Ultraviolet-proof environmental-friendly polyvinyl chloride (PVC) modified material and preparation method thereof

A modified material and anti-ultraviolet technology, which is applied in the field of anti-ultraviolet and environmentally friendly PVC modified materials and its preparation, can solve the problems of harmful plastic cables, optical cables, poor thermal stability, and poor fluidity, so as to prolong the service life and improve the processing performance , the effect of reducing the melt viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

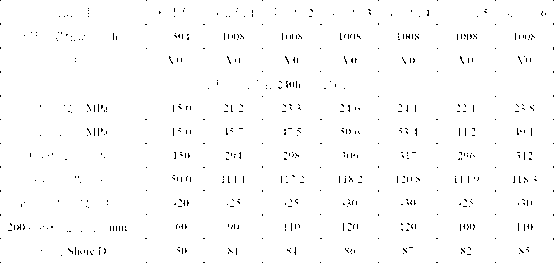

Examples

Embodiment 1

[0065] Weigh raw material SG-5 PVC resin 80Kg, colloidal calcium carbonate 30Kg, dioctyl adipate 40Kg, epoxy soybean oil 1Kg, antimony trioxide 0.5Kg, magnesium hydroxide 0.5Kg, rare earth stearate 0.5Kg , barium stearate 0.5Kg, chlorinated polyethylene 3Kg with 25% chlorine content, butyl acrylate-methyl methacrylate copolymer with 50% butyl acrylate unit content 2Kg, paraffin 0.1Kg, stearic acid 0.1 Kg, 2-hydroxyl-4-n-octyloxybenzophenone 0.1Kg, 2-(2'-hydroxyl-3',5'-di-tert-phenyl)-5-chlorinated benzotriazole 0.2Kg, 4-benzoyloxy-2,2,6,6-tetramethylpiperidine 0.2Kg, tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester 0.1 Kg and 0.1Kg of tris[2,4-di-tert-butylphenyl]phosphite are mixed; put the mixed raw materials into a high-speed blender, and stir for 25min at 100°C; pass the stirred raw materials through double The screw extruder is extruded and granulated to obtain an anti-ultraviolet environment-friendly PVC modified material; the screw tem...

Embodiment 2

[0067]Weigh raw material SG-7 PVC resin 90Kg, colloidal calcium carbonate 28Kg, dioctyl adipate 46Kg, epoxy soybean oil 2Kg, antimony trioxide 1Kg, magnesium hydroxide 2Kg, fatty acid rare earth 1Kg, barium laurate 1Kg , 4Kg of chlorinated polyethylene with 30% chlorine content, 3Kg of butyl acrylate-methyl methacrylate copolymer with 55% butyl acrylate unit content, 0.3Kg of oxidized paraffin wax, 0.2Kg of stearic acid, 2-hydroxy- 4-n-octyloxybenzophenone 0.2Kg, 2-(2'-hydroxy-3',5'-di-tert-phenyl)-5-chlorinated benzotriazole 0.4Kg, 4-benzoyloxy Base-2,2,6,6-tetramethylpiperidine 0.4Kg, tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester 0.2Kg, tris[2, Mix 0.2Kg of 4-di-tert-butylphenyl] phosphite; put the mixed raw materials into a high-speed blender, and stir at 140°C for 15 minutes; extrude the stirred raw materials through a twin-screw extruder Granulate to obtain UV-resistant and environmentally friendly PVC modified materials; the screw temp...

Embodiment 3

[0069] Weigh raw materials SG-5 type PVC resin 100Kg, colloidal calcium carbonate 46Kg, dioctyl adipate 52Kg, epoxy soybean oil 4Kg, antimony trioxide 2Kg, magnesium hydroxide 4Kg, salicylic acid rare earth 2Kg, stearin Calcium acid calcium 2Kg, chlorine content is 35% chlorinated polyethylene 5Kg, butyl acrylate-methyl methacrylate copolymer 4Kg with 60% butyl acrylate unit content, liquid paraffin 0.5Kg, stearic acid 0.4Kg, 2 -Hydroxy-4-n-octyloxybenzophenone 0.3Kg, 2-(2'-hydroxyl-3',5'-di-tert-phenyl)-5-chlorinated benzotriazole 0.6Kg, 4-benzene Formyloxy-2,2,6,6-tetramethylpiperidine 0.6Kg, tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester 0.3Kg, tri [2,4-di-tert-butylphenyl] phosphite 0.3Kg mixed; put the mixed raw materials into a high-speed blender, and stir at 120°C for 20 minutes; extrude the stirred raw materials through twin-screws Machine extruded and granulated to obtain an anti-ultraviolet environment-friendly PVC modified material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com