Patents

Literature

283results about How to "Reduce the amount of material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Balancing lead smelting process for comprehensive resource utilization and device thereof

InactiveCN101514399AHigh melting temperaturePromote oxidation reactionPhotography auxillary processesProcess efficiency improvementIndiumElectrolysis

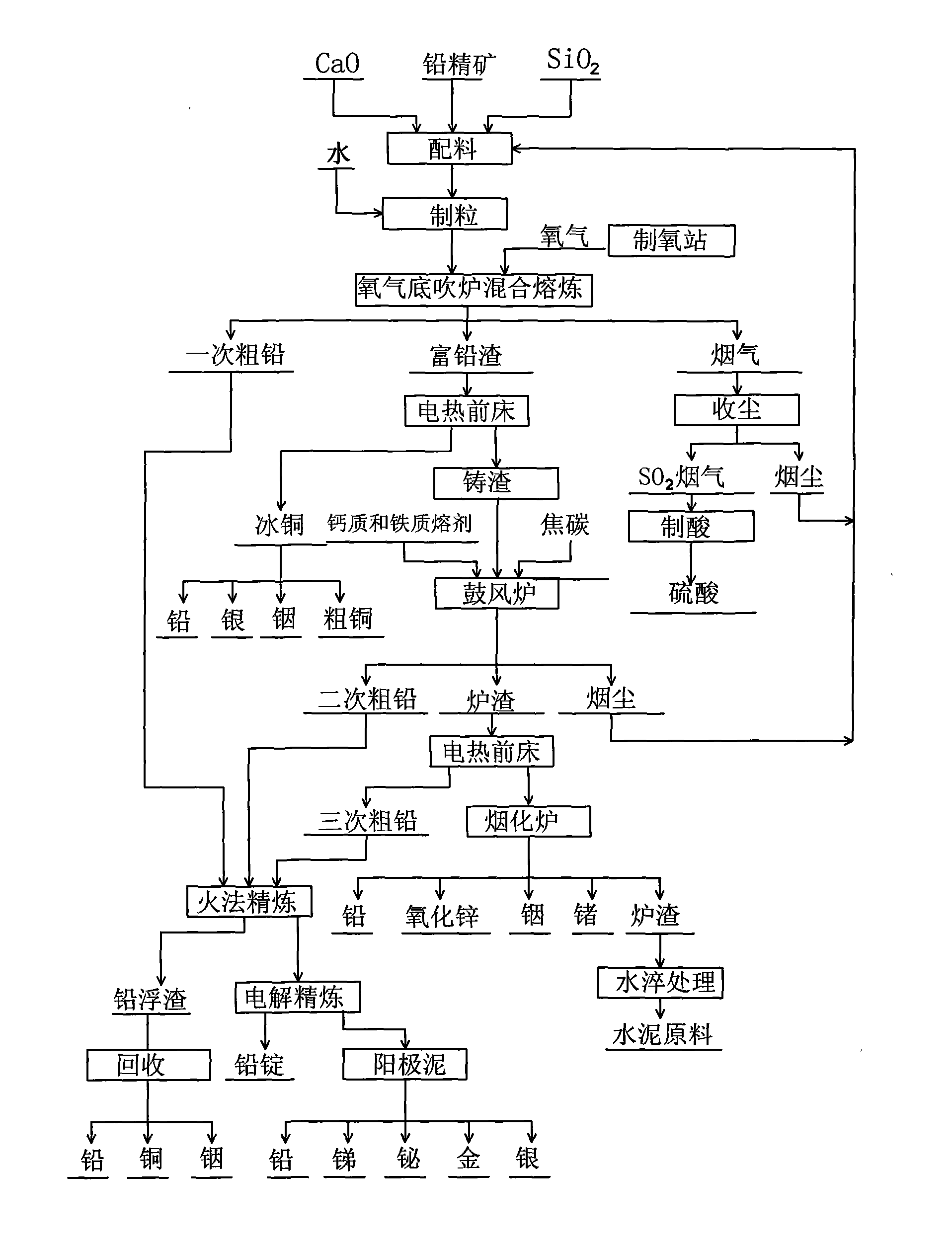

The invention relates to a balancing lead smelting process for comprehensive resource utilization and a device thereof. The process comprises the following steps: granulating a raw material containing lead and a fluxing agent after proportioning, sending to an oxygen bottom-blown smelting furnace for smelting to produce primary crude lead, lead ash and flue gas of SO2; sending the flue gas of SO2 to a sulfuric acid system for acid making after recovering waste heat by a waste heat boiler and duct collection by a dust arrester installation; adjusting form of the lead ash and adding the lead ash to a blast furnace together with coking coal for reducing smelting to produce secondary and third crude lead; electrorefining the crude lead to obtain refined lead and anode slime, treating and recovering the anode slime to obtain lead, stibium, bismuth, gold and silver metals; and separating slag of the blast furnace from the crude lead and sending to a fuming furnace to recover zinc oxide, the lead, indium and germanium. A system for realizing the process comprises the oxygen bottom-blown smelting furnace, an oxygen lance, an electrically-heated settler, a slag casting device, the waste heat boiler with a vertical ascending segment of membrane wall structure, the blast furnace, the fuming furnace and a ventilating device. The process design and system improvement help realize balancing optimized recovery of Pb, Zn, Au, Ag, Bi, Cu, In, Sb and S elements.

Owner:CHENZHOU YUTENG CHEM IND

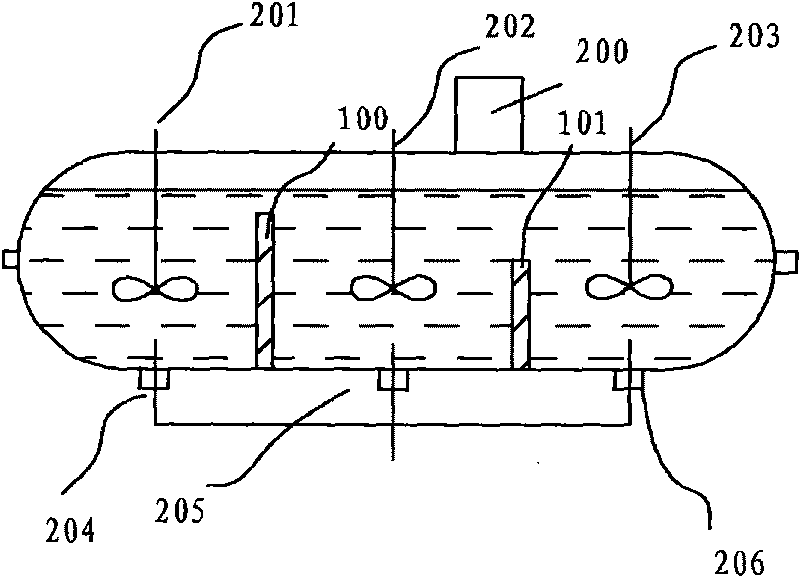

One-step copper smelting technology and device thereof

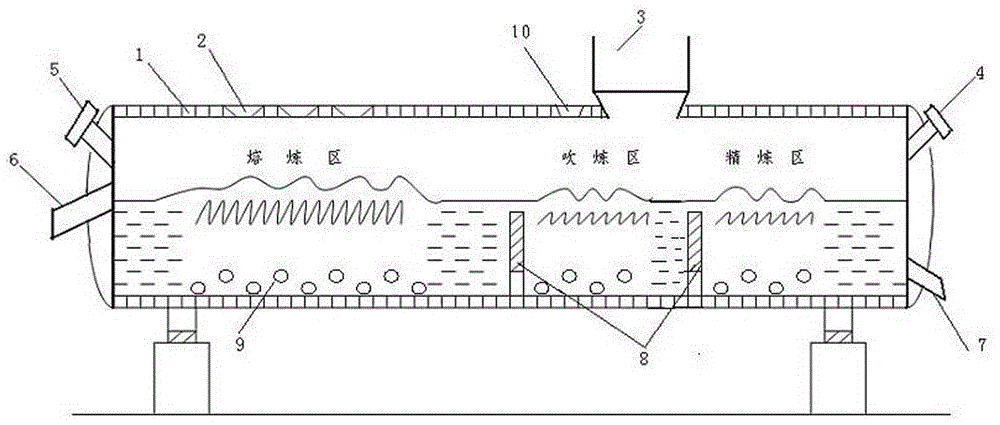

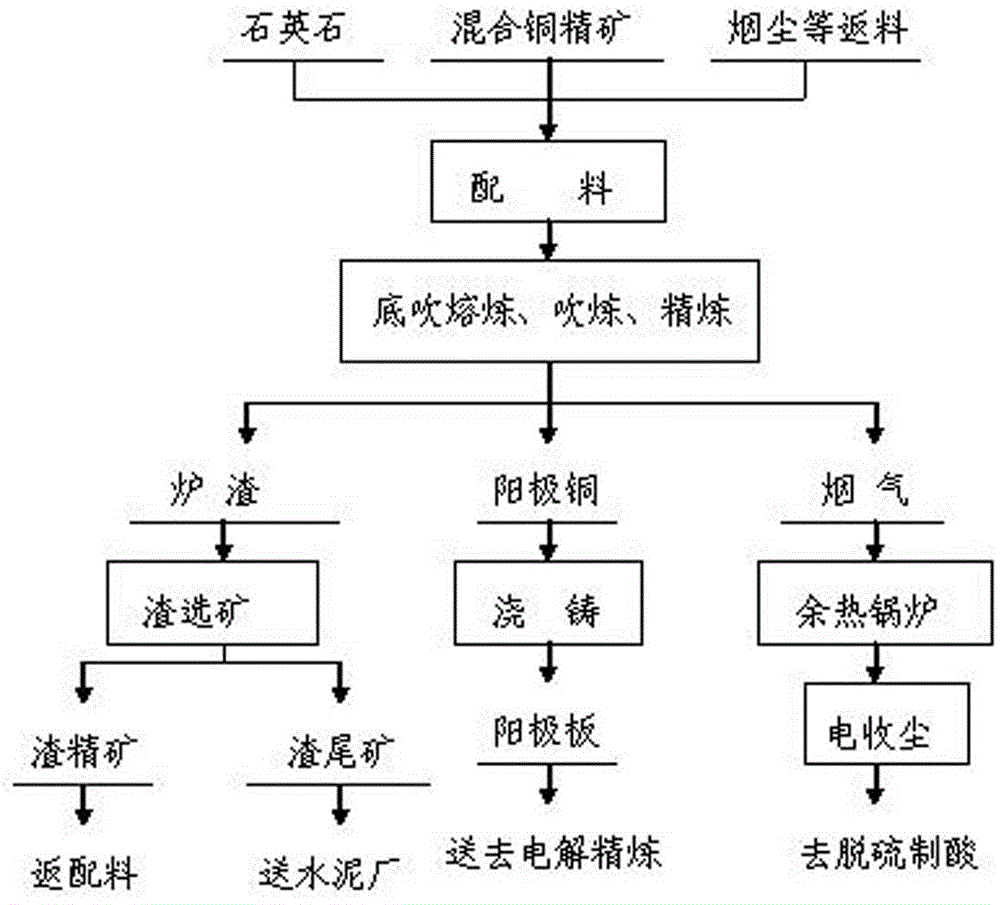

The invention relates to a one-step copper smelting technology and a device thereof. The interior of a furnace body is divided into three zones, namely a smelting zone, a blowing zone and a refining zone, by a retaining wall; and two rows of spray guns which are arranged in a staggered manner and have an included angle with a vertical line are arranged at the bottoms of the zones; return dust is mixed and then added into mixed copper concentrate and a solvent through a charging opening of the smelting zone, oxygen-enriched air is sprayed through the spray guns to carry out self-heating smelting, to generate copper matte; the spray guns in the blowing zone spray oxygen-enriched air so as to blow copper matte into crude copper and slag; the spray guns in the refining zone supply oxygen-enriched air for oxidization, and supply natural gas as a reductant for reduction, and the generated anode copper with high purity is interruptedly discharged form a copper discharging opening, so that the low-altitude pollution problem caused by SO2 can be solved, the operation environment can be greatly improved, the utilization rate of sulfur and heat can be obviously increased, and further the economic benefits can be increased further; in addition, the invention provides a one-step copper smelting technology which is more advanced, shorter in flow, lower in investment, lower in comprehensive energy consumption, higher in recovery rate, and better in comprehensive utilization in comparison with the existing continuous copper smelting technology.

Owner:DONGYING LUFANG METAL MATERIAL

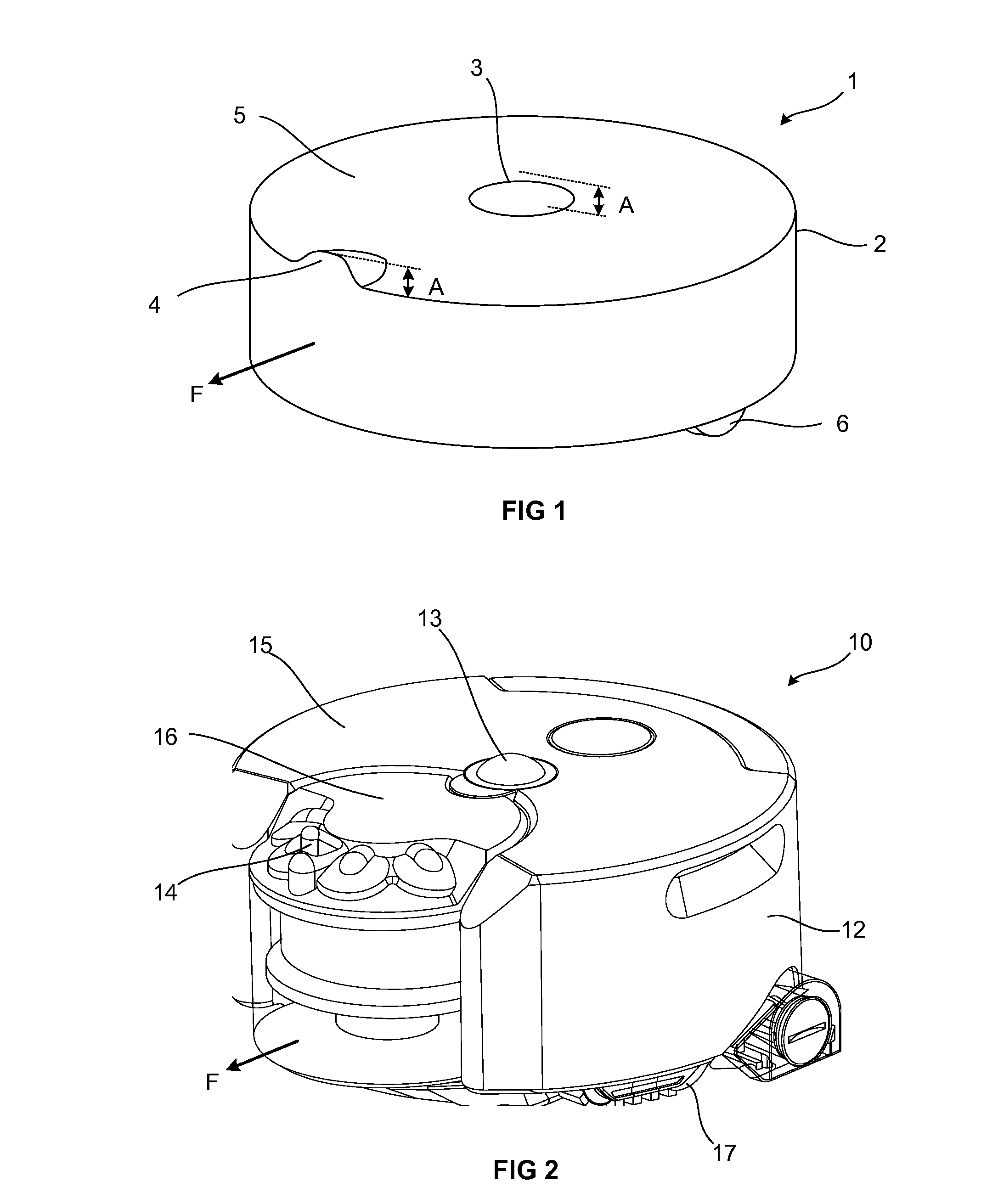

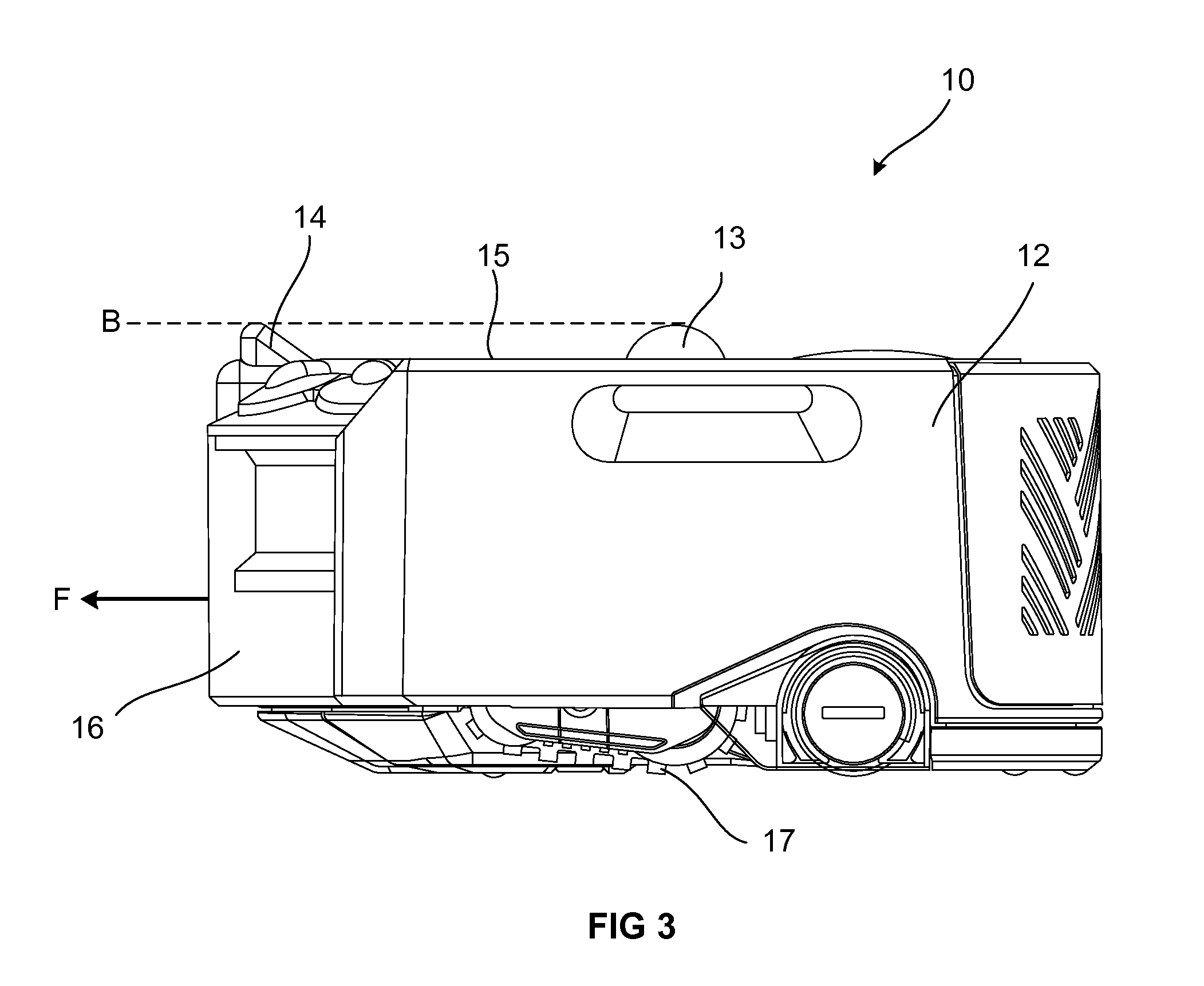

Robot cleaner

InactiveUS20160058261A1Increased riskMaximize effectivenessAutomatic obstacle detectionCombination devicesEngineeringRobot

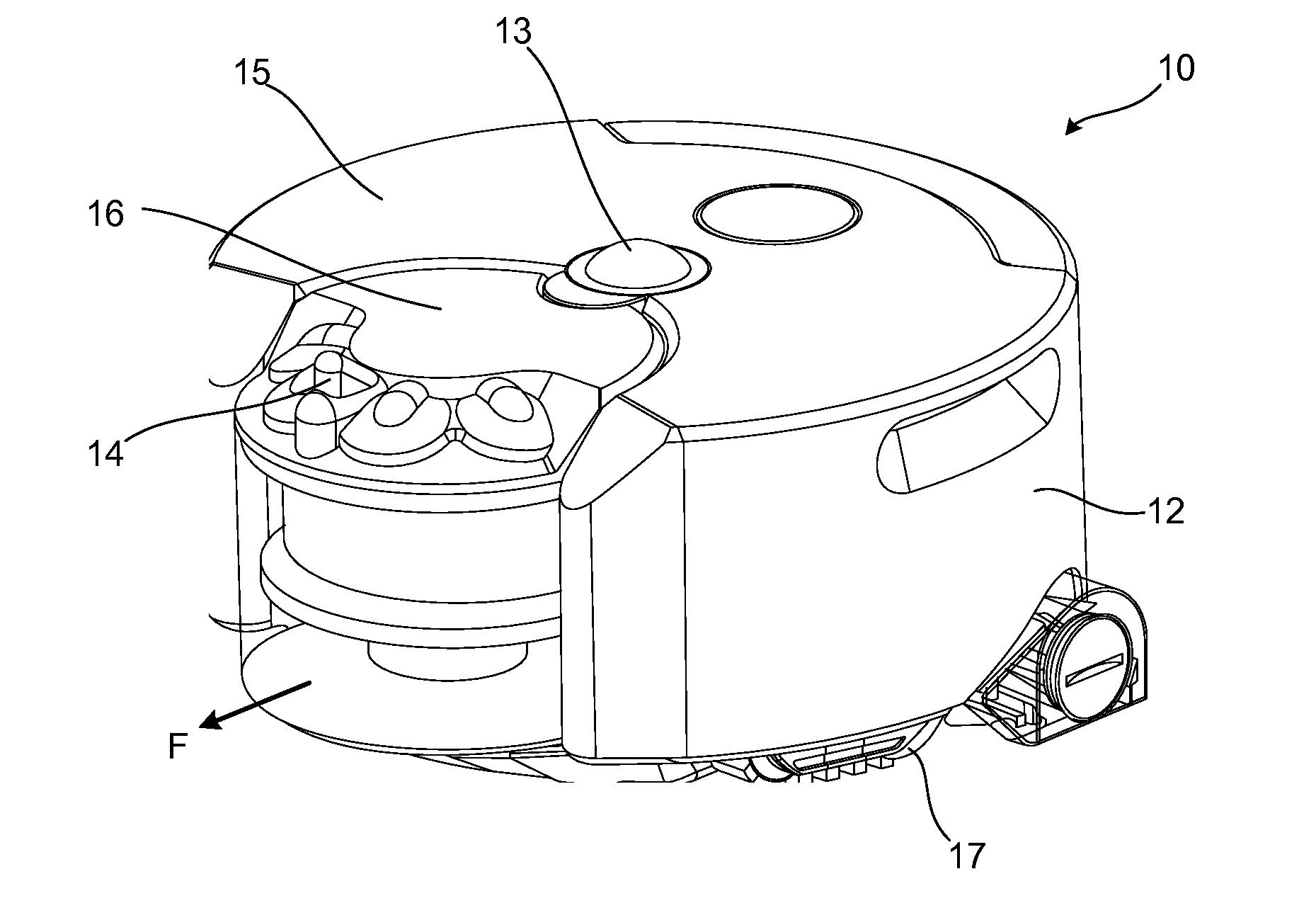

A robot cleaner comprising: a body; and a sensor protruding from a top surface of the body, wherein the body comprises a protrusion positioned forward of the sensor relative to a forward driving direction of the robot cleaner, the protrusion extending to a height that is at least equal to the height of the sensor.

Owner:DYSON TECH LTD

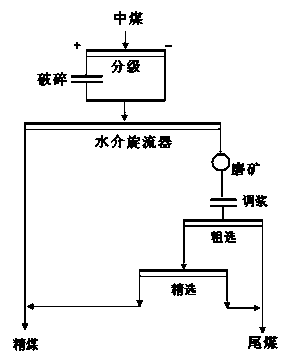

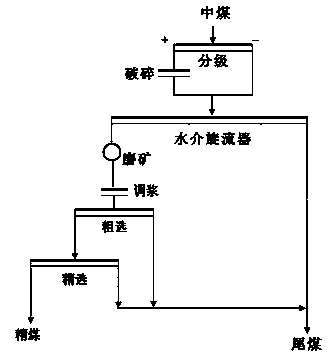

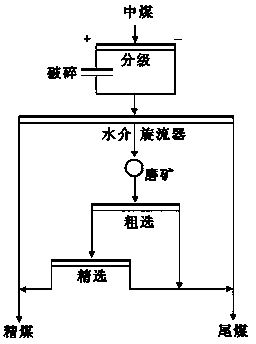

Gravity-flotation joint separation technology for coking middlings

The invention relates to a gravity-flotation joint separation technology for coking middlings and belongs to the technical field of mineral processing. The technology comprises the steps of crushing the coking middlings, water medium whirlcone gravity concentration, and ore grinding-floatation of gravity concentration middle products. The technology is characterized in that the water medium whirlcone is adopted for gravity concentration, so that equipment is few in link and simple in technology; no heavy media need consuming, so that operation cost is low; head pulling or tail throwing is adopted for gravity concentration, so that subsequent ore grinding materials are made to be reduced in number, and energy consumption is saved.

Owner:TAIYUAN UNIV OF TECH

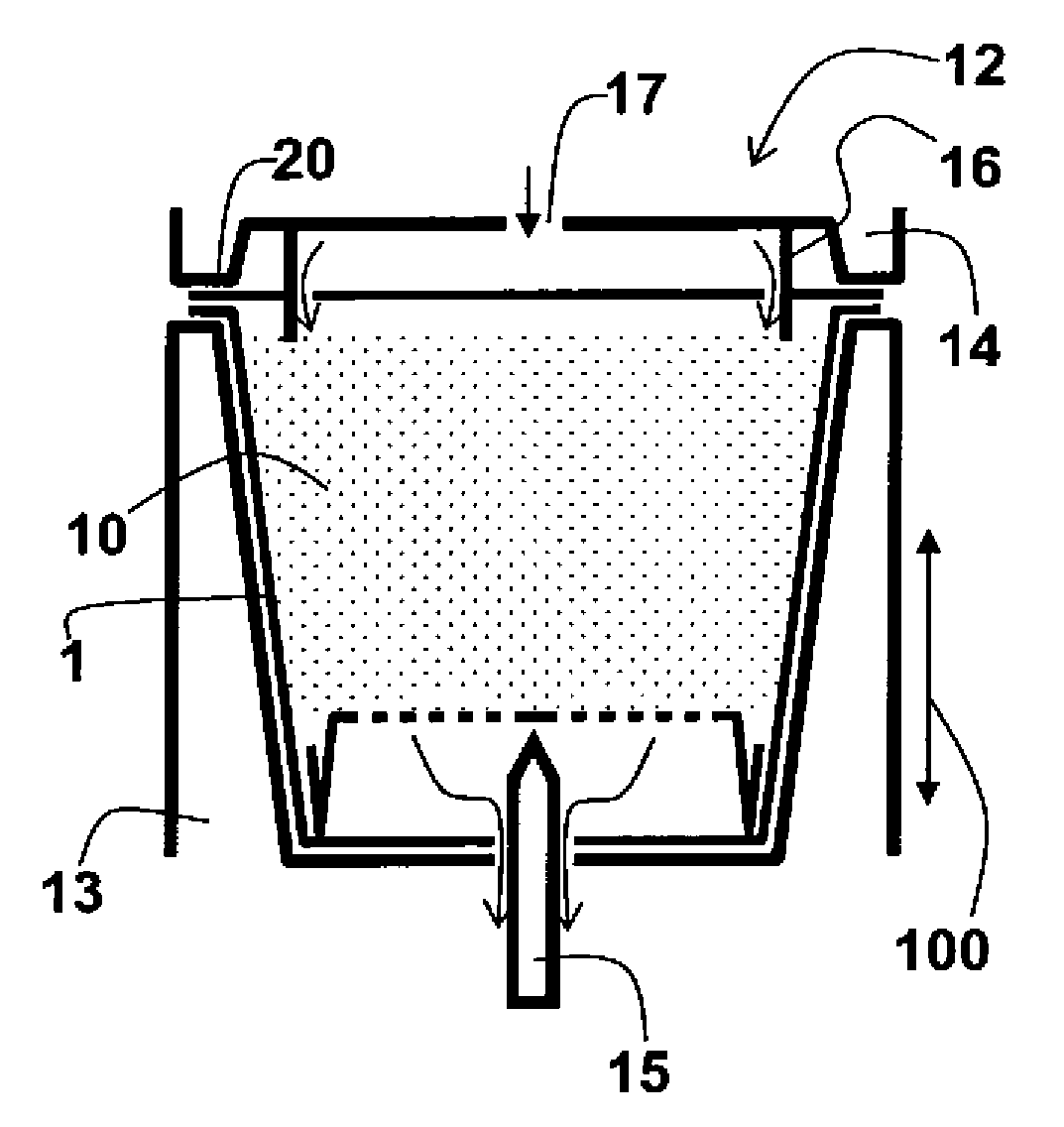

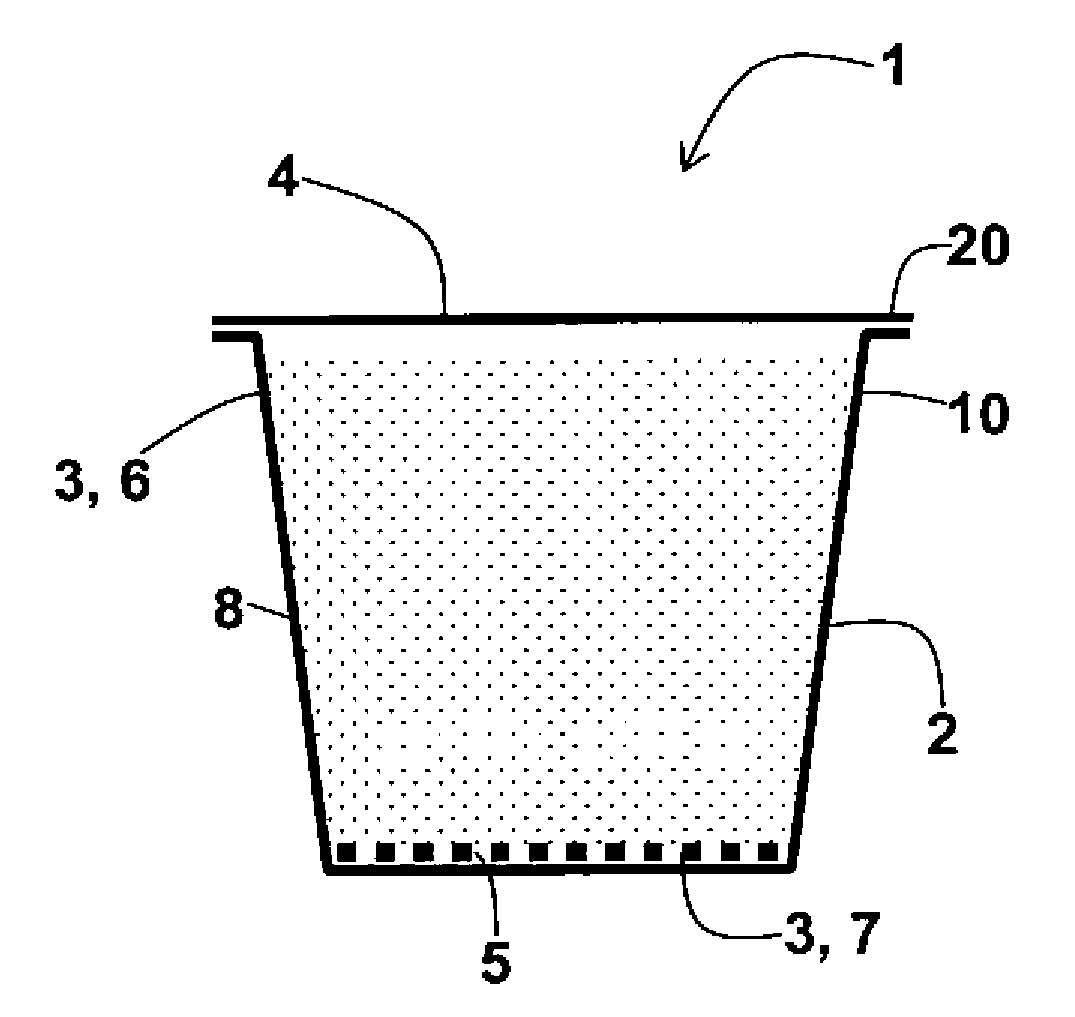

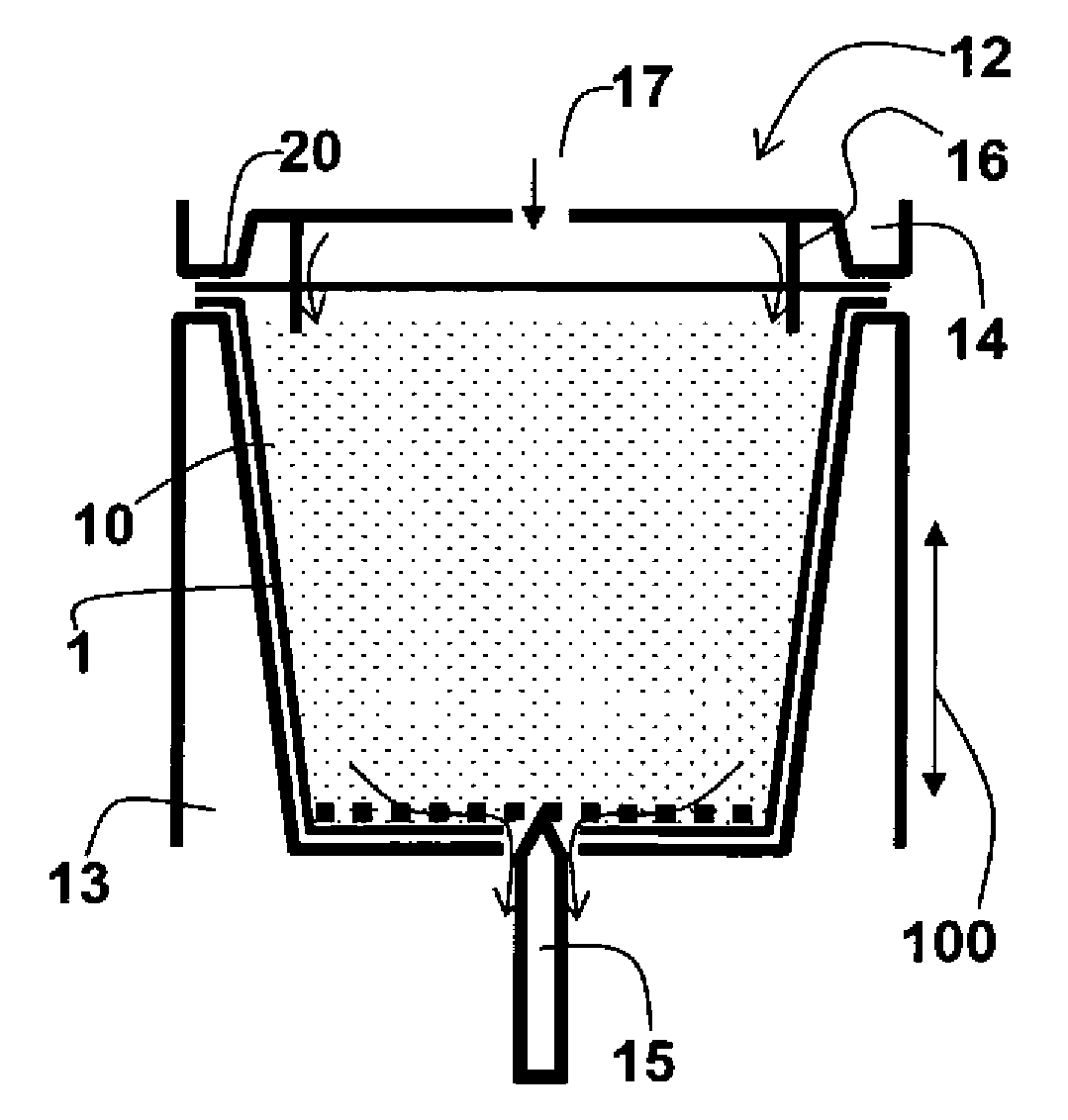

Beverage substance, portion capsule, and method for producing a beverage

ActiveCN103501624AEfficient brewingFaster and cleaner brewingPre-extraction tea treatmentTea extractionParticulatesFood science

Owner:K FEE SYST

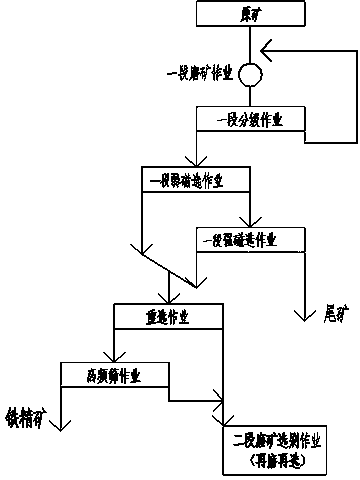

Magnetic ore rescreening process for mixed iron ore

ActiveCN104190522AReasonable workmanshipReliable technologyGrain treatmentsWet separationMonomerMaterials science

The invention discloses a magnetic ore rescreening process for mixed iron ore. The process comprises the following process steps: performing primary ore grinding, performing primary grading, performing primary low intensity magnetic separation, performing primary strong magnetic separation, rescreening, performing high frequency screening and performing secondary ore grinding and selecting. According to the invention, partial qualified iron ore concentrate and partial tailings are thrown out preferentially under the condition that the dissociation degree of useful mineral monomers is insufficient after the primary ore grinding operation, the amount of materials subjected to secondary regrinding and reselecting is reduced, and the aim of reducing the ore dressing cost is achieved.

Owner:ANHUI JINRISHENG MINING

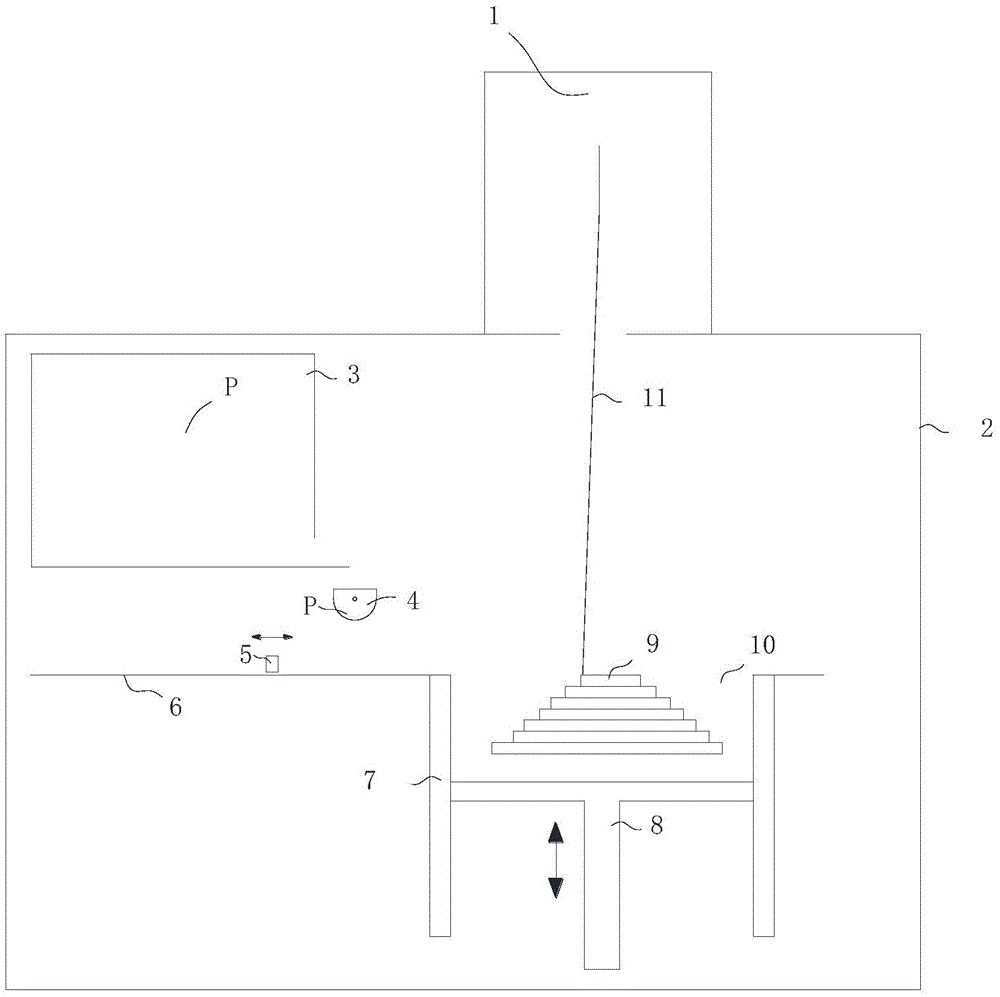

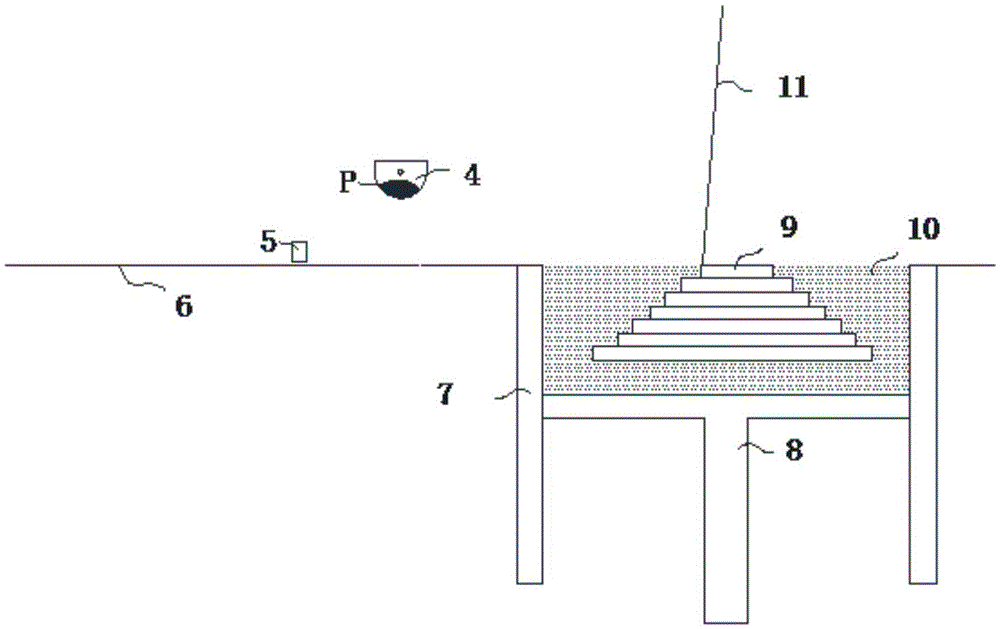

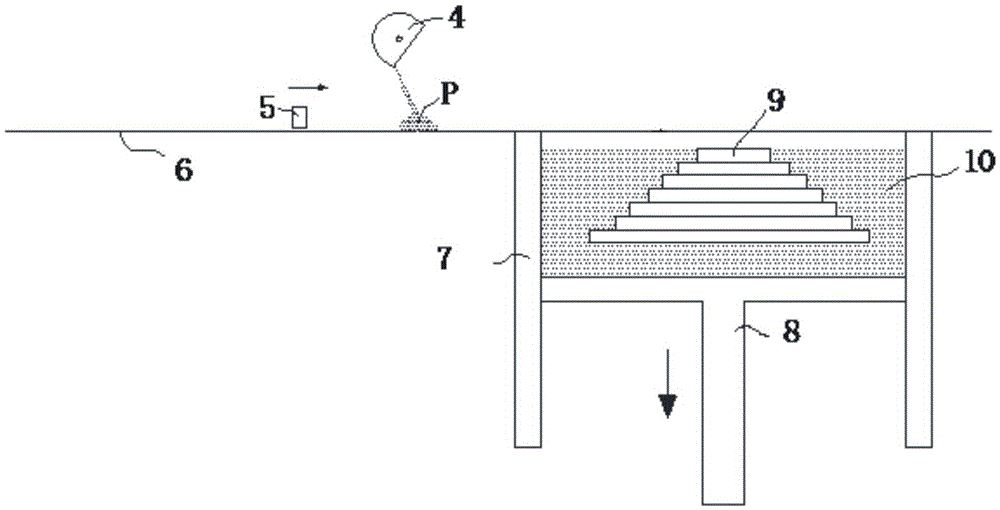

Additive manufacturing device and method

ActiveCN105458260ADoes not reduce manufacturing efficiencyDoes not increase preprocessing timeAdditive manufacturing apparatusTransportation and packagingPretreatment methodMetallurgy

The invention discloses an additive manufacturing device and method. The device comprises an electron beam generating device and a forming chamber. The electron beam generating device is located above the forming chamber and used for generating rays used for melting powder materials. The forming chamber is used for providing a closed cavity needed by manufacturing. The forming chamber is further internally provided with a powder receiving box and powder tanks. The powder receiving box is arranged at the position of outlets below the powder tanks and used for receiving powder materials discharged out of the powder tanks and carrying out pretreatment. The pretreatment method comprises the step of pouring out the powder materials after heating the powder materials to the preset temperature. In the additive manufacturing method, powder is pretreated layer by layer in the layer-to-layer powder laying process; and powder material pretreatment occupies no extra time, and the additive manufacturing efficiency is not lowered. According to the additive manufacturing device, the powder materials heated every time has the thickness of one layer, material consumption is small, and water is more thoroughly removed.

Owner:QUICKBEAM CO LTD +1

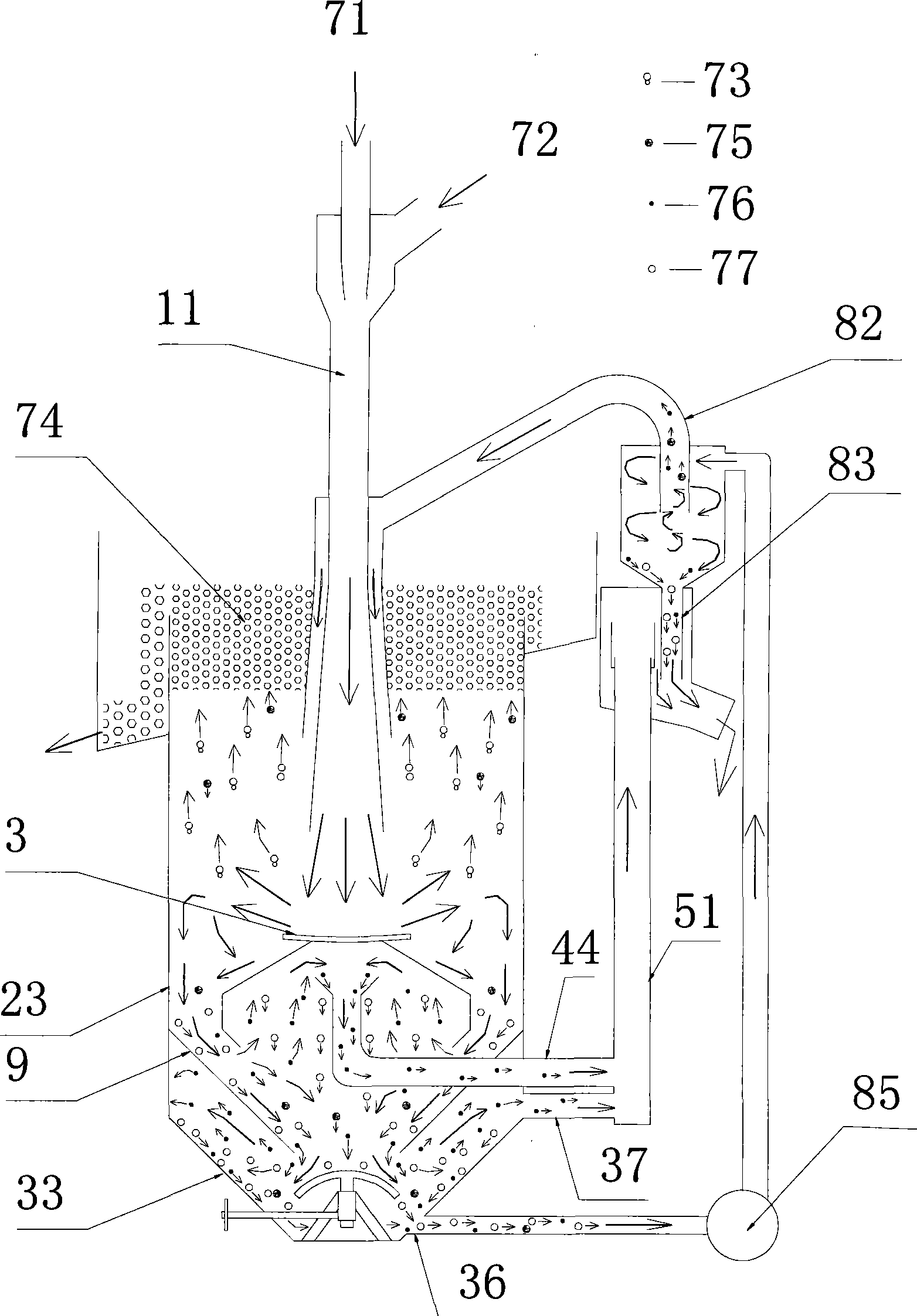

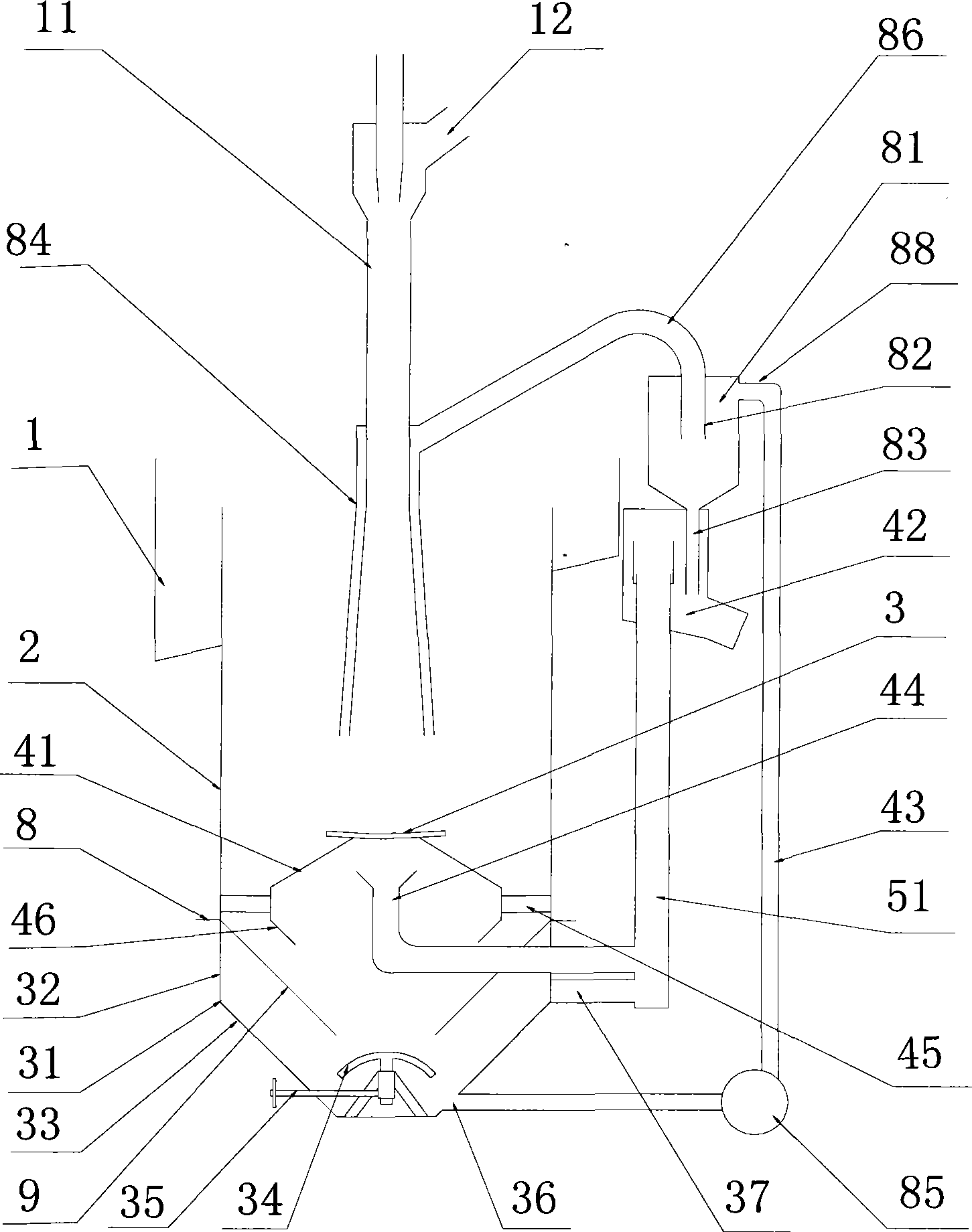

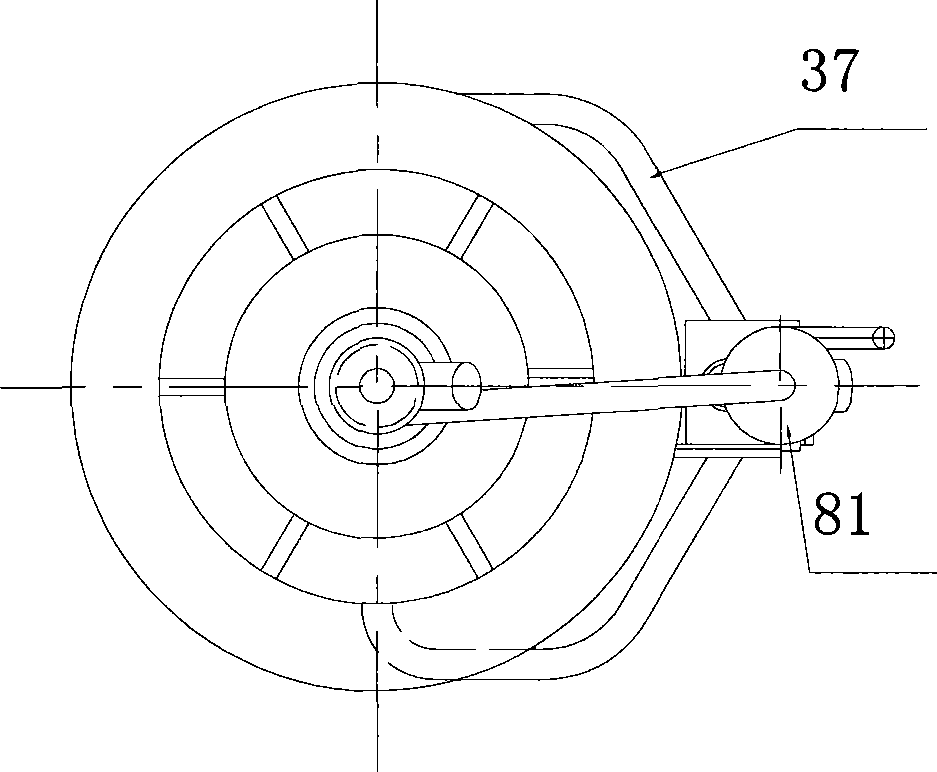

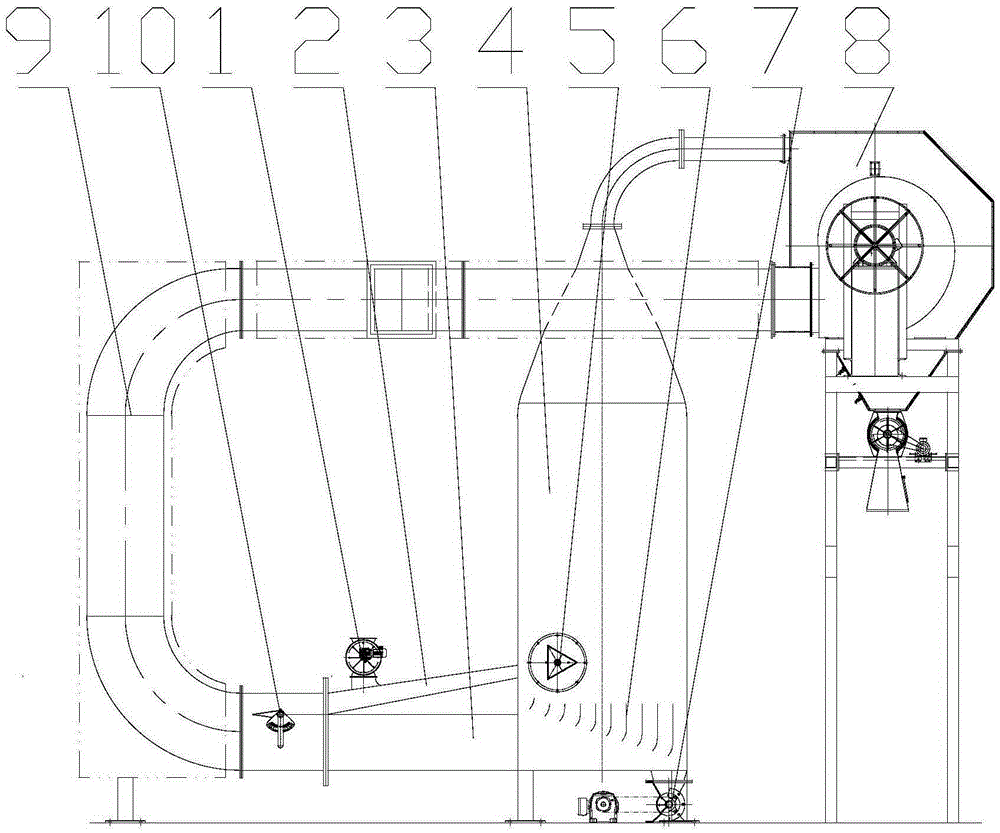

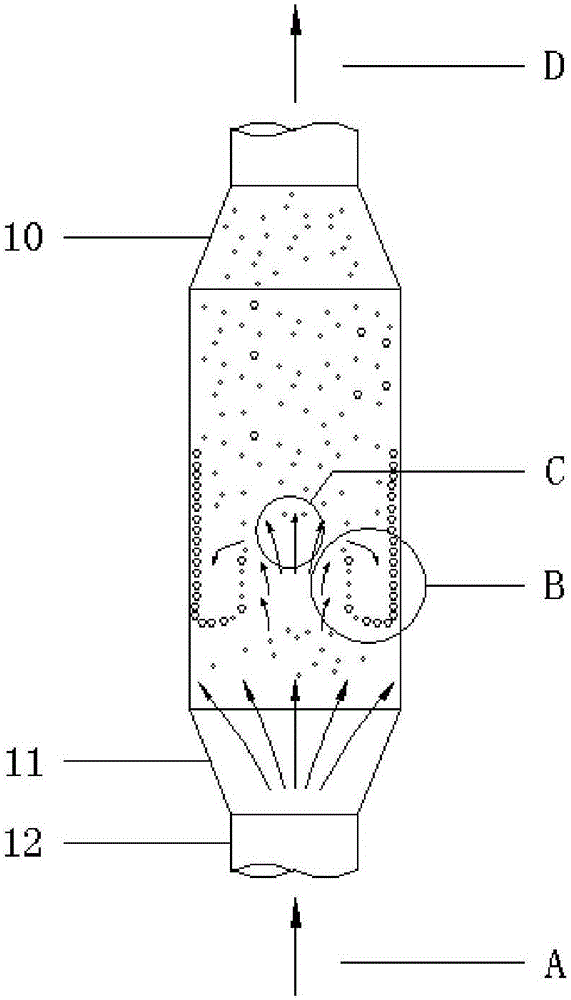

Double tail-removing gravity-flotation combined sorting method and device

The invention relates to a double-tailing discharging gravity-floating combined separation method and a device thereof, and belongs to a double-tailing discharging gravity-floating combined separation method aiming at slime and a device thereof. The aim of the invention is to solve the technical problems existing in the prior flotation machine that the separation effect of ultrafine grains is low and the upper limit of the column flotation is difficult to be effectively related with the lower limit of the heavy medium separation. The method comprises three steps of crude ore flotation and rough separation and graded tailing discharging, gravity scavenging tailing discharging and gravity separation finished ore reflotation. The double-tailing discharging gravity-floating combined separation machine comprises a jet flow flotation column, a first tailing discharging graded device and a secondary tailing discharging graded device; the first tailing discharging graded device is arranged below the jet flow flotation column, a cyclical middling underflow opening of the first tailing discharging graded device is connected with the secondary tailing discharging graded device, and a central ore feeding pipe of the secondary tailing discharging graded device is connected with the jet flow flotation column. The method and the device have multiple effects of coarse slime separation and highly selective floatation of fine coal and ultrafine coal, thereby improving the efficiency of the gravity-floating combined separation.

Owner:TAIYUAN UNIV OF TECH

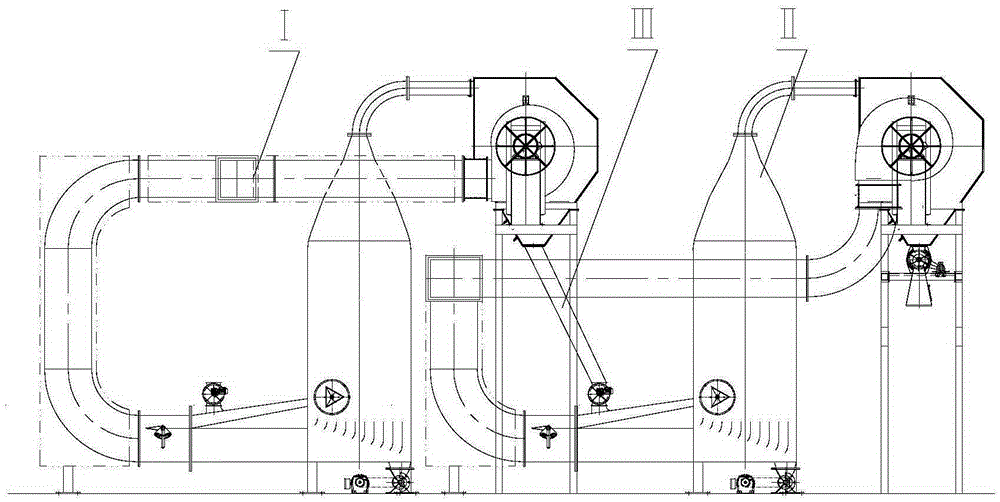

Method and device for efficiently winnowing tobacco shreds

ActiveCN105396782AAchieve uniform distributionGood dispersionGas current separationEngineeringEqualization

The invention provides a method and device for efficiently winnowing tobacco shreds. Tobacco materials are fed into a winnowing chamber through conveying air, and the tobacco materials are loosened by a material equalization roll in the winnowing chamber and evenly distributed in the winnowing chamber; winnowing air is fed into the winnowing chamber, suspension winnowing is carried out on the tobacco materials in the winnowing chamber, and sundries are separated out; and meanwhile, the caked tobacco materials are suspended on air equalization plates in the winnowing chamber and are repeatedly jolted to be loosened under the action of upward blown winnowing air and gravity. A multilevel winnowing scheme is further designed, the amount of the materials subjected to secondary winnowing is greatly reduced, and therefore the purity of the tobacco shreds is improved, and energy consumption for winnowing is effectively reduced. According to the method and device, the winnowing efficiency is high, the purity of the tobacco shreds is high, and crushing is greatly reduced.

Owner:ZHISI HLDG GRP

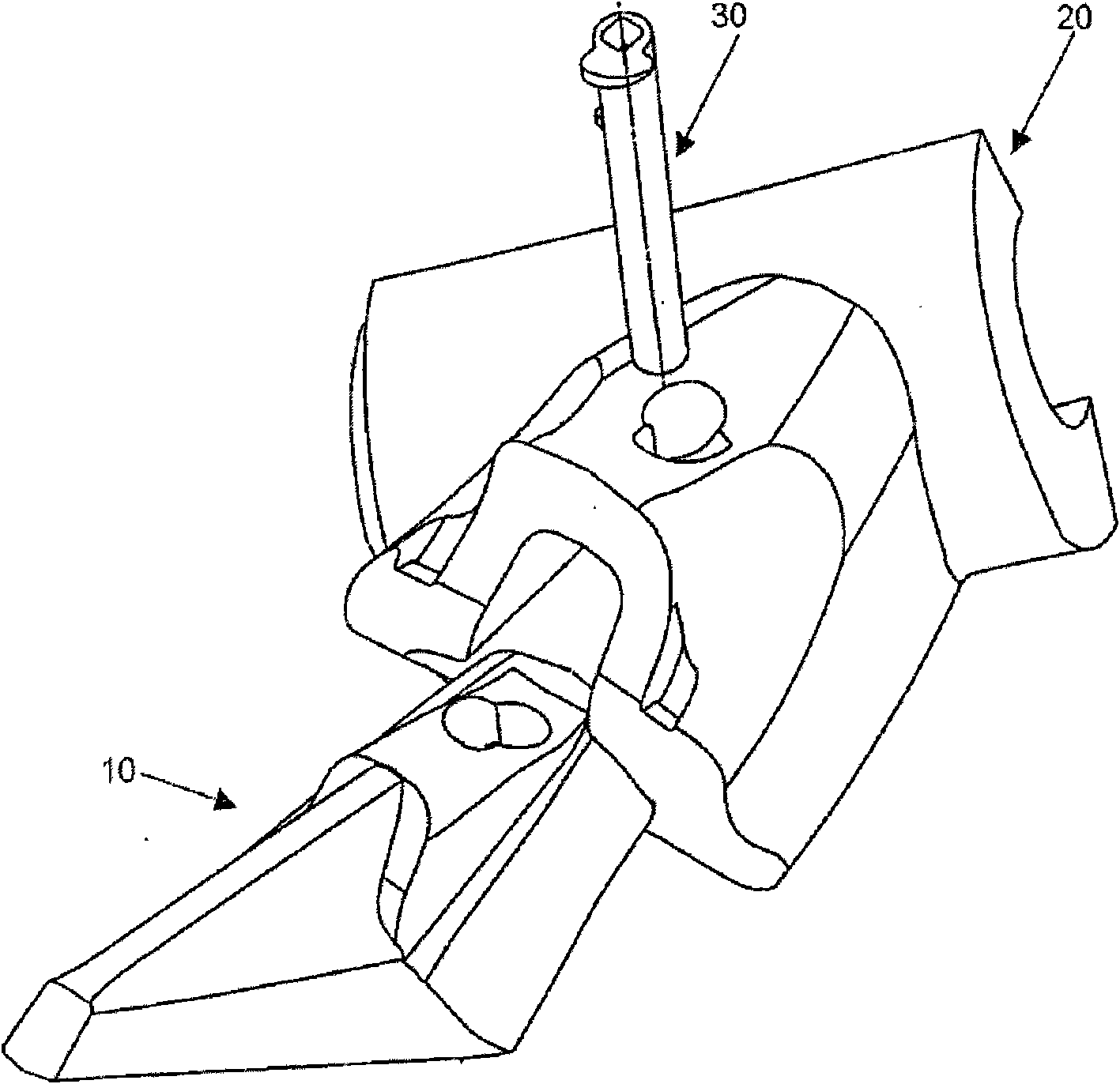

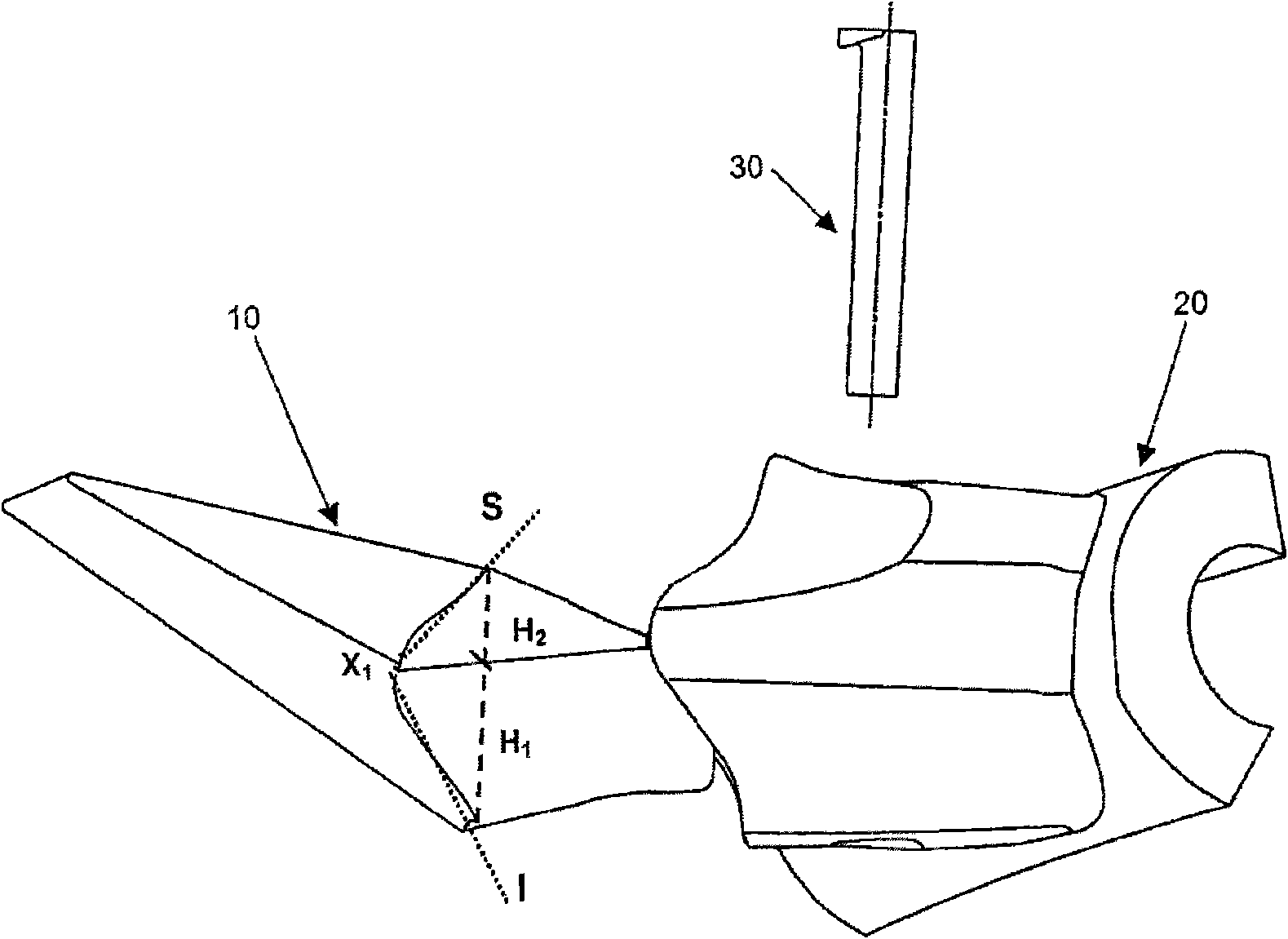

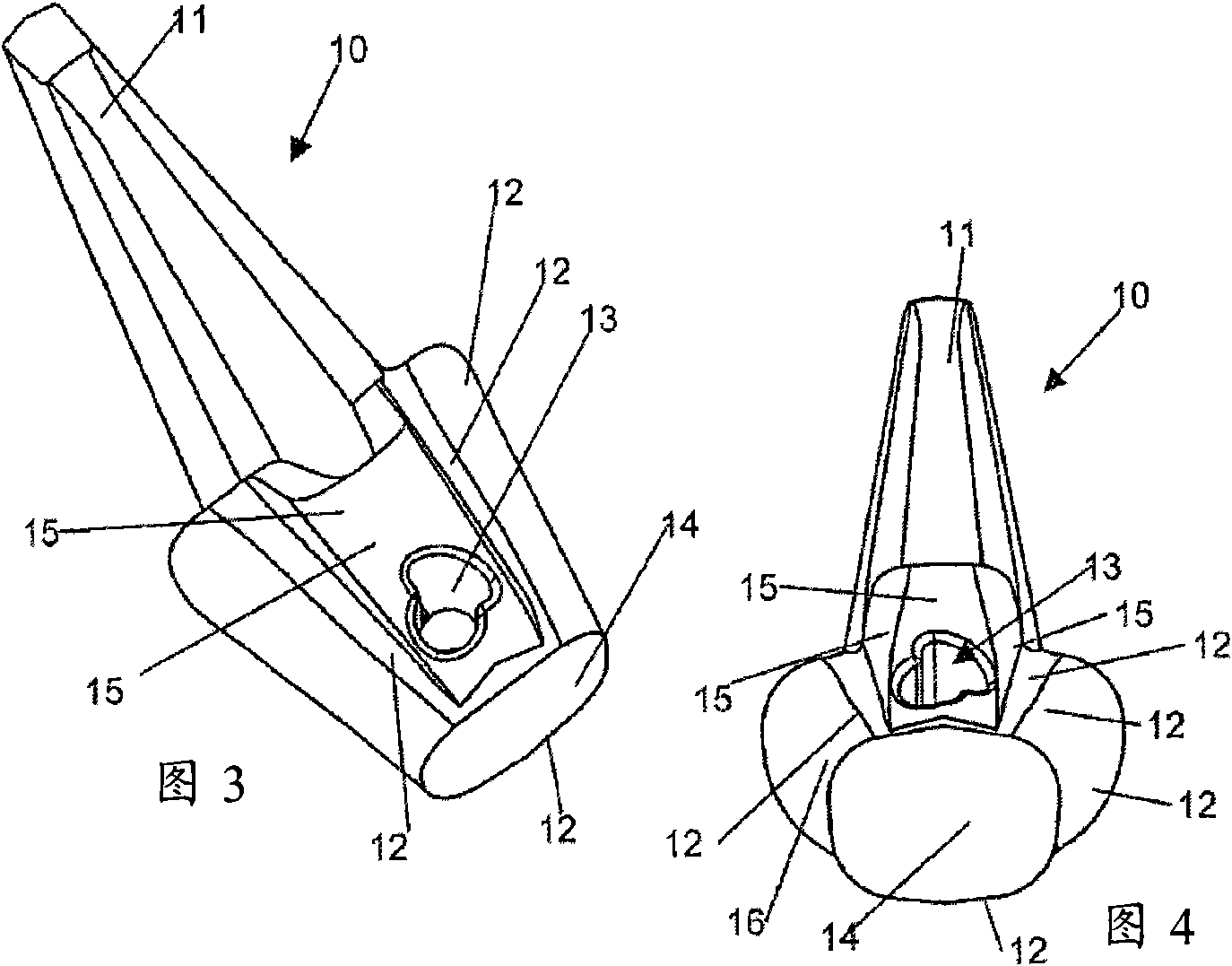

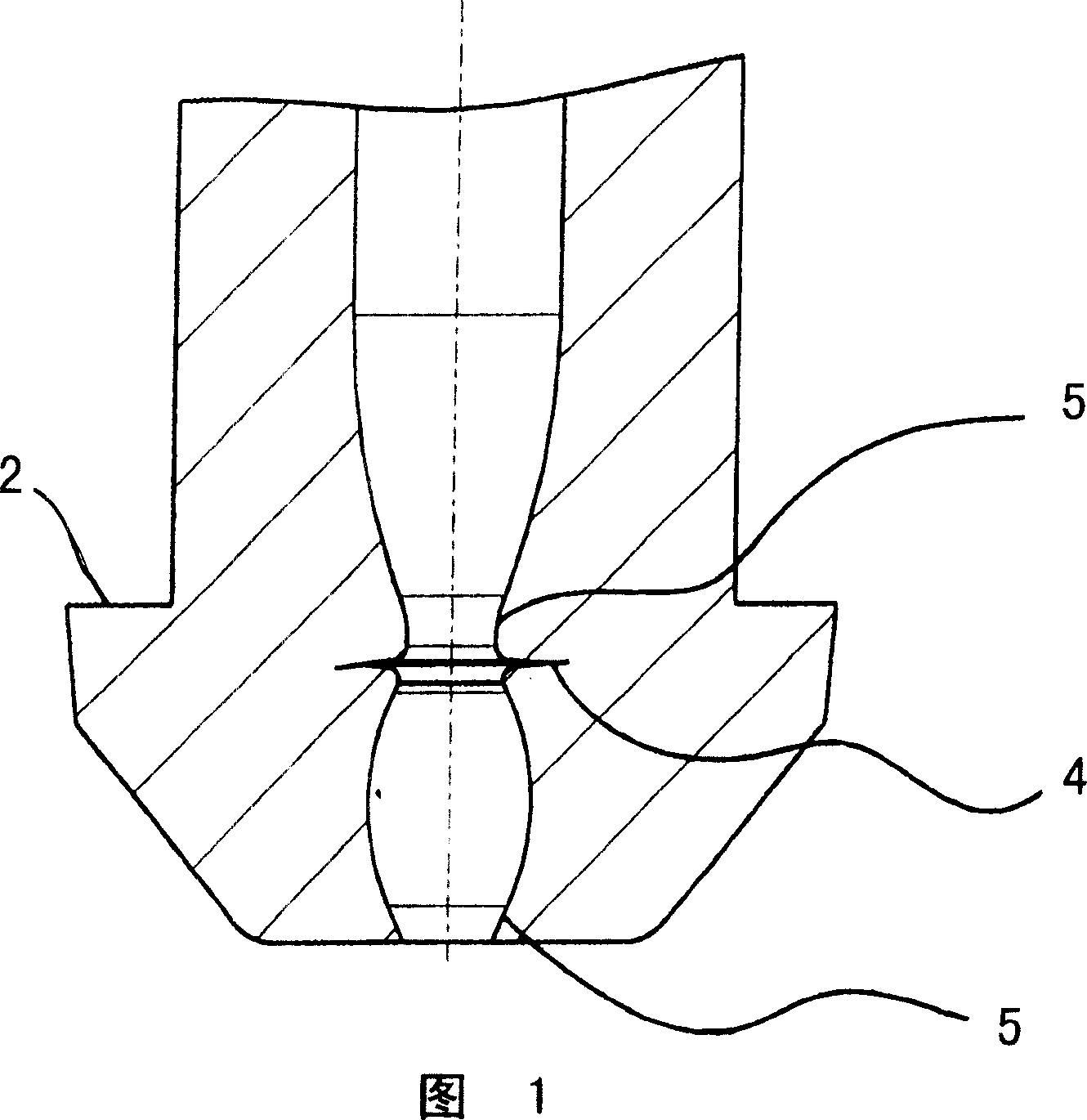

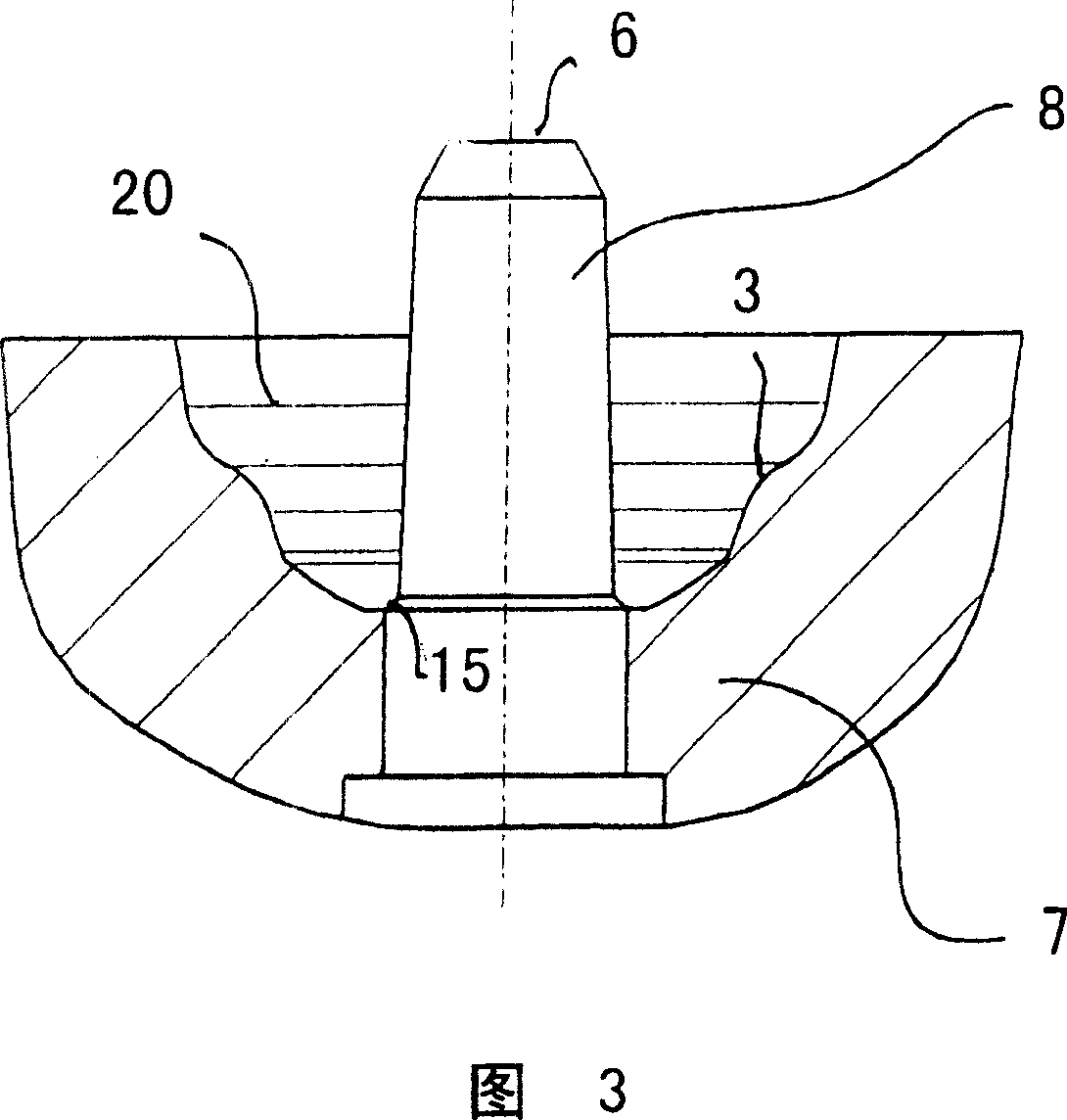

Prong and fitting for a dredging machine

The invention relates to a prong for a dredging machine, comprising a tip (11) and a nose (12) for coupling same to a fitting (20). The nose includes a lower base body (16) having a cross-section formed by at least four sides and an upper surface (120) which converges in the direction of the lower surface (123) towards the end of the nose (12) located farthest from the tip (11). The upper surface (120) is provided with an upper trapezoidal attachment (15), the upper (153) and lower (154) ends of which also converge in the direction of the end of the nose. The upper attachment (15) and the base body (16) have an equal maximum cross-section at a point from which the lower surface (123) and the upper end (153) converge in the direction of the tip. A flange having a constant or variable cross-section can be provided between the nose (12) and the tip (11).; The prong is fixed to the blades of the dredger propeller using a fitting (20) having a cavity that matches the nose (12) of the prong and a pin (30) which extends through the corresponding vertical housings in the nose (12) of the prong and the fitting.

Owner:METALOGENIA SA

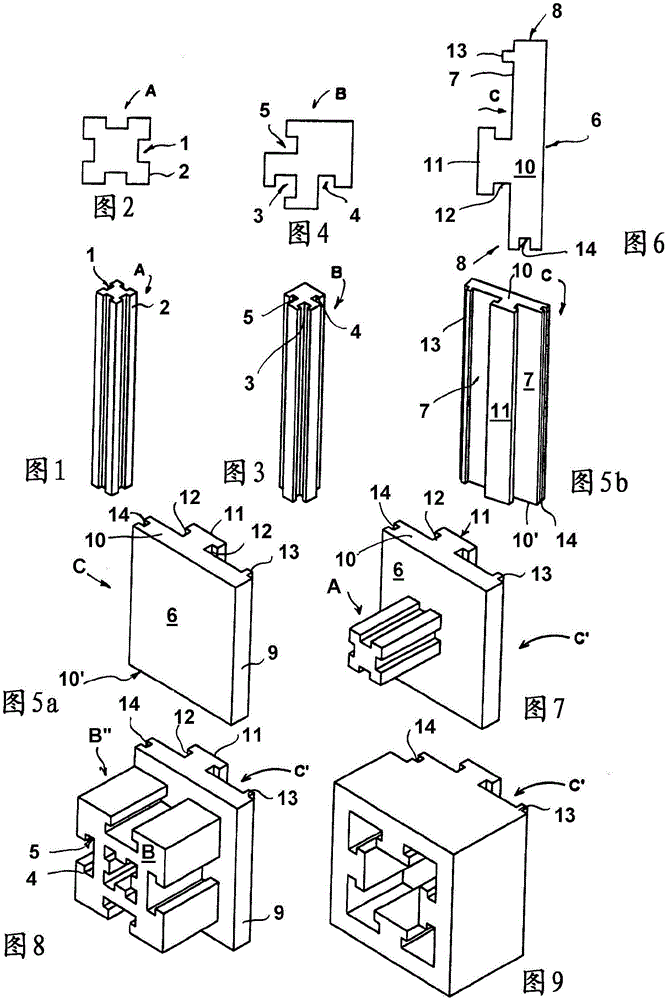

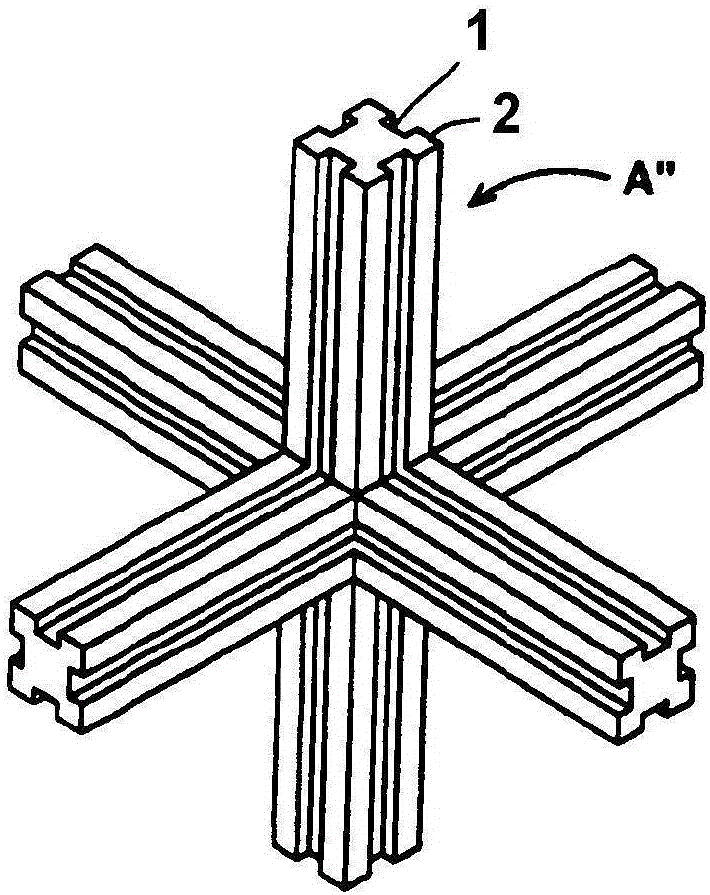

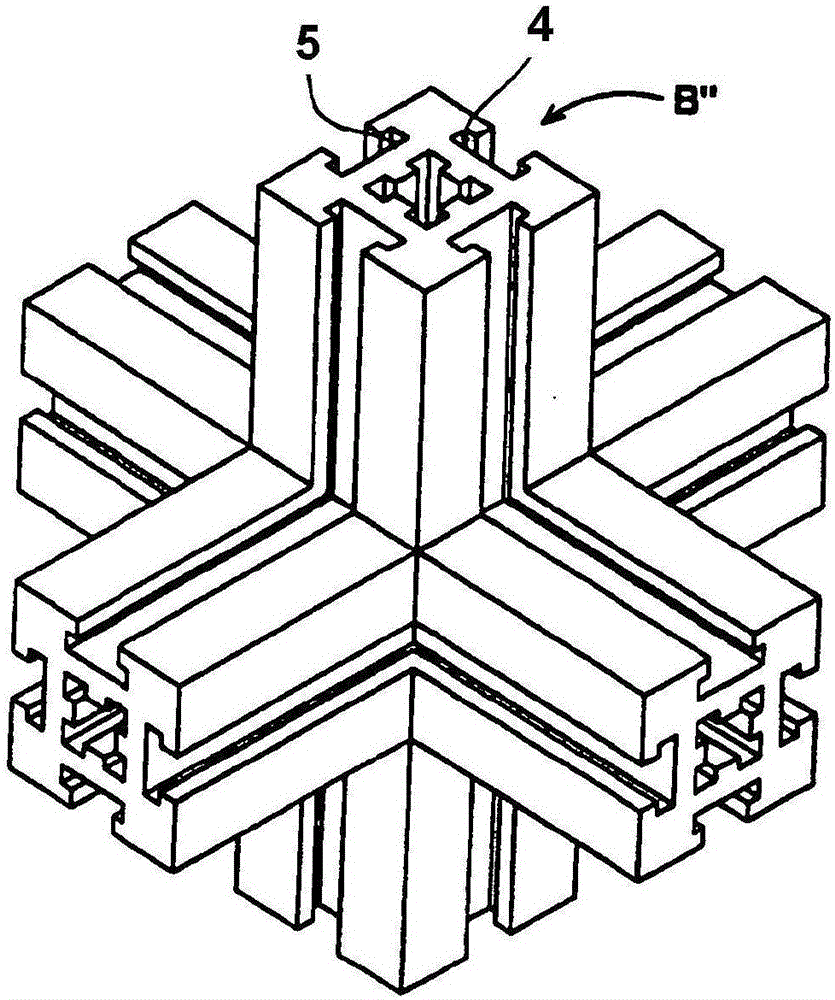

Modular structural system

ActiveCN106030004AImprove performanceImproved performance characteristicsFurniture joining partsStrutsModularityEngineering

The invention relates to a modular structural system obtained from the combination, in sliding engagement form, of generically elongated elements A, B, C, D having sections whose perimeter is provided with protrusions and recesses which, in the spatial development of the elements A, B, C, D, form sliding channels or tracks for mutual sliding of the elements which form the structural system. The structural system may also be provided with node elements C shaped so as to have two parallel opposite surfaces, one of which is provided with sliding channels or tracks for mutual male / female engagement in corresponding sliding channels or tracks and the other surface of which is provided with a permanent or releasable connection with other elements A, B, C, D at a connection angle of 0<a<180 degrees with respect to said opposite surfaces. The structural system may also be provided with nodes A", B", C" instead of the node elements C.

Owner:塞蒂米奥卡斯泰利

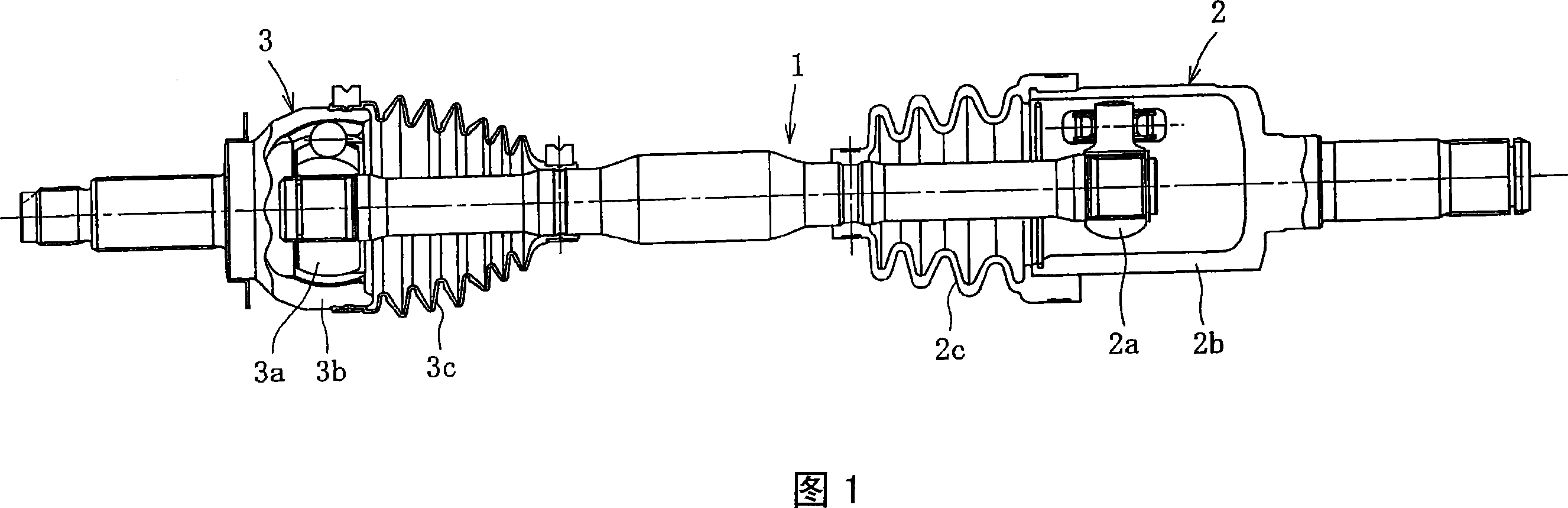

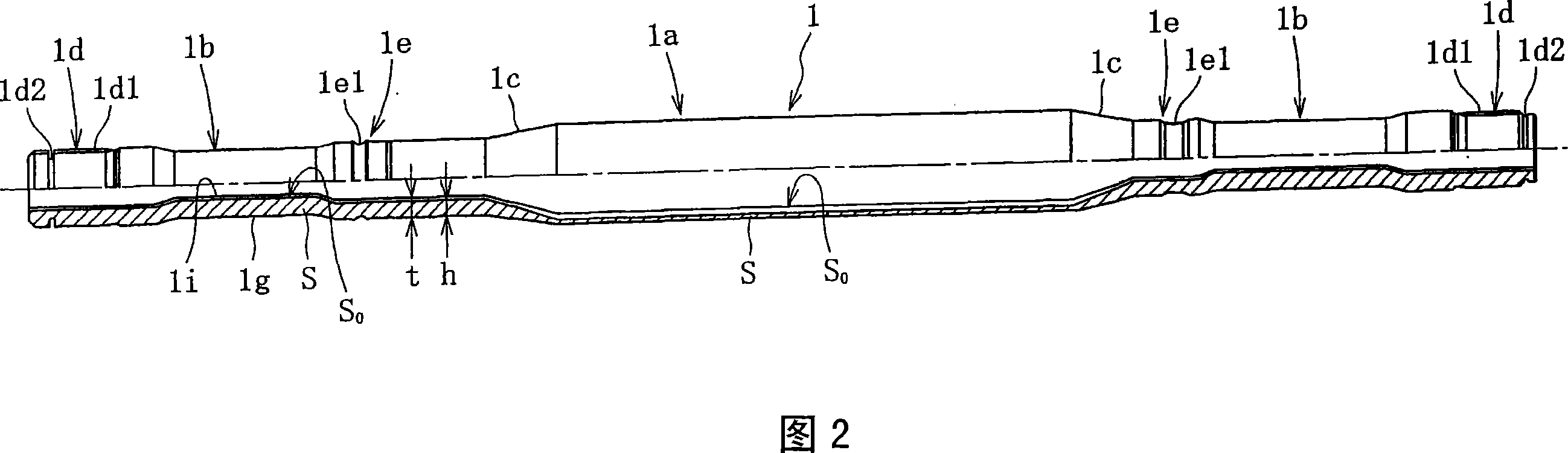

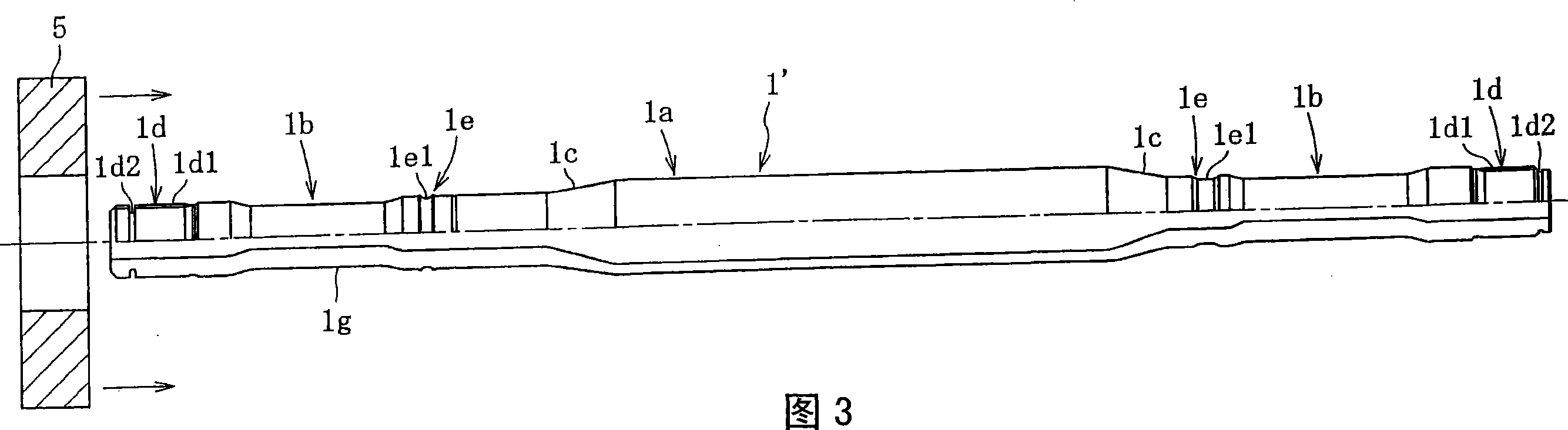

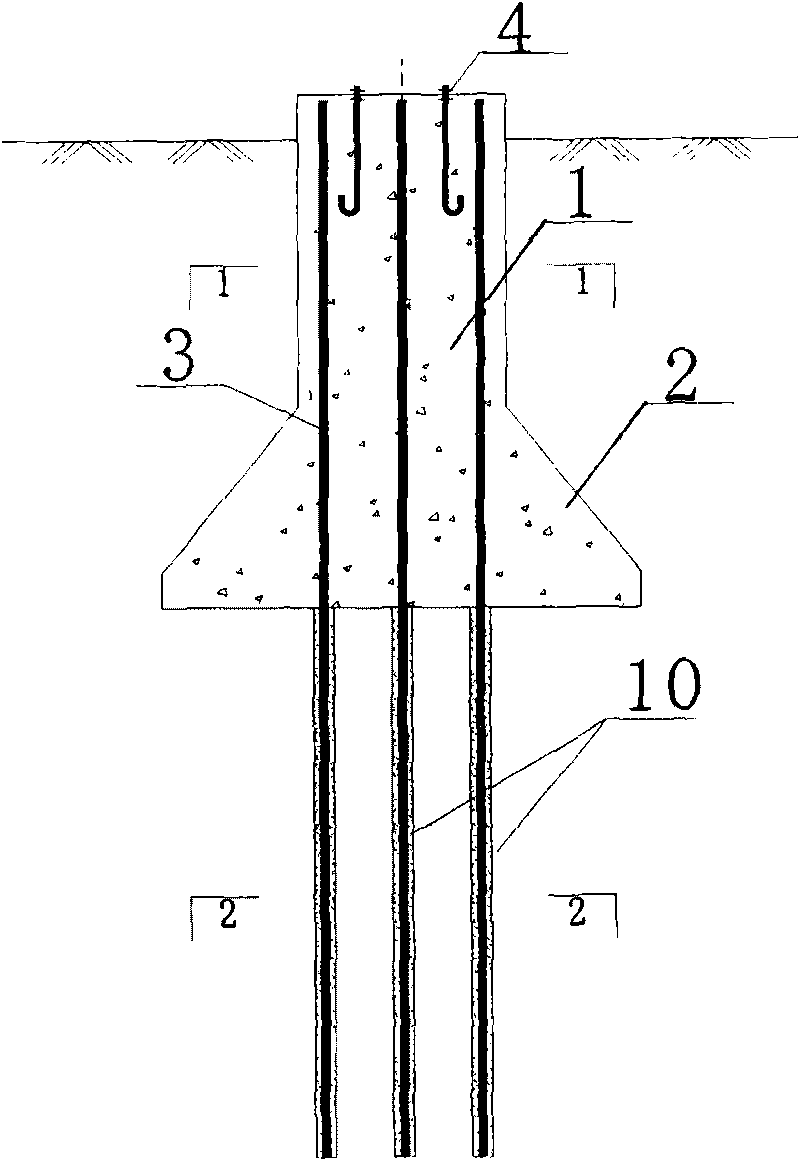

Hollow power transmission shaft and method of manufacturing the same

ActiveCN1989351ASuppression of tooth thickness increaseReduce the amount of materialShaftsEngineeringMotive power

The invention provides a method of manufacturing a hollow power transmission shaft capable of securing stable quality even if a difference in wall thickness and a difference in hardening rate are present in the axial direction of the transmission shaft. A movable induction heating coil (5) is wrapped around the outer peripheral surface (1g) of a hollow shaft raw material (1'), and moved in the axial direction while flowing a high-frequency current with a specified frequency to the induction heating coil (5) to induction-harden the shaft raw material from the outer peripheral surface (1g). In this case, for small diameter parts (1b) with a rather large wall thickness, the frequency of the high-frequency current led to the induction heating coil (5) is relatively reduced, and for a large diameter part (1a) with a rather small wall thickness, the frequency of the high-frequency current led to the induction heating coil (5) is relatively increased.

Owner:NTN CORP

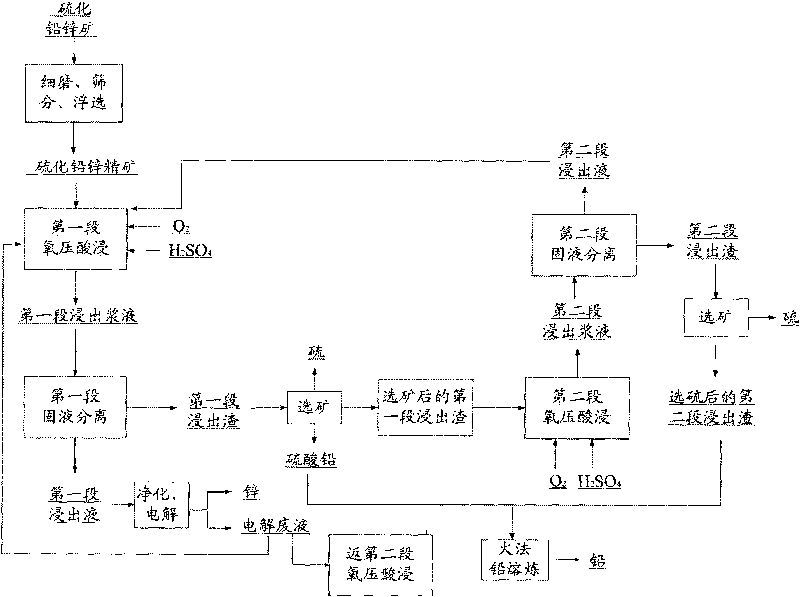

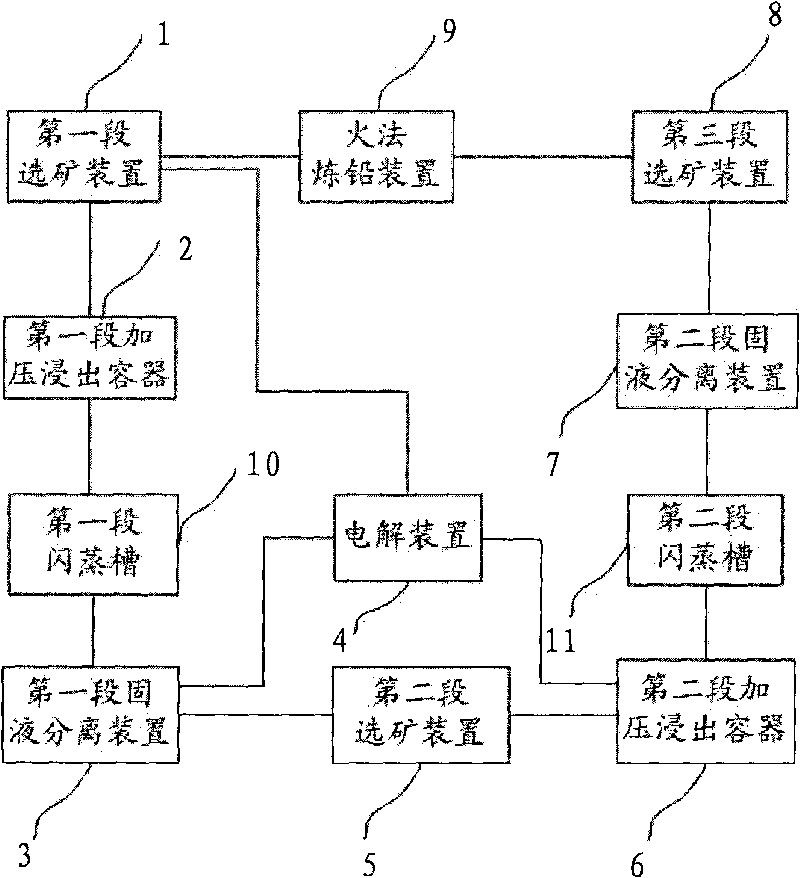

Method and system for treating lead-zinc sulfide ores

InactiveCN101709373AHigh recovery rateReduce usagePhotography auxillary processesSulfur preparation/purificationSlagSlurry

The invention discloses method and system for treating lead-zinc sulfide ores. The method comprises the following steps of: dressing the lead-zinc sulfide ores to obtain concentrate lead-zinc sulfide ores; fine grinding the concentrate lead-zinc sulfide ores and pulpifying the fine-grinded concentrate lead-zinc sulfide ores by using sulfuric acid; carrying out a first stage of oxygen pressure acid leaching on the pulpified concentrate lead-zinc sulfide ores; after solid-liquid separation of the serosity leached from the first stage, purifying and electrolyzing the leached solution from the first stage to obtain a metal zinc, and dressing the slag leached from the first stage to obtain a simple substance of sulfur and part of lead sulfate; carrying out a second stage of oxygen pressure acid leaching on the leached slag of the first stage and conducting solid-liquid separation on the serosity leached from the second stage; returning the leached liquid of the second stage into a first stage pressurizing leaching container, and dressing the sulfur from the leached slag of the second stage; and sending the zinc sulfate and the second stage leached slag in which the sulfur is dressed out to a pyrogenic process for zinc melting. The method remarkably improves recovery rate of the lead and the zinc without generating large quantities of mineral dressing wastewater which is difficulty to treat. The invention also discloses a treatment system of lead-zinc sulfide ores.

Owner:KUNMING METALLURGY INST

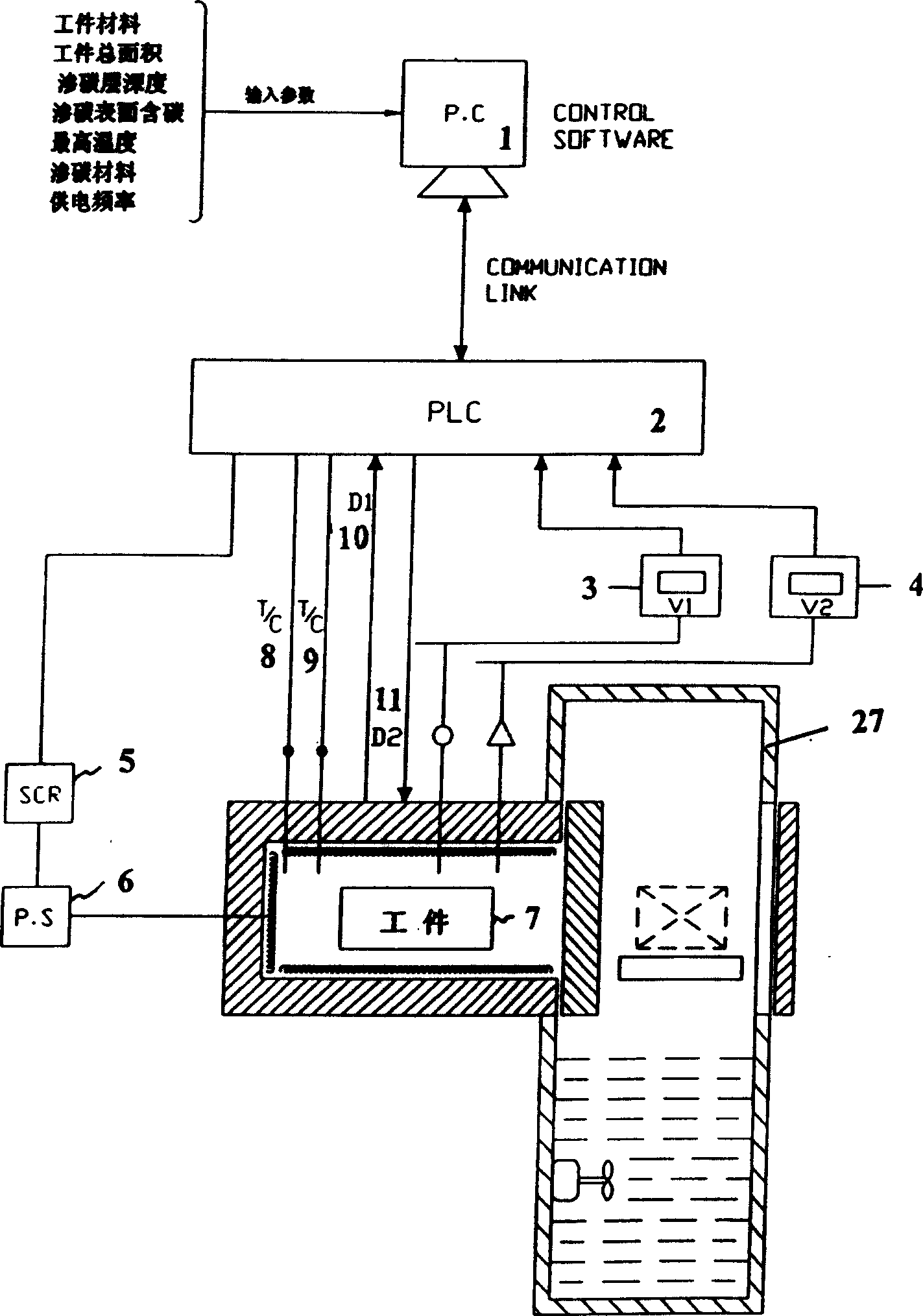

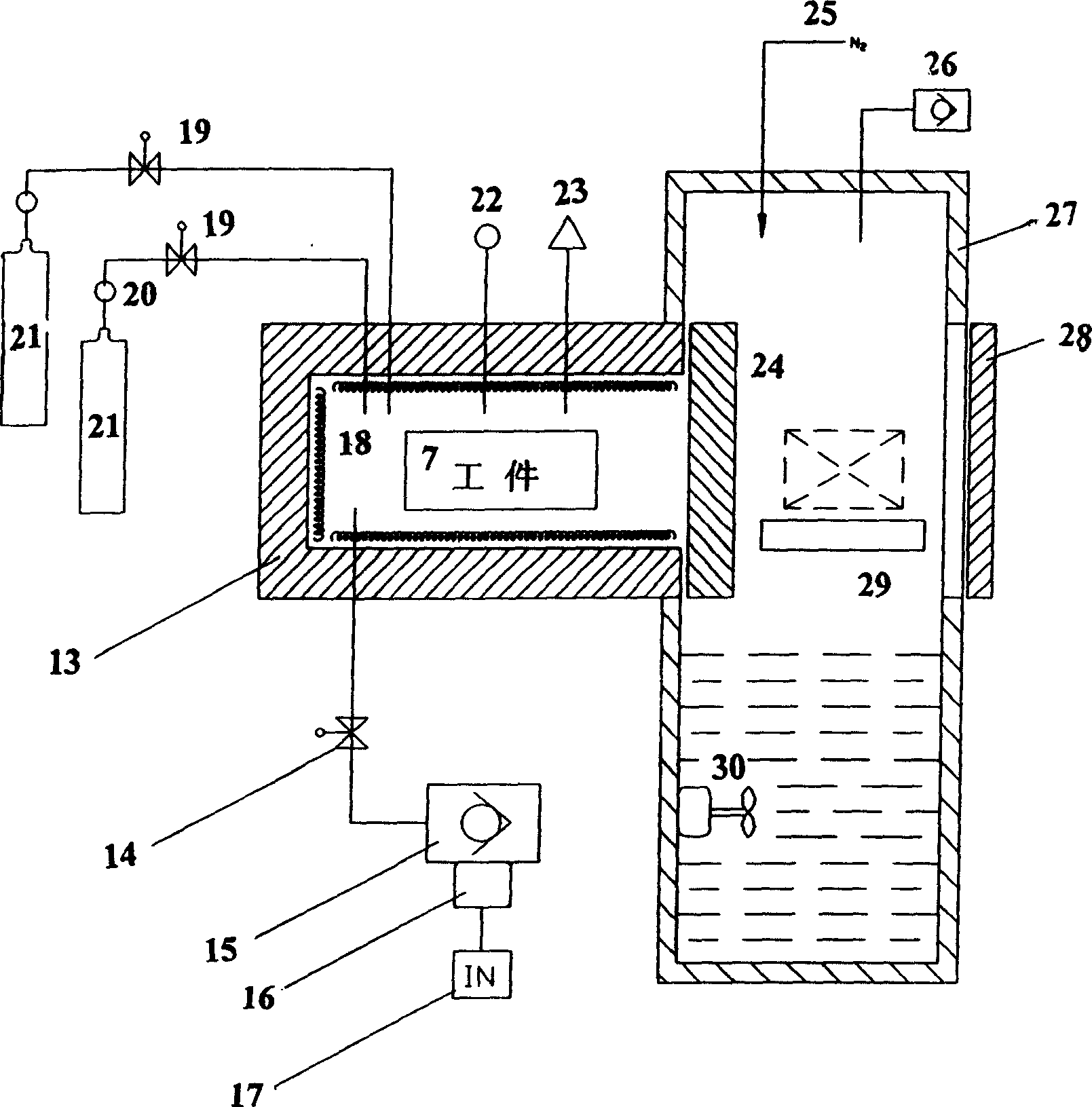

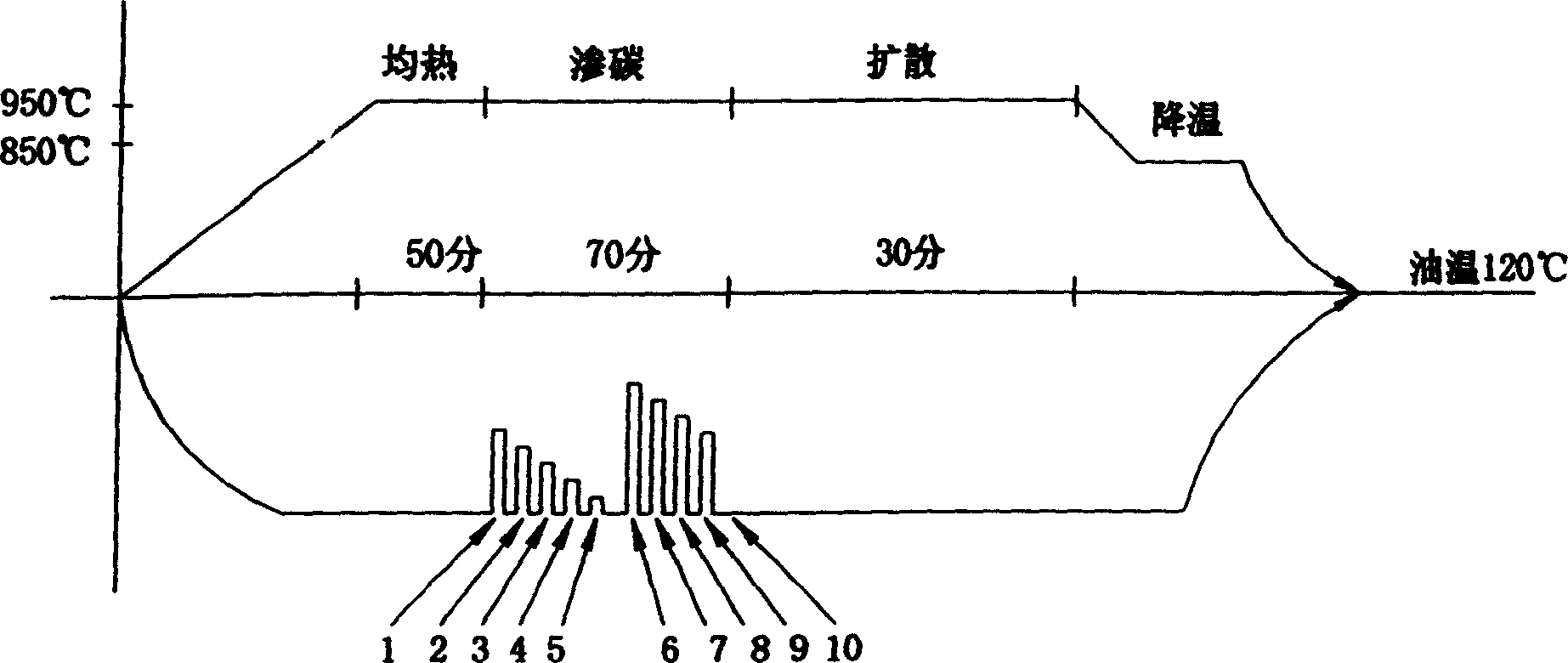

Dynamic control system for low-pressure carburating heat treament furnace

InactiveCN1560317AImprove uniformityIncrease loading capacitySolid state diffusion coatingAutomatic controlControl system

The invention is a control system relating to a vacuum carburizing heat-treatment technique, especially a dynamic control system used in low-pressure carburizing heat-treatment furnace, including a corresponding device and the concrete working steps, where the device is mainly composed of computer and control software, PLC, thermocouple, vacuum meter, power supply, workpiece, quenching room, etc, adopting a multi-parameter input computer as control basis, and using above two kinds of vacuum meters, the computer calculates and makes real-time dynamic control according to various inputted parameters, and controls a motor inverter to command the necessary suction of a vacuum pump system, repeating this many time until the depth of carburized layer. Its advantages: it can save carburizing materials; increase loading capacity of the furnace; improves carburizing uniformity; reduce carbon accumulation of the vacuum system; automatically generate complex making course in dynamic control mode; and complete automatic control by computer, eliminating the possible errors caused by artificial operation.

Owner:上海宝华威热处理设备有限公司

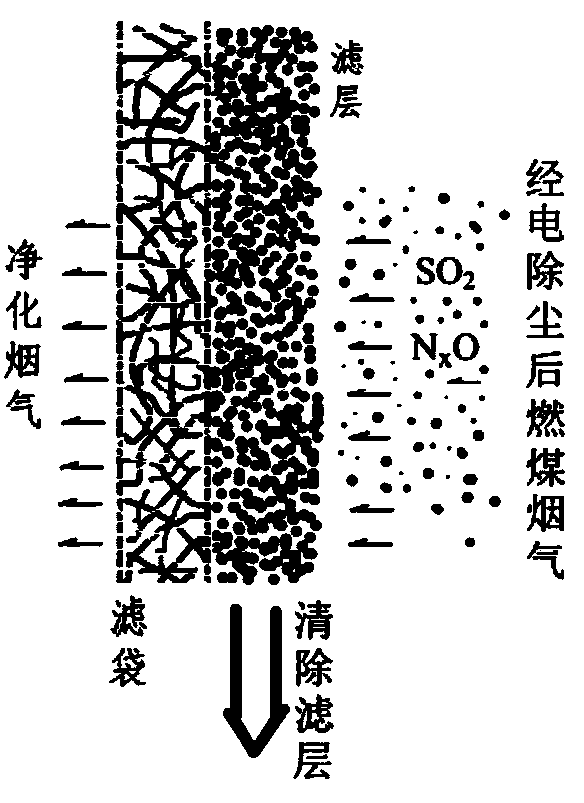

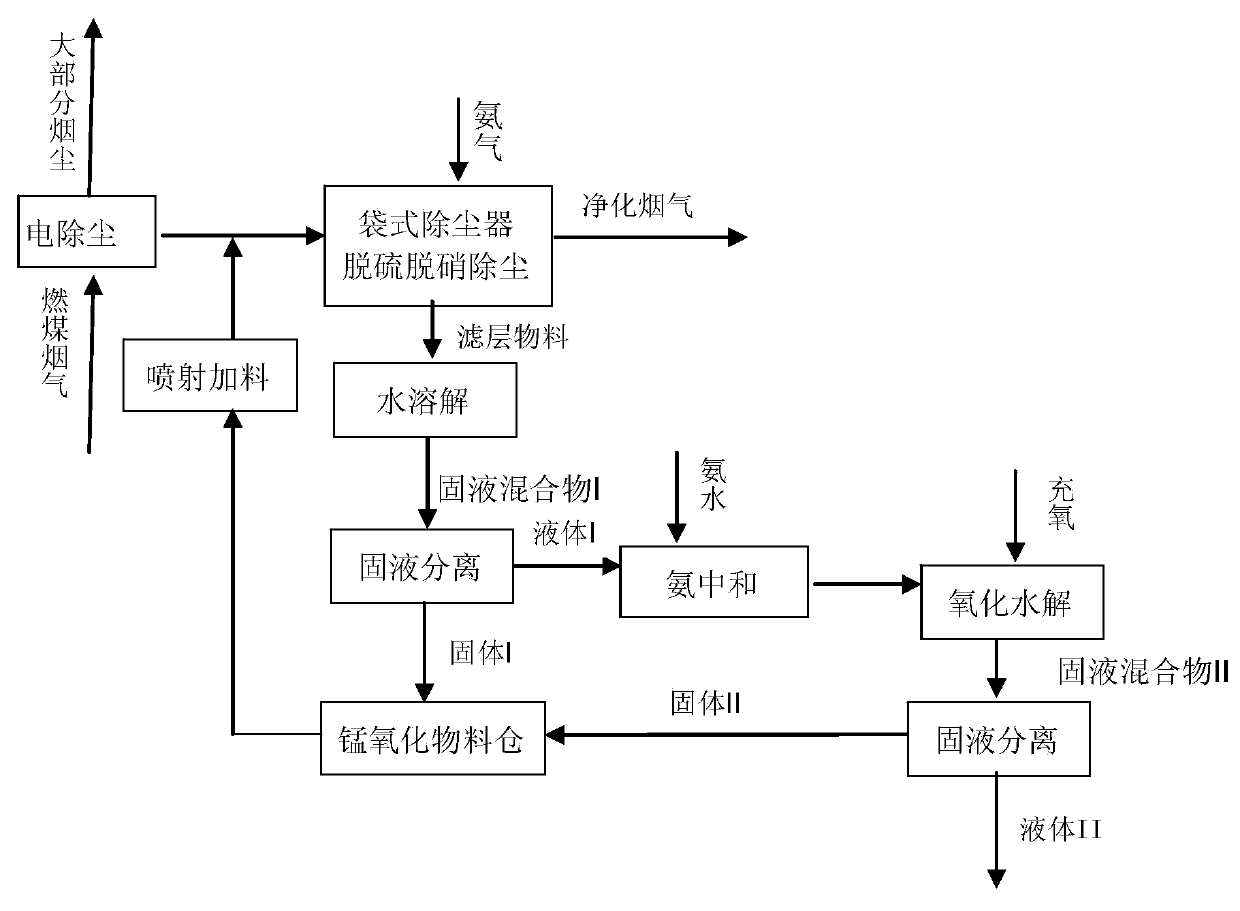

Method for performing synchronous desulfurization, denitrification and dust removal in bag type dust collector

The invention discloses a method for performing synchronous desulfurization, denitrification and dust removal in a bag type dust collector. The method is characterized by comprising the following steps: by taking the bag type dust collector as a reaction device, introducing coal-fired flue gas subjected to electric precipitation into the bag type dust collector through a connecting pipeline, and injecting manganese oxides into the connecting pipeline, so that the manganese oxides are used for performing desulfurization and denitrification on the coal-fired flue gas; allowing the unreacted manganese oxides, desulfurization and denitrification products and smoke dust to enter a filter bag of the bag type dust collector along with the coal-fired flue gas, and retaining the unreacted manganese oxides, desulfurization and denitrification products and smoke dust on the surface of the filter bag to form a filter layer; spraying ammonia gas into the coal-fired flue gas entering the bag type dust collector, and thus reducing the residual nitric oxides in the coal-fired flue gas into nitrogen by virtue of the ammonia gas; recovering and regenerating the materials on the filter layer, and recycling the obtained manganese oxides to be injected into the connecting pipeline. According to the invention, the bag type dust collector serves as a core device, the manganese oxides are taken as active materials, and synchronous and integrated desulfurization, denitrification and dust removal on the flue gas can be realized in the bag type dust collector through a series of separation, regeneration and recycling operations.

Owner:HEFEI UNIV OF TECH

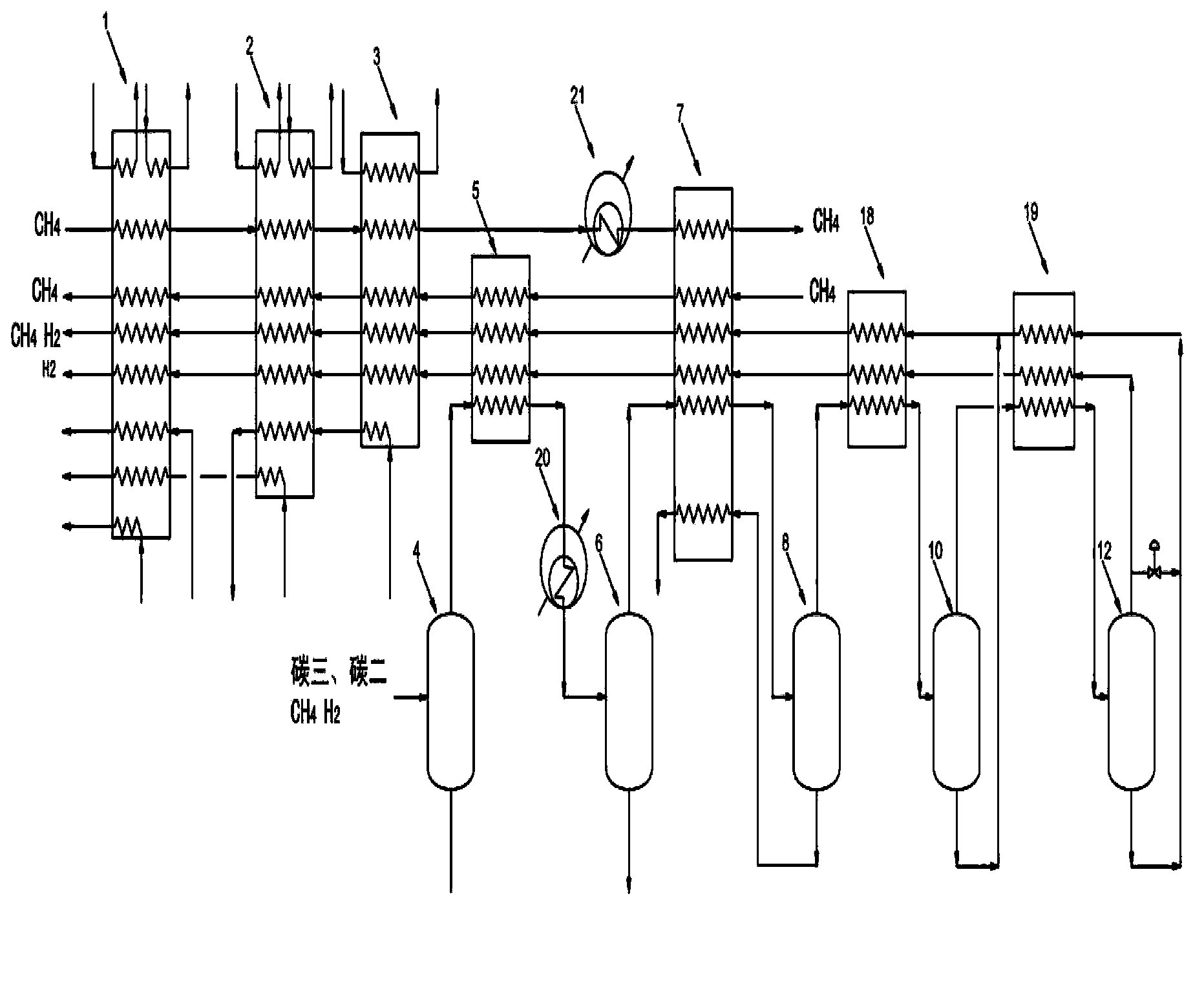

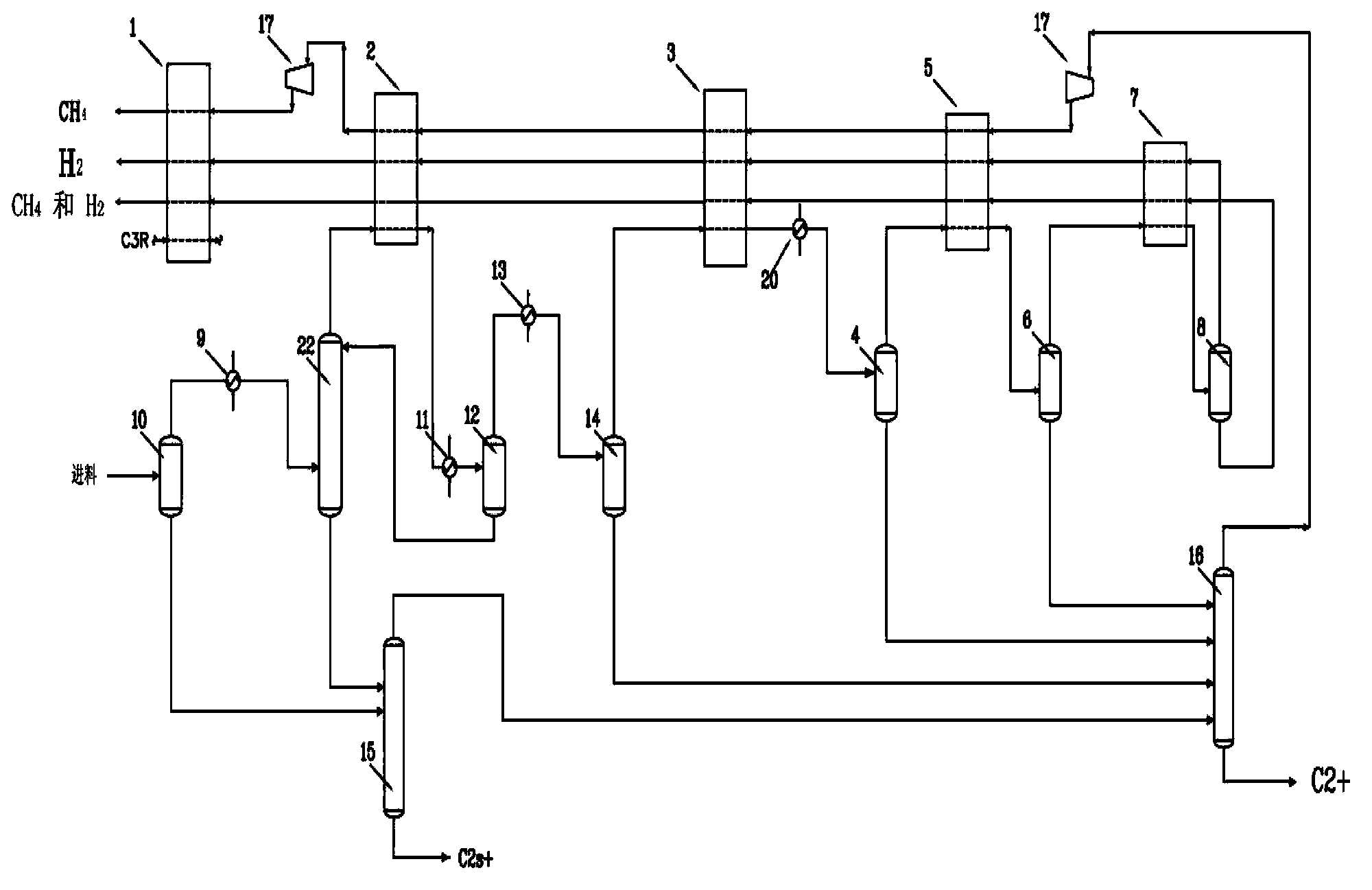

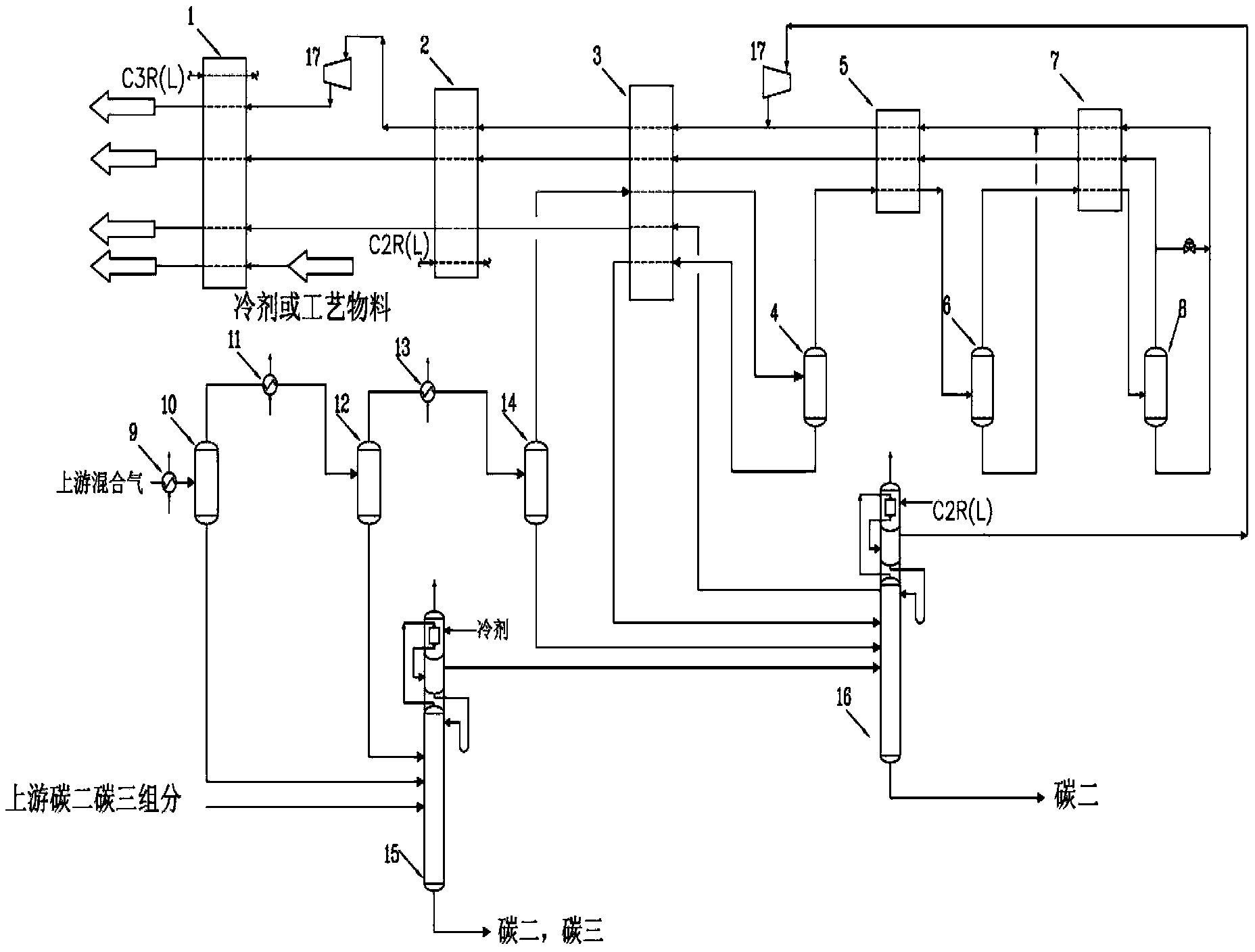

Ethylene cryogenic separation method for large-sized ethylene device

ActiveCN103542693AGuaranteed operational stabilityReduce the amount of materialSolidificationLiquefactionChemistrySeparation method

Owner:PETROCHINA CO LTD +1

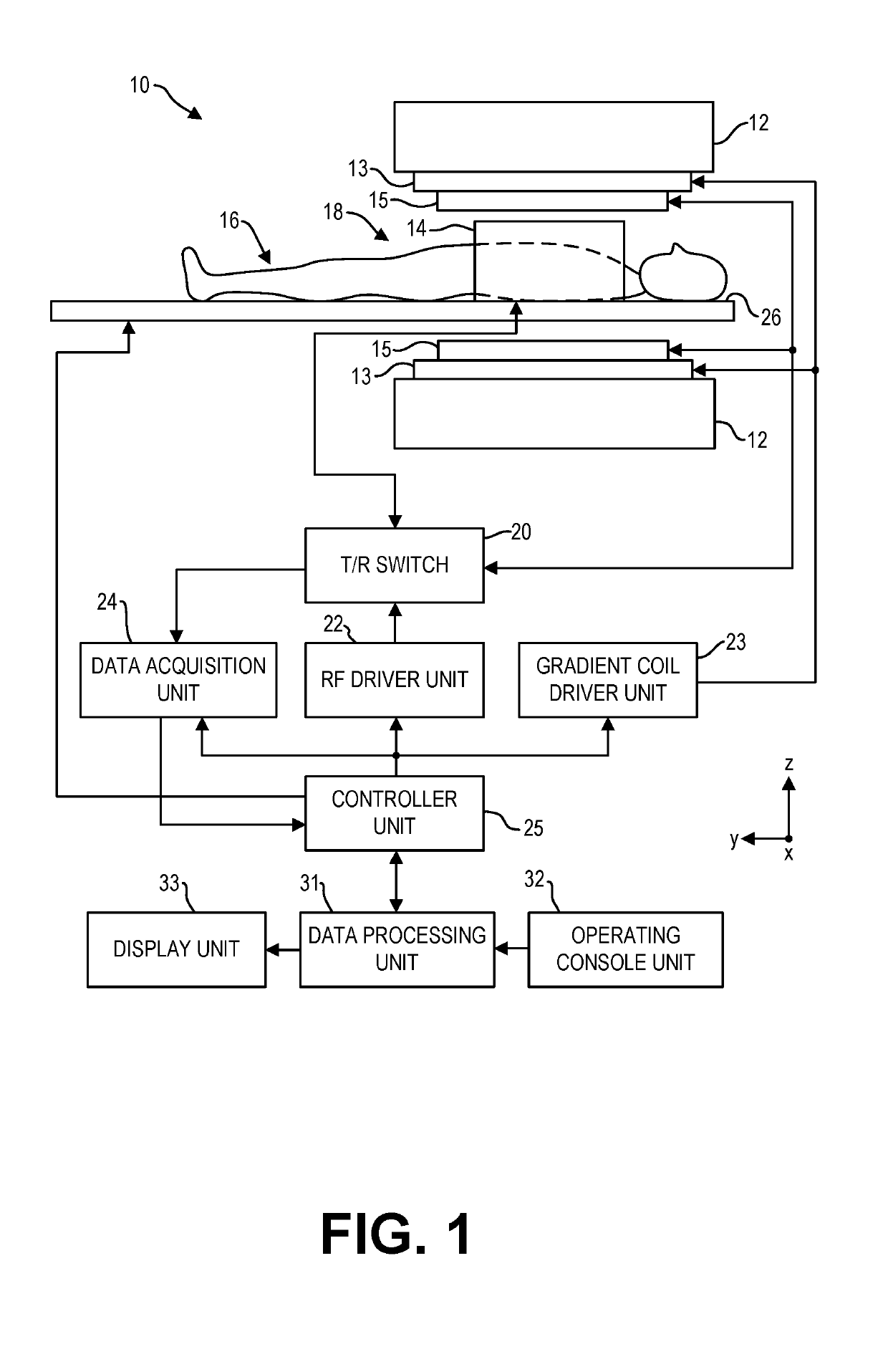

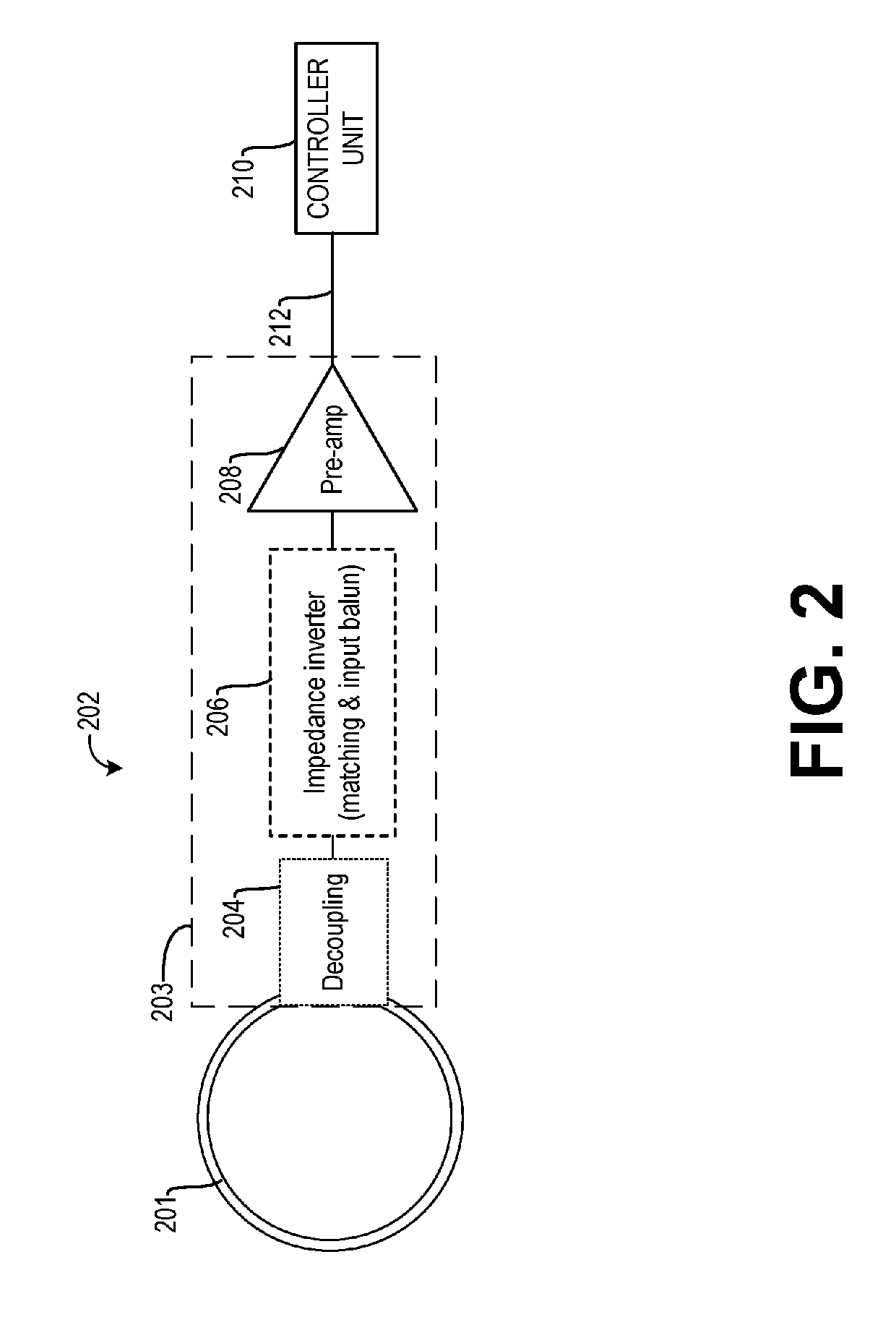

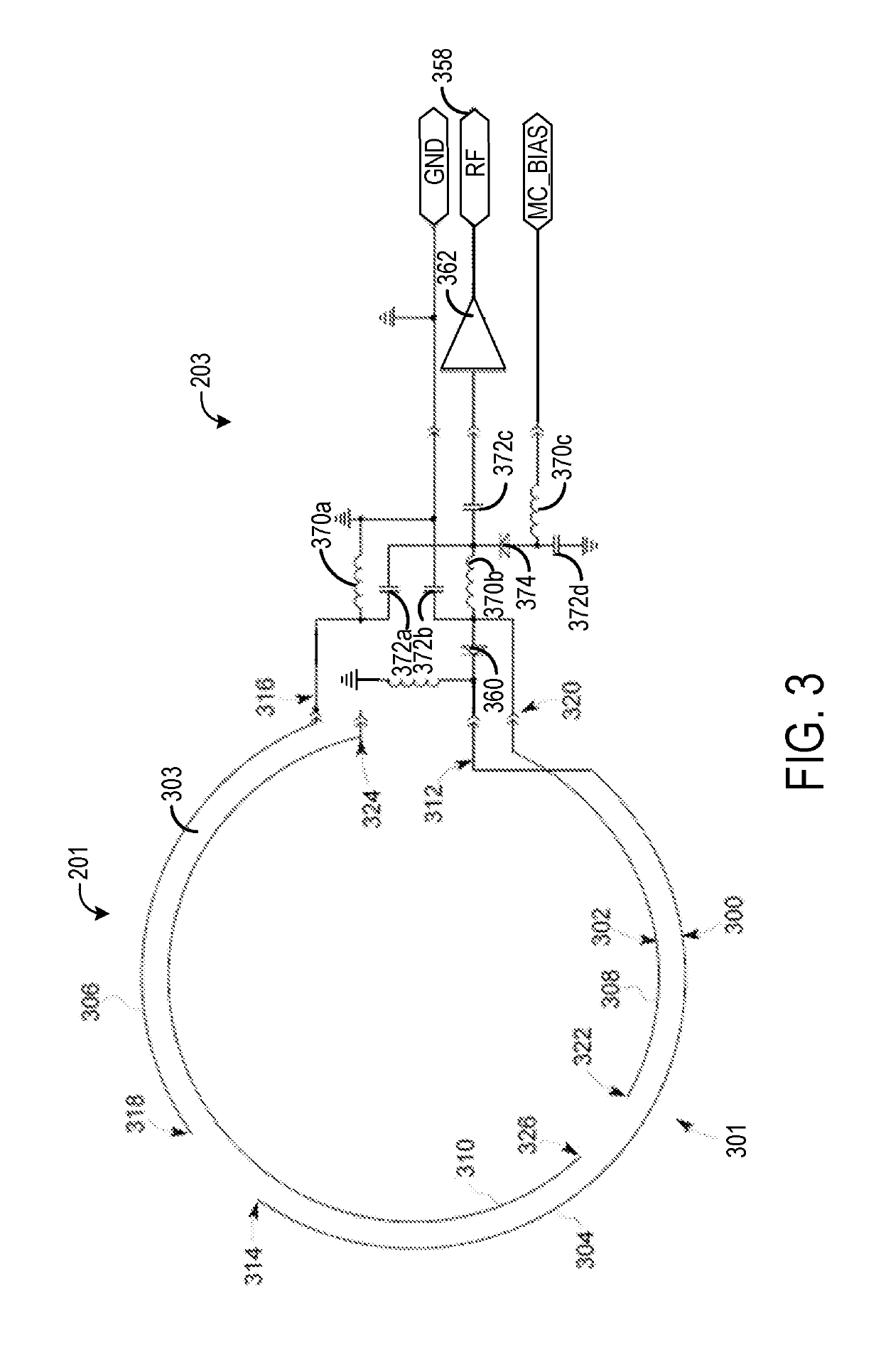

Systems for a radio frequency coil for mr imaging

ActiveUS20190310327A1Low costReduce weightDiagnostic recording/measuringSensorsCapacitanceEngineering

Various methods and systems are provided for a flexible, lightweight, and low-cost disposable radio frequency (RF) coil of a magnetic resonance imaging (MRI) system. In one example, an RF coil assembly for an MRI imaging system includes a loop portion comprising distributed capacitance conductor wires, a coupling electronics portion including a pre-amplifier; and a disposable material enclosing at least the loop portion, the disposable material comprising one or more of paper, plastic, and / or cloth.

Owner:GENERAL ELECTRIC CO

Roasting-ammonia leaching processing method for brown iron type laterite nickel ore

A roasting-ammonia leaching processing method for brown iron type laterite nickel ore includes the steps that firstly, suspension fluidized roasting is performed on ore powder of the brown iron type laterite nickel ore and reduction gas, nickel oxide and cobalt oxide in the ore powder are fast and dynamically reduced into metal nickel and metal cobalt within 20-120 s, brown iron is reduced into magnetic iron, roasted ore is obtained, and according to the technological condition of roasting, temperature is 600-900 DEG C, and the volume percentage of CO in reducing gas is 2-7%; secondly, magnetic separation is performed on the roasted ore, and magnetite concentrate containing metal nickel and metal cobalt is obtained through separation; and thirdly, ammonia leaching is performed on the magnetite concentrate, and nickel and cobalt leaching agents and magnetic iron leaching slag are obtained. The method achieves the purpose of extracting and purifying nickel and cobalt and comprehensively recovering iron.

Owner:湖南长拓高科冶金有限公司

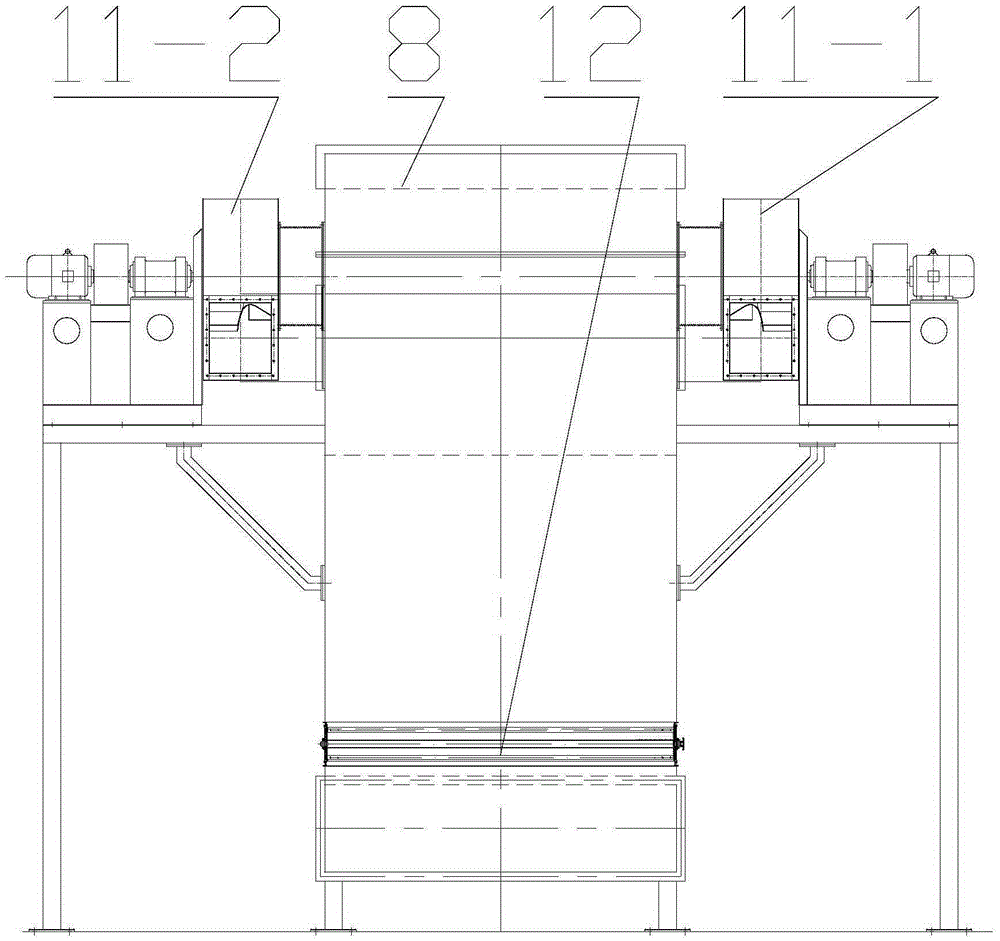

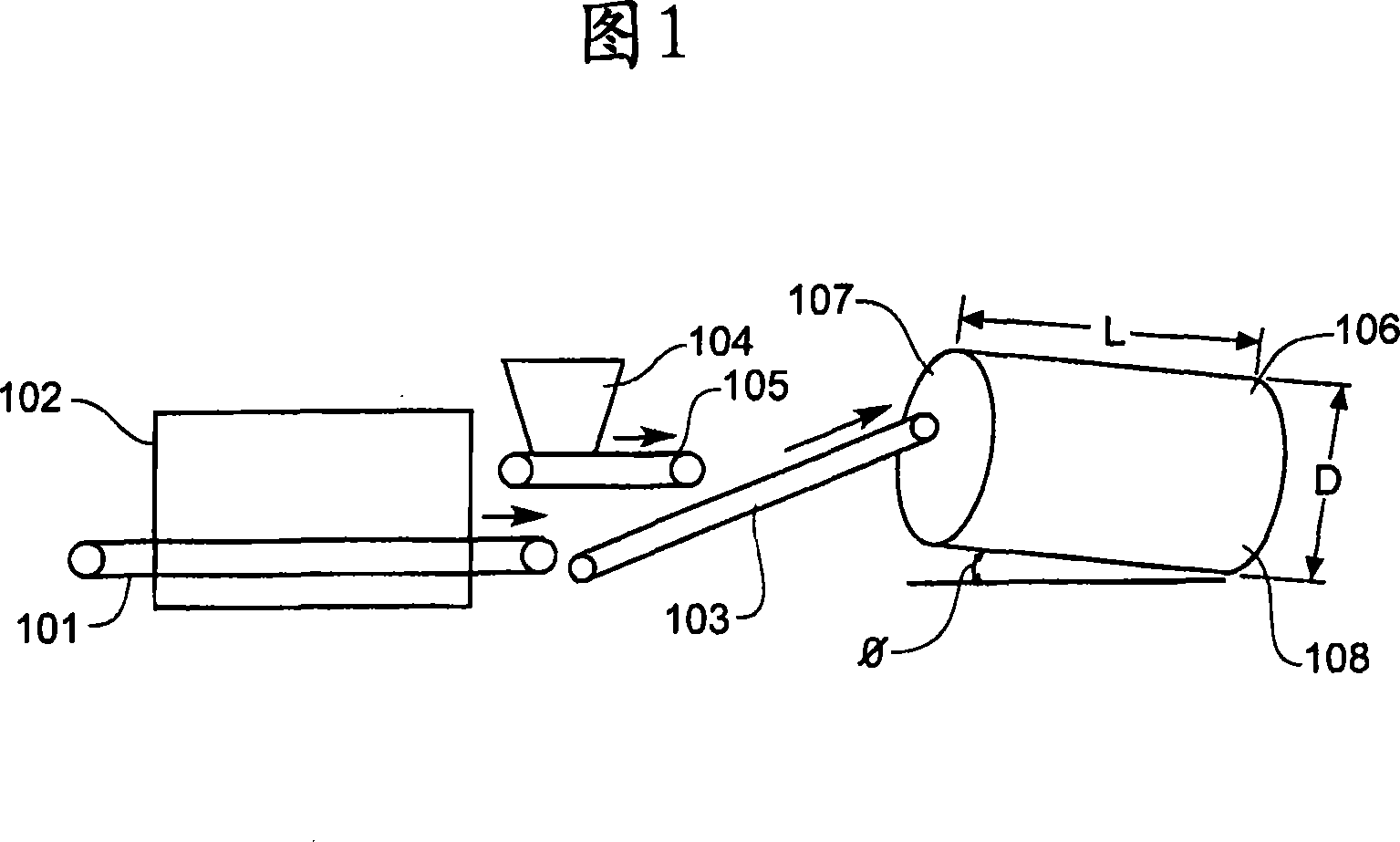

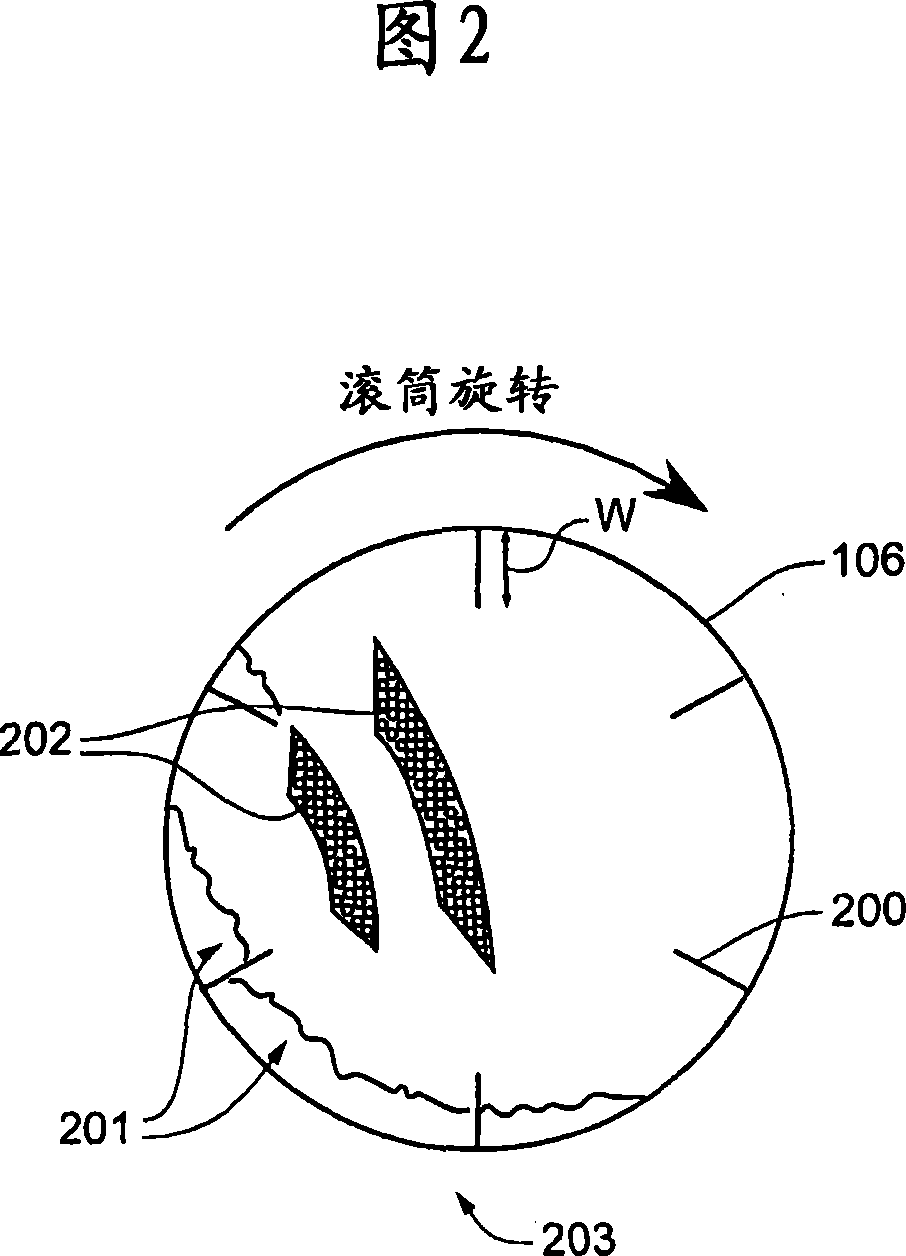

Improved tumbledrum design and method for coating objects

InactiveCN101057624ASimple designReduce the possibilityRotating receptacle mixersLiquid surface applicatorsParticulatesEngineering

A method of impregnating surfaces of objects with particulates comprising optionally, applying a liquid or semi-fluid binder to the objects to form pre-coated objects; adding the objects and particulates to a rotatable drum having at least an inlet, a length (L) and a diameter (D), the drum comprising at least 1 flight; and rotating the drum wherein each flight lifts and then drops the objects and particulates, wherein the impact of the falling objects and particulates drives the particulates into the objects or into the coating of the pre-coated objects.

Owner:THE QUAKER OATS CO

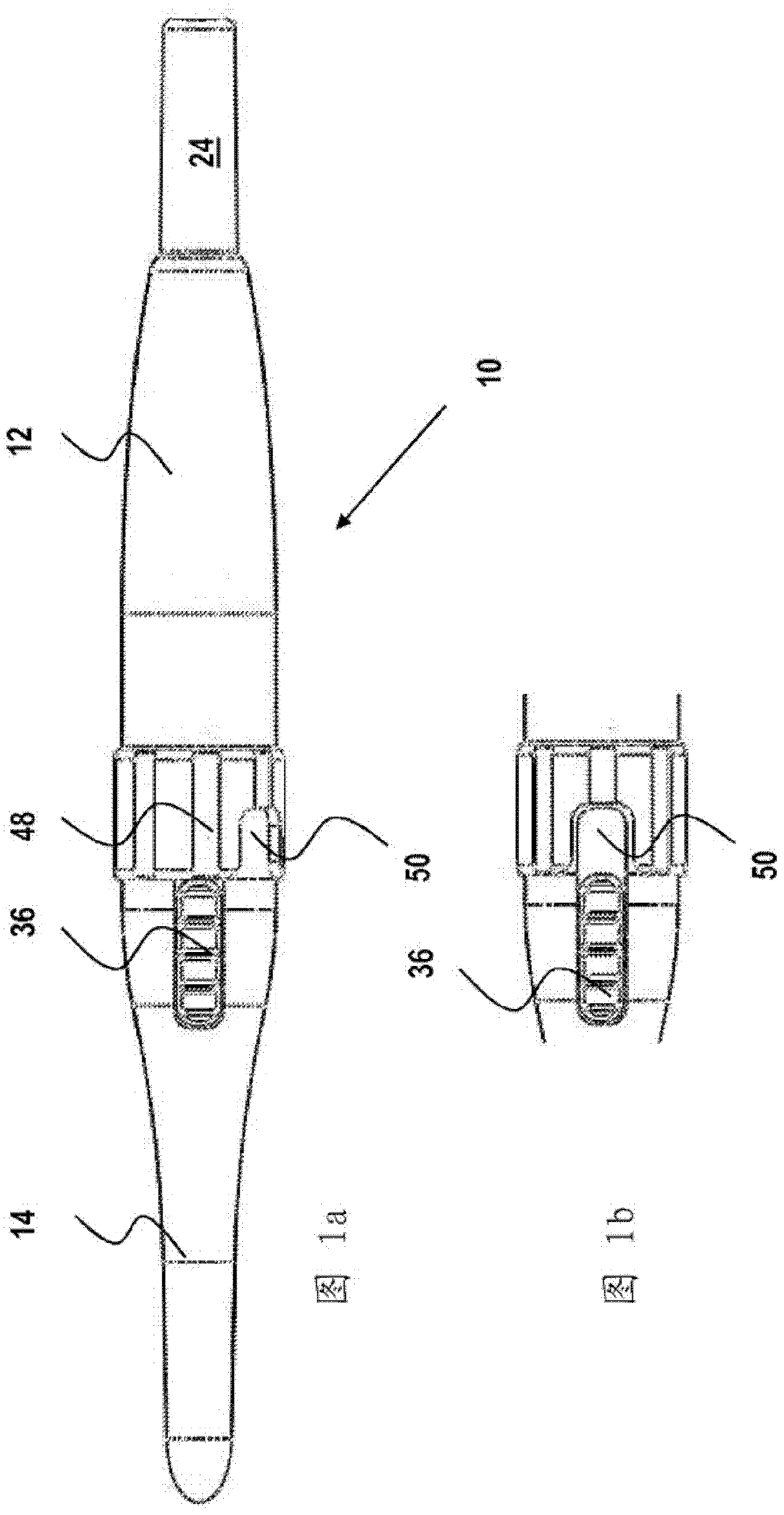

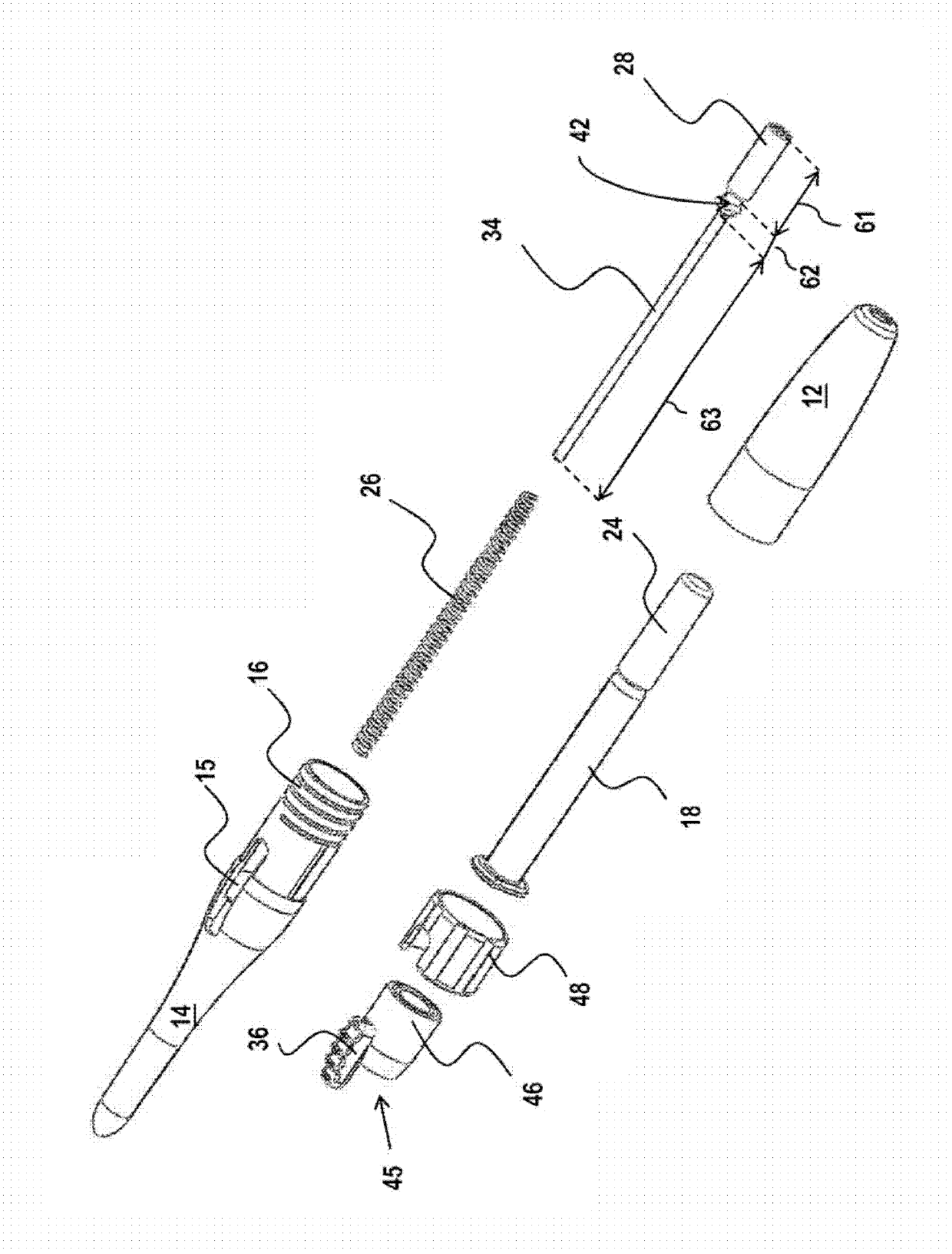

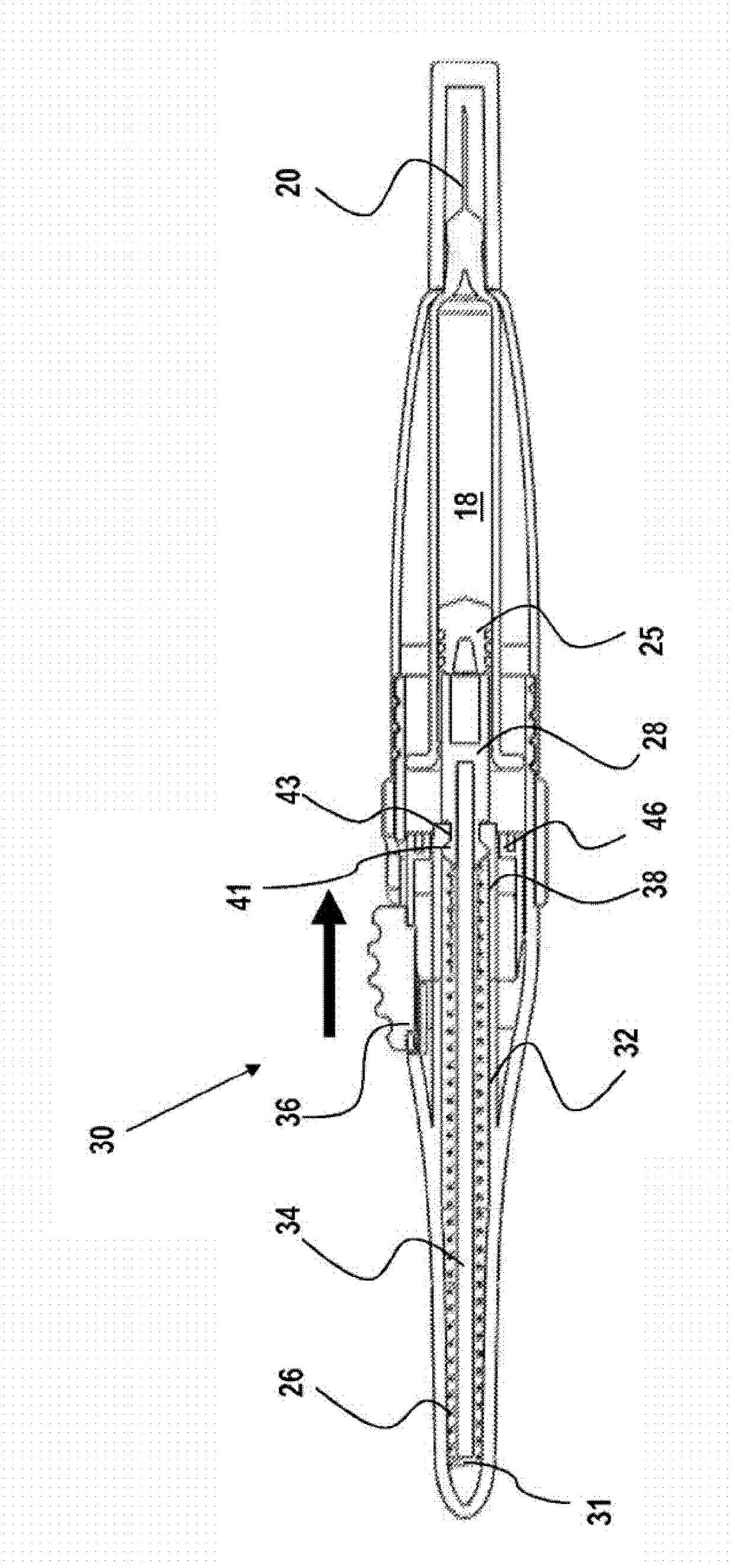

Medicament delivery device

InactiveCN102245234AShorten the lengthSmall outer diameterAmpoule syringesAutomatic syringesBiomedical engineering

The present invention relates to a medicament delivery device (10) comprising a front housing (12) and a rear housing (14) connected to each other; a medicament container (18) disposed within the front housing (12), wherein the container (18) has a front opening with or for a delivery member for delivering the medicament therethrough and at least one movable stopper (25); and a compression spring (26) having a predetermined compressed length and a predetermined outer diameter, wherein the compressed length is the length of the spring when it is in a pre-tensioned state; wherein the device further comprises a first guide means comprising a front part (28) having a predetermined first length (61), a middle part (42) having a predetermined second length (62), and a rear part (34) having a predetermined third length (63), wherein said predetermined third length corresponds to the predetermined compressed length of the compression spring, wherein the front part (28) is arranged to be in contact with the movable stopper (25), wherein the middle part comprises an annular ledge (41) and first lock-release means (43), and wherein the rear part (34) is fully surrounded by the compression spring when it is in its pre-tensioned state; and a second guide means which constitutes a generally tubular inner wall (32) of the rear housing (14) having a predetermined fourth length (64), a rear end surface (31), a predetermined inner diameter, and second lock-release means, wherein the predetermined fourth length corresponds to the predetermined first (61) and the predetermined second (62) lengths together, and wherein the predetermined inner diameter of the second guide means is somewhat larger than the predetermined outer diameter of the compression spring, such that the compression spring is fully arranged inside said second guide means between the rear end surface (31) and the annular ledge (41) when it is in its pre-tensioned state.

Owner:SHL GRP AB

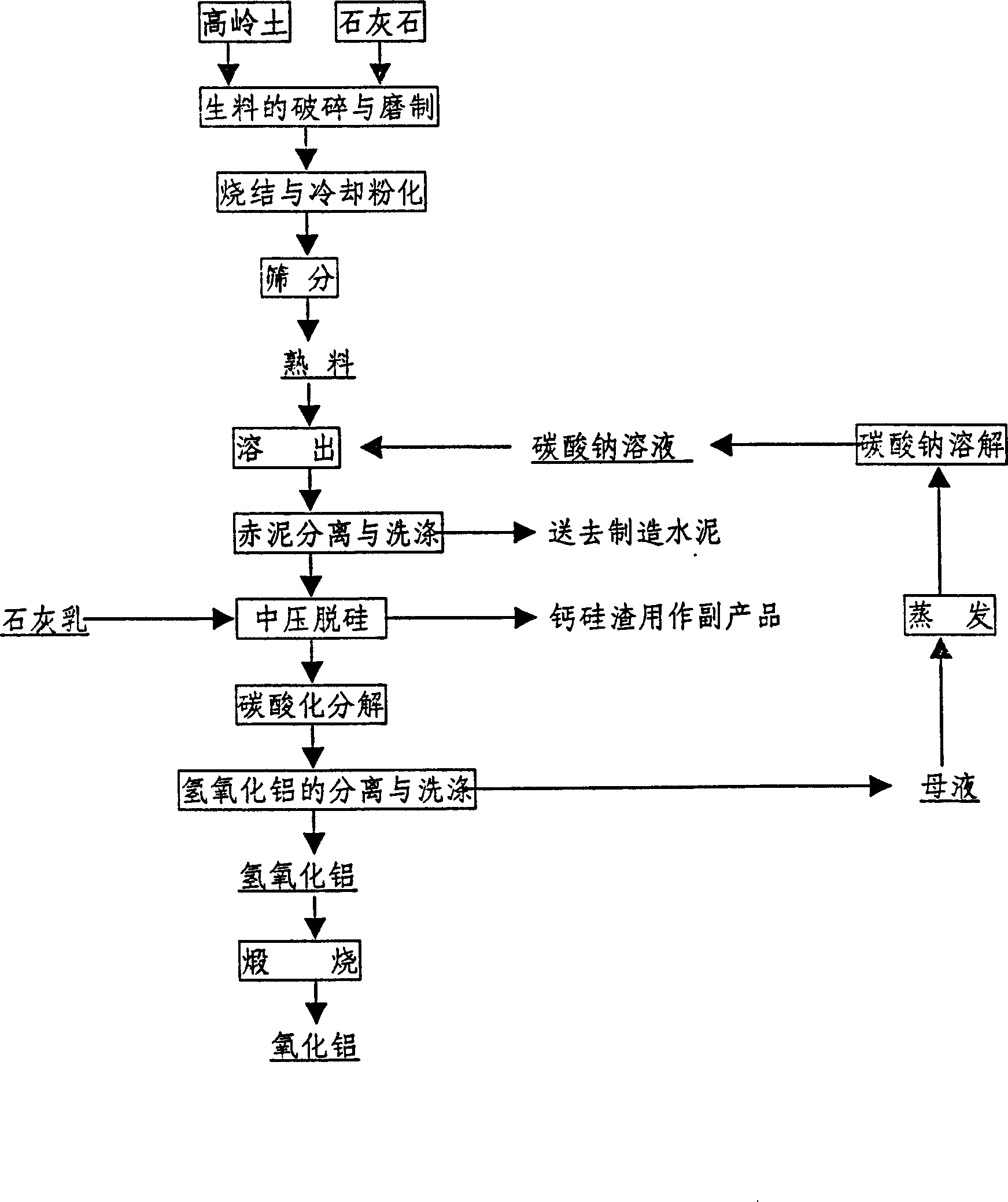

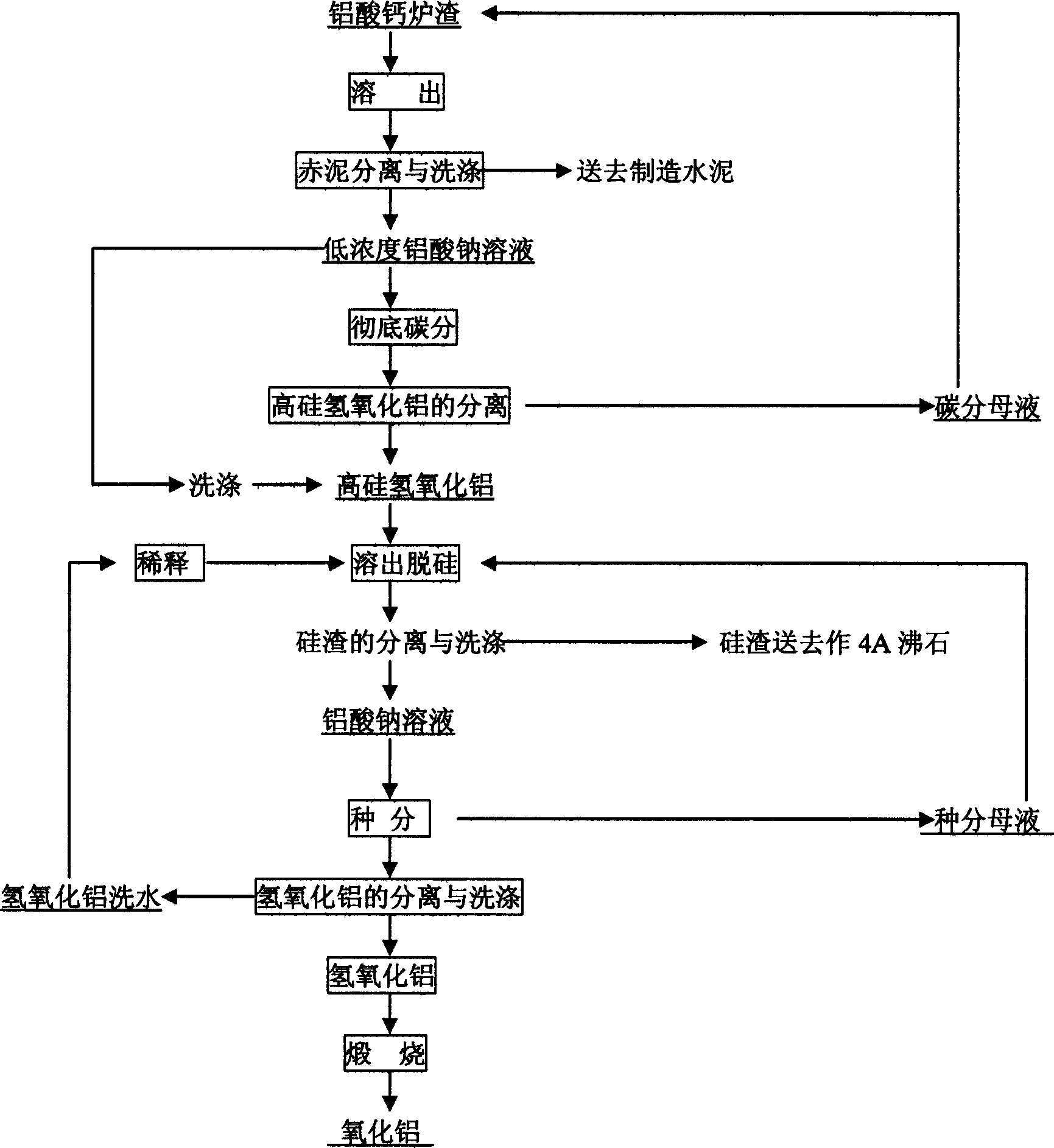

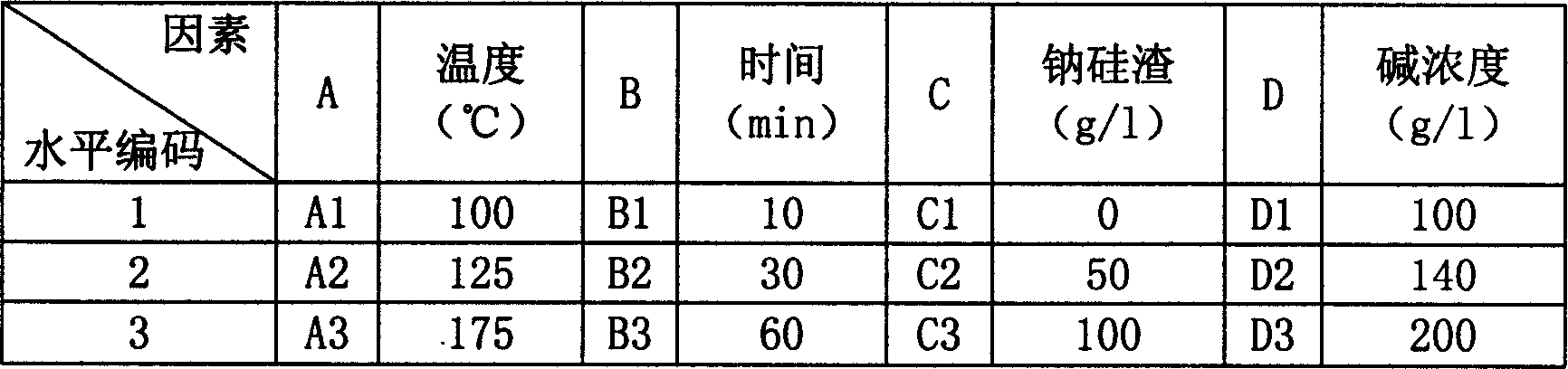

Technique for extracting alumina from materiel containing calcium aluminate

InactiveCN1562756AImprove product qualityStable productionAlkaline-earth metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminateDecomposition

The invention provides a new technology for extracting aluminium oxide from the material containing carbon aluminate. The carbon aluminate is dissolved out the material by weak sodium carbonate solution to be made into carbon aluminate solution that density is less than 100 g / f, gas CO2 is send into the carbon aluminate solution to do decomposition to generate high-silicon aluminium hydroxide and carbon decomposition mother solution which circulately dissolving out carbon aluminate, the high-silicon aluminium hydroxide is processed by low-temp. dissolving, seed-decomposed decomposing and burning to produce quality sand-type aluminium oxide.

Owner:邝中

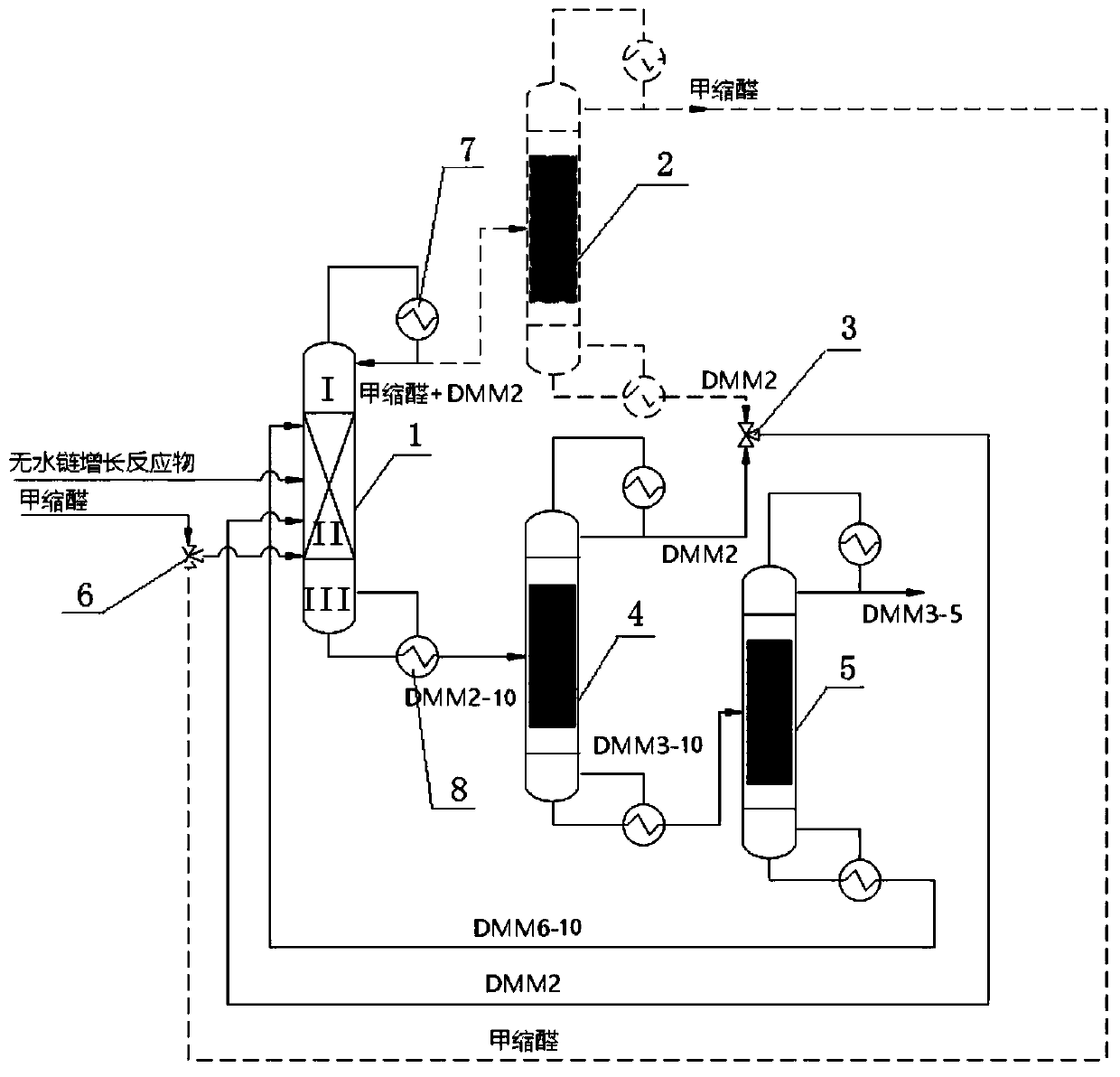

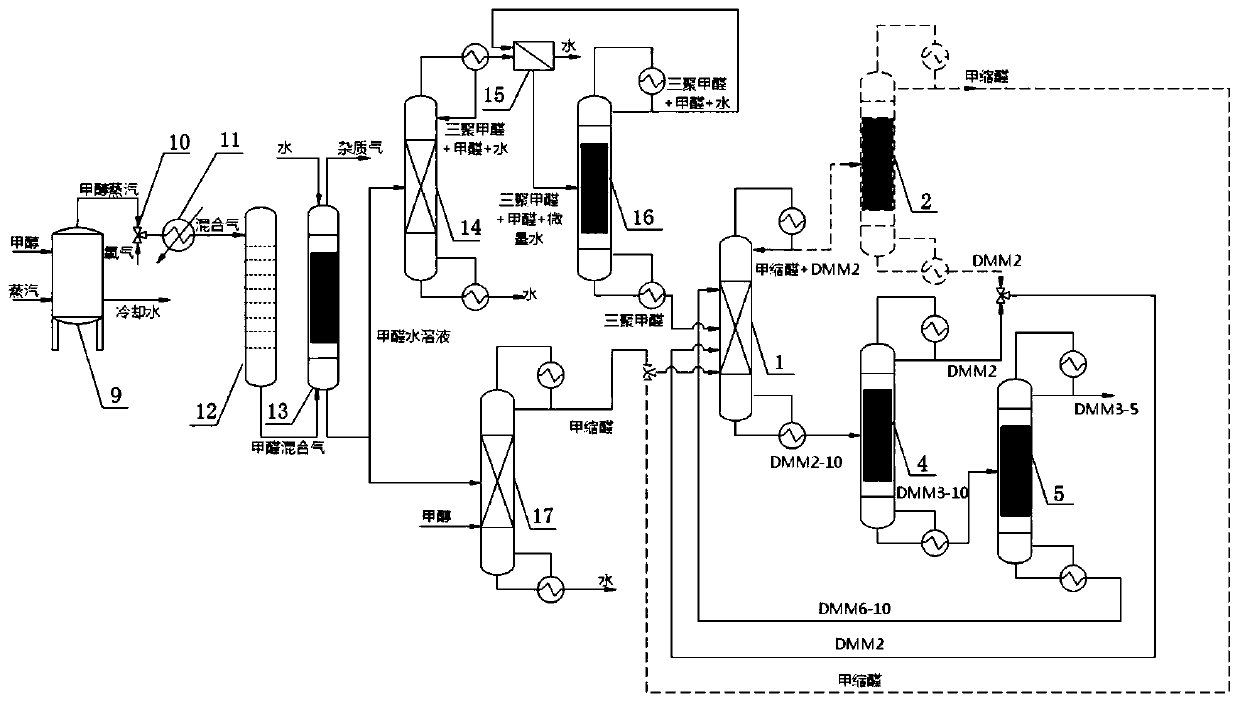

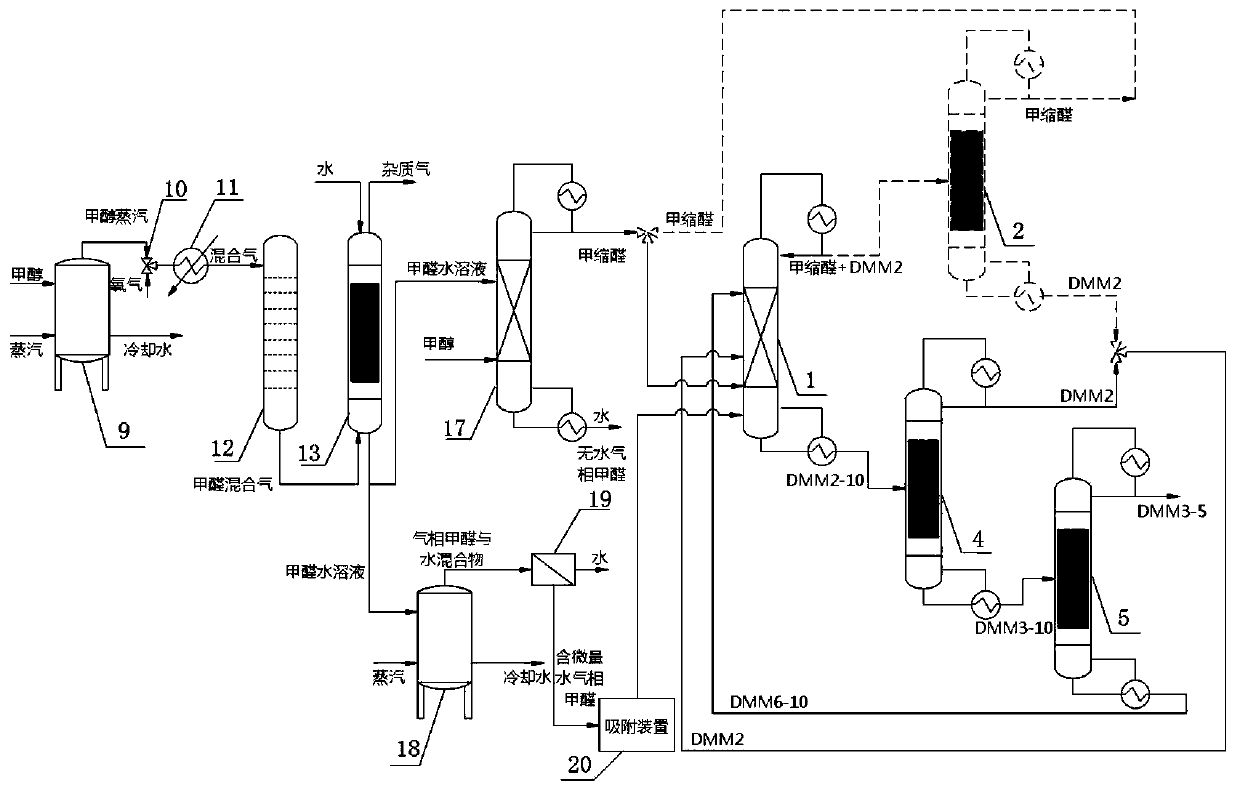

Reactive distillation process device and method for synthesis of PODEn (polyoxymethylene dimethyl ethers)

ActiveCN110078600AImprove conversion rateHigh yieldOrganic chemistryOrganic compound preparationGas phaseParaformaldehyde

The invention provides a reactive distillation process device and method for synthesis of PODEn (polyoxymethylene dimethyl ethers). According to the method, industrial methylal for product chain termination and one or a mixture of two or more of trioxymethylene, paraformaldehyde and gas-phase formaldehyde for product chain propagation are taken as raw materials, no water exits in a reaction system, a PODEn mixed product with multiple degrees of polymerization is obtained through a reaction under the action of an acidic catalyst, a reaction product with the degree of polymerization higher than2 is recovered from the column bottom under the separation action of a PODEn reactive distillation reaction column, and DMM2 with low degree of polymerization and incompletely reacted methylal are recovered from the column top; a product recovered from the column bottom is separated by a production refinery column, a target product DMM3-5 is obtained, DMM2 with low degree of polymerization and DMM6-10 with high degree of polymerization are returned to the PODEn reactive distillation reaction column; incompletely reacted methylal is recycled as a raw material. By use of the characteristic of reactive distillation, excessive methylal is adopted in the reaction process, the conversion rate of formaldehyde substances is substantially increased, and the selectivity and the yield of DMM3-5 are increased.

Owner:TIANJIN UNIV

Lead plaster desulfurization transforming method for waste lead-acid storage batteries

InactiveCN103000968AHigh recovery rateReduce pollutionWaste accumulators reclaimingProcess efficiency improvementThermodynamicsProcess engineering

The invention discloses a lead plaster desulfurization transforming method for waste lead-acid storage batteries, which belongs to the field of waste battery disposal. The method comprises the following steps: (1) the preparation of a lead plaster original sample: carrying out decomposition on waste lead-acid storage batteries, taking out a grid alloy, taking out lead plaster from a grid, removing impurities in the lead plaster, drying the lead plaster in an environment at a temperature of 80-90 DEG C, and grinding the lead plaster in a grinding machine for 10-30 min so as to obtain the lead plaster original sample with a particle size of 50-300 mu m; (2) the configuration of a desulfurization transforming agent: preparing a desulfurization transforming agent into transforming liquid, and heating the desulfurization transforming liquid to 20-90 DEG C by using a constant-temperature water bath bed; (3) full reaction: adding weighted lead plaster into the transforming liquid obtained in step (2), and stirring the obtained mixture, so that the mixture is fully reacted; and (4) after the transforming is completed, cooling and filtering the obtained product, and carrying out repeated washing and residue filtering on the obtained product for many times by using distilled water. According to the method, the desulfurization transforming process parameters of lead plaster in waste lead-acid storage batteries are determined, PbSO4 is effectively transformed into easily-decomposed PbCO3, the energy consumption is lowered, and the environmental pollution is reduced.

Owner:高金菊

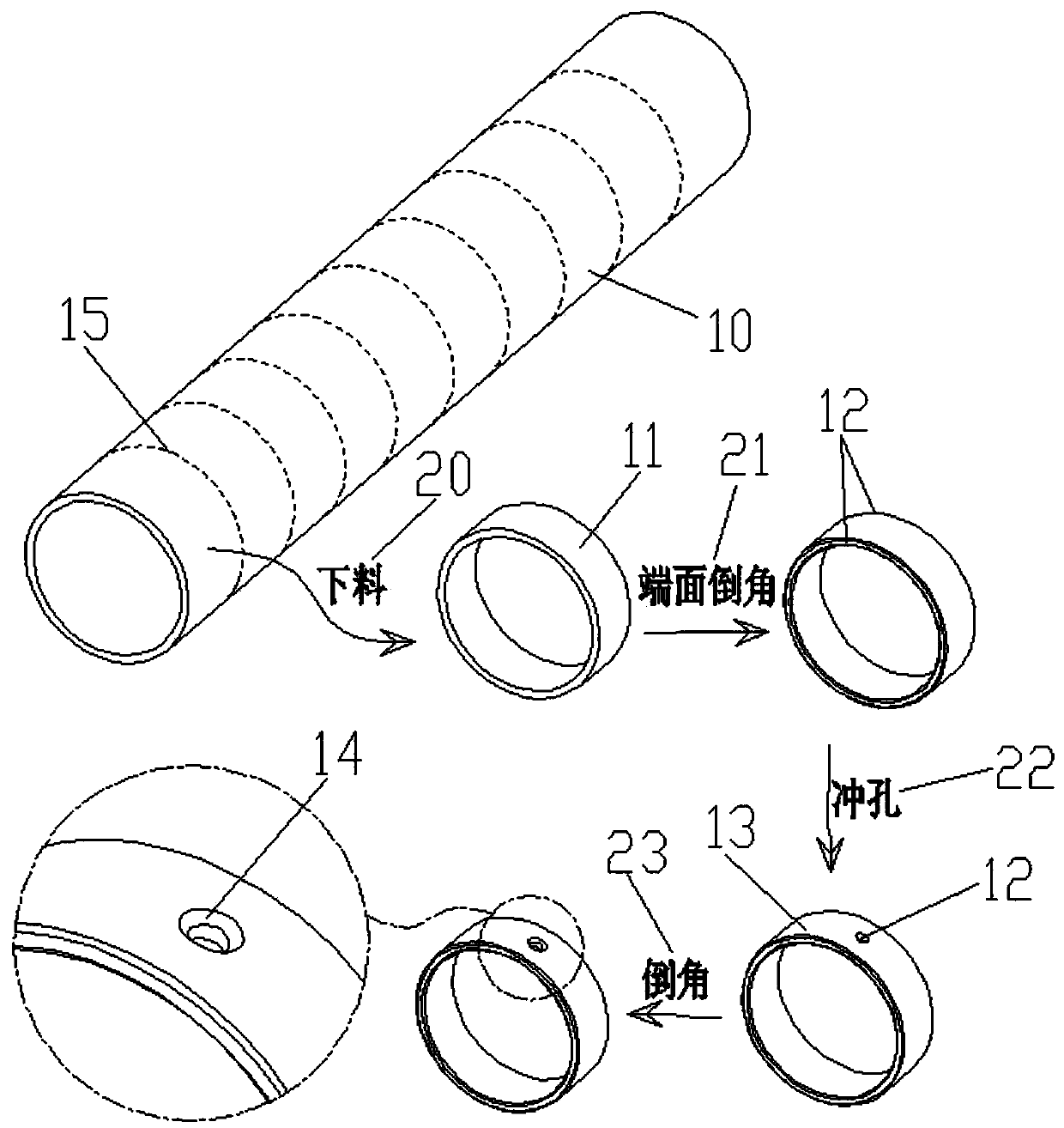

Sliding bearing machining process

The invention relates to a mechanical manufacturing process, and in particular relates to a process of manufacturing and material processing of sliding bearings. The invention discloses a sliding bearing machining process, comprising the following steps: blanking, end surface chamfering, end surface grinding, punching, chamfering of an oil filling hole, quenching and tempering, centerless grinding, squeezing, and surface grinding. Through the sliding bearing machining process, a sliding bearing is used for lowering frictional resistance of machine running, and is high in machining precision. On the premise of satisfying the machining precision of the sliding bearing, the efficiency and the product quality can be improved by the machining process.

Owner:余晓娜

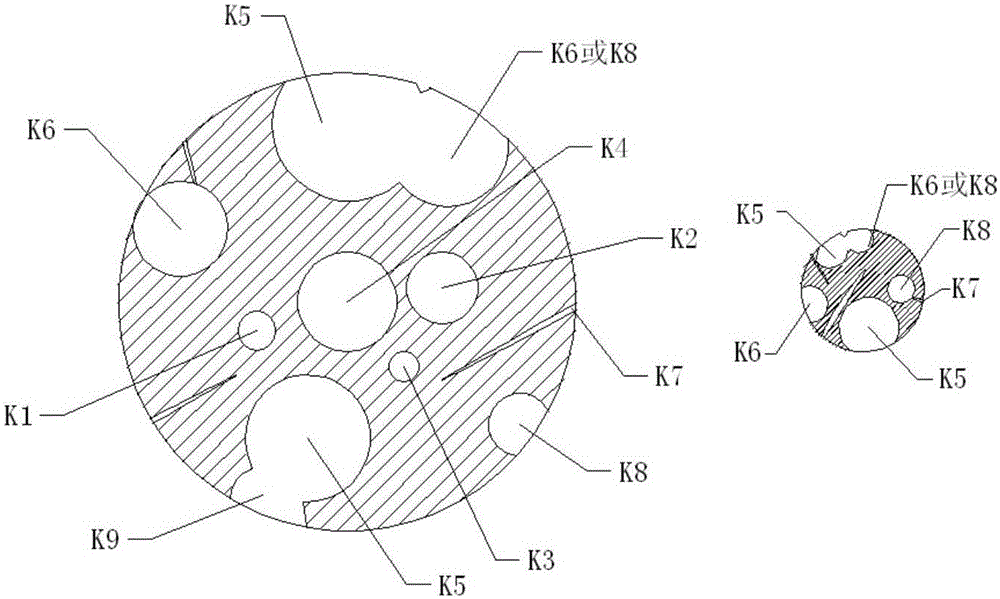

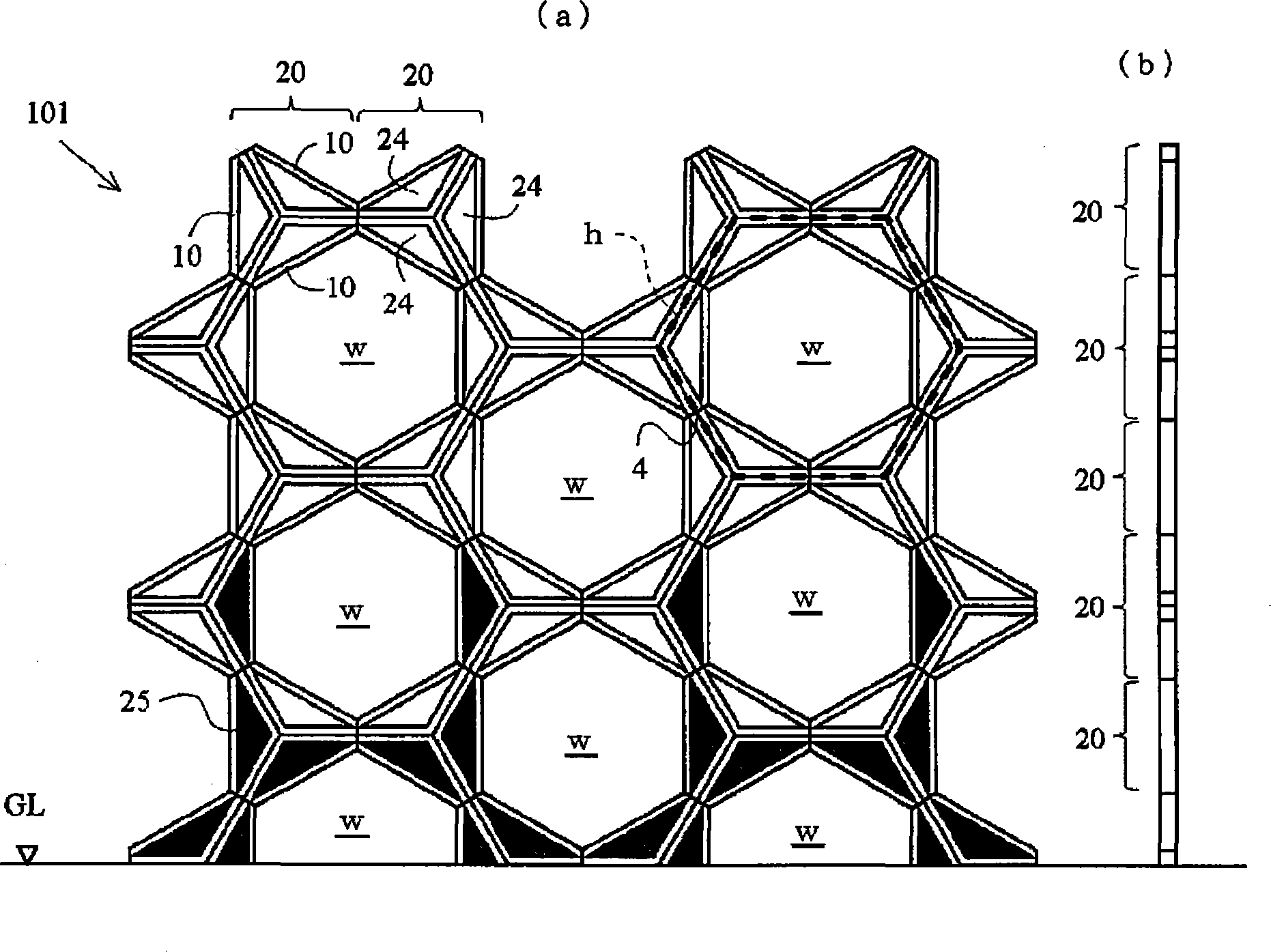

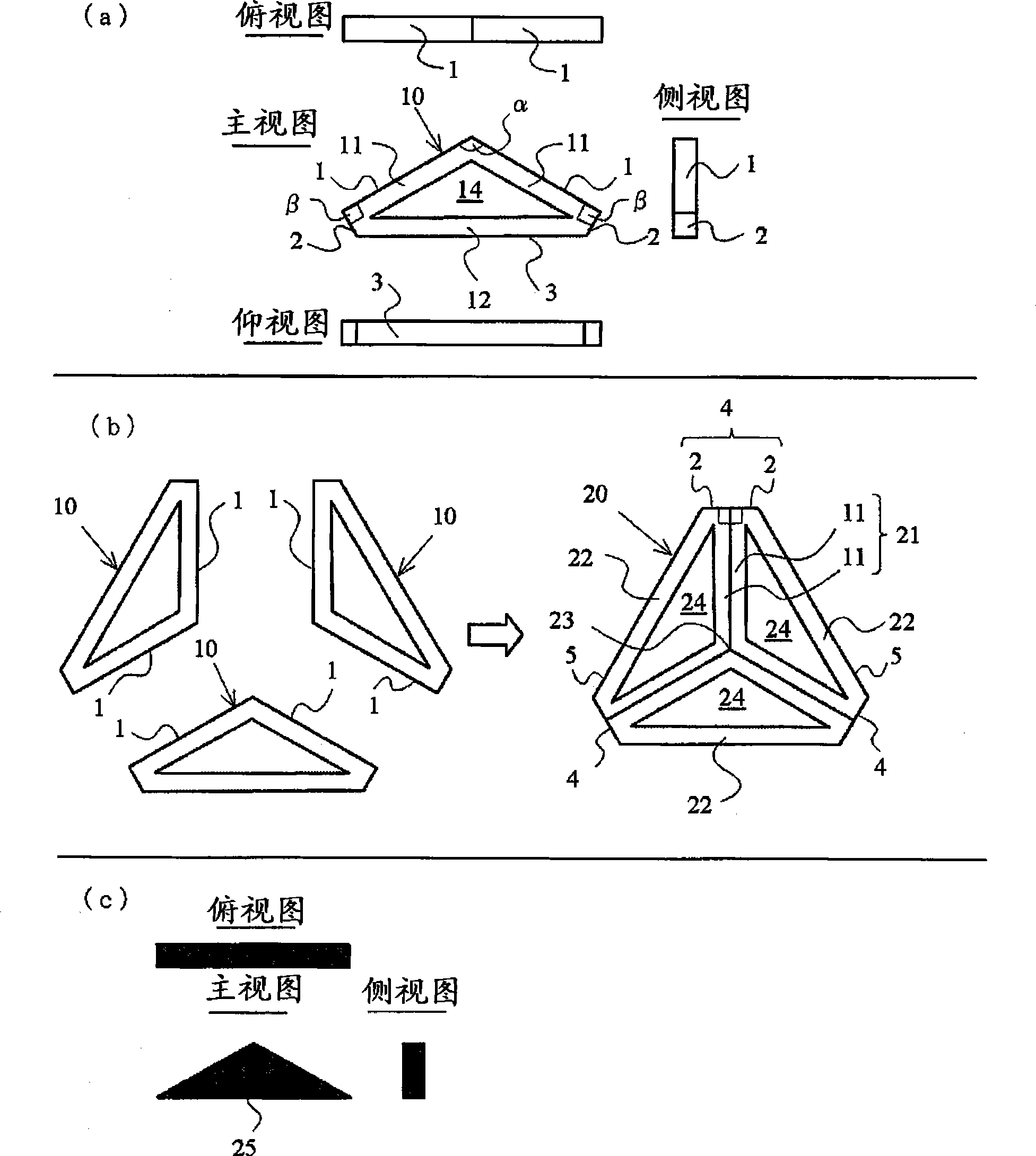

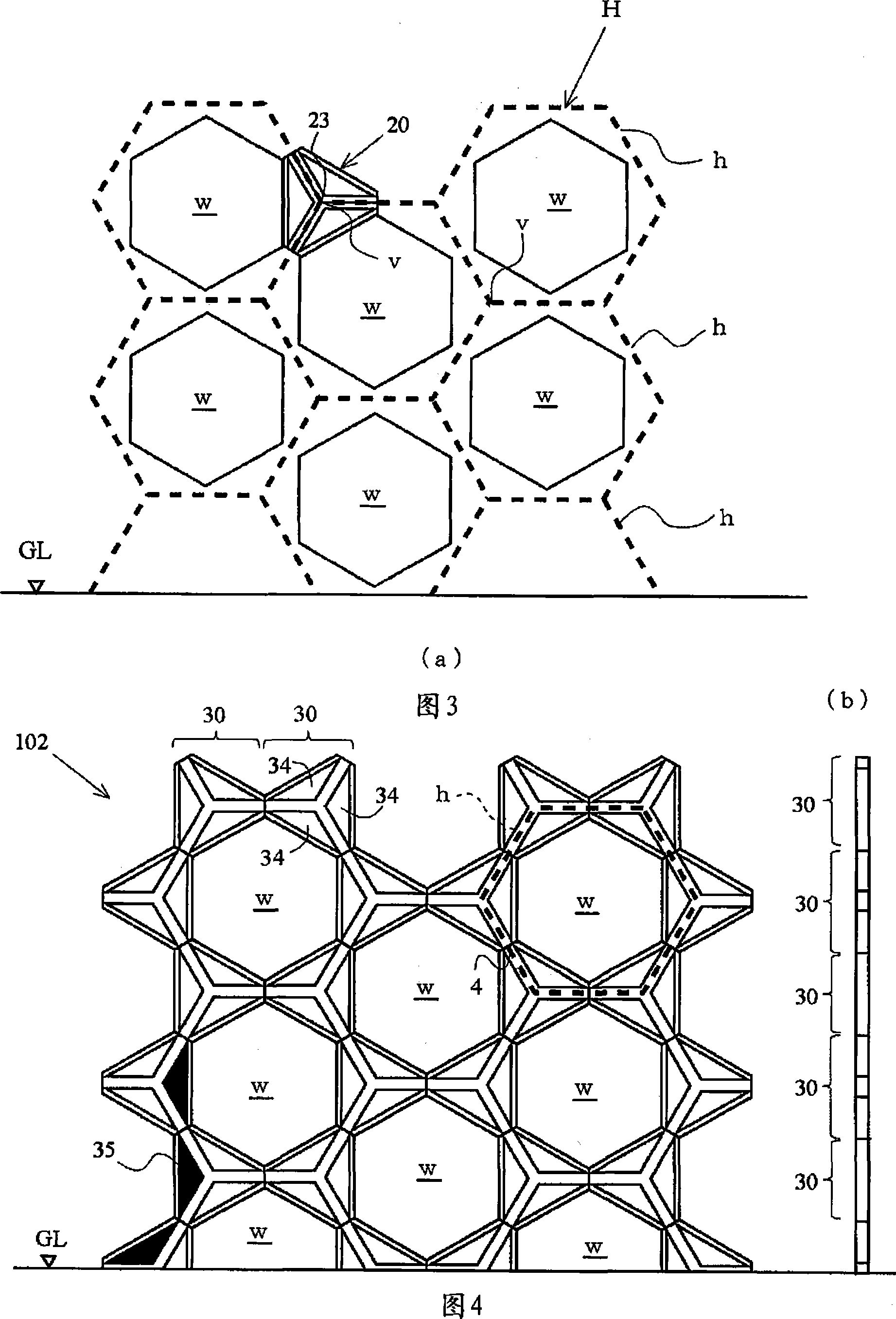

Honeycomb building tectosome

InactiveCN101415891ARigid constructionGuarantee stabilityExtraordinary structuresMarine engineeringEngineering

An architectural honeycomb structure exhibiting strong aseismatic resistance and wind pressure resistance and suitable for high-rise and super high-rise buildings,is provided. The architectural honeycomb structure (101, 102) bonding a plurality of frame units in the shape of honeycomb comprises a compound truss unit (20) which is a frame unit arranged to include one vertex of a hexagonal lattice (h) constituting a standing virtual honeycomb shape (H) and formed to have a hexagonal contour, a means for bonding two adjoining compound truss units such that the bonding surface (4), i.e. the outer circumferential surface corresponding to every other side of hexagon in the compound truss units, is located on the side of the hexagonal lattice of virtual honeycomb shape to intersect the side, and a first hexagonal opening (w) surrounded by six composite truss units.

Owner:SEKISUI CHEM CO LTD

Industrial preparation method of high-yield cinnamaldehyde

InactiveCN102718638AReduce the chance of oxidationLess side effectsOrganic compound preparationCarbonyl compound preparationDistillationBenzaldehyde

The invention provides an industrial preparation method of high-yield cinnamaldehyde. The method includes the following steps of: A, adding a solid catalyst and a water solution of polyethylene glycol 400 to a reaction vessel, then adding benzaldehyde; B, adding dropwisely 30 % to 50% by mass of an acetaldehyde water solution slowly with stirring, after the dropwisely adding, controlling the temperature from 25 DEG C to 30 DEG C for a reaction for 3 to 5 hours; C, performing washing after the completion of the reaction, and allowing the mixture to stand for delamination; and D, performing distillation after separating out an oil layer to obtain the cinnamaldehyde. The method in the invention is advantaged in operational simplicity, easiness in obtaining raw materials and in preparation of the catalyst, simple recovery, environmental friendliness, continuous operation, fast forward reaction speed compared with common processes, low probability of a side reaction, reduced unit energy consumption of a product as well as stable quality, high yield, and high purity of the produced cinnamaldehyde.

Owner:湖北远成赛创科技有限公司

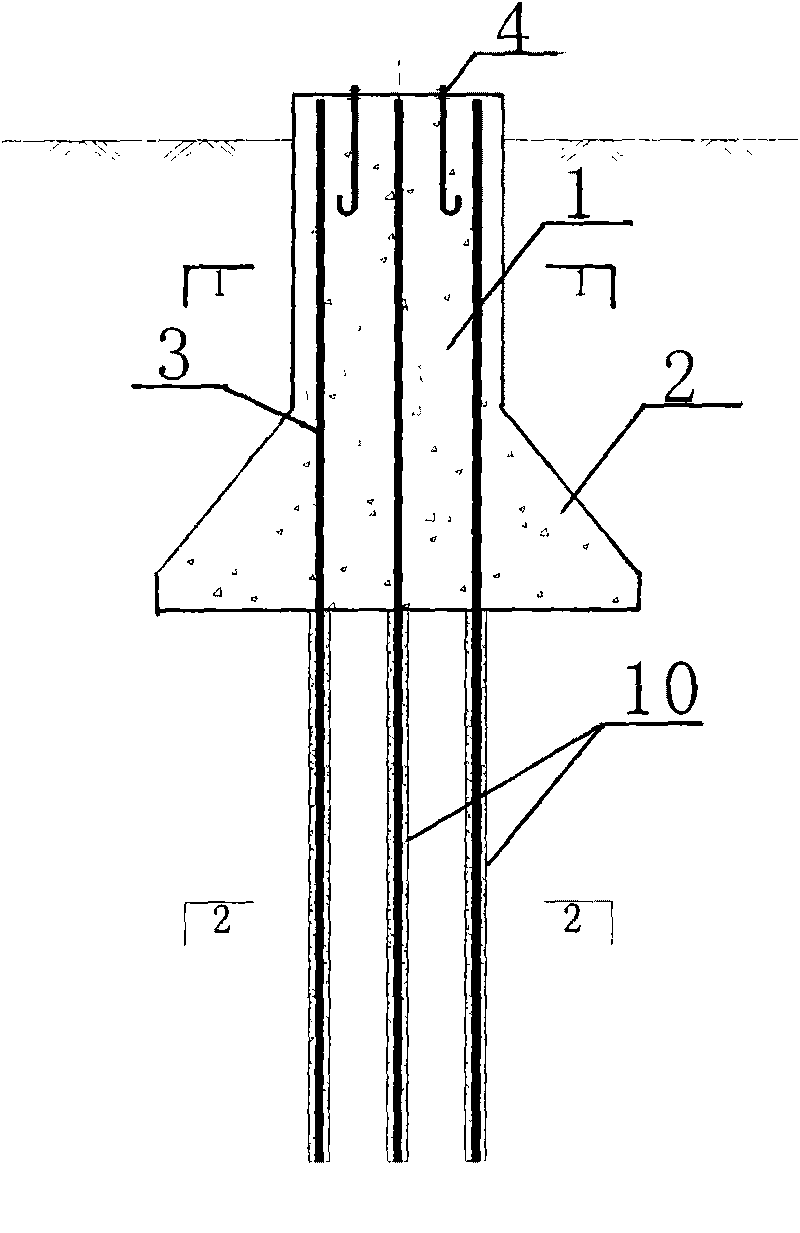

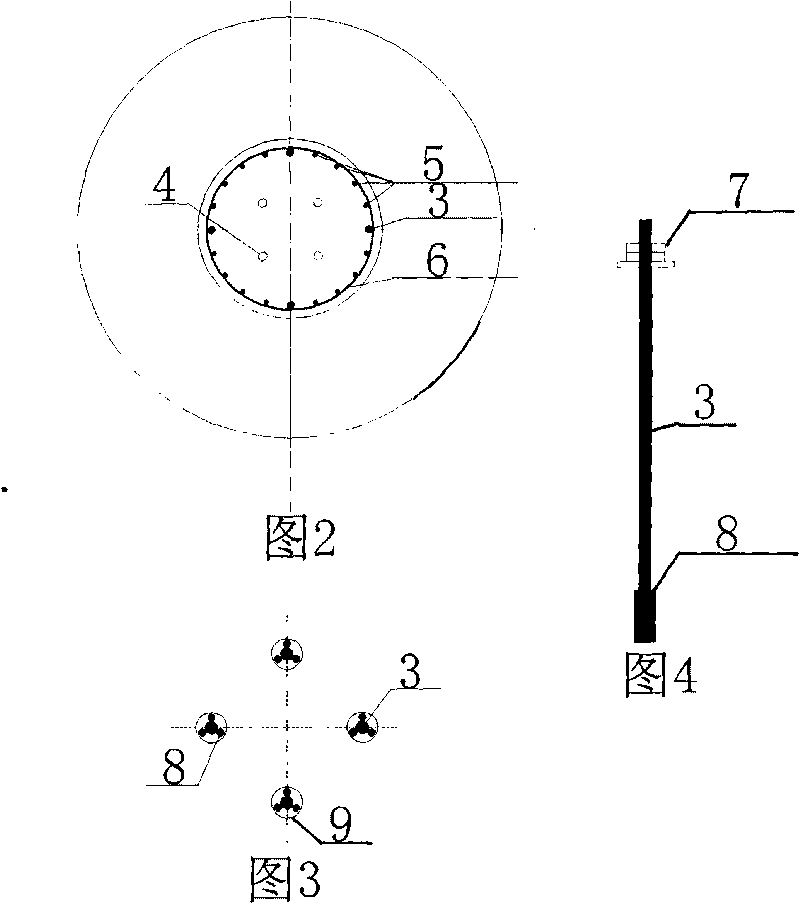

Construction method for digging composite environmental protection base of anchorage bar adding rock

InactiveCN101691759AImprove bearing capacityReduce distortionFoundation engineeringEngineeringSlurry

The invention discloses a construction method for digging a composite environmental protection base of an anchorage bar adding rock, comprising the following steps: firstly, adopting a construction machinery to drill holes on the ground, putting anchorages into holes after designed depth is achieved; grouting gaps around the anchorages; when slurry is solidified and cured to reach 30% of designed strength, artificially digging foundation pit earth body and achieving designed depth; after the foundation pit is shaped, shaving off cured slurry around the anchorages of the parts above the pit bottom; putting a basic main post reinforcement cage composed of a main reinforcement and a stirrup, binding or welding anchorages and the basic main post reinforcement cage into a whole; buckling the screw thread part of the upper part of anchorages with a nut and a spacer; and casting concrete in the foundation pit and simultaneously embedding a foundation bolt. By analytical calculation and experimental verification, the construction method well resists exterior load, and meets the requirement of environmental protection of engineering construction, thereby saving the usage of material, reducing the volume of stone and earthwork, and reducing influence on the environment.

Owner:NORTHEAST ELECTRIC POWER DESIGN INST CO LTD OF CHINA POWER ENG CONSULTING GRP

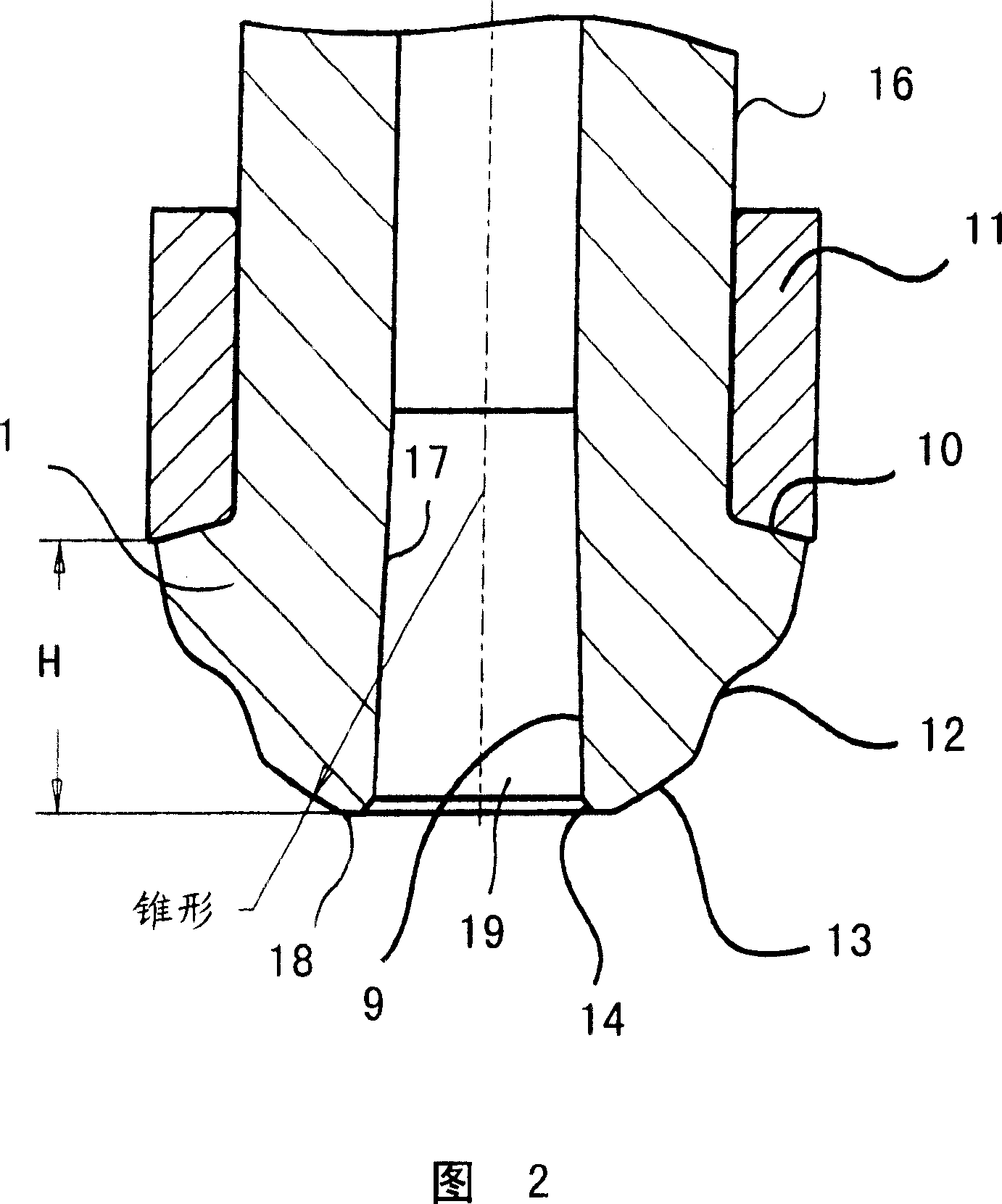

Pressure pipe with formed connecting head

ActiveCN1959174AGood use strengthImprove surface qualityFluid pressure sealed jointsJoints with sealing surfacesEngineeringHigh pressure

The pressure line, for example as a high-pressure fuel injection line, has a cold-worked connection (1) at the end of the line (16). The joint (1) is frustoconical and has a surrounding sealing surface on its enveloping surface, which is pressed against the connection part with a corresponding fit by means of a preload transmitted via the pressure shoulder (10). Wherein the outer surface of the pipe (16) encloses an angle greater than 90° with a surface of the pressure shoulder (10).

Owner:MAN ENERGY SOLUTIONS SA

Method for extracting aluminum oxide from sodium-free desiliconized fly ash

InactiveCN101759212AReduce the amount of materialReduced process flowAluminium oxides/hydroxidesSlagLow sodium

The invention relates to a method for extracting aluminum oxide from sodium-free desiliconized fly ash, which comprises the following steps of: taking dried sodium-free desiliconized fly ash, carrying out saturation calcium matching with limestone powder and / or slaking slag powder, sintering at 1330-1390 DEG C, controlling to cool the sintered material to obtain the self-pulverizing material, putting into a Na2CO3 solution to quickly dissolve out aluminum oxide, separating a solid from a liquid, extracting aluminum oxide according to the conventional method, and washing residues to obtain the low-sodium calcium-silicon slag. In the method, sodium-free desiliconized fly ash from which silicon dioxide is extracted and sodium oxide is removed is adopted as the raw material; the limestone sintering process can be used for extracting aluminum oxide, and low-sodium calcium-silicon slag can be obtained after extracting aluminum oxide; and both the aluminum oxide and the low-sodium calcium-silicon slag can be used as the raw materials of cement, thereby thoroughly eliminating secondary pollution.

Owner:SHUOZHOU RUNZE INVESTMENT DEV

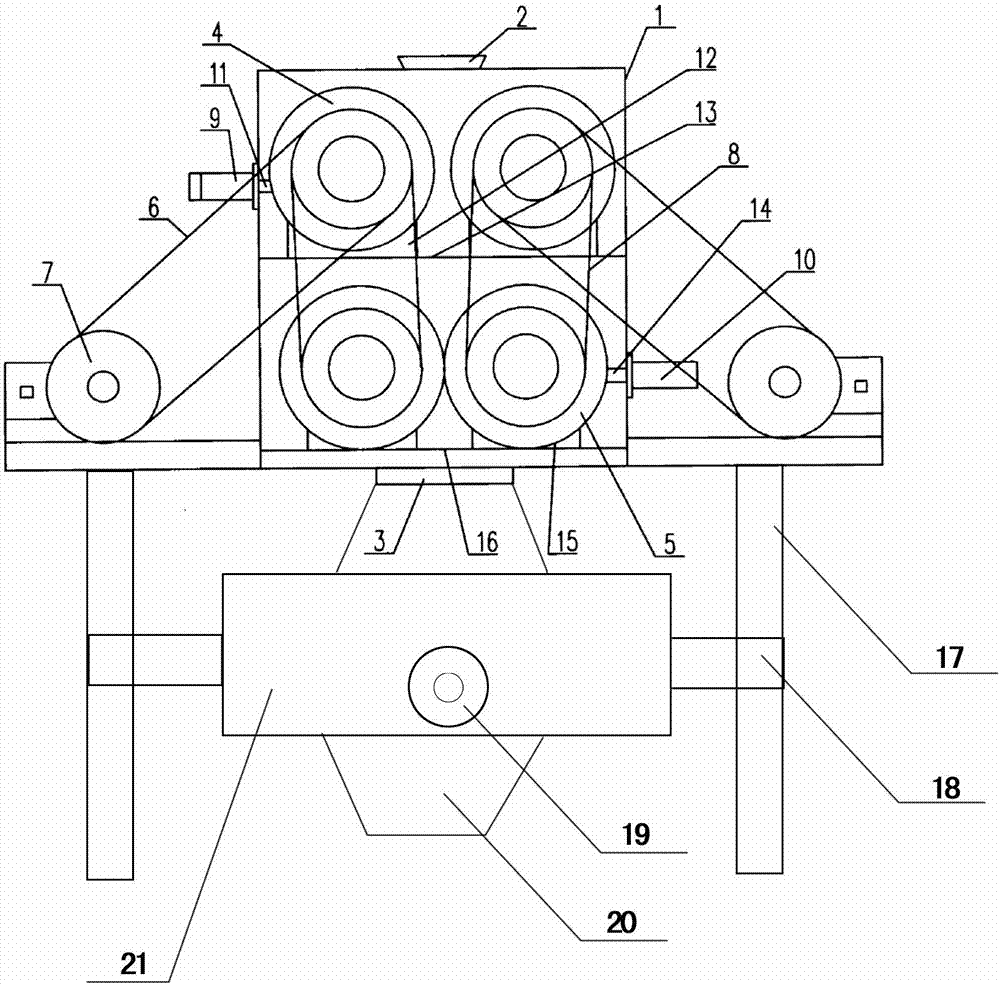

Using method for feed pulverizer with separating screen

The invention discloses a using method for a feed pulverizer with a separating screen. The using method comprises the following steps that A, during working, raw materials such as corns and bones are extruded and pulverized when entering a gap between coarse crushing rollers through a material inlet and then are extruded and pulverized again through the gap between the coarse crushing rollers; B, the coarse crushing rollers are adjusted: a control device controls a piston rod of an upper adjustment cylinder to extend to push one of the coarse crushing rollers to slide on a sliding rail so as to adjust the gap between the two coarse crushing rollers; C, fine crushing rollers are adjusted: the control device controls a piston rod of a lower adjustment cylinder to extend to push one of the fine crushing rollers to slide on the sliding rail so as to adjust a gap between the two fine crushing rollers; D, the separating screen vibrates to screen materials falling down from a material outlet of a stander, and fine materials are led out along a fine material outlet so as to be collected; a coarse material outlet in the side surface of the separating screen is used for introducing large-particle materials into the material inlet through a conveying belt for secondary pulverization. The using method disclosed by the invention is simple; a used product is simple in structure and convenient to use; the materials can be screened after being pulverized, so that secondary screening can be reduced.

Owner:QINGDAO ZHONGTAI POULTRY IND PROFESSIONAL COOP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com