Patents

Literature

301 results about "Thermite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermite (/ˈθɜːrmaɪt/) is a pyrotechnic composition of metal powder, which serves as fuel, and metal oxide. When ignited by heat, thermite undergoes an exothermic reduction-oxidation (redox) reaction. Most varieties are not explosive, but can create brief bursts of heat and high temperature in a small area. Its form of action is similar to that of other fuel-oxidizer mixtures, such as black powder.

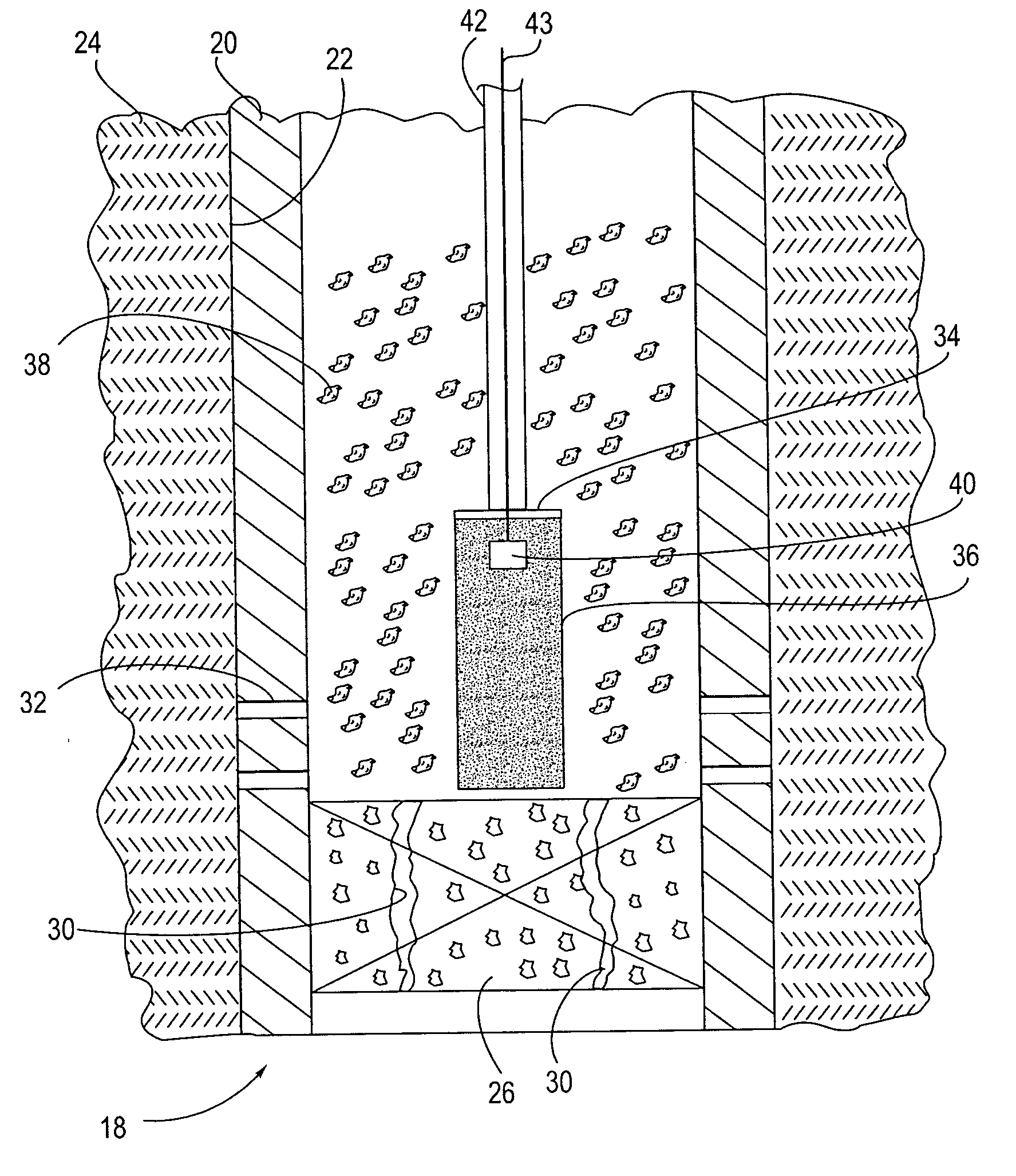

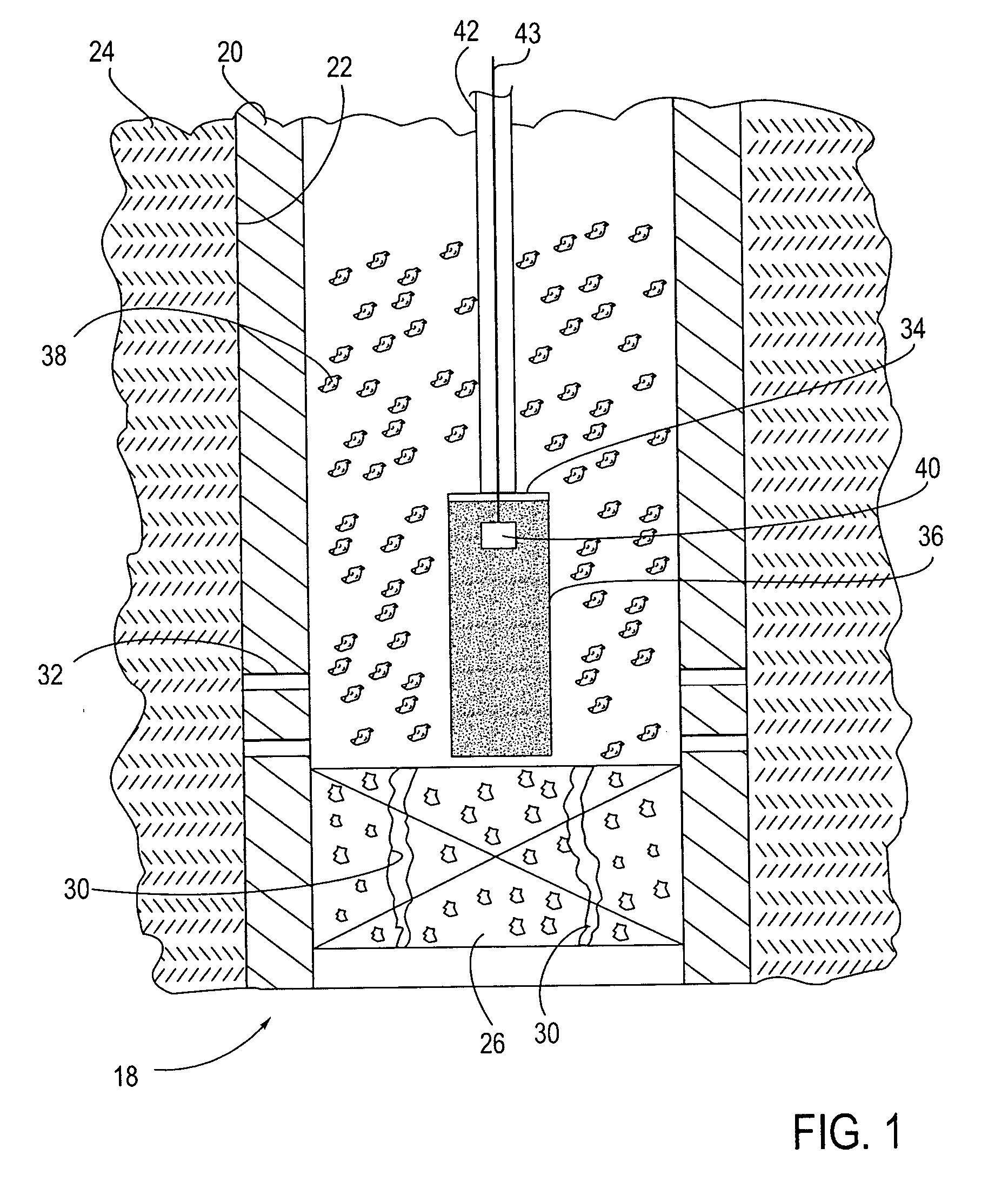

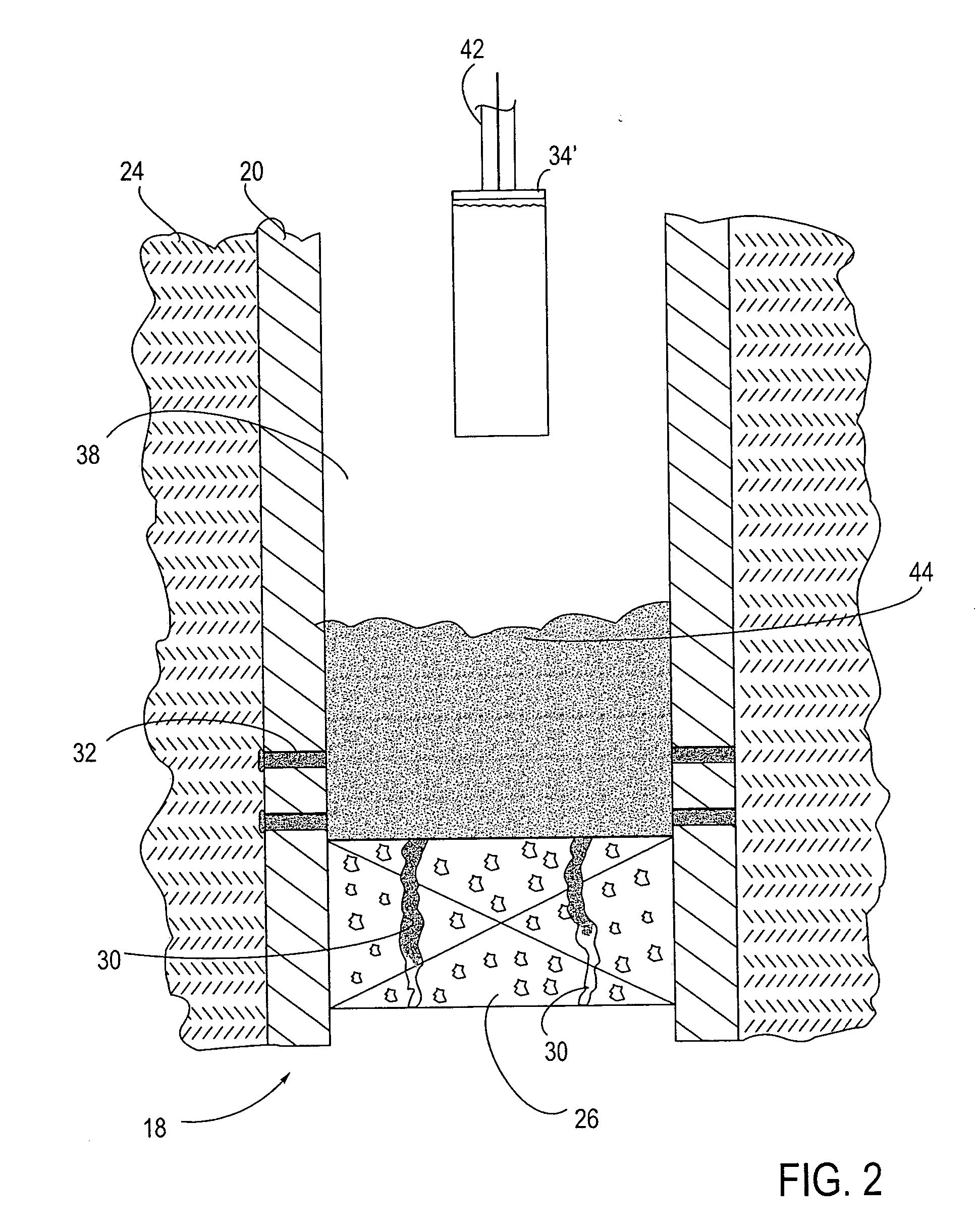

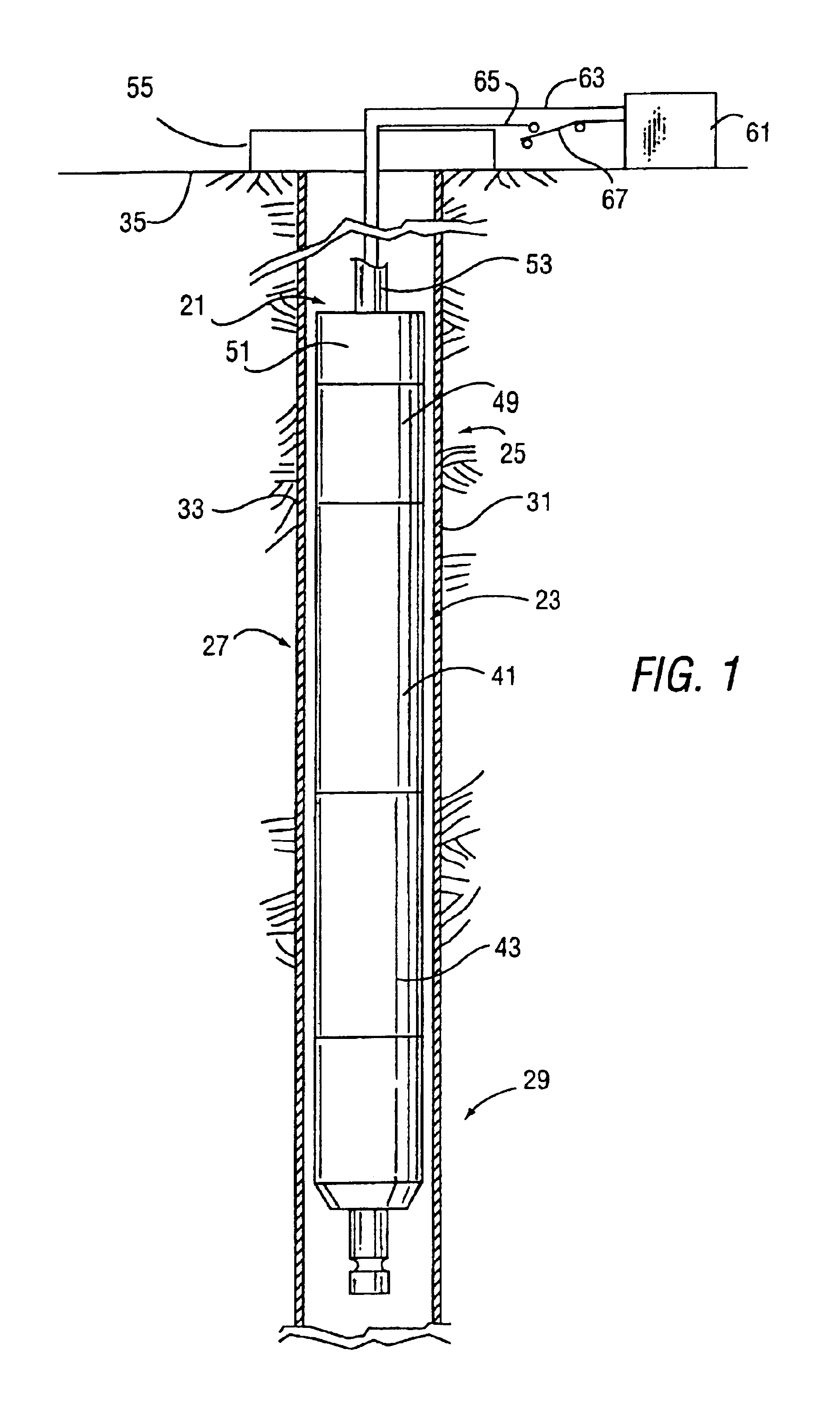

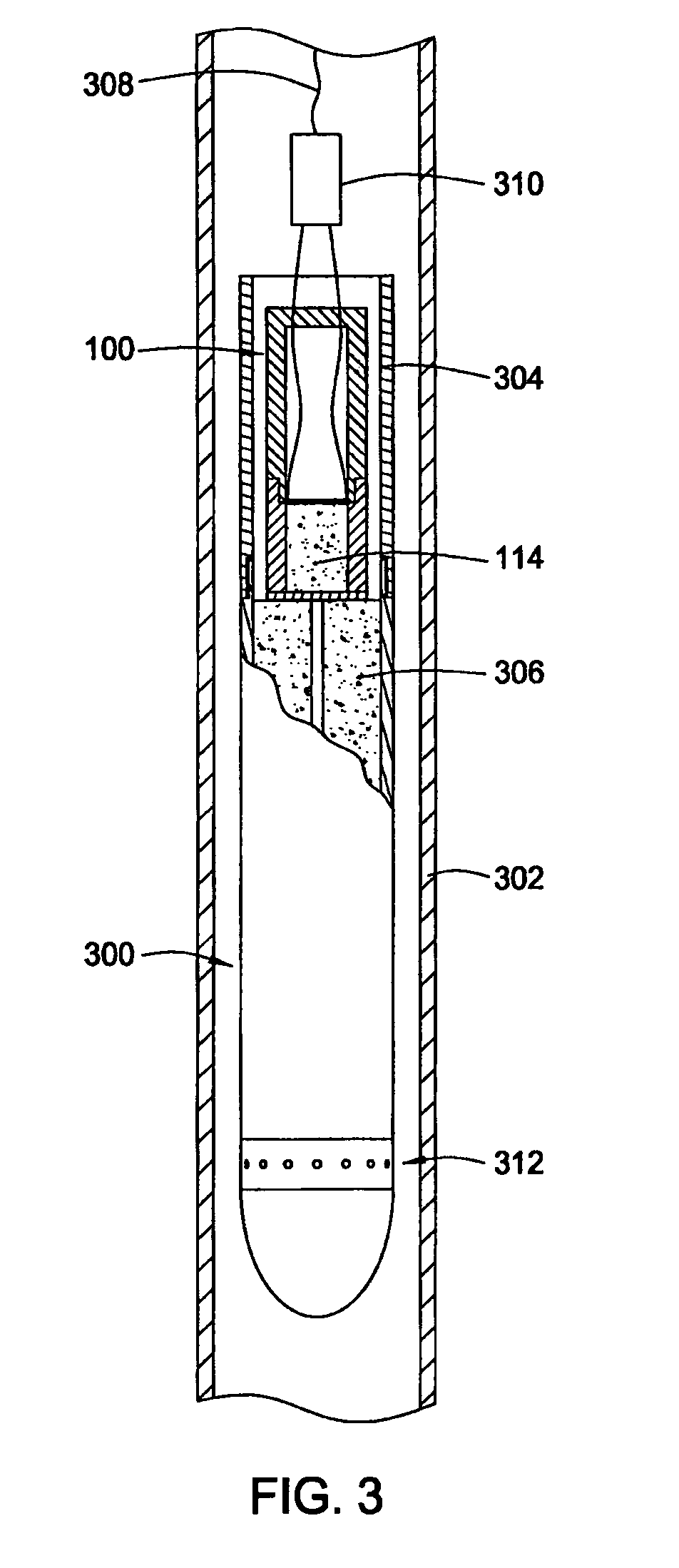

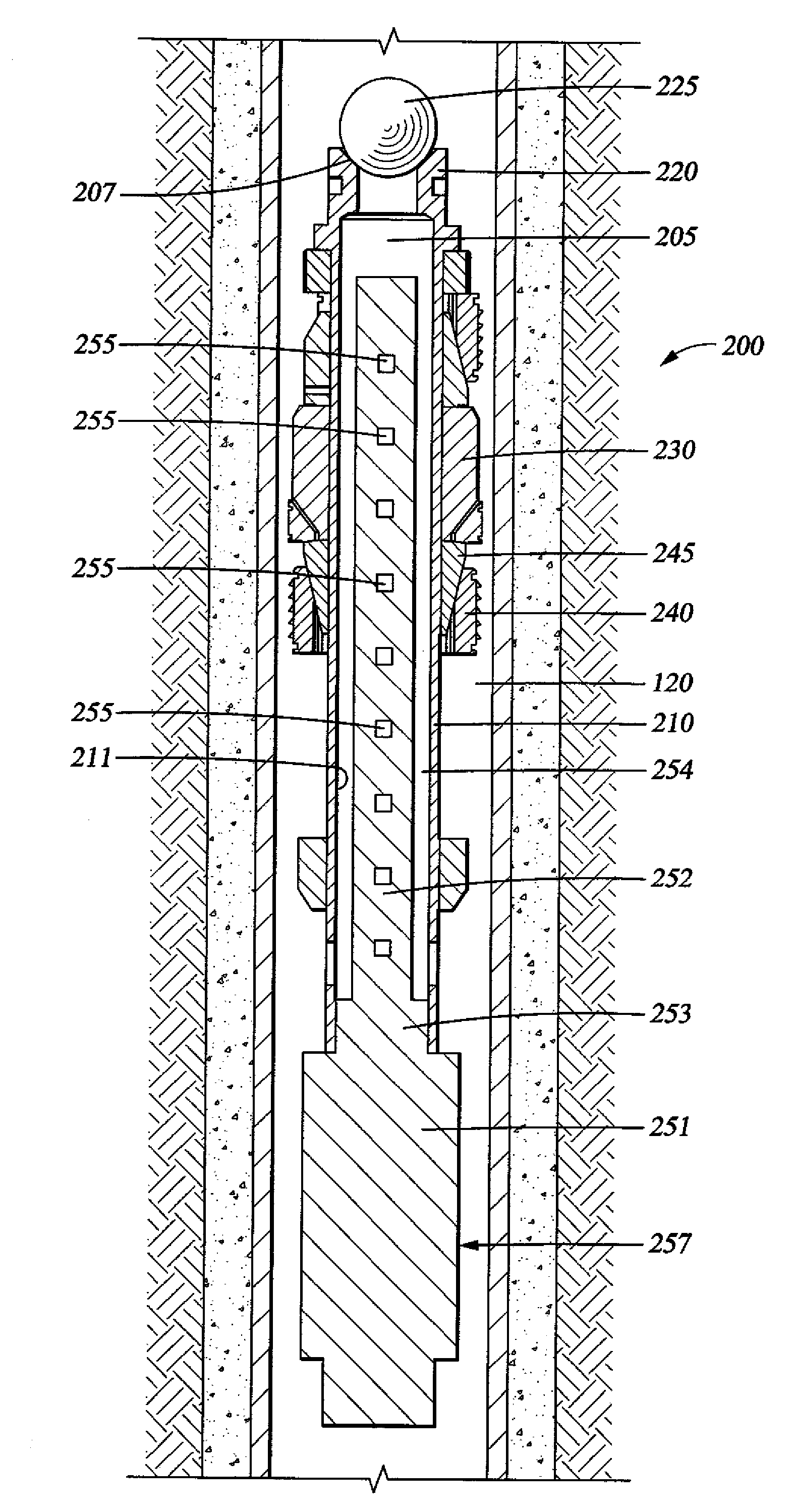

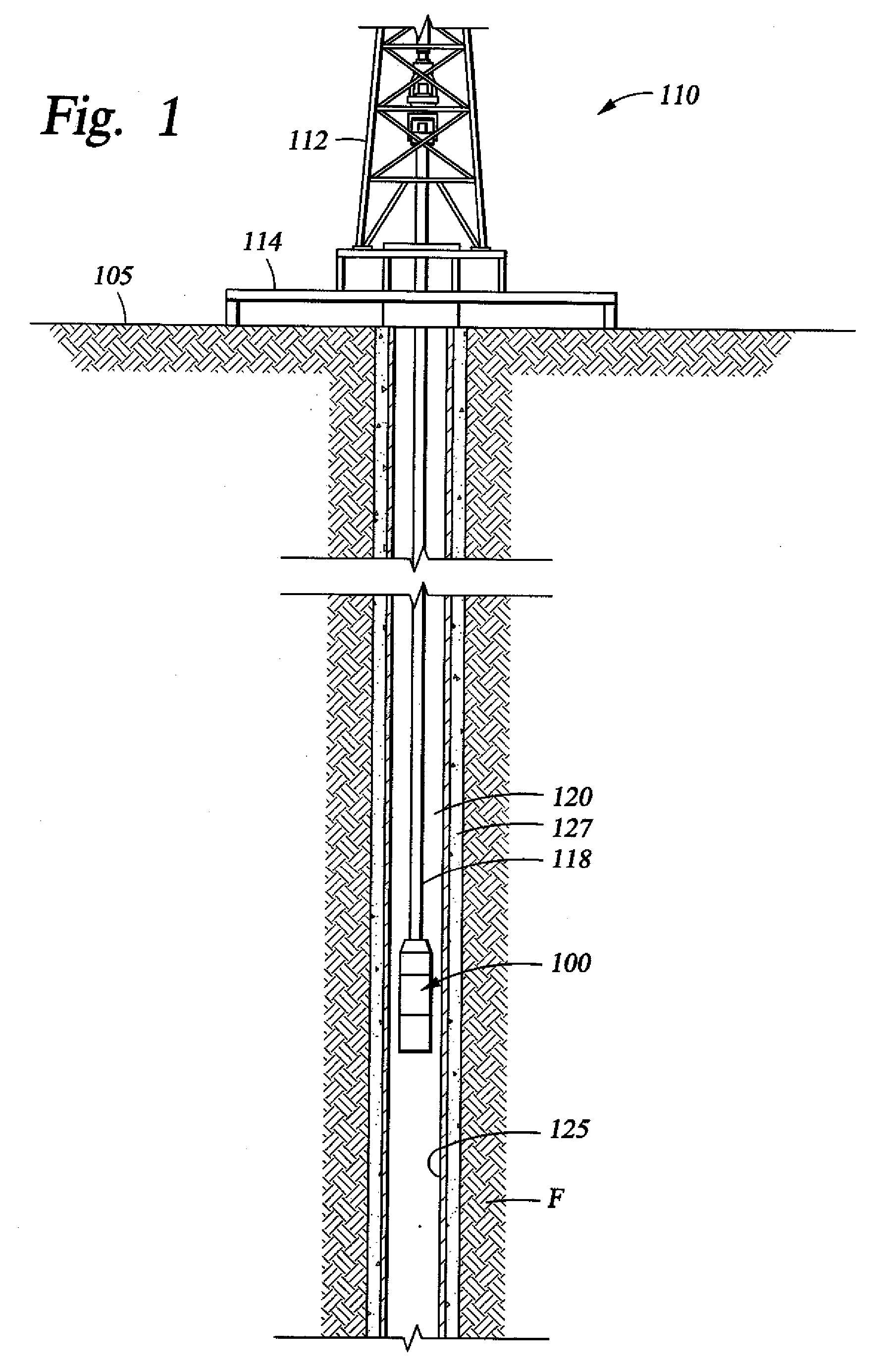

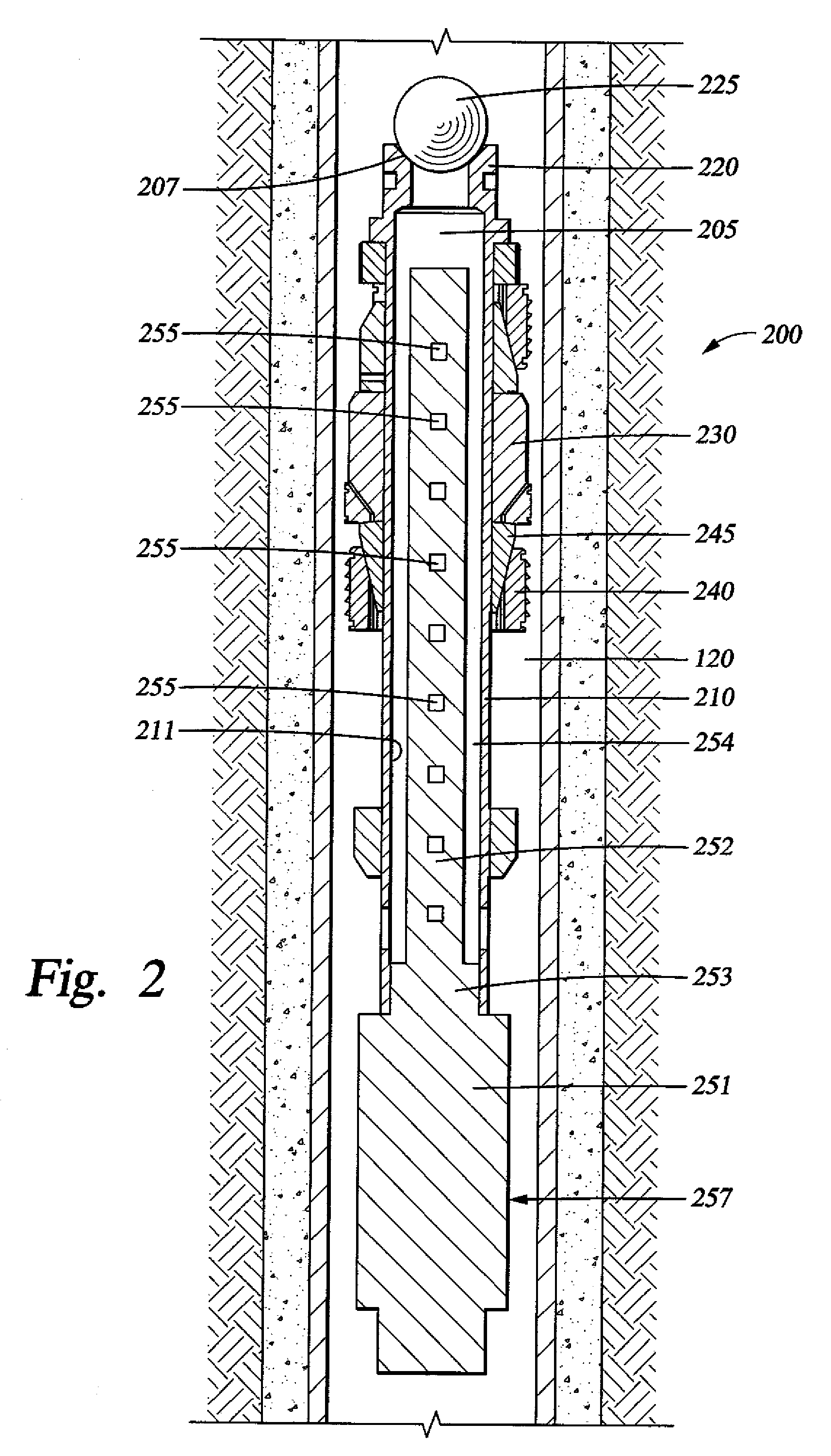

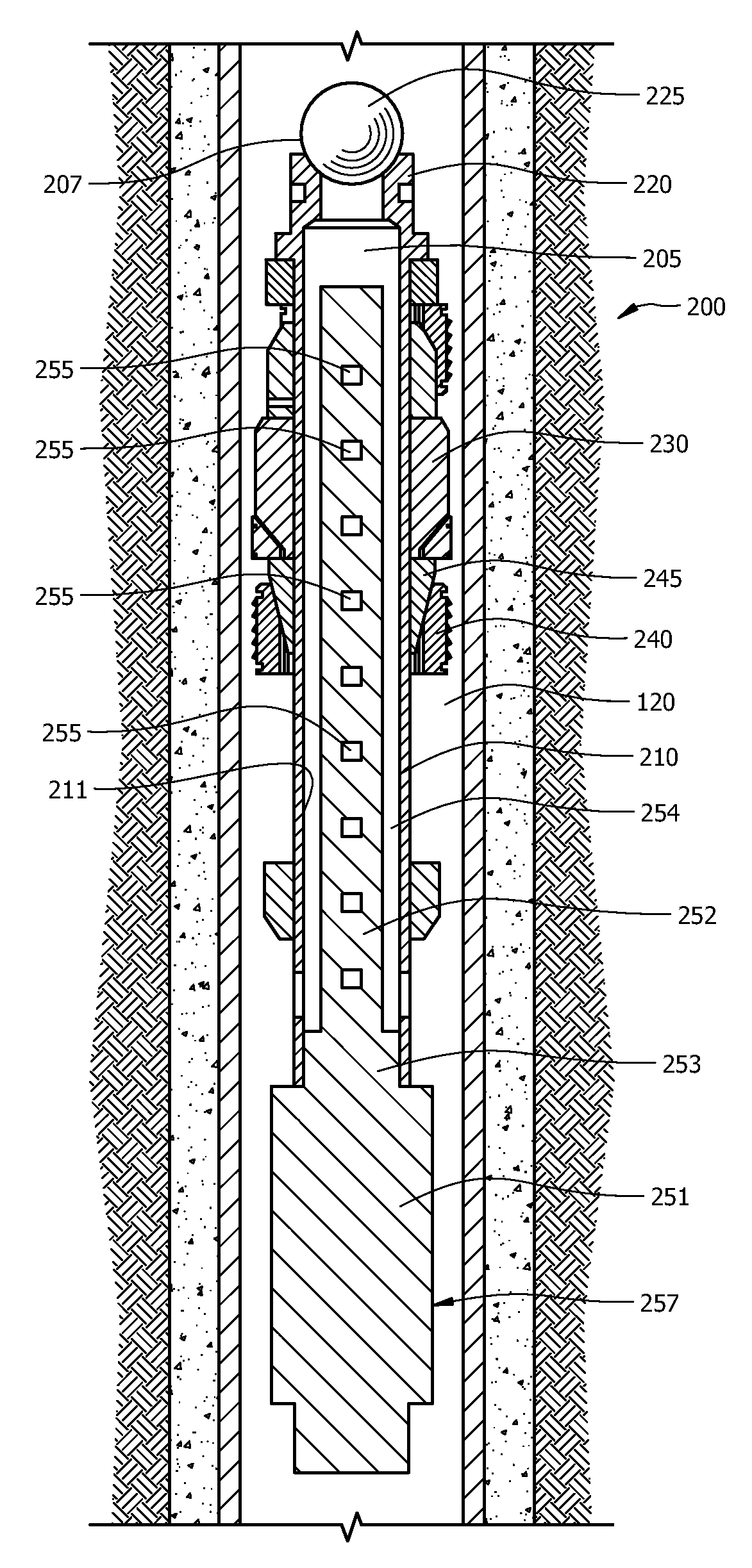

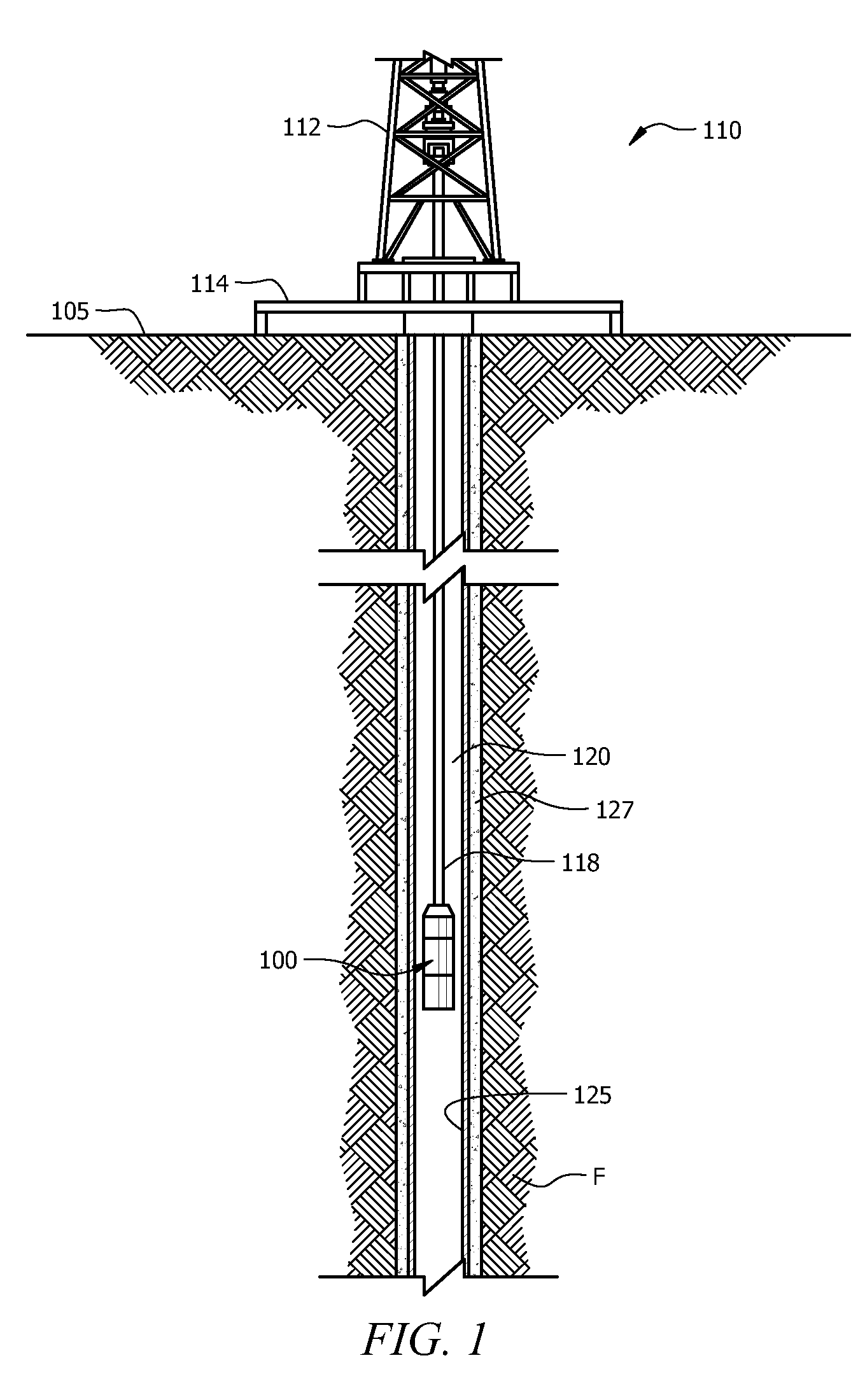

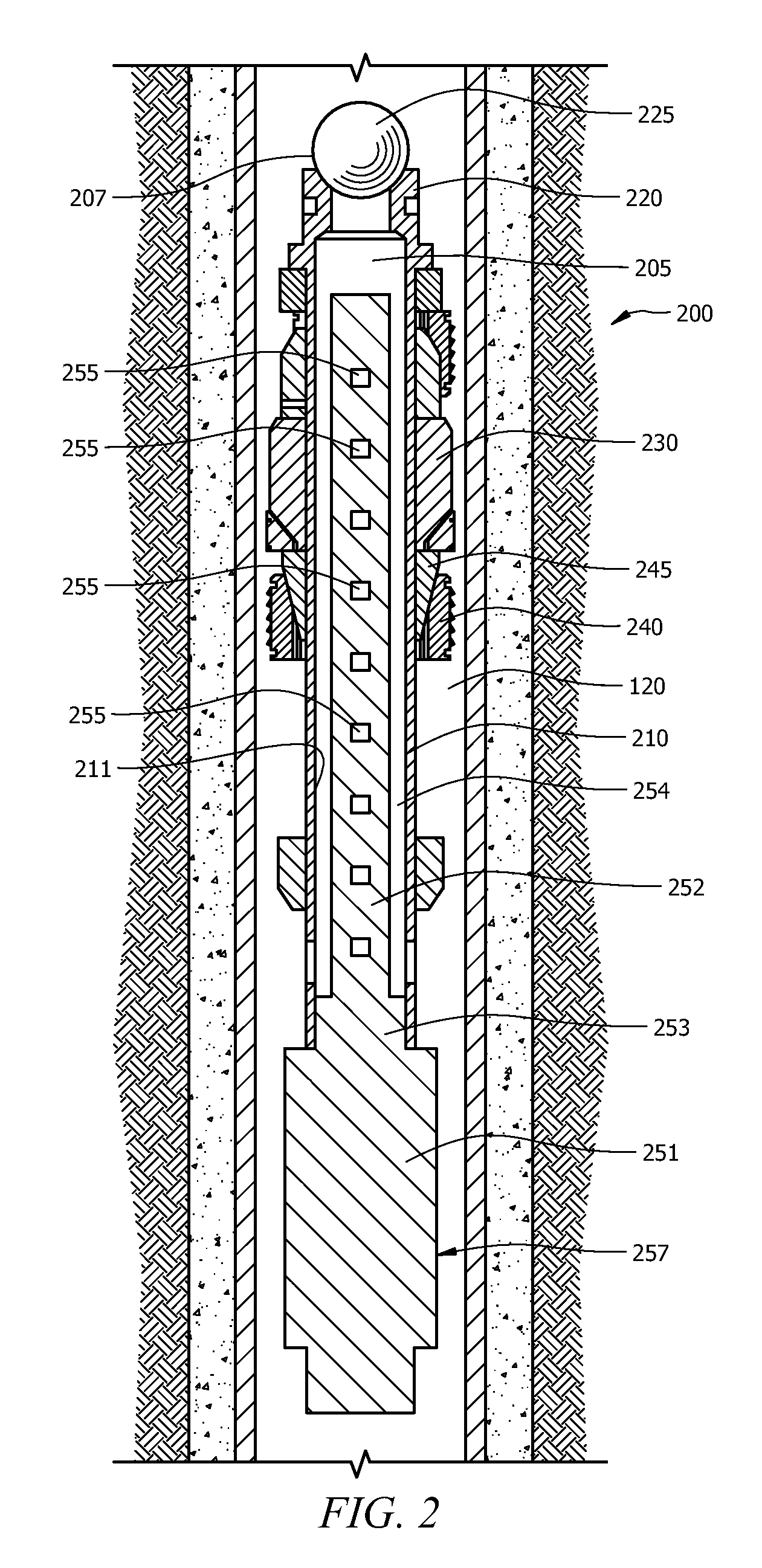

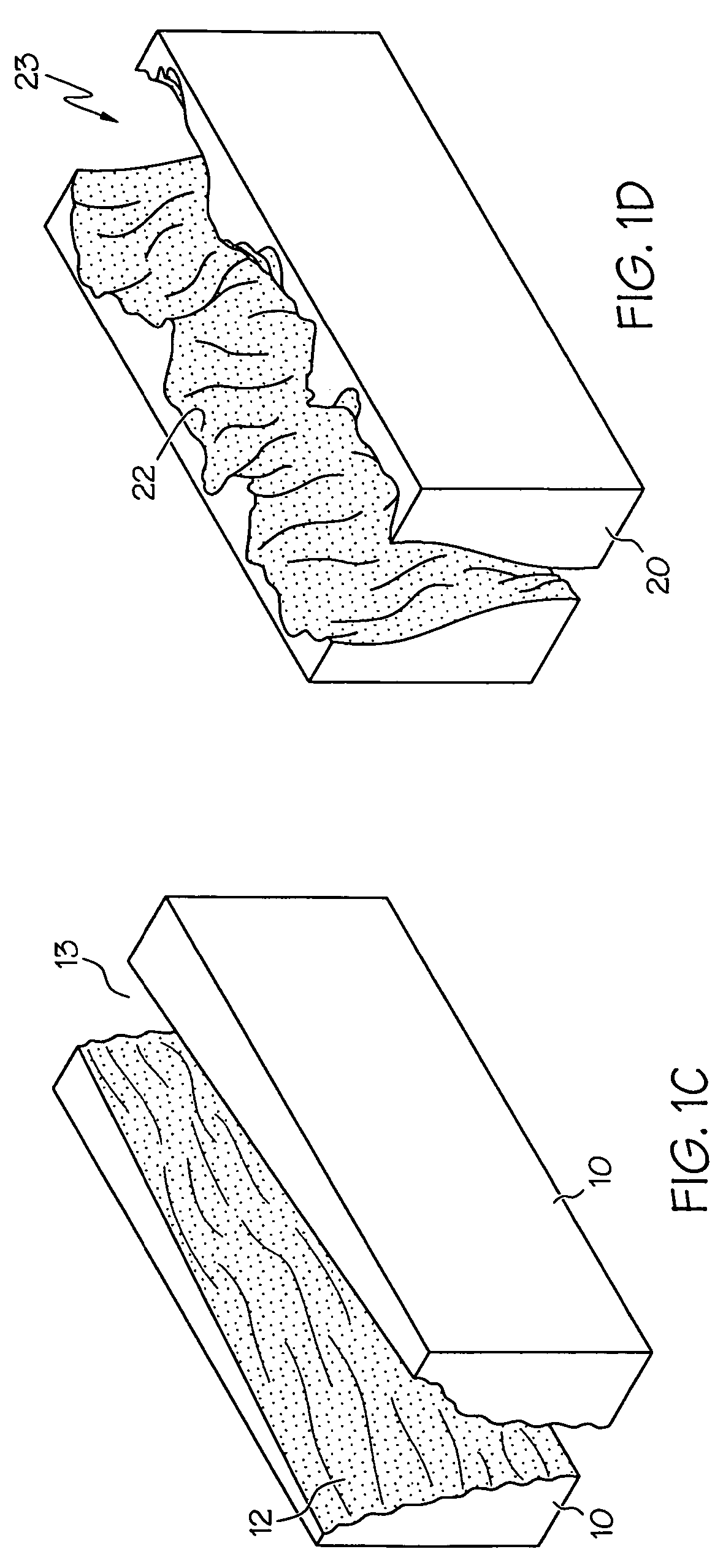

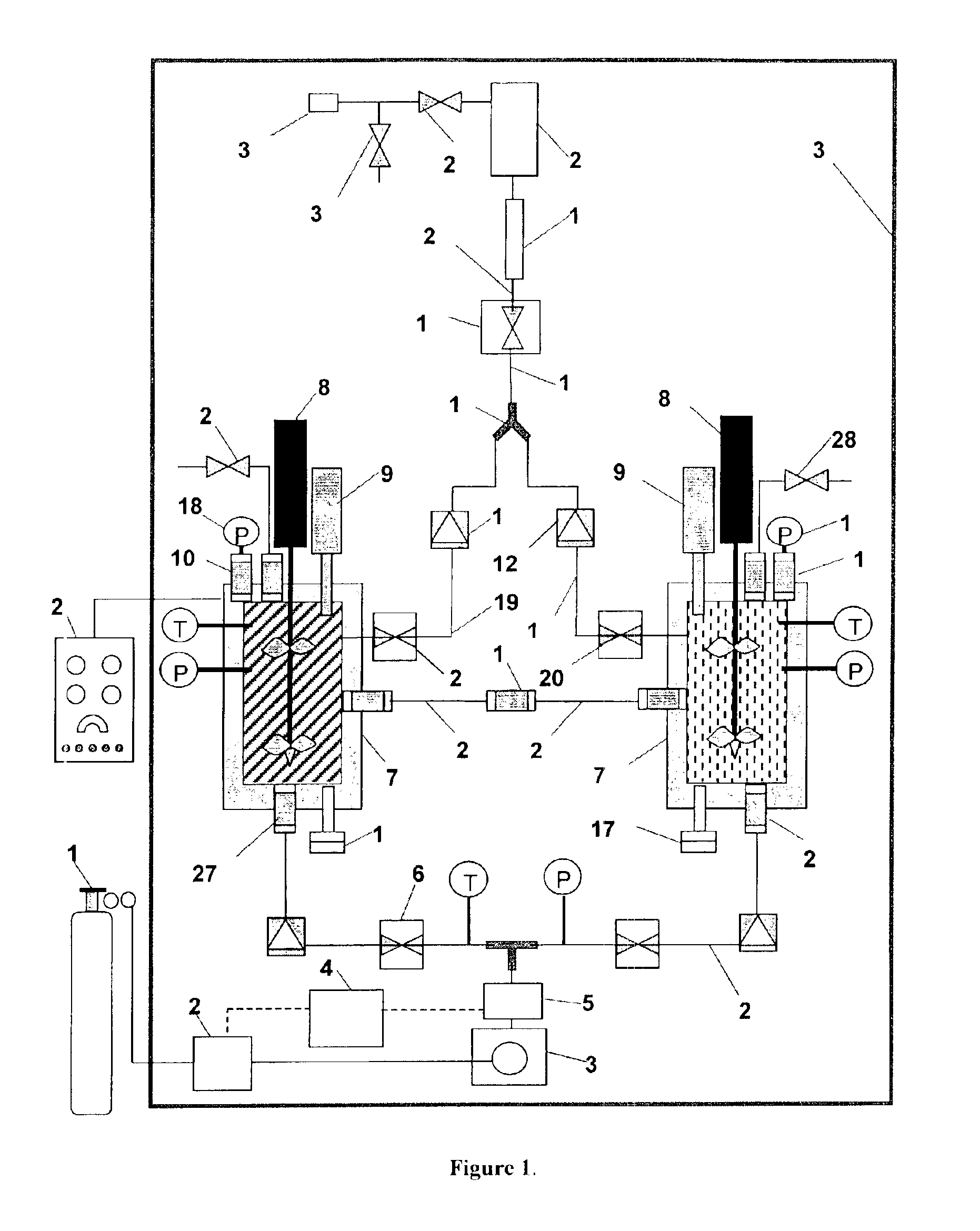

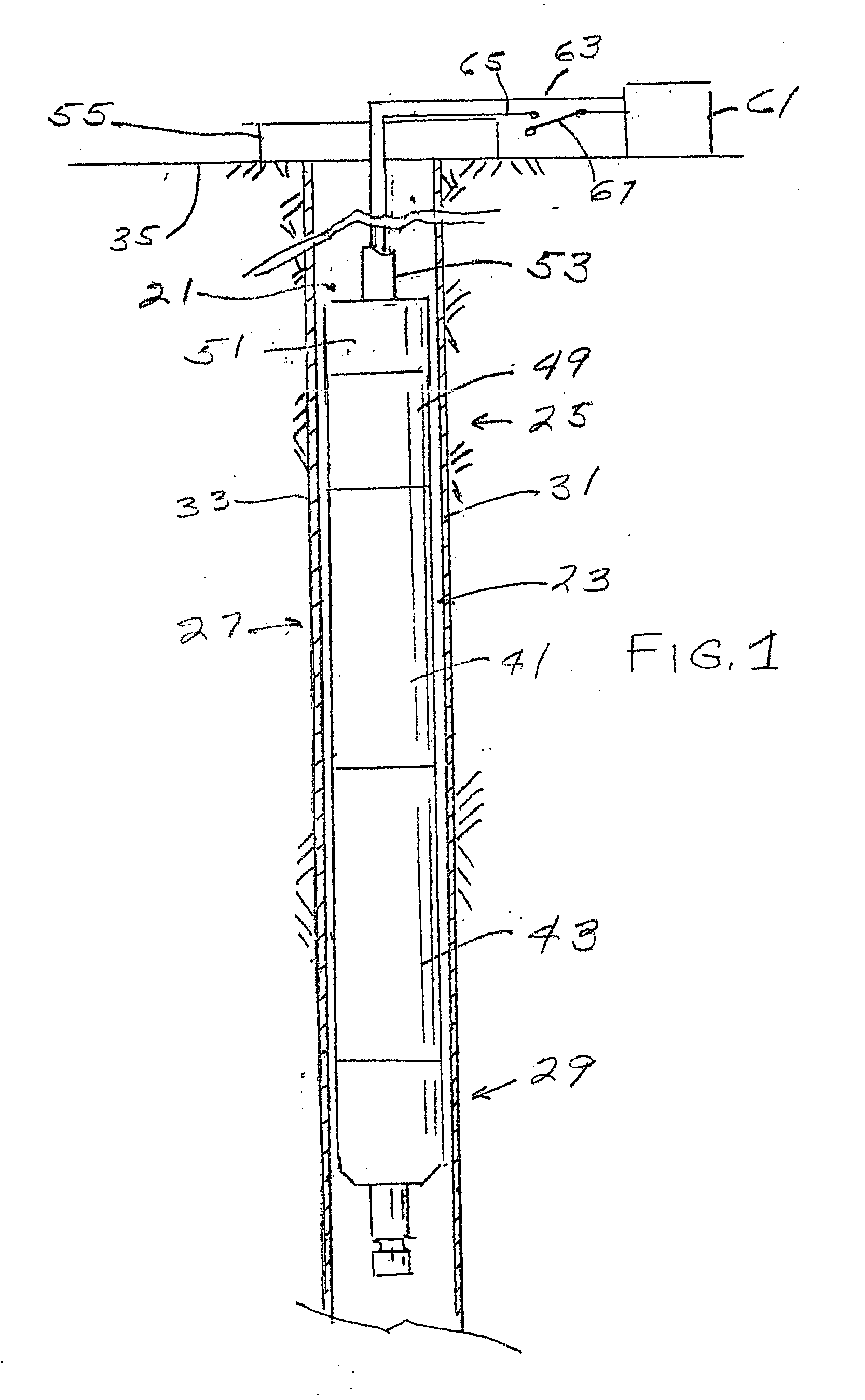

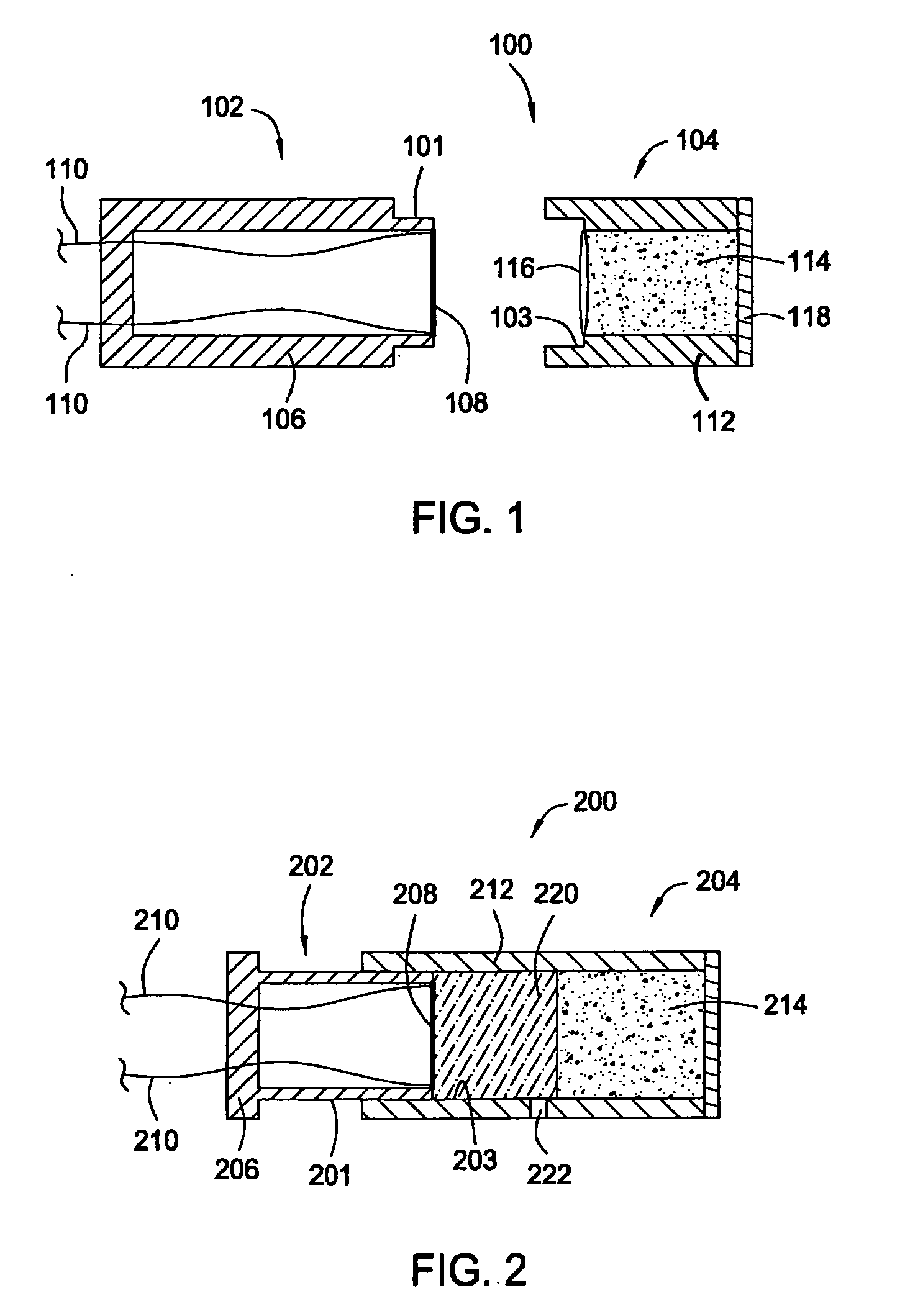

Method and apparatus for repair of wells utilizing meltable repair materials and exothermic reactants as heating agents

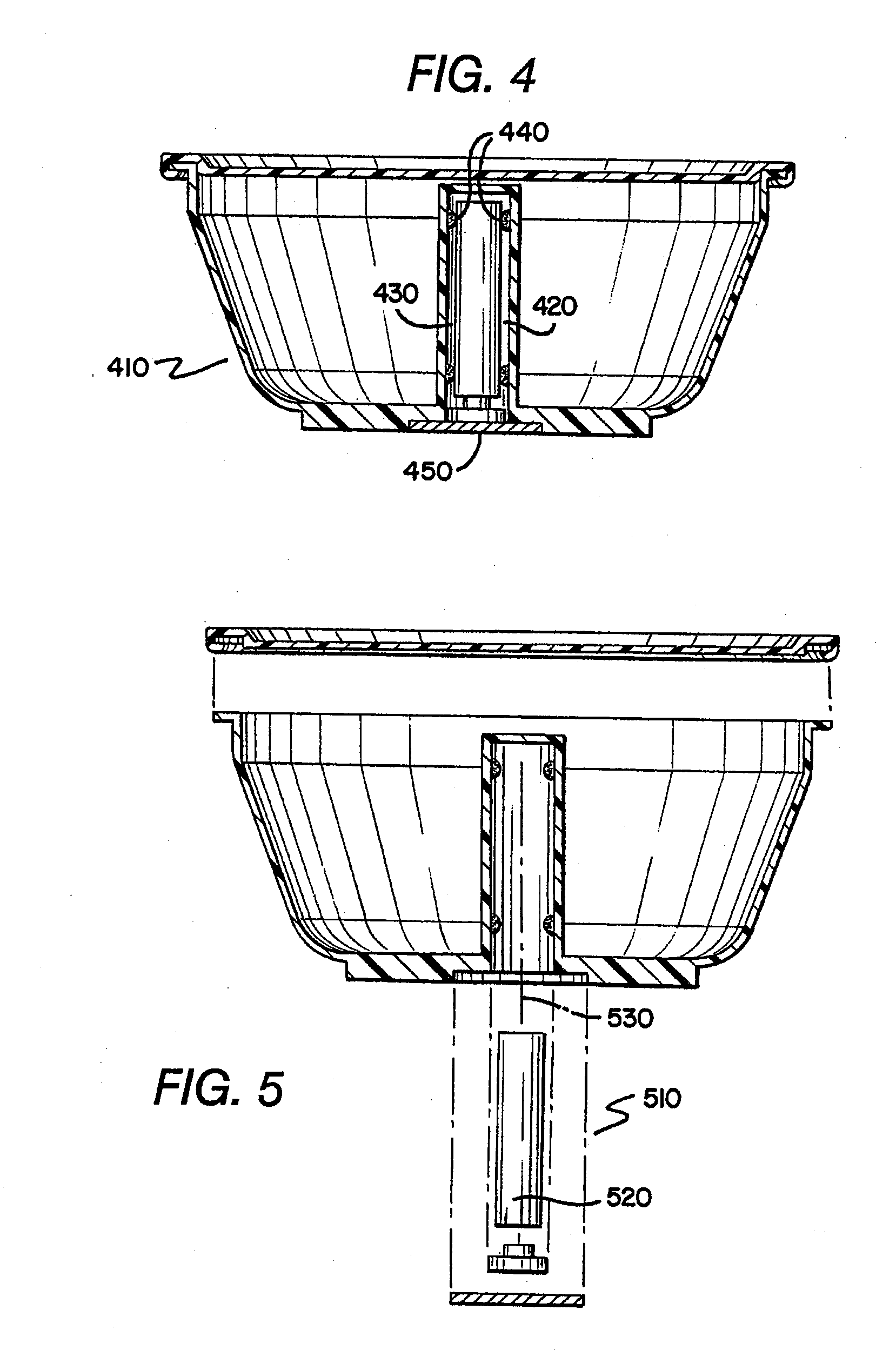

A method and apparatus are described for creating a fluid seal in a subterranean well structure having a fluid seal defect. The method comprises introducing a meltable repair material proximate a structure in a subterranean well which has a fluid seal defect or enhanced seal capacity is required or it is desired to temporarily or permanently hydraulically isolate a portion the well or strengthen the structural integrity of well tubulars or tubular hangers. Exothermic reactant materials are located proximate the meltable repair material. The exothermic reactant material is ignited or an exothermic reaction otherwise initiated which supplies heat to and melts the meltable repair material into a molten mass. The molten mass flows and solidifies across the structure and the fluid seal defect to effect a fluid seal in the subterranean well structure or the structural integrity is enhanced. Examples of preferred exothermic reactant materials include thermite, thermate, fusible chemical reactants such as ammonium chloride and sodium nitrate, and oxidizers and accompanying hydrocarbon based fuels. Examples of preferred meltable repair materials include solder or brazing materials and eutectic metals which expand upon cooling and solidifying from a molten state.

Owner:CHEVROU USA INC

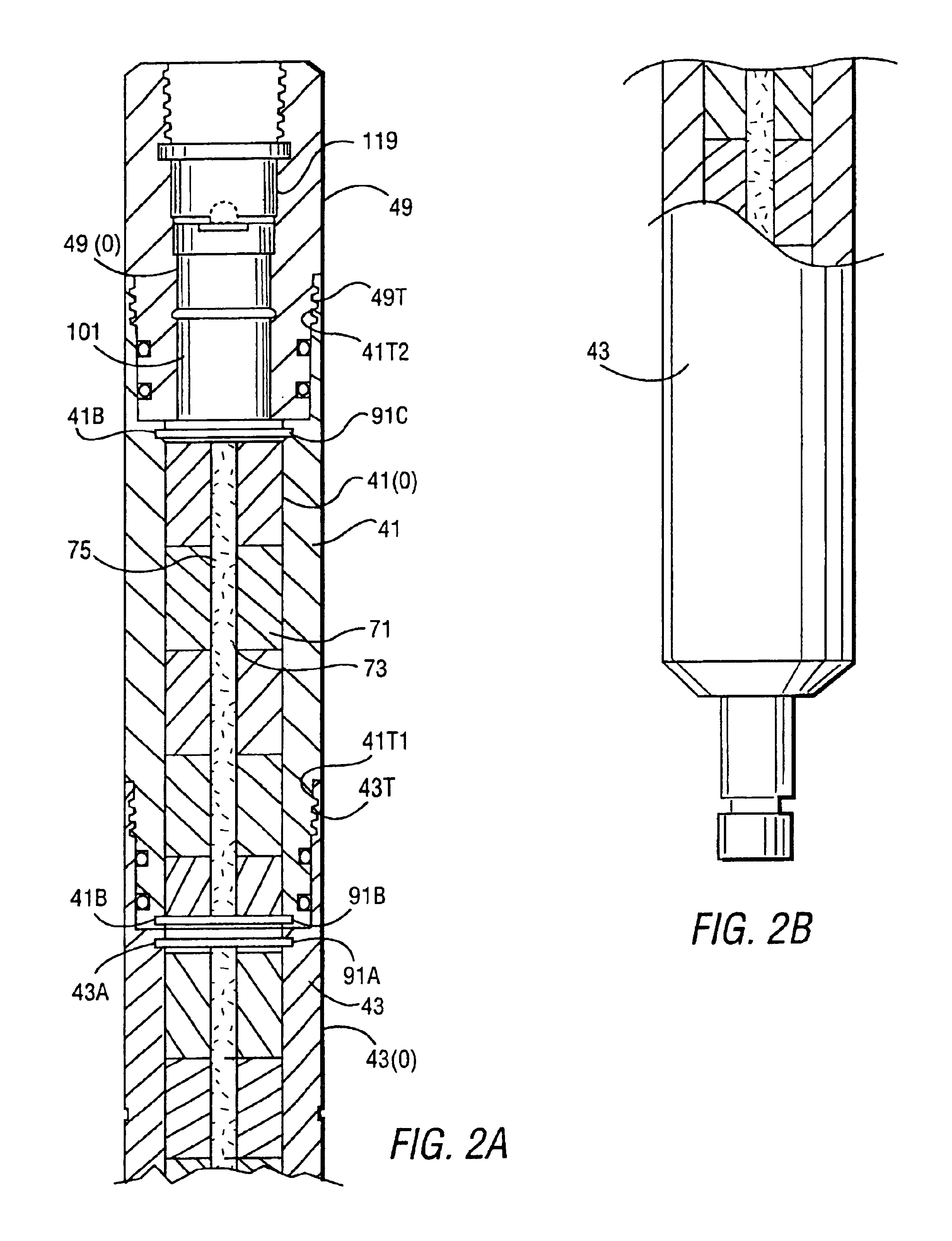

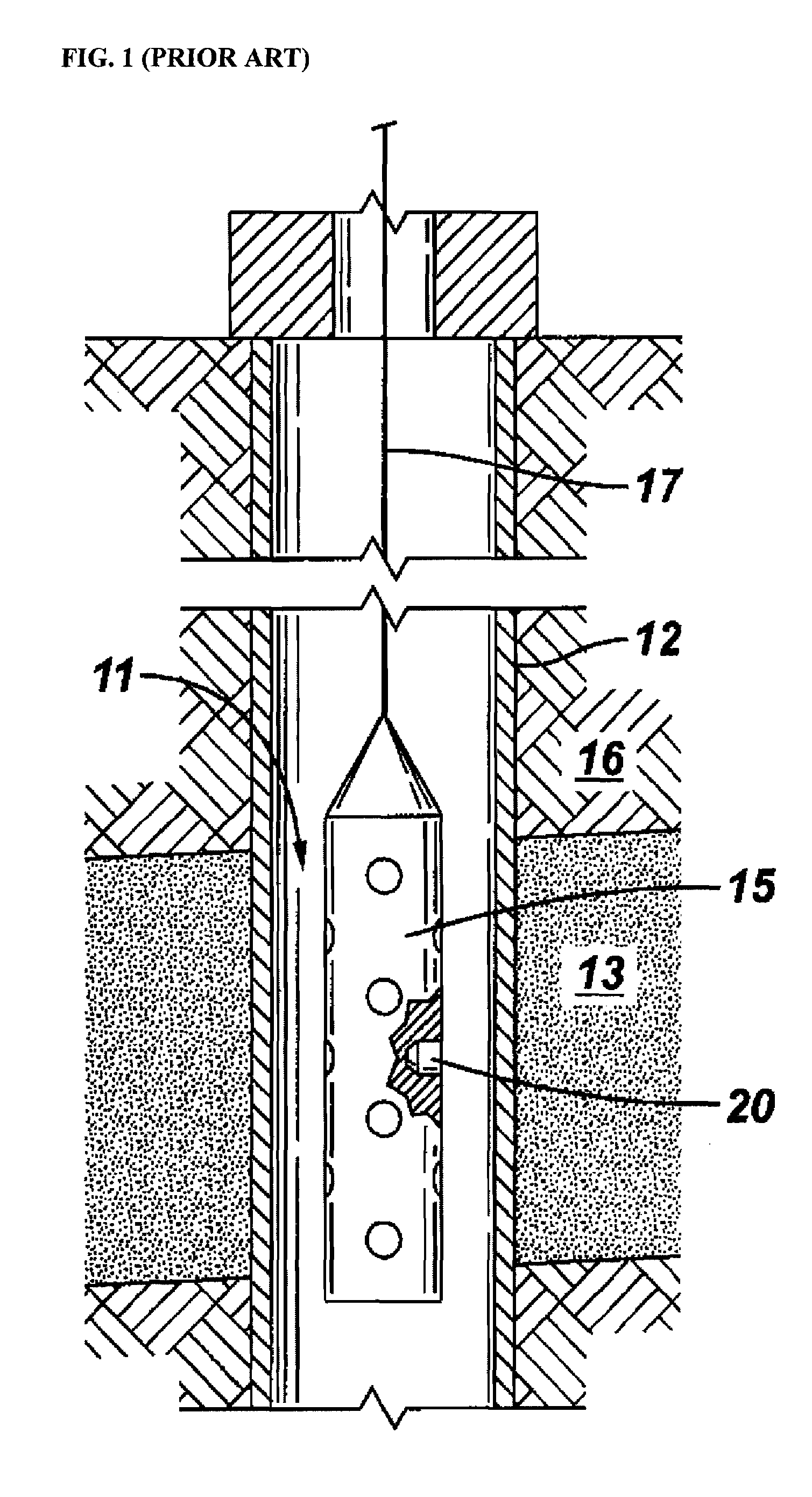

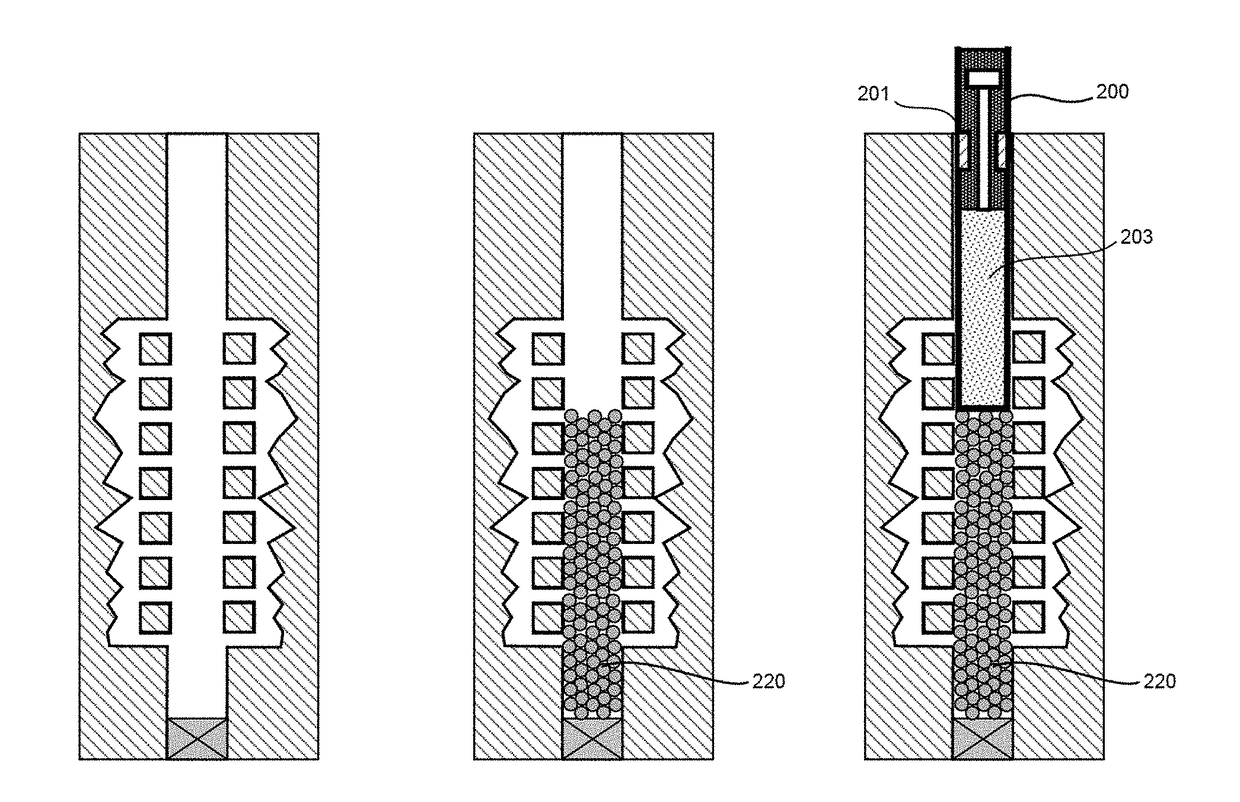

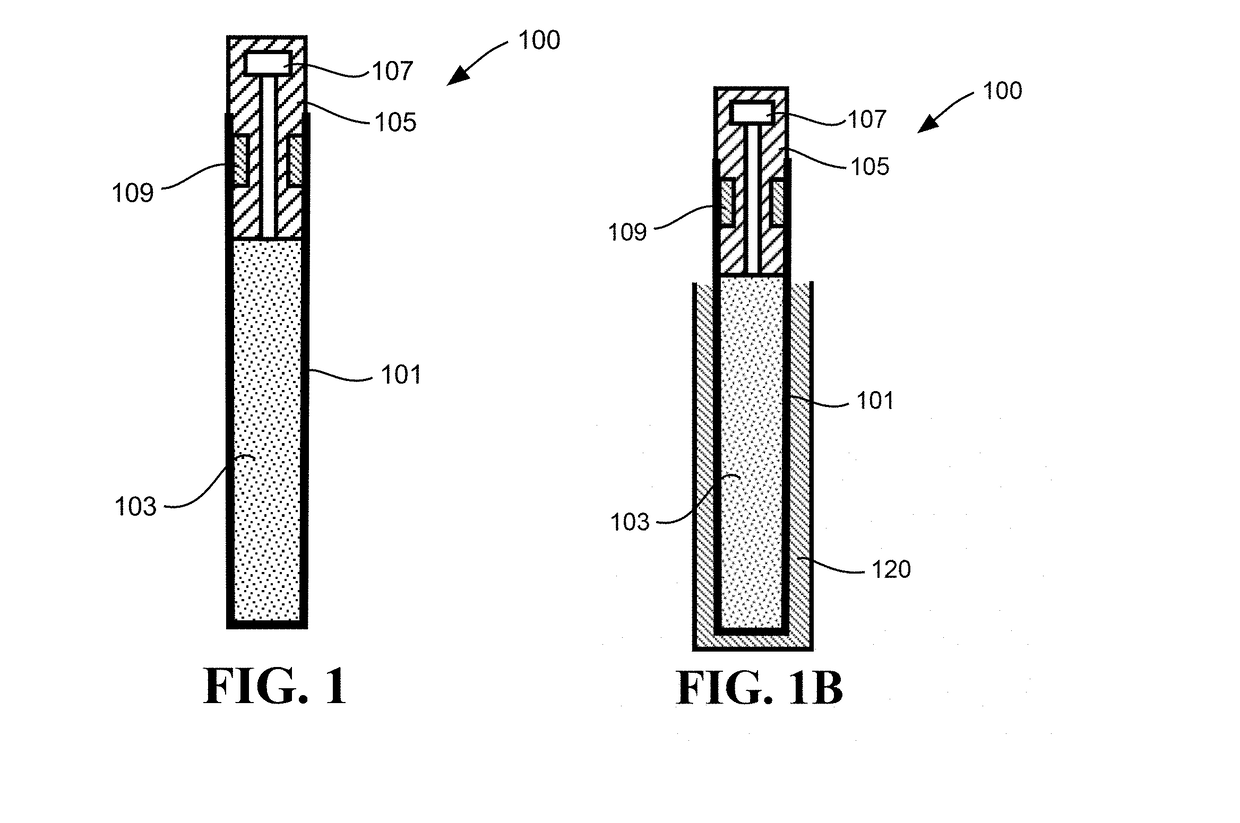

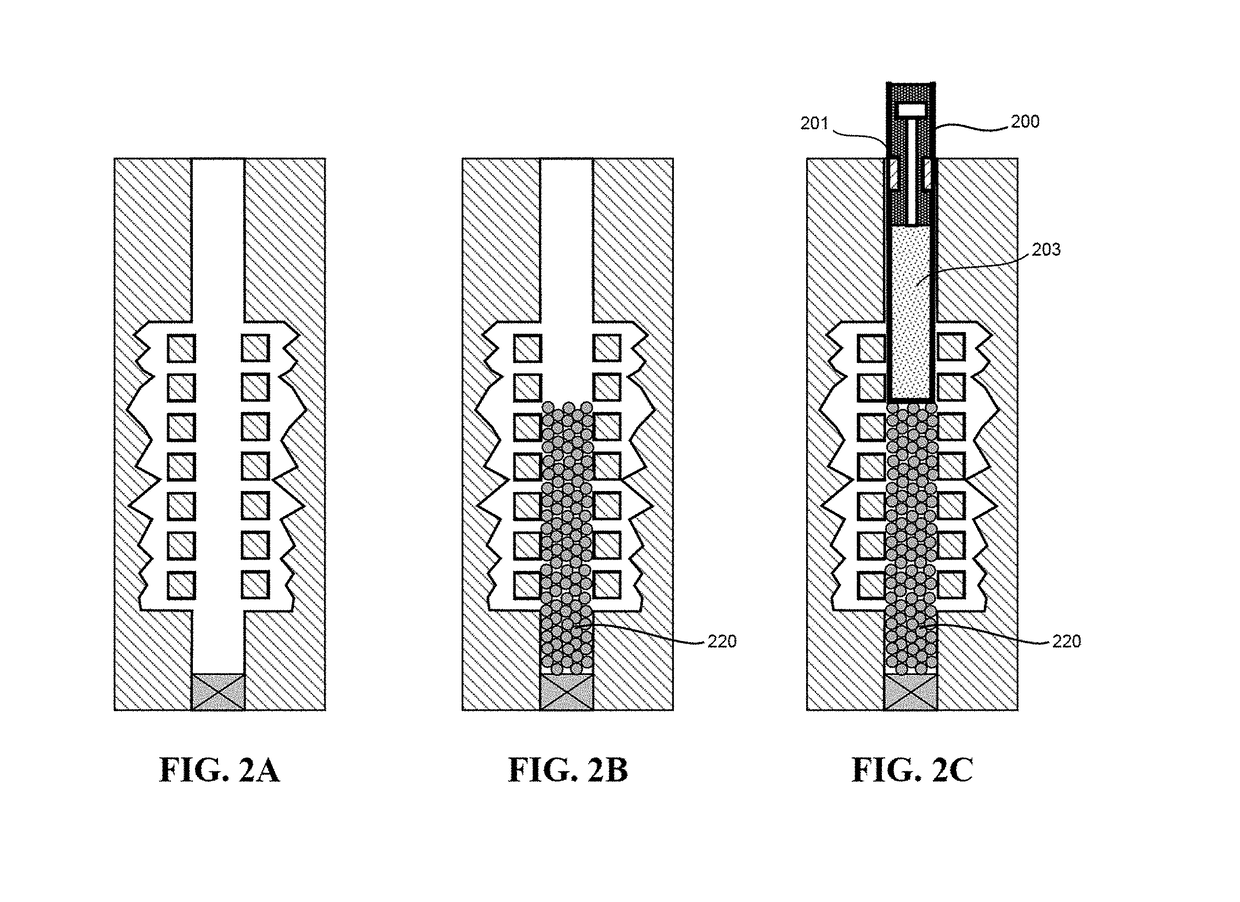

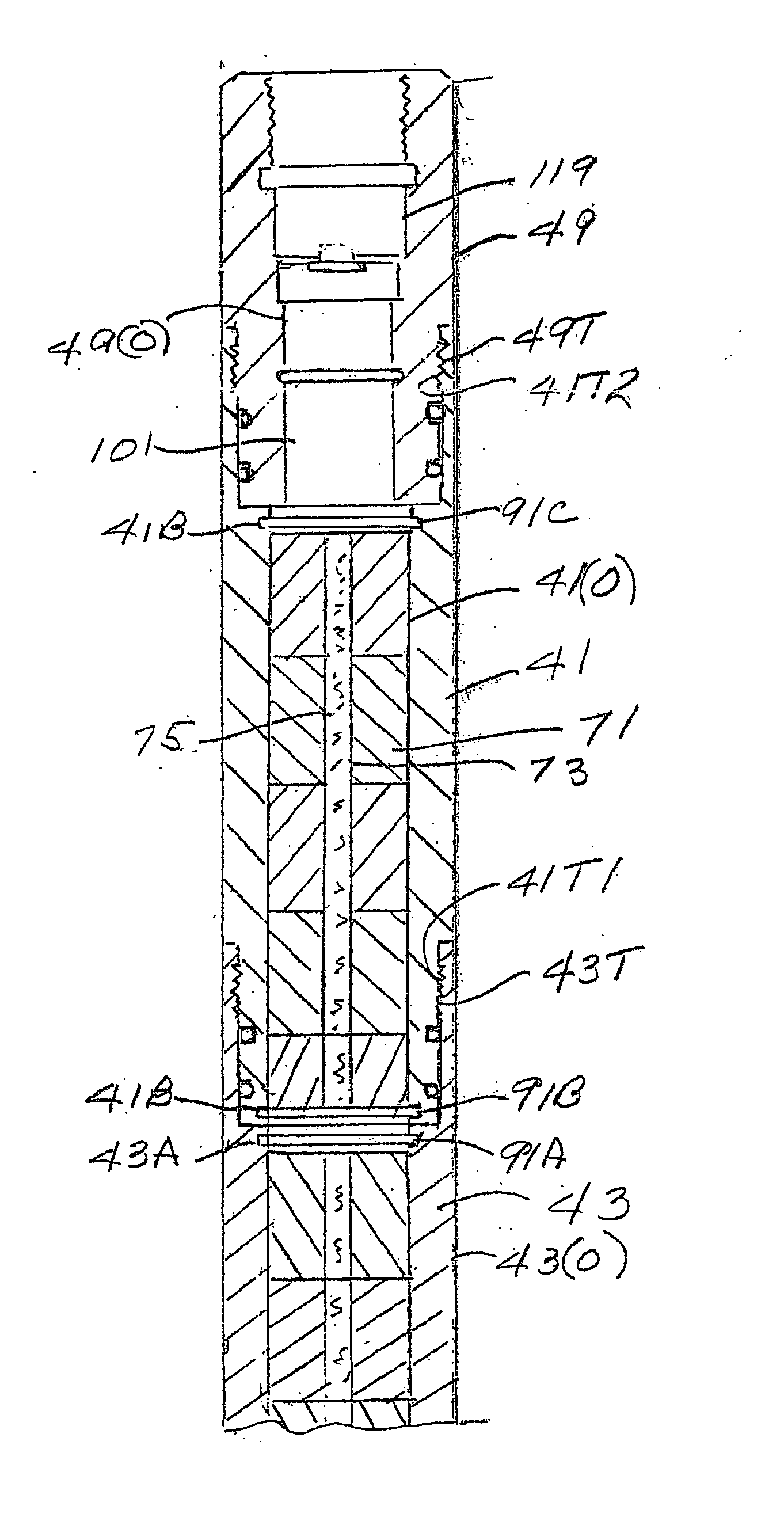

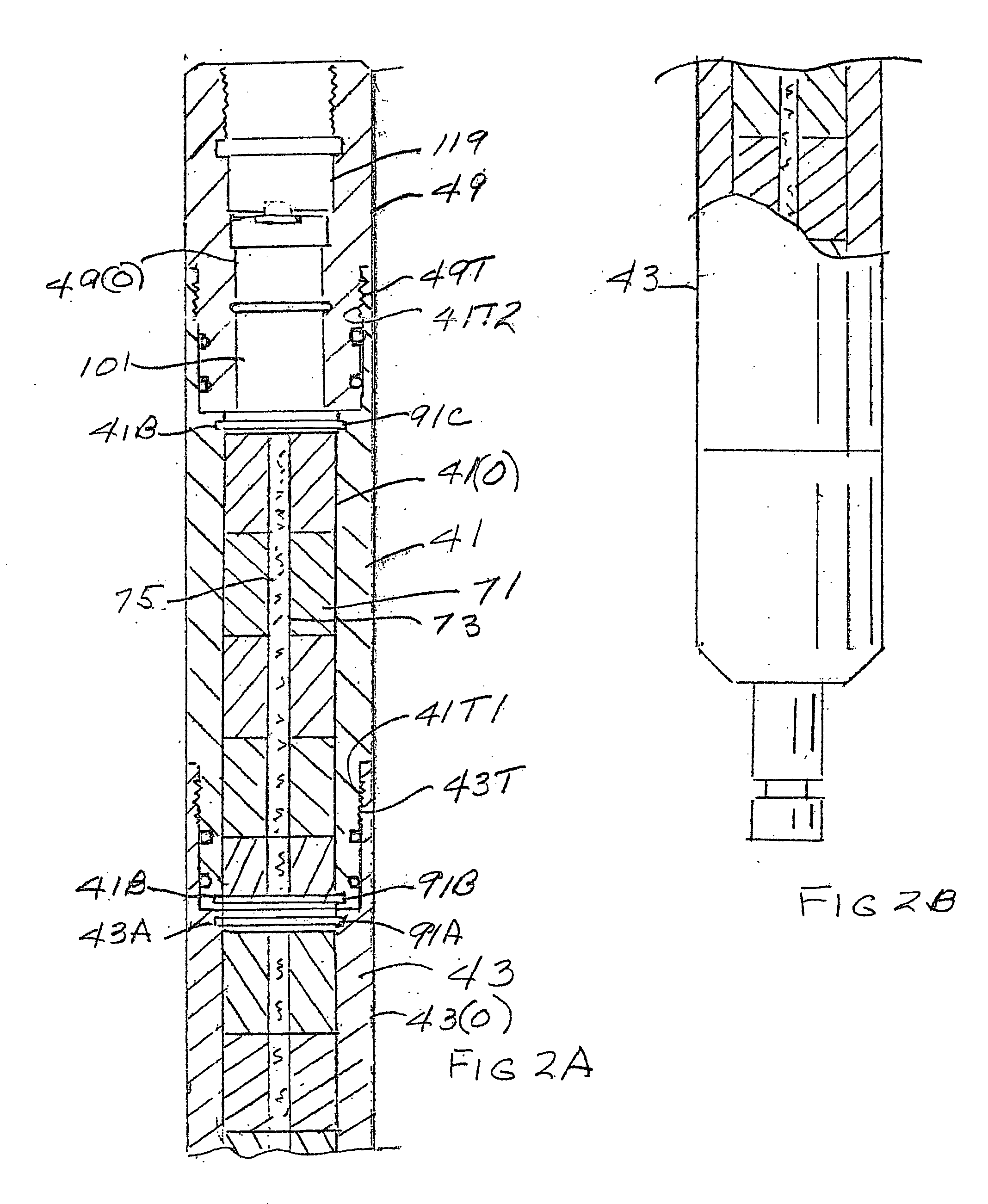

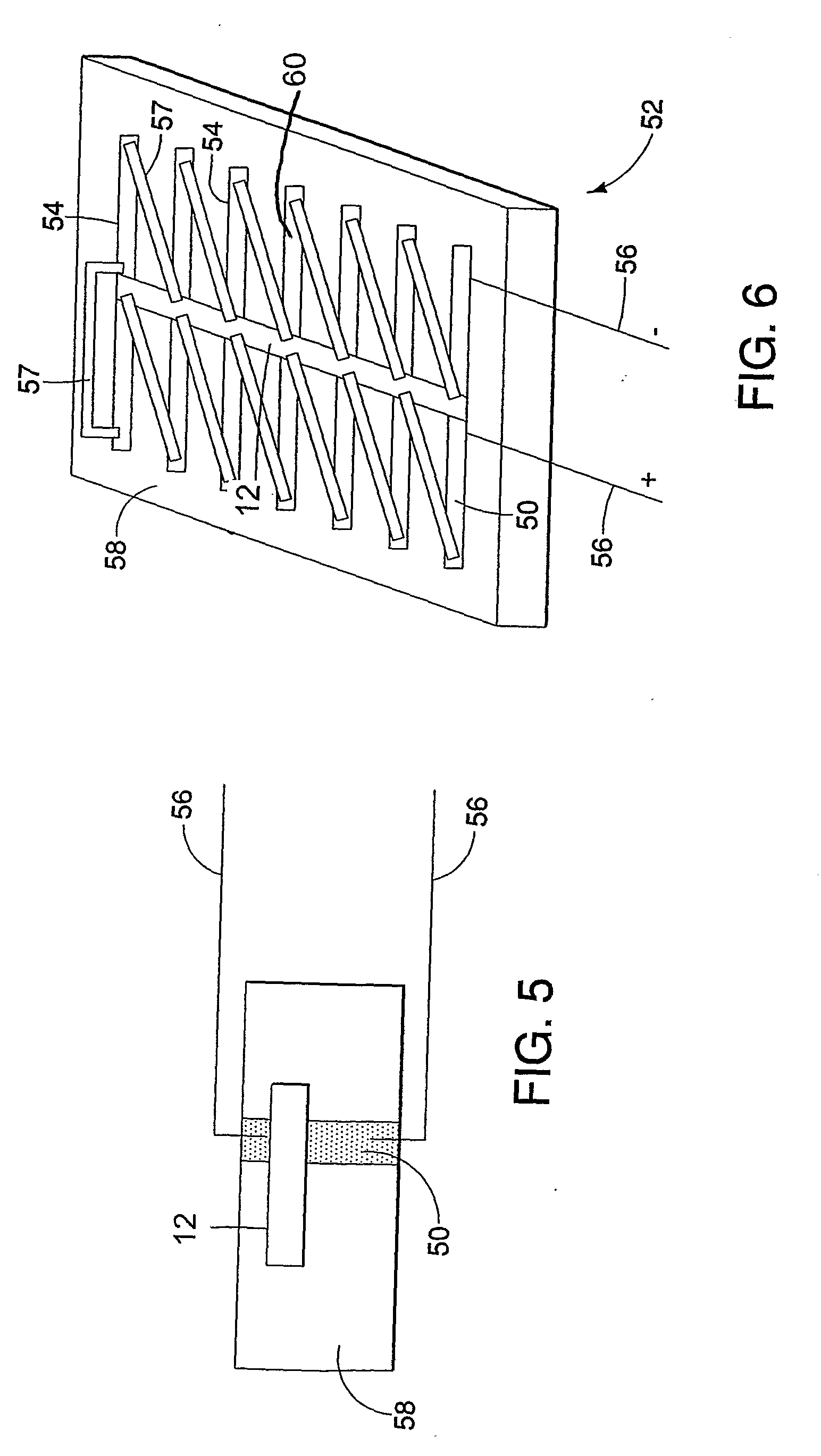

Thermal generator for downhole tools and methods of igniting and assembly

InactiveUS6925937B2Incandescent ignitionFluid removalElectricityElectrical resistance and conductance

Owner:ROBERTSON MICHAEL C

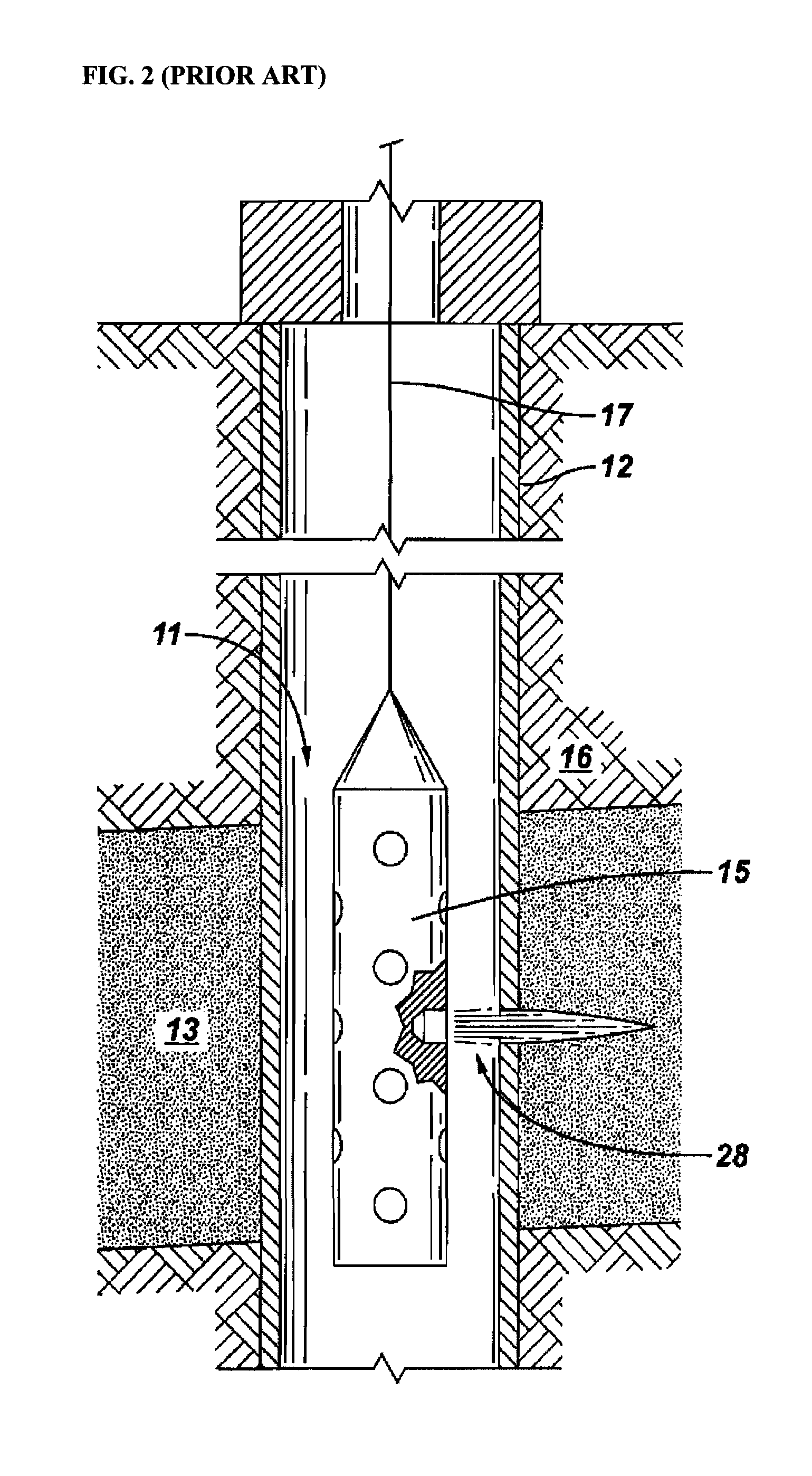

Non-explosive two component initiator

Owner:WEATHERFORD TECH HLDG LLC

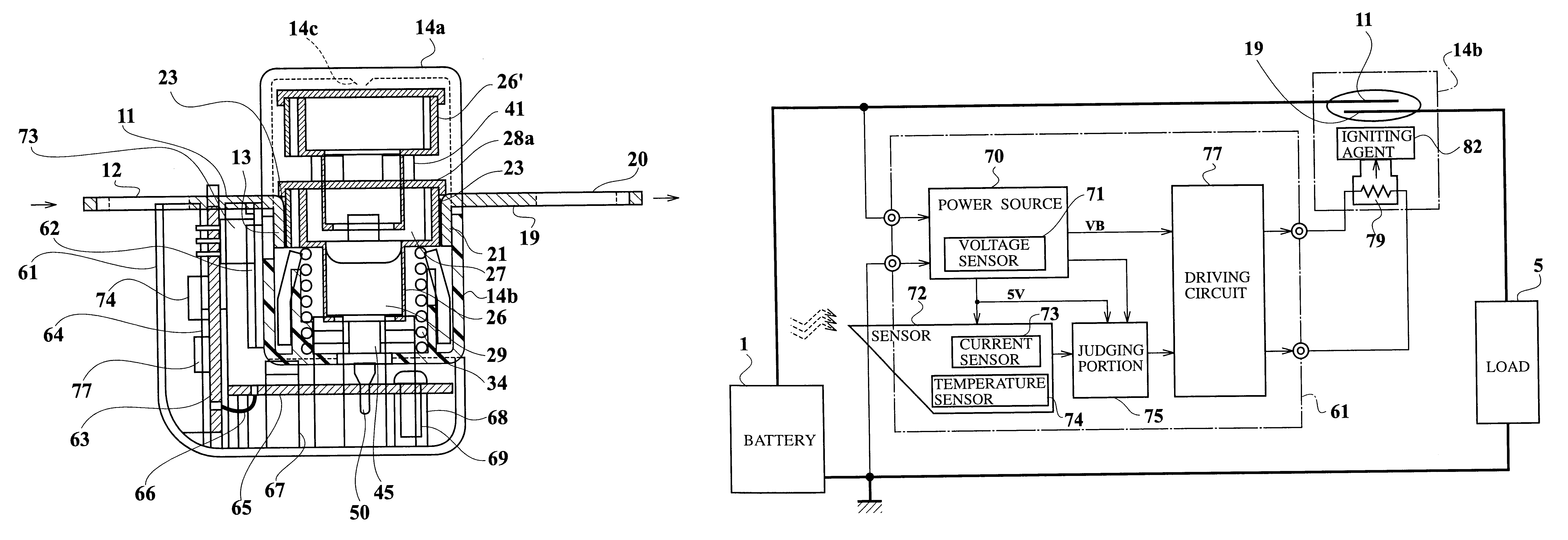

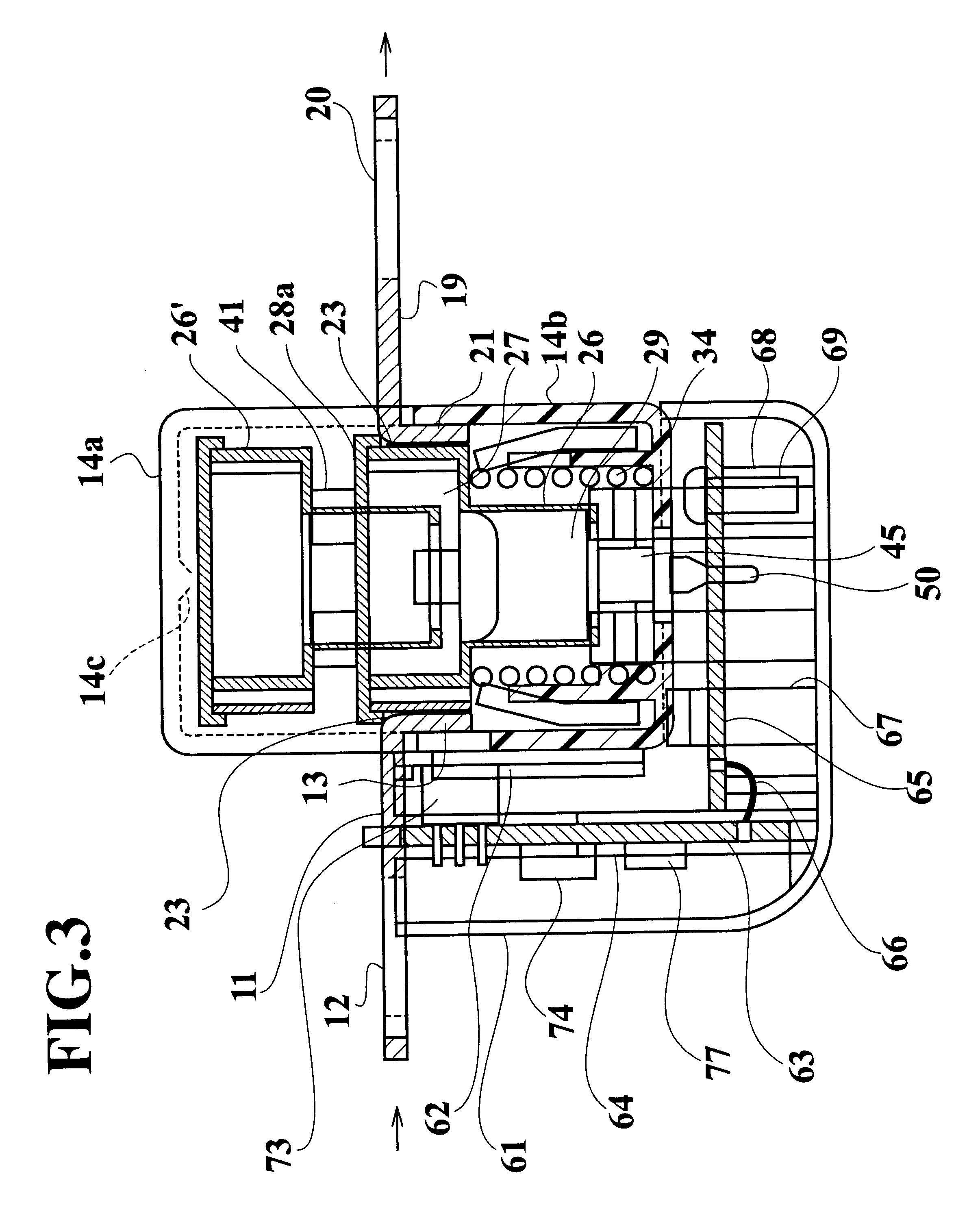

Circuit breaker

A current sensor 73 detects a current flowing through a first buss bar 11. When a current value detected by the current sensor 73 became equal to or greater than a threshold current value, a CPU 74 outputs a driving control signal to a driving circuit 77, and the driving circuit 77 operates an, ignitor 29 through a second substrate 65 and a terminal 50. Therefore, the ignitor 29 ignites, a second projection 41 is melted by heat of a heating agent 27, a compression spring 34 is expanded and a thermite case 26 jumps up. Thus, electrical connection between the thermite case 26 and the first and second buss bars 11, 19 is interrupted. Further, since an outer container 61 in which the current sensor 73, the CPU and the driving circuit 77 are accommodated is integrally assembled with the cap 14a and the resin case 14b in which the thermite case 26, the ignitor 29, the compression spring 34 and the second projection 41 are accommodated, non-operational state of the ignitor 29 due to disconnection of electric wire is not generated.

Owner:YAZAKI CORP

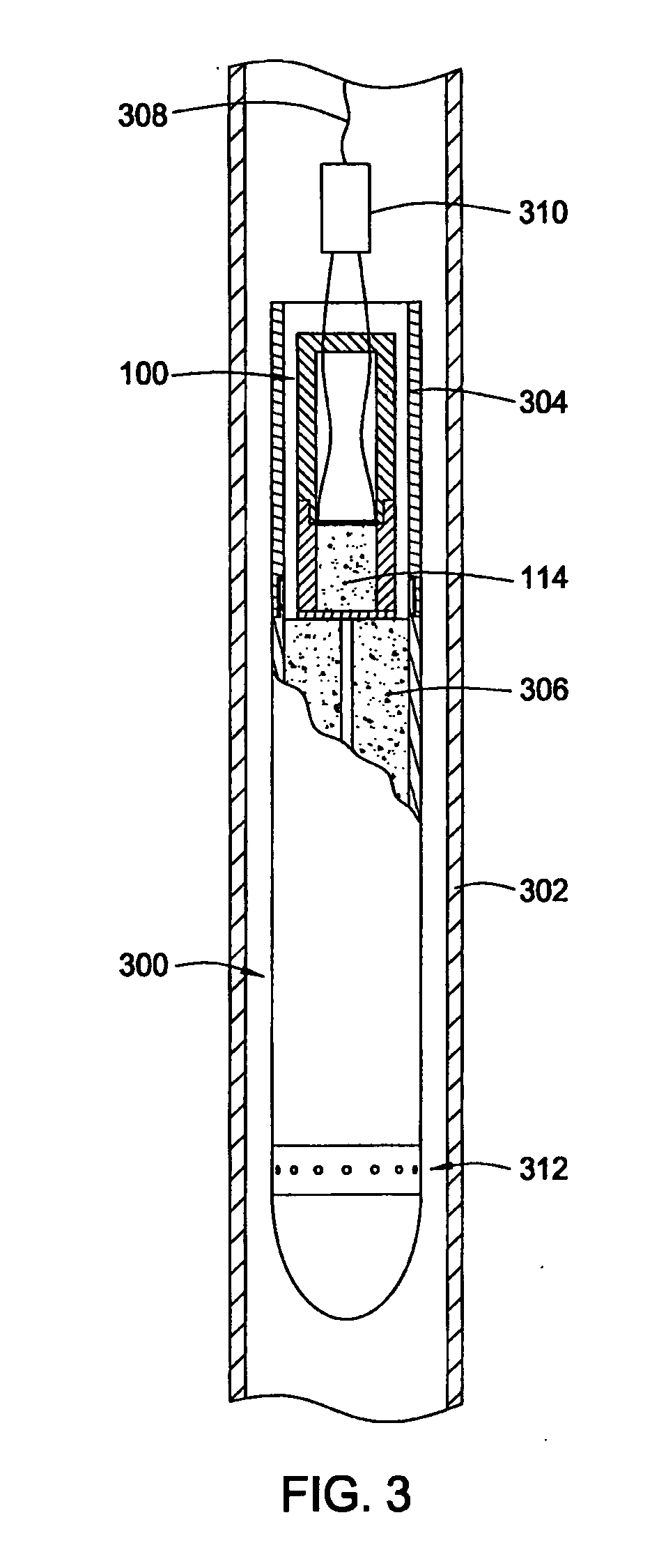

Nano-thermite Well Plug

Owner:CONOCOPHILLIPS CO

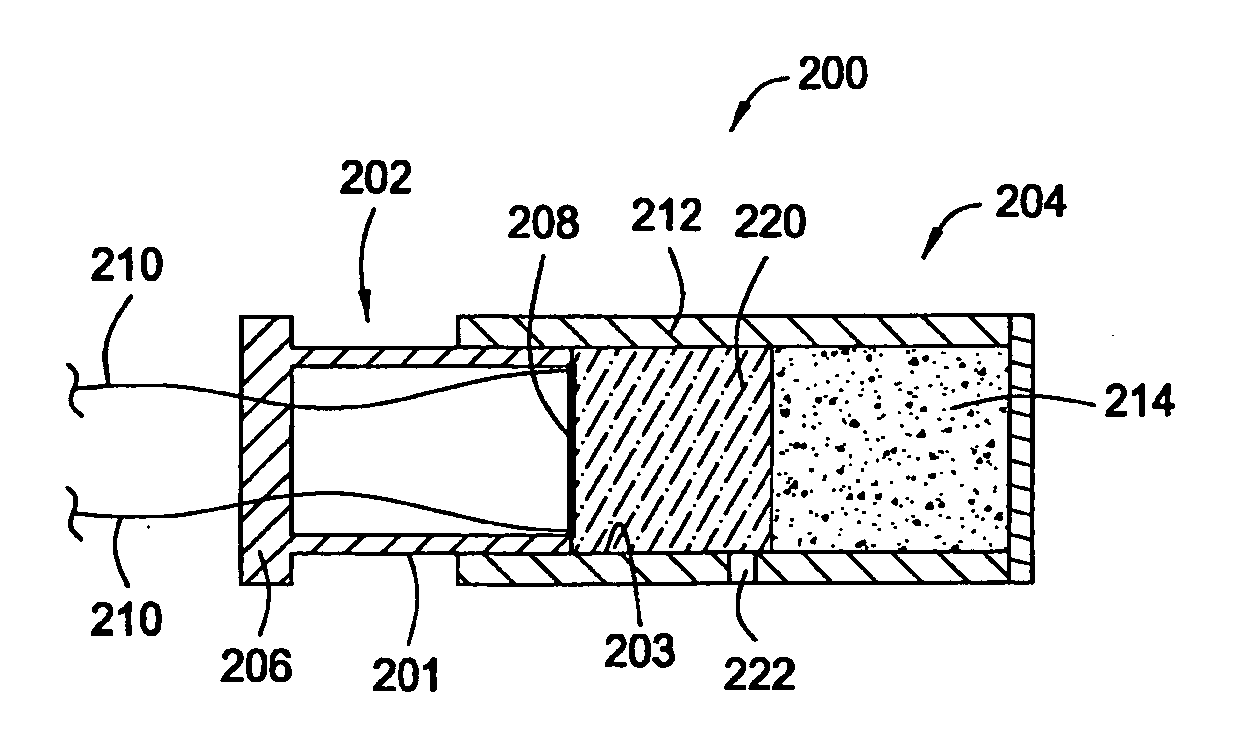

Consumable downhole tools

A downhole tool having a body or structural component comprises a material that is at least partially consumed when exposed to heat and a source of oxygen. The material may comprise a metal, such as magnesium, which is converted to magnesium oxide when exposed to heat and a source of oxygen. The downhole tool may further comprise a torch with a fuel load that produces the heat and source of oxygen when burned. The fuel load may comprise a flammable, non-explosive solid, such as thermite.

Owner:HALLIBURTON ENERGY SERVICES INC

Consumable Downhole Tools

A downhole tool having a body or structural component comprises a material that is at least partially consumed when exposed to heat and a source of oxygen. The material may comprise a metal, such as magnesium, which is converted to magnesium oxide when exposed to heat and a source of oxygen. The downhole tool may further comprise a torch with a fuel load that produces the heat and source of oxygen when burned. The fuel load may comprise a flammable, non-explosive solid, such as thermite.

Owner:HALLIBURTON ENERGY SERVICES INC

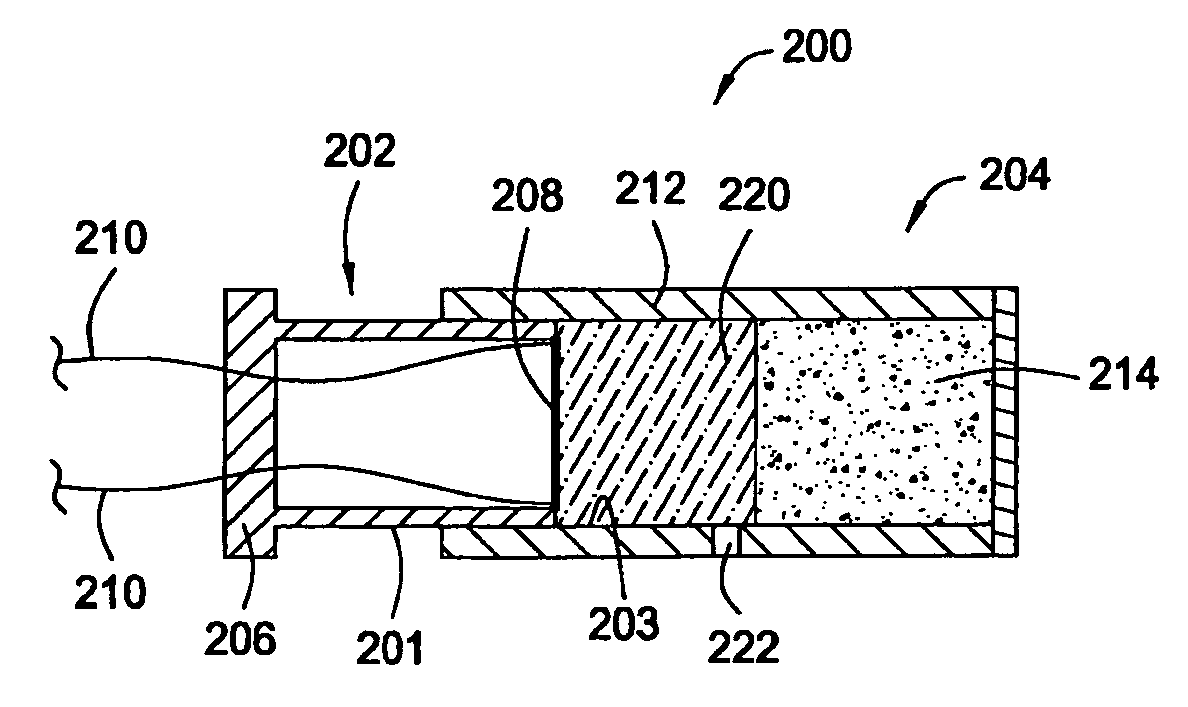

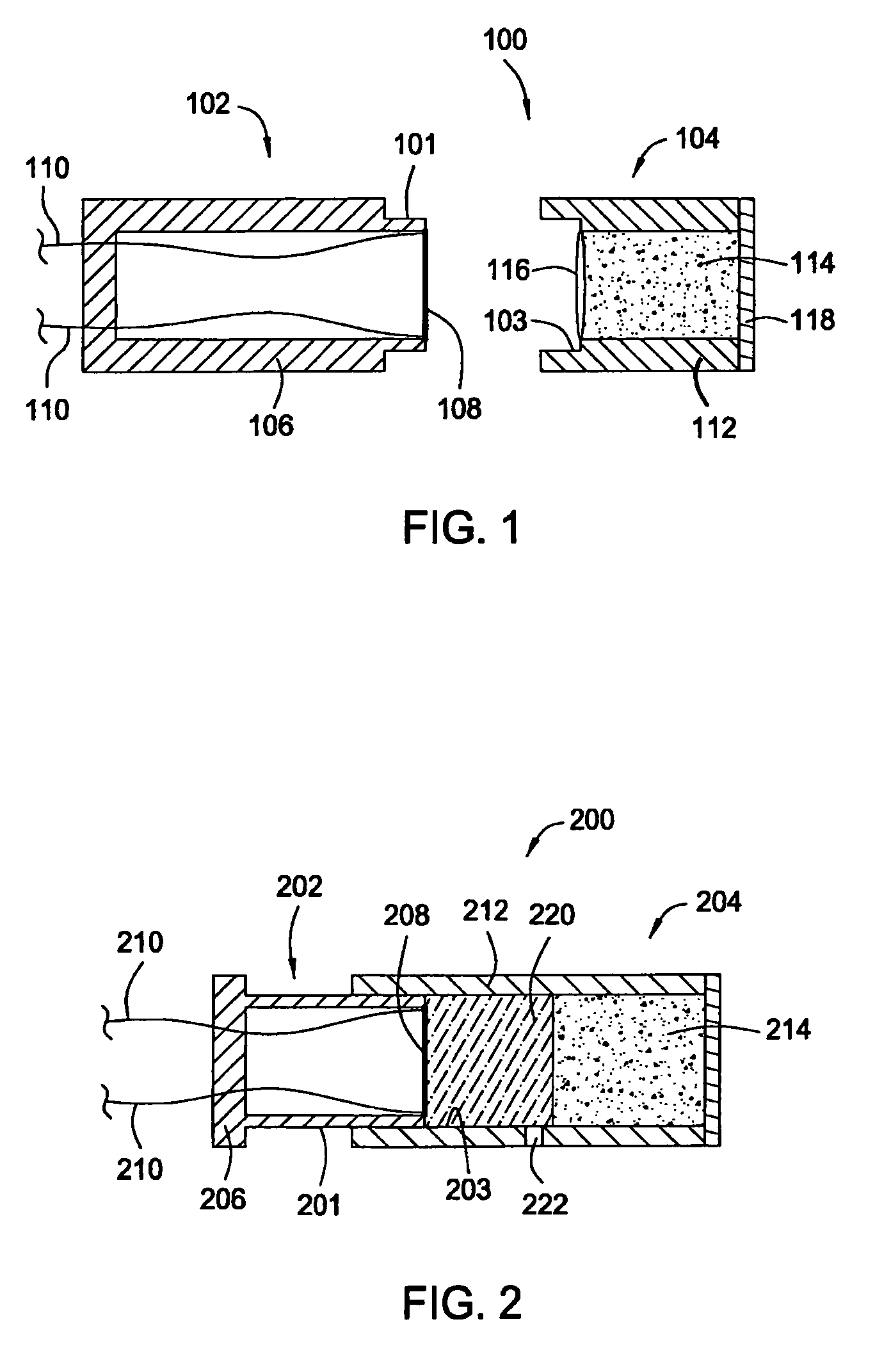

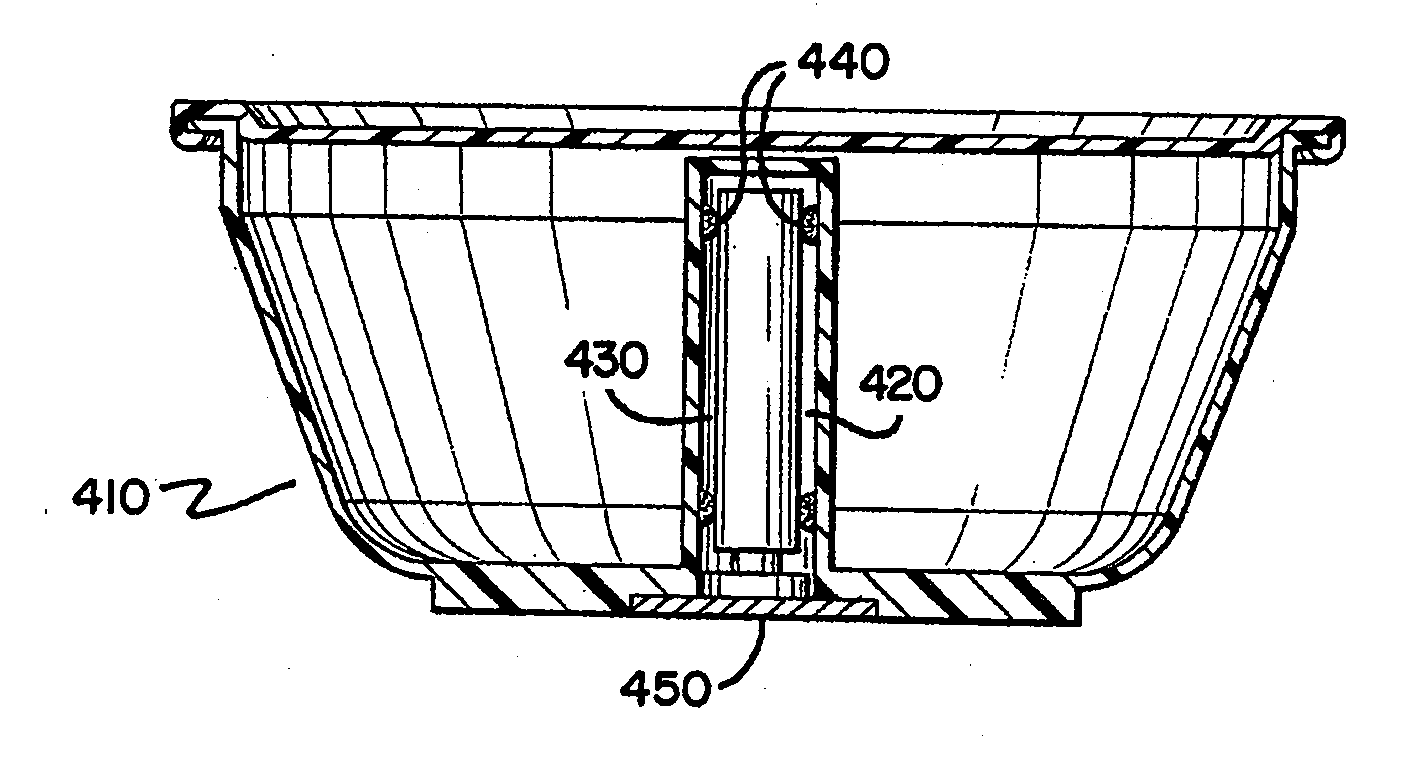

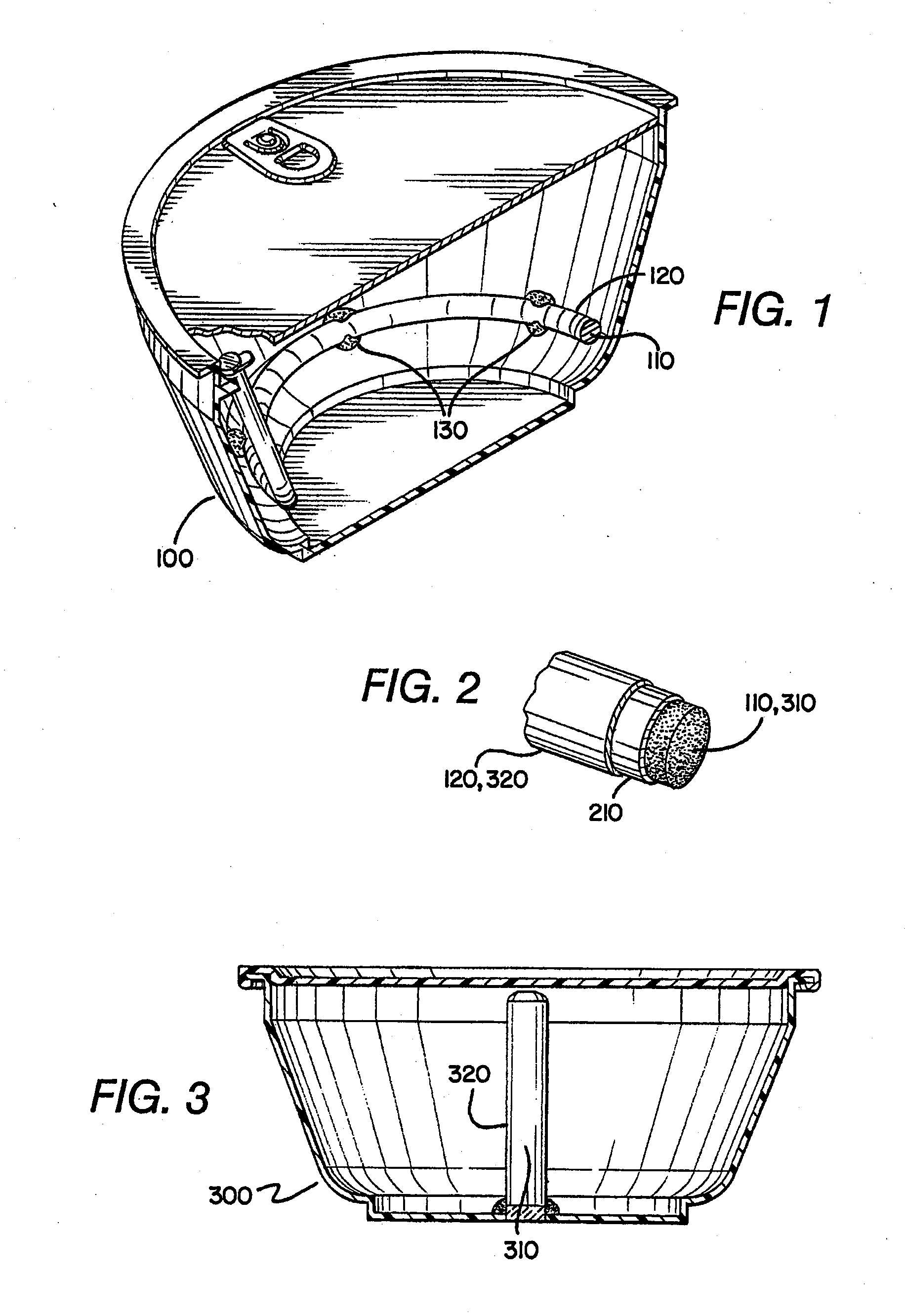

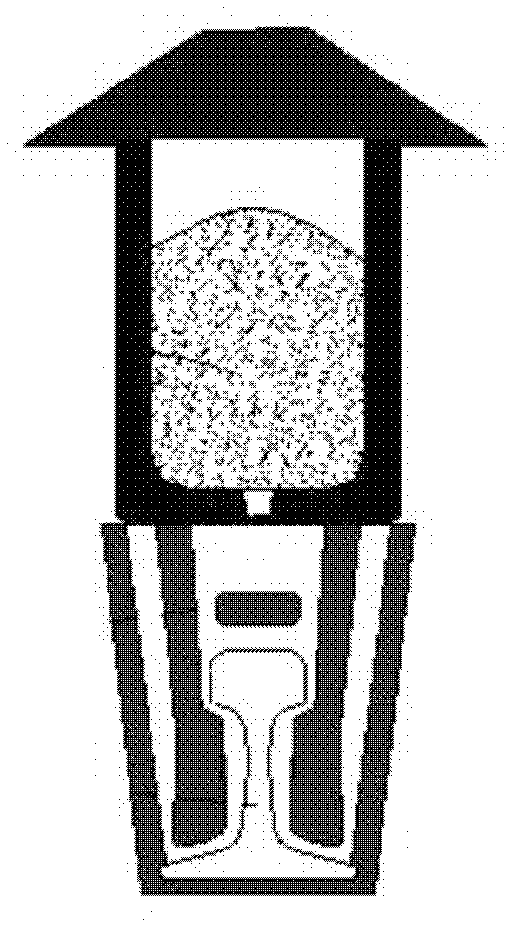

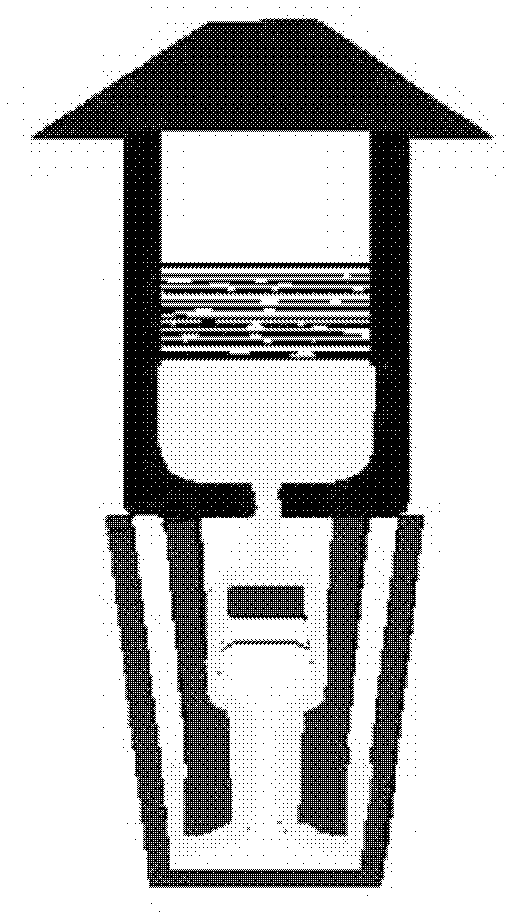

Package heating apparatus

ActiveUS20100252023A1Exothermal chemical reaction heat productionOther heat production devicesInterior spaceDiluent

A solid state thermite reaction composition is provided comprising a fuel component, an initiating oxidizer, a primary oxidizer, a fluxing agent and a thermal diluent. According to other aspects, a heating device, a heating element and an activation mechanism are provided. The heating device comprises a heating chamber defining an interior space for receiving and storing a substance to be heated, a reaction chamber disposed within the heating chamber, a solid state thermite reaction composition disposed within the reaction chamber such that it is physically isolated from and in thermal communication with the interior space of the heating chamber, and an activation mechanism having an actuator. The activation mechanism is in communication with the composition disposed within the reaction chamber and the reaction composition is inert until the activator mechanism is actuated.

Owner:HEATGENIE

Perforating devices utilizing thermite charges in well perforation and downhole fracing

Owner:SCHLUMBERGER TECH CORP

Simple electroless welding pen and preparation method of electroless welding pen

InactiveCN102699521AEasy to makeThe welding operation is simple, fast and safeWelding/cutting media/materialsSoldering mediaSlagManganese

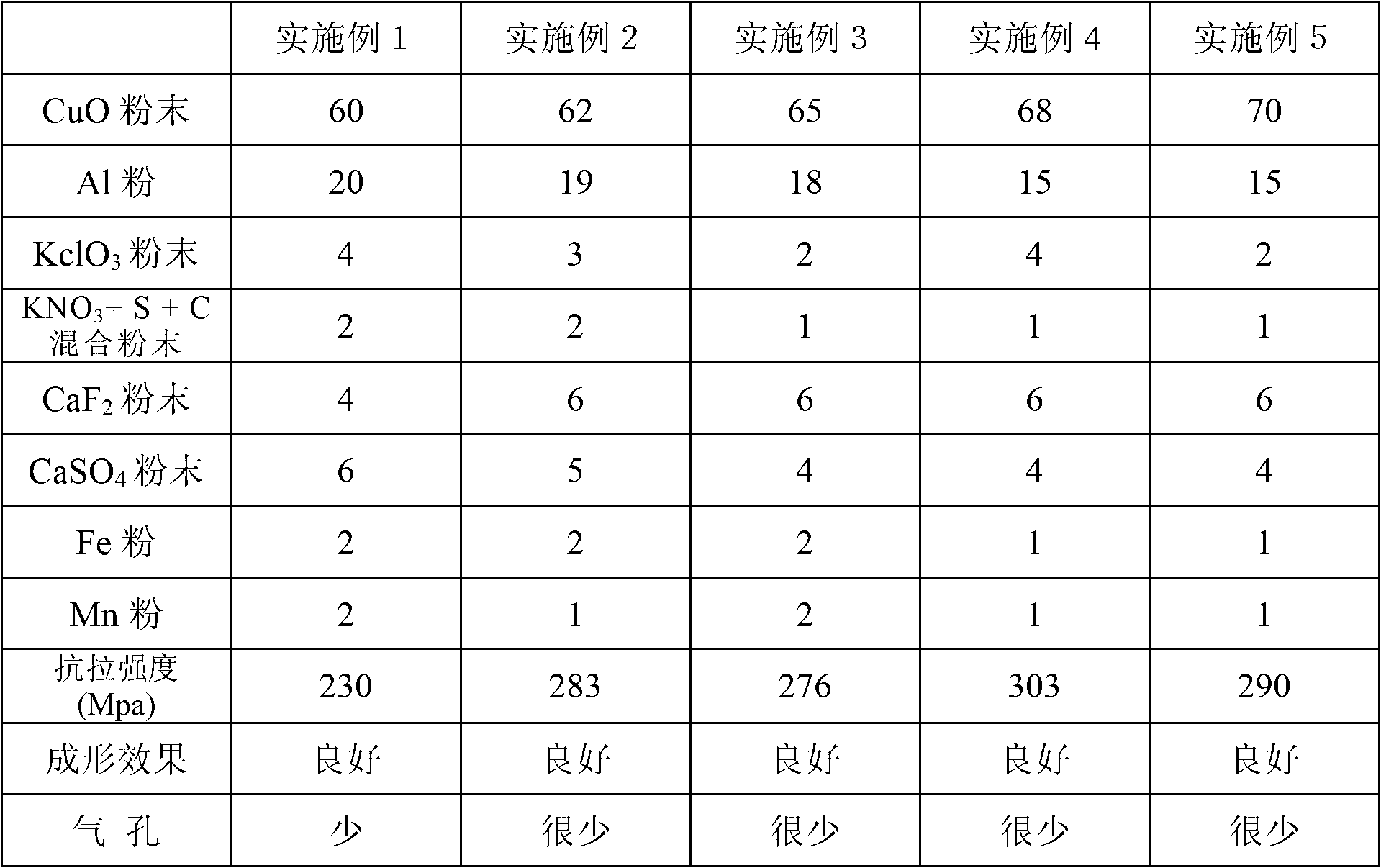

The invention discloses a simple electroless welding pen, which comprises a cartridge, welding flux and a lead. The welding flux is thermite; the simple electroless welding pen comprises the raw material constituents by weight percent: 60-70% of CuO (cupric oxide) powder, 15-20% of Al (aluminum) powder, 2-4% of KClO3 (potassium chlorate), 1-2% of KNO3 (potassium nitrate)+S (sulfur)+C (carbon) mixed powder, 4-6% of CaF2 (calcium fluoride) powder, 4-6% of CaSO4 (calcium sulfate) powder, 1-2% of Fe (Ferrum) powder and 1-2% of Mn (manganese) powder; and the mixed powder is KNO3, S and C freely mixed. According to the method disclosed by the invention, the problems of inexhaustive slag separation and more welding line defects in the welding lines in the prior art are solved without any welding device and power supply. The preparation method has the advantages of simple preparation process and simple, fast and safe welding operation, and is particularly suitable for field emergency operation.

Owner:TIANJIN UNIV

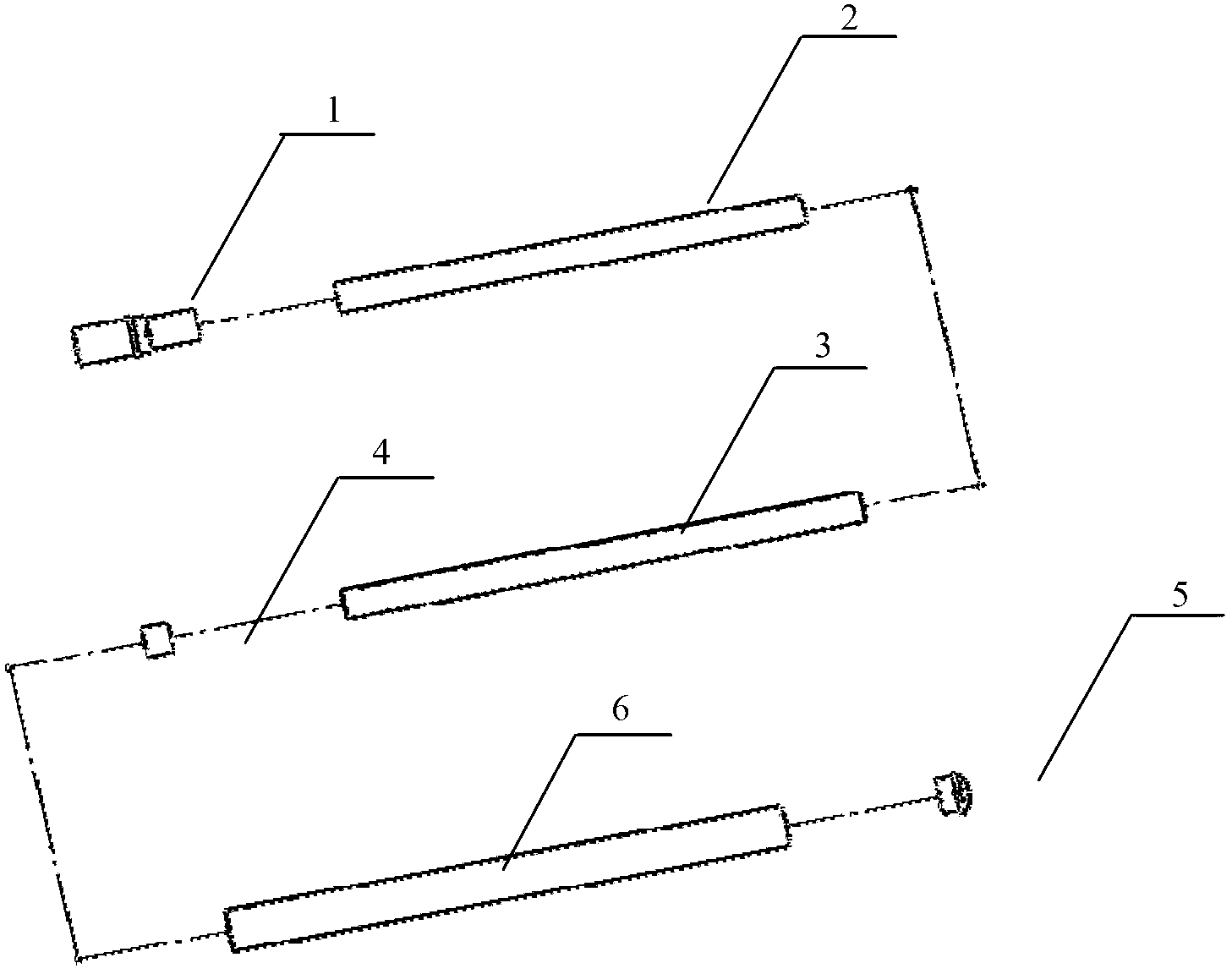

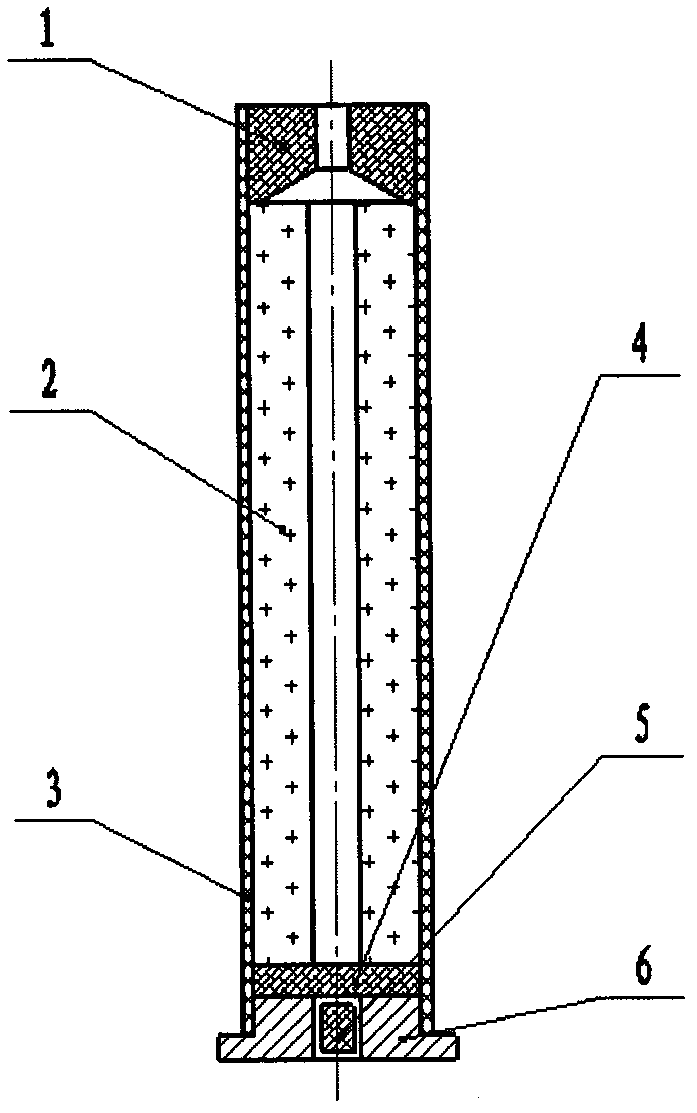

Electroless welding type welding rod and preparation and welding method thereof

InactiveCN102990240ASolving Quick Weld RepairsTackling Emergency Welding RepairsWelding/cutting media/materialsAlumino-thermic welding apparatusEmulsionThermite

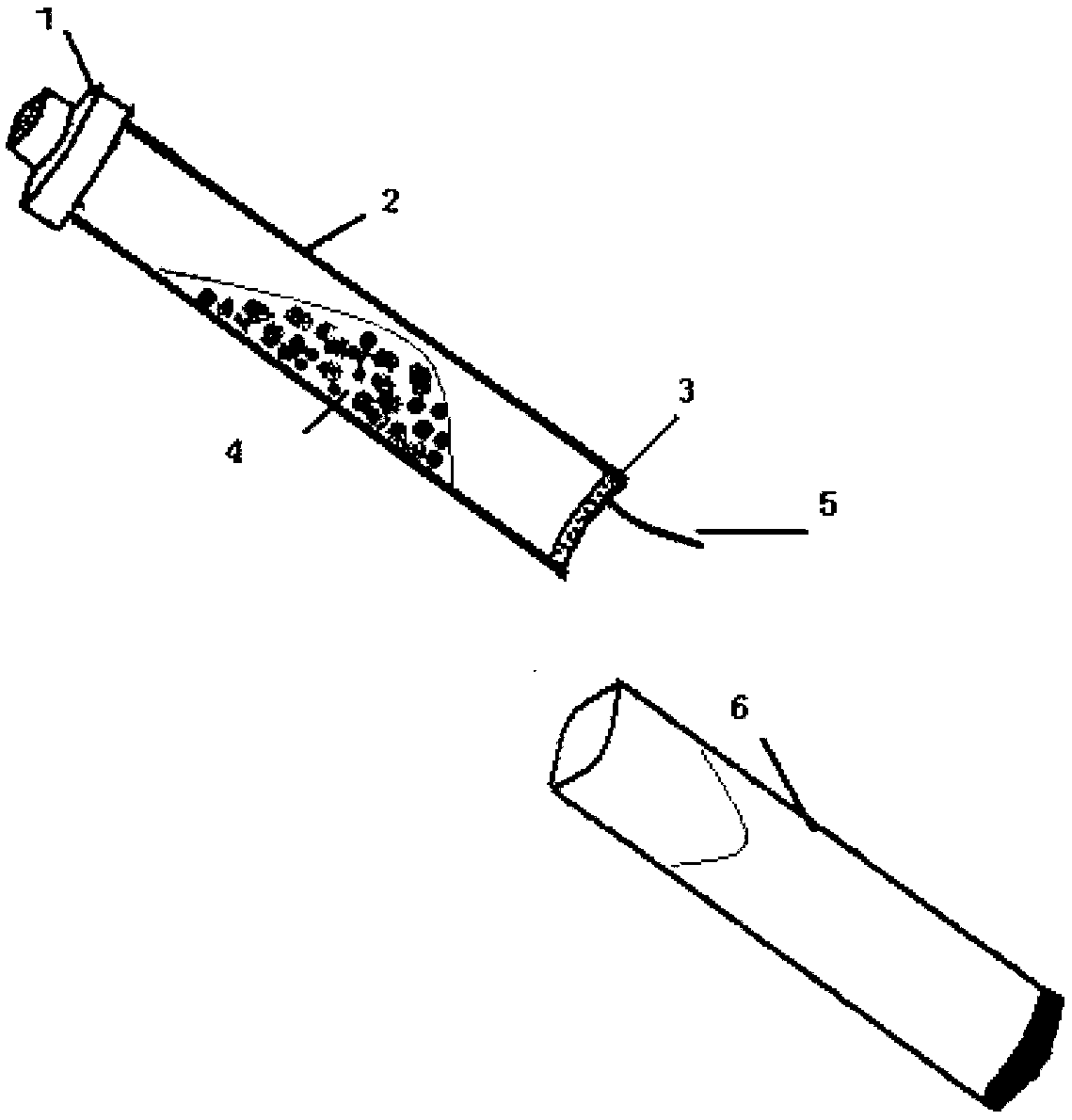

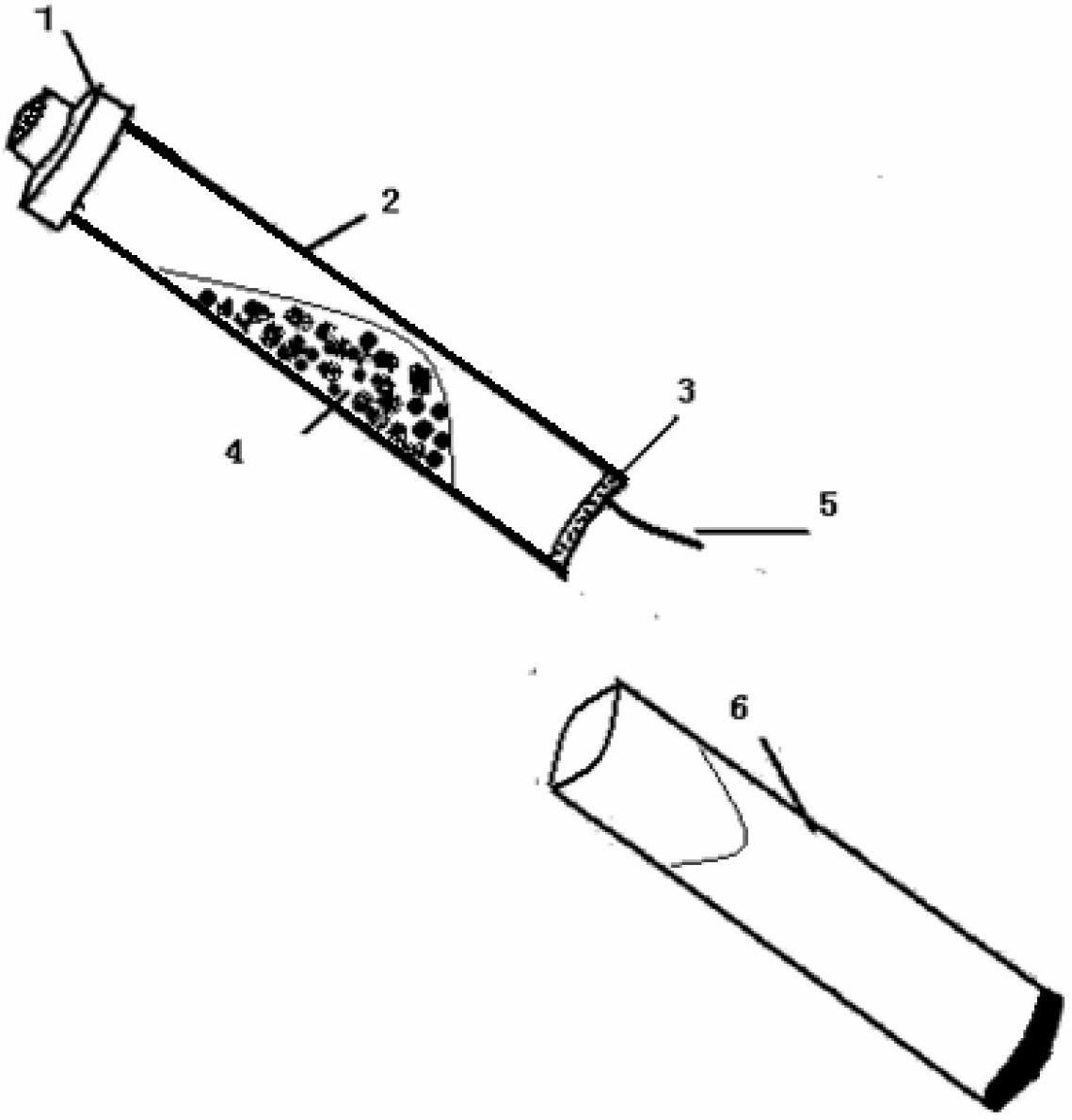

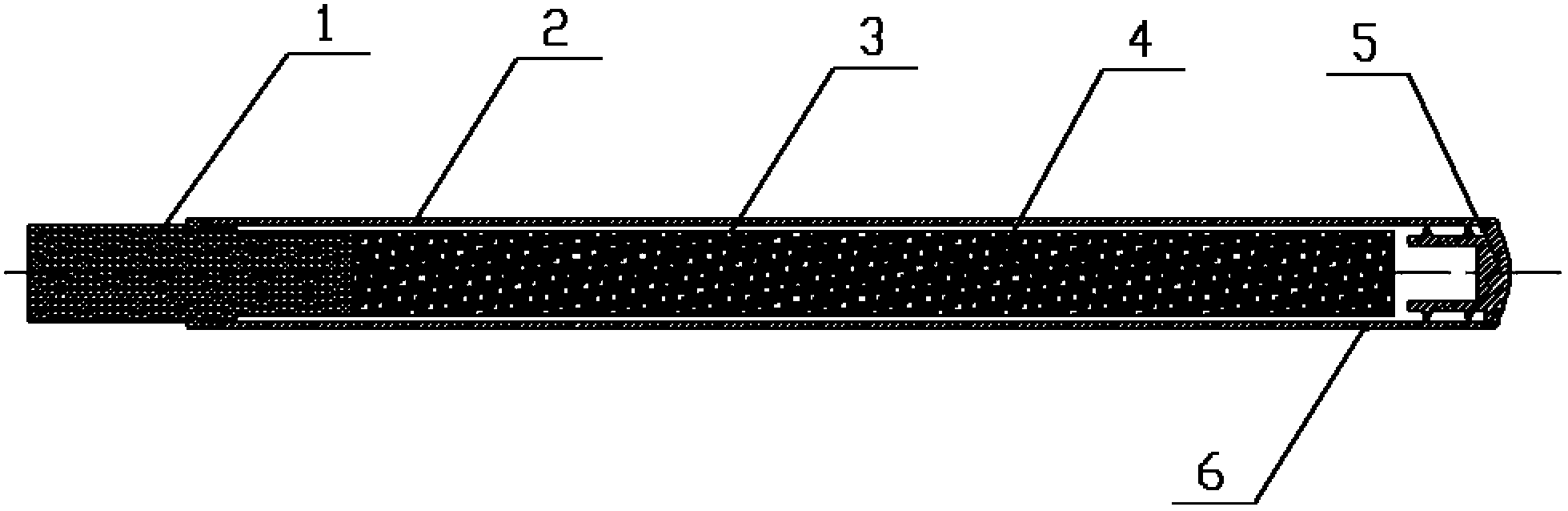

The invention discloses an electroless welding type welding rod and a preparation and welding method thereof. The electroless welding type welding rod comprises a plug, a grain, a paper pipe, an igniting cap, a pipe plug and a sleeve pipe, wherein the plug and the paper pipe are coaxially adhered together through emulsions; the grain and the igniting cap are formed in the paper pipe; the sleeve pipe is sleeved on the paper pipe; one end of the sleeve pipe is connected with the plug in a close fit way, and the other end of the sleeve pipe is sealed through the pipe plug. According to the electroless welding type welding rod, a welding material is manufactured into a special hand-held pencil, the special hand-held pencil can initiate reaction by being only ignited through matches, a reaction product and a parent material are molten by taking the self-releasing chemical energy of a thermite as a welding heat source, and the firm connection of the welded parent material is realized through mechanisms such as wetting, diffusion and reaction crystallization.

Owner:ARCHITECTURAL ENG INST GENERAL LOGISTICS DEPT P L A

Combustion jet cutter used for steel structure member cutting

ActiveCN103182609ACombustion synthesis reaction is fastIncrease energy densityWelding apparatusPotassium nitrateEngineering

The invention discloses a combustion jet cutter used for steel structure member cutting. The combustion jet cutter consists of a jet cutter bottom, primer, a shell case, ignition agent, cutting agent and a nozzle, wherein thermite is based on plain thermit in the cutting agent; the plain thermit roughly accounts for 65-85wt% of the cutting agent; gas-forming agent is based on potassium nitrate which roughly accounts for 5-25wt% of the cutting agent; and slagging constituent and alloying agent roughly account for 7-20wt% of the cutting agent. During cutting, the combustion jet cutter is filled into a cutting gun, the cutting gun is held with a hand to aim at a cutting part, the jet cutter primer is triggered, inner ignition agent the jet cutter is ignited by the primer, the cutting agent is ignited by the ignition agent to generate high-temperature metallurgical melt and high-pressure gas, and a product is injected after being subjected to energy-gathering compression by the nozzle to locally melt the steel structure member so as to realize cutting. The jet cutter is mainly used for the quick thermal cutting and the underwater cutting of various steel structure members.

Owner:PEOPLES LIBERATION ARMY ORDNANCE ENG COLLEGE

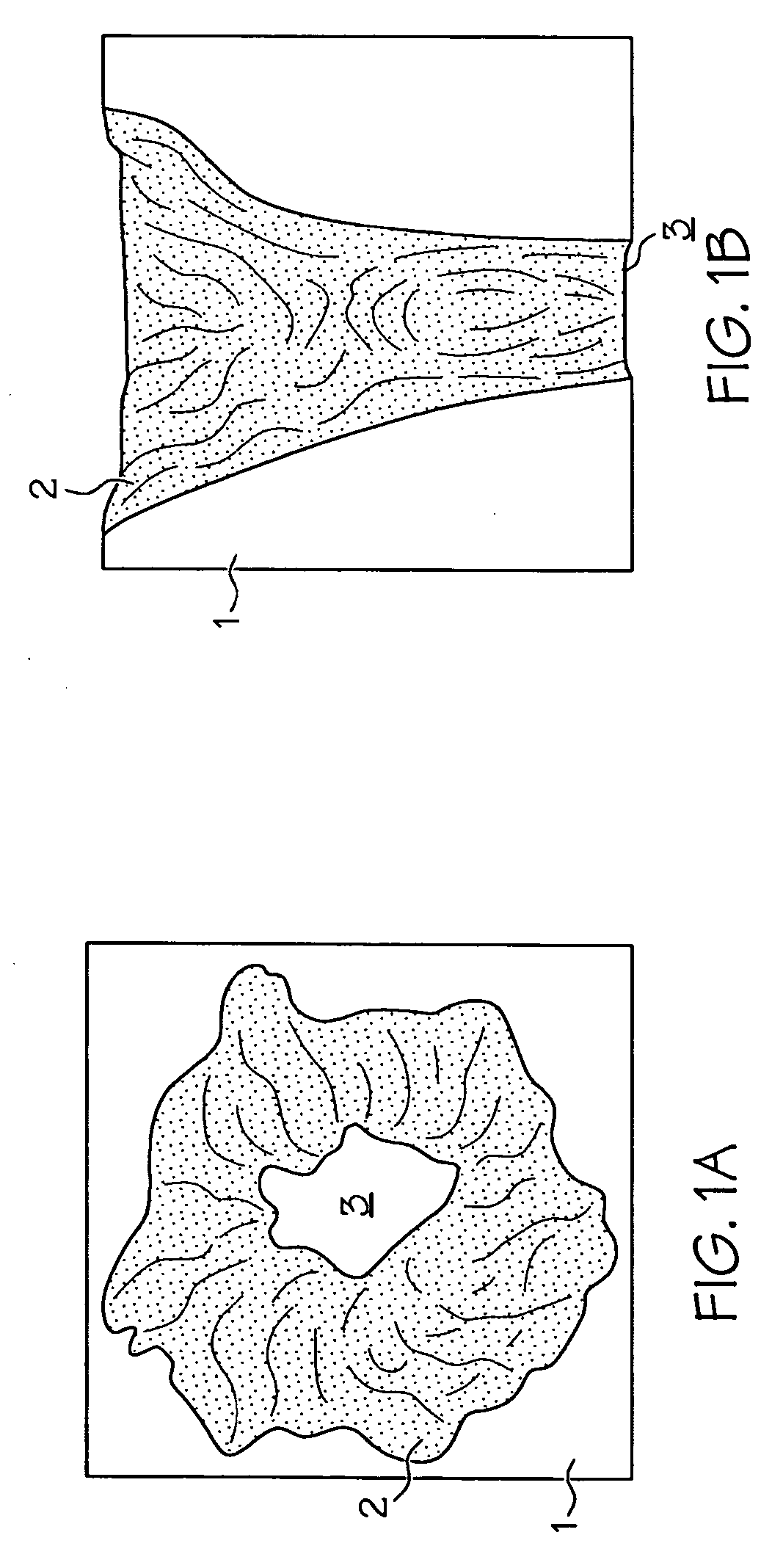

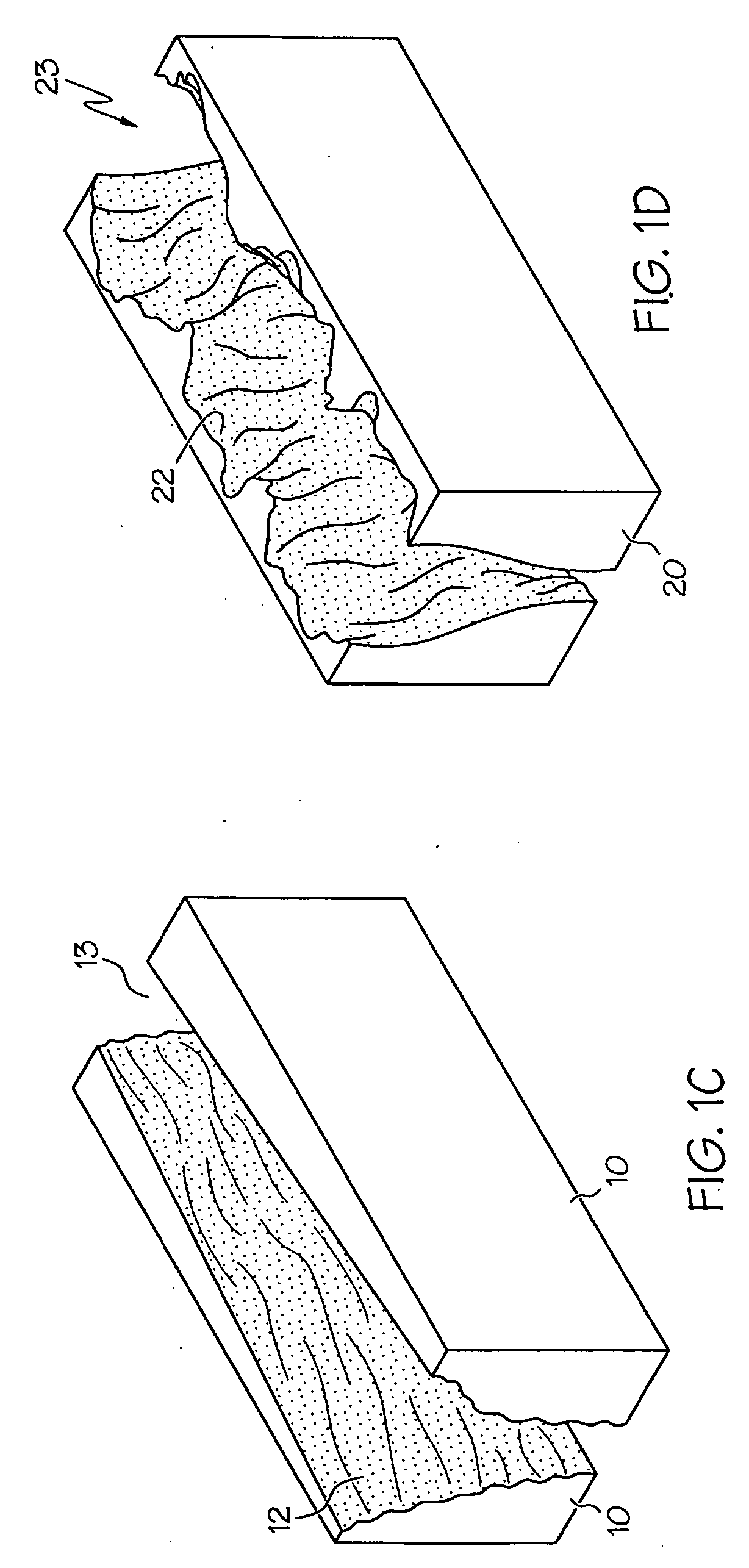

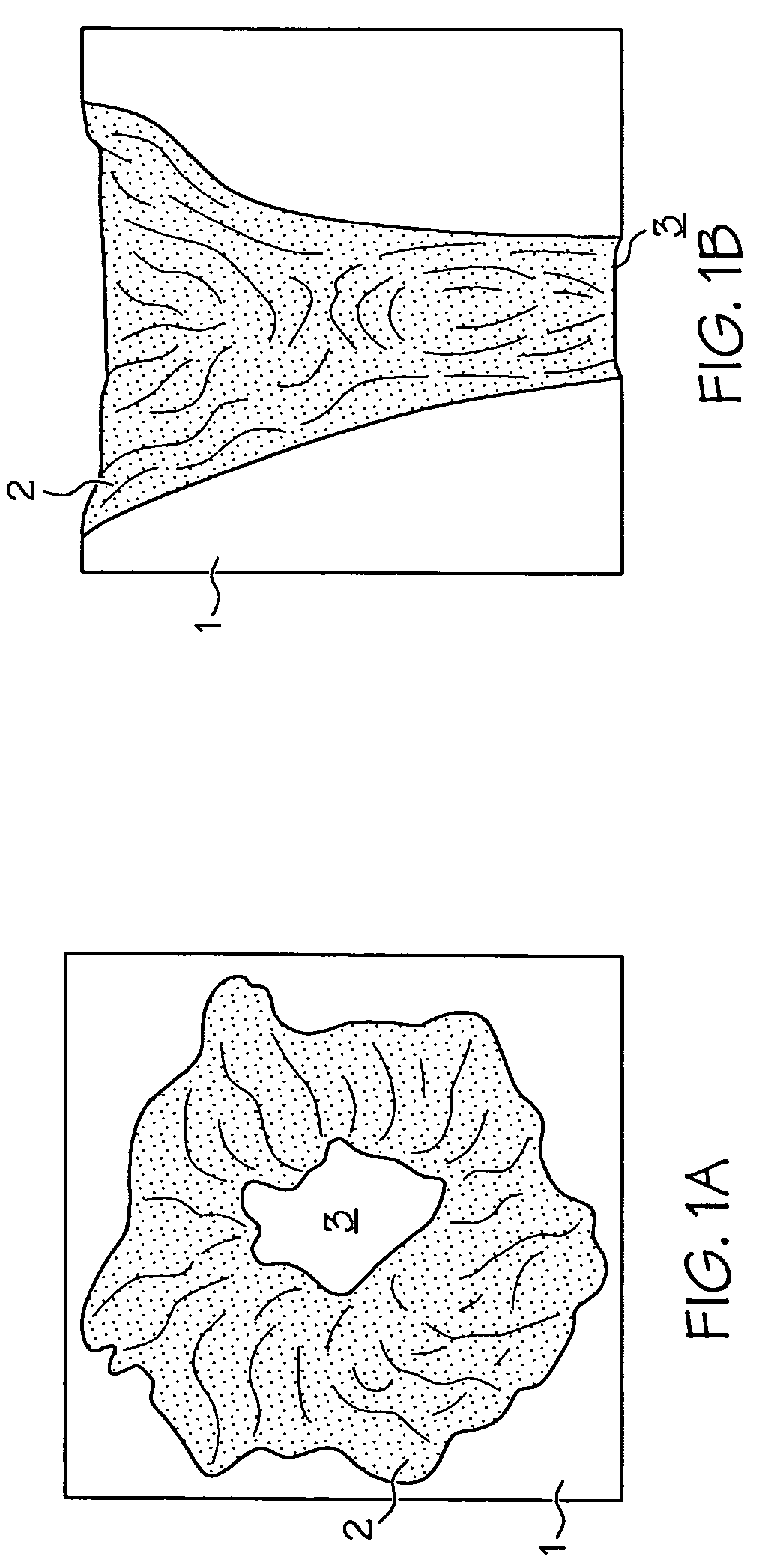

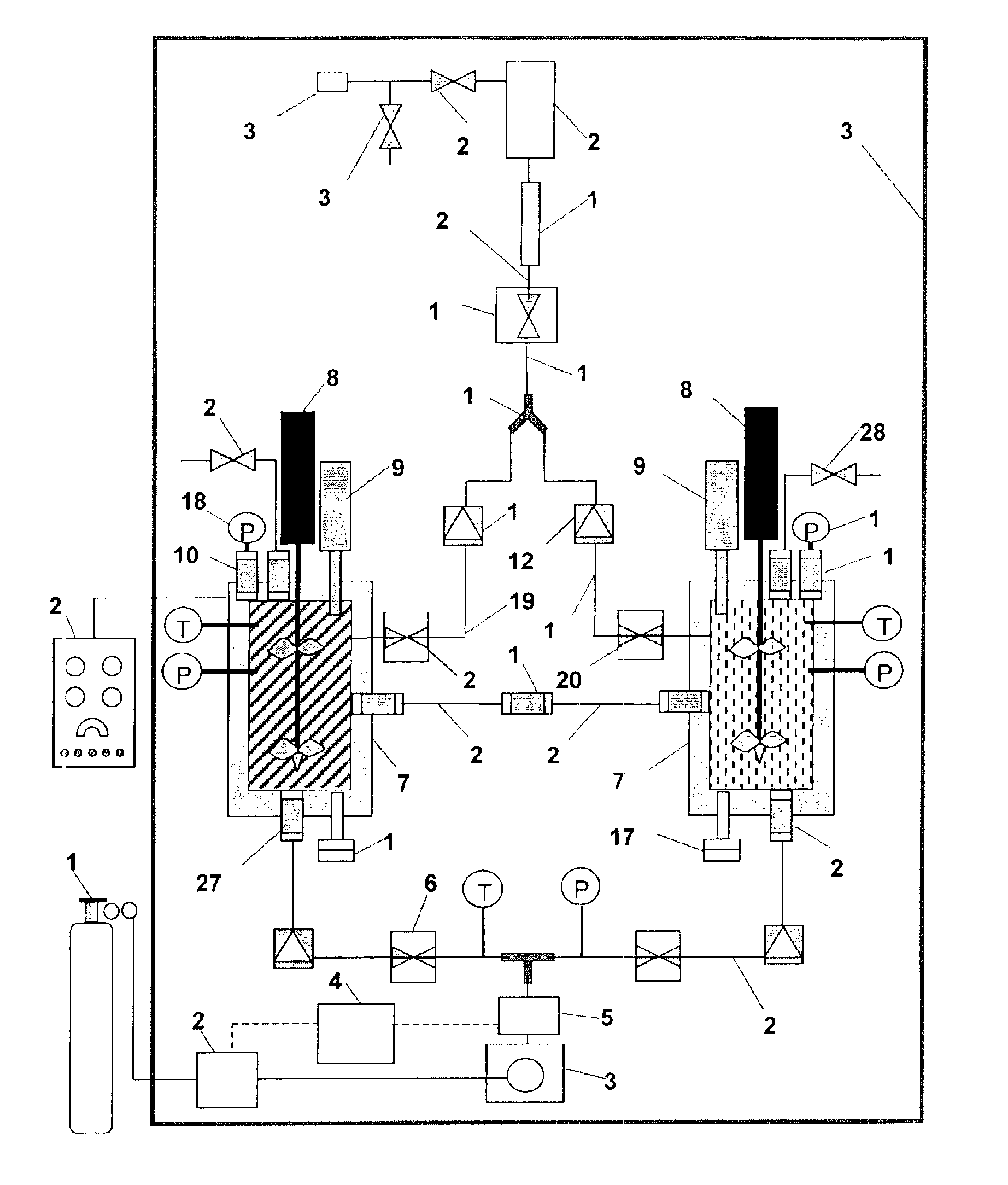

Steel rail thermite welding system and method

The invention provides a steel rail thermite welding system, which comprises a sand mould, a crucible and fluxes, wherein the crucible is arranged above the sand mould, the fluxes are filled in the crucible, and the sand mould comprises a polyhedral body cast with molding sand. The body comprises a bottom die, a left side die and a right side die, the bottom die is made of refractory materials, and the left side die and the right side die are the same in structure and respectively comprise three risers, wherein two risers are positioned on the outer side of a rail base angle of base metal of a steel rail so that liquid steel can flow through the rail base angle to promote welding, and the other riser is positioned at a position close to the rail base angle in a triangular rail base area and is communicated with the inside of a cavity at the position of a rail head, so that solidifying contraction of liquid steel in the rail base angle area and a rail head area is simultaneously compensated. By the aid of the system, the steel rail can be welded without rail matching under the condition of a wide rail gap exceeding 30mm. The invention further provides a method for welding the steel rail by using the steel rail thermite welding system.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI

Pyrotechnic thermite composition

A thermite formulation for use in thermite torch applications made up of from about 3 percent by weight to about 35 percent by weight Mg / Al alloy, from about 30 percent by weight to about 70 percent by weight CuO, and from about 15 percent by weight to about 35 percent by weight MoO3. Additionally, the formulation may also include a binder material.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Tool for metal plugging or sealing of casing

ActiveUS20180148991A1Great amount of materialImprove sealingSurveySolid-state devicesEngineeringMaterial Perforation

Owner:CONOCOPHILLIPS CO

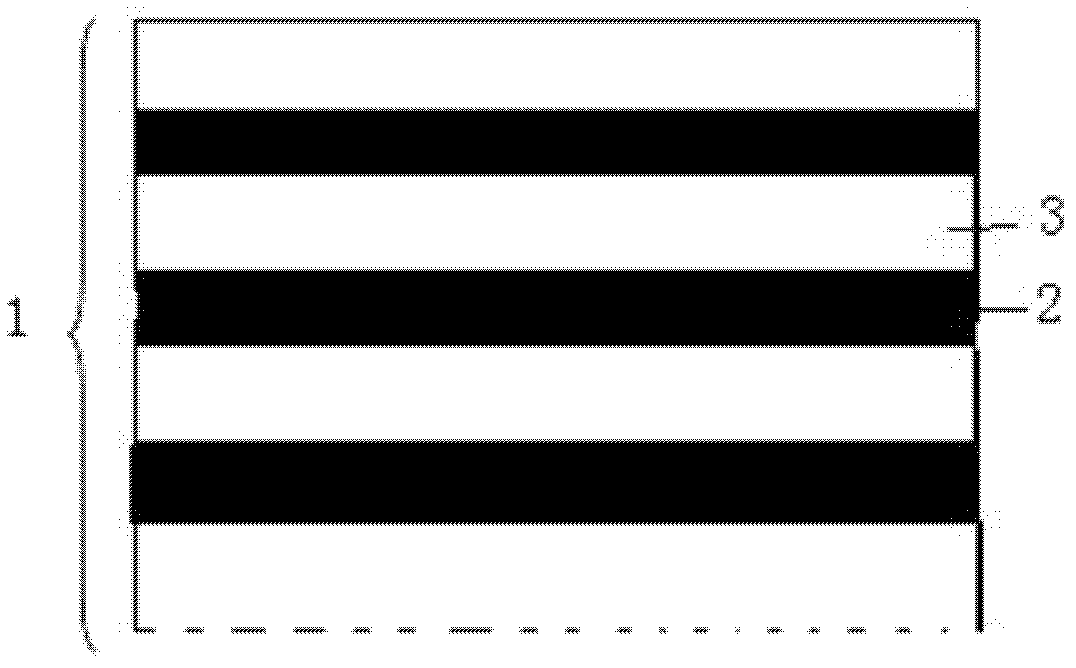

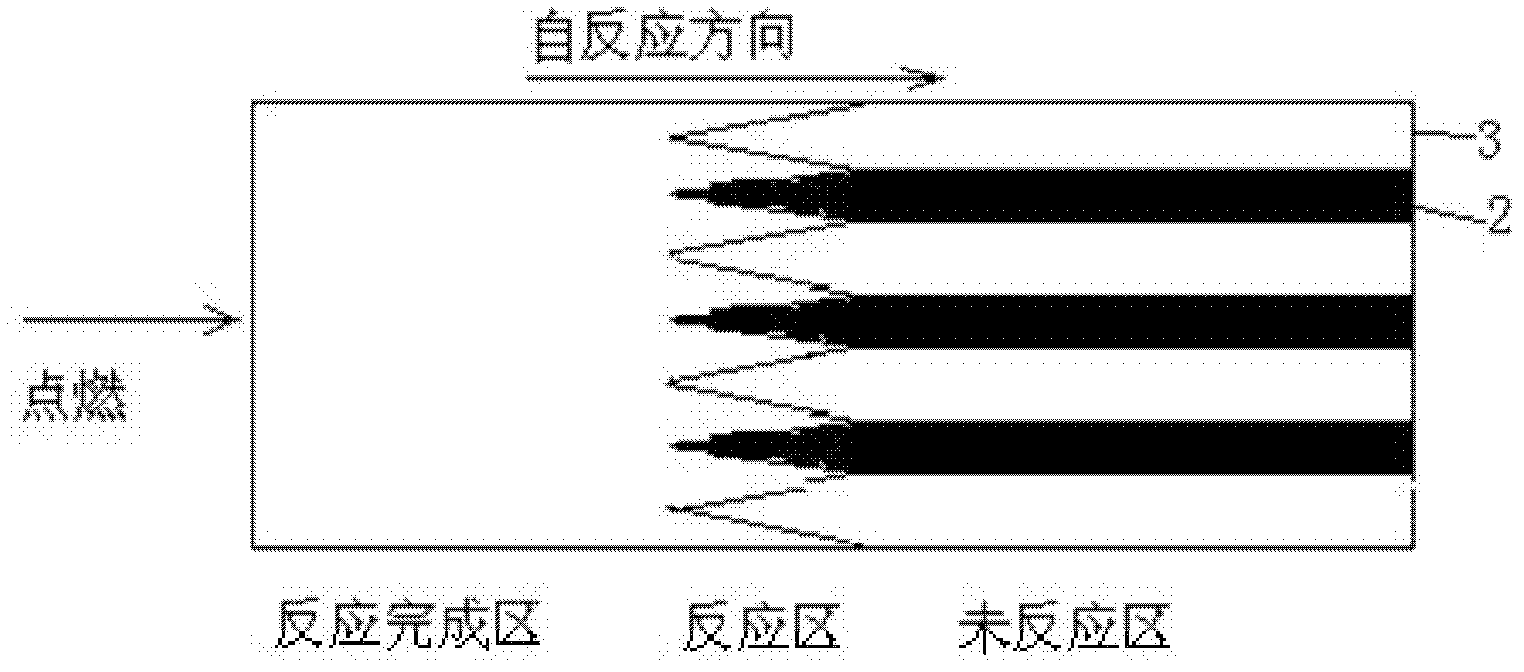

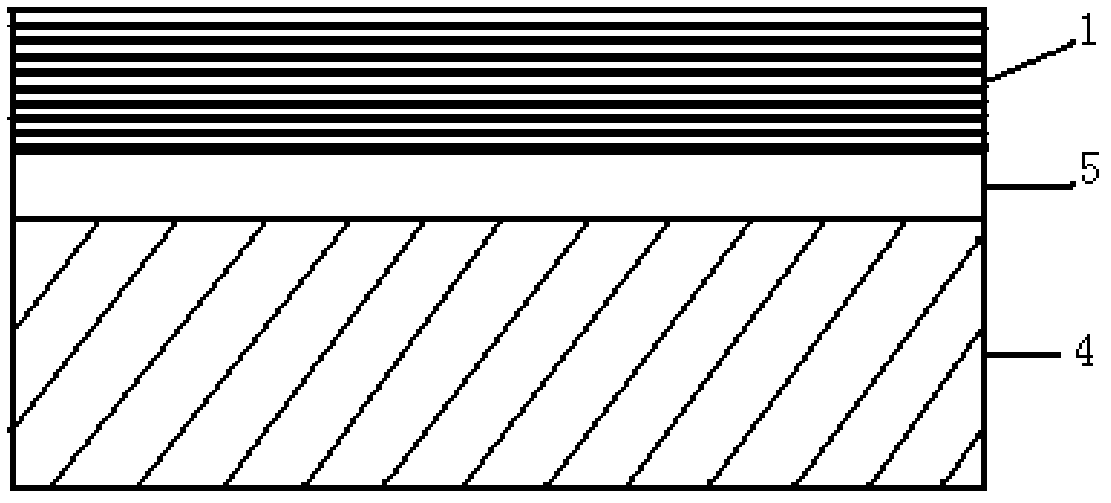

Thermit reaction foil, manufacturing method thereof and application thereof to welding process

InactiveCN102248280AQuick responseFast welding speedWelding/cutting media/materialsSoldering mediaThermal expansionUltimate tensile strength

The invention belongs to the technical field of thermit welding and discloses a thermit reaction foil. The thermit reaction foil consists of aluminum and a metal oxide capable of generating the thermit reaction with the aluminum, wherein each of the aluminum and the metal oxide has a laminated structure with at least one layer; and the aluminum layer and the metal oxide layer are arranged sequentially in an overlapping mode. When excitation with certain heat is applied to one end face of the thermit reaction foil, the thermit reaction foil generates self-propagating reaction instantly and other thermite or melting solder is ignited by heat released by the reaction, so that materials are welded. Therefore, compared with the prior art, the thermit reaction foil has reaction time of only several milliseconds, high reaction heat release, high welding speed and high welding strength, can weld the materials with different coefficient of thermal expansion, and is easy to operate, applicable to welding of various armors and parts and emergent welding repair of battlefields and also applicable to welding of various fine parts.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

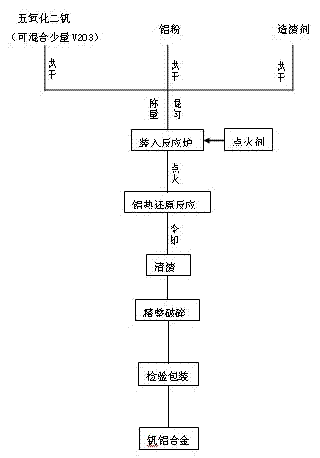

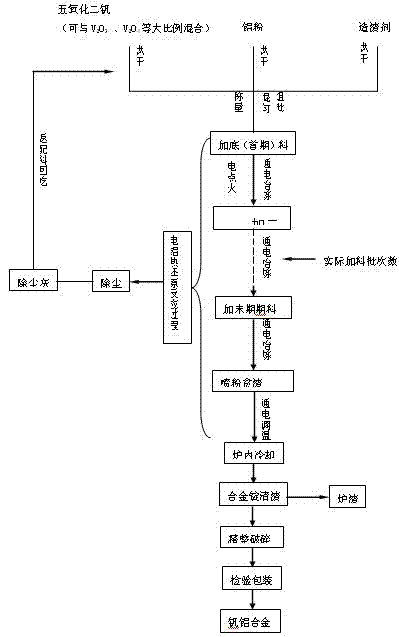

Method for smelting vanadium-aluminum alloy by electro-aluminothermic process

Owner:HEBEI IRON AND STEEL

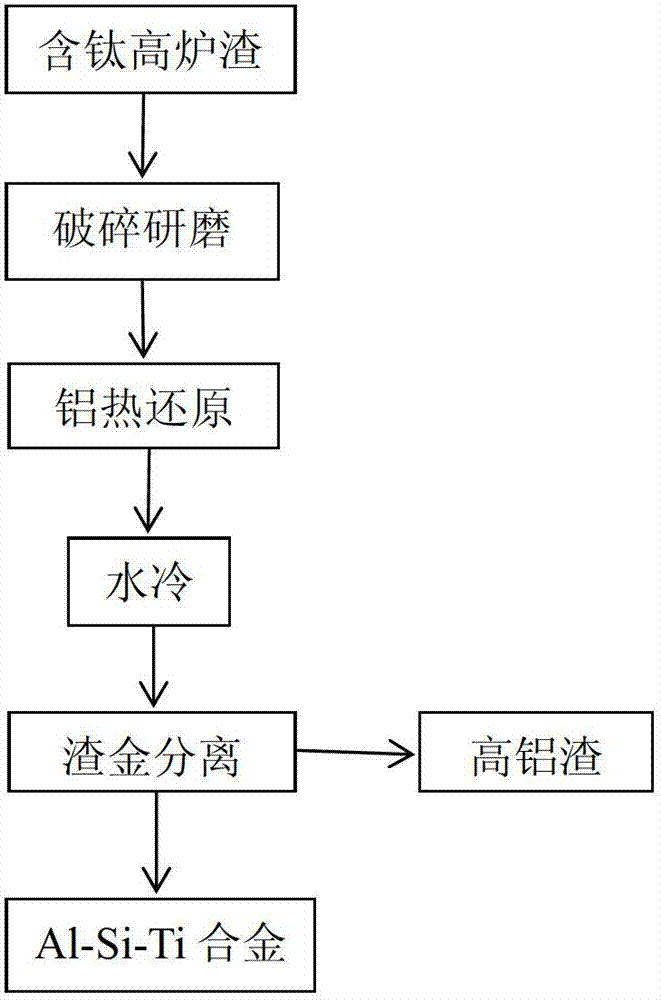

Process for extracting titanium from titanium-containing blast furnace slag through aluminothermic method

The invention relates to a process for extracting titanium from titanium-containing blast furnace slag through an aluminothermic method, and the process comprises the following steps of: crushing the titanium-containing blast furnace slag which contains the main components of TiO2, SiO2, CaO, Al2O3 and MgO, and grinding to 180 meshes; blending slag, aluminum powder and CaO according to a certain mass ratio; aluminothermic reduction: raising the temperature of an electric tube furnace to set the temperature at the atmosphere of argon shield, placing a blended mixture into an aluminum oxide crucible, placing into the electric tube furnace at high temperature, and preserving the temperature for a certain time; water cooling: taking out at high temperature, and placing into water for cooling; and mechanically separating the slag and an alloy. According to the invention, the completely preprocessed titanium-containing blast furnace slag is reduced by using the aluminum powder, and the slag and metal are separated through the water cooling after the reduction is completed; and finally, the main components of the slag are CaO, MgO and Al2O3, the metal components are Si and Ti, and the slag also contains a small amount of Al.The process disclosed by the invention is simple in process and stable in process parameter, and can realize the enriched extraction of titanium contained in blast furnace slag in a short time.

Owner:UNIV OF SCI & TECH BEIJING

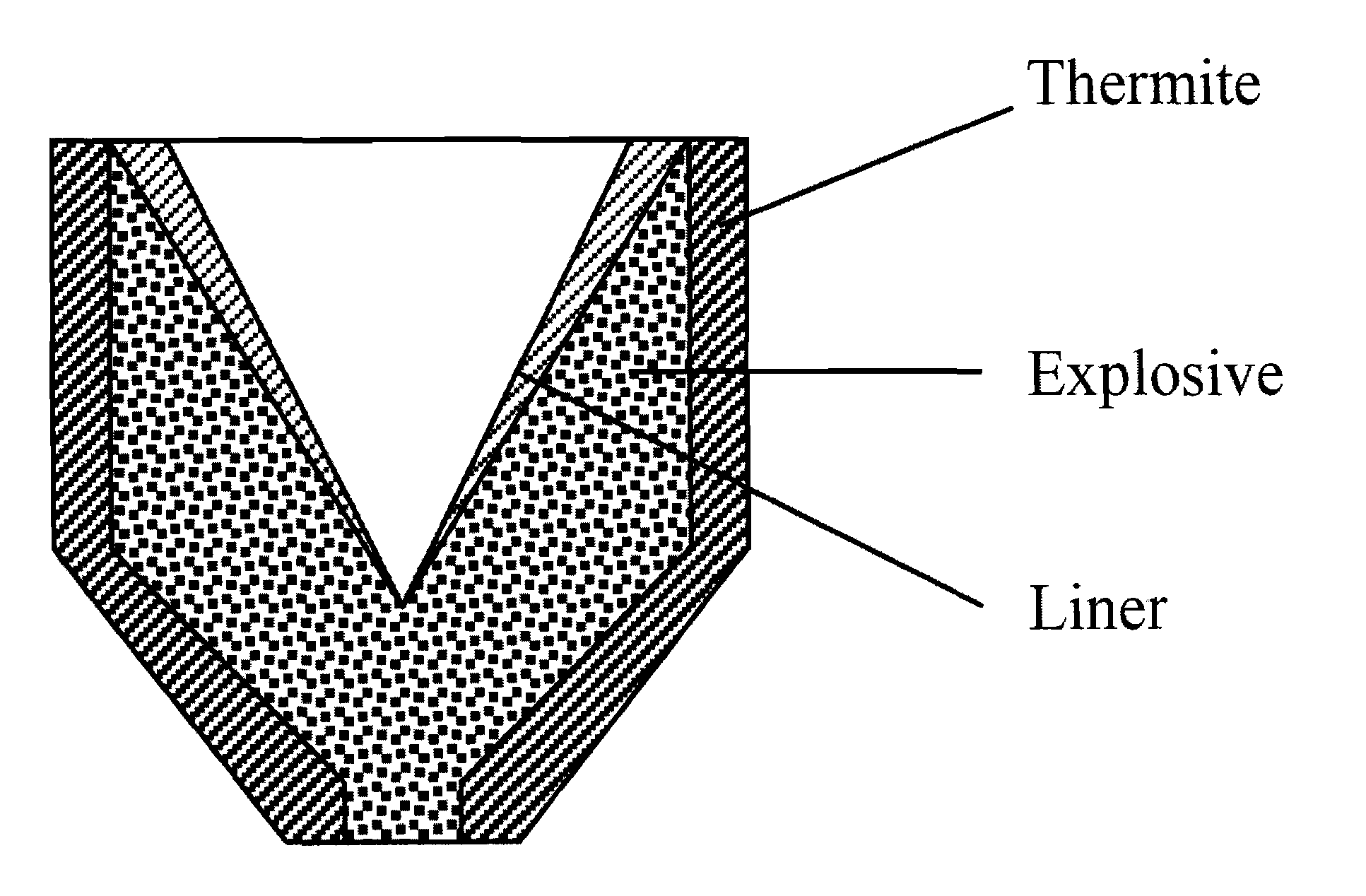

Thermite charge

ActiveUS20060266204A1Improve securityIncrease temperatureExplosive chargesBlasting cartridgesEngineeringThermite

Owner:BATTELLE MEMORIAL INST

Thermite charge

ActiveUS7555986B2Improve securityIncrease temperatureExplosive chargesBlasting cartridgesEngineeringThermite

Owner:BATTELLE MEMORIAL INST

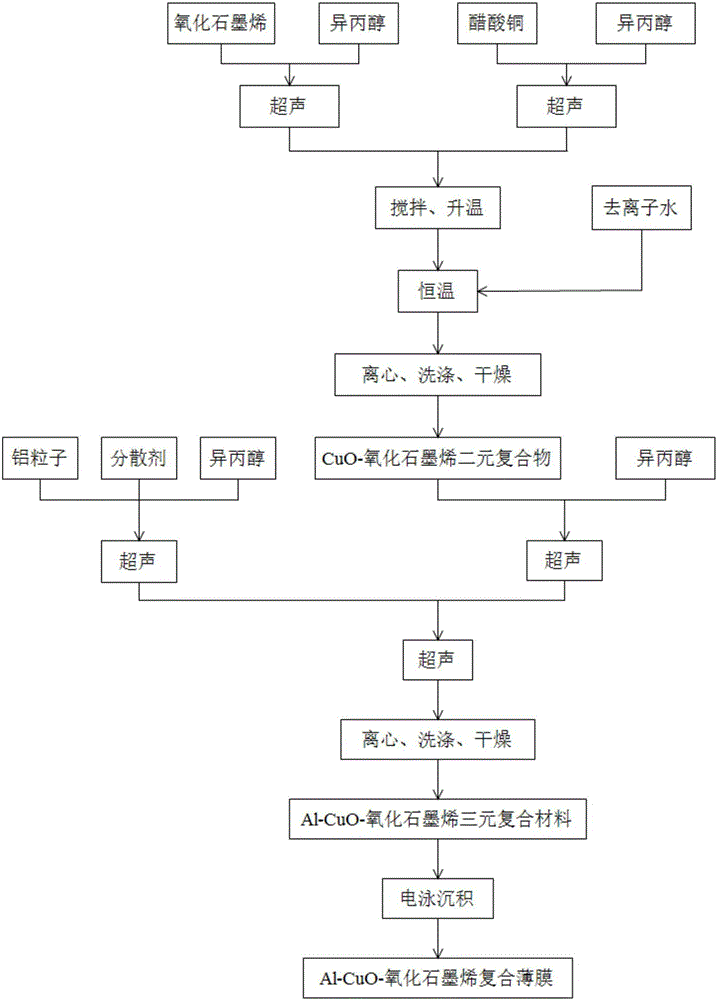

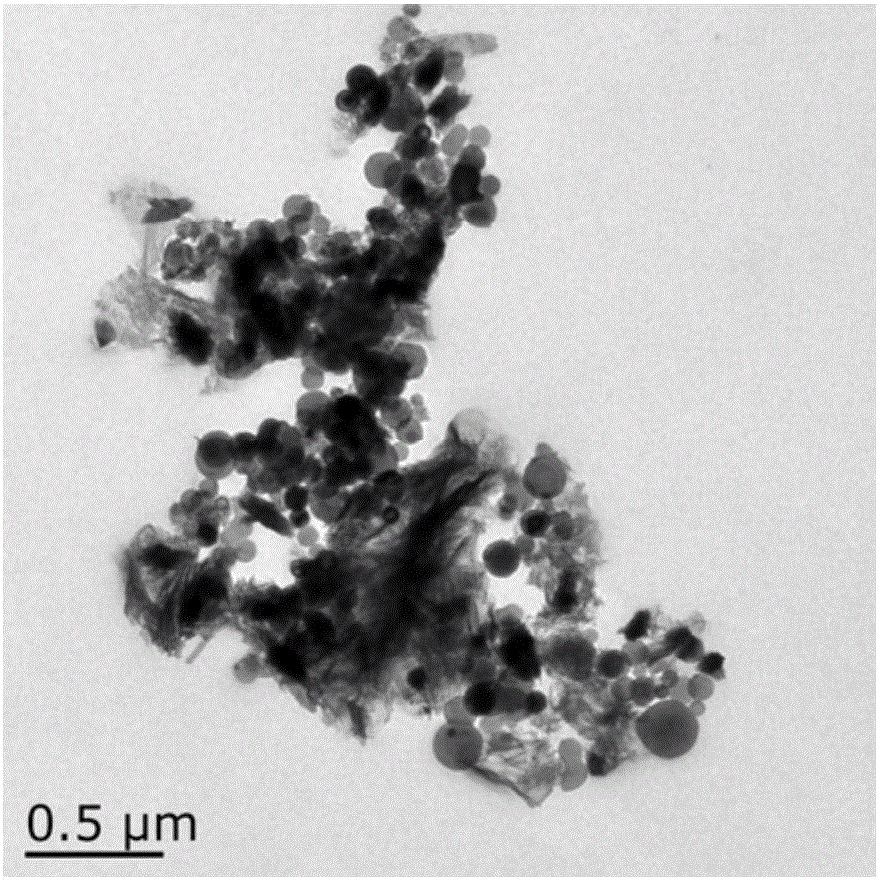

Energy-containing film made of aluminum-copper oxide-graphene oxide ternary composite material and preparation method for energy-containing film

ActiveCN105780089AMild conditionsSimple and fast operationElectrophoretic coatingsN dimethylformamidePole piece

The invention discloses an energy-containing film made of an aluminum-copper oxide-graphene oxide ternary composite material and a preparation method for the energy-containing film. The method includes the steps that firstly, a CuO-graphene oxide binary compound is placed in isopropyl alcohol to be ultrasonically dispersed; secondly, aluminum particles and a dispersing agent are ultrasonically dispersed in the isopropyl alcohol to be ultrasonically mixed with dispersing liquid obtained from the first step; thirdly, a product obtained from the second step is centrifuged, washed and dried; fourthly, a material obtained from the third step is placed in a mixed solution of the isopropyl alcohol and N,N-dimethylformamide to be ultrasonically dispersed, and the electric potential is adjusted; and fifthly, the dispersing liquid obtained from the fourth step serves as electrophoretic deposition liquid, a copper sheet serves as a cathode pole piece, stainless steel or a platinum electrode serves as an anode pole piece, electrophoretic deposition is conducted, and the energy-containing film is obtained. By the adoption of the energy-containing film and the preparation method, graphene oxide is introduced into a thermite system, energy released by oxygen-containing groups in the graphene oxide in the thermal deoxidization process is used for further inducing a redox reaction of aluminum and CuO, and therefore energy output by the system is multiplied.

Owner:NANJING UNIV OF SCI & TECH

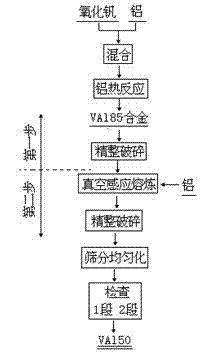

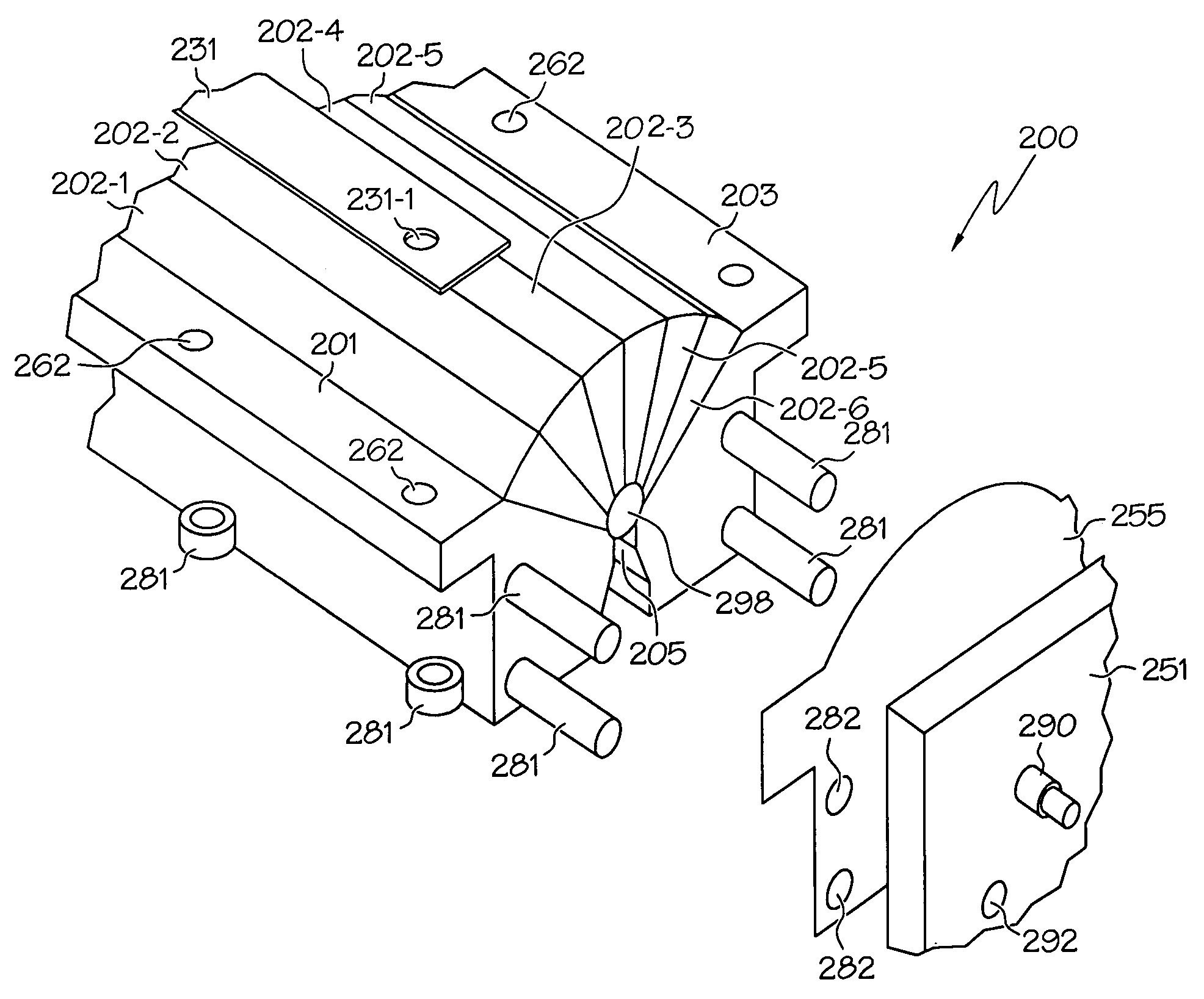

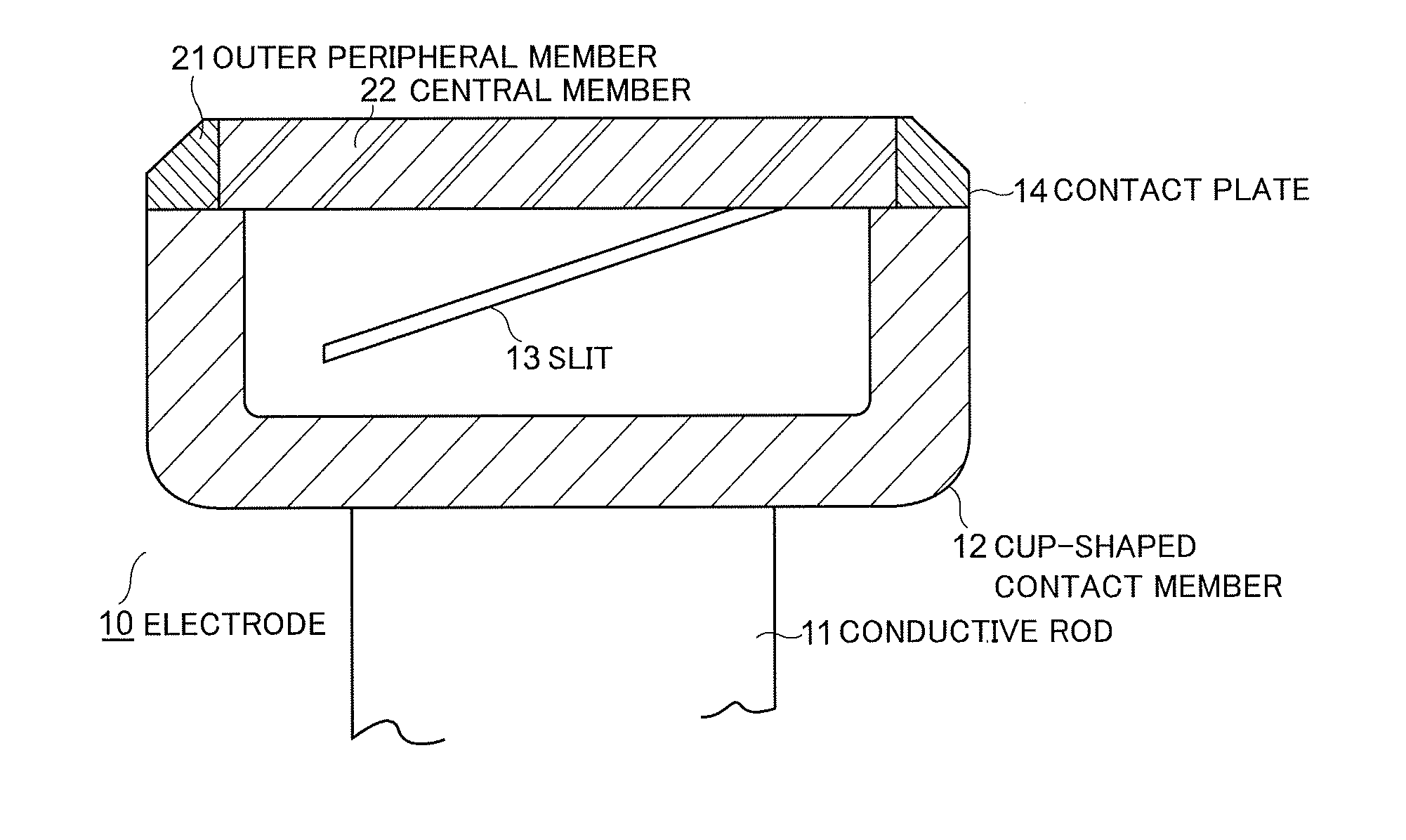

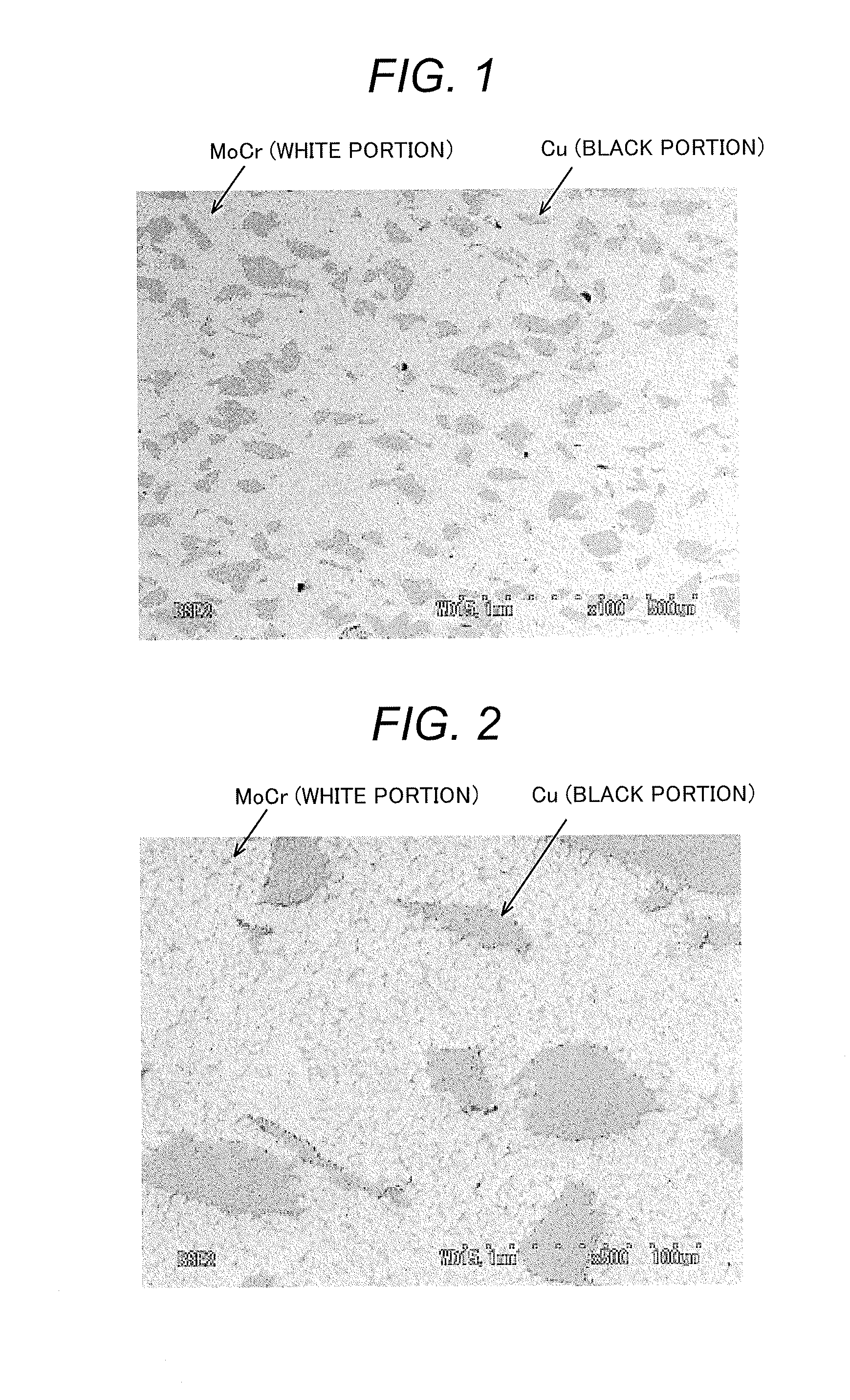

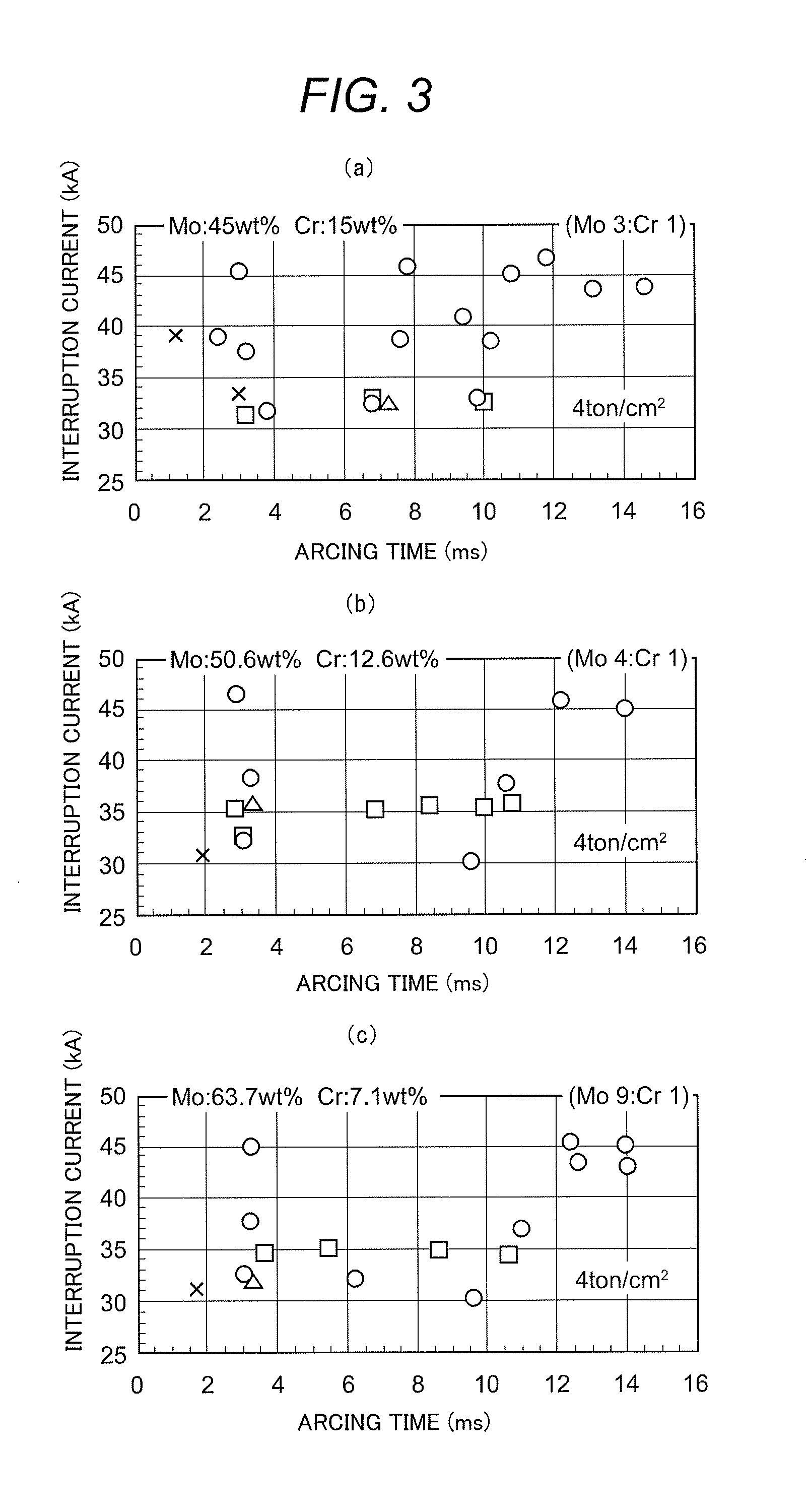

Method for Producing Electrode Material for Vacuum Circuit Breaker, Electrode Material for Vacuum Circuit Breaker and Electrode for Vacuum Circuit Breaker

ActiveUS20130199905A1Easy to produceHigh hardnessContact materialsContact surface shape/structureEngineeringHeating furnace

Provided are: a method for producing an electrode material for a vacuum circuit breaker, whereby withstand voltage, high current interruption performance and capacitor switching performance can be improved; an electrode material for a vacuum circuit breaker; and an electrode for a vacuum circuit breaker.The electrode material for a vacuum circuit breaker is produced by a method comprising a mixing step, a press sintering step, and a Cu infiltration step. In the mixing step, an Mo powder having a particle diameter of 0.8 to 6 μm is homogeneously mixed with a thermite Cr powder having a particle diameter of 40 to 300 gm in such a manner as giving a mixing ratio (Mo:Cr) of 1:1 to 9:1 and satisfying the weight relation Mo≧Cr. In the press sintering step, the resultant mixture is pressure molded under a press pressure of 1 to 4 t / cm2 to give a molded article. Next, said molded article is sintered by maintaining the same at a temperature of 1100 to 1200° C. for 1 to 2 hours in an heating furnace to give a partially sintered article. In the Cu infiltration step, a thin Cu plate is placed on said partially sintered article and maintained at a temperature of 1100 to 1200° C. for 1-2 hours in a heating furnace so that Cu is liquid-phase sintered and infiltrated into the partially sintered article. A contact material of an electrode for a vacuum circuit breaker has an integral structure consisting of a central member and a Cu—Cr outer peripheral member, said central member having been produced as described above and comprising 30 to 50 wt % of Cu of a particle diameter of 20 to 150 μm and 50 to 70 wt % of Mo—Cr of a particle diameter of 1 to 5 μm, while said outer peripheral member being formed of a material, which is highly compatible with the central member, shows excellent interruption performance and had high withstand voltage, and being provided outside the central member and fixed thereto.

Owner:MEIDENSHA ELECTRIC MFG CO LTD

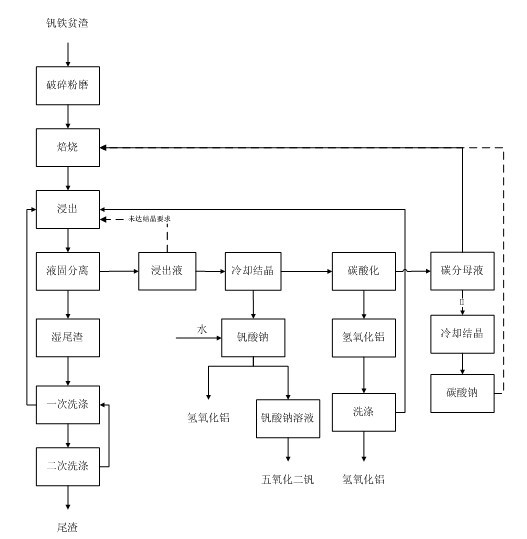

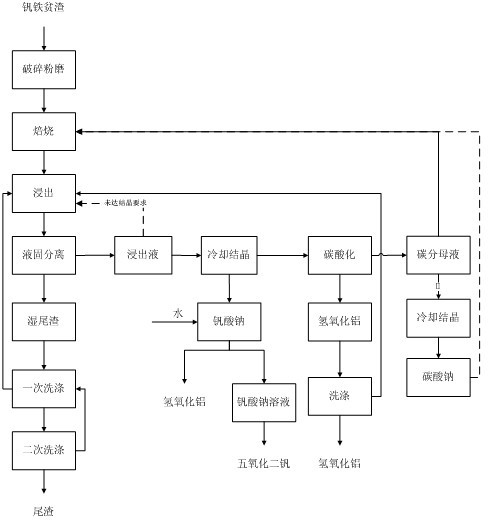

Cleaner production process for synchronously extracting vanadium and aluminum from aluminothermic vanadium iron slag

ActiveCN102586610ARealize co-existenceAchieve separationProcess efficiency improvementSlagAluminium hydroxide

The invention relates to a cleaner production process for synchronously extracting vanadium and aluminum from aluminothermic vanadium iron slag, and belongs to the technical field of metallurgy. The technical scheme is that: the vanadium iron slag is subjected to sodium oxide roasting by using high-proportion Na2CO3 as a roasting transforming agent, vanadium and aluminum of a clinker obtained after sodium oxide roasting are synchronously dissolved out by using an aqueous solution, sodium vanadate crystals containing aluminum hydroxide are crystallized, the purity of the obtained Al(OH)3 is over 95 percent, the purity of vanadium pentoxide is over 98 percent, the co-extraction of the vanadium and the aluminum, the separation of the vanadium and the aluminum and the cyclic utilization of sodium salt are realized, the recovery rate of the vanadium is over 85 percent, the recovery rate of the aluminum is over 60 percent, the weight of tailings is reduced by 40 to 50 percent after leaching, and the tailings can be used for preparing an aluminum-magnesium flocculant by an acid method. The high-efficiency extraction of the vanadium is realized, the resource reutilization of an aluminum element in the slag is also realized, wastewater discharge is avoided in the whole production process, CO2 gas for carbonation can be replaced by roasting flue gas, the proportion of carbon emission isreduced, and the process has remarkable economic and environmental benefits, and can be effectively applied to the treatment of the aluminothermic vanadium iron slag and related materials.

Owner:HEBEI IRON AND STEEL

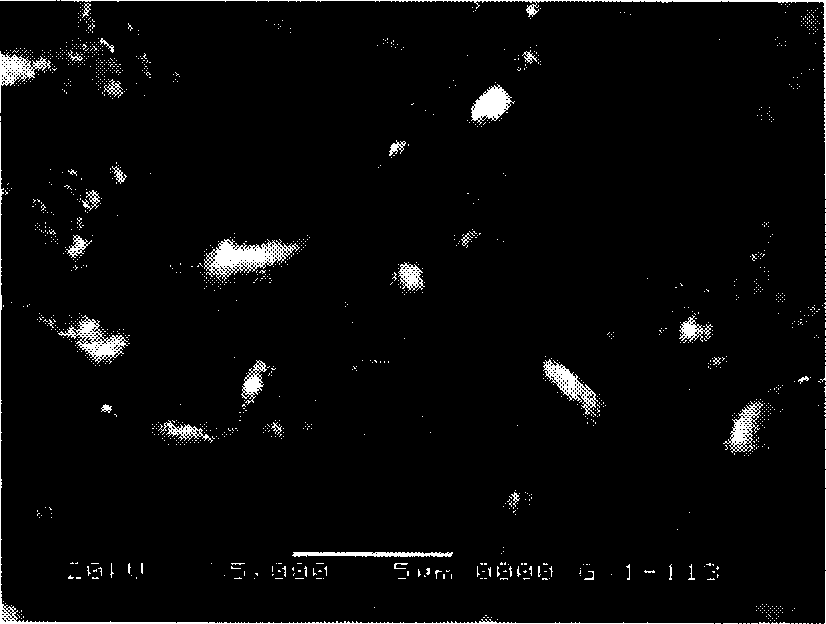

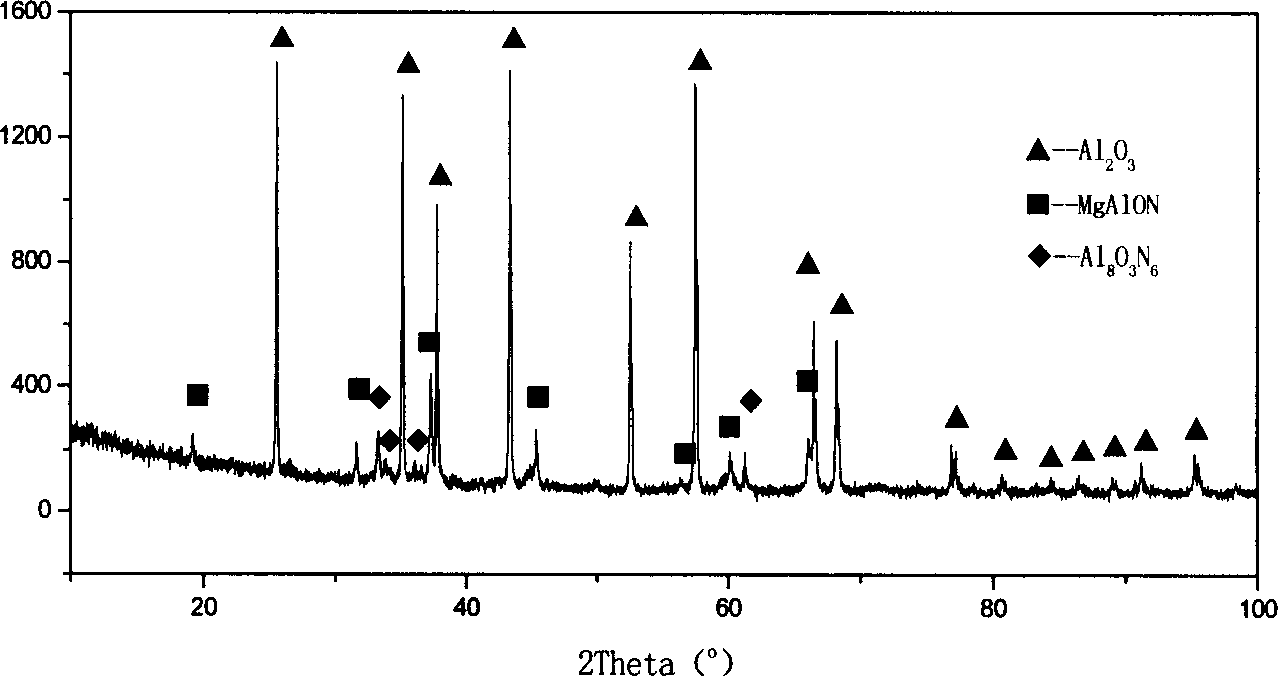

Microporous MgAlON composite corindon material preparation method

A preparing method of micro porous MgAlON composite alumina material belongs to the area of fire resistive material technology. The invention with the aggregate being multi-granular alumina and the base material being the mixture of active aluminum oxide powder, aluminum powder or alumina silica or aluminum-magnesium alloy powder containing the same quantity of aluminum, magnesium oxide powder or magnesite powder or magnesium aluminate spinel containing the same quantity of magnesium oxide produces the micro porous MgAlON composite alumina material by thermite azotizing reaction. The combination reaction of MgAlON is completed at he same time of sintering, that simplifies the preparing process of micro porous MgAlON composite alumina material; the micro porous MgAlON composite alumina material produced from the process with the fine crystal particle in base material and most of the diameters of gas pore being less than 1-2 mum can improve the strength of materials, stability of heat shock and slag resistance, and extend the use life. The invention can save the production cost largely, improve the ability of the material, favor the use in the industry of metallurgy, organic chemical industry, ceramics and aerospace technology, and etc.

Owner:ZHENGZHOU UNIV

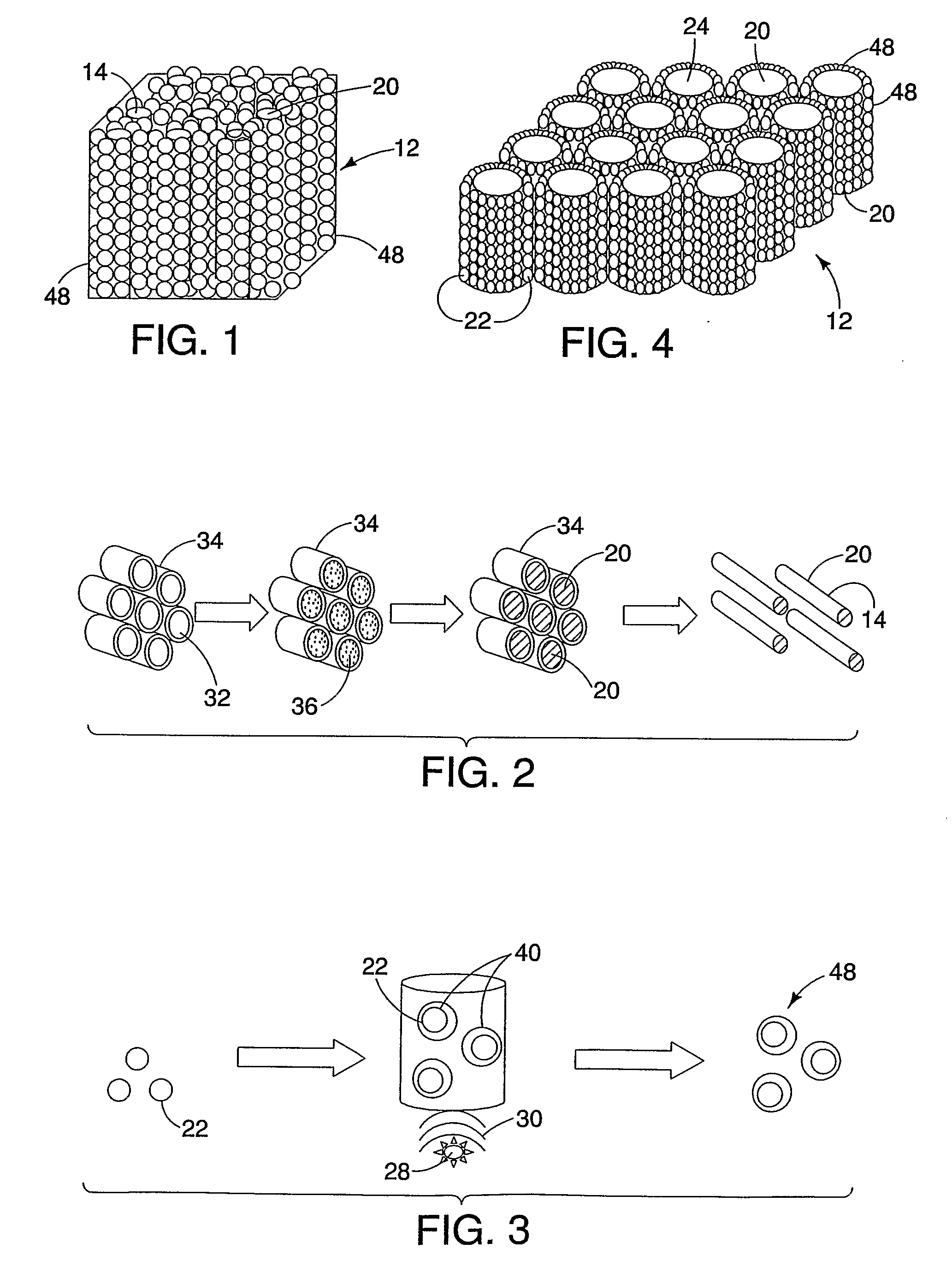

Process for mixing particulates

A process for producing a mixture of particulates using compressed gas and sonication. The process is particularly useful to mix reactive particulates, such as thermites.

Owner:TECH CORPORATION CO LTD

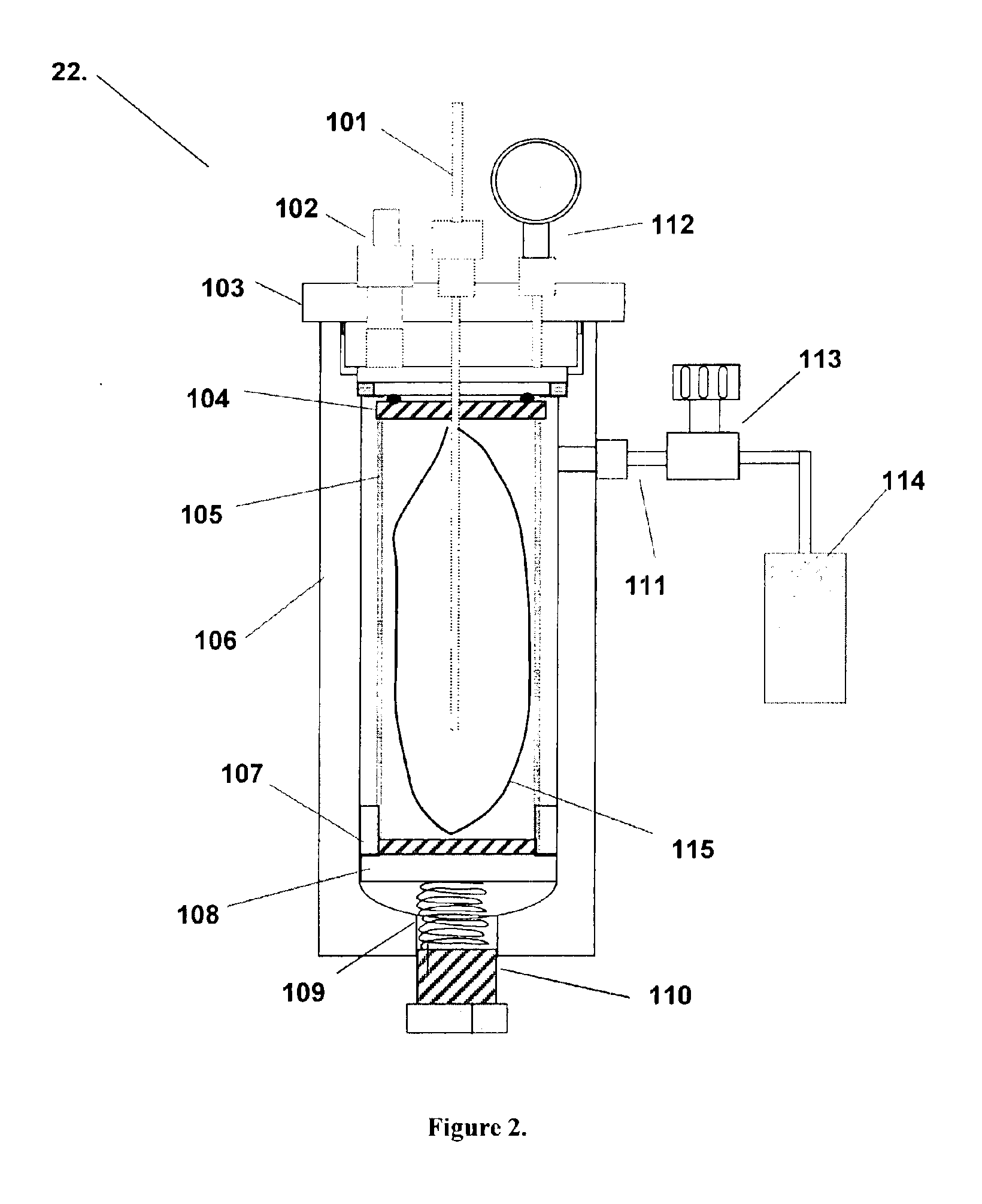

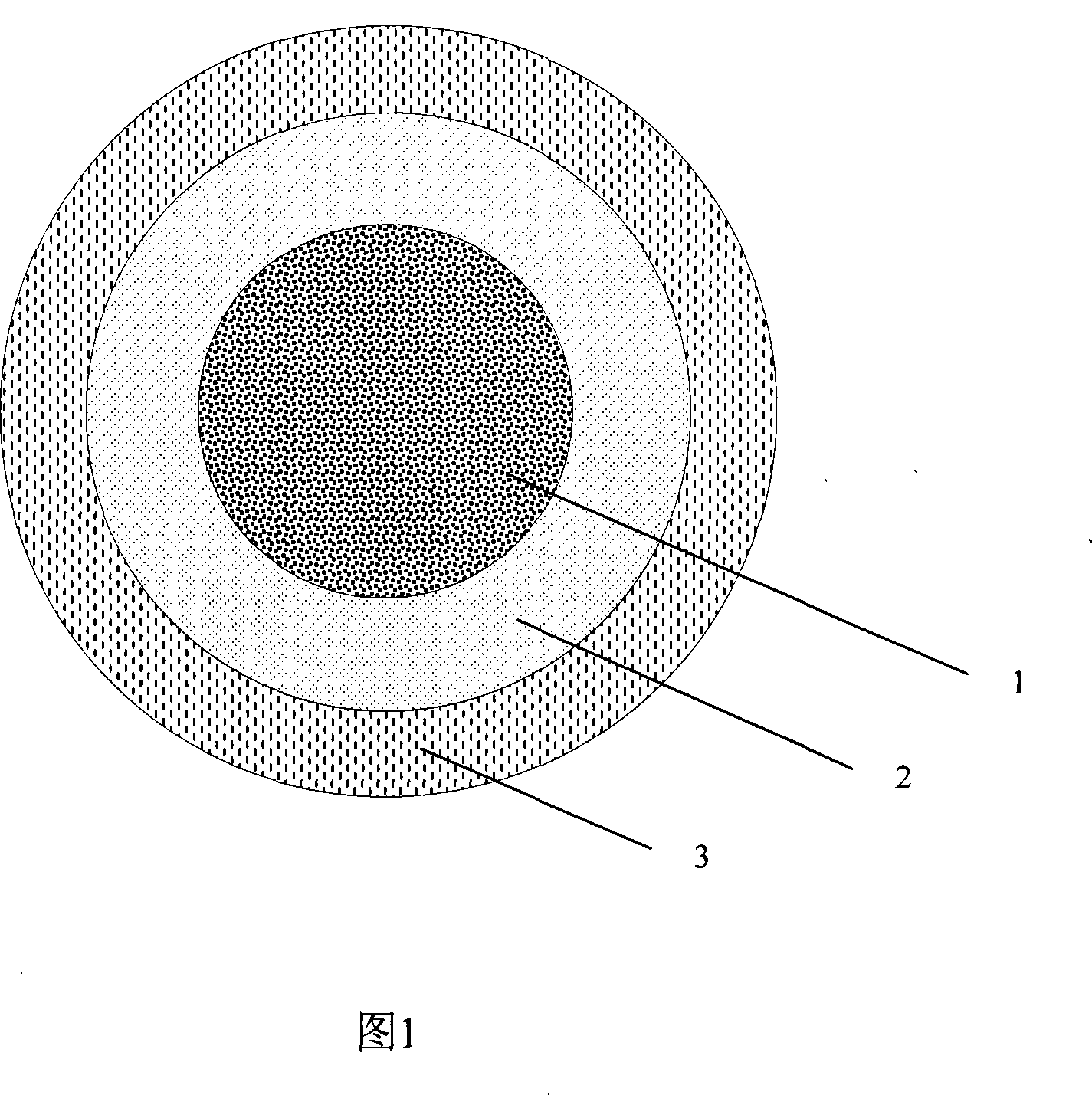

Method of preparing ceramic coating by flame heat spray painting thermit packaged silicon carbide particles

The present invention relates to a preparation method for ceramic coating of flame thermal spraying thermite coated silicon carbide grain, which comprises the steps of that: firstly, the ferric oxide powder and the aluminum powder are compounded to form thermite; and then the thermite, the alumina grain and the silicon carbide grain are compounded and rebuilt by macromolecule anchoring agent to form the spherical compounded grain with a three layers packaged structure, that is an inner layer of silicon carbide, a middle layer of thermite and an outer layer of alumina; finally, the spherical compounded grain is loaded in the powder bucket of the spraying gun, and the thermal spraying is executed by means of oxy-acetylene flame to form ceramic coating. In the present invention, the spraying raw materials are rebuilt and compounded, so that the silicon carbide grain will not contact with the flame directly in the oxy-acetylene flame thermal spraying process, which effectively prevent the silicon carbide grain from thermal sublimation in high temperature, thereby the silicon carbide grain can sediment onto the surface of the substrate uniformly and compactly so as to obtain the high performance ceramic thermal spraying coating of alumina enhanced by silicon carbide.

Owner:SHAANXI UNIV OF SCI & TECH

Method for smelting vanadium iron

The present invention provides a method for smelting vanadium iron, comprising the steps of: (1) contacting a raw material including quick lime, iron and a vanadium oxide and aluminum under the conditions of the first thermite reaction to obtain a first alloy liquid and a first slag; wherein the amount of aluminum used is 0.75-0.9 moles relative to per mole of oxygen in the vanadium oxide, and the total vanadium content is not higher than 0.2 wt% in the first slag resulted from the first thermite reaction conditions; (2) contacting the first alloy liquid and the slag including iron oxides and quick lime and without vanadium oxide under the conditions of the second thermite reaction to obtain a second alloy liquid and a second slag; wherein the aluminum element content in the second alloy liquid is not more than 1.5 wt% and the total vanadium content in the second slag is not more than 0.8 wt% resulted from the second thermite reaction conditions. By the method, the technical solution provided by the present invention effectively improves the recovery rate of vanadium.

Owner:PANZHIHUA IRON AND STEEL +1

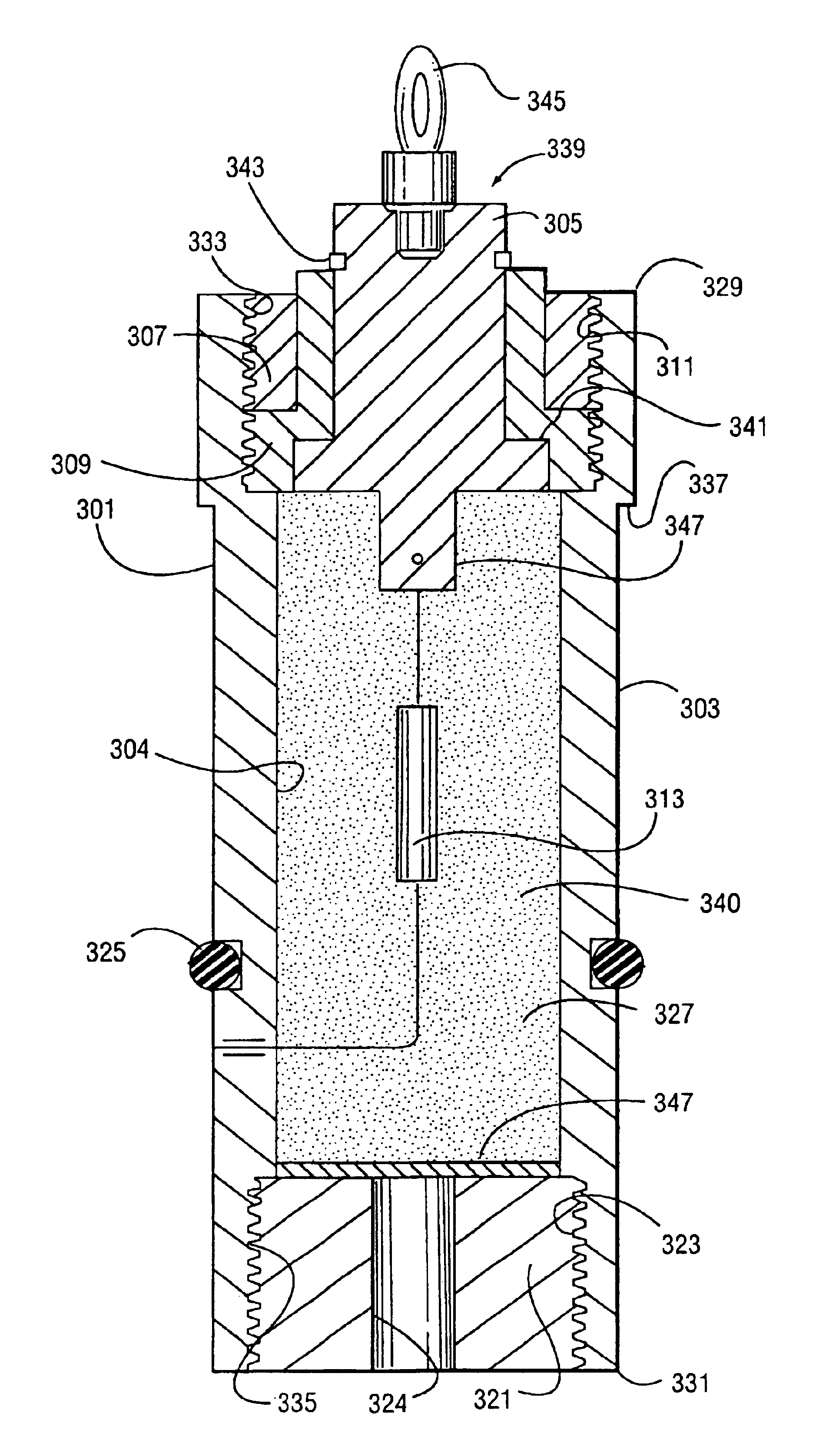

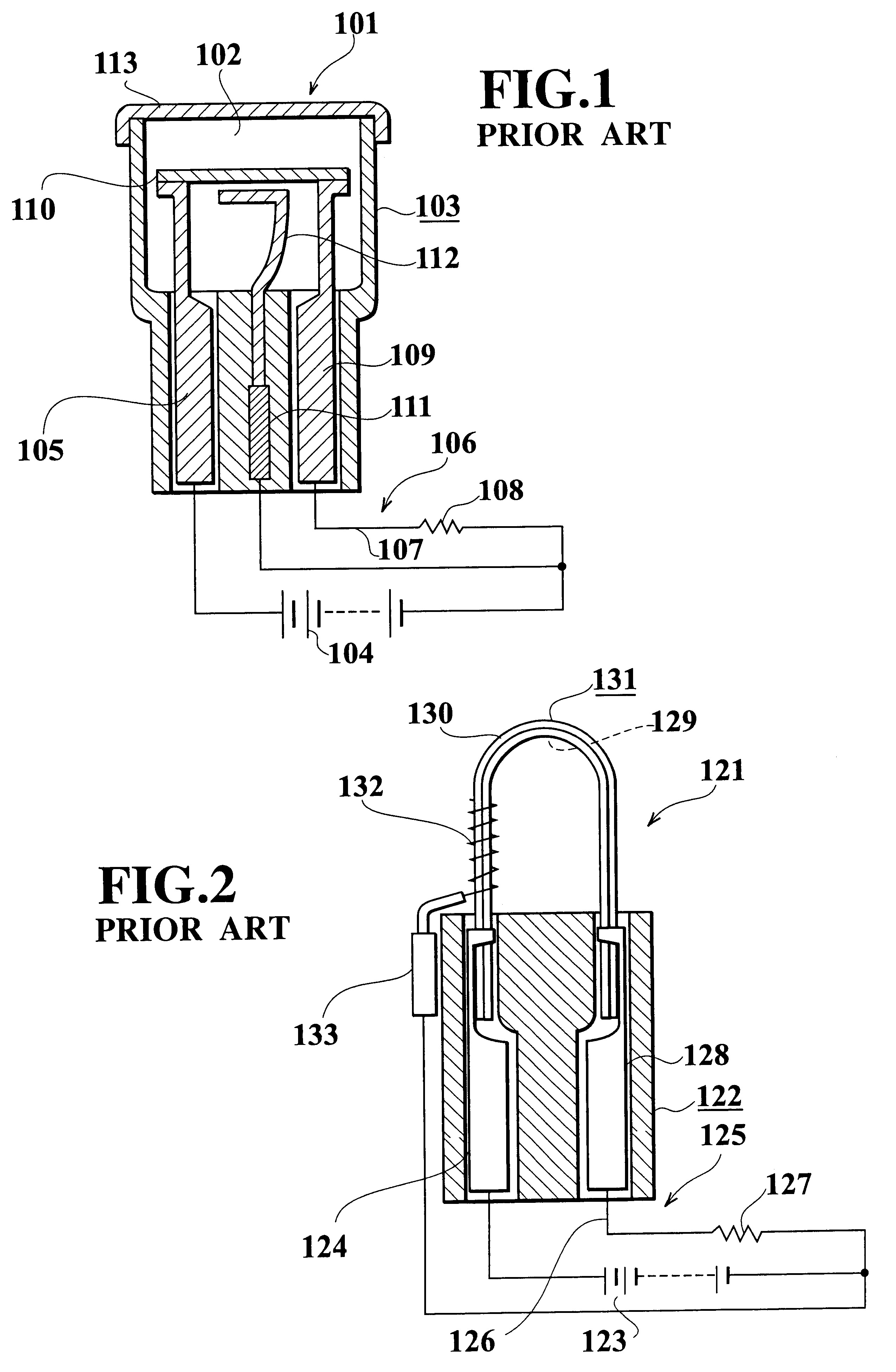

Thermal generator for downhole tools

InactiveUS20050072568A1Incandescent ignitionFluid removalElectricityElectrical resistance and conductance

An ignition device for a downhole tool includes a body with a cavity, a thermite material and a resistive element within the cavity. The resistive element, which is heated to the high temperature needed for ignition of the thermite material, has a non-galvanic outer surface at the ignition temperature. A large amount of electrical power is required to reach the ignition temperature, making the device safe and unlikely to accidentally ignite. The device has an electrical connector that is located within a sealed chamber when downhole.

Owner:ROBERTSON MICHAEL C

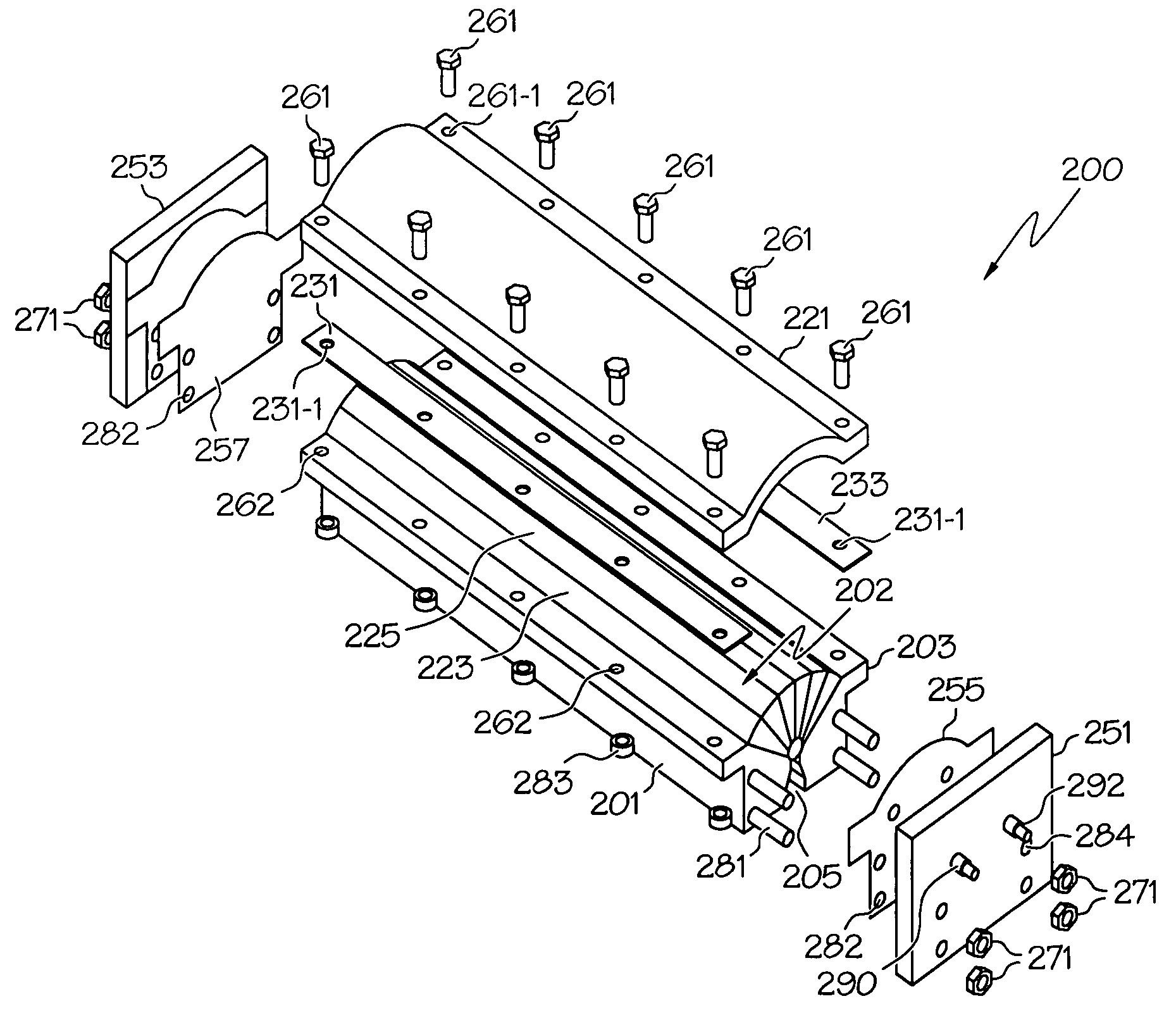

Non-explosive two component initiator

Methods and apparatus for detonating explosives or igniting flammables are disclosed. According to some embodiments of the invention, initiators include an initiating component holding an exploding bridgewire (EBW) or an exploding foil initiator (EFI) and a flammable component housing thermite. An end of the flammable component mates with a corresponding end of the initiating component. A method of initiating the explosives or flammables includes connecting the two components to assemble the initiator, disposing the initiator proximate the explosives or flammables, and activating the initiator to cause ignition of the thermite that then initiates the explosives or flammables. Additionally, a non-explosive kit for the initiator includes the two components with the EBW or EFI initially spaced from the thermite within the flammable component to make the initiator disarmed until final assembly thereof. Cutting torches and perforating guns provide examples of downhole tools that benefit from aspects of the invention.

Owner:WEATHERFORD TECH HLDG LLC

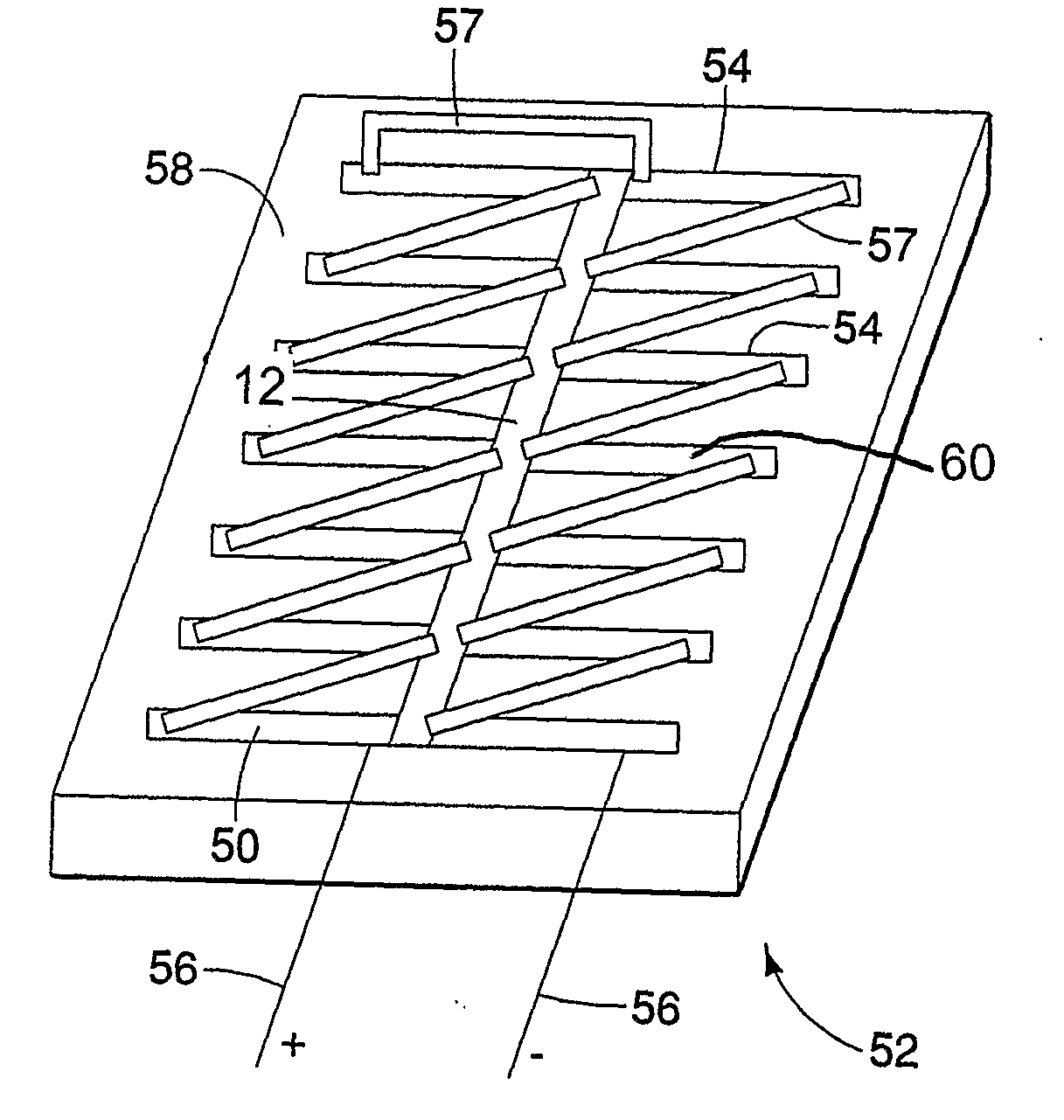

Shock Wave and Power Generation Using on-Chip Nanoenergetic Material

InactiveUS20090152873A1Precise power controlThermoelectric device with peltier/seeback effectMachines/enginesShock waveElectricity

A method of generating power uses a nanoenergetic material. The nanoenergetic material comprising thermite is obtained and deposited on a substrate. An igniter is placed on the nanoenergetic material. When power is desired, the nanoenergetic material is ignited. A transducer receives thermal, sonic, magnetic, optic and / or mechanical energy from combustion of the nanoenergetic material and converts it into electrical energy. Preferably, the transducer is a thermoelectric, piezoelectric or magneto device. Preferably, multiple transducers are integrated in one power generators to maximize the power from nanoenergetic thermites.

Owner:UNIVERSITY OF MISSOURI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com