Patents

Literature

70 results about "Clamper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A clamper is an electronic circuit that fixes either the positive or the negative peak excursions of a signal to a defined value by shifting its DC value. The clamper does not restrict the peak-to-peak excursion of the signal, it moves the whole signal up or down so as to place the peaks at the reference level. A diode clamp (a simple, common type) consists of a diode, which conducts electric current in only one direction and prevents the signal exceeding the reference value; and a capacitor, which provides a DC offset from the stored charge. The capacitor forms a time constant with the resistor load, which determines the range of frequencies over which the clamper will be effective.

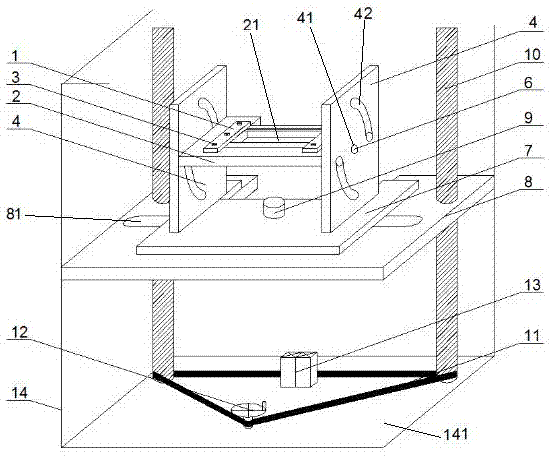

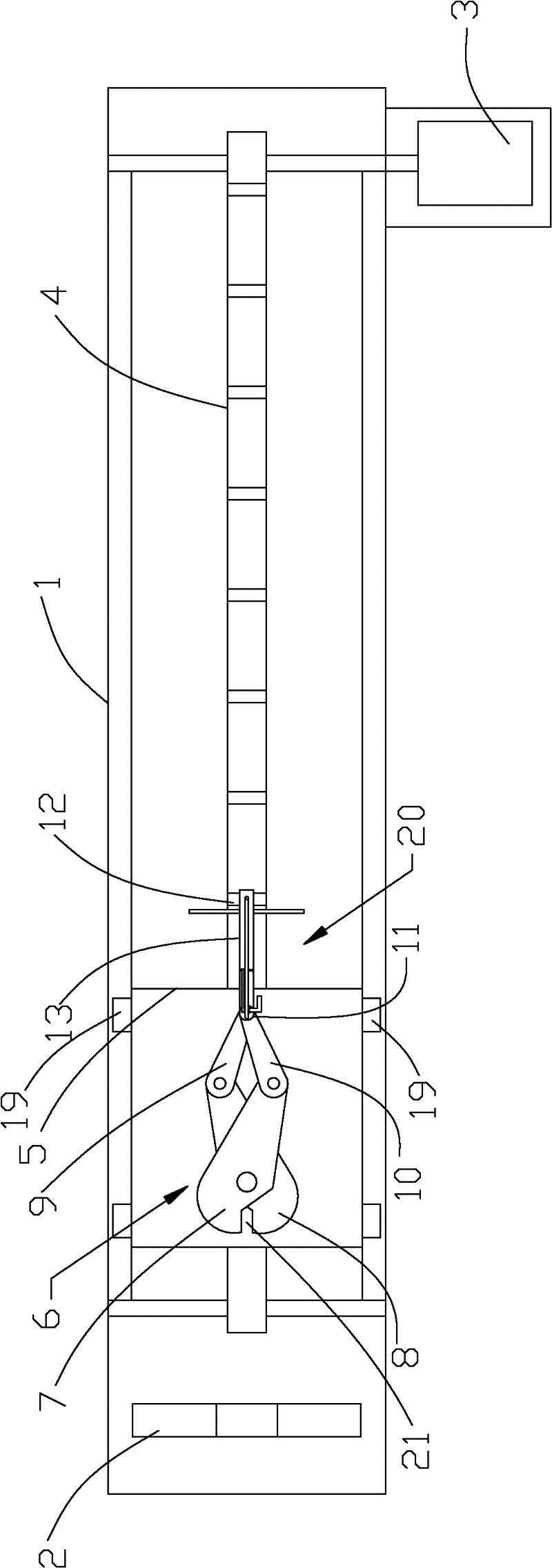

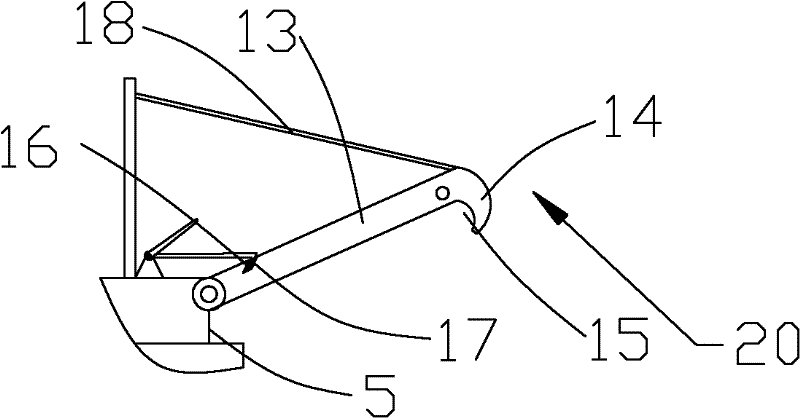

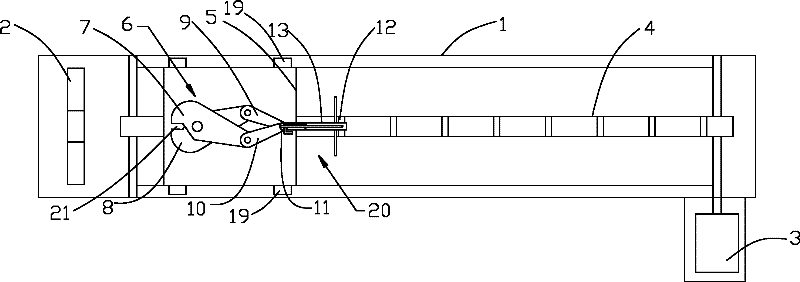

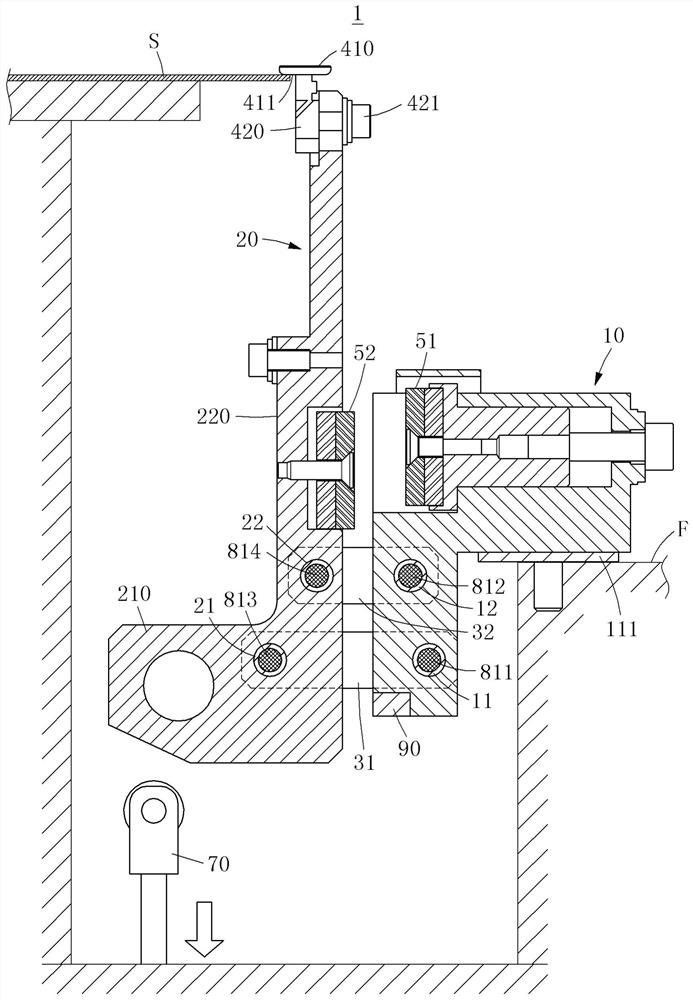

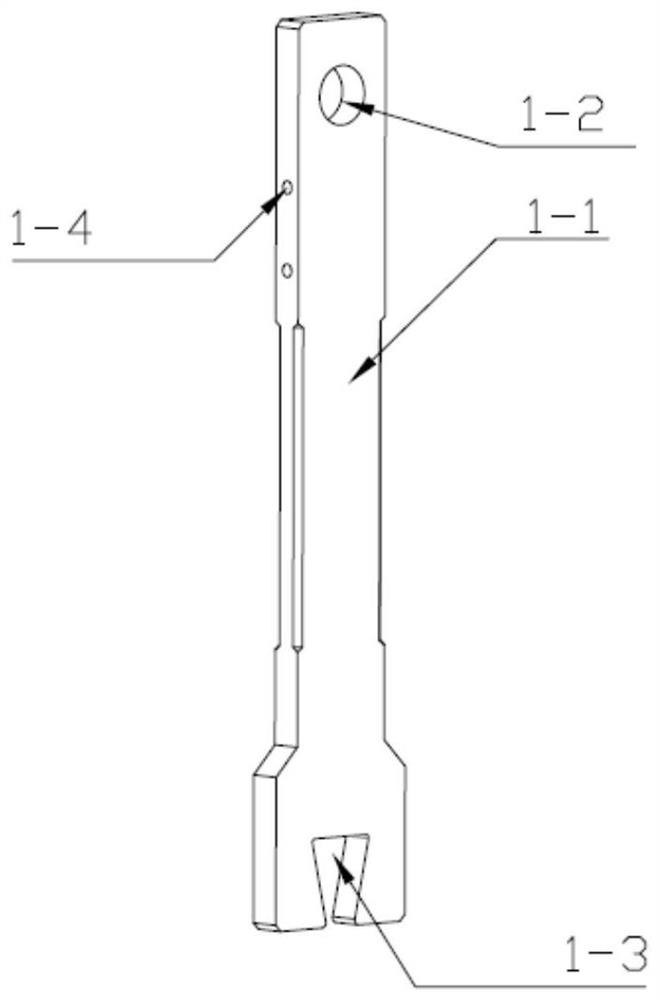

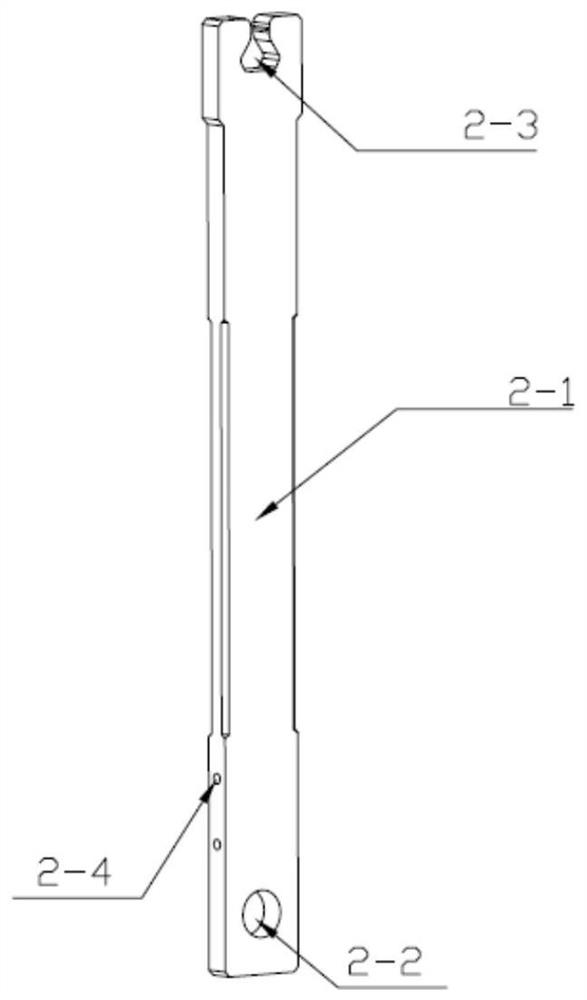

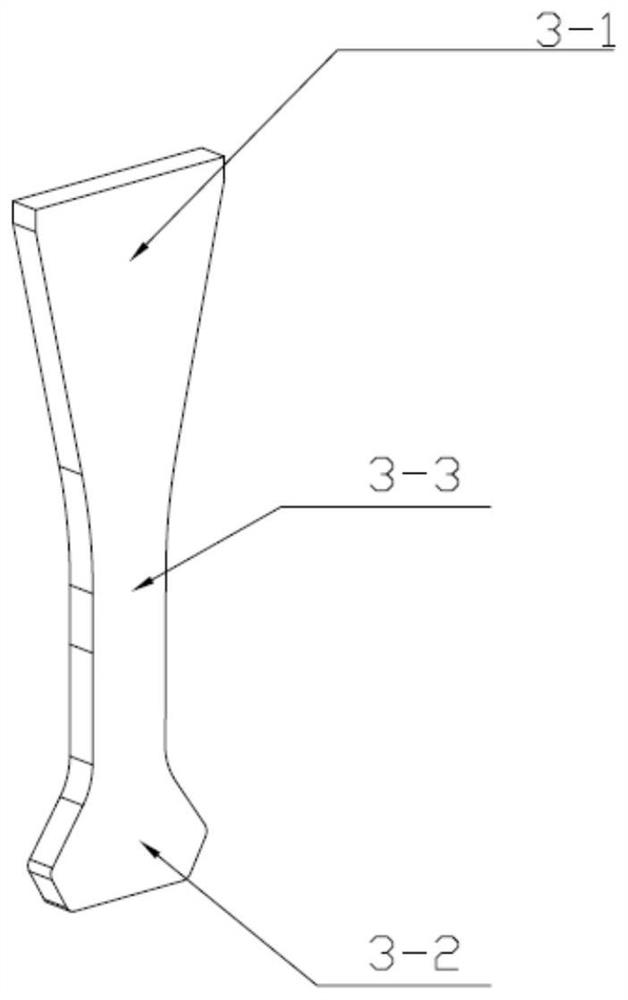

Plate clamper platform for falling weight impact test, and impact speed measurement method

PendingCN106940275ARealize multi-angle impactIncrease flexibilityDevices using optical meansStrength propertiesEngineeringLaser sensor

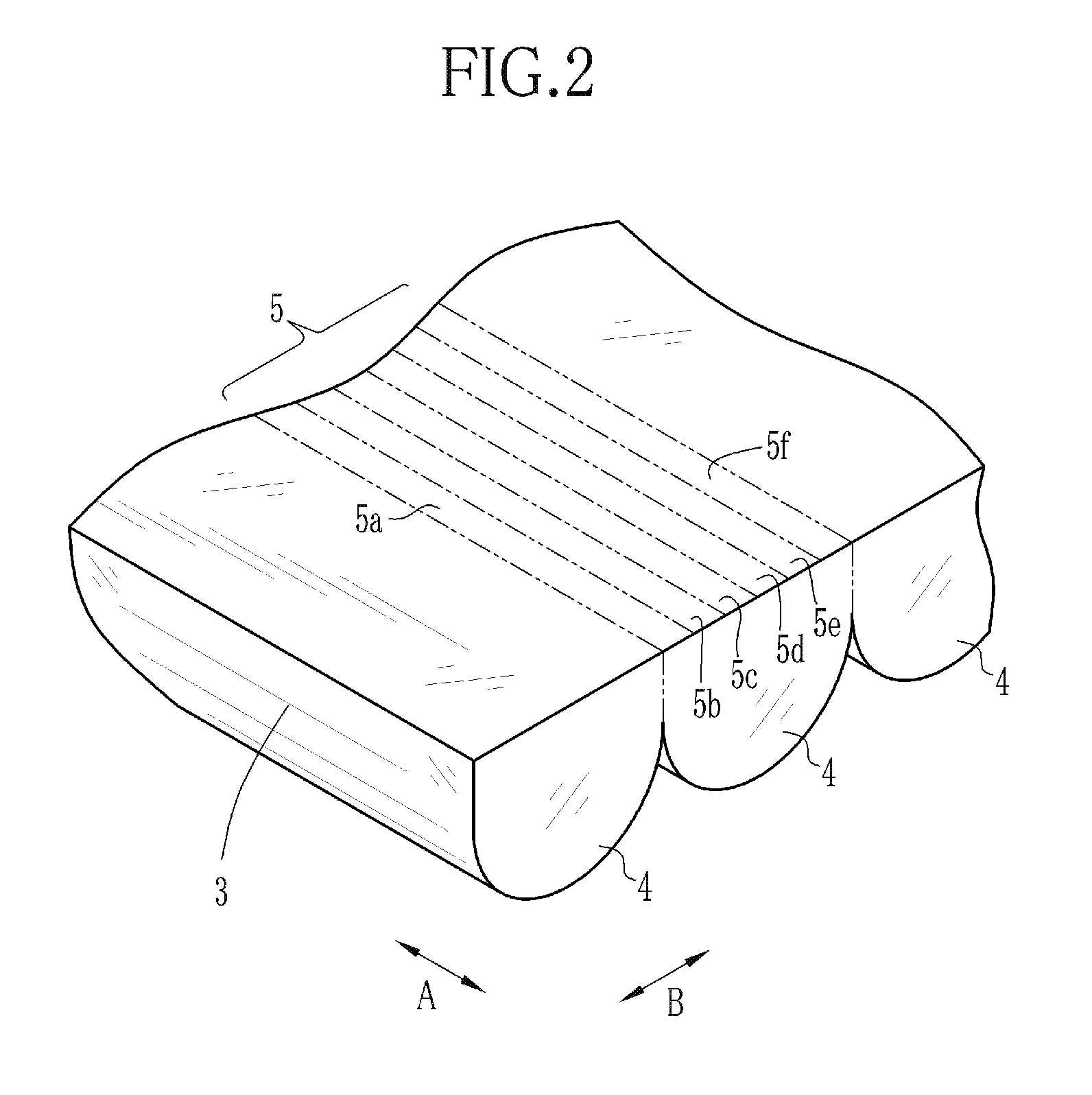

The invention discloses a plate clamper platform for a falling weight impact test, and an impact speed measurement method. The plate clamper platform comprises a clamper structure, a supporting lifting structure and a laser sensor, wherein the clamper structure comprises a plate clamping device, a multi-angle rotation device and a clamper bottom plate, the multi-angle rotation device comprises wall plates, wall plate bolts and a bottom plate bolt, each wall plate is provided with a central hole and two arc-shaped grooves, the two arc-shaped grooves are symmetrically arranged relative to the central hole, clamping plates can rotate along the arc-shaped grooves after the wall plate bolts are completely loosened, the supporting lifting structure comprises a platform and a lifting driving device, the clamper bottom plate can rotate by adopting the bottom plate bolt as the center and can slidably move along a straight strip hole, and the laser sensor is arranged below the weight tray positioned on the periphery of a hammer head. With the plate clamper platform and the impact speed measurement method of the present invention, the composite material plate specimen can be tightly clamped, the multi-angle impact on the specimen can be achieved, and the speed change during the drop hammer falling and impact process can be real-timely measured.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

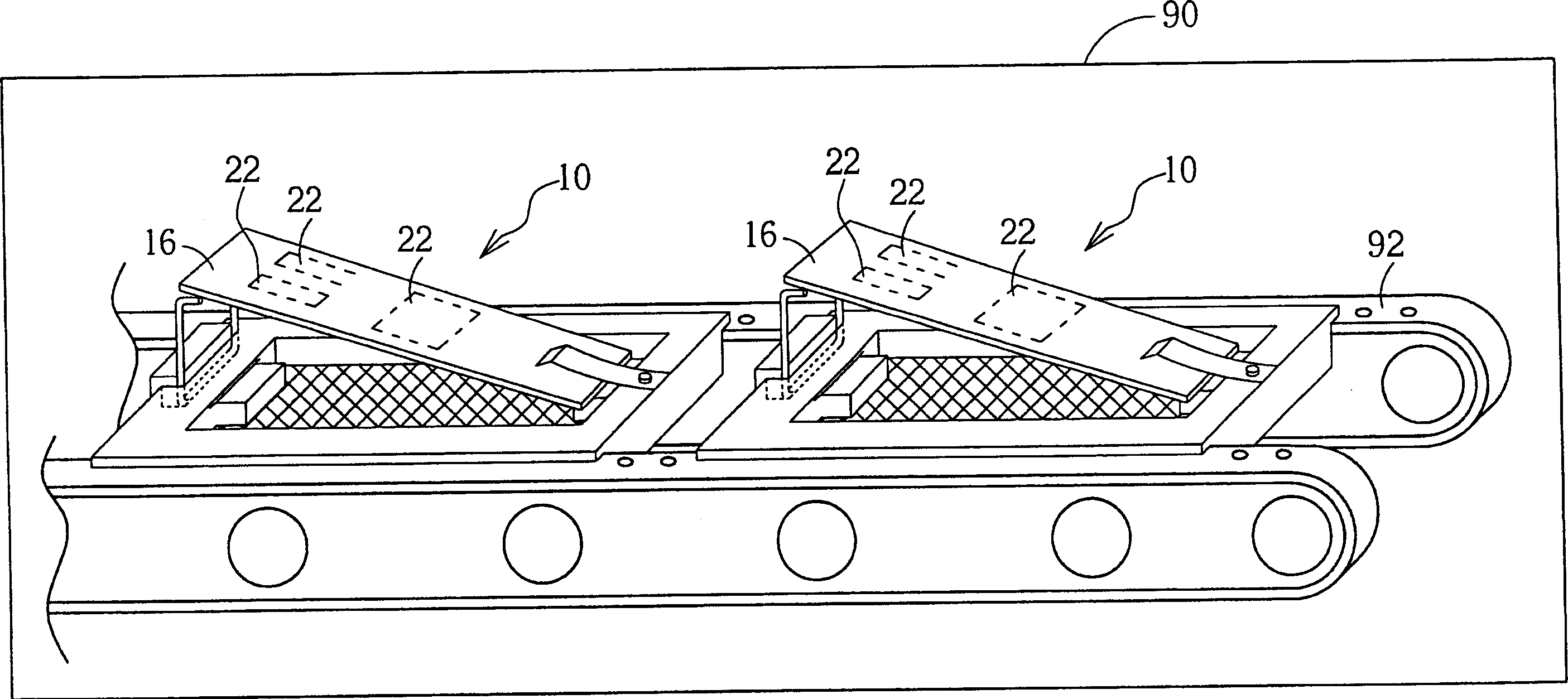

Electronic component carrier and method for shattering and loading electronic components on circuit board

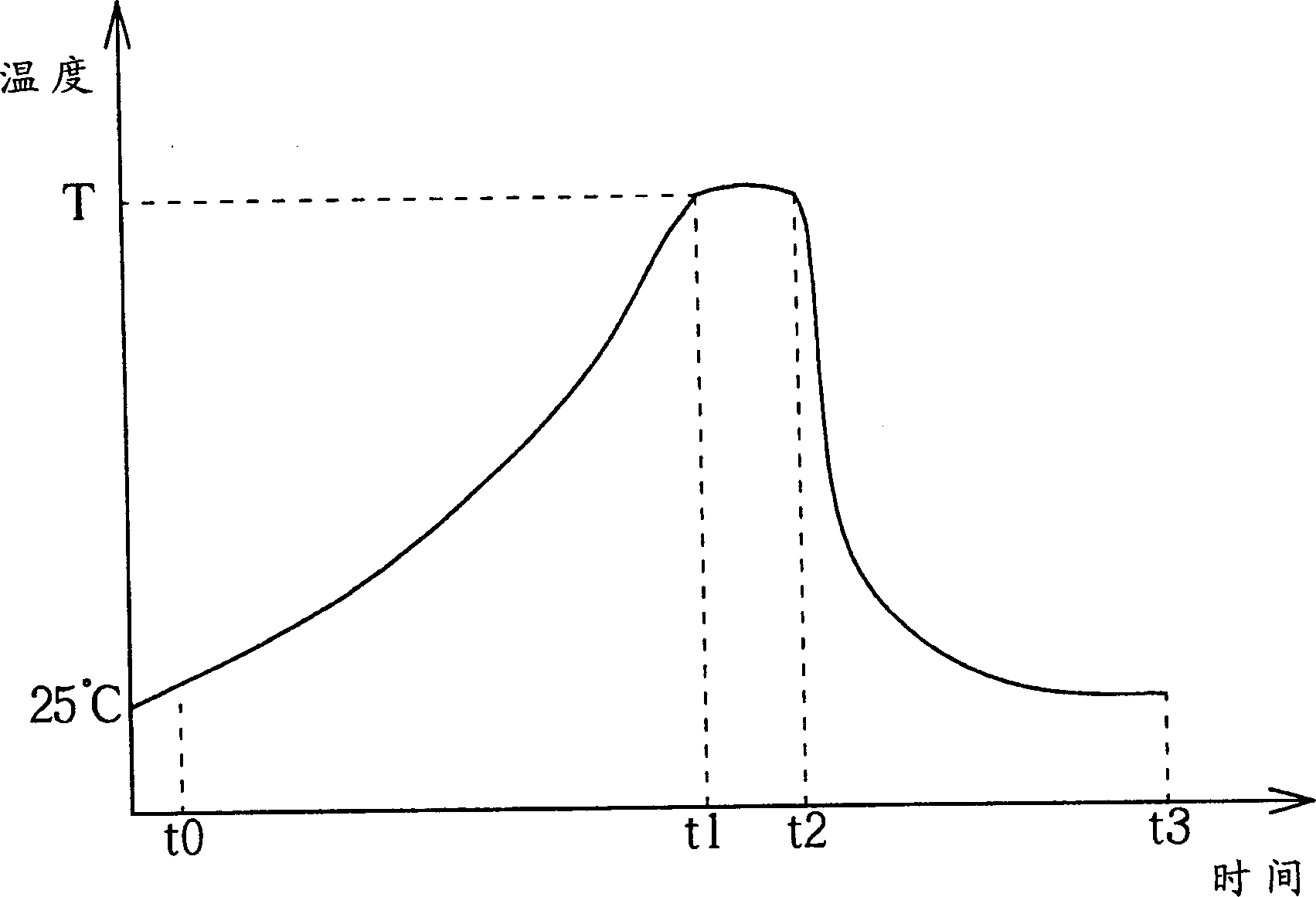

An electronic element carrier is composed of a fixed frame, a clamper fixed to said fame and clamping a circuitboard on said frame, an impacter for impacting the circuitboard to separate the electronic elements from the circuitboard when the temp in a welding furnace is higher than a predefined temp, and a carrier for collecting the separated electronic elements.

Owner:HTC CORP

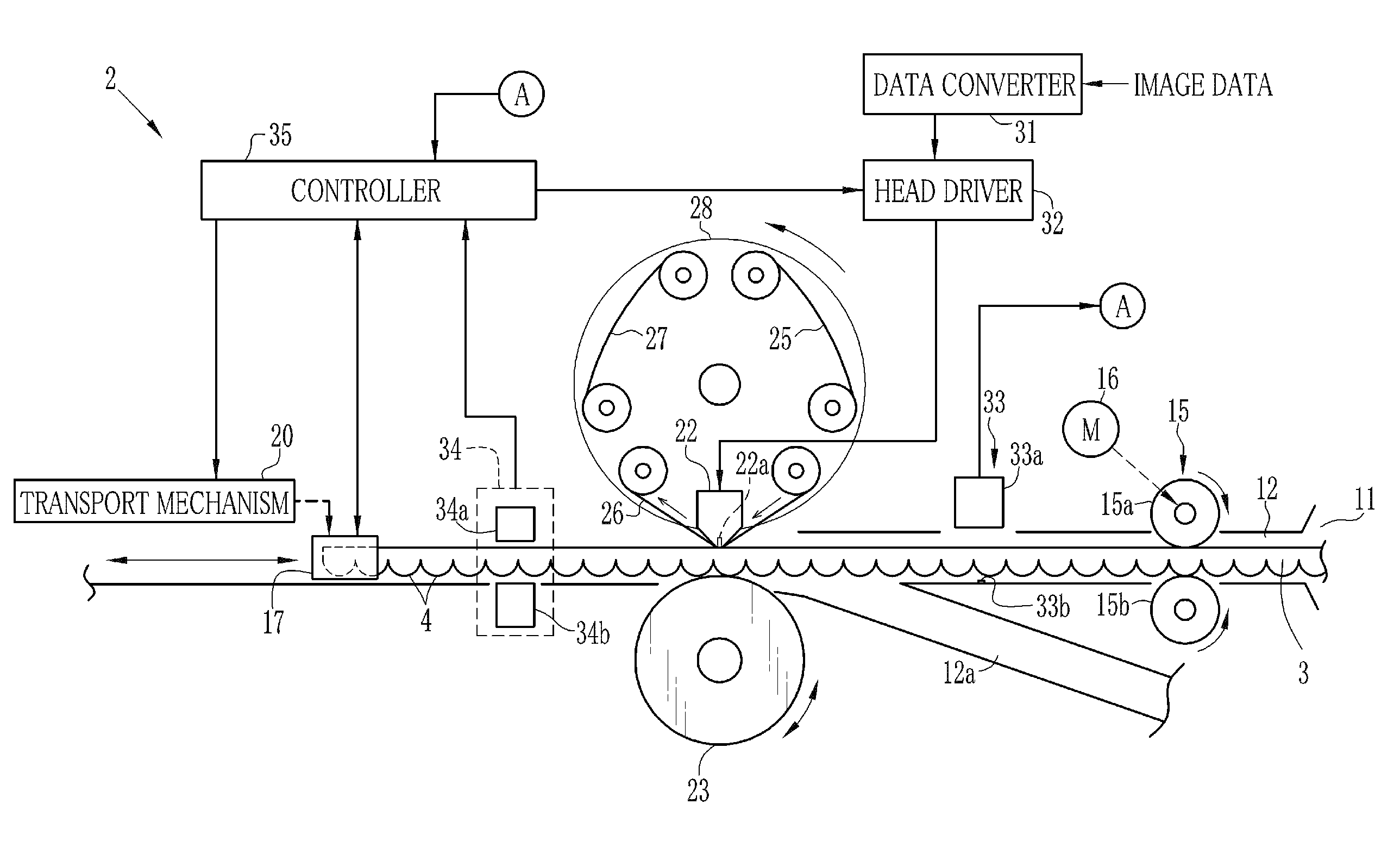

Printer and printing method

A clamper clamps an edge of a lenticular sheet and is transported in a sub-scanning direction. After obliquie transportation of the lenticular sheet is corrected based on a detection result from an oblique transportation detector, transportation of the lenticular sheet for forming an image receptor layer on the rear side of the lenticular sheet is performed with a thermal head contacting said lenticular sheet. In this transportation, a lens sensor is activated to optically detect a lens pitch and so on. The lens sensor is positioned between the thermal head and the clamper.

Owner:FUJIFILM CORP

Electromagnetic residual current action protector and its protecting method

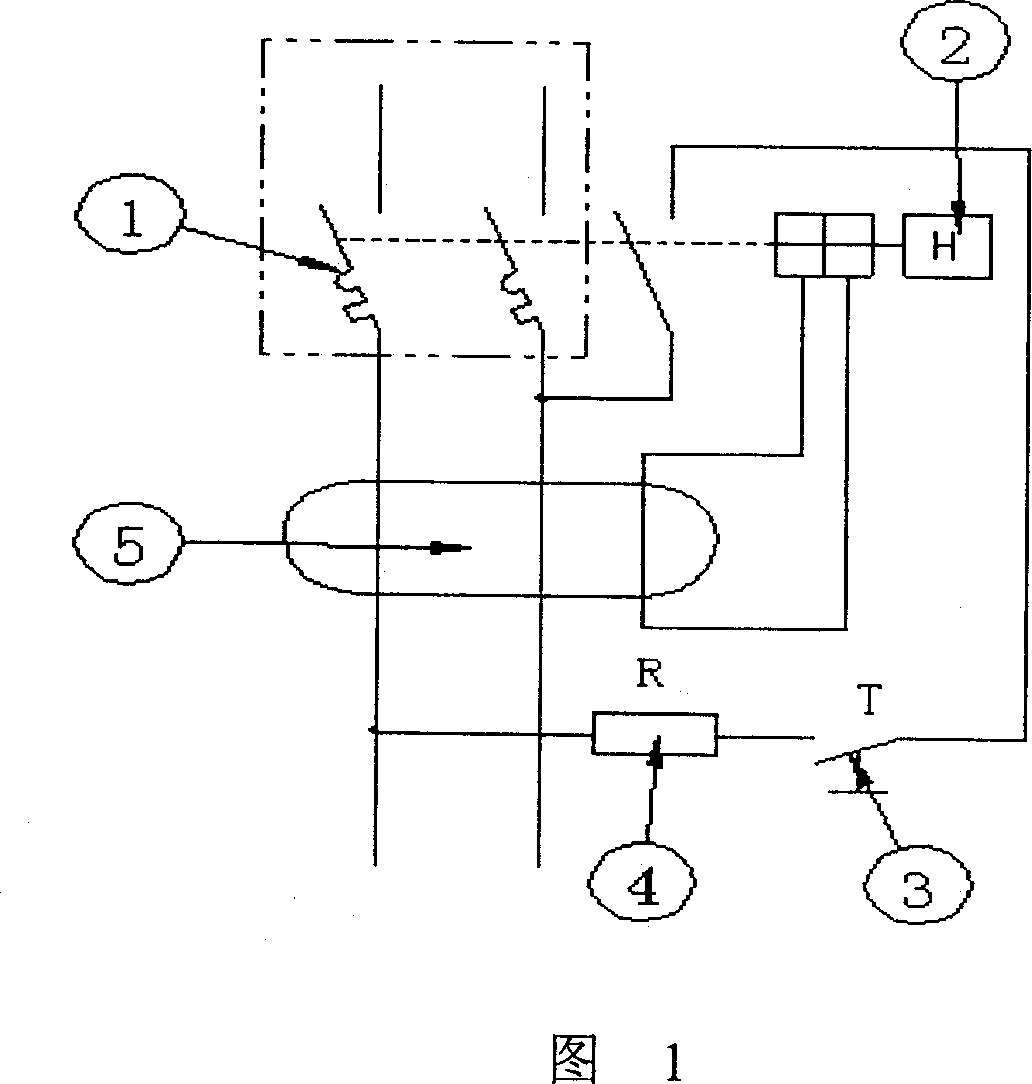

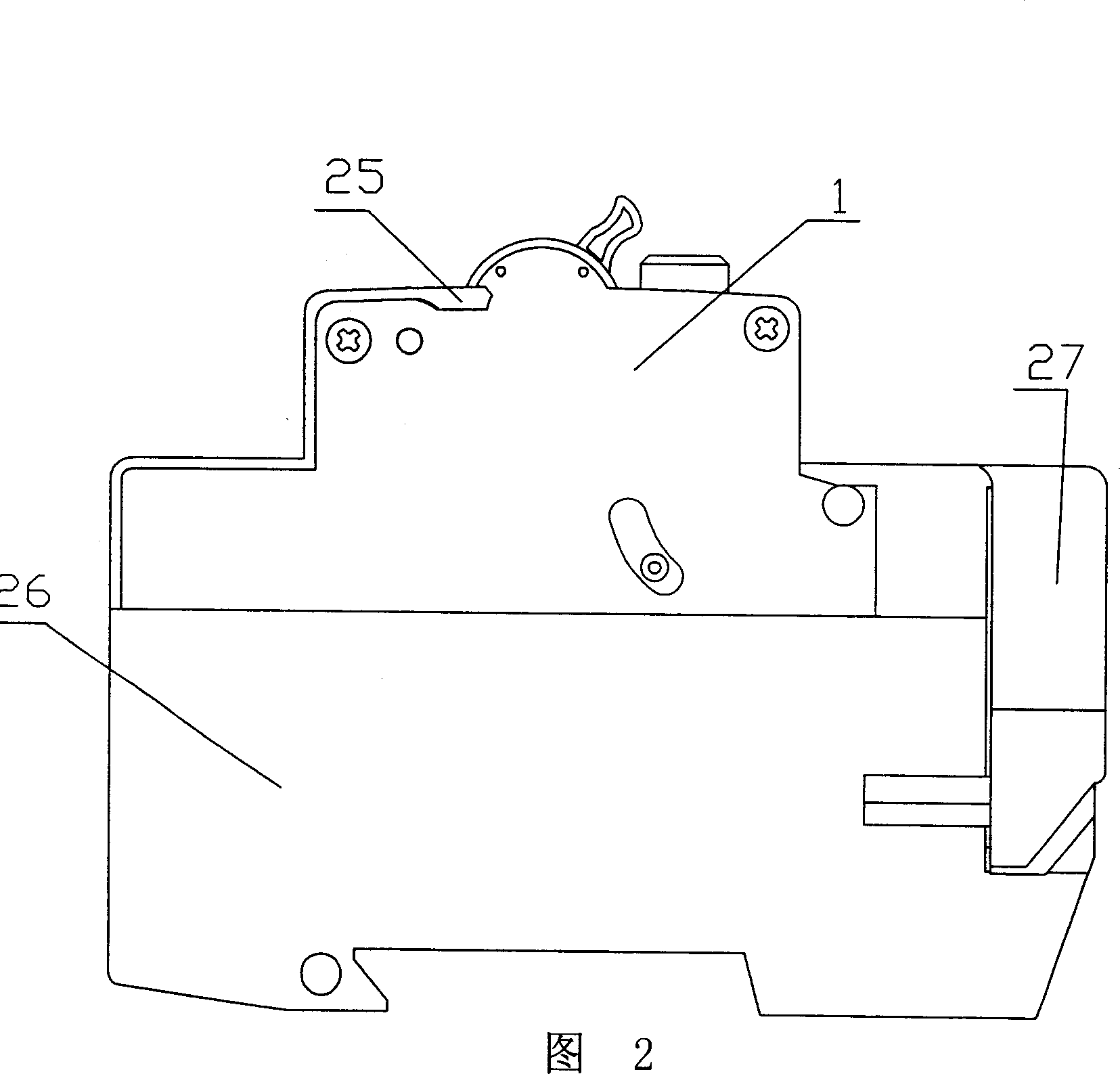

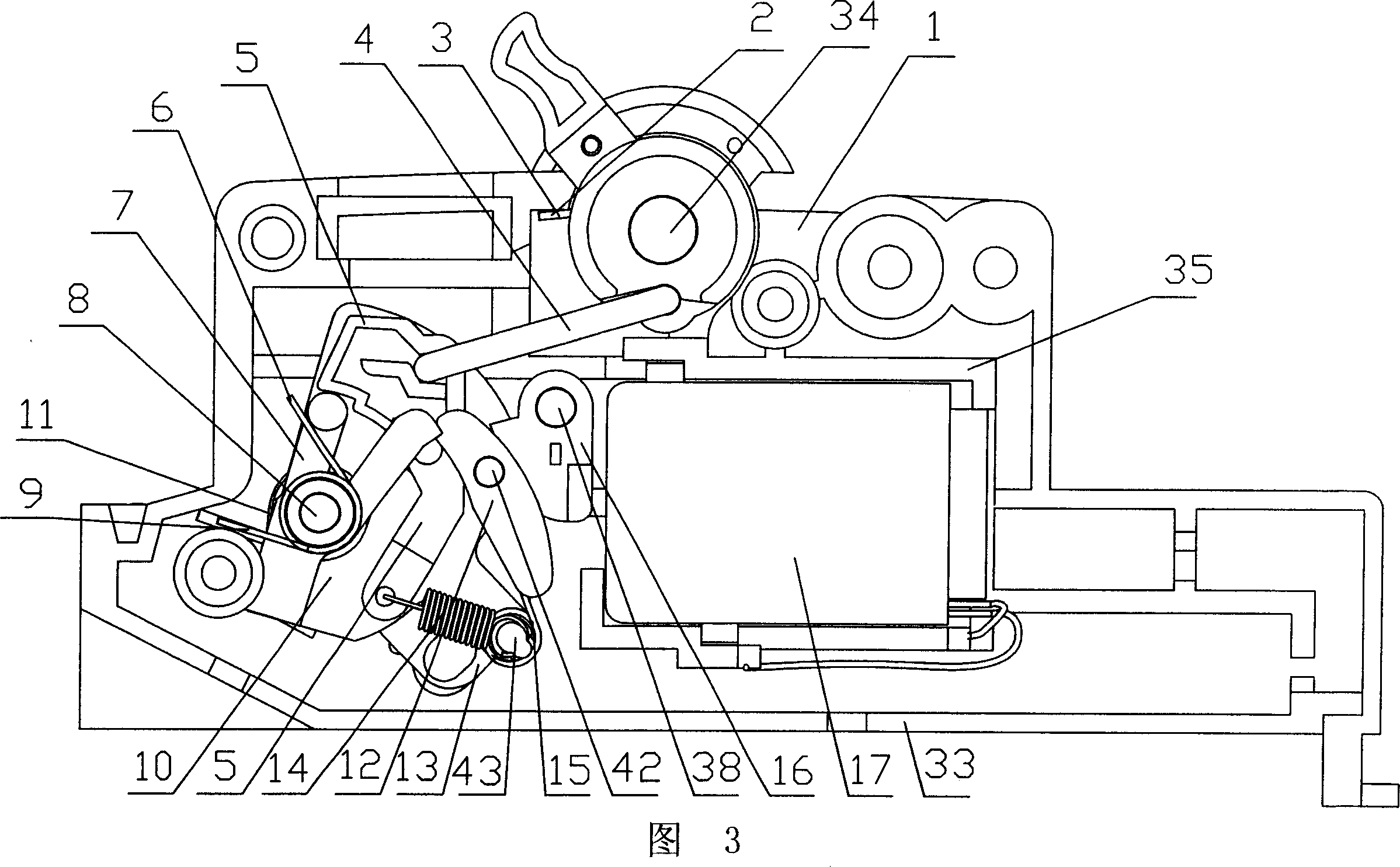

InactiveCN1967762AReduce scrap rateSimple processEmergency protective arrangements for automatic disconnectionProtective switch operating/release mechanismsSpring forceEngineering

The invention relates to an electromagnetic current protector and relative method, wherein it has up and low structures; the low base is matched with track, while it contains mutual inductor, wiring base and main circuit; the up base is matched to mount executor and test circuit; the elements are tree layered in base and compressing plate while they are covered by compressing plate, and fixed via screw; the base and compressing plate are connected via one main axle; the elements rotate around main axle; the rotation disc is on two steps of base; the jump clamper and disc will operate via the spring force; the disc will not make whole device incline via the spring force. The invention has high reliability, while the return element and disc are matched via grooves, to prolong service life.

Owner:LEGRAND LOW VOLTAGE ELECTRICAL APPLIANCES WUXI

Method for preparing radial glass packaged thermosensitive resistor

InactiveCN1921031AEasy to operateIncrease productivityEnvelope/housing resistor manufactureResistors adapted for applying terminalsHeat sensitiveNickel alloy

The invention relates to a production of thermal-sensitive resistance packed by radial glass. Wherein, it positions the glass tube with clamper; the chip is inside the glass frame; the clamper positions the copper-coated iron and nickel alloy wire; it uses clamper to sheath the copper-coated iron and nickel alloy wire into glass frame; makes the silver layer of chip parallel with copper-coated iron and nickel alloy wire, between two copper-coated iron and nickel alloy wires to be pushed; the silver layer of chip, the silver layer of copper-coated iron and nickel alloy wire and the glass frame contact each other, via high-temperature packed, to be radial glass packed product, the invention uses chemical device to correct copper-coated iron and nickel alloy wire, plate silver layer, sheath glass frame, and mount the glass frame, with simple operation, high efficiency, and high yield.

Owner:广州市番禺区大通电子有限公司

Drawing machine

The invention discloses a drawing machine. A quadrilateral connecting rod structure is composed of a first clamp block, a second clamp block, a first connecting rod and a second connecting rod. The quadrilateral structure is not stable, so, when drawing, one end of things to be drawn passes through a mould and enters into a clamping opening aperture, and is clamped by the first clamp block and the second clamp block; and clamps are driven to move toward a direction away from the mould by a rotating shaft which is connected with a clamper and which is arranged between the first connecting rod and the second connecting rod, when the clamper is taken to move far away from the mould by a chain of a connecting mechanism. Due to the presence of drawing resistance, the first connecting rod and the second connecting rod are close up, the first clamp block and the second clamp block are also close up, and the clamping opening aperture is reduced, when the quadrilateral connecting rod structure begins to co-move, so that things to be drawn can be clamped more tightly, move toward the direction away from the mould along with the chain, and be drawn to appropriate sizes through the mould. Smoothly drawing of the mould is realized through transmission chains by the drawing machine.

Owner:苏州中信科技股份有限公司

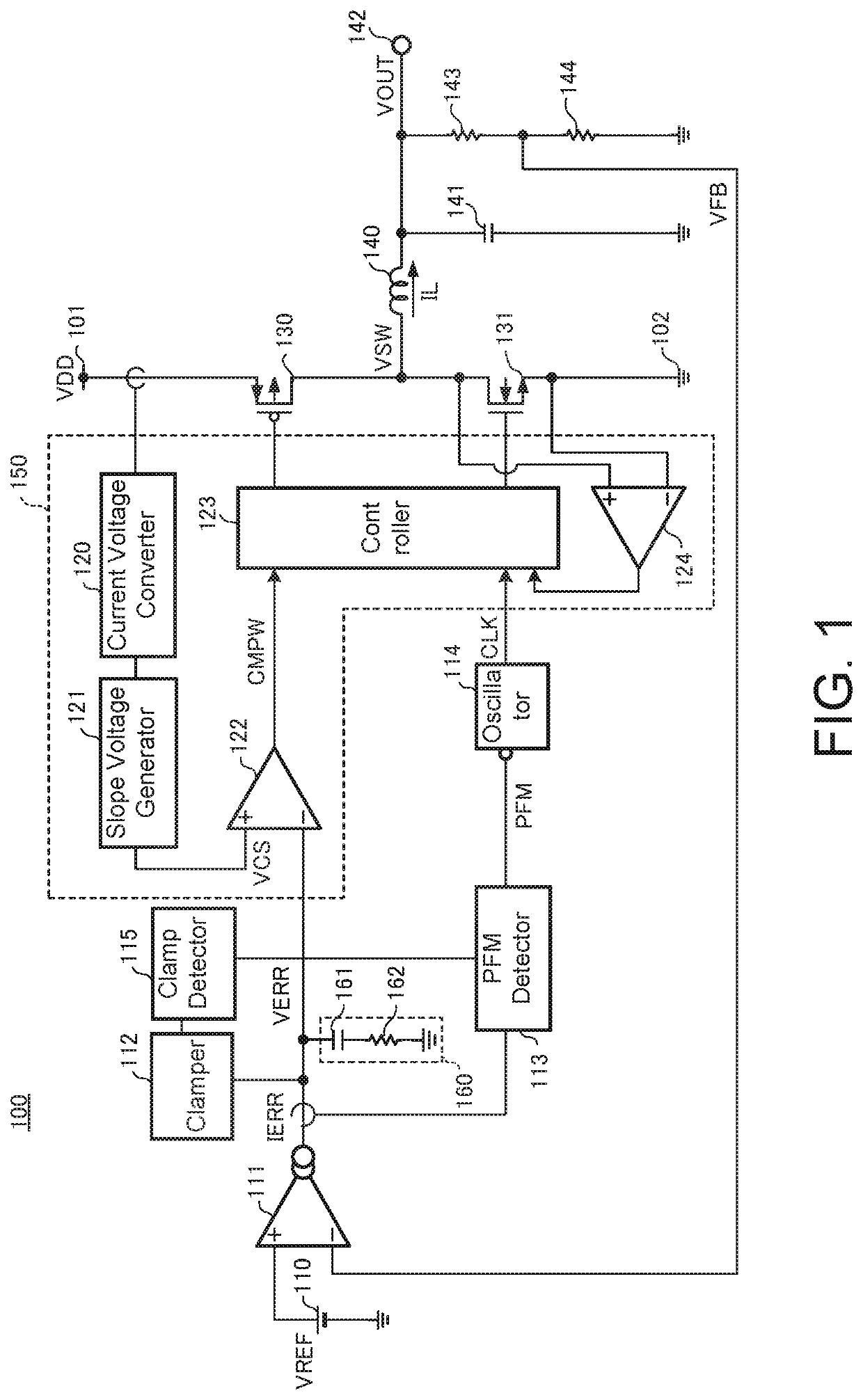

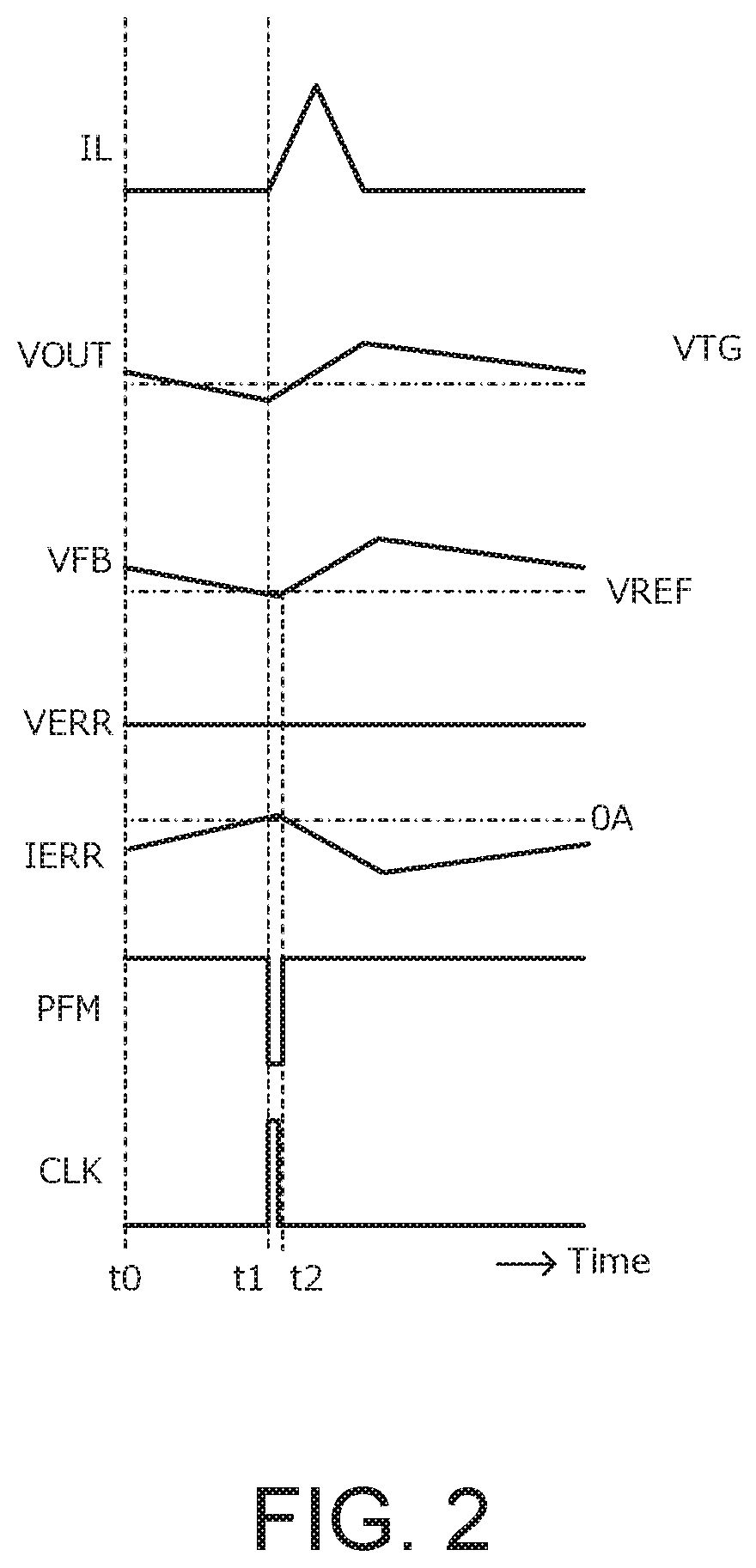

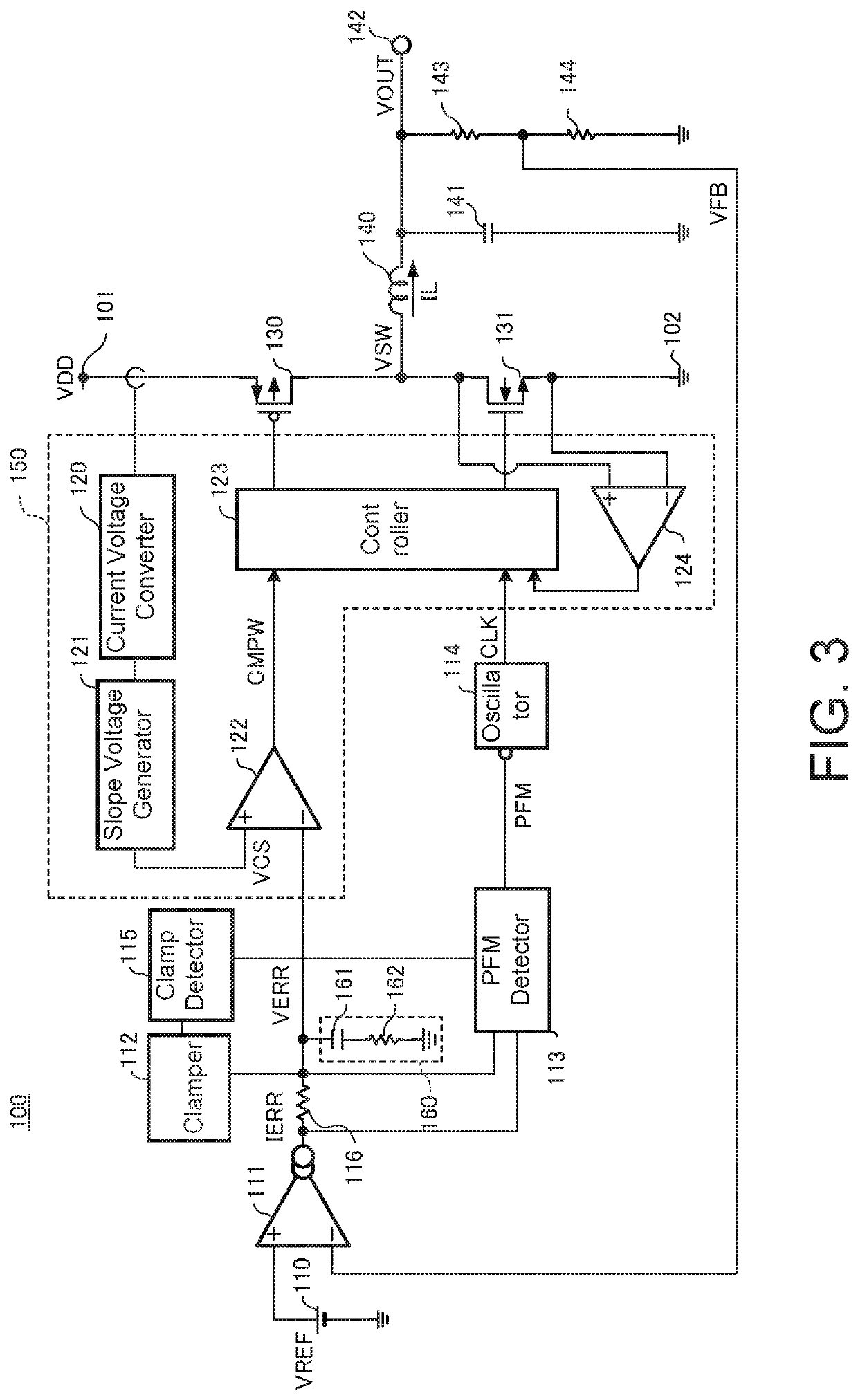

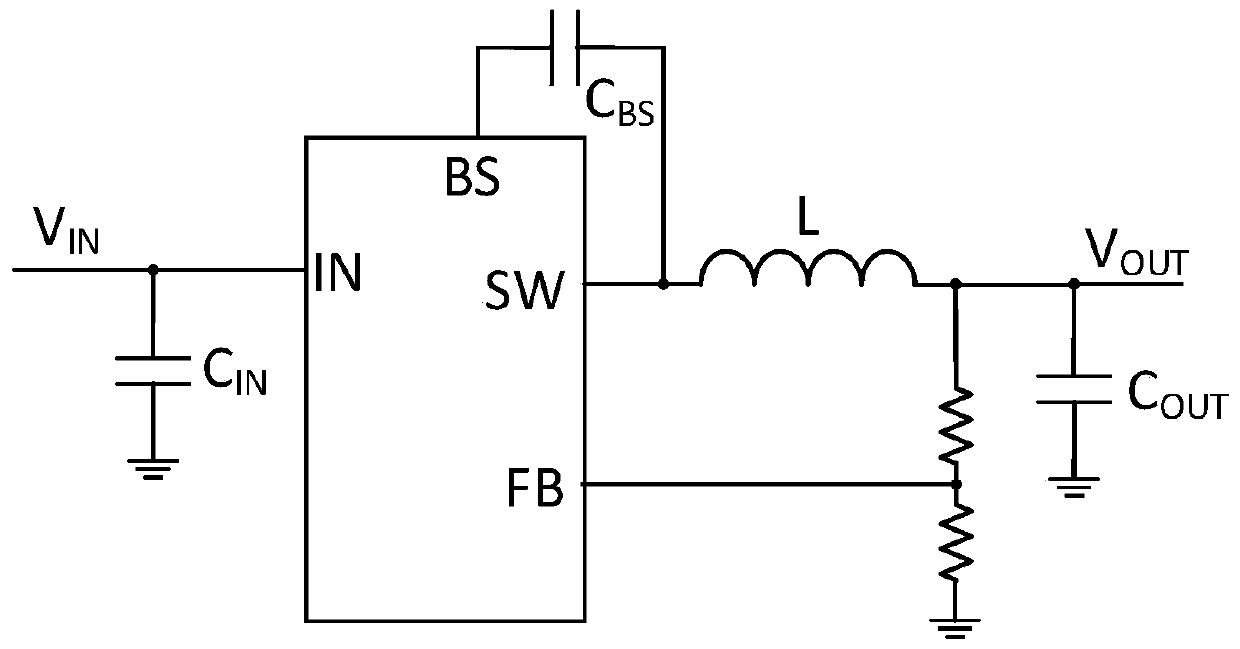

Switching regulator

ActiveUS20200127561A1Suppression of excessive switching operationReduce ripple voltageDc-dc conversionElectric variable regulationSoftware engineeringMechanical engineering

Owner:ABLIC INC

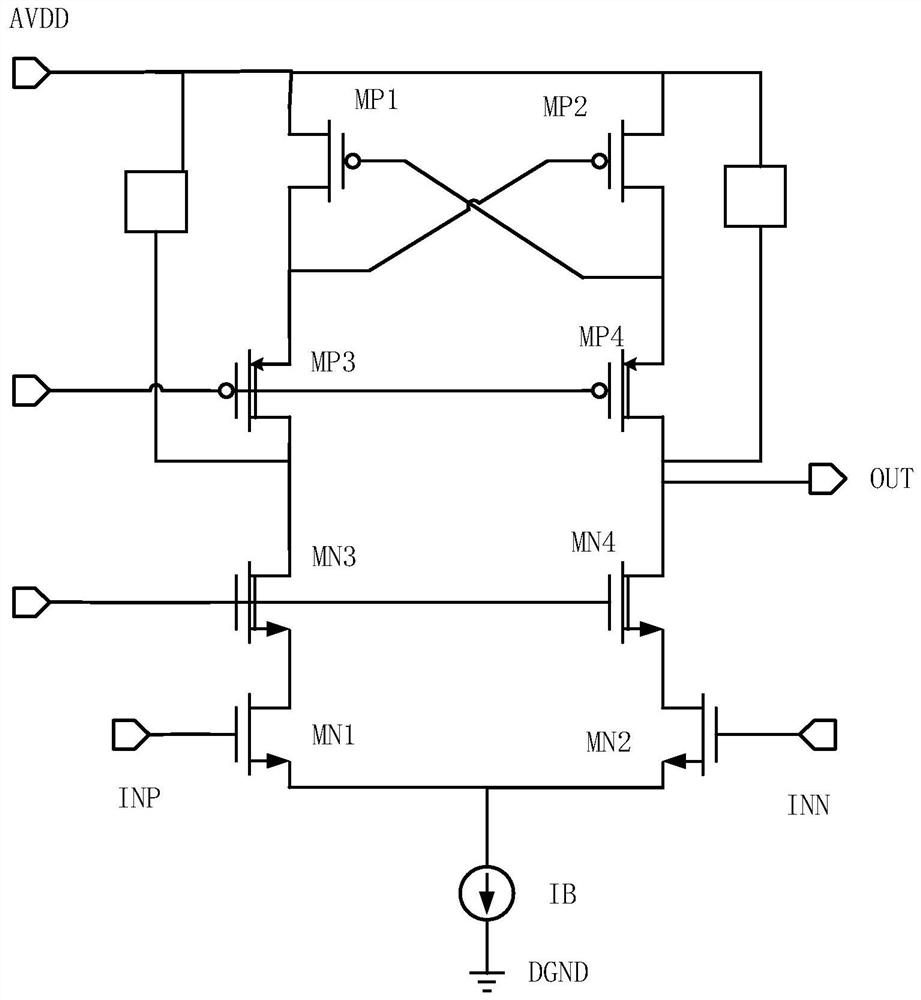

Level shifter

PendingCN112073054AGuaranteed to workReduce power consumptionLogic circuits coupling/interface using field-effect transistorsOvervoltageConverters

The invention discloses a level shifter which comprises an output end, a first input end, a second input end, a latch circuit, a level overturning pull-down circuit and a voltage clamping circuit. Thelatch circuit comprises a first PMOS tube, a second PMOS tube, a first NMOS tube and a second NMOS tube. The voltage clamping circuit comprises a first clamping device, a second clamping device, a third NMOS tube, a fourth NMOS tube, a fifth PMOS tube and a sixth PMOS tube. The level overturning pull-down circuit comprises a fifth NMOS transistor and a sixth NMOS transistor; the first clamping device is used for clamping the voltage of the grid electrodes of the fifth PMOS tube and the sixth PMOS tube; the second clamping device is used for clamping the voltage of the grid electrodes of the third NMOS tube and the fourth NMOS tube. Under the condition that the ground level of the high-voltage driving signal is changed, level conversion is completed at high speed and low power consumption,and the cost is low. A gate oxide layer of a transistor device in the level shifter can be protected from being broken down through the voltage clamping circuit, and the high voltage of the output end is isolated; zero static power consumption and rapid level overturning are achieved through the latch circuit and the level overturning pull-down circuit, and high driving capacity is achieved.

Owner:WILL SEMICON (SHANGHAI) CO LTD

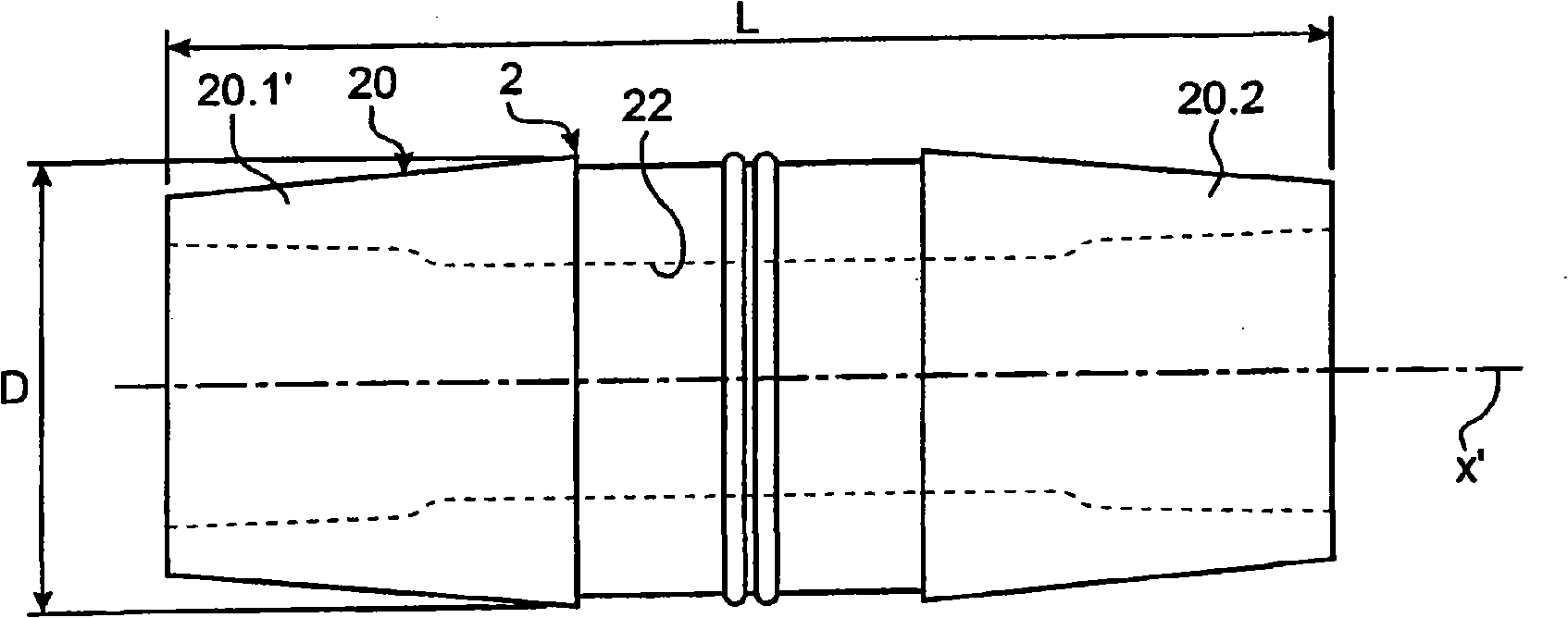

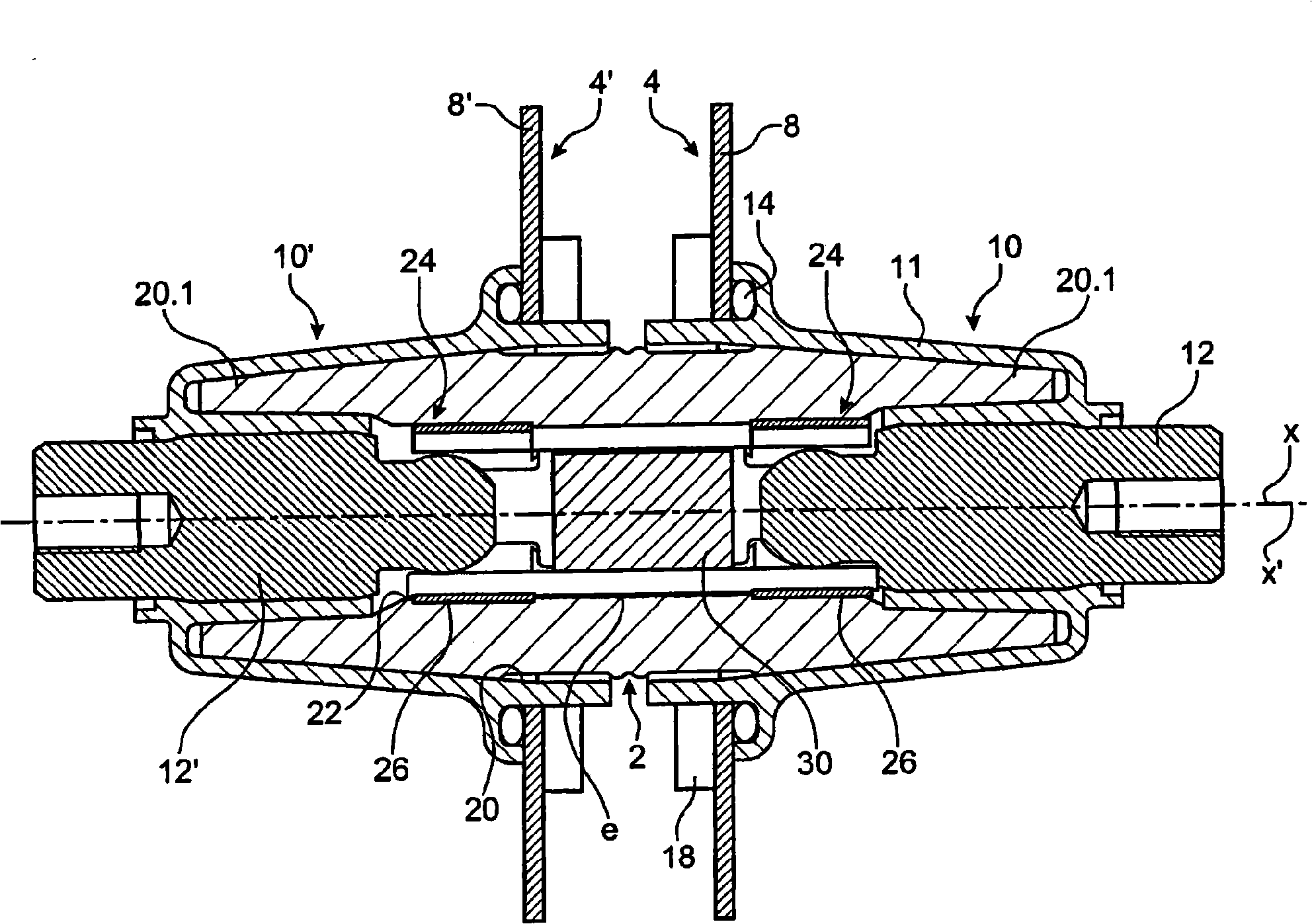

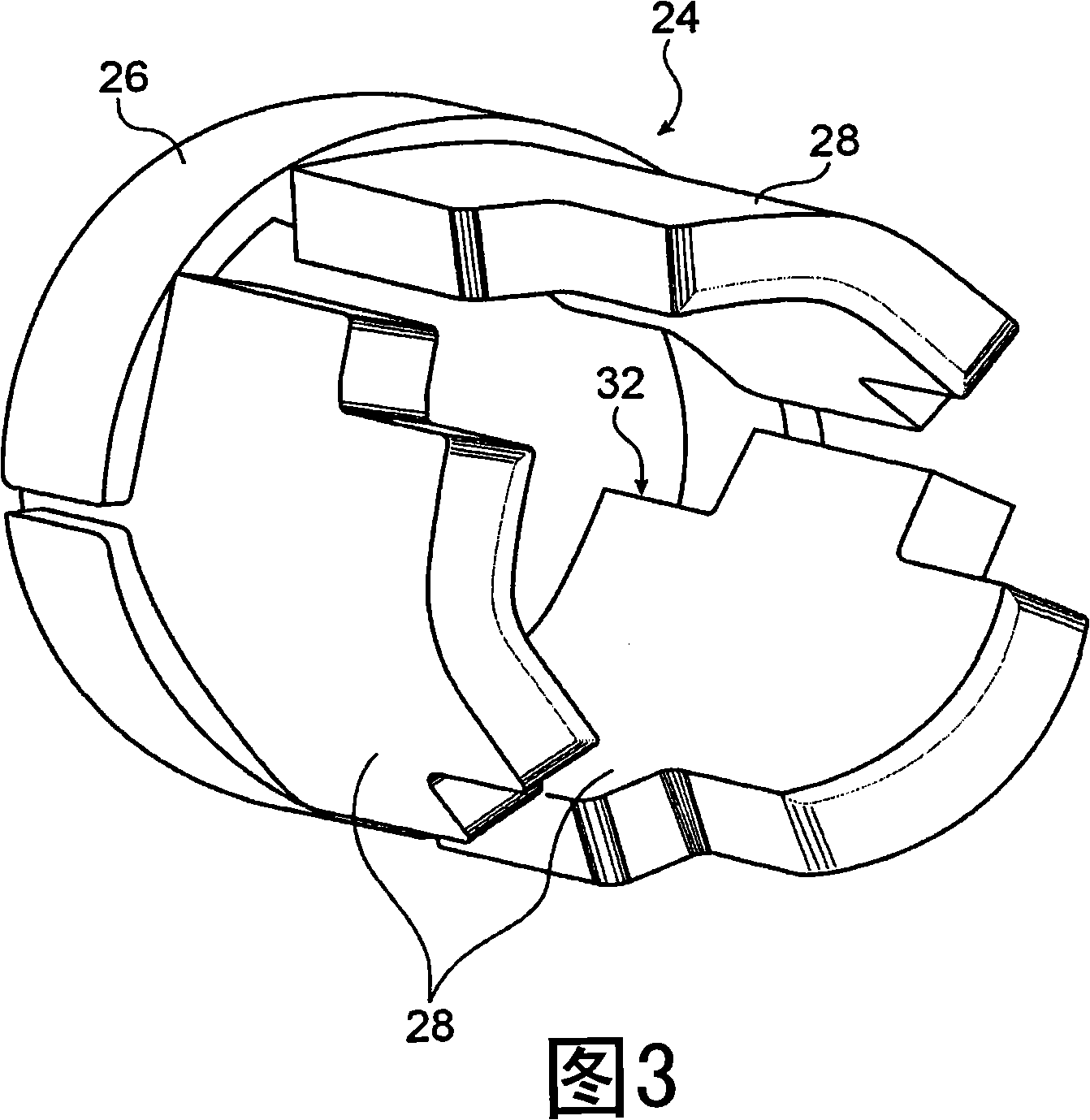

Electrical connection device between two medium- or high-voltage cells and distribution substation containing at least one such device

ActiveCN101359814AReduce the amount of materialReduce manufacturing costSwitchgear arrangementsCouplings bases/casesElectrical connectionHigh pressure

The invention discloses a connecting device for electrically connecting the adjacent middle-high voltage frames, comprising a lining sleeve (20) composed with the electrically insulating and flexibly deforming materials limiting the vertical axial line (X'); a first and second connecting clamper (24) provided in the lining sleeve (20) along the vertical axial line (X'); the first and second connecting clampers (24) are distributed as the contact component (12) connecting the first frame (4) and the contact component (12') connecting the first frame (4'); and a first and second tubular springs (26) respectively circling the first and second clampers to apply the axial force.

Owner:AREVA T&D

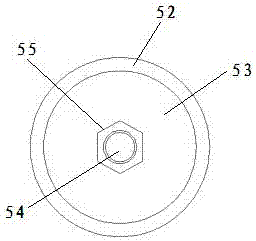

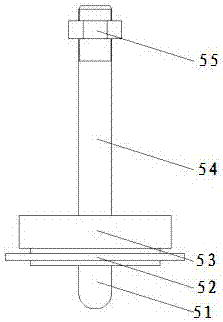

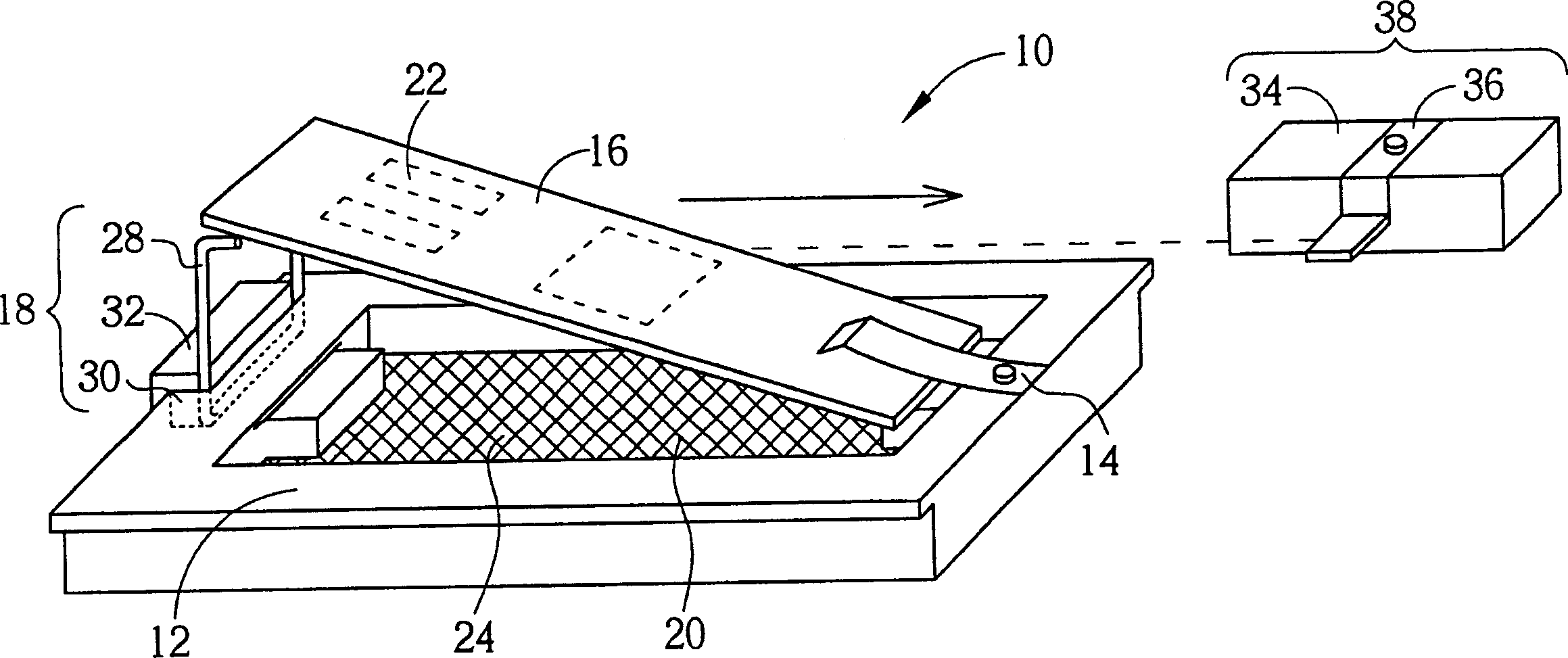

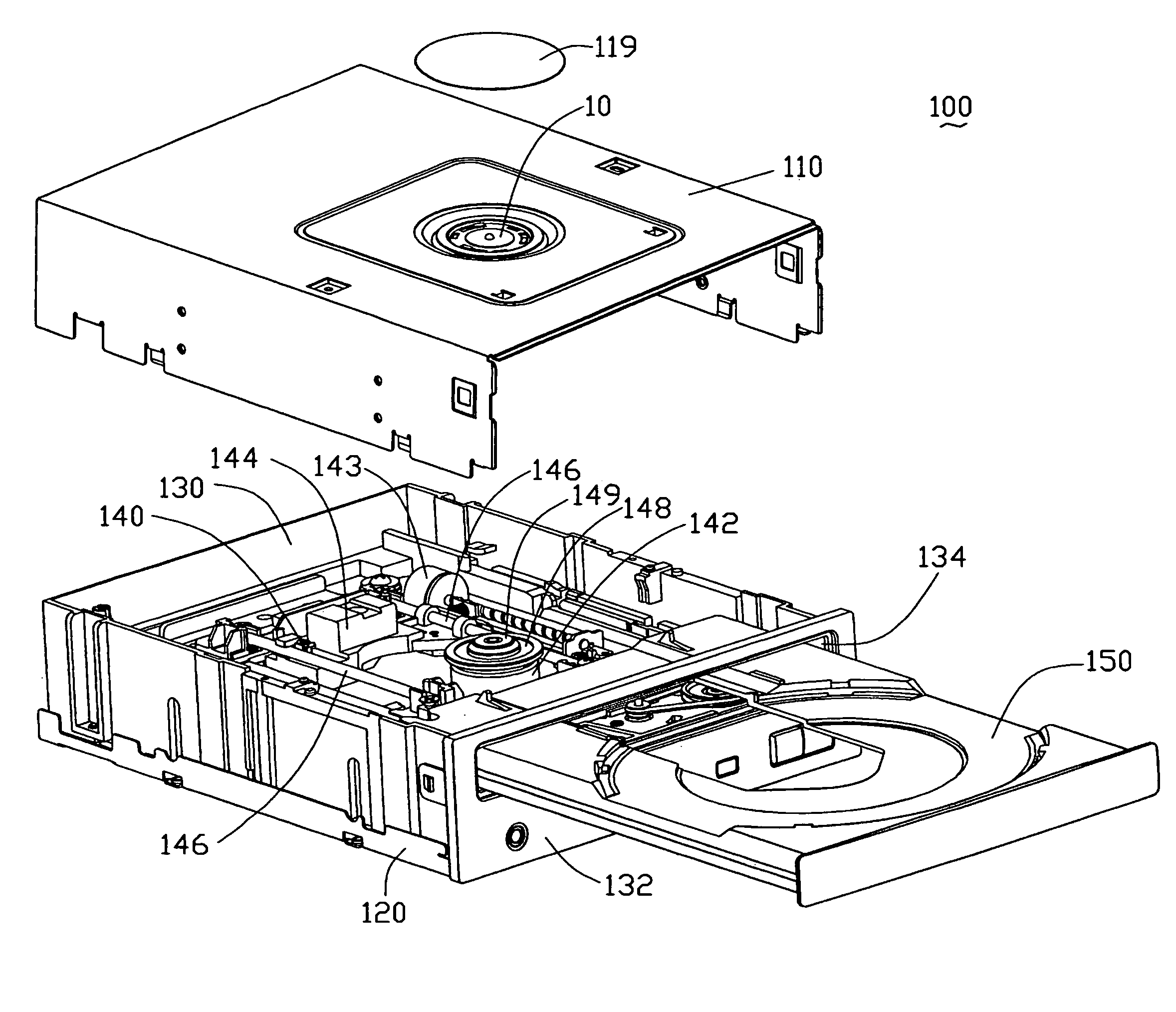

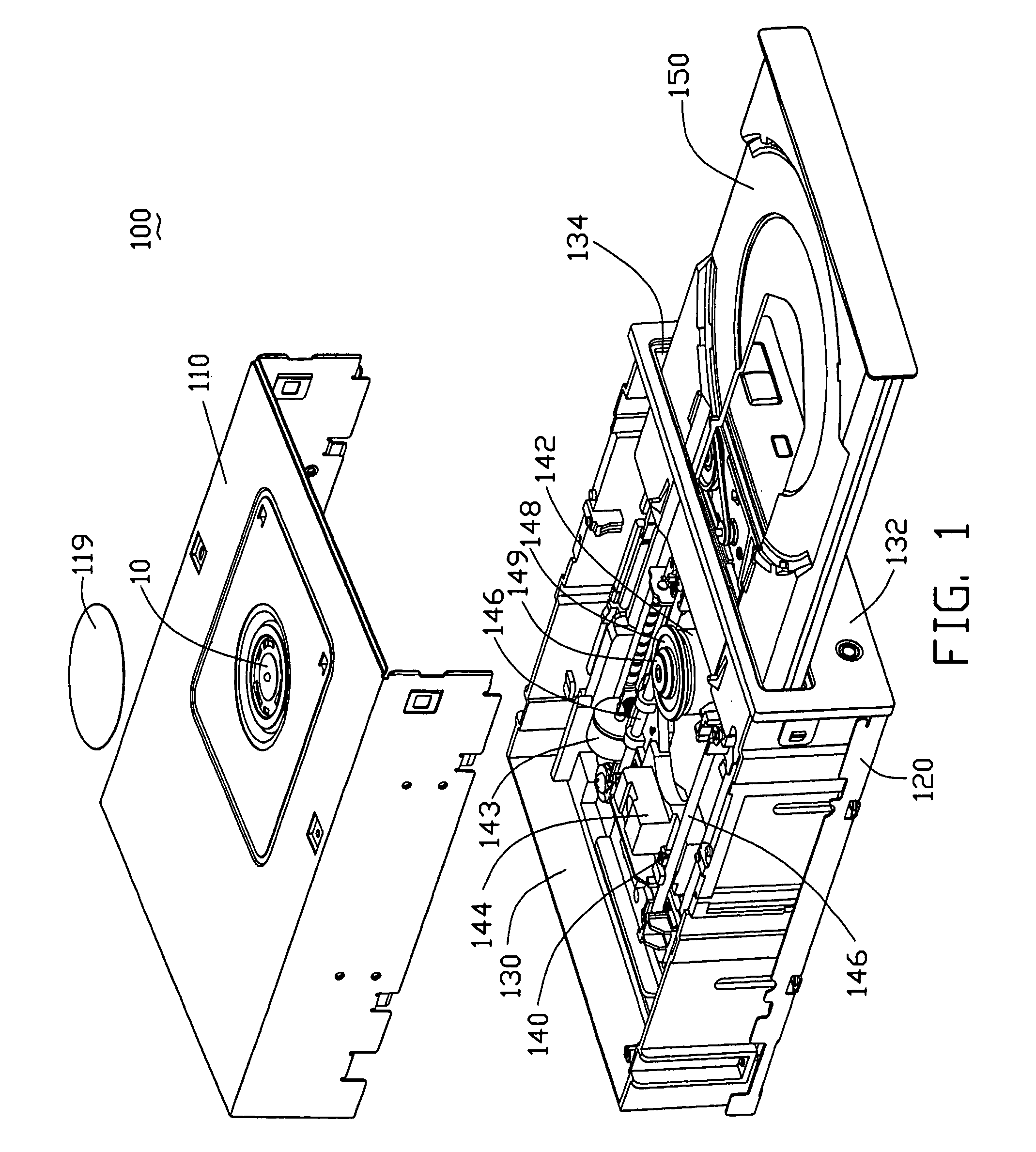

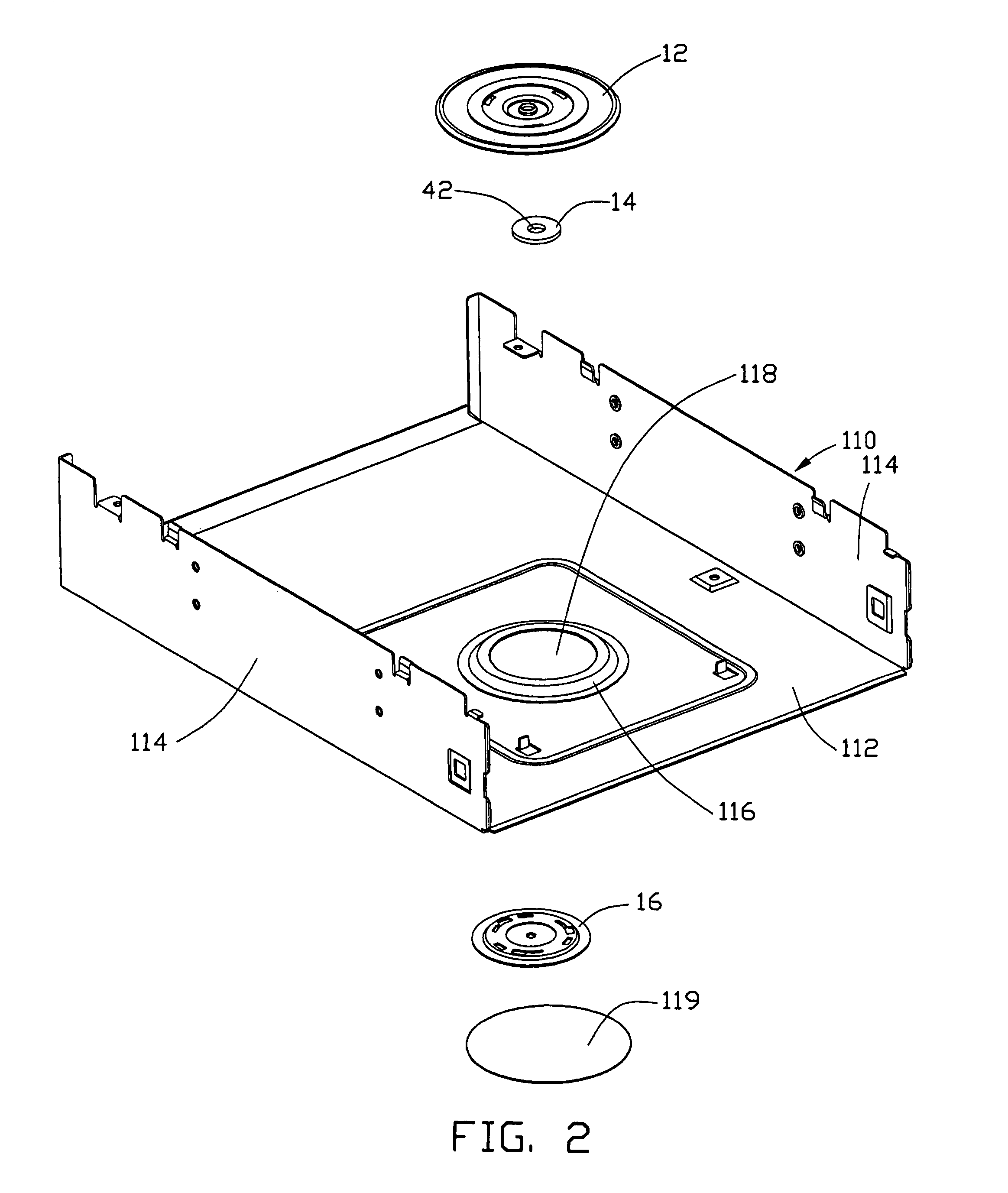

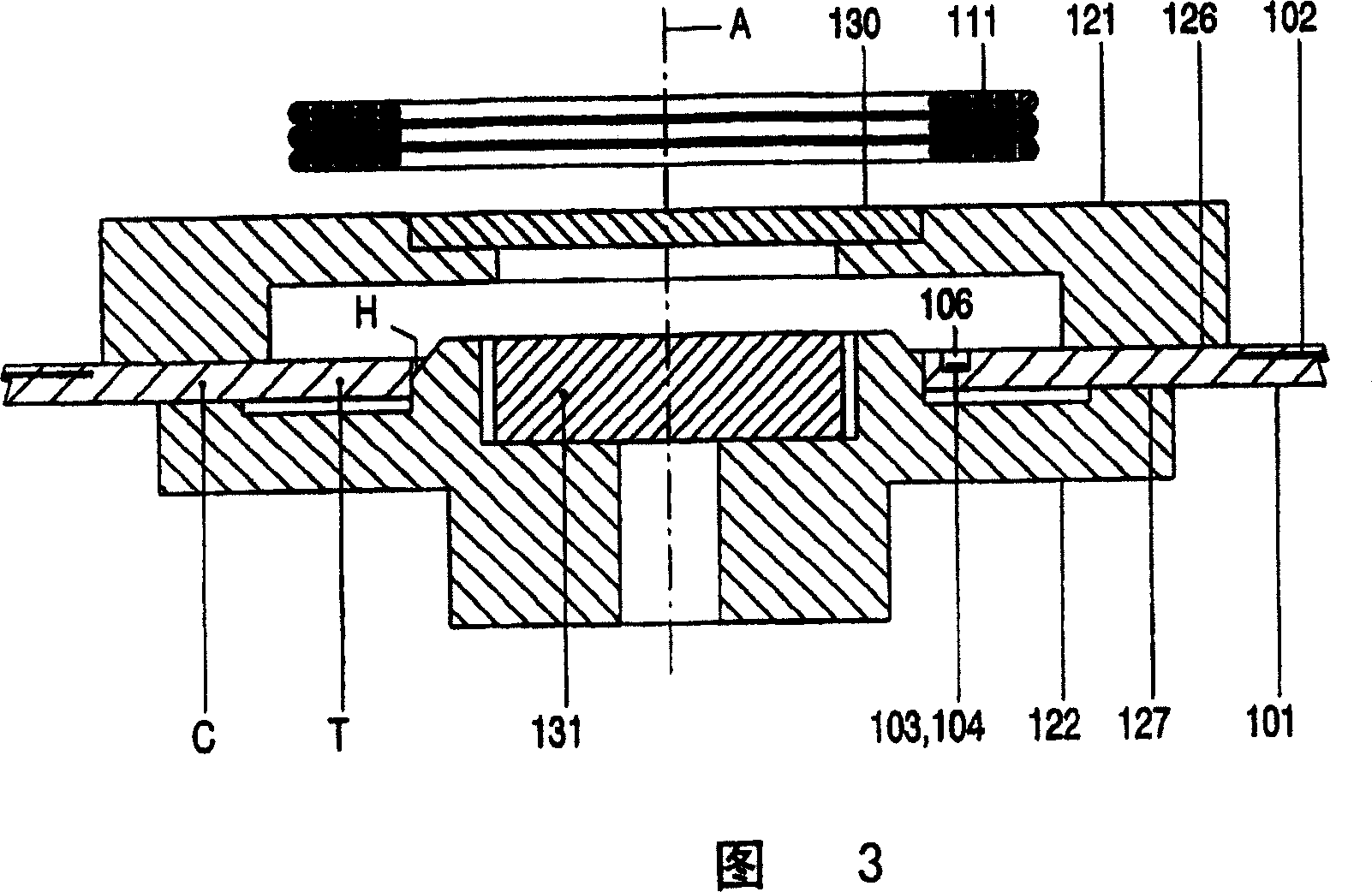

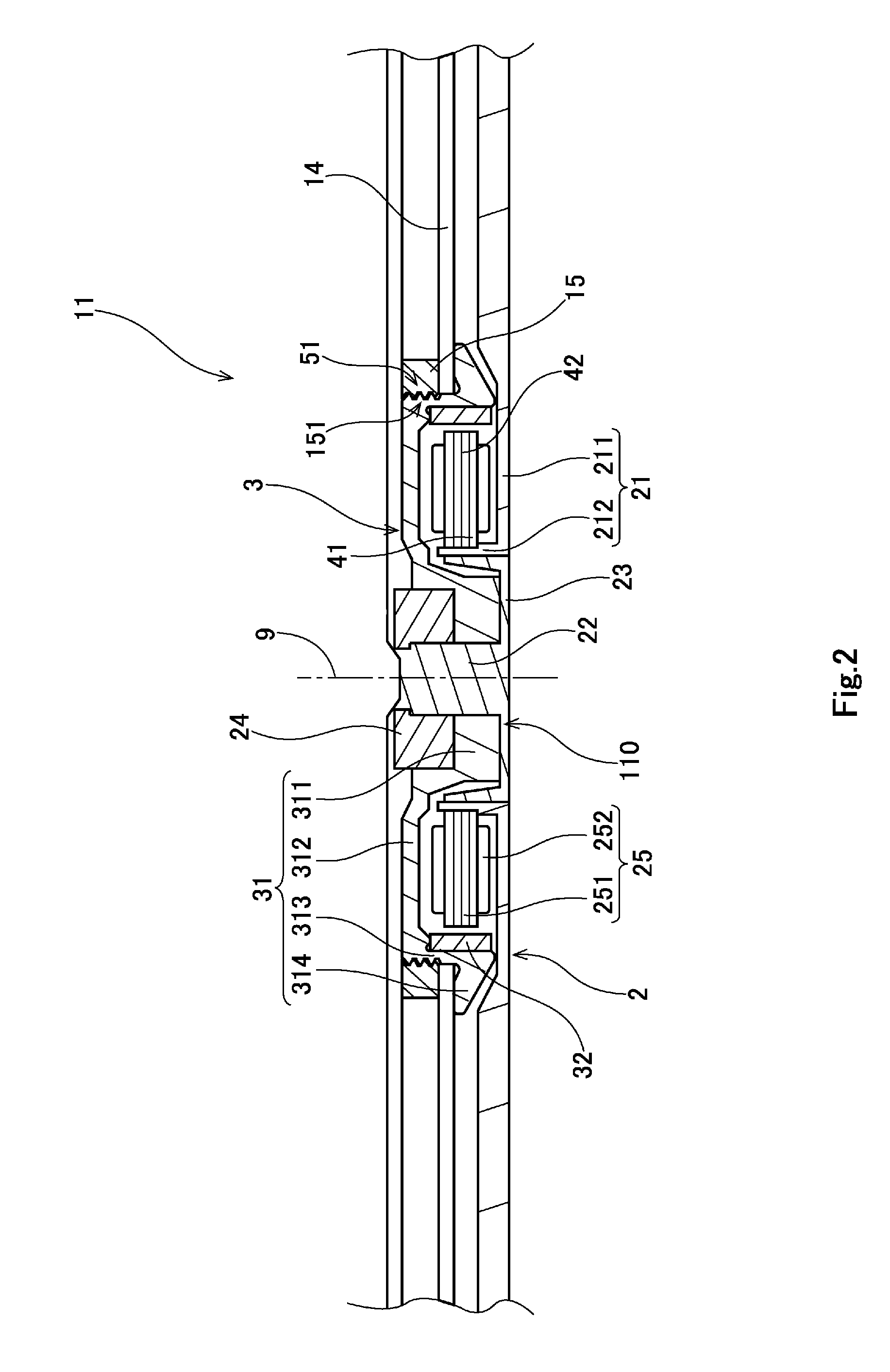

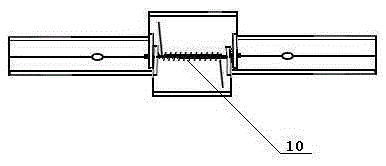

Optical disk recording and/or reproducing apparatus

InactiveUS7225449B2Simple structureAvoid misreadingRecord information storageRecord carrier contruction detailsMechanical engineeringMagnet

An optical disk recording and / or reproducing apparatus (100) includes a first case (110), a base (130), and a main body (140). The first case includes a supporting device (116) with a hole (118) defined therein, and a disk clamper (10). The main body is accommodated in the base, and includes a spindle motor (142) and a turntable (148). A magnetic element (149) is positioned on the turntable. The disk clamper includes a clamping body (12), a magnet (14), and a clip (16). The clamping body and the clip are respectively positioned on lower and upper sides of the supporting device, and fixed together through the hole. The magnet is sandwiched between the clamping body and the clip. In use, because of attraction of the magnet and the magnetic element, opposite sides of an optical disk (220) are respectively clamped by the clamping body and the turntable.

Owner:HON HAI PRECISION IND CO LTD

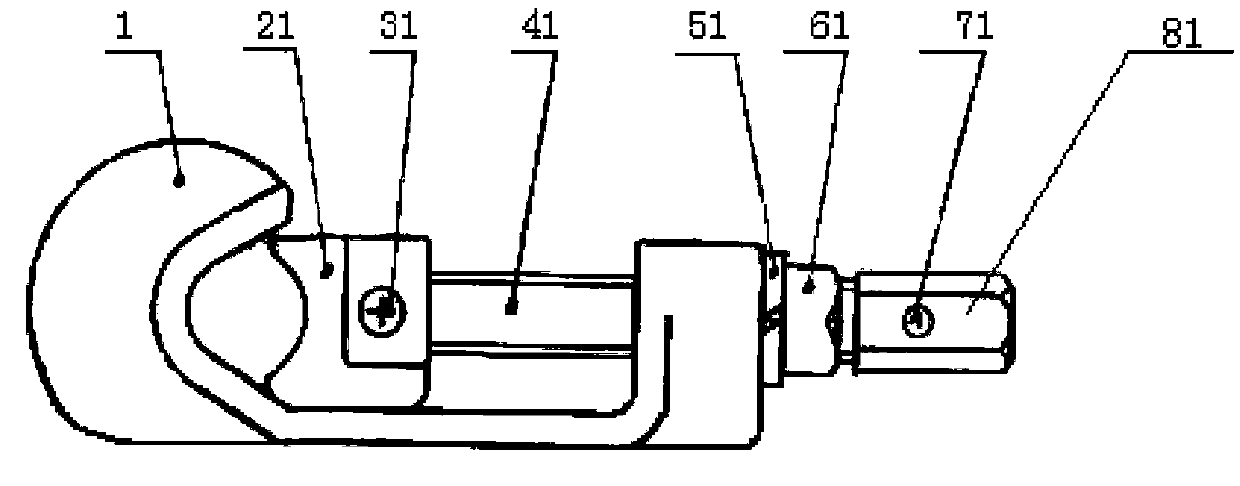

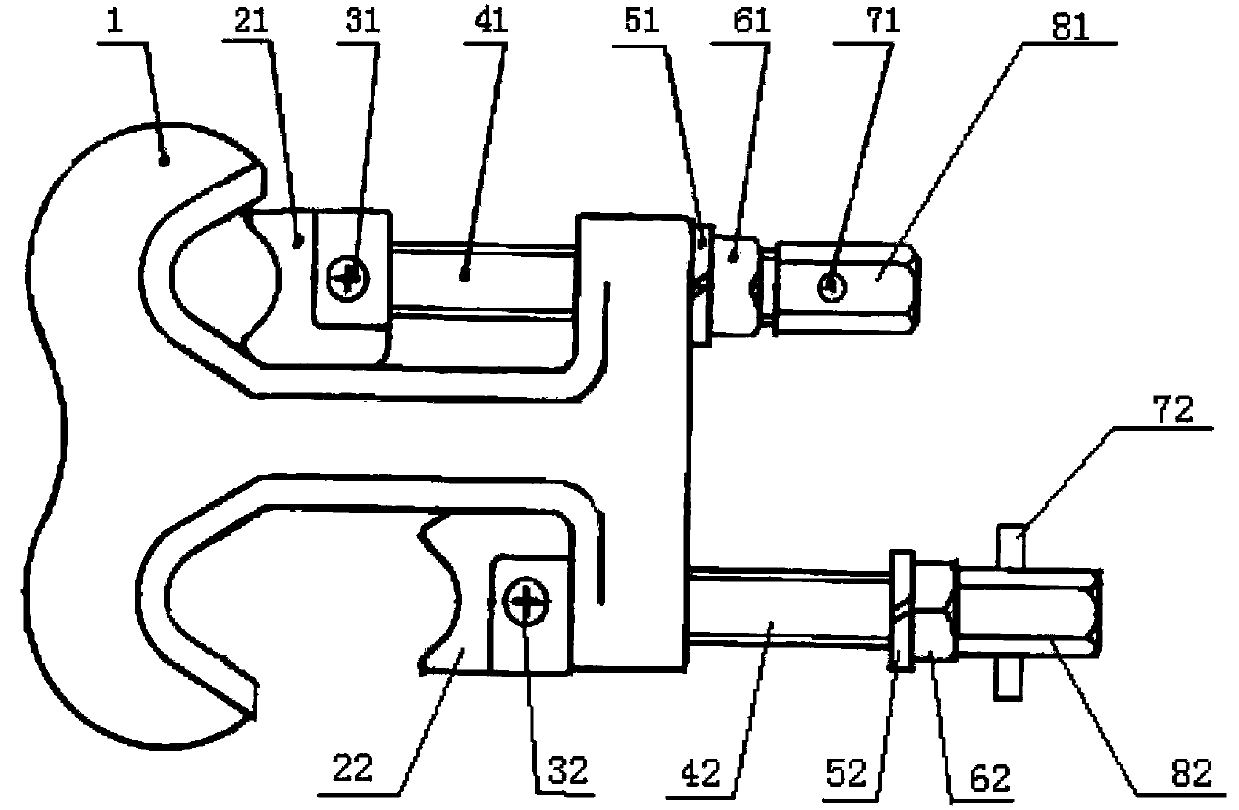

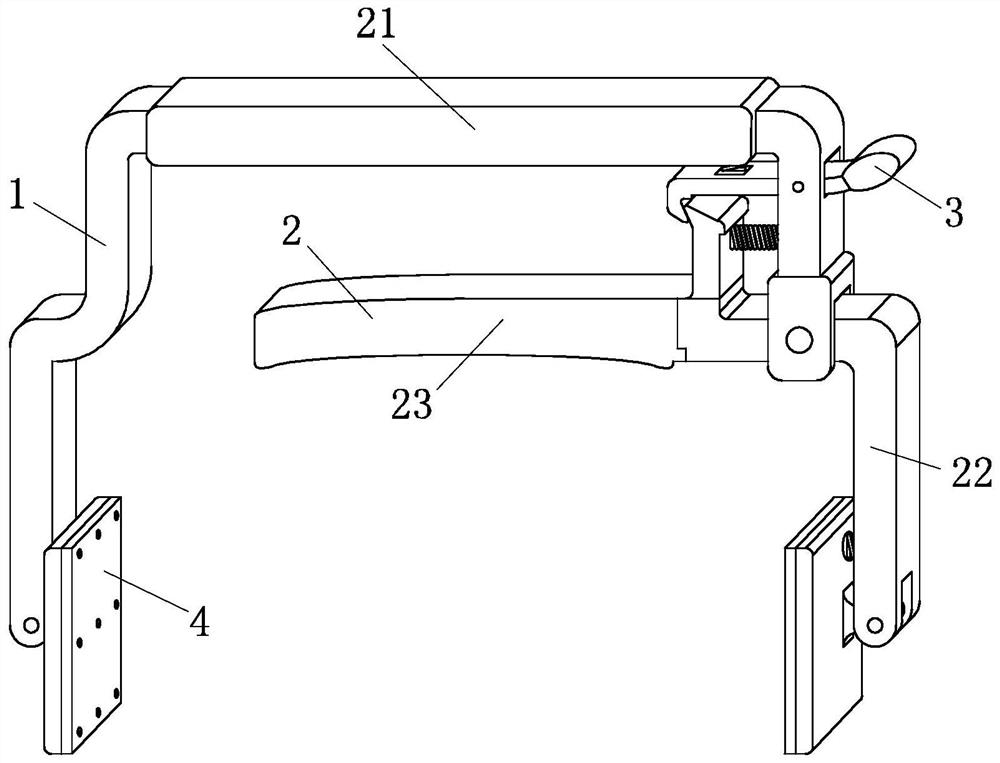

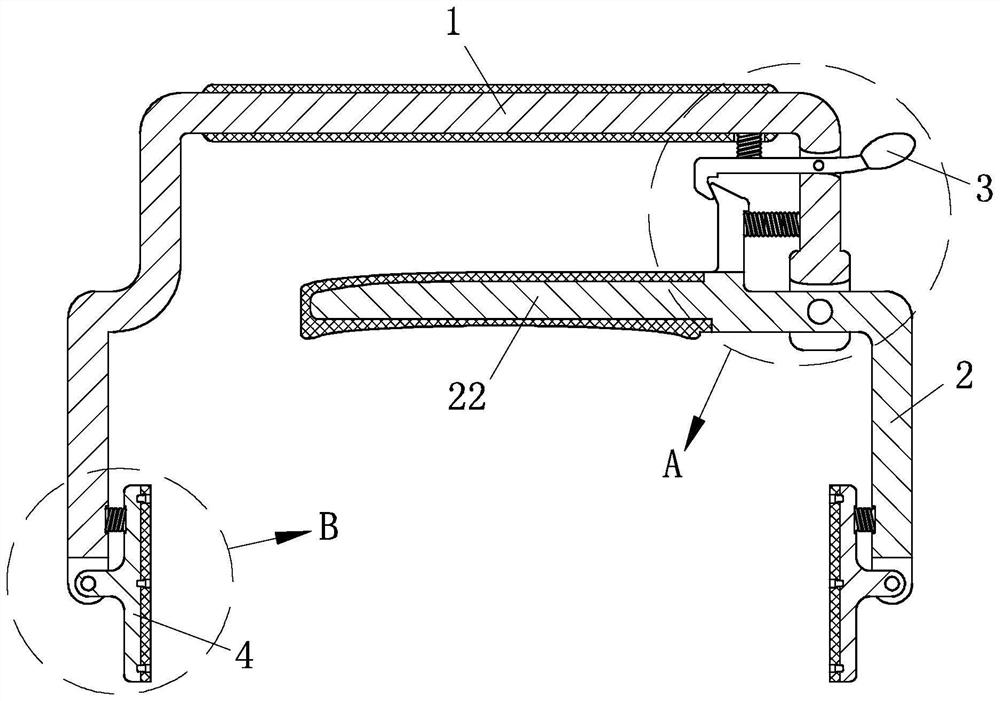

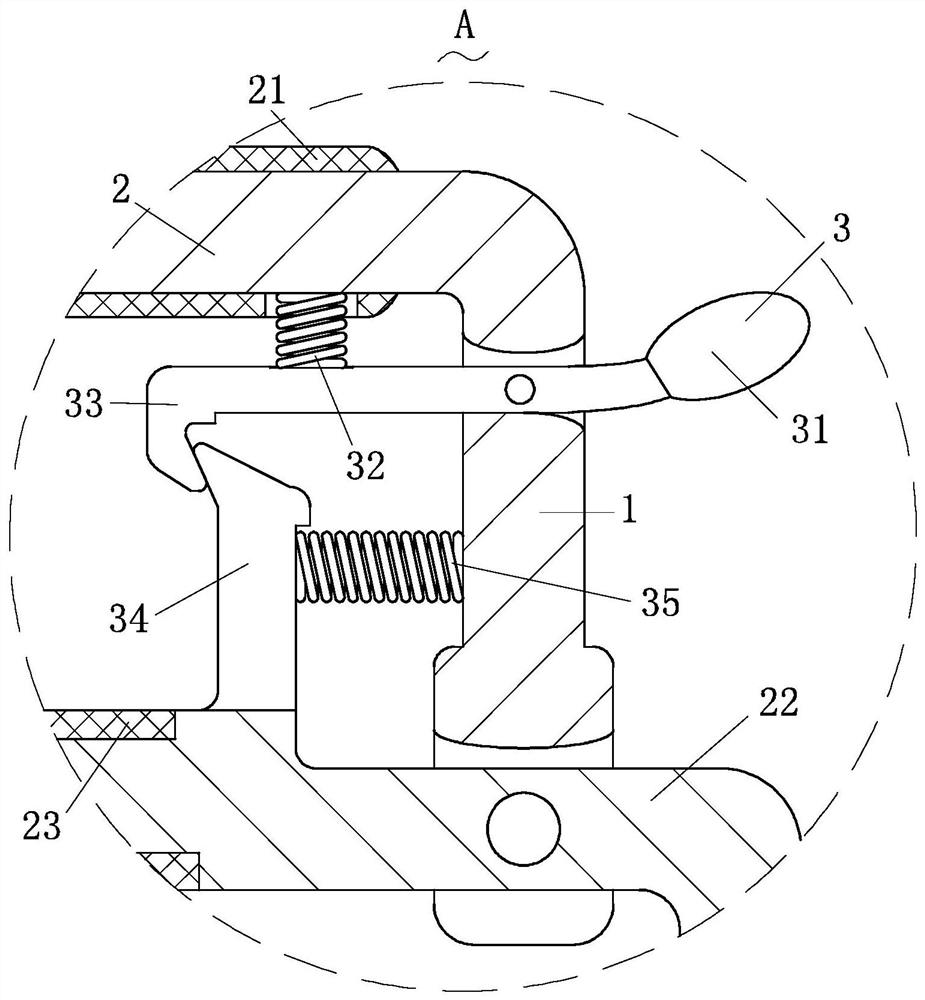

Novel jumper conductor clamper

InactiveCN103872476AEasy to masterSimple structureElectric connection structural associationsClamped/spring connectionsControl theoryMechanical engineering

The invention provides a novel jumper conductor clamper, which comprises a jumper conductor clamper main body, a first pressing block and a first driving device, wherein the first pressing block is matched with the jumper conductor clamper main body for forming a first area for clamping a conductor, and the first driving device drives the first pressing block to move towards the direction close to or far away from the jumper conductor clamper main body, so that different clamping areas for clamping different conductors are formed. For jumper conductors of different specifications, the first driving device can drive the first pressing block to move so as to change the size of the first clamping area for clamping the conductor between the pressing block and the jumper conductor clamper main body for clamping the jumper conductors of different specifications, the structure is simple, the cost is low, the operation is convenient and flexible, the novel jumper conductor clamper is suitable for being used on different conductor types and different materials on one jumper conductor, a working method is easy to master and popularize, and workers can operate the novel jumper conductor clamper only after being trained for a short term.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

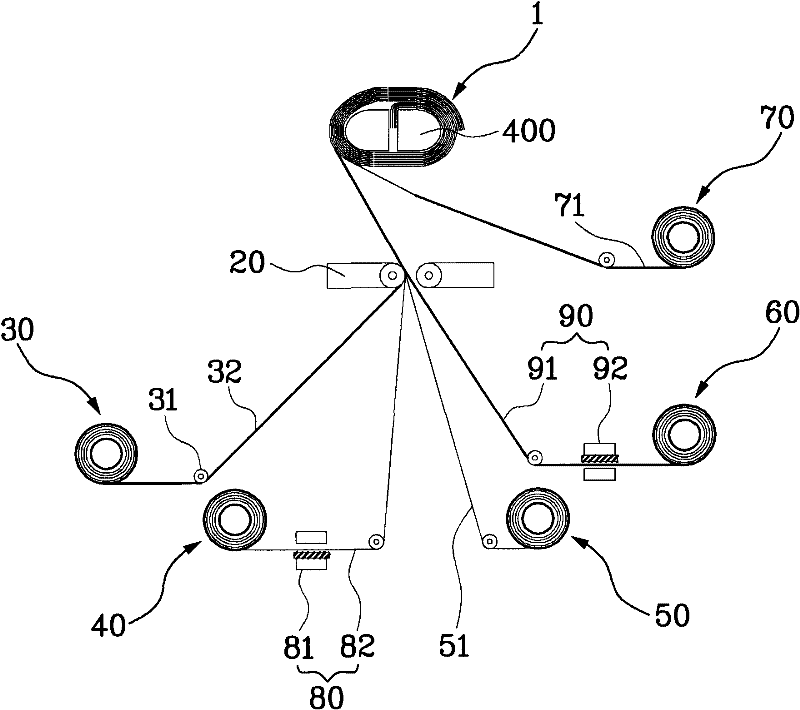

Apparatus and method for winding electrode assembly

ActiveCN102130327APrevent disengagementWinding firmlyAssembling battery machinesCell electrodesElastomerLithium

The present invention relates to an apparatus and a method for winding an electrode assembly which forms a lithium ion secondary battery or a capacitor, and more particularly to an apparatus and a method for winding the electrode assembly that is clamped by a clamper thereby preventing disengagement between the electrode assembly and a winding part and causing stable winding so as to improve operation efficiency and productivity. For this purpose, the apparatus for winding the electrode assembly which forms the capacitor and secondary battery is characterized by comprising the following components: a clamp part which is provided with a first clamper and a second clamper that are formed oppositely and is provided with a first elastomer that can cause the first clamper and the second clamper to deviate with a preset distance; the winding part which is provided with a first winding roller formed outside the first clamper and a second winding roller formed outside the second clamper; a clamper driving part which compresses the first elastomer for causing the first clamper and the second clamper to cling with each other and fastens an end of the electrode assembly provided therebetween; and a winding driving part which causes the first winding roller and the second winding roller to outside part with a preset distance through connecting the second elastomer with the first winding roller and the second winding roller.

Owner:李癸卨

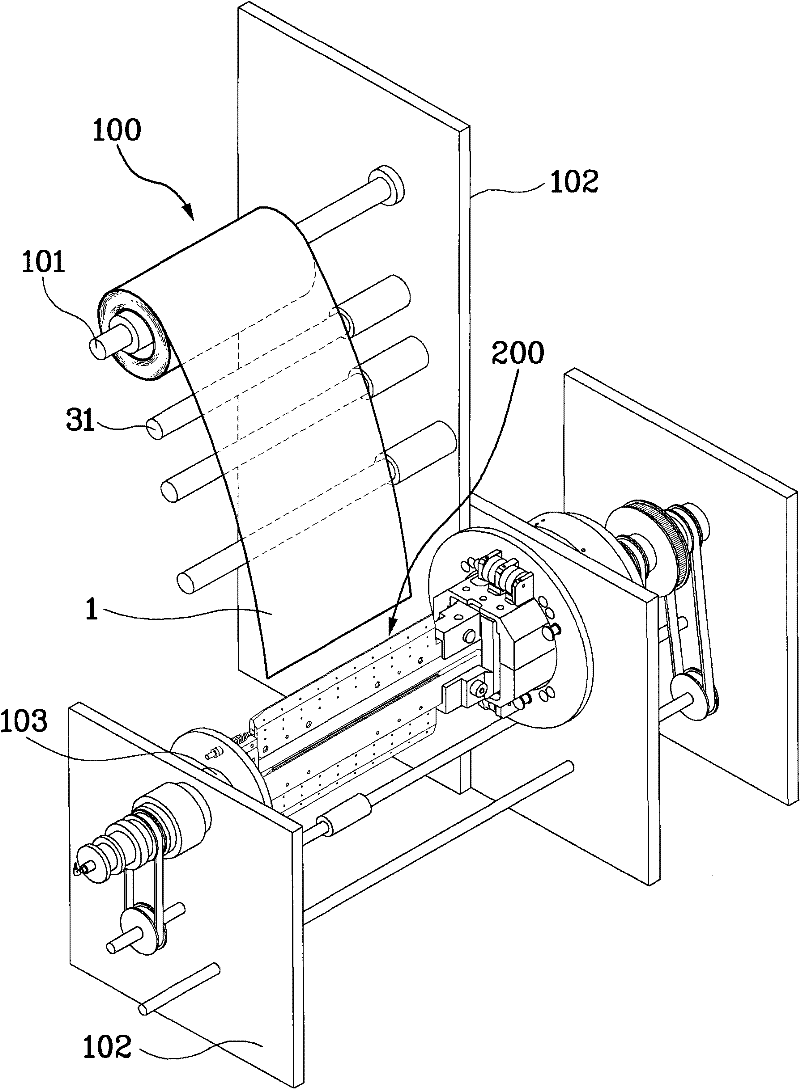

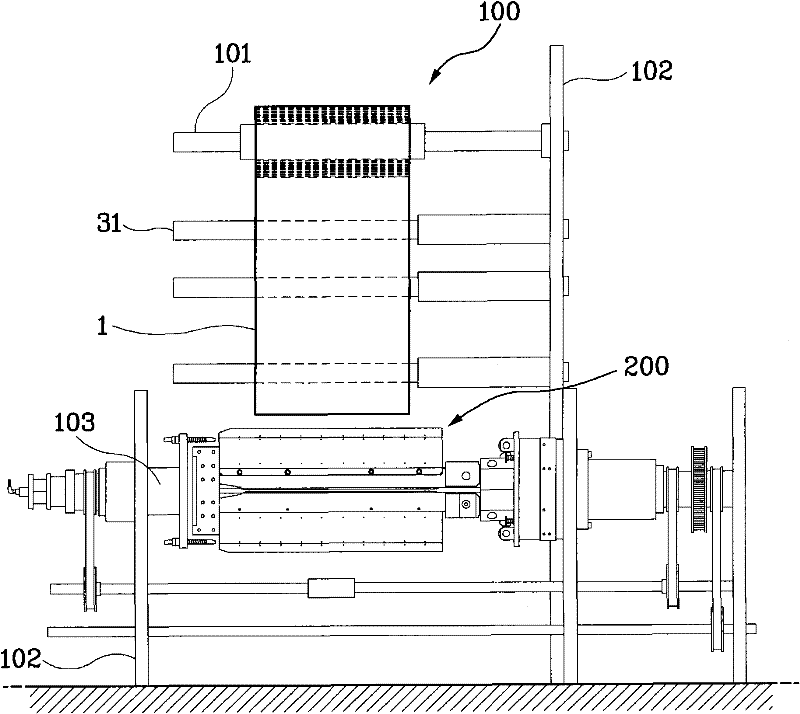

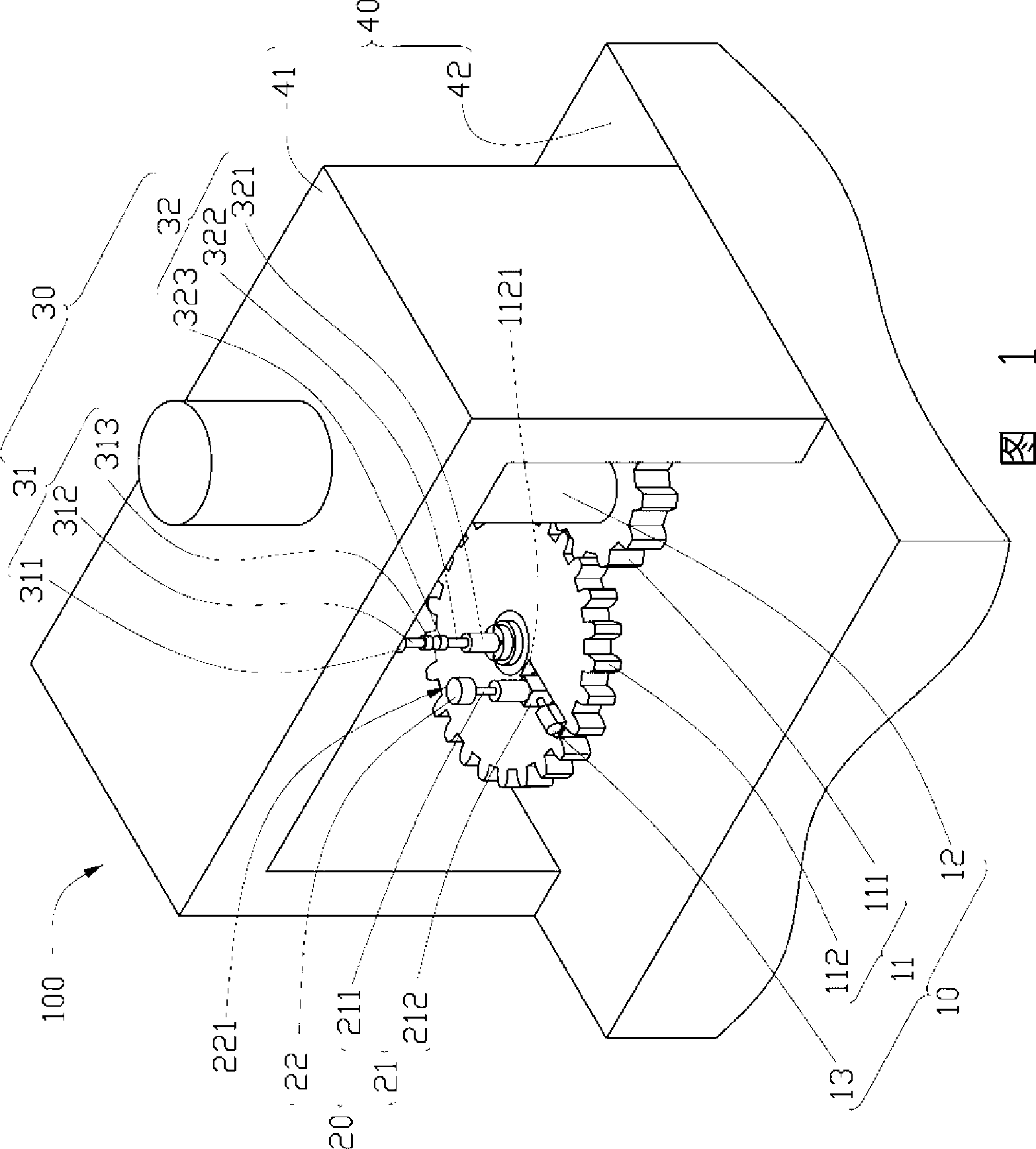

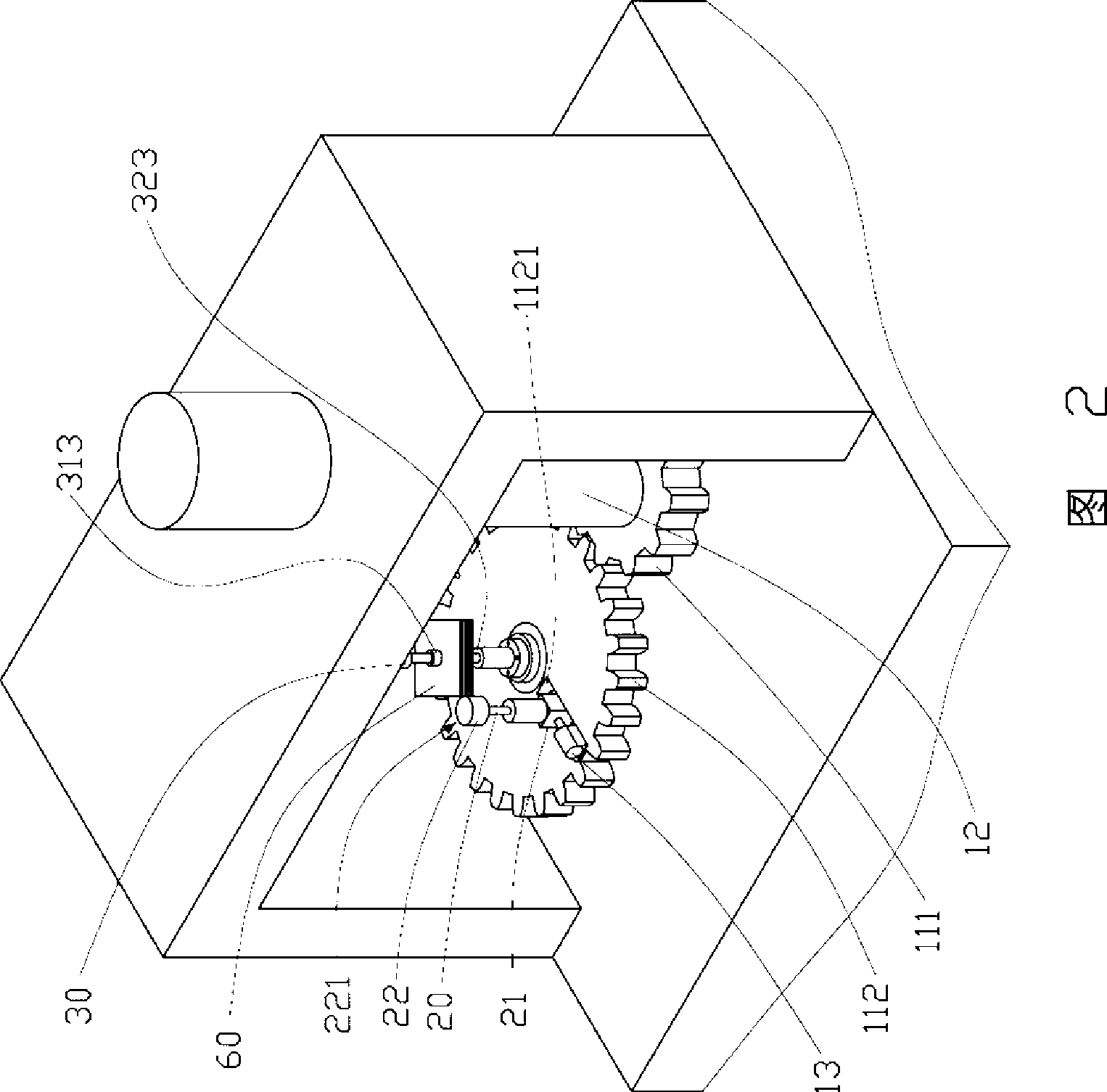

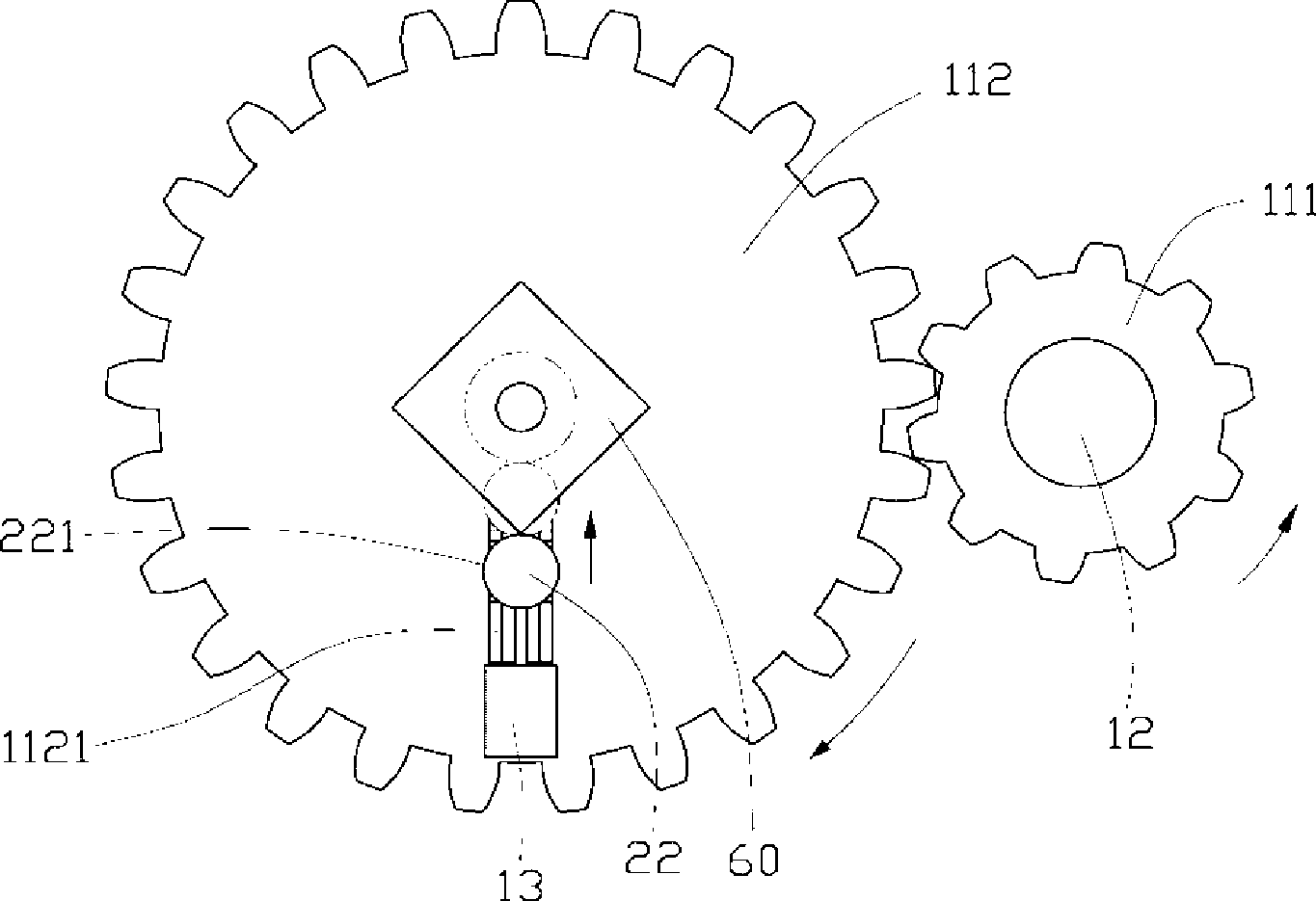

Rolling device and method

The invention relates to a rounding device which can be used to round a plate-shaped or a slice-shaped work piece, including a fixture, a rounding part, a drive device and a machine table. The fixture comprises a first fixture and a second fixture which is arranged oppositely to first clamper, the fixtures are used to clamp an awaiting work piece to be rounded. The rounding part comprises a grinding surface which is used to round the awaiting work piece to be rounded. The drive device comprises a transmission device, and a first drive device and a second drive device which are connected with the transmission device. The first drive device is used to drive the transmission device and the second drive device is also connected with the work piece to be rounded, so as to adjust the distance between the rounding part and the awaiting work piece to be rounded, drive the self-rotation of the rounding part, and drive the the rounding part rotating around the fixture axis. The machine table is used to place the fixture, the drive device and the rounding part. The invention also provides a method for rounding a work piece. The rounding device of the technical proposal does not need to change grinding wheels of different sizes when rounding a work piece, thereby improving the producing efficiency and reducing the cost.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

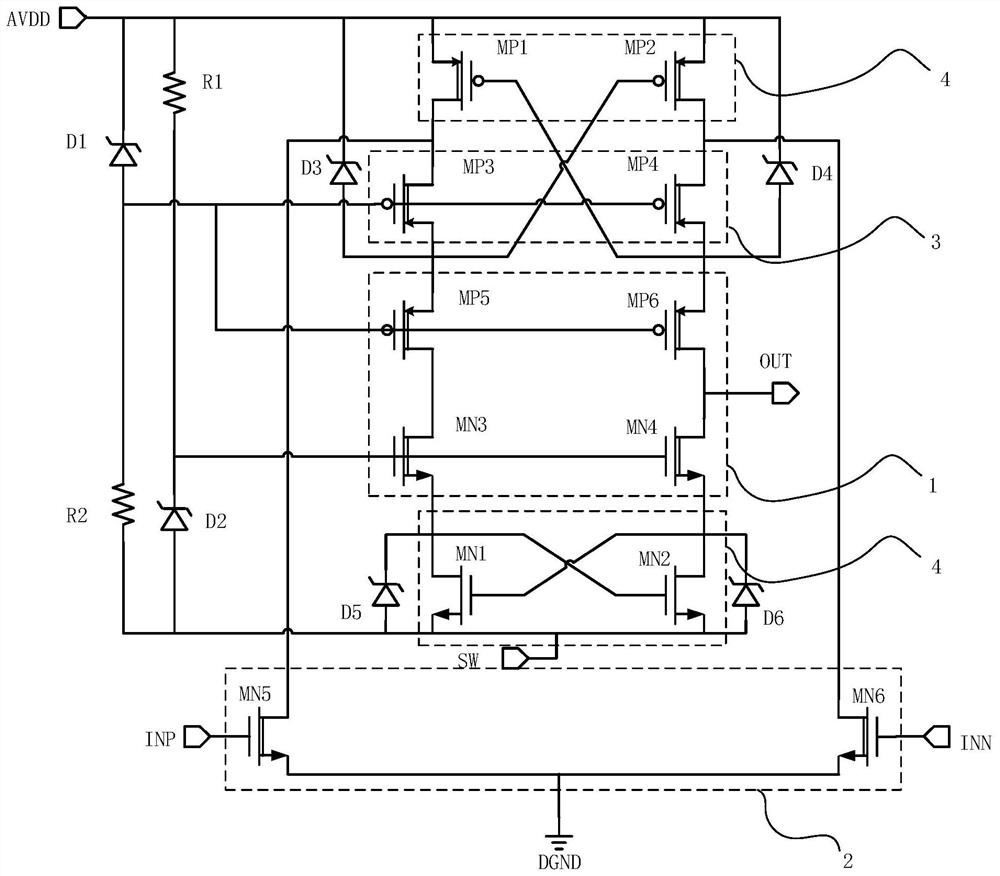

High-voltage PMOS drive circuit

PendingCN111245428AHighly integratedLow costPower reduction in field effect transistorsPower reduction by control/clock signalCapacitanceTerminal voltage

The invention discloses a high-voltage PMOS drive circuit. The circuit comprises a double-layer potential translation circuit, a clamper and a buffer. The double-layer potential translation circuit receives a low-end logic signal and a bias voltage provided by the clamper and outputs a high-end logic level to the buffer, and the buffer generates a high-end driving voltage as an output of the high-voltage PMOS drive circuit to control on and off of a high-voltage PMOS transistor. The output end of the clamper provides a negative end voltage for the buffer, so that the buffer works in a safe area, and the clamper provides a bias voltage for the double-layer potential translation circuit. Under the condition that an external capacitor is not needed, the voltages of a load element, a latch andthe buffer are all controlled within a safe working range, the integration level is high, and the cost is low. The voltage difference generated on the load element in the double-layer potential translation circuit is stable and reliable and is not easy to interfere with, and a latch required in the traditional technology can be omitted, so that the cost is saved.

Owner:苏州源特半导体科技有限公司

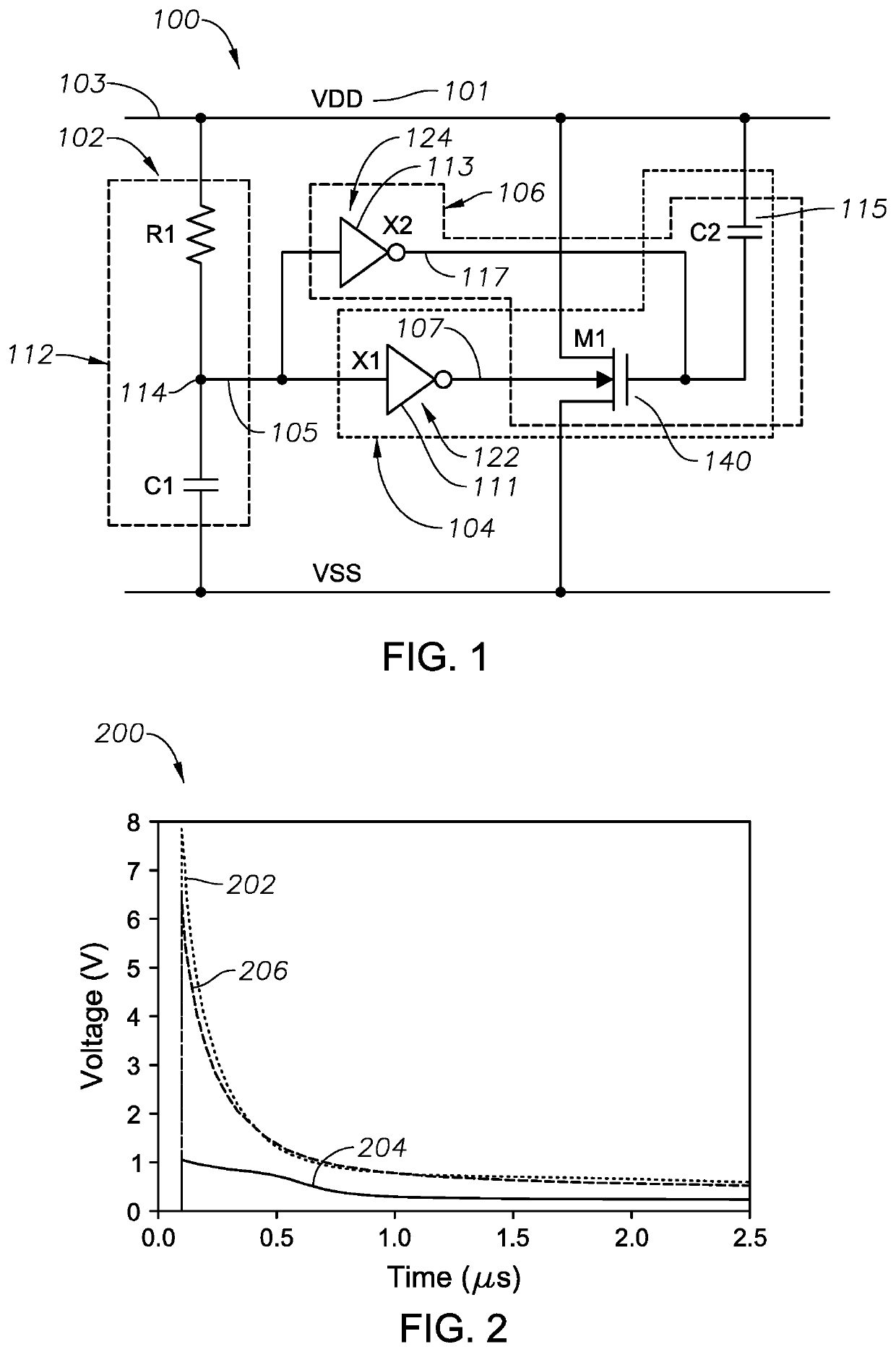

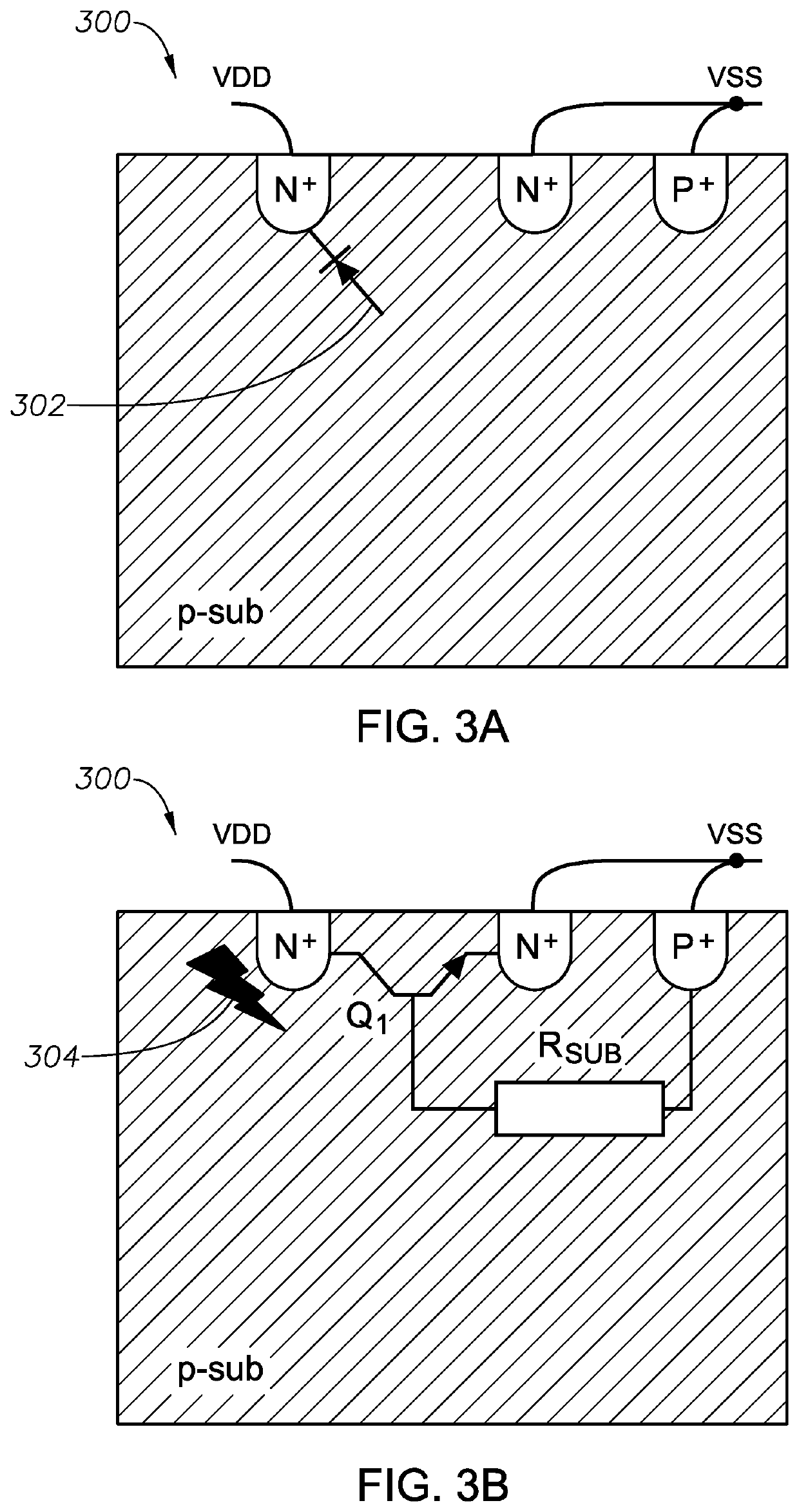

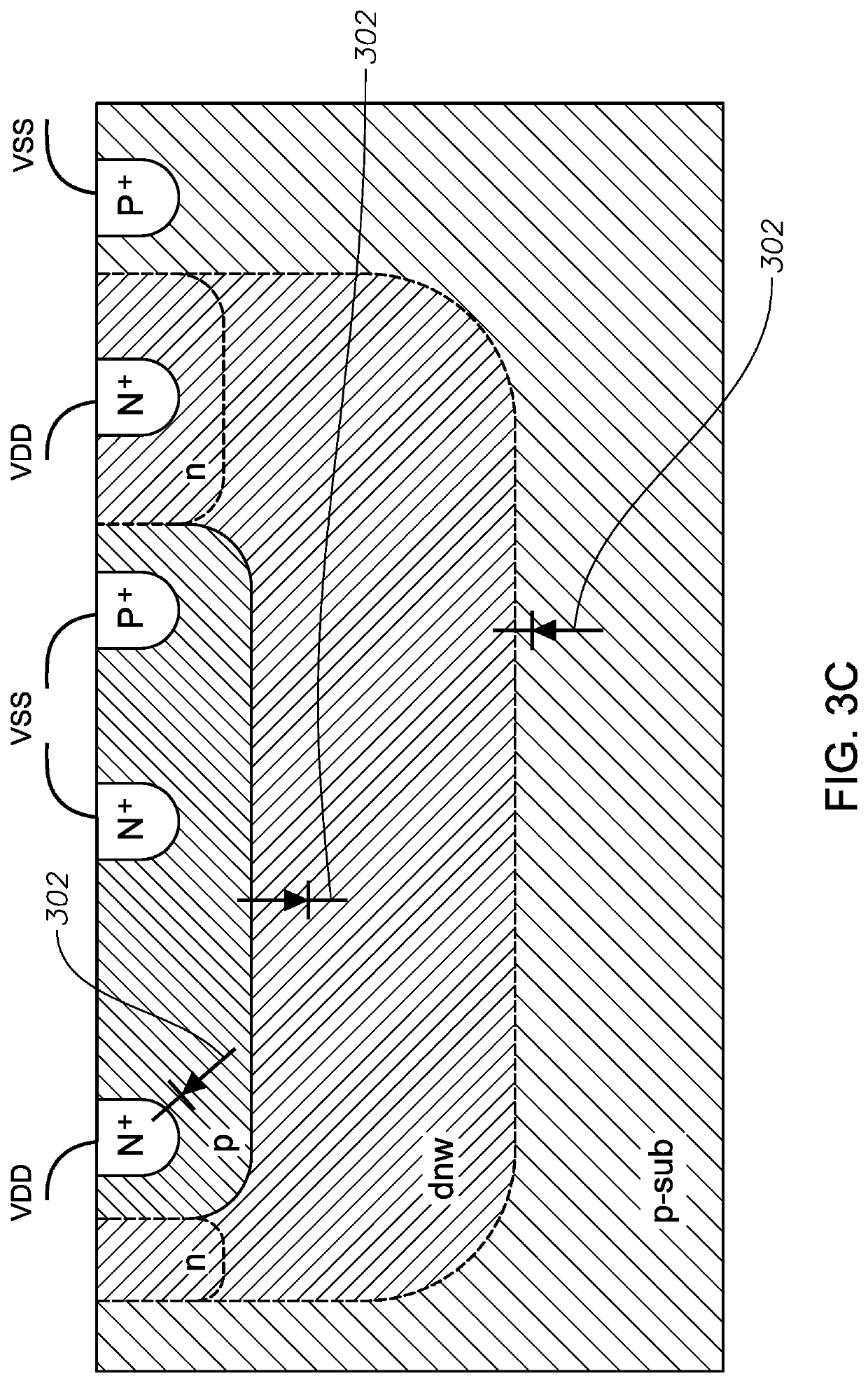

Devices and Methods to Control Clamping Devices

In a particular implementation, an apparatus to control clamping devices includes a first control circuit and a second control circuit. The first control circuit is responsive to a detection signal and generates a first drive signal to control a body diode of a clamping device. The second control circuit is responsive to the detection signal and generates a second drive signal to control the gate terminal of the clamping device.

Owner:ARM LTD +1

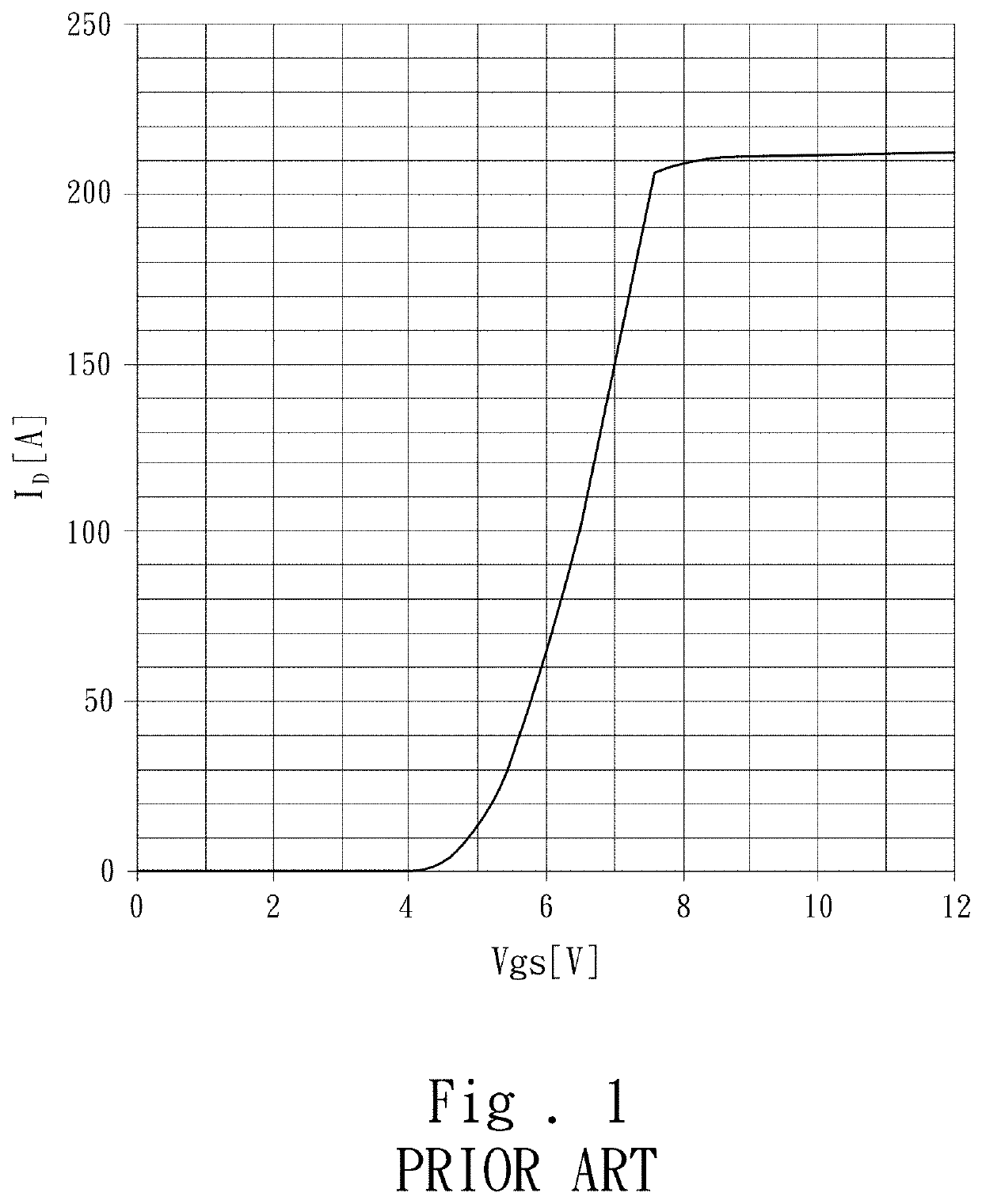

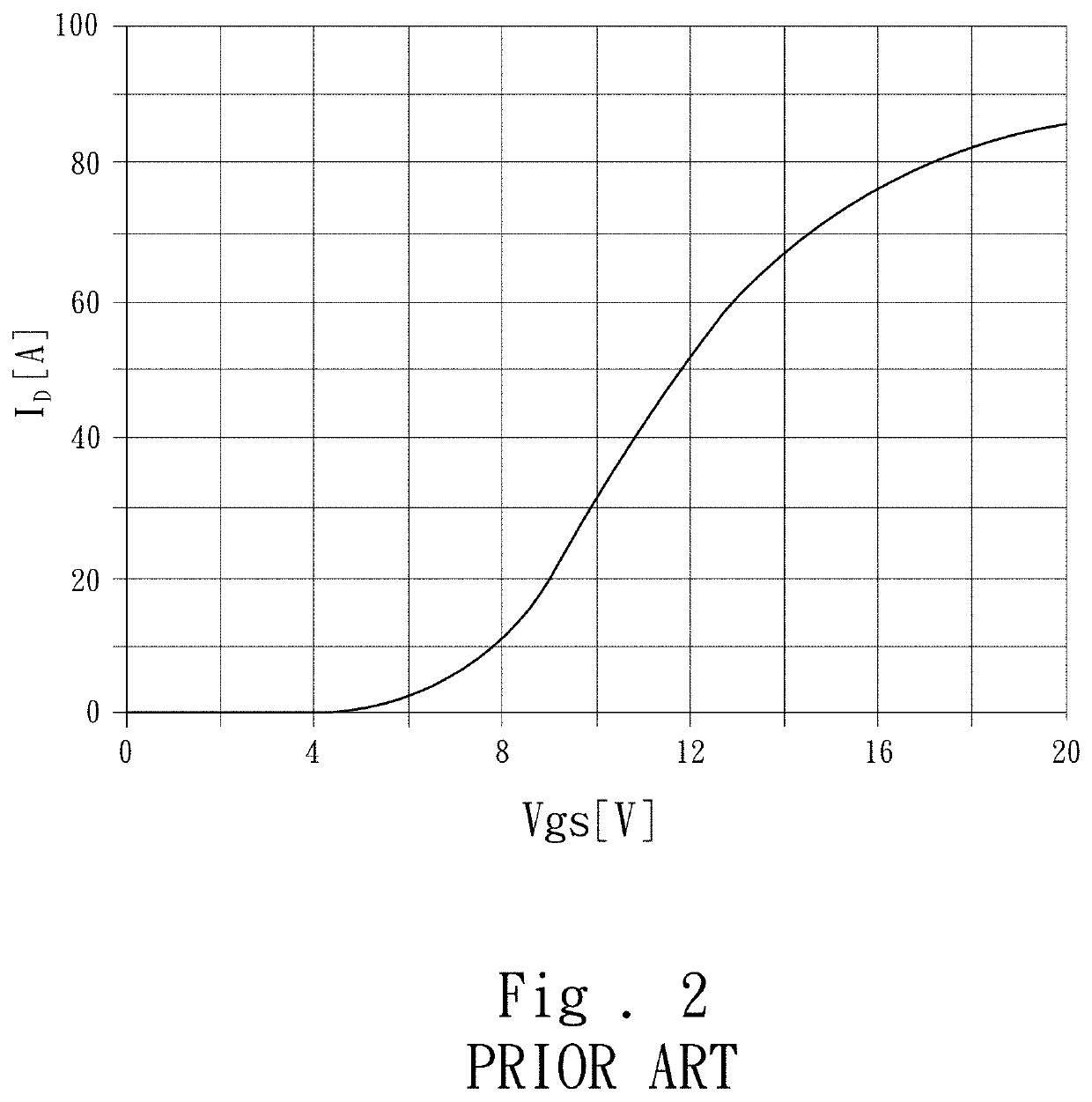

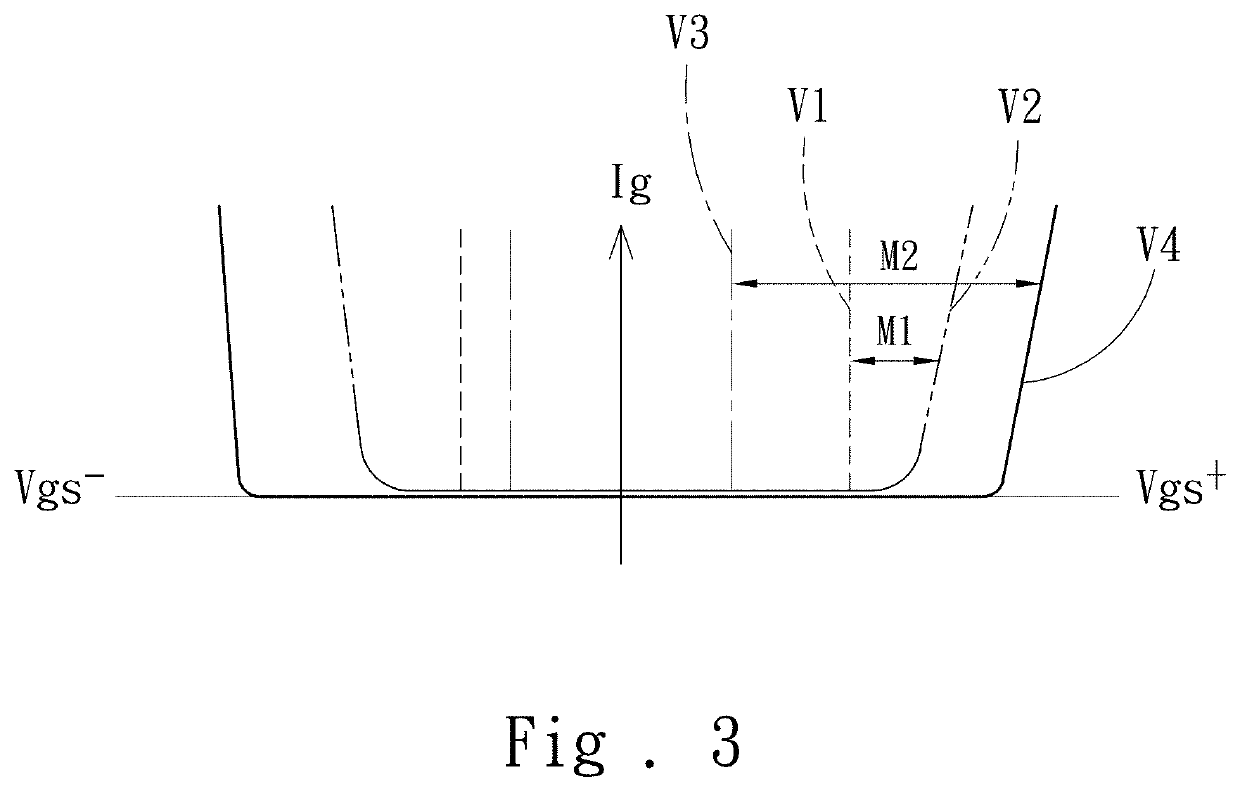

Silicon carbide semiconductor device integrating clamper circuit for clamping voltage

The present invention provides a silicon carbide (SiC) semiconductor device integrating a metal-oxide-semiconductor field-effect transistor (MOSFET) and a bidirectional voltage clamping circuit. An object of protecting a device is achieved by using the simple structure above, effectively preventing device damage that may be caused by a positive overvoltage and a negative overvoltage between a gate and a source.

Owner:SHANGHAI HESTIA POWER INC

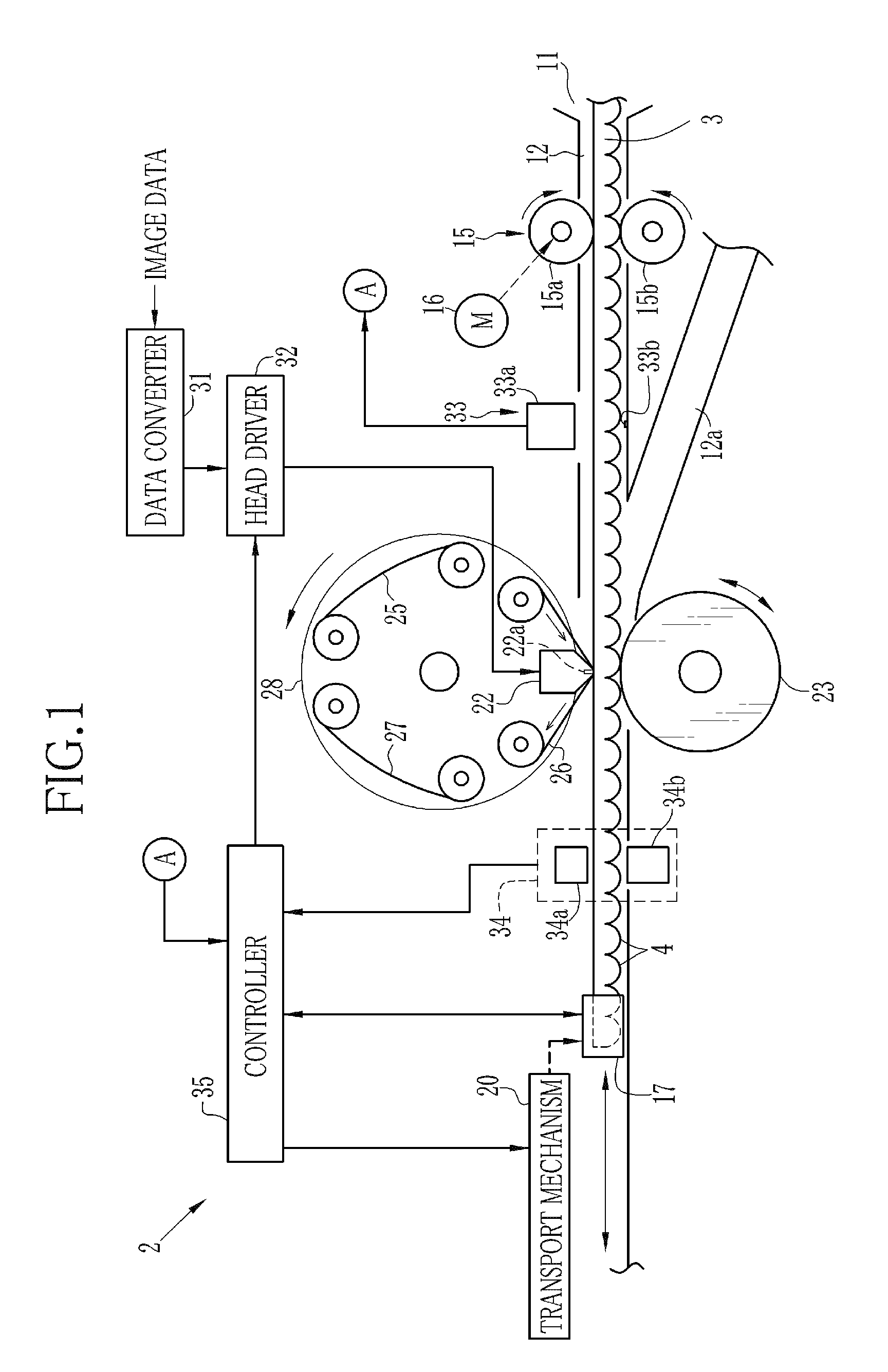

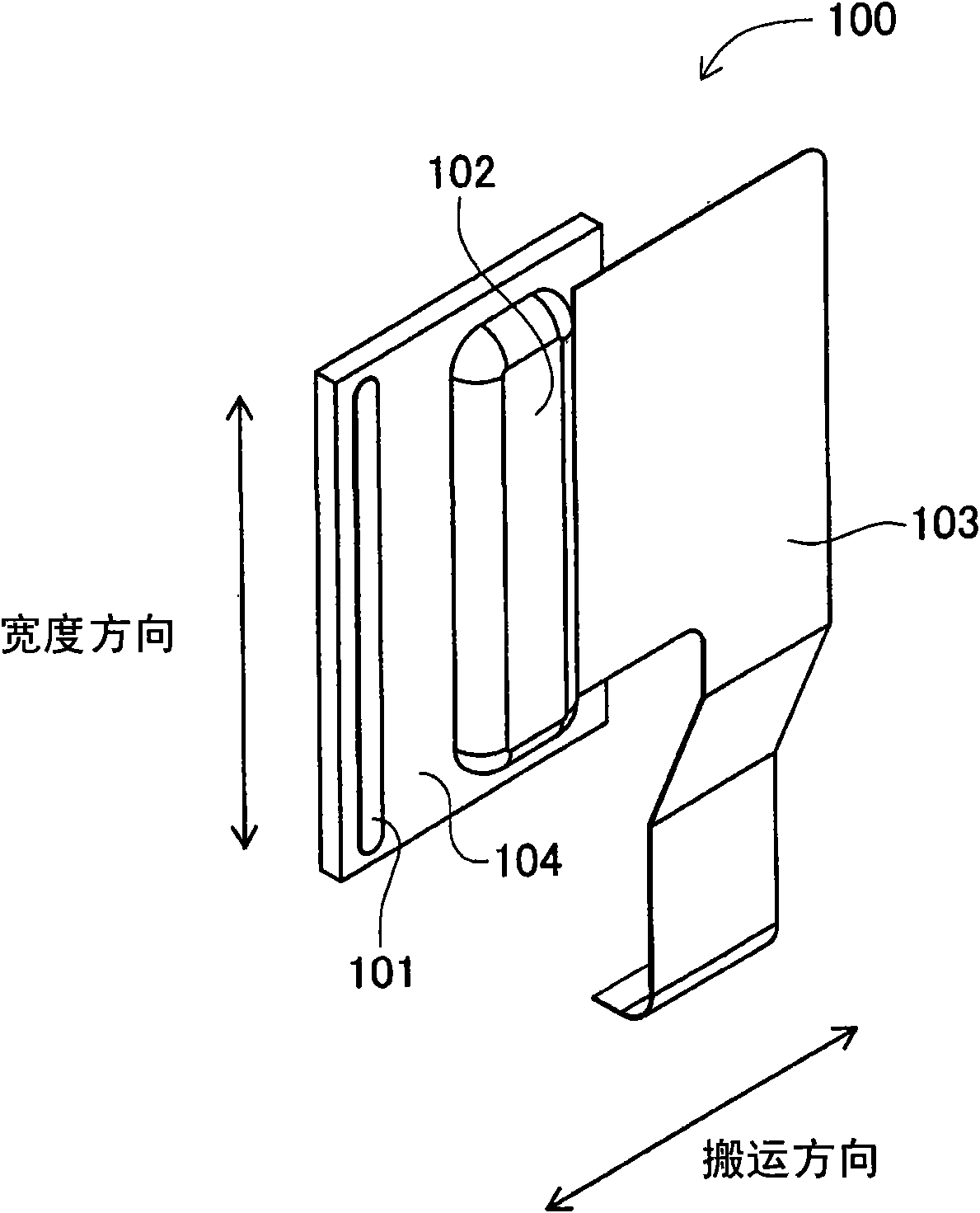

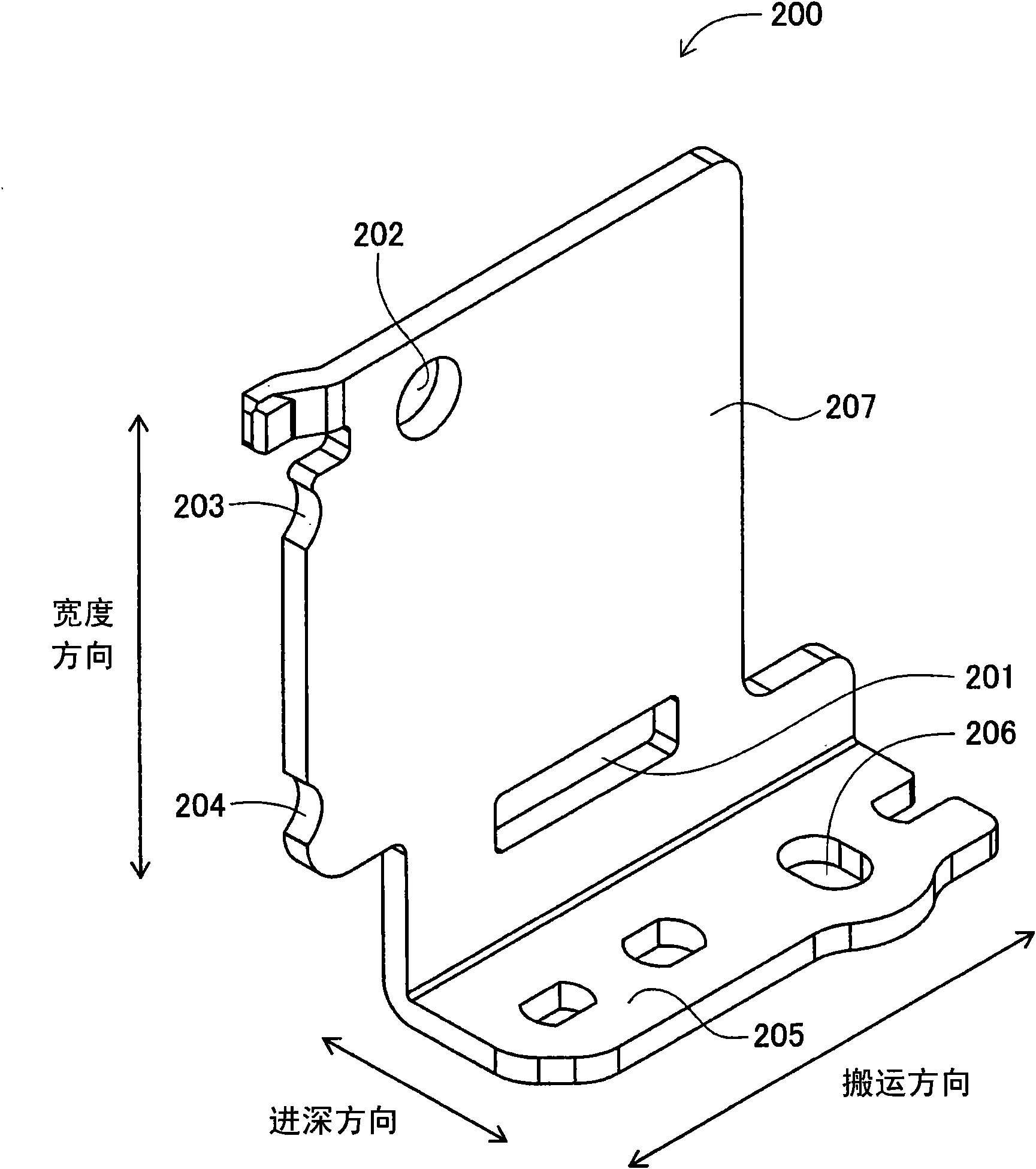

Manufacturing method of thermal head unit, thermal head unit thereof and printer comprising the same

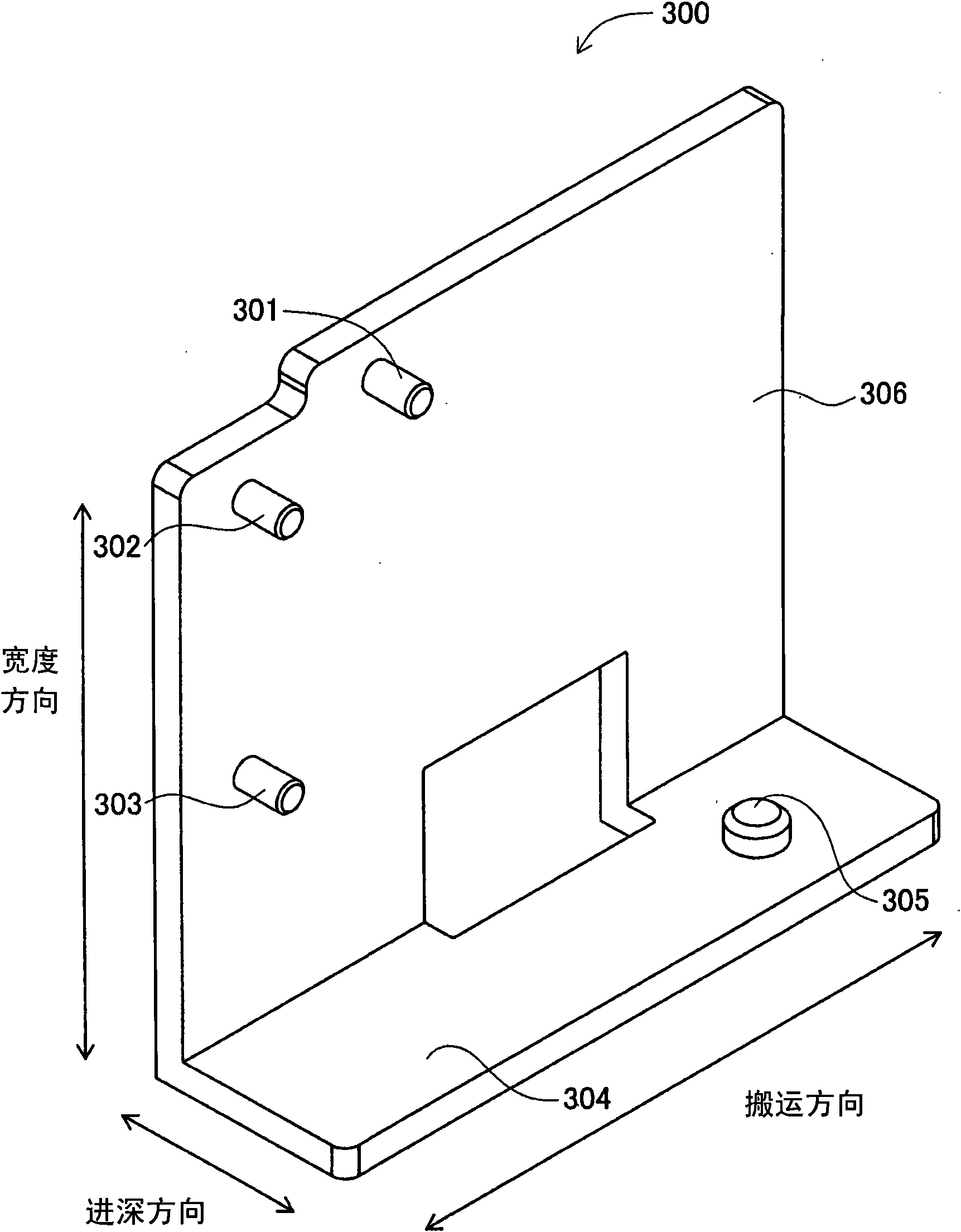

The present invention provides a manufacturing method of a thermal head unit, the thermal head unit thereof and a printer comprising the same. A radiating board (200) is positioned and fixed to a preset position on a clamper (300) through inserting a fourth pin (305) of the clamper (300) through a positioning hole (206) of the radiating board (200). Afterwards, the thermal head (100) is positioned to a preset position of the radiating board (200) fixed to the clamper (300) through contacting the contact part of the thermal head (100) with a first pin (301), a second pin (302) and a third pin (303) of the of the clamper (300). In this state, a clearance is formed between the opposite part of the radiating board (200) opposite to the first pin (301), the second pin (302) and the third pin (303) of the clamper (300) and each pin (301), (302), (303). Additionally, the thermal head (100) is adhibited and fixed to the radiating board (200) through the adhesive (S) coated to the back surface of the thermal head (100) thereby binding the radiating board (200) with the thermal head (100).

Owner:BROTHER KOGYO KK

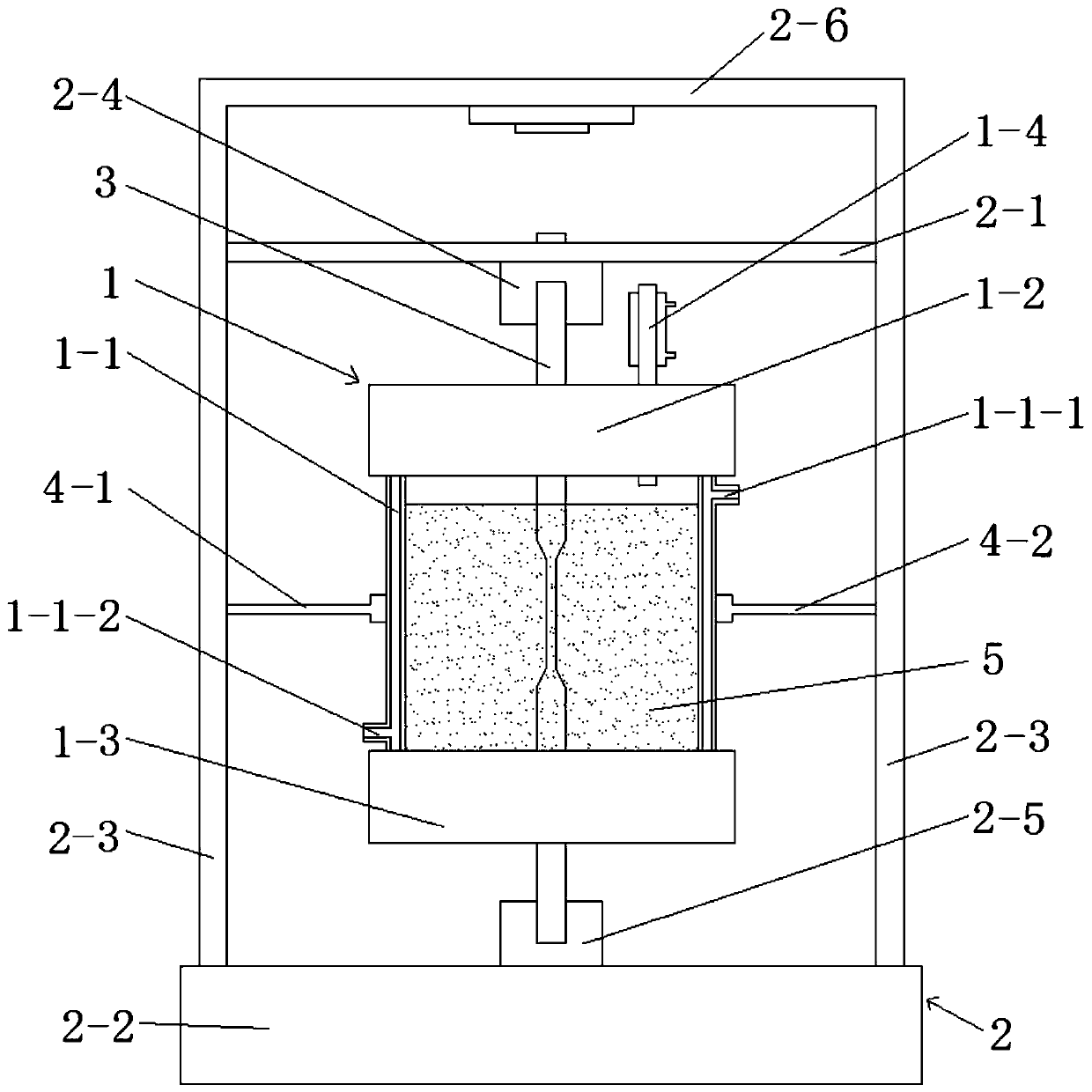

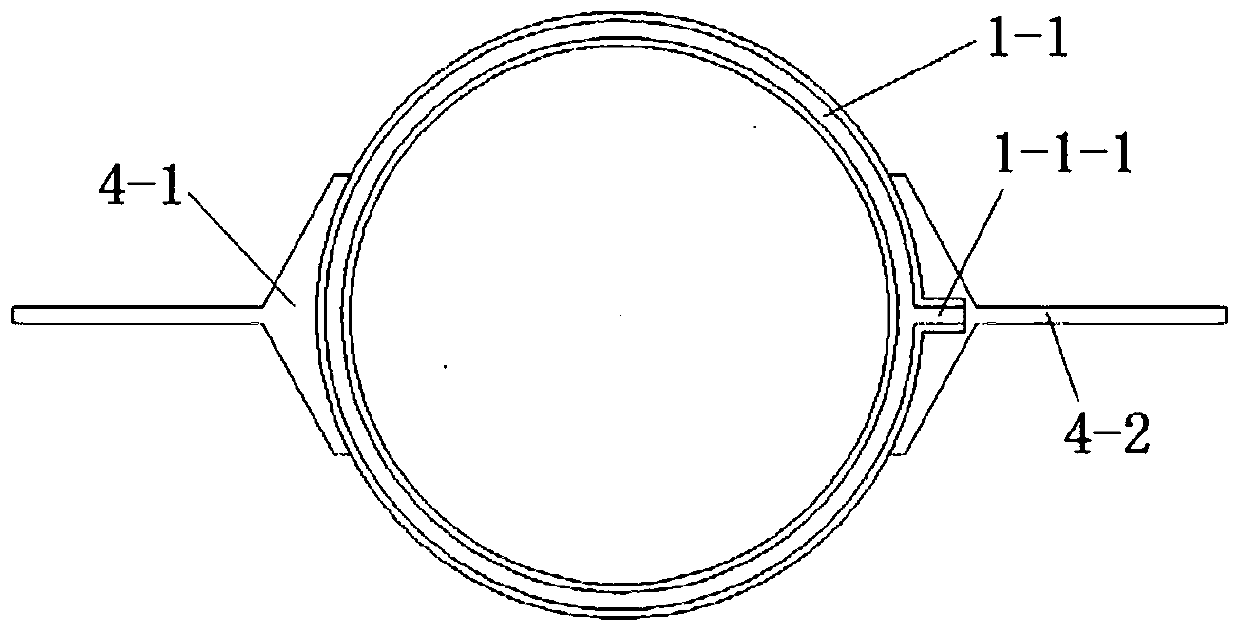

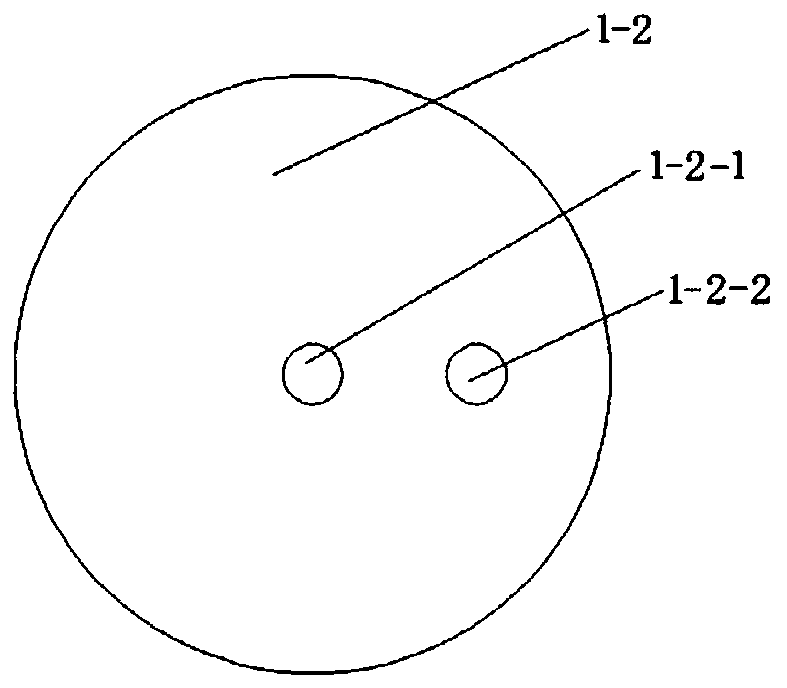

Device and method for carrying out stress corrosion experiment in high-temperature liquid-phase corrosion environment

PendingCN111504801AImplement stress corrosion experimentsAccurate and controllable stress corrosion testMaterial strength using tensile/compressive forcesFluid phaseEngineering

The invention discloses a device for carrying out a stress corrosion experiment in a high-temperature liquid-phase corrosion environment. The device comprises a universal testing machine and a stresscorrosion experiment box clamped with the universal testing machine through a clamper; the stress corrosion experiment box comprises a double-layer glass cylinder, and an upper plug and a lower plug which are hermetically connected with the double-layer glass cylinder; an upper plug sample through hole and a condensing device through hole matched with the condensing device are formed in the upperplug, a lower plug sample through hole is formed in the lower plug, and the upper plug sample through hole and the lower plug sample through hole are connected with the stress corrosion experiment sample in a sealed mode. Besides, the invention also discloses a stress corrosion experiment method, and the method comprises the following steps: loading a stress corrosion experiment sample and corrosive liquid into the stress corrosion experiment box by using a universal testing machine to obtain the loaded experiment sample and data. According to the invention, the universal testing machine is prevented from being contacted with corrosive liquid, a stress corrosion experiment is carried out in a high-temperature liquid-phase corrosion environment, and accurate loading and real-time observation can be realized.

Owner:西安稀有金属材料研究院有限公司

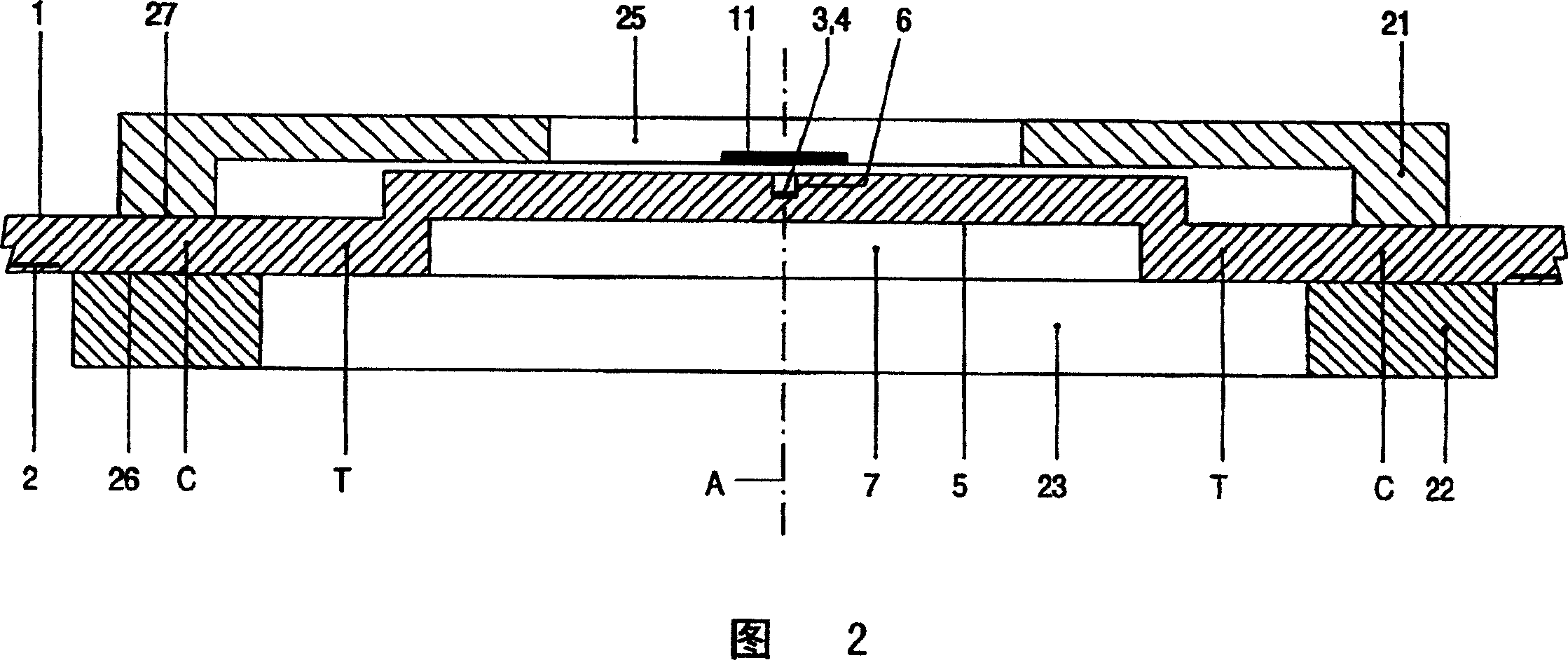

Information carrier, a device for recording and/or reproducing information, as well as a method for manufacturing an information carrier

InactiveCN1942967AEasy transferAccessories for auxillary signalsRecord information storageComputer hardwareComputer science

Information carrier, comprising a disc (101) which is provided with at least one data layer (102) for optically reading and / or writing information, wherein the disc comprises an annular clamping part (C), to be held by a clamper (121) during use, wherein the disc comprises at least one integrated circuit (103), wherein said integrated circuit comprises a first communicator (104) for communication with at least a second, external, communicator (111) during use, wherein the first communicator extends in a centre area (T) which is enclosed by said annular clamping part.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

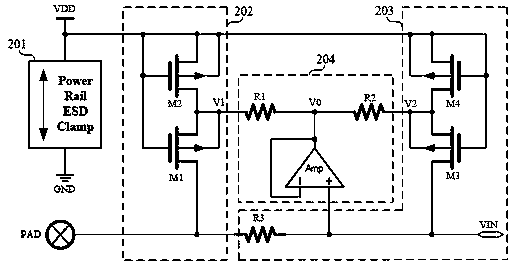

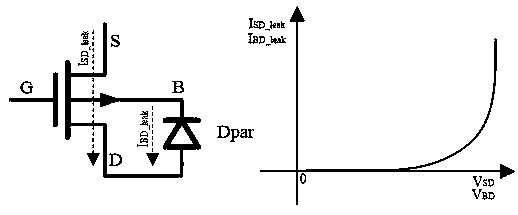

Chip input pin ESD protection circuit architecture with ultralow leakage current

ActiveCN109830478AImprove reliabilityAchieve height setSolid-state devicesSemiconductor devicesAudio power amplifierInput impedance

The invention discloses a chip input pin ESD protection circuit architecture with ultralow leakage current. The chip input pin ESD protection circuit architecture with ultralow leakage current comprises a power ground ESD clamp, a first-stage ESD protection module, a second-stage ESD protection module and a leakage current transfer absorption buffer. The first-stage ESD protection module includesfirst and second PMOS transistors and a first voltage input terminal. The second-stage ESD protection module includes third and fourth PMOS transistors, a third resistor, a second voltage input terminal and a high-impedance input terminal. The leakage current transfer absorption buffer includes a first resistor, a second resistor, and an amplifier, and is configured to intercept the leakage current originally flowing to an input pin to implement zero input pin leakage current. The power ground ESD clamp has a positive terminal and a negative terminal, and has an electrostatic discharge capability for ESD positive and negative pulses between the power source and the ground. The chip input pin ESD protection circuit architecture can be integrated into a SOC chip to realize ESD protection ofthe input pin with ultrahigh input impedance.

Owner:HANGZHOU SDIC MICROELECTRONICS

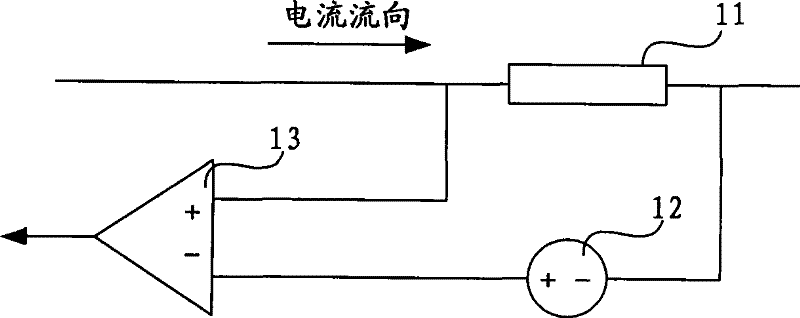

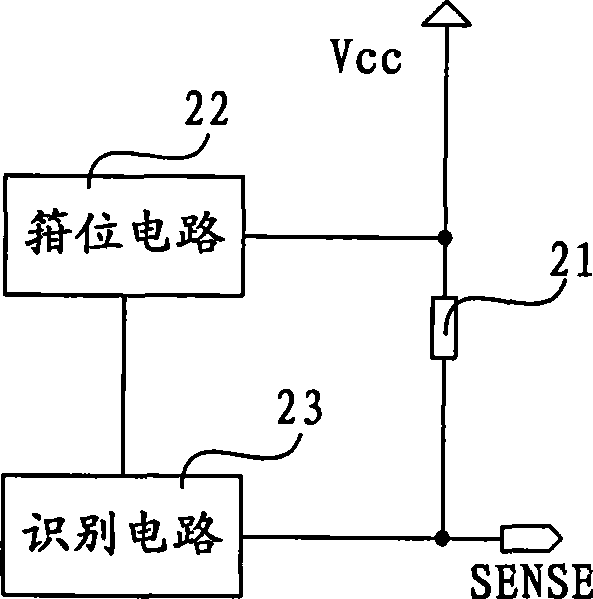

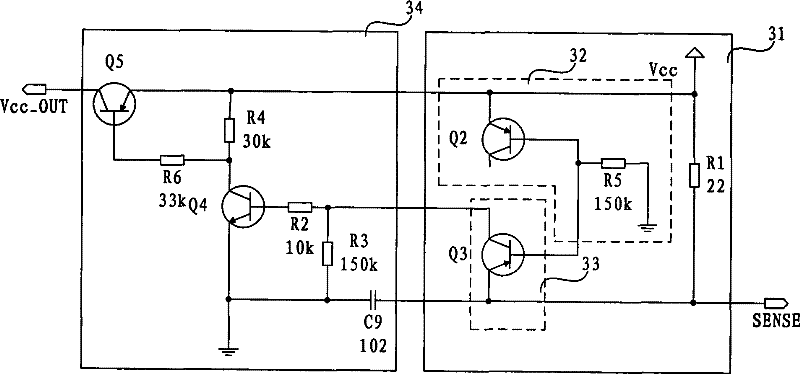

Micro current detection circuit, micro current switching circuit

InactiveCN101353237BRealize detectionRealize switchingSolid waste managementCurrent/voltage measurementTerminal voltageHemt circuits

The invention relates to a microcurrent detection circuit and a microcurrent switch circuit. The microcurrent detection circuit comprises a sampling resistor, one end of the sampling resistor is connected with a detection end of a recognition circuit and a detected circuit, the other end of the sampling resistor is connected with power supply and a clamper circuit, the recognition circuit is connected with the clamper circuit; both the recognition circuit and the clamper circuit comprise a triode, the triodes in the recognition circuit and the clamper circuit have the same model, an emitter bias voltage of the triode in the clamper circuit equals to the supply voltage minus the clamper voltage, an emitter bias voltage of the triode in the recognition circuit equals to the detection end voltage minus the clamper voltage; the clamper voltage is a voltage at a connection point of the recognition circuit and the clamper circuit. The recognition voltage of the recognition circuit is around 0.2V, therefore, the microcurrent detection circuit can detect mA stage current which flows through the sampling resistor; in the microcurrent switch circuit, the microcurrent detection circuit is connected with a switch circuit; the switch circuit is controlled according to the detected current to realize circuit switch.

Owner:王红艳

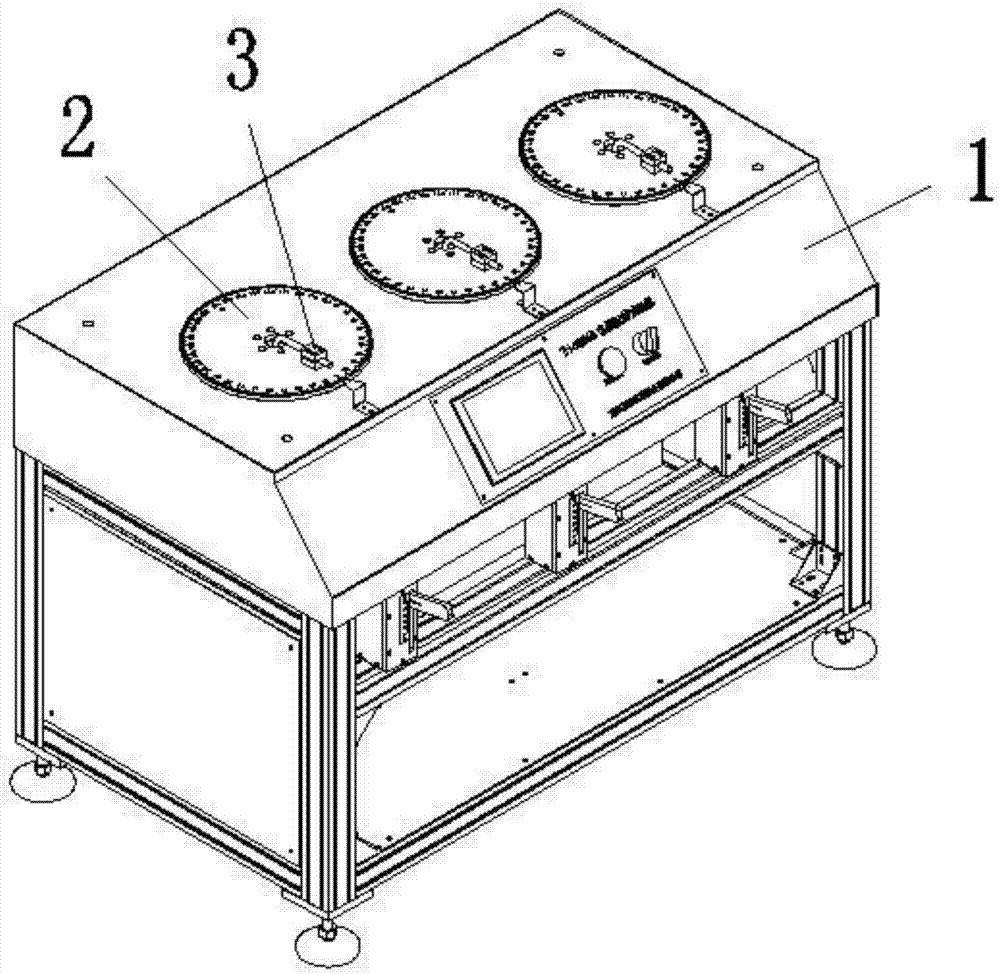

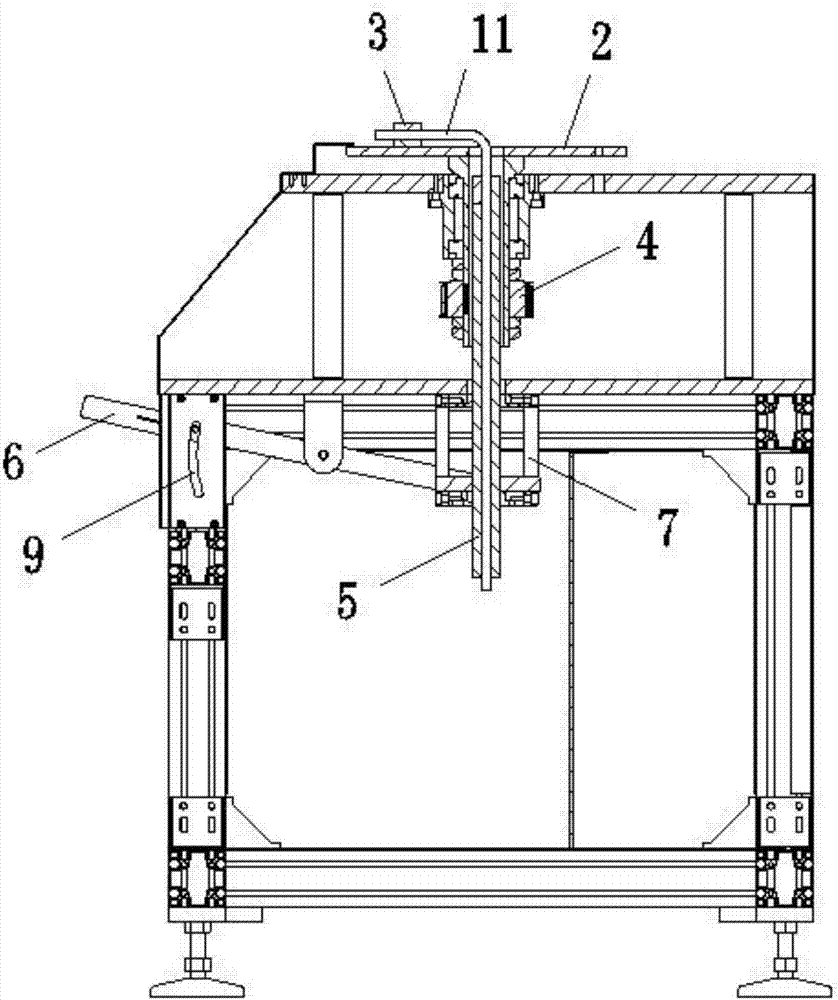

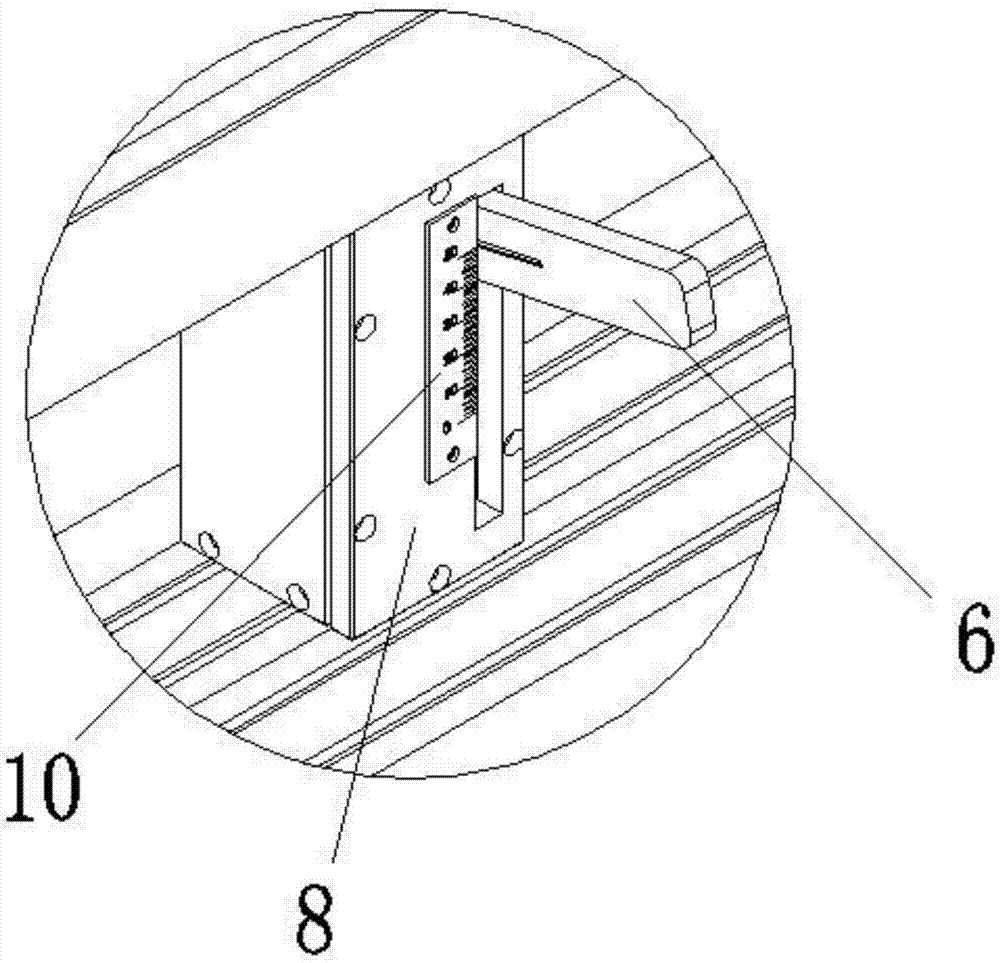

Electric wire torsion testing machine

The present invention discloses an electric wire torsion testing machine, which comprises a rack, wherein the rack is provided with a control system, a transmission system and plural groups of test assemblies, the test assembly comprises a rotation disc, a clamper, a transmission assembly and a regulation assembly, the rotation disc is arranged on the rack and is matched with the transmission system through the transmission assembly, the clamper is arranged on the rotation disc, the front end of an electric wire to be tested and the clamper are matched, and the rear end of the electric wire to be tested and the regulation assembly are matched. According to the present invention, the clamper is driven by the rotation disc so as to make the front end of the electric wire to be tested be continuously subjected to the repeated torsion test along with the rotation disc, such that the electric wire torsion testing machine is suitable for TUV, VDE, UL and other highly flexible electric cables; and the bending point length and the clamping point length can be regulated through the clamper and the regulation assembly, such that the repeated torsion test can be performed on the samples having other specifications through the electric wire torsion testing machine of the present invention, the application range is wide, and the electric wire torsion testing machine is suitable for quality supervision industry, metal industry, machinery industry, electric cable wires, steel wire ropes, and other manufacturers.

Owner:苏州拓博机械设备有限公司

Device for manufacture including a deposition mask

ActiveUS9296012B2Reducing and preventing generation of wrinkleAvoid controlLiquid surface applicatorsSpraying apparatusBiomedical engineeringEngineering physics

Owner:SAMSUNG DISPLAY CO LTD

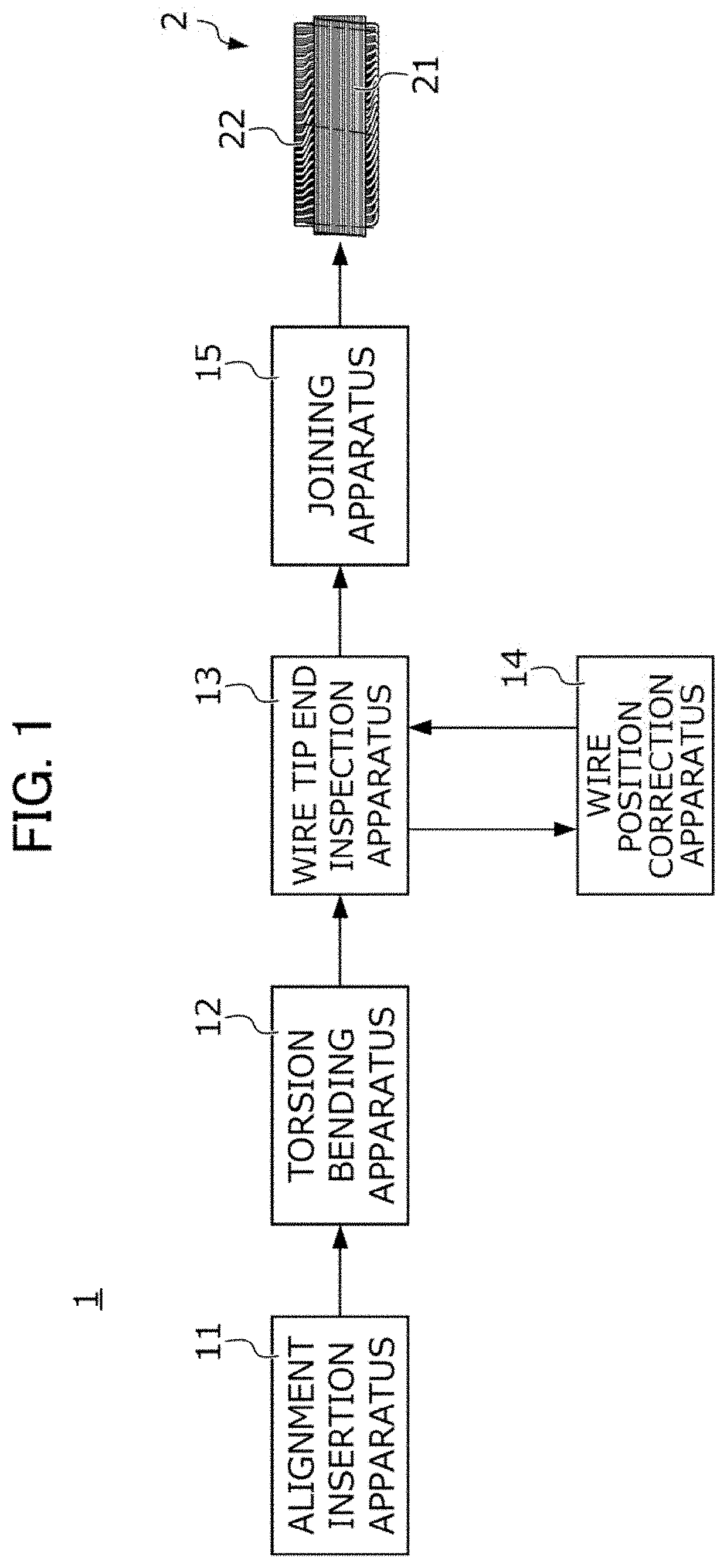

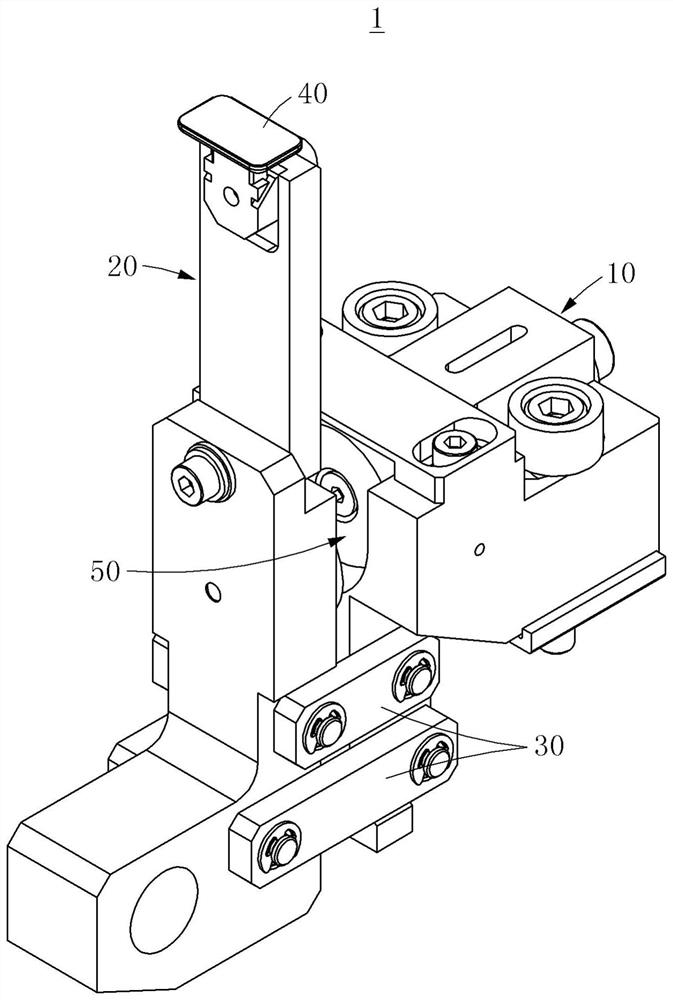

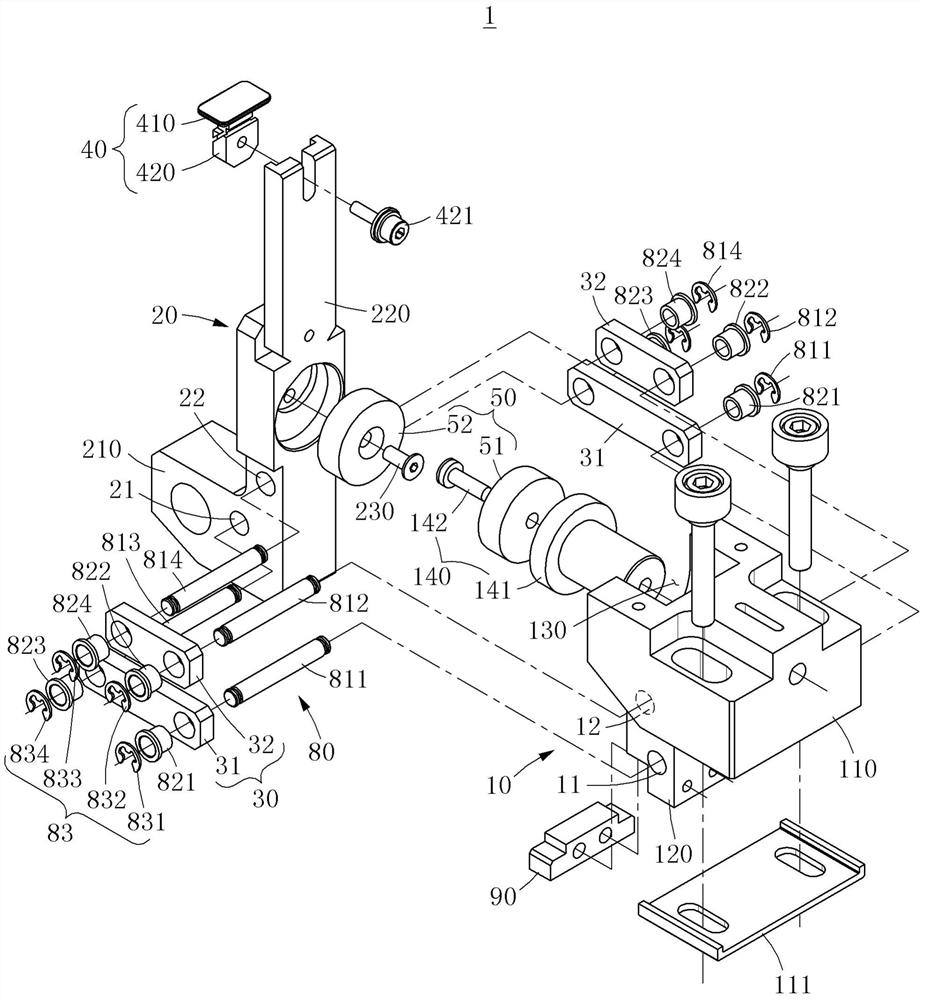

Wire position correction method and wire position correction apparatus

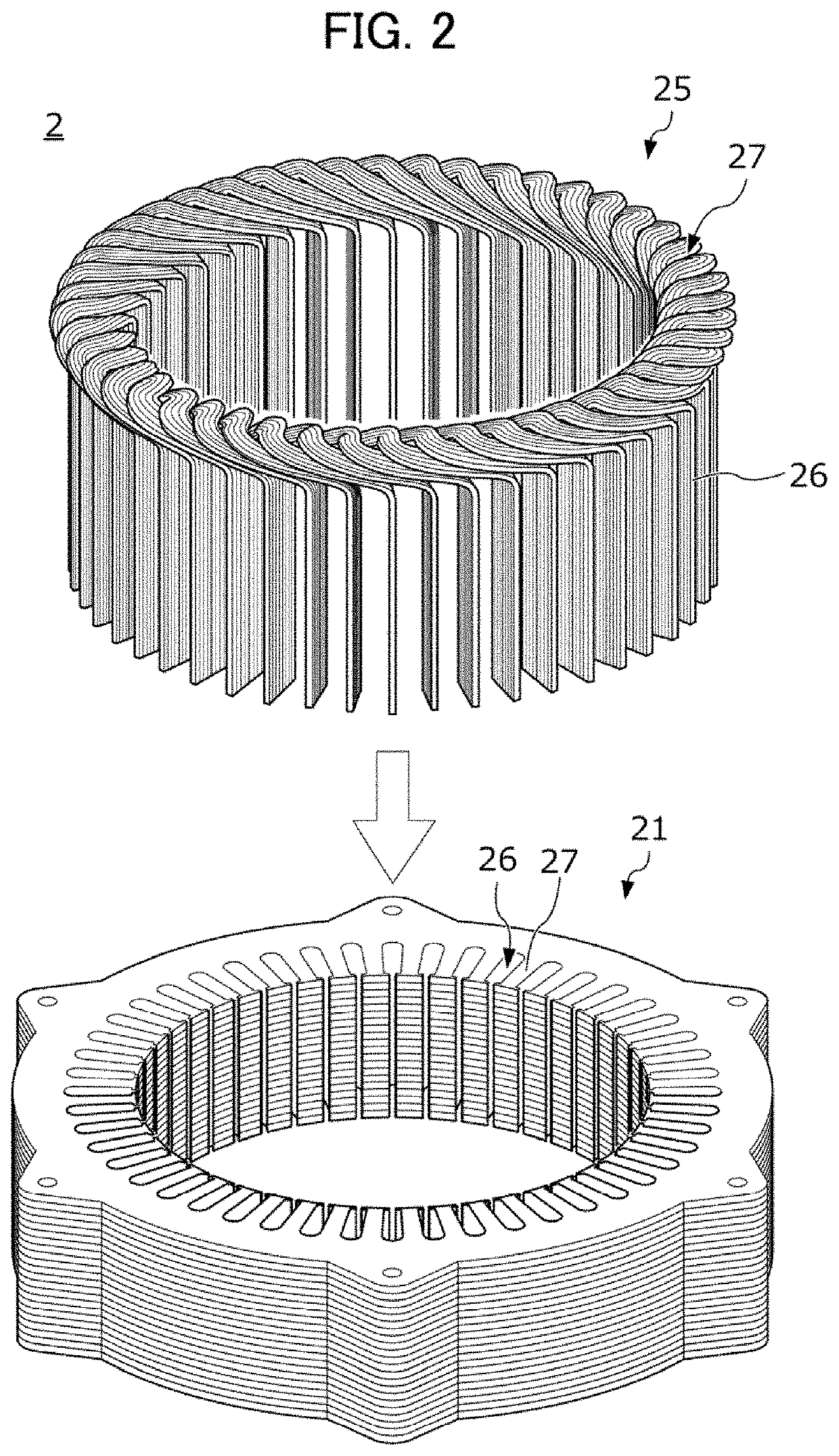

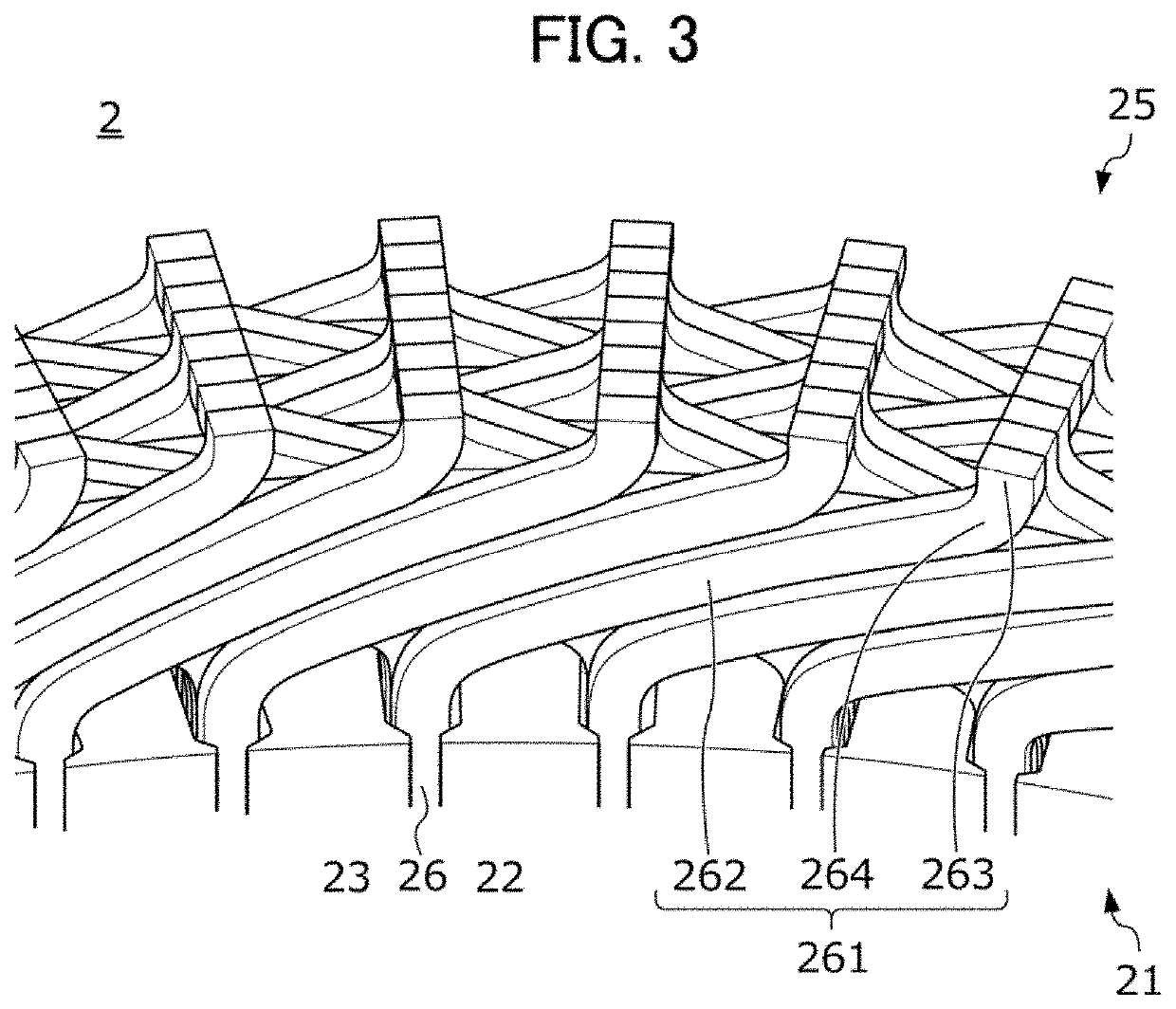

PendingUS20210296973A1Improve accuracyNarrow downMagnetic circuit stationary partsEmbedding prefabricated windingsControl theoryElectric wire

A wire position correction apparatus 14 corrects, in a stator 2 including an annular stator core 21 formed with a plurality of slots and a plurality of wires arranged in the slots, a tip end position of a wire leg portion 261 of the wire protruding from the slot to a reference position. The wire position correction apparatus 14 includes a wire clamper 4 that holds a tip end portion 263 of the wire leg portion 261, a turning mechanism 5 that supports the wire clamper 4 and turns the wire clamper 4 about a center axis passing through a base point P such that the tip end position moves in a direction approaching the reference position, and a movement mechanism 6 that moves the wire clamper 4 and the turning mechanism 5 along the vertical direction and circumferential and radial directions of the stator core 21.

Owner:HONDA MOTOR CO LTD

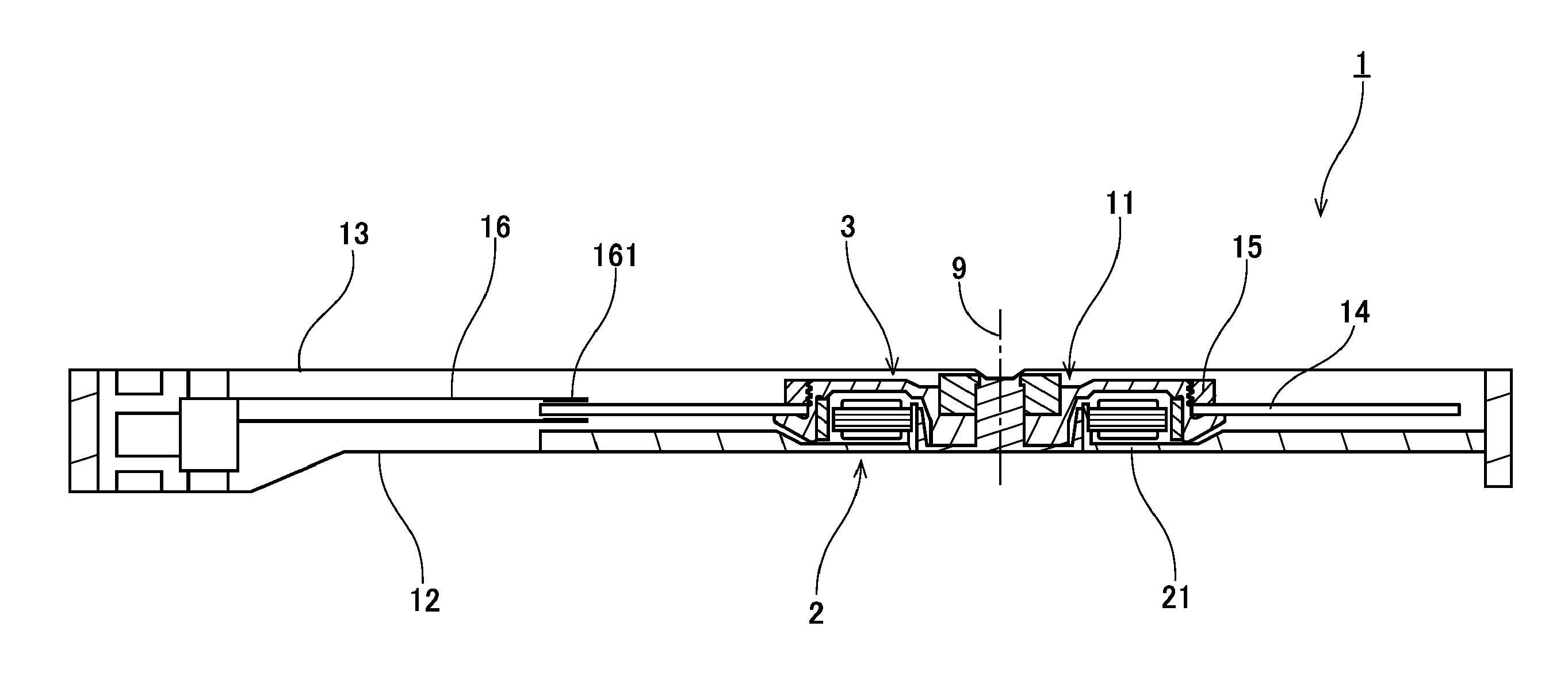

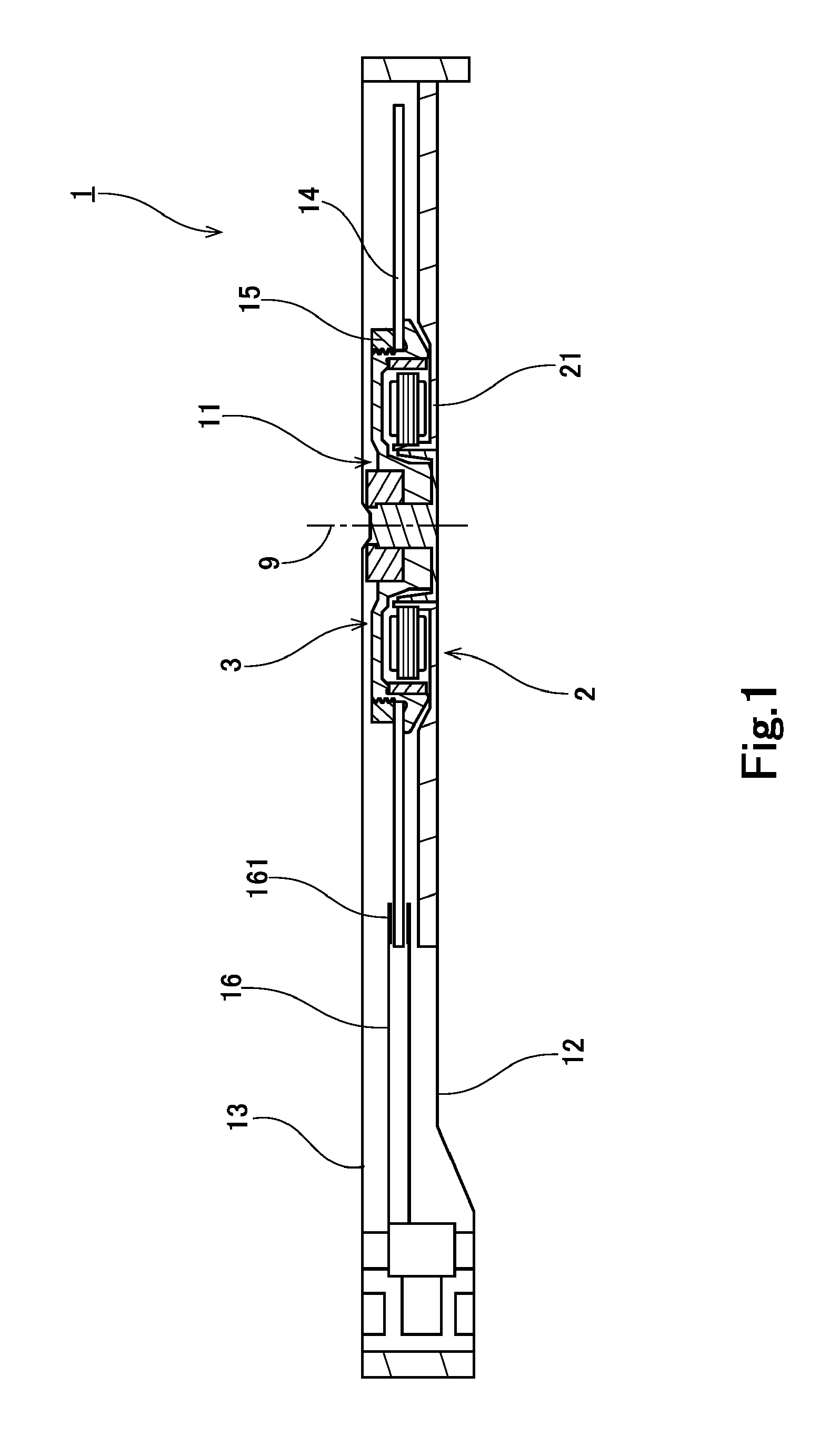

Method of manufacturing disk drive apparatus and method of manufacturing spindle motor

InactiveUS20140082927A1Efficiently screwedReduce and prevent generationRecord information storageManufacturing stator/rotor bodiesEngineeringMechanical engineering

A disk drive apparatus includes a rotor hub including an outer surface with a hub screw groove and a hub information mark indicative of a start position of the hub screw groove. A method of manufacturing the disk drive apparatus includes the steps of preparing a spindle motor including the rotor hub, preparing a clamper including a clamper screw groove, and fitting a recording disk to the spindle motor. The method further includes the steps of detecting a position of the hub information mark and, based on the detected position of the hub information mark, positioning each of the clamper and the spindle motor in a circumferential direction, and screwing the clamper to the spindle motor.

Owner:NIPPON DENSAN CORP

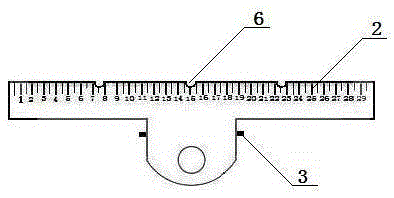

A clamper for archiving data binding

InactiveCN103350583BBinding steps simplifiedSimplify binding operationsSheet bindingEngineeringMechanical engineering

The invention relates to a clamper for filing data binding, which is composed of a scale clamp and a drilling pad. The scale clip is marked on the upper clip or the lower clip near the edge of the clip, and three semicircular holes are opened along the quartering points of the clip length as the drilling positions for binding and archiving data. The drilling pad is a cuboid with three strip-shaped hollow grooves, which correspond to the positions of the three semicircular holes on the scale clip one by one. The center of the semicircular holes is used as the drilling point for filing data. The side of the drilling pad is provided with a strip-shaped hollow groove on one side, and a pass is opened on the upper part, and the scale clamp extends into the pass to clamp the archived materials, and the clamping is firm. Utilizing the clamper for binding archives, the traditional "three points and one line" manual thread binding tool components are integrated, the binding steps are simplified, and the efficiency is improved.

Owner:QILU UNIV OF TECH

A brick gripper with safety protection function

The invention discloses a brick gripper with safety protection function, which comprises a first clamping seat, a clamping mechanism, a second clamping seat, a locking mechanism, a conflicting spring, buckles, bayonet pins and a fastening mechanism. The beneficial effects of the present invention are: by pulling the second card base, the bottom of the second card base and the other end of the first card base are rotated, and the bricks are resisted and clamped under the action of the fastening mechanism, and then the first card is extracted. The seat keeps the second card seat in a state of stress all the time, and it is convenient to extract and stack multiple bricks. The limit between the seat and the first card seat is not easy to rotate, which is beneficial to prevent the rotation of the second card seat and the first card seat during the long-term clamping and handling process, so that the bricks are separated. When they are separated, they can be rotated upward by pressing the buckle , so that the bayonet is separated, and then the external force of the second clamping seat is removed, so that the two splints are loosened, which is conducive to the separation of the bricks.

Owner:石门和峰环保建材有限公司

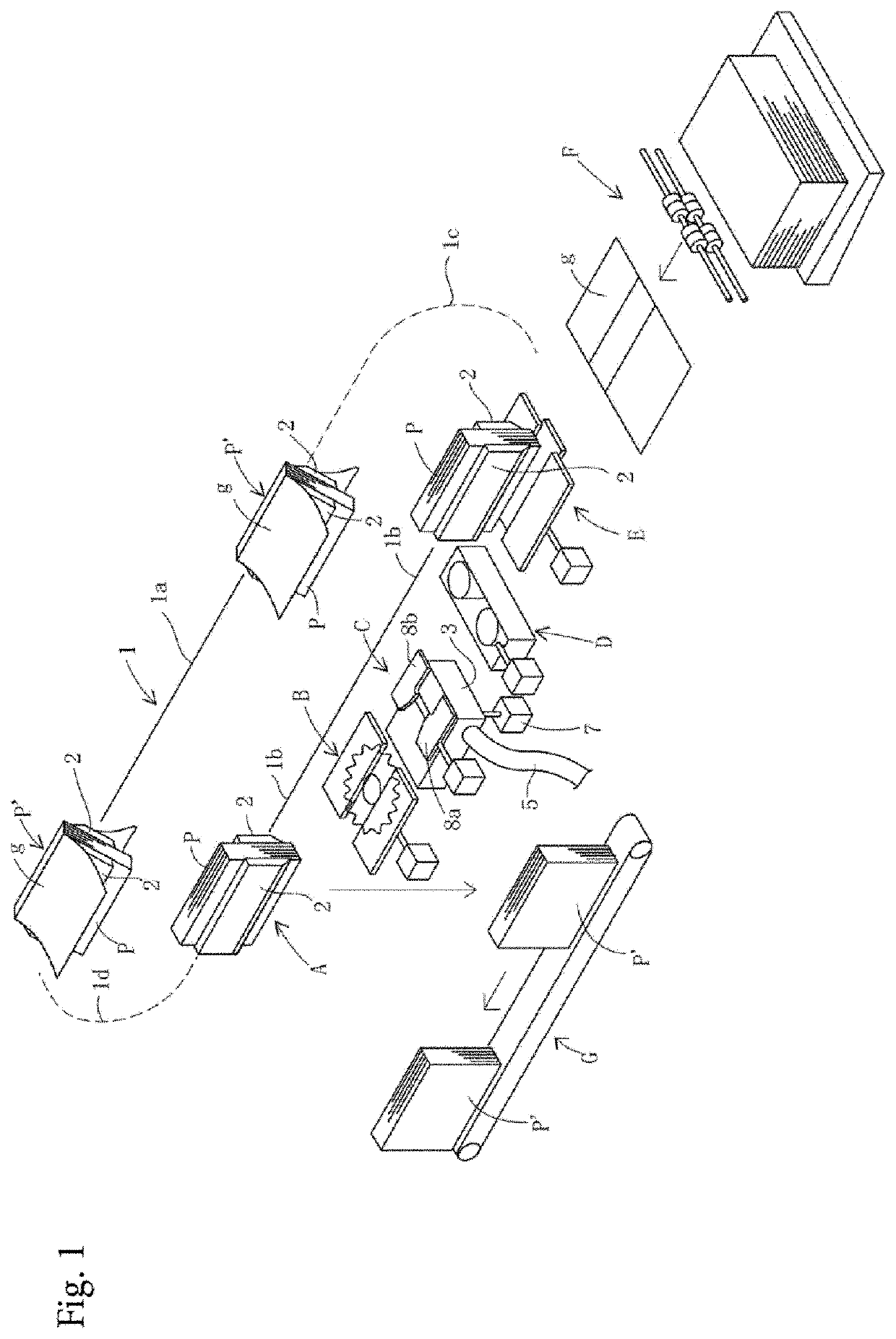

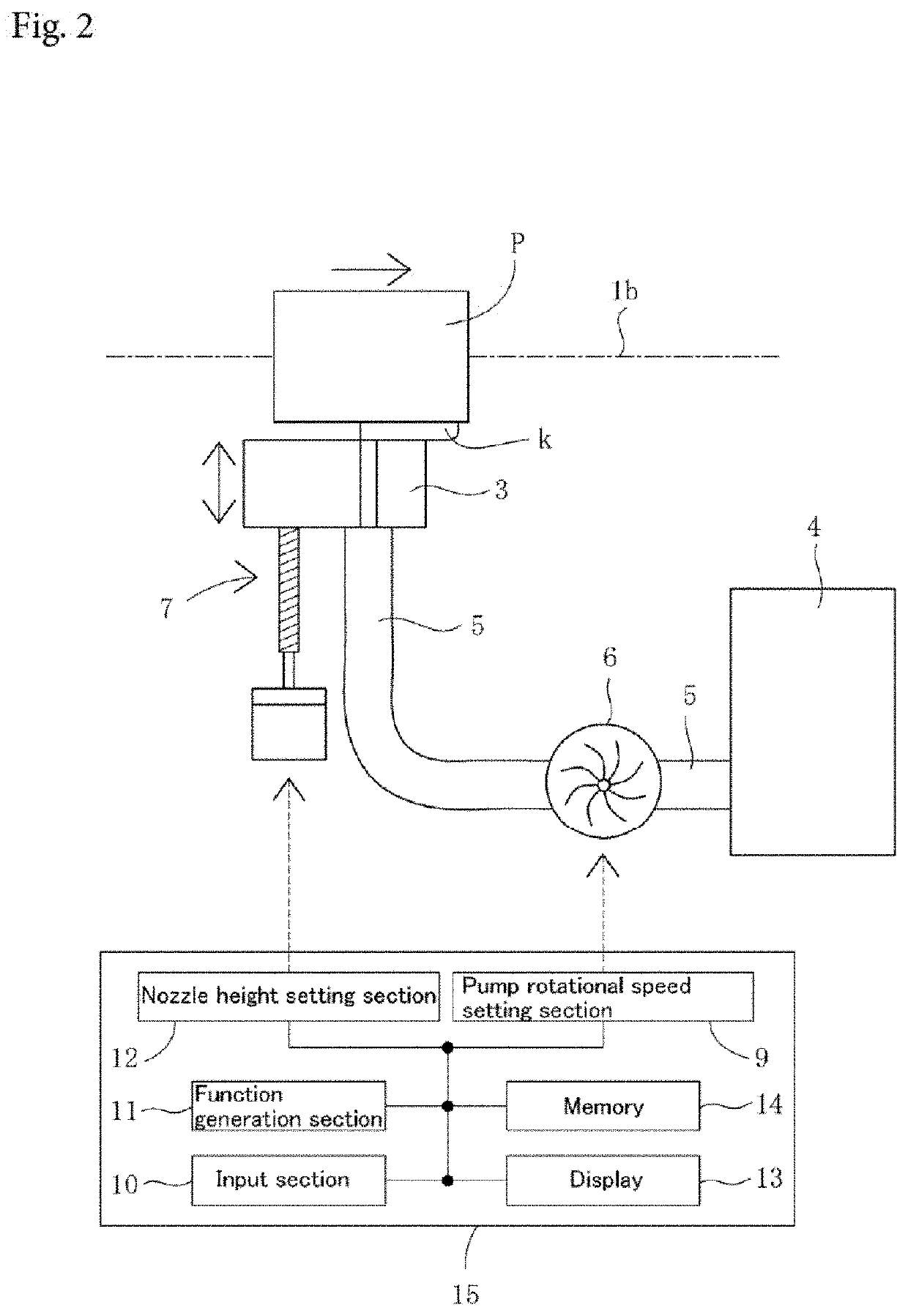

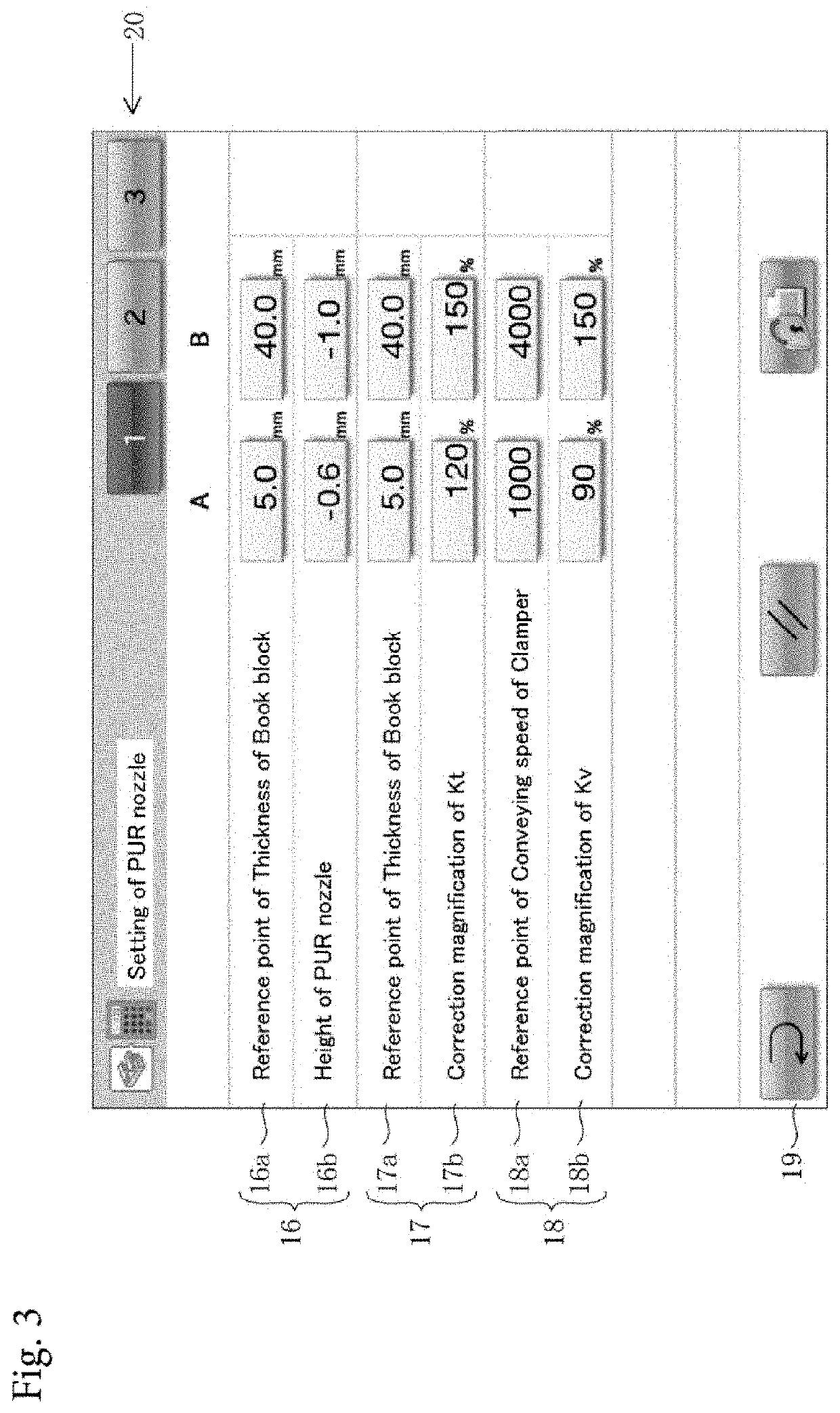

Bookbinding machine

ActiveUS20200147991A1Reduce workloadEasy to set upLiquid surface applicatorsBook making processesEngineeringMachine

A bookbinding machine calculates a rotational speed coefficient, which represents the percent change of a rotational speed of a pump 6 relative to the reference rotational speed of the pump, depending on a thickness of a book block P to be bound and a conveying speed of a clamper by use of a first function defining a relationship between the thickness of the book block and the rotational speed coefficient and a second function defining a relationship between the rotational speed coefficient and the conveying speed of the clamper, calculates the set value of the rotational speed of the pump based on the rotational speed coefficients and the reference rotational speed, and sets the rotational speed of the pump according to the set value of the rotational speed.

Owner:HORIZON INTERNATIONAL INC

Rotary clamping device

ActiveCN109311605BImprove qualityHigh yieldConveyorsSemiconductor/solid-state device manufacturingClassical mechanicsEngineering

Owner:ULVAC KOREA +1

High-temperature tensile test fixture for structural simulation parts with online observation and full strain pick-up

ActiveCN108680429BAvoid damageMaterial strength using tensile/compressive forcesEngineeringHeating furnace

The present invention relates to a clamper for carrying out tensile test on a structure simulation member under a high temperature condition. The whole clamper comprises an upper clamper and a lower clamper, wherein the main bodies of the upper clamper and the lower clamper are rectangular parallelepiped plate type chucks, the chuck is made of a high-temperature alloy material, the lower portion of the upper chuck is provided with a dovetail type clamping groove, the upper portion of the lower chuck is provided with a clamping groove adapted to the geometric shape of a to-be-researched structure simulation member, and the upper chuck and the lower chuck are respectively provided with a hole for installing the clamper on the outside-furnace clamper of a tensile test machine. According to the present invention, the high-temperature tensile test clamper is used for the high-temperature heating furnace with the observation window so as to meet the online observation and full-strain information picking of the structure simulation member; and the upper chuck and the lower chuck are subjected to asymmetrical structure design, wherein the upper chuck has the large size in the width direction compared to the lower chuck, the size of the clamping groove is correspondingly increased, and the clamping groove of the lower chuck is designed to be adapted to the geometric shape of the to-be-researched structure simulation member, such that the mechanical properties of different parts made of various composite material can be tested.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com