Patents

Literature

373 results about "Electroplated nickel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electromigration-Resistant Flip-Chip Solder Joints

InactiveUS20080251927A1Enhance formation of voidLow reliabilitySemiconductor/solid-state device detailsSolid-state devicesElectrical resistance and conductanceCopper interconnect

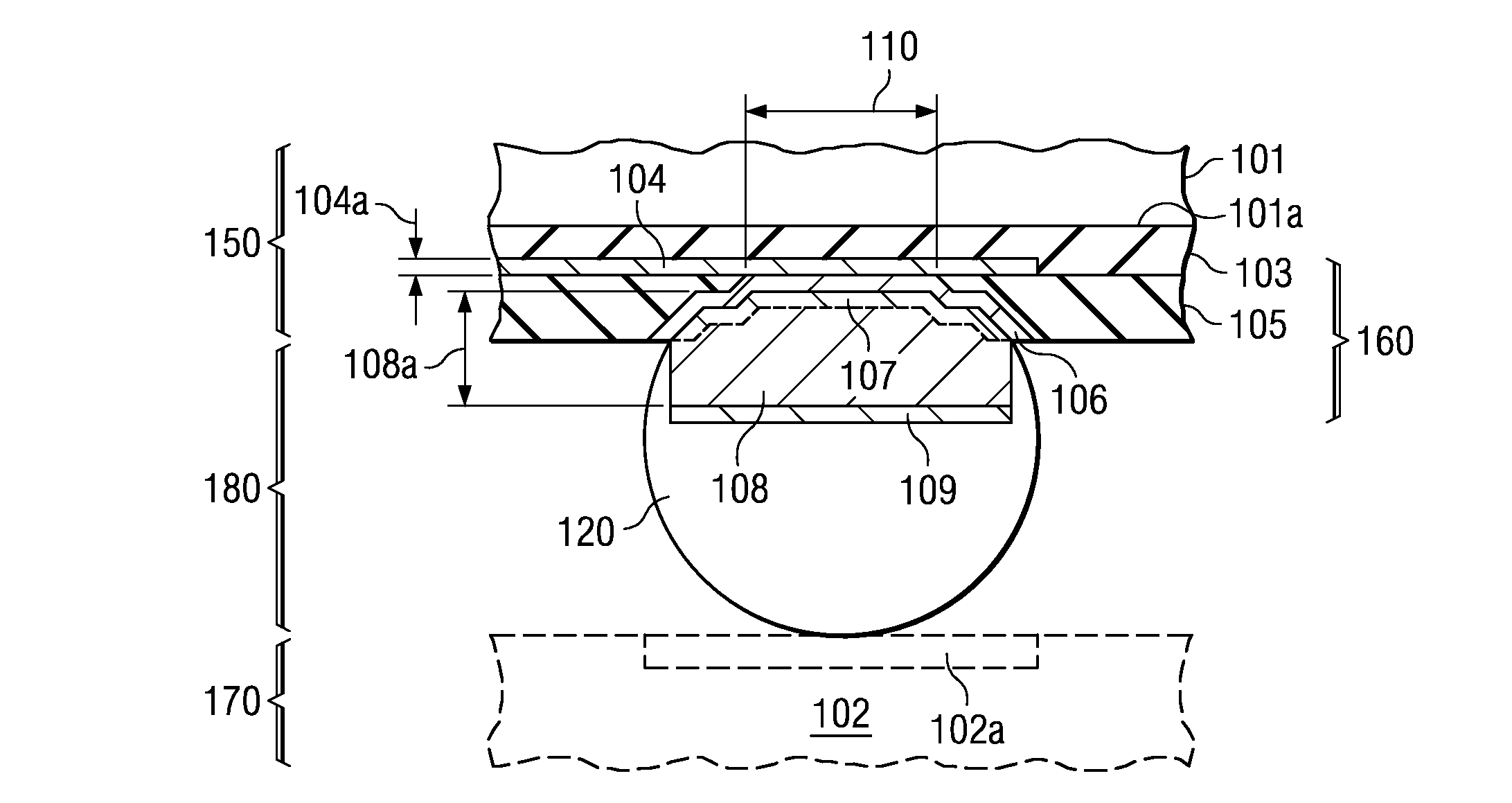

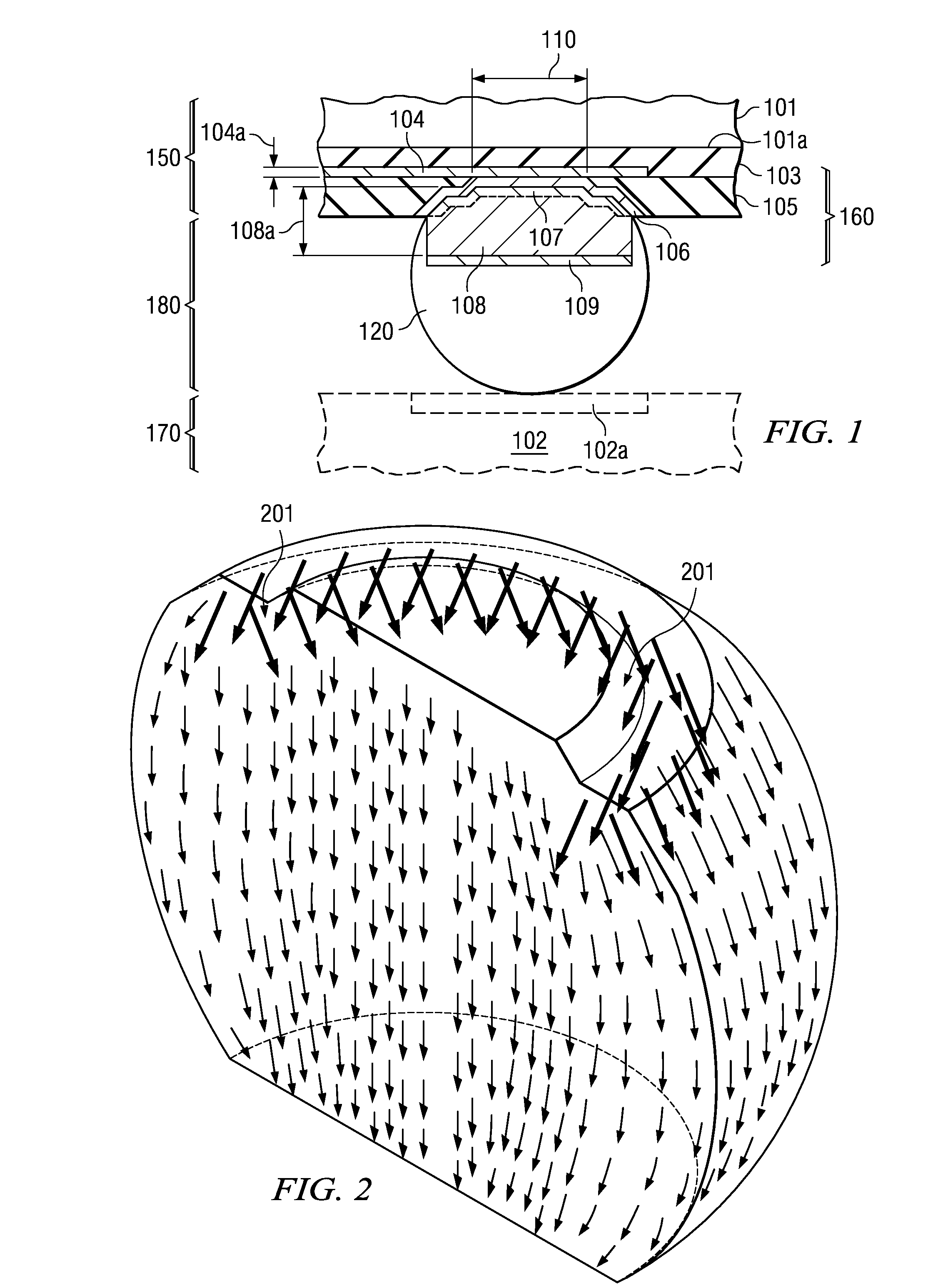

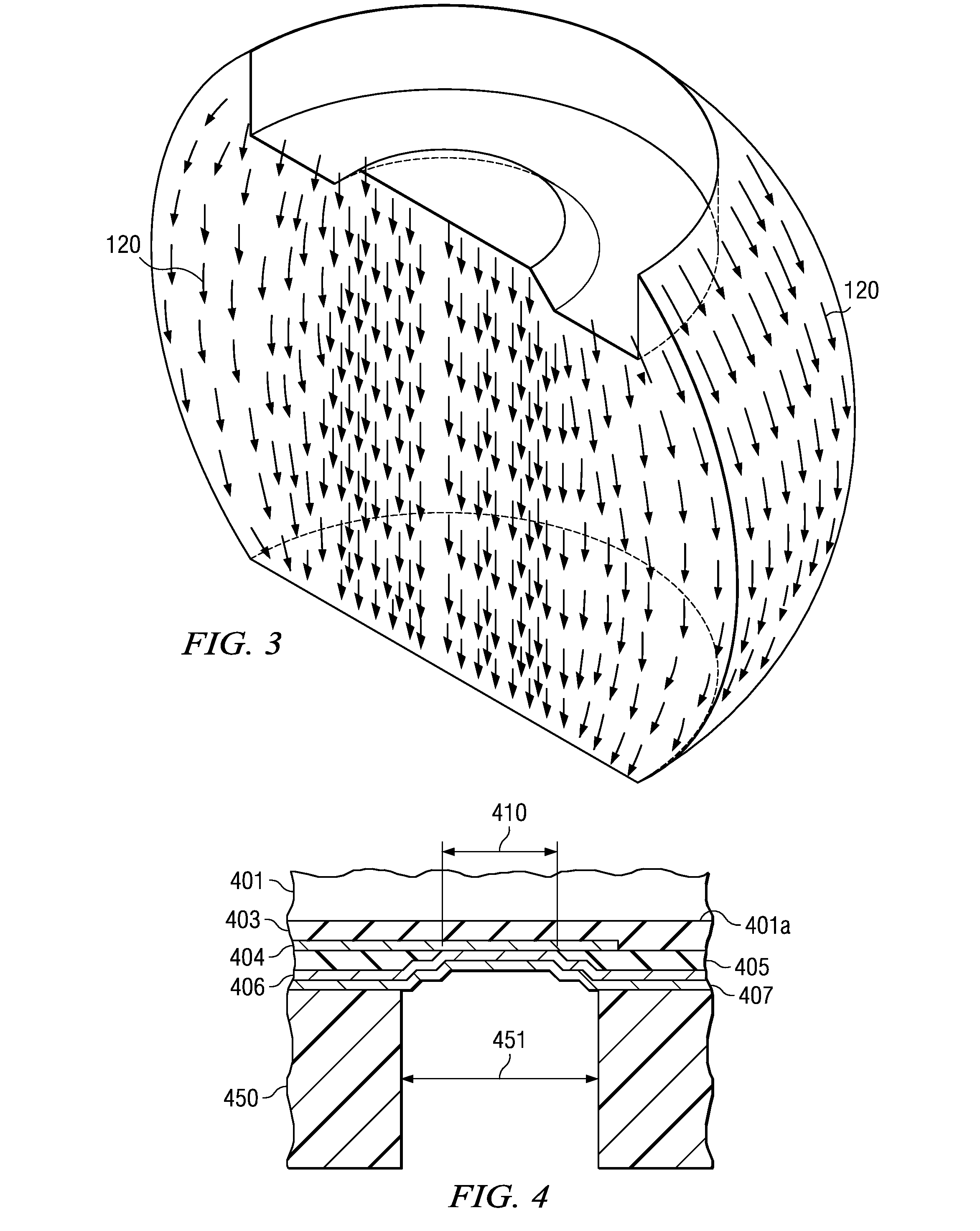

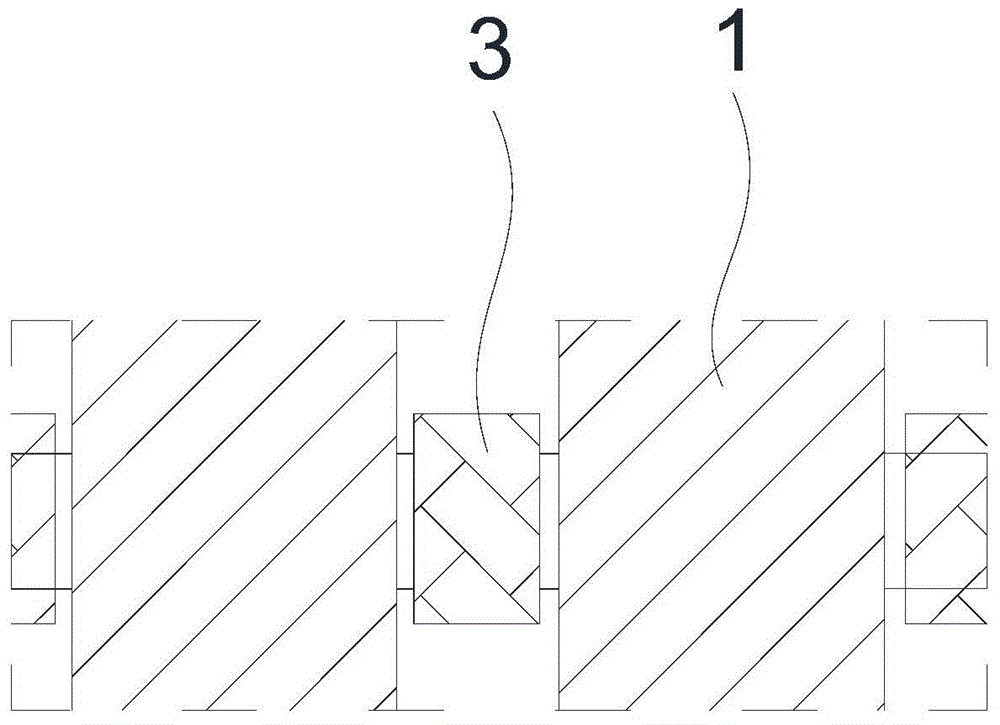

A semiconductor device contact structure practically eliminating the copper diffusion into the solder as well as the current crowding at the contact with the subsequent electromigration in the solder. A column-like electroplated copper stud (108) is on each contact pad. The stud is sized to provide low, uniform electrical resistance in order to spread the current from the contact to an approximately uniform, low density. Preferably, the stud height (108a) is at least ten times the thickness of the copper interconnect layer (104). Stud (108) is capped by an electroplated nickel layer (109) thick enough (preferably about 2 μm) to suppress copper diffusion from stud (108) into solder body (120), thus practically inhibiting intermetallic compound formation and Kirkendall voiding.

Owner:TEXAS INSTR INC

Mickel coated steel strap for deep drawing and preparation method

This invention provides a method for processing nickel-plated deep shocked steel band. The processing procedures are: (1). low carbon band is proceeded continuous electro-deposition of nickel; (2) under the protective atmosphere (H2 75%, N2 25%), proceeding continuous annealing, then continuous laser thermal shock treatment; (3). cold-rolling. This invention also provides the nickel-plated, deep-shocked steel band produced by above-said method. This inventive steel band has advantages of: tensile strength=270-420 MPa, the ductility ratio being not less than 30%, hardness=120-200, thickness of nickel=2-3 micrometer, porosity ratio being less than 4 holes / sq cm, extension ratio being not less than 8%, corrosion property reaching grade 8. It is can be used for the shell of cells with high performance.

Owner:XIANGTAN UNIV

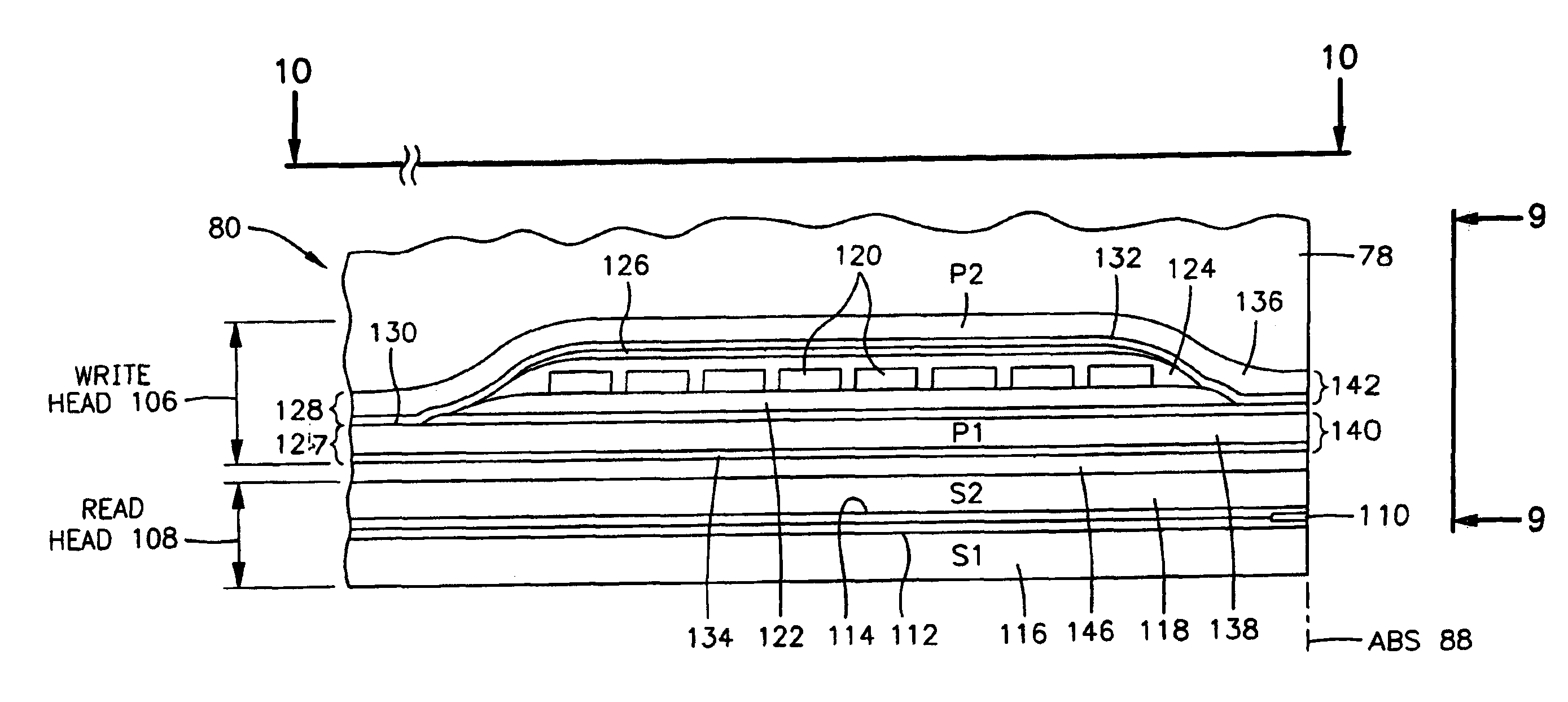

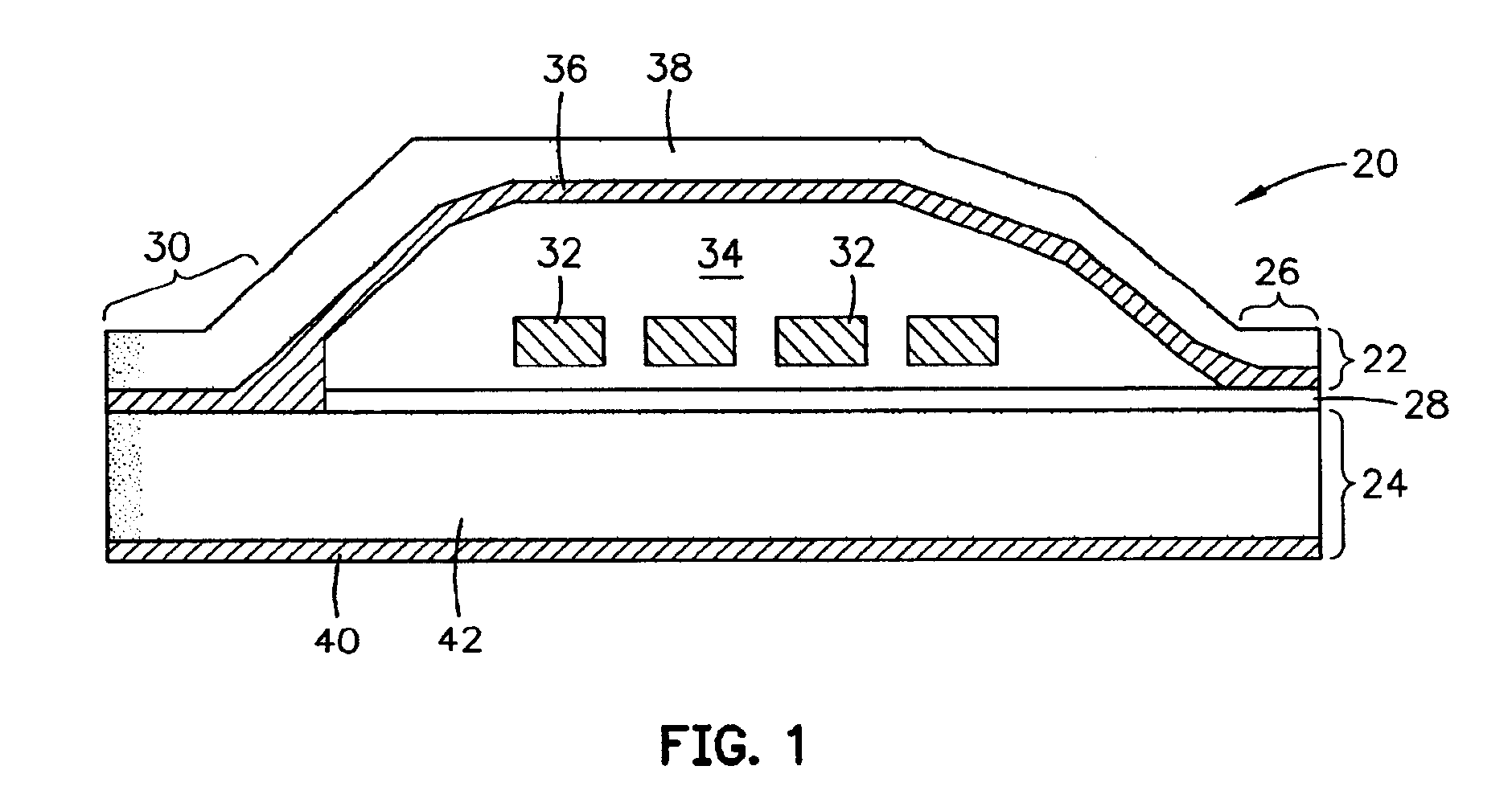

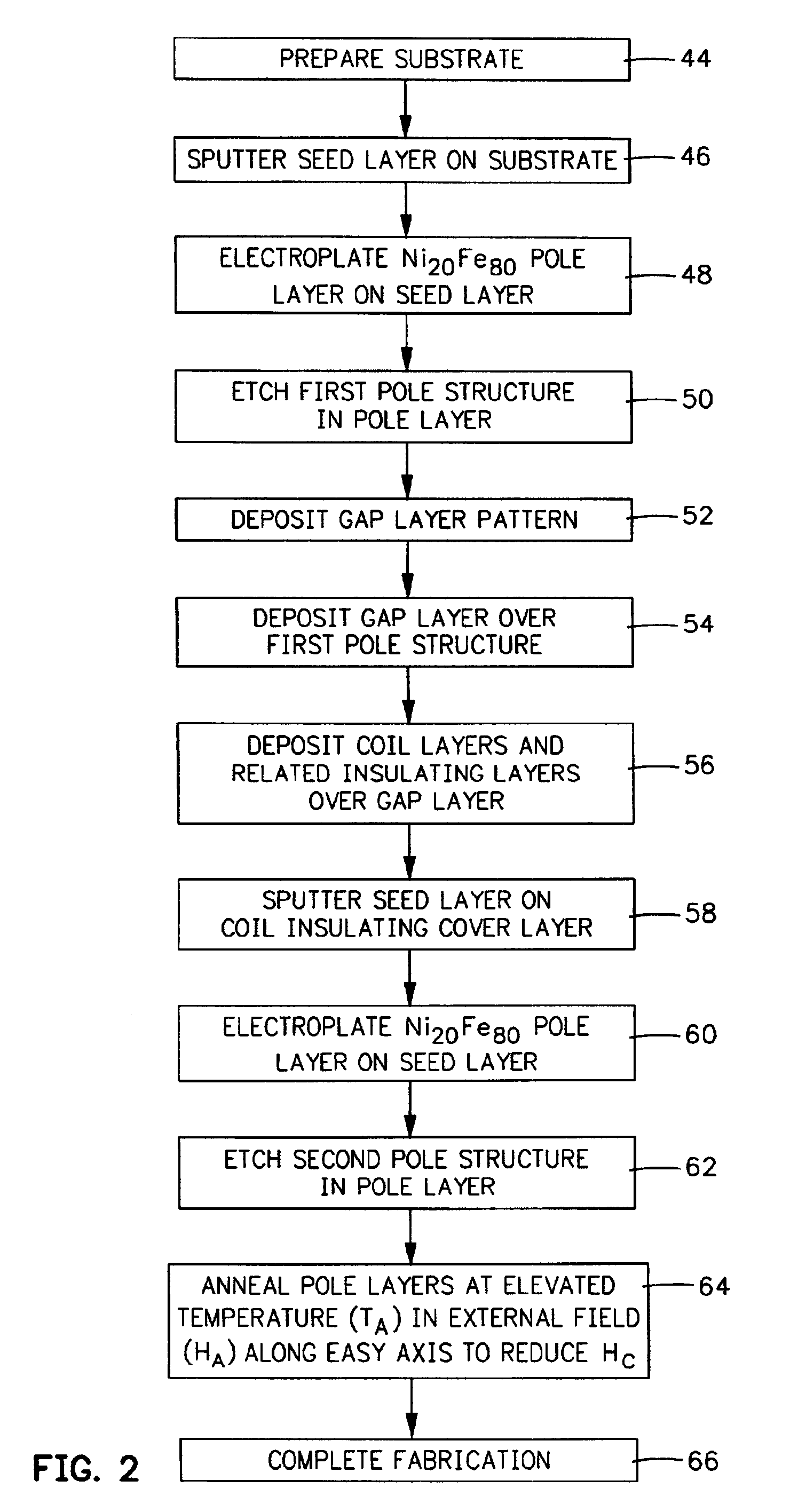

High-saturation thin-film write head for high-coercivity magnetic data storage media

InactiveUS6876507B2High level of magnetic fluxImproving data storage densityConstruction of head windingsManufacture head surfaceMagnetic anisotropyAlloy

A thin-film write head employing pole pieces formed of an electroplated body-centered cubic (BCC) nickel-iron alloy with a saturation flux density (BS) of 1.9 to 2.3 T (19 to 23 kG) and an acceptable coercivity (HC) of about 80 to about 160 A / m (1-2 Oe). The iron content of the electroplated nickel-iron alloy is from 64% to 81% by weight. The two-layer pole fabrication process holds magnetic anisotropy and coercivity to useable values while improving saturation flux density and optimizing magnetostriction. This is accomplished by first electroplating a BCC nickel-iron layer onto an underlying seed layer and then annealing the two layers to reduce coercivity to less than about 160 amps / meter and raise magnetization to acceptable levels.

Owner:IBM CORP

Method of manufacturing an aluminum product

InactiveUS6383661B2High densityIncrease line speedLiquid surface applicatorsThin material handlingAlloyPre treatment

The invention relates to a method of manufacturing an Al or Al alloy workpiece, including the steps of (a) providing an Al or Al alloy workpiece, (b) pre-treating of the outersurface of the Al or Al alloy workpiece, and (c) plating a metal layer including nickel onto the outersurface of the pre-treated Al or Al alloy workpiece. During step (c) the metal layer including nickel is deposited by electroplating both nickel and bismuth using an aqueous bath comprising a nickel-ion concentration in a range of 10 to 100 g / l and a bismuth-ion concentration in the range of 0.01 to 10 g / l. The invention further relates to an aqueous plating bath for use in the method of this invention.

Owner:CORUS ALUMINUM WALZPRODUKTE GMBH (DE)

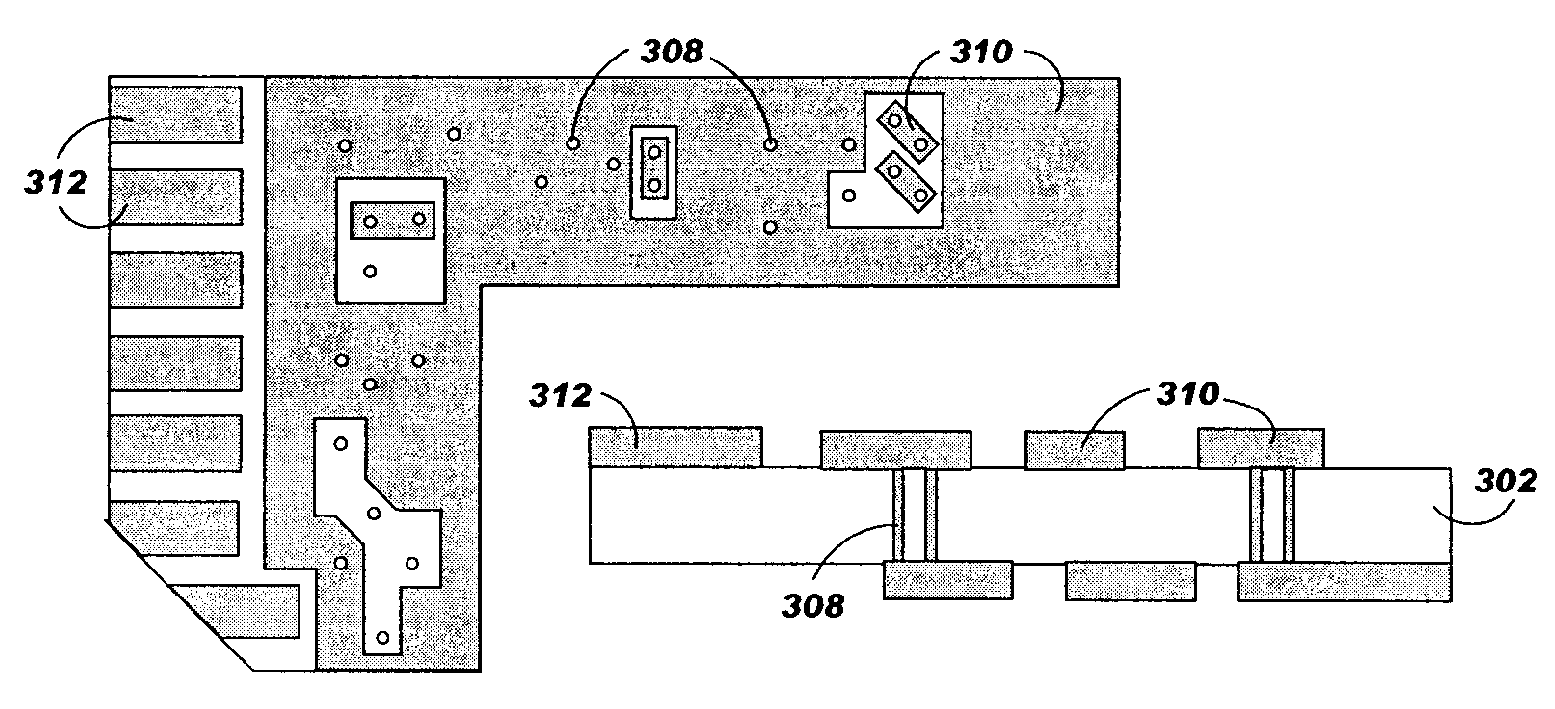

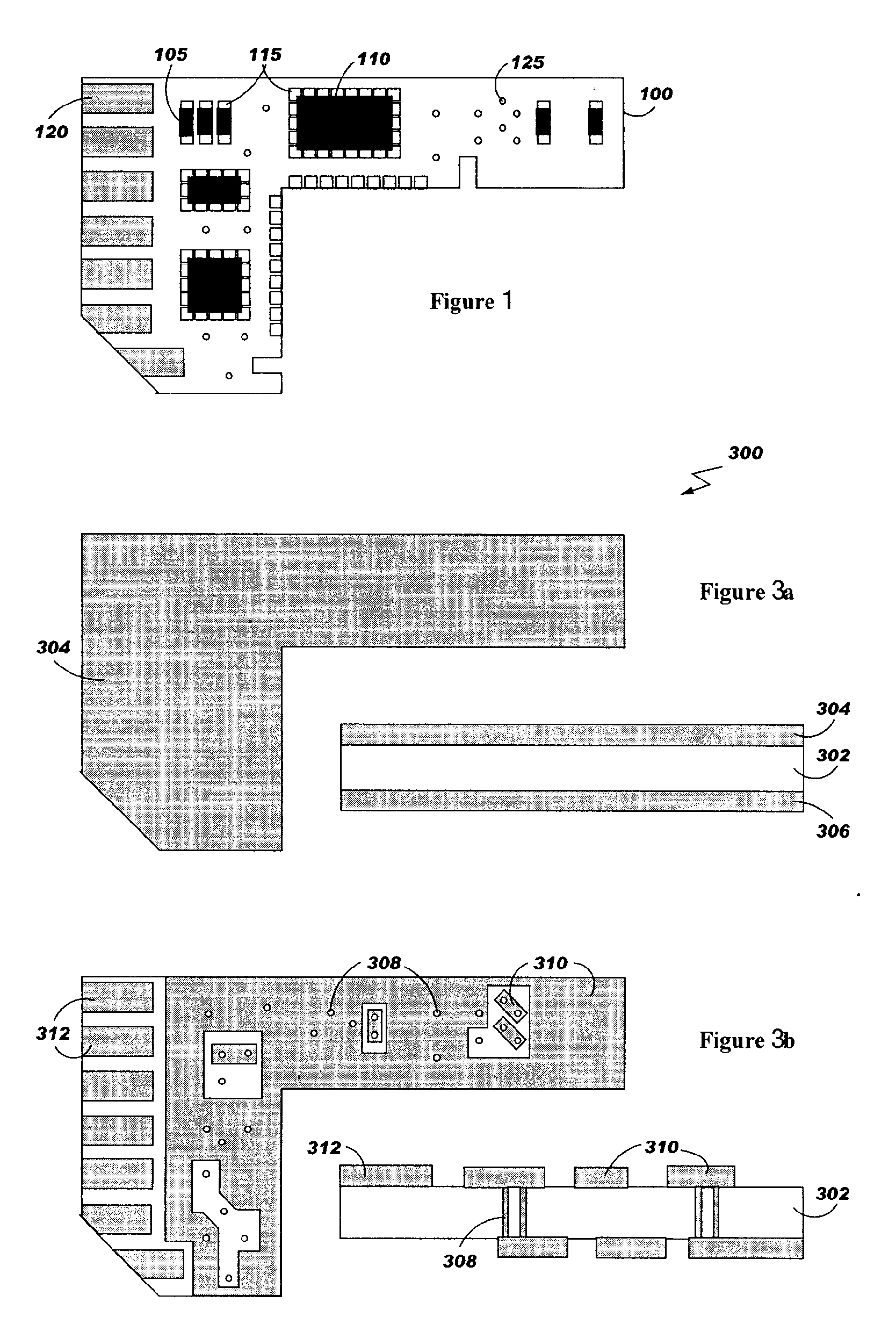

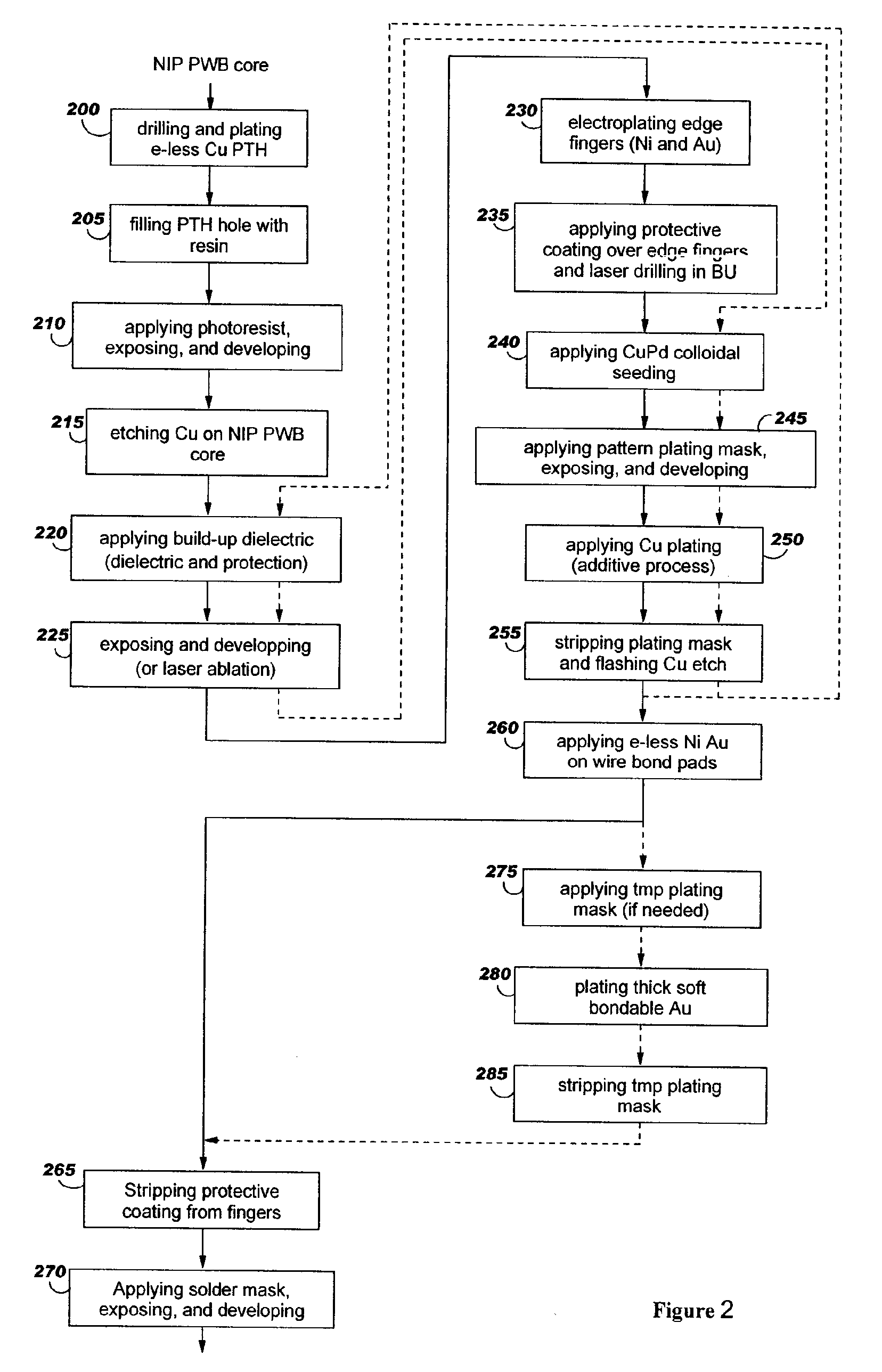

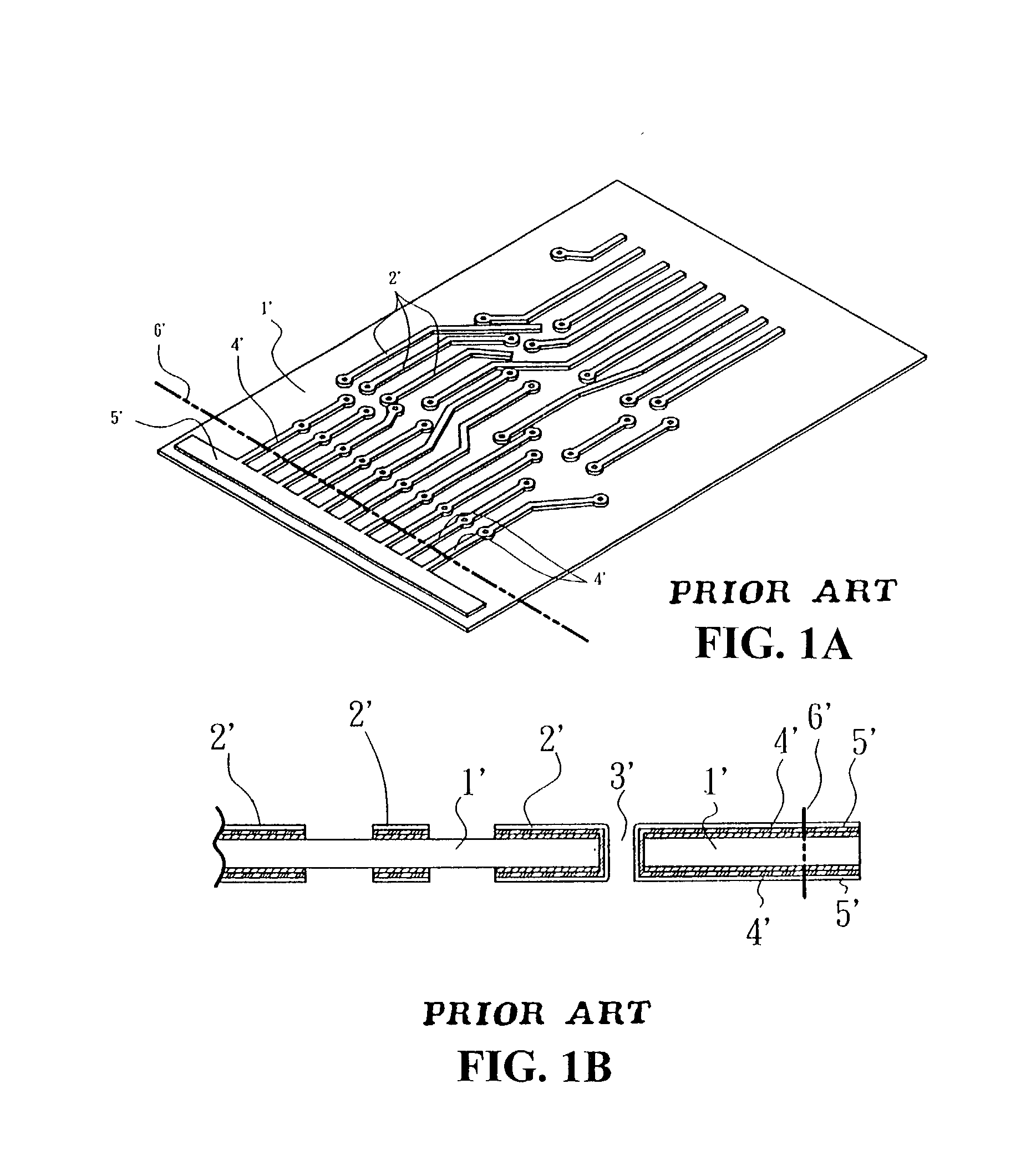

Optimized plating process for multilayer printed circuit boards having edge connectors

InactiveUS20060008970A1Printed circuit aspectsSemiconductor/solid-state device manufacturingLead bondingEngineering

A process for manufacturing printed wire boards with hard plated sliding contact tabs and soft plated wire bond pads. Sliding contact tabs are covered by a protective coating after being hard plated thus allowing the soft plating of wire bond pads without damaging the hard plated sliding contact tabs. In a preferred embodiment, the hard plating includes the step of electroplating nickel on the sliding contact tabs, followed by electroplating an alloy of gold and cobalt, using standard electroplating process. An electro-less soft plating process includes the steps of plating a nickel layer on the wire bond pads and then a gold layer after having “flash-etched” the copper seeding.

Owner:IBM CORP

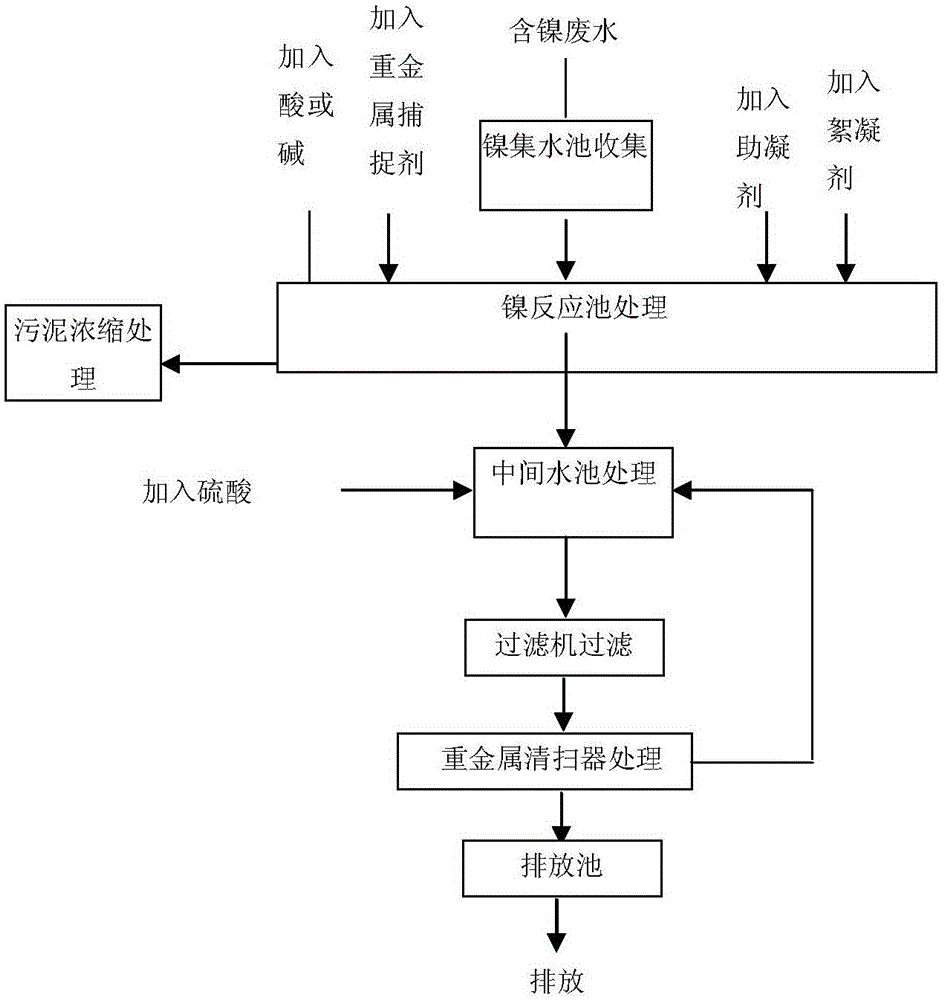

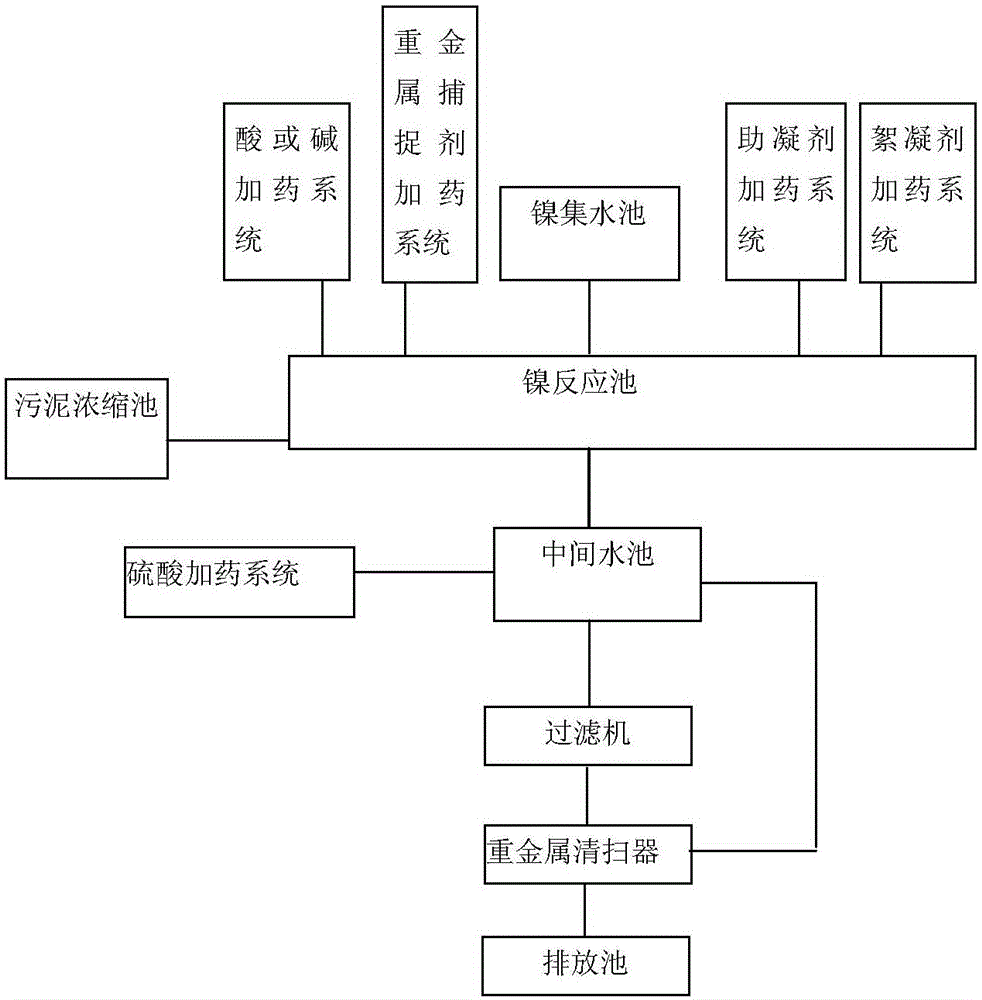

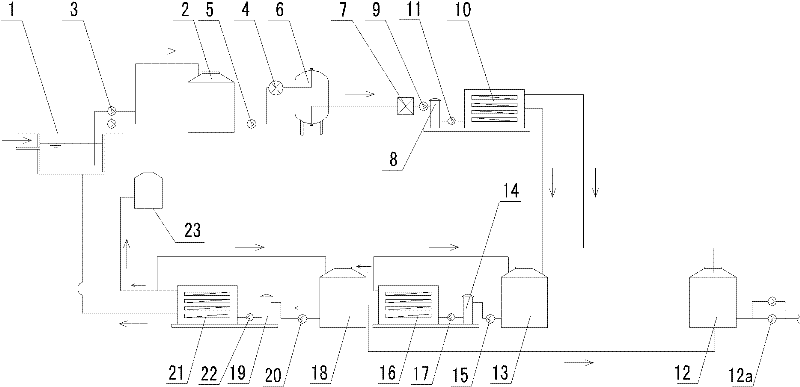

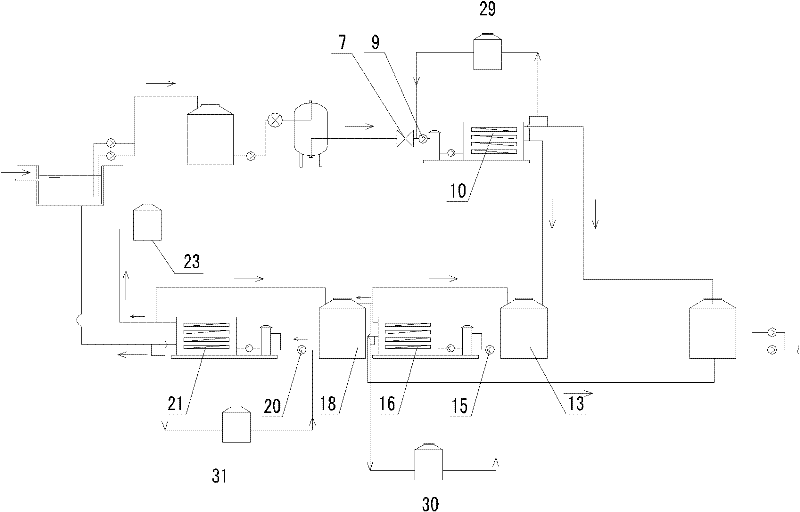

Treatment method and system of nickel-containing wastewater conforming to Water Pollutant Table III Discharge Standard

InactiveCN105084603AMeet industrial production requirementsEasy to operateWater contaminantsMultistage water/sewage treatmentScavengerEmission standard

The invention discloses a treatment method and system of nickel-containing wastewater conforming to Water Pollutant Table III Discharge Standard. The method comprises the following steps: sending nickel-containing wastewater into a wastewater collecting tank, and pumping into a nickel reaction tank by a water pump to perform pretreatment; regulating the pH value, adding a heavy metal capturing agent, thoroughly mixing to react, adding a coagulant aid and a flocculant, sufficiently and uniformly stirring, and standing to precipitate or sending into a solid-liquid separation device; sending into an intermediate water tank, and adding a sulfuric acid solution to regulate the pH value to 7-8; and pumping water in the intermediate water tank into a heavy metal scavenger by a filtering machine, and treating to achieve the Table III Limit Discharge Standard. The method and system solve the problem that the existing nickel-containing wastewater in electroplating industry can not satisfy the Table III Discharge Standard in Water Pollutant Special Limits, so that the electroplating nickel-containing wastewater can stably satisfy the discharge requirements.

Owner:杭州太一科技有限公司

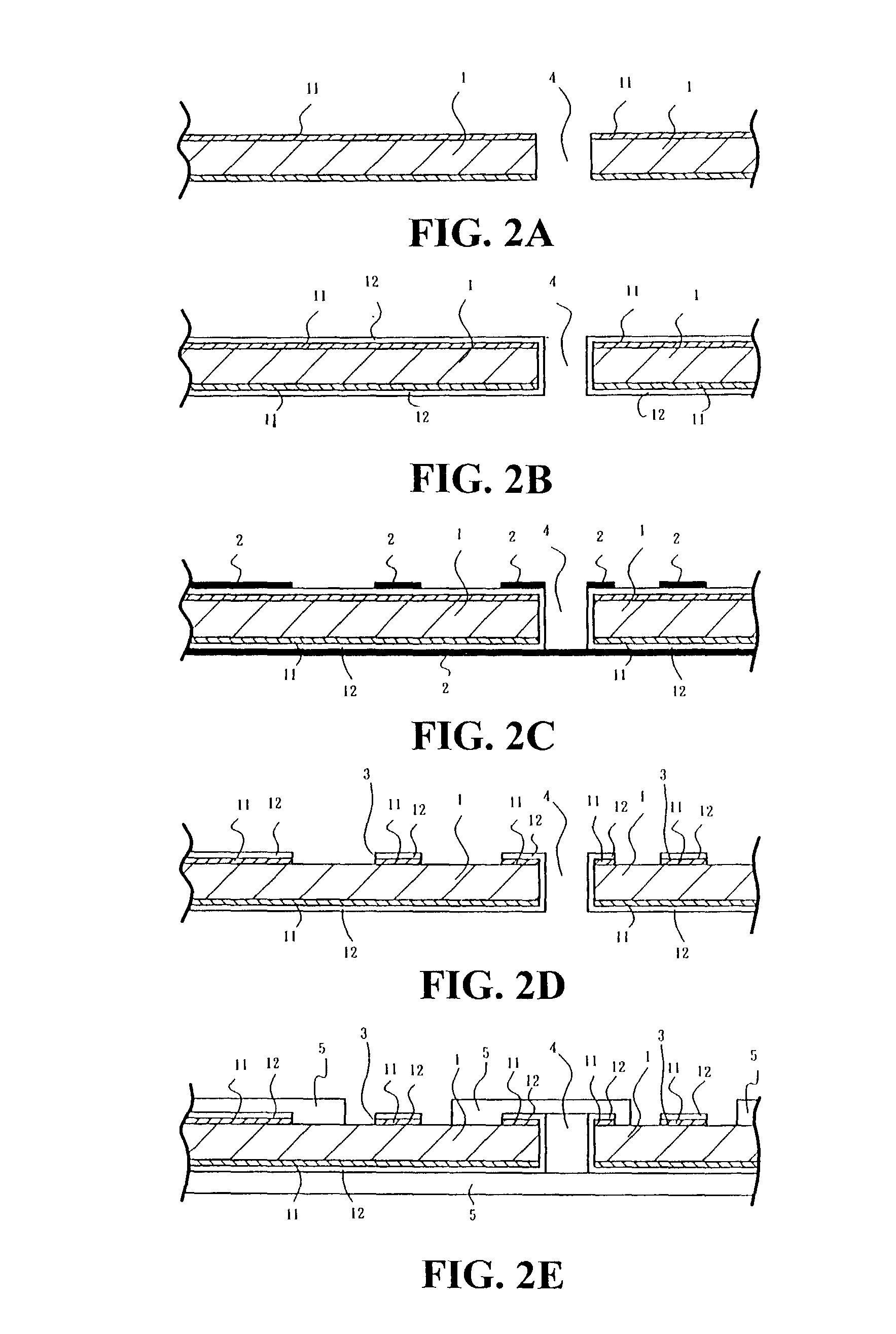

Making method of electric nickel and golden circuit board for saving nickel and gold dosage

InactiveCN101267713AOvercoming major deficienciesReduce dosageConductive material chemical/electrolytical removalCopper platingSecondary circuit

A manufacturing method of an electrolytic nickel and gold wiring board capable of saving dosage of nickel and gold, comprises broaching, copper precipitation, and copperizing on a copper-coated plate. The method is characterized by further comprising: a, adhering a dry film or printing a wet film on the wiring board, then adhering a positive sheet, exposing and developing to form a primary circuit; b, electroplating nickel and gold on all positions to be welded and copper surfaces of metal holes, then stripping; c, printing a wet film or adhering a dry film, then adhering a negative sheet, exposing and developing to form a secondary circuit; d, etching a circuit diagram, removing non-circuit portions, holding circuit portions, then performing stripping and etching detection; e, performing deoxidation treatment to the wiring board to remove oxides on the copper surfaces; f, after deoxidation treatment, resistance welding, exposing, developing, printing element symbols and machining shapes so as to manufacture the electrolytic nickel and gold wiring board only at the positions to be welded and the metal hole positions. With the method, the area of the nickel and gold can be reduced by 40-60%, thereby saving the noble metal nickel and gold and effectively reducing enterprise production cost.

Owner:陈国富

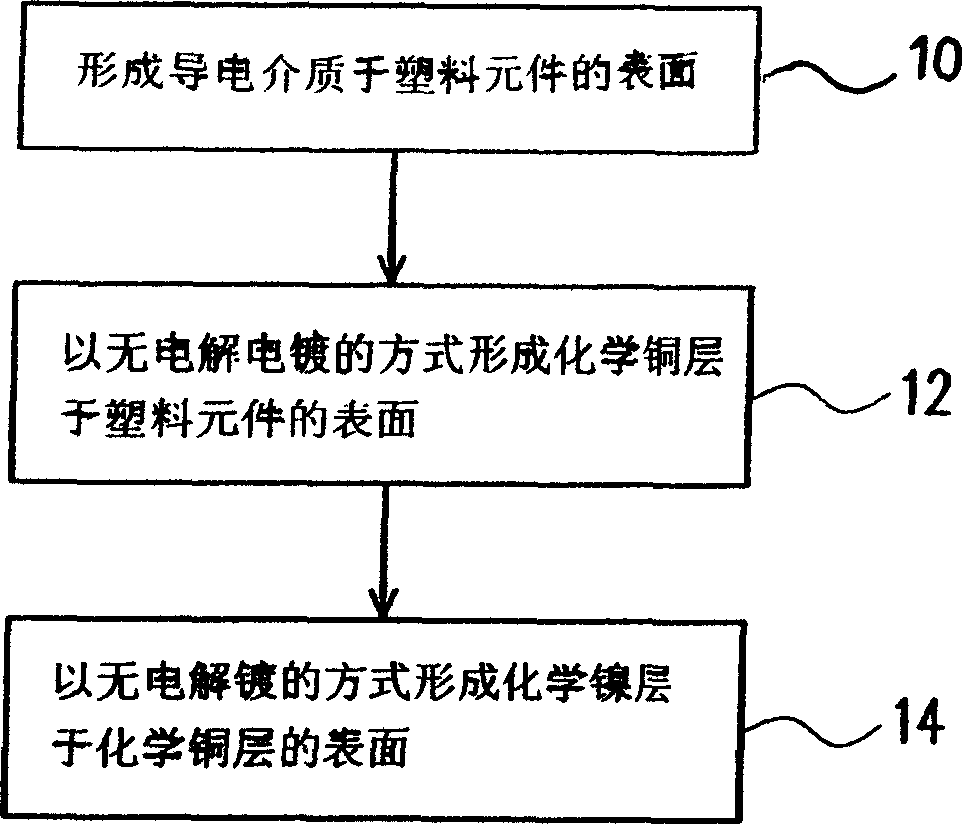

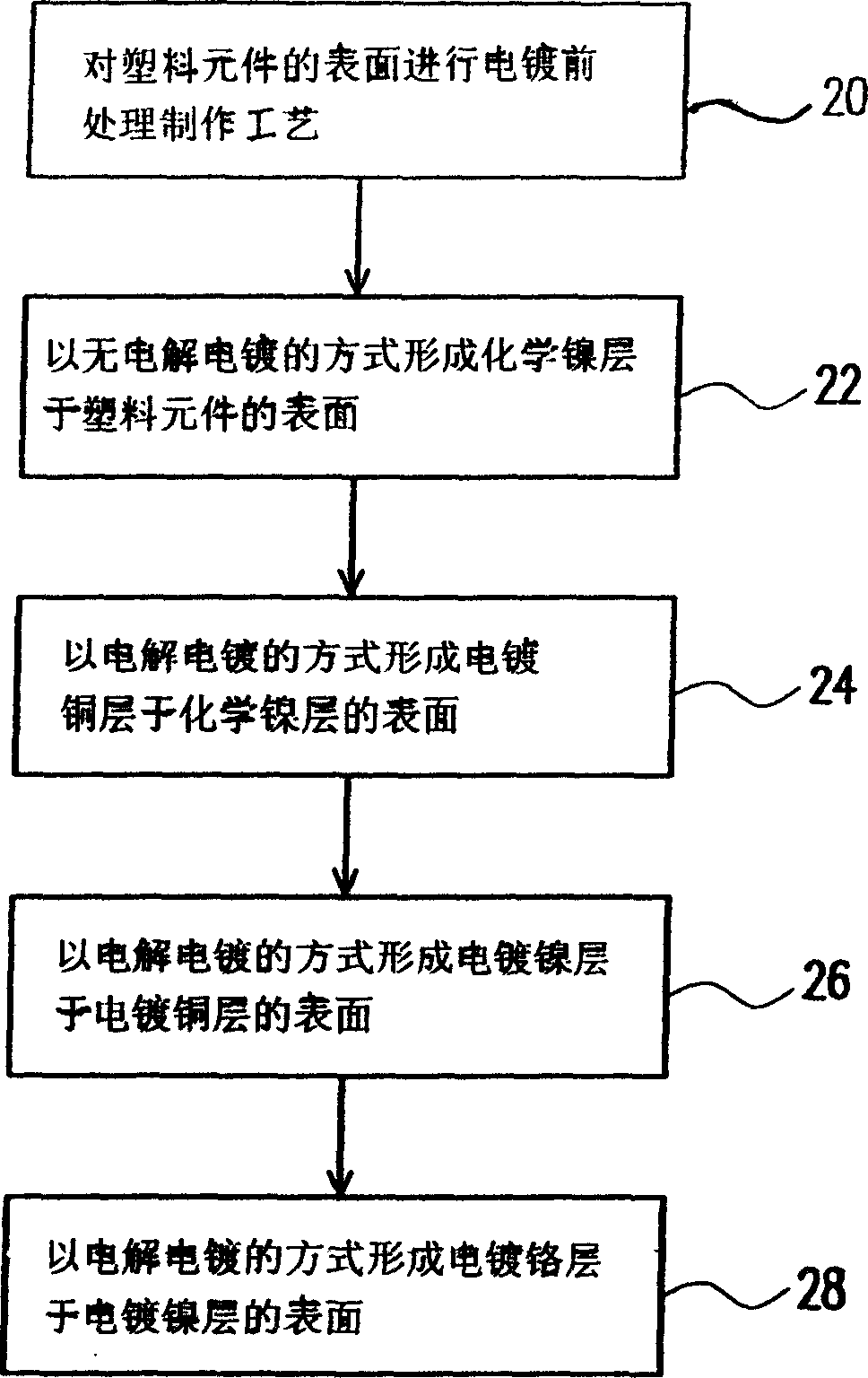

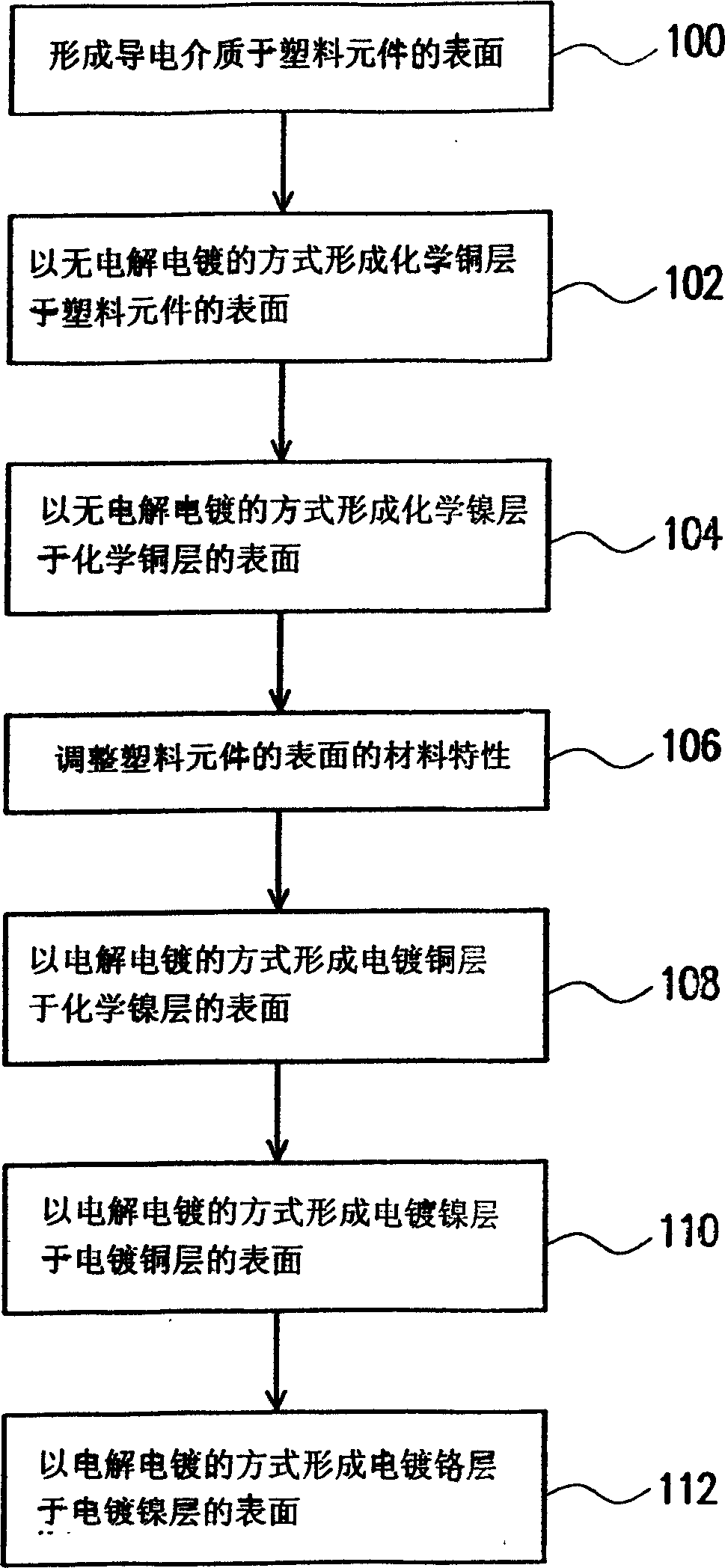

Process for making plastic surface by electroplating

The present invention relates to an electroplating process on plastic surface. It is applicable for forming a multiple metal layer on surface of plastic element. Said process includes the following steps: firstly, forming an electroconductive medium on surface of plastic element, then adopting electrolysis-free electroplating mode to form at least one chemical metal layer (for example chemical copper layer and chemical nickel layer) on surface of plastic element, then regulating material characteristics of surface of plastic element and adopting electrolytic electroplating mode to form at least one electroplated metal layer (for example electroplated copper layer, electroplated nickel layer and electroplated chrome layer). Said electroplated metal layer has high structure strength and high conductivity.

Owner:HTC CORP

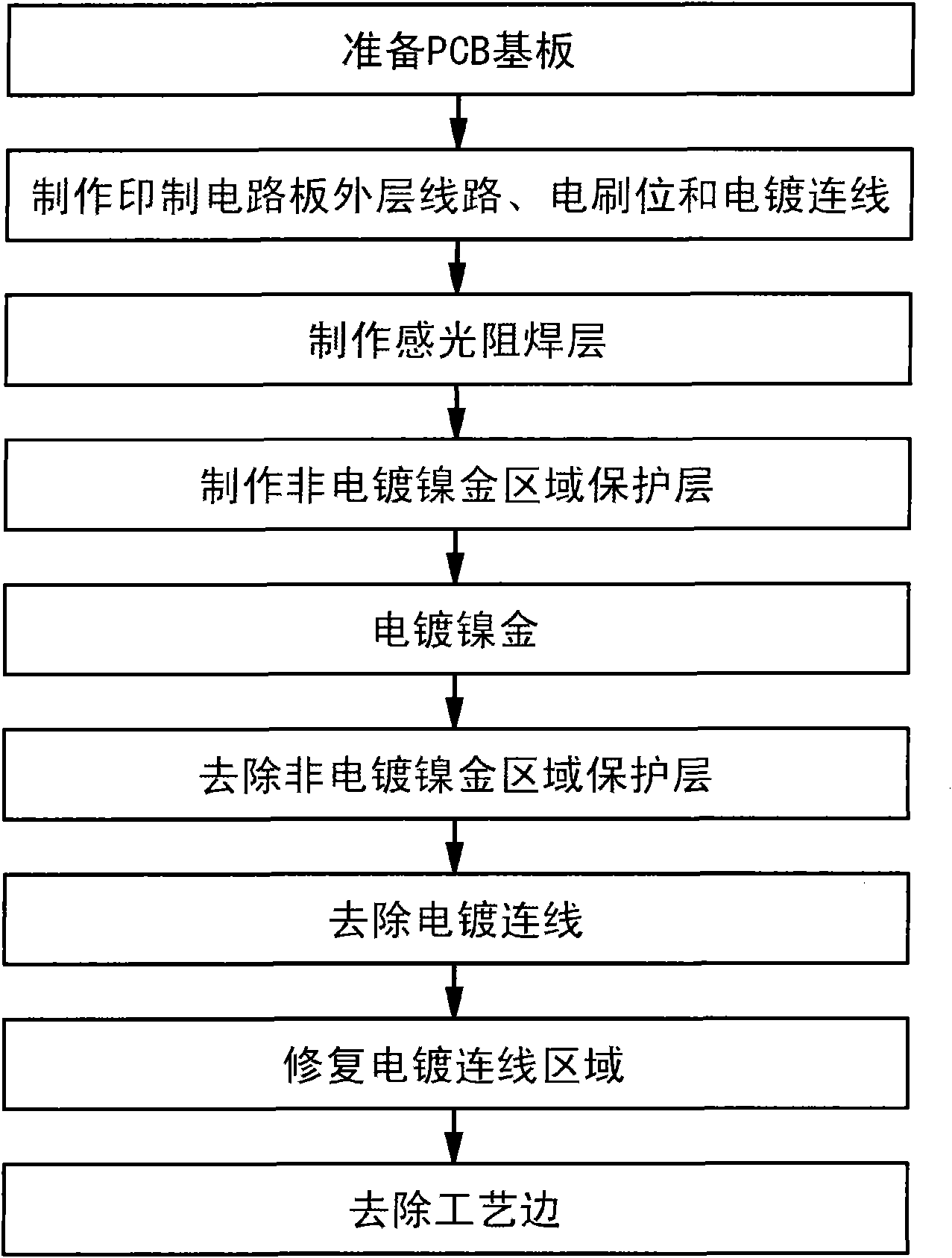

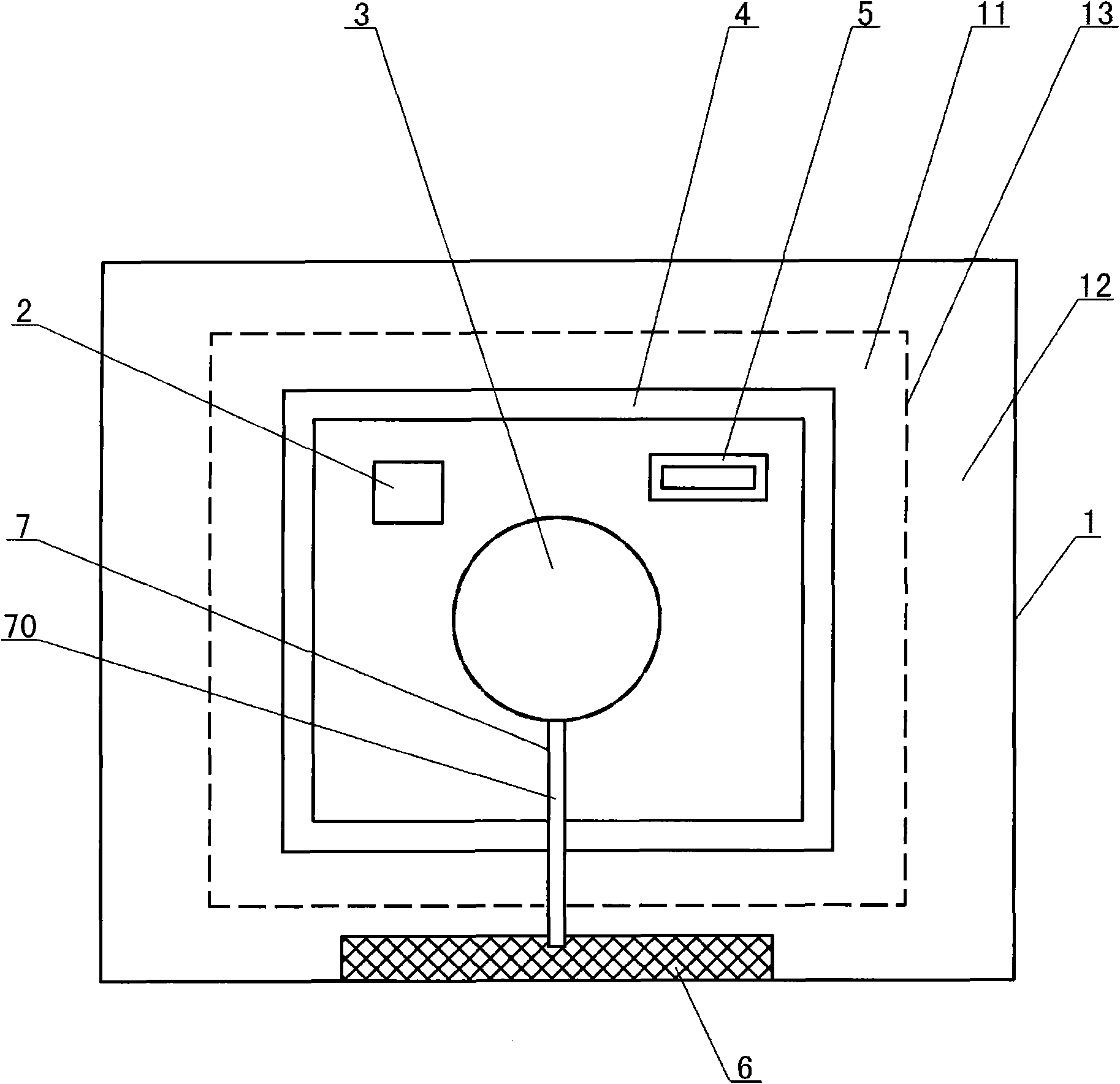

Nickel-gold electroplating process of PCB

InactiveCN101835346AHigh feasibilityAvoid residuePrinted circuit secondary treatmentElectricityEngineering

The invention relates to a nickel-gold electroplating process of a PCB, which comprises the following steps of: (1) preparing a PCB substrate; (2) making an outer circuit, an electric brush part and an electroplating connecting line of the PCB; (3) making a photosensitive soldering-resistant layer; (4) making a non-nickel-gold electroplating region protection layer; (5) electroplating nickel and gold; (6) removing the non-nickel-gold electroplating region protection layer; (7) removing the electroplating connecting line; (8) repairing an electroplating connecting line region; and (9) removing a process edge. In the nickel-gold electroplating process, the electric brush part on the process edge is communicated with a non-marginal to-be-electroplated region by the designed electroplating connecting line to electroplate a non-marginal region on the PCB, the electroplating connecting line is removed after nickel-gold electroplating, and the electroplating connecting line region is repaired to avoid the problem of electroplating connecting line residue and ensure the reliability of the PCB. Meanwhile, the non-marginal to-be-electroplated region and the electroplating connecting line can be freely selected according to actual needs. Accordingly, the nickel-gold electroplating process has high practicability.

Owner:CHINA CIRCUIT TECH SHANTOU CORP

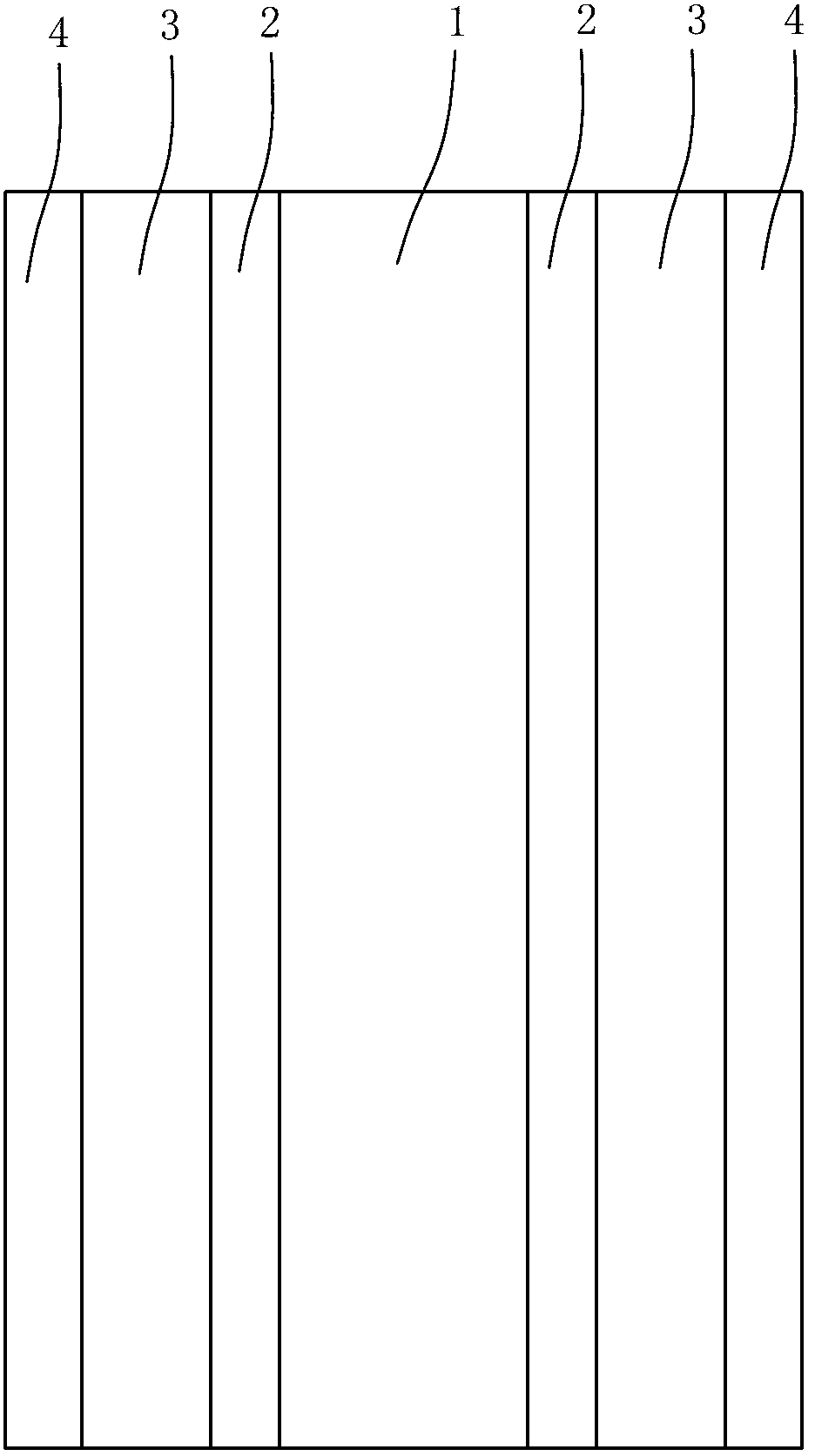

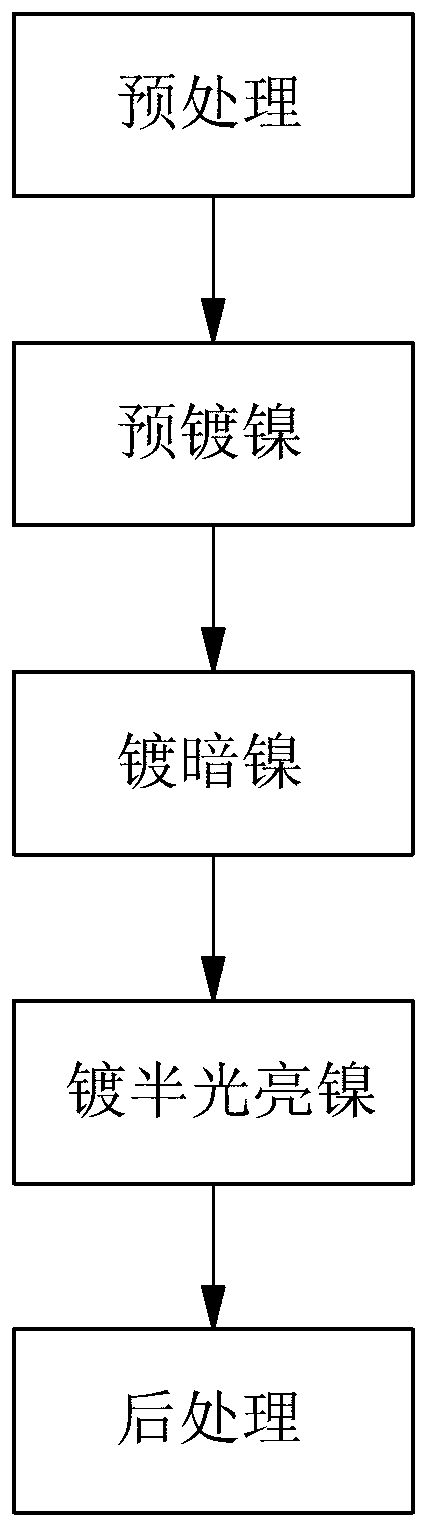

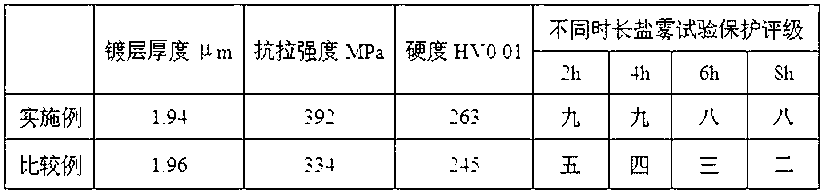

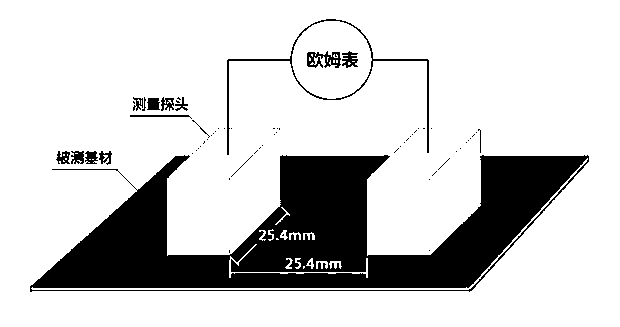

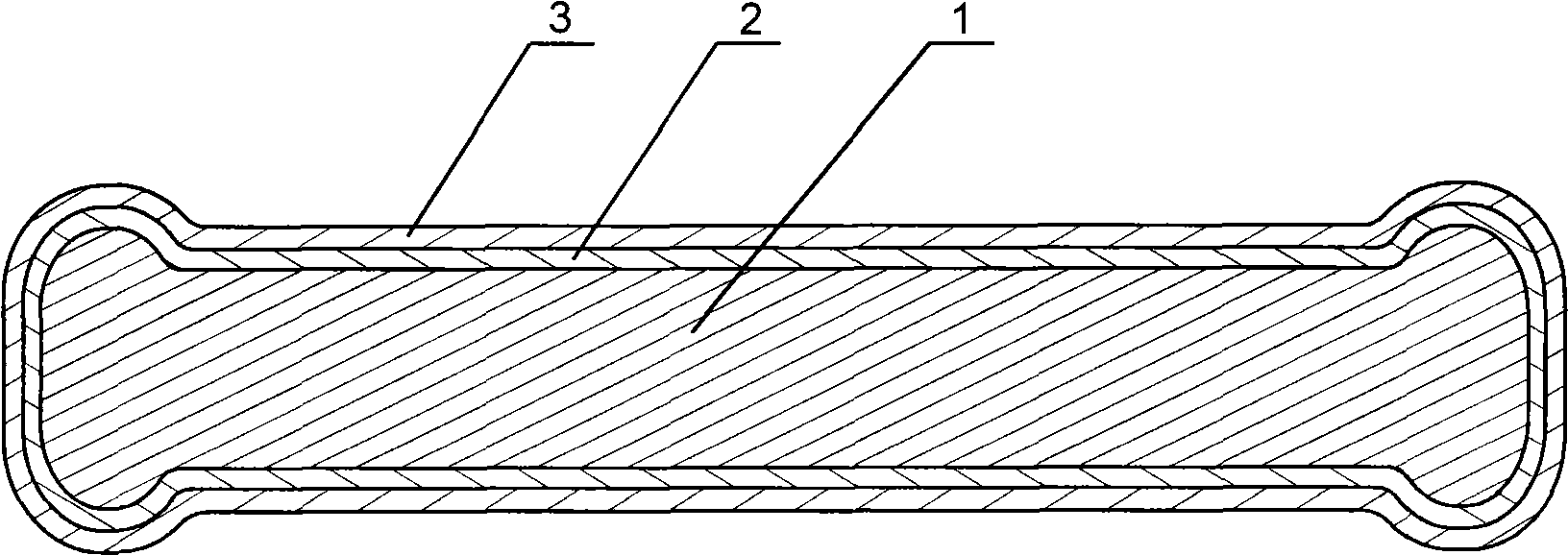

Nickel-plated steel strip and preparation method thereof

InactiveCN103343367AImprove bindingImprove corrosion resistanceMetal layered productsPulse electroplatingNickel binding

The invention relates to a nickel-plated steel strip and a preparation method thereof. The nickel-plated steel strip comprises a steel base strip, wherein a first iron-nickel binding layer, a dark nickel layer and a semi-bright nickel layer are orderly electroplated at two sides of the steel base strip from inside to outside; an electroplating process of the iron-nickel binding layer and the semi-bright nickel layer is a pulse electroplating process; the electroplating process of the dark nickel layer is a direct-current electroplating process. The preparation method comprises the following steps: pretreatment; electroplating, namely electroplating a layer of ultra-thin nickel-plated layer at the outer surface of the steel base strip which is preprocessed by the pulse electroplating process as the iron-nickel binding layer, electroplating a layer of dark nickel layer at the outer surface of the ultra-thin nickel-plated layer by adopting the direct-current electroplating process, and electroplating a layer of semi-bright nickel layer at the outer surface of the dark nickel layer by using the pulse electroplating process; post-treatment, namely cleaning and drying the electroplated nickel-plated steel strip, and finally carrying out thermal treatment. Three layers of different clad layers are formed at the surface of the steel base strip by the electroplating process, so that the binding force of the coating and the steel base strip is enhanced; the performances such as corrosion resistance, soldering resistance and the like are obviously improved.

Owner:深圳市中金高能电池材料有限公司

Preparation method of conductive sponges

InactiveCN103215590ASolve pollutionOvercome easy fall offSuperimposed coating processPolyesterCopper metal

The invention discloses a preparation method of conductive sponges, which is implemented by taking a coiled material or sheet material of polyester sponges or polyether sponges with a thickness of not more than 10 mm as a base material through the steps of carrying out chemical pretreatment on the base material, coating a carbon conductive layer on the base material subjected to chemical pretreatment, carrying out gas-phase physical deposition of metal nickel or metal copper on the base material, carrying out electro-nickelling on the base material subjected to the gas-phase physical deposition of nickel or copper, and carrying out water washing and drying on the obtained product so as to obtain a conductive sponge; or sequentially carrying out electro-coppering and electro-nickelling on the base material subjected to the gas-phase physical deposition of nickel or copper, and carrying out water washing and drying on the obtained product so as to obtain a conductive sponge. The preparation method disclosed by the invention is environment-friendly, overcomes product defects caused by that a film layer is easy to fall off in the process of directly carrying out gas-phase physical deposition of metal nickel or metal copper, and also solves the problem that the base material is incompletely plated due to thickness limitation.

Owner:WUZHOU HGP ADVANCED MATERIALS TECH CORP

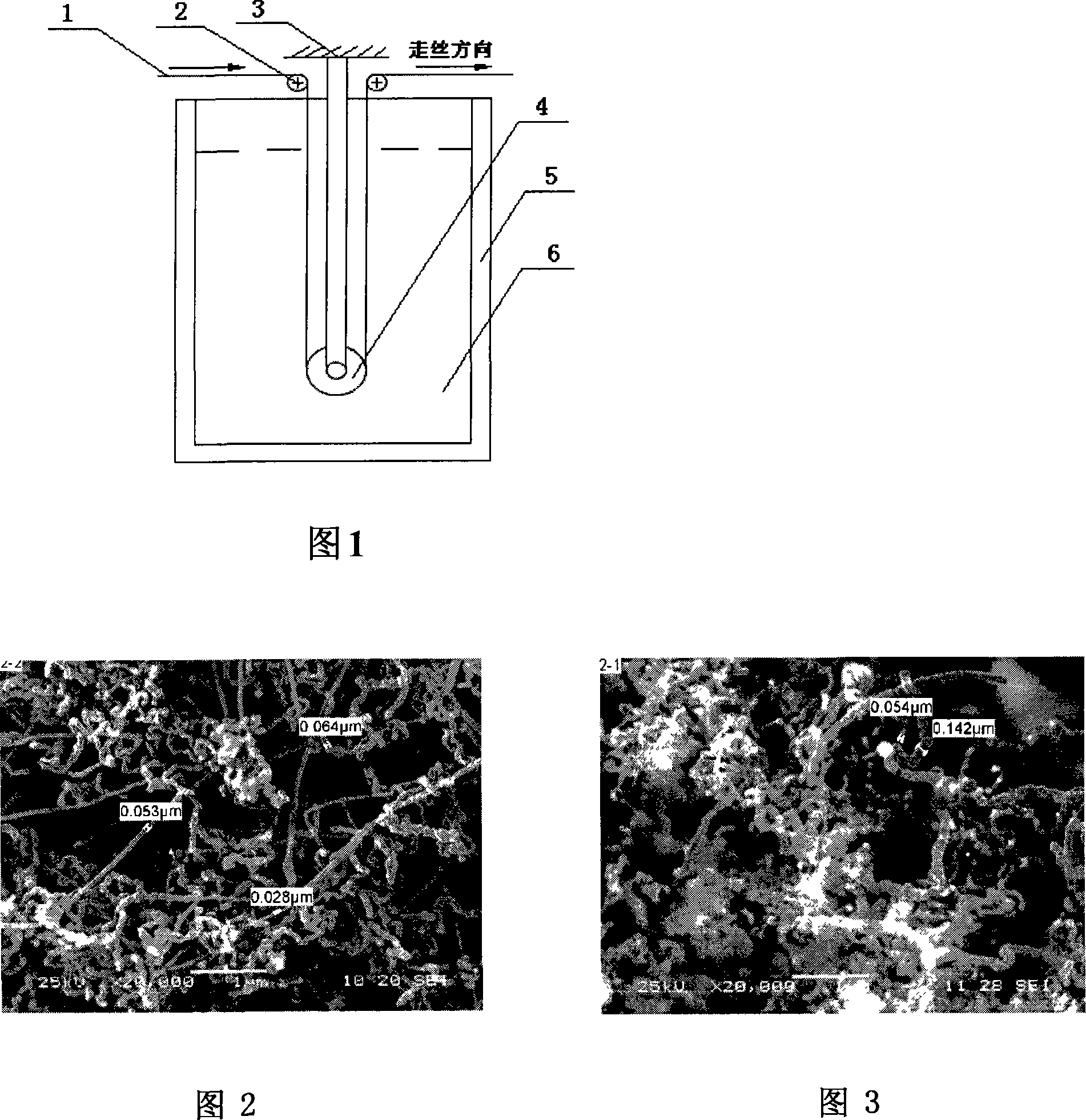

Preparation method of composite diamond fretsaw

InactiveCN101838838AImprove control abilityImprove sharpnessElectrolytic coatingsFine working devicesHydrogenGranularity

The invention relates to a preparation method of a composite diamond fretsaw, which comprises the following steps: 1, taking protogenetic diamond micro powder with the granularity of 5-45 Mu m and crushed diamond micro powder, mixing uniformly according to the proportion to obtain mixed diamond micro powder; taking the mixed powder of tungstic oxide powder and molybdenum powder as well as the mixed diamond micro powder, and mixing uniformly according to the proportion; 2, heating the product generated in step 1 and leading in rinsed hydrogen to form a diamond micro powder matrix / tungsten-molybdenum carbide interface / surface-metallized mixed diamond micro powder of tungsten-molybdenum alloy; and 3, taking electronickelling watt solution added with the surface-metallized mixed diamond micro powder as the electroplate liquid and taking a steel wire rope as a cathode to carry out the composite plating of metallized diamond and matrix nickel on the surface of the steel wire rope so as to obtain the composite diamond fretsaw of the invention. The invention has the advantages of simple process and easy operation, the prepared product has good edging performance, excellent wear-resisting compressive property, high processing speed and long service life, the utilization rate of the diamond fretsaw is high, the section flatness and the glossiness are high, the method is suitable for industrial production, and the prepared product is particularly suitable for the cutting processing with high efficiency, high quality and high cost performance on gems and other high-value materials.

Owner:CHANGSHA DIAT NEW MATERIAL SCI & TECH

Manufacturing method for flowered nickel screen die roll

InactiveCN101559663AEasy to prepareReduce processScreen printersForme preparationCopper platingLaser engraving

The invention relates to a manufacturing method for a flowered nickel screen die roll. The technical process comprises the following steps: machining, copper plating, grinding, glue coating, pattern fabrication, laser engraving, corrosion, rubber filling and nickel plating. The preparation method is characterized in that: the pattern fabrication process comprises the following steps: applying a 70 mesh screen to a needed pattern grey scale file to obtain square mesh points with various sizes and directly form a pattern; eliminating screen pattern information loss caused by screen wires of a common nickel screen; synthetically sorting a grey chart file, the laser engraving expansion, the corrosion expansion and the die roll nickel plated screen expansion to form a laser engraved file which is represented by grey scale values from 0 to 100; and adopting a file with the grey scale value above 98 to fabricate a minimal screen wall, and adopting a file with the grey scale value below 3 to fabricate a maximal screen wall. The method adopts the grey chart and the screen with the same meshes and different mesh sizes to form the pattern, and directly fabricates the pattern on the die roll of a nickel plated circular screen. The electroplated nickel circular screen is directly used for printing without pattern information loss, and has rich gradual change gradations.

Owner:上海希尔彩印制版有限公司

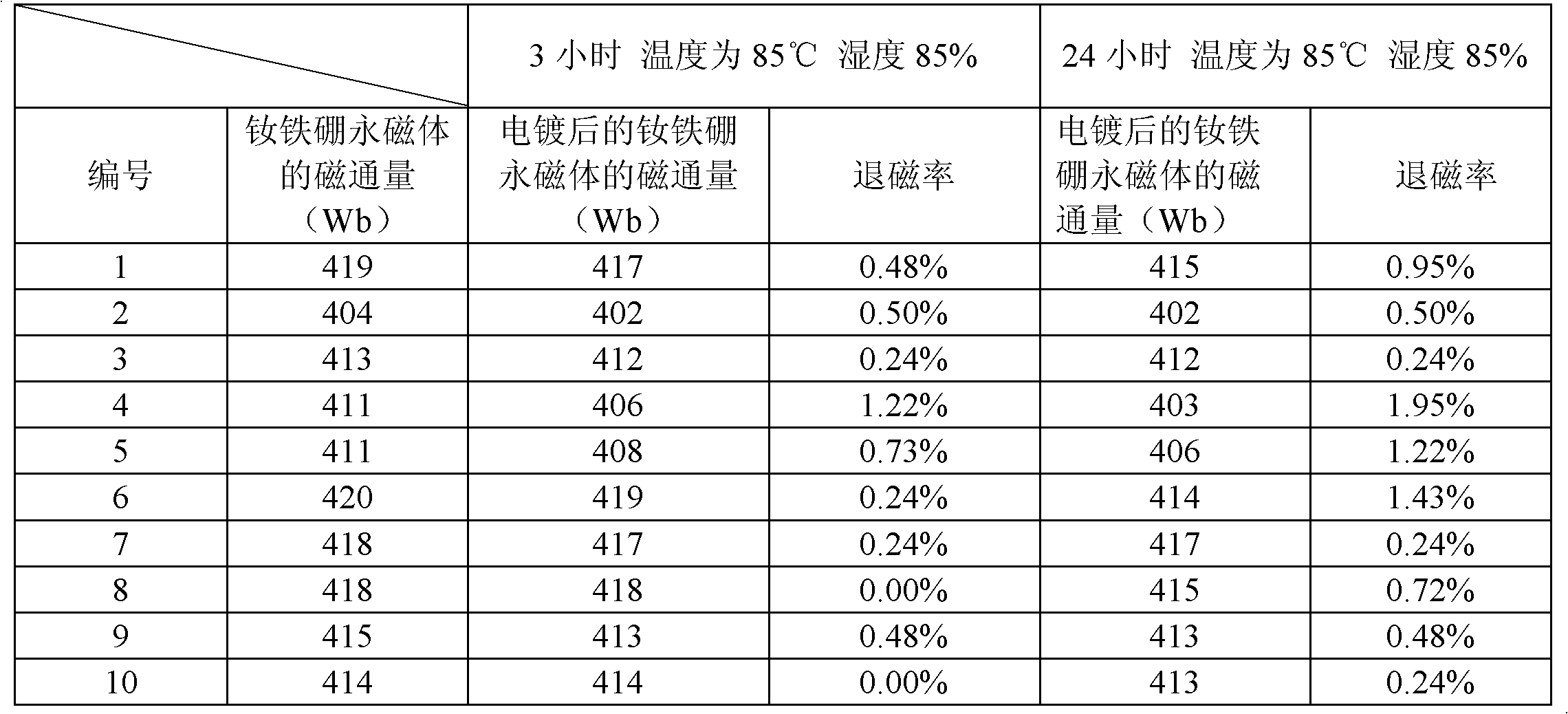

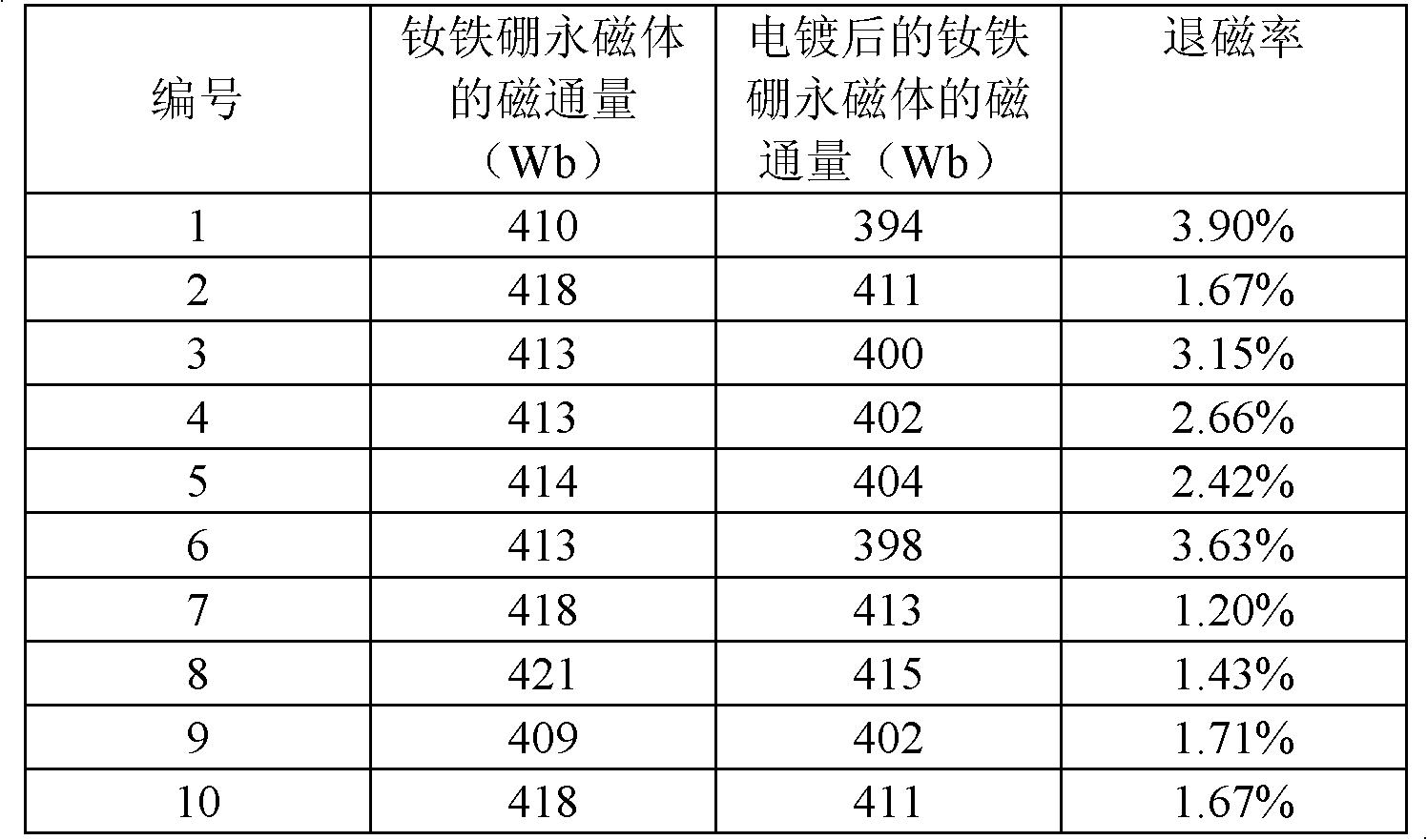

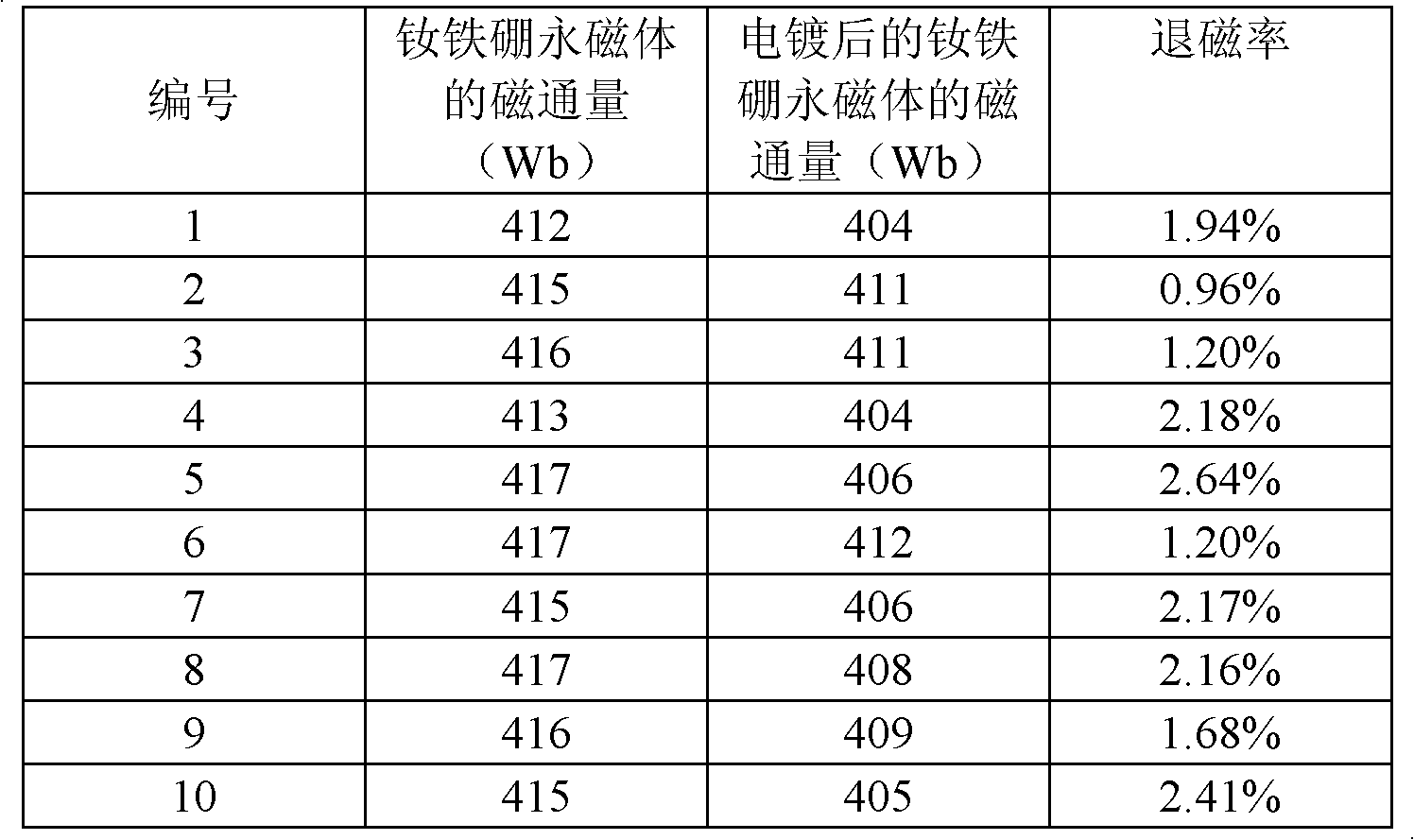

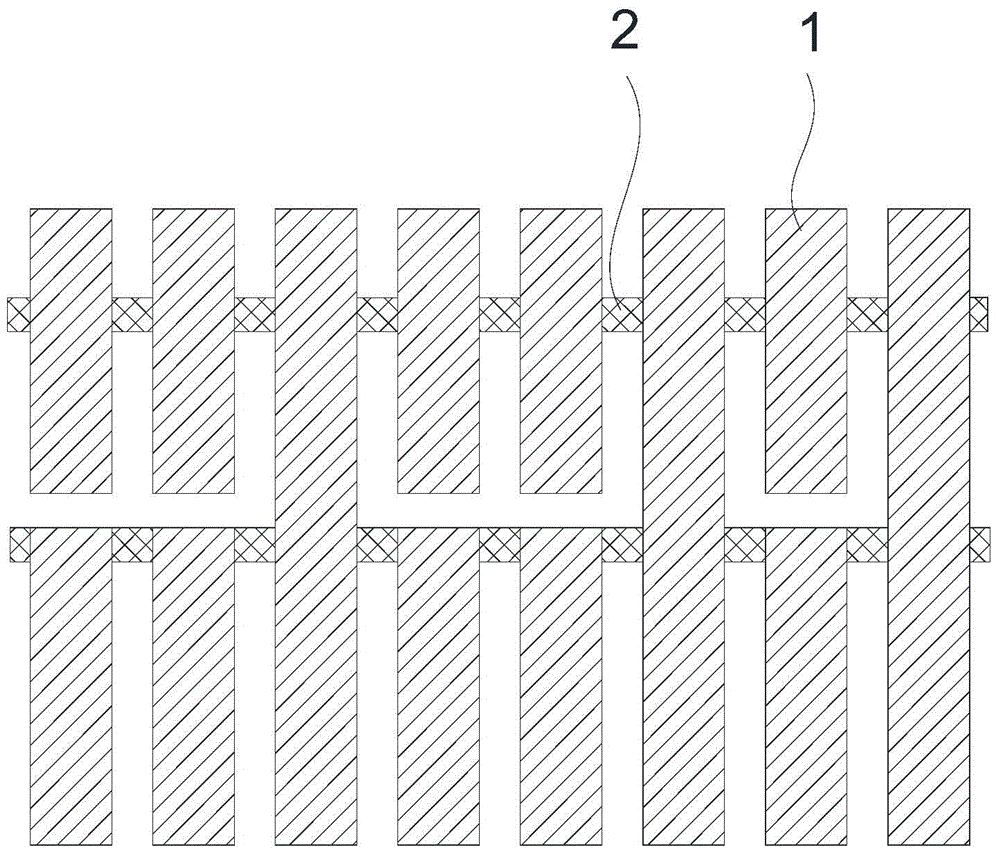

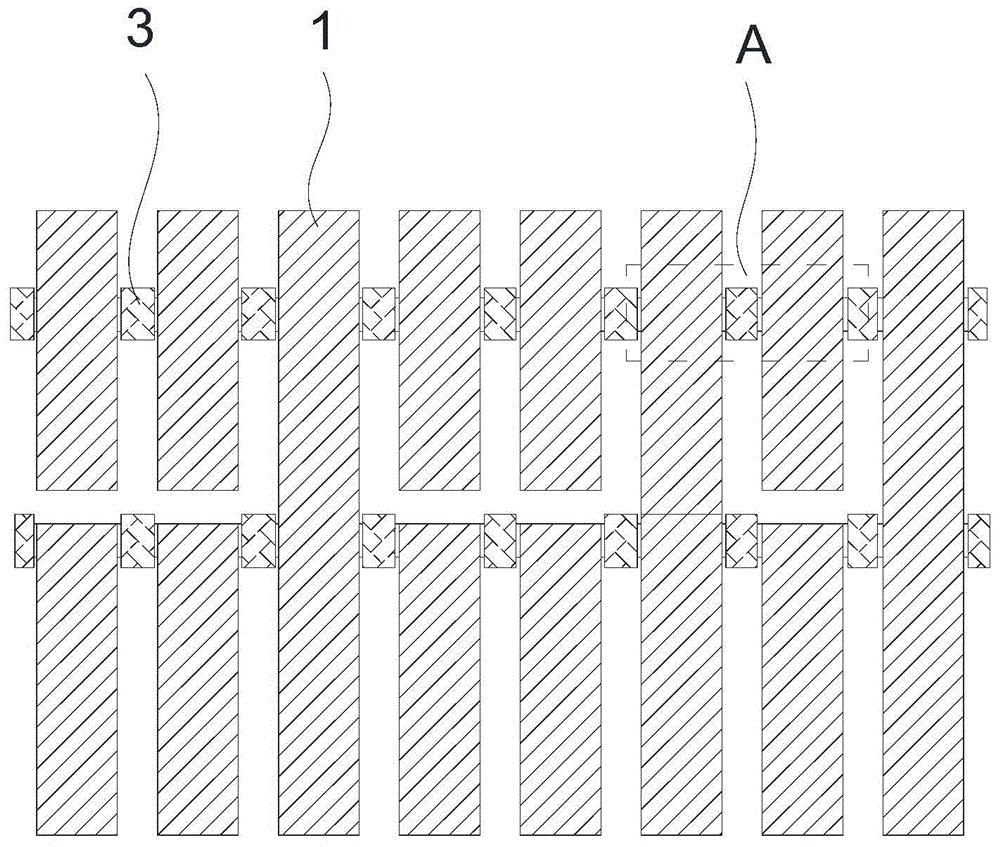

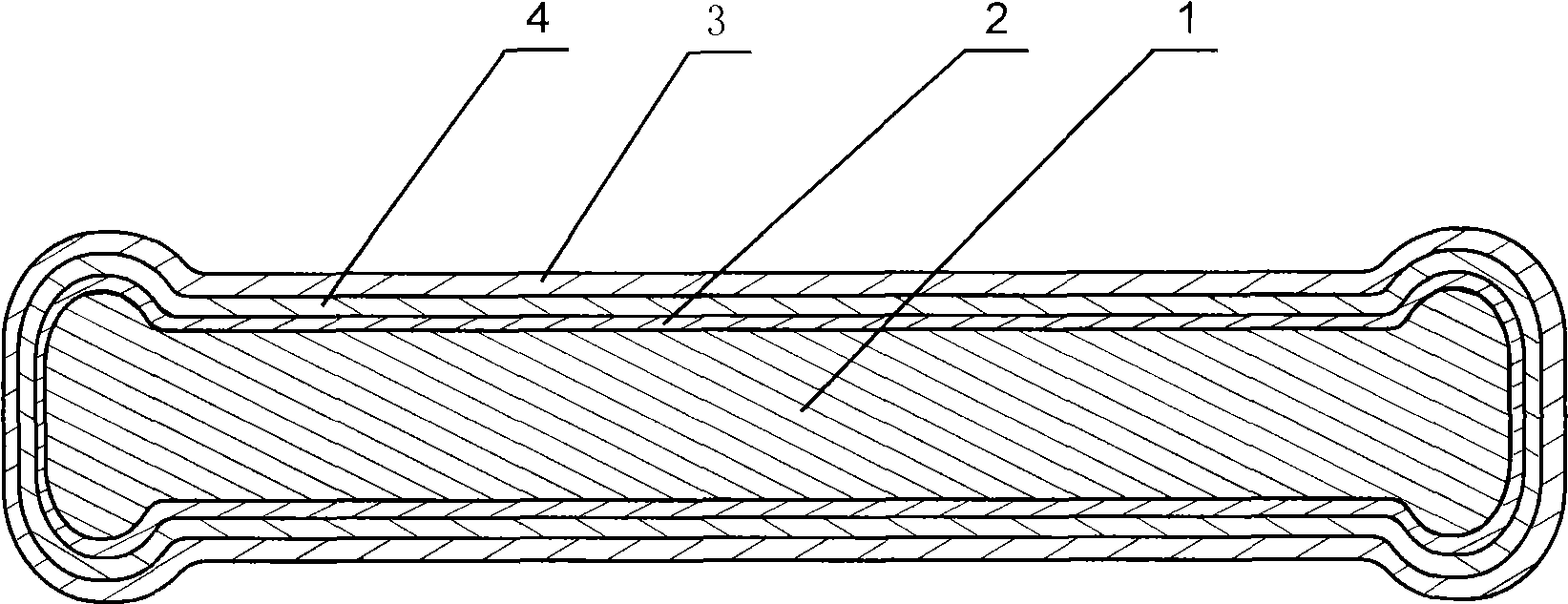

Process method for reducing magnetic loss of neodymium-iron-boron permanent magnet under high-temperature and high-humidity conditions

ActiveCN102586829AImproved ability to withstand heat and humidity testsQuality improvementHigh humidityBiological activation

The invention relates to the technical field of electroplating protection of neodymium-iron-boron permanent magnet materials, in particular to a process method for reducing the magnetic loss of a neodymium-iron-boron permanent magnet under high-temperature and high-humidity conditions. The process method comprises the following steps of: performing chamfering, deoiling, acid cleaning and activation pretreatment processes, an electroplating process and an electroplating post-treatment process on the neodymium-iron-boron permanent magnet, wherein in the electroplating process, a bottom nickel plated layer, an intermediate copper layer and an outer nickel plated layer are sequentially plated from inside to outside, the thickness of the bottom nickel plated layer is 5-10 mu m, the thickness of the intermediate copper layer is 5-7 mu m and the thickness of the outer nickel plated layer is 5-10 mu m. According to the process method disclosed by the invention, the magnetic loss of the sintered neodymium-iron-boron permanent magnet under the moisture and heat-resistant conditions by combining the plated layers with the different thicknesses, the quality of an electroplated nickel layer and the performances of the sintered neodymium-iron-boron permanent magnet material are significantly improved, and the neodymium-iron-boron permanent magnet material further has broader application prospects.

Owner:SHENYANG GENERAL MAGNETIC

New process for electroplating non-metal material surface and its special conductive paint

InactiveCN1944718ATo achieve the purpose of metallizationThe purpose of metallization is wideElectrically-conductive paintsCopper platingMetallic materials

The simplified process for electroplating non-metal material surface includes the steps of chemically deoiling the surface of non-metal material, spraying conducting paint for metallizing the non-metal material, and final electroplating copper, nickel or chromium. The conducting paint consists of filming resin 20-40 wt% , flaky conducting metal powder 28-40 wt%, coupler 0.5-2 wt%, orientating arranging agent 1-1.25 wt%, mixed diluent 20-40 wt% and assistant 0.5-2 wt%. The process is simple, low in production cost, high in work efficiency and environment friendship, and may be used in matallizing various non-metal material with complicated shape.

Owner:昆明亘宏源科技有限公司

Manufacturing method for PCB golden finger

InactiveCN104918421AAvoid gap-prone problemsPrinted element electric connection formationScreen printingCopper

The invention discloses a manufacturing method for PCB golden fingers, which belongs to the technical field of circuit board production and manufacturing. The manufacturing method comprises the steps of: S1, manufacturing copper base bodies in a golden finger region and electroplated lead wires connecting the adjacent copper base bodies, wherein each electroplated lead wire is arranged between the adjacent copper base bodies; S2, screen-printing antistatic gold ink for covering and protecting the electroplated lead wires, wherein the coverage area of the antistatic gold ink is 0.15 to 0.2mm greater than one-sided width of each electroplated lead wire and spaced from each copper base body at a distance ranging from 0.07 to 0.1mm; S3, electroplating nickel-gold on the copper base bodies in the golden finger region; S4, and removing the antistatic gold ink coating the electroplated lead wires, and etching the electroplated lead wires away. The manufacturing method for the PCB golden fingers can effectively avoid the occurrence of problems of golden finger notches and projections on side surfaces of the golden fingers during the manufacturing process of the golden fingers by adding the electroplated lead wires to the side surfaces of the copper base bodies of the golden fingers and setting a pre-enlarging value of the screen-printed antistatic gold ink.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

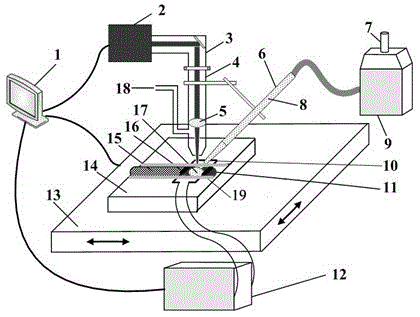

Laser-induction compounded cladding method for repairing continuous casting crystallizer

InactiveCN102909325AThickness is easy to controlLow dilution rateMetallic material coating processesAlloyCopper

A laser-induction compounded cladding method for repairing a continuous casting crystallizer is characterized by comprising the following steps: conducting deoiling, derusting, crack or scratch excavating, activating, and electronickelling or chemical nickel plating on a damaged part of the continuous casting crystallizer; then adopting laser-induction compounded cladding dedicated copper-base alloy powder to repair the damaged part of the continuous casting crystallizer, wherein the dedicated copper-base alloy powder comprises the following chemical constituents by weight percent: 7 to 9 percent of Ni, 8 to 12 percent of Sn, 5 to 15 percent of Al, 0.8 to 2 percent of Si and Cu in balancing amount. According to the invention, laser-induction compounded cladding repairing can be conducted on the damaged part of the continuous casting crystallizer under the condition that the cladding efficiency is improved by 1 to 5 times, so as to solve the problem that the conventional repairing coating of the continuous casting crystallizer is thin, easy to peel and low in thermal conductivity.

Owner:NANCHANG HANGKONG UNIVERSITY

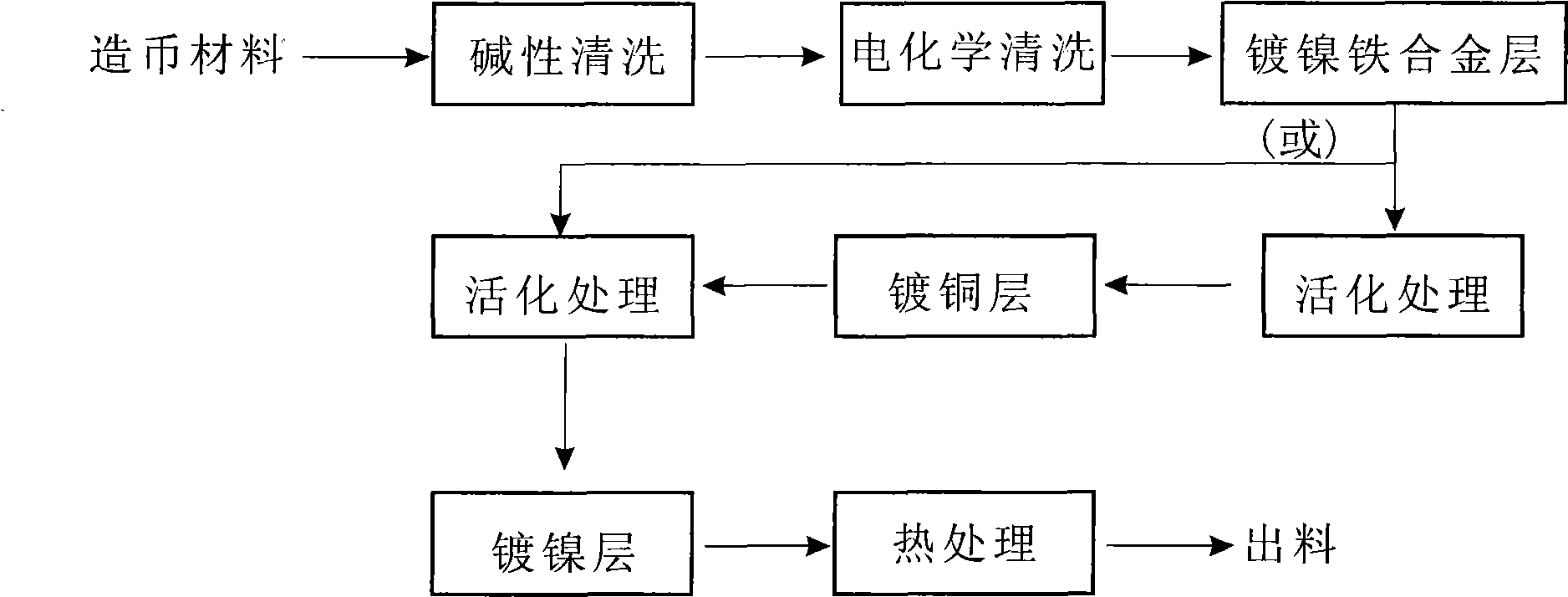

Application process of multi-layer electroplated coinage materials and products thereof

ActiveCN101532155ASolve the problem of poor corrosion resistanceDifferent electromagnetic signalsCoinsMetal layered productsAlloyCopper

The invention discloses an application process of multi-layer electroplated coinage materials and products thereof. The process is characterized in that the coinage material is applied to the manufacturing of planchet cakes after the multi-layer electroplating. The multi-layer electroplating is characterized in that a Ni-Fe alloy layer and a nickel layer or a Ni-Fe alloy layer, a copper layer and a nickel layer are successfully electroplated on the coinage material. The specific process comprises alkali washing, electrochemical washing, activating treatment and Ni-Fe alloy layer, copper layer and nickel layer electroplating procedures. The application process can lower the production cost and improve the production efficiency. The prepared coinage planchet cakes have good processing performance and specific electromagnetic signals. The machine-readable anti-conterfeiting performance of circulation coins is strengthened. Simultaneously, the poor corrosion resistance problem of the Ni-Fe alloy which is used as a surface coating under the moist environment is solved.

Owner:SHANGHAI MINT +1

Method for preparing nano carbon fiber

The invention discloses a method for preparing carbon nanofiber, which uses carbon fibers as matrix. The surface of the carbon fibers is pretreated and then catalyst nickel coating and simple substance are prepared on the surface by electroplating method; finally the carbon nanofiber is produced on the carbon fibers by chemical vapor deposition method. The invention comprises the steps that: (1) the surface pretreatment of the carbon fibers; (2) the surface electro nickelling of the carbon fibers; (3) the carbon nanofiber produced by chemical vapor deposition method; (4) drawacharge. The invention is a method for preparing the carbon nanofiber with high quality and high purity without damaging the carbon fiber matrix.

Owner:CENT SOUTH UNIV

Continuous electroplating process for weldable aluminum coiled material

The invention relates to a continuous electroplating process for a weldable aluminum coiled material. The process is characterized by comprising the following process steps of: (1) preparing alkali liquor, acid liquor, zinc alloy liquor, zinc removing solution, nickel plating solution and tin plating solution; (2) removing oil; (3) performing primary washing; (4) etching with the alkali liquor; (5) performing secondary washing; (6) performing acid washing; (7) performing tertiary washing; (8) dipping a zinc alloy for the first time; (9) removing zinc by using nitric acid; (10) dipping the zinc alloy for the second time; (11) plating nickel, namely electroplating nickel for the aluminum coiled material which is subjected to zinc alloy dipping treatment for the second time, wherein the current density for electroplating the nickel is between 2 and 10A / cm<2>; and (12) electroplating tin, namely electroplating tin for the nickel-plated aluminum coiled material, wherein the current density for electroplating the tin is between 2 and 15A / cm<2>, and the temperature of the tin plating solution is between 30 and 60 DEG C. The continuous electroplating process guarantees high bonding force between a tin electroplated layer and an aluminum material, so that the tin electroplated layer does not bubble, fall off or peel; and the continuous electroplating process has the advantages of low cost and light pollution.

Owner:WUXI XINDAZHONG STEEL SHEET

Method for electroplating nickel rare earth-titanium diboride composite coating

The invention discloses a method for electroplating a nickel rare earth-titanium diboride composite plating coat. The method comprises the following steps: (a) titanium diboride microparticle is cleaned by acetone and then is soaked in a hydrochloric acid solution so as to carry out sucking filtration; then the titanium diboride microparticle is washed to neutrality by water and is dried; (b) a rare earth oxide is dissolved in acid so as to be prepared into rare earth salt solution with the concentration of rare earth of between 20 and 50 g / L; (c) aqueous solution of nickel sulfate, nickel chlorite and boric acid is added in the rare earth salt solution, and the pH value of the solution is adjusted so as to prepare nickel sulfate-nickel chlorite-boric acid-rare earth salt mixed solution; (d) the titanium diboride microparticle and the mixed solution of the nickel sulfate-nickel chlorite-boric acid-rare earth salt are mixed with a surface-active agent and then are ground and stirred inside a mortar; and the mixture is treated by ultrasonic wave so as to prepare an electroplate liquid; and (e) a plating part is put in the electroplate liquid so as to carry out electroplating. The nickel rare earth-titanium diboride composite plating coat obtained by electroplating has obviously increased hardness and abrasion resistance.

Owner:SHANGHAI INST OF TECH

Diamond wire saw and rapid production method thereof

ActiveCN103388170AIncreased chance of collisionIncrease capture rateElectrolytic coatingsChemical platingHeat treated

The invention discloses a diamond wire saw and a rapid production method thereof. The surfaces of diamond grits are respectively coated with a nickel layer by chemical plating, the nickel layers are fixed on a copper-plated piano wire substrate pre-plated with a nickel layer through electroplating, and then the nickel layers are thickened, so that the diamond grits are solidified more firmly. The rapid production method of the diamond wire saw comprises the following steps of: 1, removing greases and oxides on the surfaces of diamond grits, and carrying out sensitization, activation and chemical nickel plating on the diamond grits; 2, removing greases and oxides on the surface of a metal substrate, and pre-plating nickel layers as buffer layers; and 3, carrying out composite electroplating, thickened electroplating and heat treatment on the diamond wire saw. According to the invention, diamond grits are subjected to chemical nickel plating to achieve an effect of electric conduction, so that the diamond grits carry out sequential movement under the action of an electric field, and chemical consolidation is realized; and in addition, intense agitation is introduced in an electroplating process, so that high-current / density electroplating is realized, and a highly efficient and rapid method is provided for the industrial production of diamond wire saws.

Owner:江西核工业兴中科技有限公司

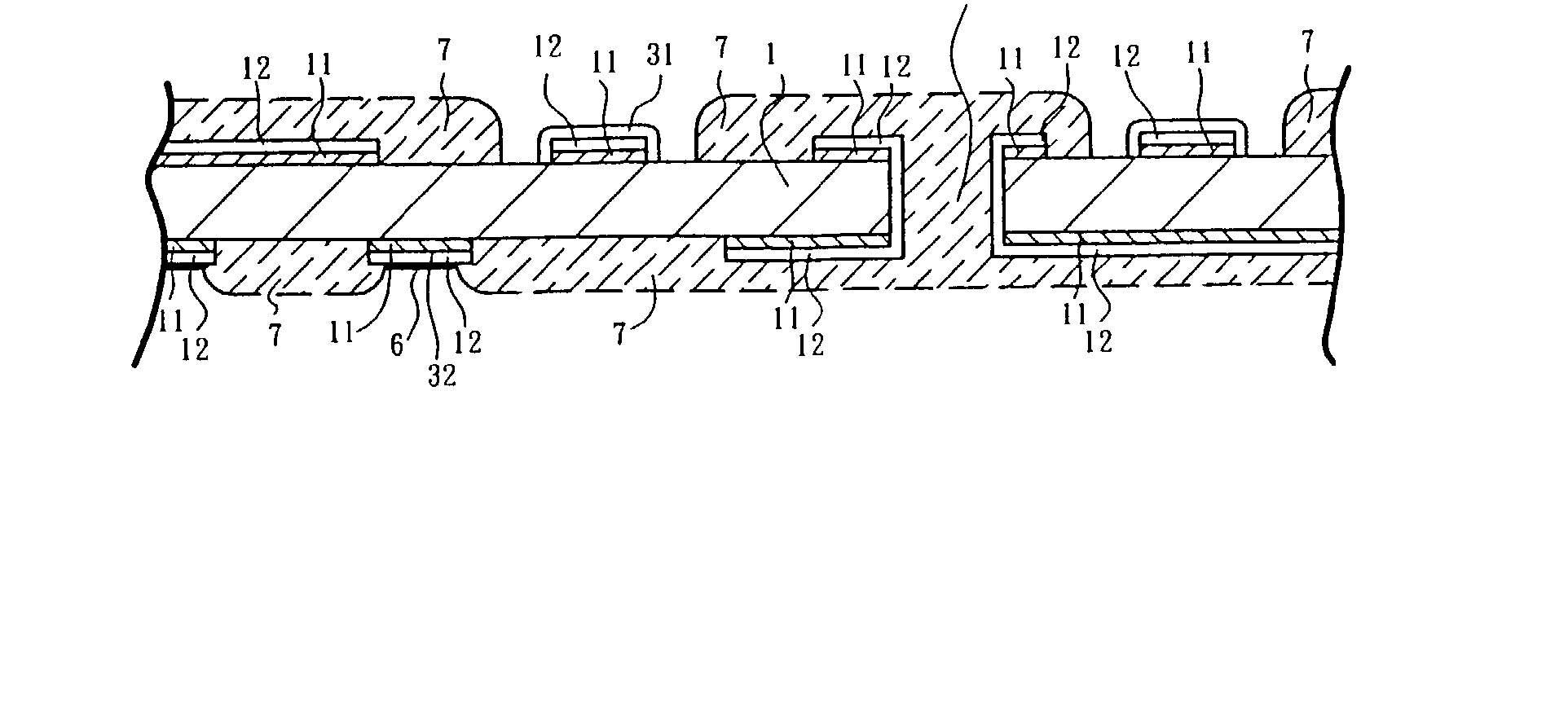

Method of metal electro-plating for IC package substrate

A method of metal-electro-plating for IC package substrate comprising the steps of: forming vias on the package substrate coated with copper film on both sides thereof; electro-plating the vias to form electrical conductive holes between the top layer and the bottom layer of the package substrate; coating a resisting agent where the patterns should be formed on the top layer and on the entire bottom layer of the package substrate; etching the pattern to form circuit without plating lines on the top layer of the substrate, and removing the resisting agent; coating with a resisting agent on the top side and the bottom side of the package substrate but the wiring position to be electro-plated as surface finish for wire-bonding electro-plating on the top side of the package substrate not being applied with the resisting agent; electro-plating the substrate with nickel and gold, and removing the resisting agent; fabricating the circuit on the bottom side of the package substrate and coating with a resisting agent to cover the entire top side and where the circuit is to be formed on the bottom side; etching the substrate to obtain the circuit on the bottom side of the package substrate; and coating solder resist on the region other than the circuit section and applying pre-flux onto the circuit section to form into a protective film.

Owner:ORIENT SEMICON ELECTRONICS

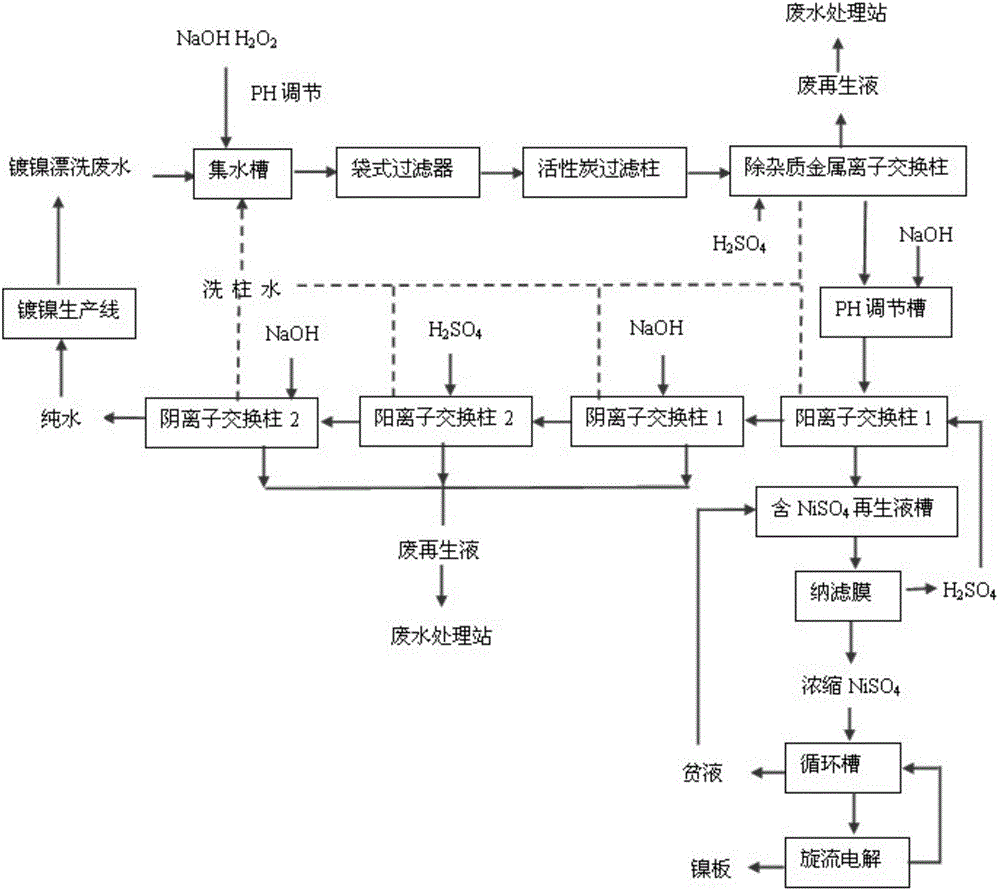

Recycling treatment process for recovering pure water and pure nickel from electro-nickelling rinsing wastewater

ActiveCN105858987AEnable direct recyclingReduce the amount addedPhotography auxillary processesTreatment involving filtrationCycloneElectrolysis

The invention relates to a recycling treatment process for recovering pure water and pure nickel from electro-nickelling rinsing wastewater. The recycling treatment process adopts a variety of ion exchange resin-acid stabilizing nanofiltration membrane-cyclone electrolysis combined processes and has the advantages that pure water and metal nickel can be directly recovered from the wastewater, the nickel recovery rate is greater than or equal to 90%, the electrolytic nickel purity is greater than or equal to 99.95%, the wastewater recovery rate is greater than or equal to 70%, and the electrical conductivity of the recovered water is smaller than or equal to 10 micro-seconds / cm. Compared with other methods, the recycling treatment process is high in resource recovery rate and good in economic benefit, can ensure stable operation of a wastewater treatment system and the quality of recovered substances and is suitable for nickel recovery from nickel-containing wastewater and other nickel-containing industrial wastewater and wastewater recycling treatment in the electroplating industry, electronic industry and metallurgical industry.

Owner:NANJING LINEHOME ENVIRONMENTAL TECH CO LTD

Multiple-layer metallization processing method for epoxy resin package electronic component surface

InactiveCN102936726AImprove conductivityGuaranteed dense and smoothSuperimposed coating processEpoxyHemt circuits

The invention relates to a multiple-layer metallization processing method for an epoxy resin package electronic component surface. The method includes: first forming a chemical nickel-plating bottom plated layer on the epoxy resin package electronic component surface, and then forming a nickel and gold composite plated layer or a copper, nickel and gold composite plated layer on the chemical nickel-plating bottom plated layer. The detailed operation steps include: pin protection, oil removing, washing for the first time, coarsening, washing for the second time, ultrasonic washing, washing for the third time, pickling, pre-sensitizing, activating, washing with running water, peptizing, washing for the fourth time, chemical nickel-plating, washing for the fifth time, electro-coppering, washing for the sixth time, electro-nickeling, washing for the seventh time, drying and gold plating. By means of the method, coarsening liquid, pre-sensitizing liquid, activating liquid, chemical nickel-plating liquid, electro-coppering liquid and relevant process conditions are improved. The multiple-layer metal plating achieves non-falling during etching of circuits, is good in electric conduction and can be used as an electric conduction terminal of an electric component directly to achieve circuit design.

Owner:HEFEI UNIV OF TECH

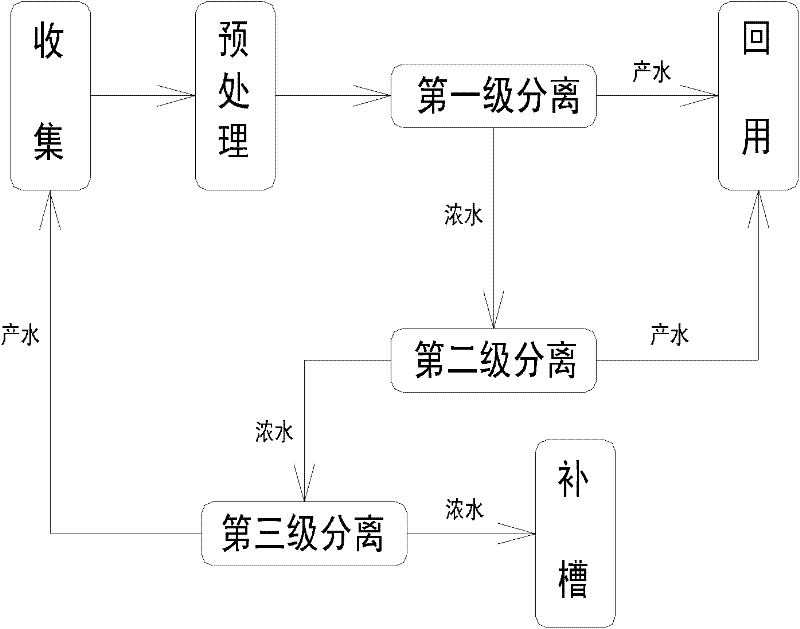

Integrated membrane electroplated nickel-contained rinsing water zero-discharging process and special equipment thereof

ActiveCN102515377AReduce pollutionReduce manufacturing costWaste water treatment from metallurgical processWater/sewage treatment bu osmosis/dialysisParticulatesThree stage

The invention provides an integrated membrane electroplated nickel-contained rinsing water zero-discharging process and special equipment thereof. The process comprises the following steps of: first, collecting electroplated nickel-contained rinsing waste water; adjusting the quantity of the collected rinsing waste water so that the water quality of the rinsing waste water is uniform; next, pre-treating the adjusted rinsing waste water; filtering the rinsing waste water so as to remove particulates with diameters of more than 100 microns in the rinsing waste water; and then carrying out three-stage separation on the pre-treated rinsing waste water. After the rinsing waste water of an electroplating factory is treated by using the recycling treatment special equipment designed according tothe process provided by the invention, the metal nickel in the rinsing waste water is recycled; and the rinsing waste water is filtered to enter a producing system to be reused so that the recycling rate of the rinsing waste water reaches zero discharge, the pollution of the sewage to the environment is reduced and the production cost is saved.

Owner:SHANGHAI JINGYU ENVIRONMENT ENG

Nickel plating method for silicon-aluminum alloy

The invention discloses a nickel plating method for a silicon-aluminum alloy, and the method comprises the following steps: washing silicon-aluminum alloy parts with alkali and acid; then putting the silicon-aluminum alloy parts in a hydrofluoric acid solution so as to be activated; putting the activated silicon-aluminum alloy parts into a chemical nickel leaching solution so as to be processed; and finally electroplating nickel, dewatering and drying the processed silicon-aluminum alloy parts to form a firm nickel plating layer, wherein the chemical nickel leaching solution comprises 300-700 g / L of nickel chloride, 30-45 g / L of boric acid and 5-20 ml / L of hydrofluoric acid. The nickel plating layer can not foam or fall off at the high temperature of 33 DEG C, and the percent of pass of nickel electroplating is more than 98%, so the technical requirements of electroplating nickel on the silicon-aluminum alloy can be fully met.

Owner:CHINA ZHENHUA GRP YONGGUANG ELECTRONICS CO LTD STATE OWNED NO 873 FACTORY

All-directional conductive foam and producing method thereof

ActiveCN101431885AIncrease elasticityGood flexibilityMagnetic/electric field screeningLiquid/solution decomposition chemical coatingPolyesterChemical plating

The present invention relates to unidirectional conductive foam and a manufacture method thereof. The technical problem to be solved through the invention is to provide unidirectional conductive foam and a manufacture method, and the conductive foam produced in the way described in the invention has excellent compressibility and softness, can guarantee good conductive contact area with excellent electromagnetic shielding performance. The technical solution is as following: unidirectional conductive foam characterized in that substrate of the conductive foam is flake high elastic foaming sponge with polyester, polyether or PET as its main components; wrap the unidirectional conductive foam with breathable mesh cloth and the thickness of wrapped foam is between 1mm to 10mm; chemical plating copper layer, electroplating nickel layer and resin protective layer are provided from inside to outside in series. The invention can be used in producing electromagnetic shielding material in housing, industrial and military device and instruments.

Owner:ZHEJIANG SAINTYEAR ELECTRONICS TECH

Efficient treatment method for electroplating nickel-containing waste water

InactiveCN105800841AAvoid secondary pollutionEasy to operateWaste water treatment from metallurgical processMultistage water/sewage treatmentWastewaterWater ph

The invention discloses an efficient treatment method for electroplating nickel-containing waste water.The method comprises the following steps that 1, under the acidic condition, the electroplating nickel-containing waste water is subjected to a microelectrolysis reaction in a microelectrolysis reactor till the pH value of the electroplating nickel-containing waste water ranges from 4.0 to 5.0; 2, an oxidizing agent is added, and the electroplating nickel-containing waste water is subjected to secondary microelectrolysis in the microelectrolysis reactor continuously; 3, an alkaline solution is added, and the pH value of the electroplating nickel-containing waste water ranges from 9.5 to 11.0; 4, coagulant and flocculant are added to the electroplating nickel-containing waste water in sequence for coagulating sedimentation, and final supernate is treated waste water capable of being discharged.The efficient treatment method for the electroplating nickel-containing waste water is easy to operate and stable in effect, chemicals such as a heavy metal chelating agent and sodium sulfide which are bad for the environment do not need to be added, and secondary pollution to environment is avoided; the occupied area is saved, the requirements on reaction conditions are low, the waste water pH can be increased in the reaction process, the alkali quantity needed by follow-up alkali adjustment is decreased, and a product obtained through treatment can be recycled.

Owner:李小琴

Method for manufacturing chip-type linear positive temperature coefficient thermistor

ActiveCN103050204AReduce volumeReduce weightPositive temperature coefficient thermistorsHeat sensitiveEngineering

The invention particularly discloses a method for manufacturing a linear positive temperature coefficient thermistor. The method comprises the following steps: manufacturing a surface electrode and a back electrode, manufacturing a resistor, packaging, trimming the resistor by using laser, slivering, sintering, coating an end electrode and electroplating, particularly selecting a substrate and polishing and cleaning the substrate, printing the surface electrode and the back electrode, sintering the surface back electrode and the back electrode, printing secondary glass, performing magnetron sputtering on a target material to form the resistor, performing heat treatment, removing a barrier layer to expose the resistor, trimming the resistor by using the laser, printing and packaging, solidifying a packaging layer, slivering primarily, coating the end electrode, sintering the end electrode, slivering secondarily, and electroplating nickel and tin-lead alloy. The manufactured chip-type linear positive temperature coefficient thermistor is small in size, light in weight, low in manufacturing cost and high in stability and quality reliability.

Owner:CHINA ZHENHUA GRP YUNKE ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com