Patents

Literature

5845results about "Screen printers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

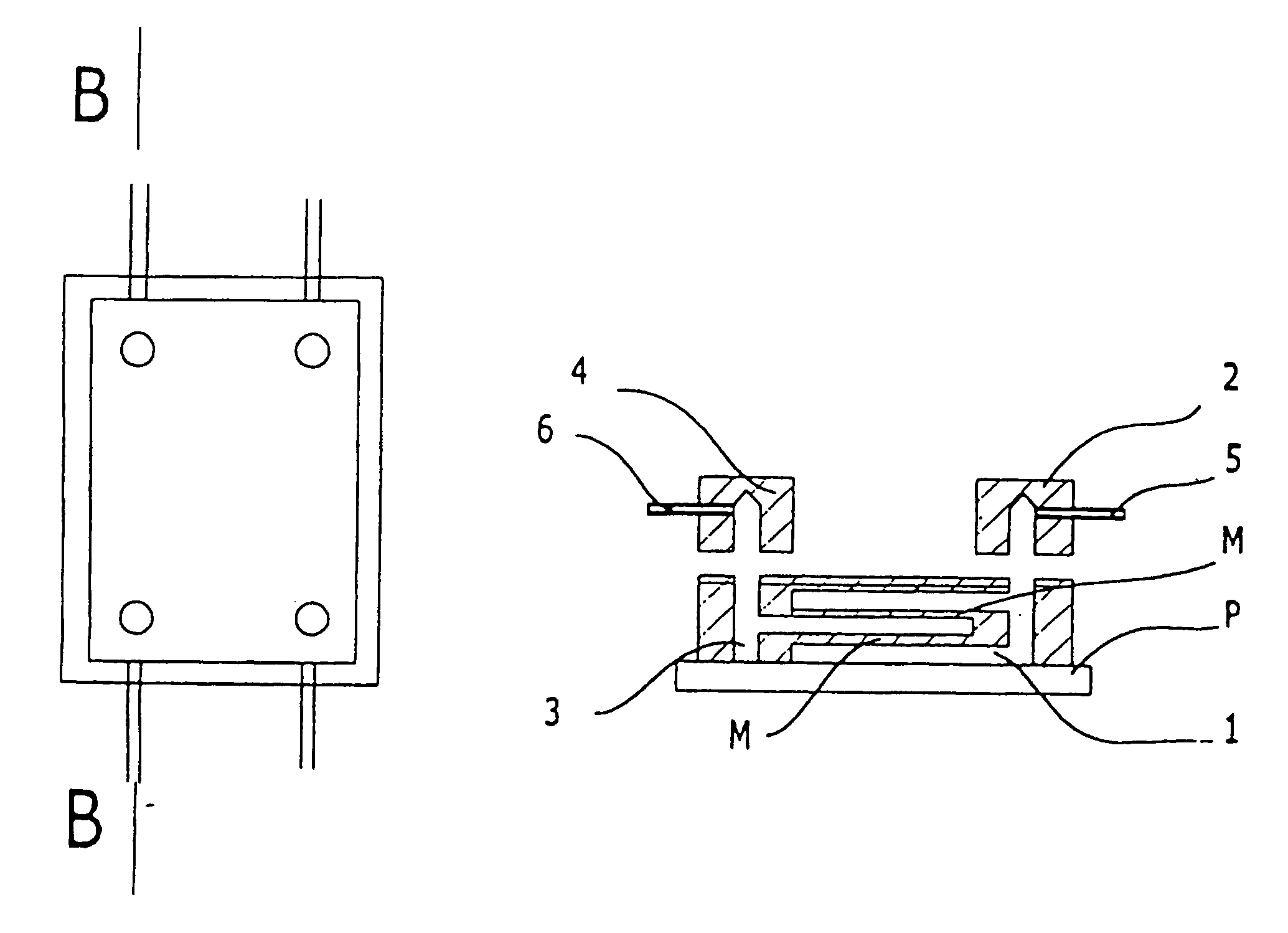

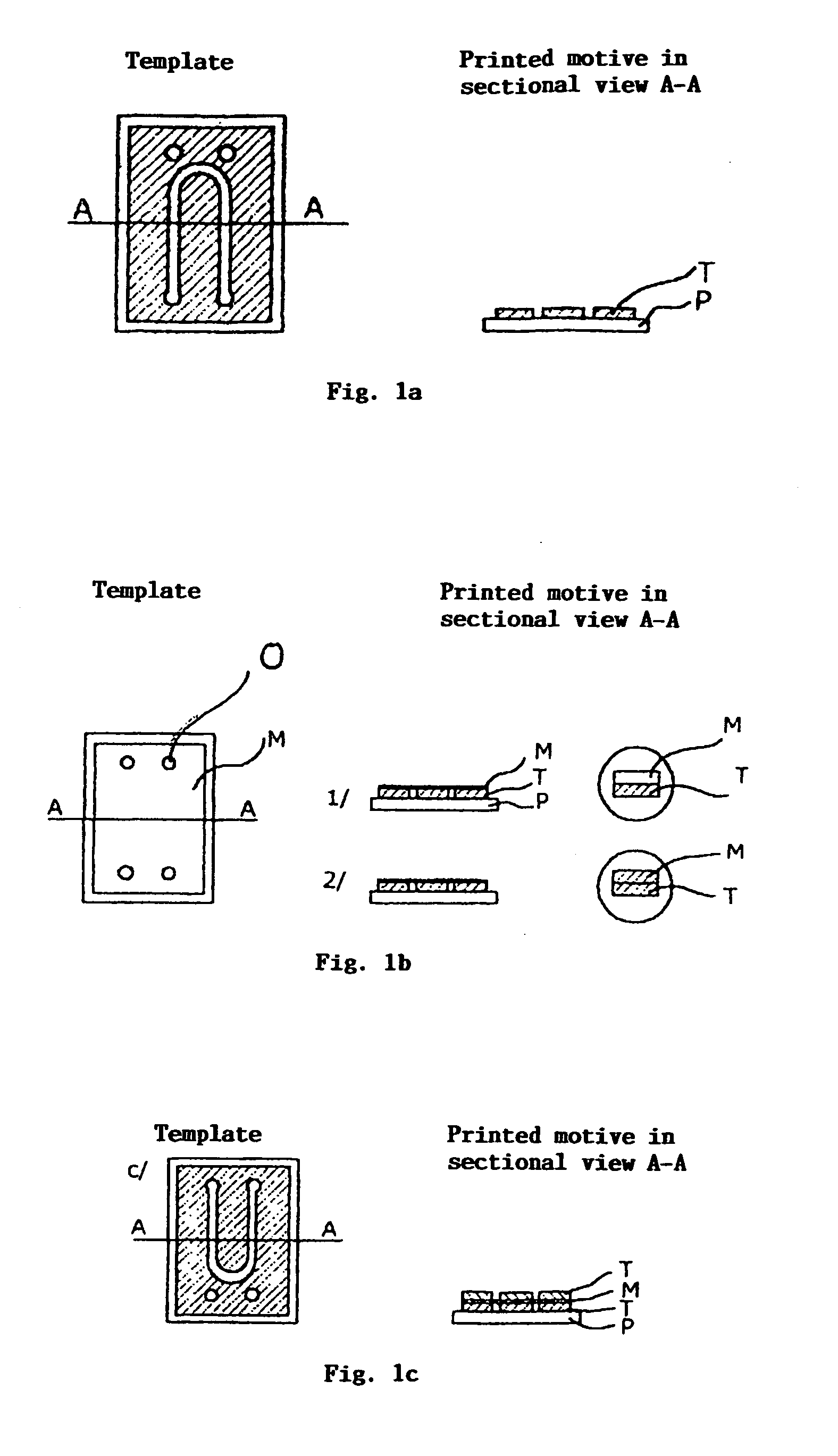

Three-dimentional components prepared by thick film technology and method of producing thereof

Object of the present invention are components with three dimensional structure prepared by thick film technology by print, where between the printed layers is inserted at least one membrane. The membrane is according to the present to invention at least in a part of the final product. The membrane can be provided with holes which are necessary for next technological steps. The inserted membranes can have pores of the size of 50˜tm to 10 nm and a thickness of 1 to 200˜tm. Method of producing of components with three-dimensional structure by thick film printing technology according to the invention lies in that between some of the printed layers is inserted a suitable membrane, which allows to lay on next layers without influence to previous layers. The printing can be done by screen-printing.

Owner:ING ILJA KREJCI ENG

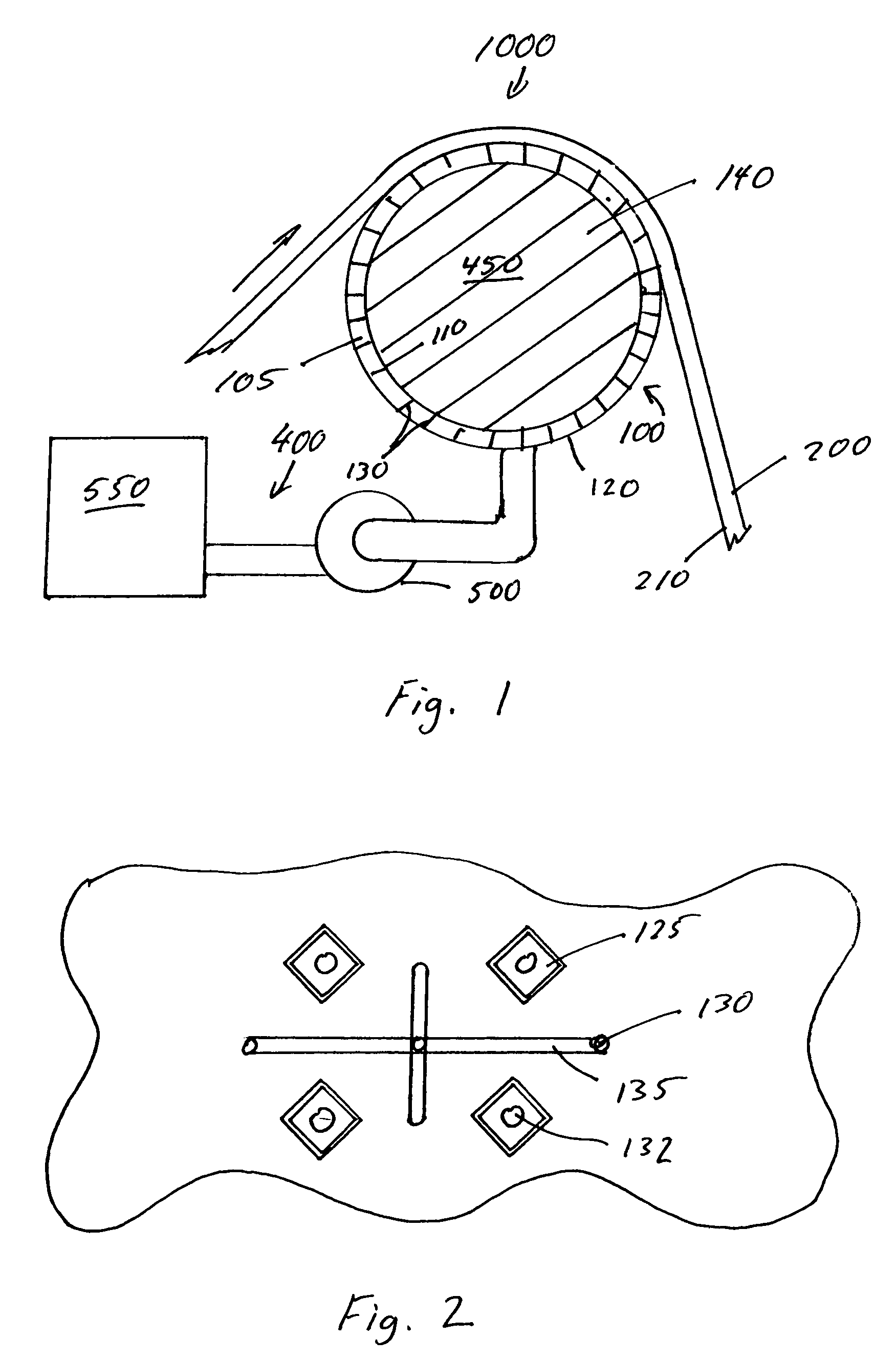

Apparatus and method for the transfer of a fluid to a moving web material

An apparatus and method for enabling the transfer of a fluid to a web material, the apparatus comprising a fluid transfer component having a first surface, a second surface, and a non-random pattern of distinct pores. The pores connect the first surface and the second surface and are disposed at preselected locations to provide a desired pattern of permeability. The apparatus also comprises a fluid receiving component comprising a fluid receiving surface, a fluid supply adapted to provide a fluid in contact with the first surface of the fluid transfer component, and a fluid motivating component adapted to facilitate transport of the fluid from the first surface through the pores to the second surface. The method comprises steps of providing the apparatus, motivating a fluid through the pores and bringing the fluid receiving component into contact with the motivated fluid.

Owner:PROCTER & GAMBLE CO

Combined stencil and digital printing system

InactiveUS20060249039A1Increase surface tensionScreen printersTypewritersStencil printingEngineering

A printing system comprising a stencil printing apparatus and a digital printing apparatus for high speed printing of images having details of high resolution, rich colors, or variability, optionally also comprising a wetting apparatus operative to wet at least a part of the printed object prior to the digital printing.

Owner:KORNIT DIGITAL TECHNOLOGIES LTD

Process for printing adhesives, adhesive articles and printing equipment

The present invention relates to a process for printing specific adhesives onto articles, such as absorbent articles or release paper, using a specific transfer tool and / or a specific adhesive, having a specific peel force, viscosity, elastic loss modulus, elastic modulus, surface energy and loss tangent modulus; the invention also relates to articles comprising the specific adhesives and to specific printing rolls.

Owner:THE PROCTER & GAMBLE COMPANY

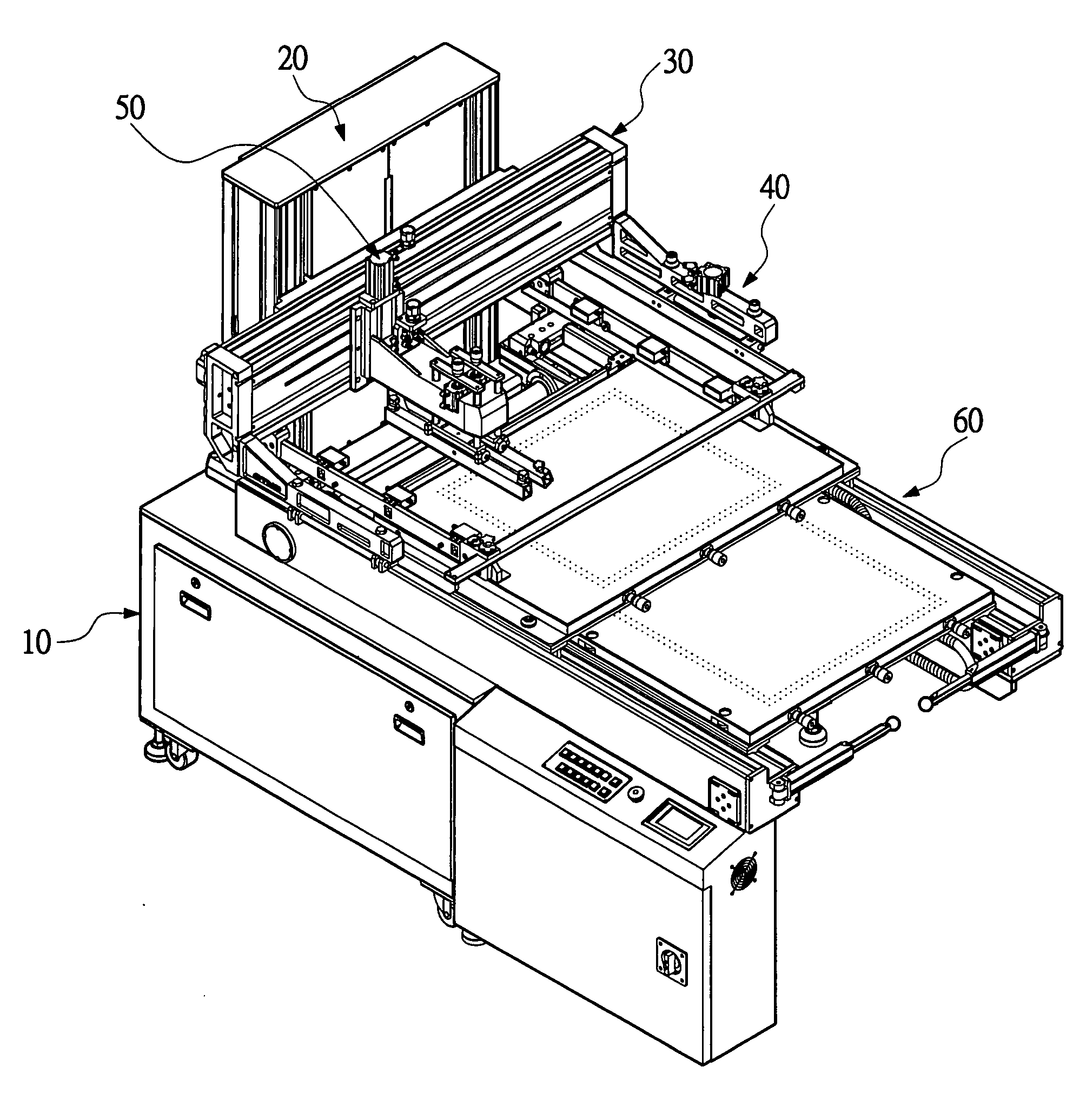

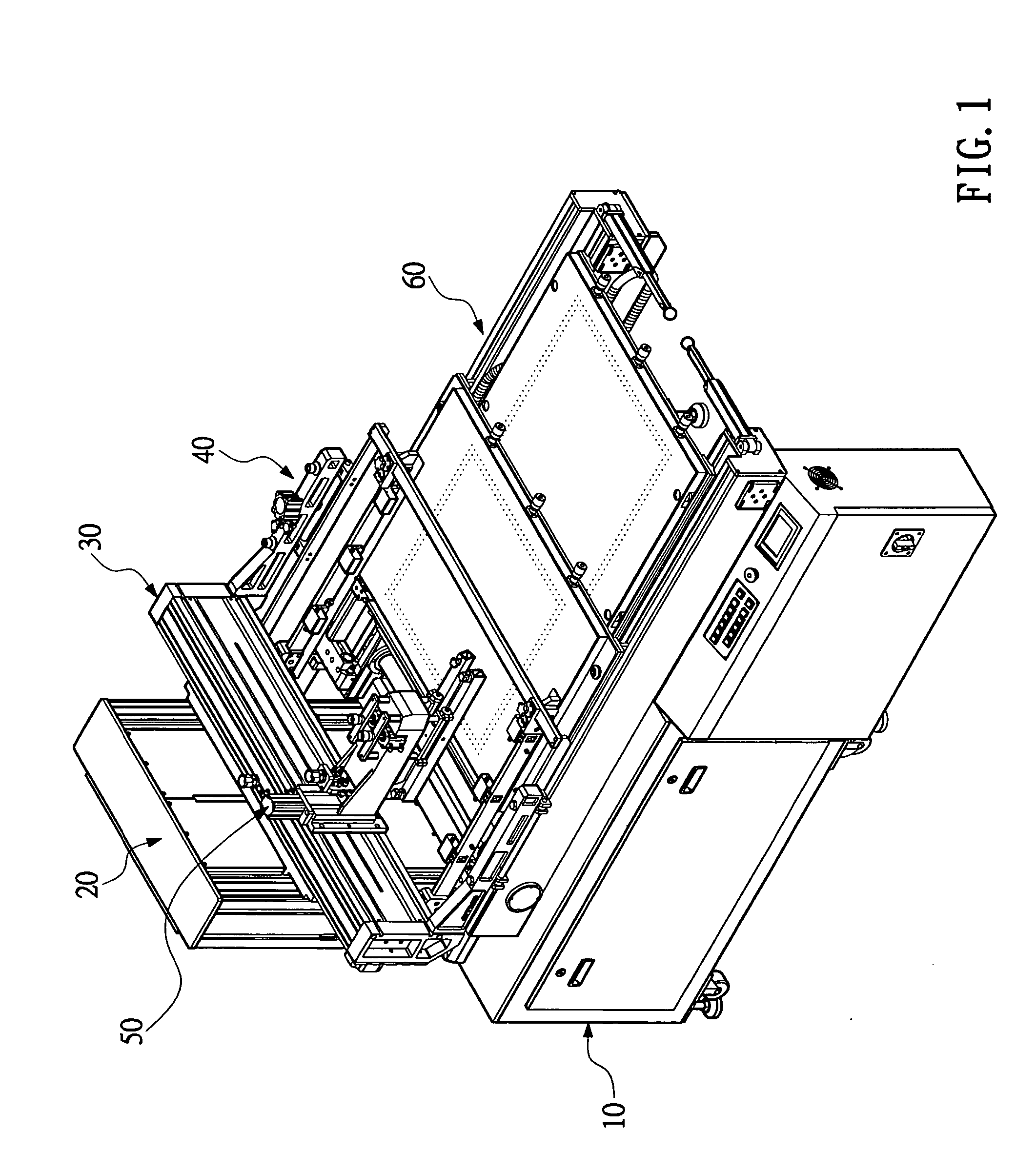

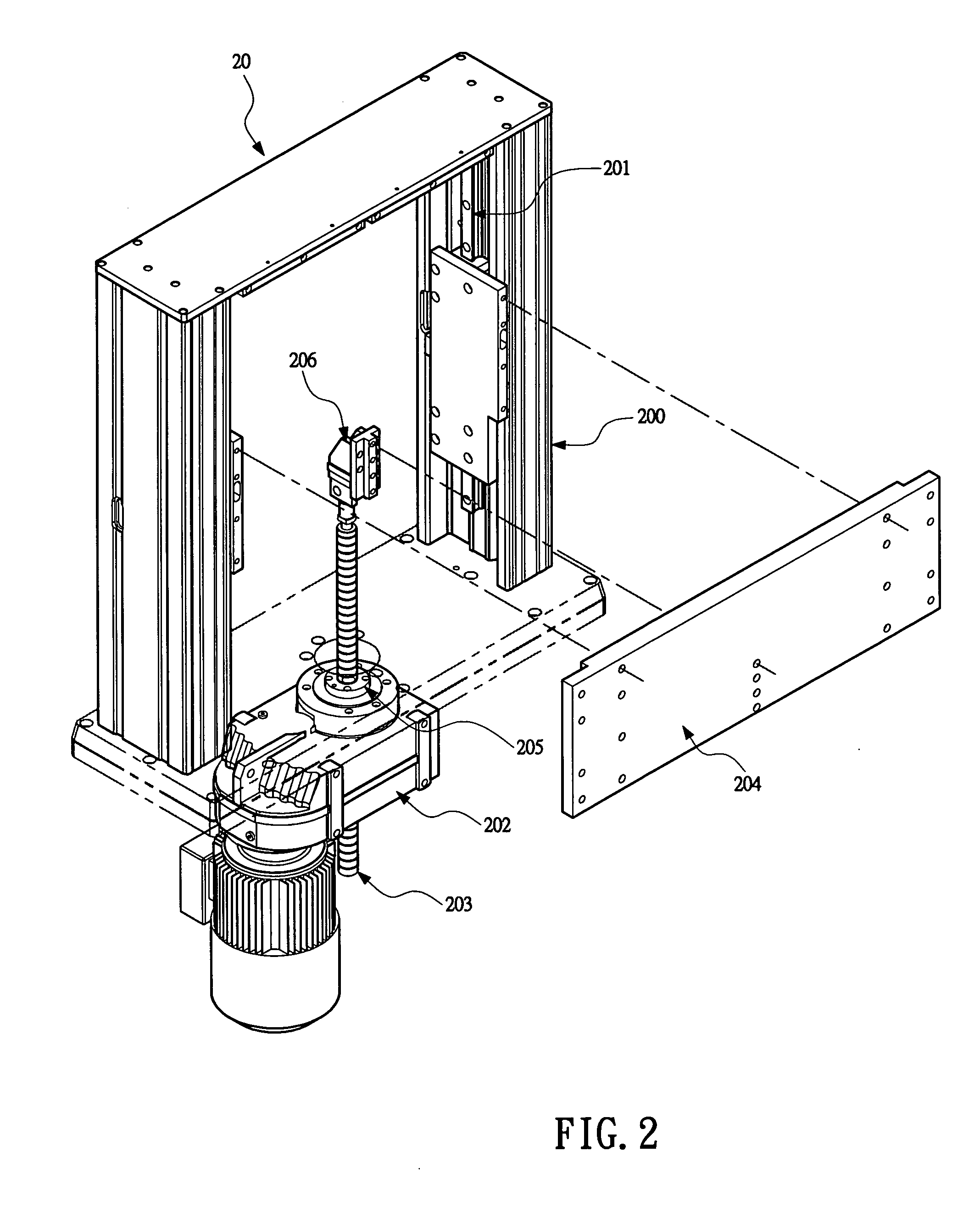

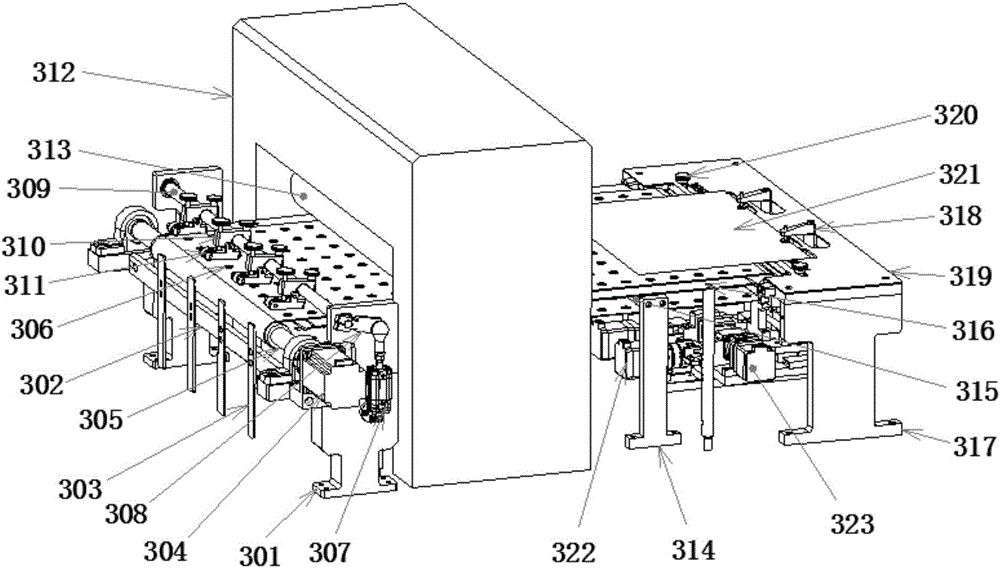

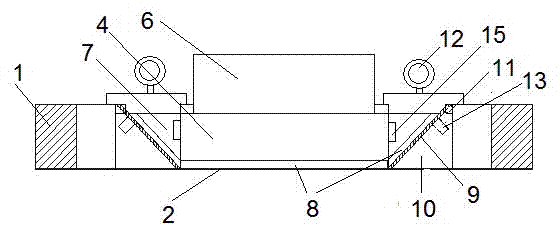

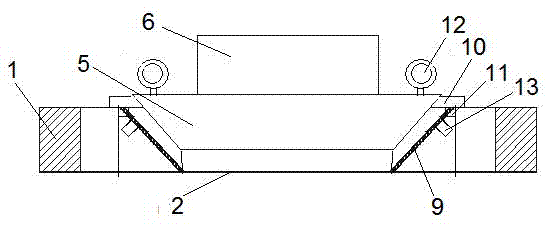

Cantilever type screen-printing machine with double platform

InactiveUS20050263017A1Prevent movementPrecise positioningLiquid surface applicatorsScreen printersGear wheelReducer

The present invention discloses a cantilever type screen-printing machine with double platforms that possess a gear reducer motor with a hollow shaft to rotate a screw of a threaded screw unit and further drive a threaded rod to move upward and downward without rotation inside the hollow shaft thus make a transverse sliding assembly move vertically and synchronously with the threaded rod. Moreover, by a rectangular frame and two sets of horizontal micro adjustable chase clamping mechanism transversely fixed on the rectangular frame, the relative position between the chase and the print materials is adjusted directly. The upper and the lower platforms are driven and powered by two gear reducer motors and a homocentric coaxial-type driving mechanism respectively. By the simplified driving mechanism, the printing efficiency and productivity are enhanced.

Owner:ATMA CHAMP ENTERPRISE

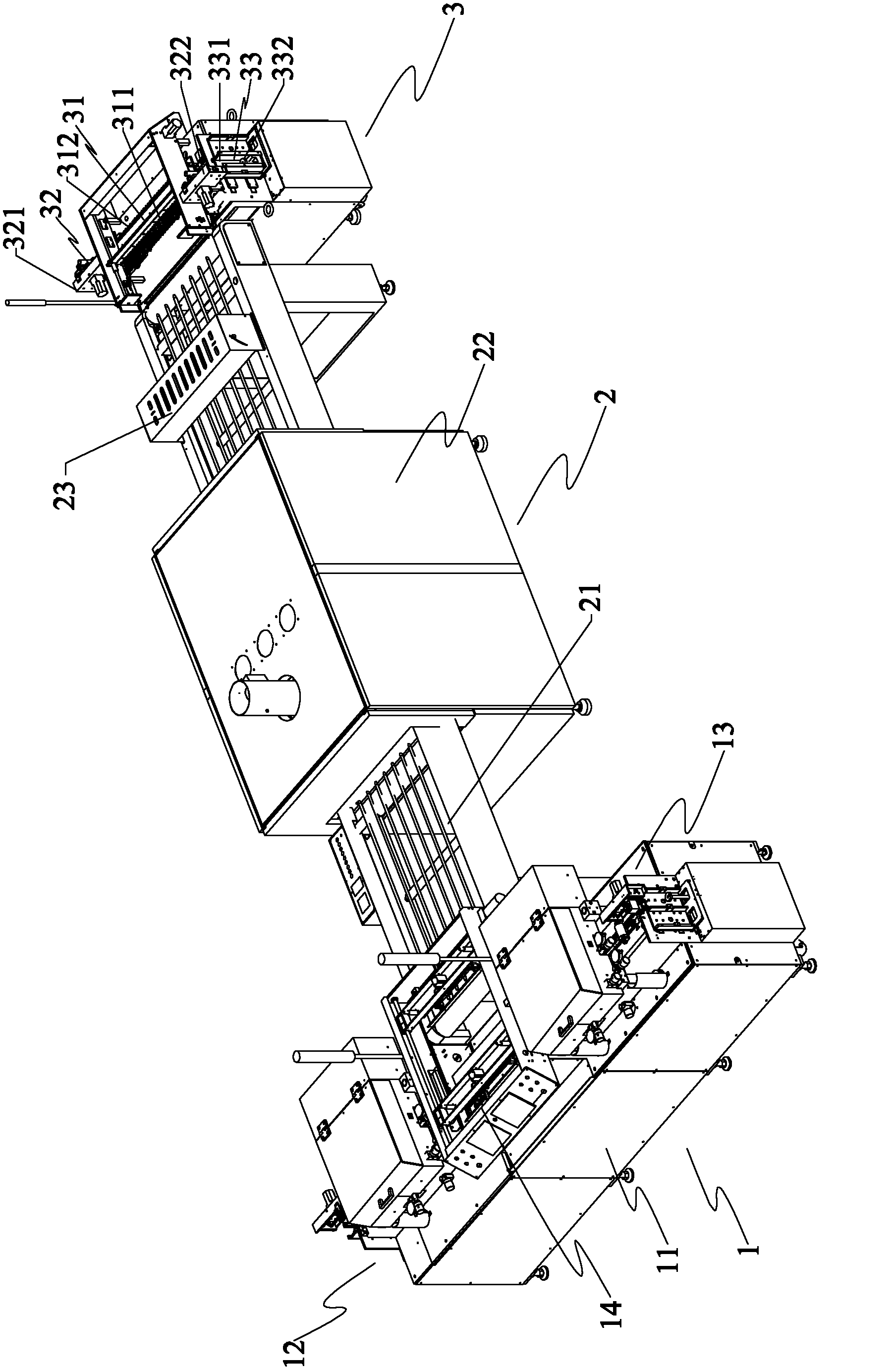

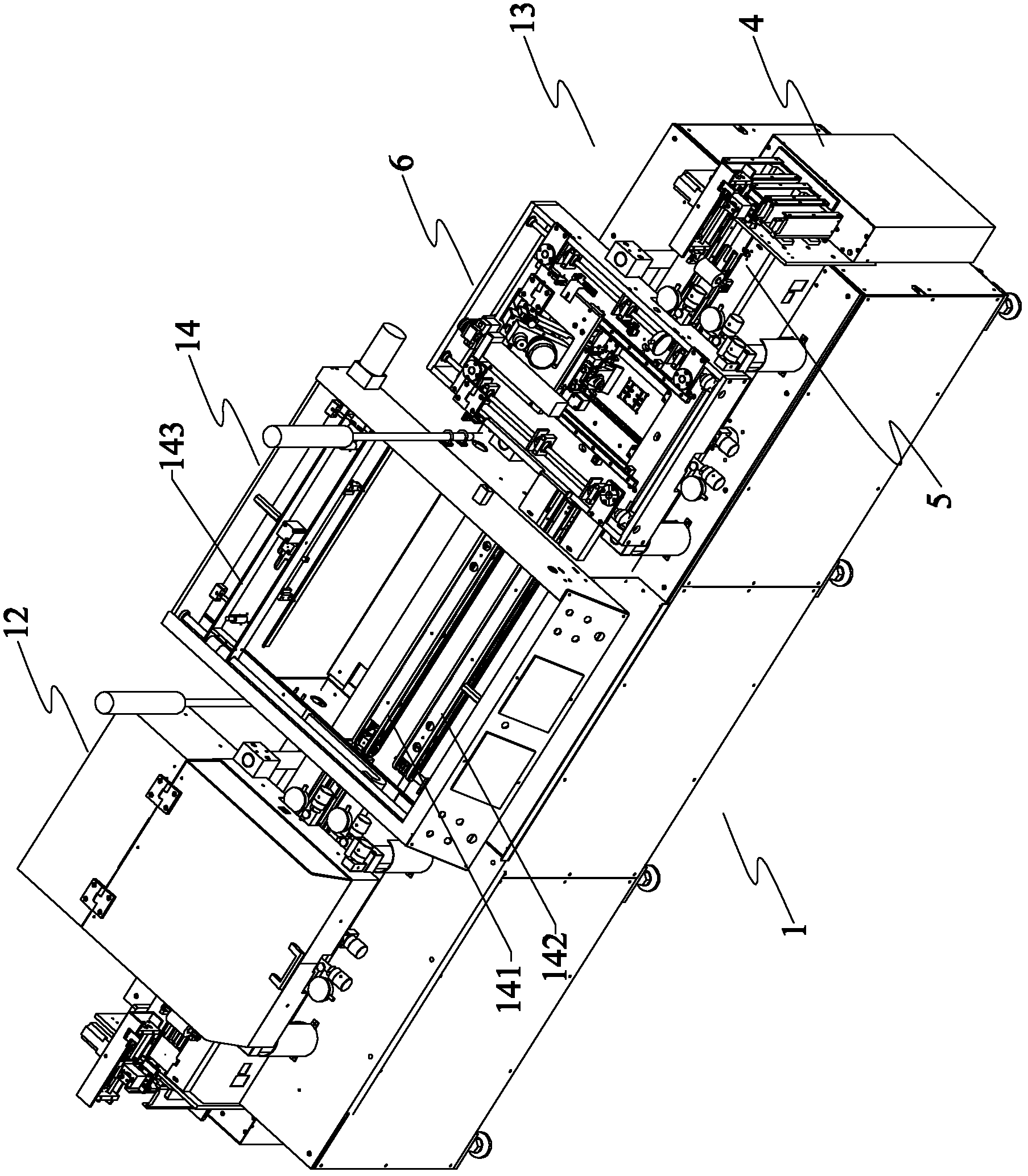

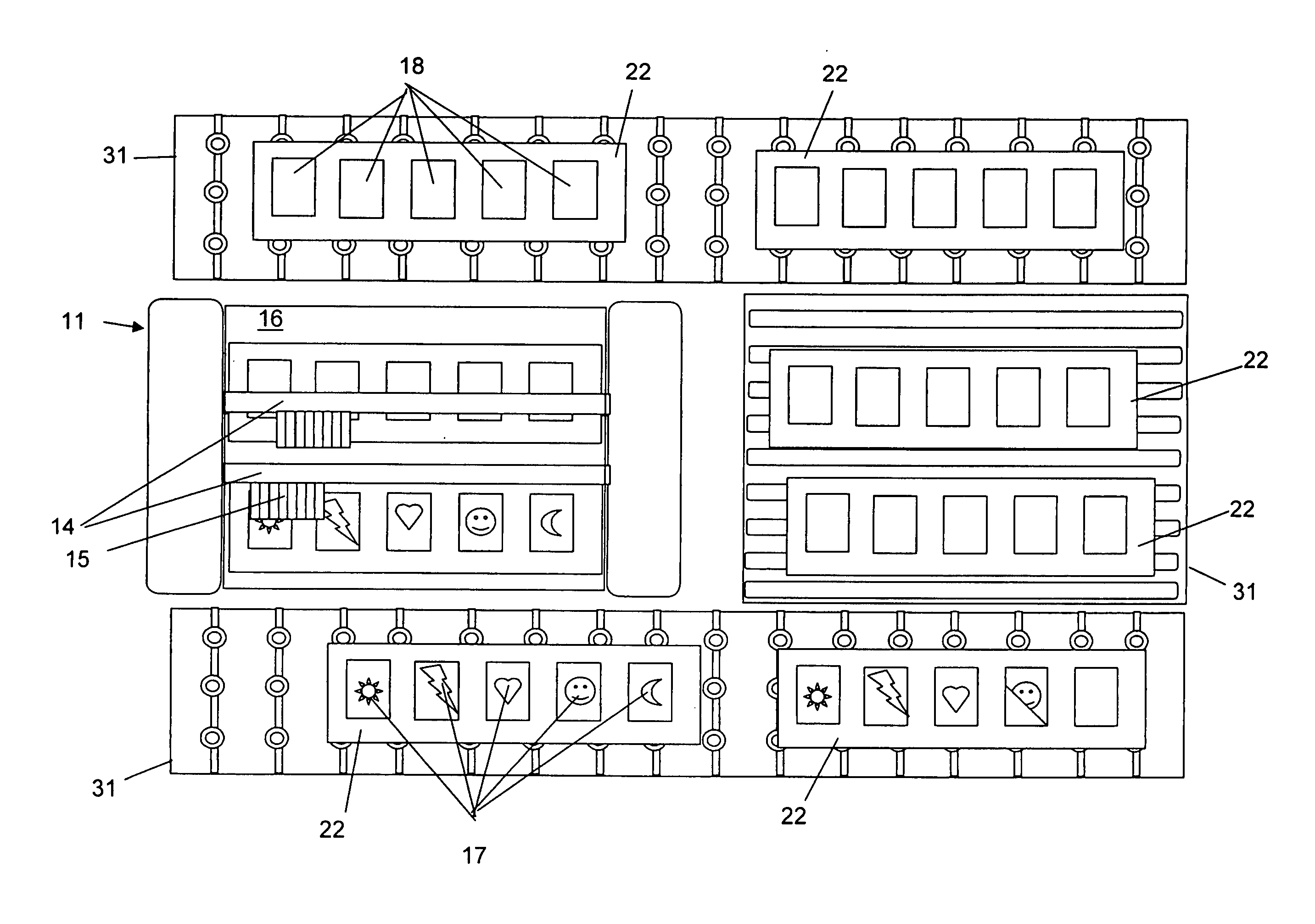

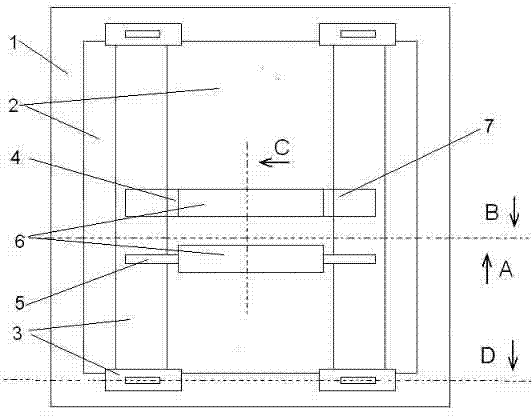

Full-automatic double-work-station screen printing machine

The invention discloses a full-automatic double-work-station screen printing machine, which comprises a printing system, a drying system and an electronic control system, wherein the printing system comprises a base, a left work station printing device, a right work station printing device and a leveling device, wherein the left work station printing device and the right work station printing device are mutually independent and mounted above the base; the leveling device is arranged between the left work station printing device and the right work station printing device; each work station printing device comprises a material loading mechanism, a substrate transmitting and positioning mechanism and a screen printing mechanism which move in a matched manner. Compared with the prior art, the full-automatic double-work-station screen printing machine has the beneficial effects that the full-automatic double-work-station screen printing machine is provided with the left and the right double-work-station printing systems, each work station printing system can independently complete the printing operation, the whole process of material feeding, transmitting, positioning, printing, leveling, drying and collection is automatically controlled at the same time, the efficiency is high, the cost is low, the maintenance is convenient, and the requirements of batch production and the production requirements of high-end products can be effectively met.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

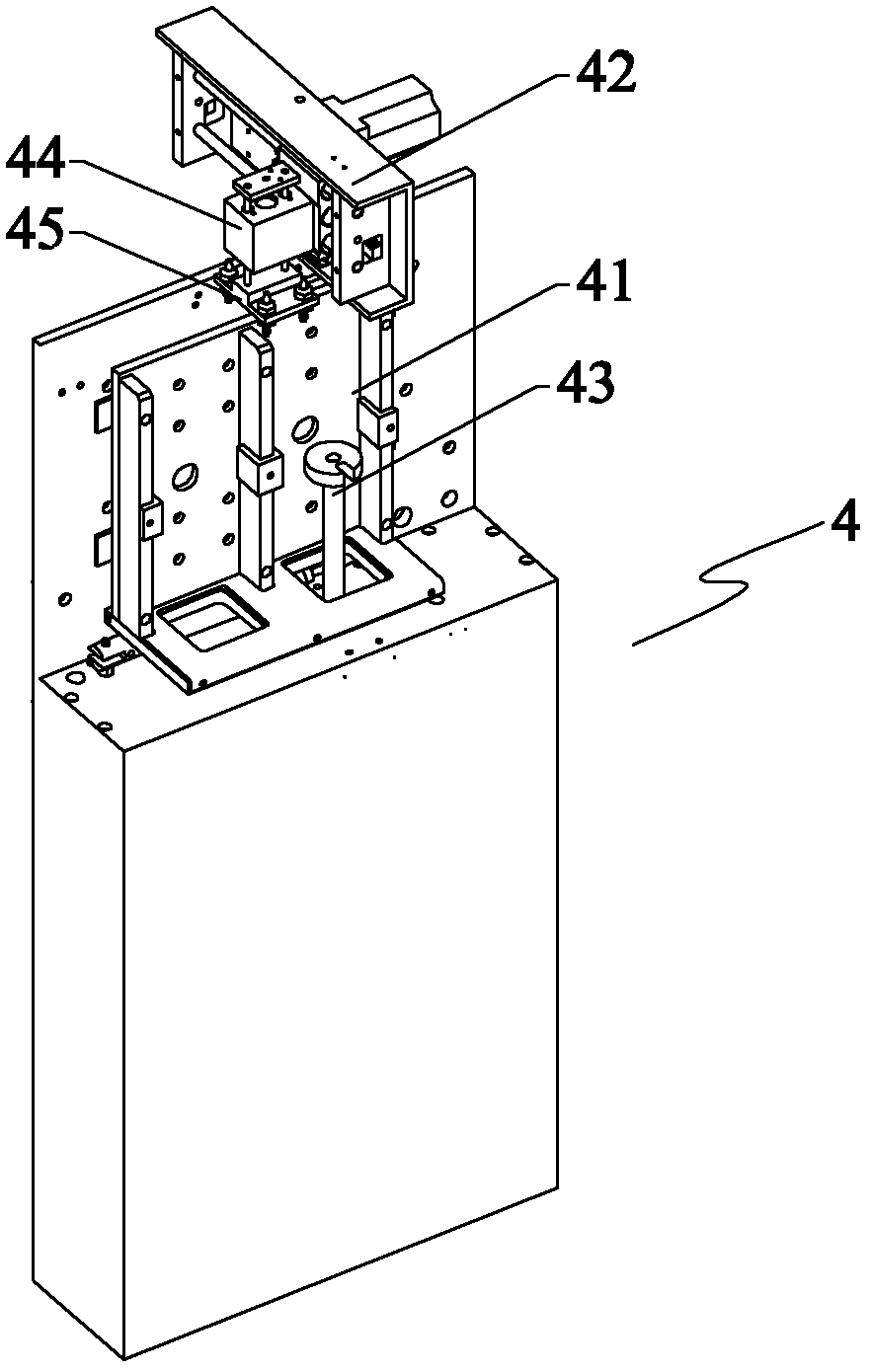

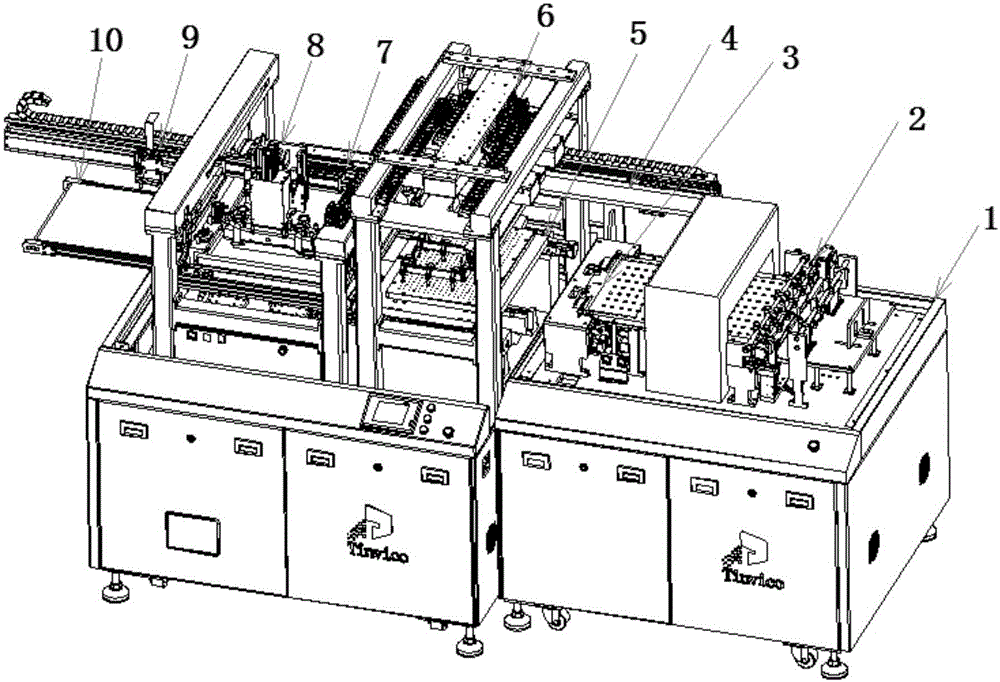

Full-automatic high-precision double-printing-platform screen printing machine

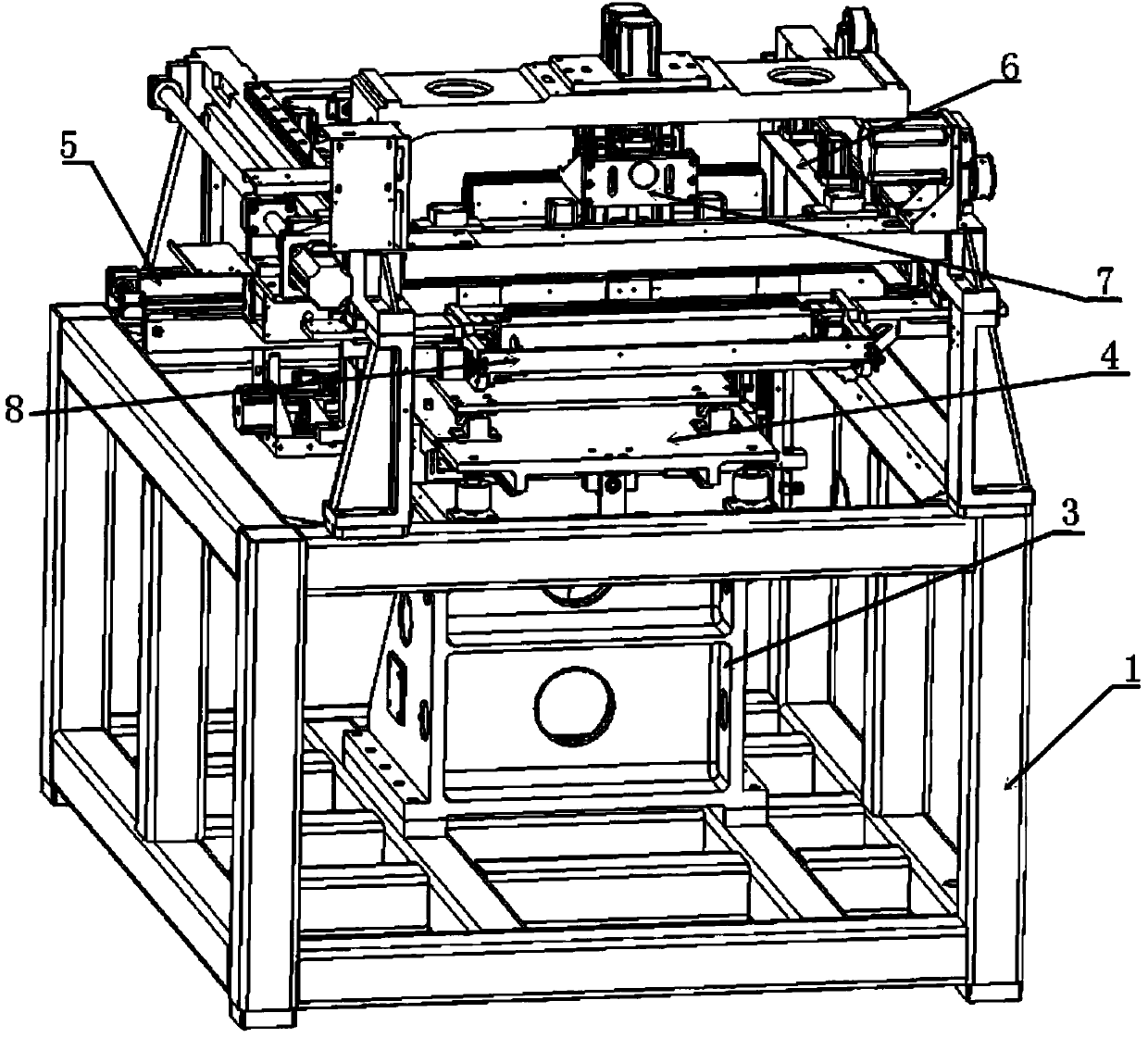

InactiveCN106671579ASolve the problem of manual loading and unloadingReasonable layoutScreen printersConveyor partsEngineeringPrinting press

The invention discloses a full-automatic high-precision double-printing-platform screen printing machine. The full-automatic high-precision double-printing-platform screen printing machine comprises a machine frame, material conveying mechanism, a screen printing plate mounting and alignment mechanism and a screen printing mechanism and further comprises a double-printing-platform transfer assembly located on the machine frame, wherein the material conveying mechanism is located on the machine frame; the double-printing-platform transfer assembly comprises a positioning position, a printing position, a lifting printing platform and a printing platform, the lifting printing platform and the printing platform are located in the positioning position or the printing position alternately and switched between the positioning position or the printing position; the material conveying mechanism is used for conveying to-be-printed materials to the positioning position; and the screen printing plate mounting and alignment mechanism and the screen printing mechanism are arranged above the printing position for printing the to-be-printed materials located in the printing position. By means of the full-automatic high-precision double-printing-platform screen printing machine, while one to-be-printed material is printed, another to-be-printed material is automatically fed onto the printing platform and photographed and positioned, and the technical problems that most of existing full-automatic flexible-plate screen printing machine adopts single-platform linear material conveying, and consequently the system efficiency is low are solved.

Owner:SHENZHEN TINVICO TECH CO LTD

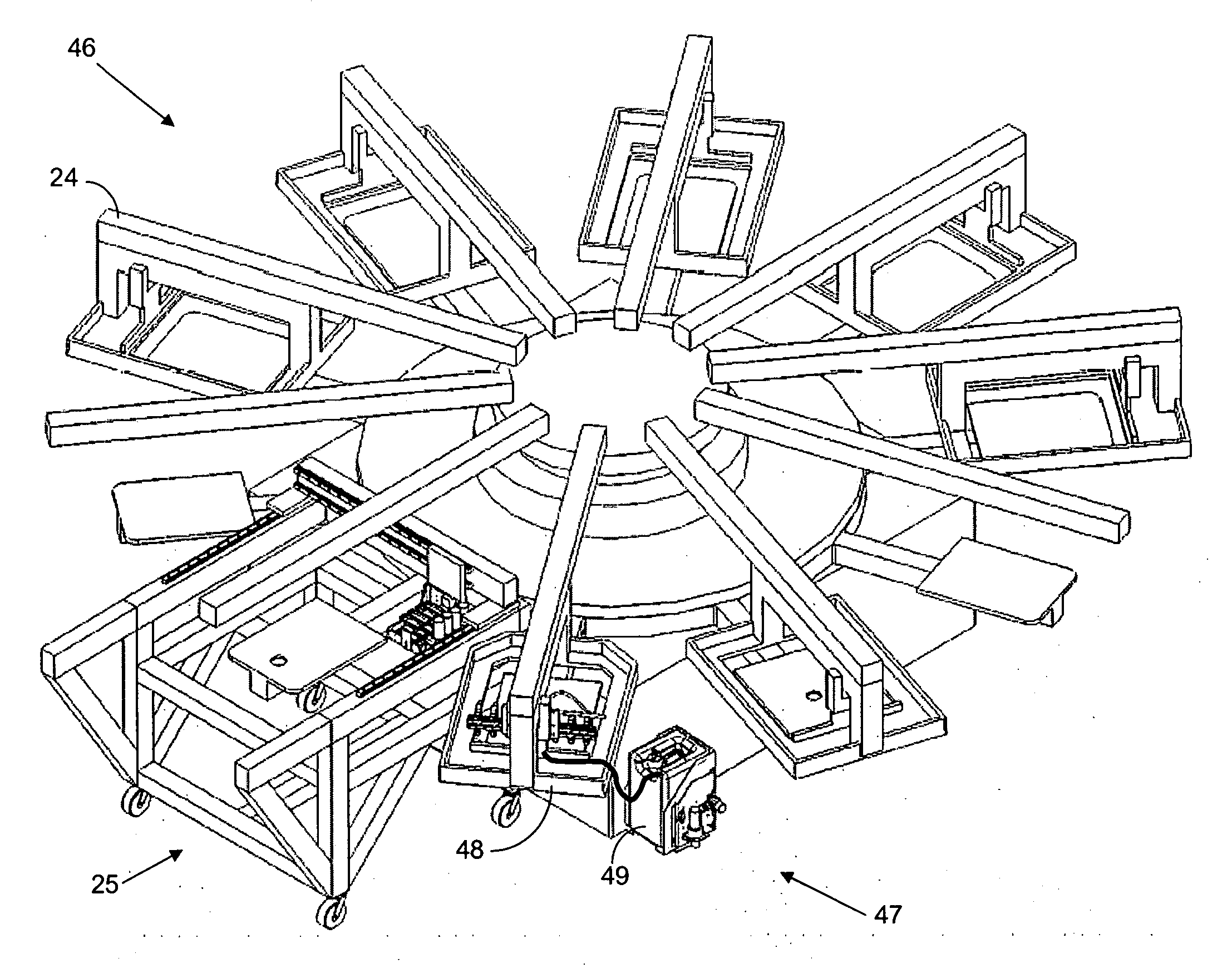

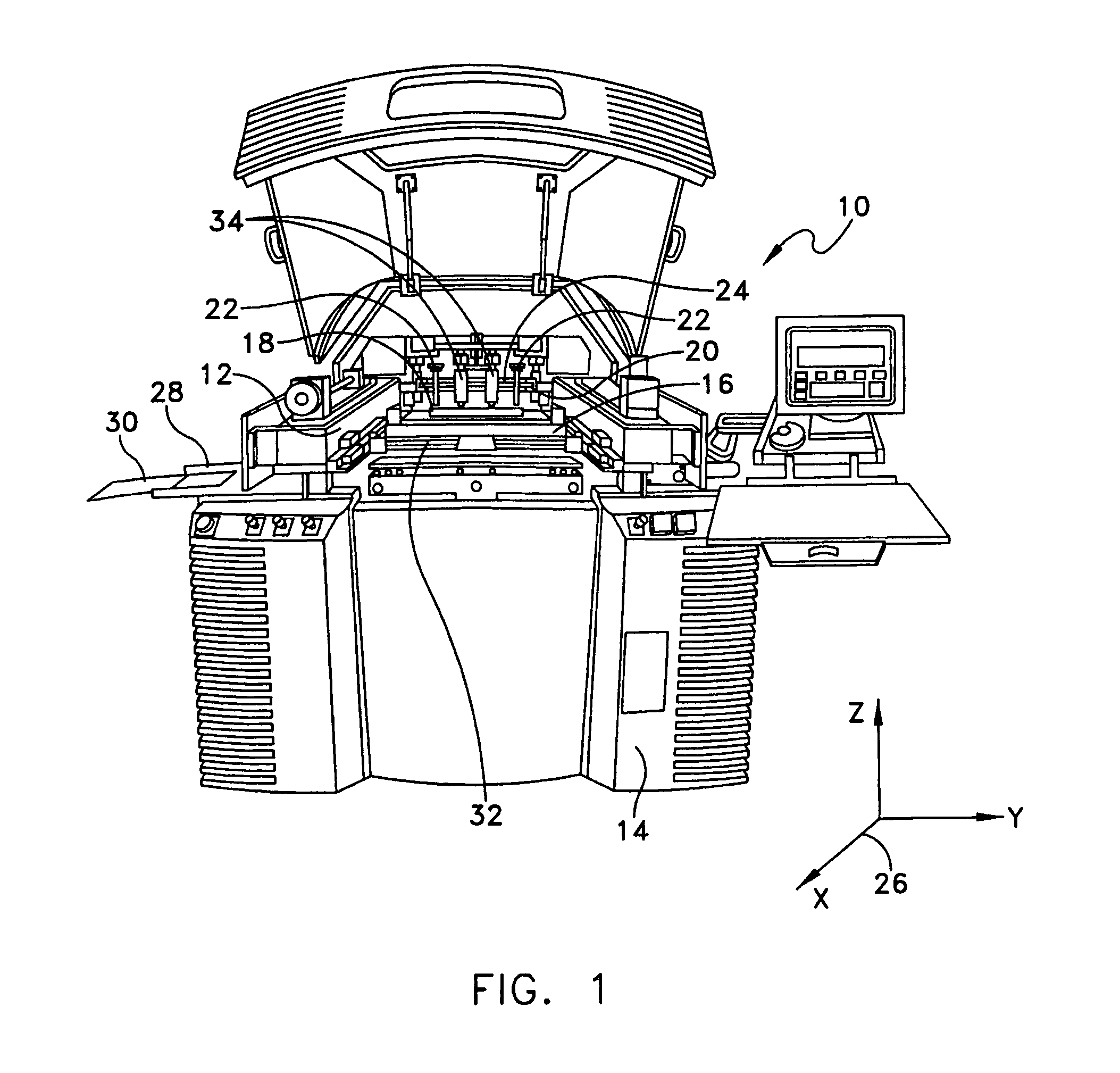

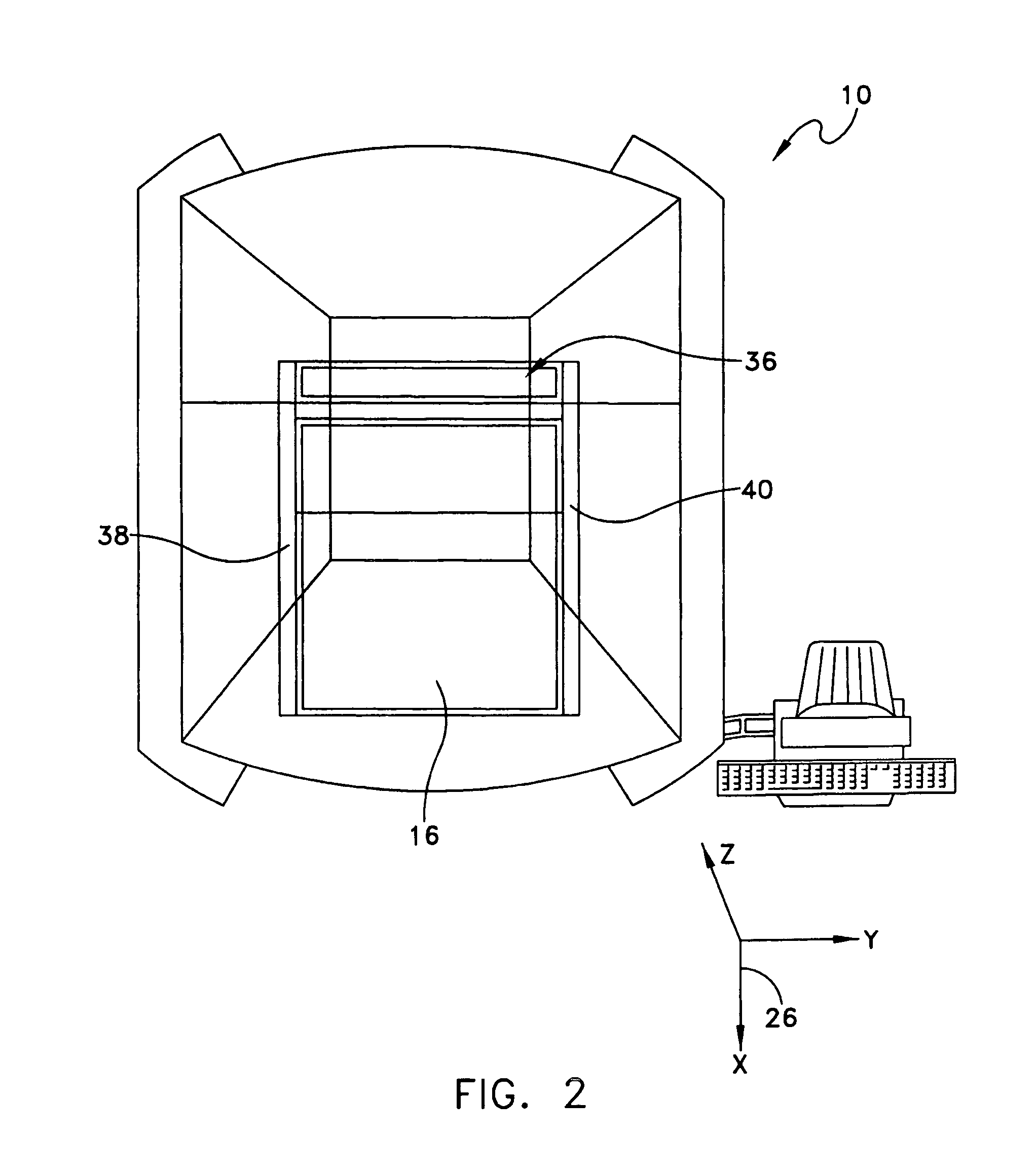

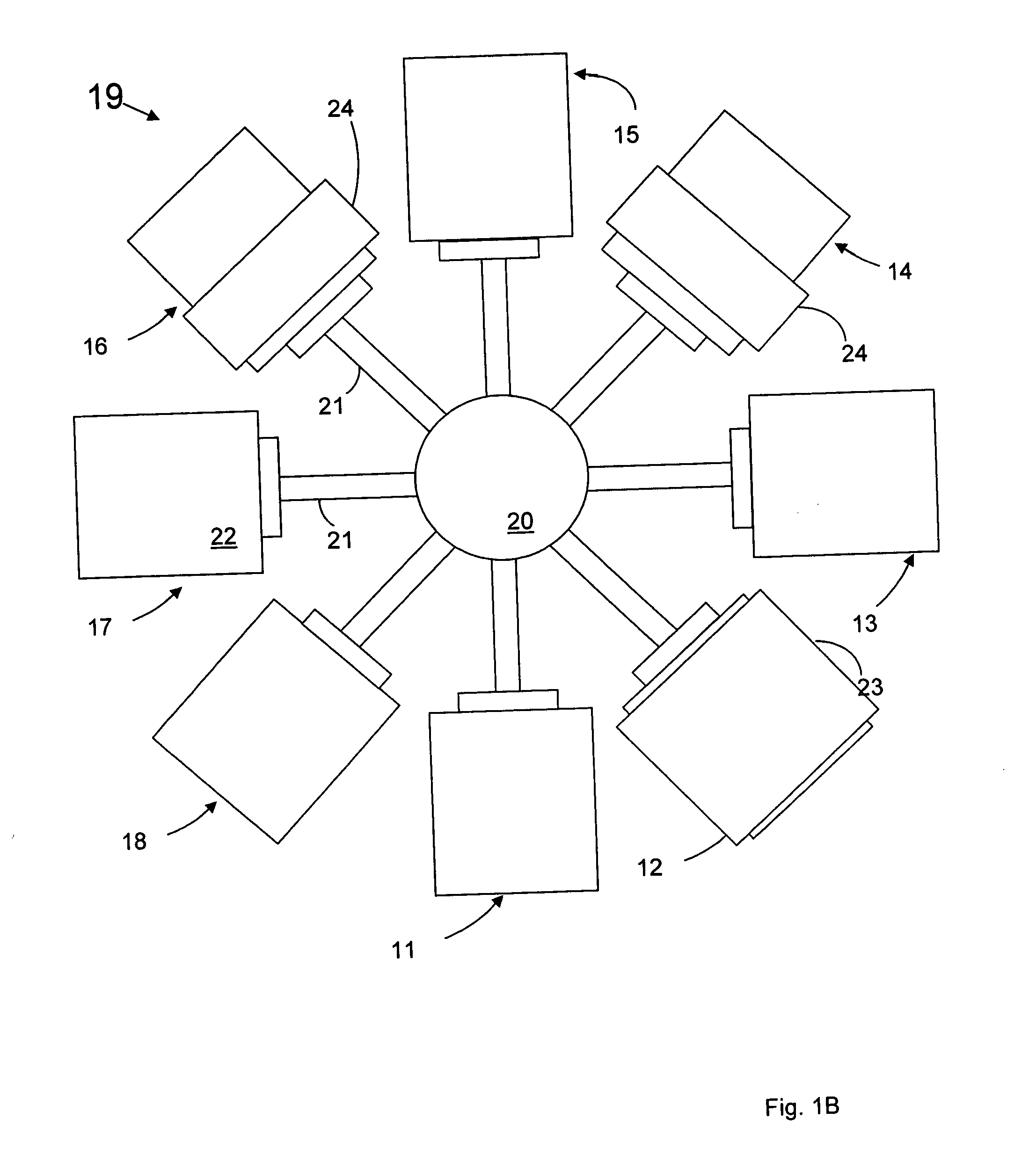

High volume inkjet garment printer with heat presses

InactiveUS20070068403A1Easy to transportIncrease volumeScreen printersTypewritersEngineeringHeat press

A method and apparatus for printing images on a high volume of printable substrates such as garments is disclosed. The apparatus comprises an inkjet printer, a conveyor system, heat presses and beds. The beds are trays with garment attachments such as platens for holding multiple garments in place during printing. In the preferred embodiment, the method first involves loading garments onto the beds and platens. The beds then travel along the conveyor system which includes one or more conveyor tables and optional heat presses. The beds are preferable placed under a heat press for pre-pressing the garments. Then the conveyor system facilitates the transfer of the beds to a high volume inkjet printer, where both an underbase and an image can be printed on each garment. After printing images on the garments, the beds are transferred again to the conveyor system and optionally delivered to another heat press to cure the image. Finally, the garments are unloaded from the beds and new un-printed garments are loaded.

Owner:GRAPHIC ARTS ACQUISITION

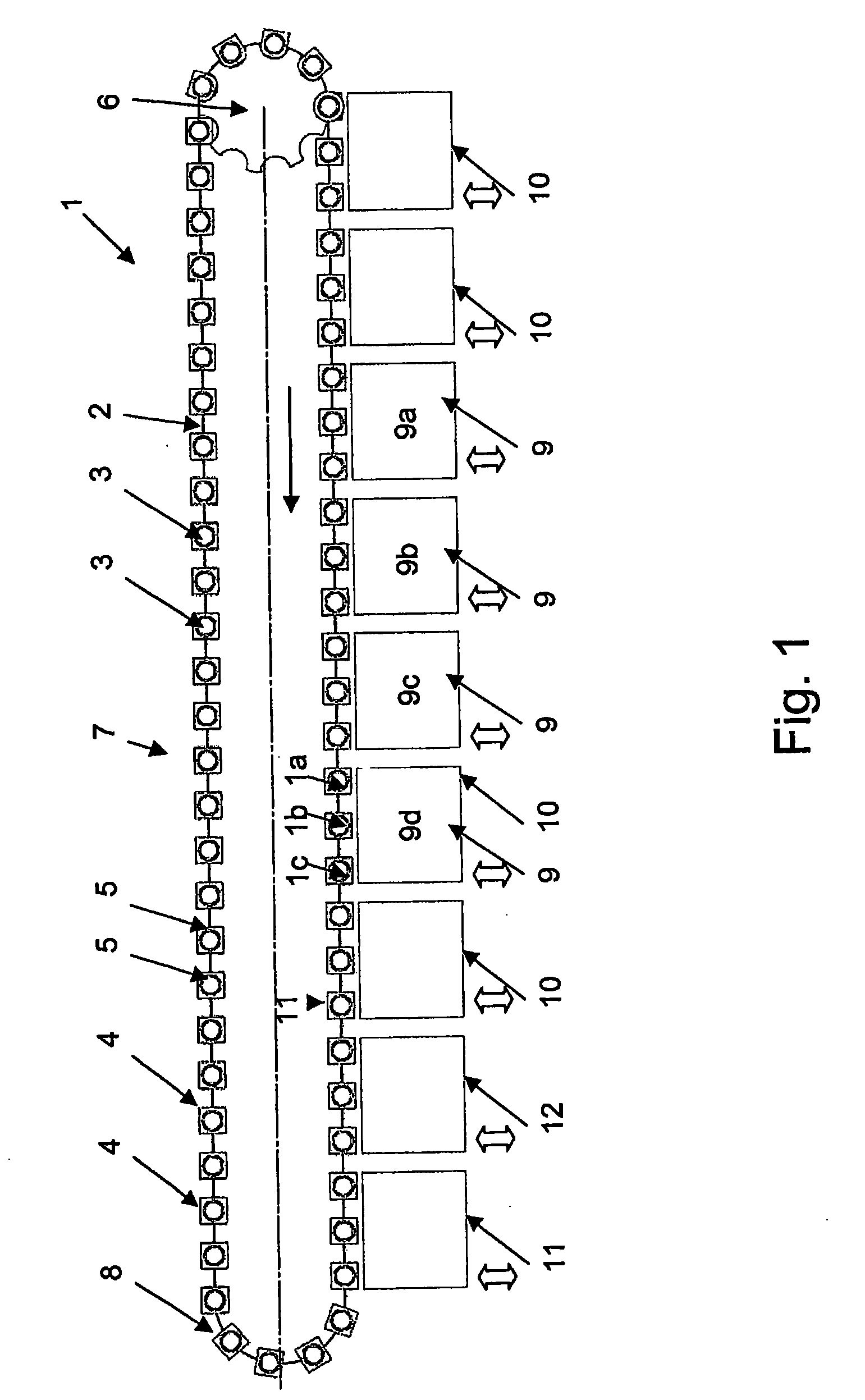

Modular linear printing press for printing hollow articles by means of different printing processes

InactiveUS20110067584A1Increase productionMethod is differentScreen printersTypewritersScreen printingTransport system

A linear printing machine with exchangeable printing modules for printing on hollow bodies. The machine includes a transport system including a drive, using which the hollow bodies to be printed on are transported through the linear printing machine and at least a first printing station and a second printing station which is arranged downstream of the first printing station in the conveying direction of the hollow bodies. At least one drying station dries the ink on the hollow bodies which have been printed on. A machine controller controls at least the transport of the hollow bodies through the linear printing machine, wherein each of the printing stations is prepared to accommodate a printing module comprising a drive of its own, and wherein the printing module can be connected to the machine controller via an interface, wherein the printing modules print on the hollow bodies using a printing method selected from screen printing and / or flexographic printing and / or offset printing and / or cold embossing and / or hot embossing and / or laser colour transfer and / or inkjet.

Owner:POLYTYPEAG

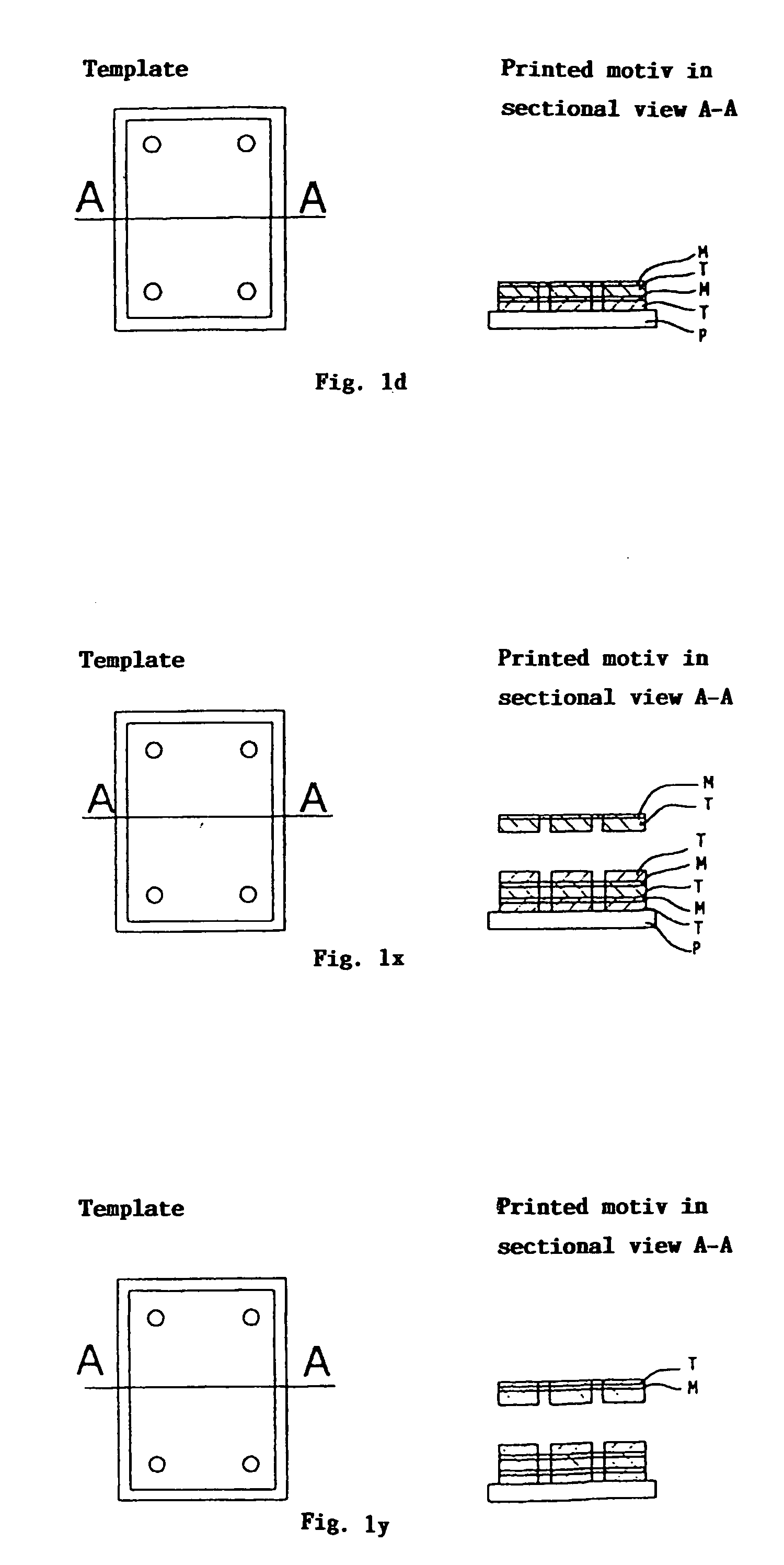

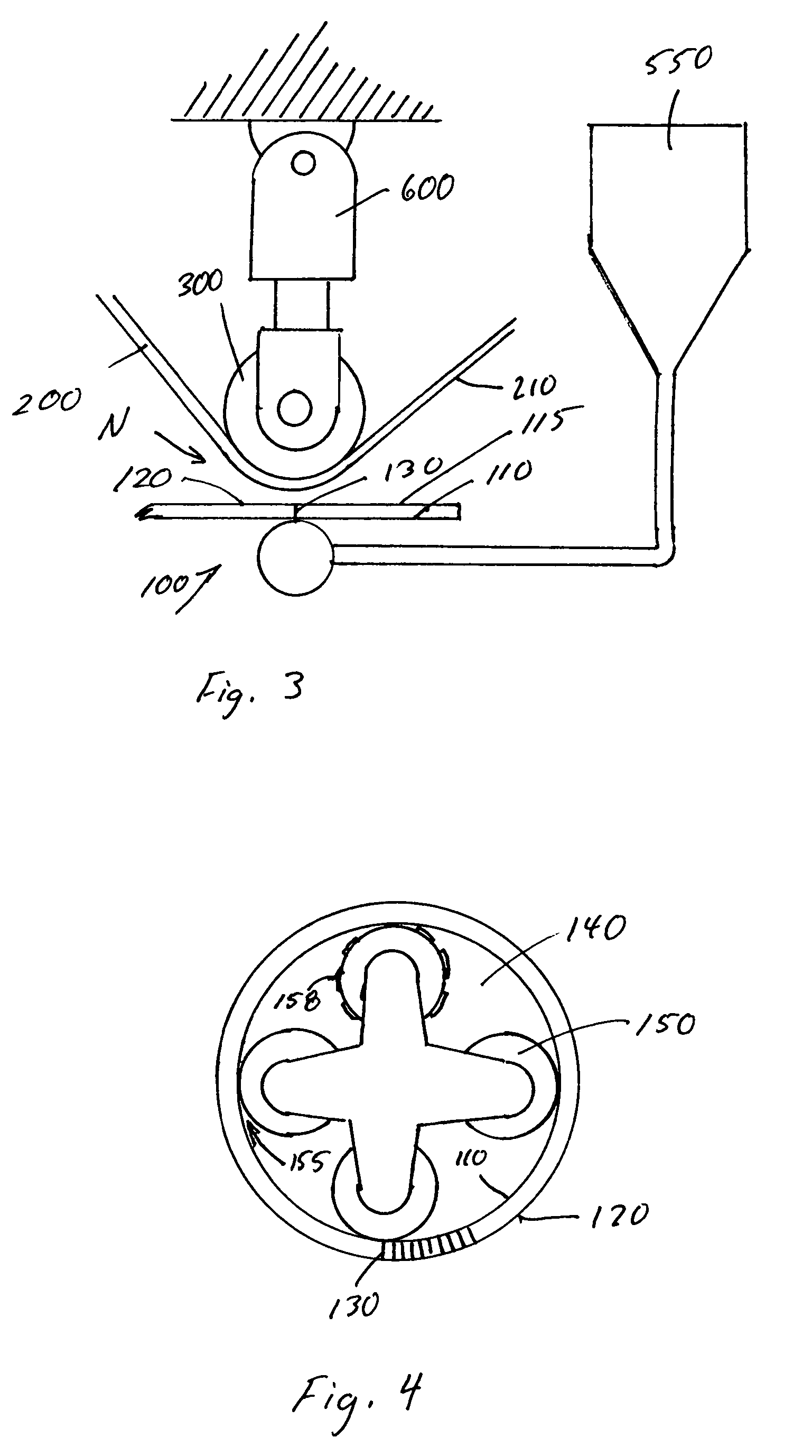

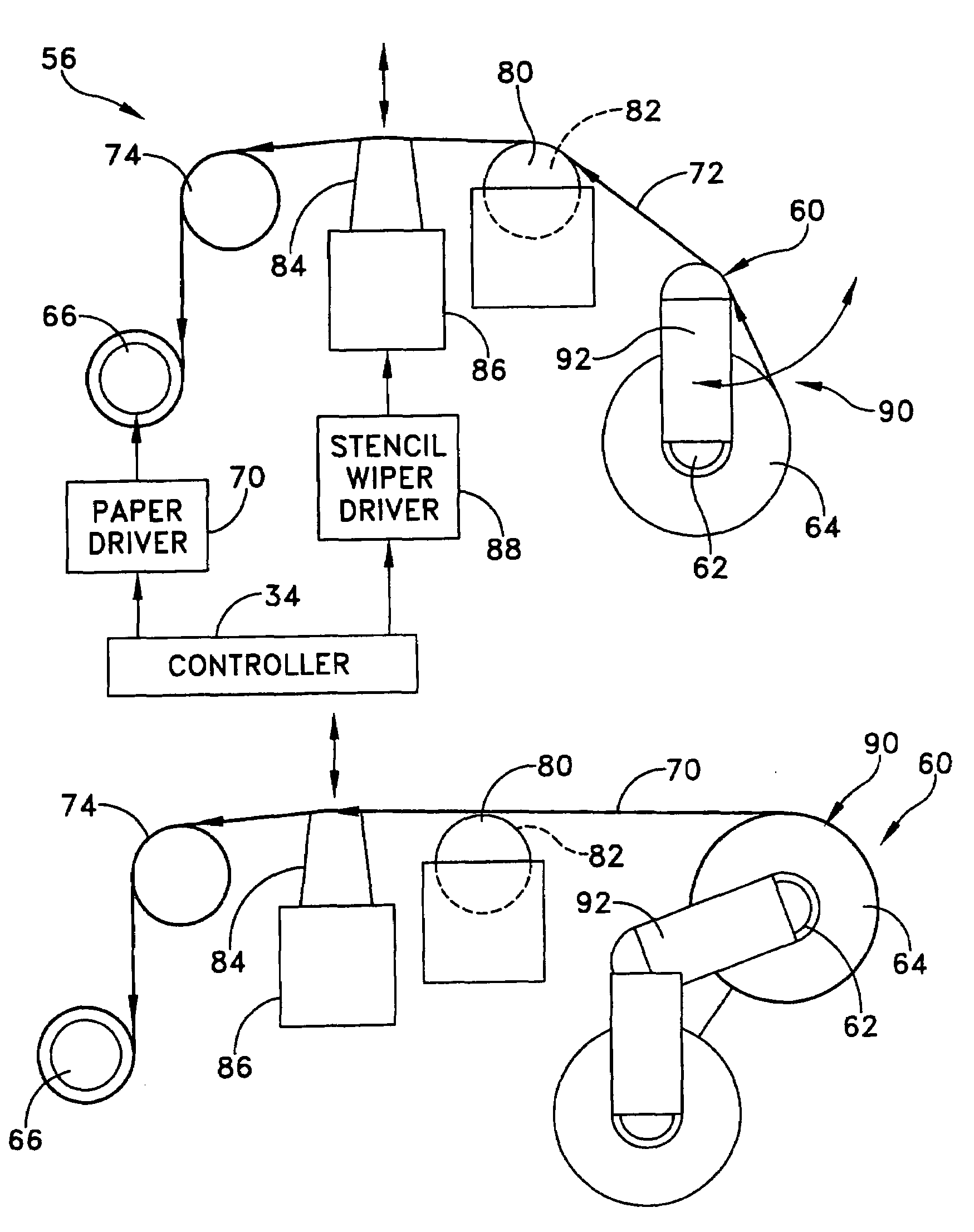

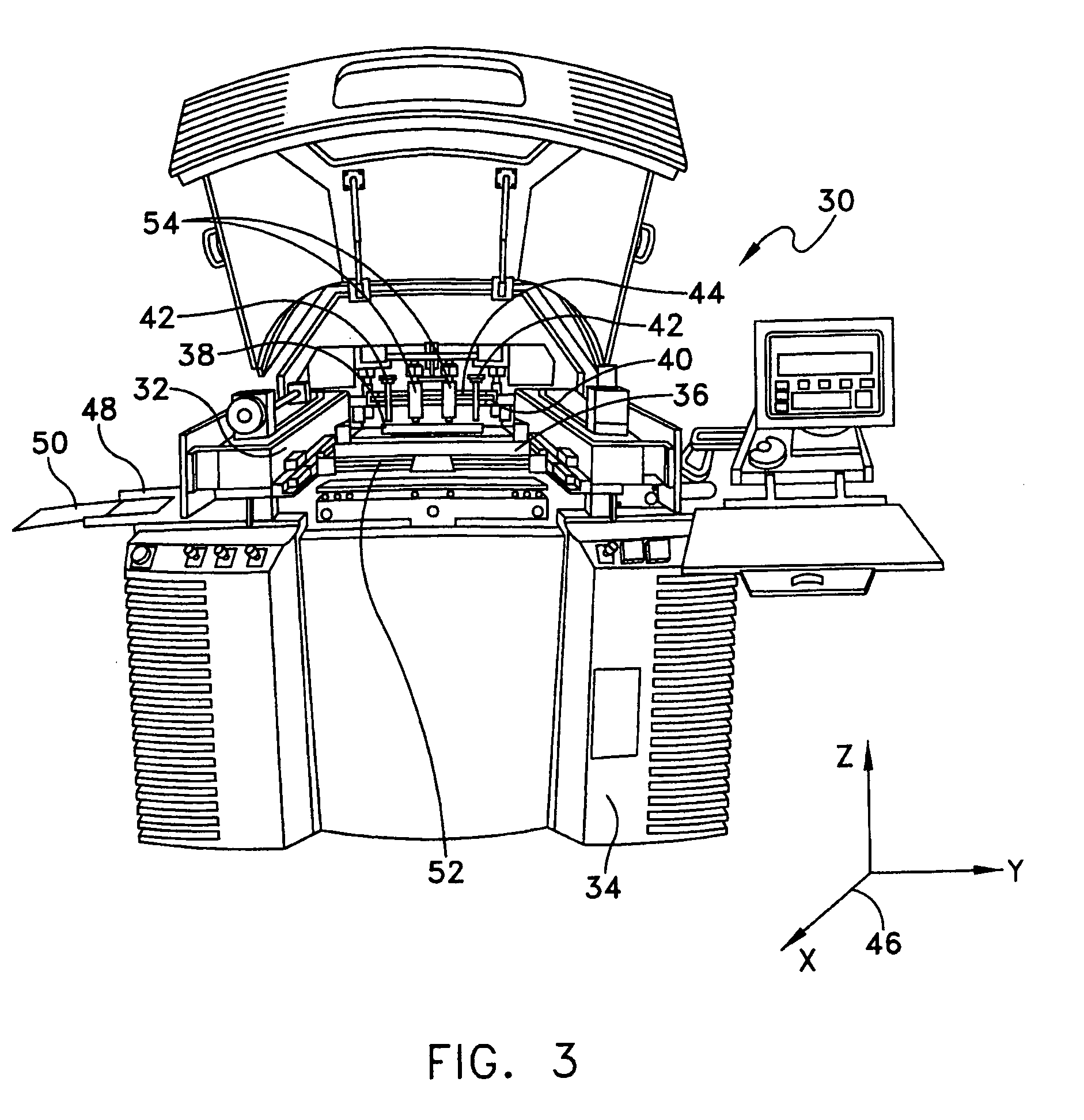

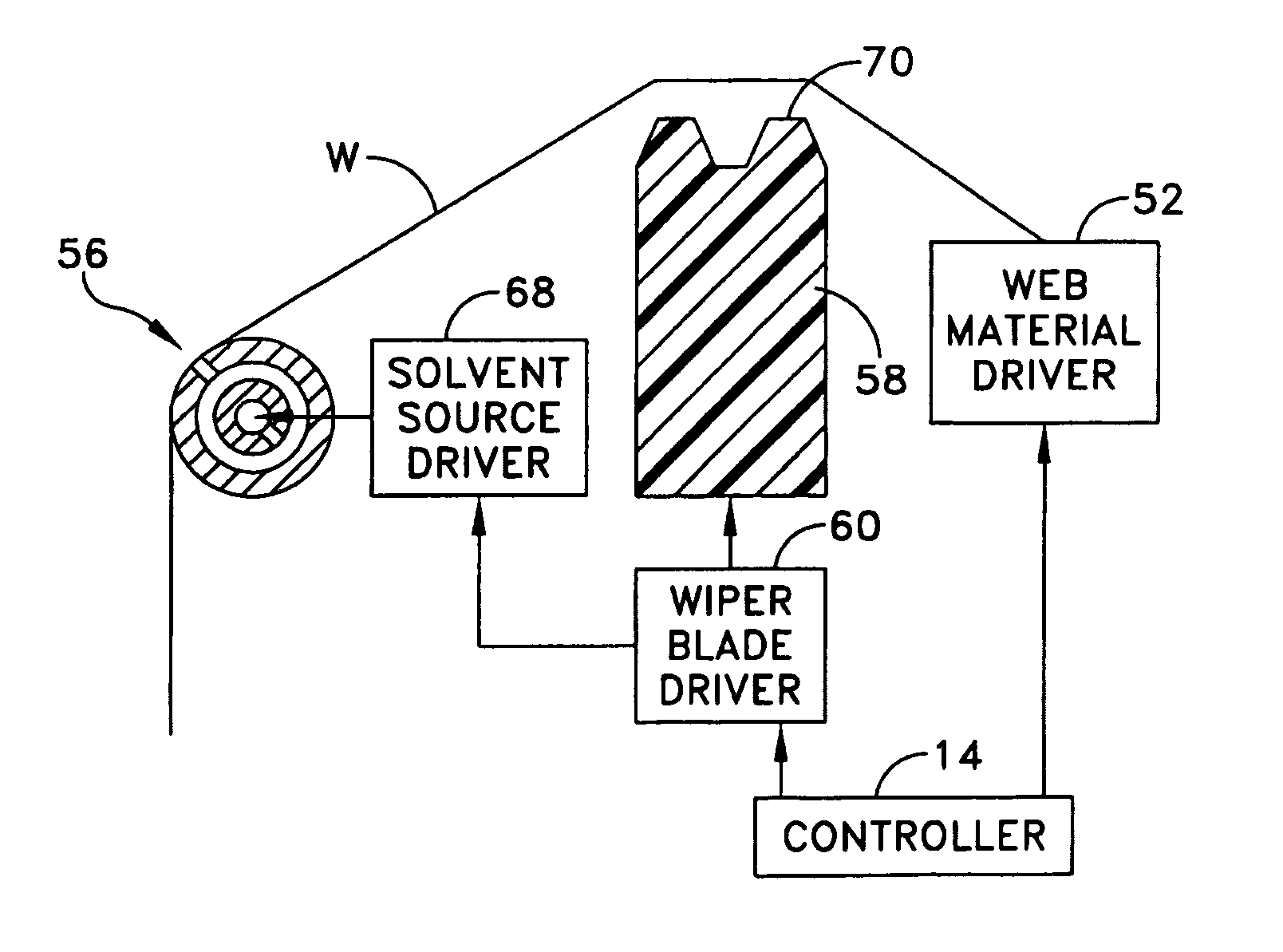

Self-contained vacuum module for stencil wiper assembly

A vacuum plenum module of a stencil wiper assembly for wiping and removing excess material from a stencil of a stencil printer includes a wiper blade to wipe the stencil, a plenum chamber in fluid communication with the wiper blade, and a vacuum generator attached to and in fluid communication with the plenum chamber to create a vacuum within the plenum chamber. The vacuum plenum module further includes a fluid supply to introduce pressurized fluid into the vacuum generator, and an exhaust to exhaust fluid from the vacuum generator. The vacuum generator includes at least one vacuum ejector adapted to create the vacuum. The vacuum plenum module is further configured to move between a first position in which the vacuum plenum is spaced away from the stencil and a second position in which the vacuum plenum engages the stencil. A method of cleaning a stencil is further disclosed.

Owner:KPS SPECIAL SITUATIONS FUND II LP

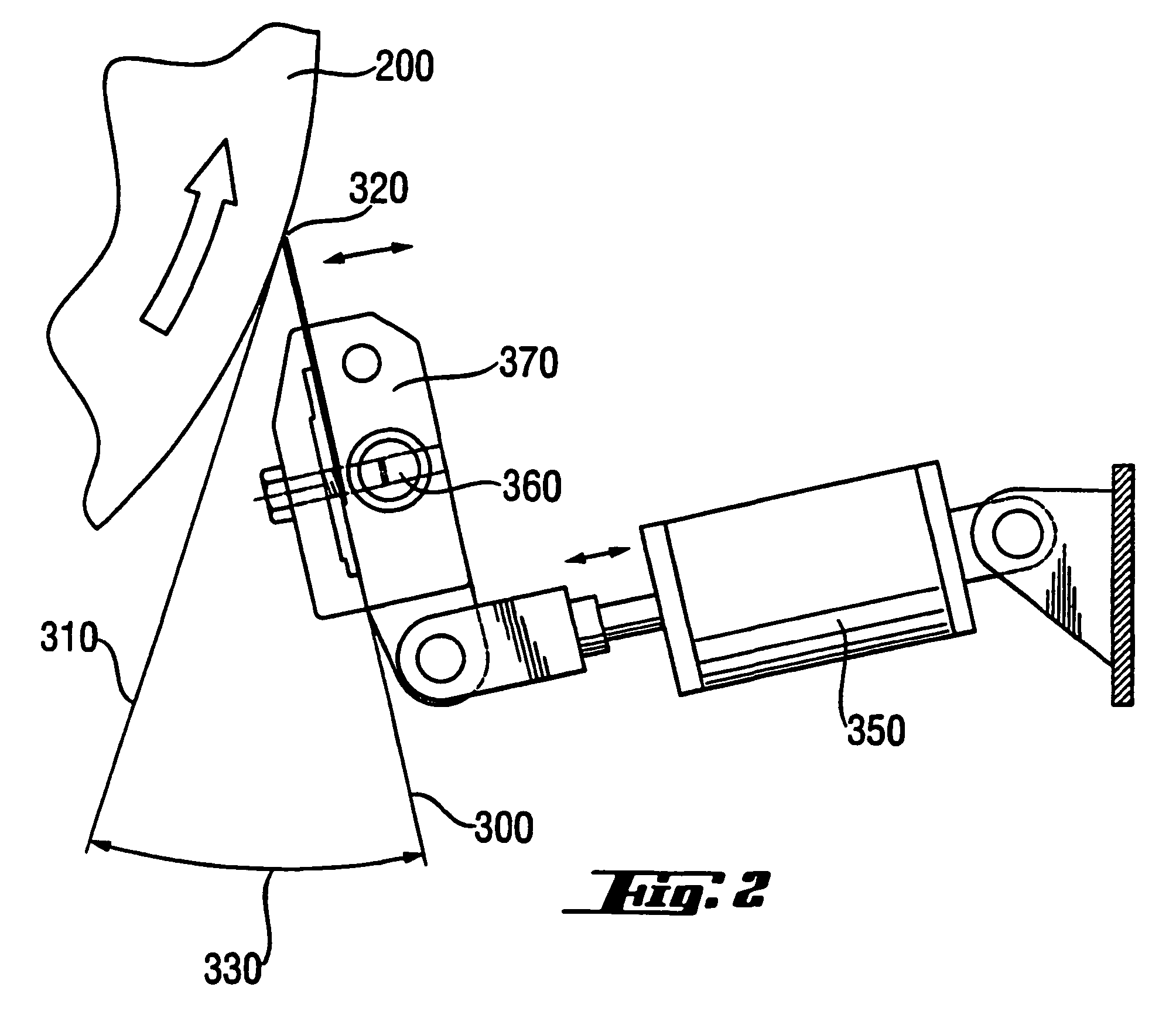

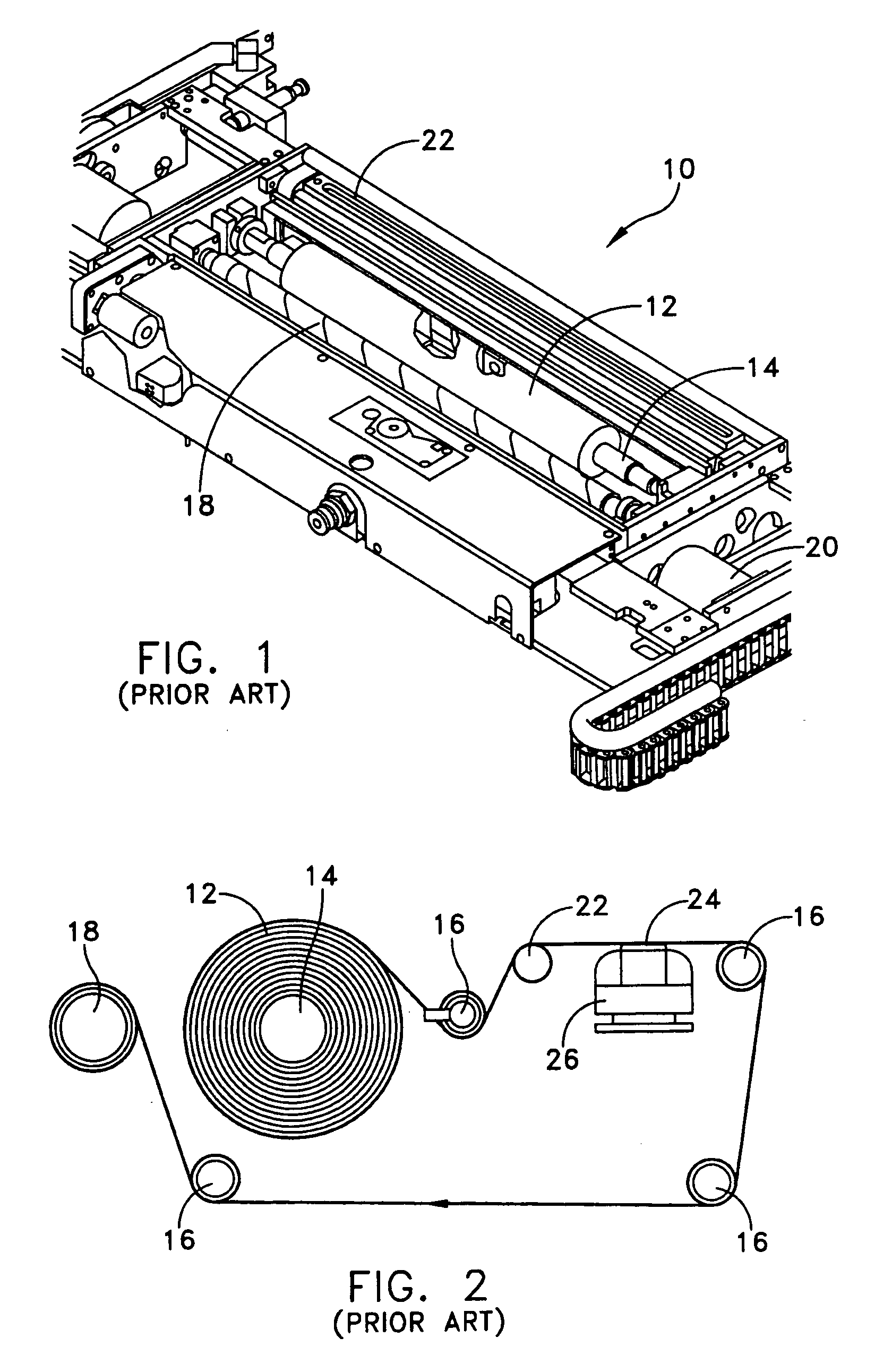

Methods and apparatus for changing web material in a stencil printer

A quick-change material module of a stencil wiper assembly for wiping a stencil of a stencil printer includes a supply roller to receive a roll of material, a take-up roller to receive used material, and a drive to move the material across the stencil between the supply roller and the take-up roller. The supply roller is designed to move between an operating position in which the module functions to wipe the stencil and a changing position in which the supply roller is accessible to change the roll of material. A pivot mechanism is further disclosed for pivoting the supply roller between the operating and changing positions. A frame supports the supply roller, the take-up roller, and the drive. The pivot mechanism includes at least one pivot arm having one end rotatably attached to the supply roller and an opposite end pivotably attached to the frame. A method for changing a roll of material within a quick-change material module of a stencil wiper assembly designed to wipe a stencil of a stencil printer is further disclosed.

Owner:KPS SPECIAL SITUATIONS FUND II LP

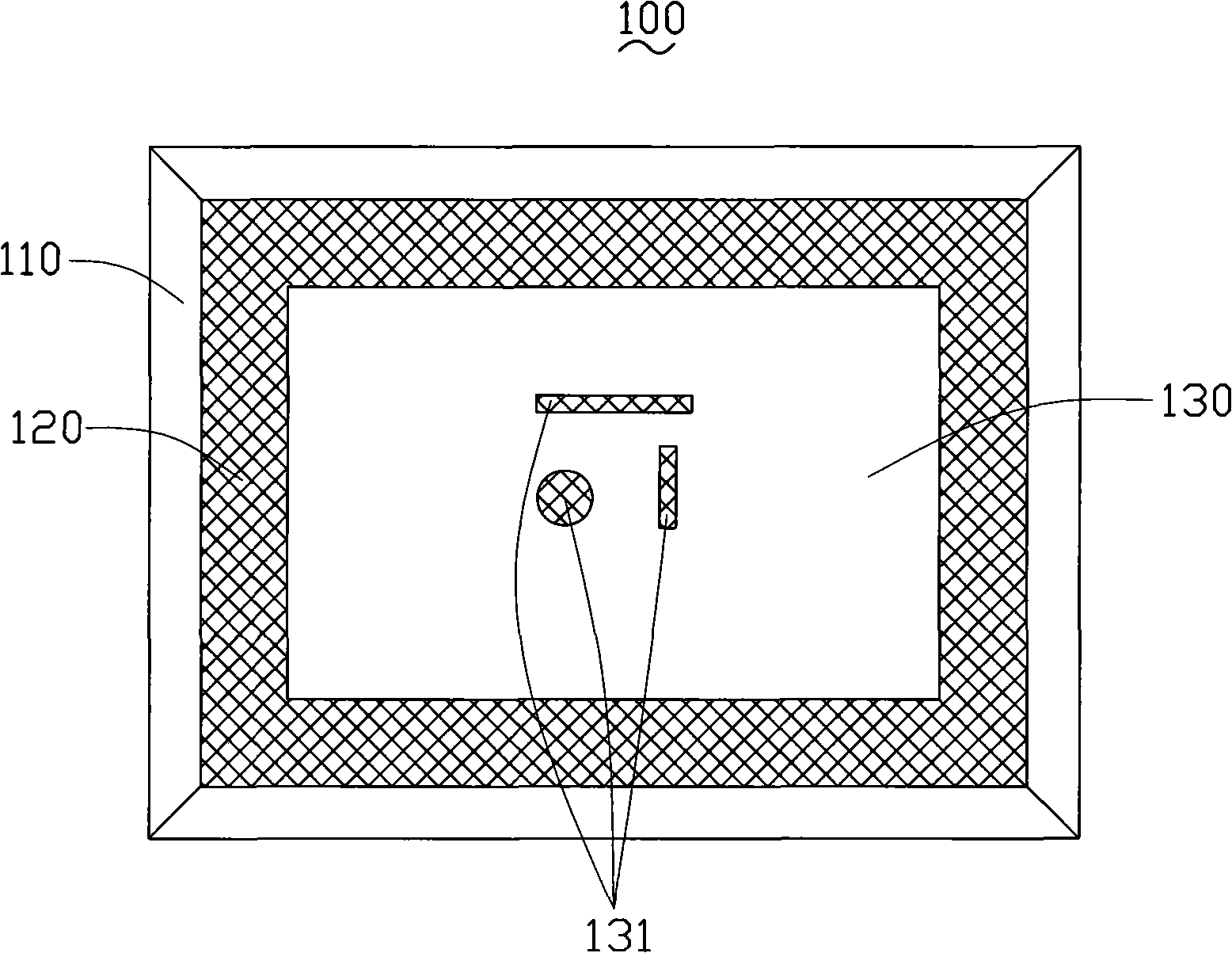

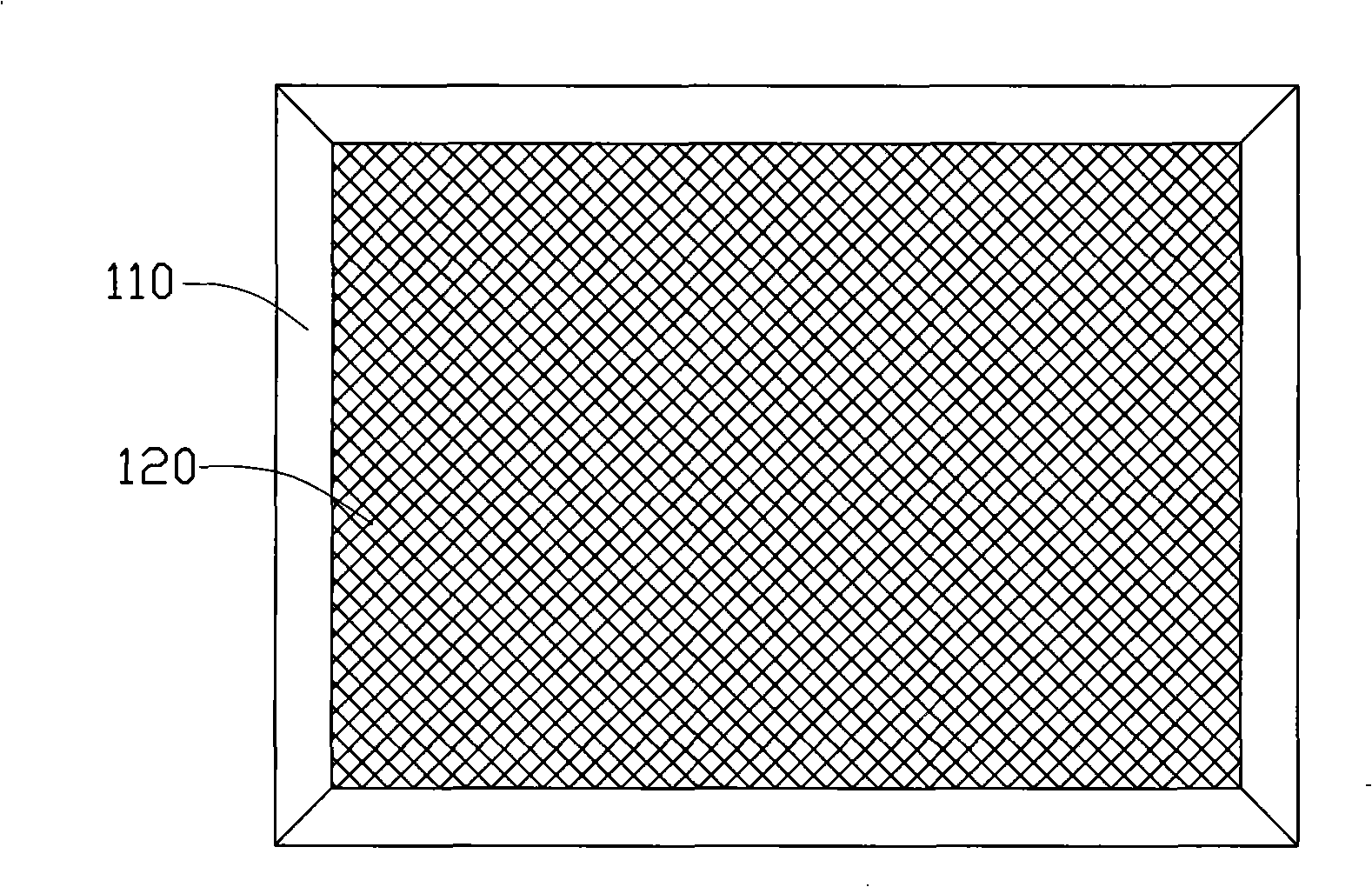

Screen printing plate and manufacturing method thereof

InactiveCN101318401AEasy to prepareAvoid scrappingLiquid surface applicatorsScreen printersScreen printingHigh density

The invention relates to a printing screen which comprises a screen frame, a silk screen and a metal sheet with a screen printing pattern; the silk screen is arranged at the screen frame in a tightening way; the metal sheet is fixed on the surface of the silk screen; the screen printing pattern of the metal sheet is ablated by the laser; the precision of the screen printing pattern is +0.005 to +0.02mm or -0.02 to -0.005mm. The invention also relates to a manufacturing method of the printing screen. The printing screen with high precision is beneficial to a circuit board with high density to carry out precise screen printing, can effectively prevent the scrapping of the circuit board caused by the screen printing and improve the yield of manufacturing the circuit board.

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

Screen printing device for solar batteries

InactiveCN102336051ASimple structural designLittle impact on deformabilityFinal product manufactureScreen printersScreen printingSlurry

The invention discloses a screen printing device for solar batteries. The screen printing device comprises a printing scraper, an auxiliary scraper, a feed back knife and a printing screen. The device is characterized in that two baffle structures are mounted on the printing screen, at two sides close to the ends of the printing scraper, wherein each baffle structure is mainly composed of a baffle surface, a baffle frame and an installation rack; the bottom of the baffle surface is in split type contact with a screen surface, or adhered to the screen surface through a flexible material; edges of the feed back knife, the printing scraper and the auxiliary scraper are in seamless contact with the baffle surface; a printing head drives the scrapers and the feed back knife to contact the baffle surface in a sliding manner, so that the paste moves in a range defined by the baffle surfaces at the two sides, the scraper and the feed back knife, and slurry is prevented from flowing to the two sides; and the device can ensure uniform fluidity, viscosity and thixotropy of the slurry and avoid the local drying and waste of the slurry, thereby improving electrode printing efficiency and printing quality.

Owner:NANCHANG UNIV

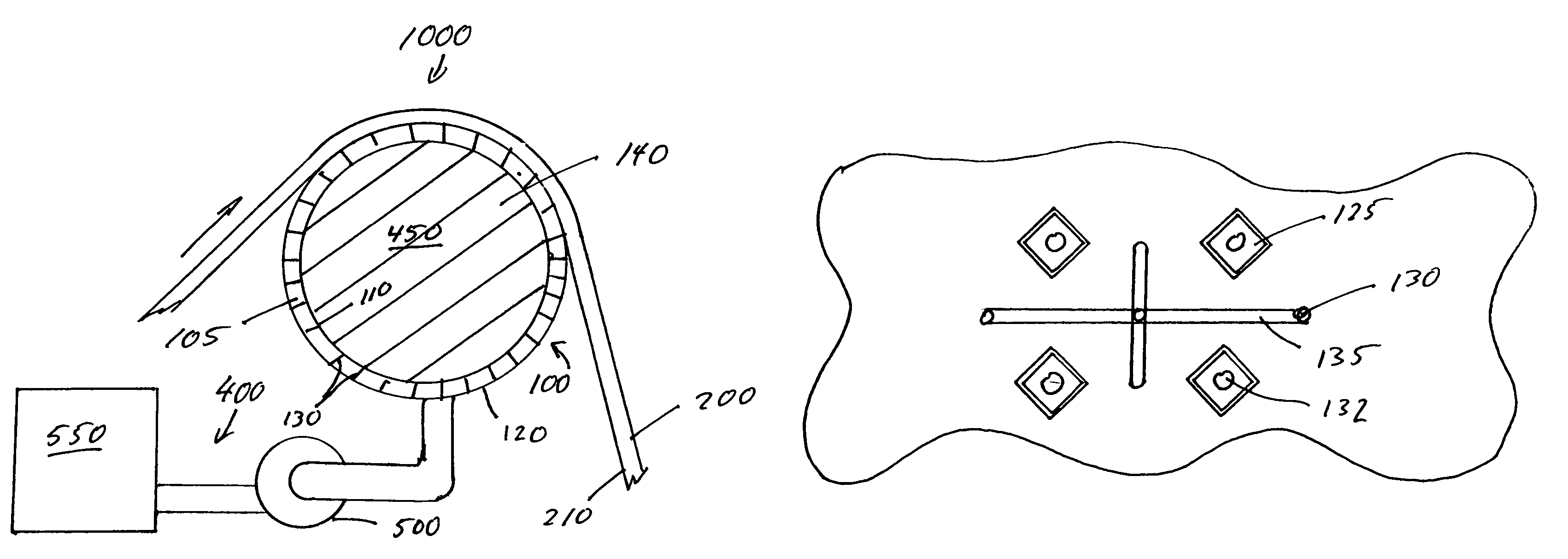

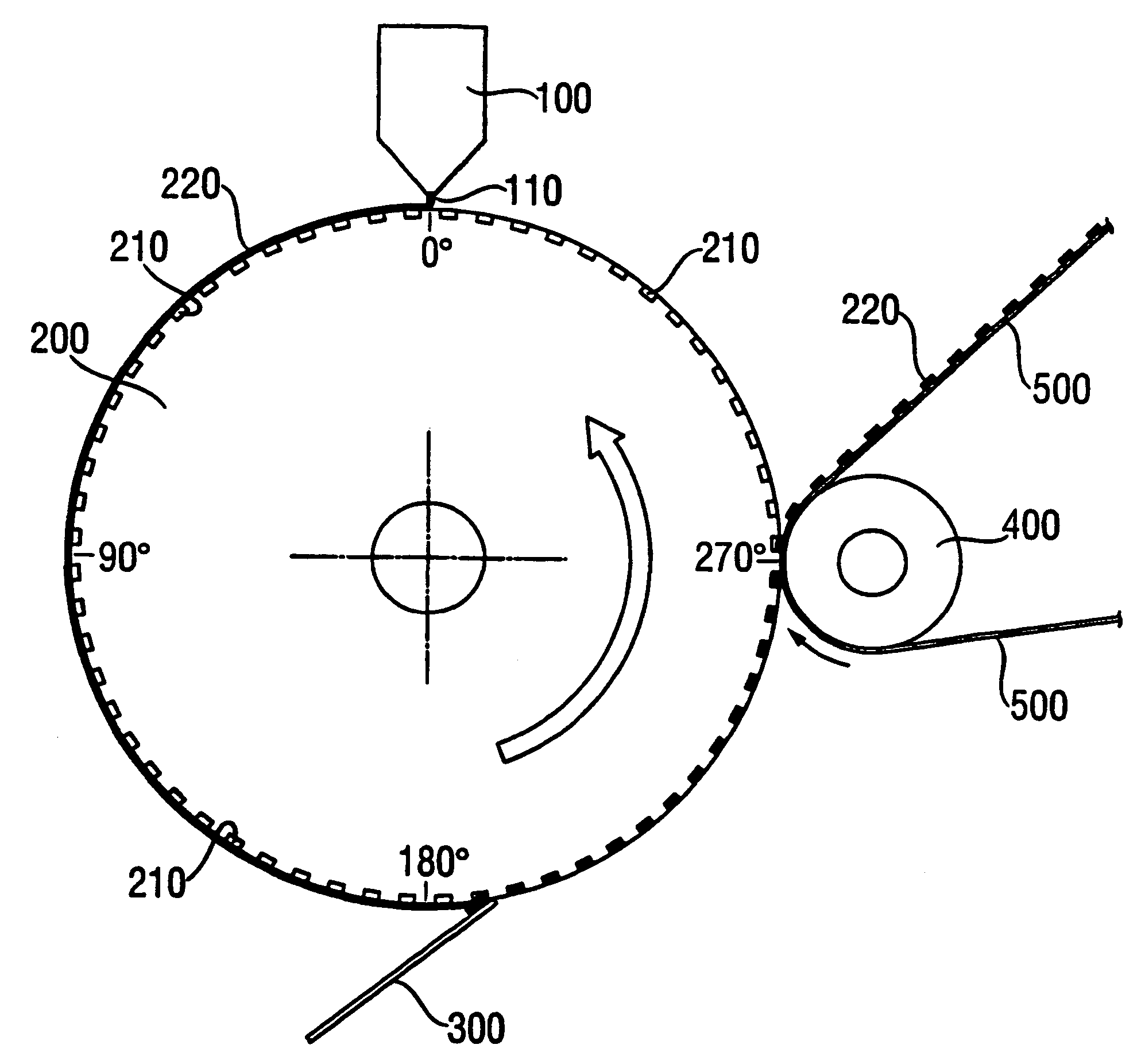

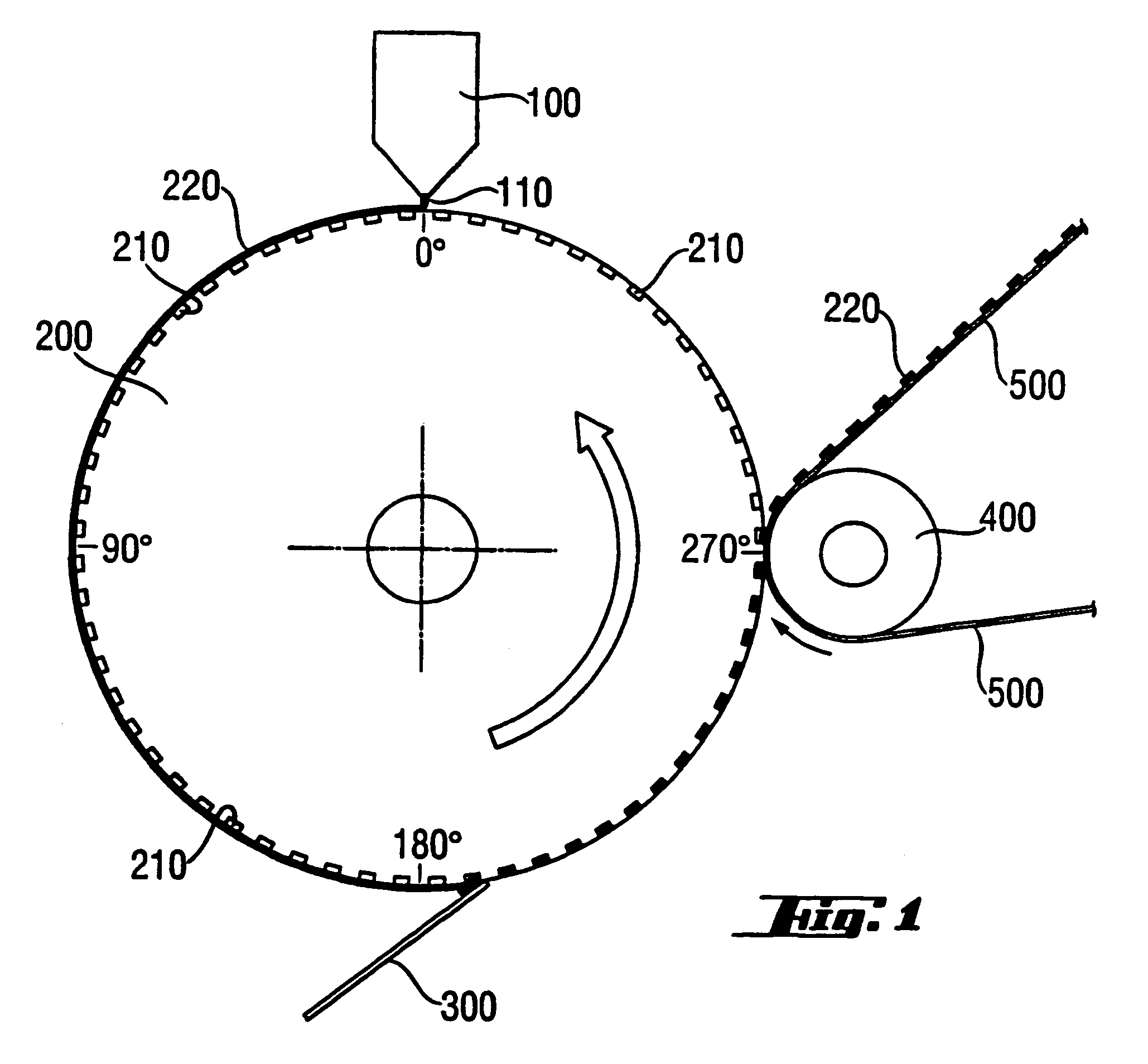

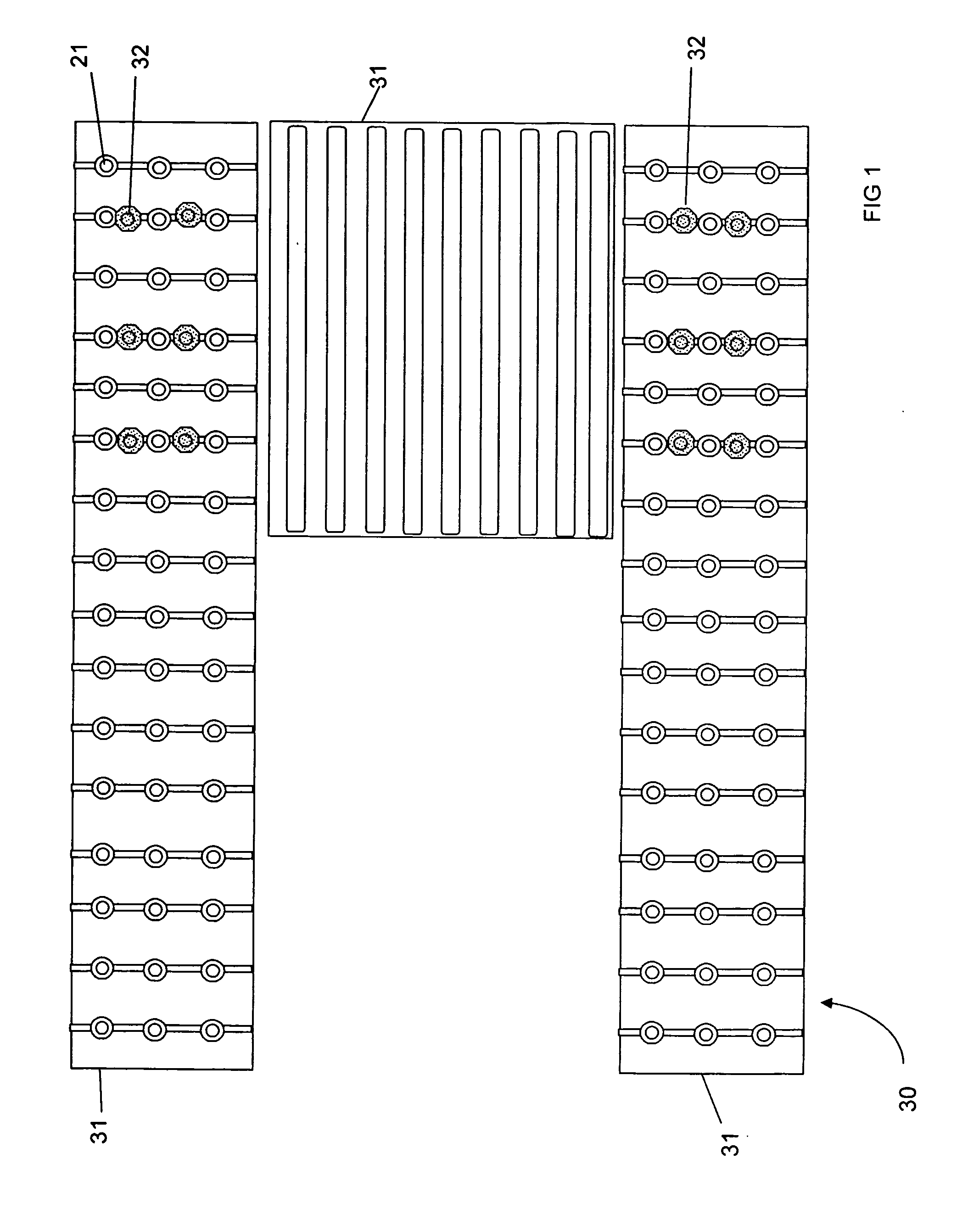

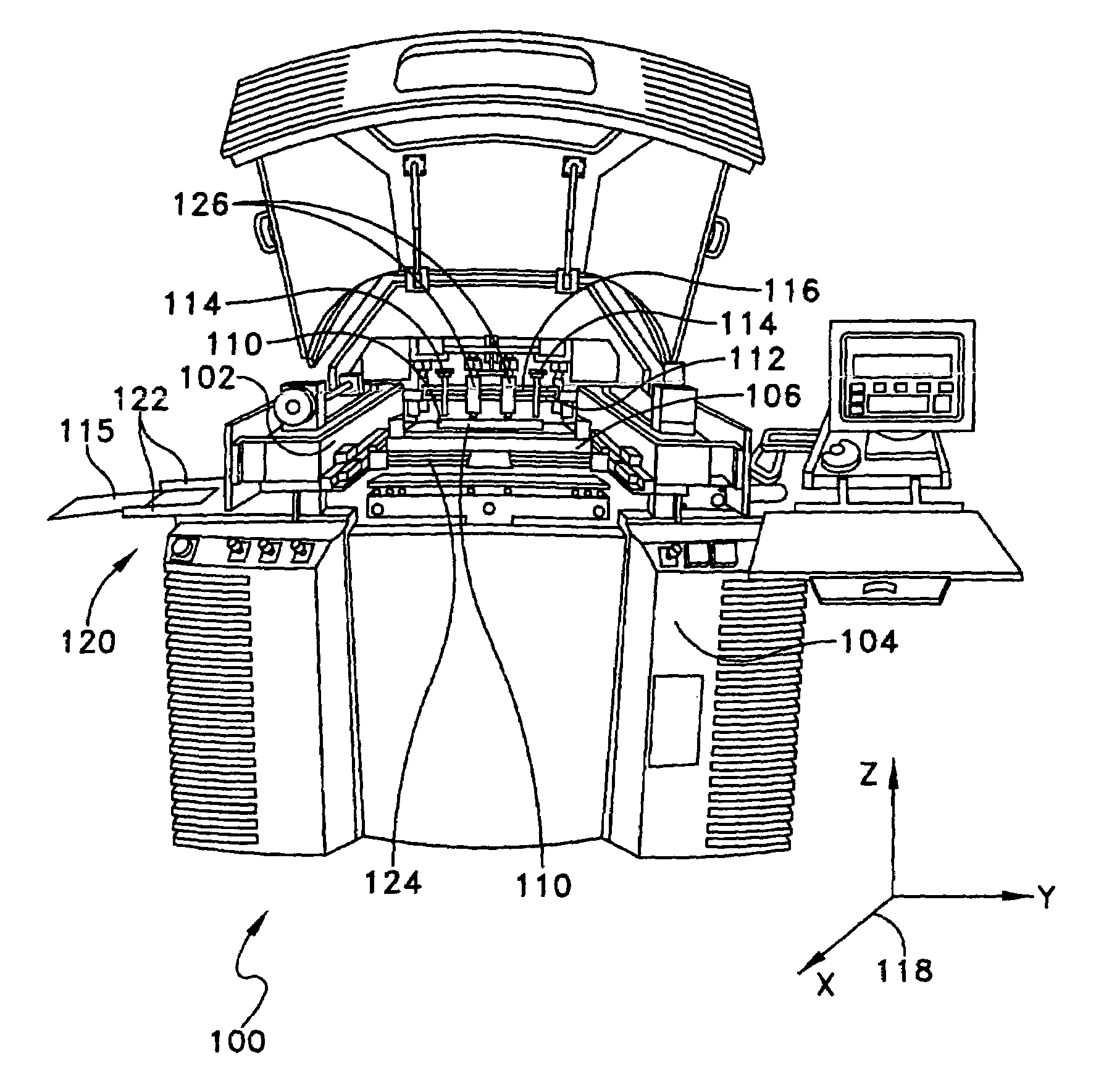

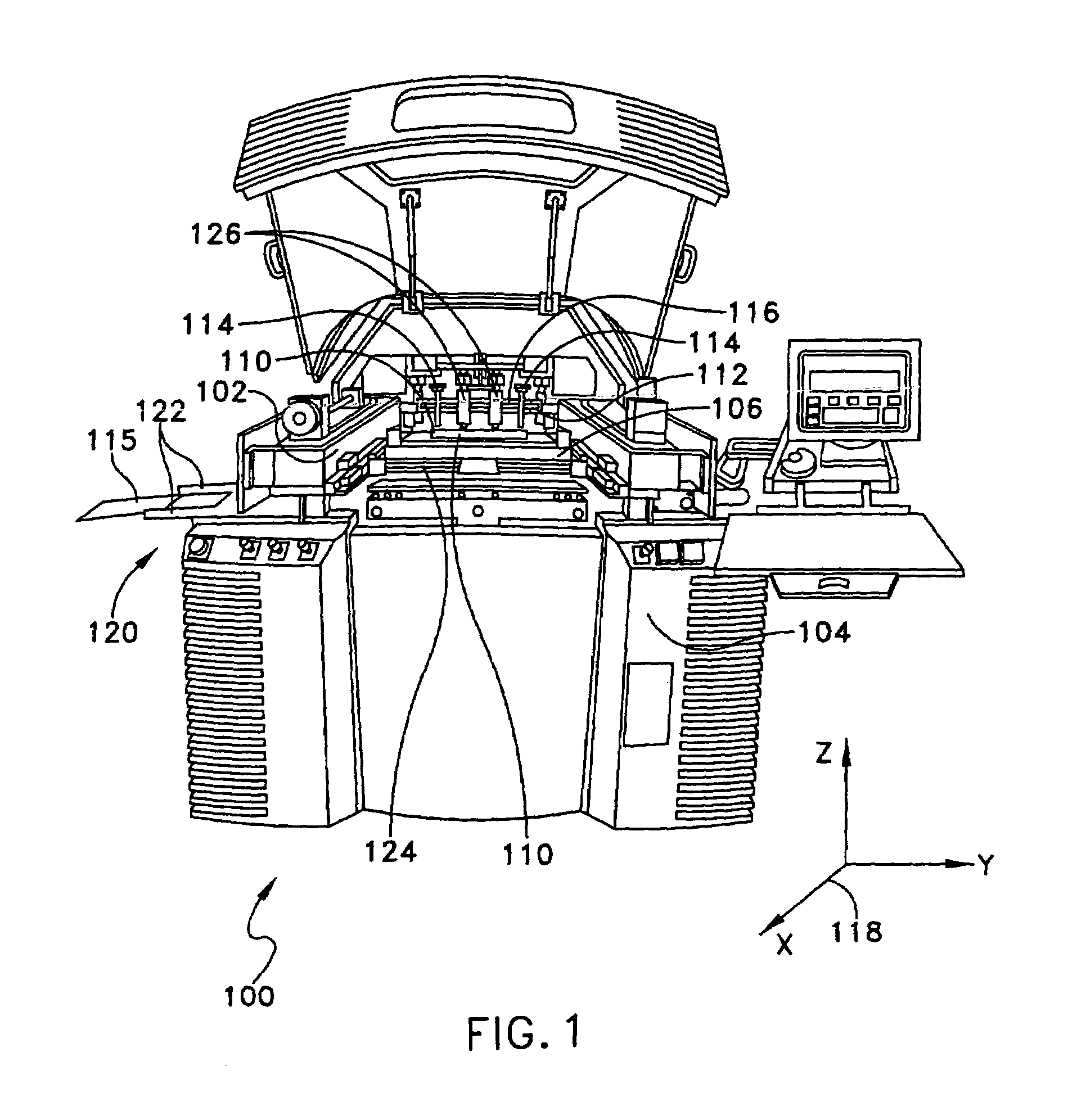

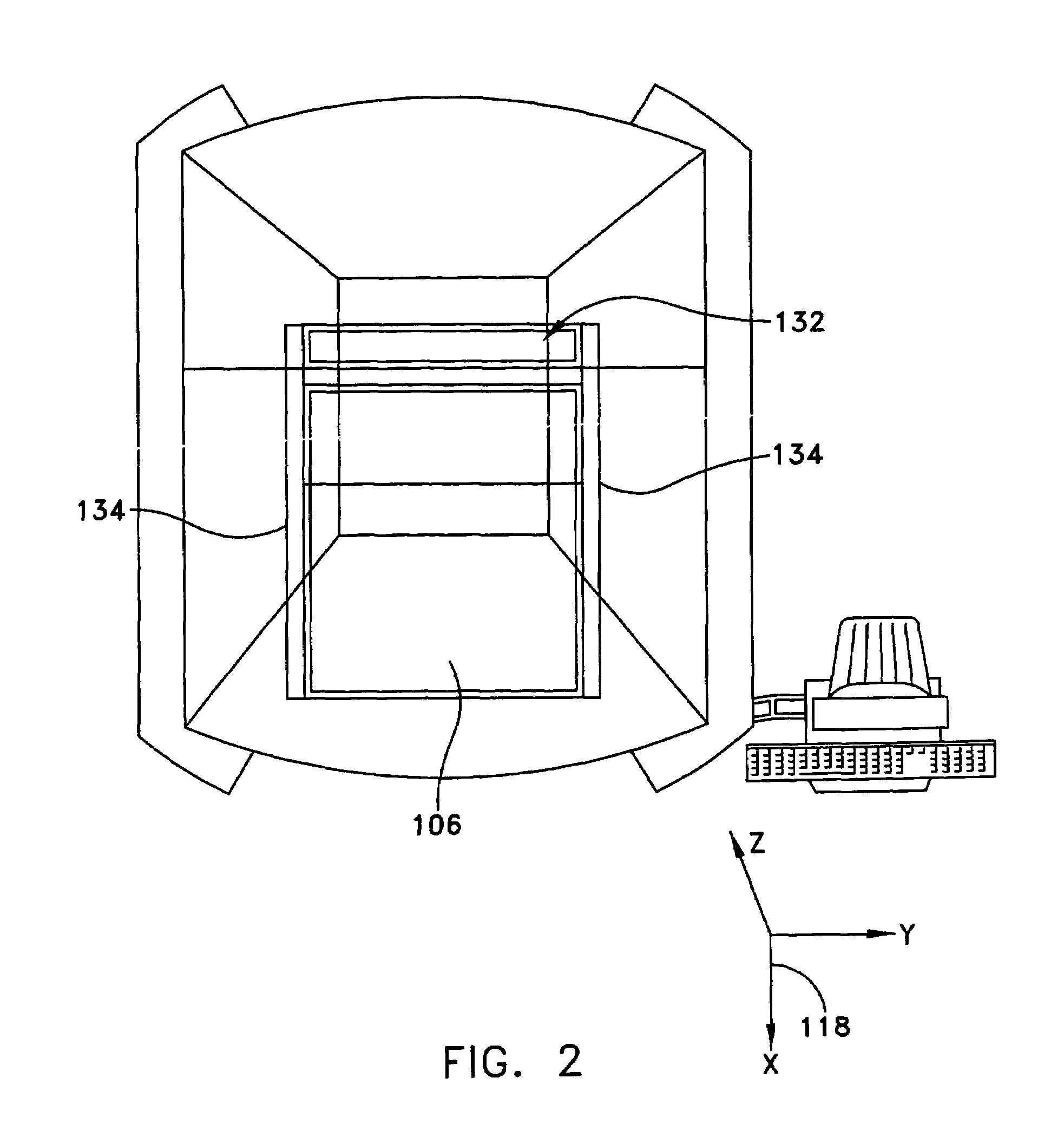

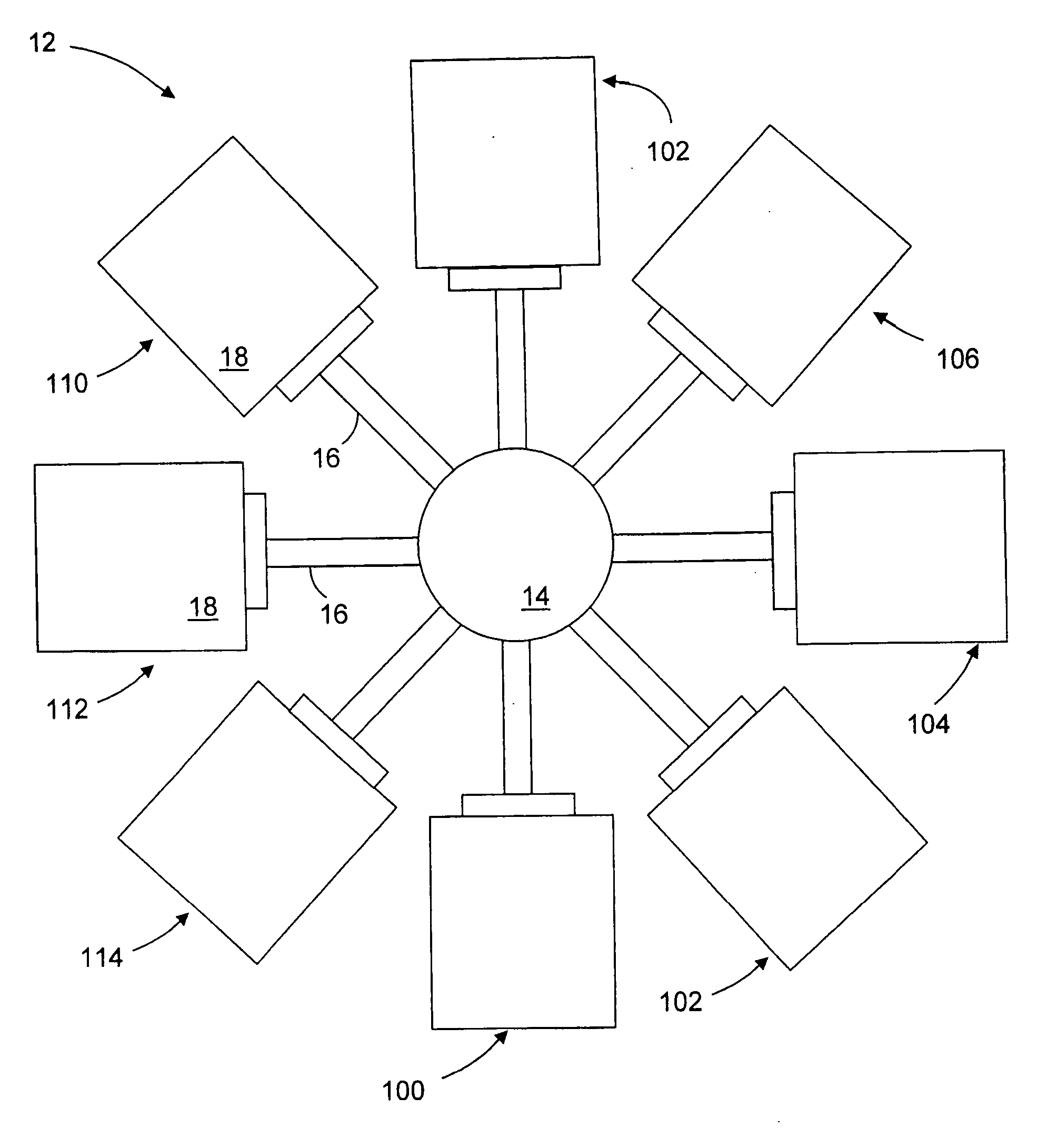

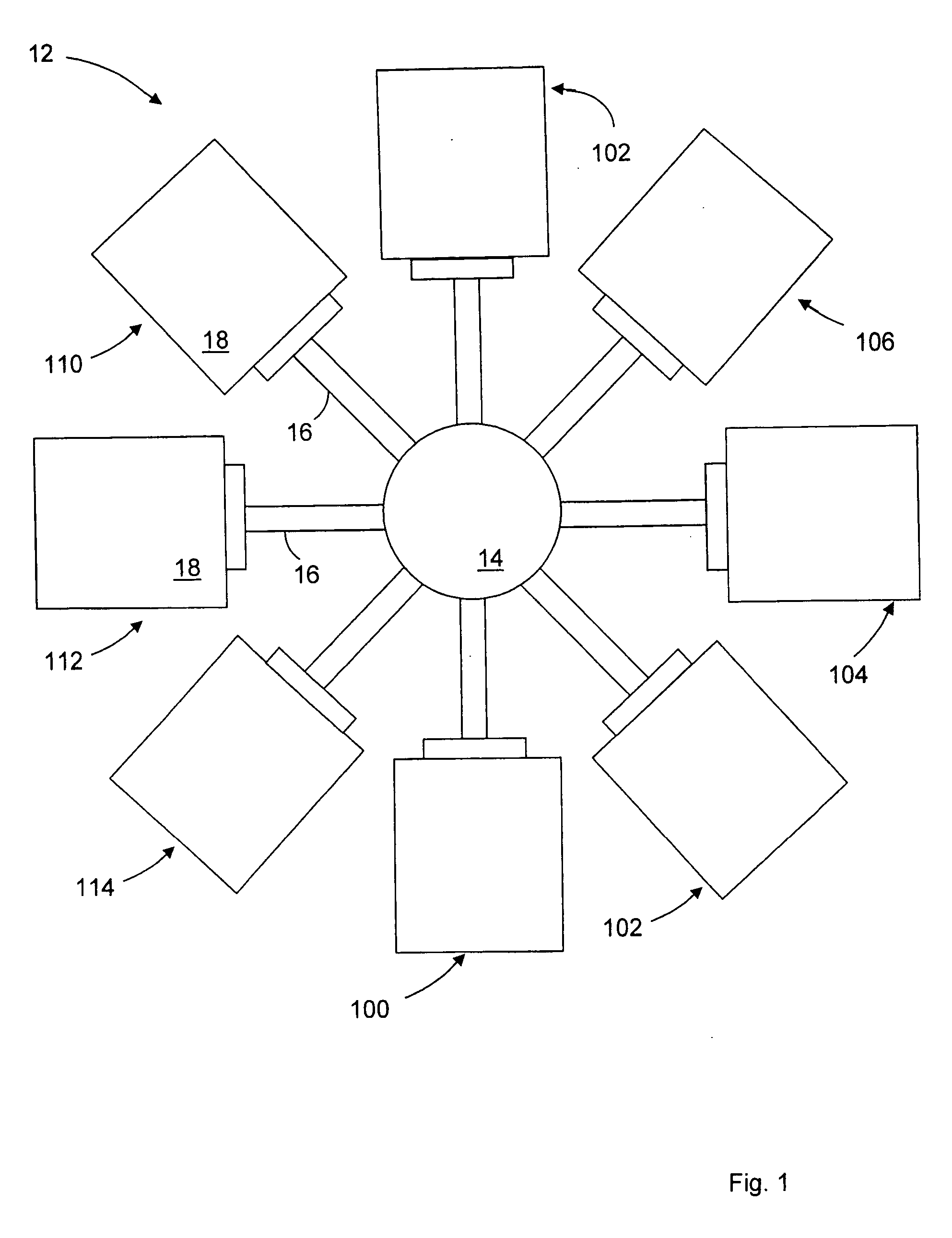

Accurate conveyance system useful for screen printing

The present invention(s) provide an apparatus and method for processing substrates in a screen printing chamber that can deliver a repeatable and accurate screen printed pattern on one or more processed substrates. In one embodiment, the screen printing chamber is adapted to perform a screen printing process within a portion of a crystalline silicon solar cell production line in which a substrate is patterned with a desired material. In one embodiment, the screen printing chamber is a processing chamber positioned within the Rotary line tool or Softline™ tool available from Baccini S.p.A., which is owned by Applied Materials, Inc. of Santa Clara, Calif.

Owner:APPLIED MATERIALS INC

Method for inkjet printing light colors on dark textiles

A method and apparatus for printing on dark textiles such as black t-shirts is disclosed. The method includes screen printing an underbase onto the textile and then using an inkjet printer to print an image over the underbase. In the preferred embodiment, a white, opaque image is screen printed onto a black t-shirt, followed by inkjet printing a white image on top of the screen-printed image.

Owner:GRAPHIC ARTS ACQUISITION

Methods and apparatus for cleaning a stencil

A stencil wiper apparatus for wiping a stencil of a stencil printer includes a material supply assembly having a supply roller to deliver a roll of material, a take-up roller to receive the material, and a drive to move the material across the stencil between the supply roller and the take-up roller. The apparatus further includes a fluid delivery assembly to wet the material. The fluid delivery assembly includes an outer tube, an inner tube and a fluid delivery source. The outer tube is designed to engage the material and to deliver fluid to the material. The inner tube is positioned within the outer tube, and designed to deliver fluid to the outer tube. The fluid delivery source delivers fluid to the inner tube. A method for wiping a stencil of a printing machine is further disclosed.

Owner:KPS SPECIAL SITUATIONS FUND II LP

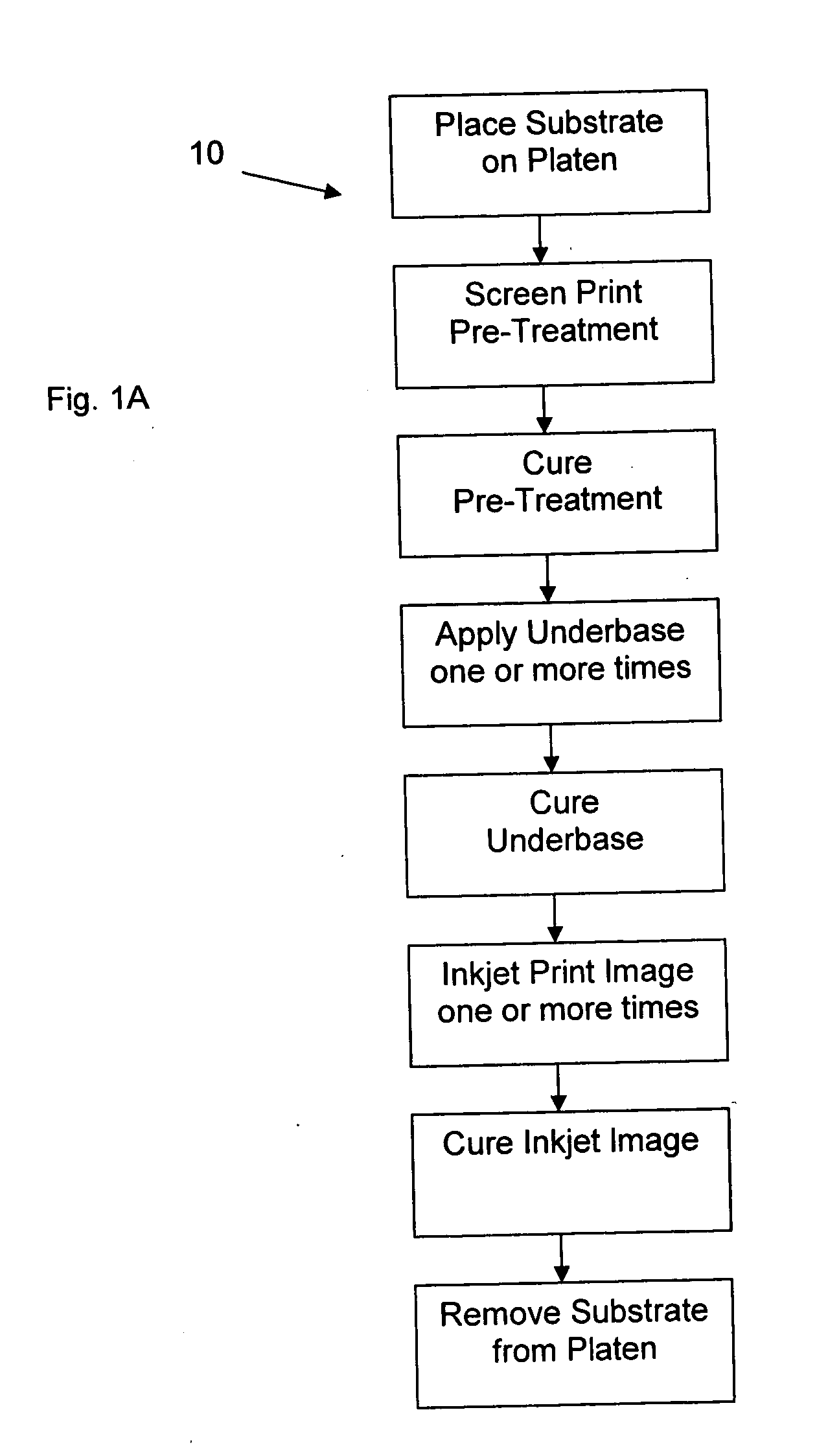

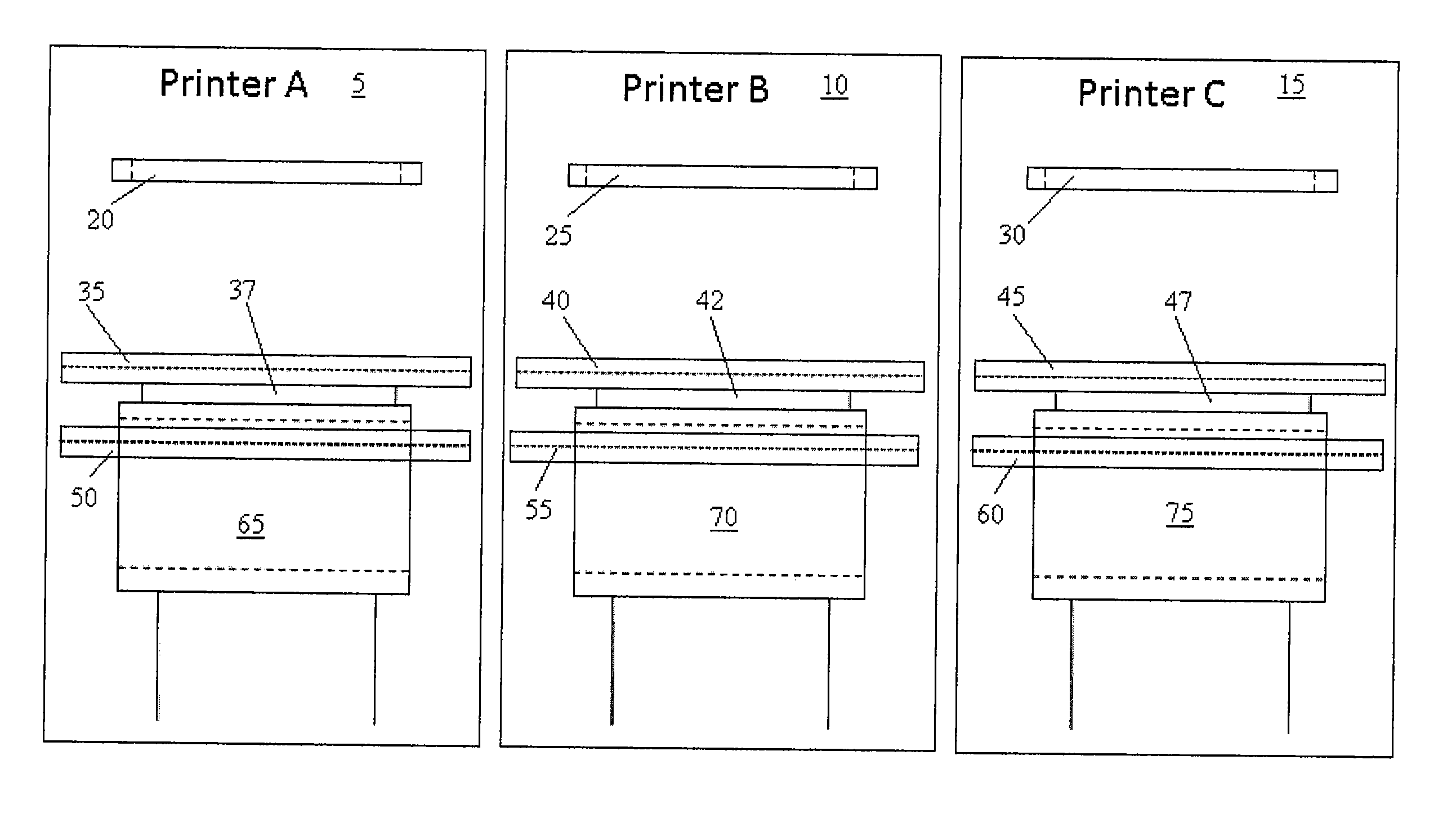

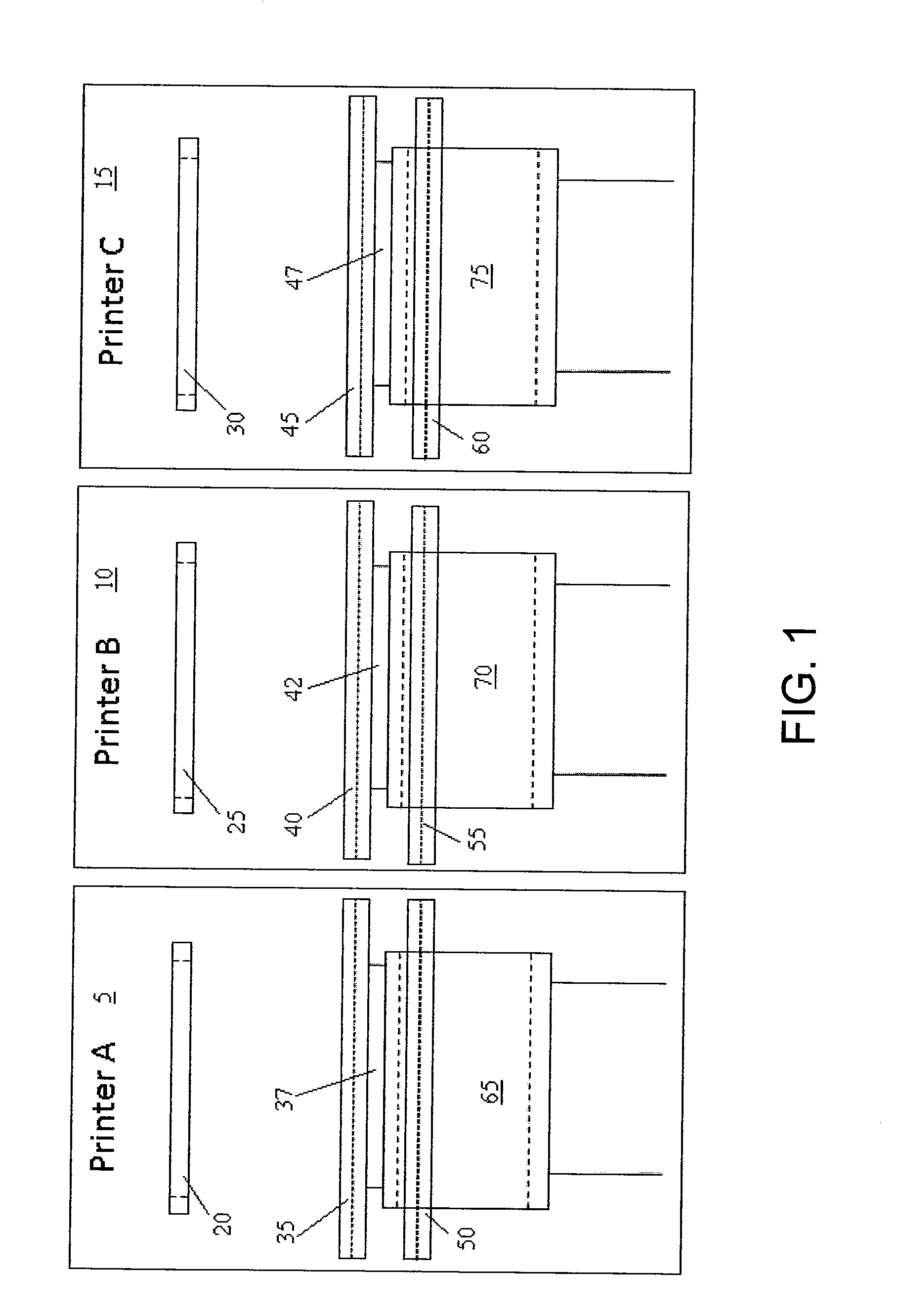

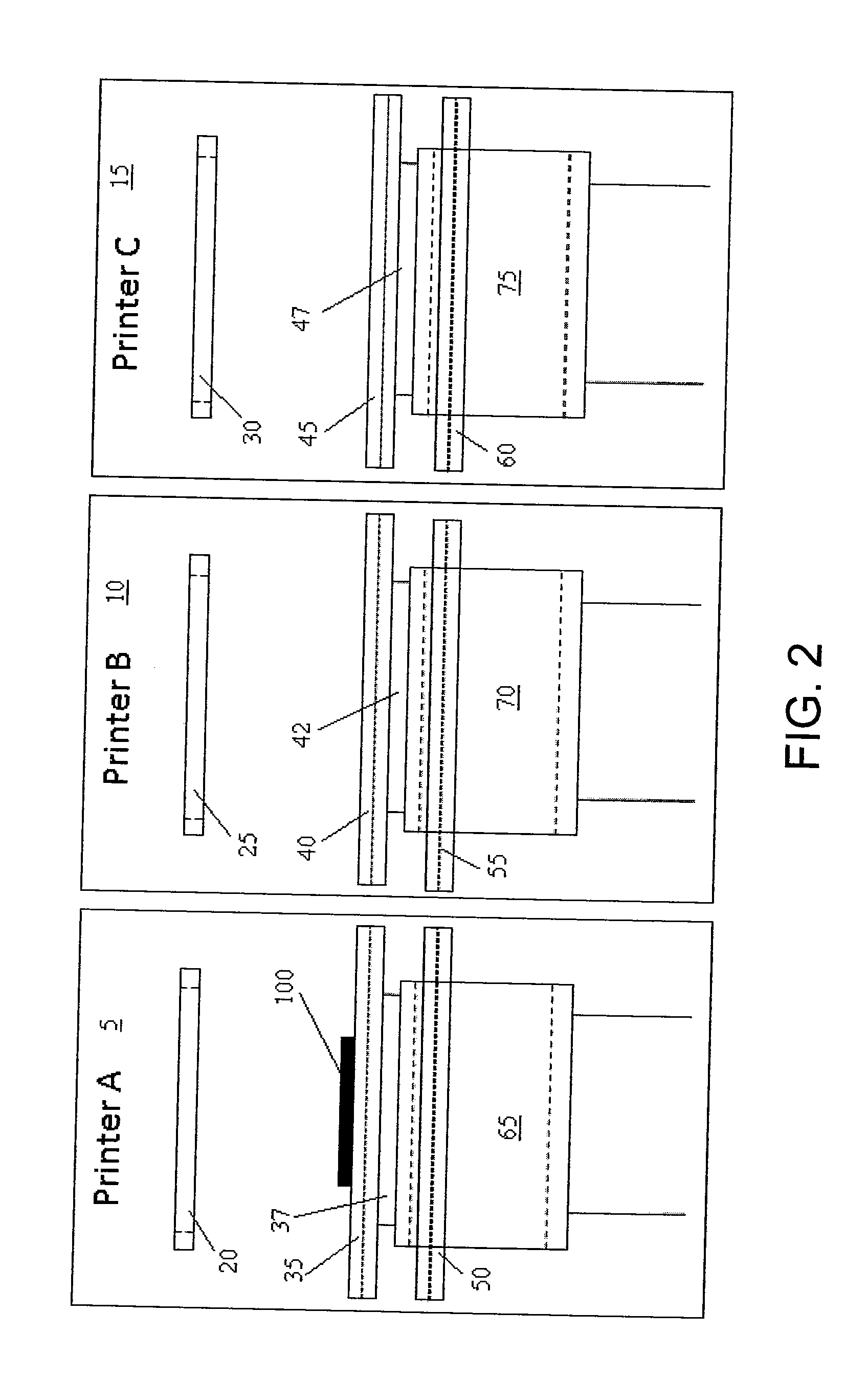

Method for printing white on dark textiles using screen-printers and inkjet printers

A method for printing light colors on dark substrates such as black textiles is disclosed. The method includes screen printing a pre-treatment onto a textile, inkjet printing an underbase on the textile, inkjet printing an image over the underbase, and counting and displaying the number of printings of the underbase and image. In the preferred embodiment, a pre-treatment is screen printed onto a black t-shirt, then a white, opaque underbase is inkjet printed onto the black t-shirt, and finally a white image is inkjet printed over the white underbase. In alternative embodiments, a white image is inkjet printed directly on the black t-shirt without any underbase or is inkjet printed over a screen printed underbase.

Owner:GRAPHIC ARTS ACQUISITION

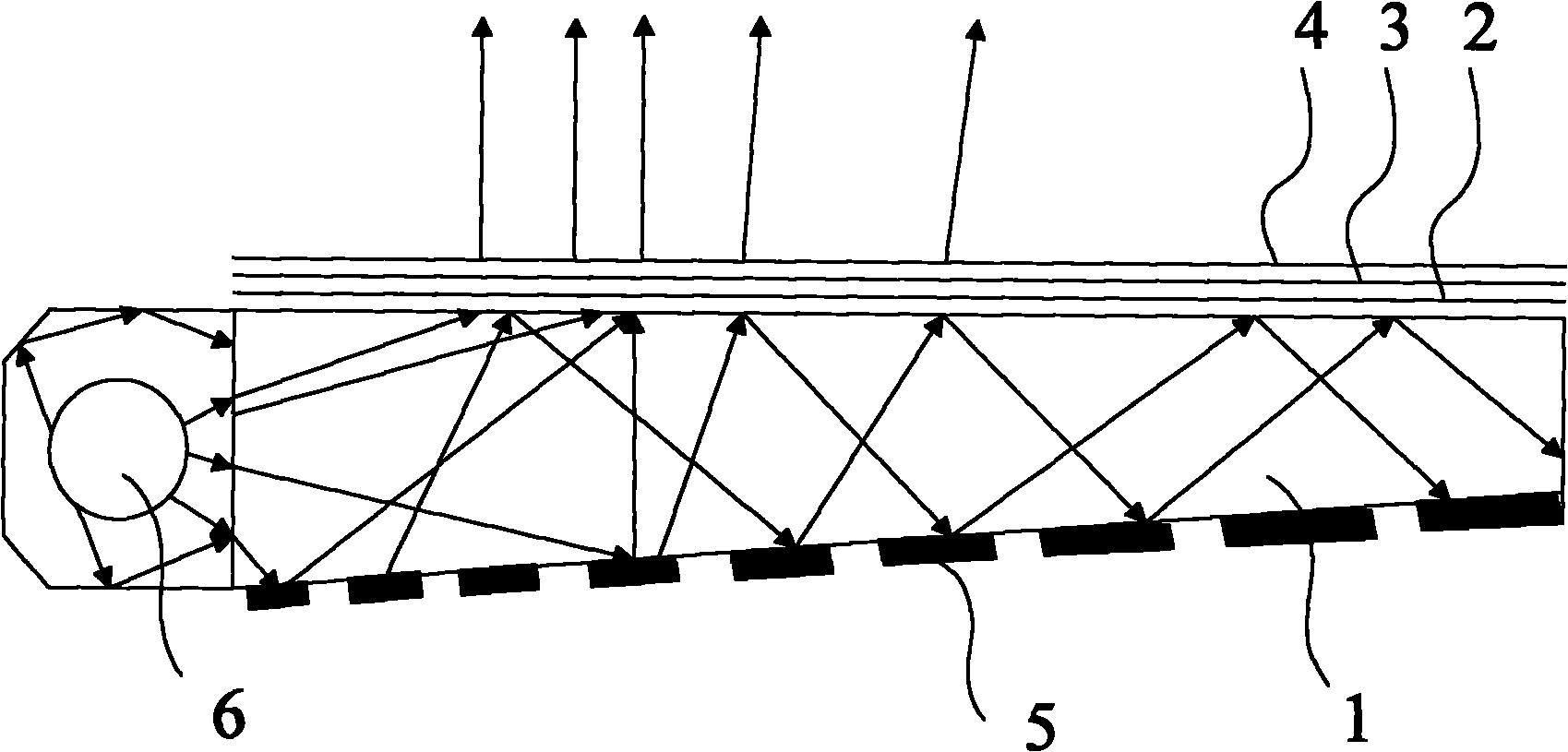

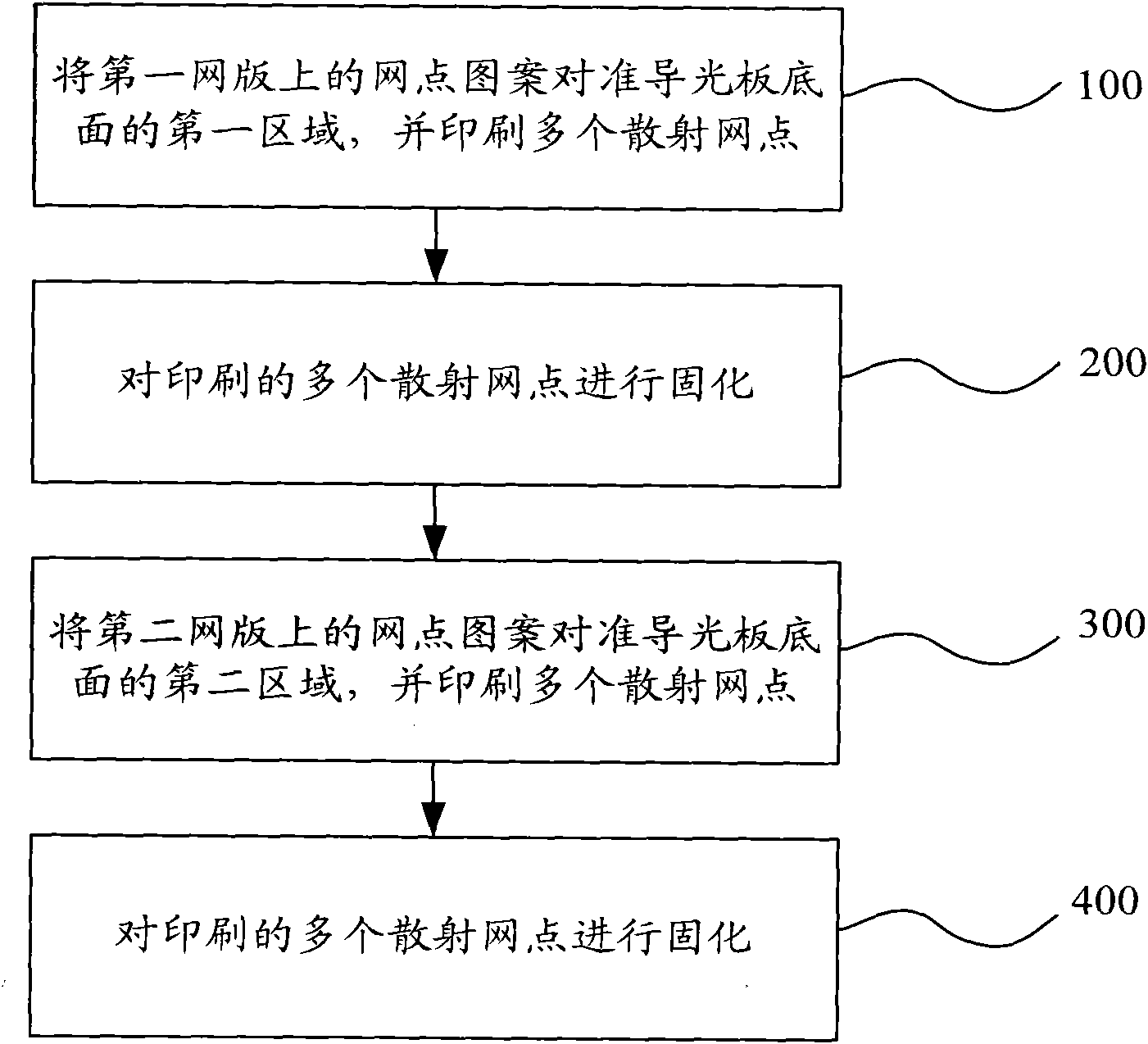

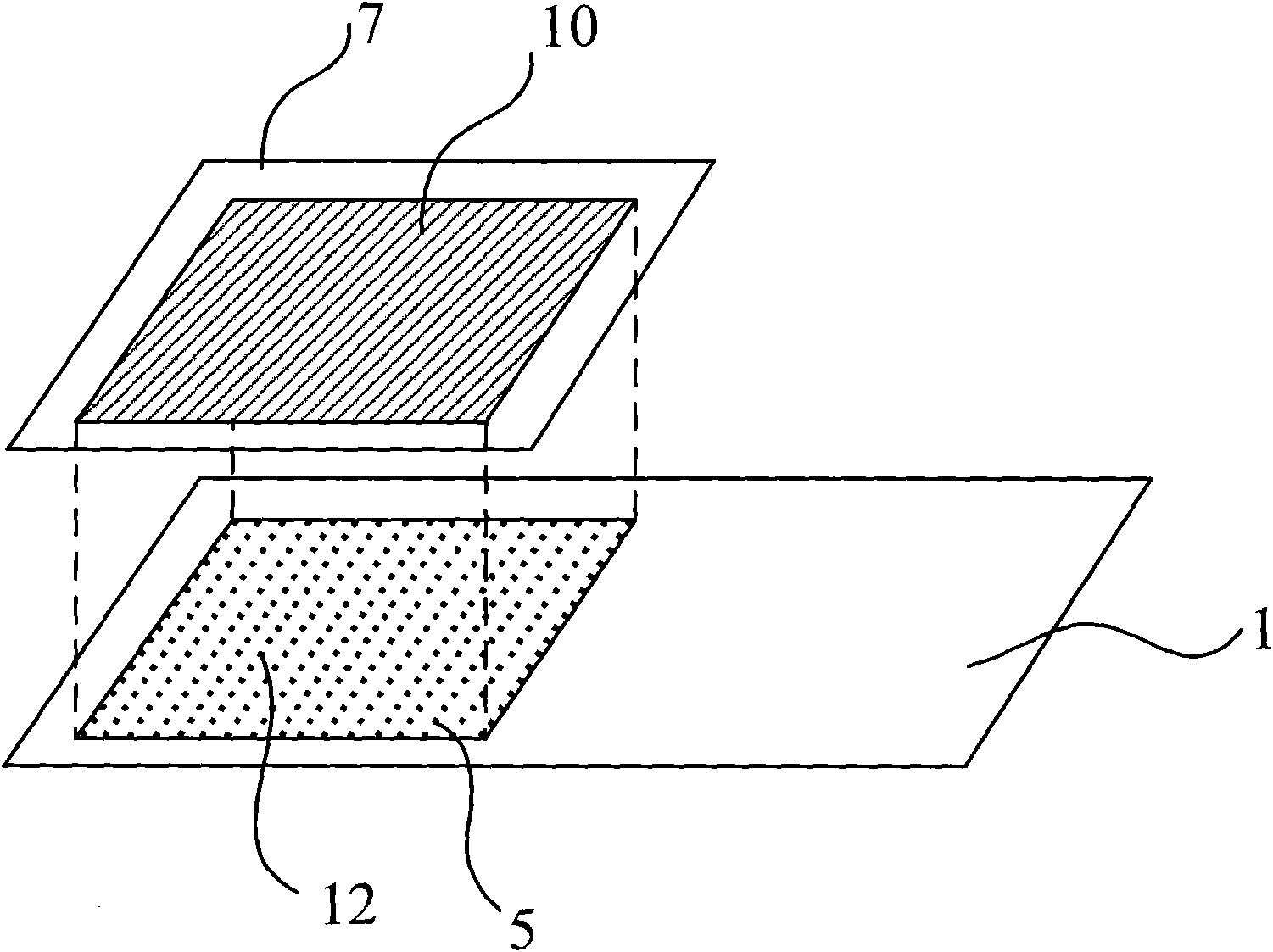

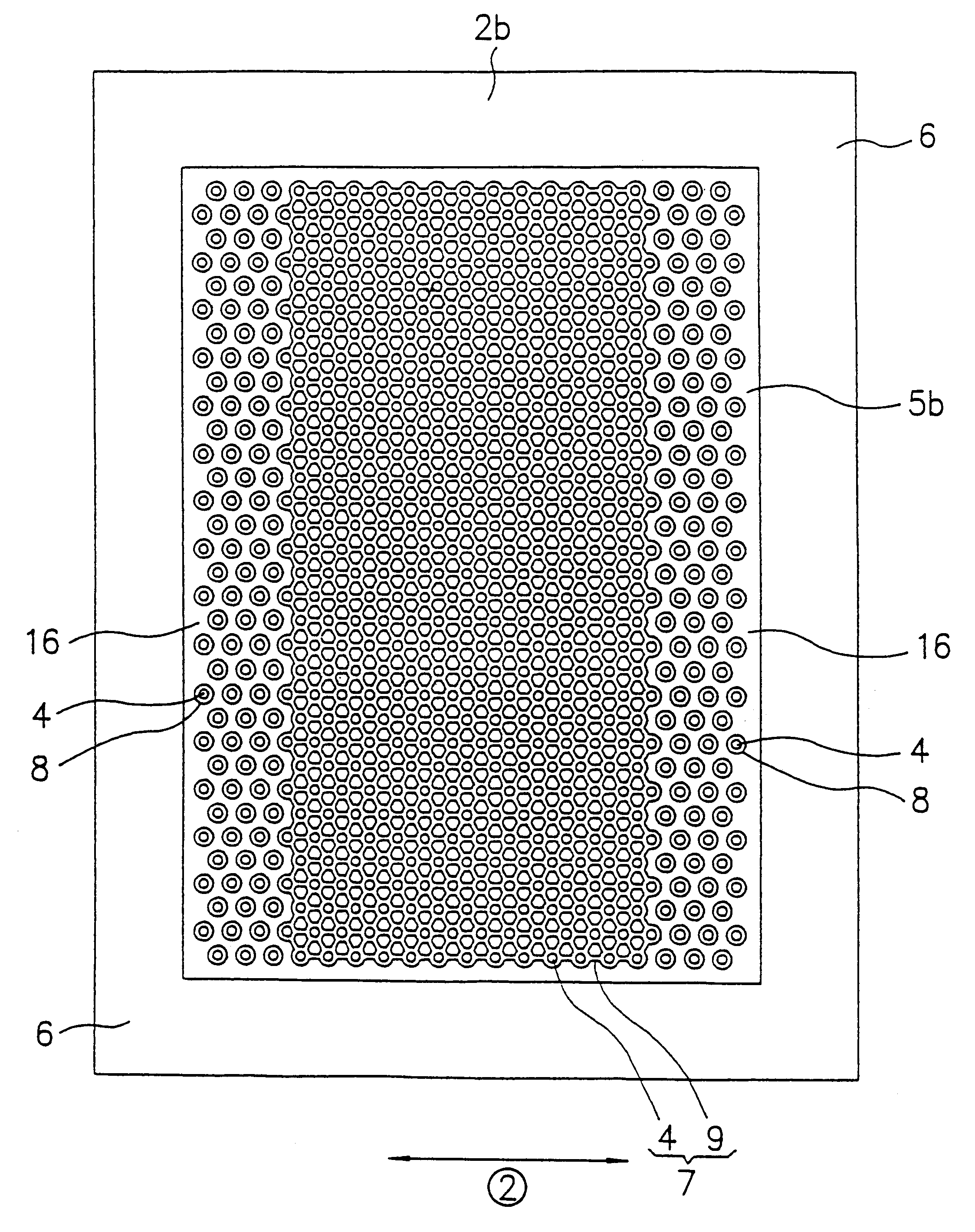

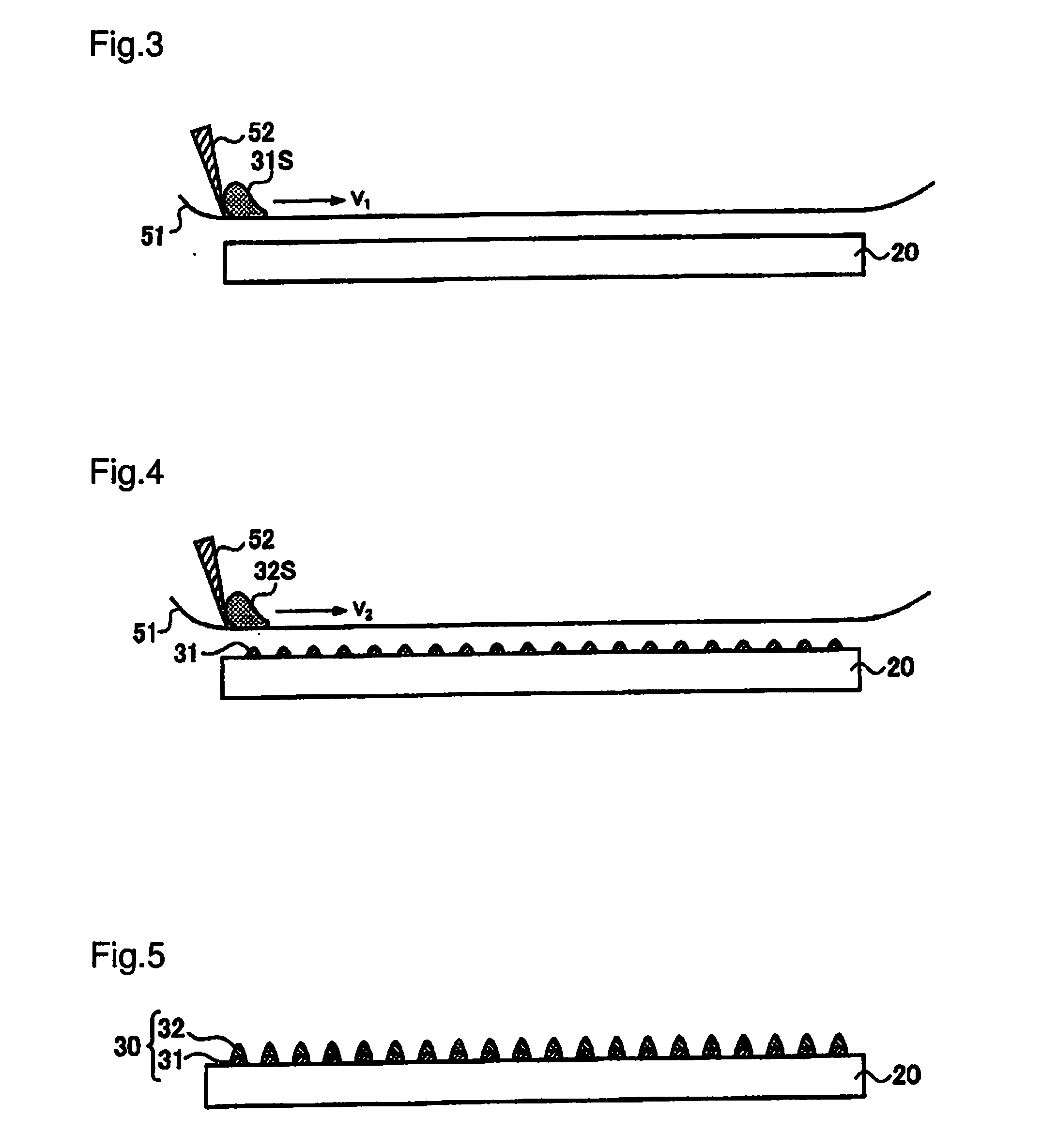

Light-guiding plate and printing method thereof and backlight module

ActiveCN102059865ALow costOvercoming high printing costsMechanical apparatusScreen printersScreen printingLight guide

The invention relates to a light-guiding plate and a printing method thereof and a backlight module. The printing method comprises the following steps of: printing a plurality of scattering screen dots in a first region at the bottom surface of the light-guiding plate by using a first screen printing plate and adopting a screen printing technology; solidifying the plurality of printed scattering screen dots; printing a plurality of scattering screen dots in a second region of the bottom surface of the light-guiding plate by using a second screen printing plate to form a splicing zone between the first region and the second region; and solidifying the plurality of printed scattering screen dots. The backlight module comprises a light-guiding plate, a diffusing plate, a prism sheet, a light source and a reflecting plate. The bottom surface of the light guide plate is printed with a plurality of scattering screen dots, wherein the scattering screen dots are respectively at least formed in the first region and the second region adjacent to the first region, and the splicing zone is formed between two adjacent printing regions. By adopting the splicing printing technology, the printing cost of the large-scale light-guiding plate can be reduced, and the large-size light-guiding plate and the backlight module are obtained.

Owner:BOE TECH GRP CO LTD +1

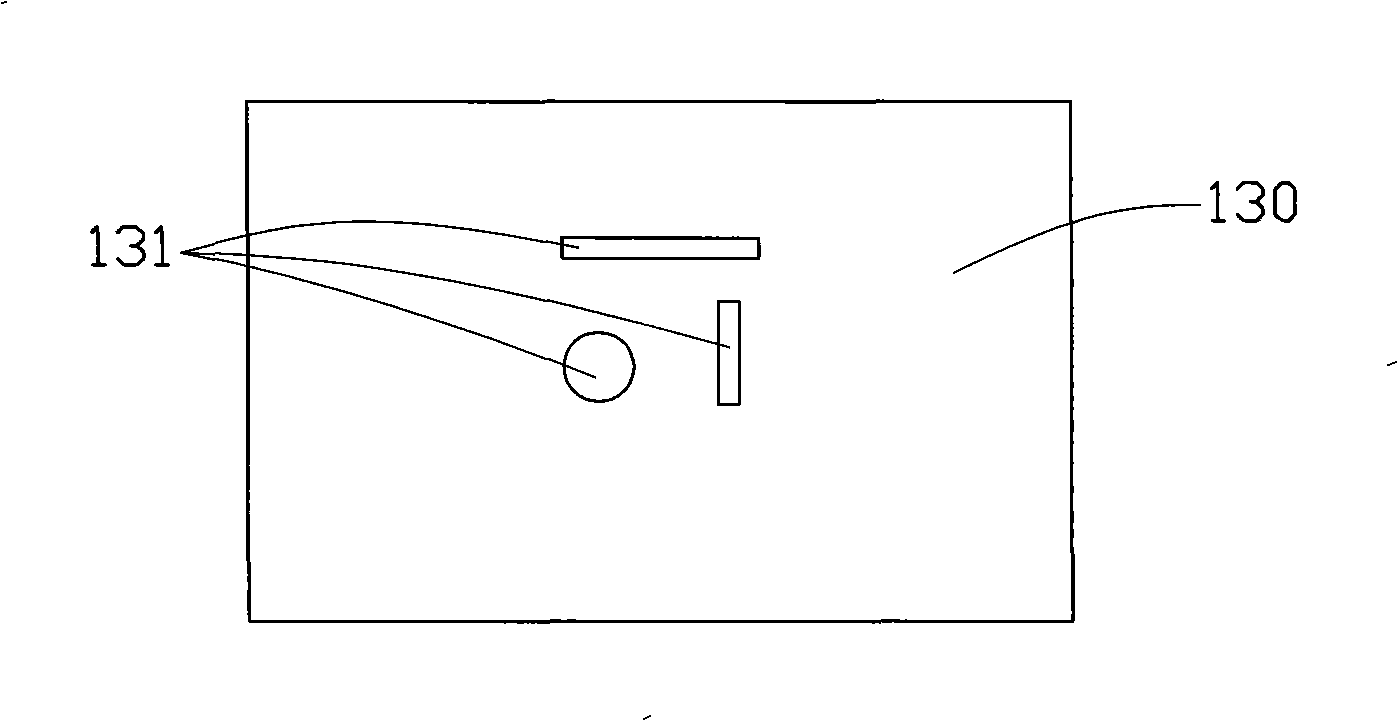

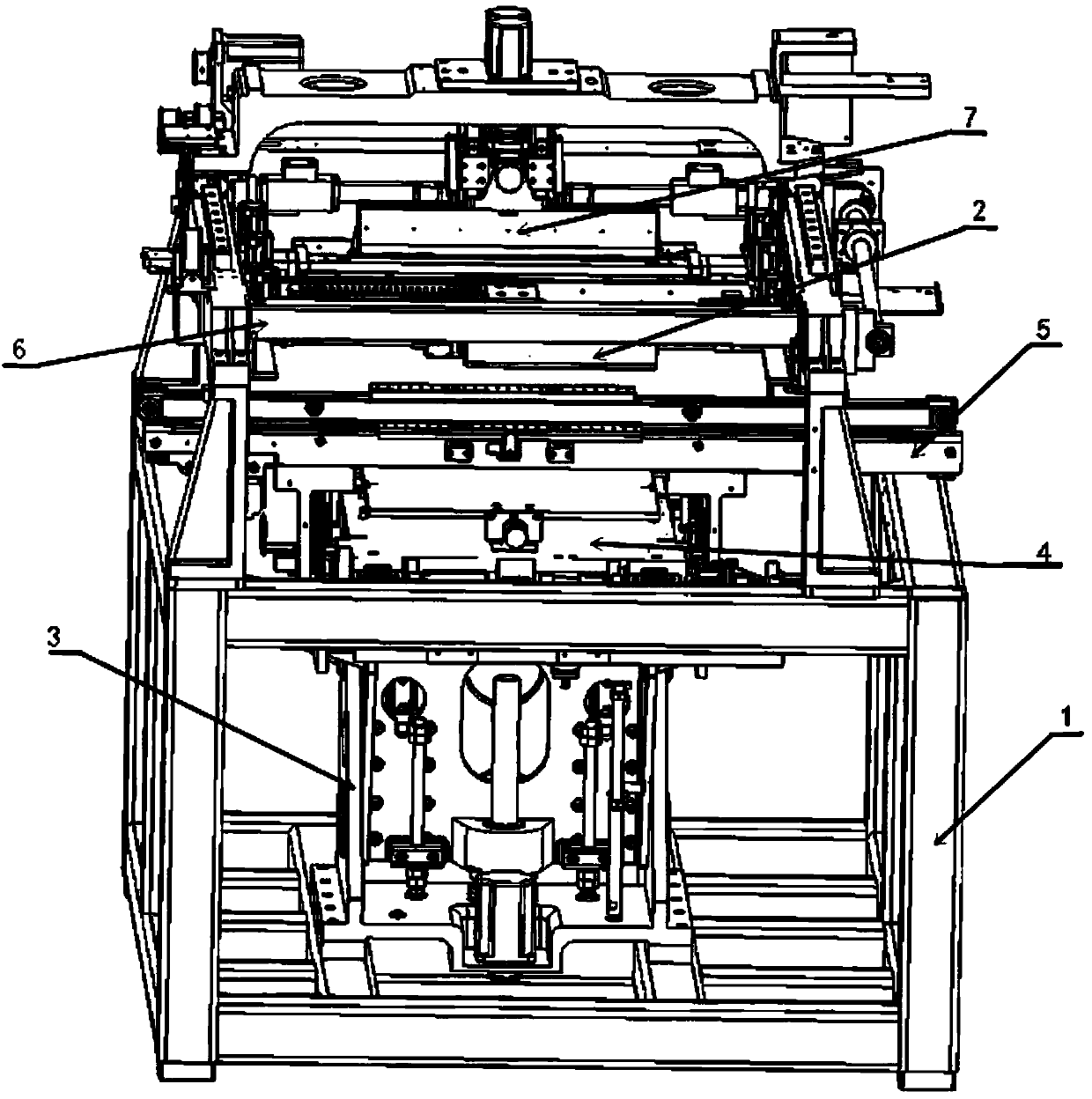

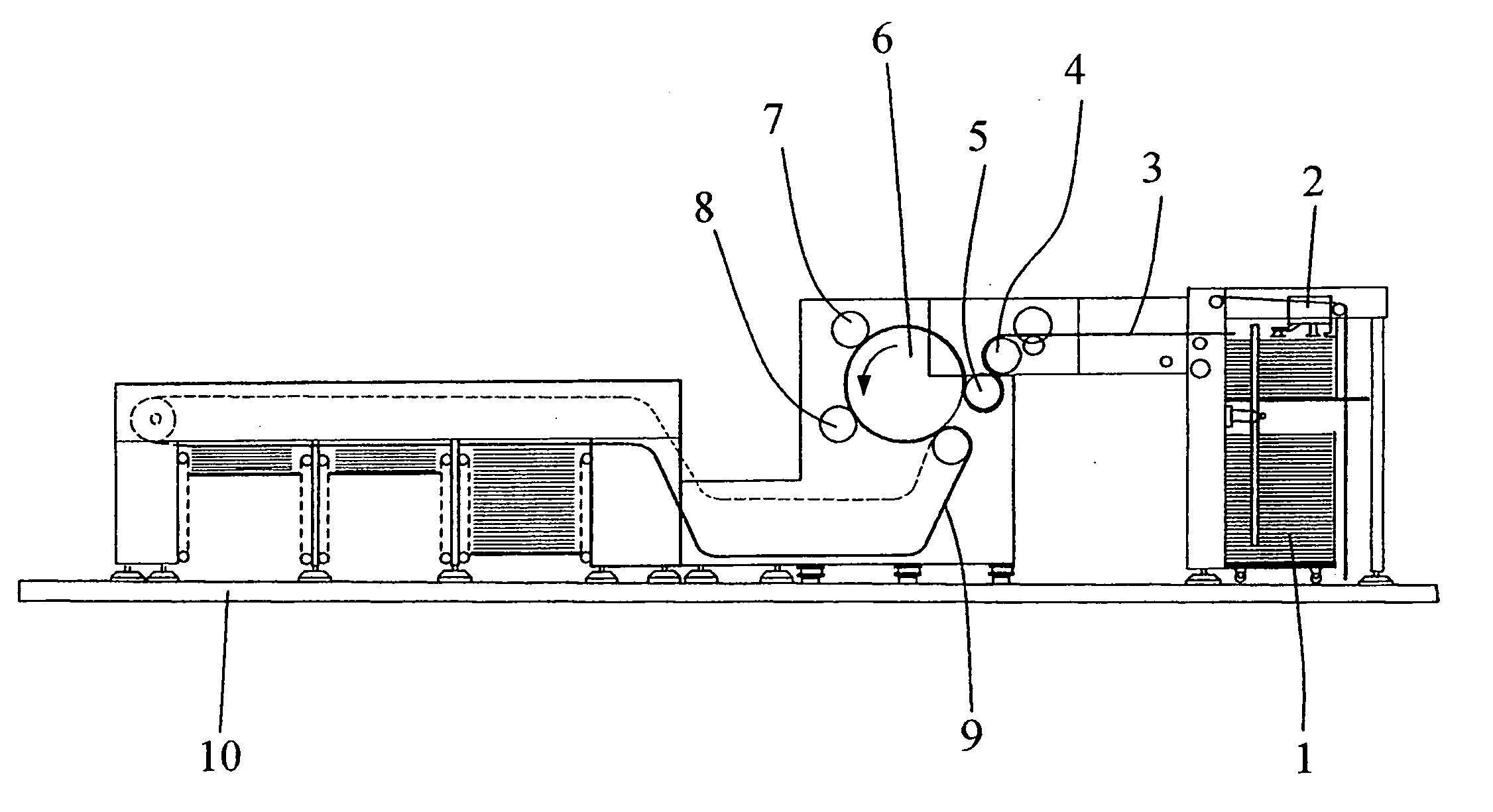

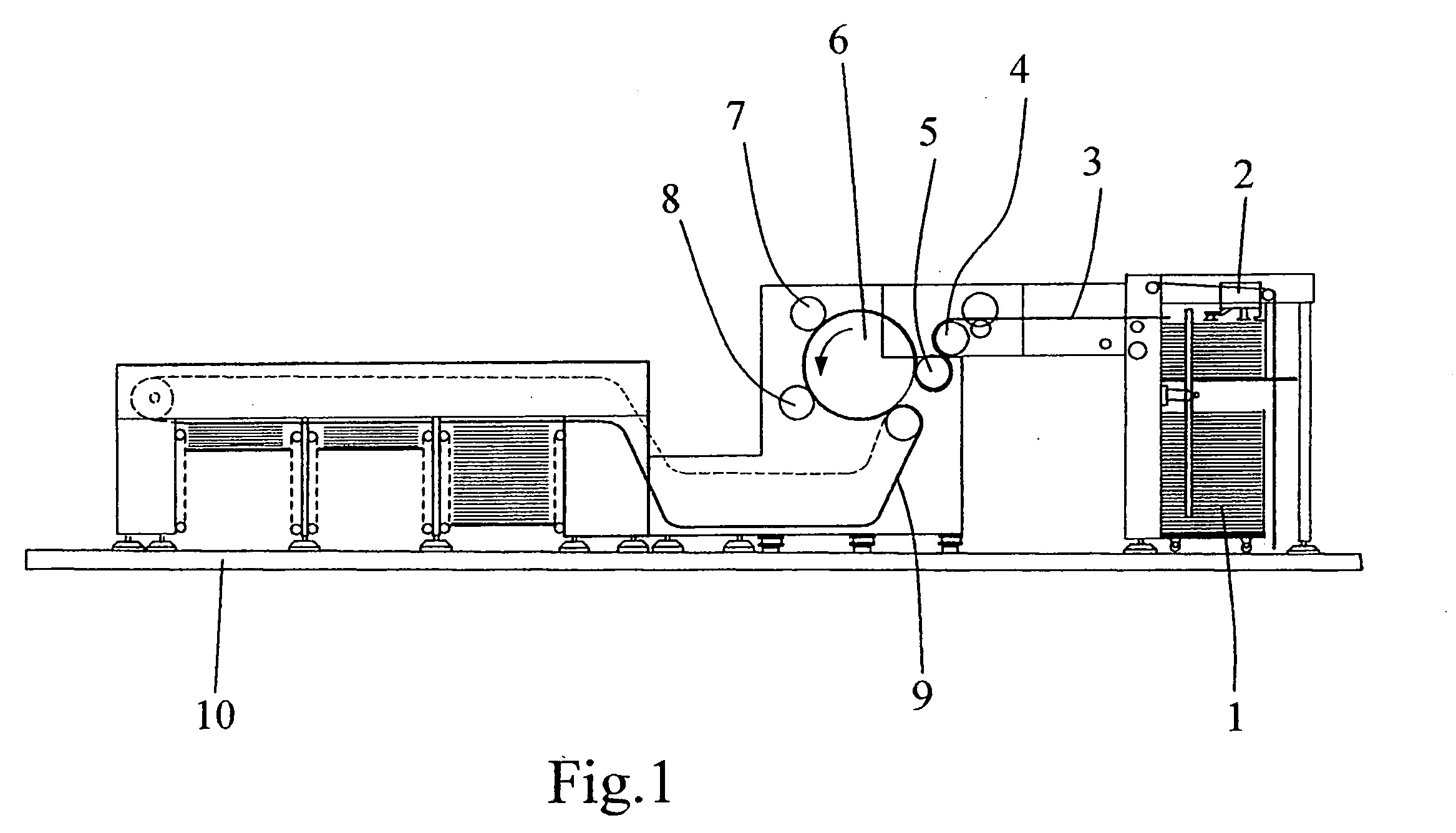

Photovoltaic solar printer

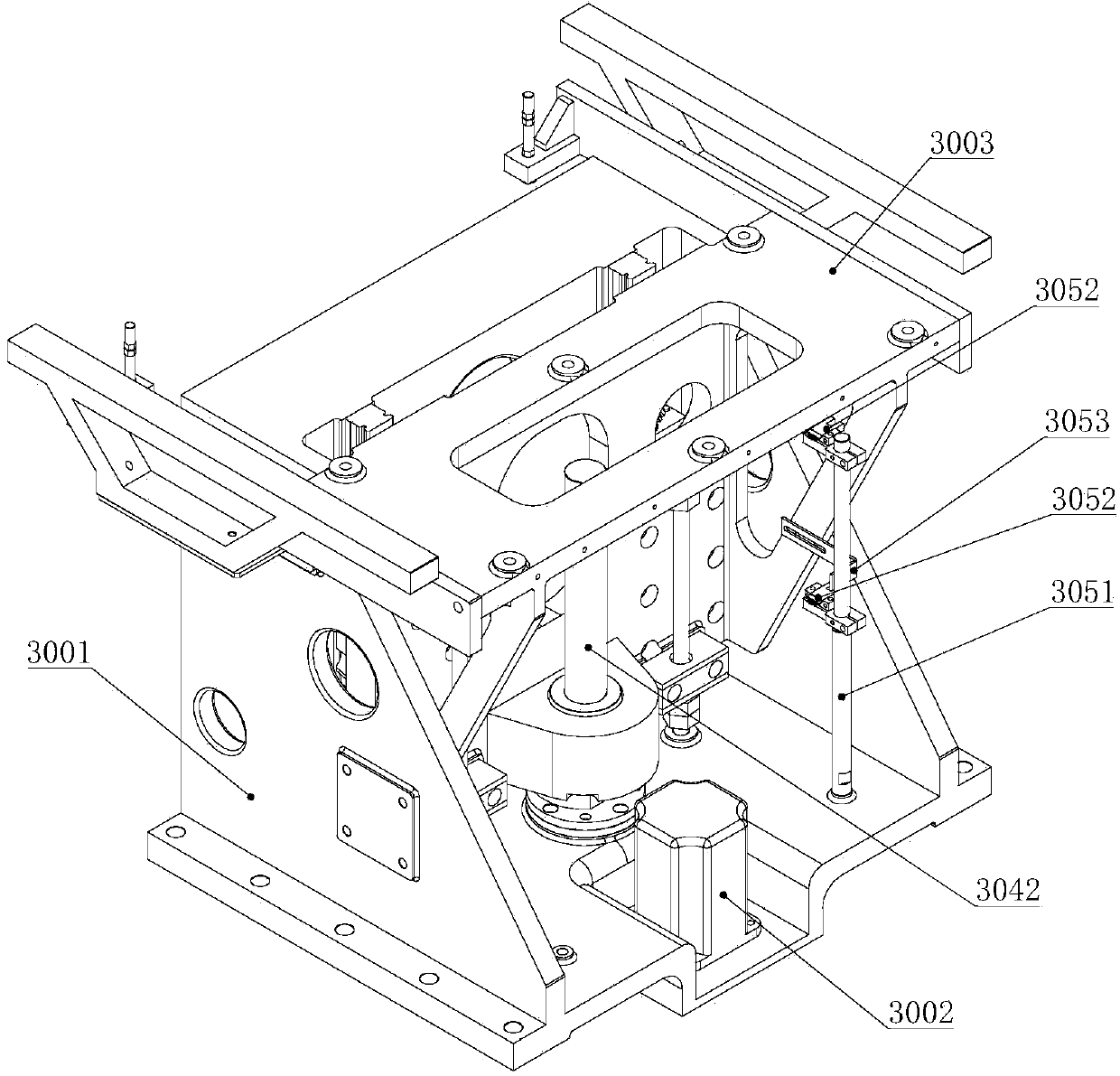

ActiveCN101961947APrecise positioningImprove printing effectFinal product manufactureScreen printersPhotovoltaic solar energyEngineering

The invention relates to the technical field of photovoltaic equipment, in particular to a photovoltaic solar silicon chip printer. The photovoltaic solar printer comprises a framework, an industrial control device and an operating disk mechanism, a transport mechanism, a carrier plate mechanism, a vacuum suction plate mechanism, a steel screen seat mechanism, a screen pressing and regulating mechanism, a scraper mechanism and a vision system device, wherein the operating disk mechanism, the transport mechanism, the carrier plate mechanism, the vacuum suction plate mechanism, the steel screen seat mechanism, the screen pressing and regulating mechanism, the scraper mechanism and the vision system device are connected with the industrial control device. The photovoltaic solar silicon chip printer has the advantages of accurate positioning, good printing effect, high printing accuracy and high production efficiency.

Owner:FOLUNGWIN AUTOMATIC EQUIP CO LTD

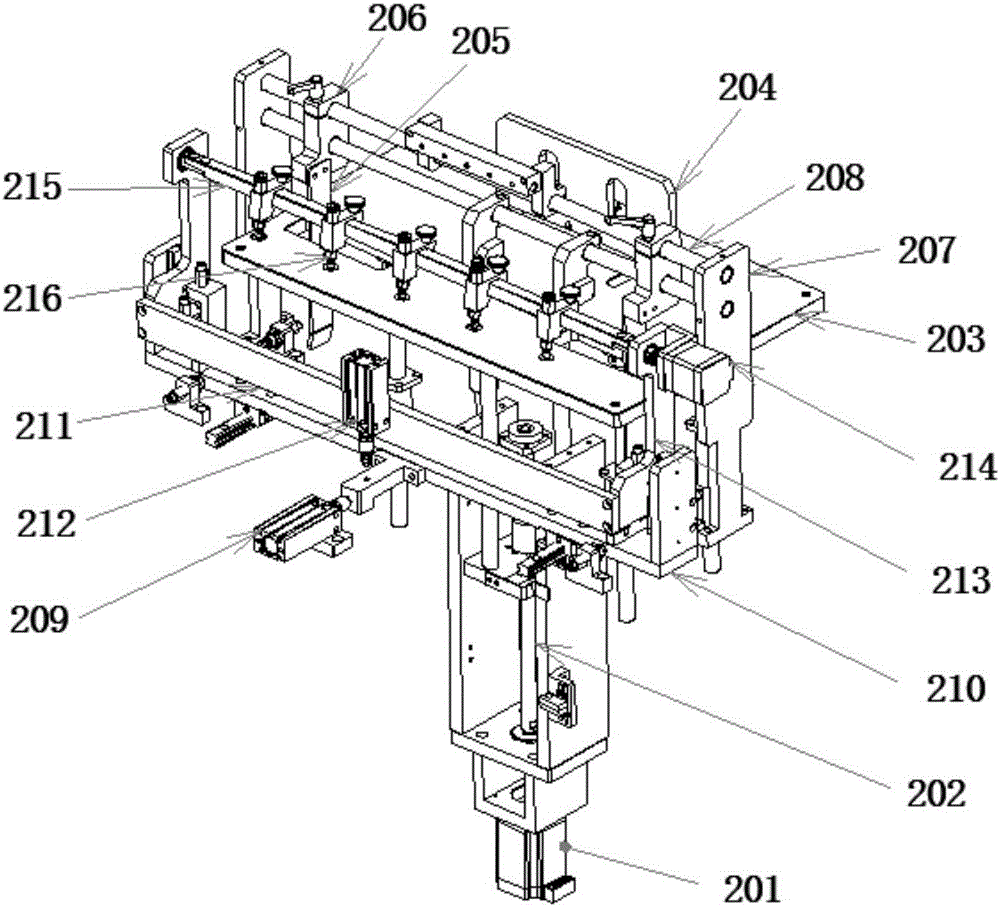

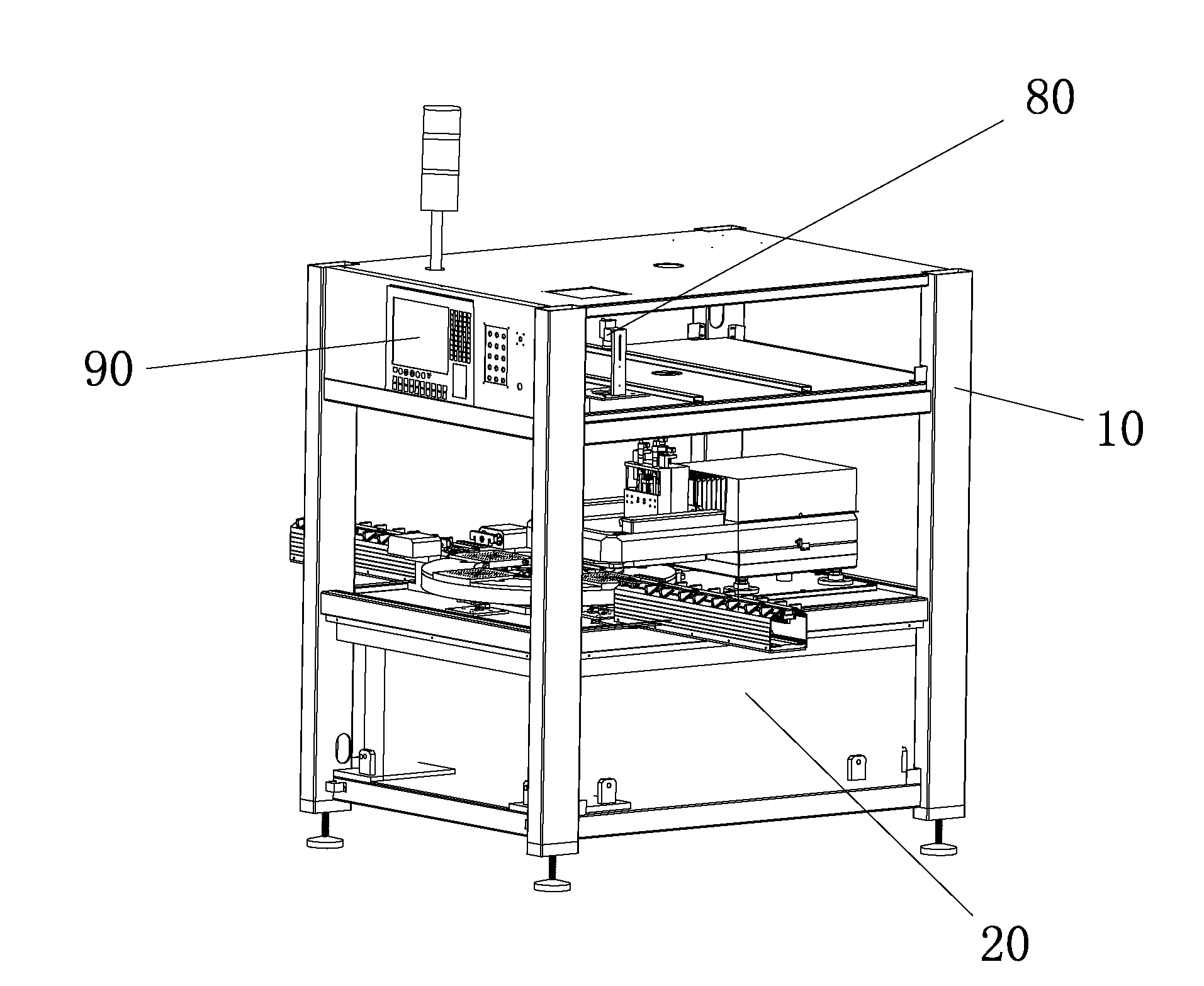

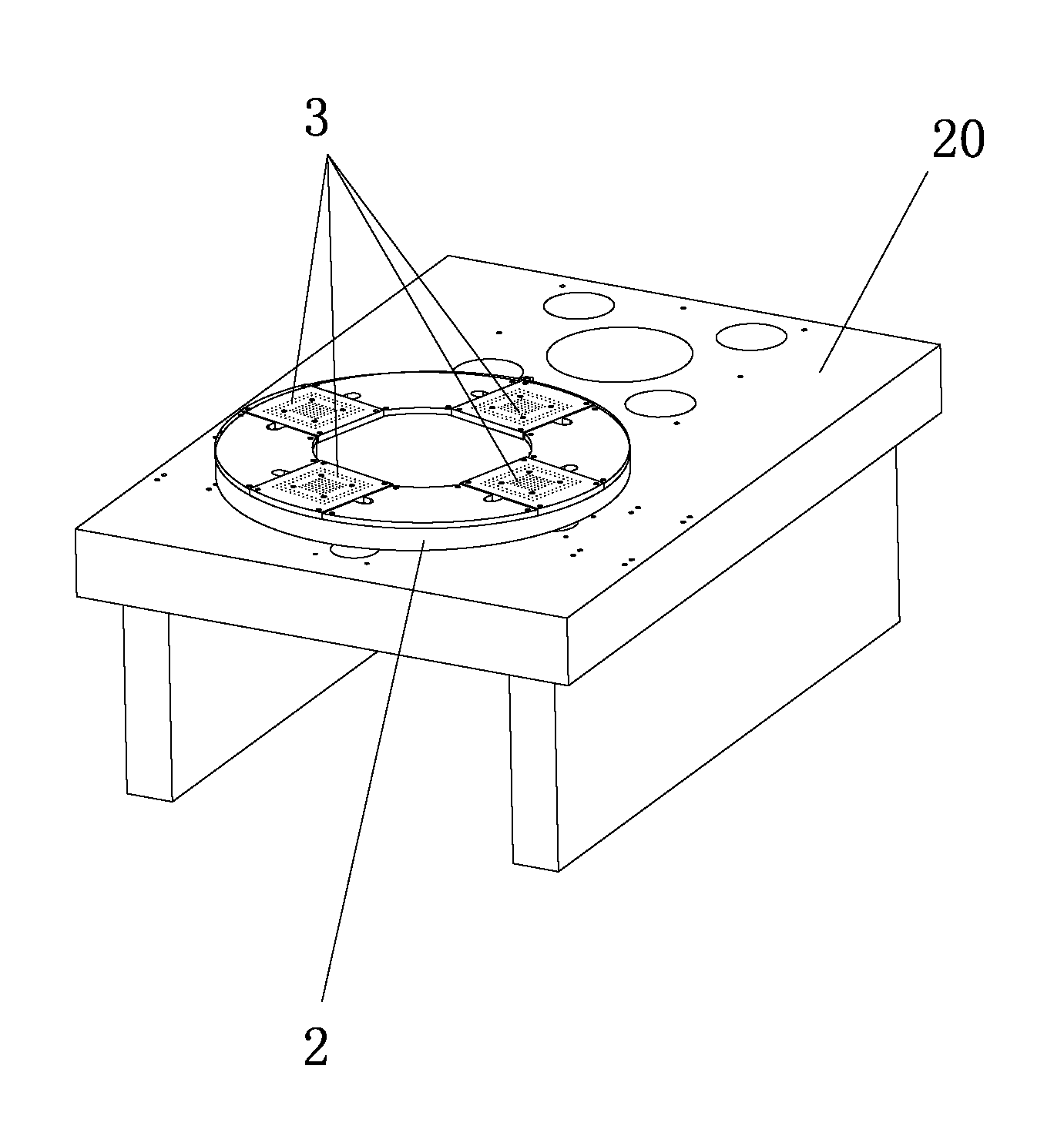

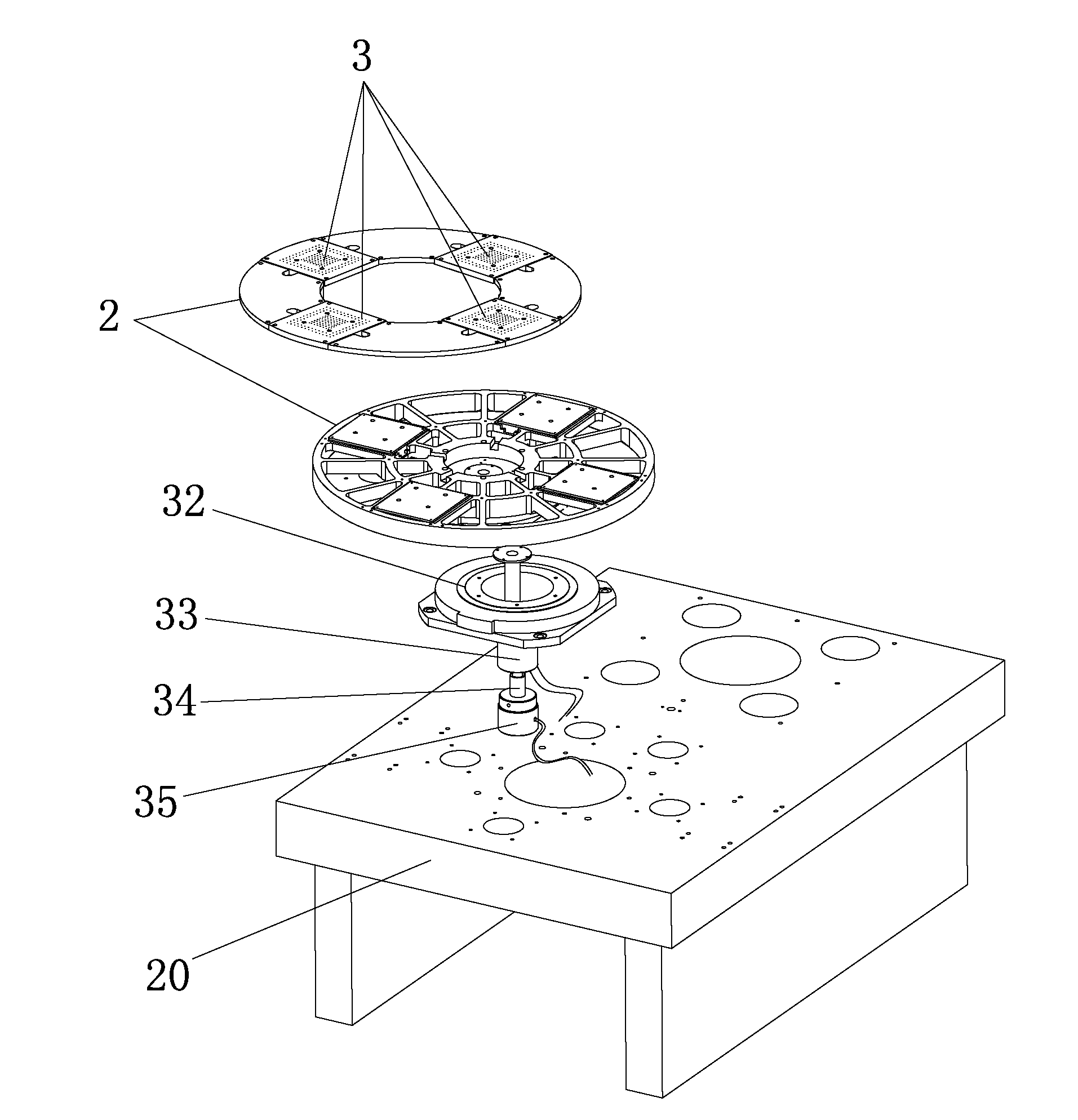

Full-automatic solder paste printer

ActiveCN104191808AEasy to cleanControl pressureScreen printersPrinting press partsPrinting pressSolder paste

The invention discloses a full-automatic solder paste printer. The full-automatic solder paste printer comprises a rack subassembly, wherein a Z-axis lifting system is installed at the bottom end of the rack subassembly, and a platform correcting system is installed at the top end of the Z-axis lifting system and provided with a guide rail transporting system; the rack subassembly is provided with a steel screen frame clamping system, a scraper blade printing system and an automatic cleaning system; the Z-axis lifting system makes lifting movement stable and positioning fast and accurate and solves the problem that responding speed is low because large-inertia lifting control is low in positioning accuracy; the difficult problem that manual PCB correction is not accurate is solved through the platform correcting system, and printing quality is improved; a steel screen frame is cleaned in any combination mode of a drying cleaning mode, a wet cleaning mode and a vacuum cleaning mode, so that the cleaning effect of the steel screen frame is greatly improved, manual cleaning time is shortened, and labor intensity is relieved; through the scraper blade printing system, pressure of a scraper blade can be accurately controlled and regulated, and the problem that the scraper blade pressure of a traditional printer cannot be controlled is solved.

Owner:SHENZHEN GRANDSEED TECH DEV

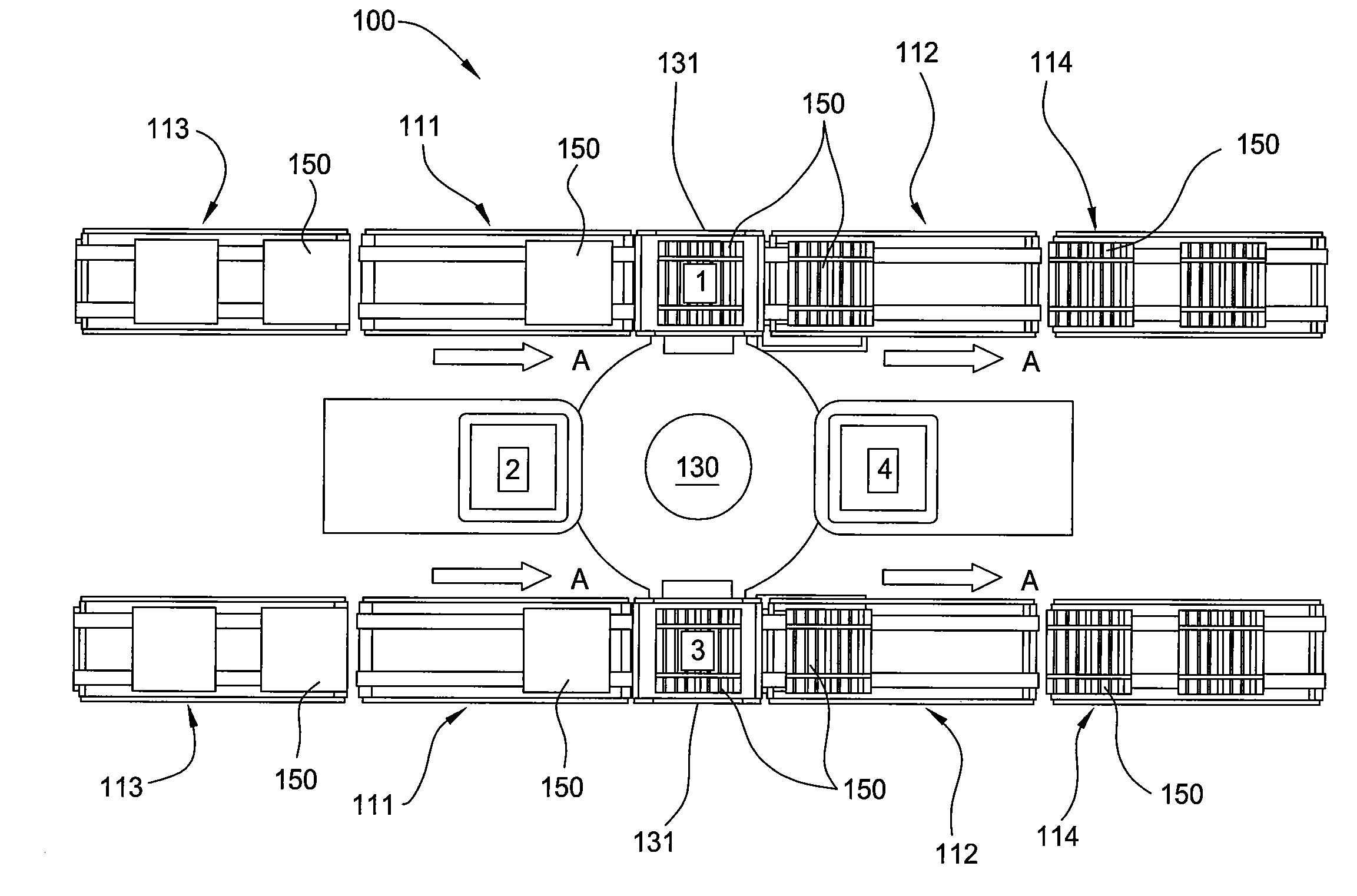

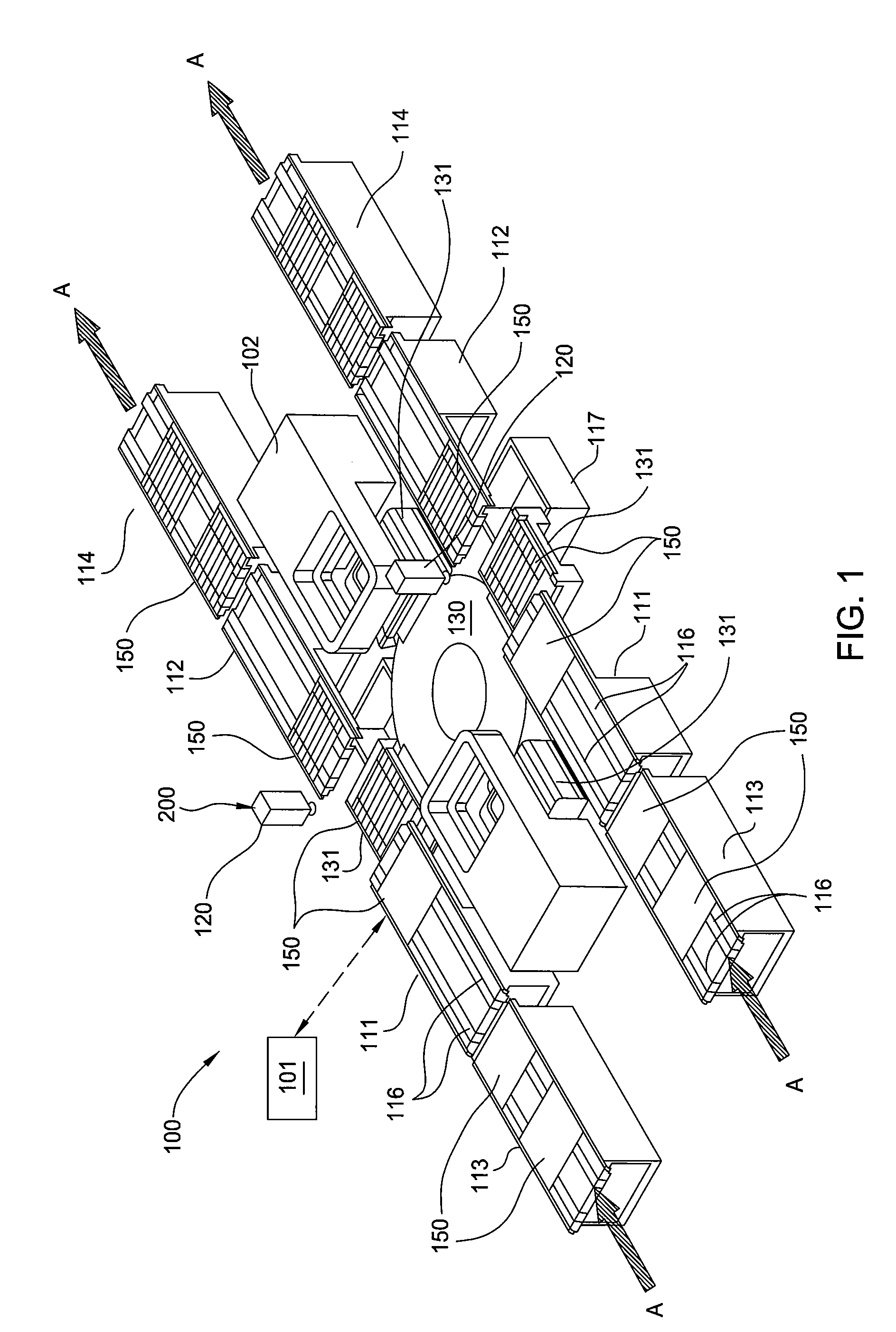

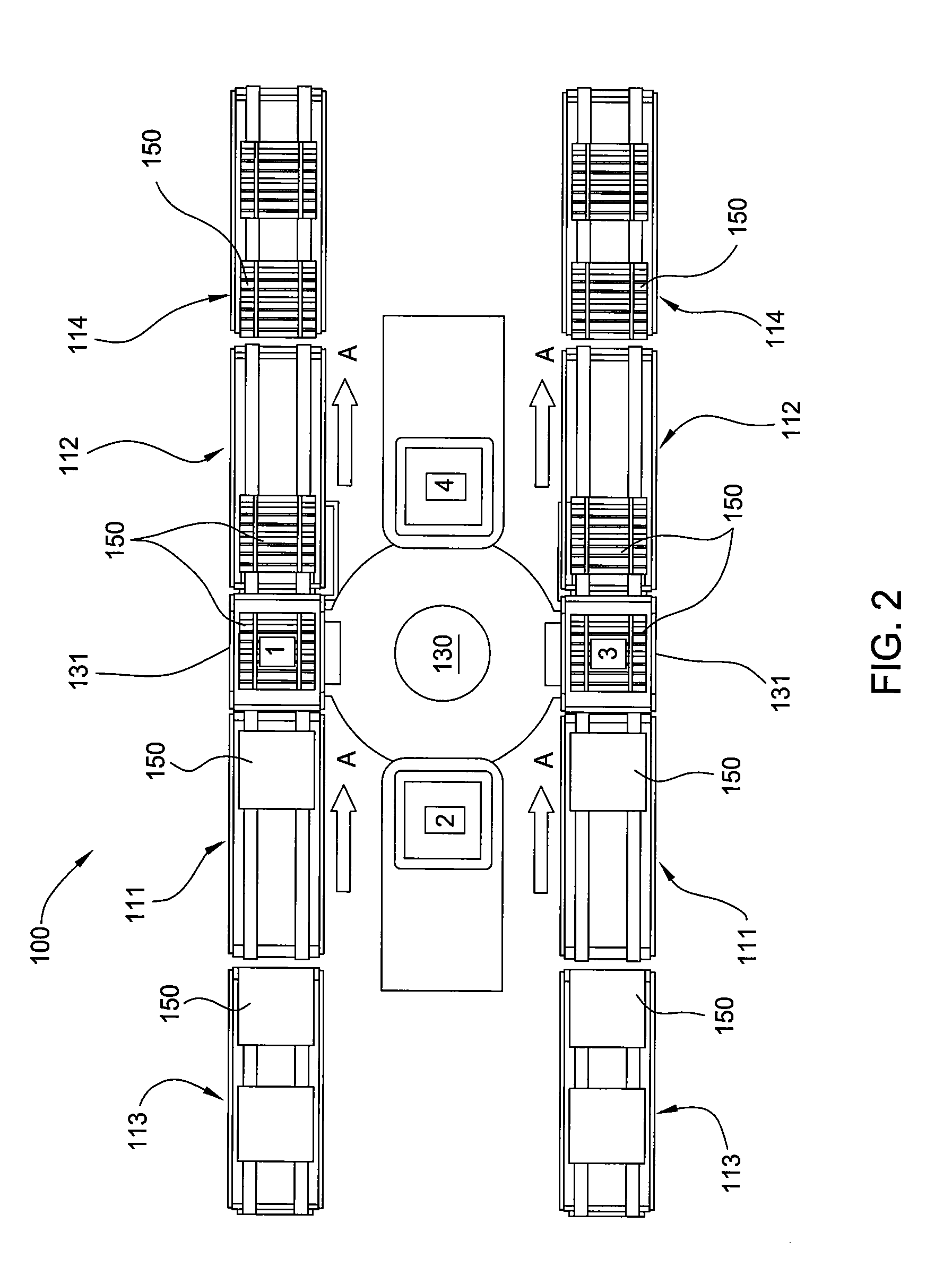

Vertically separated pass through conveyor system and method in surface mount technology process equipment

InactiveUS20100122633A1Printed circuit assemblingLiquid surface applicatorsProcess equipmentTransport system

Disclosed herein is an apparatus for depositing viscous material on an electronic substrate. The apparatus comprises a frame, an assembly material applicator coupled to the frame and configured to apply assembly material to the electronic substrate, a substrate support assembly, coupled to the frame, configured to support and secure the electronic substrate in a material application position, and a transport system, coupled to the frame, to shuttle electronic substrates to and from the substrate support assembly, the transport system including an upper track and a lower track disposed below the upper track.

Owner:ILLINOIS TOOL WORKS INC

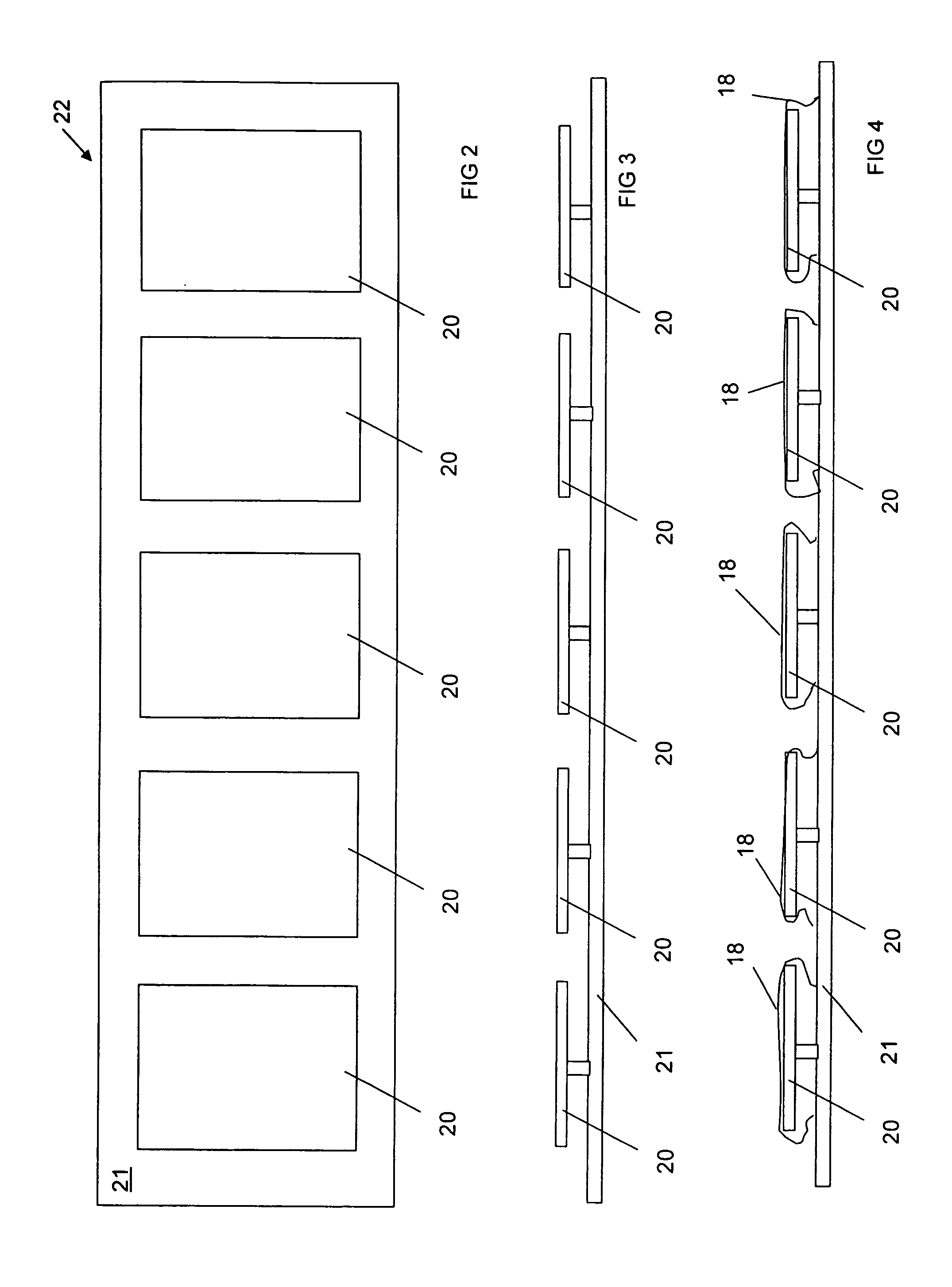

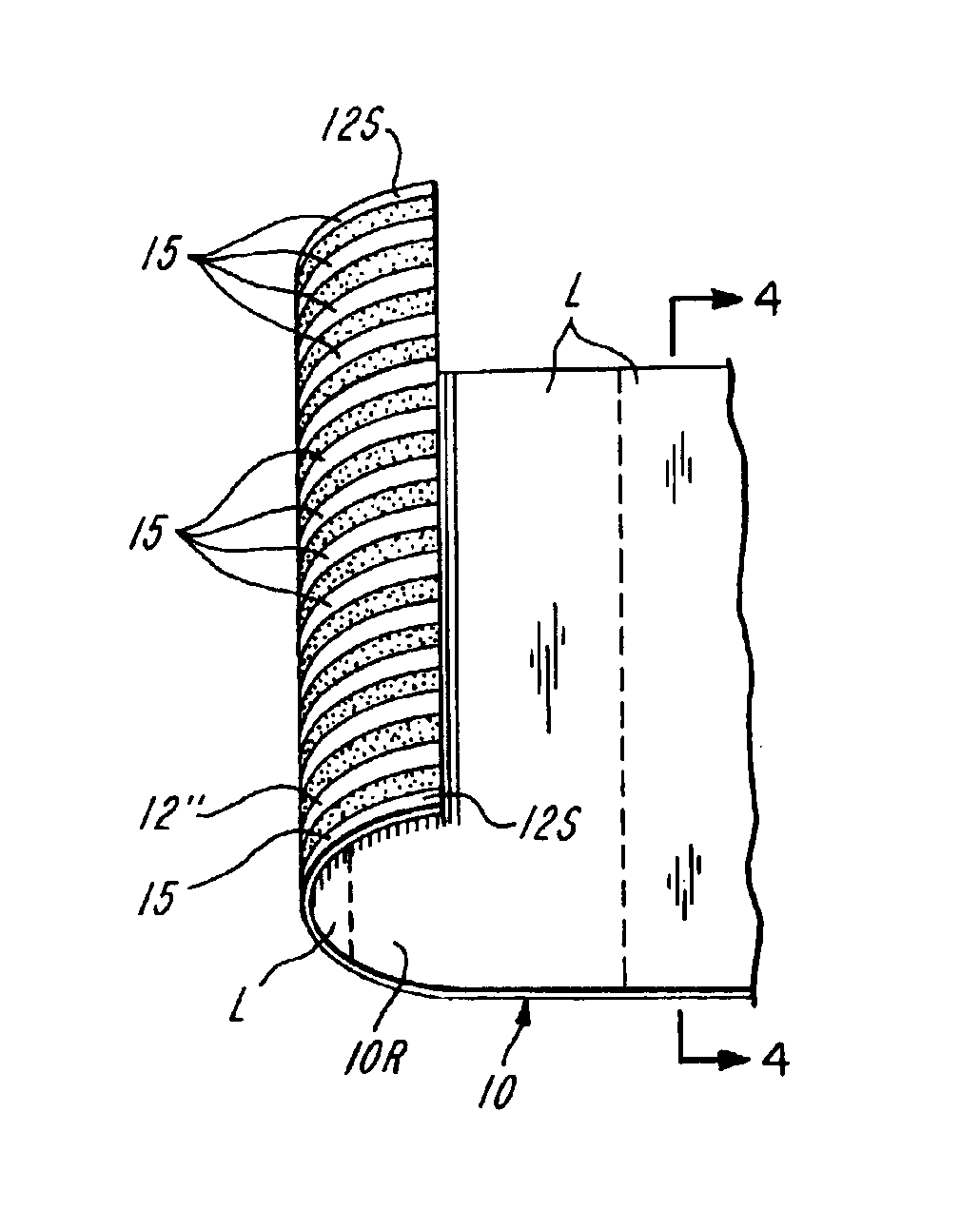

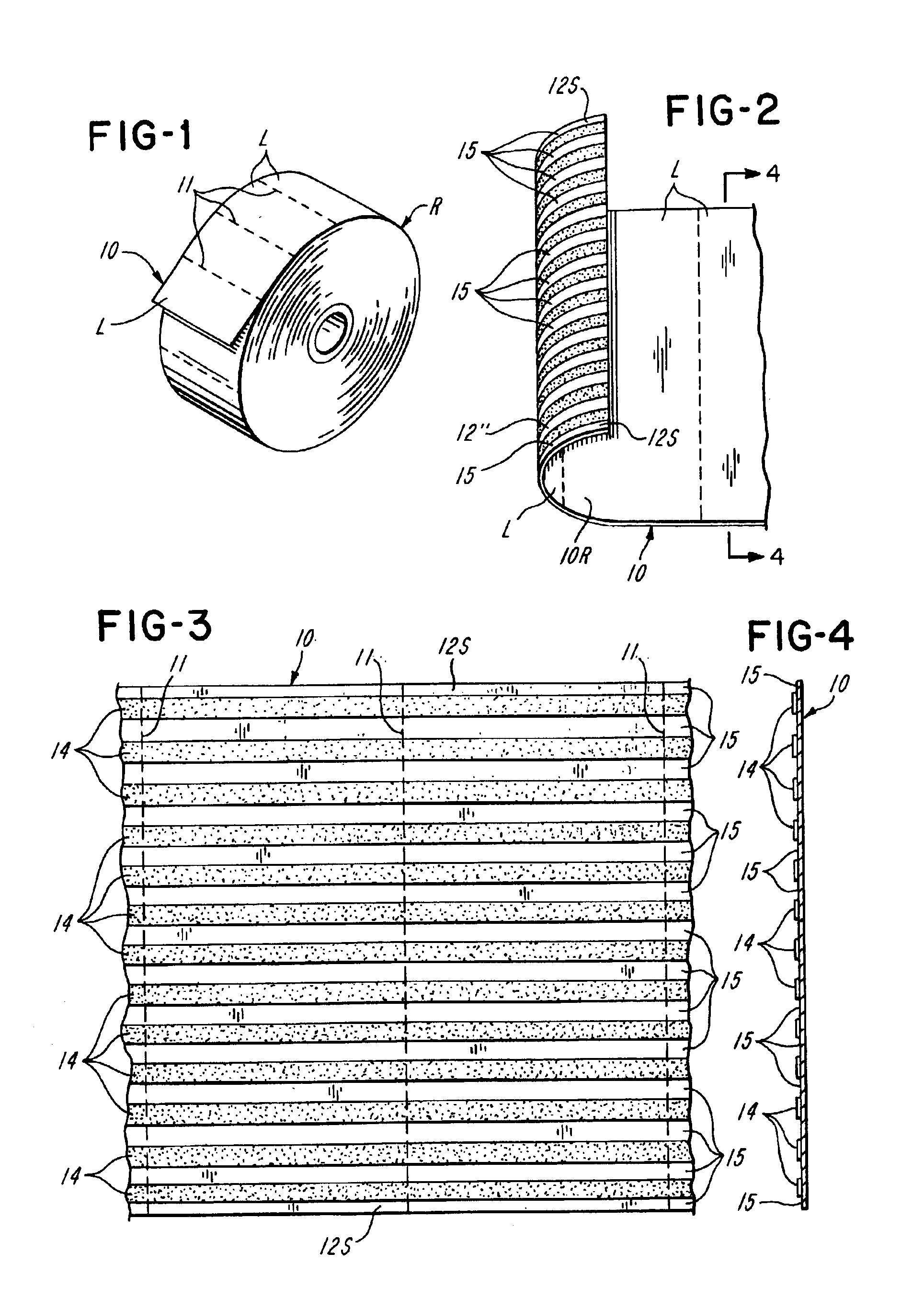

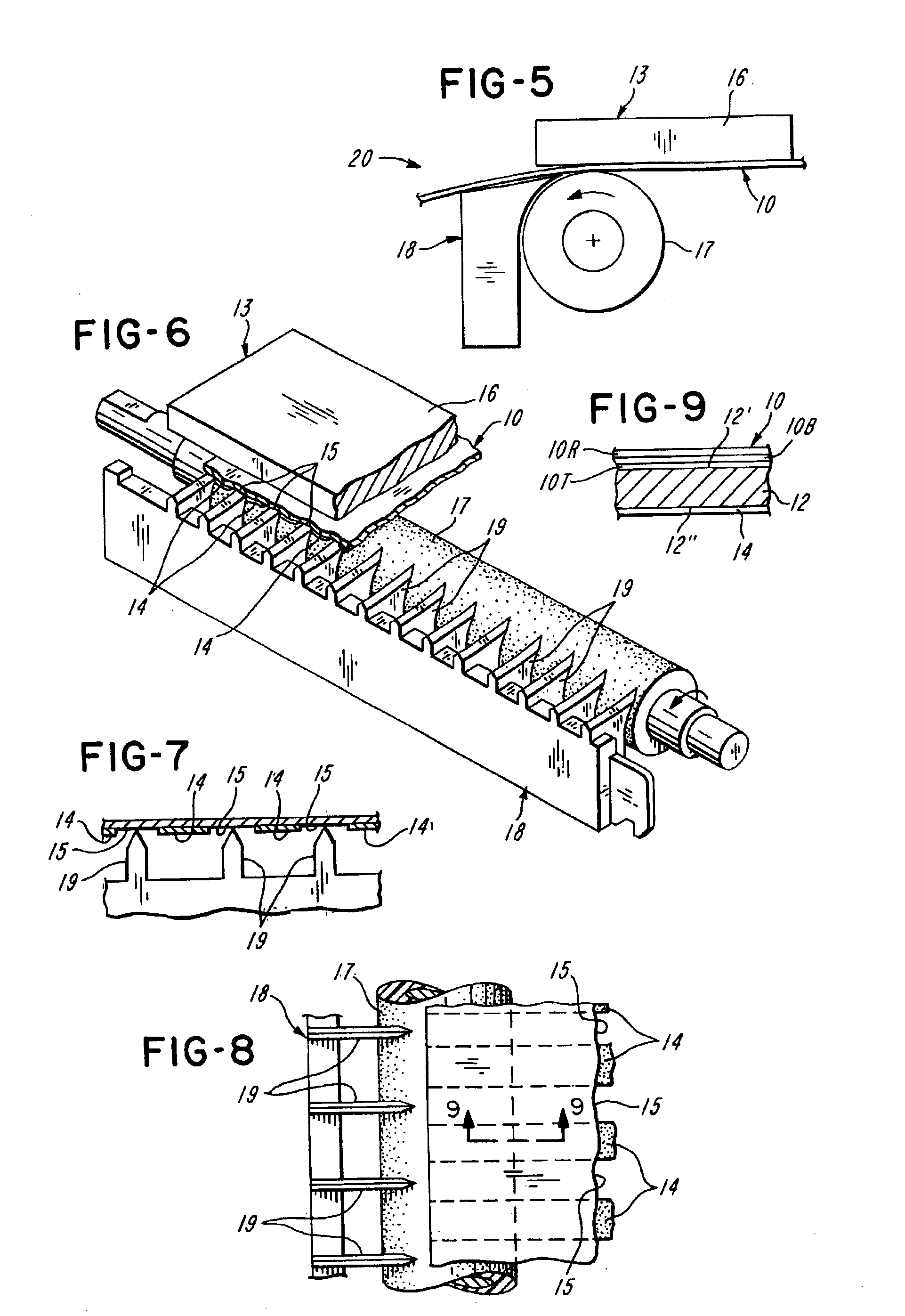

Method and system for handling a linerless label web

There is disclosed a linerless label web roll wherein the label web has a patterned coating of pressure sensitive adhesive on its underside between marginal side edges and at marginal side edges of the label web. The adhesive is provided in longitudinally extending laterally spaced stripes of adhesive with intervening adhesive-free zones. The label web can be supported and / or guided by support or guide elements which contact the adhesive-free zones in a suitable utilization device such as a printer or label applicator.

Owner:AVERY DENNISON CORP

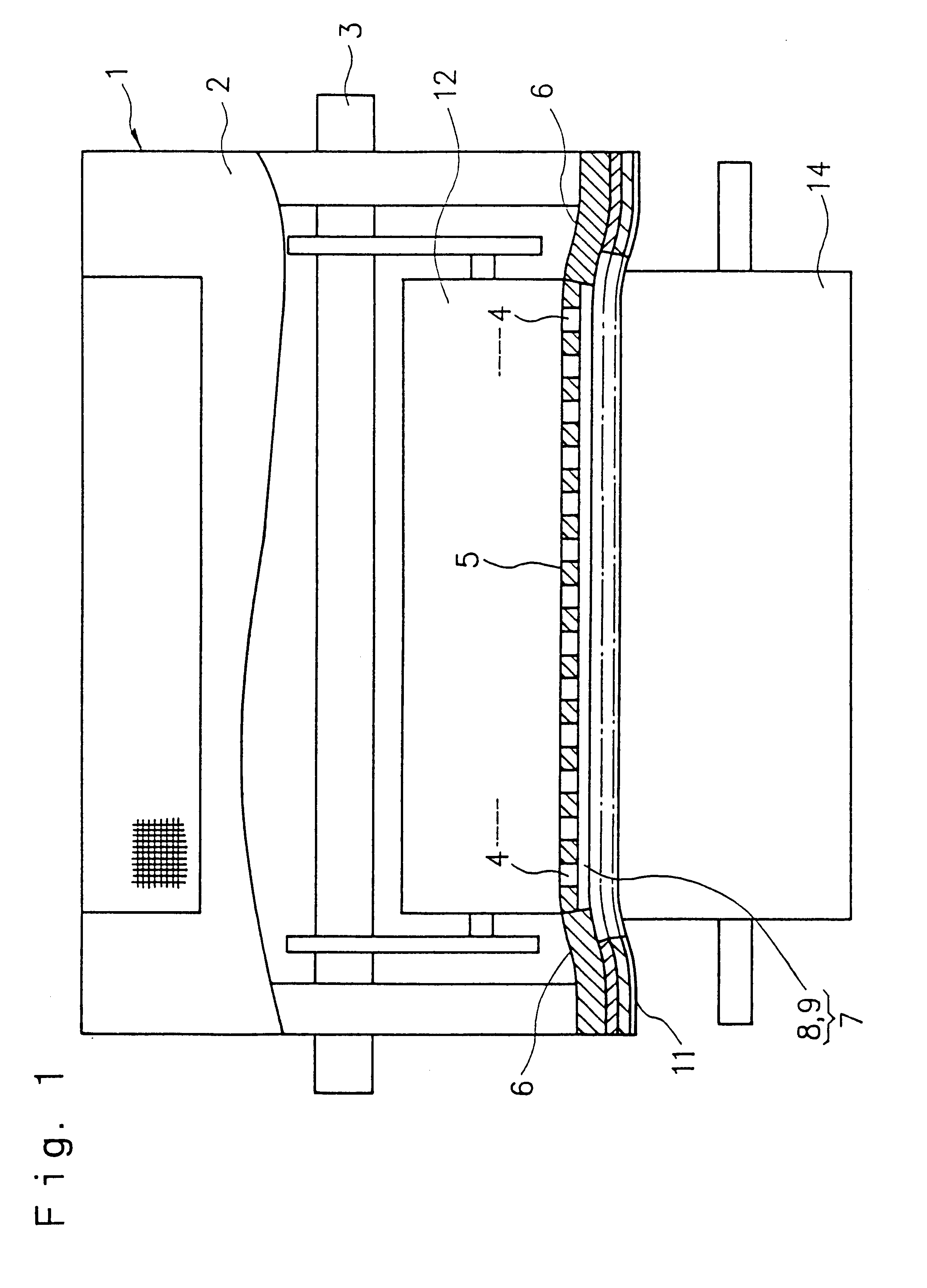

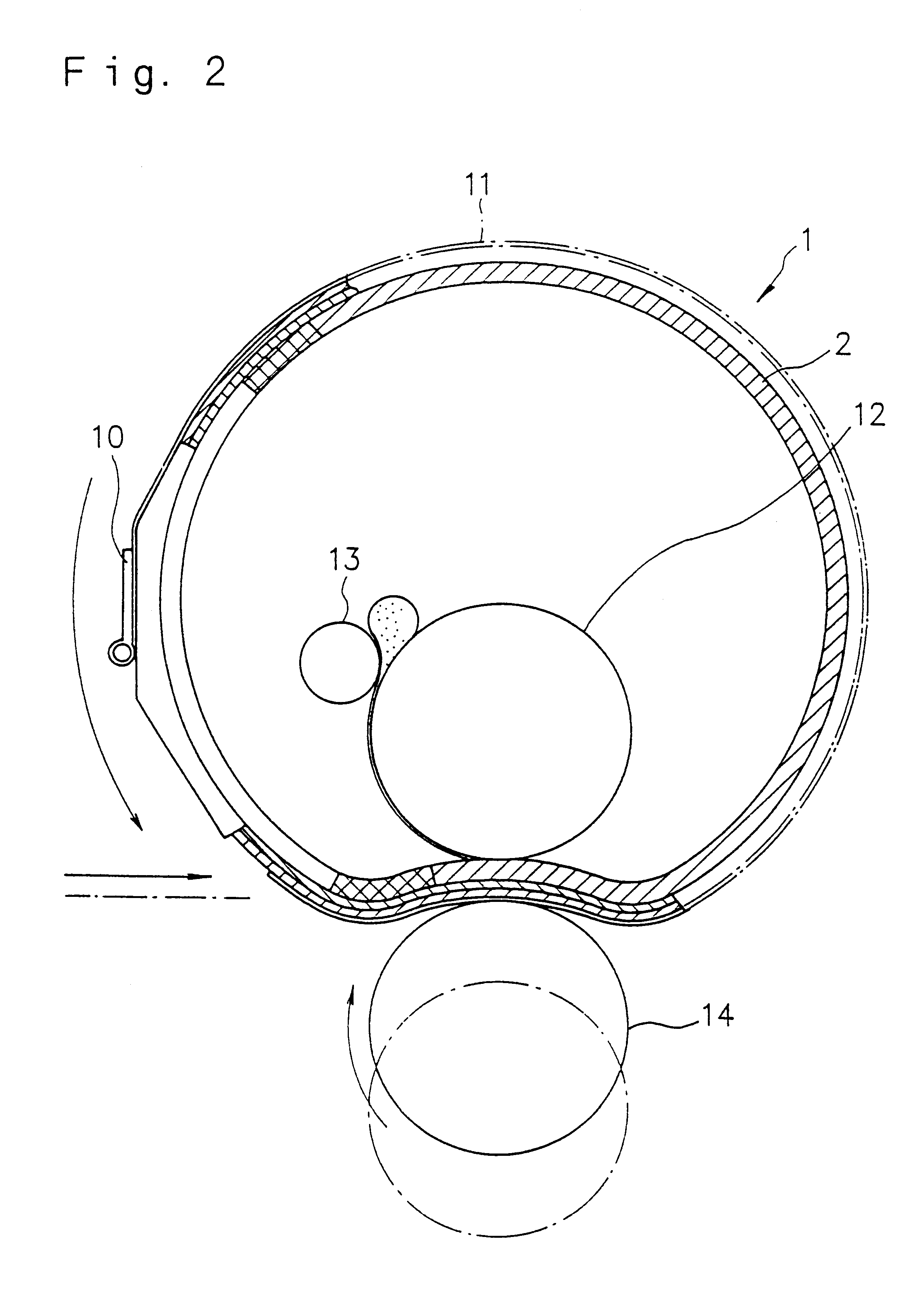

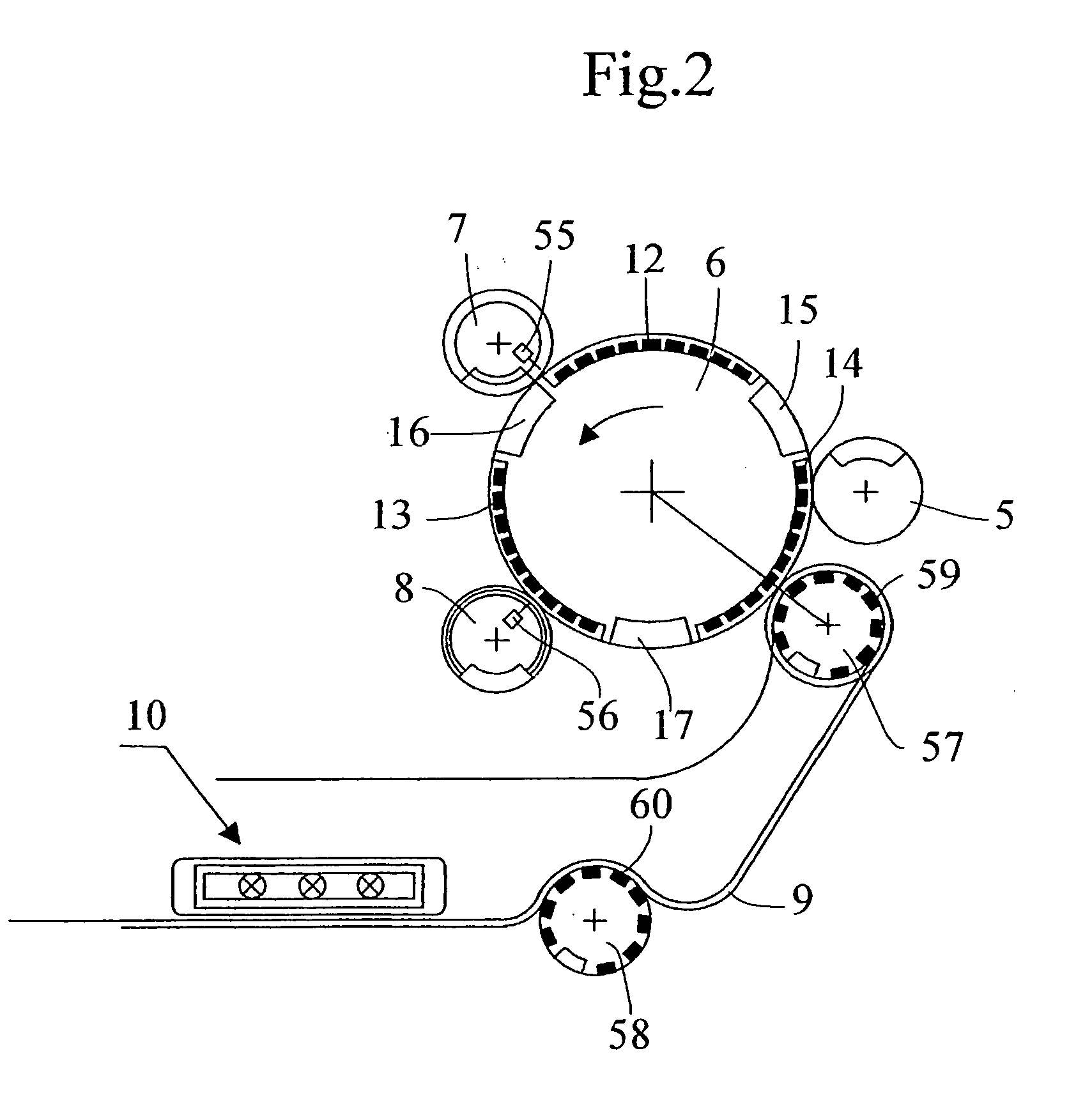

Stencil printing machine and stencil printing drum

A stencil printing machine has a printing drum having a cylindrical circumferential wall adapted to receive a perforated stencil sheet wrapped on an outer circumferential surface thereof and driven to rotate around a central axis thereof the circumferential wall having an opening portion with many through holes formed therein, a non-opening portion formed around the opening portion, and at least one recessed portion formed in at least one part of the opening portion adjacent to the non-opening portion in an axial direction of the circumferential wall; an ink supplying roller situated in the printing drum for supplying ink to an inner circumferential surface of the cylindrical circumferential wall of the printing drum; and a press roller situated adjacent to the printing drum and being urged against the outer circumferential surface of the cylindrical circumferential wall of the printing drum.

Owner:RISO KAGAKU CORP

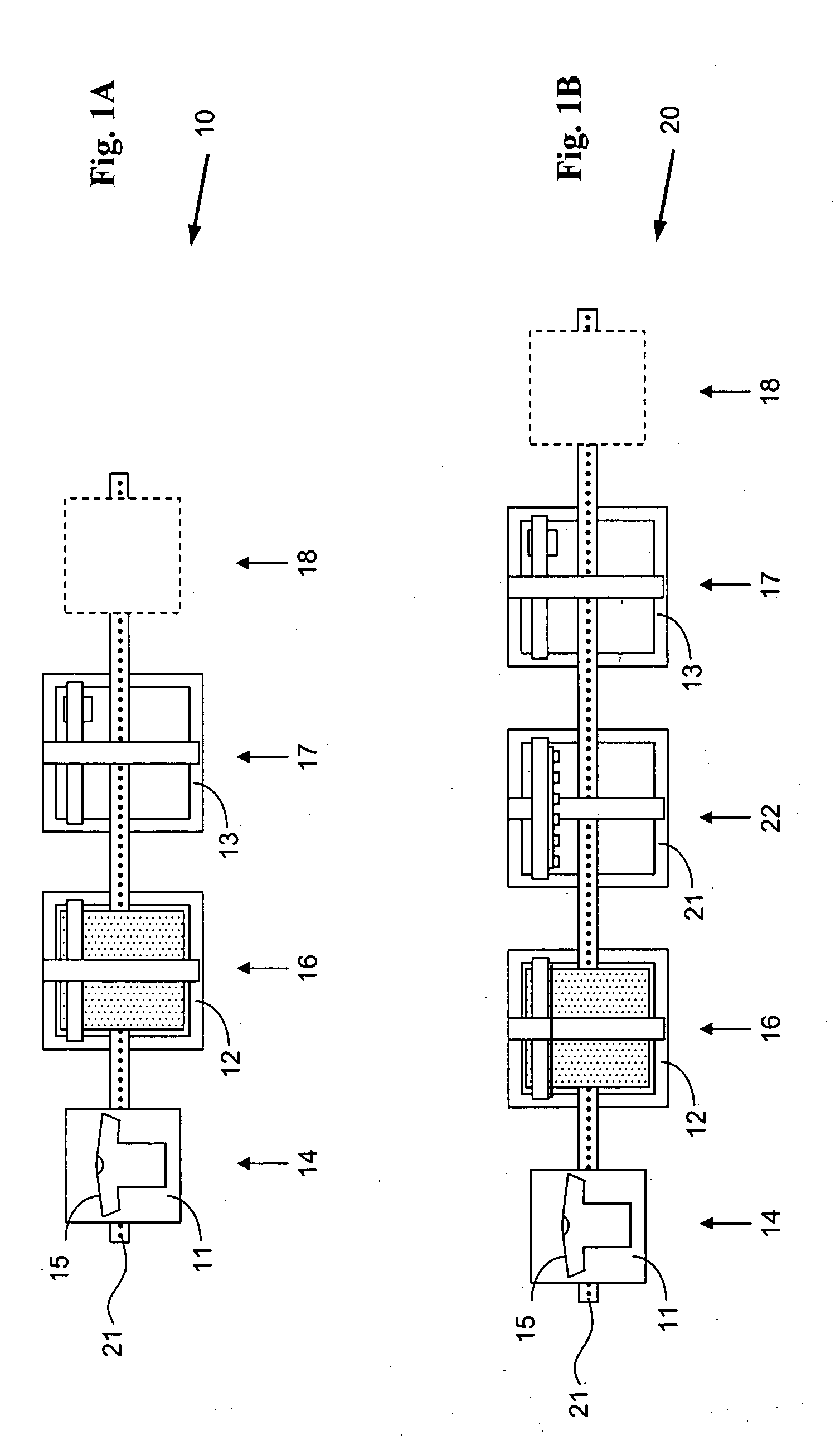

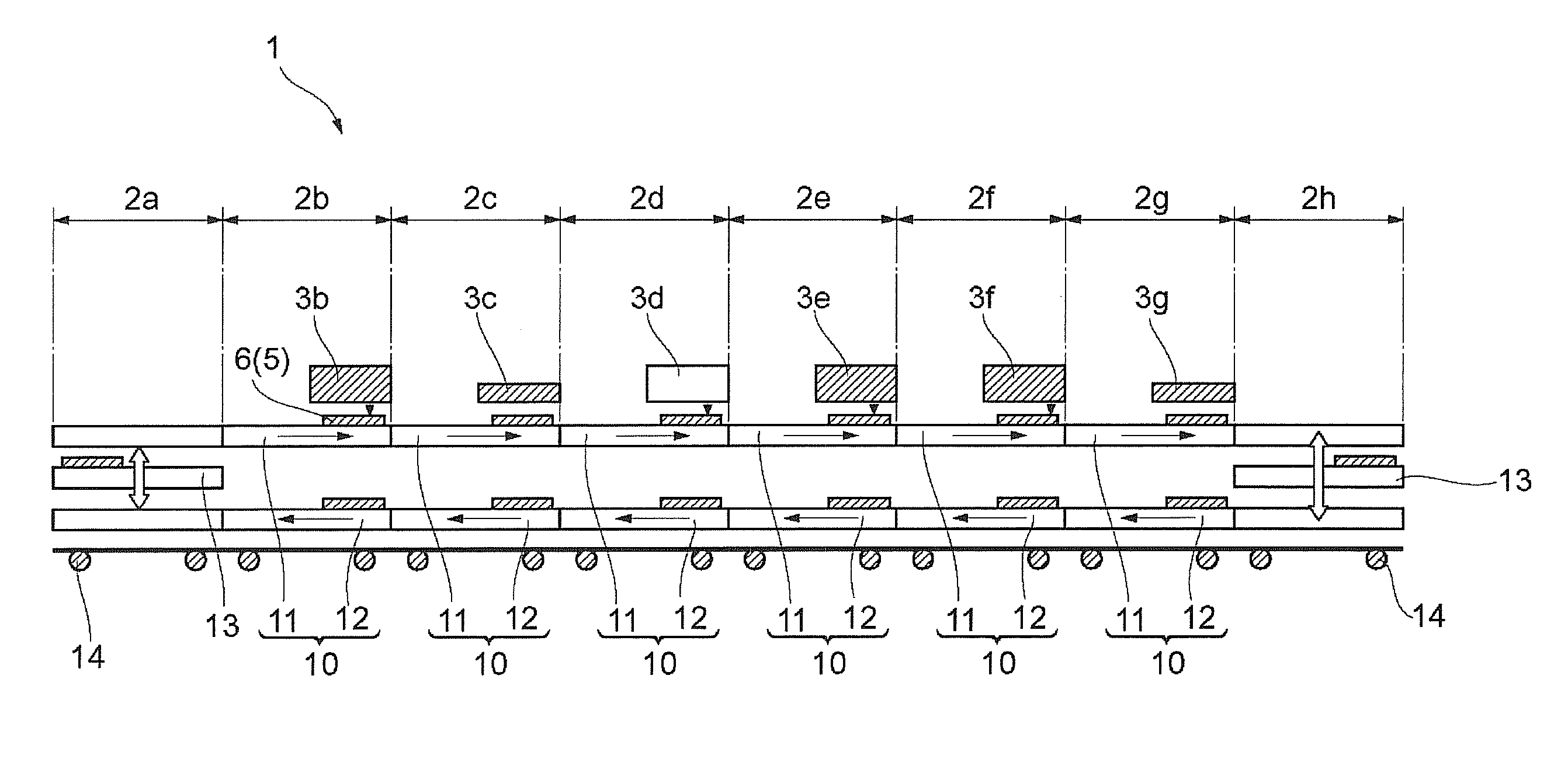

Printing apparatus

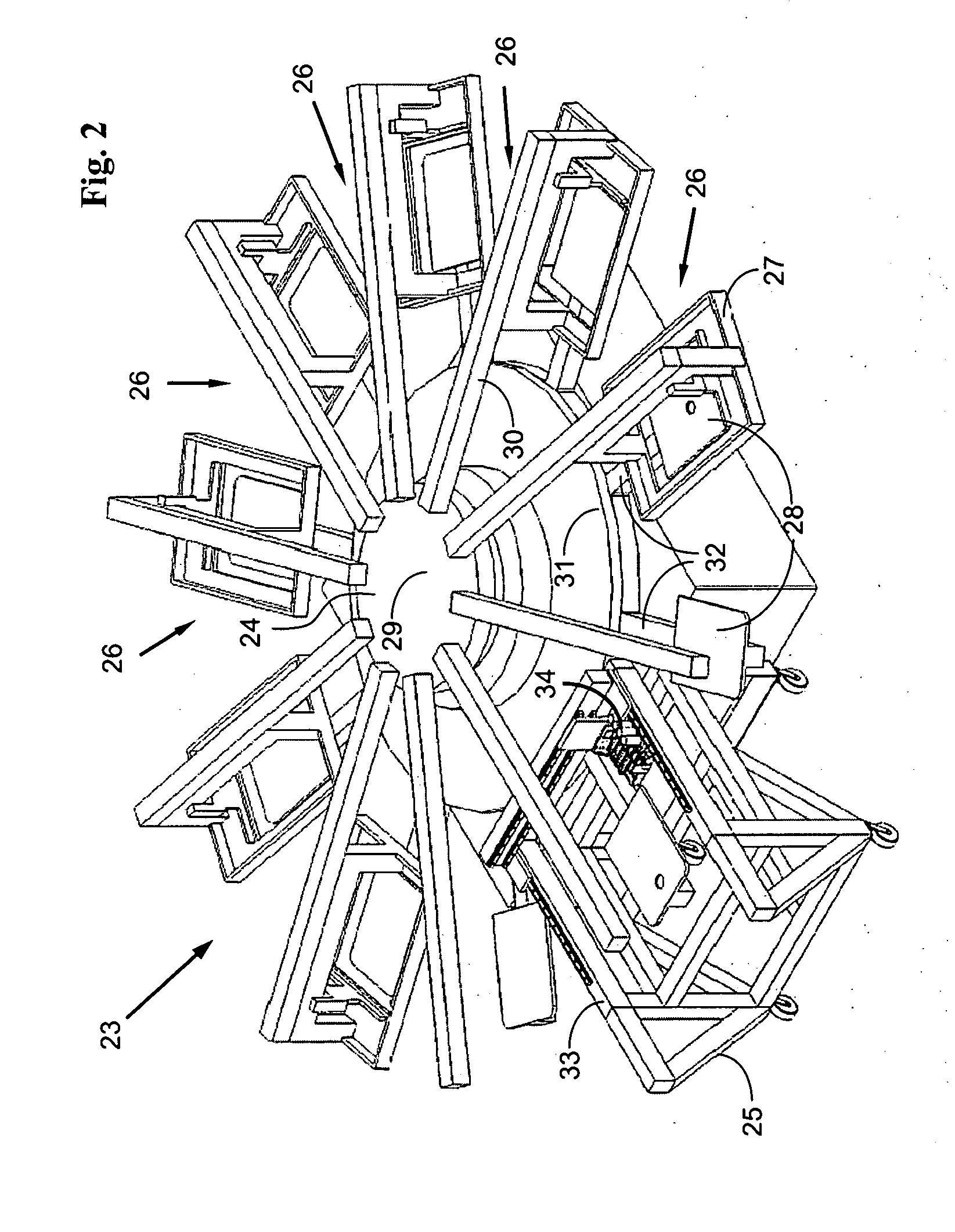

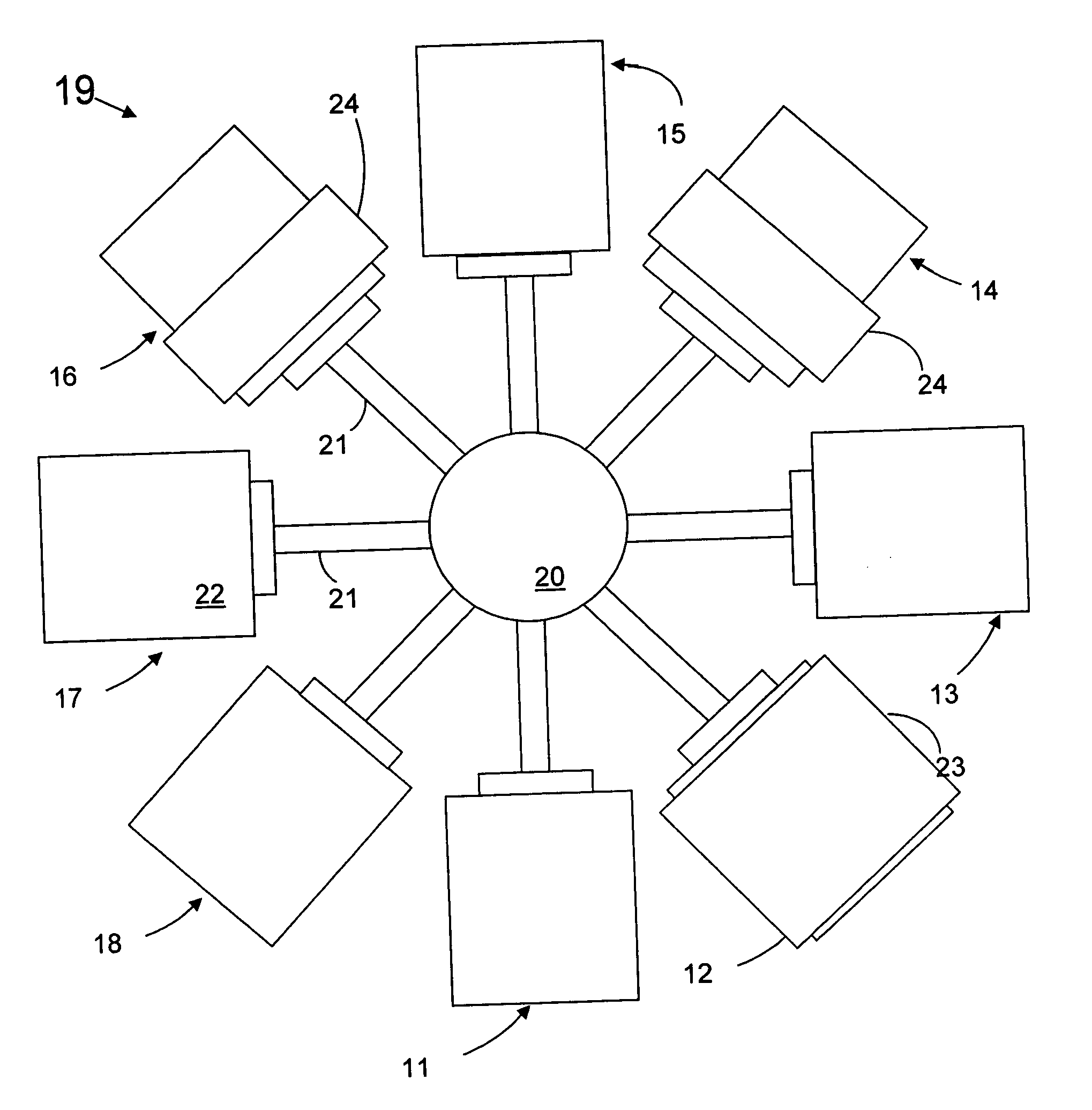

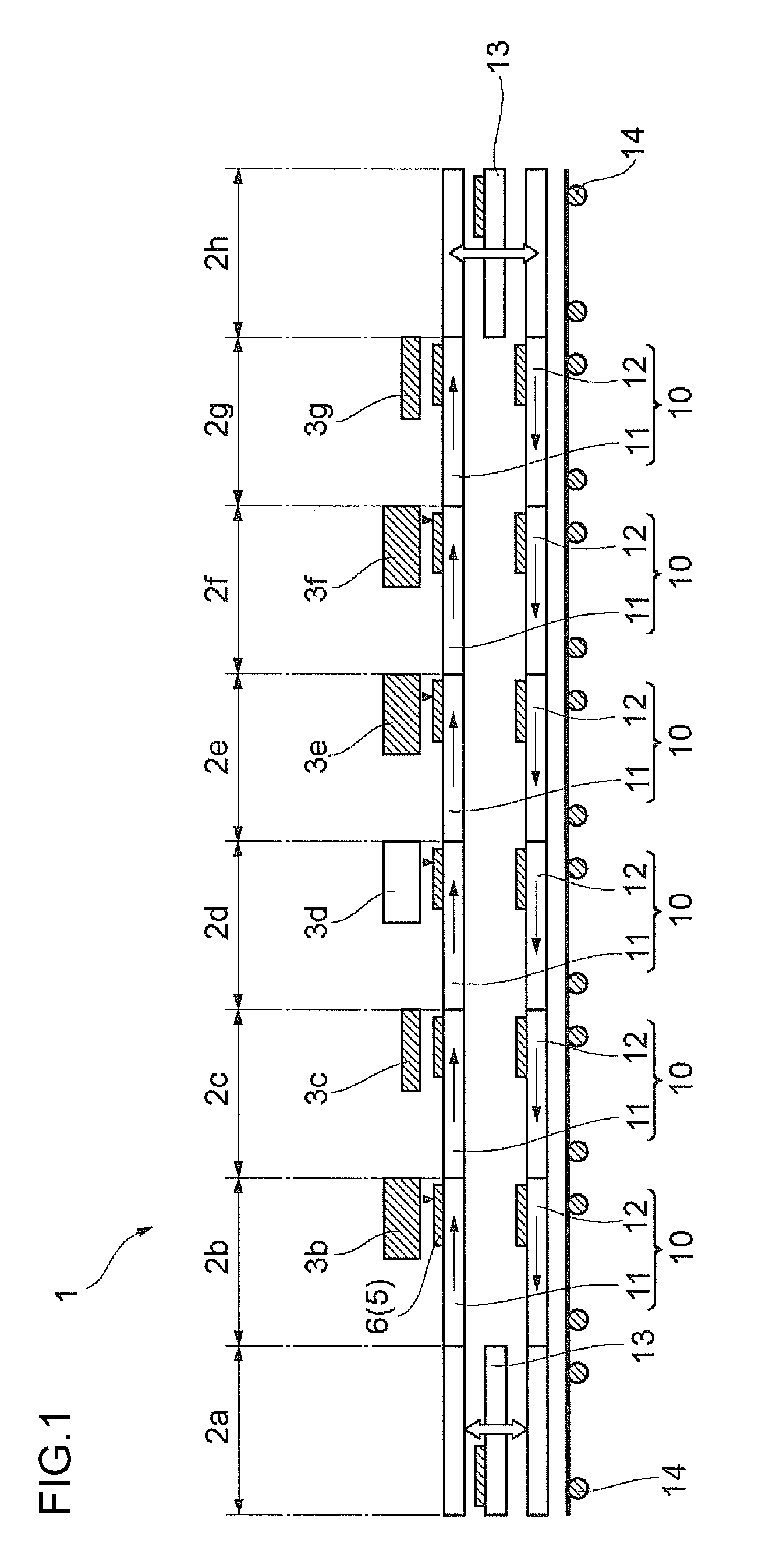

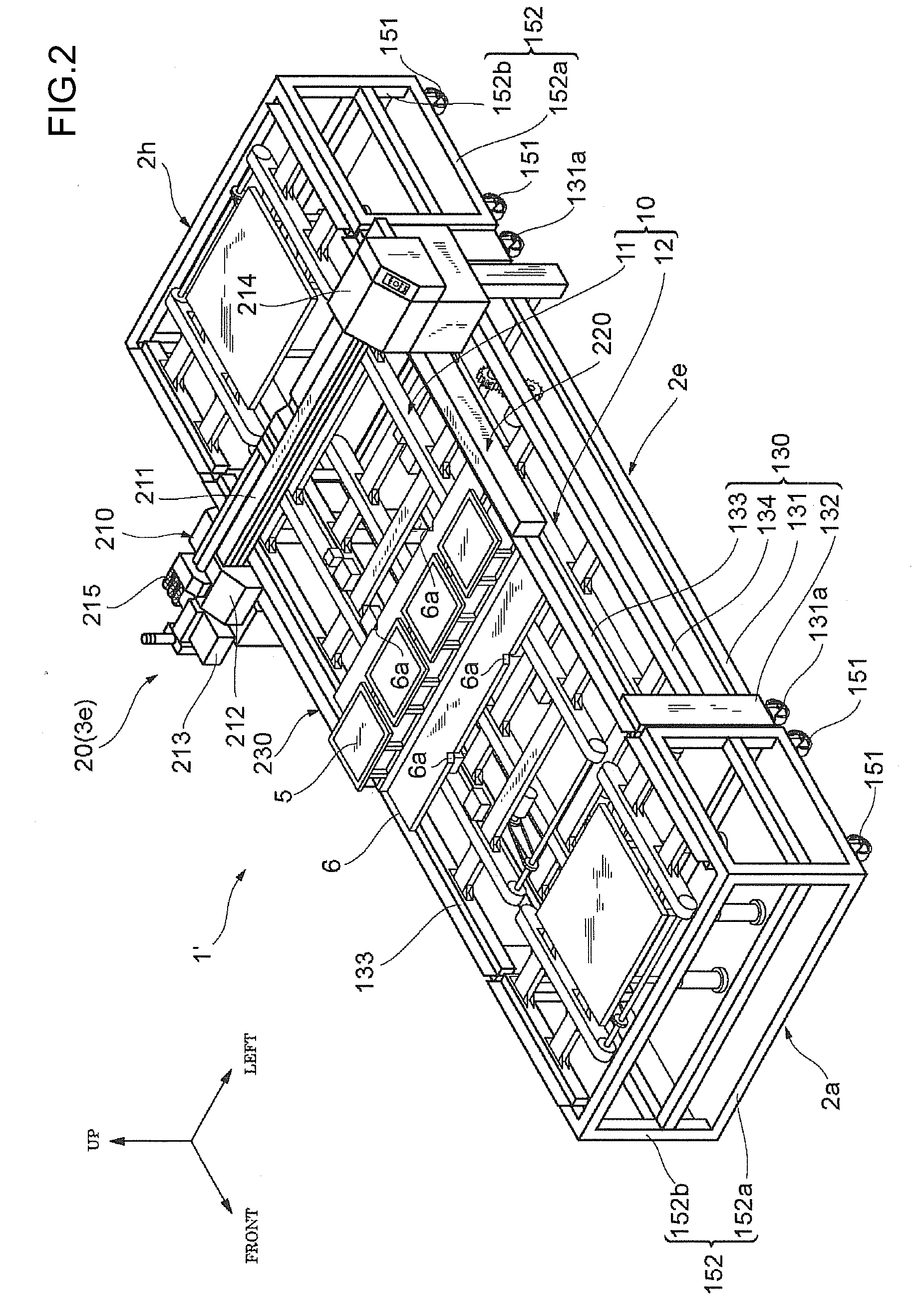

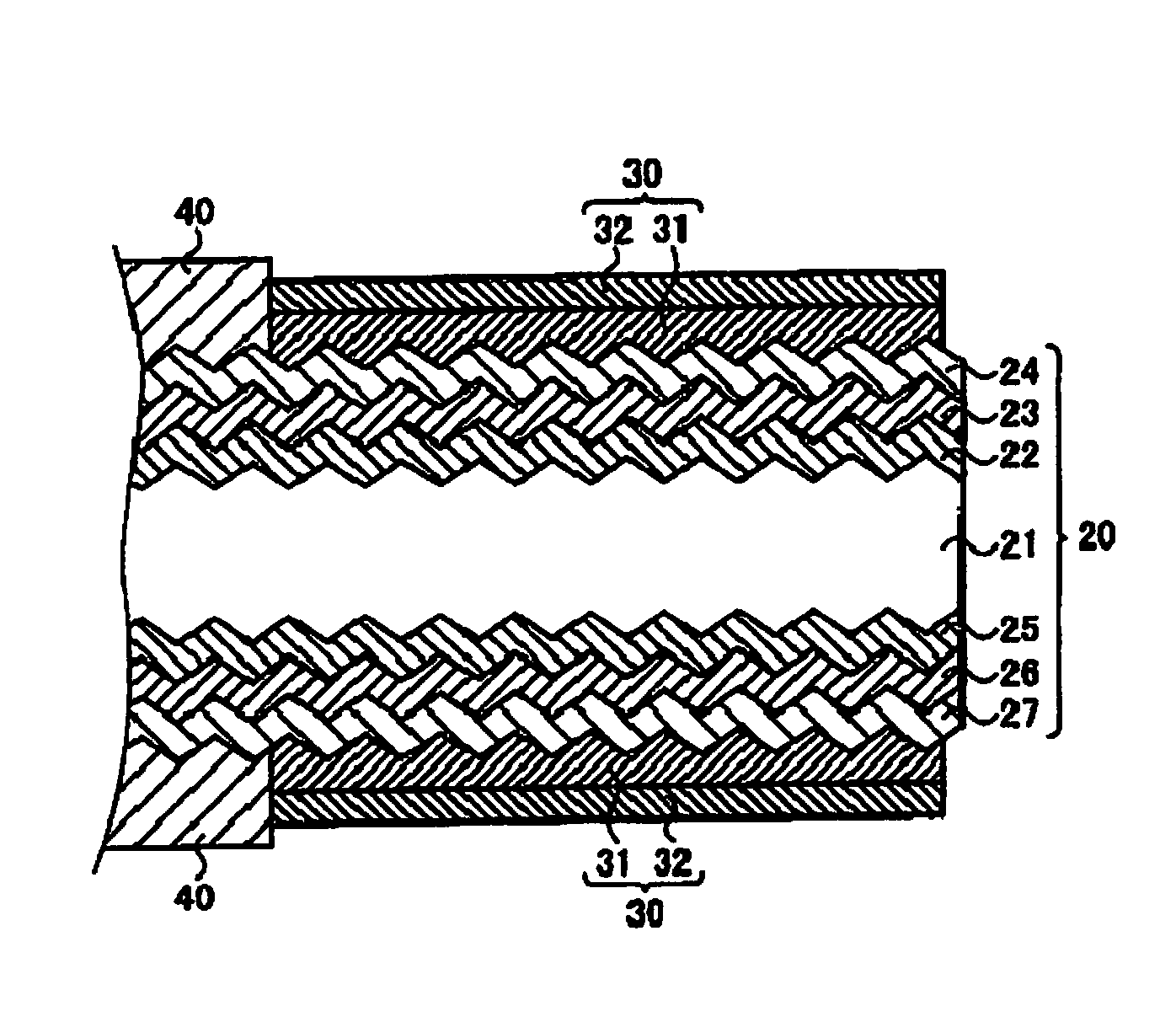

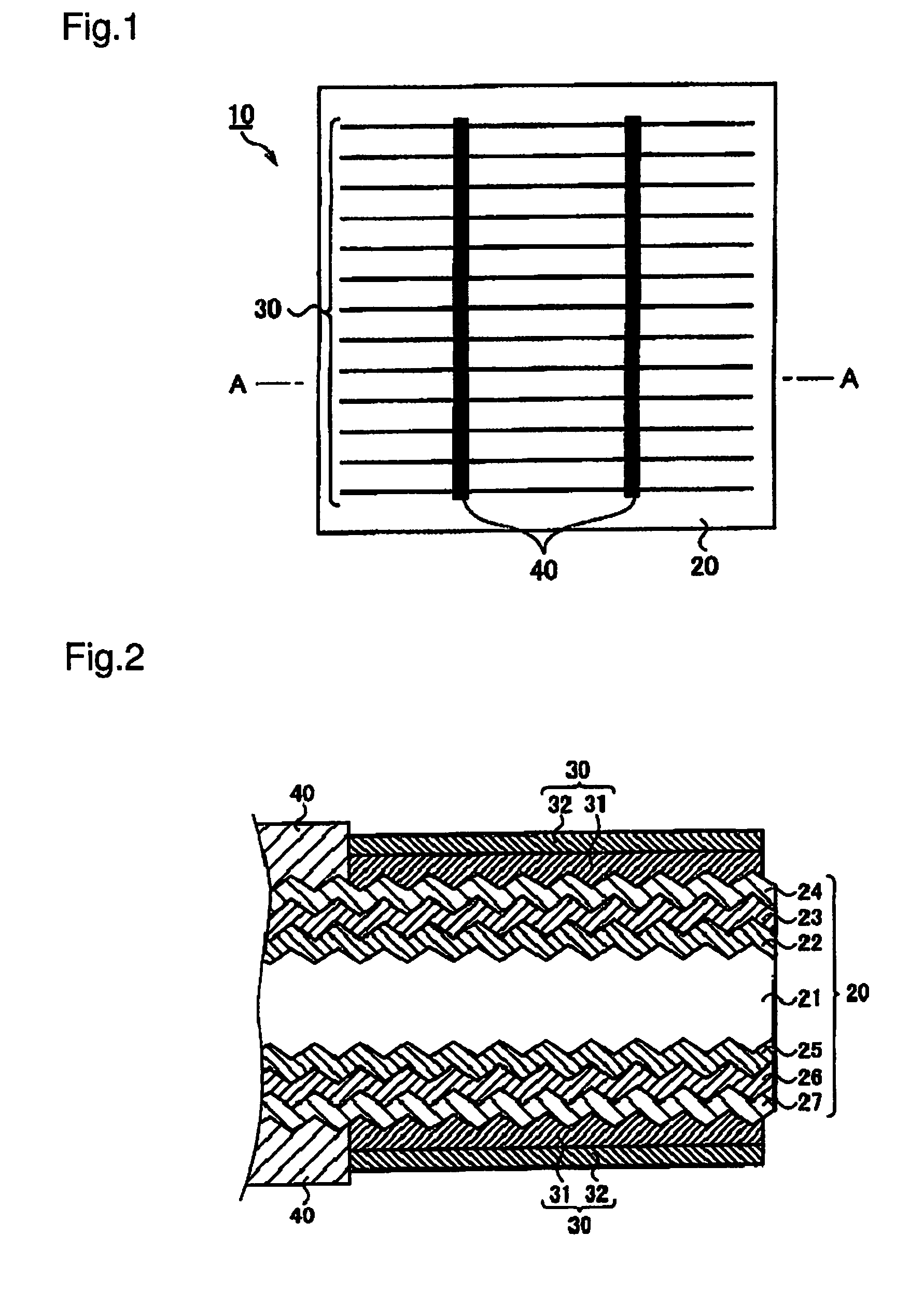

A printing apparatus for printing on a print substrate by sequentially conducting a plurality of processing operations. The printing apparatus includes a pallet configured to receive the print substrate, and work station units each comprising a conveyer mechanism configured to convey the pallet and a work mechanism configured to conduct a predetermined processing operation to the print substrate on the pallet. A plurality of the work station units are aligned adjacent to each other, and the work station units are configured to be replaceable or rearrangeable to change the sequence of the plurality of processing operations.

Owner:MIMAKI ENG +1

Solar cell and manufacturing method thereof

ActiveUS20100018577A1Increase printing speedNarrow line widthScreen printersSemiconductor/solid-state device manufacturingConductive pastePhotoelectric conversion

Provided is a solar-cell manufacturing method that is capable of preventing a conductive paste from bleeding and spreading on a photoelectric conversion body. In the provided method of manufacturing a solar cell, a first printing speed at which a first conductive material is printed is faster than a second printing speed at which a second conductive material is printed on the first conductive material.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

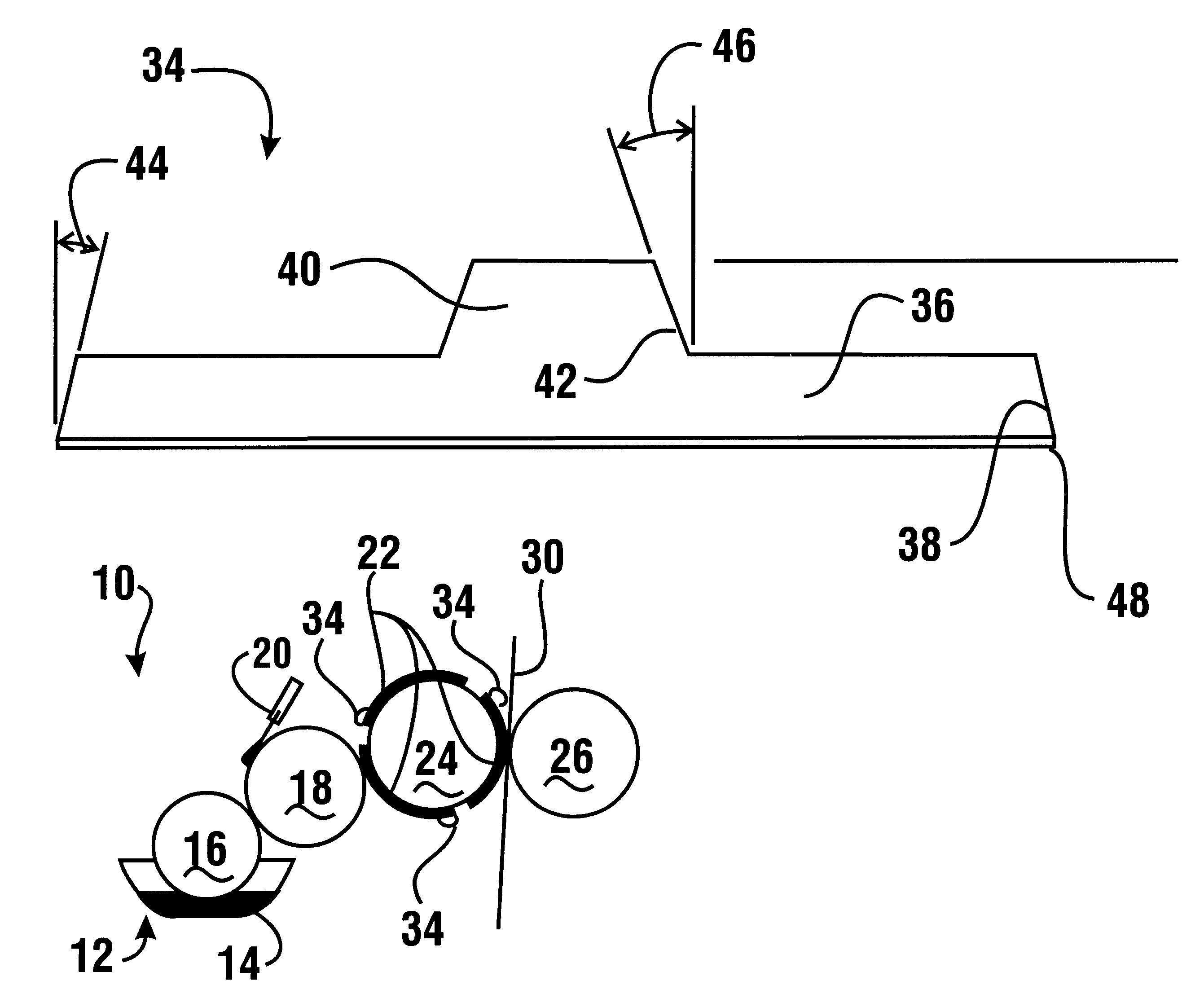

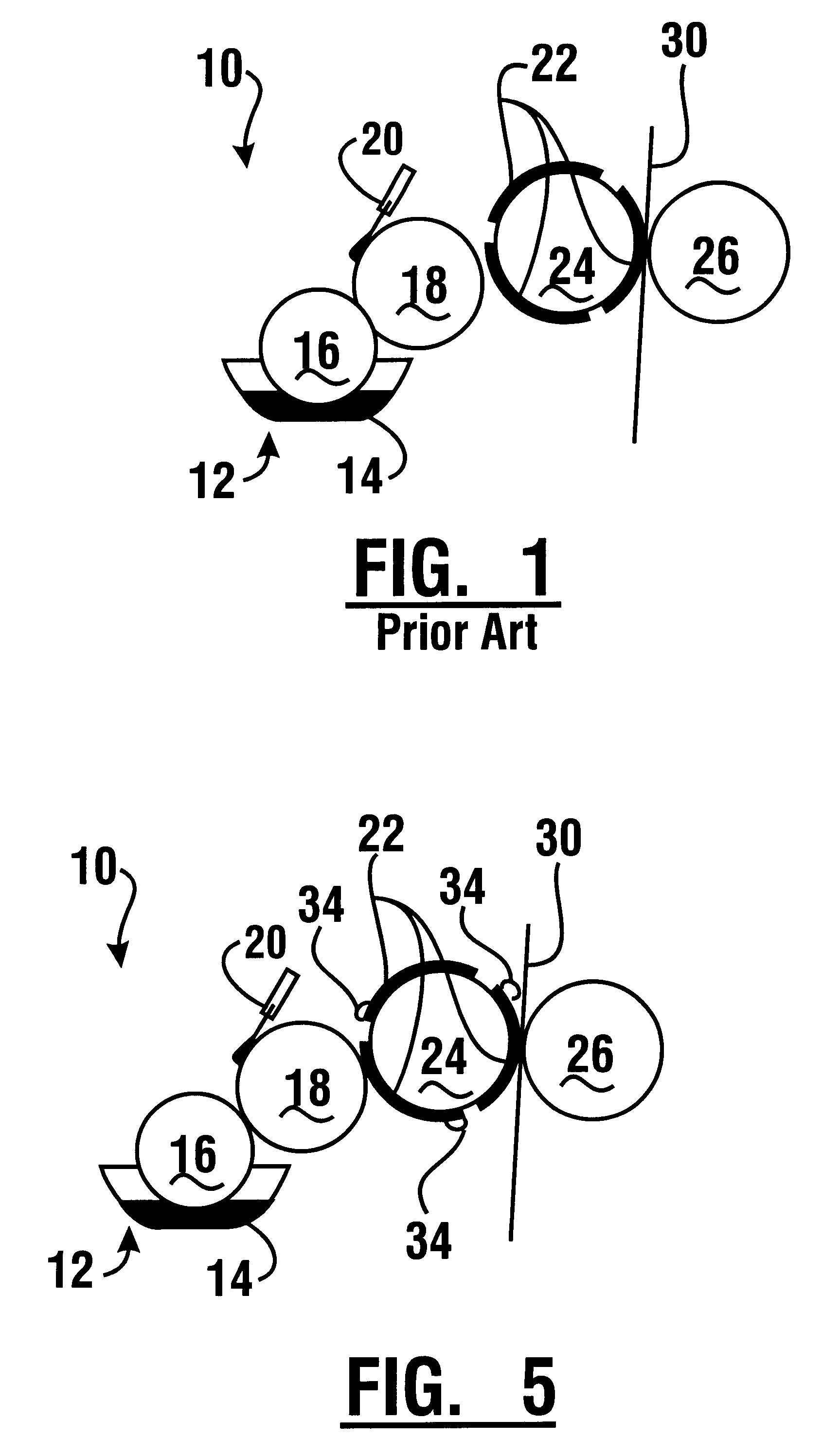

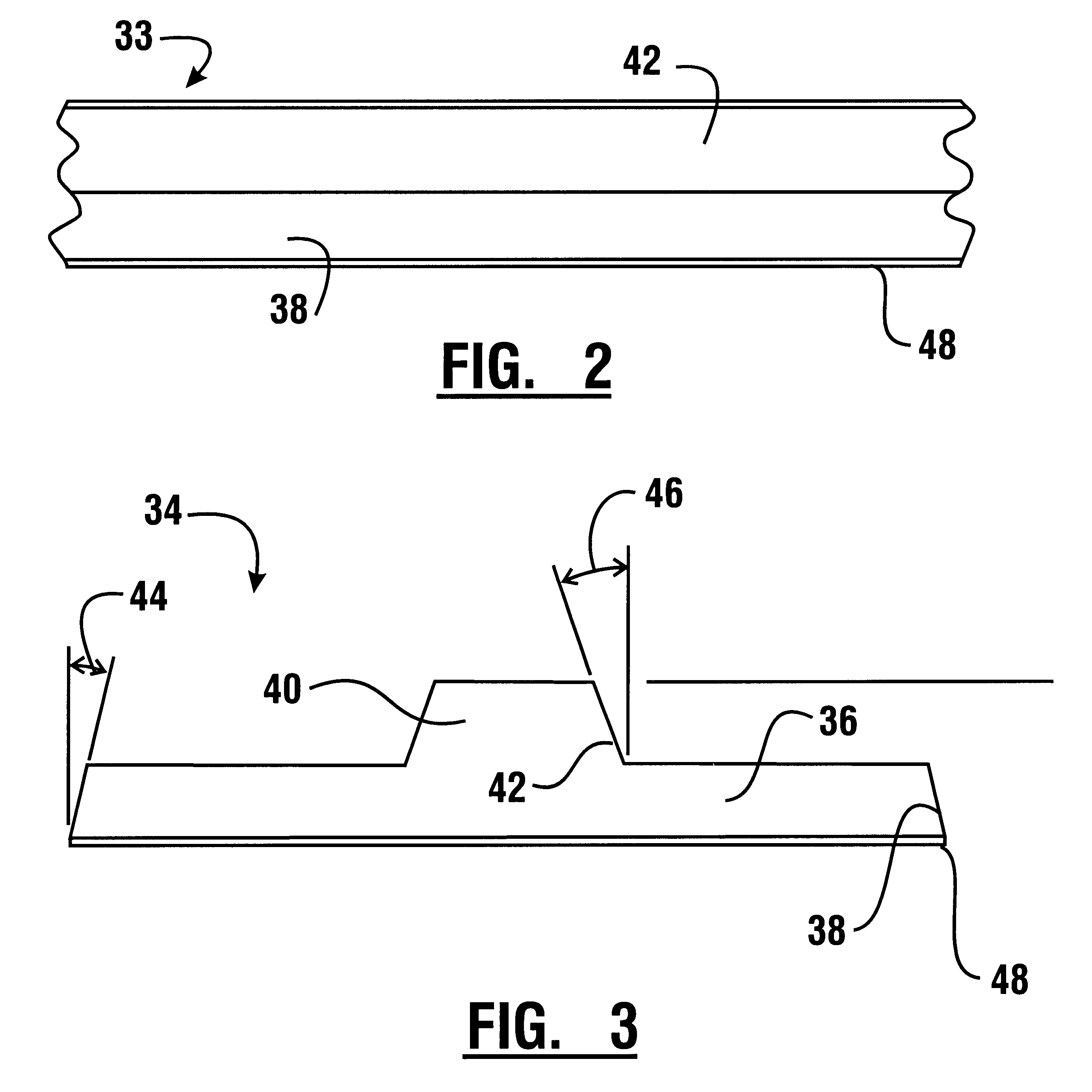

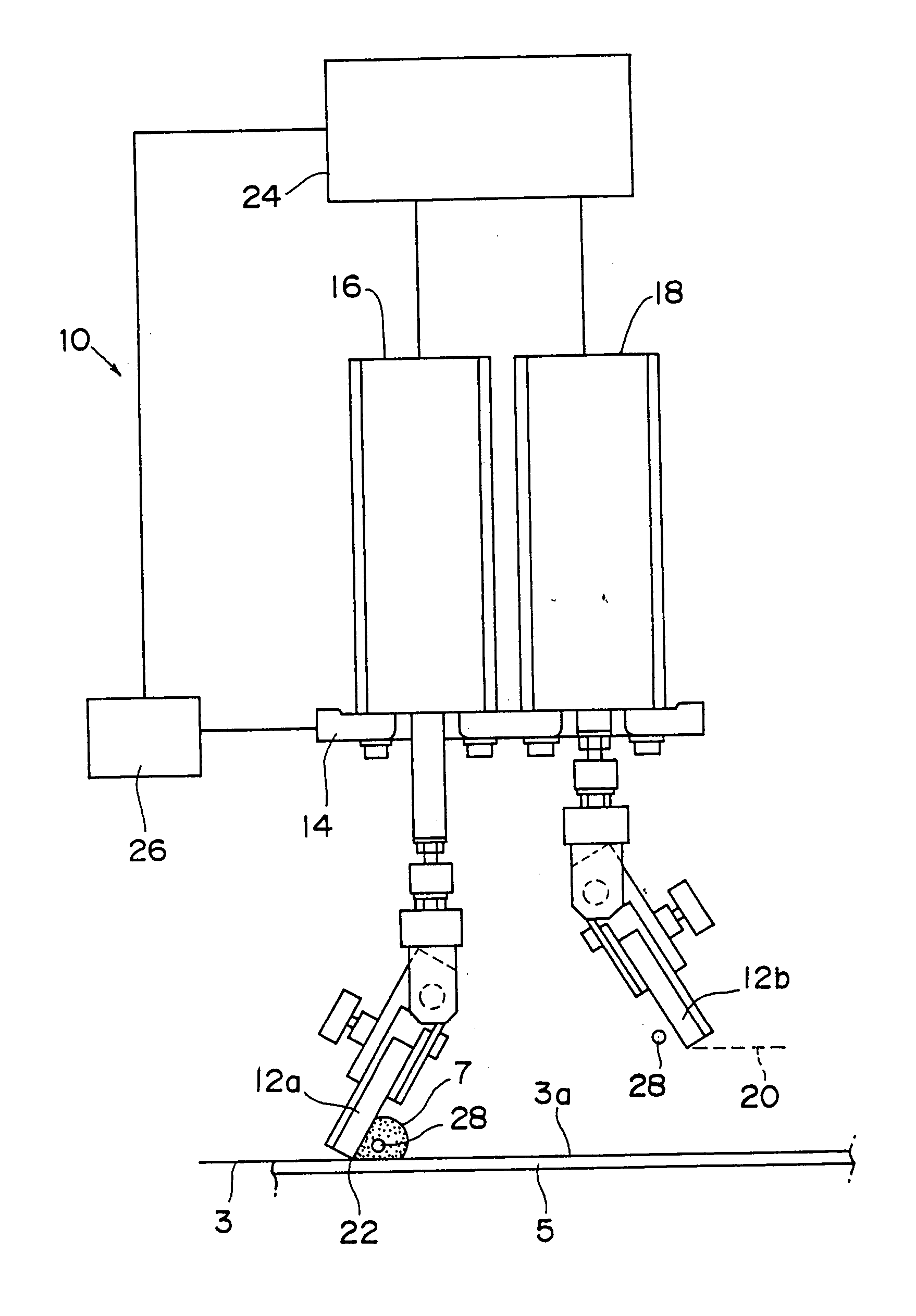

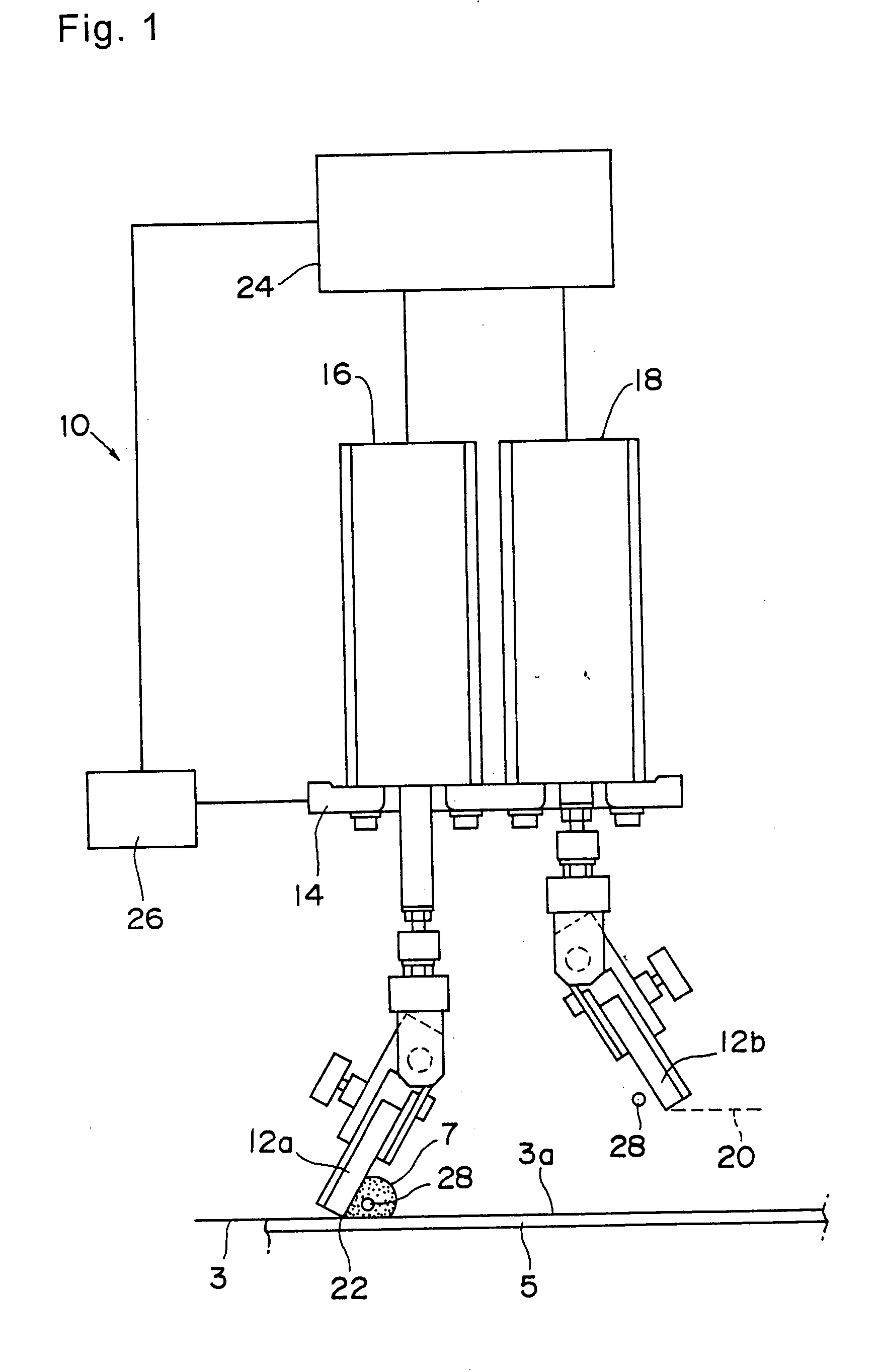

Flexographic printing apparatus and method

A pull band (34) is attached to a printing plate (22) in a flexographic printing operation to hold a flexible substrate (30) in a selected orientation for transfer of ink in a selected pattern. The pull band overcomes differences in friction between the printing plate and the substrate in areas of different amounts of ink to maintain the selected orientation. A specific length pull band may be selected and cut from a roll of pull band material. Pull bands may be attached parallel and perpendicular to the direction of rotation of the printing plate.

Owner:FEESLER DOUGLAS W

Solder past printing apparatus and printing method

InactiveUS20040108368A1Evenly filledTakingLiquid surface applicatorsScreen printersEngineeringSolder paste

When solder paste passes through a first gap (34) located between a pressurizing member (28) and a printing mask (3) during solder paste printing, a pressure directed toward the printing mask is applied from the pressurizing member to the solder paste.

Owner:PANASONIC CORP

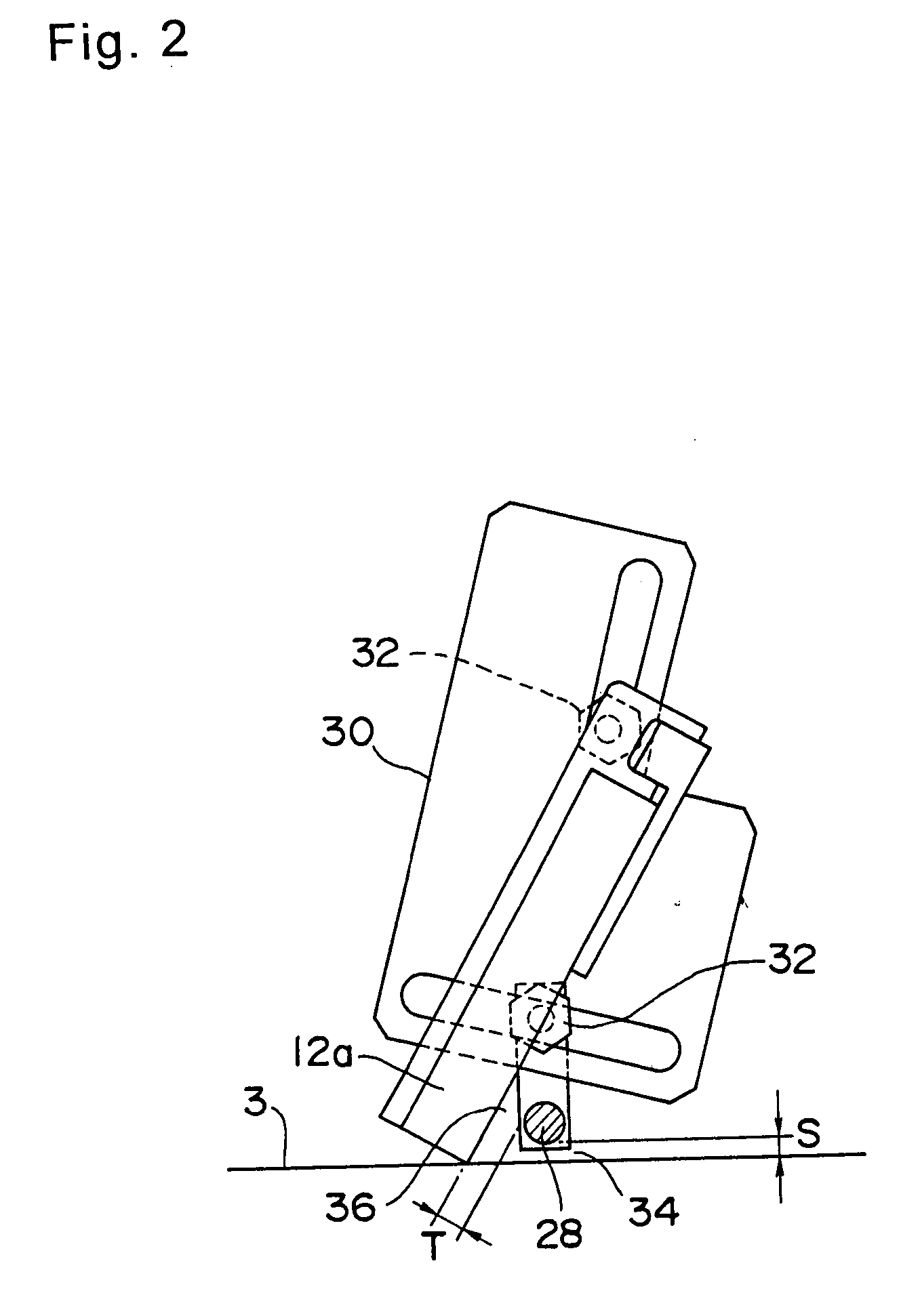

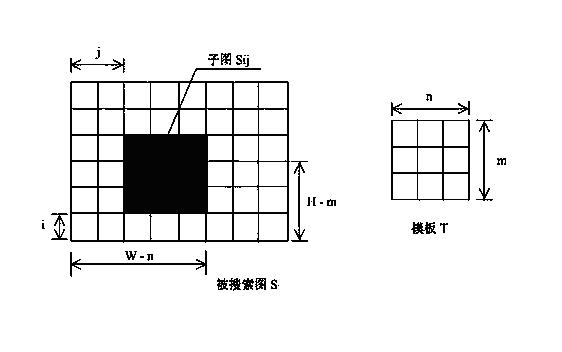

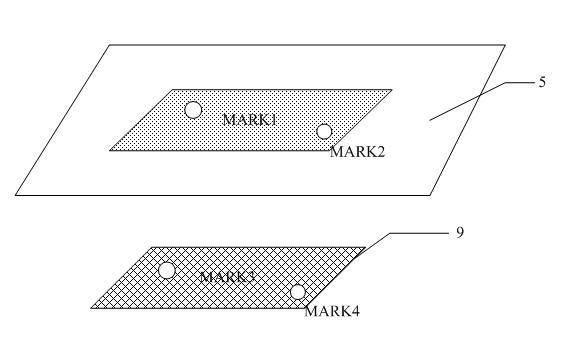

Positioning method in novel silk screen printing CCD (charge coupled device) image identification

InactiveCN102328493AHigh precisionHigh-precision alignment accuracyScreen printersScreen printingAngular deviation

The invention discloses a positioning method in novel silk screen printing CCD (charge coupled device) image identification, comprising the following steps of: (a) conveying PCBs (printed circuit boards) to an operating platform part to be initially positioned and clamped by virtue of an introducing part and an operating platform conveying part; (b) obtaining a CCD positioning identification template by adopting a manually programming method; (c) calculating angular deviation and distance deviation by virtue of the PCBs and MARK points on a silk screen, controlling the operating platform to correspondingly adjust position and angle; and (d) moving an image acquisition device to the position above the PCBs and the MARK points, respectively shooting the PCBs and the MARK points of the silk screen by virtue of a CCD camera, matching the obtained image with the CCD positioning identification template, and carrying out automatic printing after a matching requirement is achieved. The invention provides a whole set of system, the system can automatically detect offset between the center of an object window required to be retrieved by a user and the center of any pattern, the offset is namely correction, the correction is added during counterpoint calculation, and counterpoint actuating quantity is calculated and a counterpoint action is executed. For various patterns used for counterpoint of a base plate, the various patterns can be simply counterpointed without high correction proficiency requirement, and printing counterpoint accuracy can be improved.

Owner:PANDA ELECTRONICS GROUP +1

Printing machine

The printing machine comprises at least one transfer system (5) for conveying a substrate (1) onto an impression cylinder (6) and at least one screen (7, 8) of cylindrical or flat shape, with a doctor blade, said screen collaborating with the impression cylinder (6) and intended to print the substrate with an ink containing pigments that can be orientated by a magnetic field and an unloading system (9) for carrying the substrate (1) away. The impression cylinder comprises at least one magnetic element on its impression surface, said magnetic element being positioned at a point corresponding to said impression performed by said screen (7, 8) on said substrate.

Owner:KBA NOTASYS SA

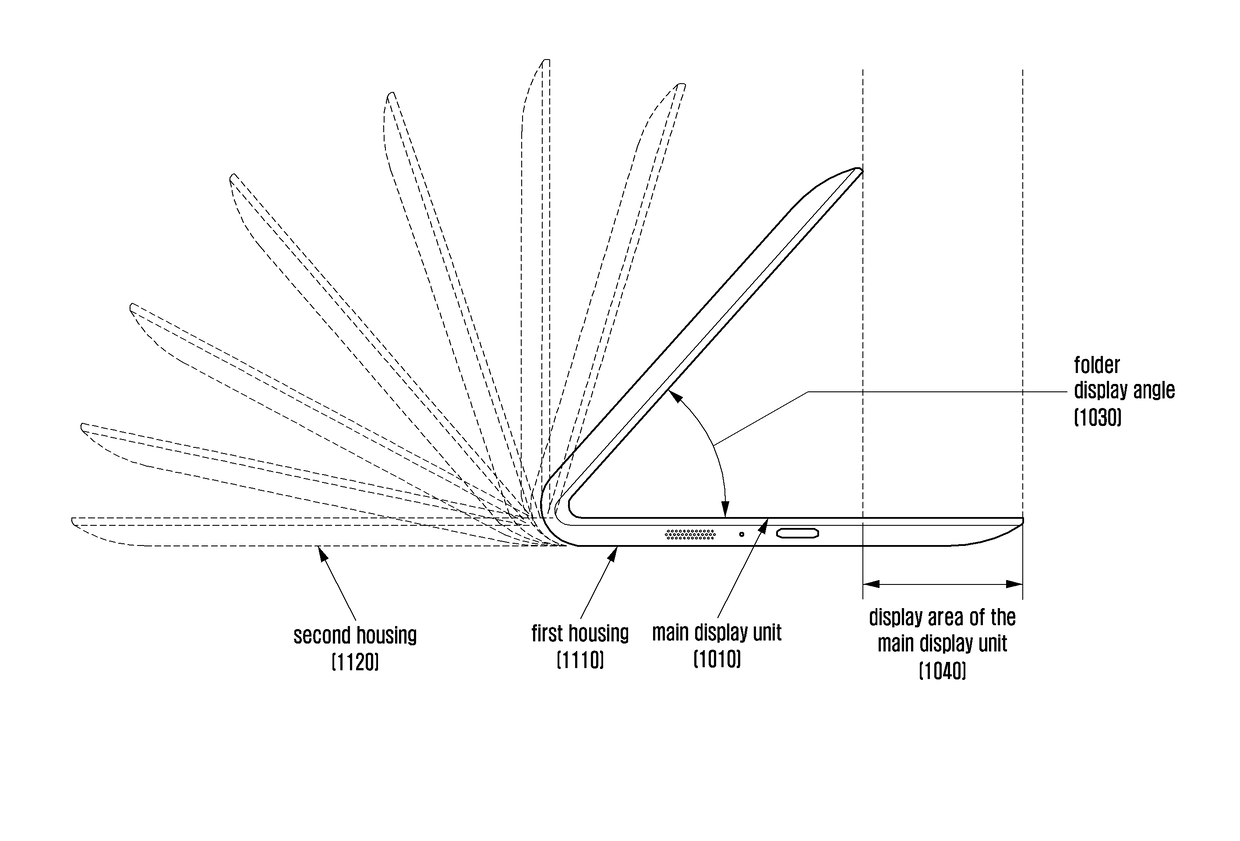

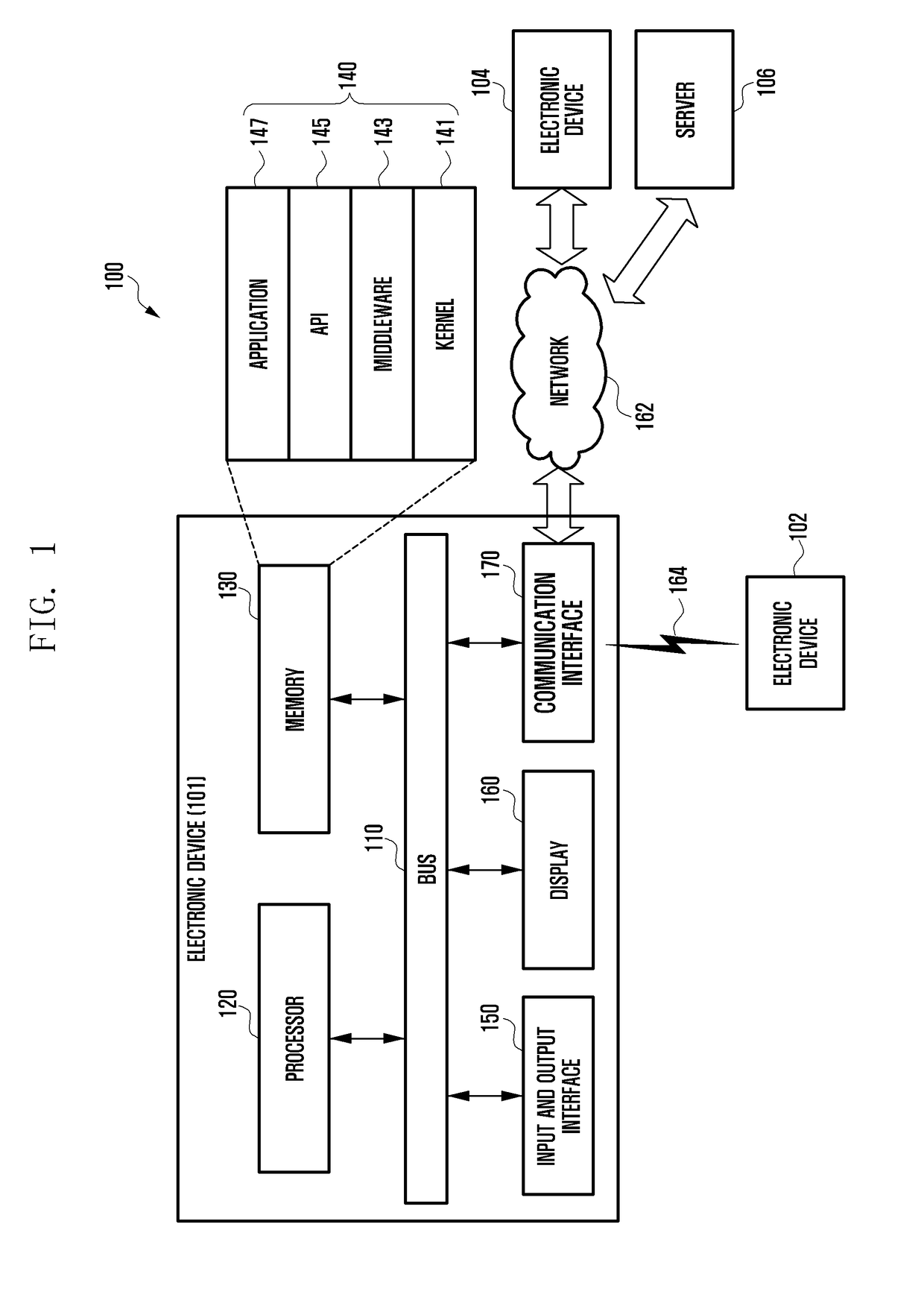

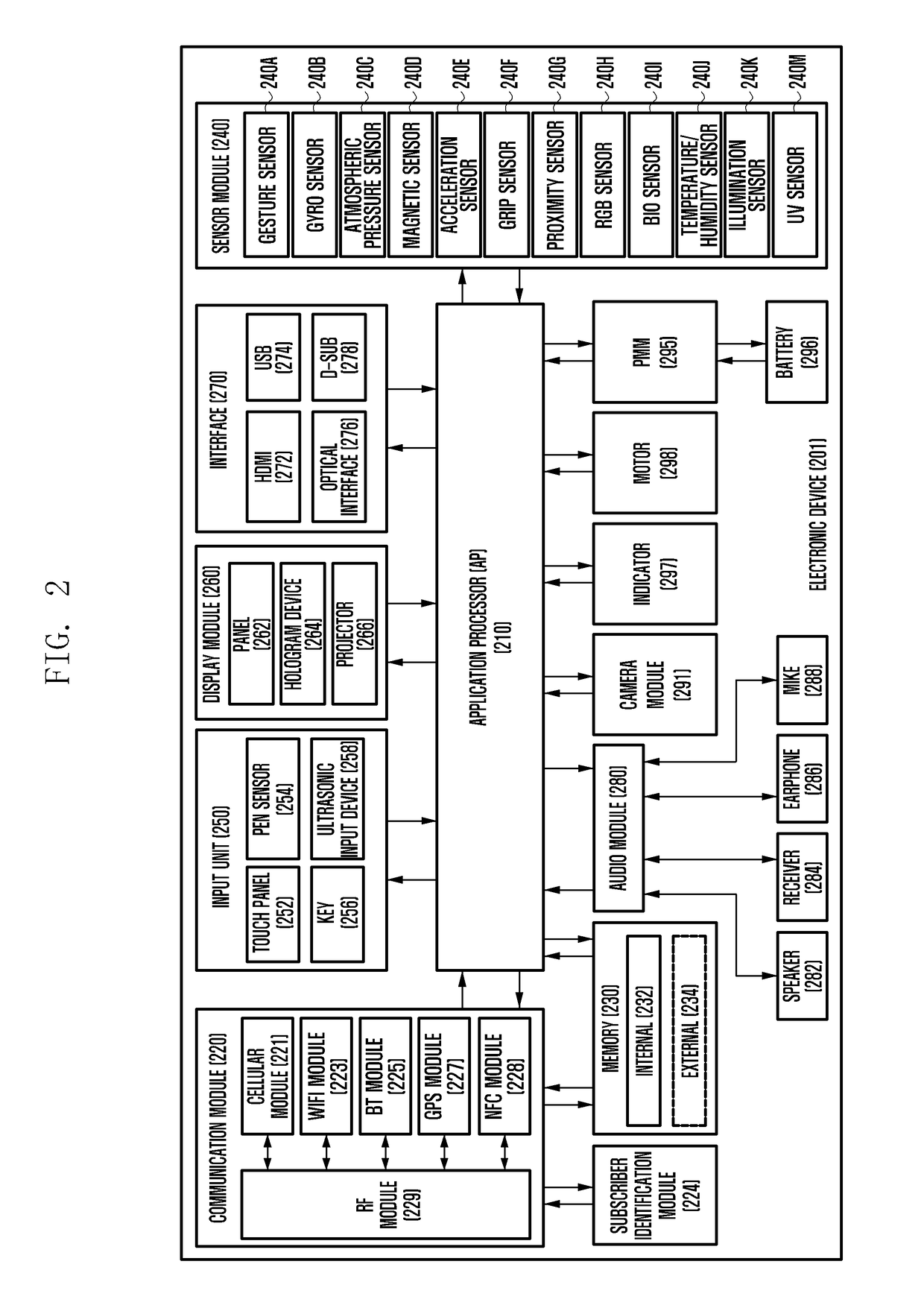

Display controlling method and electronic device adapted to the same

ActiveUS20170206049A1Control brightnessScreen printersCathode-ray tube indicatorsIlluminanceDisplay device

An electronic device is provided. The electronic device includes a foldable housing. The foldable housing includes a first housing including a first display and an illuminance sensor on a front surface, and a second housing, adjacent to the first housing, including a hole formed through a front surface and a rear surface of the second housing. The front surface of the first housing faces the front surface of the second housing when the second housing is folded in a first direction with respect to the first housing, and a rear surface of the first housing faces the rear surface of the second housing when the second housing is folded in a second direction with respect to the first housing.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com