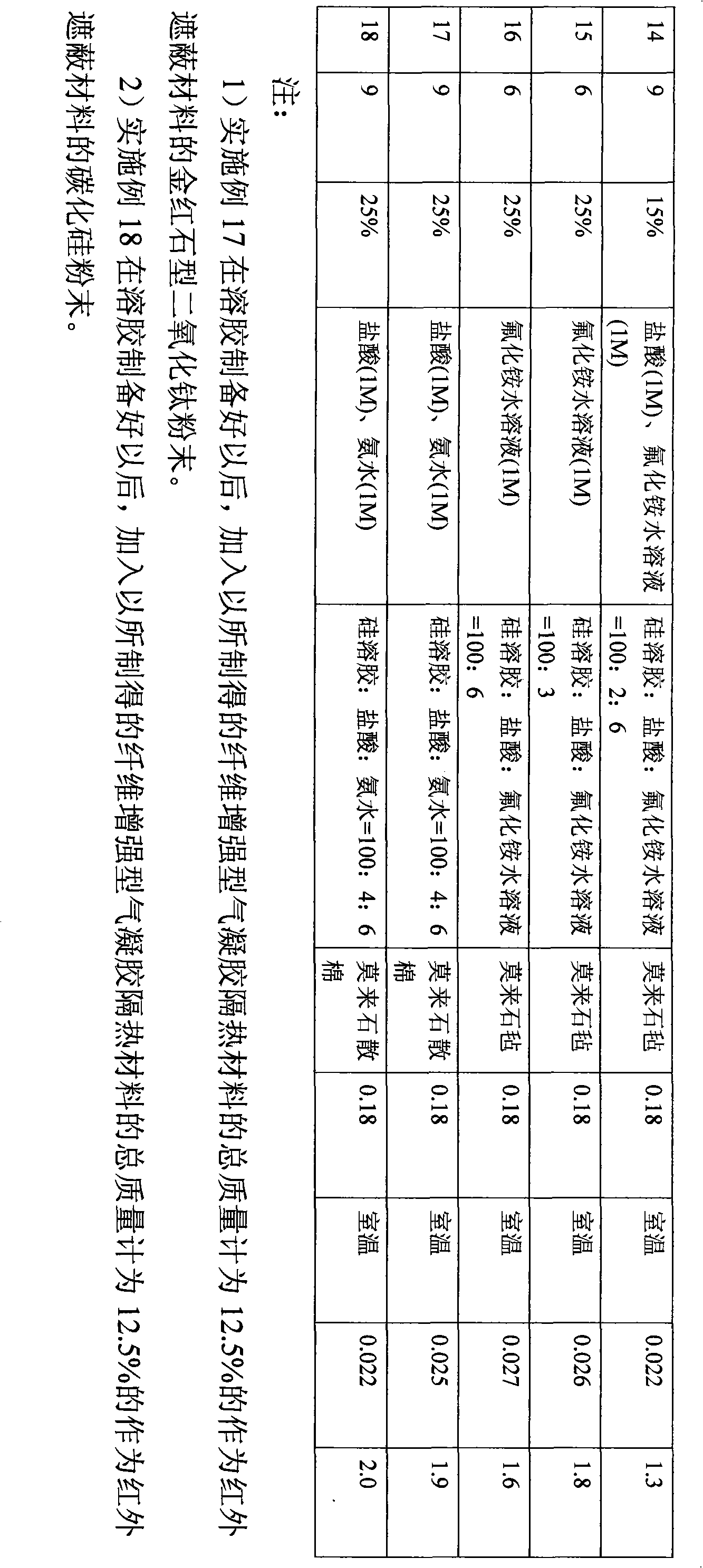

Patents

Literature

14659results about How to "High compressive strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

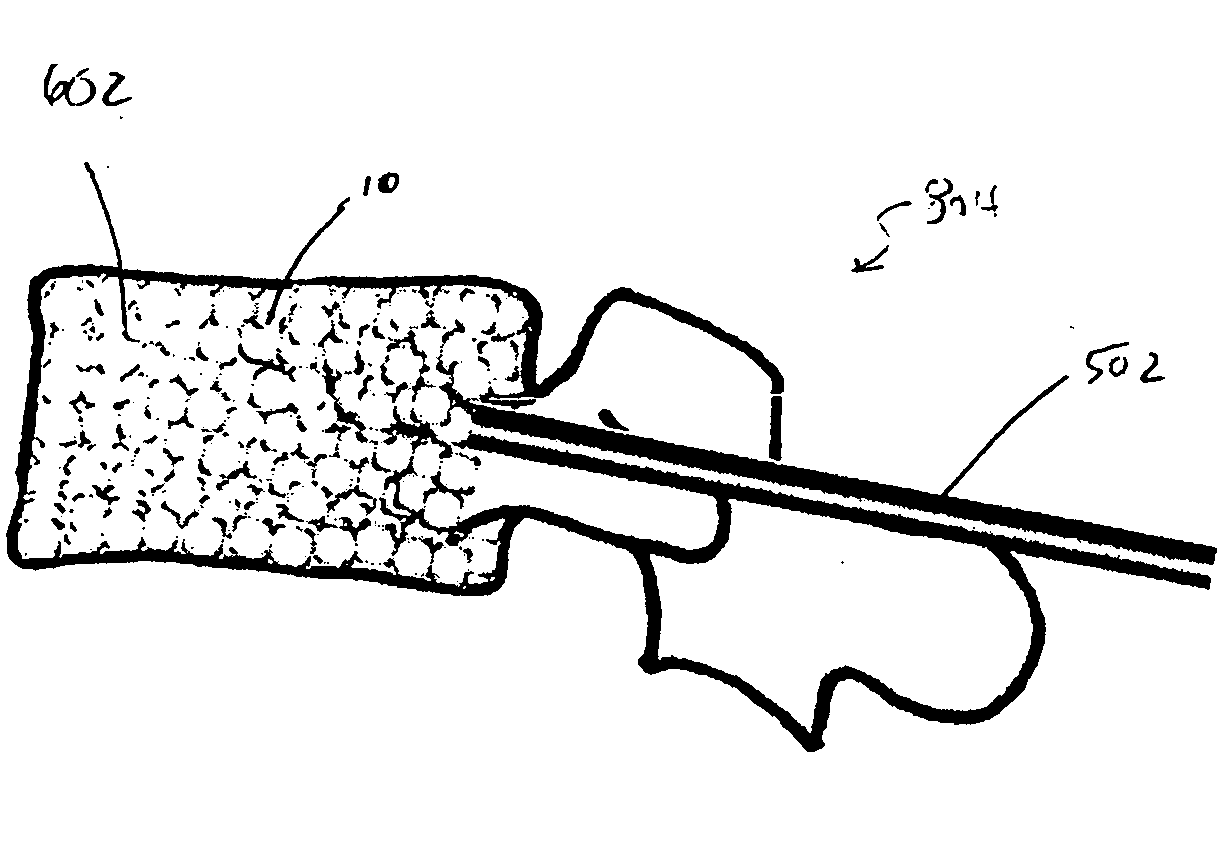

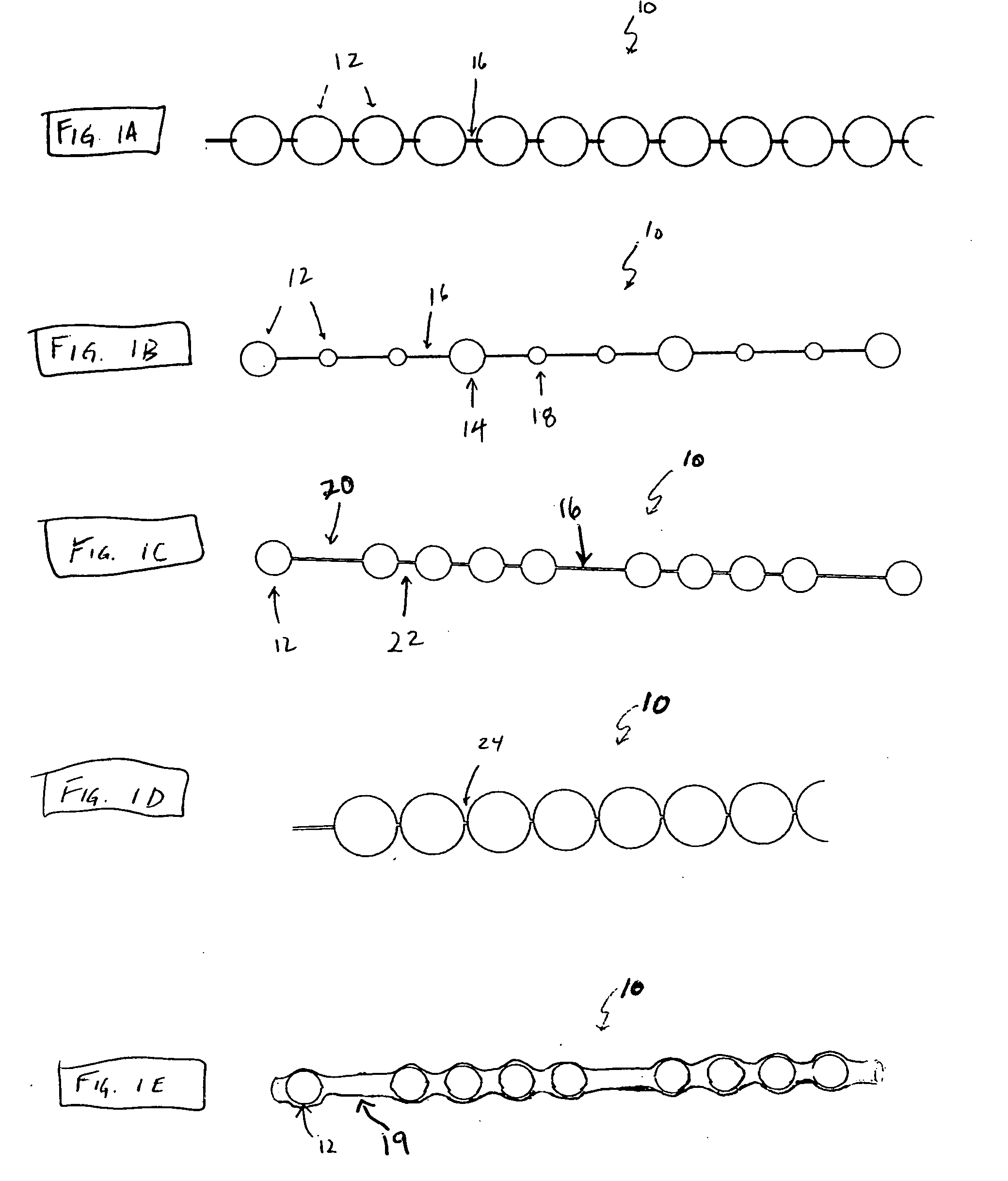

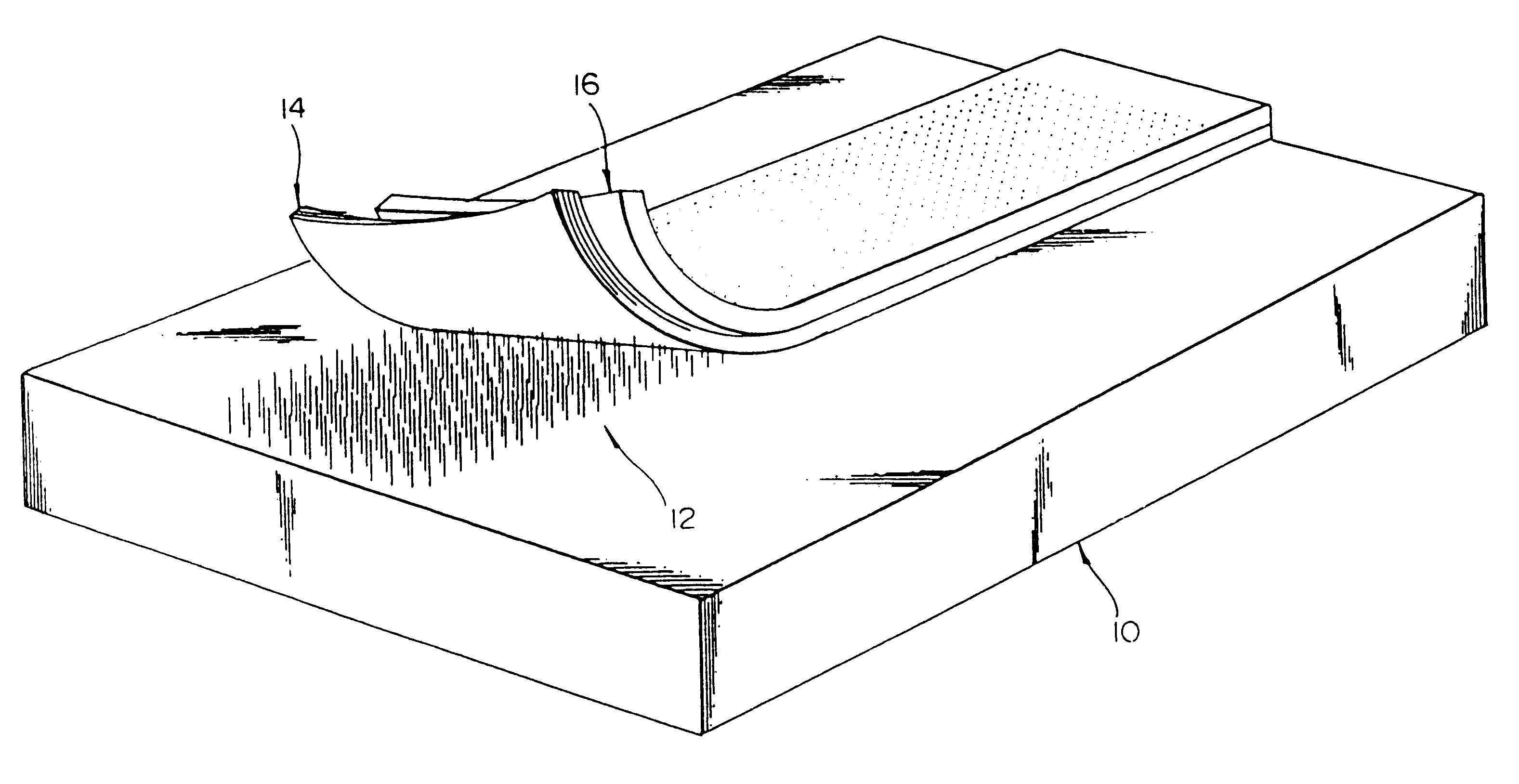

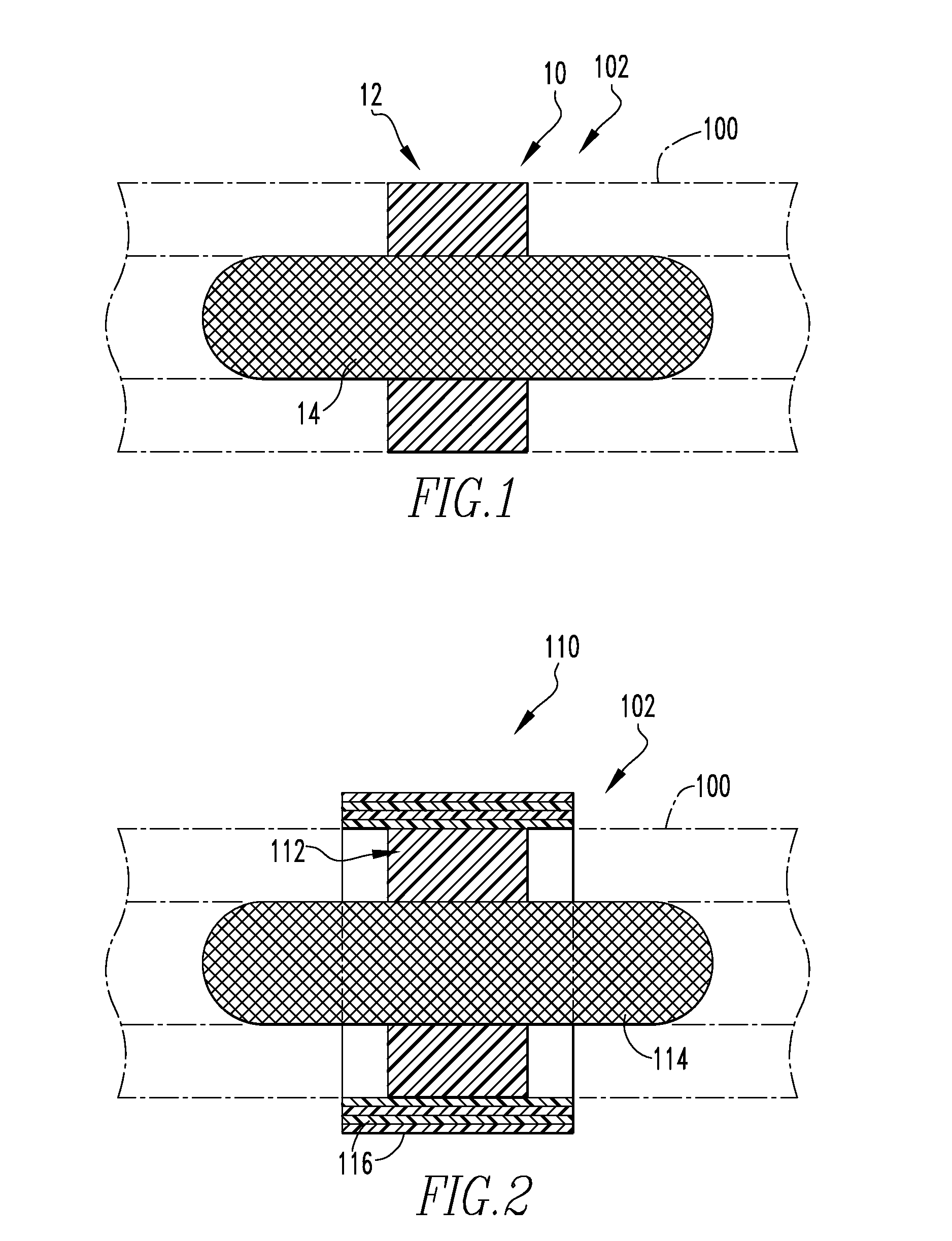

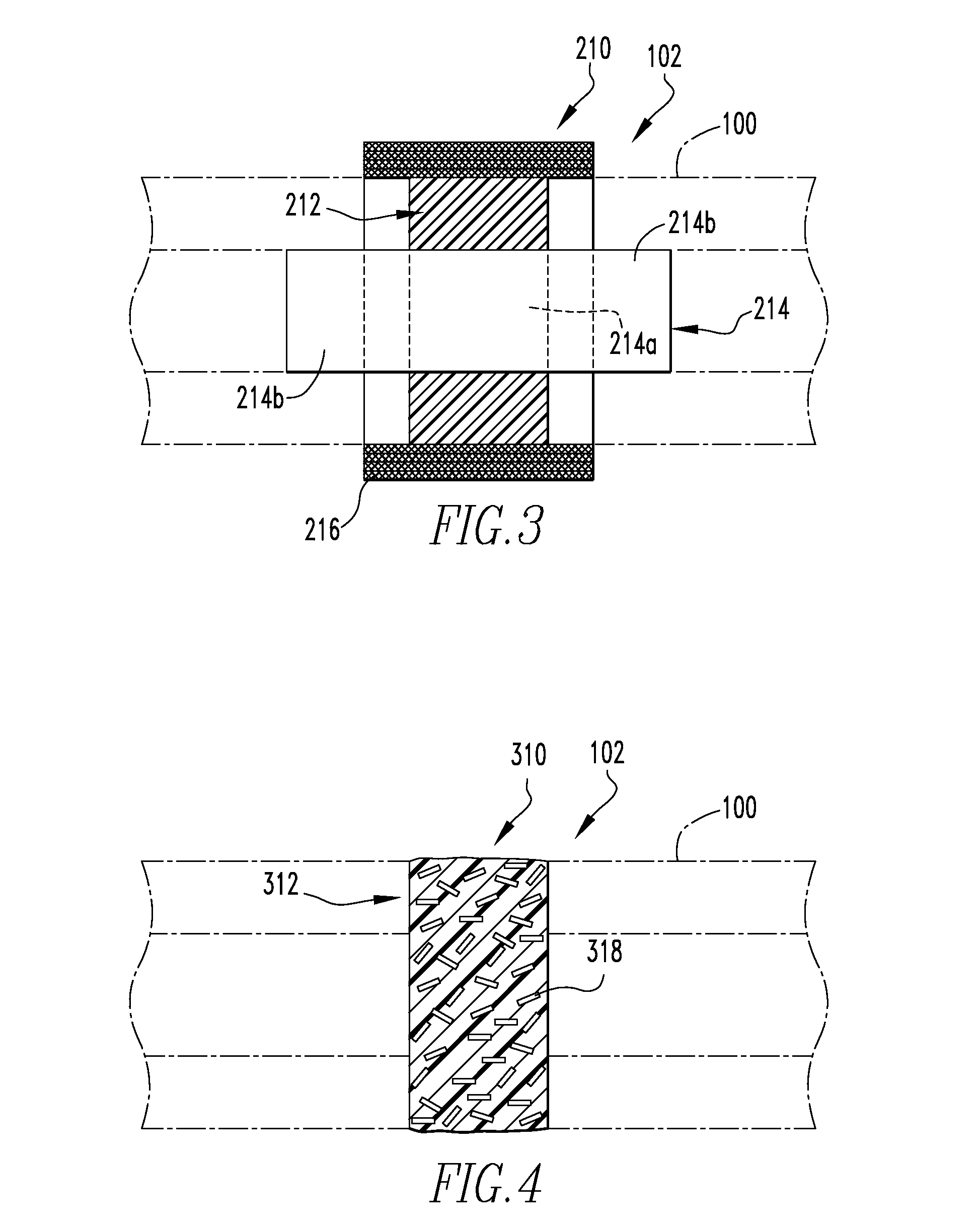

Method and apparatus for filling a cavity

InactiveUS20050278023A1High material strengthHigh compressive strengthInternal osteosythesisBone implantUltimate tensile strengthBiomedical engineering

An implant for filling and / or distracting a body region, particularly a non-soft tissue cavity, has a plurality of segments wherein at least two of the segments are flexibly connected. The segments have a crush-strength sufficient to create and / or maintain the distraction of two or more non-soft tissue body surfaces, and to maintain the stability of the body region. The implant may be inserted into a cavity by an applicator having a cannula with a distal opening, and a rotary driver for applying force to move the implant within the cannula.

Owner:SPINAL VENTURES

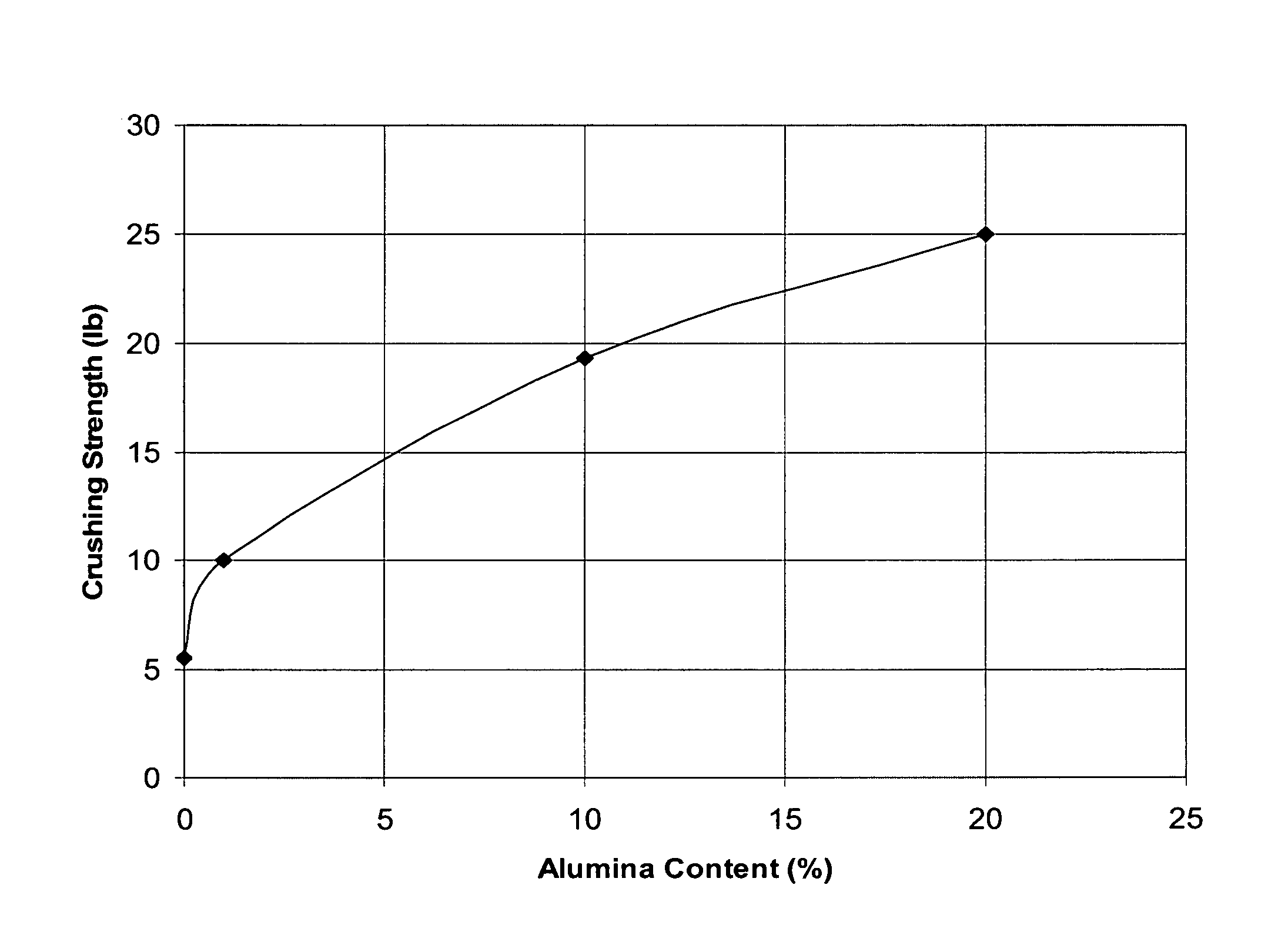

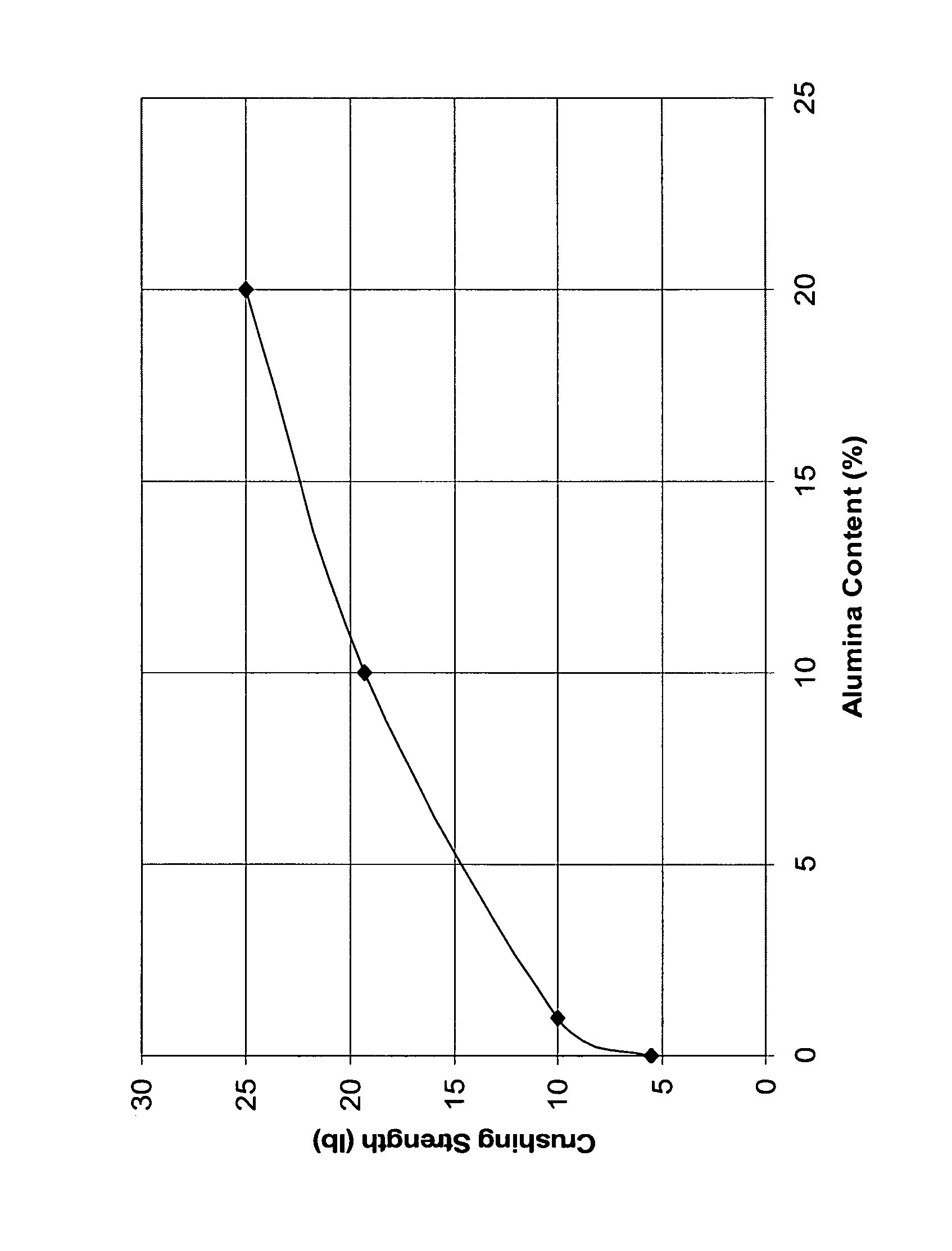

Titania-alumina supported palladium catalyst

InactiveUS8507720B2High activityHigh compressive strengthOther chemical processesOrganic compound preparationPalladium catalystOrganic chemistry

A catalyst comprising palladium supported on a titania-alumina extrudate is disclosed. The extrudate comprises at least 80 wt % titania and 0.1 to 15 wt % alumina. A palladium catalyst prepared from the titania-alumina extrudate has significantly higher crush strength. Its catalytic performance in vinyl acetate production is improved.

Owner:LYONDELLBASELL ACETYLS

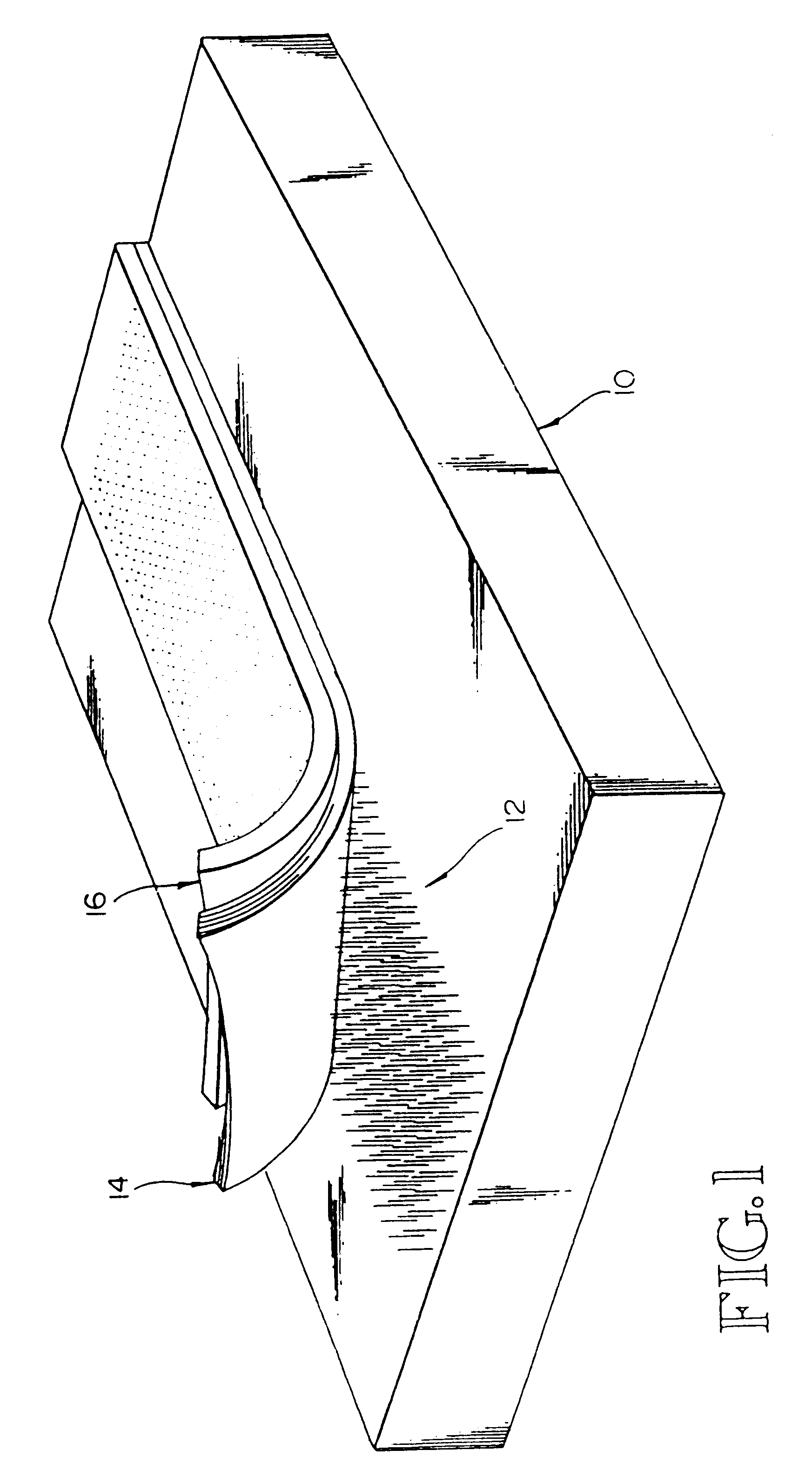

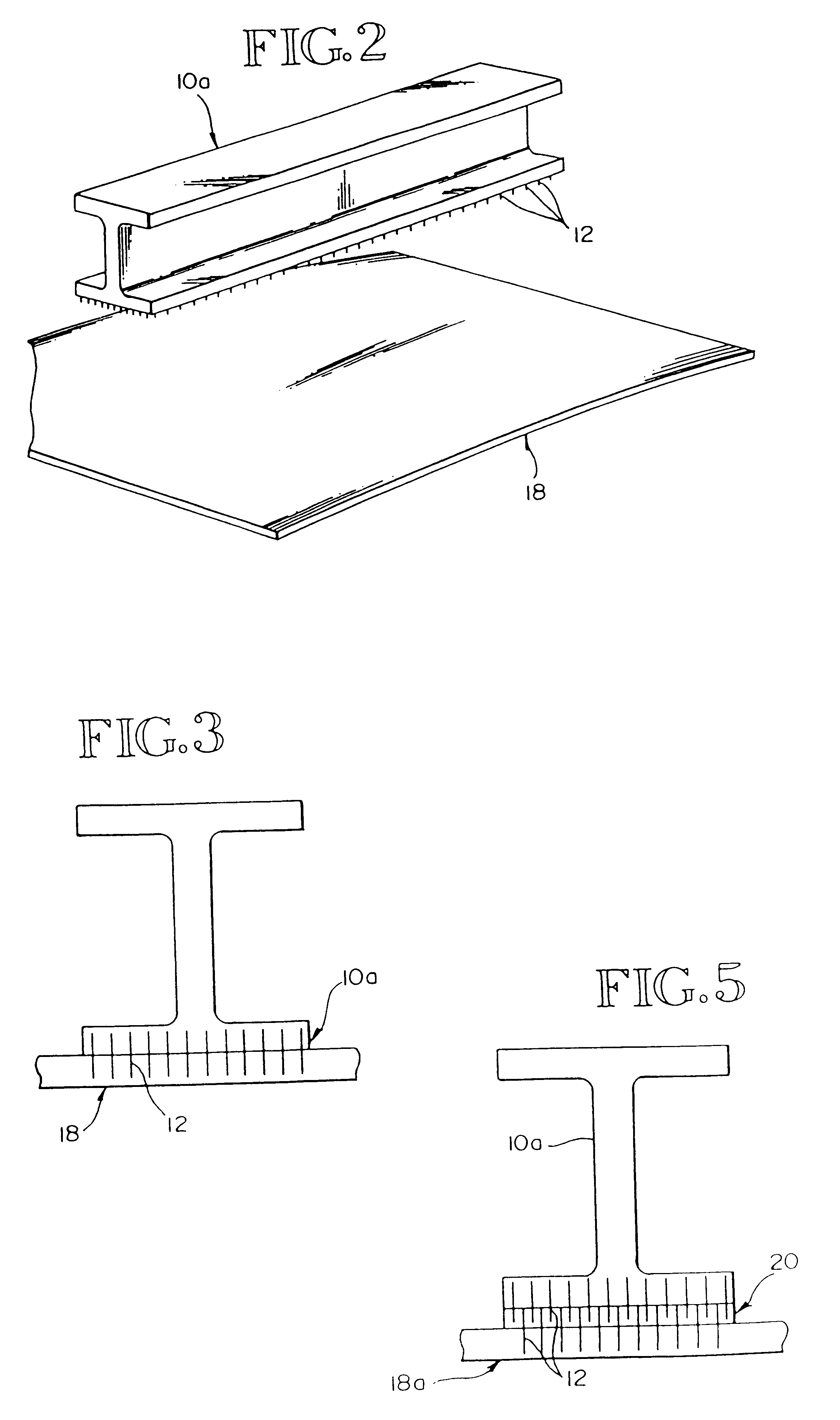

Polymer wood composite

InactiveUS6015612AHigh modulusHigh compressive strengthWood working apparatusRecord information storageFiberThermoplastic

The invention relates to a composition comprising a polymer and wood fiber composite that can be used in the form of a linear extrudate or thermoplastic pellet to manufacture structural members. The polymer and wood fiber composite structural members can be manufactured in an extrusion process or an injection molding process. The linear extrudate or pellet can have a cross-section of any arbitrary shape, or can be a regular geometric. The pellet can have a cross-section shape having a volume of at least about 12 mm3. Preferably the pellet is a right cylindrical pellet having a minimum radius of about 1.5 mm and a minimum length of 1 mm weighing at least 14 mg. The invention also relates to an environmentally sensitive recycle of waste streams. The polymer and wood fiber composite contains an intentional recycle of a waste stream comprising polymer flakes or particles or wood fiber. The waste stream can comprises, in addition to polymer such as polyvinyl chloride or wood fiber, adhesive, paint, preservative, or other chemical stream common in the wood-window or door manufacturing process, or mixtures thereof. The initial mixing step before extrusion of the composite material insures substantial mixing and melt contact between molten polymer and wood fiber. The extruded pellet comprises a consistent proportion of polymer, wood fiber and water. During the extrusion, water is removed intentionally to dry the material to a maximum water content of less than about 10 wt-% based on the pellet weight. To make a structural unit, the pellet is introduced into an extruder or injection molding apparatus wherein, under conditions of temperature and pressure, the composite pellet material is shaped into a useful cross-section. Alternatively, the extruded thermoplastic mass, in the form of a elongated linear extrudate without a pelletizing step, can be immediately directed after formation into an extruder or injection molding apparatus.

Owner:ANDERSEN CORPORATION

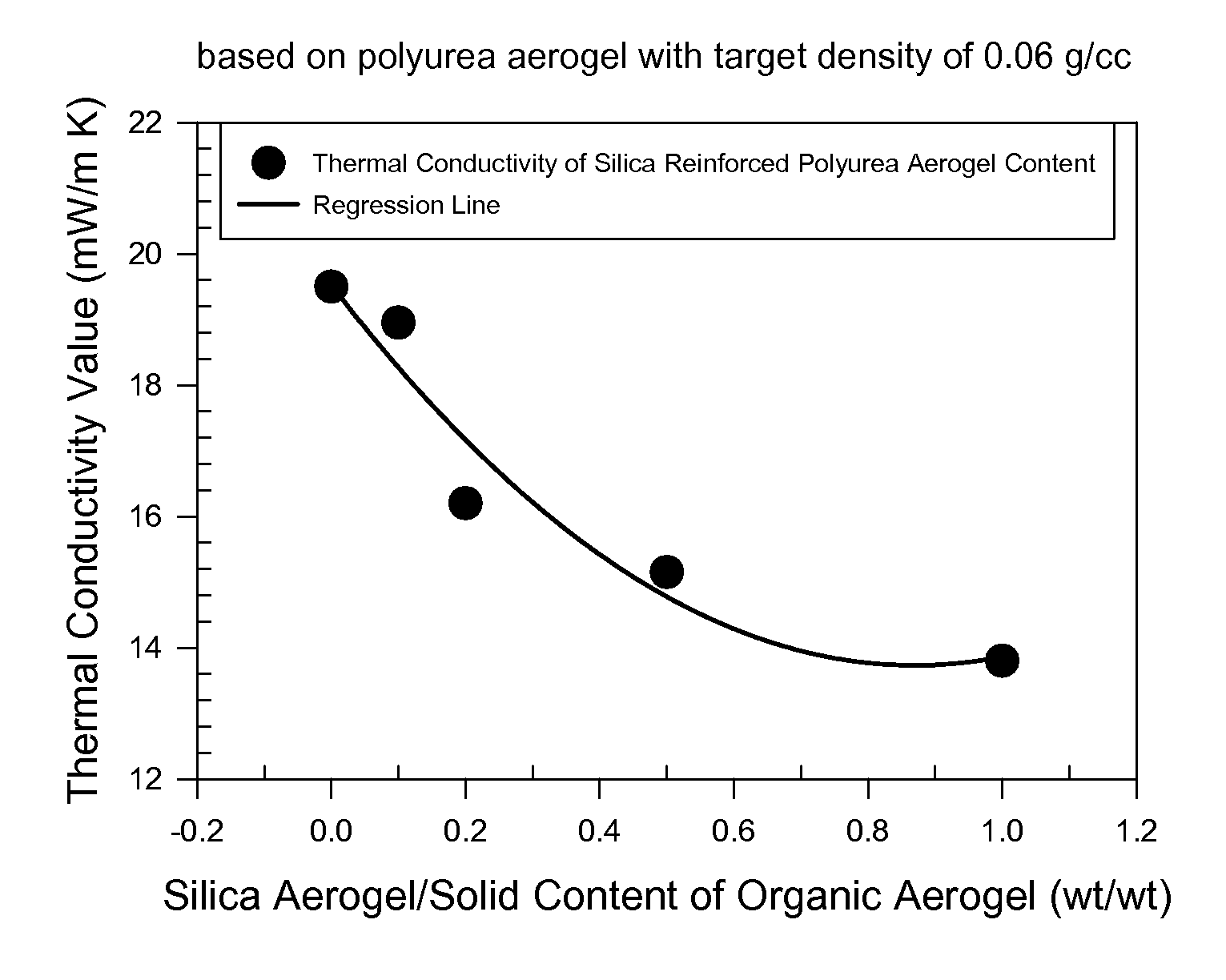

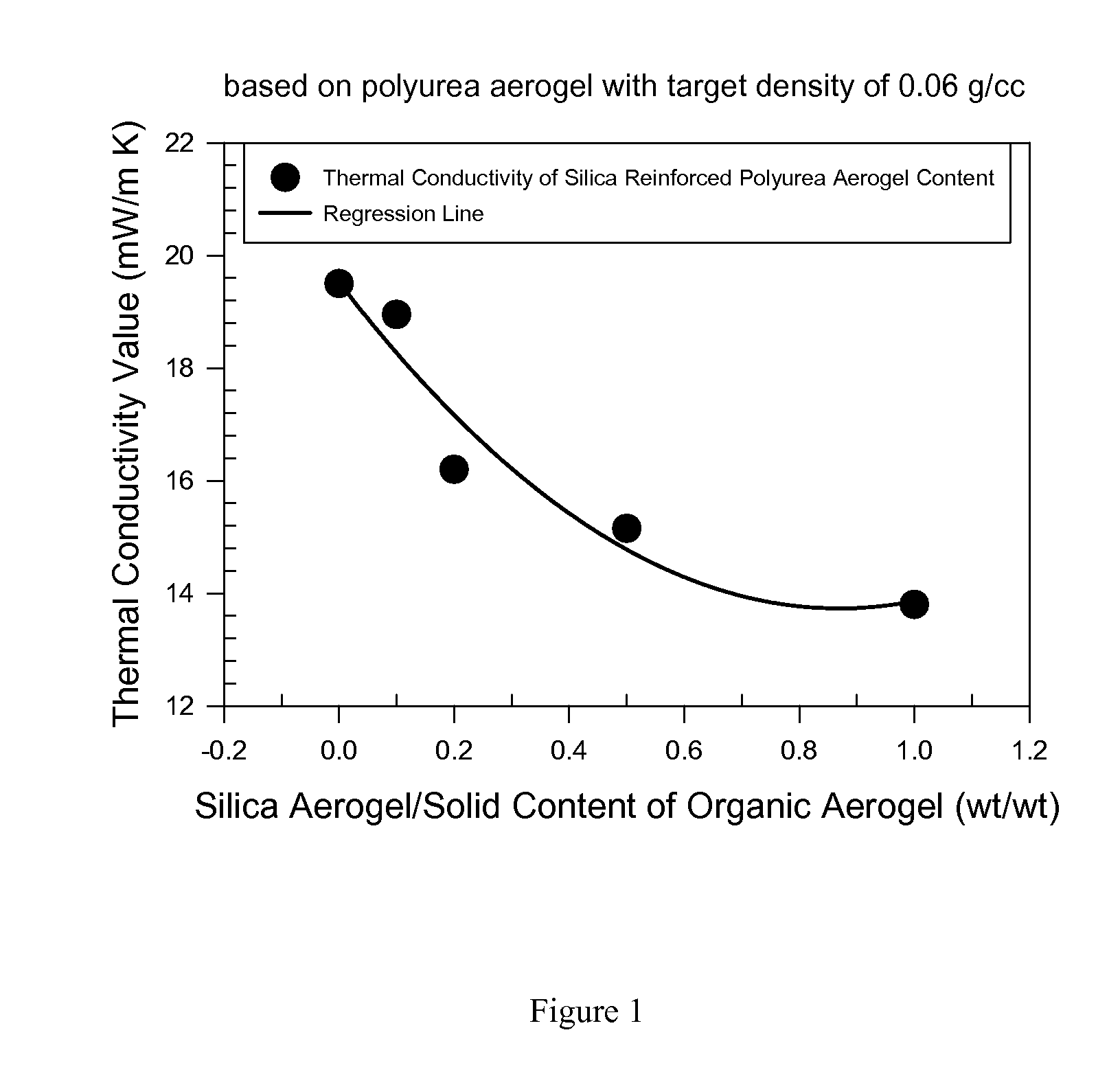

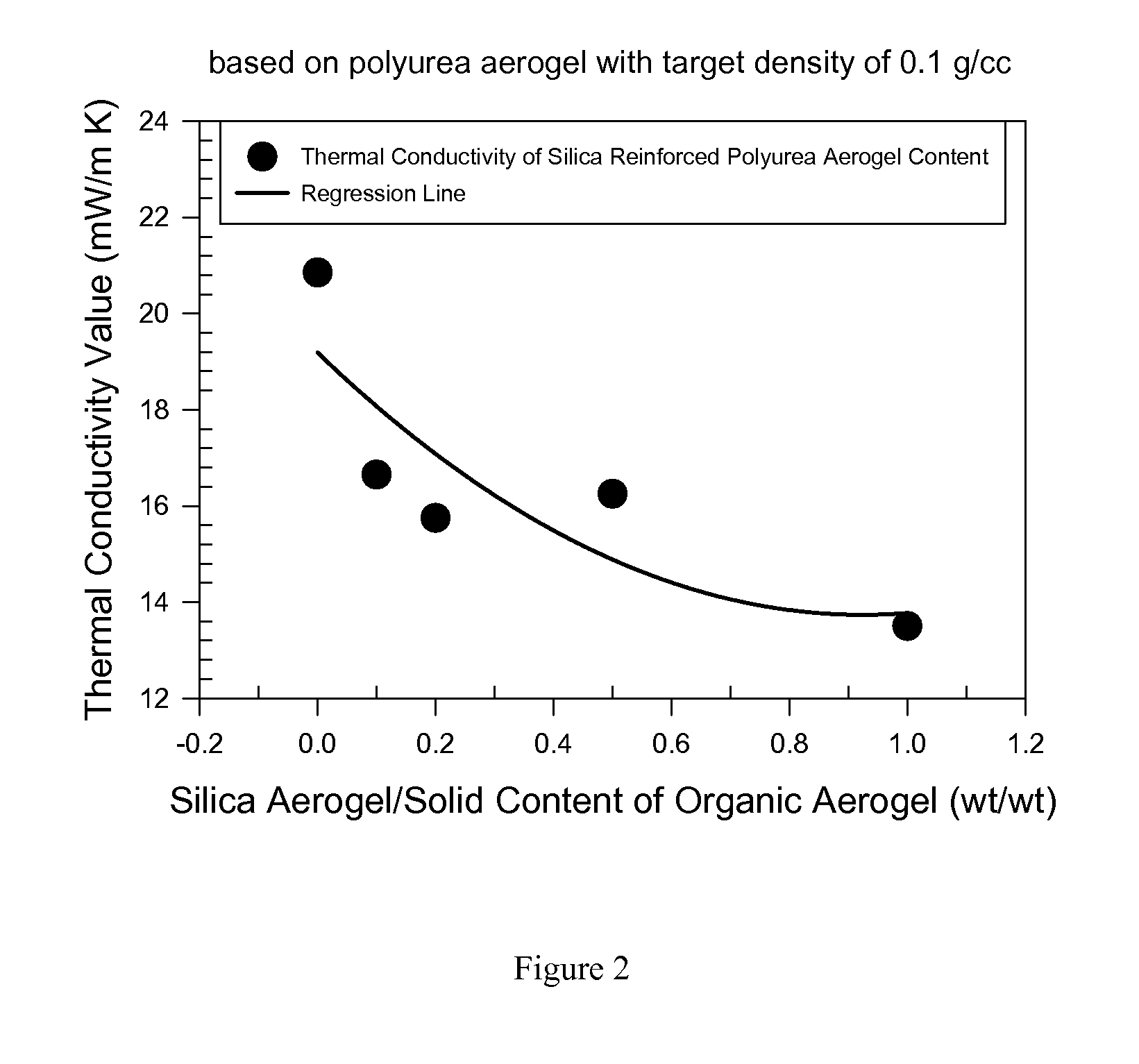

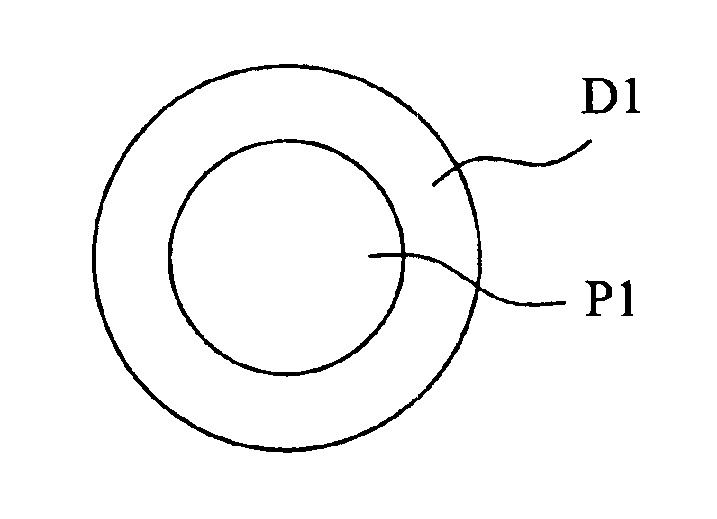

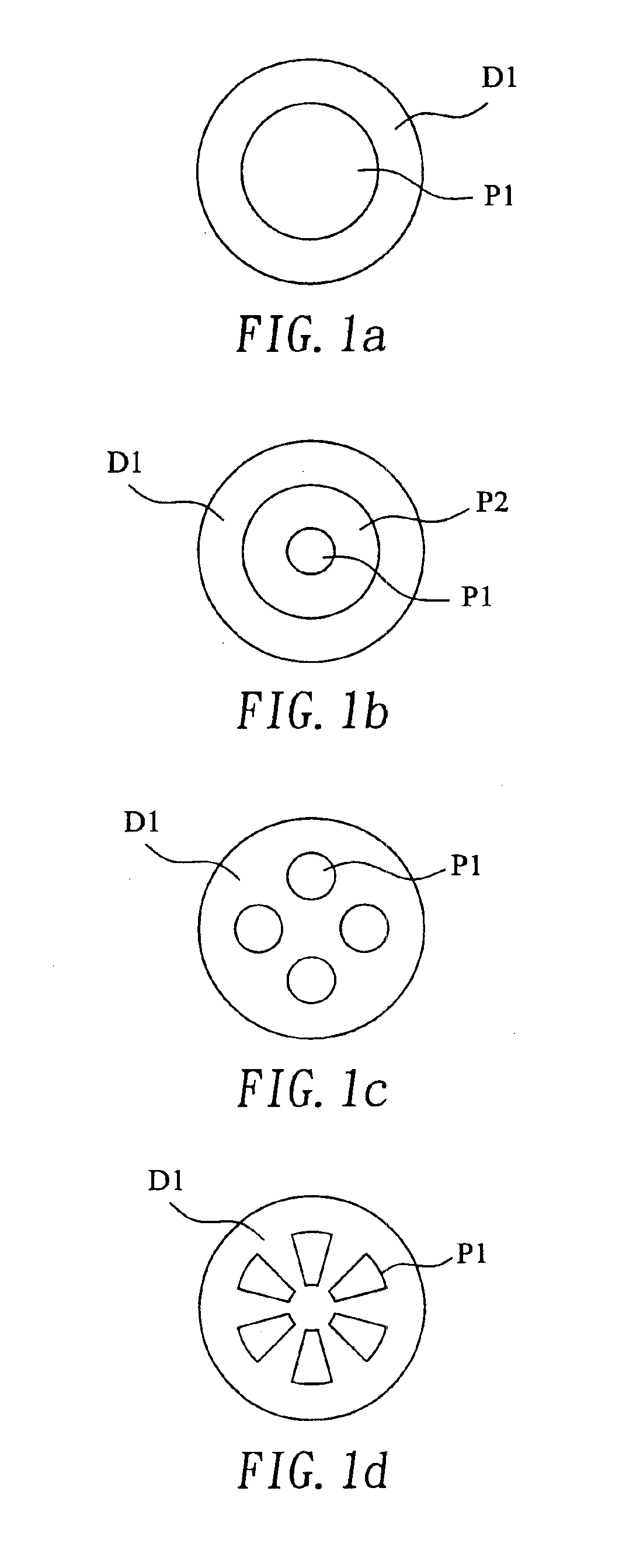

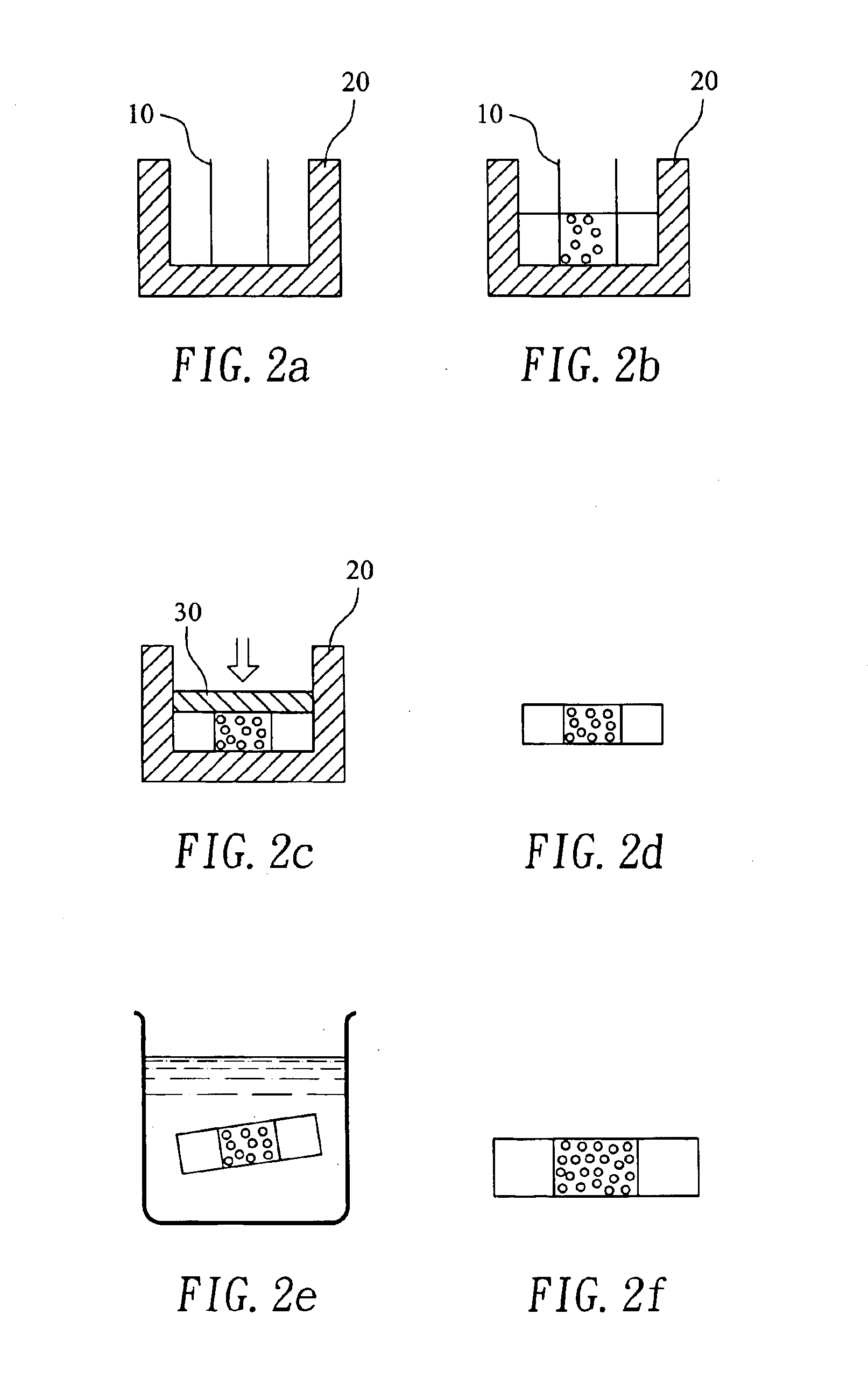

Organic aerogels reinforced with inorganic aerogel fillers

Composites comprising organic aerogel matrix and inorganic aerogel fillers are described. The methods of manufacturing such composite aerogels are also described. Inorganic aerogels fillers are demonstrated to improve the thermal performance of organic aerogels. Composite aerogels with various organic aerogels and inorganic aerogel fillers are described.

Owner:ASPEN AEROGELS INC

Strontium-apatite-cement-preparations, cements formed therefrom, and uses thereof

ActiveUS20050142211A1Facilitated releaseTo promote metabolismBiocideSurgical adhesivesO-Phosphoric AcidPowder mixture

Calcium-strontium-hydroxyphosphate (strontium-apatite-) cement preparations are described, comprising a powder mixture, which contains molar quantities of the components calcium (Ca), strontium (Sr) and phosphate (P) in the mixture in the ranges 1.00<Ca / P≦1.50 and 0<Sr / P<1.5, together with an alkali salt or an ammonium salt of phosphoric acid, and with water and / or an aqueous solution. The powder mixture particularly contains, as the Ca-component, Ca3(PO4)2 (TCP), and as the Sr-component SrHPO4 and / or Sr3(PO4)2 and optionally additional SrCO3. As the aqueous mixing solution for the formation of the strontium-apatite cement, an aqueous solution of an alkali salt or an ammonium salt of the phosphoric acid is suitable.

Owner:KYPHON

Advanced polymer wood composite

InactiveUS6015611AHigh modulusHigh compressive strengthSynthetic resin layered productsPlastic recyclingWater basedThermoplastic

A composition in the form of pellets comprising a thermoplastic and wood fiber composite material suitable for forming structural members as a replacement for wood in the manufacture of doors and windows. The composite has less than about 10 wt % water based on pellet weight and a Young's modulus of at least about 500,000. Structural members are typically formed from the composite in an extrusion or an injection molding process.

Owner:ANDERSEN CORPORATION

Dual function prosthetic bone implant and method for preparing the same

InactiveUS6994726B2Penetrate fastHigh compressive strengthBone implantWood working apparatusBone implantBody fluid

The present invention discloses a prosthetic bone implant made of a hardened calcium phosphate cement having an apatitic phase as a major phase, which includes a dense cortical portion bearing the majority of load and a porous cancellous portion allowing a rapid blood / body fluid penetration and tissue ingrowth.

Owner:CALCITEC

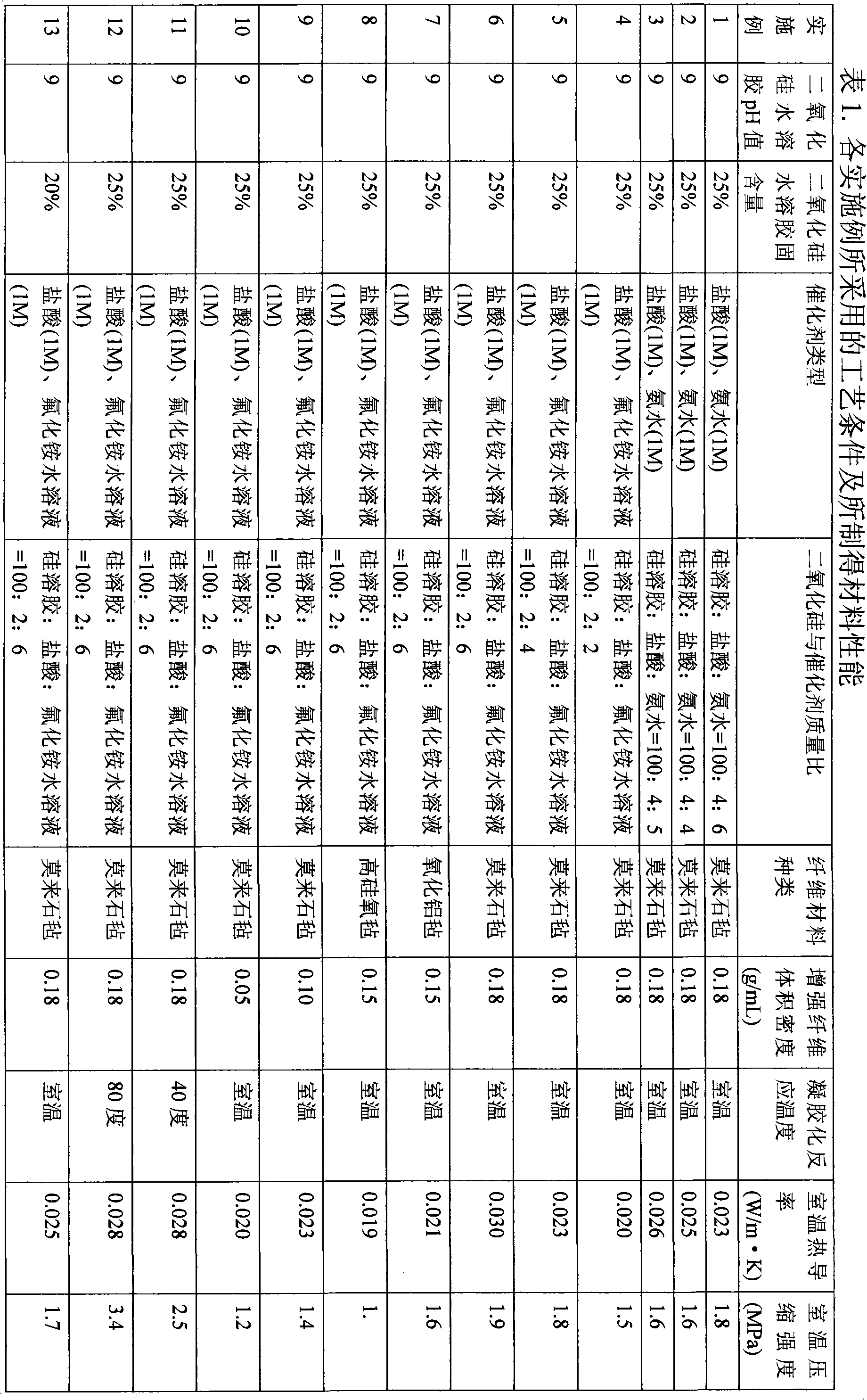

High-performance thermal insulation material and preparation method thereof

The invention provides a high-performance thermal insulation material and a preparation method thereof. The thermal insulation material comprises silicon dioxide aerogel and a fiber material, wherein, the silicon dioxide aerogel takes silicon dioxide hydrosol as a raw material, and is prepared by adding a catalyst. The method comprises the following steps: sol preparing, sol dipping, gelating, gel ageing, hydrophobization treating and drying and the like. The method can conveniently and selectively prepare the materials of planes, abnormal-shape surfaces and multiple sizes, has simple and convenient operation and small environmental pollution. The material has excellent mechanical performance, good high-temperature stability and heat insulation performance, and has wide application prospect in the fields of civilian industries, space flight and aviation industries, military industries and the like.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

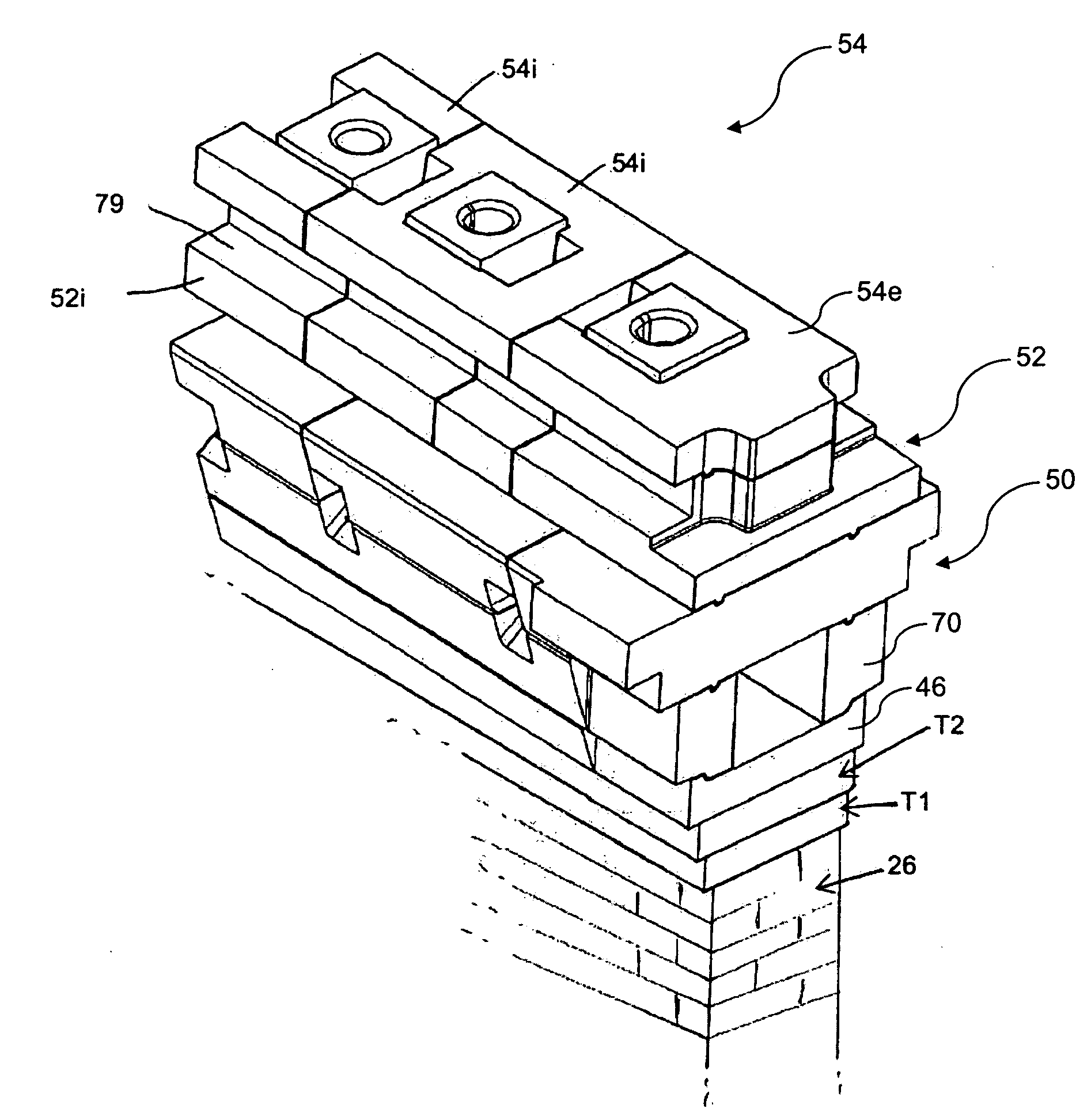

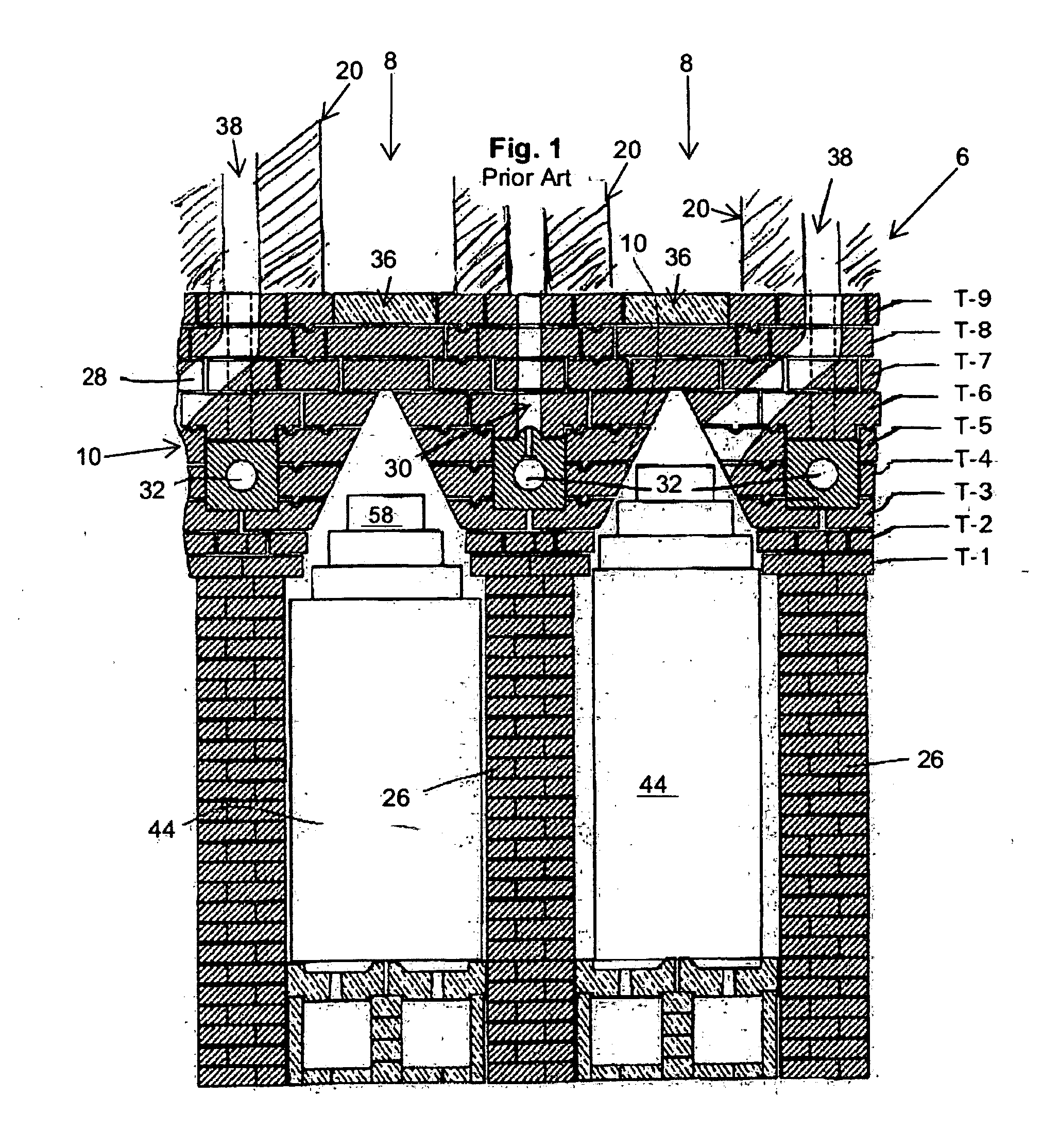

Corbel repairs of coke ovens

ActiveUS8266853B2Cost-effective constructionSave significant amountFurnace componentsFloorsEngineeringCoke oven

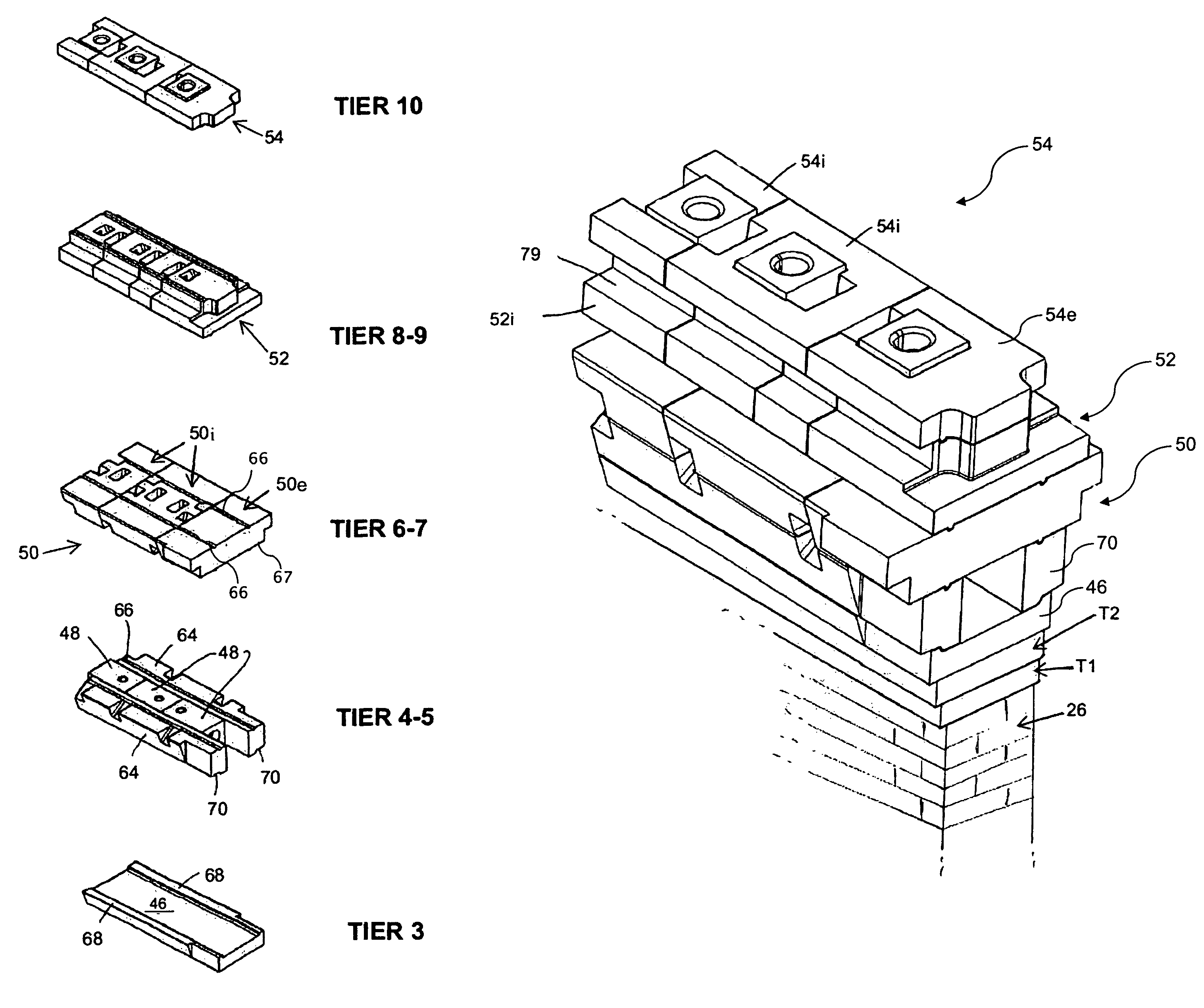

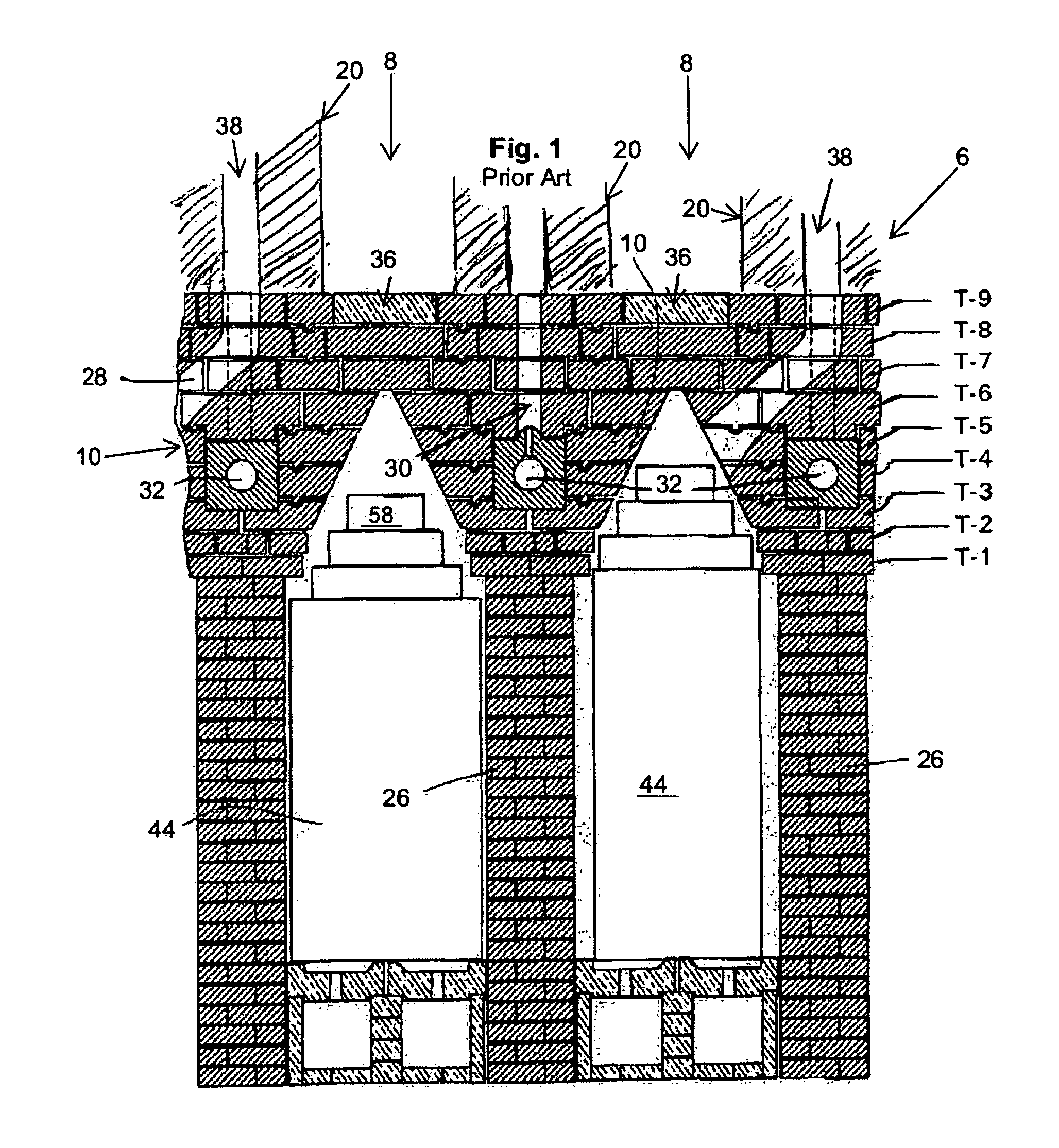

An improved corbel includes a first tier having first blocks and a second tier having second blocks. Each of the first blocks includes a first aperture extending through the block from a first surface to a back surface and a second aperture formed through a top surface of the block, extending into the first aperture. The first blocks are arranged on a substantially planar surface to align the respective first apertures to define a first passageway. Each of the second blocks includes a third aperture extending through the second block from a top surface to a bottom surface. The second blocks are disposed above the first tier to align the third aperture of each of the second blocks with the second aperture of the first blocks to form a second passageway.

Owner:VANOCUR REFRACTORIES LLC

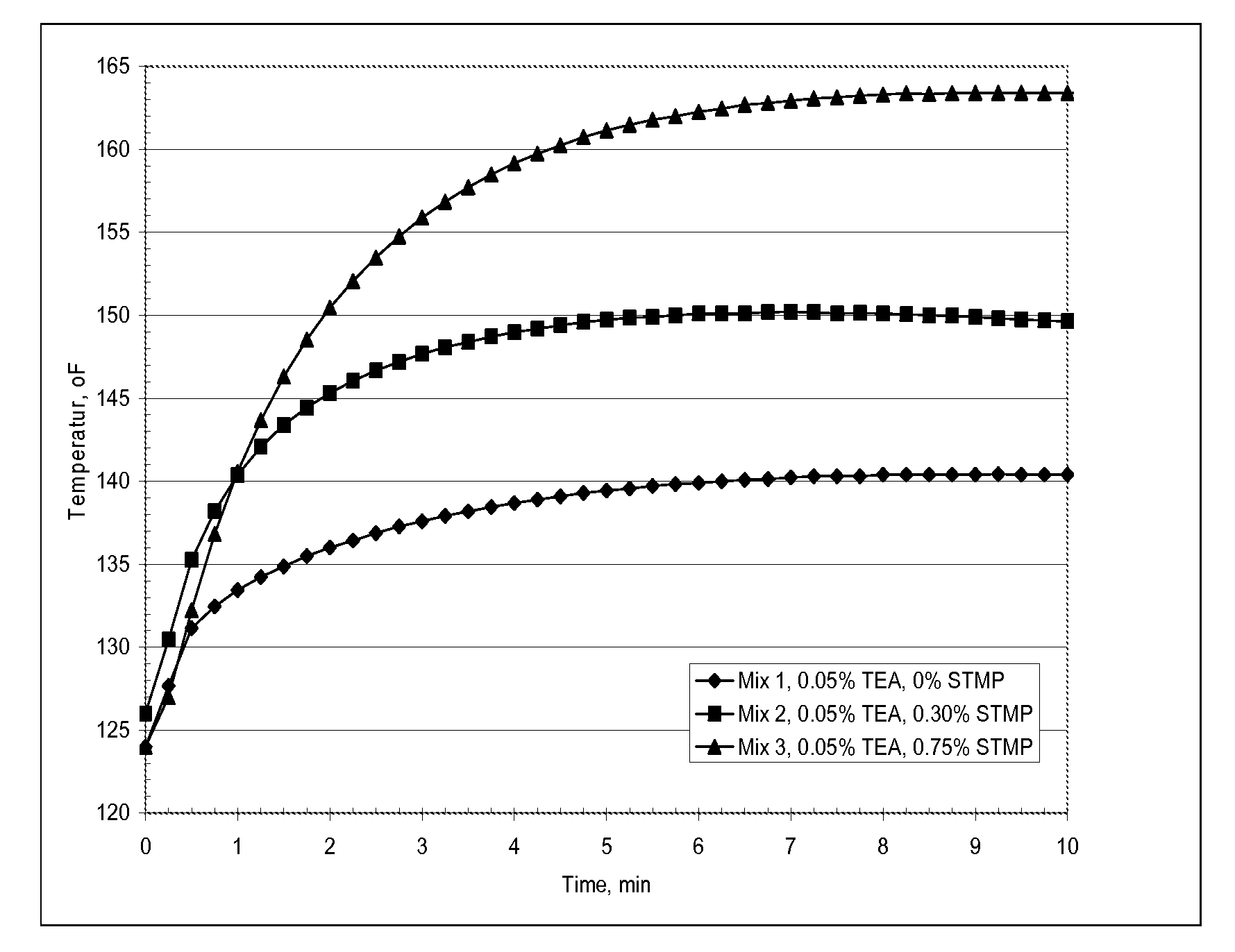

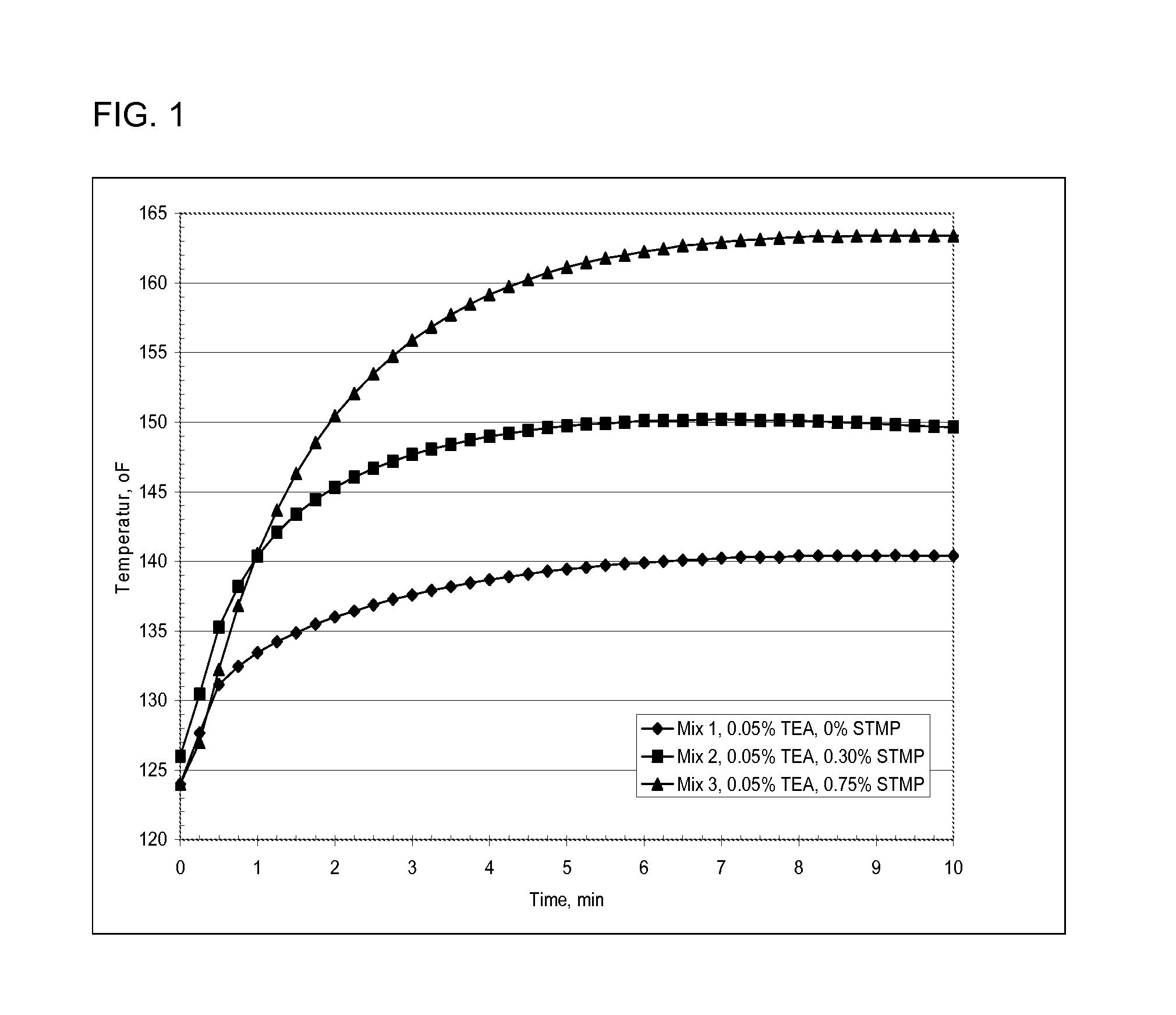

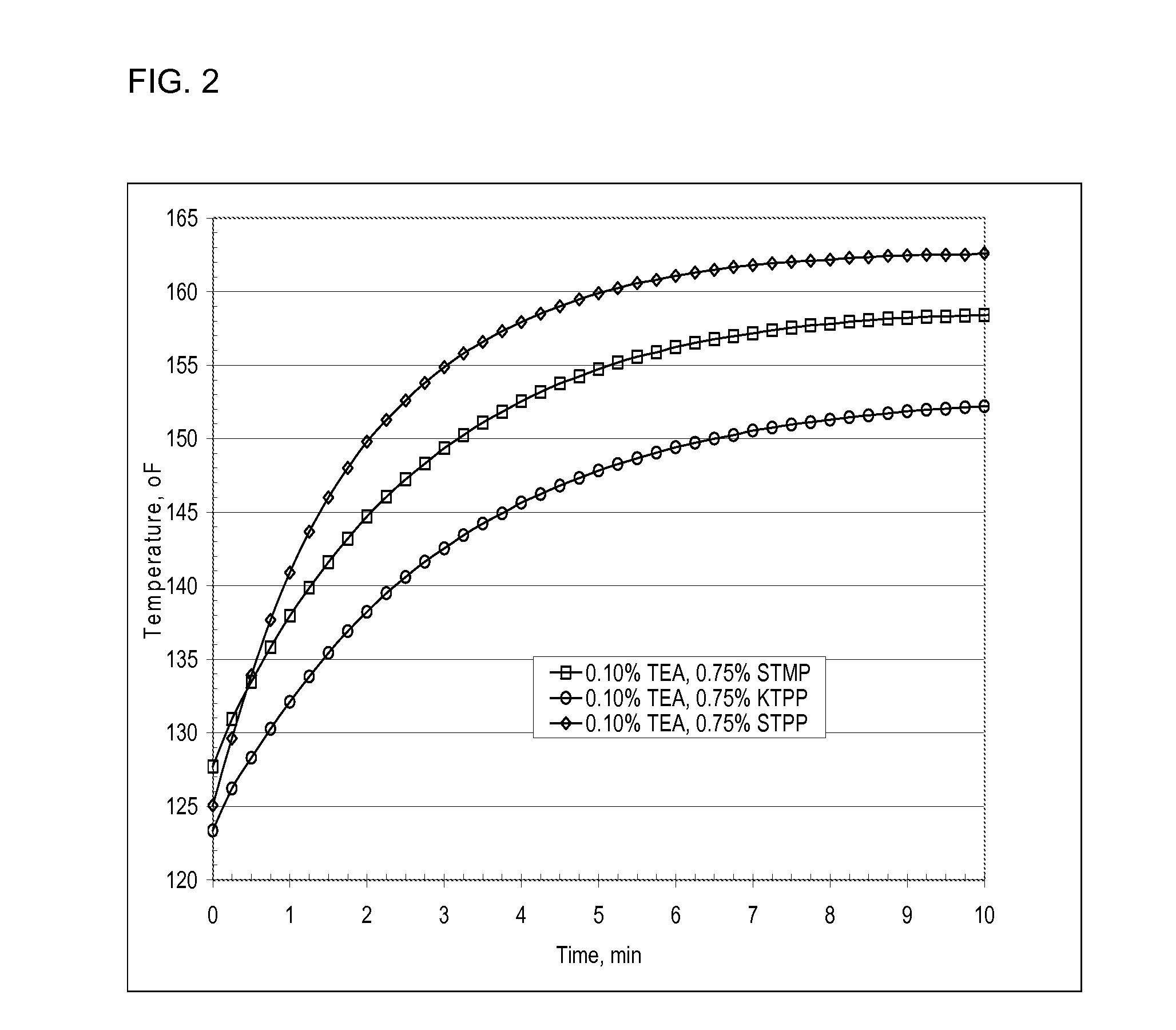

Very fast setting cementitious composition with high early-age compressive strength

ActiveUS7670427B2Addressing slow performanceHigh compressive strengthSolid waste managementPortland cementCement board

A method of making a rapid setting composition for cement boards is disclosed. Compositions including portland cement, fly ash, gypsum, alkanolamine and phosphate are disclosed. A synergistic interaction between the alkanolamine and phosphate increases the effectiveness of accelerating reactions thus allowing for quick setting and increased early-age compressive strength compositions.

Owner:UNITED STATES GYPSUM CO

Composites joined with z-pin reinforcement

InactiveUS6436507B1Easy to manufactureLasting shelf-lifeFuselage framesLayered productsEngineeringBond line

Prefabricated composite detail parts use precured strips that include Z-pin reinforcement along the bond line. Each strip has Z-pin stubble protruding from opposed faces so that the pins are embedded into the detail parts when the joint forms.

Owner:THE BOEING CO

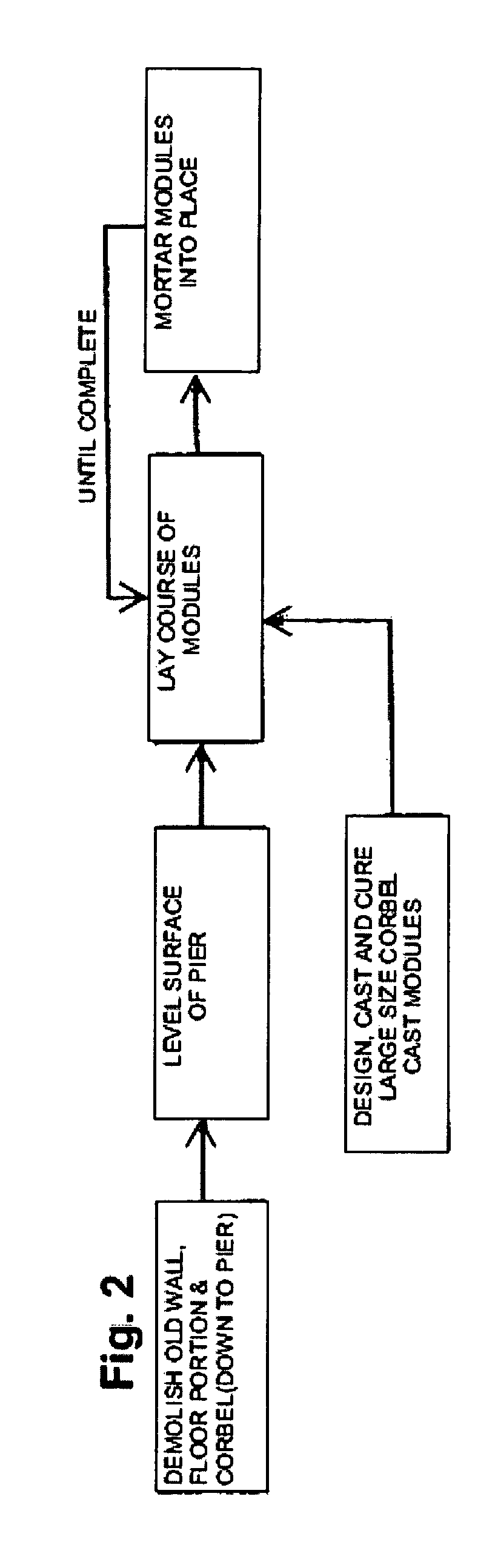

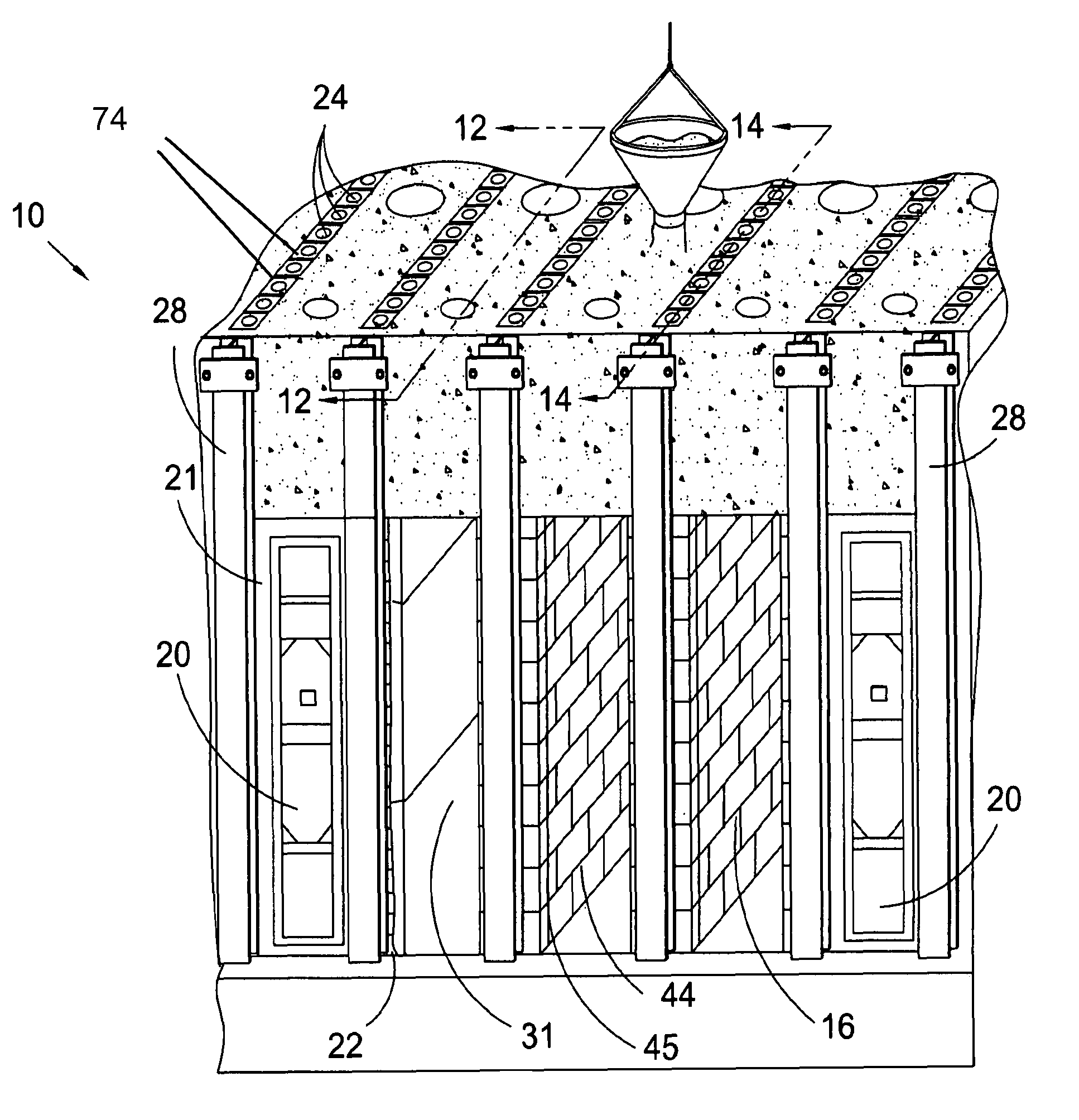

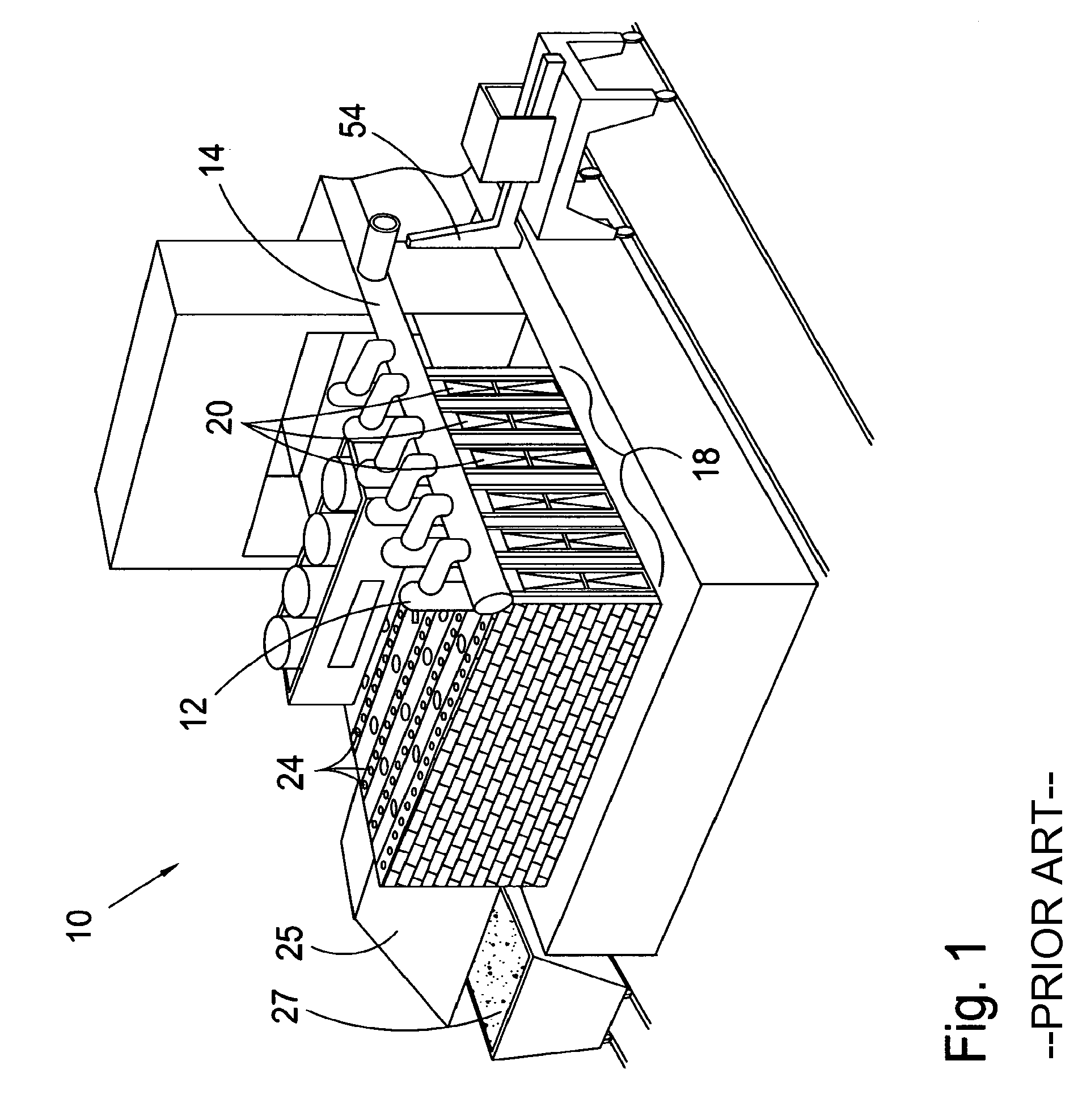

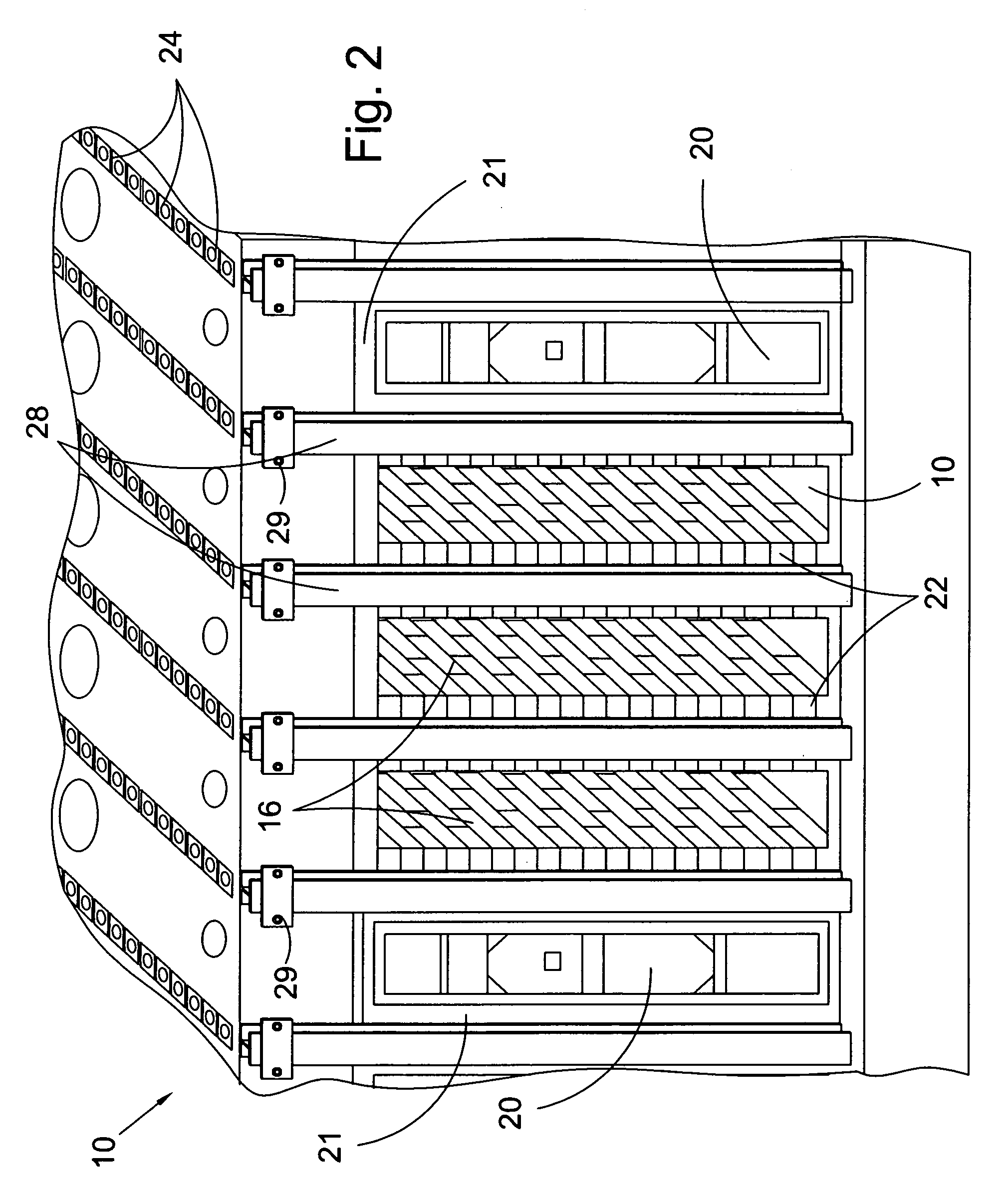

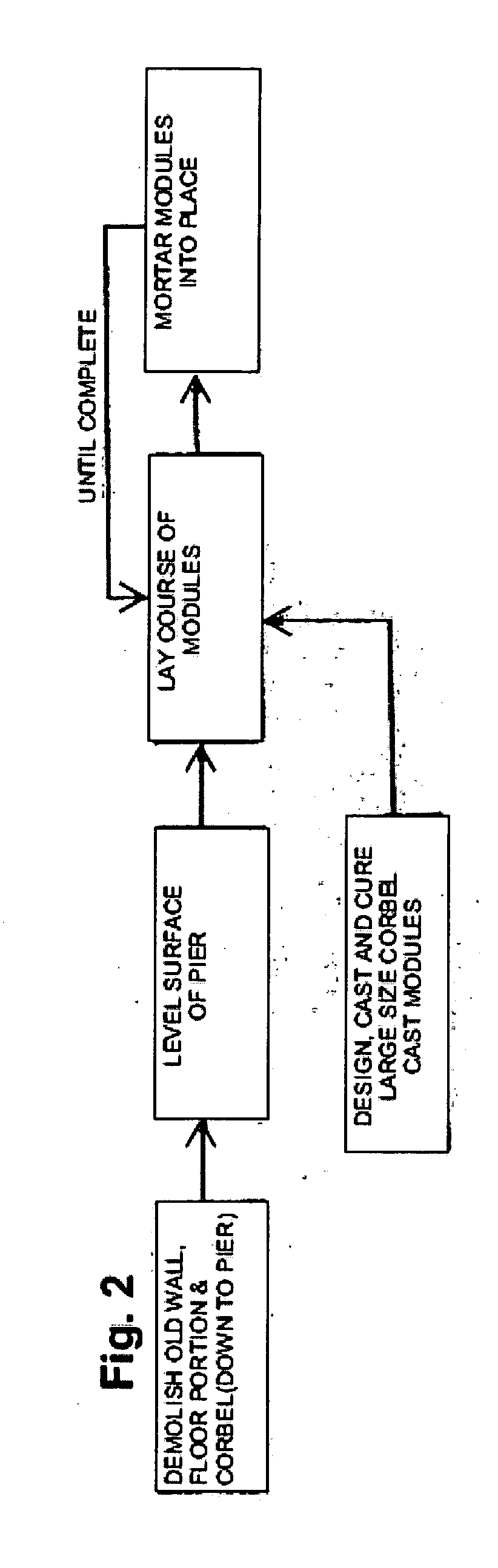

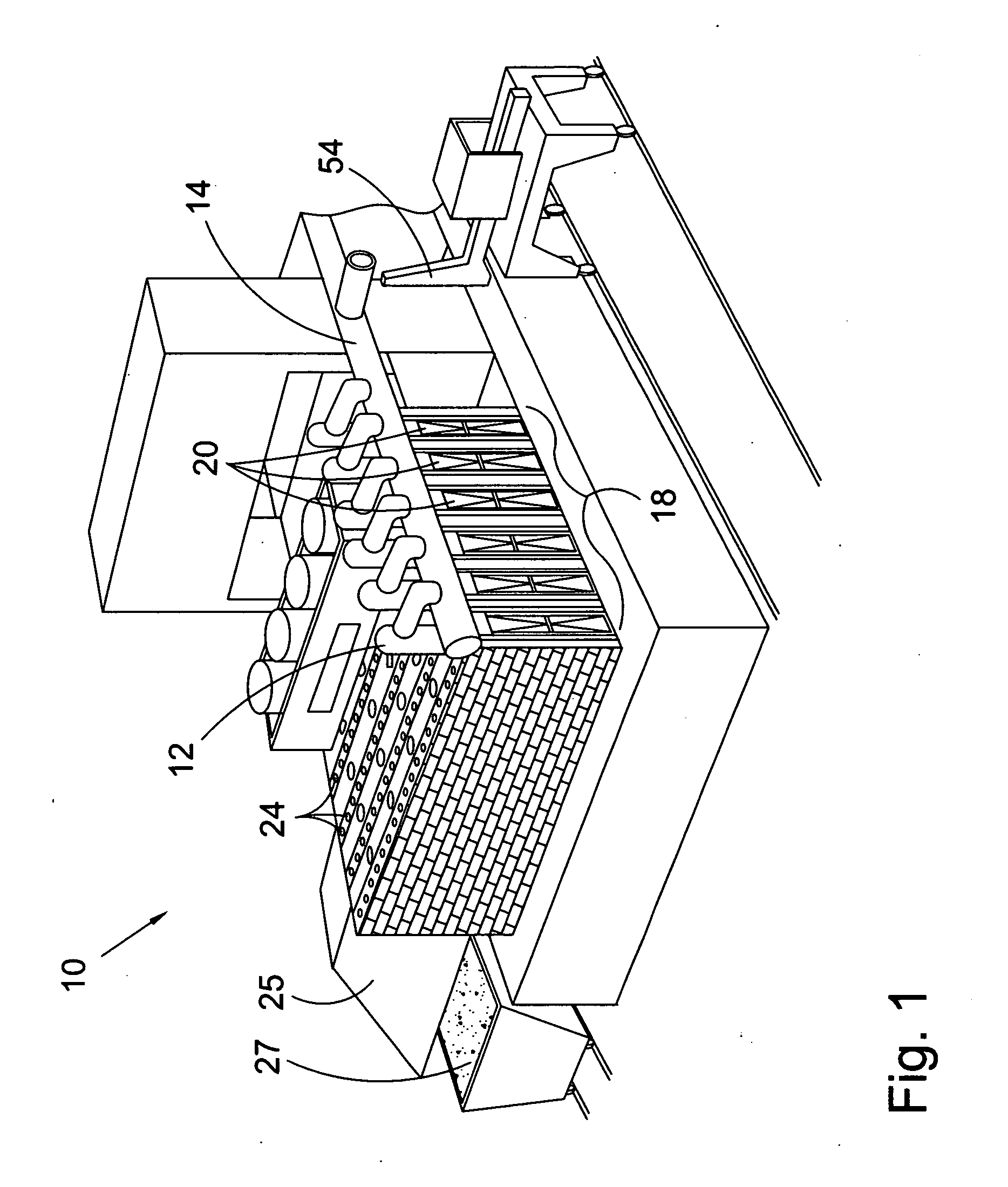

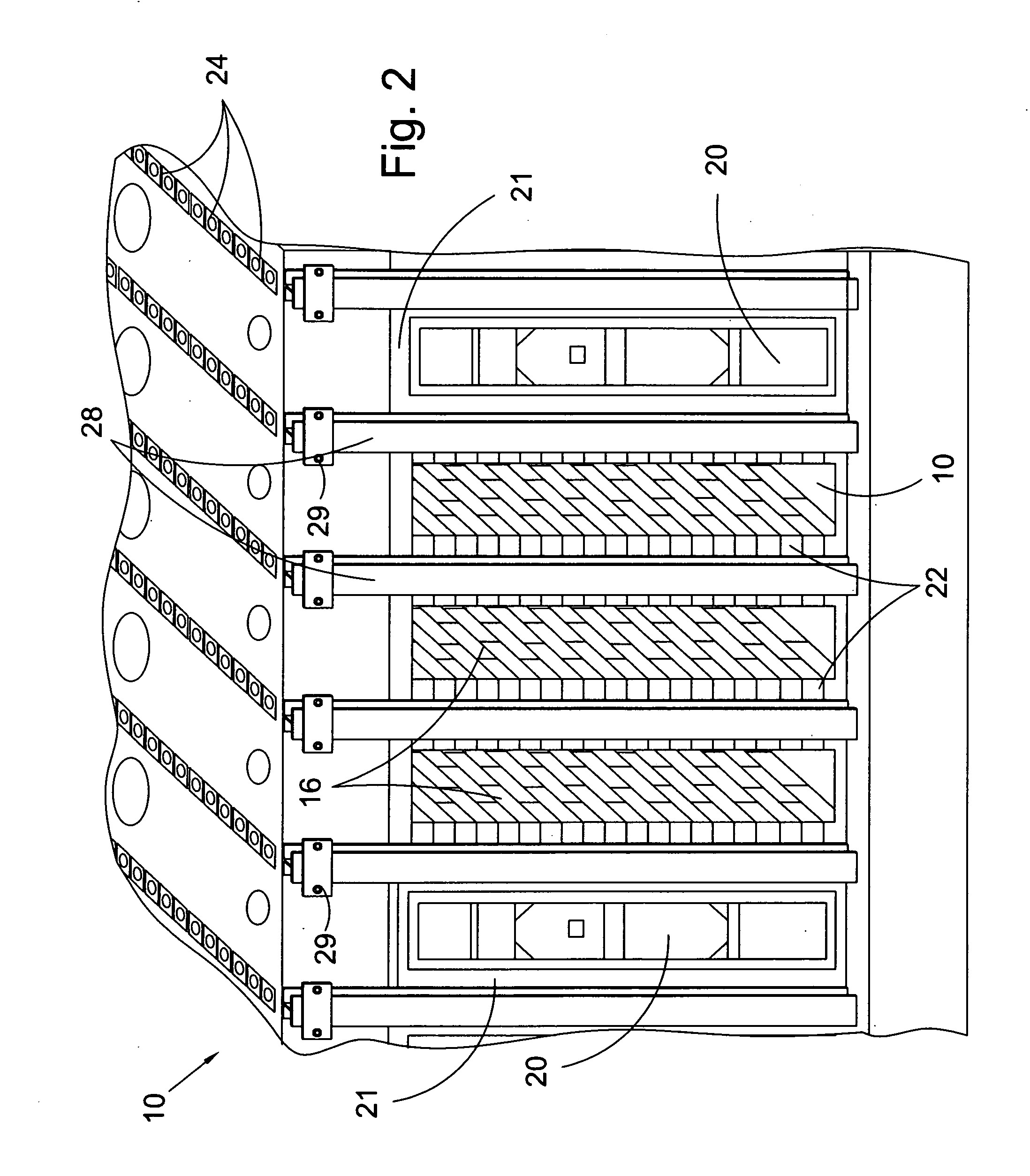

Coke oven reconstruction

ActiveUS7827689B2Good dimensional stabilityNegligible heatingConstruction materialCoke oven brickworkComputer moduleEngineering

A new, faster and more efficient process to replace heating walls and ceilings in coke oven batteries. Thus, when replaced, at least one heating wall is constructed of thermally stable non-expanding large size modular cast modules from end to end and the ceiling adjacent the heating wall is constructed of thermally stable non-expanding large modular cast blocks.

Owner:VANOCUR REFRACTORIES LLC

Corbel repairs of coke ovens

ActiveUS20100287871A1Cost-effective constructionSave significant amountFurnace componentsWallsEngineeringCoke oven

An improved corbel includes a first tier having first blocks and a second tier having second blocks. Each of the first blocks includes a first aperture extending through the block from a first surface to a back surface and a second aperture formed through a top surface of the block, extending into the first aperture. The first blocks are arranged on a substantially planar surface to align the respective first apertures to define a first passageway. Each of the second blocks includes a third aperture extending through the second block from a top surface to a bottom surface. The second blocks are disposed above the first tier to align the third aperture of each of the second blocks with the second aperture of the first blocks to form a second passageway.

Owner:VANOCUR REFRACTORIES LLC

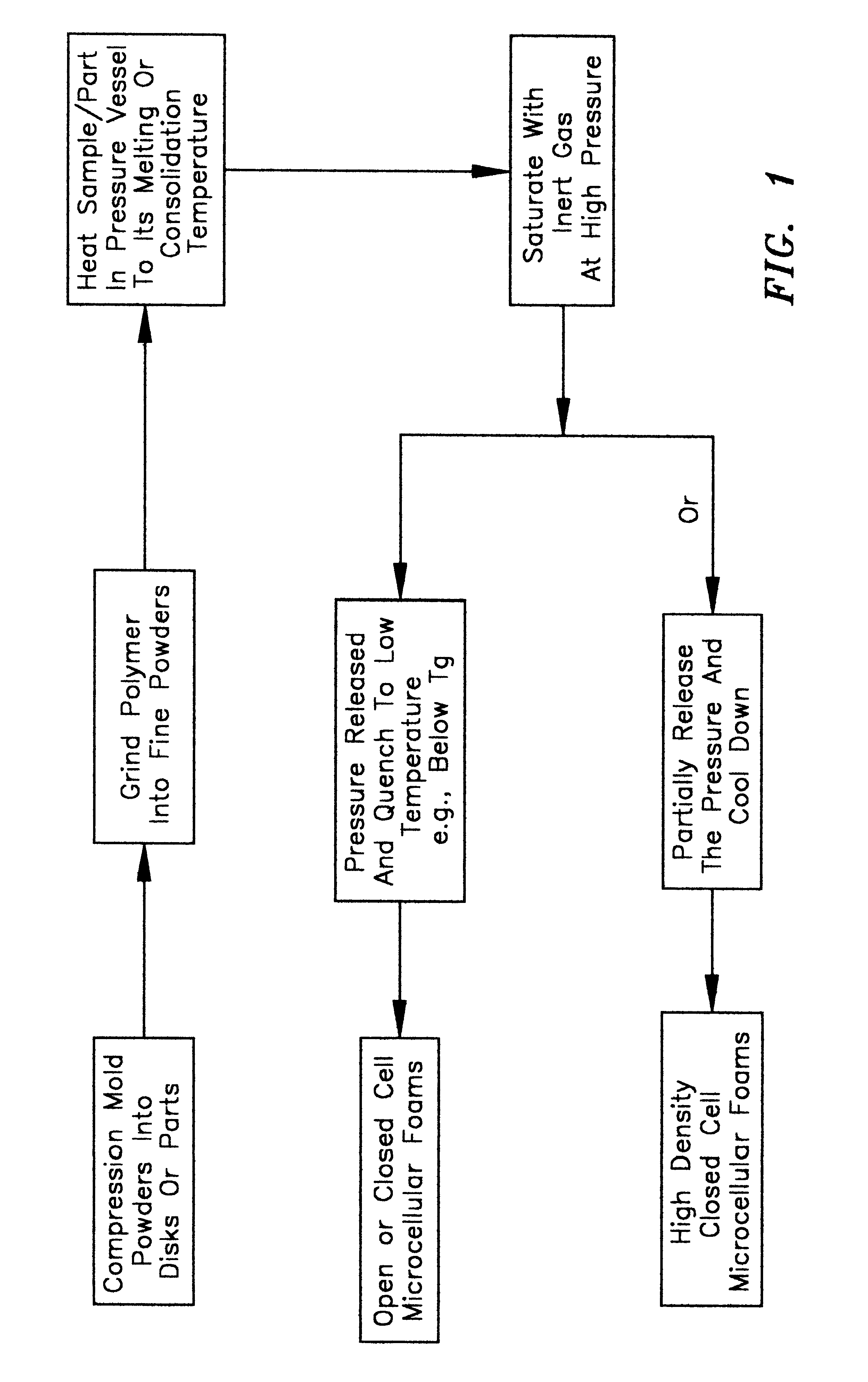

Microcellular polymer foams and method for their production

An environmentally friendly, commercially practicable process for the production of microcellular polymer foams from amorphous, semi-crystalline and crystalline polymers that comprises consolidating the polymer into a polymer shape, saturating the polymer shape with an inert gas at elevated temperature, above the Tg of the polymer, and under elevated pressure, releasing the pressure and cooling, i.e. quenching, the saturated polymer polymer shape under controlled temperature and pressure conditions to produce either a closed or open celled, low to medium density microcellular foam or a closed cell, high density microcellular foam.

Owner:TAN SENG C

Methods and compositons for forming subterranean fractures containing resilient proppant packs

InactiveUS20040040713A1Point becomes highEasy to paintFluid removalFlushingFracturing fluidHigh intensity

Improved methods of forming fractures containing resilient proppant particle packs which prevent the production of sand and fines with produced fluids and prevent proppant flow-back in a subterranean zone penetrated by a well bore are provided. As the fractures are formed, a liquid hardenable resin component is mixed with a liquid hardening agent component and a liquid rubber component to form a hardenable resin composition. The hardenable resin composition is coated onto dry proppant particles which are suspended in the fracturing fluid and placed in the fractures. The hardenable resin composition on the resin composition coated proppant particles is allowed to harden and consolidate the proppant particles into high strength resilient permeable packs.

Owner:HALLIBURTON ENERGY SERVICES INC

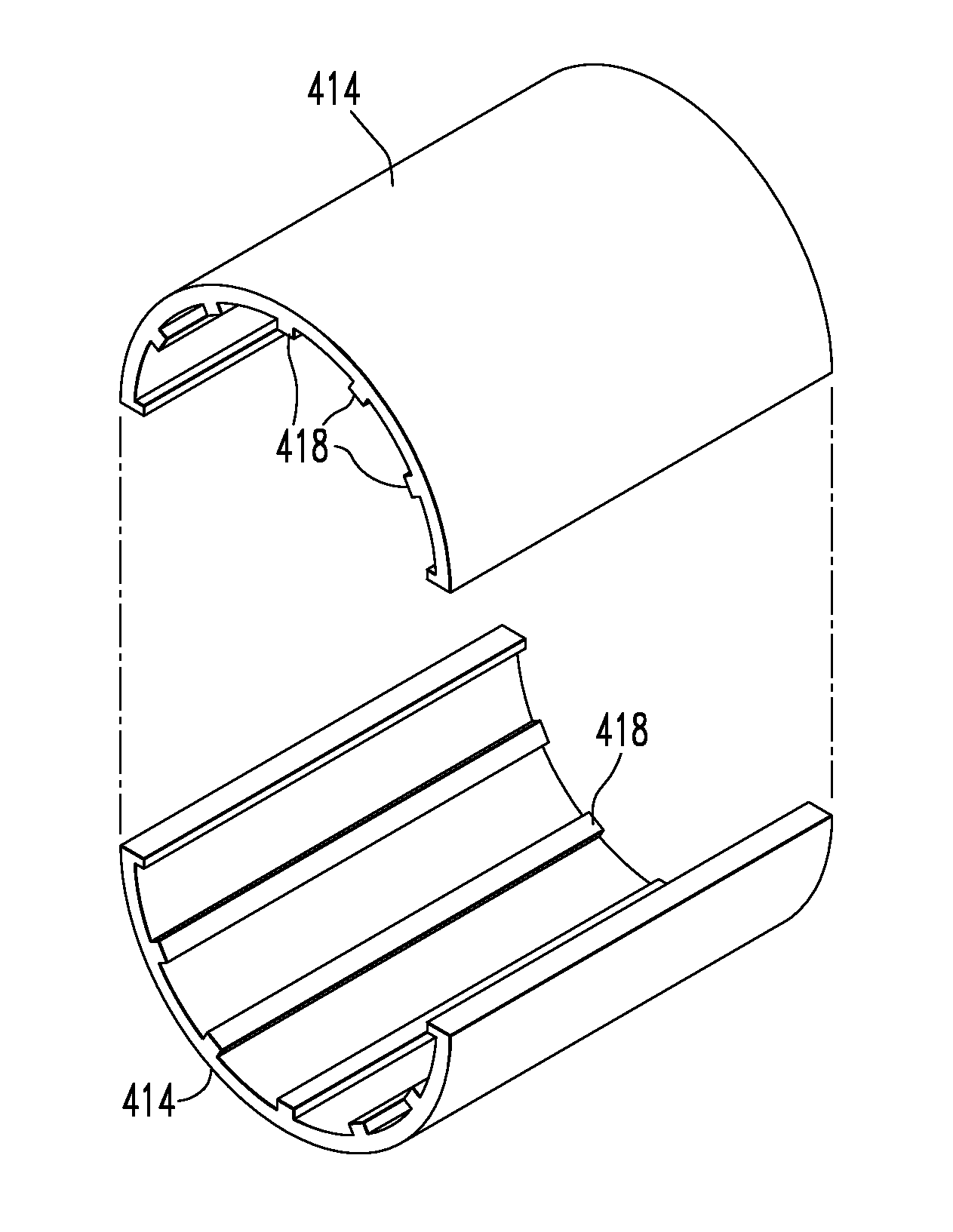

Fracture fixation systems

ActiveUS20120029102A1Firmly connectedImprove permeabilityImpression capsSurgical adhesivesResorbable polymersPolymer resin

Systems for bone fracture repair are disclosed. One system includes a biocompatible putty that may be packed about a bone fracture to provide full loadbearing capabilities within days. The disclosed putties create an osteoconductive scaffold for bone regeneration and degrade over time to harmless 5 resorbable byproducts. Fixation devices for contacting an endosteal wall of an intramedullary (IM) canal of a fractured bone are also disclosed. One such fixation device includes a woven elongated structure fabricated from resorbable polymer filaments. The woven elongated structure has resilient properties that allow the woven 10 structure to be radially compressed and delivered to the IM canal using an insertion tube. When the insertion tube is removed, the woven structure expands towards its relaxed cross-sectional width to engage the endosteal wall. The woven elongated structure is impregnated with a resorbable polymer resin that cures in situ, or in the IM canal.

Owner:SMITH & NEPHEW INC

Heat insulation wall integral pouring material and construction method

InactiveCN101376582AImprove insulation effectEarly benefitsSolid waste managementFiberCrack resistance

The invention discloses an insulation wall body integral-casting material and a construction method thereof. The insulation wall body integral-casting material is characterized in that the ratio of a binder, an insulation aggregate and an additive is 1000:(5-5000):(0-300); the binder is a cement-based binder or a gypsum-based binder; the constitutes of the cement-based binder are 300-1000 parts of cement, 0-200 parts of silica fume, 0-400 parts of fly ash, 0-700 parts of slag powder, 0-300 parts of zeolite powder, 0-200 parts of ash-calcium powder and 0-40 parts of gypsum; the constituent of the gypsum-based binder is 1000 parts of gypsum; and the constituents of the insulation aggregate are 0-100 parts of expanded polystyrene granules, 0-1500 parts of expanded perlite, 0-1500 parts of expanded vermiculite, 0-1500 parts of expanded vitrified microspheres, 0-5000 parts of expanded ceramisite and 0-200 parts of sepiolite fibers. The invention also comprises the construction method. The wall bodies casted by the insulation wall body material have good insulating and thermal performances, higher strength, and good water resistance, crack resistance and permeability resistance performances, as well as good compatibility and good security towards the subsequent decorating process.

Owner:湖南江盛新型建筑材料有限公司

Lightweight wall plaster

InactiveCN101691292AReduce lossWith thermal insulationSolid waste managementPlasterworkThermal insulation

The invention discloses a lightweight wall plaster which comprises the following components by weight percent: 65-90% of inorganic cementing material, 5-30% of lightweight aggregate, 0-30% of filler and 0-10% of functional additive, wherein the inorganic cementing material is a desulfurized plaster or a building plaster. The lightweight wall plaster is a single-component dry mixed material produced by a factory and can be used on a construction site by only adding water for stirring, the lightweight wall plaster has a certain thermal insulation function and excellent fire prevention performance, the bonding performance is good, and the compressive strength is high, thereby being capable of replacing the traditional plastering mortar to be plastered on inner sides of external walls, partition walls, room separating walls, ceilings and other occasions and further improving the thermal insulation performance of wall bodies.

Owner:谢日清

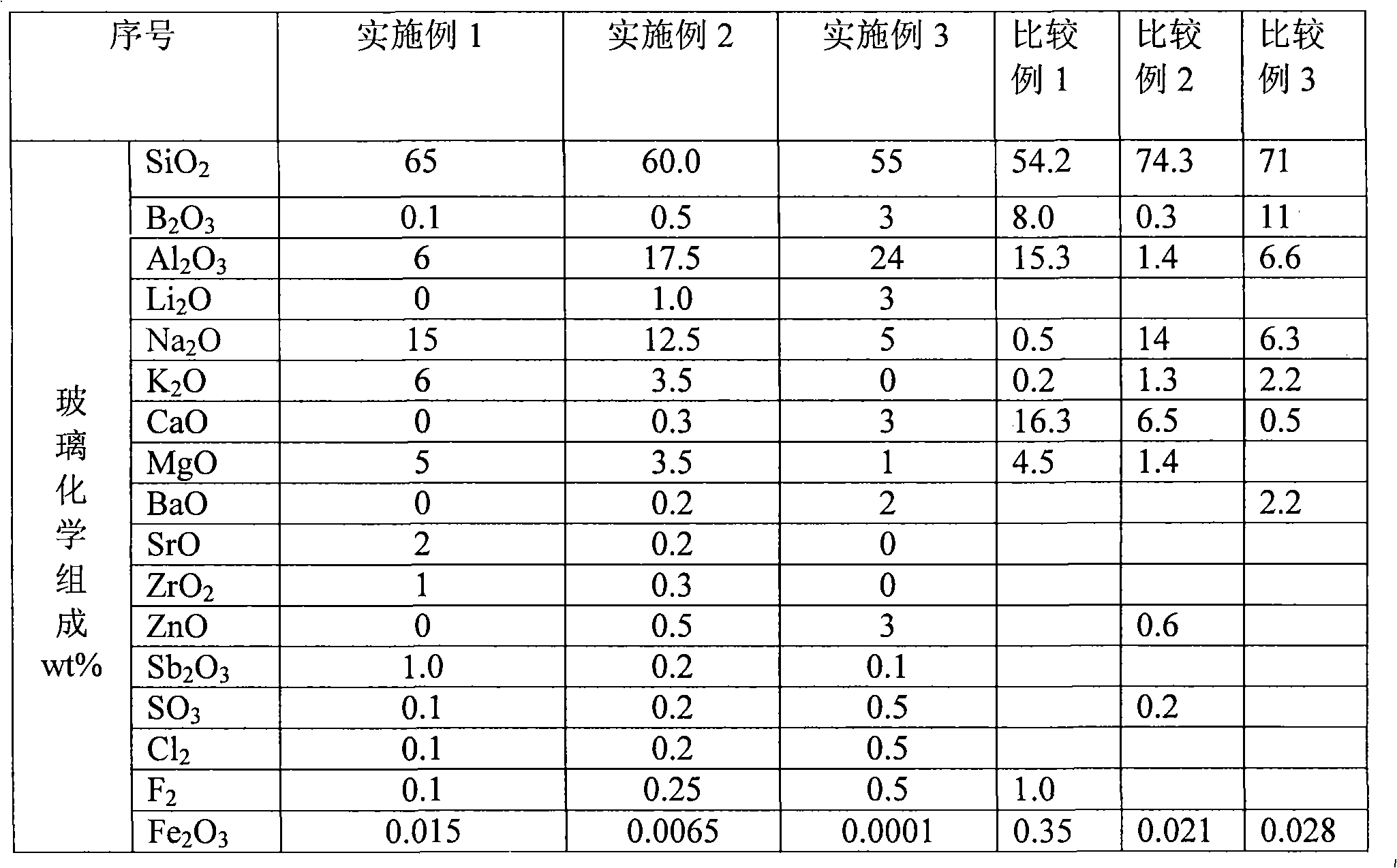

High strength aluminosilicate glass and chemically toughening process thereof

ActiveCN101337770AMeet the screen saver functionProtective functionGlass tempering apparatusAlkali freeShock resistance

The invention relates to a high-strength aluminate silicate glass and a chemical toughening method thereof, and belongs to the silicate glass field. The glass comprises the following chemical components (weight percent): 55 to 65 weight percent of SiO2, 0.1 to 3 weight percent of B2O3, 6 to 24 weight percent of Al2O3, 3 to 9 weight percent of MgO plus CaO plus BaO plus SrO, 0 to 1 weight percent of ZrO2, 0 to 2 weight percent of ZnO, 0.1 to 0.5 weight percent of Cl2, 0.1 to 1.0 weight percent of Sb2O3, 0.1 to 0.5 weight percent of SO3 and 0.1 to 0.5 weight percent of F2, and belongs to a aluminate silicate glass system. The high-strength aluminate silicate glass is prepared through a known plate glass production method, and then is subjected to the strengthening treatment by adopting the chemical toughening method. The glass has high permeability of visible light, and relatively common soda lime glass, neutral medicine glass and alkali-free high-aluminum glass have good shock resistance property, high scratch resistance property and high durability. The high-strength aluminate silicate glass is applied to the screen surface protection of plasma display products and liquid crystal display products, the protection of touch screens, the screen protection of automated teller machines, and the screen protection of other electronic products (Mobile phones, PDAs and media machines, etc.), thereby effectively preventing the impact and the scratch damage to the glass surface of display products. The high-strength aluminate silicate glass contains no harmful elements.

Owner:SUZHOU SHINWU OPTRONICS TECH

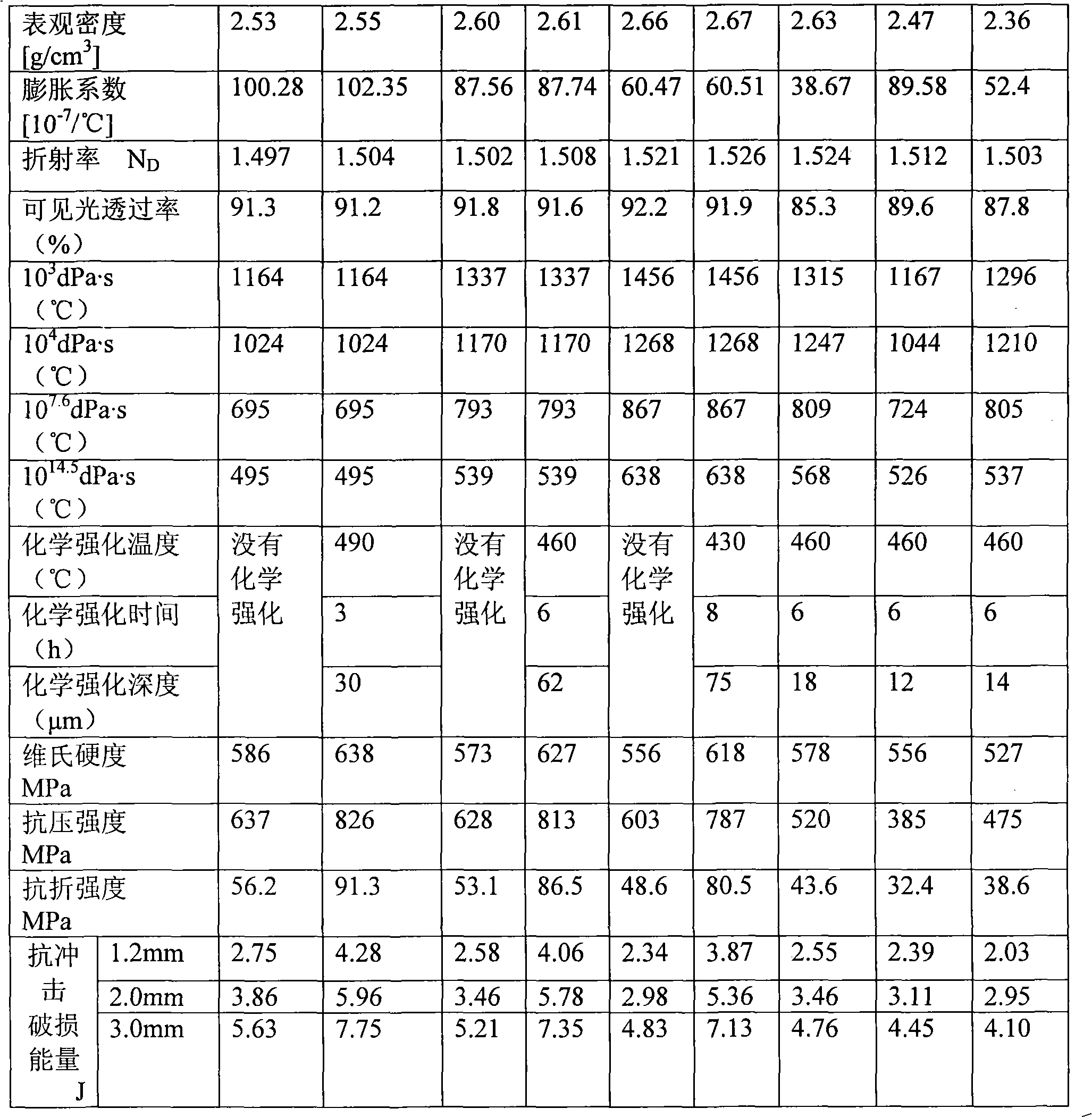

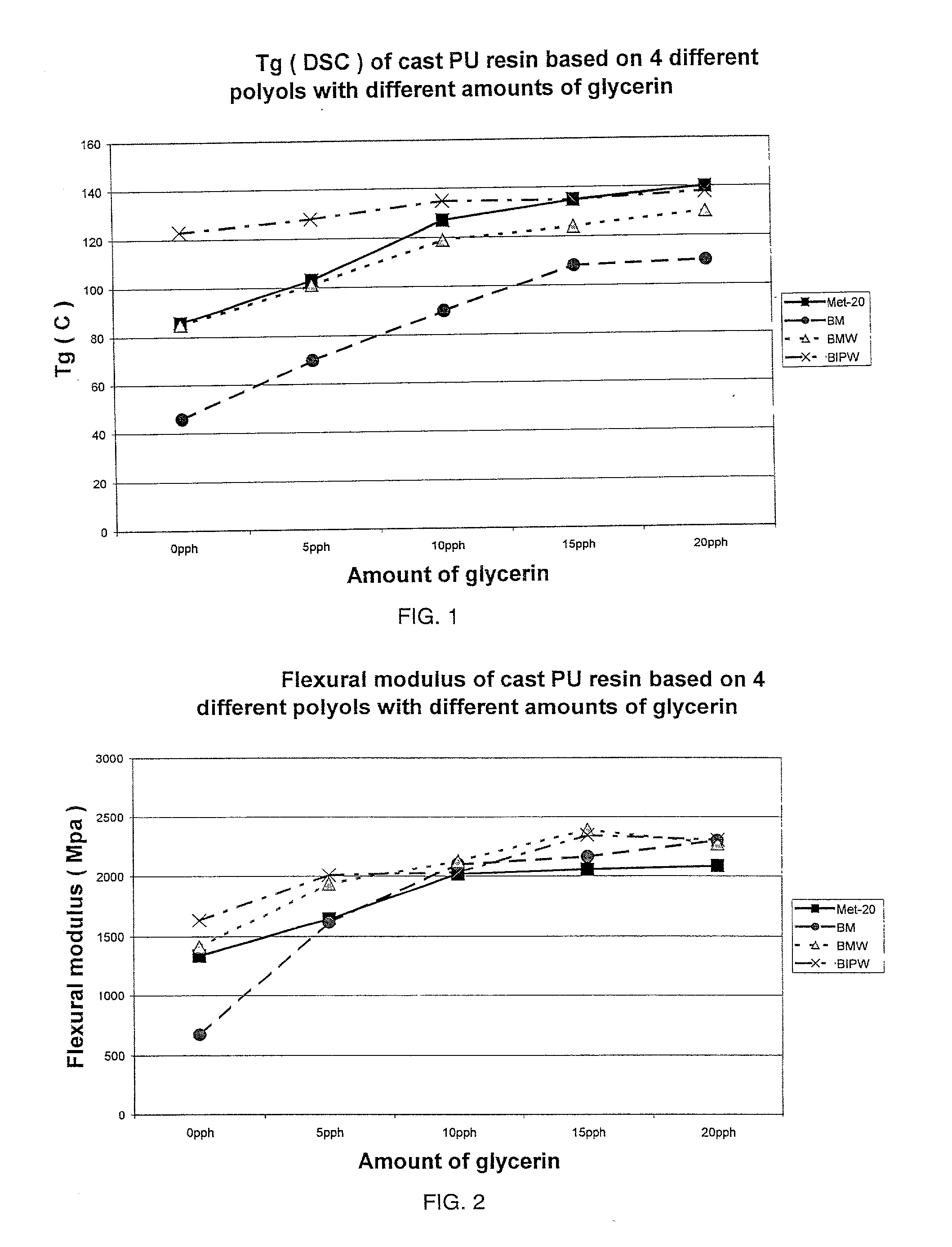

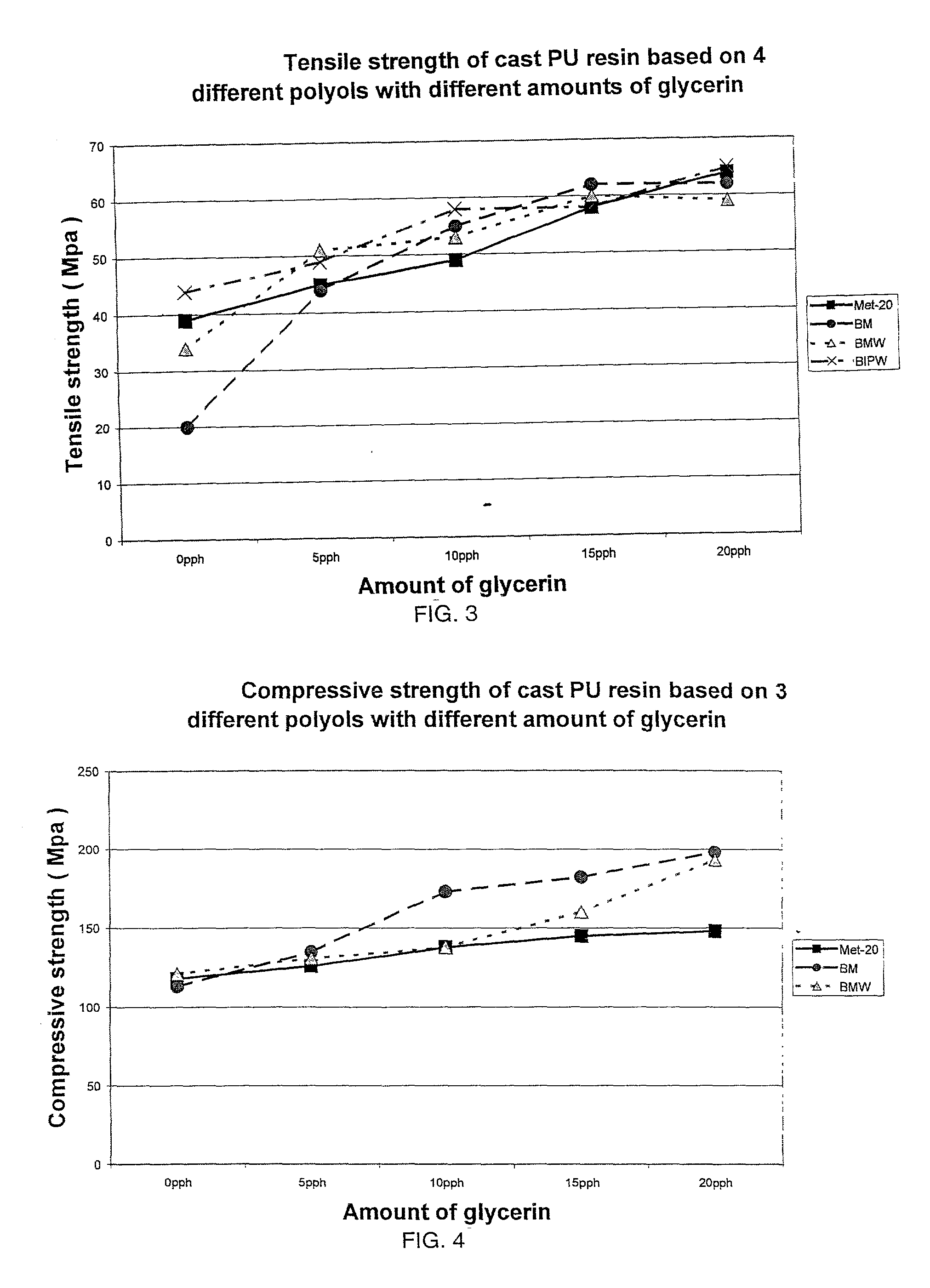

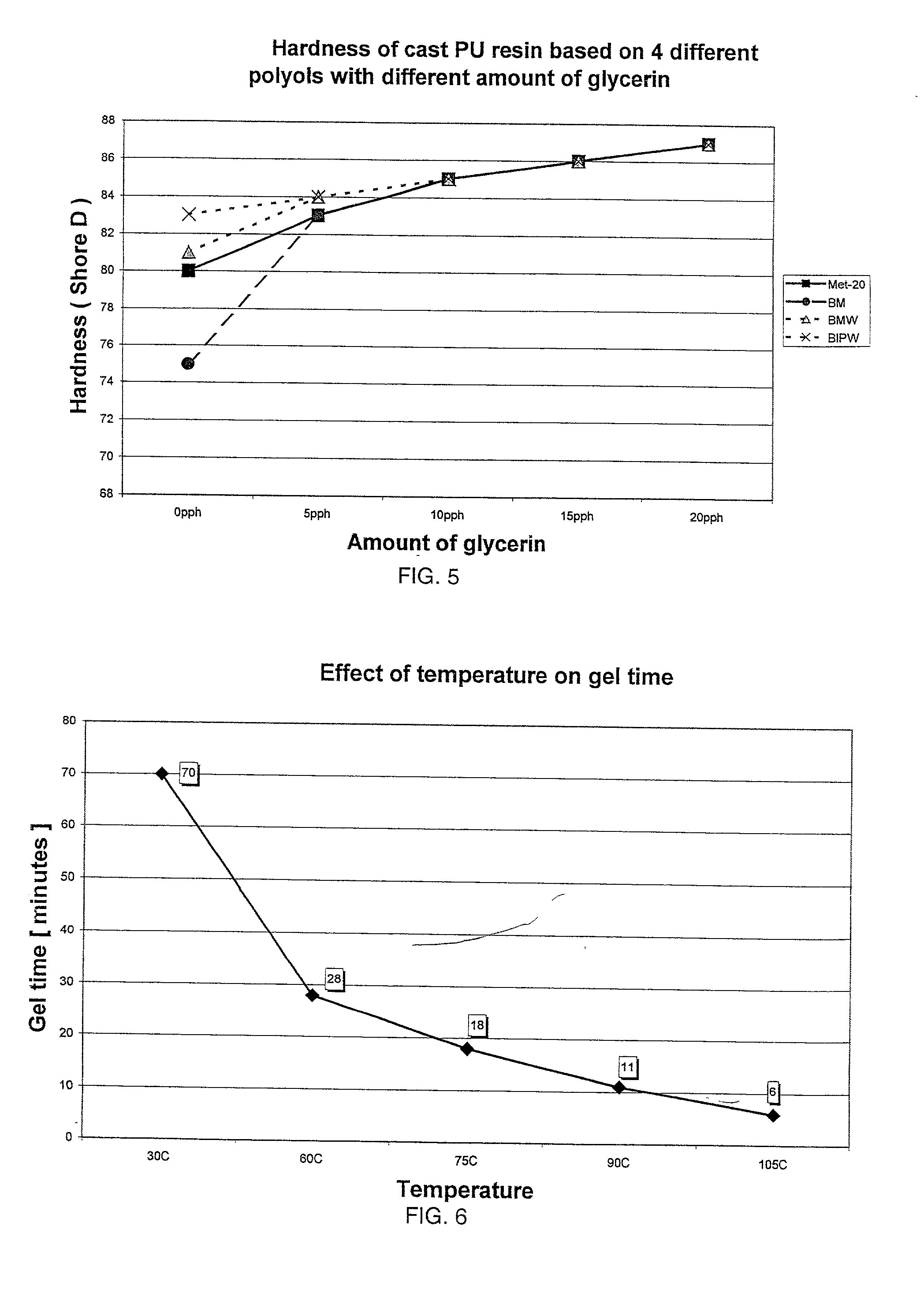

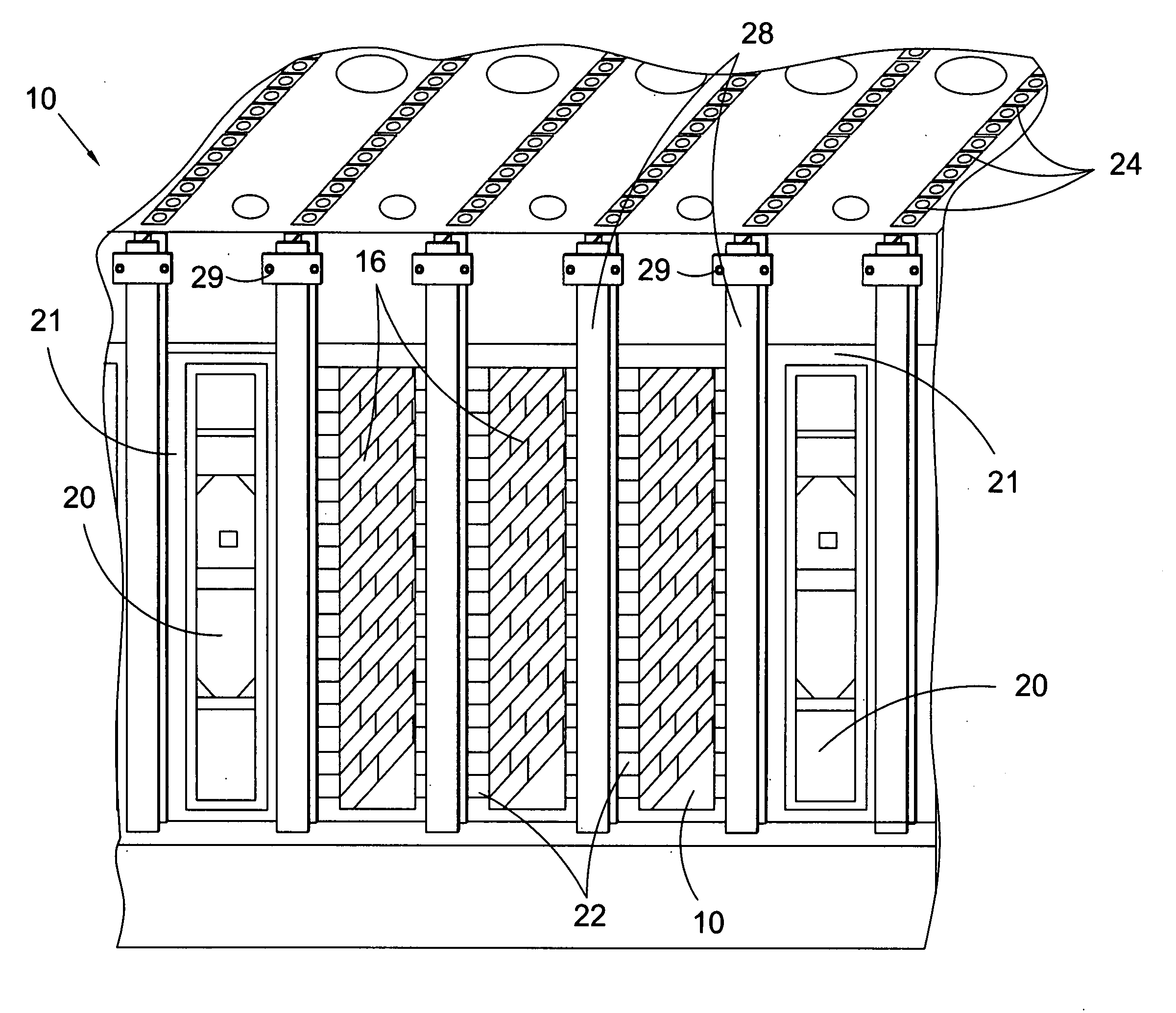

Polymer concrete and method for preparation thereof

InactiveUS20030090016A1High compressive strengthGood splitting tensile strength and flexural strengthSolid waste managementBuilding constructionsIsocyanatePolymer chemistry

A soy-based polyol is mixed with an isocyanate and aggregate to produce a soy-based polyurethane having superior mechanical properties. The aggregate composition may be varied to obtain different mechanical properties, as can the amount of resin. The resin may be crosslinked using a low molecular weight polyol, such as glycerine, to also improve structural performance. A catalyst may be added to accelerate curing time without reducing structural performance.

Owner:PETROVIC ZORAN +3

Coke oven reconstruction

ActiveUS20080169578A1High dimensional stabilityRepair time be approximately halvedConstruction materialCoke oven brickworkEngineeringCoke oven

A new, faster and more efficient process to replace heating walls and ceilings in coke oven batteries. Thus, when replaced, at least one heating wall is constructed of thermally stable non-expanding large size modular cast modules from end to end and the ceiling adjacent the heating wall is constructed of thermally stable non-expanding large modular cast blocks.

Owner:VANOCUR REFRACTORIES LLC

Heat preservation and energy saving type lightweight, gas filled wall bricks, and preparation method

This invention relates to a method for preparing heat-insulating and energy-saving lightweight aerated wall bricks, which are prepared from aggregate, gelation agent, aeration agent, heat-insulating material and water. The aggregate is composed of slag or river sand, glass microbeads, floating beads, closed perlite, and expanded perlite. The gelation agent is composed of cement, gypsum and lime. The aeration agent is Al powder. The fiber heat-insulating material is composed of high-Al powder, tripolite, ceramic fibers, mineral wool, sepiolite, expanded vermiculite, glass cotton and palygorskite. The wall bricks have such advantages as high compressive strength, low heat conductivity, high heat-insulating performance, high fireproof and damp-proof performances, rapid and convenient construction, and no need for composite heat-insulating layer.

Owner:徐振飞

Lightweight leveling mortar

The invention discloses a lightweight leveling mortar material for a variety of wall surfaces and floors inside and outside buildings, and the lightweight leveling mortar material comprises the following components by weight percent: 65-90% of inorganic cementing material, 5-30% of lightweight aggregate, 0-30% of filler and 0-10% of functional additive. The lightweight leveling mortar material is a single-component dry-mixed material produced by a factory and can be used on a construction site by only adding water for stirring. The lightweight leveling mortar has a certain thermal insulation function and excellent fire prevention performance, the bonding performance is good, and the compressive strength is high, thereby being capable of replacing the traditional mortar to be plastered on a variety of wall surfaces and floors of buildings and further improving the thermal insulation performance of wall bodies.

Owner:谢日清

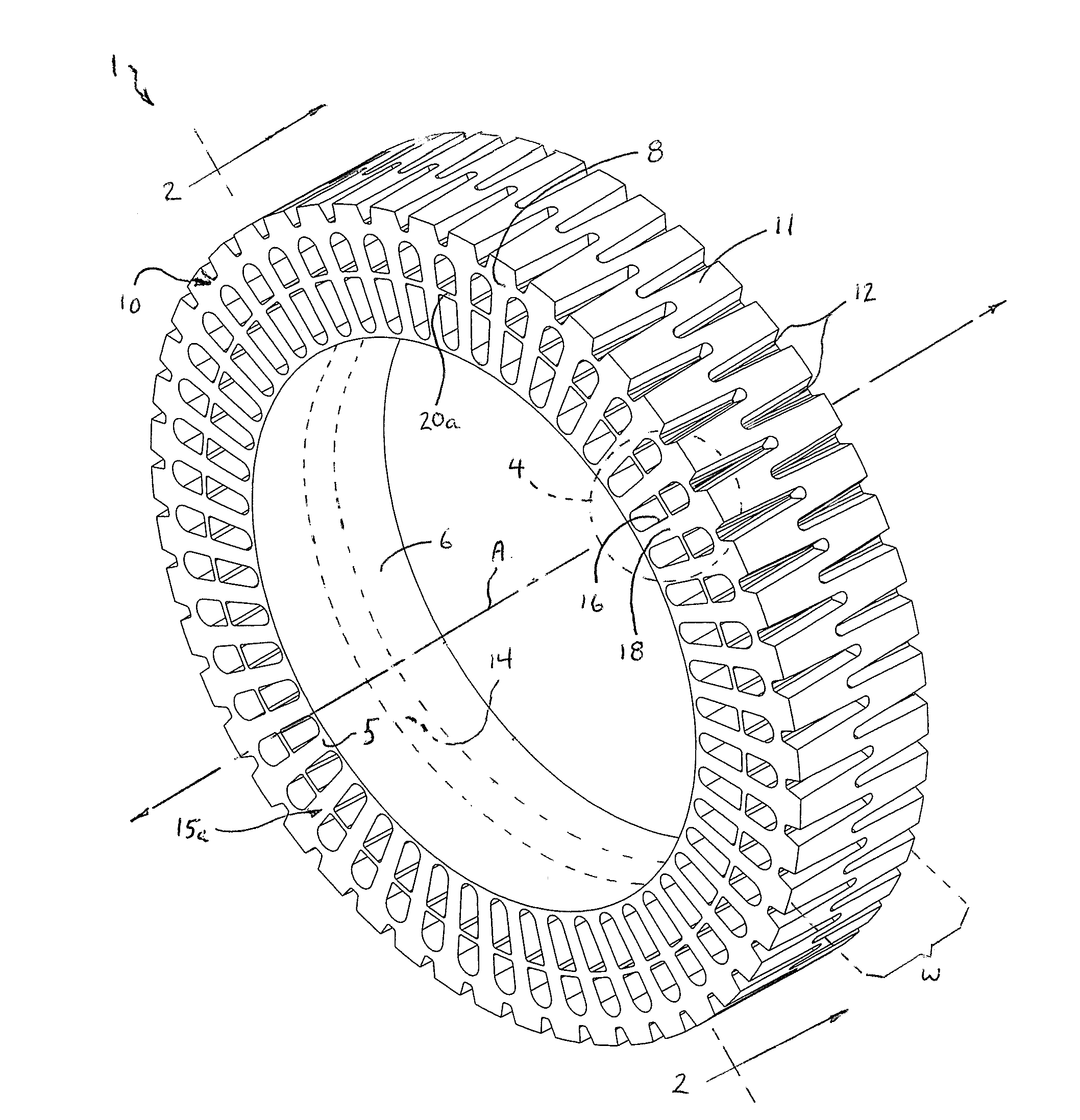

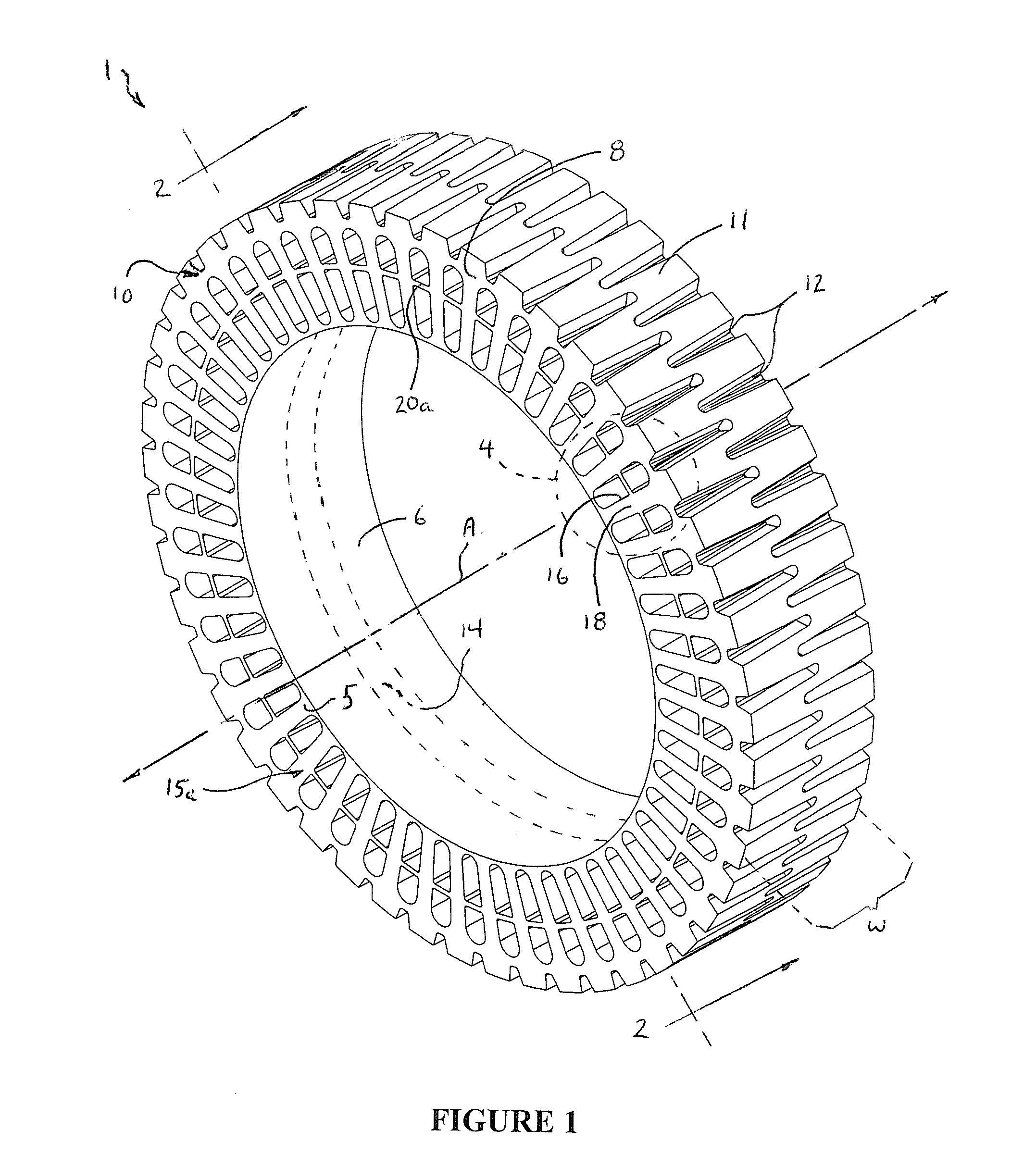

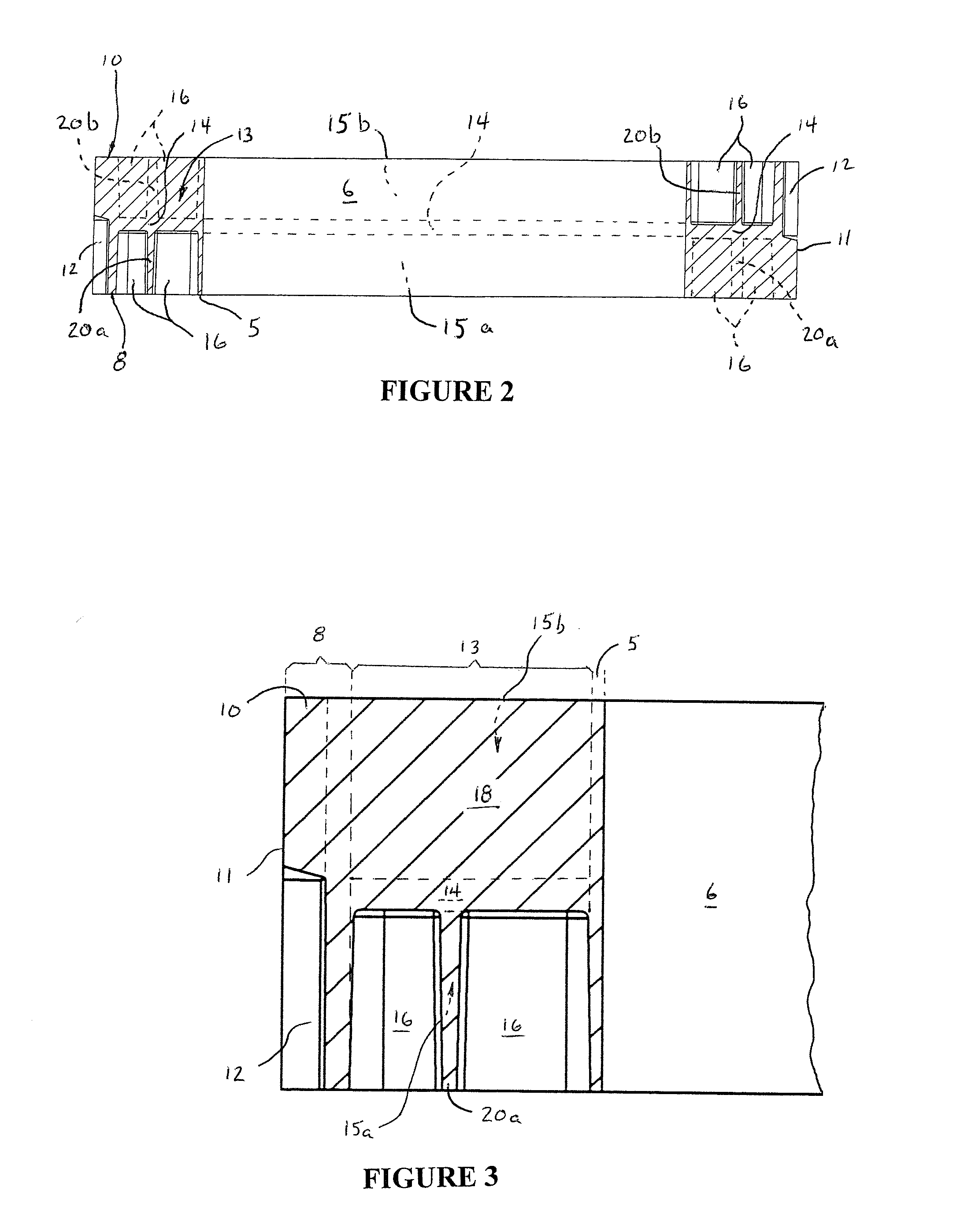

Non-pneumatic tire with annular spoke reinforcing web

InactiveUS20120234444A1Increased bending stiffnessIncrease the maximum loadNon-inflatable tyresLoad carryingEngineering

A non-pneumatic tire is provided with an annular reinforcing web that reduces the bending of compression spokes formed in the tire and reduces stresses and strains in the tire. The non-pneumatic tire includes an inner hoop member having an inner surface that defines the inner diameter of the tire, and an outer hoop member having a tread groove region that defines the outer diameter of the tire. A disc-shaped central web portion connects the inner and outer hoop members. A plurality of elongated, radially aligned cavities on either side of the central web defines integrally-formed compression spokes which connect the inner and outer hoop members. The annular reinforcing web is located on and affixed to either side of the central web portion and interconnects a mid portion of each spoke to a mid portion of the spokes on either side of it. Preferably, the annular reinforcing web is reinforced with fiber webbings on its outer side for added strength. The annular reinforcing web allows the tire to be made with less polyurethane material with no reduction in load carrying capability.

Owner:CATERPILLAR INC

Strontium-apatite-cement-preparations, cements formed therefrom, and uses thereof

ActiveUS7273523B2Facilitated releaseTo promote metabolismBiocideSurgical adhesivesPowder mixturePhosphate

Calcium-strontium-hydroxyphosphate (strontium-apatite-) cement preparations are described, comprising a powder mixture, which contains molar quantities of the components calcium (Ca), strontium (Sr) and phosphate (P) in the mixture in the ranges 1.00<Ca / P≦1.50 and 0<Sr / P<1.5, together with an alkali salt or an ammonium salt of phosphoric acid, and with water and / or an aqueous solution. The powder mixture particularly contains, as the Ca-component, Ca3(PO4)2 (TCP), and as the Sr-component SrHPO4 and / or Sr3(PO4)2 and optionally additional SrCO3. As the aqueous mixing solution for the formation of the strontium-apatite cement, an aqueous solution of an alkali salt or an ammonium salt of the phosphoric acid is suitable.

Owner:KYPHON

Moldable-foam moldings composed of expandable pelletized filled polymer materials

InactiveUS20070112082A1High compressive strengthLow thermal conductivityPelletizingThermoplastic polymer

Moldable-foam moldings whose density is in the range from 8 to 200 g / l, obtainable via fusion of prefoamed foam beads composed of expandable pelletized filled thermoplastic polymer materials, and a process for preparing the expandable pelletized polymer materials.

Owner:BASF SE

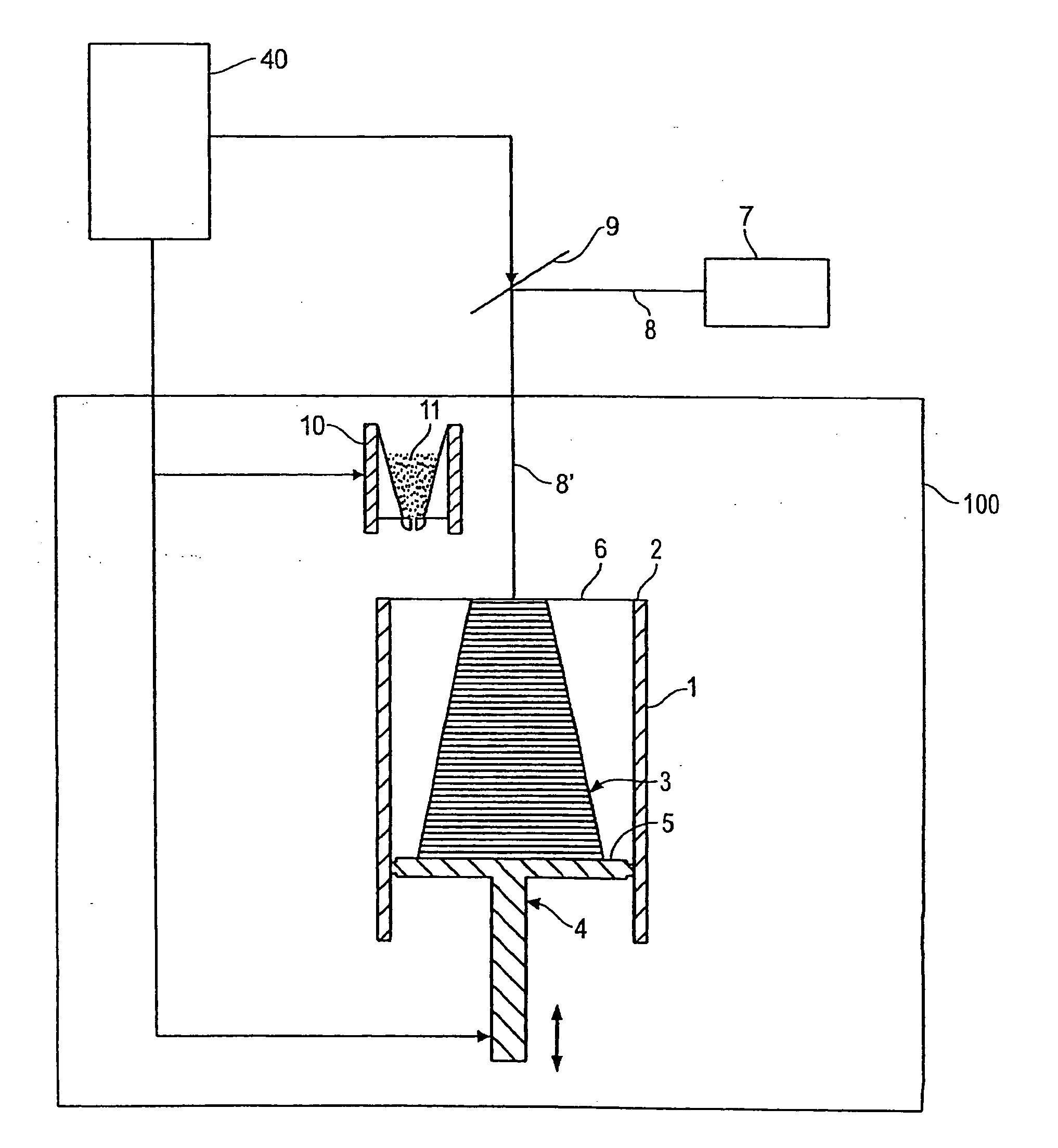

Selective sintering of structurally modified polymers

ActiveUS20090295042A1Improve mechanical propertiesSpeed up the processAdditive manufacturing apparatusLiquid surface applicatorsSelective laser sinteringPolymer science

A three-dimensional object is manufactured by selective sintering by means of electromagnetic radiation, wherein the powder comprises a polymer or copolymer having at least one of the following structural characteristics:(i) at least one branching group in the backbone chain of the polymer or copolymer, provided that in case of the use of polyaryletherketones (PAEK) the branching group is an aromatic structural unit in the backbone chain of the polymer or copolymer;(ii) modification of at least one end group of the backbone chain of the polymer or copolymer;(iii) at least one bulky group within the backbone chain of the polymer of copolymer, provided that in case of the use of polyaryletherketones (PAEK) the bulky group is not selected from the group consisting of phenylene, biphenylene, naphthalene and CH2— or isopropylidene-linked aromatics;(iv) at least one aromatic group non-linearly linking the backbone chain.

Owner:EOS ELECTRO OPTICAL SYST

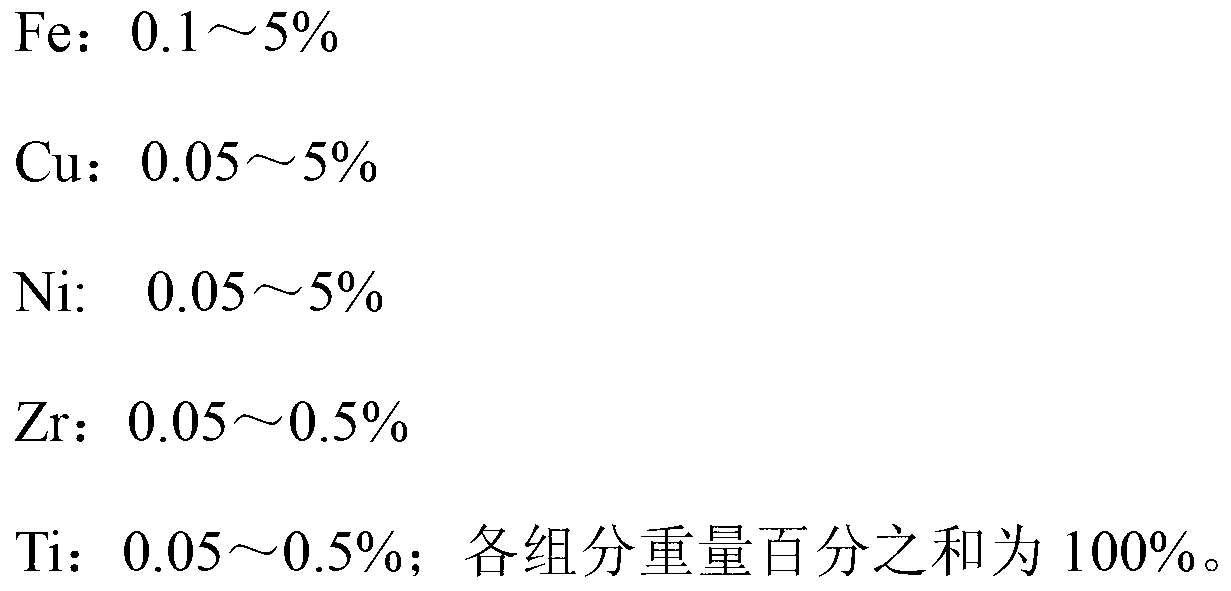

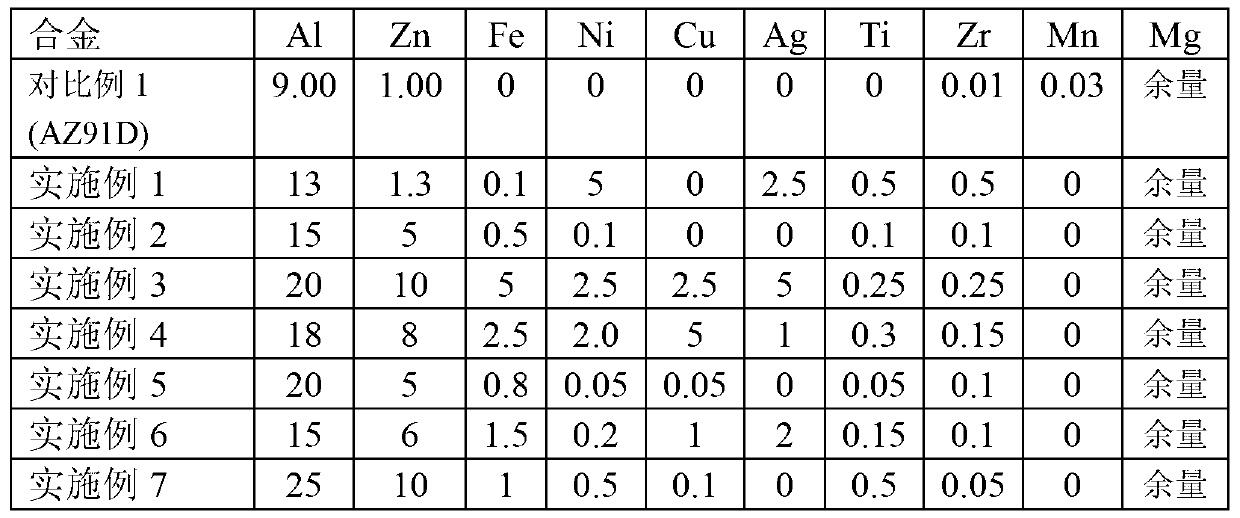

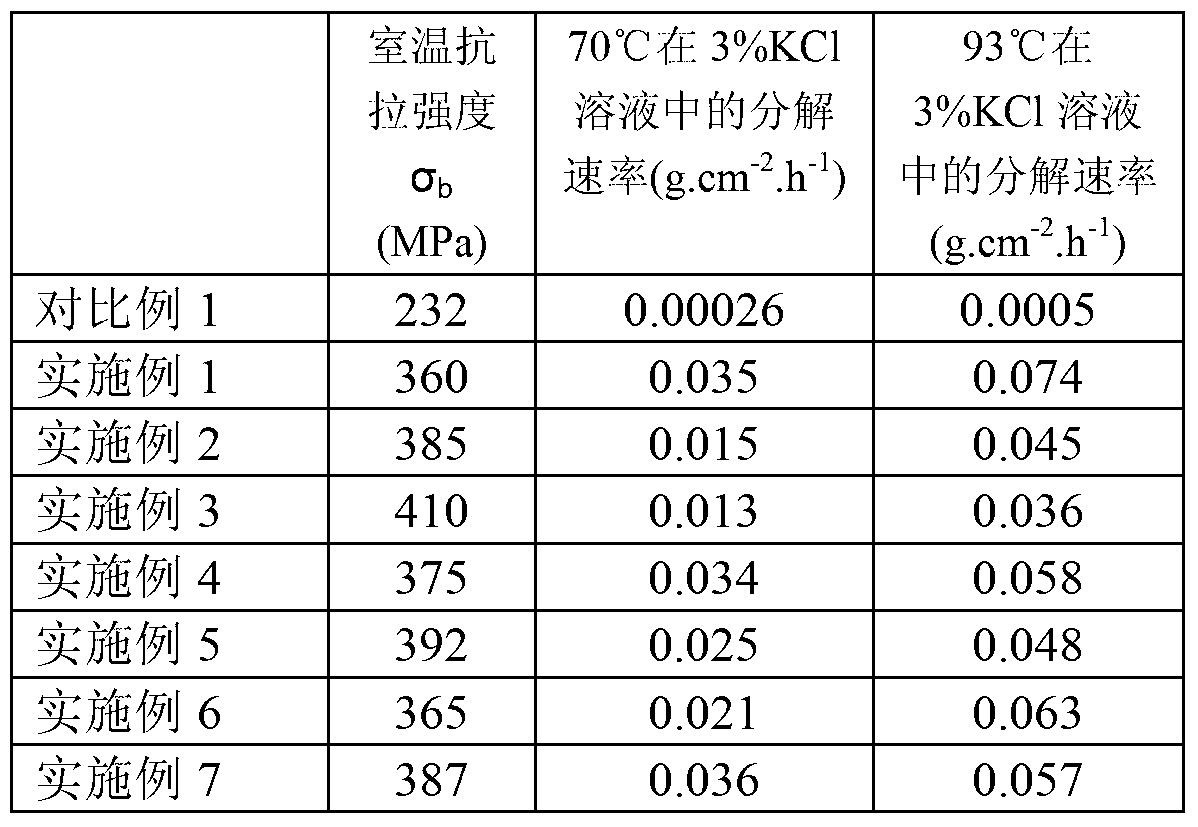

Light and pressure-proof fast-decomposed cast magnesium alloy

The invention discloses light and pressure-proof fast-decomposed cast magnesium alloy which can be used as a tripping ball material for a multi-stage sliding sleeve staged-fracturing technique. The light and pressure-proof fast-decomposed cast magnesium alloy is prepared from the following components: 13-25% of Al, 2-15% of Zn, 0.1-5% of Fe, 0.05-5% of Cu, 0.05-5% of Ni, 0-5% of Ag, 0.05-0.5% of Zr, 0.05-0.5% of Ti, and the balance of Mg. The preparation method comprises the following steps of: weighing the components according to the designed component ratio of the magnesium alloy; firstly, putting pure magnesium and pure aluminum into a smelting furnace, putting pure zinc and intermediate alloy of other components into magnesium-aluminum alloy melt after melting; refining, degassing, and stewing after warming to melt; then casting in a protective atmosphere. The light and pressure-proof fast-decomposed cast magnesium alloy is reasonable in component ratio, and simple in craft process; the light and pressure-proof fast-decomposed cast magnesium alloy can be obtained by controlling the ingredients of the alloy; the alloy decomposition performance exceeds that of the traditional cast magnesium alloy; the demands of the multi-stage sliding sleeve staged-fracturing technique on the decomposition performance of the tripping ball material can be met; industrialized application can be achieved; application of the magnesium alloy in the field of exploitation of petroleum and gas is expanded.

Owner:中山市宏镁科技有限公司

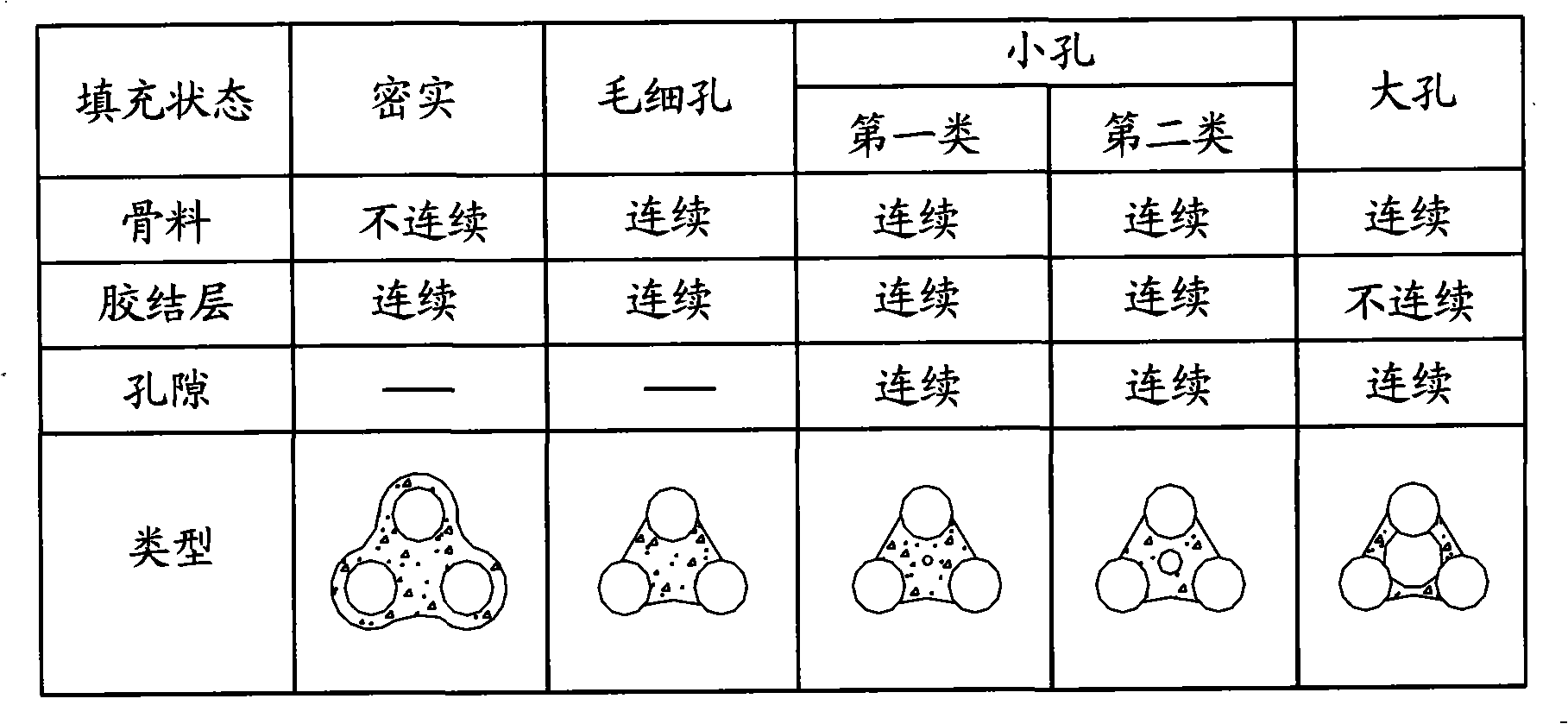

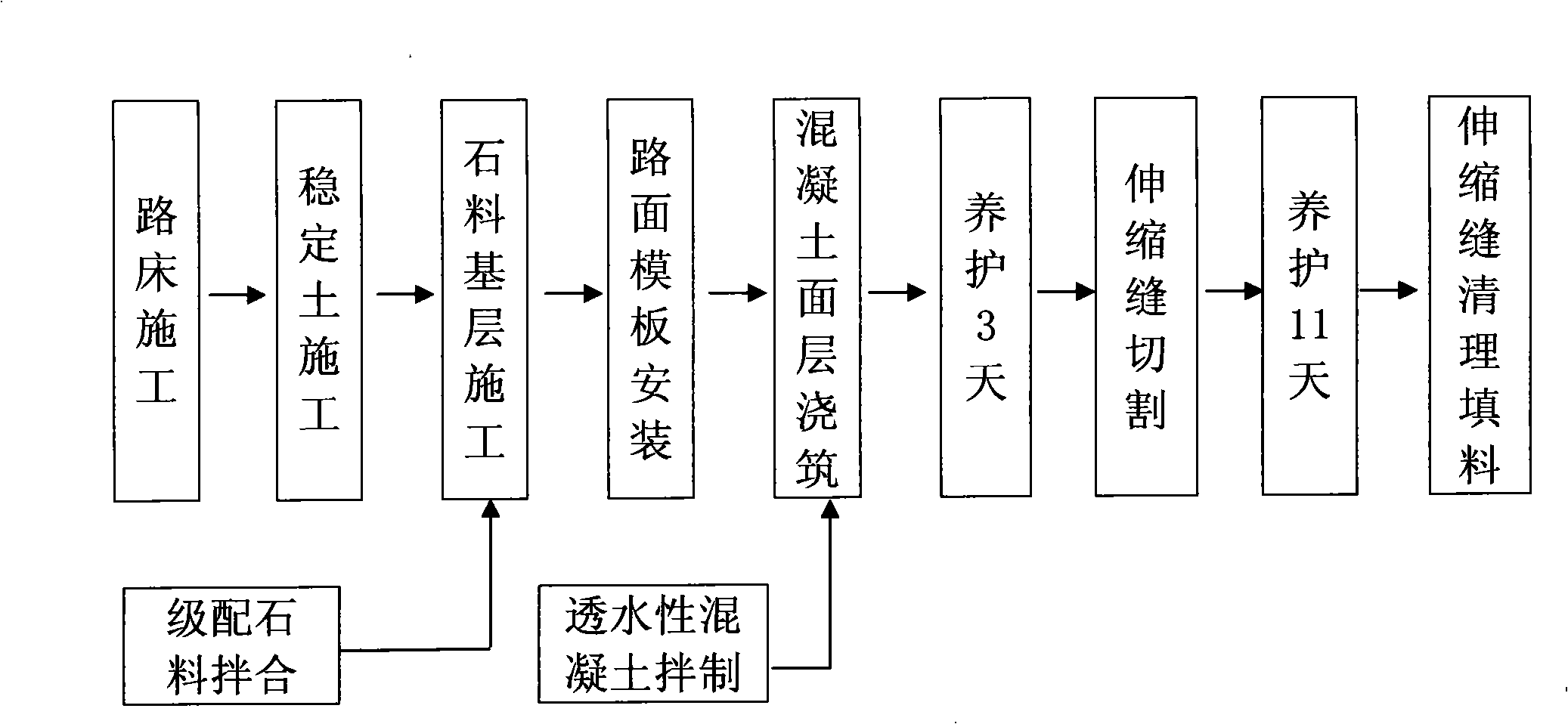

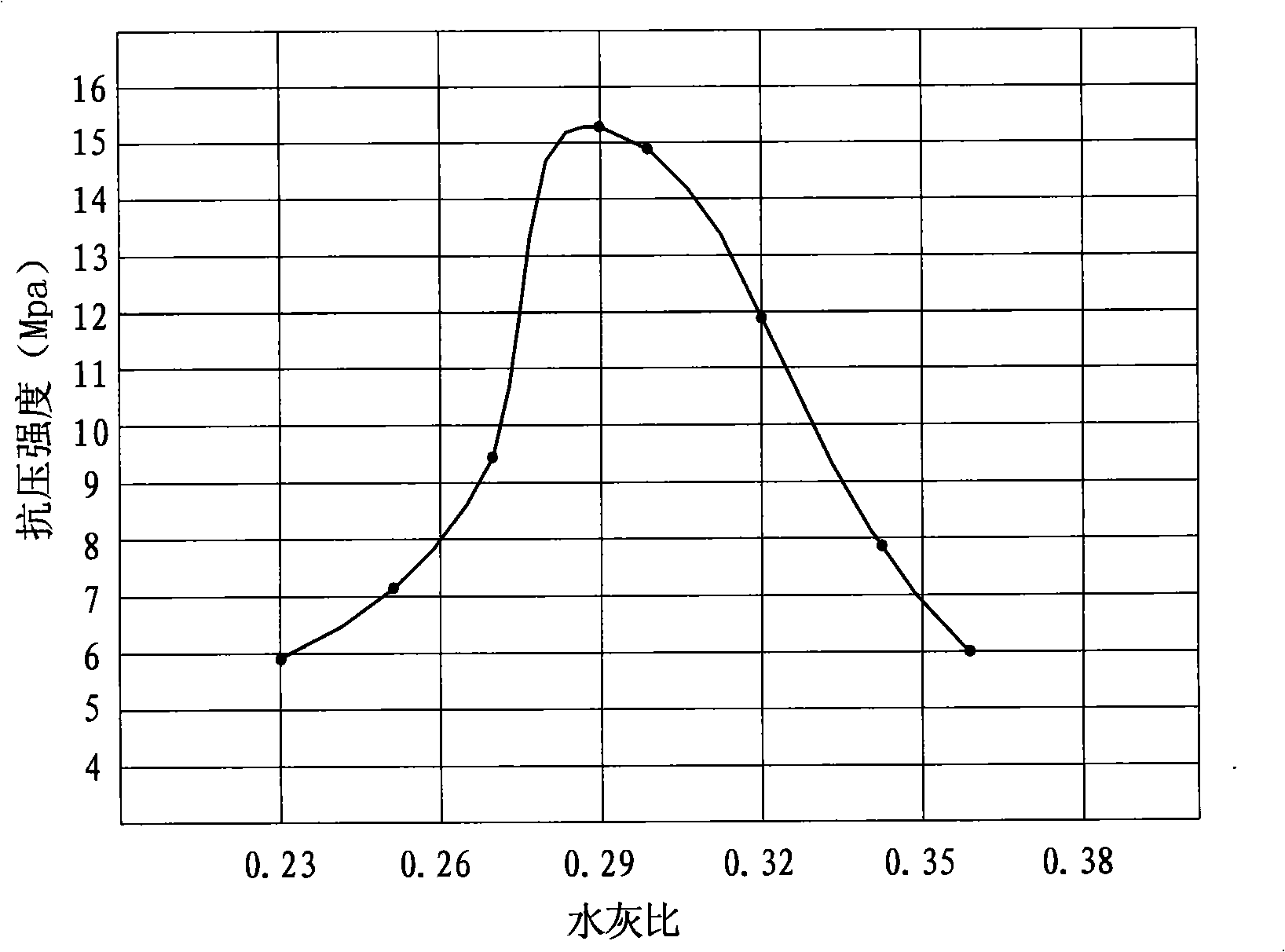

Water permeable concrete and pavement construction method

InactiveCN101293763AHigh strengthGood water permeabilityIn situ pavingsSolid waste managementFlexural strengthRoad surface

The invention discloses permeable concrete and a pavement construction method. The permeable concrete comprises the following components: 1350 to 1800 parts of broken stones, 90 to 150 parts of water, 300 to 350 parts of cement, 10 to 70 parts of mineral powder, 10 to 70 parts of silicon ash and 0.3 to 7 parts of water reducing agent; if necessary, organic intensifying agent can be added. The construction method comprises the following steps: permeable concrete is mixed, poured and cured, an expansion joint is cut, and the filling and the other processes are performed. Concrete pavement prepared by the method has higher strength and water permeability, and the compression strength can reach or exceed 30 MPa; the flexural strength is above 4 MPa; the coefficient of water permeability is more than or equal to 1 mm / s; the requirements for the permeable concrete pavement can be fully satisfied. The permeable concrete is suitable for the construction of permeable concrete pavement, squares and parking lots; by adopting the method, the consumption of cement is small, the construction is simple, and the method is favorable for being popularized.

Owner:HENAN GUOJI CONSTR GRP +1

Methods and compositions for coating pipe

InactiveUS20040191439A1Improve stabilityHigh strengthSolid waste managementPretreated surfacesUltimate tensile strengthMechanical property

The present invention includes cement compositions and methods for using such cement compositions to coat pipe surfaces, particularly usefull for providing protection from hostile conditions that may otherwise lead to corrosion of the pipe surface. These cement compositions have improved mechanical properties including tensile strength, elasticity, and ductility.

Owner:HALLIBURTON ENERGY SERVICES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com