Patents

Literature

1944 results about "Vacuum evaporation" patented technology

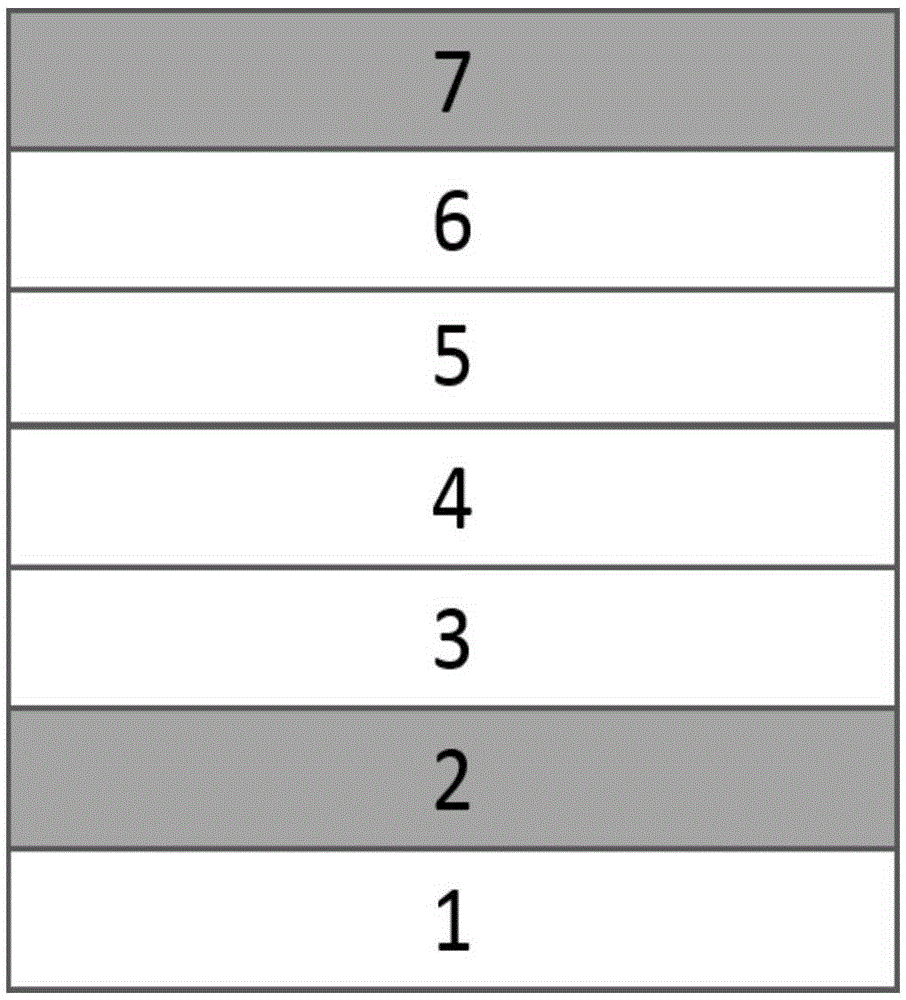

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vacuum evaporation is the process of causing the pressure in a liquid-filled container to be reduced below the vapor pressure of the liquid, causing the liquid to evaporate at a lower temperature than normal. Although the process can be applied to any type of liquid at any vapor pressure, it is generally used to describe the boiling of water by lowering the container's internal pressure below standard atmospheric pressure and causing the water to boil at room temperature.

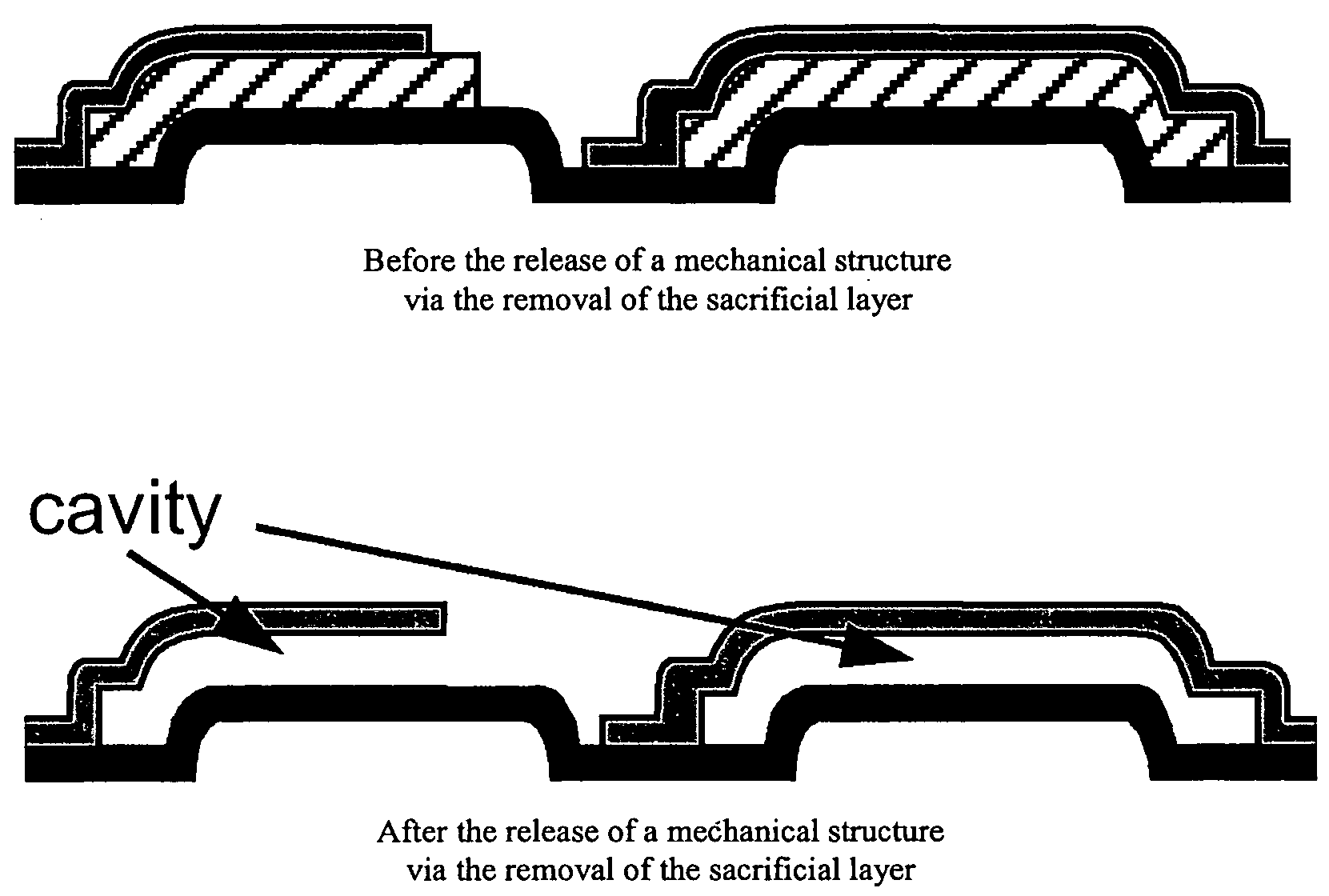

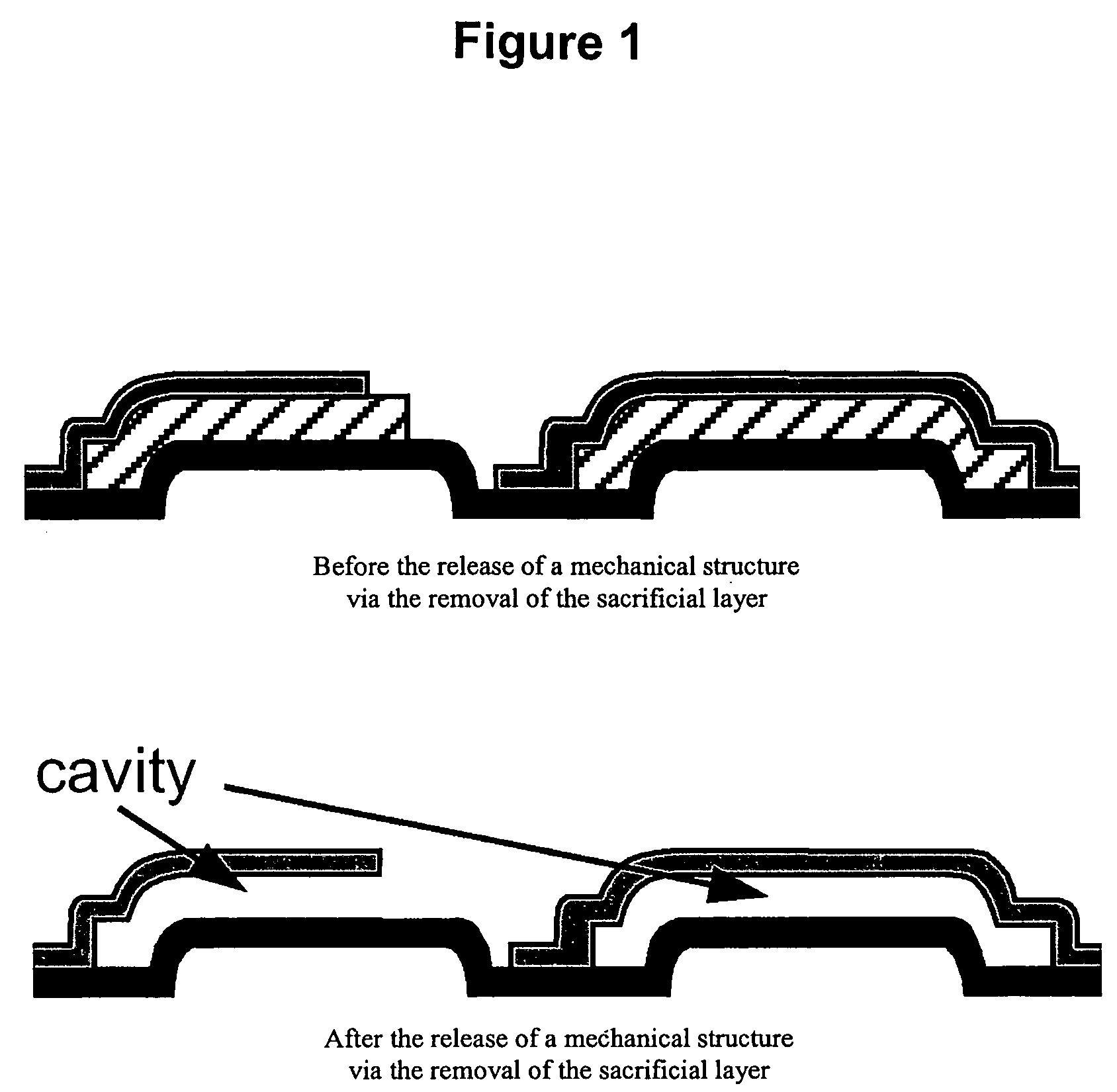

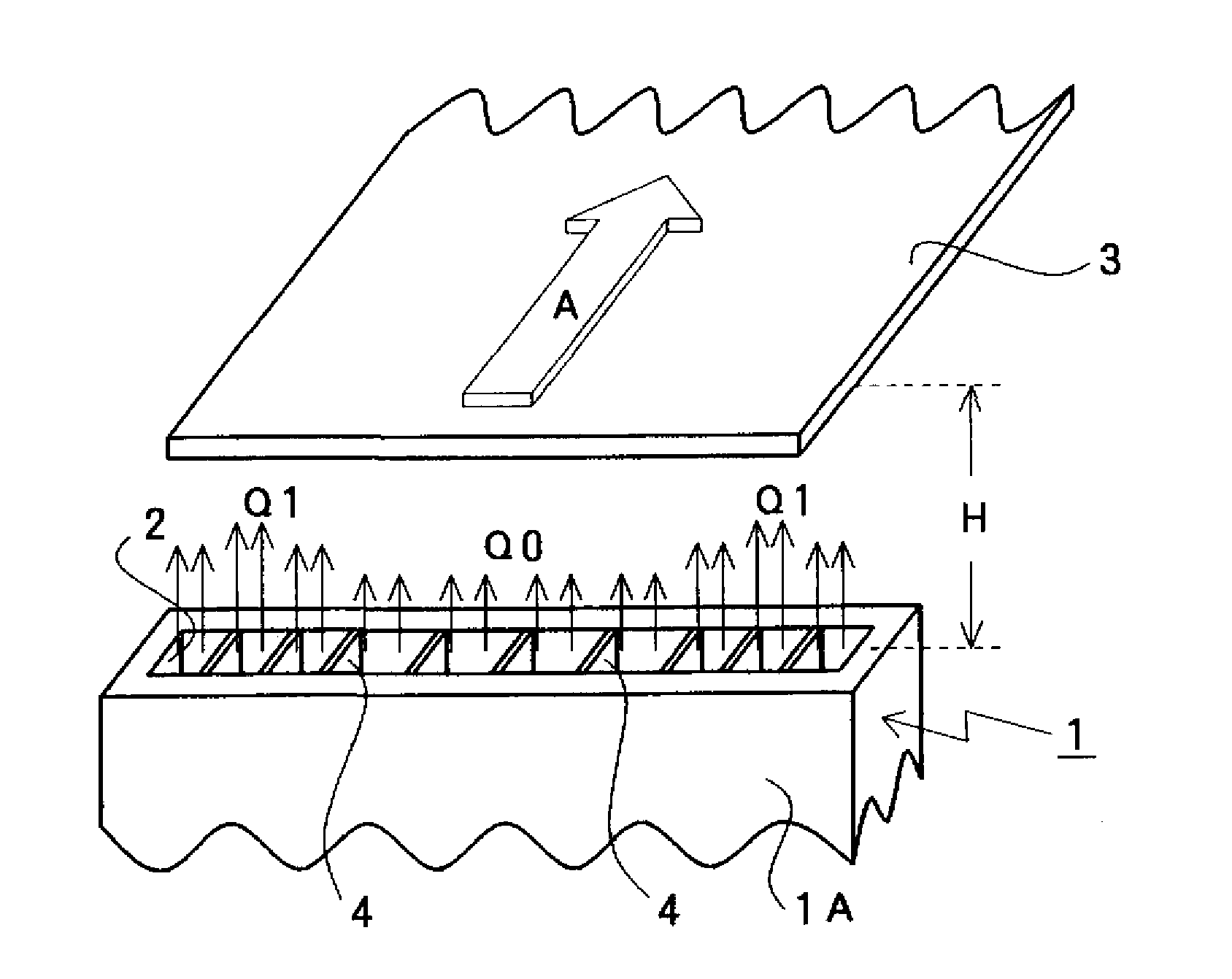

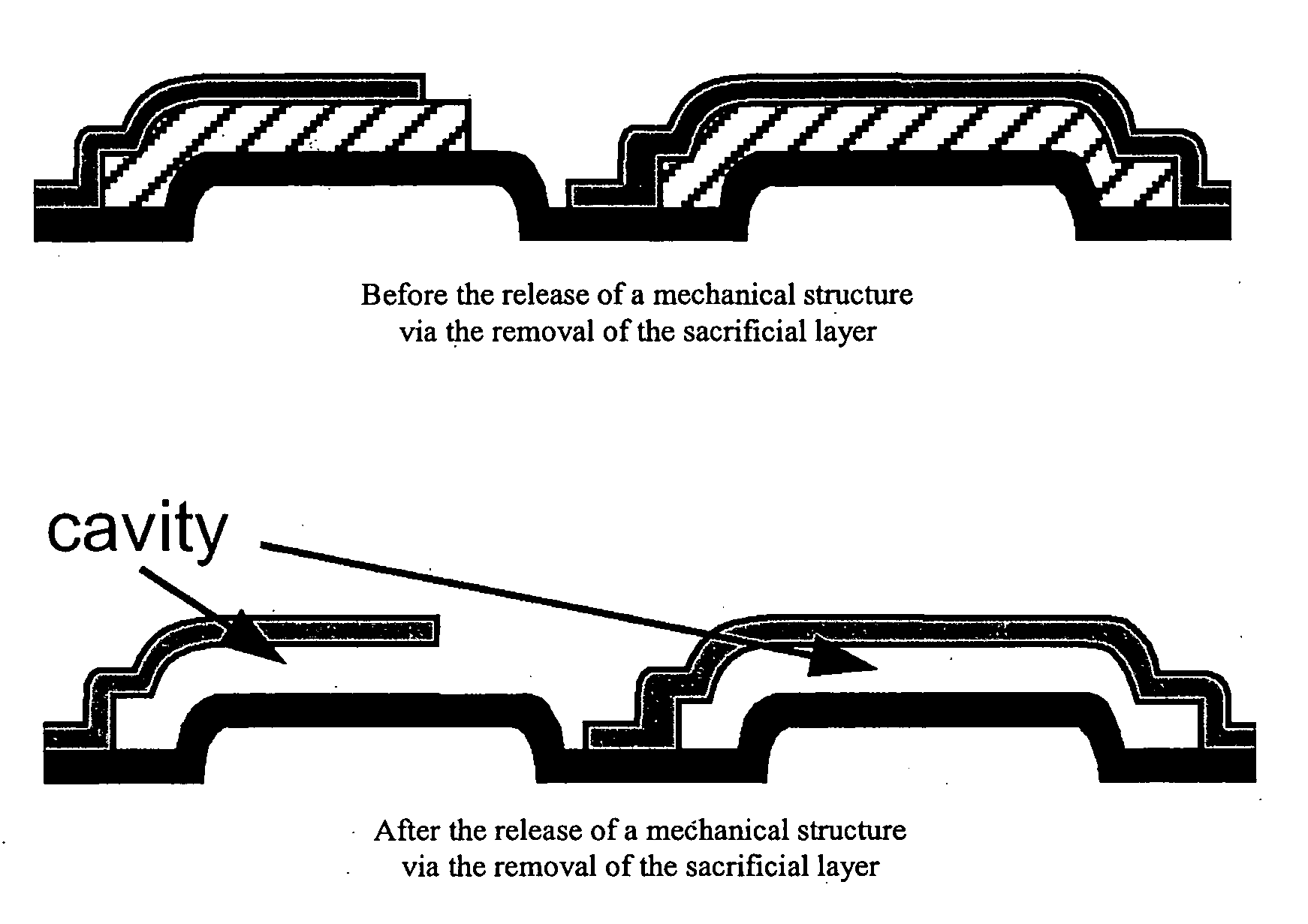

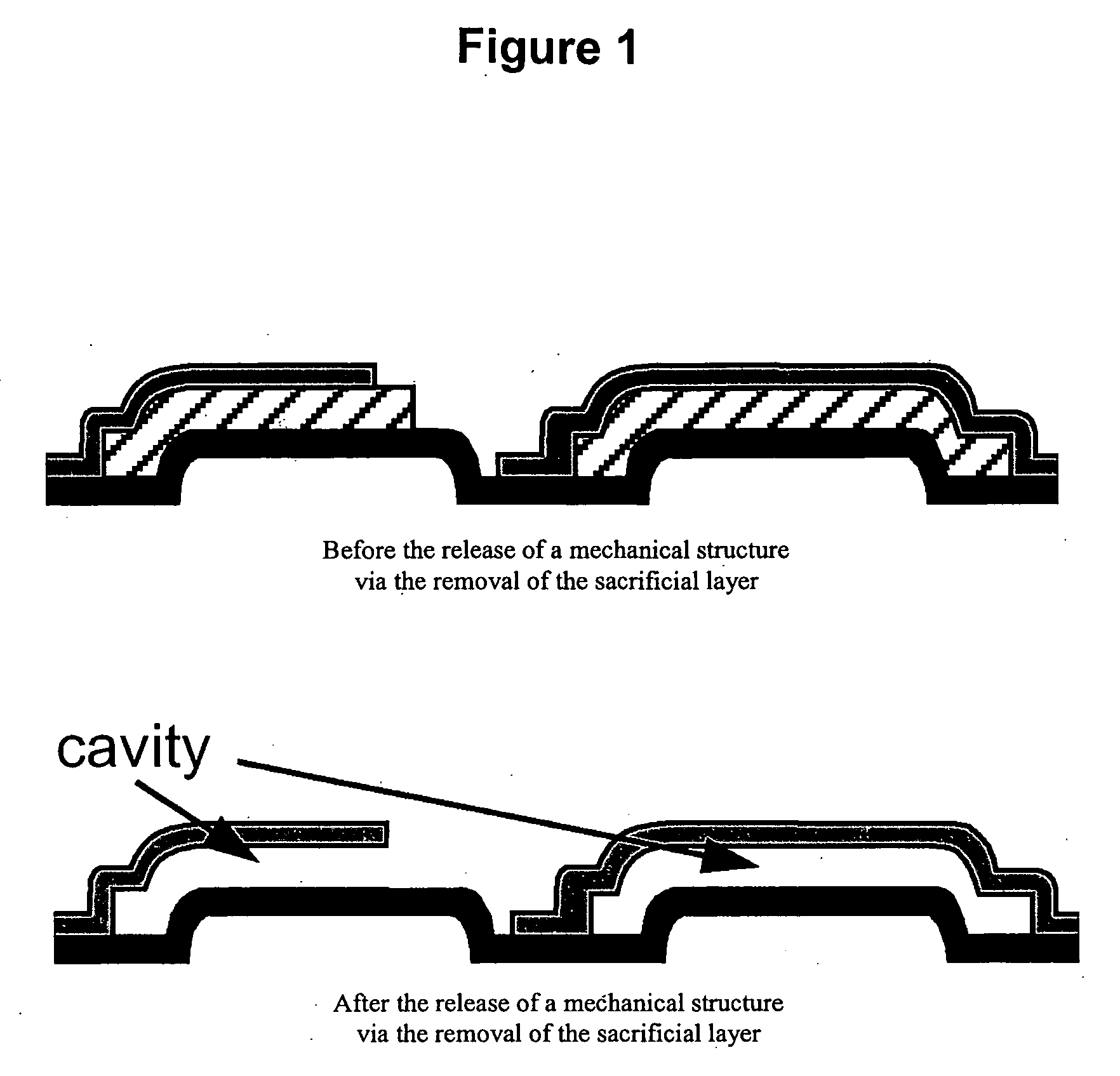

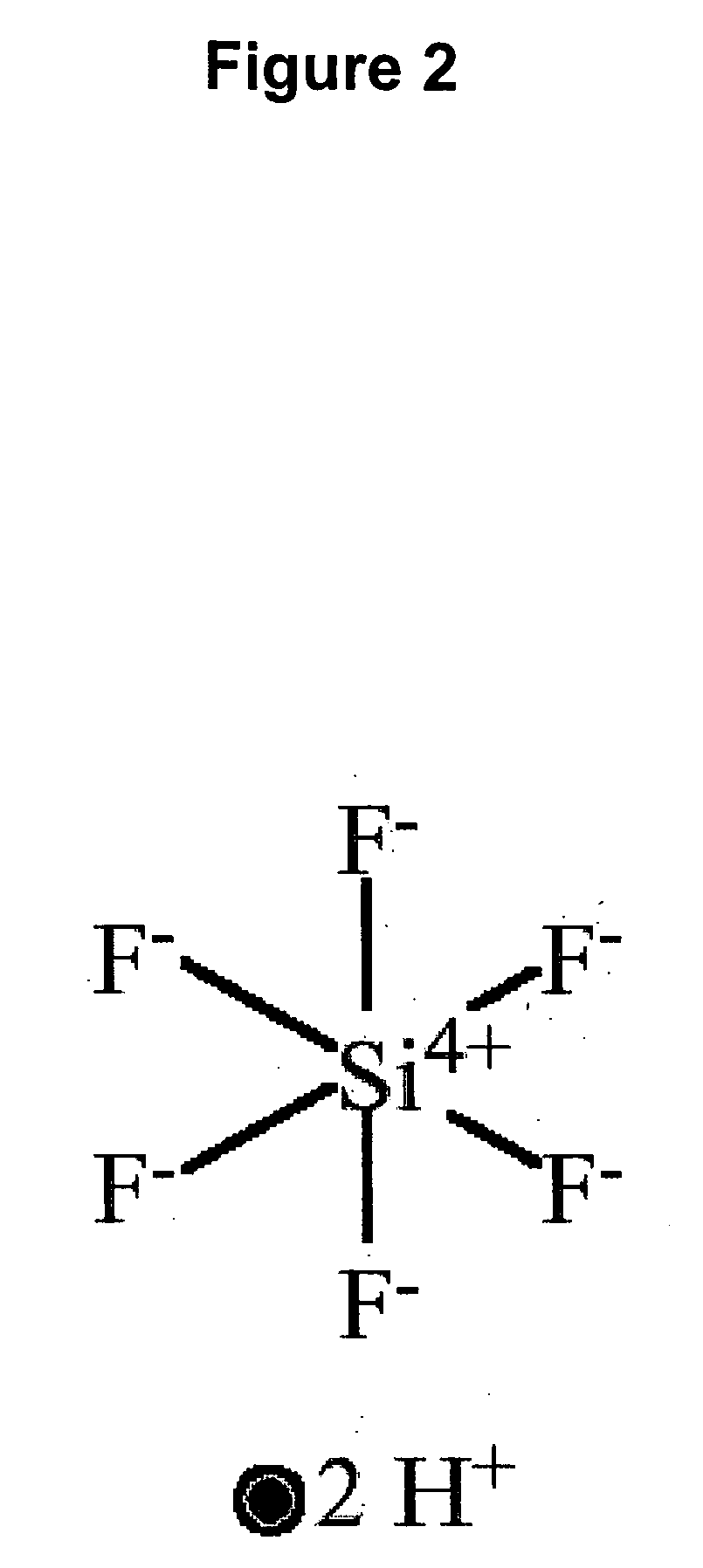

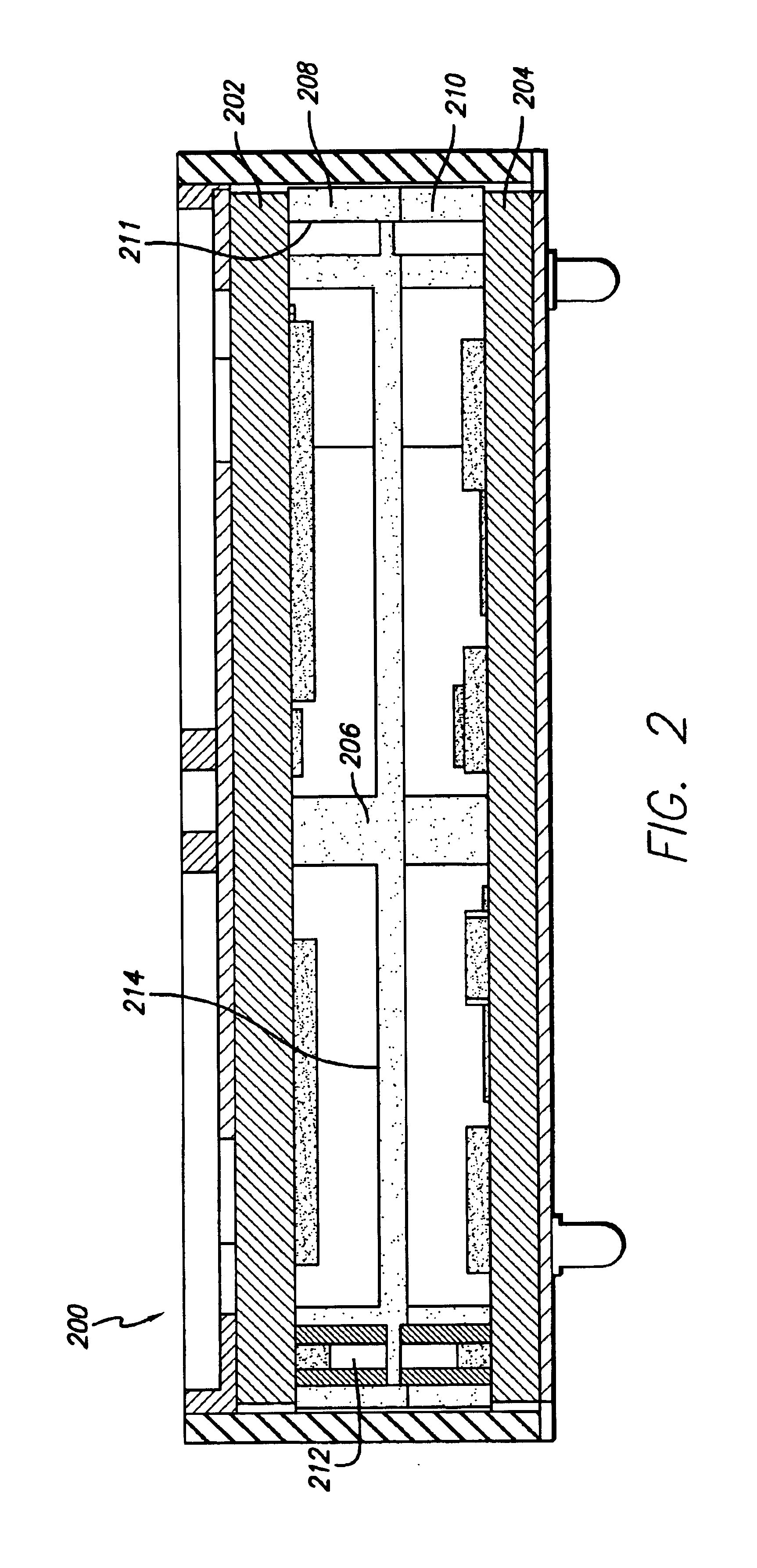

Anhydrous HF release of process for MEMS devices

ActiveUS7365016B2Prevent undesirable metal incompatibility effectDecorative surface effectsSemiconductor/solid-state device manufacturingPhysical chemistryVacuum level

A method of etching a sacrificial oxide layer covering an etch-stop silicon nitride underlayer, involves exposing the sacrificial oxide to anhydrous HF at a temperature of less than about 100° C. and / or at vacuum level lower than 40 Torr; and subsequently performing an in-situ vacuum evaporation of etch by-products at a temperature of more than about 100° C. and at vacuum level lower than the 40 Torr without exposure to ambient air.

Owner:TELEDYNE DIGITAL IMAGING INC

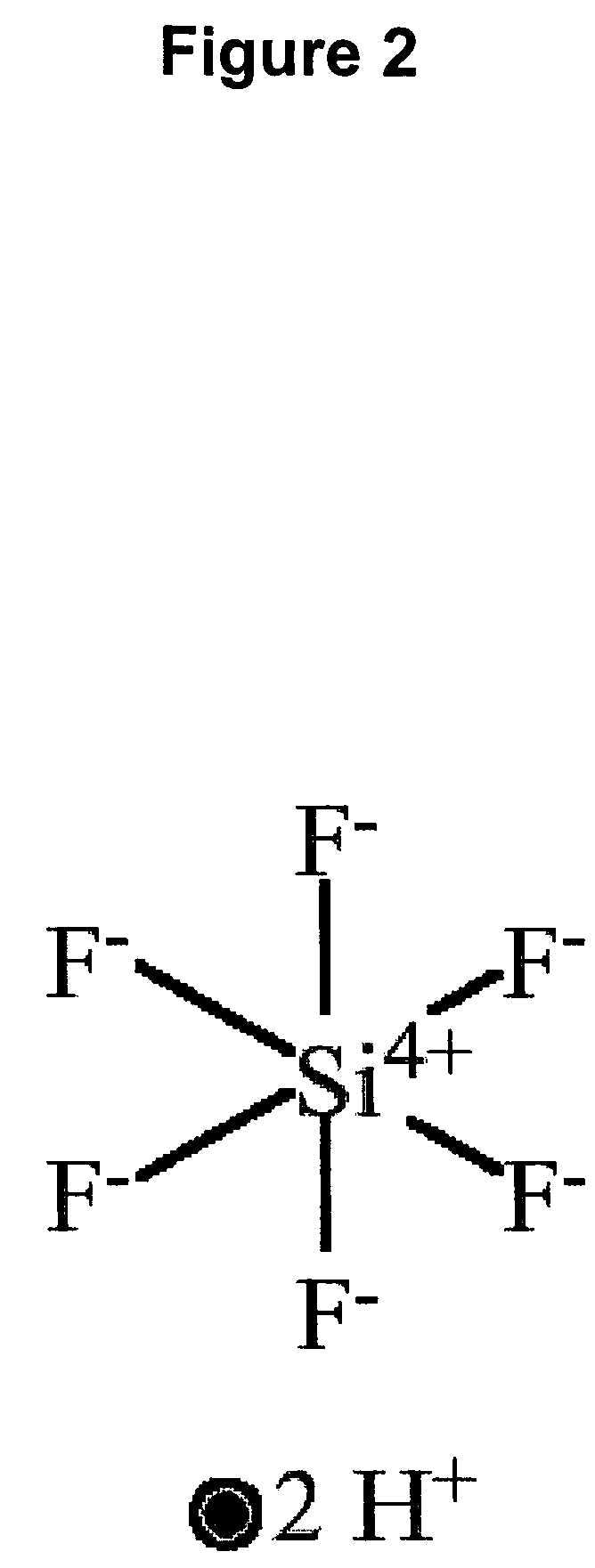

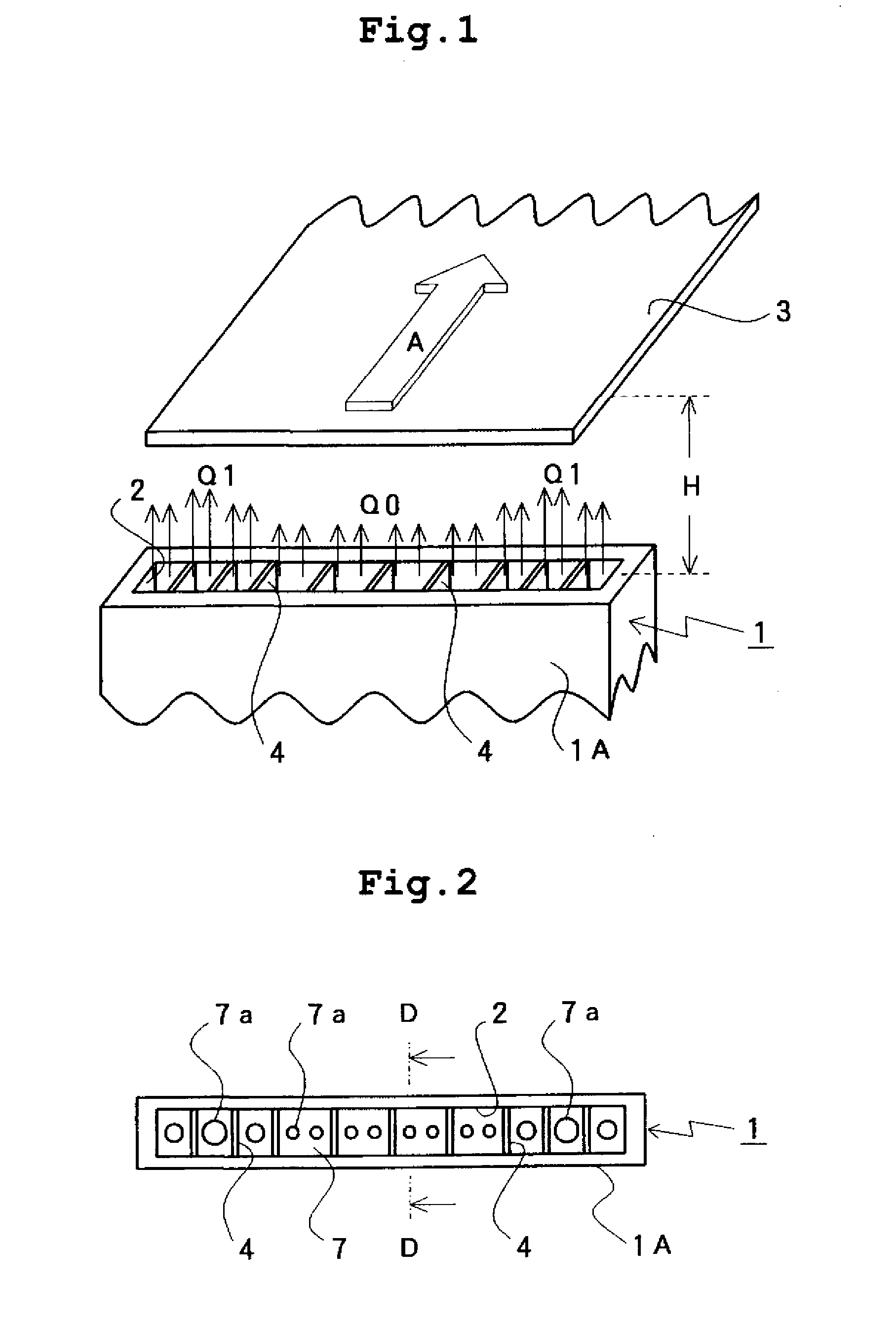

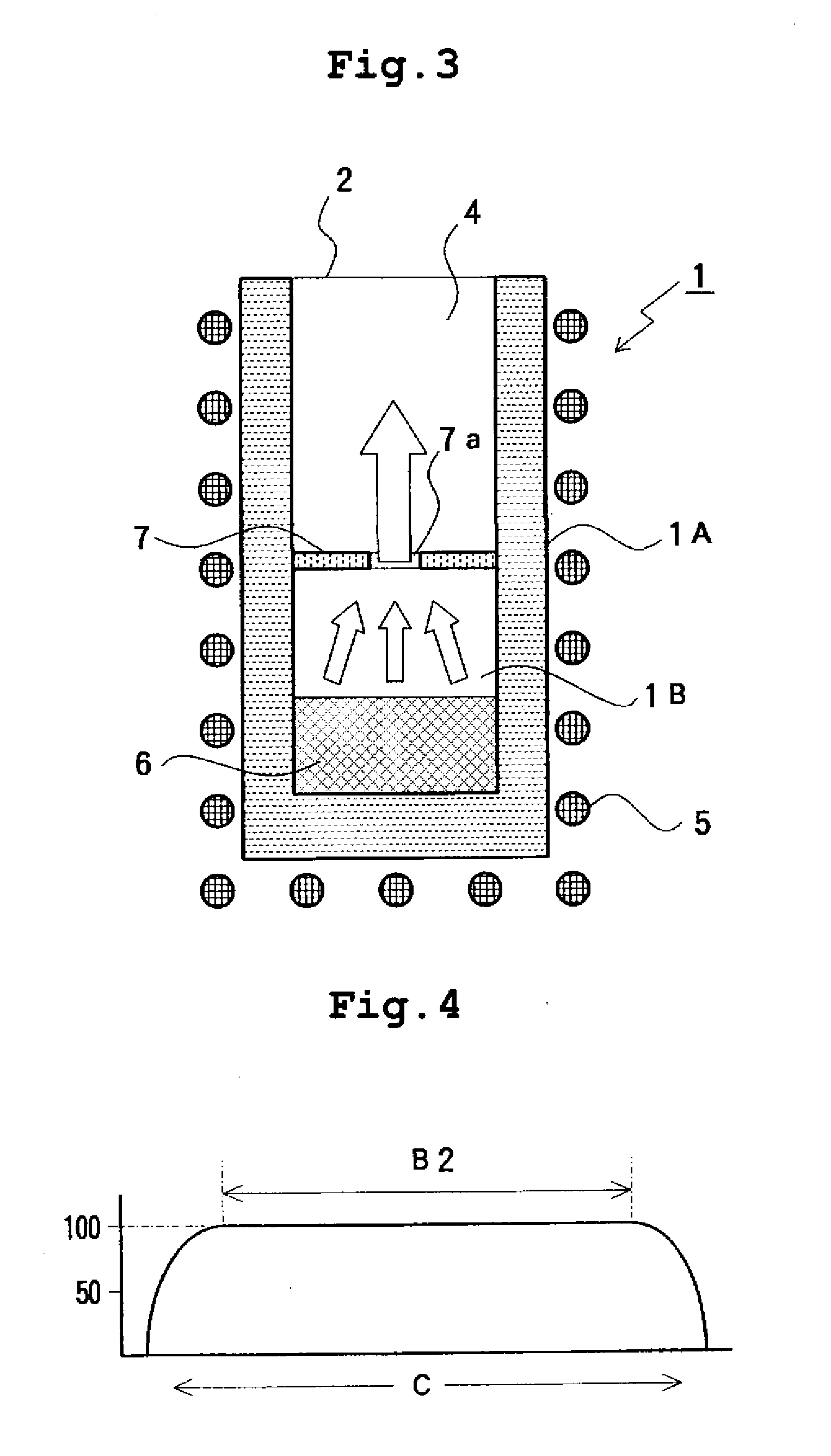

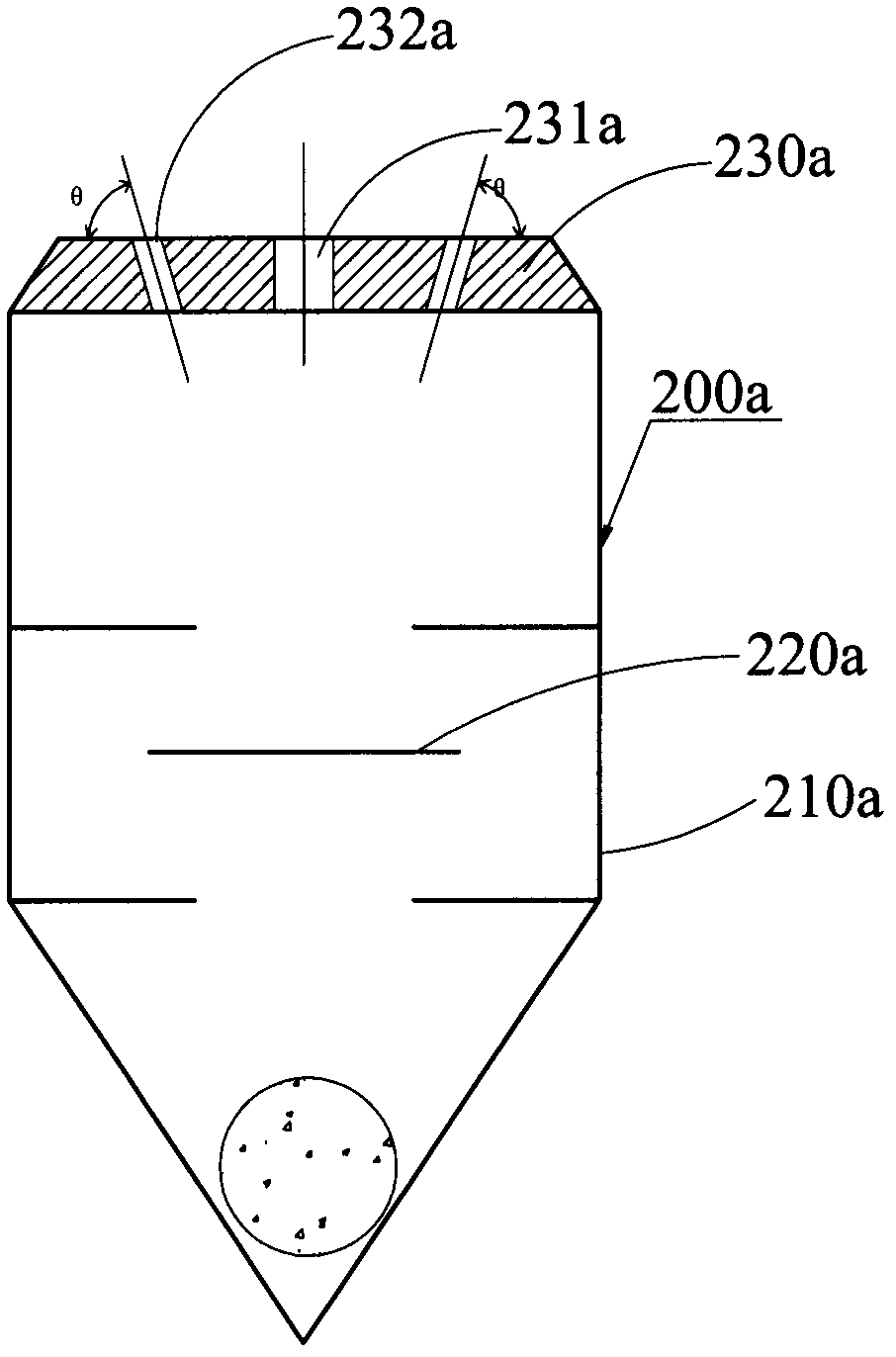

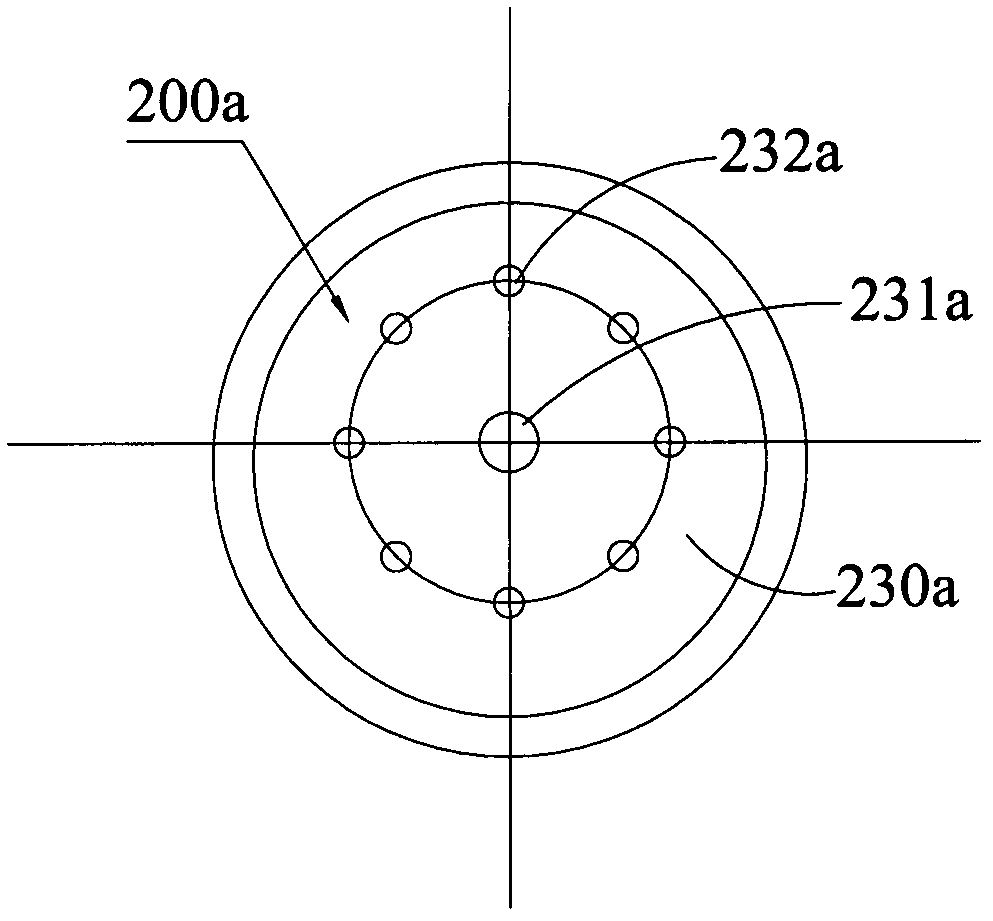

Evaporation source and vacuum evaporator using the same

ActiveUS20080115729A1Evenly distributedImprove utilization efficiencyVacuum evaporation coatingSputtering coatingEngineeringVacuum evaporation

An evaporation source having a nozzle structure that makes the distribution of film thickness uniform in the width direction of a substrate and a vacuum evaporator using the same are provided. A vapor produced by evaporation or sublimation by heating to evaporation material is discharged from a long nozzle opening like a band. A deposited substrate is transferred in a direction perpendicular to the longitudinal direction of the nozzle opening while facing the nozzle opening. A discharge flow rate of vapor per unit area in the longitudinal direction of the nozzle opening is made to be maximum in a portion at a nozzle width direction position corresponding to a substrate edge position rather than a central part of the nozzle opening and a plurality of partition plates providing directivity to the flow of vapor are arranged inside the nozzle opening.

Owner:MITSUBISHI HEAVY IND LTD

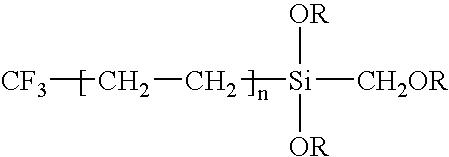

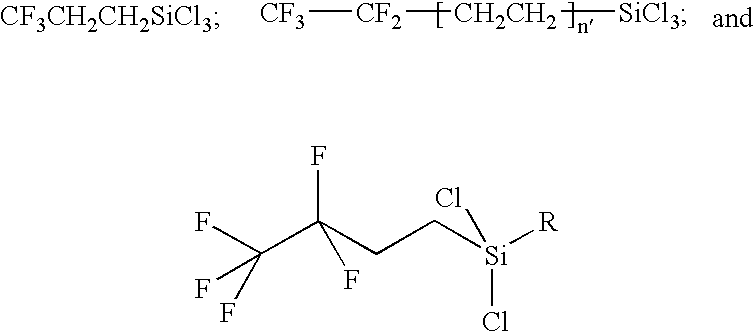

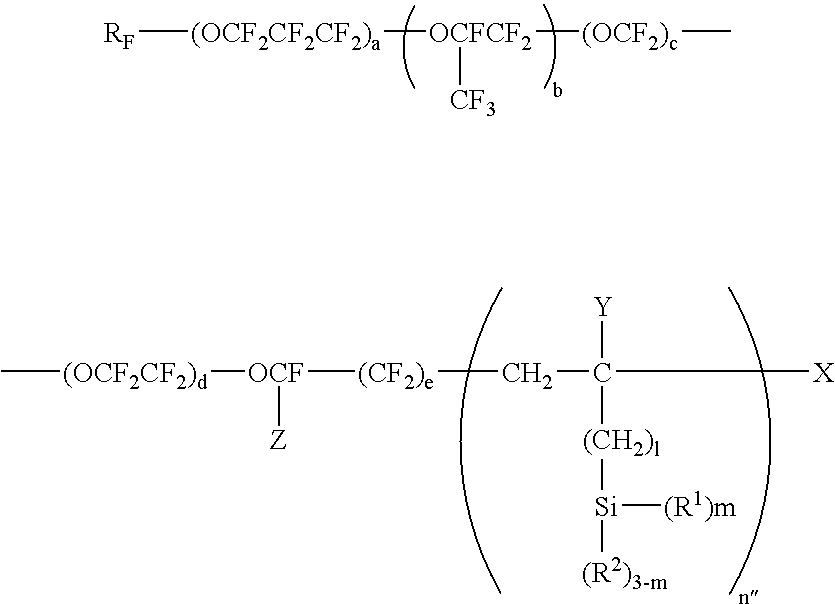

Process for coating an optical article with an anti-fouling surface coating by vacuum evaporation

ActiveUS20070104891A1Improve adhesionPretreated surfacesSpecial surfacesChemical modificationVacuum evaporation

The invention relates to a process for depositing an anti-fouling top coat onto the outermost coating layer of a coated optical article, comprising the following steps: a) providing an optical article having two main faces, at least one of which being coated with an outermost layer; b) treating said outermost layer with energetic species resulting in surface physical attack and / or chemical modification; and c) vacuum evaporating a liquid coating material for an anti-fouling top coat by means of an evaporation device, resulting in the deposition of the evaporated coating material onto the treated outermost layer of the optical article, wherein prior to the vacuum evaporation step of the liquid coating material, said liquid coating material has been treated with energetic species.

Owner:ESSILOR INT CIE GEN DOPTIQUE

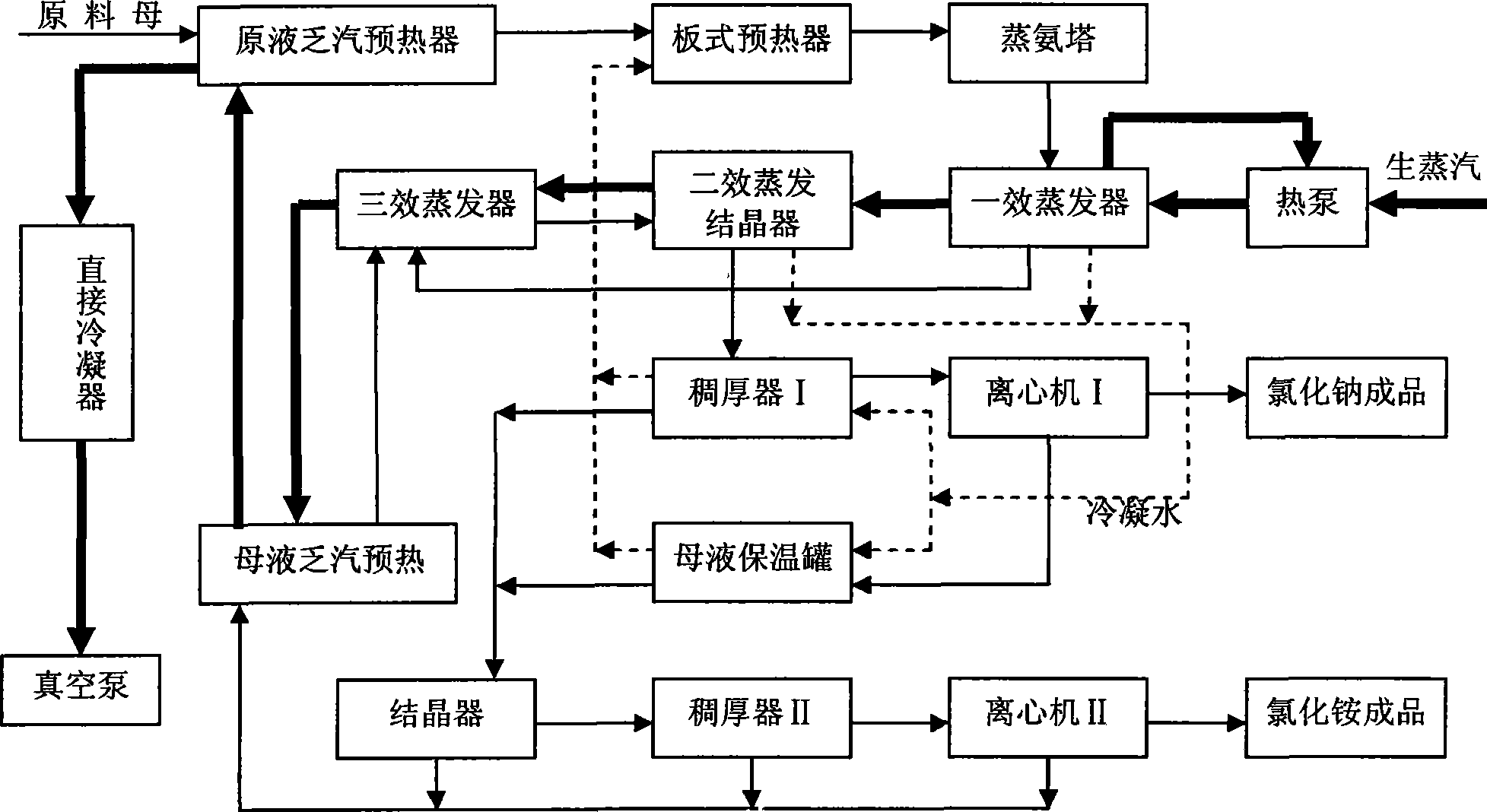

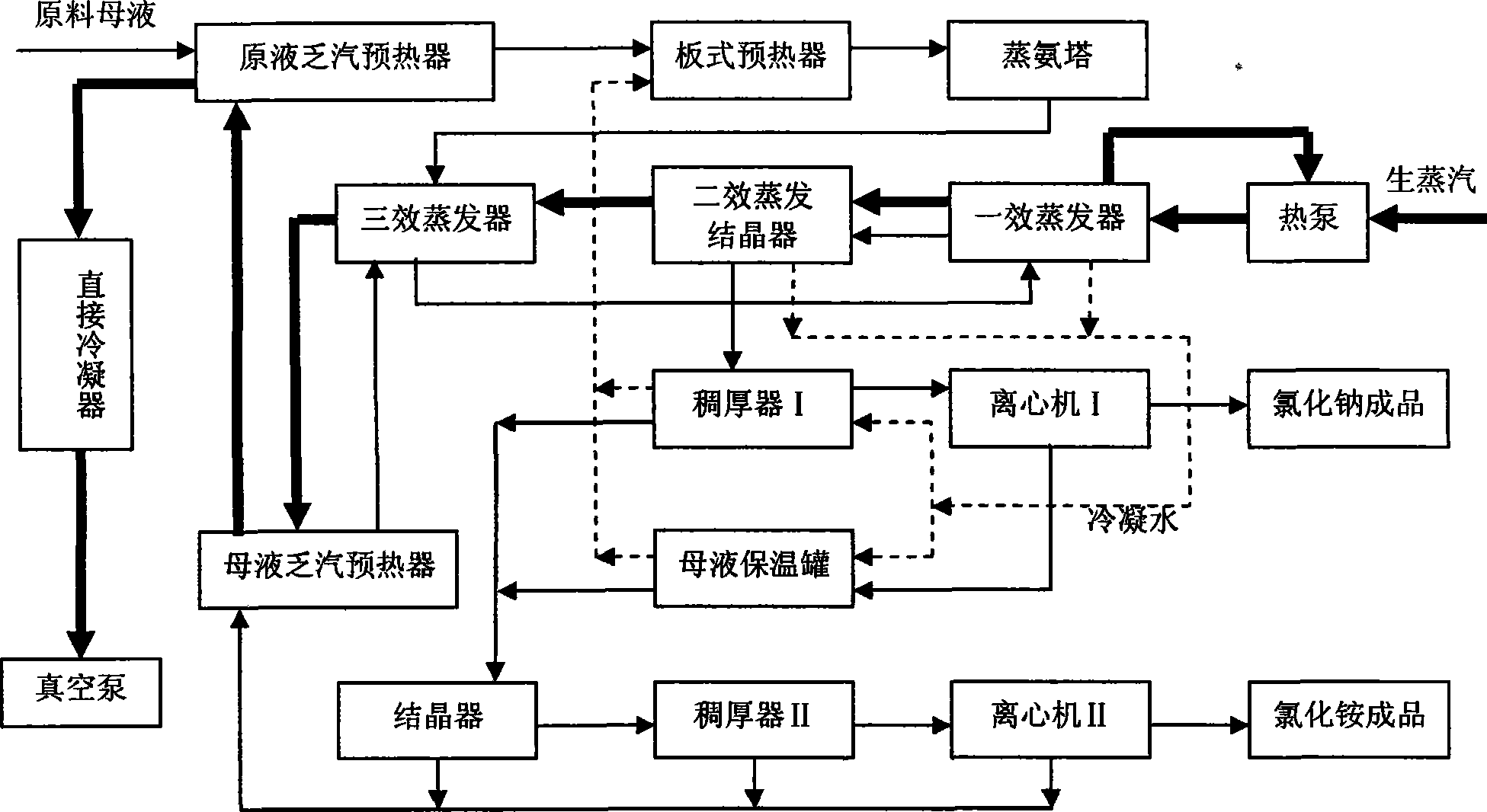

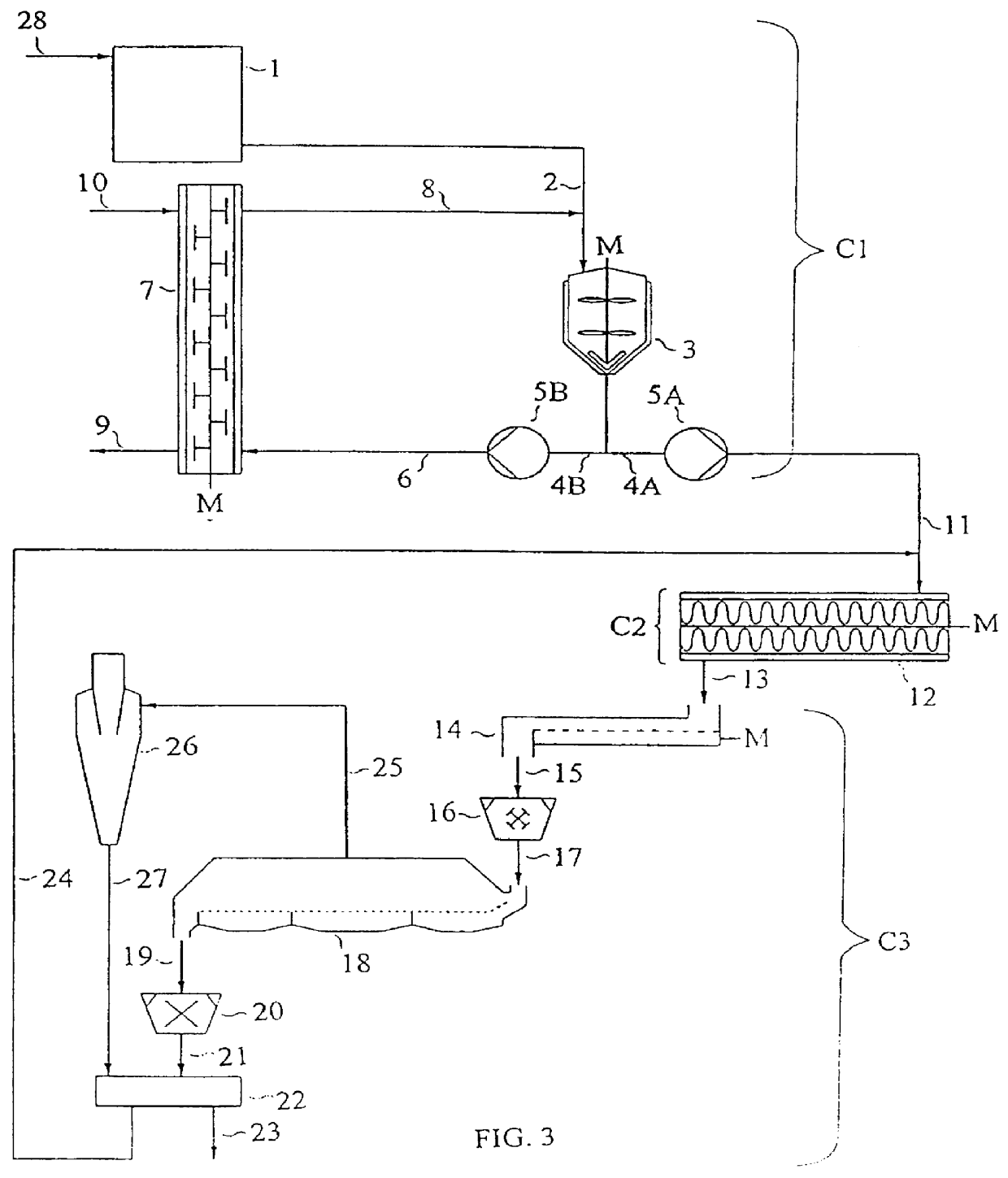

Process method for recovering ammonium chloride and sodium chloride from waste water containing ammonium chloride and sodium chloride

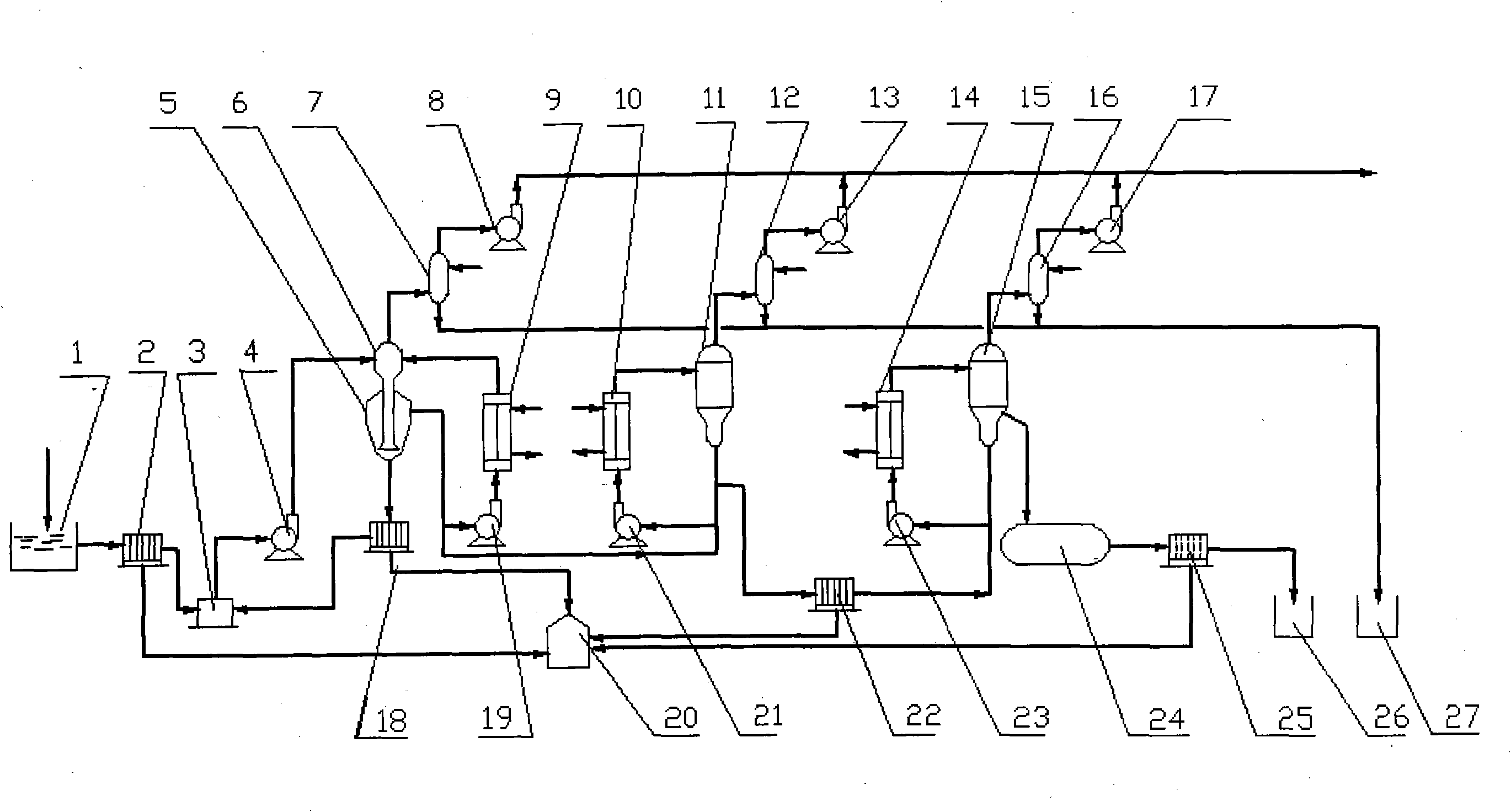

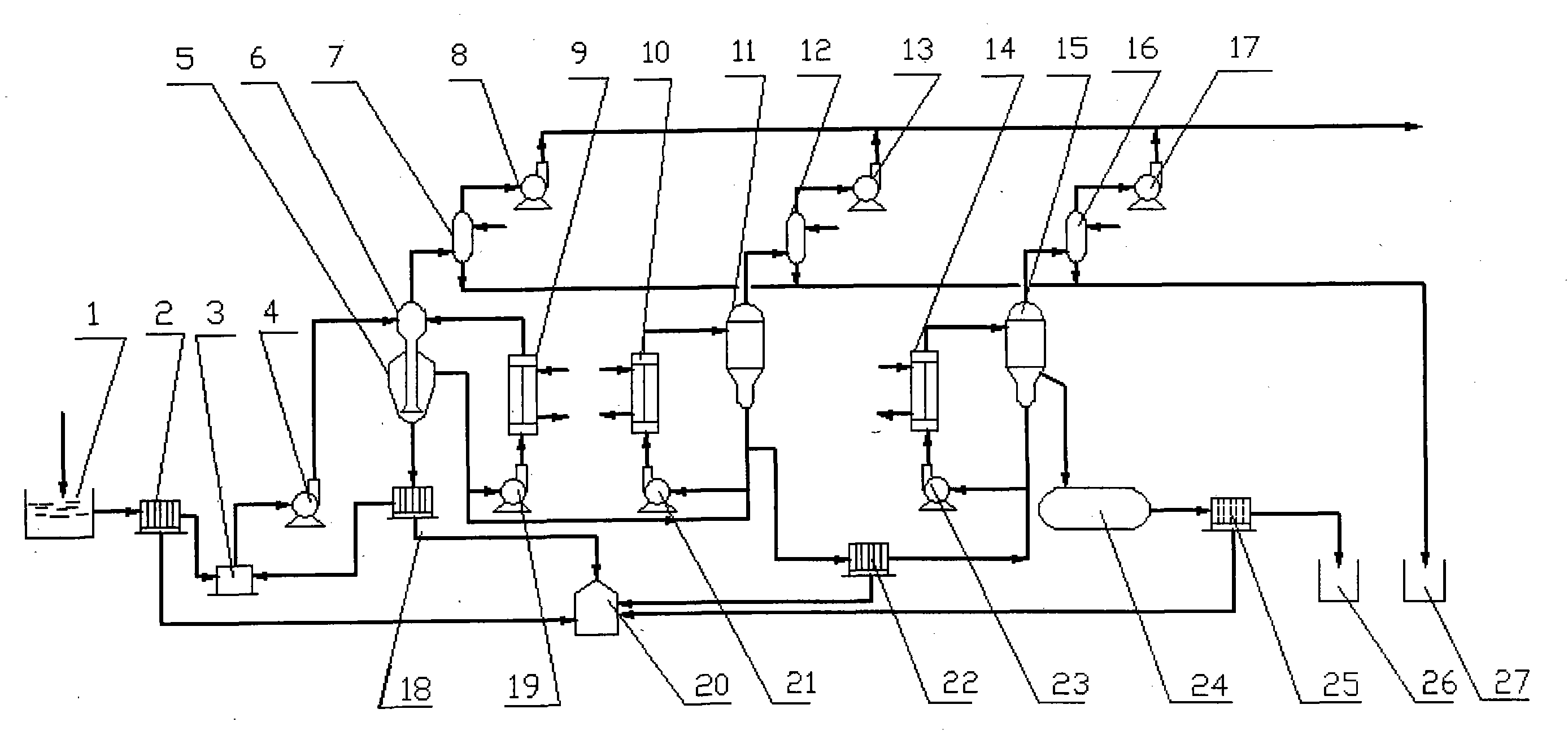

InactiveCN101544437AFully recycleReduce energy consumptionEnergy inputSolution crystallizationSodium bicarbonateDecomposition

The invention relates to a process method for recovering ammonium chloride and sodium chloride from waste water containing the ammonium chloride and the sodium chloride, which produces the ammonium chloride and the sodium chloride by using mother solution which is generated in a process for producing sodium bicarbonate by natural bittern double decomposition reaction and contains the ammonium chloride and the sodium chloride as raw materials. The method adopts ammonium still, evaporation, crystallization and separation process to treat, wherein the evaporation adopts multiple-effect, a heat pump and a vacuum evaporation process, and selects a falling film evaporator and a forced circulation type evaporator to perform triple-effect mixed-flow procedure, so that sodium chloride is crystallized and separated in the evaporation; and the ammonium chloride is crystallized and separated by cooling after the evaporation. The method effectively reduces the operation temperature of the equipment, can repeatedly use secondary steam and condensed water, reduces erosion of the ammonium chloride solution to the equipment, saves the energy, reduces the cost, improves the production efficiency, and reduces environmental pollution.

Owner:HEBEI UNIV OF TECH +1

Anhydrous HF release of process for MEMS devices

ActiveUS20060211163A1Prevent undesirable metal incompatibility effectDecorative surface effectsSemiconductor/solid-state device manufacturingPhysical chemistryVacuum level

A method of etching a sacrificial oxide layer covering an etch-stop silicon nitride underlayer, involves exposing the sacrificial oxide to anhydrous HF at a temperature of less than about 100° C. and / or at vacuum level lower than 40 Torr; and subsequently performing an in-situ vacuum evaporation of etch by-products at a temperature of more than about 100° C. and at vacuum level lower than the 40 Torr without exposure to ambient air.

Owner:TELEDYNE DIGITAL IMAGING INC

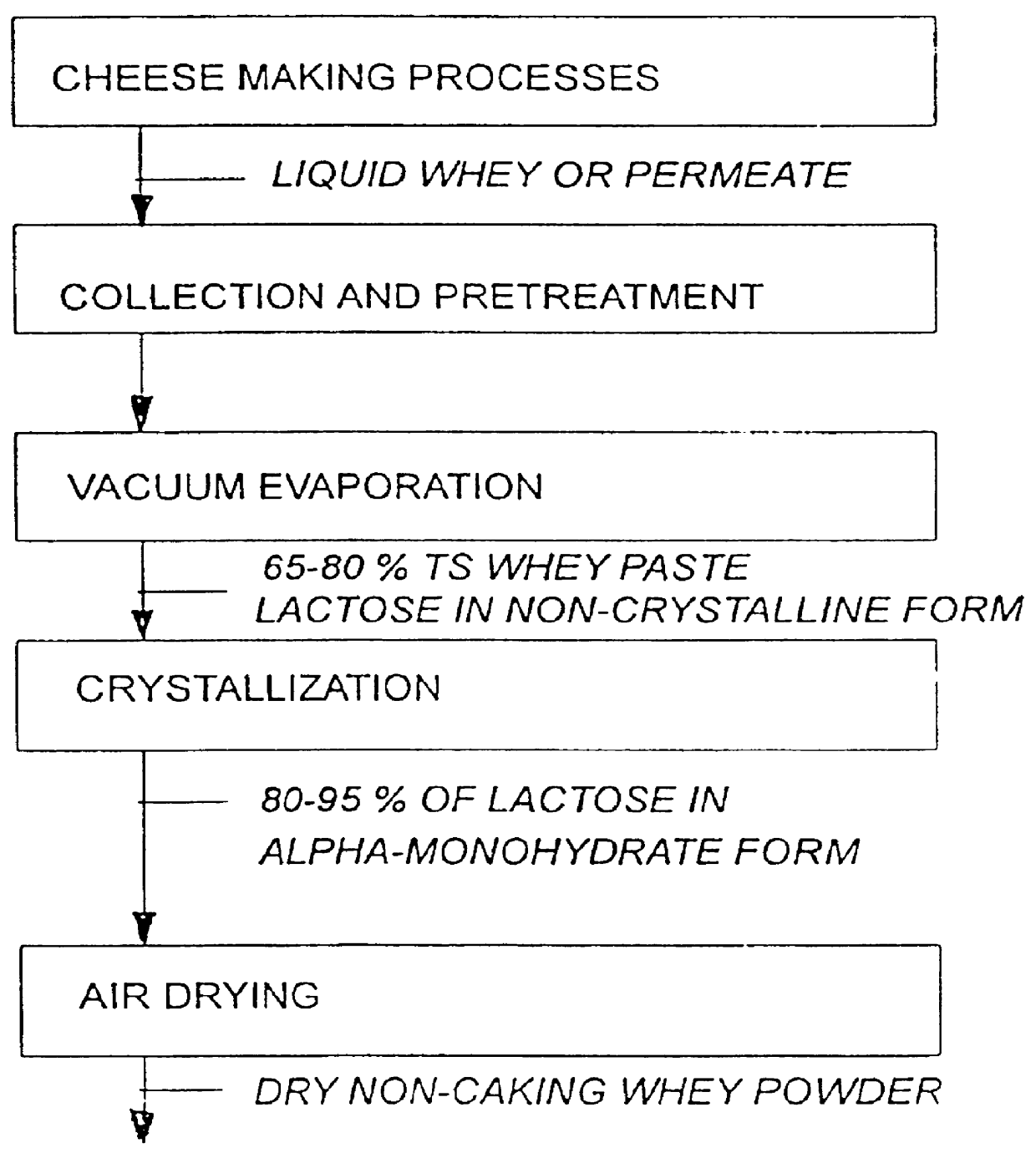

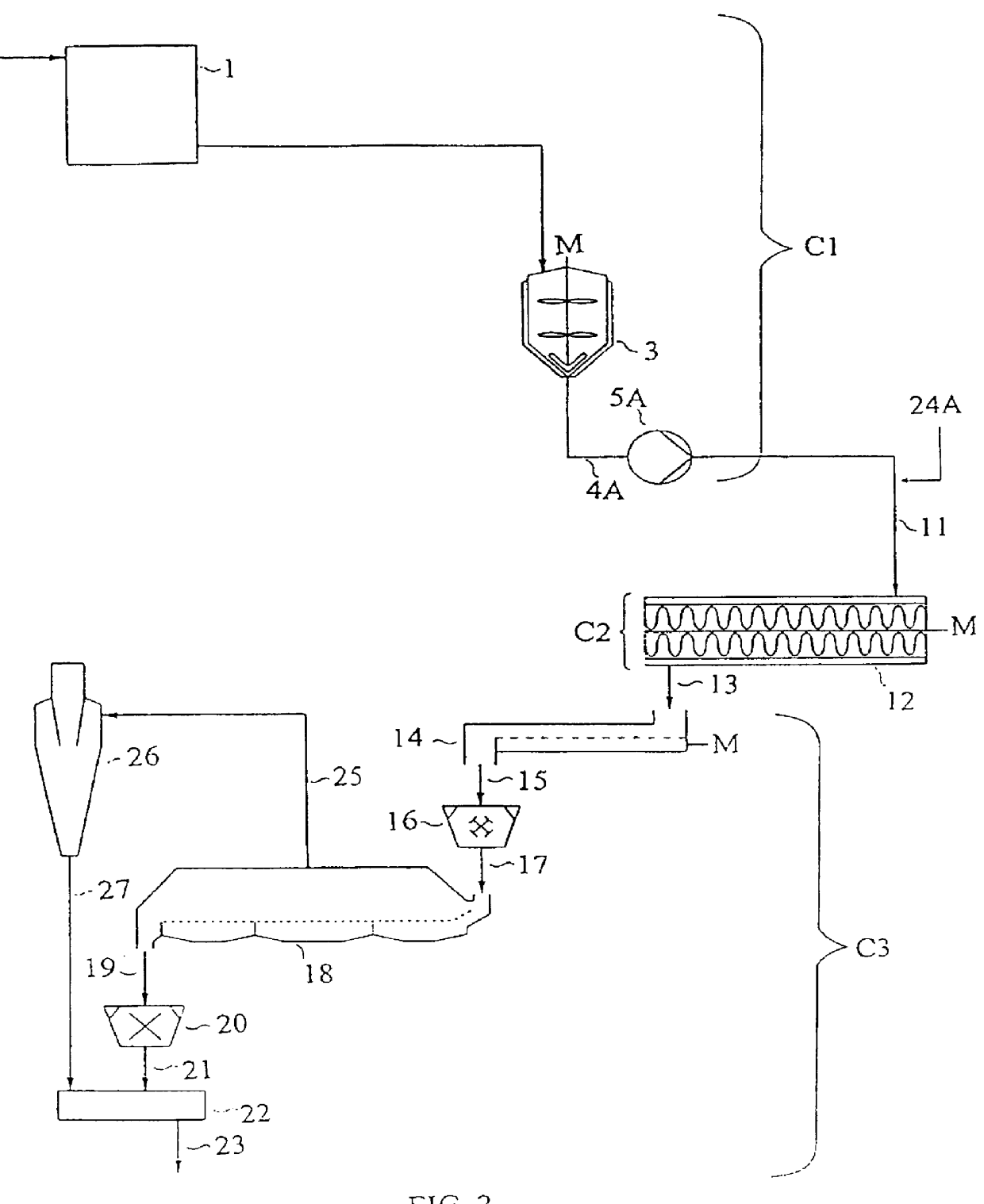

Process and apparatus for converting liquid whey into powder

InactiveUS6048565AIncrease contentHigh nutritional valueMilk preparationMilk preservationSolid contentVacuum evaporation

Owner:SPX FLOW TECH DANMARK

Fuel cell ordered porous nano-fiber single electrode, membrane electrode and preparation method

InactiveCN103413947AShorten the transmission distanceIncrease profitMaterial nanotechnologyCell electrodesPorositySlurry

The invention discloses a fuel cell ordered porous nano-fiber single electrode, a membrane electrode and a preparation method. Polymer nano-fibers are deposited on one side of a gaseous diffusion material through an electro-spinning technology; metal nanoparticles with catalytic activity are deposited on the surfaces of the polymer nano-fibers by using magnetron sputtering and vacuum evaporation methods, or catalyst slurry is directly sprayed to one side of a nano-fiber thin film to form a porous single electrode; then two single electrodes and a layer of proton exchange membrane are combined into a three-in-one membrane electrode. The fuel cell ordered porous nano-fiber single electrode, the membrane electrode and the preparation method have the beneficial effects that the conventional micro-porous layer is substituted by the nano-fiber layer with high porosity and high specific surface area, prepared by electro-spinning, so that the catalytic activity area is increased and the three-phase reaction interface and the mass transfer are facilitated, and an active metal catalytic layer formed by magnetron sputtering and vacuum evaporation has high adhesion, is uniform in coating and has controllable thickness, so that the using amount of the active metal catalyst is reduced and the utilization rate of the catalyst is also greatly increased.

Owner:WUHAN UNIV OF TECH

Flexible organic light emitting diode (OLED) and preparation method thereof

ActiveCN102760846AHigh light transmittanceGood flexibilitySolid-state devicesSemiconductor/solid-state device manufacturingFlexible organic light-emitting diodeEtching

The invention discloses a preparation method for a flexible organic light emitting diode (OLED), comprising the following steps: (1) a polyethylene terephthalate (PET) sheet is fixed at a support plate by binder as a base plate; the surface of the base plate is cleaned and dried; a barrier layer which is formed by successive alternating deposit of thin polymer films and thin inorganic material films with high transmittance is prepared on the base plate; the refractive index of the thin polymer films and the thin inorganic material films matches with the refractive index of the base plate; (2) an indium tin oxide (ITO) film and a metal layer are prepared at the base plate equipped with the barrier layer and etching of a metal line and an ITO line and making of polyimide (PI) patterns and RIB patterns are completed; during etching of the metal line and the ITO line, mechanical stirring or ultrasonic stirring are performed on the etching liquid; (3) then the base plate is put in an evaporation chamber for evaporation of an organic function layer and a negative electrode; (4) a thin film packaging layer is prepared on the surface of the negative electrode by vacuum evaporation and the packaging layer is formed by alternating deposit of at least one layer of organic material and at least one layer of inorganic material; and (5) the base plate is stripped off the support plate.

Owner:TRULY SEMICON

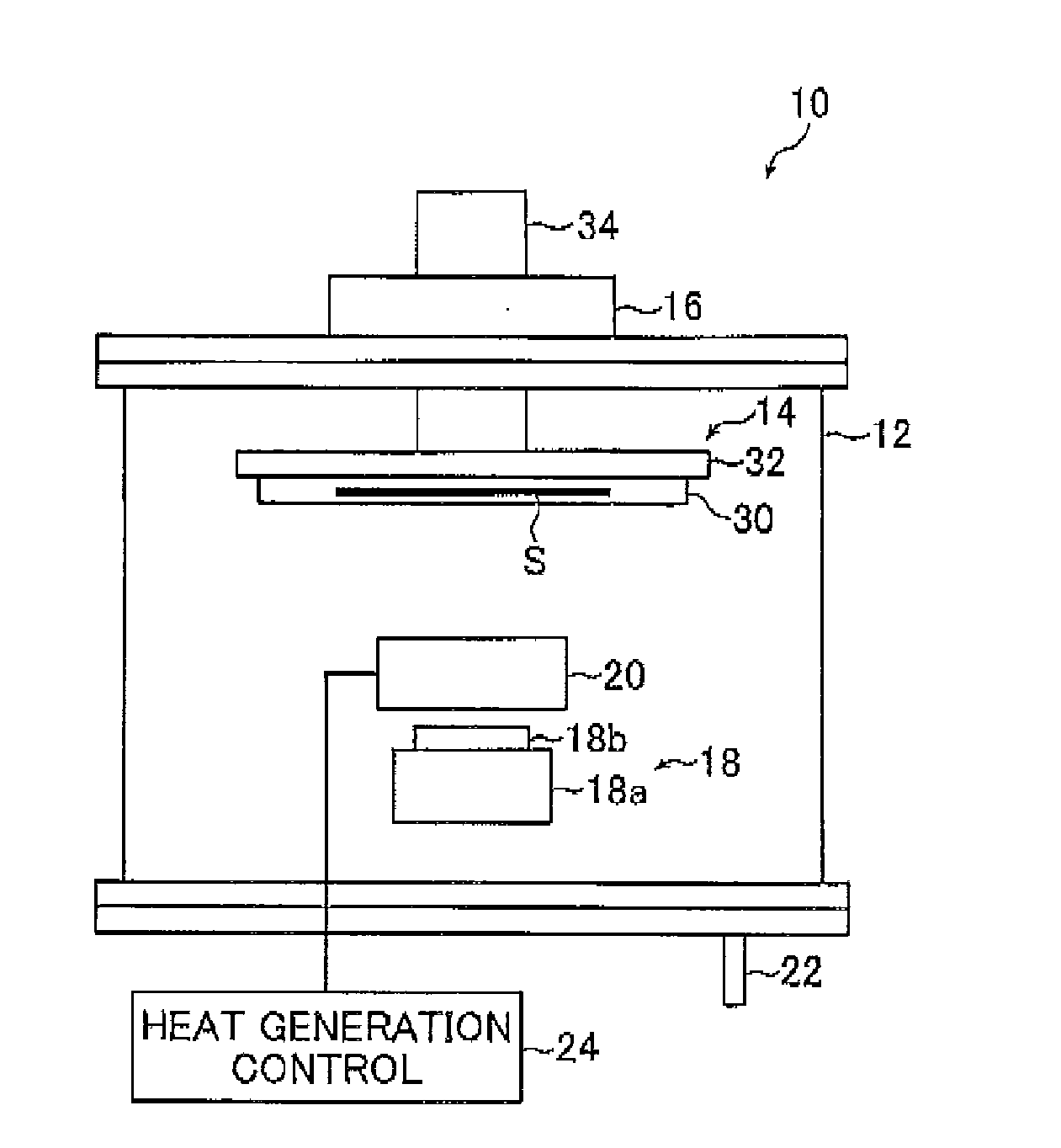

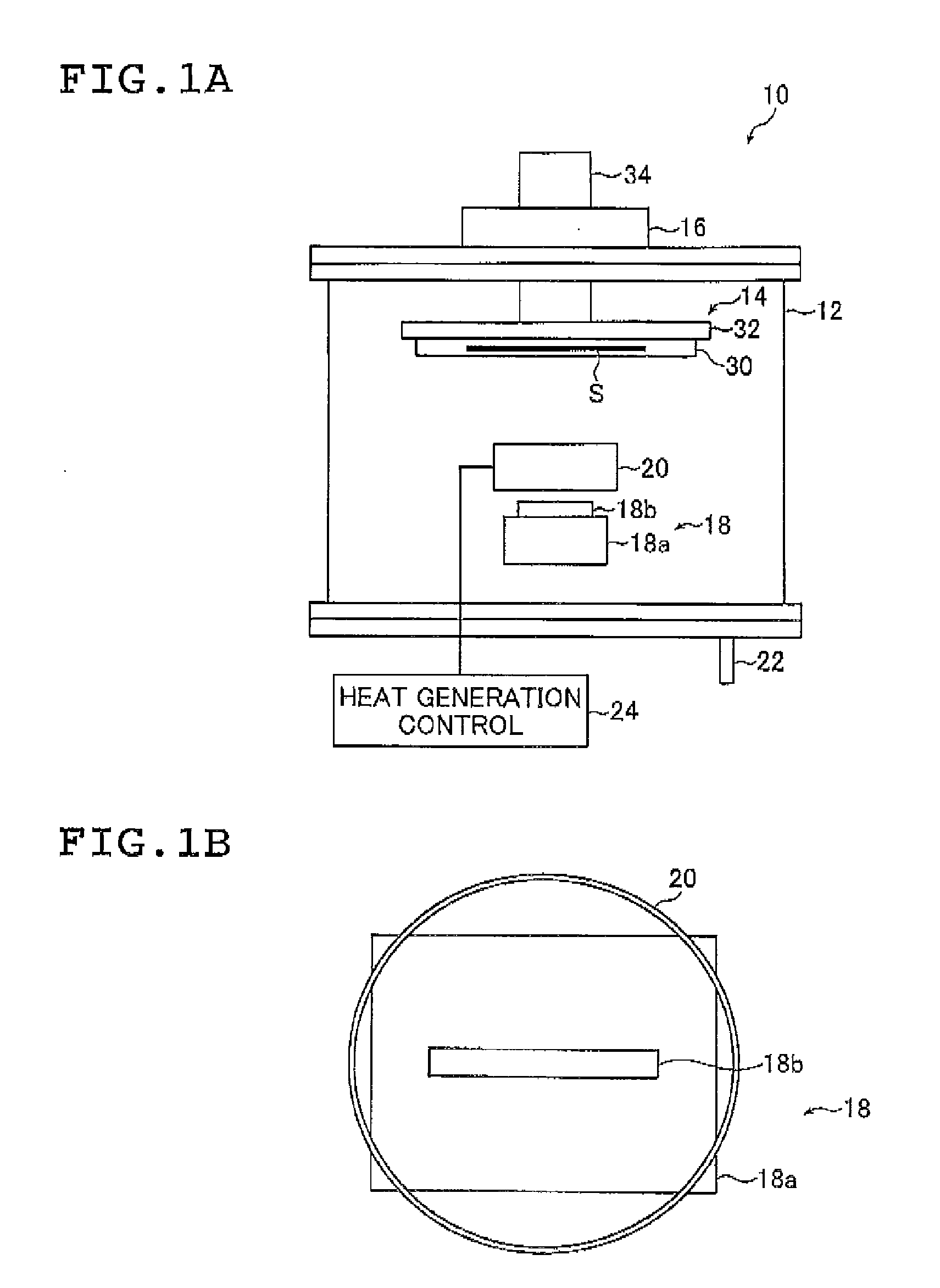

Vacuum evaporation method

InactiveUS20080286461A1Improve efficiencyPreventing phosphorVacuum evaporation coatingSputtering coatingBoiling pointPhosphor

The vacuum evaporation method provides a heating element between an evaporation source of a film-forming material and a substrate; and forms a phosphor layer of an alkali halide-based phosphor on a surface of said substrate by vacuum evaporation while causing the heating element to generate heat at a temperature t (° C.) satisfying Formula (1):T−200≦t<T (1)where T is a boiling point (° C.) of the film-forming material. This method is capable of using the film-forming material making up the phosphor layer with higher efficiency owing to a heating element while preventing the substrate and the phosphor layer from being adversely affected by heat from the heating element.

Owner:FUJIFILM CORP

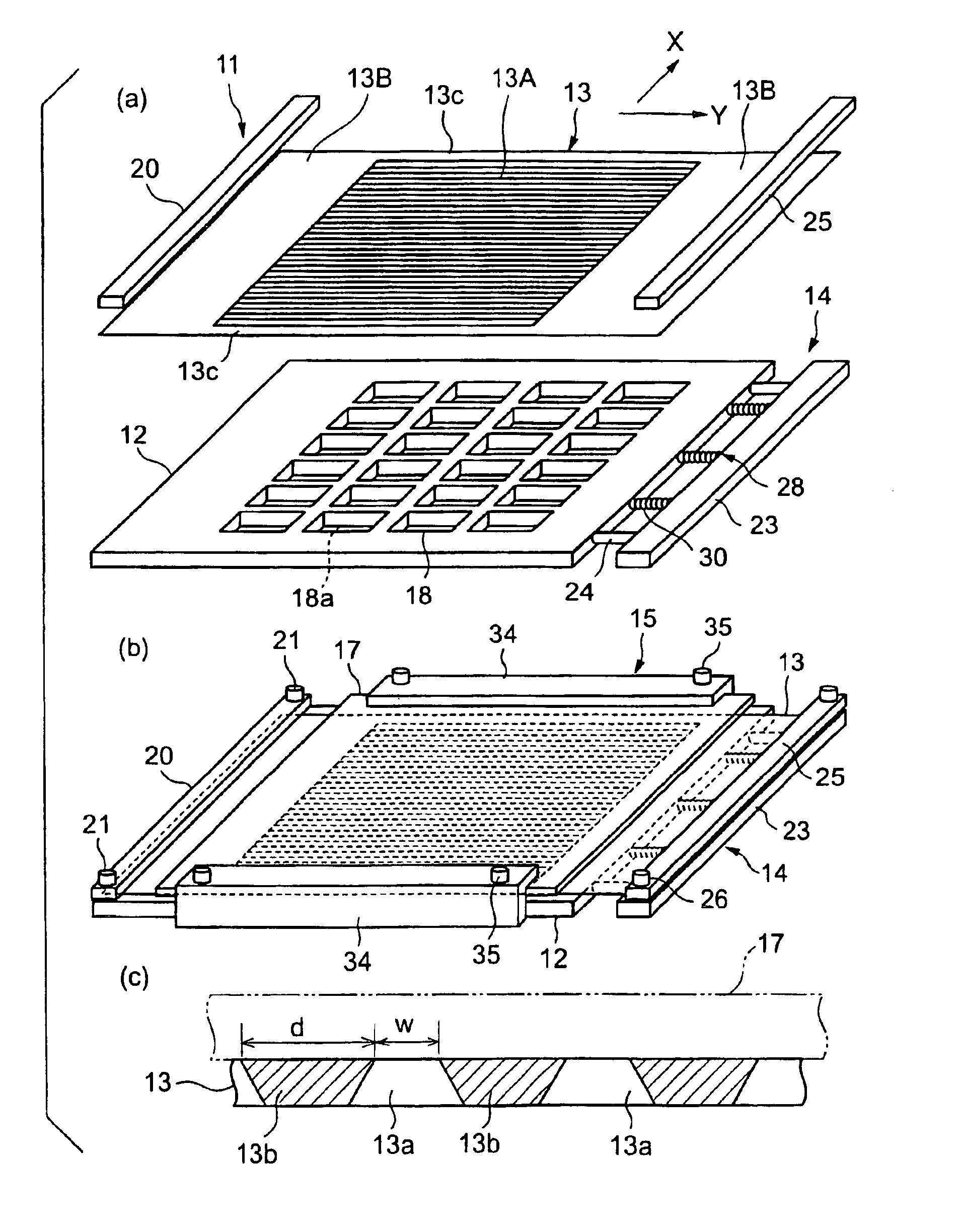

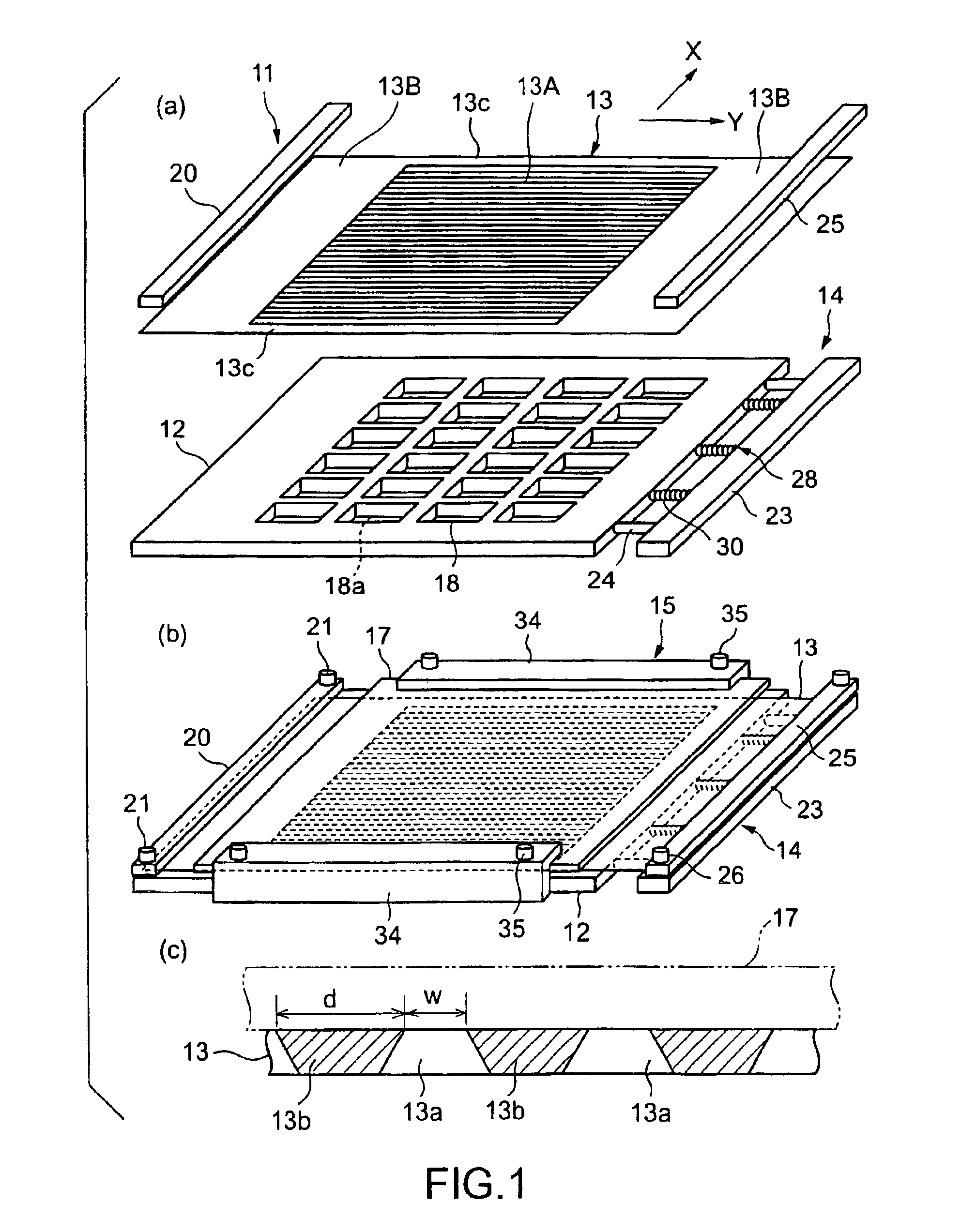

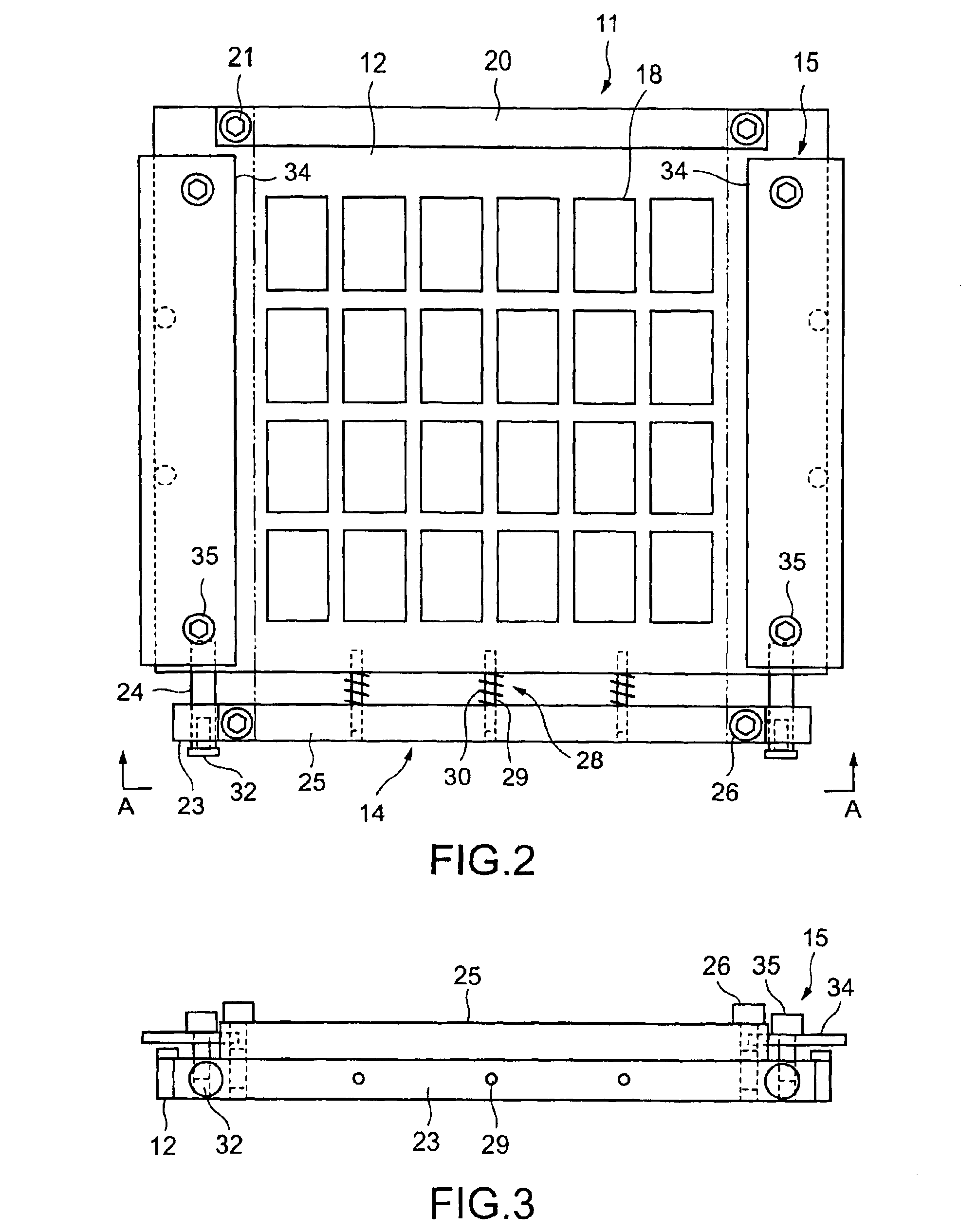

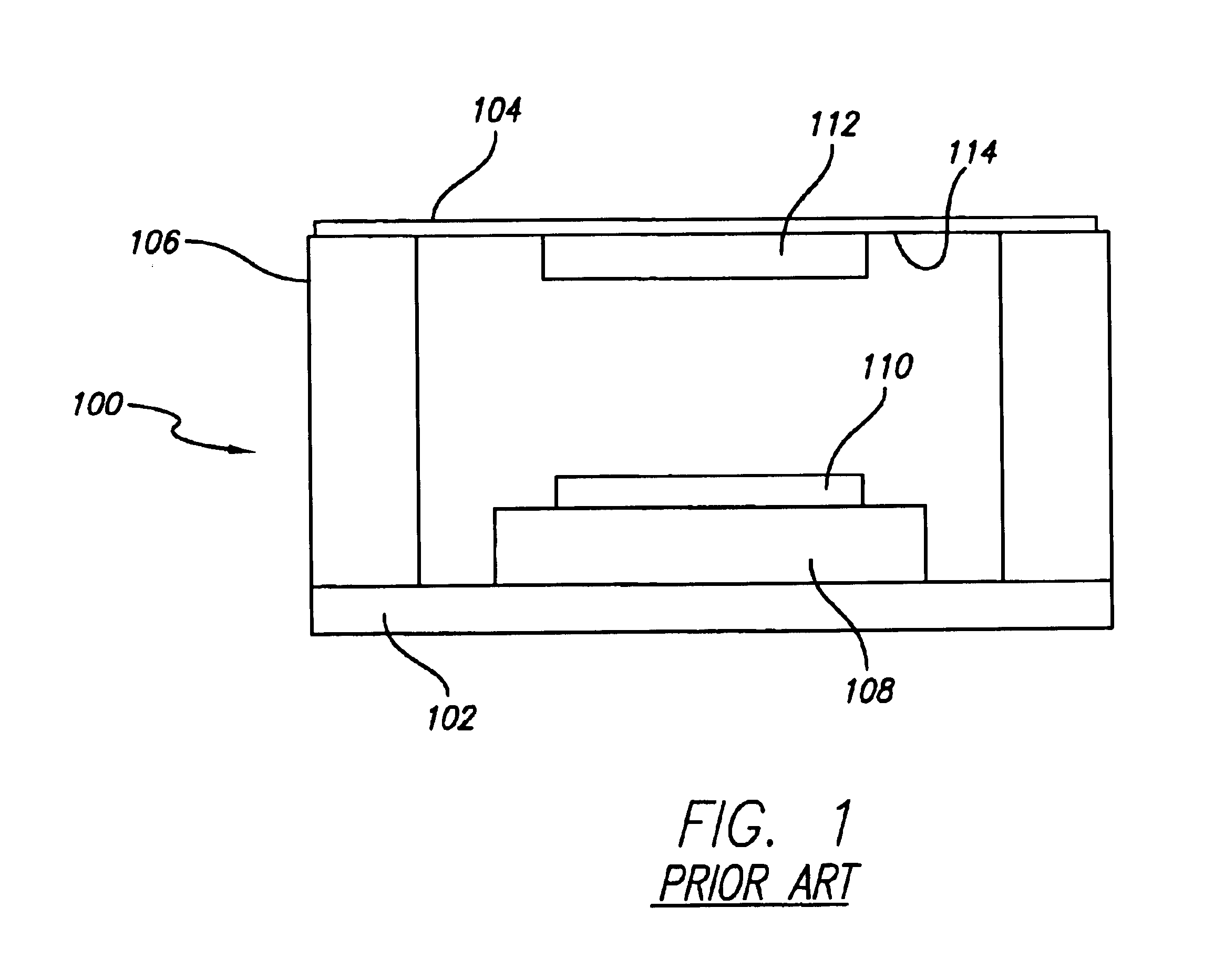

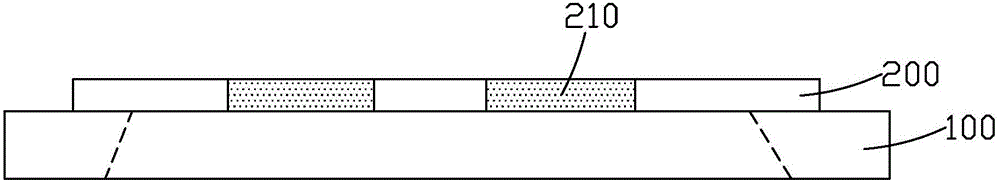

Multi-face forming mask device for vacuum deposition

InactiveUS6890385B2Easy to adjustImprove productivityLiquid surface applicatorsElectroluminescent light sourcesEngineeringVacuum evaporation

A second metal mask (13) having a screen part (13A) provided with a plurality of parallel, fine slits (13a) arranged at very small intervals is placed on a base plate (12) serving also as a first metal mask and provided with a plurality of windows (18) defining regions in which a material is to be deposited. One end of the second metal mask (13) is fastened to the base plate (12) by a mask clamp (20) and the other end of the same is fastened to a slider (23). Resilient force is applied to the slider (23) by compression coil springs (30). Thus, the screen part (13A) of the second metal mask (13) is tensioned and thereby the slits (13a) are stretched straight and are extended at predetermined pitches. A substrate (17) placed on the second mask (13) is subjected to a vacuum evaporation process to form fine patterns on the substrate (17) in a gang-patterning mode.

Owner:DAI NIPPON PRINTING CO LTD

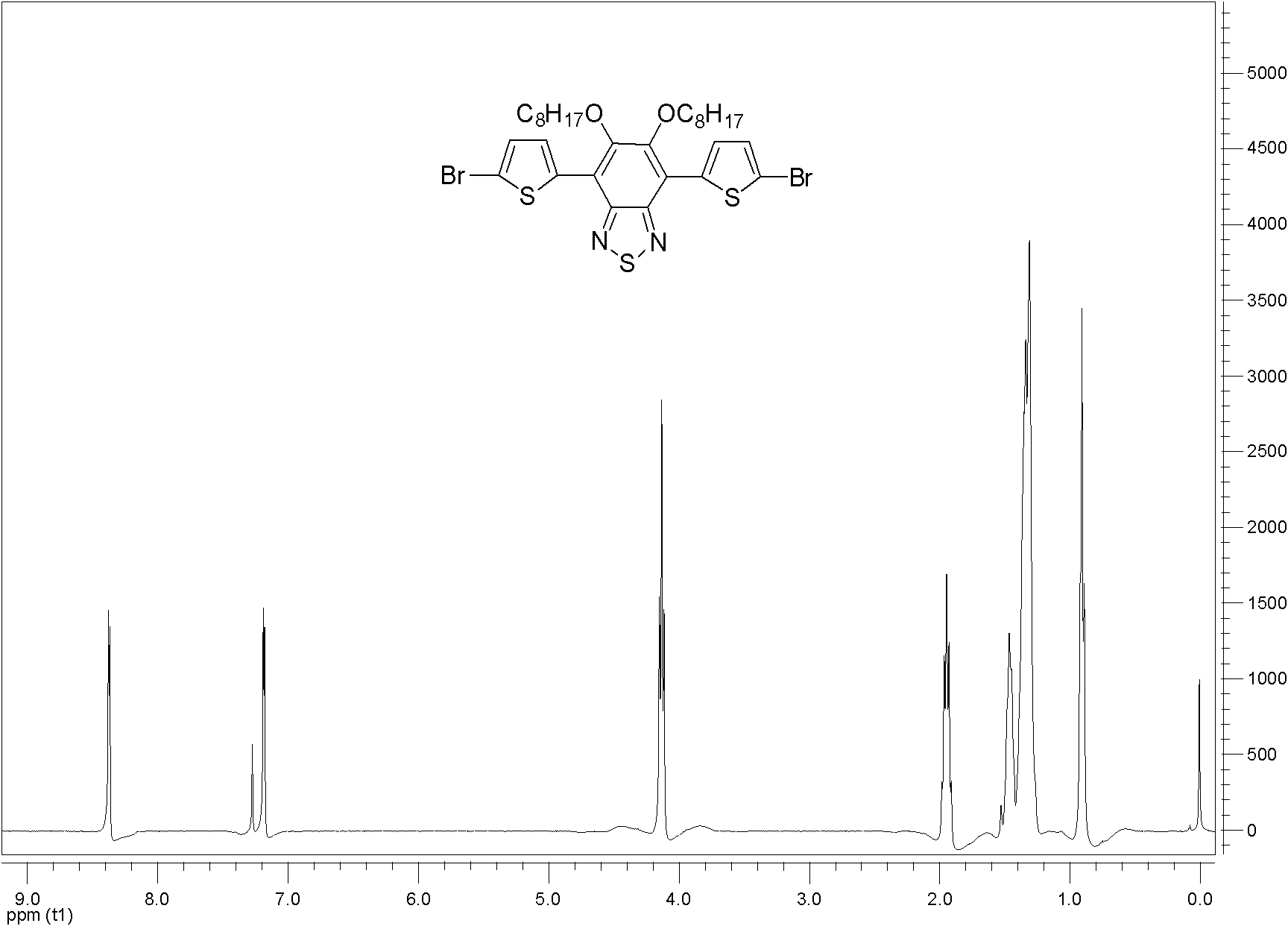

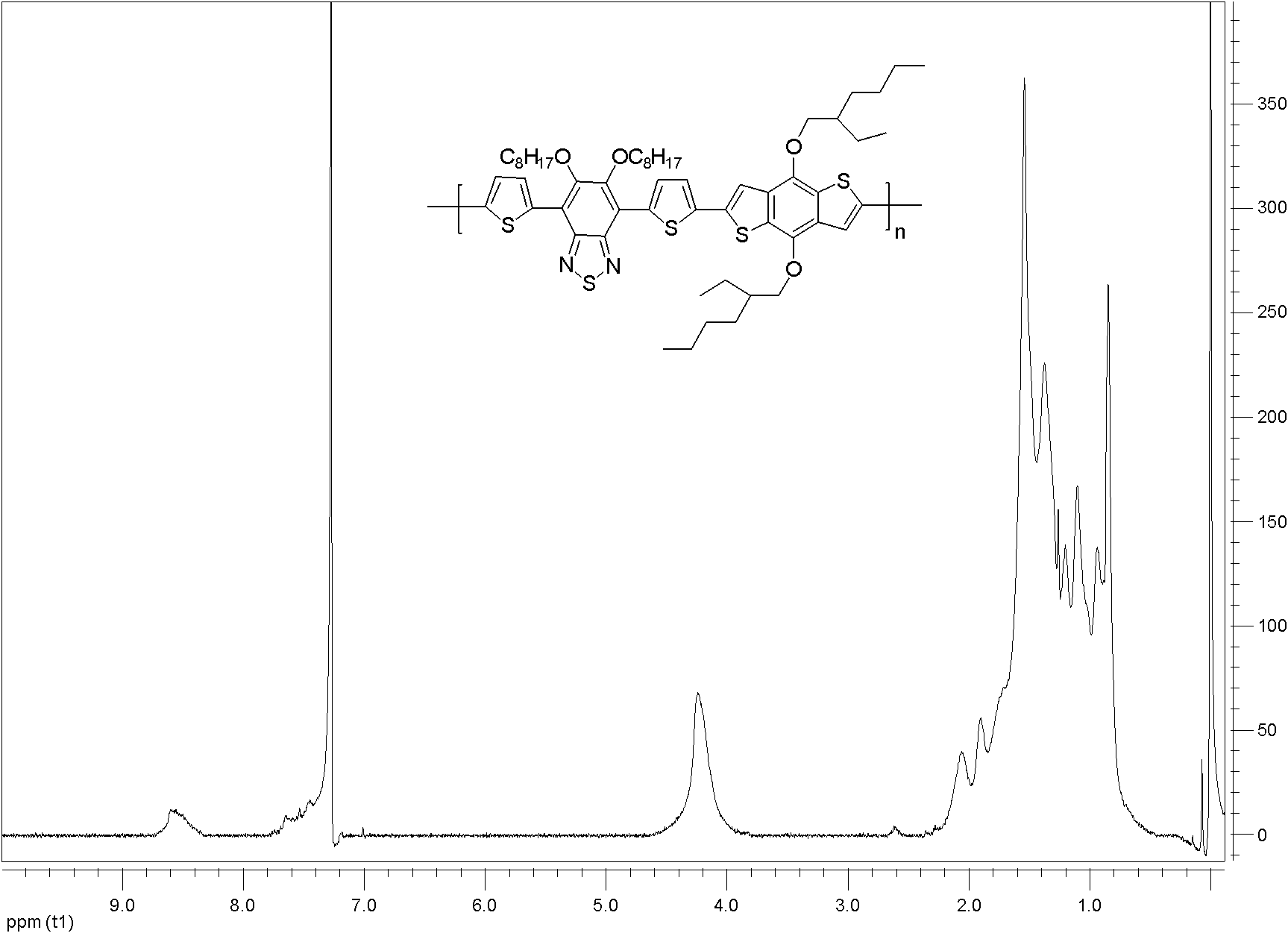

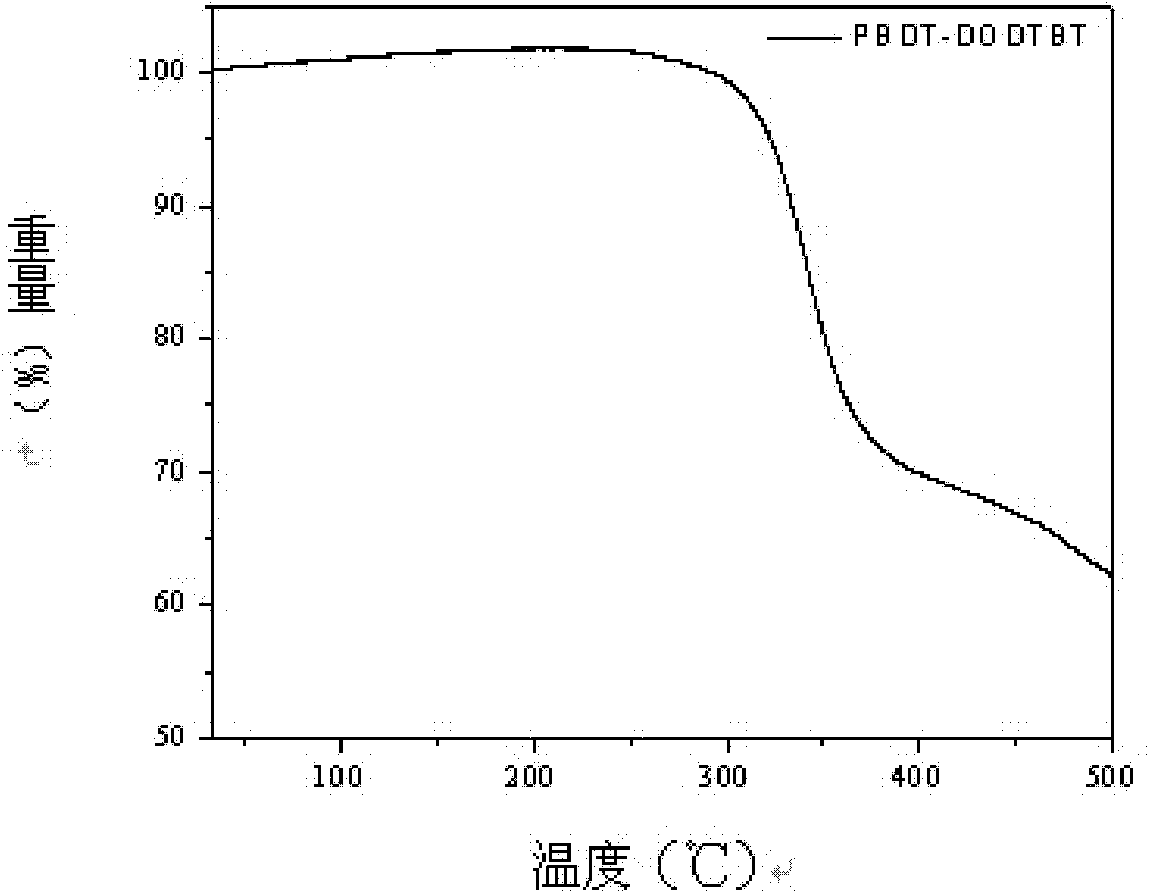

Copolymer of bithiophene diazosulfide and dibenzothiophene (BDT) and application thereof

InactiveCN101875717AGood photoelectric conversion functionSolid-state devicesSemiconductor/solid-state device manufacturingBenzenePolymer science

The invention relates to a copolymer of bithiophene diazosulfide and dibenzothiophene (BDT) and application thereof. 4,7-bithiophene-5,6-dioctyloxy-diazosulfide (DODTBT) and a di-tin compound of the BDT are coupled through Stille to obtain poly-[2,6-(4',8'-di-iso-octyl-benzene-(1',2'-b;3',4'-b)-bithiophene)-CO-4,7-bithiophene-5,6-dioctyloxy-diazosulfide (PBDT-DODTBT). The polymer has good photoelectric conversion function and can be widely applied to polymer solar cells. Particularly, the PBDT-DODTBT is used as a donor material and mixed with a C60 receptor, and an obtained mixture is coated on ITO (Indium Tin Oxid) conducting glass to prepare a semitransparent thin film; and then a metal electrode is evaporated on the polymer through a vacuum evaporation mode to prepare a polymer solar cell device, wherein the preliminary survey energy conversion efficiency (PCE) of the device reaches 4.02 percent.

Owner:CENT SOUTH UNIV

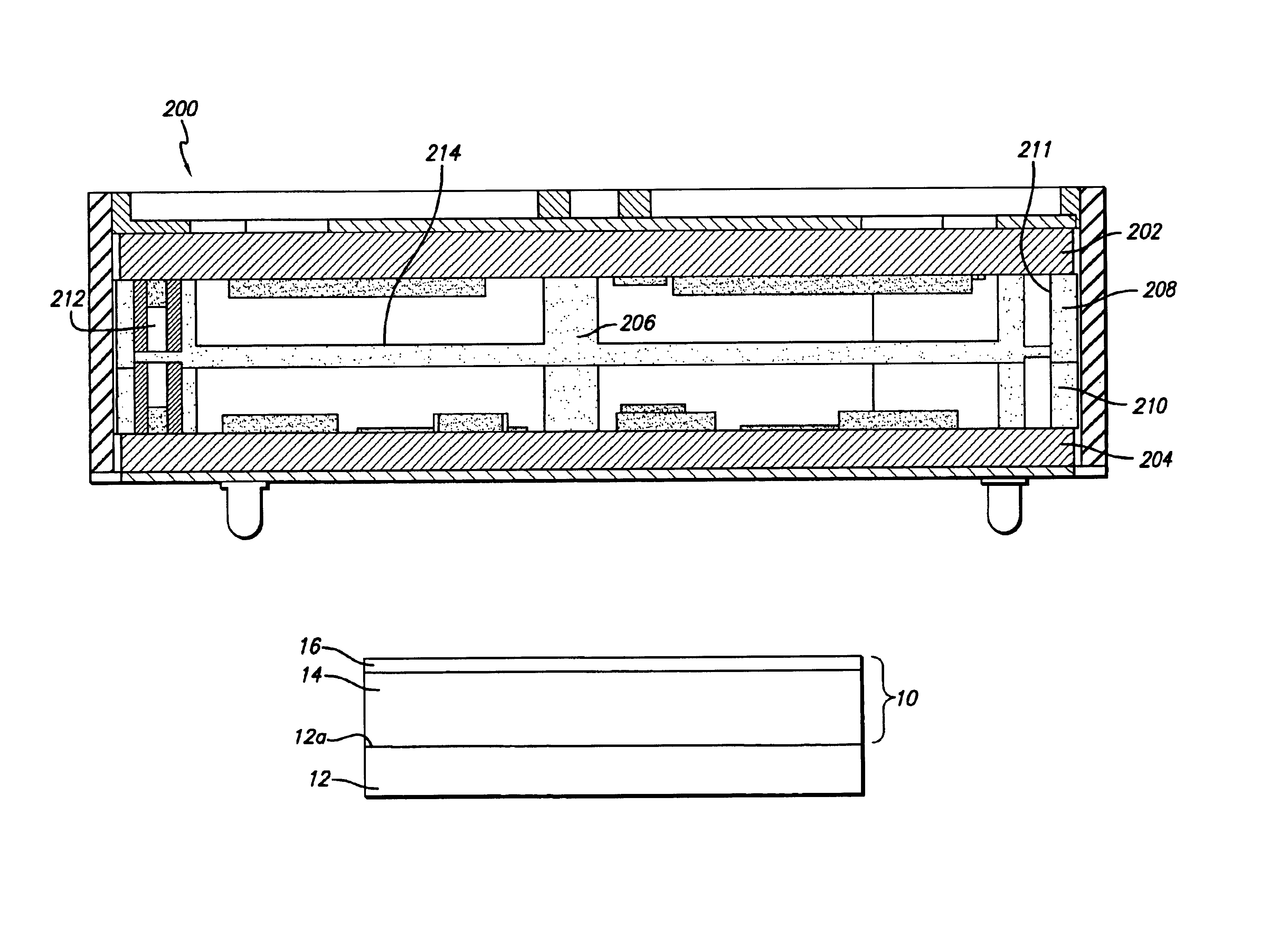

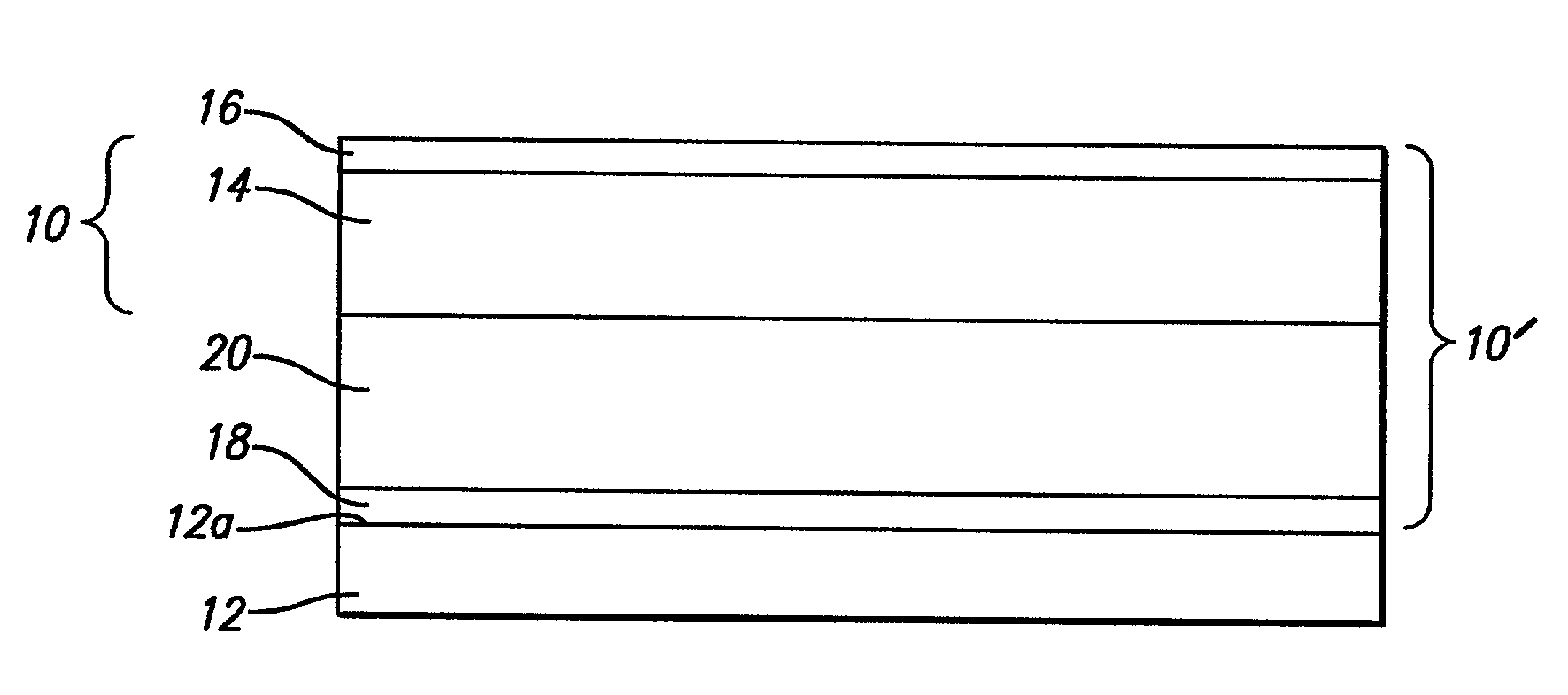

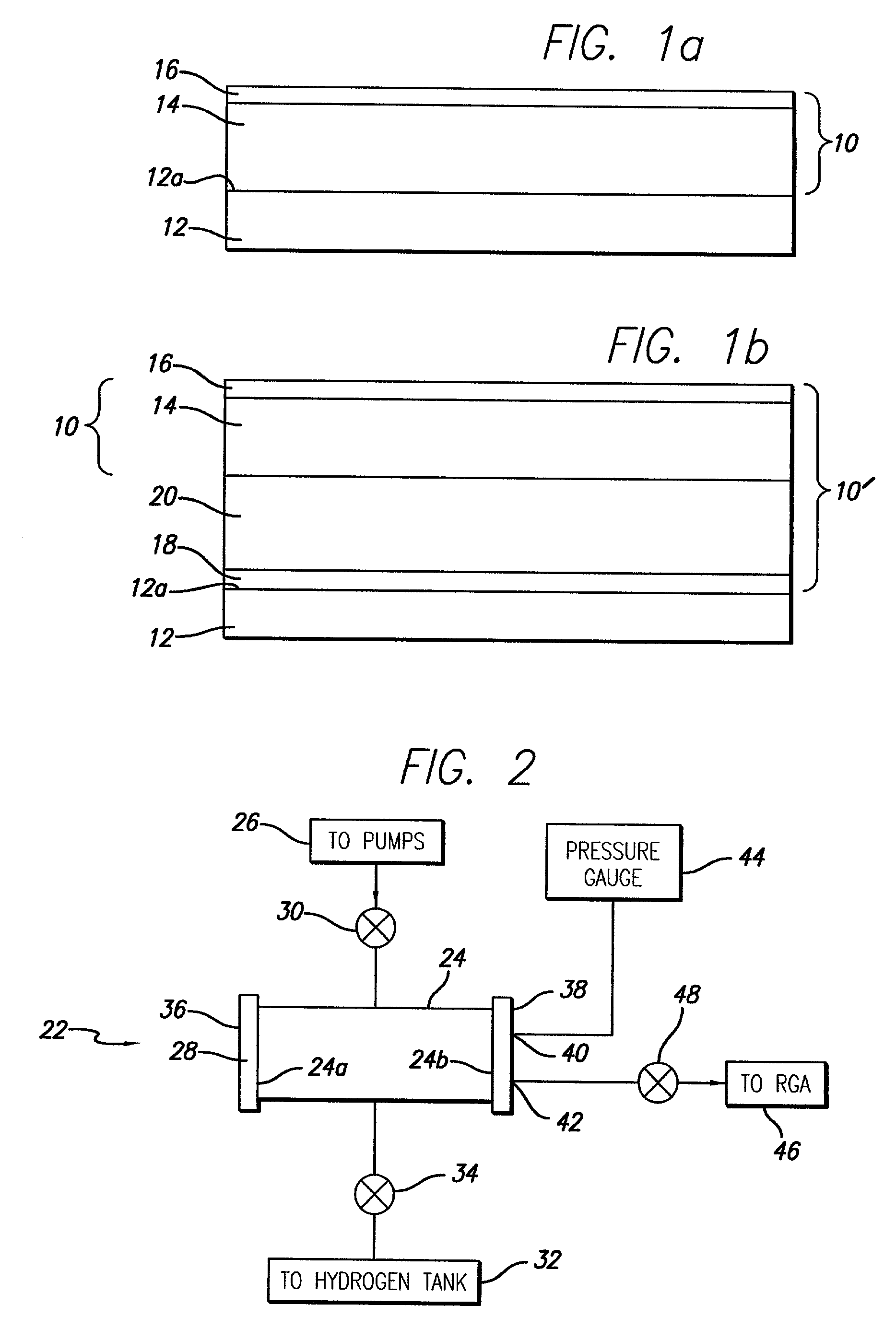

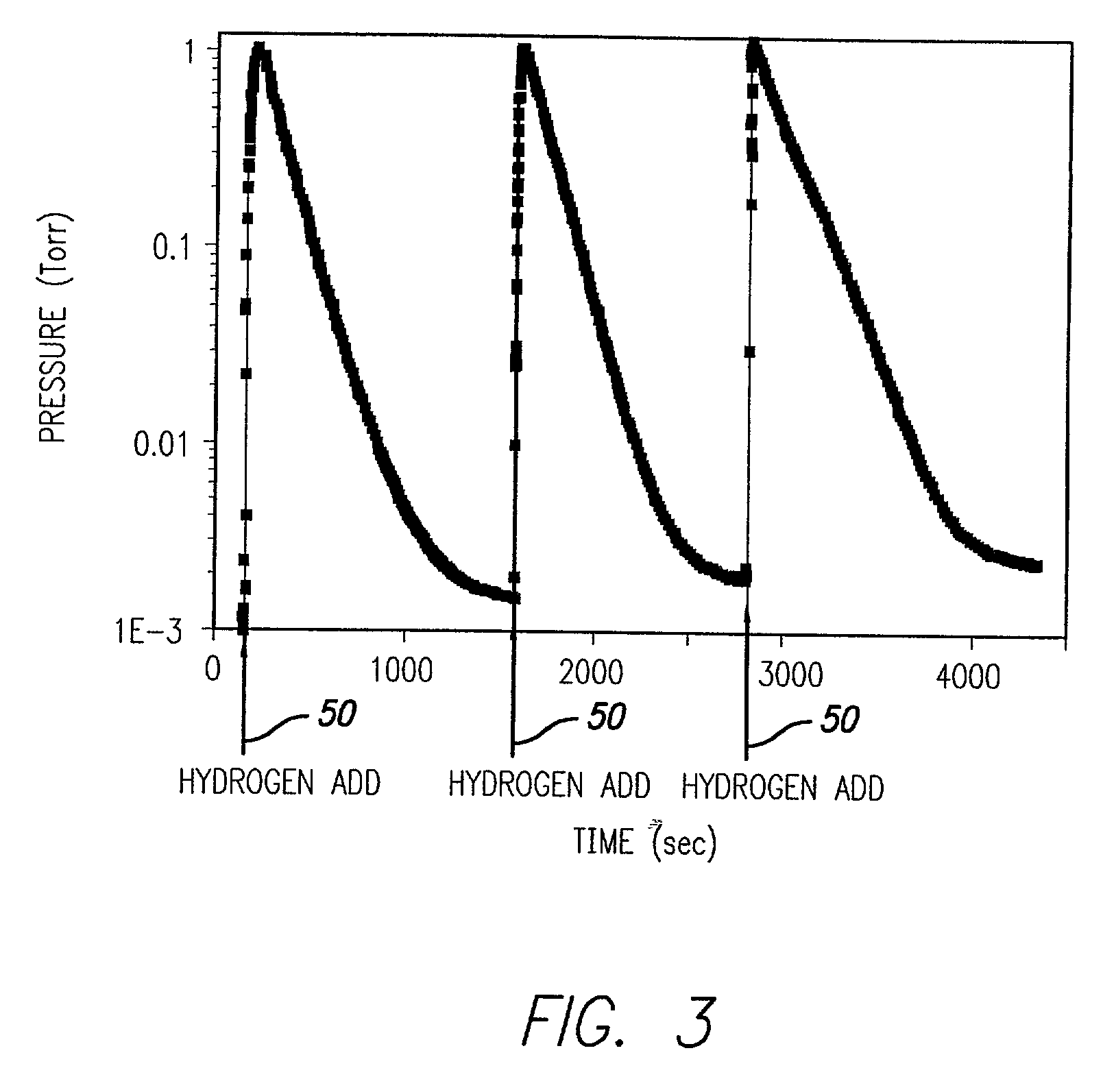

Multilayer thin film hydrogen getter and internal signal EMI shield for complex three dimensional electronic package components

InactiveUS6822880B2High absorption ratePrevent oxidationMagnetic/electric field screeningSemiconductor/solid-state device detailsVacuum evaporationElectron

A thin film hydrogen getter and EMI shielding are provided for protecting GaAs circuitry sealed in an hermetic package. The thin film getter comprises a multilayer metal film that is deposited by vacuum evaporation techniques onto a conductive metal, such as aluminum or copper, that serves as the EMI shielding. The conductive layer is first formed on an interior surface. The multilayer hydrogen getter film comprises (1) a titanium film and (2) a palladium film that is deposited on the titanium film. Both the titanium and the palladium are deposited during the same coating process run, thereby preventing the titanium from being oxidized. The palladium continues to prevent the titanium from being oxidized once the getter is exposed to the atmosphere. However, hydrogen is easily able to diffuse through the palladium into the titanium where it is chemically bound up, since palladium is highly permeable to hydrogen.

Owner:RAYTHEON CO

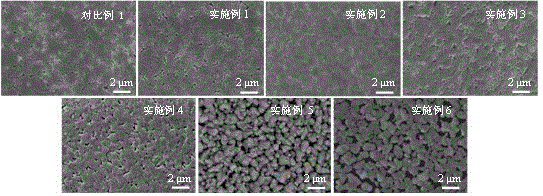

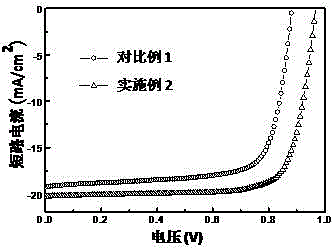

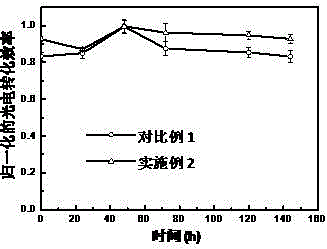

Perovskite solar cell preparation method

InactiveCN105070841AIncrease the open circuit voltageIncrease short circuit current densitySolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellHole transport layer

The invention provides a perovskite solar cell preparation method. The preparation method comprises the following steps: (1) substrate cleaning and ozone treatment are carried out; (2) spin coating of a hole transport layer is carried out; (3) a water-doped CH3NH3PbI3-xClx precursory solution is prepared; (4) spin coating of the CH3NH3PbI3-xClx precursory solution is carried out; (5) spin coating of an electron transport layer is carried out; (6) spin coating of an interface modification layer is carried out; and (7) vacuum evaporation of a metal cathode is carried out, and thus, a perovskite solar cell is obtained. The perovskite solar cell obtained by the preparation method provided by the invention has the advantages of high photoelectric conversion efficiency and good cell stability.

Owner:SUZHOU UNIV

Process for recovering sulfuric acid and sulfate from waste acid generated in preparation of titanium dioxide by using sulfuric acid method

InactiveCN102079512AImprove recycling ratesIncrease concentrationSulfur-trioxide/sulfuric-acidIron sulfatesHigh concentrationWater vapor

The invention relates to a process for recovering sulfuric acid and sulfate from waste acid generated in the preparation of titanium dioxide by using a sulfuric acid method, belonging to the technical field of waste acid treatment in the industrial production. The invention recovers sulfuric acid and sulfate products from waste acid generated in the production process for preparing the titanium dioxide by using the sulfuric acid method through the sedimentation pretreatment and the simple process including the first segment of flash evaporation-crystallization, concentration and separation, the second segment of vacuum evaporation, concentration and separation and the third segment of vacuum evaporation, concentration and separation. The invention has simple process, convenience of operation, simple equipment, high performance price ratio and high yield, high concentration and less impurities of the product acid, can recycle resources without waste liquid or waste residue emission and can be favorable to environmental protection and energy saving, and emitted exhaust mainly contains air and less vapor, is non-toxic to the environment and can effectively overcome the difficulties of fouling and clogging of the equipment. The invention can be widely applied to the recovery of waste acid in the industrial production and be particularly suitable for recovering the waste acid generated in the preparation of titanium dioxide by using the sulfuric acid method.

Owner:CHONGQING UNIV

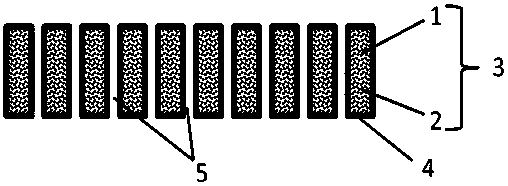

A flexible porous current collector and a preparation method thereof

InactiveCN109216703AImproved magnification performanceImprove flexibilityElectrode carriers/collectorsLow densityVacuum evaporation

The invention relates to a flexible porous current collector and a preparation method thereof, belonging to the technical field of battery current collector materials. The current collector comprisesa flexible porous conductive substrate and an ultrathin conductive metal layer plated on the surface of the flexible porous conductive substrate; The flexible porous conductive substrate is a porous film formed by uniformly dispersing the conductive powder material in the polymer material. At first, that polymer and the conductive pow material are melted and uniformly mix, and a flexible porous conductive substrate is prepared on a lithium battery separator production equipment by a dry double-pulling method; Then an ultra-thin conductive metal layer is deposited on the surface of the flexibleporous conductive substrate by vacuum evaporation or electroplating to obtain the flexible porous current collector. The invention has the advantages that the base material is a conductive powder andthe polymer are uniformly compounded, and has the characteristics of good flexibility, high tensile strength, high conductivity and low density, and the conductivity and tensile strength of the basematerial can be further improved after an ultra-thin conductive metal layer is plated on the base material.

Owner:ZHUHAI COSMX BATTERY CO LTD

Catalyst Layer for Solid Polymer Electrolyte Fuel Cell and Method of Producing

InactiveUS20070212591A1High activityImprove utilizationFinal product manufactureActive material electrodesPolymer electrolytesFuel cells

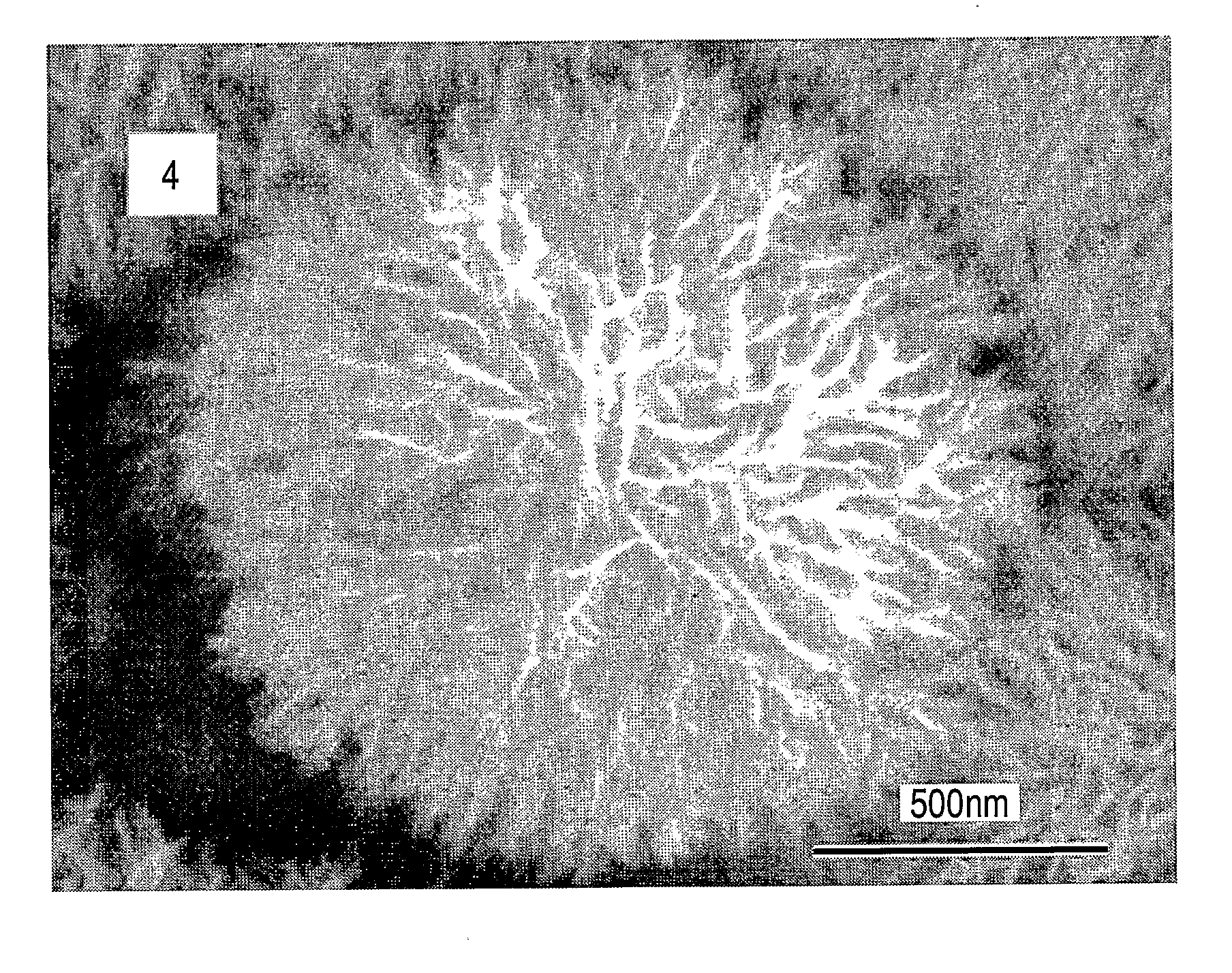

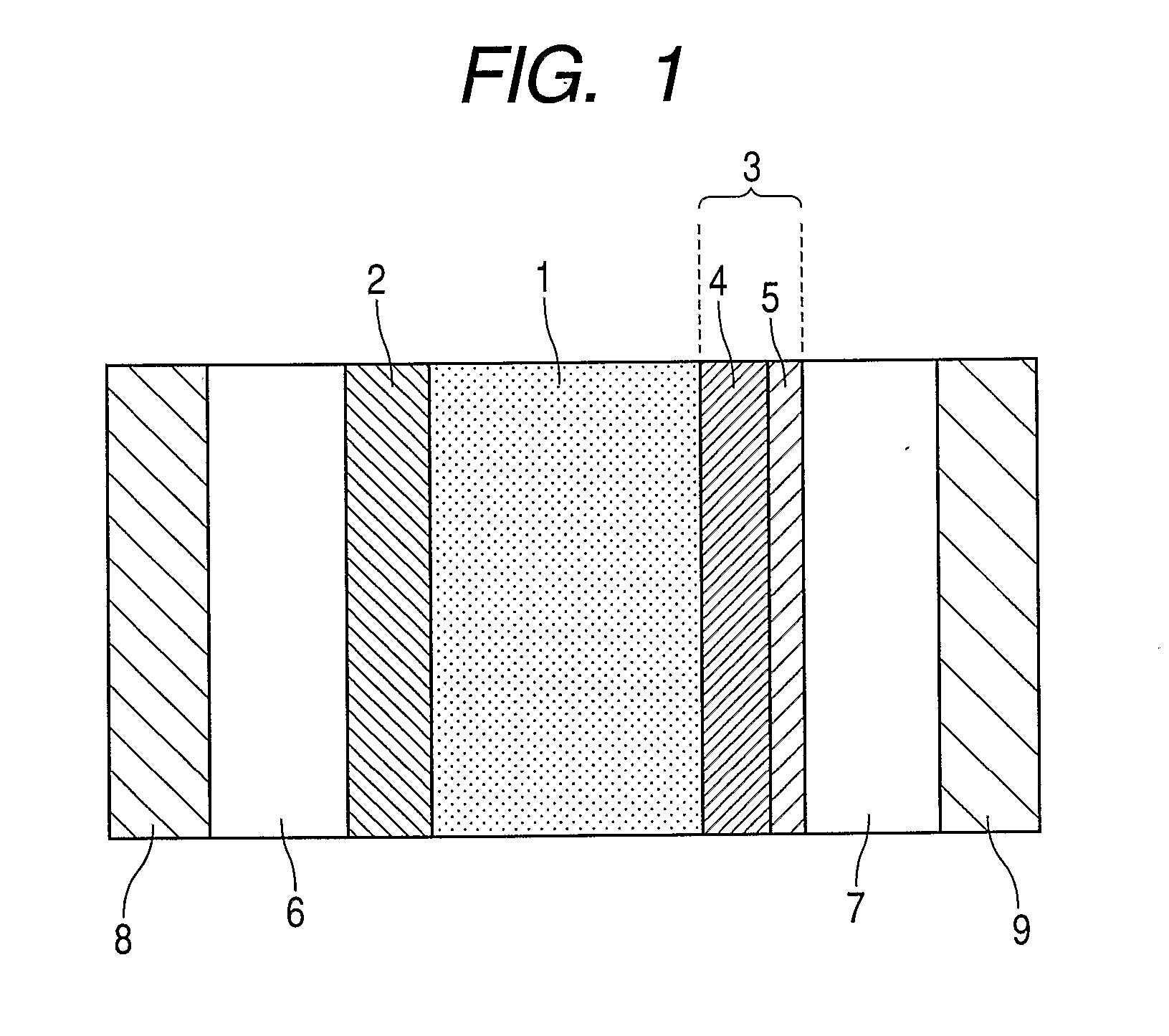

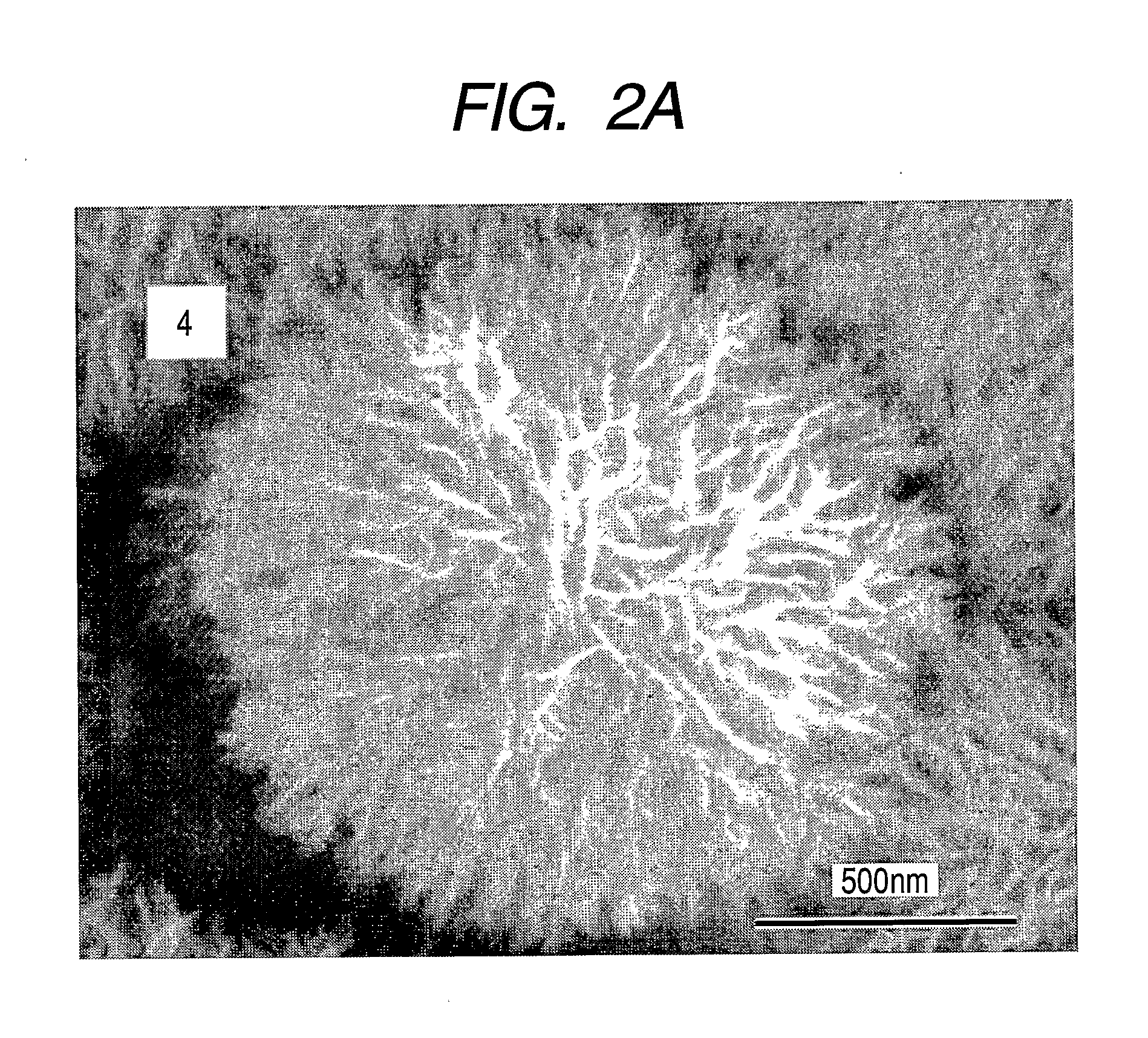

There is provided a dendritic catalyst layer for a solid polymer electrolyte fuel cell including: a solid polymer electrolyte membrane; electrodes; and catalyst layers each provided between the solid polymer electrolyte membrane and the respective electrode, the catalyst layer for a solid polymer electrolyte fuel cell includes a catalyst with a dendritic structure. The catalyst with a dendritic structure is formed through vacuum evaporation such as reactive sputtering, reactive electron beam evaporation, or ion plating. The catalyst layer for a solid polymer electrolyte fuel cell can improve catalytic activity, catalyst utilization, and substance transport performance in the catalyst layer.

Owner:CANON KK

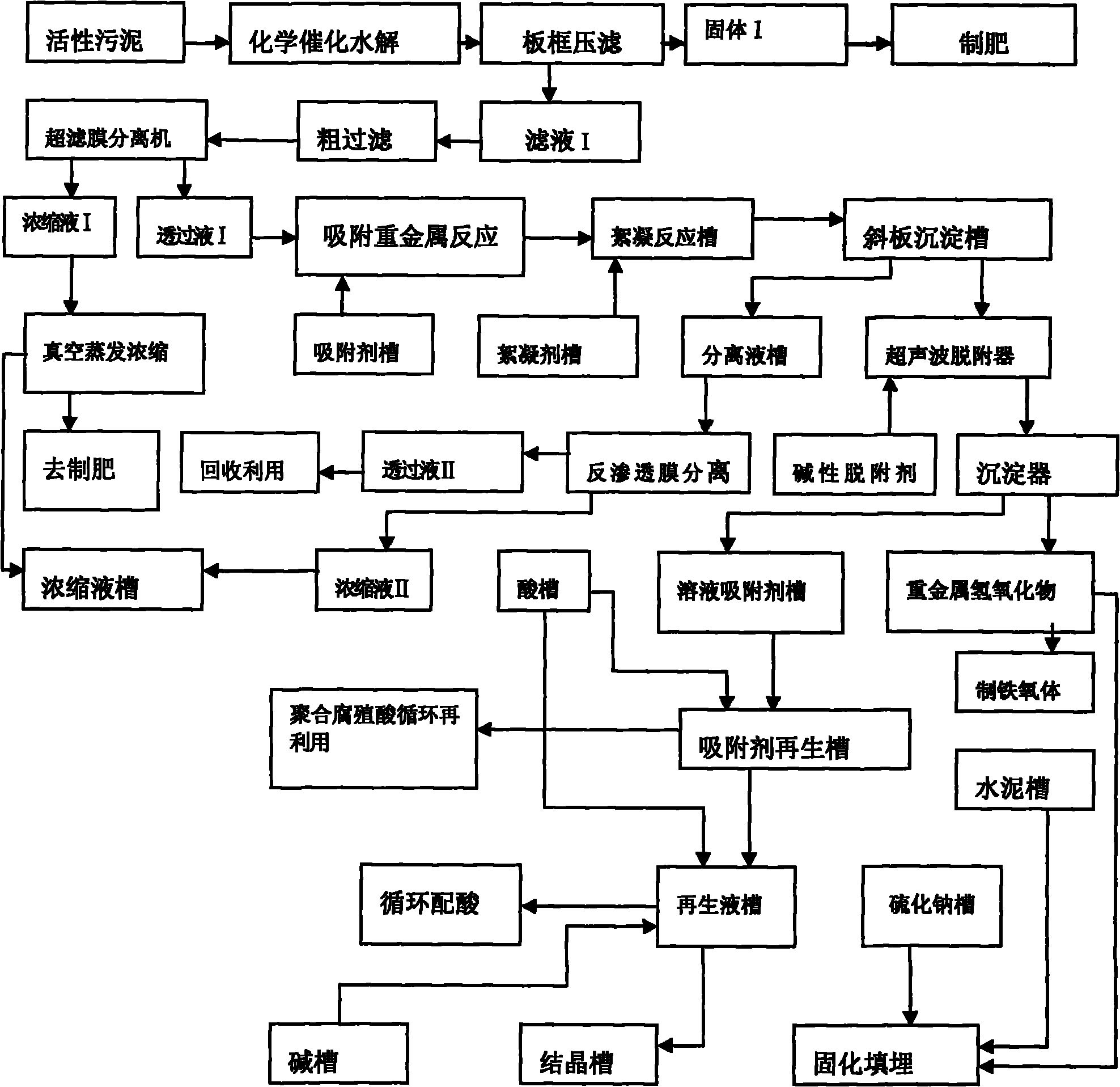

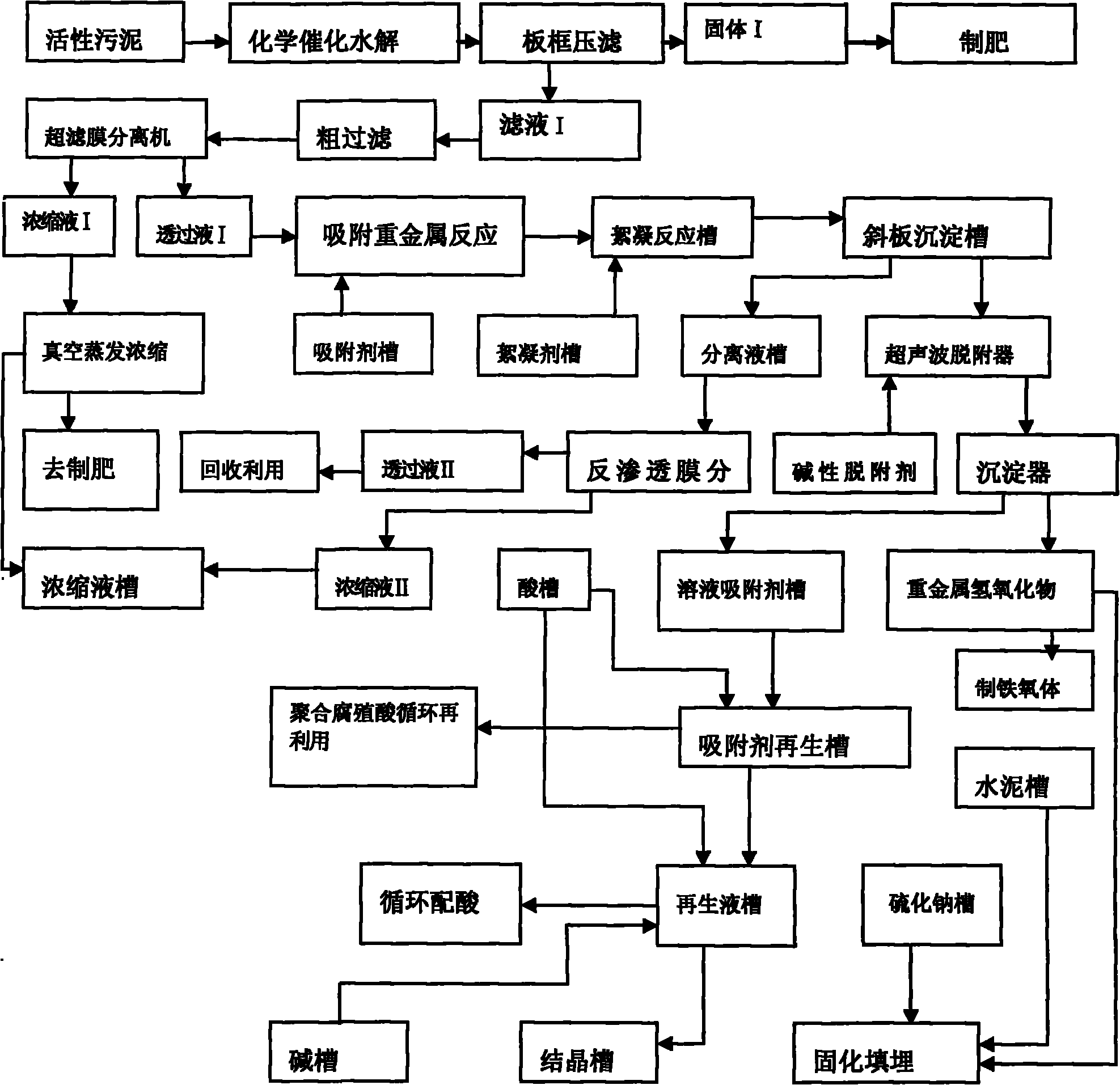

Method for removing heavy metals from activated sludge

A method for removing heavy metals from activated sludge is characterized in that through chemical catalytic hydrolysis and solid-liquid separation, the heavy metals exist in the filtrate; the filtrate is subjected to rough filtration pretreatment and ultrafiltration membrane separation in sequence; the permeate adopts adsorbent polyhumic acid to adsorb the heavy metals; the removal rate of the adsorbed heavy metals is higher than 95%; ultrasonic waves are used for desorption treatment; the heavy metals are in the state of hydroxide precipitation so as to be desorbed from the adsorbent in thedissolved state; the adsorbent is regenerated and reused; the heavy metal hydroxides are prepared for ferrite to recycle through recycling or harmless treatment, the process of harmless treatment is carried out through cement solidification and filling after stabilization; the concentrated solution of the ultrafiltration membrane and reverse osmosis membrane is subjected to vacuum evaporation andconcentration to produce fertilizers; the permeate of the reverse osmosis membrane is pure water which can be reused; the desorbed alkaline solution containing polyhumic acid is subjected to adsorbent recycling; and the regenerated acid liquid is recycled for acid blending, thus realizing zero emission of closed cycle. The method is conductive to environmental protection and resource recycling, simple in process, lower in cost and suitable for popularization and use.

Owner:SHANGHAI MULIANG IND CO LTD

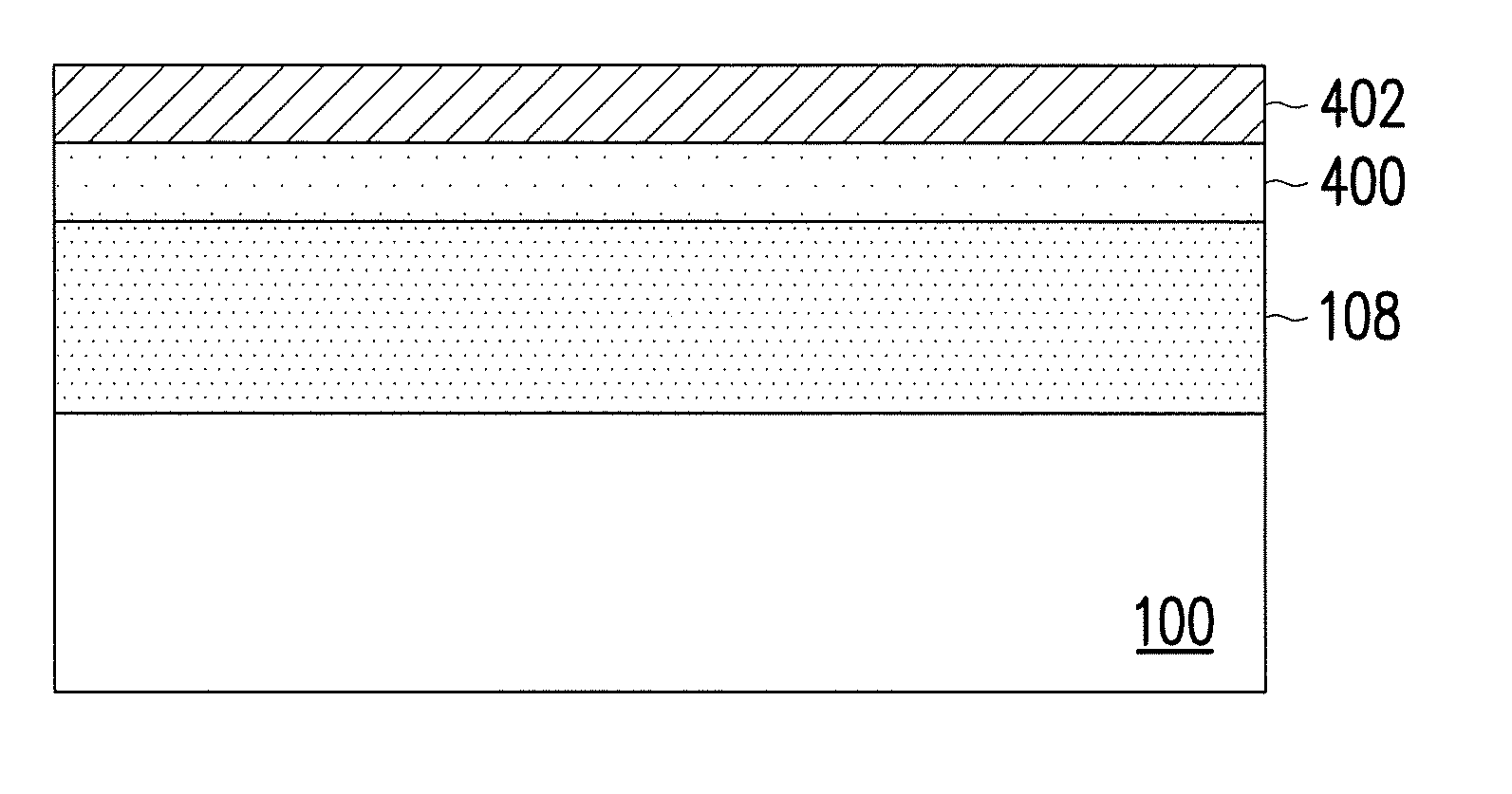

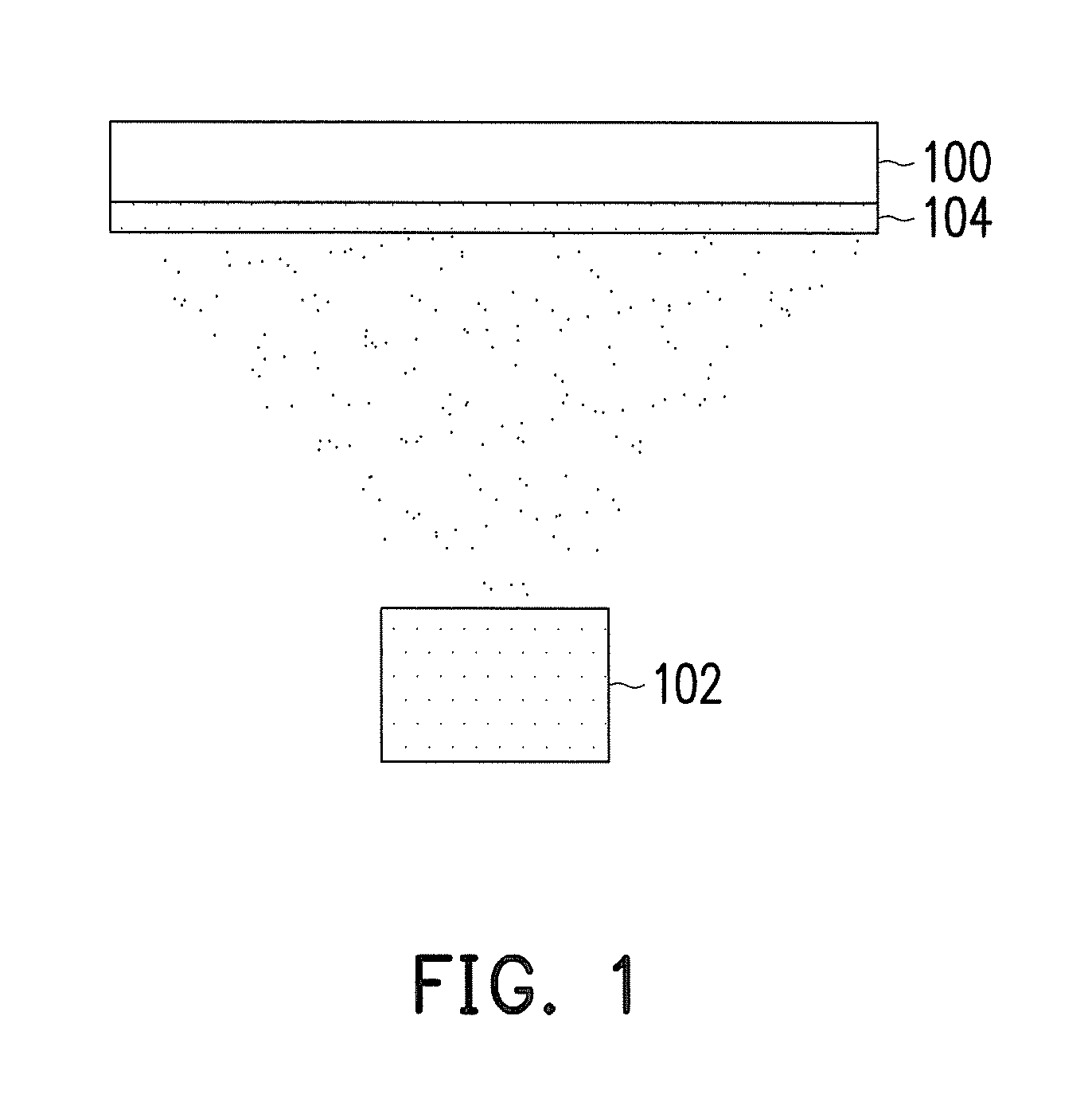

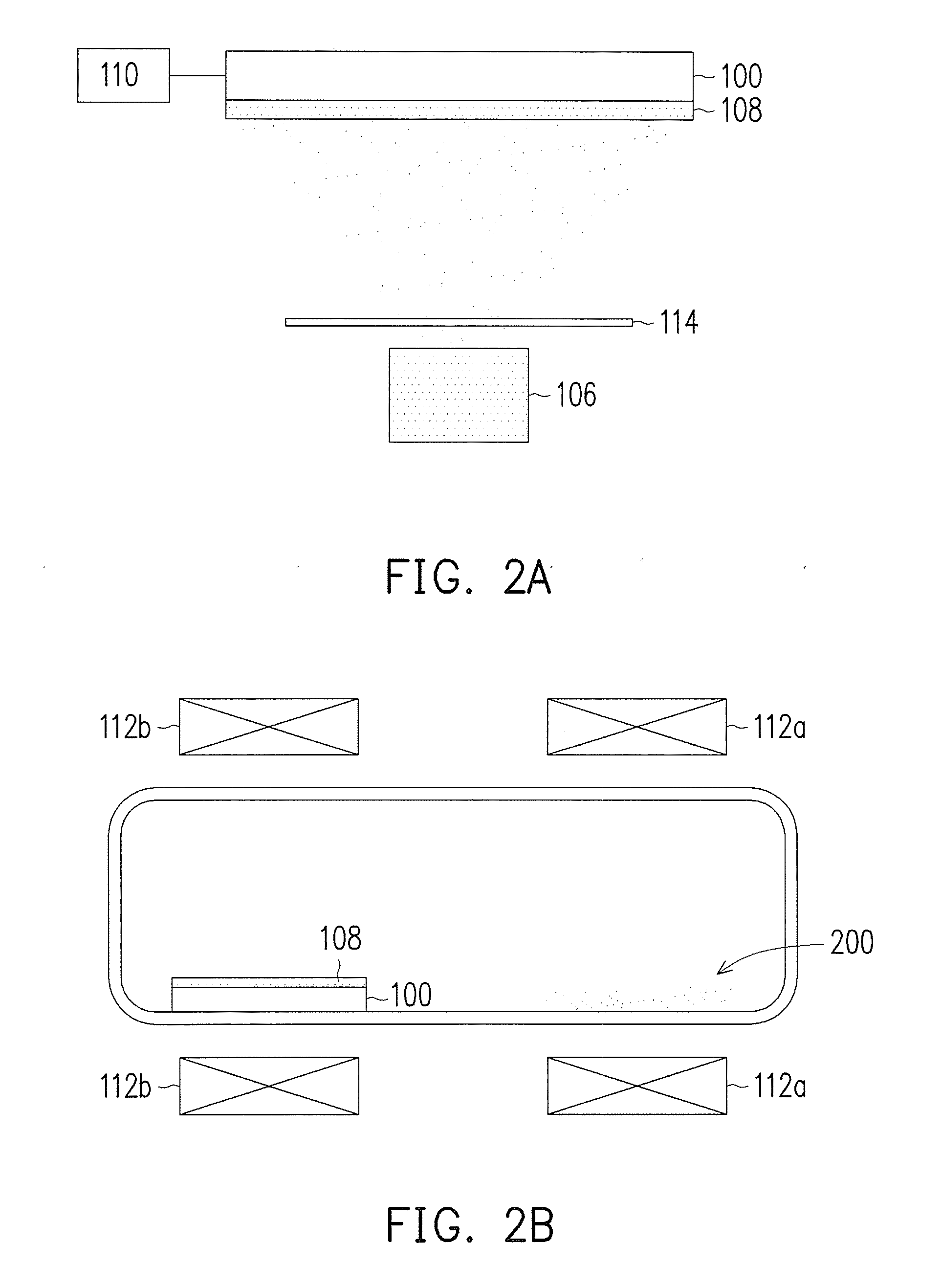

Method of fabricating perovskite solar cell

ActiveUS20160049585A1Improve conversion efficiencyAvoid disadvantagesSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellEngineering

A method of fabricating a perovskite solar cell includes forming a hole transport layer on a transparent electrically conductive substrate, and forming a perovskite layer on the hole transport layer via a two-stage vacuum evaporation process. Then, an electron transport layer and an electrode layer are formed in order. The two-stage vacuum evaporation process includes first vacuum evaporating a first material on the hole transport layer and then vacuum evaporating a second material on the first material so as to react the first material with the second material in situ and form the perovskite layer.

Owner:NATIONAL TSING HUA UNIVERSITY

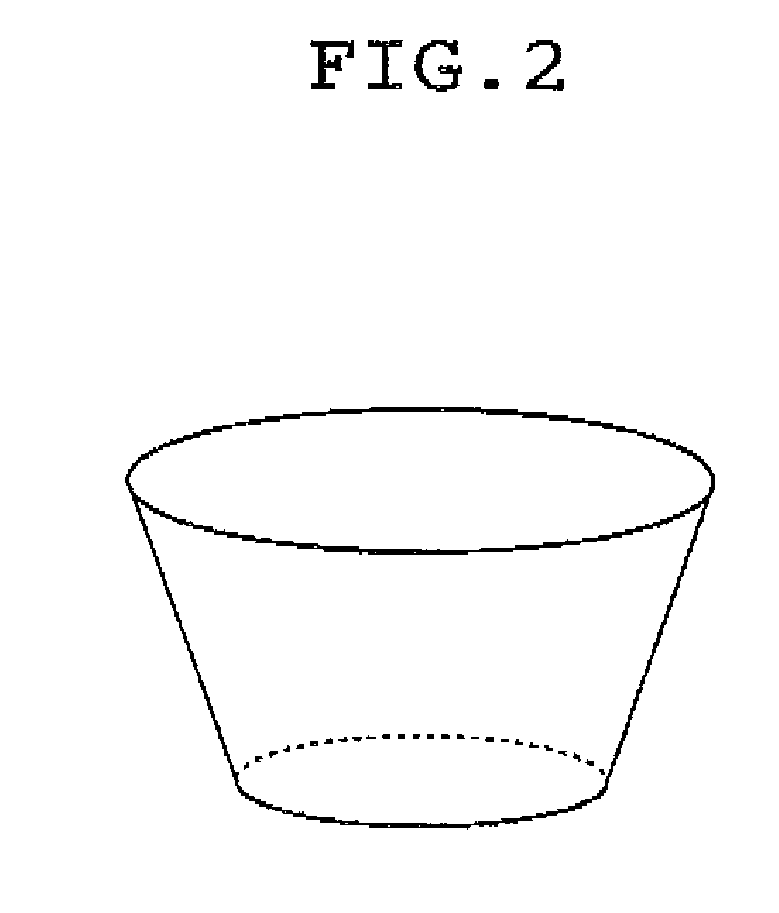

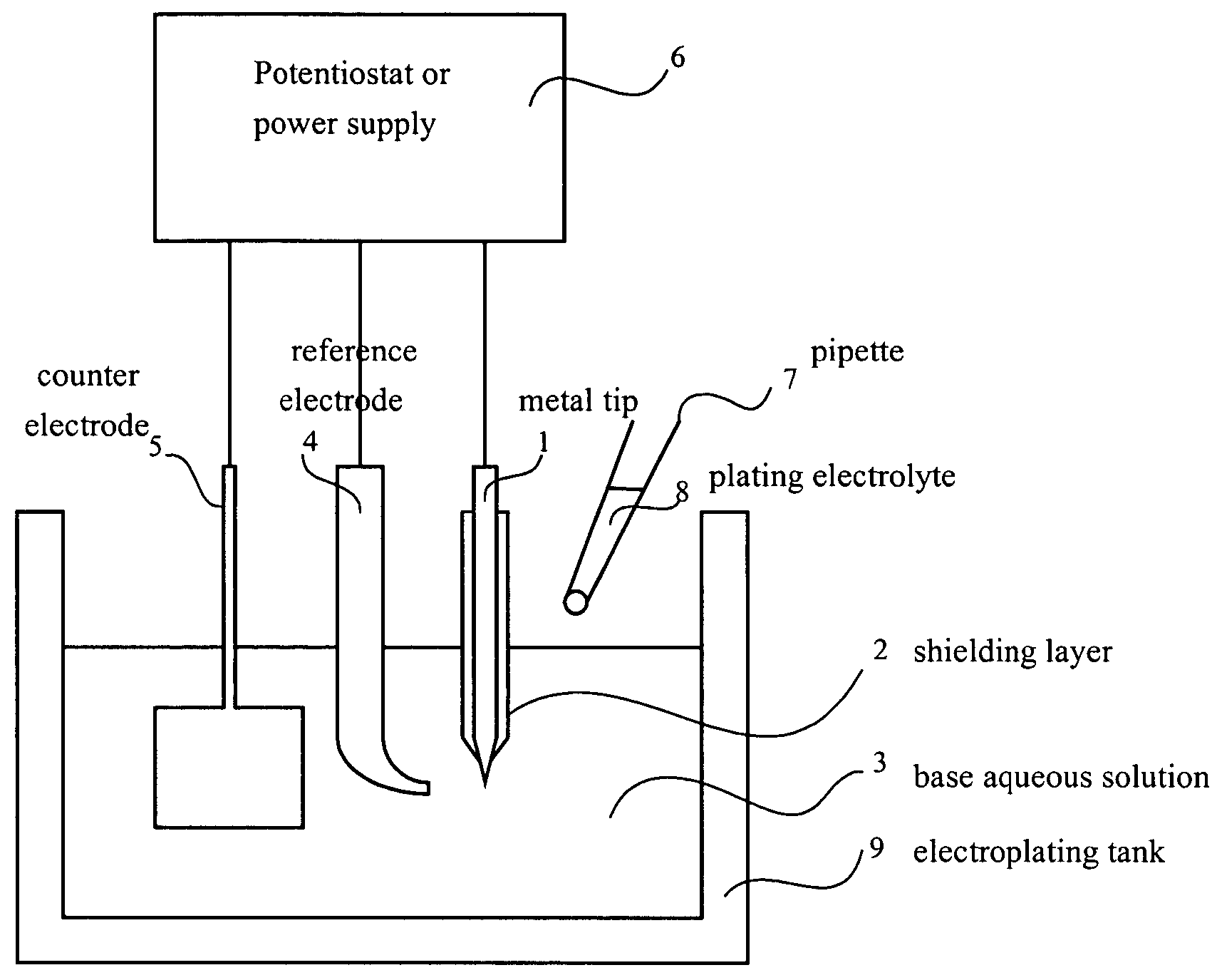

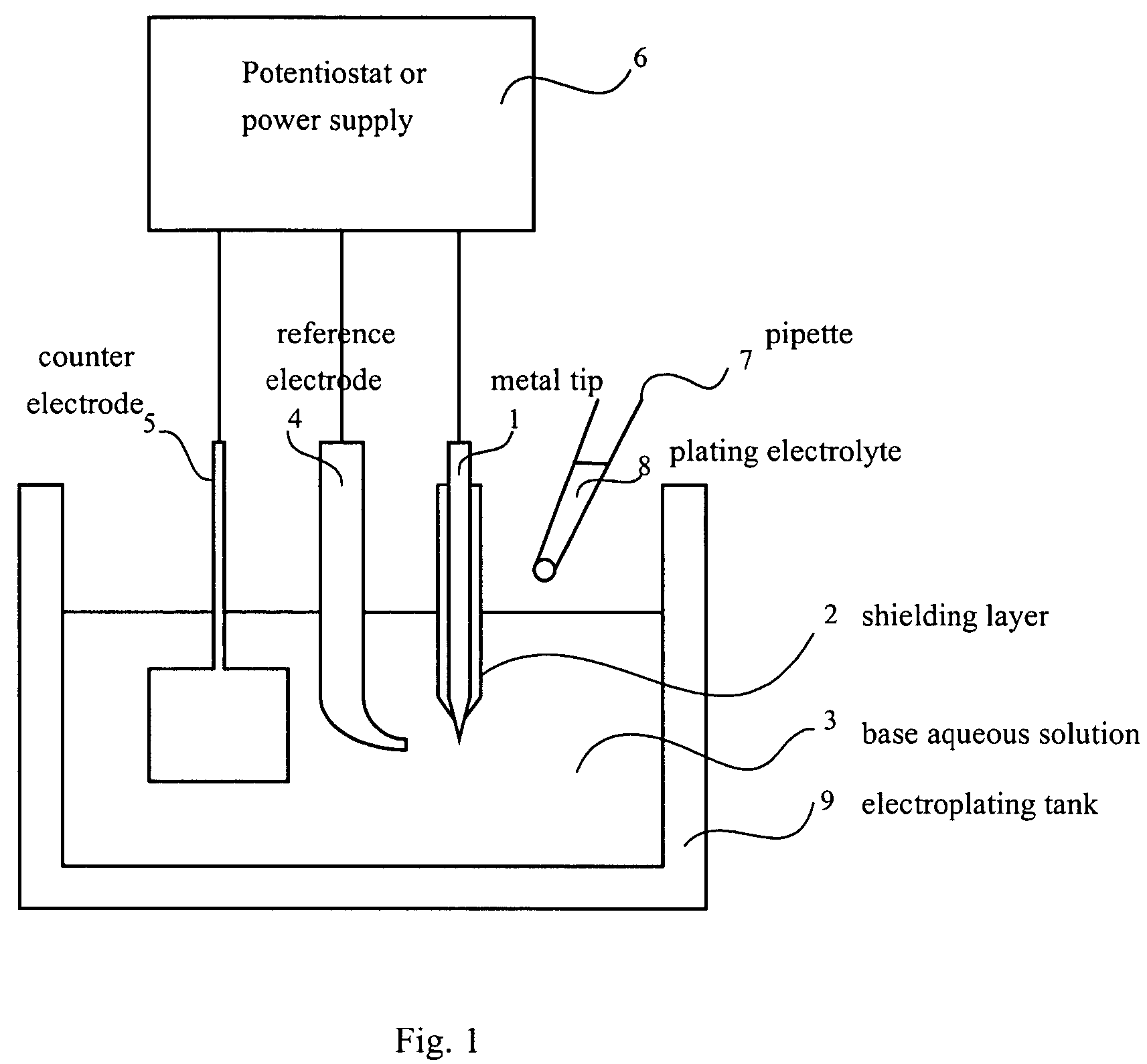

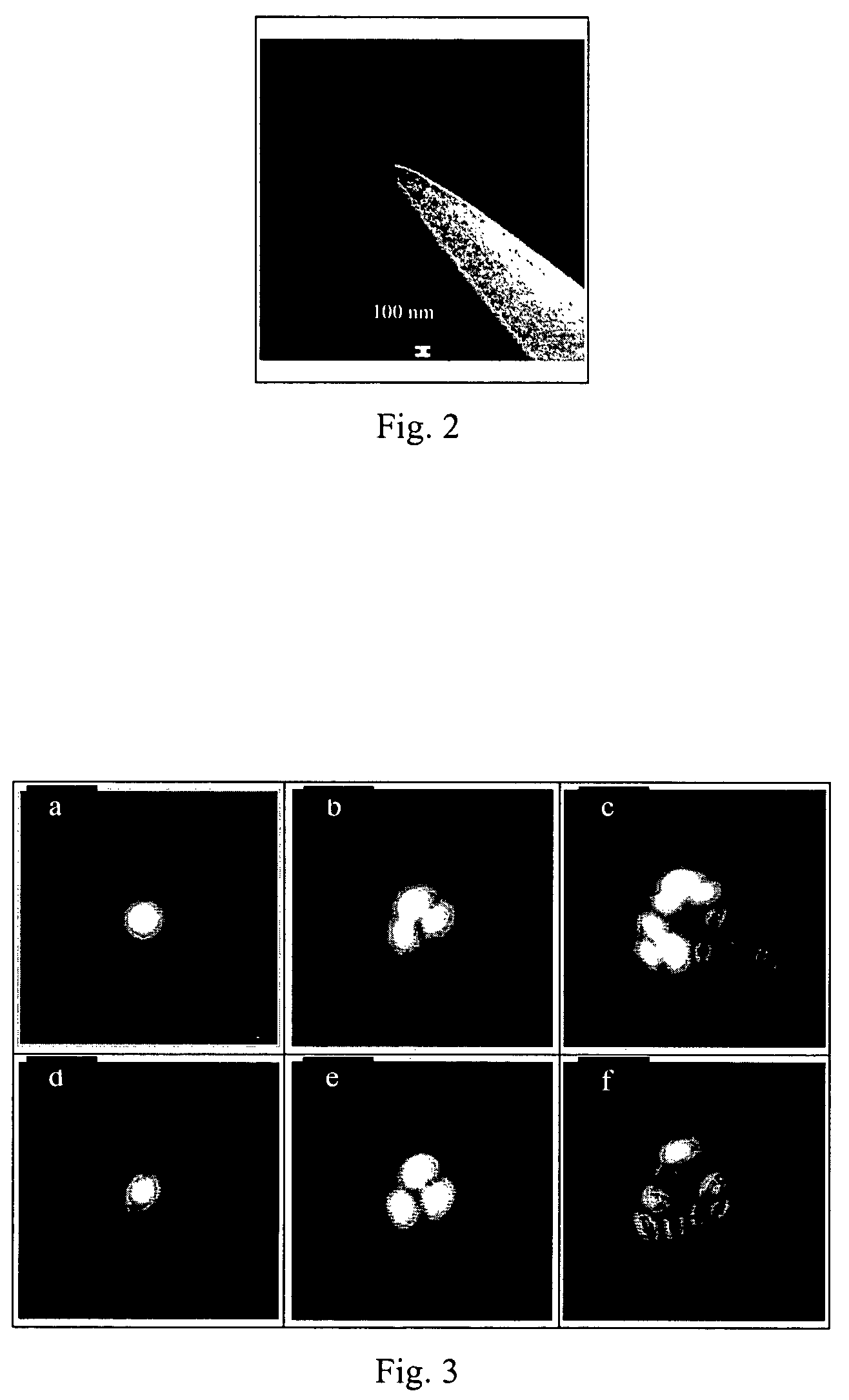

Single-atom tip and preparation method thereof

ActiveUS7507320B2Simple methodElectrolysis componentsWave amplification devicesSingle crystalElectrochemistry

Owner:ACAD SINIC

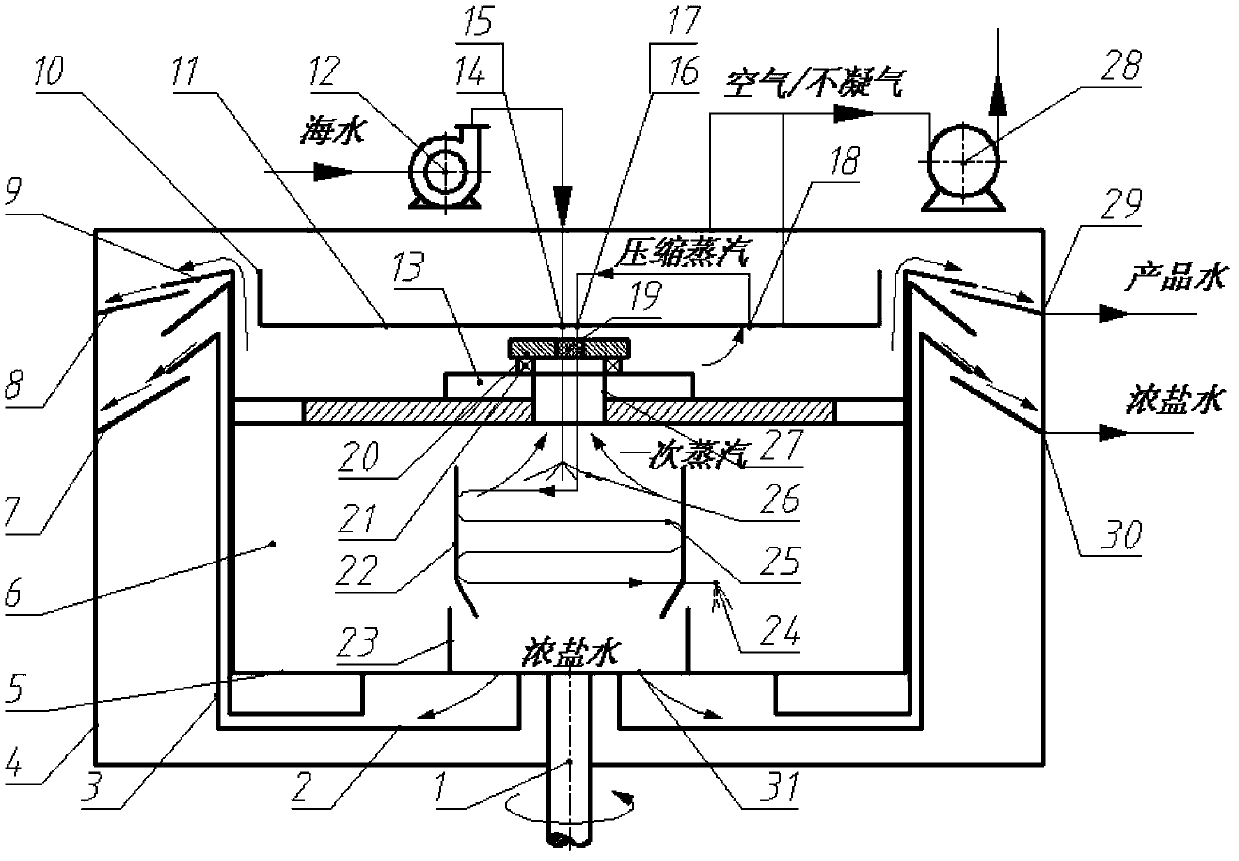

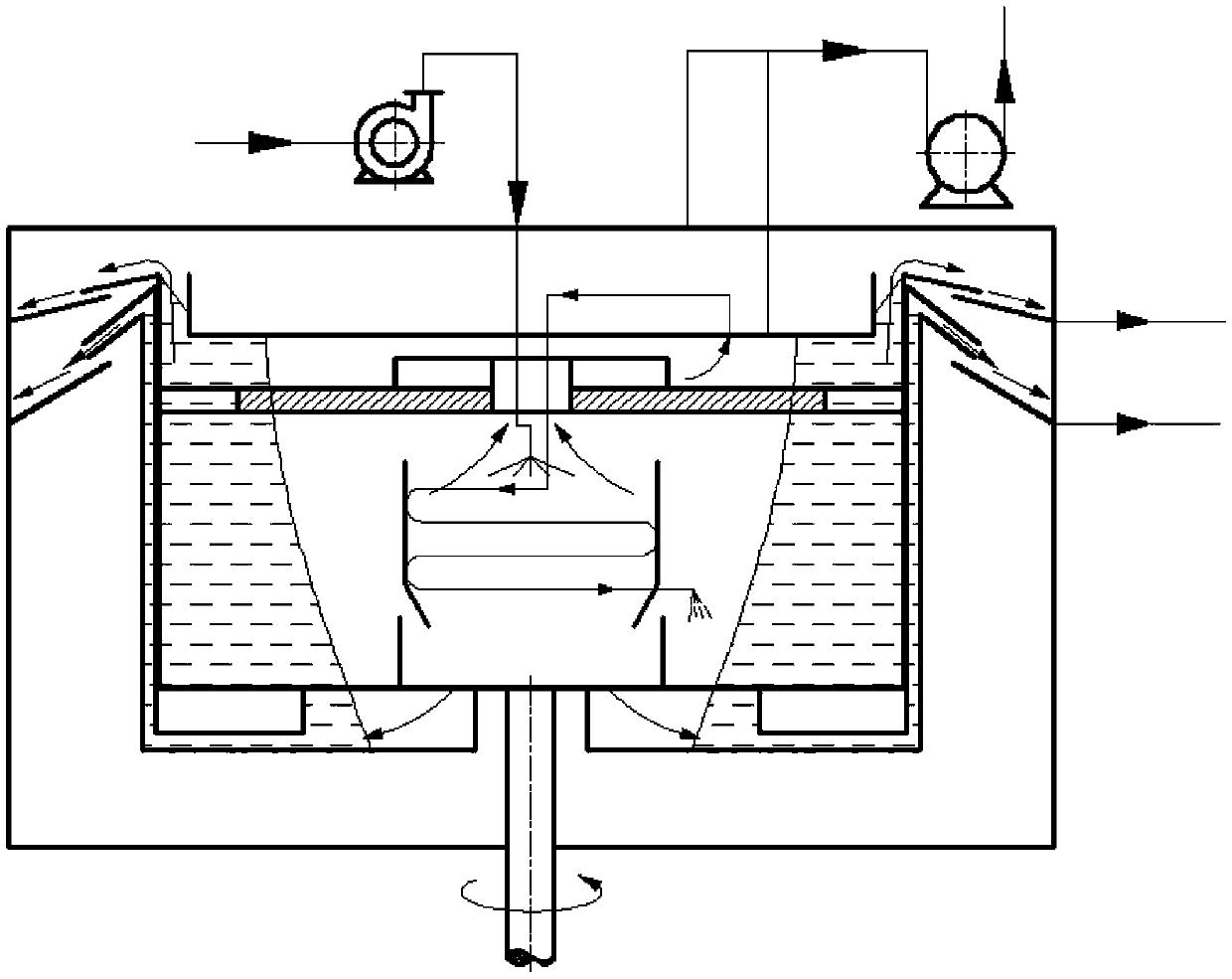

A vacuum vapor compression distillation sea water desalination device

InactiveCN103387270AIncrease water production rateIncrease heat and mass transfer rateGeneral water supply conservationSeawater treatmentWater desalinationSteam condensation

The present invention relates to a vacuum vapor compression distillation sea water desalination device comprising: a sea water pump, a seal chamber, a vacuum evaporation chamber and a vacuum pump and other components. In operation, a drive shaft drives the vacuum evaporation chamber filled with fresh water to rotate, after the formation of a vacuum area without water, sea water is fed in, and at the same time working vapor is fed in a vapor pipe coil, heat transfer between the vapor in the vapor pipe coil and the outside sea water enable the condensation of the vapor to obtain fresh water, while the sea water volatilizes to form primary vapor; and after temperature and pressure rise via a impeller, the primary vapor is fed in the vapor pipe coil as the working vapor for continuous vapor compression distillation to achieve sea water desalination. According to the device of the invention, centrifugal force is employed to replace the gravity to obtain a vacuum environment, operations are all in room temperature, no external heat source is required, and circular energy supply is achieved by the utilization of latent heat of the vapor; the water production rate and the energy utilization rate of the system are high; and the device has advantages of a simple process, a compact structure, little corrosion and scaling, etc.

Owner:HAINAN UNIVERSITY +1

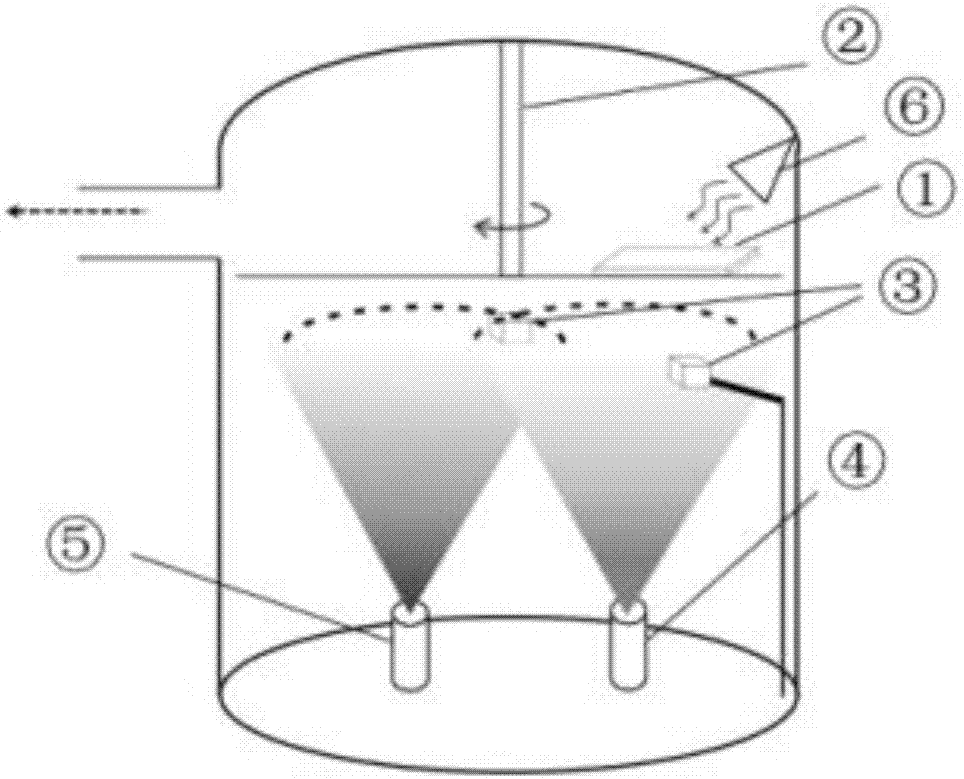

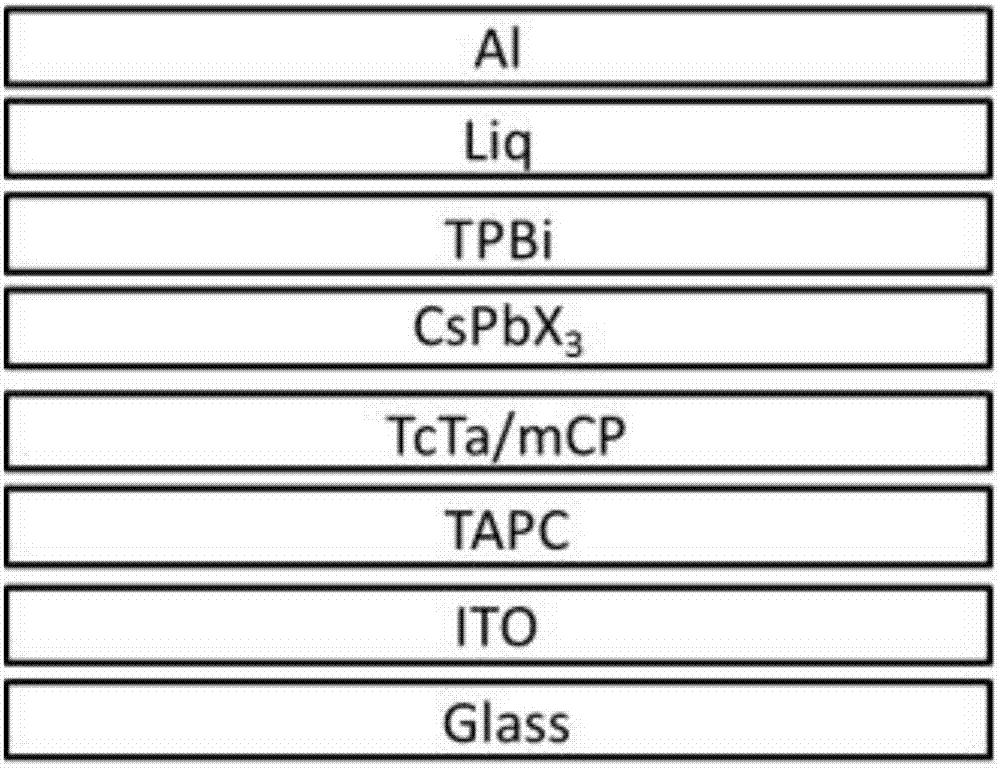

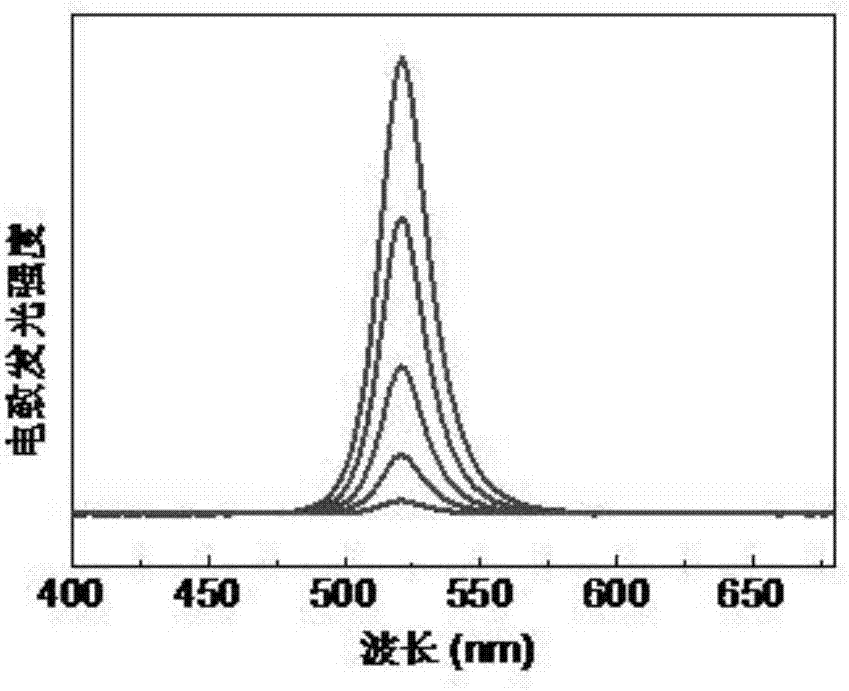

Pure inorganic perovskite light emitting diode device manufacturing method

InactiveCN107275523AImprove performanceReduce leakage currentSolid-state devicesSemiconductor/solid-state device manufacturingLight-emitting diodeVacuum evaporation

The invention provides a pure inorganic perovskite light emitting diode device manufacturing method. The method comprises the following steps: (1) an ITO transparent conductive glass substrate is subjected to standardized cleaning and drying and then pretreatment; (2) the ITO is transferred to a vacuum cavity, and evaporation on a hole injection layer and a transport layer is carried out; (3) a dual source co-evaporation method is adopted, and a pure inorganic CsPbX3 perovskite light emitting layer thin film is formed through evaporation; (4) an infrared thermal radiation device is used to carry out thermal treatment on the CsPbX3 perovskite film; and (5) an electron transport layer, an electron injection layer and a metal cathode are formed through thermal evaporation. The manufacturing process is simple and convenient, the manufacturing difficulty is low, the full vacuum evaporation method is adopted to manufacture the device, the manufacturing is easy, the repeatability is good, and the device performance is stable; and through the dual source co-evaporation manufacturing method, the smoothness and the uniformity of the thin film are improved, replacement of a subject material and an object material is facilitated, the ratio of the two can be changed, and regulation on the position of a light emitting peak is realized.

Owner:SUZHOU UNIV

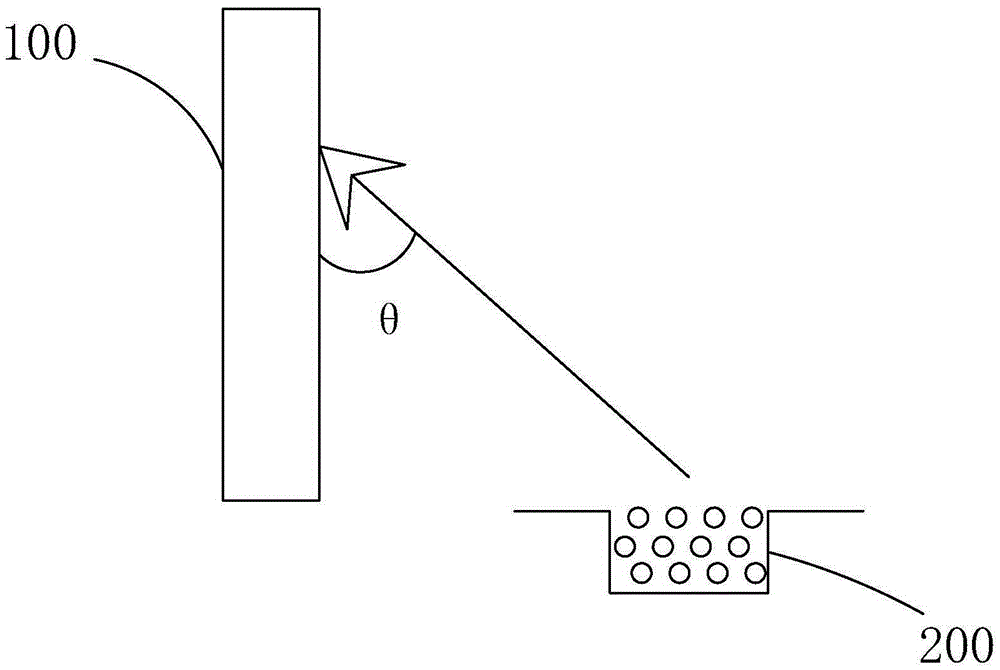

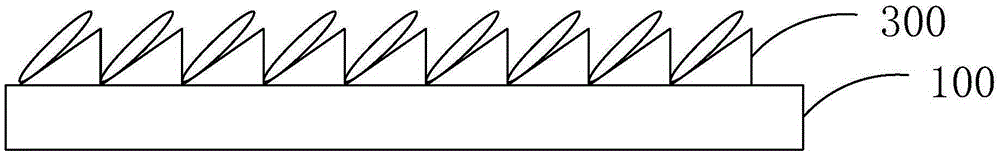

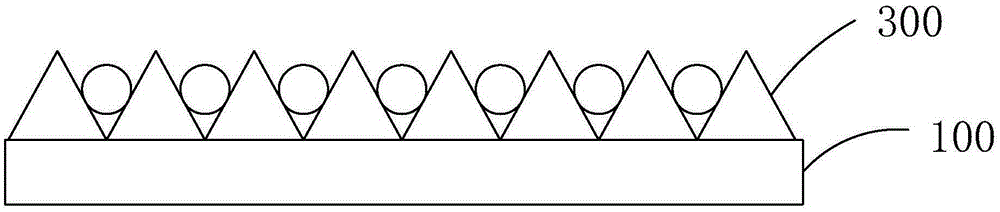

Liquid crystal display device and making method thereof

InactiveCN105301828AIncrease display brightnessReduce manufacturing costVacuum evaporation coatingSputtering coatingLiquid-crystal displayTransmittance

The invention provides a liquid crystal display device and a making method thereof. According to the liquid crystal display device, a quantum rod orientation layer (2) is arranged for conducting parallel orientation on a quantum rod layer (3), and the quantum rod layer (3) obtained after orientation can replace a traditional lower polarizer plate. The making method of the liquid crystal display device includes the steps that the quantum rod orientation layer (2) is prepared through an inclined vacuum evaporation process, a plurality of trenches (21) which are arranged in parallel and are perpendicular to a penetrating shaft of an upper polarizer plate (7) in the extension direction are formed in the quantum rod orientation layer (2), then the quantum rod layer (3) is prepared on the quantum rod orientation layer (2), the direction of long shafts of multiple quantum rods (31) in the prepared quantum rod layer (3) is parallel to the extension direction of the trenches (21), and in another word, the quantum rod layer (3) conducts parallel orientation. The quantum rod layer (3) obtained after orientation can replace the traditional lower polarizer plate, so that light transmittance and the backlight utilization rate can be raised, display brightness is increased, and the production cost is saved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

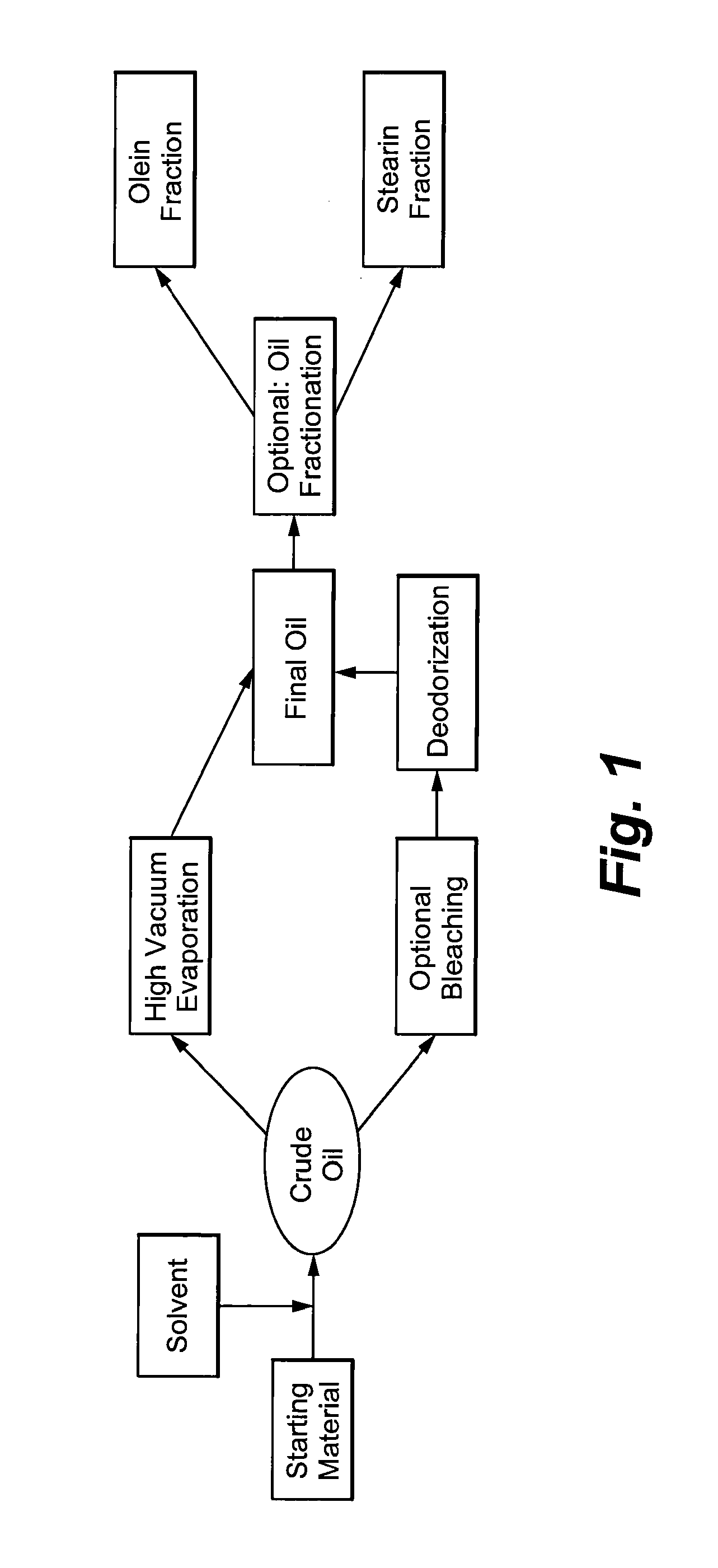

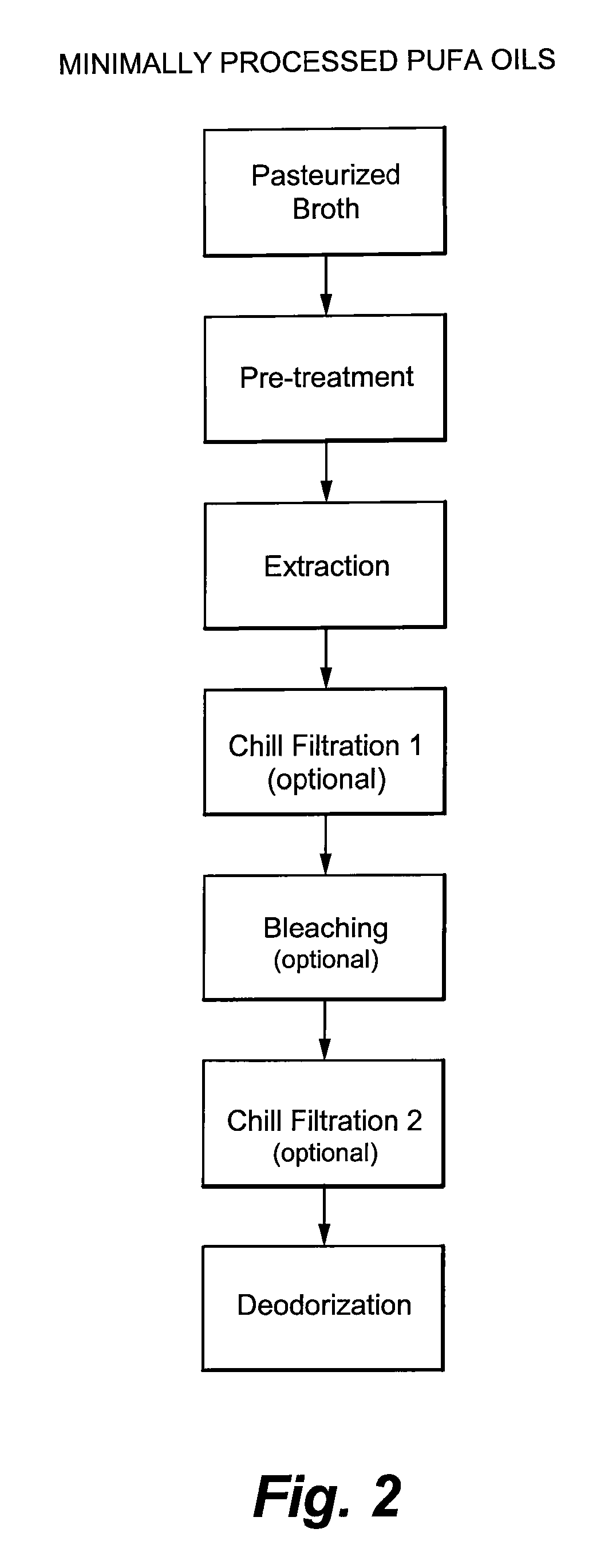

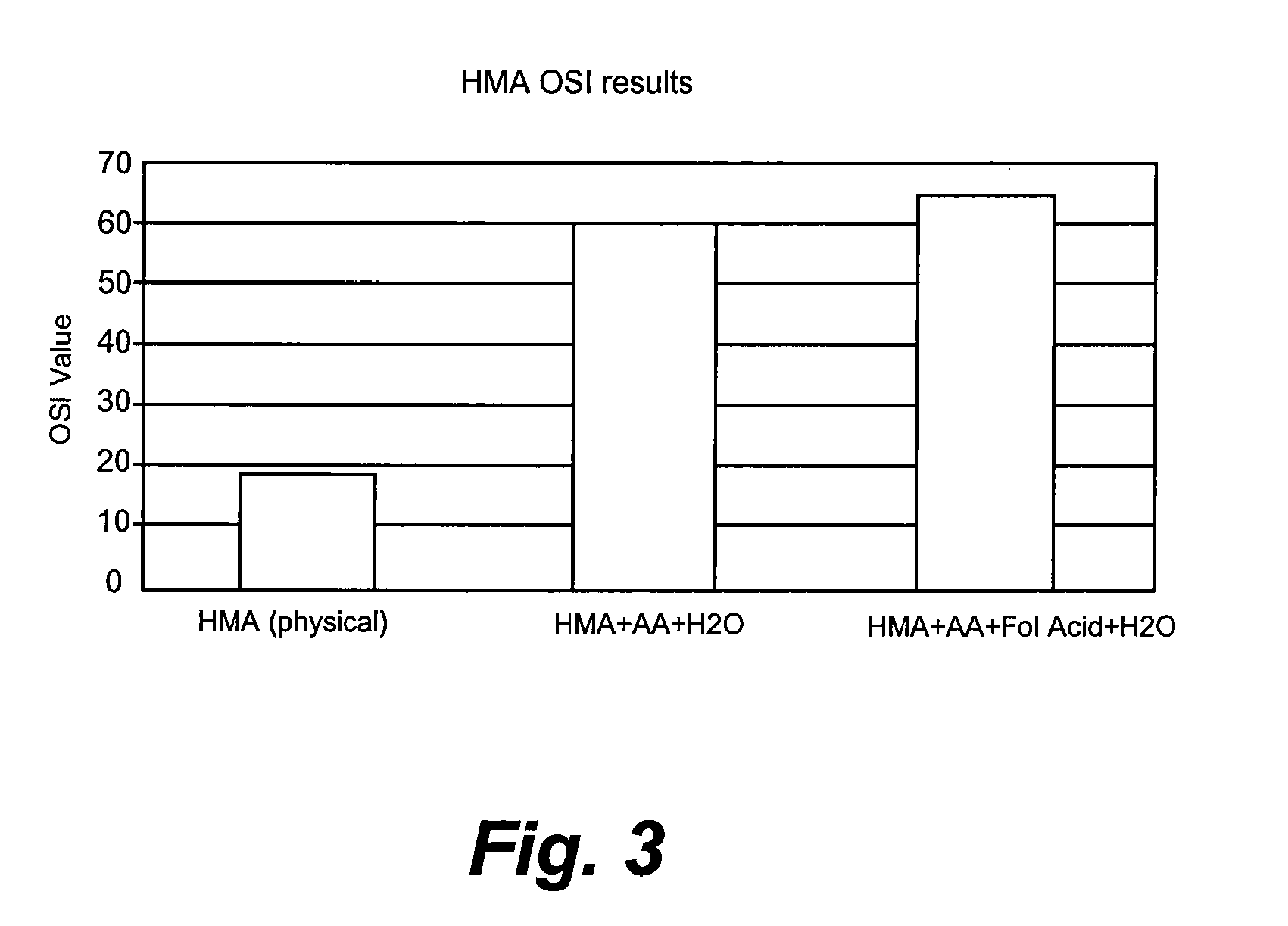

Polyunsaturated Fatty Acid-Containing Oil Product and Uses and Production Thereof

InactiveUS20080026103A1Function increaseNervous disorderFatty-oils/fats/waxes solidificationMicrobial oilFiltration

Owner:DSM IP ASSETS BV

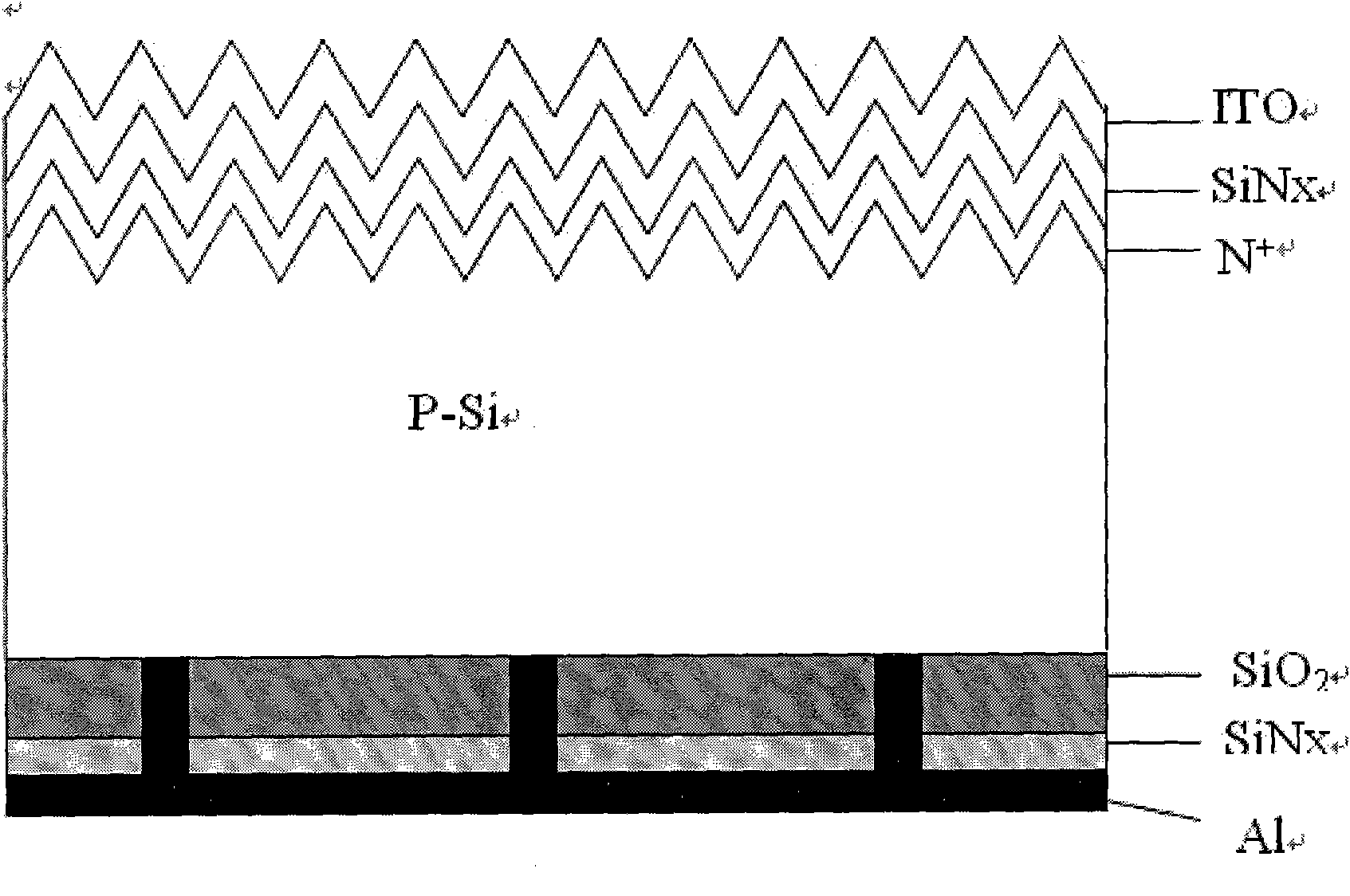

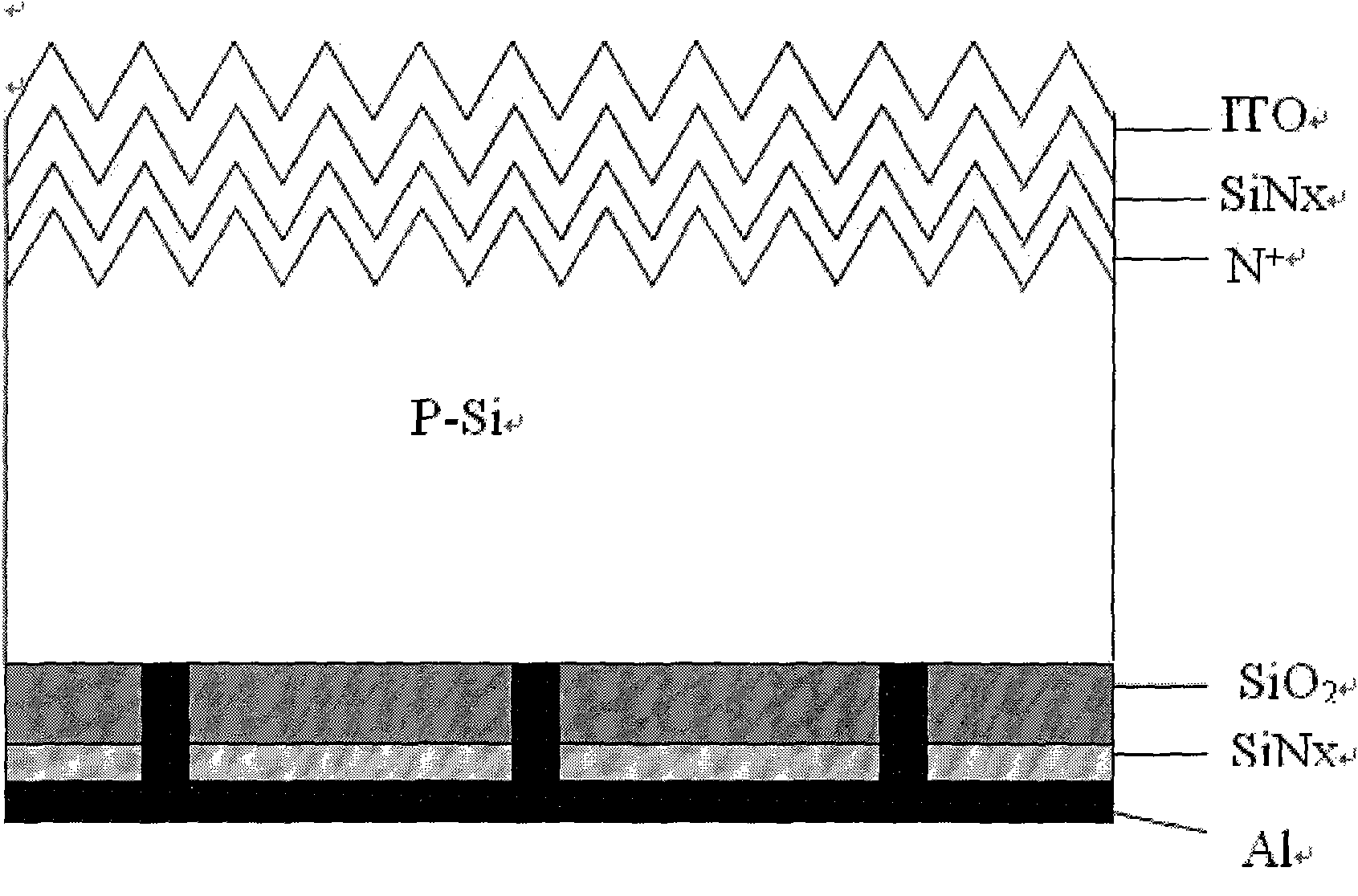

Preparation method of solar cell with buried charge layer

ActiveCN101882650AIncrease short circuit currentAvoid churnFinal product manufactureSemiconductor devicesCharge layerElectrode Contact

The invention relates to a monocrystalline silicon solar cell and a preparation method thereof, in particular to a monocrystalline silicon solar cell with a buried charge layer introduced into a passivating dielectric layer, and belongs to the technical field of the preparation of solar cell devices. The monocrystalline silicon solar cell is developed based on the preparation scheme of the general monocrystalline silicon solar cell and adopts a structure of partial back contact, and the preparation method is characterized by comprising the steps of: growing an SiO2 layer on the back of a solar cell by utilizing a thermal oxidation or atomic layer deposition technology, growing a layer of SiNx thin film by using PECVD (Plasma Enhanced Chemical Vapor Deposition), etching a back electrode contact area by using a laser grooving technology, then injecting electrons with a corona mode, and finally depositing an Al electrode with a vacuum evaporation mode. The invention can effectively improve the solar cell efficiency.

Owner:南通东湖国际商务服务有限公司

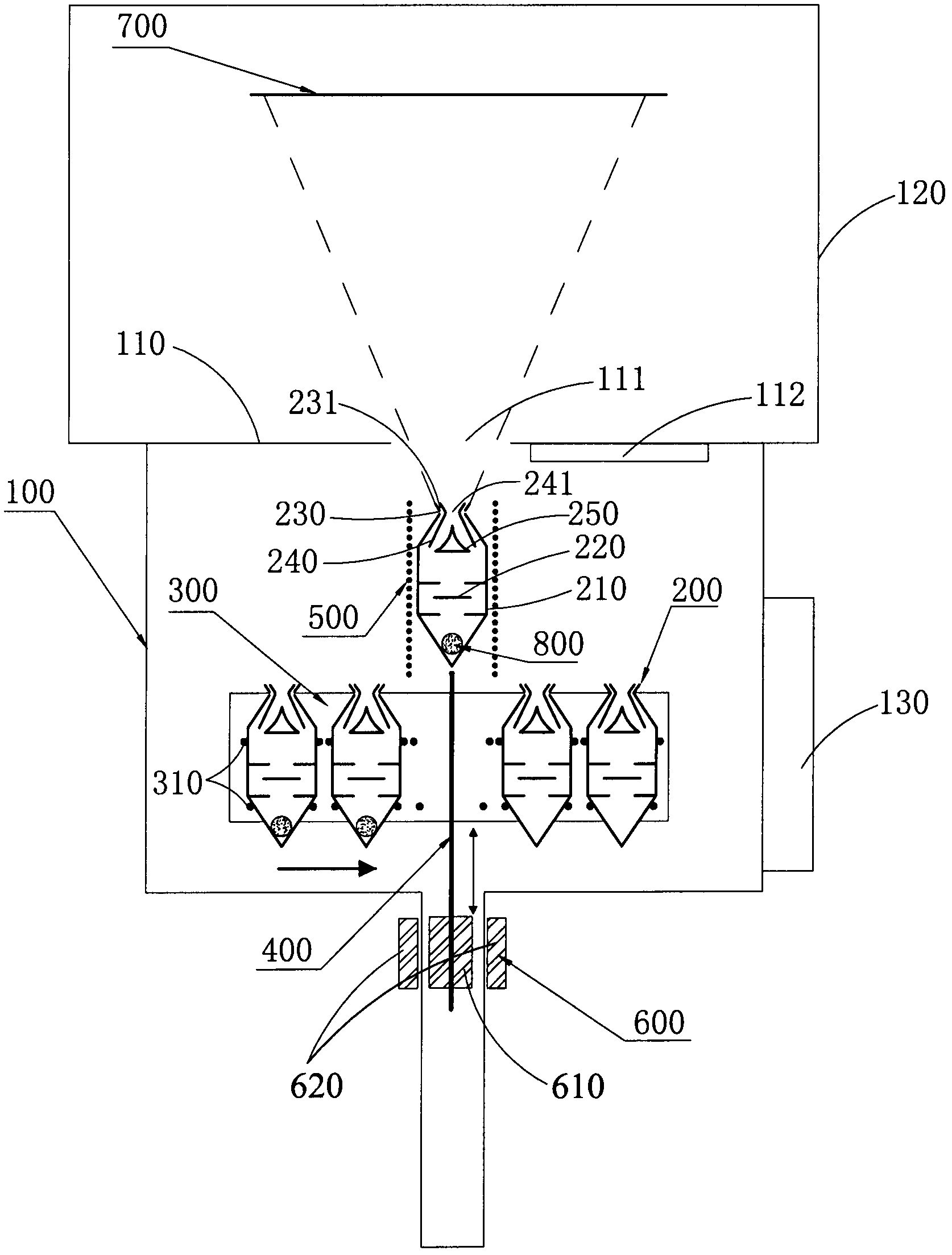

Vacuum evaporation system

ActiveCN103160788AReduce consumptionSimple structureVacuum evaporation coatingSputtering coatingControllabilityVacuum evaporation

The invention relates to a vacuum evaporation system. The vacuum evaporation system comprises a vacuum cavity chamber, evaporation sources, an electromagnetic coil and a tray. The tray is arranged on the bottom of the vacuum cavity chamber, the electromagnetic coil is arranged above the tray and opposite to the tray, the evaporation sources are multiple, the vacuum evaporation system further comprises a movable support, the multiple evaporation sources are arranged on the movable support, the movable support conveys the evaporation sources above the tray, the tray conveys the evaporation sources inside the electromagnetic coil to carry out evaporation through electromagnetic induction heating, and enables the evaporation sources to return to original positions after the evaporation is finished, and therefore the evaporation sources are arranged at the original positions on the support. The movable support moves to put the next evaporation source above the tray to carry out the next evaporation when the movable support puts the evaporation sources to the original position. The vacuum evaporation system replaces the evaporation sources through movement of the movable support, achieves continuous production, greatly simplifies the structure of a system, lowers energy consumption, improves production efficiency and controllability in a large range, and ensures product qualities.

Owner:SHANGHAI UNIV

Quantum dot ink and preparing method thereof

The invention discloses quantum dot ink and a preparing method thereof. The quantum dot ink comprises, by mass, 0.01%-20% of quantum dots and 80%-99.99% of mixed solvent. The mixed solvent comprises at least one alkane organic solvent and at least one small-molecule alcohol organic solvent, wherein the small-molecule alcohol organic solvent is 1% to 80% of the total weight of the mixed solvent, the boiling point of the alkane organic solvent ranges from 150 DEG C to 320 DEG C, the boiling point of the small-molecule alcohol organic solvent is lower than that of the alkane organic solvent. The quantum dot ink prepared with the method has the high viscosity and the high surface tension, the requirement of an ink-spraying printing device and the requirement of the printing technology can be well met, and the organic solvent of the quantum dot ink can be removed in a vacuum evaporation or heat evaporation mode and the like to form a film of a quantum dot material.

Owner:TCL CORPORATION

Multilayer thin film hydrogen getter

InactiveUS20030062610A1Excellent high electrical conductance metalImprove circuit performanceDecorative surface effectsSemiconductor/solid-state device detailsHydrogenTitanium

A thin film hydrogen getter is provided for protecting GaAs circuitry sealed in an hermetic package. The thin film getter which comprises a multilayer metal film which is deposited by vacuum evaporation techniques onto a surface of the packaging. The multilayer film comprises (1) a titanium film and (2) palladium film which is deposited onto the titanium film. Both the titanium and the palladium are deposited during the same coating process run, thereby preventing the titanium from being oxidized. The palladium continues to prevent the titanium from being oxidized once the getter is exposed to the atmosphere. However, hydrogen is easily able to diffuse through the palladium into the titanium where it is chemically bound up, since palladium is highly permeable to hydrogen. If EMI shielding is desired, a conductive metal, such as aluminum or copper, can first be formed between the packaging and the titanium layer.

Owner:RAYTHEON CO

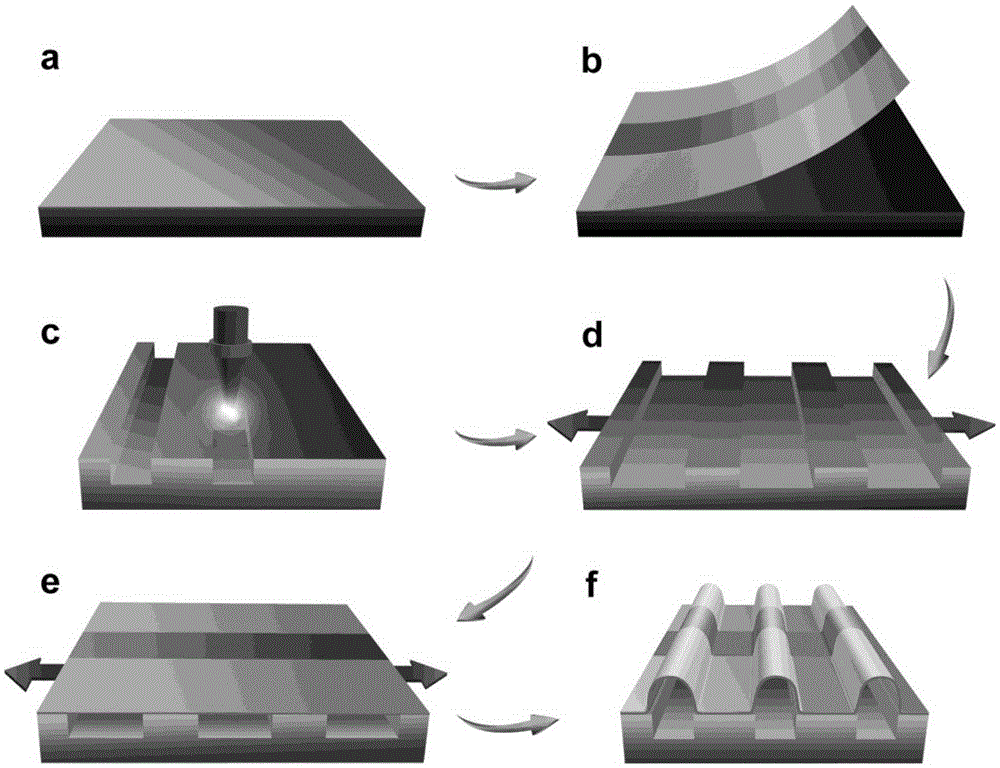

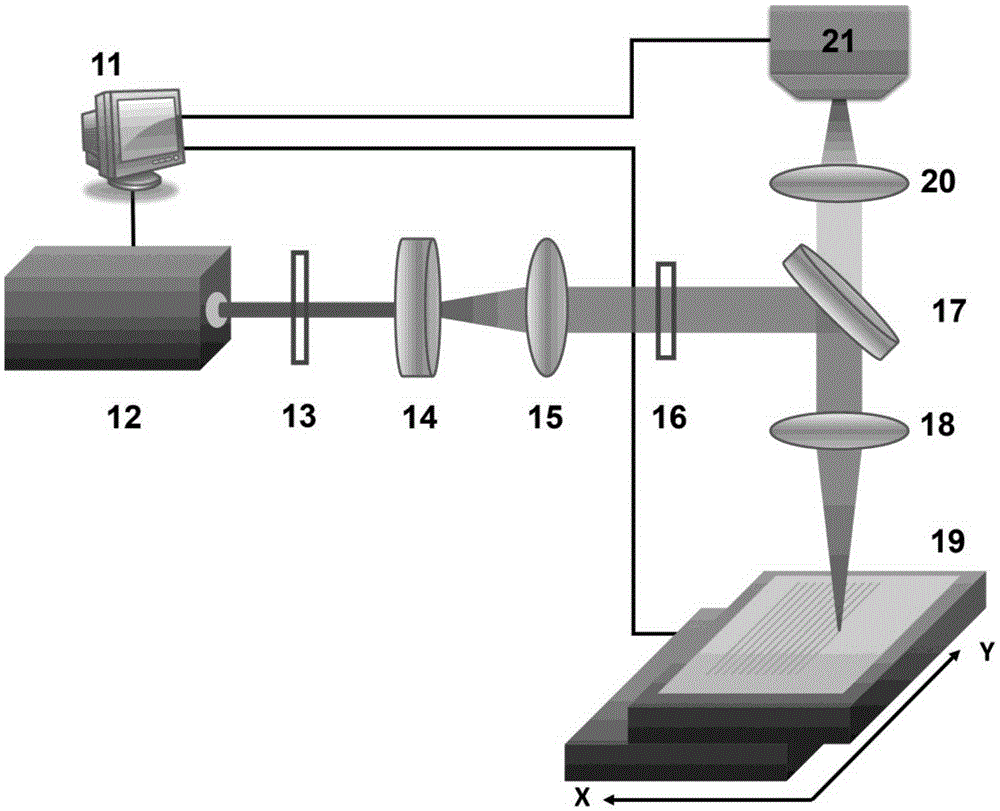

Stretching organic electroluminescence device with periodically regular crease structure

ActiveCN105405983AImprove flexibilityFlat surfaceSolid-state devicesSemiconductor/solid-state device manufacturingGratingElastic substrate

The invention discloses a stretching organic electroluminescence device with a periodically regular crease structure, belongs to the technical field of photoelectrons, and particularly relates to the stretching organic electroluminescence device with a periodically regular crease, which is high in efficiency, high in stability and high in tensile strength. The stretching organic electroluminescence device is prepared by the following steps: processing a long-period grating structure on the surface of an elastic substrate by a femtosecond laser ablation process; obtaining an organic electroluminescence device by combining a vacuum evaporation technology and a demolding technology; and finally combining the elastic substrate with the long-period grating structure and the organic electroluminescence device. The stretching organic electroluminescence device has very high stretching stability; the photoelectric property of the device only slightly fluctuates along with the change of the tensile strength; and more importantly, the properties of the device only lightly attenuate in multiple repeated tensile tests, so that the stretching organic electroluminescence device has very high practical value.

Owner:JILIN UNIV

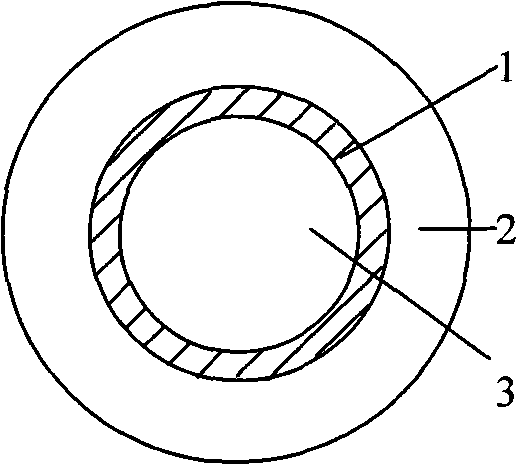

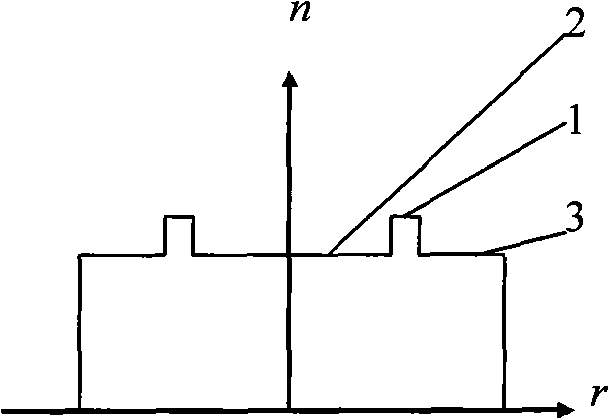

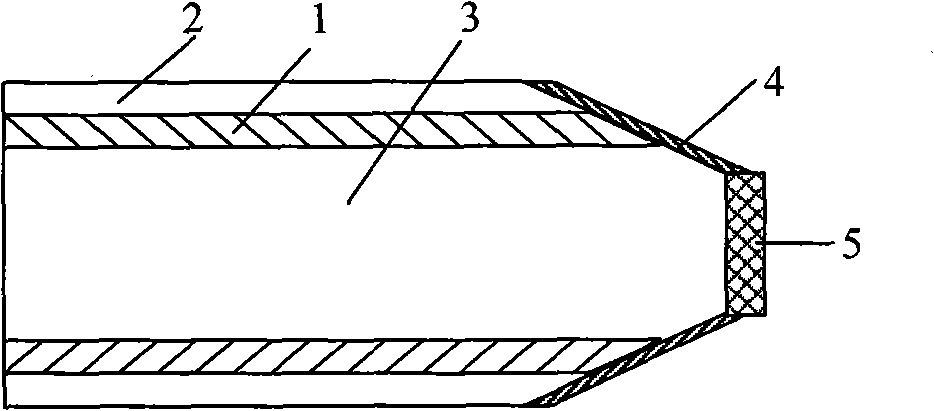

Plasma resonant type optical fiber biosensor based on annular core wave guide

InactiveCN101769857AFew mechanical partsEasy to integrateMaterial analysis by optical meansDistance detectionOptical fiber coupler

The invention provides a plasma resonant type optical fiber biosensor based on annular core wave guide, which consists of a broad band light source, an optical fiber coupler, an optical fiber probe, a detector, an optical spectrometer and a signal processor through being connected, wherein the optical fiber coupler is formed by single mode optical fiber and annular core optical fiber through being coupled, the single mode optical fiber of the optical fiber coupler is connected with the output of the broad band light source, and the annular core optical fiber is connected with the optical fiber probe. The optical fiber probe belongs to an optical fiber probe manufactured by a method comprising the following steps: grinding the annular core single mode optical fiber into a frustum with the designed angle and the designed height; using vacuum evaporation film plating equipment for plating a golden film for depositing a layer of golden film on the surface of the frustum; and carrying out secondary film plating for forming a reflecting film on the end surface of the optical fiber. The invention has the small size, reduces mechanical parts of the biosensor, is suitable for remote distance detection, is convenient for the instrument integration, and can detect the change of the external environment in real time. The invention has higher optical coupling efficiency than the traditional single mode optical fiber. The manufacture of the sensing probe is convenient, and the repetitiveness is good. The detection sensitivity is high, and the test results are stable and reliable.

Owner:HARBIN ENG UNIV

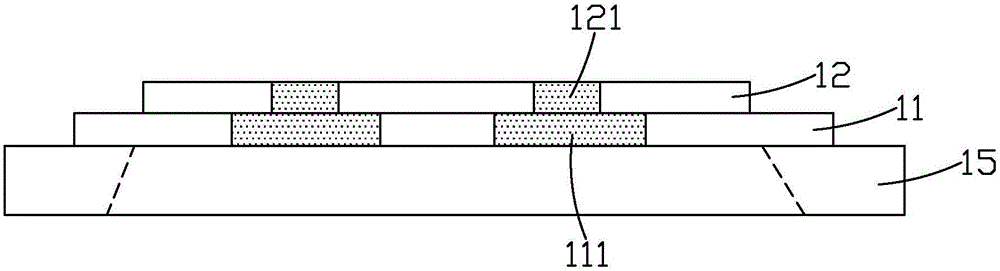

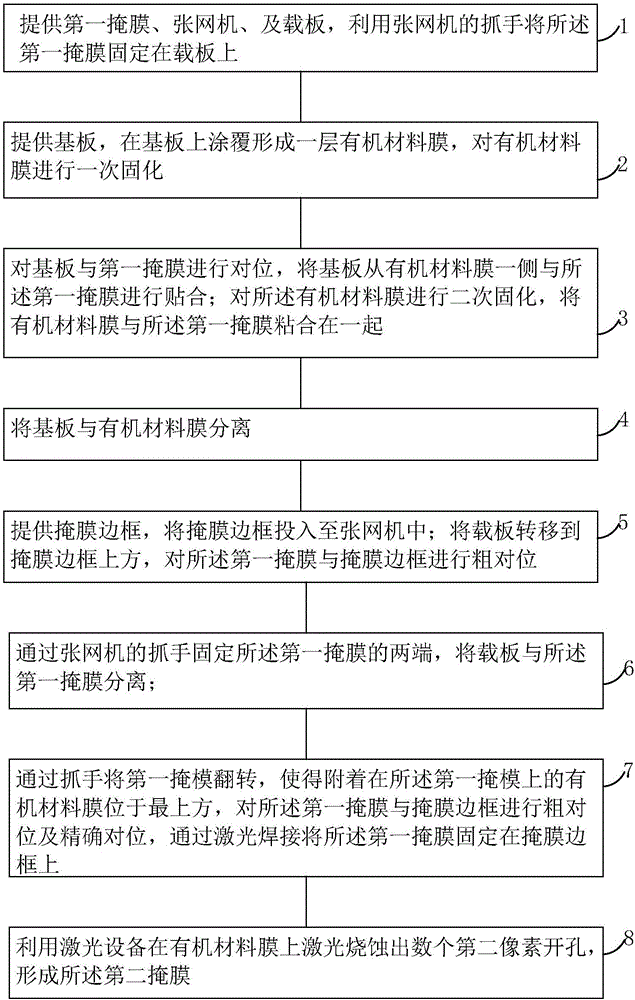

Fine mask plate and manufacturing method thereof

ActiveCN106591776AHigh resolutionSmall hole wall slopeVacuum evaporation coatingSputtering coatingEngineeringVacuum evaporation

The invention provides a fine mask plate and a manufacturing method thereof. The fine mask plate comprises a mask frame, a first mask made of a metal material and a second mask made of an organic material; the first mask is provided with a plurality of first pixel holes; one or more second pixel holes are formed in the areas, corresponding to all the first pixel holes, of the second mask; as the second pixel holes are formed in the areas corresponding to the first pixel holes, compared with existing FMM, the pixel holes of the smaller size can be provided, and accordingly, OLED devices of the smaller size in the vacuum evaporation process can be manufactured, and the resolution of OLED display products is improved; meanwhile, the hole wall gradient of the second pixel holes can be controlled to be smaller, the second pixel holes are used in the vacuum evaporation process, and thus the incident angle of an evaporation material at the edges of the second pixel holes can be smaller; and accordingly, a coating film shadow area can be decreased, and the resolution of the OLED display products is further improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com