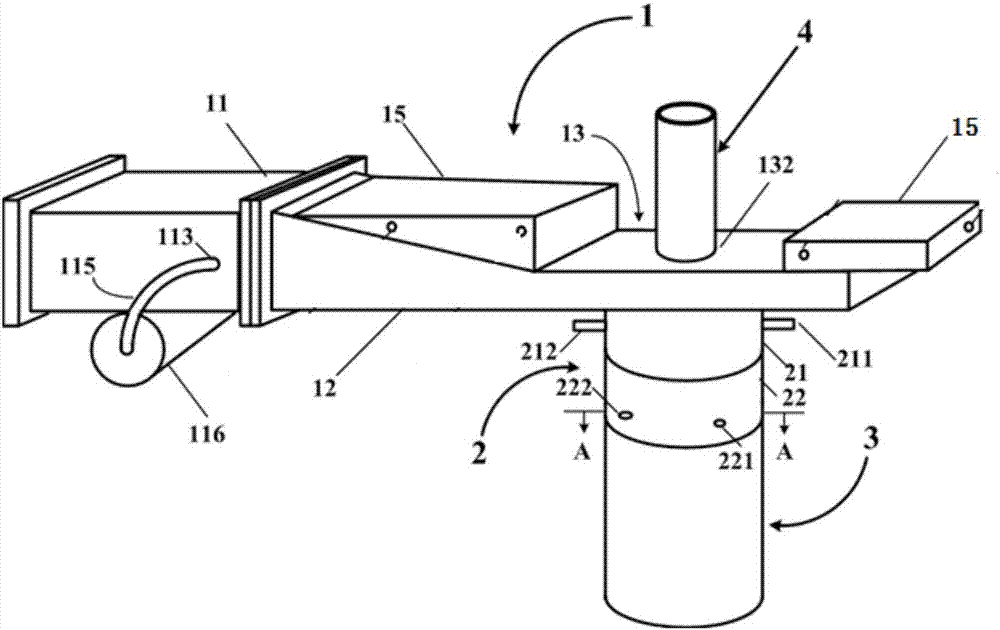

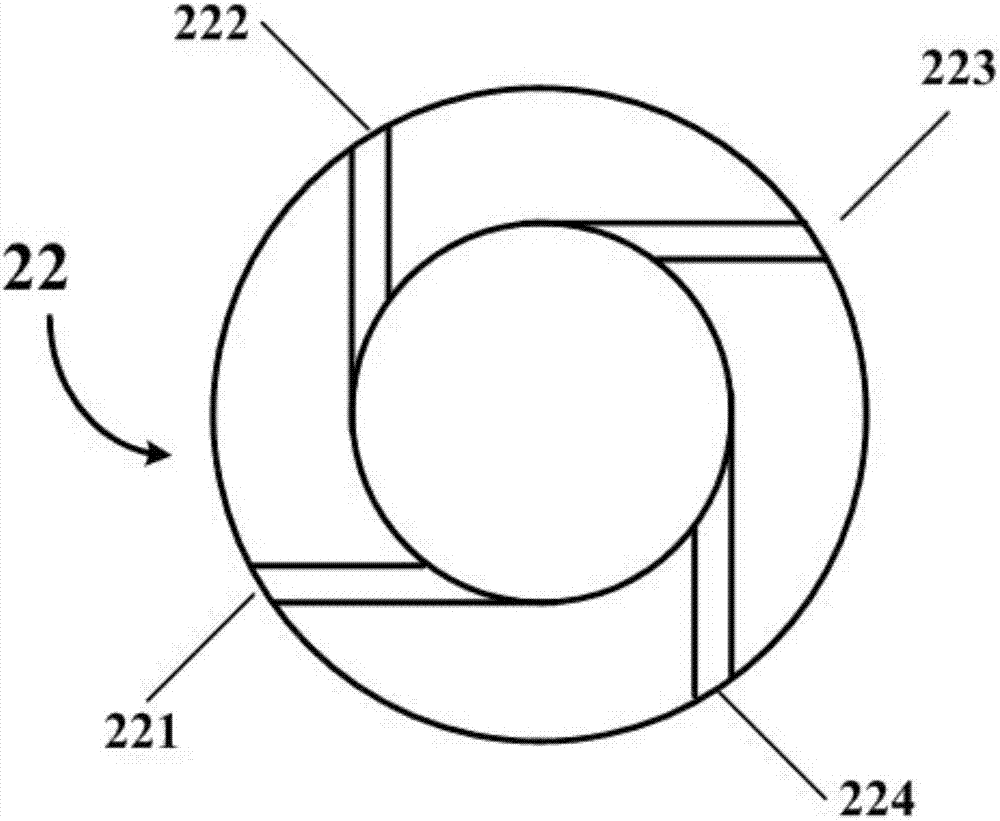

Elongating arc plasma jet ignition device

ActiveCN104454290AIncrease the speed of flame spreadStrong penetrating powerMachines/enginesEngine ignitionPlasma jetFlame spread

Disclosed is an elongating arc plasma jet ignition device. A swirler is fixed to the bottom of an inner cavity of a shell; a positive pole is located in the shell and fixedly connected with the swirler; the lower end of an insulation sleeve is installed in a central hole of the swirler, and an air chamber is formed in the gap between the outer peripheral surface of the middle of the insulation sleeve and the inner surface of the shell. A negative pole is embedded on a negative pole installation base, and the arc end of the negative pole extends out of the lower end of the insulation sleeve to be located in the positive pole. An arcing distance 2-8 mm long is kept between the arc end of the negative pole and a nozzle of the positive pole; an air inlet pipe is located at the upper end of the shell and communicated with the space of the air chamber formed between the insulation sleeve and the shell. The taper angle beta of the arc end of the negative pole is 40 degrees. The taper angle alpha of a contraction section of the positive pole is 60-90 degrees. Eight swirling holes with the spiral angle of 45 degrees are evenly distributed in an end surface of the swirler, and work media passing through the swirler generate swirling flow. The elongating arc plasma jet ignition device has the advantages of being high in flame spreading speed, high in penetrating power and rich in active air plasma.

Owner:AIR FORCE UNIV PLA

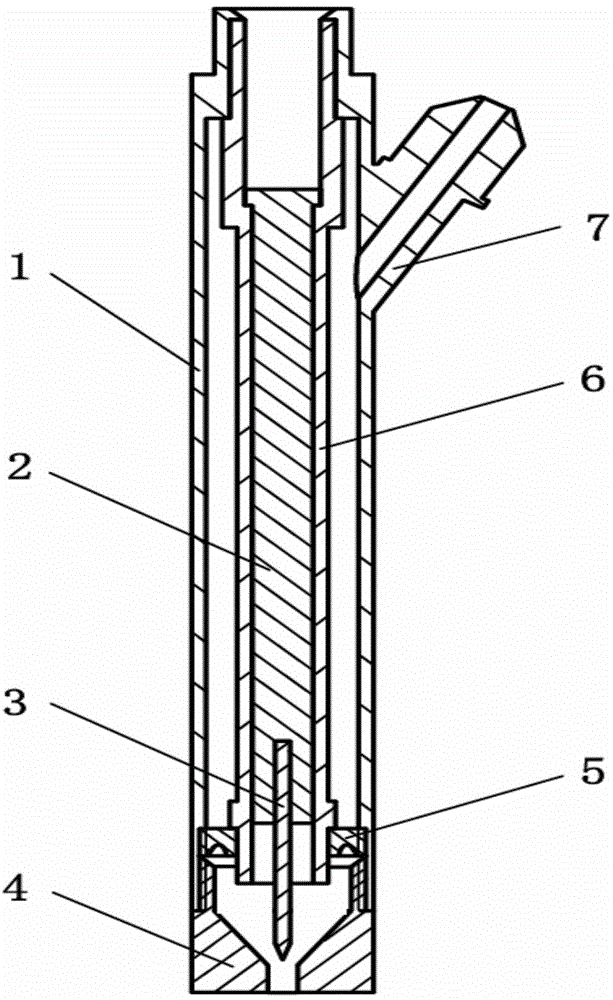

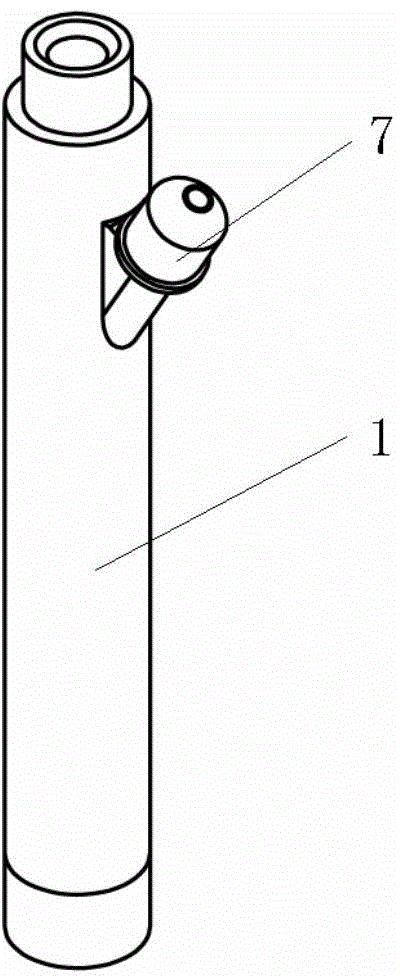

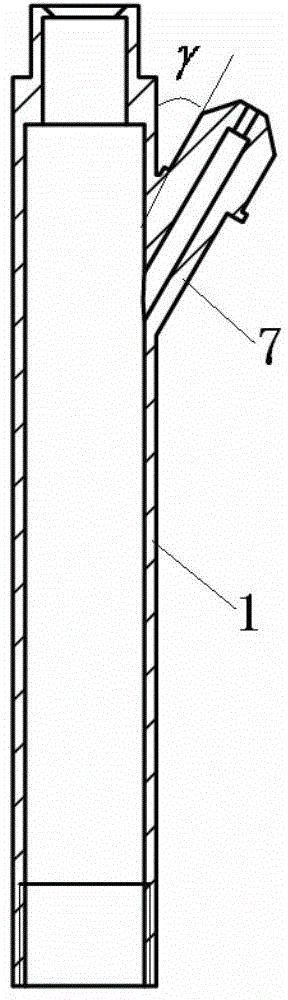

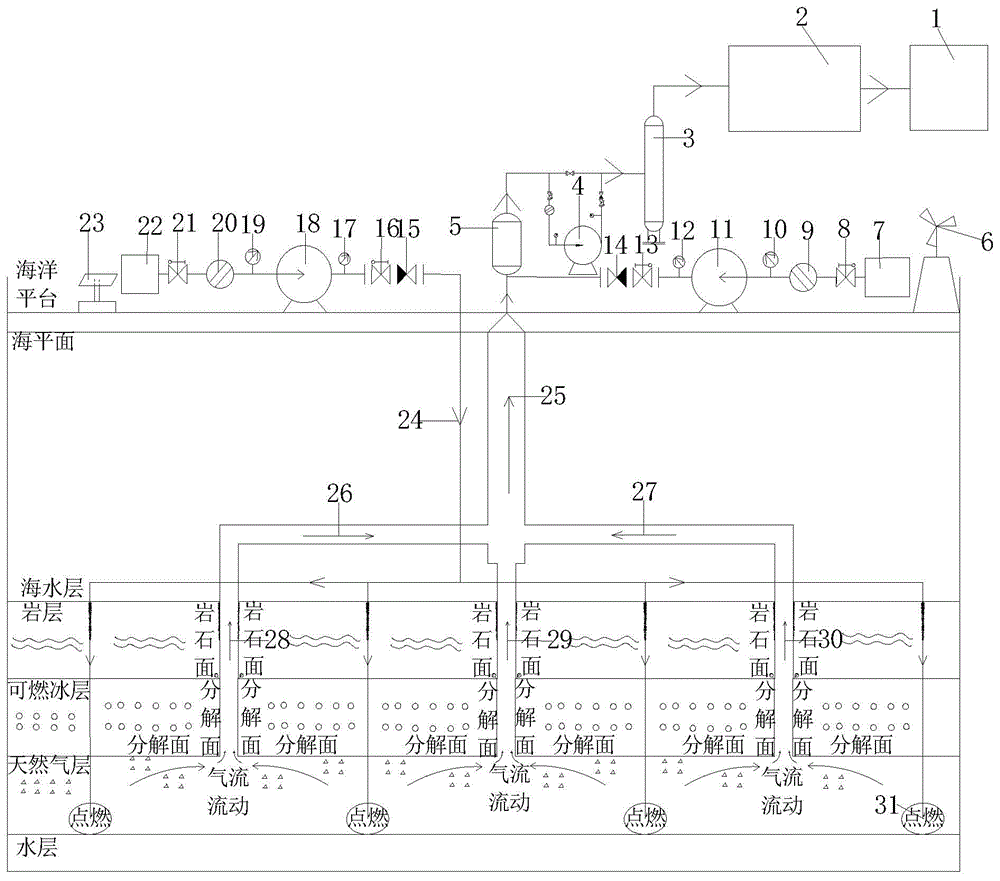

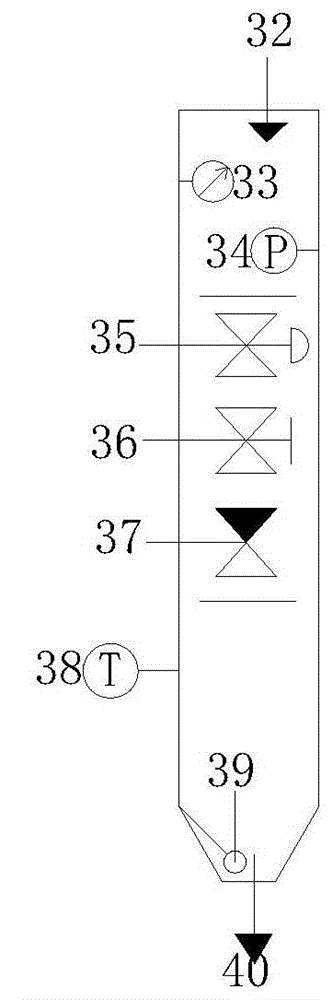

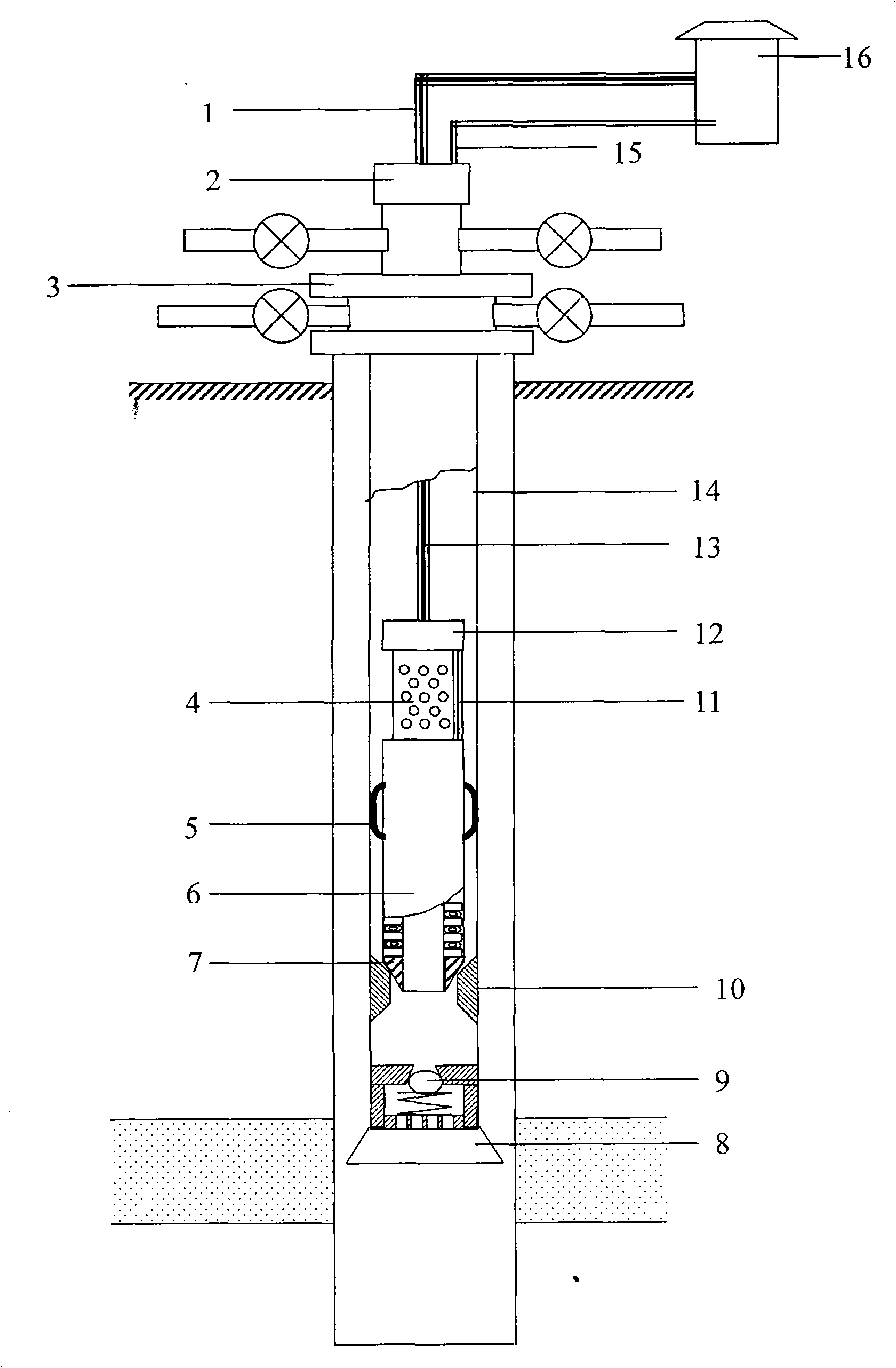

Method and device for exploiting combustible ice in seabed

InactiveCN104481467AHigh purityReduce the impact of airflowConstructionsFluid removalCombustionDecomposition

Combustible ice, also called as Natural Gas Hydrate (NGH), is formed at the high pressure and low temperature, and much of the combustible ice is reserved in the seabed and tundra layer and is the third energy source human found. The invention provides a method and a device for exploiting combustible ice in the seabed by seabed firing. The method includes injecting combustion-supporting gas into a natural gas layer of the seabed combustible ice, strictly controlling flow velocity and flow of the combustion-supporting gas, firing through an electromagnetic ignitor, providing head for decomposition of NGH by burning a small part of natural gas, and accelerating decomposition of the combustible ice so as to improve gas production efficiency. Due to burning, the temperature of the natural gas is slightly higher than the balance temperature of the combustible ice, high pressure of gas reservoir of the combustible ice can be kept, and no hydrate of the integral seabed gas collection area is generated.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

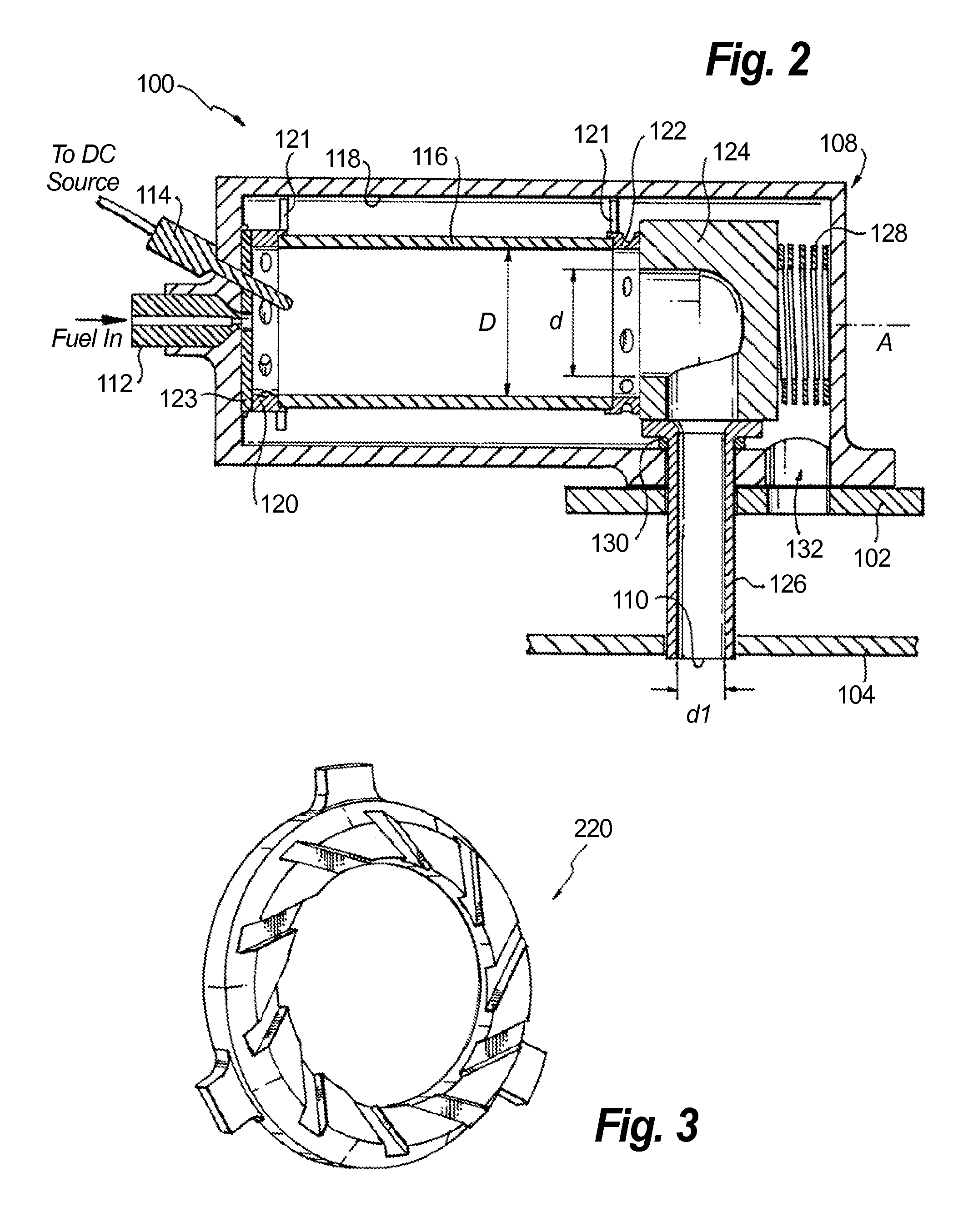

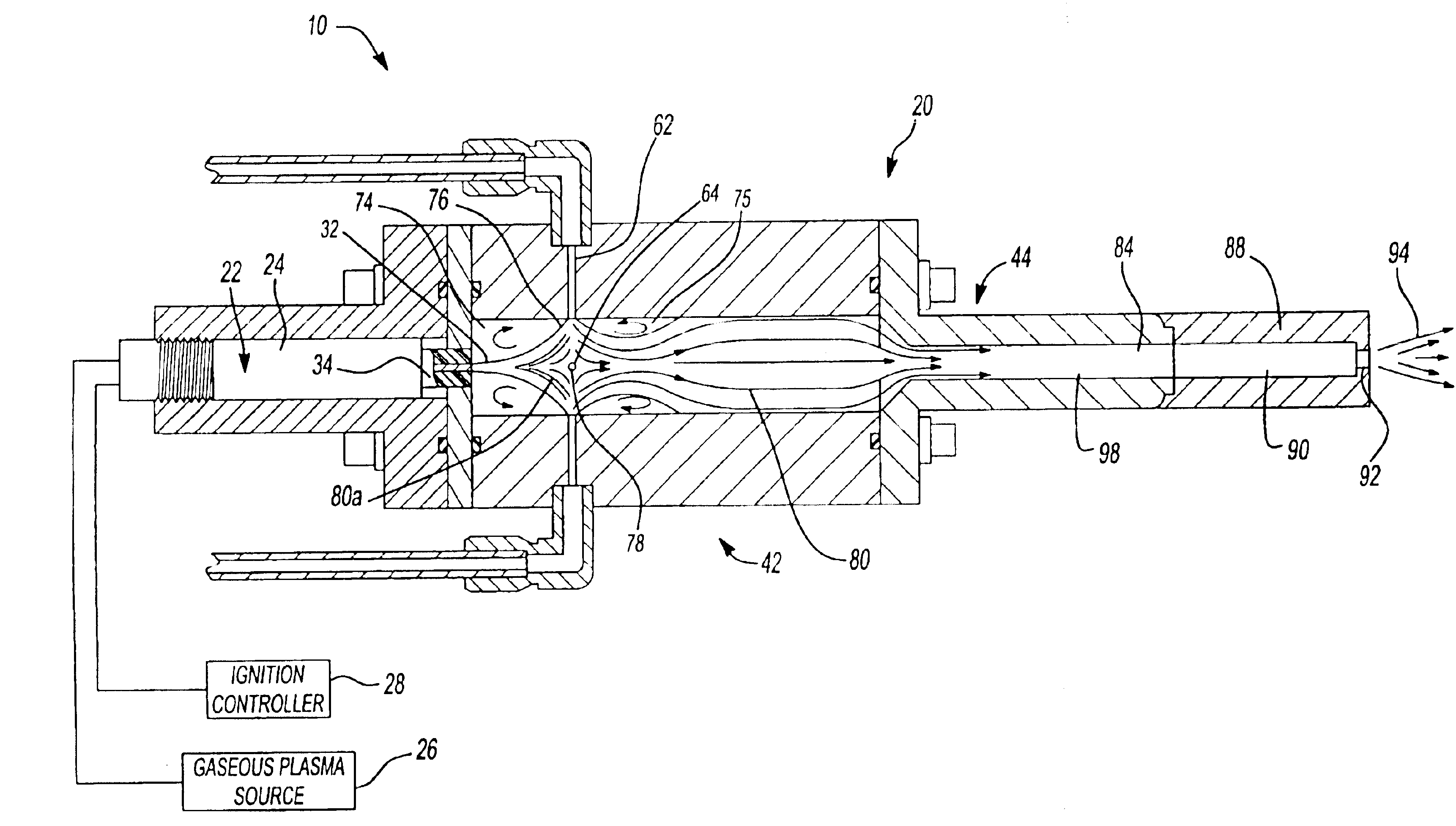

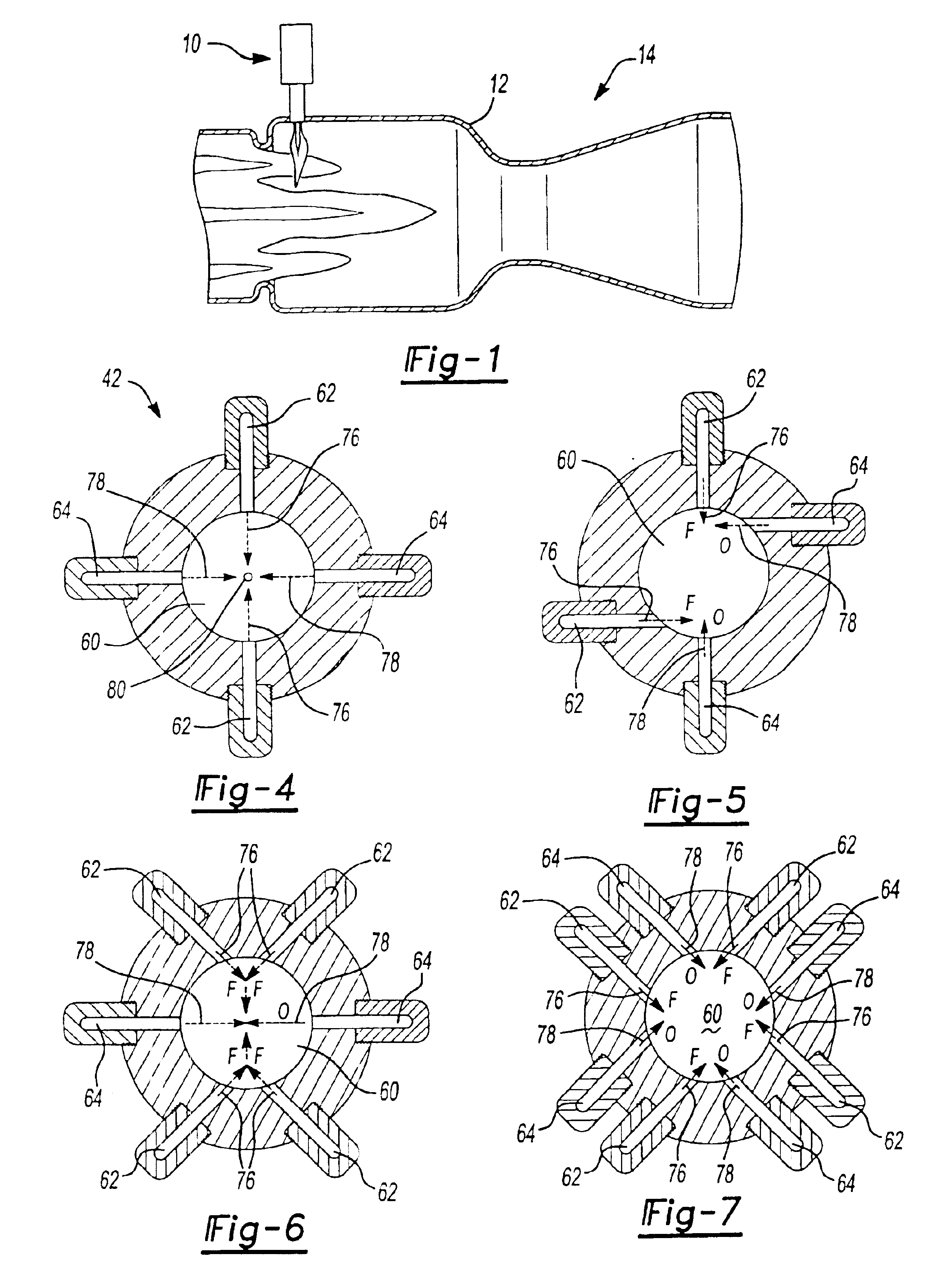

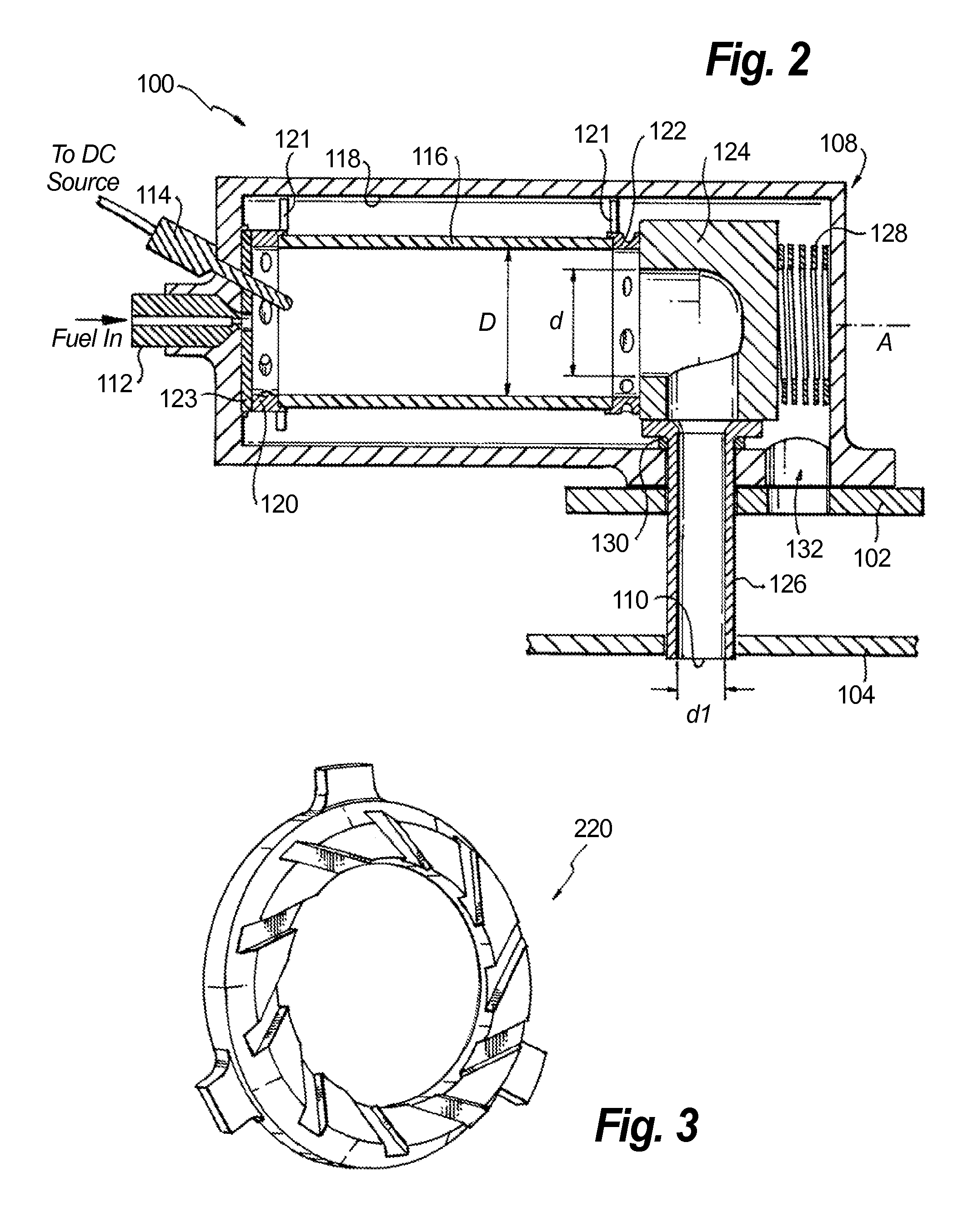

Torch igniter

An improved torch igniter for use in devices such as thrust augmenters, gas turbine engines, ramjets, combined-cycle engines and industrial burners. The torch igniter includes a housing with a combustion chamber. Fuel and oxidizer are delivered into the combustion chamber and ignited by an electronic ignition source, such as a plasma jet igniter or a spark igniter, so that an upstream recirculation zone and a downstream recirculation zone are created. The upstream recirculation zone stabilizes and pilots combustion within the combustion chamber, while the downstream recirculation zone augments the combustion event. Byproducts of the combustion event within the torch igniter provide a high mass flux with high thermal energy and strong ignition source radicals that are discharged through a neck portion of the housing and are thereafter employed to initiate a primary combustion event in a primary combustor.

Owner:THE BOEING CO

Furnace using plasma ignition system for hydrocarbon combustion

InactiveUS20050208446A1Improve fuel efficiencyMany timesBurnersInternal combustion piston enginesCombustorFuel efficiency

An apparatus and method for the creation, placement and control of an area of electrical ionization within an internal combustion engine combustion chamber or a fuel burner for a furnace is disclosed. A furnace includes a fuel source, a fuel burner, a plasma nozzle and igniter assembly, and the associated housing and flue structures. The plasma nozzle and igniter assembly is arranged so that the fuel sprayed out from the nozzle into the combustion area passes through or in close proximity to the area of plasma ionization. A fuel burner equipped with this electrical ionization device has its fuel efficiency enhanced by the complete and immediate combustion of substantially all of the fuel that passes through the area of plasma ionization. Exhaust gas recirculation using this system is also disclosed.

Owner:JAYNE MICHAEL E

Staged combustion system with ignition-assisted fuel lances

Combustion system comprising a furnace having a thermal load and a combustion atmosphere disposed therein; one or more fuel lances adapted to inject fuel into the combustion atmosphere; and one or more igniters associated with the one or more fuel lances and adapted to ignite the fuel injected by the one or more fuel lances into the combustion atmosphere.

Owner:AIR PROD & CHEM INC

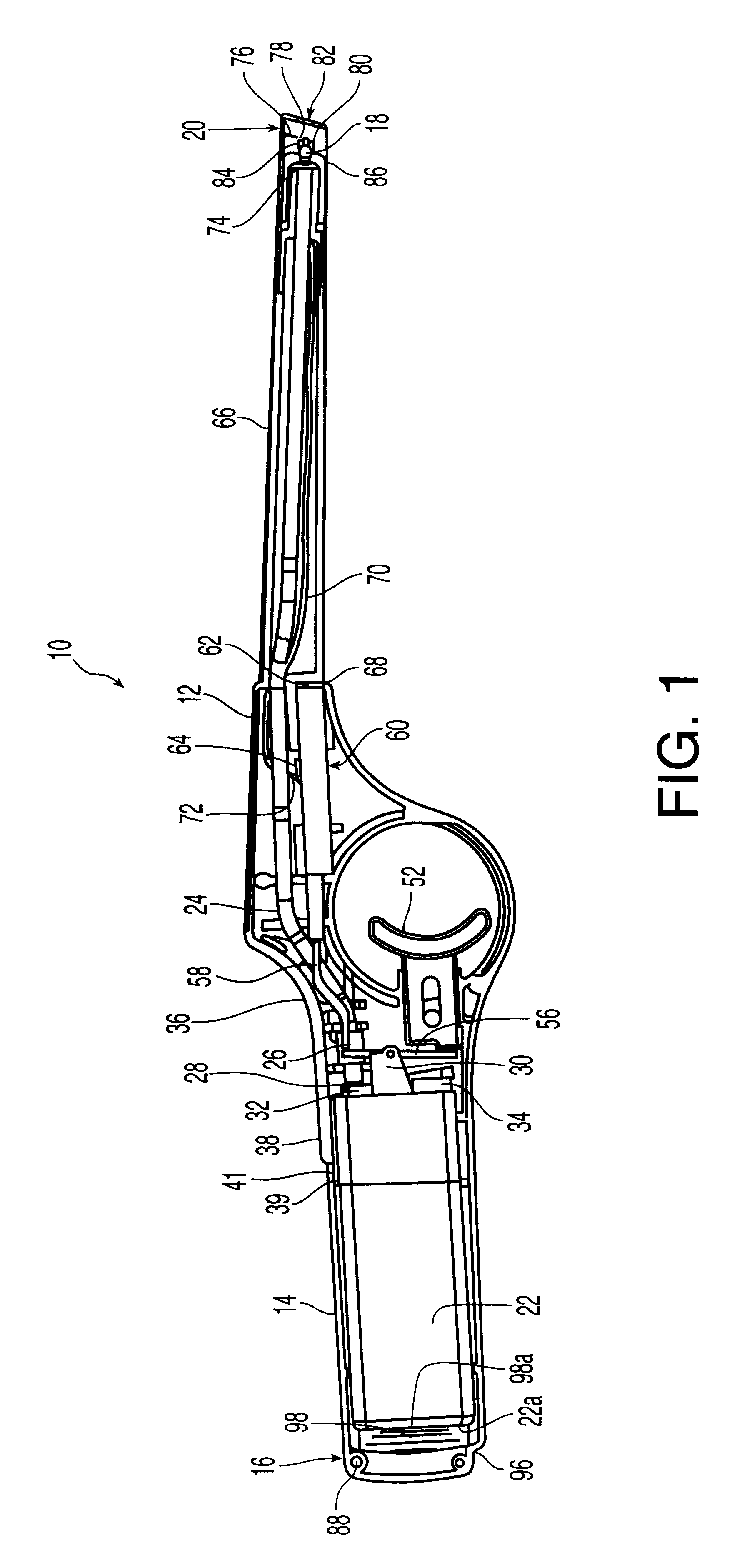

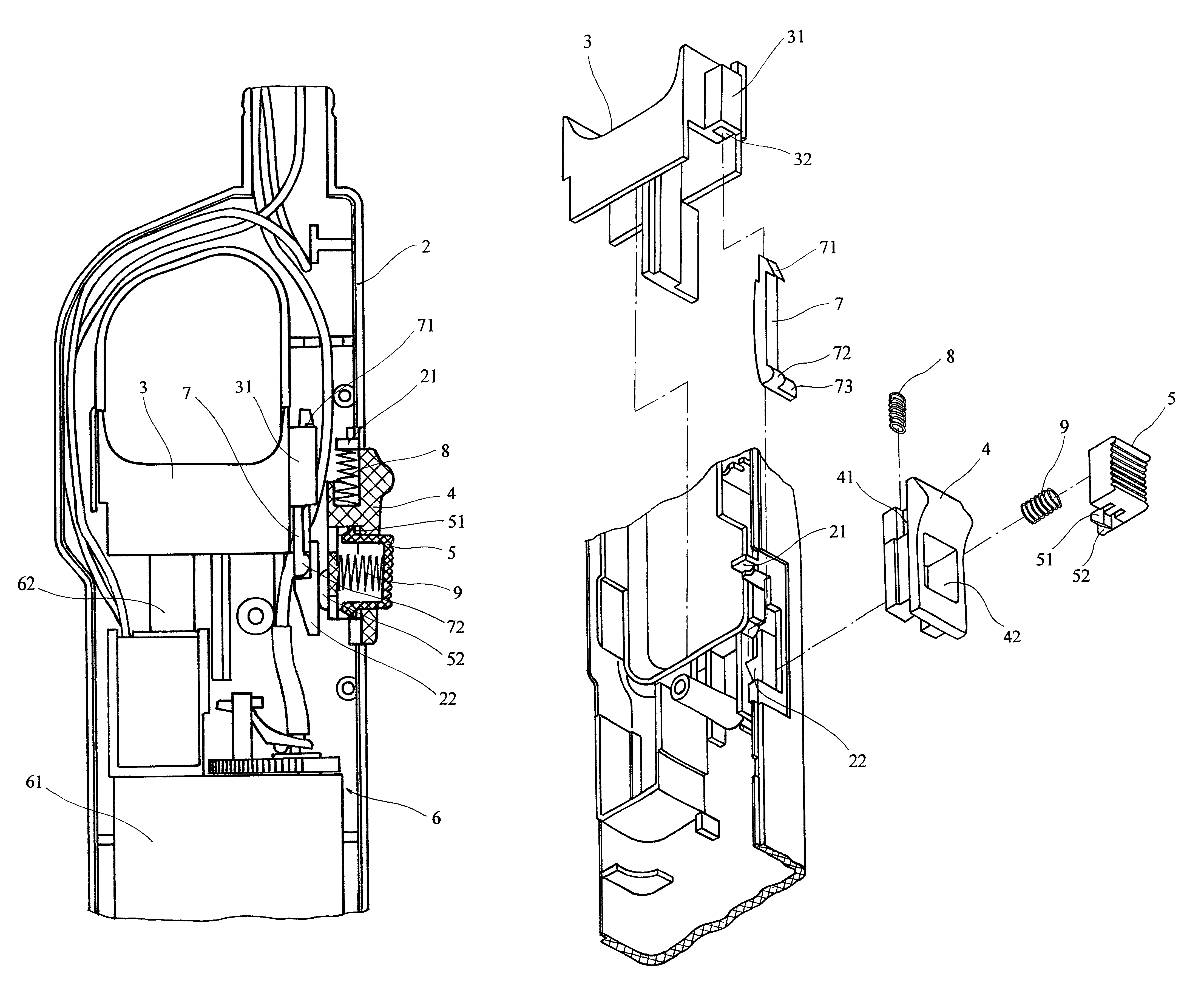

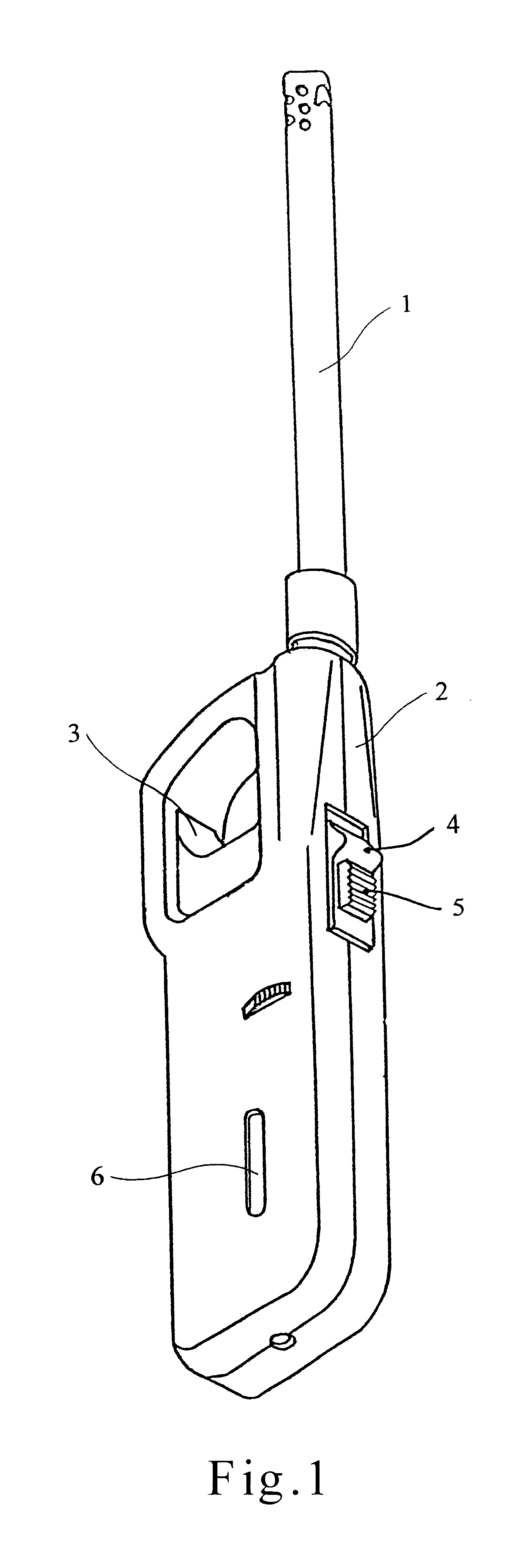

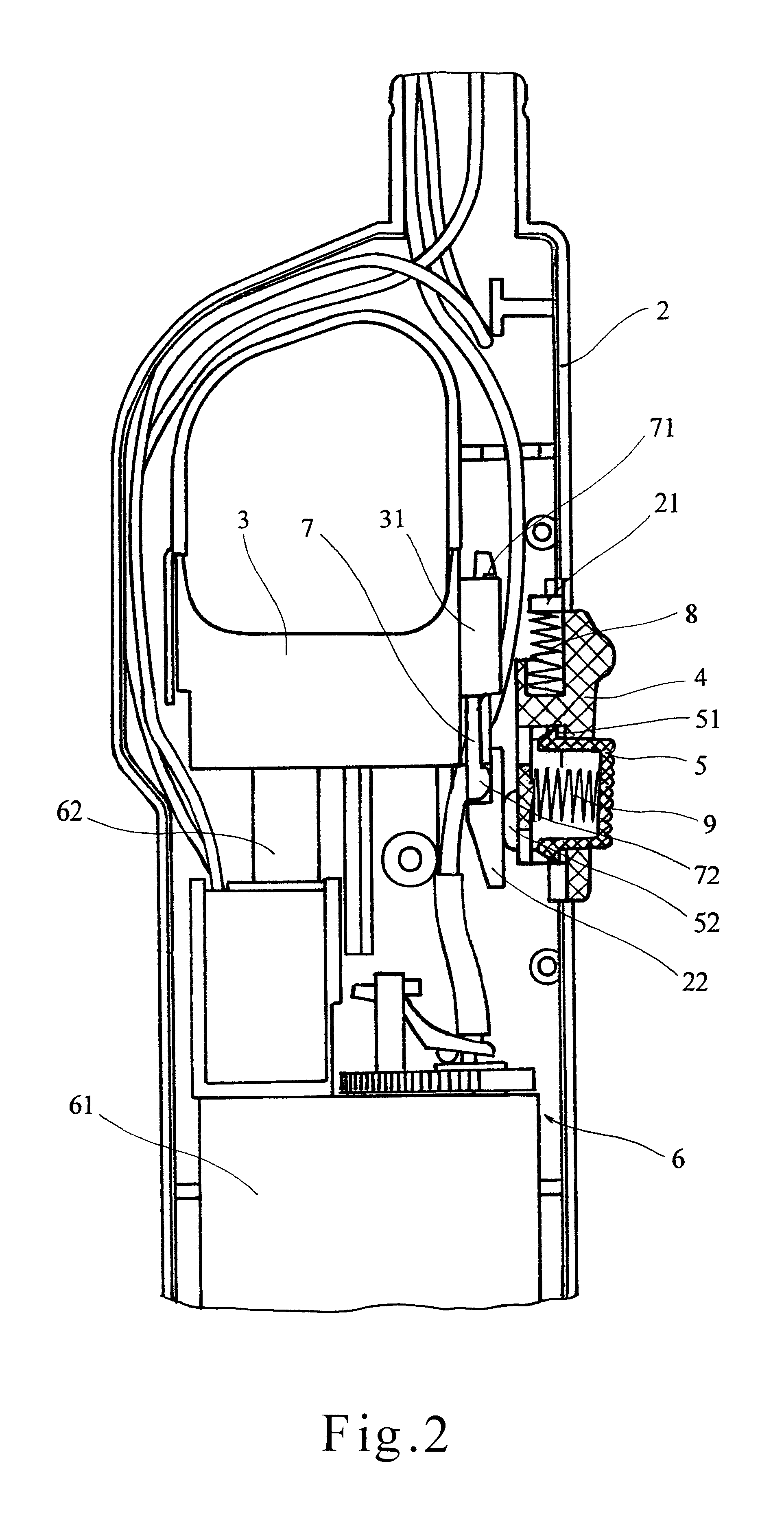

Igniter with a push-button and an elastic bar

InactiveUS6887072B2Promote fireSolve the real problemBranding equipmentIncandescent ignitionNatural statePush ups

Igniter with safety unit, the safety unit comprises a push-button that is arranged at the backside of the gun body and partially protrudes out of the gun body, it can be pushed forward and return relative to the gun body; a elastic limit bar that is arranged at the side of the part of the ignition trigger that is towards the backside of the gun body, in natural condition, its end keeps against a barrier block which is integrated with the inner wall of the gun body; a button that is arranged in the push-button and protrudes out of the push-button, it can be pressed into the gun body and return. A protruding part arranged on the button's inner side protrudes towards a mid-portion of the gun body. In natural condition, the protruding part is towards the blank part, but when the push-button is in pushed up condition, the protruding part is near the end of the elastic limit bar and opposite to it. Thereby, if the button is pressed down, the protruding part of the button pushes the end of the elastic limit bar to make it distort and deflect from the barrier block on the inner wall of the gun body. The locking situation of the ignition trigger can be released. The apparatus can fire the flammable gas only by doing the two compound actions i.e. pressing down the button and pushing up the push-button simultaneously, thus further improving the safety of the ignitor.

Owner:JUDENG ZHANG

Non-thermal plasma ignition arc suppression

ActiveUS20120112620A1Eliminates arcingReduces arcingSpark gapsEngine ignitionCombustion chamberEngineering

An igniter (20) of a corona ignition system emits a non-thermal plasma in the form of a corona (30) to ionize and ignite a fuel mixture. The igniter (20) includes an electrode (32) and a ceramic insulator (22) surrounding the electrode (32). The insulator (22) surrounds a firing end (38) of the electrode (32) and blocks the electrode (32) from exposure to the combustion chamber (28). The insulator (22) presents a firing surface (56) exposed to the combustion chamber (28) and emitting the non-thermal plasma. A plurality of electrically conducting elements (24) are disposed in a matrix (26) of the ceramic material and along the firing surface (56) of the insulator (22), such as metal particles embedded in the ceramic material or holes in the ceramic material. The electrically conducting elements (24) reduce arc discharge during operation of the igniter (20) and thus improve the quality of ignition.

Owner:FEDERAL MOGUL IGNITION

Fire flood eclectic ignition method

InactiveCN101539011AImprove mobilityEasy to control temperatureFluid removalIntermediate frequencyElectric ignition

The invention relates to a fire flood eclectic ignition method. An ignition device adopted by the fire flood eclectic ignition method comprises a steam injection pipe column and an ignition system, wherein the steam injection pipe column comprises a flare opening, a check valve, a bracket, an oil pipe and a wellhead device from top to bottom; the electric ignition system comprises a ground part and an underground part, wherein the ground part comprises an intermediate frequency power supply control cabinet, a loop cable, a cable conductor and a cable sealer, and the underground part comprises a conductor, an igniter, an insulated centralizer, a screen pipe, the cable conductor, an insulated isolation wire connector and the cable conductor from bottom to top. The fire flood eclectic ignition method is easy to operate, the ignition device has high maneuverability, repeatable use, controllable temperature and uniform heating temperature, and fire flood eclectic ignition can obtain good effect by utilizing the ignition device.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

Continuous ignition

ActiveUS9080772B2High flame intensityReduced strengthBurnersContinuous combustion chamberCombustorIgnition point

An ignition system includes a housing defining an interior and an exhaust outlet. The housing is configured and adapted to be mounted to a combustor to issue flame from the exhaust outlet into the combustor for ignition and flame stabilization within the combustor. A fuel injector is mounted to the housing with an outlet of the fuel injector directed to issue a spray of fuel into the interior of the housing. An igniter is mounted to the housing with an ignition point of the igniter proximate the outlet of the fuel injector for ignition within the interior of the housing.

Owner:COLLINS ENGINE NOZZLES INC

Extinguishing apparatus combined pyrotechnical aerosol with powder extinguishing agent

A fire extinguisher using pyrotechnic aerosol and dried fire extinguishing powder is composed of ignitor, end cover, casing, burning chamber, net filtering, connector, chemical cooling chamber full of the microspheres prepared from the mixture of potassium nitrate and potassium carbonate, physical cooling chamber full of spherical Al2O3, dried fire extinguishing powder module, pressure buffering chamber, sealing film and nozzle.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com