Process method for recovering ammonium chloride and sodium chloride from waste water containing ammonium chloride and sodium chloride

A process method, ammonium chloride technology, applied in the direction of chemical instruments and methods, ammonium halide, alkali metal chloride, etc., can solve the problems of strong corrosion of centrifuges, strong equipment, no sodium chloride, etc., to solve equipment corrosion , Reduce energy consumption and save water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

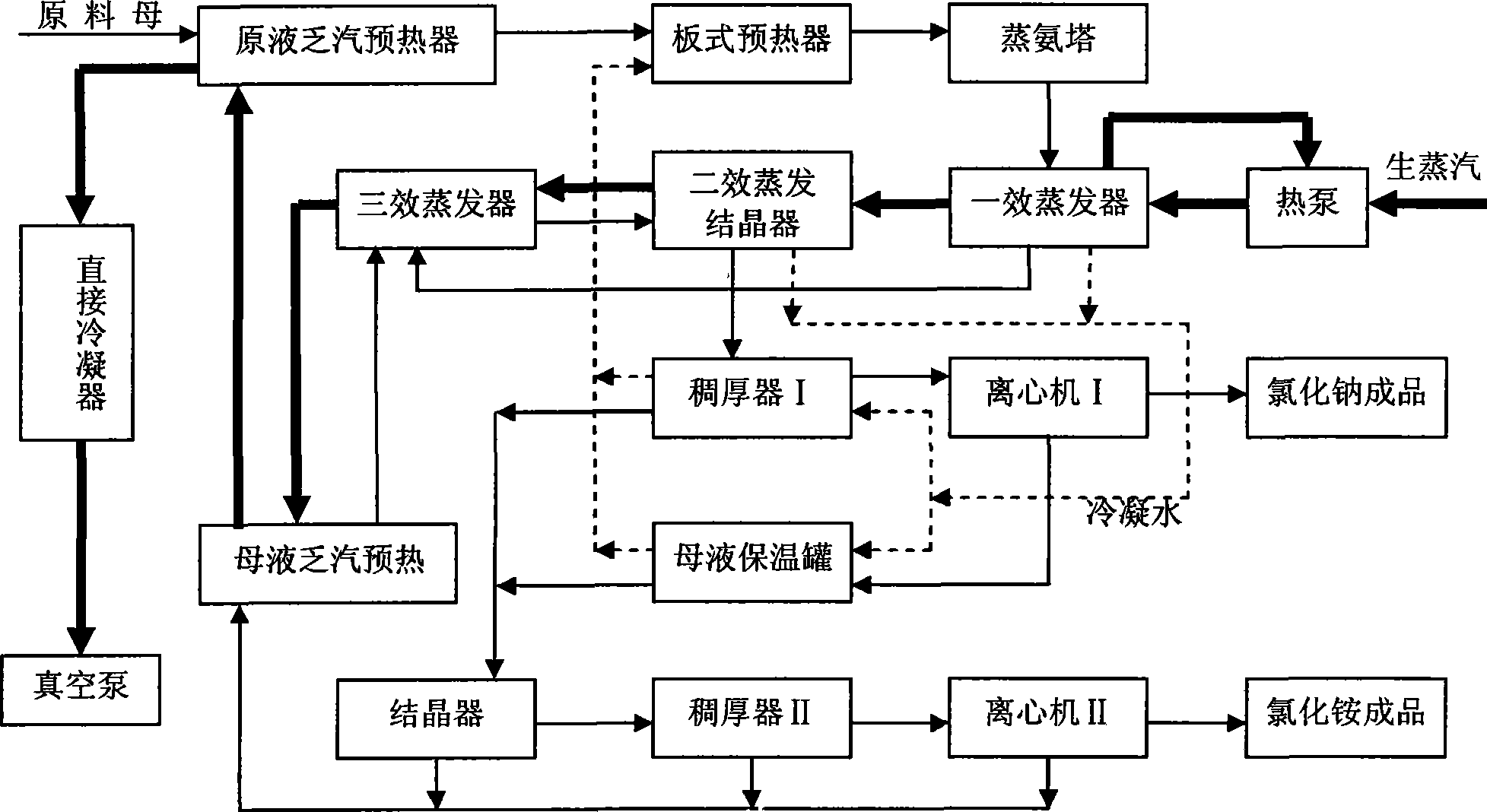

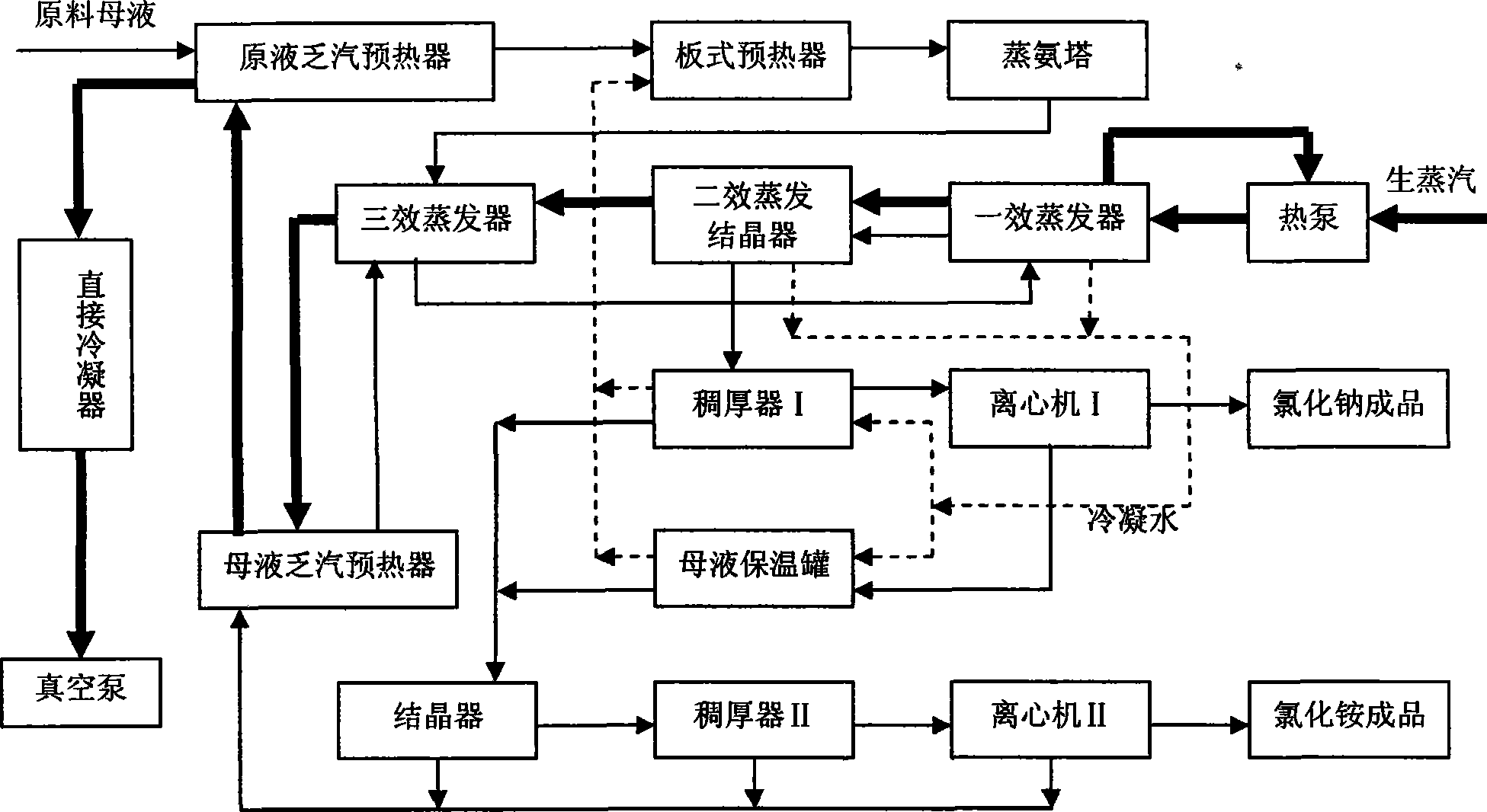

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: the mother liquor (containing ammonium chloride 17.5%, sodium chloride 7.5%) that metathesis reaction produces baking soda process is preheated to 70 ℃ continuously through stoste exhaust steam preheater and plate preheater, pump flow rate 20m 3 / h, into the ammonia distillation tower for deammonization treatment; then the mother liquor is sequentially input into the third effect evaporator (φ650×12000), the first effect evaporator (φ800×12000), and the second effect evaporator (φ750×13000) for heating Evaporation, the boiling point of the third-effect solution is controlled at 60°C, concentrated to a concentration of 32%, the boiling point of the first-effect solution is controlled at 120°C, concentrated to a concentration of 42%, the second-effect evaporation crystallizer is heated to evaporate and crystallized, and the boiling point of the solution is controlled at 90 ℃, concentrated to a concentration of 43%, and the crystallization temperature is contr...

Embodiment 2

[0030] Embodiment 2: the mother liquor (containing ammonium chloride 17%, sodium chloride 8%) that metathesis reaction produces sodium bicarbonate process produces, is preheated to 65 ℃ continuously through stoste exhaust steam preheater and plate preheater, pump flow 30m 3 / h, into the ammonia distillation tower for deammonization treatment; then the mother liquor is sequentially input into the third effect evaporator (φ750×12000), the first effect evaporator (φ900×12000), and the second effect evaporator (φ850×13000) to evaporate The boiling point of the solution in the first effect evaporator is controlled at 110°C and concentrated to a concentration of 43%. The boiling point of the solution in the third effect evaporator is controlled at 58°C and concentrated to a concentration of 30%. The second effect evaporator crystallizer is heated to evaporate and crystallize , the boiling point of the solution is controlled at 86°C, concentrated to a concentration of 42%, and the cry...

Embodiment 3

[0034] Embodiment 3: the soda-making mother liquor (containing ammonium chloride 16%, sodium chloride 6.4%) that produces in the production of soda ash is preheated continuously to 55 ℃ through stoste exhaust steam preheater and plate preheater, pump flow 50m 3 / h, into the ammonia distillation tower for deammonization treatment; then the mother liquor is sequentially input into the third effect evaporator (φ1200×12000), the first effect evaporator (φ900×12000), and the second effect evaporator (φ950×13000) to evaporate The boiling point of the solution in the third effect evaporator is controlled at 55°C and concentrated to a concentration of 28.5%. The boiling point of the solution in the first effect evaporator is controlled at 115°C and concentrated to a concentration of 40%. The second effect evaporator crystallizer is heated to evaporate and crystallize , the boiling point of the solution is controlled at 92°C, concentrated to a concentration of 43%, and the crystallizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com