Patents

Literature

13697results about "Sludge treatment by de-watering/drying/thickening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production of biodiesel and other valuable chemicals from wastewater treatment plant sludges

ActiveUS20050112735A1Reduce the environmentPromote digestionBio-organic fraction processingByproduct vaporizationLipid formationSludge

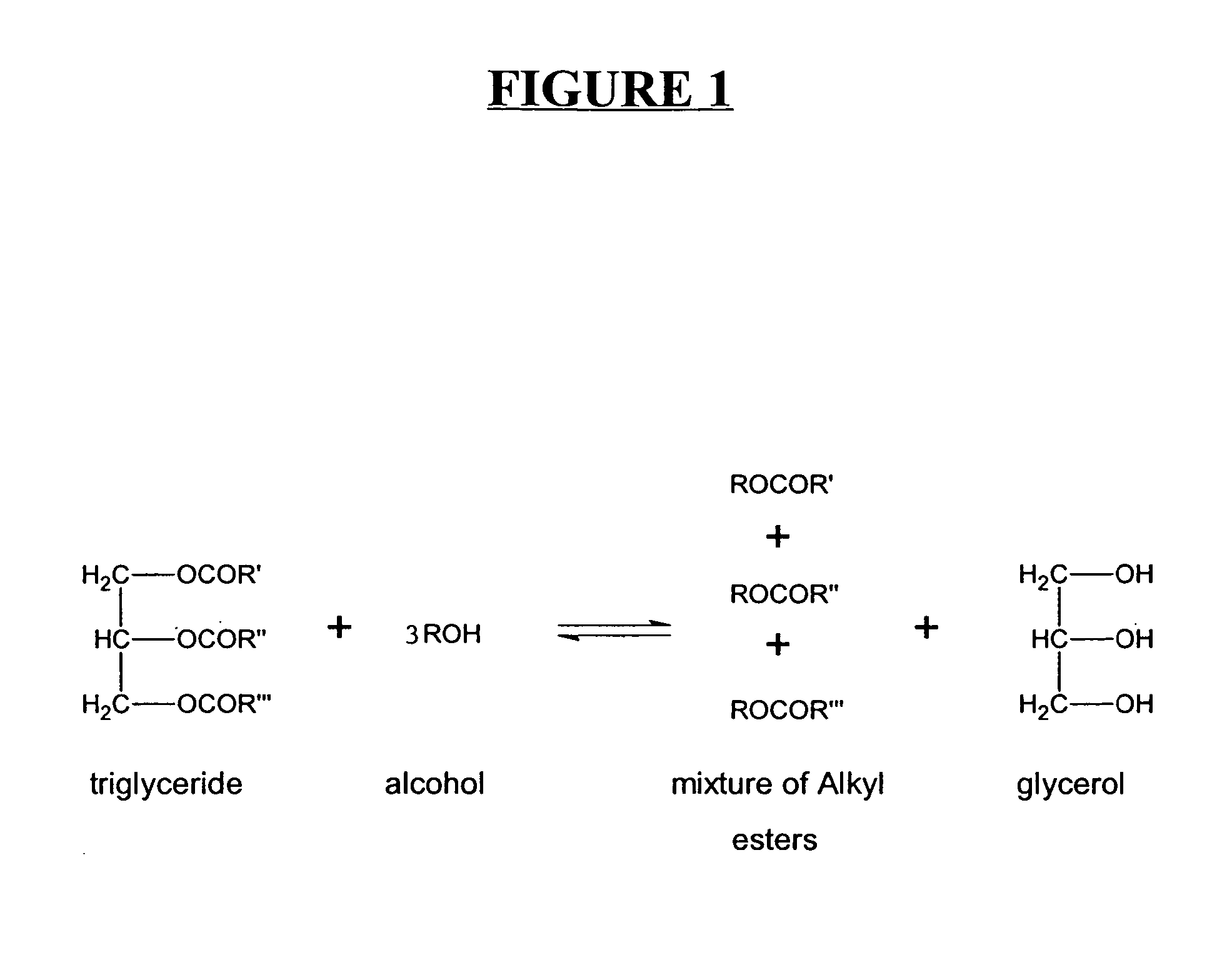

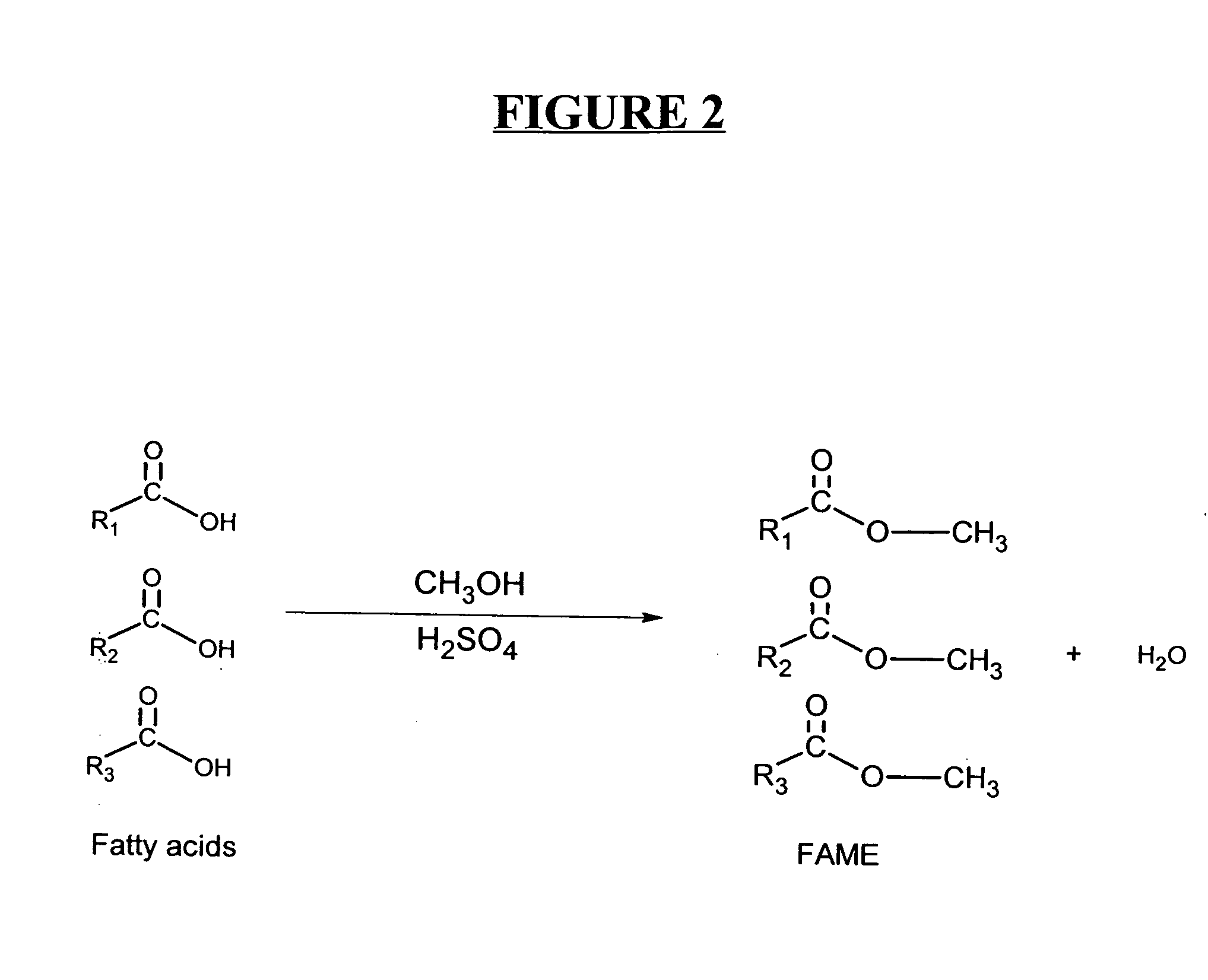

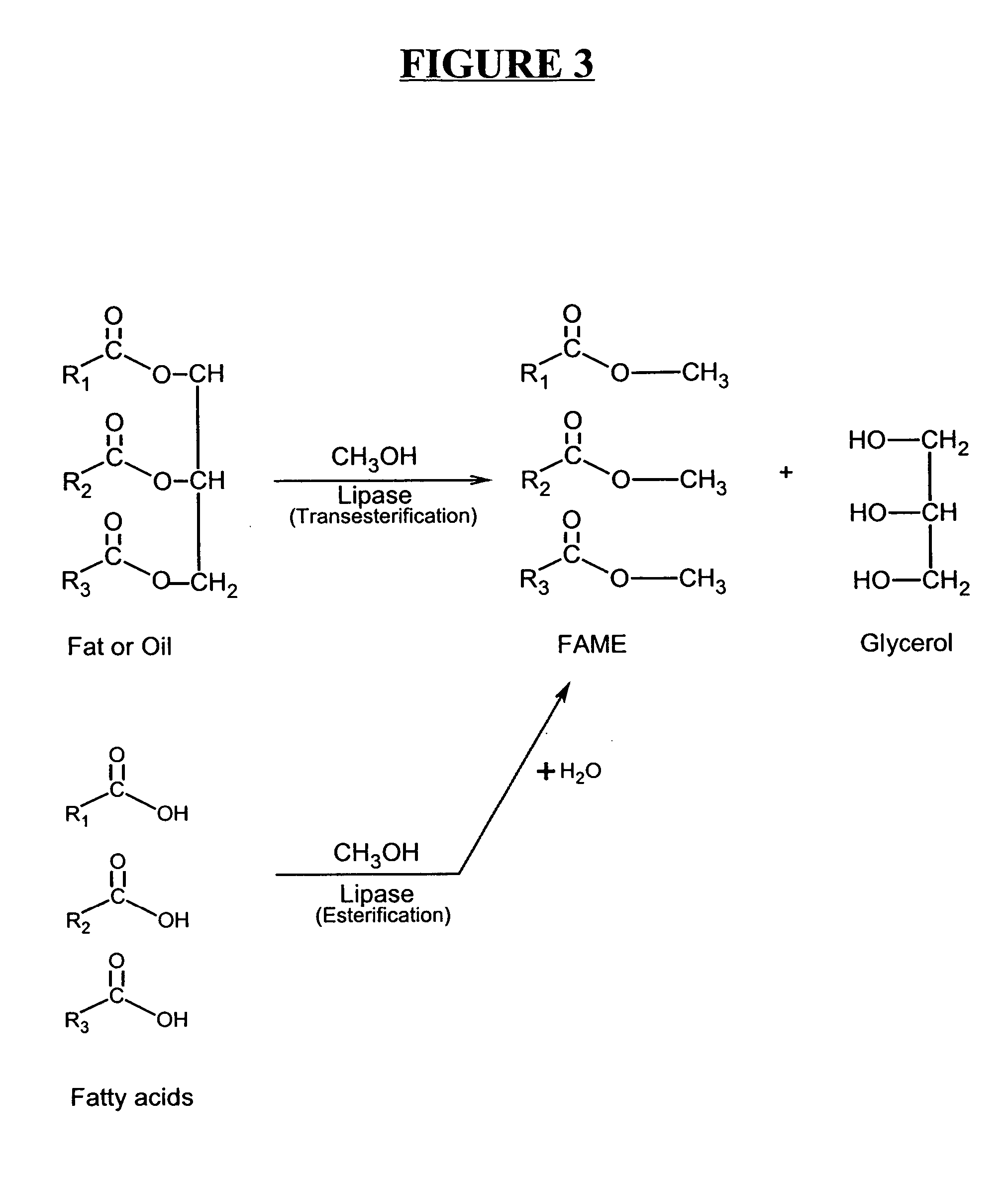

A process for producing biodiesel has been invented by first extracting lipids from the sludges generated during primary and / or biological treatment of municipal, agricultural, and industrial wastewaters using primary, secondary, and tertiary treatments followed by the transesterification of the extracted lipids using transesterification conversion into alcohol-based esters. The resulting products from this process include biodiesel, glycerol, lipid-free proteins, various other useful chemicals and an aqueous-based substrate well suited for optimized digestion within subsequent biological digestion (either aerobic or anaerobic). The lipids extracted from the sludges containing high levels of microorganisms are phospholipids which can also be directly used as lecithin. The extraction of the lipids from the sludges will be performed using chemical extraction techniques with the transesterification of the extracted lipids accomplished using basic, acidic, and / or a combination of the two transesterification techniques.

Owner:MISSISSPPI STATE UNIV RES & TECH

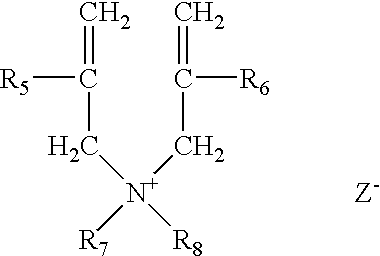

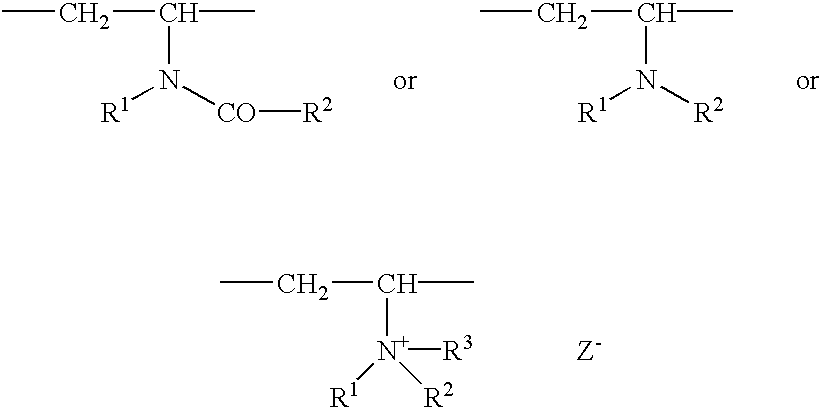

Method for making hydrophobically associative polymers, methods of use and compositions

InactiveUS6417268B1Cosmetic preparationsSludge treatment by de-watering/drying/thickeningHydrophilic monomerSludge

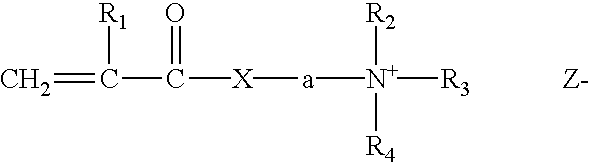

Method for producing an hydrophobically associative polymer is provided which is characterized by forming a monomer solution comprising a surfactant, at least one hydrophobic ethylenically unsaturated monomer, at least one hydrophilic monomer selected from nonionic ethylenically monomers, cationic ethylenically unsaturated monomers, anionic ethylenically unsaturated monomers or mixtures thereof, and water; forming a salt solution comprising a multivalent salt and water; mixing the monomer solution and salt solution to form a mixed solution; and charging the mixed solution with an initiator, thereby polymerizing the monomers to form the hydrophobically associative polymer in a dispersion. Aqueous dispersion containing the hydrophobically associative polymer formed by the method. The aqueous dispersion containing the hydrophobically associative polymer may be used in a paint formulation, in a mobility control fluid useful in enhanced oil recovery, in a secondary or tertiary oil recovery system, in an enhanced oil recovery method, in a cementious composition, in an oil well drilling mud formulation, in a fracturing fluid formulation, in a wastewater treatment system, or in a dewatering sludge system.

Owner:SOLENIS TECH CAYMAN

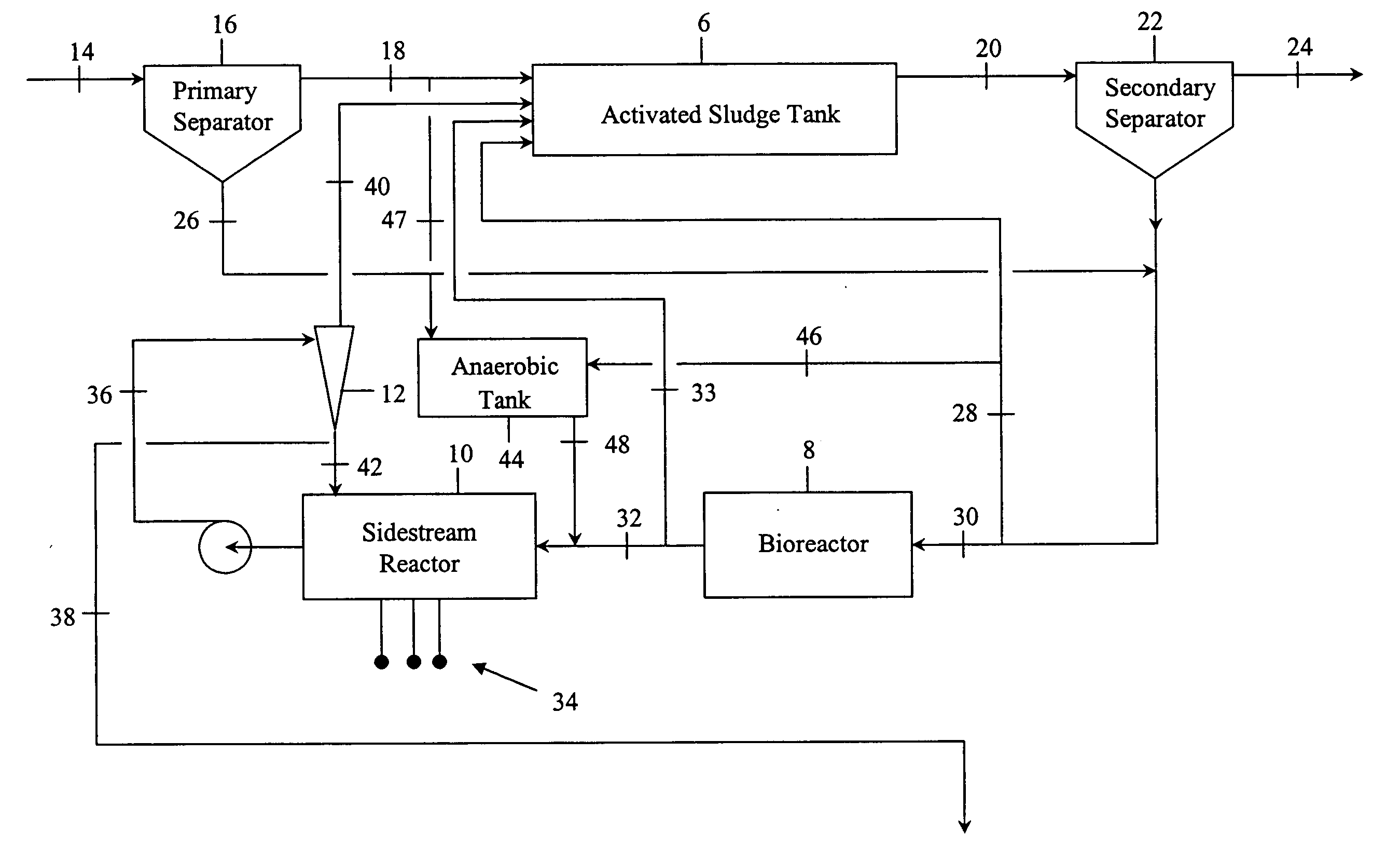

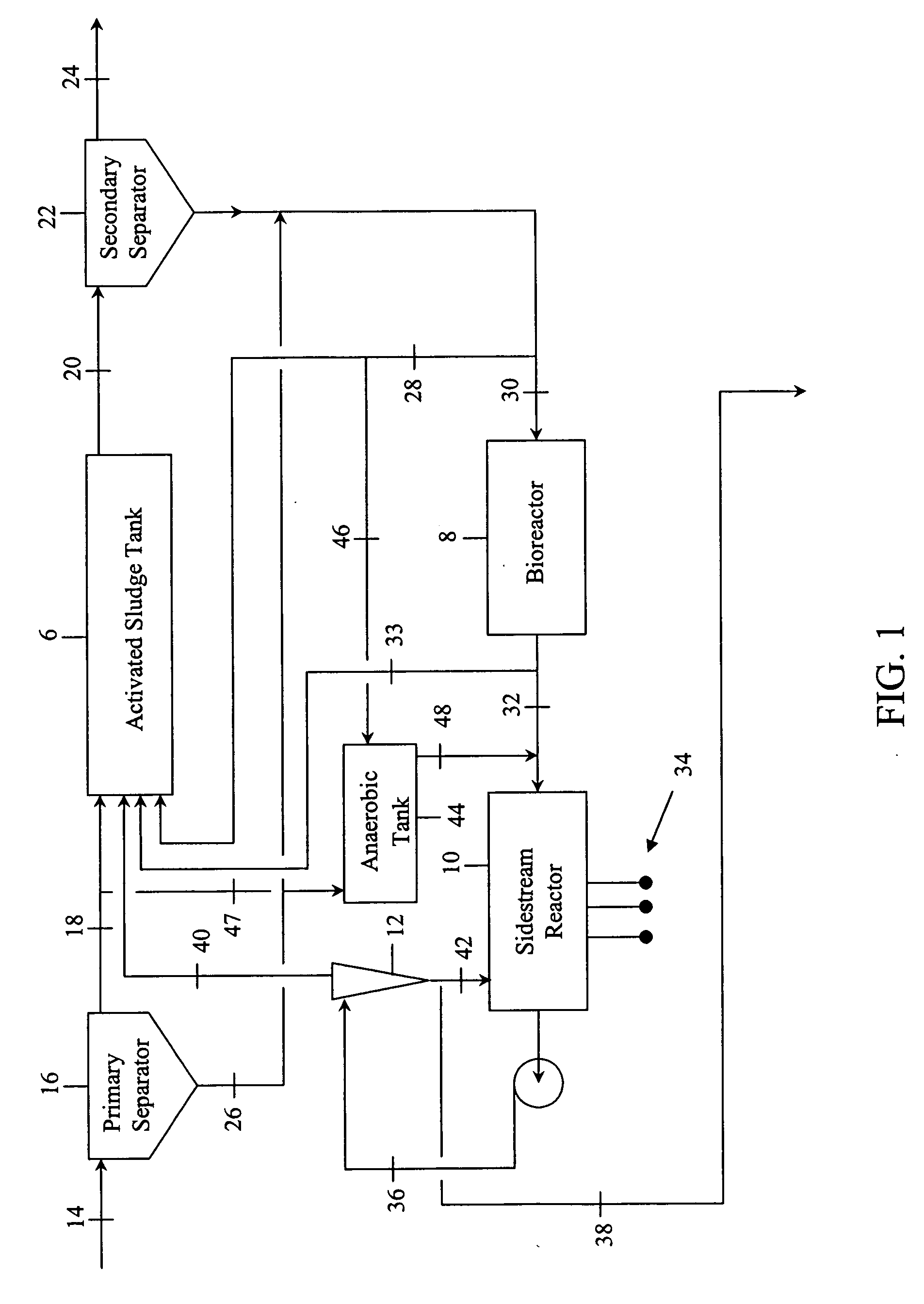

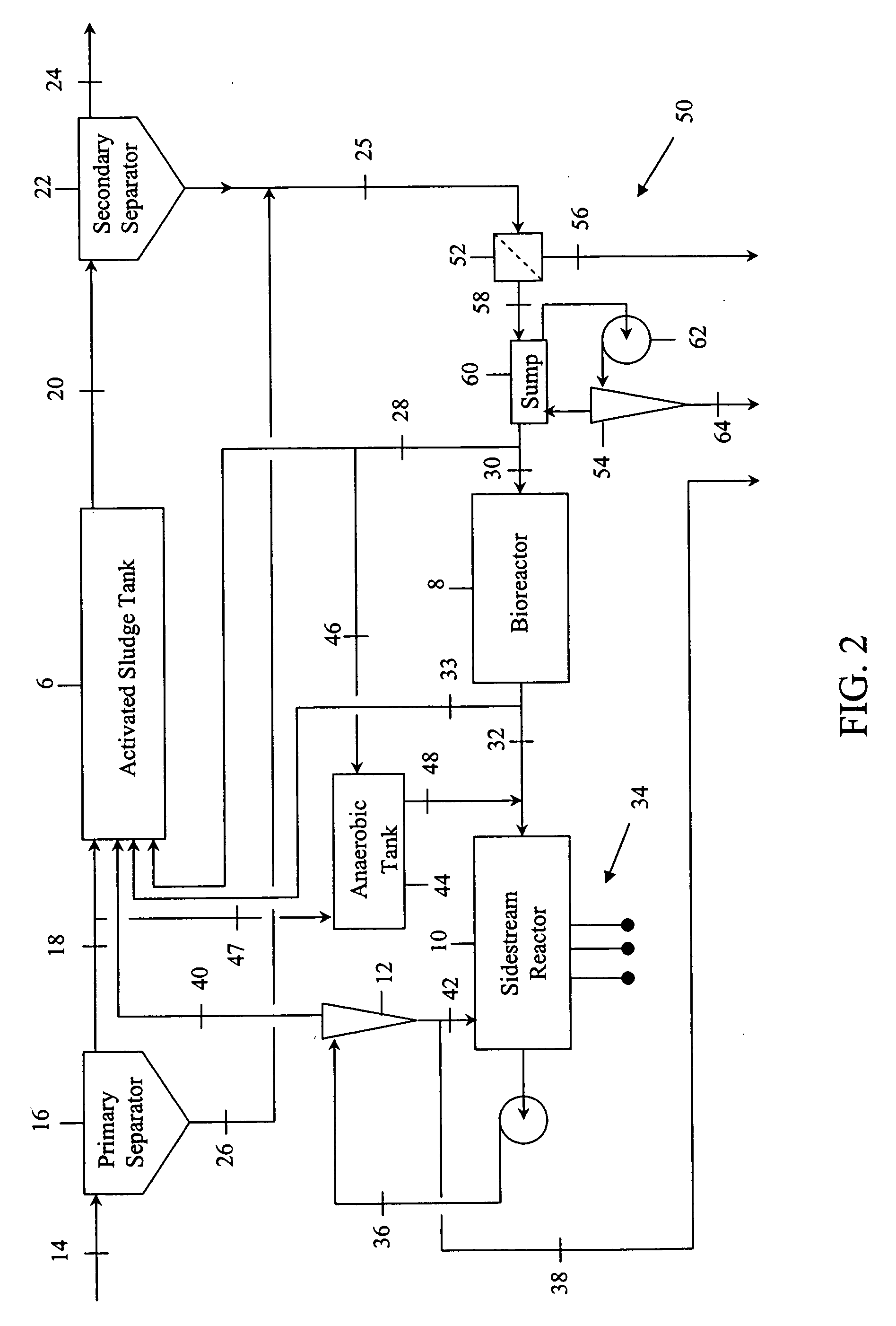

Process to enhance phosphorus removal for activated sludge wastewater treatment systems

InactiveUS20070000836A1Water/sewage treatment by centrifugal separationWater treatment parameter controlActivated sludgePhosphate

Contaminated wastewaters comprising biochemical oxygen demand (BOD), nitrogen and phosphorus are treated by an activated sludge process. The process utilizes an activated sludge tank, a solid-liquid separator, and a bioreactor to significantly reduce, or eliminate, waste activated sludge (WAS) within a sludge stream. A sidestream reactor is employed downstream from the bioreactor to remove soluble phosphates left in the sludge stream by the low WAS process. Within the sidestream reactor, a source of multivalent metal ions is added to a slightly alkaline sludge stream to precipitate the phosphates. The solid phosphates have a specific gravity higher than that of the organic matter in the sludge stream and may be separated from the sludge stream based upon differential settling velocity.

Owner:EVOQUA WATER TECH LLC

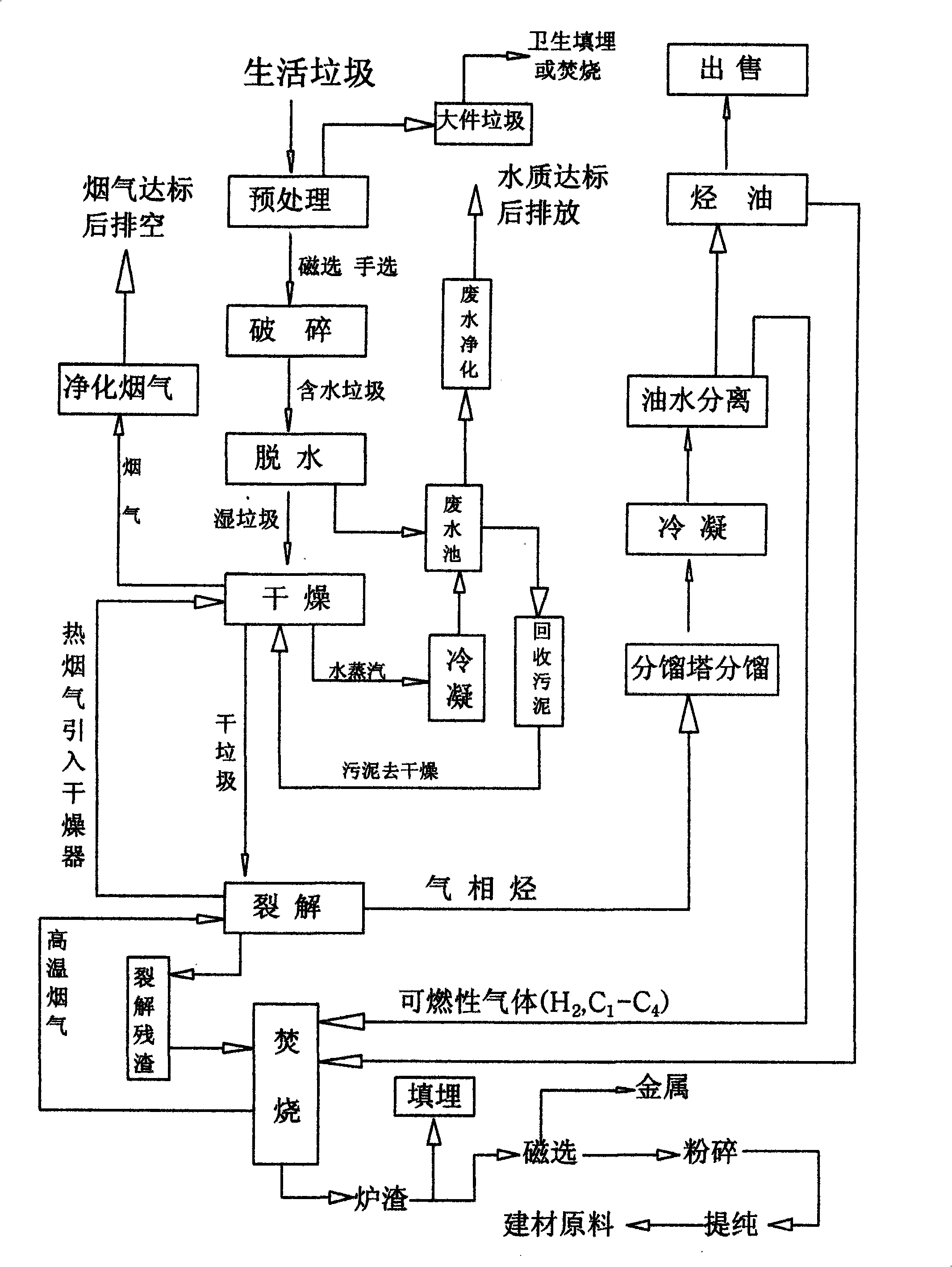

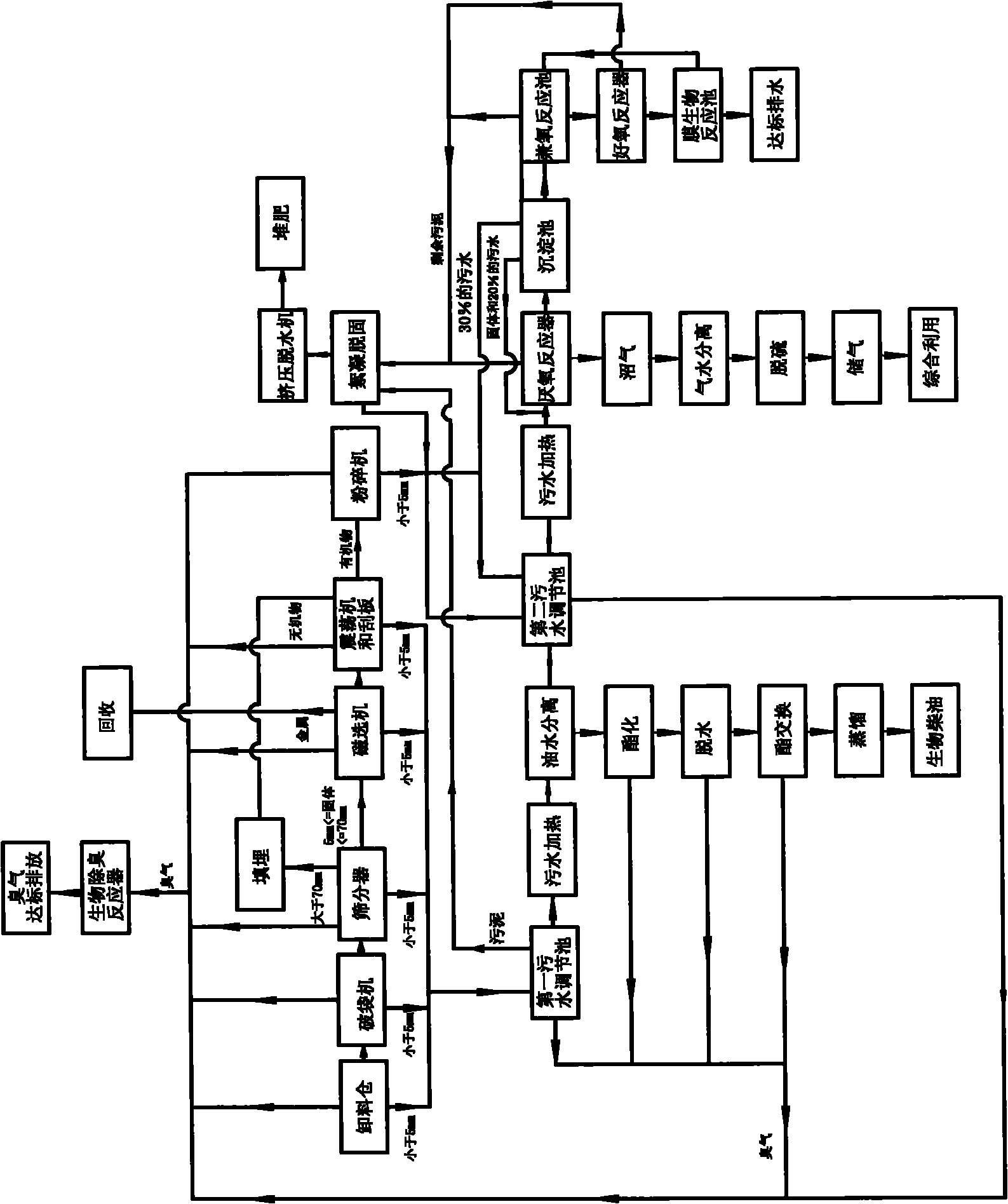

Method for sequentially processing consumer waste

ActiveCN101352721AHarmless treatmentIncrease throughputSludge treatment by de-watering/drying/thickeningSolid waste disposalLitterMature technology

The invention discloses a method for continuously treating domestic garbage, more specifically belongs to a method for continuously treating domestic garbage according to the process flows of pretreatment, crushing, dehydration, drying, cracking, incineration, etc. Dioxin C2H4O2 is not produced in the garbage treatment process; and the method can realize various requirements of massive and continuous treatment, reclamation (the energy in the garbage is stored in a manner of collecting hydrocarbon oil), energy saving, environmental protection, high efficiency, and the like, in domestic garbage treatment. The devices adopted in the method belong to standardized commodities for industrial use, and have the advantages of reliable operation, mature technology, simple structure and low investment. The method of the invention belongs to the continuous garbage treatment process, can completely and thoroughly implement reduction, harmless treatment and reclamation of mountains of domestic garbage, and is characterized by good novelty, creativity and industrial applicability.

Owner:北京康乔世纪环境科技有限公司 +1

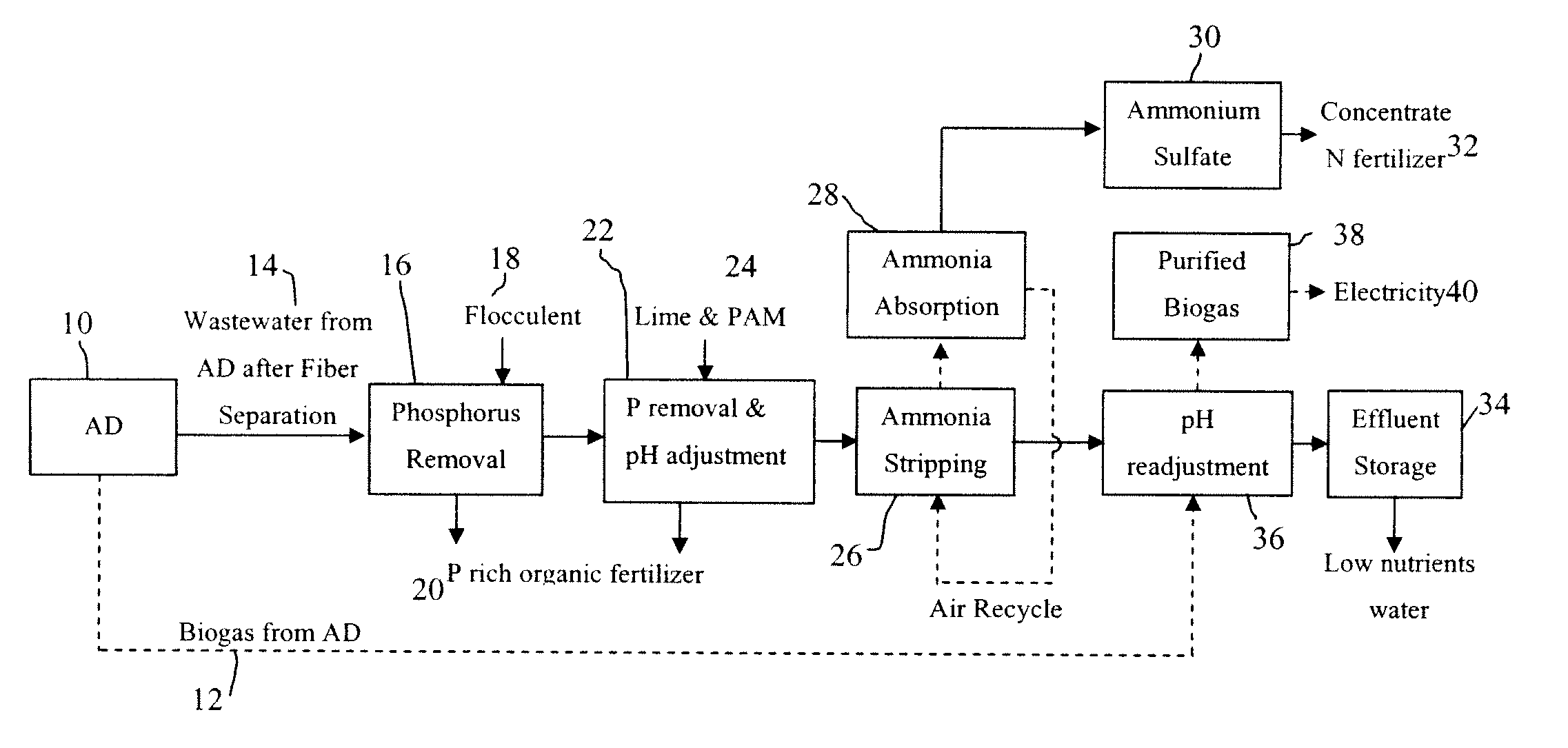

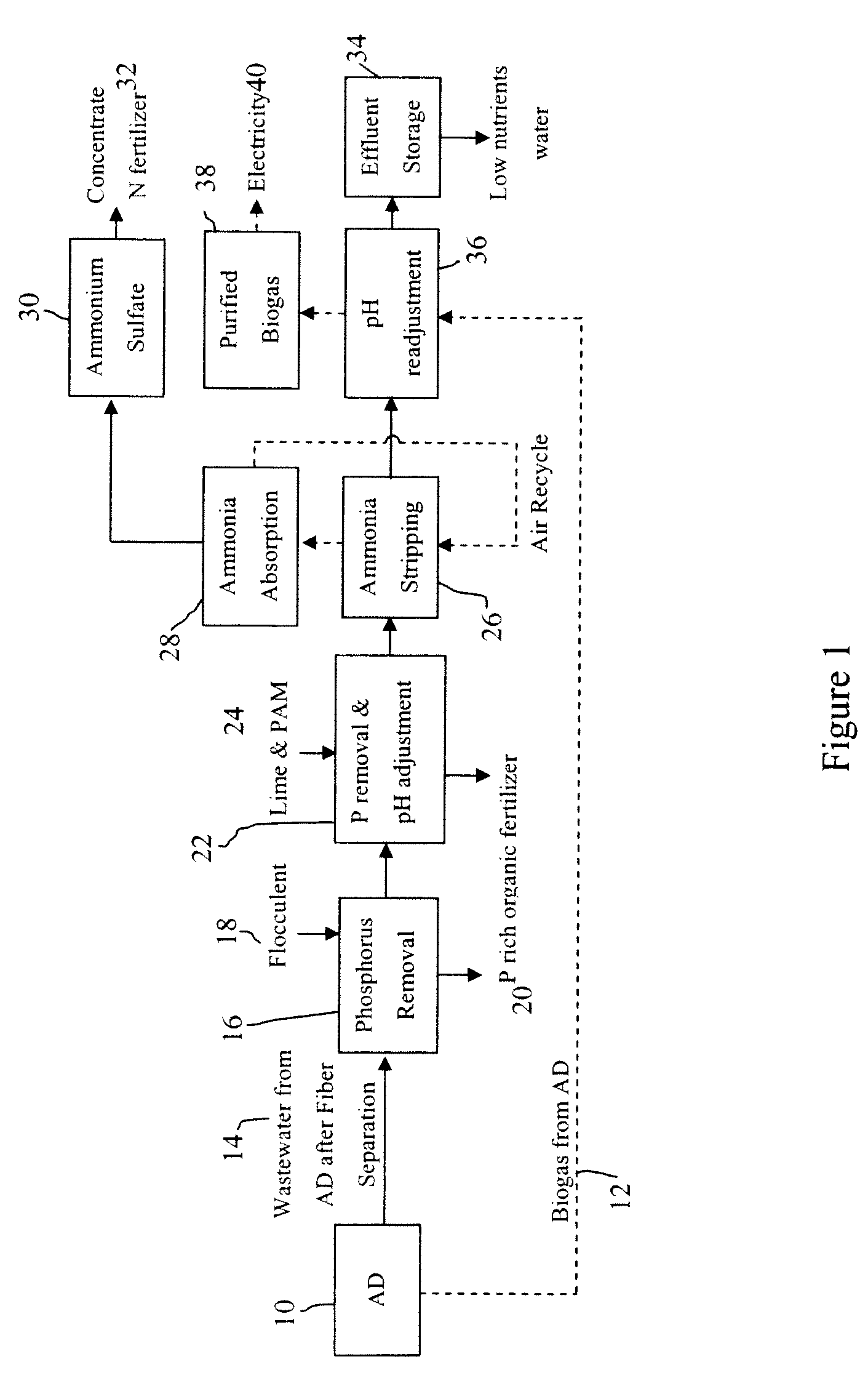

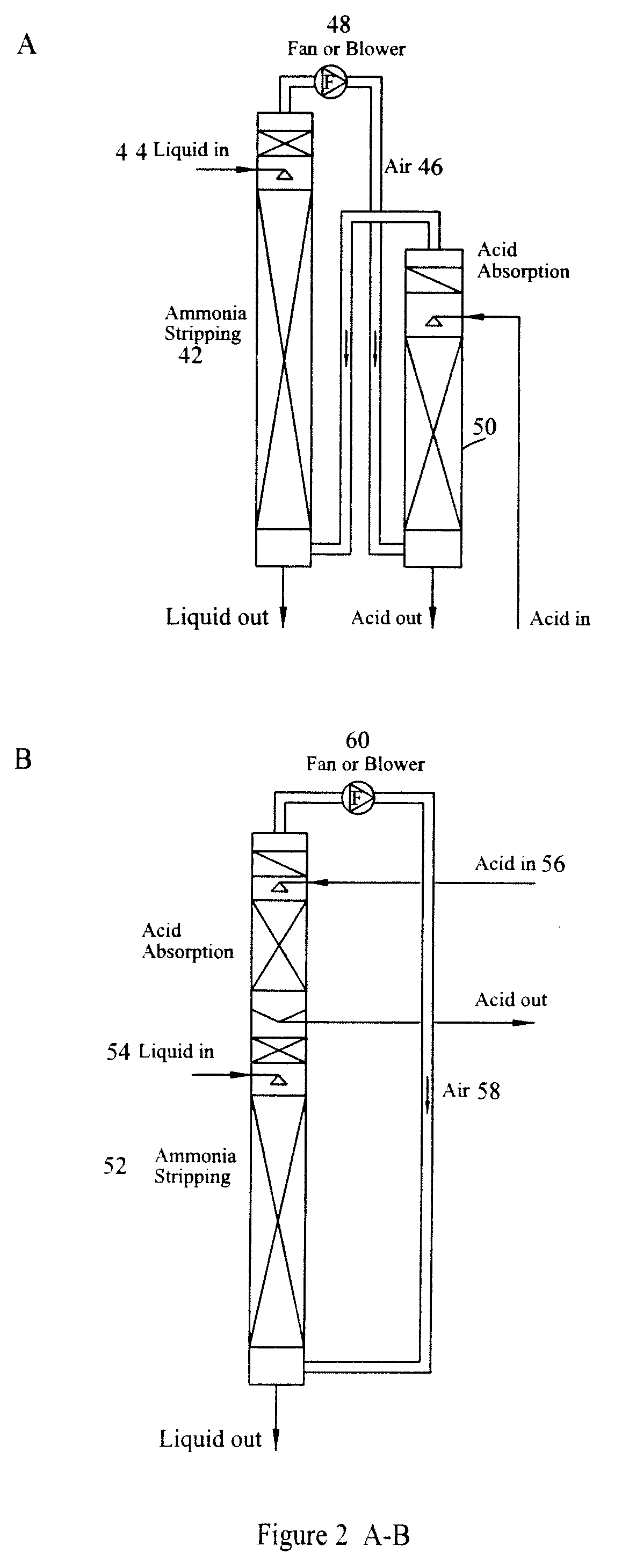

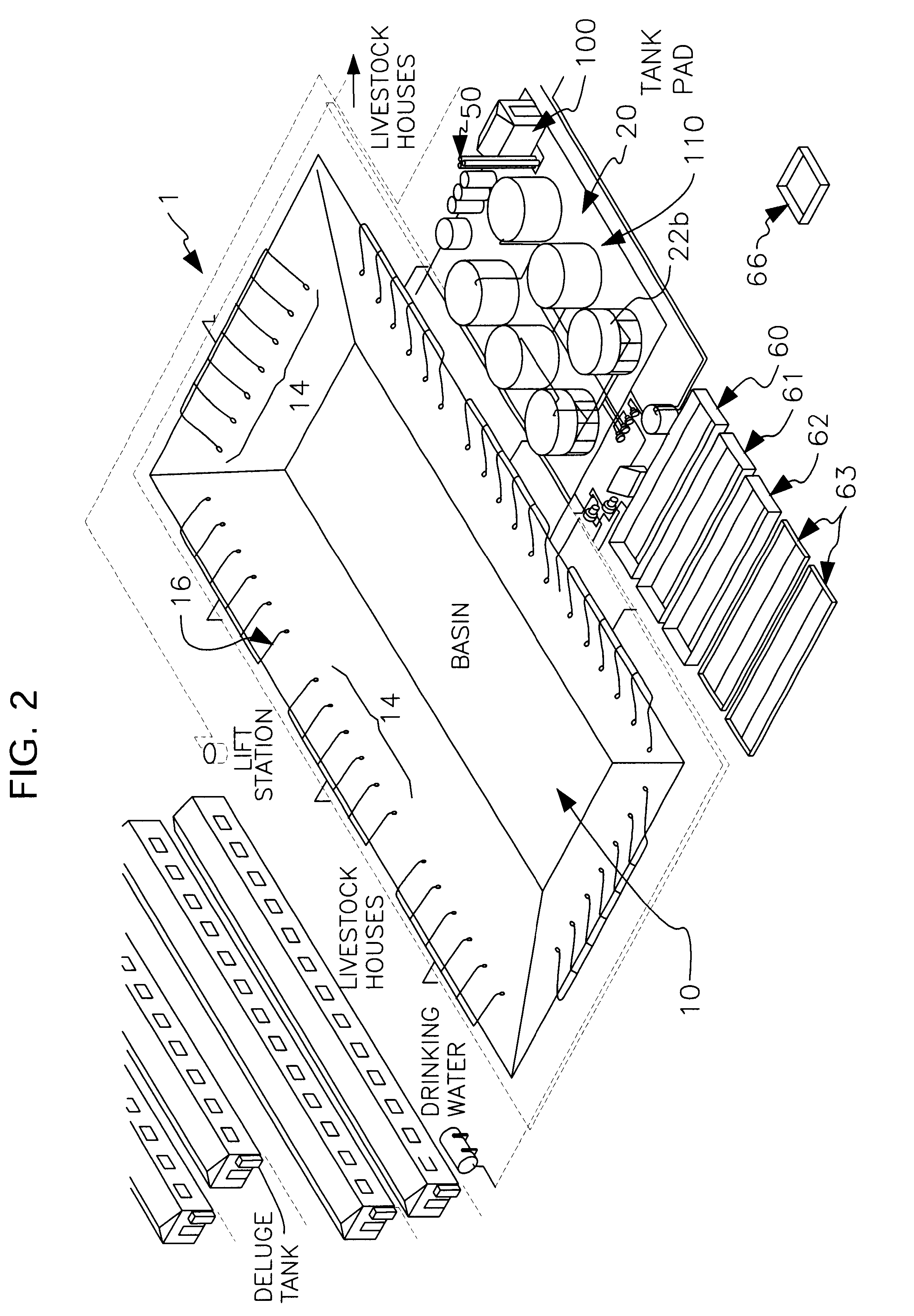

Combined nutrient recovery and biogas scrubbing system integrated in series with animal manure anaerobic digester

InactiveUS20090206028A1Inherent flexibilityIncrease flexibilityBio-organic fraction processingBiological substance pretreatmentsFecesNitrogen

An economical, integrated system works in series with anaerobic digestion of animal waste to recover nitrogen and phosphorous, while also scrubbing the produced biogas.

Owner:WASHINGTON STATE UNIV RES FOUND INC

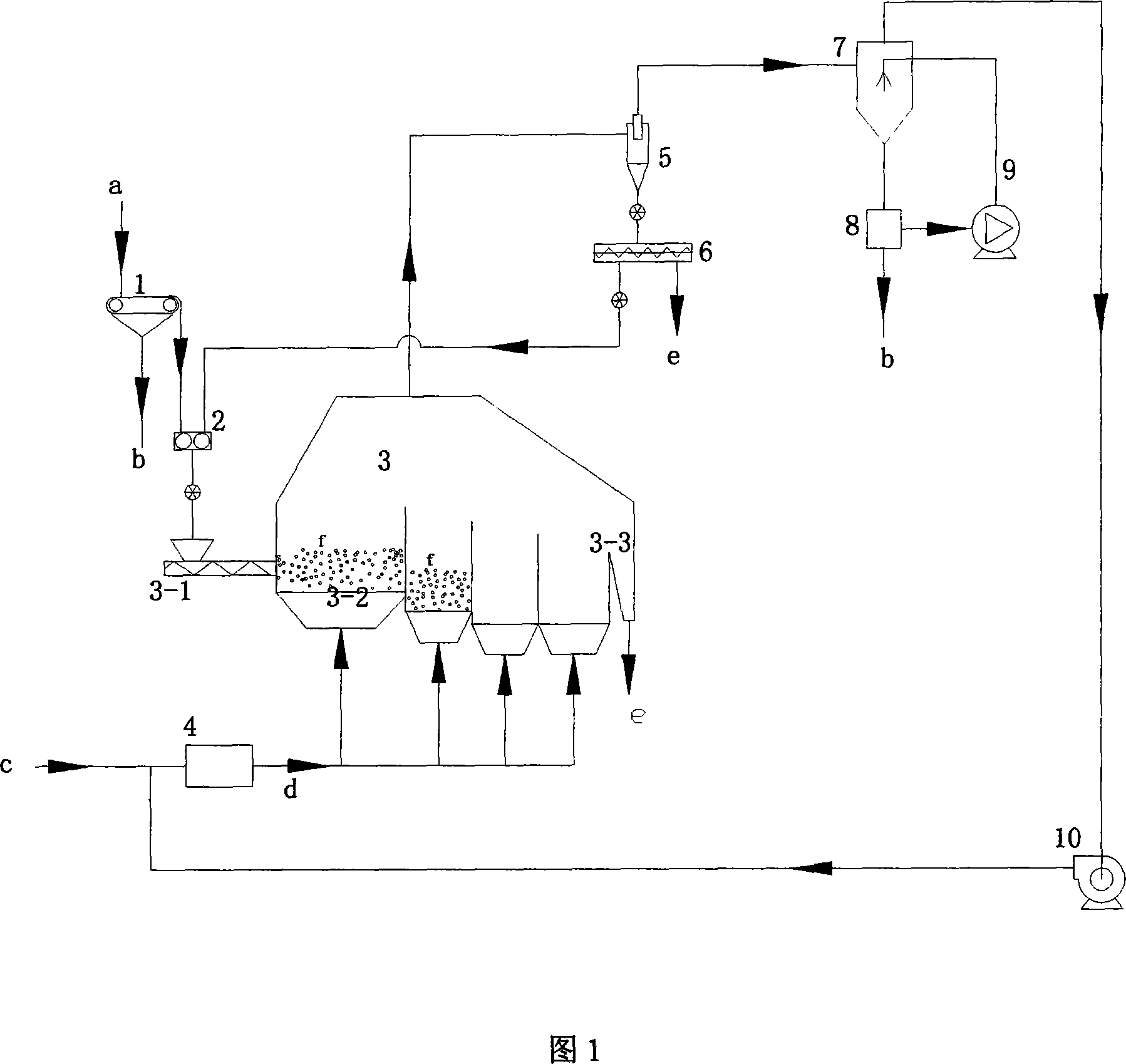

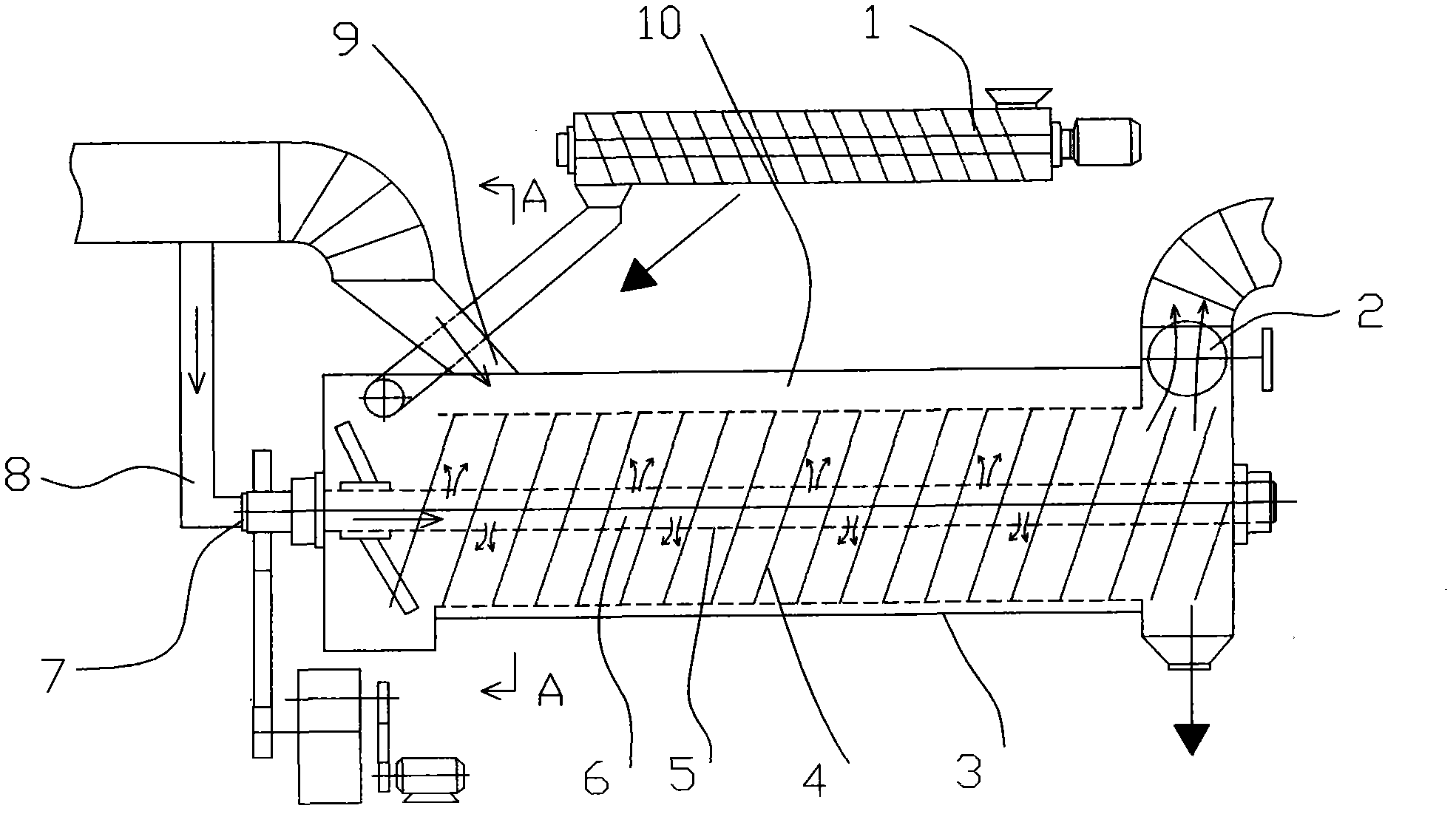

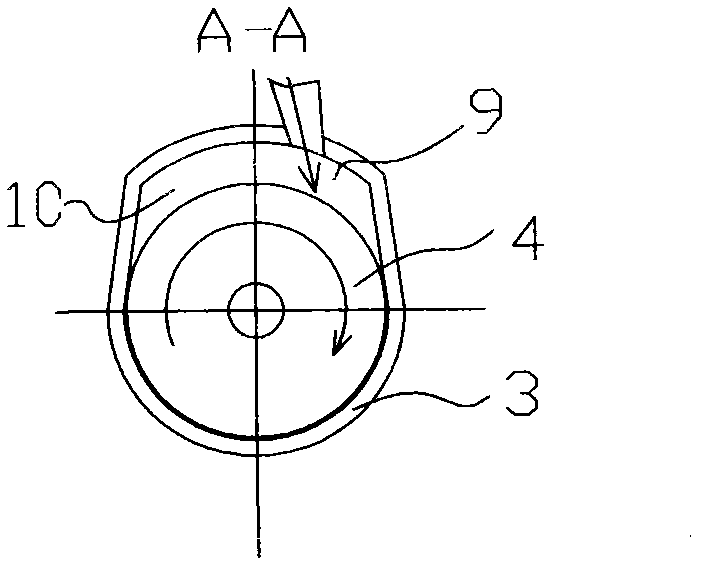

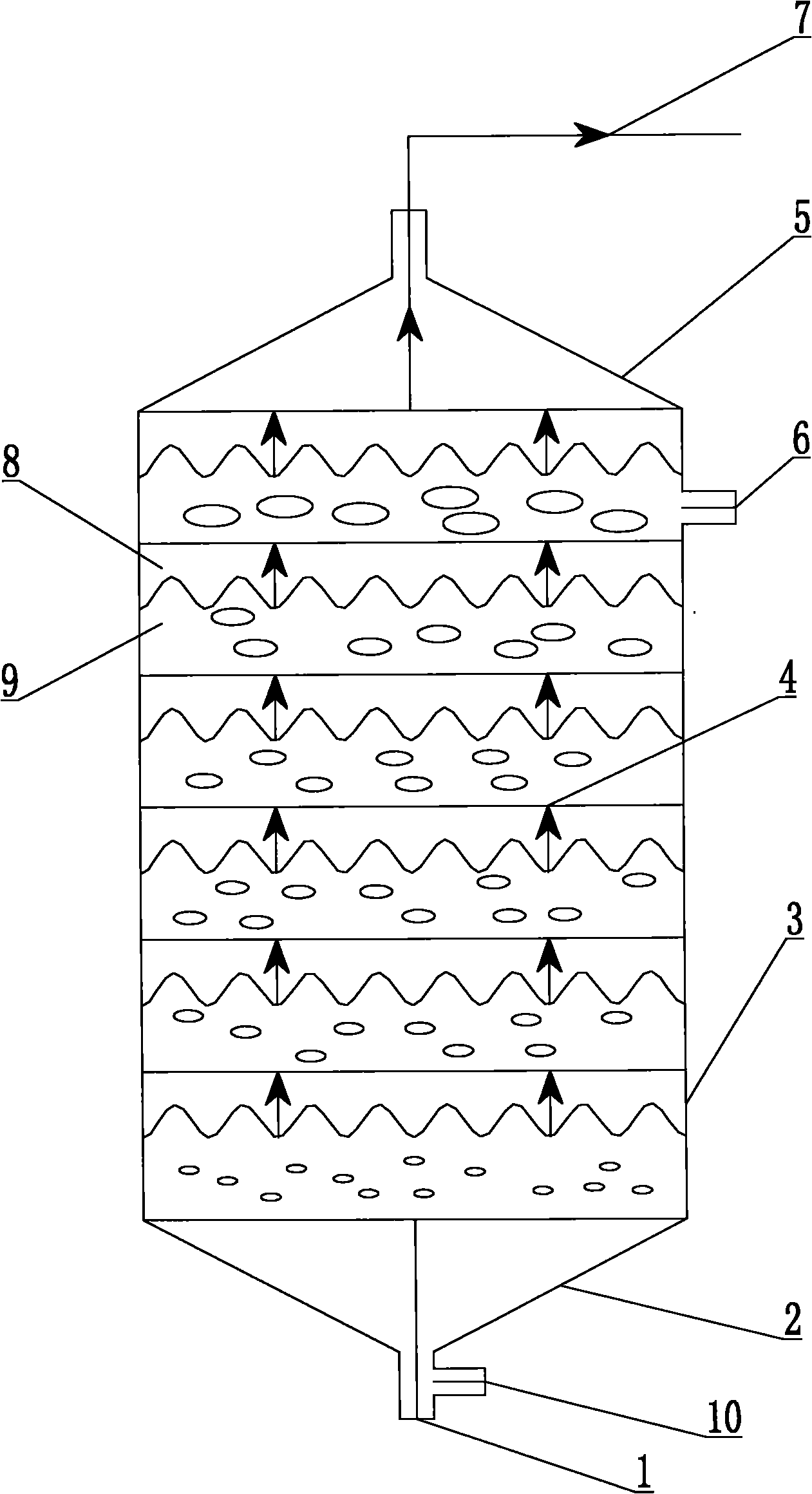

Enclosed multi-chamber fluidized bed drying method for sludge

InactiveCN101186422AUniform humidityReduce breakageSludge treatment by de-watering/drying/thickeningLiquid wasteFluidized bed drying

A closed multi-room fluidized bed sludge drying method is provided, which is a sludge drying method having the advantages of simple equipment structure, convenient operation, strong sludge adaptability, high thermal efficiency, safety, continuity, stability, etc. After the mechanically dewatered sludge is mixed with the back-mixed sludge, the mixture is dried room by room in an inert particles multi-room fluidized bed dryer (3). The first room and the second room of the inert particles multi-room fluidized bed dryer (3) adopt inert particles (f) as heat storage medium. Gas from a cyclone separator (5) goes through a spray tower (7) and returns into an air heating unit (4) through a circulating fan (10). Part of dried sludge (e) at the lower part of the cyclone separator (5) enters the inert particles multi-room fluidized bed dryer (3) through the back-mixing in a mixer (2). Waste liquid from the bottom of the spray tower (7) enters a waste liquid circulating pool (8), with part of waste liquid circulating into the spray tower (7) and part into a sewage treatment system.

Owner:SOUTHEAST UNIV

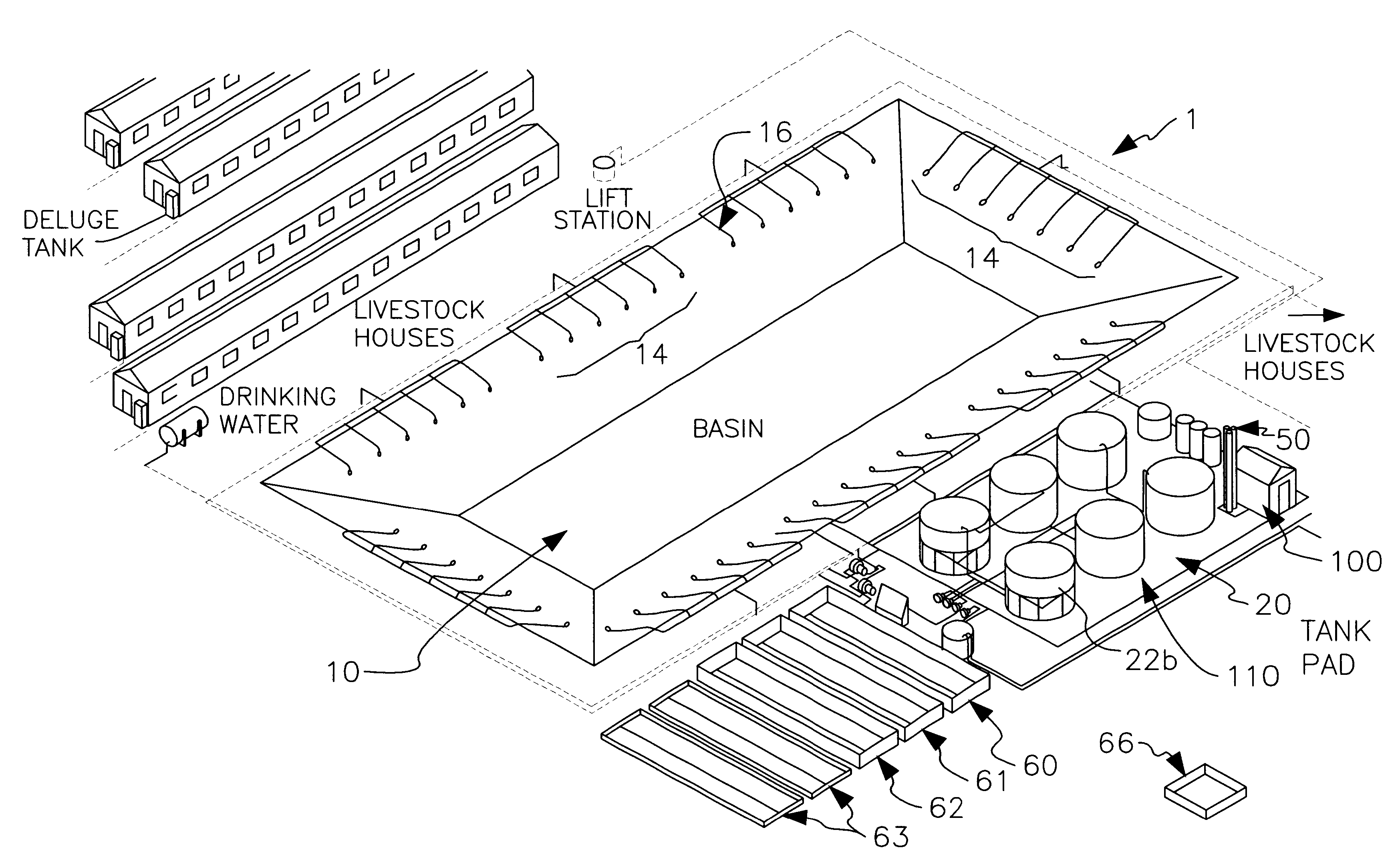

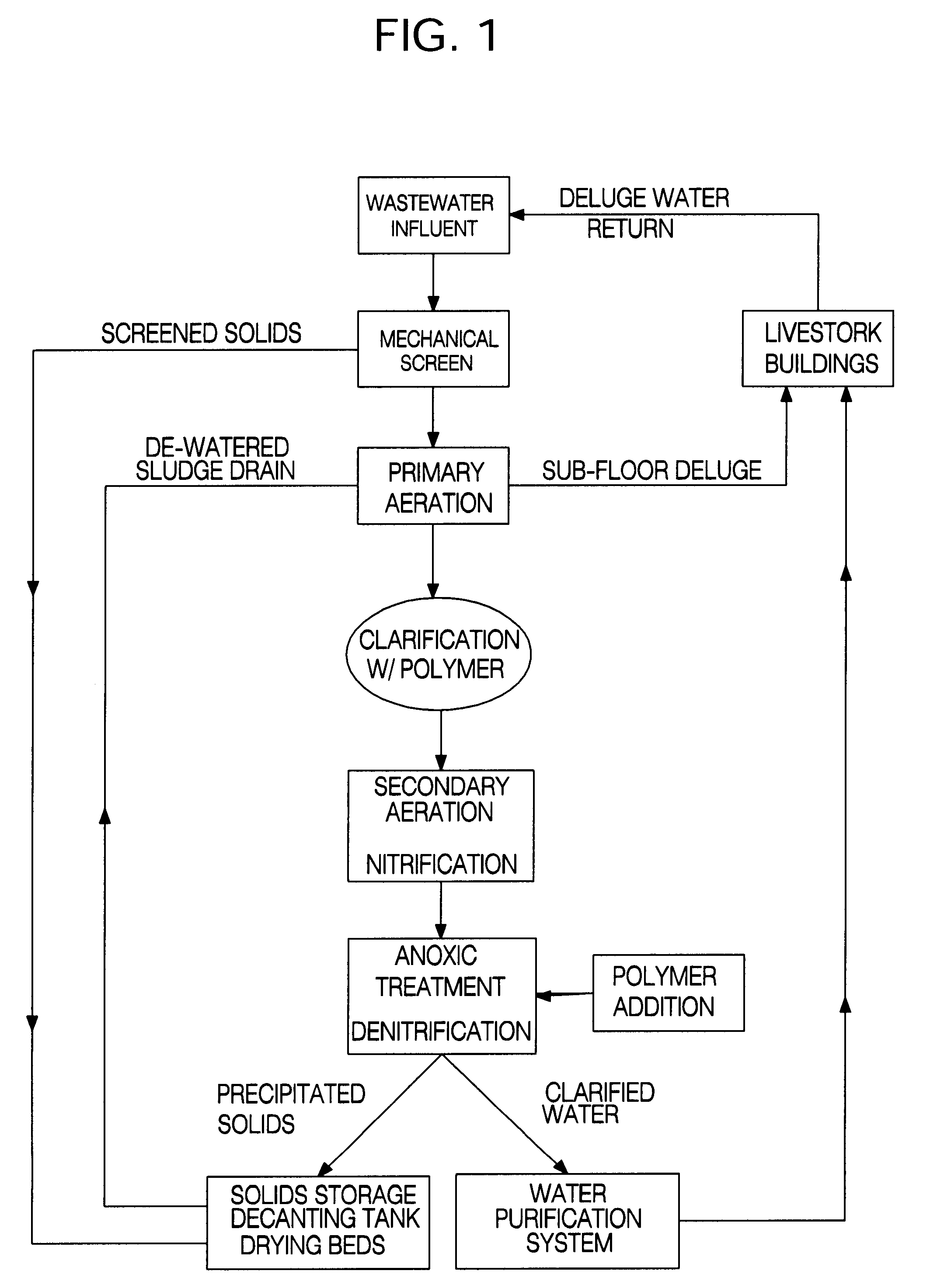

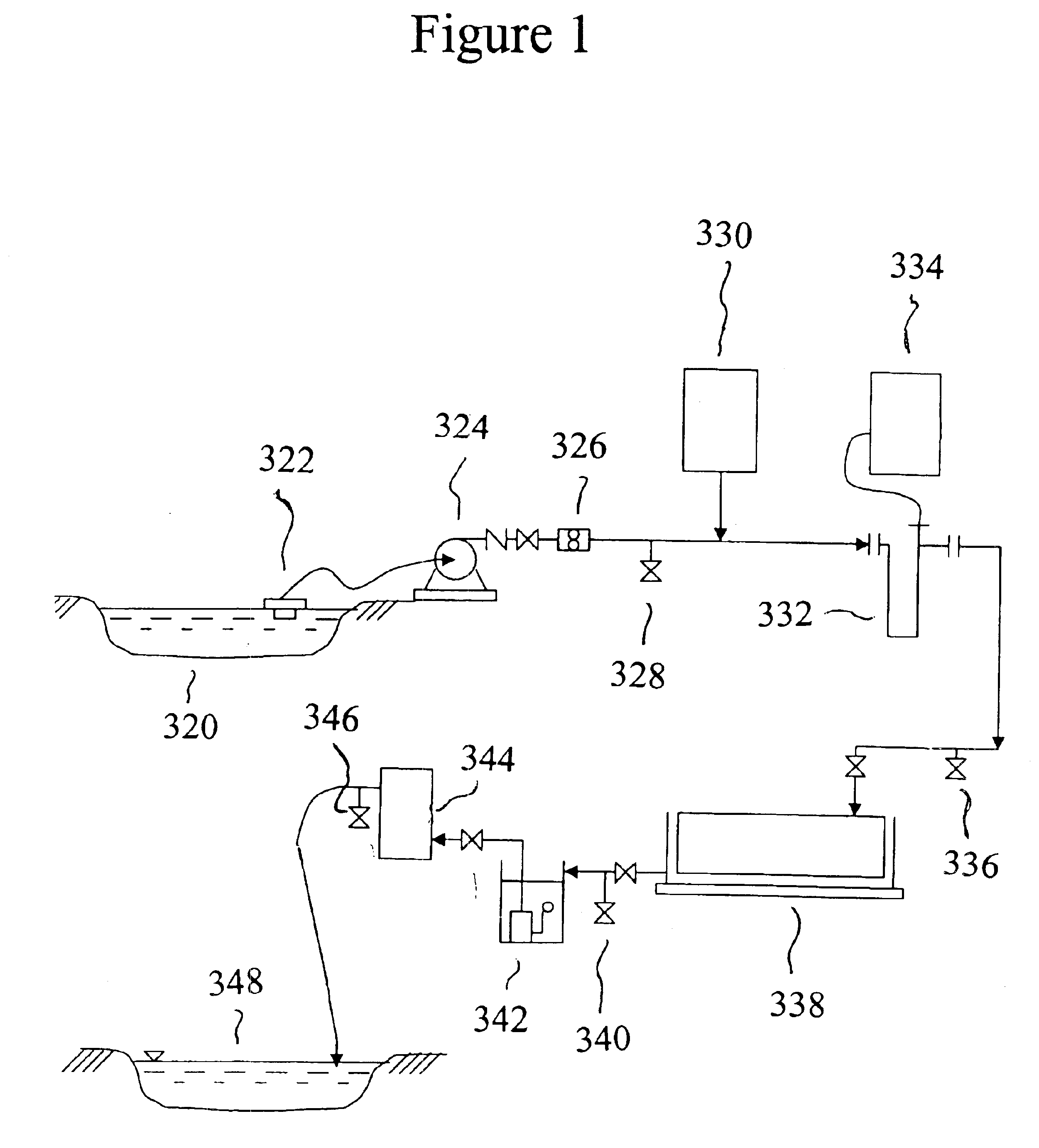

Aerobic treatment of liquids to remove nutrients and control odors

InactiveUS6398959B1Effective treatment of wastewaterReduce nutrientsTreatment using aerobic processesWaste water treatment from animal husbandrySludgeWastewater

The present invention is drawn to a unique apparatus and method for treating and reusing the wastewater discharged from agricultural animal farms. The apparatus and method of the present invention may be readily-sized and configured depending upon the amount and constituent(s) of the wastewater to be treated. In a first embodiment, the apparatus and method of the present invention is designed to be a zero discharge system in which no wastewater will be discharged or land applied. In use, the apparatus and method of the first embodiment may actually require addition of make-up water during periods of low rainfall to make up water losses due to evaporation and drift. It is contemplated that the only byproduct of the apparatus and method of the first embodiment may be a beneficial sludge if a sufficient number of installations are operated. In a second embodiment, the apparatus and method of the present invention provides a treatment system capable of reducing the nutrient loading in a step-wise fashion so that the wastewater can be used from different steps of treatment in order to apply the varying nutrient loads required by crops on a seasonal basis.

Owner:AGRIMOND USA CORP

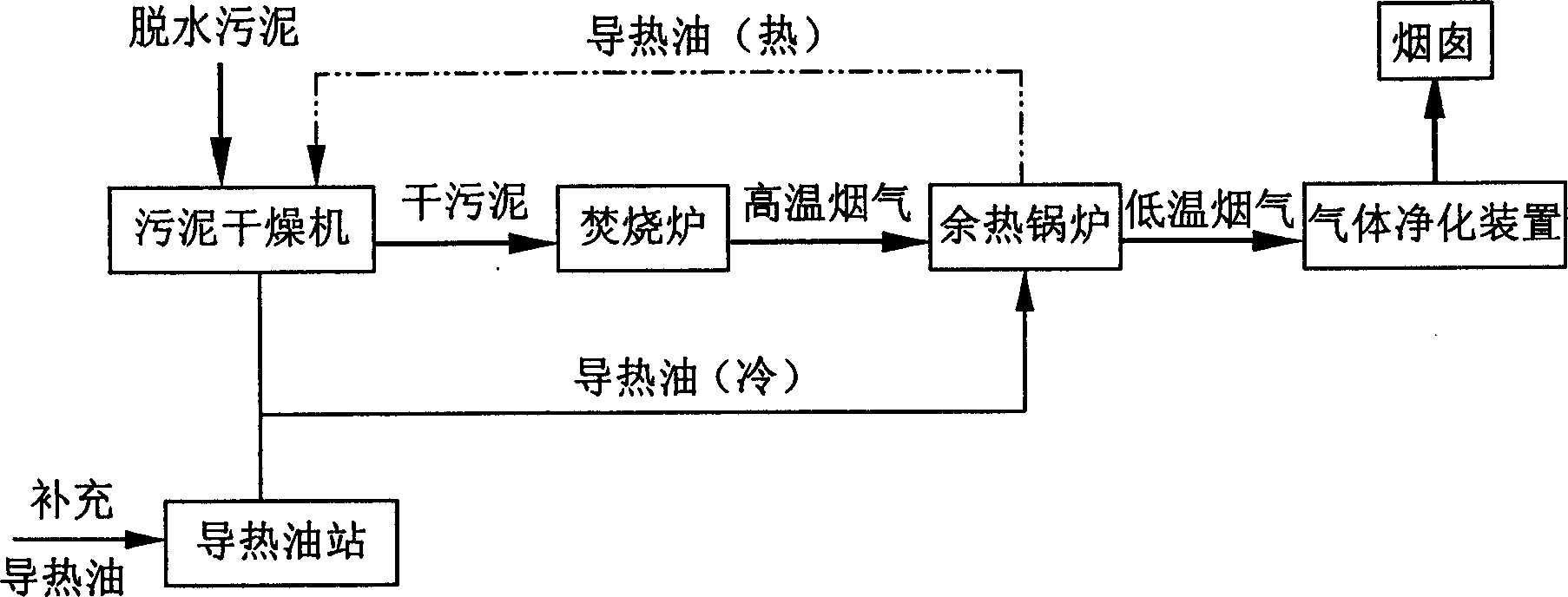

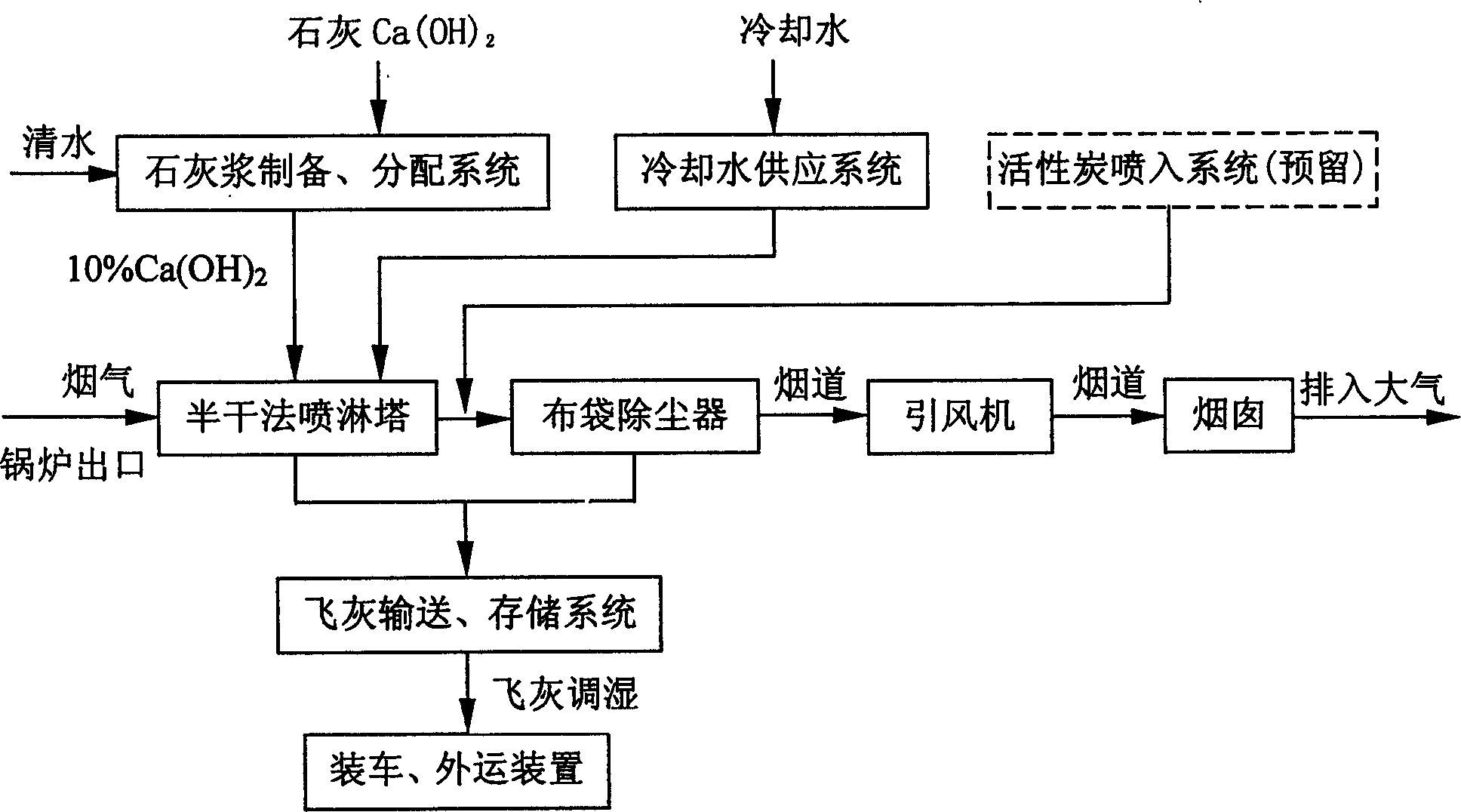

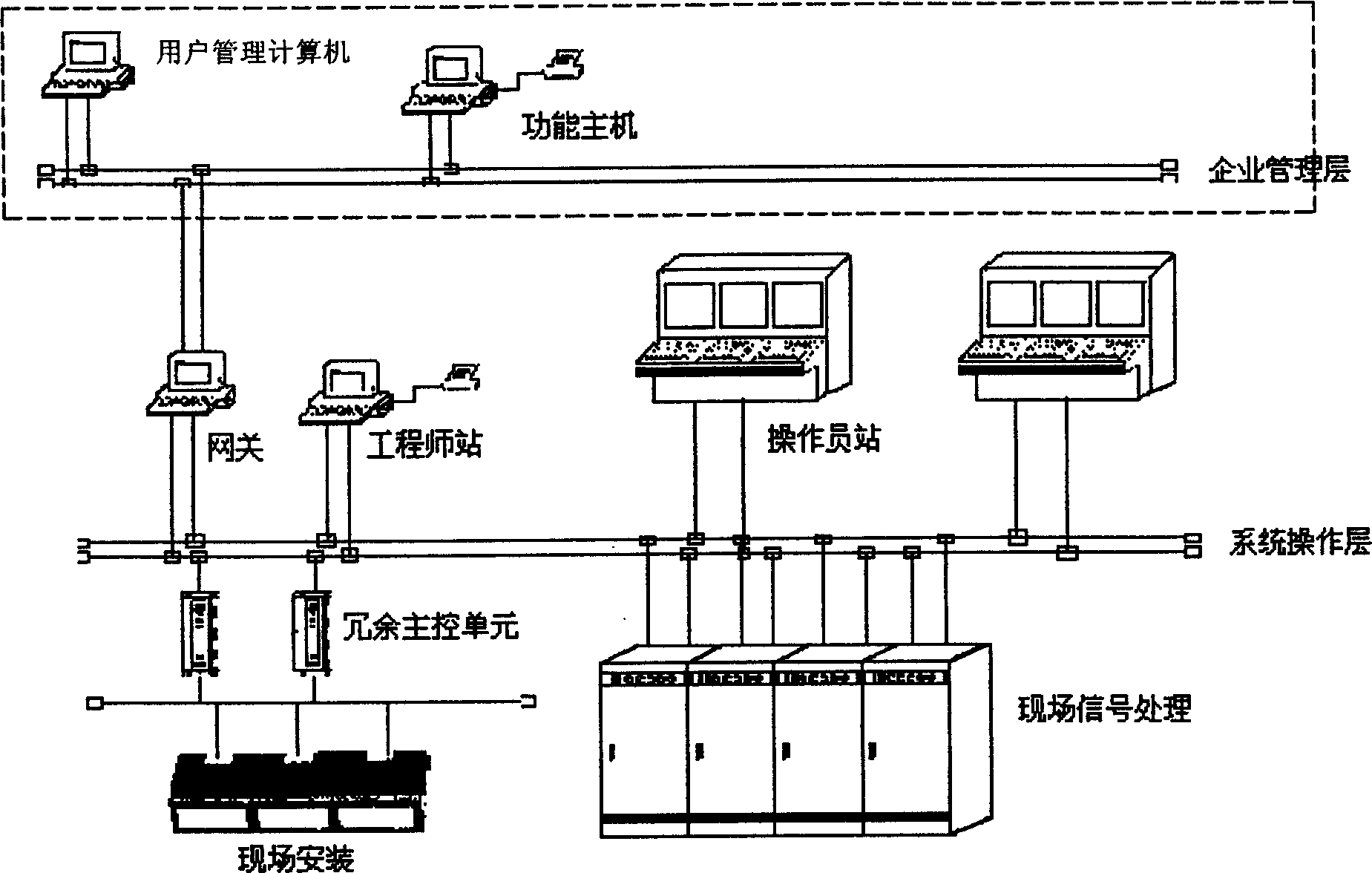

Sludge anhydration and burning process, and its systematic device

ActiveCN1800062ALow investment costLow running costSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationAir preheaterHeat conducting

The invention relates to a sludge drying and burning technique and its system devices, applying to the handling of active sludge in urban sewage treatment plants, its process flows through: wet sludge stock house, measuring bin, sludge mixer, sludge dryer, granular splitter, cooler, drying products storage bin, incinerator, smoke gas cleaning devices, which is characterized by: said incinerator is bubbling fluid bed incinerator with coal economizer, air heater fixed in its end part, high-heat smoke gas generated by burning is used to heat heat-conducting oil and cool air individually, and heat-conducting oil after being heated is transferred to sludge dryer through the circulating pump to dry wet-sludge. The invention is characterized by: take heat-conducting oil as heating medium, use the heat generated by burning dry sludge to heat heat-conducting oil and then dry wet-sludge to make full use of resources; the volume-reducing quantity after drying and burning could reach over 90%; the percentage of desulphurization in incinerator could reach 75% as a result of adopting two stage technology of sulfur removal, and the gross percentage of desulphurization meets national environmental legislation requirements. The invention accomplishes the resources, volume reduction, and innocence of sludge.

Owner:贵州筑信水务环境产业有限公司

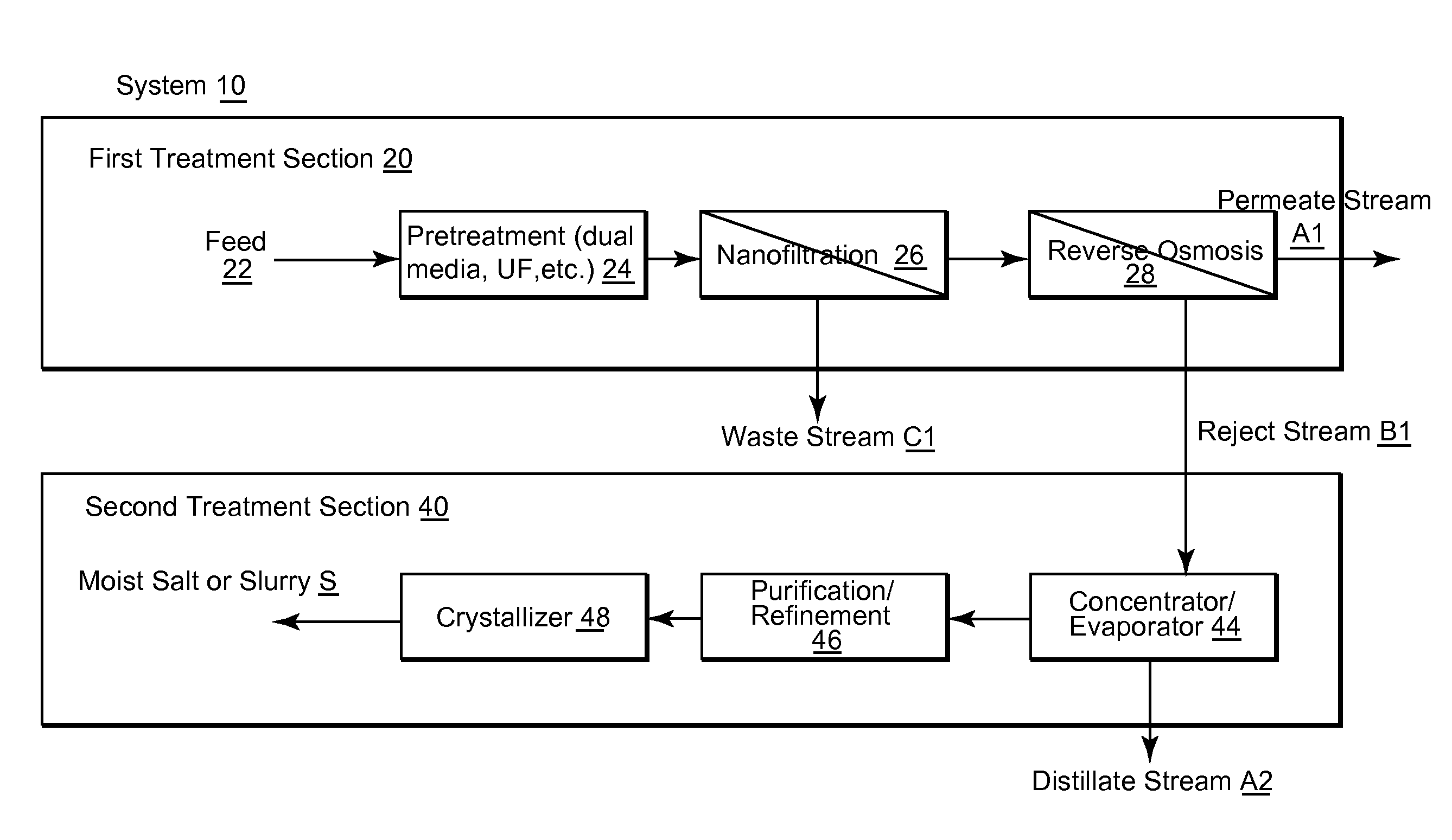

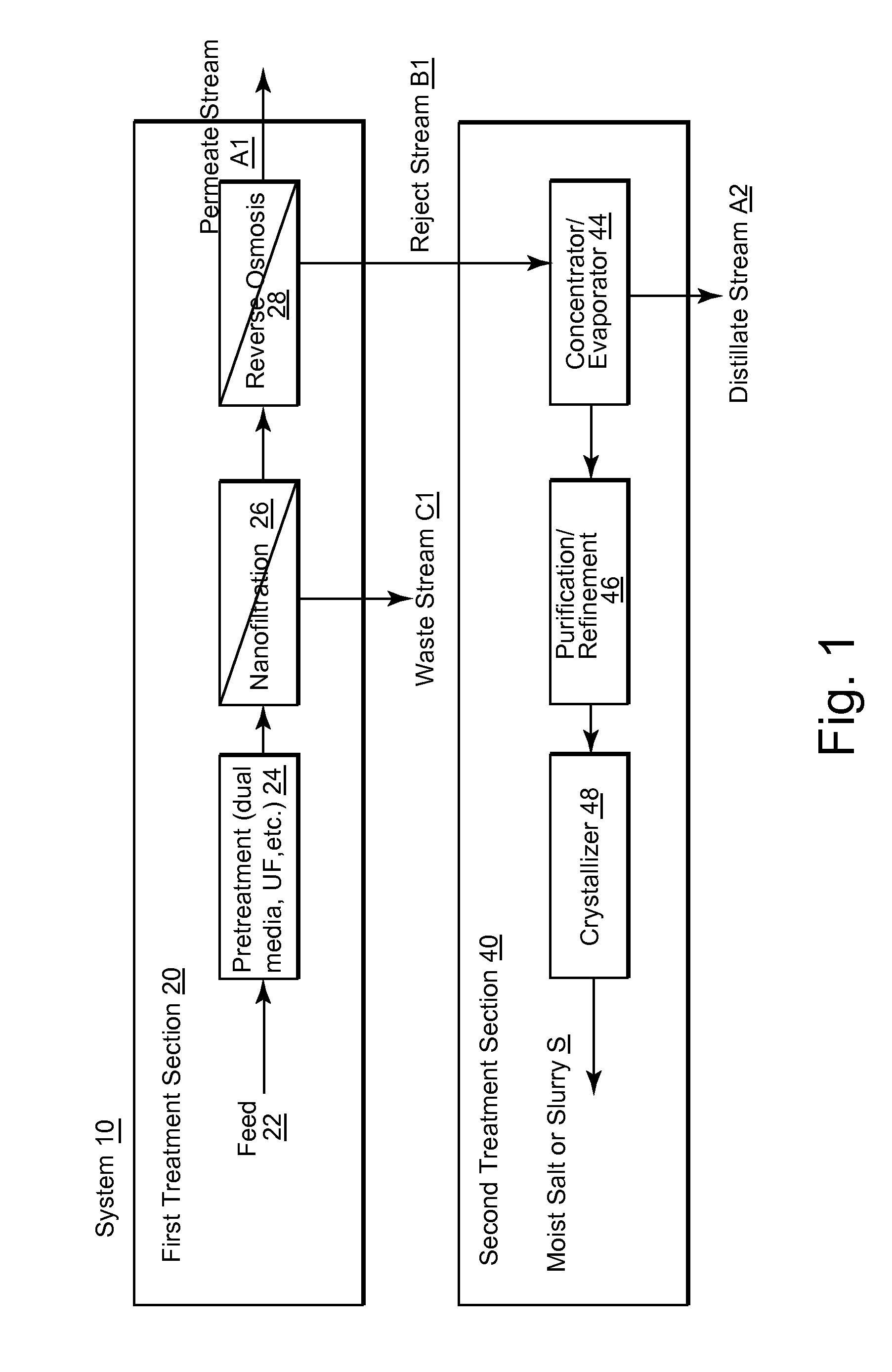

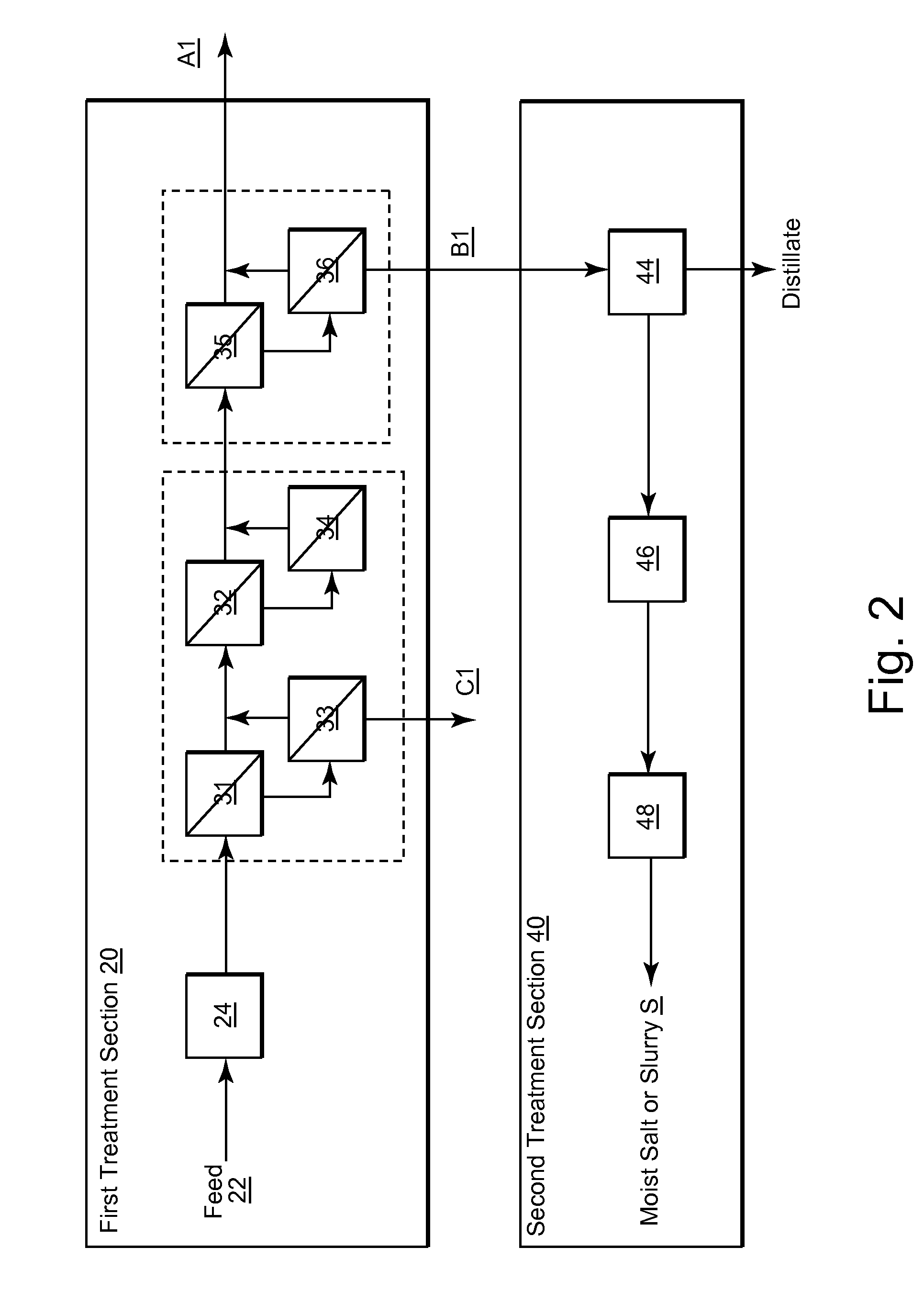

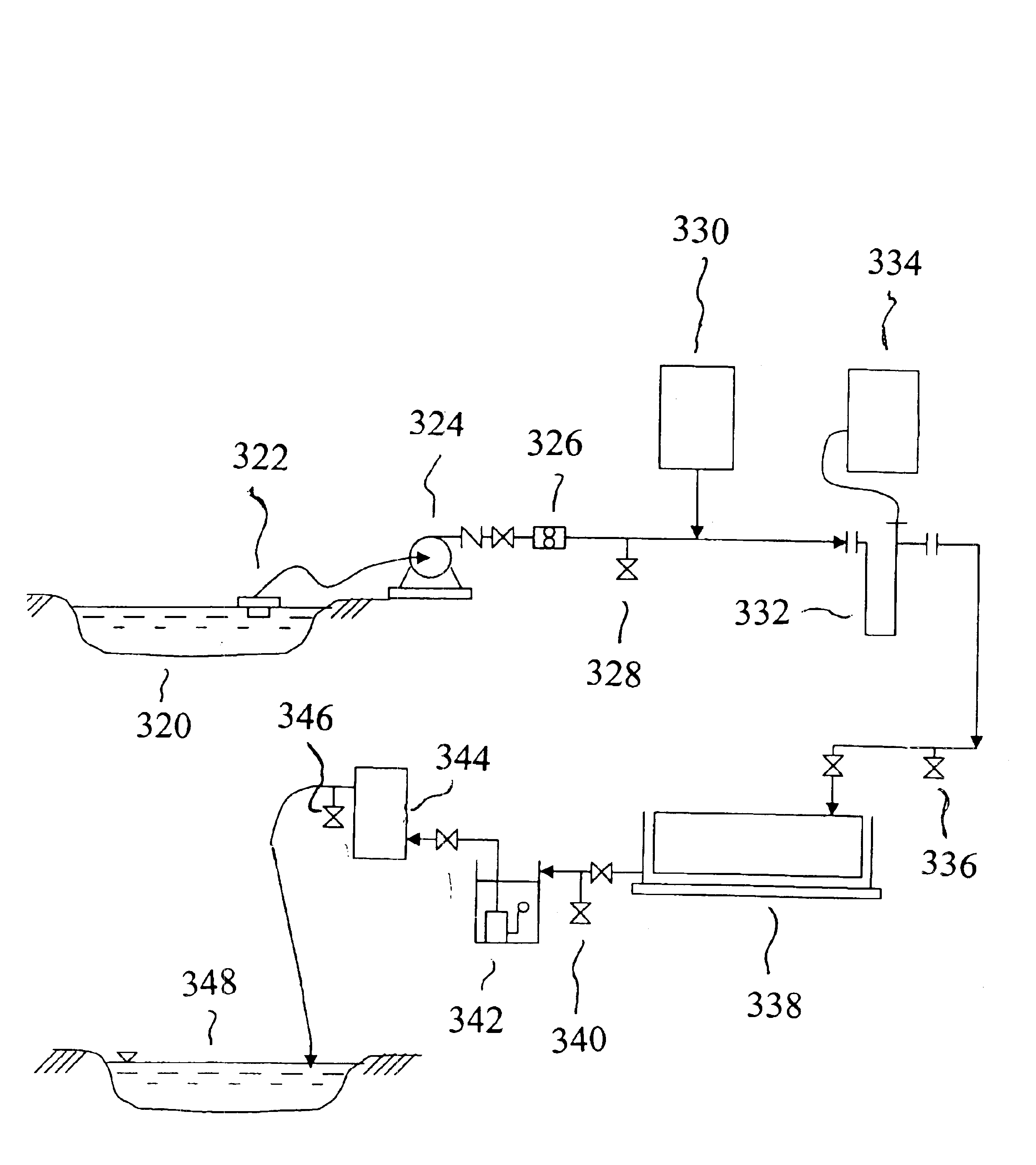

Water desalination plant and system for the production of pure water and salt

InactiveUS20120160753A1Enhanced commercial NaCl productionGeneral water supply conservationSeawater treatmentSaline waterWater desalination

A desalination plant for treating a sea water or brackish water feed is provided. The desalination plant includes a first treatment section to effectively remove scaling species, the first treatment section including nanofiltration section, the nanofiltration section including at least two stages and at least two passes; and a reverse osmosis section that operates at high recovery to produce a purified permeate stream and a selectively NaCl salt-enriched reject stream as a saline output.

Owner:VORA NISHITH +4

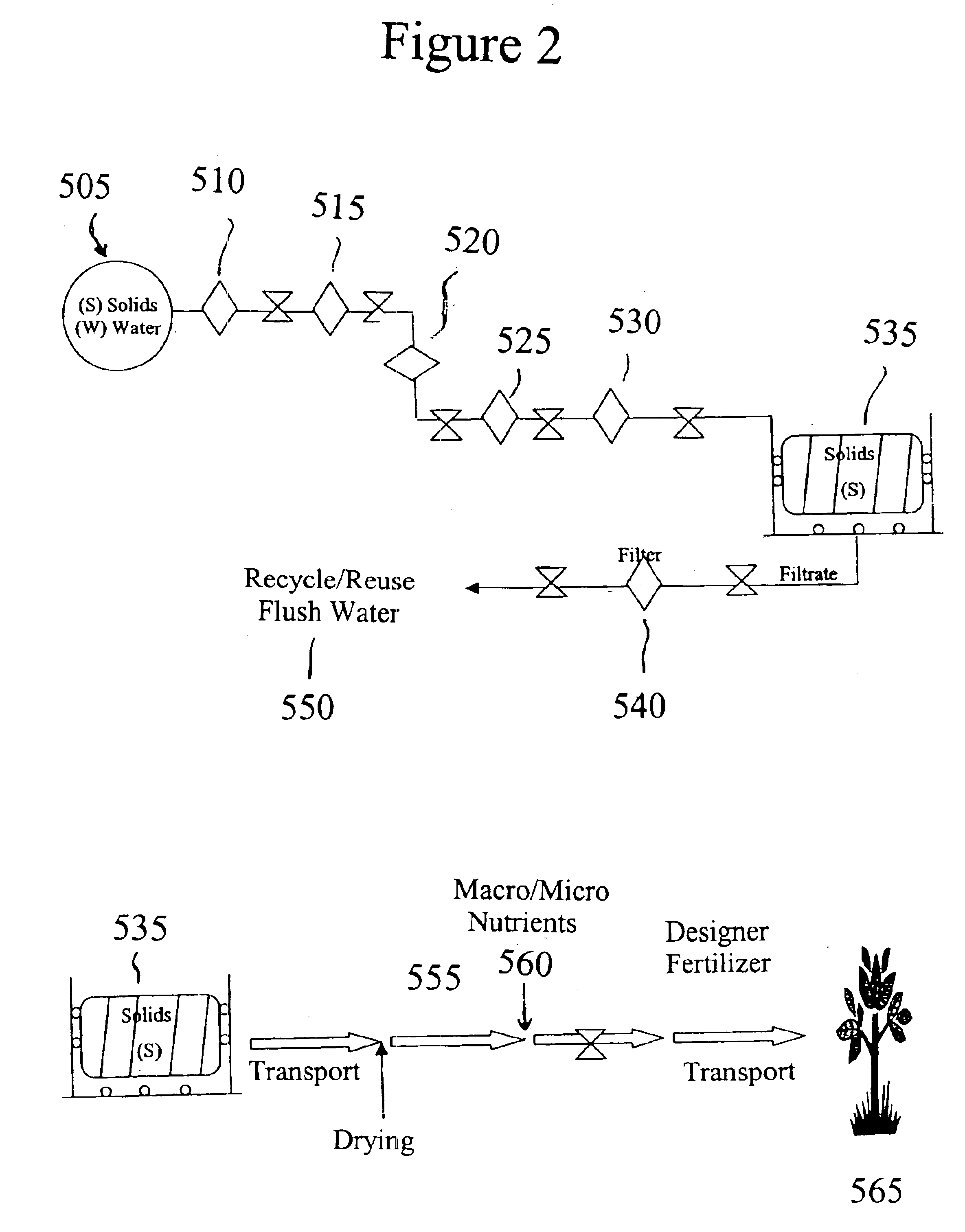

Animal waste effluent treatment

Animal waste such as fecal material from swine, chicken, turkey, and cattle is converted into useful forms such as fertilizer, other types of soil builders, and even nutrient feed additives. Devices, systems, and methods are provided that allow economical conversion and in many instances, alleviate the production and release of undesirable gases such as sulfide and ammonia. In one embodiment, undesirable anaerobic and facultative anaerobic bacteria are killed at a greater rate than desirable soil compatible aerobic bacteria. The use of low temperature killing diminishes off gassing commonly associated with other techniques, and the use of gas trapping additives such as zeolites provides enhanced soil building qualities such as slow release of nitrogen and slow release of moisture to soil. The methods allow convenient adjustment of composition, allowing conversion of waste into tailored designer fertilizer suited for particular soils. Other embodiments provide other soil building qualities as well as nutrient qualities for feedstock used in animal husbandry such as aquaculture.

Owner:SHEETAB SR RICHARD G

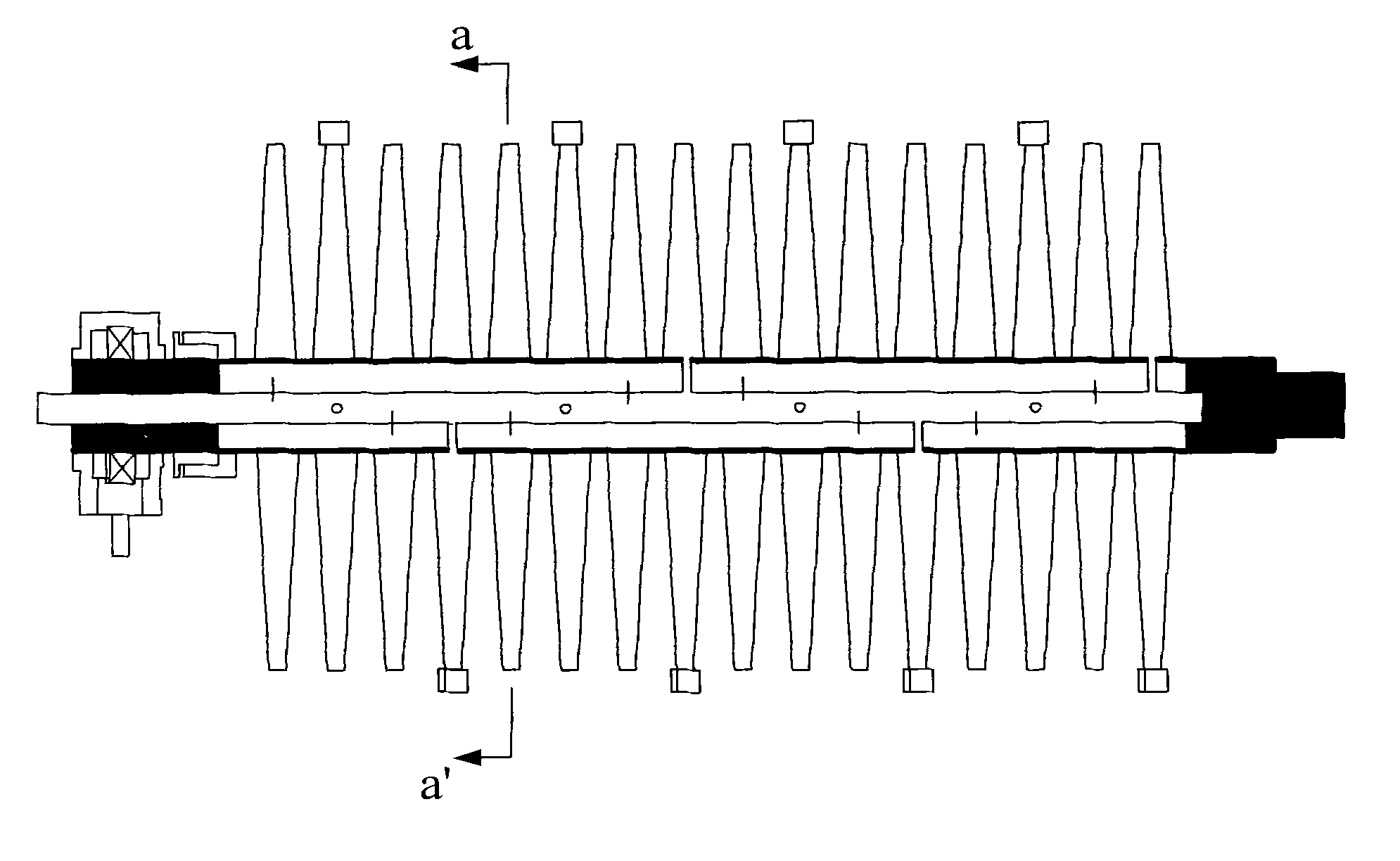

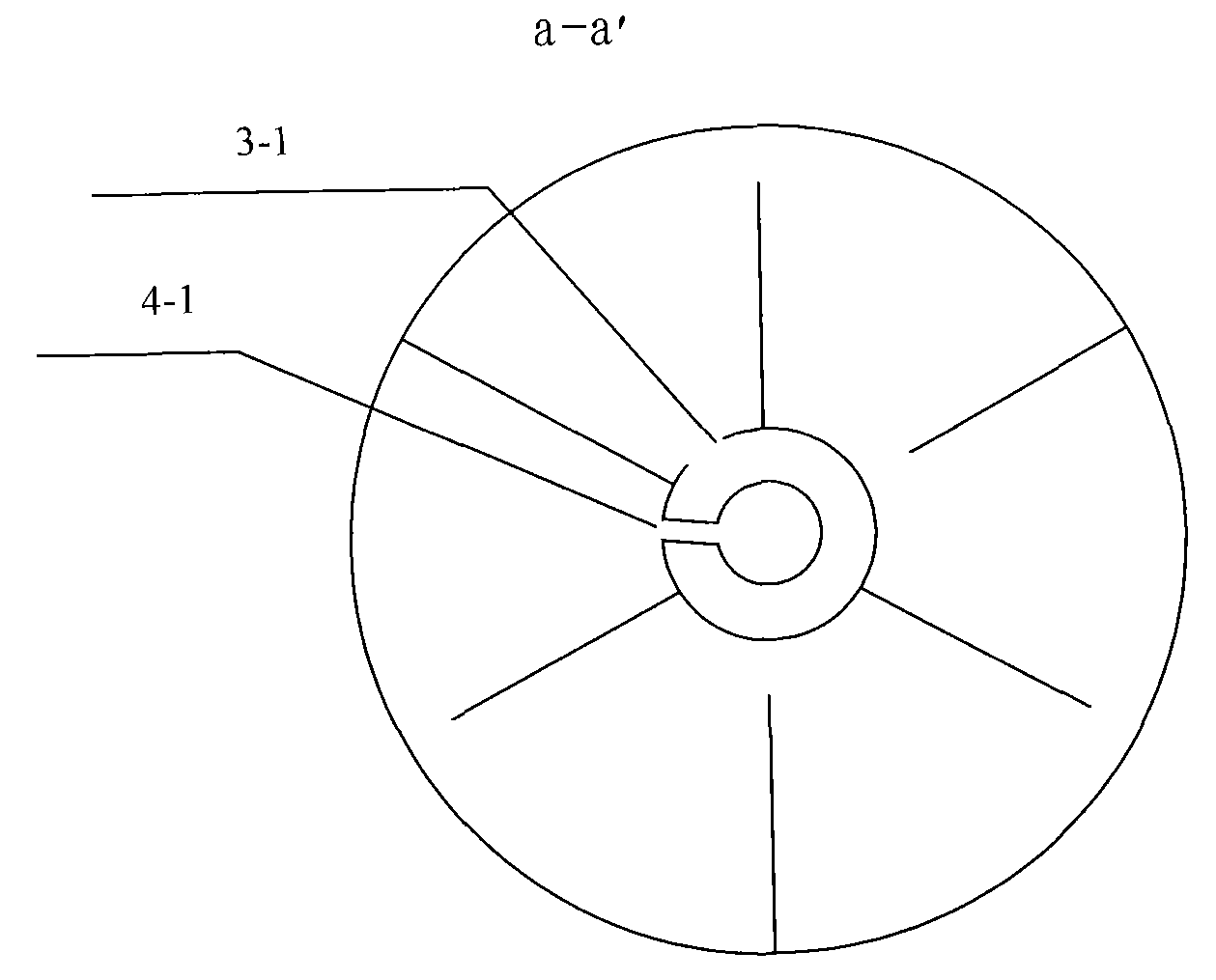

Drying device for drying sludge by using flue gas

InactiveCN102464441AAvoid stickingPrevent liquidity lossSludge treatment by de-watering/drying/thickeningSludgeFlue gas

The invention provides a drying device for drying sludge by using flue gas. The invention relates to an environment-friendly treatment device, in particular to a drying device for dynamically drying wet sludge by using high-temperature (120-200 DEG C) flue gas. The drying device comprises a flue gas conveying pipeline and a sludge conveying device. The drying device is characterized by comprising a cylinder body, a hollow shaft, a material conveying spiral and a gas inlet duct communicated with the flue gas conveying pipeline. Aiming at the problems, the invention provides the drying device for online drying wet sludge by using flue gas so as to greatly improve treatment efficiency and reduce environmental pollution.

Owner:JIANGDU SUNENG ELECTRICAL EQUIP

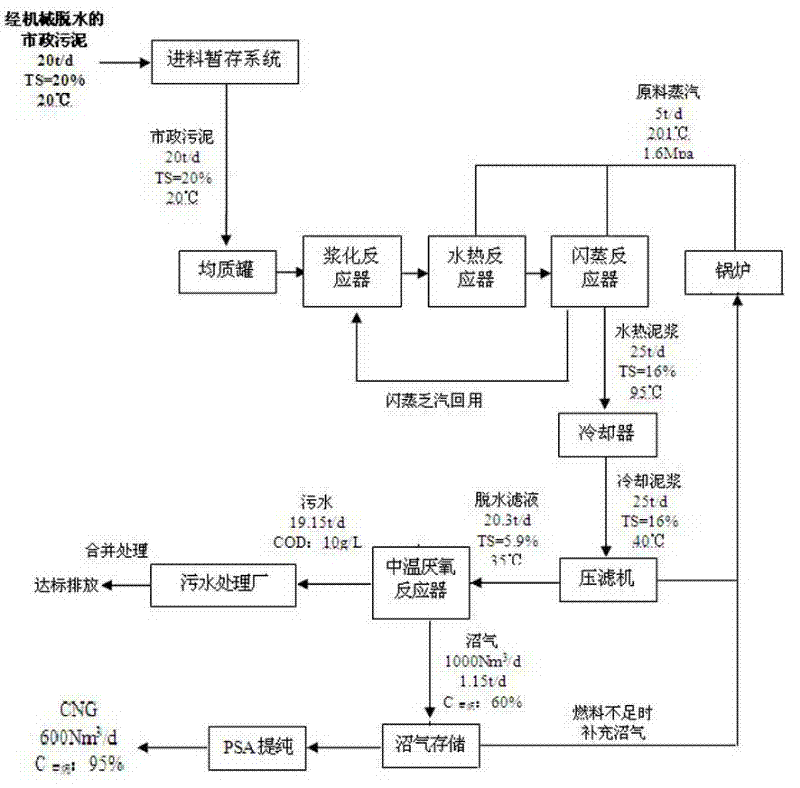

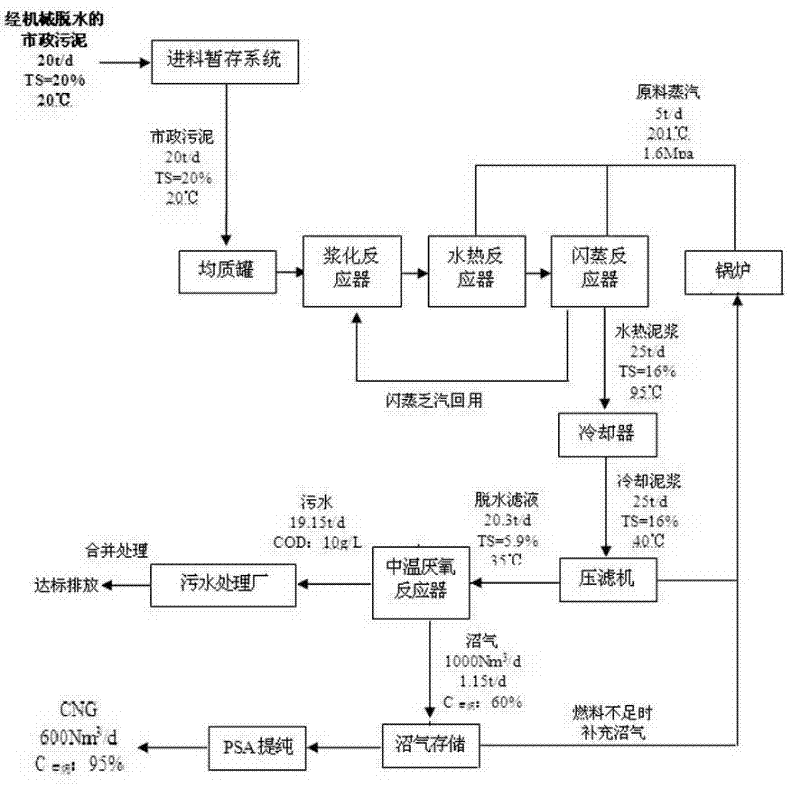

Sludge treatment process based on hydrothermal modification technology

InactiveCN102381820AAdvanced technologyHighlight energy savingSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningAnaerobic reactorHigh pressure

The invention relates to a sludge treatment process based on a hydrothermal modification technology. The sludge treatment process is carried out by comprising the following steps of: (1) temporarily storing the sludge which is subjected to mechanical dehydration and has the water content of 70-85% to a pretreatment unit and deodorizing the sludge; (2) introducing to a homogeneous device, fully mixing and homogenizing, introducing the homogenized sludge to a slurrying device, introducing the slurried sludge to a hydrothermal reactor for hydrothermal reaction, and introducing the hydrothermal sludge to a flash evaporator for decompression and flash evaporation; (3) cooling to 35-45 DEG C by using a cooler, then introducing to a high-pressure diaphragm pressure filter for pressure filtering and dehydration to obtain a dehydrated mud cake with the solid content of 35-45% and dehydrated filtrate; (4) introducing the dehydrated filtrate to an intermediate temperature anaerobic reactor, wherein the residence time is for 5.5-7.5d, the inlet water temperature is controlled below 40 DEG C, and the anaerobic reaction temperature is 30-40 DEG C; and (5) preparing a biomass fuel rod by using the dehydrated mud cake, and introducing the biomass fuel rod to a boiler to provide steam for the hydrothermal reactor and the flash evaporator. The sludge treatment process has the advantages of goodtreatment effect, obvious volume reduction effect, high harmless degree, recycling of methane, good economic benefit and the like.

Owner:FUZHOU DEV ZONE SANSHUI ENVIRONMENTAL PROTECTION TECH

Structurally-modified polymer flocculants

InactiveCN1426429ASludge treatment by de-watering/drying/thickeningSedimentation separationCross-linkStructural Modifier

This invention is directed to structurally-modified water-soluble polymers prepared by initiating polymerization of an aqueous solution of monomers under free radical polymerization conditions to form a polymer solution and adding at least one structural modifier to the polymer solution after at least 30 % polymerization of the monomers has occurred, and to use of the water-soluble cross-linked polymers as flocculating agents.

Owner:ONDEO NALCO

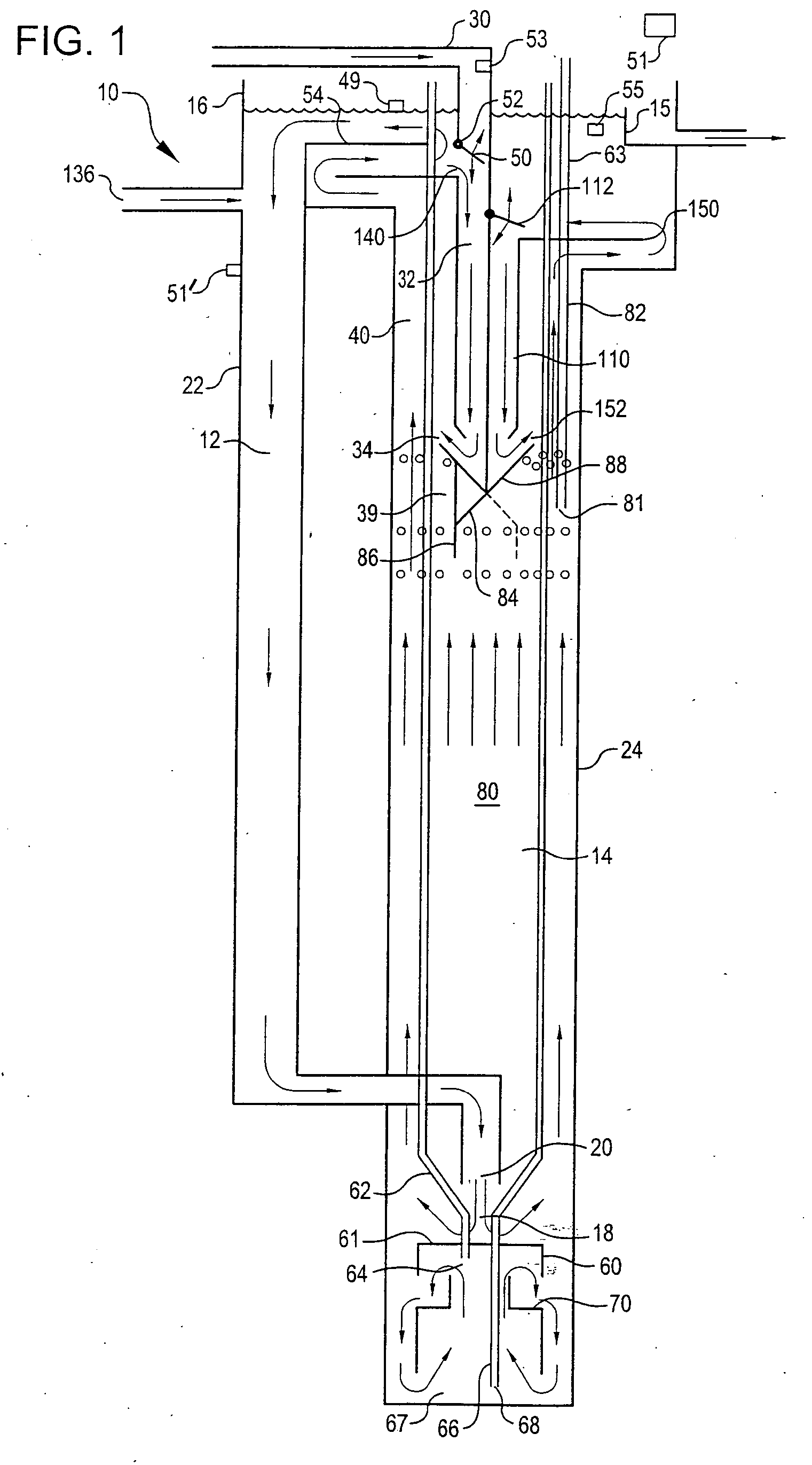

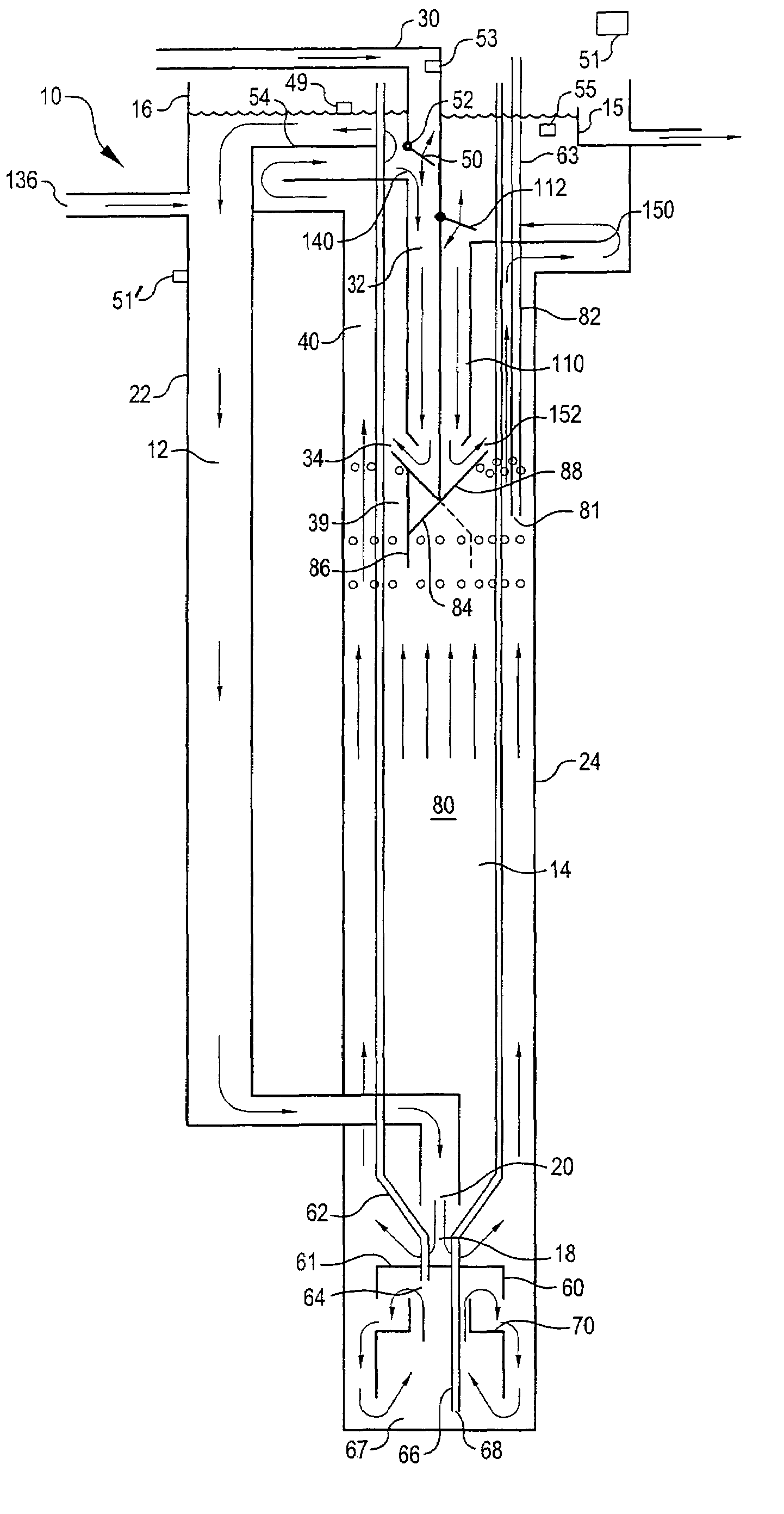

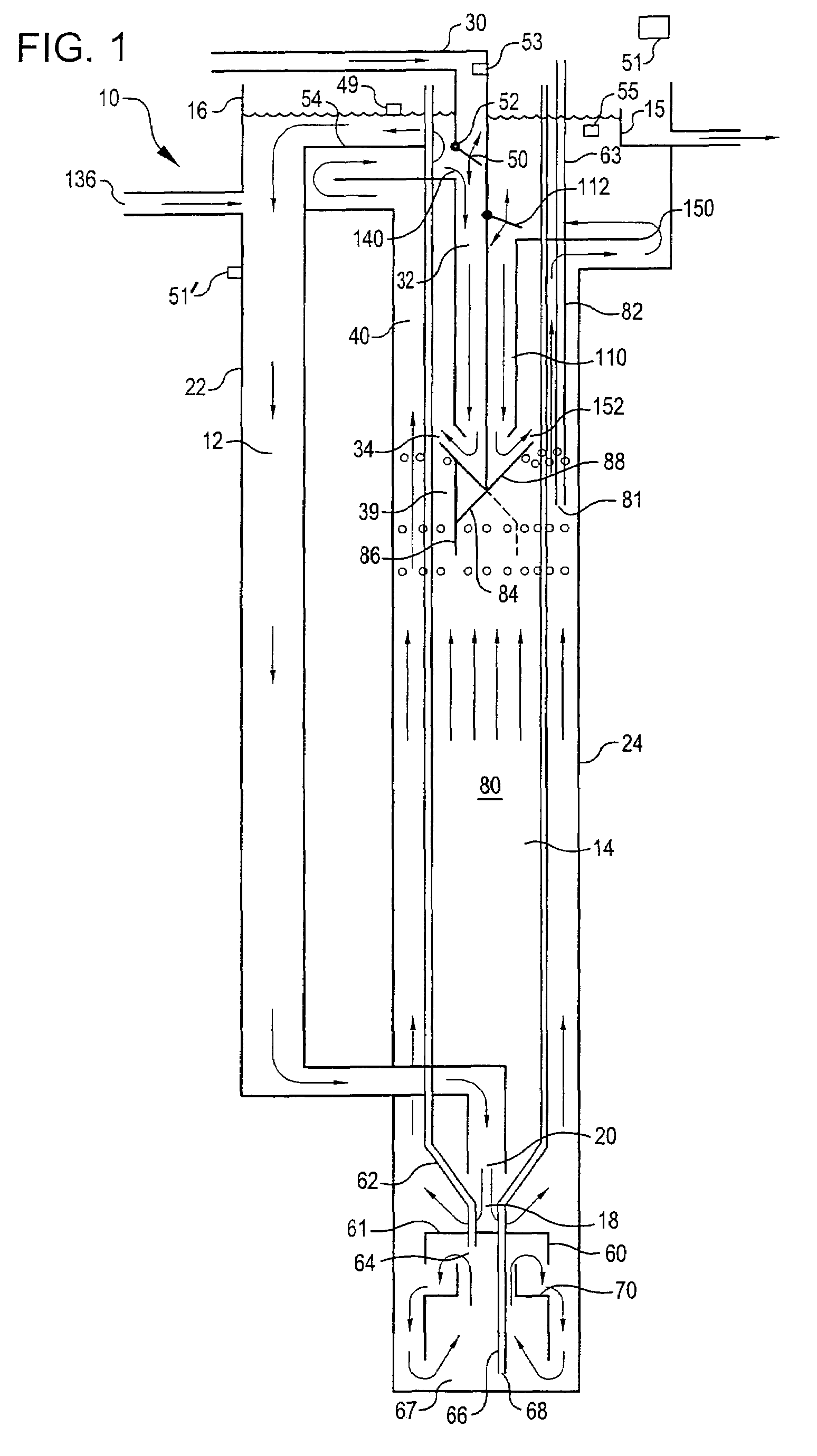

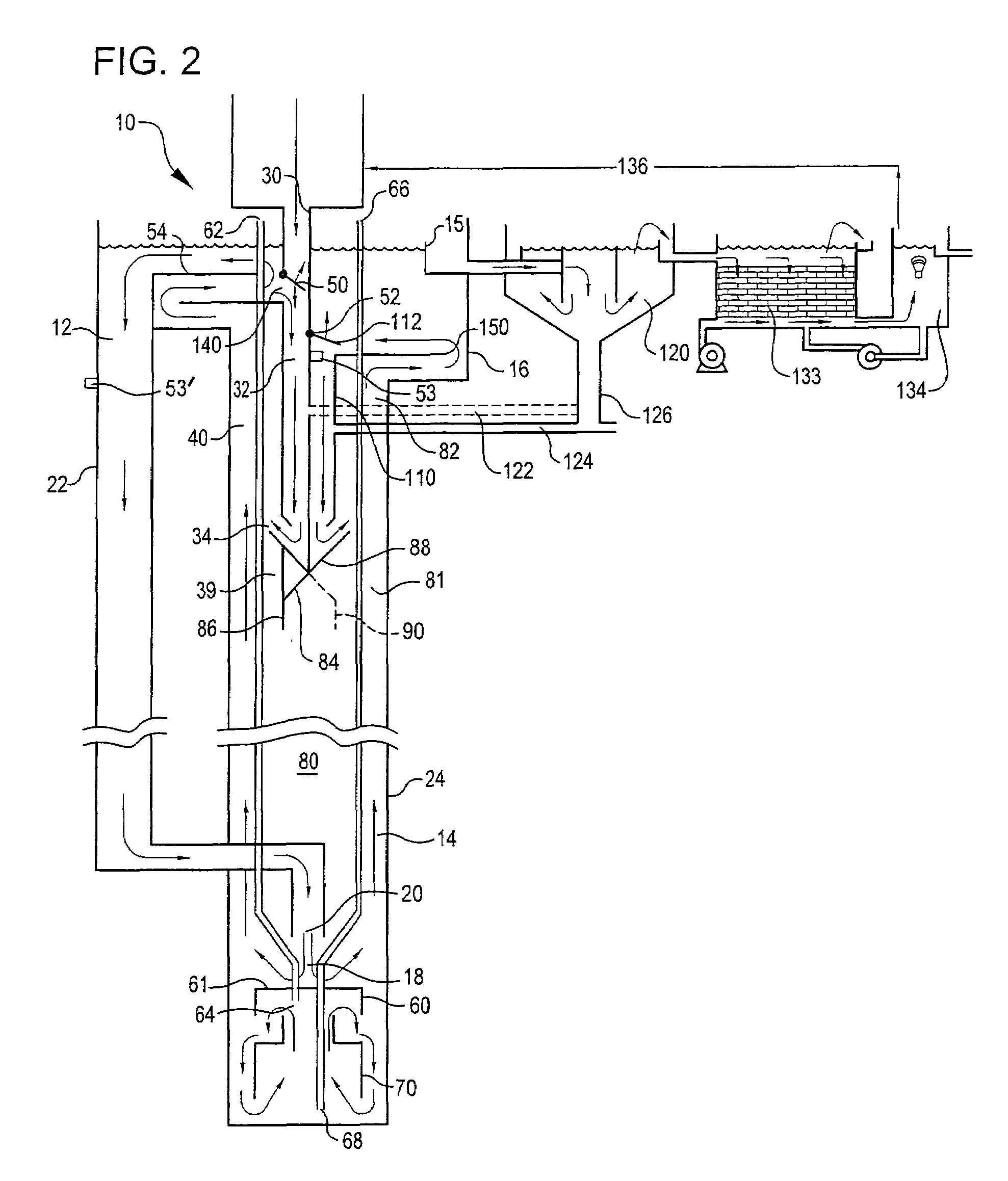

Methods and apparatus for biological treatment of waste waters

InactiveUS20050115880A1Liquid degasificationTreatment using aerobic processesIndustrial effluentPasteurization

In a vertical shaft bioreactor, improved devices and methods are provided for enhanced secondary and / or tertiary treatment of wastewater, including residential, municipal and industrial wastewater. The devices and methods of the invention are useful for enhanced secondary wastewater treatment, including BOD and TSS removal. Tertiary treatment can alternately or additionally be achieved in the bioreactor with nitrification of ammonia, with nitrification and denitrification, and with nitrification, denitrification, and chemical phosphorus removal. A vertical shaft bioreactor is also provided which achieves thermophilic aerobic digestion and pasteurization of sewage sludges, optionally to produce class A biosolids.

Owner:VOST ENVIRONMENTAL TECH

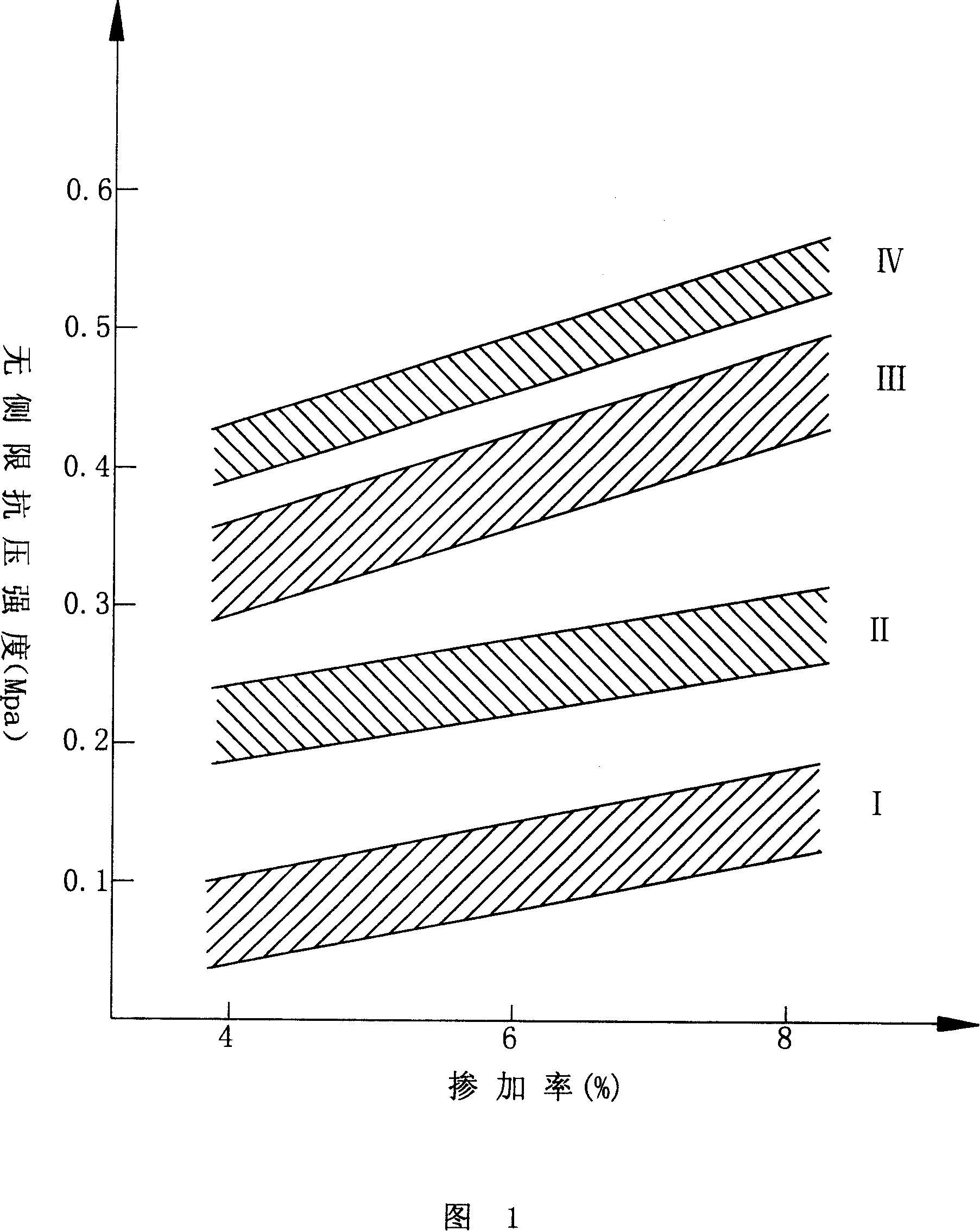

Sludge curing agent and application thereof

ActiveCN101081718AGood boardIncreased durabilitySludge treatment by de-watering/drying/thickeningSolid waste managementSludgeSlag

The present invention is sludge curing agent and its application, and belongs to the field of soil treating chemicals technology. The sludge curing agent includes powdered components and liquid components, the powdered components include cement clinker 30-60 weight portions, slag 30-60 weight portions, lime 3-8 weight portions, gypsum 1-7 weight portions and other sulfates 1-7 weight portions; and the liquid components include polyacrylamide 5-30 weight portions, polyaluminum chloride 0-20 weight portions, mannitol 0-30 weight portions, lignosulfonate 20-80 weight portions, lignosulfonate-iron or chromium ion complex 0-30 weight portions, alkylphenol ethoxylate 0.2-2 weight portions, tannin 0-10 weight portions, humate 0-10 weight portions, and alpa-olefin sulfonate 0.2-2.5 weight portions. The sludge curing agent has low cost, small consumption, high cumulate strength and high cumulate water tolerance, and may be applied widely.

Owner:BEIJING ZHONGYONGJI FIRMING AGENT TECH DEV

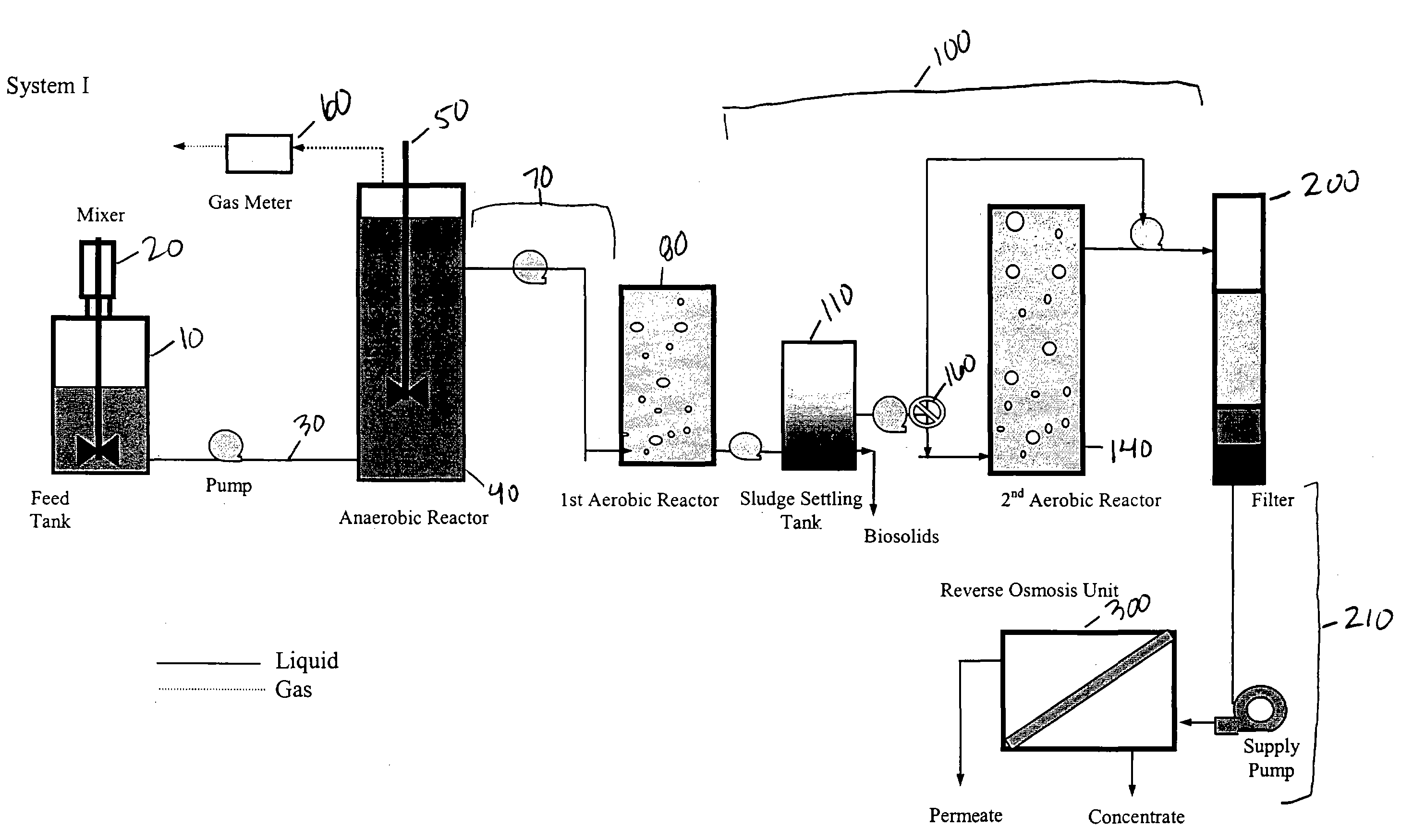

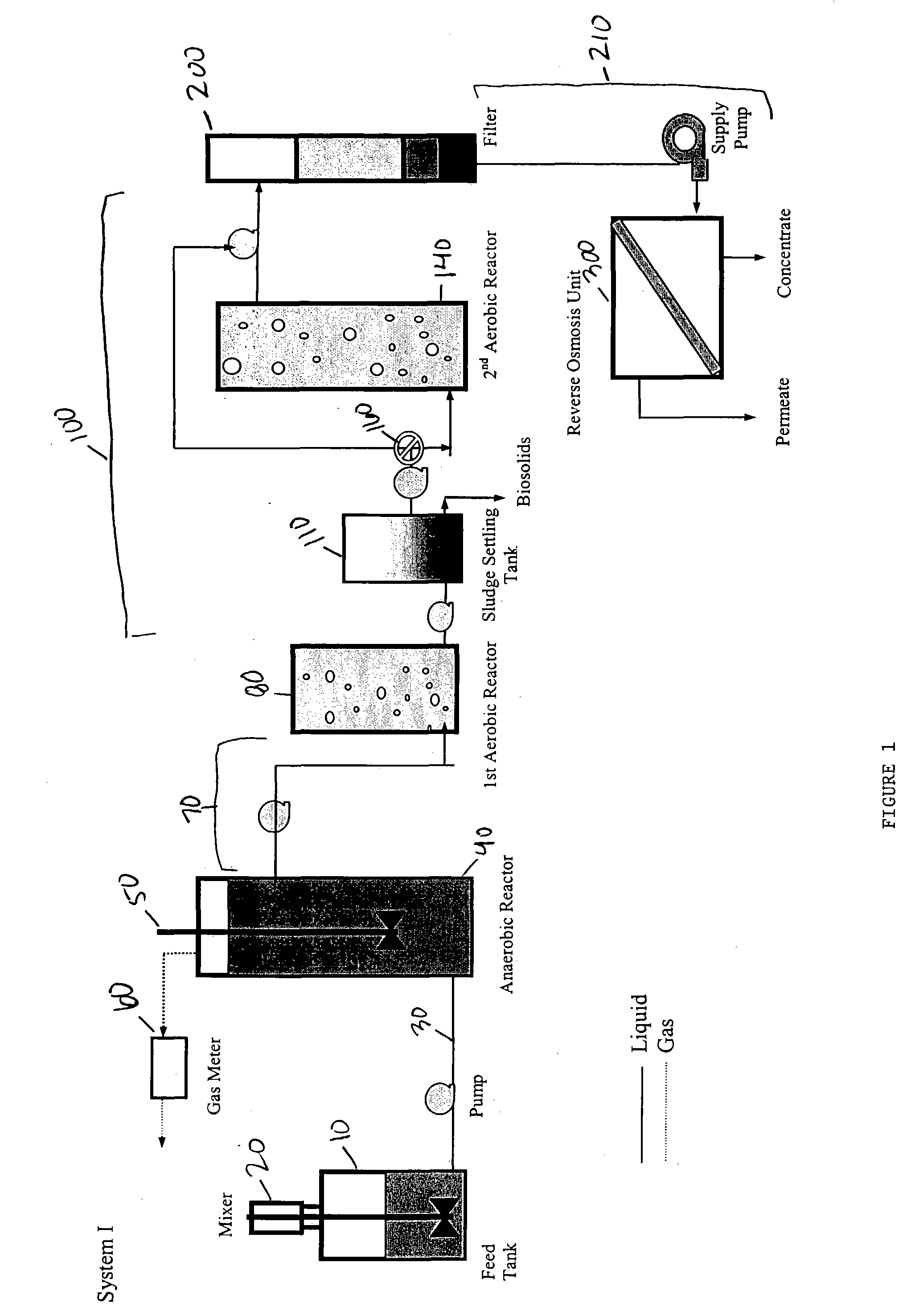

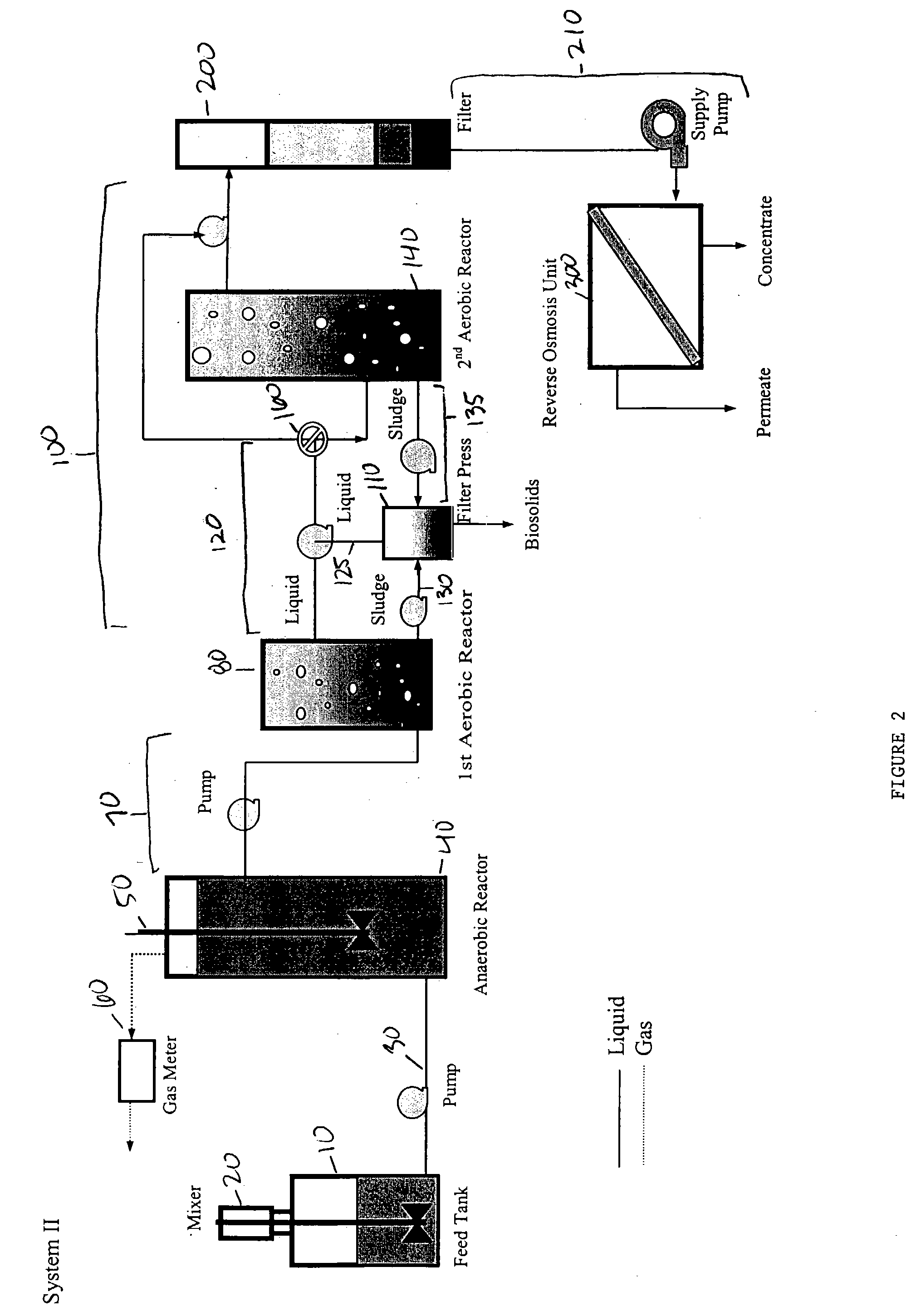

Treatment of swine wastewater by biological and membrane separation technologies

InactiveUS20050035059A1Bio-organic fraction processingWaste water treatment from animal husbandryFiltrationSeparation technology

The present invention provides an integrated system for treatment of biodegradable waste, including sewage sludge, forestry waste, food waste, agricultural waste, municipal waste, and the like. The integrated system comprises an anaerobic reactor, at least one aerobic reactor, a filtration device, and a desalinization device.

Owner:RGT UNIV OF CALIFORNIA

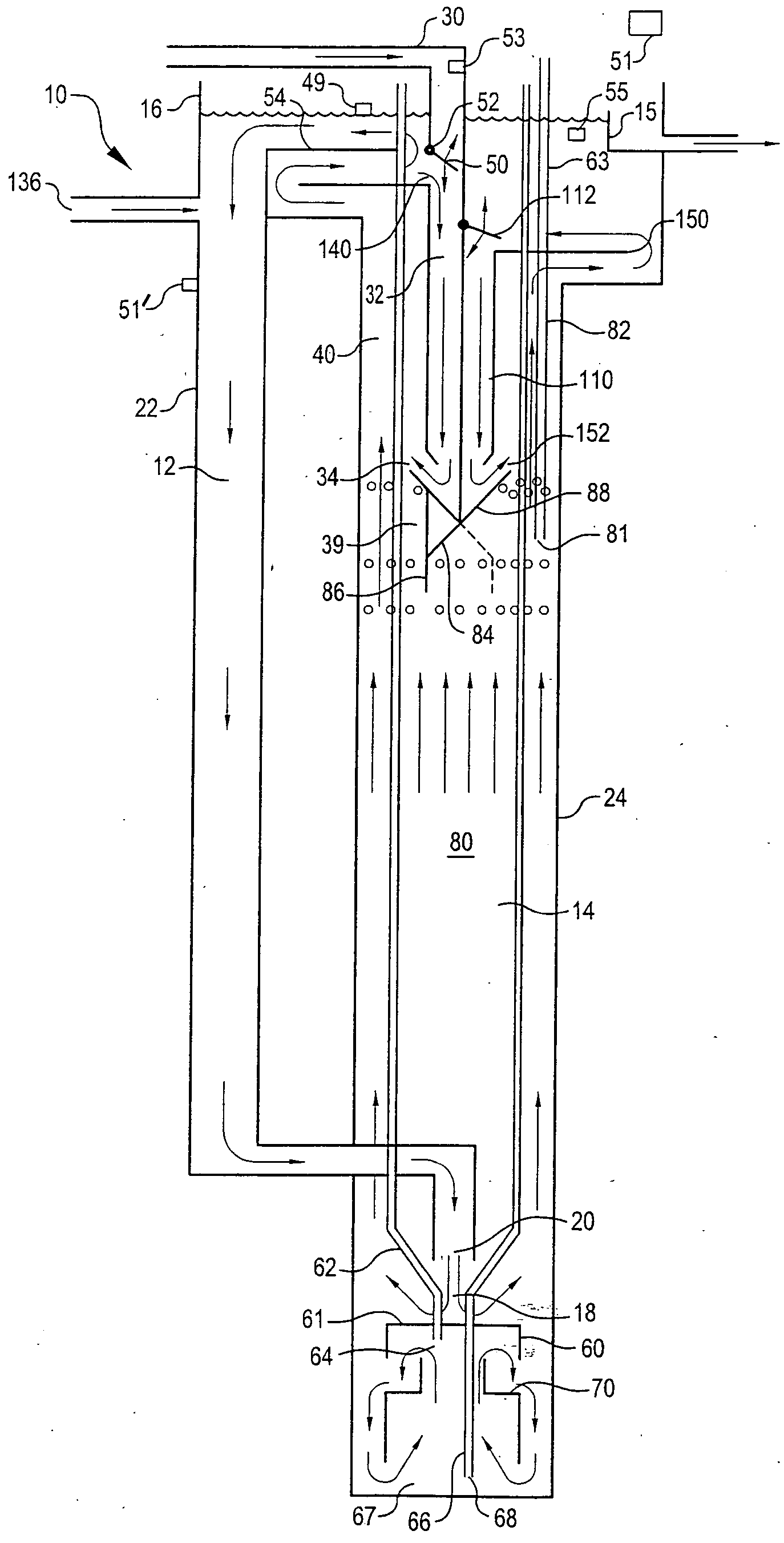

Apparatus for biological treatment of waste waters

InactiveUS7018530B2Liquid degasificationTreatment using aerobic processesIndustrial effluentPasteurization

In a vertical shaft bioreactor, improved devices and methods are provided for enhanced secondary and / or tertiary treatment of wastewater, including residential, municipal and industrial wastewater. The devices and methods of the invention are useful for enhanced secondary wastewater treatment, including BOD and TSS removal. Tertiary treatment can alternately or additionally be achieved in the bioreactor with nitrification of ammonia, with nitrification and denitrification, and with nitrification, denitrification, and chemical phosphorus removal. A vertical shaft bioreactor is also provided which achieves thermophilic aerobic digestion and pasteurization of sewage sludges, optionally to produce class A biosolids.

Owner:VOST ENVIRONMENTAL TECH

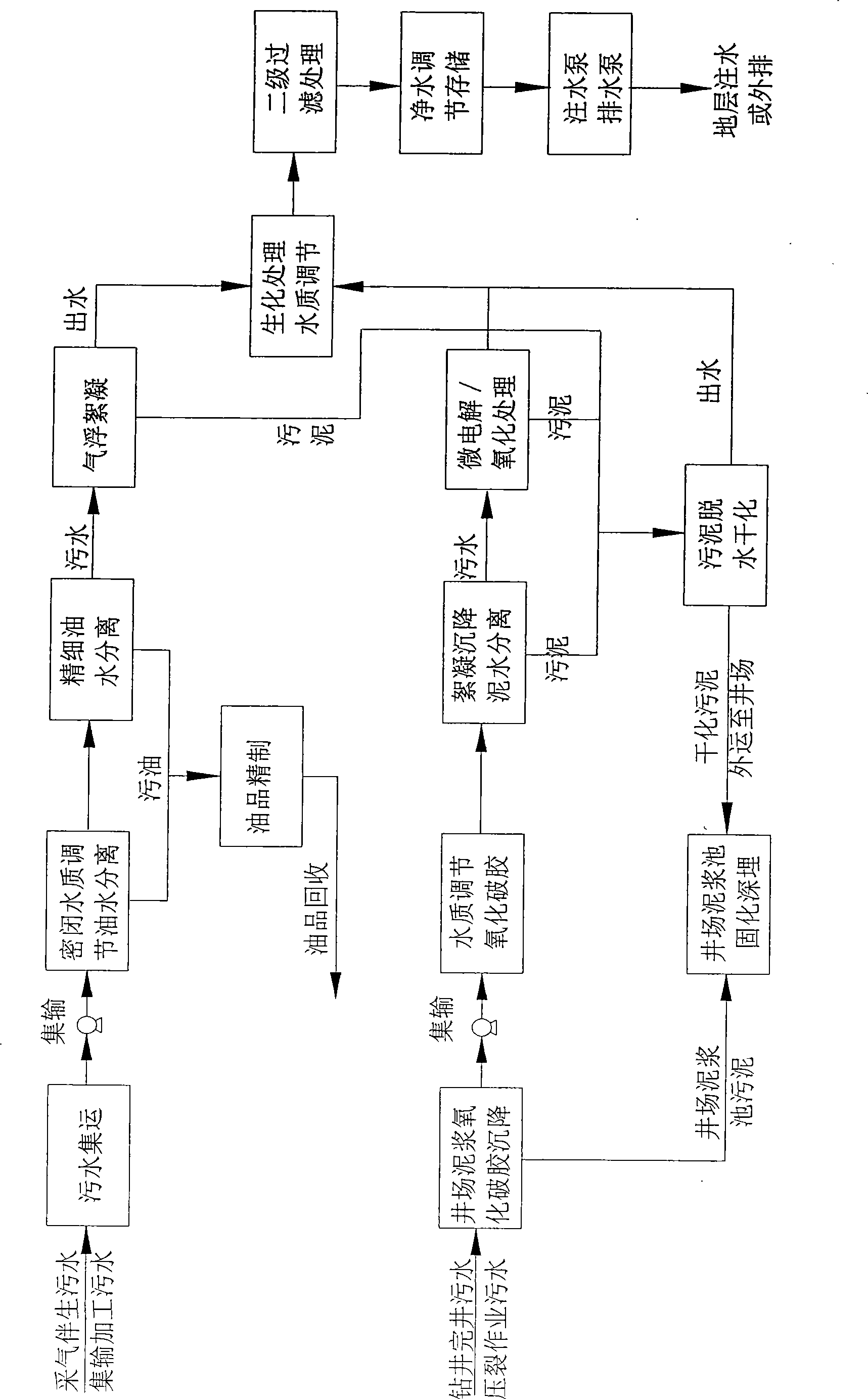

Gas field sewerage and solid pollutant comprehensive processing technological process

InactiveCN101475285AEasy to handleReduce pollutionSludge treatment by de-watering/drying/thickeningFatty/oily/floating substances removal devicesSocial benefitsSludge

The invention relates to a comprehensive treatment process method for sewage and solid pollutants in a natural gas field. The process method comprises five process units, namely, purification treatment for gas production accompanying sewage, purification treatment for drilling mud sewage, biochemical treatment for yielding water and water quality adjustment, fine filtering discharge of the yielding water, mud purification and solidification treatment for the solid pollutants. From the reality of development and production of the natural gas field, the comprehensive treatment process method for the sewage and the solid pollutants in the natural gas field combines environmental protection requirement, has strong comprehensiveness and practicality, is easy to execute, can effectively treat the sewage and the solid pollutants in the natural gas field, changes waste into valuable, effectively reduces environment pollution, and acquires good economic and social benefits.

Owner:LIAONING TIANYI IND CO LTD

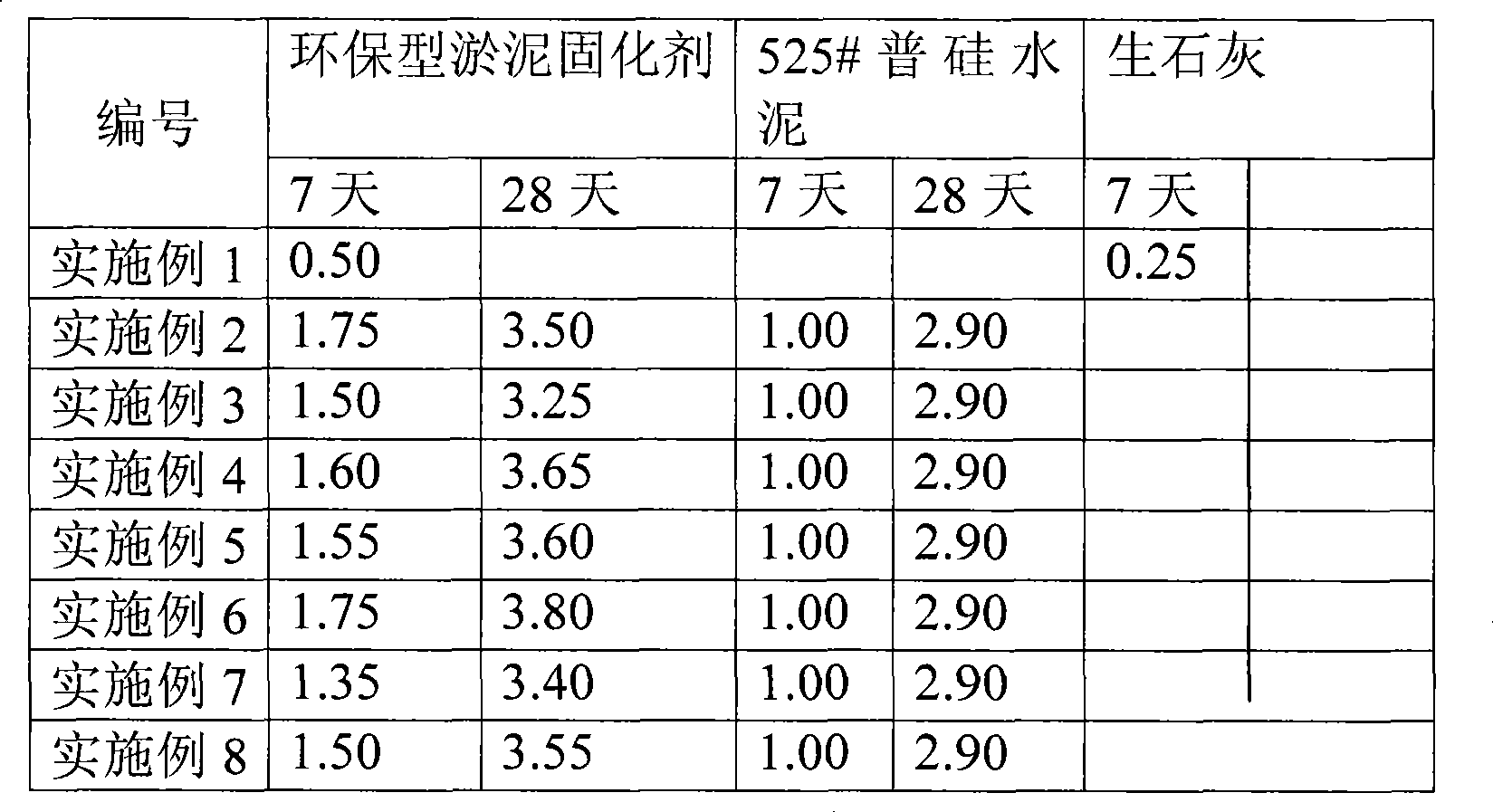

Environment-friendly type sludge firming agent

InactiveCN101381194AImprove curing abilityImprove curing effectSludge treatment by de-watering/drying/thickeningRoad engineeringSlag

The invention provides an environment-friendly silt curing agent, which is manufactured through the following steps: one or two among fly ash, calcium sulfate, sodium sulfate, sodium carbonate and potassium carbonate, one or two among slag, slag combination, potassium hydroxide, calcium oxide, sodium silicate or silicon dioxide, one or two among carbide slag, lime or gypsum, as well as one or two among triethanol amine surfactant, calcium lignosulfonate or sodium lignosulfonate form a plurality of optimal compound formulations according to respective attributes, are optimized, compounded, ground till the Brinell specific surface areas are between 300 and 900 m2 / kg respectively and then mixed, wherein particle sizes are between 0.00040 and 0.5 mm. As a large amount of waste is utilized, the curing agent saves raw materials, solves the problems about waste discharge and environmental pollution, controls waste through waste, and has important significance to environmental protection. The invention aims to provide the environment-friendly silt curing agent which has strong adaptability to a plurality of types of silt and soil, is good in curing effect, good in durability after curing and capable of utilizing industrial waste, and can be widely applied to fill engineering, embanking or embankment reinforcement engineering, road engineering and other fields.

Owner:天津渤海环保工程有限公司 +1

Organic containing sludge to fertilizer alkaline conversion process

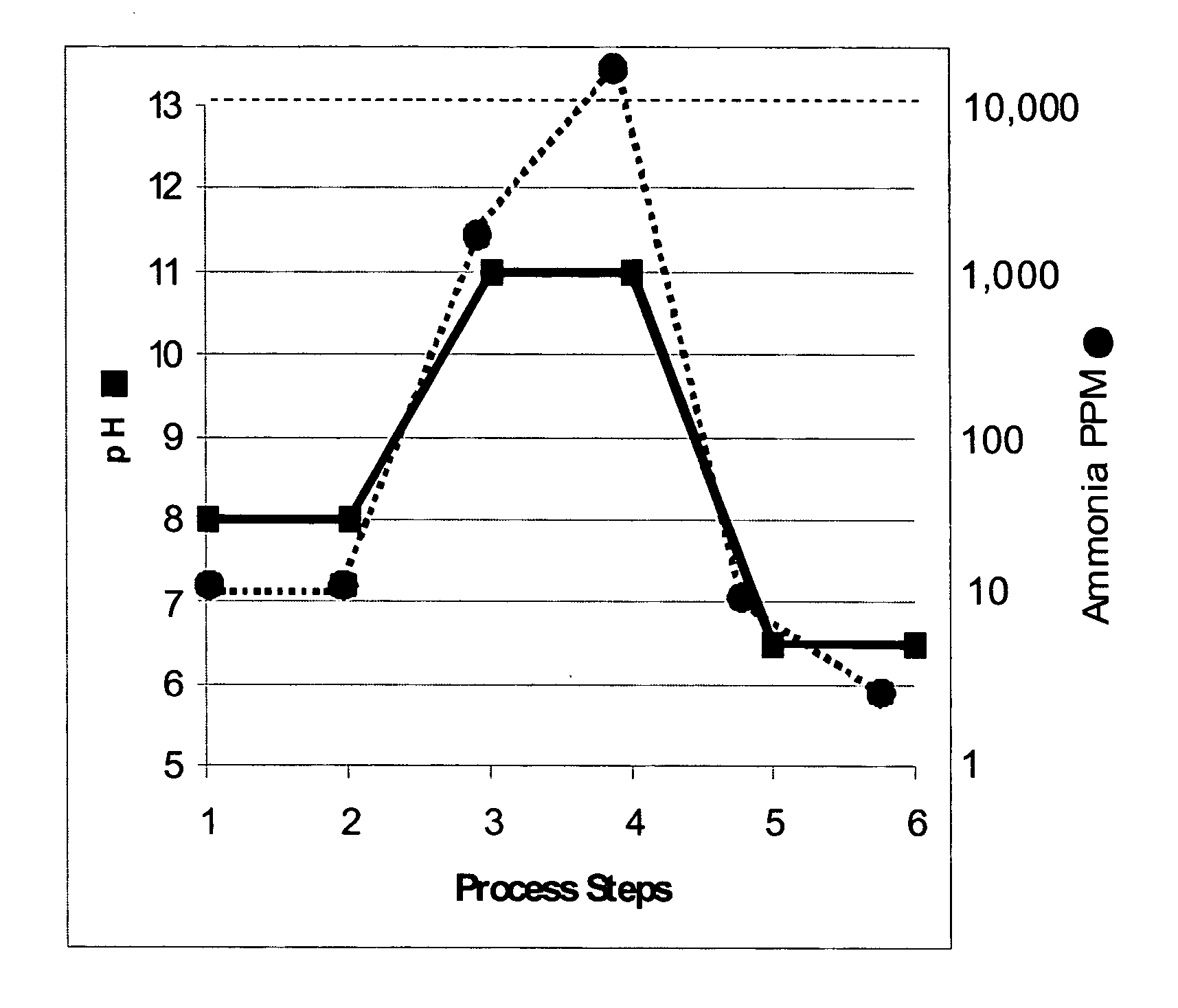

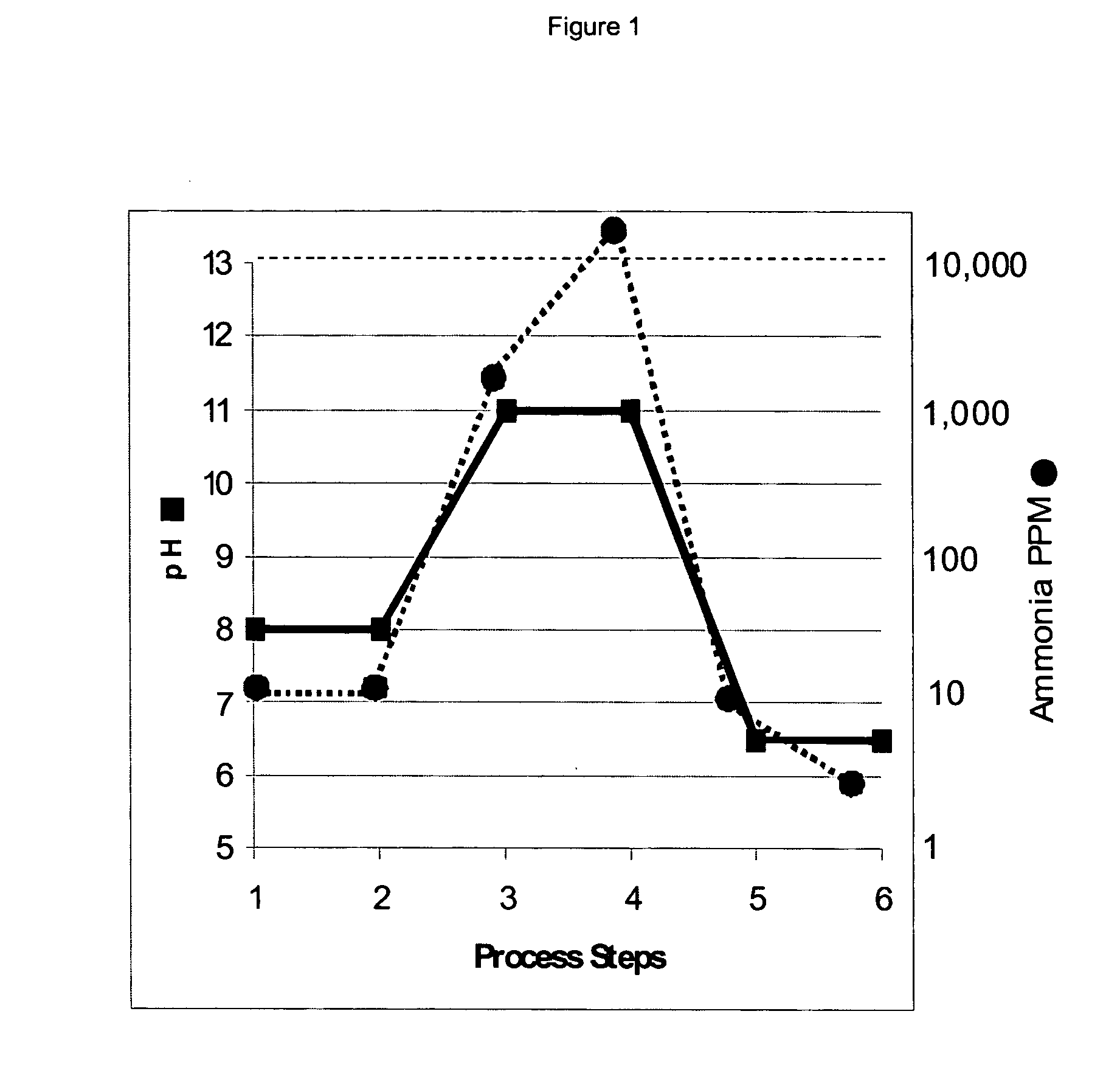

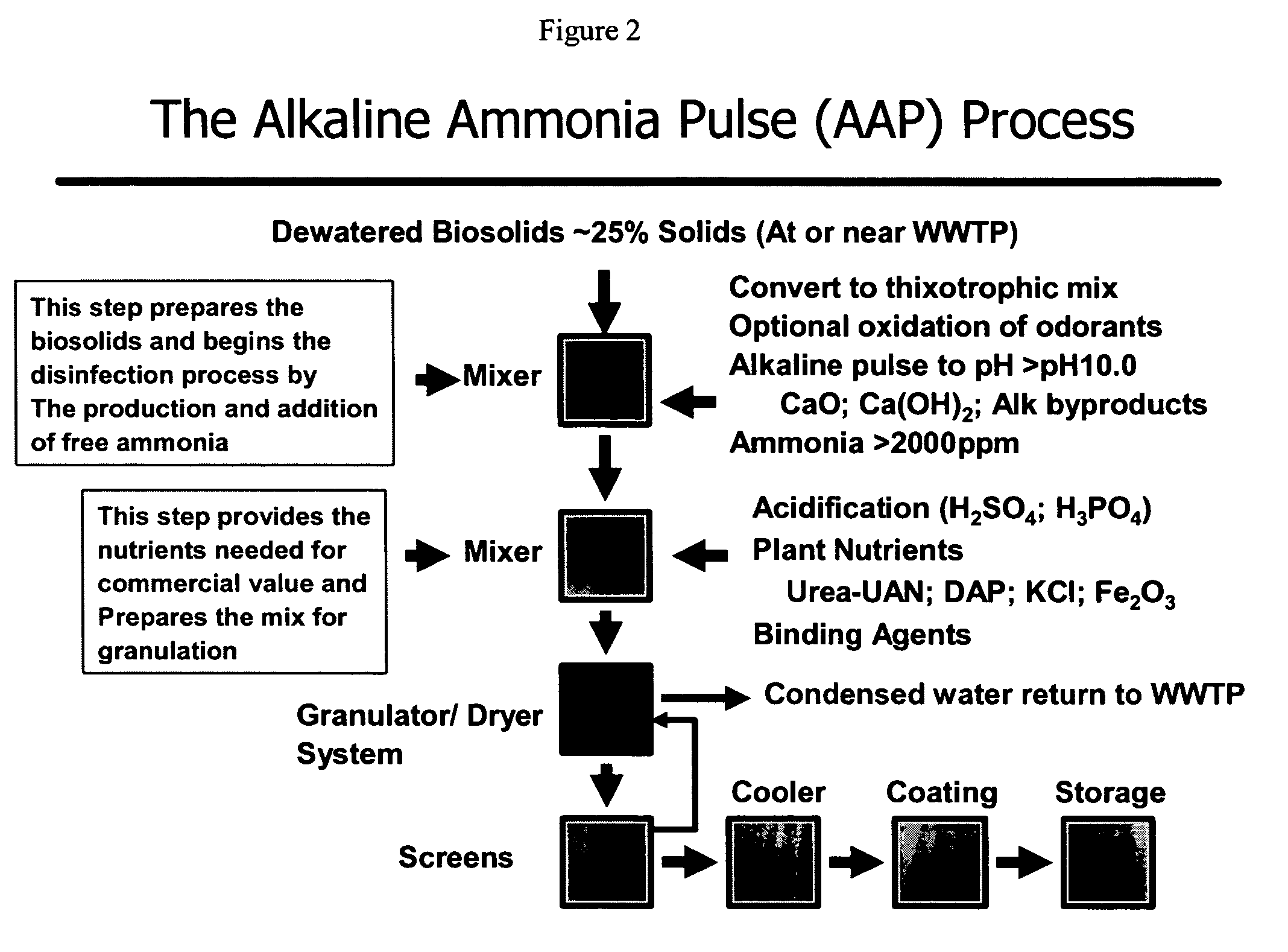

InactiveUS20070062233A1Increases plant nutrient contentReduce odorCalcareous fertilisersBio-organic fraction processingSludgeOrganic manure

This invention is directed to systems, devices and methods for treating organic-containing sludges and converting such sludges to high value fertilizers containing both inorganic and organic fertilizer components, which creates an inorganically-augmented bioorganic fertilizer. The invention describes methods to create a thixotrophic or paste-like material via the application of mixing energy to the organic sludge followed by an alkaline treatment and a subsequent ammoniation. The invention further describes a method to increase the plant nutrient content in the organic containing product to a level which permits the finished granular fertilizer product to compete in the commercial agricultural fertilizer marketplace. Further, the invention reduces odors associated with said organic-containing sludges.

Owner:GENERATE LENDING LLC

Centralized kitchen waste treatment method

ActiveCN101837366ARealize harmless treatmentRecycling is possibleFatty oils/acids recovery from wasteBio-organic fraction processingResource utilizationOil water

The invention relates to a centralized kitchen waste treatment method which comprises the following steps of: (A) sorting kitchen waste; (B) separating oil from water; (C) treating oil; (D) treating sewage; and (E) treating odor. Compared with a traditional kitchen waste burying method, by using the centralized kitchen waste treatment method, a great amount of soil is saved and an available methane resource is generated, kitchen waste reaches 100 percent of harmlessness, more than 95 percent of resource utilization and more than 95 percent of quantitative reduction, and the harmless treatmentof waste and the recycle of resources are truly realized.

Owner:北京昊业怡生科技有限公司

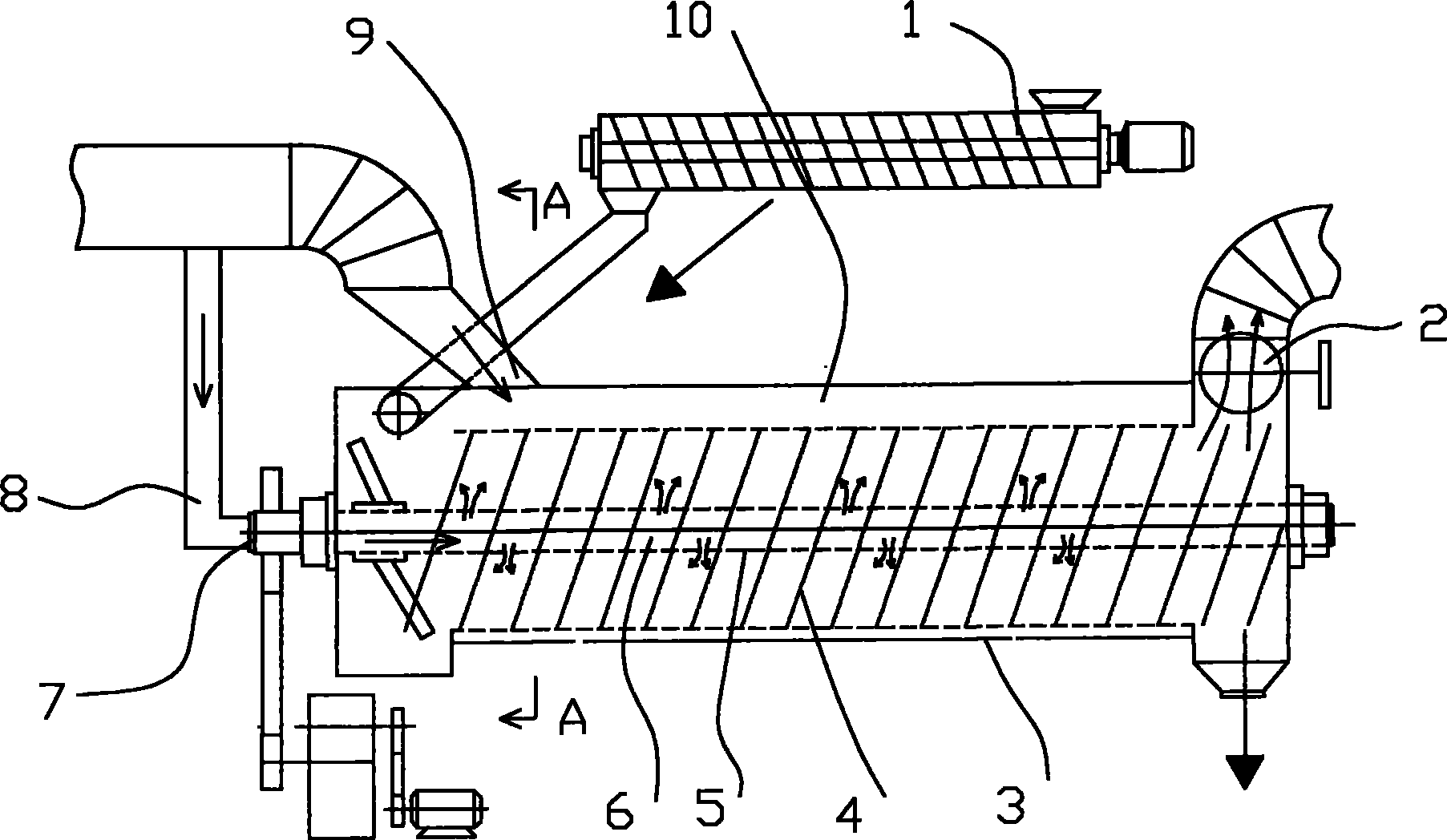

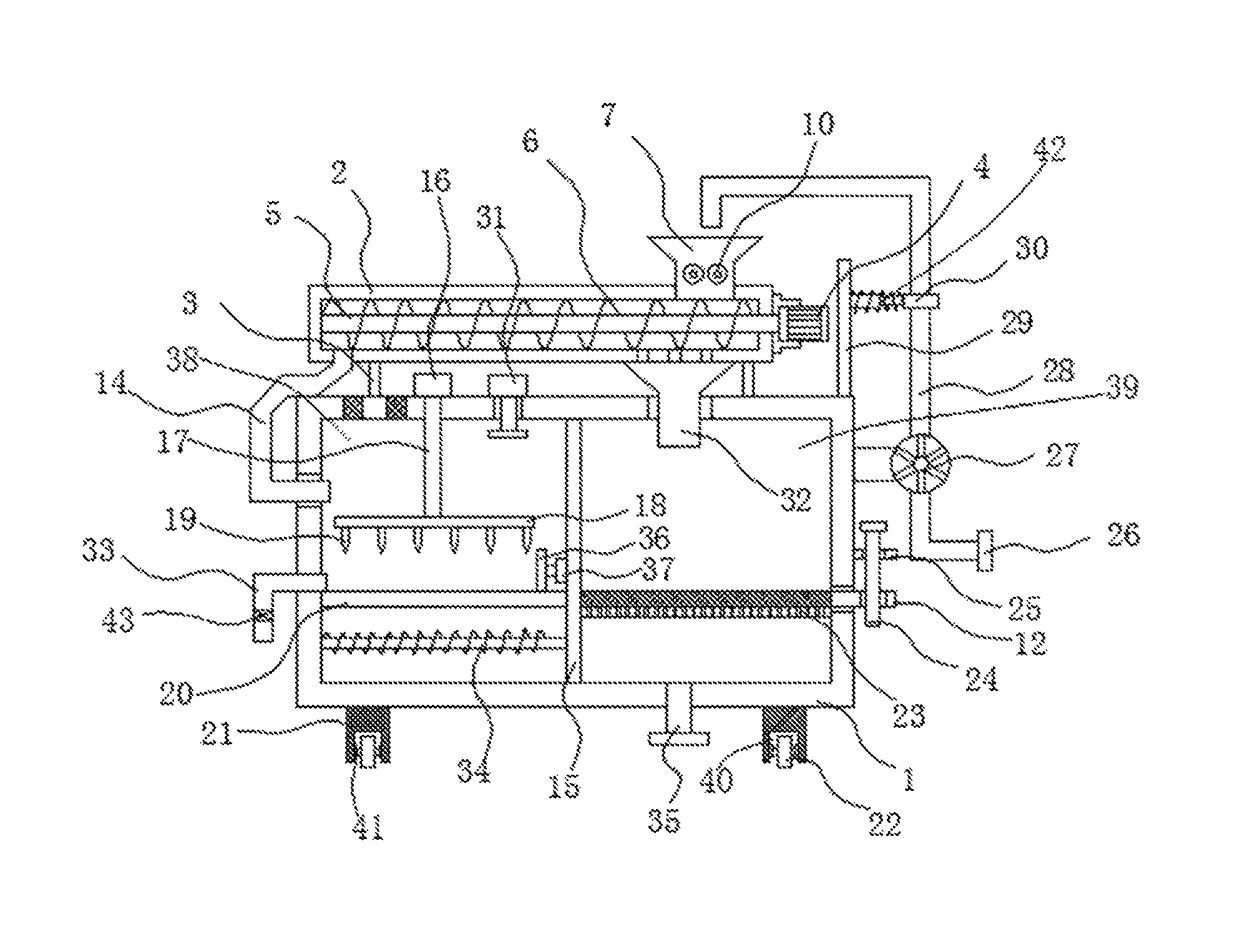

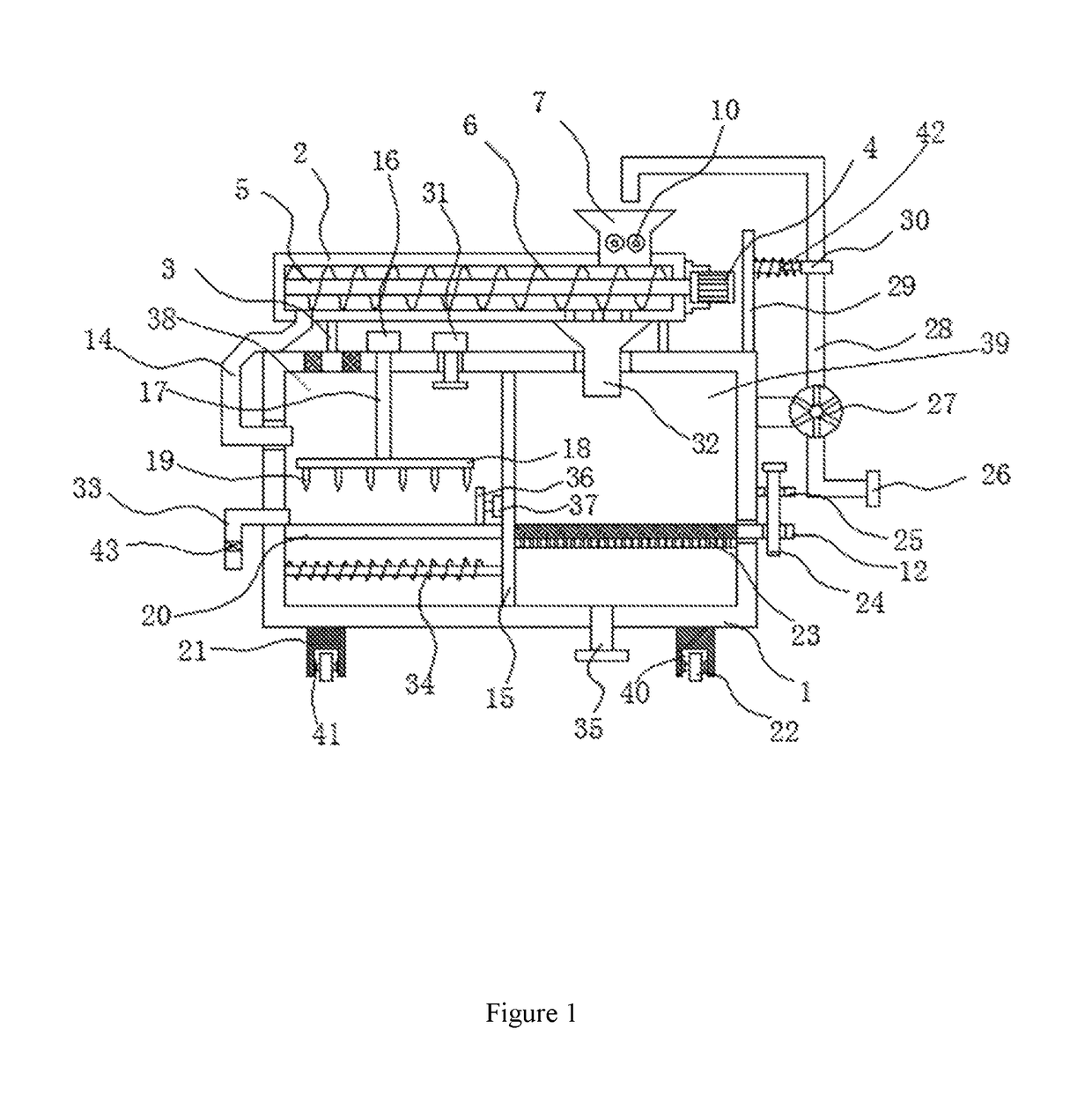

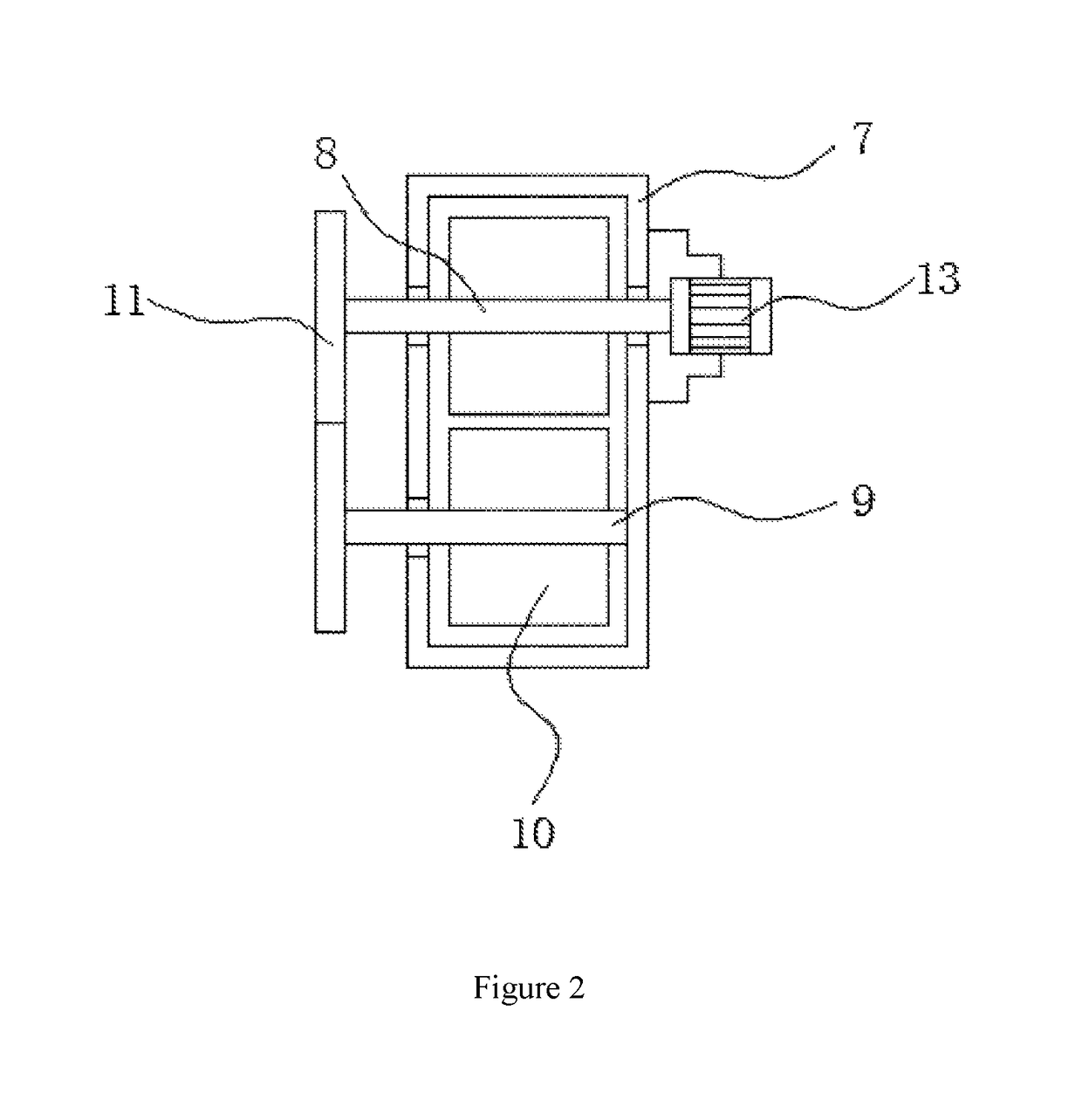

Device for separating water from sludge

InactiveUS10053385B1Convenient guidanceEfficient and cheapSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSpiral bladeSludge

A device for separating water from sludge comprising a processing box, wherein a feeding cylinder is disposed above the processing box, and the feeding cylinder is fixedly connected to the processing box through a plurality of connecting rods; a rotating rod is rotationally connected into the feeding cylinder; a first rotating motor is fixedly connected to one side of the feeding cylinder; the output end of the first rotating motor penetrates through the side wall of the feeding cylinder, and is fixedly connected to the rotating rod; a spiral blade is fixedly sleeved with the rotating rod, and the outer side of the spiral blade is matched with the inner side wall of the feeding cylinder.

Owner:ZHU ZIYU

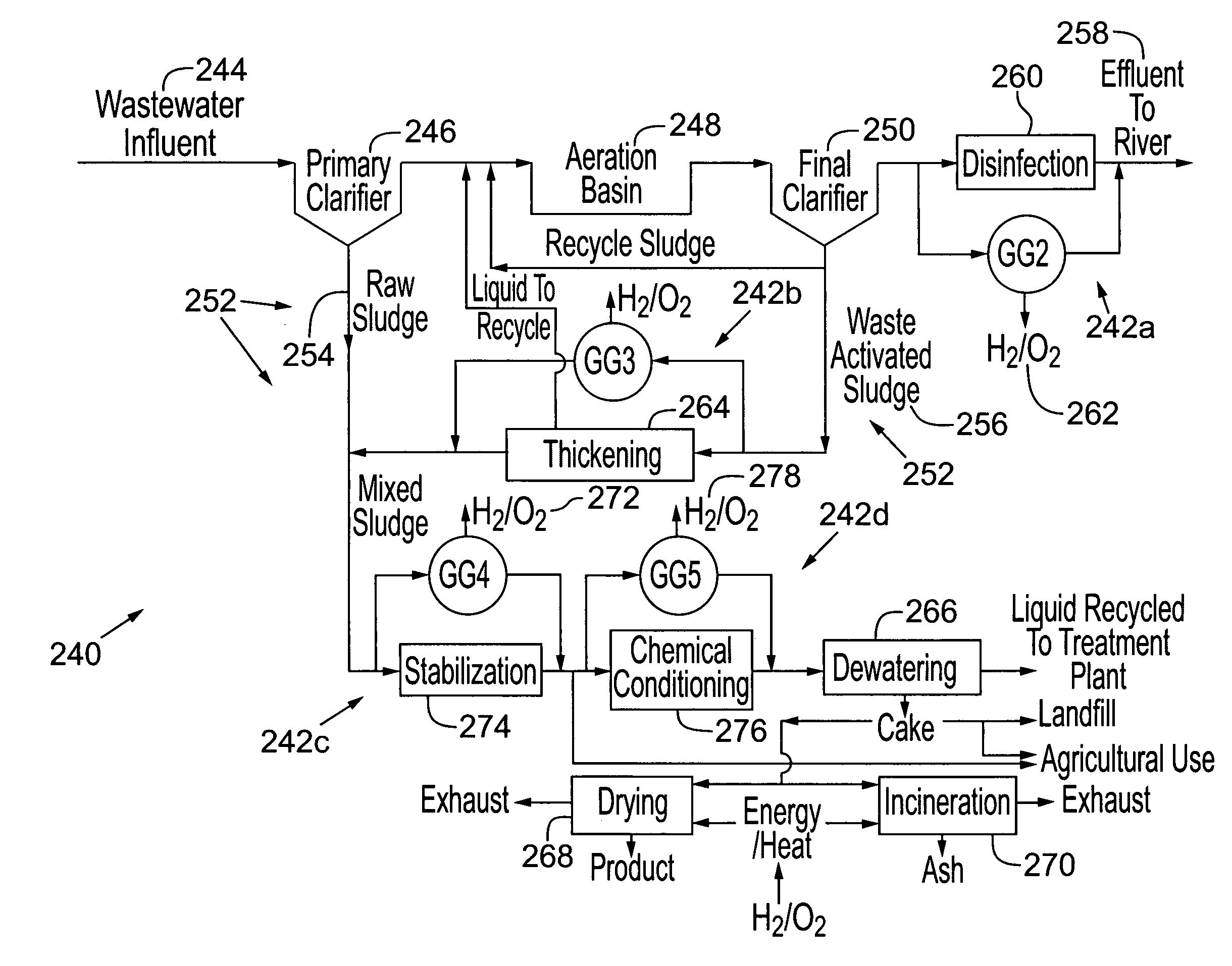

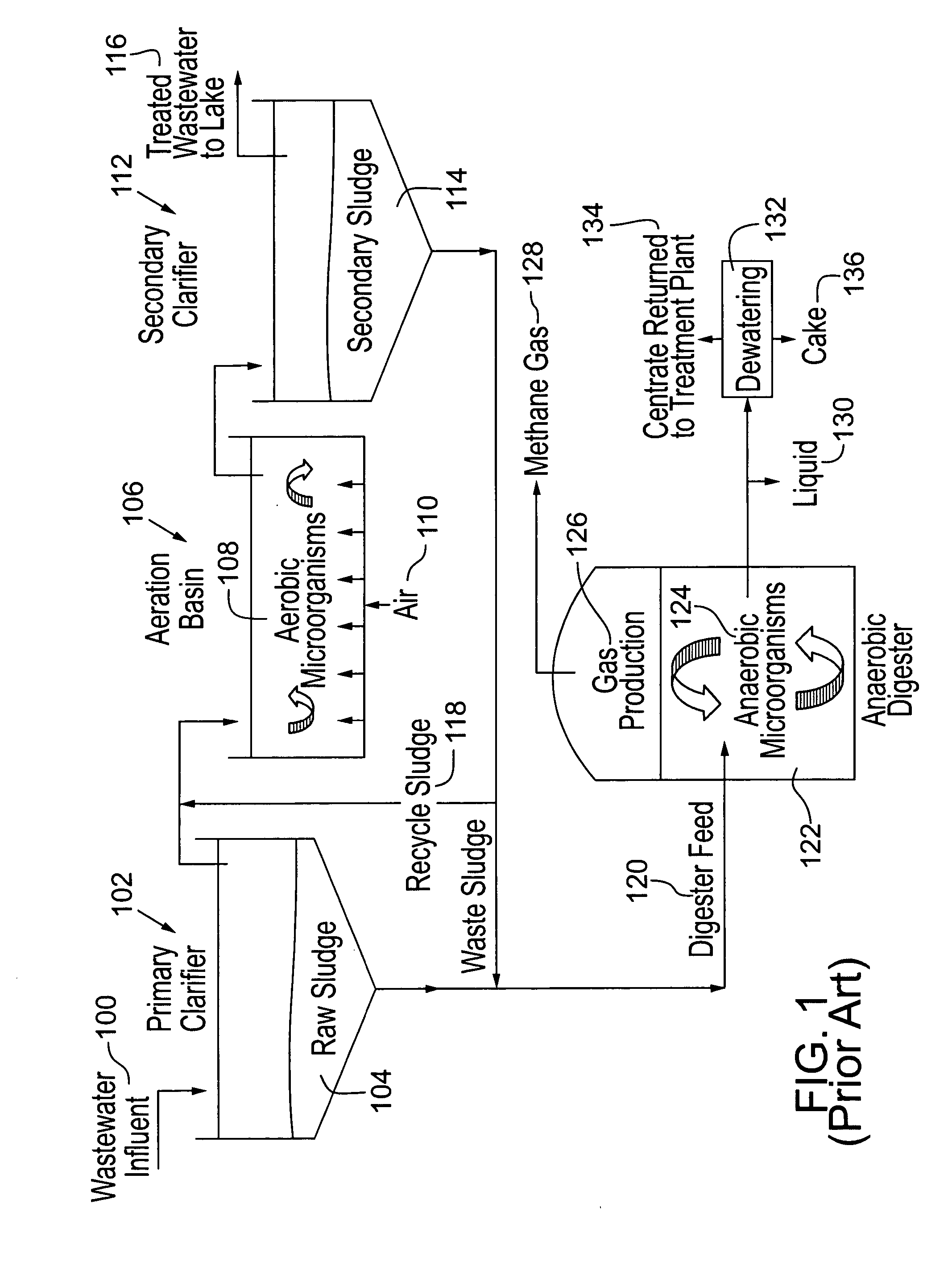

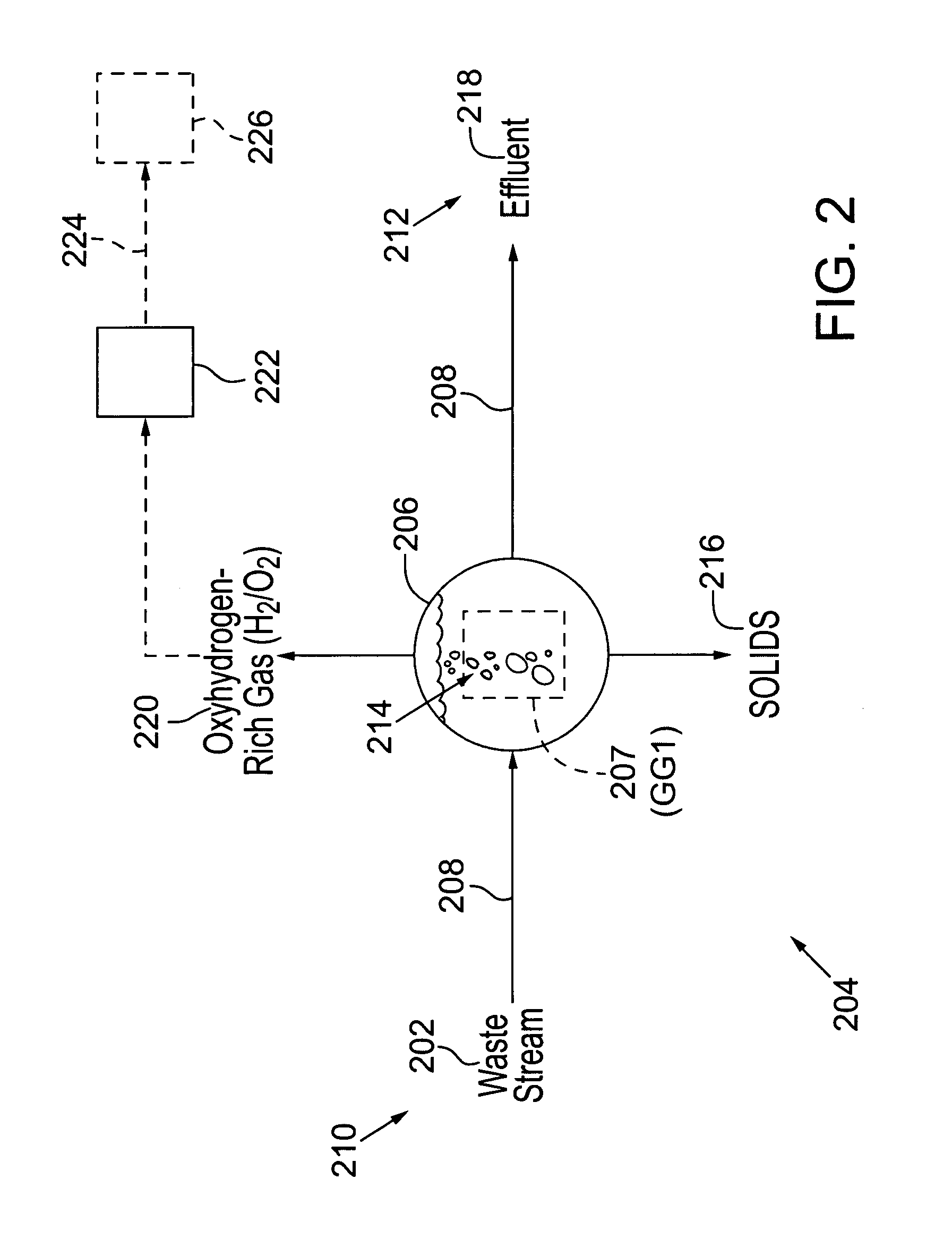

Treatment of a waste stream through production and utilization of oxyhydrogen gas

Methods and systems for treating a waste stream in a waste treatment system involve performing a unit process of the waste treatment system by contacting the waste stream with oxyhydrogen-rich gas generated on-site by an oxyhydrogen gas generator that implements water dissociation technology. In a preferred embodiment, the oxyhydrogen gas generator involves applying a pulsed electrical signal to a series of closely-spaced electrodes that are submerged in the waste stream to produce oxyhydrogen-rich gas from a water component of the waste stream. Operation of the oxyhydrogen gas generator in the waste stream may accomplish one or more unit processes for waste treatment, such as conditioning, stabilization, thickening, and dewatering, among others. At least a portion of the oxyhydrogen-rich gas can be conveyed for a second use in the waste treatment system, such as a source of combustible fuel for incineration or power generation, for example.

Owner:XOGEN TECH

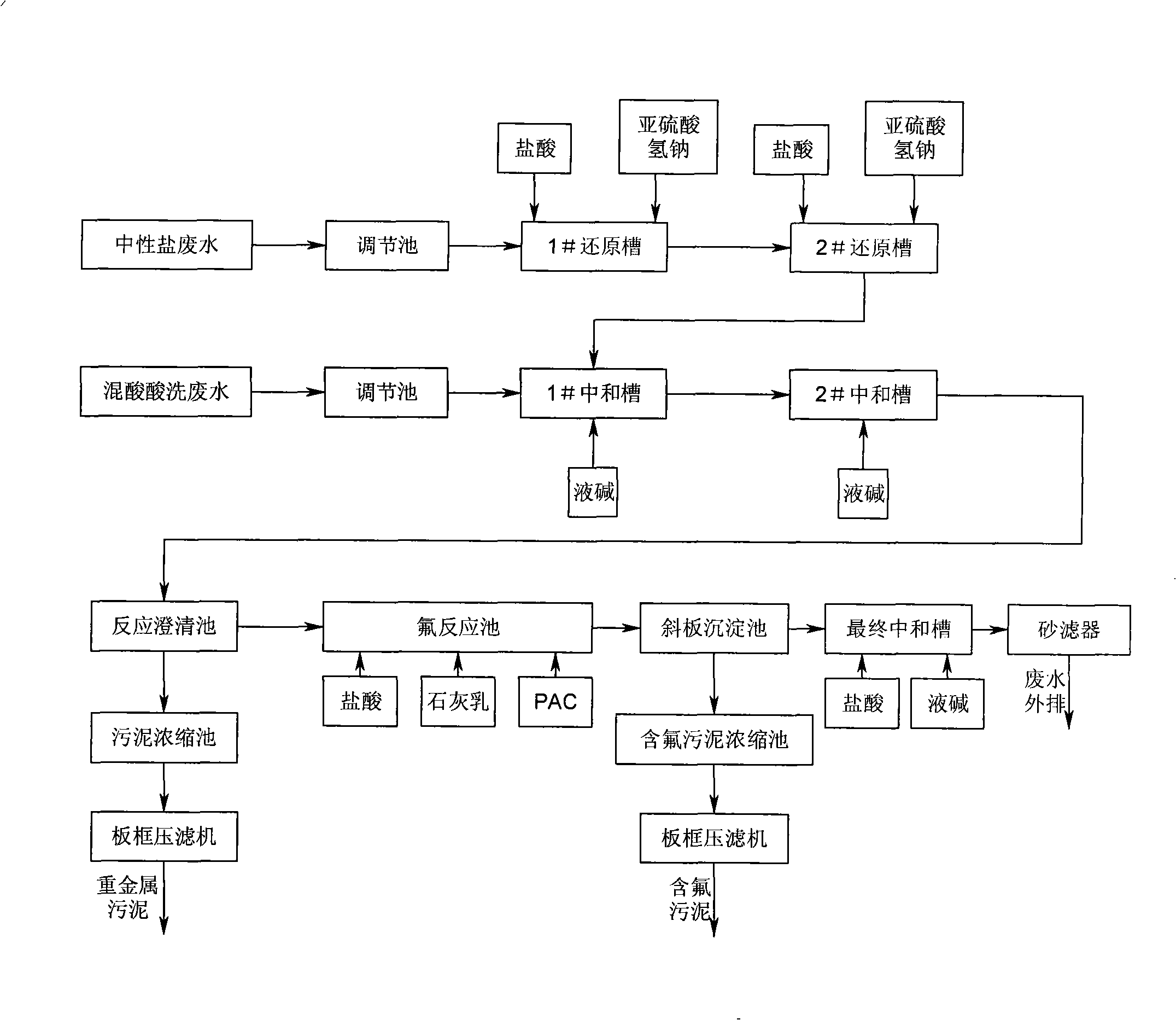

Processing method for stainless steel acid cleaning waste water and liquid

InactiveCN101269889AMeet emission compliance requirementsMeet compliance requirementsSludge treatment by de-watering/drying/thickeningIron oxides/hydroxidesLiquid wasteSludge

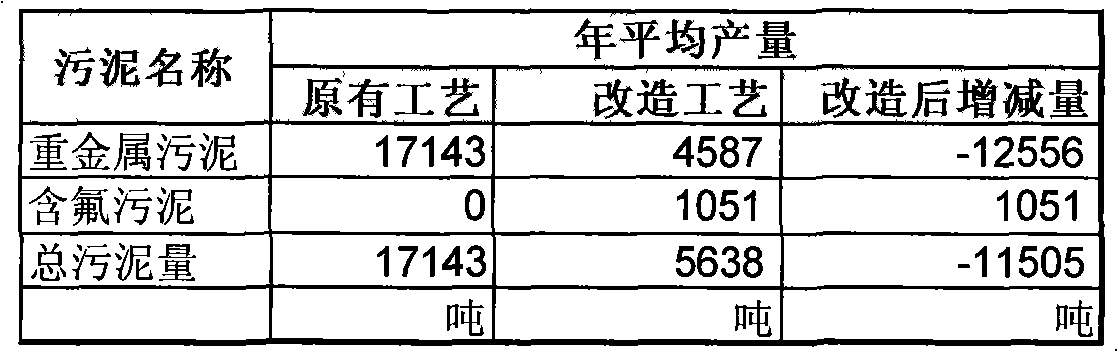

The invention relates to a processing method of stainless steel pickling waste liquid, which is characterized in that the processing method includes the steps that: neutral salt wastewater flows into a neutral reduction cell, and mixed acid pickling waste waters flow into a neutralizing tank; reducing agent is added into the neutral reduction cell, and then the reduced wastewater liquid is put into the neutralizing tank and is mixed with the adjusted mixed acid pickling waste waters, and liquid alkali is added into the neutralizing tank; the separated clear waste liquid removes fluorin ions in a settlement tank; neutralizing liquid is added into a final neutralizing tank to cause the pH value of treatment liquid to adjust to be neutralized wastewater liquid which passes through a sand filter to be discharged. The processing method has the advantages that metal ions and fluorin ions are performed the subsection treatment, and neutralizing agent is changed into the liquid alkali from lime cream, the requirement of reaching the standard of the waste liquid emission is not only achieved, but also the mud quantity produced by a mass of lime cream is greatly reduced, heavy metal mud of a retention pond only contains heavy metal compound, the salts of calcium fluoride and calcium sulphate, etc. are separated from the inclined plate settlement tank during the fluoridation stage, thereby the treatment cost is effectively lowered.

Owner:NINGBO BAOXIN STAINLESS STEEL

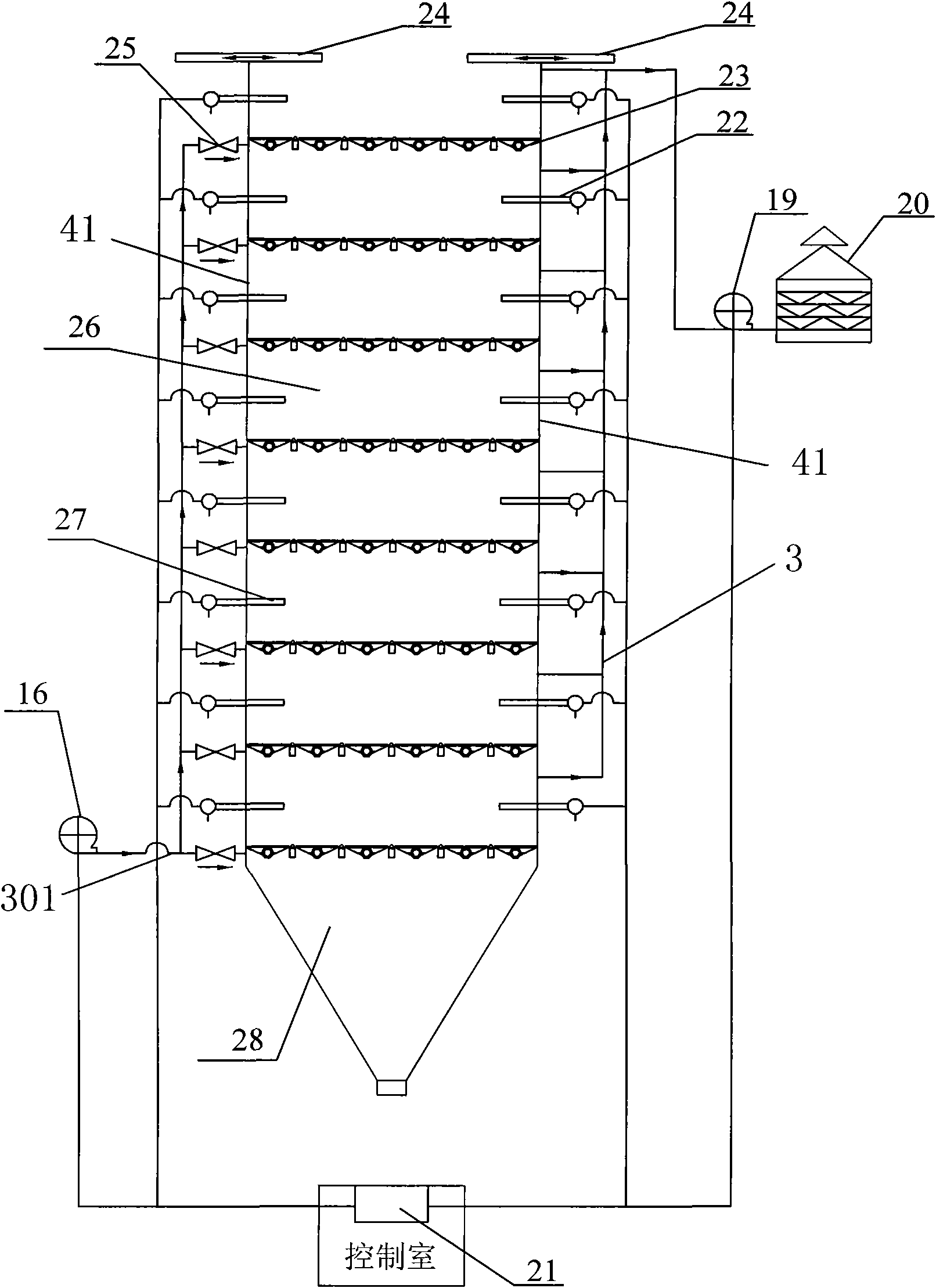

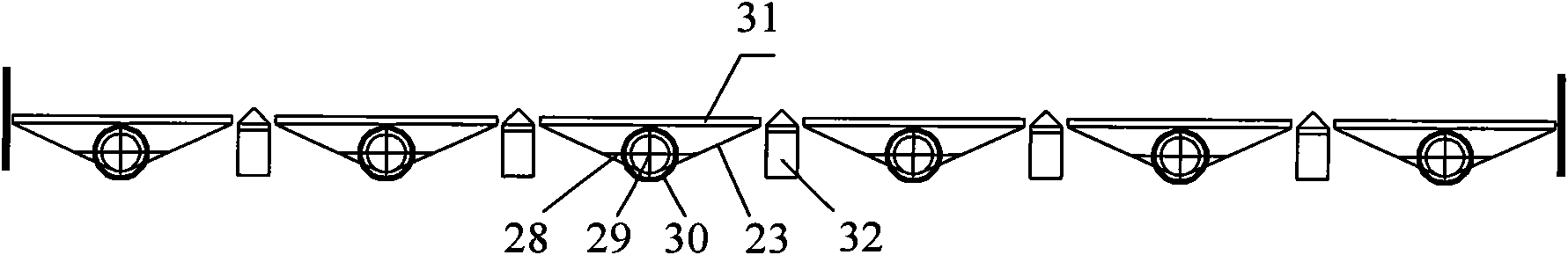

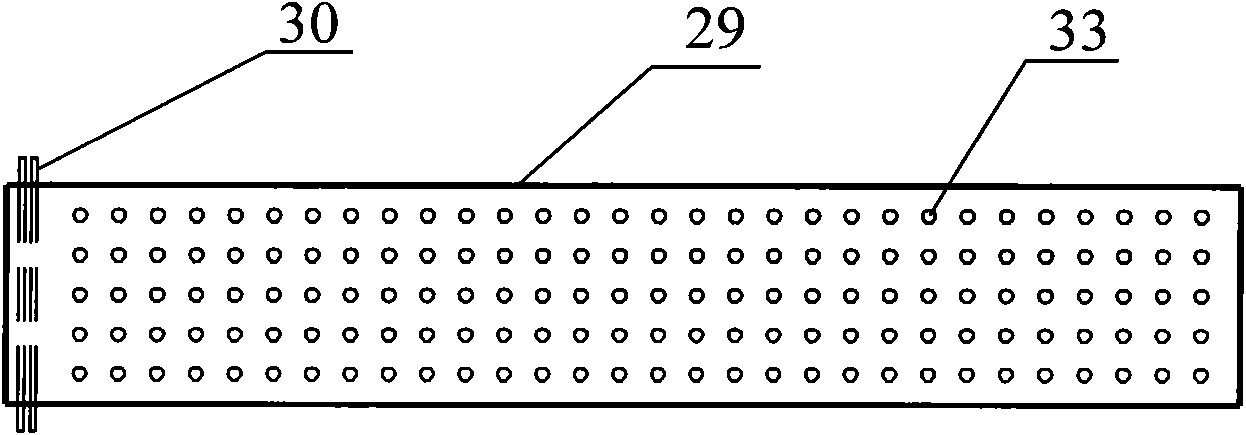

Circulating sludge biological fermentation tank, processing system and processing method

ActiveCN102153388AReduce wind pressureReduce air volumeBio-organic fraction processingSludge treatment by de-watering/drying/thickeningSludgeControl room

The invention discloses a circulating sludge biological fermentation tower which comprises a tower body, an openable tower cover, a storage tank and a plurality of rotatable fermentation devices, wherein the openable tower cover is arranged on the top of the tower body; the storage tank is arranged at the bottom of the tower body; the rotatable fermentation devices are arranged in the tower body in parallel; the fermentation devices divide an inner cavity of the tower body into a plurality of layers of fermentation bins along the axial direction; the lower part of each layer of fermentation device is provided with a ventilating oxygen supply pipeline communicated with a blower; the upper part of each layer of fermentation device is provided with an air outlet pipeline communicated with aninduced draft fan and a monitoring device; the monitoring device is controlled by a control room; and a mechanism for driving the fermentation devices and the tower cover to move, the blower and the induced draft fan are all controlled by the control room. The invention also discloses a circulating sludge biological processing system and a processing method. By the circulating sludge biological fermentation tower, the circulating sludge biological processing system and the processing method, industrial biological fermentation desiccation treatment can be continuously and stably carried out onsludge under the conditions of high efficiency and low energy consumption.

Owner:深圳市如茵生态环境建设有限公司

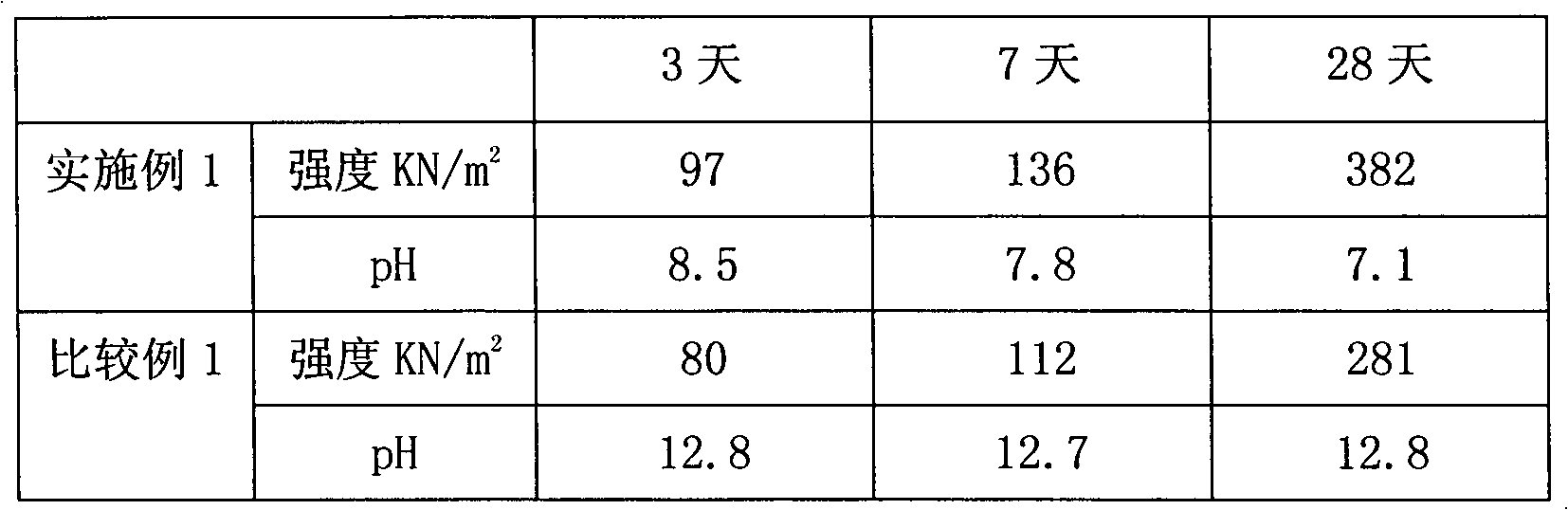

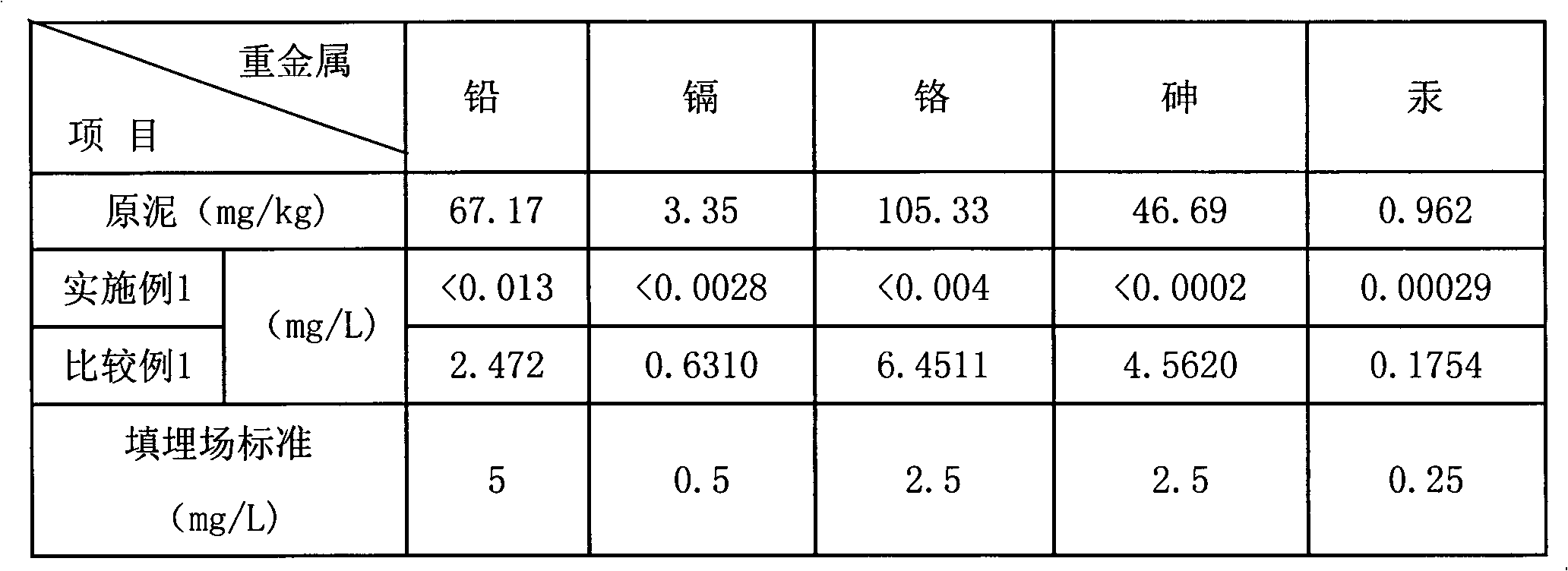

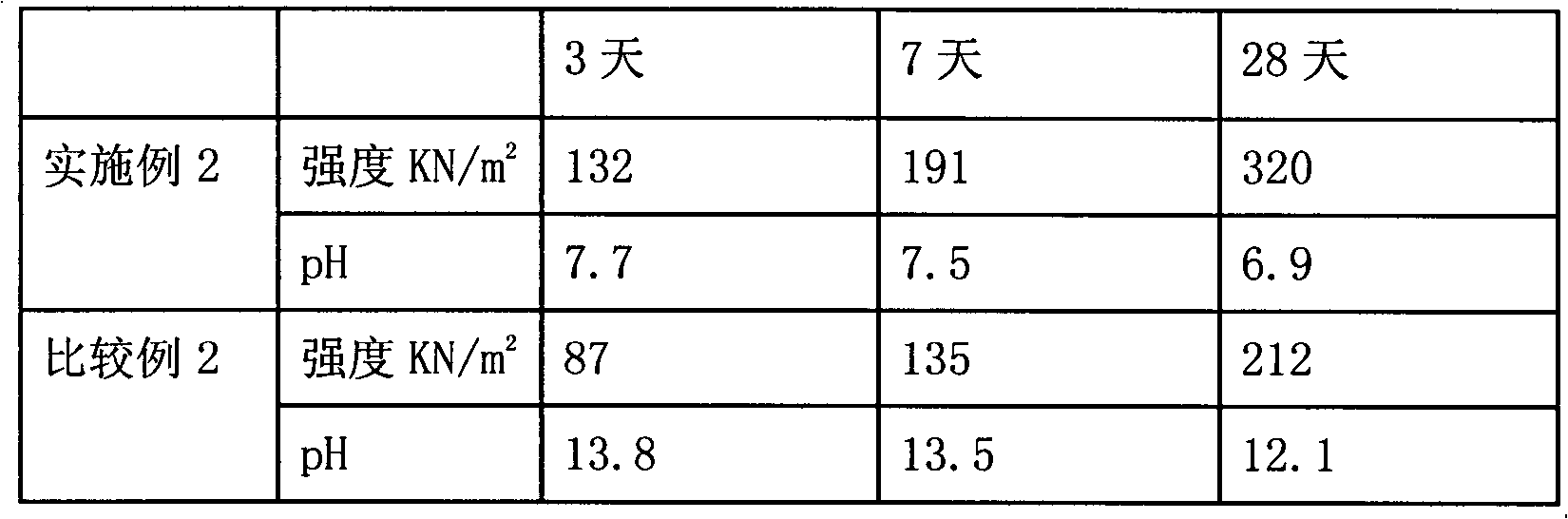

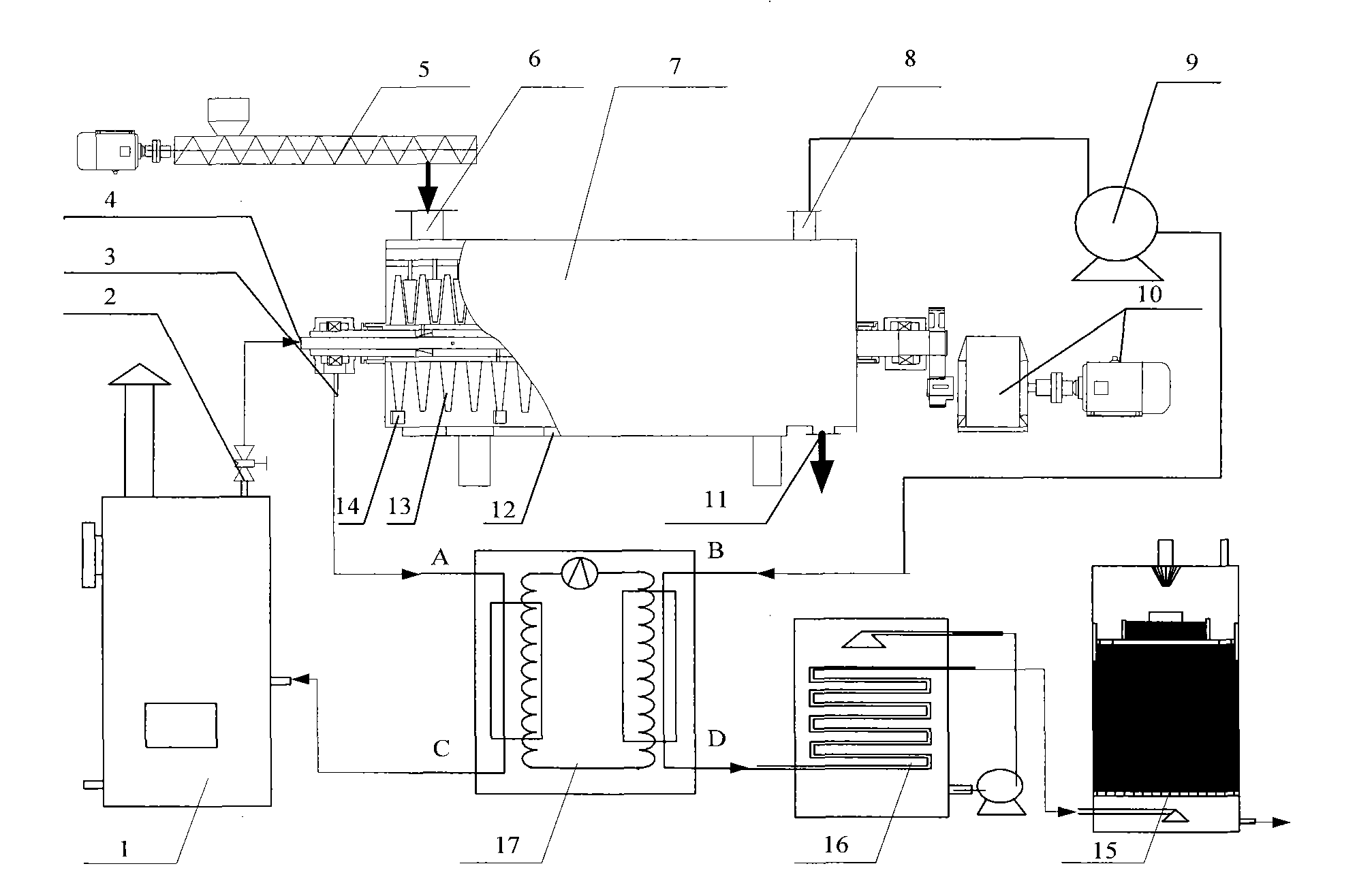

Neutral inorganic composite material for dehydration, solidification and modification of high water content sludge

ActiveCN101955345ASolving Alkaline ProblemsHigh compressive strengthSludge treatment by de-watering/drying/thickeningSolid waste managementHazardous substanceHigh water content

The invention discloses a neutral inorganic composite material for dehydration, solidification and modification of high water content sludge. The composite material comprises a powdery mixture consisting of the following components in part by weight: 100 parts of water hardened solidifying material consisting of hydrated gypsum and magnesium oxide, 80 to 120 parts of inorganic water absorption ash material, 20 to 40 parts of inorganic substance aid hardened material, 1 to 10 parts of high polymer coagulant and 1 to 5 parts of modifying functional agent. After being treated by the neutral inorganic composite material, the solidified sludge has high compressive strength; the pH of the lixivium is neutral, and meanwhile, harmful substances such as heavy metal and the like in the sludge can be effectively solidified; the treated sludge meets the requirement of landfill soil, soil for earthwork or soil for greening and farmlands; and the neutral inorganic composite material can be widely applied to the dehydration, solidification and modification of the high water content sludge such as sludge from waterworks, dredged bottom mud of rivers and lakes, residual building soil and the like.

Owner:江苏艾特克环境工程有限公司

Latent heat recoverable multi-phase change sludge drying method and device

ActiveCN101774743AReduce drying costsEnergy balanceSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningThermal energyBrick

The invention discloses a latent heat recoverable multi-phase change sludge drying method and a latent heat recoverable multi-phase change sludge drying device, which are designed for solving the technical problems that the energy consumption is high, the latent heat of the sludge vapor cannot be recovered and reused, the dried tail gas pollutes the environment, the operating cost is high and the like in the conventional sludge drying technology. Due to the combination of a low-temperature vapor turntable dryer, a sludge waste vapor latent heat recover heat pump and a tail gas purification device, and the use of indirect phase change heat exchange for low-temperature vapor, the heat exchange is improved, and the loss of organic components of the sludge is low. The latent heat of the sludge drying tail gas is recovered by using the latent heat recover heat pump, and the recovered heat energy is reused for sludge drying. Therefore, the heat efficiency is improved, the operating cost is reduced, and the problems that the heat utilization ratio is low, the operating cost is high and the like in the sludge drying process are better solved. The dried products meet the requirement of baking light and energy-saving bricks and producing cement laminated products, and over 90 percent of heat value of the original sludge is maintained. Therefore, the resource utilization value of the sludge is maximized.

Owner:SHENYANG INST OF AERONAUTICAL ENG

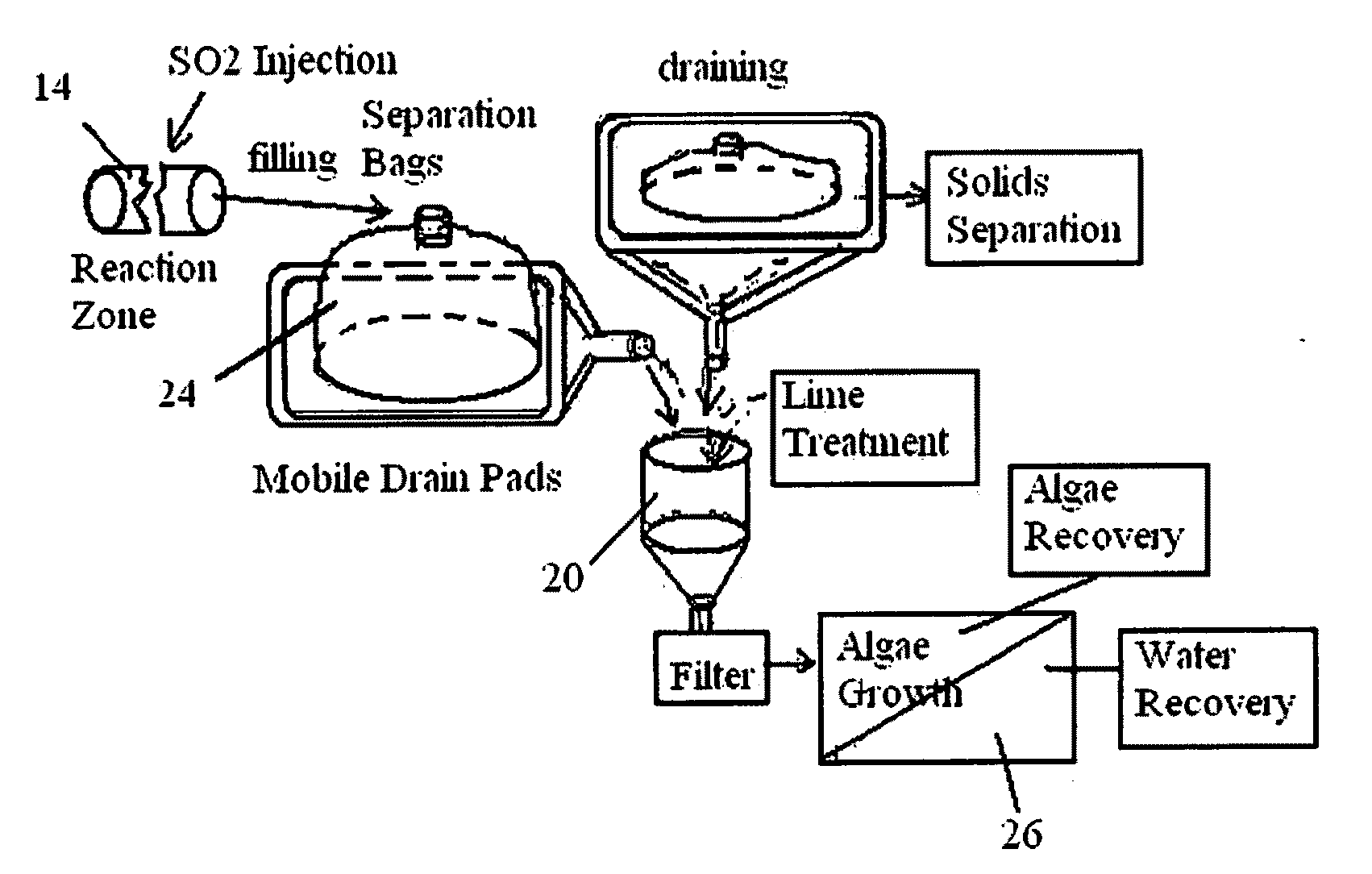

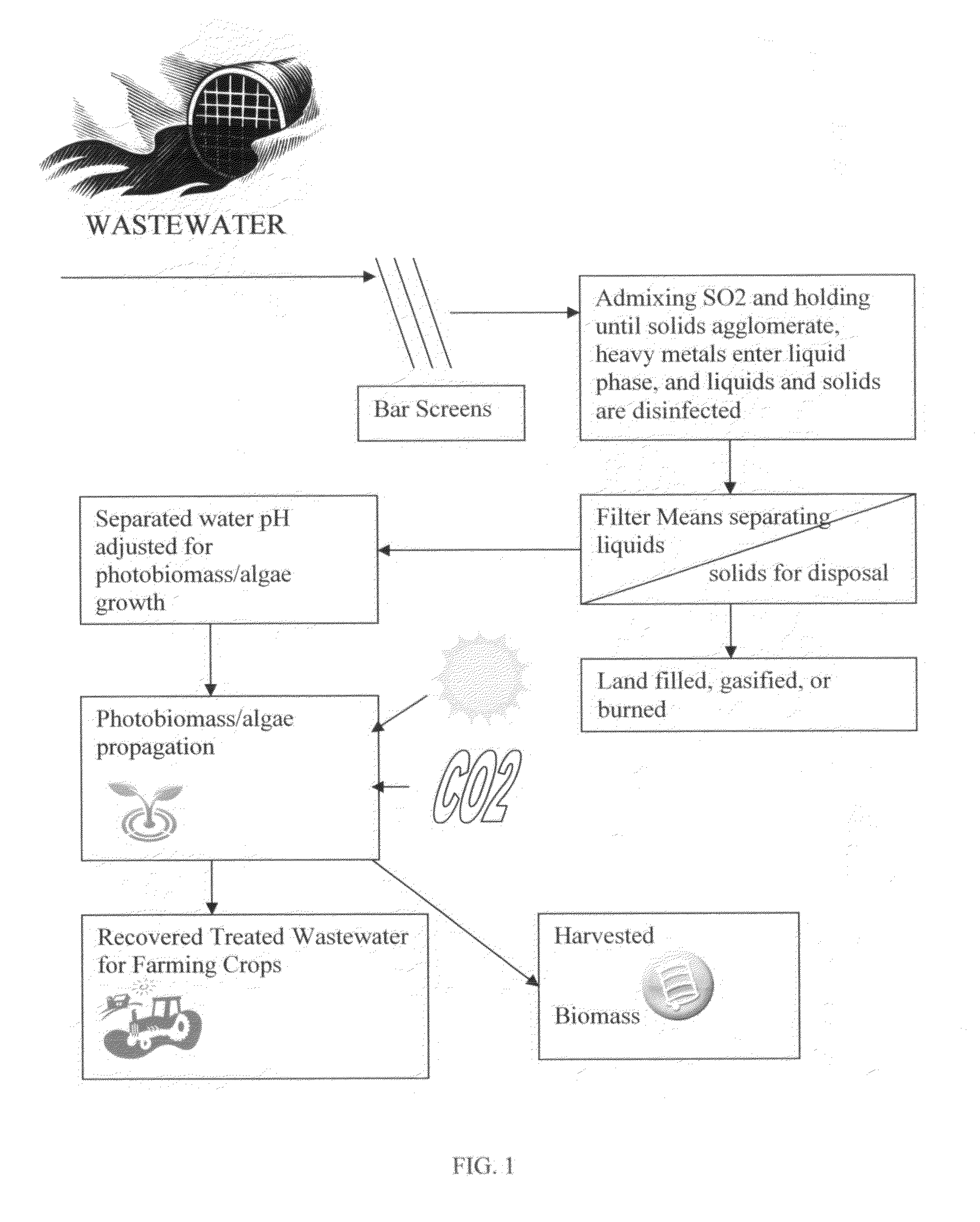

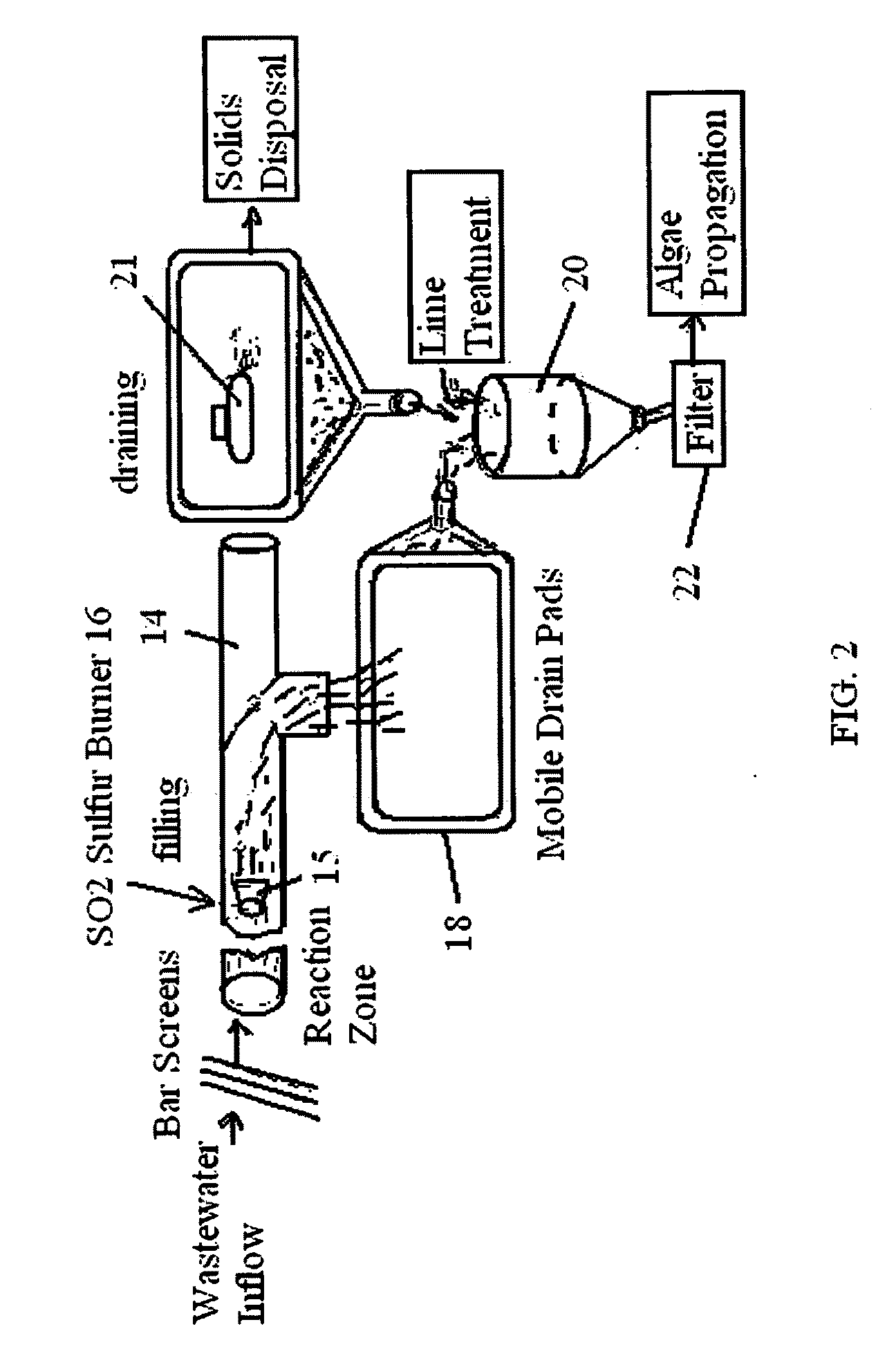

Wastewater photo biomass/algae treatment method

ActiveUS20090294354A1Minimizing stream eutrophicationPrevent eutrophicationUnicellular algaeEnergy based wastewater treatmentCarbon creditBiofuel feedstock

A treatment method for wastewater employing sulfur dioxide and lime chemical dewatering technology in conjunction with an environmental photo biomass / algae biological treatment system growing photo biomass / algae to reduce dissolved solids, heavy metals, and ammonia in the wastewater to produce recovered treated wastewater for vegetation consumption, biofuel feedstock, and biofuel and carbon credits.

Owner:EARTH RENAISSANCE TECH

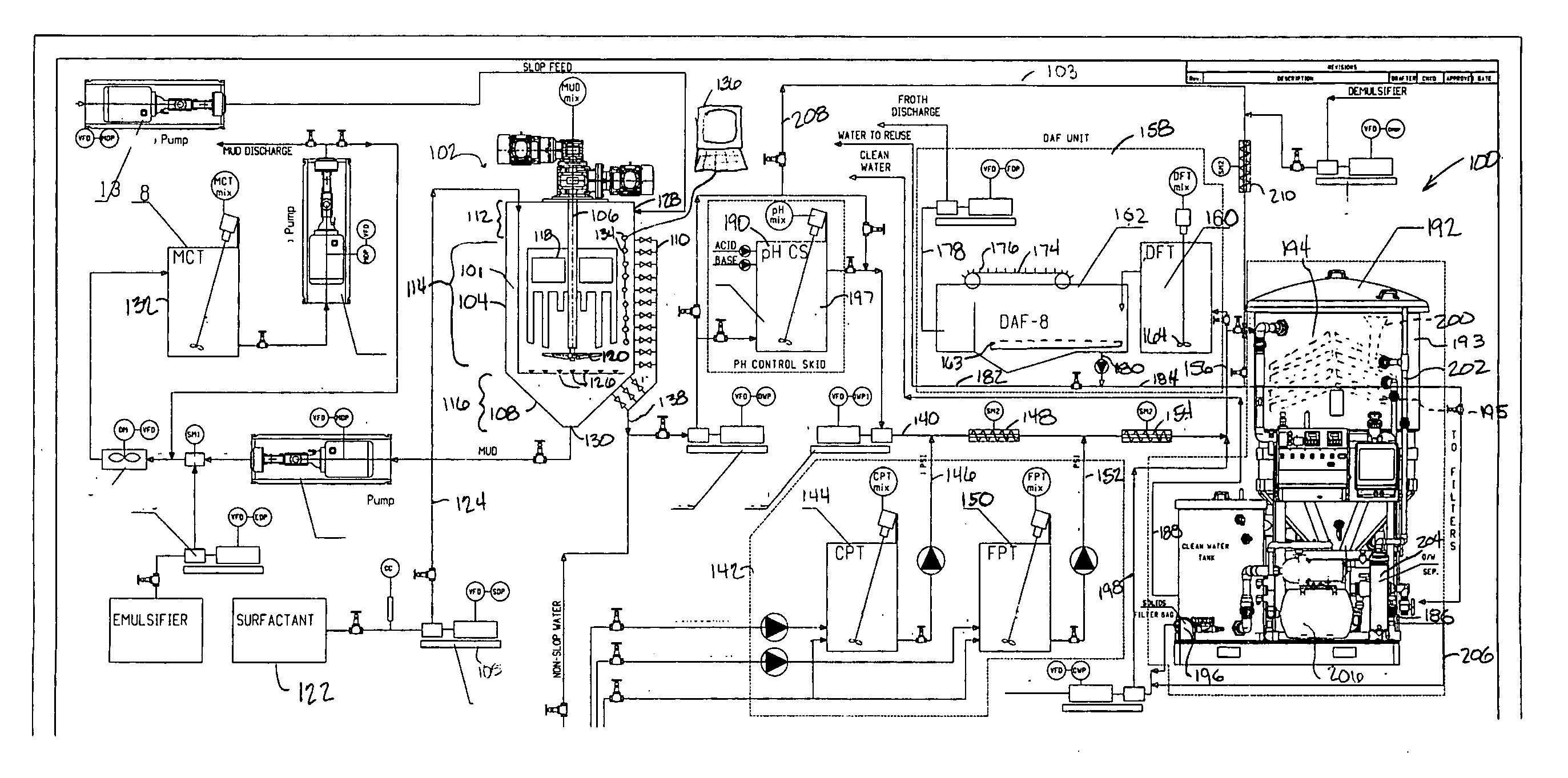

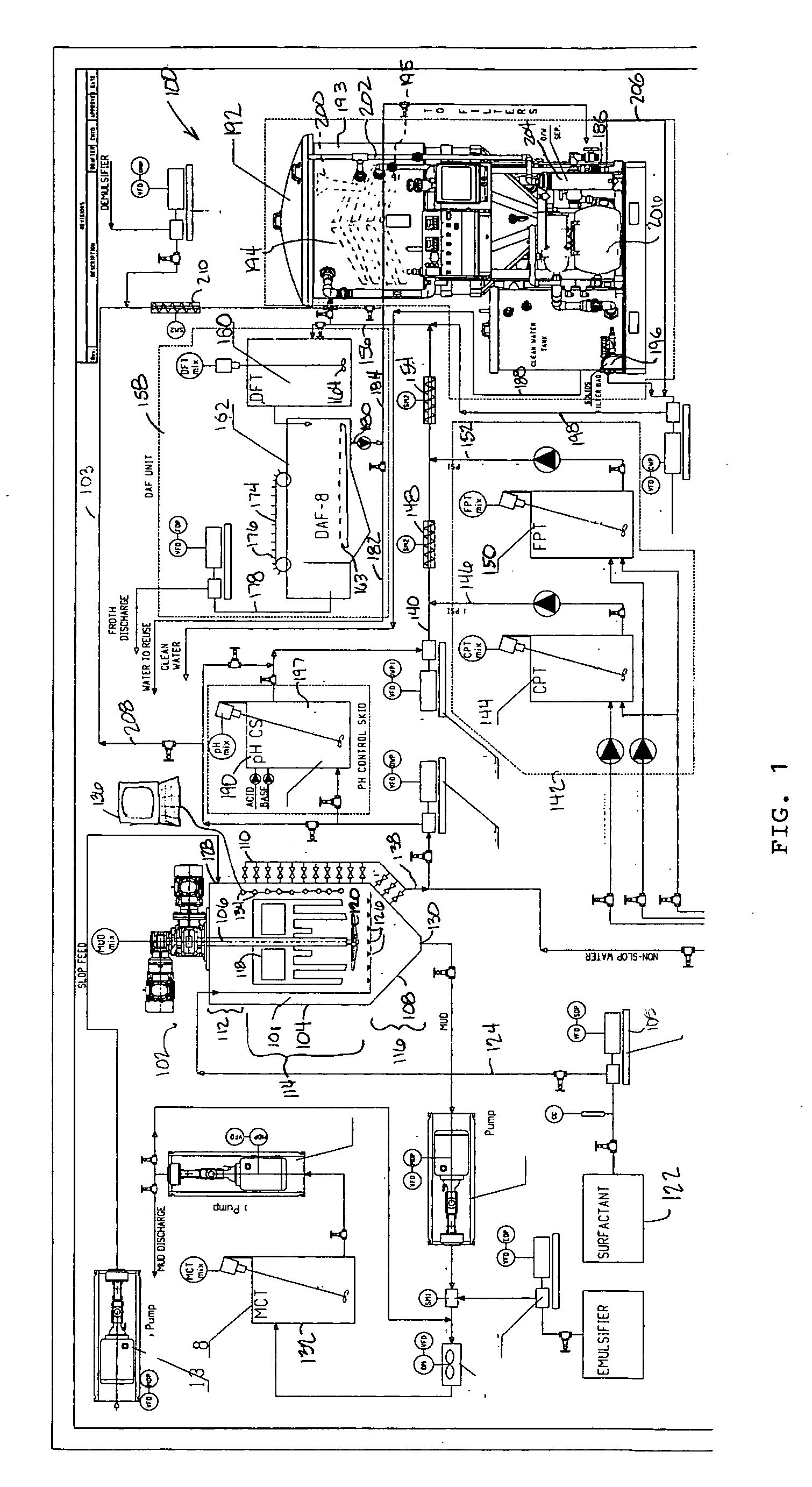

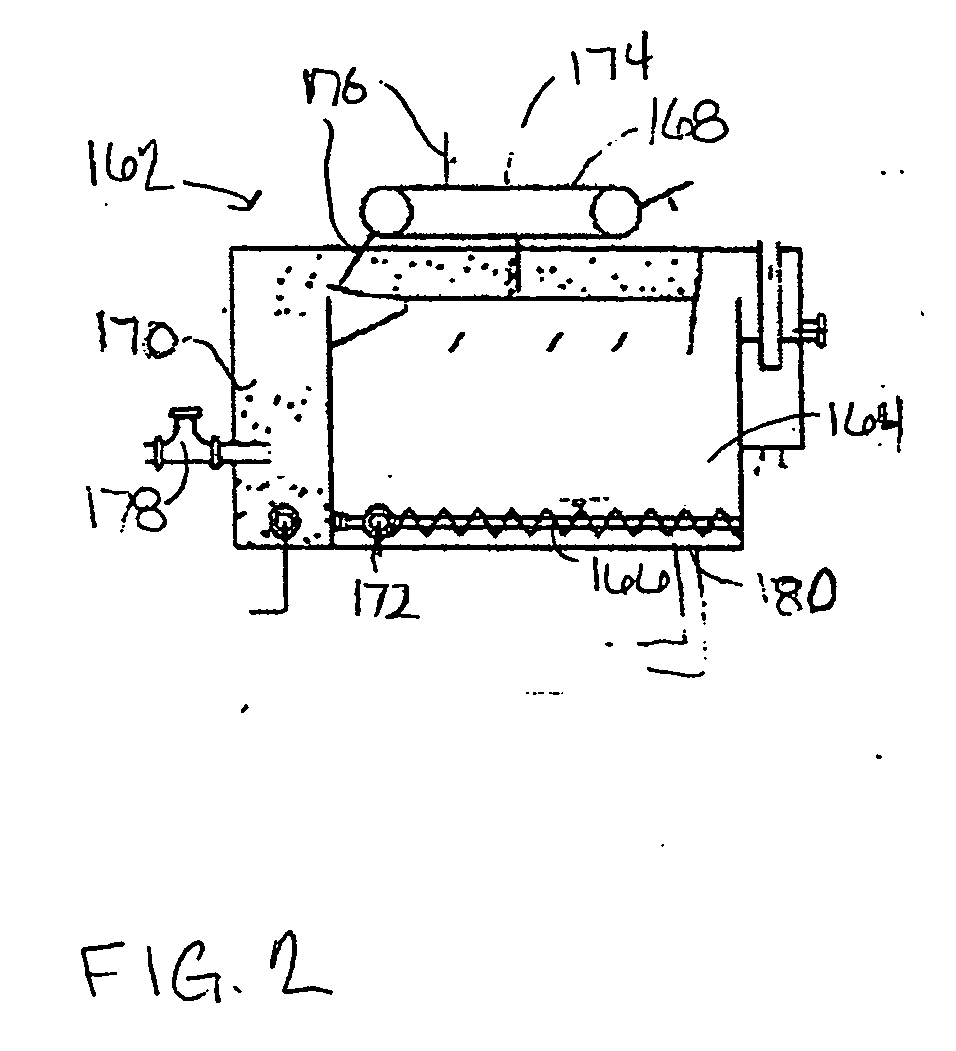

Apparatus for separation of water from oil-based drilling fluid and advanced water treatment

InactiveUS20060186056A1Shorten the timeIncrease the number ofWaste water treatment from quariesTreatment involving filtrationChemical treatmentFiltration

An apparatus for separating water from oil-based drilling fluid includes an separation tank, a chemical treatment apparatus having one or more de-oiling polymer preparation tanks, and a dissolved air flotation unit. Slop mud is directed into the separation tank where surfactant is added to separate the drilling fluid from oily water. The drilling fluid is drained for further processing. The oily water is removed by an outlet arrangement from the separation tank and directed to an initial treatment line. One or more de-oiling polymers are added to the oily water in the initial treatment line and mixed therewith. The mixture may then be directed to the dissolved air flotation unit where dissolved air is released into the bottom of the mixture. The dissolved air adheres to suspended solids in the mixture and lifts them to the top surface as a froth. The froth is skimmed from the top surface of the mixture and collected. The de-frothed water is reused or directed to a filtration system where it is prepared for discharge. A clarifying tank may be included after the de-oiling polymers are added to further separate the oil and water. The oil is removed from the top surface by a weir while the water is directed to the filtration system and discharged.

Owner:MI

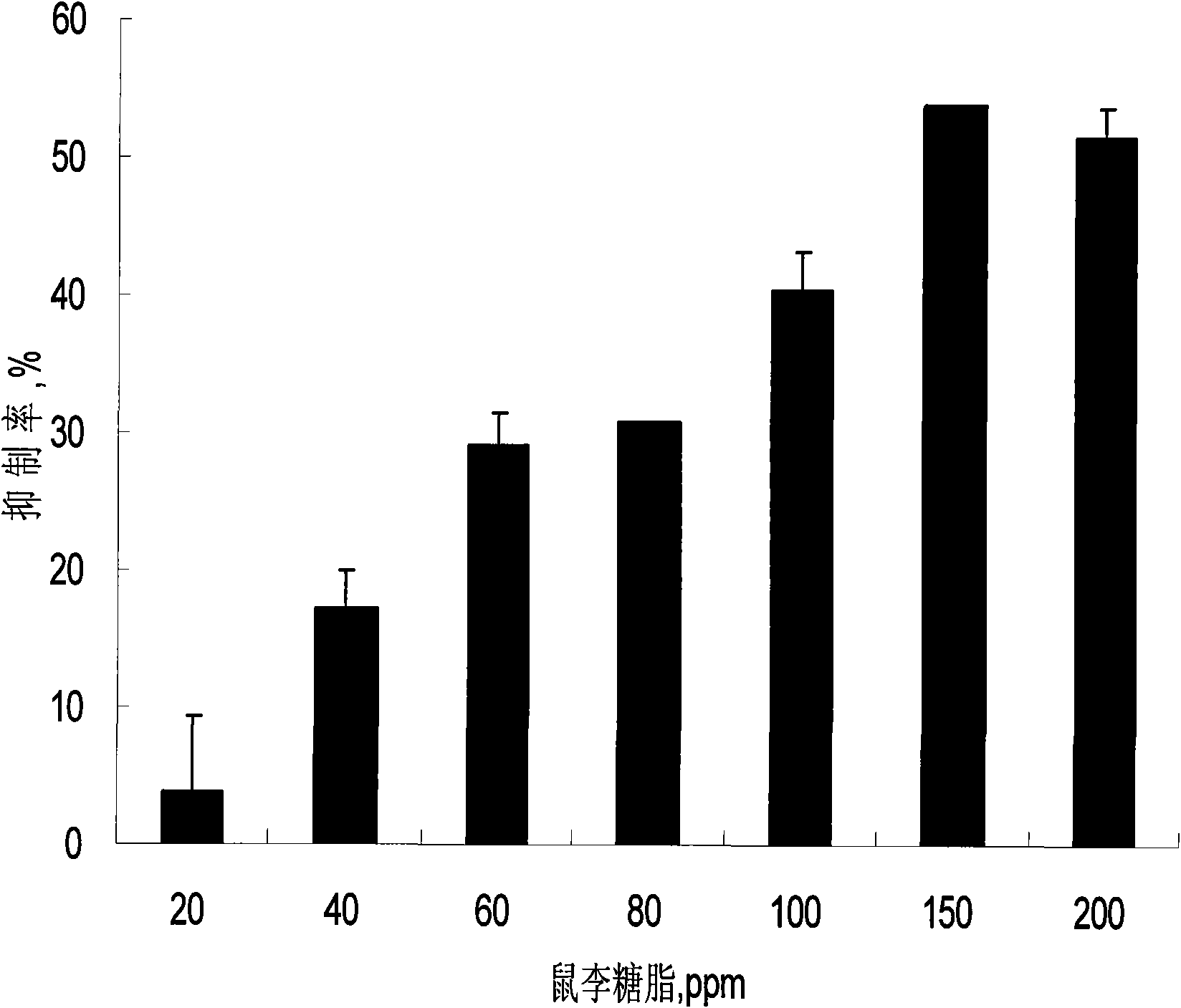

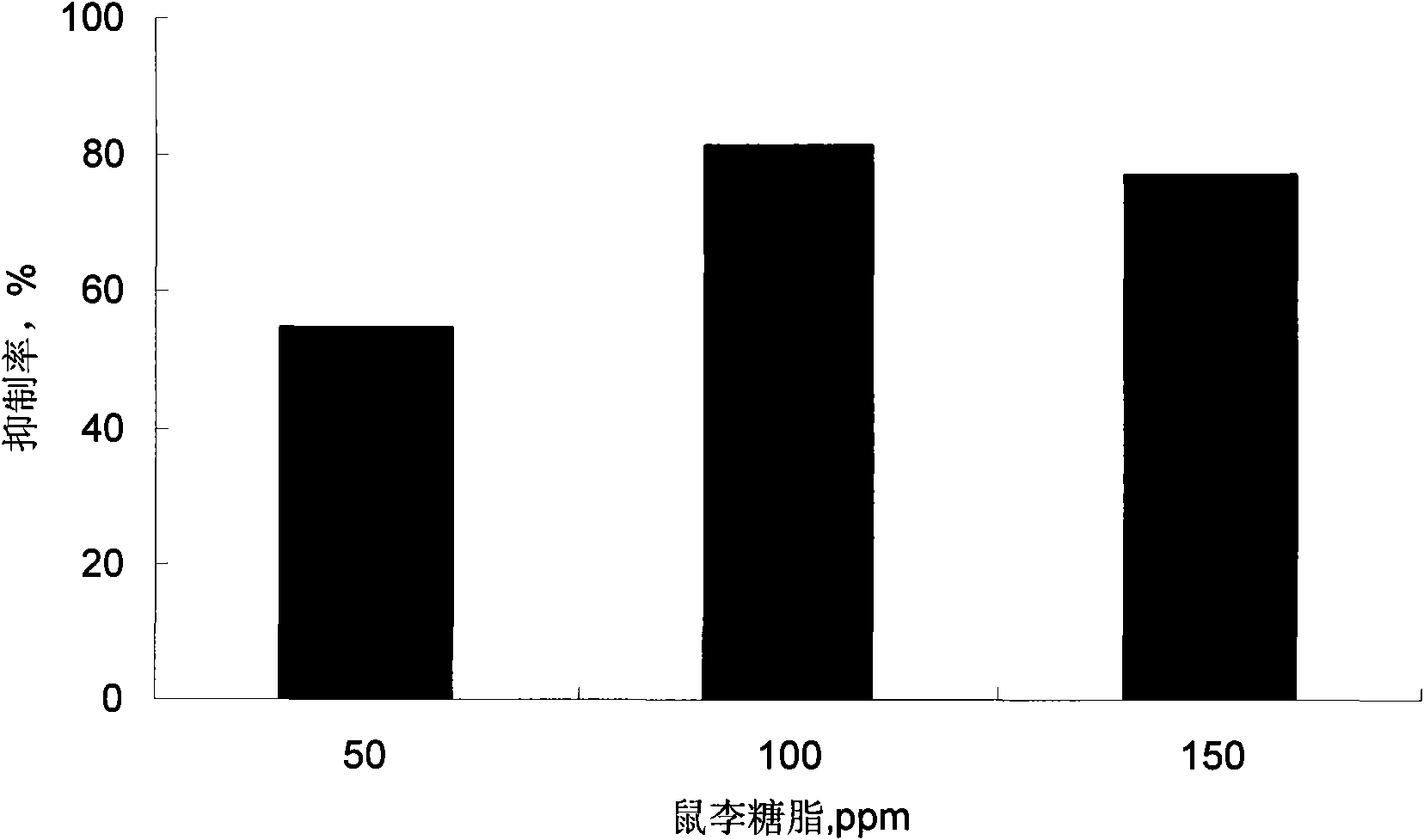

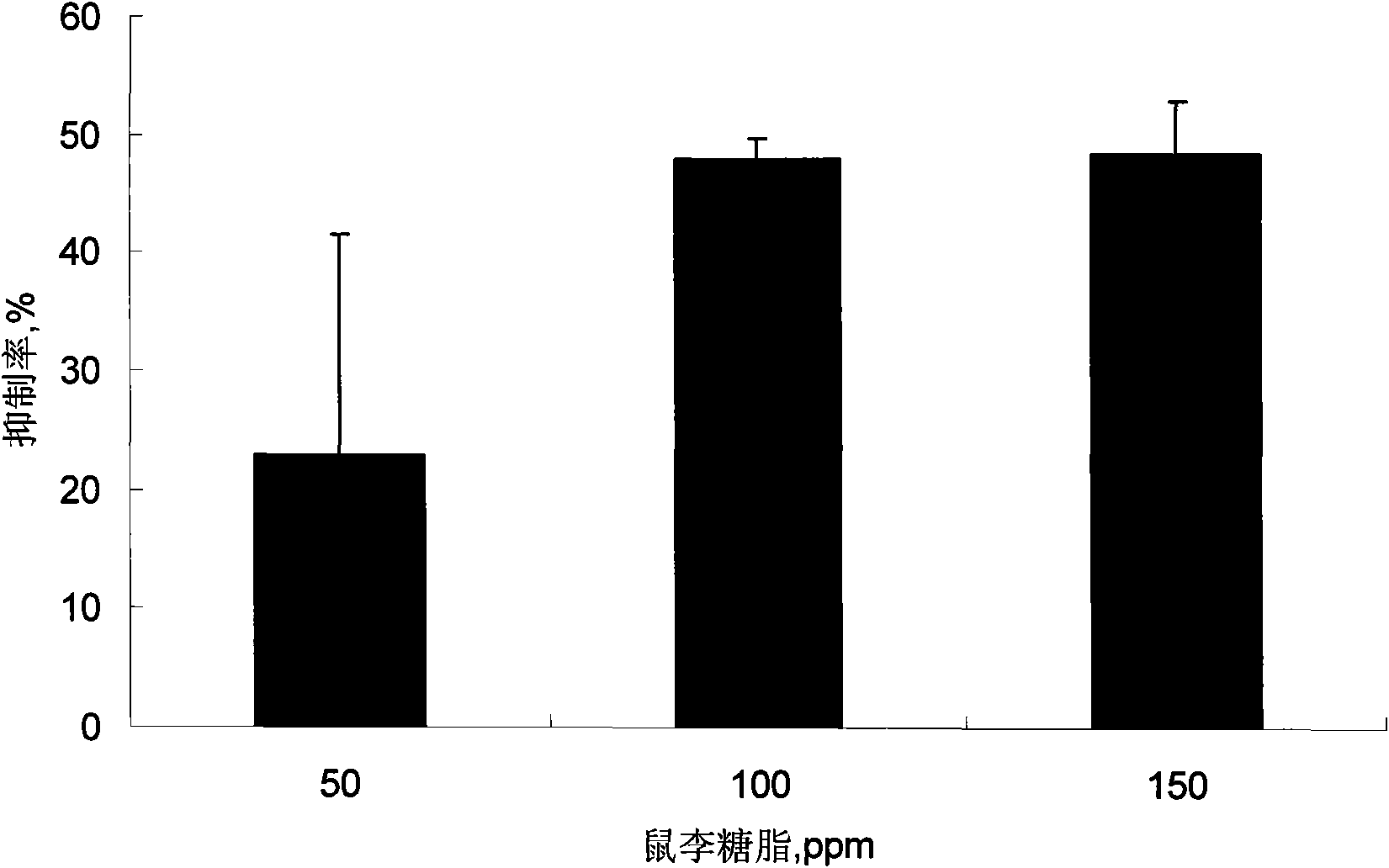

Preparation method and application of rhamnolipid

ActiveCN101845468AReduce manufacturing costLow costBiocideSludge treatment by de-watering/drying/thickeningDiseaseSpore germination

The invention discloses a preparation method and application of rhamnolipid. In the method, the rhamnolipid is produced by using waste grease as carbon source, and utilizing the fermentation of pseudomonas aeruginosa; and with the combination of the defoaming effect of ethanol, the yield of the rhamnolipid can reach 35 to 50 g / L and the cost is about 25 to 40 percent lower than that of the conventional method. When the solution containing 20 to 500 mg / L of rhamnolipid is used for processing plant disease fungus, the ratio of inhibiting disease fungal mycelium growth and spore germination can reach 40 to 90 percent and the plant fungal diseases can be effectively inhibited; the solution containing 20 to 500 mg / L of rhamnolipid has an obvious effect of killing cockroaches and aphids; and in addition, when the rhamnolipid is used as an aid of pesticide, fertilizer and feed and a dehydrating agent of oil-contained sludge by replacing a chemical surface active agent, the effect is obvious.

Owner:浙江圣达紫金生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com