Method and system for treating lead-zinc sulfide ores

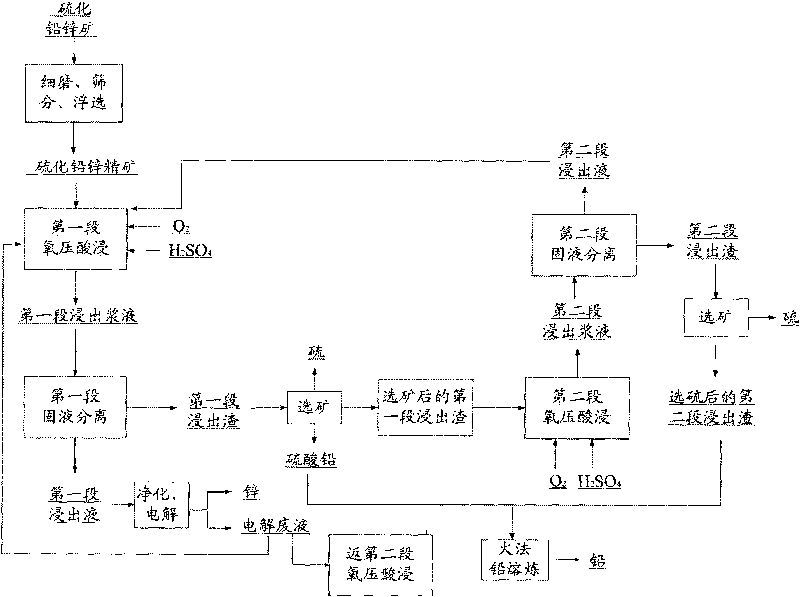

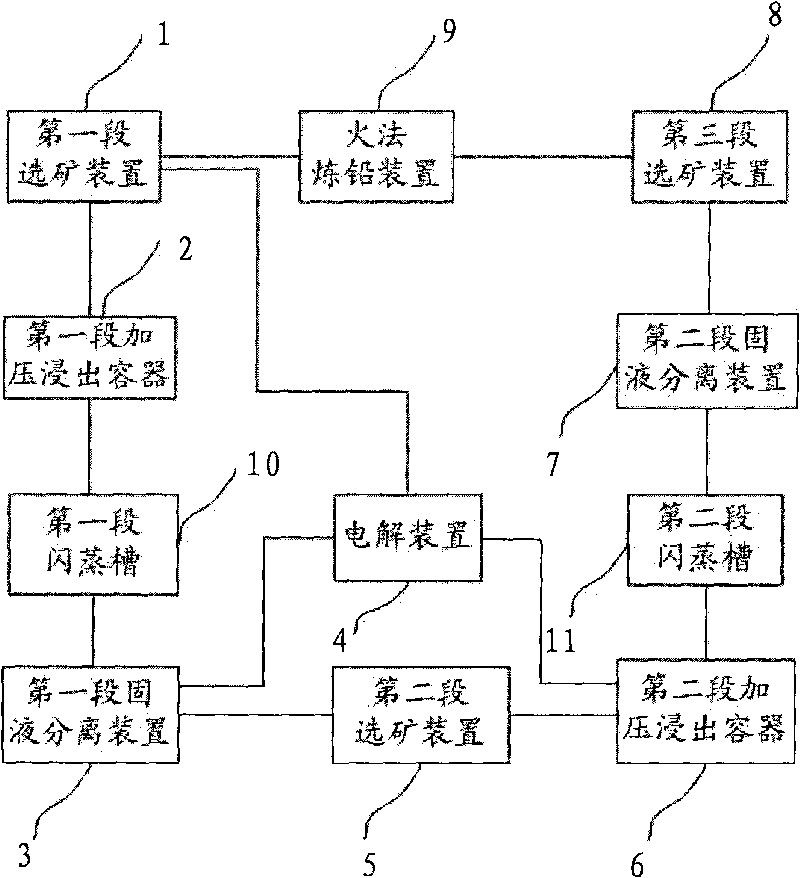

A technology of lead-zinc sulfide and treatment method, which is applied in the field of extracting zinc from lead-zinc sulfide ore by oxygen pressure acid leaching method, treatment system of lead-zinc sulfide ore, lead and sulfur, treatment field of lead-zinc sulfide ore, can solve Solve problems such as low zinc and lead recovery rates, achieve the effect of reducing energy consumption, reducing material volume, and eliminating loss problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

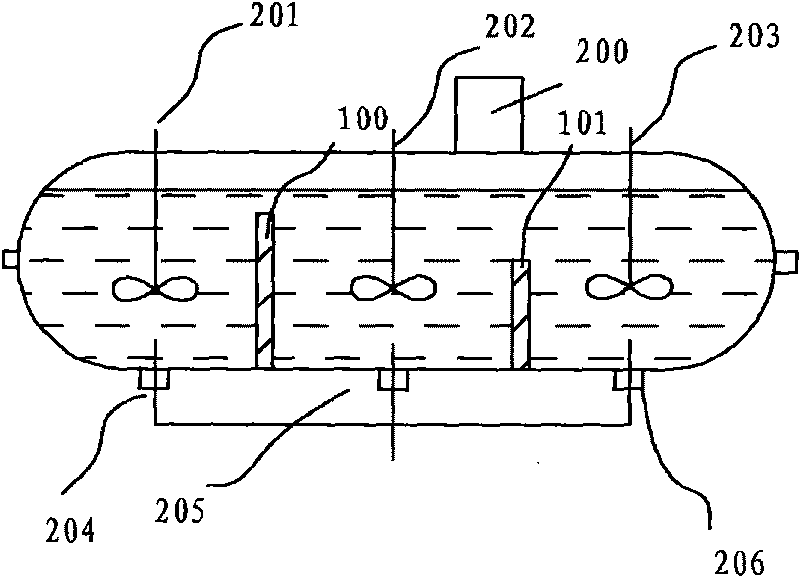

[0070] Get lead-zinc sulfide ore (lead content is 2.6wt%, zinc content is 4.0wt%), after fine grinding, screening, adopt mixed flotation method to carry out ore dressing to lead-zinc ore sulfide, obtain lead-zinc sulfide concentrate (lead content is 15.0wt%, and the zinc content is 37.5wt%), and it is finely ground into a mineral powder whose particle size is less than 320 mesh and the particle size is 100%. Add a sulfuric acid solution with a concentration 3 times the weight of the mineral powder to 78g / l to the finely ground mineral powder, stir fully to make the mineral powder slurry, and inject the slurry into the first continuous horizontal autoclave. Oxygen was introduced into the autoclave, the temperature was raised to 150° C., the oxygen pressure during the reaction was maintained at 1.0 MPa, and the rotational speed of the stirrer in the autoclave was 220 rpm. After 45 minutes, the reaction was completed, and the reacted slurry was discharged, and after flashing trea...

Embodiment 2

[0073] Get lead-zinc sulfide ore (lead content is 5.1wt%, zinc content is 8.4wt%), after fine grinding, screening, adopt mixed flotation method to carry out ore dressing to lead-zinc ore sulfide, obtain lead-zinc sulfide concentrate (lead content is 18.3wt%, and the zinc content is 39.5wt%), and it is finely ground into a mineral powder with a particle size of less than 320 mesh and a particle ratio of 98.5%. Add a sulfuric acid solution with a concentration of 65g / l that is 5 times the weight of the mineral powder to the finely ground mineral powder, stir fully to make the mineral powder slurry, and inject the slurry into the first continuous horizontal autoclave. Oxygen was fed into the autoclave, the temperature was raised to 145° C., the oxygen pressure during the reaction was maintained at 0.8 MPa, and the rotational speed of the stirrer in the autoclave was 230 rpm. After 60 minutes, the reaction is completed, and the reacted slurry is discharged, and after flashing trea...

Embodiment 3

[0076] Get lead-zinc sulfide ore (lead content is 7.9wt%, zinc content is 15.6wt%), after fine grinding, screening, adopt mixed flotation method to carry out ore dressing to lead-zinc ore sulfide, obtain lead-zinc sulfide concentrate (lead content is 19.5wt%, and the zinc content is 39.6wt%), and then through the gravity separation process, the lead-zinc sulfide concentrate is separated into lead-zinc sulfide concentrate with low lead content (the weight ratio of Zn:Pb is greater than 1.5, and Zn and Pb The total content of elements is greater than 40wt%) and lead concentrate (lead content is 10.2wt%, zinc content is 42.5wt%). Finely grind it into mineral powder with a particle size of less than 320 mesh and a particle ratio of 98.7%. Add the finely ground mineral powder into the first slurry mixing tank, add a sulfuric acid solution with a concentration of 70g / l that is 6 times the weight of the mineral powder, stir fully to make the mineral powder slurry, and inject the slur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com