Patents

Literature

1387results about "Ultra-high pressure processes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermally stable diamond bonded materials and compacts

InactiveUS20050263328A1Improve thermal stabilityGood adhesionDrill bitsConstructionsMaterials scienceTemperature and pressure

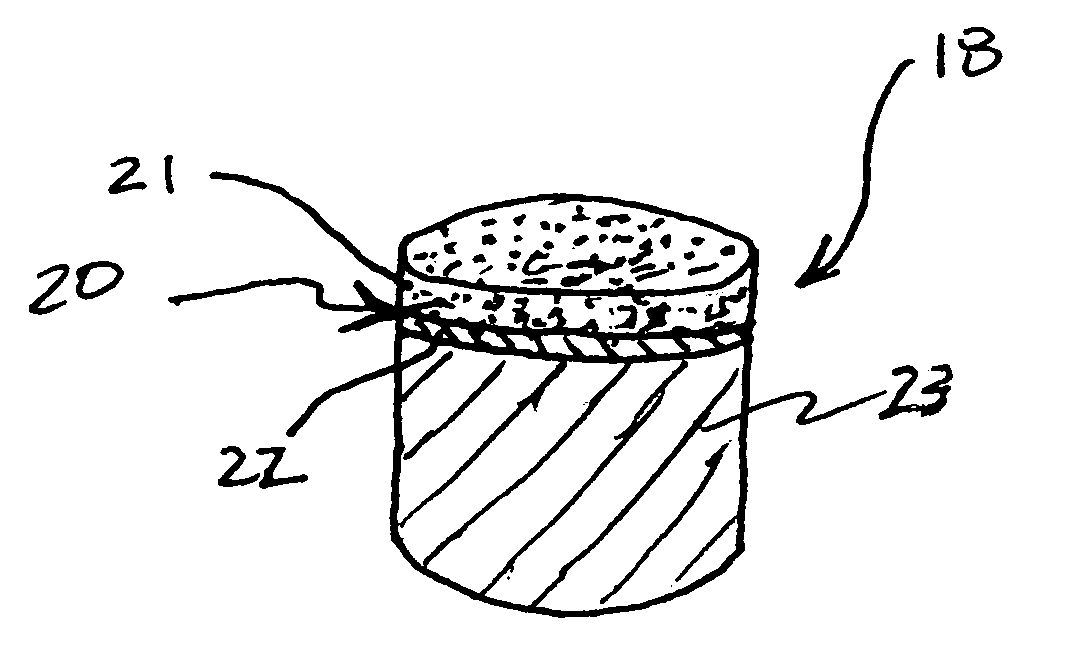

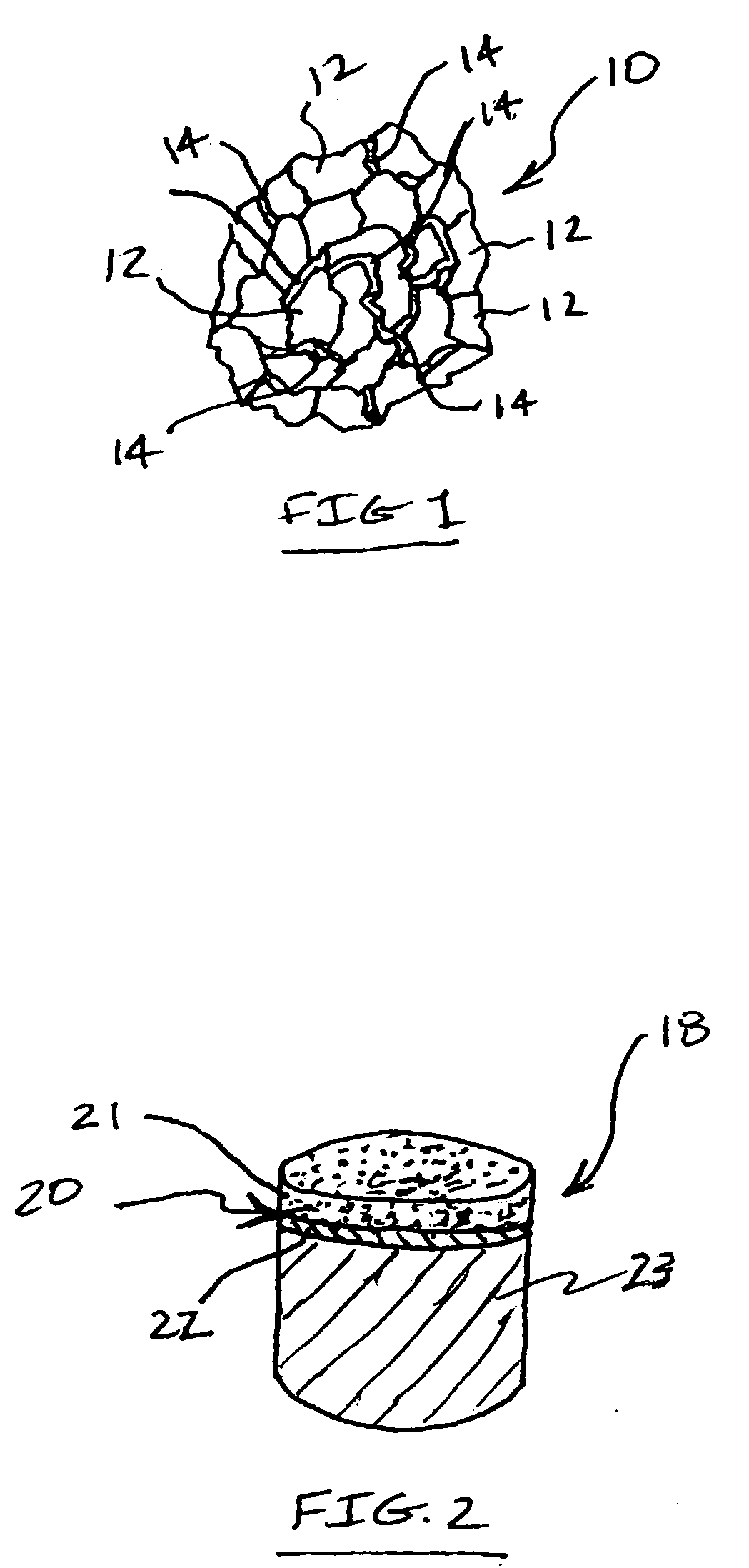

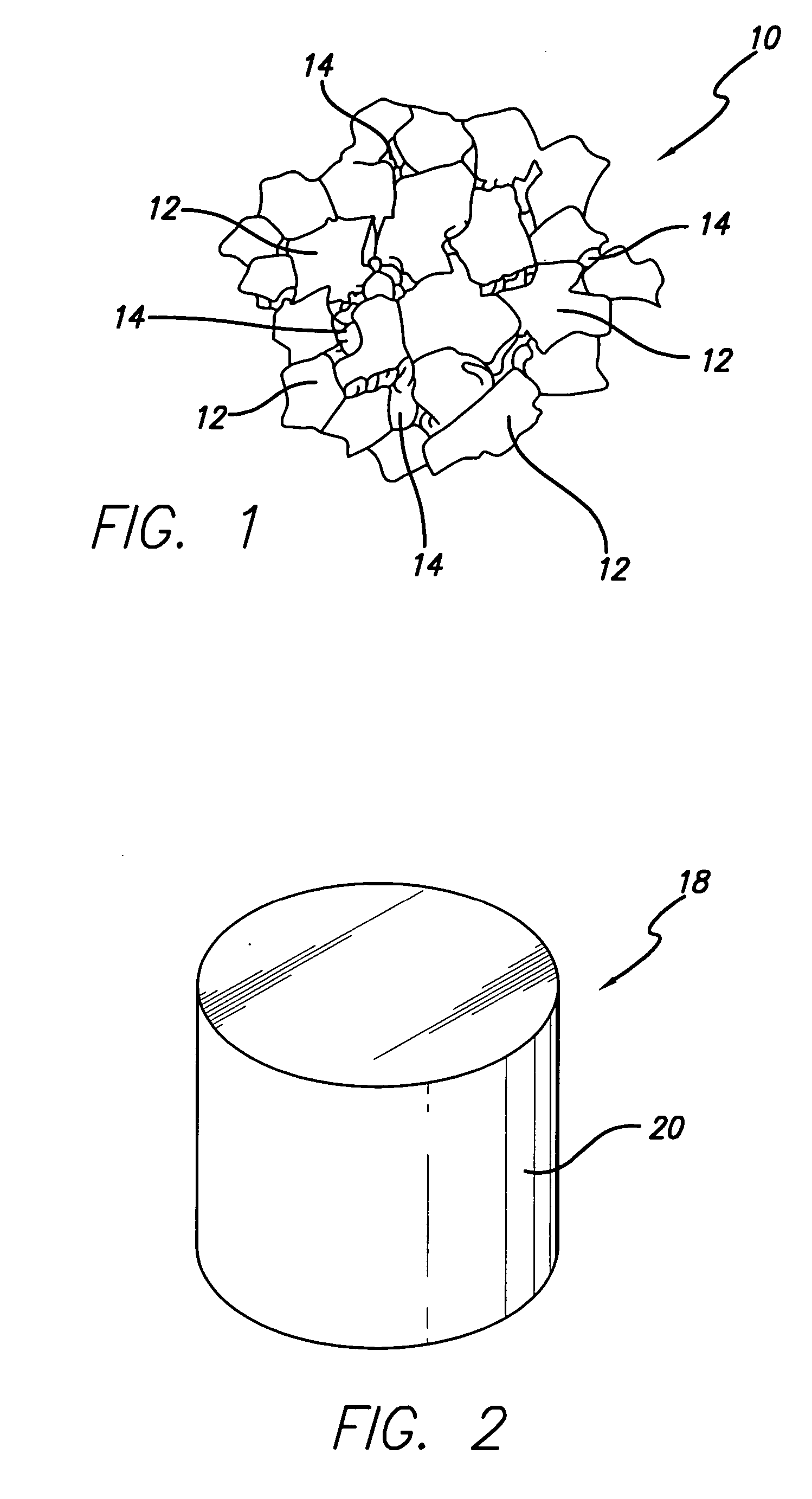

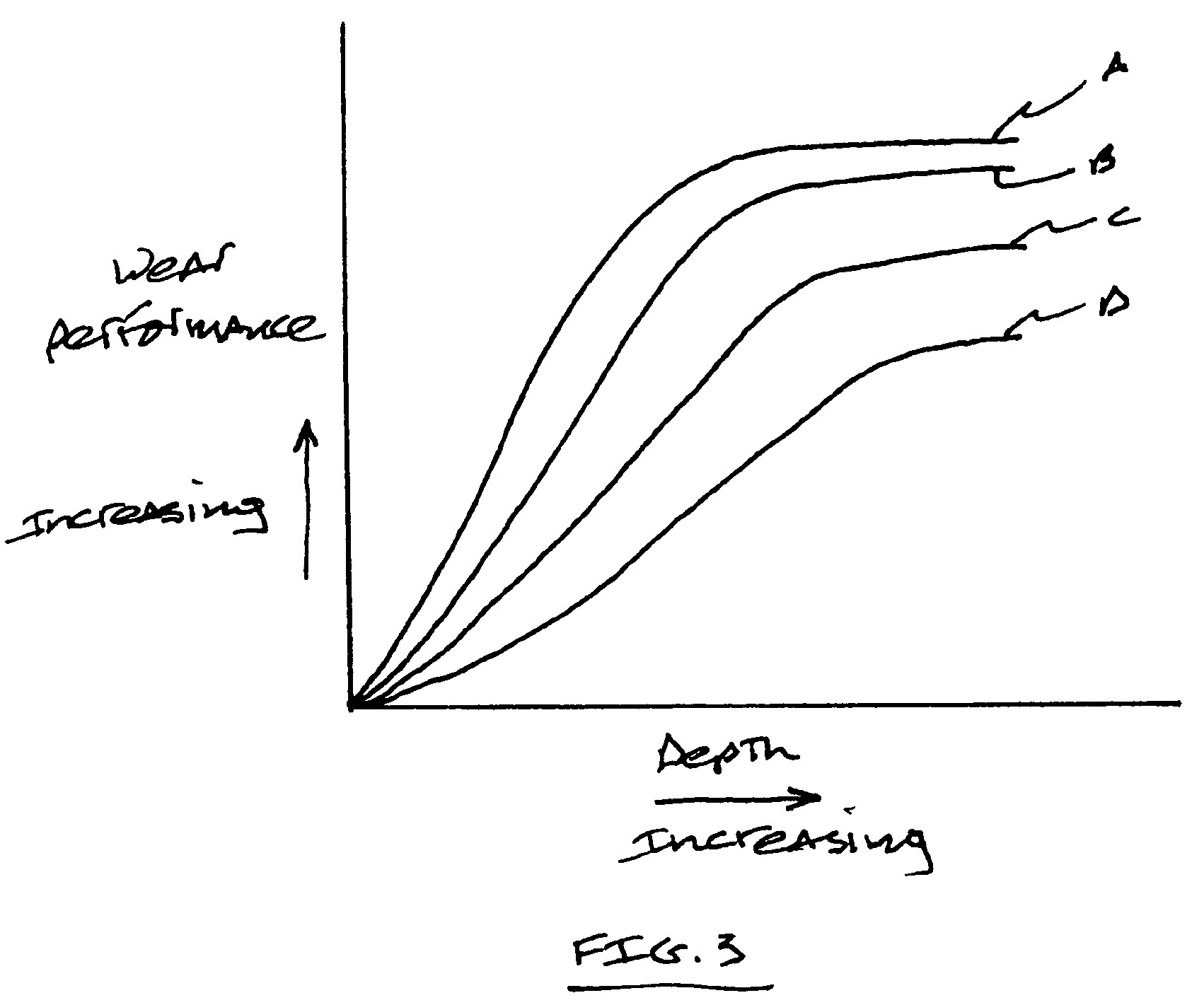

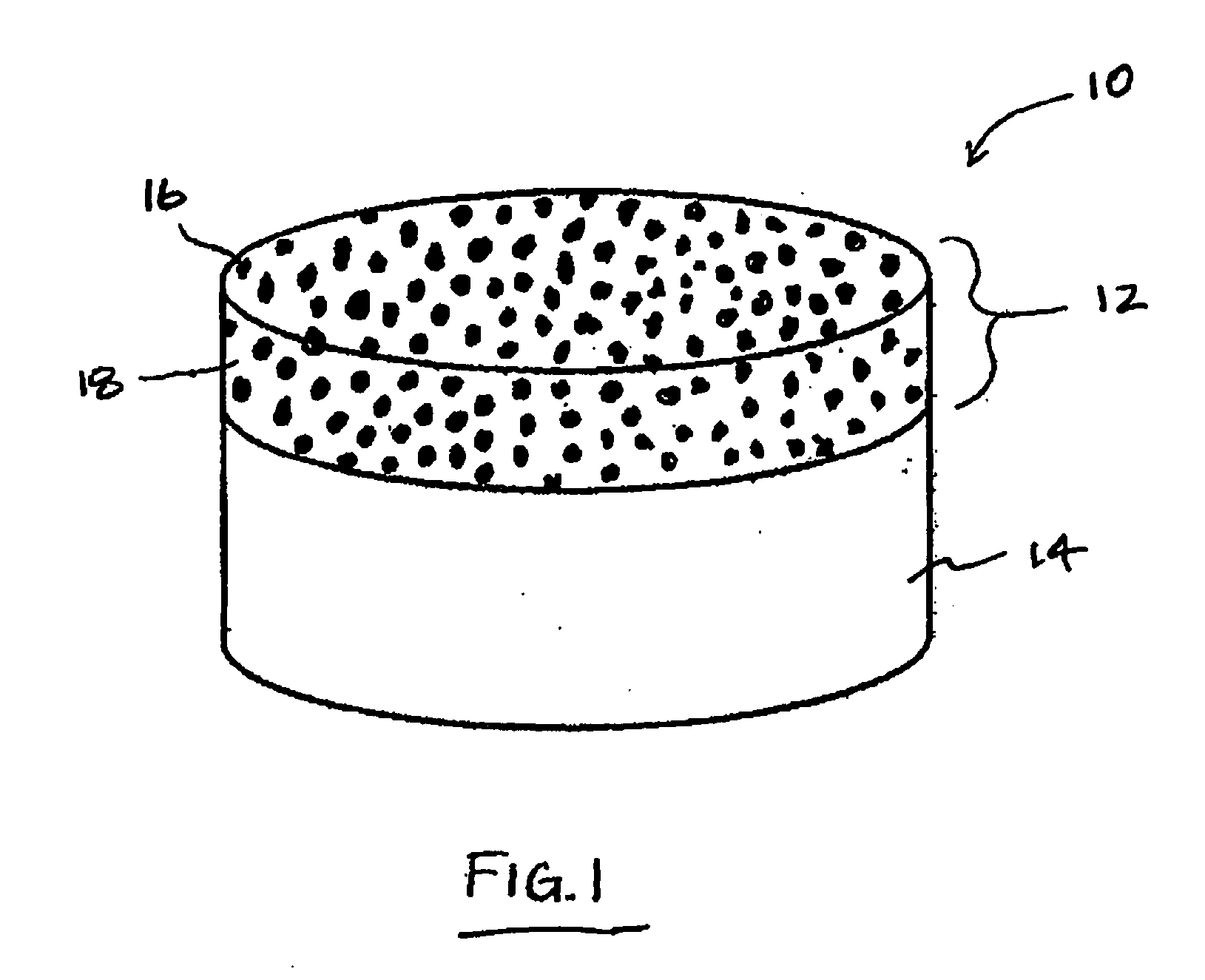

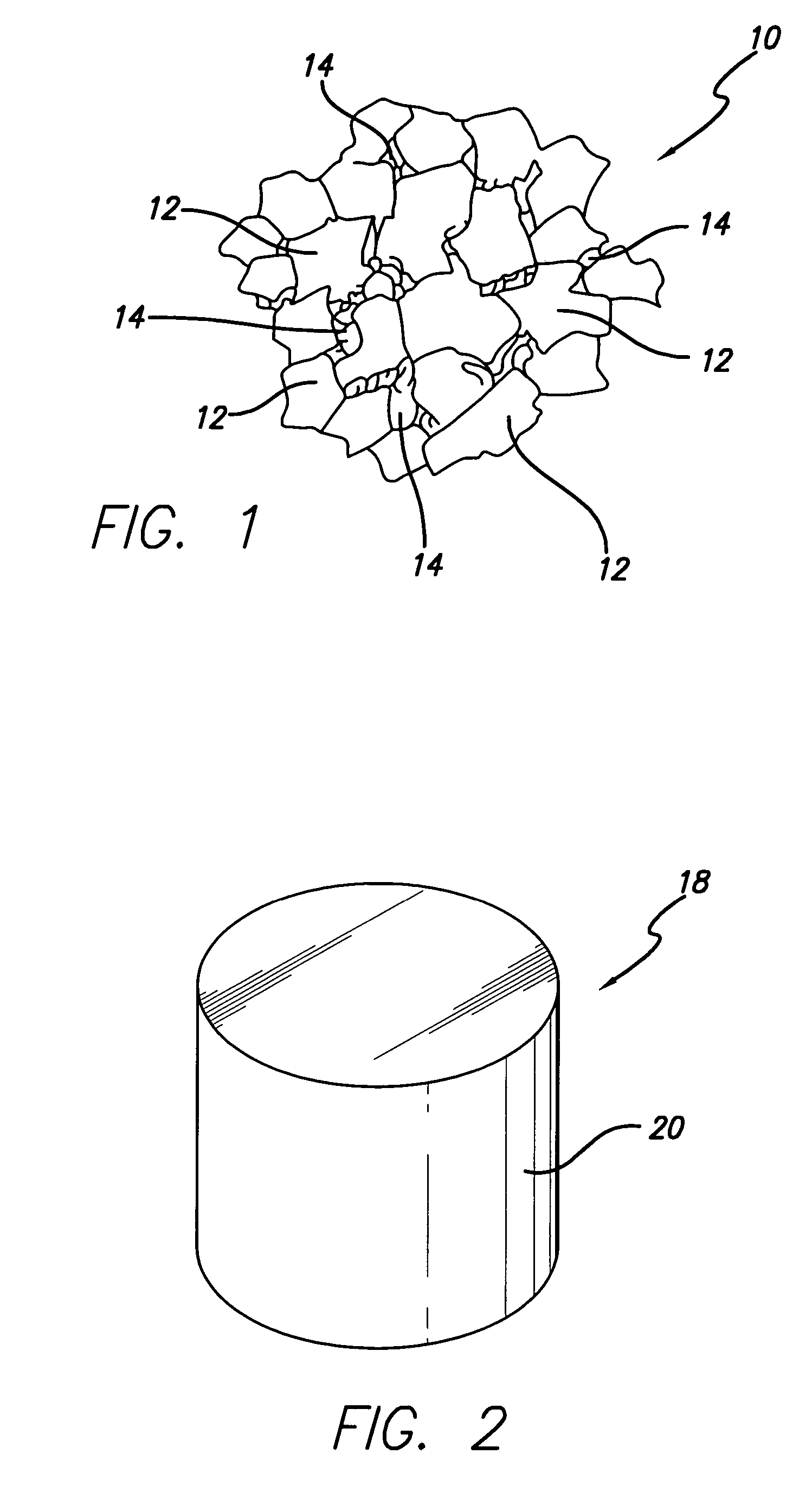

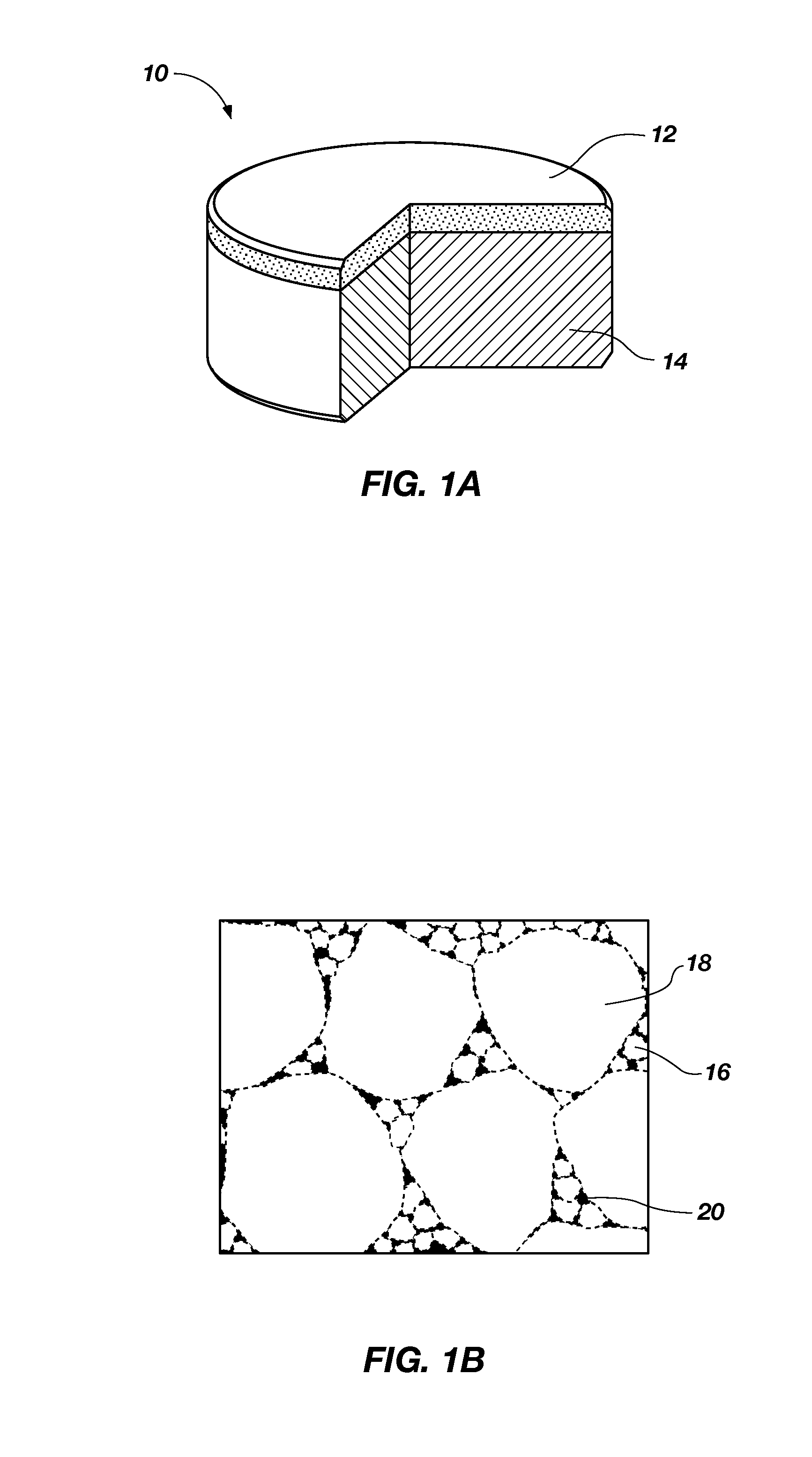

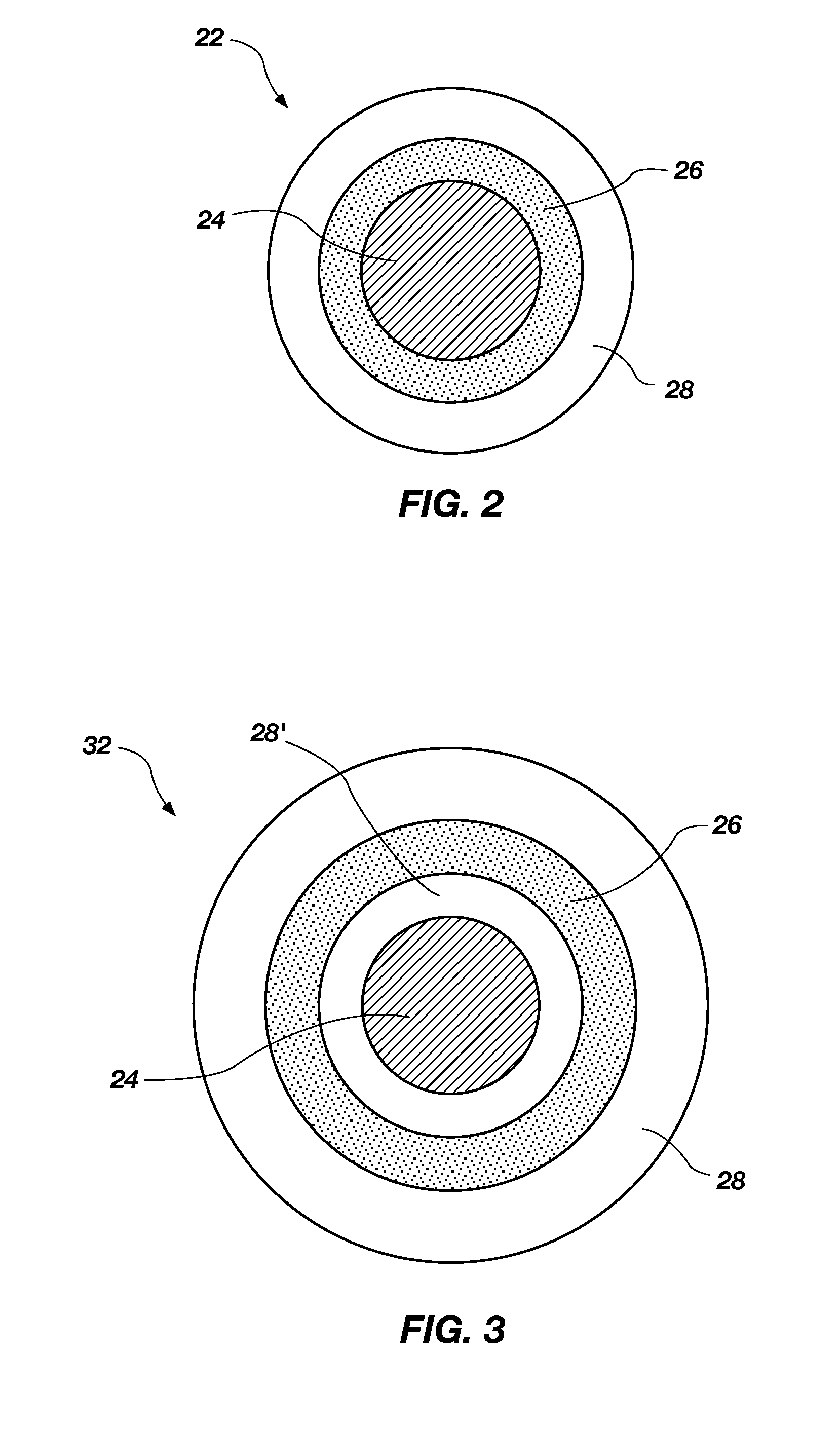

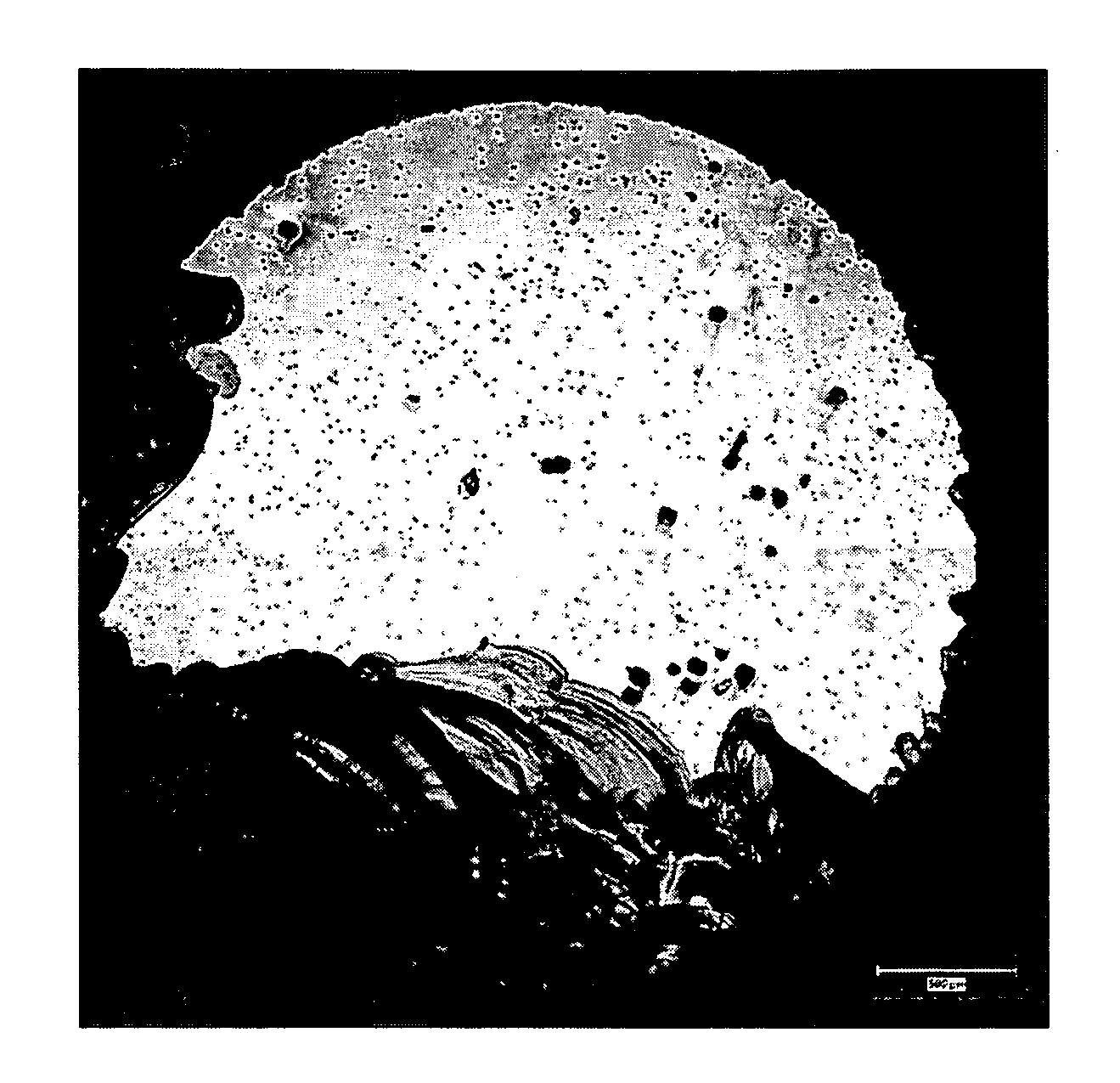

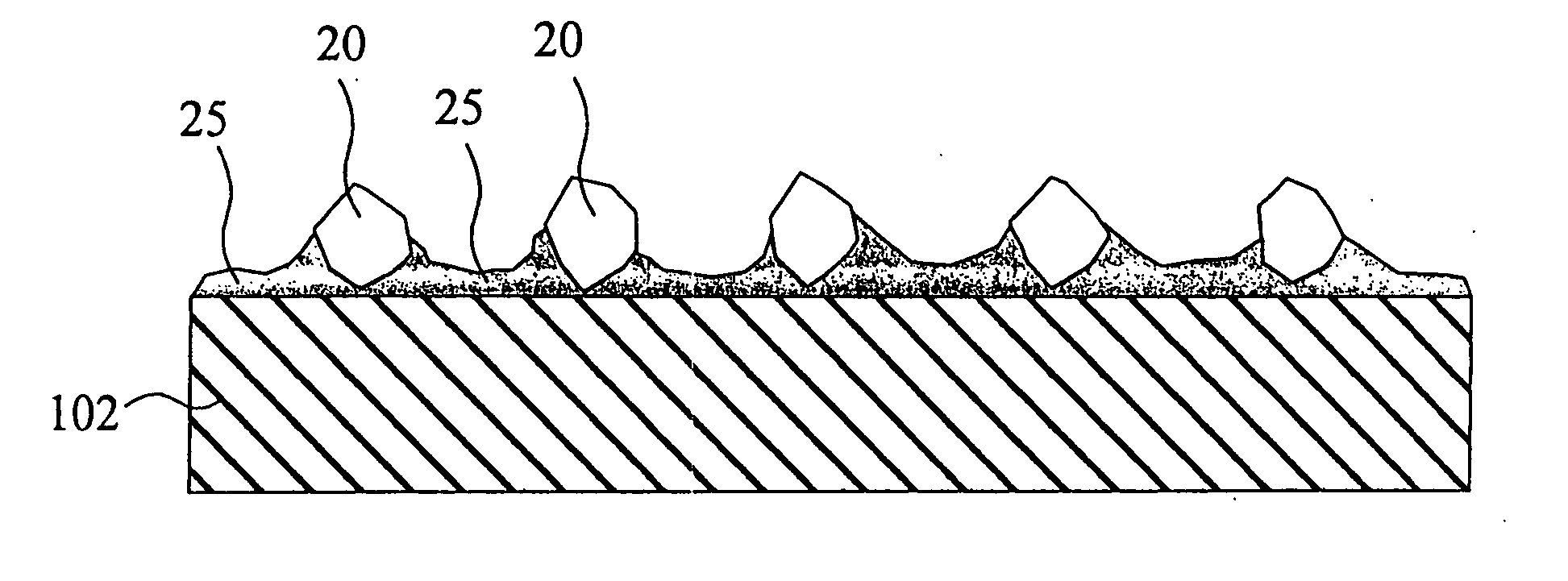

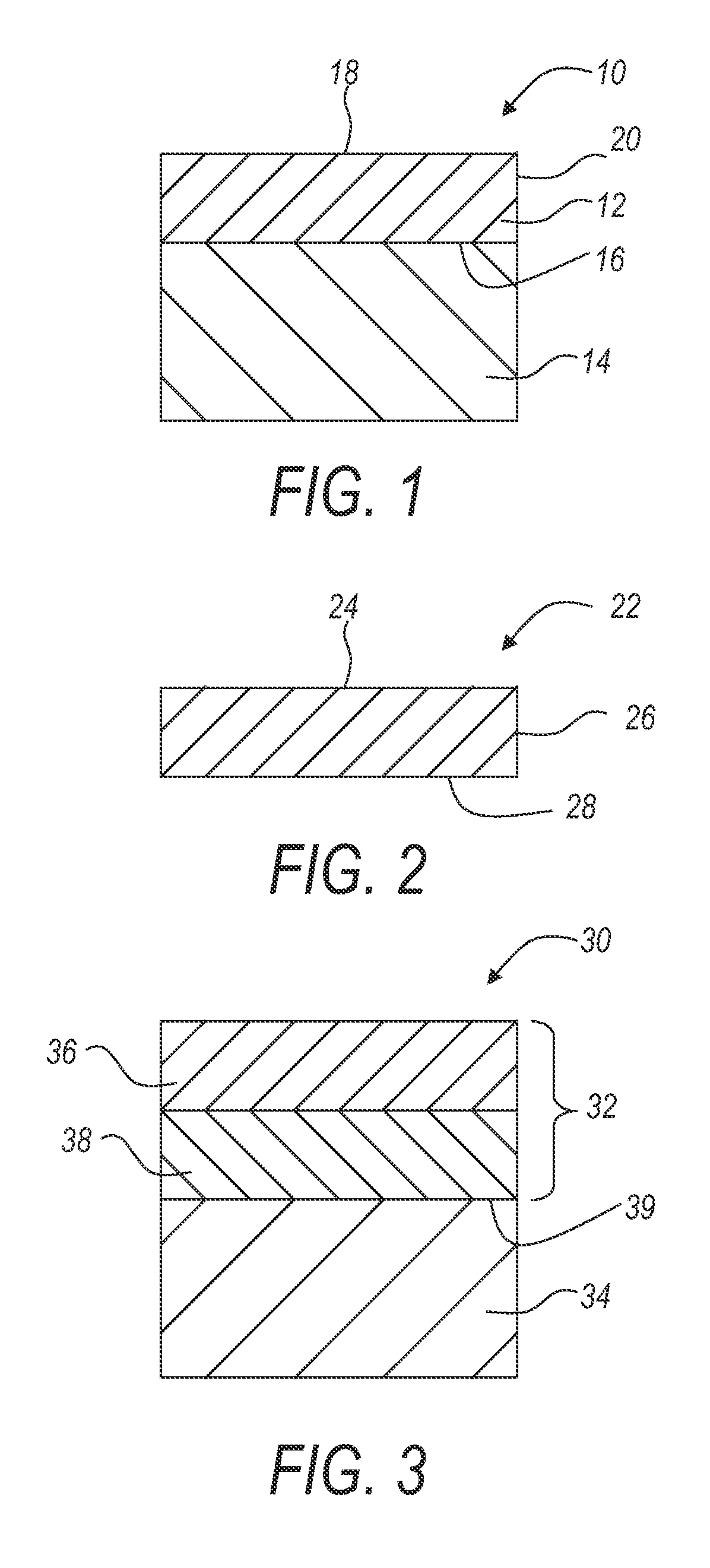

Thermally stable diamond bonded materials and compacts include a diamond body having a thermally stable region and a PCD region, and a substrate integrally joined to the body. The thermally stable region has a microstructure comprising a plurality of diamond grains bonded together by a reaction with a reactant material. The PCD region extends from the thermally stable region and has a microstructure of bonded together diamond grains and a metal solvent catalyst disposed interstitially between the bonded diamond grains. The compact is formed by subjecting the diamond grains, reactant material, and metal solvent catalyst to a first temperature and pressure condition to form the thermally stable region, and then to a second higher temperature condition to both form the PCD region and bond the body to a desired substrate.

Owner:SMITH INT INC

Polycrystalline diamond constructions having improved thermal stability

ActiveUS20080223623A1Good adhesionImprove thermal stabilityDrill bitsConstructionsDiamond crystalPolycrystalline diamond

Owner:SMITH INT INC

Thermally-stable polycrystalline diamond materials and compacts

InactiveUS20050230156A1Improve thermal stabilityImprove bindingDrill bitsConstructionsDiamond crystalPolycrystalline diamond

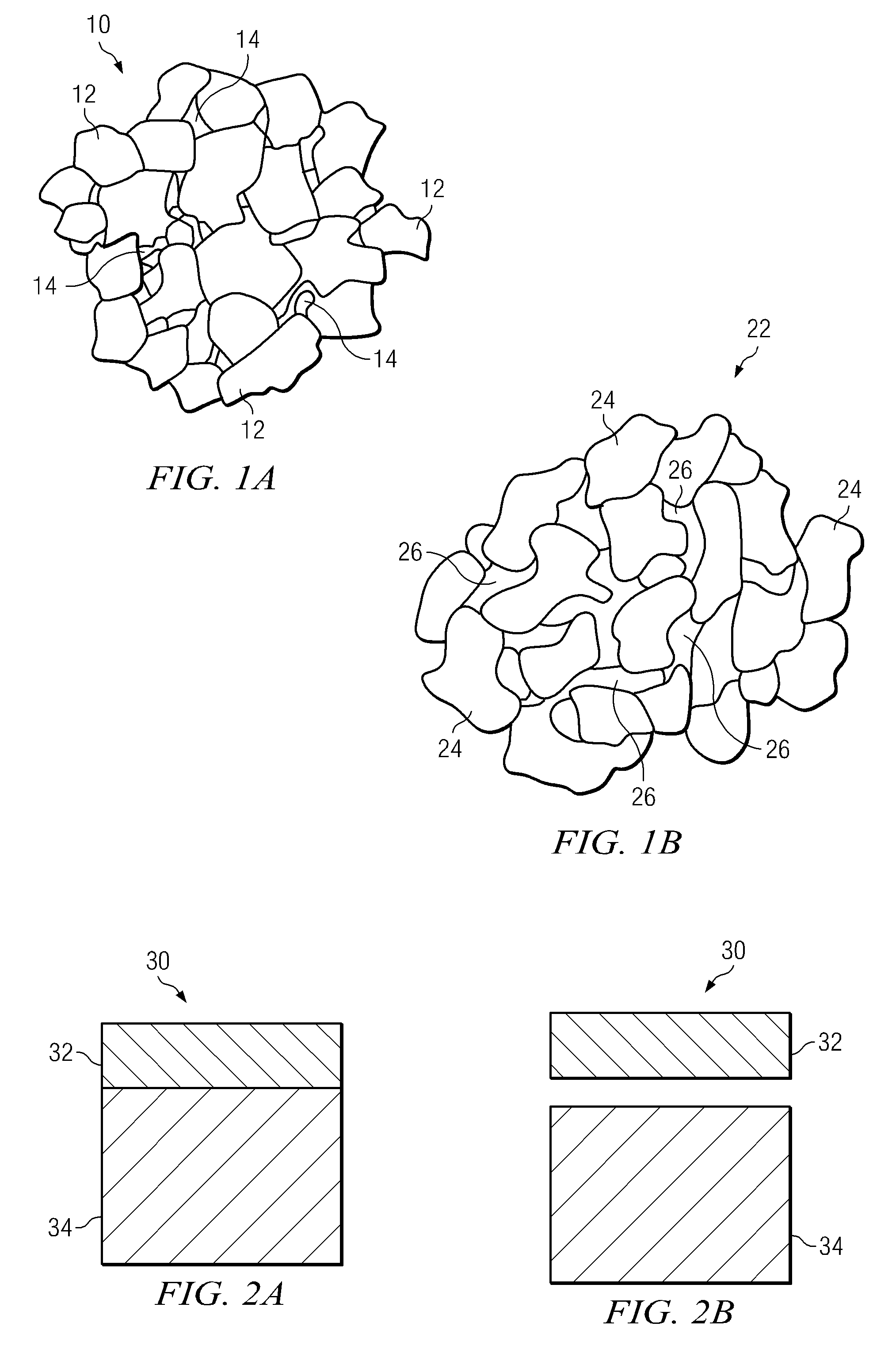

Thermally-stable polycrystalline diamond materials of this invention comprise a first phase including a plurality of bonded together diamond crystals, and a second phase including a reaction product formed between a binder / catalyst material and a material reactive with the binder / catalyst material. The reaction product is disposed within interstitial regions of the polycrystalline diamond material that exists between the bonded diamond crystals. The first and second phases are formed during a single high pressure / high temperature process condition. The reaction product has a coefficient of thermal expansion that is relatively closer to that of the bonded together diamond crystals than that of the binder / catalyst material, thereby providing an improved degree of thermal stability to the polycrystalline diamond material.

Owner:SMITH INT INC

Polycrystalline diamond materials having improved abrasion resistance, thermal stability and impact resistance

ActiveUS20060266559A1Improve propertiesDrill bitsConstructionsDiamond crystalPolycrystalline diamond

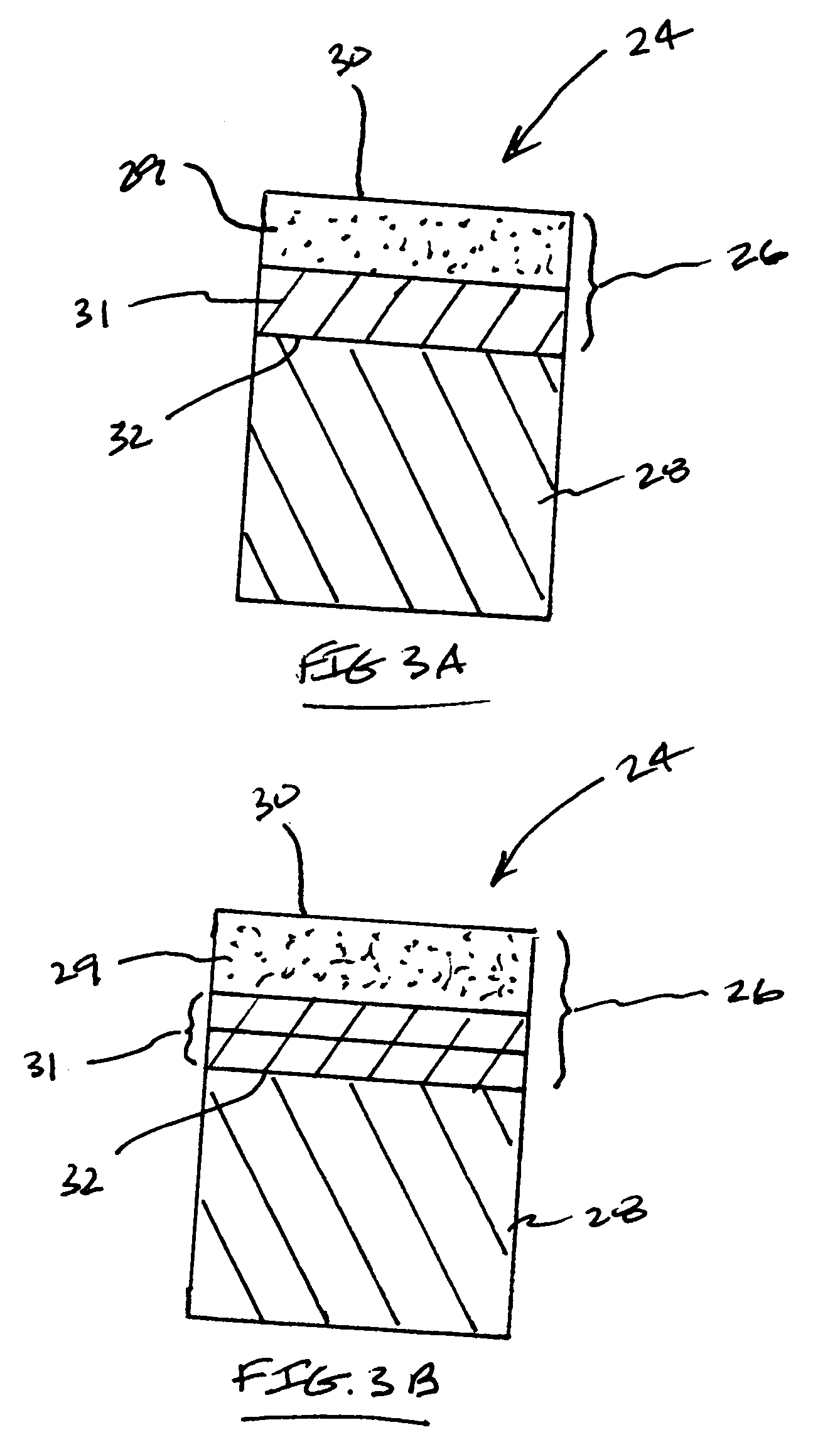

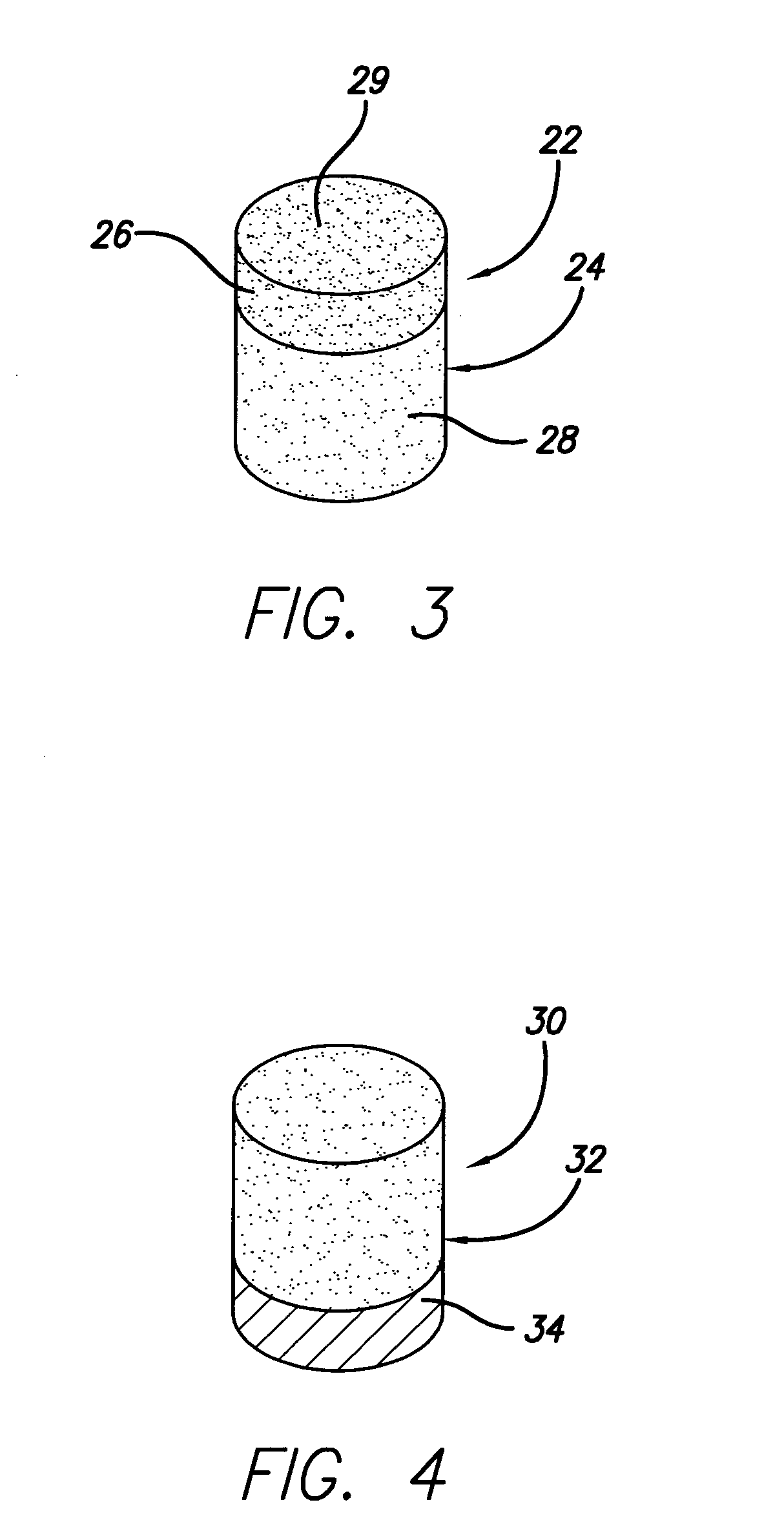

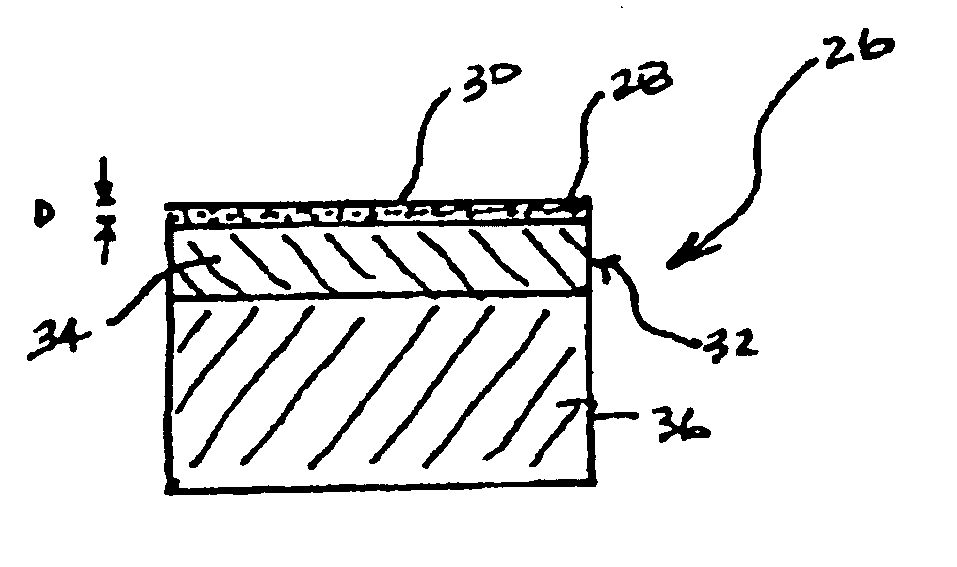

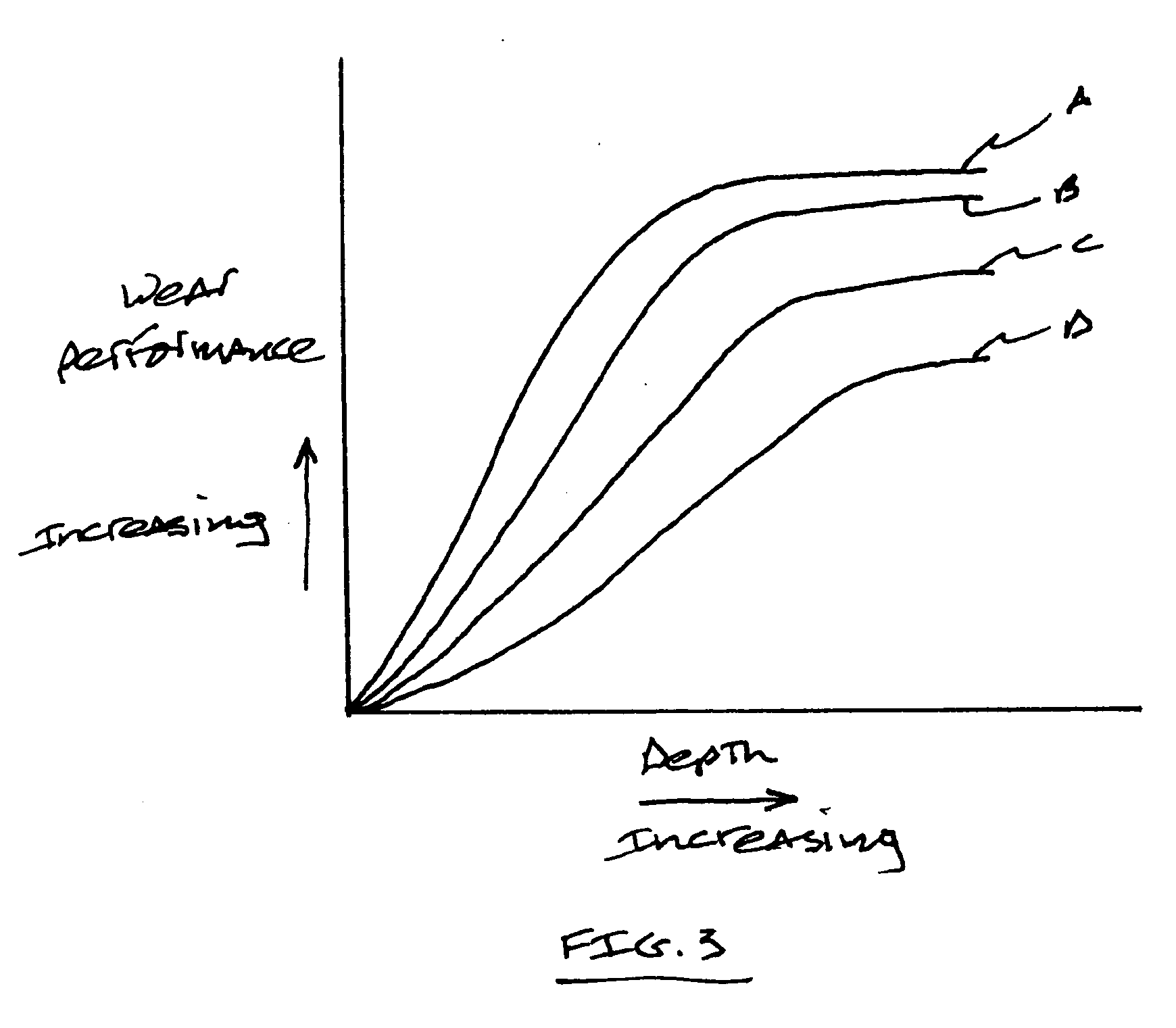

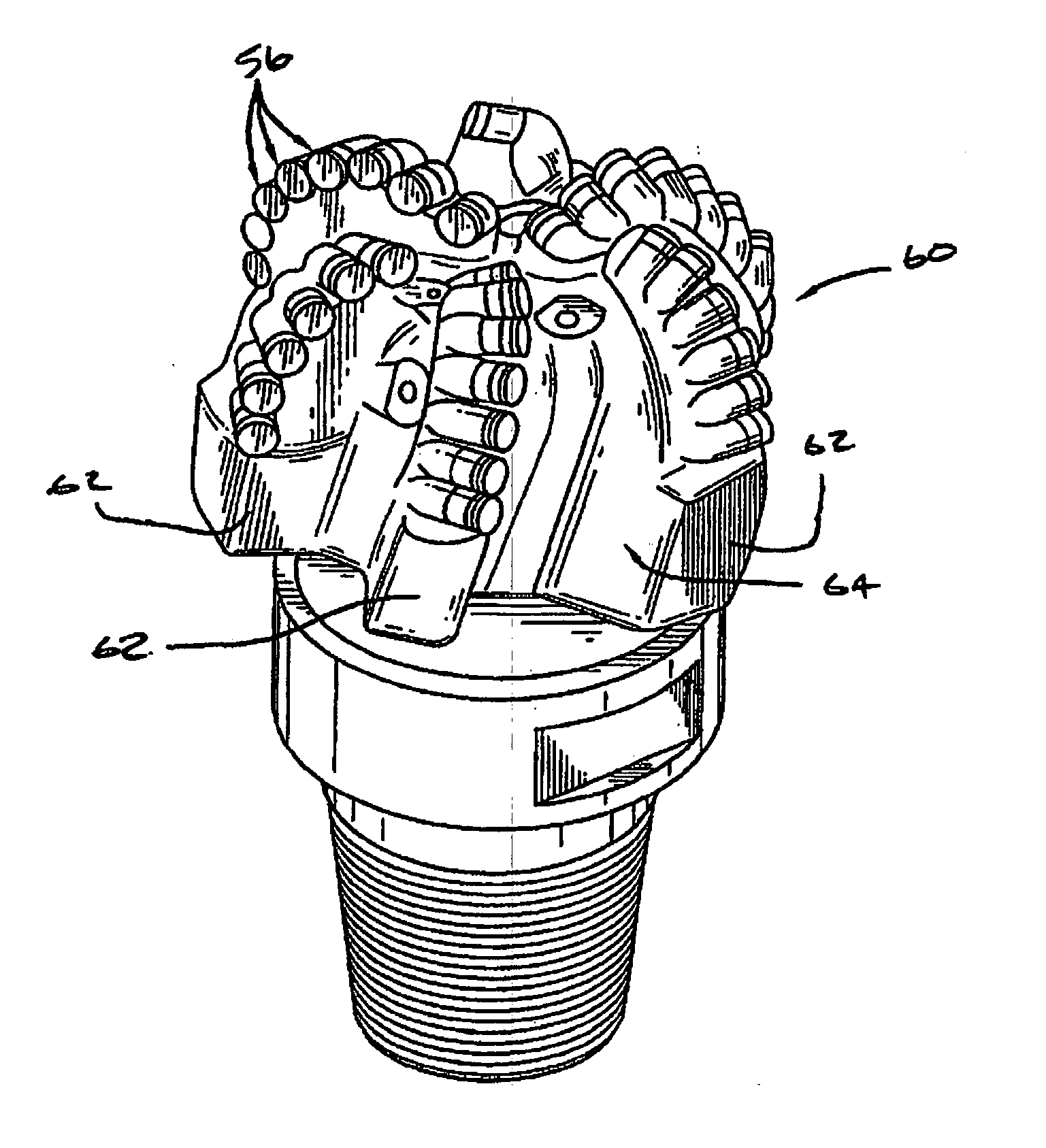

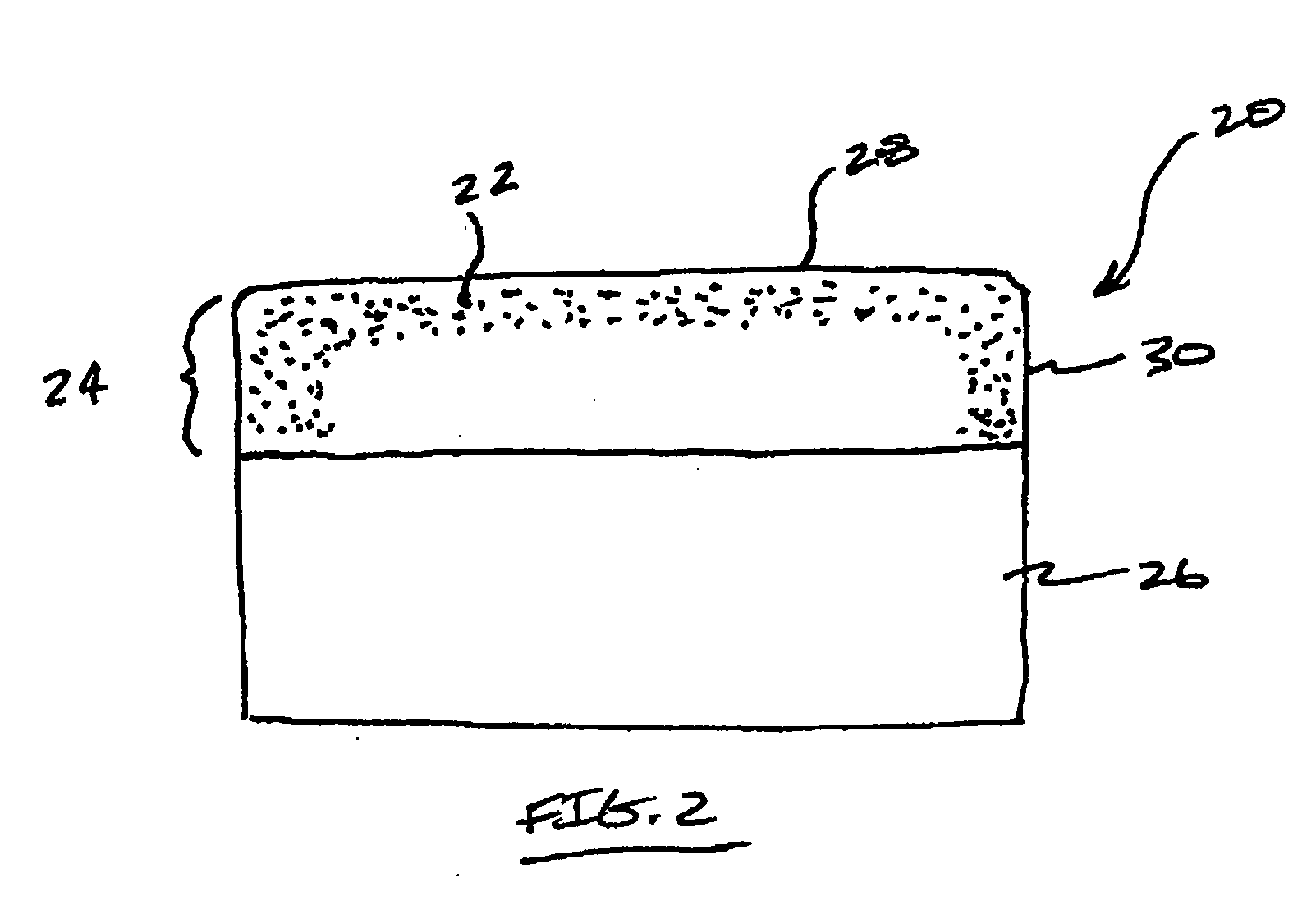

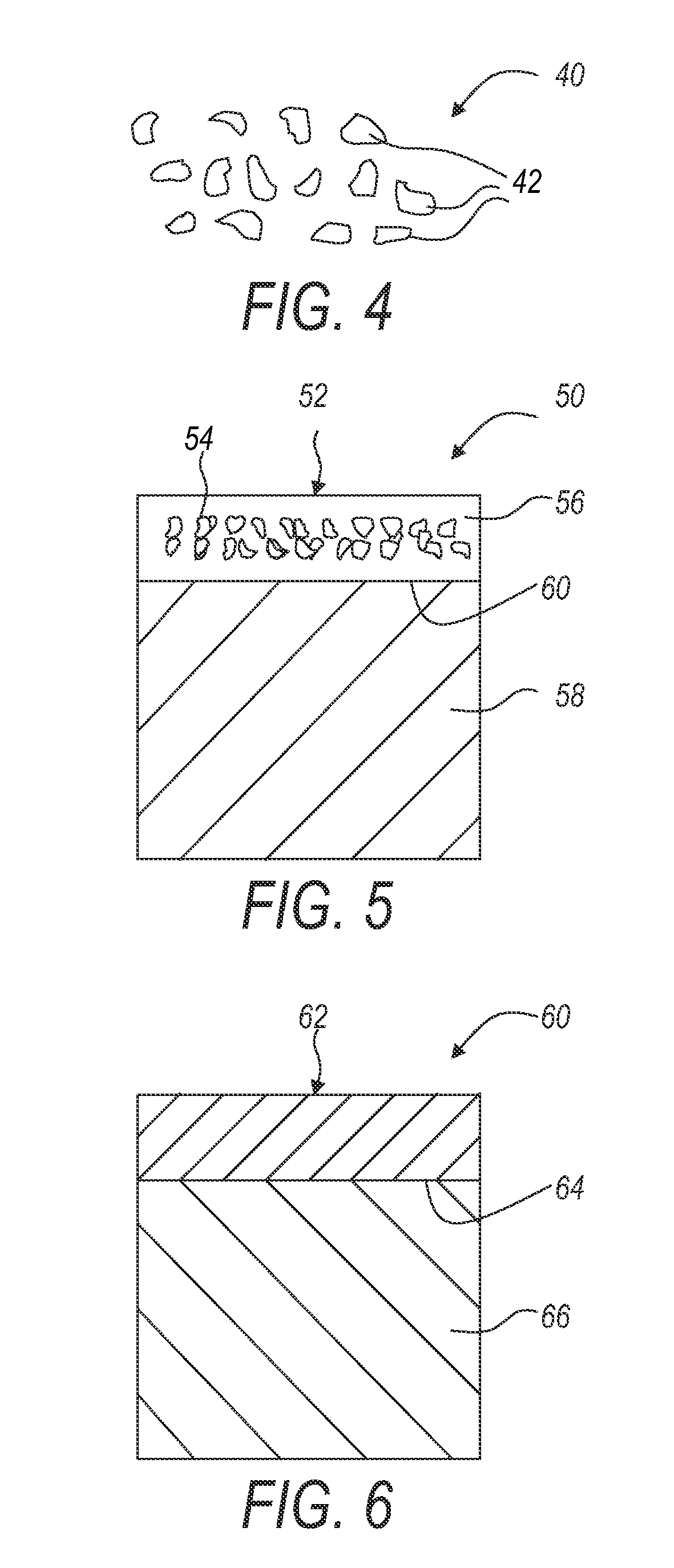

PCD materials comprise a diamond body having bonded diamond crystals and interstitial regions disposed among the crystals. The diamond body is formed from diamond grains and a catalyst material at high pressure / high temperature conditions. The diamond grains have an average particle size of about 0.03 mm or greater. At least a portion of the diamond body has a high diamond volume content of greater than about 93 percent by volume. The entire diamond body can comprise high volume content diamond or a region of the diamond body can comprise the high volume content diamond. The diamond body includes a working surface, a first region substantially free of the catalyst material, and a second region that includes the catalyst material. At least a portion of the first region extends from the working surface to depth of from about 0.01 to about 0.1 mm.

Owner:SMITH INT INC

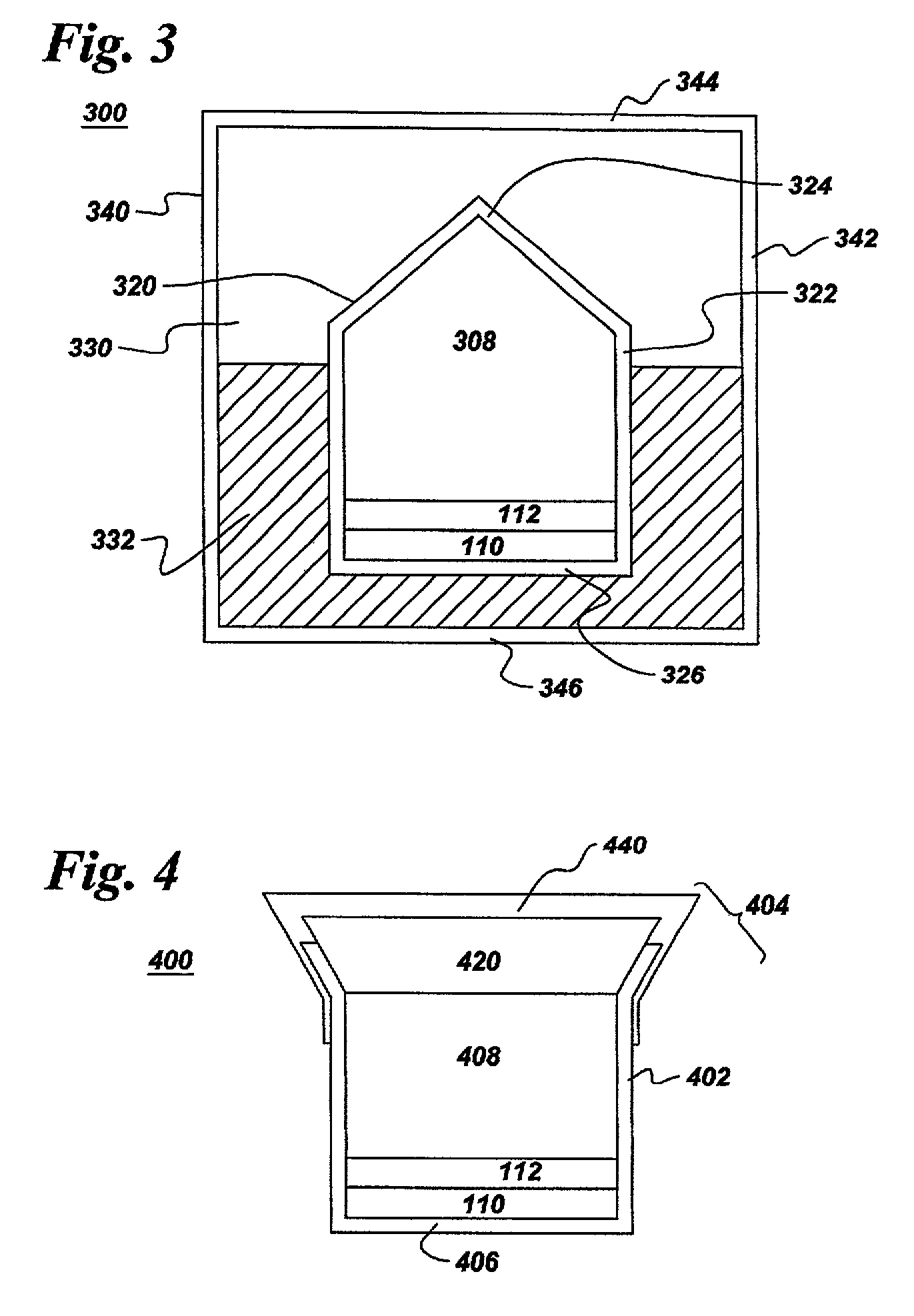

Apparatus for processing materials in supercritical fluids and methods thereof

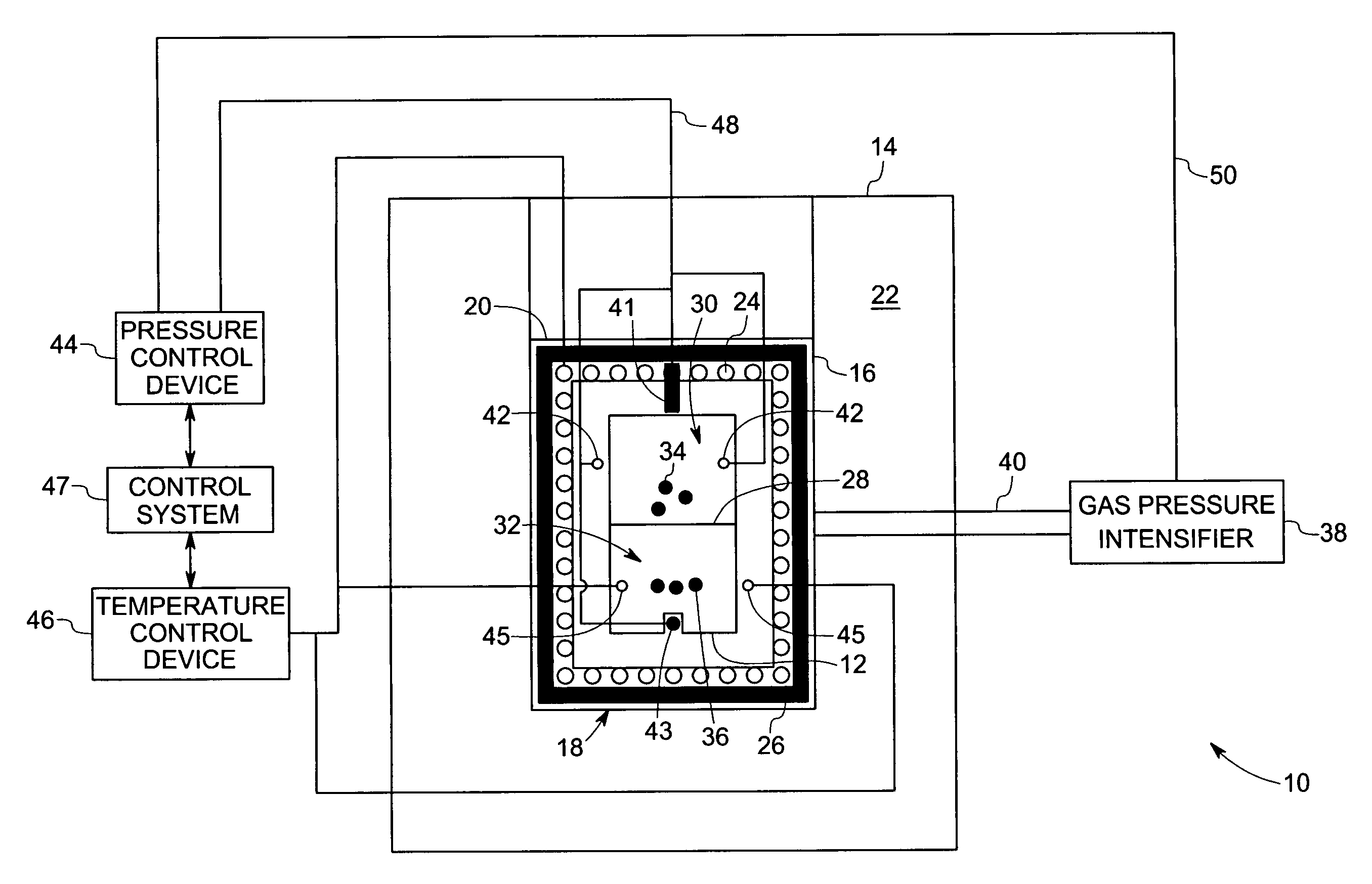

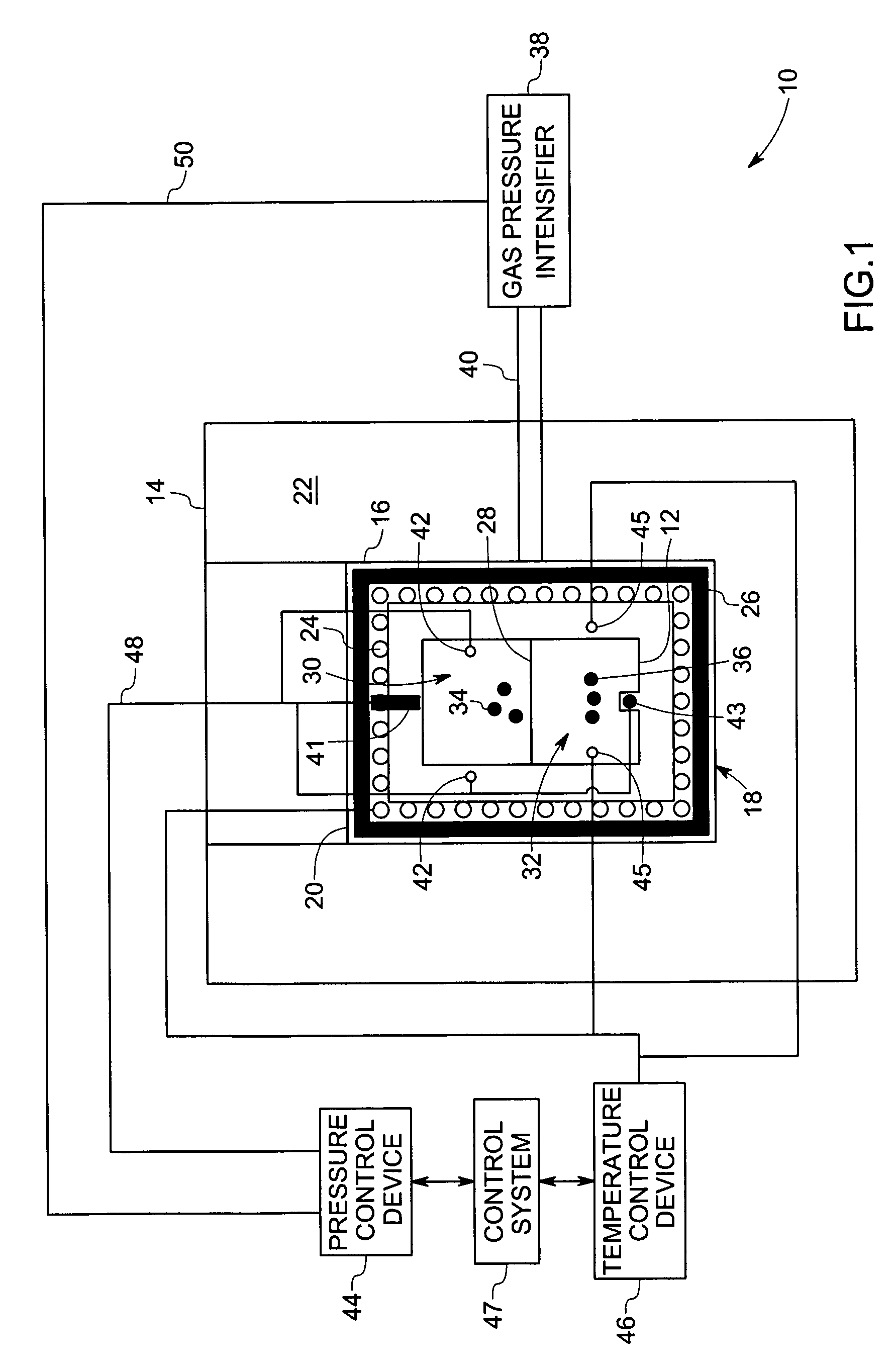

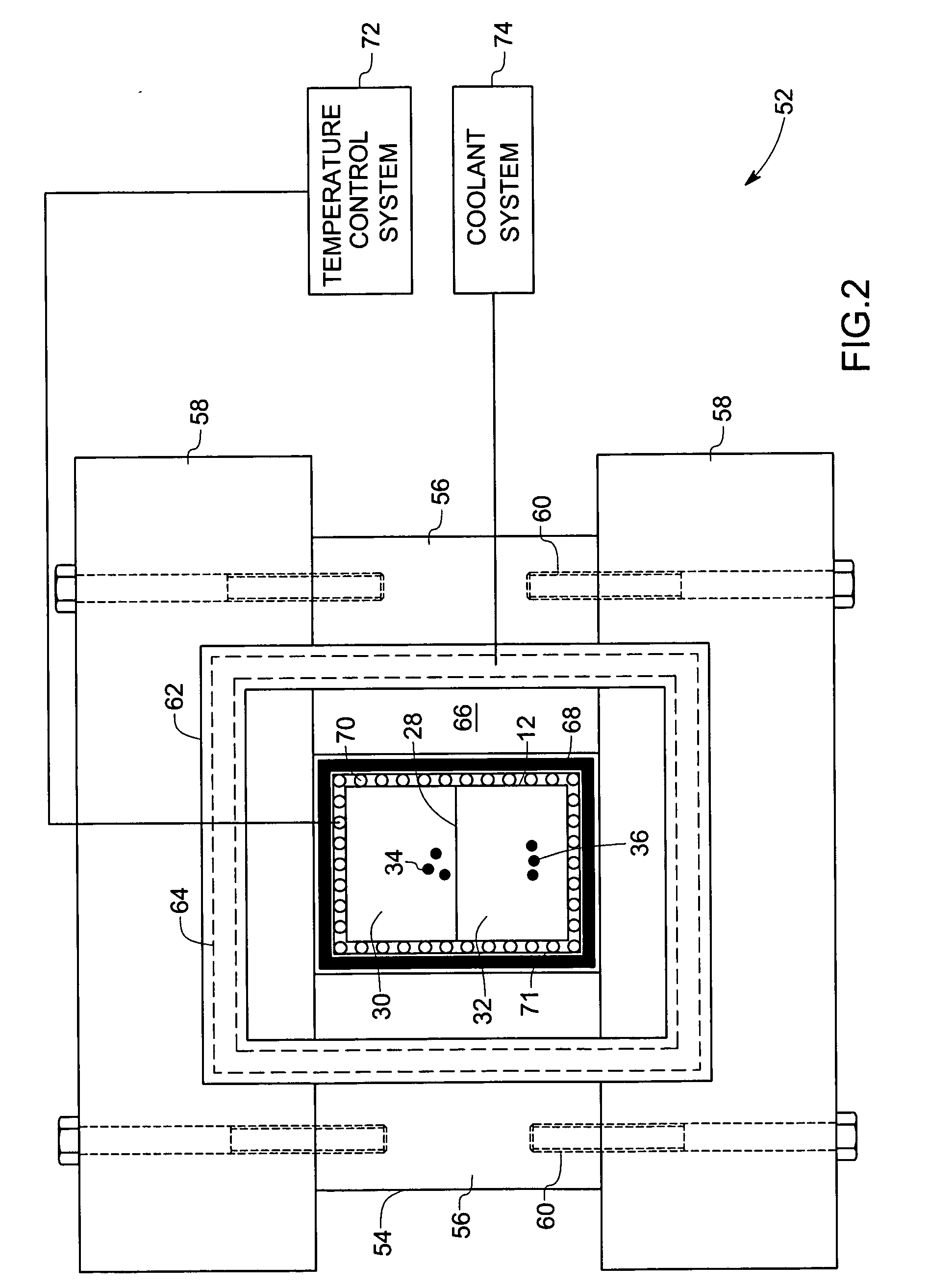

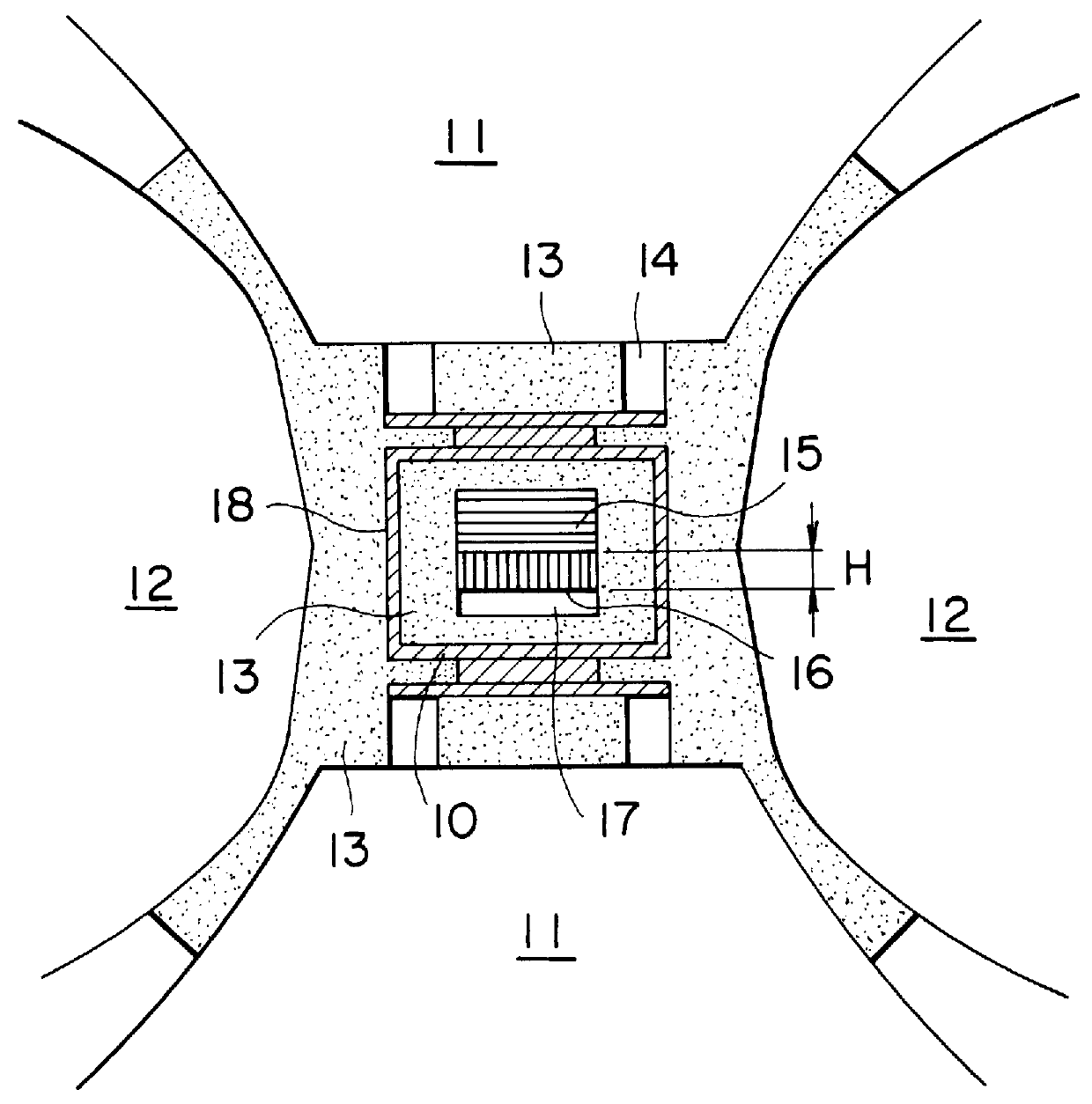

ActiveUS20060177362A1After-treatment apparatusUltra-high pressure processesHigh intensityPressure difference

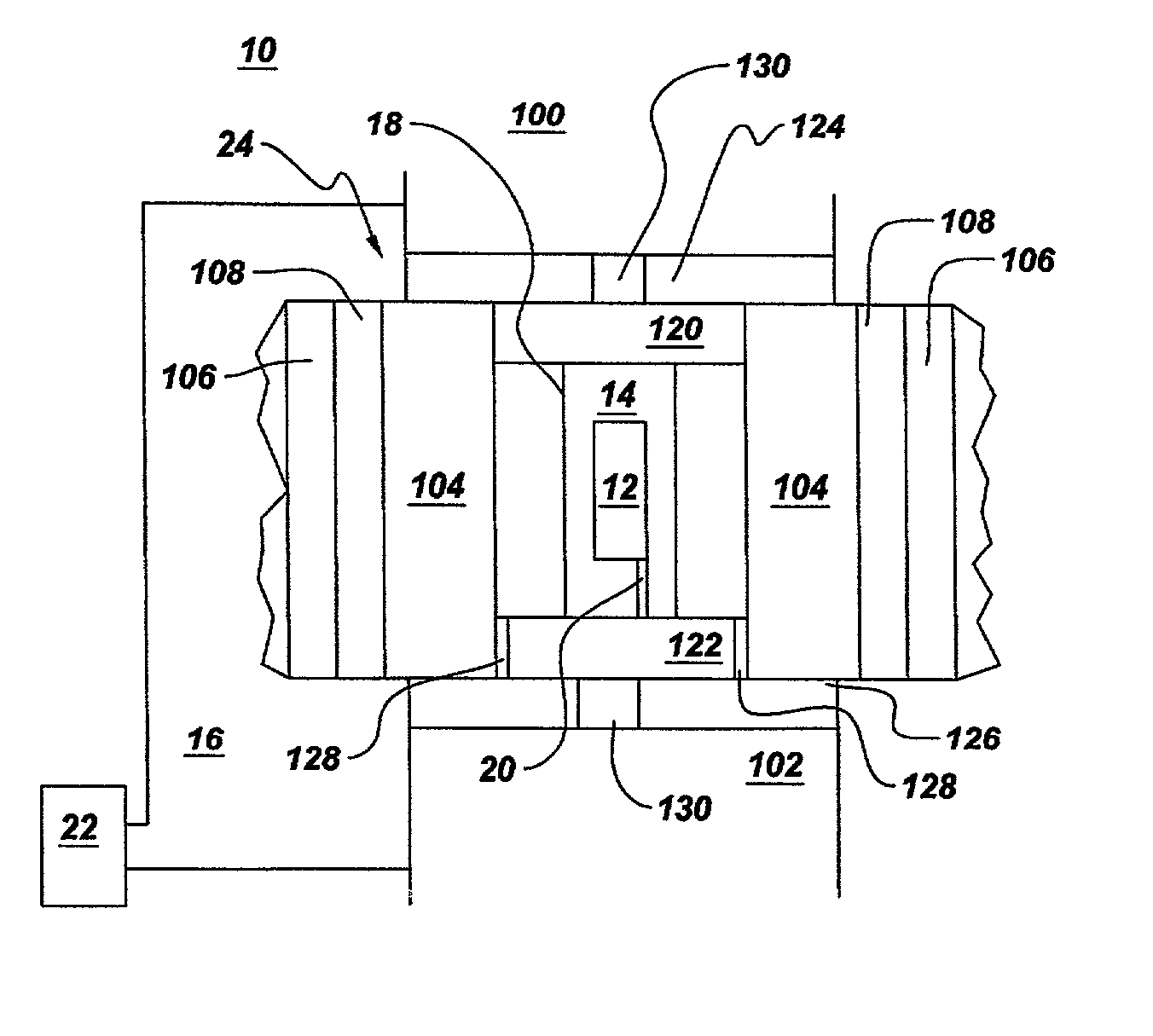

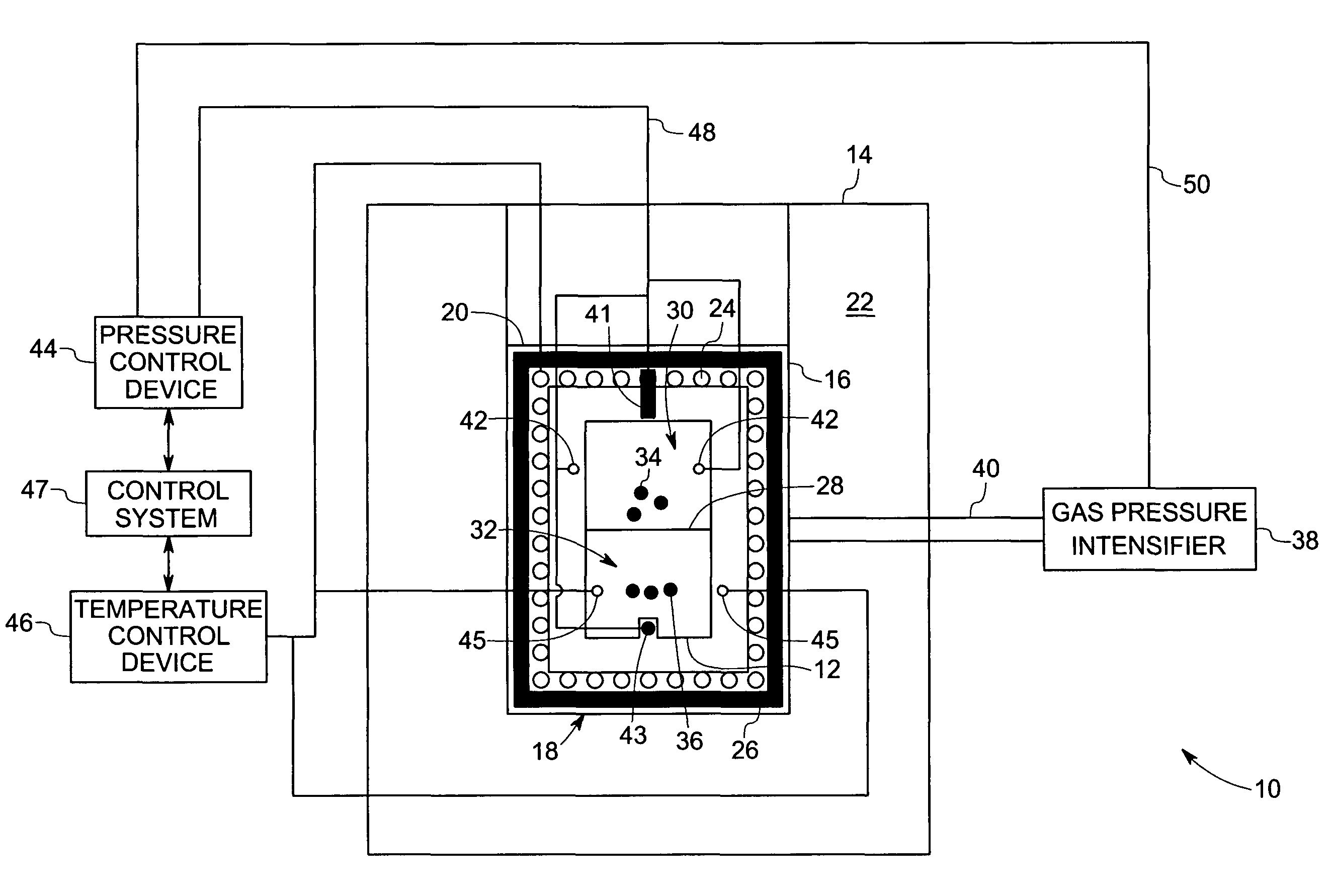

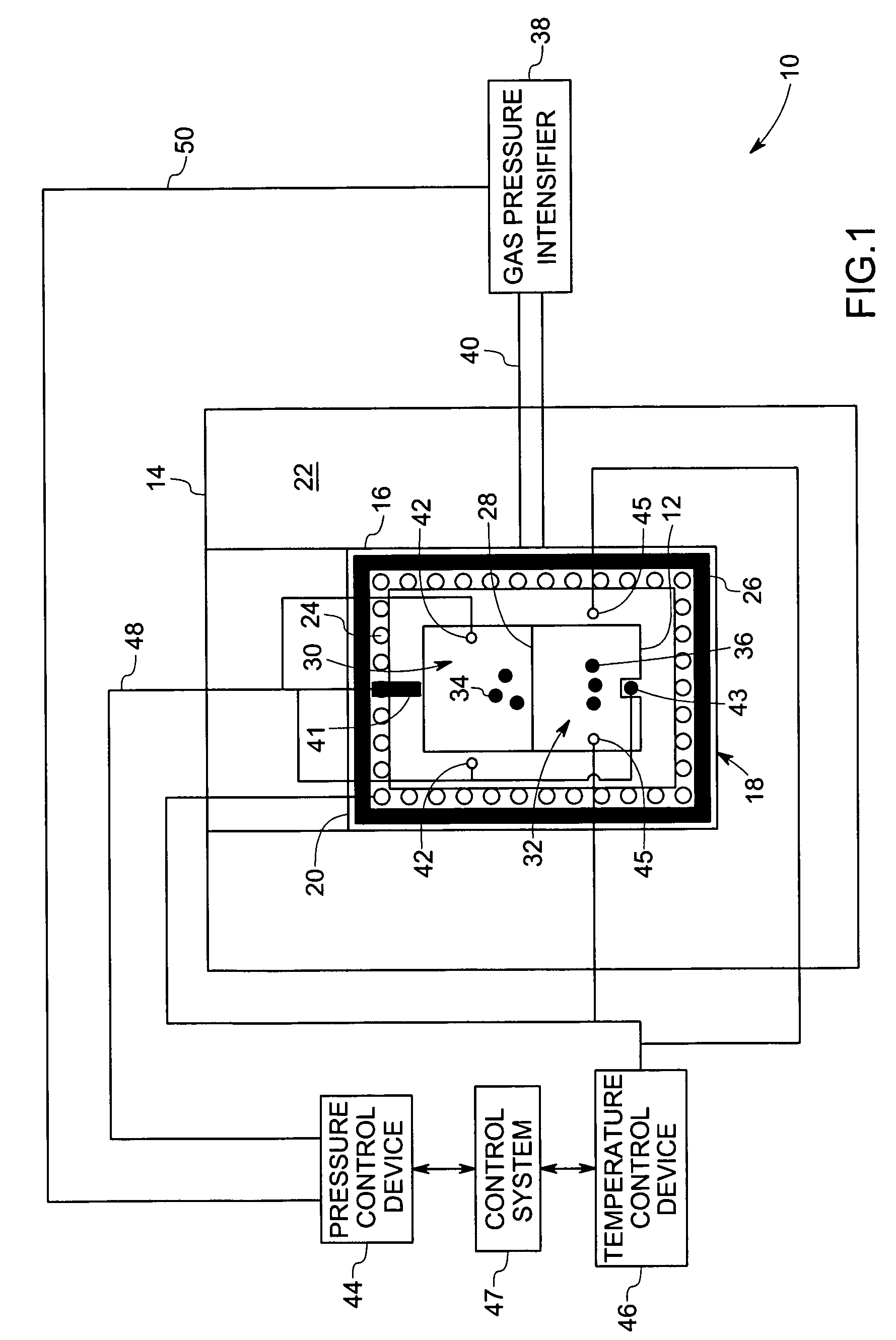

An apparatus and method for processing materials in supercritical fluids is disclosed. The apparatus includes a capsule configured to contain a supercritical fluid, a high strength enclosure disposed about the capsule and a sensor configured to sense pressure difference between an interior and an exterior of the capsule. The apparatus also includes a pressure control device configured to adjust pressure difference of the capsule in response to the pressure difference sensed by the sensor. The apparatus further includes at least one dividing structure disposed within the capsule that divides the capsule into a seed growing chamber and a nutrient chamber.

Owner:SLT TECH

Polycrystalline diamond materials having improved abrasion resistance, thermal stability and impact resistance

PCD materials comprise a diamond body having bonded diamond crystals and interstitial regions disposed among the crystals. The diamond body is formed from diamond grains and a catalyst material at high pressure / high temperature conditions. The diamond grains have an average particle size of about 0.03 mm or greater. At least a portion of the diamond body has a high diamond volume content of greater than about 93 percent by volume. The entire diamond body can comprise high volume content diamond or a region of the diamond body can comprise the high volume content diamond. The diamond body includes a working surface, a first region substantially free of the catalyst material, and a second region that includes the catalyst material. At least a portion of the first region extends from the working surface to depth of from about 0.01 to about 0.1 mm.

Owner:SMITH INT INC

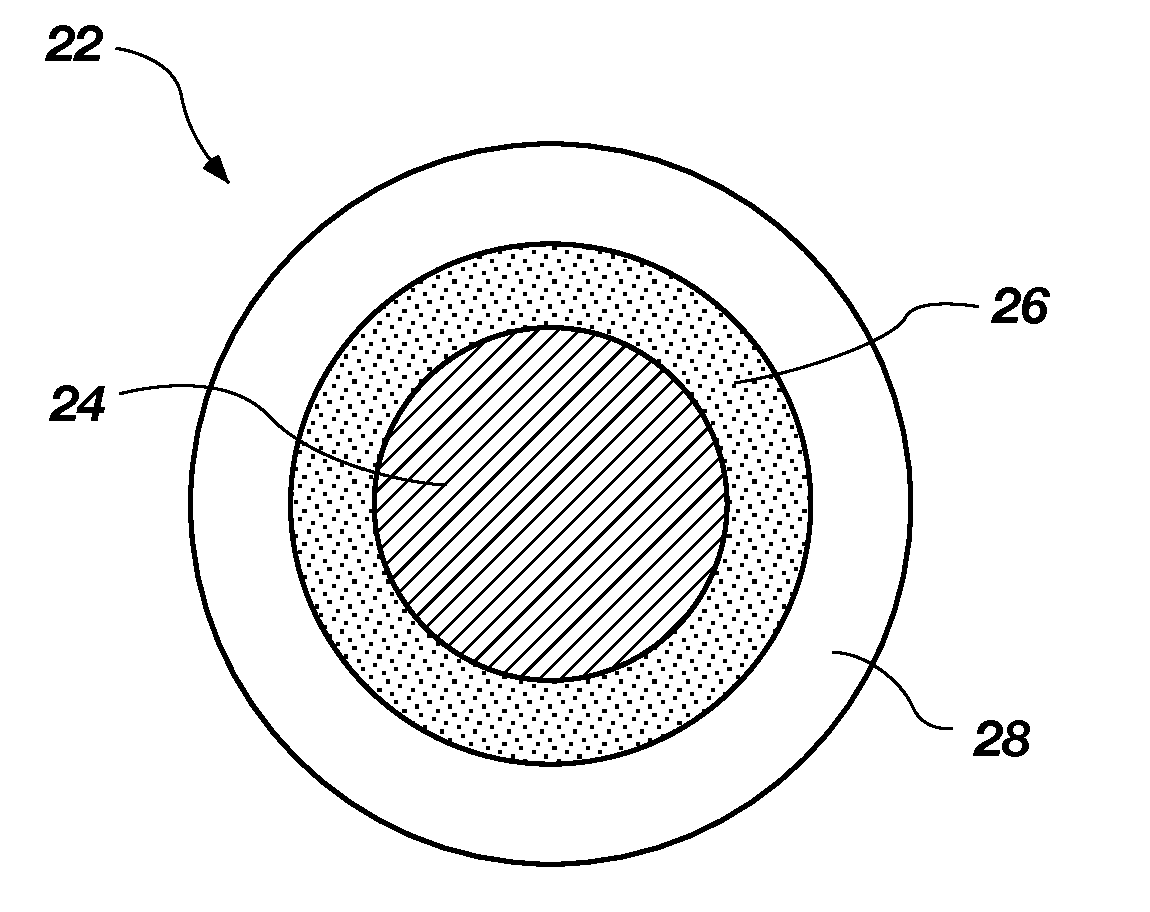

Polycrystalline diamond composites

InactiveUS20080073126A1Good adhesionDrill bitsConstructionsPolycrystalline diamondVolumetric Mass Density

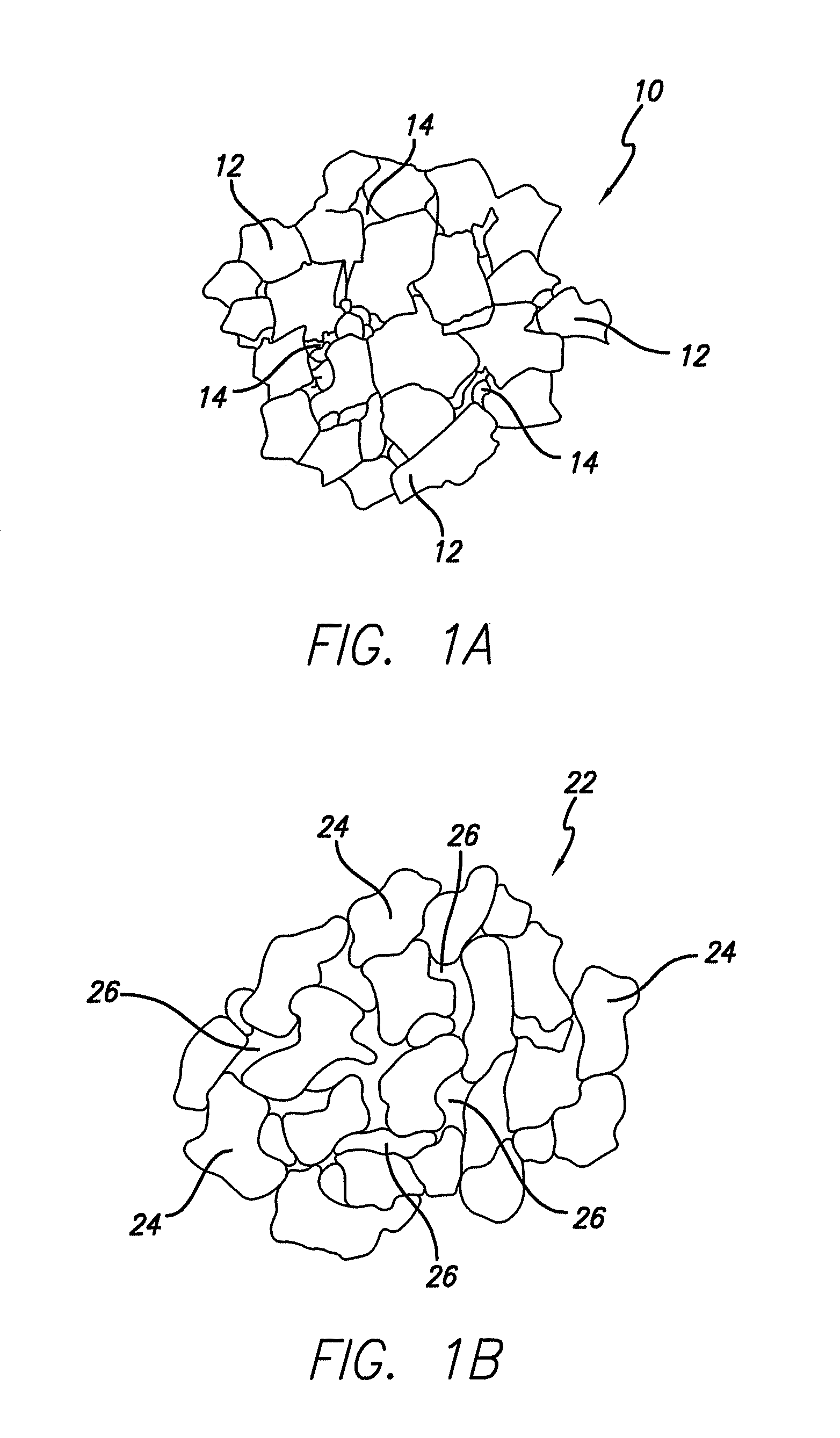

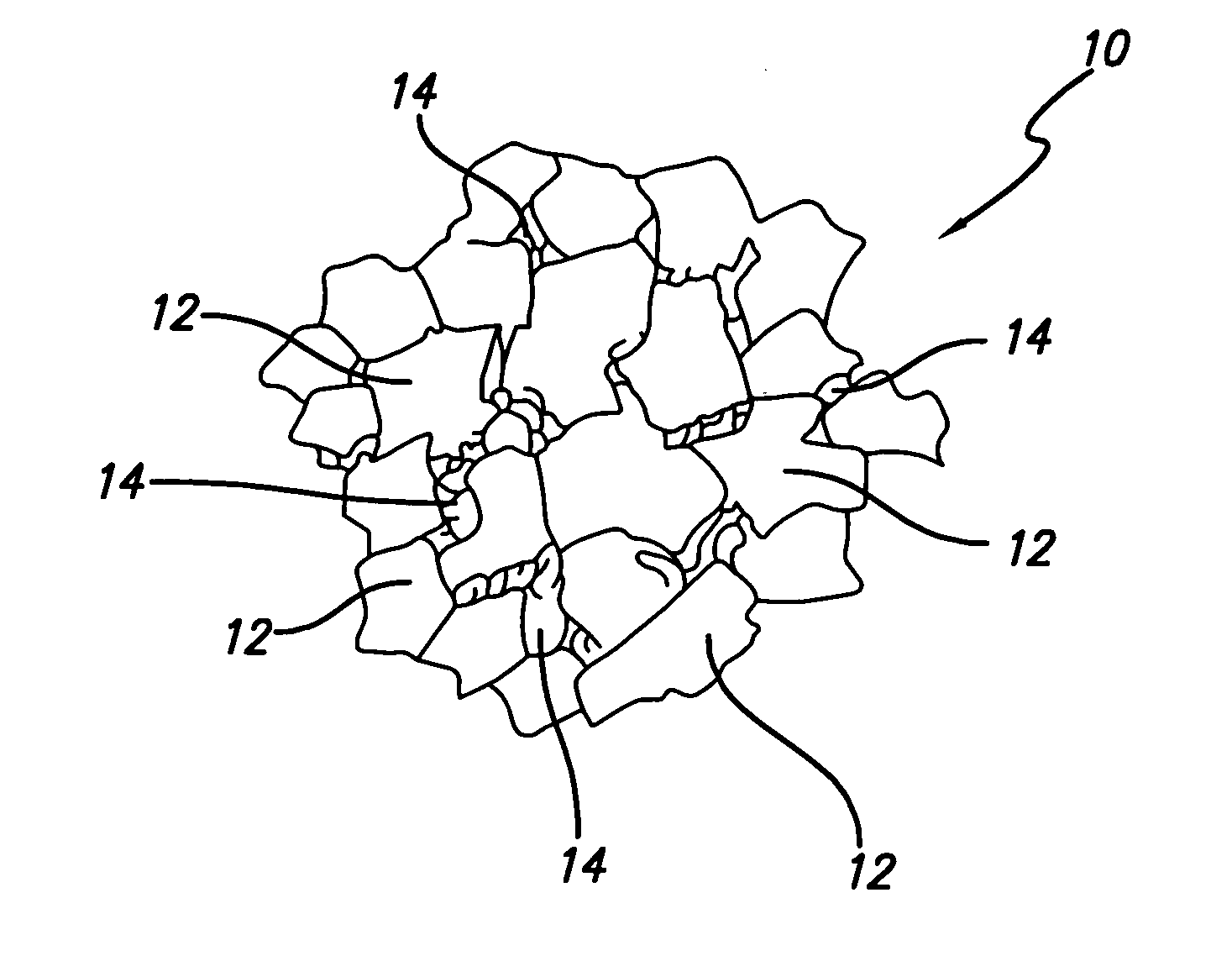

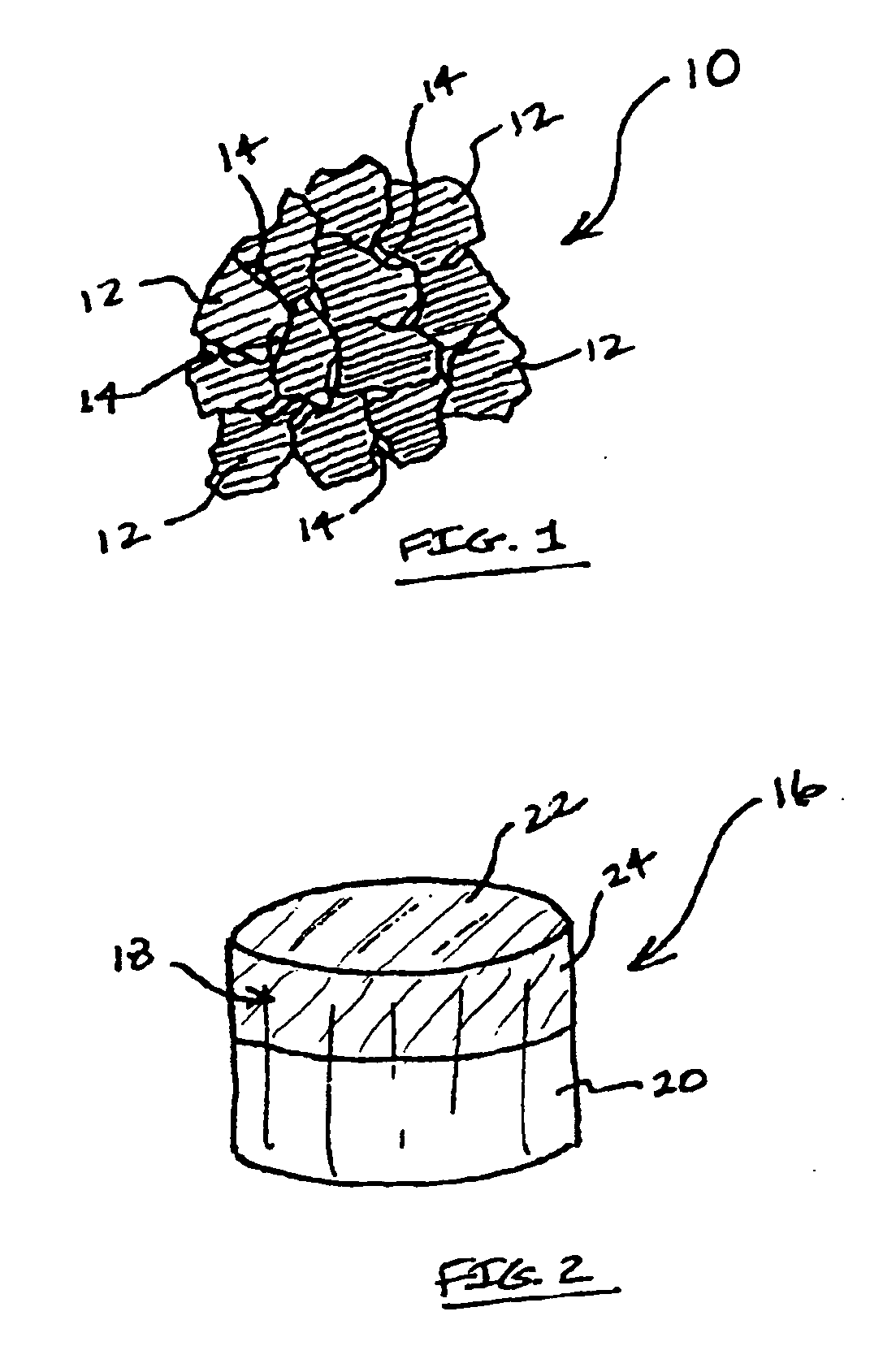

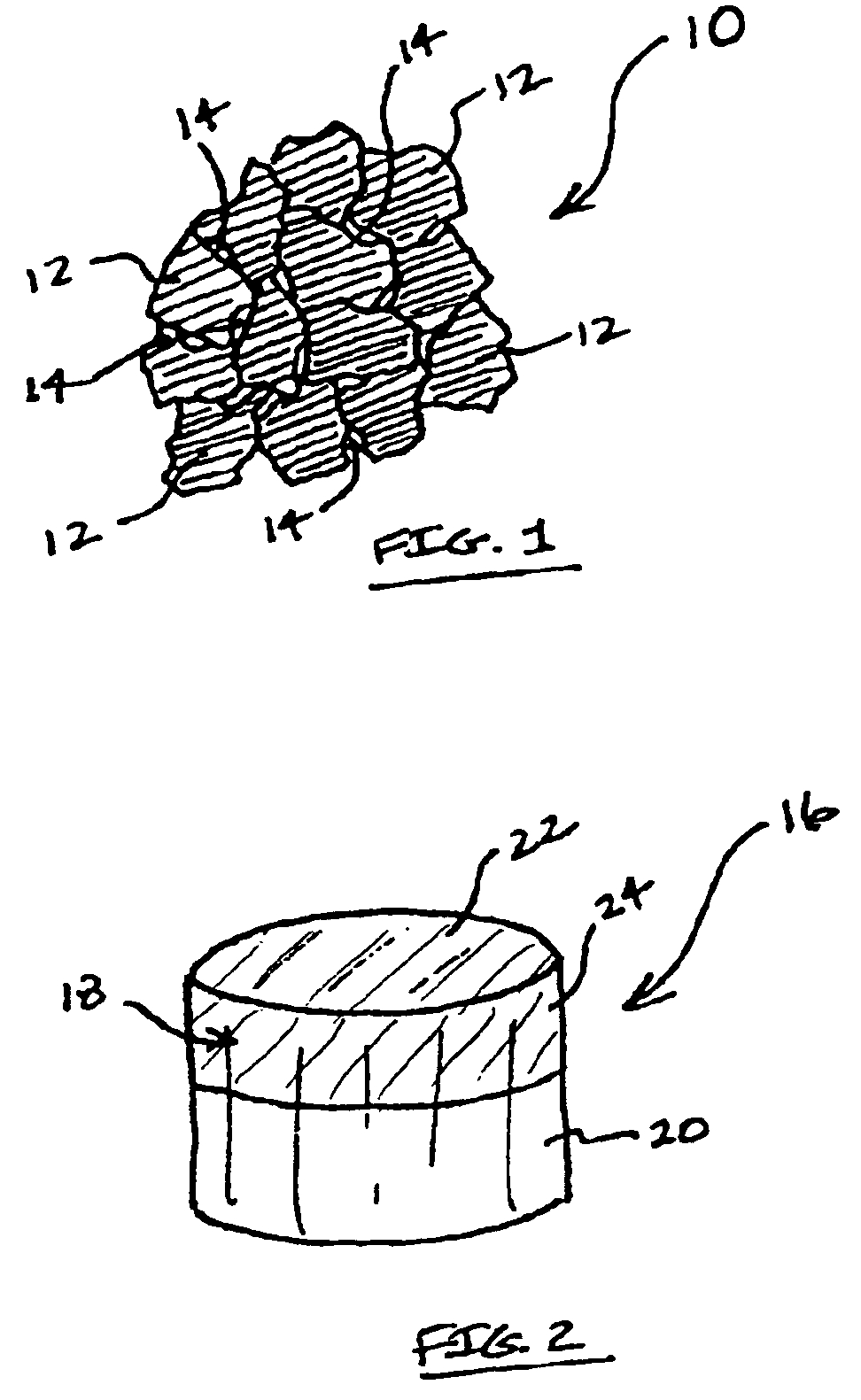

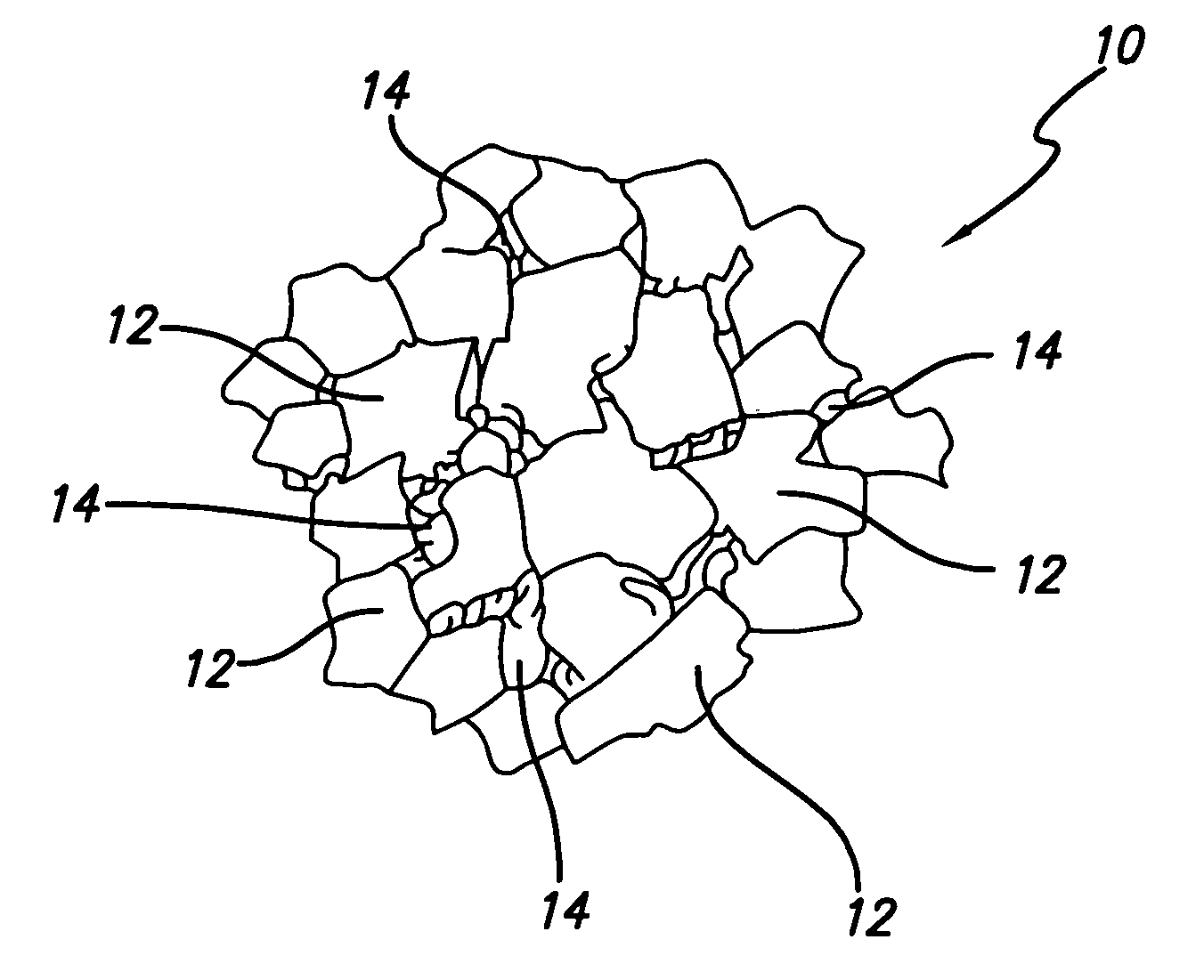

Polycrystalline diamond composites comprise a polycrystalline diamond body having a plurality of ultra-hard discrete regions dispersed within a polycrystalline diamond second region. The plurality of discrete regions has an density different from of the polycrystalline diamond second region. A metallic substrate can be joined to the body. The discrete regions can be relatively more thermal stable than, have a higher diamond density than, and / or may comprise a binder material that is different from the polycrystalline diamond second region. Polycrystalline diamond composites can be formed by combining already sintered granules with diamond grains to form a mixture, and subjecting the mixture to high pressure / high temperature conditions, wherein the granules form the plurality of discrete regions, or can be made by forming a plurality of unsintered granules, combining them with diamond grains to form a mixture, and then subjecting the mixture to first and second high pressure / high temperature conditions.

Owner:SMITH INT INC

Thermally-stable polycrystalline diamond materials and compacts

InactiveUS7473287B2Improve thermal stabilityImprove bindingPigmenting treatmentDrill bitsDiamond crystalPolycrystalline diamond

Thermally-stable polycrystalline diamond materials of this invention comprise a first phase including a plurality of bonded together diamond crystals, and a second phase including a reaction product formed between a binder / catalyst material and a material reactive with the binder / catalyst material. The reaction product is disposed within interstitial regions of the polycrystalline diamond material that exists between the bonded diamond crystals. The first and second phases are formed during a single high pressure / high temperature process condition. The reaction product has a coefficient of thermal expansion that is relatively closer to that of the bonded together diamond crystals than that of the binder / catalyst material, thereby providing an improved degree of thermal stability to the polycrystalline diamond material.

Owner:SMITH INT INC

Brazed diamond tools and methods for making the same

Owner:SUNG CHIEN MIN

Pressure vessel

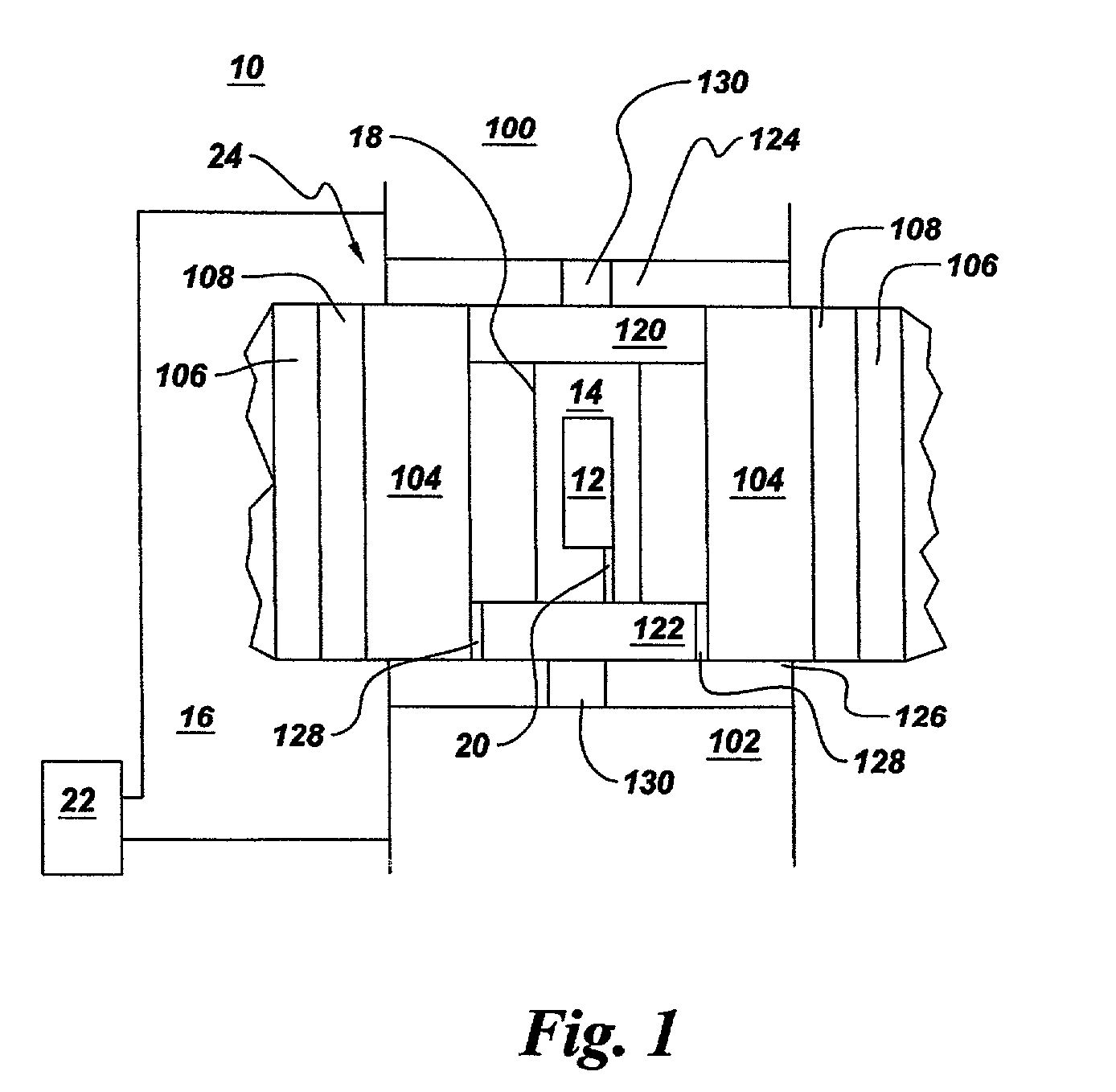

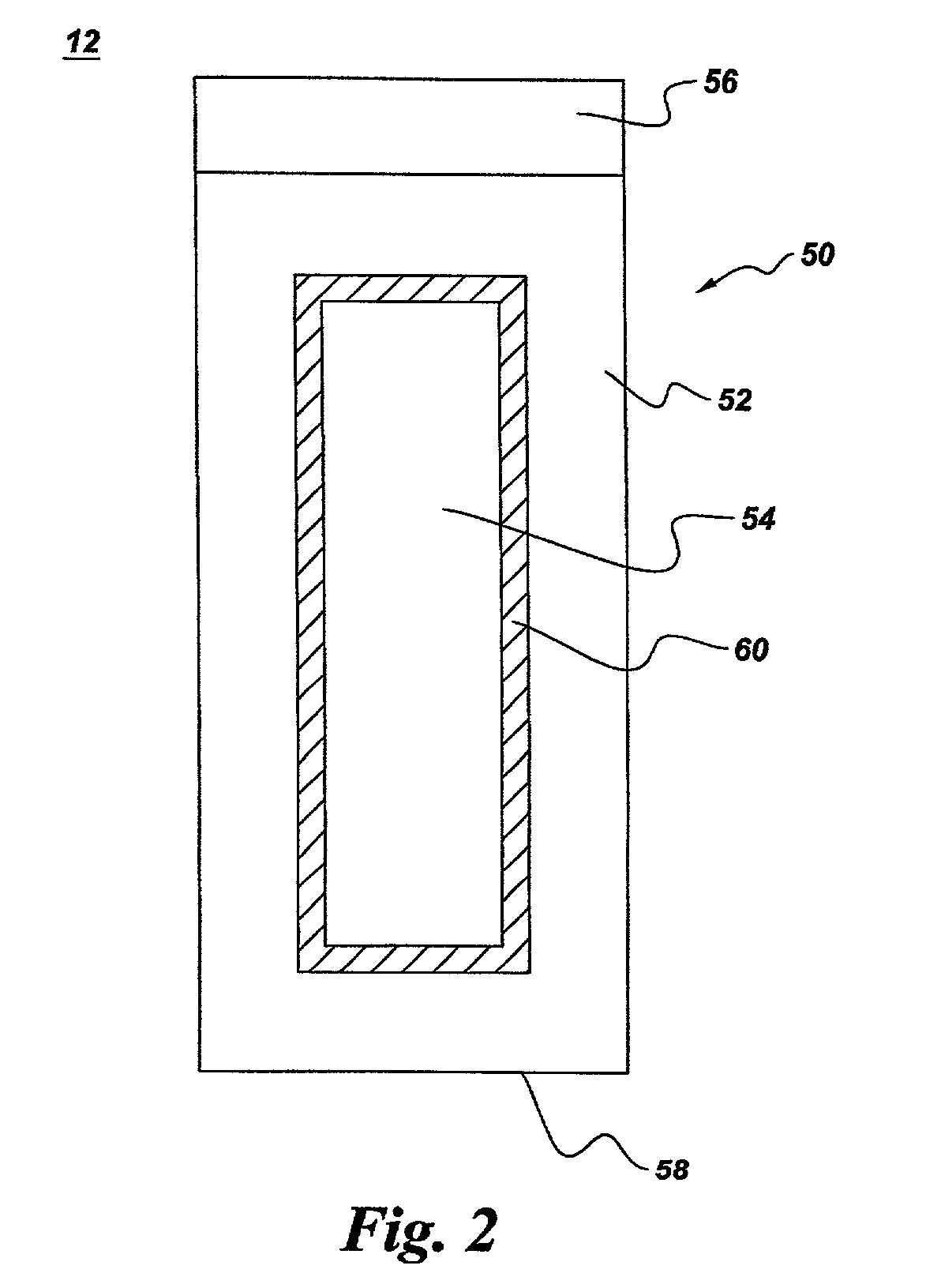

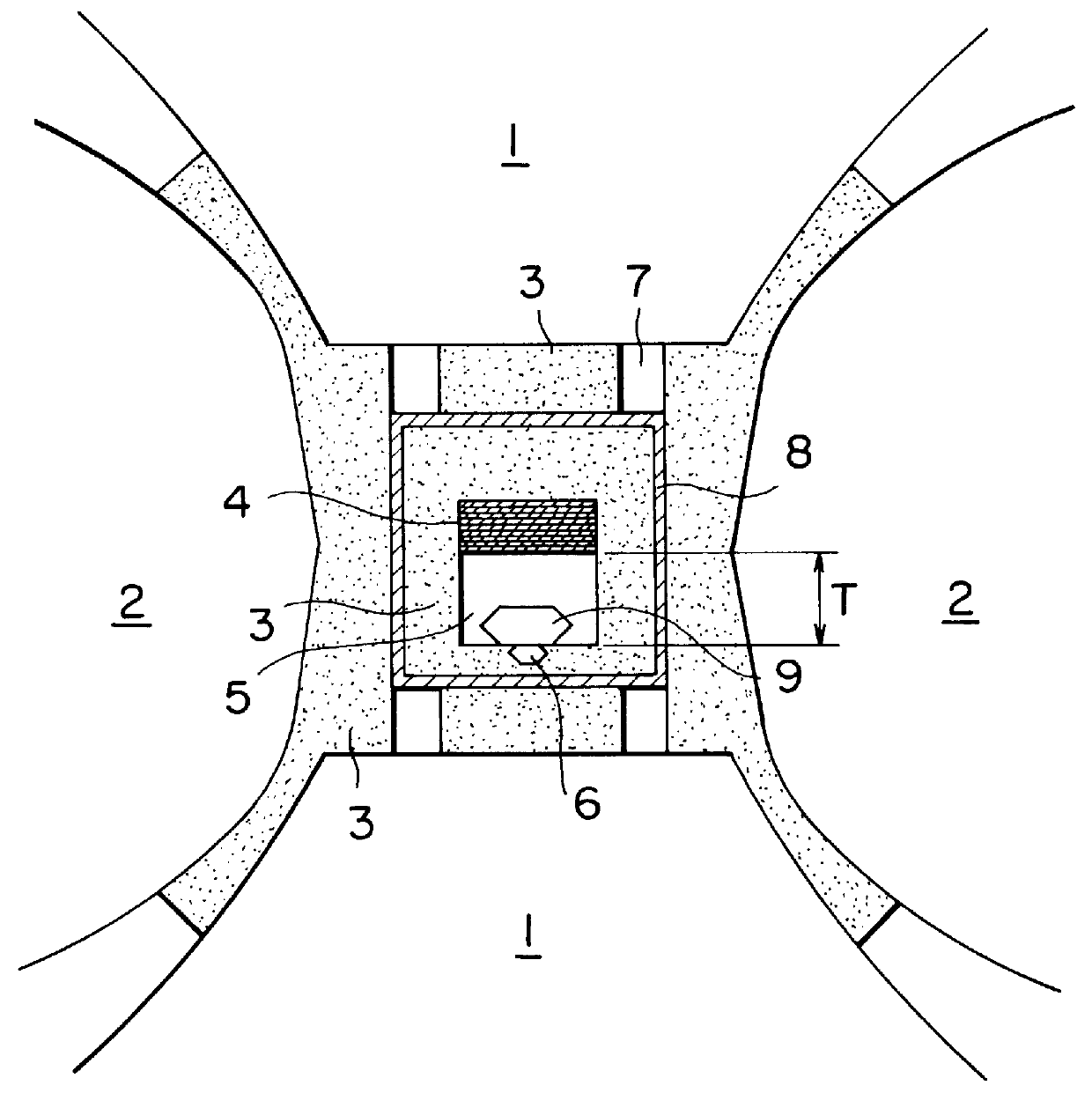

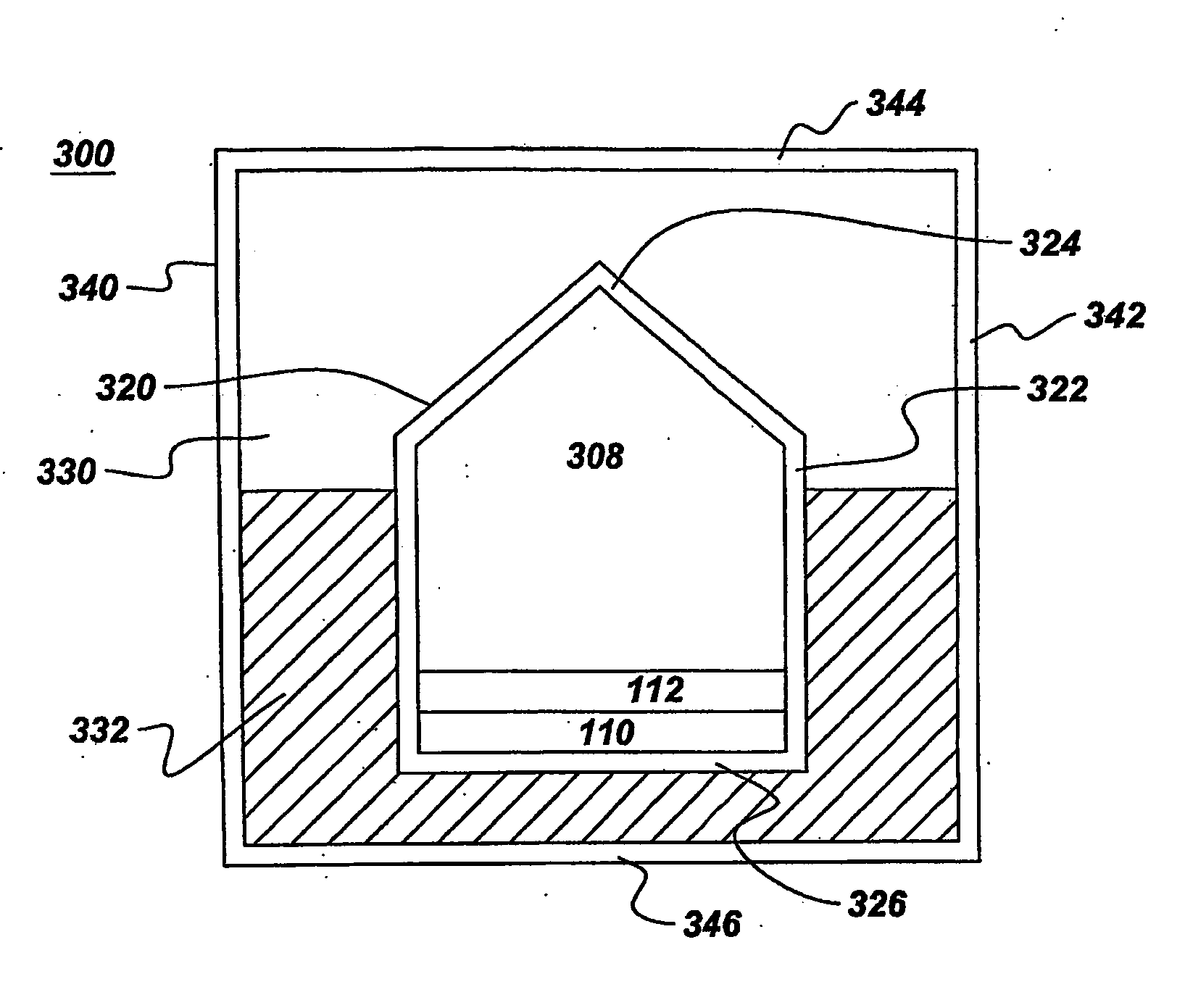

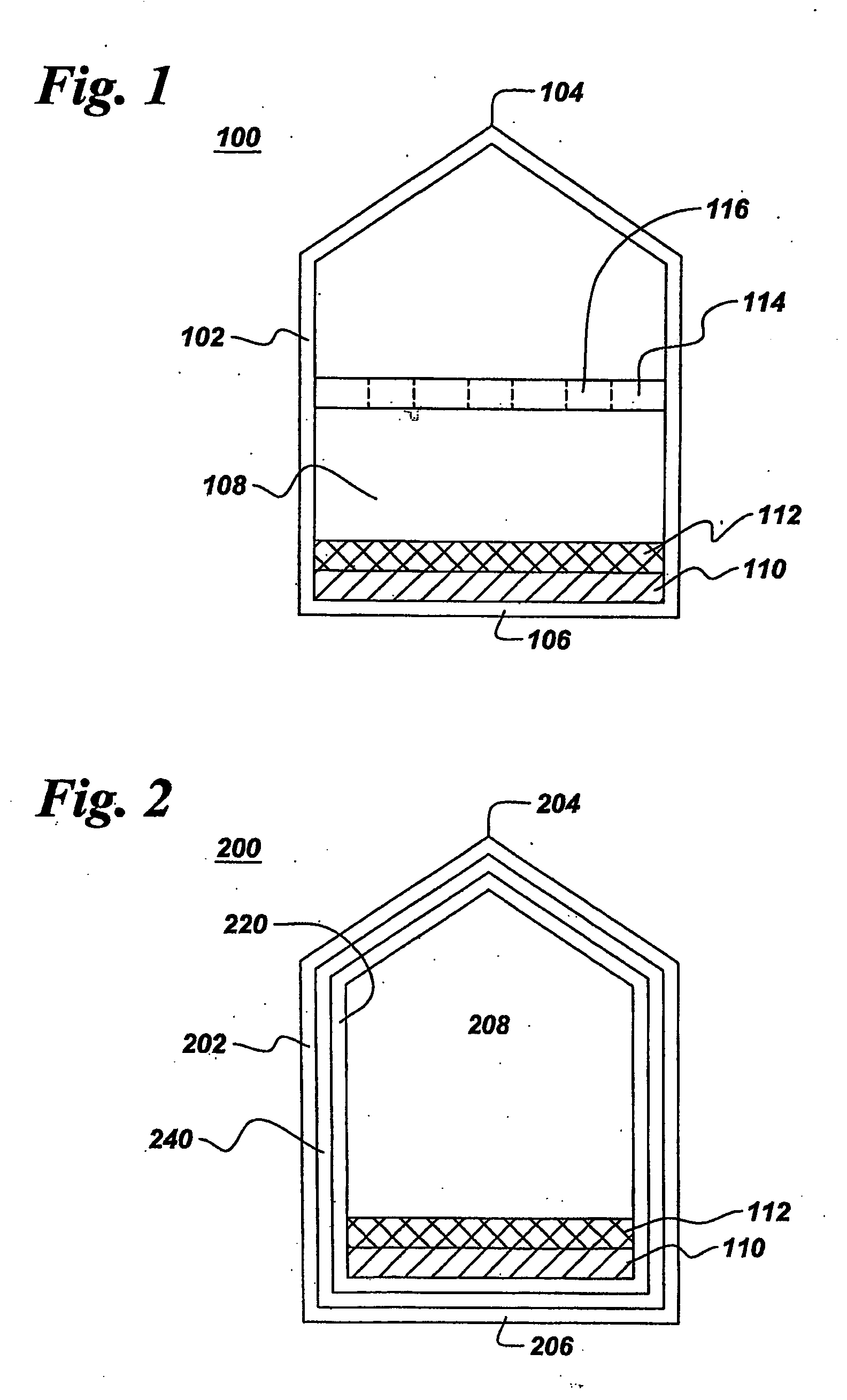

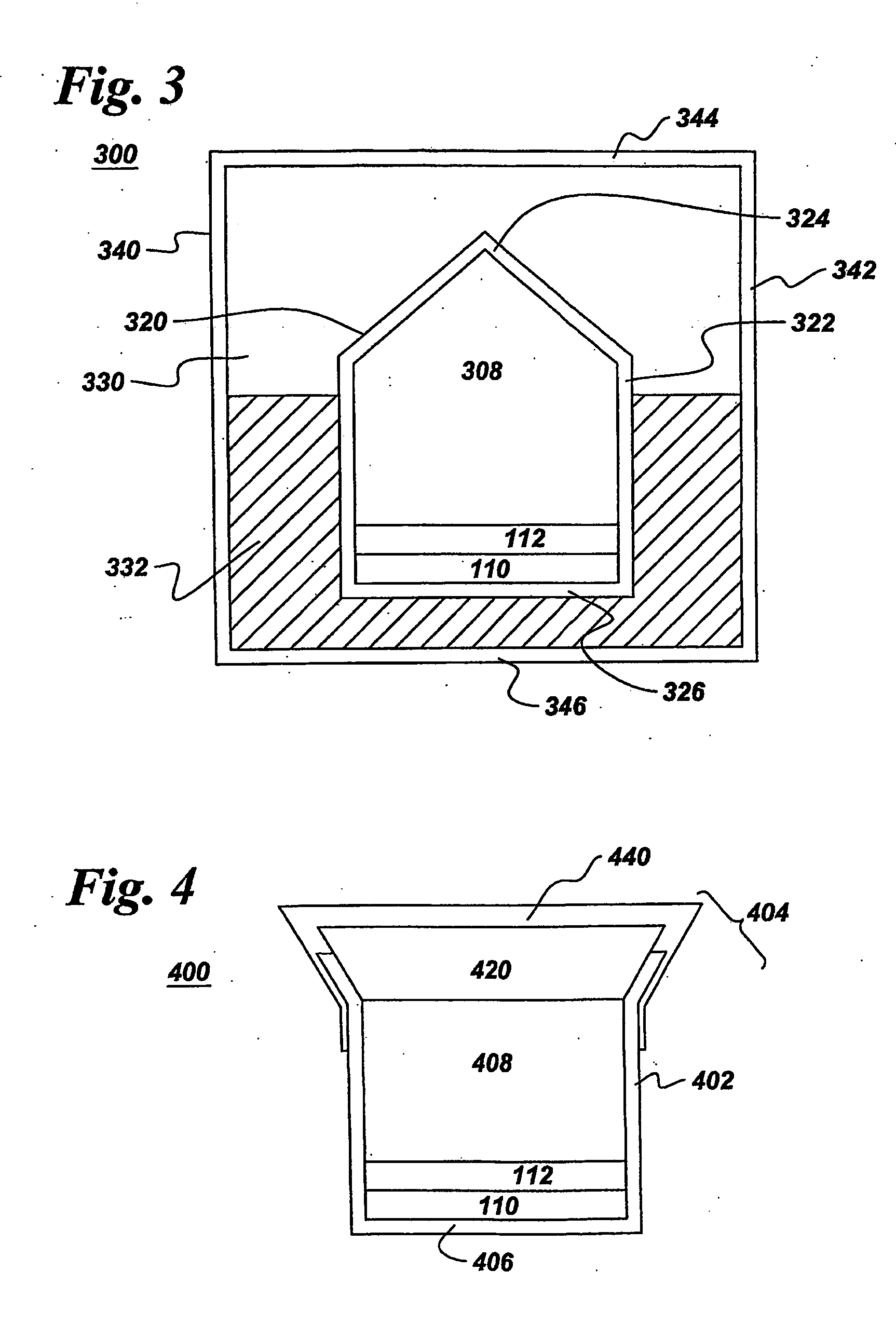

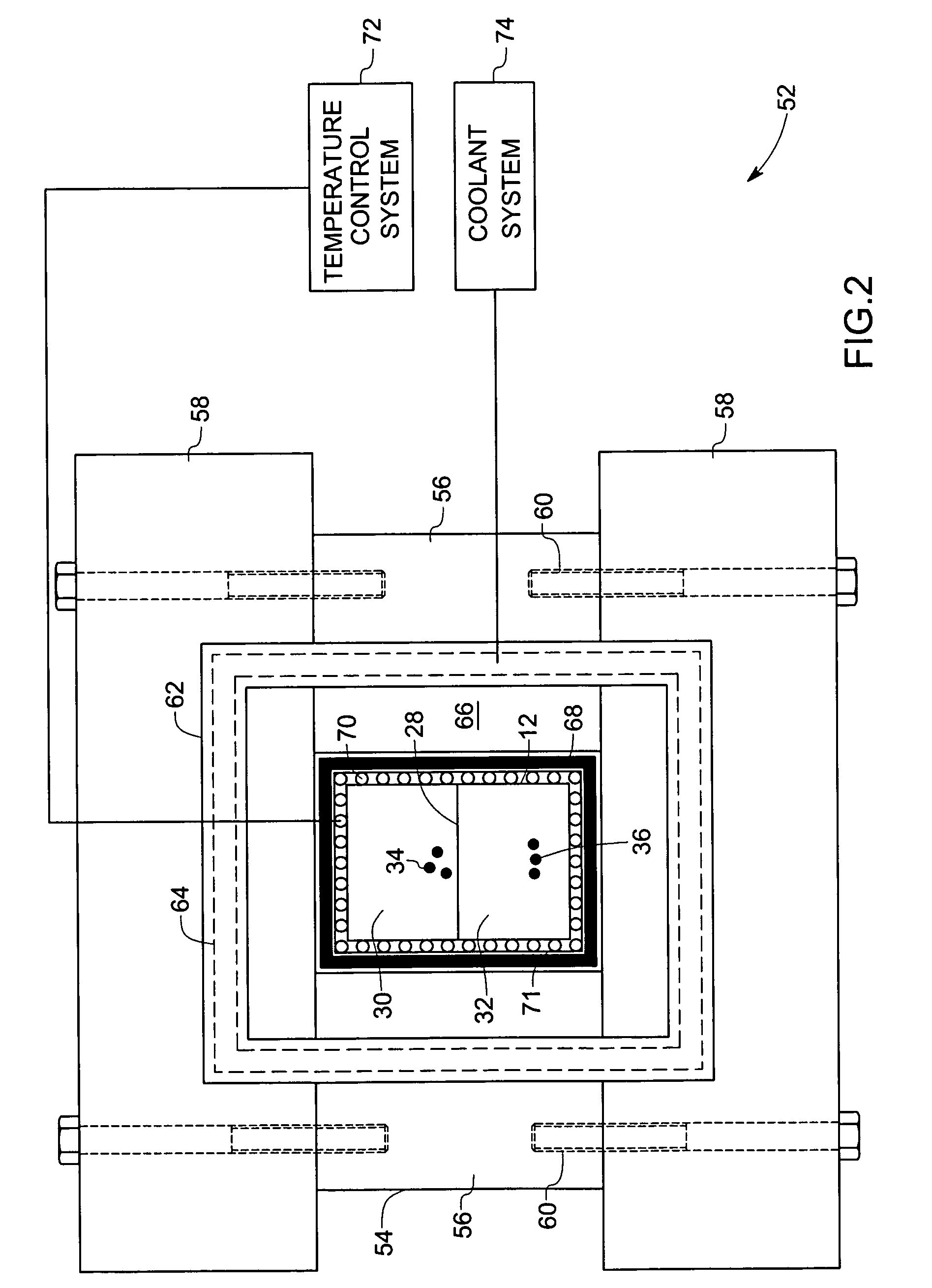

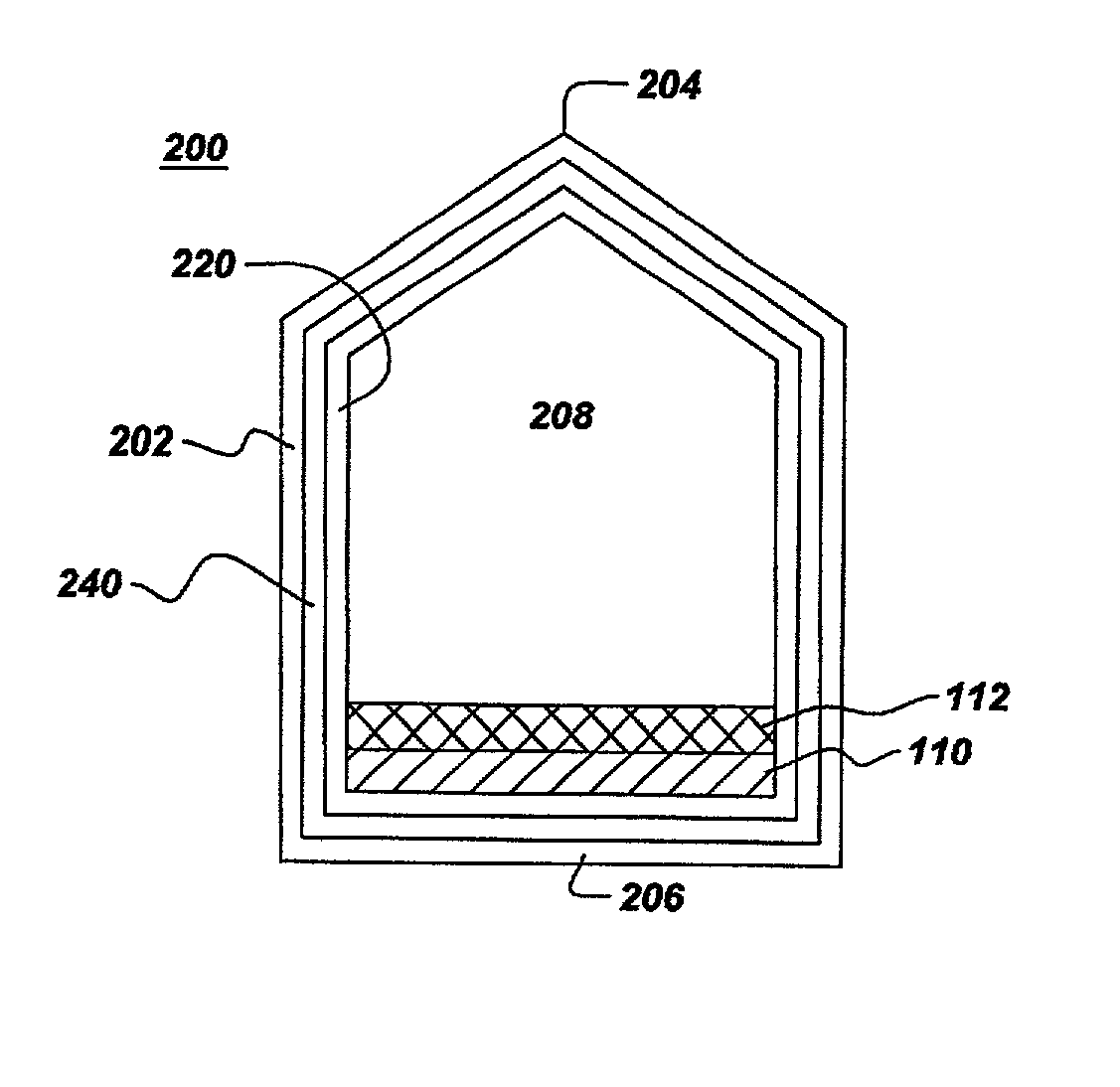

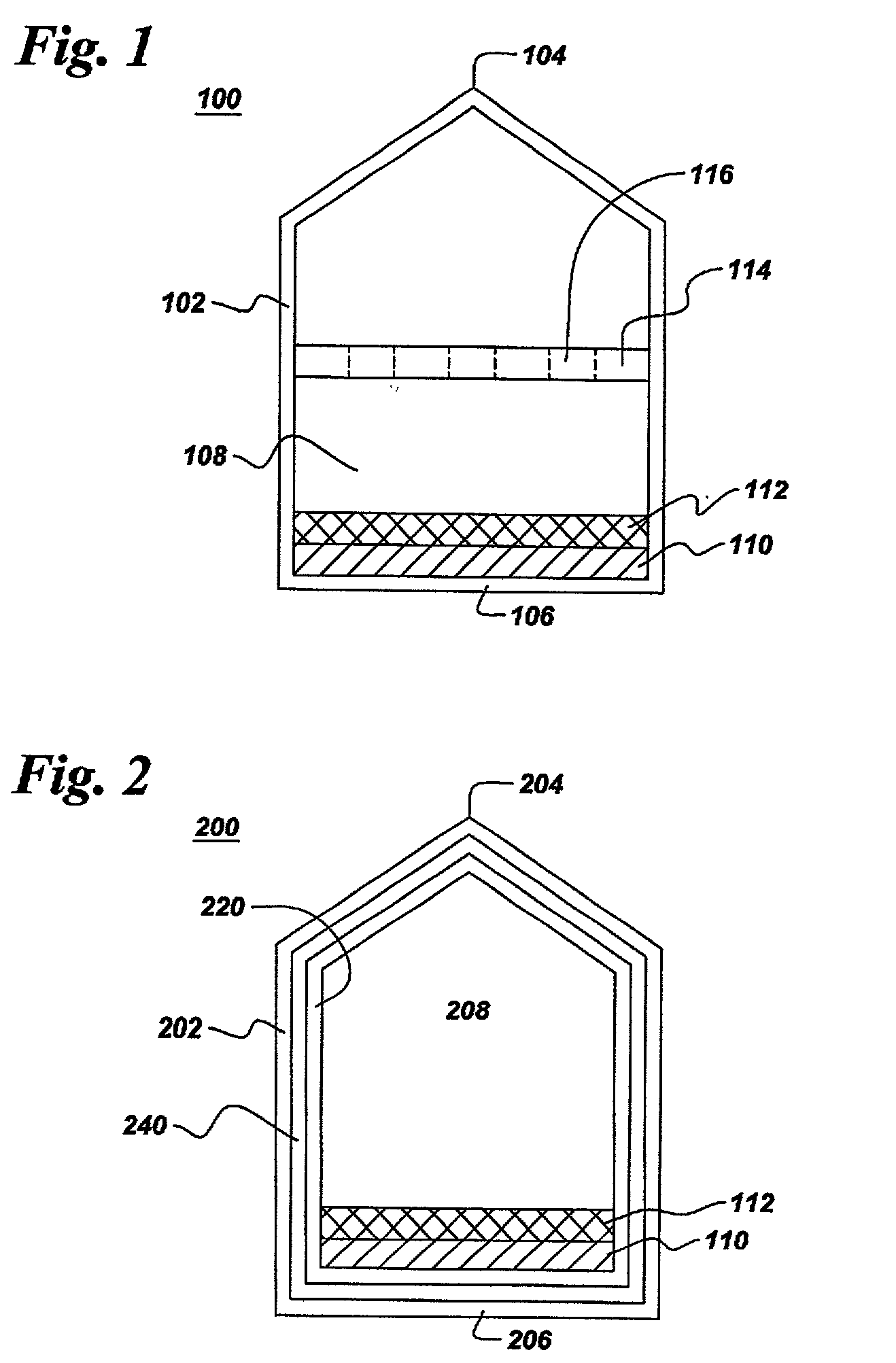

InactiveUS20030140845A1Prevent escapeAvoid creatingFrom gel statePolycrystalline material growthTemperature controlPressure transmission

A pressure vessel for processing at least one material in a supercritical fluid. The pressure vessel includes a self-pressurizing capsule for containing at least one material and the supercritical fluid in a substantially air-free environment, a pressure transmission medium surrounding the capsule for maintaining an outer pressure on the capsule, at least one heating element insertable in the pressure transmission medium such that the heating element surrounds the capsule, a temperature measurement means for measuring a temperature of the capsule, a temperature controller for controlling the temperature and providing power to the heating element, a restraint to contain and hold in place the capsule, the pressure transmission medium, and the heating element, and at least one seal between the restraint and the pressure transmission medium for preventing escape of the pressure transmission medium. Methods of using the pressure vessel, processing a material at high temperature and high pressure in the presence of a supercritical fluid within the capsule are also described.

Owner:SORAA

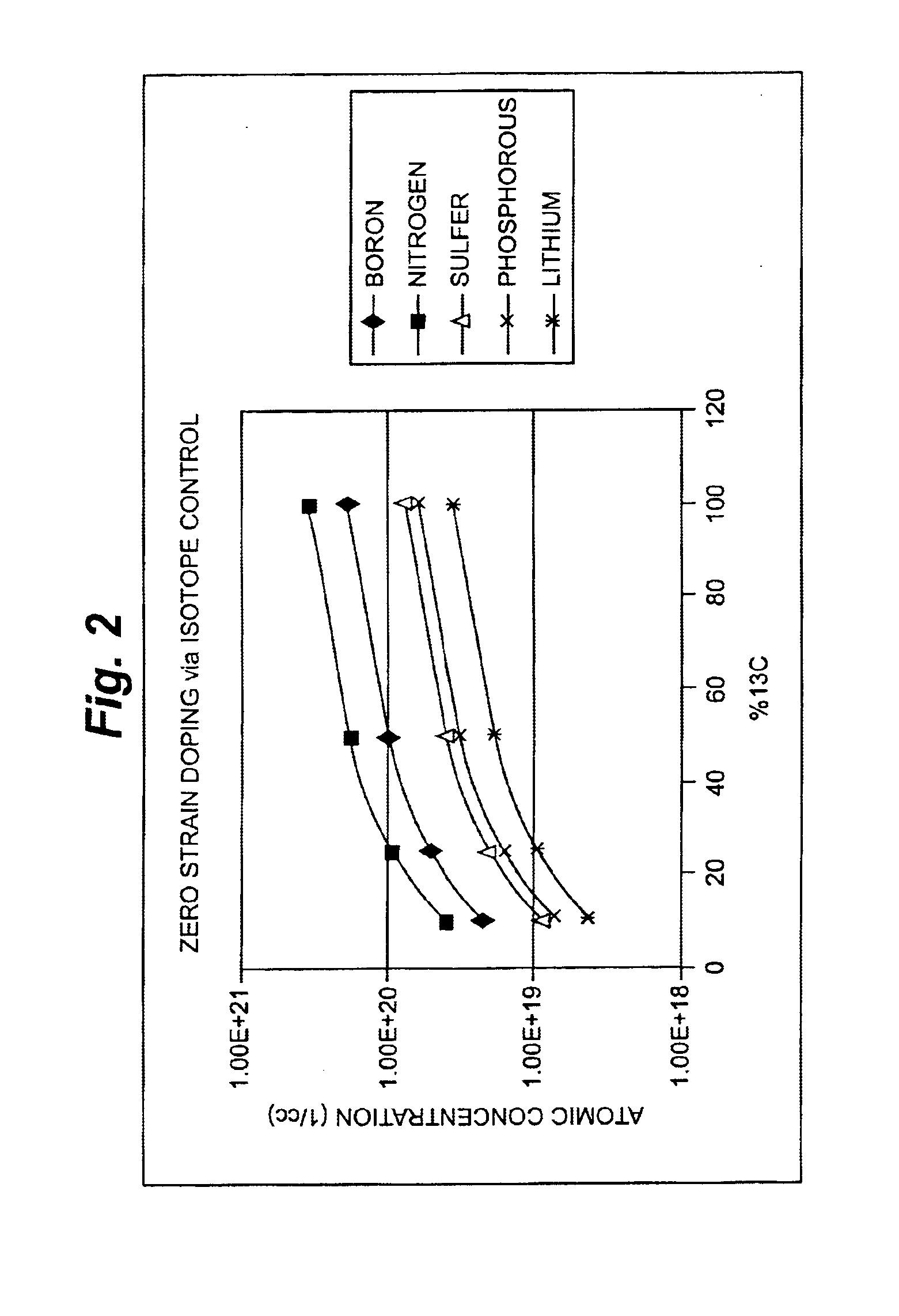

Tunable CVD diamond structures

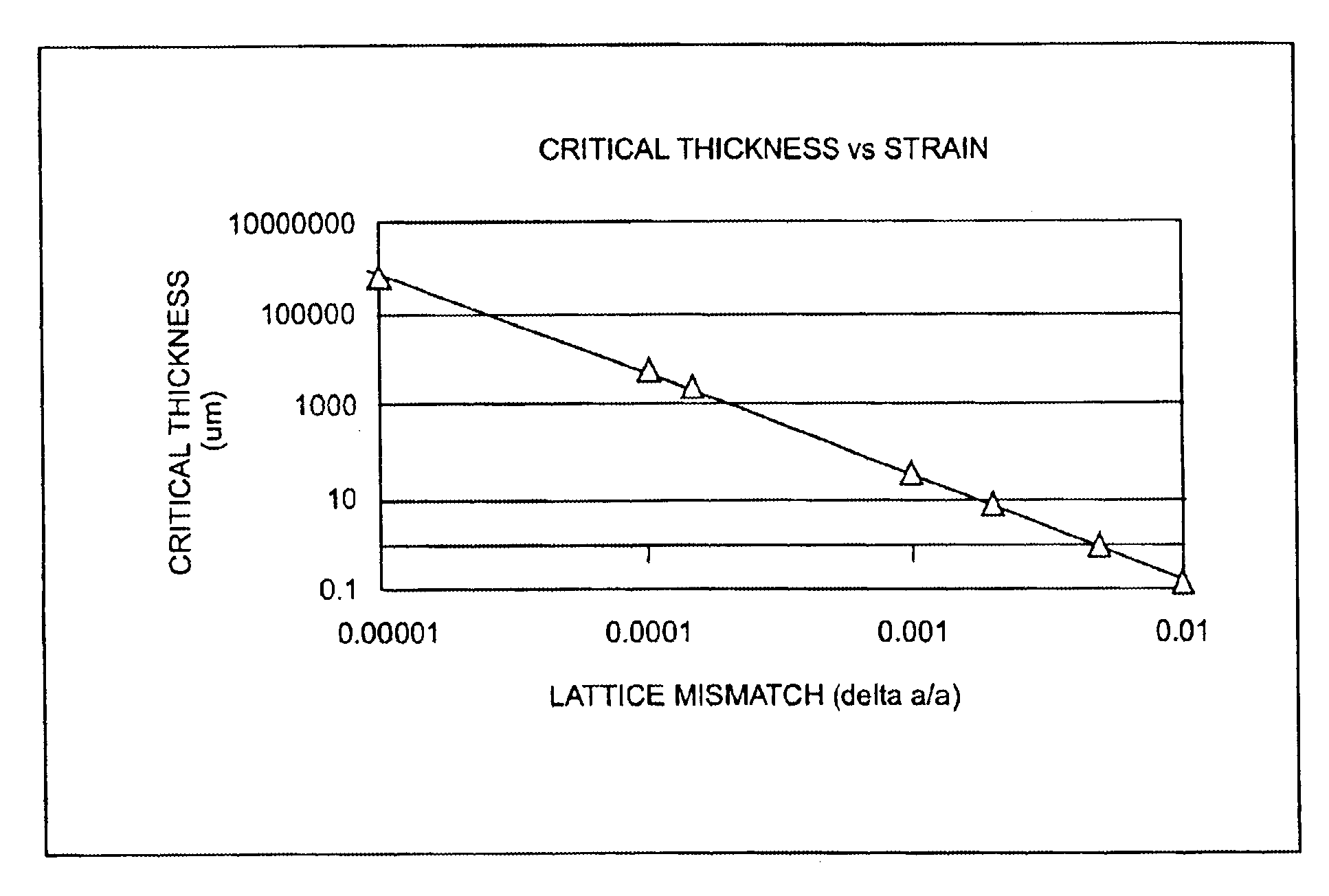

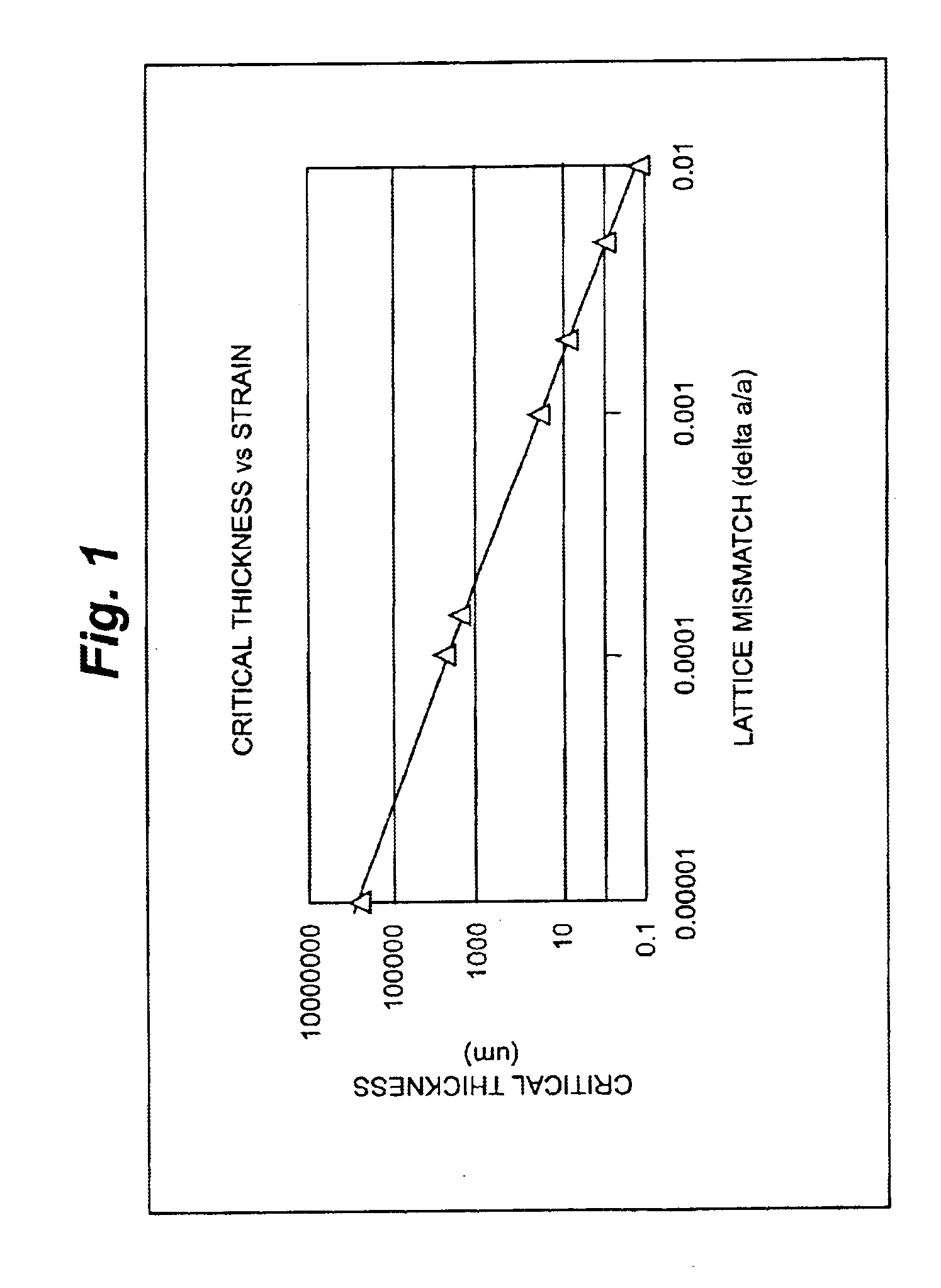

InactiveUS6858080B2Improve propertiesPolycrystalline material growthUltra-high pressure processesLattice mismatchMonocrystalline silicon

Monocrystalline diamond, adapted for use as in applications such as semiconductor devices, optical waveguides, and industrial applications, in the form of a single crystalline diamond structure having one or more diamond layers, at least one of which is formed by a CVD process. The diamond layers are “lattice-matched” or “lattice-mismatched” to each other to provide a desired level of strain.

Owner:SCIO DIAMOND TECHNOLOGY CORPORATION

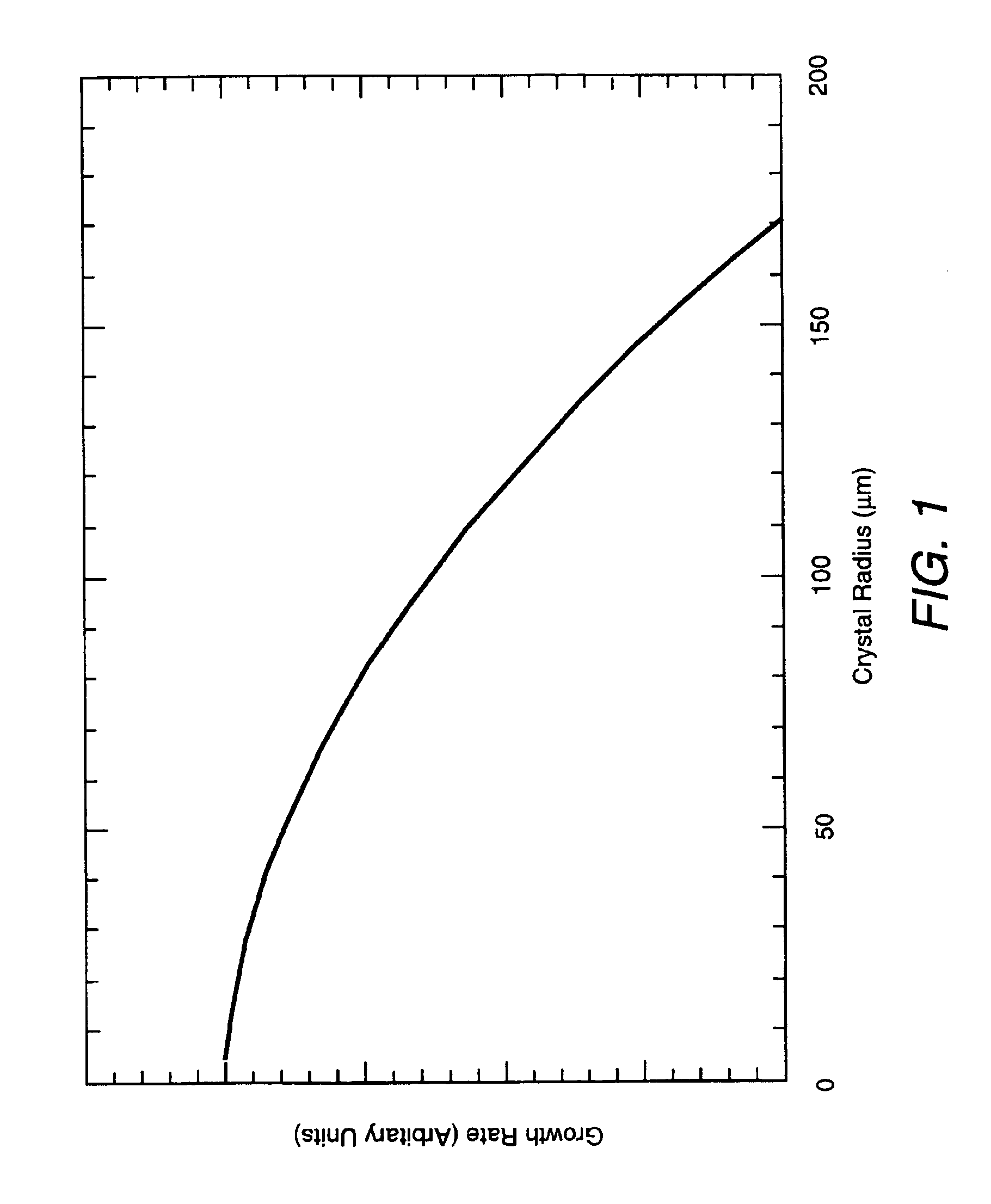

Method for reducing defect concentrations in crystals

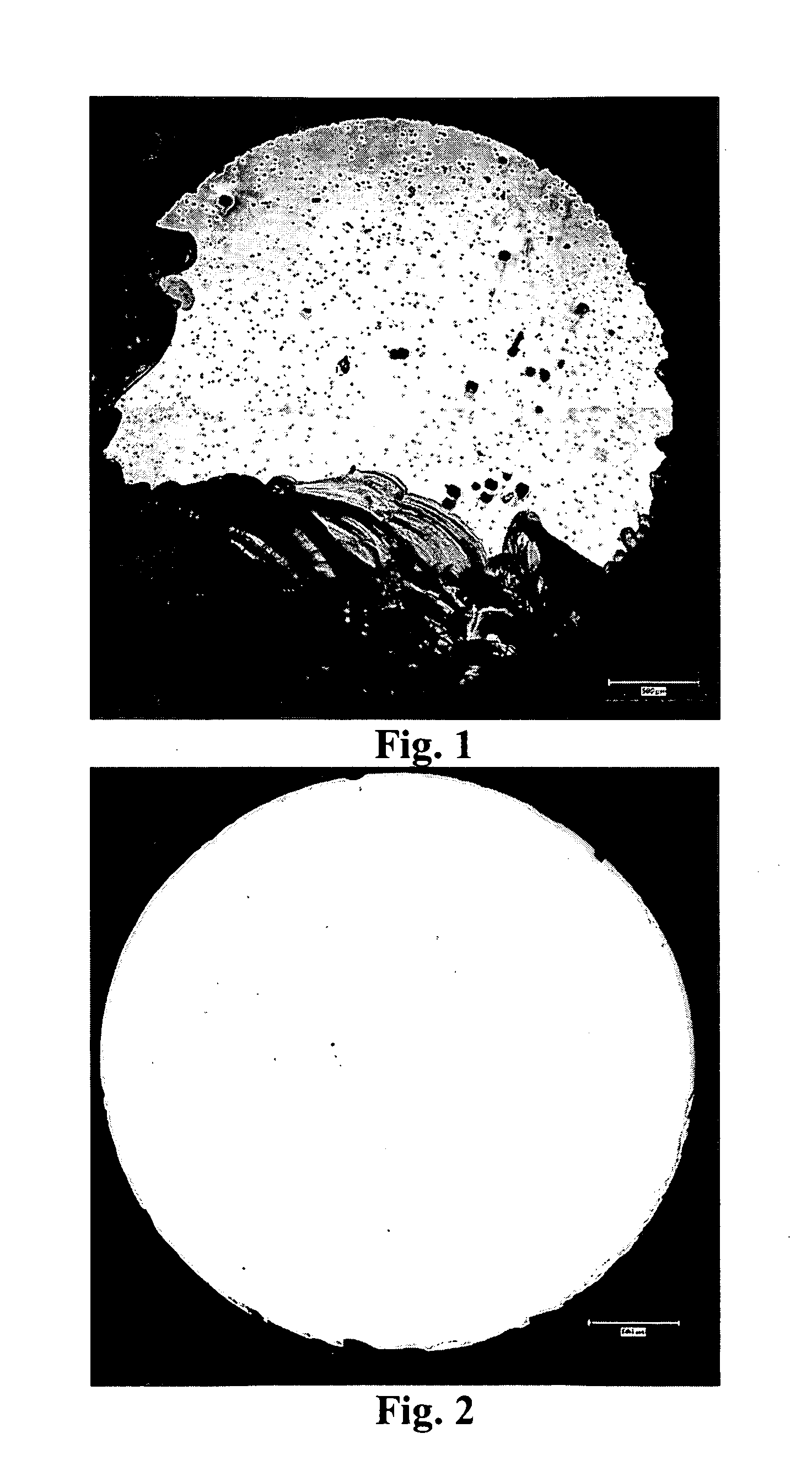

InactiveUS7175704B2Polycrystalline material growthFrom normal temperature solutionsSufficient timeDiamond crystal

A method for removing defects at high pressure and high temperature (HP / HT) or for relieving strain in a non-diamond crystal commences by providing a crystal, which contains defects, and a pressure medium. The crystal and the pressure medium are disposed in a high pressure cell and placed in a high pressure apparatus, for processing under reaction conditions of sufficiently high pressure and high temperature for a time adequate for one or more of removing defects or relieving strain in the single crystal.

Owner:DIAMOND INNOVATIONS INC

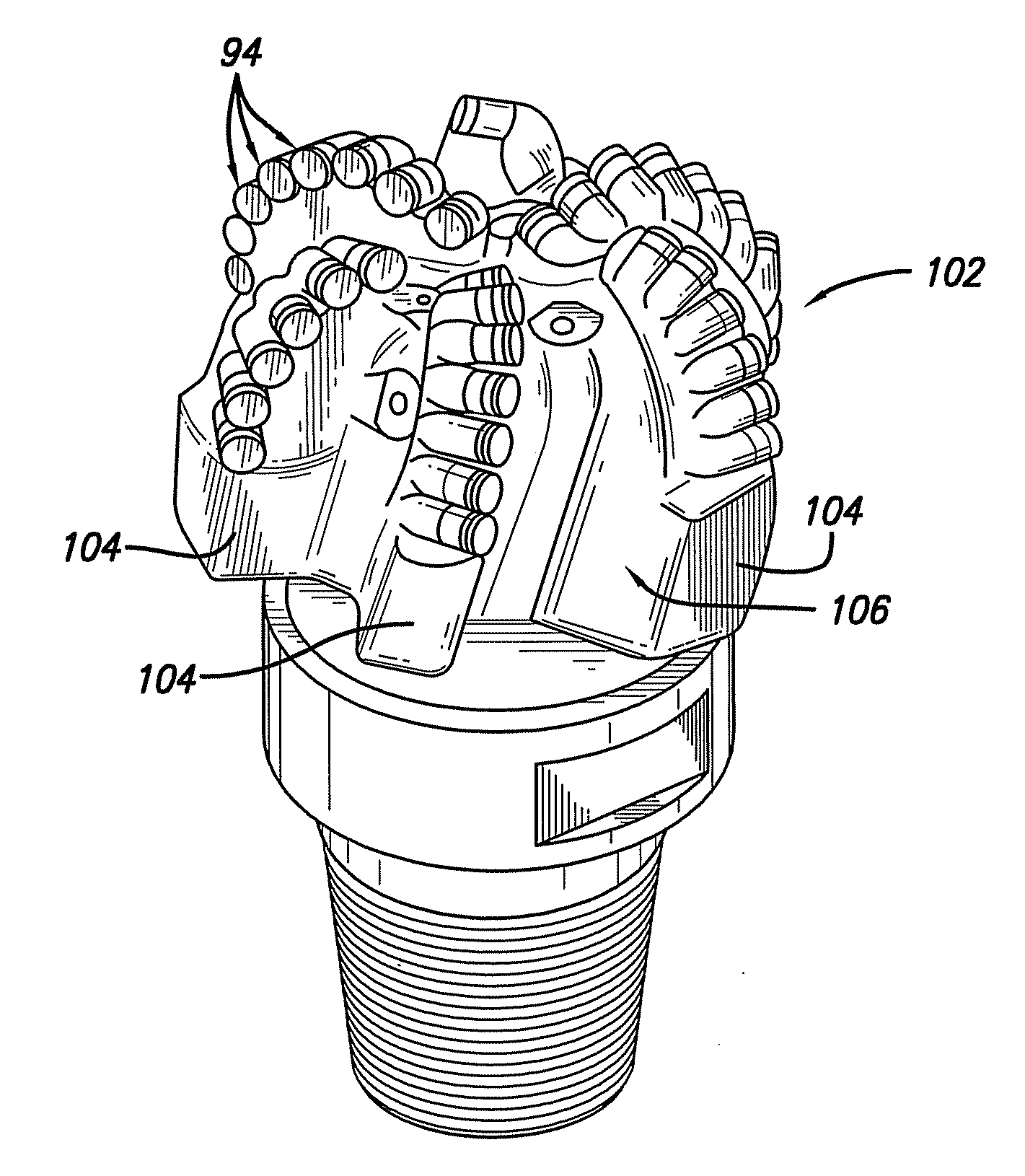

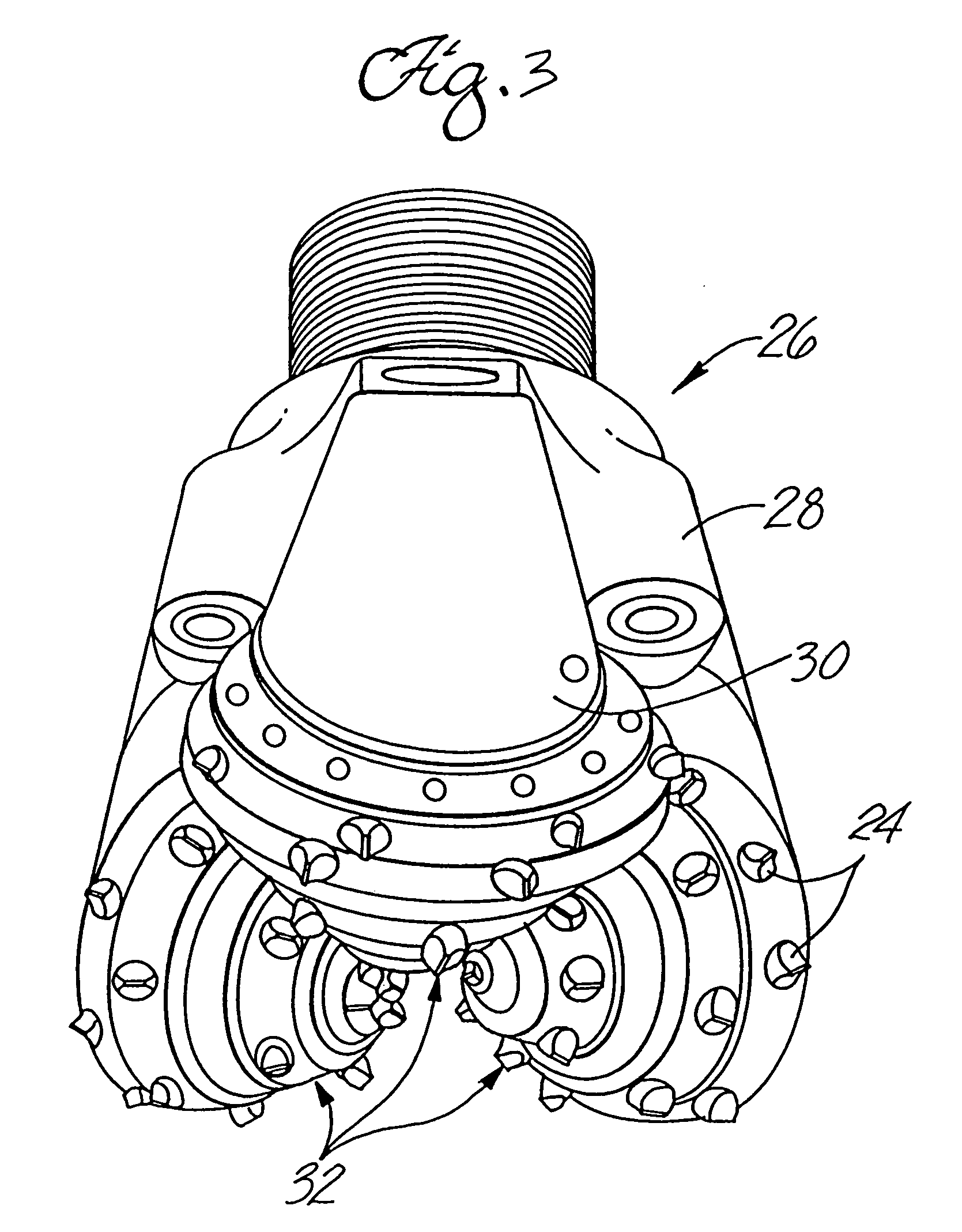

Polycrystalline compacts including in-situ nucleated grains, earth-boring tools including such compacts, and methods of forming such compacts and tools

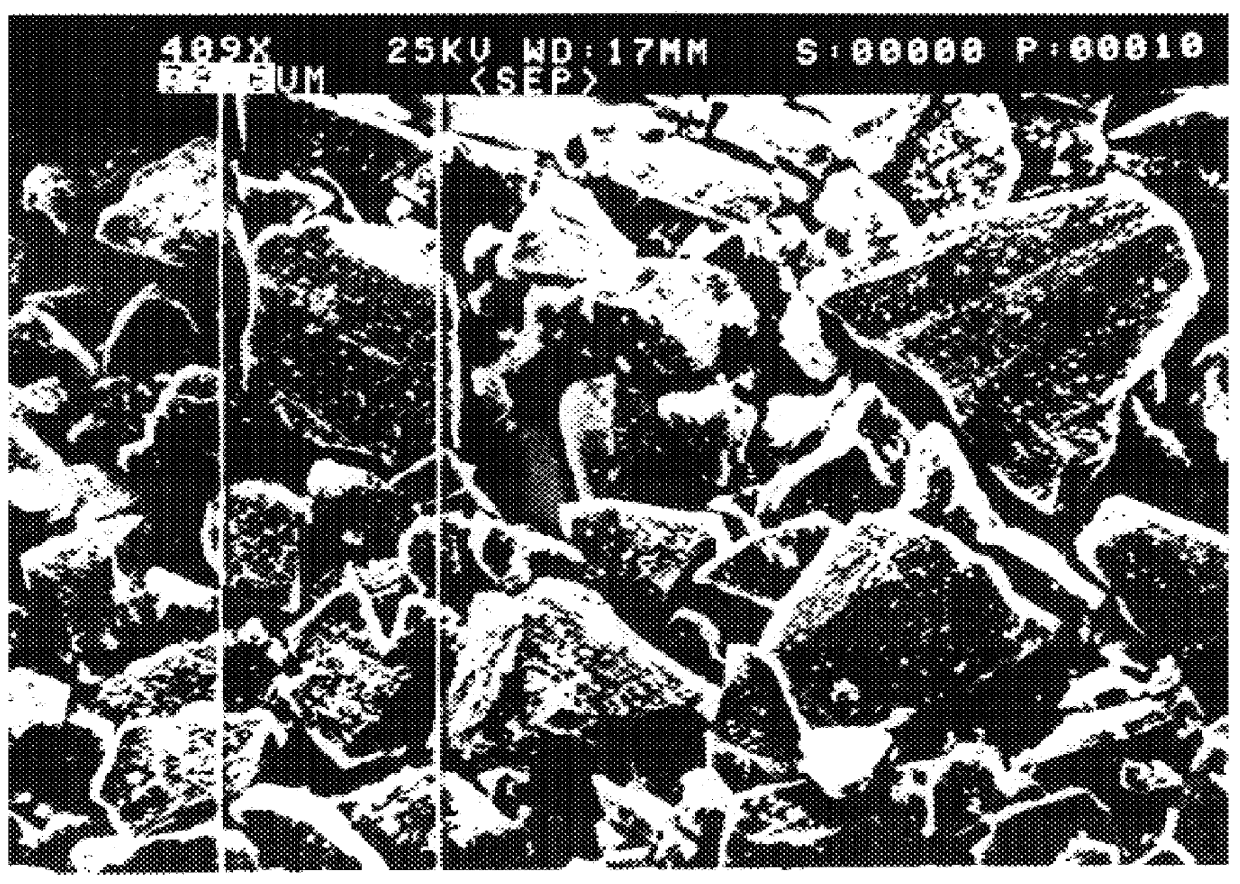

Polycrystalline compacts include hard polycrystalline materials comprising in situ nucleated smaller grains of hard material interspersed and inter-bonded with larger grains of hard material. The average size of the larger grains may be at least about 250 times greater than the average size of the in situ nucleated smaller grains. Methods of forming polycrystalline compacts include nucleating and catalyzing the formation of smaller grains of hard material in the presence of larger grains of hard material, and catalyzing the formation of inter-granular bonds between the grains of hard material. For example, nucleation particles may be mixed with larger diamond grains, a carbon source, and a catalyst. The mixture may be subjected to high temperature and high pressure to form in smaller diamond grains using the nucleation particles, the carbon source, and the catalyst, and to catalyze formation of diamond-to-diamond bonds between the smaller and larger diamond grains.

Owner:BAKER HUGHES INC

Method for reducing defect concentration in crystals

ActiveUS20060096521A1Reduce defect concentrationRelieve pressureAfter-treatment detailsUltra-high pressure processesDiamond crystalHigh pressure cell

A method for removing defects at high pressure and high temperature (HP / HT) or for relieving strain in a non-diamond crystal commences by providing a crystal, which contains defects, and a pressure medium. The crystal and the pressure medium are disposed in a high pressure cell and placed in a high pressure apparatus, for processing under reaction conditions of sufficiently high pressure and high temperature for a time adequate for one or more of removing defects or relieving strain in the single crystal.

Owner:SLT TECH

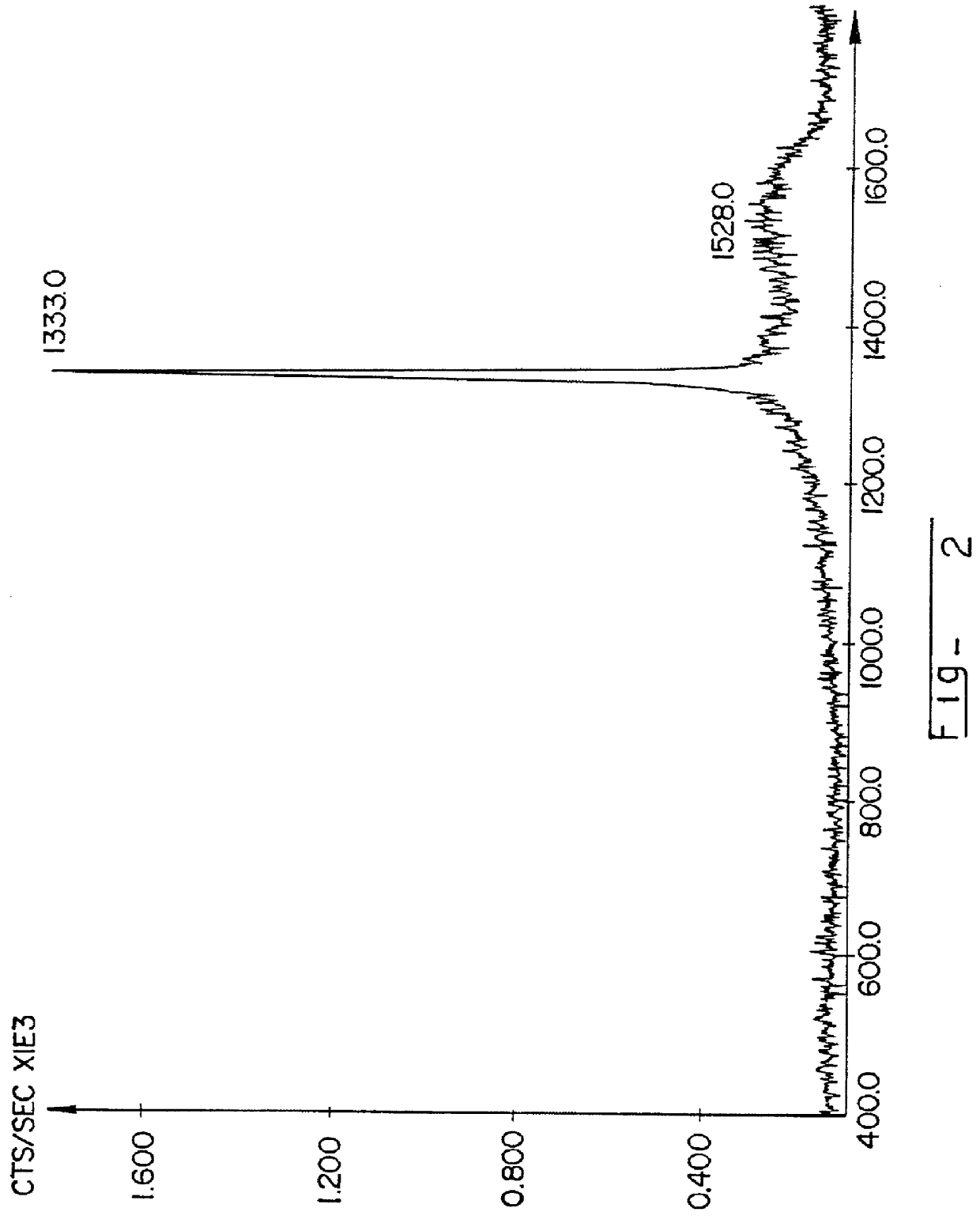

Process for the synthesis of diamond

InactiveUS6129900ALess inclusionReduce the impactUltra-high pressure processesUltra high pressureDiamond crystal

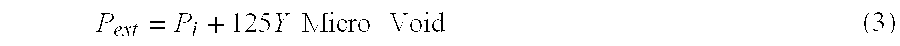

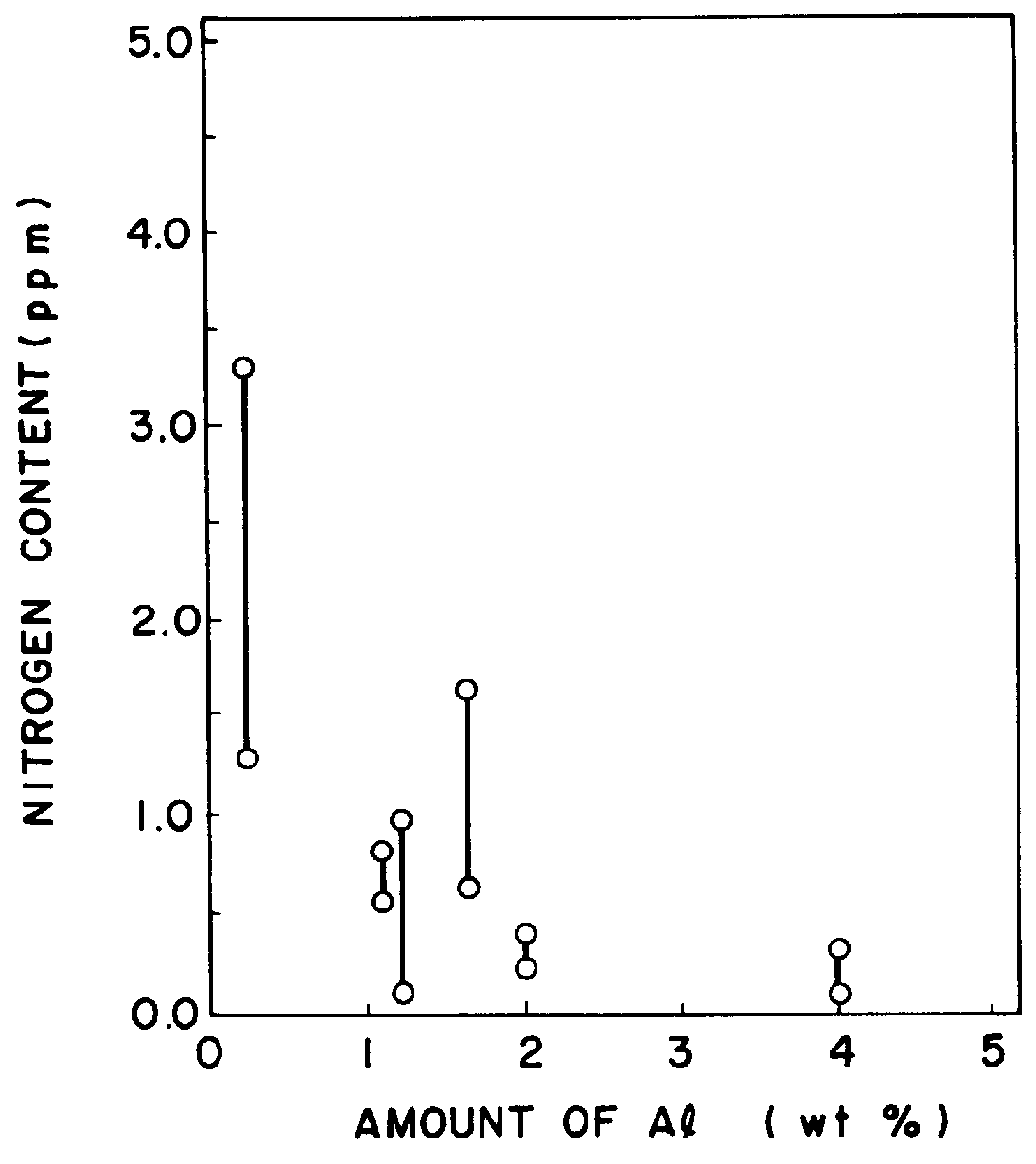

PCT No. PCT / JP92 / 00149 Sec. 371 Date Oct. 14, 1992 Sec. 102(e) Date Oct. 14, 1992 PCT Filed Feb. 14, 1992 PCT Pub. No. WO92 / 14542 PCT Pub. Date Sep. 3, 1992A colorless and transparent, substantially inclusion-free diamond crystal which can be applied to decorative uses and optical parts is synthesized by a process using a temperature gradient method in an ultra-high pressure apparatus. This process comprises using, as a solvent for the growth of the crystal, at least one metal selected from the group consisting of Fe, Co, Ni, Mn and Cr (at least two metals in the case of containing Fe) and as a nitrogen getter for the removal of nitrogen in the solvent, at least one metal selected from the group consisting of Al, Ti, Zr, Hf, V, Nb and Ta in a proportion of 0.5 to 7% by weight (at most 2% by weight when using only Al) to the solvent metal.

Owner:SUMITOMO ELECTRIC IND LTD

High temperature high pressure capsule for processing materials in supercritical fluids

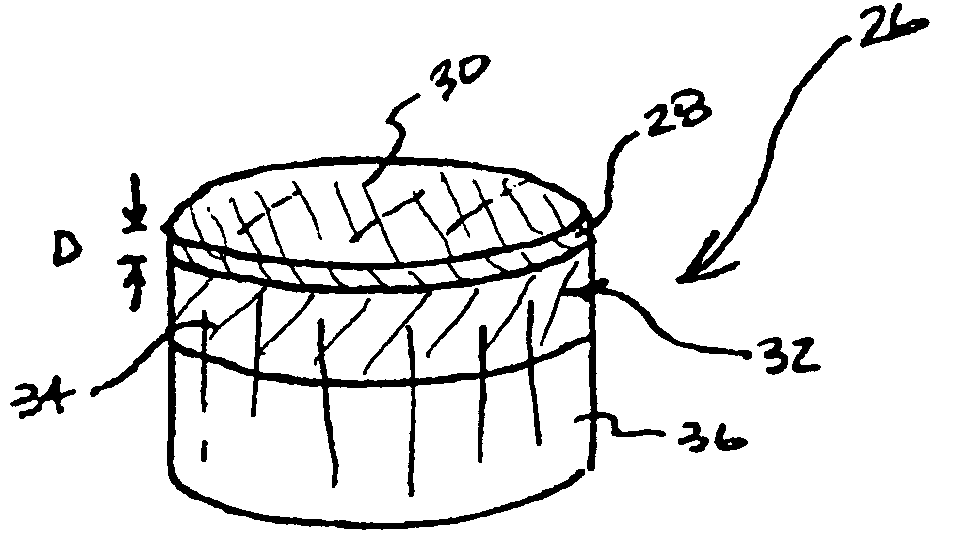

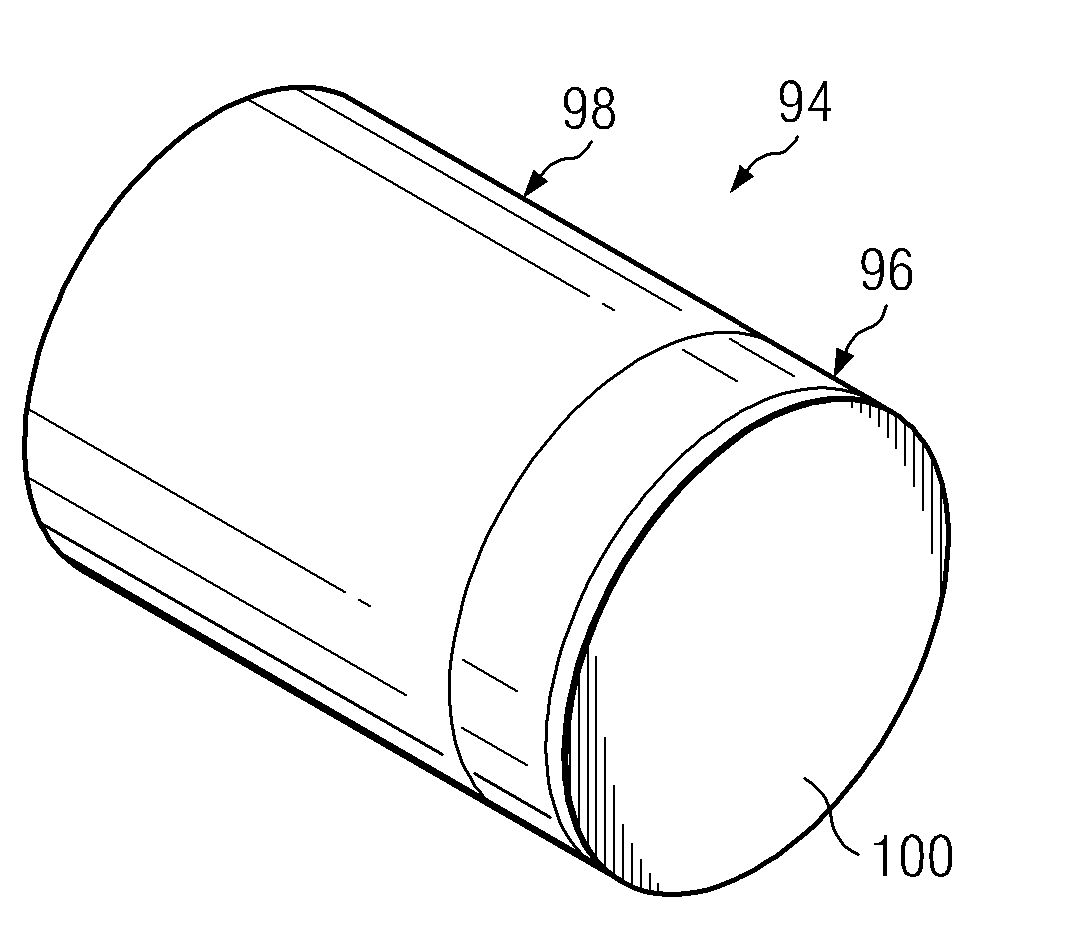

InactiveUS20050152820A1From normal temperature solutionsUltra-high pressure processesHigh pressureSolvent

A capsule for containing at least one reactant and a supercritical fluid in a substantially air-free environment under high pressure, high temperature processing conditions. The capsule includes a closed end, at least one wall adjoining the closed end and extending from the closed end; and a sealed end adjoining the at least one wall opposite the closed end. The at least one wall, closed end, and sealed end define a chamber therein for containing the reactant and a solvent that becomes a supercritical fluid at high temperatures and high pressures. The capsule is formed from a deformable material and is fluid impermeable and chemically inert with respect to the reactant and the supercritical fluid under processing conditions, which are generally above 5 kbar and 550° C. and, preferably, at pressures between 5 kbar and 80 kbar and temperatures between 550° C. and about 1500° C. The invention also includes methods of filling the capsule with the solvent and sealing the capsule, as well as an apparatus for sealing the capsule.

Owner:SLT TECH

Brazed diamond tools and methods for making the same

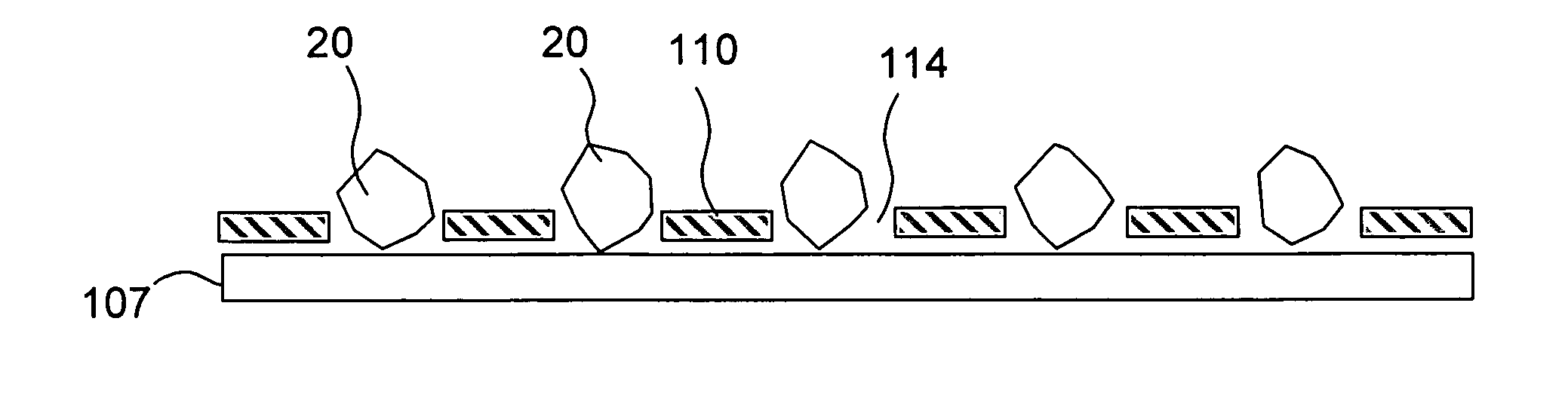

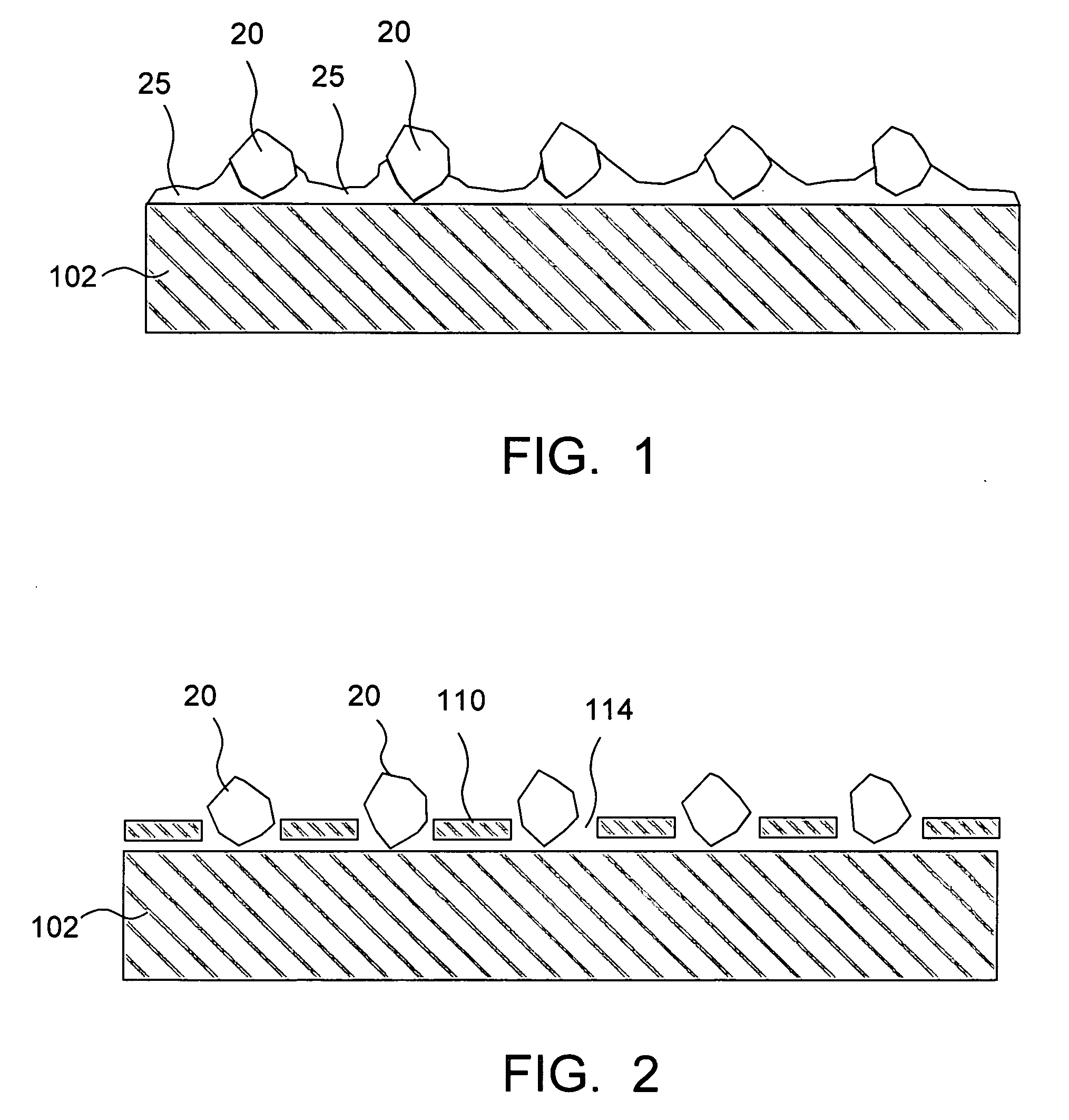

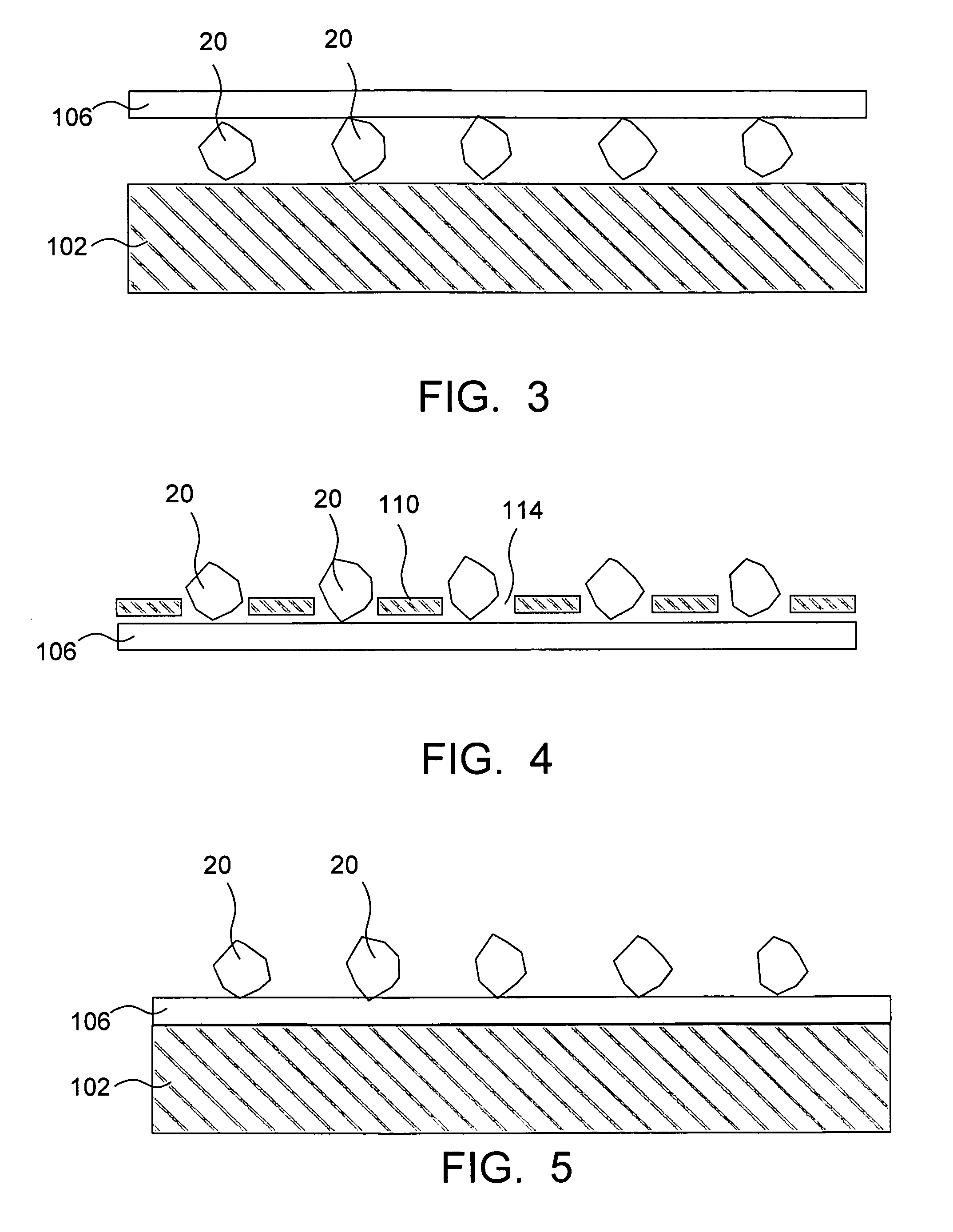

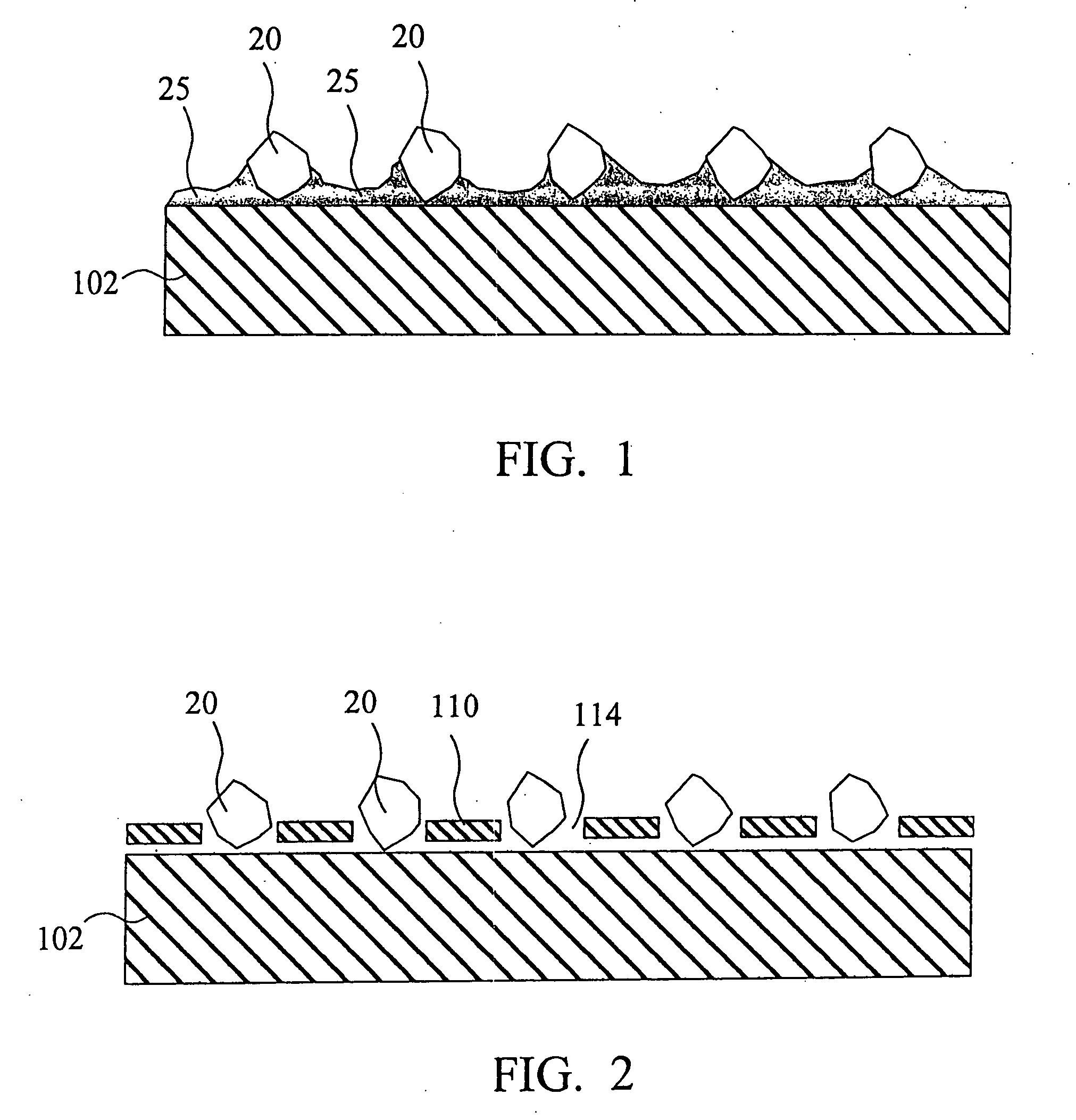

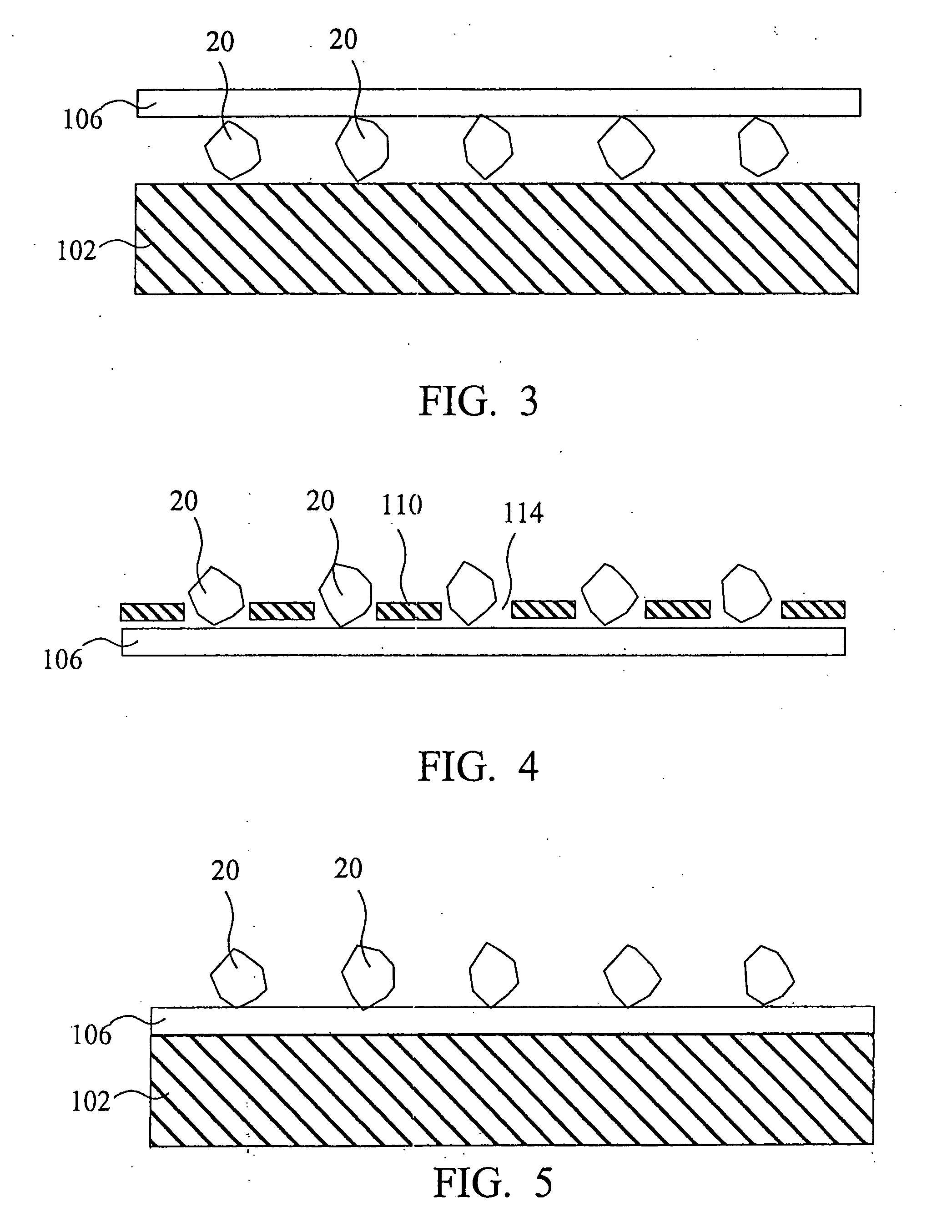

InactiveUS20040112359A1Avoid large movementsImprove cutting efficiencyDrill bitsConstructionsChemical LinkageBraze alloy

Superabrasive tools and methods for the making thereof are disclosed and described. In one aspect, superabrasive particles are chemically bonded to a matrix support material according to a predetermined pattern by a braze alloy. The brazing alloy may be provided as a powder, thin sheet, or sheet of amorphous alloy. A template having a plurality of apertures arranged in a predetermined pattern may be used to place the superabrasive particles on a given substrate or matrix support material.

Owner:SUNG CHIEN MIN

Apparatus for processing materials in supercritical fluids and methods thereof

ActiveUS7704324B2After-treatment apparatusUltra-high pressure processesHigh intensityPressure difference

An apparatus and method for processing materials in supercritical fluids is disclosed. The apparatus includes a capsule configured to contain a supercritical fluid, a high strength enclosure disposed about the capsule and a sensor configured to sense pressure difference between an interior and an exterior of the capsule. The apparatus also includes a pressure control device configured to adjust pressure difference of the capsule in response to the pressure difference sensed by the sensor. The apparatus further includes at least one dividing structure disposed within the capsule that divides the capsule into a seed growing chamber and a nutrient chamber.

Owner:SLT TECH

Thermally stable polycrystalline diamond constructions

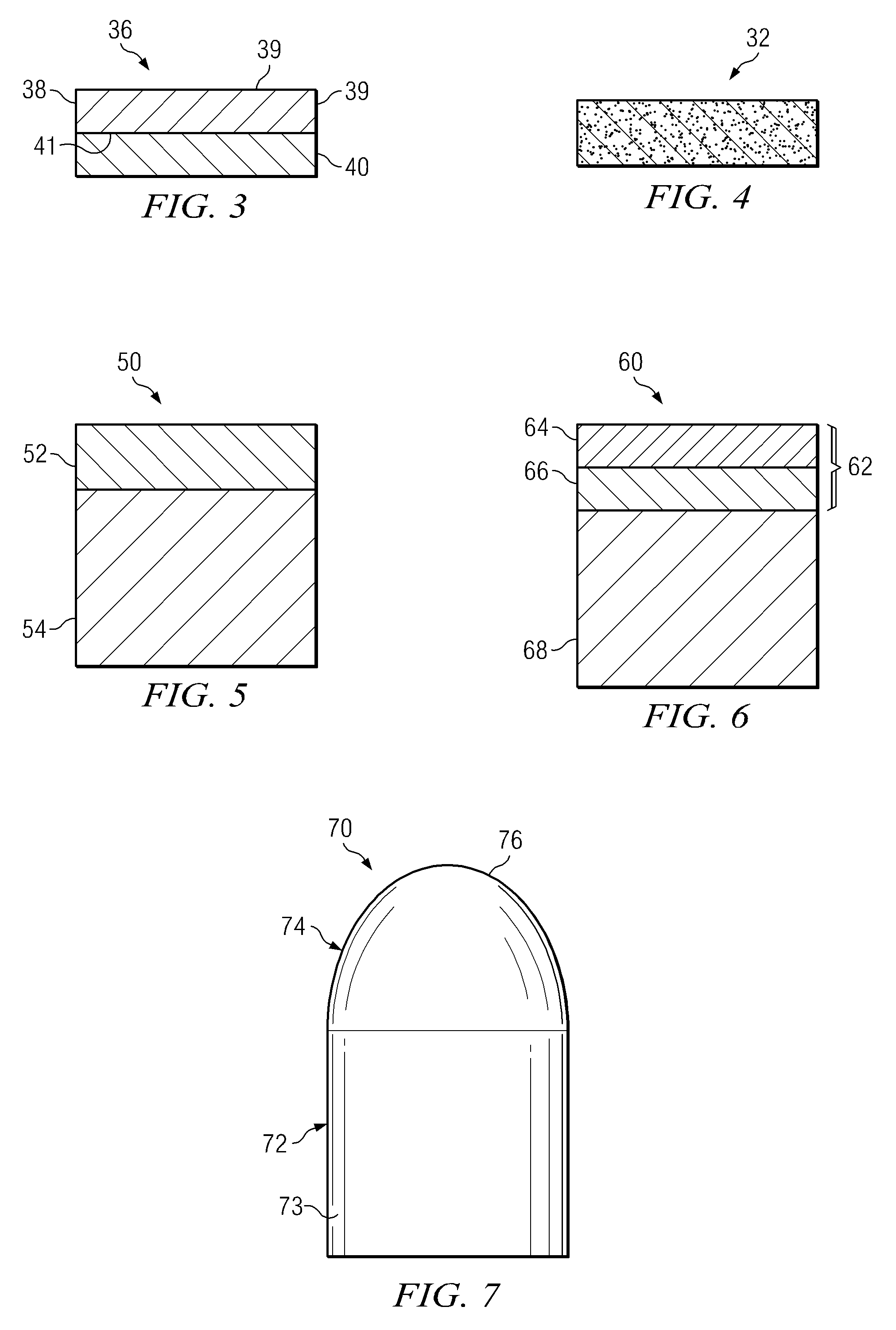

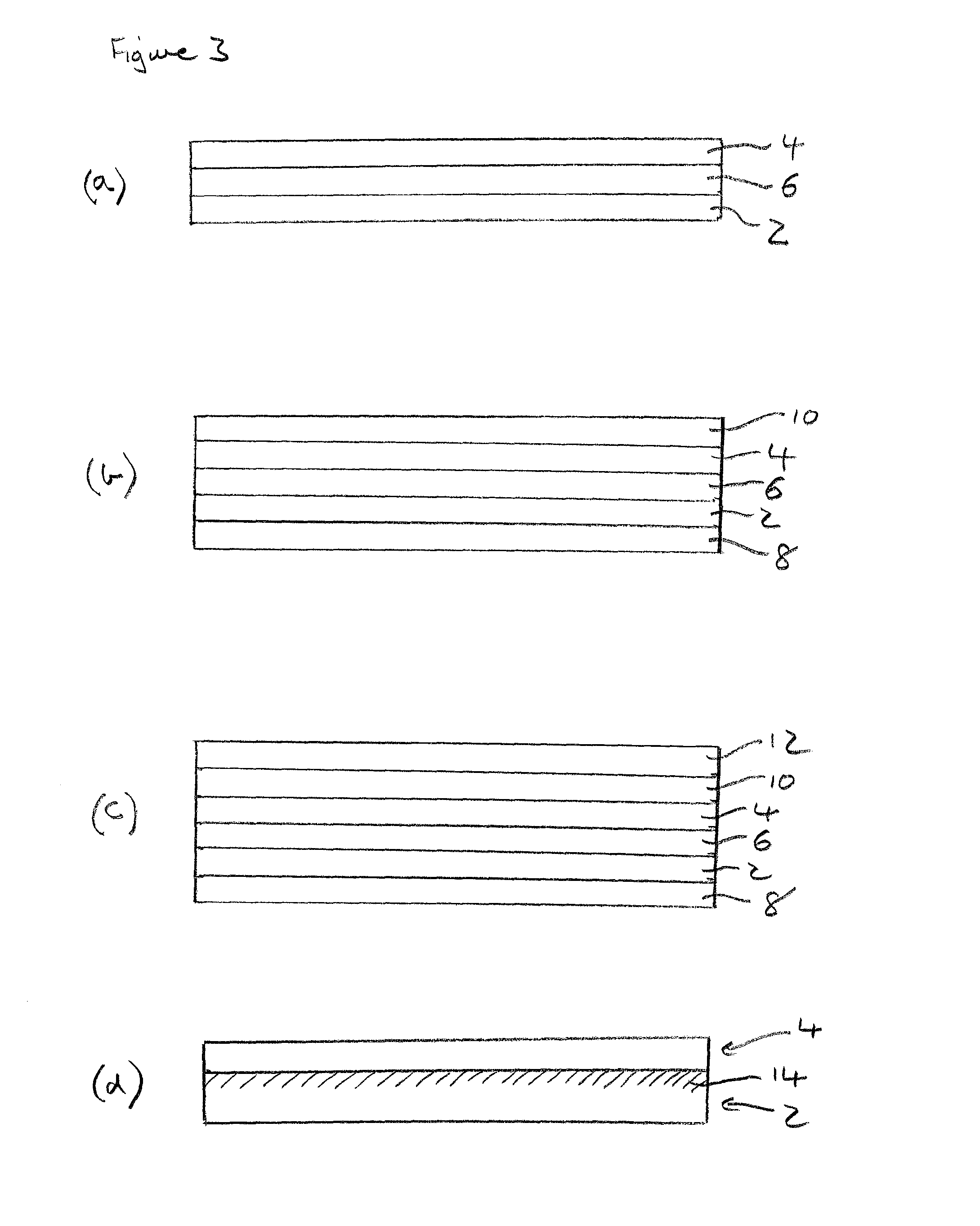

InactiveUS20110036643A1Improve thermal characteristicsReduces and eliminates crack formationPigmenting treatmentDrill bitsNon solventSized small

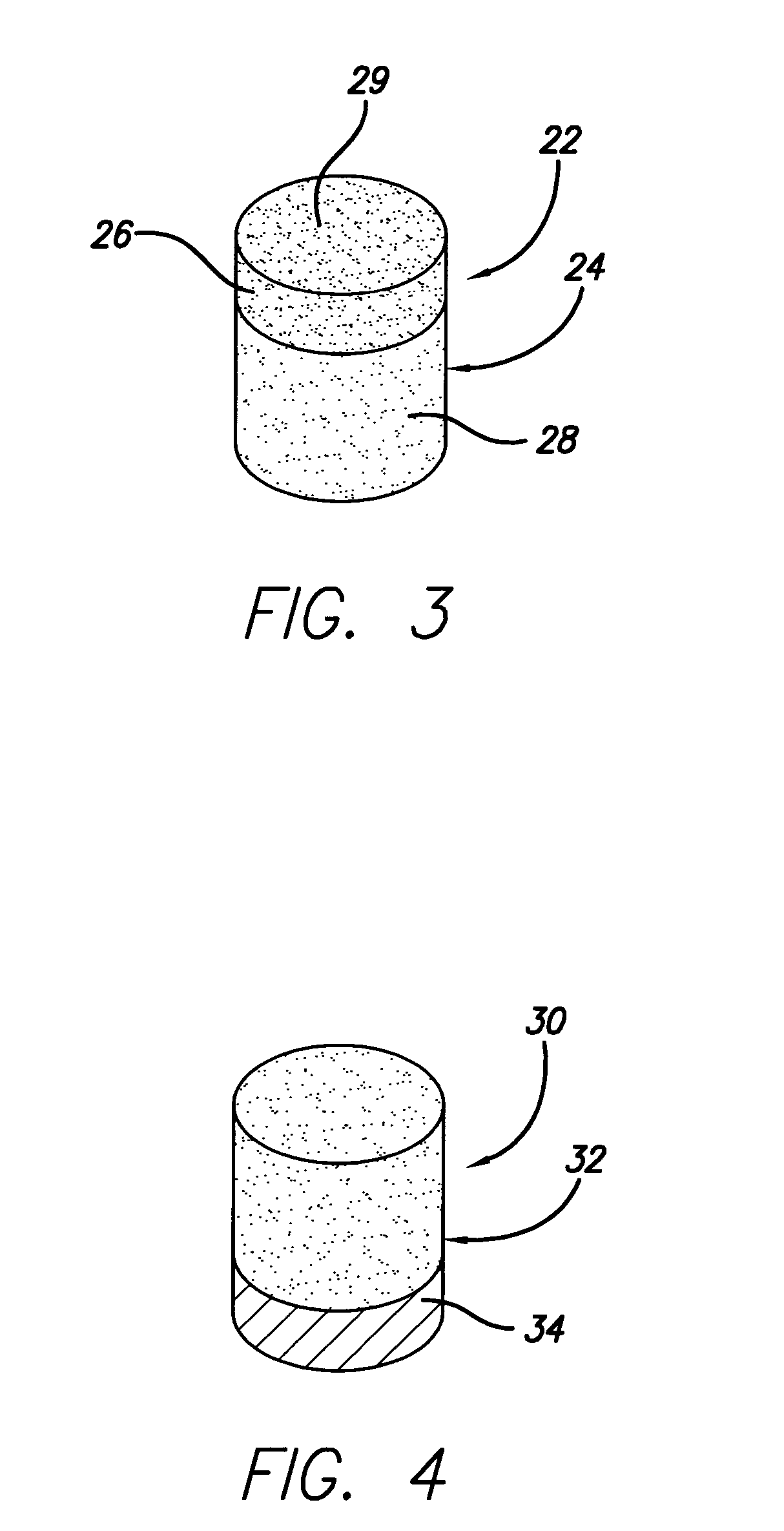

Thermally stable polycrystalline constructions comprise a diamond body joined with a substrate, and may have a nonplanar interface. The construction may include an interlayer interposed between the diamond body and substrate. The diamond body preferably has a thickness greater than about 1.5 mm, and comprises a matrix phase of bonded together diamond crystals and interstitial regions disposed therebetween that are substantially free of a catalyst material used to sinter the diamond body. A replacement material is disposed within the interstitial regions. A population of the interstitial regions may include non-solvent catalyst material and / or an infiltrant aid disposed therein. The diamond body comprises two regions; namely, a first region comprising diamond grains that may be sized smaller than diamond grains in a second region, and / or the first region may comprise a diamond volume that is greater than that in the second region.

Owner:SMITH INT INC

Method for synthesizing solids such as diamond and products produced thereby

InactiveUS6342195B1Enhanced interactionIncreasing amount of possibleUltra-high pressure processesDiamondHydrogenBoron nitride

The present invention relates generally to methods for the synthesis of various solids such as diamonds, diamonds films, boron nitride and other similar materials. This invention specifically relates to utilizing novel sources of reaction species (e.g., in the case of diamond formation, novel sources of carbon and / or hydrogen and / or seeds) for the manufacture of various materials and the use of such materials for various commercial purposes.

Owner:PENN STATE RES FOUND

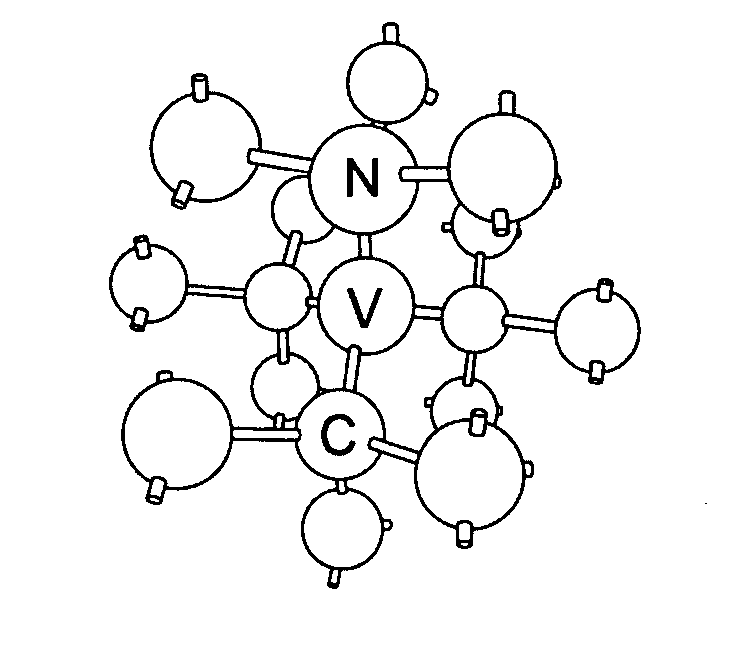

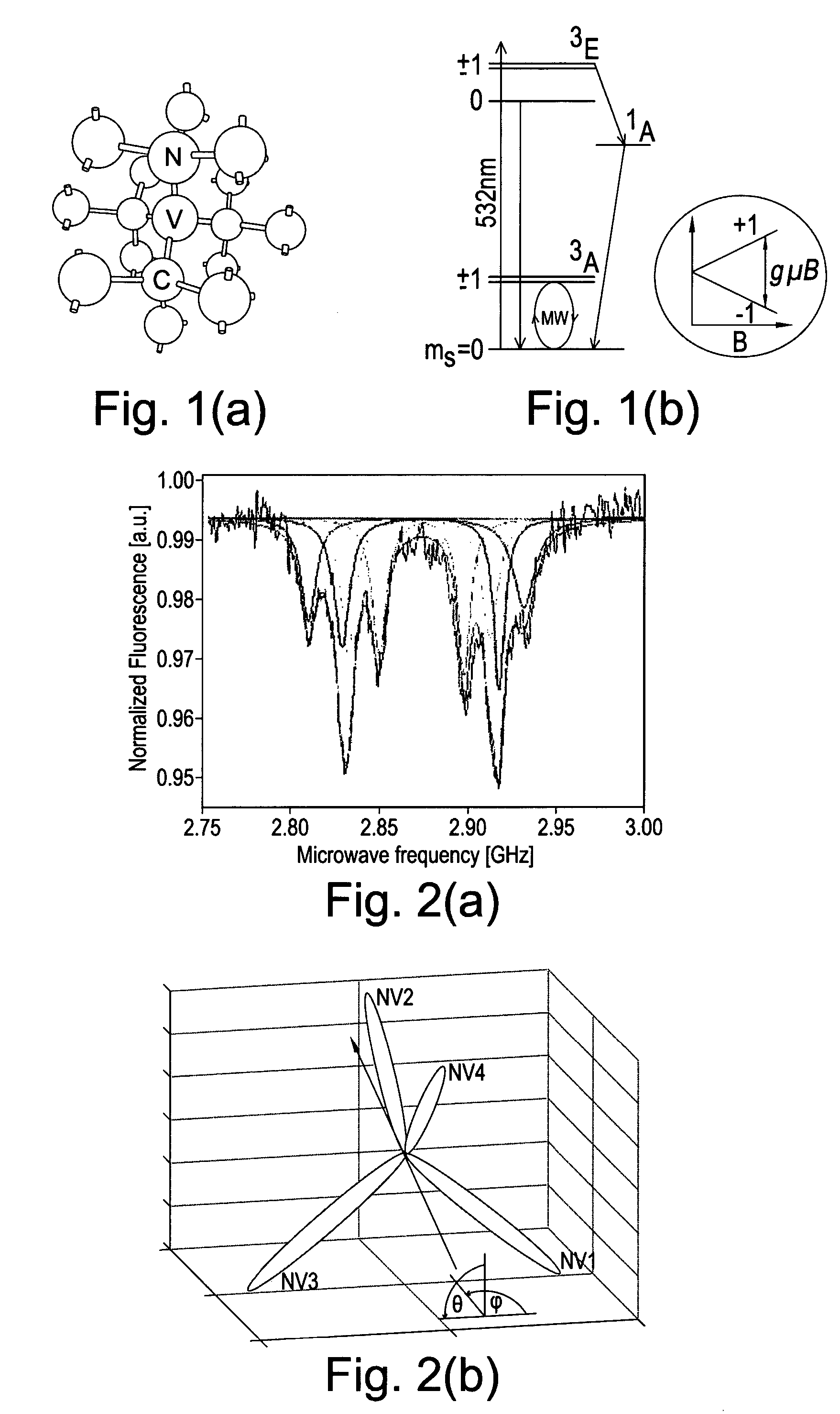

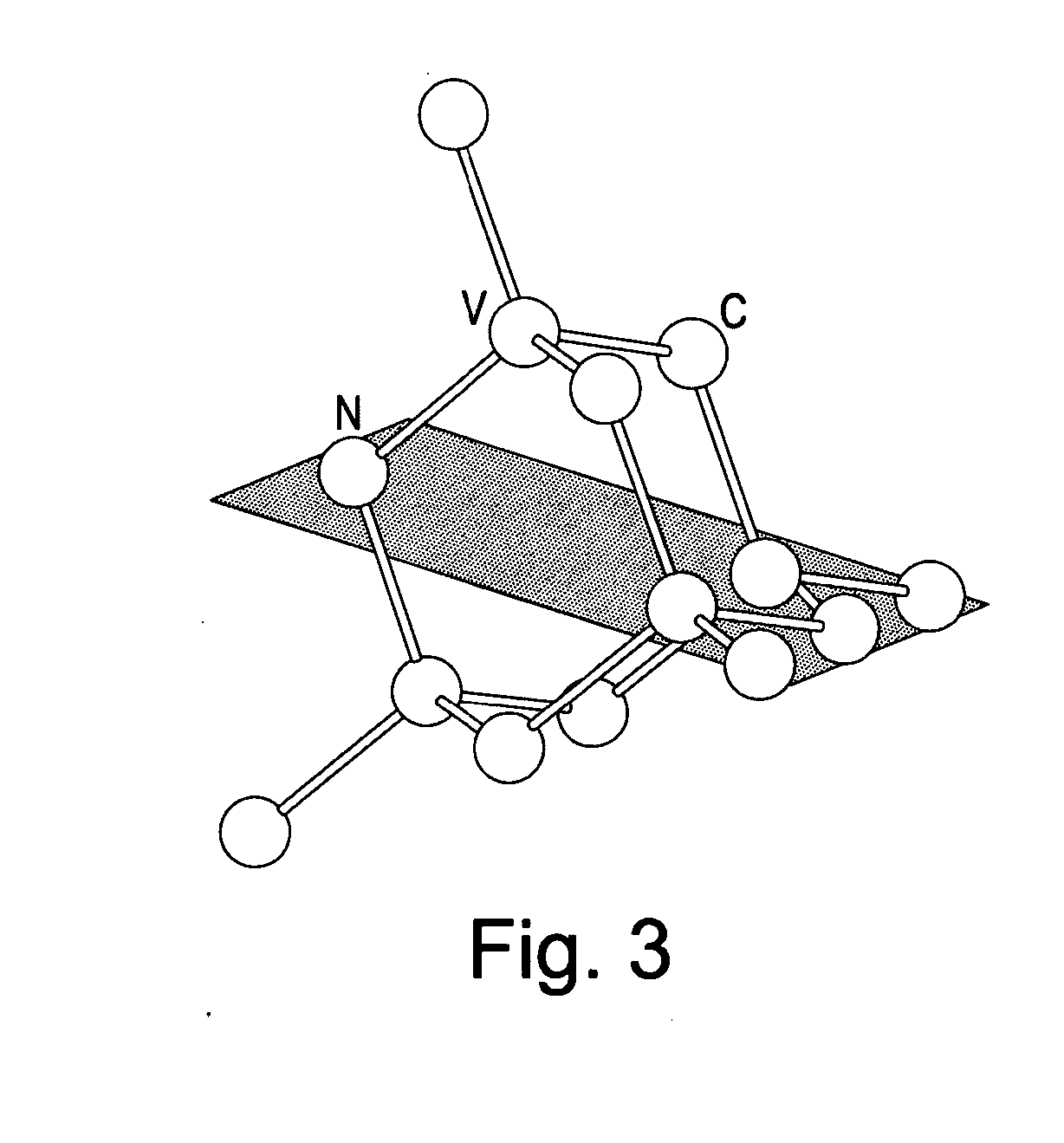

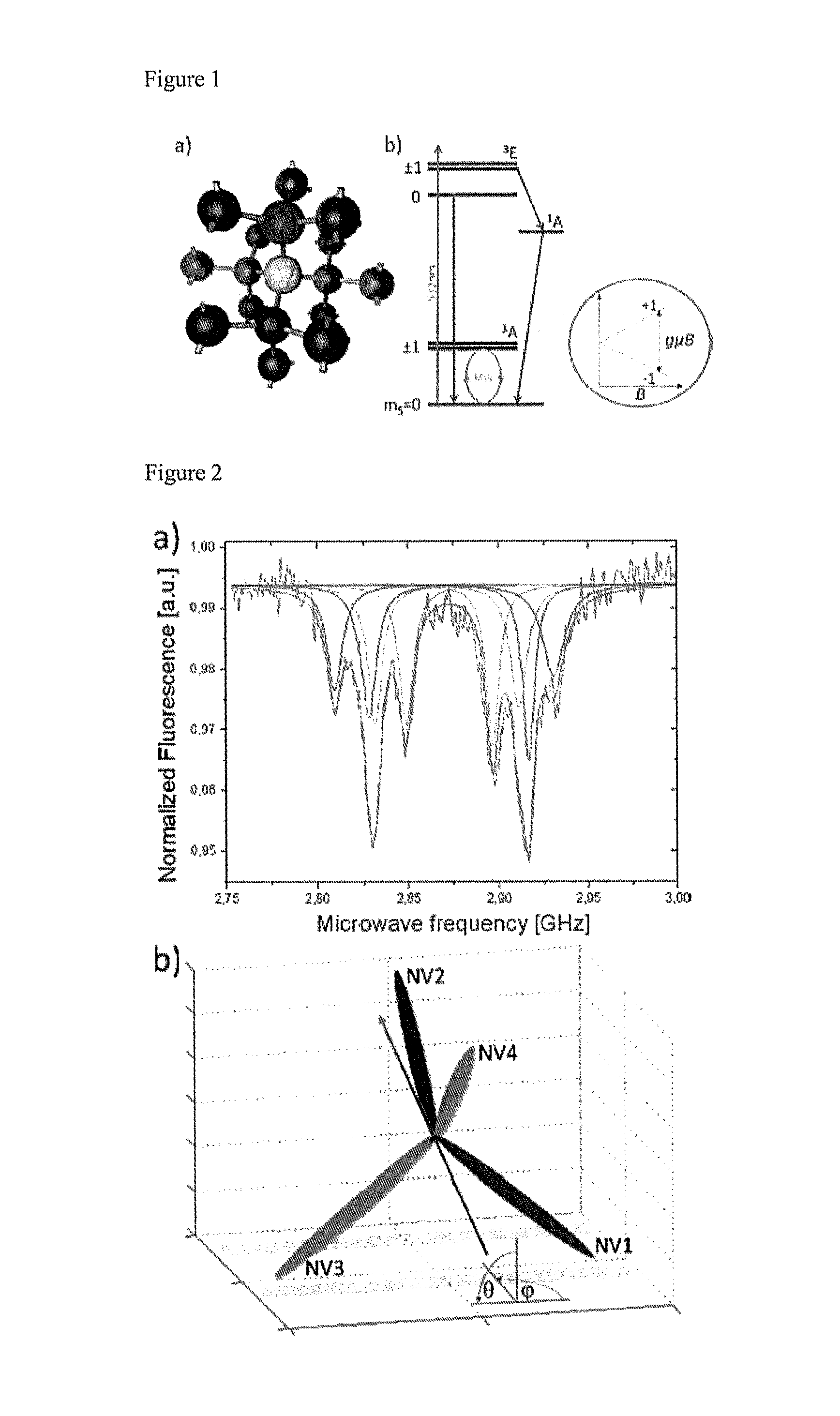

Diamond sensors, detectors, and quantum devices

ActiveUS20140061510A1Improve light outcoupling efficiencyEnhanced couplingPolycrystalline material growthUltra-high pressure processesVacancy defectPreferential alignment

A single crystal synthetic CVD diamond material comprising: a growth sector; and a plurality of point defects of one or more type within the growth sector, wherein at least one type of point defect is preferentially aligned within the growth sector, wherein at least 60% of said at least one type of point defect shows said preferential alignment, and wherein the at least one type of point defect is a negatively charged nitrogen-vacancy defect (NV−).

Owner:ELEMENT SIX LTD

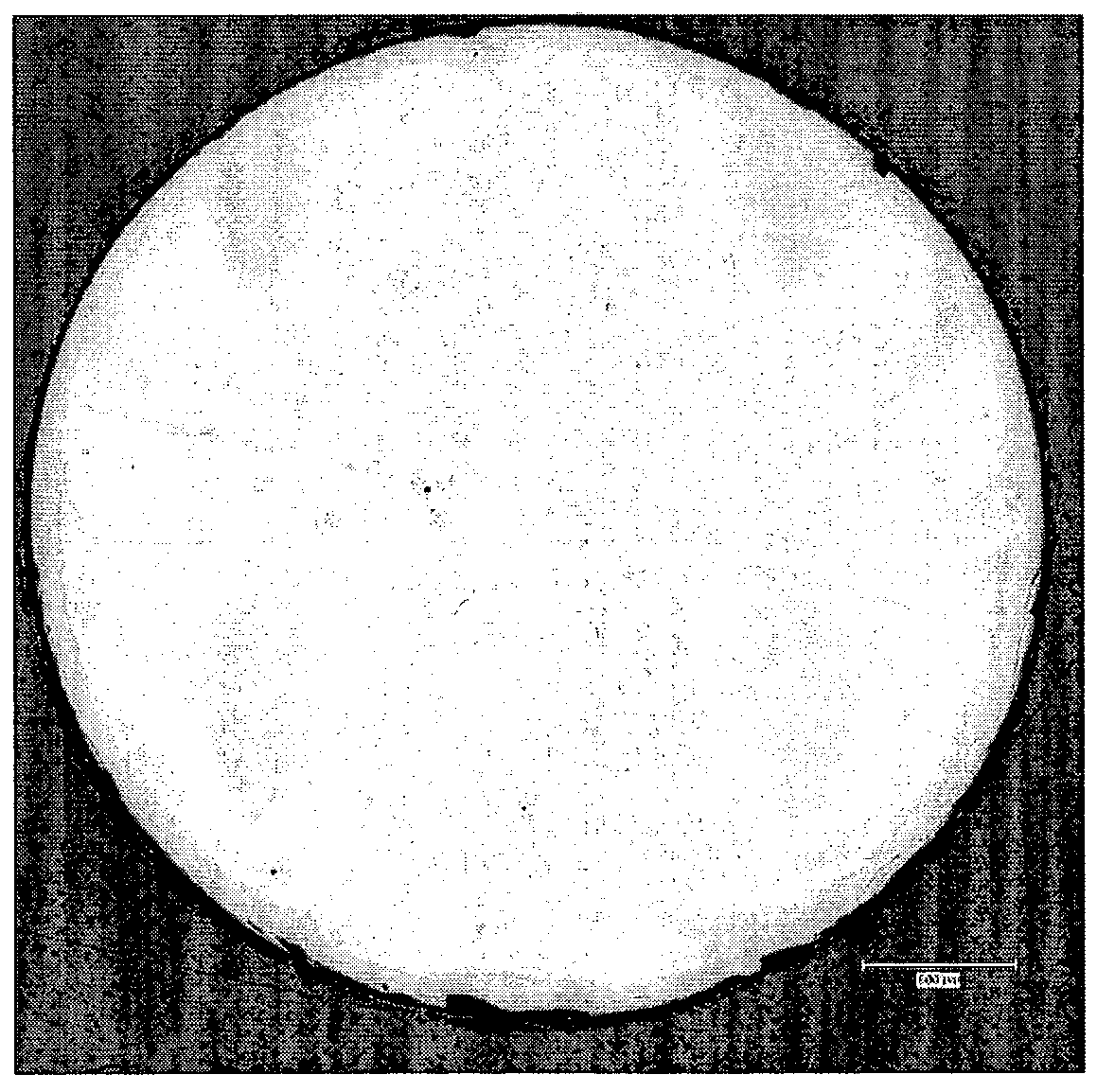

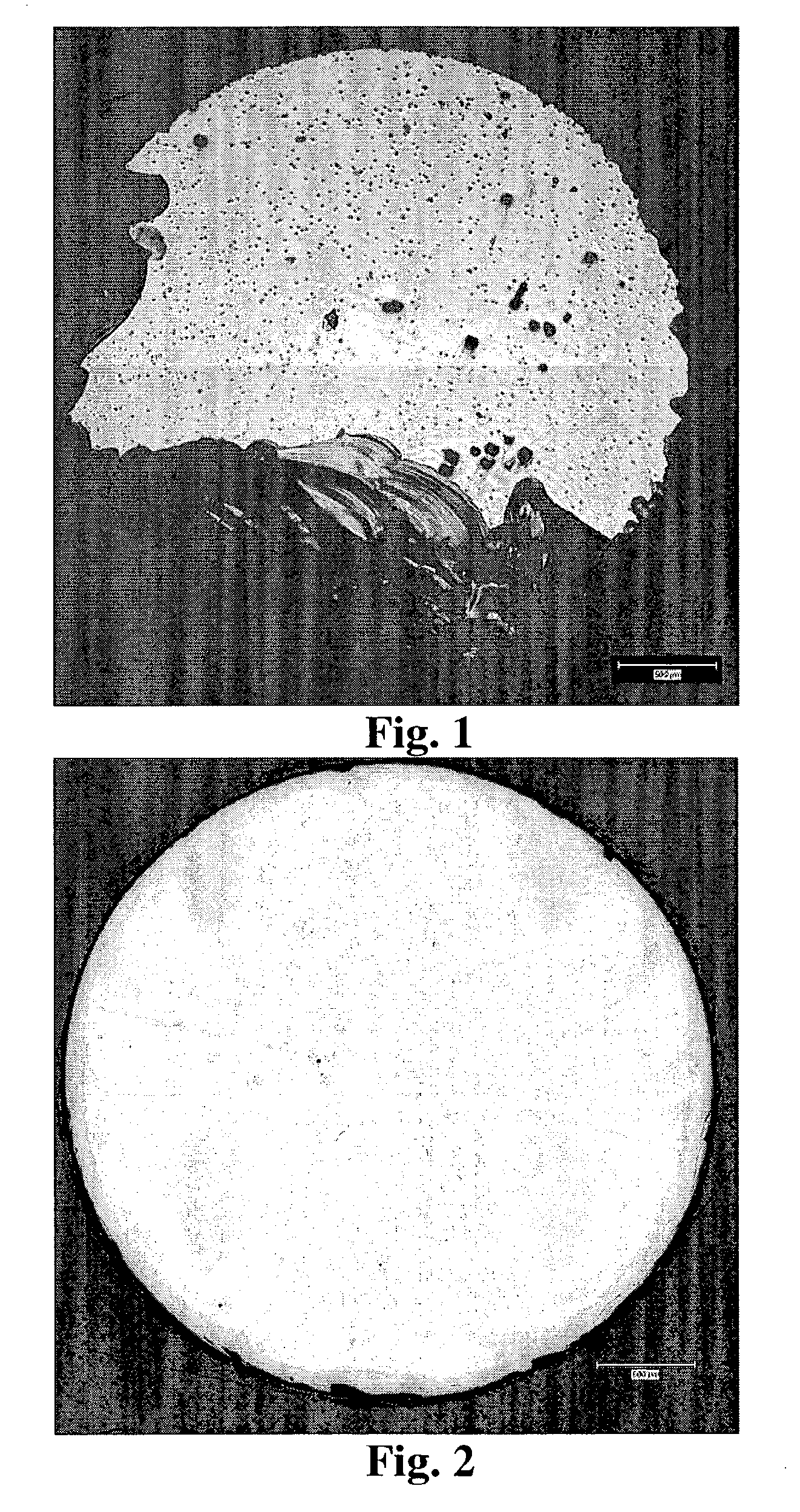

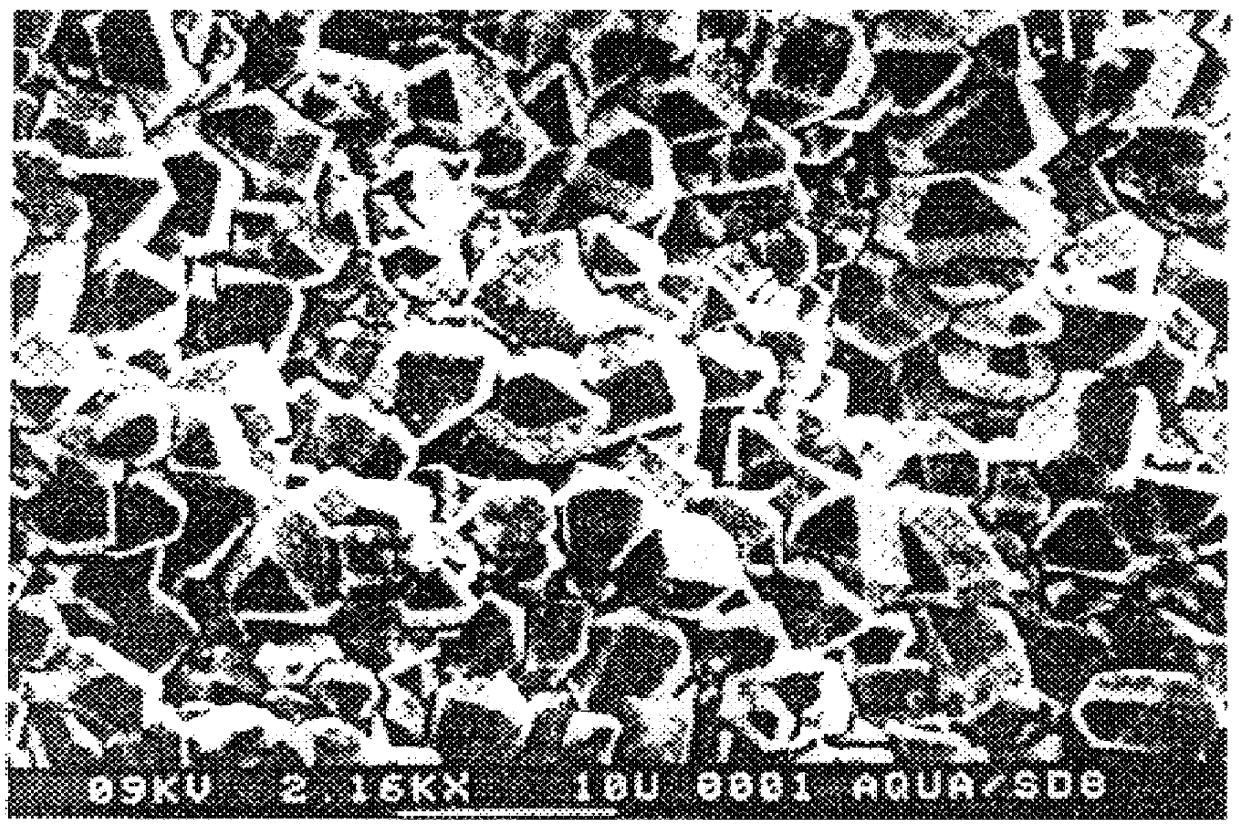

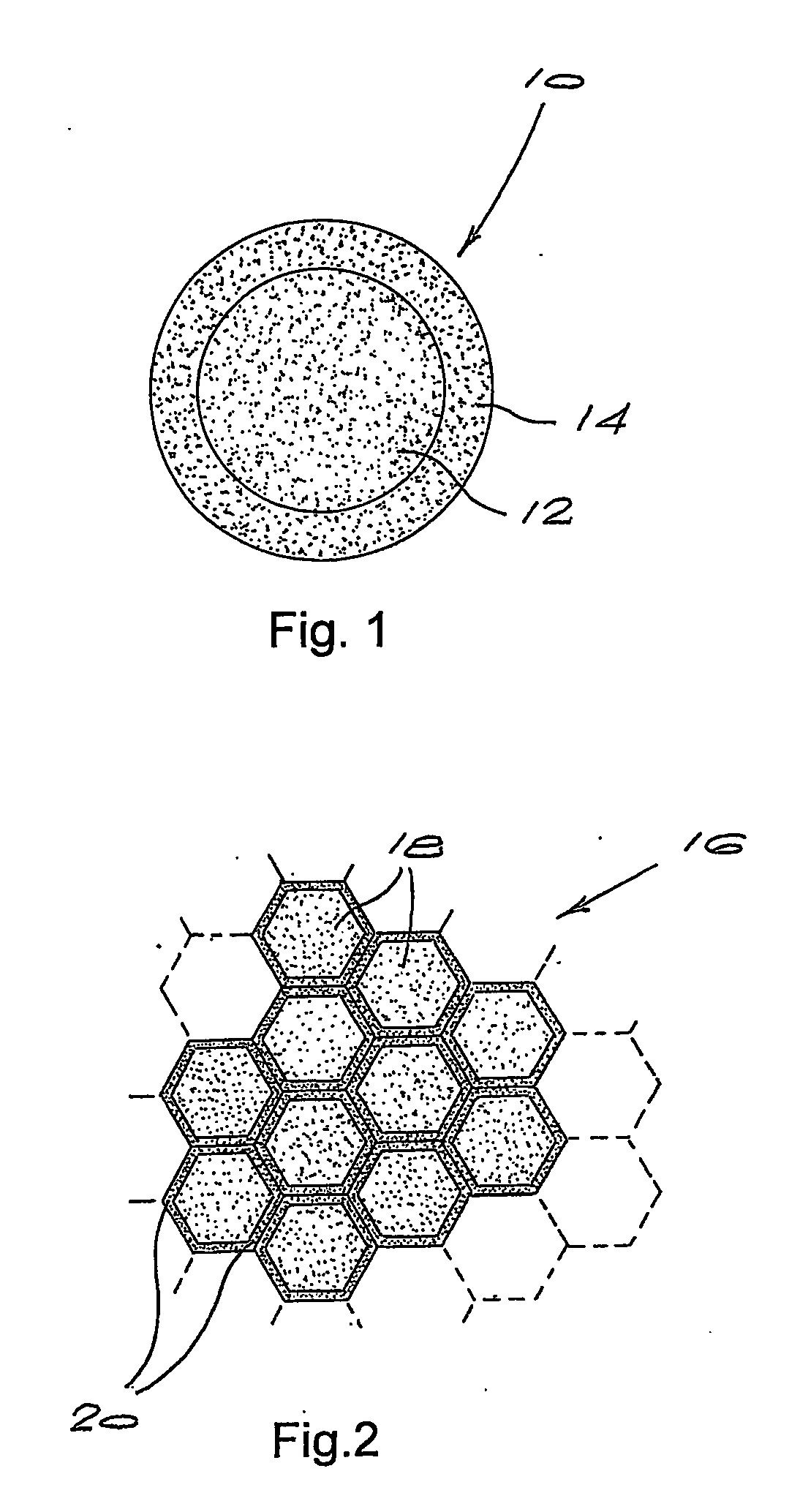

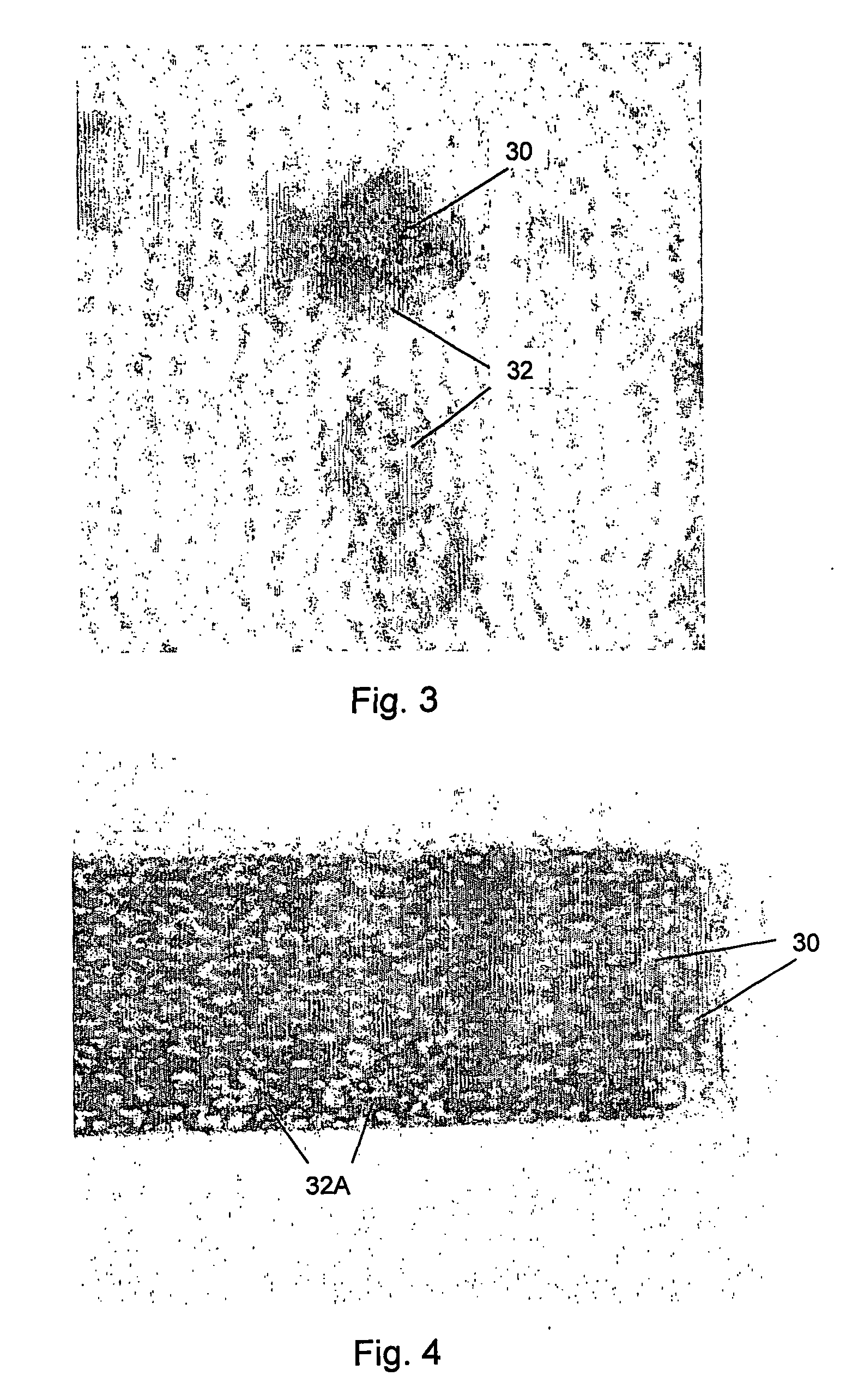

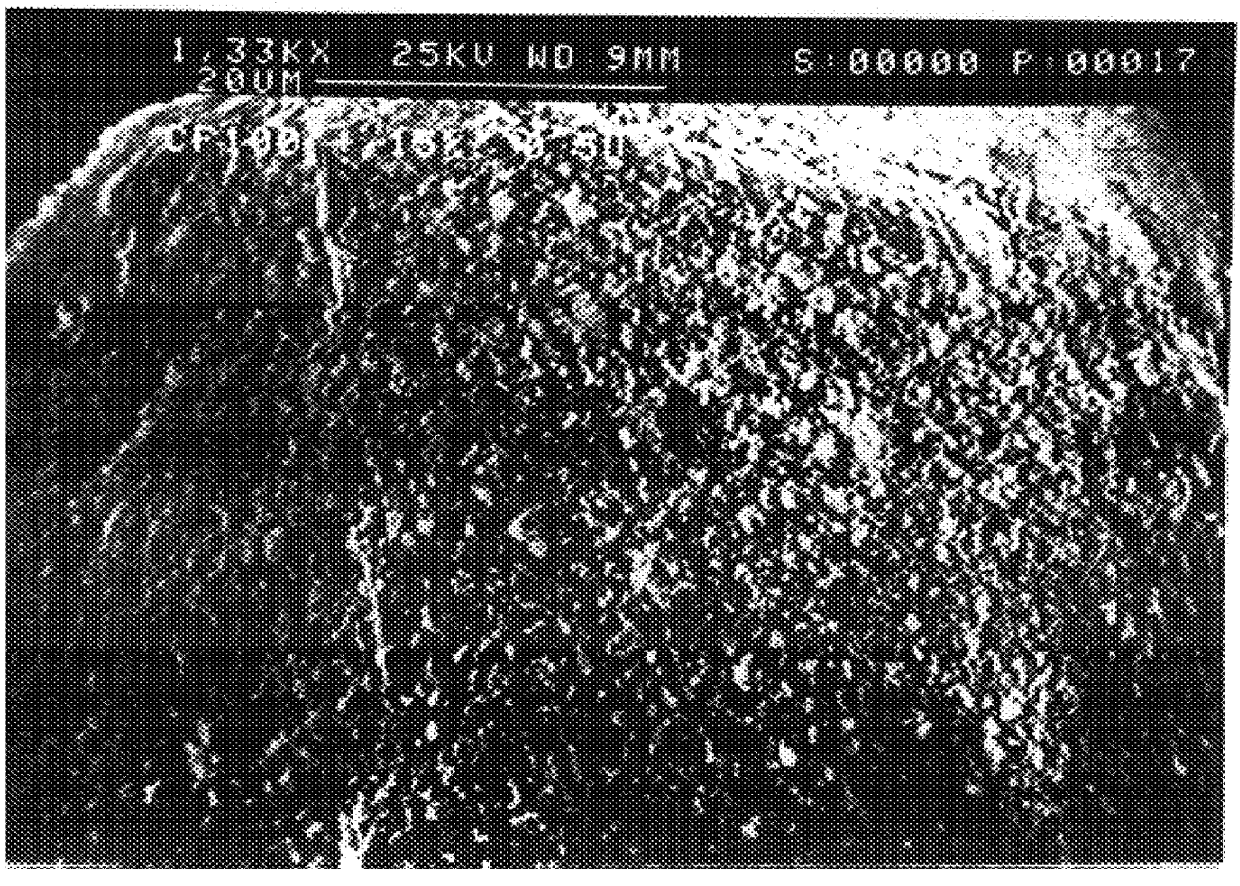

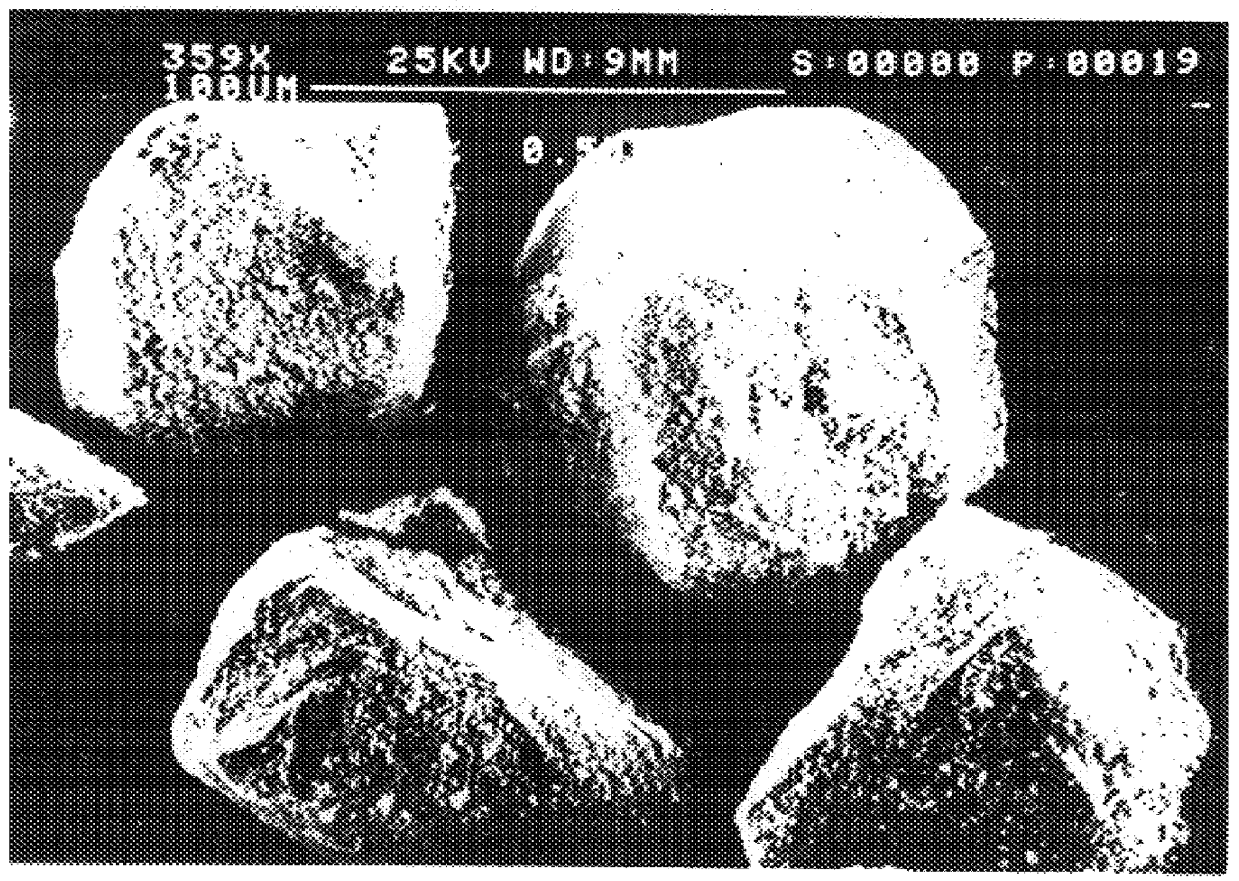

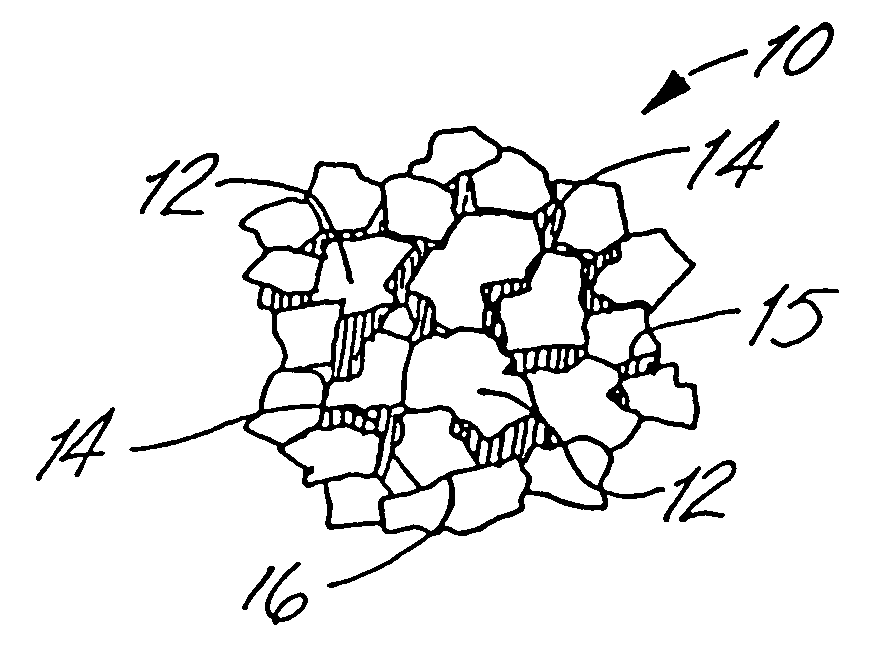

Composite material for drilling applications

A composite material consists of a plurality of cores dispersed in a matrix. The cores are formed of ultra-hard material, or the components for making an ultra-hard material. The matrix is formed of the components for making an ultra-hard material of a grade different to that of the cores, and a suitable binder. The ultra-hard material is polycrystalline in nature and is typically PCD or PcBN. The cores are typically provided as granules coated with the components for making an ultra-hard material and the binder. The composite material typically takes on a honeycomb structure of an ultra-hard material and cores within the pores of the honeycomb structure bonded to the honeycomb structure. The pores of the honeycomb structure may be ordered or random.

Owner:SIGALAS IAKOVOS +1

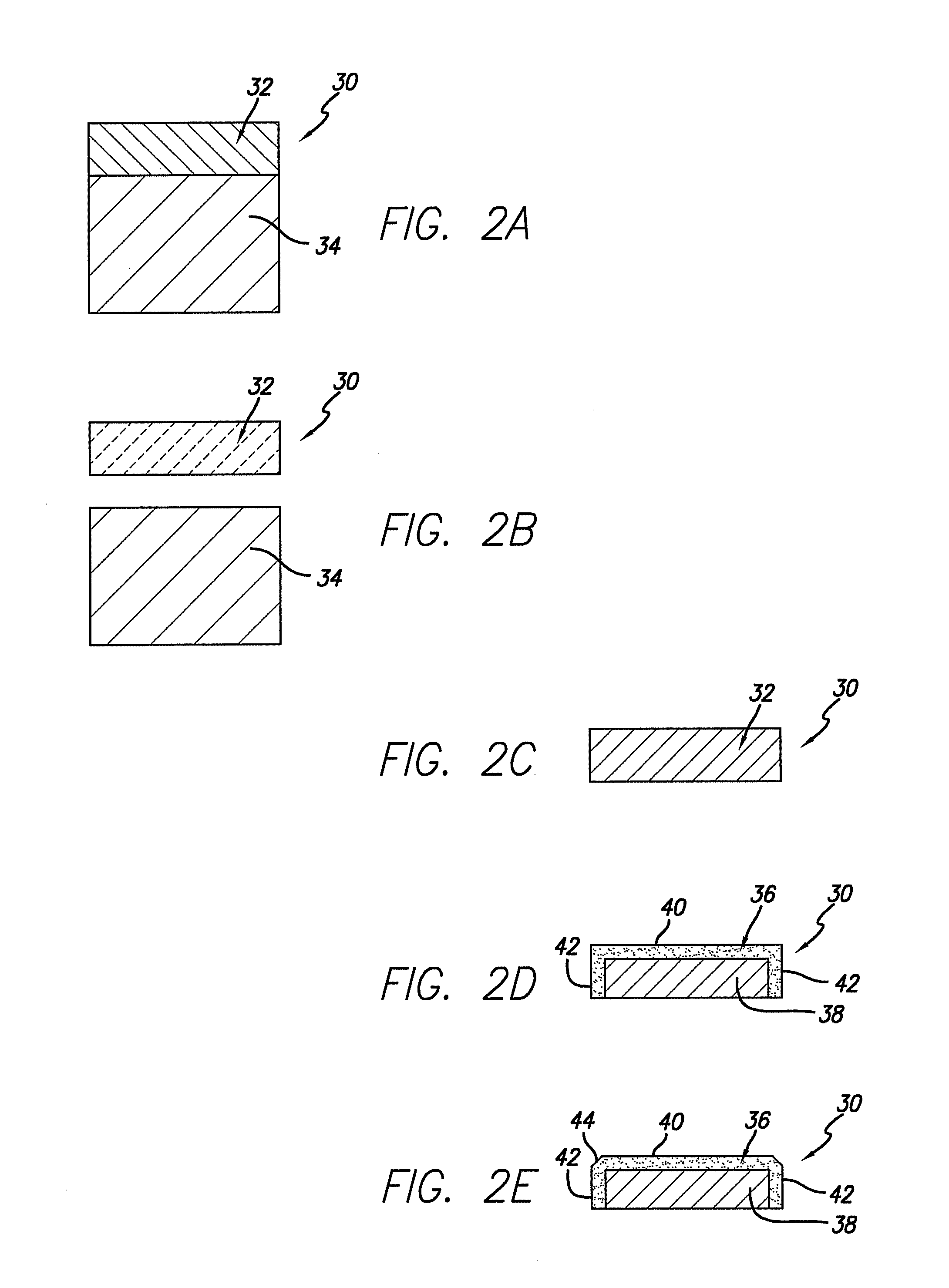

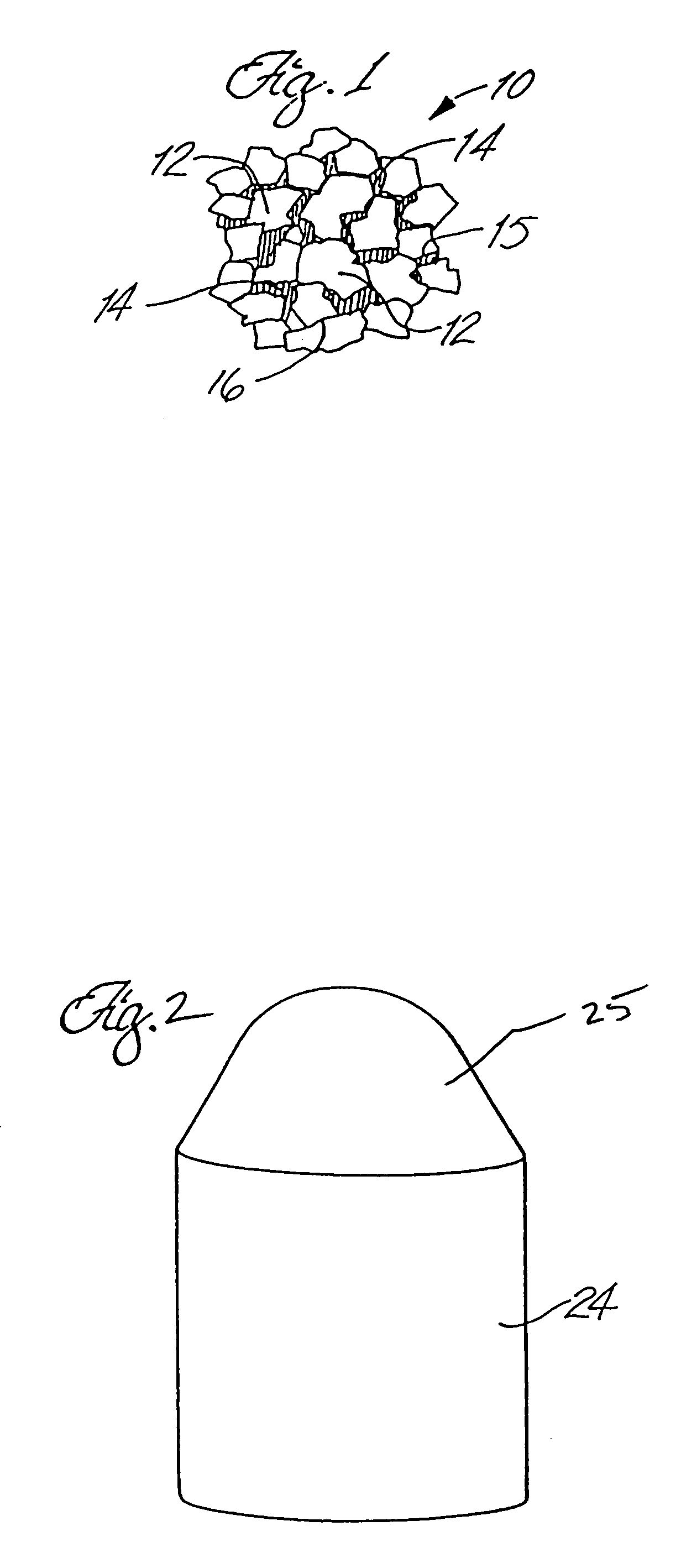

Diamond Bonded Construction Comprising Multi-Sintered Polycrystalline Diamond

InactiveUS20110083908A1Lower Level RequirementsImprove sintering performancePigmenting treatmentDrill bitsPolycrystalline diamondVolume content

Diamond bonded constructions comprise a diamond body attached to a substrate, wherein the body includes a first diamond bonded volume, and a second diamond bonded volume attached thereto. The second volume may be provided in the form of a powder or a presintered mass prior to attachment, and the first volume may be provided in the form of presintered pieces when combined with the second volume. The first volume diamond volume content is greater than about 94 percent, and is the same or greater than that of the second volume. The first volume is sintered during a first HPHT process, and the second volume is sintered and / or attached to the first volume during a second HPHT process. The first HPHT pressure is greater than the second HPHT pressure. The substrate is not an infiltration substrate used to form the first diamond volume. The diamond body may be thermally stable.

Owner:SMITH INT INC

High temperature high pressure capsule for processing materials in supercritical fluids

InactiveUS20030141301A1Easy to controlSufficient pressureFrom normal temperature solutionsUltra-high pressure processesSolventMechanical engineering

A capsule for containing at least one reactant and a supercritical fluid in a substantially air-free environment under high pressure, high temperature processing conditions. The capsule includes a closed end, at least one wall adjoining the closed end and extending from the closed end; and a sealed end adjoining the at least one wall opposite the closed end. The at least one wall, closed end, and sealed end define a chamber therein for containing the reactant and a solvent that becomes a supercritical fluid at high temperatures and high pressures. The capsule is formed from a deformable material and is fluid impermeable and chemically inert with respect to the reactant and the supercritical fluid under processing conditions, which are generally above 5 kbar and 550° C. and, preferably, at pressures between 5 kbar and 80 kbar and temperatures between 550° C. and about 1500° C. The invention also includes methods of filling the capsule with the solvent and sealing the capsule, as well as an apparatus for sealing the capsule.

Owner:SLT TECH

Surface impurity-enriched diamond and method of making

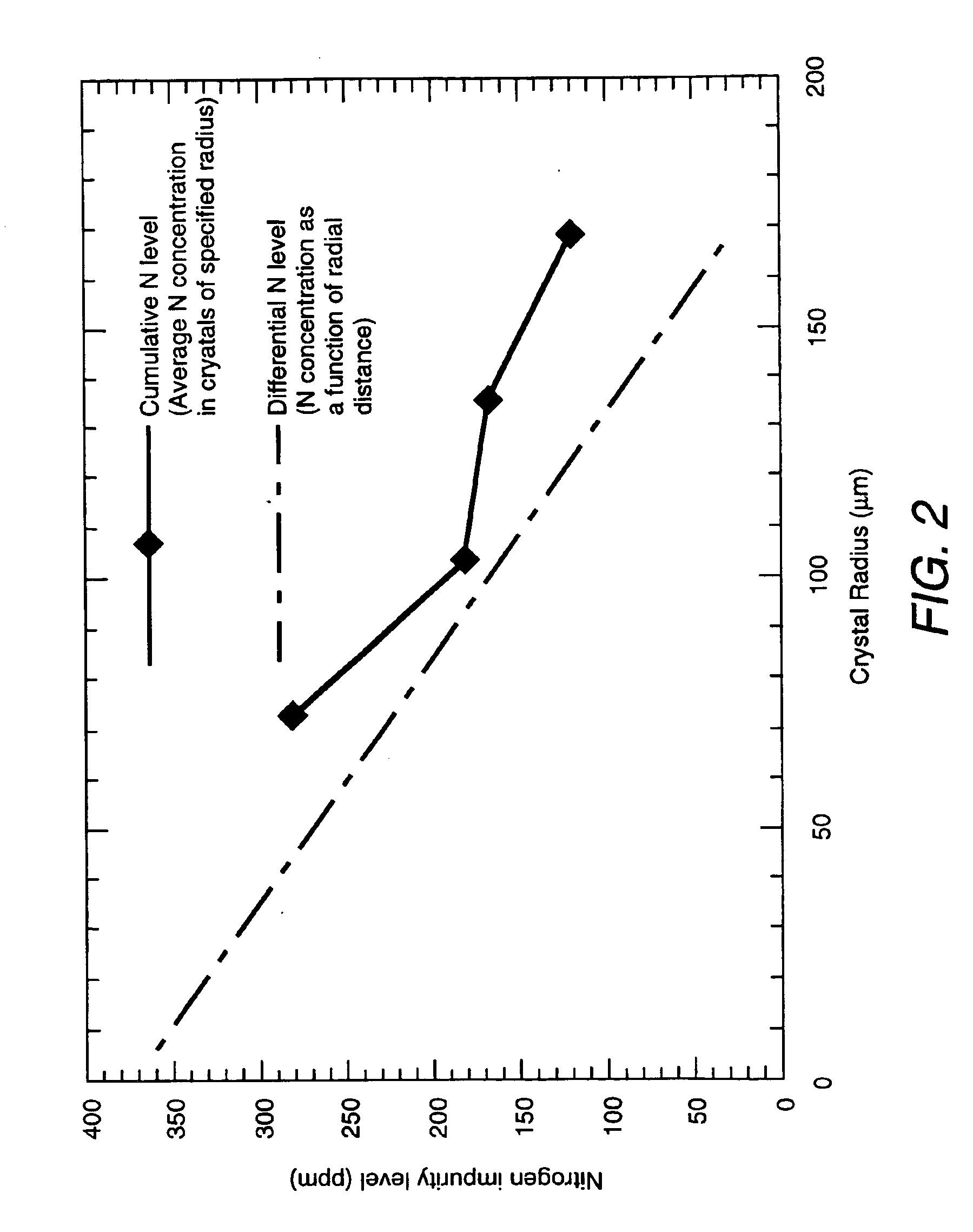

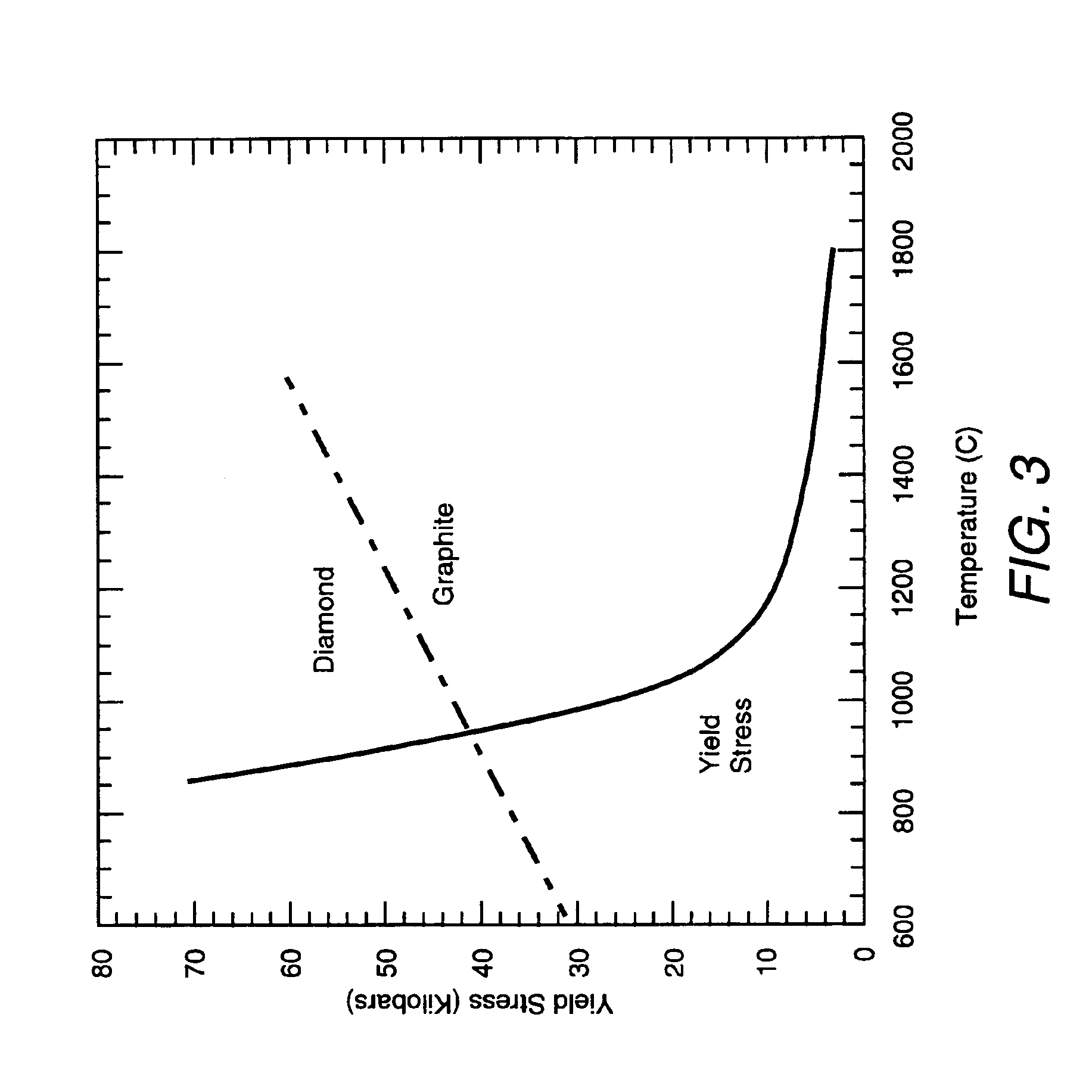

InactiveUS6887144B2Increases compressive fracture strengthHigh breaking strengthPolycrystalline material growthUltra-high pressure processesDopantMicrometer

An element-doped diamond crystal is disclosed herein. The crystal includes at least one dopant element which has a greater concentration toward or near an outermost surface of the crystal than in the center of the crystal. The concentration of the dopant element is at a local minimum at least about 5 micrometers below the surface. The concentration-profile of the dopant element for these diamond crystals causes an expansion of the diamond lattice, thereby generating tangential compressive stresses at the surface of the diamond crystal. These stresses beneficially increase the compressive fracture strength of the diamond.

Owner:DIAMOND INNOVATIONS INC

Method for producing abrasive compact with improved properties

InactiveUS6132675AImproved abrasionImprove stabilityUltra-high pressure processesCeramic shaping apparatusPolycrystalline diamondCarbide

Metal carbide supported polycrystalline diamond (PCD) compacts having improved abrasion / impact resistance properties and a method for making the same under high temperature / high pressure (HT / HP) processing conditions. The PCD compact is characterized as having a mixture of submicron sized diamond particles and large sized diamond particles.

Owner:DIAMOND INNOVATIONS INC

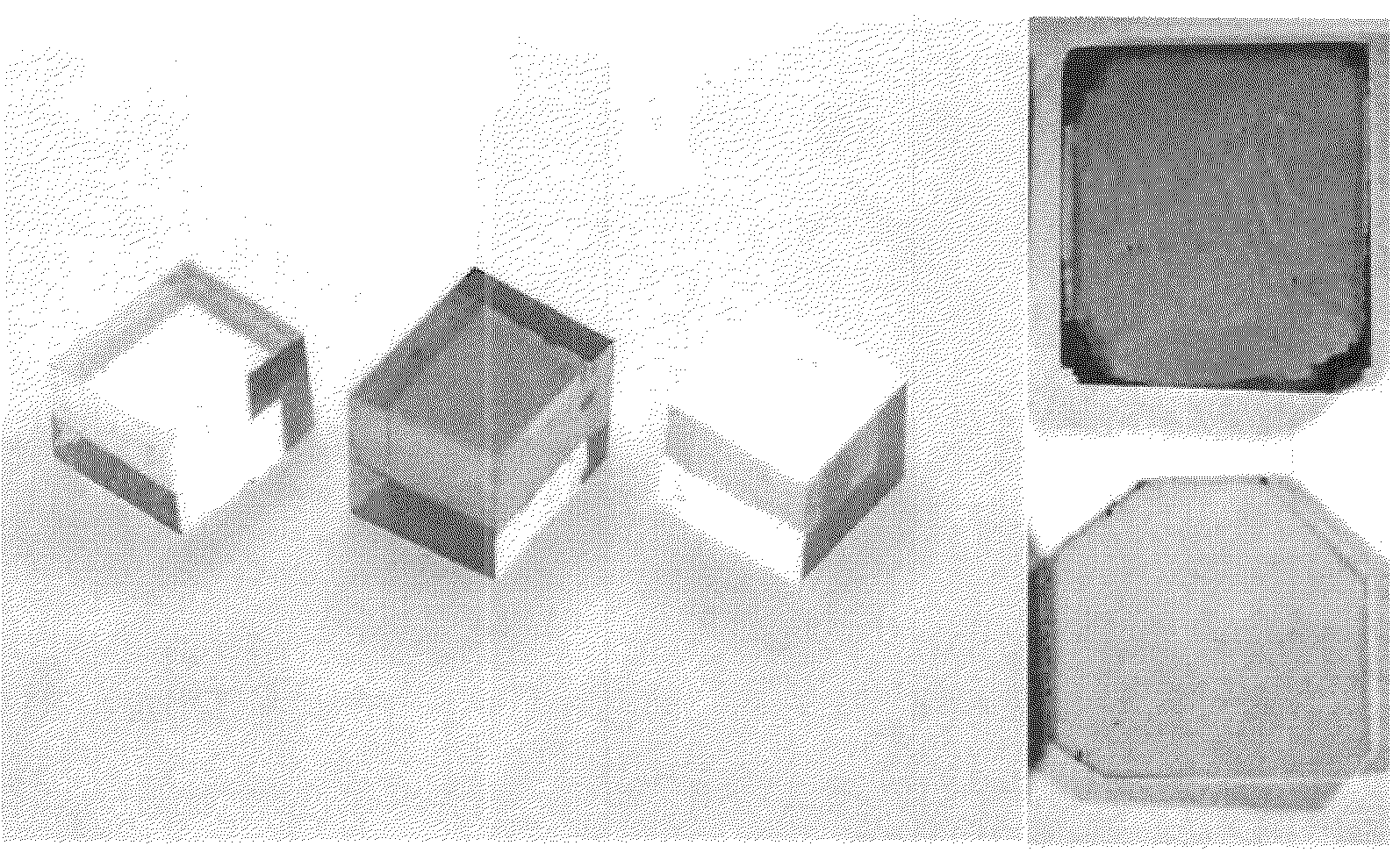

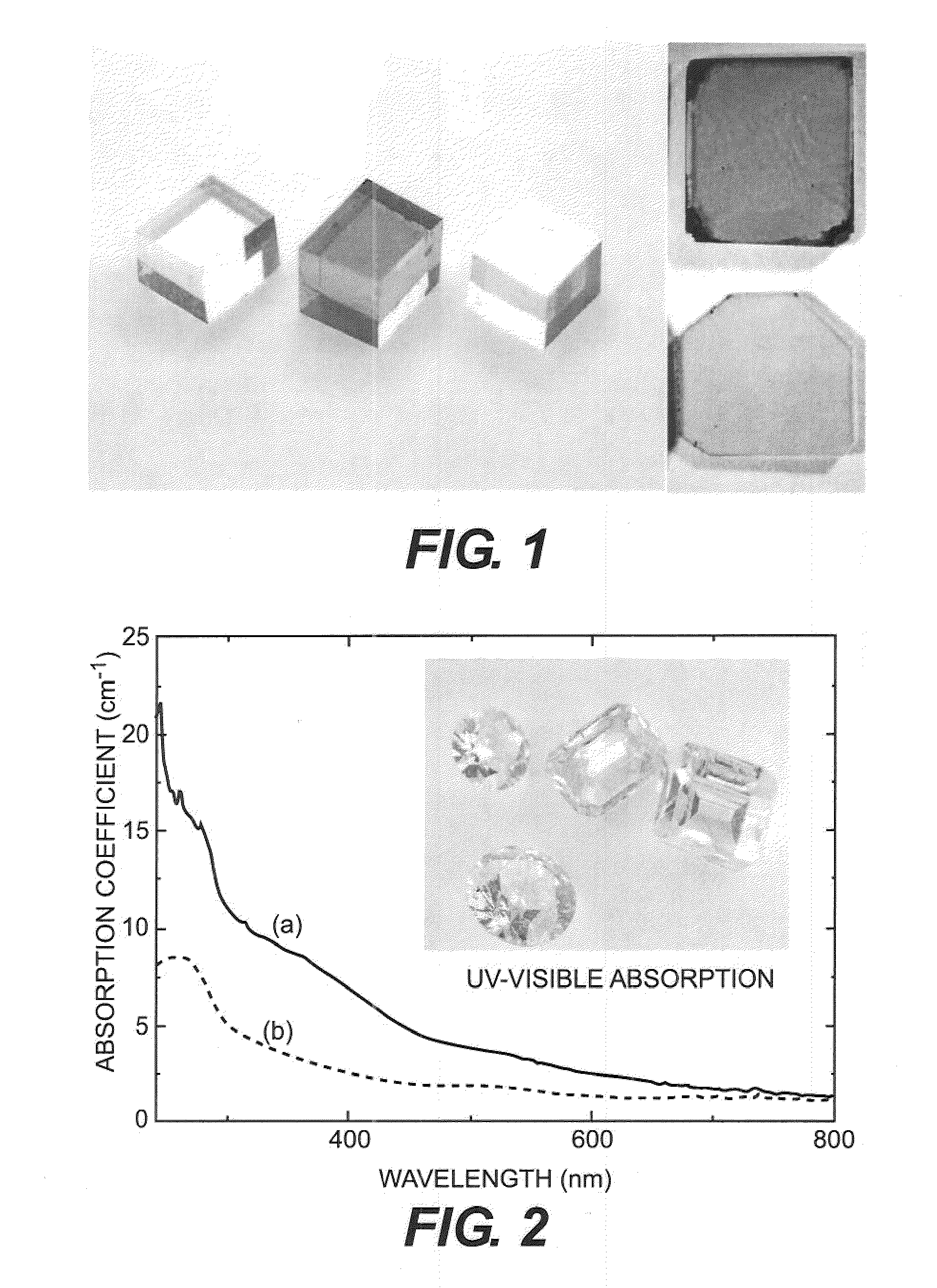

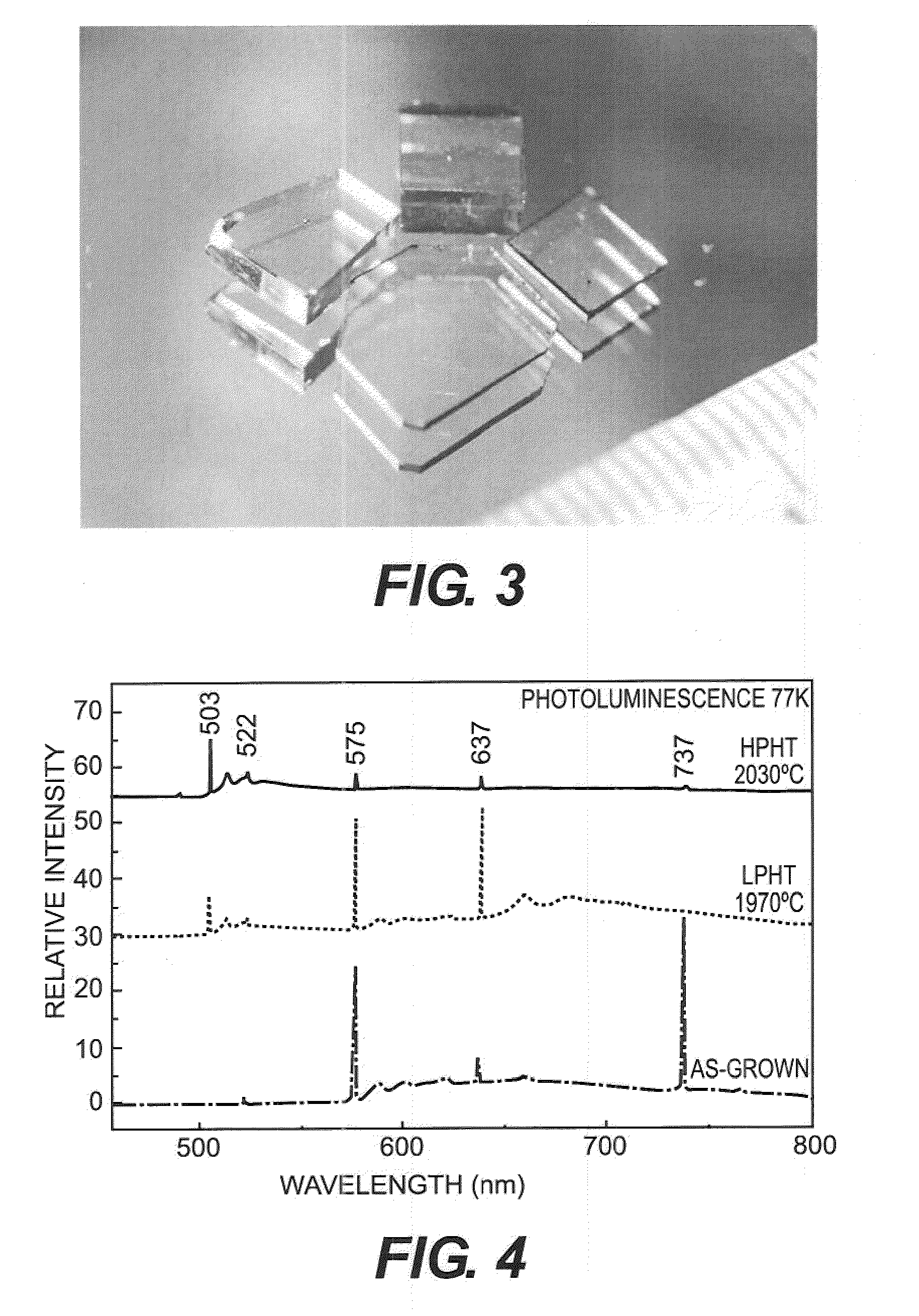

Enhanced Optical Properties of Chemical Vapor Deposited Single Crystal Diamond by Low-Pressure/High-Temperature Annealing

InactiveUS20100104494A1Good optical performanceIncrease probabilityPolycrystalline material growthCyanogen compoundsOptical propertyGas phase

The method of improving the optical properties of single crystal CVD diamond which comprises annealing the crystals at a temperature of up to 2200° C. and a pressure below 300 torr.

Owner:CARNEGIE INSTITUTION OF WASHINGTON

Polycrystalline diamond materials formed from coarse-sized diamond grains

InactiveUS6951578B1Improve fatigue resistanceImproved property of impactDrill bitsUltra-high pressure processesMicrometerDiamond crystal

PCD materials of this invention comprise diamond crystals that are bonded together with a catalyst / binder material. The PCD material is prepared by combining diamond grains with a catalyst / binder material either as a premixture or by infiltration during sintering. The PCD material comprises 15 percent by volume or less diamond grains sized 20 micrometers or less. The diamond grains are pressurized under elevated temperature conditions to form the desired PCD material. PCD materials of this invention can constitute the exclusive material phase of a PCD construction, or can form one or more material phase in a multi-phase material microstructure, wherein the multiple material phase can be arranged in an ordered / oriented or random fashion. PCD materials of this invention display improved properties of impact and fatigue resistance, and functional toughness, when used in complex wear environments, when compared to conventional PCs materials comprising intentionally added fine-sized diamond grains.

Owner:SMITH INT INC

Optical quality diamond material

ActiveUS7740824B2Prevent or reduce local strain generating defectsPrevent and reduce absorptionPolycrystalline material growthAfter-treatment detailsOptical reflectionGrating

Owner:ELEMENT SIX TECH LTD

Diamond sensors, detectors, and quantum devices

ActiveUS20140037932A1High purityMinimizes strainQuantum computersPolycrystalline material growthElectron donorQuantum devices

A synthetic single crystal diamond material comprising: a first region of synthetic single crystal diamond material comprising a plurality of electron donor defects; a second region of synthetic single crystal diamond material comprising a plurality of quantum spin defects; and a third region of synthetic single crystal diamond material disposed between the first and second regions such that the first and second regions are spaced apart by the third region, wherein the second and third regions of synthetic single crystal diamond material have a lower concentration of electron donor defects than the first region of synthetic single crystal diamond material, and wherein the first and second regions are spaced apart by a distance in a range 10 nm to 100 μm which is sufficiently close to allow electrons to be donated from the first region of synthetic single crystal diamond material to the second region of synthetic single crystal diamond material thus forming negatively charged quantum spin defects in the second region of synthetic single crystal diamond material and positively charged defects in the first region of synthetic single crystal diamond material while being sufficiently far apart to reduce other coupling interactions between the first and second regions which would otherwise unduly reduce the decoherence time of the plurality of quantum spin defects and / or produce strain broaden of a spectral line width of the plurality of quantum spin defects in the second region of synthetic single crystal diamond material.

Owner:ELEMENT SIX LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com