Patents

Literature

6291results about How to "Reasonable layout" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

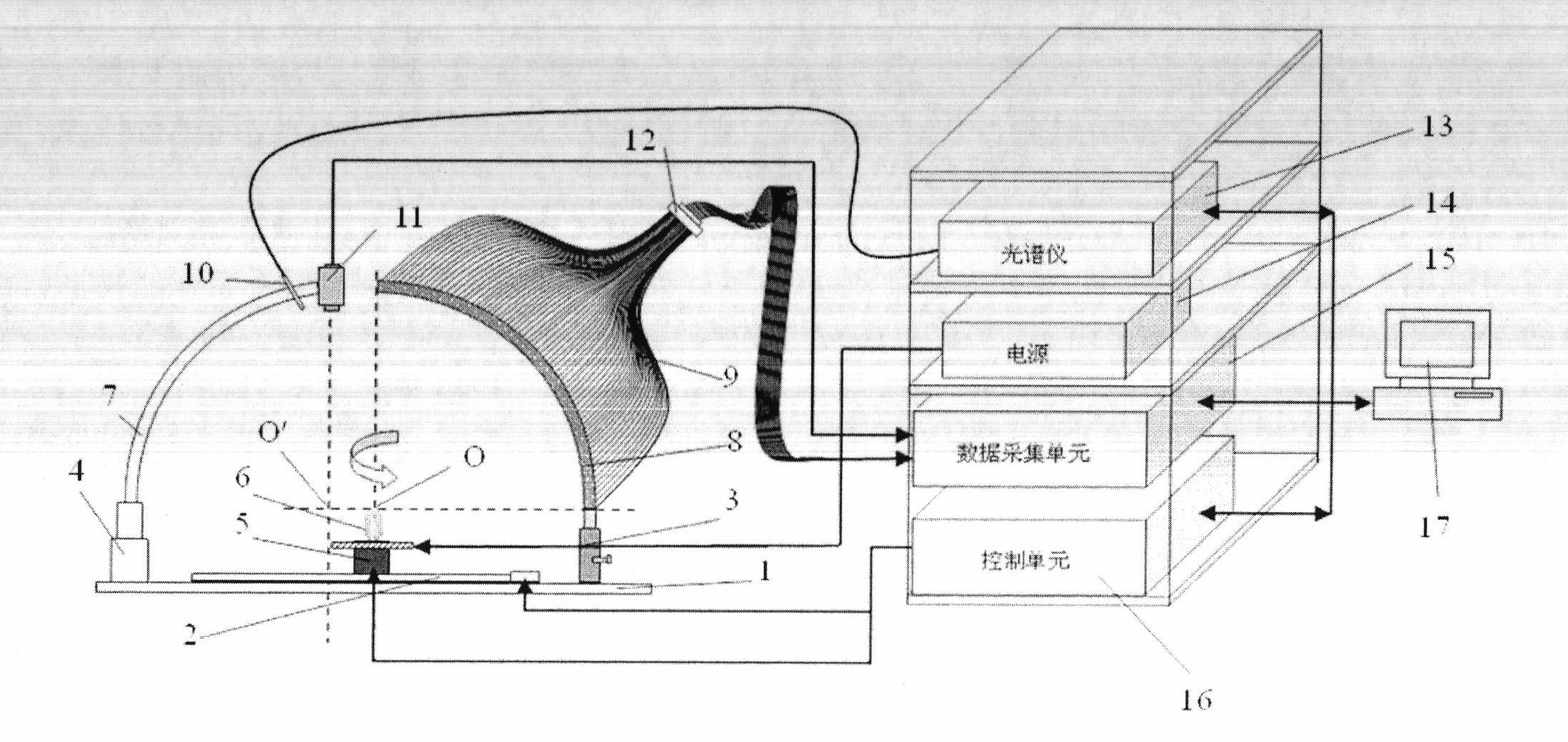

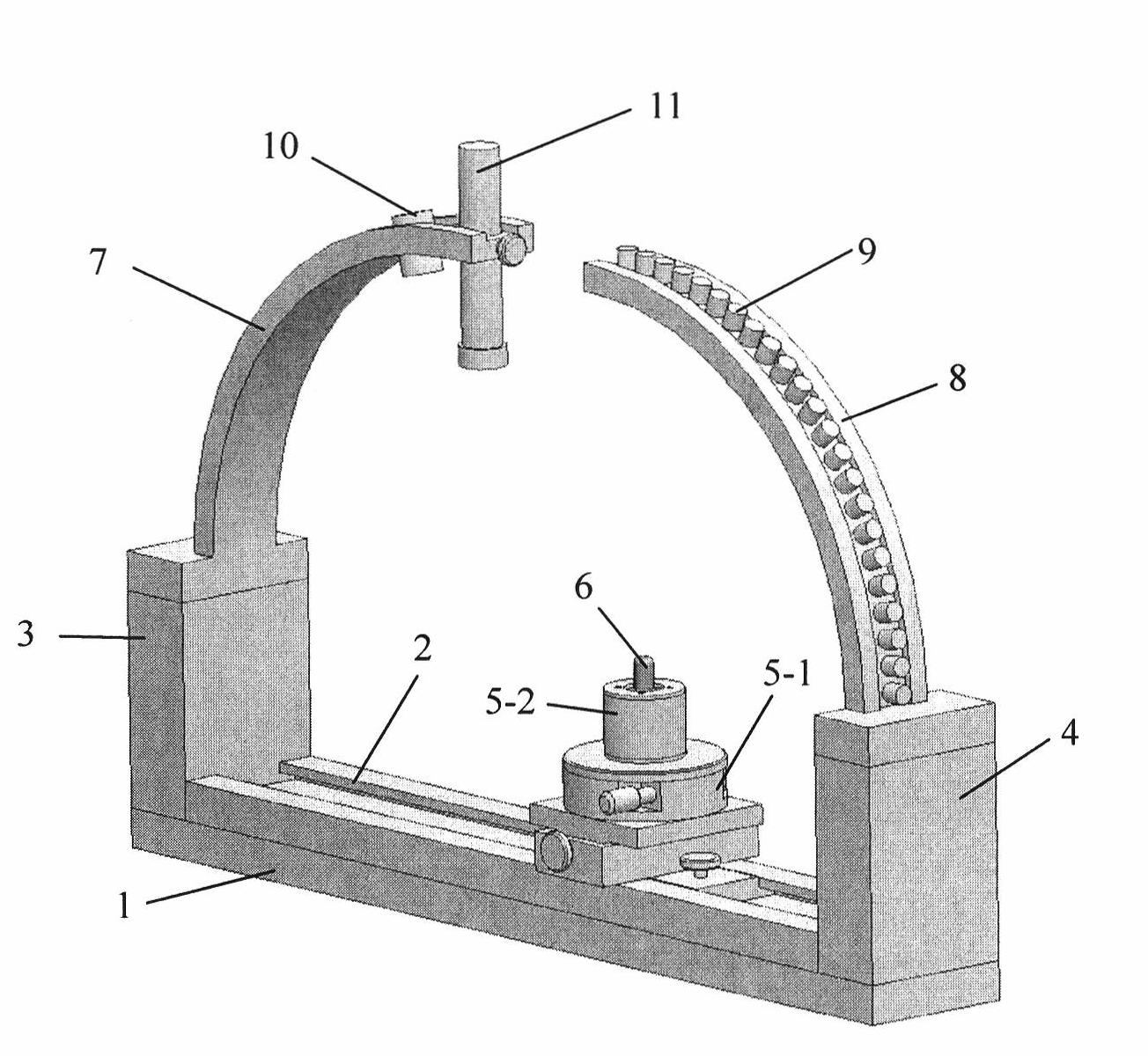

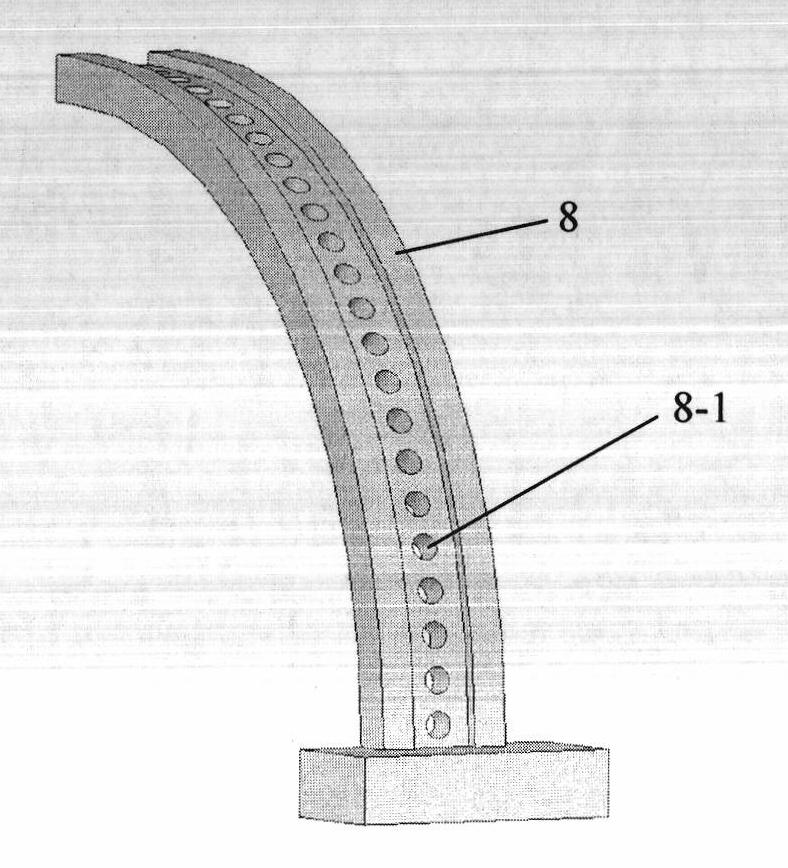

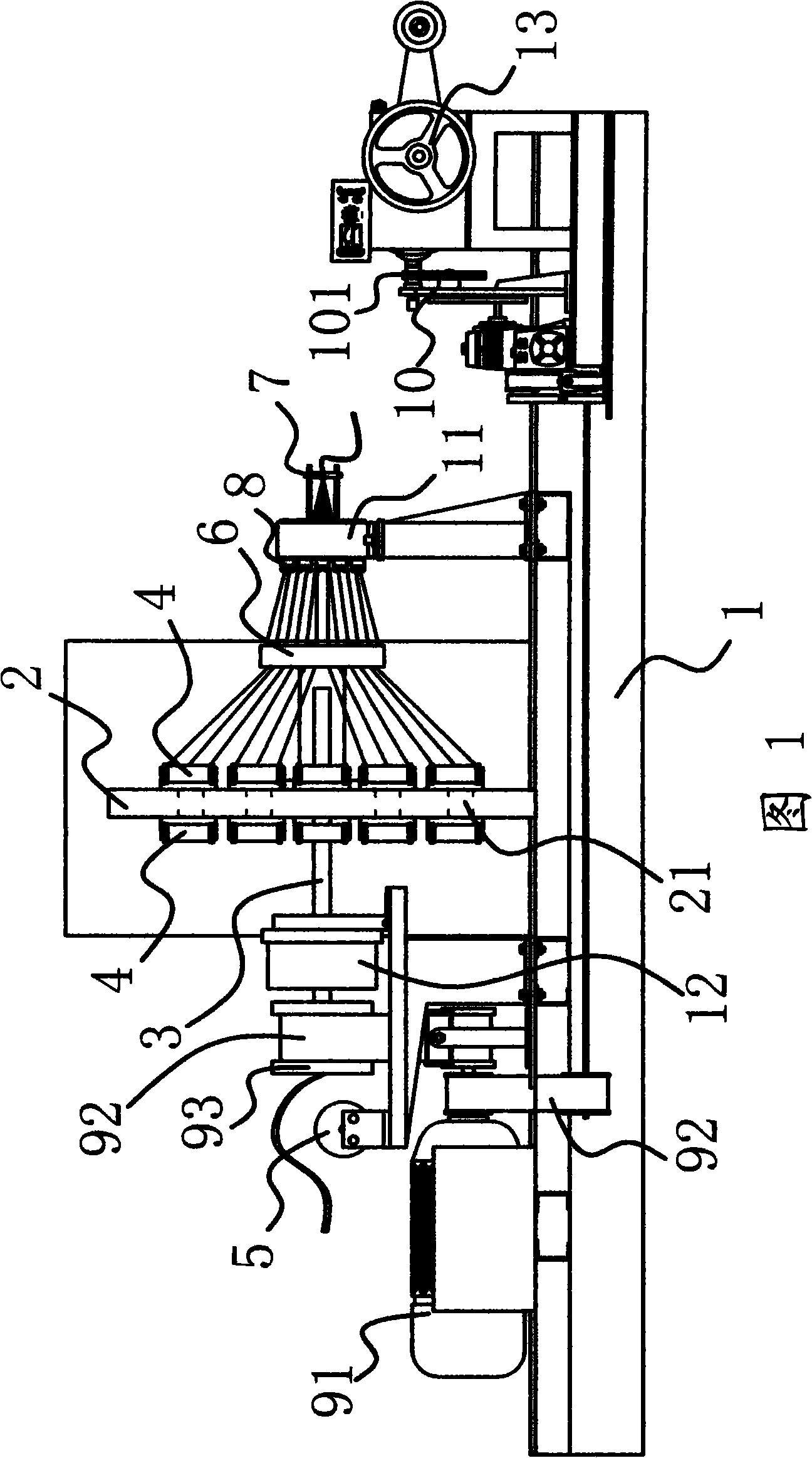

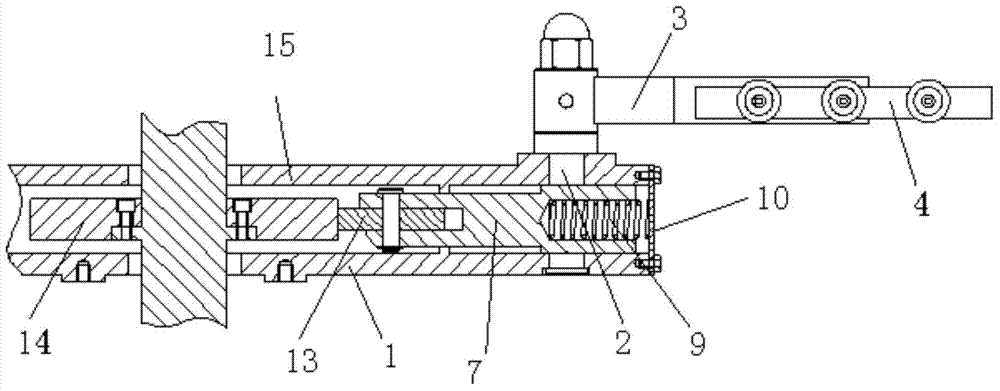

LED optical parameter comprehensive testing device

ActiveCN102213615AEfficient use ofAccurate measurementSpectrum investigationColor measuring devicesFiberMeasuring instrument

The invention discloses an LED optical parameter comprehensive testing device, belonging to the technical field of optical parameter measurement. The LED optical parameter comprehensive testing device is technically characterized in that one end of a horizontal base provided with a one-dimensional mobile platform is fixedly provided with an arc-shaped clamp provided with a fiber-optic probe and astandard luminosity probe, the other end of the horizontal base is fixedly provided with an arc-shaped light collector consisting of an arc fiber-optic array and a linear array CCD (Charge Coupled Device), and a rotary clamping table for holding an LED to be tested is arranged on the one-dimensional mobile platform; light information acquired by the fiber-optic probe is converted into a spectrum band by a spectrograph and then is sent into a computer, outputs of the standard luminosity probe and the linear array CCD are sent to the computer through the data acquisition unit, the computer performs corresponding processing and operation on measurement data through measurement software to finally obtain the luminescence characteristics of the LED to be tested. According to the invention, theproblem on comprehensively measuring the LED on a single measurement instrument is solved; and the LED optical parameter comprehensive testing device has the characteristics of simplicity for operation, compact structure, fastness for measurement, easiness for realization and the like.

Owner:CHINA NORTH IND NO 205 RES INST

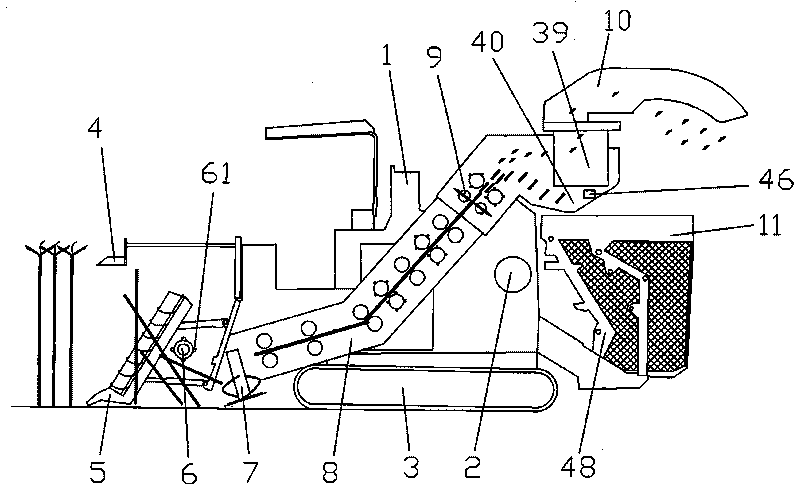

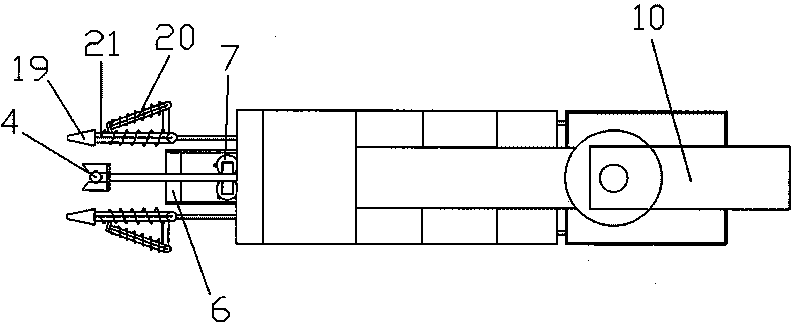

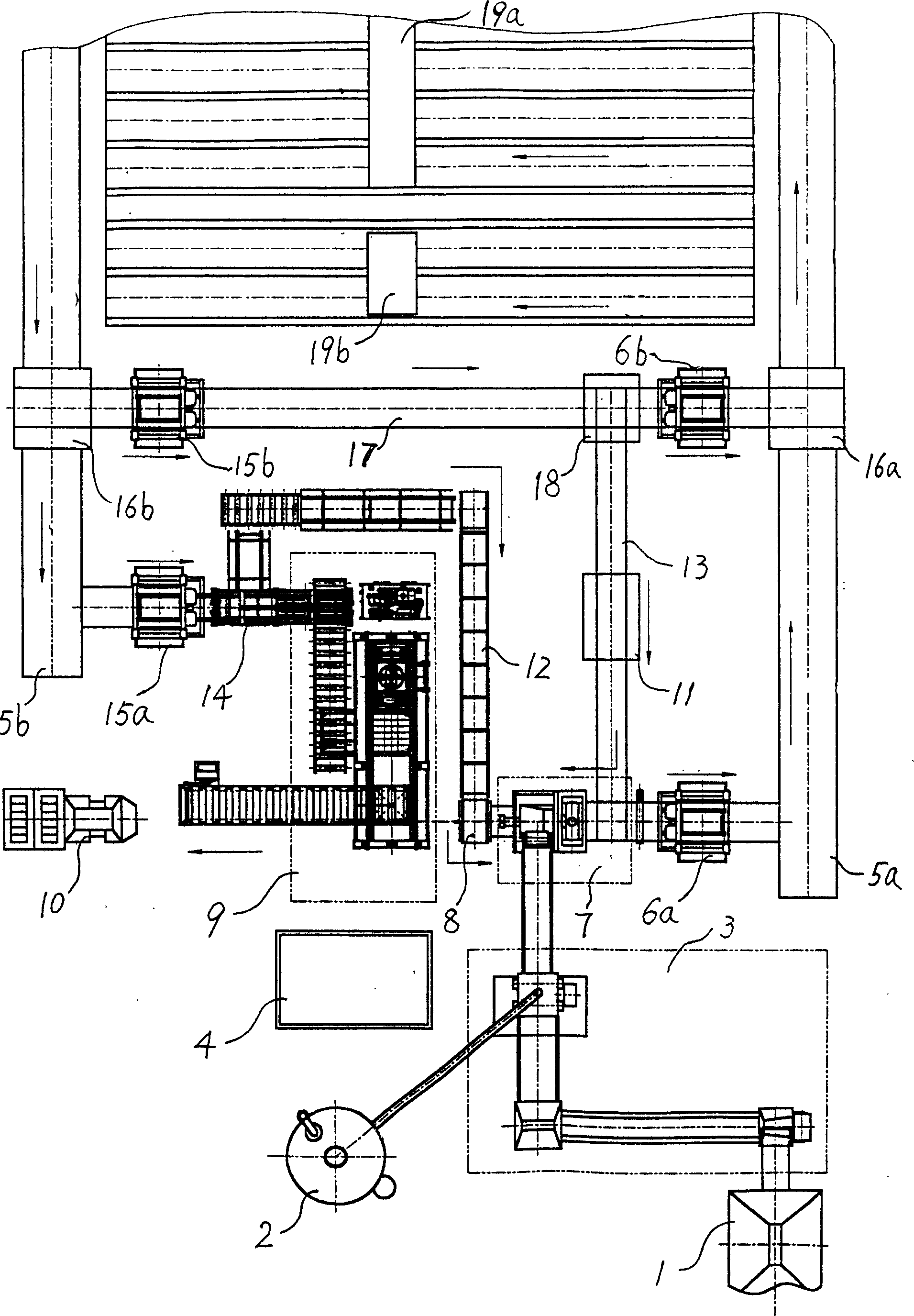

Segmenting type sugar cane combine harvester

InactiveCN101690449AAvoid cloggingReduce cloggingMowersAgricultural lifting devicesControl systemAgricultural engineering

The invention discloses a segmenting type sugar cane combine harvester, which comprises a machine frame, an engine, a crawler type traveling mechanism, a hydraulic power and control system, a sugar cane topper device, a sugar cane supporting device, a sugar cane pressing combing roller, a cutting device, a conveying leaf-removing device, a segmenting device, an impurity discharging device and a collecting device, wherein the cutting device comprises a left set of cutting component and a right set of cutting component, and each set of cutting component comprises a screw conveying rod, a rotary shaft sleeve, a cutter head and a plurality of blades; and the sugar cane supporting device comprises a left set of sugar cane supporting mechanism and a right set of sugar cane supporting mechanism, and each set of sugar cane supporting mechanism is controlled by an independent adjusting mechanism. The segmenting type sugar cane combine harvester has the advantages of having high capability of separating and harvesting sugar canes which are seriously flattened and / or intertwisted, lessening the choking phenomenon occurring in a process of harvesting sugar canes, improving fully removing rate of sugar cane leaves of the harvested sugar canes, reducing the impurity content in sugar cane segments, conveniently collecting sugar cane segments, avoiding the use of a following transport vehicle for collection and storage, along with compact structure, reasonable configuration, convenient travel and use in fields, good harvesting effect, high automation, low manufacturing cost and the like.

Owner:GUANGDONG KOLEA MODERN AGRI EQUIP

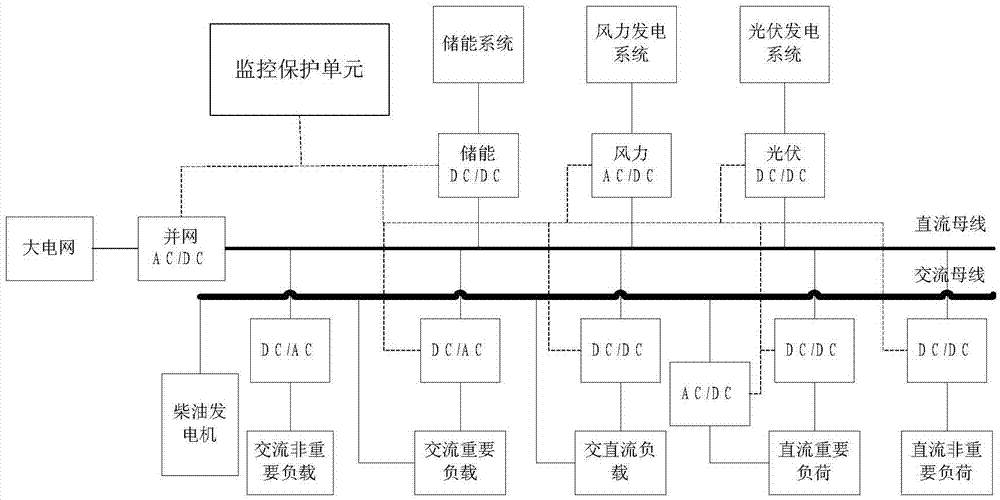

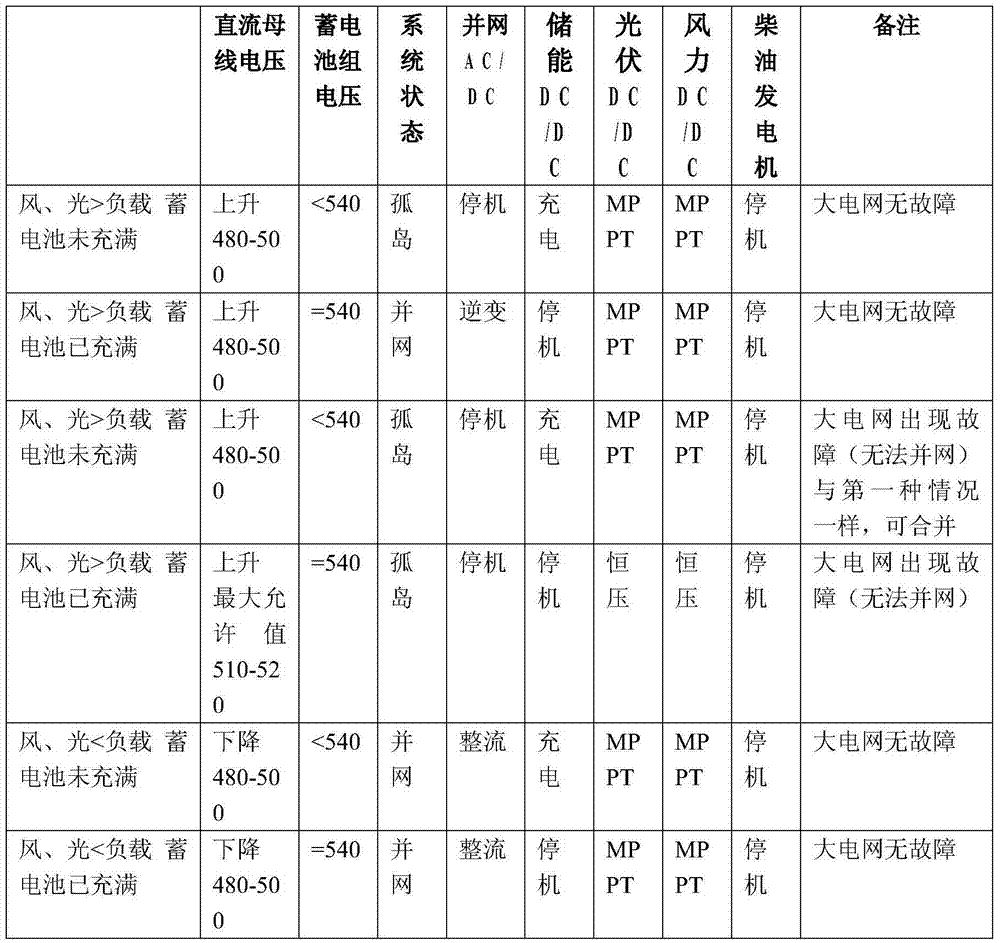

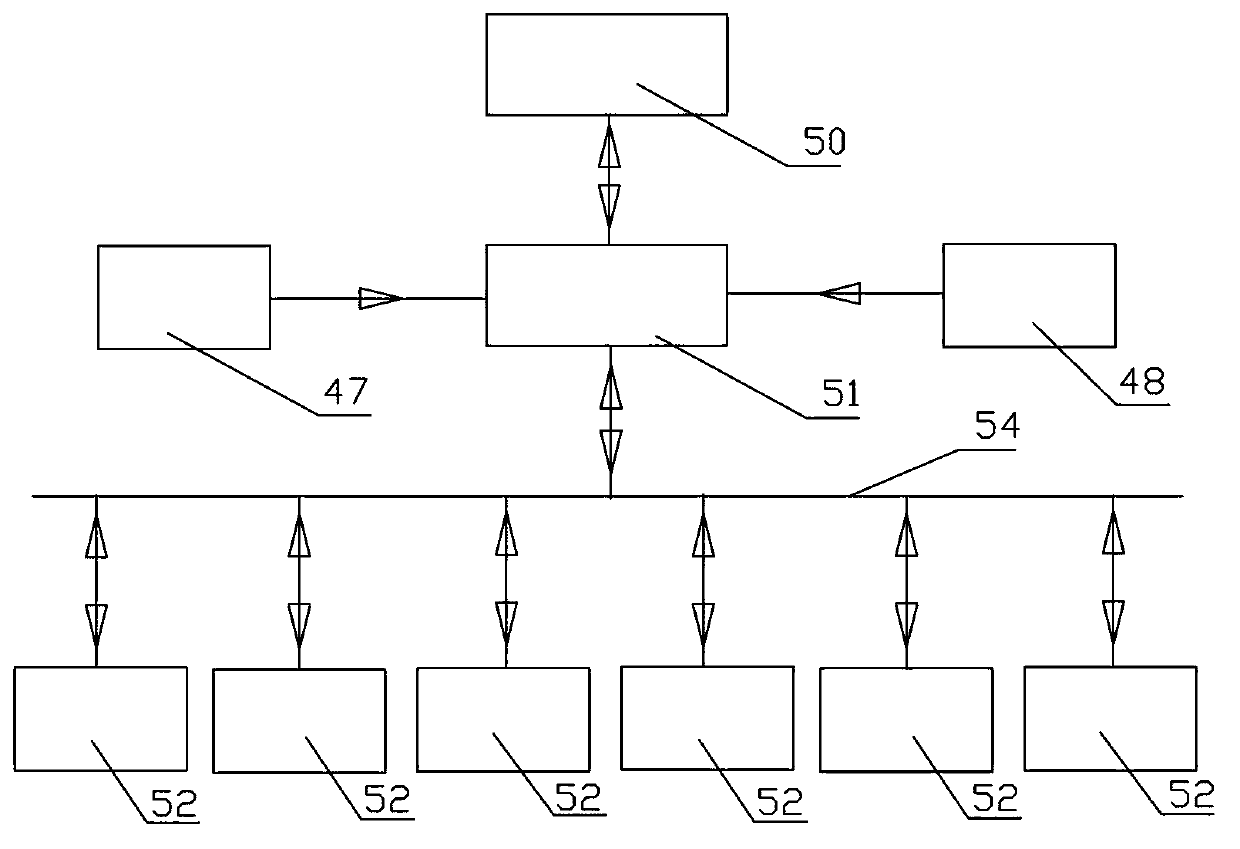

Alternating current and direct current hybrid micro-grid system and control strategy thereof

ActiveCN104505867AReasonable layoutReasonable useLoad balancing in dc networkSingle network parallel feeding arrangementsAlternating currentMicro grid

The invention discloses an alternating current and direct current hybrid micro-grid system and a control strategy of the micro-grid system. The micro-grid system comprises multiple generation units, load, a distribution line for connecting the generation units and the loads, and a monitoring protection unit; each generation unit comprises a large power grid, grid-connected AC / DC (alternating current / direct current) of the large power grid, an energy storage system, a DC / DC (direct current / direct current) converter of the energy storage system, a wind power generation system, an AC / DC converter of the wind power generation system, a photovoltaic power generation system, a DC / DC converter of the photovoltaic power generation system, and a diesel generator; said load includes AC non-significant load, AC significant load, AC / DC load, DC significant load and DC non-significant load; the distribution line comprises a DC distribution line and an AC distribution line; the operating status of each energy conversion device can be monitored in real time by the monitoring protection unit, two operating ways such as grid connection and isolation of the system can be realized by different control strategies, the distributive generation unit and the energy storage unit realize coordination and cooperation by controlling energy storage DC / DC, photovoltaic DC / DC, and wind power AC / DC, so that the power supply reliability is improved and the significant load can continuously operate.

Owner:南京国臣信息自动化技术有限公司

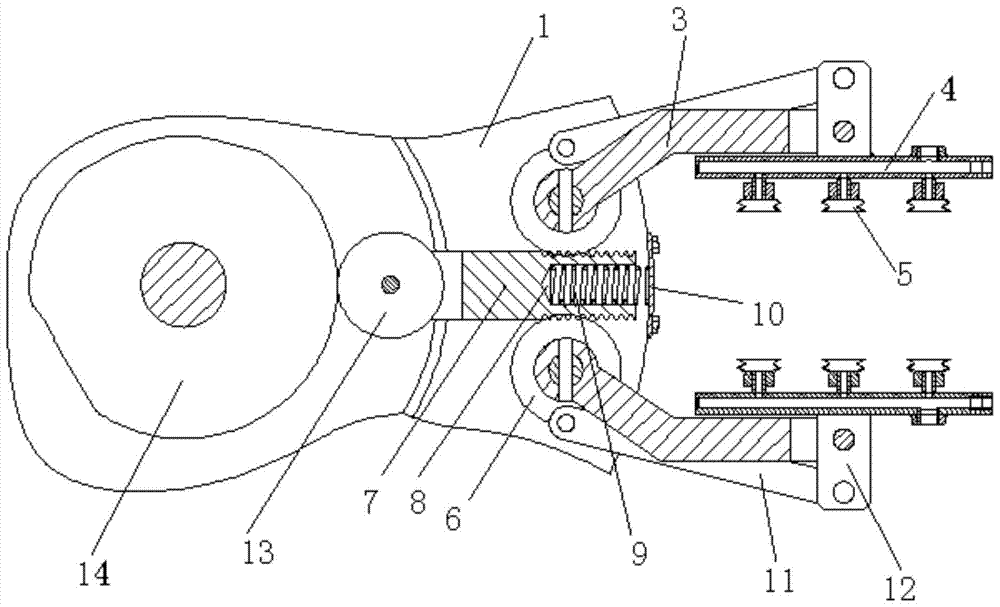

Flexible gripper with two fingers

The invention relates to a two-finger clamper, which is formed by a mechanical body, a driving device, a transmission device and a driving unit. Wherein, the driving device, transmission device and driving unit are mounted on the finger base of mechanical body; said mechanical body comprises a finger base, a left-and-right slide element, and a left-and-right finger element; said driving device is formed by a motor and a code disc; said transmission device is formed by a large gear wheel, a small gear wheel and a leading screw; and said driving unit is formed by a sensor, a single chip and a driving circuit. The invention uses single chip to send control signal to the driving circuit to control the clamper; at the same time, the signals of sensors at different parts of clamper via the driving plate are transmitted to the single chip, to be checked and realize loop-closed control; the mechanical body is powered by motor, to rotate leading screw after being reduced speed via gear wheel, therefore, the left-and-right finger element can be translated; and the clamper can be opened and closed.

Owner:BEIHANG UNIV

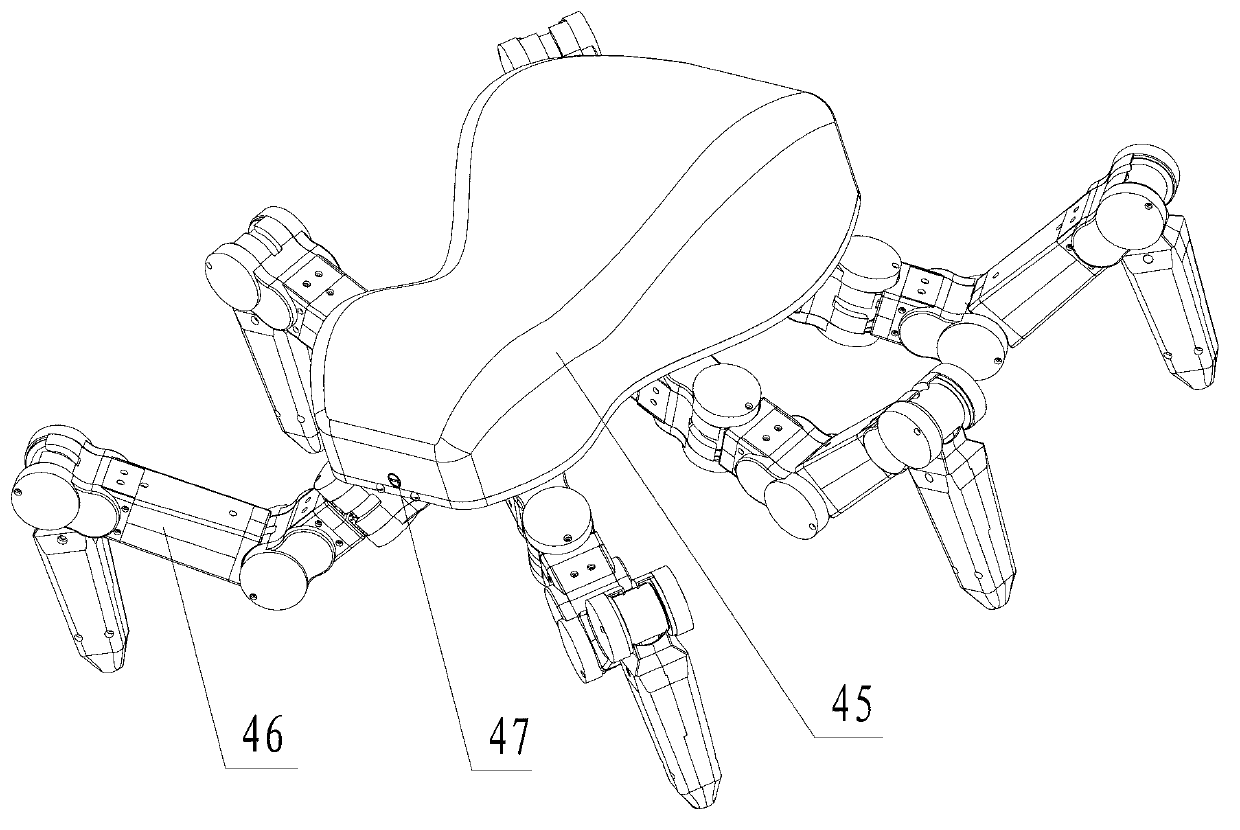

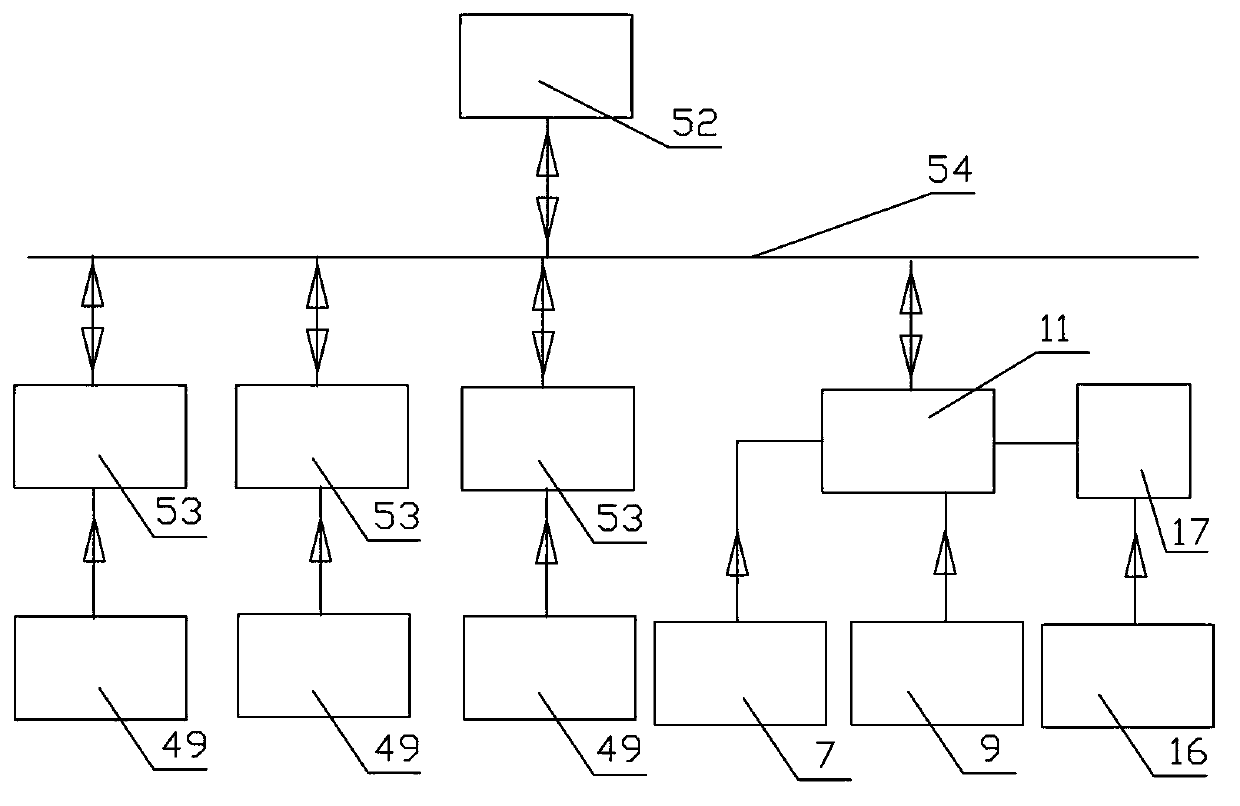

Novel six-foot robot

The invention discloses a novel six-foot robot, and belongs to the field of bionic robots. The novel six-foot robot solves the problems that an existing six-foot robot is poor in environment sensing ability, and has no ability to sense self states, and the integration degree is not high. The novel six-foot robot comprises a body, mechanical legs, a sensing system and a control system, wherein each mechanical leg comprises connecting elements, a body-coxa joint, a coxa beam, a coxa-femur joint, a femur beam, a femur-tibia joint and a tibia beam which are sequentially connected. The control system comprises a computer terminal, a main control board, single-leg control modules, joint drivers and a controller area network (CAN) bus, wherein the computer terminal and the main control board are connected through the Ethernet, the number of the single-leg control modules is six, the single-leg control modules and the joint drivers are arranged in the body, the main control board is connected with the single-leg control modules through the CAN bus, and the joint drivers on six mechanical legs are connected with the CAN bus. The novel six-foot robot is used for transportation, detection and extreme environment work and the like.

Owner:HARBIN INST OF TECH

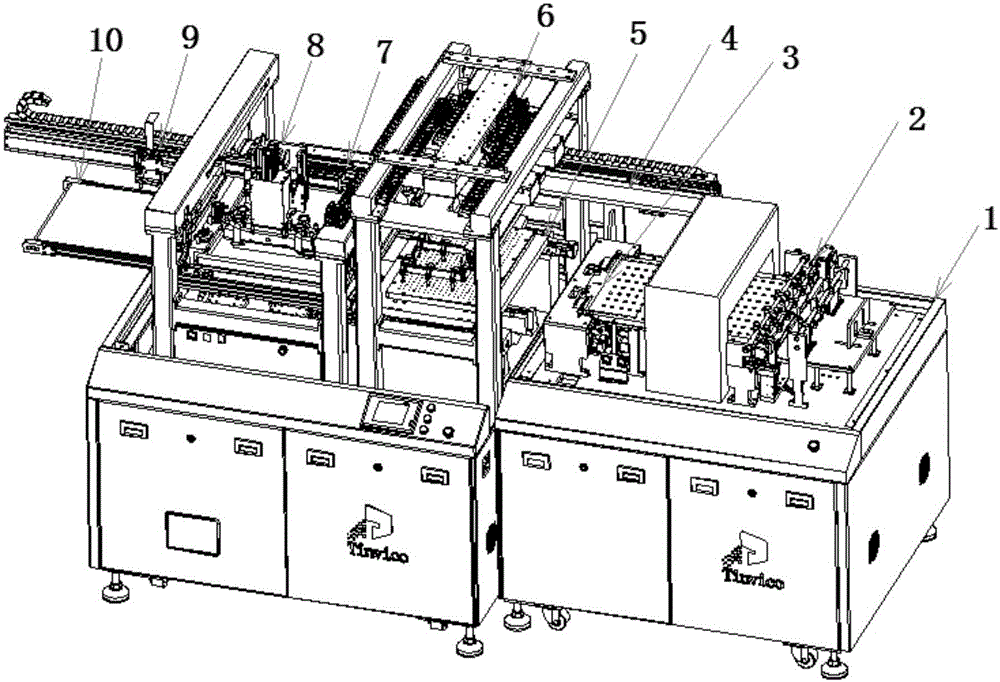

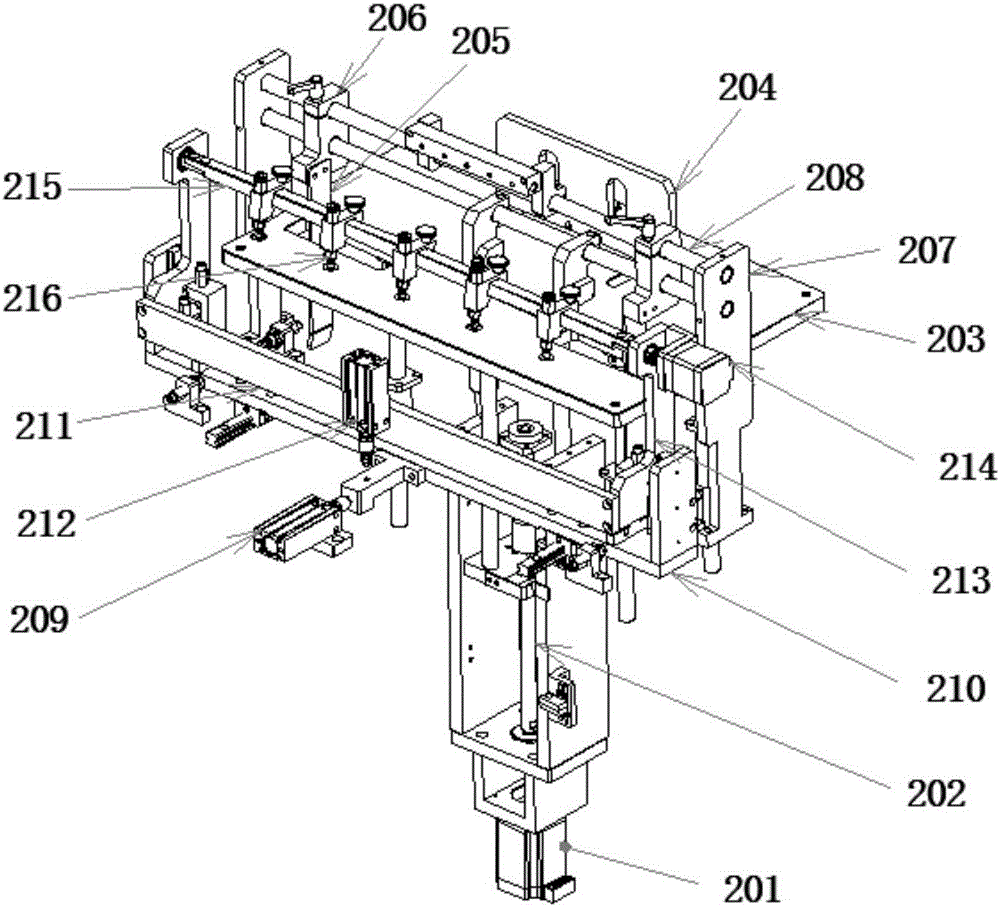

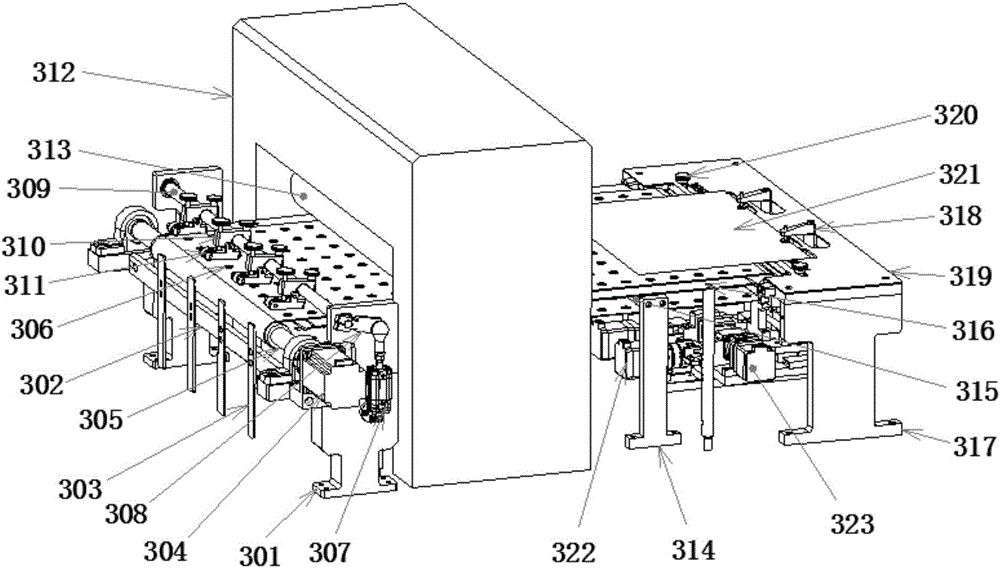

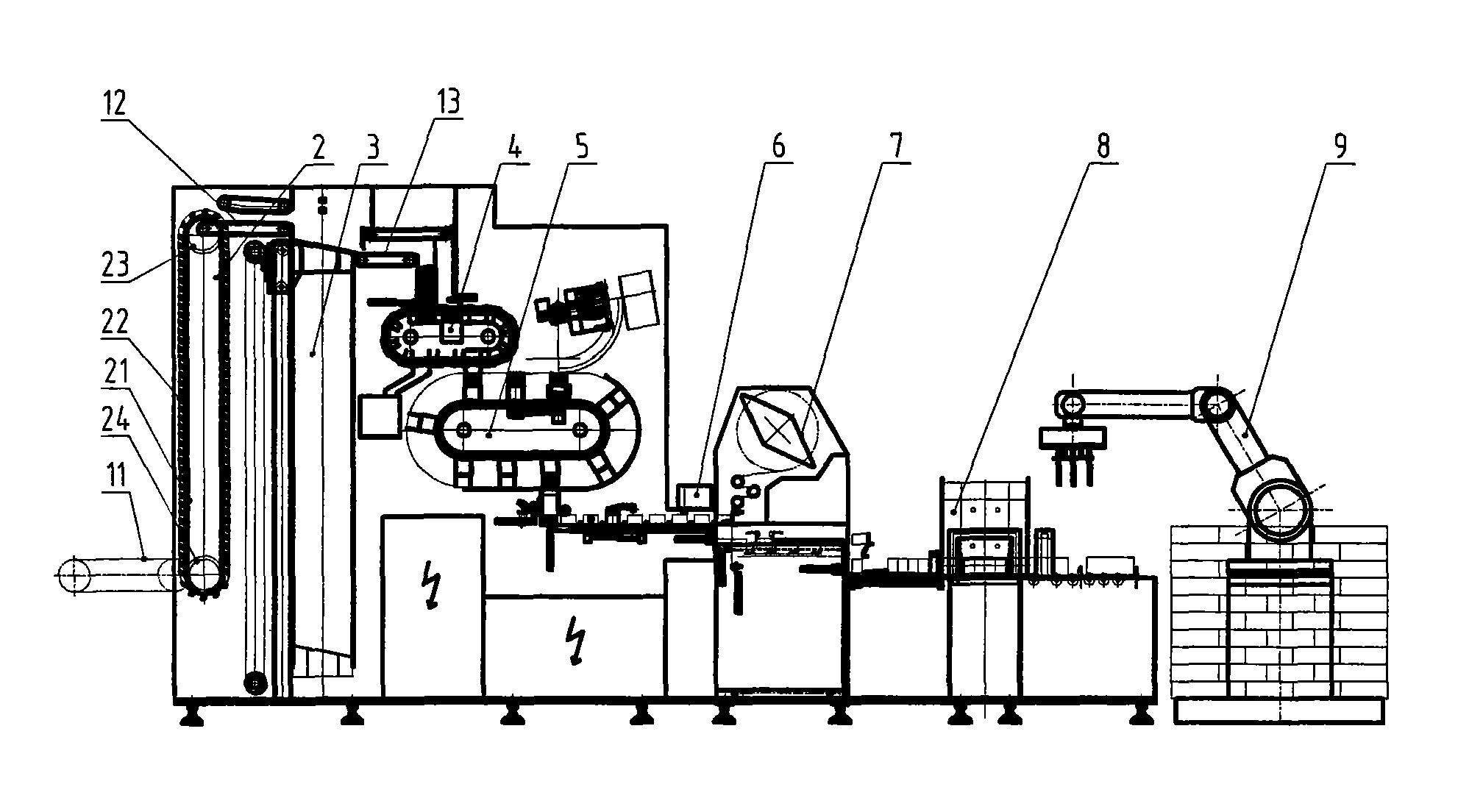

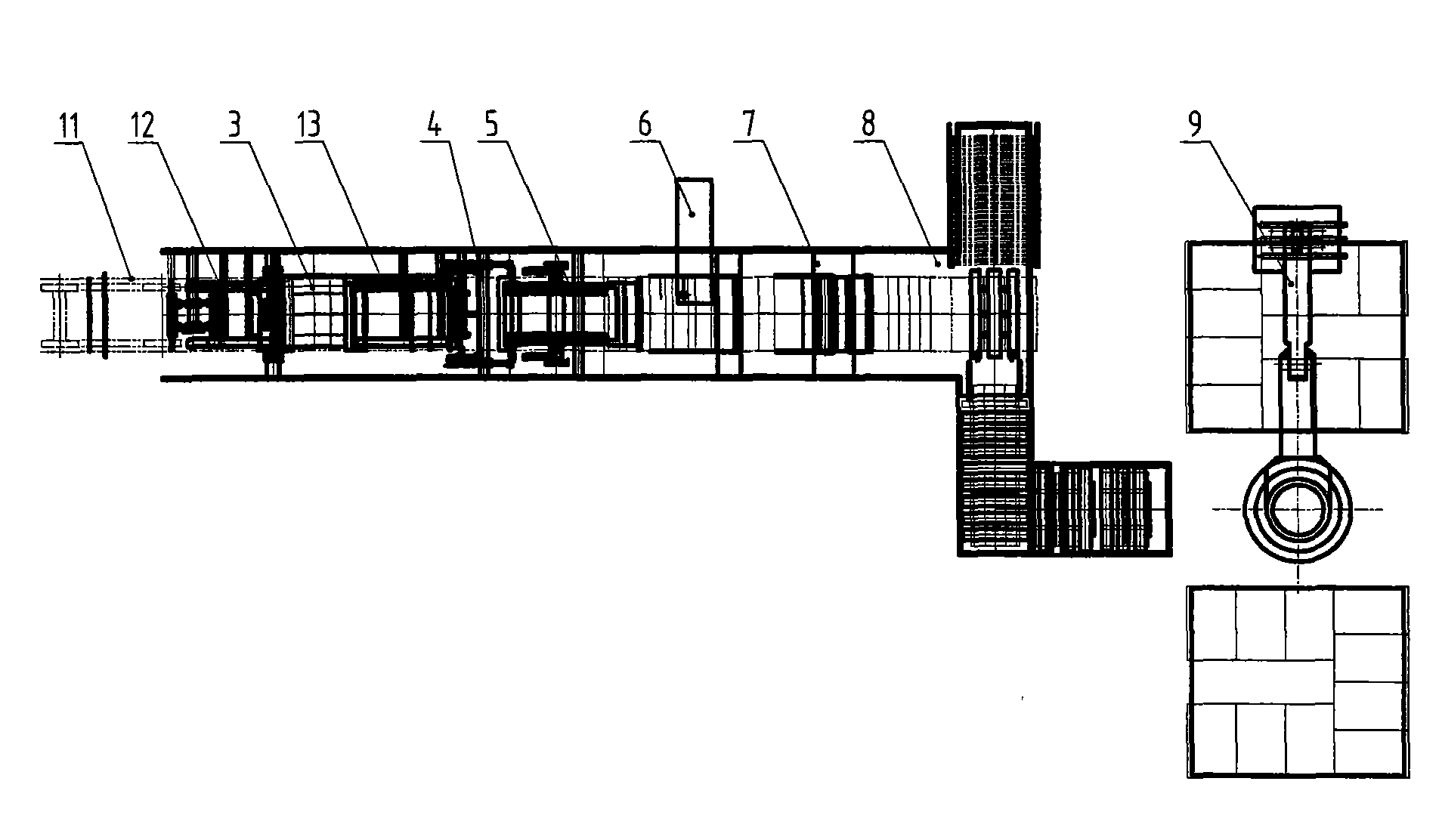

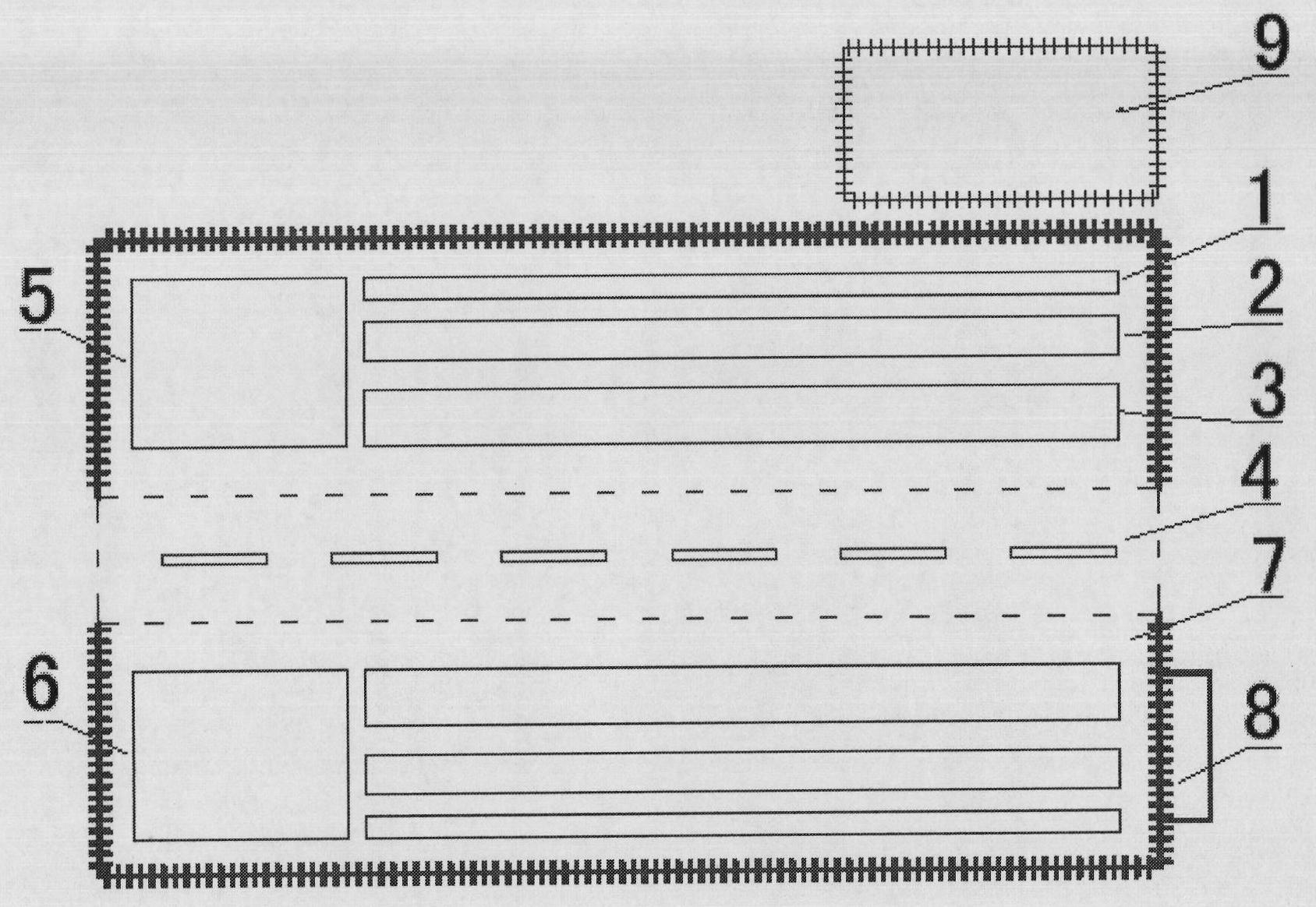

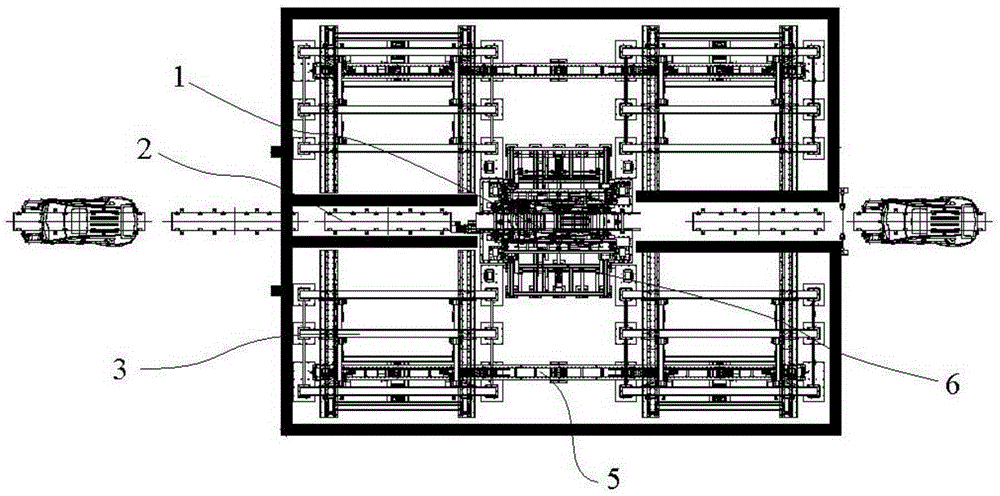

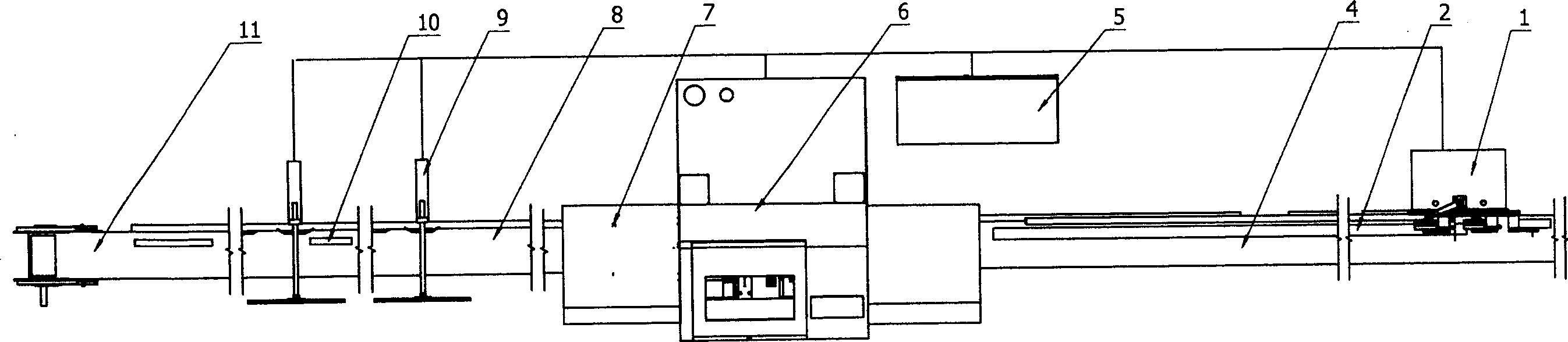

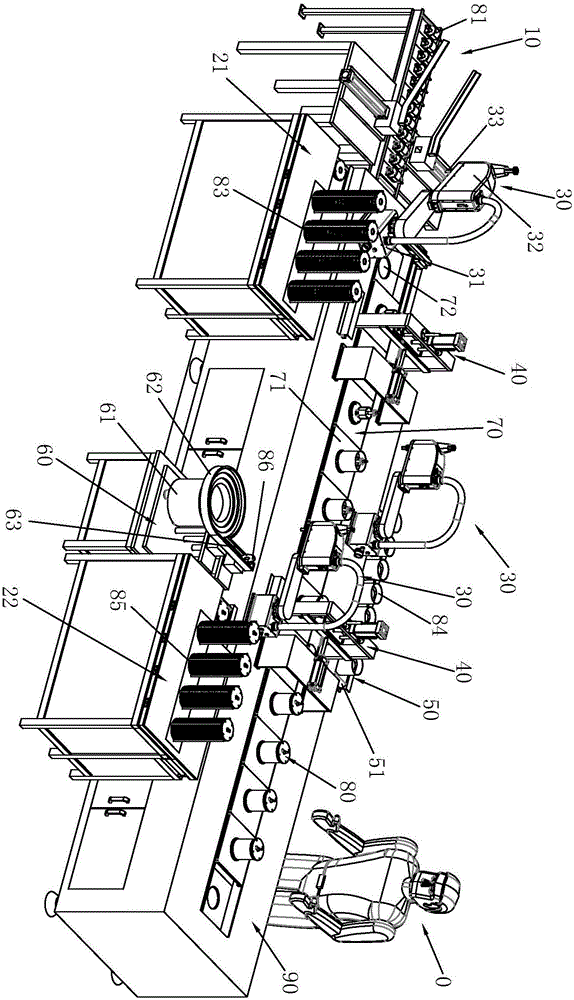

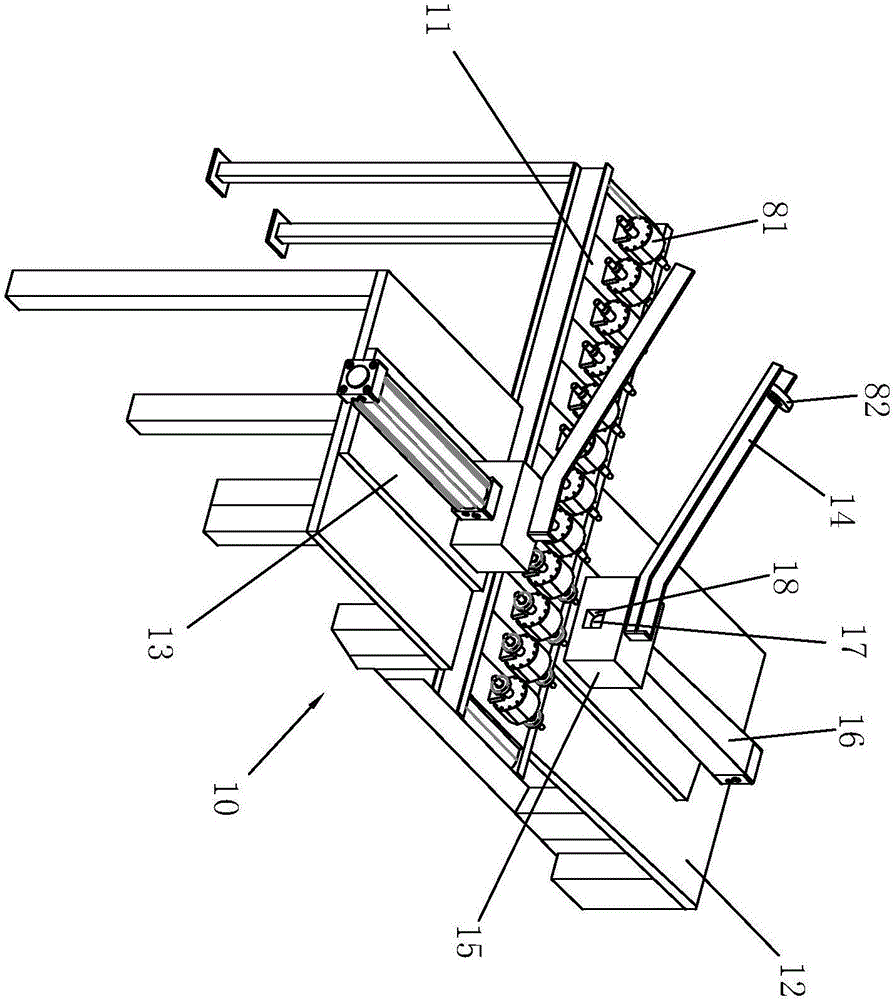

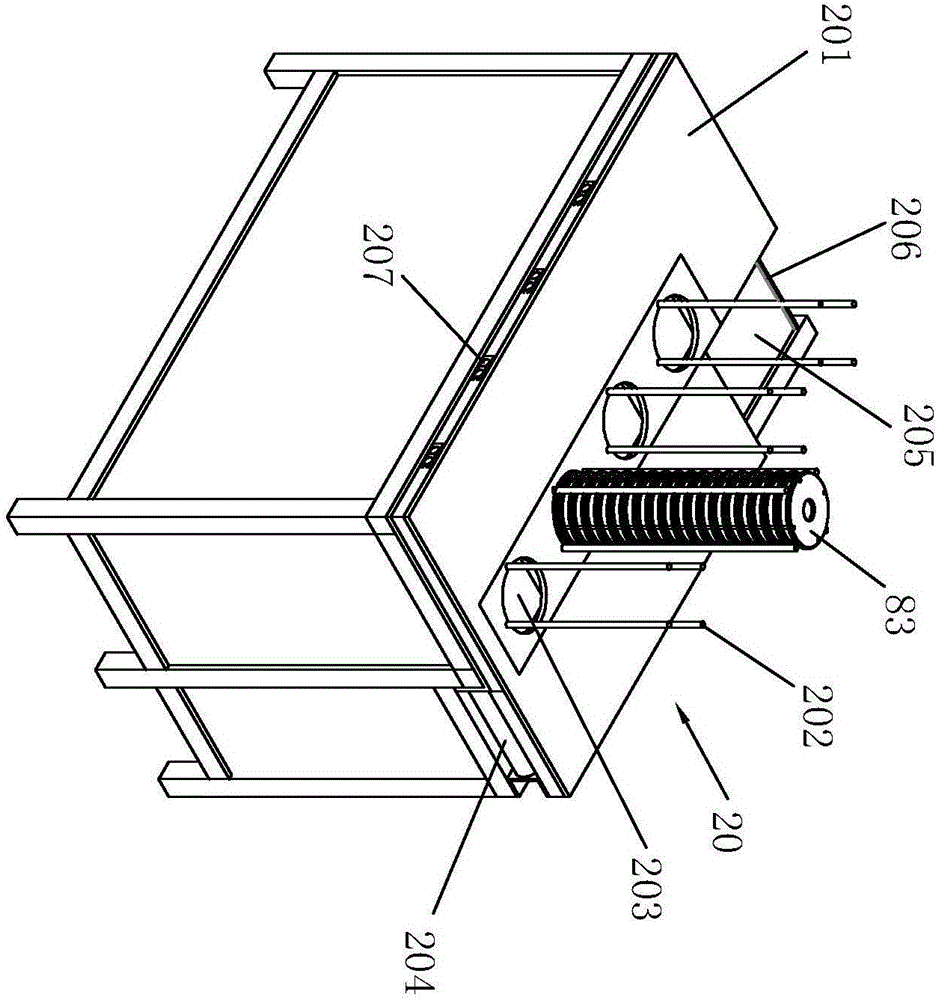

Full-automatic high-precision double-printing-platform screen printing machine

InactiveCN106671579ASolve the problem of manual loading and unloadingReasonable layoutScreen printersConveyor partsEngineeringPrinting press

The invention discloses a full-automatic high-precision double-printing-platform screen printing machine. The full-automatic high-precision double-printing-platform screen printing machine comprises a machine frame, material conveying mechanism, a screen printing plate mounting and alignment mechanism and a screen printing mechanism and further comprises a double-printing-platform transfer assembly located on the machine frame, wherein the material conveying mechanism is located on the machine frame; the double-printing-platform transfer assembly comprises a positioning position, a printing position, a lifting printing platform and a printing platform, the lifting printing platform and the printing platform are located in the positioning position or the printing position alternately and switched between the positioning position or the printing position; the material conveying mechanism is used for conveying to-be-printed materials to the positioning position; and the screen printing plate mounting and alignment mechanism and the screen printing mechanism are arranged above the printing position for printing the to-be-printed materials located in the printing position. By means of the full-automatic high-precision double-printing-platform screen printing machine, while one to-be-printed material is printed, another to-be-printed material is automatically fed onto the printing platform and photographed and positioned, and the technical problems that most of existing full-automatic flexible-plate screen printing machine adopts single-platform linear material conveying, and consequently the system efficiency is low are solved.

Owner:SHENZHEN TINVICO TECH CO LTD

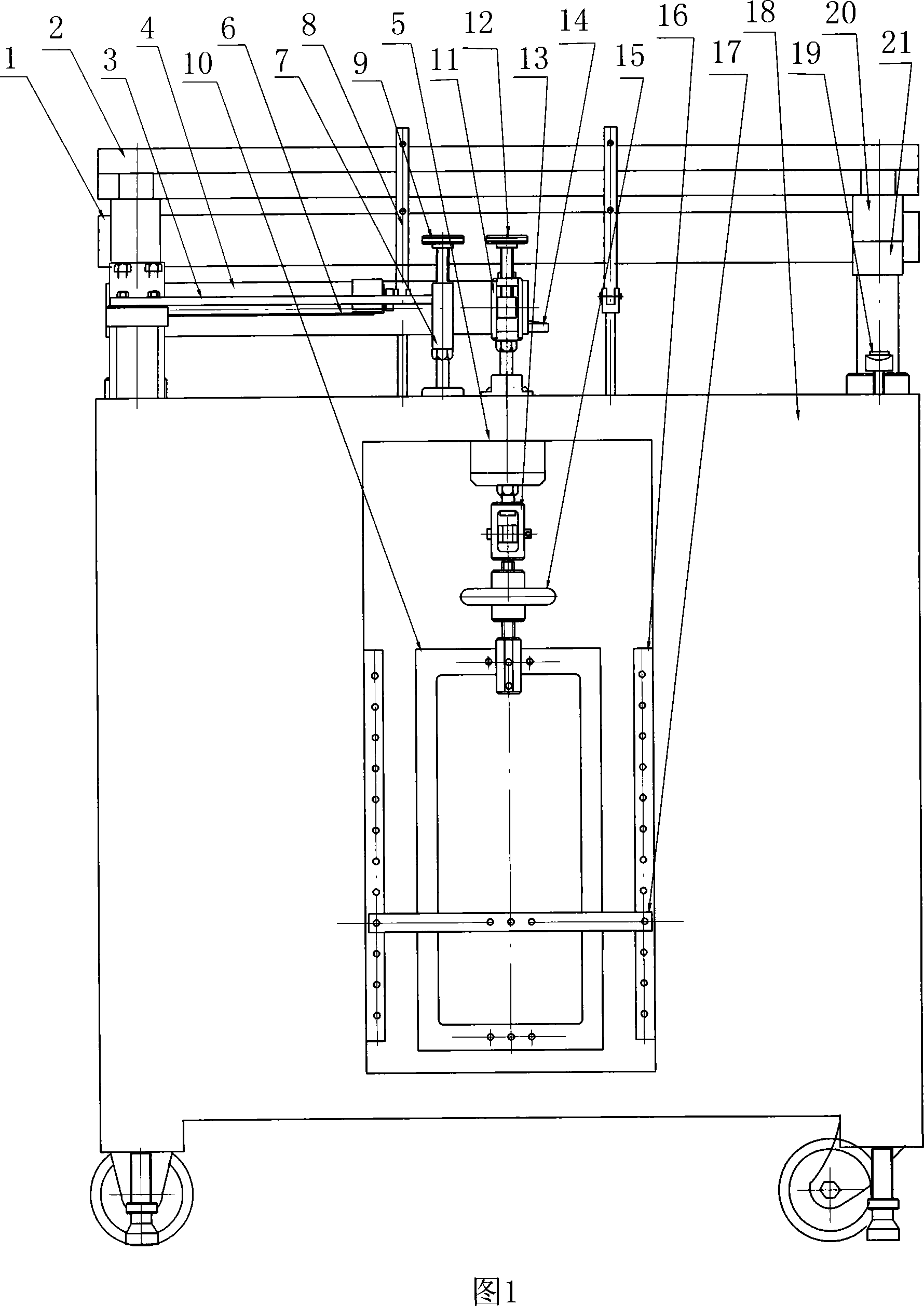

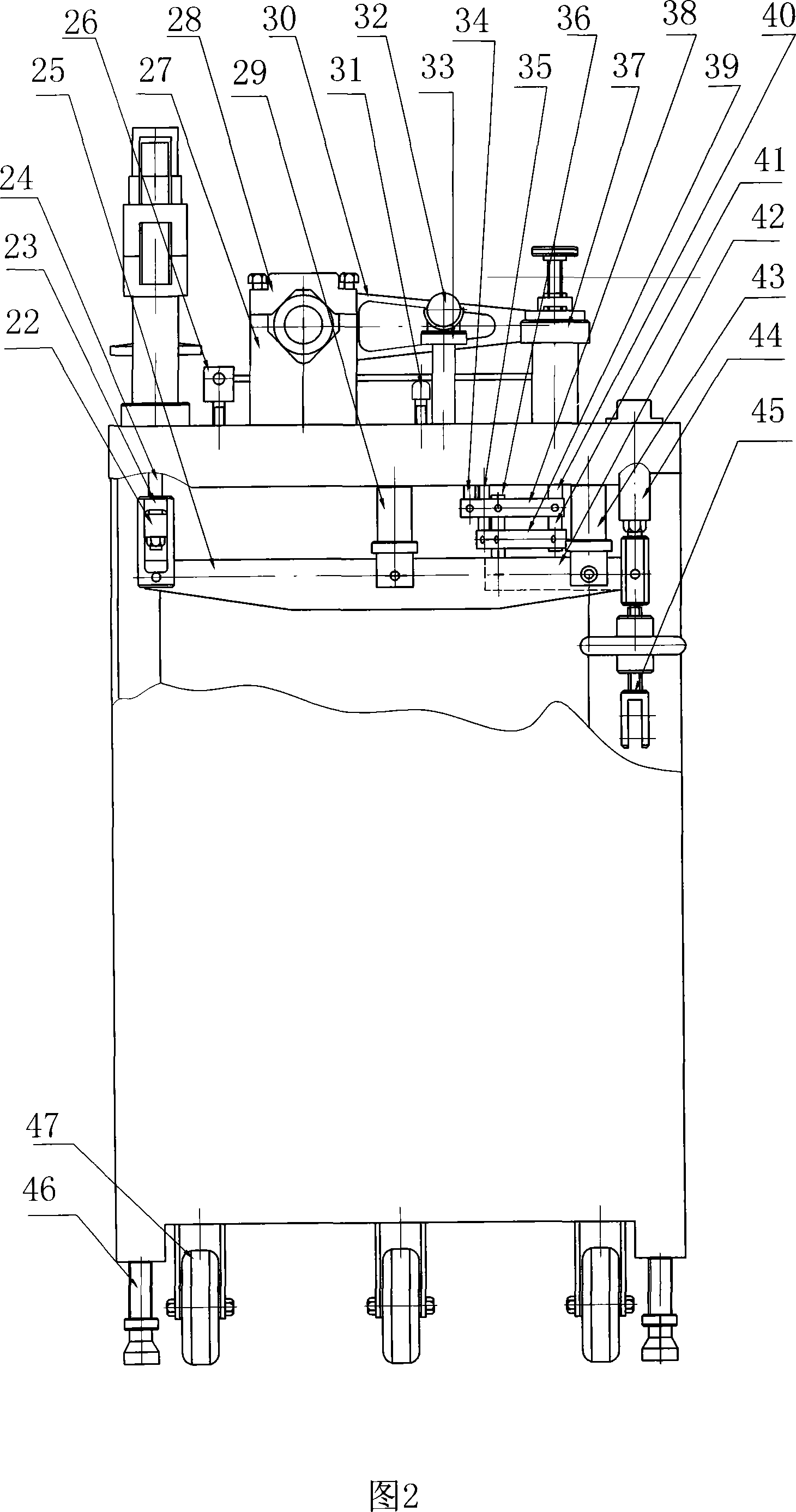

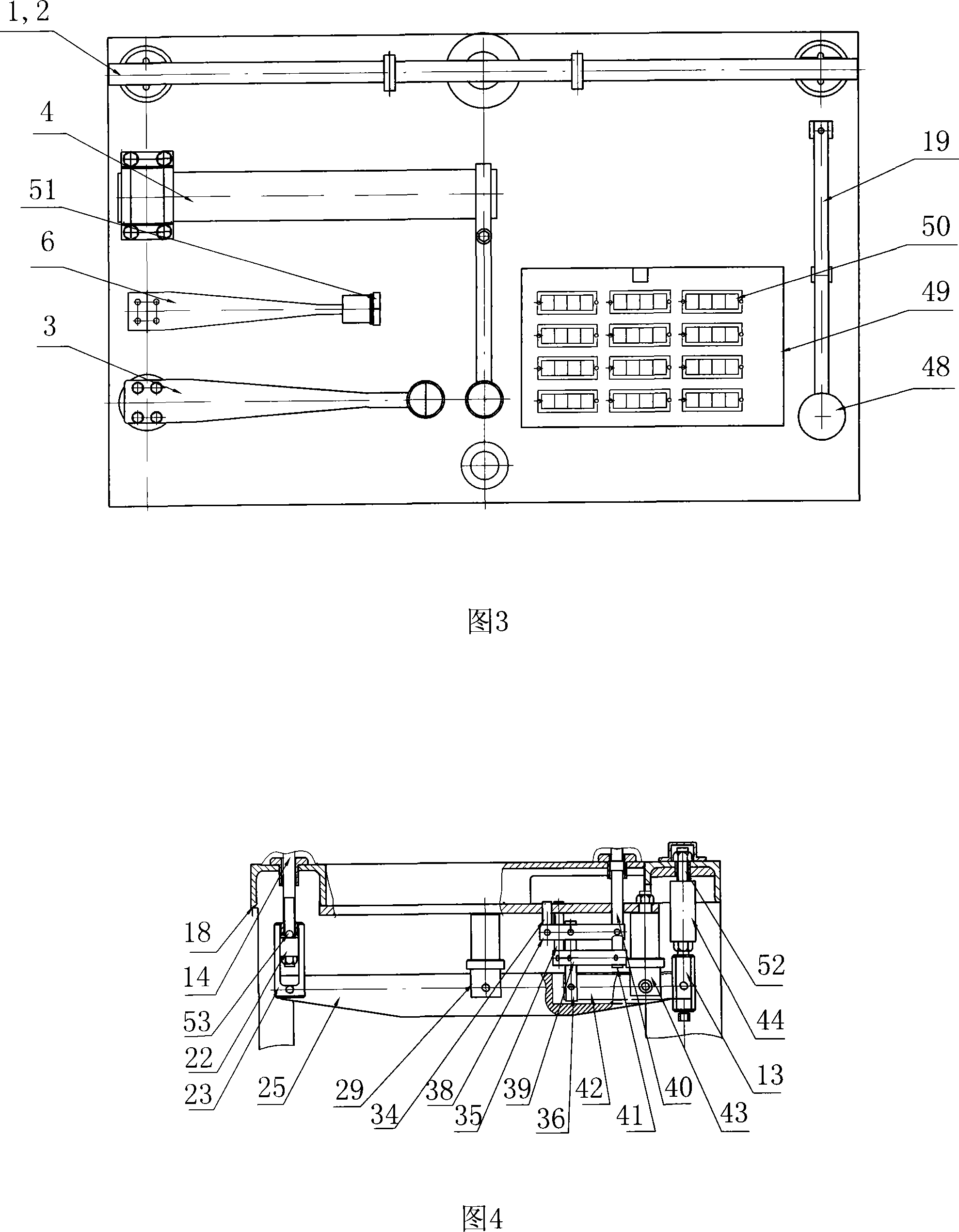

Dynamic and static mechanics integrated test platform

InactiveCN101144764AReasonable layoutCompact structureStructural/machines measurementUsing mechanical meansElectric machineryHelical wheel

The invention discloses a dynamic and static mechanics comprehensive test bench, which relates to mechanics experimental equipment. Nowadays the mechanics test bench in the market has the disadvantages of single function, inconvenient operation, big size of the equipment and high price. A pure beam bending device, a composite beam bending device, a cylinder crankling device, a dynamic beam device, an equal strengthen beam device, a stretching and compressing device and a sinker rod are arranged on a main bench frame; the pure beam bending device, the composite beam bending device, the equal strengthen beam device, the cylinder crankling device and the stretching and compressing device respectively adopt a hand operated helical wheel to load, a sensor to measure the power, and transfer a load through a combined type lever power transmission system; the dynamic beam device uses a motor with an eccentric wheel to vibrate hardly; an interface board which is connected with the lead wire of a strain meter is arranged on the bench surface. The invention has the functions of combining and arranging various experiments of the basic mechanics and skill training of various basic experiments. The invention has the advantages that the comprehensive function is powerful, the cost performance ratio is high, the structure is compact, and the operation is convenient.

Owner:ZHONGBEI UNIV

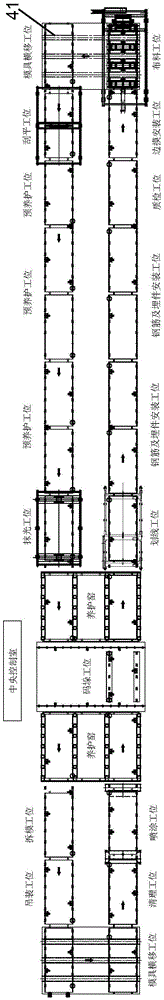

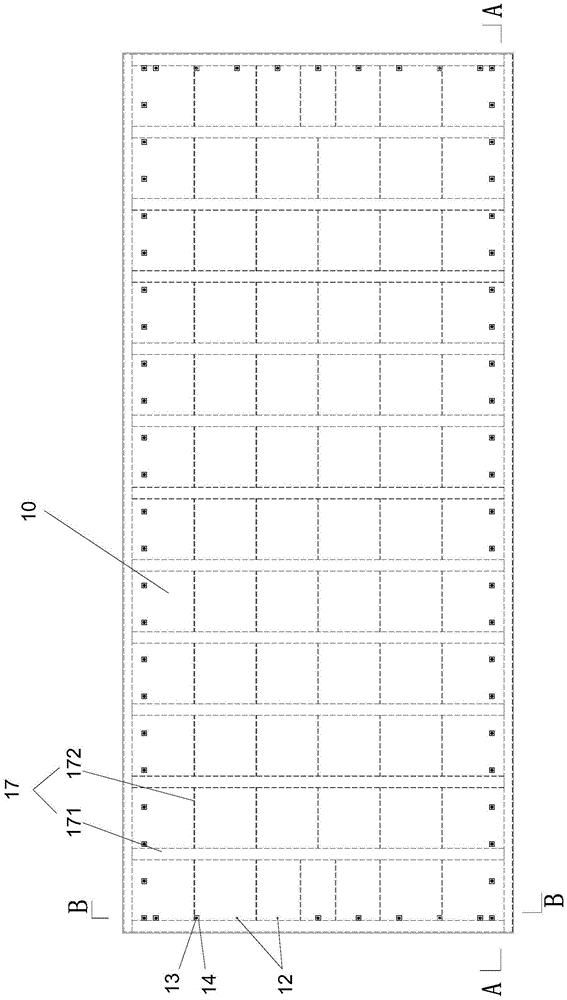

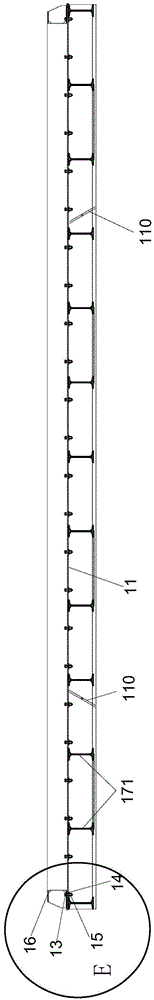

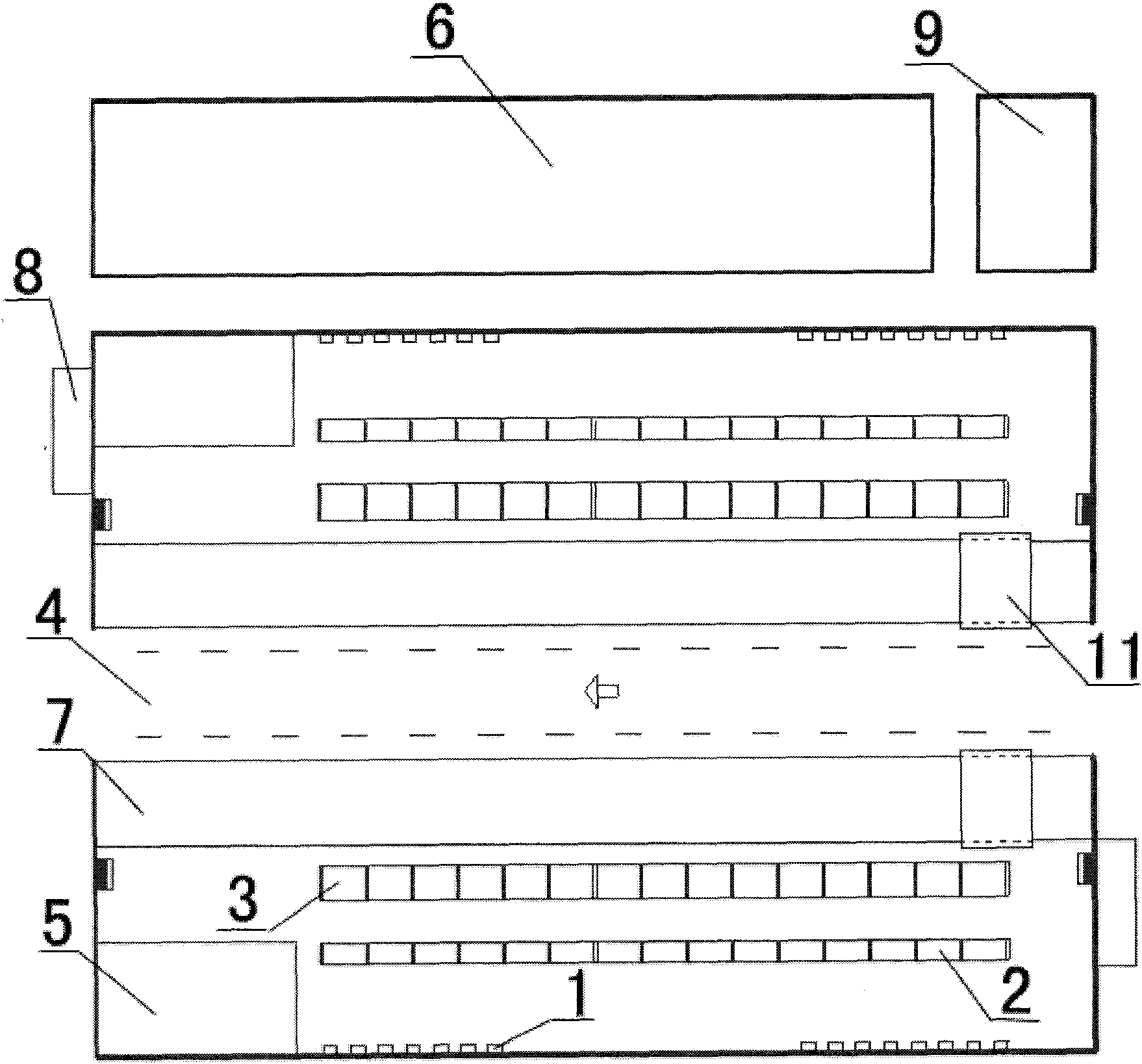

PC component production line

ActiveCN105459258AReduce wasteReduce manufacturing costCeramic shaping plantsFeeding arrangmentsProduction lineMaterial resources

The invention provides a PC component production line. The PC component production line comprises a clearing work station, a spraying work station, a scribing work station, a reinforcing steel bar and embedded part mounting work station, a quality inspection work station, a side die mounting work station, a laying work station, a die transverse movement work station, a leveling work station, a pre-curing work station, a smoothing work station, a curing kiln, a stacking work station, a die removing work station, a lifting work station and the like, which are connected by a conveying rail. A die component moves with the conveying rail in the order of the work stations and is processed by the procedures of all the work stations. Various models and sizes of PC components can be produced and manufactured. The layout of the production line is reasonable. Various PC components can be cyclically produced on one production line, so that various sizes of fixing dies do not need to be manufactured. The waste of material resources is greatly reduced, the production cost is reduced, and the production efficiency is improved.

Owner:HEBEI YUGOU BUILDING MATERIALS CO LTD

Fully automatic jproduction line for building block of heat retaining building mould for polyphenylene concrete

ActiveCN1695912AReasonable layoutOptimize layoutDischarging arrangementProduction lineControl system

A full-automatic production line for the insulating building blocks made of polyphenylene concrete is composed of raw materials proportioning stirrer, shaping machine, pallet supplying unit, two program-controlled kiln cars, curing kilm consisting of precuring kiln for the moulds of building block and curing kiln for building blocks, demoulding unit, mould pushing unit, pallet-building block separator, stacking system, two pallet-raising unit, two pallet-lowering unit and control system.

Owner:XIAN SILVER HORSE IND DEV CO LTDRIAL DEV CO LTD

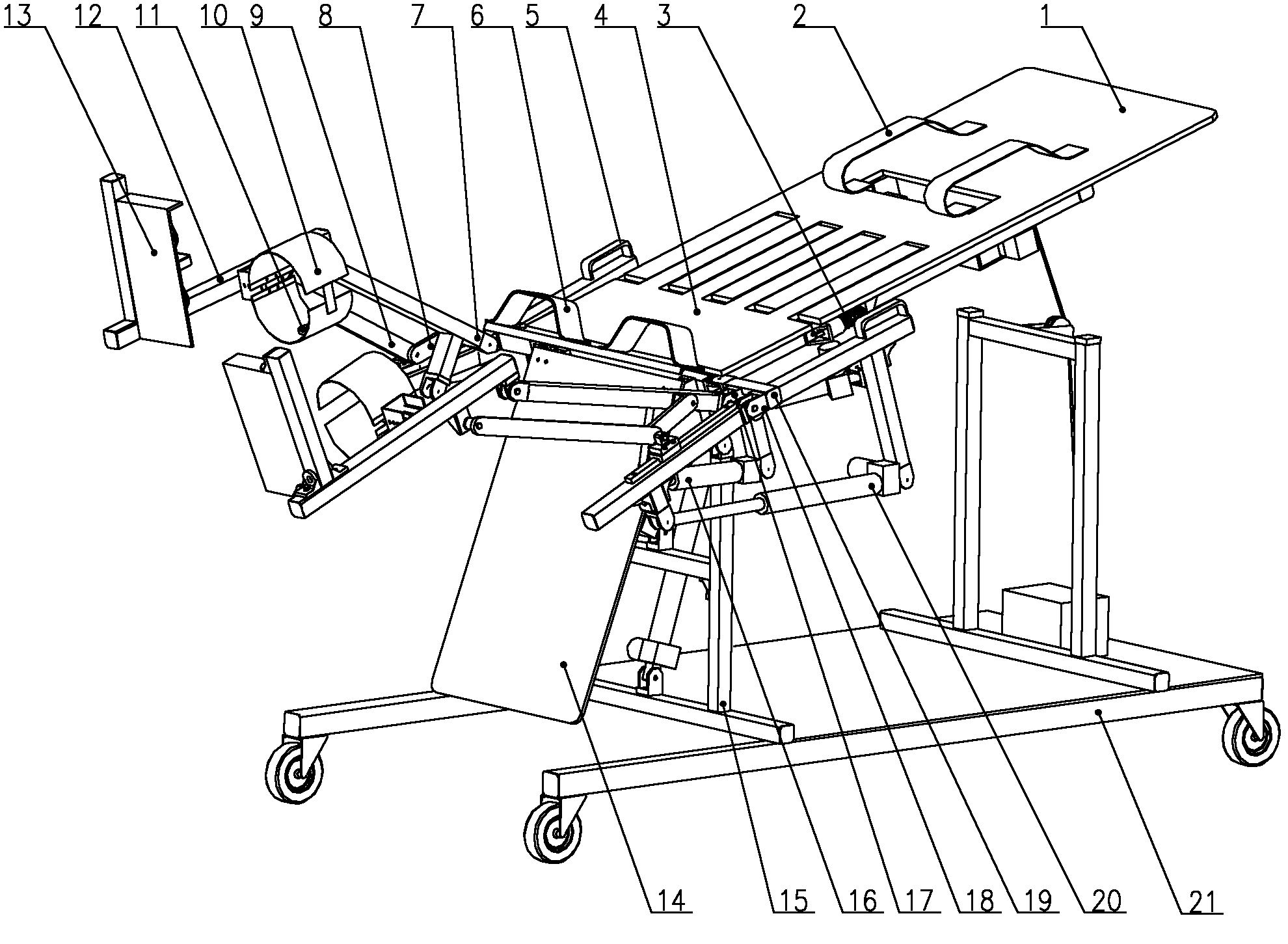

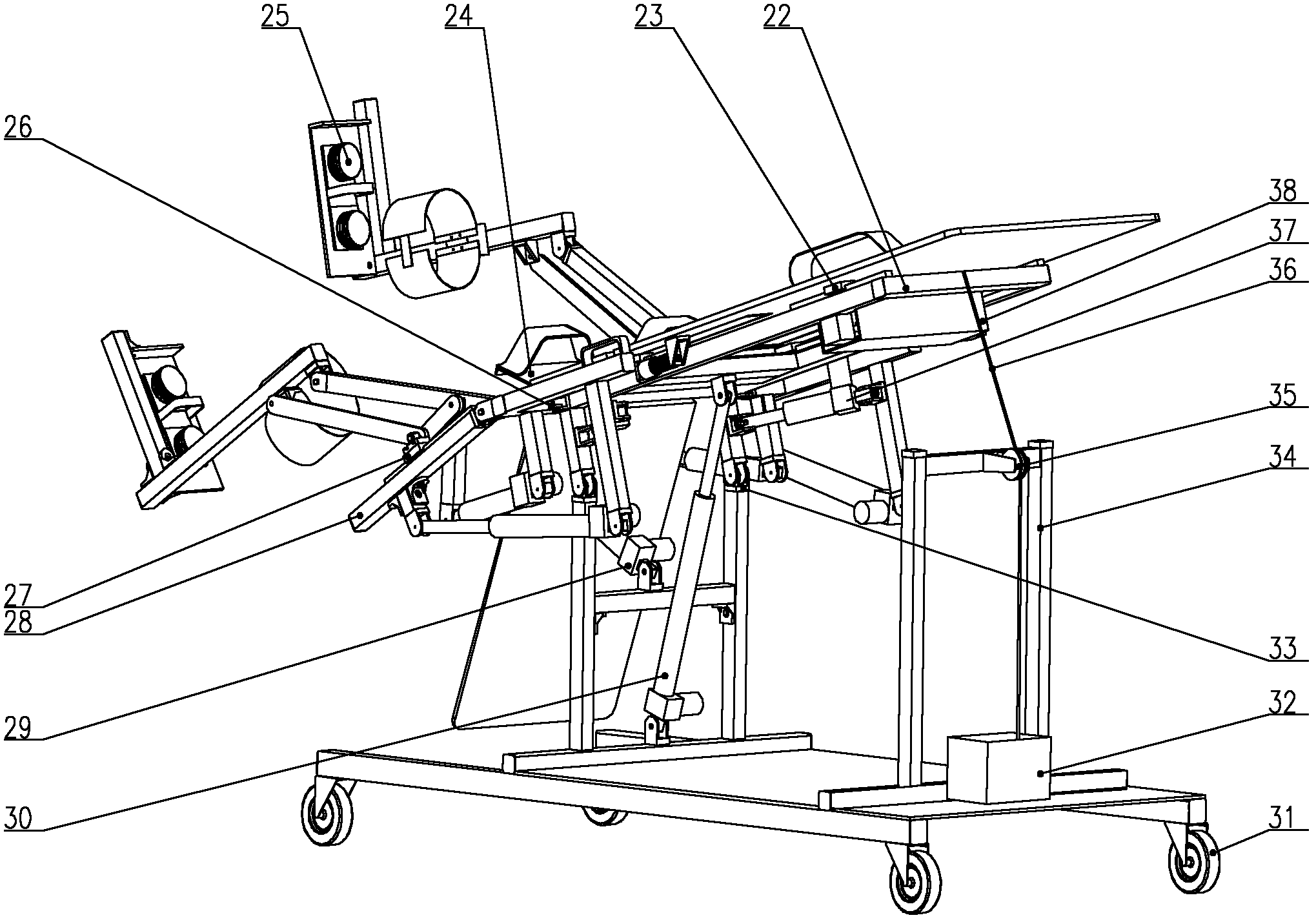

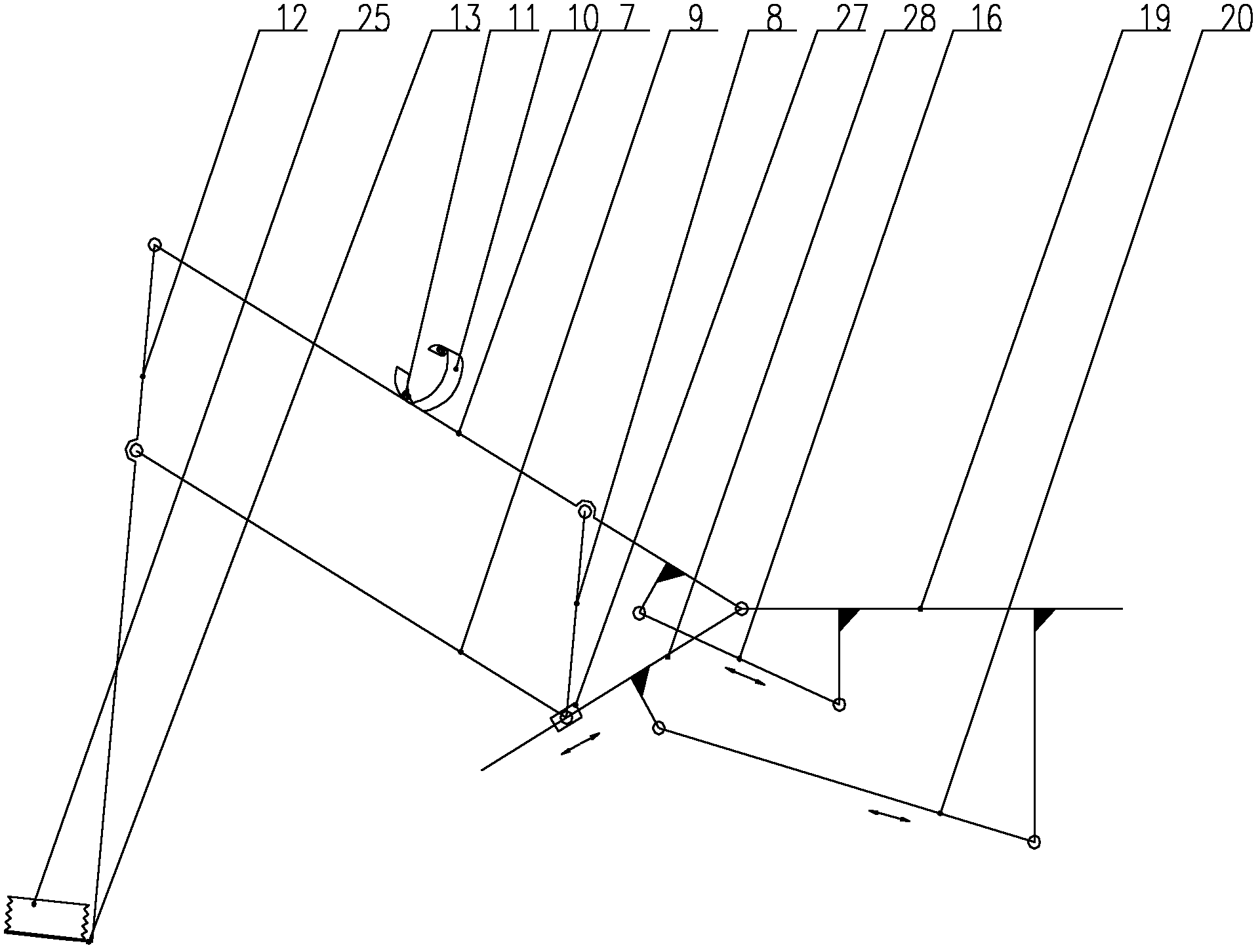

Multi-position lower limb rehabilitation training robot

InactiveCN102512307AReasonable layoutFlexible movementChiropractic devicesMuscle exercising devicesTraining effectExoskeleton

The invention belongs to the field of rehabilitation medical equipment and in particular relates to a multi-position lower limb rehabilitation training robot. The robot comprises a supporting mechanism, a patient fixing system, a lower limber training device and a control system. The lower limber training mechanism utilizes a neutral equilibrium principle, and can be conveniently converted into an outer dynamic-free training mode in a flat-lying state; a patient weight loss and fixation form of connecting the upper body of a patient and a sliding flat plate is adopted; a sole air bag training mechanism is light and flexible, and the patient can achieve a better training effect under the prompt of a lower limber vibration feedback module; exoskeleton lower limber rehabilitation equipment which can realize neutral equilibrium, a flat plate type fixed weight loss system and functional modules such as the vibration feedback module and the like are integrated to form the system, and the neutral equilibrium, the flat plate with an adjustable distance, and the more intuitive vibration feedback characteristic are fully utilized to realize the functions of the multi-position lower limb rehabilitation training robot in an active control mode, a passive control mode, an impedance control model and the like.

Owner:TSINGHUA UNIV

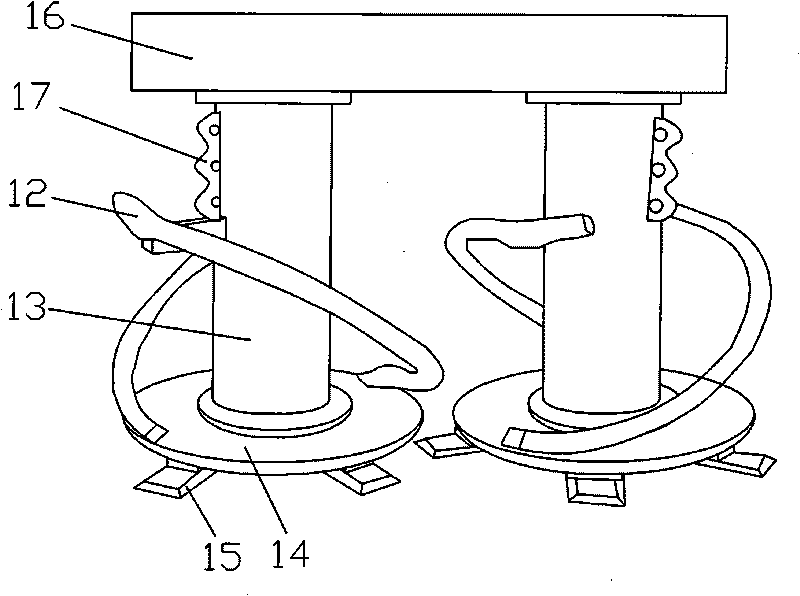

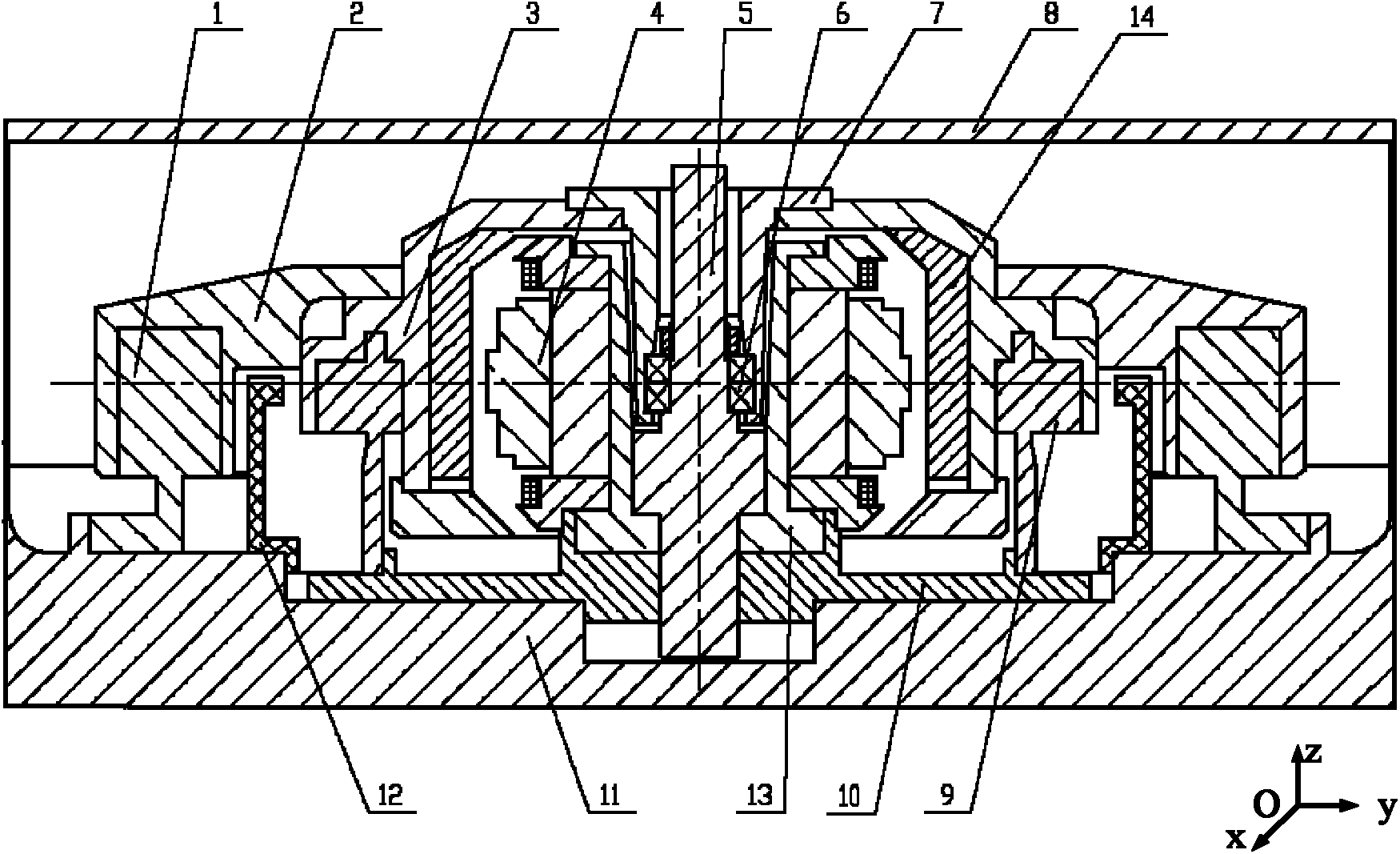

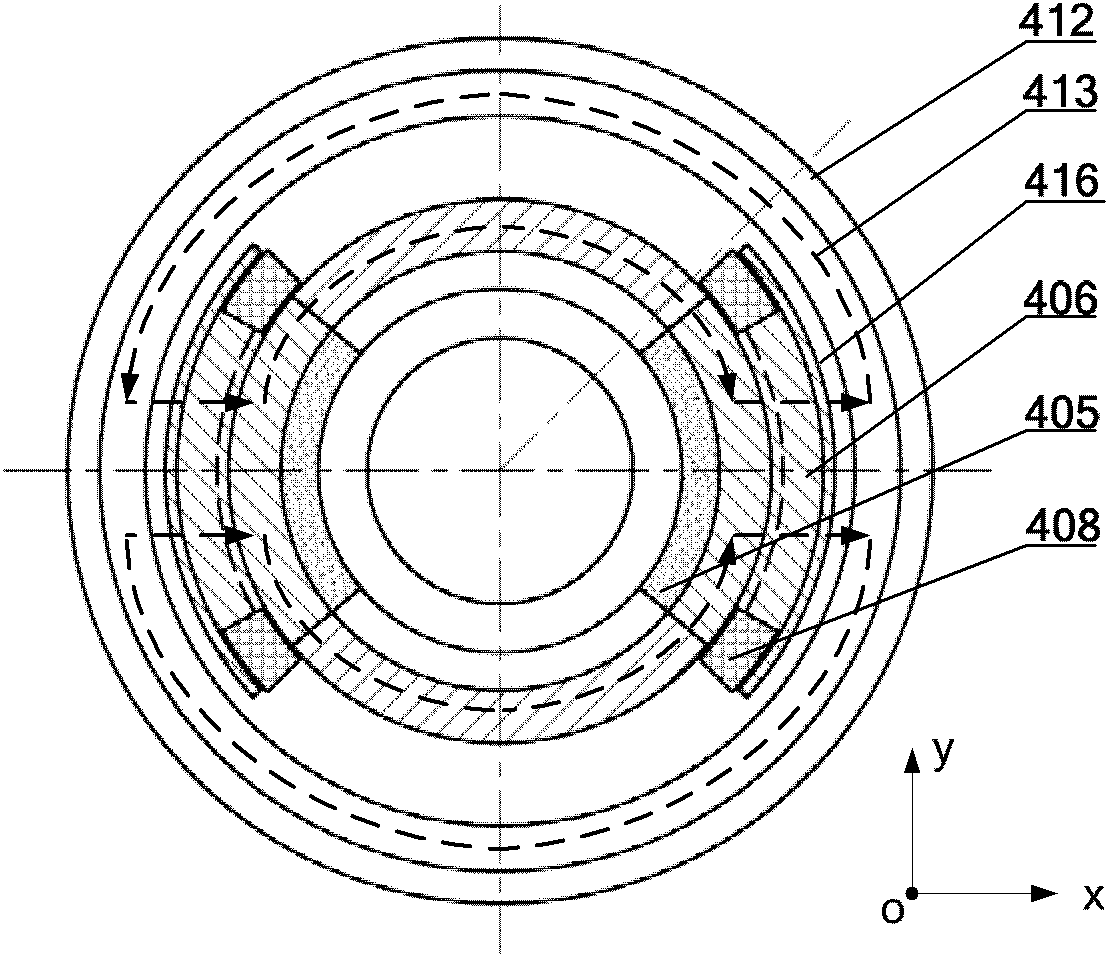

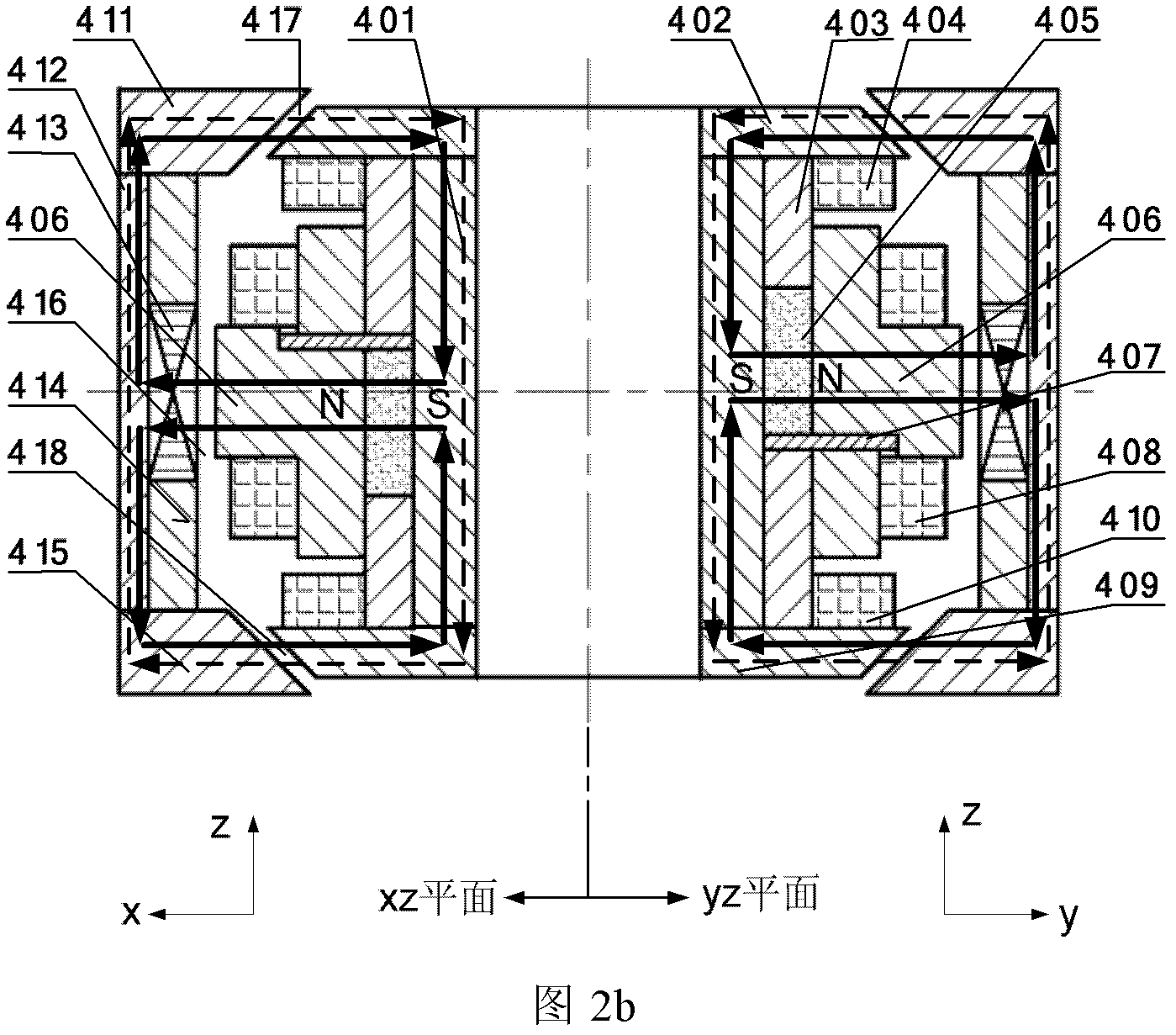

Large-torque magnetic suspension flywheel

InactiveCN102303709AAchieve outputReduce power consumptionSpacecraft guiding apparatusEarth observationMagnetic bearing

The invention discloses a large-torque magnetic suspension flywheel, which can be used as an execution mechanism for attitude stabilization and attitude maneuver of spacecrafts such as a satellite, an earth observation platform and the like. The magnetic suspension flywheel mainly consists of a base, a sealing cover, a radial decoupling conical magnetic bearing assembly, a core shaft, a rotor assembly, a Lorentz force magnetic bearing assembly, a motor assembly, a sensor assembly and the like. The core shaft is positioned in the center of the wheel body, a stator assembly is positioned at theradial outer side of the core shaft, the rotor assembly is arranged at the radial outer side of the stator assembly, the rotor assembly consists of a wheel flange and a wheel hub, and the Lorentz force magnetic bearing assembly consists of a magnetic bearing stator part and a magnetic bearing rotor part; an adapter plate is connected with the core shaft, the stator assembly and a motor stator; and the sensor assembly consists of a sensor shell and a sensor. The components of the flywheel are arranged reasonably and compactly, the flywheel can be used for attitude stabilization of the spacecraft, and attitude maneuver of the spacecraft can be realized by using large control torque provided by gyroscopic effect of the magnetic suspension flywheel.

Owner:BEIHANG UNIV

Spot welding device for battery cap and tab

ActiveCN101434008ASimple structureCompact structureWelding/soldering/cutting articlesMetal working apparatusControl systemSpot welding

The invention relates to a cell cover and polar ear spot welding device, which comprises a cell feeding mechanism which can send cells to be processed into spot welding stations, a cover guiding mechanism which can lead in covers and automatically and progressively arrange the covers in order, a cover feeding mechanism which accommodates the covers sent by the cover guiding mechanism and sends the covers into the spot welding stations, a laser spot welding mechanism which welds the cell covers and cell polar ears sent into the welding stations, and a control system which can control the motion of various mechanisms, wherein the cover feeding mechanism and the cover guiding mechanism are in matched connection and arranged above the cell feeding mechanism, so that the covers contact upper polar ears of the cells; the laser spot welding mechanism is positioned aside the cell feeding mechanism; and a laser emitting center of the laser spot welding mechanism is in the same line with the contact points of the covers and the upper polar ears of the cells. The invention provides a laser spot welding processing apparatus which can automatically send the cylindrical cells and the covers into the welding stations and perform spot welding connection on the upper polar ears of the cells and the covers.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

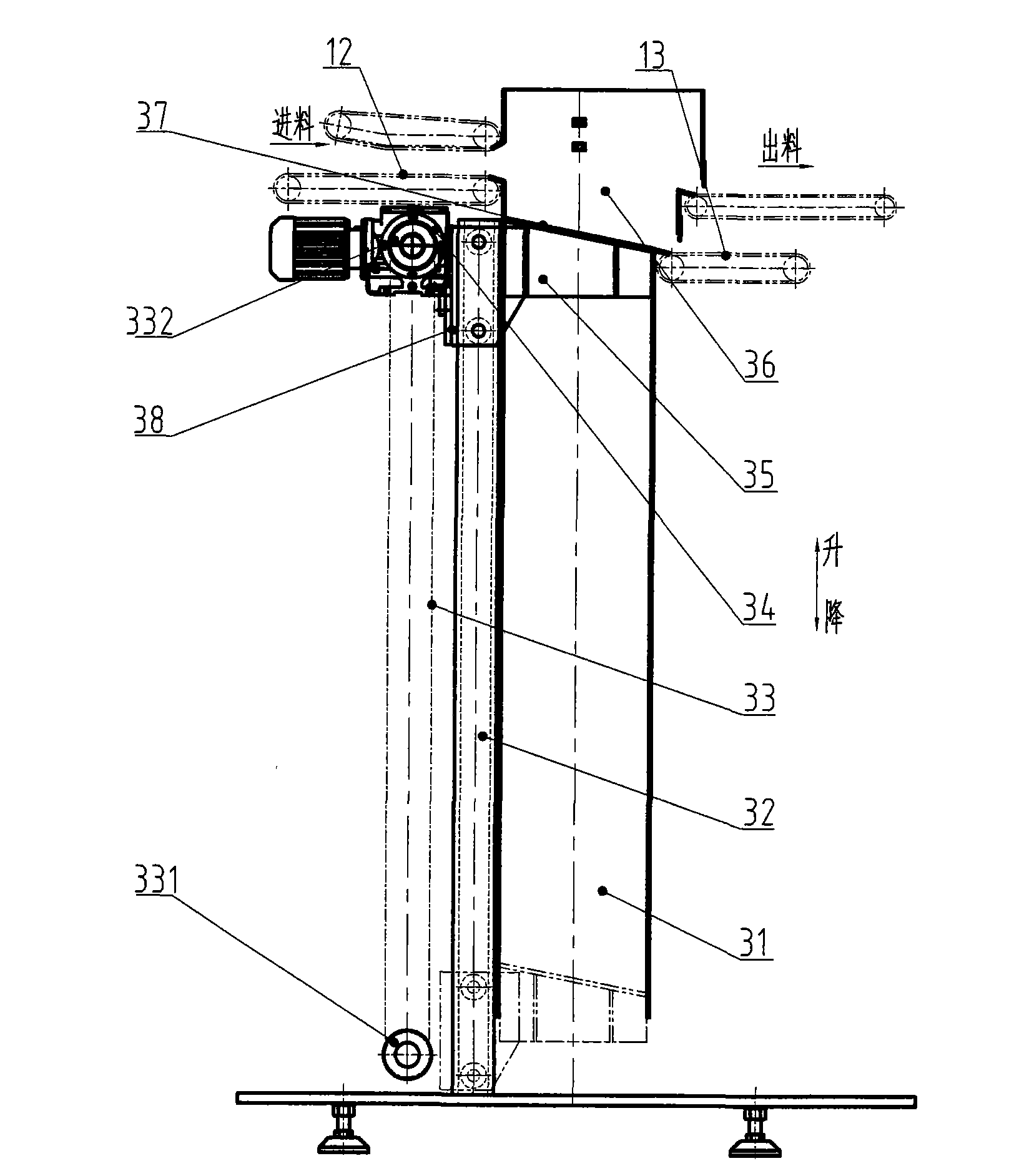

Automatic packaging machine

InactiveCN101525056AReduce laborQuality improvementWrapper twisting/gatheringSolid materialEngineeringManufacturing line

The invention provides an automatic packaging machine, comprising a conveying mechanism. The automatic packaging machine is characterized by also comprising a lifter, a storing machine, a sub-boxing weigher and a boxing and packaging machine. The materials to be packaged are conveyed by the lifter to the storing machine for temporary storage so as to maintain continuous normal operation of production lines and packaging lines, or the materials are conveyed directly to another conveyer by the storage machine, then conveyed into a material-collecting box of the sub-boxing weigher, subpackaged into a material box by a discharging channel of the lower part of the material-collecting box, weighed, measured and conveyed into a charging box of the boxing and packaging machine; packaging box paper is placed on the materials by a paper box supply mechanism, firstly box edge folding, edge ear folding and edge end folding of the packaging box paper are finished, then the rest box edge folding and edge end folding are finished in the discharging process of separation of the materials from the charging box, thus realizing full automatic sub-boxing, measuring, boxing and packaging of materials, reducing the labor of workers to a greater degree, improving working efficiency and enhancing level and quality of products. The boxing and packaging machine has compact structure and reasonable layout and does not occupy space.

Owner:KUNMING DINGCHENG TECH

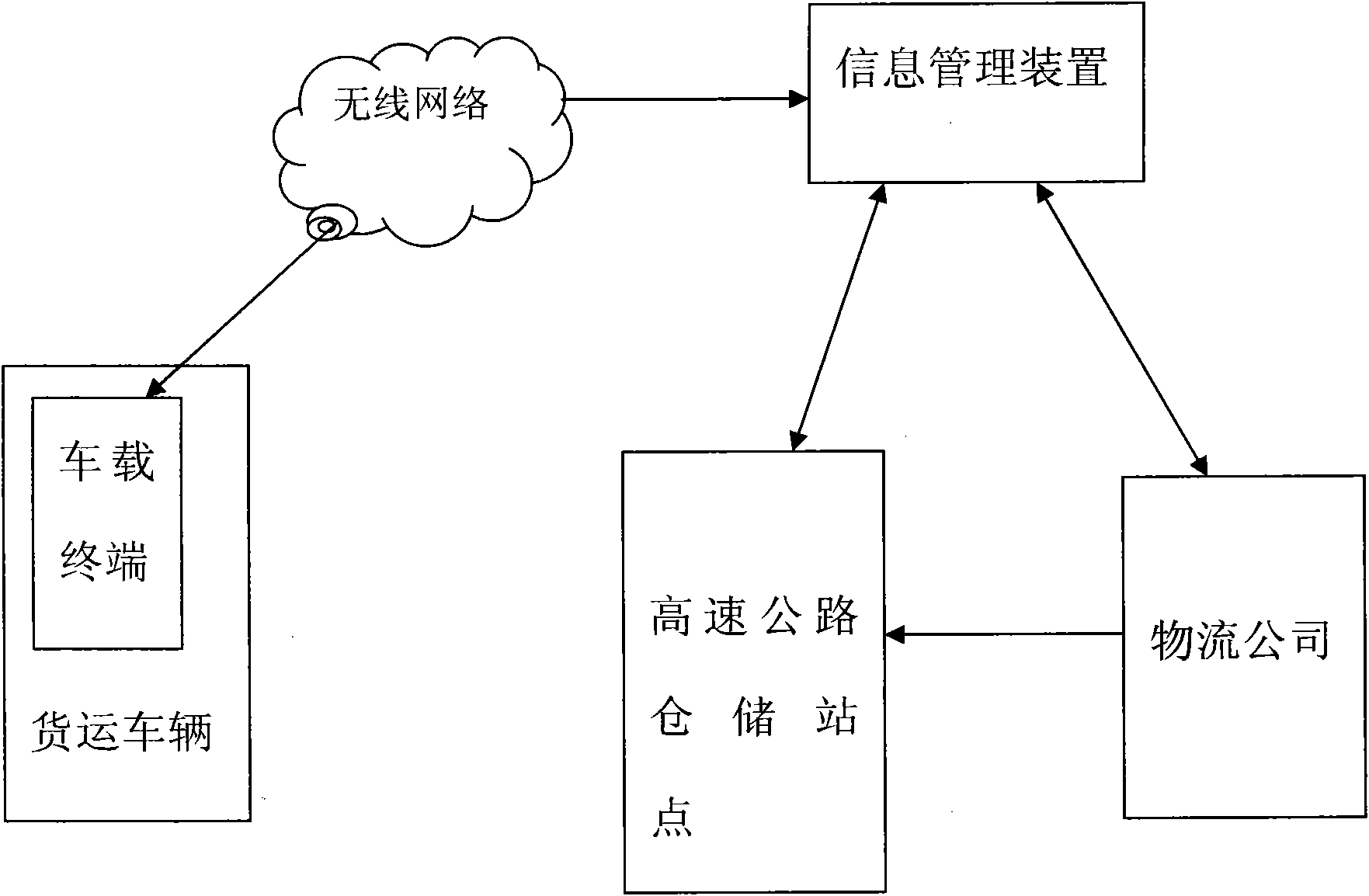

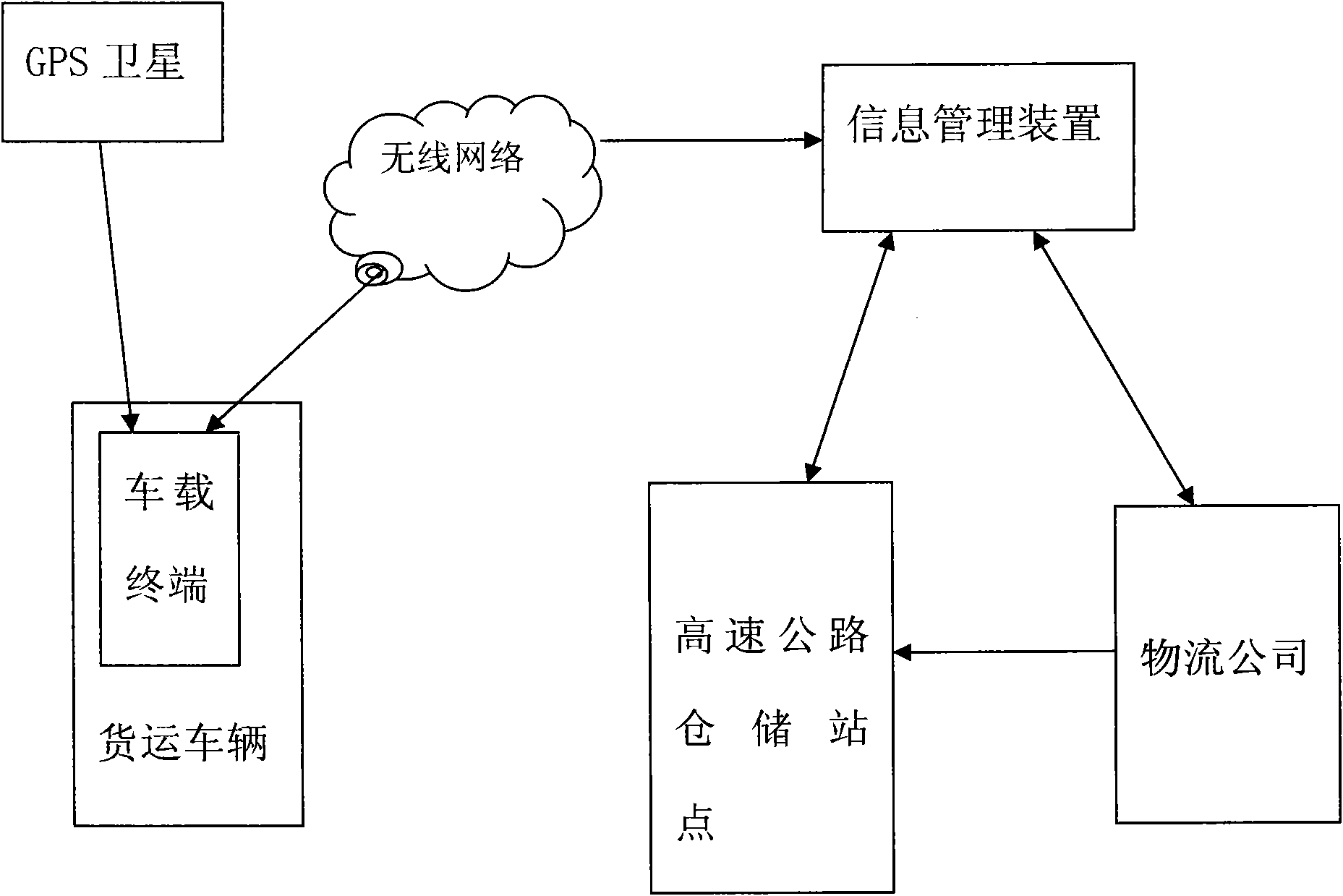

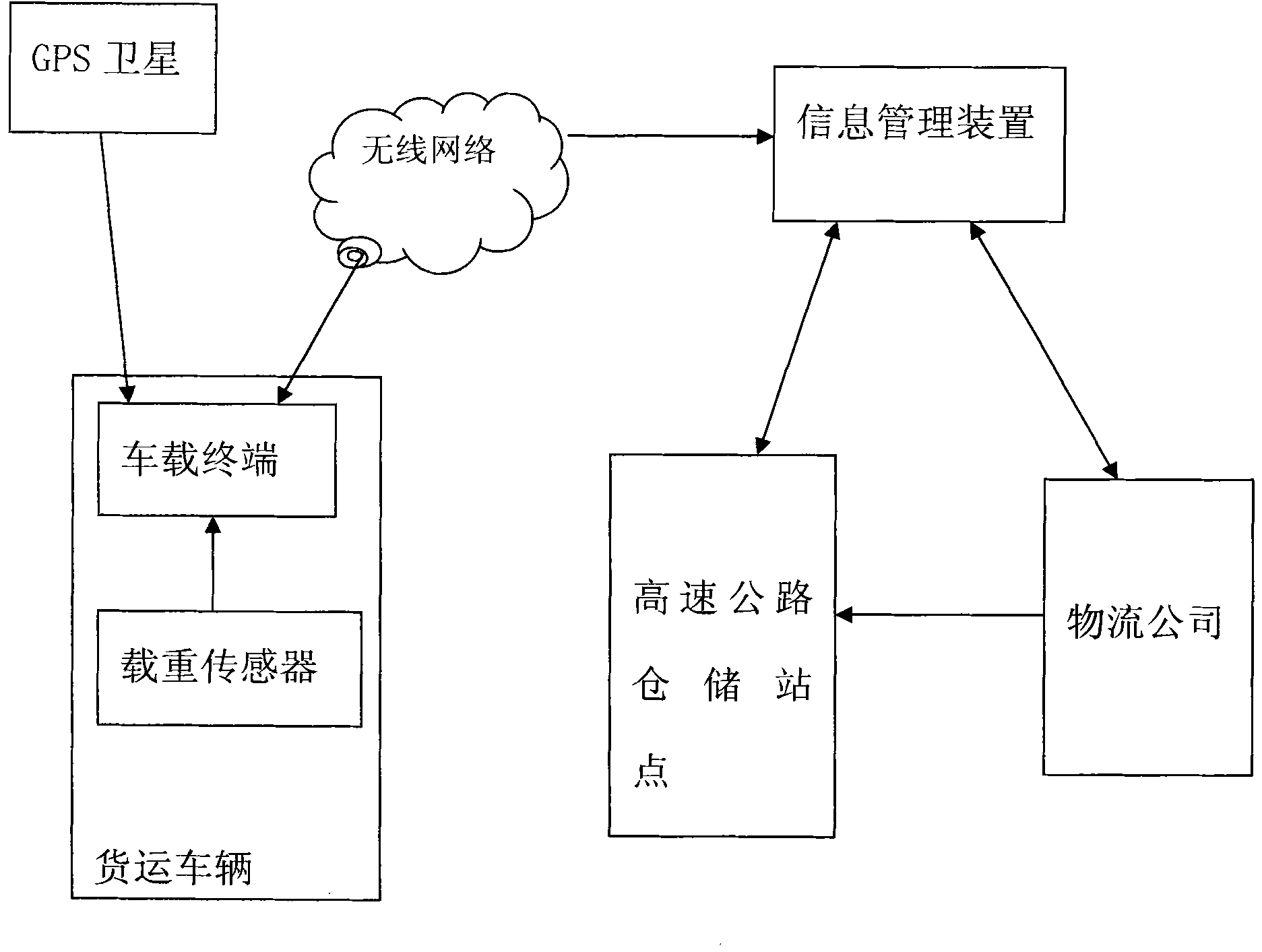

Integrated dispatch stowage system of freight logistics

InactiveCN101840536AImprove the level ofScientific schedulingLogisticsLogistics managementComputer terminal

The invention discloses an integrated dispatch stowage system system, which manages and dispatches freight vehicles by utilizing storage stations built on a highway and a computer network information platform and distributes goods at the storage station on the highway directly. The system comprises vehicle-mounted terminals arranged on the freight vehicles, a plurality of goods storage stations built on the highway and an information management device, wherein computer terminals of the freight storage stations send information of the goods needing to be carried to the information management device; and the information management device carries out wireless communication with the vehicle-mounted terminals to know whether the freight vehicles are in no load, carries out matching with the information of the carried goods, and then sends the distribution loading information to the vehicle-mounted terminals so as to carry out dispatch of the freight vehicles. The system not only realizes fast distribution and transportation, effectively reduces empty-loaded rate of transport vehicles and reduces the cost, but also avoids large transport vehicles from entering urban distribution, and reduces the pollution of urban traffic pressure and automobile exhaust on the urban environment.

Owner:童超

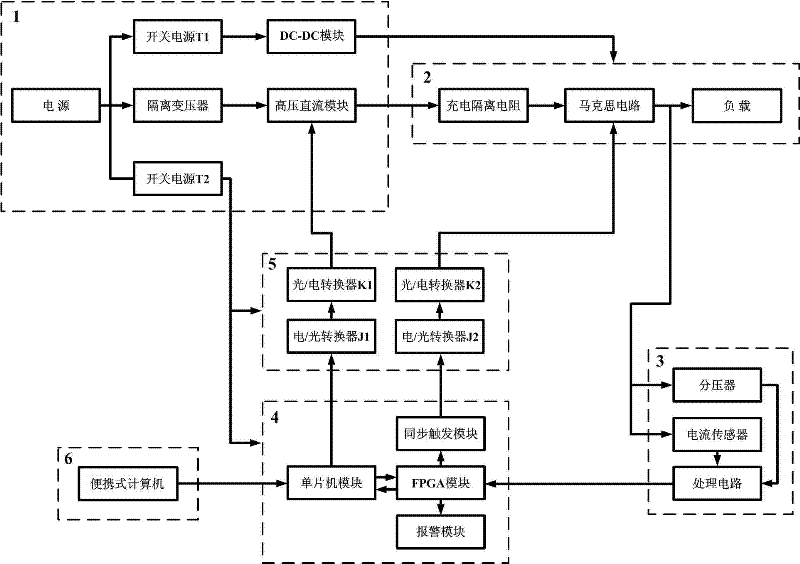

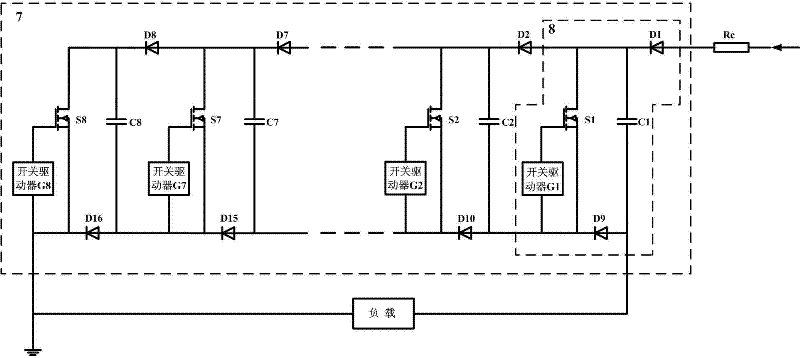

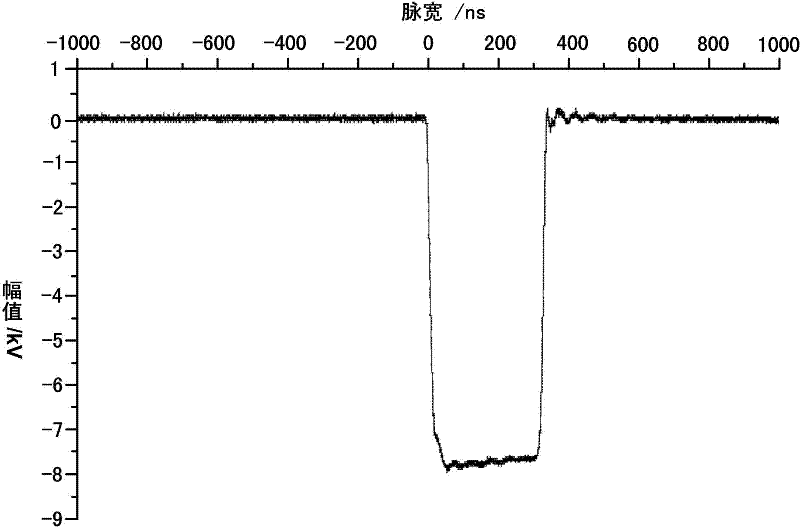

FPGA (field programmable gate array) control-based all-solid-state high-voltage nanosecond pulse generator

ActiveCN102441231AReduce volumeReduce lossElectrotherapyStress based microorganism growth stimulationFailure rateTreatment effect

The invention provides an FPGA (field programmable gate array) control-based all-solid-state high-voltage nanosecond pulse generator, and belongs to the field of bio-electromagnetic technology. The nanosecond pulse generator mainly comprises a power supply system, a pulse forming system, a pulse measurement system, an FPGA control system, a signal conversion system and a portable computer. In the generator, the output pulse amplitude is between 0 and 10kV, the pulse width is between 200 and 1000ns, the pulse frequency is between 1 and 1000Hz, the falling edge is between 30 and 40ns, the number of pulse is between 1 and 1000, and particular parameters are determined according the requirement of tumor treatment. The FPGA control-based all-solid-state high-voltage nanosecond pulse generator has the characteristics of intelligent regulation of pulse parameters (pulse amplitude, width, frequency and number), optical fiber transmission, high parameter accuracy, long service life, small size, low failure rate, good security and the like; and the generator outputs high pulse frequency, and is advantageous to quick searching of the optimal window parameters for inducing tumor cell apoptosis by virtue of intelligent regulation, so that the tumor treatment effect is improved. The FPGA control-based all-solid-state high-voltage nanosecond pulse generator can be widely applied to tumor treatment.

Owner:REMEDICINE CO LTD

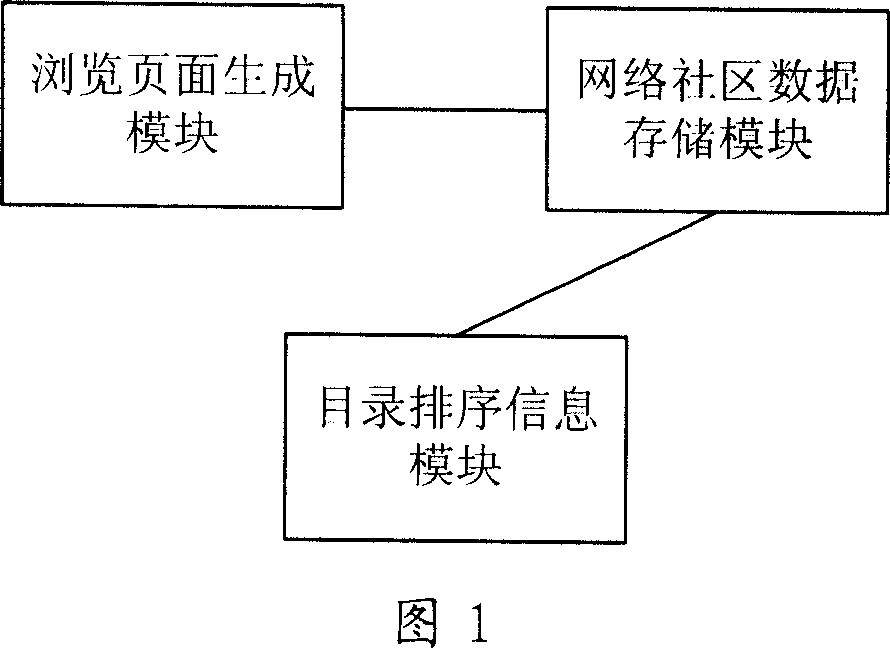

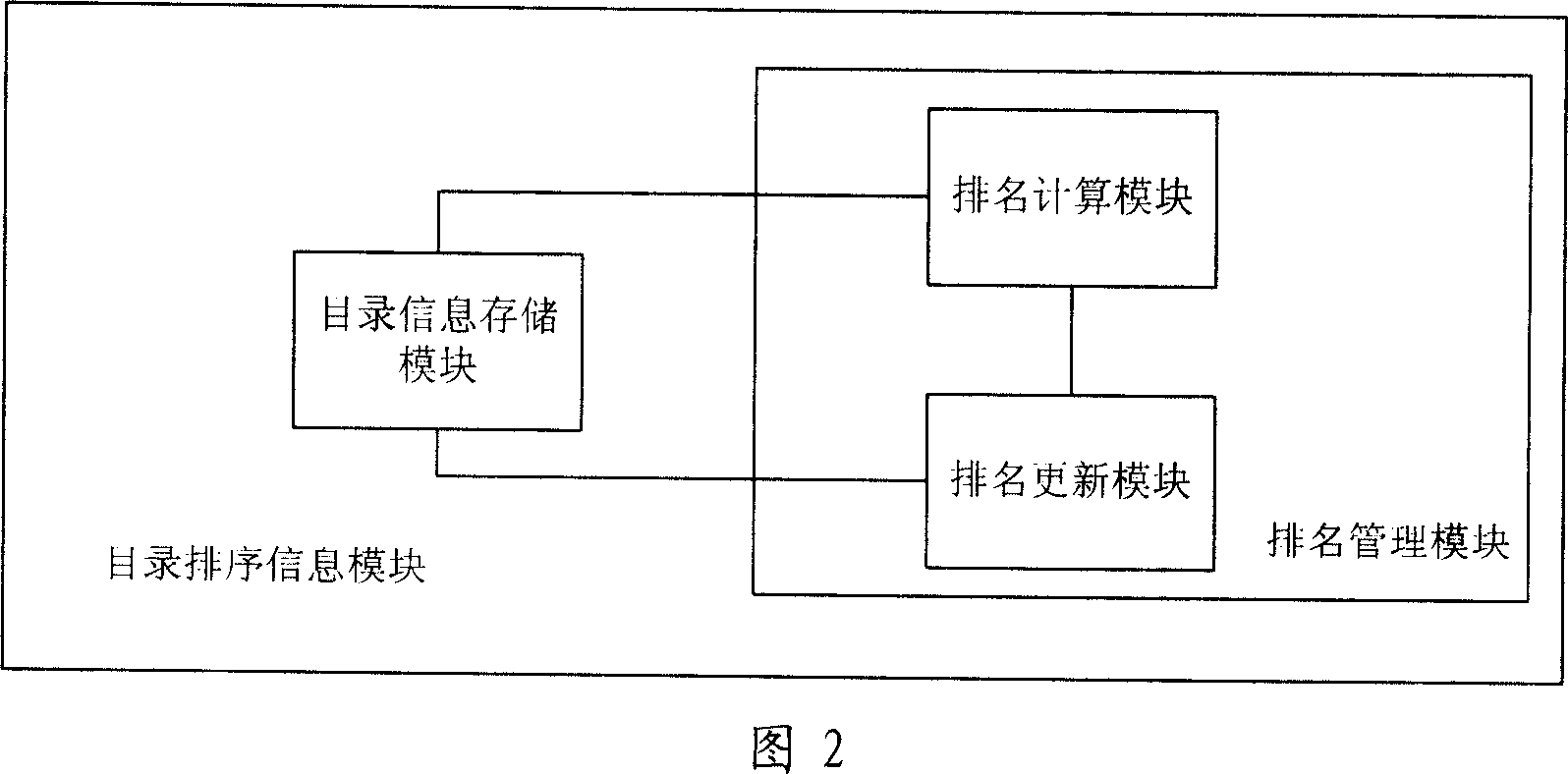

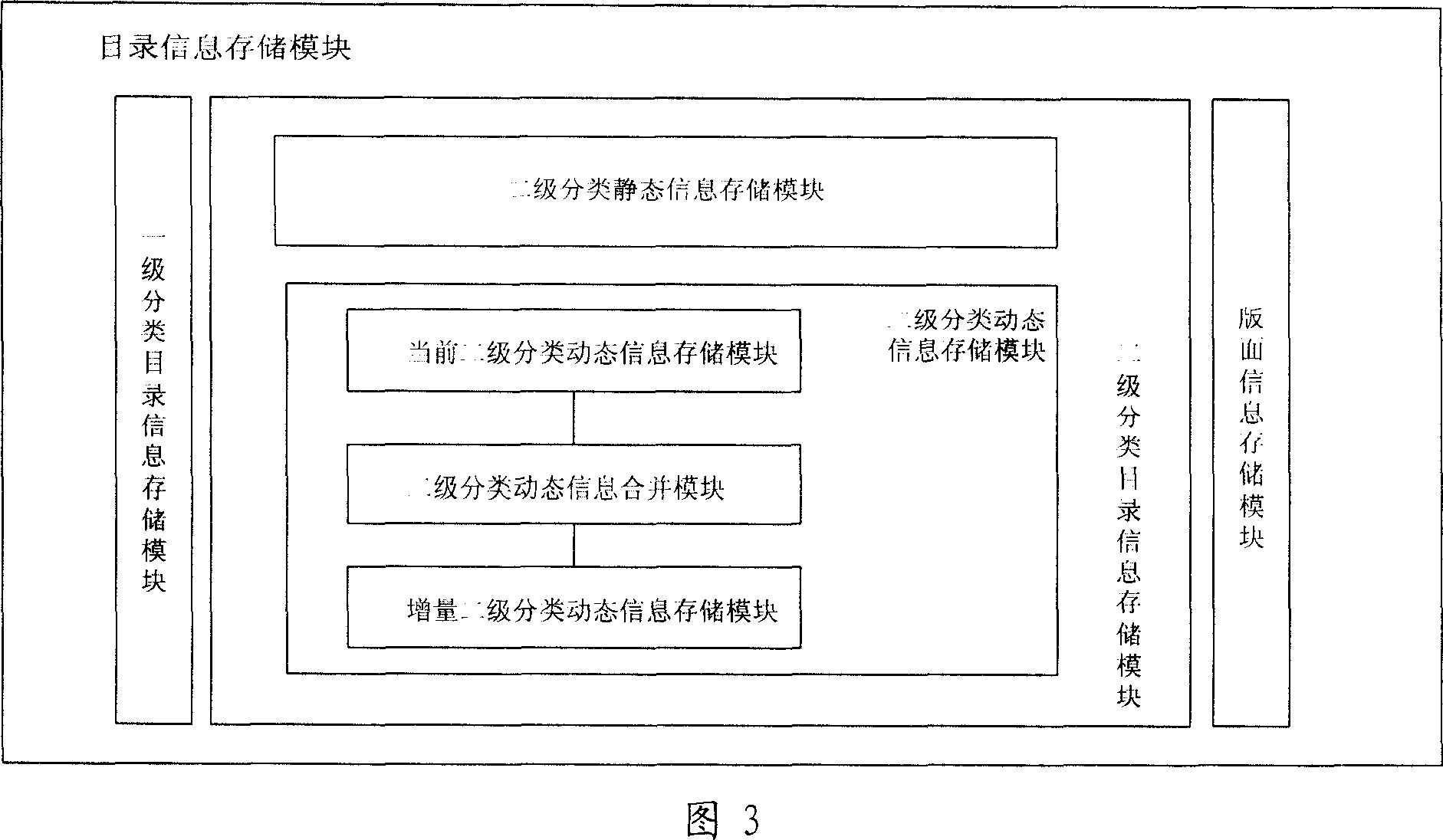

Structuring system and method of network community dynamic list

ActiveCN1949220ARealize dynamic creationEasy to findSpecial service provision for substationSpecial data processing applicationsStructure systemLarge scale network

The invention relates to network community dynamic contents establishing system. It includes interconnected network community data storage module, and browse page generating module, contents ordering module. The invention also relates to the method based on the system that it computes each page ordering information value, processes ordering for chaining bit in contents list, realize network community dynamic establishment, make large scale network community contents distribute reasonably. In addition, the user can search discussion zone according to the page attribute to enter the page.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

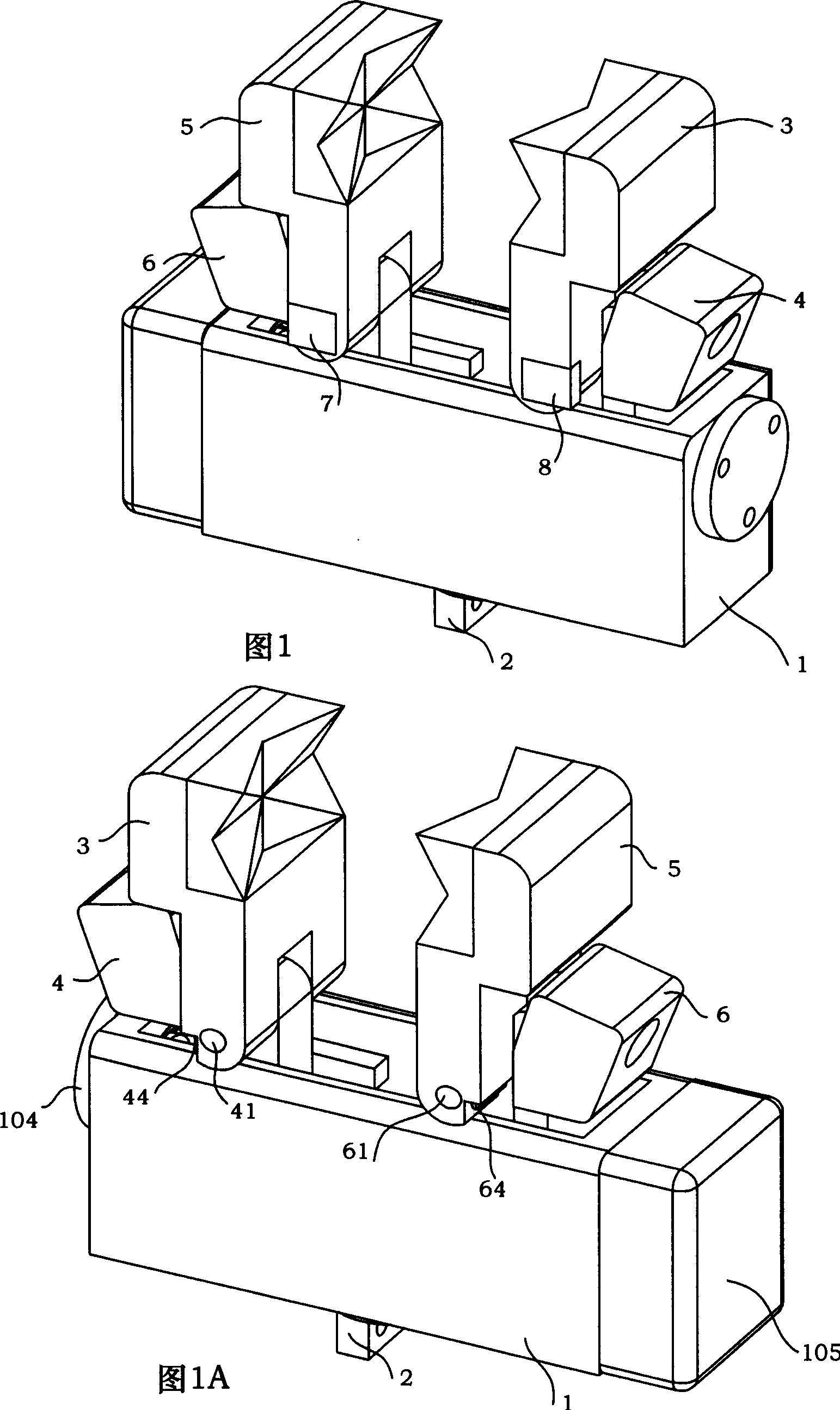

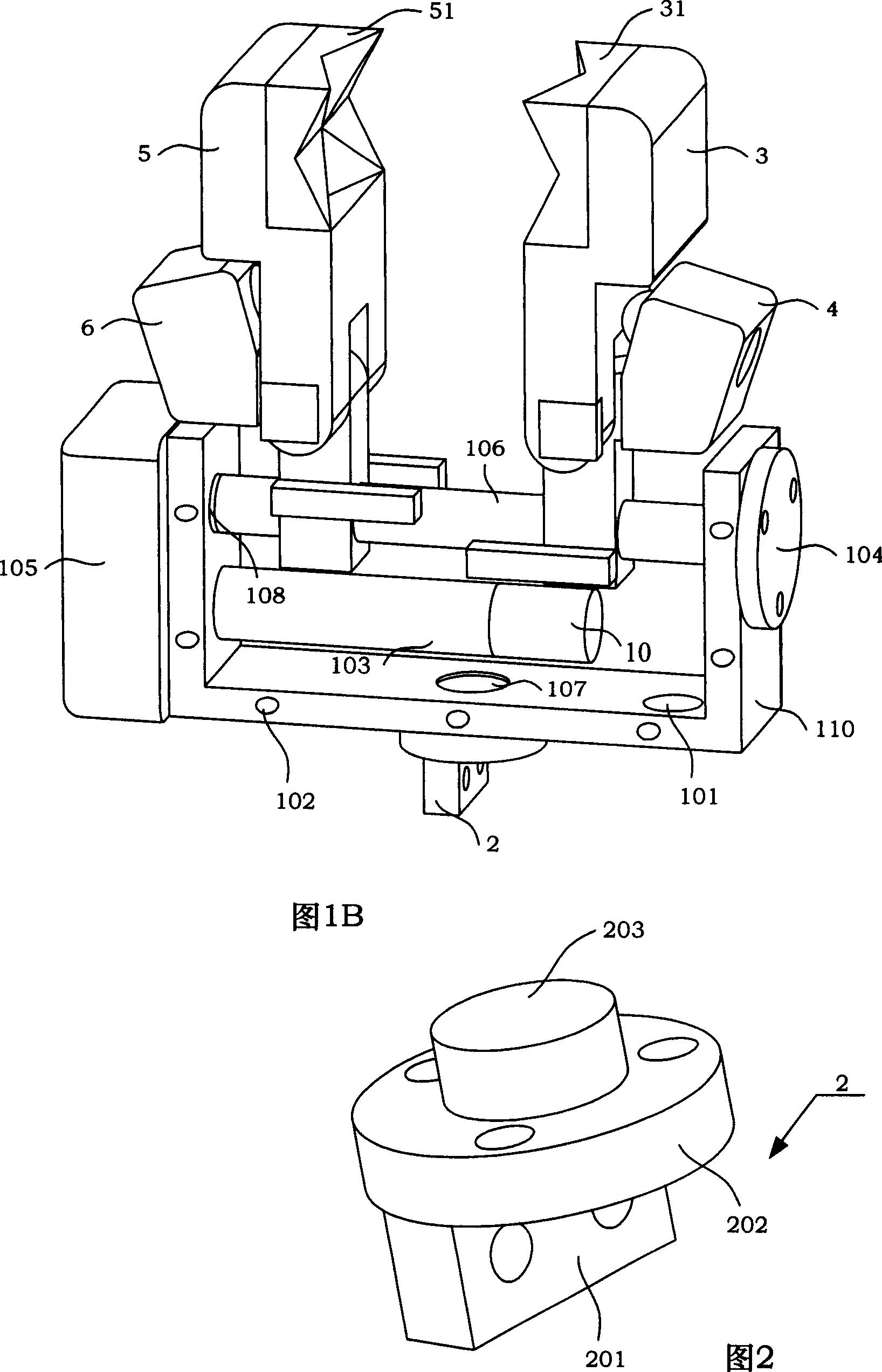

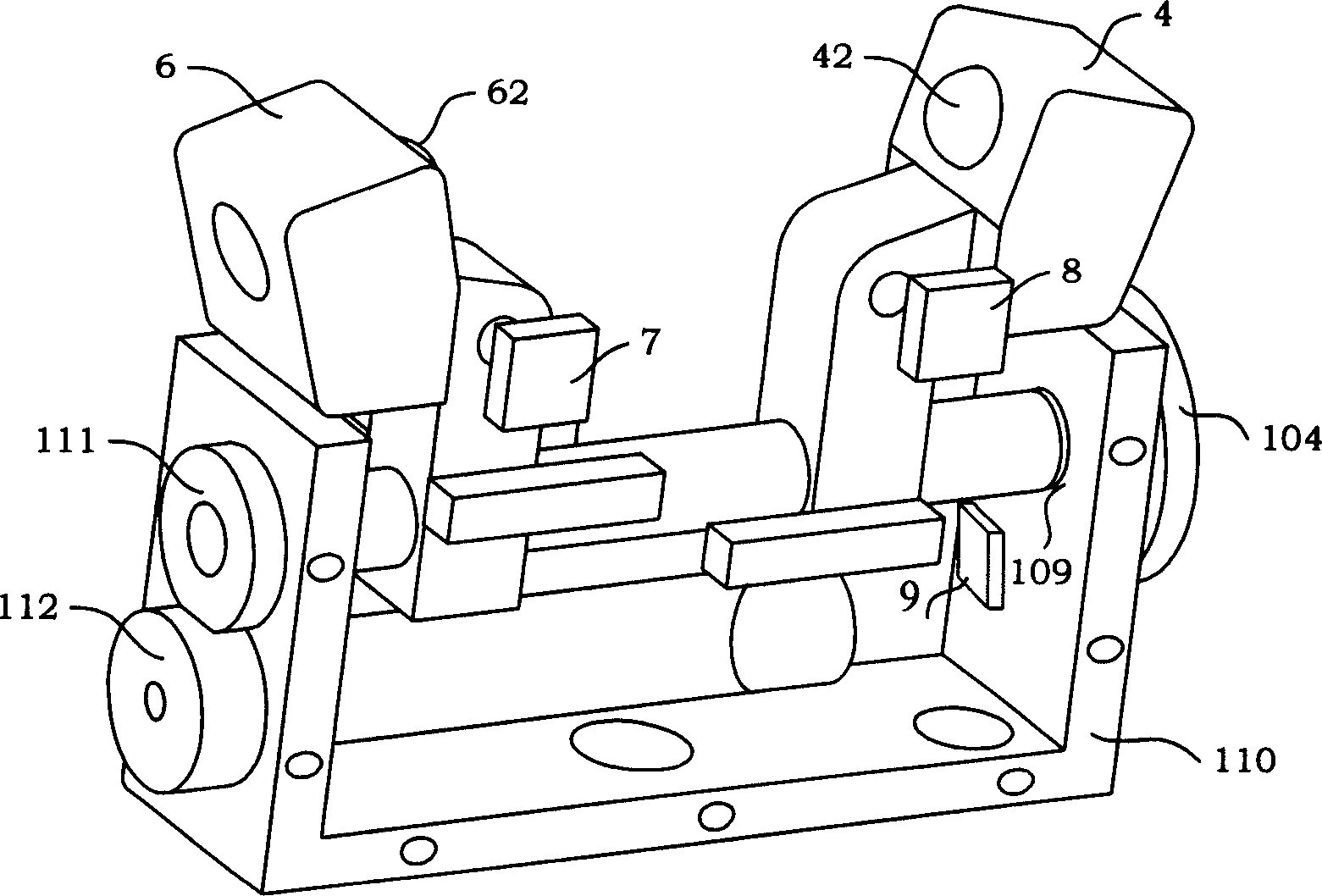

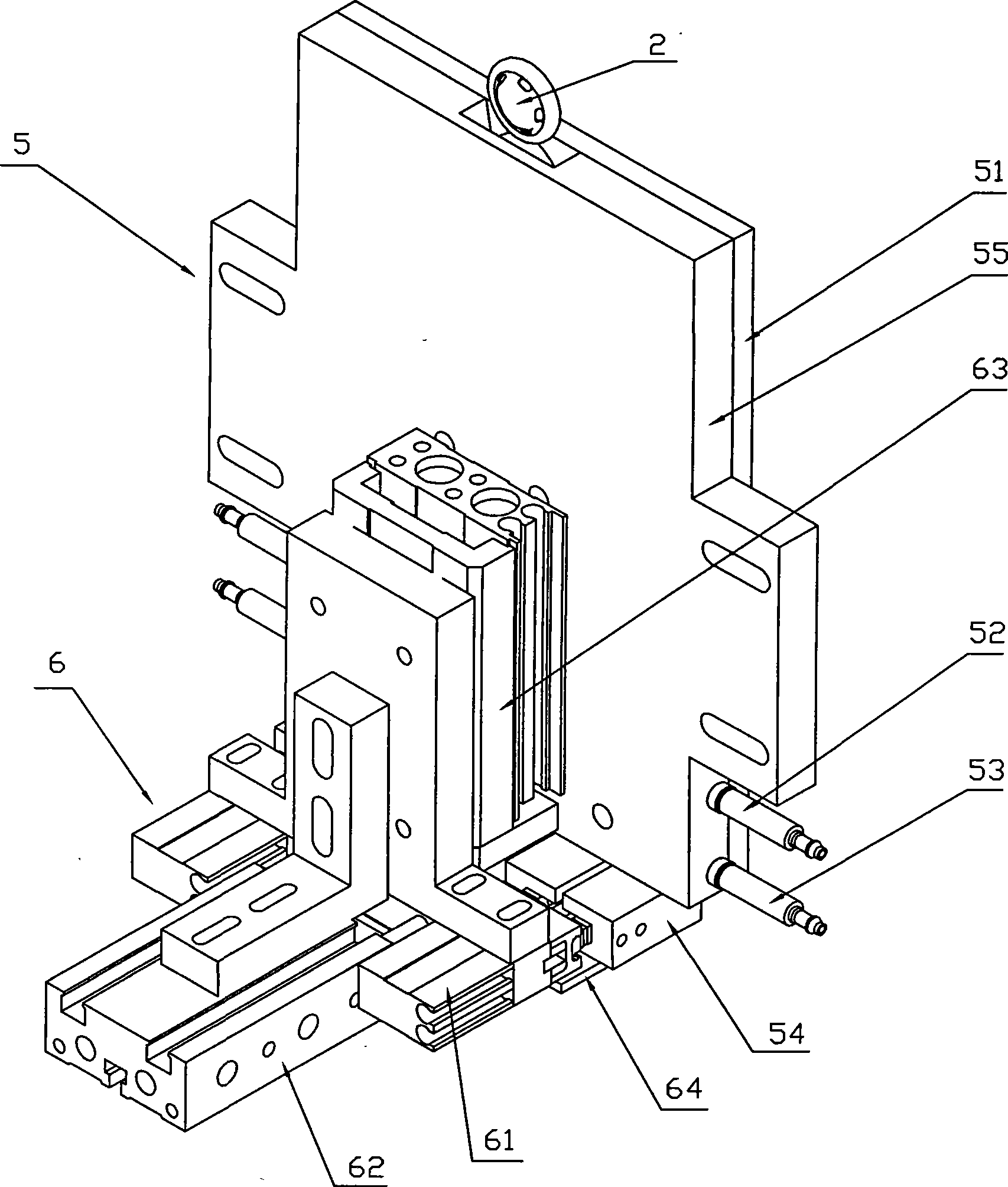

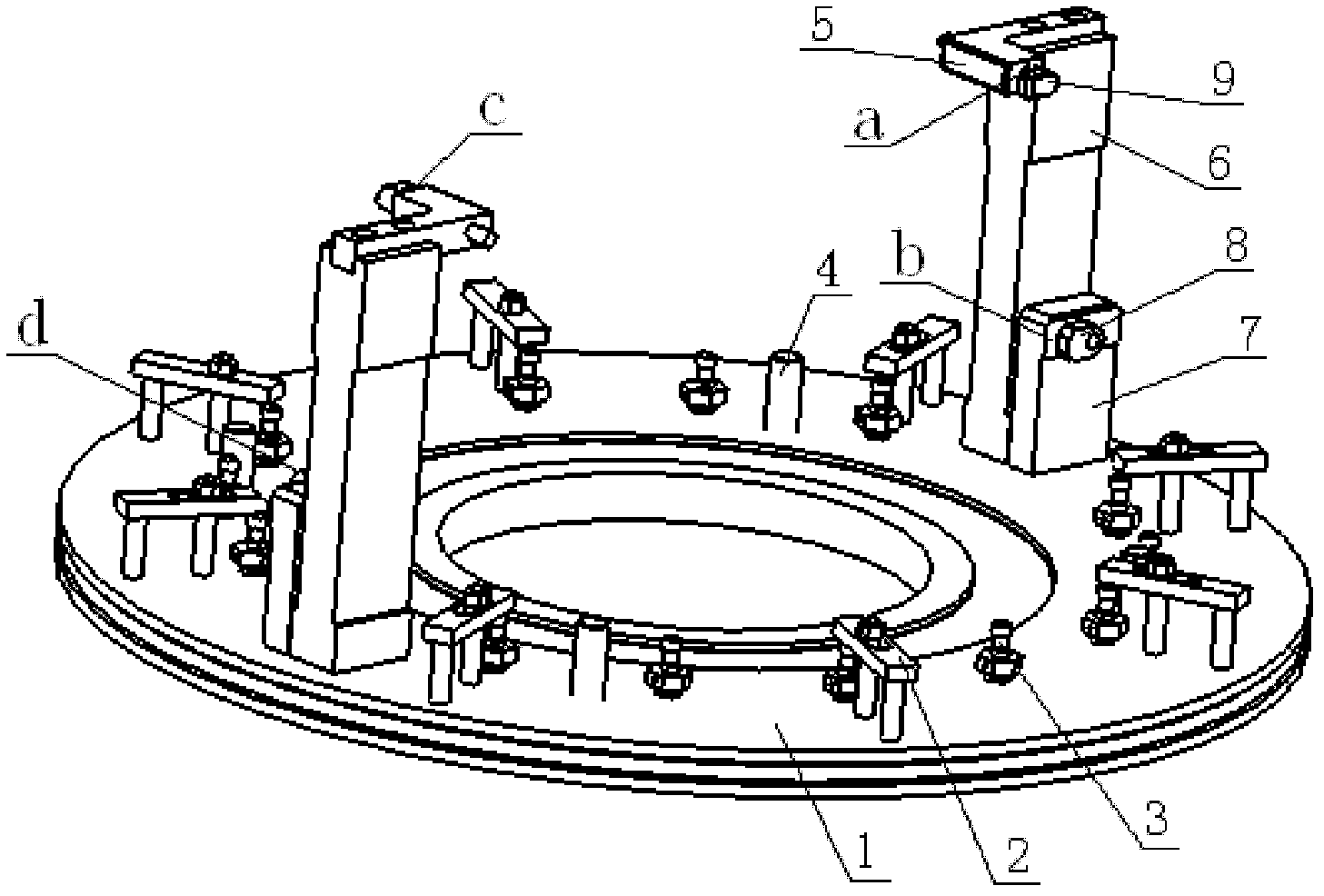

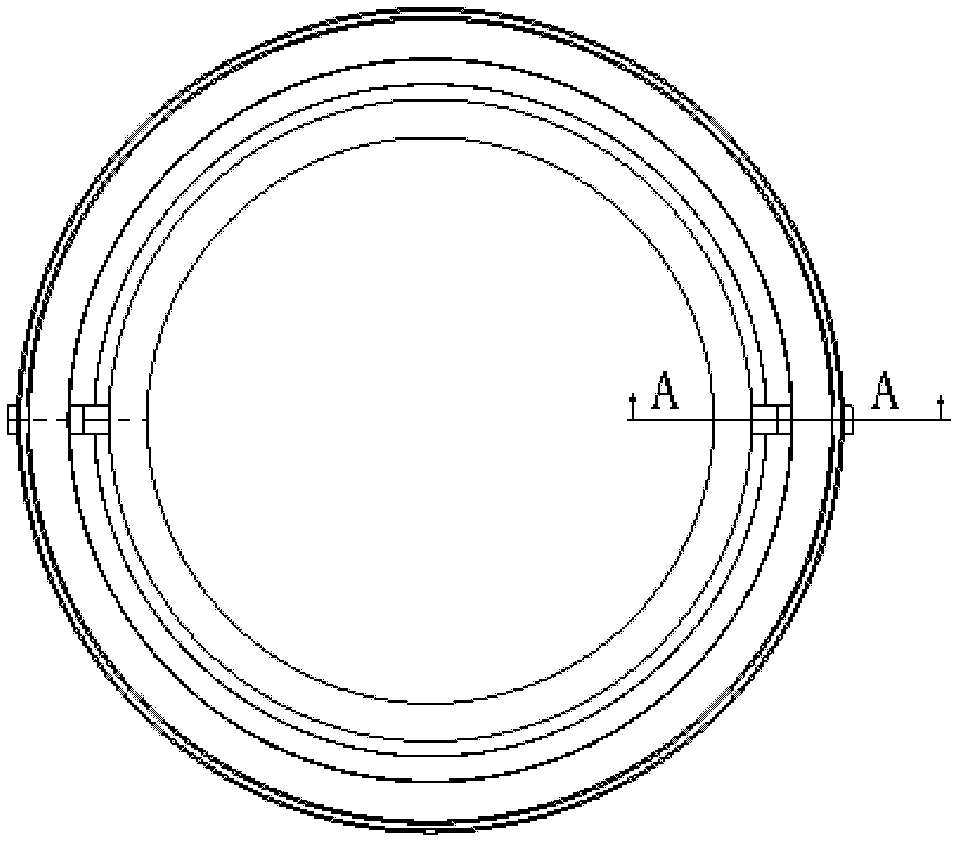

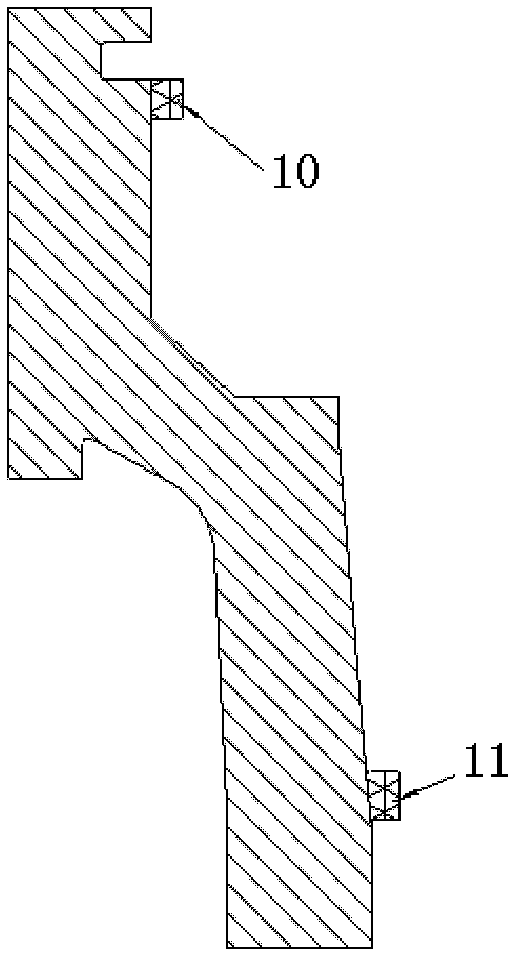

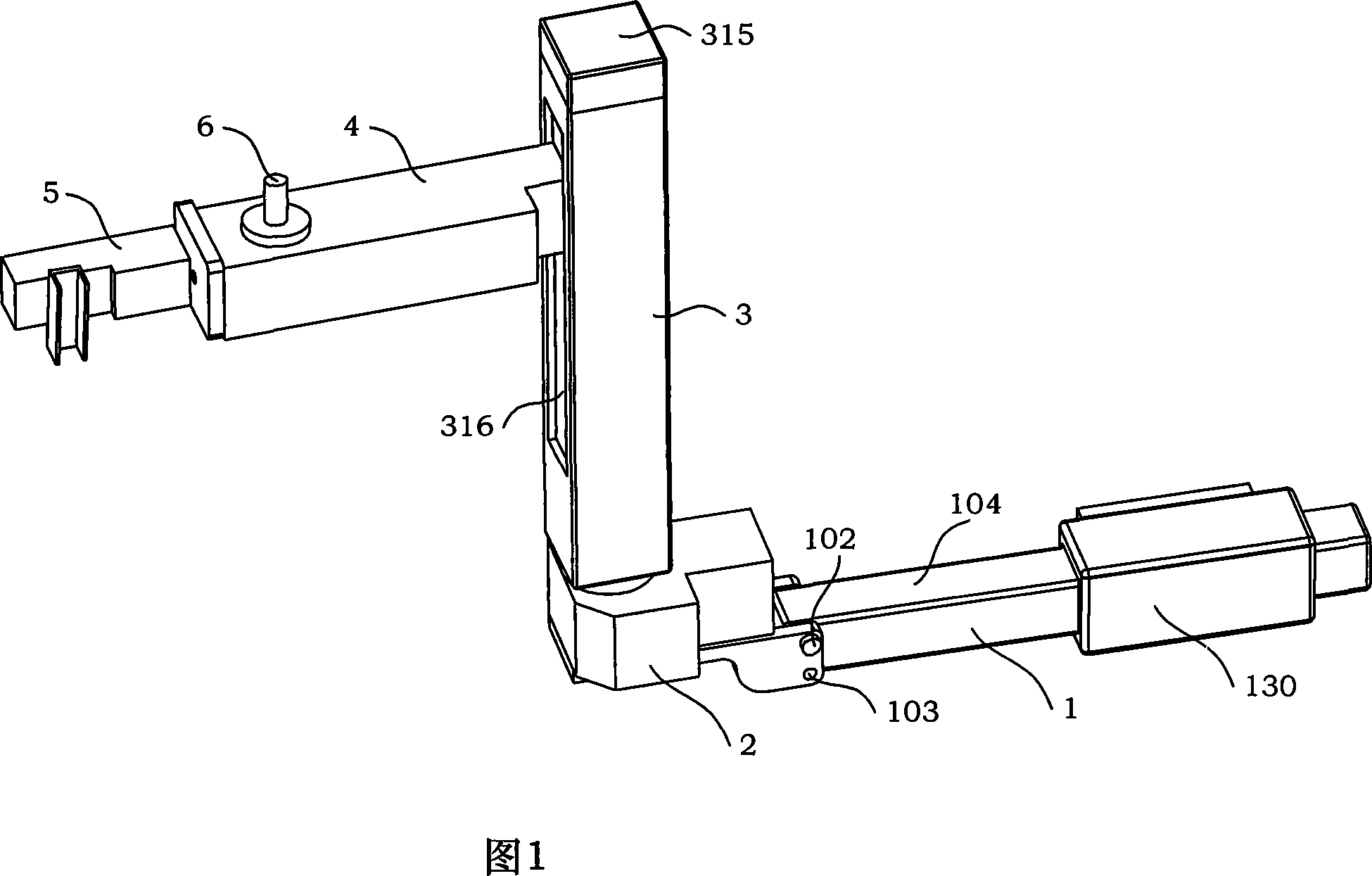

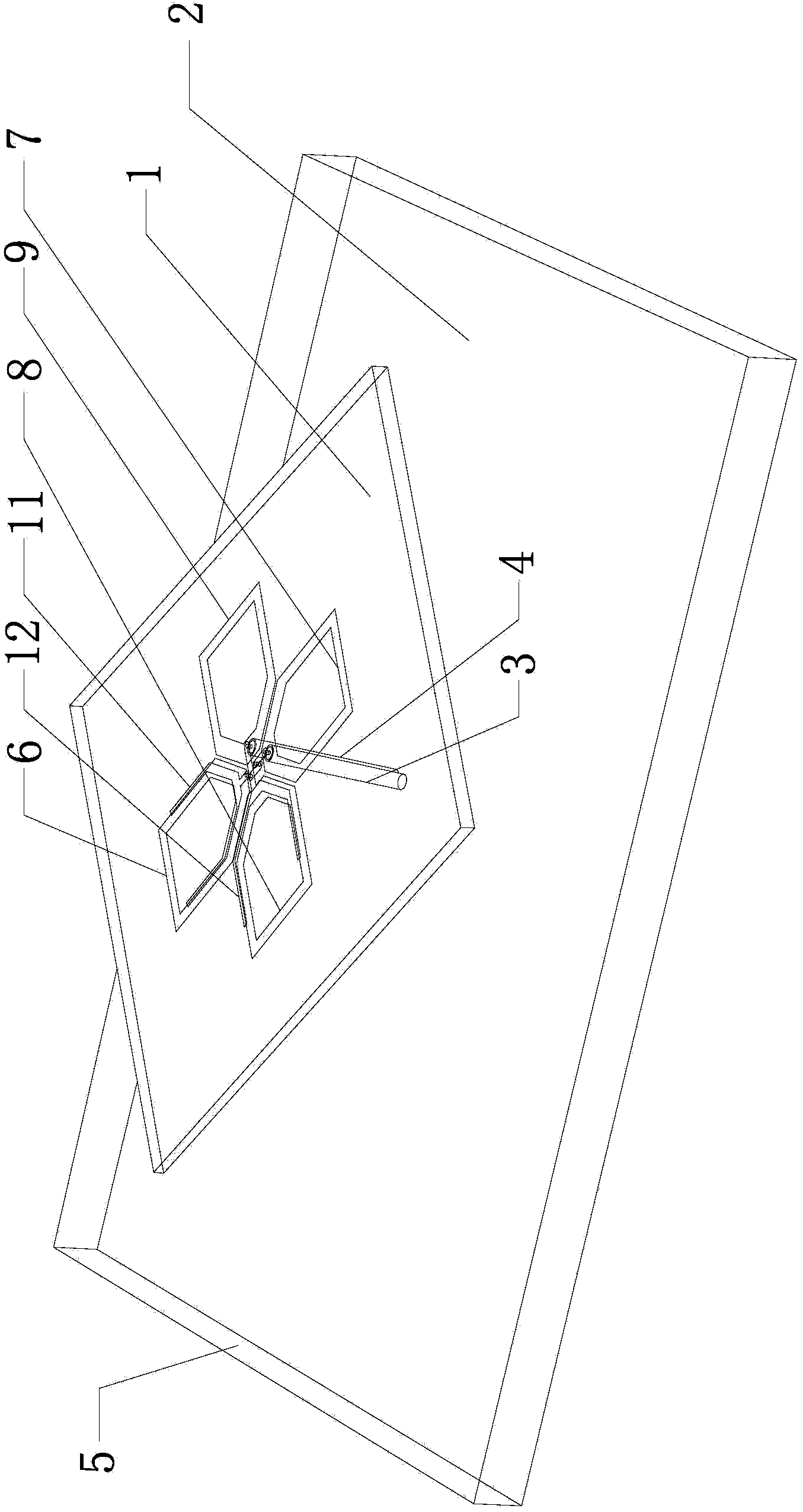

Technical method for constructing reference surface of assembled folio cartridge receiver and special clamp

ActiveCN102513803AReasonable layoutCompact structurePositioning apparatusMetal-working holdersCentrosymmetryMachining

The invention provides a technical method for constructing a reference surface of an assembled folio cartridge receiver and a special clamp. The special clamp comprises a base, pressing plates, adjustable supports, support screws and two sets of positioning components, wherein each positioning component comprises a front-end positioning block, a front-end hook-shaped pressing plate, a connection block, a rear-end positioning block and a rear-end hook-shaped pressing plate; and the two sets of positioning components are in centrosymmetry about a central axis of the base. The technical process comprises the following steps of: performing rough turning machining on an annular blank of the folio cartridge receiver, retaining flange edges, splitting the annular piece of the cartridge receiver,cutting off the flange edges on different sides, fixing two half cartridge receivers on the special clamp, and constructing the reference surface of the assembled folio cartridge receiver by adjusting the clamp. Compared with the conventional method, the technical method has the advantages that: the technical requirement of the whole machining flow is easy to realize; the whole machining flow canbe finished on the vertical lathe; the machining efficiency is high; and the reference surface of the folio cartridge receiver is machined during one-time clamping.

Owner:AECC AVIATION POWER CO LTD

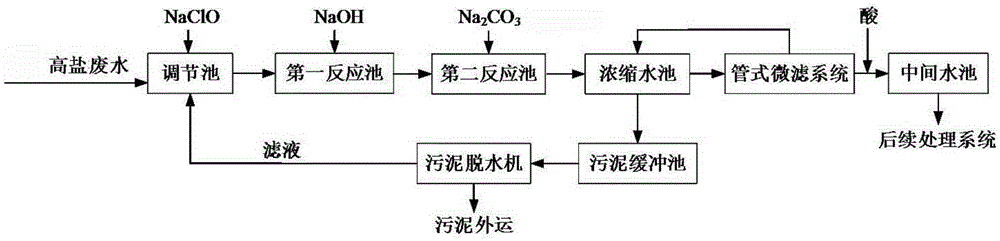

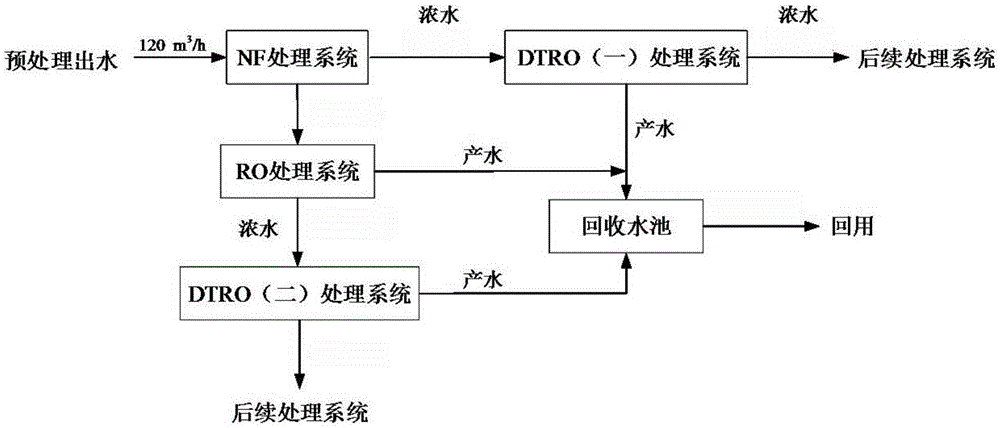

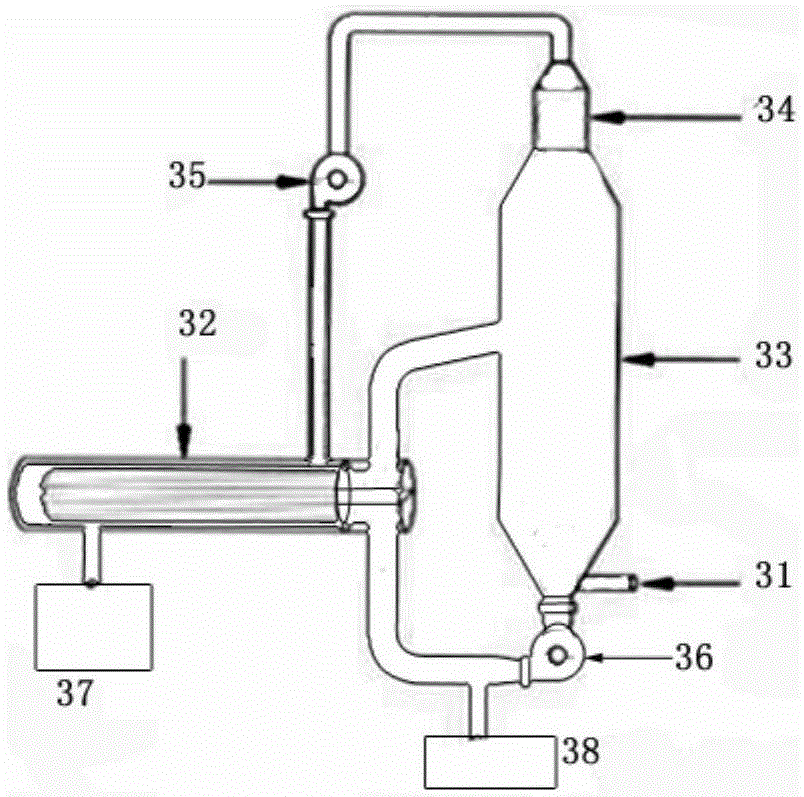

High-salt waste water zero emission and salt separation processing method and device

ActiveCN105254106AShort processReduce doseWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentChemistryPre treatment

The invention discloses a high-salt waste water zero emission and salt separation processing method and device. The method includes the following steps of 1, waste water preprocessing, 2, waste water decrement and concentration and 3, crystallization. By means of the high-salt waste water zero emission and salt separation processing method and device, waste water can be processed efficiently, liquid and salt ingredients in the waste water are effectively separated, a product obtained after waste water can be recycled or sold as other industrial products, so that zero emission of waste water is achieved. The method is simple and easy to implement, high in processing efficiency and small in energy consumption; by the adoption of the method, pollution to the environment is avoided, an active function is played on improvement of regional water environment quality, the utilization rate of waste water is raised, production cost is saved, and environmental and social benefits are quite remarkable. The device is high in operation efficiency, convenient to assemble, low in cost and small in energy consumption.

Owner:华电水务工程有限公司 +1

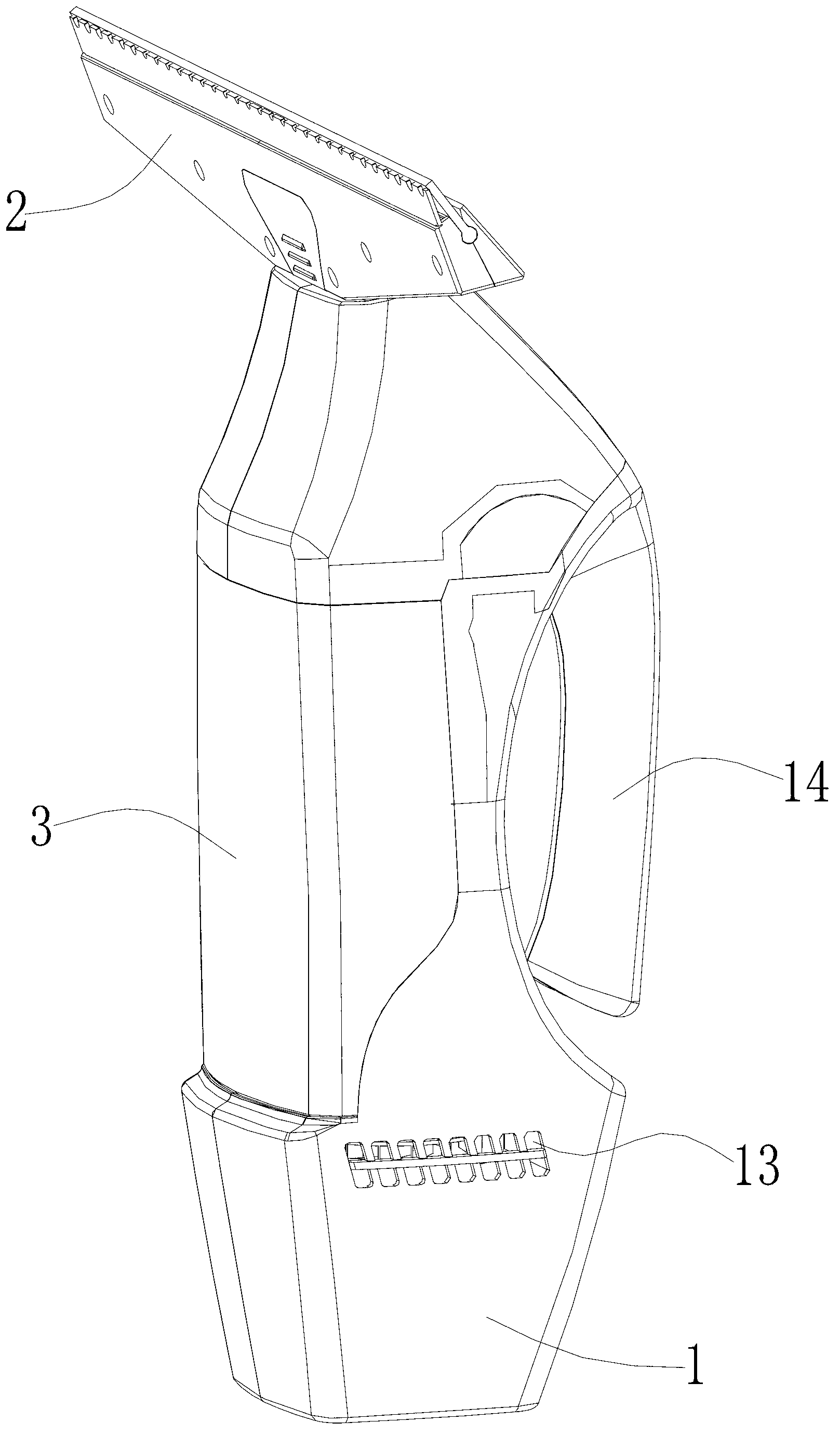

Minimal access bone operating robot based on 3D mouse operation

The invention is concerned with minimally invasive orthopaedics operation robot operated with 3D mouse, relating to landscape orientation moving groupware, reducer groupware, fluctuation moving groupware, small arm groupware, wrist groupware and 3D mouse. The 3D mouse sets on the small arm's shell of small arm groupware, the machine seat of reducer groupware connects with revolving flange of landscape orientation moving groupware, the fixing base seat of fluctuation moving groupware connects with the joint of reducer groupware through two lock poles, the sliding groove of small arm groupware connects with the C sliding groove of fluctuation moving groupware and slides in the groove, and the flange of wrist groupware connects with the output axis of reducer to small arm groupware. The robot is fit for the demand of clinic and operation with practicability and applicability. It is a orthopaedics operation robot with initiative restriction and passivity safety ensure.

Owner:BEIHANG UNIV

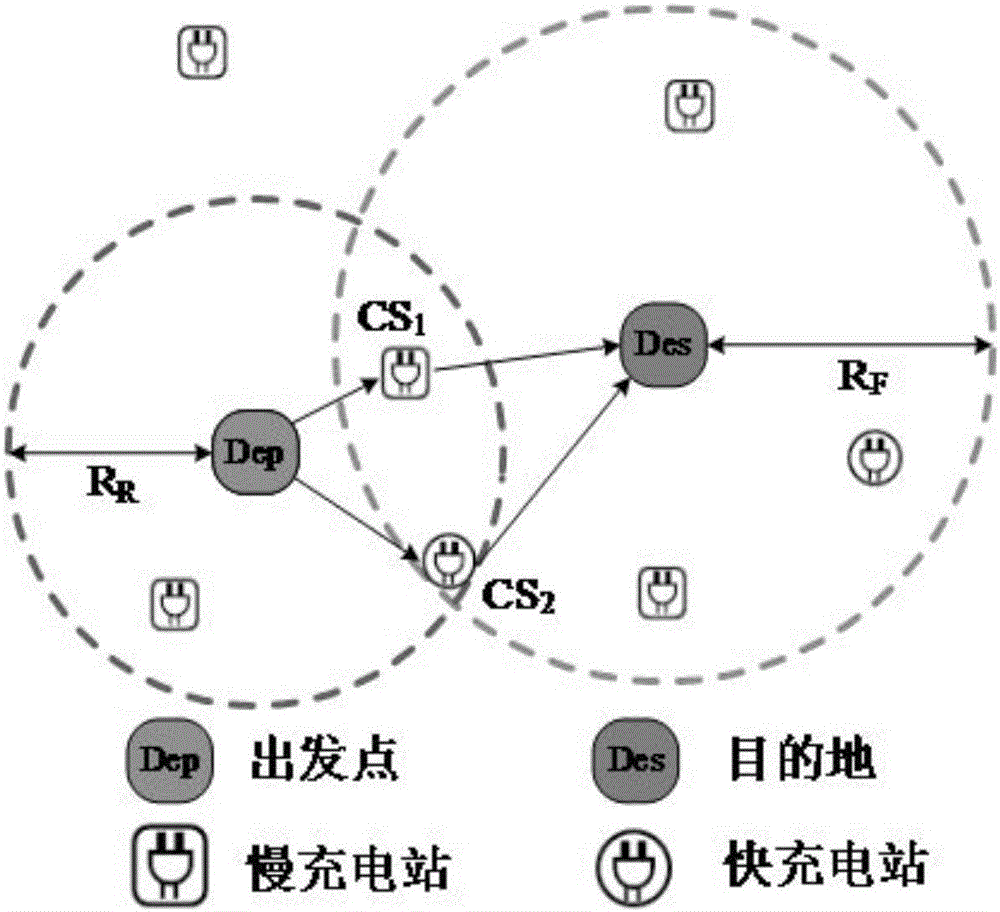

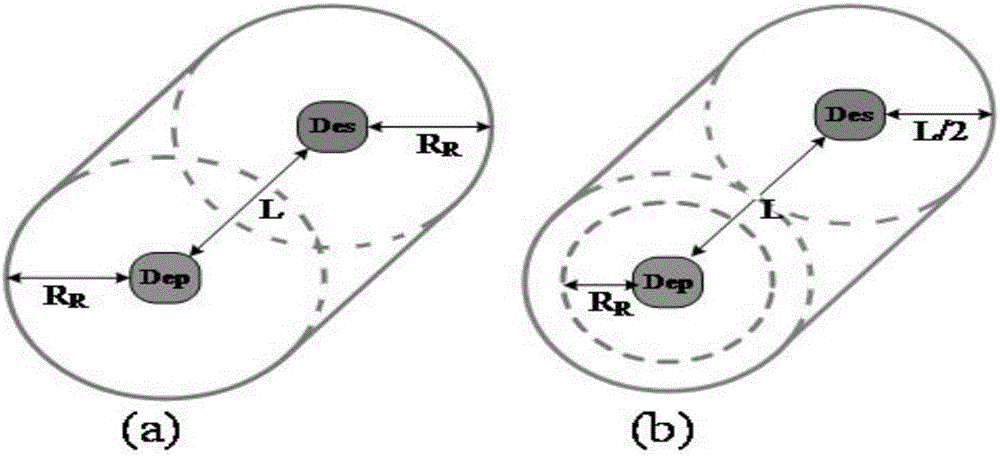

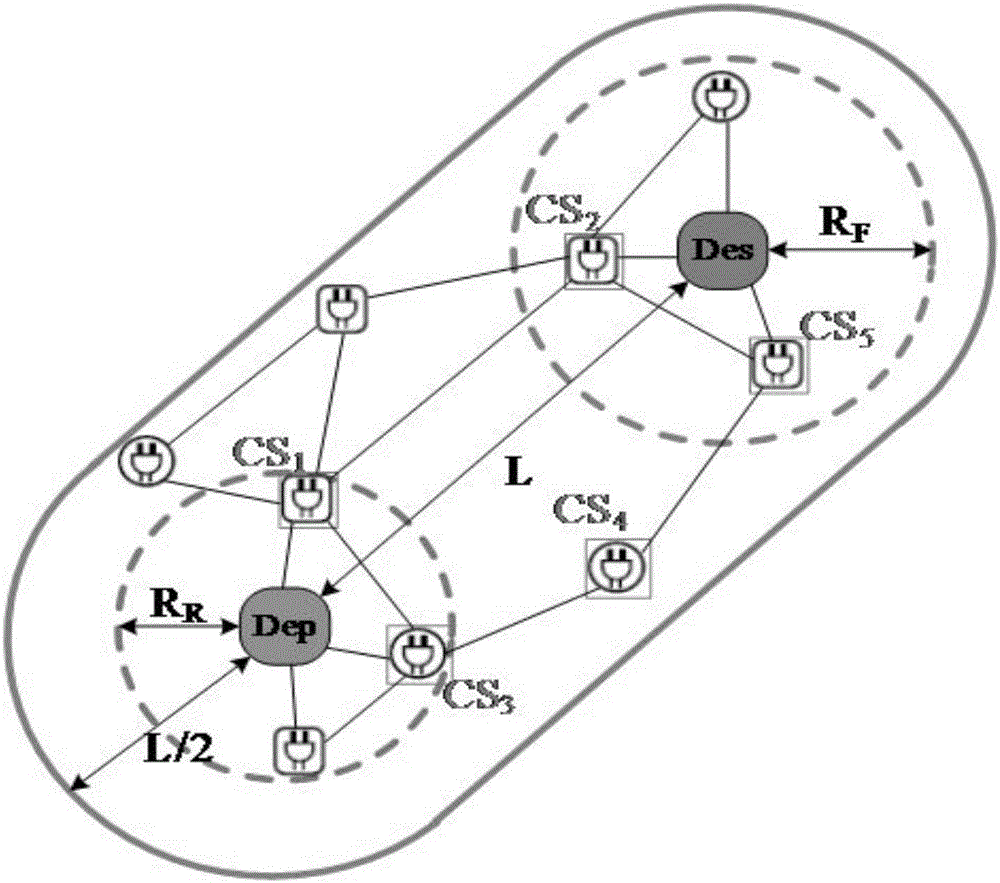

Electric car path optimal seeking method considering range and charging station position

ActiveCN106197459AReduce travel costsReasonable layoutInstruments for road network navigationEngineeringVariance method

The invention relates to an electric car path optimal seeking method considering the range and charging station position. The method overcomes defects in the prior art. According to the technical scheme, a seek idea for clearing the optimal path through an electric car auxiliary line is provided; paths, mileages and time consumption functions by adopting starting and final positions as variables are built; according to the current status of electric cars, the electric cars are divided into four types; the potential charging station attributes in the paths are considered, a slow charging station and a rapid charging station are included and distinguished through a charging efficiency variance method, and the optimal path for four types of electric cars can be given according to the types of the electric cars through the seeking method.

Owner:ZHEJIANG AICHONG NETWORK TECH CO LTD

Wire winding machine

InactiveCN101359525AReasonable layoutIncrease the number ofCable/conductor manufactureWinding machineWire twister

The invention relates to a wire strander which is particularly applicable for cable production. The strander comprises a frame and a wiring disc arranged on the frame. A rotating shaft which can rotate relatively with respect to the frame is fixed at the center of the wiring disc and is connected with a drive mechanism. A take-up device fixed on the frame is installed at the side of the wiring disc. The strander is characterized in that a plurality of coil holders are installed at two sides of the wiring disc; the heads of the wire coils on the coil holders at one side of the wiring disc can run through the wiring disc and reach the other side of the wiring disc. Compared with prior art, the strander has the advantages that: 1, the coil holders are reasonable in arrangement, thus increasing the number of the coil holders; the whole structure is compact in structure and low in cost and is easy to operate; 2, the feed pitch can be flexibly adjusted according to needs and the wires arranged on the strander will not be mixed up, so work stability is good and efficiency is high; 3, the feed pitch can be adjusted according to needs, so various products with different specifications can be produced, thereby the wire strander is widely applicable.

Owner:CHANGZHOU HENGFENG SPECIAL CONDUCTOR CO LTD

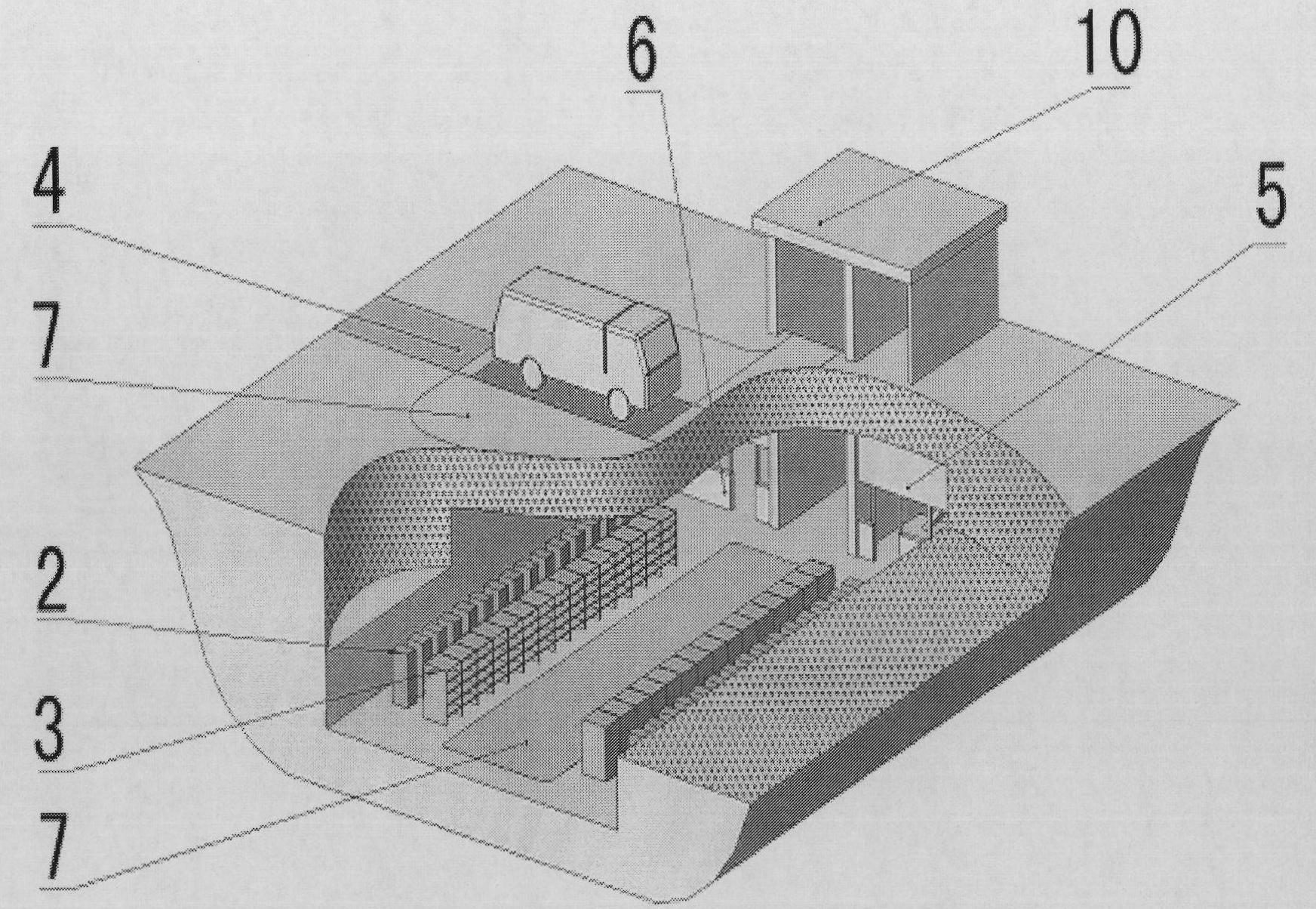

Charging station system of electric automobile and matched charging method thereof

ActiveCN101834455AReasonable layoutNovel structureBatteries circuit arrangementsElectric powerCharging stationHigh pressure

The invention provides a charging station system of an electric automobile and a matched charging method thereof. The charging station system comprises an automobile parking region, a battery replacement unit, a battery storage unit, a charging unit, a low-voltage distribution unit and a high-voltage distribution unit, wherein the automobile parking region is used for packing the electric automobile the batteries of which is to be replaced; the battery replacement unit is used for replacing the batteries of the electric automobile through battery replacement equipment; the battery storage unit is used for storing and charging the batteries; the charging unit is used for charging the batteries stored on the battery storage unit; the low-voltage distribution unit is used for supplying power to the charging unit; and the high-voltage distribution unit is used for converting inputted high-voltage power to low-voltage power. The charging station system of the electric automobile in the invention has the characteristics of reasonable layout and novel structure, can realize rapid charging, improve the charging efficiency and simultaneously replace and charge the batteries of multiple electric automobiles, and has the advantages of high economic level and stable running with lower cost.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

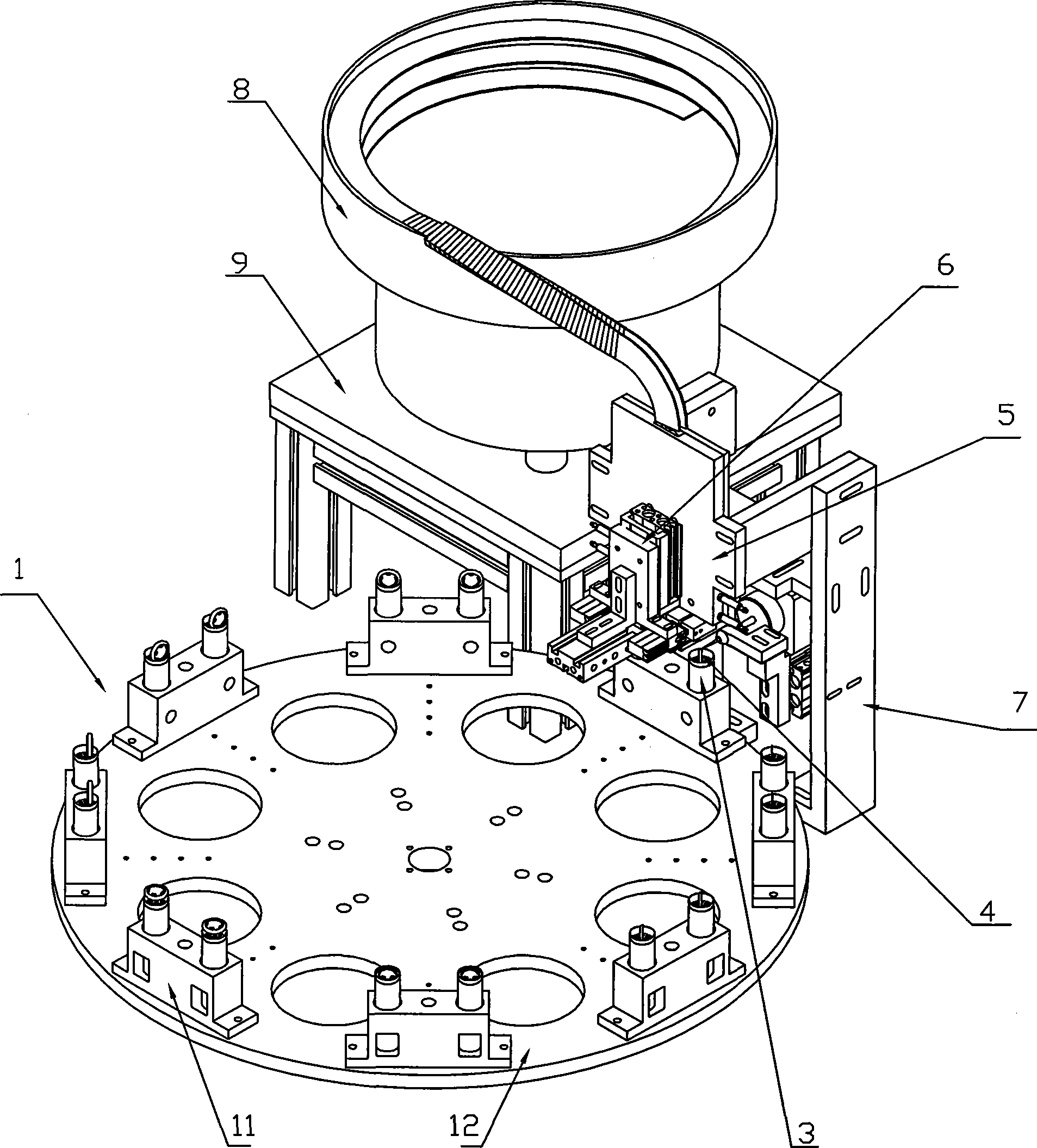

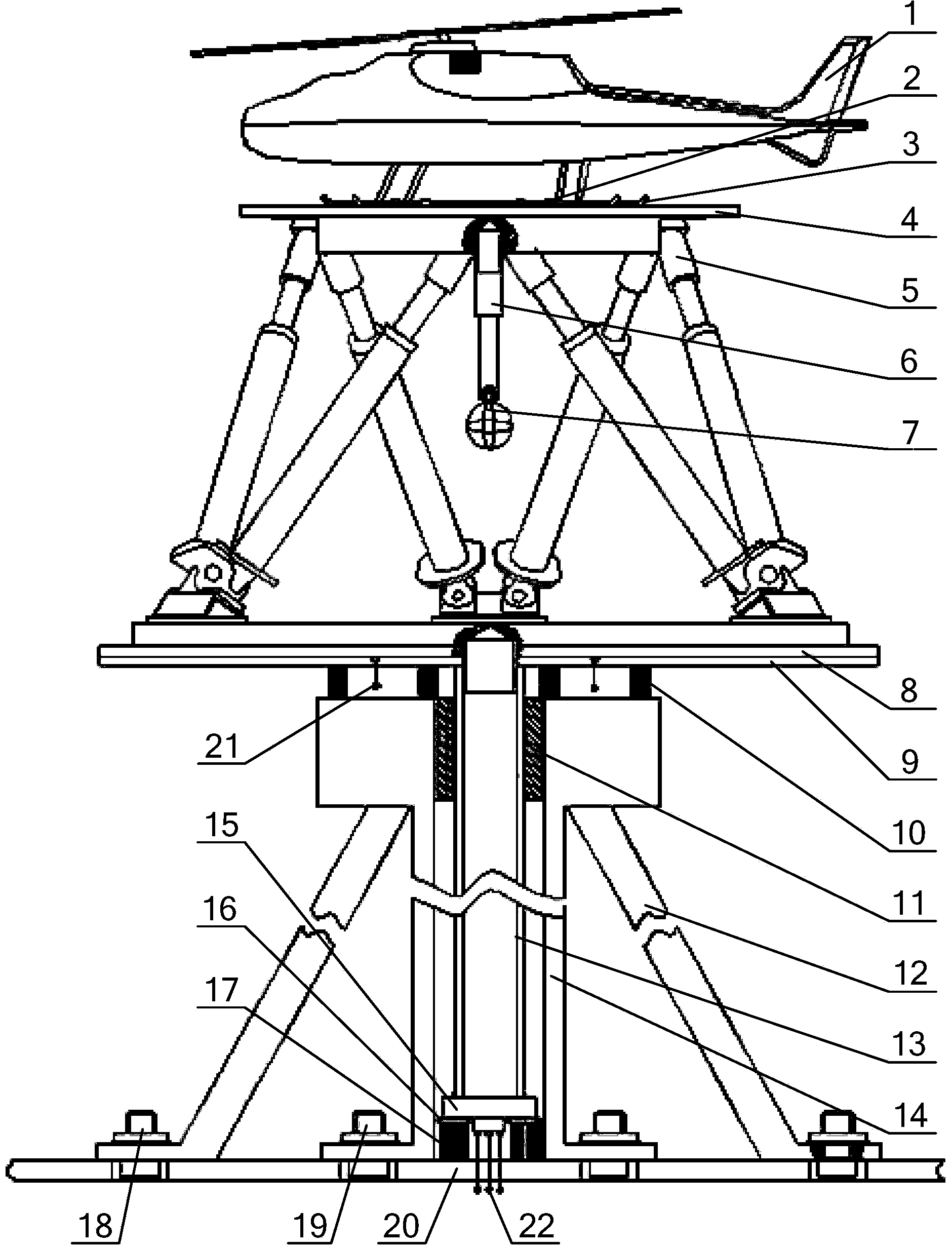

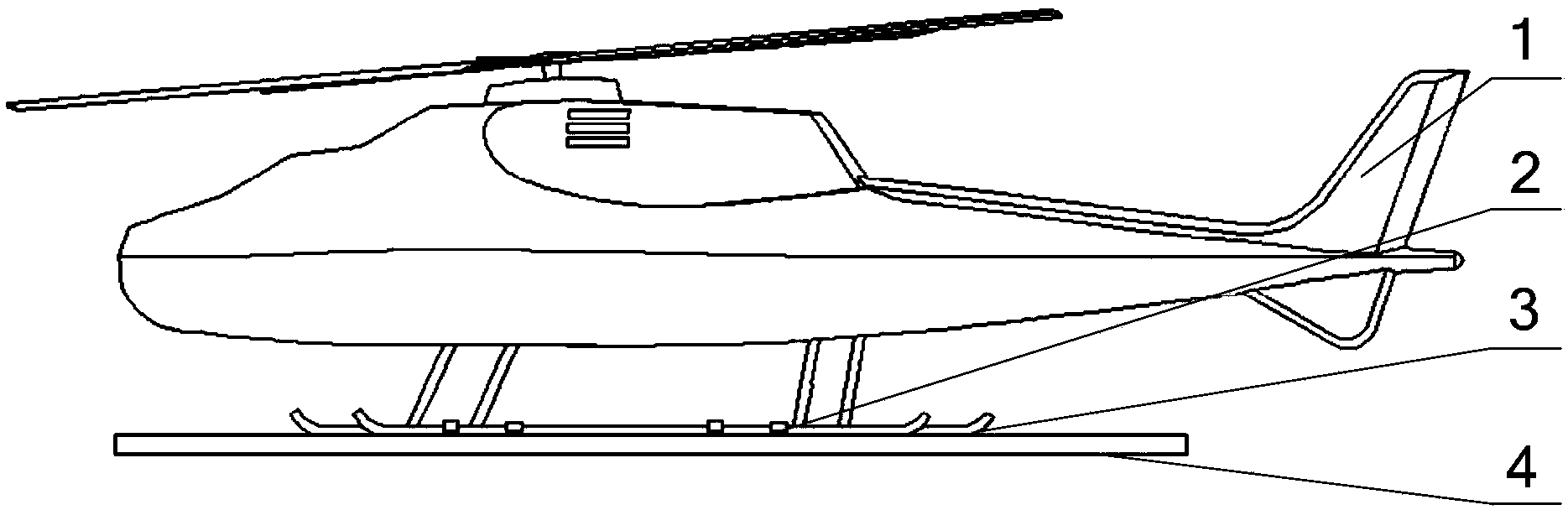

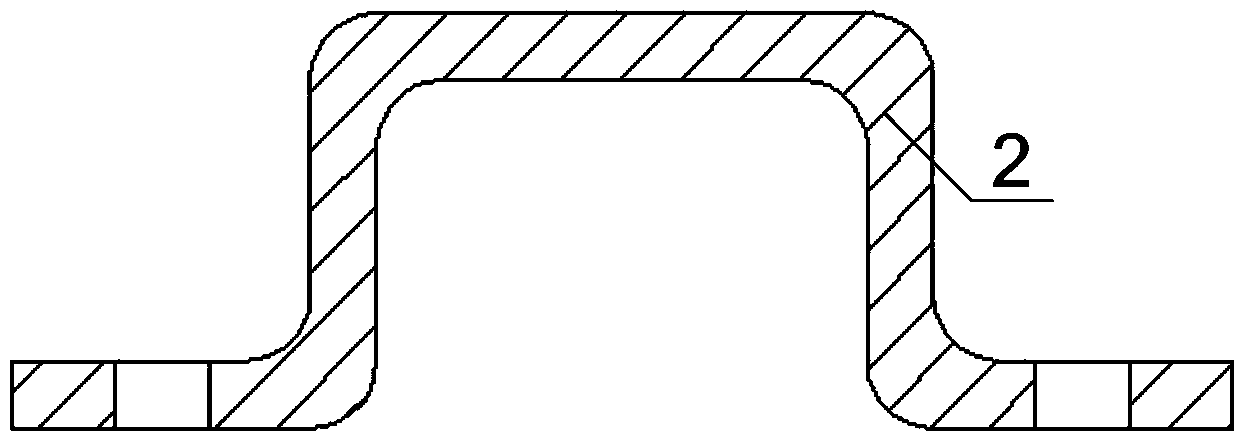

Unmanned helicopter performance testing platform

InactiveCN103863576AAvoid flying awayEnsure balanceAircraft components testingAviationMarine engineering

The invention relates to an unmanned helicopter performance testing platform, belongs to the field of aerospace technologies and aims at solving the problems that the fixing structure is unstable, the balance performance in the movement process is poor and a testing table is damaged in the prior art. The unmanned helicopter performance testing platform comprises a platform body assembly and a flight simulator, wherein an unmanned helicopter is fixedly arranged on an upper platform of a six-degree-of-freedom moving platform, and lifting force data generated during the flight of the unmanned helicopter is transmitted to a computer through a lifting force sensor A which is fixedly arranged on the lower surface of a lower platform of the six-degree-of-freedom moving platform and a lifting force sensor B which is fixedly arranged on the lower surface of an iron plate module, so as to realize performance testing. The unmanned helicopter performance testing platform has the beneficial effects that the action of the unmanned helicopter is provided by virtue of the six-degree-of-freedom moving platform and a positioning sleeve can prevent the helicopter from flying away from the testing table when the flight control of the helicopter fails or an experiment fails; since the lower surface of the lower platform of the six-degree-of-freedom moving platform is seated on the upper surface of a shock absorbing plate, the balance of the unmanned helicopter is kept; the shock absorbing plate, a large compression spring and a small compression spring also play a certain role in buffering.

Owner:JILIN UNIV

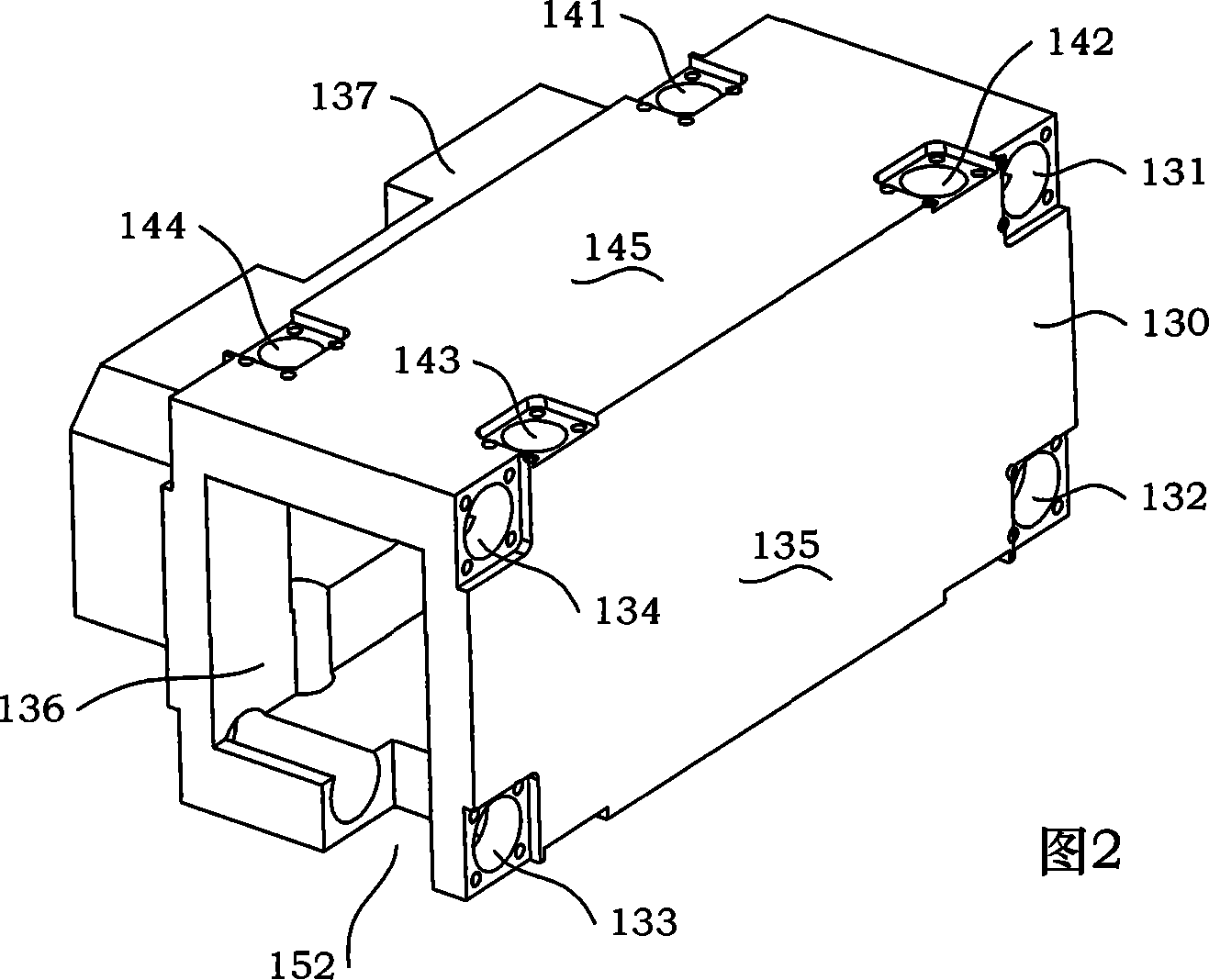

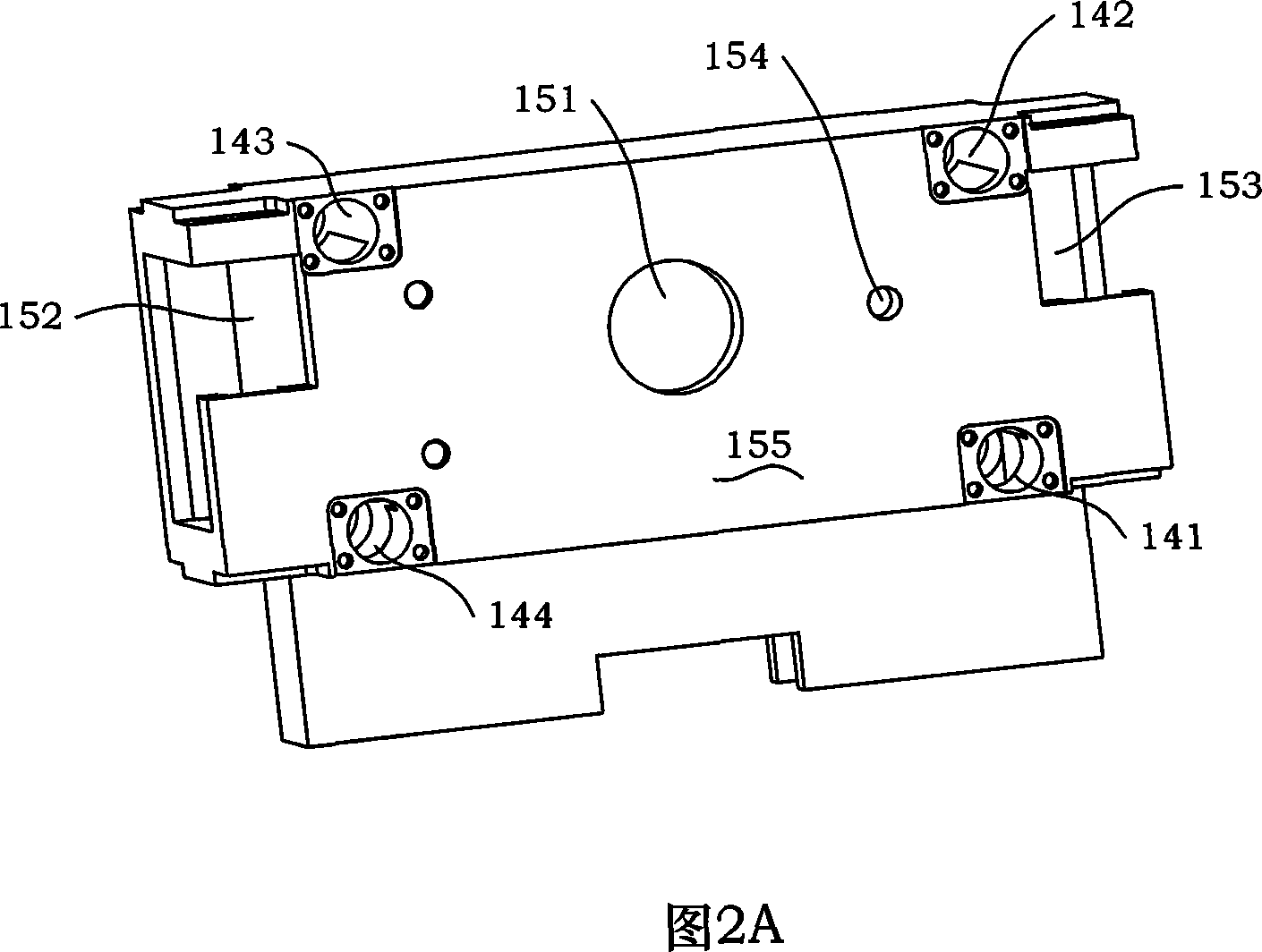

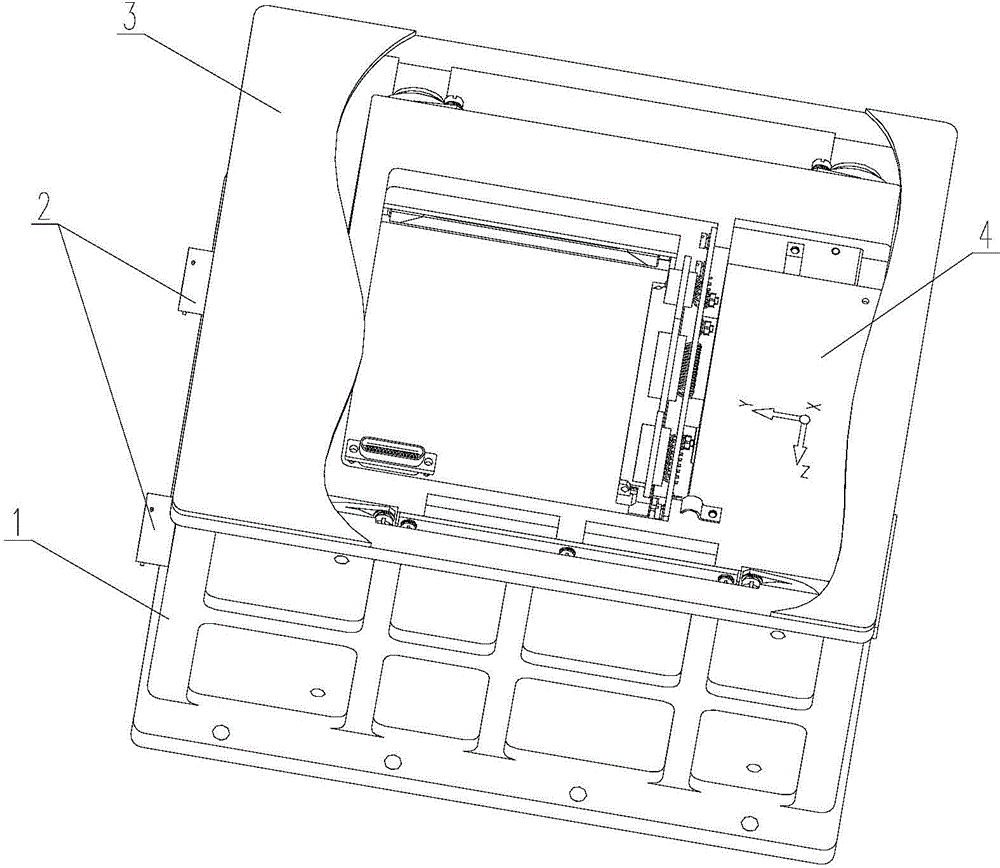

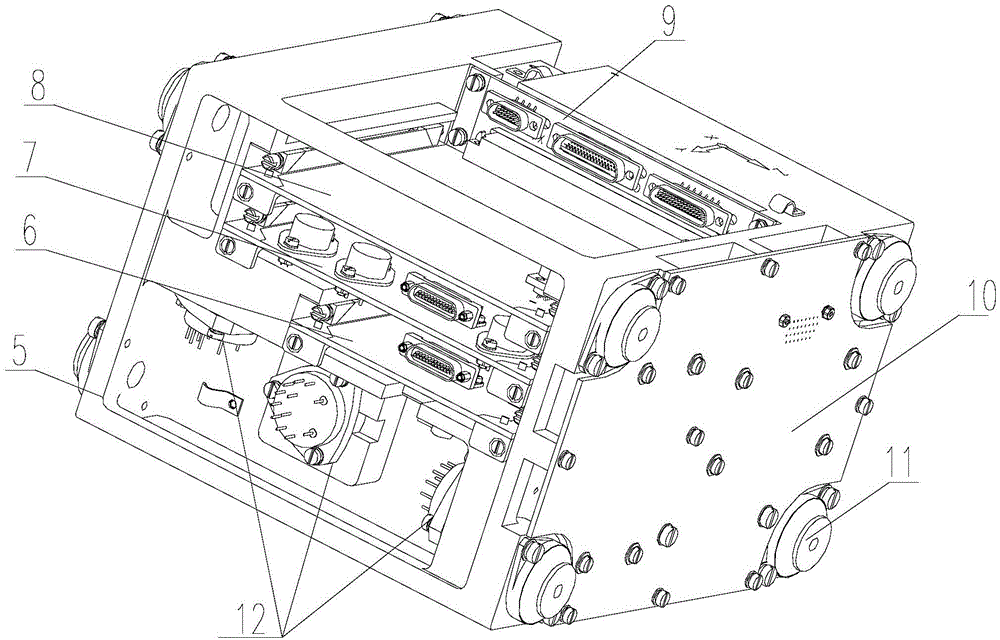

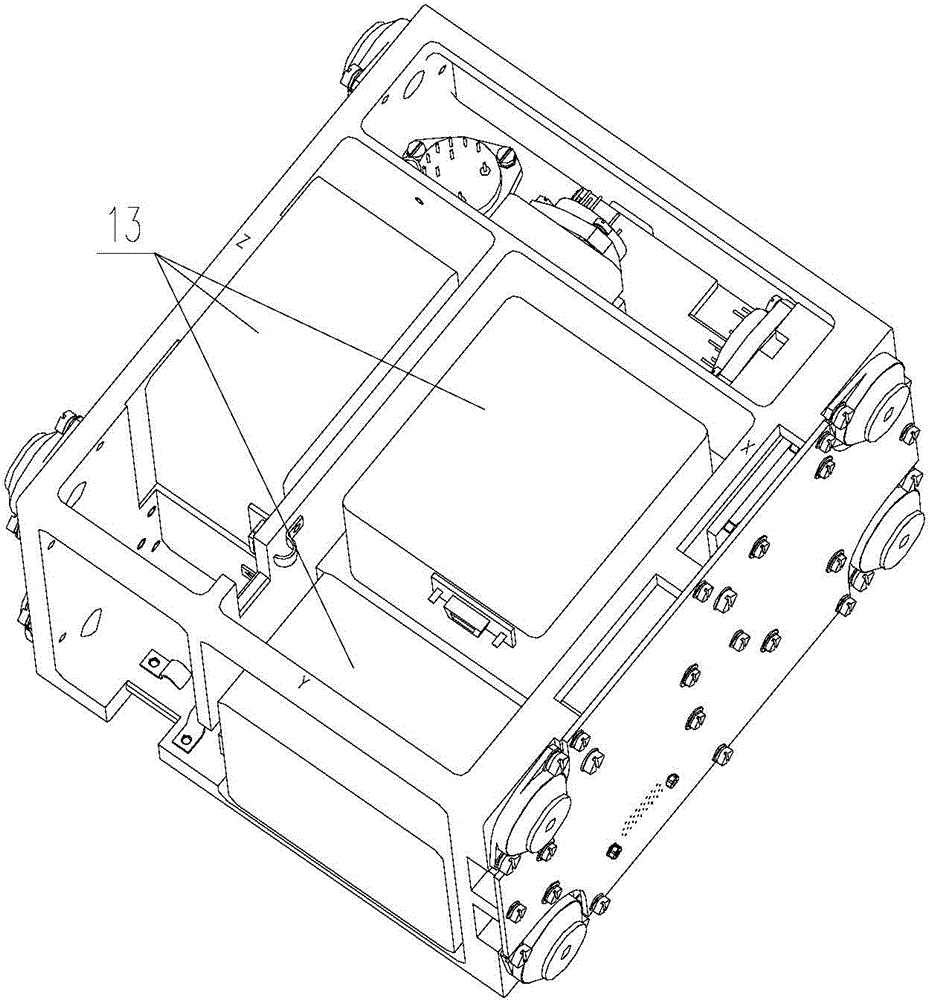

Integrated small-size laser gyroscope inertia measurement device

ActiveCN104142150ACompact layoutNoveltyNavigation by speed/acceleration measurementsMeasurement devicePower circuits

The invention relates to an integrated small-size laser gyroscope inertia measurement device which comprises a case, a cover plate and a body assembly, wherein the body assembly is mounted in the case and is sealed by the cover plate; the body assembly comprises a body seat, three laser gyroscopes, three quartz accelerometers, a functional circuit board and shock absorbers; the body seat is of a hexahedron structure; a plurality of cavities are formed in one side close to the hexahedron structure; the three laser gyroscopes are respectively mounted in the cavity a, the cavity b and the cavity c; the three quartz accelerometers are mounted in the cavity d; the cavity e is formed in the other side close to the hexahedron structure and is used for holding an accelerometer circuit board, a temperature control circuit board, a computer circuit board and a signal transferring circuit board; a power circuit board is mounted on one side wall of the hexahedron structure of the body seat; the shock absorbers are mounted at eight vertexes of the hexahedron structure of the body seat. The measurement device is compact and reasonable in whole layout, novel in style, small in size and light in weight, and has high shock absorption and impact prevention performance.

Owner:BEIJING AEROSPACE AUTOMATIC CONTROL RES INST +1

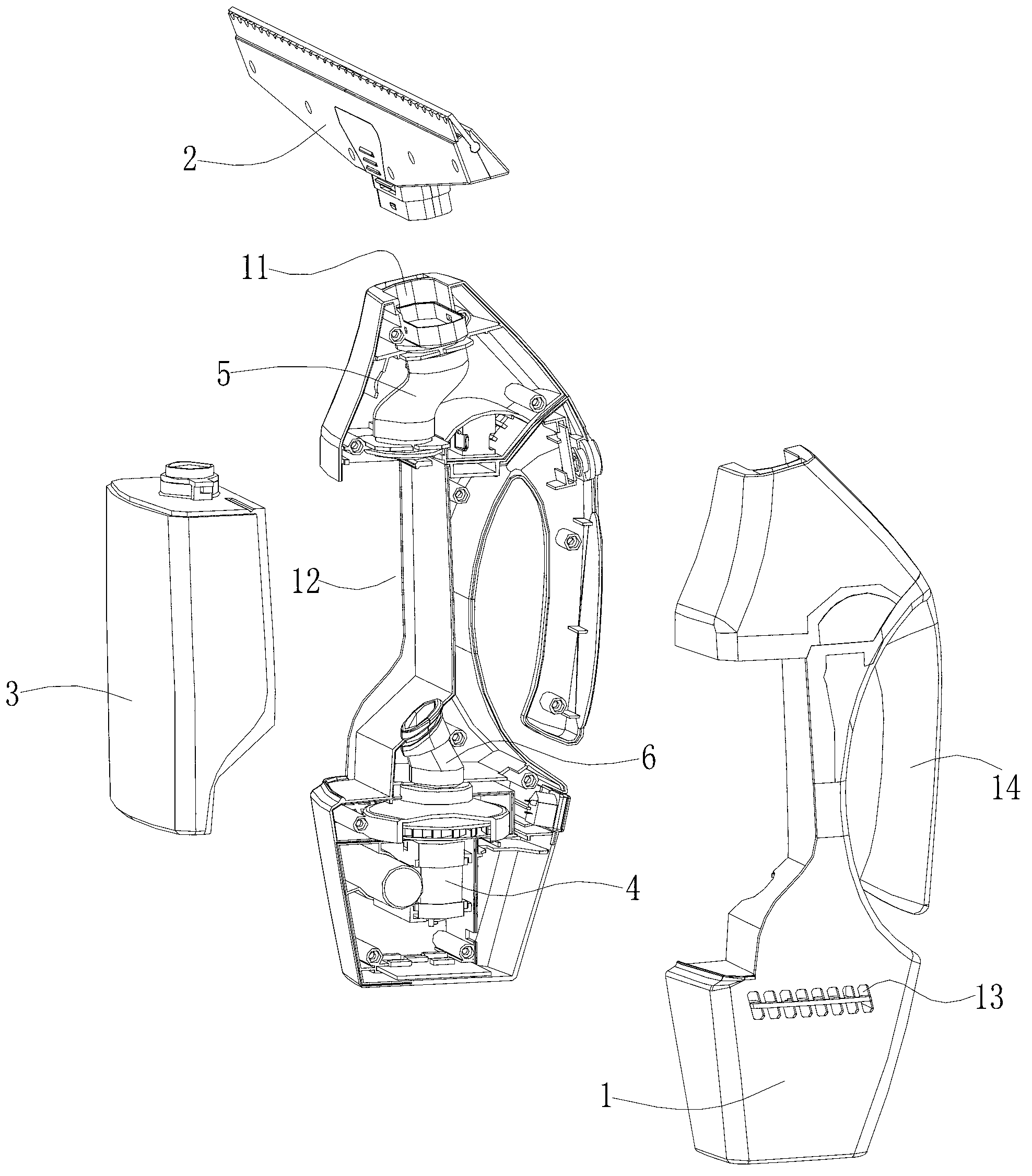

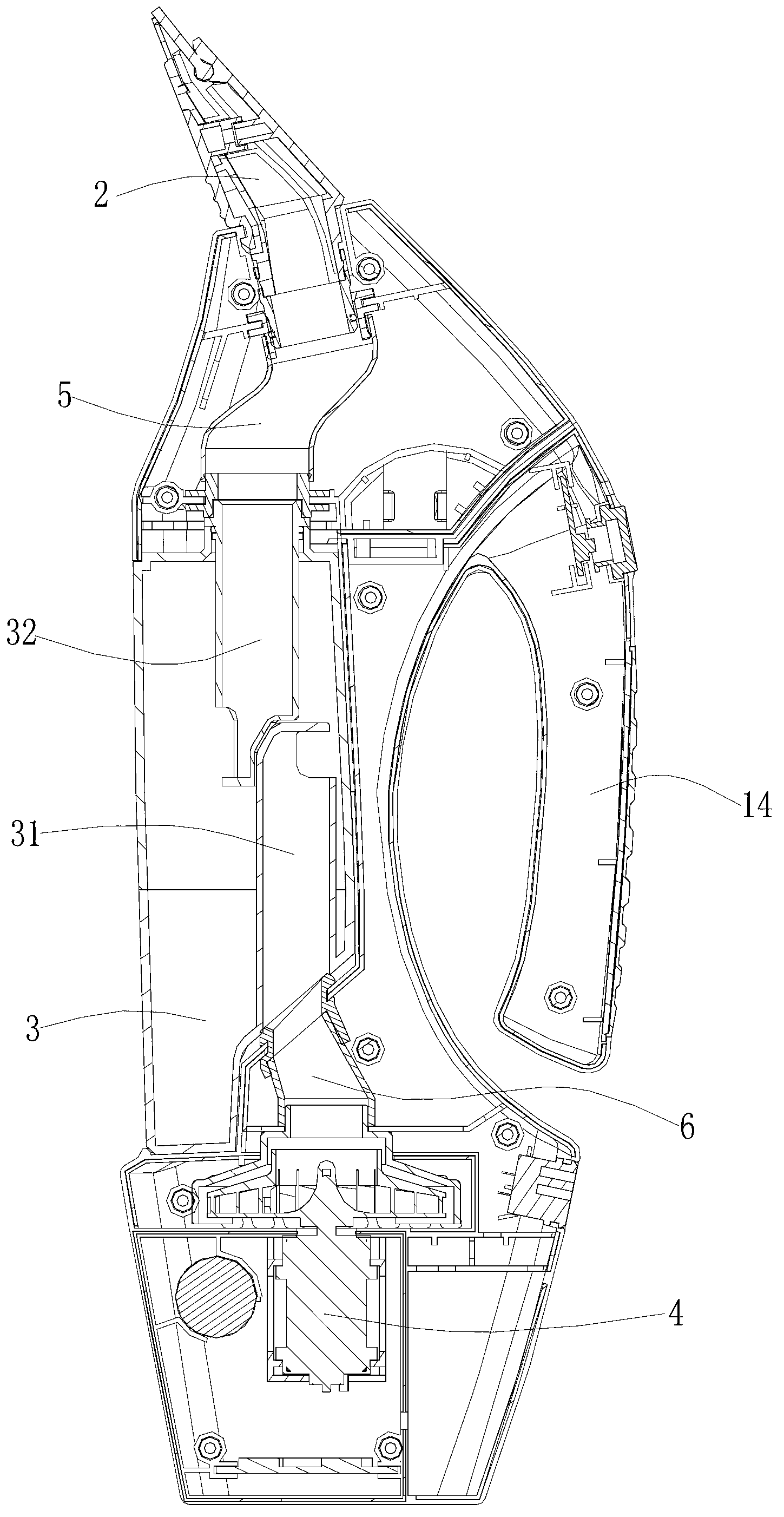

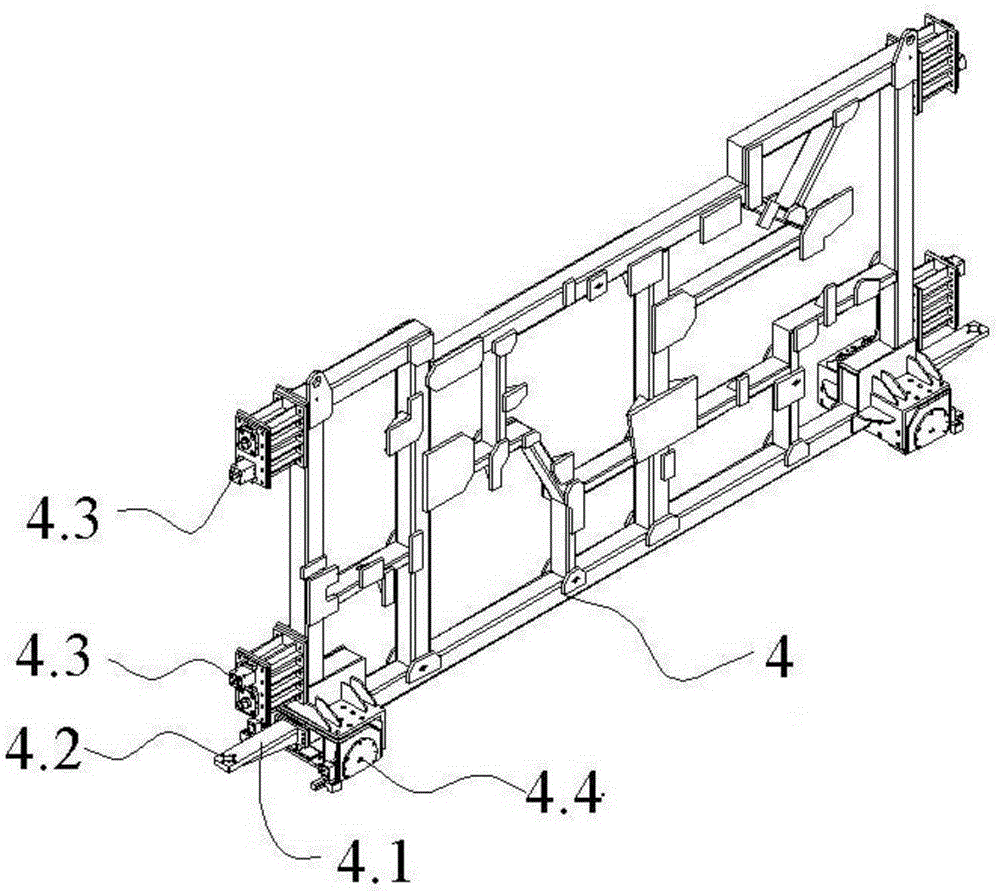

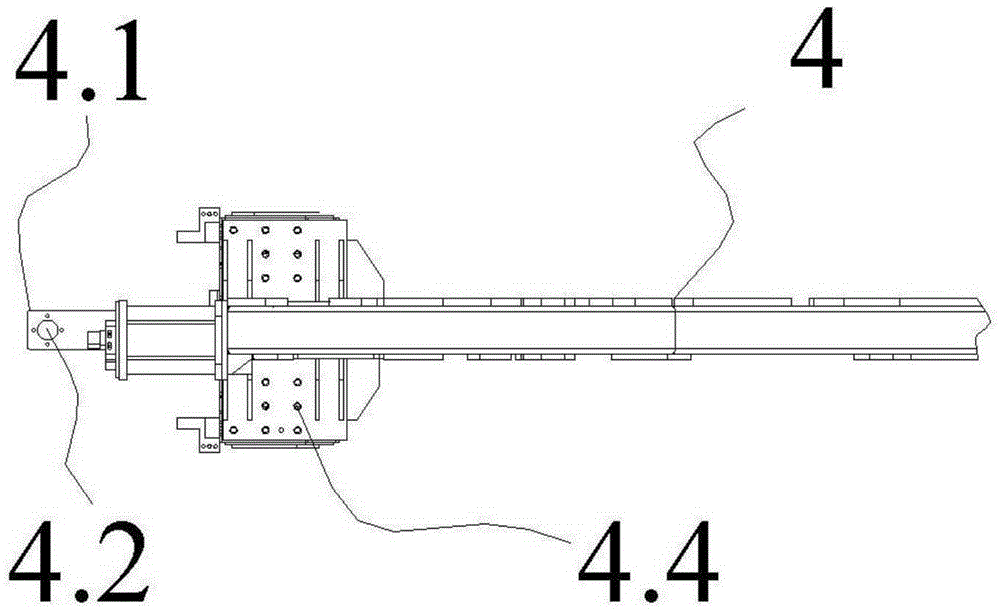

Surface cleaning device

A surface cleaning device comprises a suction nozzle, a water tank, a suction machine set, a suction pipeline and a negative pressure pipeline, wherein the suction nozzle is used for absorbing liquid on the surfaces of objects and outside air in the process of cleaning the surfaces of the objects; the water tank is provided with a cavity and used for collecting the absorbed liquid; the suction machine set is used for generating negative pressure and forming suction force; the suction pipeline is connected between the suction nozzle and the water tank and used for transporting the absorbed liquid and the outside air to the water tank; the negative pressure pipeline is connected between the suction machine set and the water tank and connected with an air path of the suction pipeline through the cavity inside the water tank. The surface cleaning device is characterized in that the suction nozzle, the suction pipeline, the water tank, the negative pipeline and the suction machine set are sequentially arranged from top to bottom; the liquid and the outside air absorbed by the suction nozzle enter the water tank along the same path through the suction pipeline from top to bottom; the liquid absorbed by the suction nozzle is collected by the water tank after entering the water tank; the outside air absorbed by the suction nozzle continues to flow along the path from top to bottom after entering the water tank and is exhausted by the suction machine set after passing through the negative pressure pipeline. The surface cleaning device is simple in structure, and can rapidly absorb the liquid on the surfaces of the objects and collect the liquid in the water tank.

Owner:ZHONGSHAN JINSHUN HOUSEHOLD WARES +1

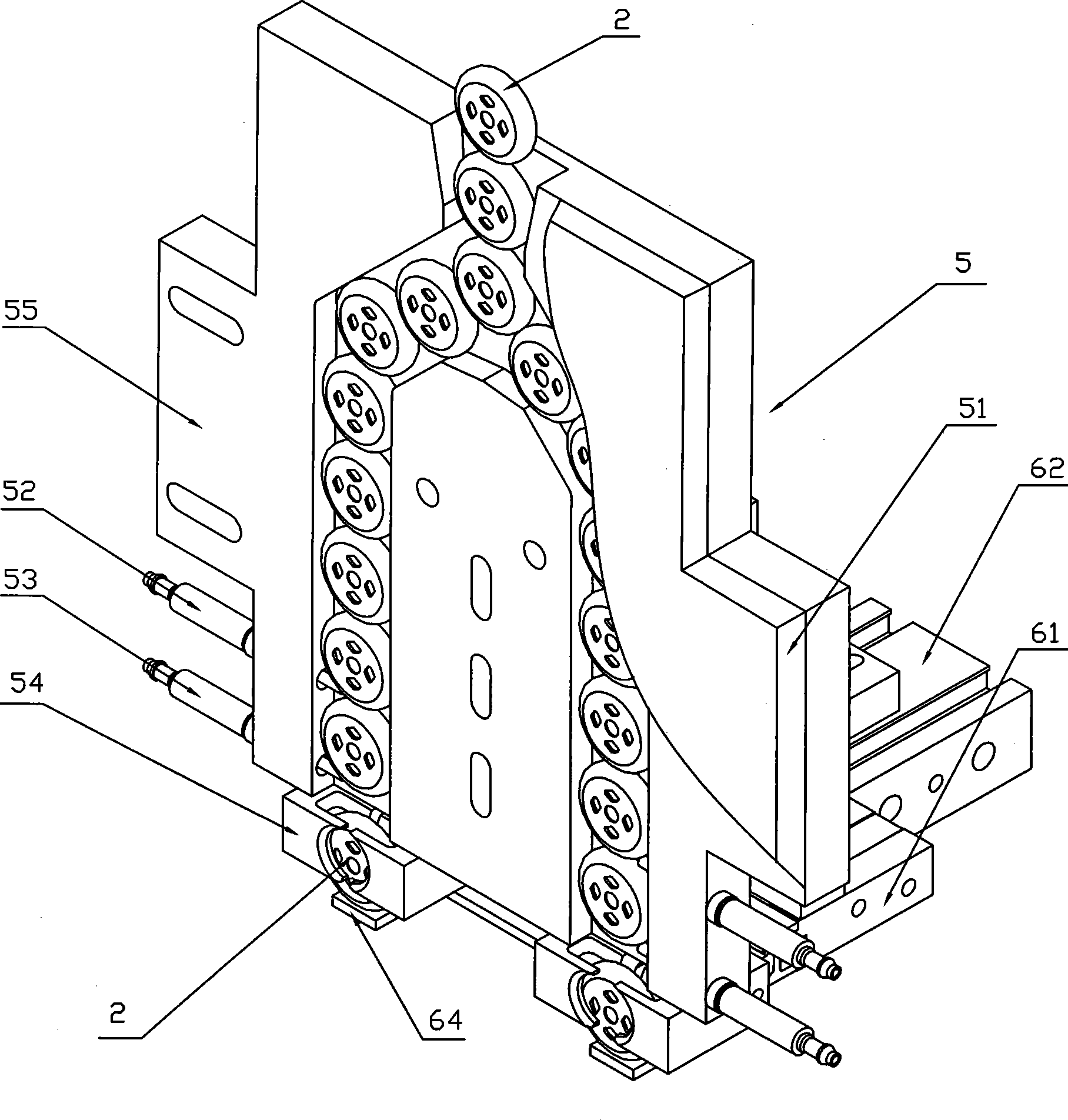

Storage switching mechanism for multi-vehicle-type vehicle body mixed line forming station clamps

ActiveCN105269187ASmooth switchingFacilitate transmissionWelding/cutting auxillary devicesAuxillary welding devicesProduction lineDelivery system

The invention relates to the field of vehicle welding in a vehicle production line, in particular to a storage switching mechanism for multi-vehicle-type vehicle body mixed line forming station clamps. The storage switching mechanism comprises four sets of clamp storage banks, and a clamp conveying device is installed below the clamp storage banks. The storage switching mechanism further comprises a clamp transfer device and a clamp in-place device. The clamp transfer device and the clamp in-place device are fixed between two sets of clamp storage banks located on the same side of a welding production line. The two ends of the clamp in-place device and the two ends of the clamp transfer device are connected with the clamp conveying device in the two sets of clamp storage banks on the same side respectively to form an annular clamp conveying system. The clamp storage banks are reasonable in arrangement structure, the occupied area of a factory is saved, the whole arrangement structure is more reasonable, the clamps can be well conveyed to designated positions through the cooperation of three-dimensional conveying mechanisms, the transfer device and the in-place device, the transfer efficiency of the clamps on the welding production line is improved, and high promotional value is achieved.

Owner:DONGFENG MOTOR CORP HUBEI

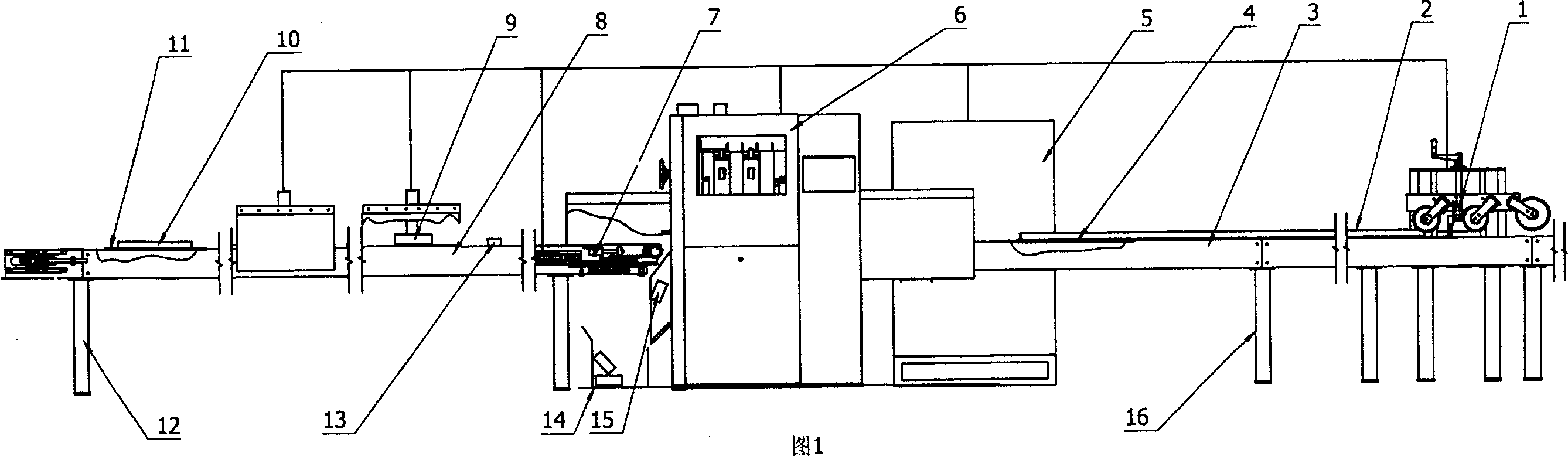

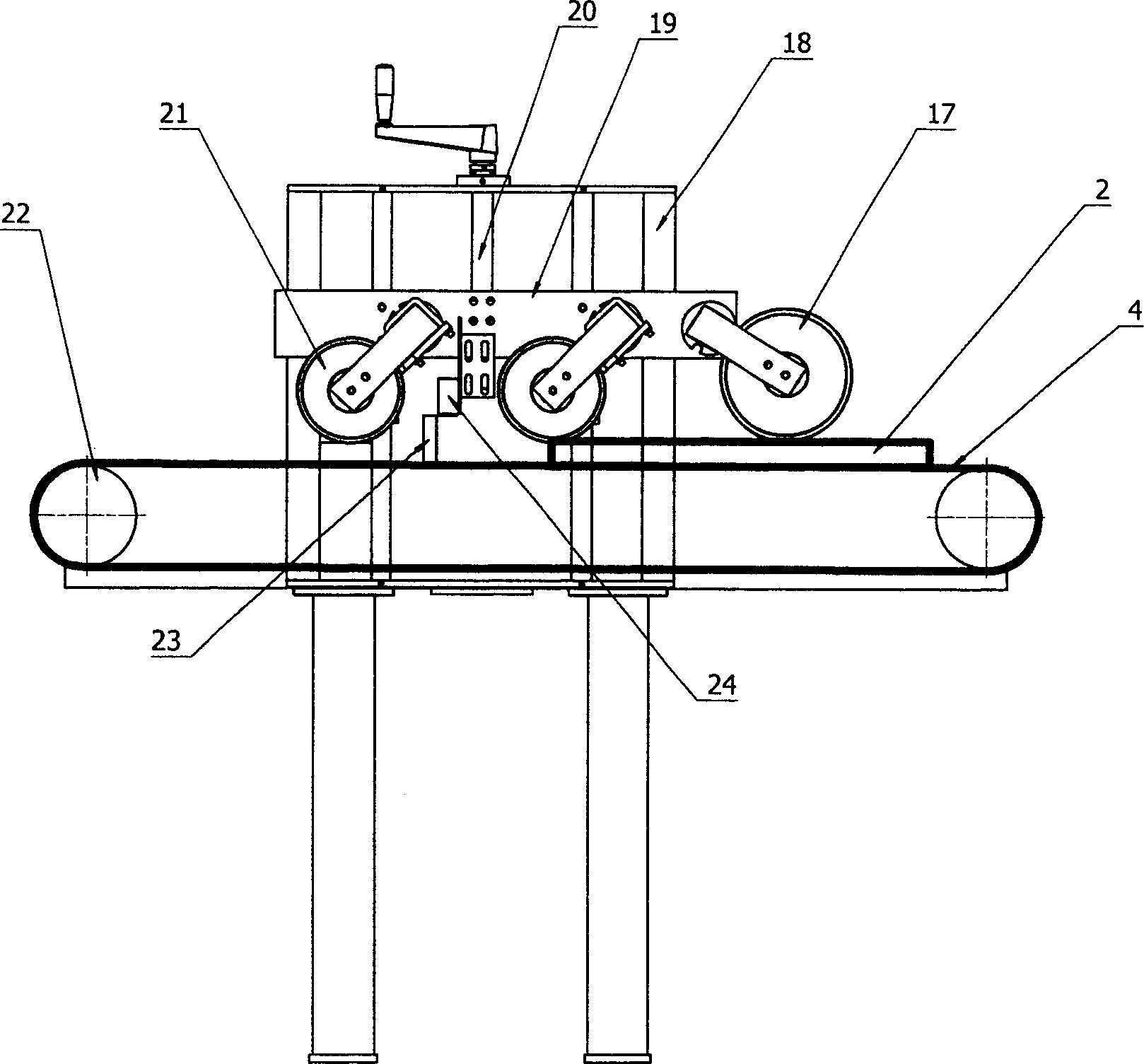

Timber selecting and chopping method and selection chopping saw therefor

InactiveCN1827319AIncrease productivityImprove operating rateLoading equipmentAdjusting equipmentComputer science

The invention discloses a timber optimized truncate method and relative optimized truncate saw. First, inputting the saw data list which comprises target saw length and quality parameters into the computer; when the sawed timber that longitudinally supplied passes the position relative to the detecting device, the detecting device reads the information of sawed timber into the computer, and the computer according to the input saw data list and said information to select the optimized sawing method; the saw machine according to said method processes truncating on the timber. Two sides of said truncate machine individually have a feeding platform and a finished product classifying platform; wherein, said feeding platform has a detecting device; said finished product classifying platform has a finished product classifying device; and a waste removing device is arranged between them.

Owner:JIANGSU JIANGJIA MACHINERY

Automatic assembly line for motor

ActiveCN106239135AHigh degree of automationImprove installation efficiencyAssembly machinesElectric machineryEngineering

The invention relates to the technical field of mechanical automatic equipment, in particular to an automatic assembly line for a motor. Compared with the prior art, the automatic assembly line for the motor comprises a bearing pressing mechanism, a pushing mechanism, a robot, a pressing mechanism, a stator conveying mechanism, a gasket feeding mechanism and a transferring mechanism. The automatic mounting process is that bearings at the two ends of a rotor are mounted automatically; a motor bottom cover is mounted automatically; a stator is mounted automatically; and an upper cover and a gasket are mounted automatically. Therefore, the main parts of the motor are all automatically fed and mounted, and the automatic assembly line for the motor has the advantages of high automatic degree and high mounting efficiency and is compact in structure, reasonable in layout and capable of saving a large amount of labor cost.

Owner:福建明鑫机器人科技有限公司

M-shaped packaging bag opening mechanism

The invention discloses an M-shaped packaging bag opening mechanism, which comprises a rotary master disc, wherein the front end of the rotary master disc is rotatably provided with two corresponding swing arm spindles; the upper ends of the swing arm spindles are respectively provided with a swing arm; the front ends of the swing arms are respectively provided with a sucking disc seat; the lower ends of the swing arms are respectively provided with a gear; a rack respectively meshed with the two gears is arranged between the gears; a guide hole is arranged in the front end of the gear; a spring is installed in the guide hole; a connecting plate is arranged between the gear and the sucking disc seat; one end of the connecting plate is rotatably installed on the outer edge of the gear; the other end of the connecting plate is rotatably installed on a fixed support plate on the sucking disc seat; an idler wheel is rotatably installed in the rear end of the rack; and the idler wheel is in rolling cooperation with a swinging cam behind the idler wheel. The M-shaped packaging bag opening mechanism disclosed by the invention has the advantages of reasonable layout, small part amount, reliability in acting, stability in operation, high bag opening efficiency, pure mechanical mechanism, small travel, high operation speed, small inertial impact, convenience in regulation, high interchangeability, good adaptation on the packaging bag material and long service life.

Owner:合肥远新包装机械有限公司

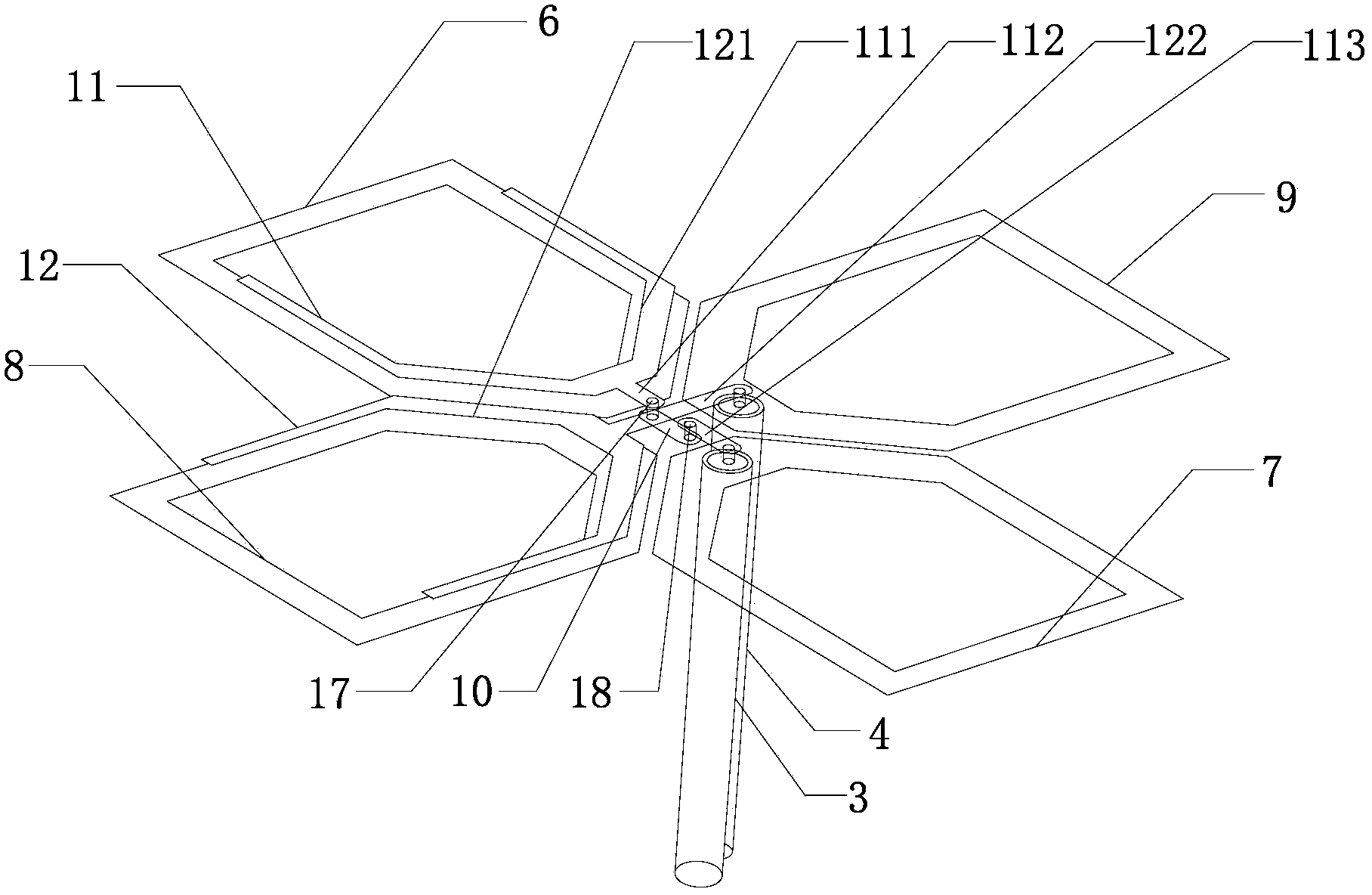

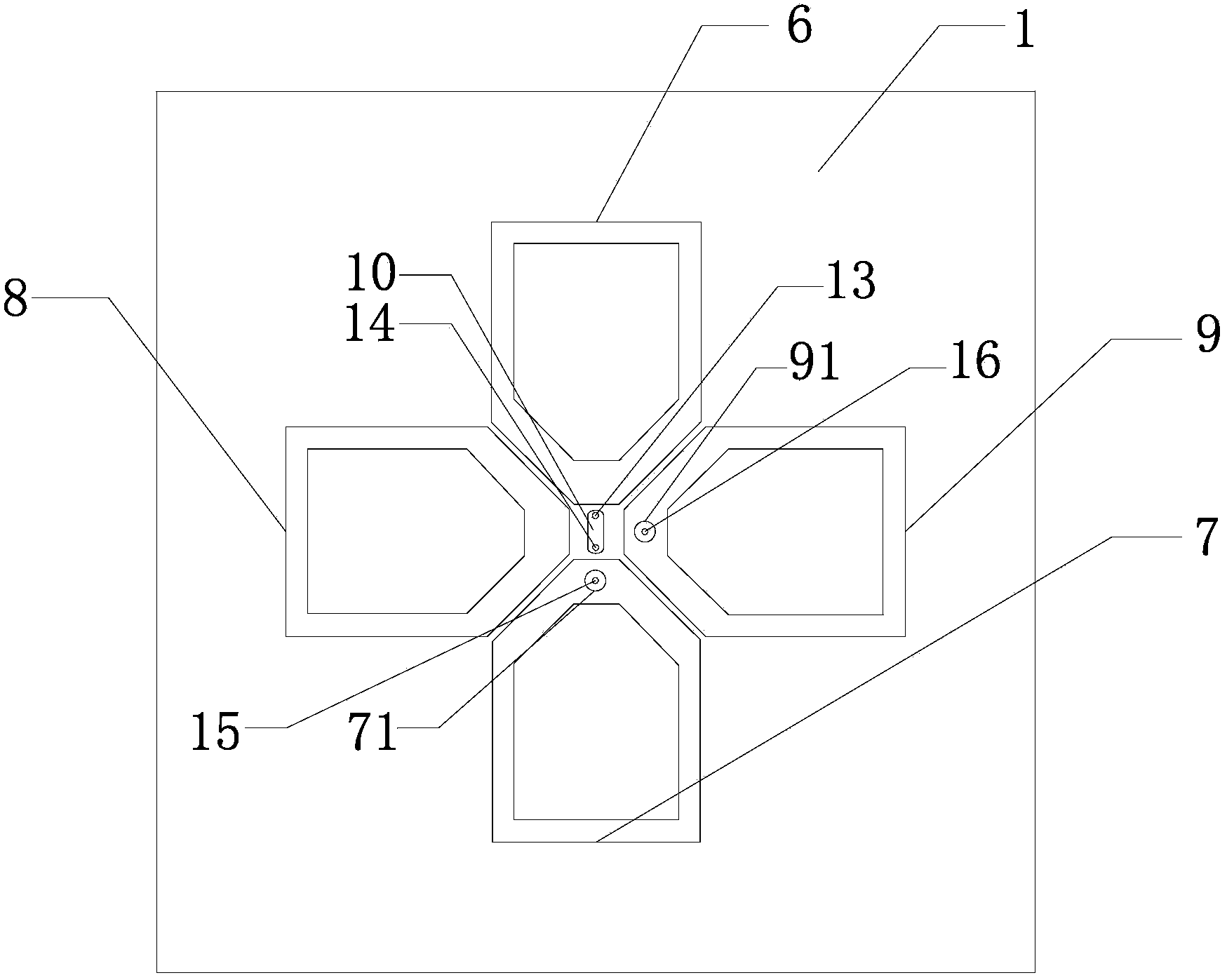

Dual polarization base station antenna with Y-shaped feed units

InactiveCN103682678AImprove performanceSimple structureRadiating elements structural formsPolarised antenna unit combinationsElectricityDielectric substrate

The invention discloses a dual polarization base station antenna with Y-shaped feed units. The dual polarization base station antenna with the Y-shaped feed units comprises a dielectric substrate, a metallic reflection plate, a first coaxial line and a second coaxial line. The two sides of the metallic reflection plate are provided with metal flanges. The lower surface of the dielectric substrate is provided with a first annular radiating element, a second annular radiating element, a third annular radiating element and a fourth annular radiating element, wherein the first annular radiating element and the second annular radiating element are in mutual symmetry to form a first antenna structure, and the third annular radiating element and the fourth annular radiating element are in mutual symmetry to form a second antenna structure. The upper surface of the dielectric substrate is provided with the first Y-shaped feed unit and the second Y-shaped feed unit. The first coaxial line is connected with the second annular radiating element and the first Y-shaped feed unit. The second coaxial line is connected with the fourth annular radiating element and the second Y-shaped feed unit. The dual polarization base station antenna is good in performance, simple in structure, easy to process, low in processing cost and convenient to adjust.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com