Patents

Literature

24072results about How to "Improve antioxidant capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

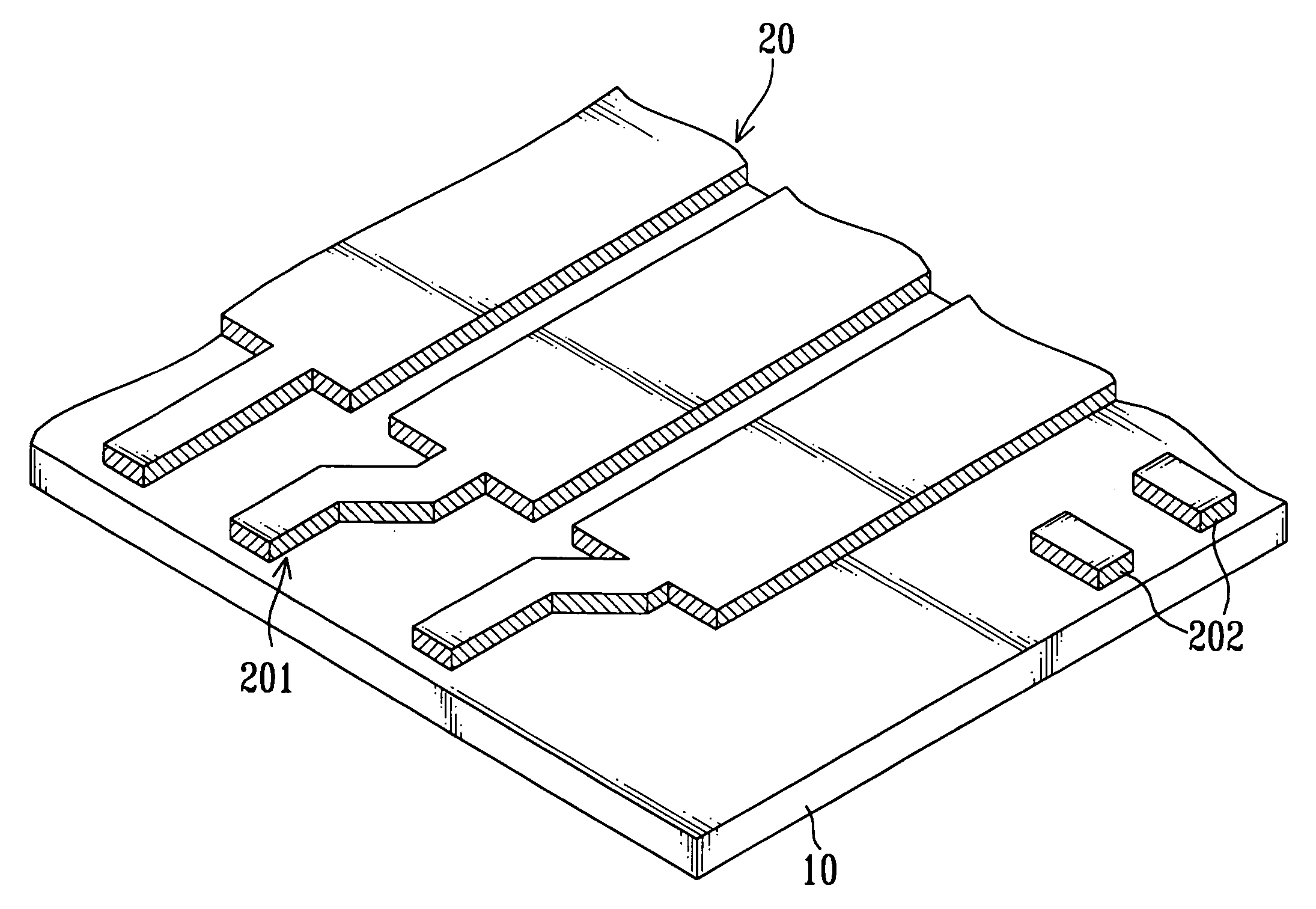

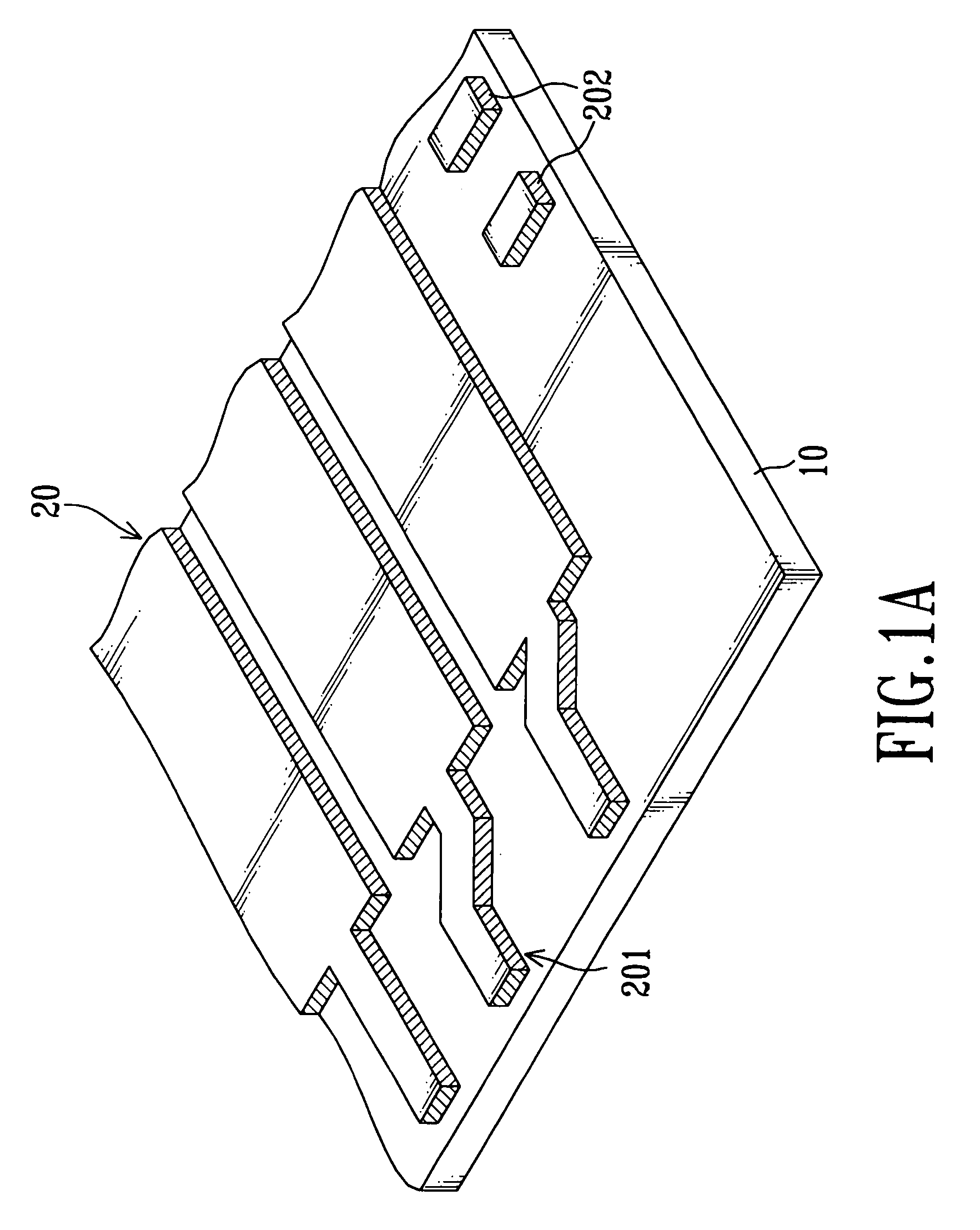

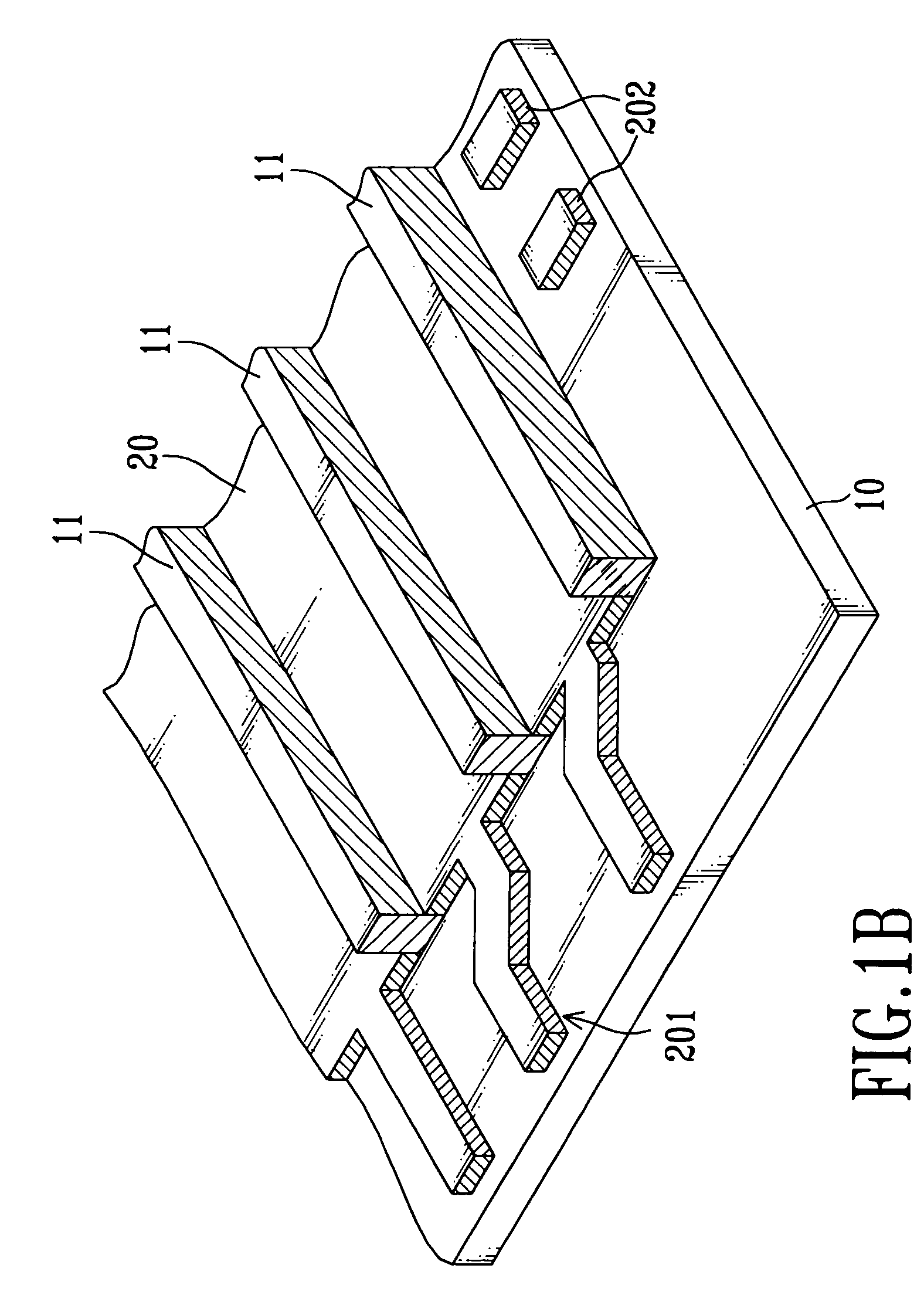

Optical-interference type display panel and method for making the same

InactiveUS7172915B2Improve antioxidant capacityConnecting qualitySemiconductor/solid-state device manufacturingVessels or leading-in conductors manufactureIndium tin oxideTransparent conducting film

Owner:SNAPTRACK

HVI-PAO in industrial lubricant and grease compositions

ActiveUS20070000807A1Good effectViscosity indexSolid fuelsLiquid carbonaceous fuelsViscosity indexWear resistance

The invention relates to industrial lubricant and grease compositions containing high viscosity index polyalphaolefins (HVI-PAO). The use of HVI-PAOs in industrial oils and greases application provides advantages in improved shear stability, wear property, foam property, energy efficiency and improved overall performance.

Owner:EXXONMOBIL CHEM PAT INC

Topical macqui berry formulation

InactiveUS20070065396A1High ORACImprove antioxidant capacityBiocideCosmetic preparationsMedicineOxygen radical absorbance capacity

The present invention provides a topical formulation and method of use where the formulation comprises macqui berry or a macqui berry extract containing anthocyanins having a very high oxygen radical absorbance capacity (ORAC). The formulation provides the macqui berry in a stabilized form which includes a glucuronide or glycuronide, a photostabilizing agent, encapsulation, or light -and / or air-blocking packaging.

Owner:TRACIE MARTYN INT

Composite water permeable brick

InactiveCN1966861AGood water permeabilityLow costSingle unit pavingsClimate change adaptationBrickAdhesive

A composite water permeable brick comprises water permeable surface and base closely combined together with aggregate and adhesive coating the aggregate, with the adhesive of the said water permeable surface including at least hydrophilicity adhesive. It can keep fine water permeability, with the brick surface fine and close and reduced in cost.

Owner:RENCHSAND ECO ENVIRONMENT PROTECTION SCI & TECH CO LTD

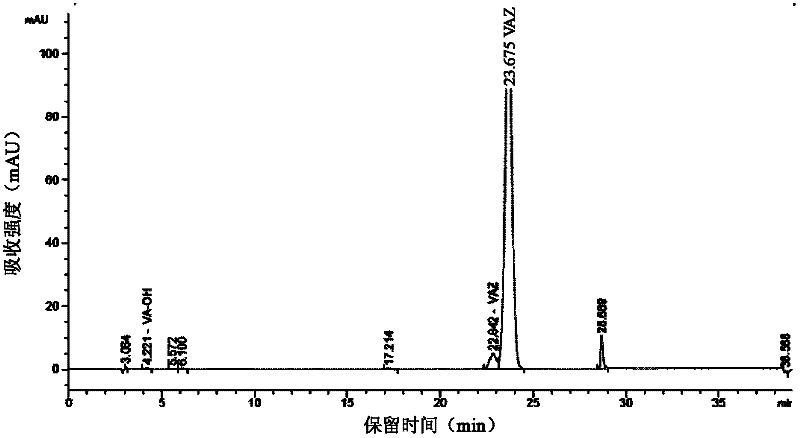

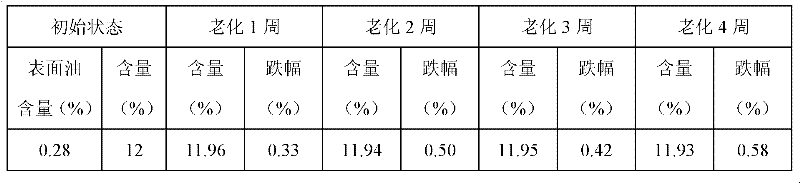

Functional oil microencapsulation and manufacturing method thereof

ActiveCN102550817AGood water solubilityImprove antioxidant capacityMetabolism disorderAlgae medical ingredientsOil and greaseWater baths

The invention provides a functional oil microencapsulation and a manufacturing method thereof and relates to a microencapsulation, and the functional oil microencapsulation has the advantages of high stability and immobilized proteinaceous pellicle. The oil microencapsulation is prepared from the following raw materials: functional oil, plant oil, an antioxidant, aqueous-phase main-wall materials, aqueous-phase auxiliary-wall materials, bio-enzyme protein and water. The plant oil serving as a carrier is mixed with the functional oil, then the antioxidant is added, and then the materials are heated and dissolved in water bath, thus obtaining an oil-phase core material solution; the aqueous-phase main-wall materials and the aqueous-phase auxiliary-wall materials are added into deionized water, and then the materials are heated and dissolved in water bath, thus obtaining an aqueous-phase wall material solution; the oil-phase core material solution is added in the aqueous-phase wall material solution, the mixture is sheared and emulsified by a shearing machine, and then is homogenized by a homogenizer, thus obtaining a nanometer-level solution with uniform oil drop diameter; and bio-enzyme is added into the nanometer-level solution, the mixture is placed in hot-water bath for heating and stirring reaction, temperature is raised after the reaction so as to enable the bio-enzyme to be inactivated, and drying is carried out, thus obtaining the functional oil microencapsulation.

Owner:XIAMEN KINGDOMWAY BIOTECH CO LTD +1

Cherry and tomato composite beverage and preparation method thereof

InactiveCN104312859AComprehensive and balanced nutritionEvenly ruddy colorAlcoholic beverage preparationThirstNutrient solution

The invention discloses a cherry and tomato composite beverage and a preparation method thereof. The cherry and tomato composite beverage is prepared from the following raw materials, by weight, 30-45 parts of cherry, 15-20 parts of tomato, 10-15 parts of guava, 10-14 parts of pitaya peel, 10-15 parts of buckwheat, 14-18 parts of red glutinous rice, 1-3 parts of stevioside, 2-3 parts of very precious flower in Plateau Snow Mountain, 2-4 parts of ginseng fruit, 3-5 parts of grapefruit flower, 1-2 parts of flower of Intermediate peashrub, 1-2 parts of Japanese metaplexis, 12-18 parts of setose abelmoschus, a proper amount of rose wine, and 8-10 parts of a nutrient solution. The cherry and tomato composite beverage prepared in the invention maximally reserves nutritional components of cherry and tomato, has the characteristics of red and uniform color, aroma, sweet and delicious taste, smooth mouthfeel, abundant and balanced nutrition, and simple and feasible technology, has the efficacies of body fluid production promoting, thirst quenching, stomach strengthening, food digesting, pressure reducing, lipid lowering, heat clearing, detoxifying, toxin expelling and face nourishing through the synergistic effect with health care components of traditional Chinese medicines, and can promote digestion, enhance muscle power and improve the oxidation resistance of human bodies through long term drinking.

Owner:徐九山

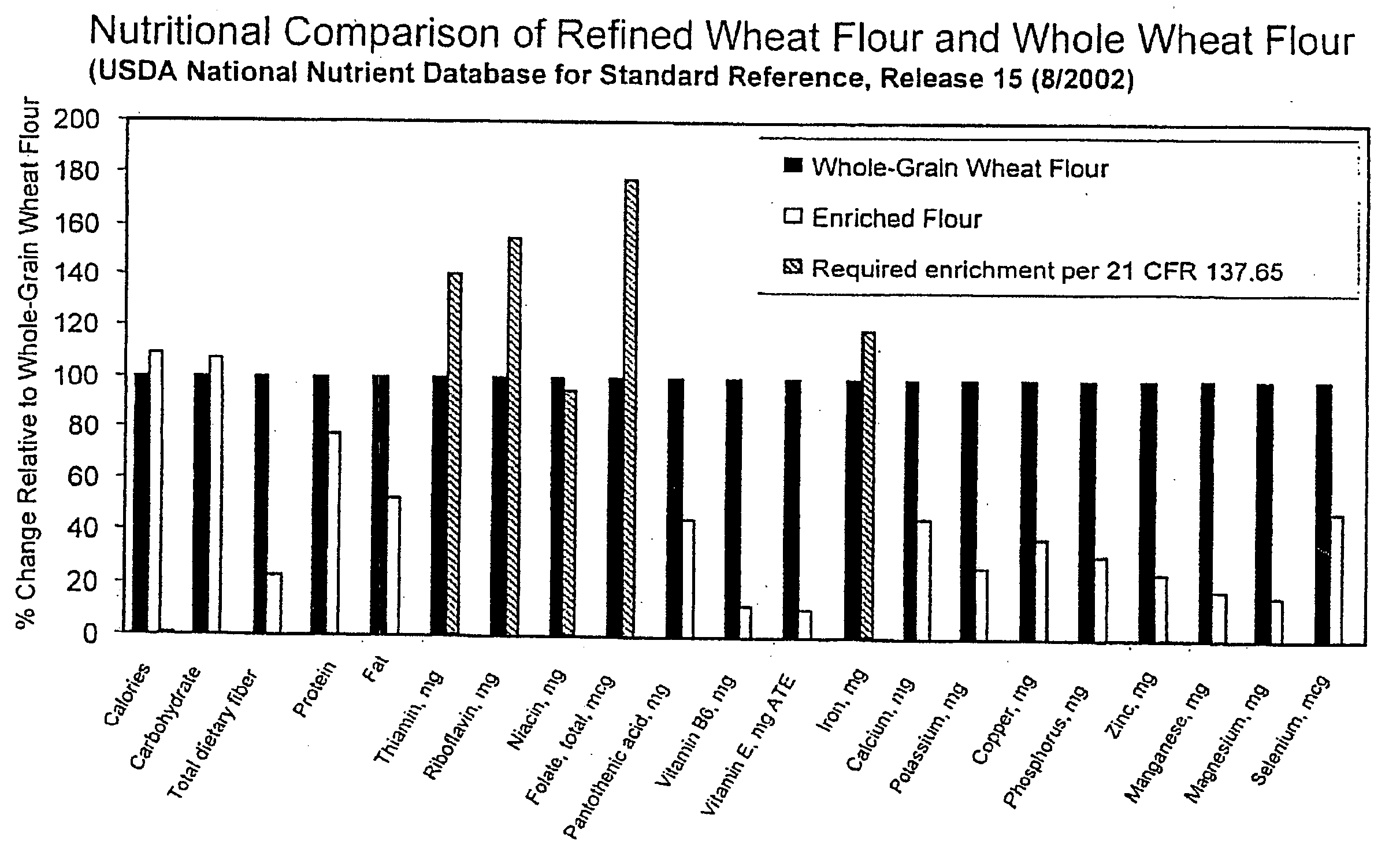

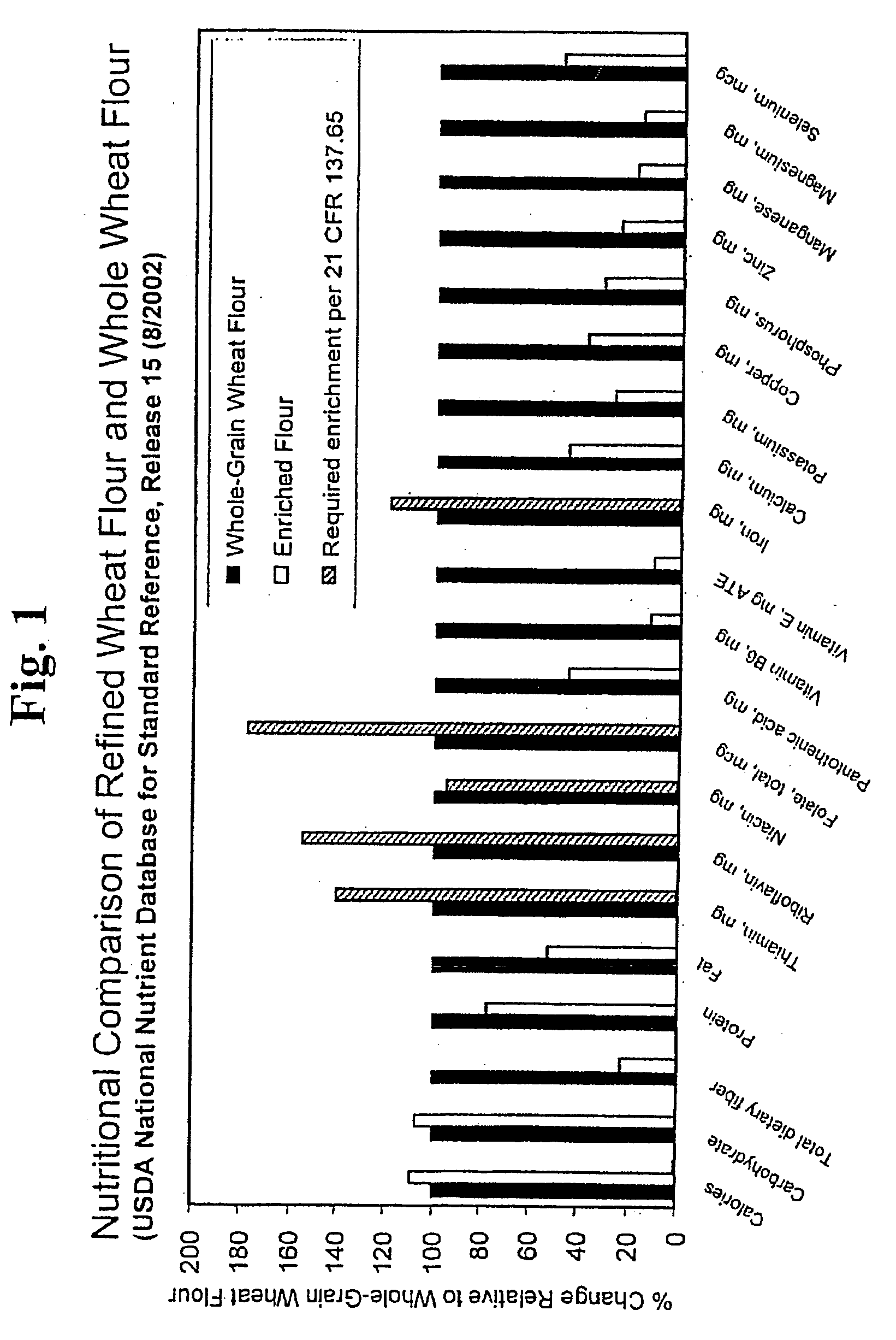

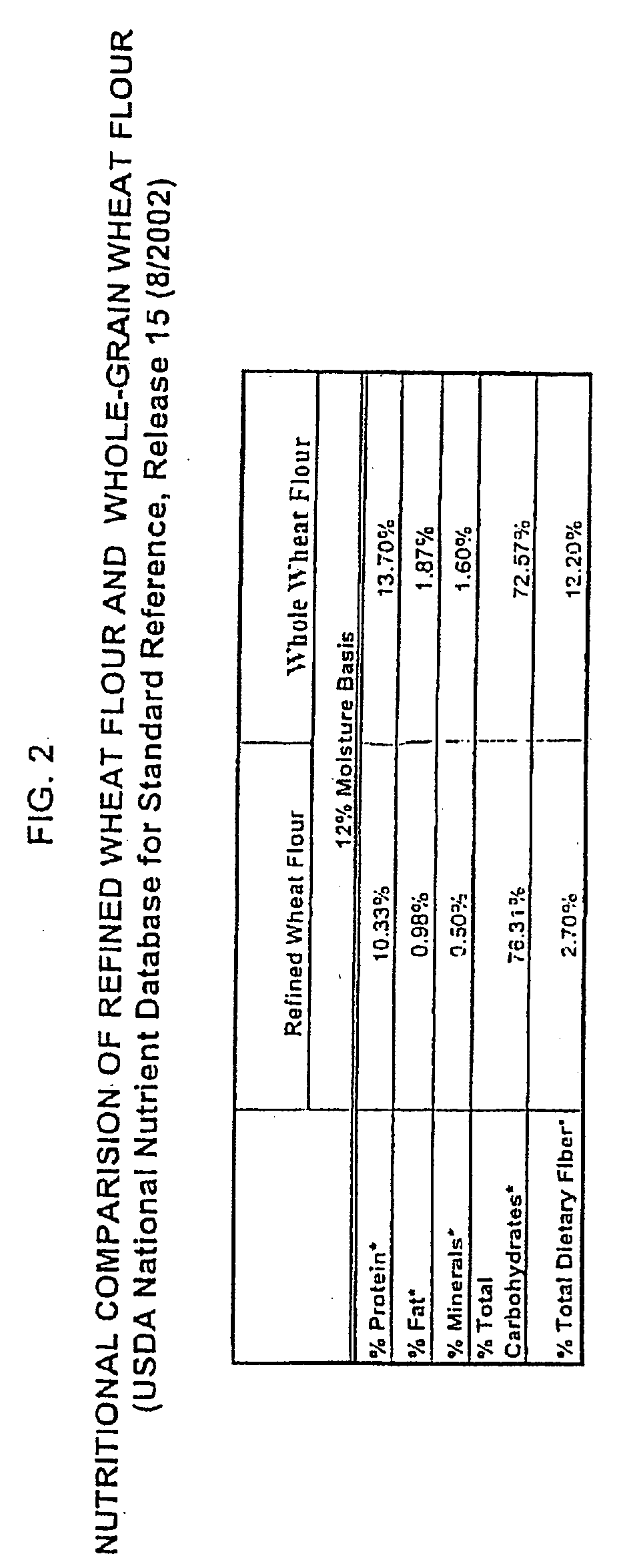

Process for producing an ultrafine-milled whole-grain wheat flour and products thereof

InactiveUS20060073258A1High nutritional valueHigh in fiberDough treatmentGrain treatmentsSnack foodUltra fine

A process for producing an ultrafine-milled whole-grain wheat flour which has the full nutritional value of wheat kernels, while retaining the texture of refined wheat flour and an appearance similar to refined wheat flour, and the products which can be made from the ultrafine-milled whole-grain wheat flour. The process can also be used for producing an ultrafine-milled coarse fraction, which can be used as a replacement and to fortify refined wheat flour. The ultrafine-milled coarse fraction can be used in bakery products, snack products and food products.

Owner:CONAGRA FOODS

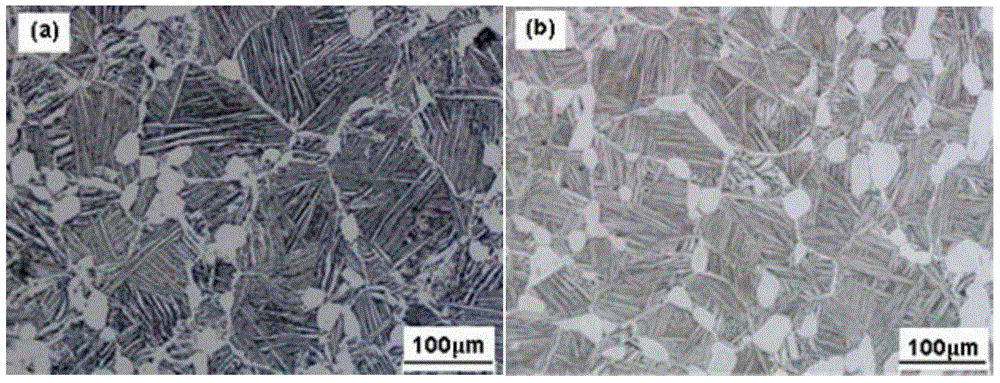

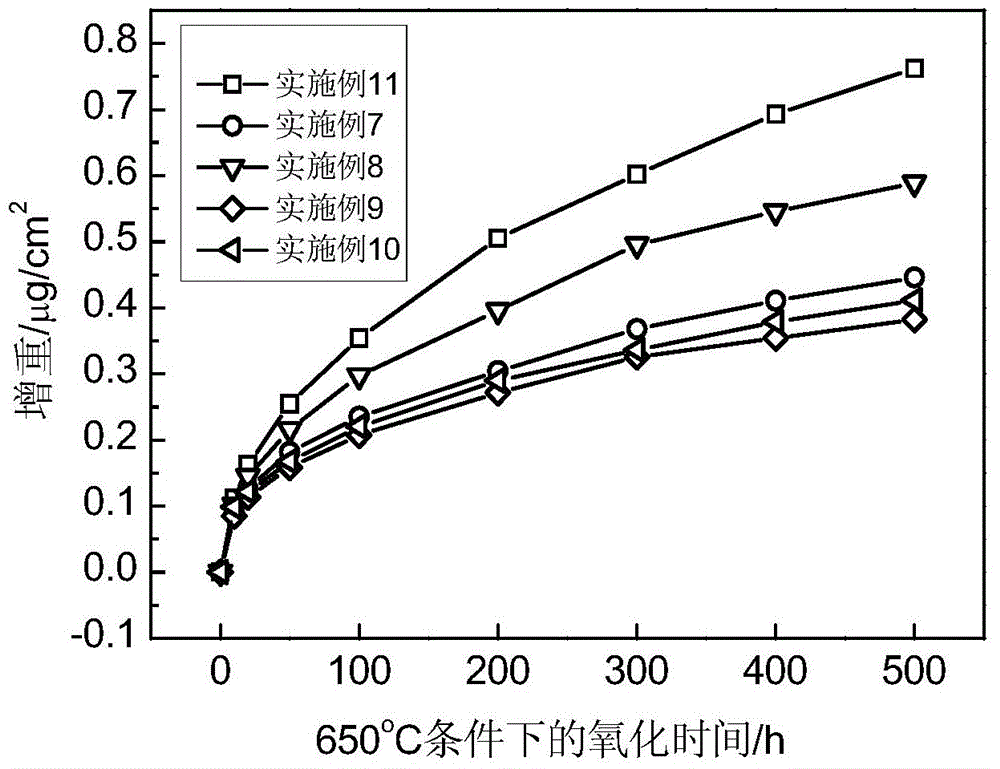

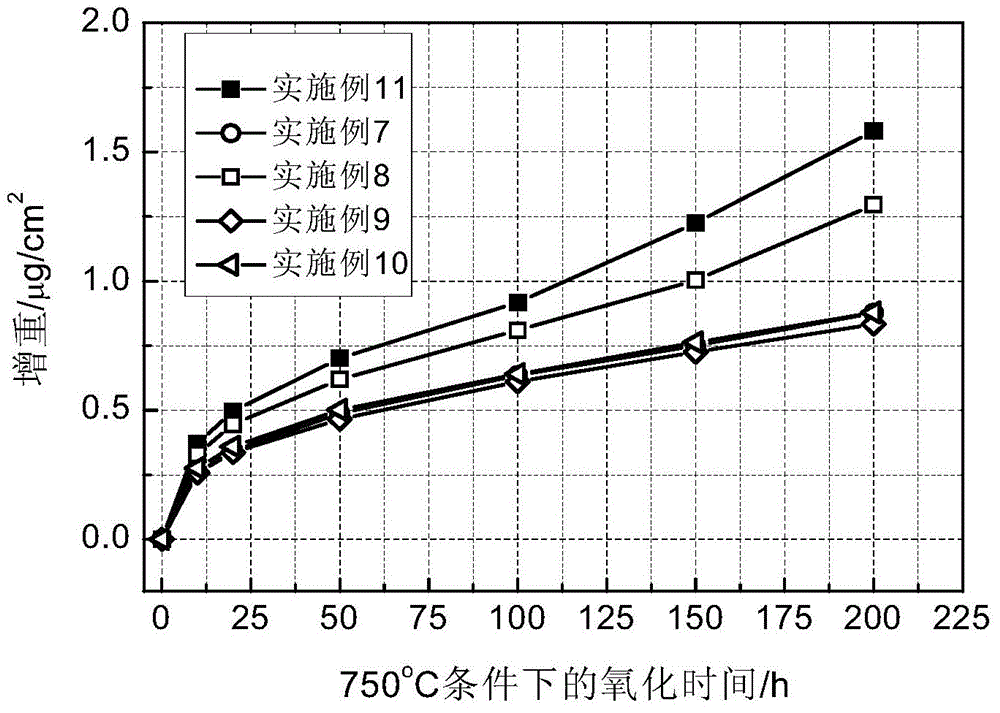

Novel heat-resisting titanium alloy and processing and manufacturing method and application thereof

The invention belongs to the field of titanium-based alloys, and particularly relates to a novel heat-resisting titanium alloy and a processing and manufacturing method and application thereof. The processing and manufacturing method comprises the composition elements of alloy components, smelting, heat processing, heat treatment and the like, wherein the alloy components are as follows (in percentage by weight): 5.4%-6.3% of Al, 3.0%-5.0% of Sn, 2.5%-6.4% of Zr, 0.0%-0.96% of Mo, 0.25%-0.5% of Si, 0.2%-0.5% of Nb, 0.3%-3.4% of Ta, 0.2%-1.6% of W, 0.0%-0.07% of C, less than or equal to 0.17% of O, less than or equal to 0.03% of Fe and the balance of Ti and inevitable impurity elements. The novel heat-resisting titanium alloy disclosed by the invention can obtain different matching of tensile strength, plasticity, permanence, creep strength and heat stability through the combination of different heat processing process and heat treatment processes, can be used for manufacturing parts, namely blades, coil assemblies and the like which are positioned on the high-temperature parts of an advanced aircraft engine, is used for a long time within a range of 600-650 DEG C, can also be used for manufacturing high temperature-resistant structural members, namely aerospace craft skin and the like, is used for a short time at about 700 DEG C and can be used as a material and the like used for high temperature-resistant corrosion-resistant valves of an automobile and a boiler.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

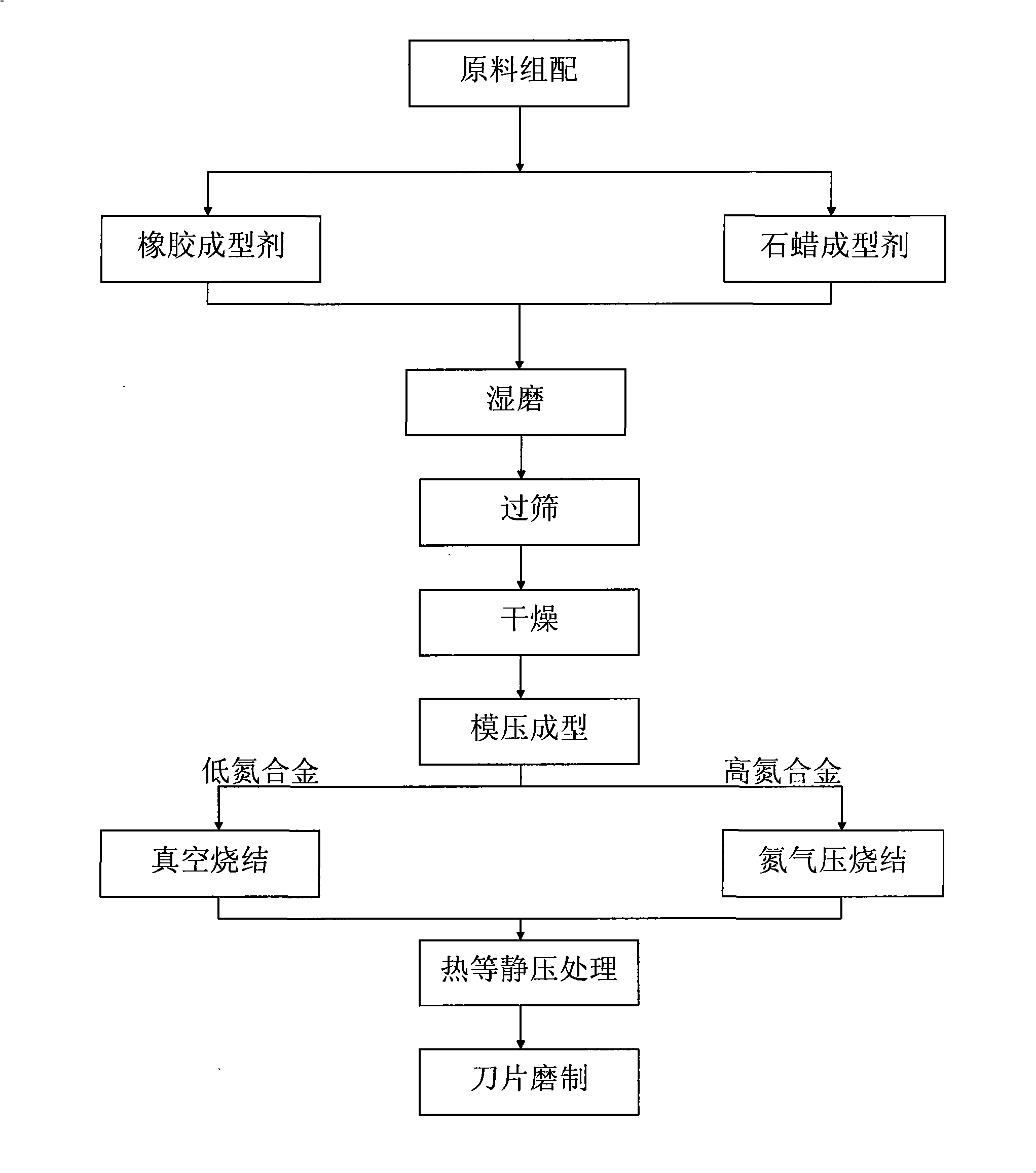

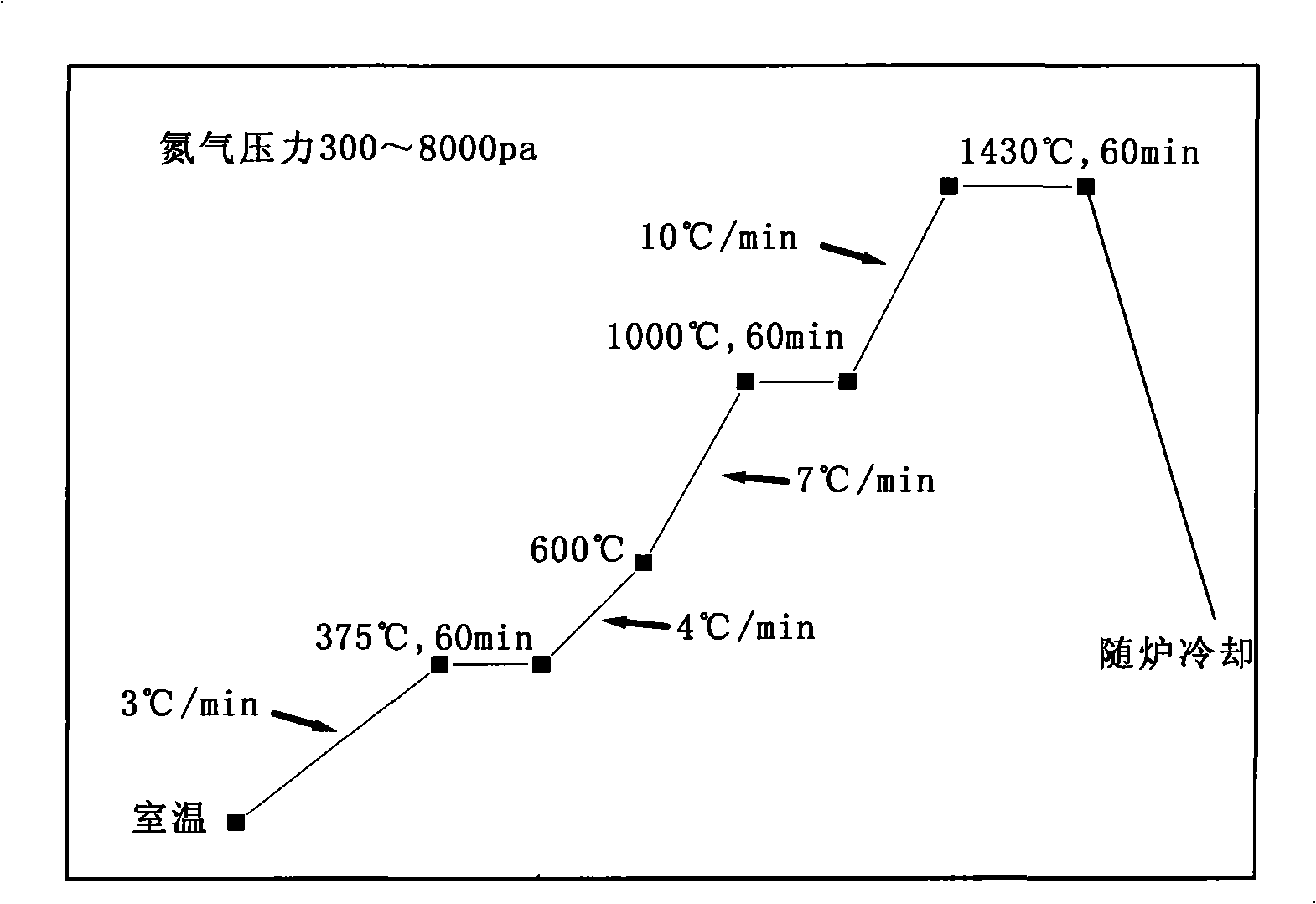

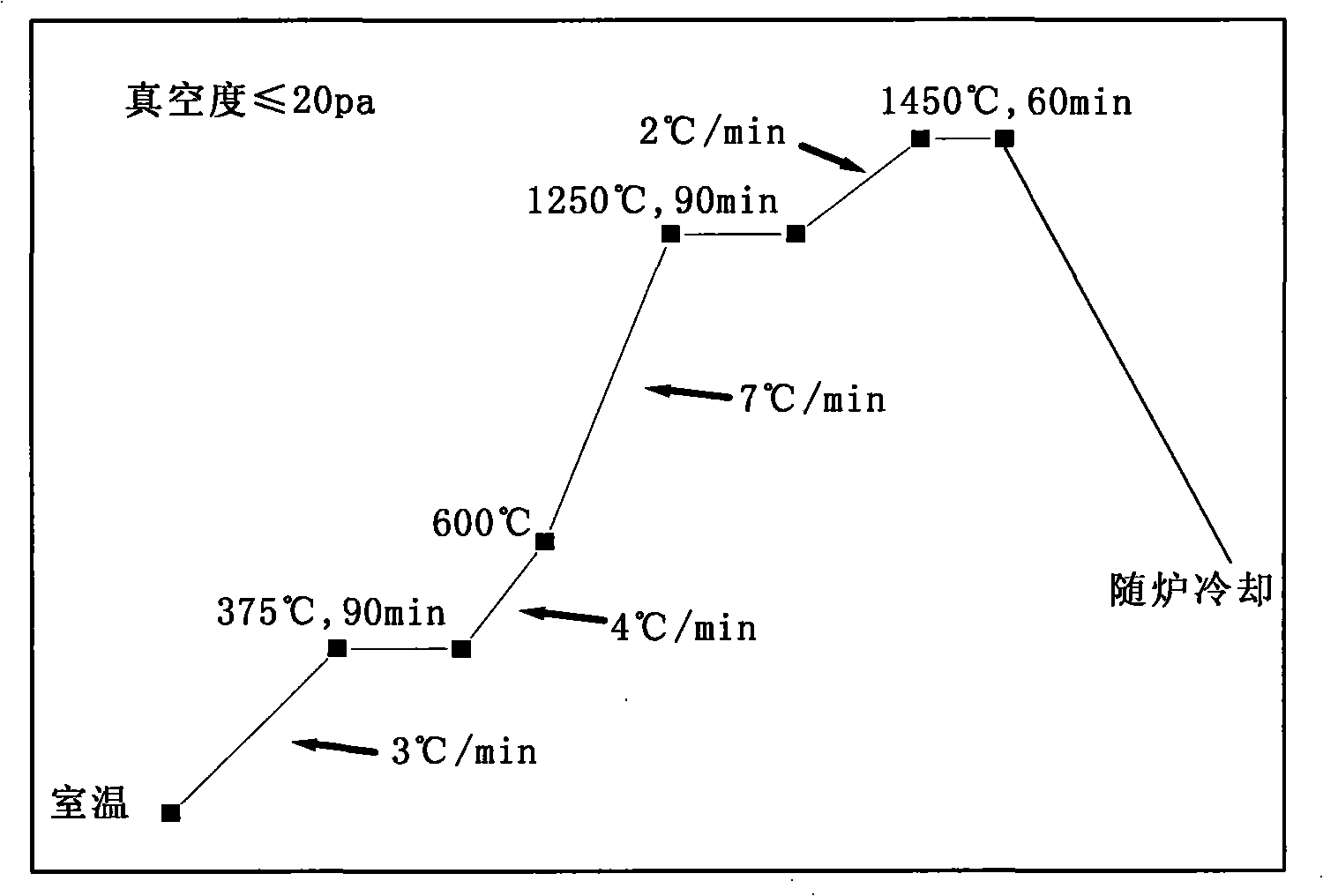

High-wear resistant Ti (C, N)-base ceramet tool bit and preparation thereof

InactiveCN101302595AReliable guarantee of high nitrogen-carbon ratioReliable Guarantee of HardnessLow nitrogenWear resistant

The invention provides a high-abrasion Ti(C, N) based metal ceramic tool and a preparation thereof. The Ti(C, N) based metal ceramic tool uses Ni and Co as a binder phase, is added with at least one carbonitride of Ti(Cx, N1-x) or (TiC)x plus (TiN)1-x as a basic batch, and consists of at least one composition of WC, Mo2C, Co, Ni, ZrC, Cr3C2, VC, TaC and NbC, and the balance being Ti(Cx, N1-x) or (TiC)x plus (TiN)1-x, wherein, an X value for adding the carbonitride of the Ti(C, N) based metal ceramic tool is as follows: X is less than or equal to 0.5 and more than or equal to 0.4, or the X is more than 0.5 and less than or equal to 0.7. The Ti(C, N) based metal ceramic tool is prepared according to the content of nitrogen by nitrogen pressure sintering or vacuum sintering combined with hot isostatic pressing treatment, thereby preventing nitrogen from escaping during the process of sintering high-nitrogen alloy, so that the high-nitrogen-carbon ratio in matrix and material hardness can be reliably guaranteed, and anti-oxidative abrasion property and anti-diffusive abrasion property of the material can be obviously increased through adding slight ZrC, Cr3C2, VC and other carbides into the basic batch; meanwhile, compactability and buckling strength of a low-nitrogen alloy structure can be obviously improved through optimally distributing each composition and content. The Ti(C, N) based metal ceramic tool is widely suitable for high-speed cutting tools of medium-low carbon steel and low alloy steel.

Owner:HUNAN UNIV OF SCI & TECH

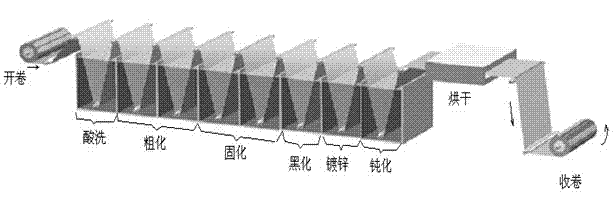

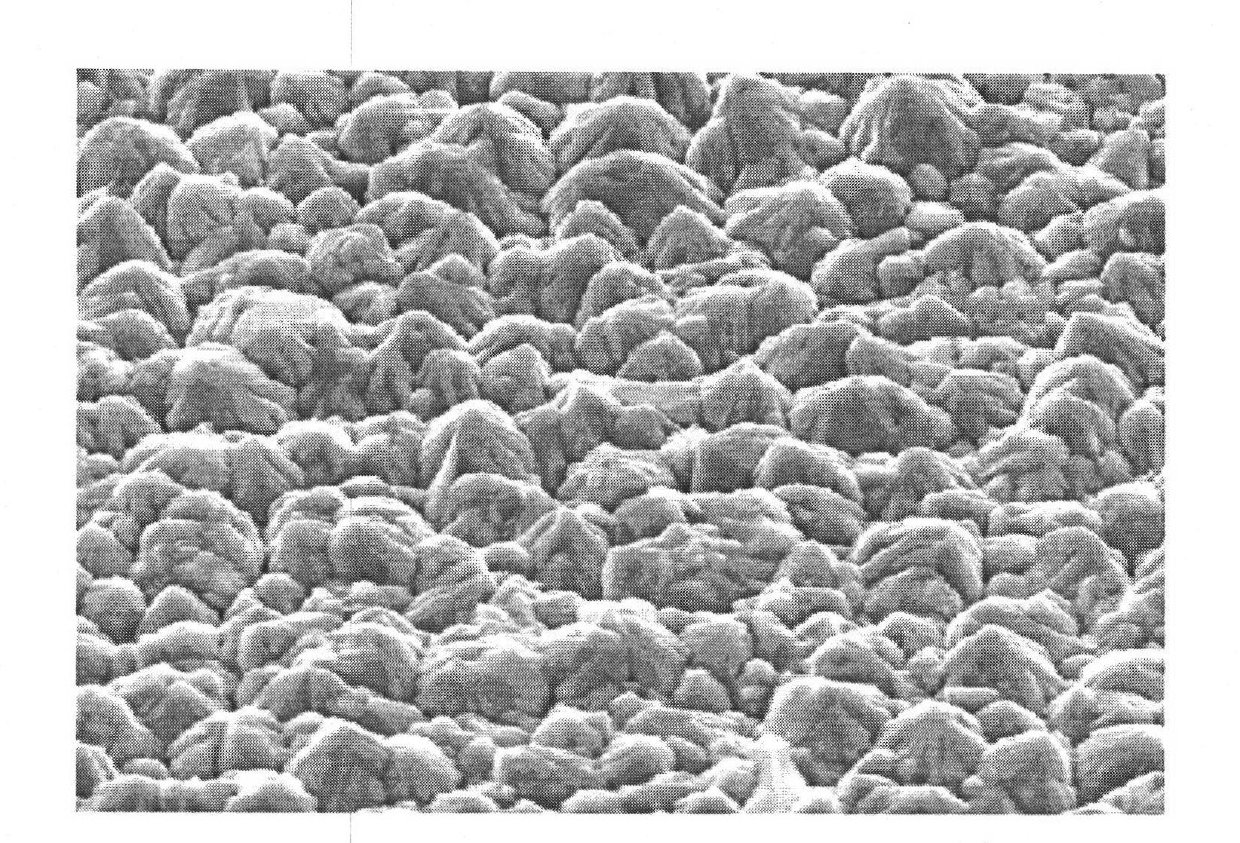

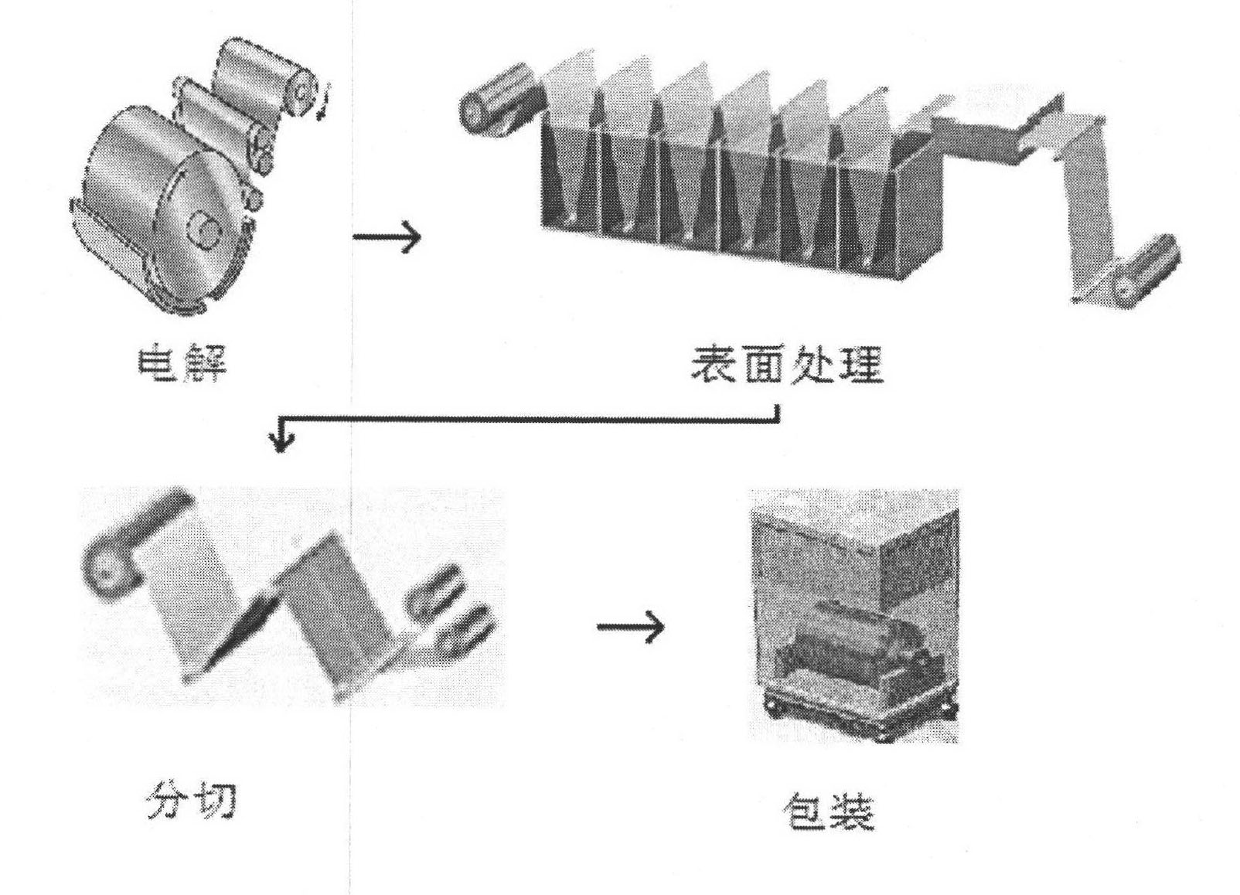

Surface treatment process of copper foil for high-Tg halogen-free plate

InactiveCN102418129AHigh peel strength and corrosion resistanceStrong antioxidantAnodisationCopper foilHexavalent chromium

The invention relates to a surface treatment process of a copper foil for a high-Tg halogen-free plate, belonging to the technical field of a production process of a high-precision electrolytic copper foil. In the surface treatment process provided by the invention, a structure shape of a coarsening layer is changed by using a special mixed additive in a coarsening step so as to improve anti-stripping strength; an ultra-fine nanoscale electroplated nickel-zinc alloy is used as a barrier layer to assure the corrosion resistance of the copper foil. Internal properties and pressure plate back color of the copper foil which is treated by the process provided by the invention are similar with those of the copper foil which is imported abroad; the anti-stripping strength on the high-Tg (Tg170) and the halogen-free plate is more than 1.5 N / mm; and the copper foil has characteristic of environmental friendliness and does not contain harmful matters, such as arsenic, antimony, mercury, cadmium, hexavalent chromium and the like.

Owner:SHANDONG JINBAO ELECTRONICS

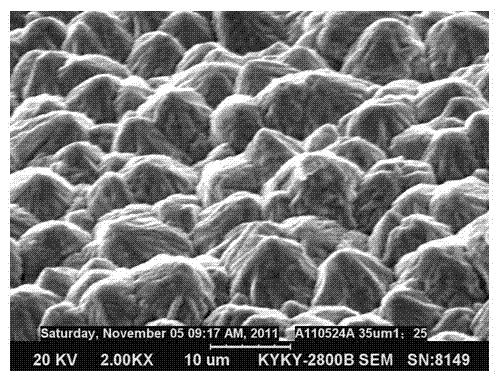

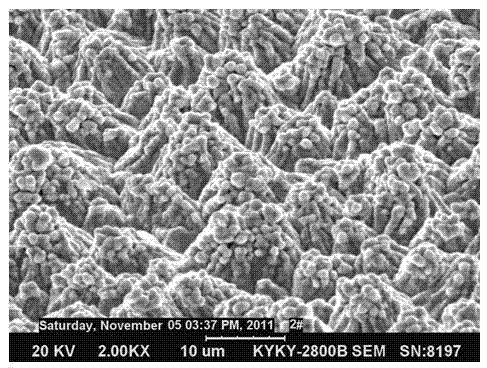

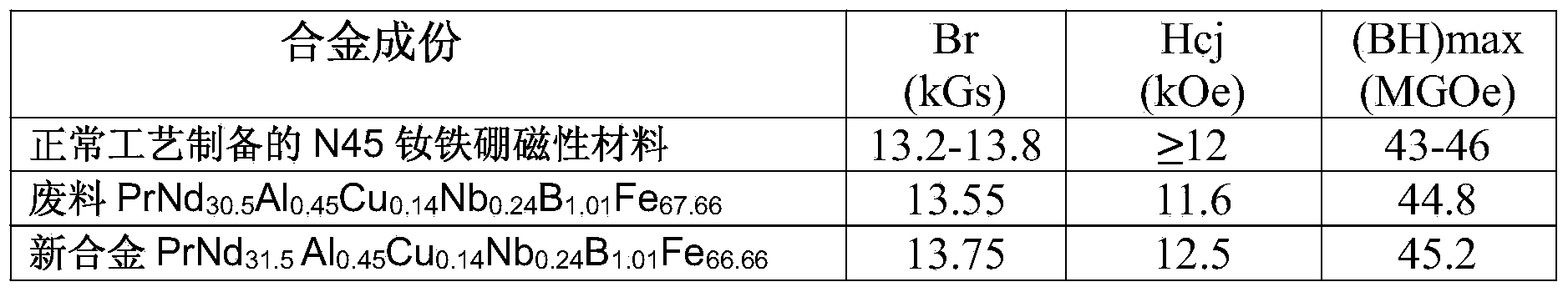

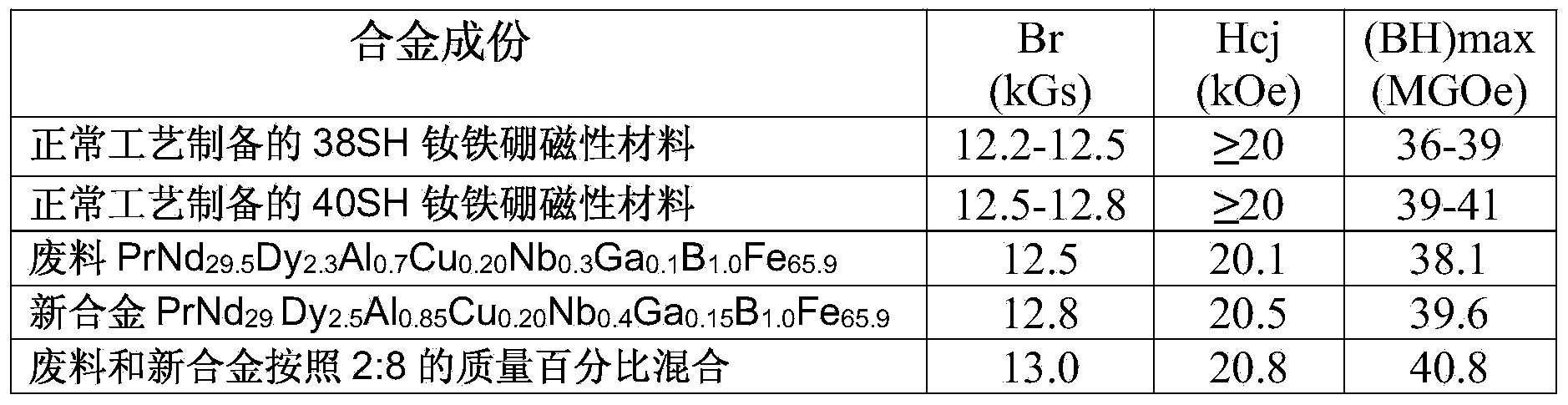

Method for preparing neodymium iron boron through regenerating waste material containing neodymium, iron and boron

ActiveCN103866127AFully absorb hydrogenImprove recycling ratesMagnetic materialsProcess efficiency improvementMetallurgyEconomic benefits

The invention provides a method for preparing neodymium iron boron through regenerating a waste material containing neodymium, iron and boron. The method comprises steps of (1) preprocessing the waste material; (2) correcting the components of the waste material; (3) crushing by hydrogen; (4) preparing into powder; (5) molding under a magnetic field; and (6) vacuum sintering. The method fully uses the waste material recycled in a production process, has high recovery rate of the waste material, can produce high performance product, has a simple and controllable flow, has high operability, uses no strong acid and strong base polluting the environment, is environment-friendly and energy-saving, and has high social and economic benefits.

Owner:CHINALCO JINYUAN RARE EARTH

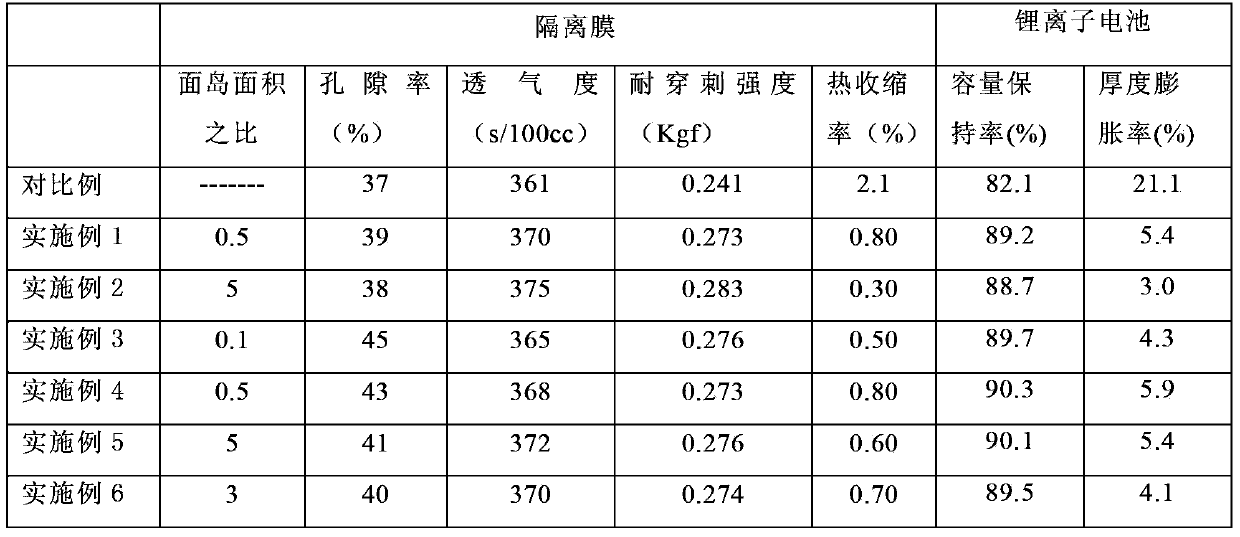

Organic/inorganic composite porous isolating membrane, preparation method thereof and electrochemical device

ActiveCN103441230AImprove breathabilityImprove conductivityHybrid capacitor separatorsCell seperators/membranes/diaphragms/spacersPorous coatingInorganic particle

The invention provides an organic / inorganic composite porous isolating membrane, a preparation method thereof and an electrochemical device. According to the first aspect of the invention, the organic / inorganic composite porous isolating membrane comprises a porous base material and an organic / inorganic composite porous coating coated on at least one surface of the porous base material, wherein the organic / inorganic composite porous coating comprises inorganic particles, a binding agent and organic particles with at least two swelling degrees, and the organic particles are swelled by a plasticizer. The preparation method of the organic / inorganic composite porous isolating membrane is used for preparing the organic / inorganic composite porous isolating membrane described in the first aspect of the invention. According to the third aspect of the invention, the electrochemical device comprises the organic / inorganic composite porous isolating membrane described in the first aspect of the invention. Therefore, the organic / inorganic composite porous isolating membrane can form an excellent interface, so that a risk that the risk of blocking holes by the organic particles is reduced, breathability of the organic / inorganic composite porous isolating membrane is improved, and electrical conductivity of the organic / inorganic composite porous isolating membrane is improved.

Owner:DONGGUAN AMPEREX TECH +1

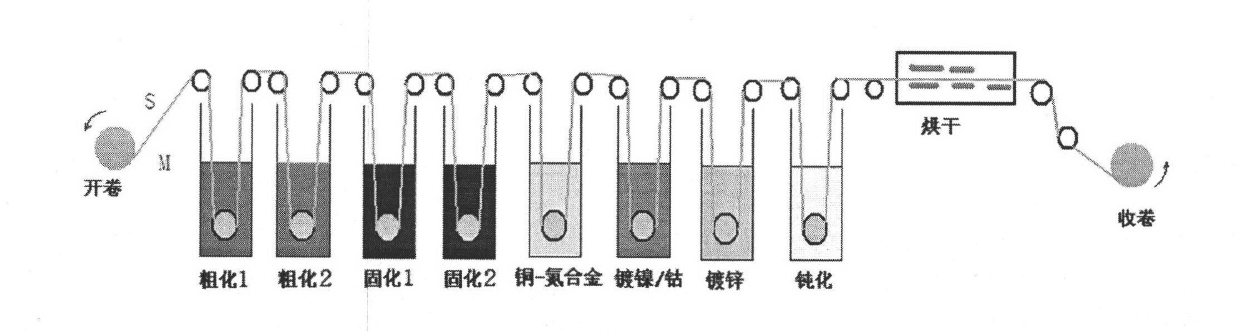

Black surface treatment process of electrolytic copper foil

ActiveCN101906630AImprove antioxidant capacityAccelerated corrosionSuperimposed coating processZinc alloysCopper foil

The invention relates to a black surface treatment process of an electrolytic copper foil, belonging to the technical field of production processes of high and precision electrolytic copper foils. The black surface treatment process of an electrolytic copper foil is characterized in that a VLP (Very Low Profile) electrolytic copper foil of 8-12 mu m is used as an electrode, and then copper or copper alloy is roughened, solidified, weakly roughened and electrically deposited at a running speed of 25.0+ / -0.1m / min; a layer of nano-scale nickel or cobalt alloy and a layer of nano-scale zinc alloy are sequentially and electrically deposited; and then alkaline chromate passivation is carried out and a layer of coupling agent is coated. In the invention, the black copper foil for an FPC (Flexible Printing Circuit) is obtained by carrying out a series of special surface treatments on the ultrathin and VLP electrolytic copper foil of 8-12 mu m, wherein the surface roughness Ra of the obtained copper foil is smaller than or equal to 0.30 mu m, Rz is smaller than or equal to 2.5 mu m; the thickness of the copper foil subjected to the surface treatments is increased by 1.40-1.80 mu m; the copper foil does not contain elements having serious damages to the human body, such as lead, mercury, cadmium, stibium, and the like and has excellent oxidation resistance as well as corrosion and etching resistance; the peel strength of the copper foil on a PI (Polyimide) film reaches higher than 1.0N / mm, and the folding strength on the PI film reach more than 100 thousand numbers of times; the copper foil has good appearance characteristics after the copper foil is microetched, and after the copper foil is made into an FCCL (Flexible Copper Clad Laminate), the copper foil has similar appearance characteristics to a rolled copper foil; and the properties of the copper foil product are equivalent to that of an electrolytic copper foil with the same specification for the FCCL.

Owner:SHANDONG JINBAO ELECTRONICS

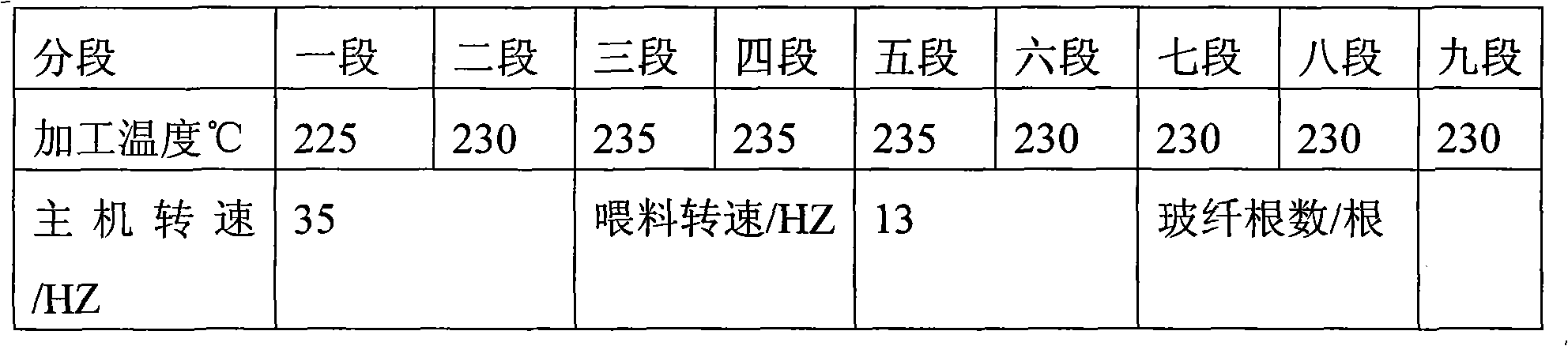

High glowing filament environmental-friendly inflaming retarding reinforced polybutylece terephthalate (PBT)/acrylonitrile butadiene styrene (ABS) alloy material and preparation method thereof

InactiveCN102108187AAvoid decompositionImprove impact performanceGlass fiberPolyethylene terephthalate

The invention relates to a high glowing filament environmental-friendly inflaming retarding reinforced polybutylece terephthalate (PBT) / acrylonitrile butadiene styrene (ABS) alloy material. The material comprises the following components in percentage by weight: 22.5-41% of PBT, 22.5-41% of ABS, 6-20% of complexing inflaming retardant, 3-15% of antimonous oxide, 20-30% of glass fiber, 2-10% of flexibilizer, 0.1-1% of antioxidant and 0.1-1% of lubrication dispersing agent. The preparation method comprises the following steps: putting raw materials weighed based on the weight proportion into a high mixer, mixing for 2-5 minutes, and then discharging; and then extruding and granulating by using an extruding machine at the processing temperature of 230-240 DEG C at the screw rotating speed of 30-40Hz. Compared with the alloy material prepared by the prior art, the high glowing filament environment-friendly inflaming retarding reinforced PBT / ABS alloy material has the advantages of high glowing filament temperature, environmental friendliness, balanced comprehensive performance and the like.

Owner:SHANGHAI SUNNY

Polymerized thylene carbonate urethane elastomer and its preparation method

ActiveCN1865311AMolecular chain softRoom temperature and good flexibilityCross-linkMedical equipment

The invention discloses a polyethylene carbonate polyurethane elastomer and making method, which produces polycarbonate polyhydric alcohol through carbon dioxide and oxirane with 20-60 percent diisocyanate, 0.05-2 percent polymerization inhibitor, 2.4-17 percent chain-extending agent and or cross linking agent and 0-0.4 percent catalyst. The method possesses better mechanic property, plasticity, anti-oxidizing property and water weakened-durability, which can be applied in the liner, screen, sealing ring and medical equipments.

Owner:JIANGSU ZHONGKE JINLONG CHEM

Medicinal plants extract using processing of herbal medicine and composition of skin external application comprising the same

InactiveUS20110052731A1InhibitionImprove antioxidant capacityAntibacterial agentsBiocideExternal applicationDrug herbal

The present invention relates to an extract of a processed herbal medicinal plant and a composition for skin external application which contains the extract. More specifically, the composition for skin external application contains an extract of processed herbal medicinal plant, prepared through a method comprising the steps of: (a) processing an herbal medicinal plant by a process of boiling, steaming, roasting, baking or heating the medicinal plant or a combination of two or more of these processes; (b) obtaining an extract of the processed medicinal plant. The composition shows an improved antioxidant effect.

Owner:AMOREPACIFIC CORP

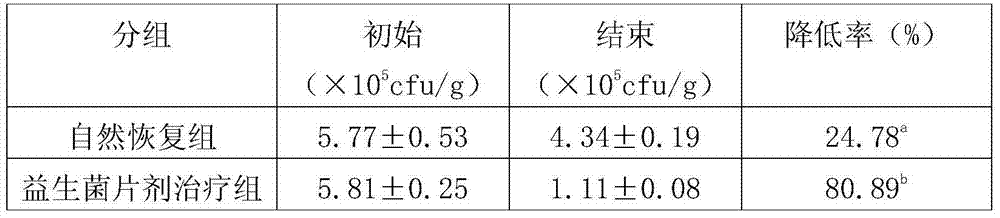

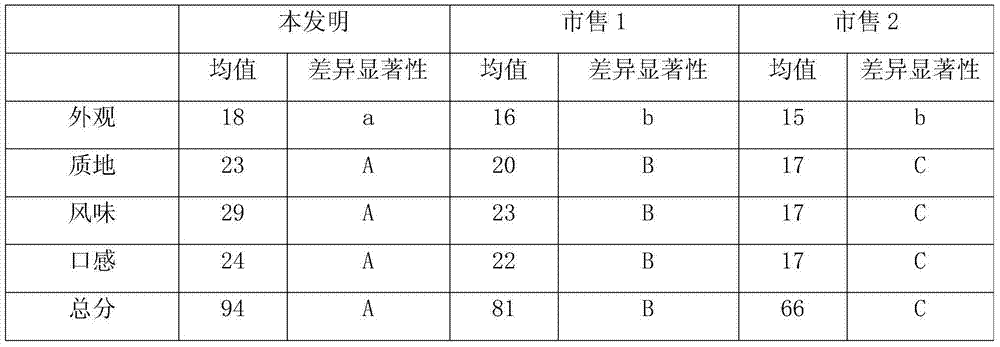

Fruit and vegetable probiotic tablet and preparation method thereof

ActiveCN104489646AHigh survival rate of live bacteriaImprove stabilityNatural extract food ingredientsFood ingredient functionsCelluloseDrug biological activity

The present invention discloses a fruit and vegetable probiotic tablet and a preparation method thereof. The fruit and vegetable probiotic tablet uses probiotic powders such as lactobacillus plantarum powder as the main raw material, and the preparation method scientifically mixes modified dietary fibers, fruit and vegetable powder, oligosaccharides, plant extracts, protein powder, tea leaf extracts and traditional Chinese medicine extracts and etc., thus improves the content of soluble celluloses which are of real significance for probiotic flora, enhances the physiological activity of celluloses, thereby increases the species of intestinal probiotic flora as well as significantly enhances the colonization ability and time of endogenous and exogenous probiotics in the human intestinal tracts, effectively inhibits the growth and reproduction of harmful intestinal bacteria, especially gram-negative bacteria, and fully regulates the composition of the intestinal probiotic flora. The prepared fruit and vegetable probiotic tablet has a high biological activity, a long human intestinal colonization time, and a significant weight loss effect, and is suitable for a wide range of people.

Owner:南京旭优食品技术有限公司

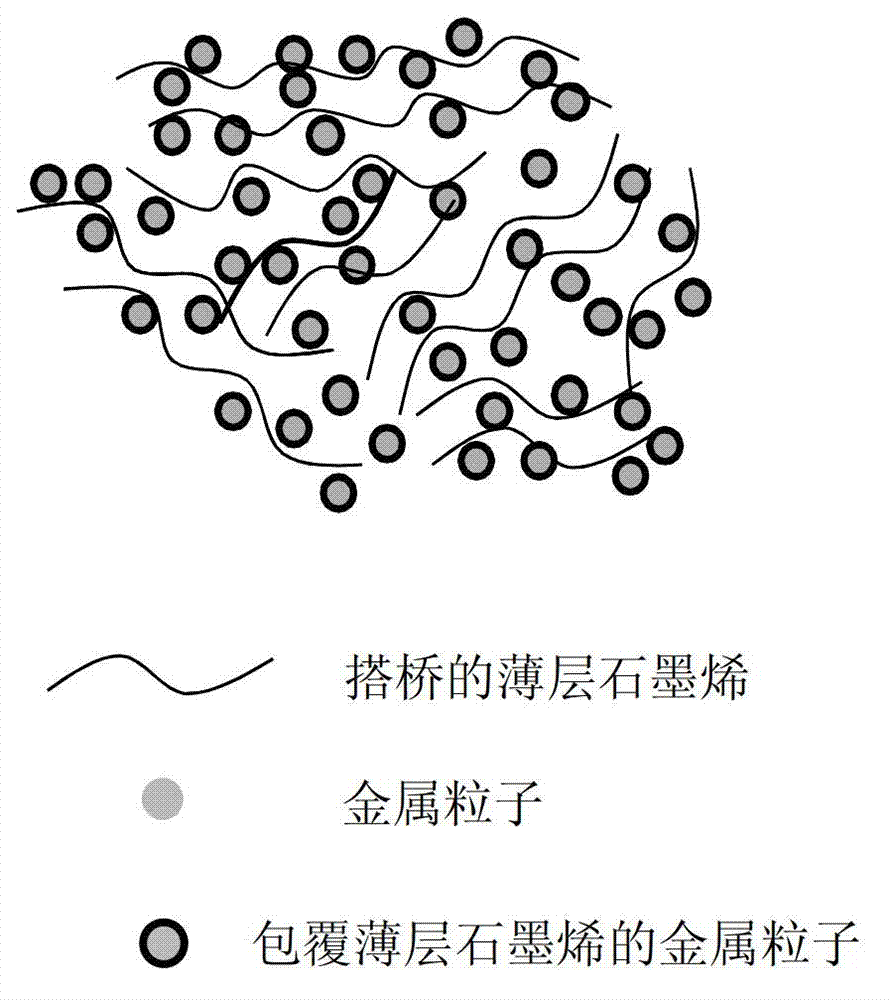

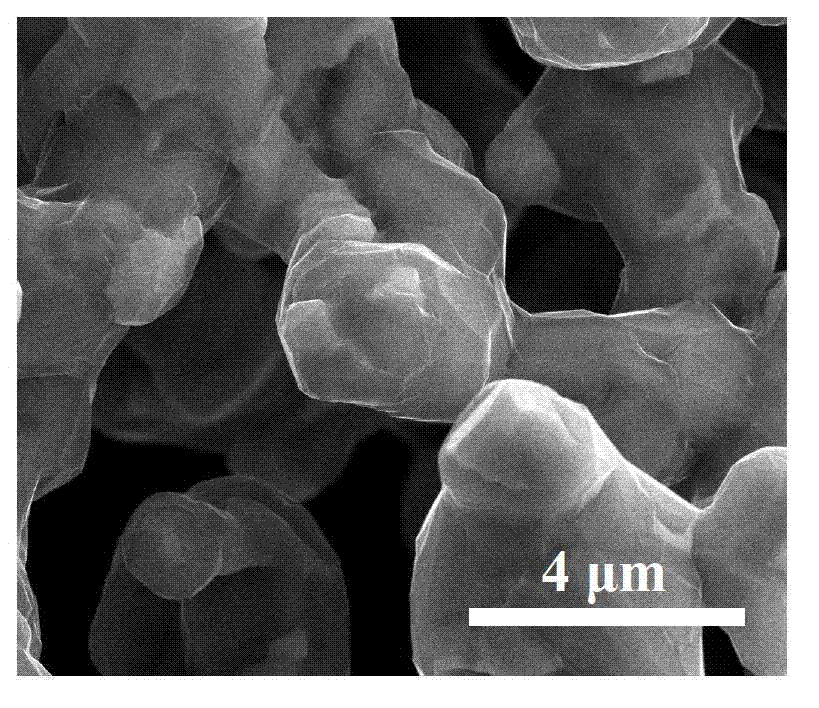

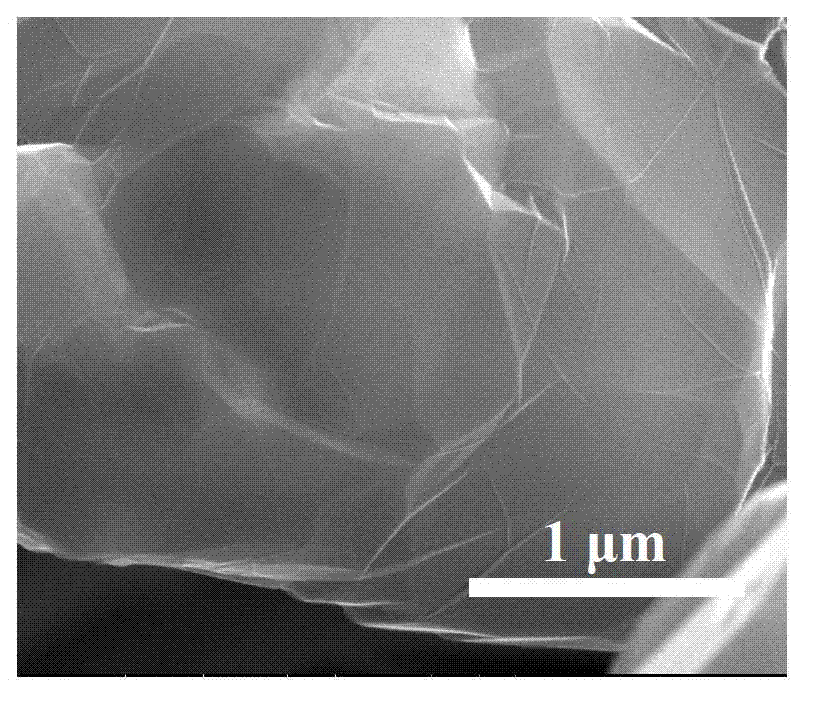

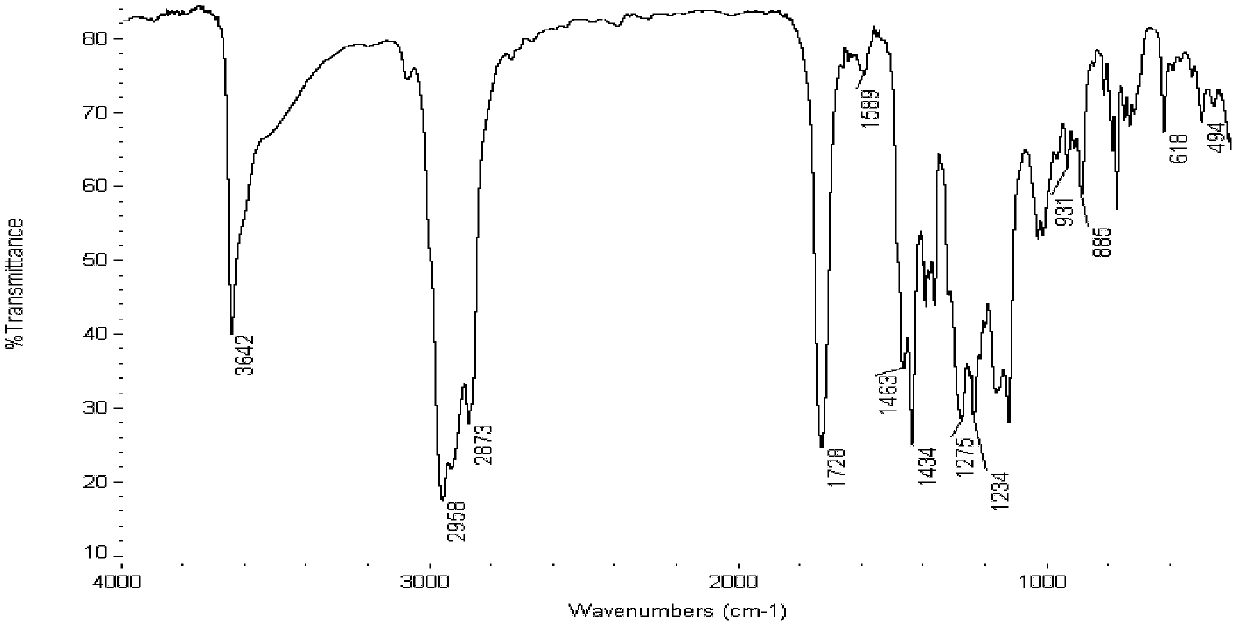

Material adopting thin graphene and metal powder composite structure, preparation method and application thereof

ActiveCN103192072AImprove antioxidant capacityImprove corrosion resistanceCarbon compoundsGas phaseSlurry

The invention discloses a material adopting a thin graphene and metal powder composite structure, a preparation method and an application thereof. The material adopting the composite structure comprises metal powder bridged by and coated with thin graphene. The preparation technology of the material comprises the steps as follows: mixing transition metal powder or reduced transition metal powder with the thin graphene, and growing the thin graphene on the surface of the transition metal powder through CVD (chemical vapor deposition) and coating the surface of the transition metal powder with the thin graphene, so as to obtain the metal powder bridged by and coated with the thin graphene; or growing the thin graphene on the surface of the transition metal powder through the CVD, and then compositing the metal powder with the thin graphene to obtain a target product. The invention has the advantages that the technology is simple; the oxidation resistance and the corrosion prevention of the metal powder can be enhanced, meanwhile, the metal powder has good heat conduction, antistatic and electromagnetic shielding properties, the service life of the metal powder can be prolonged, and the cost can be reduced; and besides, the material has a wide application prospect in antistatic performance, thermal management, heat conduction and radiation, electromagnetic shielding, catalysts, sintering activators, electro-conduction slurry, batteries, cemented carbide and the like.

Owner:苏州格瑞丰纳米科技有限公司

Process for preparing self-sealing silicon carbide ceramic based composite material

The invention relates to a method for manufacturing a self-healing silicon carbide ceramic matrix composite. The method comprises the following steps: preparing fiber preform; filtrating a pyrolytic carbon interface layer by chemical gas phase; carrying out thermal treatment on the interface layer; infiltrating silicon carbide and boron carbide substrate by chemical gas phase alternately; and depositing three silicon carbide coatings by the chemical gas phase. The method has strong designability, simple process and good repeatability. The ceramic matrix composite manufactured by the method has good high temperature resistance and oxidation resistance, has excellent mechanical performance and thermal performance, and can meet the use requirement of a sealing strip / an adjustment sheet, an interior cone and other components of a high thrust-weight ratio aeroengine.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

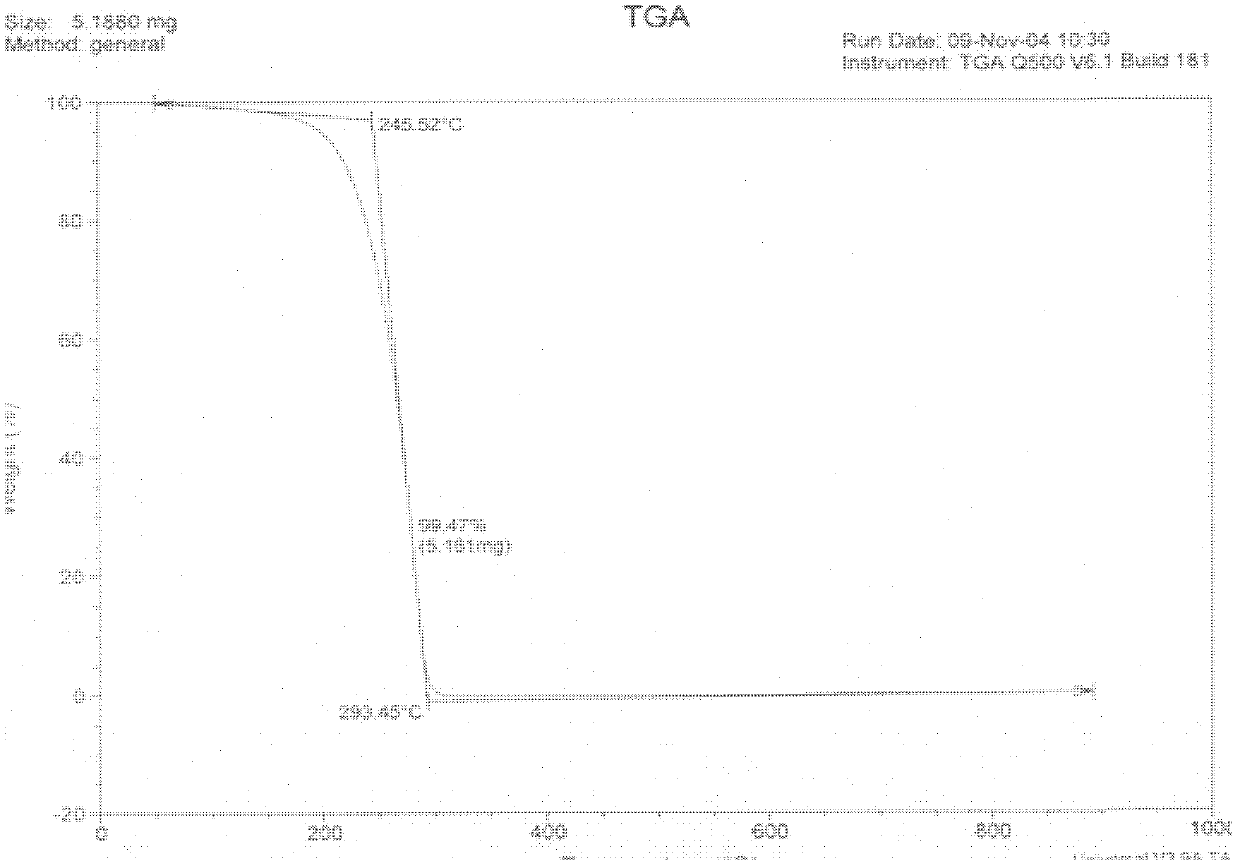

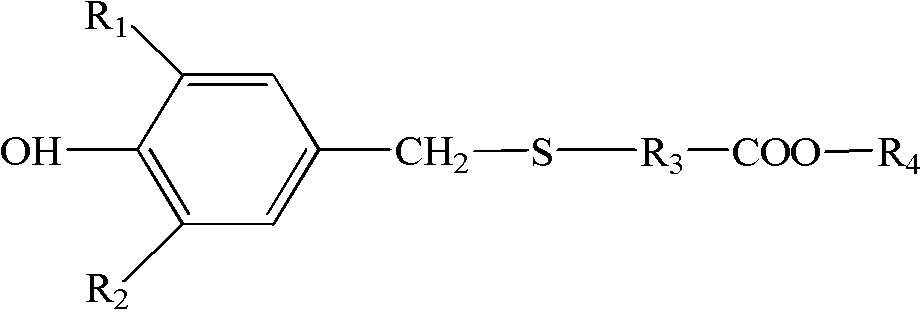

Thioether-containing hindered phenol antioxidant and preparation method thereof

InactiveCN103320198AImprove antioxidant capacityAchieve synergistic effectAdditivesSulfide preparationThioetherChemistry

The present invention provides a thioether bond structure-containing hindered phenol antioxidant and a preparation method thereof, wherein screen phenol, thiol ester and formaldehyde in a reaction medium are subjected to a reaction under a certain condition in the presence of a catalyst to obtain a thioether bond-containing hindered phenol antioxidant compound, wherein the compound has an excellent antioxidation performance in hydrogenation base oil, and can be adopted as a lubricating agent antioxidant to be separately used or is compounded with other additives to be used, and the antioxidant is applicable for internal combustion engine oils and industrial lubricating oils.

Owner:PETROCHINA CO LTD

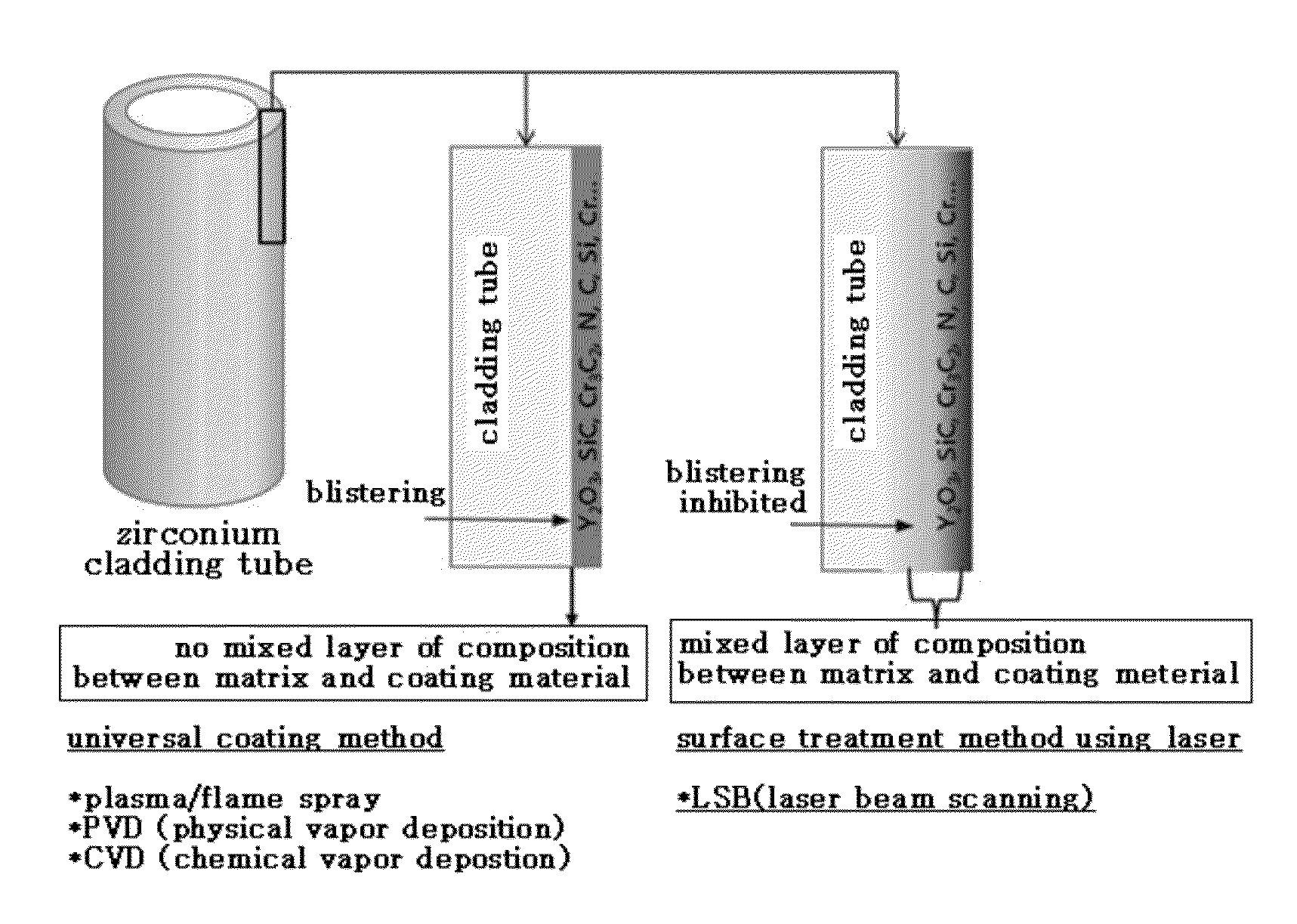

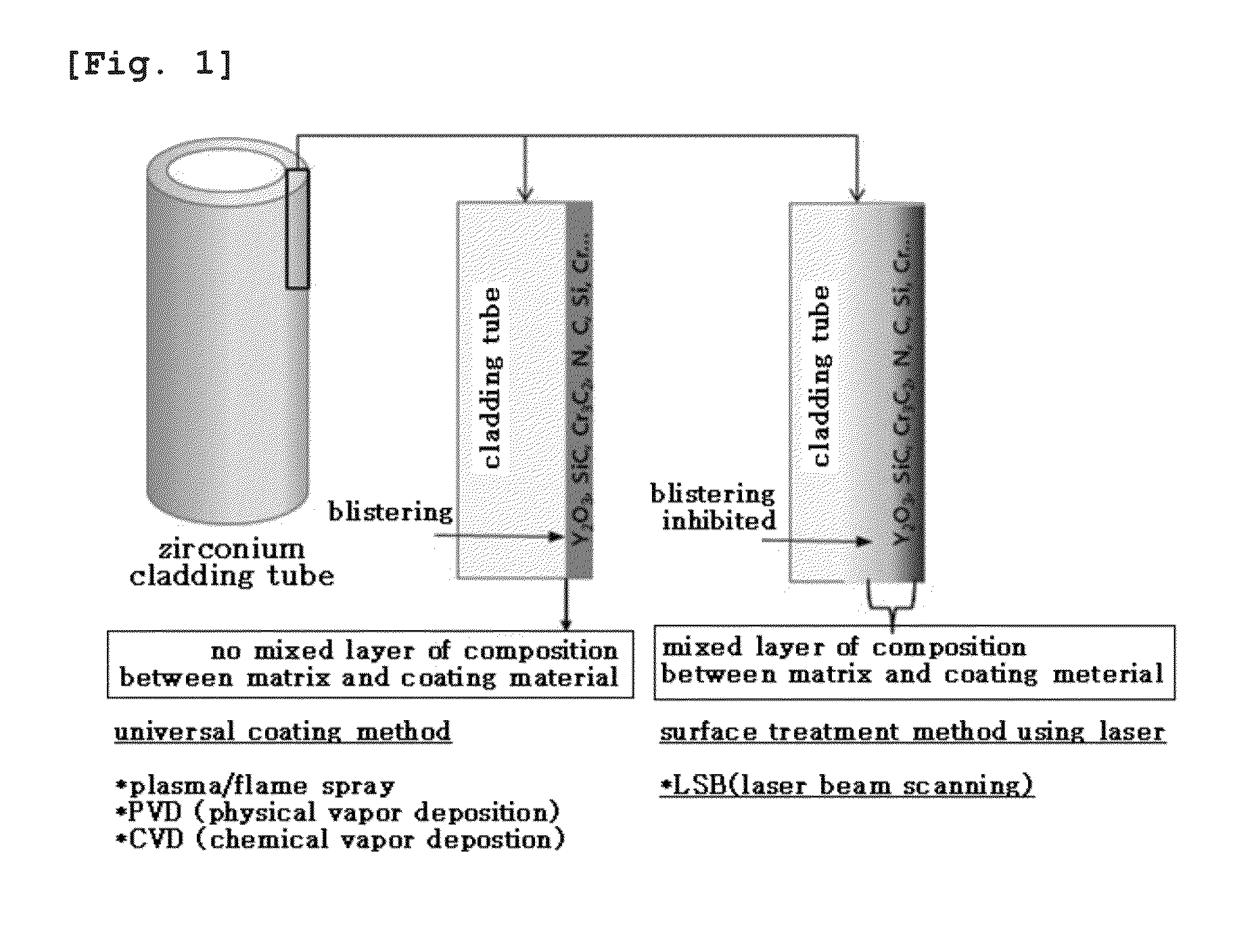

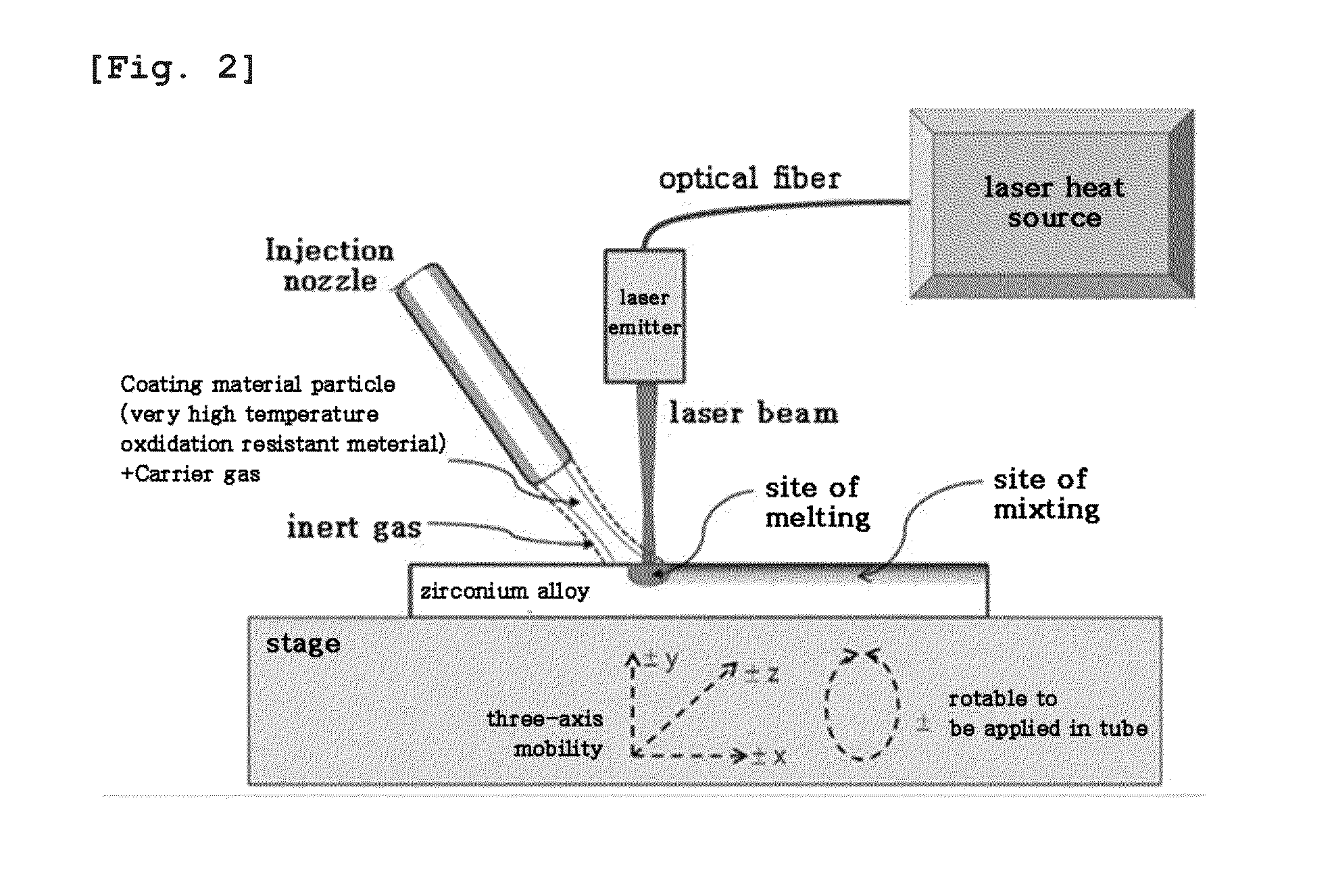

Zirconium alloy with coating layer containing mixed layer formed on surface, and preparation method thereof

InactiveUS20130344348A1High-temperature anticorrosiveAvoid physical damageAdditive manufacturingPretreated surfacesOxidation resistantZirconium alloy

A zirconium alloy with a coating layer formed on a surface comprising a mixed layer, the mixed layer comprises one or more very high temperature oxidation resistant material and zirconium alloy parent material selected from the group consisting of Y2O3, SiO2, ZrO2, Cr2O3, Al2O3, Cr3C2, SiC, ZrC, ZrN, Si and Cr, and in a vertical direction on a boundary between the mixed layer and the zirconium alloy parent material is formed a gradient of compositions between the very high temperature oxidation resistance material and the zirconium alloy parent material.

Owner:KOREA ATOMIC ENERGY RES INST +1

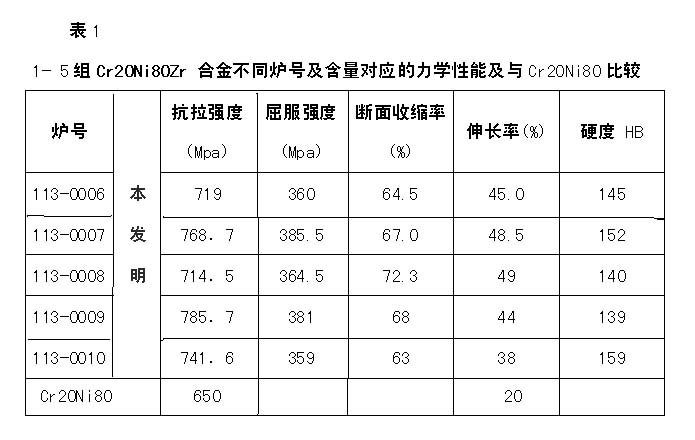

New high-resistance electrical heating alloy material and preparation method thereof

ActiveCN102191409AReasonable component designSimple manufacturing processHigh resistivityHigh resistance

The invention discloses a new high-resistance electrical heating alloy material and a preparation method thereof. The material comprises the following components by weight percent: 0.01-0.06% of C, 1.0-1.5% of Si, 0.1-0.6% of Mn, less than or equal to 0.02% of P, less than or equal to 0.015% of S, 20-23% of Cr, 74.0-78.0% of Ni, 0.1-0.25% of Al, 0.2-1.0% of Fe, 0.01-0.2% of Ti, 0.2-0.8% of Zr and the balance of inevitable impurities. The preparation method comprises the steps of smelting, forging, wiring, annealing, rinsing, drawing and the like. Compared with Cr20Ni80, the prepared new high-resistance electrical heating alloy material has better oxidation resistance and is an electrical heating alloy material with low thermal expansion coefficient, good high temperature strength, long service life and high resistivity.

Owner:JIANGSU XINHUA ALLOY ELECTRIC

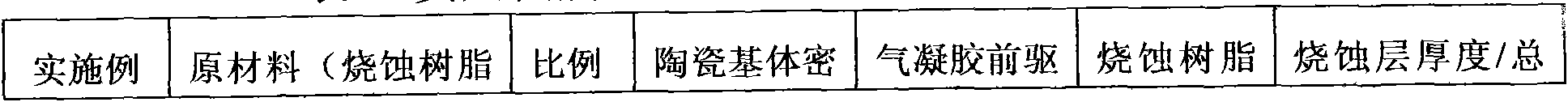

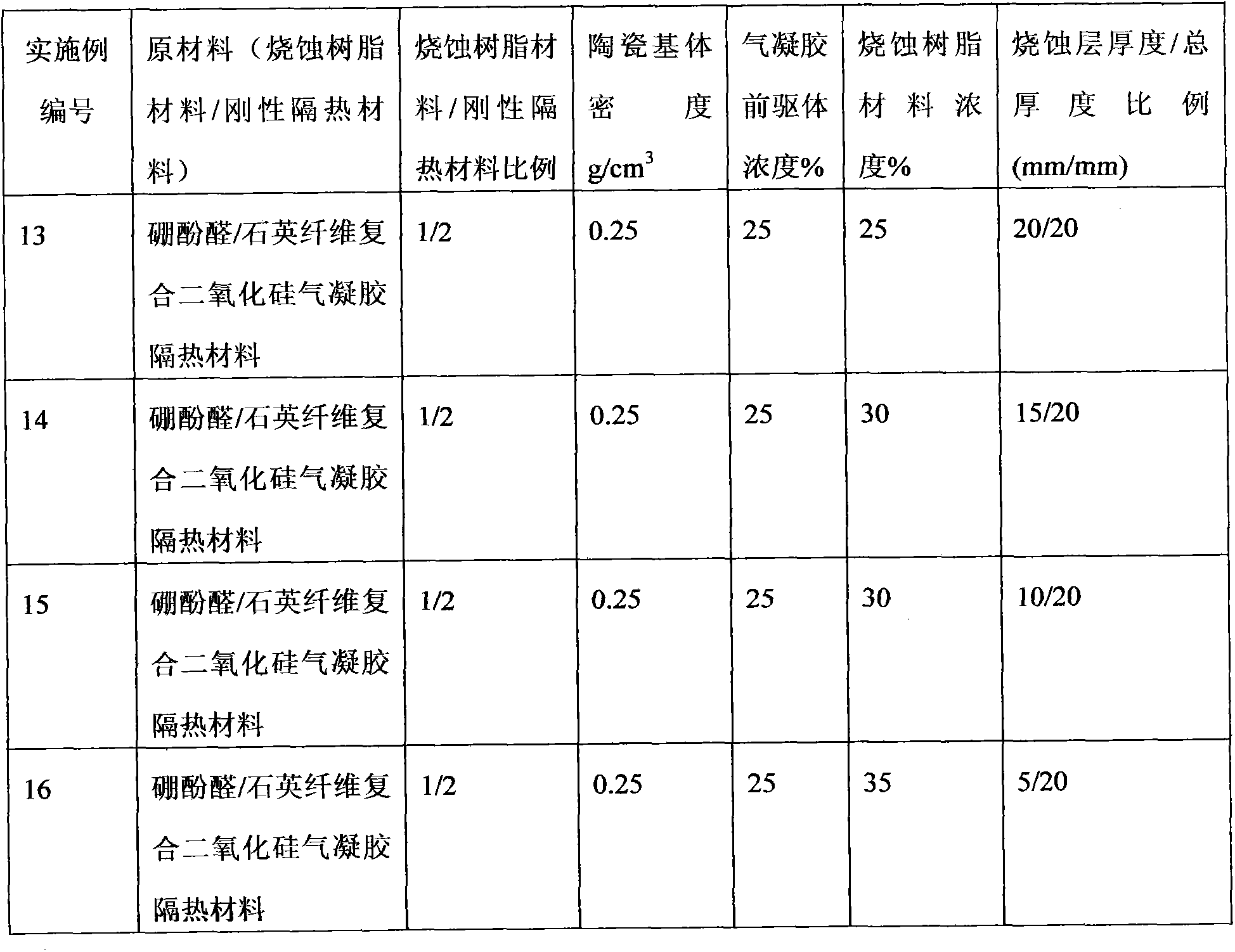

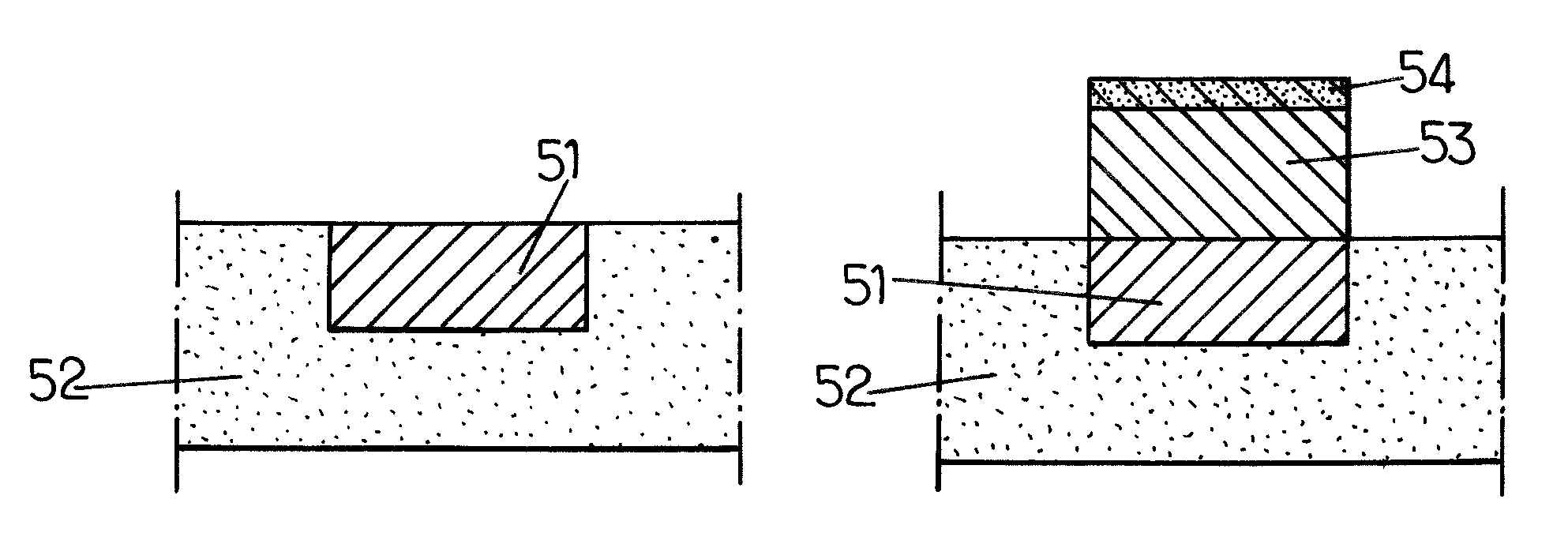

Micro-ablation insulating material and preparation method thereof

InactiveCN103449825AGood ablative thermal insulation capabilityDimensional abilityThermal insulationPolyresin

The invention discloses a micro-ablation insulating material. The micro-ablation insulating material comprises an ablation resin material and a rigid thermal-insulation material, wherein the rigid thermal-insulation material comprises a ceramic base body and an aerogel material. The invention also provides a preparation method of the micro-ablation insulating material. The method comprises the steps of compounding the aerogel material and the ceramic base body to manufacture the rigid thermal-insulation material, compounding the rigid thermal-insulation material and the ablation resin material, and gelling, drying and curing the ablation resin material. The proportions of the rigid thermal-insulation material and the ablation resin material, and the composition and the structure of the composition of the rigid thermal-insulation material and the ablation resin material in the thickness direction can be adjusted according to different using requirements. The micro-ablation insulating material has high designability, excellent superhigh-temperature heat-insulating property, strong variable-dimension ability and good processing performance, can be manufactured into various profiles and sizes, and has good application prospect in the fields of external protection of reentry type aircrafts and thermal protection of superhigh-temperature engines.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

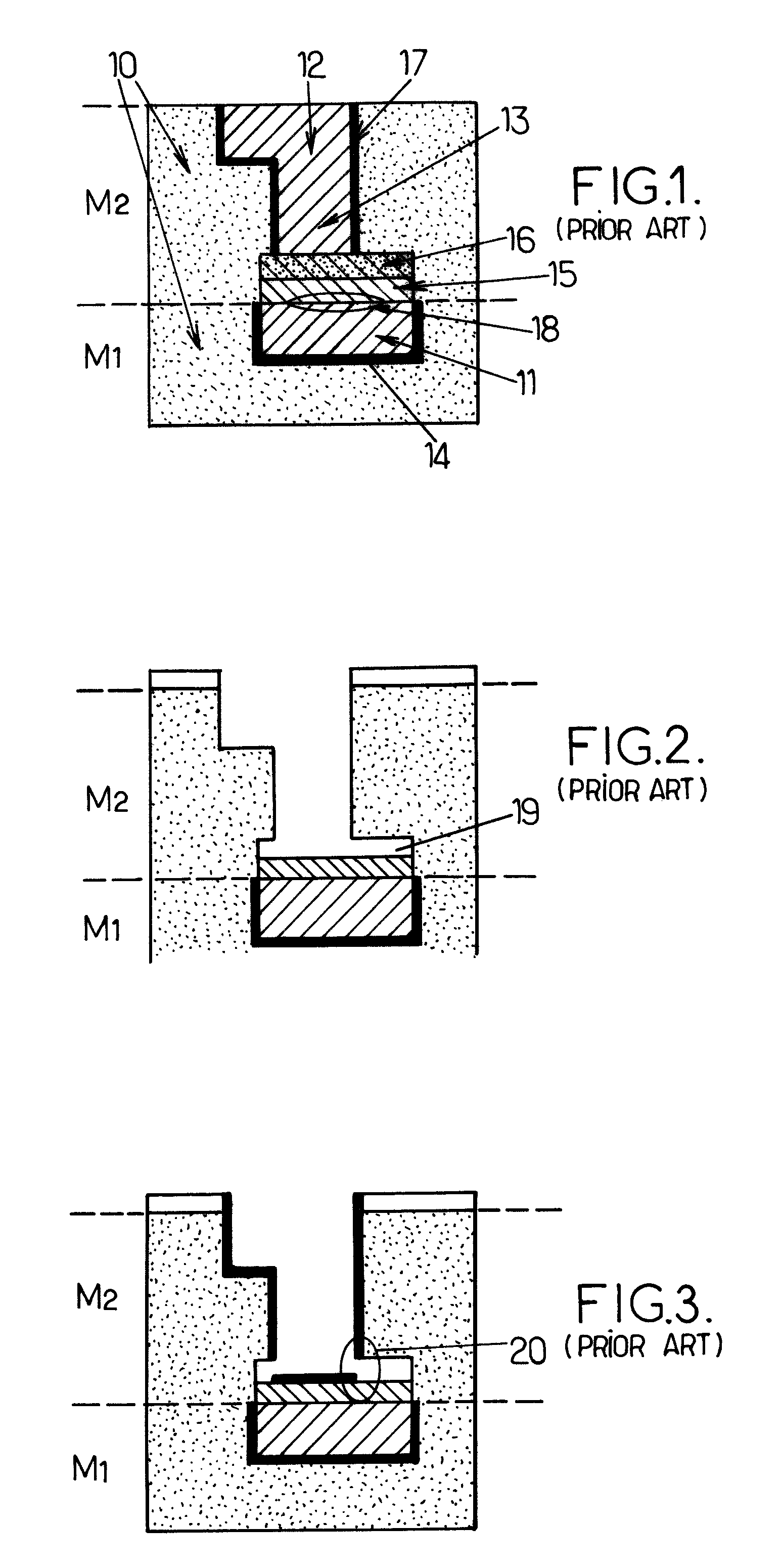

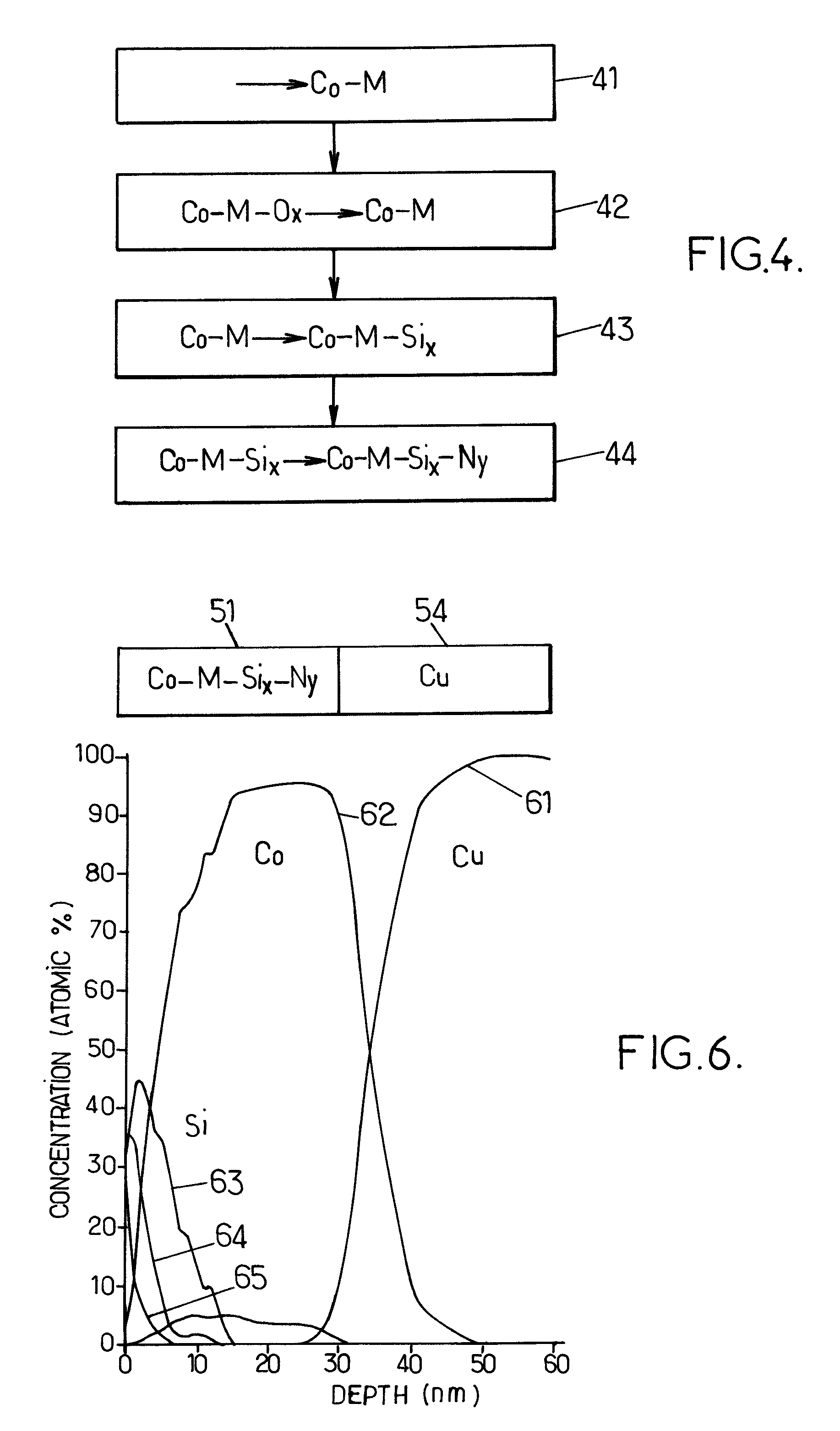

Implementation of a metal barrier in an integrated electronic circuit

ActiveUS7601636B2Improve antioxidant capacityInhibited DiffusionSemiconductor/solid-state device detailsSolid-state devicesCopper atomMetallic materials

Owner:STMICROELECTRONICS SRL

A kind of fine-grained WC-based cemented carbide material and preparation method thereof

A fine-grained WC-based cemented carbide material and a preparation method thereof. The fine-grained WC-based cemented carbide material uses fine-grained WC as a matrix, Mo or Ni as a binder, and TaC, VC, One or more types of TiC are grain inhibitors, Cr3C2 is used as a hardener, and C, SiC or rare earth metals are used as a toughener. The size of fine-grained WC is 0.8-1μm. WC of this size can It brings about an increase in hardness and flexural strength. This cemented carbide material provides an alternative to Co and has high hardness, good toughness, and excellent comprehensive wear resistance.

Owner:四川欧曼机械有限公司

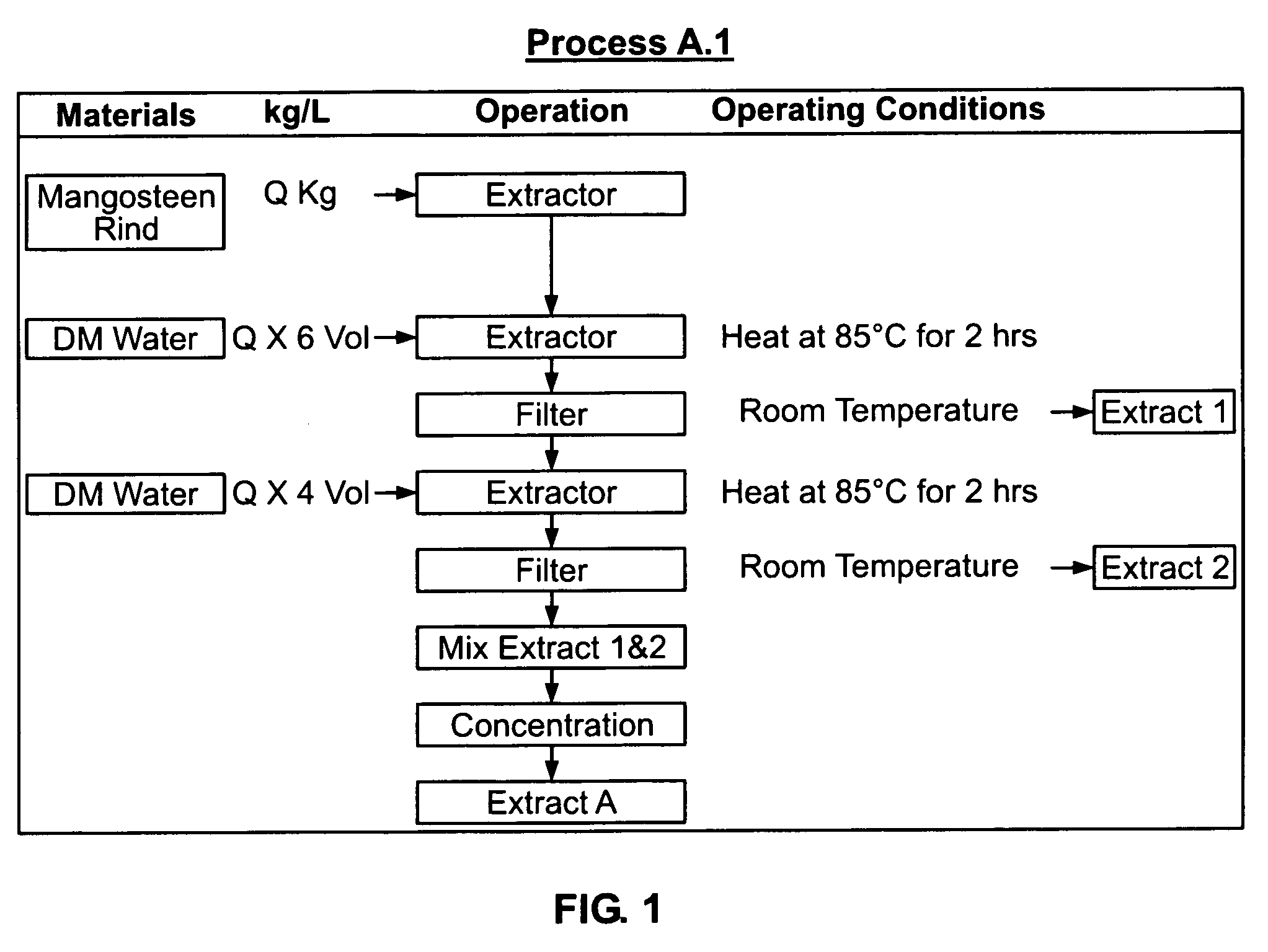

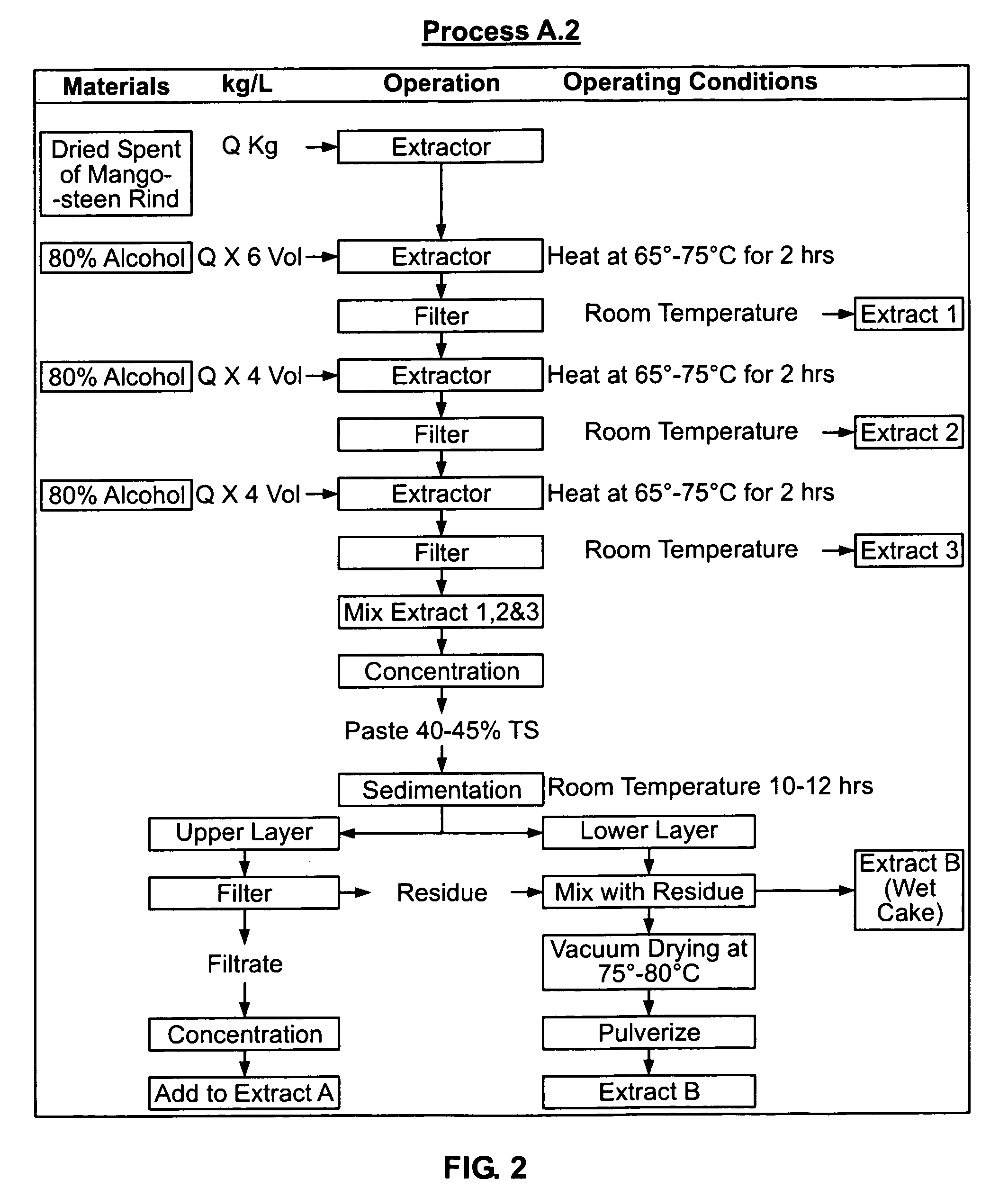

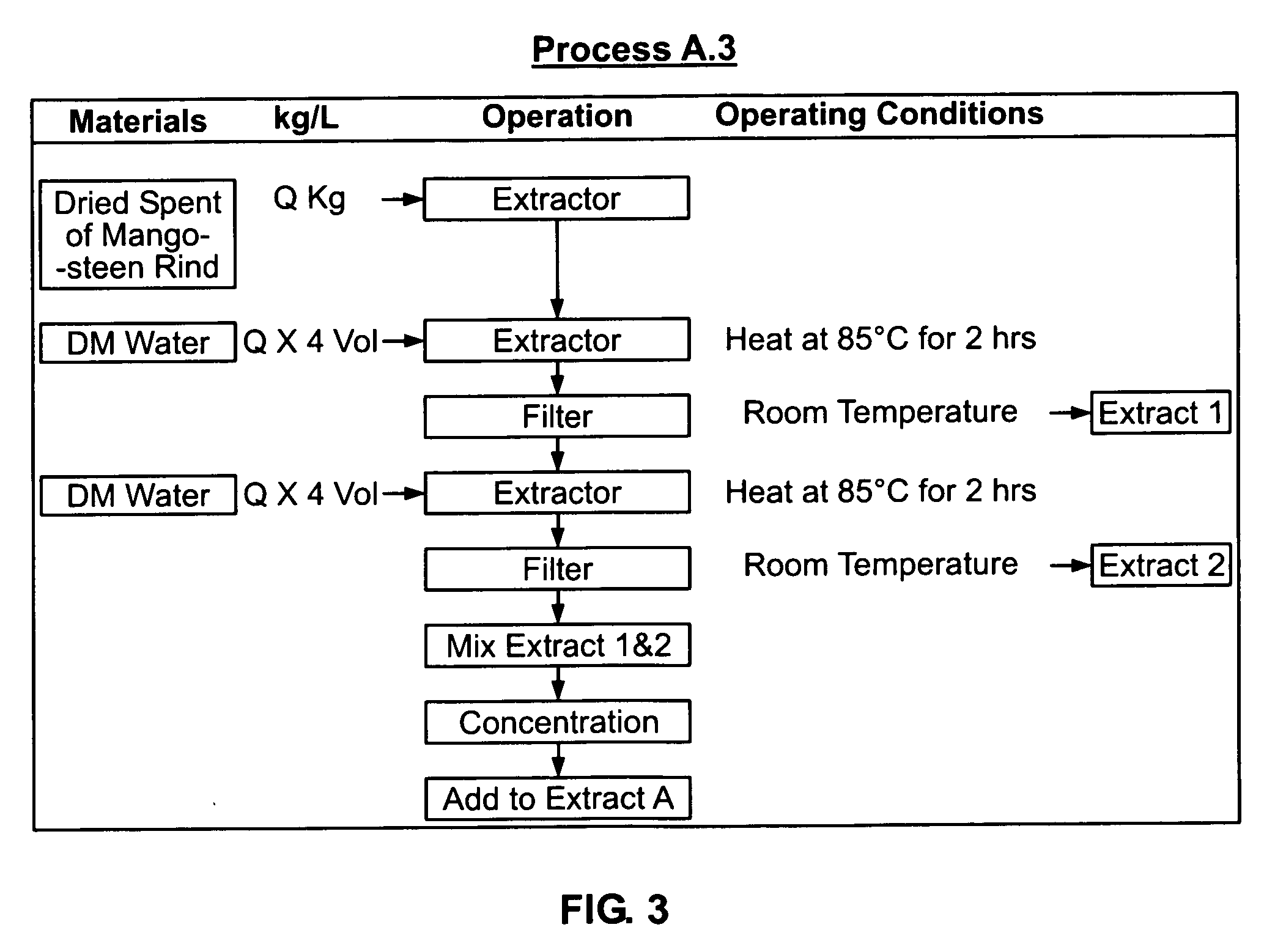

Pharmaceutical and therapeutic compositions derived from Garcinia mangostana L plant

InactiveUS20060292255A1Strong antiseptic and antibacterial and antiviral effectEasy to produceAntibacterial agentsOrganic active ingredientsMedicineXanthone

The present invention relates to pharmaceutical, therapeutic, nutritional, cosmetic, and dermatological compositions derived from the preicarp (rind) of the Garcinia mangostana L plant and the novel extraction processes used to produce those compositions. Specifically, the present invention relates, in part, to an approximately 0.01% to about 80% mixture of a xanthone-rich mangosteen pericarp (rind) extract in novel combinations for pharmaceutical, cosmetic, therapeutic or dermatological compositions that yield surprising health benefits. Additionally, the present invention relates, in part, to novel extraction processes that result in the production of the novel compositions of the invention.

Owner:RENAISSSANCE HERBS

Hollow foam material as well as preparation method and application thereof

ActiveCN108069725AConducive to quality transferEasy to passCeramicwarePolymer resinNetwork structure

The invention relates to the field of porous materials, in particular to a hollow foam material as well as a preparation method and an application thereof. The hollow foam material is formed by three-dimensional connective support framework networks from the macroscopic angle, the support frameworks are microchannels with hollow structures in three-dimensional connection, the walls of the microchannels are compact or contain nano-scale pores and / or micro-scale pores. The hollow foam material with three-dimensional connective networks is prepared from a polymer resin foam material with three-dimensional connective networks with the structure design and the preparation method. The hollow foam material has three types of pores with adjustable sizes: macroscopic three-dimensional connective open meshes, three-dimensional connective hollow microchannels and nano-scale pores and / or micro-scale pores in microchannel wall bodies. The innovative structure characteristic of the three-dimensionalconnective hollow microchannels of the hollow foam material lays a foundation for application of the hollow foam material.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

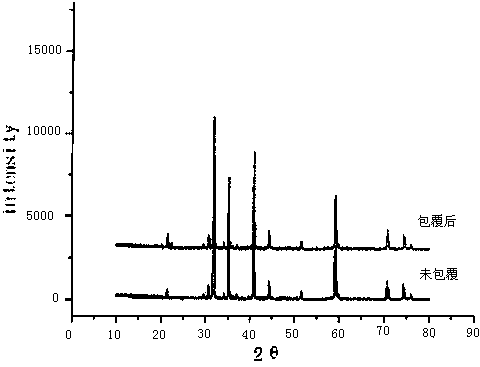

Preparation method of alumina composite nickel-cobalt lithium manganate ternary material

ActiveCN103618064AImproved magnification performanceImprove high temperature performanceCell electrodesSecondary cellsElectrochemical responseAlumina composite

The invention provides a preparation method of an alumina composite nickel-cobalt lithium manganate ternary material. The preparation method comprises the following steps: (1), preparing liquor A; (2), preparing liquor B; (3), installing and configuring a reaction flask; (4), adding the liquor A and the liquor B into the reaction flask to participate in hybrid reaction; (5), preparing liquor C, and adding into the flask for reaction; (6), obtaining a precursor by suction-filtering, washing and drying; and (7), mixing and roasting the precursor with a lithium source to prepare the alumina composite nickel-cobalt lithium manganate ternary material. The preparation method disclosed by the invention has the beneficial effects that firstly, liquid-phase coating is adopted, production preparation period is short, efficiency is high, and coating and dispersing are uniform; secondly, the coating layer alumina on the surface of the ternary material is a film with an amorphous structure, so that charging and discharging voltage difference is reduced, multiplying power performance and high-performance performance of the material are improved; and thirdly, characteristics of a solid-liquid phase interface among an anode material, electrolyte and a diaphragm are improved by alumina film-coating, so that velocity and efficiency of electrochemical reaction are improved.

Owner:博尔特新材料(银川)有限公司

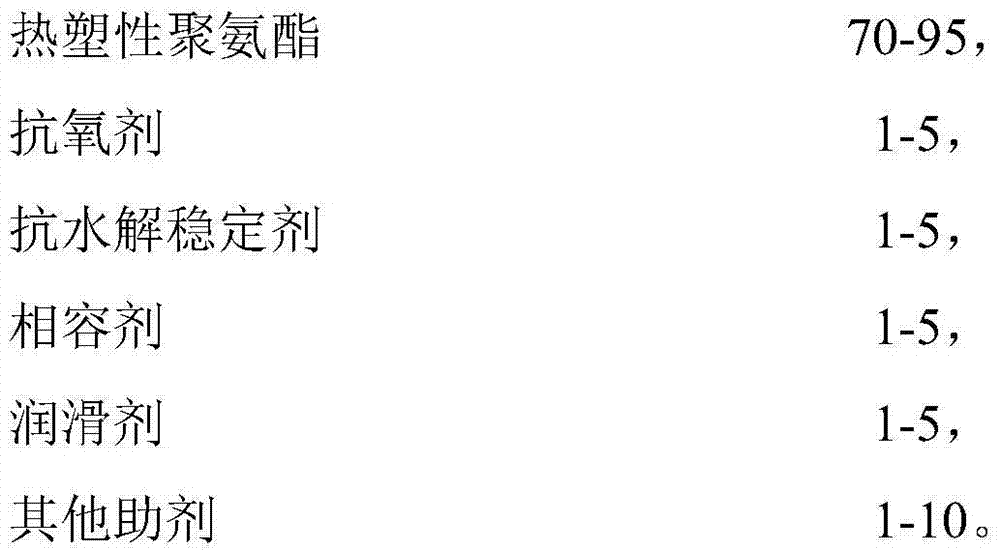

Thermoplastic polyurethane modified composite material for FDM (frequency division multiplexing) 3D printing and preparation method thereof

The invention relates to a thermoplastic polyurethane modified composite material for FDM (frequency division multiplexing) 3D printing and a preparation method thereof. The composite material is prepared from the following components in parts by weight: 70-95 parts of thermoplastic polyurethane, 1-5 parts of antioxidant, 1-5 parts of hydrolysis-resistant stabilizer, 1-5 parts of compatilizer, 1-5 parts of lubricant and 1-10 parts of other assistant. Compared with the prior art, the antioxidant, hydrolysis-resistant stabilizer, lubricant and other assistants are added, so that the modified composite material has the advantages of favorable mechanical properties, high elasticity, favorable wear resistance, higher heat stability, hydrolysis resistance, higher oxidation resistance and higher processability. When being used for FDM 3D printing, the thermoplastic polyurethane modified composite material has the characteristics of smooth printing process, no odor, smooth printing product surface, beautiful appearance, stable size, low tendency to shrinkage, favorable mechanical properties, high flexibility, high heat stability, high hydrolysis resistance, high oxidation resistance and high processability.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

Nanometer zirconium oxide thermal barrier coating and preparation method thereof

ActiveCN102094164AWon't spreadHigh strengthMolten spray coatingEfficient propulsion technologiesThermal insulationThermal barrier coating

The invention relates to a nanometer zirconium oxide thermal barrier coating and a preparation method thereof. The nanometer zirconium oxide thermal barrier coating is characterized by comprising an adhesive layer and a ceramic layer, wherein NiCrAlY is prepared on the adhesive layer by adopting supersonic flame spraying and comprises the following components in percentage by weight: 20-30% of Cr, 4.0-10% of Al, 0.3-0.7% of Y, and the balance of Ni; a ZrO2 / Y2O3 layer is prepared as the ceramic layer by adopting plasma spraying, the ceramic layer is a nanometer zirconium oxide layer comprising5%-8% of partially stable yttrium oxide, and zirconium oxide powder is at a nanometer grade. The oxidation-resisting thermal barrier coating is prepared on a metal surface by combining the supersonic flame spraying with the plasma spraying, has better combining capacity with a base body and both thermal shock resistance and thermal insulation superior to those of a common ZrO2 / Y2O3 thermal barrier coating.

Owner:沈阳天贺新材料开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com