Patents

Literature

10264 results about "Material technology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Materials technology is a relatively comprehensive discipline that begins with the production of goods from raw materials to processing of materials into the shapes and forms needed for specific applications. Materials - metals, plastics and ceramics - typically have completely different properties,...

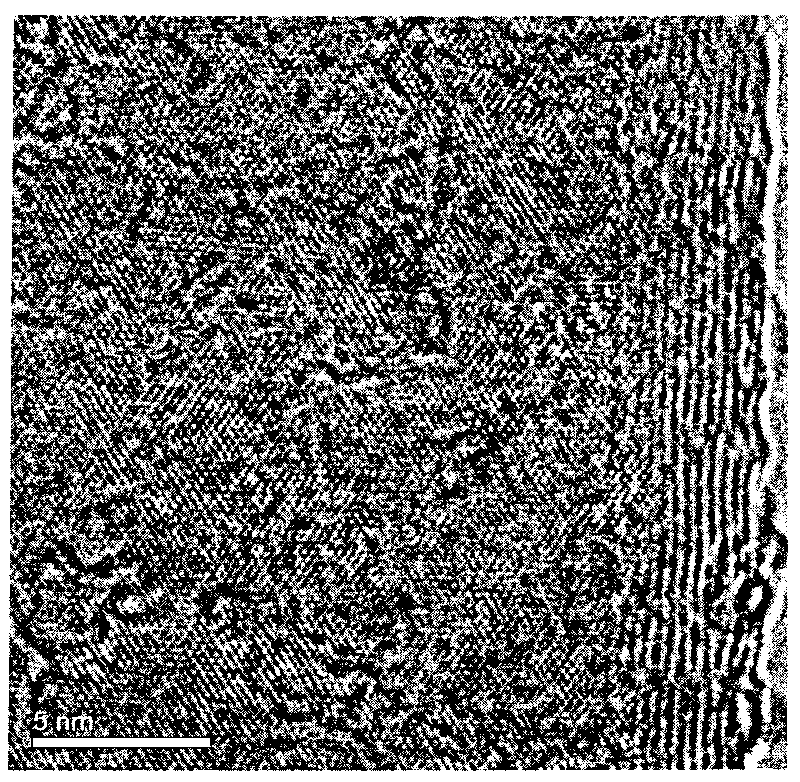

Preparation method of mesonic pore molecular sieve carrier material

The present invention belongs to the field of inorganic nanometer material technology, in particular, it relates to a method for preparing mesoporous molecular sieve carrier material by using diblockmacromolecular polymer. It is characterized by that under the acid condition it uses polyoxyethylene-polyoxybutylene diblock macromolecular surfactant as template agent and makes hydrothermal synthesis at 100 deg.C to prepare mesoporous silicon oxide material with two-dimensional hexagonal structure with high degree of order and large specific surface area and laminate silicon oxide material withhigh degree of order. These new material can be used as catalyst, catalyst carrier, adsorption film, organic-inorganic composite material, sensor and chromatographic packing, etc.

Owner:FUDAN UNIV

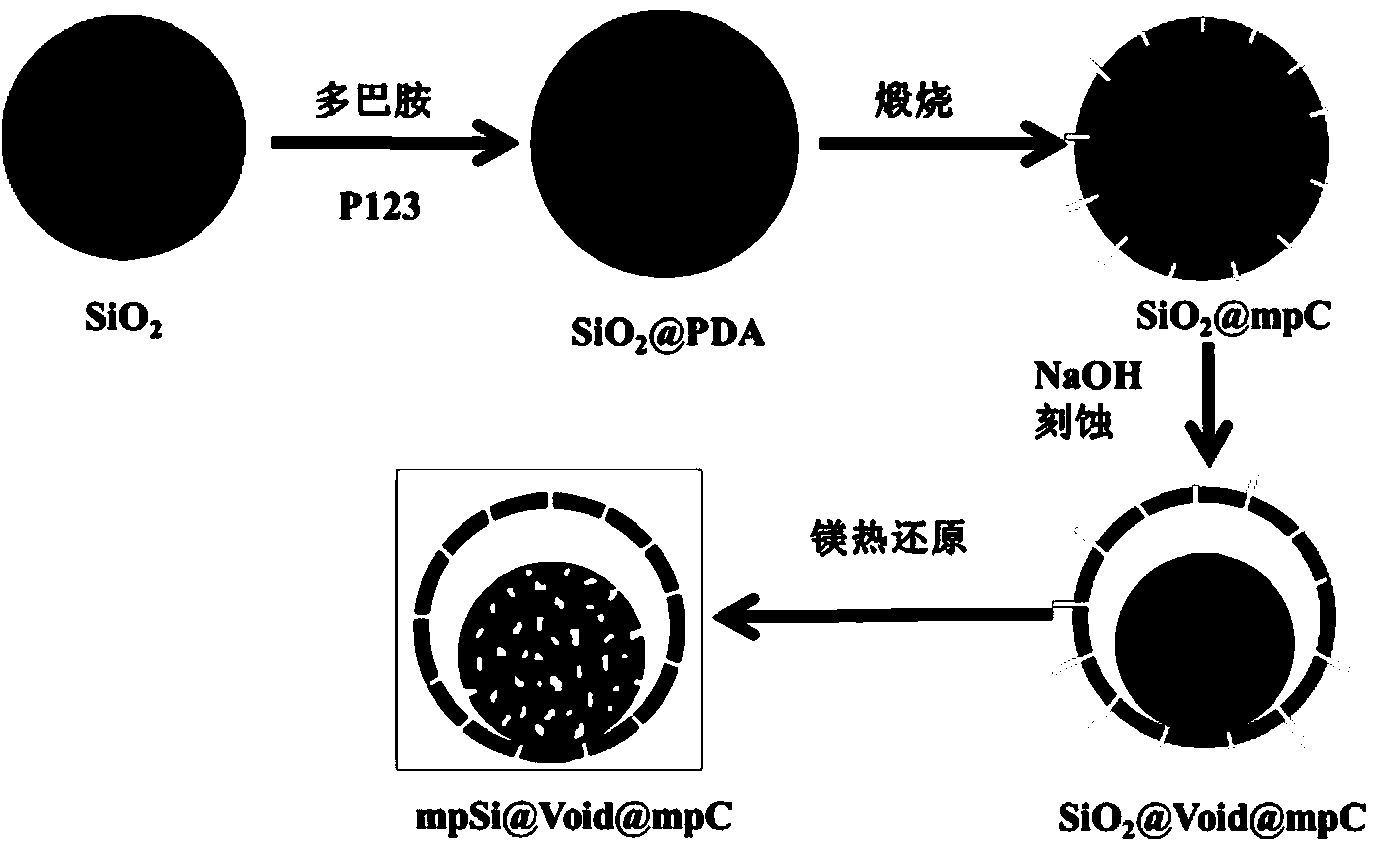

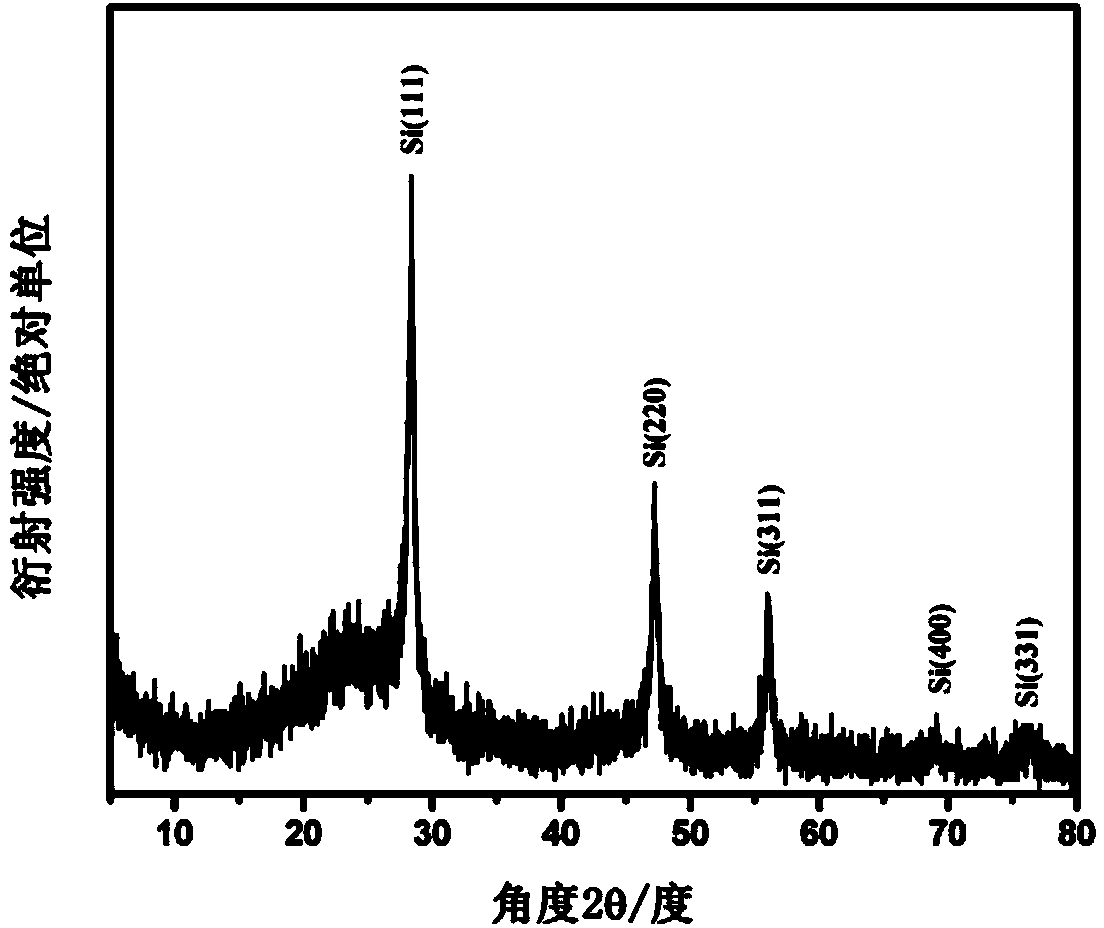

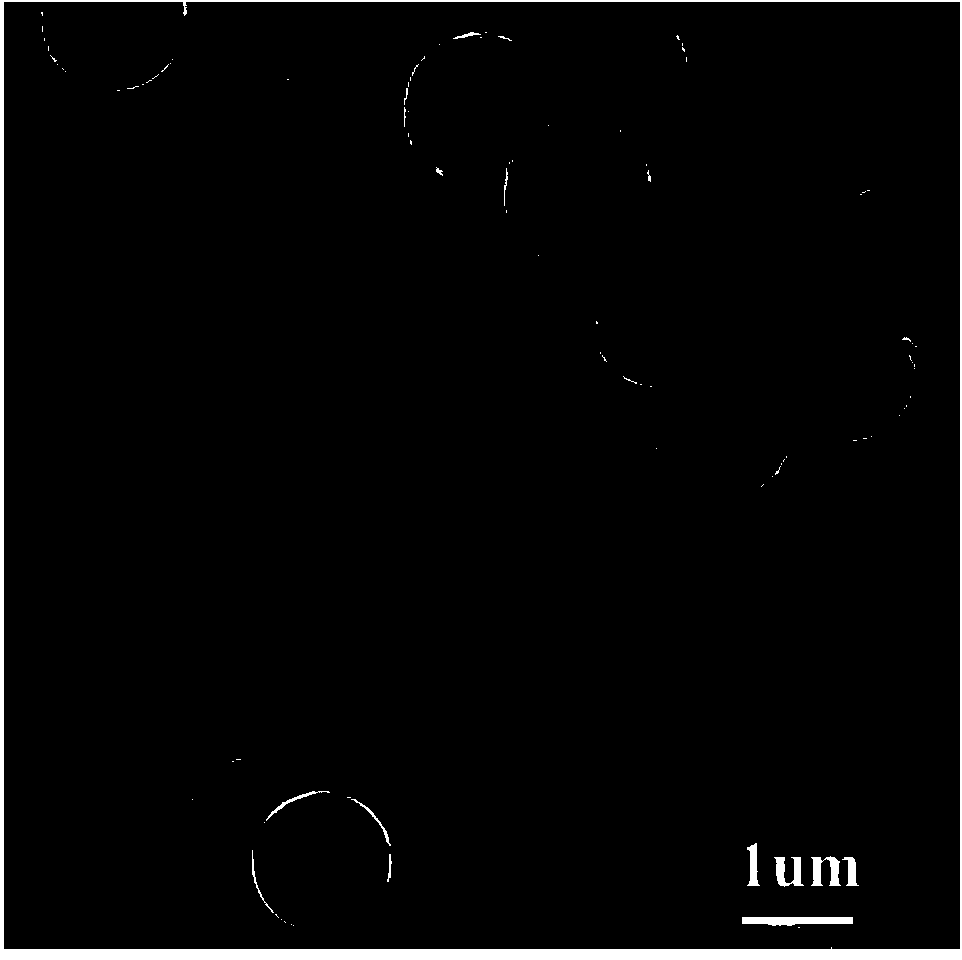

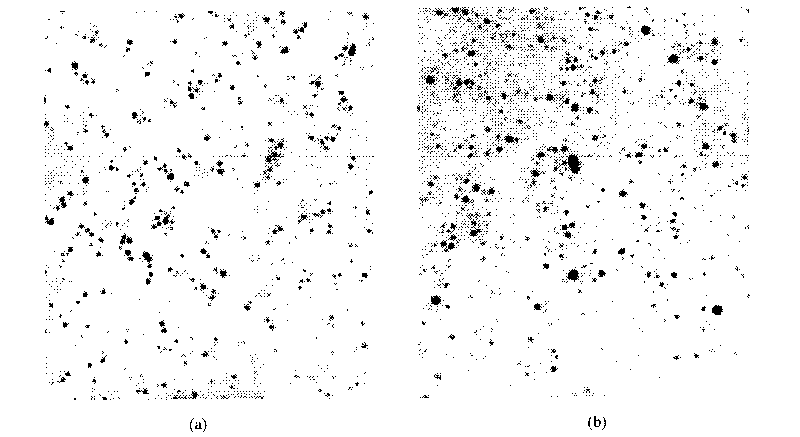

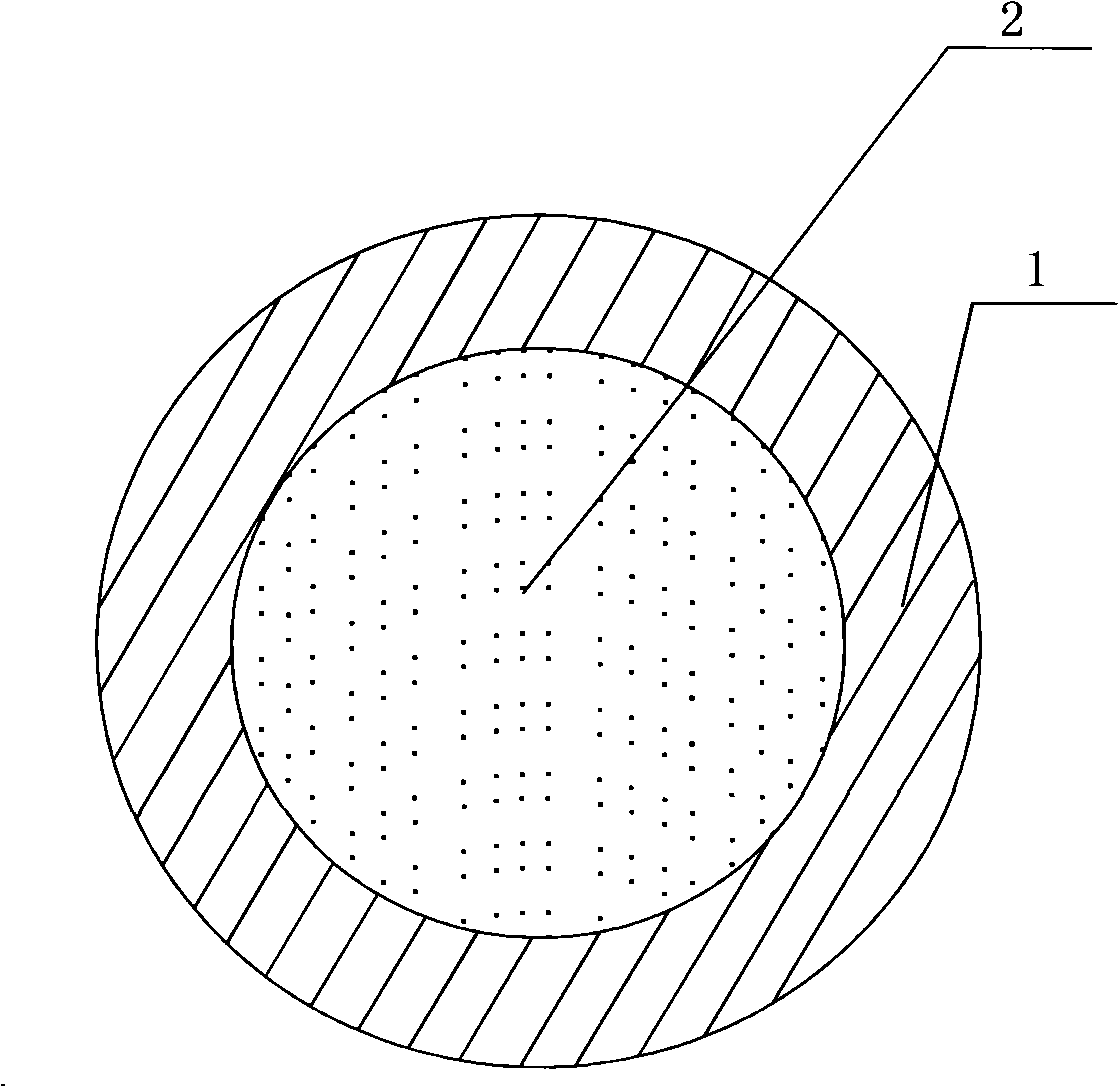

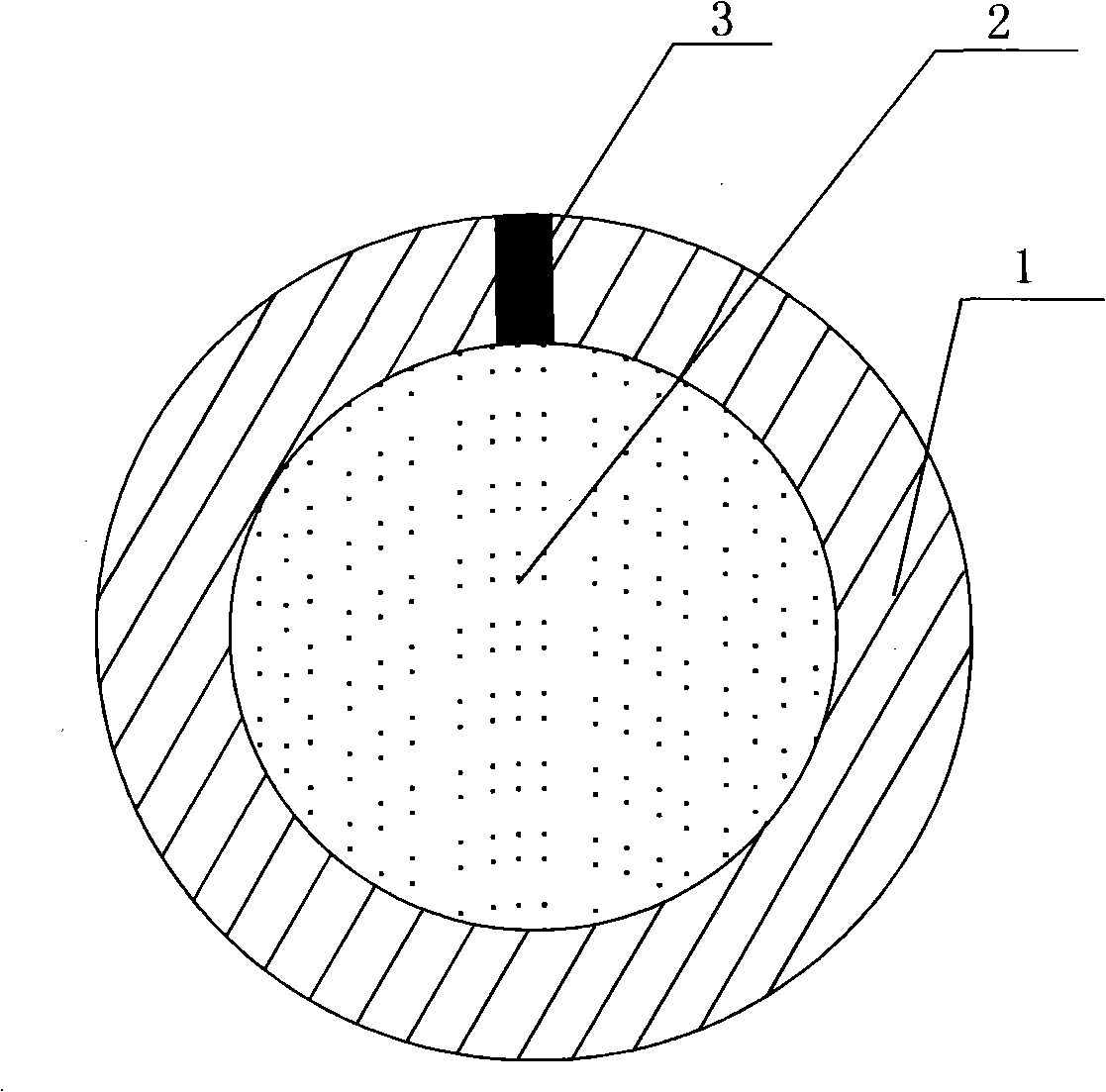

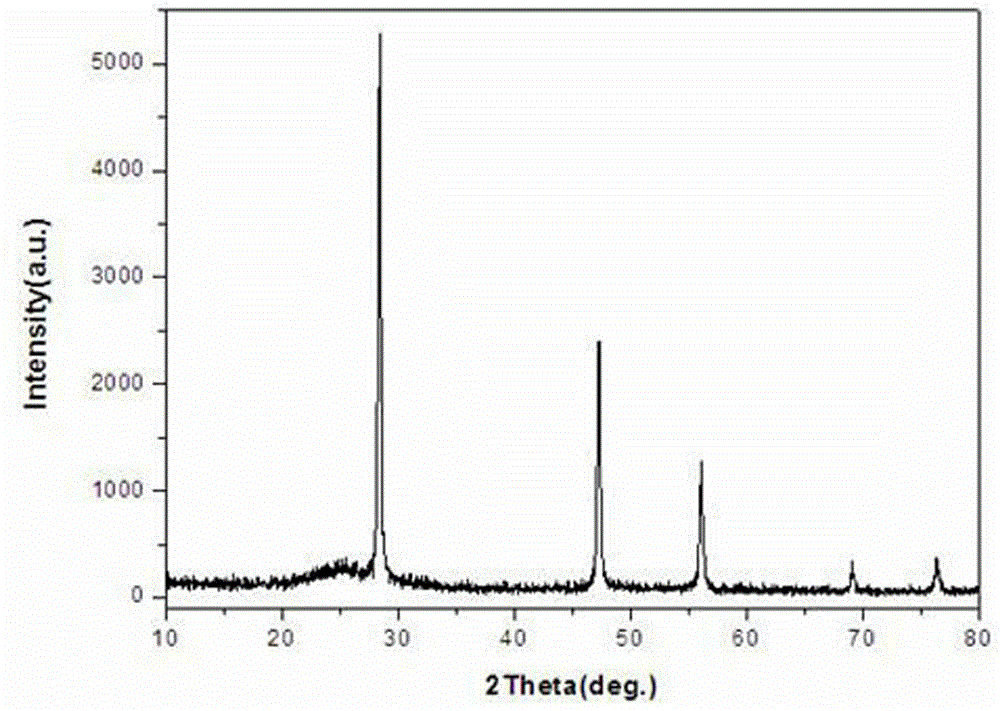

Porous silicon carbon composite microsphere with yolk-eggshell structure and preparation method therefor

InactiveCN103531760AEase of mass productionPromote infiltrationMaterial nanotechnologyCell electrodesCarbon compositesYolk

The invention provides a porous silicon carbon composite microsphere with a yolk-eggshell structure and a preparation method therefor, and belongs to the lithium ion battery electrode material technology field. The porous silicon carbon composite microsphere takes a porous submicron silicon sphere mpSi as a core with a diameter of 400-900 nm, and takes porous carbon mpC as a shell with a thickness of 10-60 nm. The inner diameter of a cavity Void is 800-1400 nm. The composition of the silicon carbon composite microsphere can be described as mpSi@Void@mpC. In addition, In the preparation method, cheap silicon dioxide is taken as a silicon source, silicon dioxide is conversed into silicon materials with electrochemical activities through a magnesiothermic reduction method. The size of gaps can be regulated and controlled through control of etching conditions. The preparation method is advantaged in that the material structure can be controlled, the cost is low, the process is simple, and the composite microsphere is convenient for large-scale production.

Owner:BEIJING UNIV OF CHEM TECH

High strength and high toughness modified poly-propylene material

The present invention belongs to the field of polymer material technology, and is especially one kind of modified polypropylene material comprising at least polymer base, strengthening agent and toughening agent. The polymer base may be polypropylene or polypropylene composition; the strengthening agent is inorganic or organic matter with great aspect ratio, such as inorganic or organic crystal whisker, fiber, mica, etc; and the toughening agent may be polypropylene beta-nucleater, rubber elastomer, etc. The modified polypropylene material has high strength, high toughness, etc and may be applied widely in automobile, pipeline, electric appliance and other fields.

Owner:FUDAN UNIV

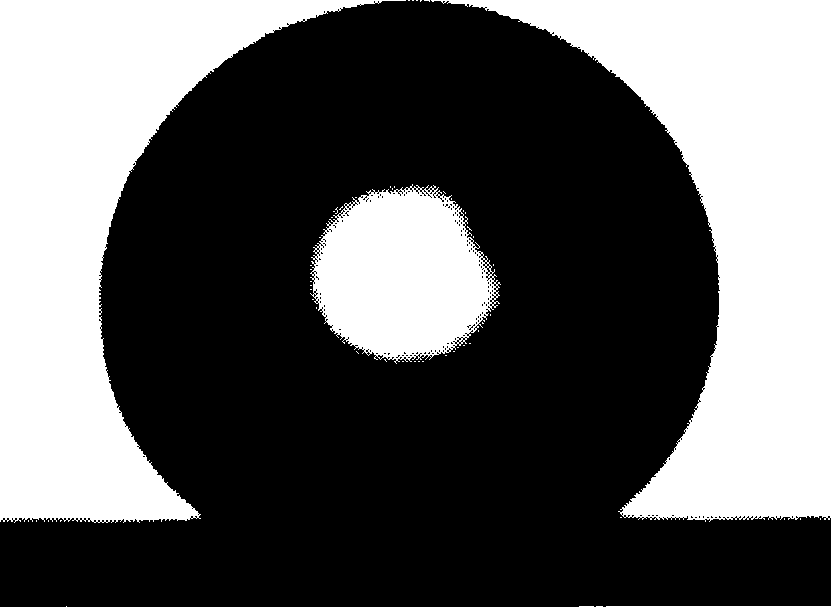

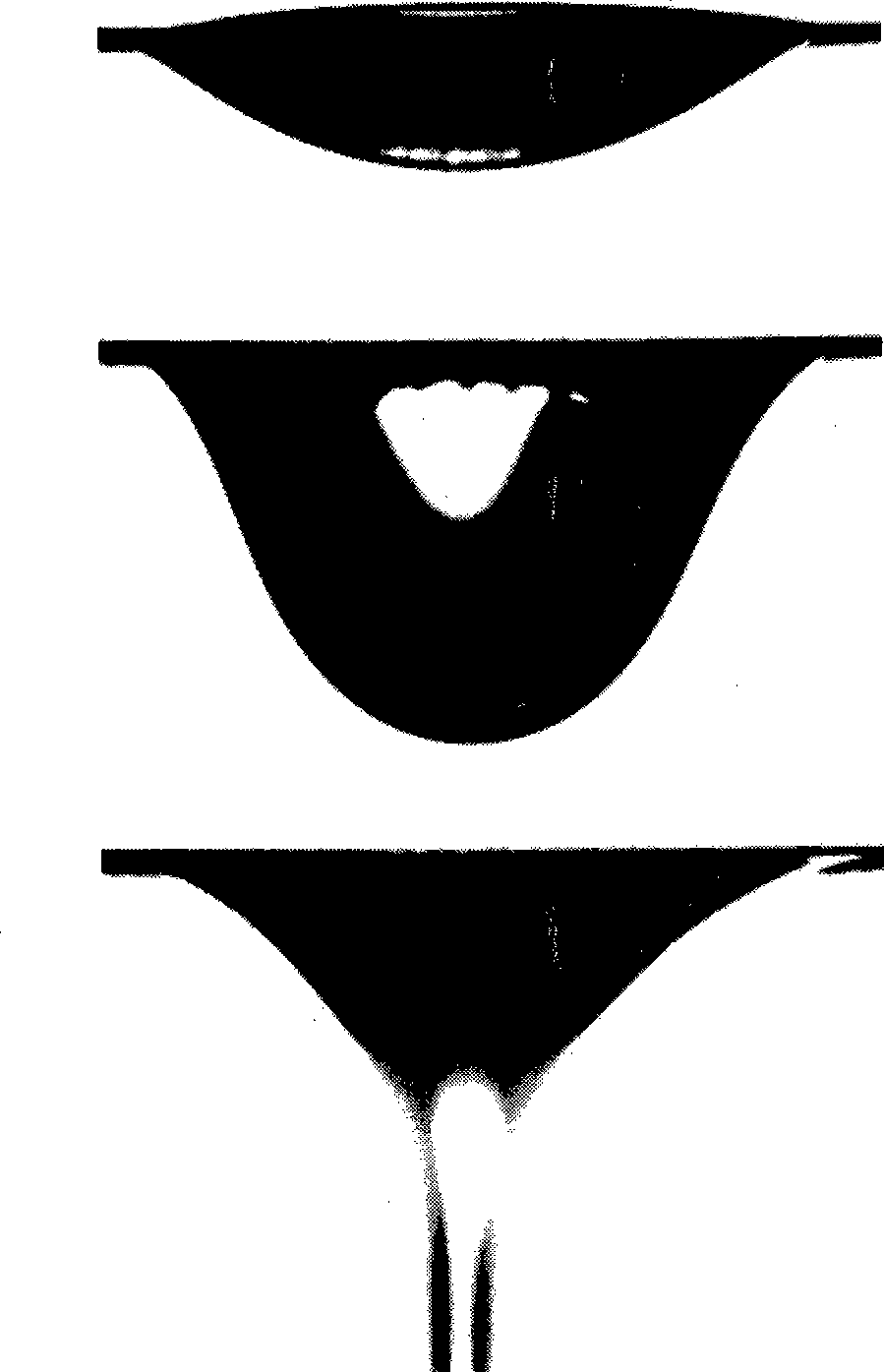

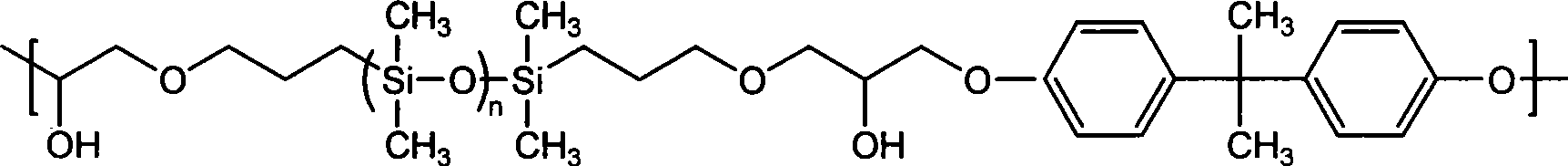

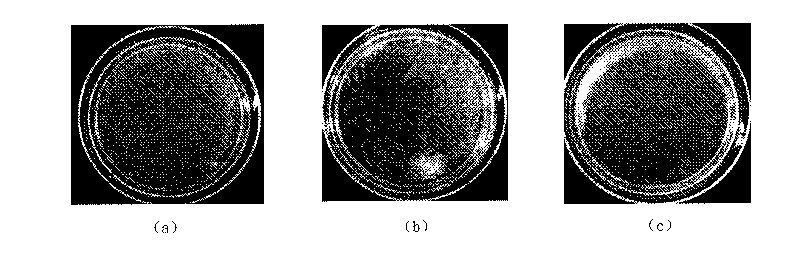

Super-hydrophobic and super-oleophilic oil-water separation mesh membrane and preparation method thereof

The invention pertains to the technical fields of chemistry, chemical industry and functional macromolecular materials, in particular relates to a super-hydrophobic and super-oleophilic oil-water separation mesh membrane and a preparation method thereof. The super-hydrophobic and super-oleophilic oil-water separation mesh membrane is prepared with a dip-coating method which comprises the steps that a proper treating agent is selected, epoxy group-terminated oligomeric siloxane is copolymerized with bisphenol A on a proper condition; the oligomeric siloxane-bisphenol A copolymer is mixed evenly with the treating agent to form a solution; the oligomeric siloxane-bisphenol A copolymer is cured on a fabric net of 100 meshes to 400 meshes to obtain the super-hydrophobic and super-oleophilic oil-water separation mesh membrane. The mesh membrane contains no fluorin, and has high hole penetration and good oil / water separation effect. The preparation method of the mesh membrane is simple.

Owner:INST OF CHEM CHINESE ACAD OF SCI

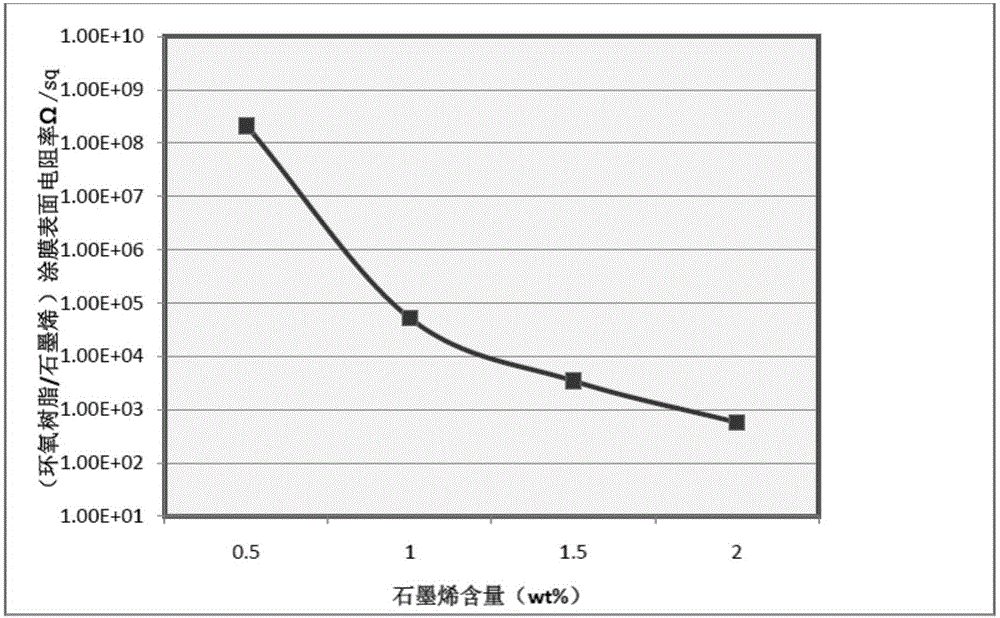

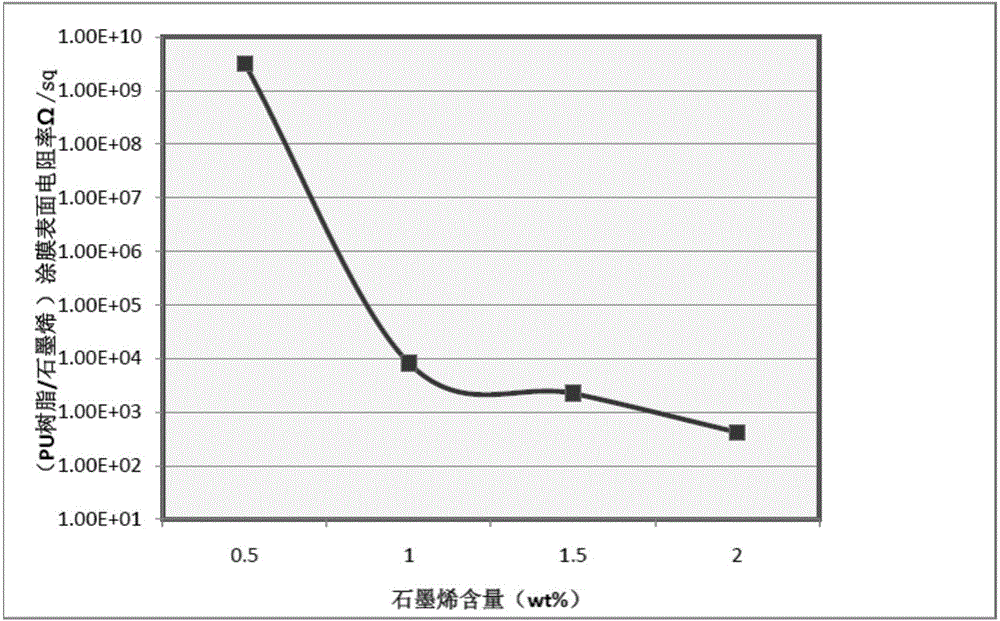

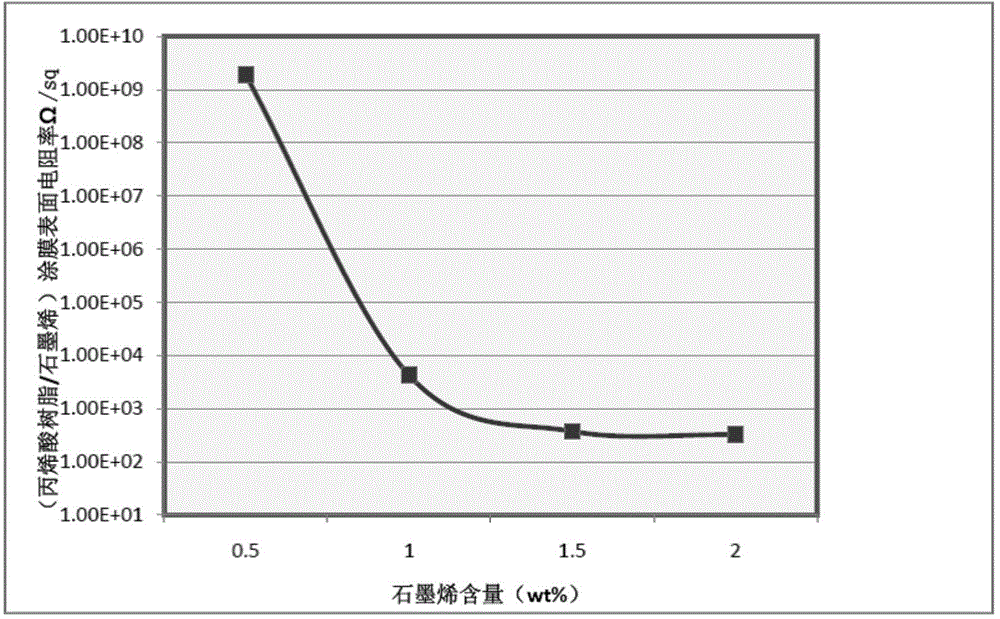

Conductive heat-conductive graphene slurry and coating

InactiveCN104163928AAdd lessReduce pollutionPolyurea/polyurethane coatingsEpoxy resin coatingsHeat conductingConductive materials

The invention relates to a conductive heat-conductive graphene slurry and a coating. The conductive heat-conductive graphene slurry comprises the following raw materials: 0.1-90wt% of conductive heat-conductive graphene slurry ( consisting of 3-20wt% of less graphene, 0-80wt% of base solvent, 0-80wt% of base resin), 0-60wt% of filler, 0-10% of dispersing agent, 10-60wt% of resin, 10-60wt% of curing agent, and 30-70wt% of solvent, wherein not only can the graphene slurry be antistatic, conductive and heat-conducting despite of less addition amount, but also the surface of a coated article is smoother and finer, firmer and more durable; compared with the addition amount of the existing conductive material, the conductive heat-conductive graphene slurry is lower in addition amount and can also reach lower resistivity.

Owner:SUPERCDONGGUAN TECH

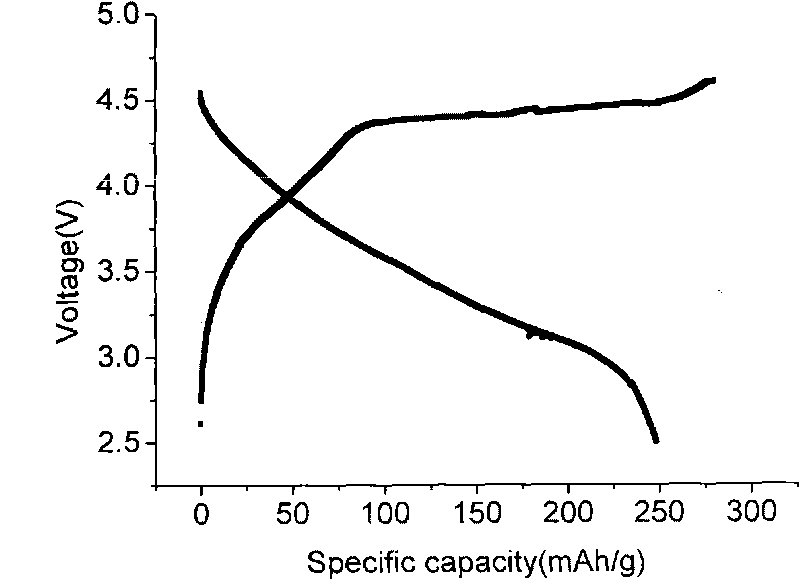

Lithium-rich manganese-based anode material and preparation method thereof

InactiveCN101694876AIncrease the charge cut-off voltageHigh specific capacityCell electrodesManganeseSpecific discharge

The invention relates to a lithium-ion secondary battery anode material technology, in particular to a lithium-rich manganese-based anode material Li(Li(1-2x) / 3Nix-aMyMn(2-x) / 3-b)O2 (M is Co, Al, Ti, Mg and Cu) and a preparation method thereof. A general formula of the lithium-rich manganese-based anode material is as follows: Li(Li(1-2x) / 3Nix-aMyMn(2-x) / 3-b)O2 (M is Co, Al, Ti, Mg and Cu), wherein x is more than 0 and less than or equal to 0.5, when M is Co and Al, y is more than 0 and less than 2x, a is equal to b, and b is equal to y / 2; when M is Ti, y is more than 0 and less than (2-x) / 3, a is equal to 0, and b is equal to y; and when M is Mg and Cu, y is more than 0 and less than x, a is equal to y, and b is equal to 0. The invention has high specific discharge capacity, excellent normal temperature and high temperature cycle performance, good safety, low raw material cost and production cost, and very high cost-performance ratio.

Owner:JIANGXI JIANGTE LITHIUM LON BATTERY MATERIAL +1

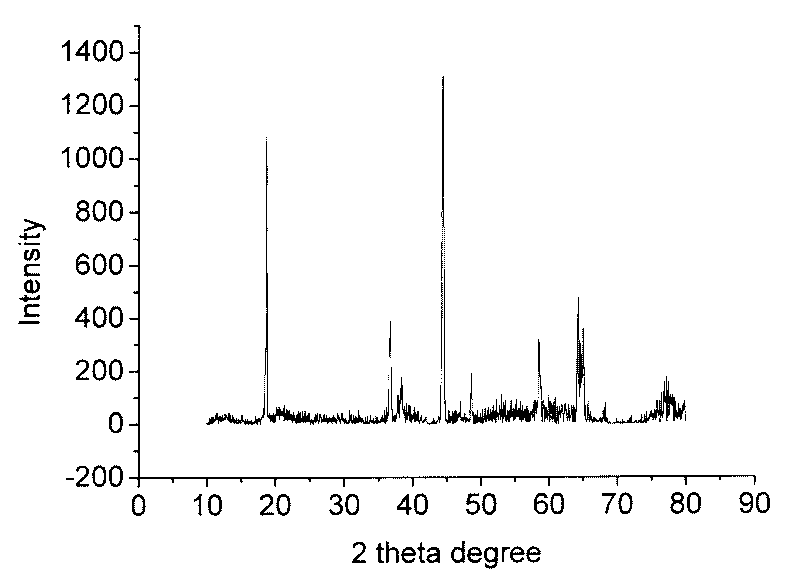

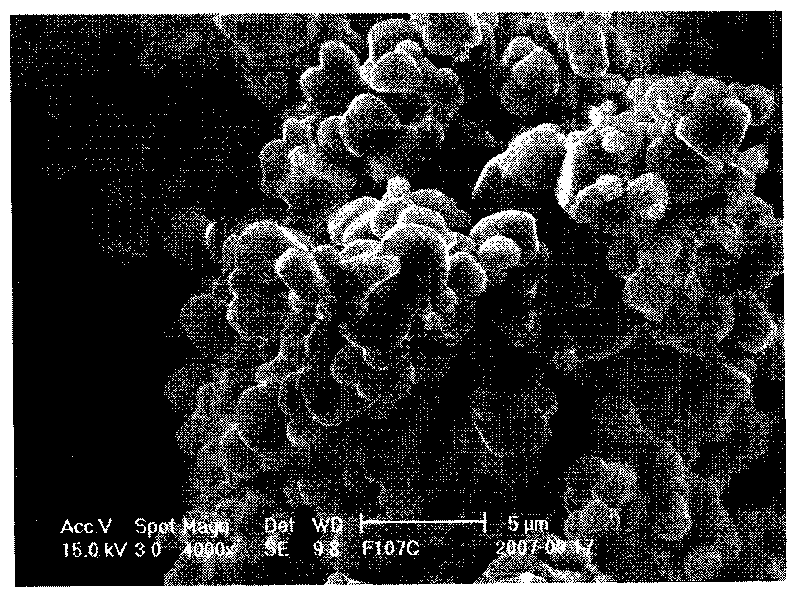

Process for preparing high density spherical nickel-cobalt lithium manganate as anode material of lithium ion cell

InactiveCN1622371AWell mixedImprove performanceElectrode manufacturing processesLithium compoundsNickel saltManganate

The present invention relates to energy source material technology, and is preparation process of high density spherical lithium nickel-cobalt-manganate as positive electrode material for lithium ion cell. The preparation process includes the reaction of nickel salt, cobalt salt, manganese salt, ammonium hydroxide and ammonian in water solution to synthesize spherical or spheroid precursor Ni1 / 3Co1 / 3Mn1 / 3 (OTHER)2, washing, drying and mixing with lithium carbonate; and high temperature treatment in the air at 750-950 deg.c for 8-48 hr to obtain spherical lithium nickel-cobalt-manganate. The spherical lithium nickel-cobalt-manganate has great bulk density reaching 2.25-2.50 g / cu cm after vibration densifying, average grain size of 3-7 microns, and reversible specific capacity up to 172-185 mA.hr / g.

Owner:TSINGHUA UNIV

Wear-resistant wood plastic floor and its production technology

The present invention is wear-resistant wood-plastic floor board and its production process, and belongs to the field of decoration material technology. Polyvinyl chloride resin or plastic material is added with waste wood powder or fiber material powder, active calcium carbonate, assistant, stuffer, etc, and the mixture is pelletized, and further treated through extruding, molding, vacuum cooling, settling, drawing and cutting to form the basic wood-plastic board. The basic wood-plastic board is polished, groove milled and covered with surface decoration layer to form the wear resistant wood-plastic floor board product. The wear resistant wood-plastic floor board is beautiful, wear resistant, fireproof, waterproof, non-skid, anticorrosive and environment friendly and has high strength, heat insulation, electrical insulation and other advantages.

Owner:无锡市中德装饰新材料有限公司

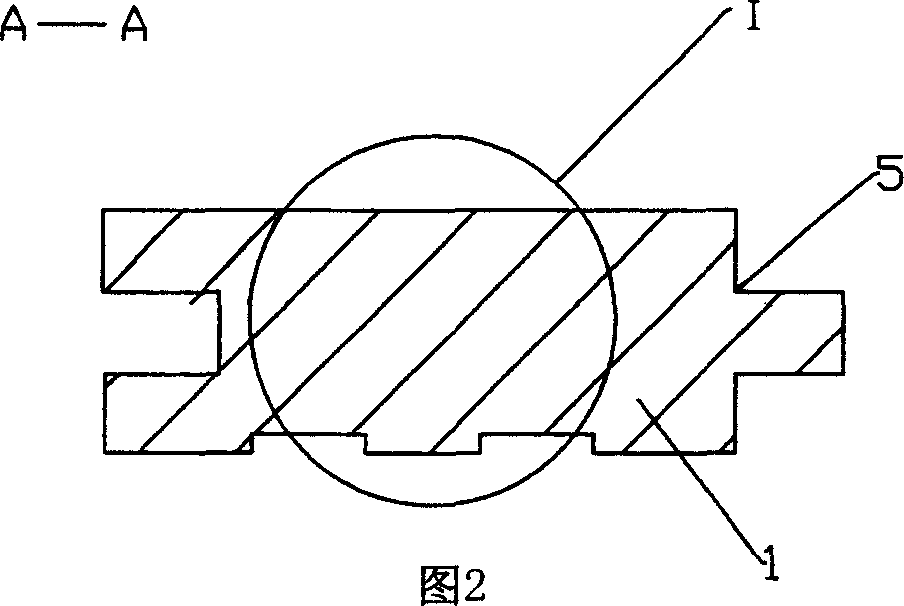

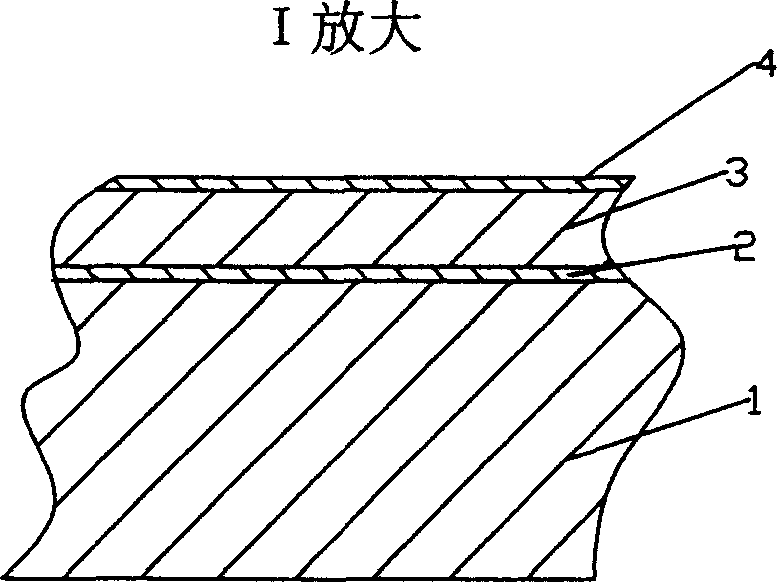

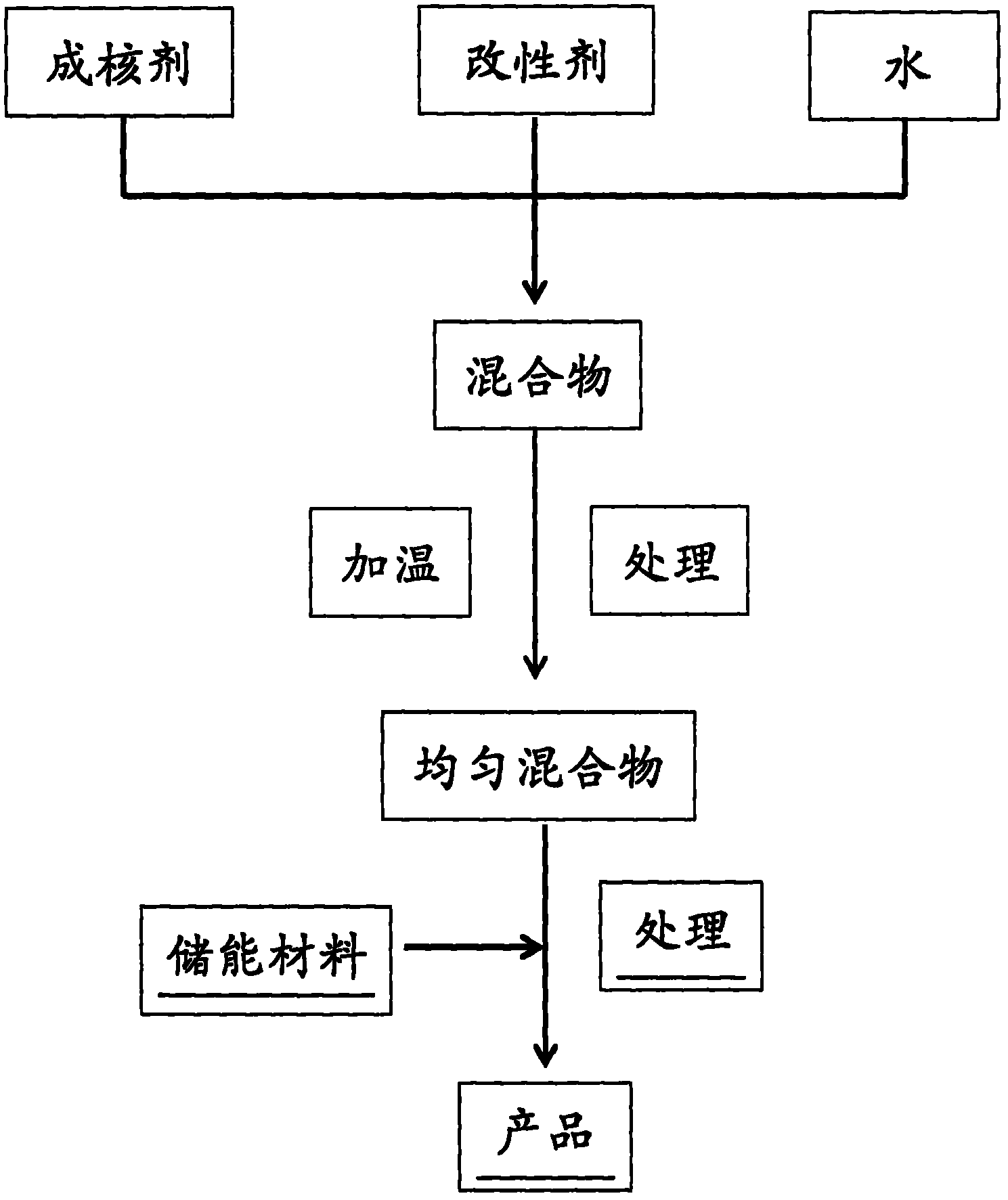

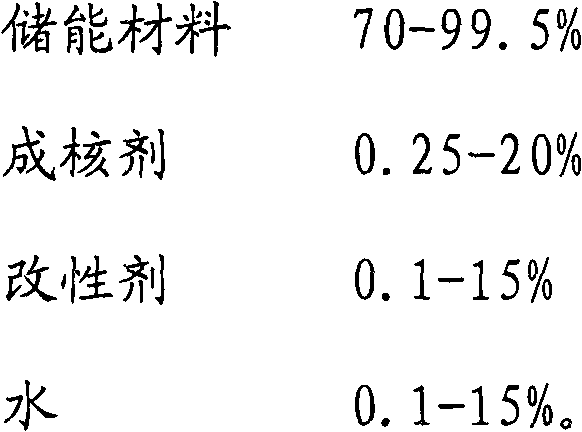

Inorganic phase change energy storage material

InactiveCN102604599AImprove liquidityPrevent Mutual AggregationHeat-exchange elementsPhase changeEnergy storage

The invention relates to the technical field of energy storage material, in particular to inorganic phase change energy storage material. The material comprises the following components by mass: 70 to 99.5 % of energy storage material, 0.25-20 % of nucleating agent, 0.1-15 % of modifying agent and 0.1-15 % of water. The bases hydrate or crystalline hydrous salt, especially the bases hydrate is adopted as energy storage material; the nucleating agent adopts carbonate; and the modifying agent is dispersant. According to the inorganic phase change energy storage material, by selecting proper nucleating agent and the ration of the nucleating agent, material phase separation can be effectively solved, especially the phase change energy storage material prepared by adding the dispersant into a system has good cycling stability, and simultaneously the potential heat value does not change after circulation for thousands of times.

Owner:SHANGHAI XUNENG NEW ENERGY TECH

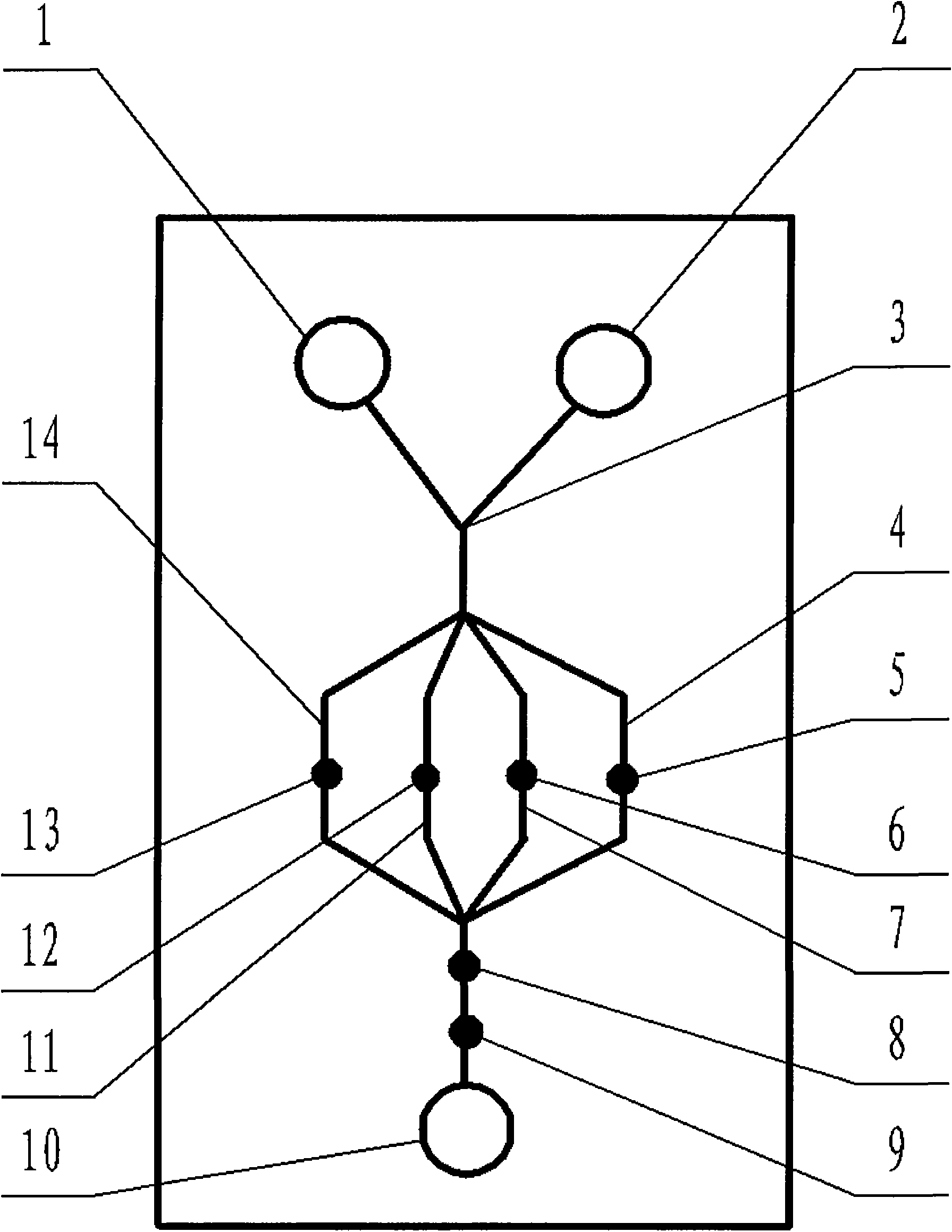

Multi-channel chip for cholera diagnosis based on structural conductive macromolecular material technology

InactiveCN101620227AReduce manufacturing costMechanically resistantMaterial analysisAgainst vector-borne diseasesCapillary channelLiquid storage tank

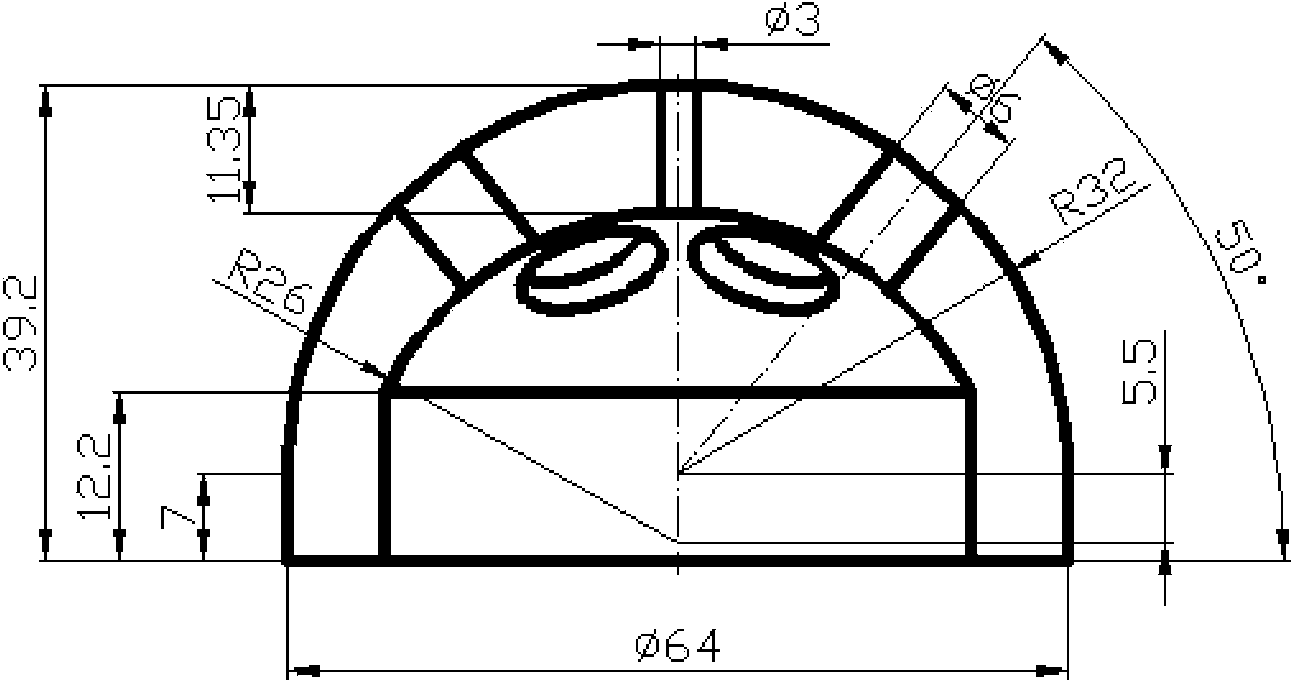

The invention relates to a multi-channel chip for cholera diagnosis based on a structural conductive macromolecular material technology, belonging to the test field. The invention aims to aid rapid and low-cost fulminating infectious disease cholera diagnosis which is one of medical technical progress expectations. The chip is provided with three micro liquid storage tanks and is characterized bycomprising capillary channels in parallel construction containing four micro channels mutually connected in parallel; four fibrous working electrodes are respectively mounted in the four micro channels; and four antibody substances, i.e. a cholera TP0821 antibody, a cholera TP0319 antibody, a cholera TP 0624 antibody and a cholera TP0139 antibody are respectively arranged on the surfaces of the four fibrous working electrodes which are originally made of a thermal-decomposition conductive macromolecular material. The chip has low cost and multiple channels.

Owner:NINGBO UNIV

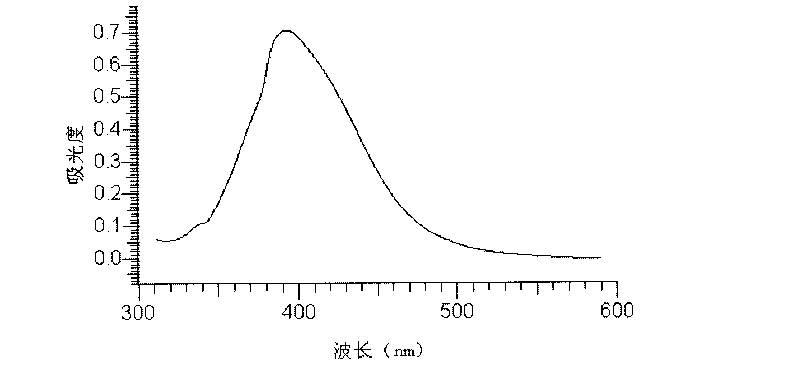

Method for preparing antibacterial nanometer silver colloid

ActiveCN101731272ASmall particle sizeUniform size distributionBiocideDisinfectantsHigh concentrationBiological materials

The invention discloses a method for preparing antibacterial nanometer silver colloid, belonging to the technical field of nanometer biological materials. The method uses a chemical reduction method, comprising the following steps: dissolving water-soluble protective agent in silver nitrate water solution with the concentration of 0.001-0.1mol / L, wherein the mass ratio of protective agent to silver nitrate is 0.5-10.0:1; carrying out ice bath on sodium borohydride water solution with the concentration of 0.001-0.2mol / L for 10-30min; and dropwise adding the silver nitrate water solution containing protective agent in the sodium borohydride water solution with the speed of 30-60 drop / min, stirring by a magnetic stirrer, stirring for 20-40min after dropwise adding to prepare the nanometer silver colloid with the grain size of 5-80nm, wherein the mol ratio of the sodium borohydride to the silver nitrate is 1.0-30.0:1. The nanometer silver colloid prepared by the invention has the advantages of high concentration, high stability, high dispensability, and obviously-enhanced antibacterial property.

Owner:INST OF BASIC MEDICAL SCI ACAD OF MILITARY MEDICAL SCI OF PLA

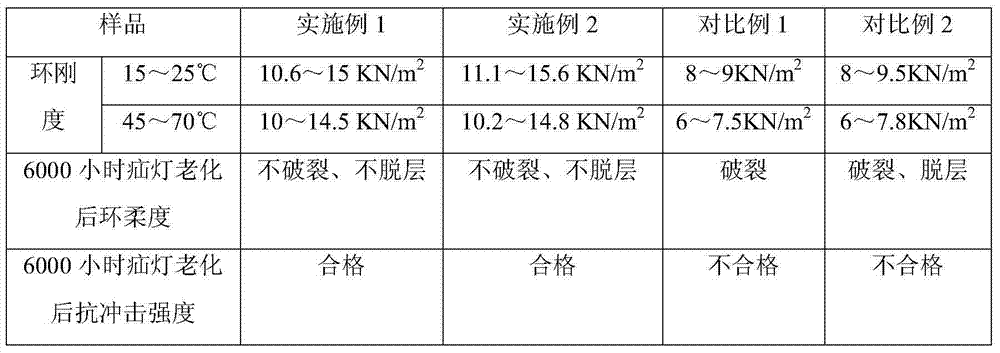

Polyethylene corrugated pipe and preparation method thereof

InactiveCN103937075AThe preparation method is simple and convenientLow costAntioxidantEngineering plastic

The invention relates to a polyethylene corrugated pipe and a preparation method thereof, belonging to the technical field of non-metal building materials. The invention aims to provide a high-strength aging-resistant polyethylene corrugated pipe which is prepared through the following steps: preliminarily mixing the following raw materials in parts by weight: 75-100 parts of polyethylene, 5-25 parts of polypropylene, 0.5-15 parts of compatibilizer, 0.5-25 parts of rigid master batch, 0.05-1.5 parts of antioxidant, 0.02-1.5 parts of light stabilizer, 0.05-5 parts of light screening agent and 0.5-10 parts of nano material, uniformly stirring, and then granulating to obtain a preliminarily mixed granulation material; adding 2-15 parts by weight of engineering plastic, blending with the preliminarily mixed granulation material, uniformly stirring, and then granulating to obtain a blended granulation material; and then extruding the blended granulation material through an extruder, sizing with a mold, cooling, pulling, and cutting.

Owner:KANGTAI PLASTIC SCI & TECH GRP

Graphene coating as well as preparation method and coating method thereof

The invention belongs to the technical field of materials and in particular relates to a graphene coating as well as a preparation method and a coating method thereof. The graphene coating is prepared from the components by weight: 5-95wt percent of less layer of grapheme, 5-95wt percent of adhesive, 0.01-50wt percent of dispersant and surfactant, 0.01-10wt percent of defoamer and the balance of solvent. With the adoption of the graphene coating, the thickness of an electricity and heat conductive coating can be controlled to be 100nm-20 microns; when the graphene coating is used on a plastic matrix, the volume resistivity can reach a range from 10<-2>ohm.cm to 10<-4>ohm.cm; while the graphene coating is used on a metal matrix, the volume resistivity can reach 10<-6>ohm.cm. The graphene coating can be applied to the metal surface so as to improve the cohesiveness, the electricity / heat conduction performance and the corrosion and oxidation resistance. When the graphene coating is coated on the plastic surface, the frictional resistance, the electricity and heat conduction performances and the static resistance can be lowered, and the graphene coating can be applied to the fields of printed circuits, electronic devices, radio frequency devices, touch screens, thin film solar energy, LEDs, magnetic shielding, radio frequency shielding and the like.

Owner:SUPERCDONGGUAN TECH

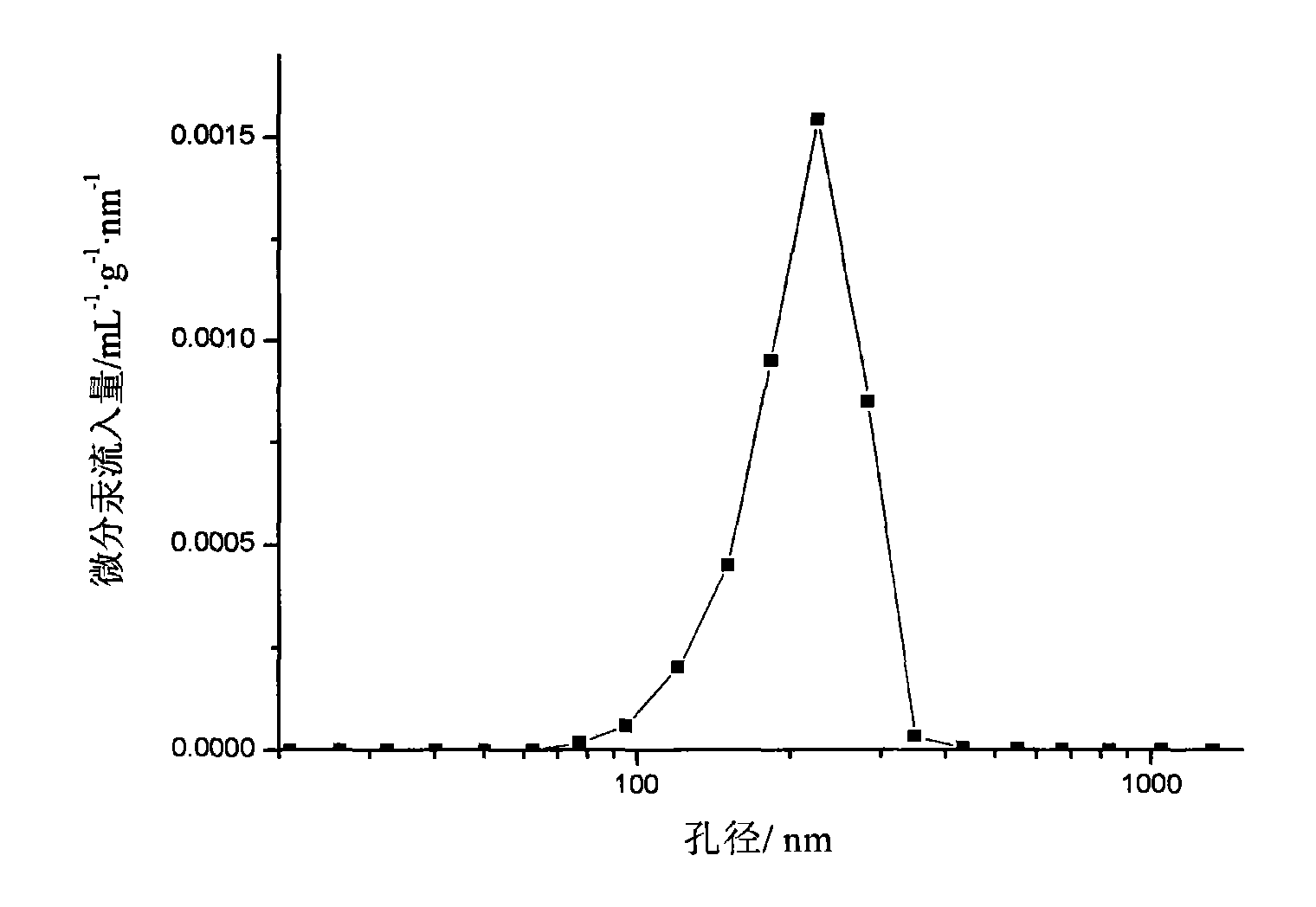

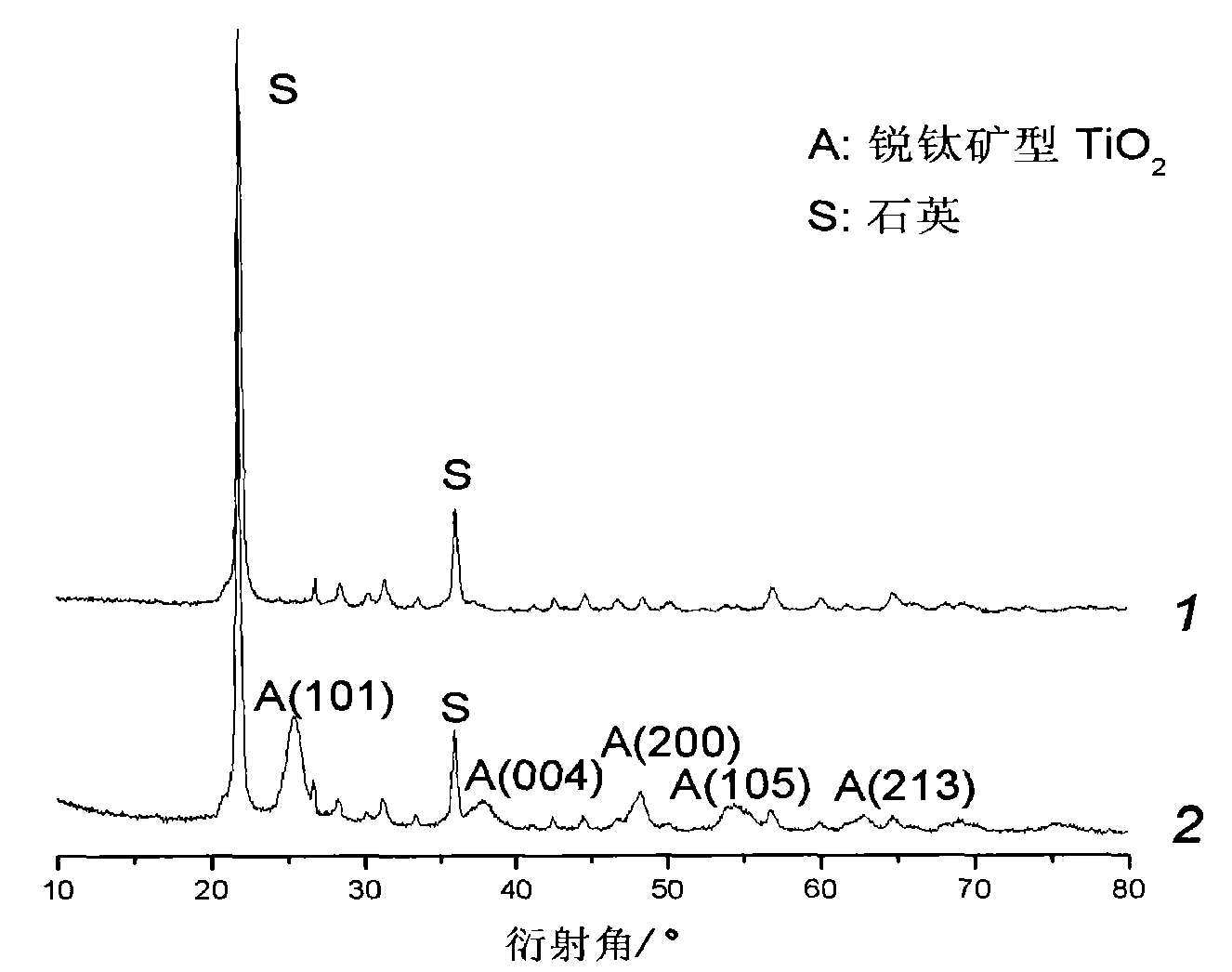

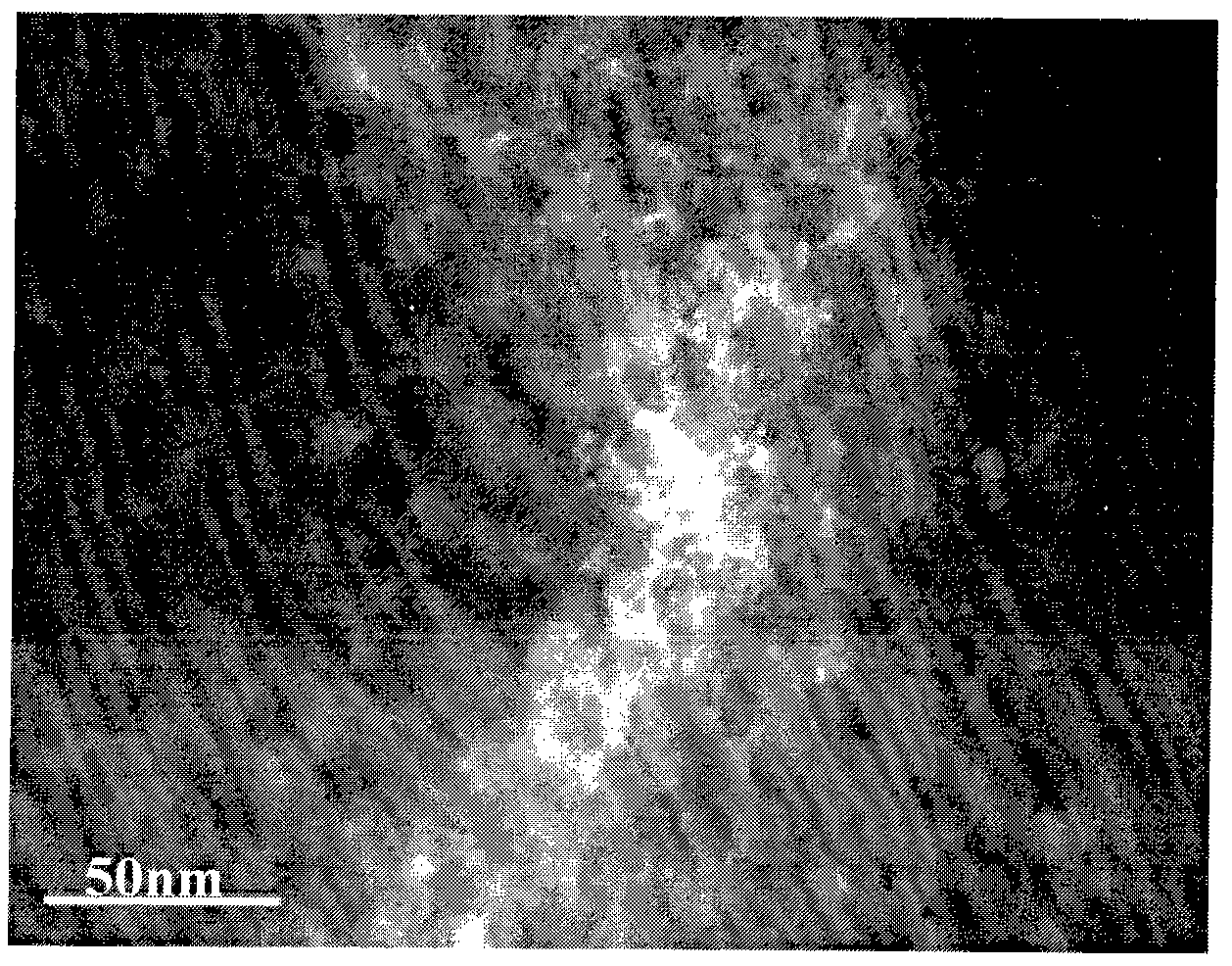

Kieselguhr-based porous ceramics and method for loading Ag doped with nano TiO2 on same

The invention relates to a kieselguhr-based porous ceramics, a preparation method thereof and a method for loading Ag doped with nano TiO2 on the same, belonging to the technical field of a kieselguhr inorganic material. The kieselguhr-based porous ceramics is made from kieselguhr, a sintering auxiliary agent, a dispersing agent, a binder and water in the weight ratio of 60-92:8-40:0.01-2:0:001-1:100-450. The kieselguhr-based porous ceramics has functions of absorption and filtration, and can absorb granules in fluid when the fluid passes through the lieselguhr-based porous ceramics. Ag doped with nano TiO2 is loaded on the kieselguhr-based porous ceramics to generate kieselguhr-based porous ceramics loading the Ag doped with TiO2. The laden anatase-type nano TiO2 has large specific surface area. The effects of filtration, photochemical catalysis and sterilization of the kieselguhr-based porous ceramics loading the Ag doped with nano TiO2 are greatly increased.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

High intensity metallic core type seamless flux-cored wire

InactiveCN101323057AImprove impact toughnessReduce the ductile-brittle transition temperatureWelding/cutting media/materialsSoldering mediaManufacturing technologyHigh intensity

The invention discloses a high strength metal core type seamless flux-cored welding wire relating to the technical field of welding materials; the invention can be manufactured by adopting the existing steel tube drawing or in-service welding seamless flux-cored welding wire manufacturing technology; the diameter of a steel tube is reduced to the extent that the filling diameter of a specified filling rate can be acquired; by using the vibration filling pattern, filler is filled from one end of the steel tube; wire drawing processing is performed by using a roller group or a wire drawing die group, and during the period intermediate annealing is carried out (under 650 DEG C for two hours). The high strength metal core type seamless flux-cored welding wire of the invention has the advantage that yield strength is larger than 785MPa, and the requirements of high strength structure steel welding can be satisfied.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Ultraviolet-proof environmental-friendly polyvinyl chloride (PVC) modified material and preparation method thereof

Owner:广东祺龙科技有限公司

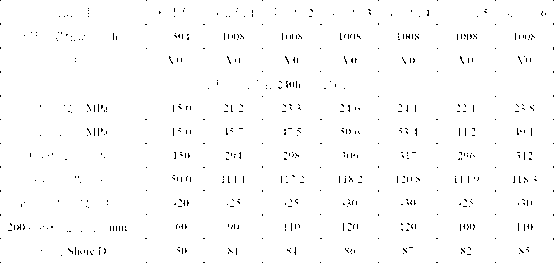

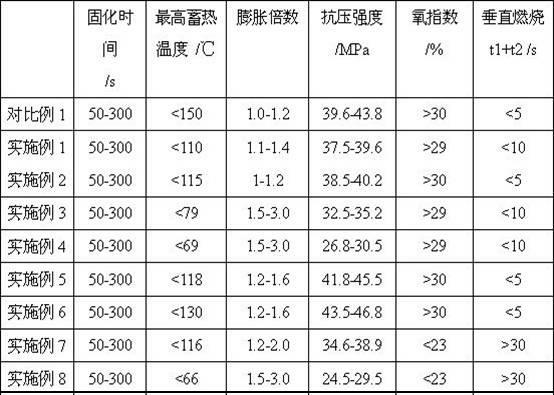

Self-temperature-limited polyurethane grouting material and preparation method thereof

The invention belongs to the technical field of materials and particularly relates to a self-temperature-limited polyurethane grouting material and a preparation method. The self-temperature-limited polyurethane grouting material is composed of three components, the component A includes isocyanate and prepolymer thereof and accounts for 30-50% of total mass of the grouting material, the component B includes polyether polyol and auxiliaries and accounts for 5-50%, preferably 30-50% of the total mass of the grouting material, and the component C includes self-temperature-limited additive with the boiling point adjustable within 66-130 DEG C and accounts for 5-55% of the total weight of the grouting material. By adding the self-temperature-limited additive into the isocyanate and the polyether polyol, heat storage temperature after the grouting material is solidified is lower than the boiling point of the self-temperature-limited additive, and accordingly, potential hazards of fire breaking due to overhigh storage heat of the grouting material are reduced, and fire disasters during grouting to underground engineering, especially coal mines are avoided.

Owner:LIAONING TECHNICAL UNIVERSITY

Preparation method of functional fabric

InactiveCN104805680AOvercome strong adsorptionDestruction of the entangled bonded statePhysical treatmentEcological environmentProcess equipment

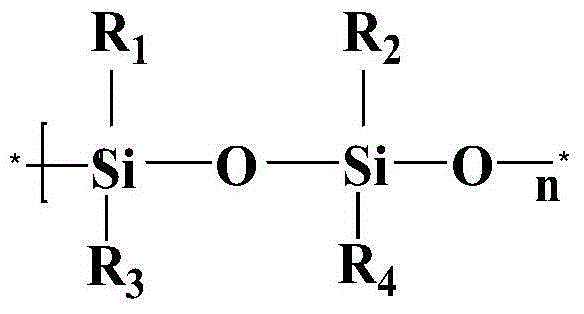

The invention relates to a preparation method of a functional fabric, and belongs to the technical field of textile materials. Functional nanoparticles are compounded on the surface of the fabric through the preparation of the functional nanoparticles and the preparation of the functional fabric. The existence of vinyl polysiloxane overcomes high adsorption capacity of functional nanoparticle aggregate, so that the uniformly dispersed functional nanoparticles are firmly adhered to the surface of the fabric, and the fabric has multiple functions of ultraviolet resistance, super-hydrophobicity, pollution resistance, antibacterial property, health and the like through the synergistic effect of the vinyl polysiloxane and the functional nanoparticles. According to the preparation method of the functional fabric disclosed by the invention, the vinyl polysiloxane is efficiently utilized, the productive value of the vinyl polysiloxane is improved, and the application of the vinyl polysiloxane to other fields is developed; moreover, the whole process is simple in equipment, relatively low in cost and free of pollution to ecological environment, and has a great application prospect.

Owner:WUHAN TEXTILE UNIV

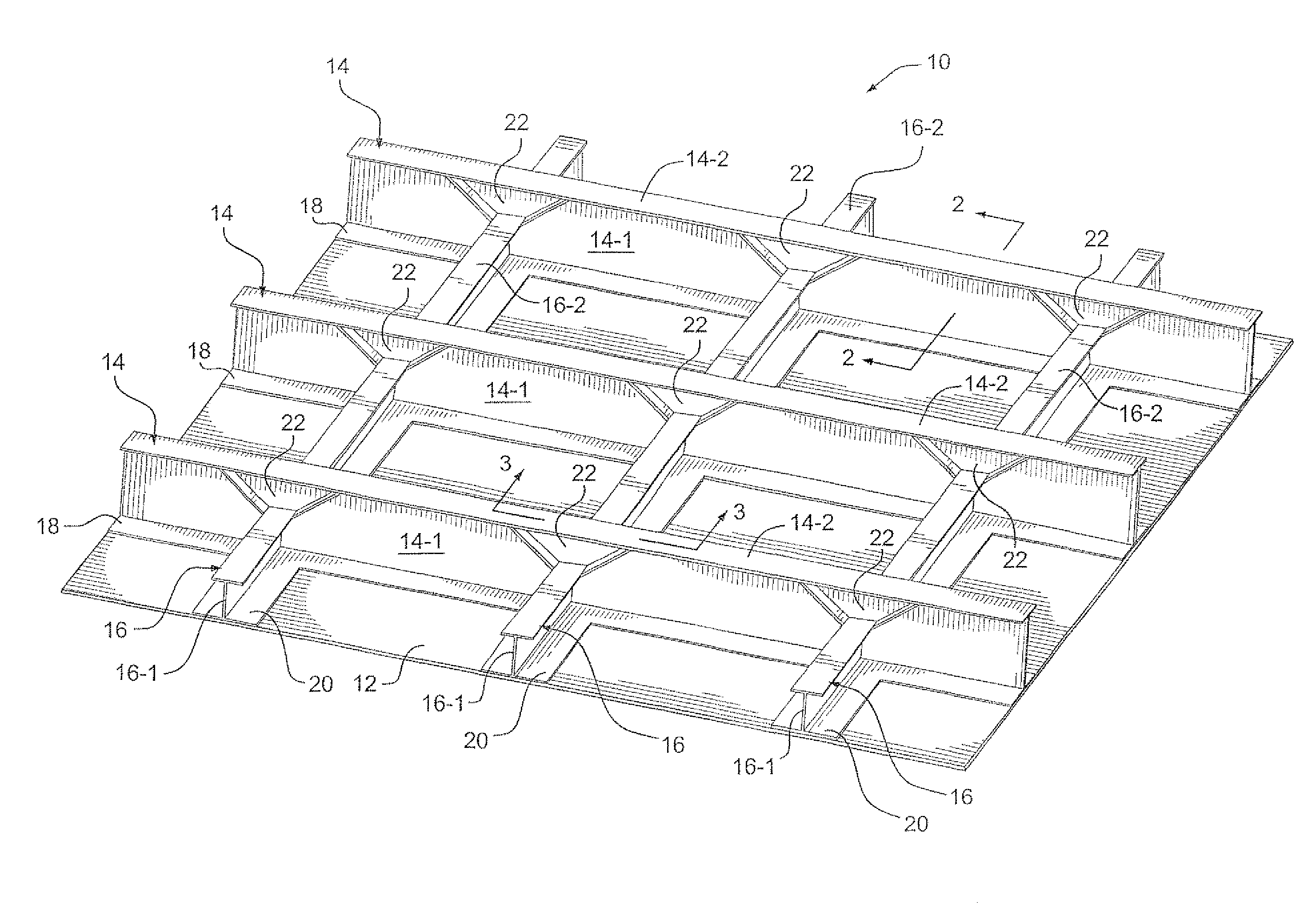

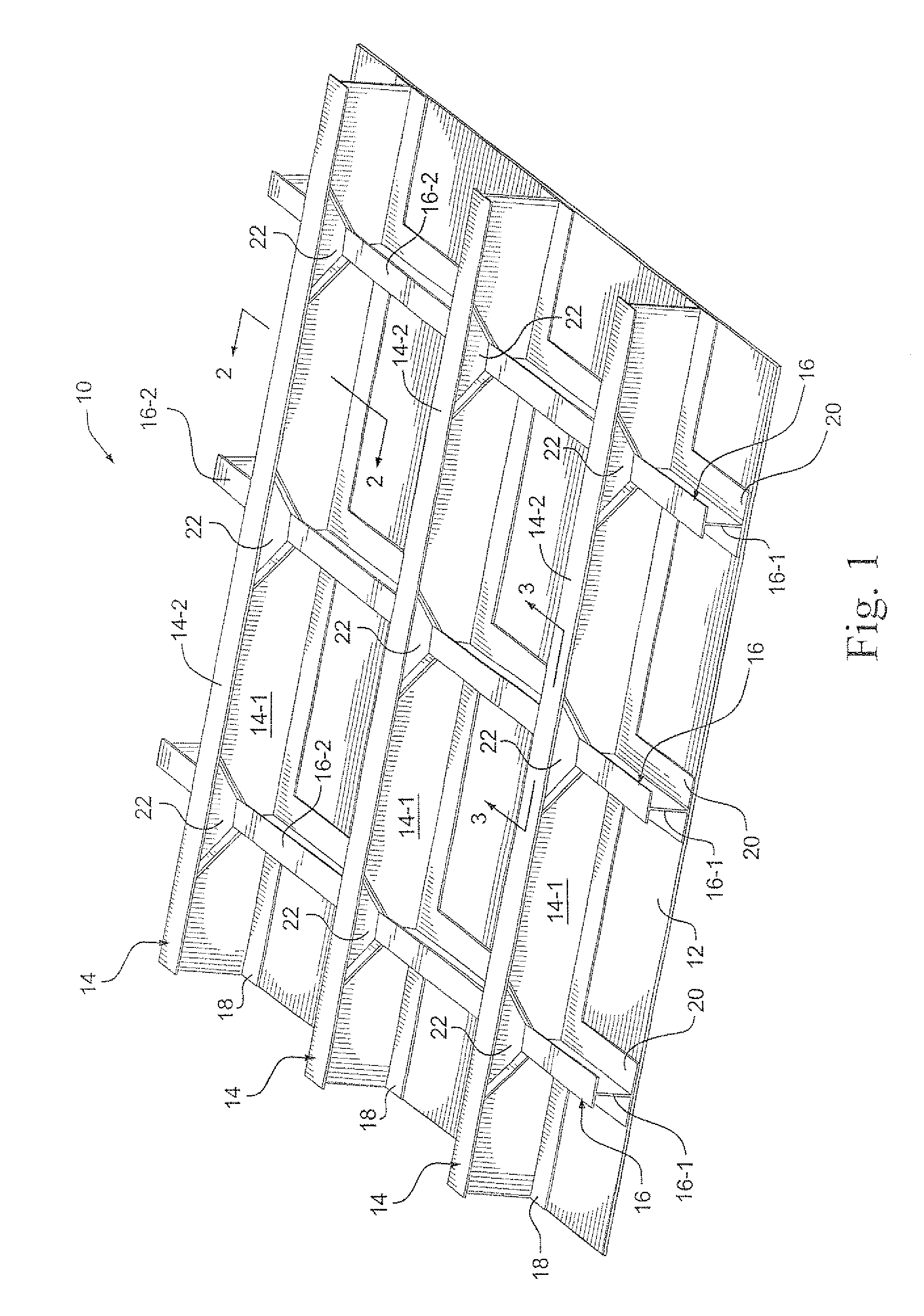

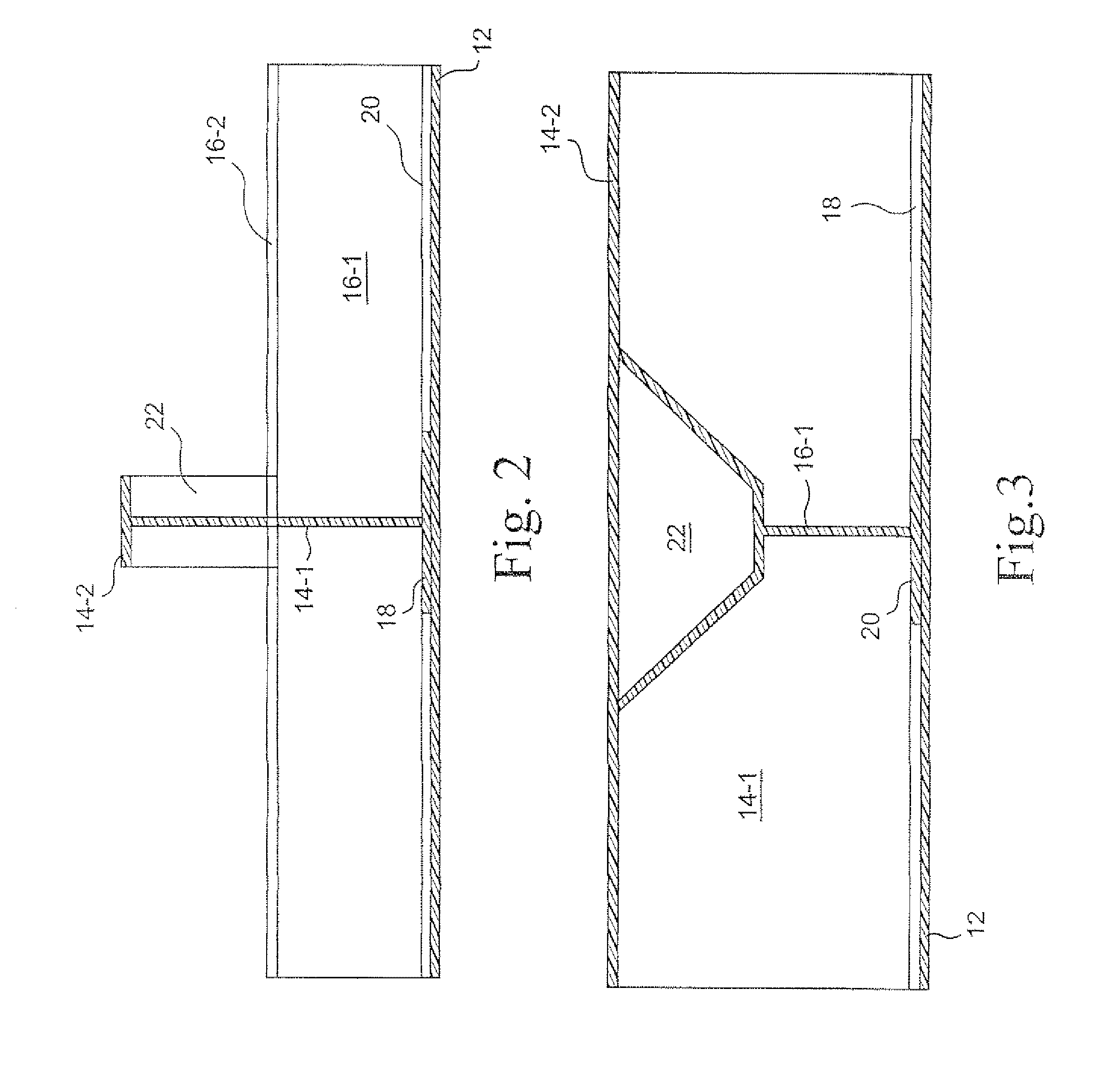

Monolithic integrated structural panels especially useful for aircraft structures and methods of making the same

Structural panels for use in manufacturing fuselage bodies and other aircraft structures are disclosed herein. In one embodiment, a monolithic integrated structural panel is configured to include a skin, an array of stiffeners and an array of frames which are preferably arranged in a mutually orthogonal layout, without the need of cut-outs in any of the crossing elements. One advantage of the disclosed embodiments is that the frame and stringer members have continuous flanges and spliced webs. The disclosed embodiments herein are compatible with composite materials technology, offering another advantage, namely the possibility of manufacturing integrated products in a single cure (“one-shot”) cycle. A structure of composite materials, e.g. carbon fiber reinforced plastics, typically comprises a skin panel, reinforced by frame and stringer members. A monolithic integrated structure constructed in accordance with the disclosed embodiments is well-suited for use as a portion of an aircraft structure, for example an aircraft fuselage, wing or empennage.

Owner:EMBRAER SA

Method for preparing silicon nitride/silicon carbide porous ceramic

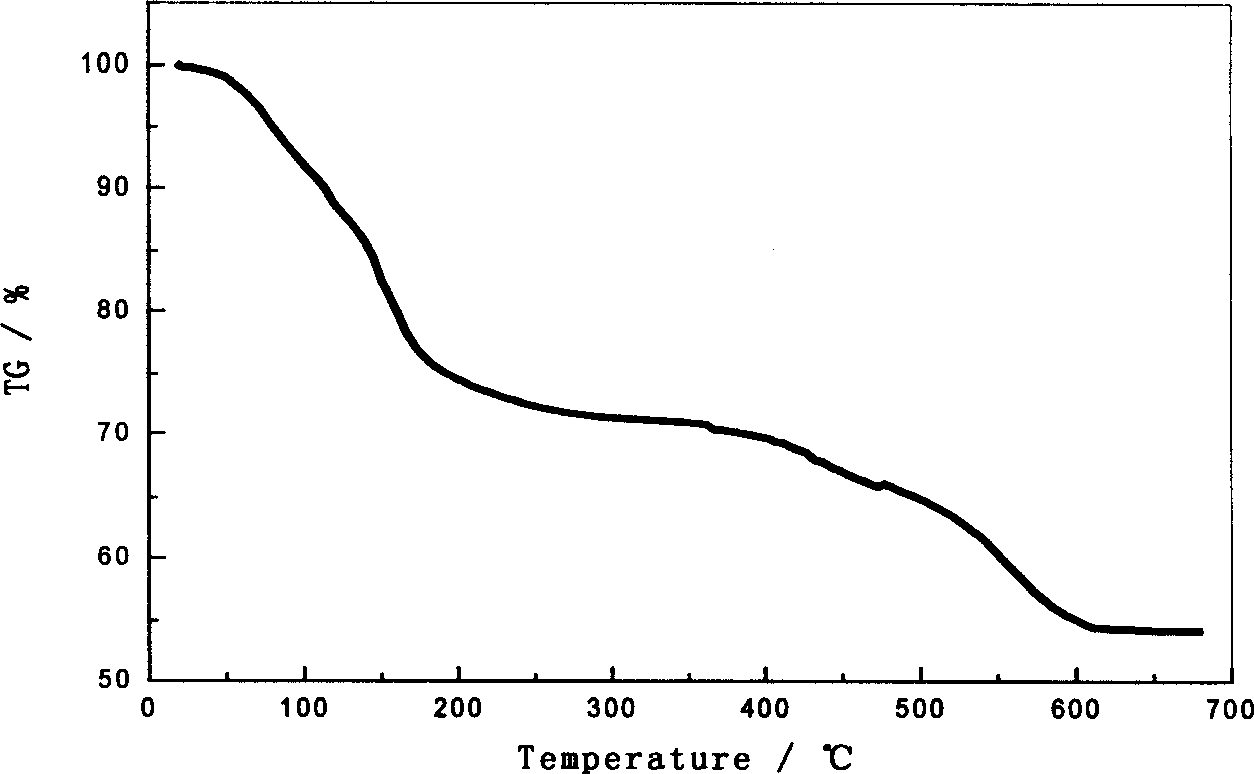

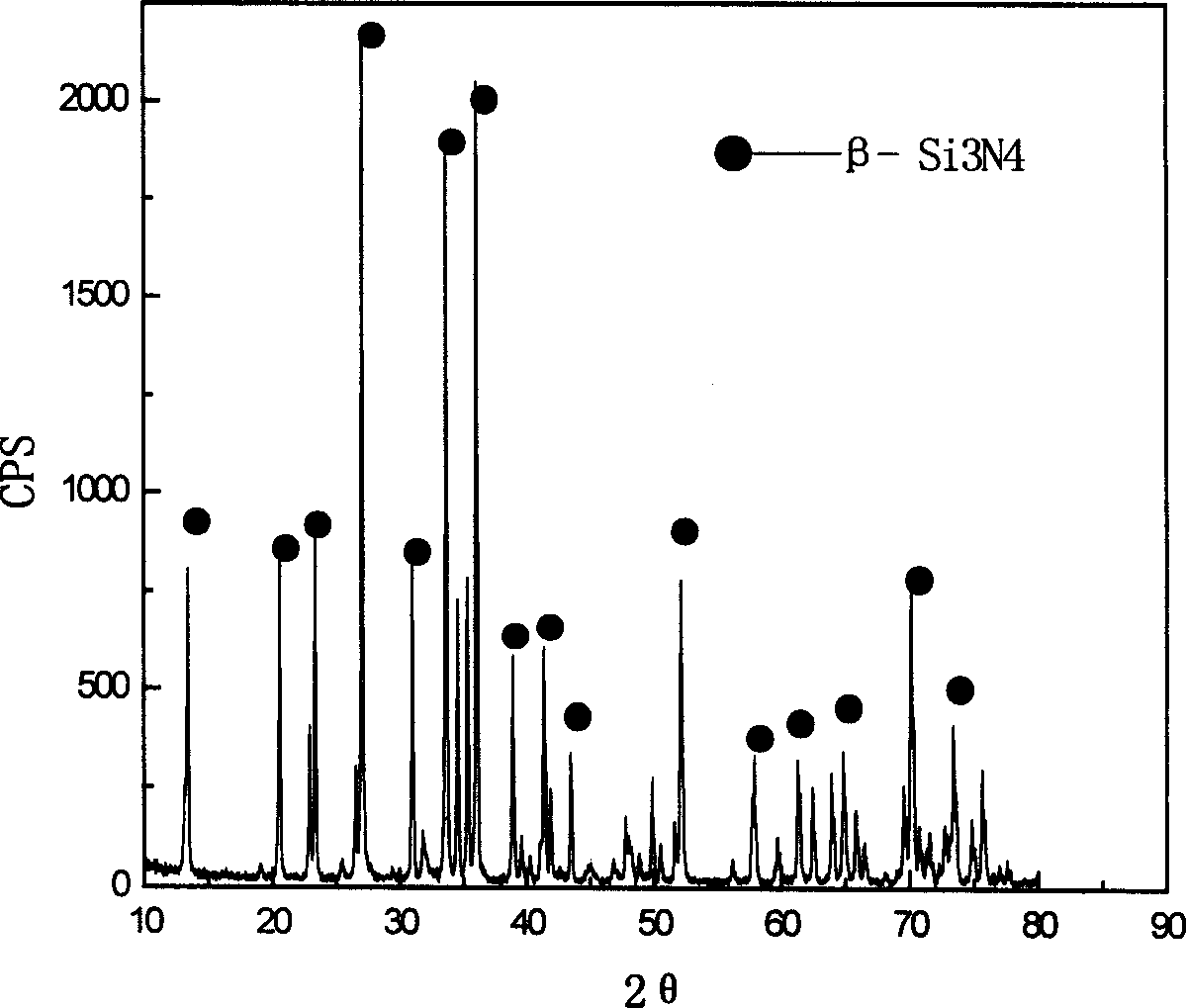

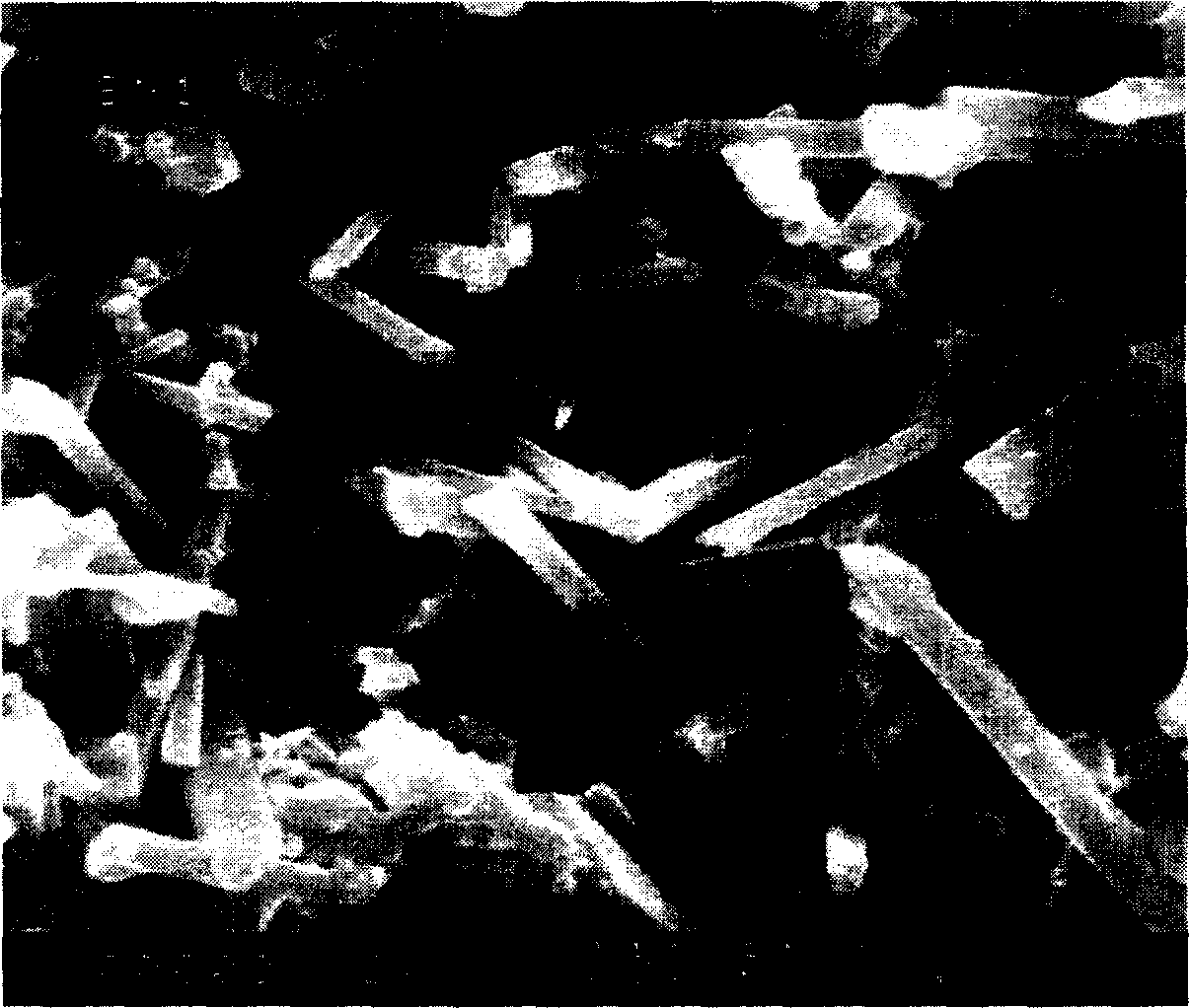

The present invention belongs to the field of porous ceramic material technology, and is the preparation process of one low cost and high performance porous silicon nitride / silicon carbide ceramic. The preparation process includes compounding material, forming and sintering as the conventional ceramic material preparing steps. It features that phenolic resin used as pore creating agent and carbon source is in-situ produced into SiC phase through the carbon hot reduction during sintering; and that Si3N4, Al2O3, Y2O3 and phenolic resin in certain proportion are produced into slurry through adding anhydrous alcohol and mixing for 12-24 hr and stoved into powder; and that the ceramic powder is processed through formation, cracking to eliminate glue, carbon hot reduction and sintering to produce the porous ceramic material with porosity of 40-70 %, strength of 70-160 MPa and low cost.

Owner:XI AN JIAOTONG UNIV

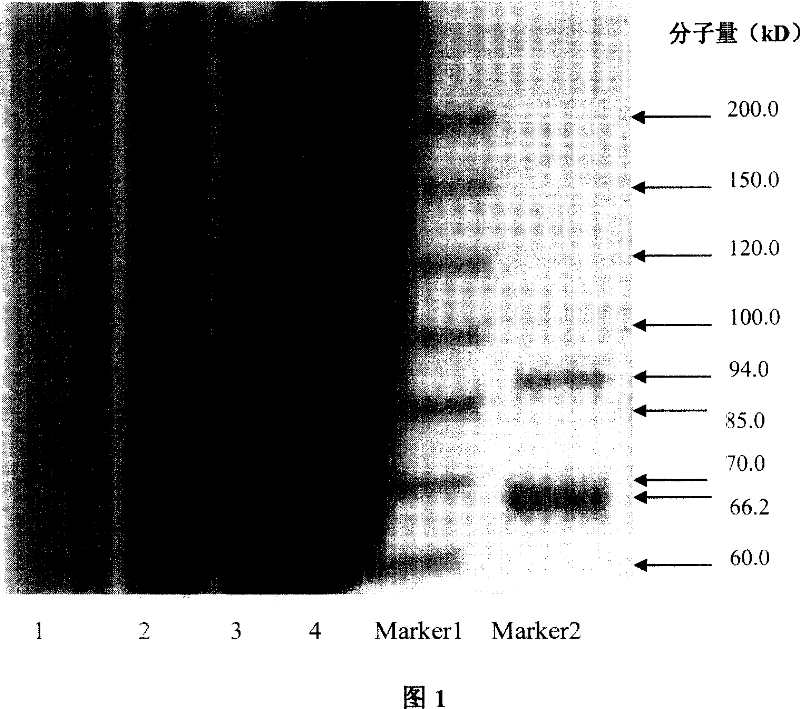

Antheraea pernyi silk fibrion biology medicine material and the preparation method

InactiveCN101036802AGood biocompatibilityIdeal induced biomedical materialsSurgeryProsthesisTissue repairReticular formation

The invention discloses bio-medical engineering material and preparation method thereof, particularly relates to 3D tissue repair material suitable for adhesively growing of cell and preparation method thereof, belonging to bio-medical material technique domain. The natural tussah silk is used as raw material. After antheraea pernyi silk fibroin dissolves, 3D non-woven web structure composed of antheraea pernyi silk fibroin fibre is obtained by electrostatic spinning, wherein the fibre diameter is 50nm-20 mu m, the hole between the fibres is 1-500 mu m, the thickness of non-woven web is 50nm-20mm, and molecular weight of the antheraea pernyi silk fibroin is 10X10<4>-20X10<5>D. The bio-medical engineering material has features of non-poison, harmless, good biocampatibility, good adhesive growth ability of cell, etc. Because of the wide materials supply and low cost, the said material will replace some high-cost bio-medical material such as collagen, and will be used for repair material such as artificial skin, tendon, cartilage, duramater and so on, particularly for histiocyte induction material.

Owner:SUZHOU UNIV

Method for preparing multi-layer graphene

ActiveCN101746755AImprove conductivityImprove thermal conductivityUltrasonic dispersionMaterials science

The invention relates to a method for preparing multi-layer graphene, and belongs to the technical field of carbon materials. The multi-layer graphene is prepared from expanded graphite serving as a raw material through ultrasonic dispersion, solid-liquid separation and drying. The thickness of the multi-layer graphene prepared by the method is between 1 and 10nm; the number of layers is between 2 and 20 layers; and the aperture is mainly between 6 and 50nm. The multi-layer graphene has the characteristics of high electrical conductivity, high heat conductivity, high electromagnetic wave absorptivity, wear resistance and the like. The method has the advantages of simpleness, convenient operation and low production cost, capability of reducing production energy consumption, no three wastes emission, environmental friendliness and convenient popularization and application. The multi-layer graphene prepared by the method can be used as the electrode materials of batteries and super capacitors, can also be used as the conductive agents of high molecular materials, ceramic materials, silicate materials and the like, and can also be used as the conductive agents of lithium batteries, alkaline batteries and nickel-metal hydride batteries.

Owner:FUJIAN XFH NEW ENERGY MATERIALS CO LTD

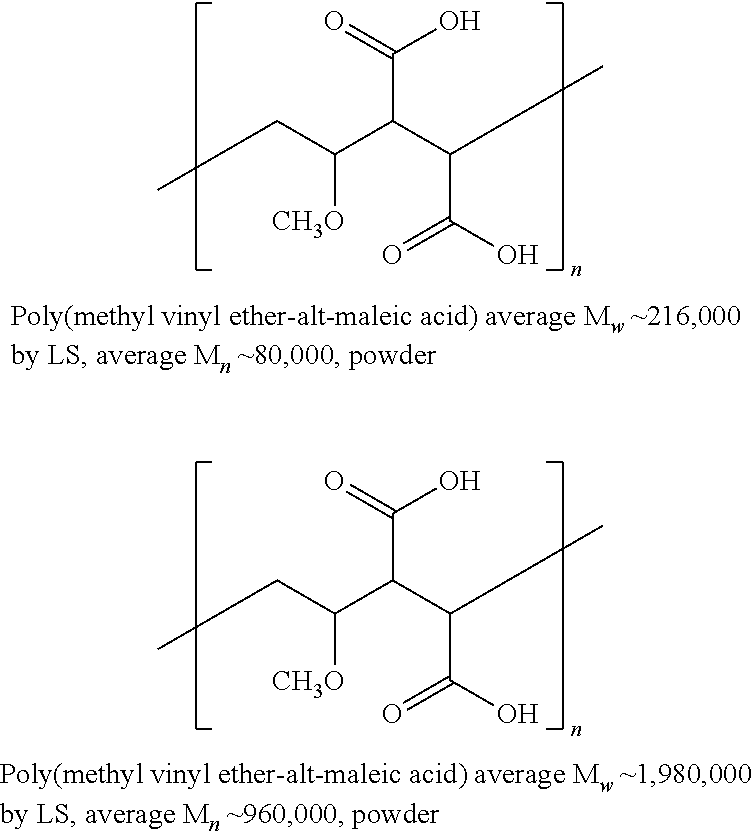

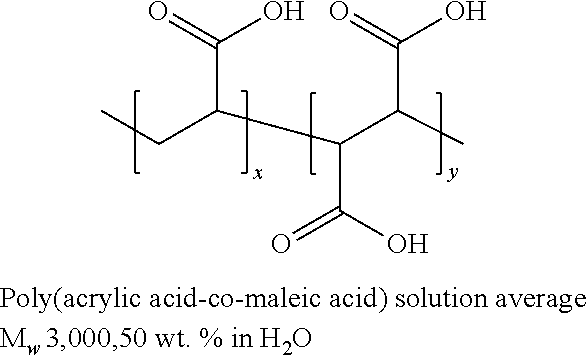

Multiple Component Materials Having A Color-Changing Composition

ActiveUS20110015599A1Effective adhesionImprove stabilityMaterial analysis by observing effect on chemical indicatorDecorative surface effectsOrganic acidColor changes

The present invention relates to a multiple-component material including a substrate and a printed layer on the substrate. The printed layer includes a color-changing composition to indicate a change in condition, such as a change in pH. The color-changing composition includes a matrix-forming component, a colorant, a surfactant and a pH adjuster. The pH adjuster includes a low molecular weight organic acid and a high molecular weight organic acid.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Magnetic composite microsphere with nucleocapsid structure and method for producing the same

InactiveCN101220187AHigh magnetic contentNarrow particle size distributionInorganic material magnetismMicrosphereMagnet

The invention belongs to the technical field of bioseparation material, in particular to a magnetic composite microsphere with nucleocapsid structure and a preparation method thereof. Nano ferroferric oxide decorated by oleic acid is firstly used as raw material, and is polymerized through template fine emulsion so as to prepare the monodisperse magnetic composite microsphere with high magnet content; and then the monodisperse micosphere is polymerized through seed emulsion and is added with different amount of shell monomer to prepare the magnetic composite microsphere with the nucleocapsid structure and the magnet content of 20wt percent to 80wt percent. The grain size of nucleocapsid composite microsphere is in narrow distribution, and the magnet content of the microsphere is controllable and the surface has functional reactive group; therefore, the microsphere of the invention can be surface-modified into a magnetic carrier of biological active molecule by chemical crosslinking to be applied in the biomedicine field. The method of the invention can be simply operated and the process of which can be controlled, thus having industrialized prospect.

Owner:FUDAN UNIV

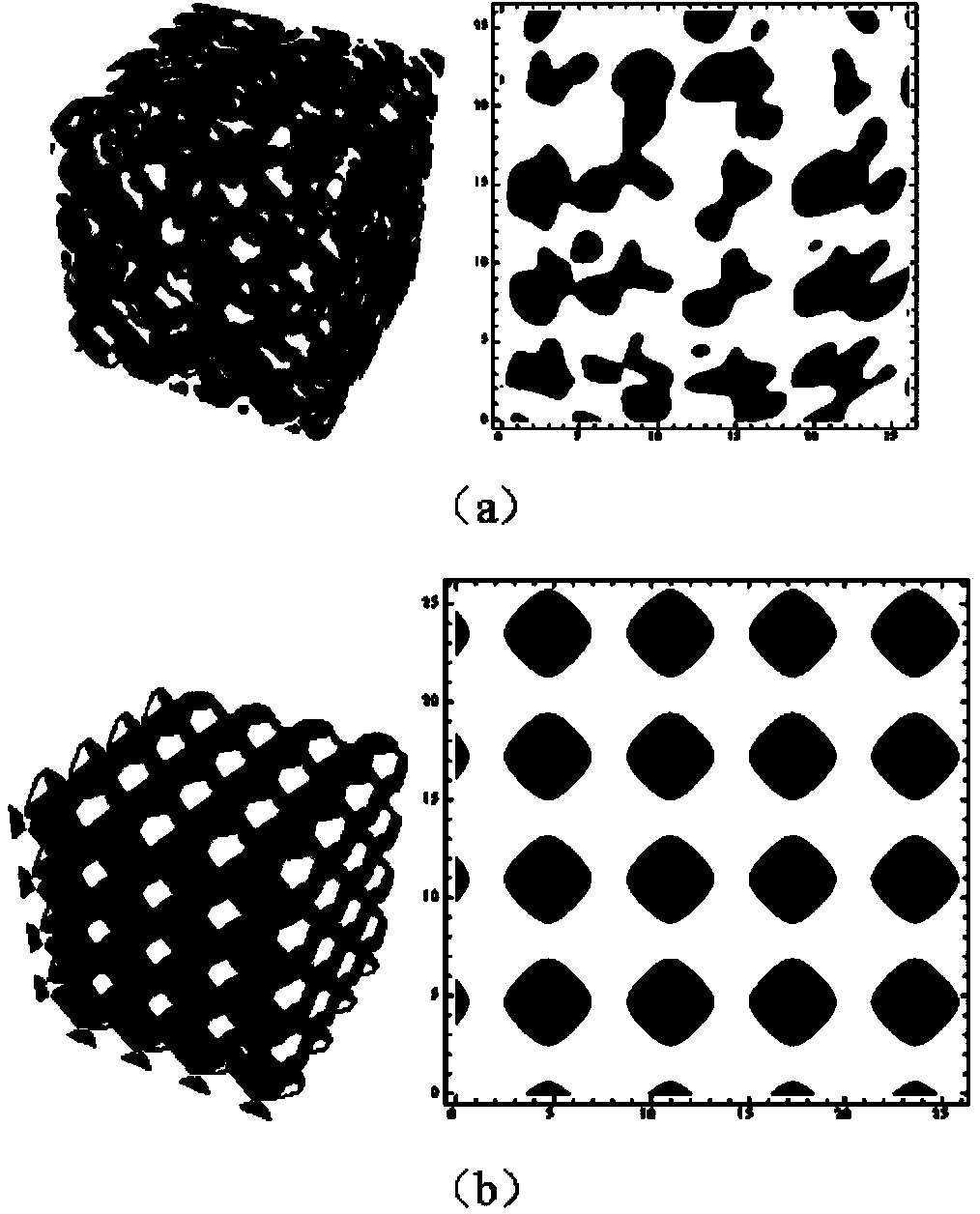

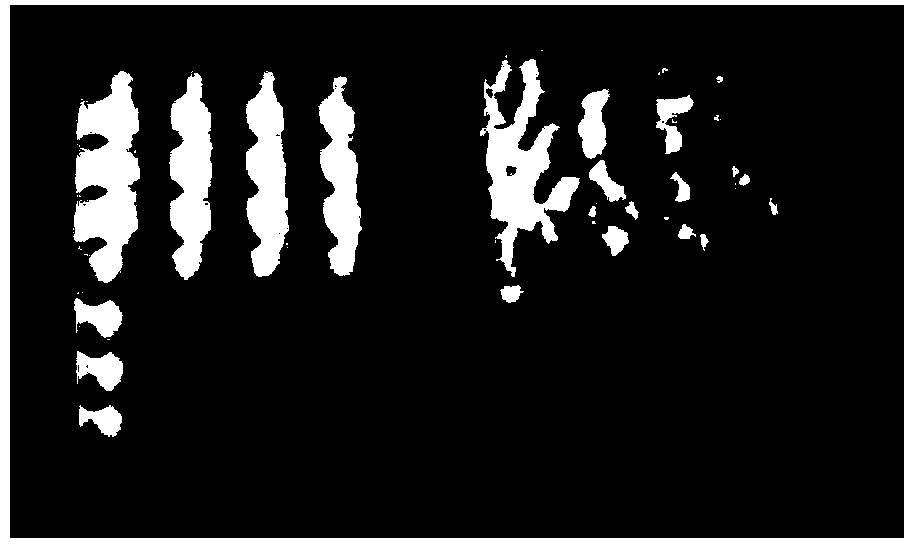

Preparation method of three-dimensional artificial random porous structure tissue engineering scaffold

The invention relates to a preparation method of a three-dimensional artificial random porous structure tissue engineering scaffold, belonging to the technical field of biomaterials. The invention aims to solve the design and manufacturing problems of the bionic structure of tissue engineering scaffold, provides a design method for constructing a random distributed scaffold porous structure with a bionic shape under expected porosity and pore size requirements, and molds by using a 3D additive manufacturing method to produce tissue substitute. The preparation method provided by the invention has the following advantages that the scaffold has a 3D through-hole structure meeting bionic requirements, and ensures nutrient substance transfer and waste metabolism and has certain bionic mechanical properties; the porosity and pore size distribution range of the scaffold can be conveniently controlled, and the random pore structure with expected function gradient is constructed to realize the bionic characteristic of the structure; and the method is suitable for a large range of materials such as metal materials, non-metal materials and medical high molecular materials, and can meets user-personalized tissue repair requirements.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

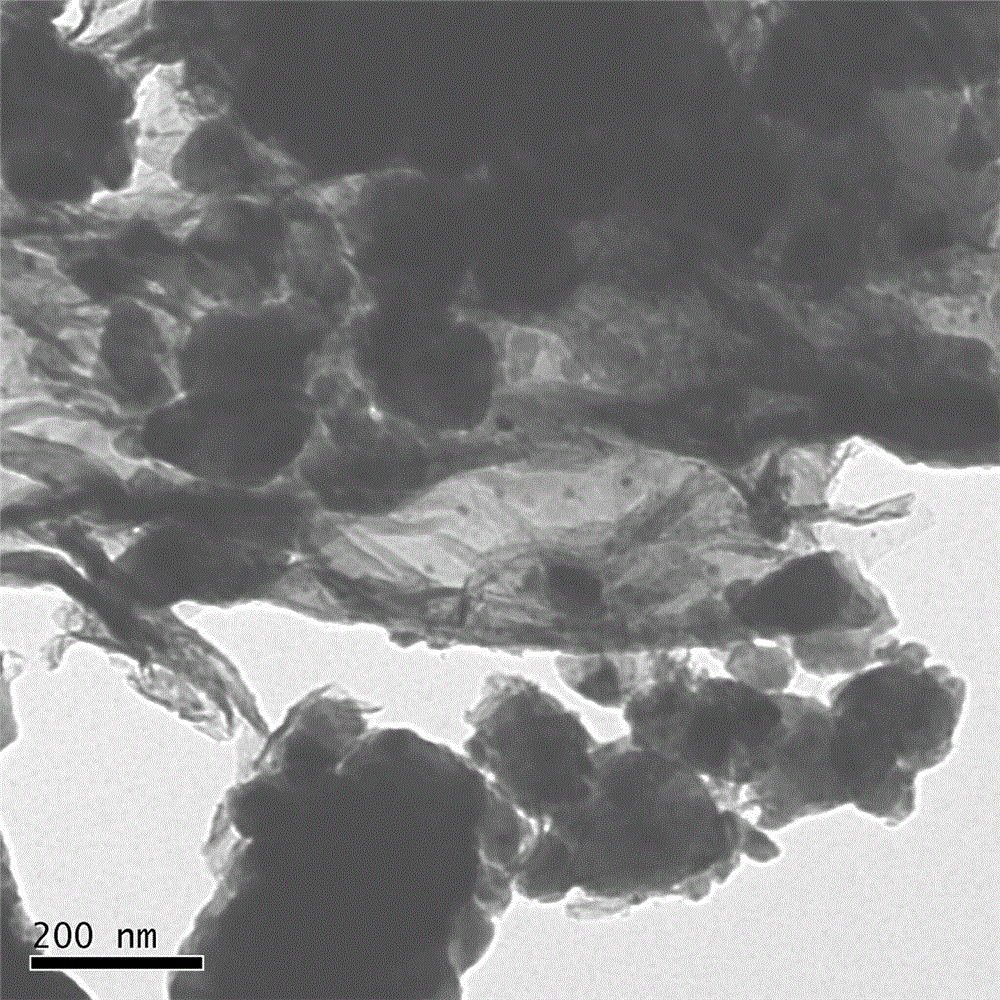

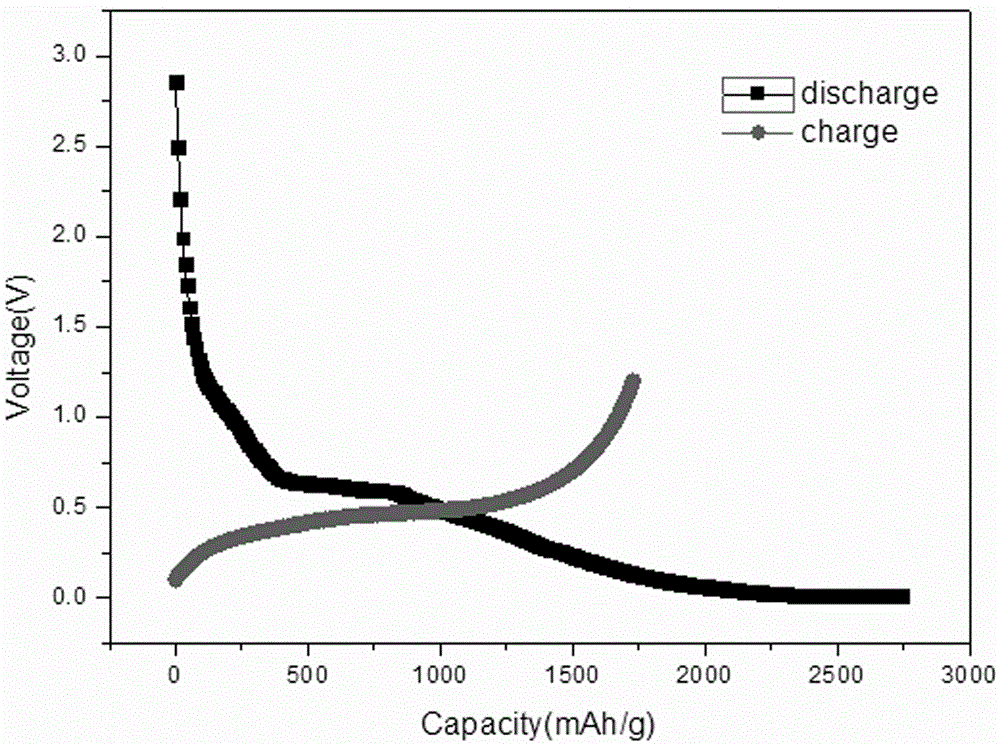

Silicon cathode material coated with graphene and preparation method thereof

InactiveCN104916826AWide variety of sourcesLow priceCell electrodesSecondary cellsOperabilitySilicon particle

The invention relates to the technical field of lithium-ion cathode material, in particular to silicon cathode material coated with graphene and a preparation method of the silicon cathode material coated with the grapheme. The preparation method comprises the following steps: A, preparing oxidized graphene suspension liquid; B, preparing nanometer silicon particle suspension liquid; and C, preparing silicon cathode material coated with grapheme. The preparation method adopts the electrostatic self-assembly synthetic technology and is wide in source of raw material, low in price, simple in synthetic method, easy for control of process conditions, strong in operability and good in repeatability. The silicon cathode material coated with grapheme is high in specific capacity and good in cycle performance and rate capability, wherein the specific discharge capacity for the first time under the electric current density of 0.01-1.2V, 200mA / g can reach 2746mAh / g, and the specific discharge capacity after 100 times of cycles can maintain 803.8mAh / g.

Owner:MCNAIR TECH +1

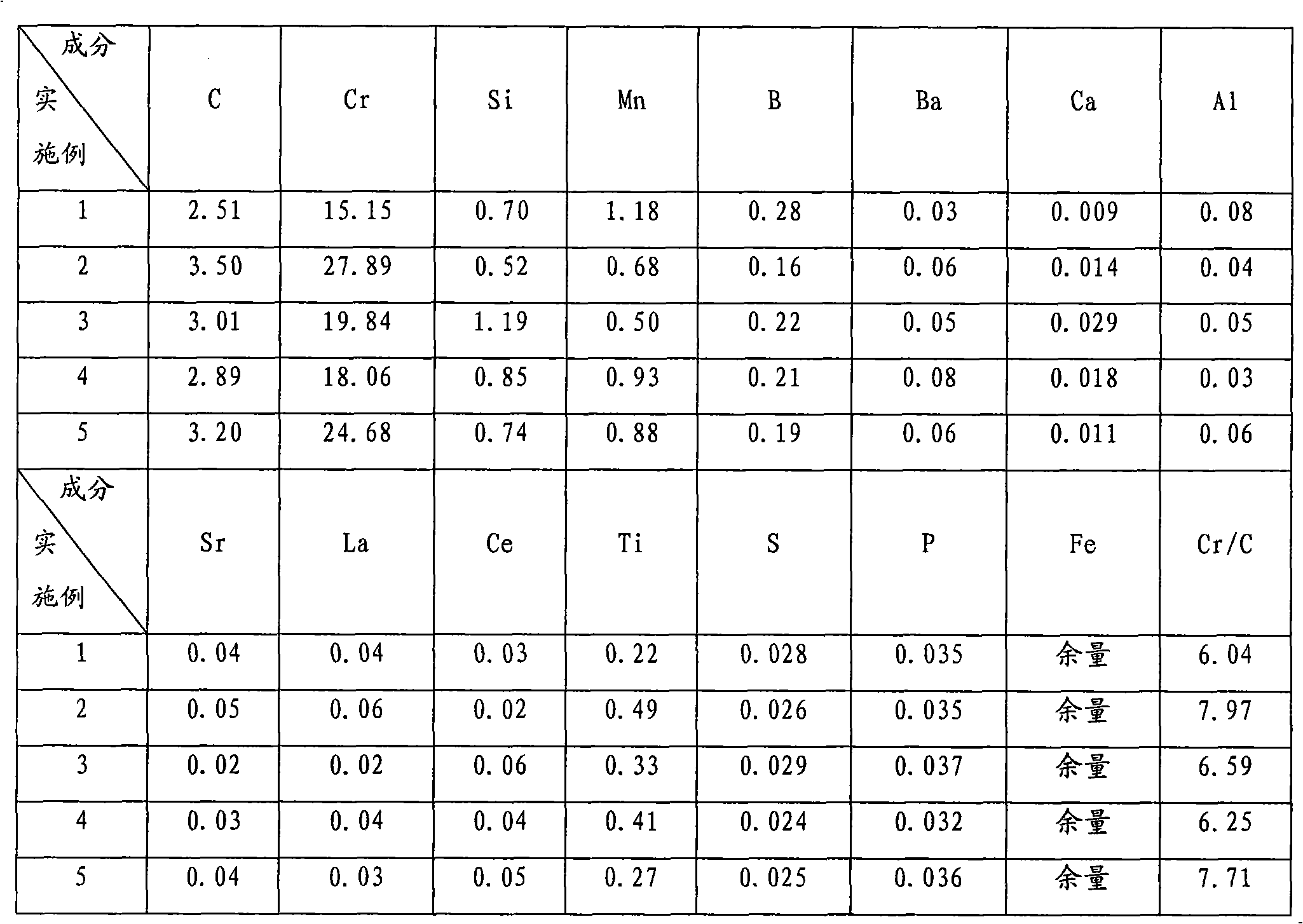

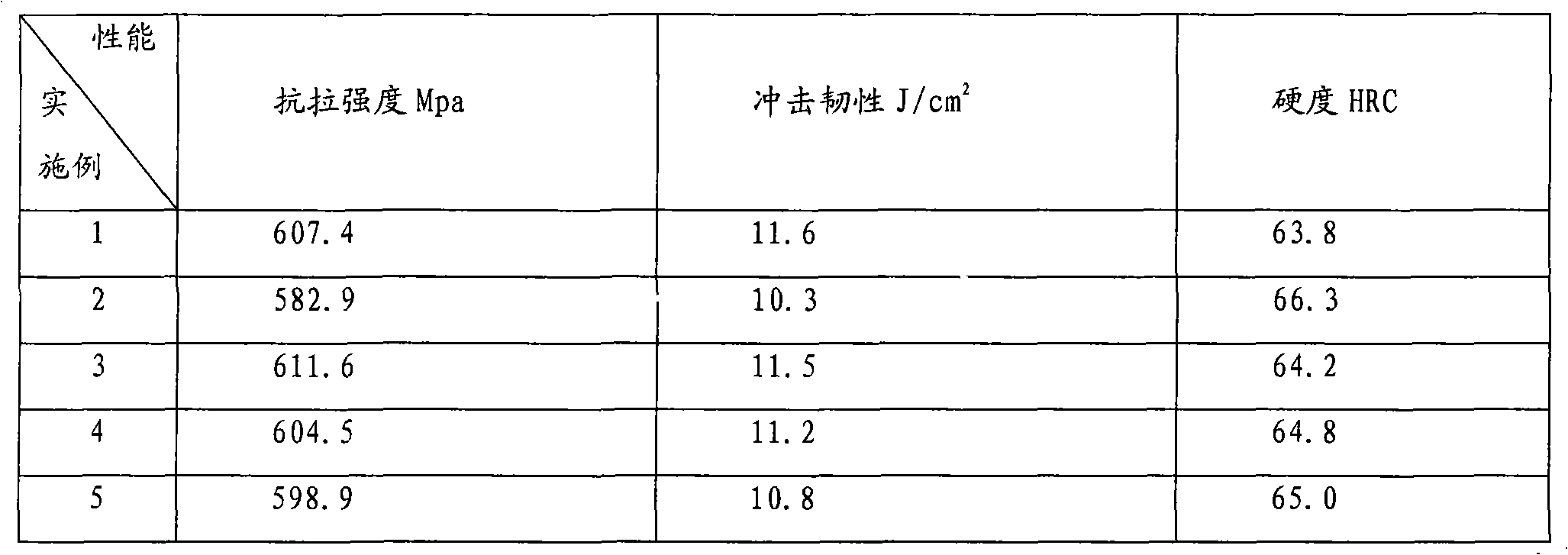

Boron-containing high-chromium abrasion-proof cast iron and preparation method thereof

InactiveCN101260497AImprove hardenabilityReduce manufacturing costProcess efficiency improvementWear resistantCerium

The invention relates to boracic high chromium wear resistant cast iron and a preparation method thereof, belonging to the wear resistant metal material technical field. The prior boracic high chromium cast iron has poor toughness and high cost. The cast iron of the invention comprises the following compositions in percentage by weight (wt percent): 2.5 to 3.5 percent of carbon, 15 to 28 percent of chromium, 0.5 to 1.2 percent of silicon, 0.5 to 1.2 percent of manganese, 0.15 to 0.3 percent of boron, 0.008 to 0.03 percent of calcium, 0.03 to 0.08 percent of barium, 0.02 to 0.05 percent of strontium, 0.03 to 0.08 percent of aluminum, 0.20 to 0.5 percent of titanium, 0.02 to 0.06 percent of lanthanum, 0.02 to 0.06 percent of cerium, less than 0.04 percent of sulfur, less than 0.05 percent of phosphor, the balance being iron; the content of lanthanum and cerium is more than or equal to 0.05 percent and less than or equal to 0.1 percent; the content of chromium or carbon is more than or equal to 6 percent and less than or equal to 8 percent. In the invention, the temperature of cast iron is kept between 980 DEG C and 1050 DEG C for 4h to 6h, then kept between 250 DEG C and 500 DEG C for 8h to 10h, thereby obtaining the cast iron. The boracic high chromium wear resistant cast iron has the advantages of high intensity and rigidity, good toughness and wear resistance, low production cost, etc.

Owner:BEIJING UNIV OF TECH

Material for bone tissue engineering scaffold and making method thereof

InactiveCN101032632AImprove mechanical propertiesGood biocompatibilityBone implantBiocompatibility TestingBiological materials

The present invention relates to biological material technology, and is especially porous magnesium, magnesium alloy and composite magnesium material used as high strength biomedicine rack material for human body hard tissue defection and its preparation process. The porous magnesium, magnesium alloy and composite magnesium material used in bone tissue engineering rack has porosity of 5-99 % and pore diameter of 50-900 microns. Owing to easy degradation and absorption of magnesium inside body, the bone tissue engineering rack of porous magnesium, magnesium alloy and composite magnesium material has excellent mechanical performance and excellent biocompatibility and can provide 3D space for cell to grow.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for preparing heavy rare earth hydride nano-particle doped sintered NdFeB permanent magnet

ActiveCN101521069AImprove coercive forceNot easily oxidizedInorganic material magnetismRare-earth elementDehydrogenation

The invention discloses a method for preparing a heavy rare earth hydride nano-particle doped sintered NdFeB permanent magnet, which belongs to the technical field of magnetic materials. The prior preparation method improves the coercive force and the temperature stability of magnets by adding heavy rare earth elements, namely terbium or dysprosium into master alloy, but the method can cause the residual magnetism of the magnets, the reduction of magnetic energy product and the increase of manufacturing cost. The method adopts heavy rare earth terbium hydride and dysprosium hydride nano-powder doping technology to prepare the sintered NdFeB permanent magnet with high coercive force and excellent magnetic property. The method comprises the following steps: preparing NdFeB powder by a rapidly solidified flake process and a hydrogen decrepitation process; preparing the terbium hydride or the dysprosium hydride nano-powder by physical vapor deposition technology; mixing the two powders, and performing magnetic field orientation and press forming; and performing dehydrogenation treatment, sintering and heat treatment on a green compact at different temperatures, and obtaining the sintered magnet. The coercive force of the magnet prepared by the method is higher than that of the prior sintered magnet with the same ingredients; and compared with the sintered magnet with the equivalent coercive force, the proportion of the terbium and dysprosium needed by the magnet prepared by the method is remarkably reduced.

Owner:BEIJING UNIV OF TECH

Weak solvent aliphatic polyurethane resin for synthetic leather and preparation method thereof

The invention relates to the technical field of materials for synthetic leather, in particular to weak solvent aliphatic polyurethane resin for synthetic leather and a preparation method thereof. The weak solvent aliphatic polyurethane resin for synthetic leather is prepared from the following components by weight percent: 2-30 percent of aliphatic diisocyanate compound, 5-40 percent of polyester or polyether polyalcohol compound, 0-10 percent of micromolecule polyol chain extender, 0.1-13 percent of micromolecule polyamine chain extender, 0.01-1.0 percent of catalyst, 0.05-5.0 percent of assistant and 45-85 percent of organic mild solvent. The invention also discloses the preparation method of the weak solvent aliphatic polyurethane resin for synthetic leather. By adopting the technical scheme, the polyurethane resin with different solid contents, different viscosities and different modulus can by synthesized, the requirement of the synthetic leather is satisfied, and the synthetic leather product with high temperature resistance, cold resistance, anti-sticking performance and better external tensility of pigment can be prepared.

Owner:ZHEJIANG SUNLIGHT MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com