Patents

Literature

953 results about "Torr" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The torr (symbol: Torr) is a unit of pressure based on an absolute scale, now defined as exactly 1/760 of a standard atmosphere (101325 Pa). Thus one torr is exactly 101325/760 pascals (≈ 133.32 Pa). Historically, one torr was intended to be the same as one "millimeter of mercury". However, subsequent redefinitions of the two units made them slightly different (by less than 0.000015%). The torr is not part of the International System of Units (SI), but it is often combined with the metric prefix milli to name one millitorr (mTorr) or 0.001 Torr.

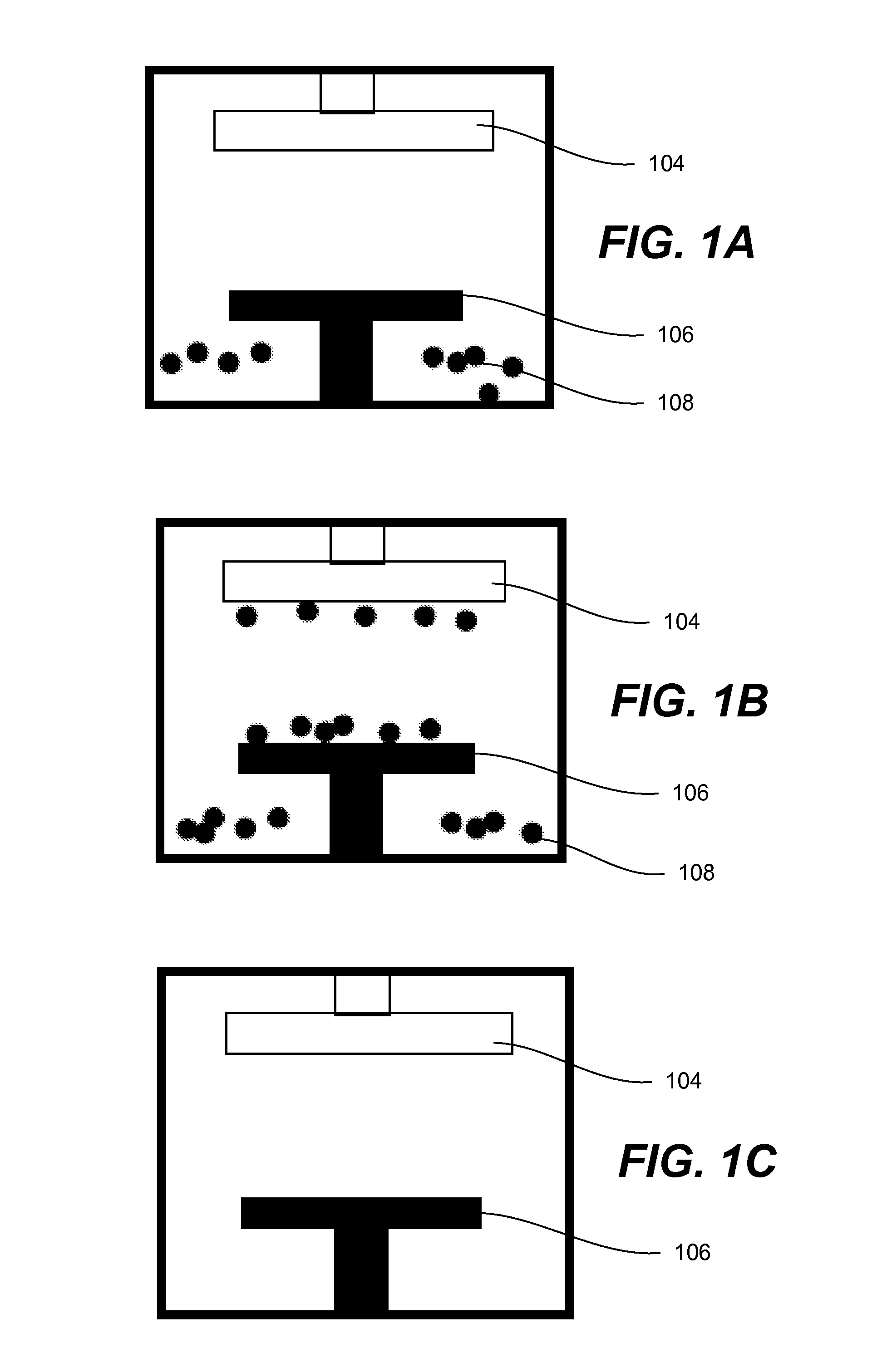

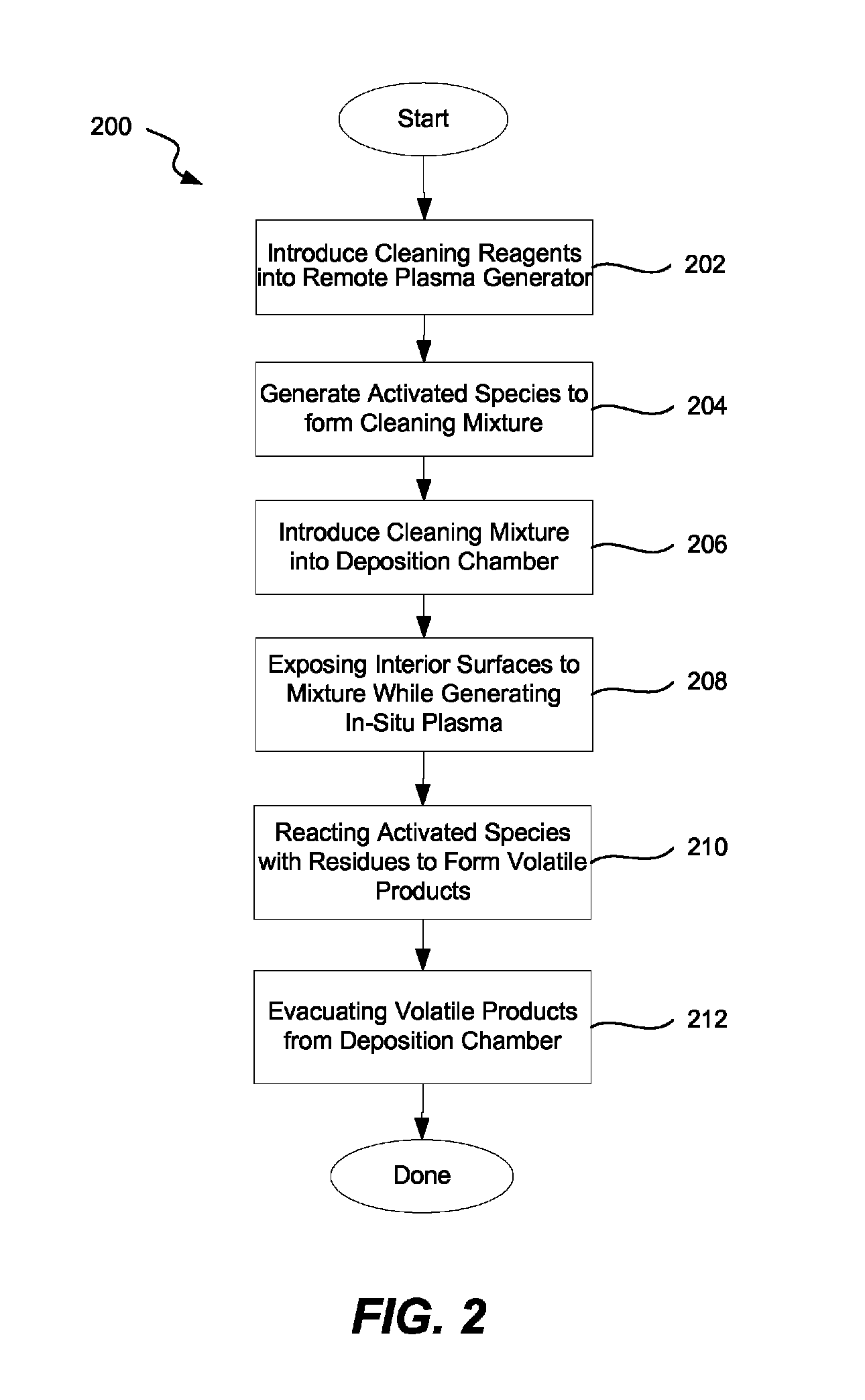

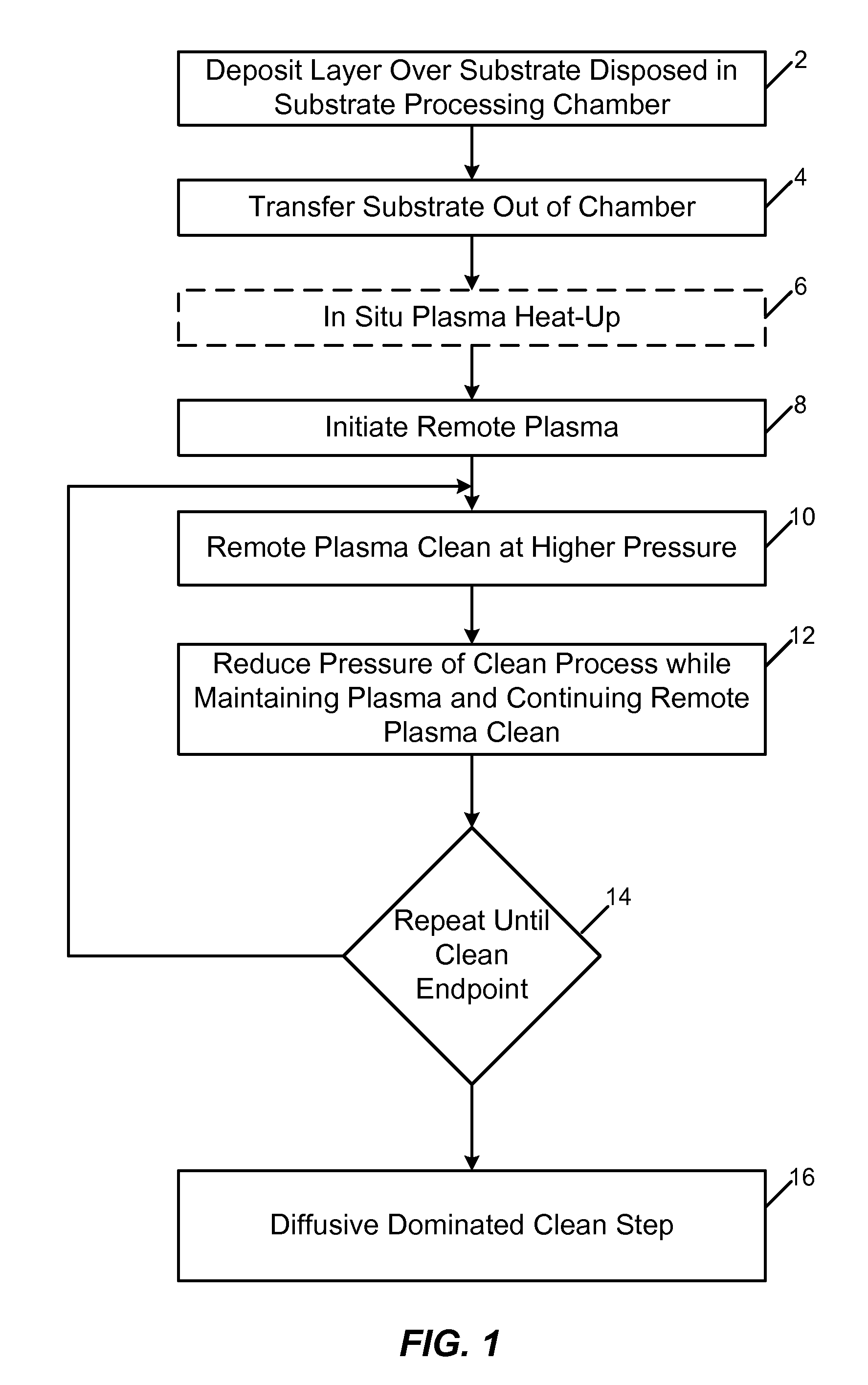

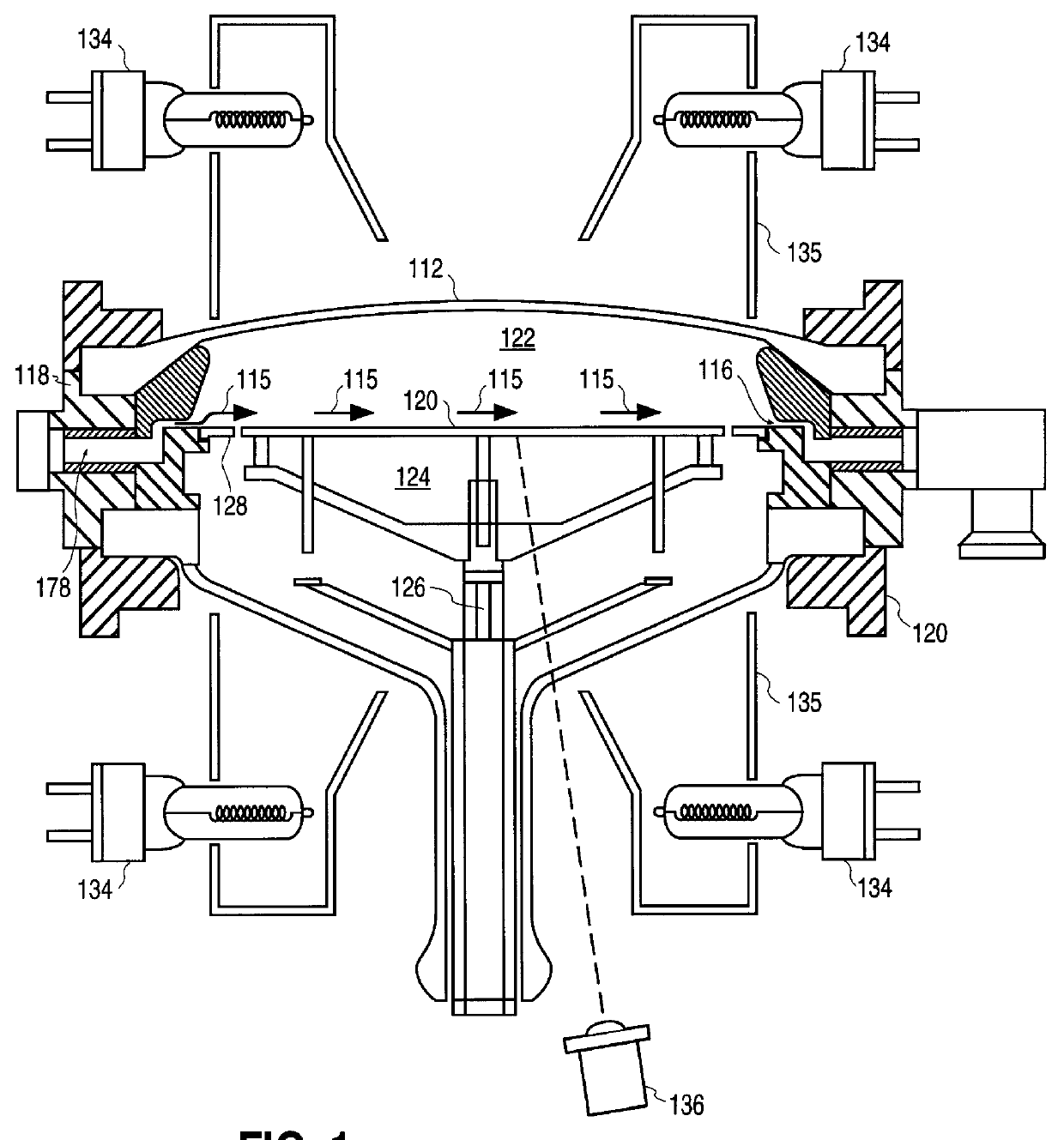

Plasma clean method for deposition chamber

ActiveUS8591659B1Improve cleaning efficiencyEasy to cleanElectric discharge tubesDecorative surface effectsRemote plasmaImproved method

Improved methods and apparatuses for removing residue from the interior surfaces of the deposition reactor are provided. The methods involve increasing availability of cleaning reagent radicals inside the deposition chamber by generating cleaning reagent radicals in a remote plasma generator and then further delivering in-situ plasma energy while the cleaning reagent mixture is introduced into the deposition chamber. Certain embodiments involve a multi-stage process including a stage in which the cleaning reagent mixture is introduced at a high pressure (e.g., about 0.6 Torr or more) and a stage the cleaning reagent mixture is introduced at a low pressure (e.g., about 0.6 Torr or less).

Owner:NOVELLUS SYSTEMS

Method for achieving improved epitaxy quality (surface texture and defect density) on free-standing (aluminum, indium, gallium) nitride ((al,in,ga)n) substrates for opto-electronic and electronic devices

A III-V nitride homoepitaxial microelectronic device structure comprising a III-V nitride homoepitaxial epi layer on a III-V nitride material substrate, e.g., of freestanding character. Various processing techniques are described, including a method of forming a III-V nitride homoepitaxial layer on a corresponding III-V nitride material substrate, by depositing the III-V nitride homoepitaxial layer by a VPE process using Group III source material and nitrogen source material under process conditions including V / III ratio in a range of from about 1 to about 105, nitrogen source material partial pressure in a range of from about 1 to about 103 torr, growth temperature in a range of from about 500 to about 1250 degrees Celsius, and growth rate in a range of from about 0.1 to about 500 microns per hour. The III-V nitride homoepitaxial microelectronic device structures are usefully employed in device applications such as UV LEDs, high electron mobility transistors, and the like.

Owner:WOLFSPEED INC

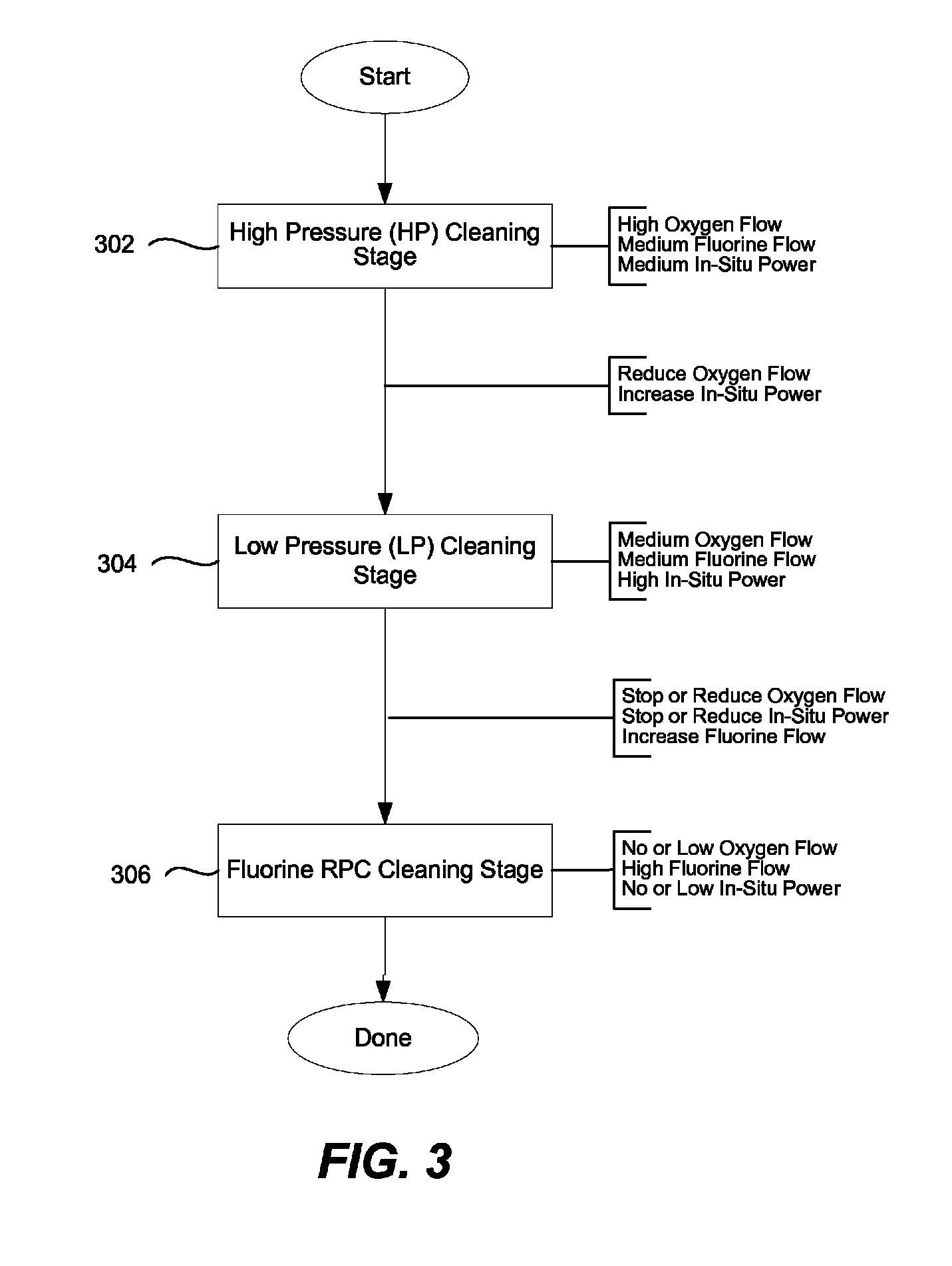

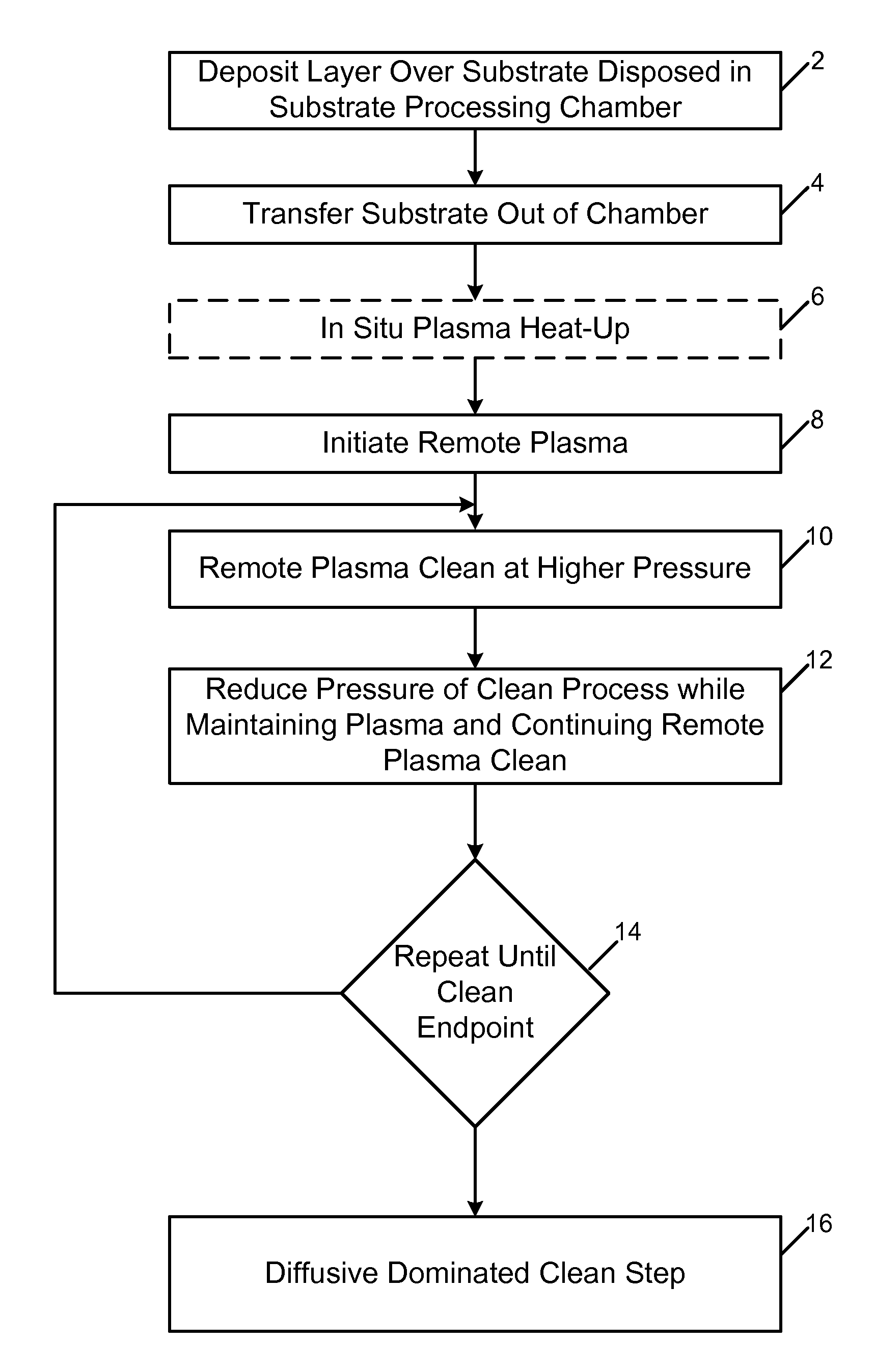

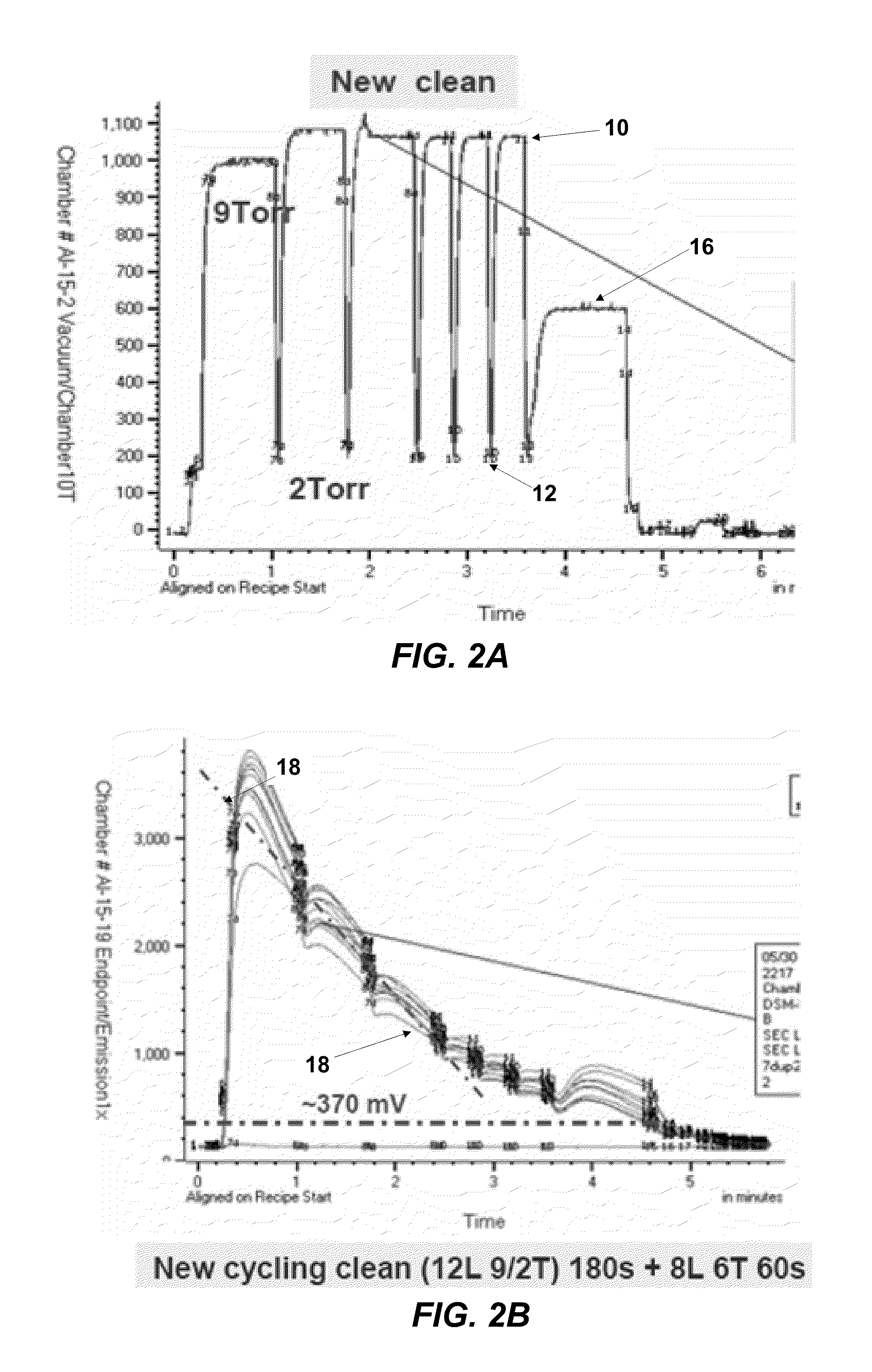

Remote plasma clean process with cycled high and low pressure clean steps

InactiveUS7967913B2Hollow article cleaningSemiconductor/solid-state device manufacturingRemote plasmaContinuous flow

A remote plasma process for removing unwanted deposition build-up from one or more interior surfaces of a substrate processing chamber after processing a substrate disposed in the substrate processing chamber. In one embodiment, the substrate is transferred out of the substrate processing chamber and a flow of a fluorine-containing etchant gas is introduced into a remote plasma source where reactive species are formed. A continuous flow of the reactive species from the remote plasmas source to the substrate processing chamber is generated while a cycle of high and low pressure clean steps is repeated. During the high pressure clean step, reactive species are flown into the substrate processing chamber while pressure within the substrate processing chamber is maintained between 4-15 Torr. During the low pressure clean step, reactive species are flown into the substrate processing chamber while reducing the pressure of the substrate processing chamber by at least 50 percent of a high pressure reached in the high pressure clean step.

Owner:APPLIED MATERIALS INC

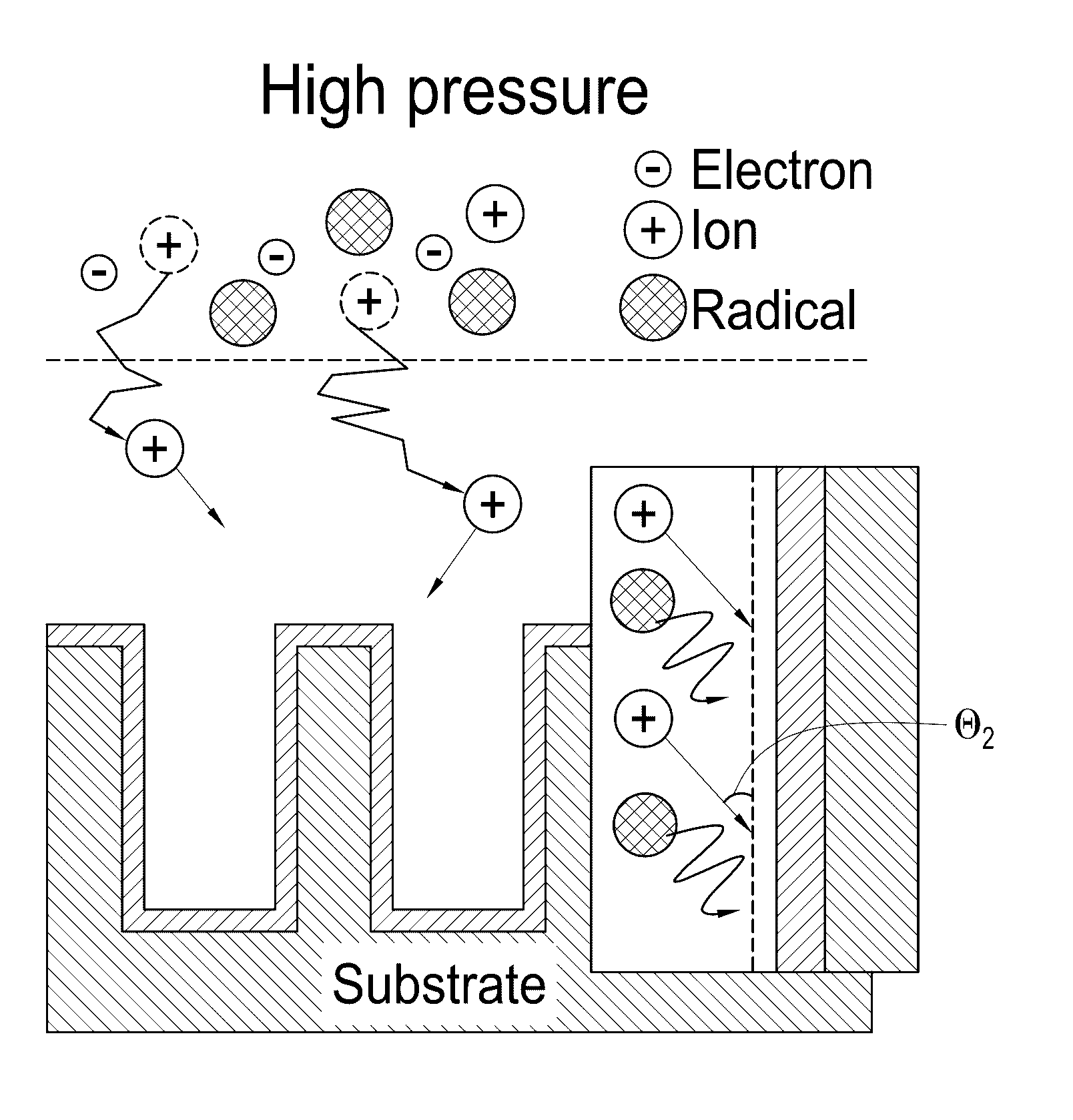

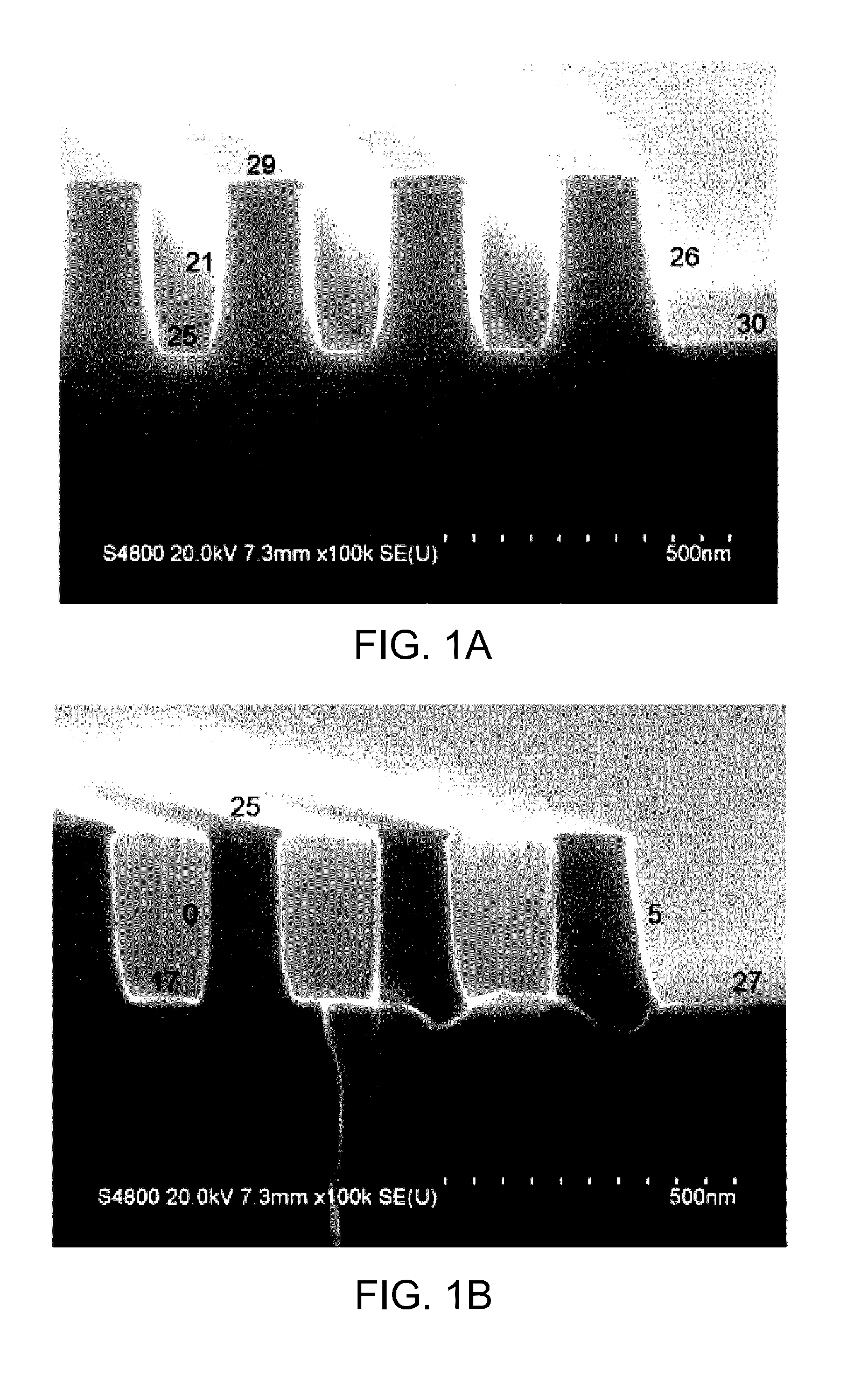

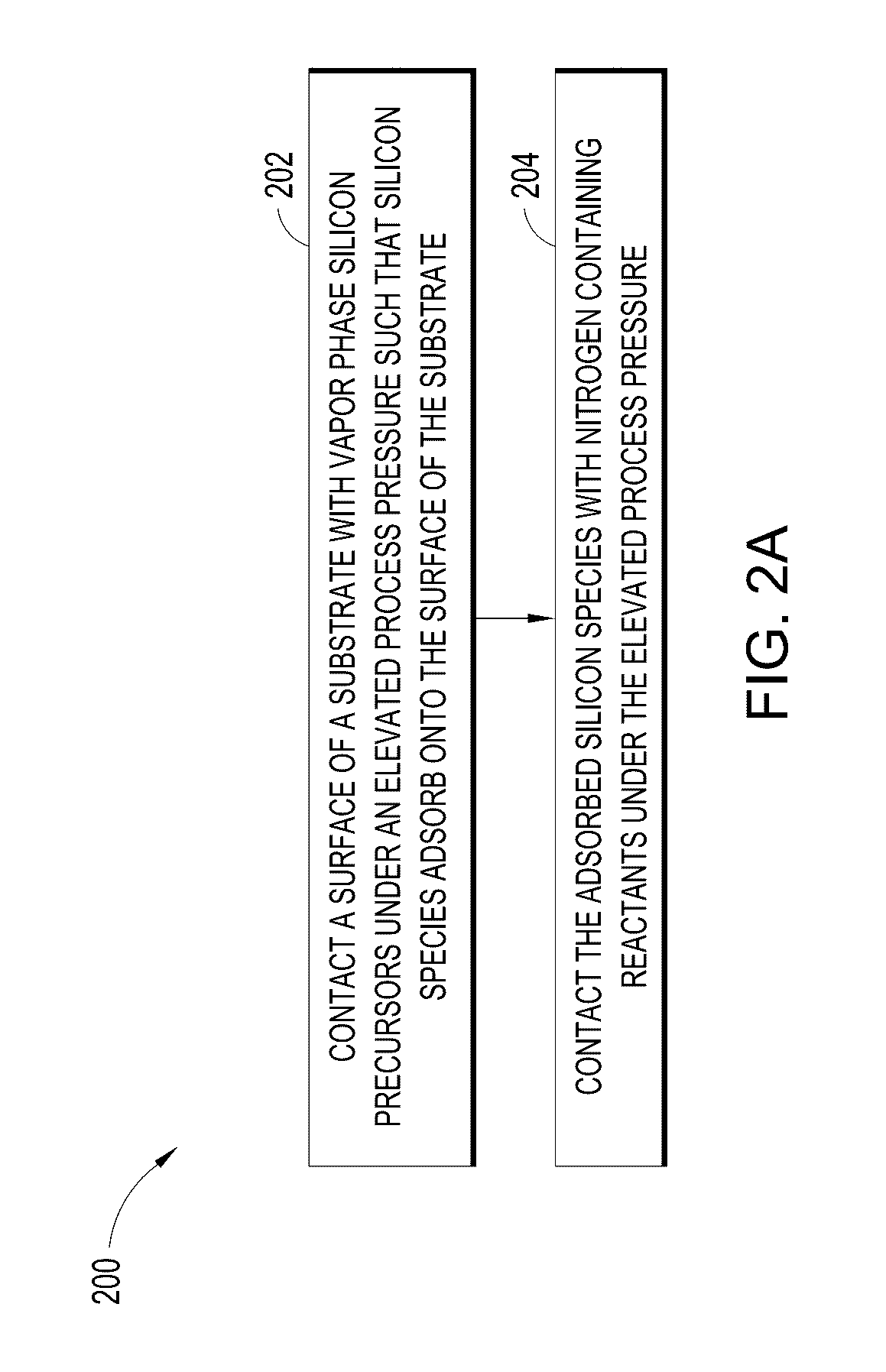

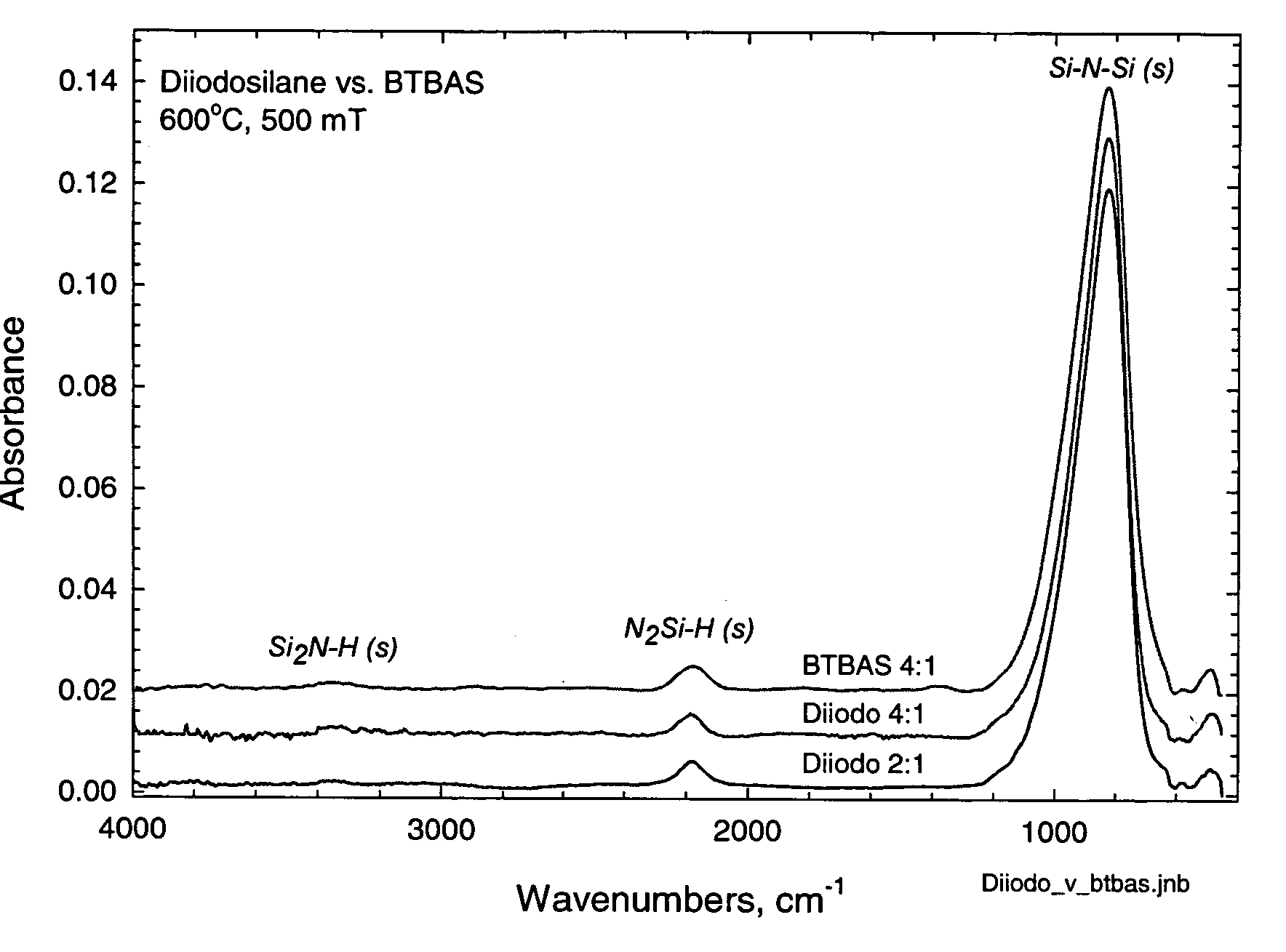

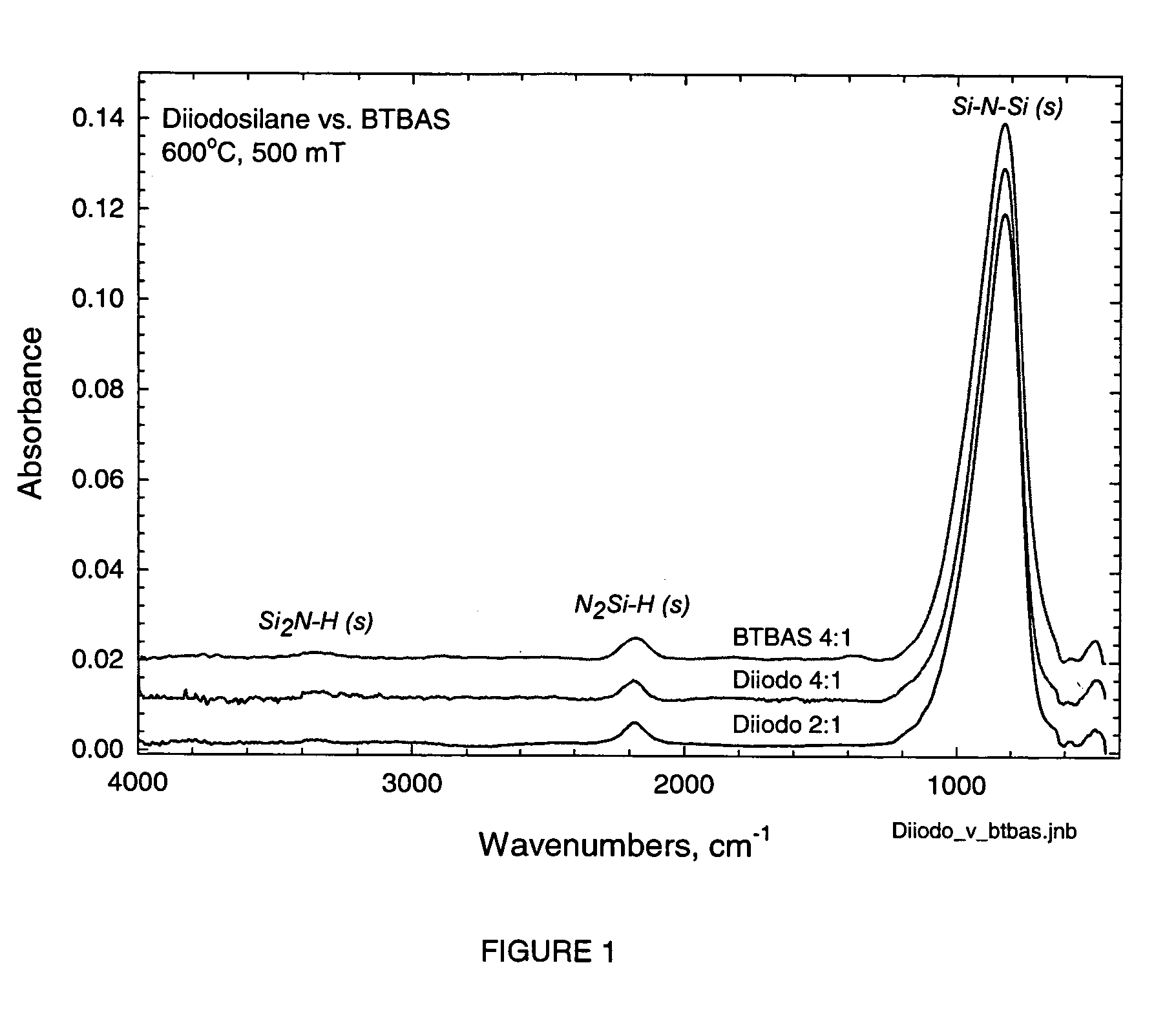

FORMATION OF SiN THIN FILMS

ActiveUS20170062204A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingNitrogen plasmaHigh pressure

Methods of forming silicon nitride thin films on a substrate in a reaction space under high pressure are provided. The methods can include a plurality of plasma enhanced atomic layer deposition (PEALD) cycles, where at least one PEALD deposition cycle comprises contacting the substrate with a nitrogen plasma at a process pressure of 20 Torr to 500 Torr within the reaction space. In some embodiments the silicon precursor is a silyly halide, such as H2SiI2. In some embodiments the processes allow for the deposition of silicon nitride films having improved properties on three dimensional structures. For example, such silicon nitride films can have a ratio of wet etch rates on the top surfaces to the sidewall of about 1:1 in dilute HF.

Owner:ASM IP HLDG BV

Methods of selective deposition of heavily doped epitaxial SiGe

ActiveUS20050079691A1Semiconductor/solid-state device manufacturingSemiconductor devicesDopantSelective deposition

The invention generally teaches a method for depositing a silicon film or silicon germanium film on a substrate comprising placing the substrate within a process chamber and heating the substrate surface to a temperature in the range from about 600° C. to about 900° C. while maintaining a pressure in the range from about 0.1 Torr to about 200 Torr. A deposition gas is provided to the process chamber and includes SiH4, an optional germanium source gas, an etchant, a carrier gas and optionally at least one dopant gas. The silicon film or the silicon germanium film is selectively and epitaxially grown on the substrate. One embodiment teaches a method for depositing a silicon-containing film with an inert gas as the carrier gas. Methods may include the fabrication of electronic devices utilizing selective silicon germanium epitaxial films.

Owner:APPLIED MATERIALS INC

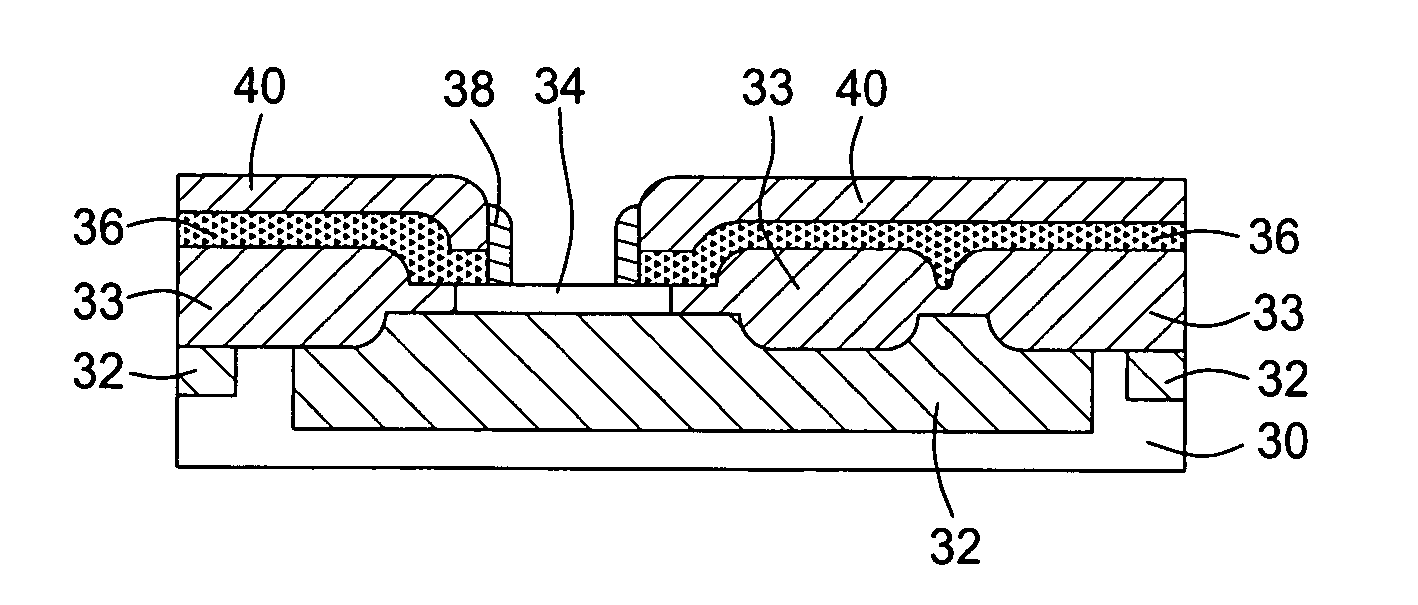

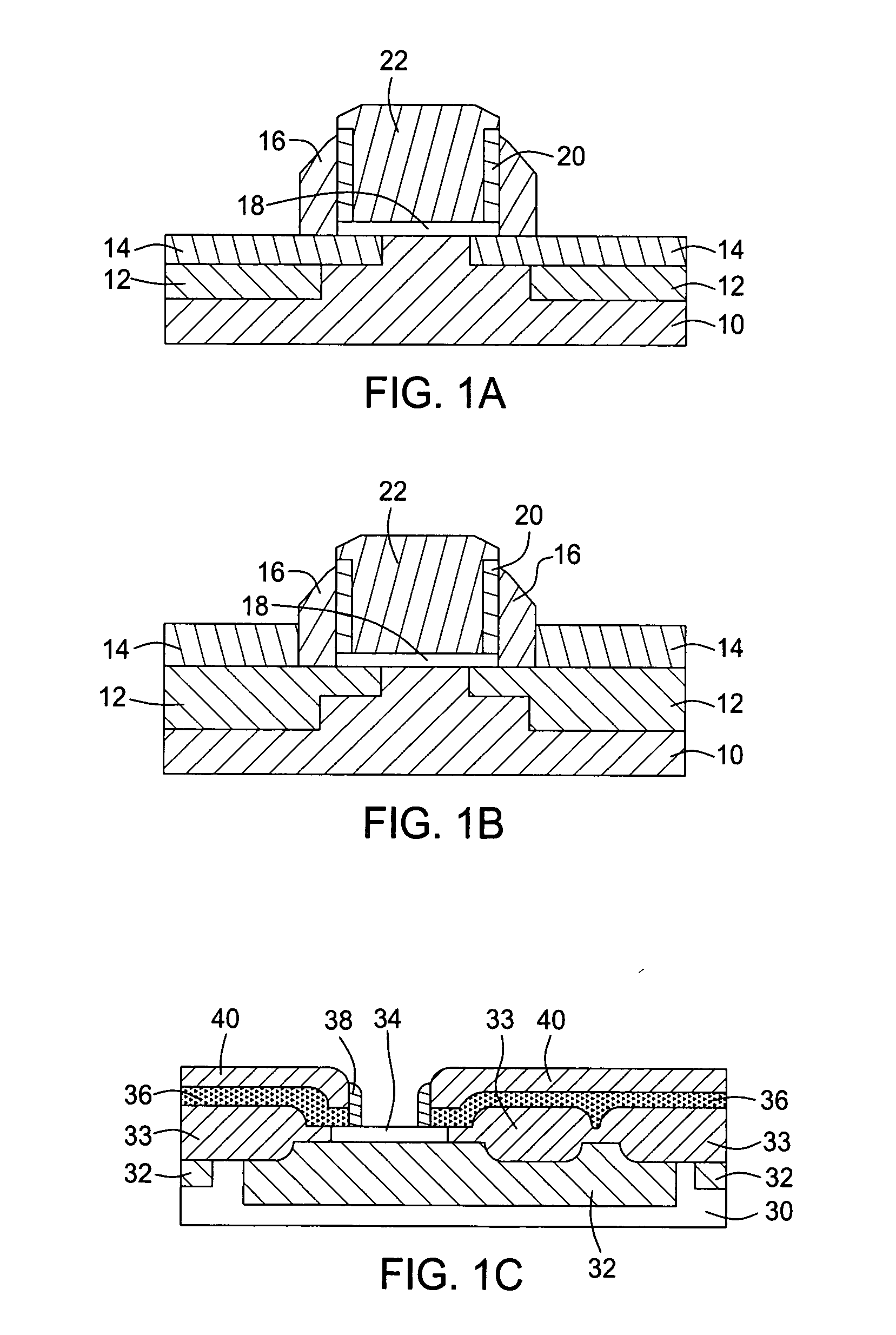

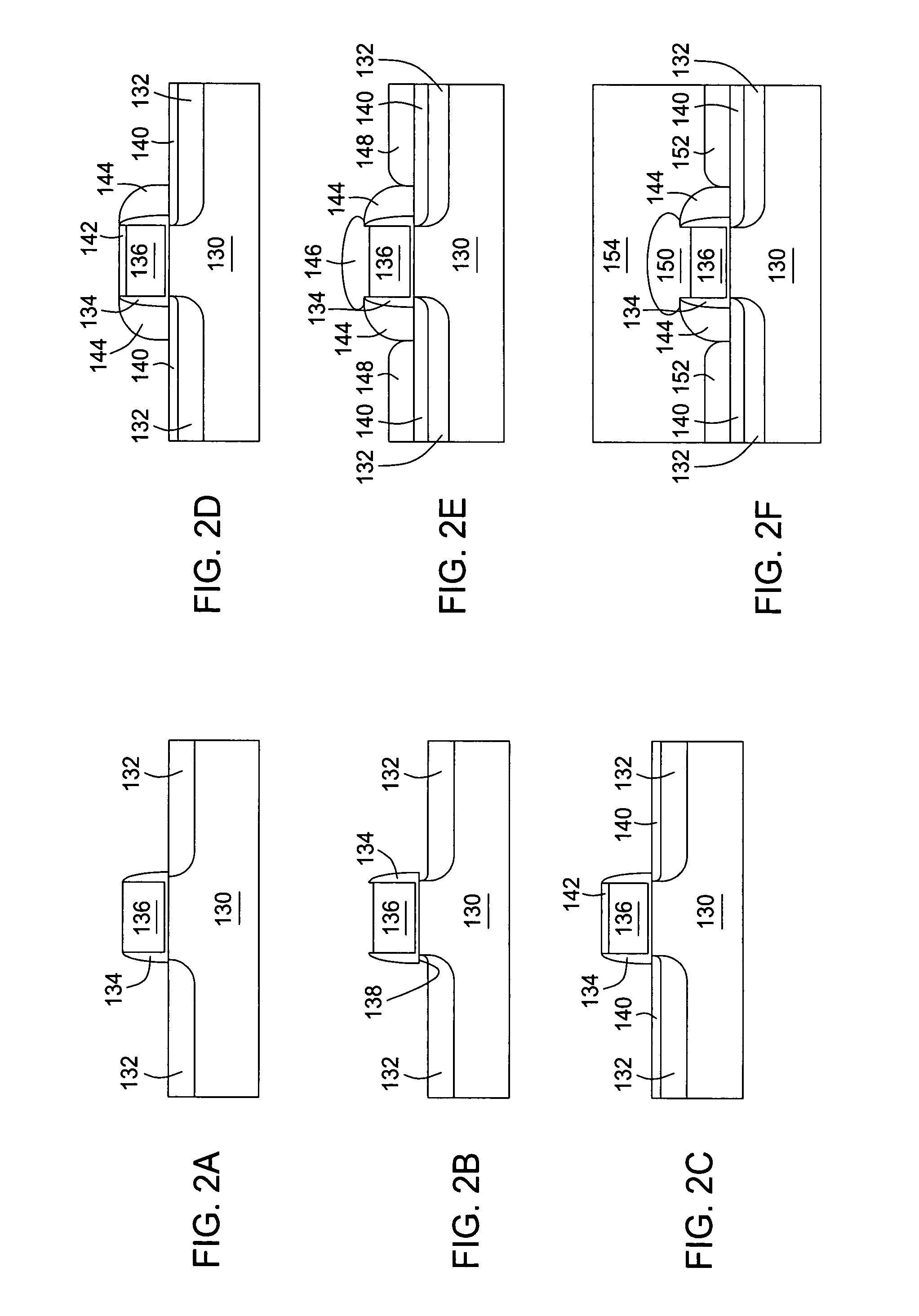

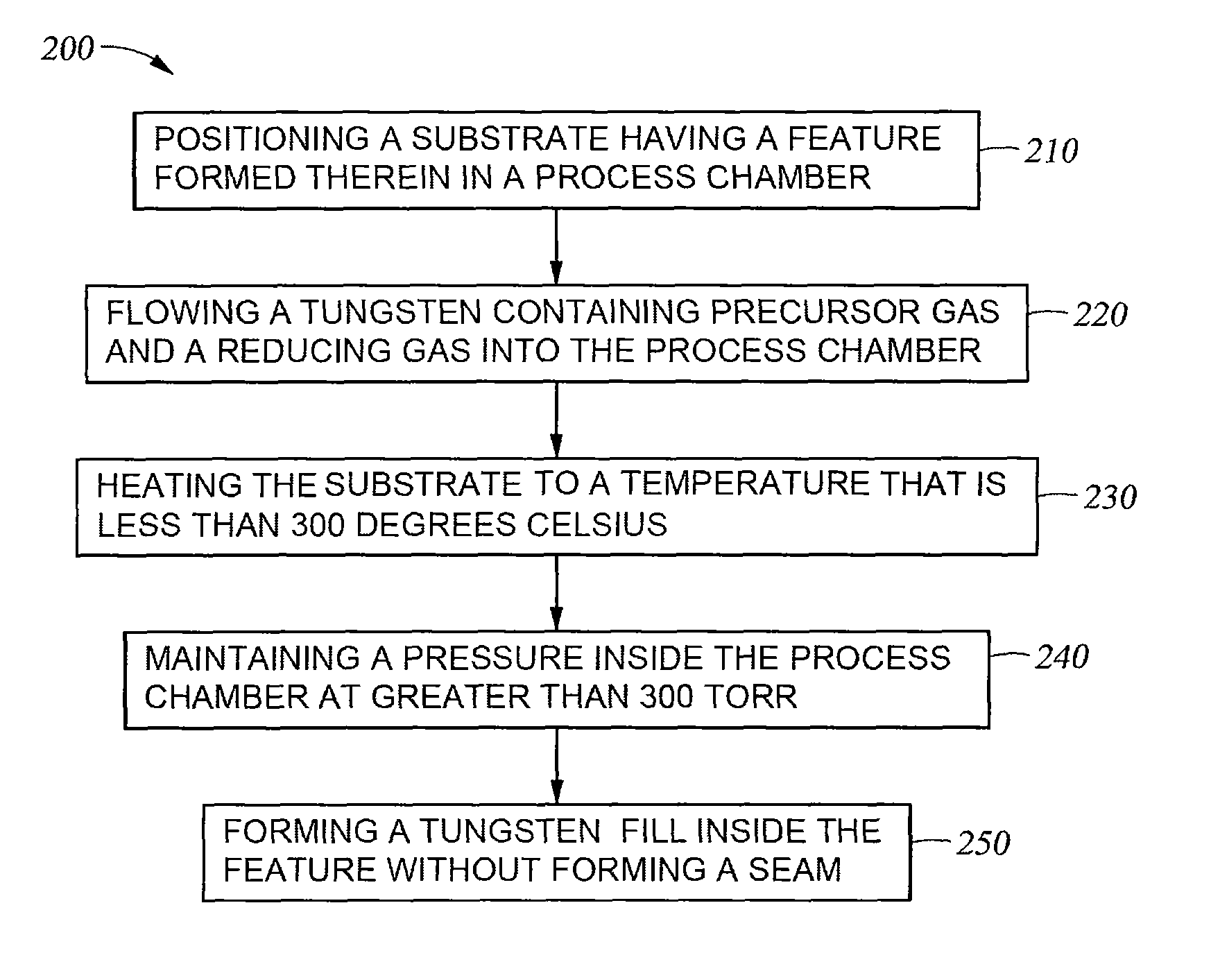

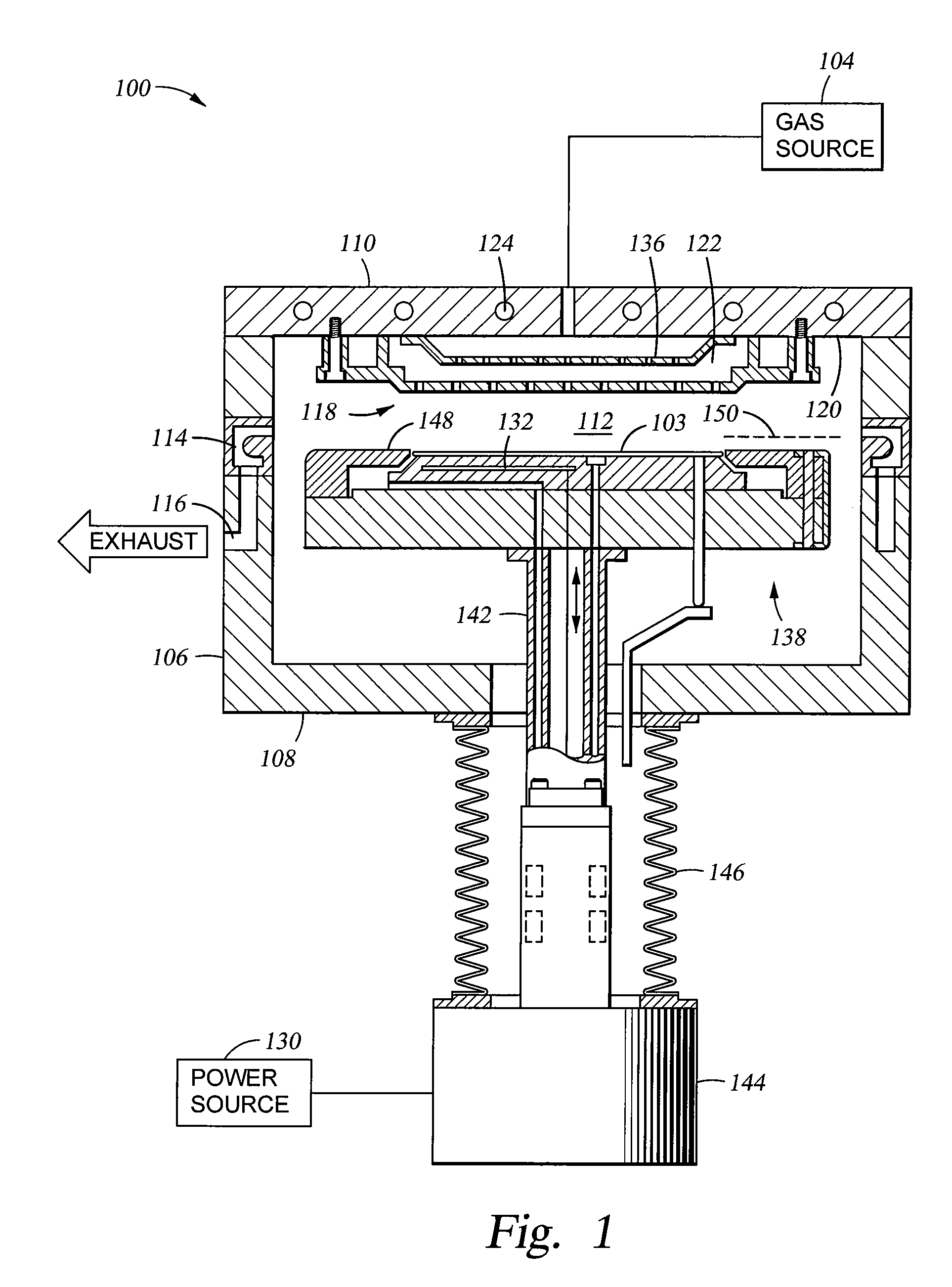

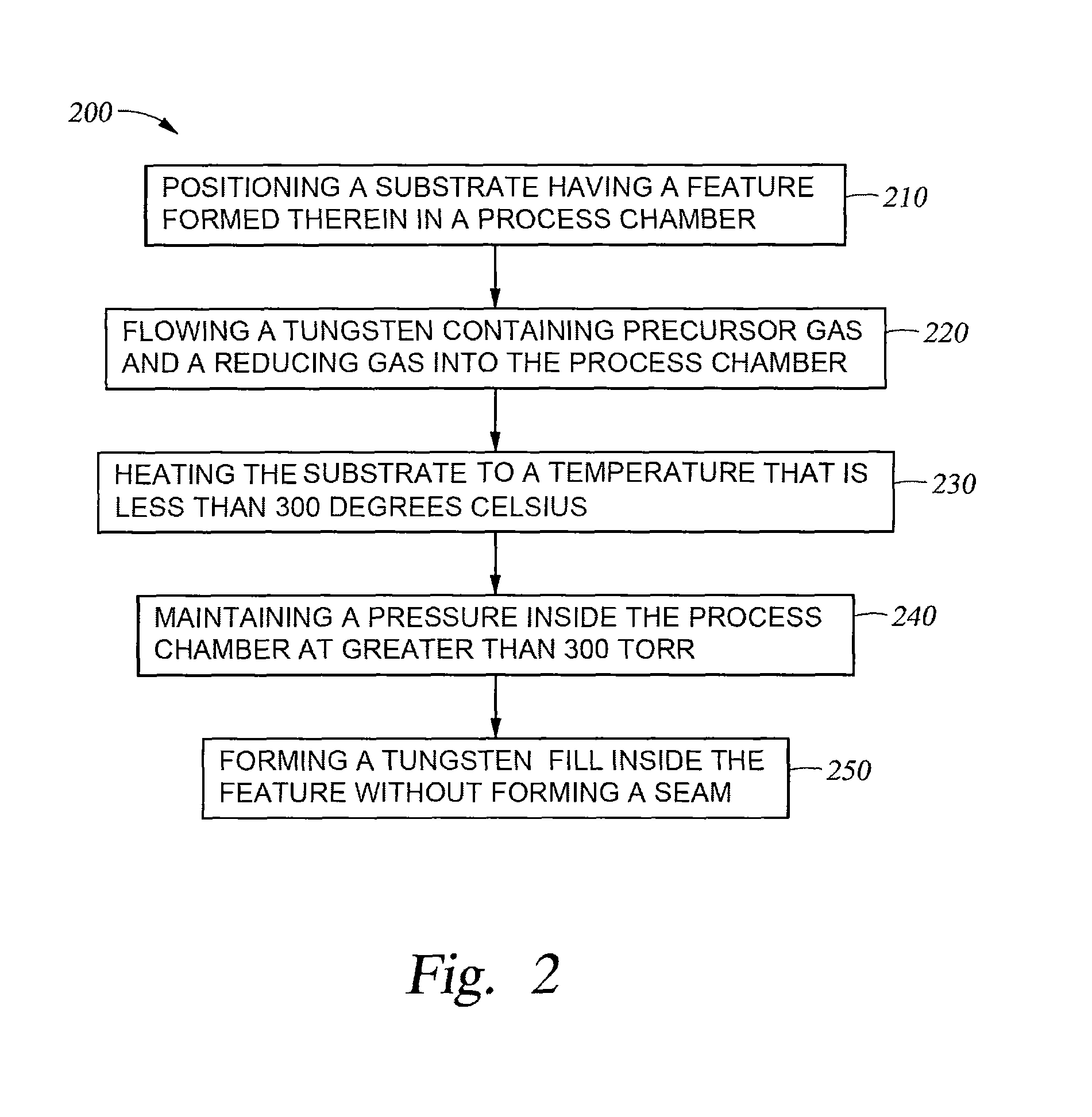

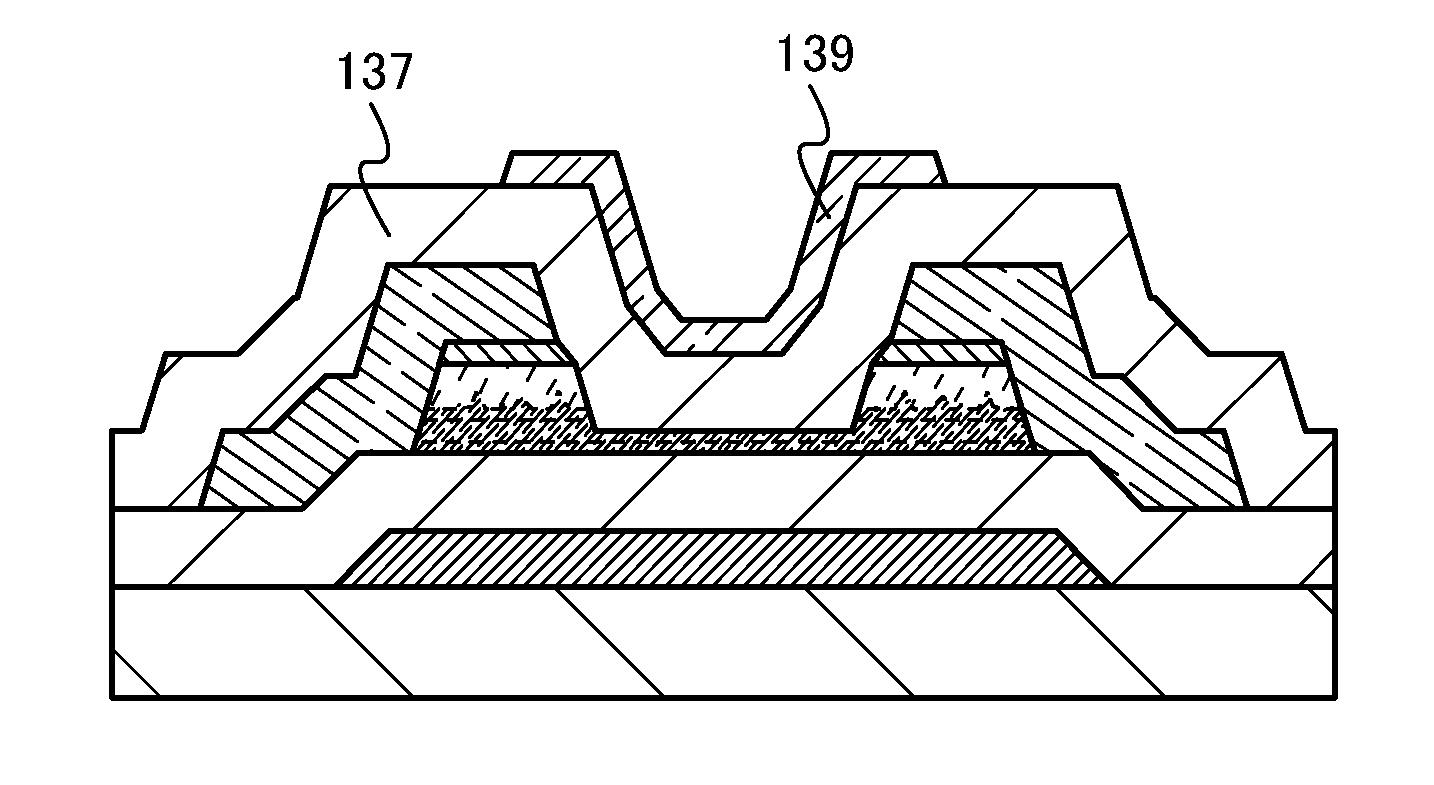

Low temperature high pressure high H2/WF6 ratio W process for 3D NAND application

ActiveUS8900999B1Semiconductor/solid-state device manufacturingCelsius DegreeThermal chemical vapor deposition

A method of filling a feature in a substrate with tungsten without forming a seam is presented. The tungsten is deposited by a thermal chemical vapor deposition (CVD) process using hydrogen (H2) and tungsten hexafluoride (WF6) precursor gases. The H2 to WF6 flow rate ratio is greater than 40 to 1, such as from 40 to 1 to 100 to 1. The substrate temperature during deposition is less than 300 degrees Celsius (° C.) and the processing pressure during deposition is greater than 300 Torr.

Owner:APPLIED MATERIALS INC

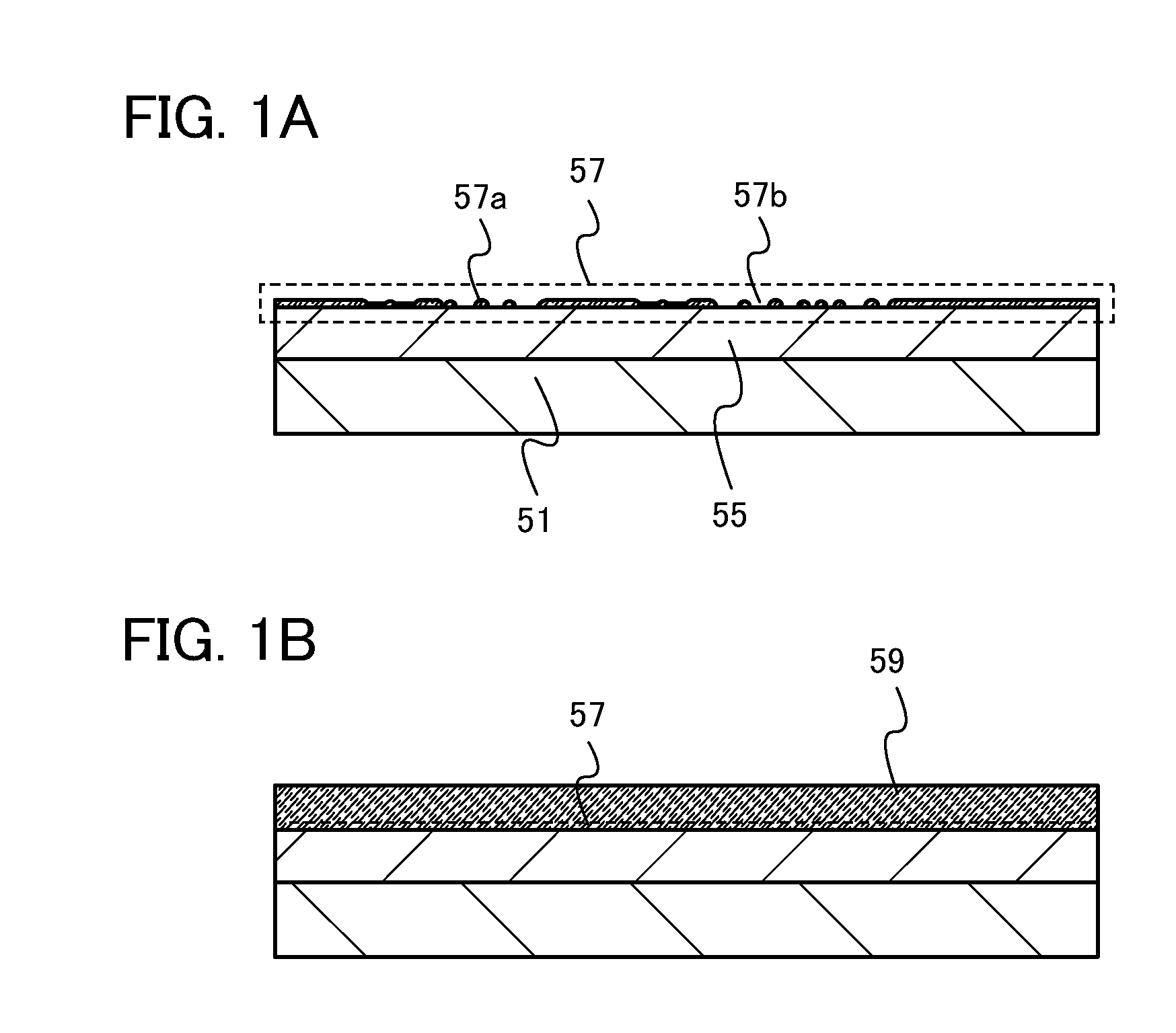

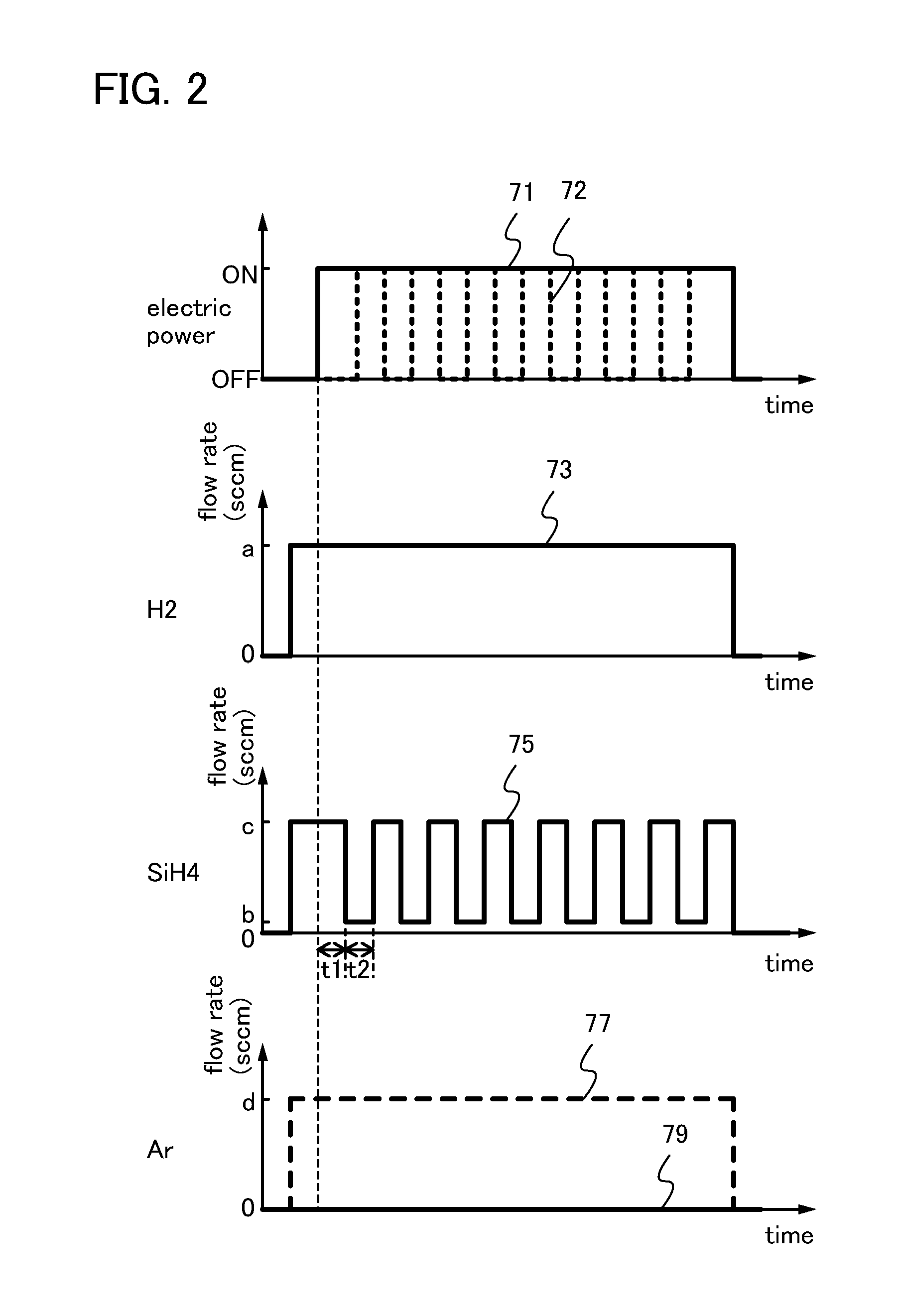

Method for manufacturing semiconductor device

InactiveUS20110318888A1High crystallinityExcellent electrical propertiesSemiconductor/solid-state device manufacturingChemical vapor deposition coatingHydrogenEngineering

A method for manufacturing a semiconductor device comprises the steps of forming a seed over the insulating film by introducing hydrogen and a deposition gas into a first treatment chamber under a first condition and forming a microcrystalline semiconductor film over the seed by introducing hydrogen and the deposition gas into a second treatment chamber under a second condition: a second flow rate of the deposition gas is periodically changed between a first value and a second value; and a second pressure in the second treatment chamber is higher than or equal to 1.0×102 Torr and lower than or equal to 1.0×103 Torr.

Owner:SEMICON ENERGY LAB CO LTD

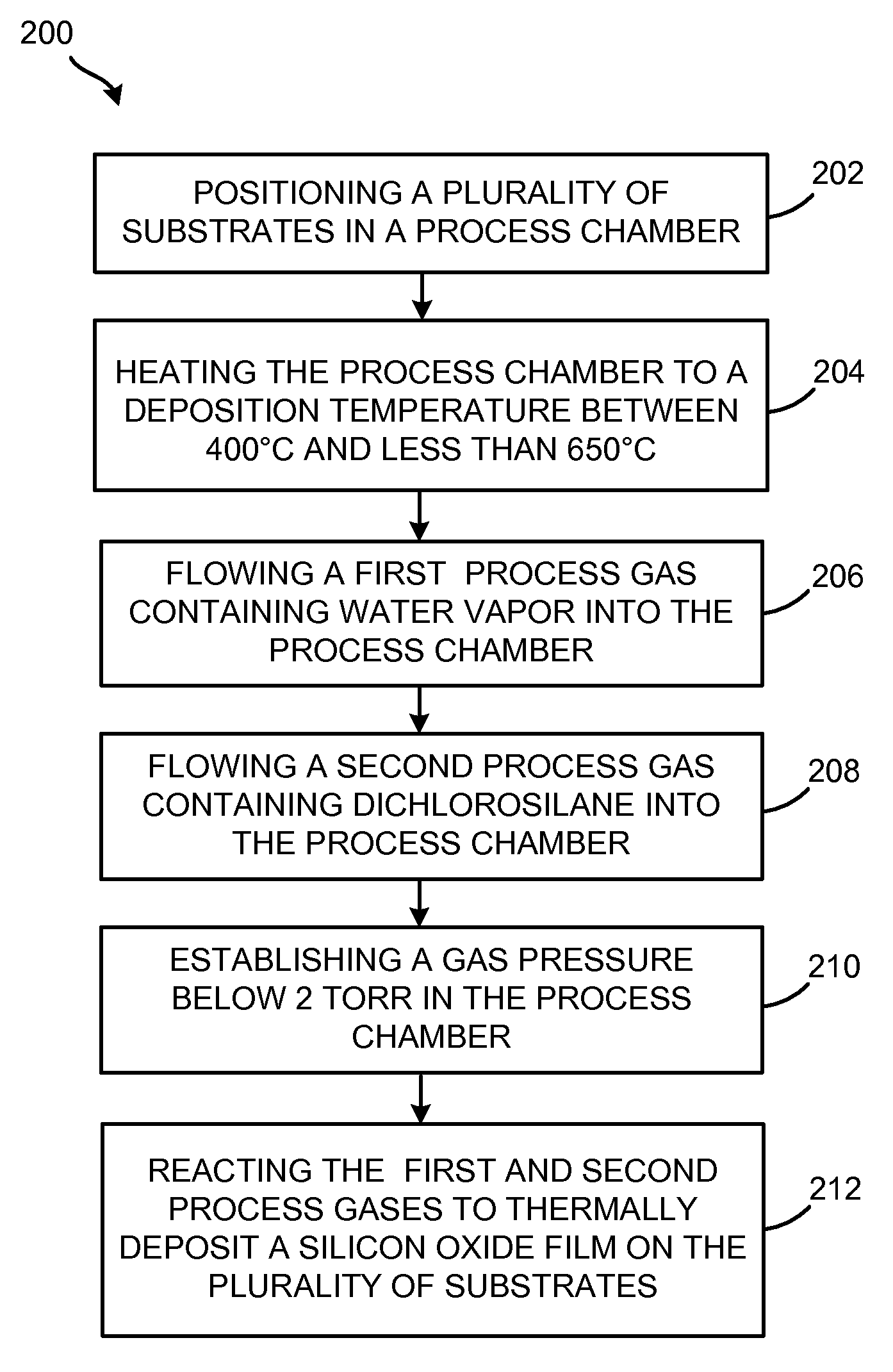

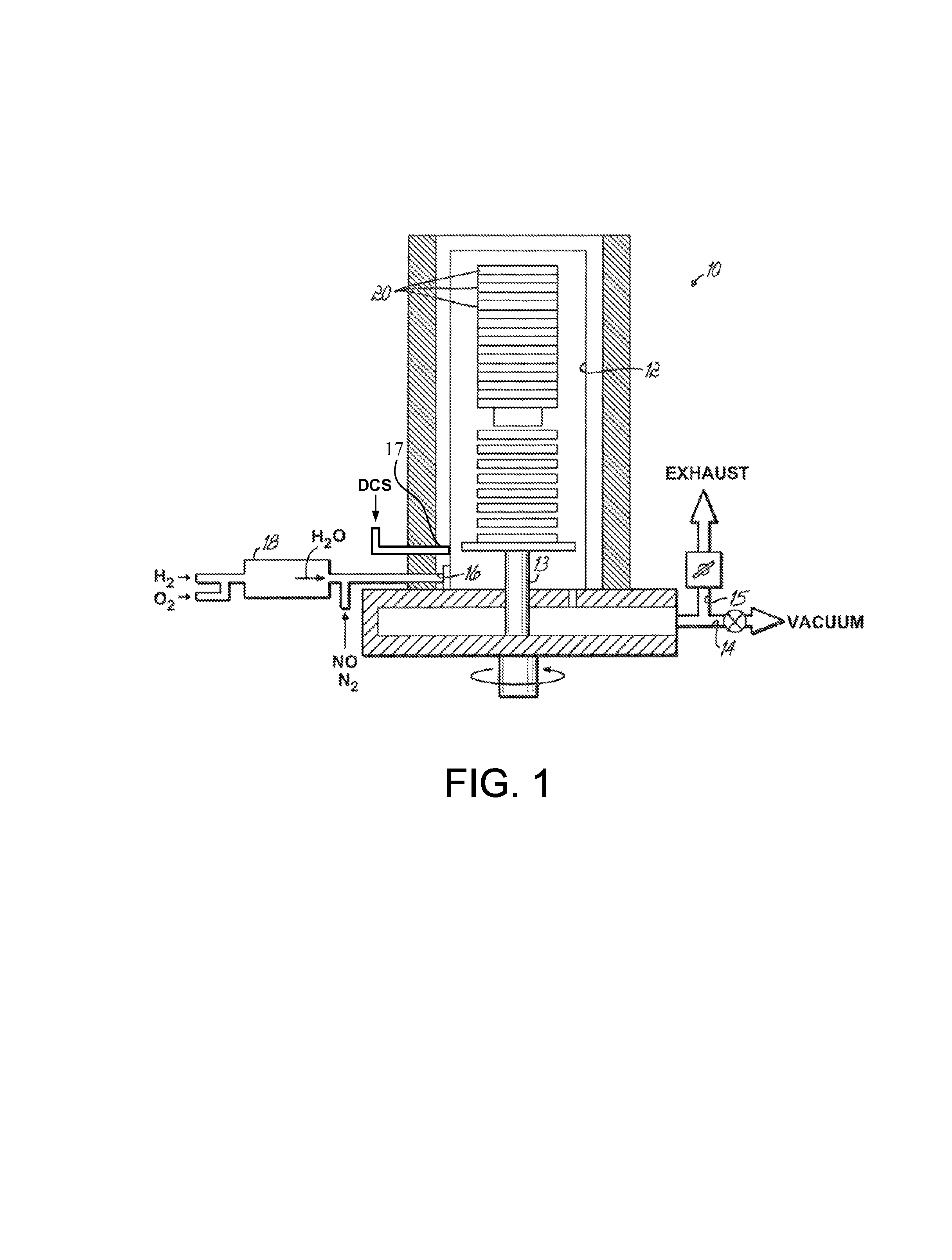

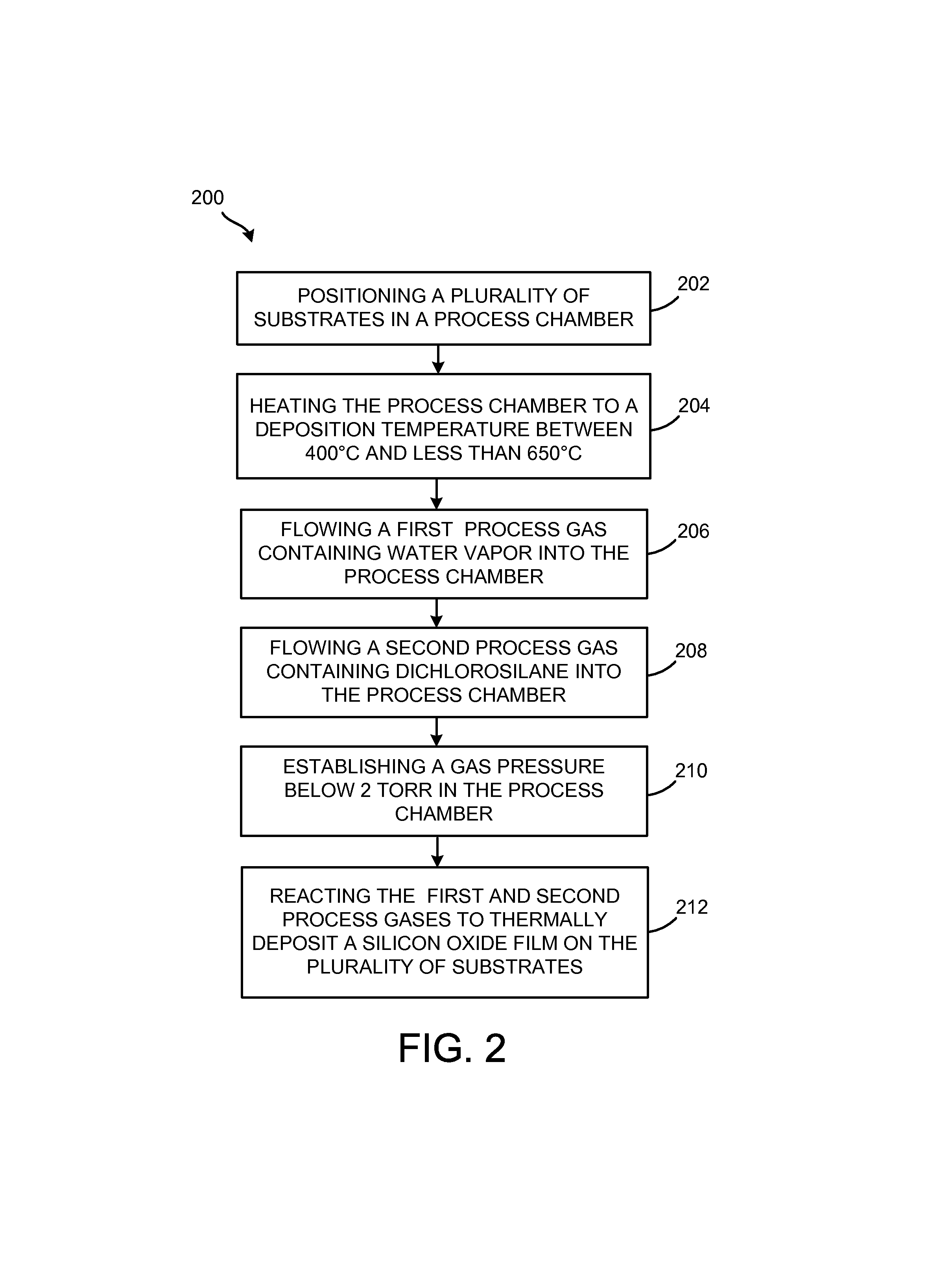

Low-temperature dielectric film formation by chemical vapor deposition

InactiveUS7994070B1Semiconductor/solid-state device manufacturingSemiconductor devicesDielectricWater vapor

A method for depositing a dielectric film on a substrate includes positioning a plurality of substrates in a process chamber, heating the process chamber to a deposition temperature between 400° C. and less than 650° C., flowing a first process gas comprising water vapor into the process chamber, flowing a second process gas comprising dichlorosilane (DCS) into the process chamber, establishing a gas pressure of less than 2 Torr, and reacting the first and second process gases to thermally deposit a silicon oxide film on the plurality of substrates. One embodiment further includes flowing a third process gas comprising nitric oxide (NO) gas into the process chamber while flowing the first process gas and the second process gas; and reacting the oxide film with the third process gas to form a silicon oxynitride film on the substrate.

Owner:TOKYO ELECTRON LTD

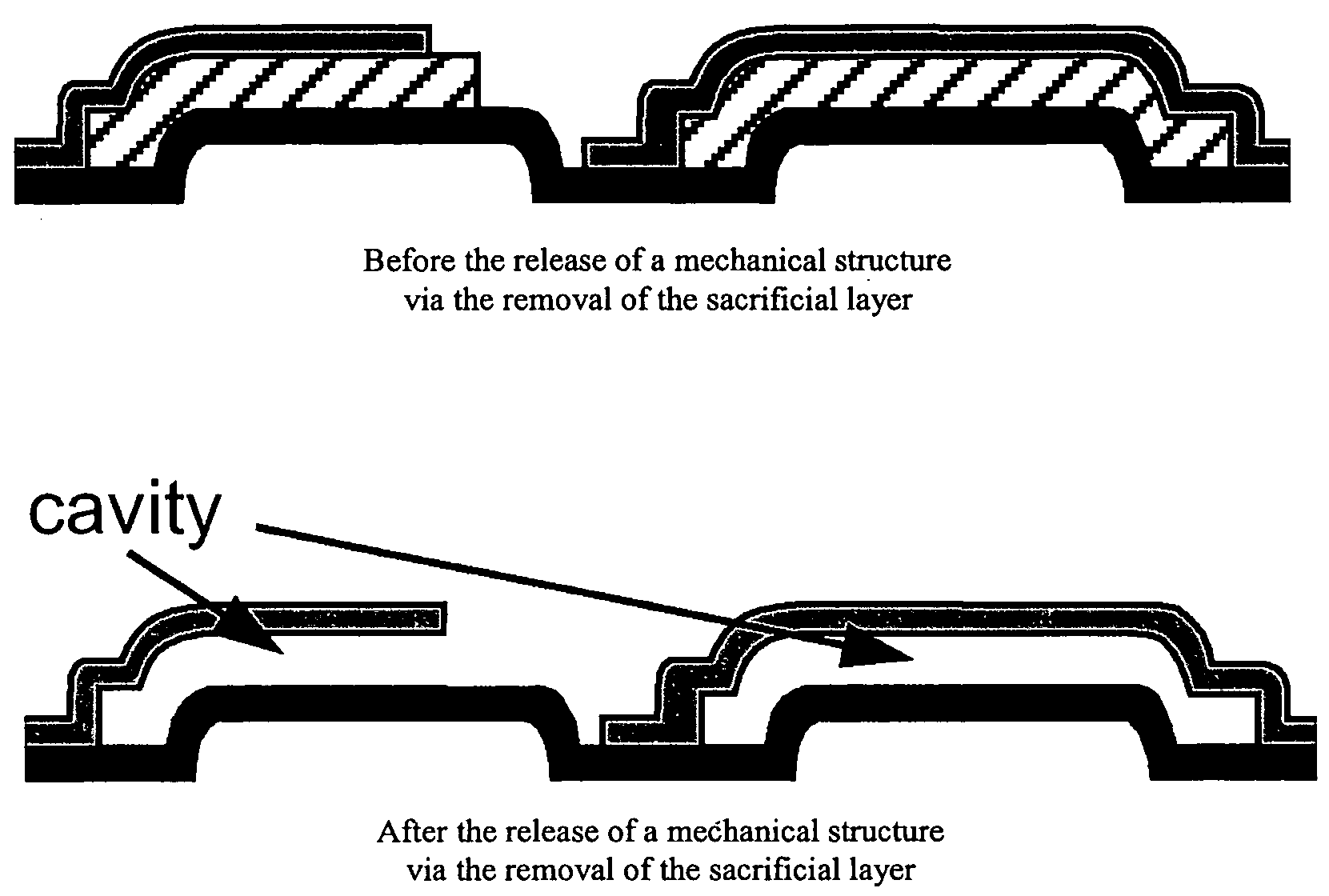

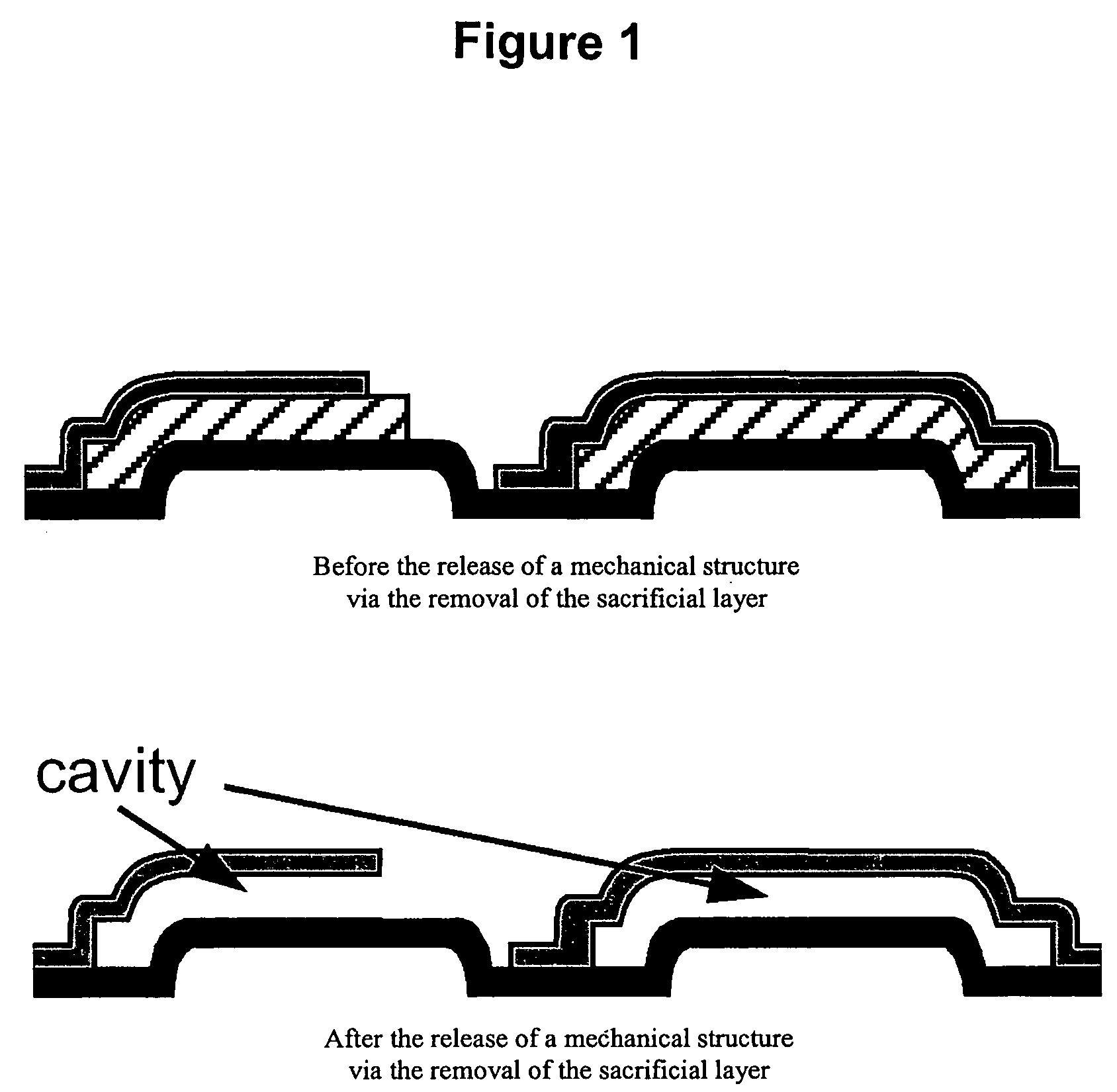

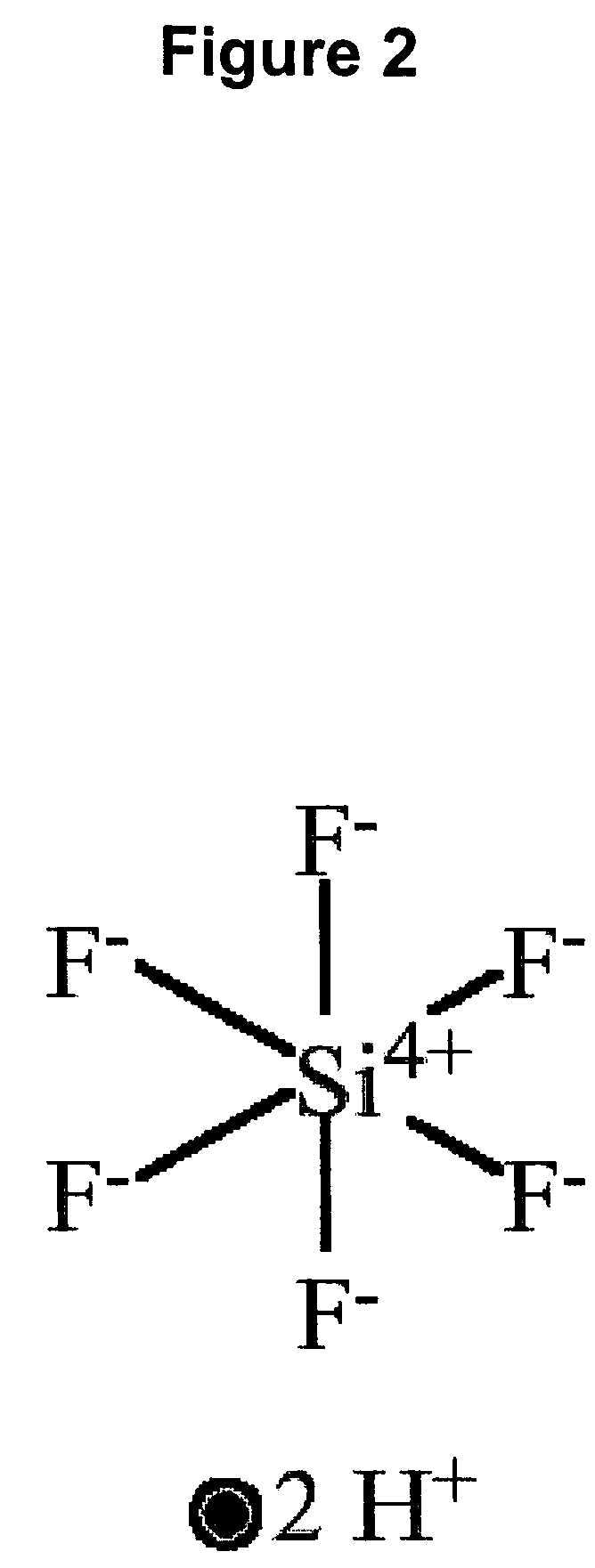

Anhydrous HF release of process for MEMS devices

ActiveUS7365016B2Prevent undesirable metal incompatibility effectDecorative surface effectsSemiconductor/solid-state device manufacturingPhysical chemistryVacuum level

A method of etching a sacrificial oxide layer covering an etch-stop silicon nitride underlayer, involves exposing the sacrificial oxide to anhydrous HF at a temperature of less than about 100° C. and / or at vacuum level lower than 40 Torr; and subsequently performing an in-situ vacuum evaporation of etch by-products at a temperature of more than about 100° C. and at vacuum level lower than the 40 Torr without exposure to ambient air.

Owner:TELEDYNE DIGITAL IMAGING INC

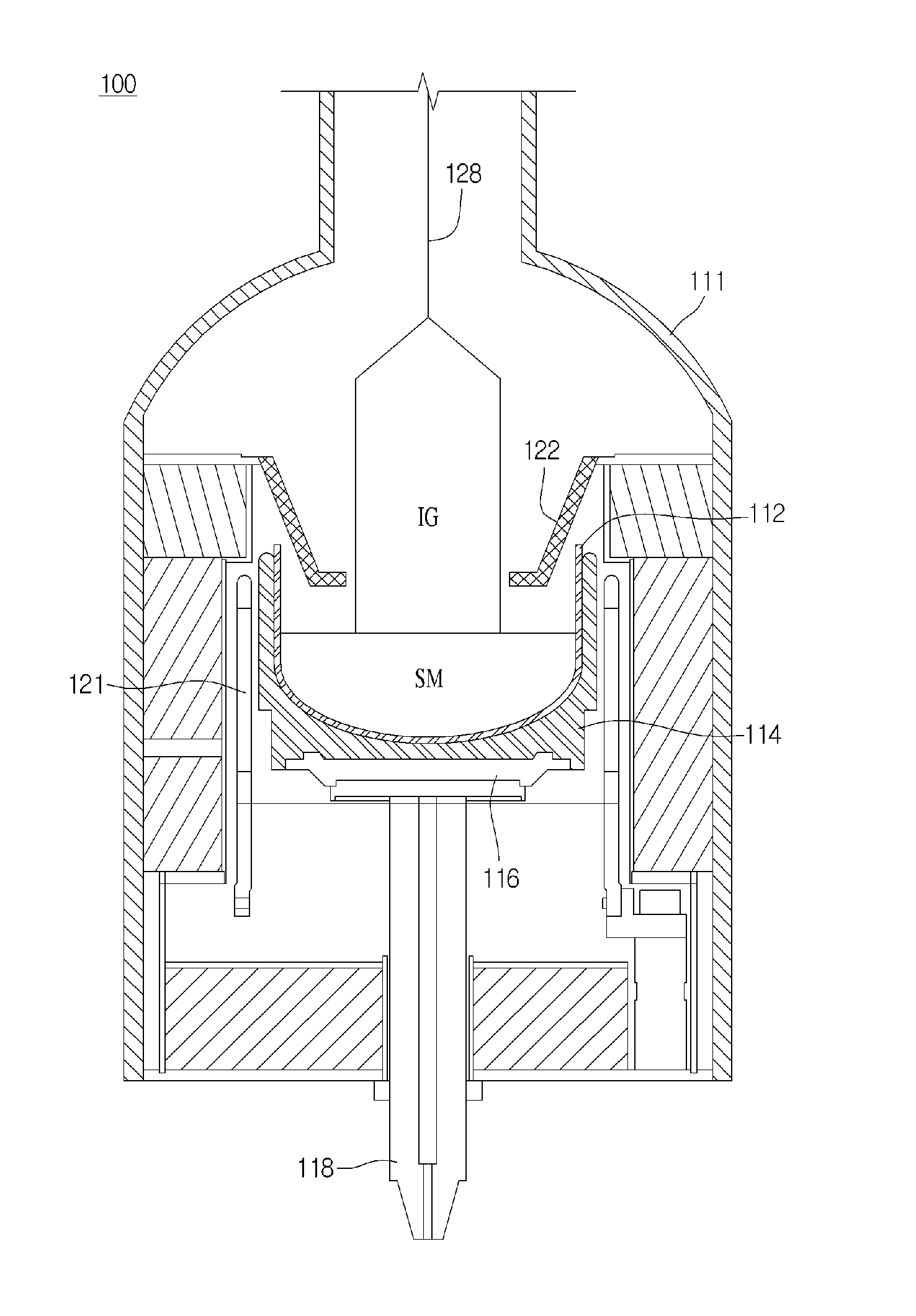

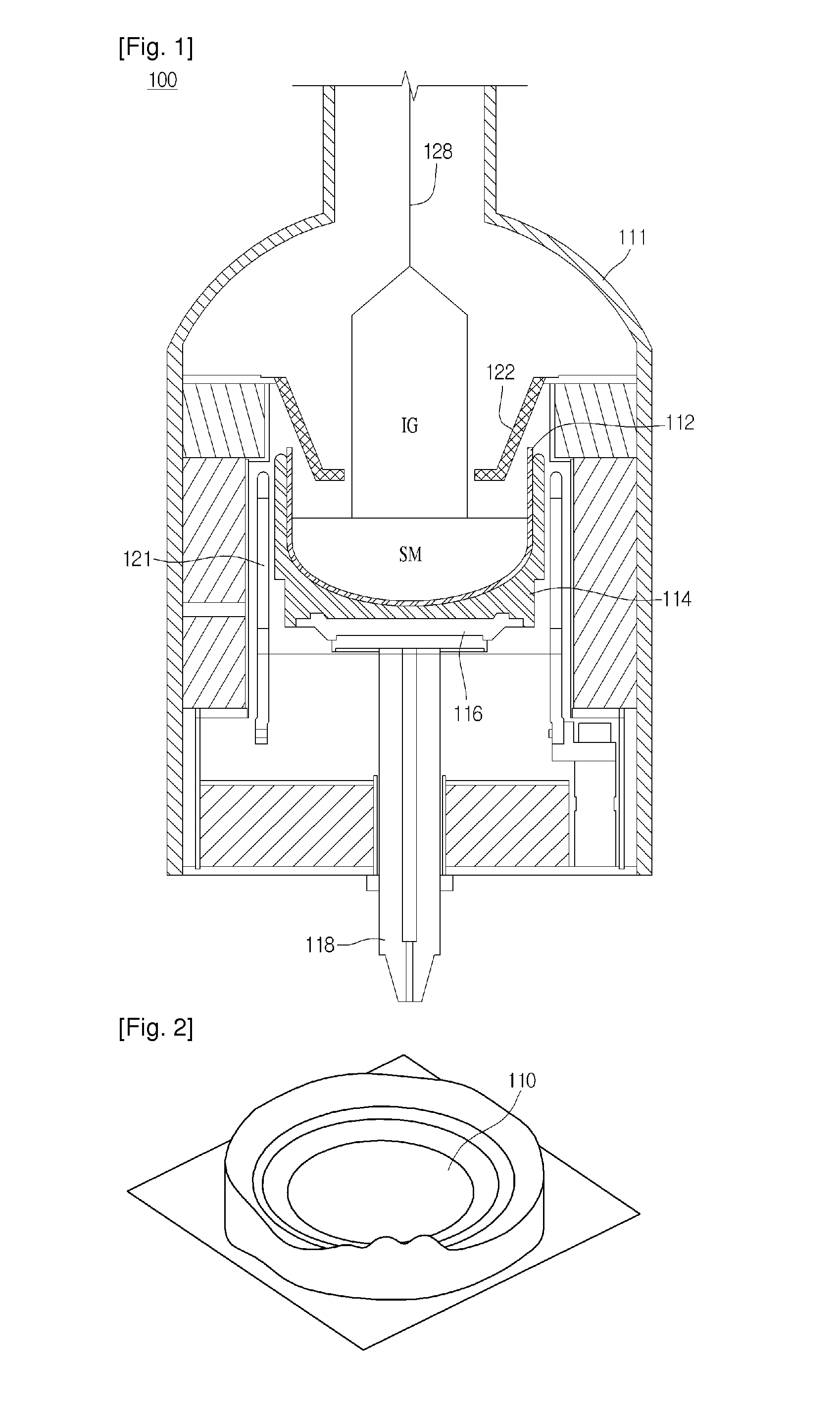

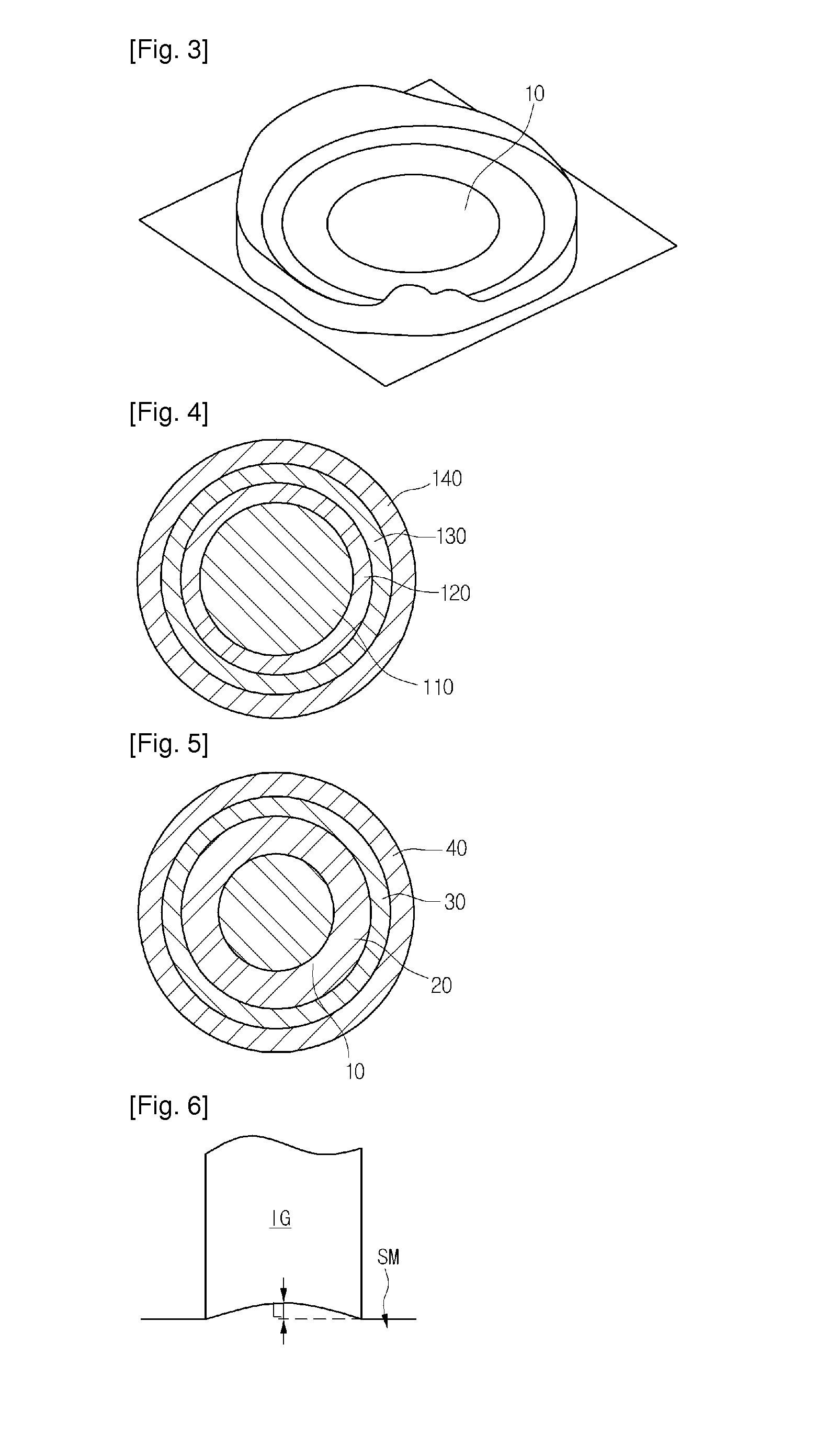

Method of manufacturing single crystal ingot, and single crystal ingot and wafer manufactured thereby

InactiveUS20140015108A1Increase productionPolycrystalline material growthSemiconductor/solid-state device manufacturingCrucibleIngot

A method of manufacturing a single crystal ingot, and a single crystal ingot and a wafer manufactured thereby are provided. The method of manufacturing a single crystal ingot according to an embodiment includes forming a silicon melt in a crucible inside a chamber, preparing a seed crystal on the silicon melt, and growing a single crystal ingot from the silicon melt, and pressure of the chamber may be controlled in a range of 90 Torr to 500 Torr.

Owner:LG SILTRON

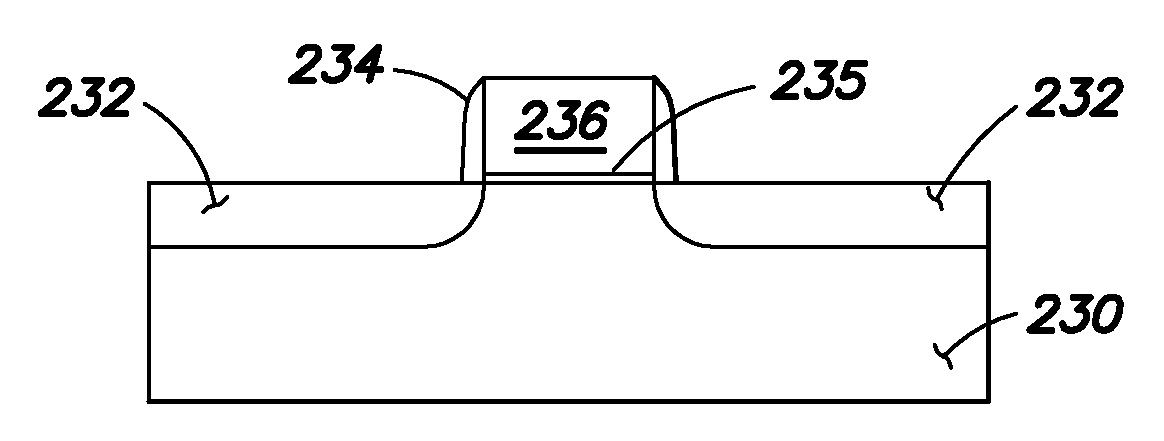

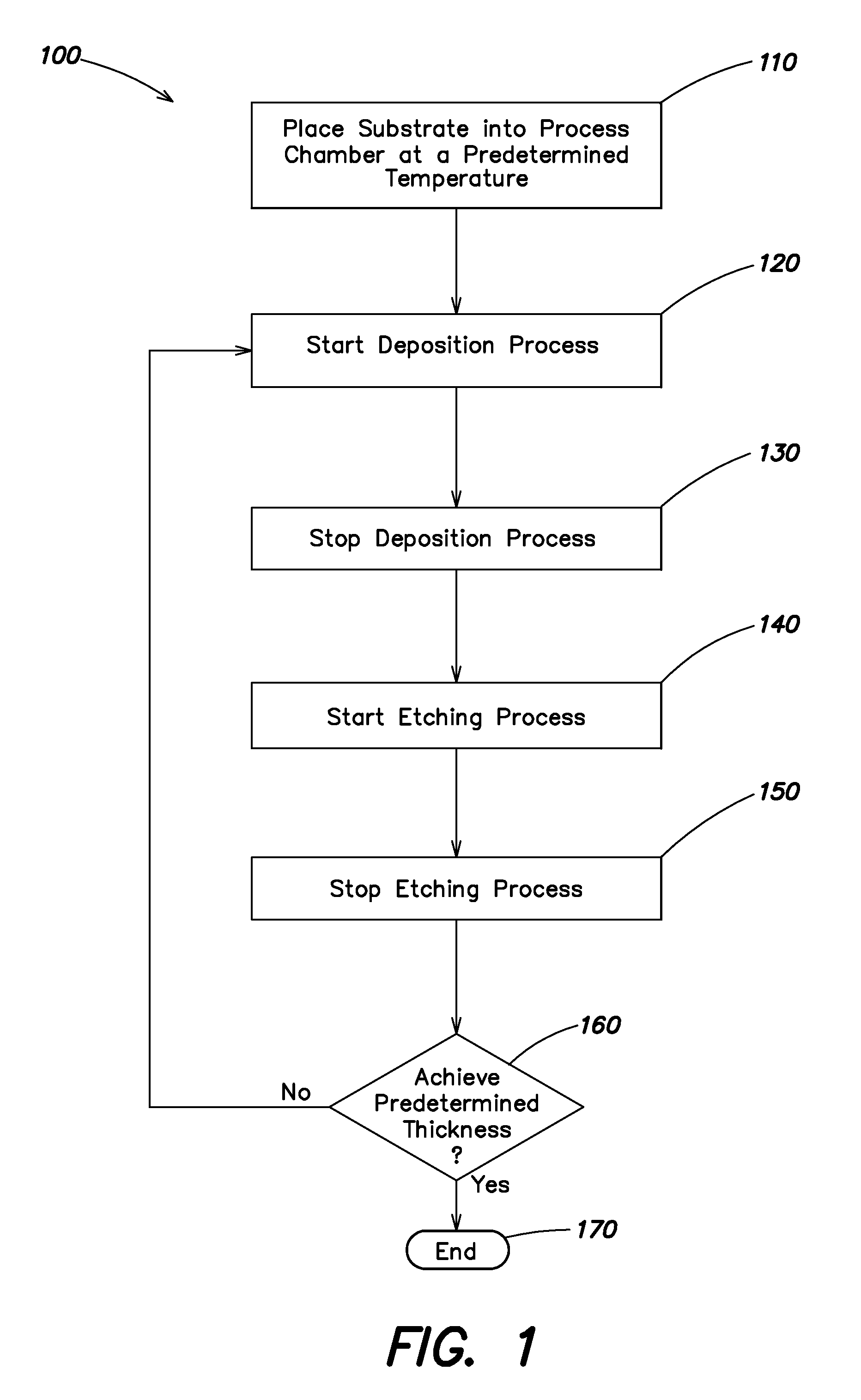

Carbon precursors for use during silicon epitaxial film formation

InactiveUS20080044932A1Polycrystalline material growthSemiconductor/solid-state device manufacturingEtchingCelsius Degree

The present invention provides systems and methods of forming an epitaxial film on a substrate. After heating in a process chamber, the substrate is exposed to a silicon source and at least one of SiH2(CH3)2, SiH(CH3)3, Si(CH3)4, 1,3-disilabutane, and C2H2, at a temperature of greater than about 250 degrees Celsius and a pressure greater than about 1 Torr so as to form an epitaxial film on at least a portion of the substrate. Then, the substrate is exposed to an etchant so as to etch the epitaxial film and any other films formed during the deposition. The deposition and etching may be repeated until a film of a desired thickness is achieved. Numerous other aspects are disclosed.

Owner:APPLIED MATERIALS INC

Chip-scale atomic clock (CSAC) and method for making same

A clock including: a portable, at least partially evacuated housing; a cell being positioned within the housing and including an internal cavity having interior dimensions each less than about 1 millimeter, an intra-cavity pressure of at least about 760 Torr, and containing a metal atomic vapor; an electrical to optical energy converter being positioned within the housing to emit light through the metal atomic vapor; an optical energy intensity detector being positioned within the housing to receive the light emitted by the converter through the metal atomic vapor; at least one conductive winding around the cavity to stabilize the magnetic field experienced in the cavity dependently upon the detector; and, an output to provide a signal from the housing dependently upon the detector detecting the light emitted by the converter through the metal atomic vapor.

Owner:SARNOFF CORP

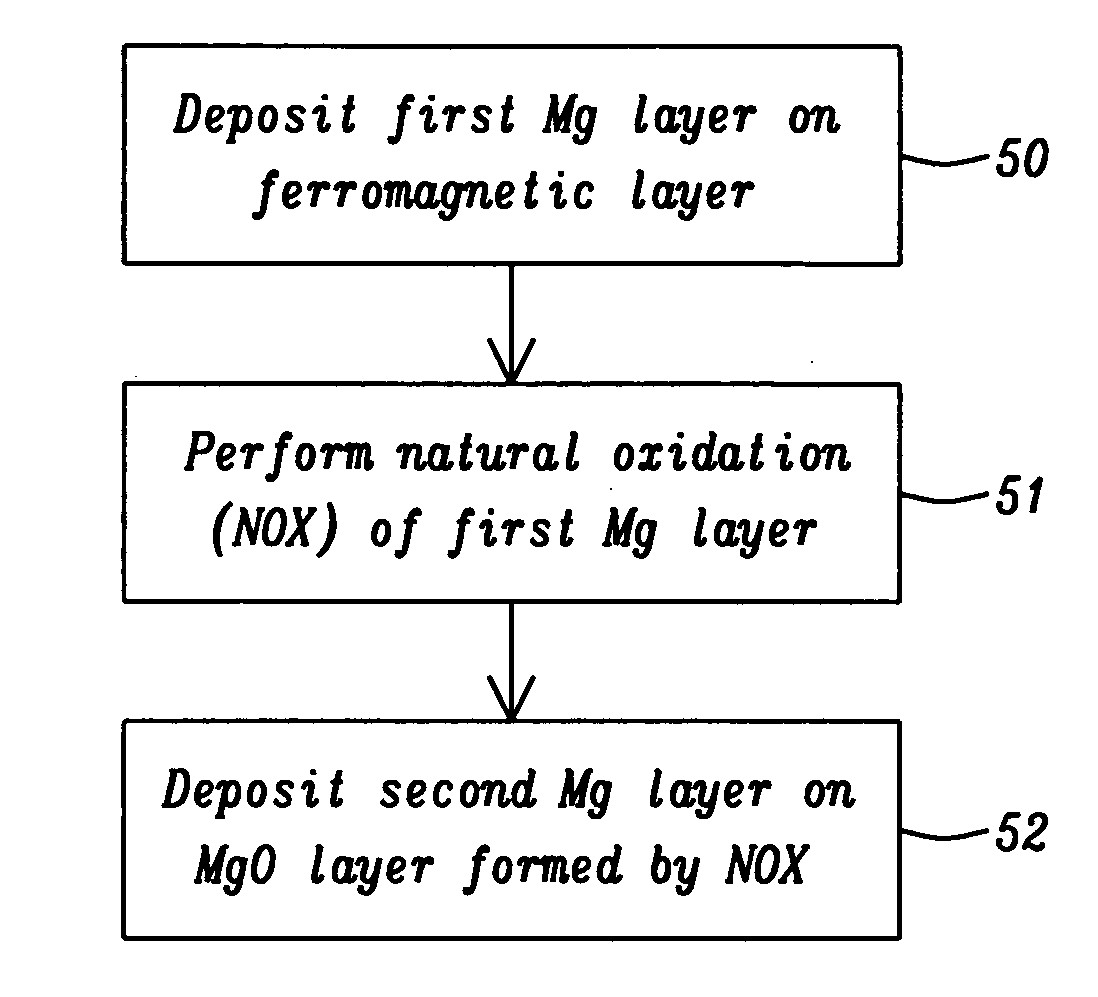

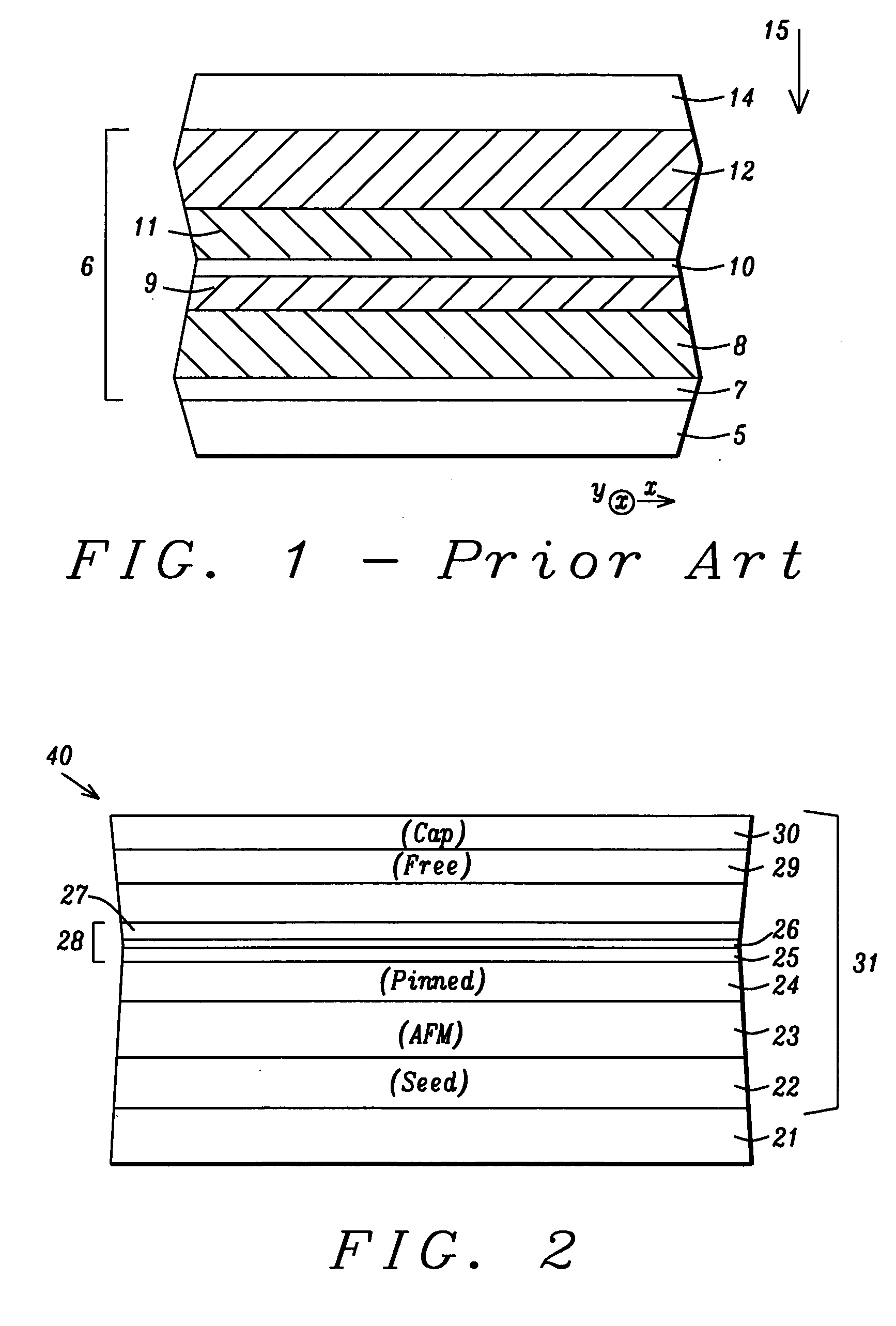

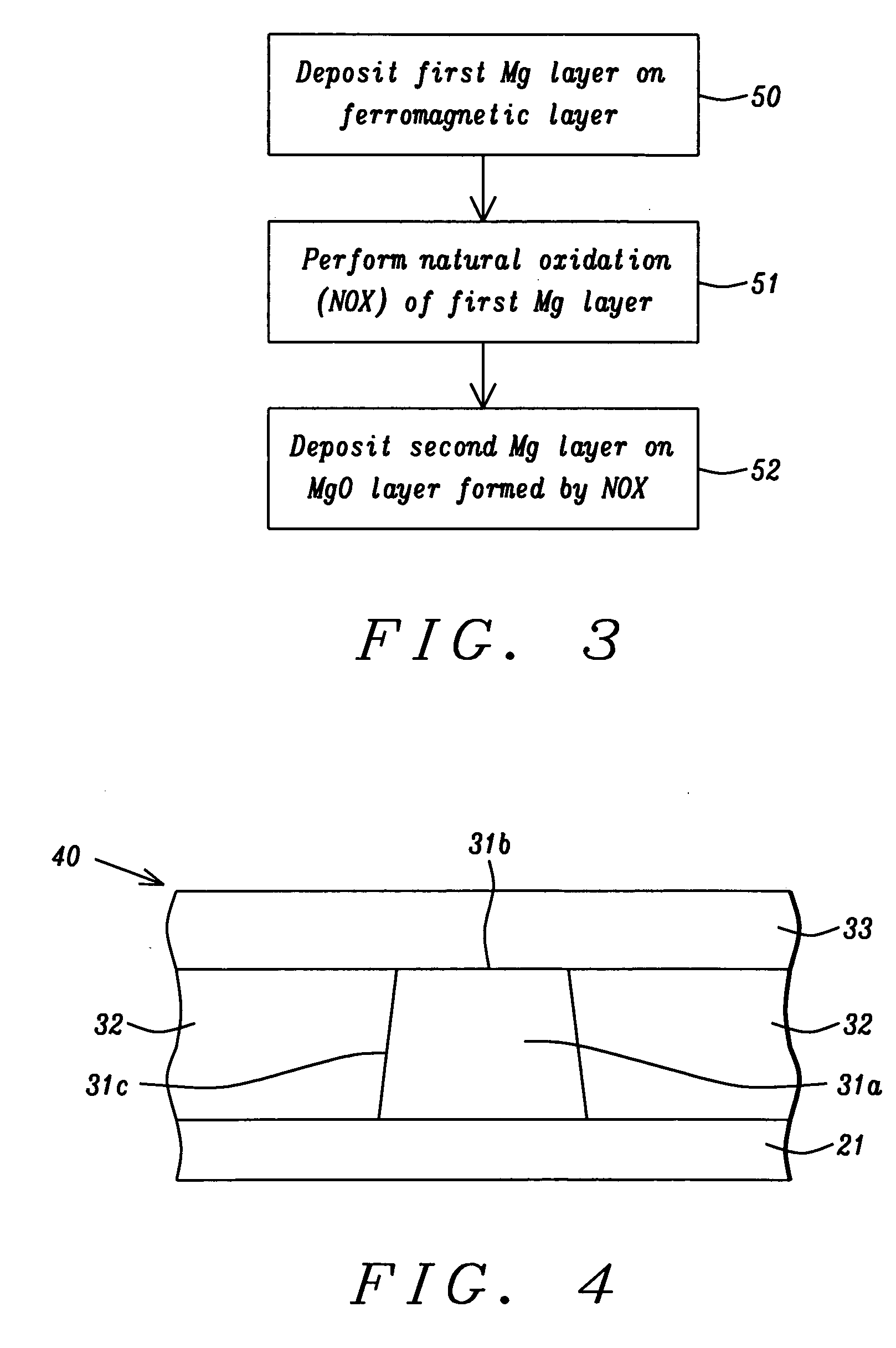

Low resistance tunneling magnetoresistive sensor with natural oxidized double MgO barrier

ActiveUS20070111332A1Improve uniformityHigh MR ratioNanomagnetismMagnetic measurementsSpin valveMaterials science

A high performance TMR sensor is fabricated by incorporating a tunnel barrier having a Mg / MgO / Mg configuration. The 4 to 14 Angstroms thick lower Mg layer and 2 to 8 Angstroms thick upper Mg layer are deposited by a DC sputtering method while the MgO layer is formed by a NOX process involving oxygen pressure from 0.1 mTorr to 1 Torr for 15 to 300 seconds. NOX time and pressure may be varied to achieve a MR ratio of at least 34% and a RA value of 2.1 ohm-um2. The NOX process provides a more uniform MgO layer than sputtering methods. The second Mg layer is employed to prevent oxidation of an adjacent ferromagnetic layer. In a bottom spin valve configuration, a Ta / Ru seed layer, IrMn AFM layer, CoFe / Ru / CoFeB pinned layer, Mg / MgO / Mg barrier, CoFe / NiFe free layer, and a cap layer are sequentially formed on a bottom shield in a read head.

Owner:HEADWAY TECH INC

High-Accuracy Mid-IR Laser-Based Gas Sensor

InactiveUS20120287418A1Good choiceImprove accuracyRadiation pyrometryTransmissivity measurementsPhotodetectorAmbient pressure

A gas sensor system is provided, comprising: a gas cell operable so as to receive a sample gas; a vacuum system fluidically coupled to the gas cell operable to maintain the sample gas within the gas cell at a sub-ambient pressure; a pressure sensor operable to sense a pressure of the sample gas; a thermally insulated enclosure having the gas cell therein; a heat source or heat exchanger operable to influence an interior temperature of the thermally insulated enclosure; a light source within the thermally insulated enclosure operable to provide a mid-infrared (mid-IR) light into and through the gas cell; a photodetector within the thermally insulated enclosure operable to receive the attenuated mid-IR; and a control system electronically coupled to the vacuum system and to the pressure sensor operable to maintain the sample gas within the gas cell at the predetermined pressure to within one torr (1 Torr).

Owner:THERMO FISHER SCI BREMEN

III-V Nitride homoepitaxial material of improved MOVPE epitaxial quality (surface texture and defect density) formed on free-standing (Al,In,Ga)N substrates, and opto-electronic and electronic devices comprising same

InactiveUS20030213964A1Improve material qualityReduce dislocation densityPolycrystalline material growthAfter-treatment detailsCelsius DegreeSource material

A III-V nitride homoepitaxial microelectronic device structure comprising a III-V nitride homoepitaxial epi layer of improved epitaxial quality deposited on a III-V nitride material substrate, e.g., of freestanding character. Various processing techniques are described, including a method of forming a III-V nitride homoepitaxial layer on a corresponding III-V nitride material substrate, by depositing the III-V nitride homoepitaxial layer by a VPE process using Group III source material and nitrogen source material under process conditions including V / III ratio in a range of from about 1 to about 10<5>, nitrogen source material partial pressure in a range of from about 1 to about 10<3 >torr, growth temperature in a range of from about 500 to about 1250 degrees Celsius, and growth rate in a range of from about 0.1 to about 10<2 >microns per hour. The III-V nitride homoepitaxial microelectronic device structures are usefully employed in device applications such as UV LEDs, high electron mobility transistors, and the like.

Owner:WOLFSPEED INC

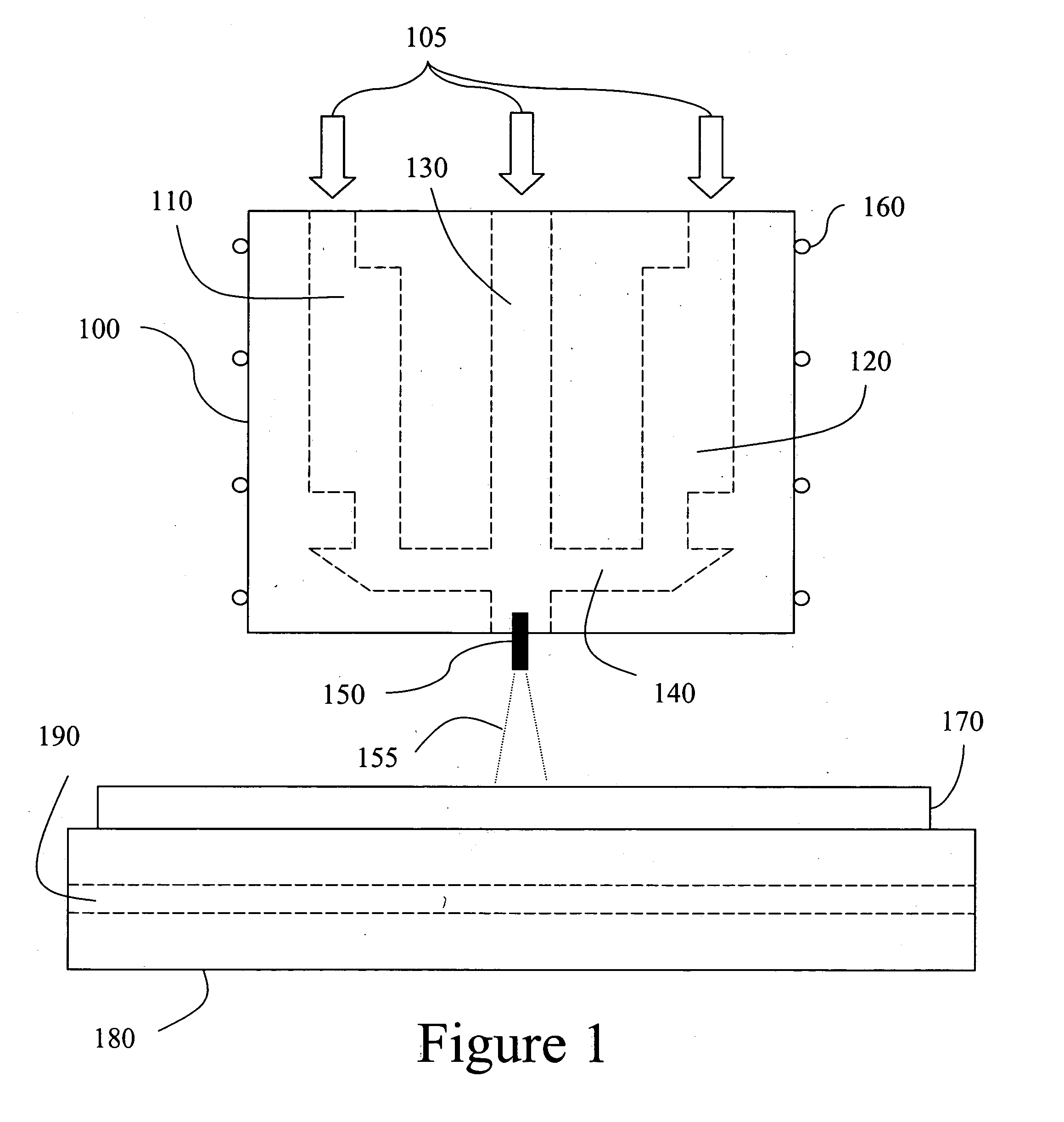

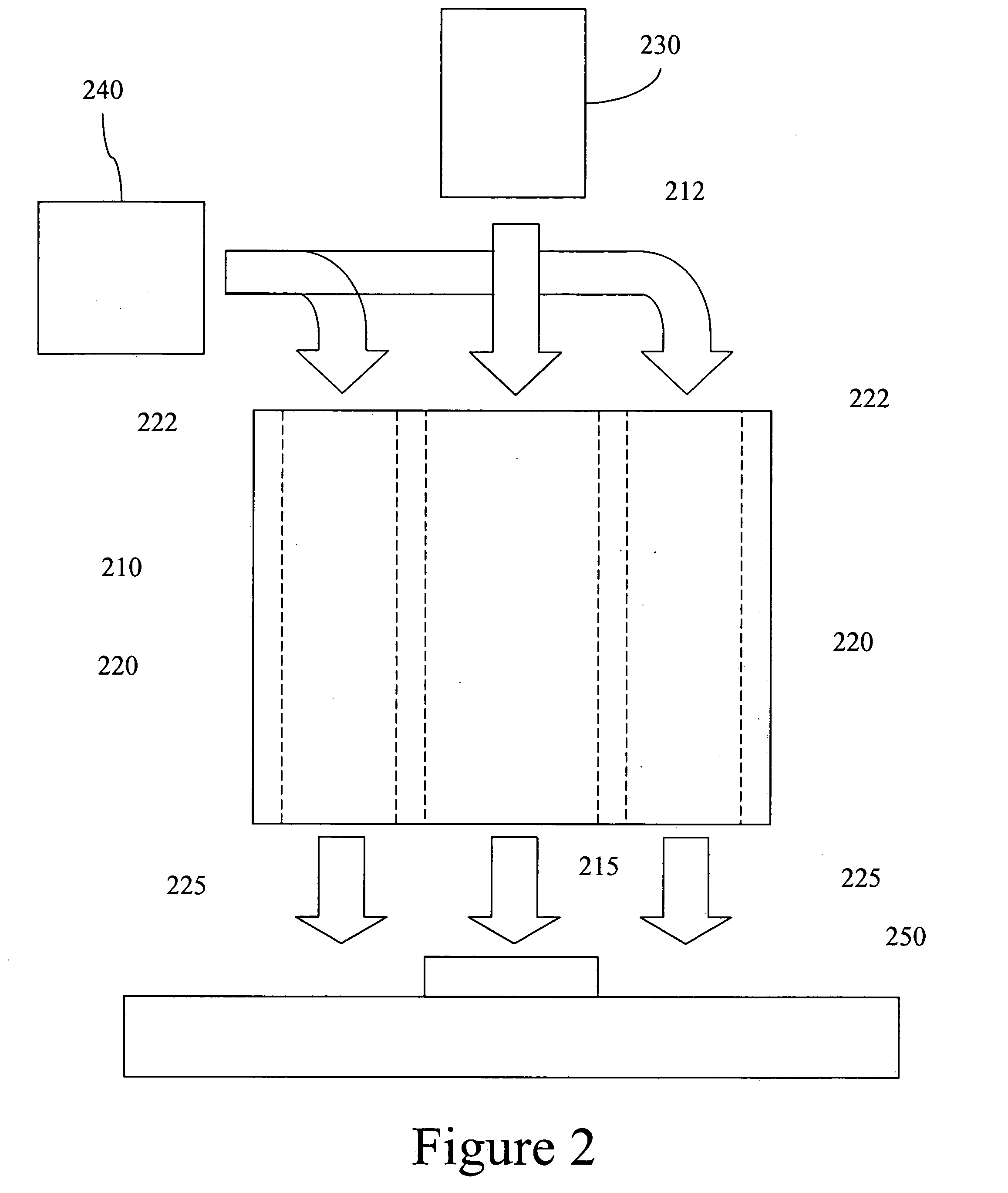

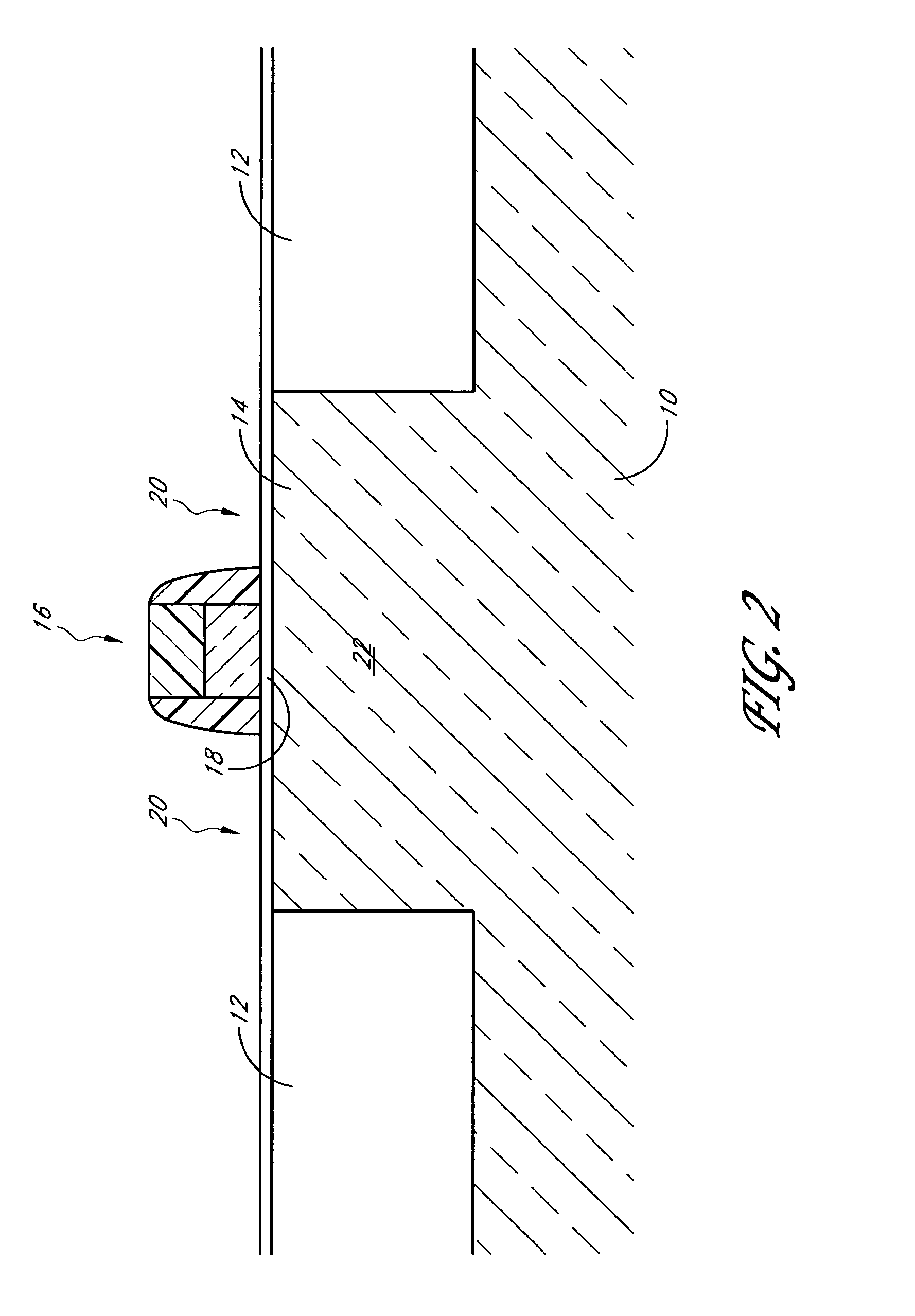

Method and apparatus for depositing material

A method of depositing organic material is provided. A carrier gas carrying an organic material is ejected from a nozzle at a flow velocity that is at least 10% of the thermal velocity of the carrier gas, such that the organic material is deposited onto a substrate. In some embodiments, the dynamic pressure in a region between the nozzle and the substrate surrounding the carrier gas is at least 1 Torr, and more preferably 10 Torr, during the ejection. In some embodiments, a guard flow is provided around the carrier gas. In some embodiments, the background pressure is at least about 10e-3 Torr, more preferably about 0.1 Torr, more preferably about 1 Torr, more preferably about 10 Torr, more preferably about 100 Torr, and most preferably about 760 Torr. A device is also provided. The device includes a nozzle, which further includes a nozzle tube having a first exhaust aperture and a first gas inlet; and a jacket surrounding the nozzle tube, the jacket having a second exhaust aperture and a second gas inlet. The second exhaust aperture completely surrounds the first tube aperture. A carrier gas source and an organic source vessel may be connected to the first gas inlet. A guard flow gas source may be connected to the second gas inlet. The device may include an array of such nozzles.

Owner:THE TRUSTEES FOR PRINCETON UNIV

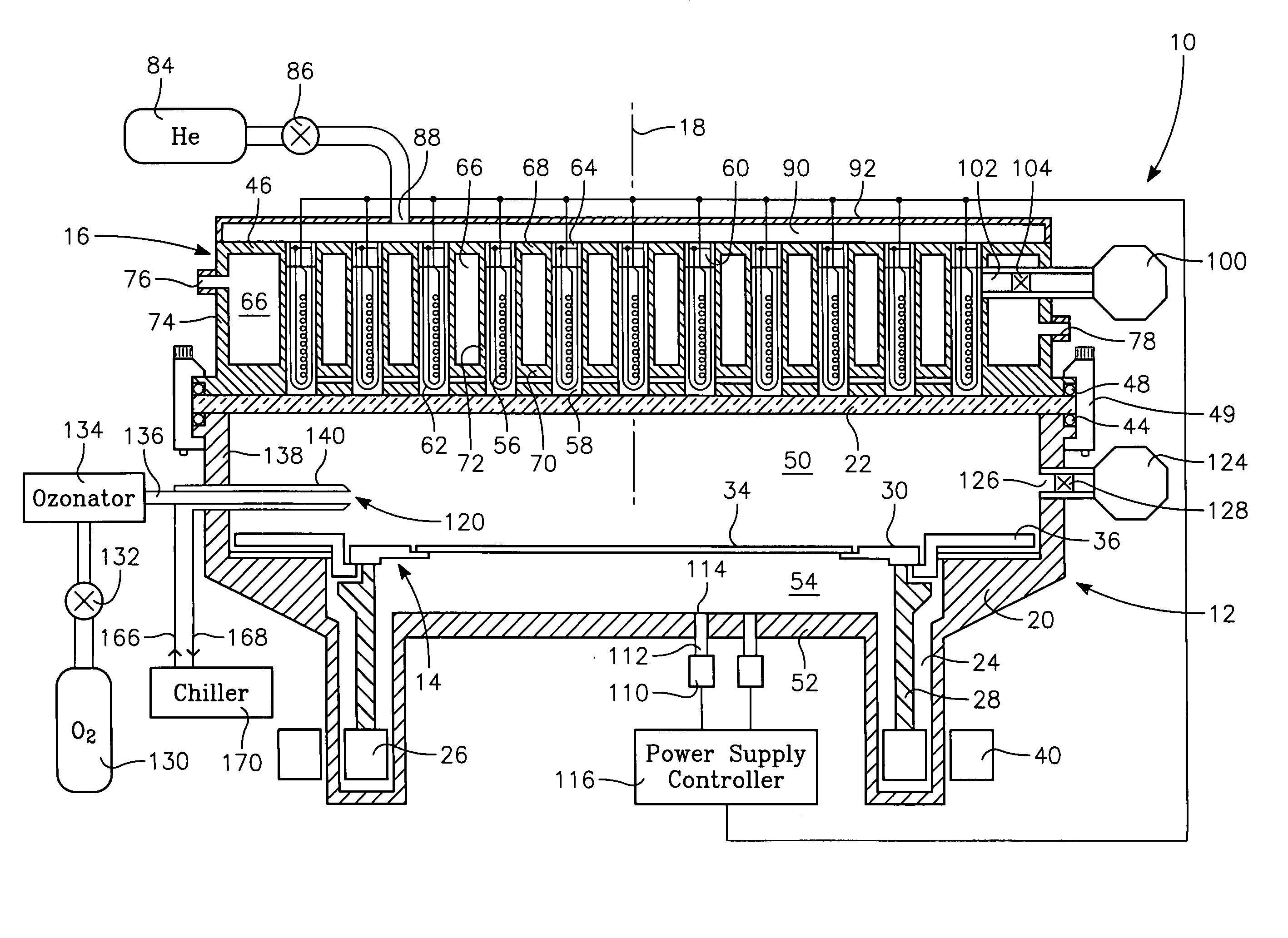

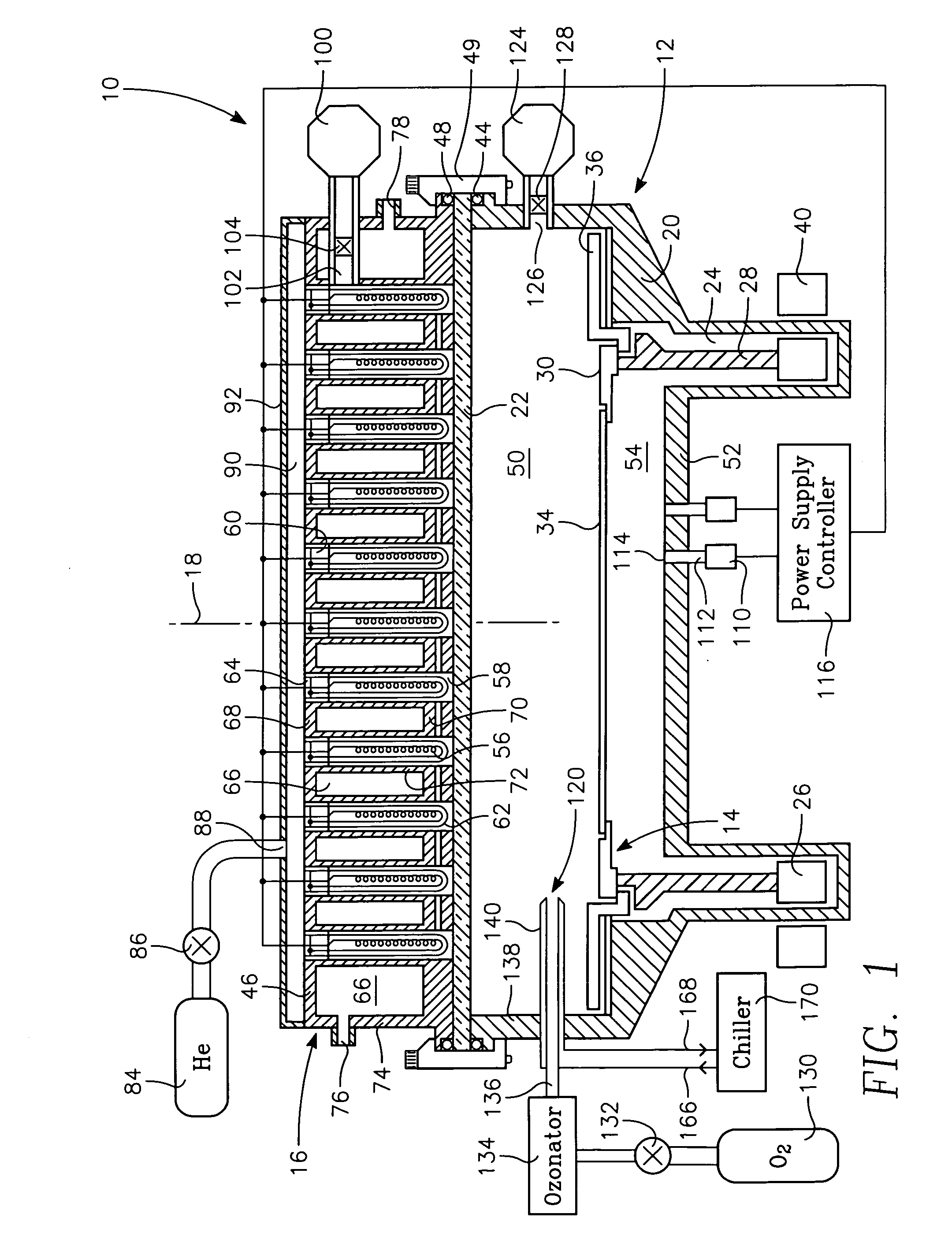

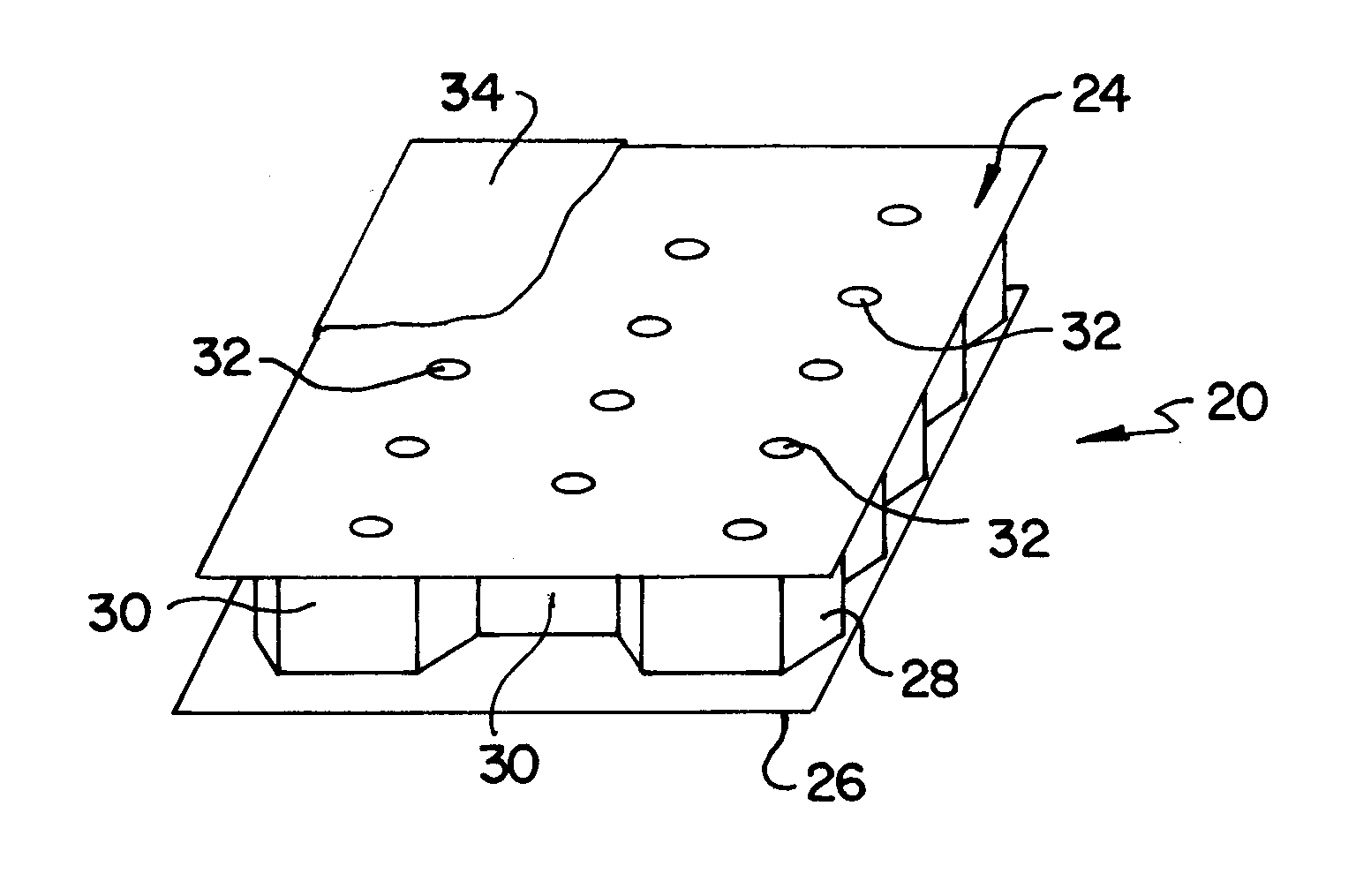

Thermal oxidation of silicon using ozone

A method and apparatus for oxidizing materials used in semiconductor integrated circuits, for example, for oxidizing silicon to form a dielectric gate. An ozonator is capable of producing a stream of least 70% ozone. The ozone passes into an RTP chamber through a water-cooled injector projecting into the chamber. Other gases such as hydrogen to increase oxidation rate, diluent gas such as nitrogen or O2, enter the chamber through another inlet. The chamber is maintained at a low pressure below 20 Torr and the substrate is advantageously maintained at a temperature less than 800° C. Alternatively, the oxidation may be performed in an LPCVD chamber including a pedestal heater and a showerhead gas injector in opposition to the pedestal.

Owner:APPLIED MATERIALS INC

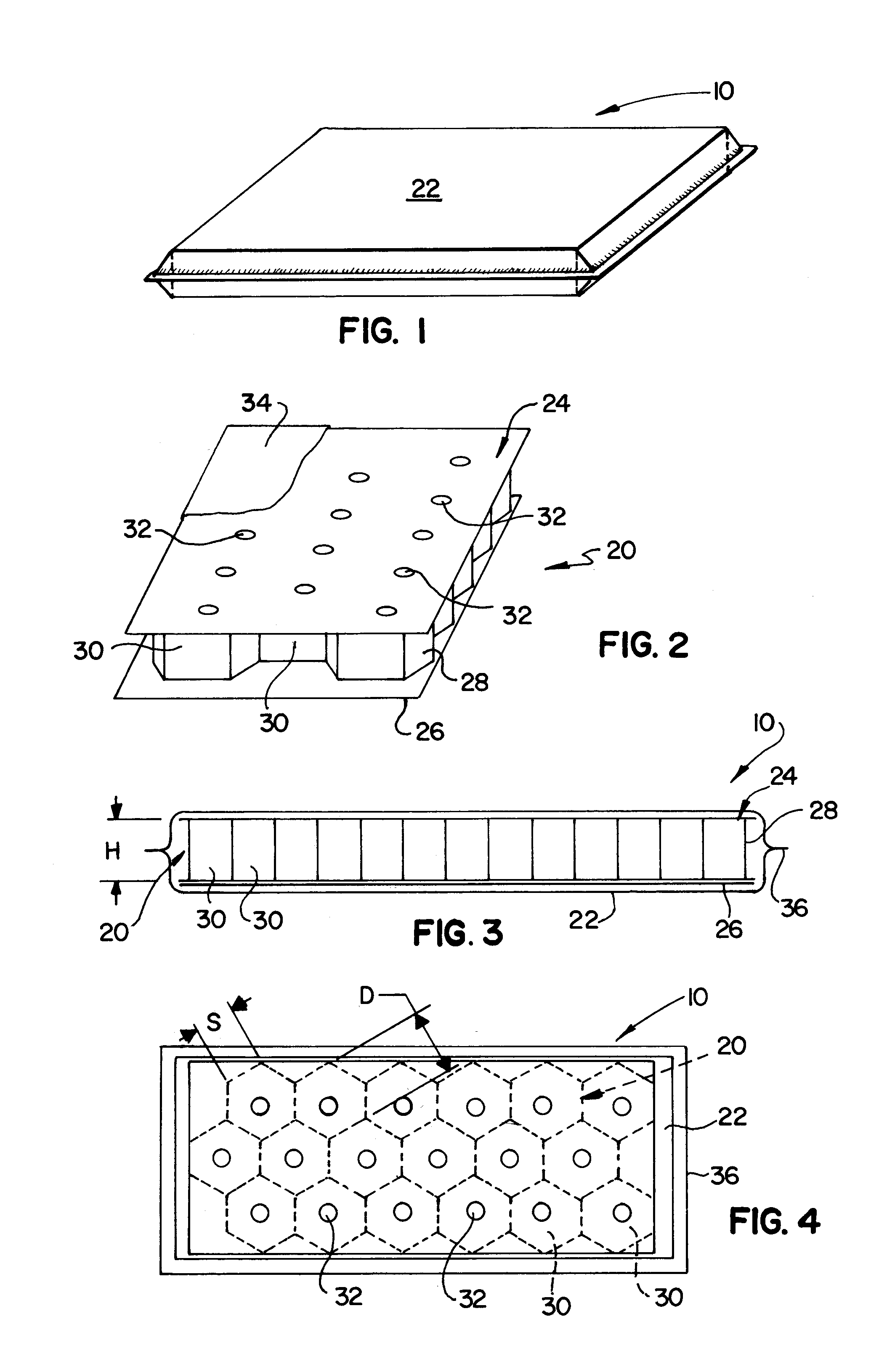

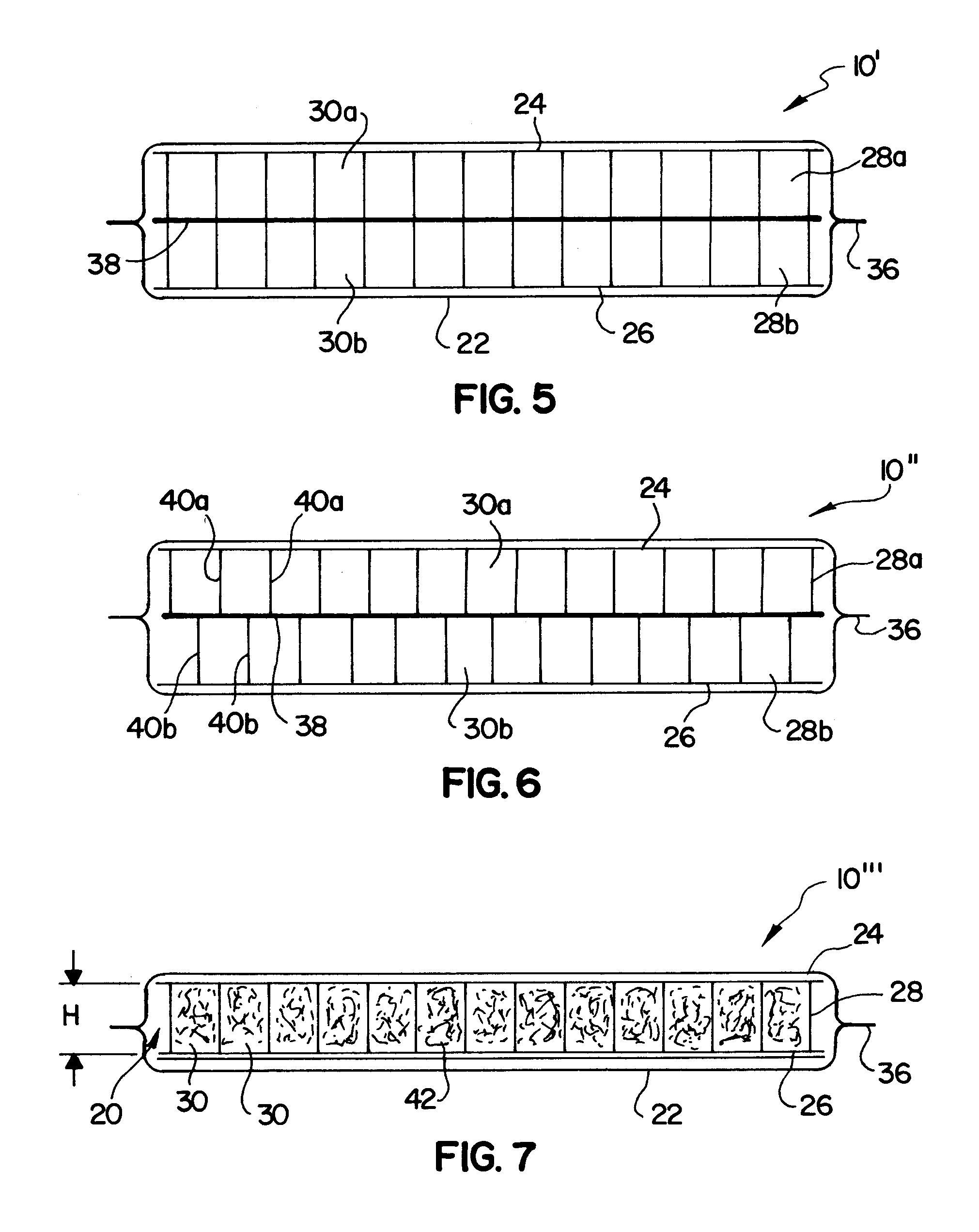

Vacuum insulation panel

InactiveUS20120031957A1Low costDomestic cooling apparatusLighting and heating apparatusEngineeringFace sheet

A vacuum insulation panel that includes a paper core made of at least one panel consisting of first and second facing sheets, made of paper, that sandwich a paper honeycomb structure. The honeycomb structure preferably includes a plurality of cells that extend from the first facing sheet to the second facing sheet. The panel also includes an outer shell that surrounds the core, wherein the outer shell is made of a material of low gas permeability and is sealed to form a substantially airtight container around the core. In preferred embodiments, an interior of said outer shell has been evacuated to a pressure of between approximately 1-10 Torr, resulting in an insulating panel that has an R-value of approximately 3.

Owner:PACKAGINGPRICE COM

Epitaxial deposition of doped semiconductor materials

ActiveUS7863163B2Polycrystalline material growthSemiconductor/solid-state device manufacturingSemiconductor materialsSingle crystal

A method for depositing a carbon doped epitaxial semiconductor layer comprises maintaining a pressure of greater than about 700 torr in a process chamber housing a patterned substrate having exposed single crystal material. The method further comprises providing a flow of a silicon source gas to the process chamber. The silicon source gas comprises dichlorosilane. The method further comprises providing a flow of a carbon precursor to the process chamber. The method further comprises selectively depositing the carbon doped epitaxial semiconductor layer on the exposed single crystal material.

Owner:ASM IP HLDG BV

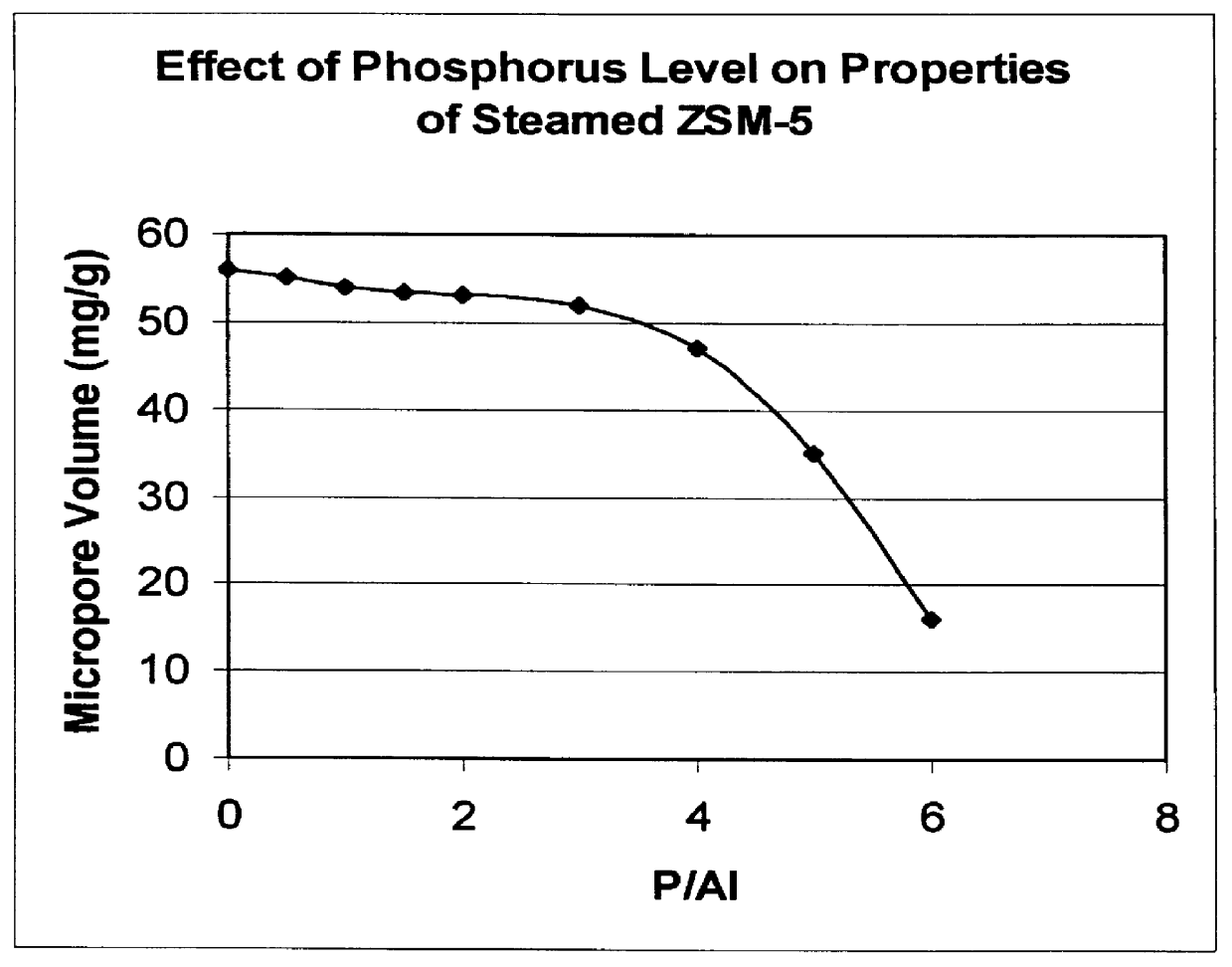

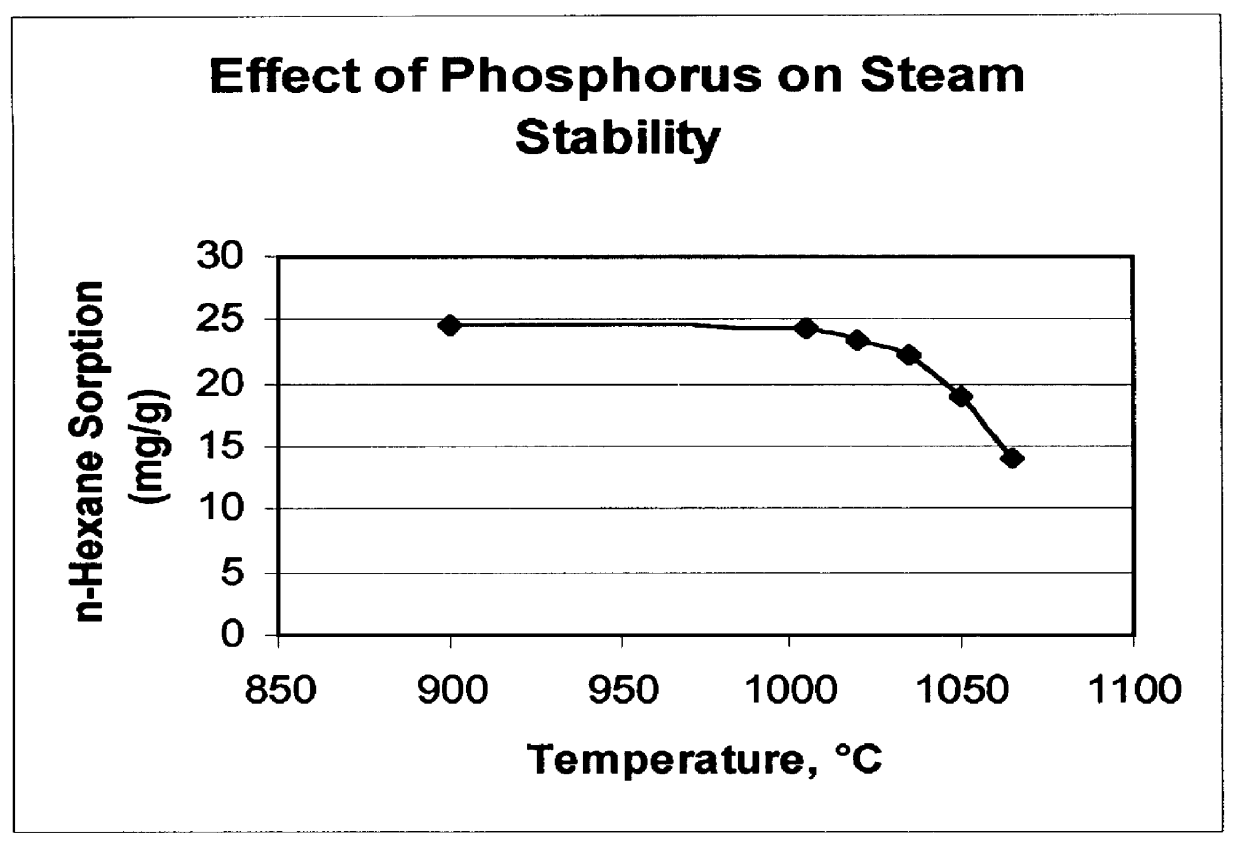

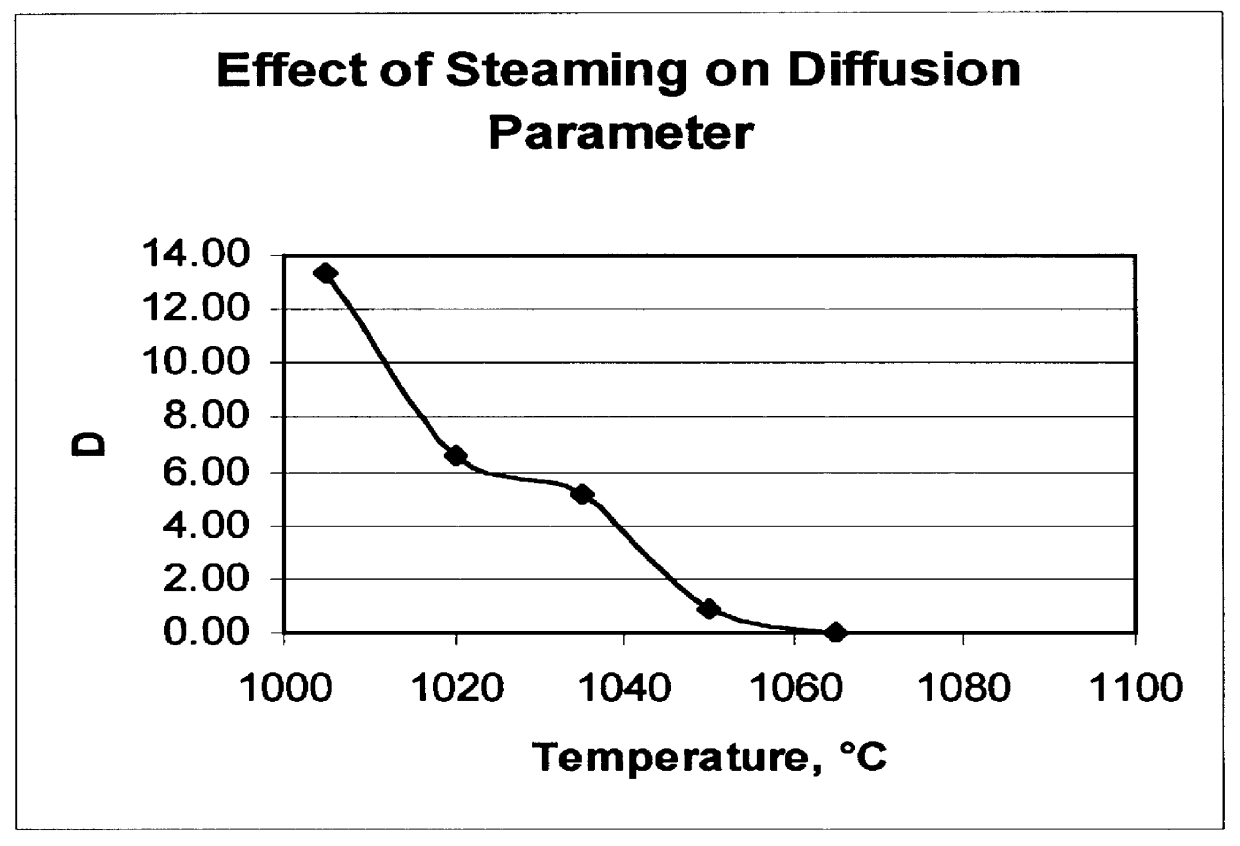

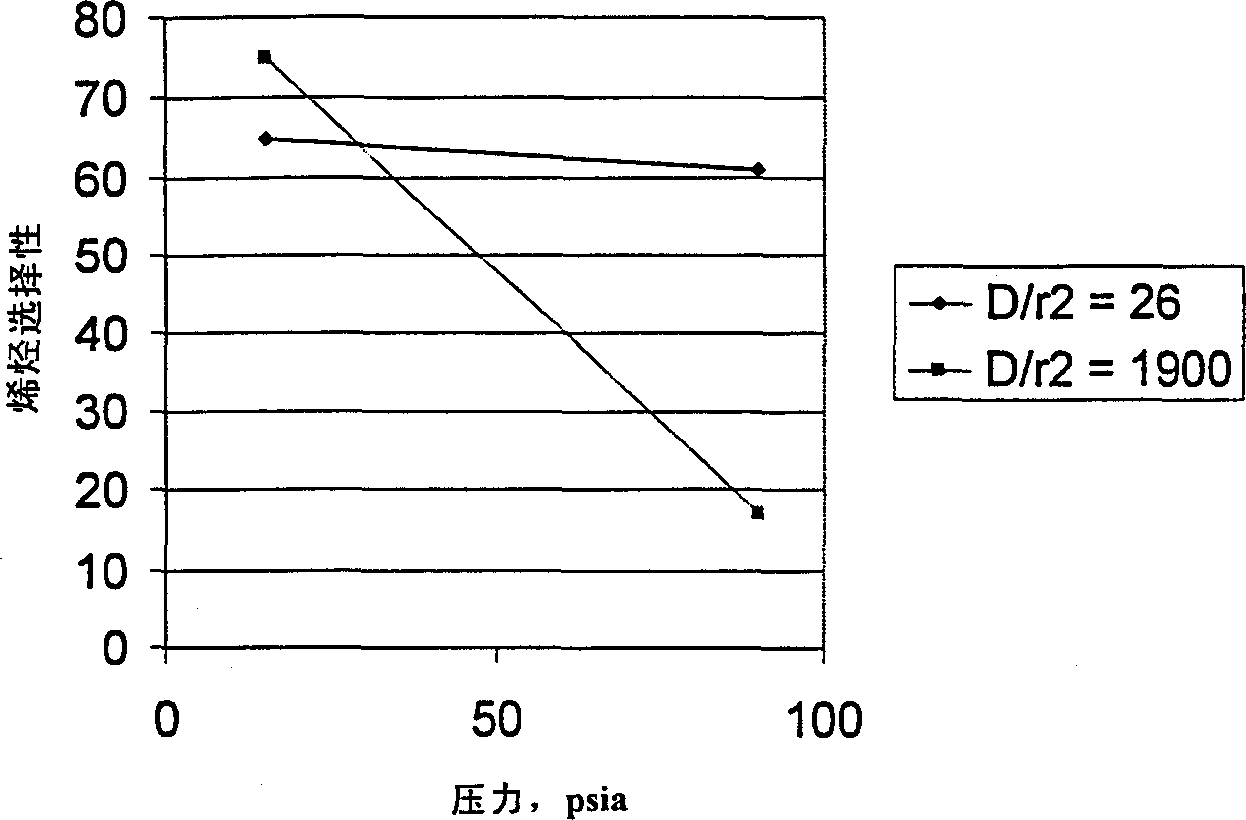

Catalyst and process for converting methanol to hydrocarbons

InactiveUS6048816AMolecular sieve catalystsMolecular sieve catalystCrystalline materialsDimethyl ether

There is provided a catalyst and a process for converting methanol or dimethyl ether to a product containing C2 to C4 olefins. The catalyst comprises a porous crystalline material having a Diffusion Parameter for 2,2-dimethylbutane of about 0.1-20 sec-1 when measured at a temperature of 120 DEG C. and a 2,2-dimethylbutane pressure of 60 torr (8 kPa). In addition, the catalyst is characterized by a hydrothermal stability such that, after steaming the catalyst at 1025 DEG C. for 45 minutes in 1 atmosphere steam, the catalyst exhibits a methanol conversion activity of at least 50% when contacted with methanol at a methanol partial pressure of 1 atmosphere, a temperature of 430 DEG C. and 0.5 WHSV. The porous crystalline material is preferably a medium-pore zeolite, particularly ZSM-5, which contains phosphorus and has been severely steamed at a temperature of at least 950 DEG C.

Owner:MOBIL OIL CORP

Quantum wires formed on a substrate, manufacturing method thereof, and device having quantum wires on a substrate

InactiveUS6130143ASmall diameterSufficient quantum effectPolycrystalline material growthSemiconductor/solid-state device manufacturingSilanesSurface oxidation

While a silicon substrate is heated, gold is evaporated thereon at a thickness of 0.6 nm, whereby melted alloy droplets are formed on the substrate surface. Then, the silicon substrate is heated to 450.degree.-650.degree. C. in a silane gas atmosphere of less than 0.5 Torr. As a result, a silane gas decomposition reaction occurs with the melted alloy droplets serving as catalysts, whereby silicon wires grow on the substrate surface. Subsequently, the metal alloy droplets at the tips of the silicon wires are removed and surface portions of the silicon wires are oxidized. Resulting surface oxide films are thereafter removed. As a result, silicon quantum wires that are thinner by the thickness of the surface oxide films are obtained.

Owner:SONY CORP

Precursors for depositing silicon-containing films and processes thereof

InactiveUS20050181633A1Satisfies needSemiconductor/solid-state device manufacturingChemical vapor deposition coatingHydrogenReactive gas

Inorganic precursors, namely iodosilane precursors, for the low temperature, low pressure deposition of silicon-containing films is provided therein. In one aspect, there is provided a process for forming a silicon-containing film process comprising: introducing a substrate and gaseous reagents comprising an iodosilane precursor having three or less iodine atoms bound to the silicon atom and at least one reagent selected from an oxygen-containing reactive gas, a nitrogen-containing reactive gas, a hydrogen-containing reactive gas and mixtures thereof into a reaction chamber; heating the reaction chamber to one or more temperatures ranging from 200° C. to 900° C. to form the silicon containing film on the substrate, provided that if the iodosilane precursor has three iodine atoms bound to the silicon atom then the heating step is conducted at one or more pressures less than 600 Torr.

Owner:VERSUM MATERIALS US LLC

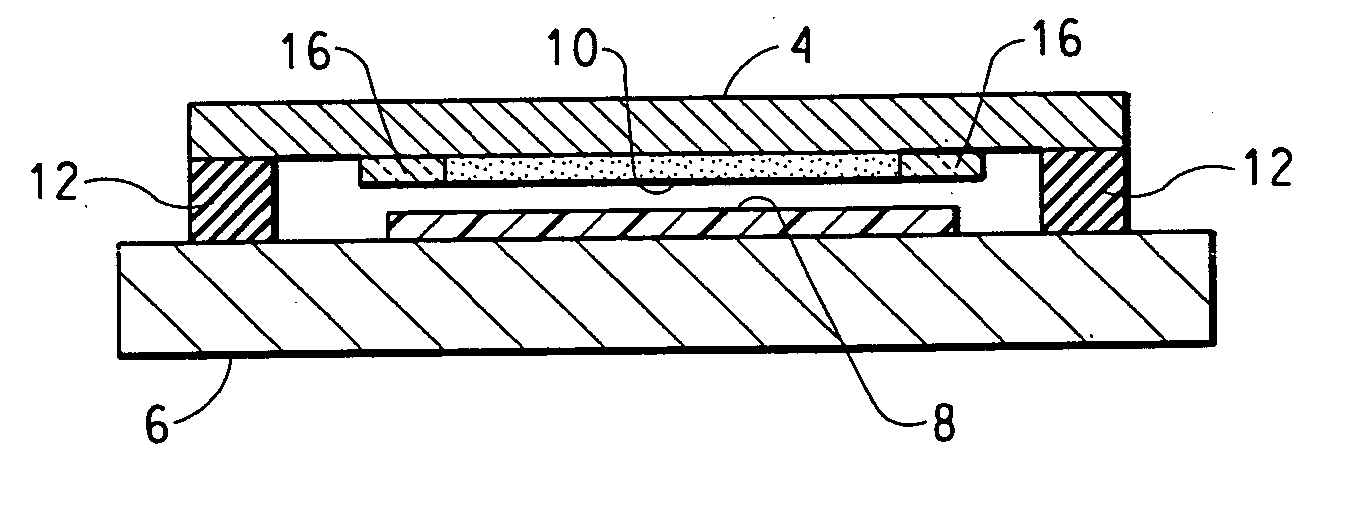

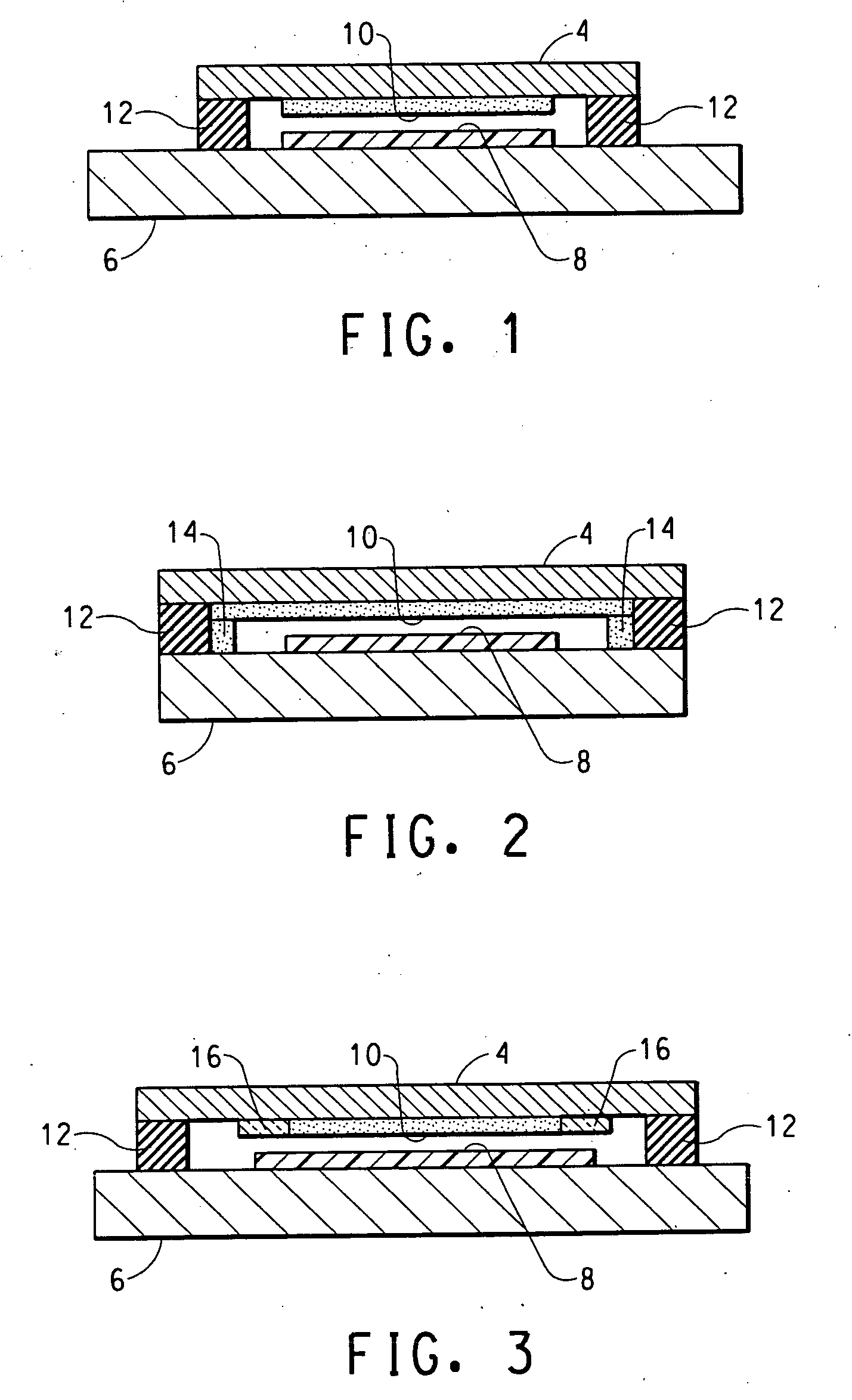

Electronic devices and a method for encapsulating electronic devices

InactiveUS20060284556A1Discharge tube luminescnet screensElectroluminescent light sourcesAmbient pressureTorr

An electronic device can include a substrate, a lid, a getter material adhered to at least a portion of at least one surface of the electronic device, wherein the portion of the surface will be an interior surface of the electronic device, and a sealing material adhered to at least a portion of the substrate and a portion of the lid. The sealing material includes a spacer material. A method for sealing the electronic device includes includes attaching the substrate and the lid in an inert atmosphere under an absolute pressure of less than 760 torr wherein the sealing material contacts both the substrate and the lid, and raising the pressure on the exterior of the device to ambient pressure.

Owner:EI DU PONT DE NEMOURS & CO +1

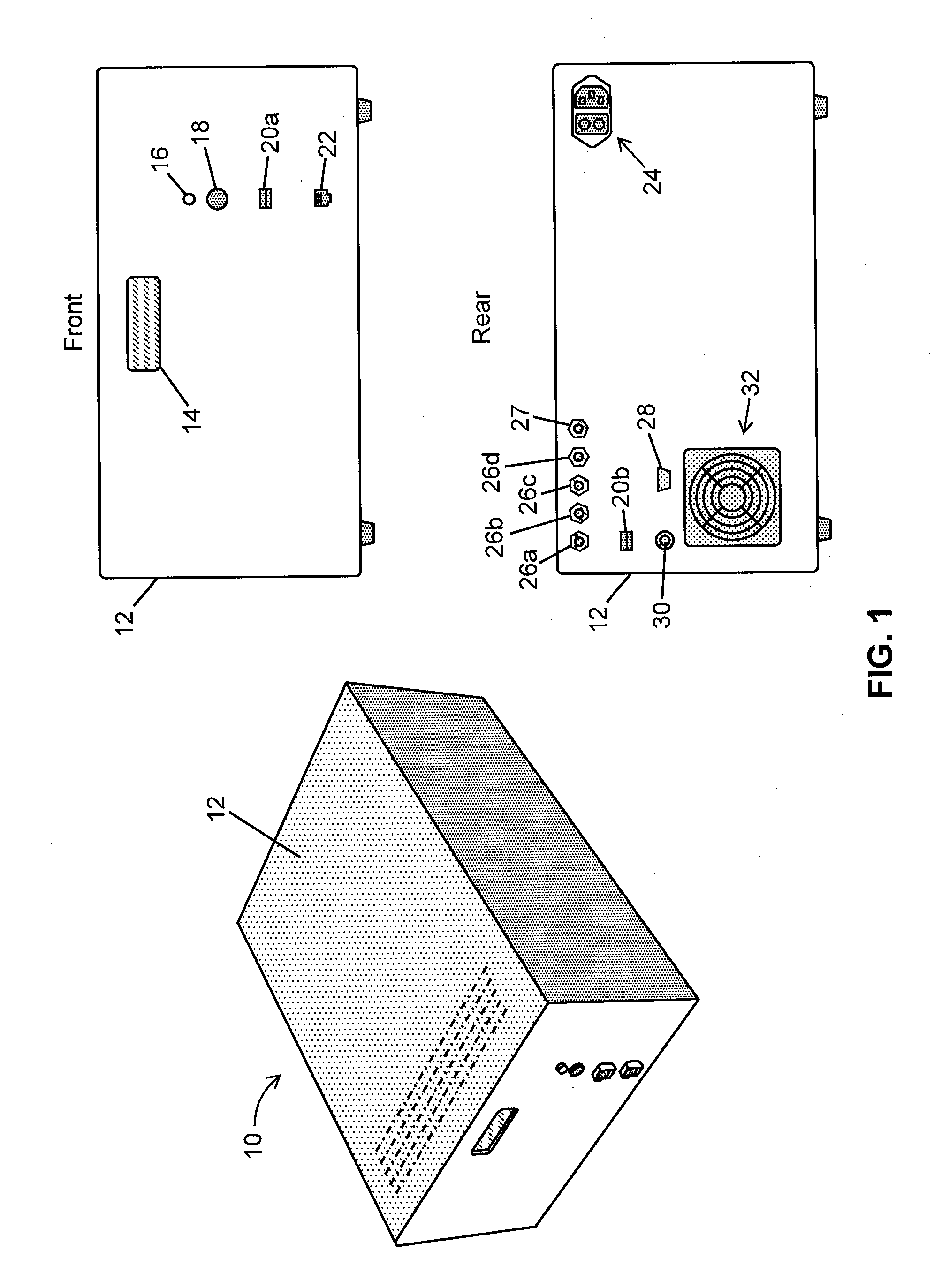

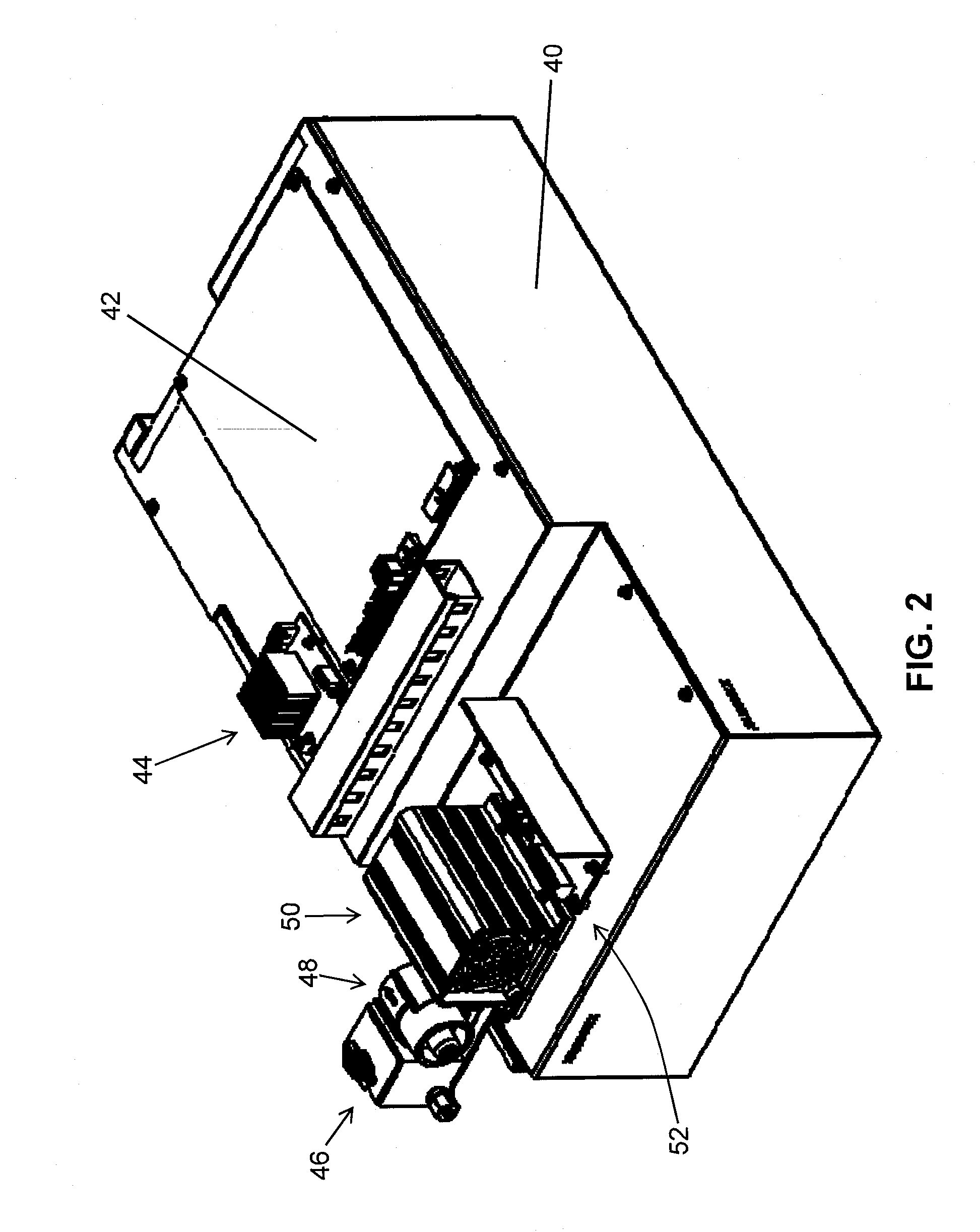

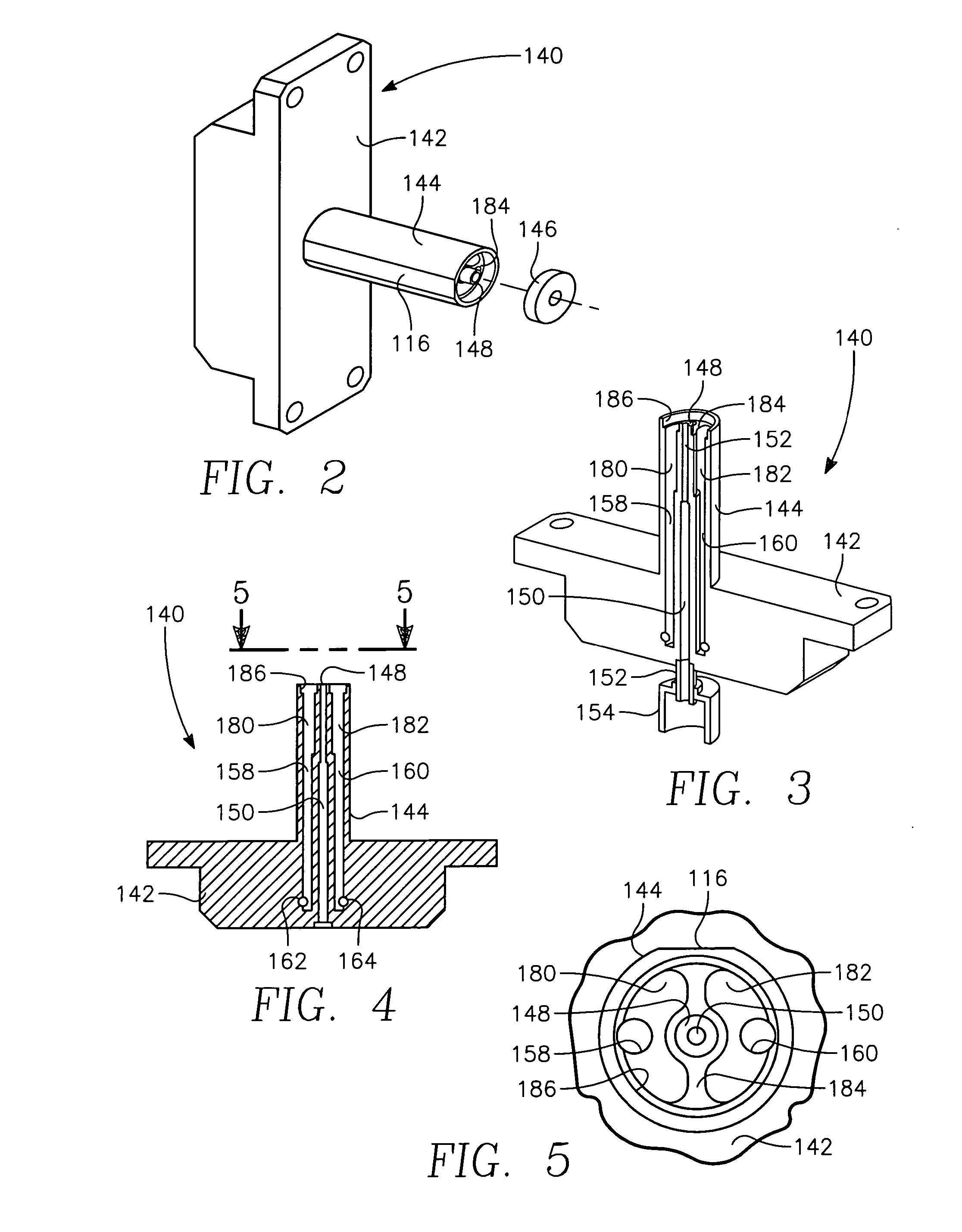

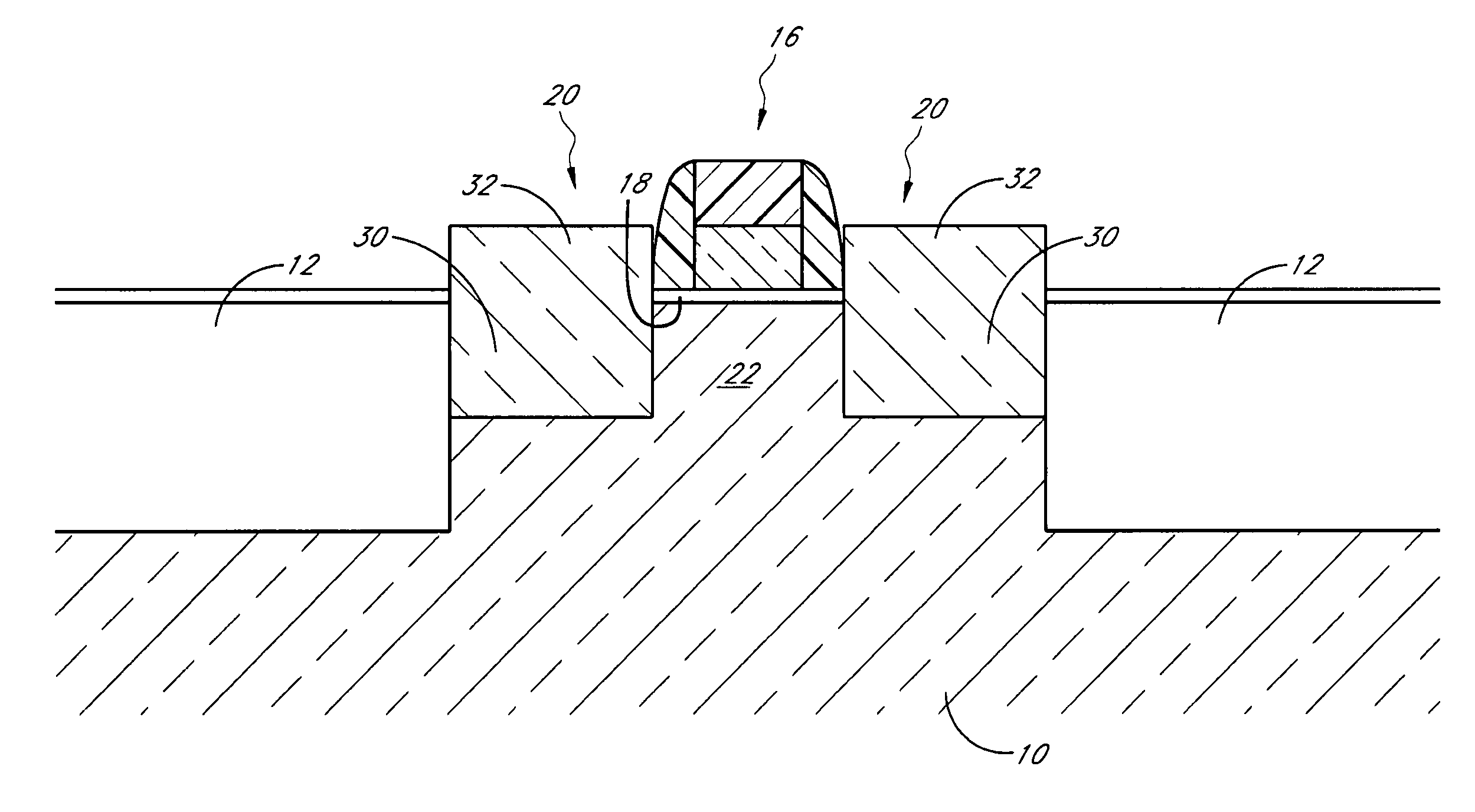

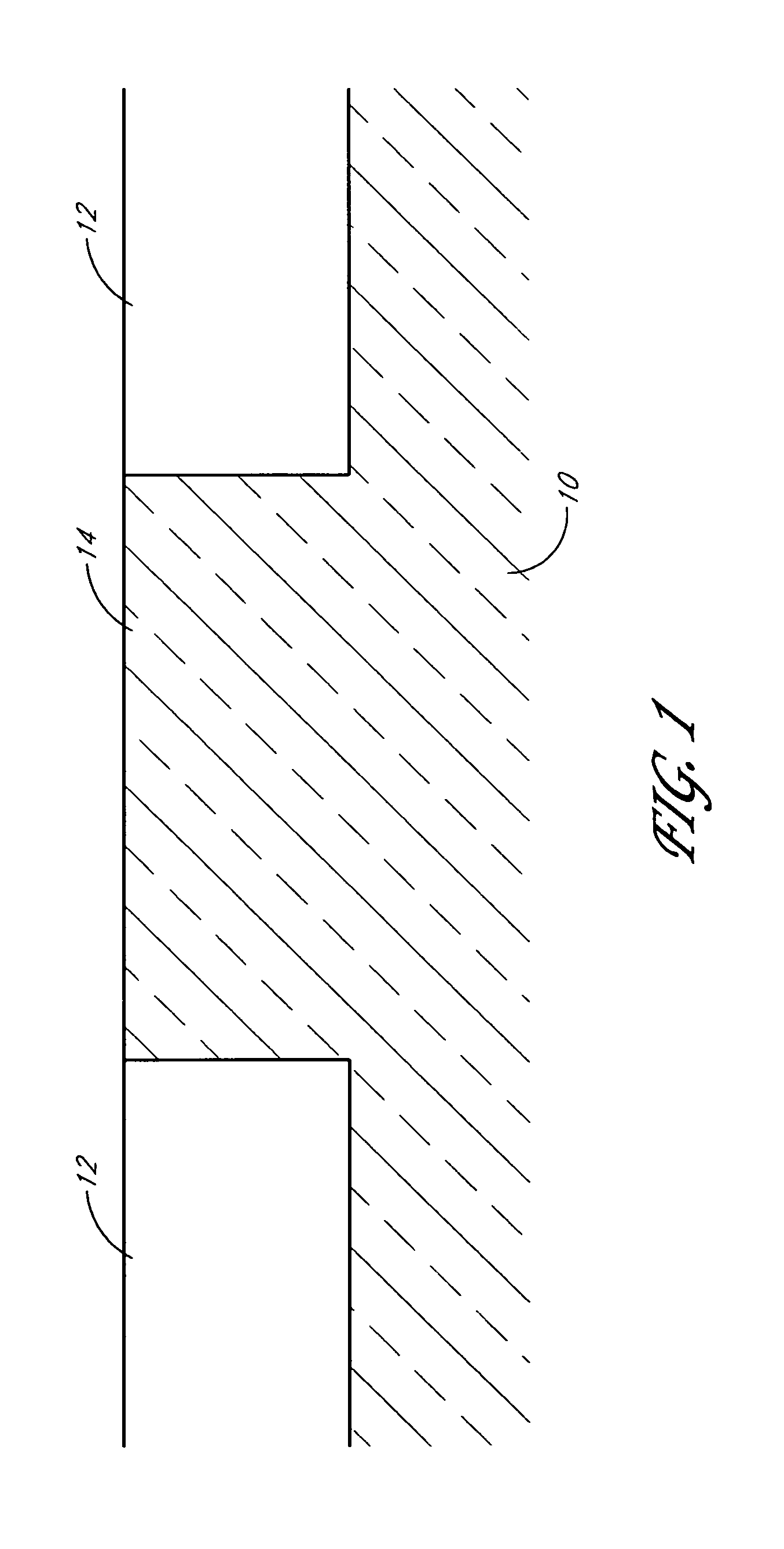

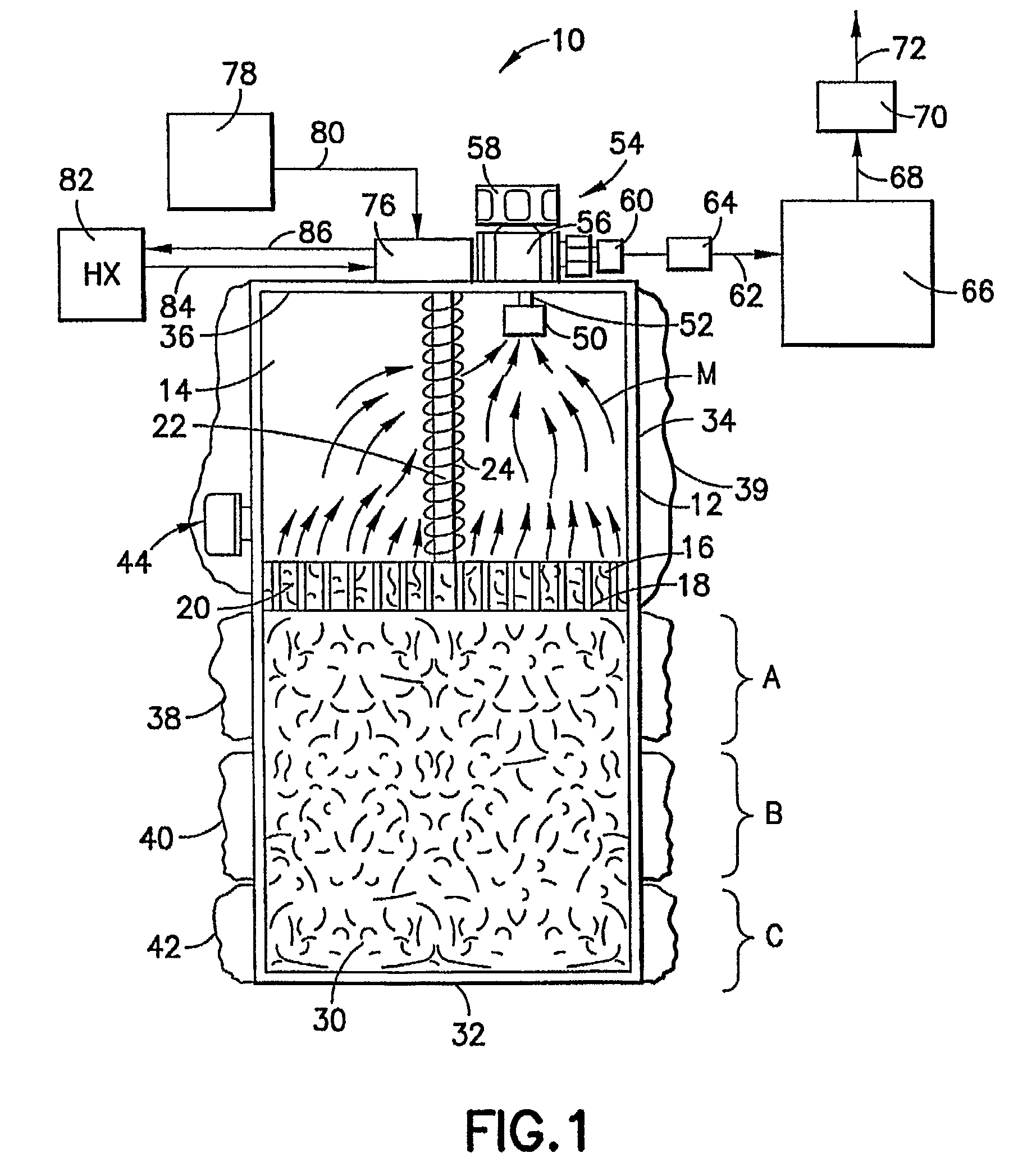

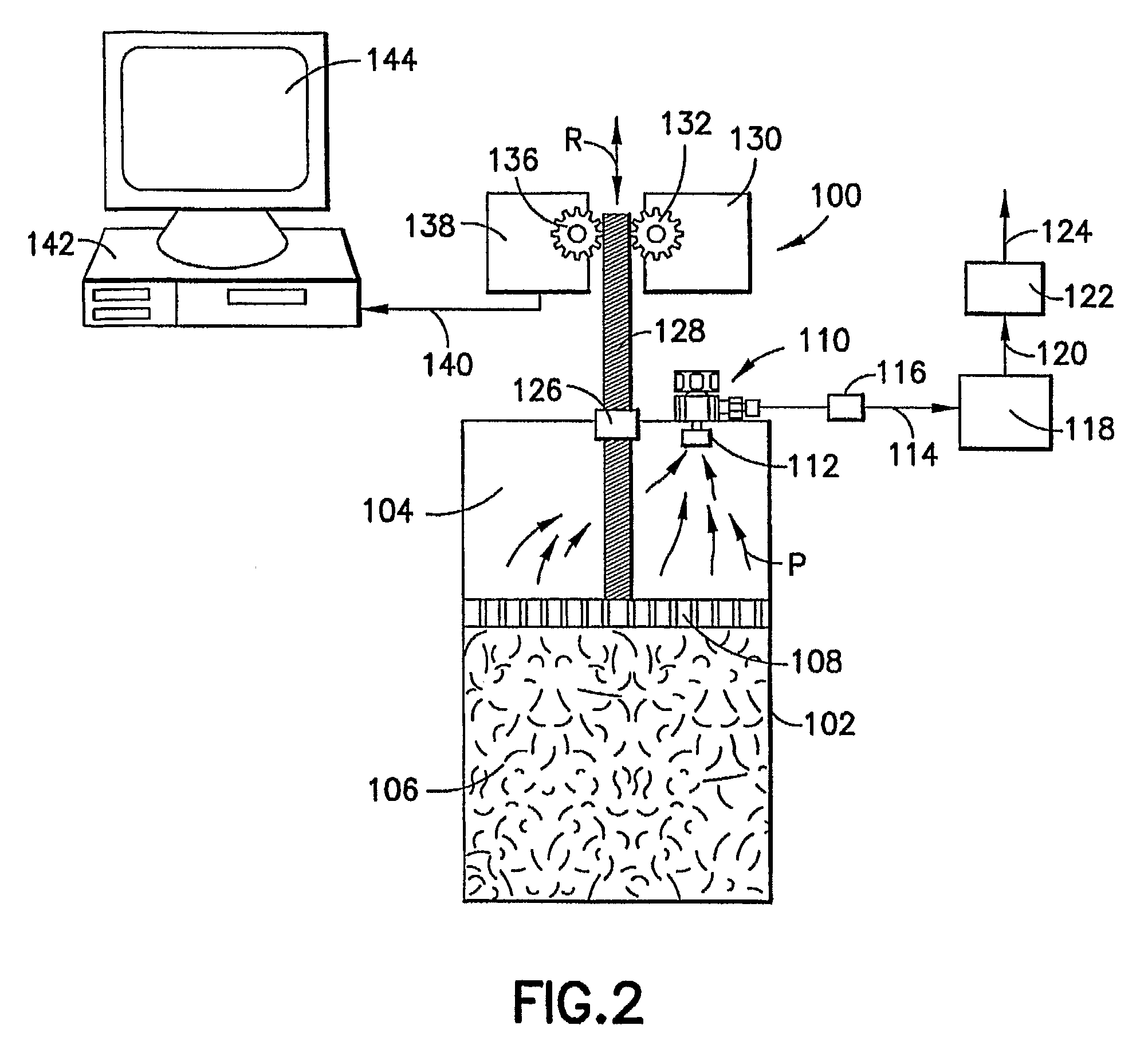

System For Delivery Of Reagents From Solid Sources Thereof

InactiveUS20080191153A1Vacuum evaporation coatingSemiconductor/solid-state device manufacturingSource materialEngineering

A system (10) for delivery of reagent from a solid source thereof, comprising a structure (16, 22, 24) arranged to retain a solid source material (30) in confinement by at least a portion of the structure, for heating and generation of vapor from the solid source material by volatilization thereof, a heat source (82) arranged to heat the solid source material for such volatilization, and a vapor dispensing assembly (52, 54) arranged to discharge the vapor from the system. A high conductance valve (1510) is also described, suitable for use as a dispensing control valve for a reagent storage and dispensing vessel, e.g., a vessel containing a semiconductor manufacturing reagent that is dispensed at low pressure. The high conductance valve includes a valve body (1512) in which inlet and outlet passages are substantially perpendicular to one another, with their interior extremities communicating with a valve chamber (1536) containing a selectively positionable valve element movable between a fully open and fully closed position. Valve flow coefficient (CV) values on the order of 2.7 to 2.9 are achievable by such high conductance valve, enabling the valve to achieve superior dispensing operation even in extremely low pressure regimes, e.g., below 20 torr.

Owner:ADVANCED TECH MATERIALS INC

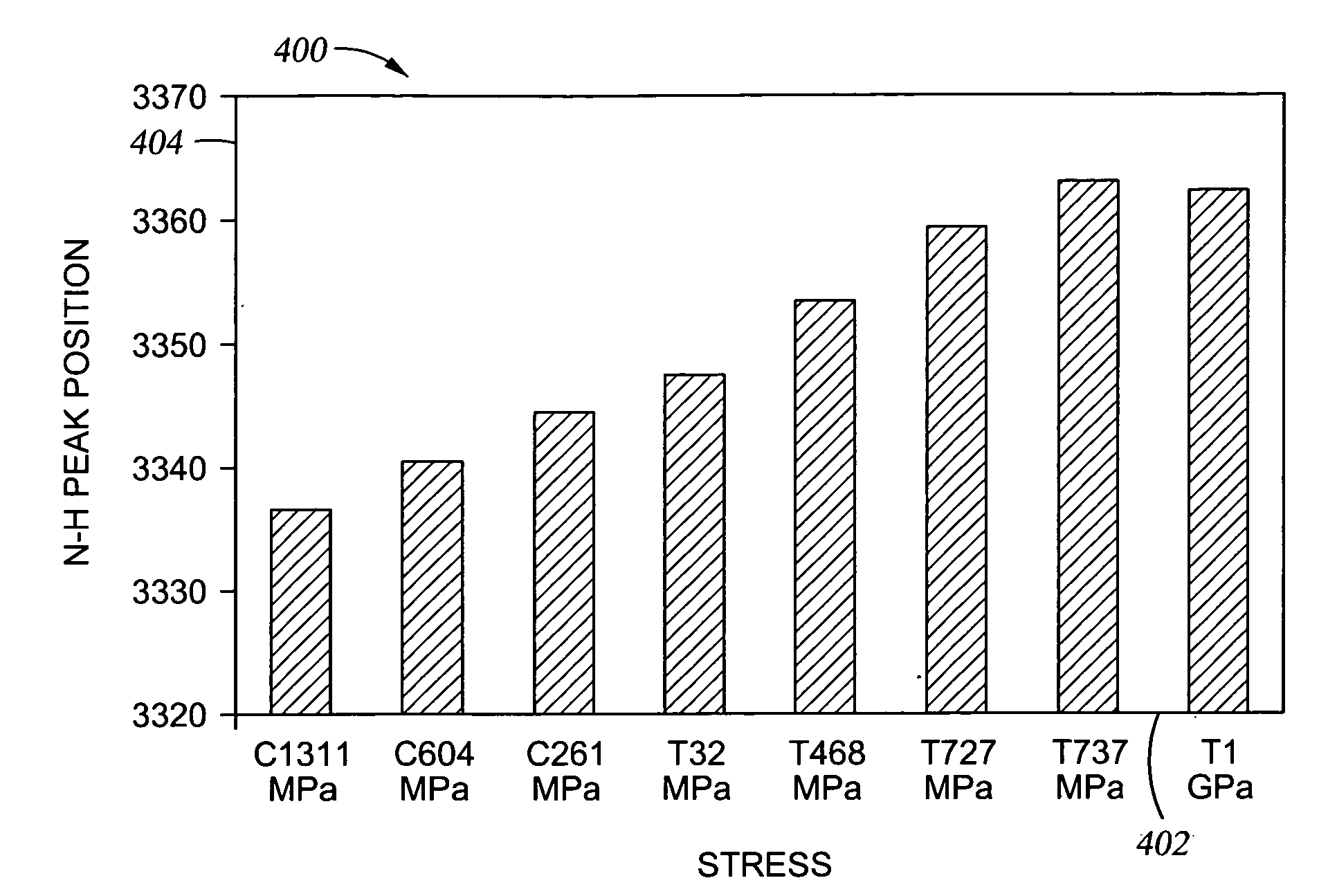

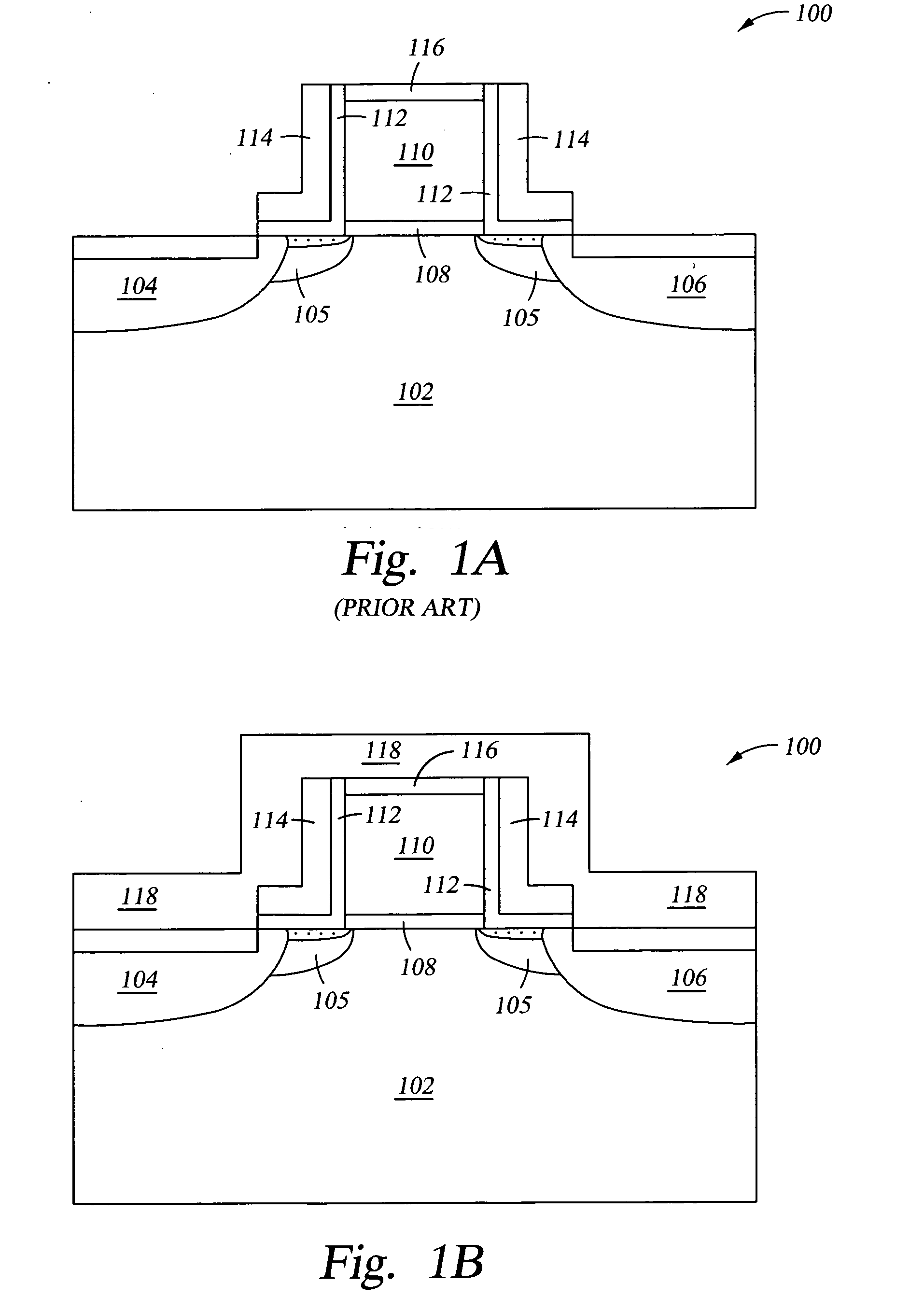

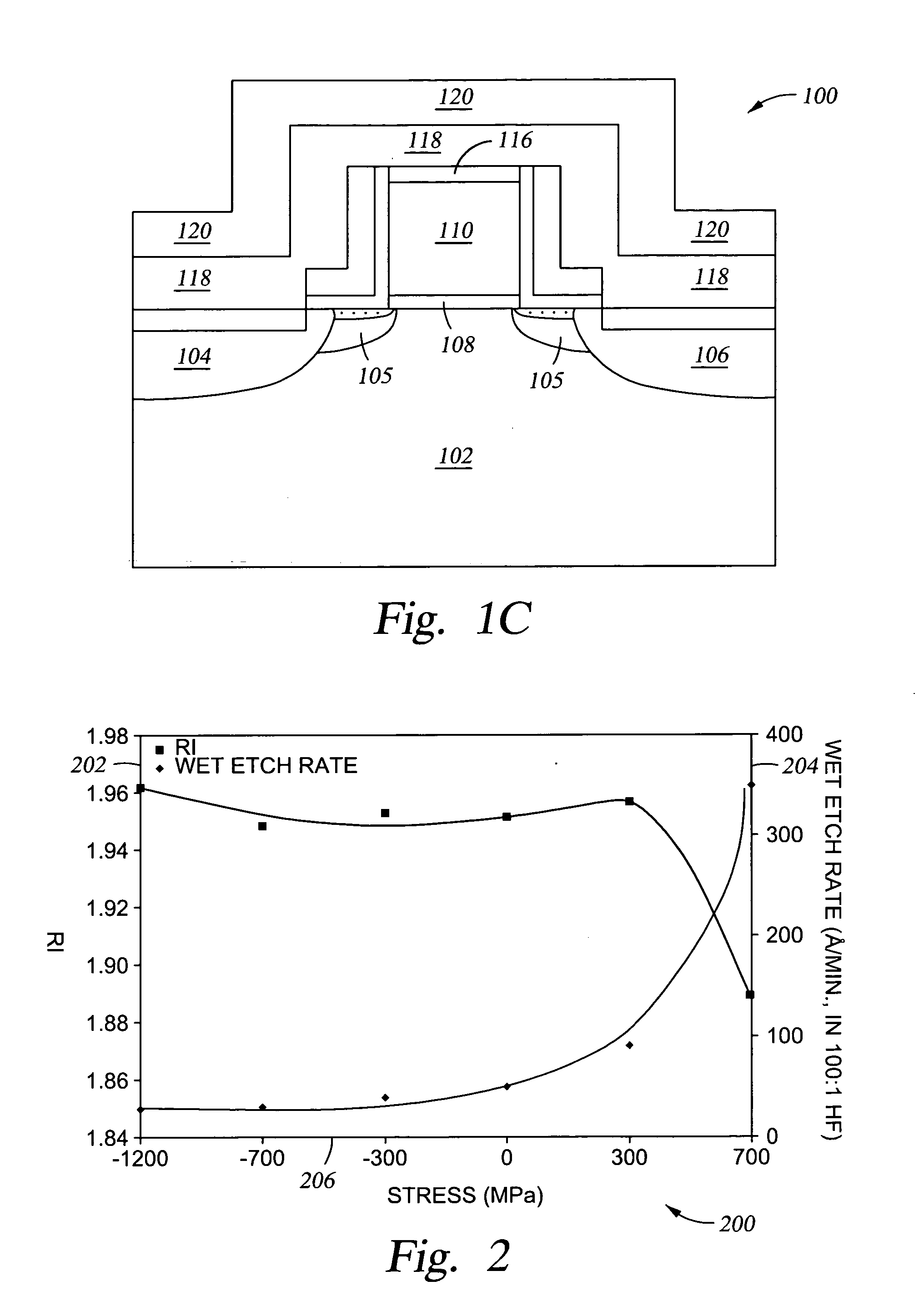

Stress-tuned, single-layer silicon nitride film

InactiveUS20050170104A1Careful control over amountHigh voltageElectric discharge tubesSemiconductor/solid-state device manufacturingDeposition temperatureChamber pressure

We have discovered that is possible to tune the stress of a single-layer silicon nitride film by manipulating certain film deposition parameters. These parameters include: use of multiple (typically dual) power input sources operating within different frequency ranges; the deposition temperature; the process chamber pressure; and the composition of the deposition source gas. In particular, we have found that it is possible to produce a single-layer, thin (300 Å to 1000 Å thickness) silicon nitride film having a stress tuned to be within the range of about −1.4 GPa (compressive) to about +1.5 GPa (tensile) by depositing the film by PECVD, in a single deposition step, at a substrate temperature within the range of about 375° C. to about 525 ° C., and over a process chamber pressure ranging from about 2 Torr to about 15 Torr.

Owner:APPLIED MATERIALS INC

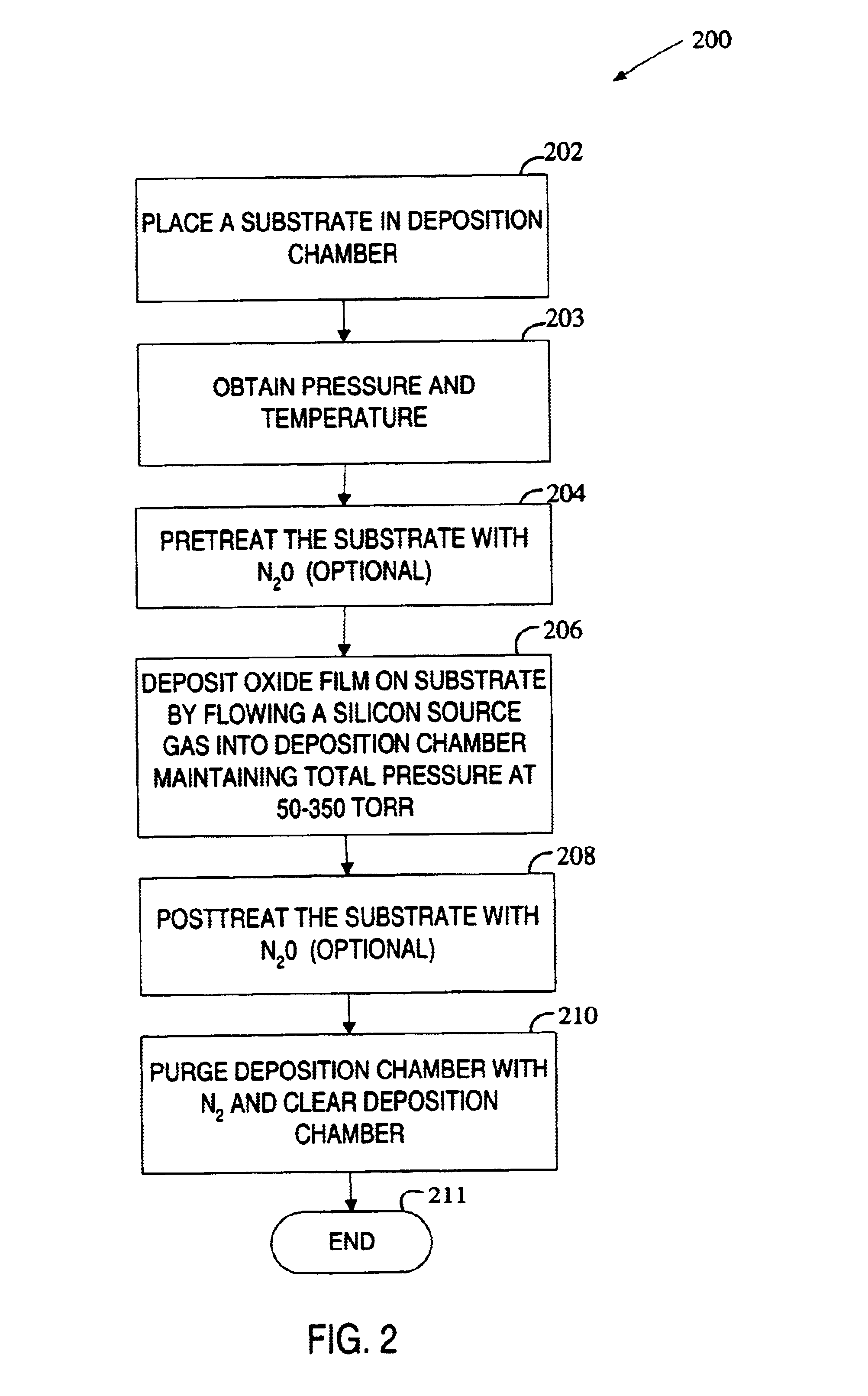

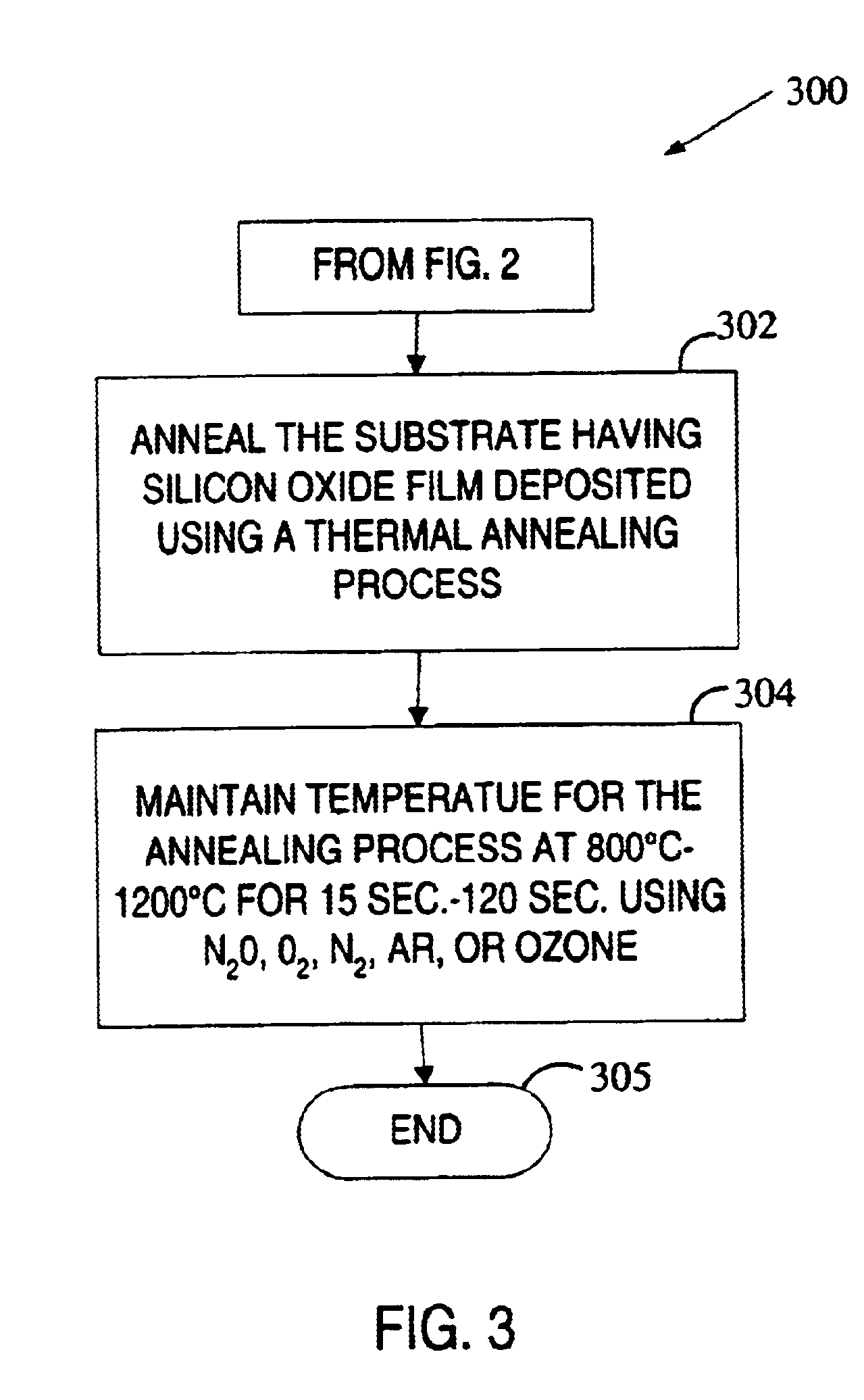

Methods for silicon oxide and oxynitride deposition using single wafer low pressure CVD

InactiveUS6713127B2Pretreated surfacesSemiconductor/solid-state device manufacturingThermal energySilicon oxide

An oxide and an oxynitride films and their methods of fabrication are described. The oxide or the oxynitride film is grown on a substrate that is placed in a deposition chamber. A silicon source gas (or a silicon source gas with a nitridation source gas) and an oxidation source gas are decomposed in the deposition chamber using a thermal energy source. A silicon oxide (or an oxynitride) film is formed above the substrate wherein total pressure for the deposition chamber is maintained in the range of 50 Torr to 350 Torr and wherein a flow ratio for the silicon source gas (or the silicon source gas with the nitridiation source gas) and the oxidation source gas is in the range of 1:50 to 1:10000 during a deposition process.

Owner:APPLIED MATERIALS INC

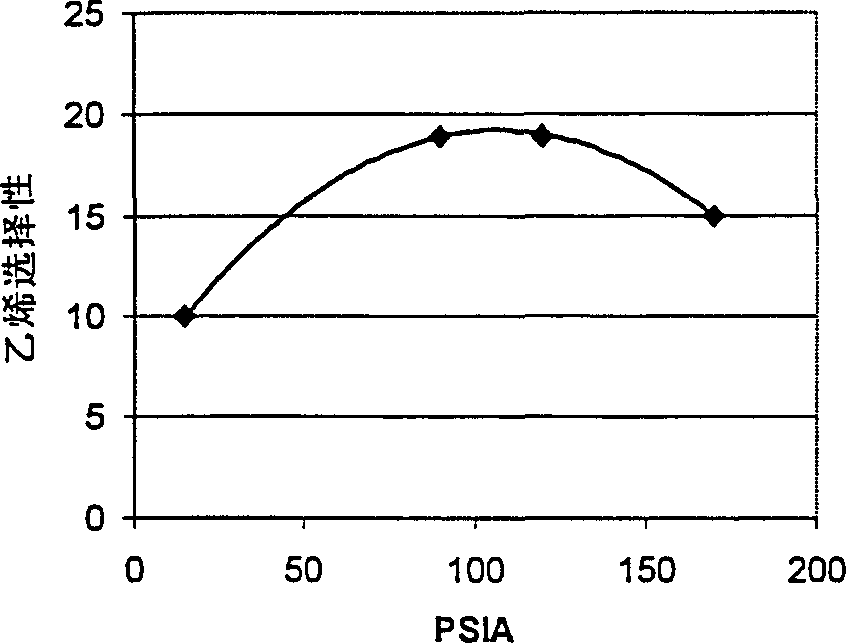

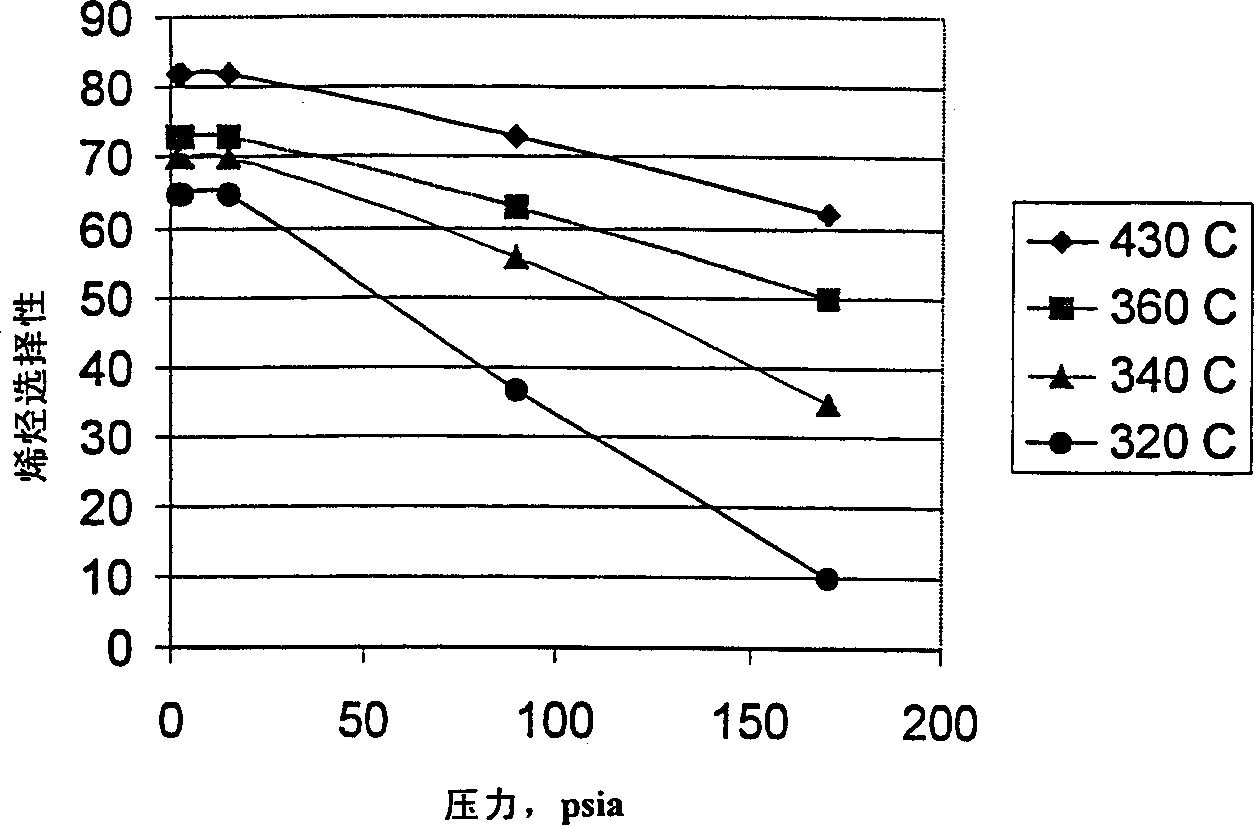

Process for converting methanol or dimethyl ether to olefins

There is provided a process for converting methanol or dimethyl ether to a product containing C2 to C4 olefins, which comprises the step of contacting a feed containing methanol or dimethyl ether with a catalyst which comprises a zeolite having 10-ring intersecting channels, such as ZSM-5, and which has a Diffusion Parameter for 2,2-dimethylbutane of less than 100 sec-1 when measured at a temperature of 120 DEG C. and a 2,2-dimethylbutane pressure of 60 torr (8 kPa). The contacting step is conducted at a temperature of 370 to 480 DEG C., a methanol partial pressure of 30 to 150 psia and a methanol conversion per pass of less than 95%.

Owner:EXXONMOBIL CORP (US)

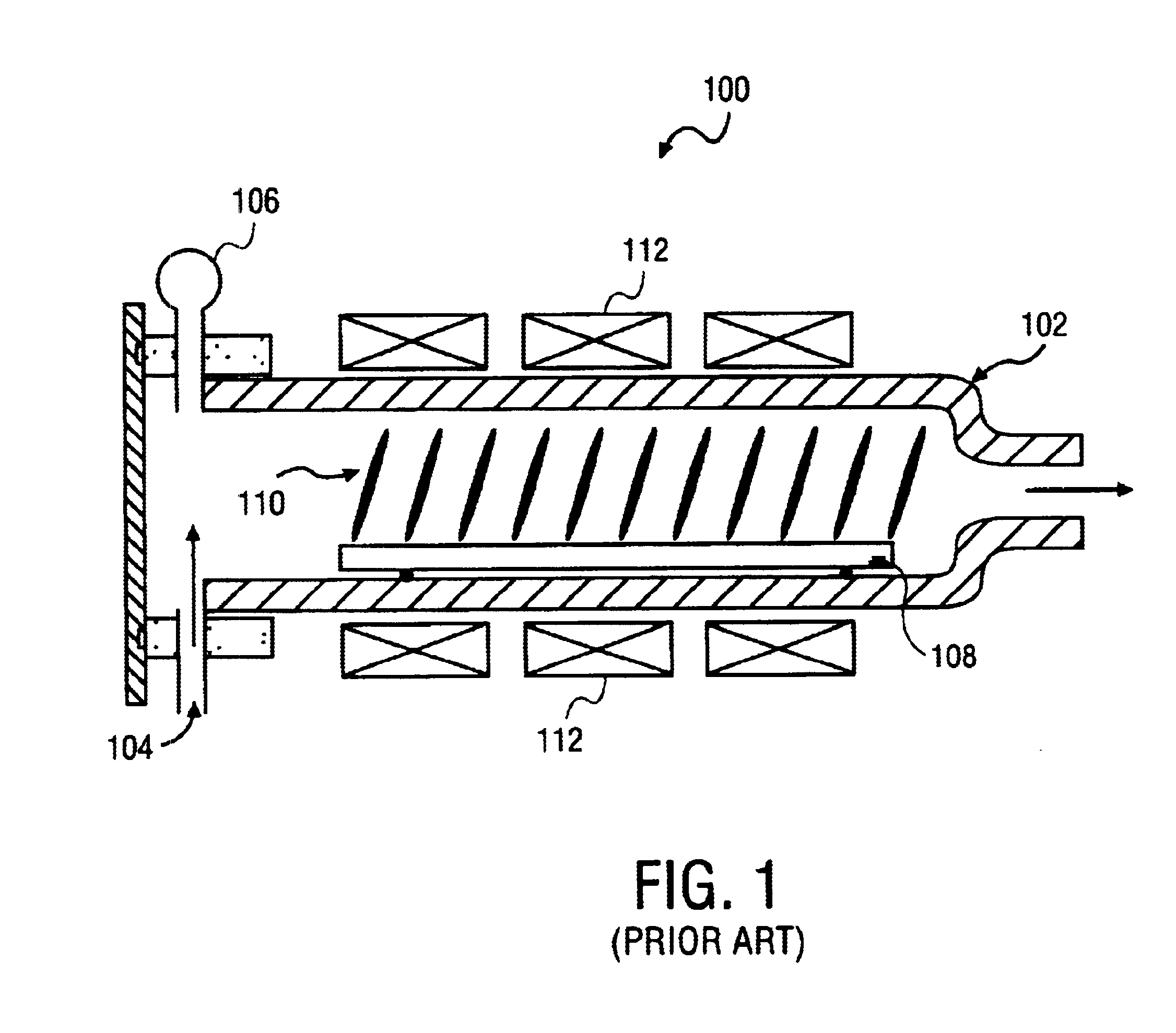

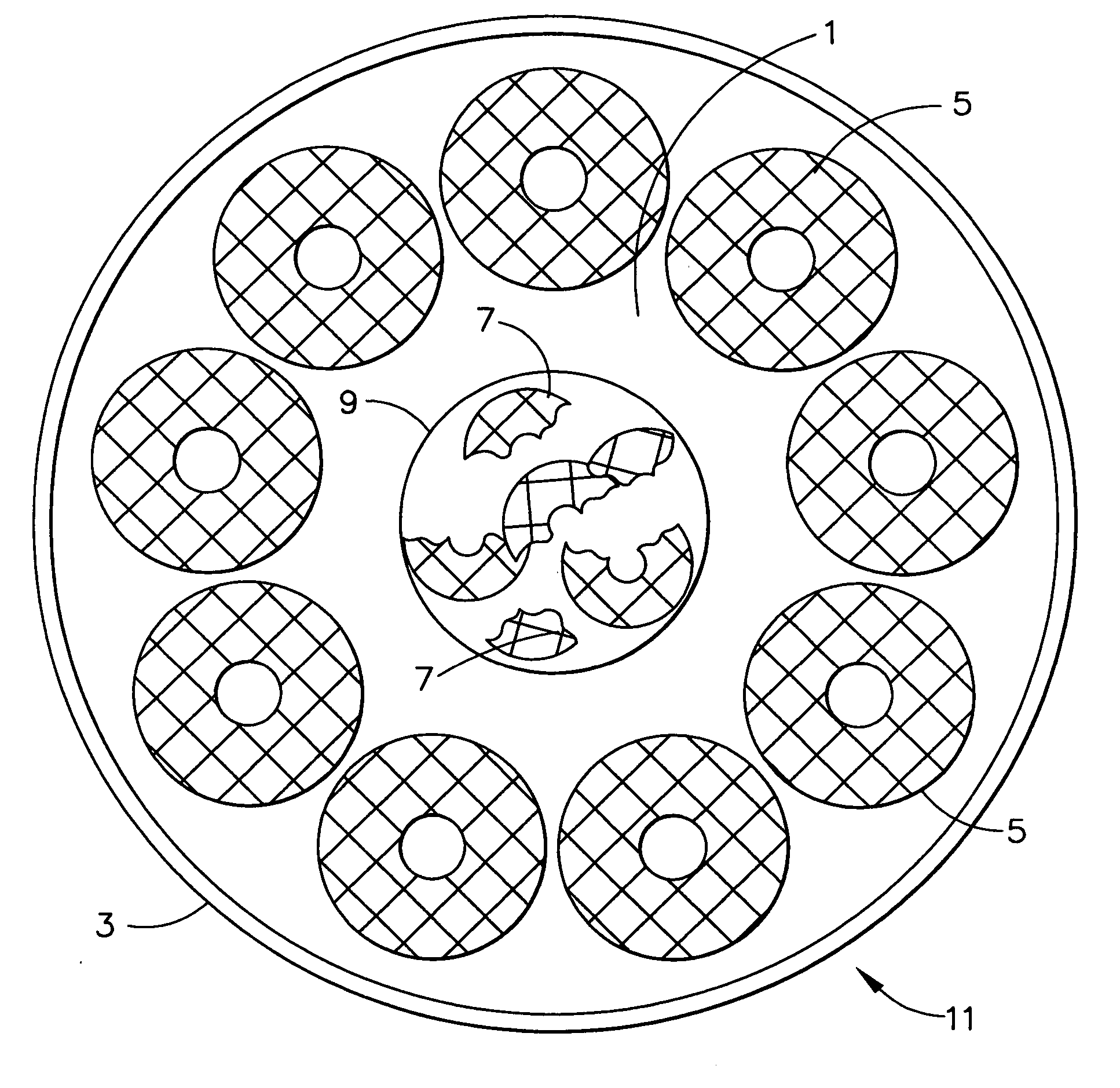

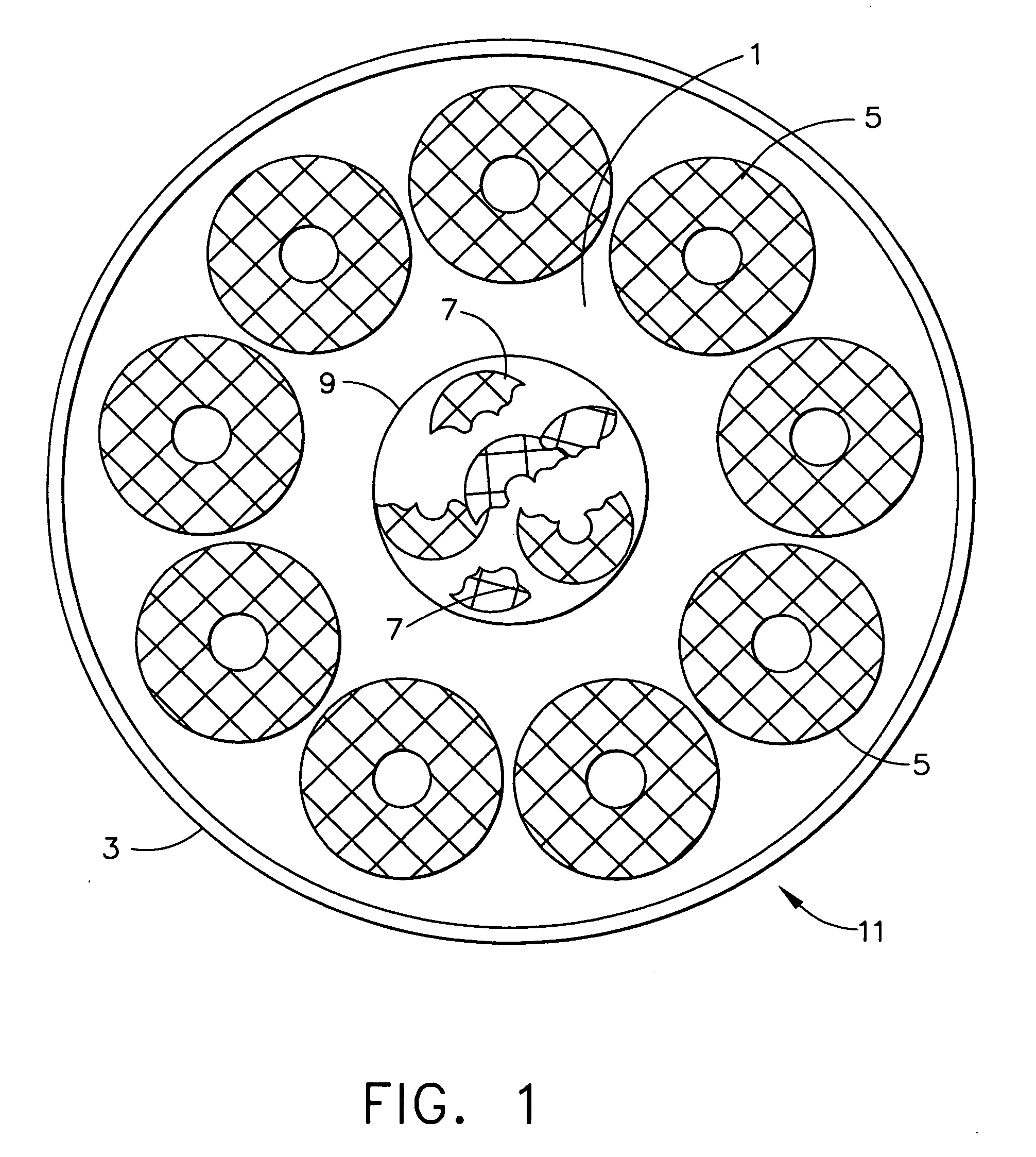

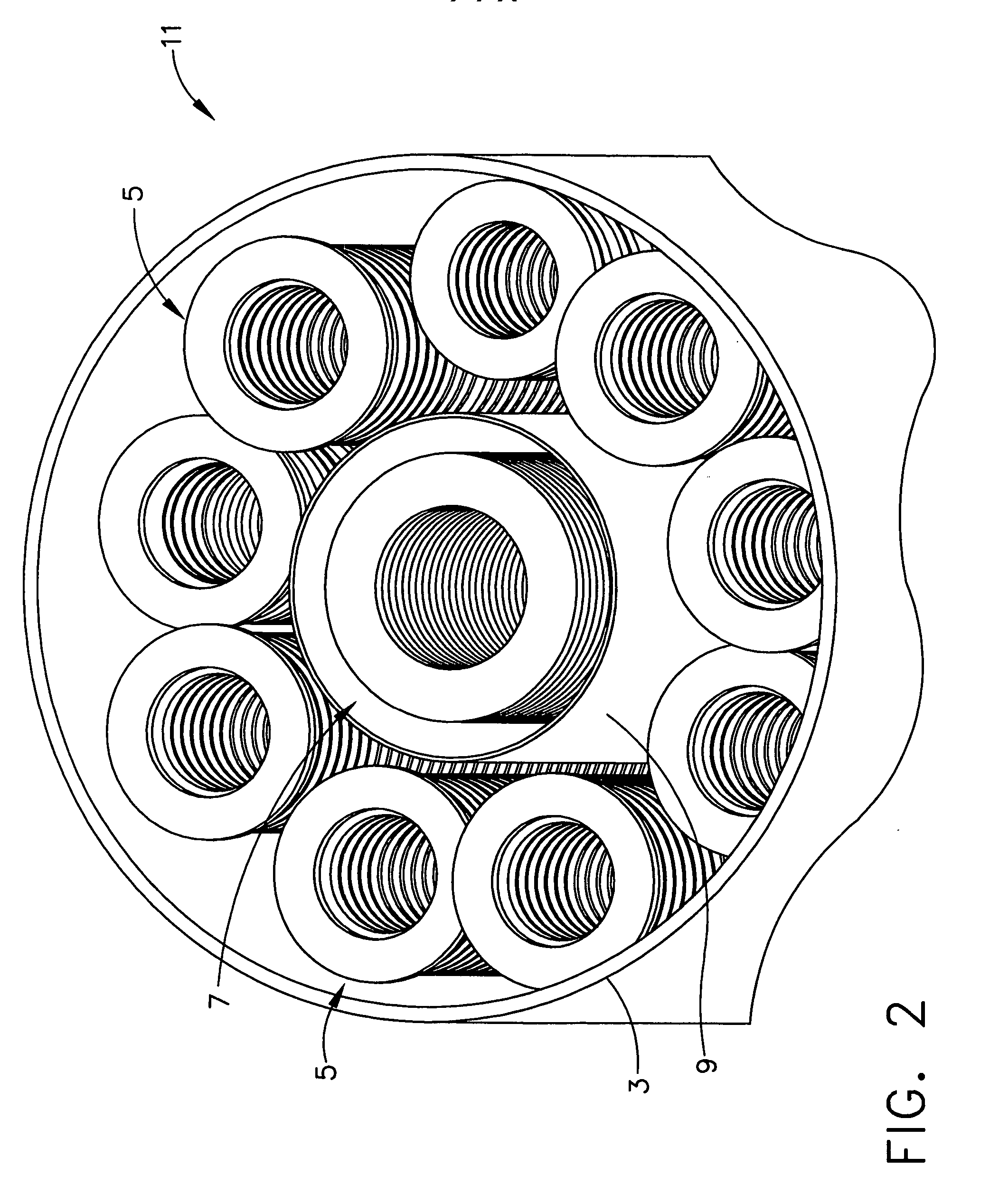

Chemical vapor deposition apparatus and method

InactiveUS20060046059A1High densityGreat and uniform weightLayered productsChemical vapor deposition coatingCarbon compositesCircular disc

Apparatus such as a furnace muffle (11) for use in a CVI / CVD furnace. The apparatus includes a bottom (12), a top (13), and an outer wall (3) defining an interior space (1) in the apparatus, and a passive heat distribution element (7, 9) located within the interior space (1) and apart from the outer wall (3). Preferably, the bottom (12) and top (12) include perforated plates and the outer wall (3) is cylindrical in shape and all are made of graphite or carbon-carbon composite material and the passive heat distribution element (7, 9) is cylindrical in shape and includes graphite or carbon-carbon composite discs having no spacers therebetween. Also, a method for densifying a porous carbon preform (5), which method includes the steps of: (a) providing the apparatus (11); (b) charging the apparatus (11) with a plurality of stacks of annular porous carbon preforms (5), the preforms being separated from one another by spacers (15); (c) locating the charged apparatus (11) in a furnace at a temperature in the range of 950-1100° C. and a pressure in the range of 5-40 torr; and (d) circulating a natural gas reactant blended with up to 15% propane through the apparatus for 150-900 hours. Also, a batch of carbon-carbon composite preforms made by the method, wherein the density of the batch of preforms is at least 0.5 g / cc higher than the density of a batch of preforms made by an otherwise identical process in which the apparatus does not contain a passive heat distribution element located within its interior. The preforms may be configured as aircraft landing system brake discs or racing car brake discs.

Owner:HONEYWELL INT INC

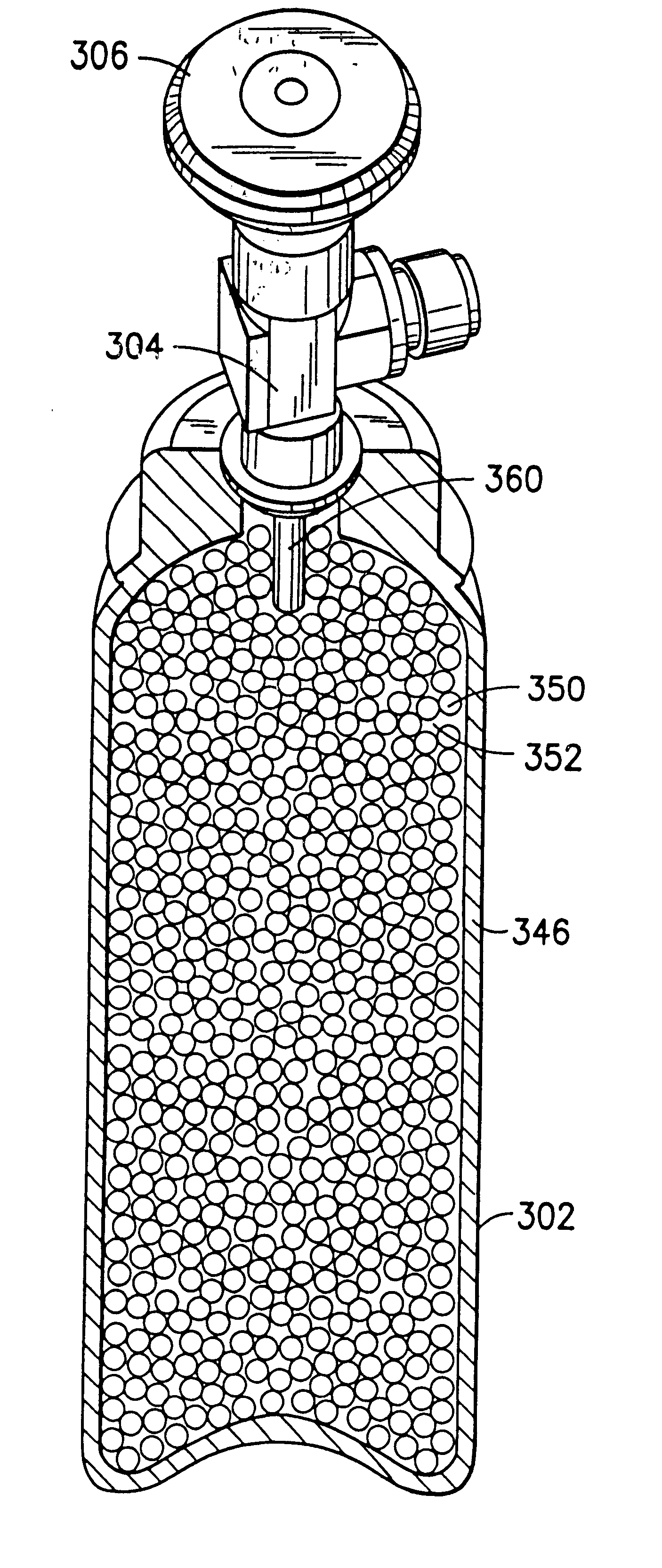

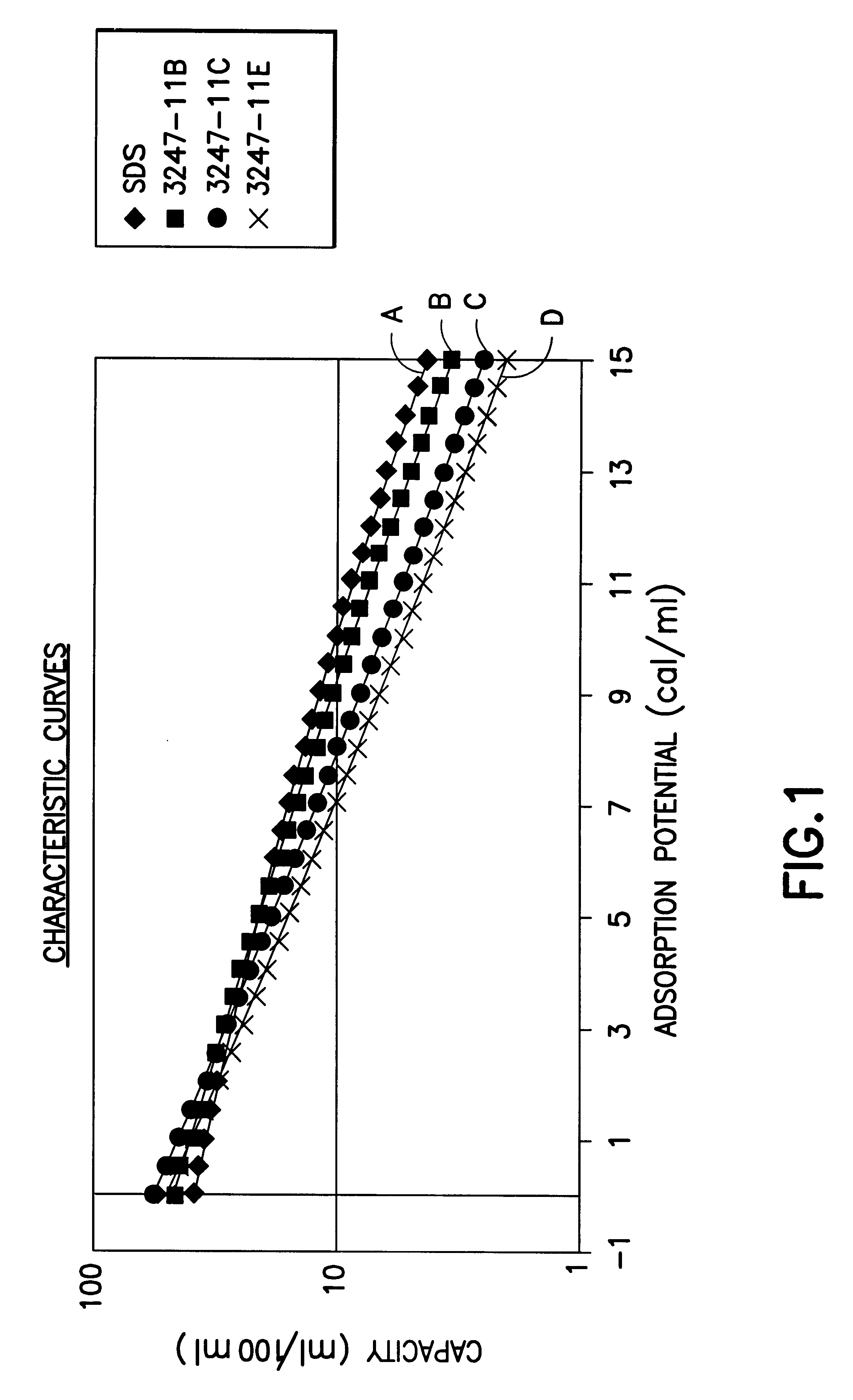

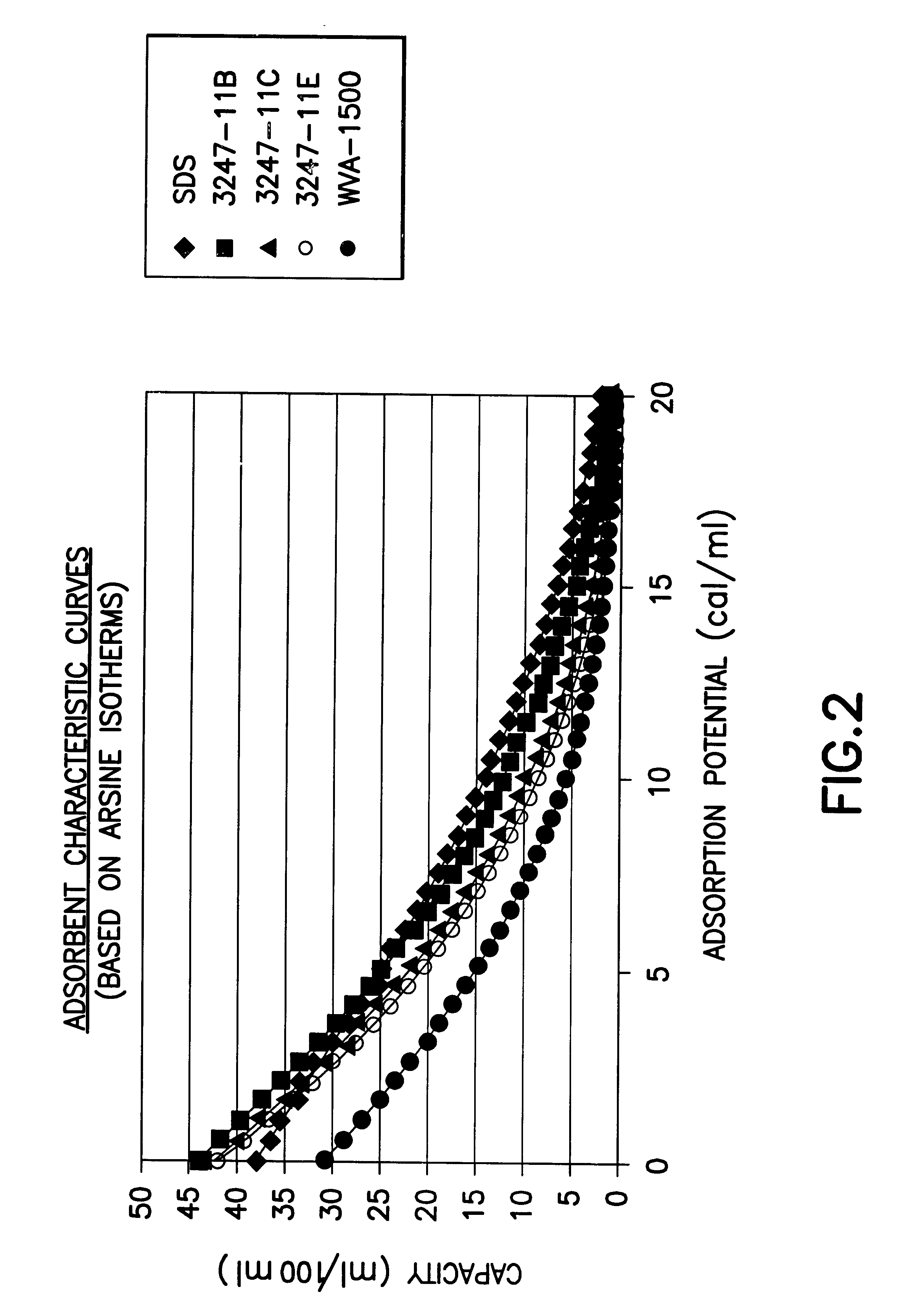

Fluid storage and delivery system utilizing low heels carbon sorbent medium

InactiveUS6592653B2Reduces sufficiencyImprove adsorption capacityGas treatmentOther chemical processesDesorptionSorbent

A fluid storage and dispensing system including a vessel containing a low heel carbon sorbent having fluid adsorbed thereon, with the system arranged to effect desorption of the fluid from the sorbent for dispensing of fluid on demand. The low heel carbon sorbent preferably is characterized by at least one of the following characteristics: (i) Heel, measured for gaseous arsine (AsH3) at 20° C. at 20 Torr, of not more than 50 grams AsH3 per liter of bed of the sorbent material; (ii) Heel, measured for gaseous boron trifluoride (BF3) at 20° C. at 20 Torr, of not more than 20 grams boron trifloride per liter of bed of the sorbent material; (iii) Heel, measured for gaseous germanium tetrafluoride (GeF4) at 20° C. at 20 Torr, of not more than 250 grams AsH3 per liter of bed of the sorbent material; (iv) Heel, measured for gaseous arsenic pentafluoride (AsF5) at 20° C. at 20 Torr, of not more than 700 grams AsF5 per liter of bed of the sorbent material; (v) Heel, measured for gaseous trimethyl silane (3MS) at 20° C. at 20 Torr, of not more than 160 grams 3MS per liter of bed of the sorbent material; and (vi) Heel, measured for gaseous ethane (C2H4) at 21° C. at 25 Torr, of not more than 10 grams ethane per liter of bed of the sorbent material.

Owner:ENTEGRIS INC

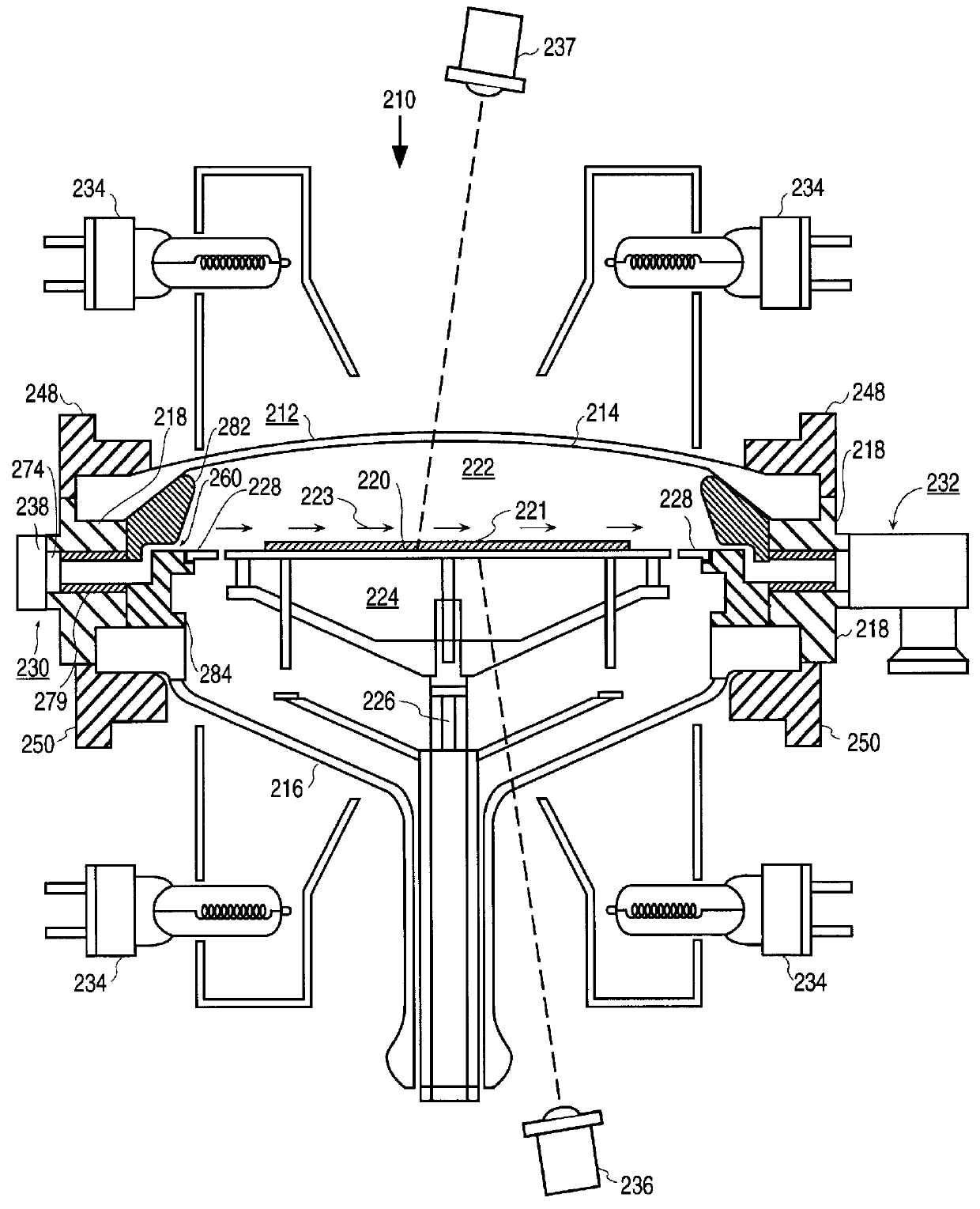

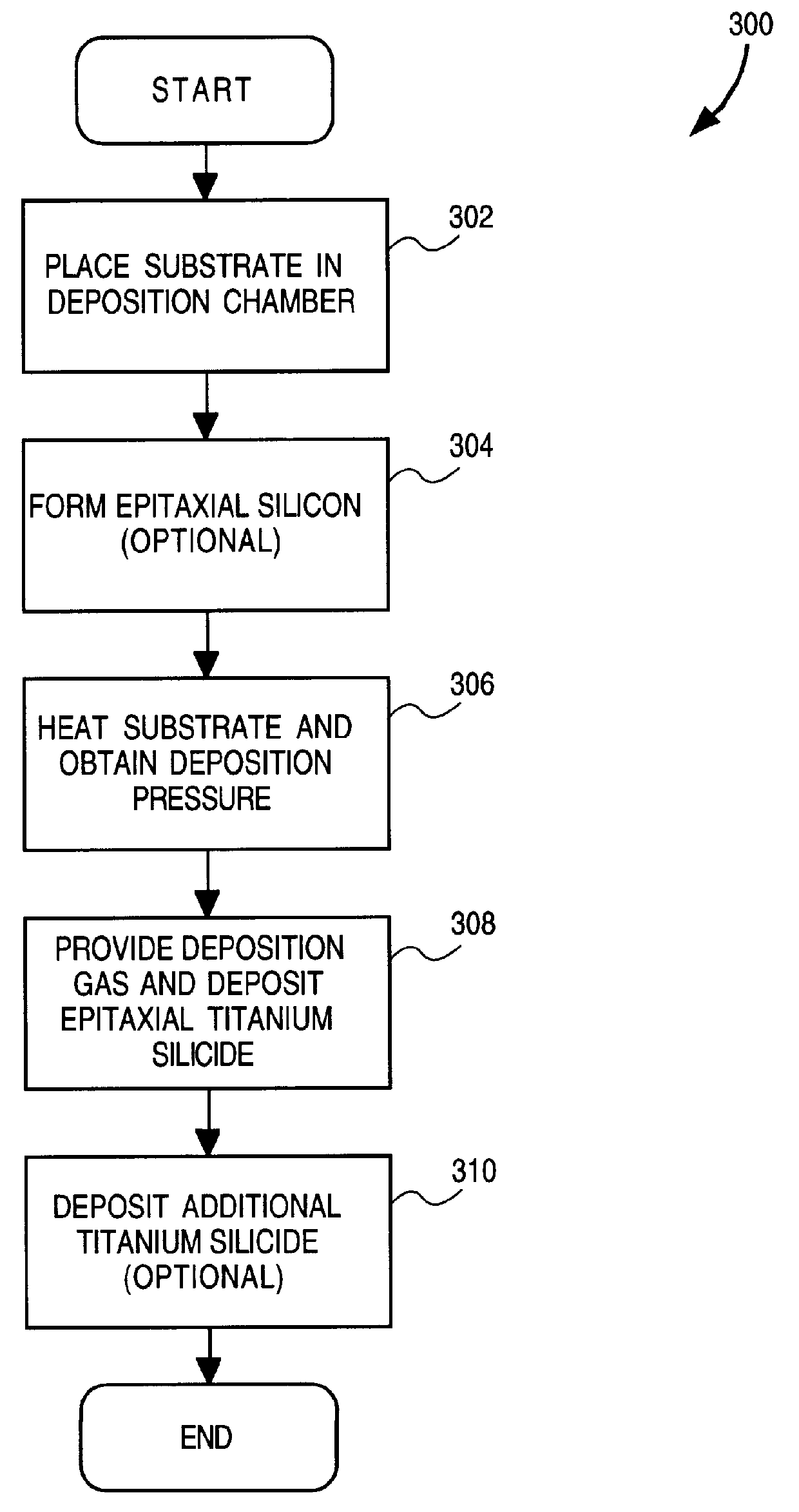

Method and apparatus for forming an epitaxial titanium silicide film by low pressure chemical vapor deposition

InactiveUS6019839APolycrystalline material growthSemiconductor/solid-state device manufacturingChemical vapor depositionTitanium tetrachloride

A method and apparatus for forming an epitaxial titanium silicide film is described. According to the present invention, a monocrystalline silicon substrate is placed in a deposition chamber and heated to a temperature between 710-770 DEG C. A silicon source gas and titanium tetrachloride are then provided into the deposition chamber. The deposition pressure is maintained between 5-10 torr. An epitaxial titanium silicide film is then formed on the substrate from the silicon source gas and the titanium tetrachloride.

Owner:APPLIED MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com