Patents

Literature

2279results about "Sulfur preparation/purification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

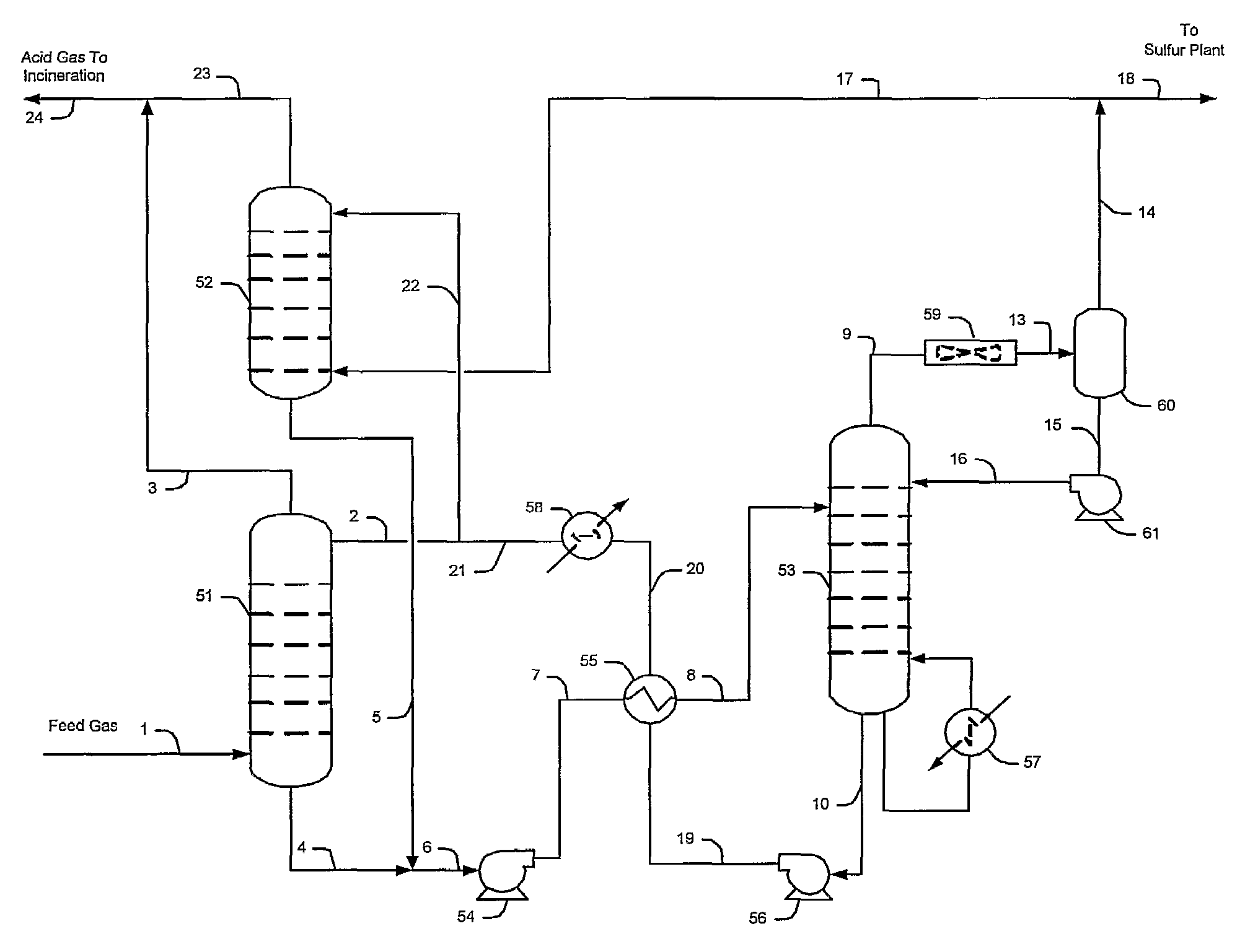

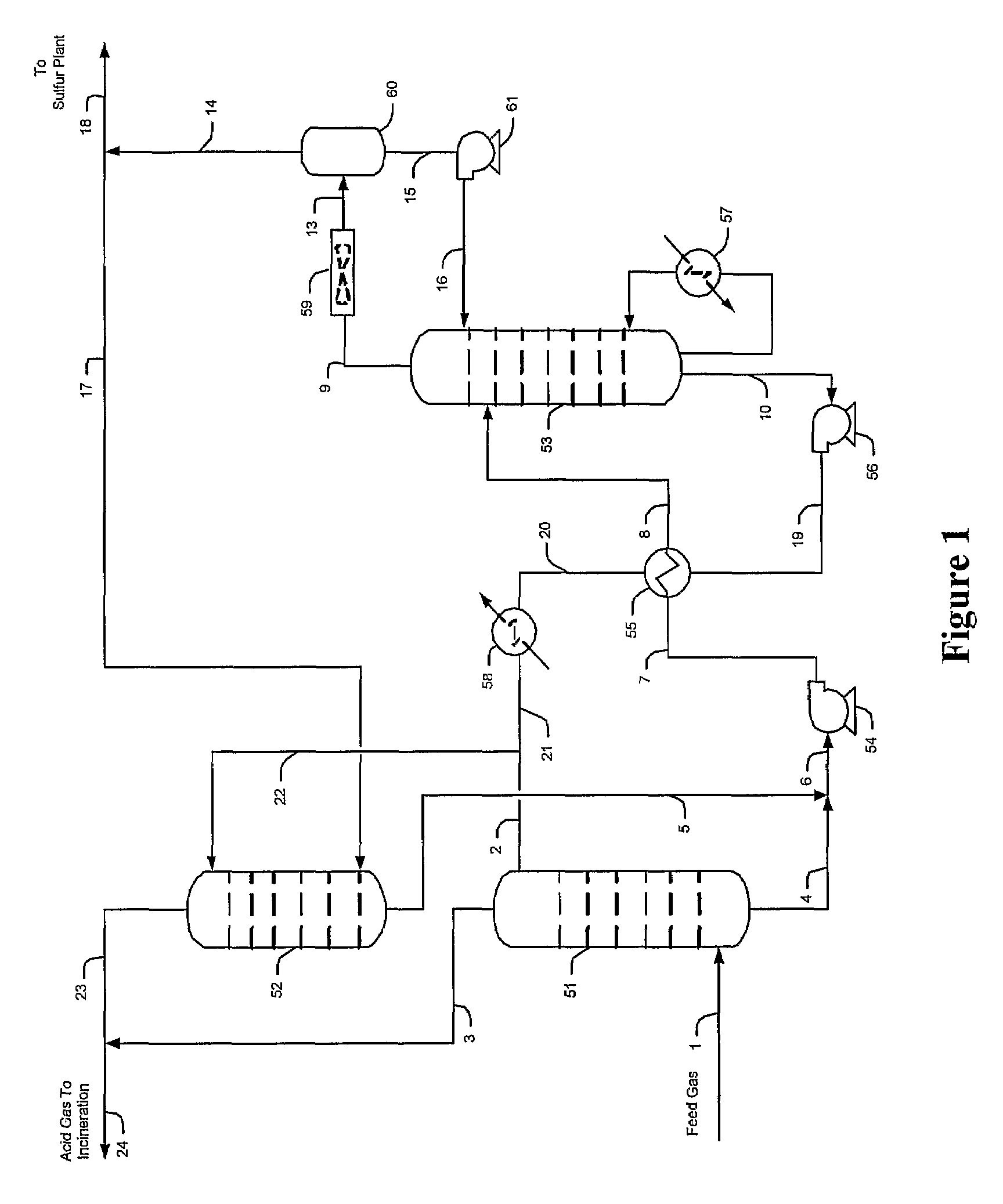

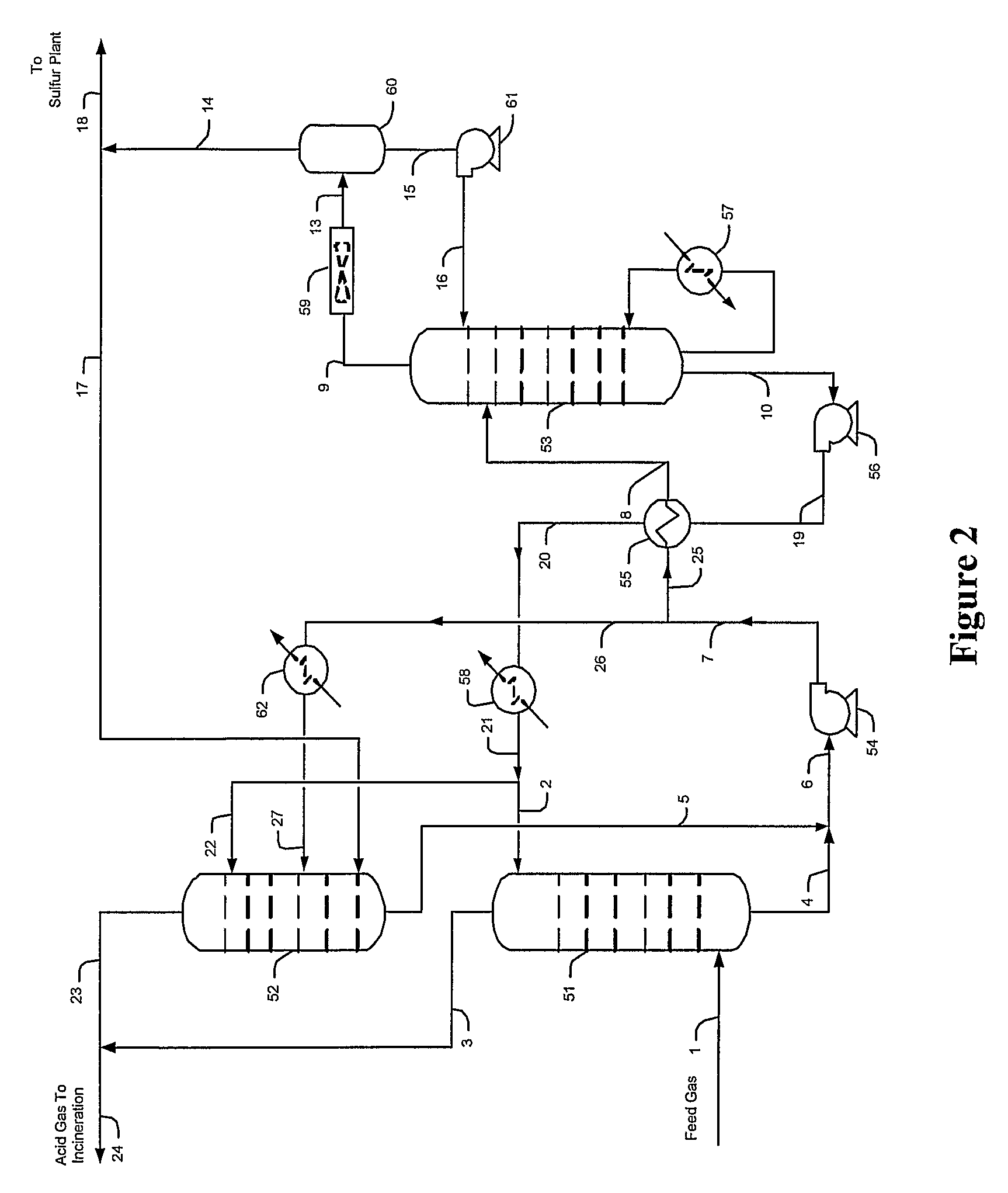

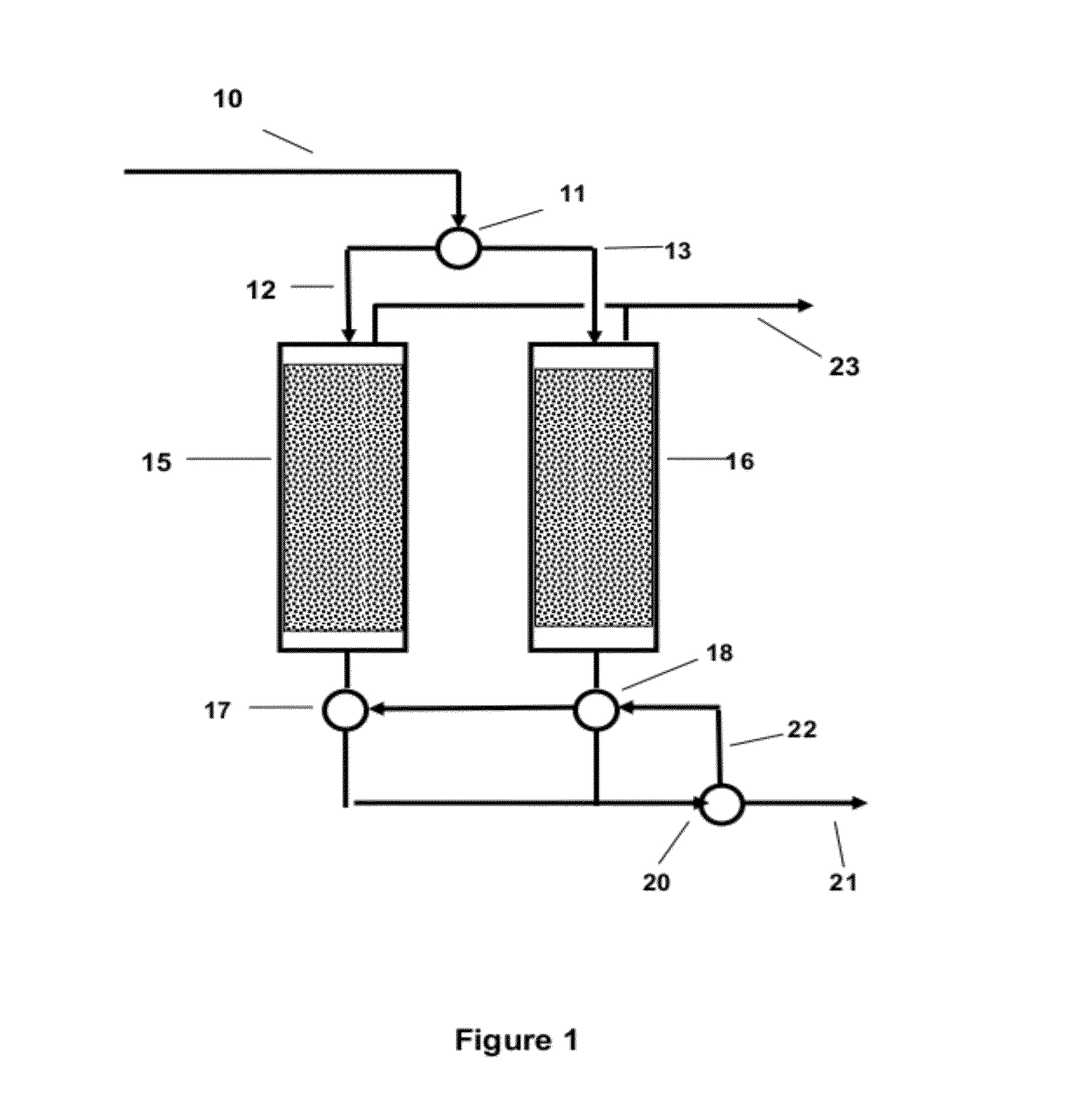

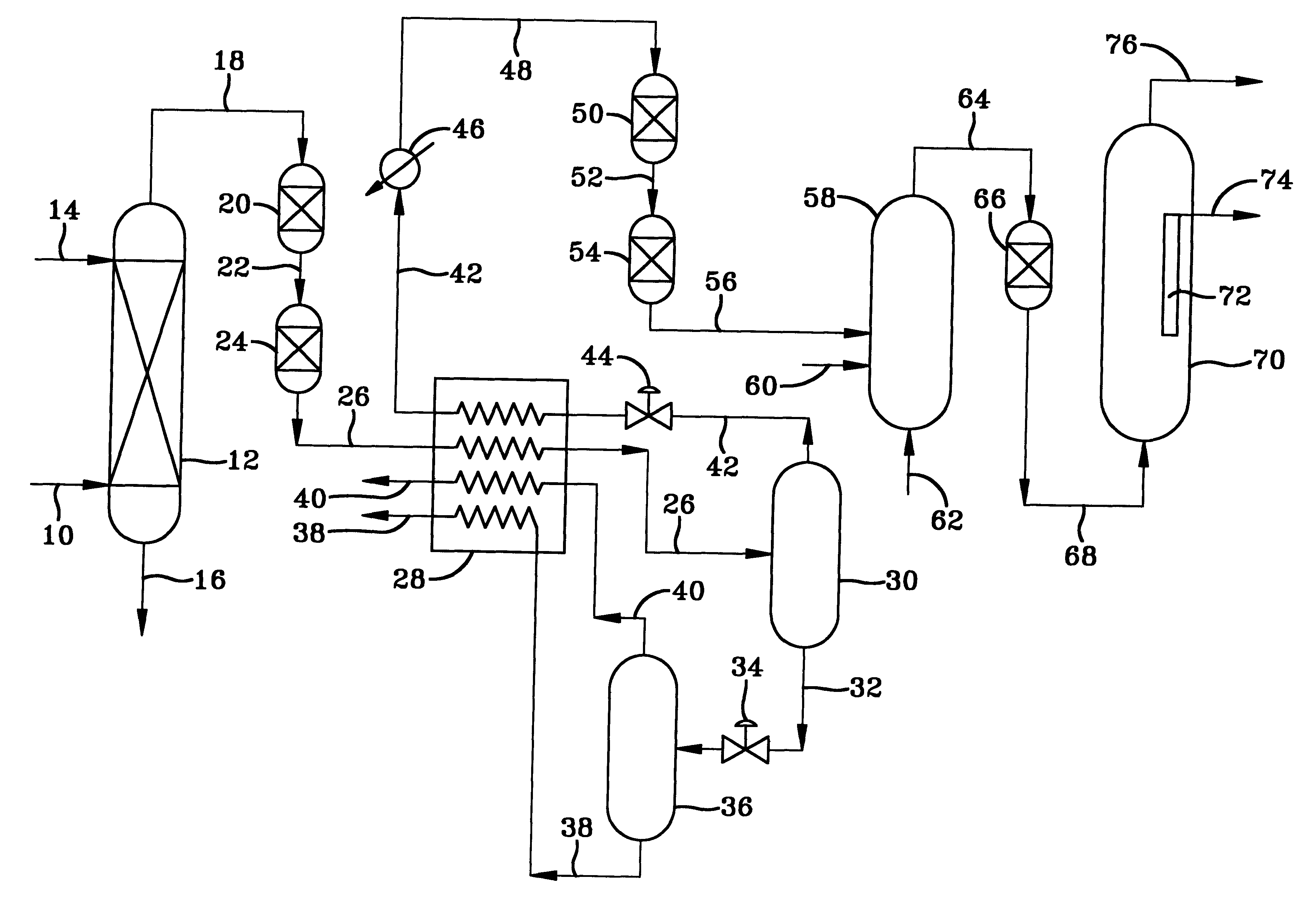

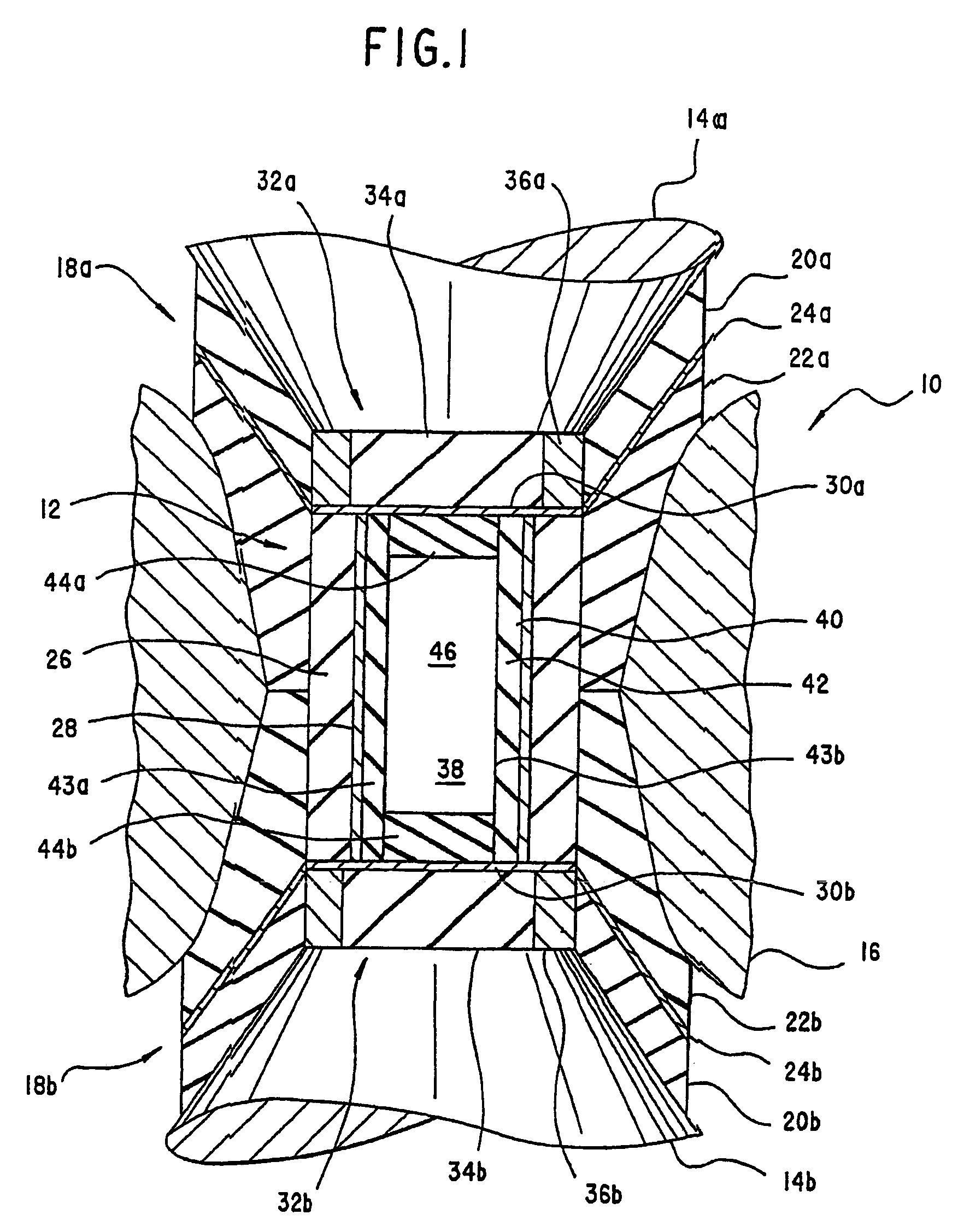

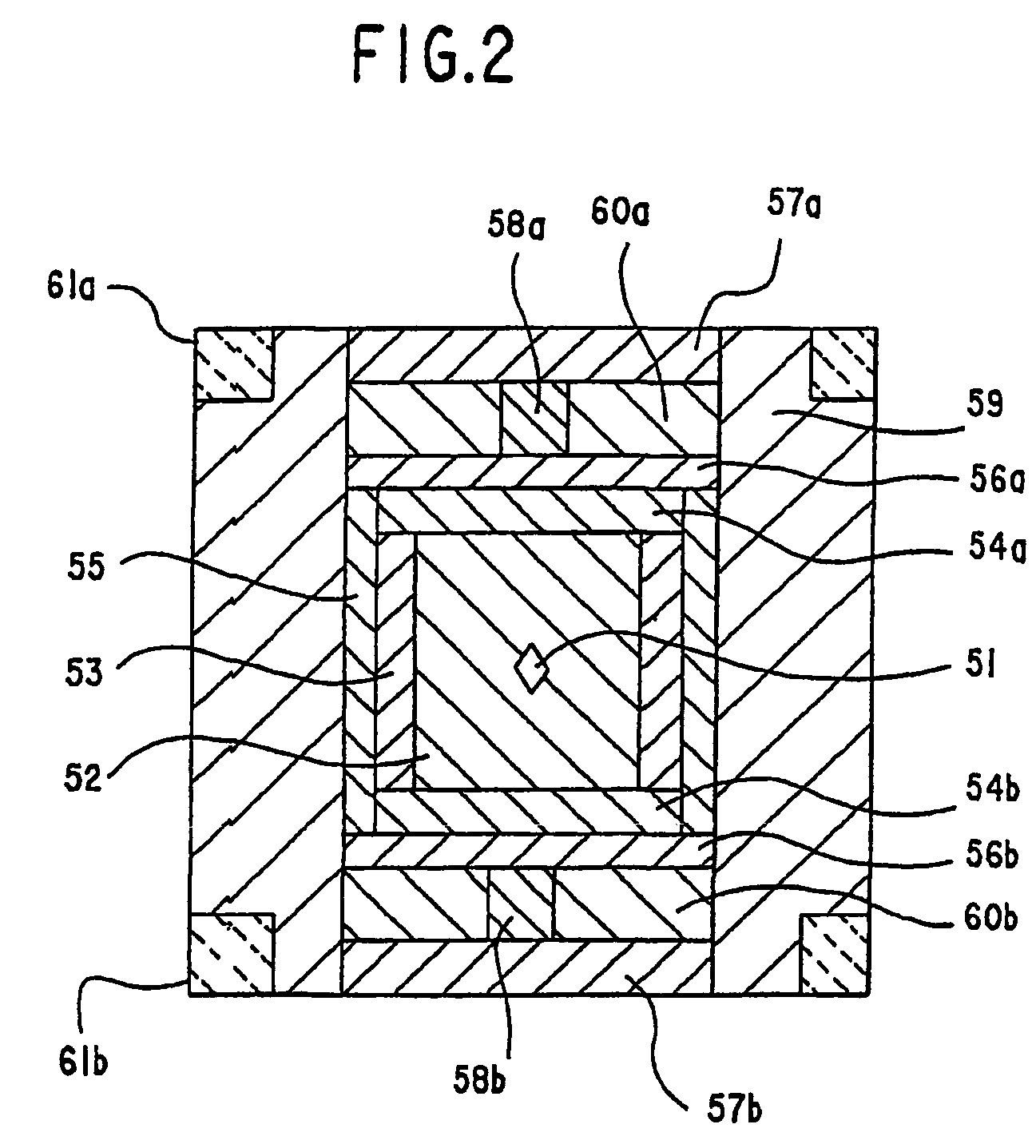

Methods and configurations for acid gas enrichment

ActiveUS7635408B2Increase the concentration of hydrogen sulfideSmall sizeGas treatmentCarbon compoundsSolventCarbon dioxide

Hydrogen sulfide is selectively enriched from an acid gas (1) that comprises relatively large quantities of carbon dioxide using a configuration in which a portion of an isolated hydrogen sulfide stream is introduced into an absorber (51) operating as a carbon dioxide rejecter. The resulting concentrated hydrogen sulfide enriched solvent (4) is then further used (directly or indirectly) to absorb hydrogen sulfide from an acid feed gas.

Owner:FLUOR ENTERPRISES

Method and apparatus for treating a sour gas

Owner:AIR PROD & CHEM INC

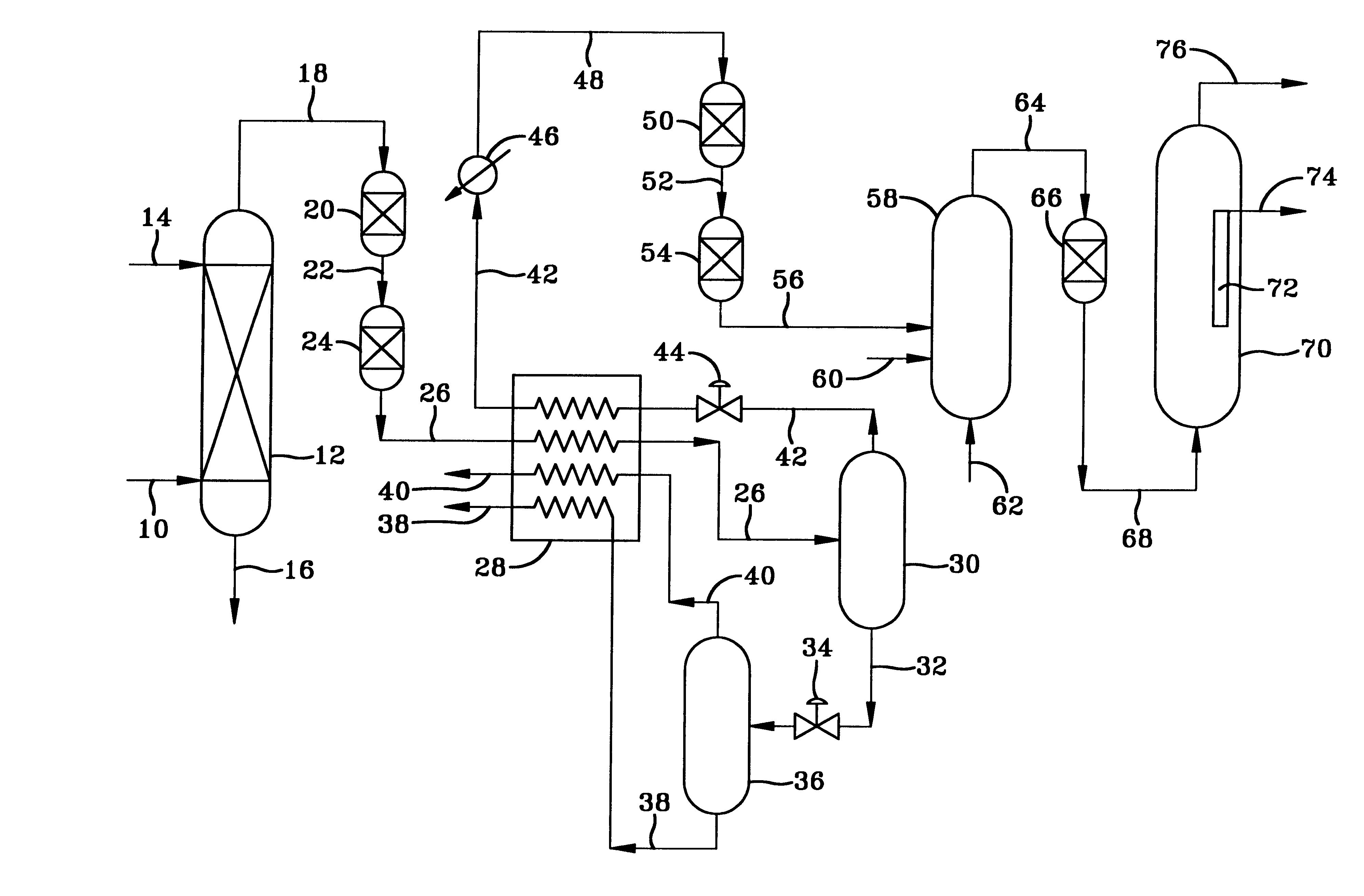

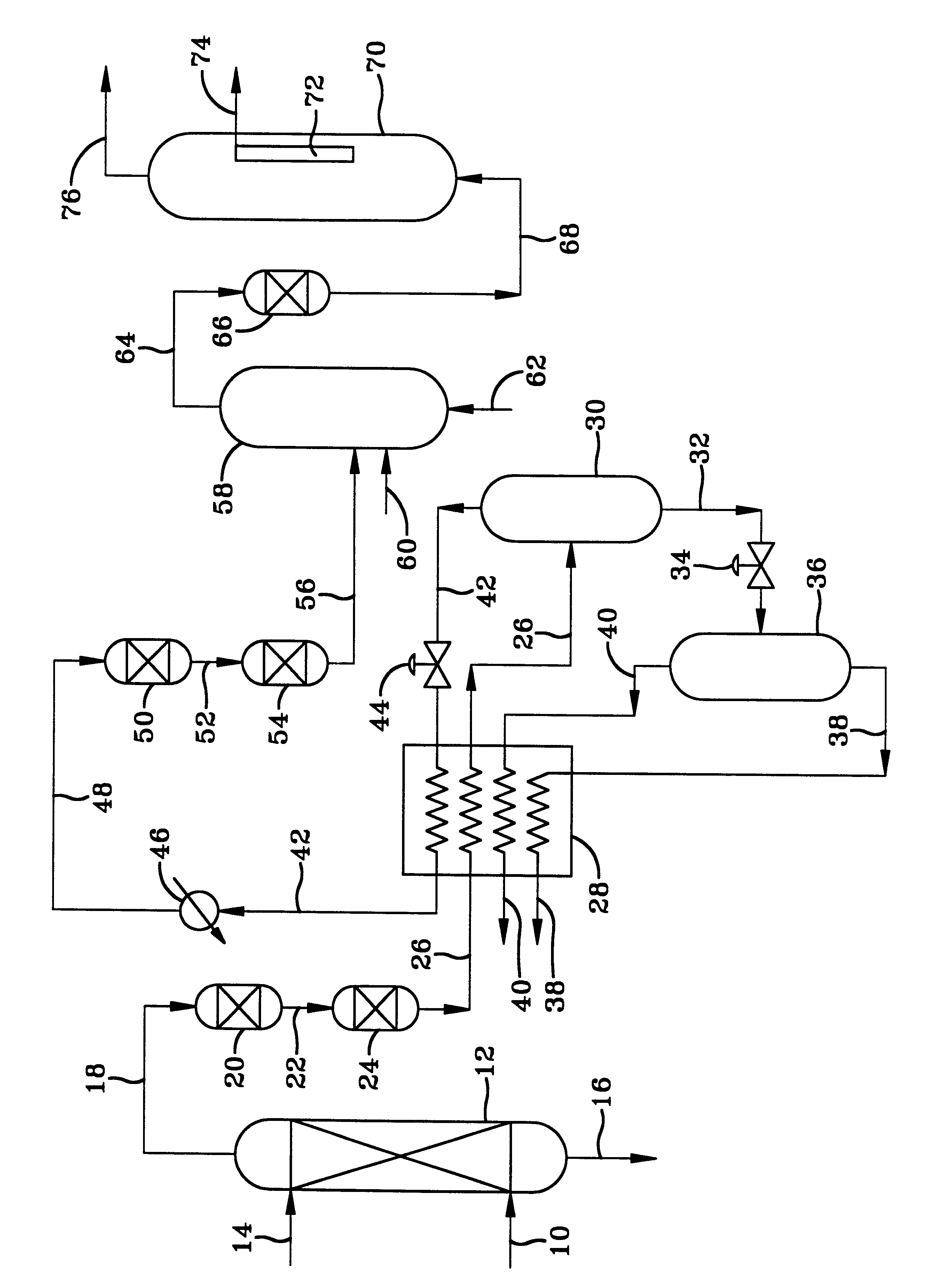

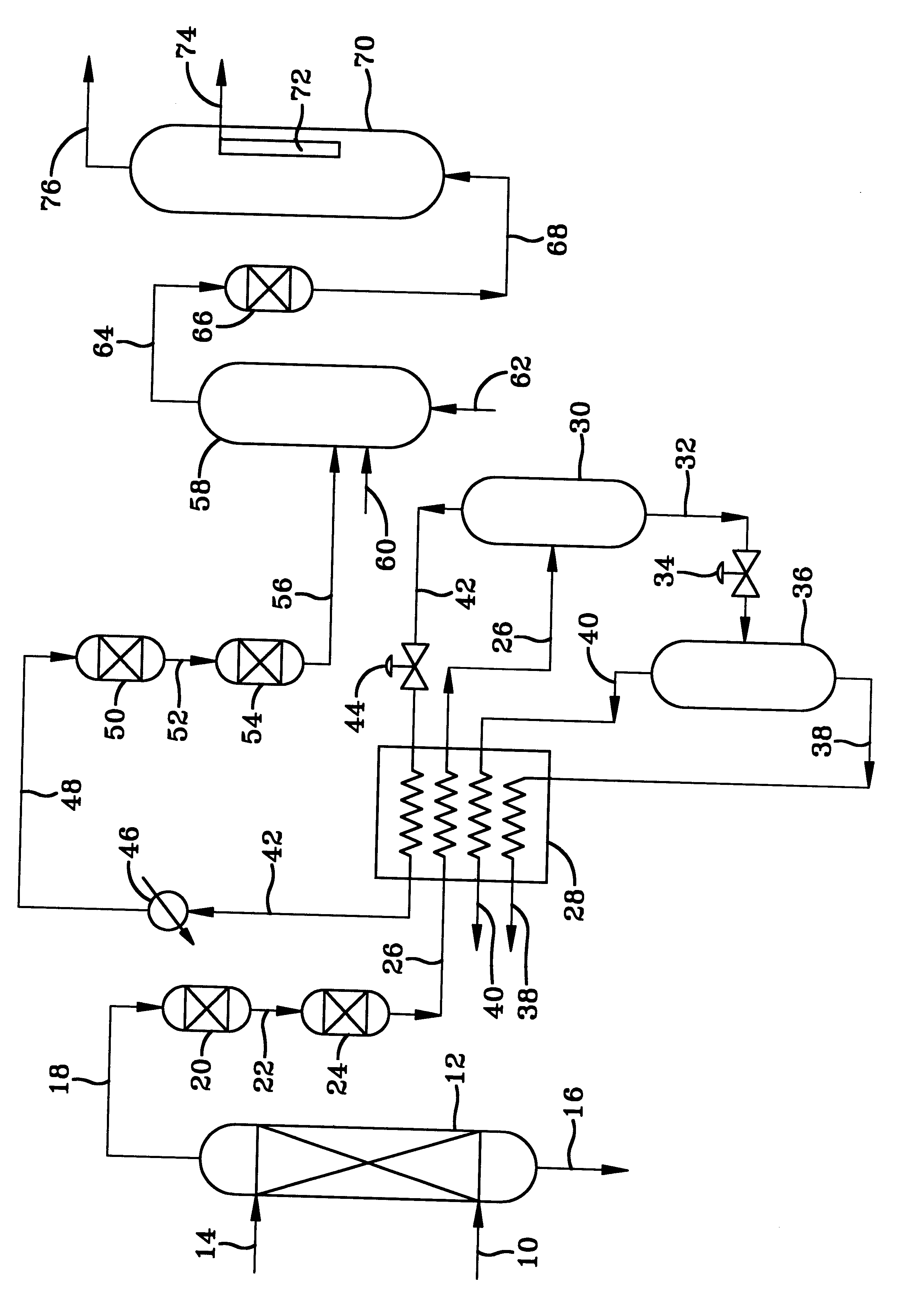

Production of low sulfur syngas from natural gas with C4+/C5+ hydrocarbon recovery

Sour natural gas is processed to remove the sulfur compounds and recover C4+ / C5+ hydrocarbons by scrubbing the gas with an amine solution to remove most of the sulfur, followed cooling the gas to remove C4+ / C5+ hydrocarbons and more sulfur compounds as liquid condensate to produce a gas having less than 20 vppm of total sulfur. The condensate is sent to a fractionator to recover the C4+ / C5+ hydrocarbons. The sulfur and hydrocarbon reduced gas is contacted first with zinc oxide and then nickel, to produce a gas having less than 10 vppb of total sulfur which is passed into a synthesis gas generating unit to form a very low sulfur synthesis gas comprising a mixture of H2 and CO. This synthesis gas is useful for hydrocarbon synthesis with increased life of the hydrocarbon synthesis catalyst and greater hydrocarbon production from the hydrocarbon synthesis reactor. Contacting the synthesis gas with zinc oxide further reduces the sulfur content to below 3 vppb.

Owner:EXXON RES & ENG CO

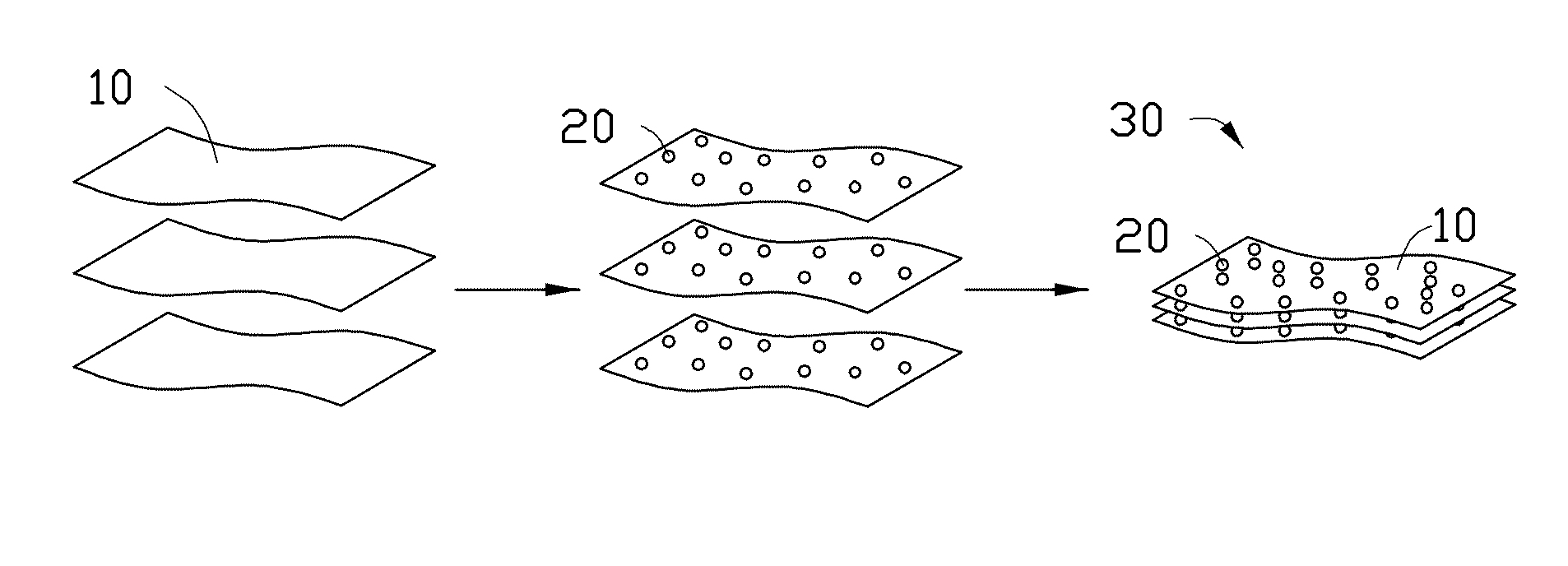

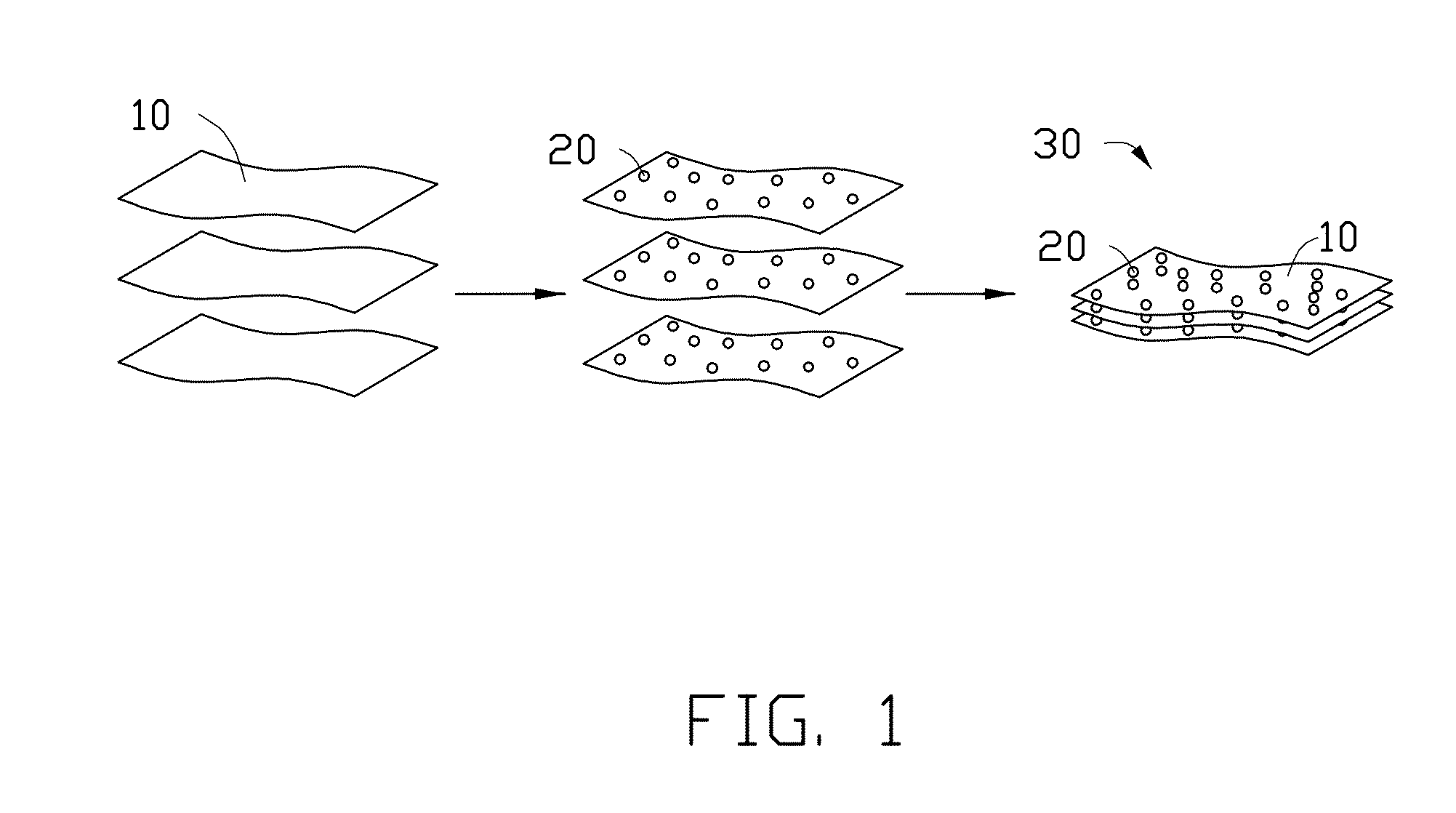

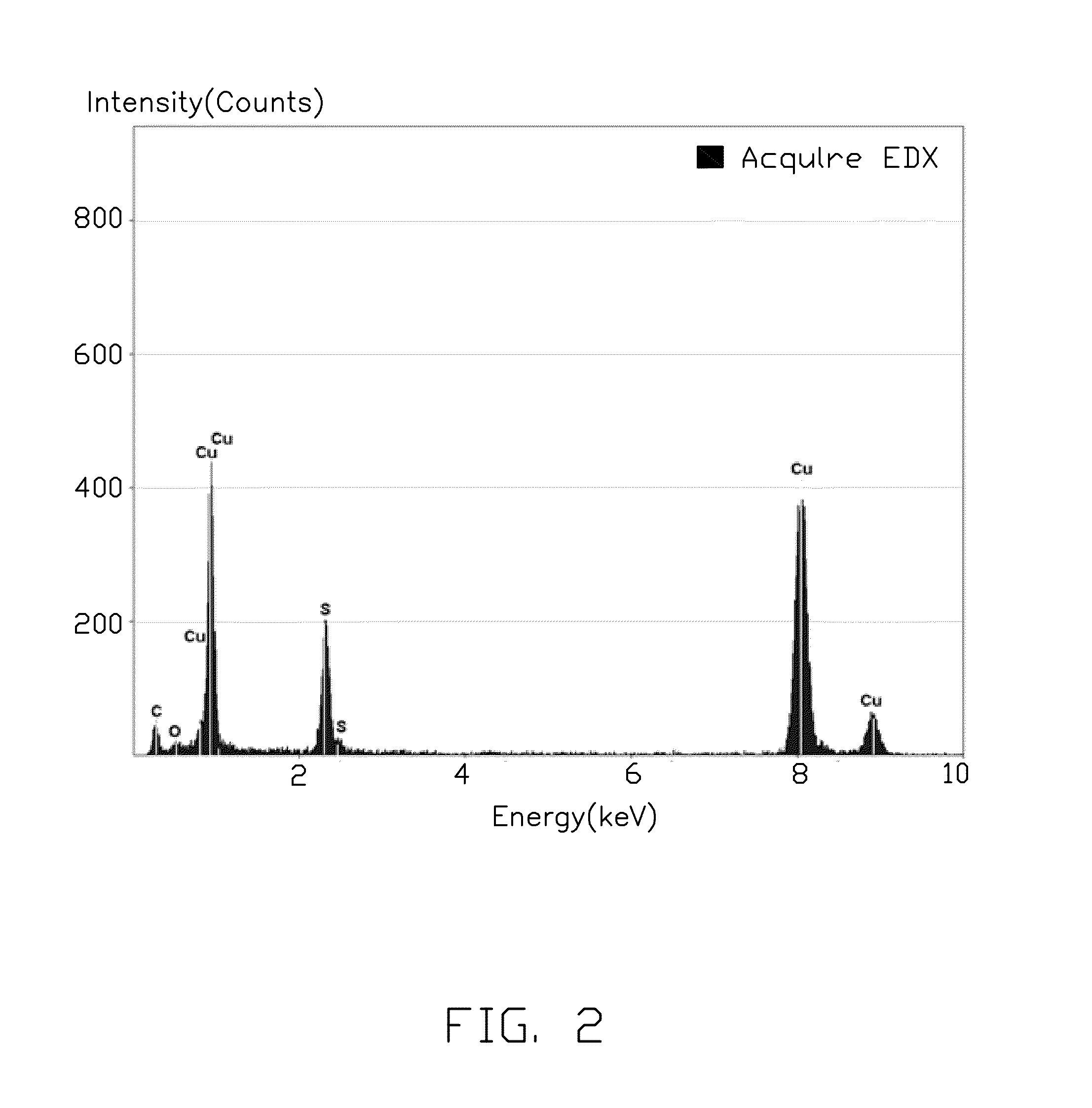

Method for making sulfur-graphene composite material

ActiveUS20130171339A1Improve cycle performanceMaterial nanotechnologyElectrode manufacturing processesChemical compoundSulfur

A method for making sulfur-graphene composite material is disclosed. In the method, a dispersed solution including a solvent and a plurality of graphene sheets dispersed in the solvent is provided. A sulfur-source chemical compound is dissolved into the dispersed solution to form a mixture. A reactant, according to the sulfur-source chemical compound, is introduced to the mixture. Elemental sulfur is produced on a surface of the plurality of graphene sheets due to a redox reaction between the sulfur-source chemical compound and the reactant, to achieve the sulfur-graphene composite material. The sulfur-graphene composite material is separated from the solvent.

Owner:TSINGHUA UNIV +1

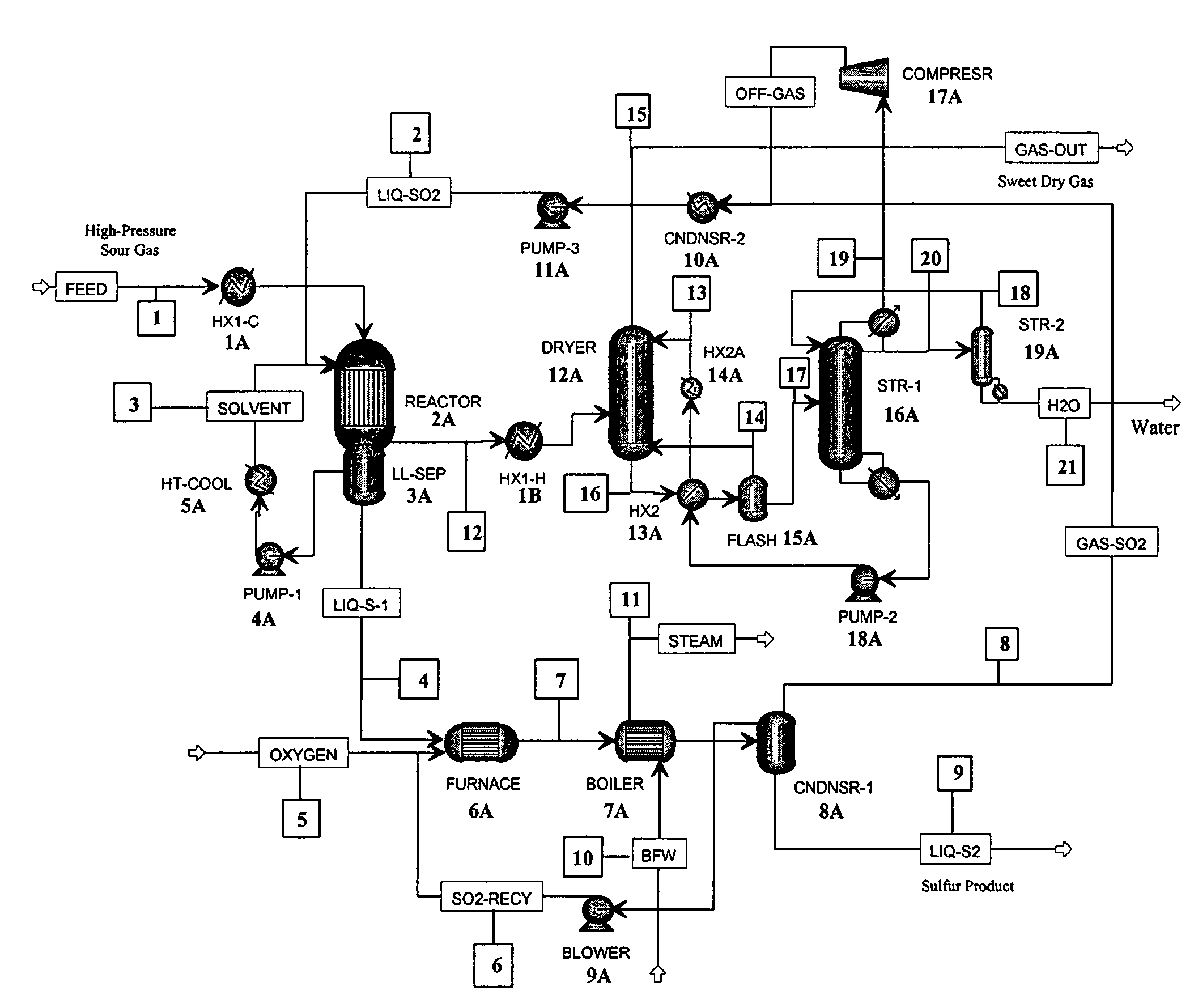

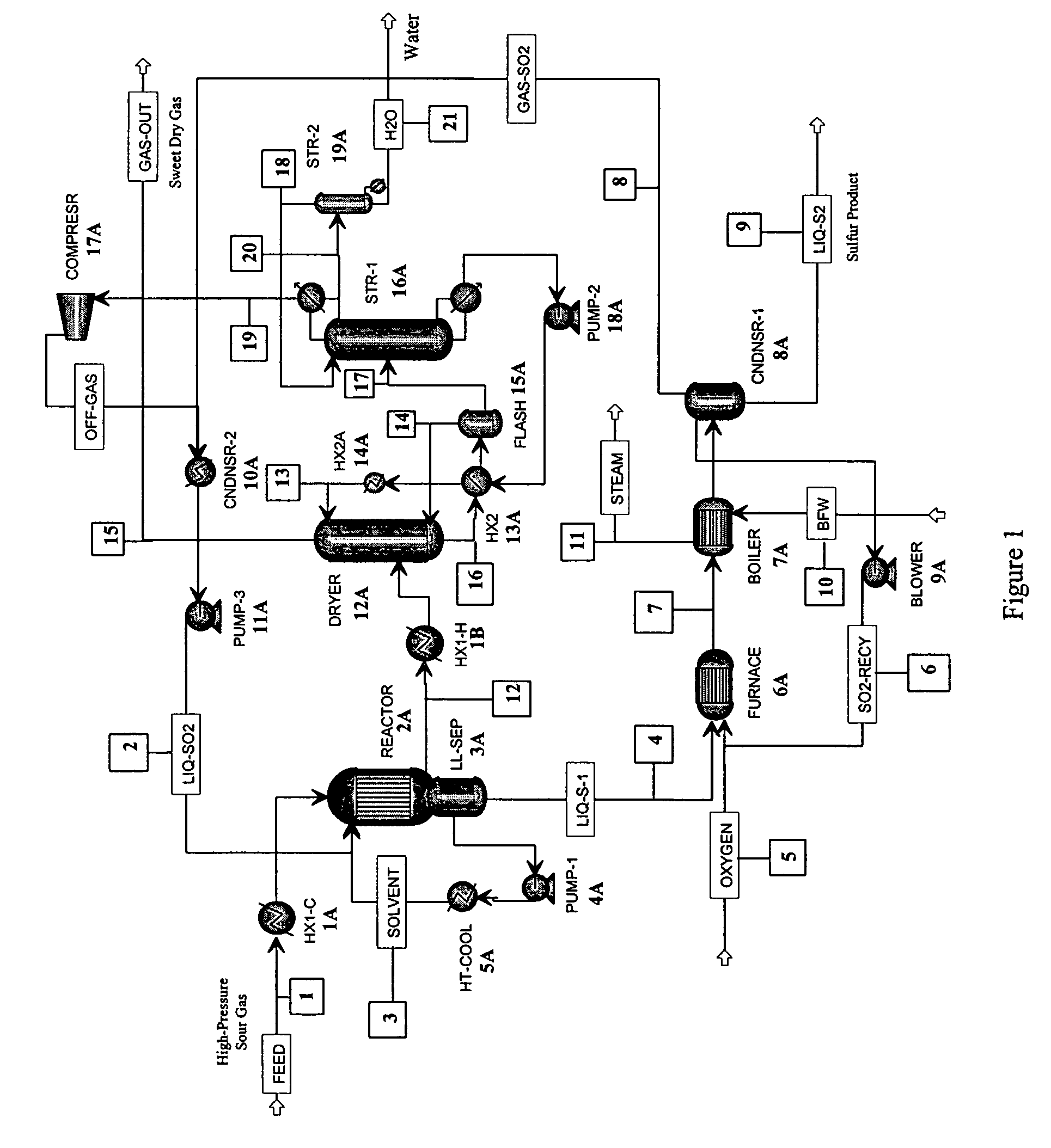

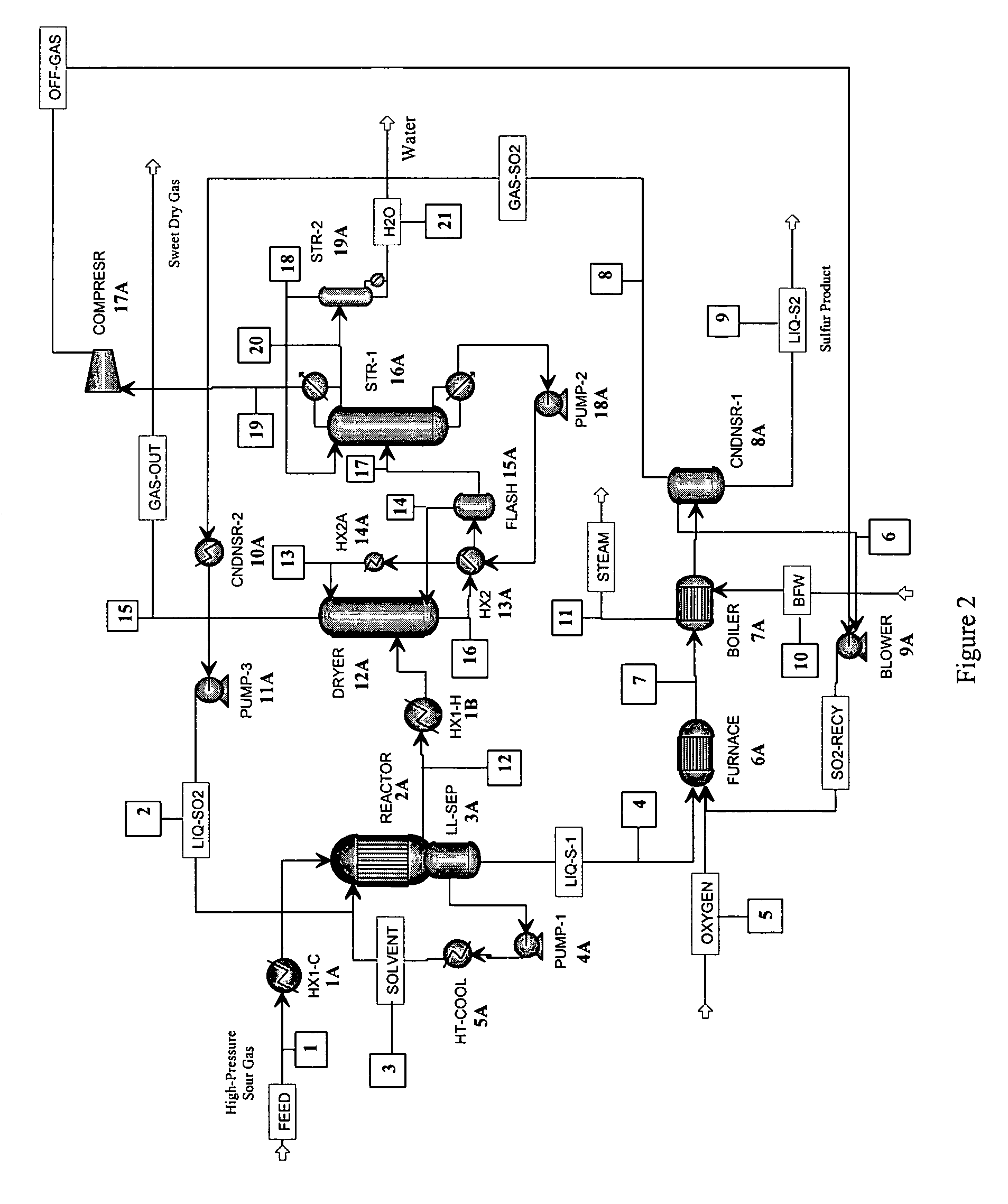

Process for sulfur removal suitable for treating high-pressure gas streams

InactiveUS7381393B2Dispersed particle separationSulfur preparation/purificationCombustionLiquid medium

H2S-containing gases, particularly such gases at elevated pressure, are treated to remove H2S by reaction in a liquid medium with SO2, the SO2 being present in stoichiometric excess with respect to the H2S. The SO2 is produced by combustion of sulfur, preferably sulfur produced in the reaction between H2S and SO2, preferably with oxygen. The process produces a treated gas that is substantially free of both H2S and SO2. An acid-gas absorber / stripper system or other system typically found in such processes to raise or concentrate the H2S level in the gas to be treated, is not needed in operations according to the invention.

Owner:RGT UNIV OF CALIFORNIA

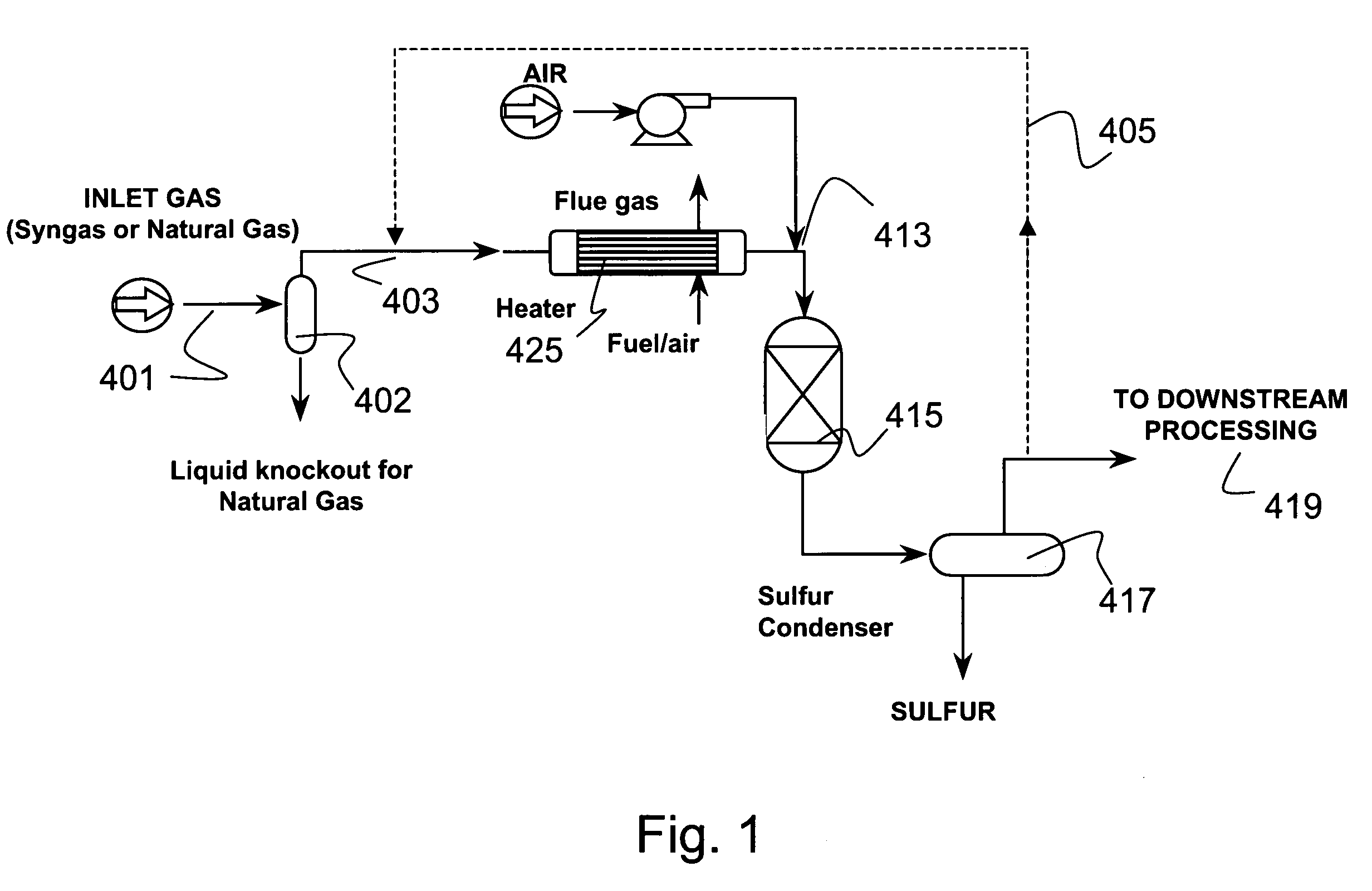

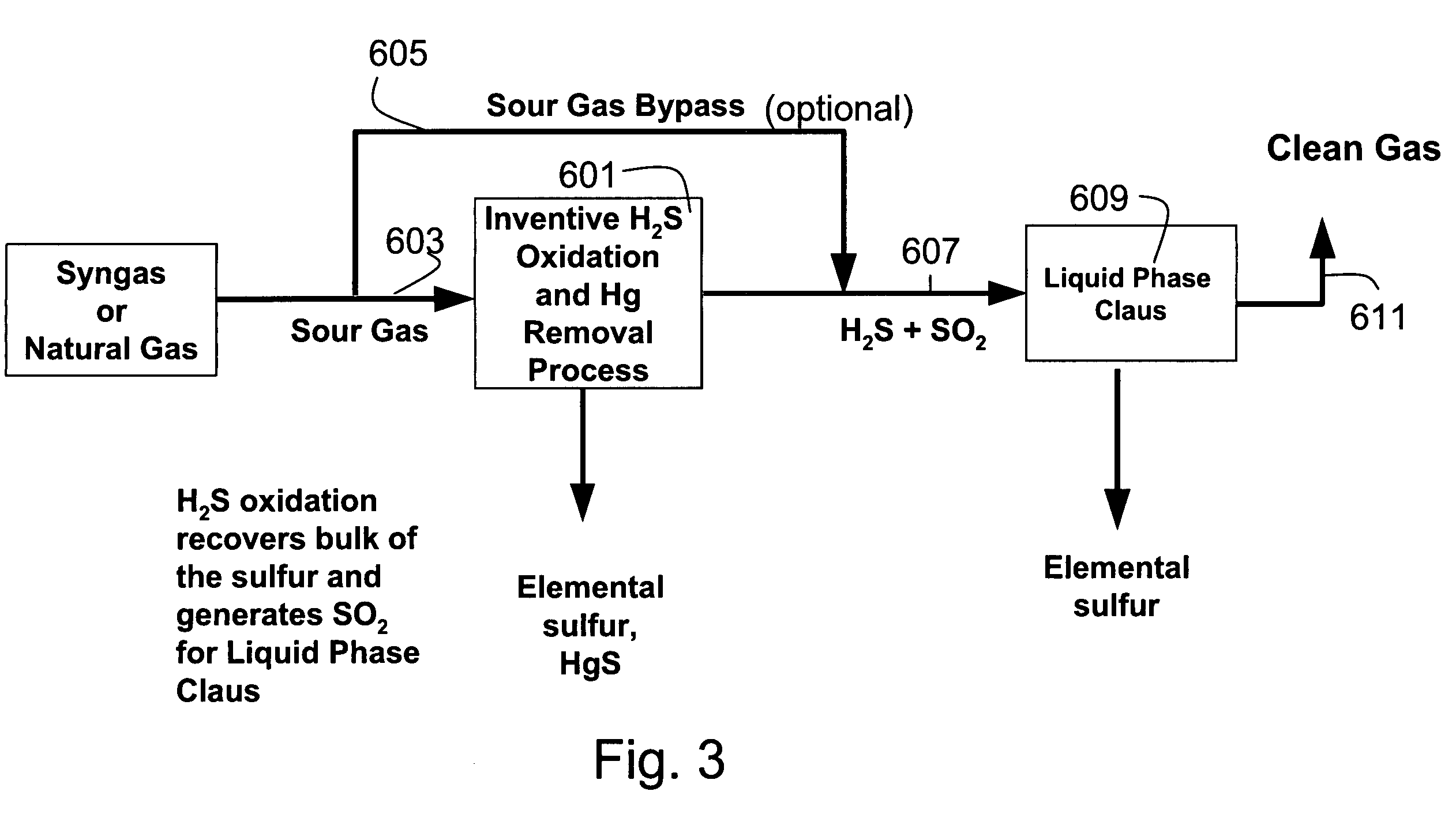

Process for the simultaneous removal of sulfur and mercury

InactiveUS7060233B1Lower capitalReduce operating costsGas treatmentUsing liquid separation agentSulfur containingInorganic sulfide

A process for removing hydrogen sulfide, other sulfur-containing compounds and / or sulfur and mercury from a gas stream contaminated with mercury, hydrogen sulfide or both. The method comprises the step of selective oxidation of hydrogen sulfide (H2S) in a gas stream containing one or more oxidizable components other than H2S to generate elemental sulfur (S) or a mixture of sulfur and sulfur dioxide (SO2). The sulfur generated in the gas stream reacts with mercury in the gas stream to generate mercuric sulfide and sulfur and mercuric sulfide are removed from the gas stream by co-condensation.

Owner:TDA RES

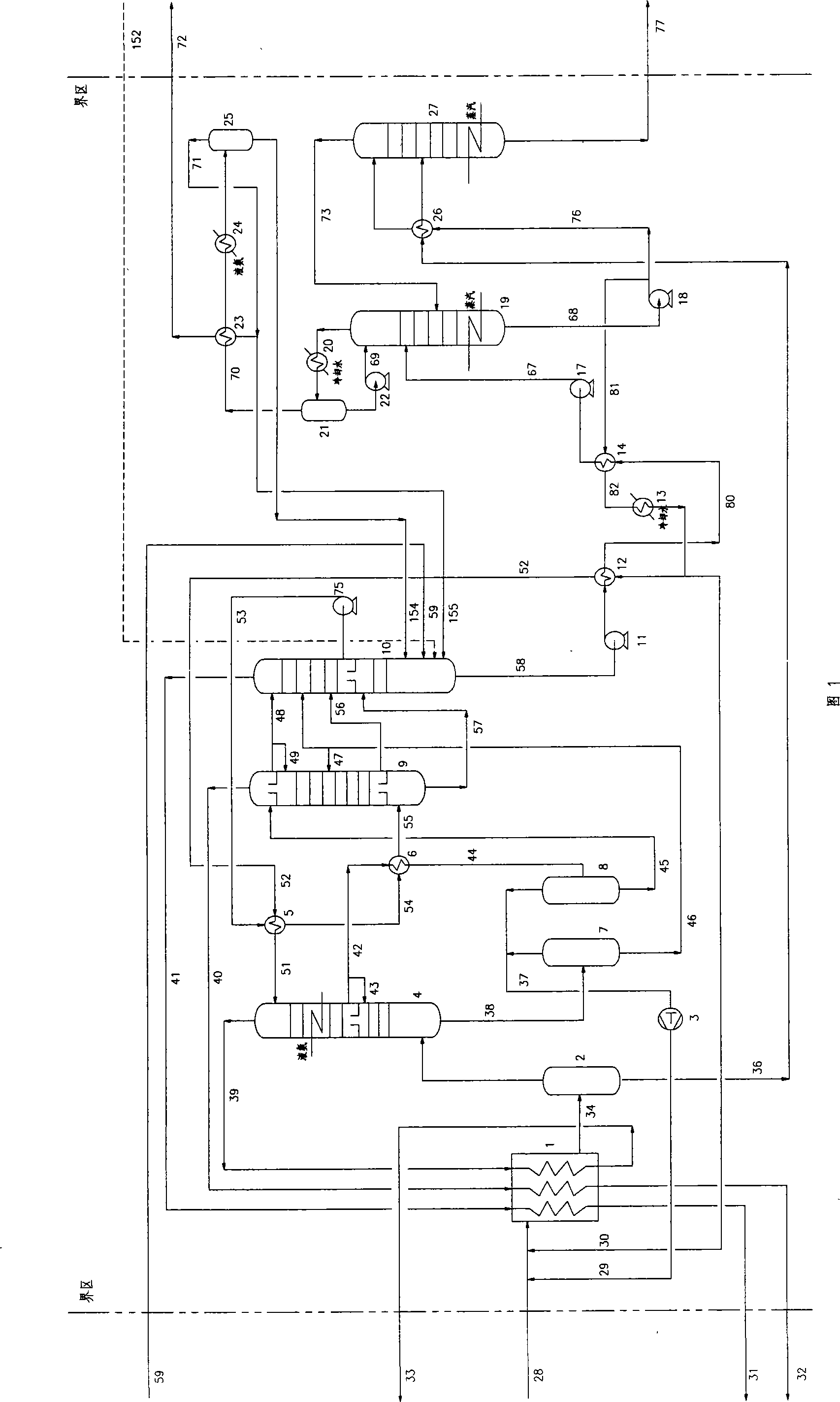

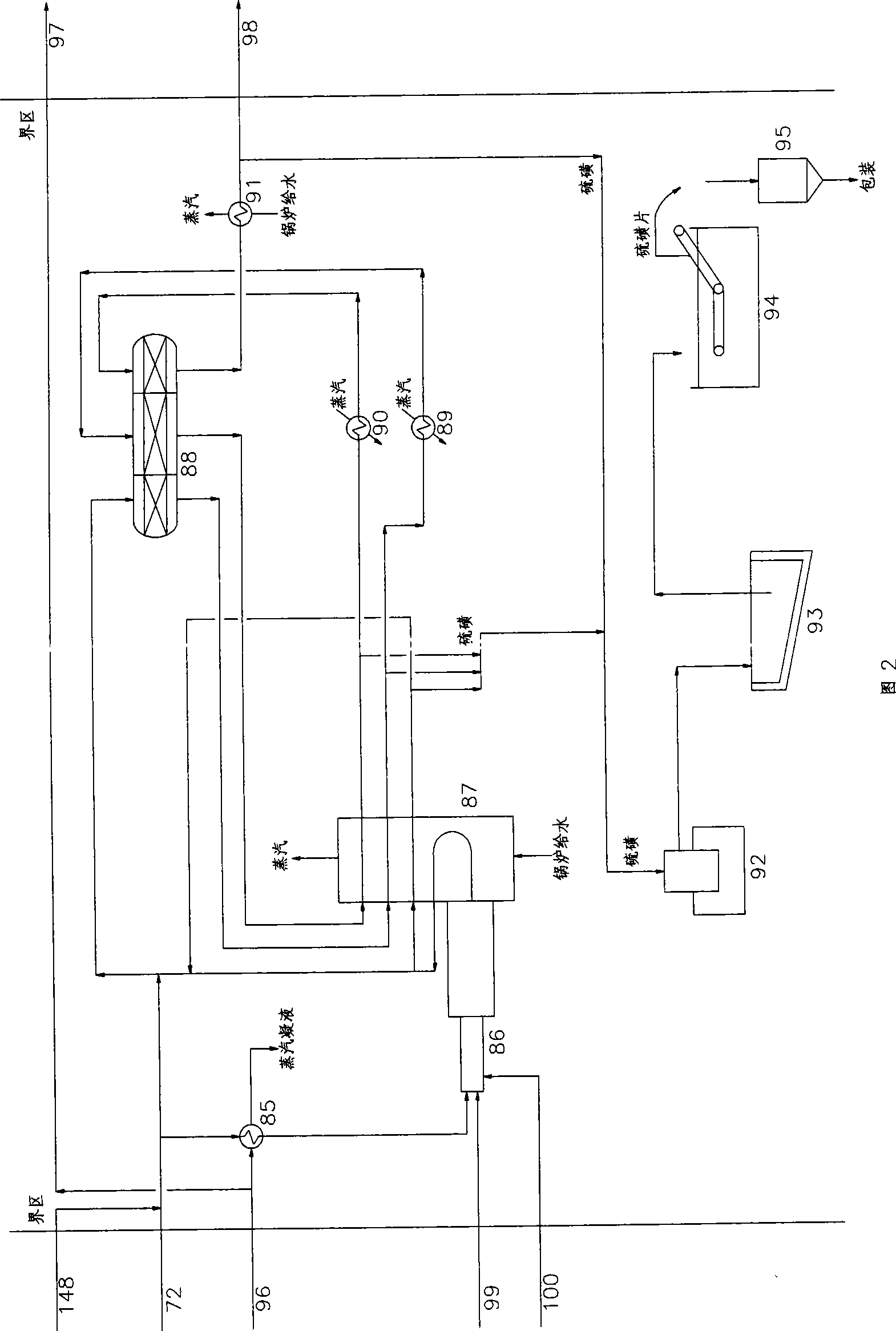

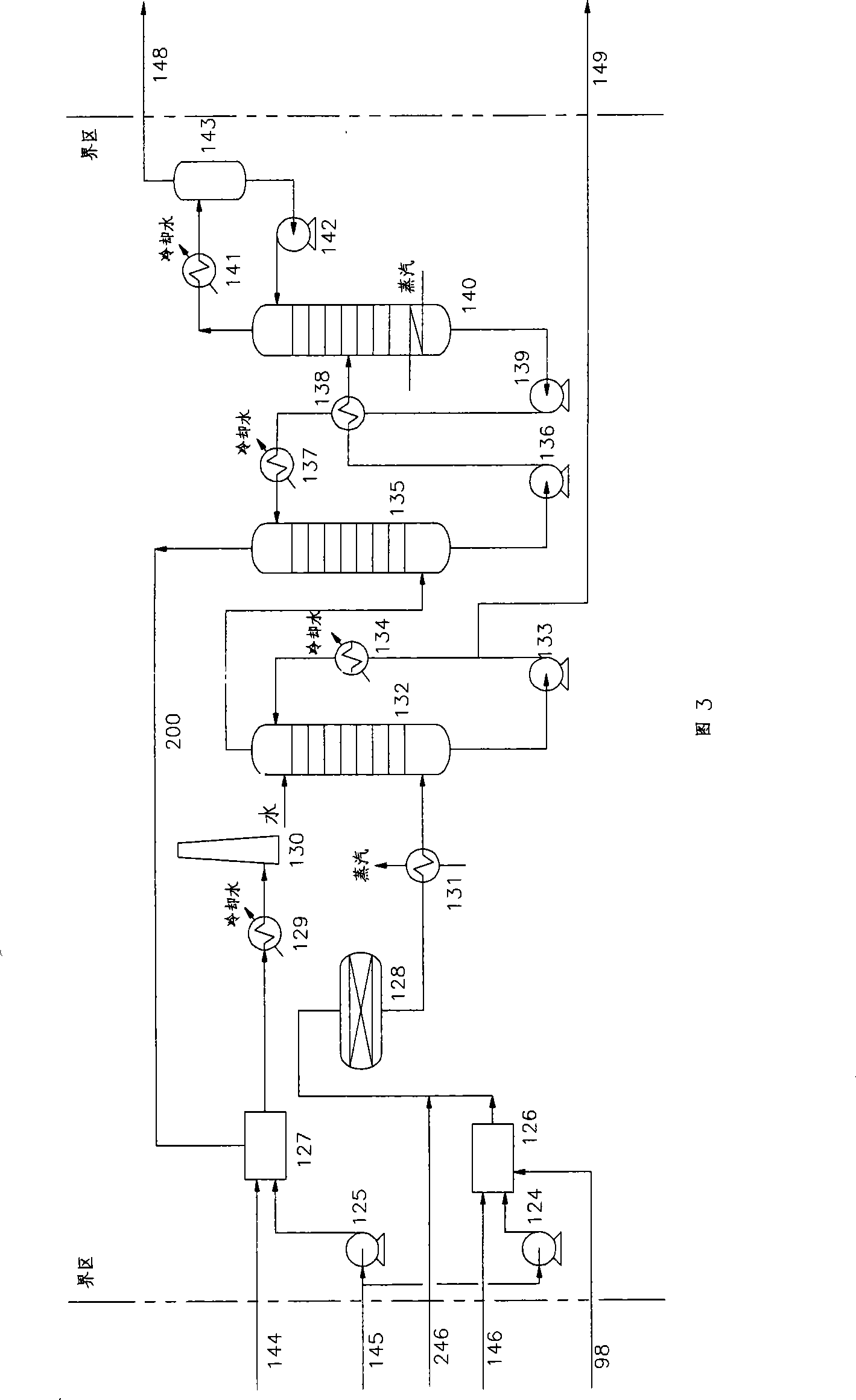

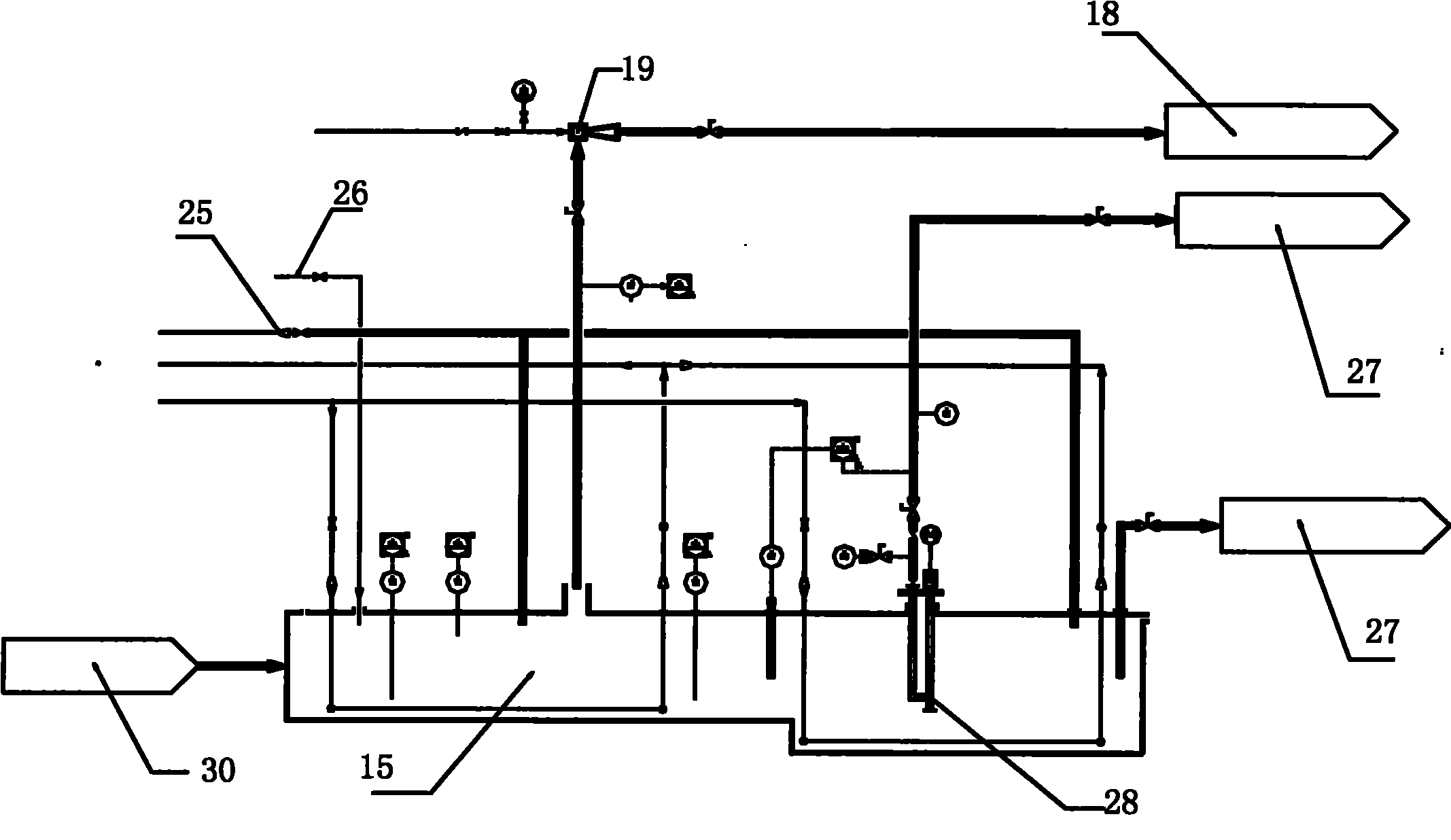

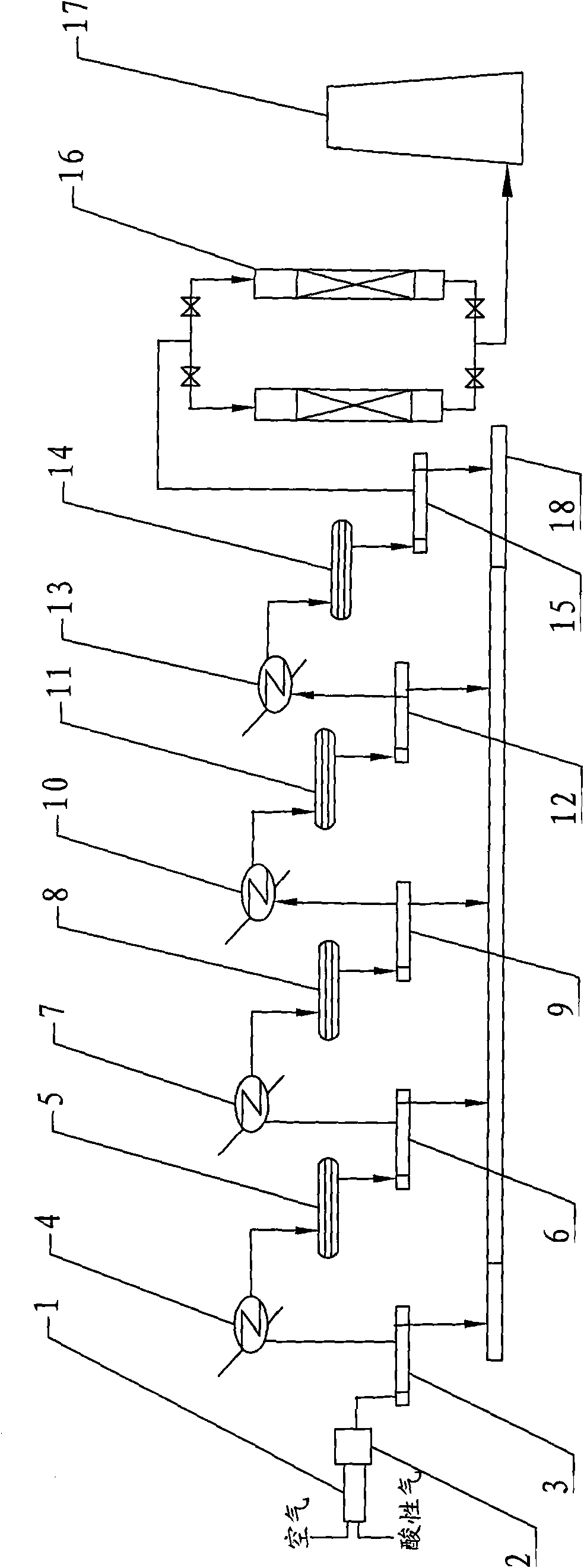

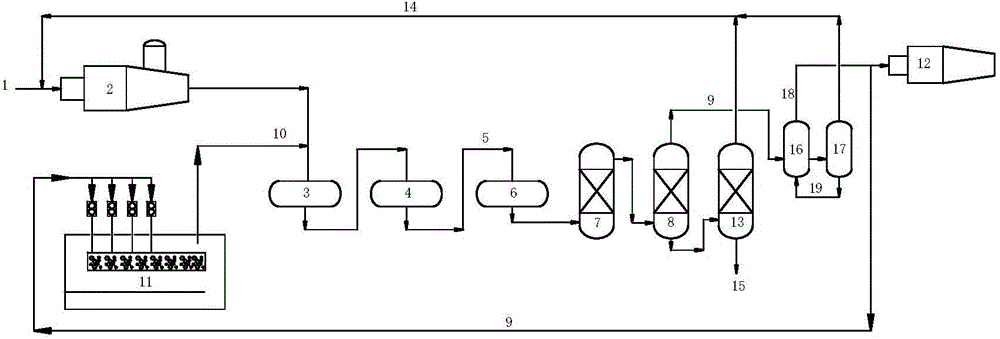

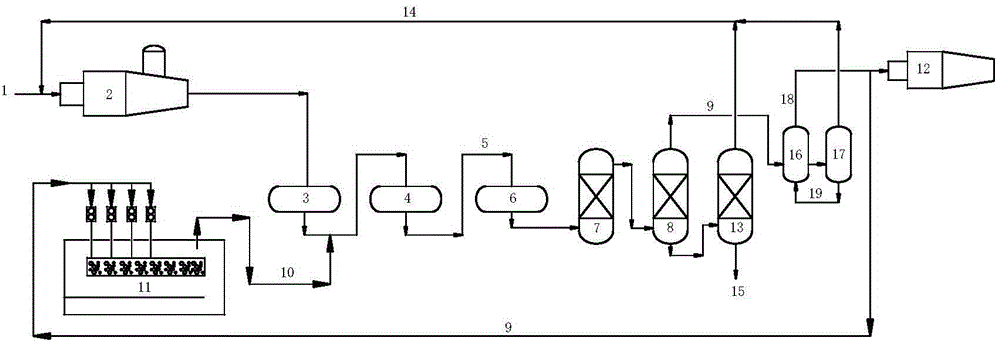

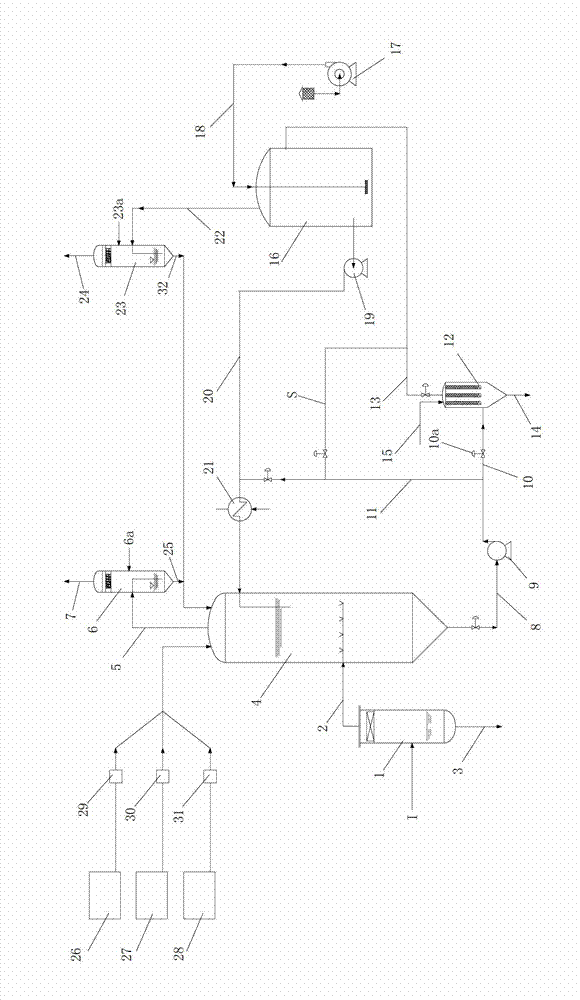

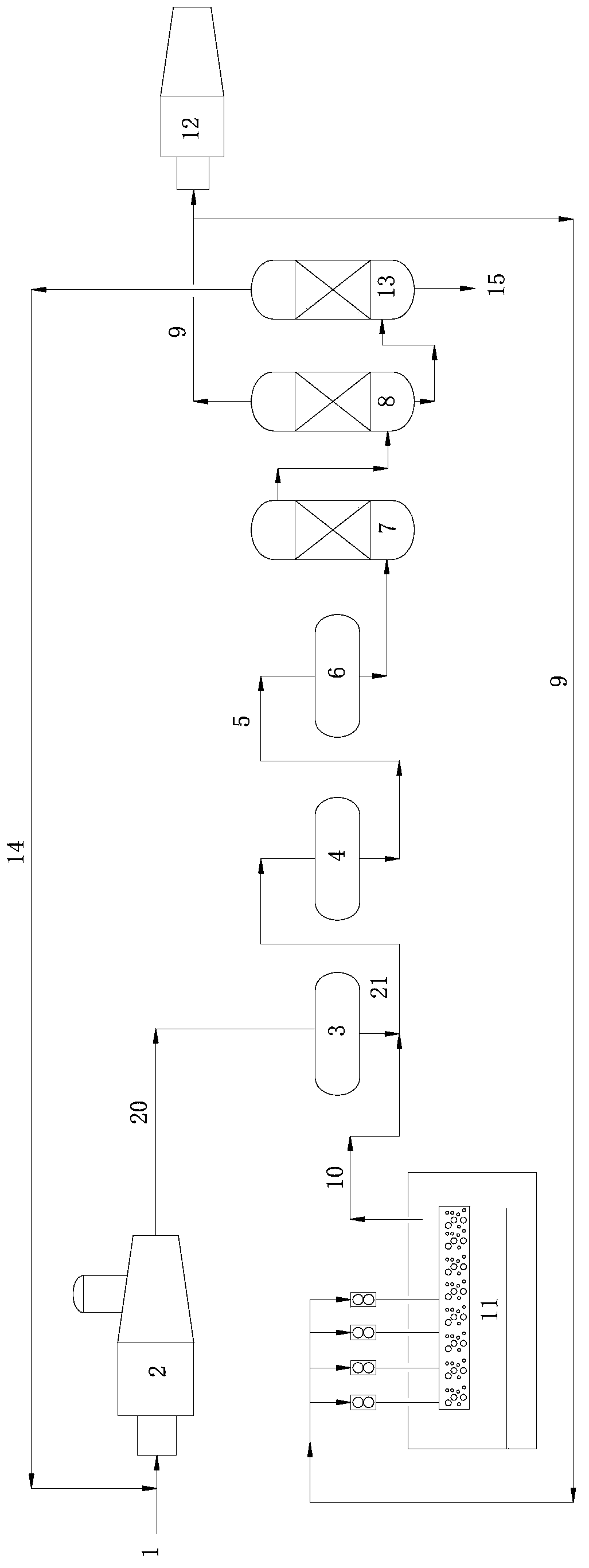

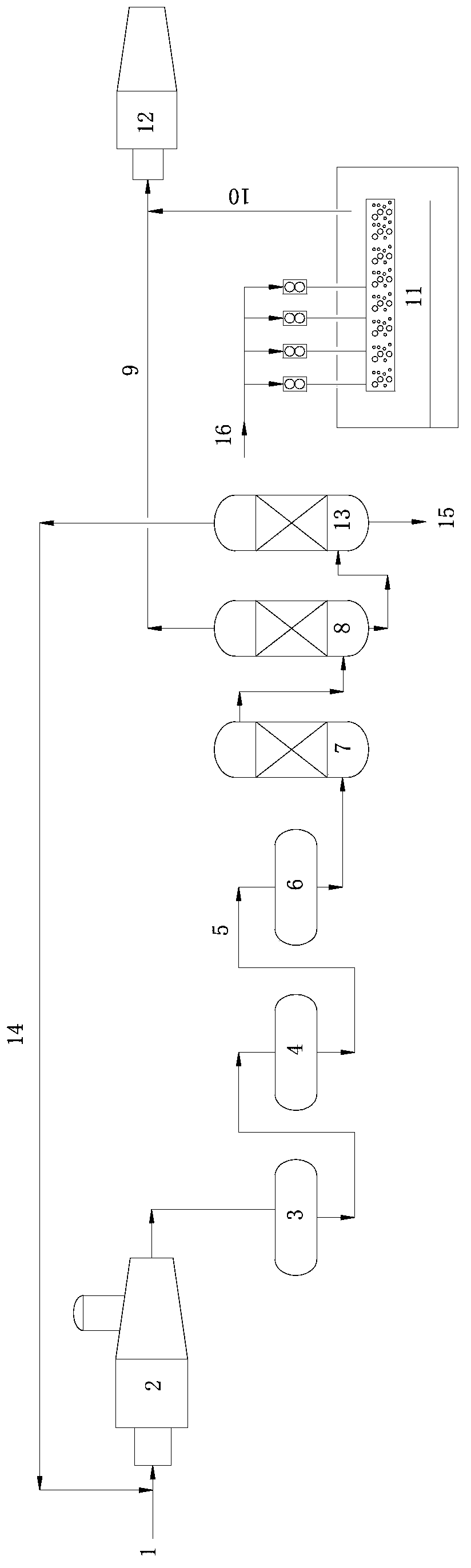

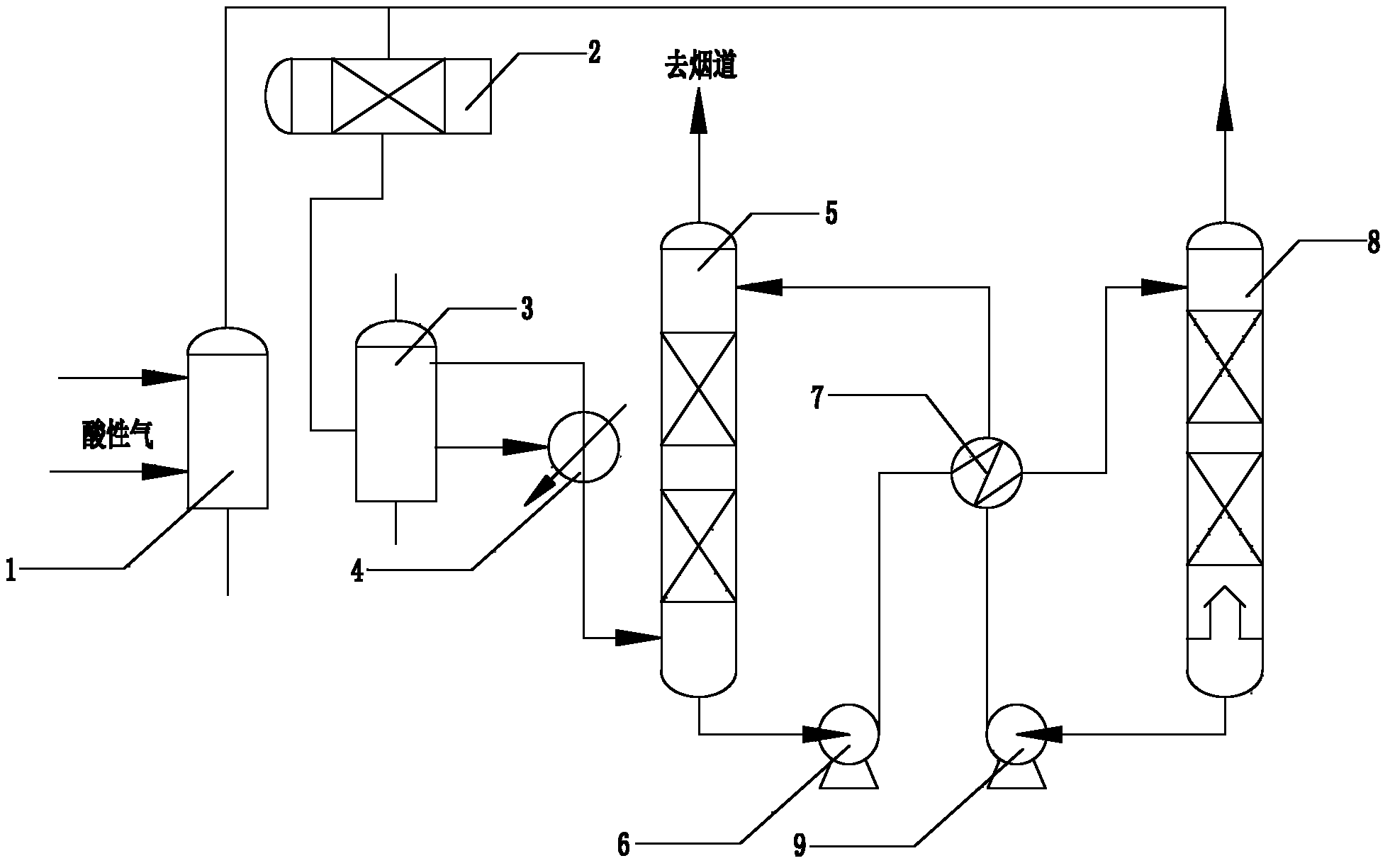

Low temperature methanol washing integrated Claus sulfur recovery system and process

ActiveCN101418246AFlexible processing capacityLow investment costProductsReagentsSulfurHydrogenation reaction

The invention relates to a reclaiming system and a process for low-temperature methanol washing integrated Claus sulfur of coal gas and natural gas. The system is additionally provided with a Claus tail gas washing tower and uses sulfur-free methanol saturated by CO2 from a CO2 product tower as a washing agent, and the washed liquid returns to an H2S concentrating tower; through combination of heating, gas stripping and pressure adjustment, concentration of H2S in acid gas washed by methanol is adjusted flexibly; at the same time, the system is additionally provided with a tail gas pre-heater before hydrogenation reaction to compensate heat loss of a hydrogenation reaction system. The process mainly comprises the following steps: removing H2S-CO2 gas, condensing H2S, reclaiming Claus sulfur, hydrogenising and reducing the gas, selectively absorbing and desulfurizing saturated cold methanol. The process has the advantages that the process can efficiently, flexibly, safely and energy-conservatively treat carbonyl gas with different pressures, temperatures, water content and sulfur concentration; and total sulfur reclamation ratio can reach more than 99.9 percent. The concentration of the H2S in emptied tail gas is below 25 mg / Nm3, so the H2S gas can meet the requirement of environmental protection, and can be exhausted directly without being burnt.

Owner:HUALU ENG & TECH

Absorbing liquid for eliminating sulfide from gas mixture

InactiveCN1421264AReduce processing stepsEconomical desulfurization methodDispersed particle separationSulfur preparation/purificationSulfolaneMorpholine

The present invention belongs to gas producing technology. The absorbing liquid for eliminating sulfide from gas mixture includes main absorbent comprising steric hindrance amine and N-methyl diethanolamine; cosolvent of one or several of sulfolane, N-methyl pyrrolidine, polyglycol dialkyl ether, morpholine and its derivative; catalyst of one or several of C2-C12 alkanolamine, piperazine and its derivative, quinoline, urea and metal phthalocyanine complex. Using the absorbing liquid can eliminate H2S, COS, mercaptan, thioether and other sulfide in less steps.

Owner:江苏蓝电环保股份有限公司

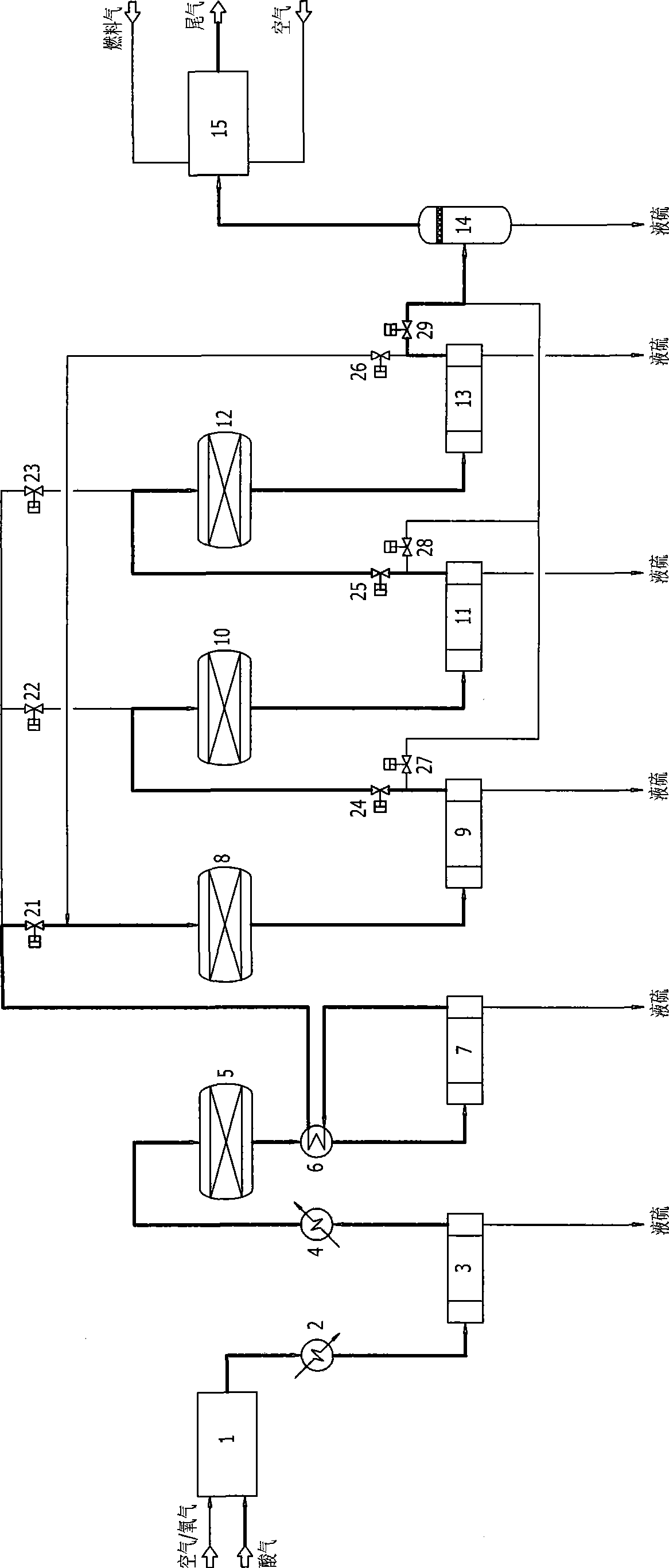

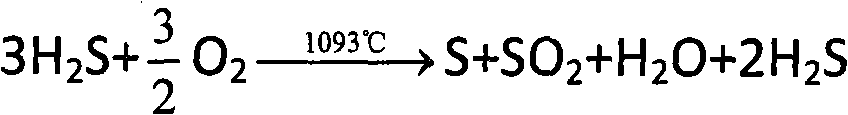

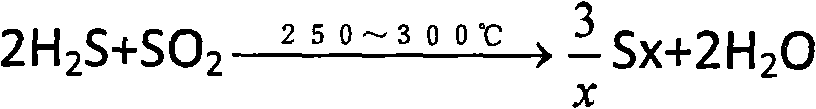

Method for recycling sulfur from acid gases containing hydrogen sulfide

InactiveCN101791517AReduce consumptionHigh purityDispersed particle separationEnergy inputCatalytic oxidationEmission standard

The invention relates to a method for recycling sulfur from acid gases containing hydrogen sulfide, comprising the following steps: (a) air supply; (b) acid gas pretreatment; (c) mixture; (d) primary direct catalytic oxidation; (e) primary sulfur condensation; (f) process gas reheating; (g) secondary direct catalytic oxidation; (h) secondary sulfur condensation; (i) sulfur re-separation; (j) degasification in a liquid sulfur tank; and (k) tail gas burning. When the volume concentration of H2S in the acid gases in the prior art is 1-15%, the recycle rate of sulfur can reach over 99% by the method of the invention, and the emission load of H2S in the acid gases processed by the method of the invention meets the emission requirement of Integrated Emission Standard of Air Pollutants (GB16297-1996).

Owner:北京至清时光环保工程技术有限公司

Selective Sulfur Removal Process

Owner:EXXON RES & ENG CO

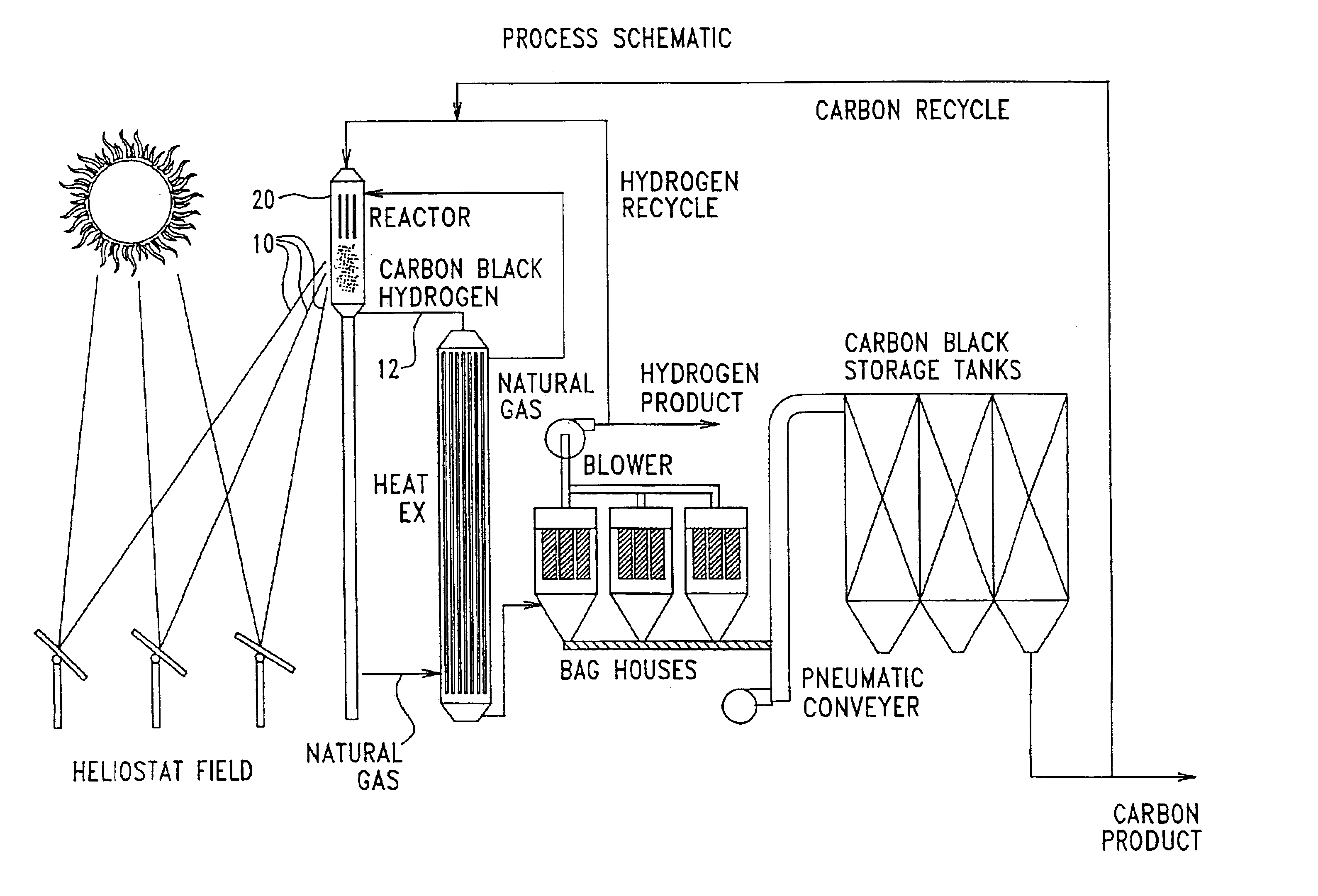

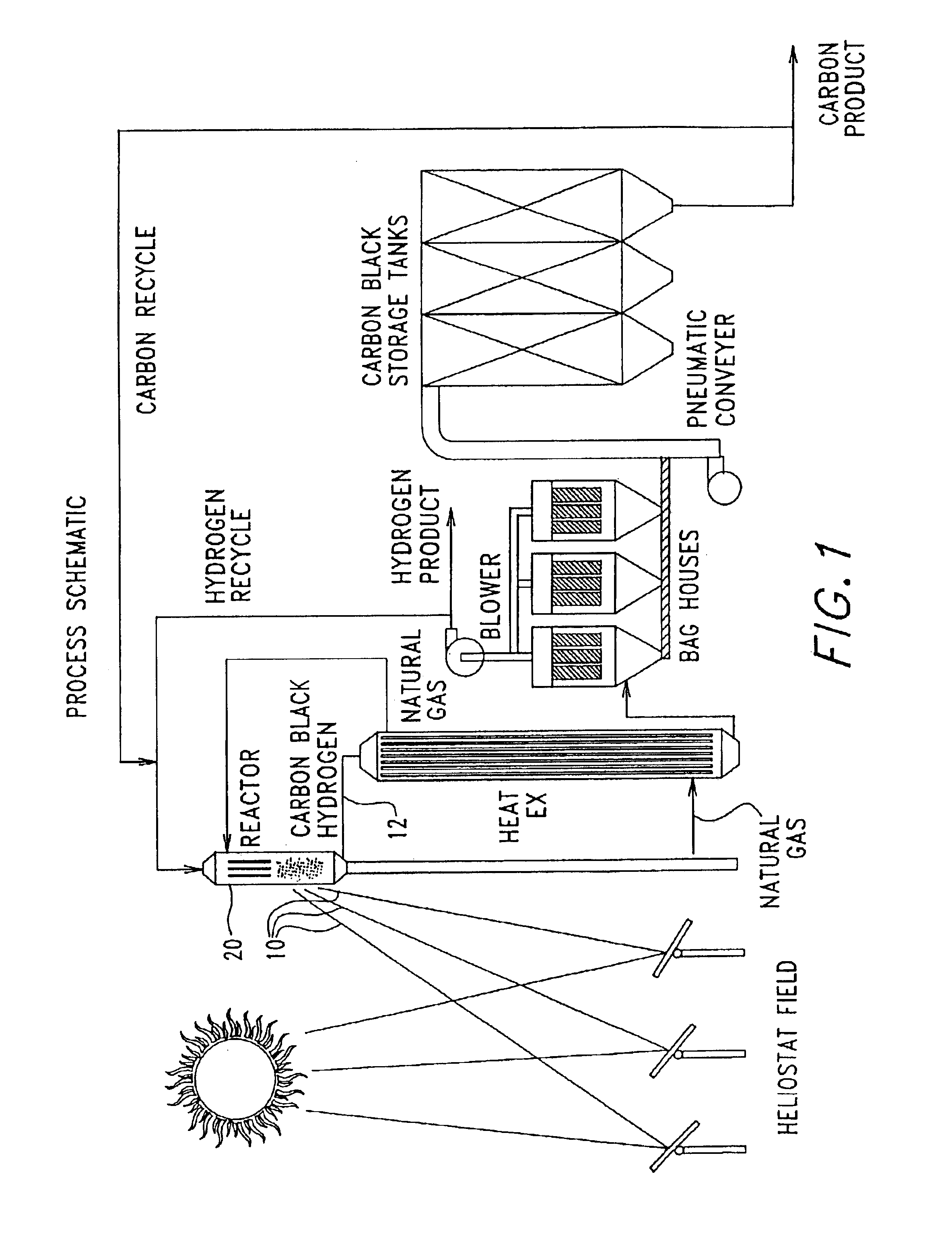

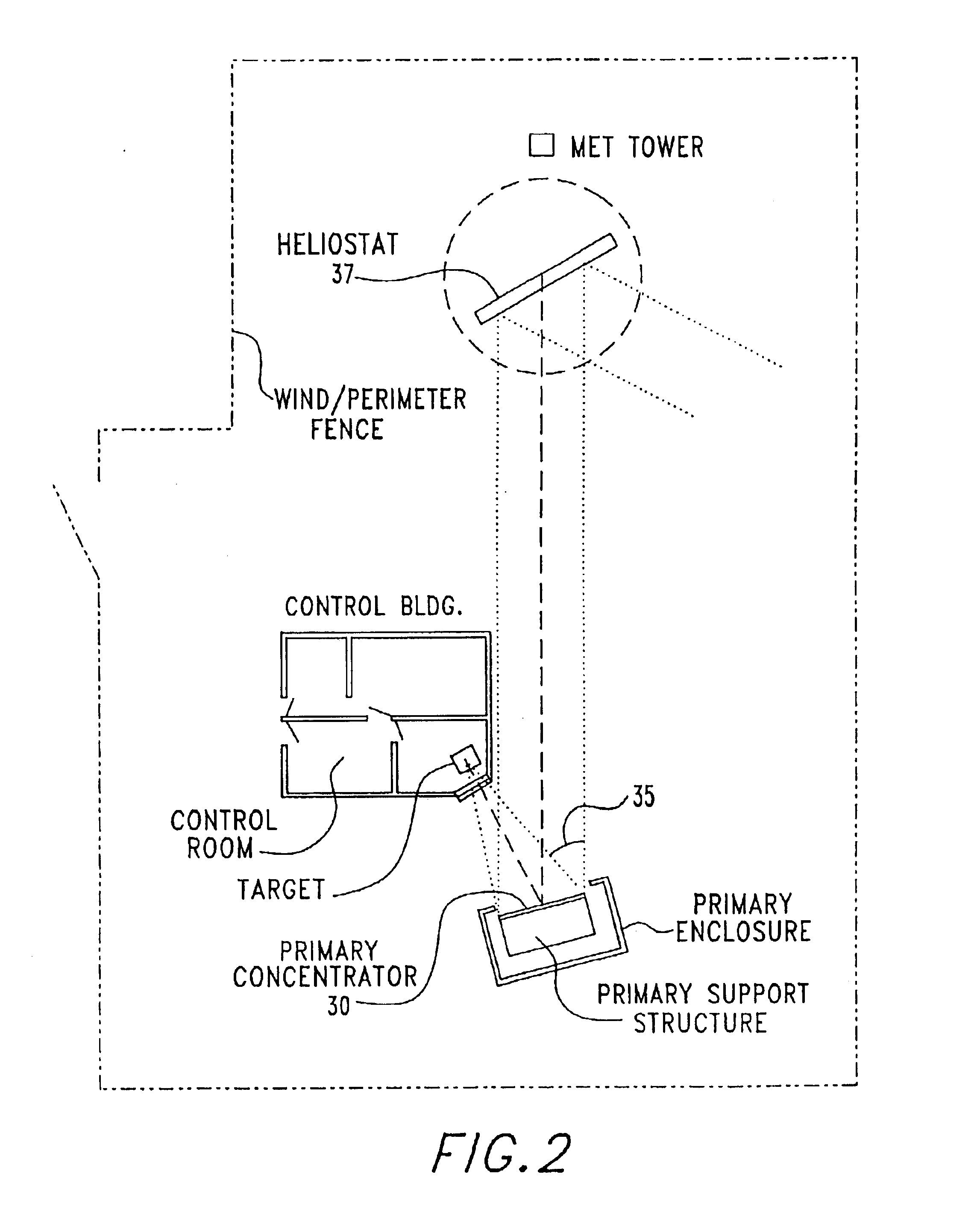

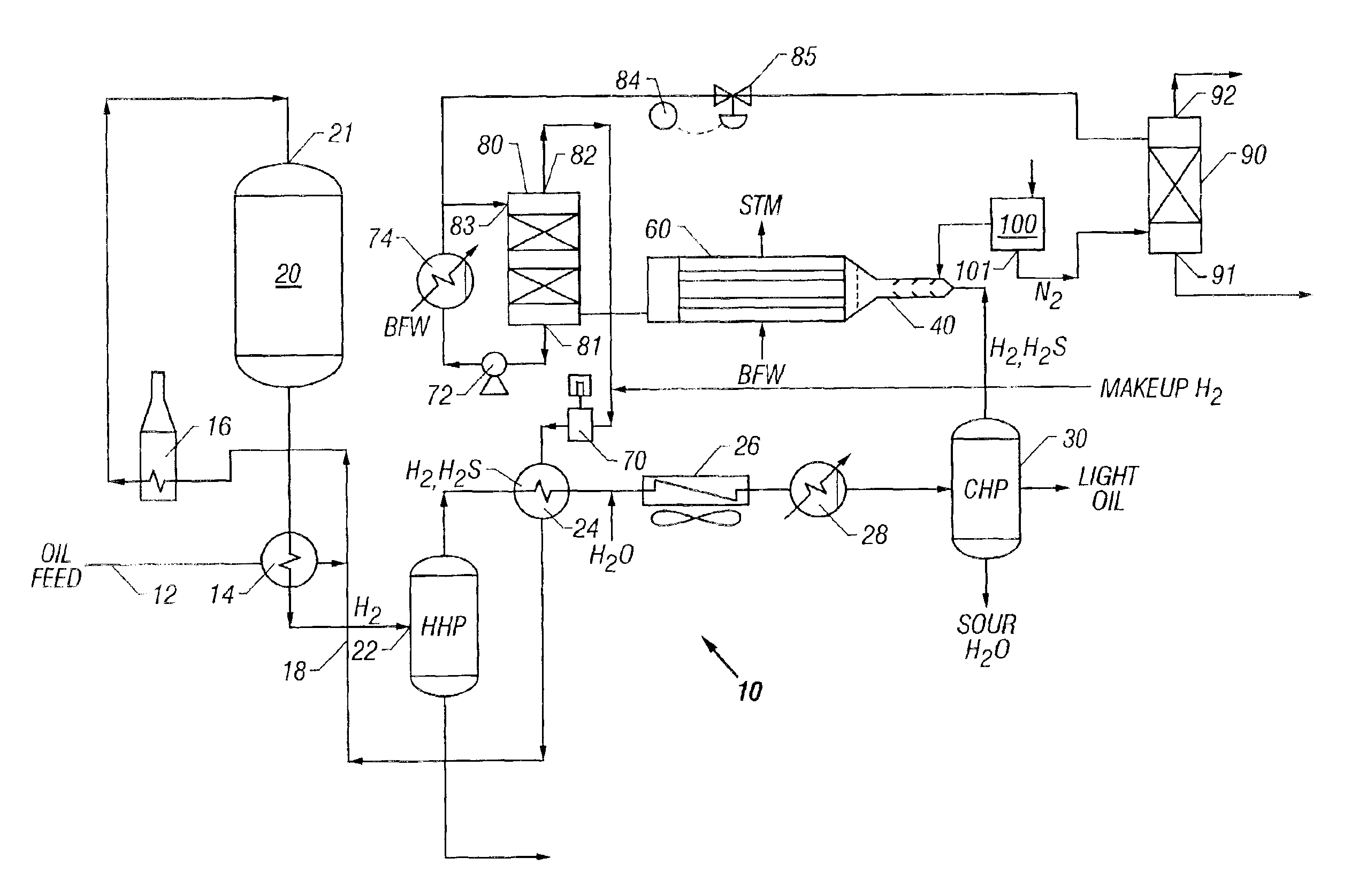

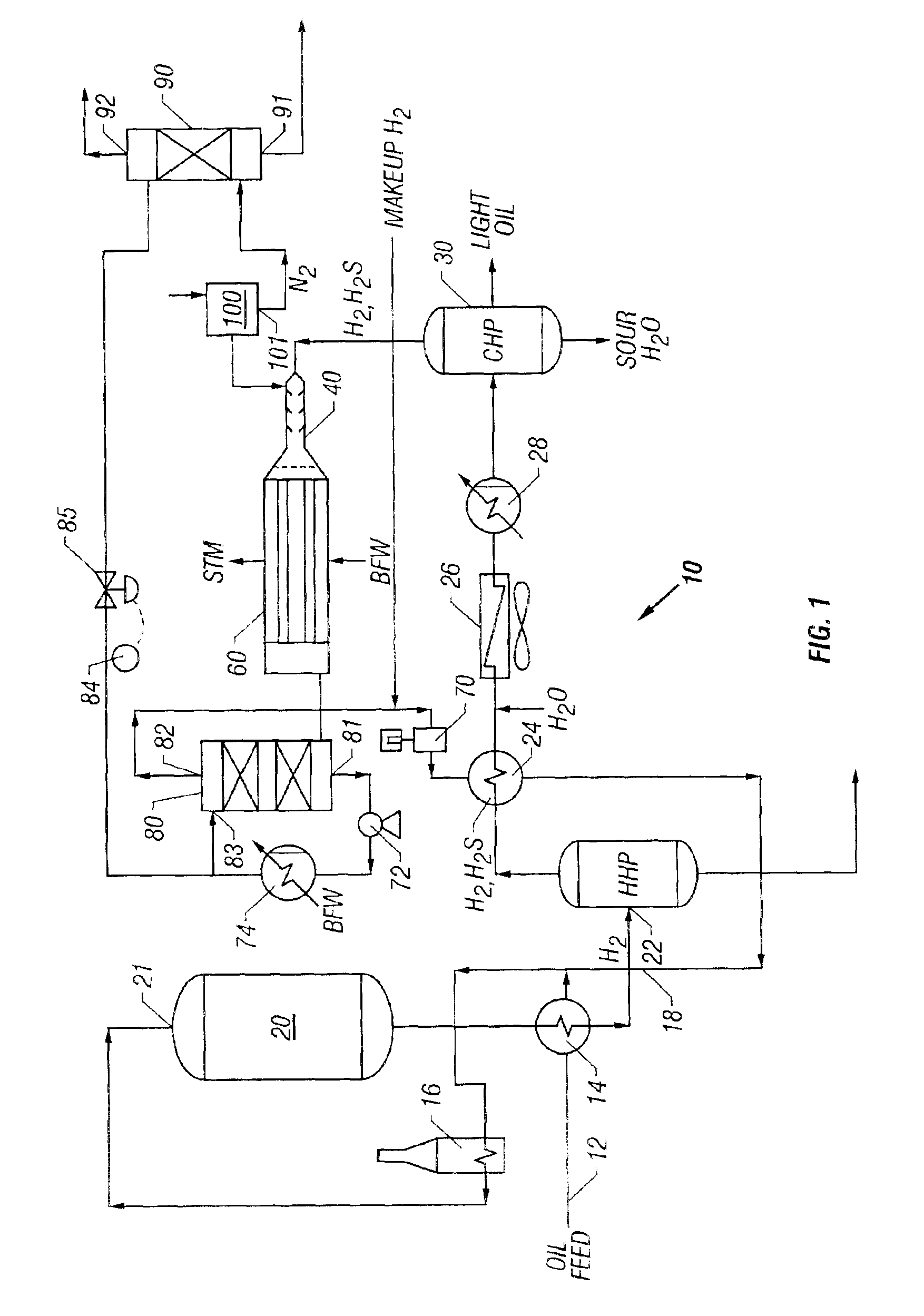

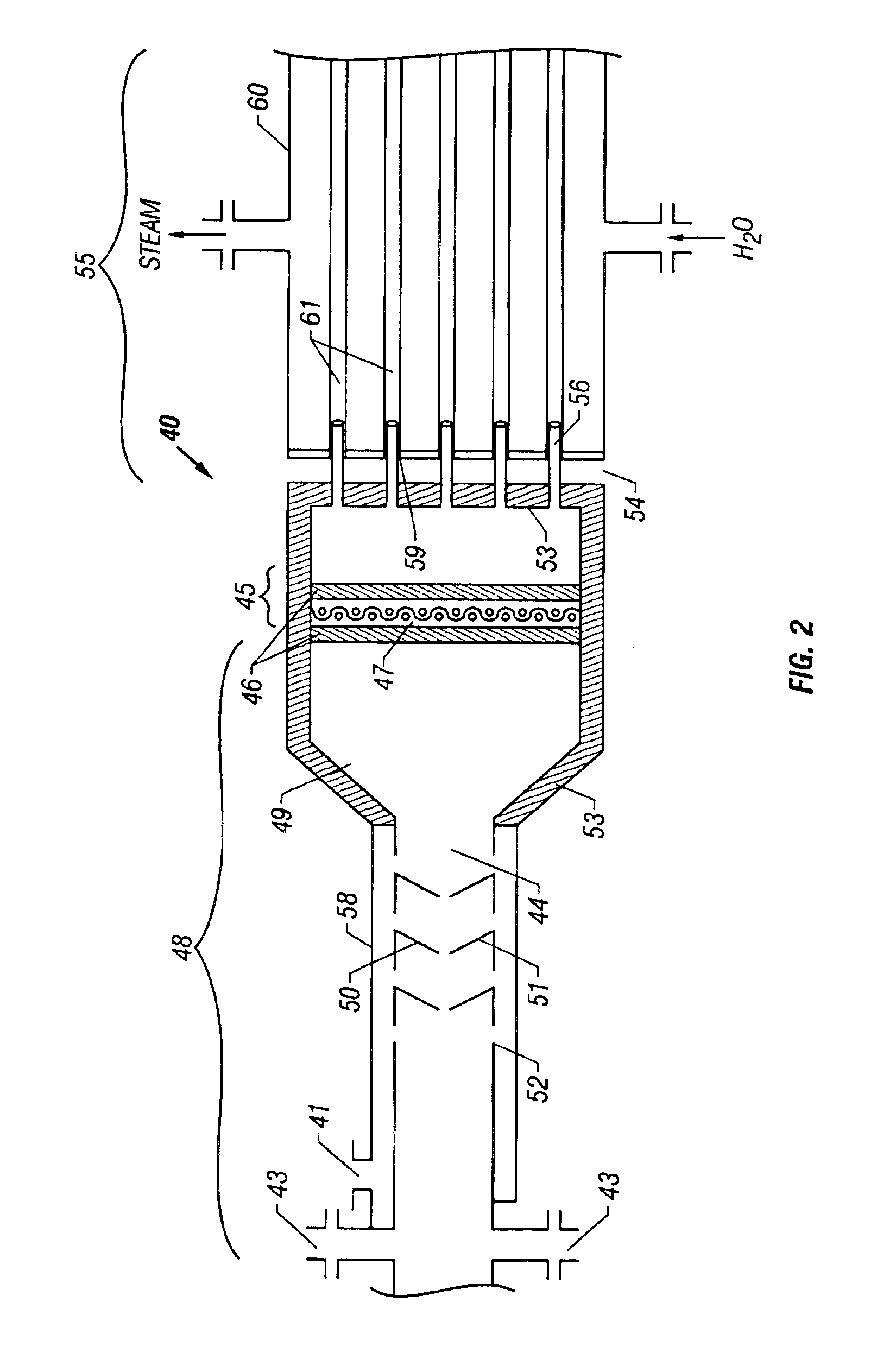

Solar thermal aerosol flow reaction process

InactiveUS6872378B2Short stayCost-effectiveSolar heating energyHydrocarbon from carbon oxidesForming gasChemical reaction

Owner:UNIV OF COLORADO THE REGENTS OF +1

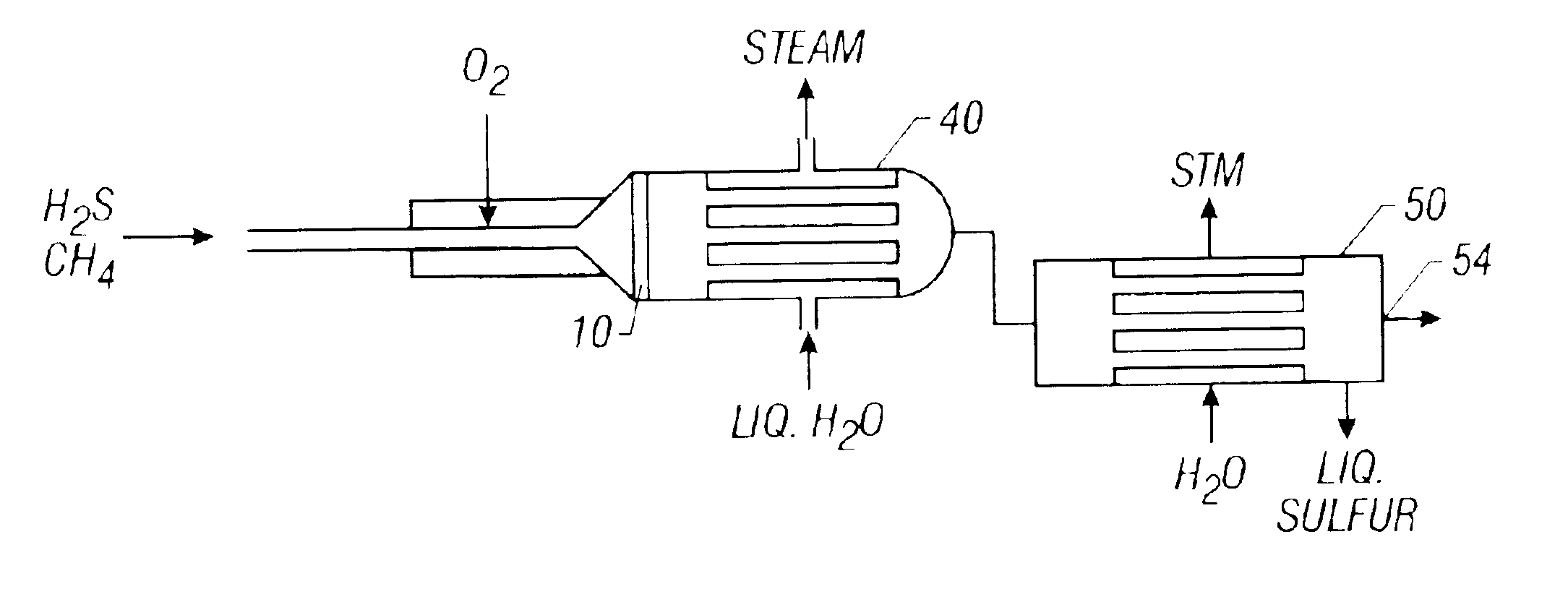

Short contact time catalytic partial oxidation process for recovering sulfur from an H2S containing gas stream

InactiveUS6946111B2Avoid contactExcess buildupHydrogenDispersed particle separationPartial oxidationSulfur

A process for removing sulfur from a H2S-containing gas stream is disclosed. A preferred embodiment of the process comprises incorporating a short contact time catalytic partial oxidation reactor, a cooling zone, and a condenser into a conventional refinery or gas plant process, such as a natural gas desulfurizer, a hydrotreater, coker or fluid catalytic cracker, in which sulfur removal is needed in order to produce a more desirable product. An H2S-containing gas stream is fed into a short contact time reactor where the H2S is partially oxidized over a suitable catalyst in the presence of O2 to elemental sulfur and water.

Owner:PHILLIPS 66 CO

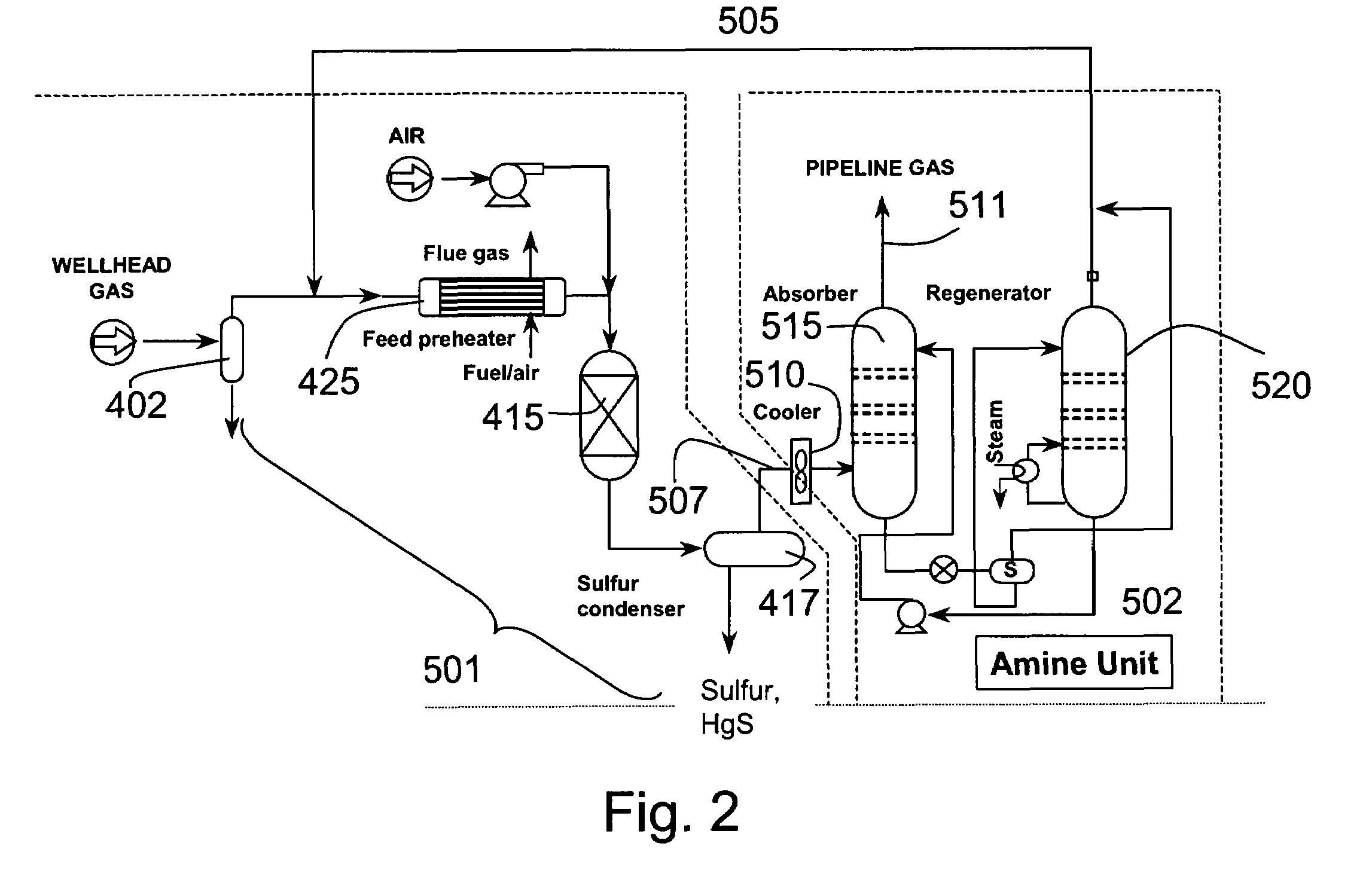

Production of low sulfer syngas from natural gas with C4+/C5+ hydrocarbon recovery

Sour natural gas is processed to remove the sulfur compounds and recover C4+ / C5+ hydrocarbons by scrubbing the gas with an amine solution to remove most of the sulfur, followed cooling the gas to remove C4+ / C5+ hydrocarbons and more sulfur compounds as liquid condensate to produce a gas having less than 20 vppm of total sulfur. The condensate is sent to a fractionator to recover the C4+C5+ hydrocarbons. The sulfur and hydrocarbon reduced gas is contacted first with zinc oxide and then nickel, to produce a gas having less than 10 vppb of total sulfur which is passed into a synthesis gas generating unit to form a very low sulfur synthesis gas comprising a mixture of H2 and CO. This synthesis gas is useful for hydrocarbon synthesis with increased life of the hydrocarbon synthesis catalyst and greater hydrocarbon production from the hydrocarbon synthesis reactor. Contacting the synthesis gas with zinc oxide further reduces the sulfur content to below 3 vppb.

Owner:EXXON RES & ENG CO

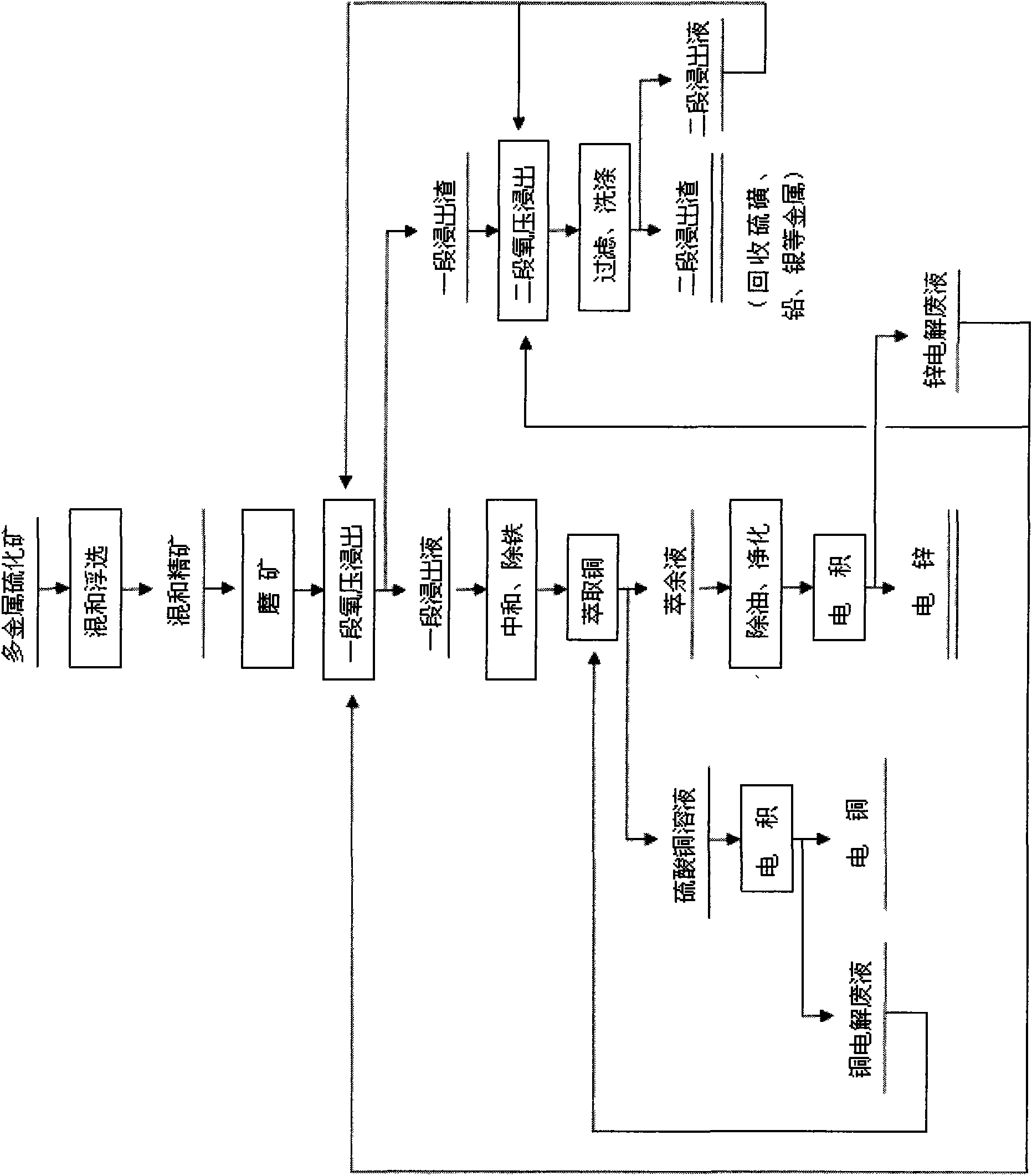

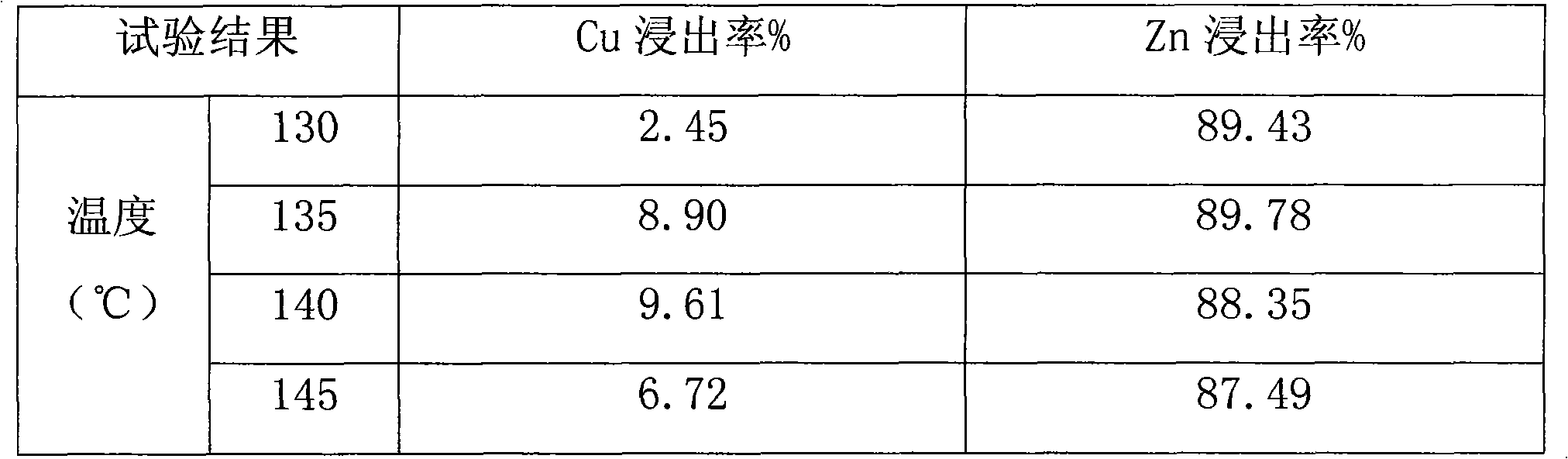

Comprehensive recovery method of complex polymetal sulphide ore containing copper, lead and zinc

InactiveCN101643857AHigh recovery rateSimple processSulfur preparation/purificationFlotationRecovery methodLead smelting

The invention discloses a comprehensive recovery method of complex polymetal sulphide ore containing copper, lead and zinc and adopts dressing-metallurgy combination method and hydrometallurgy-pyrometallurgy combination method to recover metals. The recovery method comprises the following steps: first performing bulk flotation to the complex polymetal sulphide ore, fine grinding the obtained concentrate, leaching by using two-step counter flow oxygen pressure leaching process, extracting and separating copper and zinc from the obtained leachate, electrodepositing the strip liquor of copper-loaded organic phase to obtain cathode copper, cleaning the obtained raffinate and electrodepositing to obtain cathode zinc; pressurizing leaching residue to perform flotation separation and obtain sulfur concentrate and lead silver residue, distilling sulfur concentrate to obtain sulfur; performing lead smelting process to lead silver residue to obtain electrolytic lead product and lead anodic slime; and comprehensively recovering noble metals such as gold, silver and the like from lead anodic slime. The method can greatly improve the metal recovery rate, resource utilization and the economic efficiency of mines and generate a lot of sulfur so as to obviously reduce the sulfur dioxide pollution to the atmosphere.

Owner:WESTERN MINING CO LTD

Methods of using modified natural products as dewatering aids for fine particles

InactiveUS6375853B1Reduce moistureHigh degreeDrying solid materials without heatSolid fuelsNatural productTransesterification

Naturally occurring lipids of vegetable and animal origin are broken into smaller molecules, and used as dewatering aids. The process of breaking the molecules include transesterification, interesterification, and saponification followed by acidulation. The modified lipid molecules can adsorb on the surface of the particles to be dewatered and greatly enhance their hydrophobicity, which will help increase the rate of dewatering and hence reduce cake moisture. The modified lipids are more effective dewatering aids than the naturally occurring unmodified lipids, possibly because they can more readily form close-packed monolayers of hydrophobes on the surface of the particles.

Owner:YOON ROE HOAN

Catalyst for decomposing hydrogen sulfide by photocatalysis and preparation method of hydrogen and liquid sulfur by employing same

ActiveCN101590410ARealize comprehensive utilizationHigh activityDispersed particle separationSulfur preparation/purificationAlkaline earth metalVanadate

The invention relates to a catalyst for decomposing hydrogen sulfide by photocatalysis and a preparation method of hydrogen and liquid sulfur by employing same. The catalyst comprises a carrier, active component and assistant and has the characteristics that the carrier is one or more selected from vanadate, niobate and tantalate, the active component is one or more selected from alkali metal hydroxide, alkaline earth metal hydroxide, alkali metal nonmetal oxysalt, alkali metal nonoxysalt, alkaline earth metal nonmetal oxysalt and alkaline earth metal nonoxysalt and the assistant is lanthanide oxide or VIII group oxide. The catalyst of the invention can be used for preparing hydrogen and liquid sulfur so that the produced sulfur is easy to be separated from the catalyst, the catalyst can be recycled and the sulfur contained in hydrogen sulfide can be fully recycled, thus realizing the comprehensive utilization of hydrogen sulfide.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

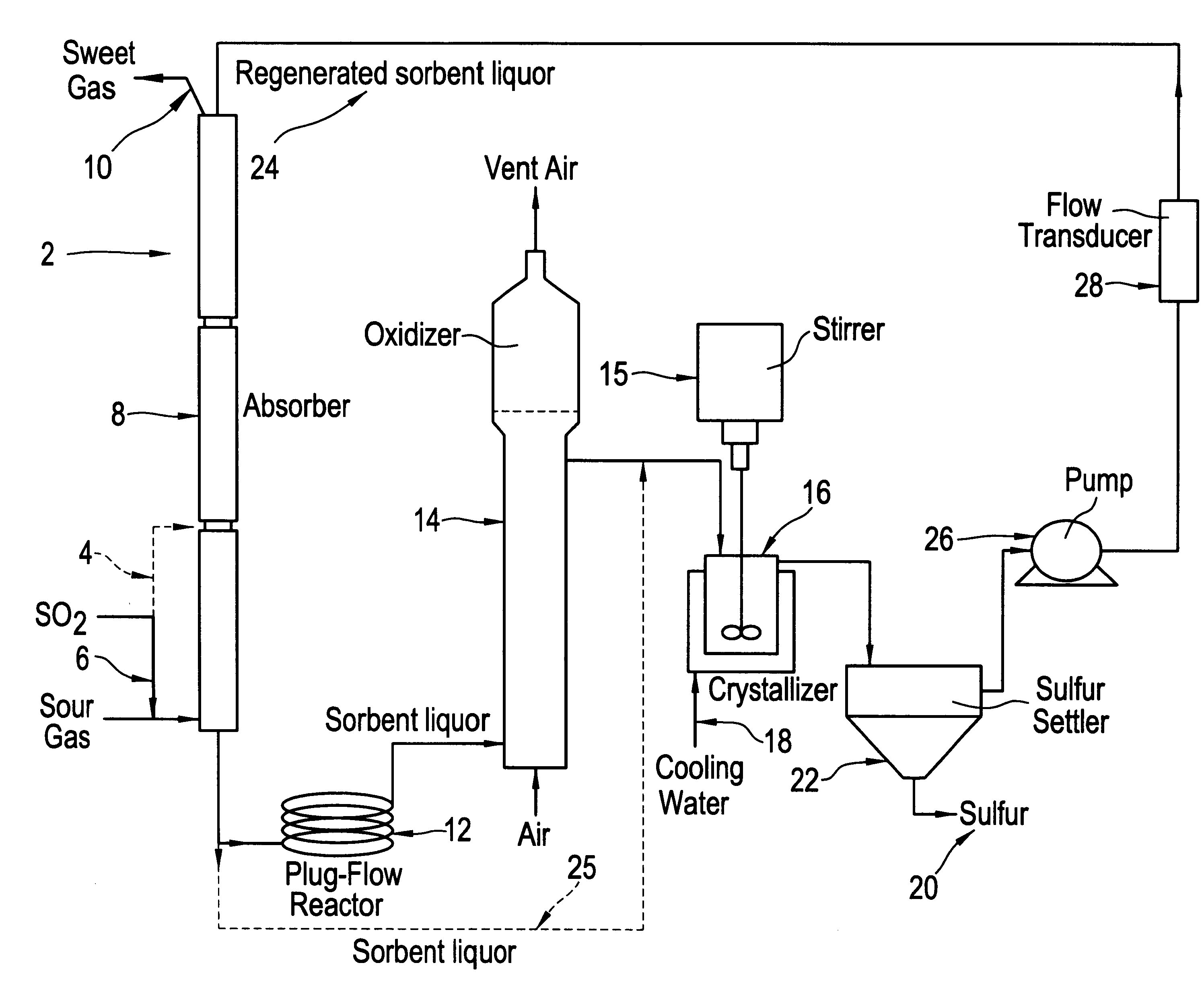

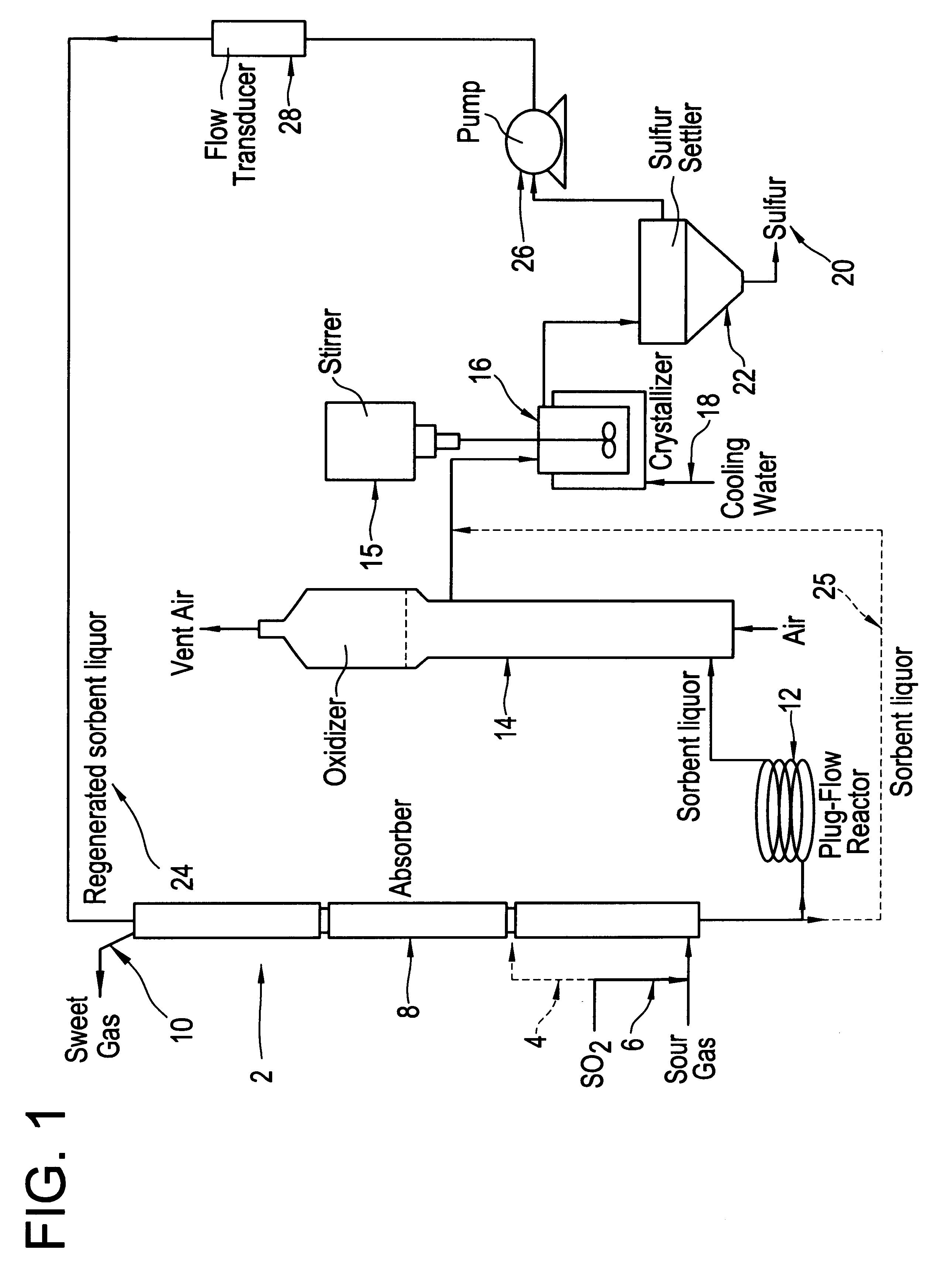

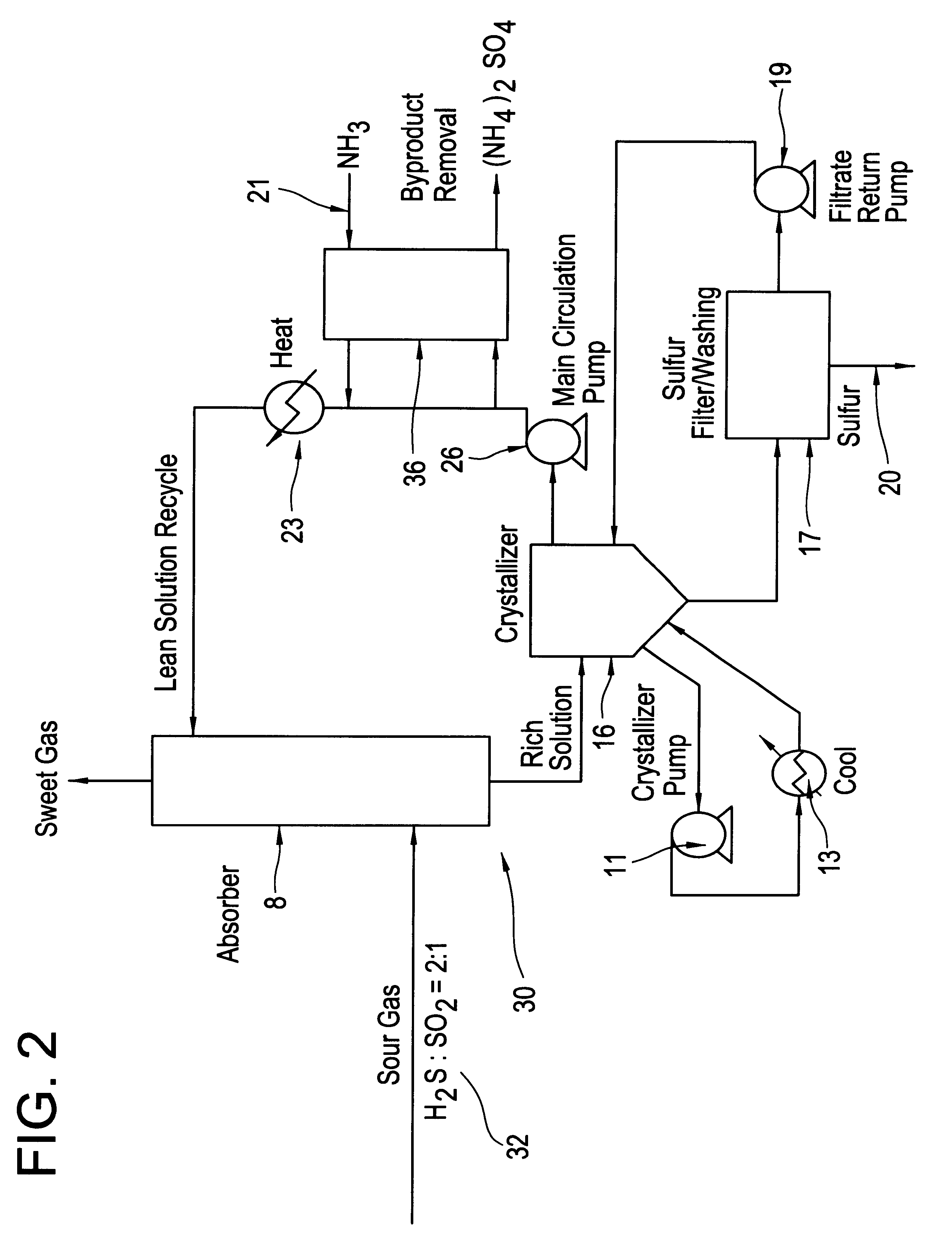

Process for removing hydrogen sulfide from gas streams which include or are supplemented with sulfur dioxide

InactiveUS6416729B1Good removal effectReduce degradationDispersed particle separationSulfur preparation/purificationOrganic solventSorbent

In a known process and system wherein hydrogen sulfide is removed from a gaseous stream, using a non-aqueous scrubbing liquor which can be an organic solvent for elemental sulfur such as a phenylxylyl ethane in which are dissolved sulfur and a reaction-promoting amine base such as a tertiary amine, sulfur dioxide is added to the sulfur-amine nonaqueous sorbent (or advantage is taken of SO2 which may already be present in the gas stream) to obtain better H2S removal, lower chemical degradation rates, and lower rates of formation of byproduct sulfur salts such as sulfates.

Owner:URS

Low temperature Claus sulfur recovery process and device therefor

InactiveCN101519192AAchieve regenerationImprove conversion rateEnergy inputSulfur preparation/purificationReaction temperatureOxygen

Owner:CHENGDU SEPMEM SCI & TECH

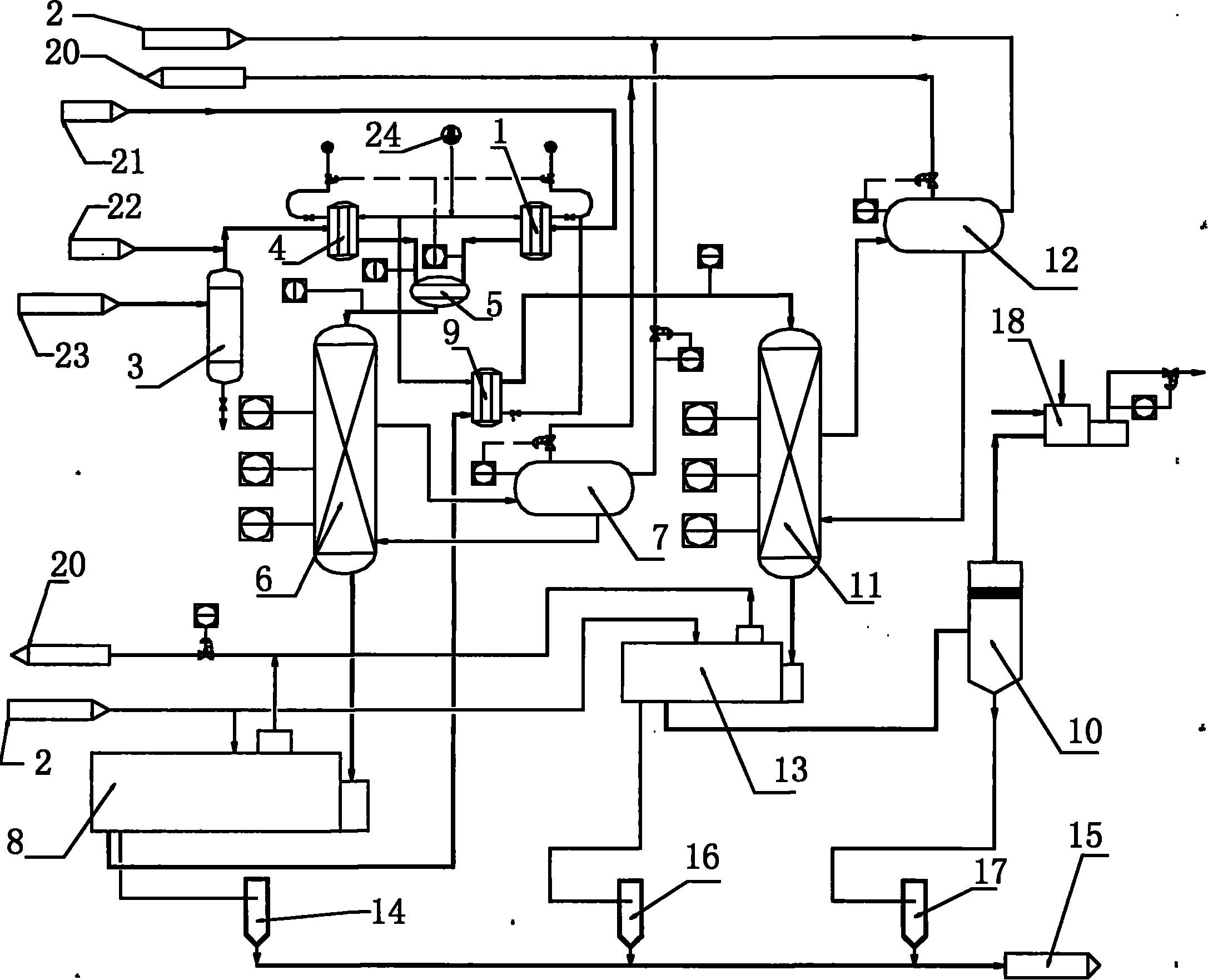

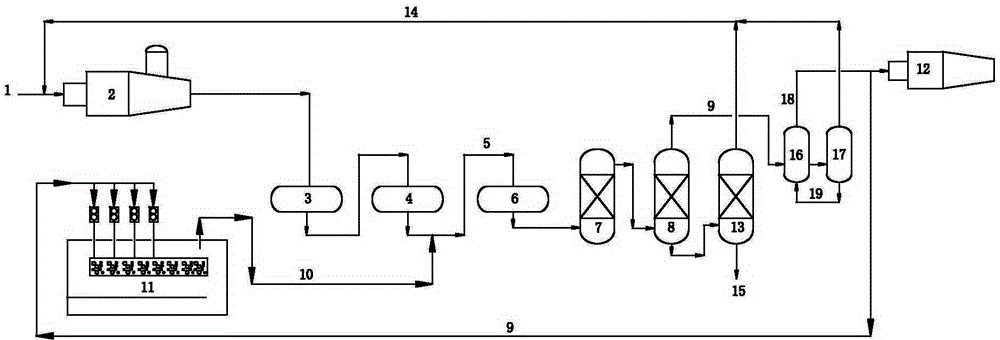

Catalyst combination process of sulfur recovering device

ActiveCN101659400AMeet the requirements of total sulfur recoveryAchieve complete hydrolysisPhysical/chemical process catalystsSulfur preparation/purificationCombustionSulfur

The invention relates to a catalyst combination process of a sulfur recovering device, belonging to the technical field of sulfur recovery, and comprising a combustion furnace, a primary clotz reactorand a secondary clotz reactor connected in series with each other. The catalyst combination process is characterized in that: behind the secondary clotz reactor, a selective hydrogenation reduction reactor, a selective oxidation reactor and two absorption desulfurizing towers connected in parallel are connected in series; a deoxygenation protection-type sulfur recovery catalyst is filled in the upper part of the primary clotz reactor, and a TiO2 sulfur recovery catalyst is filled in the lower part; an auxiliary agent type sulfur recovery catalyst is filled in the secondary clotz reactor; a SO2 selective reduction catalyst is filled in the selective hydrogenation reduction reactor and selectively reduces the SO2 into elemental sulfur; H2S selective oxidation catalyst is filled in the selective oxidation reactor and selectively oxidizes the H2S into elemental sulfur. In the invention, the recovery rate of sulfur is high, and the tail gas after desulfuration can completely reach the national discharge requirement of GB16297-1996.

Owner:山东迅达化工集团有限公司

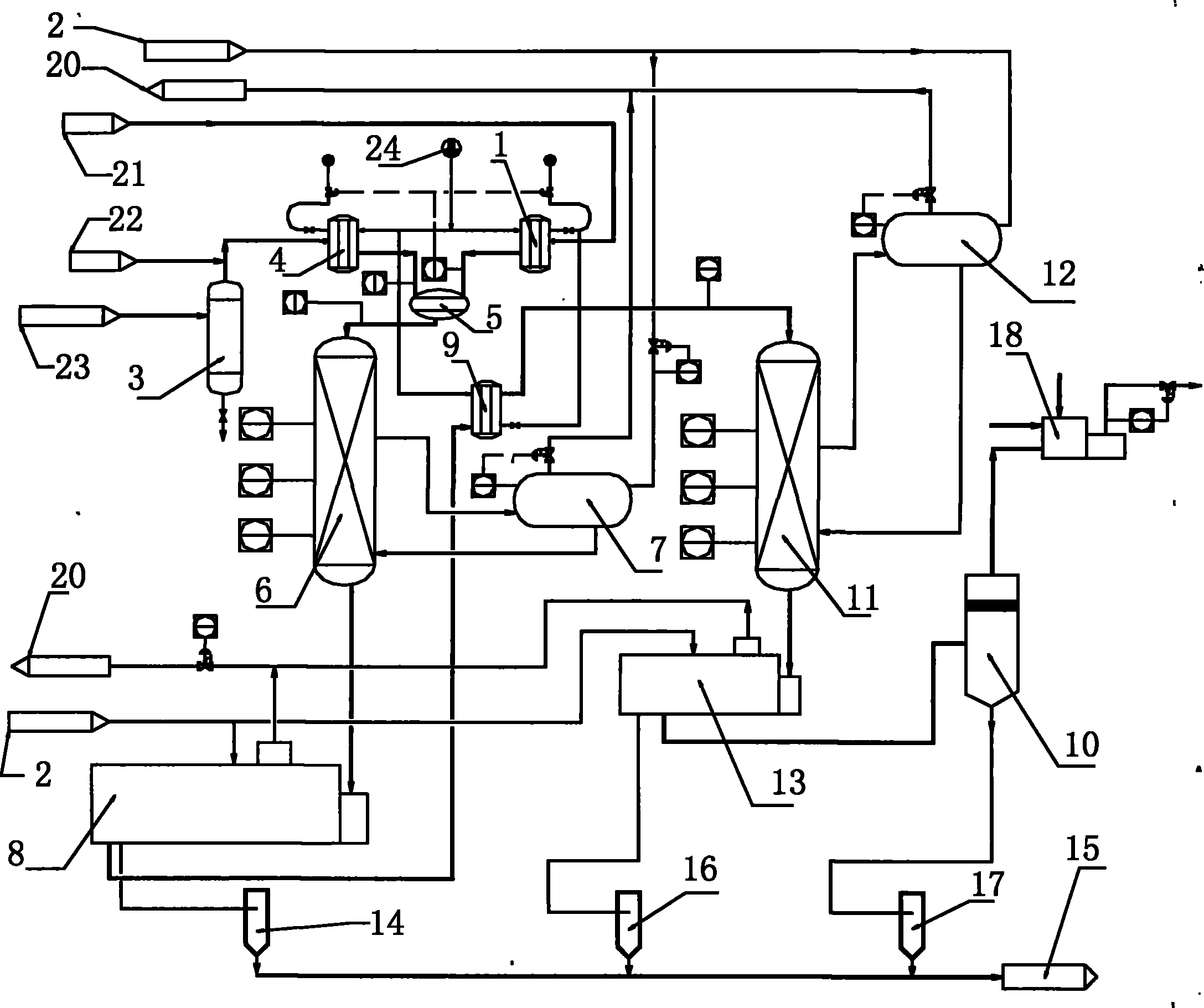

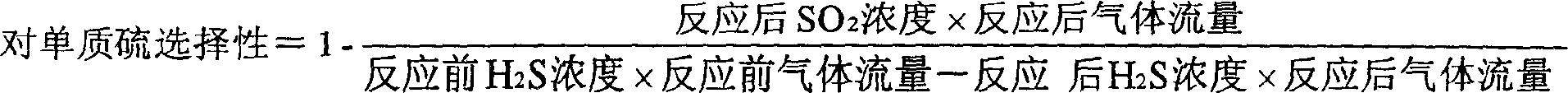

Sulfur recovery process for reducing SO2 emission

ActiveCN104555940APromote absorptionWith savingsDispersed particle separationSulfur preparation/purificationFlue gasSulfur

The invention belongs to the technical field of sulfur recovery, and particularly relates to a sulfur recovery process for reducing SO2 emission. According to the sulfur recovery process, a thermal reaction unit, a catalytic reaction unit and a tail gas purification unit are utilized; based on the traditional Claus and SCOT tail gas treatment process, an ammonia water absorption tank is additionally arranged for removing H2S from purified tail gas, so as to ensure that the H2S content in the purified tail gas is lower than 5 mg / m<3>; waste ammonia water is sent to a sewage stripping unit for treating; through the adoption of the sewage stripping device, H2S and ammonia can be respectively extracted; the extracted H2S is returned to a sulfur recovery device for sulfur recovery, and the extracted ammonia is returned to the ammonia water absorption tank for cyclic utilization; finally, the flue-gas SO2 emission concentration for the sulfur recovery device can be reduced below 100 mg / m<3>, the new environmental protection standard to be executed is satisfied, and a novel method for building a new sulfur recovery device with a small investment and low operating cost is provided. The sulfur recovery process is excellent in absorption effect, simple to operate, low in expense, environment-friendly, and economical.

Owner:CHINA PETROLEUM & CHEM CORP

High pressure and high temperature production of diamonds

InactiveUS7241434B2Good colorDecrease cracking and breakageEdge grinding machinesUltra-high pressure processesNitrogenGraphite

The present invention is directed to a method for treating discolored natural diamond, especially Type IIa diamond and Type IaA / B diamond with nitrogen as predominantly B centers, for improving its color. The method includes preblocking and preshaping a discolored natural diamond to prevent its breakage in a high pressure / high temperature (HP / HT) press, placing said discolored natural diamond in a pressure transmitting medium which is consolidated into a pill. Next, the pill is placed into a HP / HT press at elevated pressure and elevated temperature within the graphite-stable or diamond-stable range of the carbon phase diagram for a time sufficient to improve the color of said diamond. Finally, the diamond is recovered from said press. Colorless and fancy colored diamonds can be made by this method.

Owner:BELLATAIRE INT

Short contact time catalytic sulfur recovery system for removing H2S from a waste gas stream

Owner:PHILLIPS 66 CO

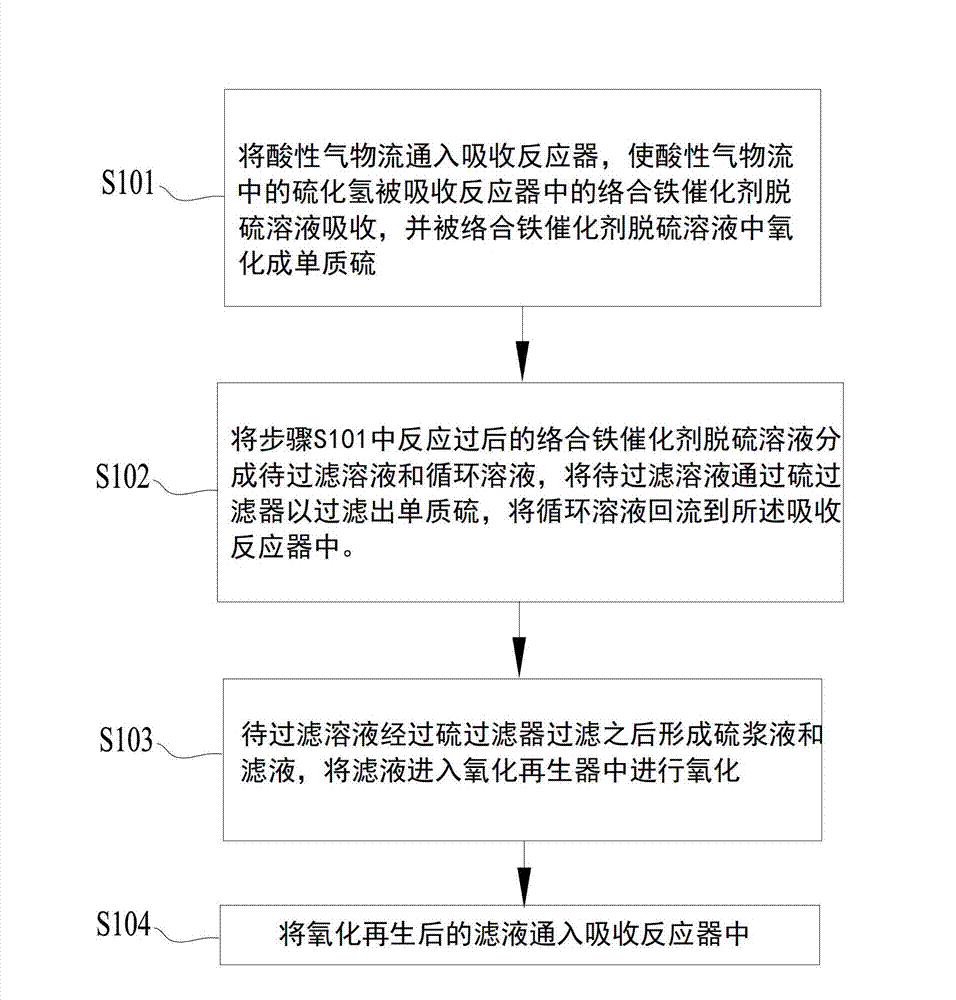

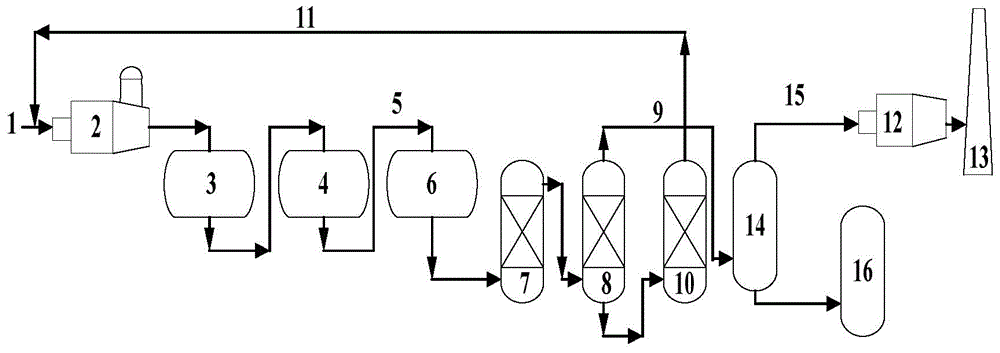

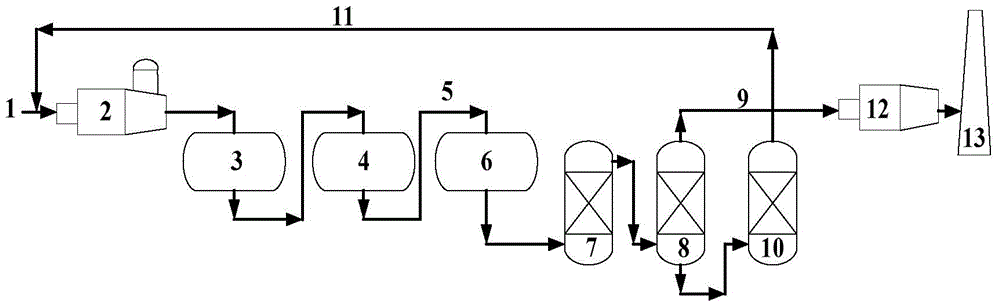

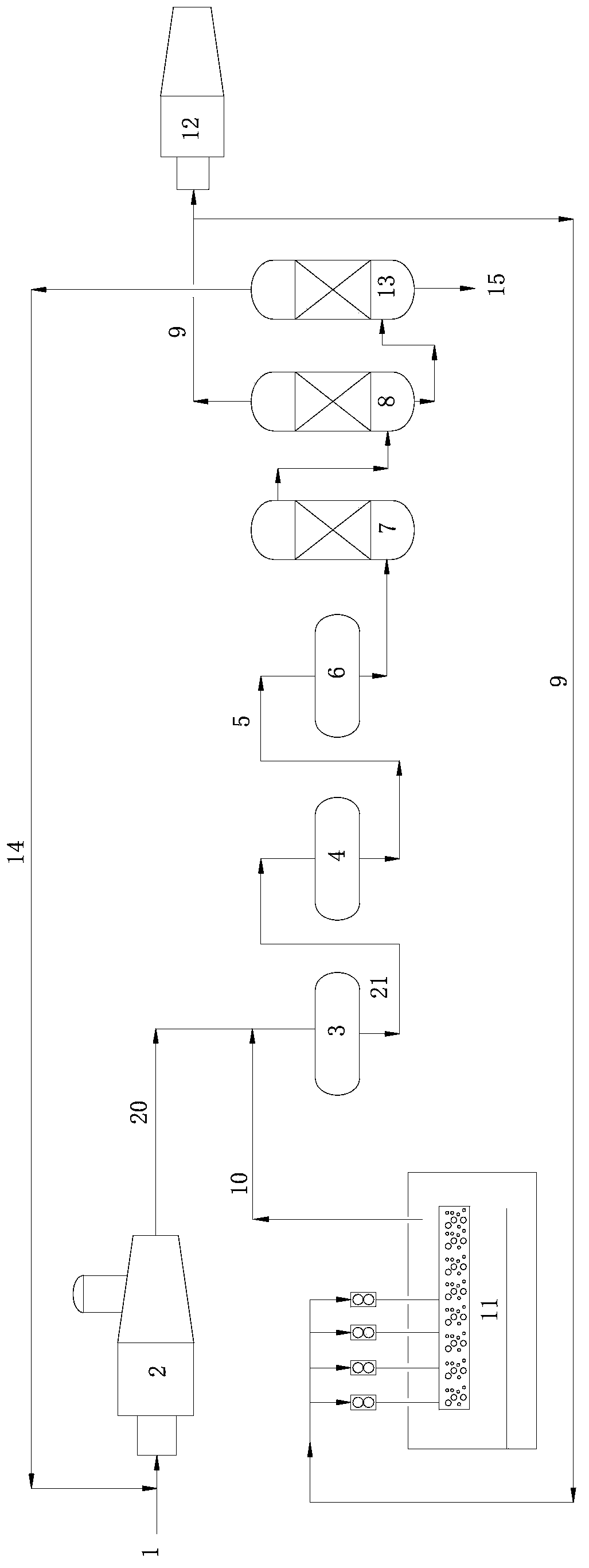

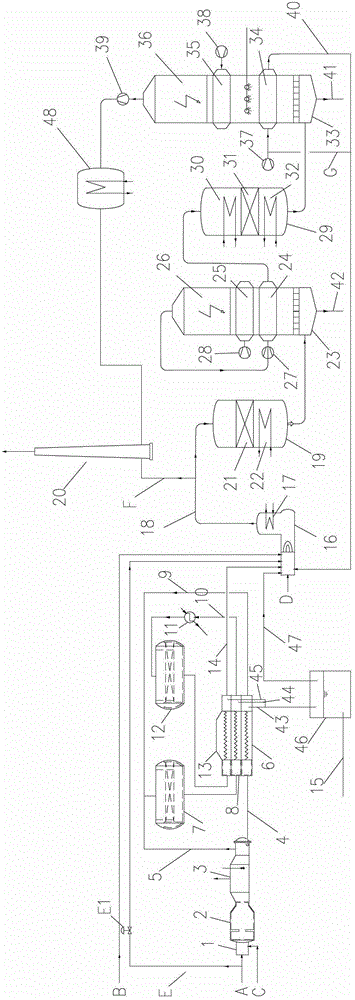

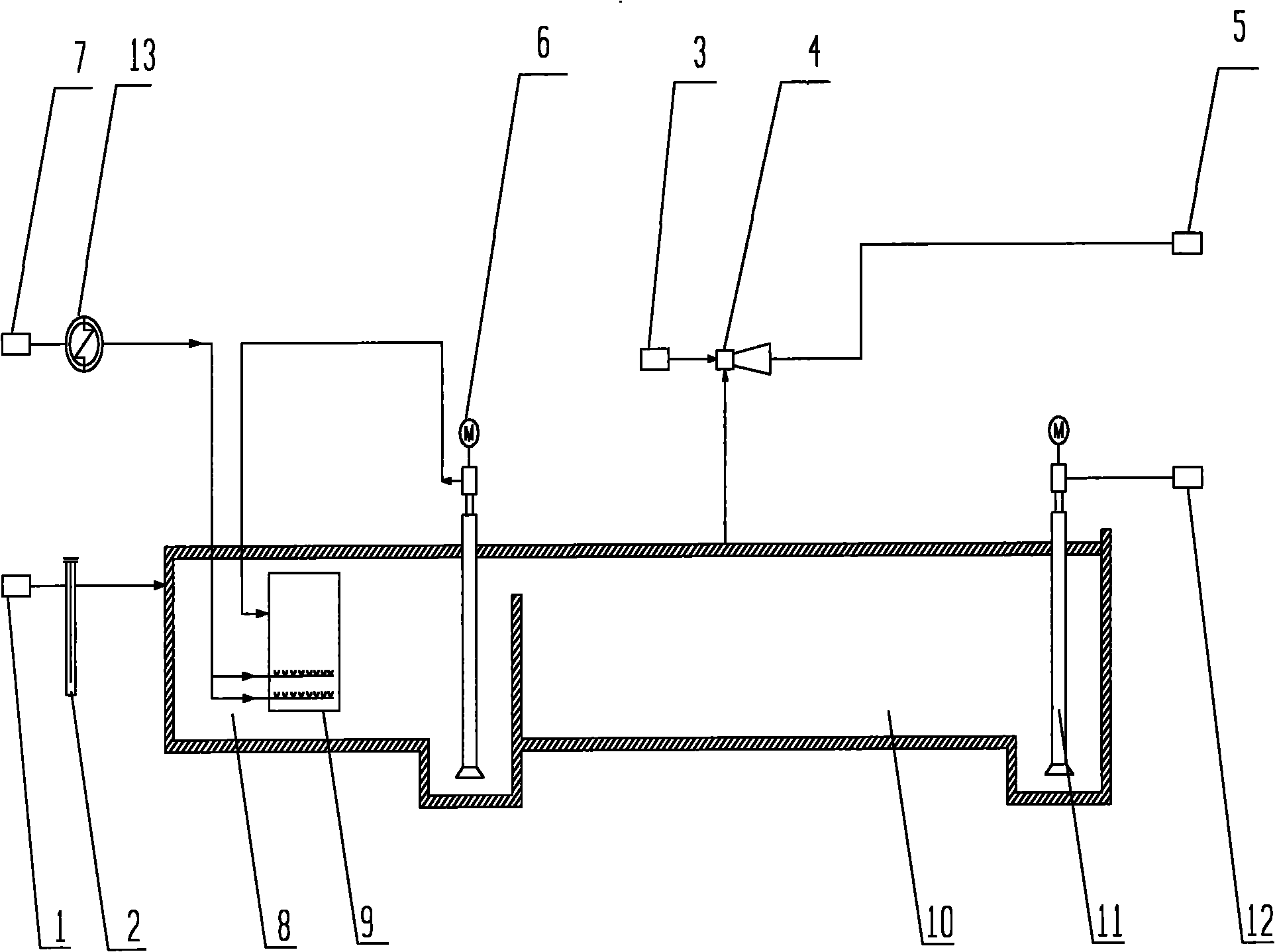

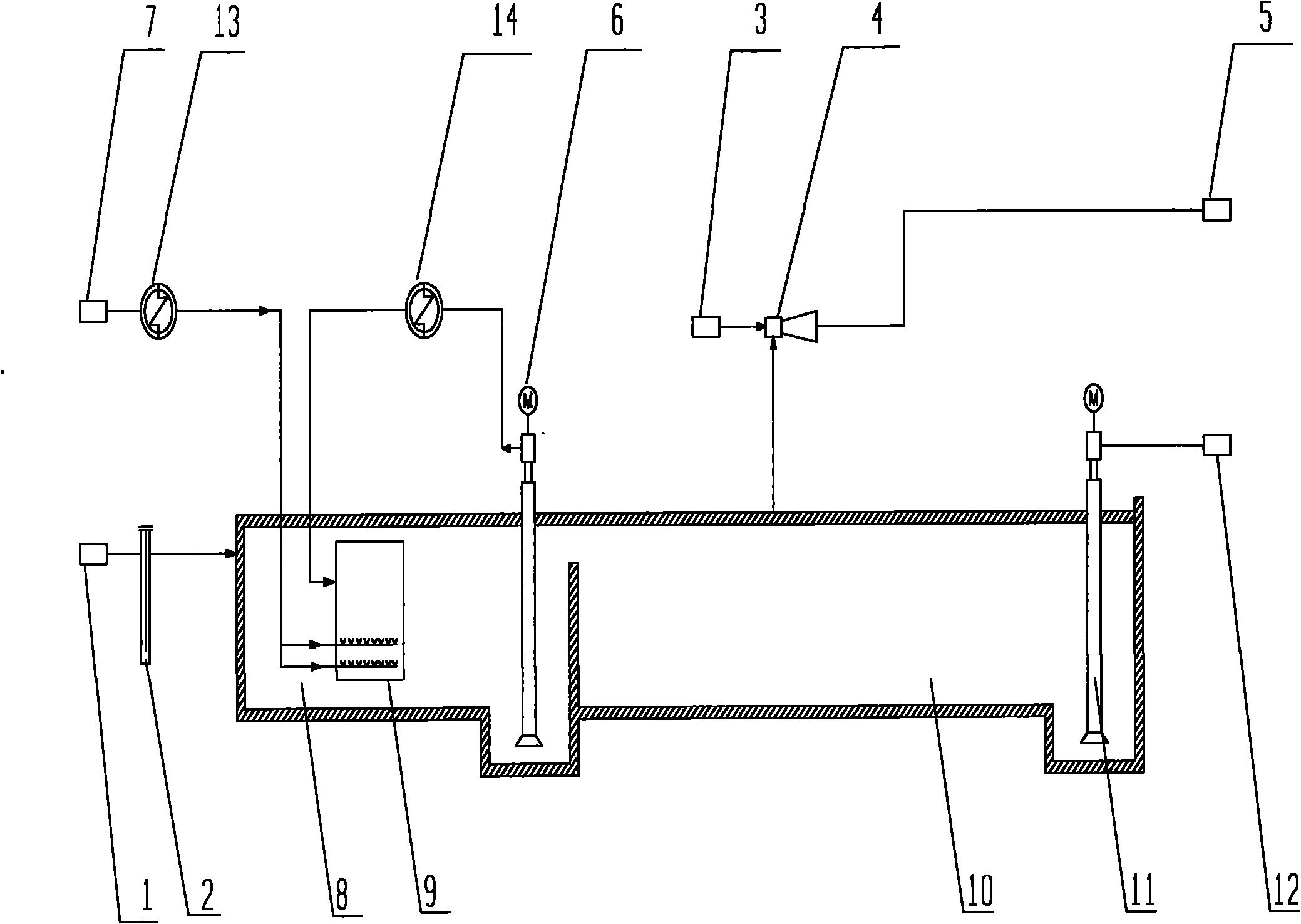

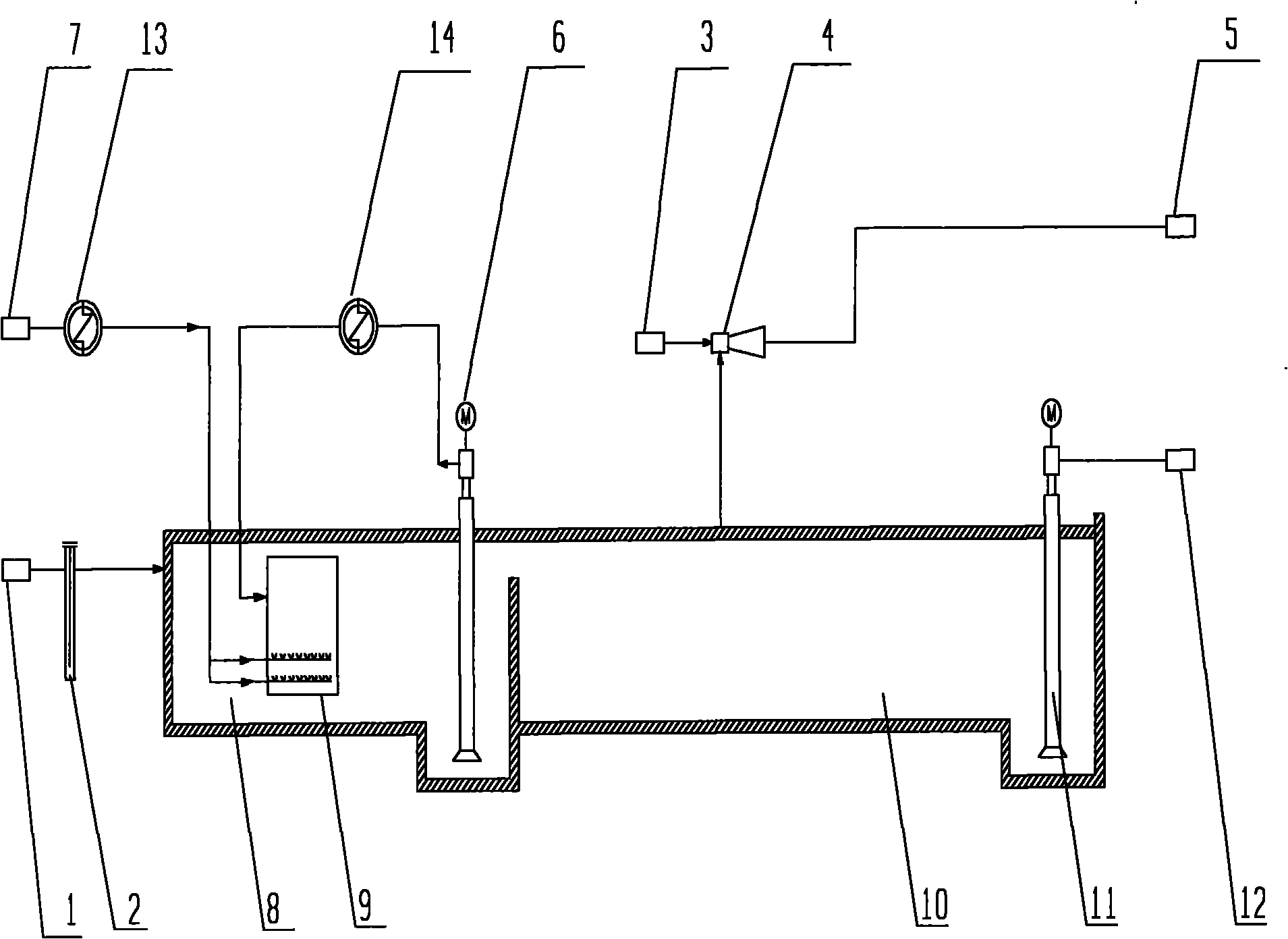

Treatment system and treatment method for removing hydrogen sulfide from acid gas

ActiveCN102895870ALow internal sulfur concentrationReduce the concentration of sulfurDispersed particle separationSulfur preparation/purificationPtru catalystPhysical chemistry

The invention relates to a treatment system and a treatment method for removing hydrogen sulfide from acid gas. The treatment system comprises an absorption reaction unit, a sulphur filtering unit, a solution regeneration unit, a temperature control unit and a medicament deliver unit, wherein the absorption reaction unit has a ferrum-catalyst desulfuration solution, is used for absorbing hydrogen sulfide contained in the acid gas introduced in the ferrum-catalyst desulfuration solution, and oxidizing the hydrogen sulfide into sulphur; the sulphur filtering unit is used for filtering the sulphur; and the solution regeneration unit is used for oxidizing and regenerating the filtered ferrum-catalyst desulfuration solution. The sulphur filtering unit is positioned between the absorption reaction unit and the solution regeneration unit. According to the system and the method, the sulphur is filtered from the solution before the step of oxidation and regeneration, so that the sulphur can not be deposited at the bottom end of an oxidization regenerator, the concentration of the sulphur in the system is low, so that the system can operate stably for a long time, and has good operational flexibility under various work conditions; the structure of equipment can be simplified; the investment is saved; and the construction period is also saved.

Owner:美景(北京)环保科技有限公司

Purified gas treatment process of sulfur recovery device

InactiveCN104555939AReduce contentDispersed particle separationSulfur preparation/purificationHydrogenation reactionSulfur

The invention relates to a purified gas treatment process of a sulfur recovery device. The purified gas treatment process comprises a thermal reaction phase, a catalytic reaction phase and a tail gas purifying treatment phase, wherein in the tail gas purifying treatment phase, the Claus tail gas generated in the catalytic reaction phase is sequentially subjected to a hydrogenation reaction, cooling in a rapid quenching tower and amine liquid absorption, then the purified tail gas is fed to alkali liquor to be subjected to H2S removal treatment, and the tail gas removed from H2S is combusted and then discharged; the amine liquid amine-rich liquid absorbing H2S is fed to a regeneration tower to be regenerated, the regenerated acid gas is mixed with the acid gas, and then returned to the thermal reaction phase to further recover elemental sulfur; the exhausted lye removed from H2S is subjected to caustic dross biological treatment or acidic water stripping treatment. With adoption of the purified gas treatment process disclosed by the invention, H2S in the purified gas can be removed to 5 mg / m<3> below, the SO2 content in the smoke is obviously reduced within the reduction range of 100-1000 mg / m<3>; the exhausted lye treatment method is further provided, and the exhausted lye is subjected to the caustic dross biological treatment or the acidic water stripping treatment, so that pollution can be reduced.

Owner:CHINA PETROLEUM & CHEM CORP

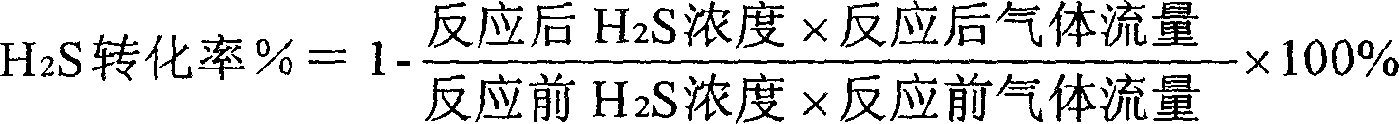

Method for reducing SO2 emission concentration of sulfur recovery device

ActiveCN104249995ASmall volumeReduce dosageChemical industryDispersed particle separationHydrogenation reactionExhaust fumes

The invention relates to a method for reducing the SO2 emission concentration of a sulfur recovery device. The method includes: at a tail gas purification processing stage, subjecting Claus tail gas to hydrogenation reaction, quench tower cooling and amine liquid absorption in turn, then taking part of purification tail gas as the stripping gas for liquid sulfur degassing, leading the residual purification tail gas into an incinerator to incinerate, letting the exhaust gas of liquid sulfur degassing enter a catalytic reaction stage, making the amine liquid absorbing hydrogen sulfide enter a regeneration tower to undergo regeneration, mixing a regenerated acidic gas with a raw material acidic gas, and returning the mixture to the thermal reaction section again for further recovery of elemental sulfur. The method for reducing the SO2 emission concentration of the sulfur recovery device provided by the invention is efficient, energy saving and economical, and greatly reduces the SO2 emission concentration.

Owner:CHINA PETROLEUM & CHEM CORP

System and method for treating waste acid gas

ActiveCN102910593ANo emissionsLower requirementEnergy inputSulfur preparation/purificationLiquid wasteSulfur

Owner:美景(北京)环保科技有限公司

Catalyst for direct oxidation and desulphurization and its prepn. method

ActiveCN1868572AHigh activityGood choiceDispersed particle separationSulfur preparation/purificationSulfurVanadium oxide

A catalyst used directly for oxidative desulfurizing to H2S gas contained acidic gas is proportionally prepared from iron oxide, aluminum oxide, titanium oxide, zinc oxide, and vanadium oxide by co-deposition method. It has high activity, selectivity and H2s conversion rate.

Owner:PETROCHINA CO LTD

SWSR (SunWay Sulfur recovery)-1 device and technique

ActiveCN103482583AReduce sulfur dioxide contentThe effect achieved is excellentDispersed particle separationSulfur preparation/purificationAntioxidantIonic liquid

The invention relates to an SWSR (SunWay Sulfur recovery)-1 device and technique. The invention relates to a tail gas treatment combination device and technique by adopting Claus sulfur recovery and ionic liquid cycle absorption process. The device comprises a sulfur production burning furnace, a Claus reaction system, a sulfur production tail gas incinerator, a rich SO2 process gas heat exchanger, an SO2 absorption tower, a rich liquid pump, a lean and rich liquid heat exchanger, an SO2 regeneration tower and a lean liquid feed pump. The technique comprises the steps: (1) enabling hydrogen sulfide-containing acid gas to generate a Claus reaction, and recovering sulfur and heat energy in the reaction process; (2) burning sulfur production tail gas to generate SO2; (3) removing SO2 from rich SO2 process gas through an ionic liquid absorption tower; and (4) feeding rich SO2 ionic liquid into a regeneration tower for separating and regenerating sulfur. The ionic liquid is an aqueous solution which takes organic positive ions and inorganic anions as main components and a little amount of activating agent and antioxidant as additives. The SWSR-1 device and technique are low in equipment investment, high in material safety, short in technique flow, safe and reliable in technique processes, high in SO2 recovery rate, and the content of SO2 in effluent gas can be reduced by 50ppm below which can meet the national regulation requirement.

Owner:SHANDONG SUNWAY PETROCHEMICAL ENGINEERING CO LTD +1

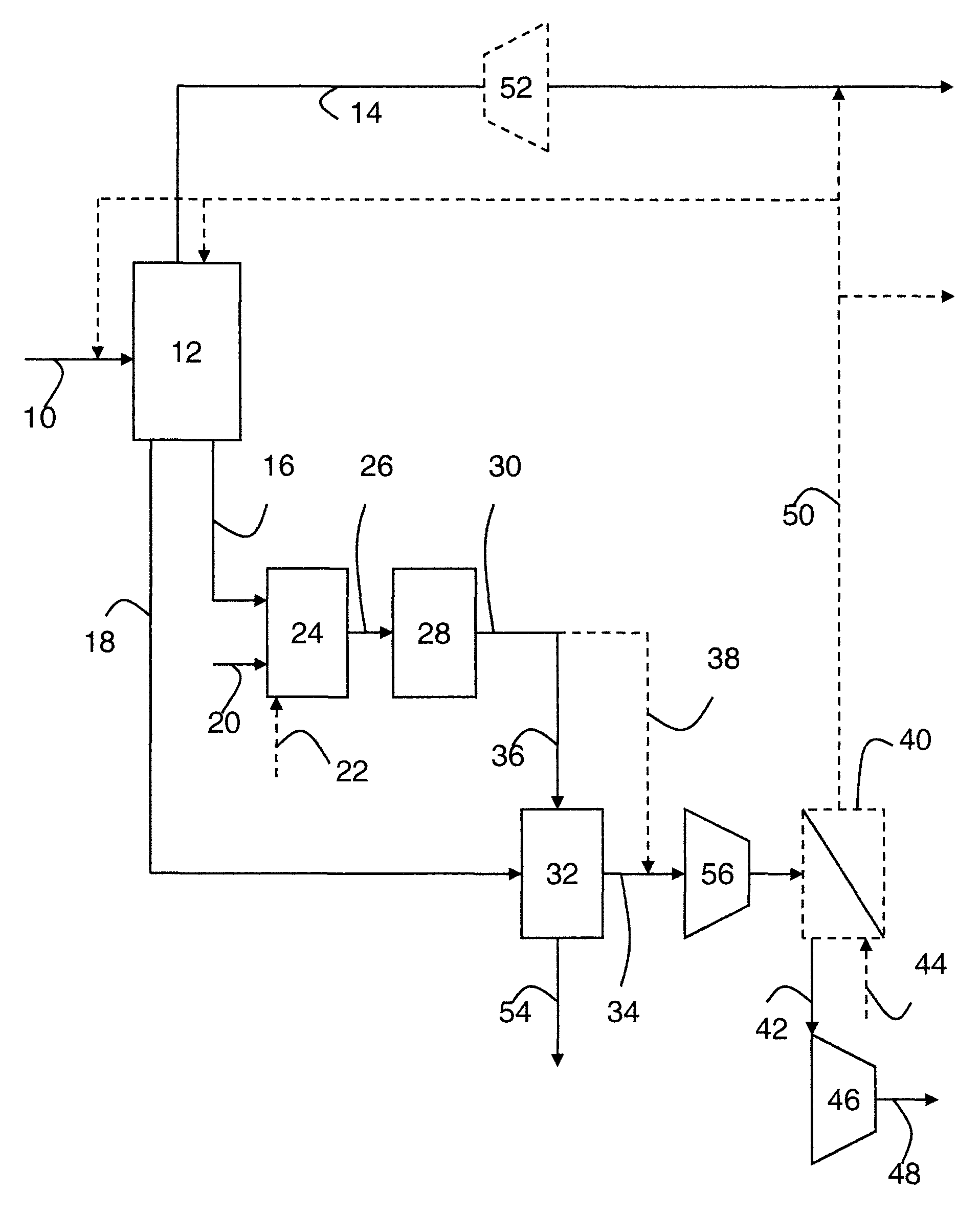

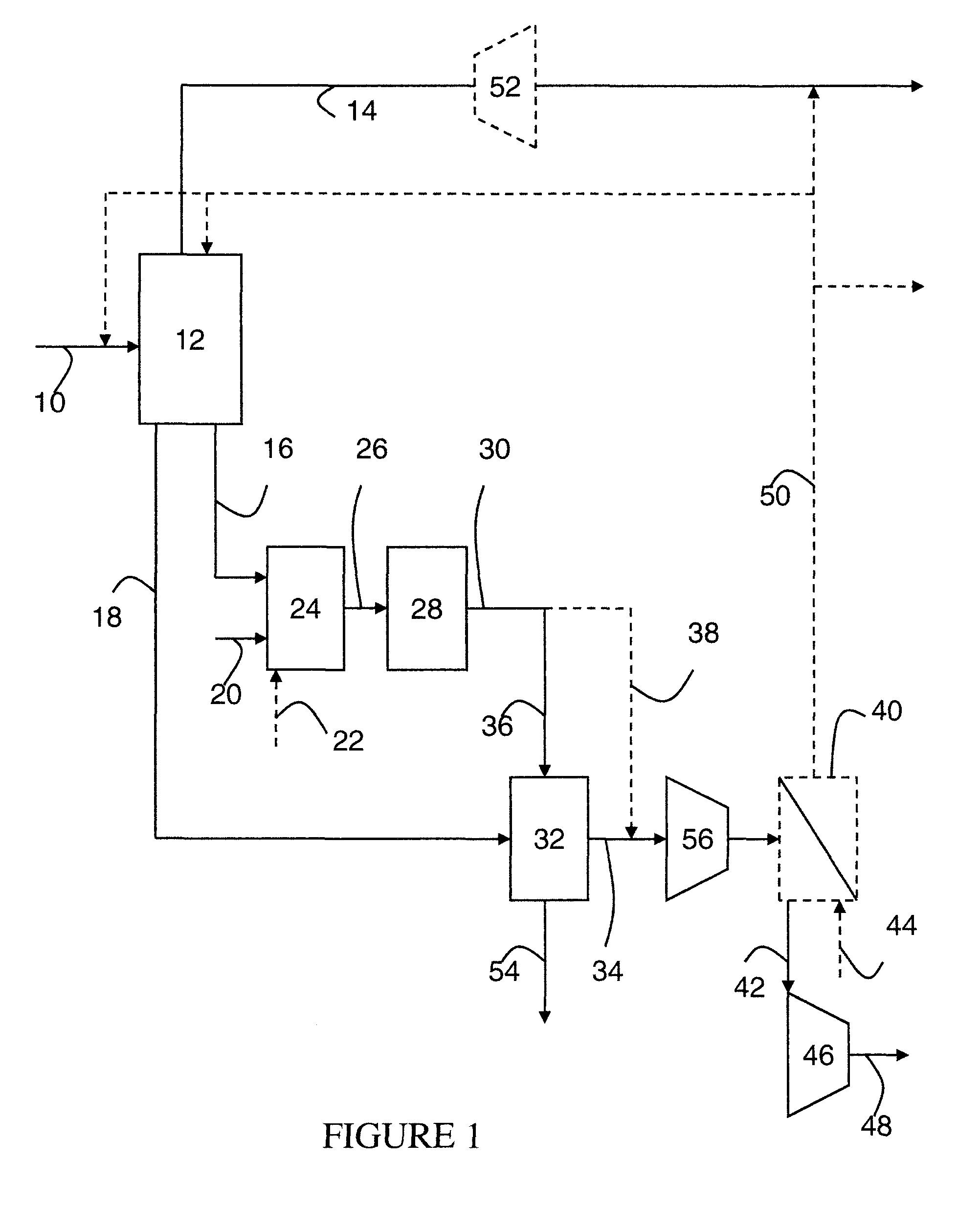

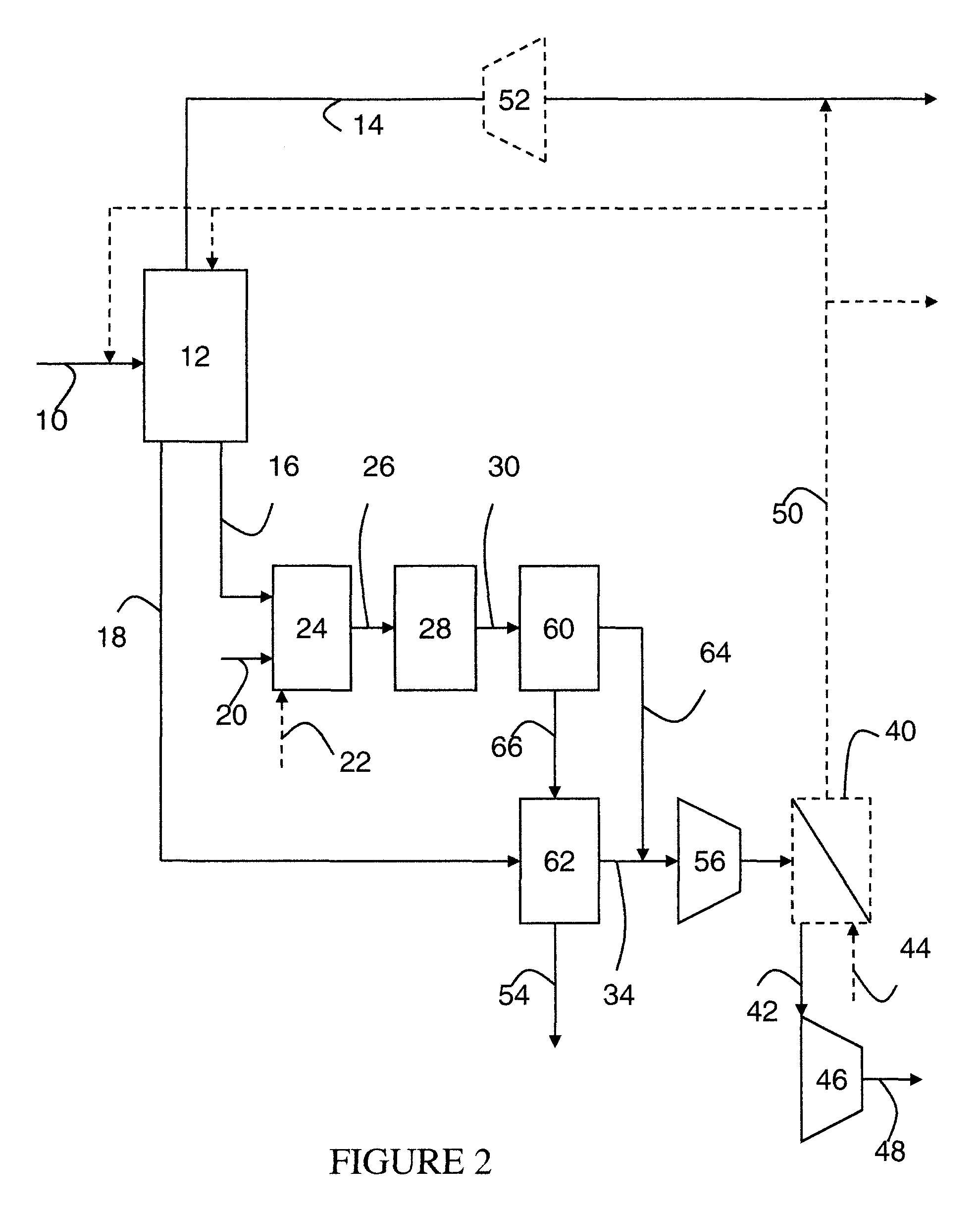

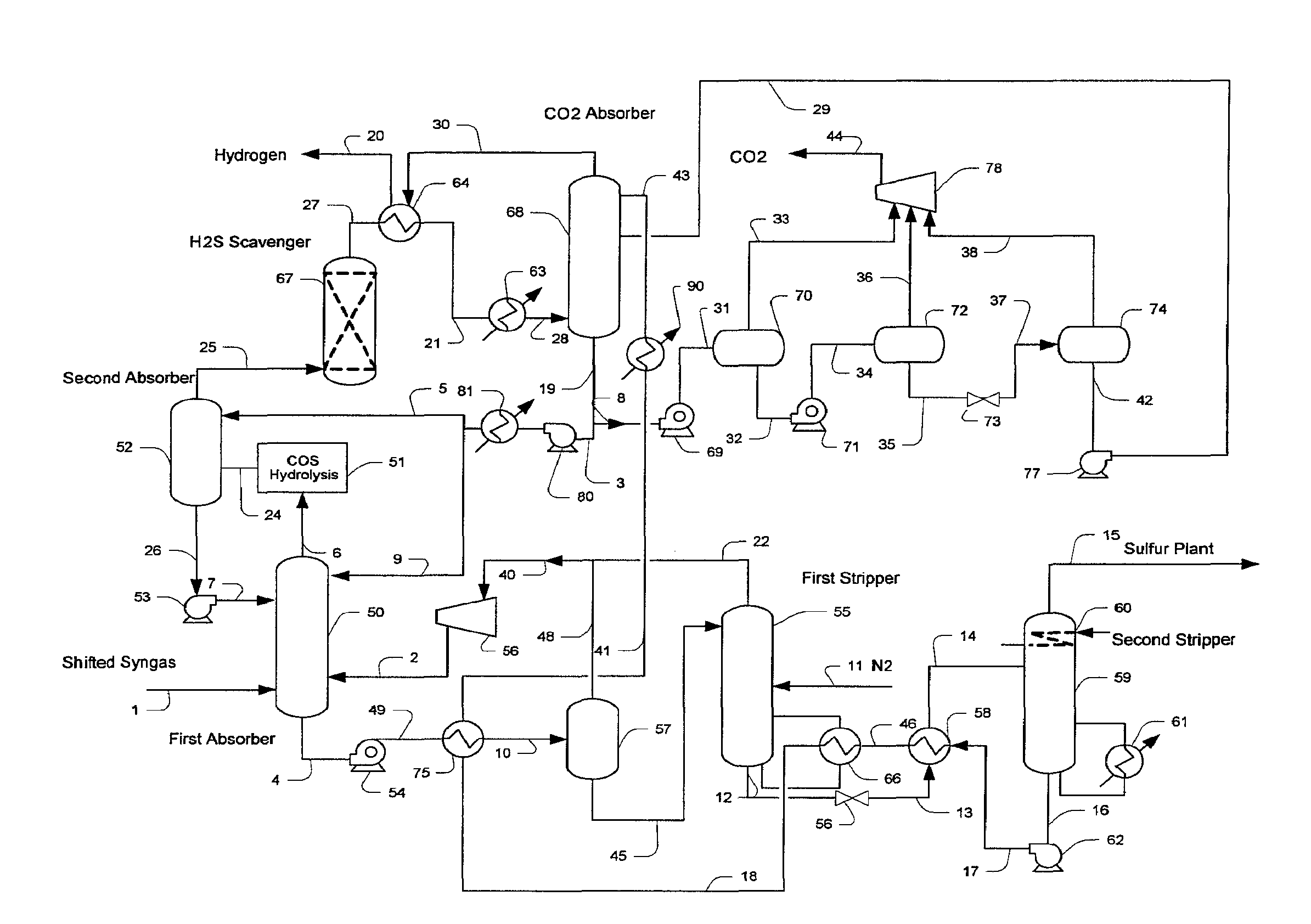

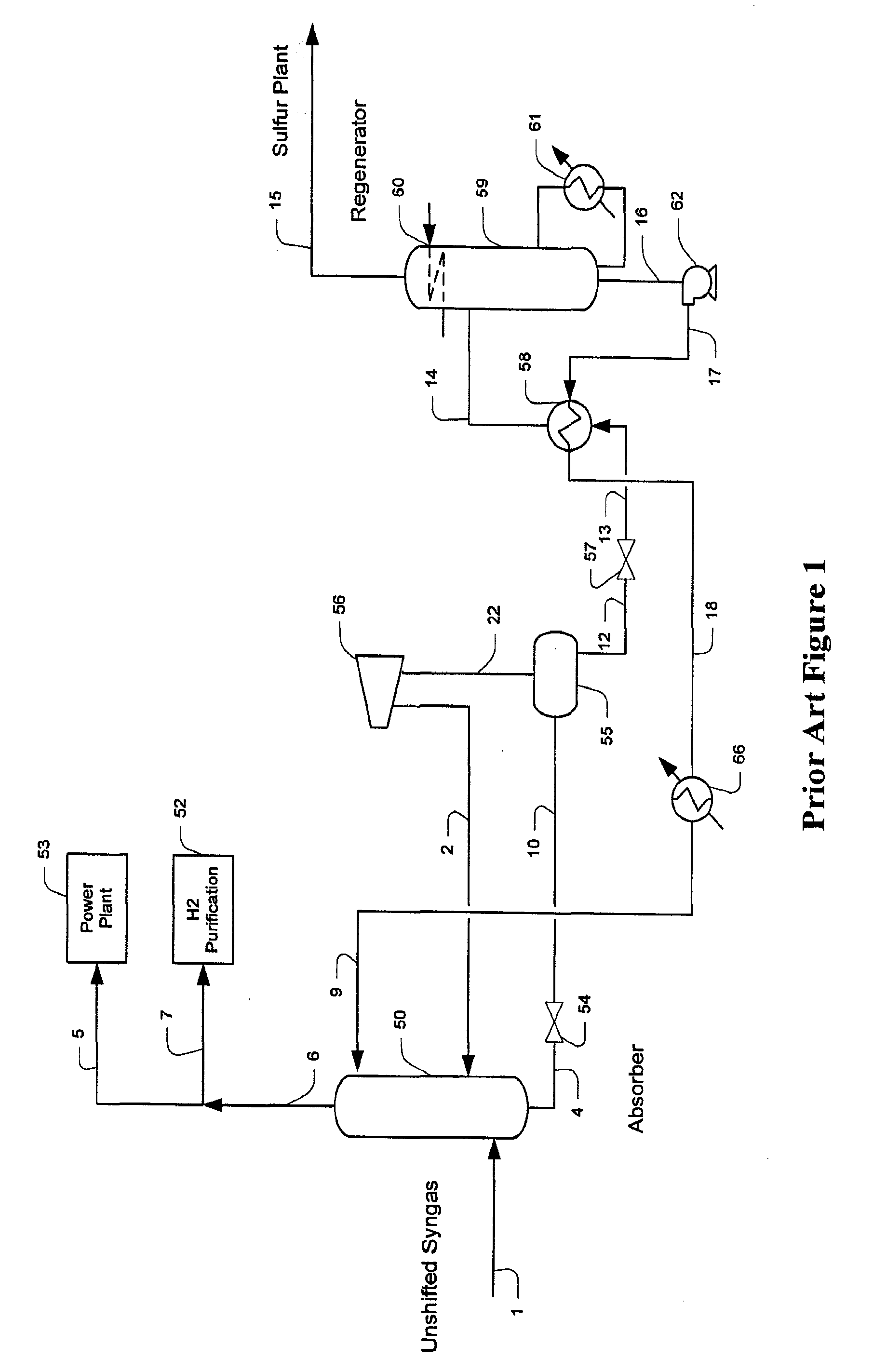

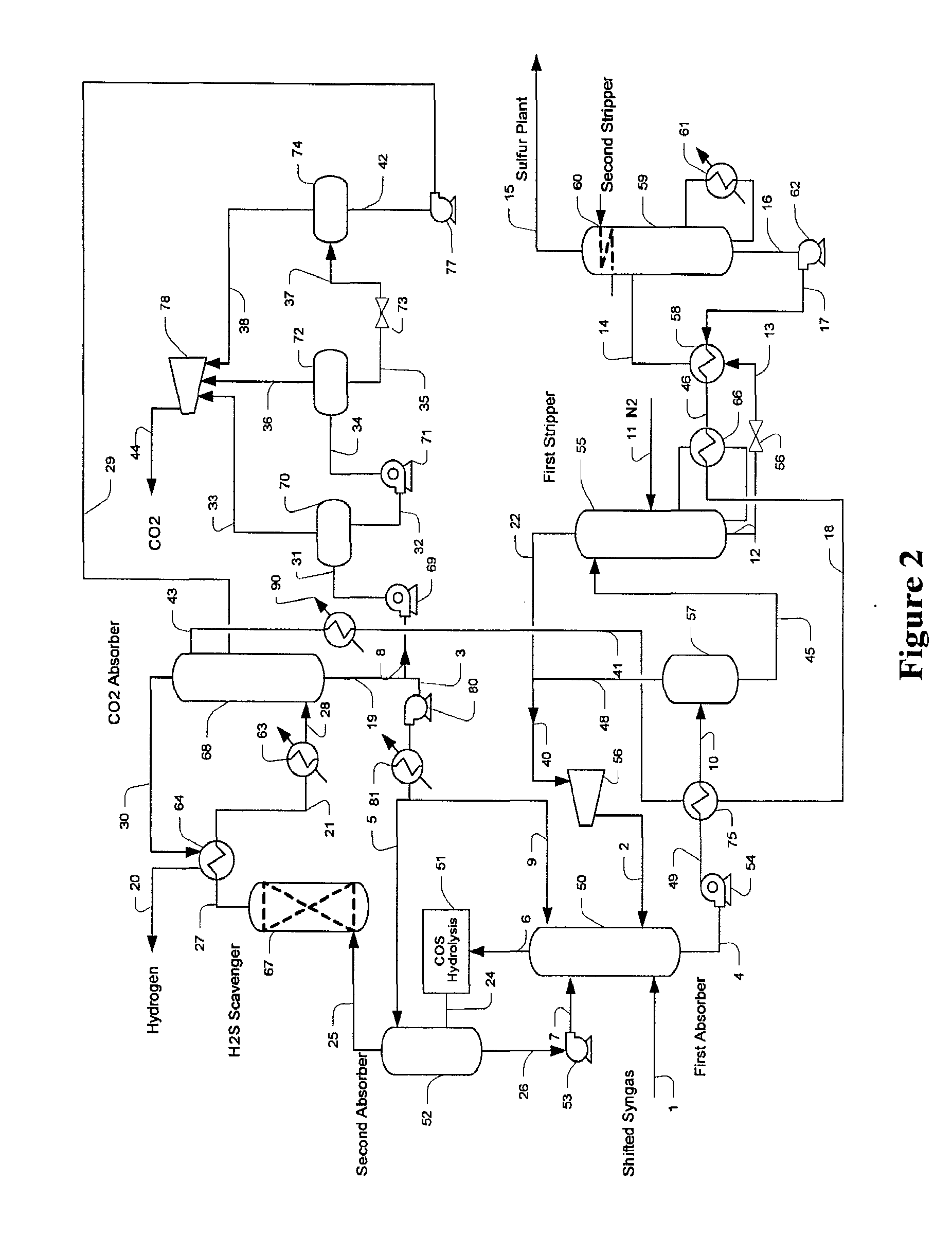

Configurations And Methods For Carbon Dioxide And Hydrogen Production From Gasification Streams

InactiveUS20100111784A1Significant energy savingSave energyCarbon compoundsHydrogen production carbon captureSyngasSolvent

A syngas treatment plant is configured to remove sulfurous compounds and carbon dioxide from shifted or un-shifted syngas in a configuration having a decarbonization section and a desulfurization section. Most preferably, the solvent in the decarbonization section is regenerated and cooled by flashing, while the solvent is regenerated in the desulfurization section via stripping using external heat, and it is still further preferred that carbonylsulfide is removed in the desulfurization section via hydrolysis, and that the so produced hydrogen sulfide is removed in a downstream absorber.

Owner:FLUOR TECH CORP

Degassing technique for liquid sulfur

InactiveCN102381685ALess investmentLow operating costSulfur preparation/purificationExhaust gasChemistry

The invention provides a degassing technique for liquid sulfur. The degassing technique can be used for solving the technical problems of the prior art that local condensation easily occurs in a bubbler, the bubbler is easily blocked and a degassing effect is unstable. The degassing technique comprises the following steps: A) entering into a degassing section after sealing the liquid sulfur, utilizing a liquid sulfur degassing pump to pressurize and send the liquid sulfur into a gas-stripping degassing column arranged in the degassing section, and circulating the liquid sulfur inside and outside the gas-stripping degassing column; B) heating compressed air and then introducing the compressed air into a bubbling device on the lower part of the gas-stripping degassing column, contacting the compressed air with the liquid sulfur in the gas-stripping degassing column, removing H2S dissolved in the liquid sulfur and burning the removed H2S after sending the removed H2S to a tail gas incinerator or an acid gas combustion furnace; and C) after overflowing the degassed liquid sulfur from the degassing section to a storage section, sending the liquid sulfur by a liquid sulfur end product pump. The degassing technique can be used for reducing the content of H2S in the liquid sulfur, preventing the bubbling device from being blocked, promoting the liquid sulfur degassing effect and achieving the content of the H2S in the liquid sulfur being less than 10ppm.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com