Patents

Literature

248results about "Coke oven brickwork" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

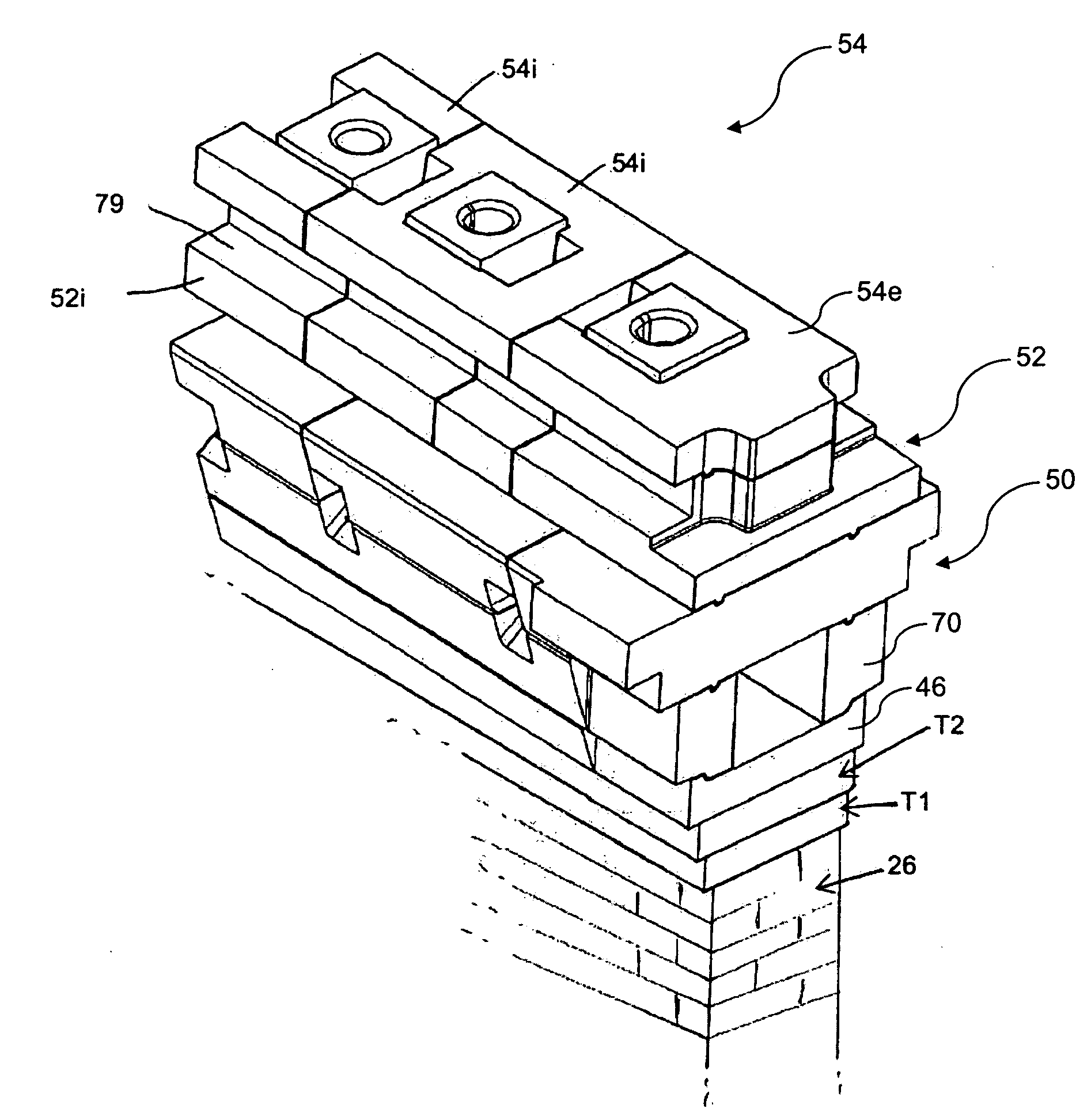

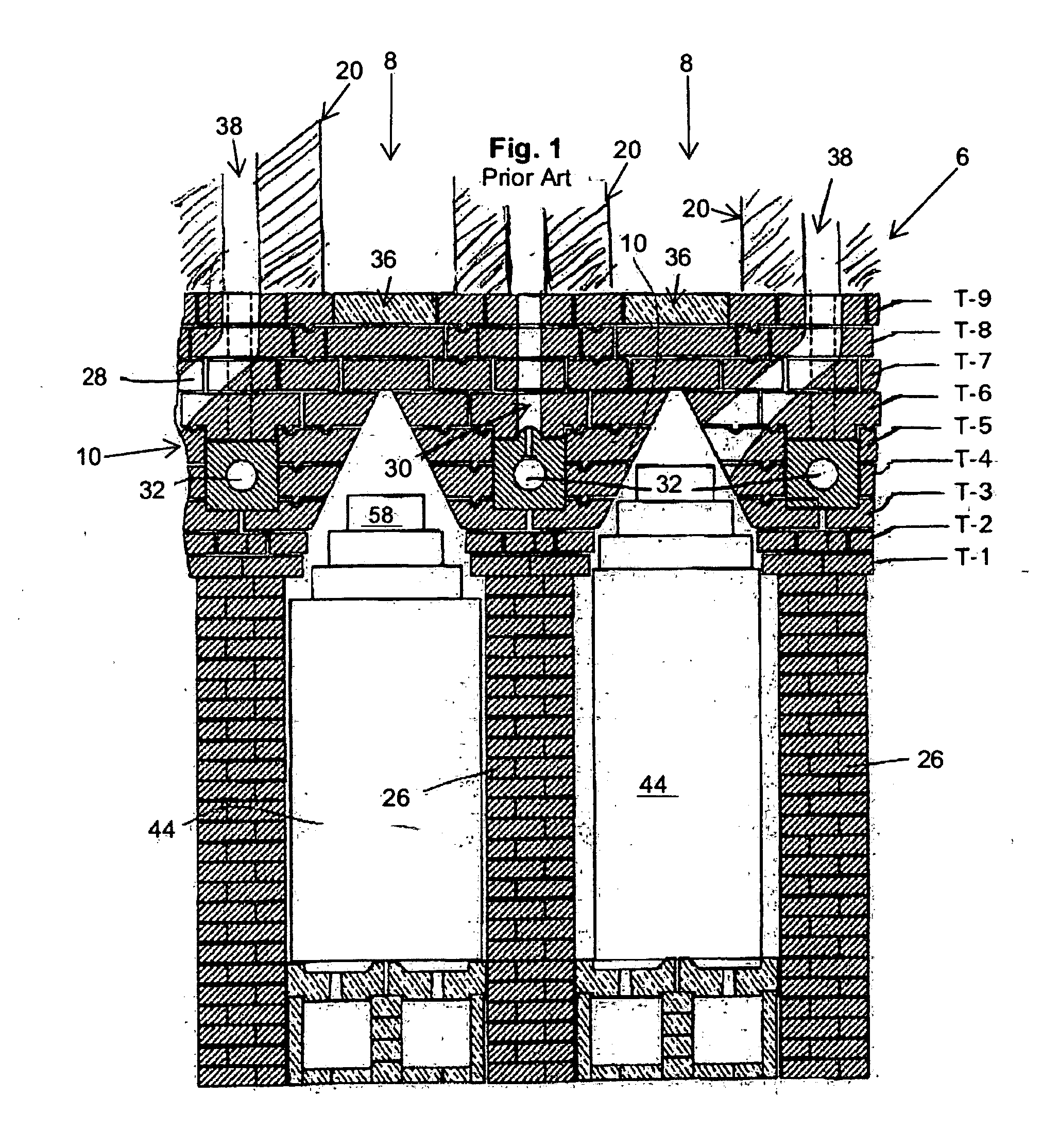

Corbel repairs of coke ovens

ActiveUS8266853B2Cost-effective constructionSave significant amountFurnace componentsFloorsEngineeringCoke oven

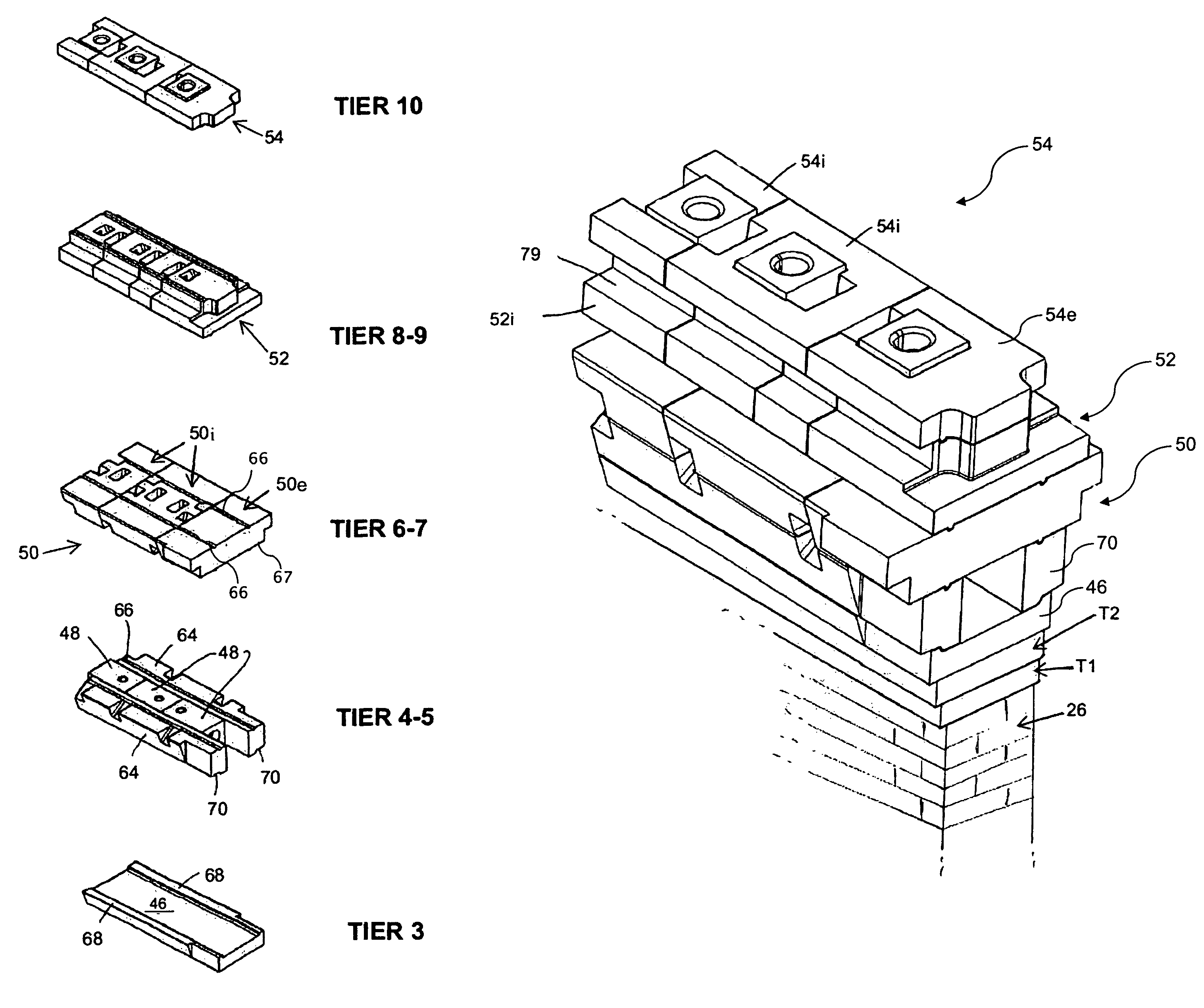

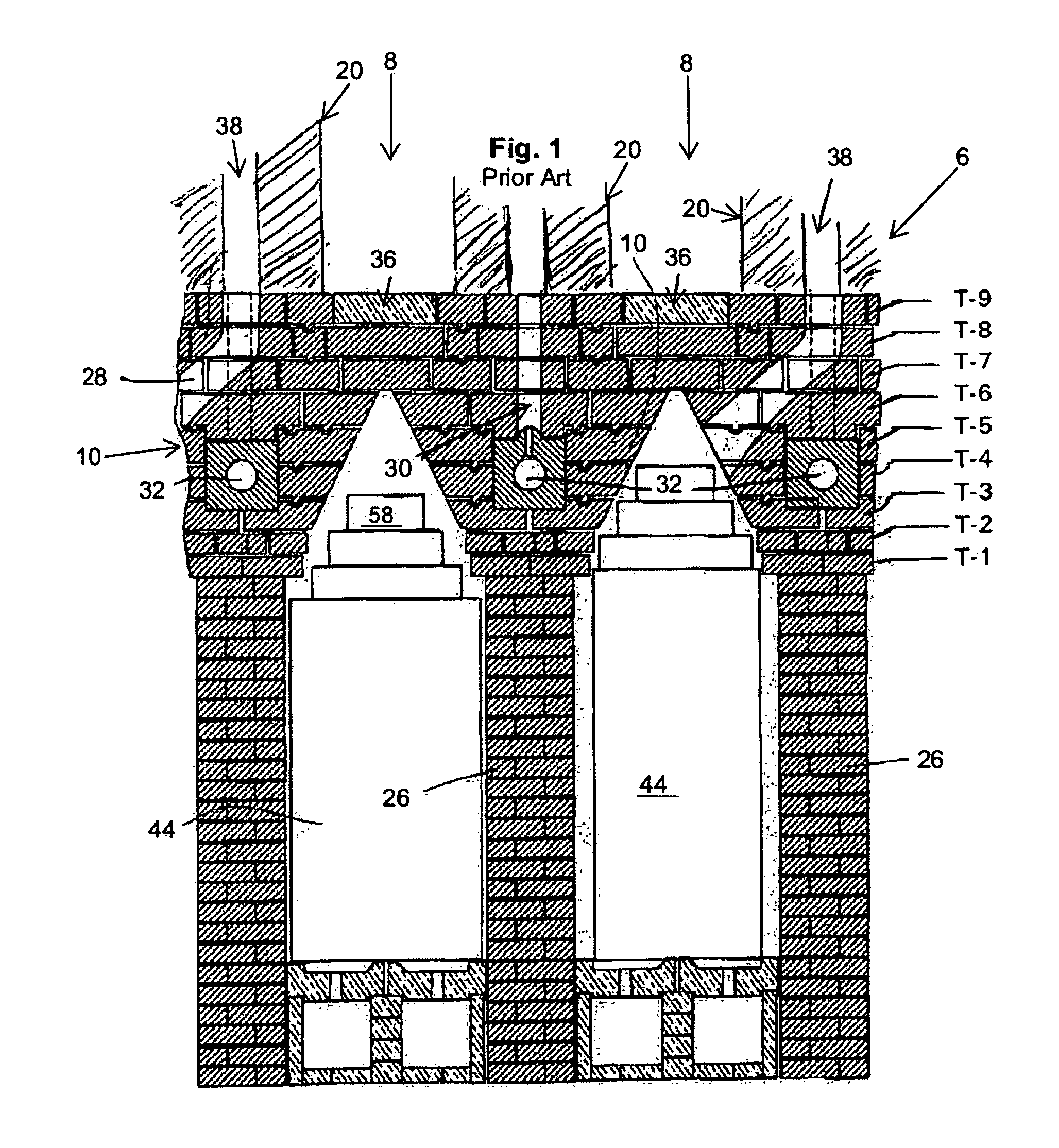

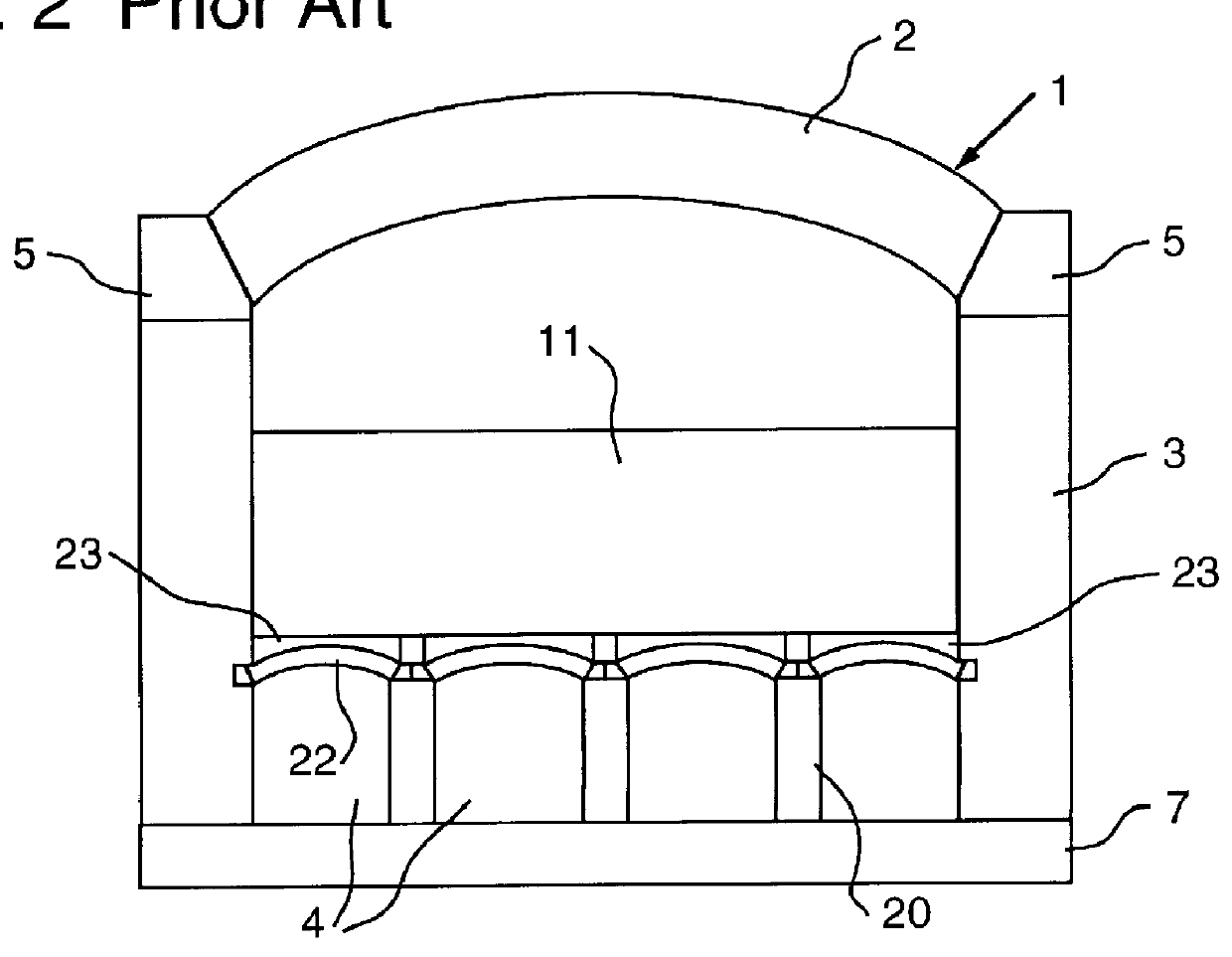

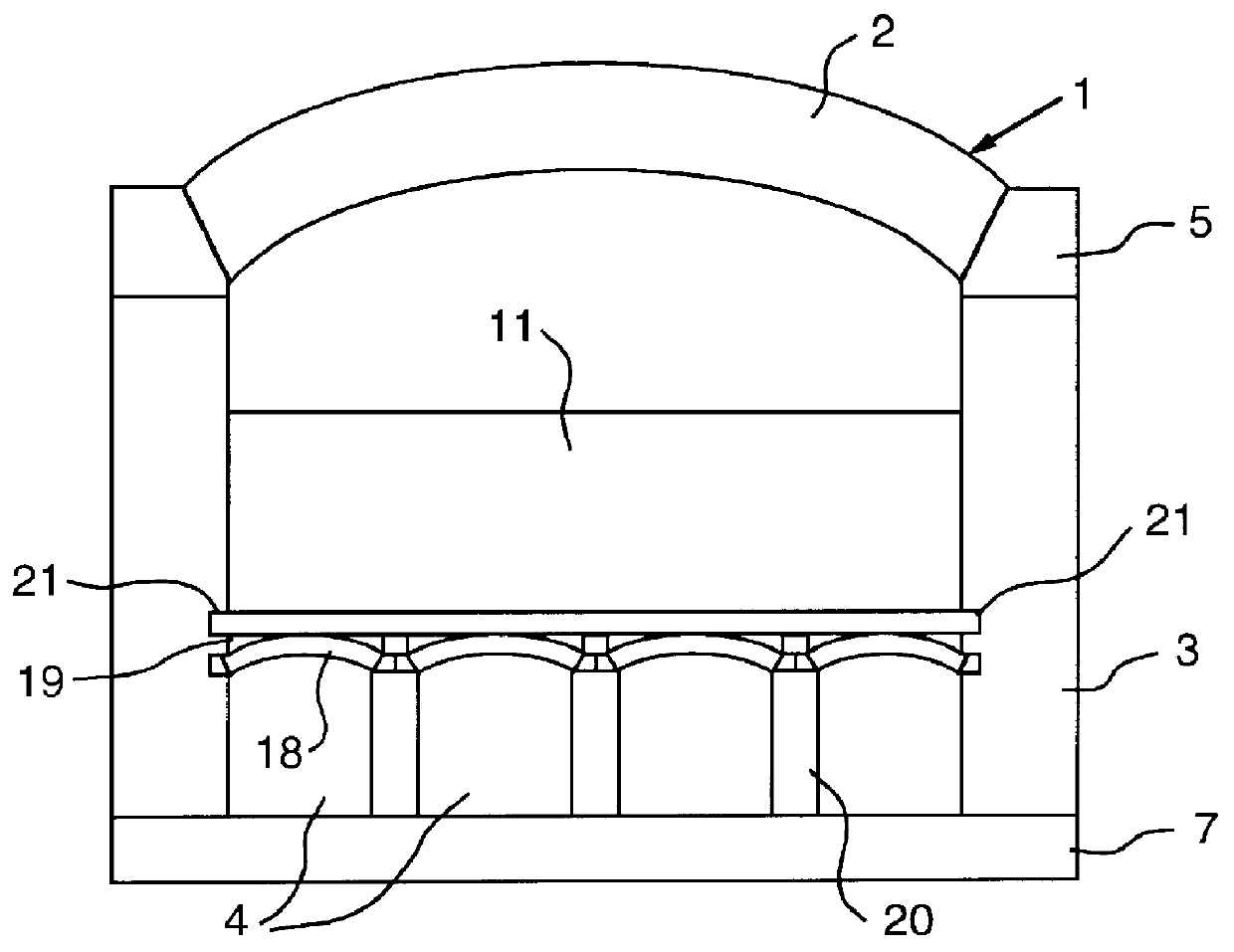

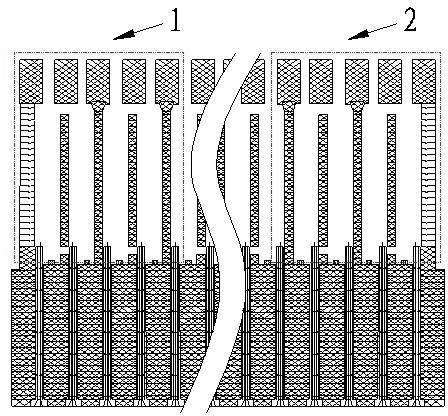

An improved corbel includes a first tier having first blocks and a second tier having second blocks. Each of the first blocks includes a first aperture extending through the block from a first surface to a back surface and a second aperture formed through a top surface of the block, extending into the first aperture. The first blocks are arranged on a substantially planar surface to align the respective first apertures to define a first passageway. Each of the second blocks includes a third aperture extending through the second block from a top surface to a bottom surface. The second blocks are disposed above the first tier to align the third aperture of each of the second blocks with the second aperture of the first blocks to form a second passageway.

Owner:VANOCUR REFRACTORIES LLC

Interlocking floor brick for non-recovery coke oven

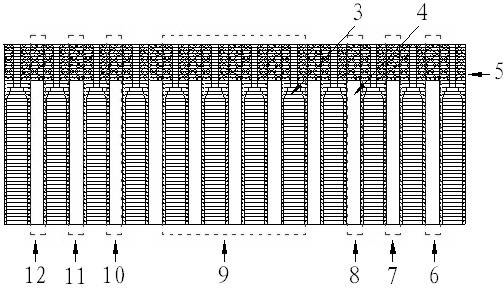

An improved non-recovery coke oven floor constructed of a single layer of refractory bricks including, for each oven sole flue, a pair of trunnion bricks and a center bridge brick spanning the width of the flue, having lower brick surfaces in the form of an arch, and joined end-to-end by a tapered tongue-and-groove joint disposed approximately perpendicular to the direction of a compression load transmitted by the center bridge brick to the trunnion bricks.

Owner:PENNSYLVANIA COKE TECH

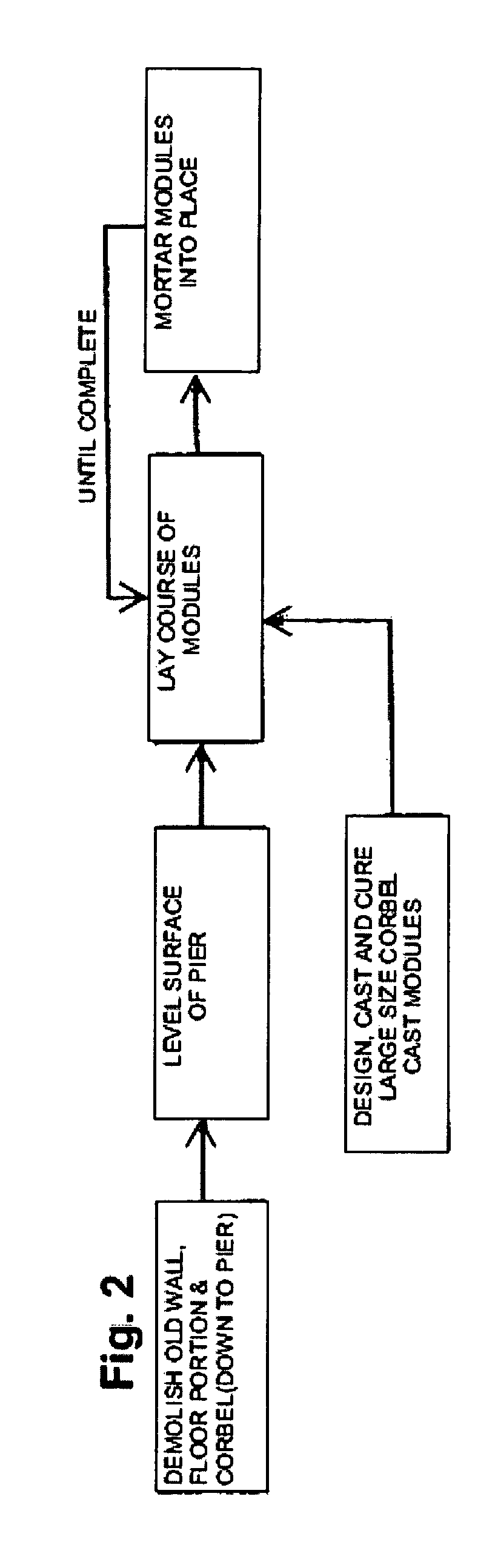

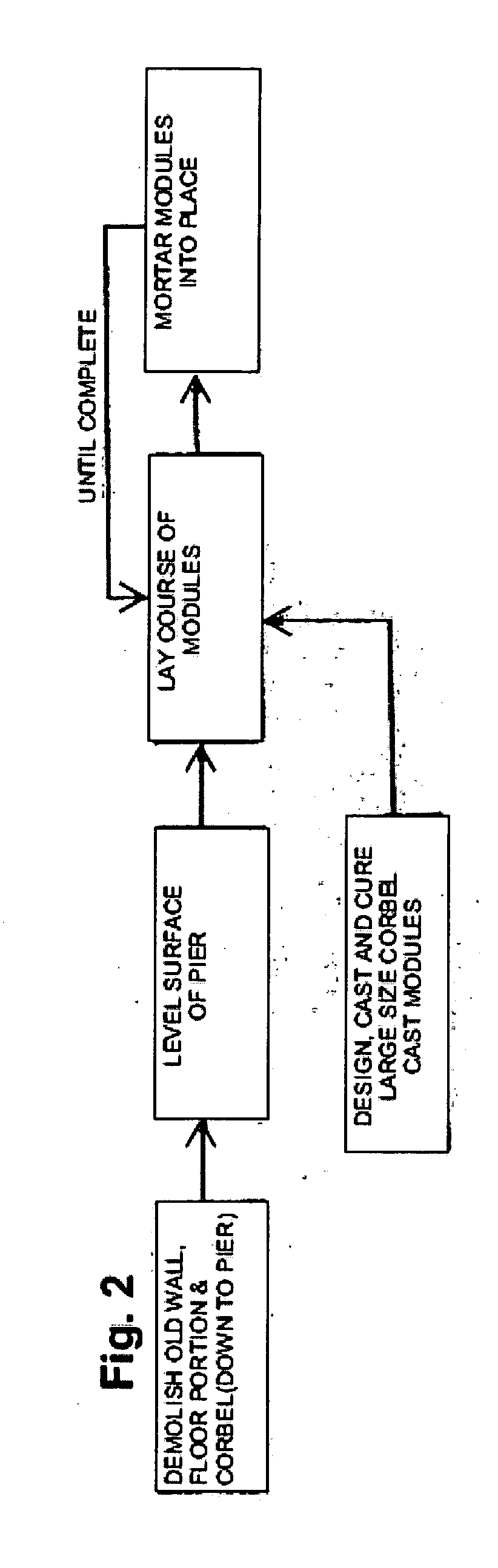

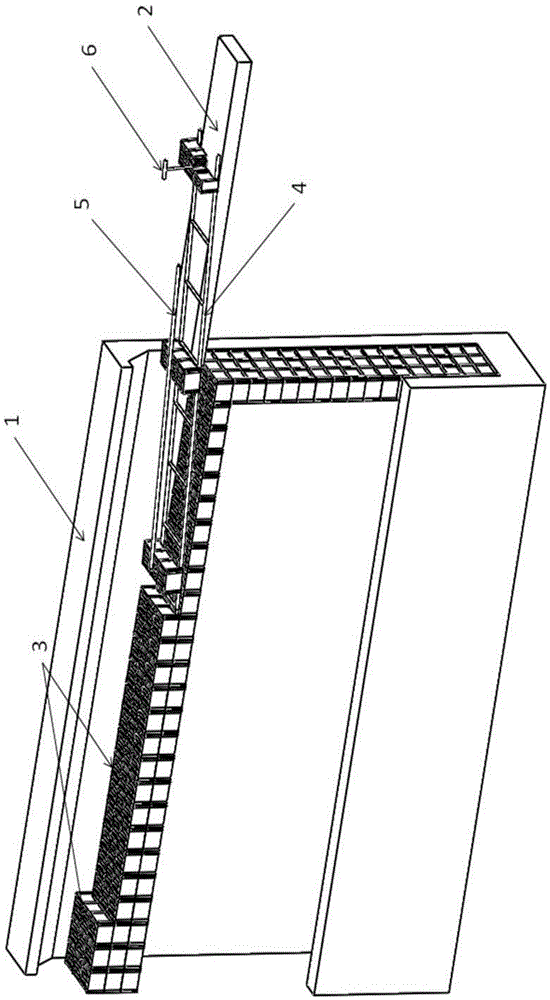

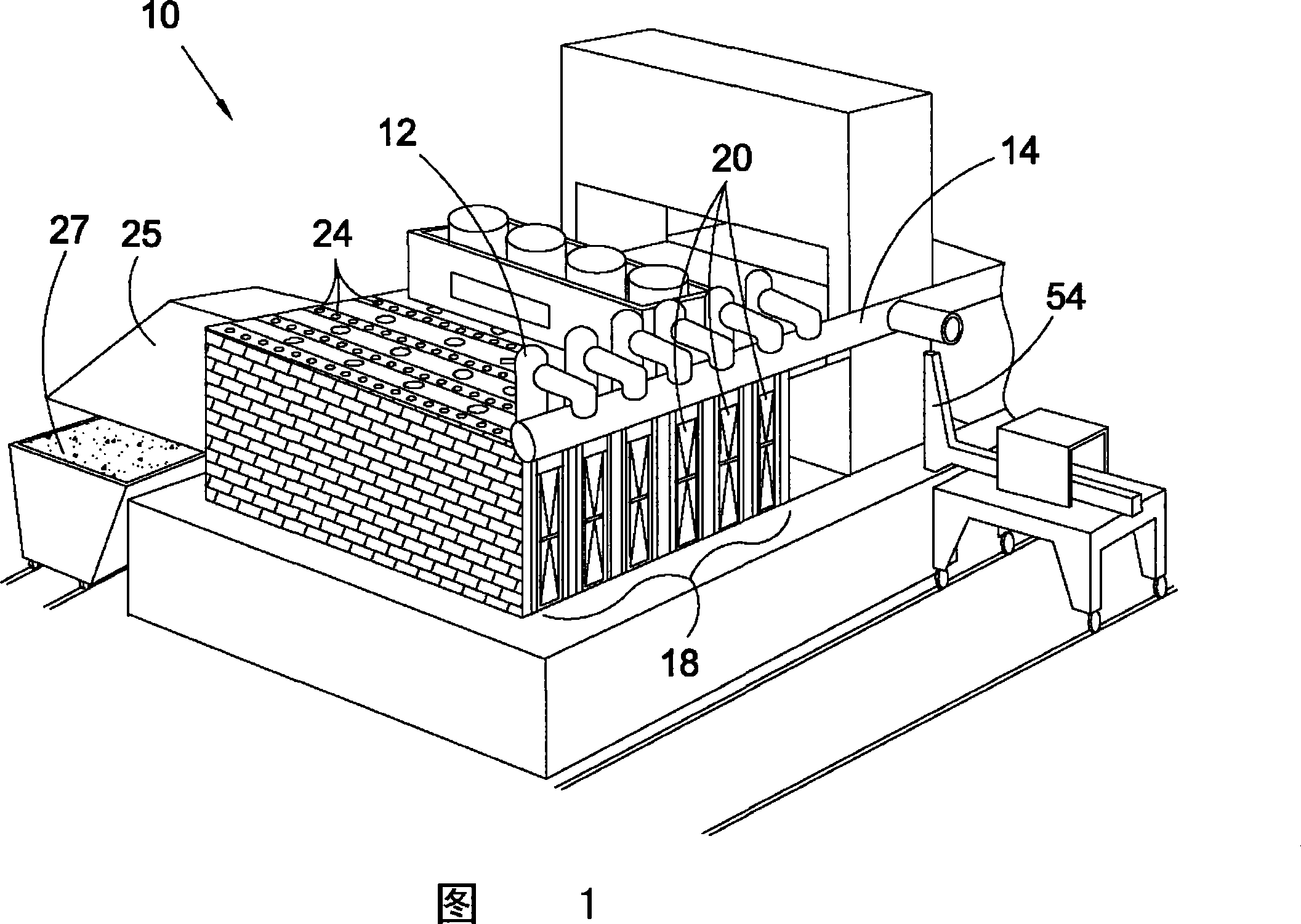

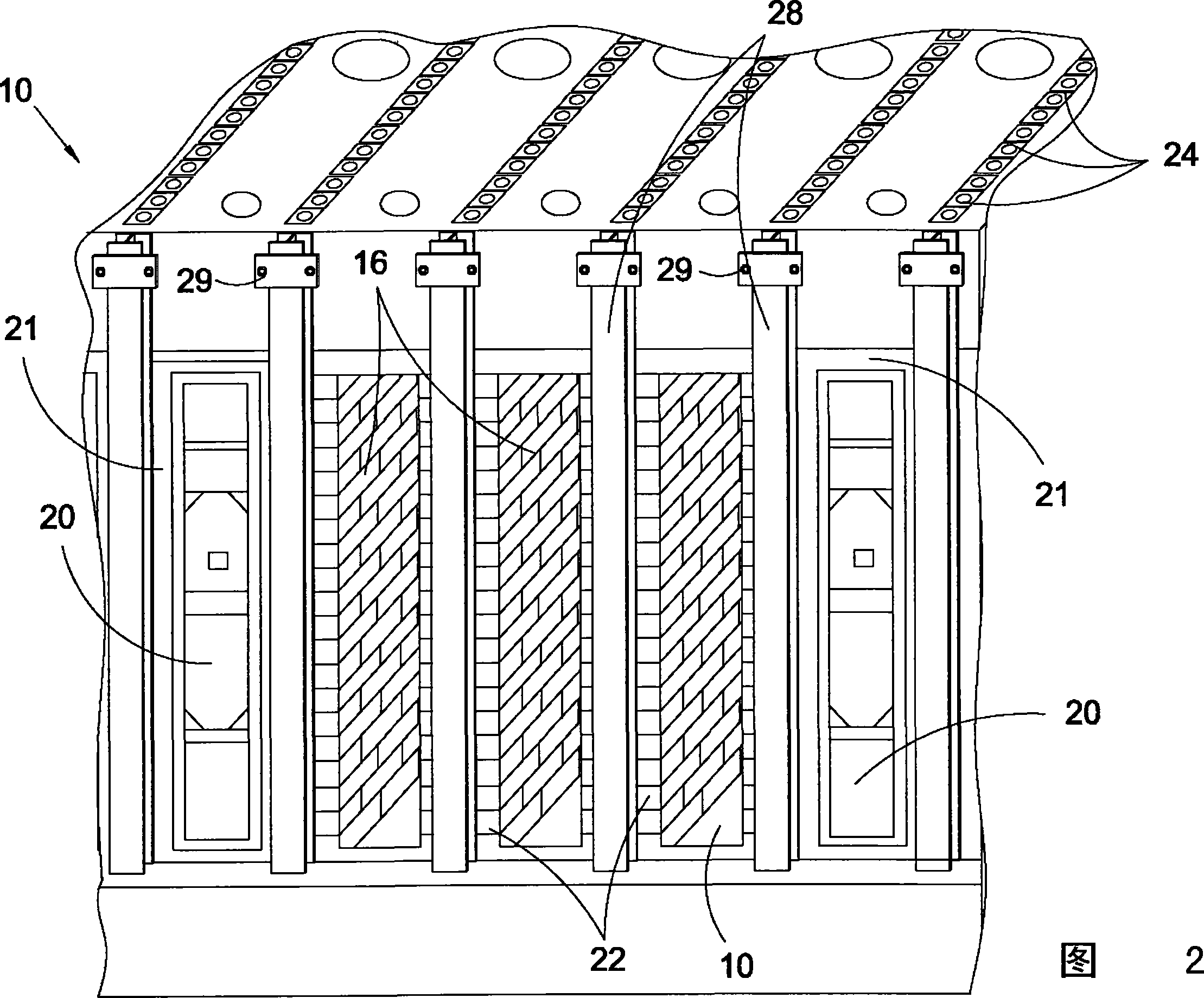

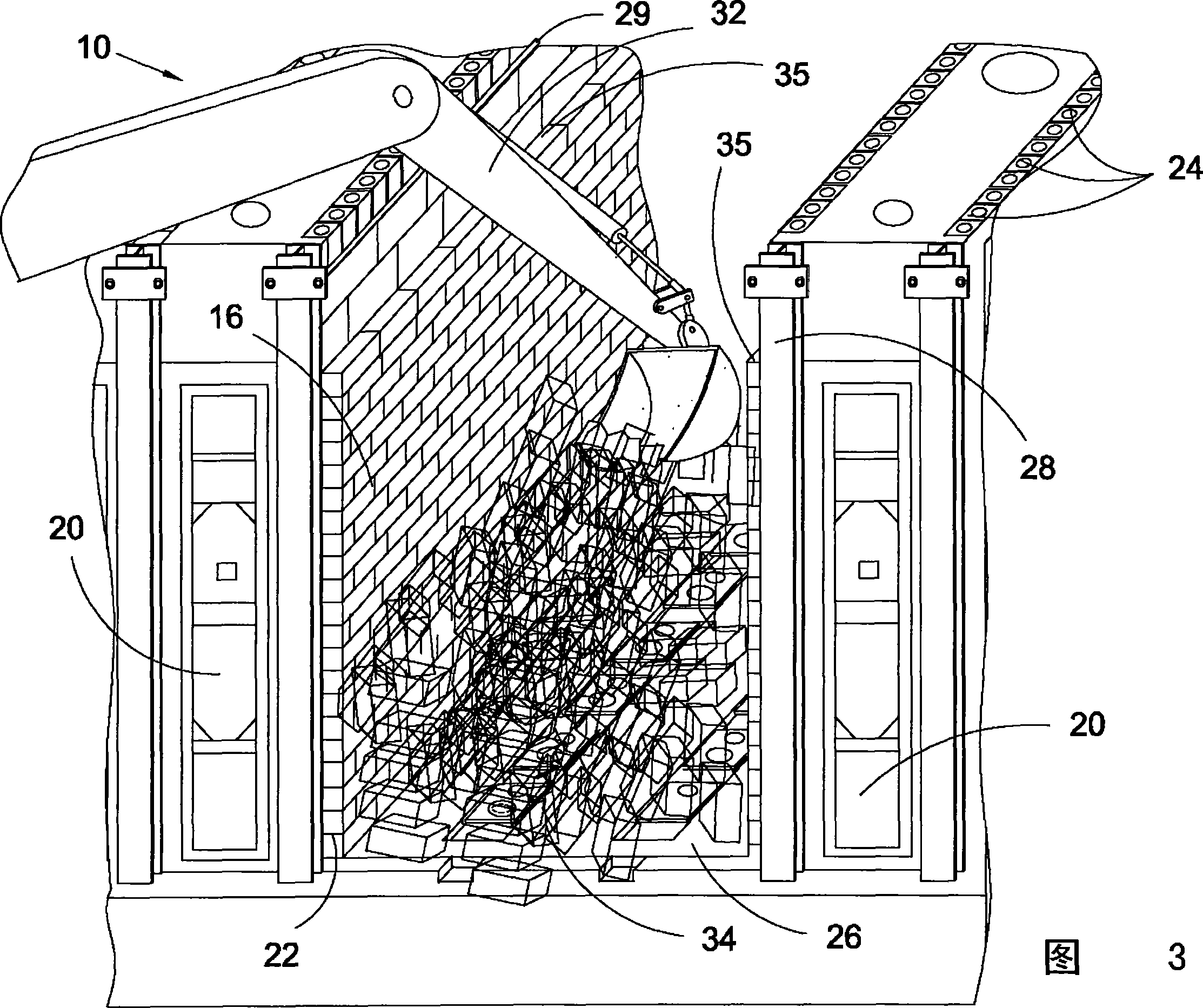

Coke oven reconstruction

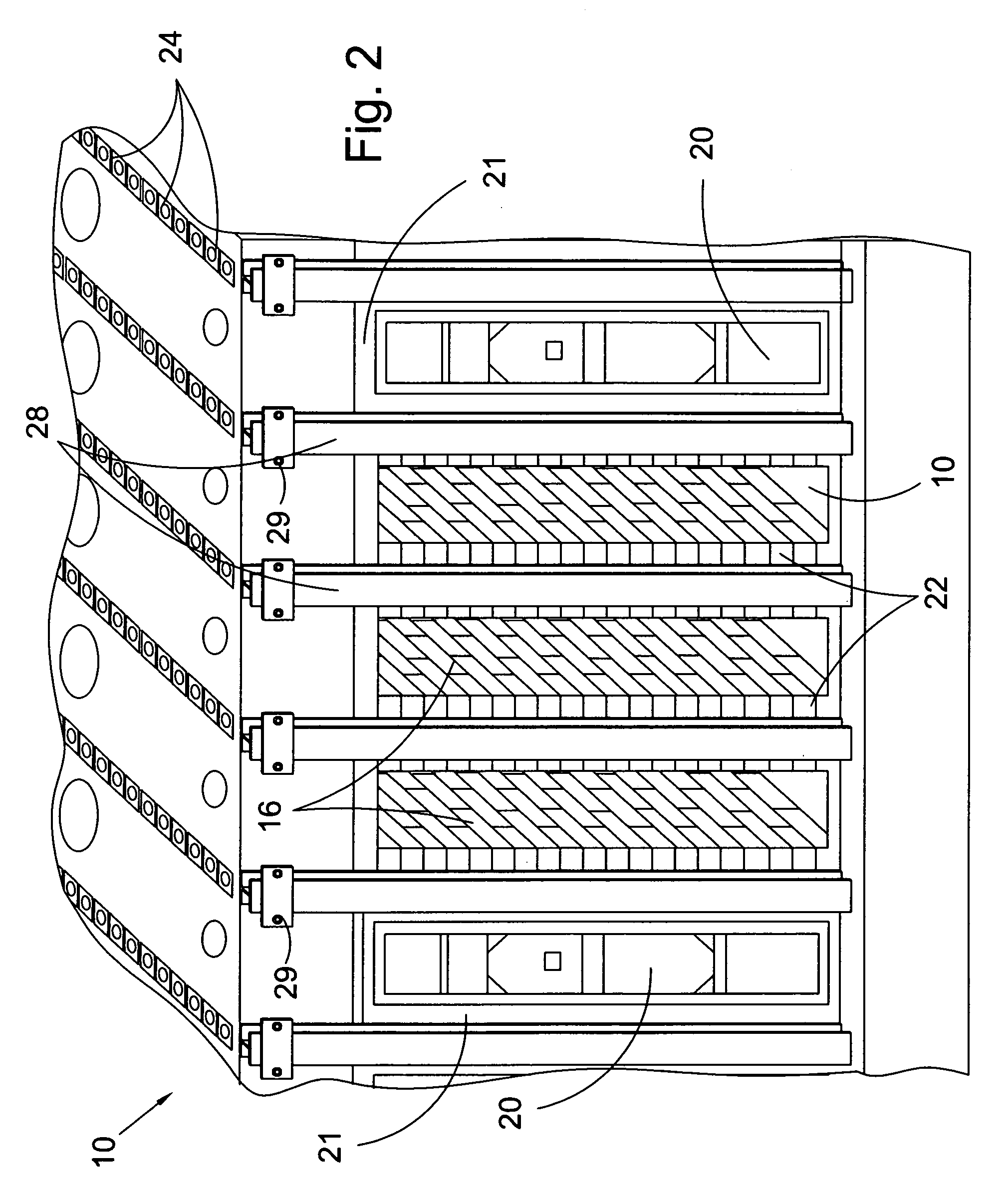

ActiveUS7827689B2Good dimensional stabilityNegligible heatingConstruction materialCoke oven brickworkComputer moduleEngineering

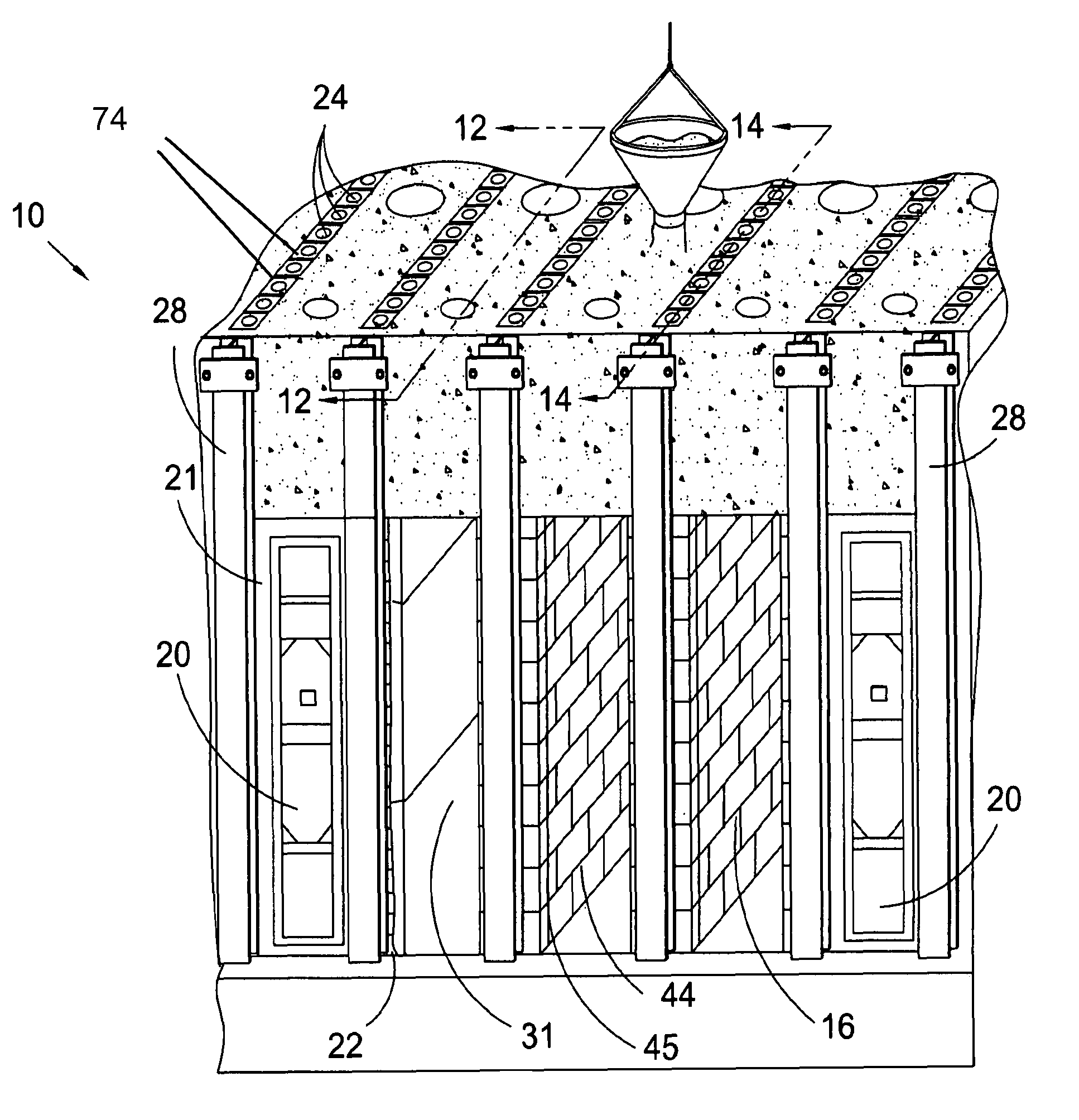

A new, faster and more efficient process to replace heating walls and ceilings in coke oven batteries. Thus, when replaced, at least one heating wall is constructed of thermally stable non-expanding large size modular cast modules from end to end and the ceiling adjacent the heating wall is constructed of thermally stable non-expanding large modular cast blocks.

Owner:VANOCUR REFRACTORIES LLC

Corbel repairs of coke ovens

ActiveUS20100287871A1Cost-effective constructionSave significant amountFurnace componentsWallsEngineeringCoke oven

An improved corbel includes a first tier having first blocks and a second tier having second blocks. Each of the first blocks includes a first aperture extending through the block from a first surface to a back surface and a second aperture formed through a top surface of the block, extending into the first aperture. The first blocks are arranged on a substantially planar surface to align the respective first apertures to define a first passageway. Each of the second blocks includes a third aperture extending through the second block from a top surface to a bottom surface. The second blocks are disposed above the first tier to align the third aperture of each of the second blocks with the second aperture of the first blocks to form a second passageway.

Owner:VANOCUR REFRACTORIES LLC

Composite fire-proof material with high refractoriness under load for coke ovens as well as furnace-building process and products thereof

InactiveCN102584294AImprove bindingWaste heat can be recovered for power generationCoke oven brickworkEnergy inputAdhesiveRefractory

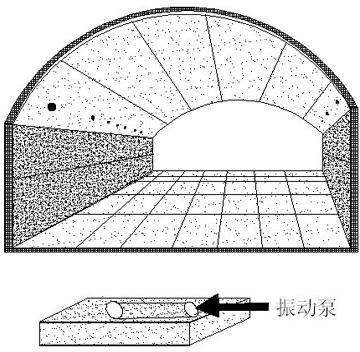

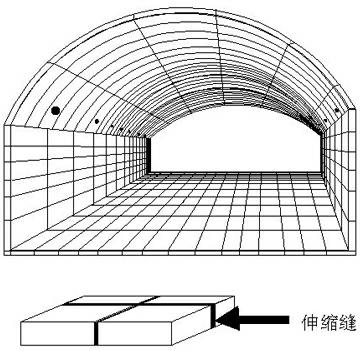

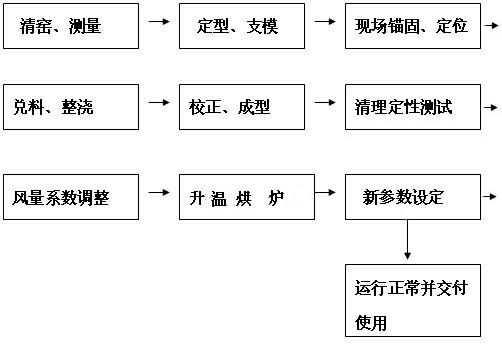

The invention discloses a composite fire-proof material with high refractoriness under load for coke ovens. The preparation method of the material comprises the following steps of: evenly mixing and crushing 40%-60% of Al2O3, 15%-30% of SiC micro powder, less than 2% of Fe2O3, 5%-10% of Si micro powder and 1%-3% of cement as an additive; adding 3%-5% of Al(H2PO4)3 as an adhesive and stirring and mixing evenly; and pouring the mixture to a working region in 20-30 minutes. The furnace-building process comprises the following steps of: cleaning a kiln, measuring, molding, positioning and supporting a mould, adding materials, pouring and correcting, cleaning, starting for warming up and testing. The coke ovens newly built by pouring is characterized in that the top of the chamber of the furnace is fan-shaped, the chamber of the furnace is built by on-site seamless overall vibration pouring according to the process above with the furnace-building materials above, afterheat of the furnace can be recycled for power generation and no chemical residues exist. The furnace is short in charring time and higher in coke recovery and can be started and used at any time between the normal temperature and 1550 DEG C.

Owner:GUIYANG DONGJIBOYU REFRACTORY MATERIALS

Fire resistive material for coke oven door

ActiveCN101134676AHigh strengthImprove performanceCoke oven brickworkCoke oven doors/closuresChemical compositionBrick

The refractory material for coke oven door consists of mullite 42-63 wt%, cordierite 20-30 wt%, micro silica powder 5-10 wt%, micro active alumina powder 4-8 wt%, kyanite 3-7 wt%, high alumina cement 3-5 wt%, and composite polyphosphate 0.2-0.5 wt%. The mullite is M60 mullite containing Al2O3 not less than 60 wt%, the cordierite contains Al2O3 33-35 wt% and MgO 13-15 wt%, the micro silica powder contains SiO2 not less than 92 wt%, the micro active alumina powder contains Al2O3 more than 98 wt%, the high alumina cement contains Al2O3 not less than 46 wt%, CaO not more than 40 wt% and SiO2 not more than 10 wt%. The refractory material may be produced into coke oven door through low temperature roasting without need of backing, and the coke oven door has service life over 4 years.

Owner:BAOSHAN IRON & STEEL CO LTD

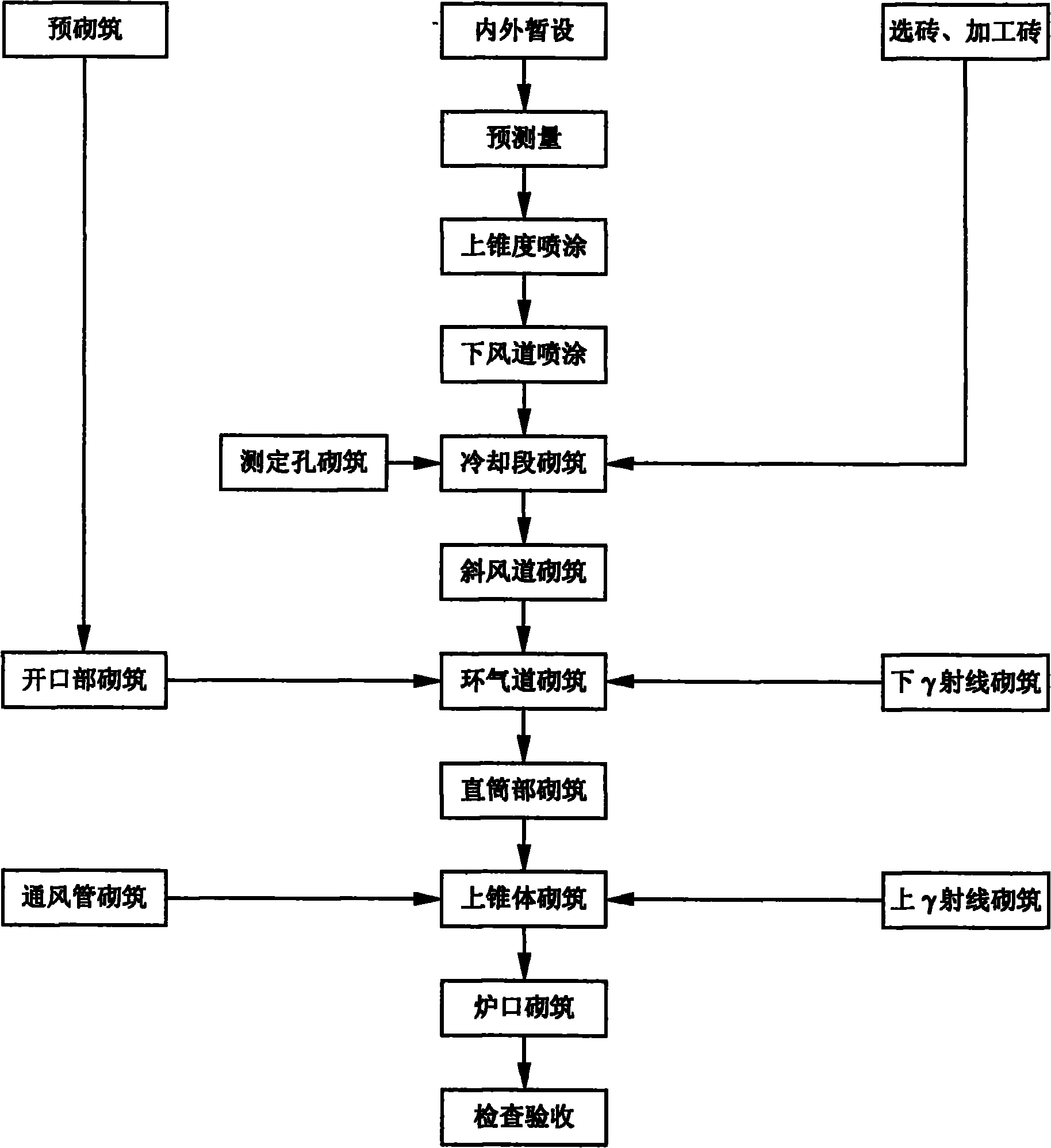

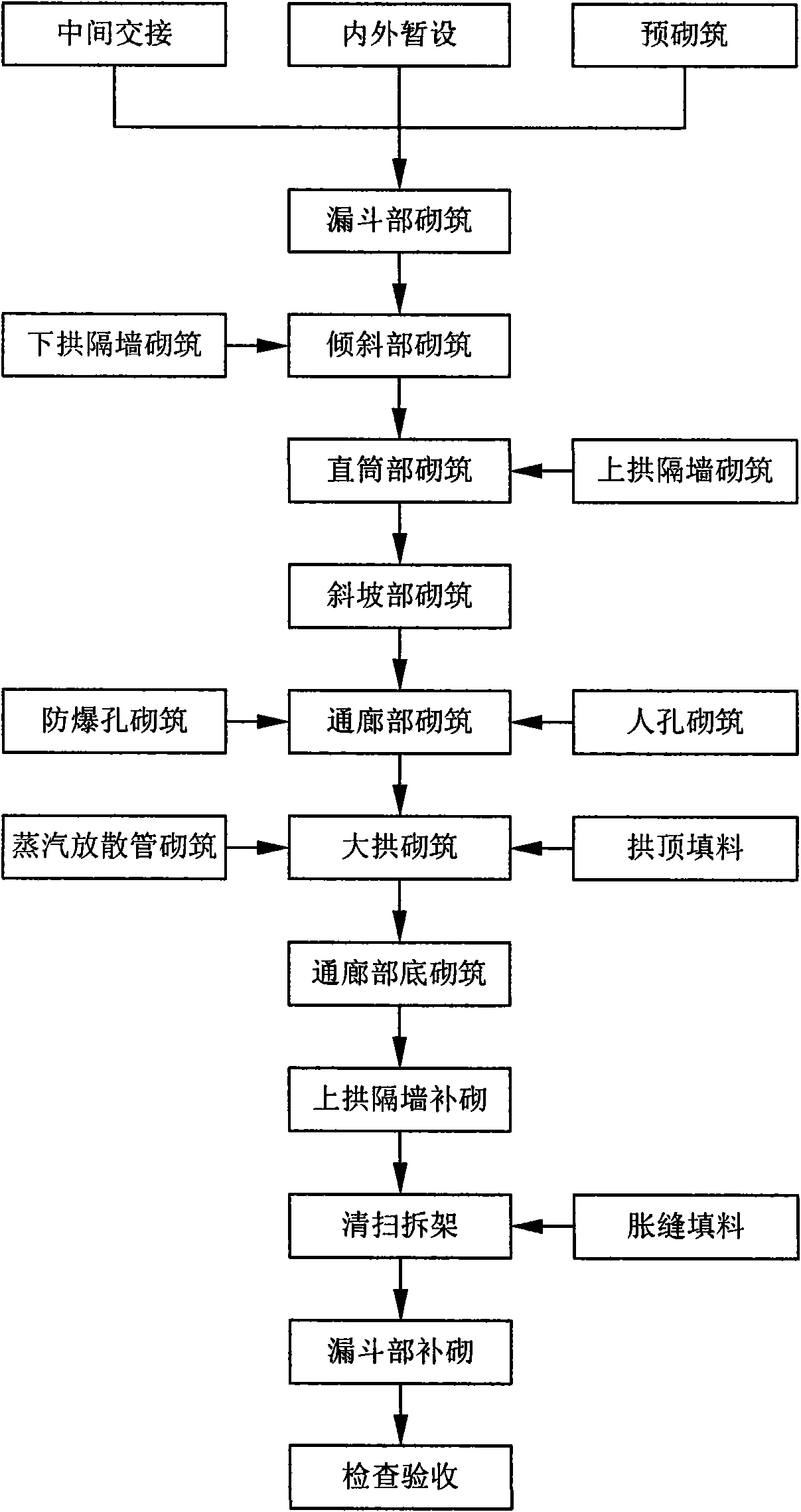

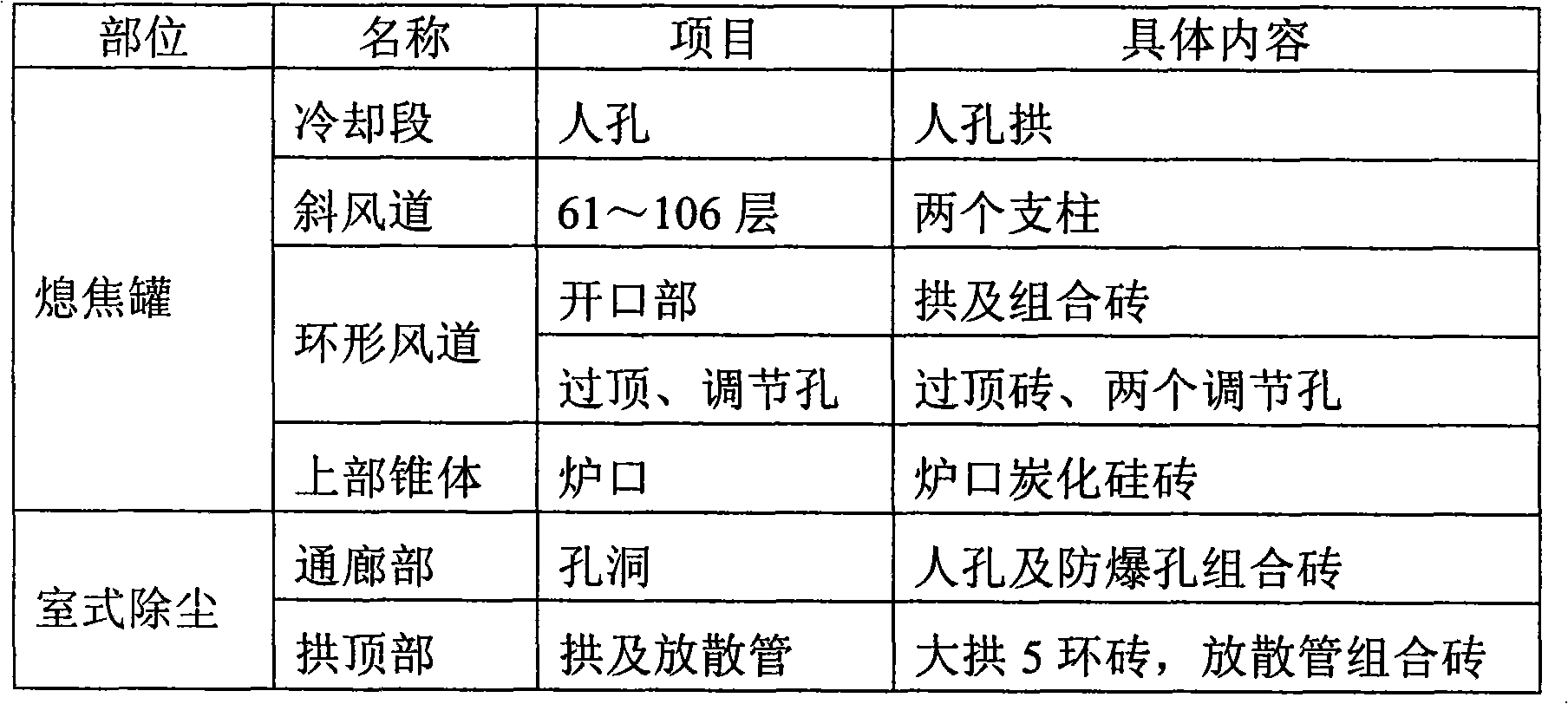

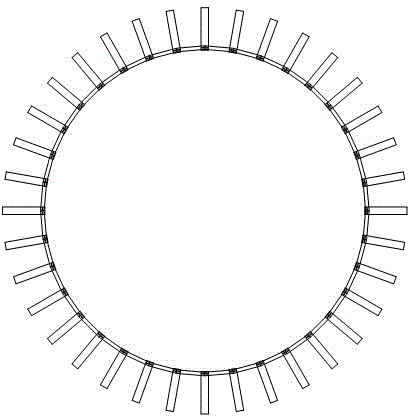

Dry quenching laying method

ActiveCN101928575AImprove construction efficiencyCoke quenchingCoke oven brickworkQuenchingMaterials science

The invention relates to the field of metallurgical equipment construction, in particular to a dry quenching laying method. The dry quenching laying method comprises the following steps of: quenching jar pre-laying, primary deduster pe-laying, quenching jar furnace building construction and primary deduster furnace building construction, wherein the quenching jar furnace building construction comprises the following steps of: 1. construction of cooling sections from the first layer to the 54th layer; 2. construction of inclined wind channels from the 55th layer to the 81st layer; 3. construction of inclined wind channels from the 82nd layer to the 114th layer; and 4. construction of prestoring section from the 115th layer to the 179th layer; and the primary deduster furnace construction comprises the following steps of: 1. setting out; 2. inclined part construction; 3. straight cylinder part construction; 4. vestibule part construction; 5. vault construction; and 6. compandor construction. The dry quenching laying method passes the installation and detection standard of strict design specifications, has the advantage of high laying operation efficiency, is safe and reliable.

Owner:MCC5 GROUP CORP SHANGHAI

Repairing method of coking chamber of coke oven by using silica bricks

ActiveCN101974339AAvoid damageReduce outputCoke oven brickworkBrickwork leakage repair/preventionFiberBrick

The invention discloses a repairing method of a coking chamber of a coke oven by using silica bricks, comprising the following steps of: burning silica bricks or coking silica bricks according to the size of a coke oven silica brick; preparing the specific fireclay by adopting a coke oven hot-patch specific high-temperature binder, wherein added materials comprise high alumina powder and fireclay; manufacturing a thermal insulation material by adopting an aluminium silicate fiber felt with a certain thickness, evenly coating glass liquid on the aluminium silicate fiber felt and pasting the aluminium silicate fiber felt to a high-temperature silica brick wall surface for insulating; insulating heat by adopting an asbestos cloth as a fire curtain; manufacturing an insulating cage and squeezing the insulating cage into the coking chamber to form an insulating seal wall; and arranging buffer ovens with 1-2 holes on both sides of the coking chamber to be repaired and discontinuously heating burning chambers of both sides of the coking chamber to be repaired to control the temperature of the silica bricks. Due to the adoption of the technical scheme, the invention realizes oven wall restoration under a heat-state condition, greatly reduces the destroy to the coke oven silica bricks in a repairing process and the influence on coke over output and overcomes the defects of short use period, frequent repair, destroy of new oven wall bricks, and the like of the traditional repairing method.

Owner:WUHU XINXING DUCTILE IRON PIPES

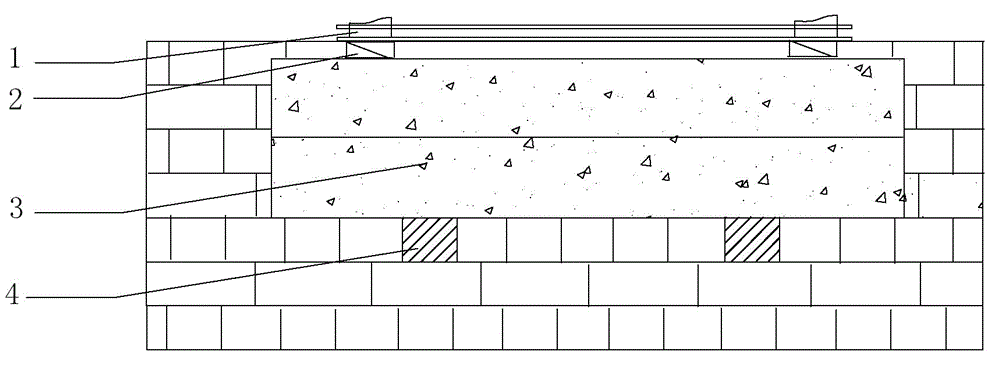

Arch stuffing supporting technology by bricking arch apex for division of flue in coke oven

The invention relates to an arch stuffing supporting technology by bricking an arch apex for division of a flue in a coke oven. The technology is characterized by comprising the following steps: a, reserving support bricks on the wall of the coke oven; b, laying crossrails on the support bricks; c, manufacturing an arch stuffing; and d, mounting the arch stuffing. The technology provided by the invention has the advantages that the arch stuffing for the division of the flue is supported simply and flexibly; the labor intensity in construction is lowered; the construction efficiency is improved; the construction period is shortened; and the engineering cost is lowered.

Owner:MCC5 GROUP CORP SHANGHAI

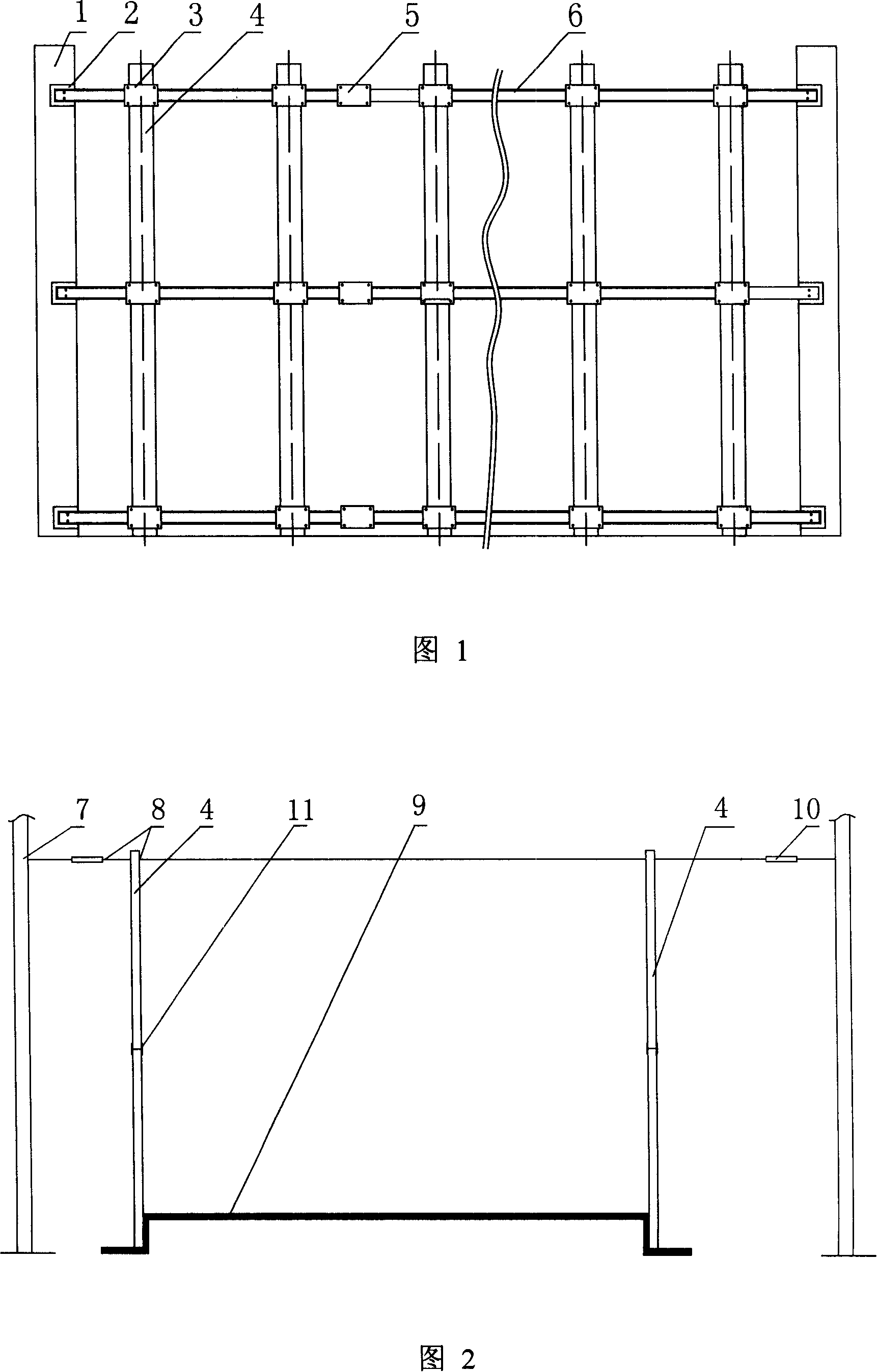

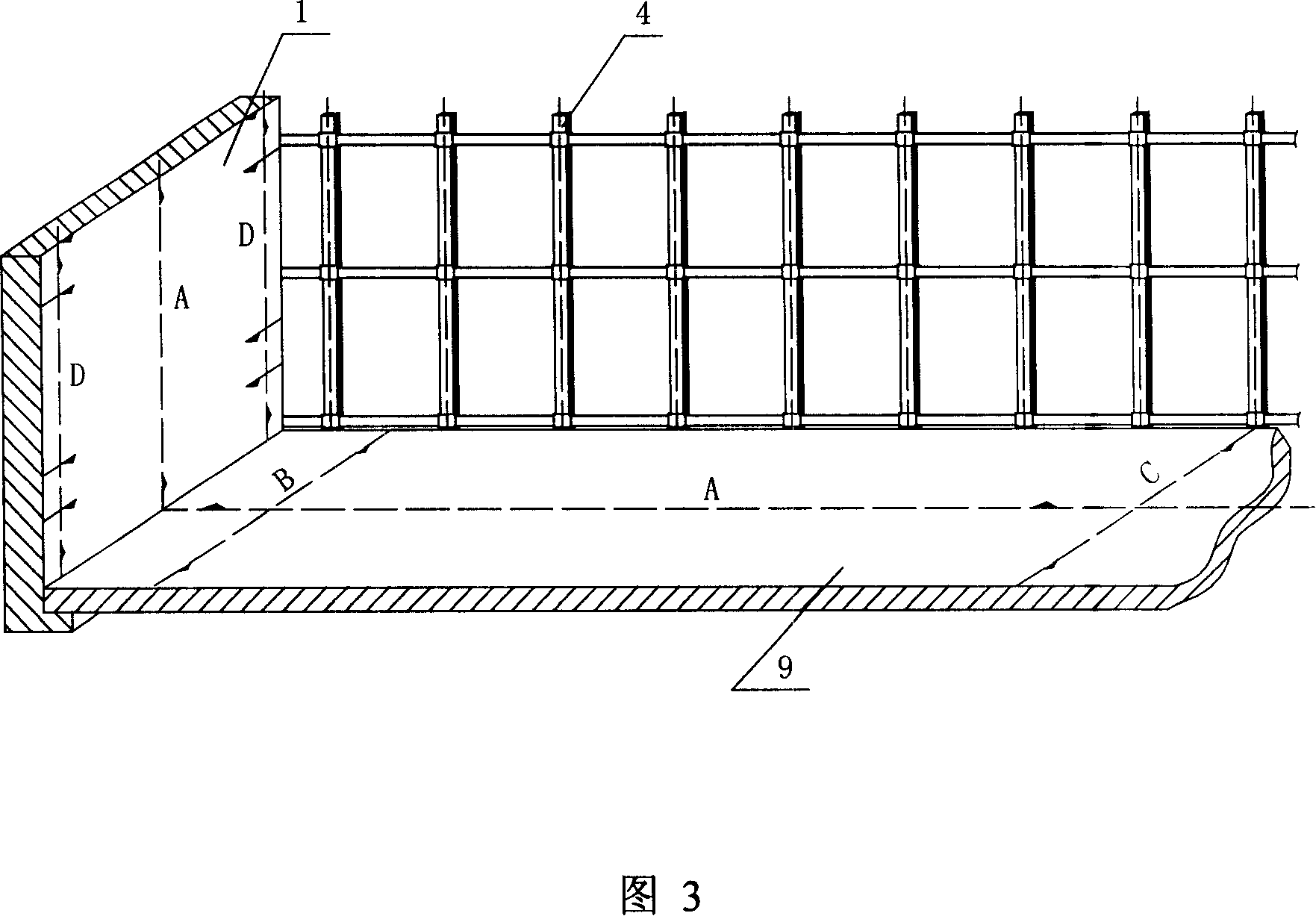

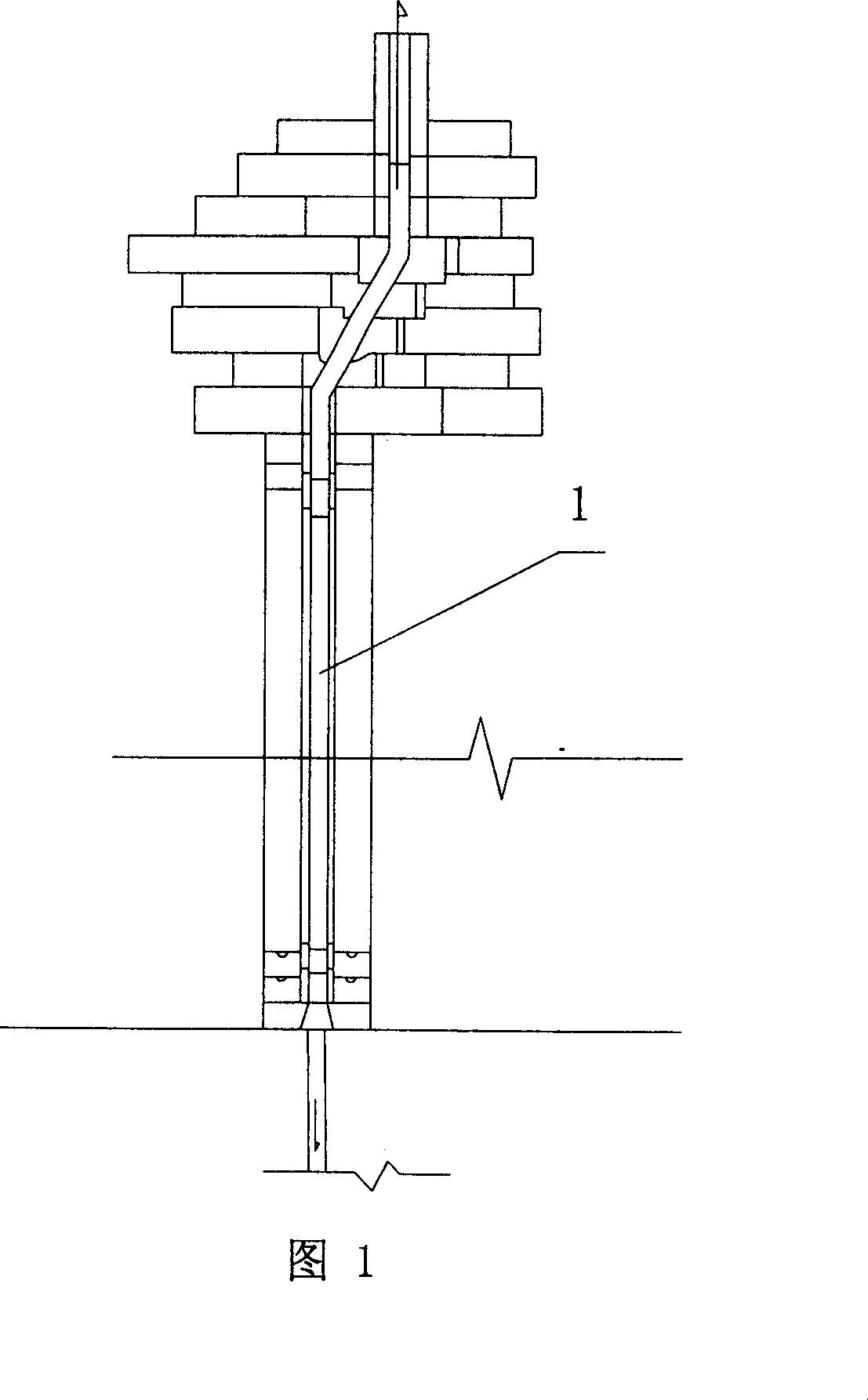

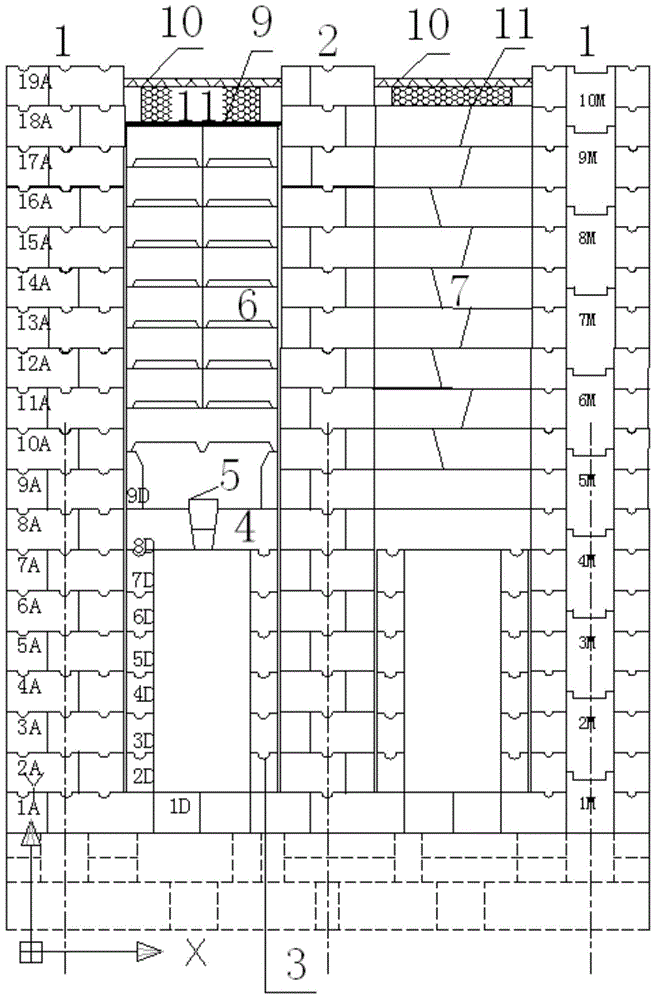

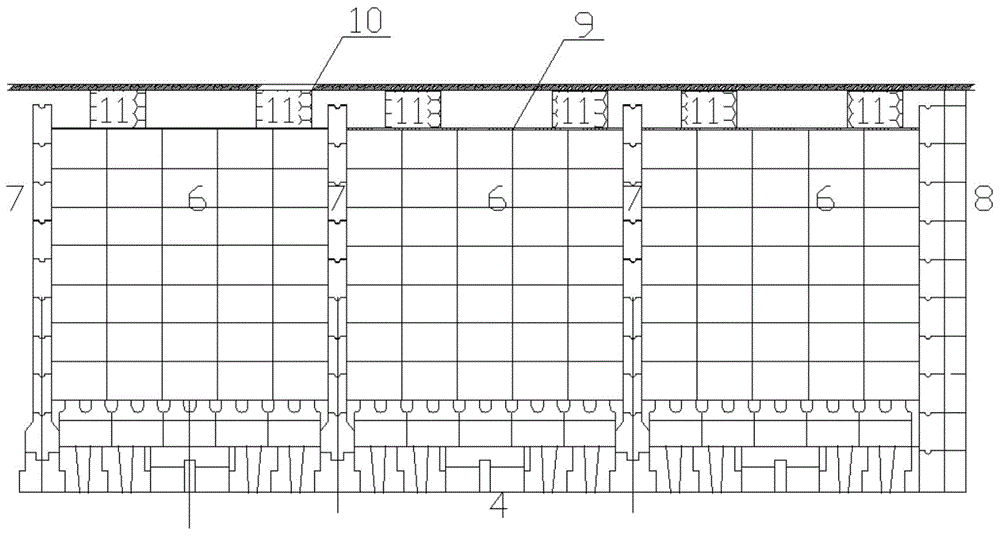

Coke oven masonry construction method employing upright line rod

ActiveCN101081986ASolve the problem of effective controlConvenient and reliable checking of dimensional errorsCoke oven brickworkVertical barCombustion chamber

The present invention relates to one improved large and medium coke oven laying construction process. The improved construction process adopting vertical bars includes the steps of burying stakes and datum marks during civil work, forming longitudinal and transverse central lines based on the datum marks, and setting vertical bars with scales. The improved construction process of the present invention can control the sizes of the coke oven effectively.

Owner:CHINA MCC5 GROUP CORP +1

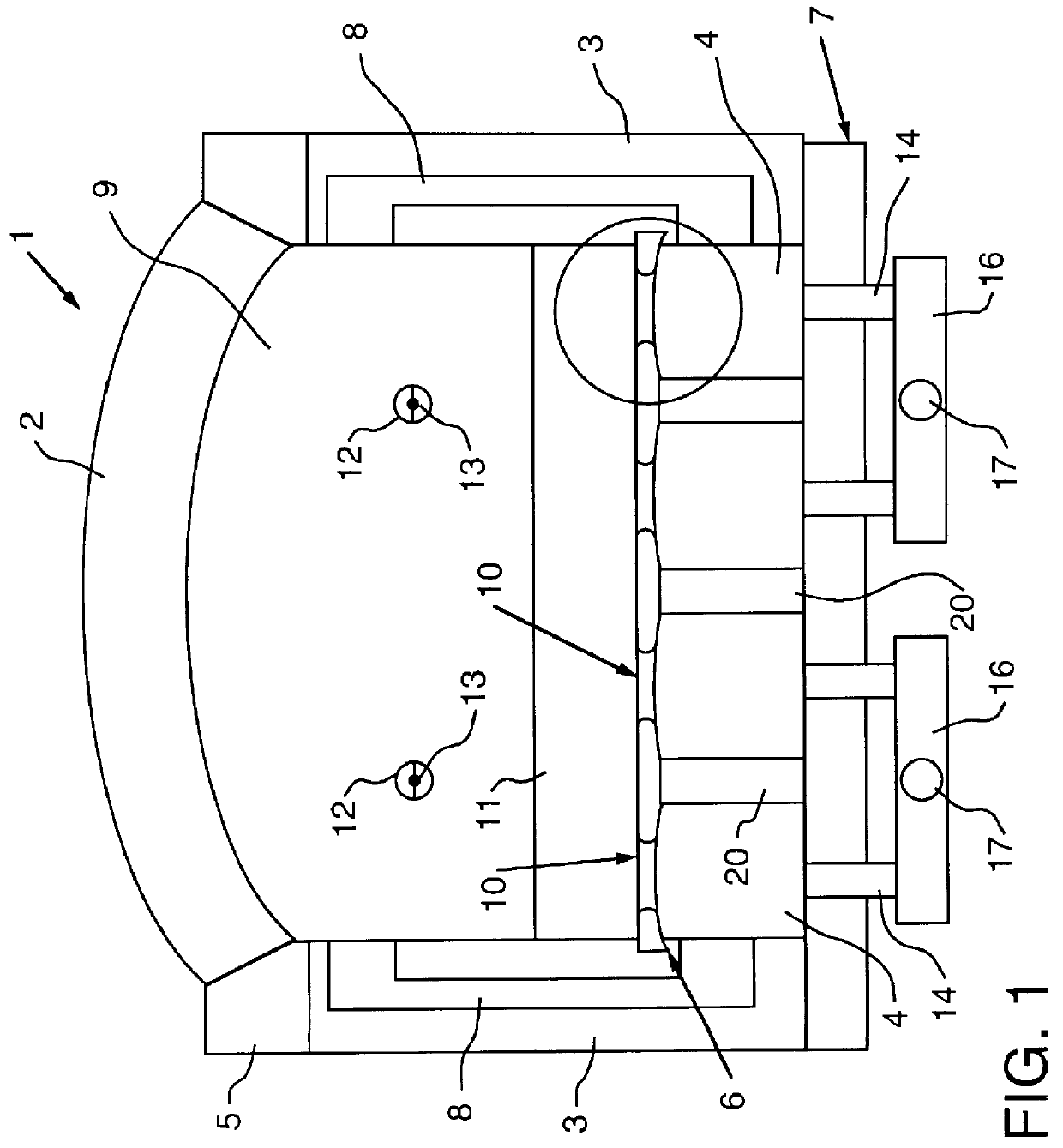

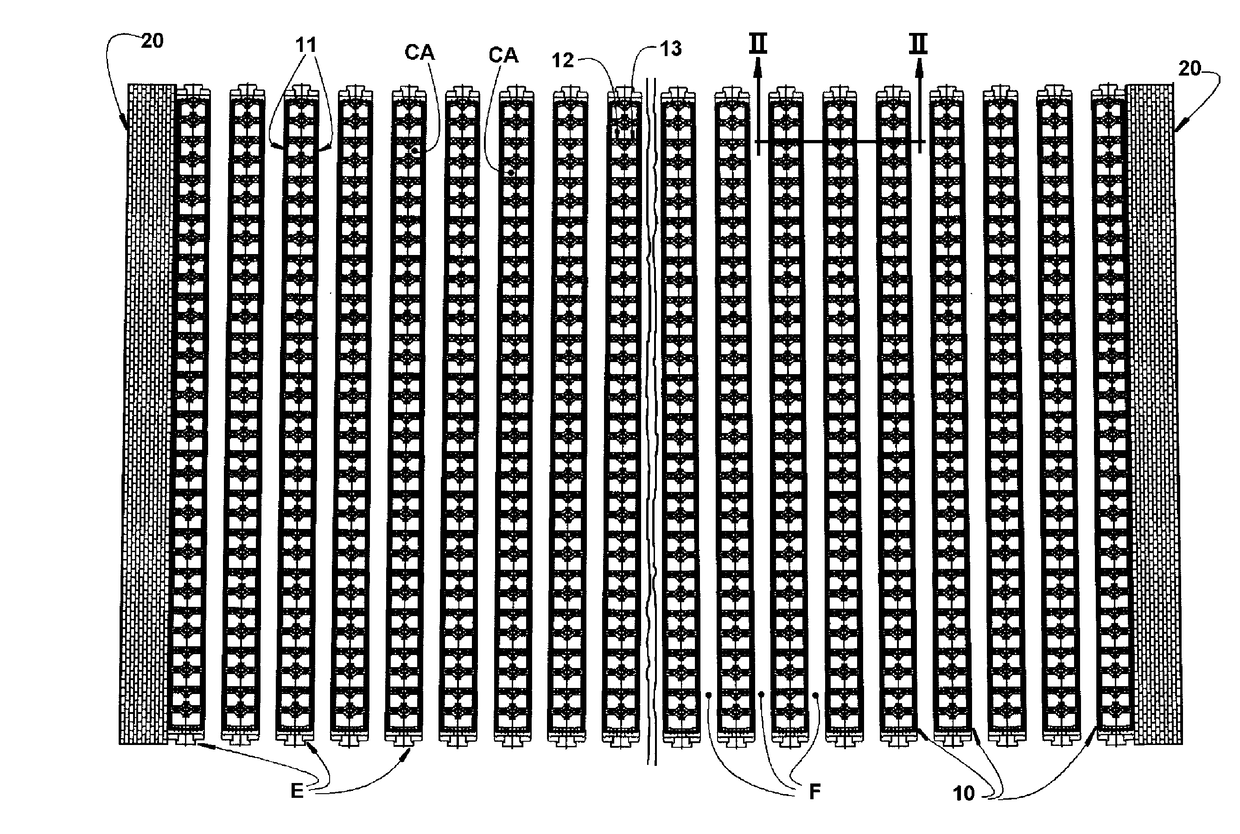

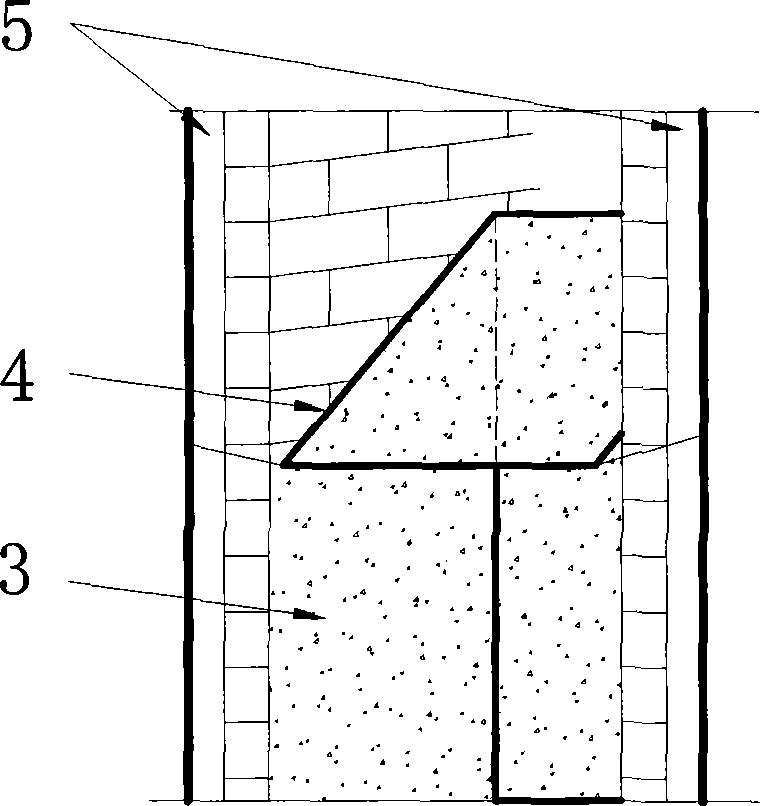

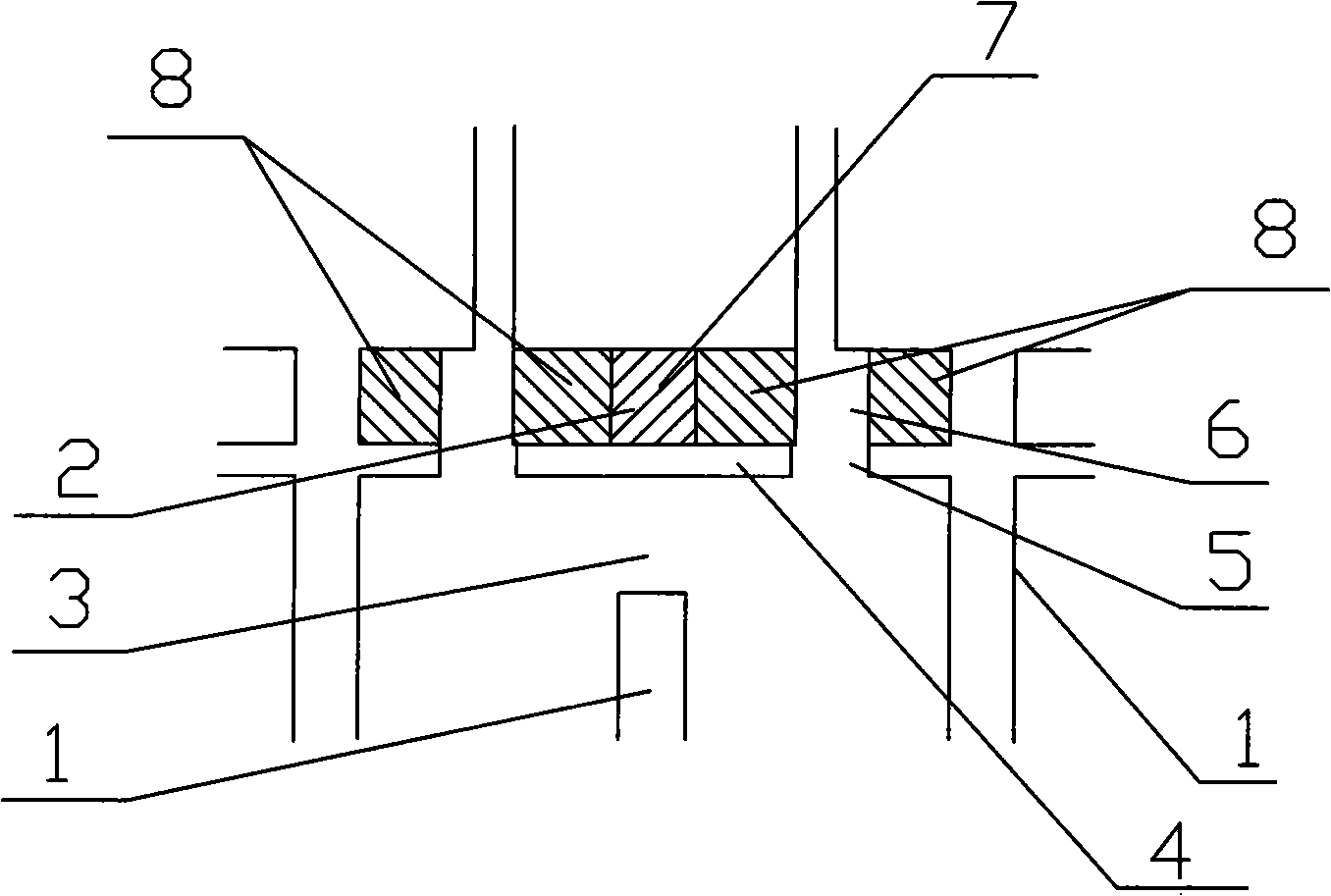

Method for coke oven repair

ActiveUS20170313943A1Quicker procedureSimple and rapid replacementCoke oven brickworkCoke oven expansion/contraction preventionBrickCoke oven

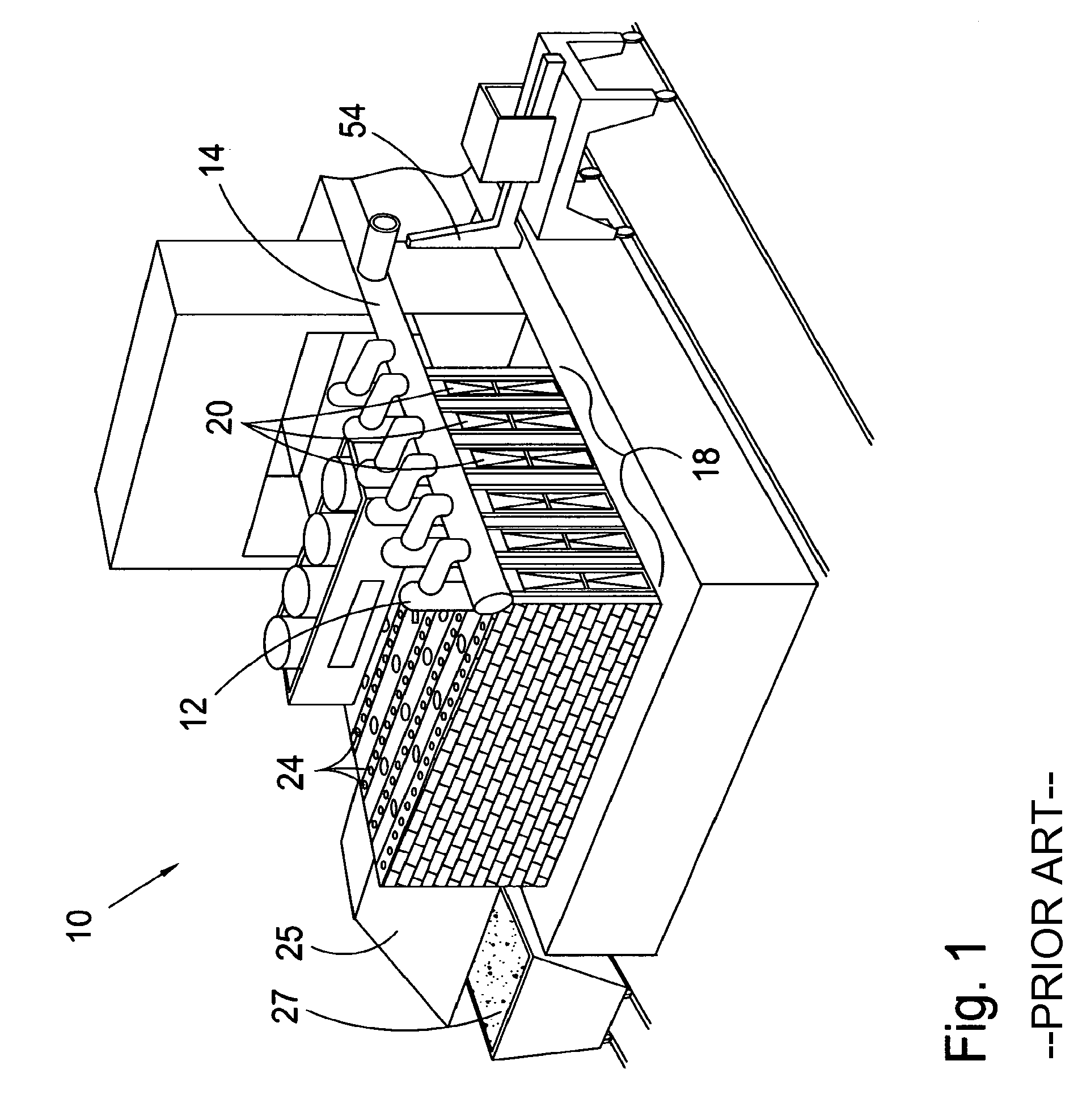

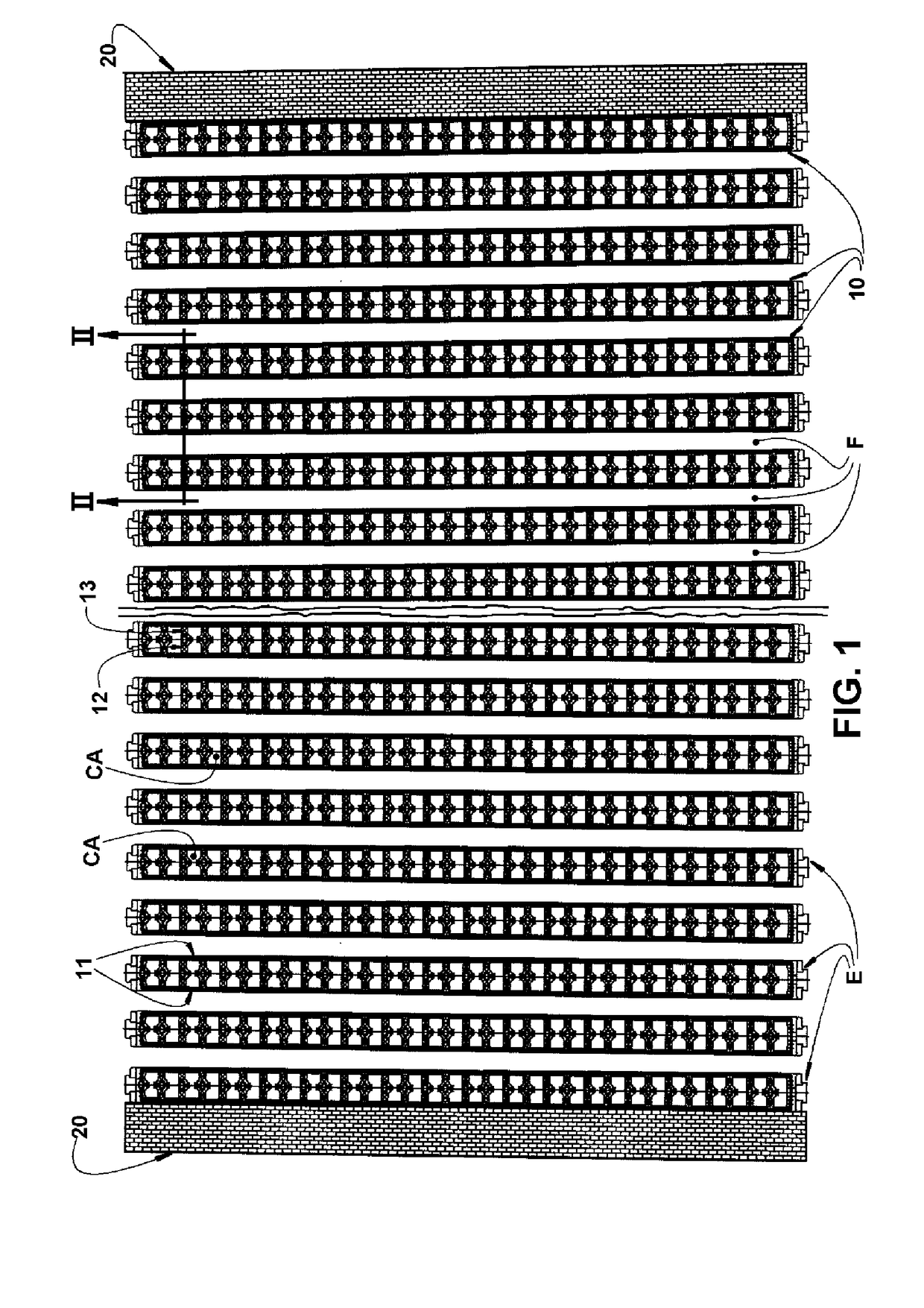

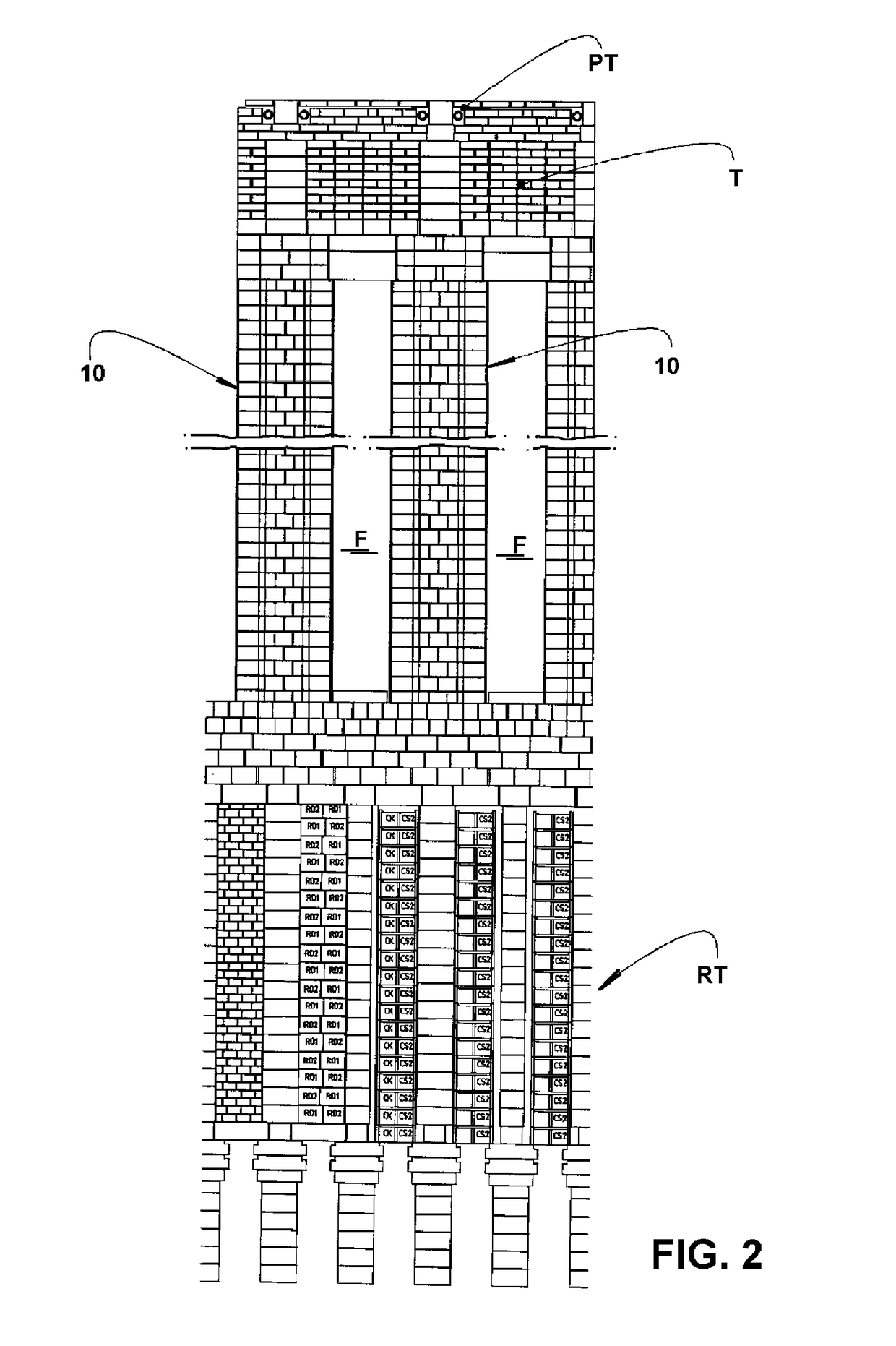

The ovens (F) are arranged side by side in a battery and are each delimited by two sidewalls (10) formed by side bricks (11) and joined by transverse bricks (12, 13). The method comprises: cutting each sidewall (10) to be repaired in accordance with a cutting plane (PC) defining a respective end flat face (14) in the middle portion of the wall (10a) to be maintained and coinciding with the face of a row of transverse bricks (12, 13) facing an adjacent end wall portion (10b) which is being removed; providing in each flat end face (14), a pair of cutouts (15), each having in a basic transverse face, a longitudinal middle channel (15c) in which a tongue (11c) of new bricks from a new end wall portion (10b) is fitted; fitting in each cutout (15) a corresponding portion of a vertical row of side bricks (11a, 11b) for the new end wall portion (10b) until the formation is complete.

Owner:PAUL WURTH DO BRASIL TECHA E SOLUCOES INDIS LTDA +1

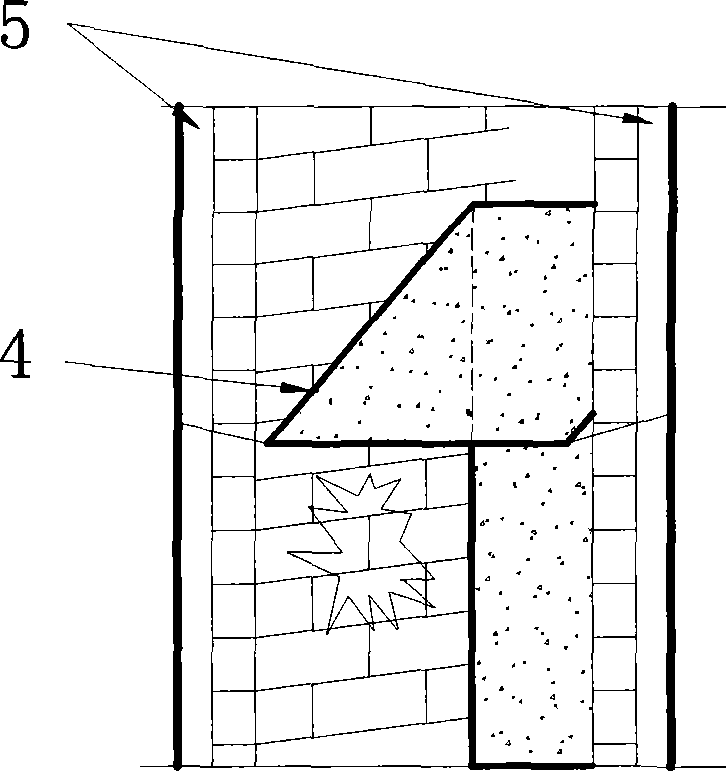

Synchronous cutting-off and unroofing repair method for coke side oven head of large-scale coke oven machine

ActiveCN102504837ASolve denudationSolve the holeCoke oven brickworkBrickwork leakage repair/preventionCombustion chamberMaterial consumption

The invention relates to a synchronous cutting-off and unroofing repair method for a coke side oven head of a large-scale coke oven machine, which belongs to a coke oven and particularly relates to a repair method for the coke oven. The synchronous cutting-off and unroofing repair method comprises the following steps of: cooling a repair area-reinforcing an oven column, correspondingly arranging a banking number and a buffer oven number, building a retaining wall, disassembling an ascending tube and cooling a repair number and relevant oven numbers; disassembling the ovens-disassembling a masonry body, installing a support and carrying out temperature monitoring on the repair number and the relevant oven numbers; repairing the building-determining a building centerline and a wall surface datum line and building according to the key points; and warming after repair-carrying out temperature rise speed control and disassembling the support and digging up the retaining wall. The repair method has the advantages that all the damaged parts of the oven head are disassembled and newly built; the wall surfaces of damaged coking chambers can be repaired within a large area so as to completely solve the abrasion and the hole through on the wall surfaces of the coking chambers and the inter-leakage of partition walls of a combustion chamber; after one-time repair, the damaged parts can beused for 5-8 years, so that the oven repair frequency, the time and the material consumption are reduced; the wall surfaces of the repaired parts are level, are small in coke pushing resistance, are beneficial to protecting a coke pusher and an oven body and producing the coke oven and also facilitates energy conservation and consumption reduction; and the high-temperature burn accident of maintenance personnel is also avoided.

Owner:MAGANG (GROUP) HOLDING CO LTD

Method for retaining cleaning of 7.63m coke oven in building process

The invention discloses a furnace cleaning maintaining method in the coking furnace masonry course, which is characterized by the following: adopting lid to block slurry; blowing the flue for three times; sealing the inlet; cleaning incidence hole for two times; sealing incidence hole; blowing fire channel after building upper circulating hole.

Owner:CHINA FIRST METALLURGICAL GROUP

Process for heat maintaining whole walls of coke carbonating chamber

A new thermo repairing process is used for whole wall of coke-oven charring house. It is carried out by: supporting the wall and retaining the temperature of the wall neighboring the coke-oven charring house, repairing the whole wall and replacing the oblique canal of charring house, making sure the new wall smooth, no expansion and depression when the temperature is increasing, making damages of neighboring wall at a low level. The mended wall is smooth and vertical. The width of charring house is uniformly. Taper and height are acceptable. The effect is good in experiment.

Owner:JIUQUAN IRON & STEEL GRP

Flue arch crown online opening pipe connecting method for smoke waste-heat utilization of coke oven

ActiveCN103374356ADoes not affect normal productionReasonable design of production stepsCoke oven brickworkEnergy inputFire brickRefractory

The invention discloses a flue arch crown online opening pipe connecting method for smoke waste-heat utilization of a coke oven. The flue arch crown online opening pipe connecting method is characterized by comprising the following steps of: a, crushing and dismantling concrete in a flue; b, building clay refractory bricks in a gap between an arch crown and the concrete of the flue; c, making and installing a profile steel wellhead ring of the arch crown of the flue; d, dismantling the refractory bricks of the arch crown of the flue; and e, jointing the profile steel wellhead ring of a flue opening with an outer flue pipe. The flue arch crown online opening pipe connecting method for smoke waste-heat utilization of the coke oven, disclosed by the invention, is reasonable in design of making steps, does not influence the normal production of the coke oven, overcomes the influence of high temperature and negative pressure suction, prevents the refractory bricks from falling in the flue andis high in production efficiency; moreover, a connector which is jointed with the openings has good airtightness,.

Owner:MCC5 GROUP CORP SHANGHAI

Manual repair technique of coking chamber wall

The invention discloses a process for manually mending the furnace wall of a carbonization chamber. The process comprises the following: (1) a step of fixing a heat isolation rack: according to a mending part, the heat isolation rack is manufactured; the surface of the heat isolation rack is coated by a heat isolation blanket; the heat isolation rack is pushed to the part of the furnace wall needing mending in the carbonization chamber; and the top of the heat isolation rack is fixed on a furnace frame; (2) a step of paving the heat isolation blanket; graphite and impurities on the bottom of the furnace are cleaned up; the heat isolation blanket and a passage plate are paved; and the heat isolation blanket is stuck on the furnace wall to be treated mended and the furnace wall on the periphery of the heat isolation rack; (3) a step of constructing the inside of the furnace of the carbonization chamber: after the furnace walls at two sides are stuck with the heat isolation blanket, no naked fire is determined to eject; and the mending construction is carried out; and (4) a step of detaching and mending a melting loss part. The mending process can carry out mending in the carbonization chamber under the environment of high temperature of 1,000 DEG C around, reduce cost, improve the service life of the coke furnace, does not influence production and is a feasible and effective method.

Owner:MCC BAOSTEEL TECH SERVICE

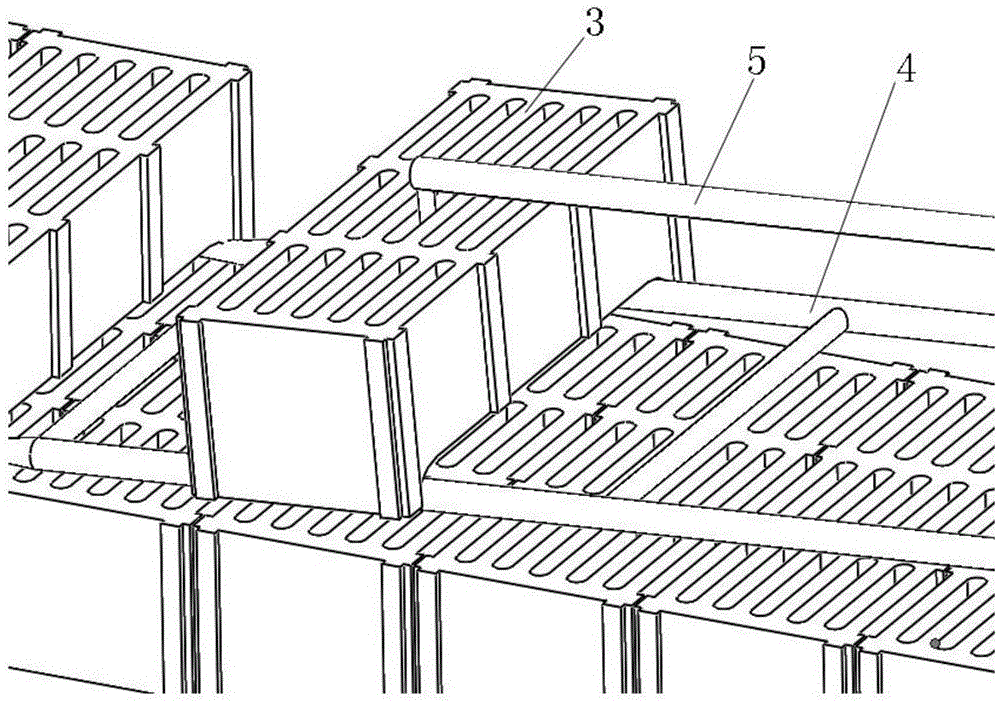

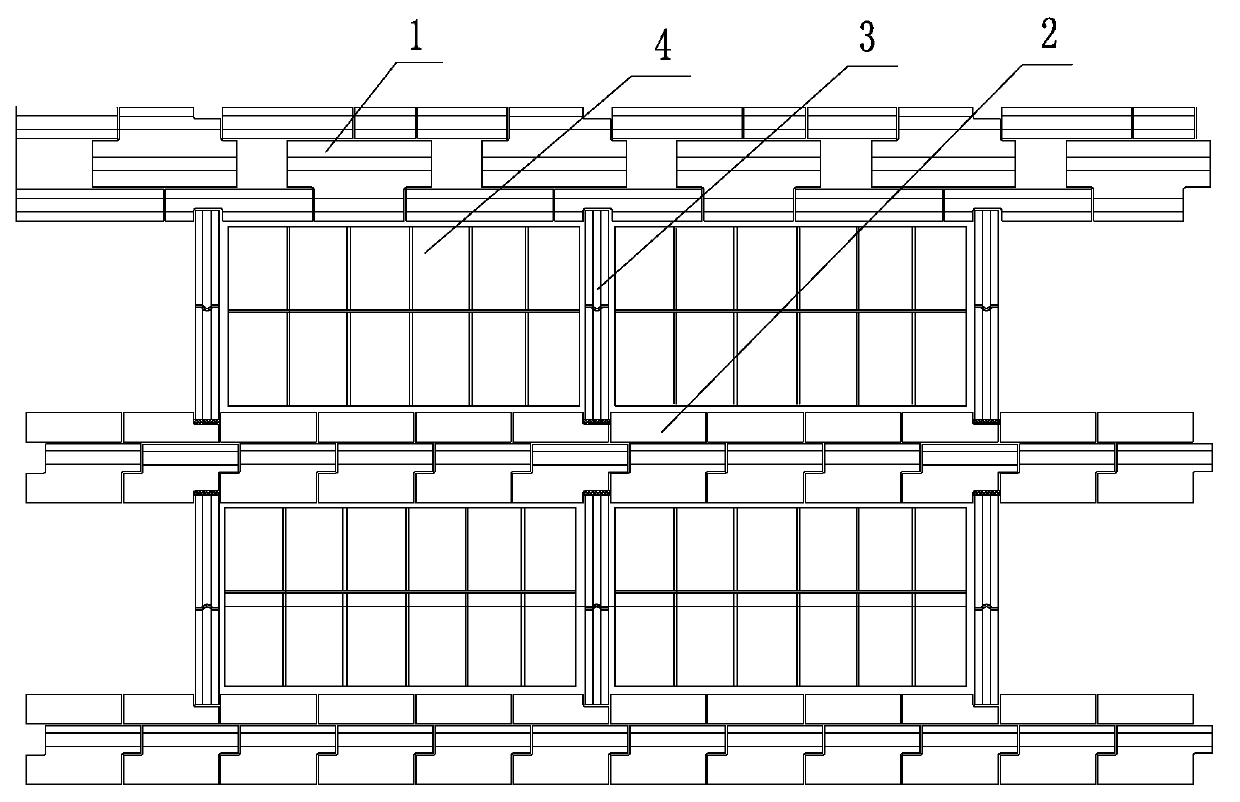

Thermal-state non-stop production replacement method of lattice bricks in regenerative chamber of coke oven

The invention relates to a thermal-state non-stop production replacement method of lattice bricks in a regenerative chamber of a coke oven. The method comprises the following steps: dismantling a coke blocking plate in a chute region at the part where a lattice brick needs to be replaced, part of sealing walls of the regenerative chamber and ancillary facilities thereof, and carrying out insulation treatment near the dismantling region; inserting the front end of a slide way into the bottom of the lattice brick needing to be replaced, hooking a through hole in the lattice brick needing to be replaced by adopting a brick hooking device, moving the lattice brick needing to be replaced out of the regenerative chamber along the slide way, then pushing a new lattice brick into the regenerative chamber by adopting the same method, and putting the new lattice brick in place; and re-building the sealing walls of the regenerative chamber, and recovering the facilities in the chute region. According to the invention, the slide way, the brick hooking device, a brick lifting device and other special tools are used for replacing lattice bricks, and the operation can be executed outside the regenerative chamber by operators, so that the construction is convenient and fast and the safety is high; and the lattice bricks are not easy to be broken, so that the problem of blockage of a lower layer of lattice bricks caused by replacing an upper layer of lattice bricks is avoided, the hot repair cost is greatly saved, and the hot repair difficulty is reduced.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

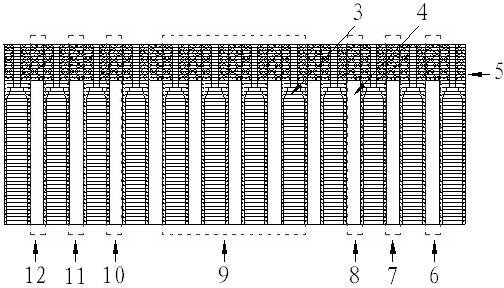

Method for building cellular regenerative chamber of coke oven

The invention discloses a method for building a cellular regenerative chamber of a coke oven. The method is characterized by comprising the following steps of: a, building a main wall and a single wall of the regenerative chamber; b, building a small cross wall of the regenerative chamber; c, building lattice bricks; d, placing rubber skins and wood boards for protection; and e, repeating the steps a-d until the building design height of the cellular regenerative chamber of the coke oven is reached. The method for building the cellular regenerative chamber of the coke oven, disclosed by the invention, has the advantages of being reasonable in construction step design and simple in operation, changing a conventional building method, being large in construction space and orderly in management of refractory materials, being capable of immediately monitoring the building quality, being safe and reliable in project quality, increasing labor efficiency, greatly reducing the construction period and lowering the project cost.

Owner:MCC5 GROUP CORP SHANGHAI

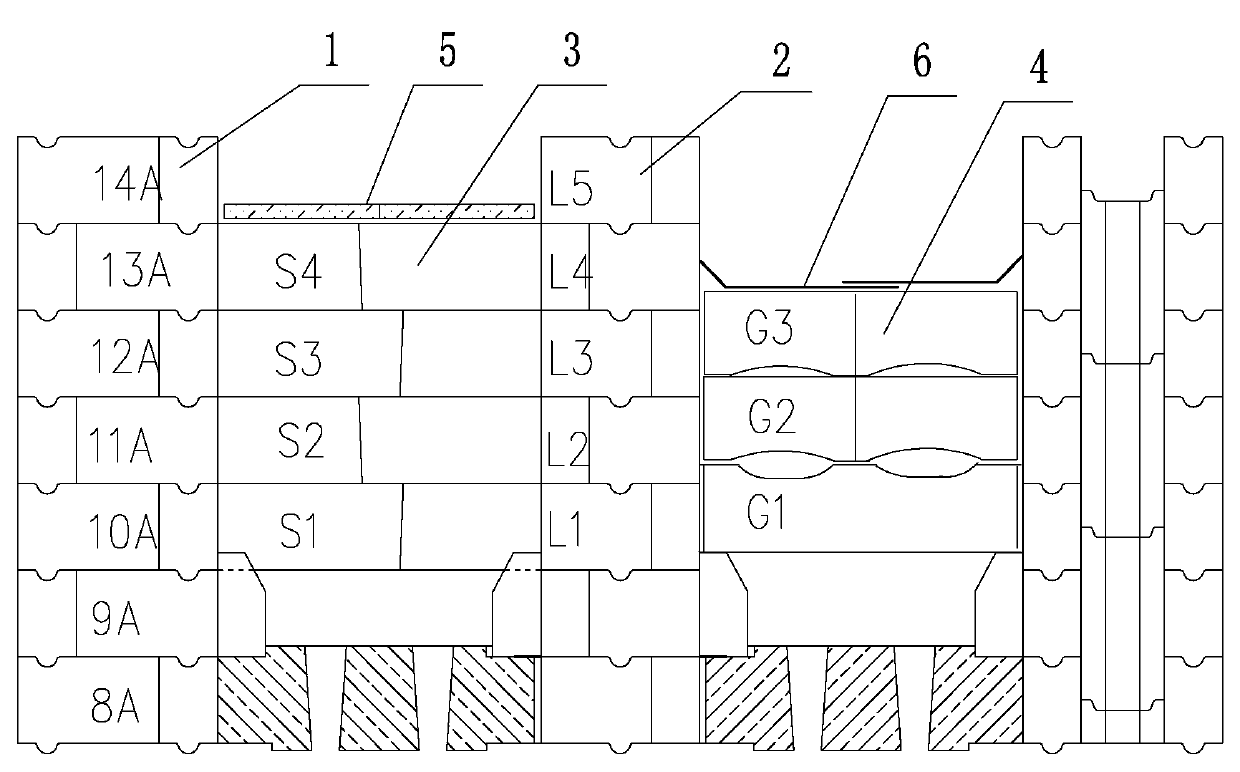

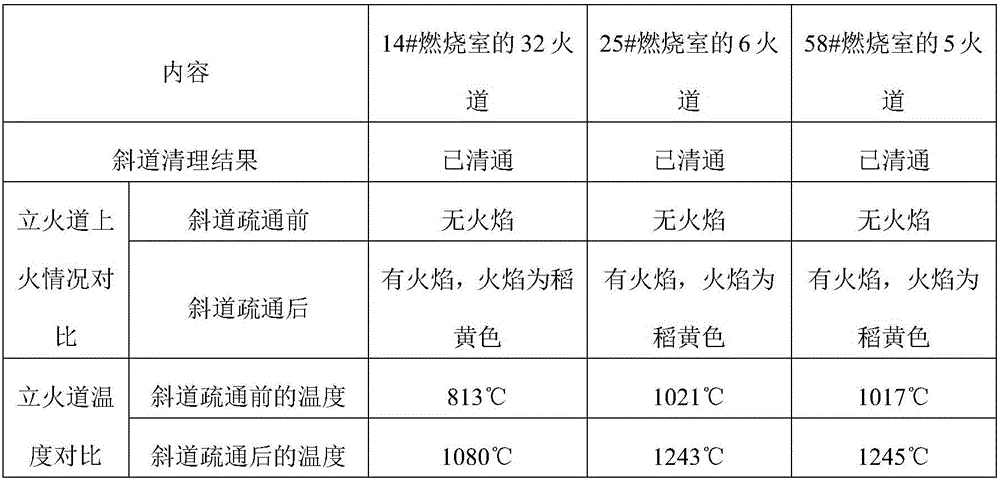

Method for cleaning coke oven chute

InactiveCN106753449AWill not harmWon't breakCoke oven brickworkOven incrustations prevention/removalBrickAfter treatment

The invention relates to a method for cleaning a coke oven chute and belongs to the method for cleaning the coke oven chute, aiming at solving the technical problems in an existing method for treating blocking of a chute of a coke oven that the working amount is great, damages to a furnace wall are great and the service life of the coke oven is influenced. The method for cleaning the coke oven chute, provided by the invention, comprises the following steps: 1, doing early-stage preparation work; 2, carrying out cooling treatment; 3, dredging the coke oven chute; 4, carrying out temperature rising treatment and recovering production. According to the method for cleaning the coke oven chute, the chute is cleaned from the top of a heat storage chamber from bottom to top and the working safety is improved; damages to silicon bricks of the furnace wall of a carbonization chamber are not caused by temperature lowering and temperature rising, and the silicon bricks of the furnace wall are not broken; after treatment, a flame path of a combustion chamber can be smoothly ignited and waste gas is discharged, so that the requirement of uniformly heating the coke oven is met.

Owner:李洪泽

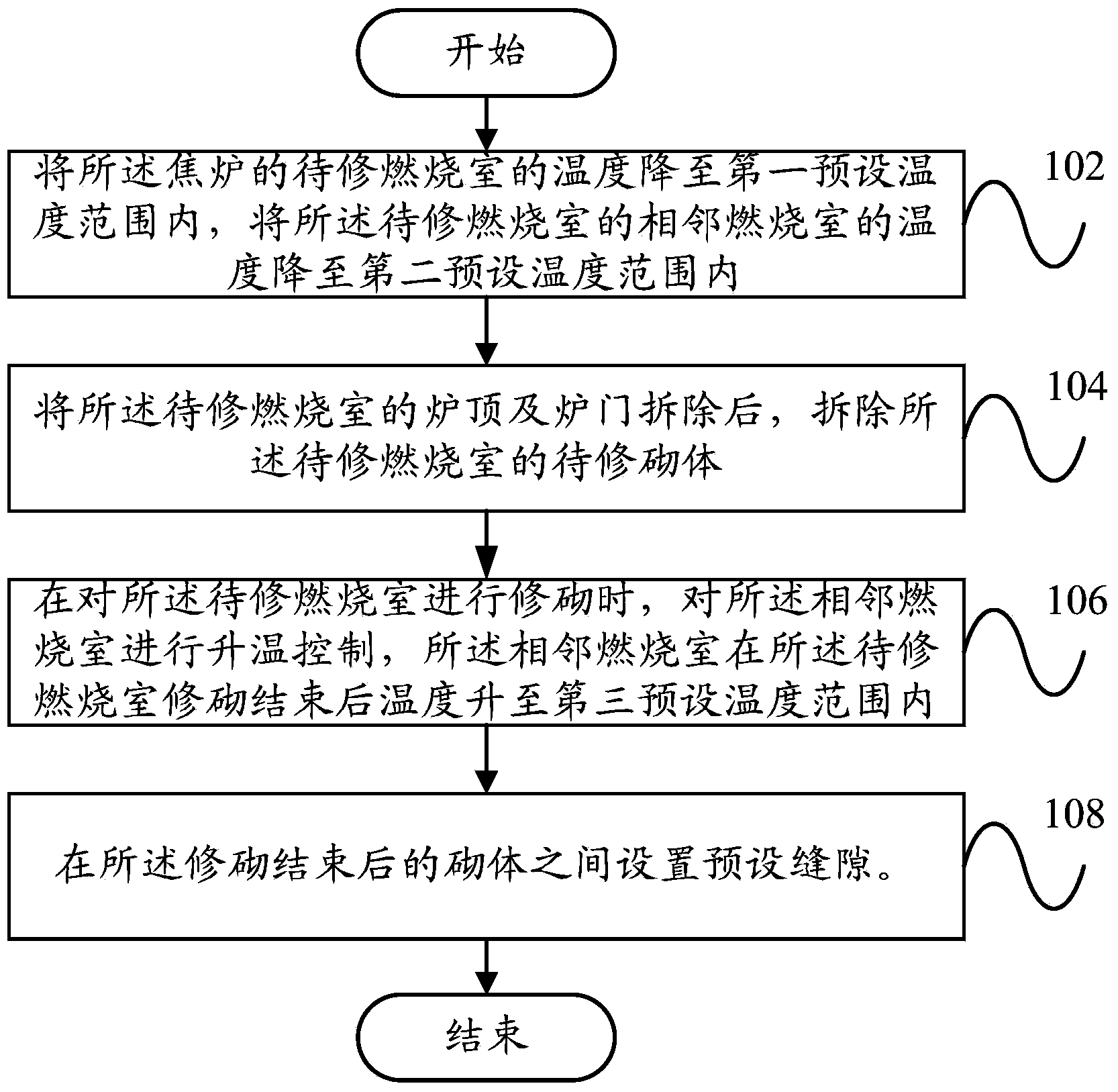

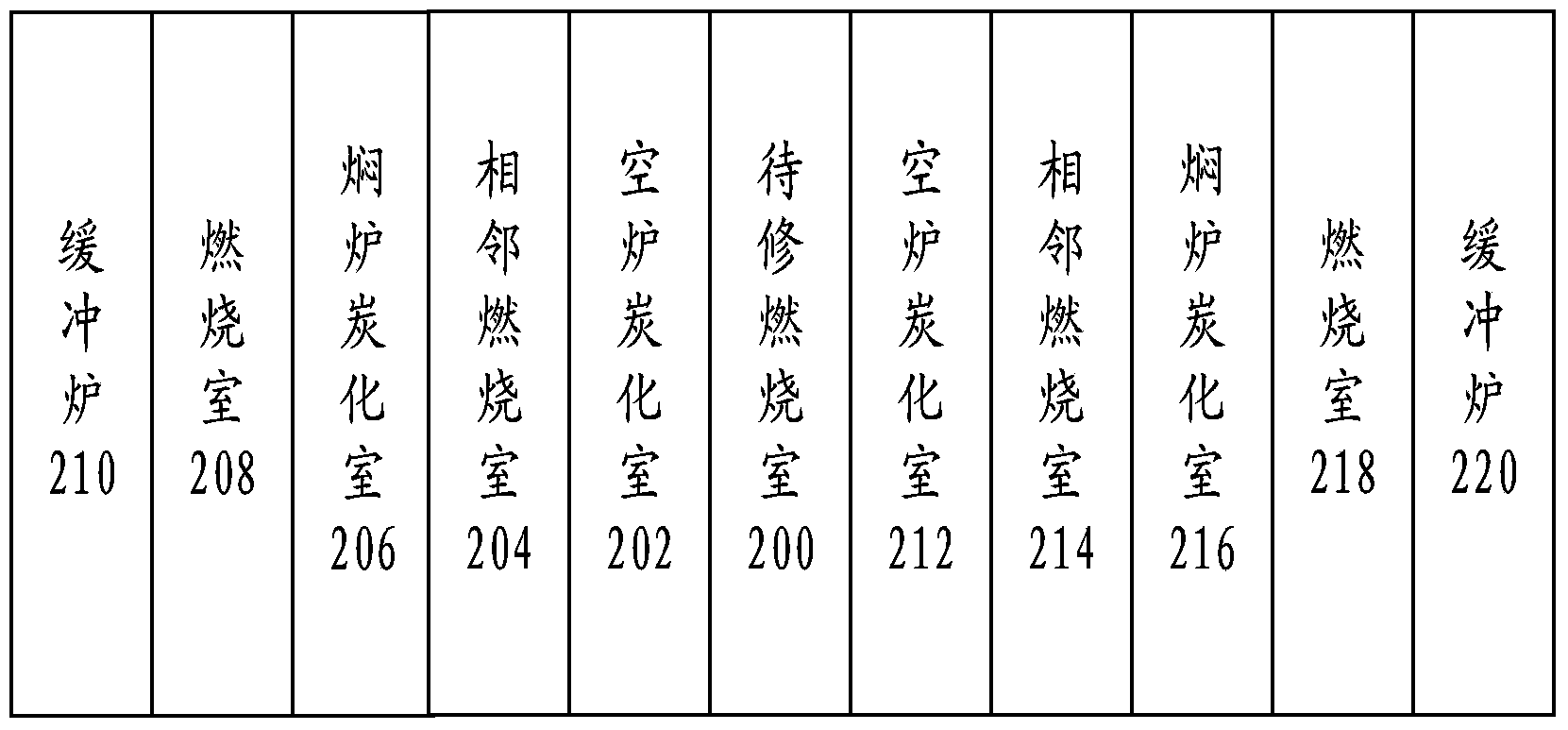

Coke oven maintenance method

ActiveCN104357067AIncrease productionShorten heating timeCoke oven brickworkBrickwork leakage repair/preventionCombustion chamberCoke oven

The invention provides a coke oven maintenance method which comprises steps as follows: the temperature of a to-be-maintained combustion chamber of a coke oven is reduced to a range of a first preset temperature, and the temperature of a combustion chamber adjacent to the to-be-maintained combustion chamber is reduced to a range of a second preset temperature; after an oven roof and an oven door of the to-be-maintained combustion chamber are dismounted, to-be-maintained brickworks of the to-be-maintained combustion chamber are dismounted; when the to-be-maintained combustion chamber is maintained, the adjacent combustion chamber is subjected to temperature rise control, and the temperature of the adjacent combustion chamber is increased to a range of a third preset temperature after maintenance of the to-be-maintained combustion chamber are finished; and preset gaps are formed between adjacent brickworks after maintenance ends. With the adoption of the technical scheme, the problem of secondary damage of an oven wall due to the fact that the brickwork temperature and the sizes of the preset gaps in the joint positions of new and old brickworks cannot be controlled effectively is solved, so that the size of the maintained combustion chamber is standard, the brickworks are neat, the loss and the cost are reduced, and the yield of the coke oven is increased.

Owner:LIAONING Z H &X METALLURGICAL TECH

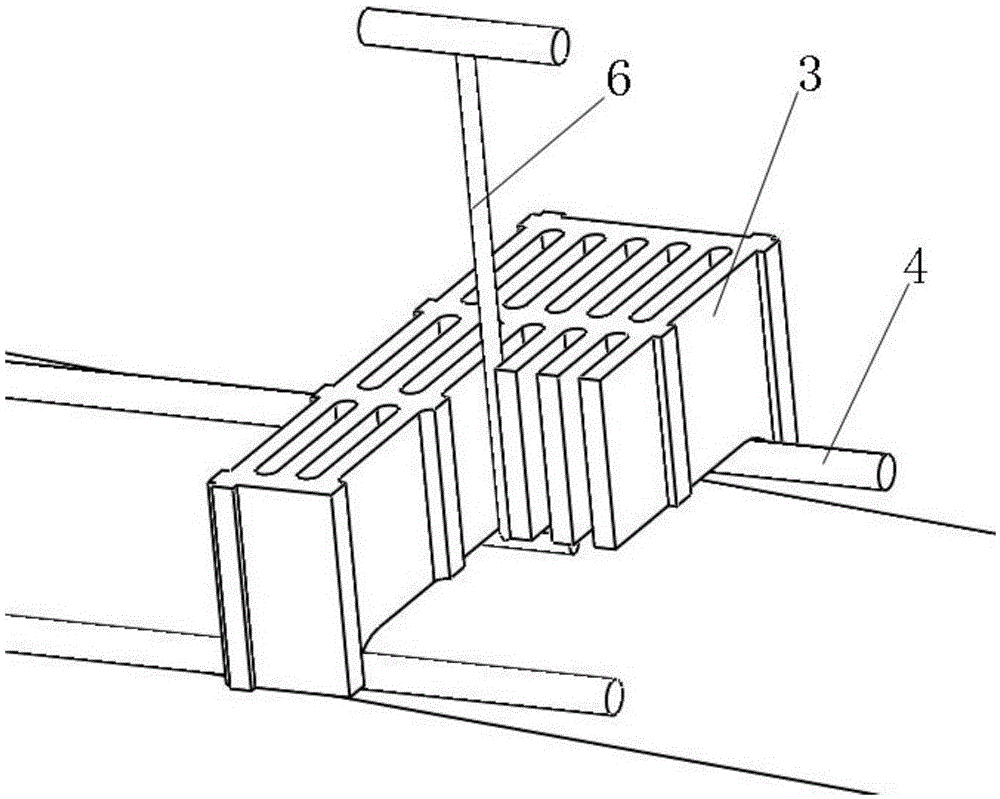

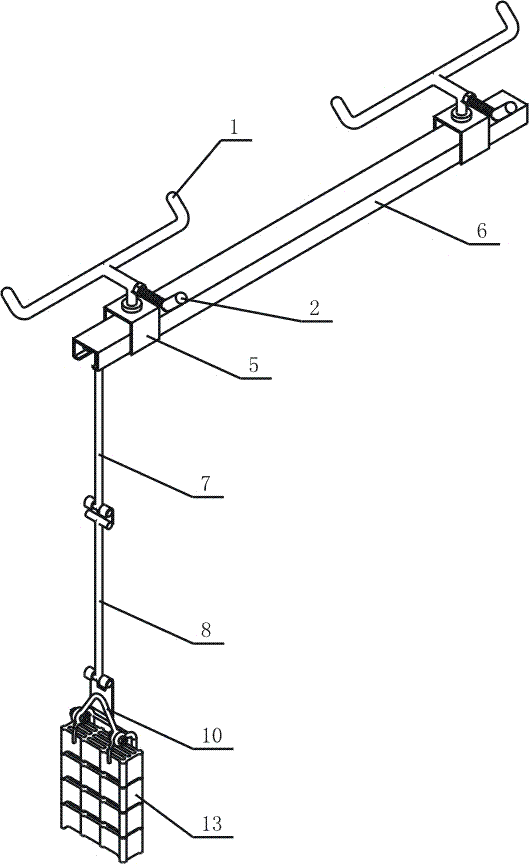

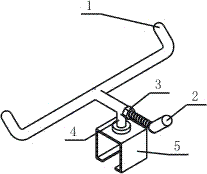

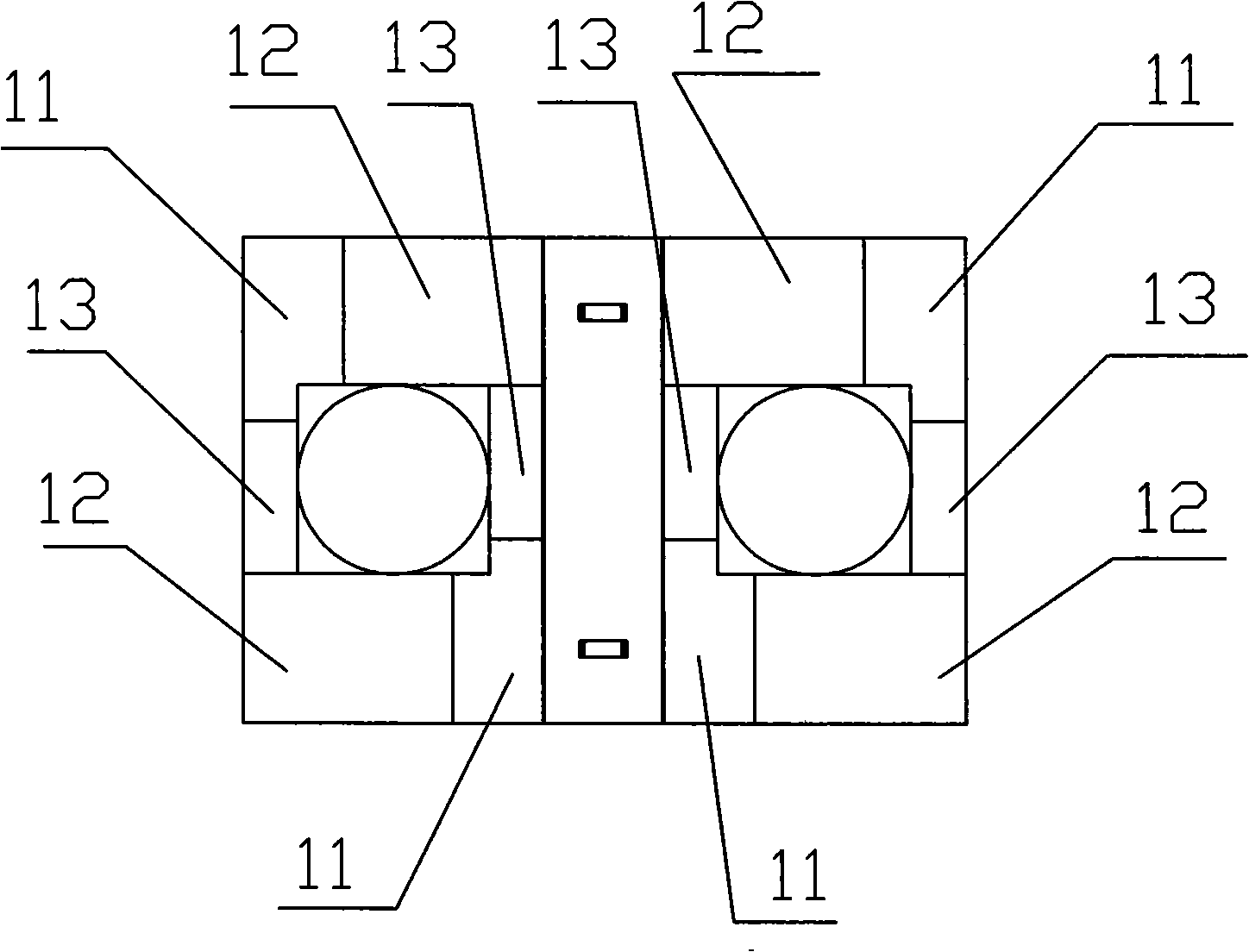

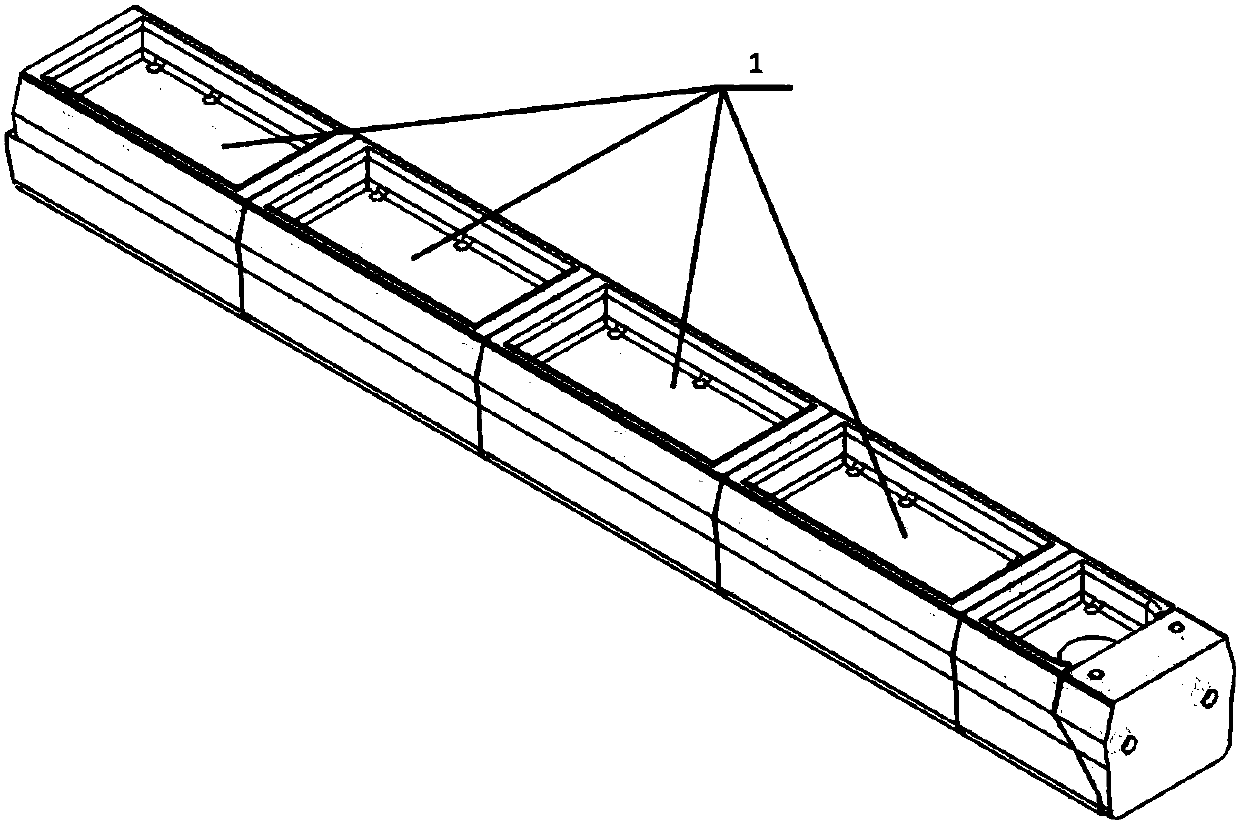

Transporting and constructing method and device for coke-oven checker bricks

The invention provides a transporting and constructing method and a transporting and constructing device for coke-oven checker bricks. The transporting and constructing device comprises a slide rail section, wherein the slide rail is arranged in a slide rail supporting base; the slide rail supporting base is connected on a fixed rod by a hanging shaft; an adjusting rod is arranged at one end of the fixed rod; a lead screw is arranged at one end of the adjusting rod; an adjusting nut is arranged for adjusting the extending length of the adjusting rod; a first hanging rod is connected at the tail end of the slide rail; a second hanging rod is hung on the tail end of the first hanging rod; and a checker brick hanging tool bag is arranged on the bottom of the second hanging rod. The invention further discloses a method for transporting the cove-oven checker bricks by adopting the device. According to the transporting and constructing method and the transporting and constructing device for coke-oven checker bricks disclosed by the invention, the slide rail is arranged at a chute port, and the hanging tool is used to replace the conventional manual transportation for transporting the check bricks, so that the labor intensity can be greatly relieved and the working efficiency can be improved.

Owner:CHINA FIRST METALLURGICAL GROUP

Method for repairing fusion holes in wall of carbonization chamber without cooling

ActiveCN102851040AExtended service lifeShorten patching timeCoke oven brickworkRepair timeCombustion chamber

The invention relates to a method for repairing fusion holes in a wall of a carbonization chamber without cooling and belongs to the technical field of coke furnace repairing. The method has a technical scheme that an operator repairs a wall of a carbonization chamber without entering into the carbonization chamber; and in repairing, the operator uses a detection tool to detect fusion hole positions and carries out spray repairing from a vertical flame path on a furnace top to the interior of the carbonization chamber so that fusion holes in the wall are repaired with mud gradual solidification and thus the method breaks through a thinking way of wall repairing from a combustion chamber to a carbonization chamber, overturns the traditional method of repairing a furnace wall of a carbonization chamber, shortens repairing time and prolongs a coke furnace service life. The method provided by the invention has the advantages that a repairing rate is fast; a normal production order is not influenced; carbonization chamber wall repairing does not need cooling so that a coke furnace service life is prolonged; the method thoroughly overturns a thinking way of wall repairing from a carbonization chamber; a spray gun structure is modified so that the spray gun structure is more suitable for carbonization chamber fusion hole repairing; an application range of a semi-drying spray repairing device for spray repairing of a carbonization chamber wall is widened; and a baffle plate avoids spray repairing material splashing in spray repairing and improves a spray repairing rate.

Owner:宣化钢铁集团有限责任公司 +1

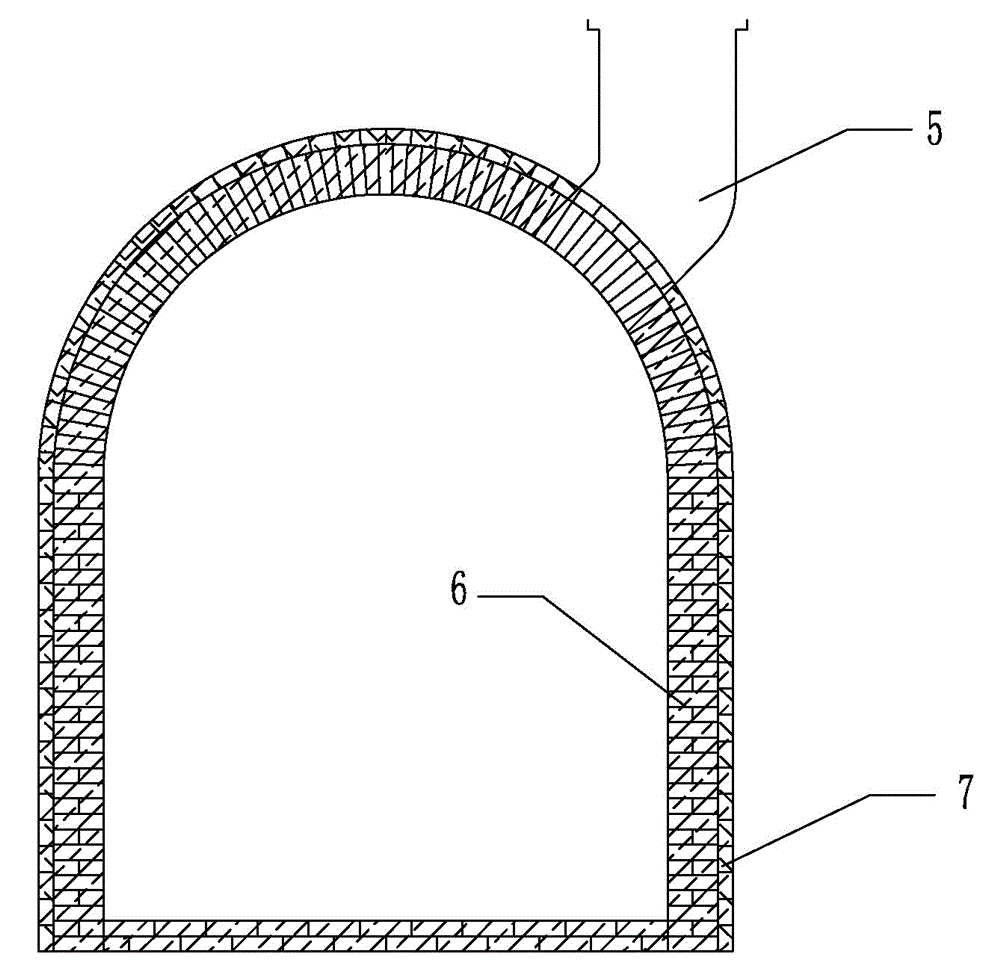

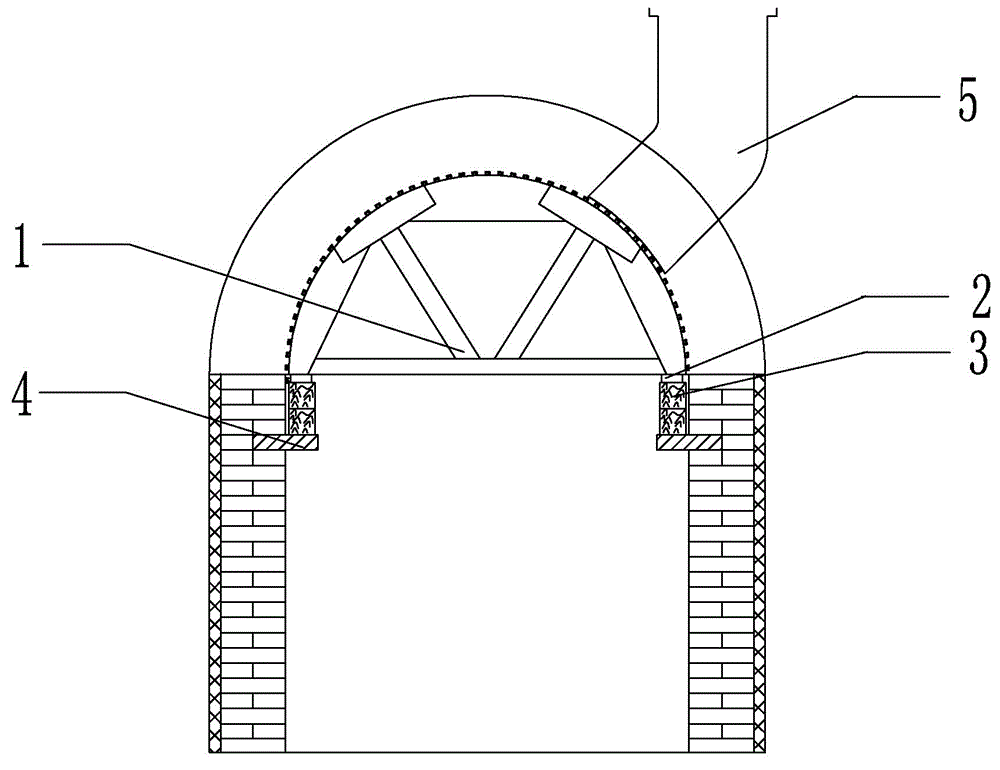

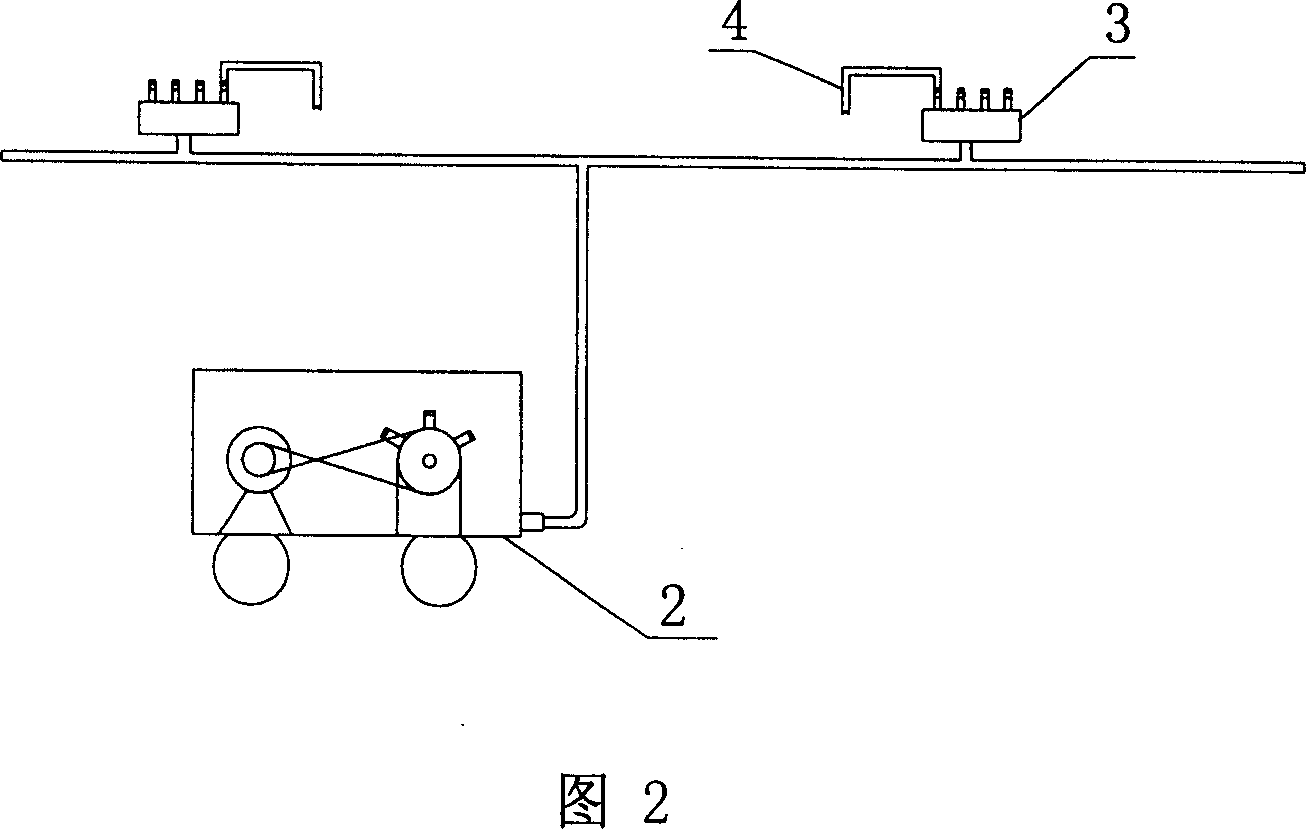

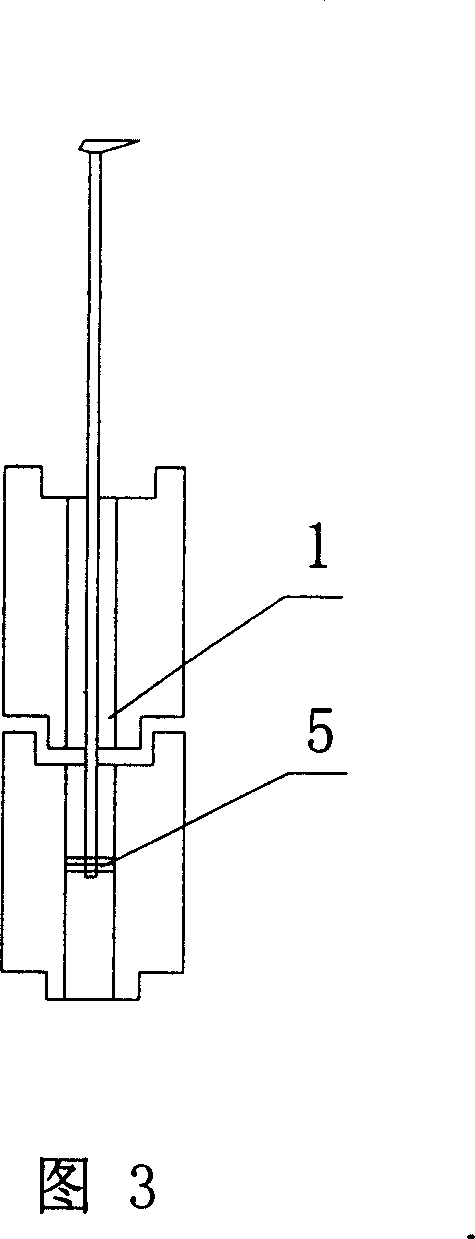

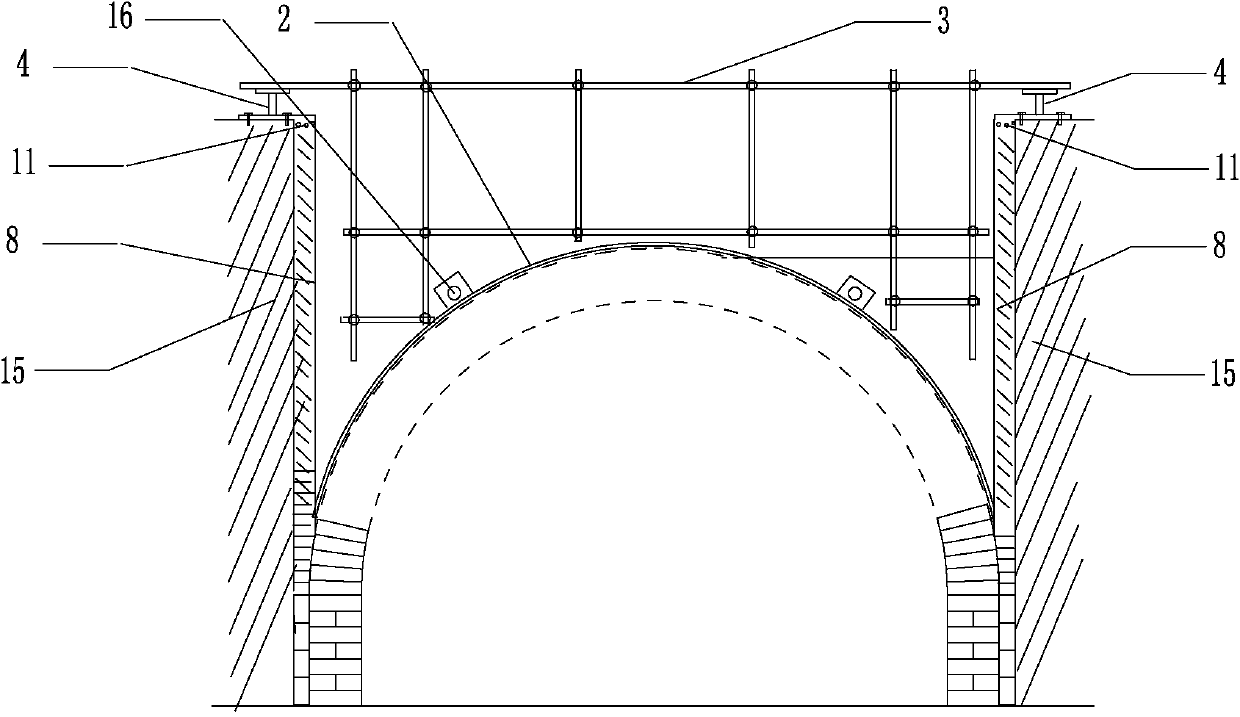

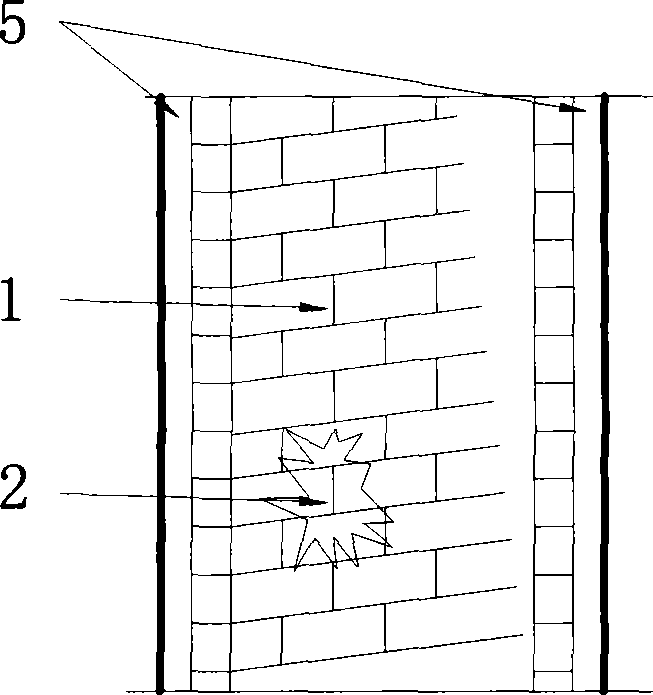

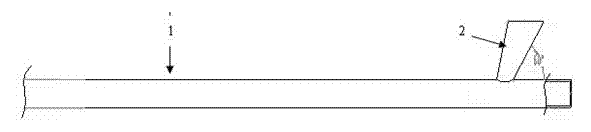

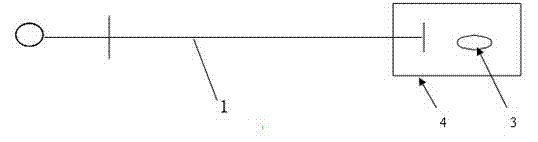

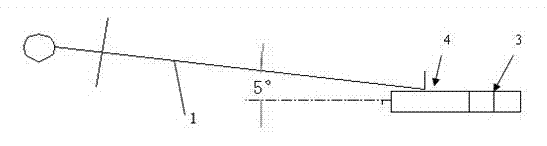

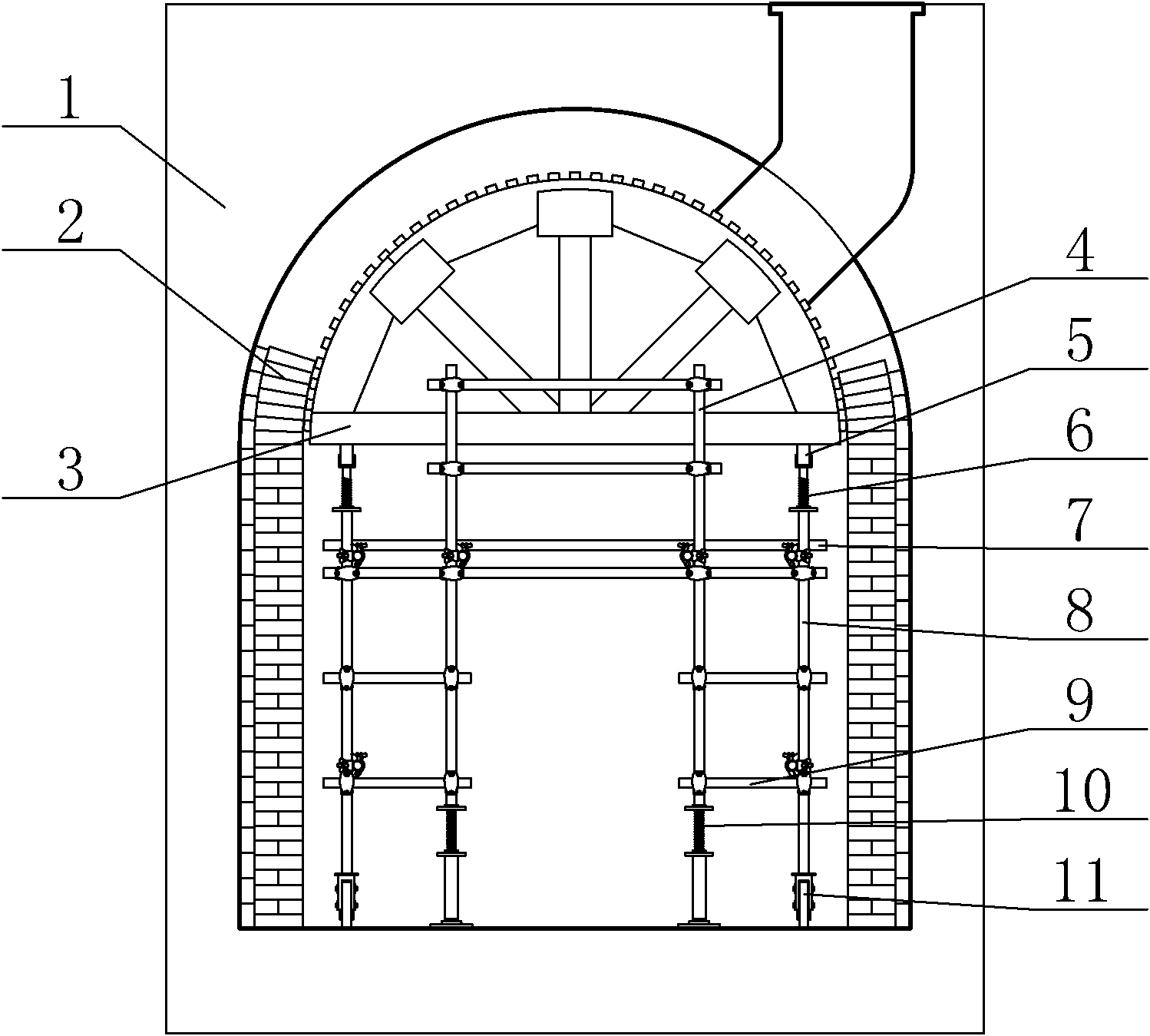

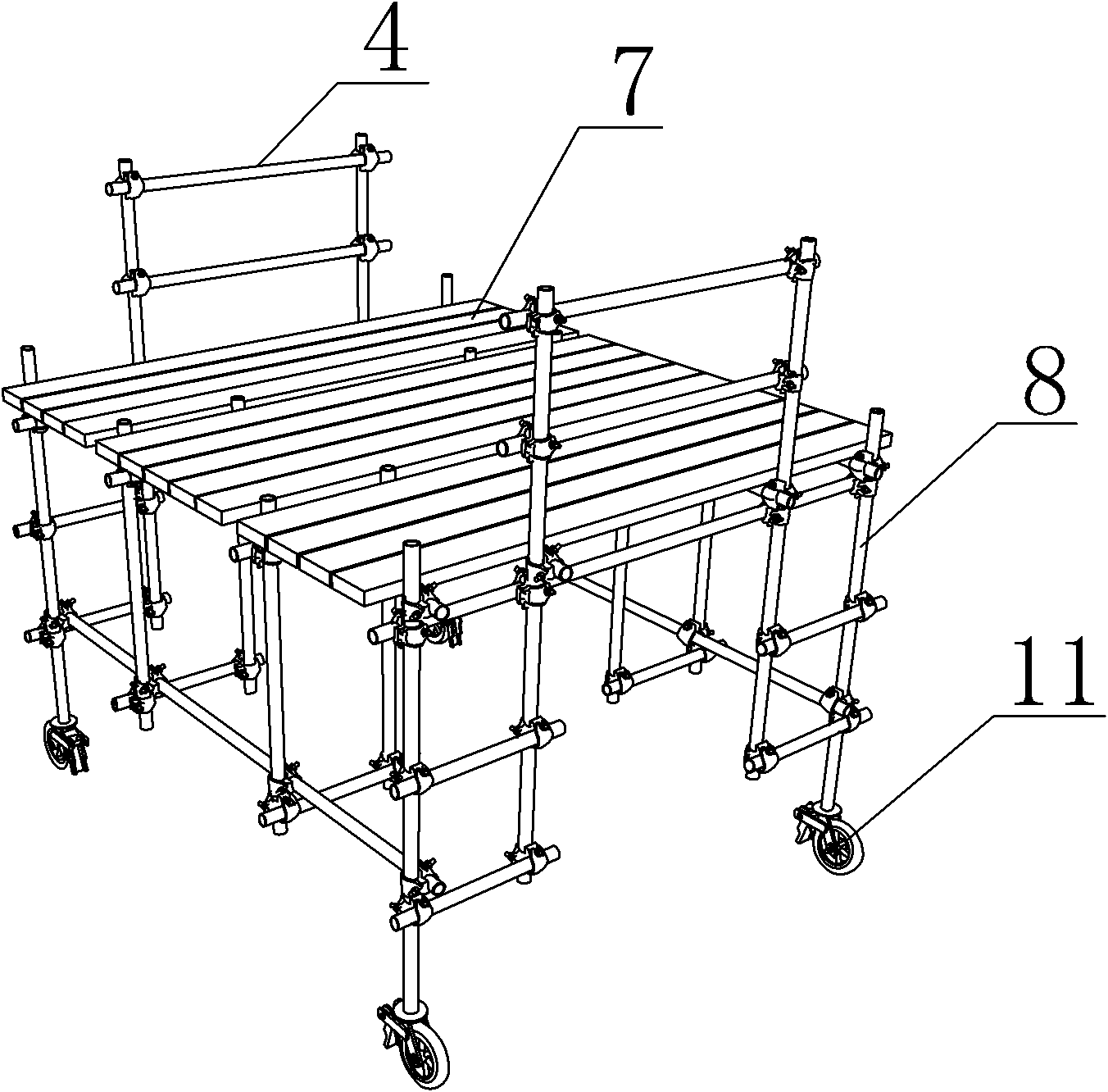

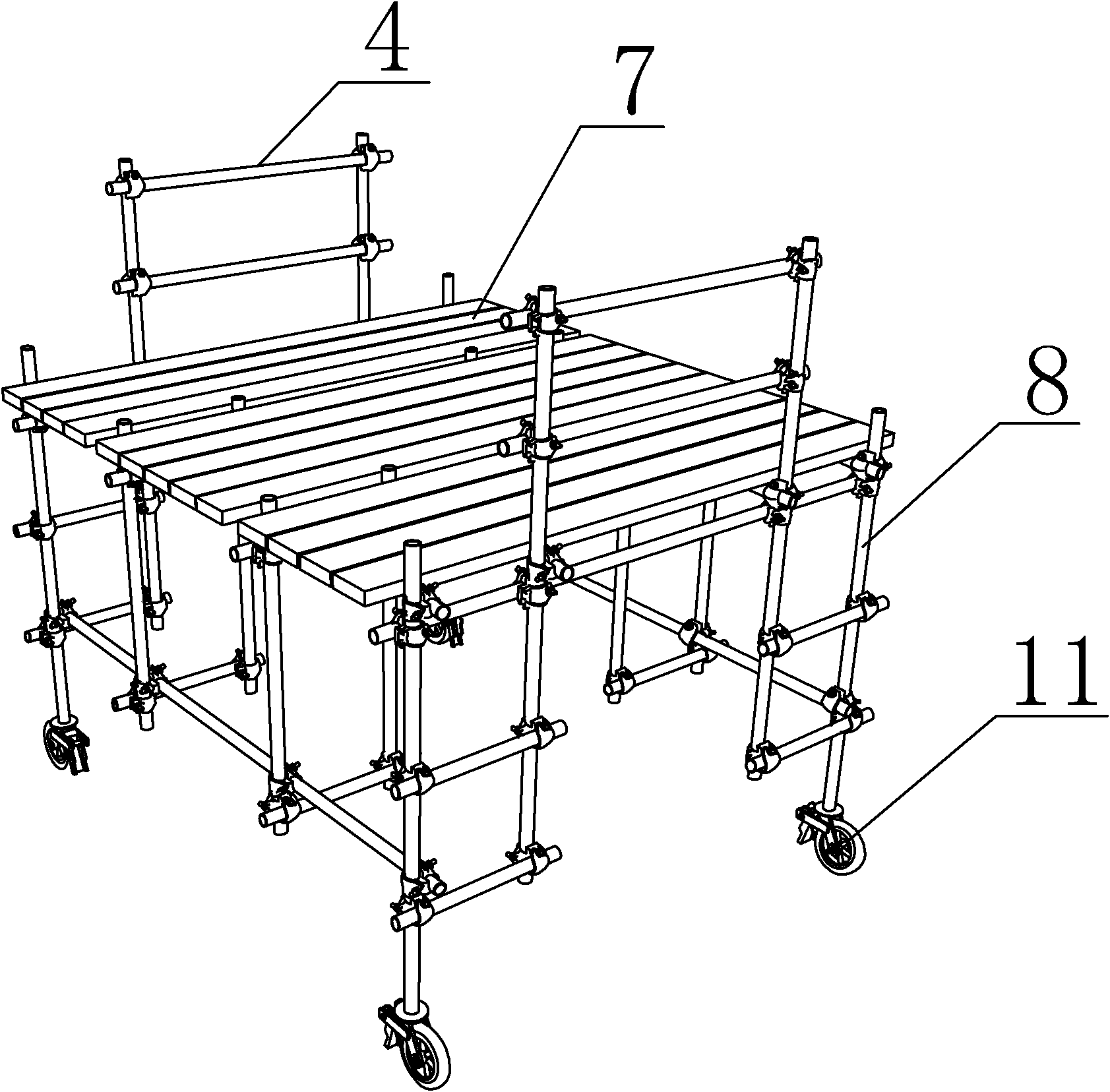

Method for building vault lining of flue

InactiveCN101870872AElevation control is simpleEasy to moveCoke oven brickworkScaffold accessoriesFire brickRefractory

The invention discloses a method for building a vault lining of a flue. The method comprises the following steps of: during building a fire-proof vault lining of a coke oven flue (1) by using fire-proof bricks (2), supporting and moving a mould (3) for building a vault by using a movable operating platform and mould support integrated bracket so as to facilitate the construction of constructors on an operating platform of the bracket, and laying a fire-proof material on the operating platform at the same time. Because a mould adjustment support is arranged on the upper part of the movable bracket, the elevation control of the mould is simple; because the movable bracket adopts truckles and the lower part of the movable bracket is provided with a bracket adjustment support, the operating platform is convenient to move and has stronger bearing capacity; the operating platform and the movable bracket which are convenient to move are adopted so as to meet the construction requirement and reasonably allocate the labor force; and the movable bracket has a simple structure, is made of a common material, has the characteristics of economy, practicability and simple and convenient operation, and is easy to popularize.

Owner:CHINA FIRST METALLURGICAL GROUP

Hot patching process for bottom brick of carbonization chamber of coke oven

InactiveCN101805622APrevent burstGuaranteed Furnace LifeCoke oven brickworkBrickwork leakage repair/preventionCarbonizationMullite

The invention belongs to the technical field of improvement on a refractory process for a coke oven body, and discloses a hot patching process for a bottom brick of a carbonization chamber of a coke oven. The process comprises the following steps: cooling the repaired oven in advance to reach a target oven temperature of 1,120 DEG C on the machine side and 1,180 DEG C on the coke side; controlling the temperature of an oven head to between 950 and 1,000 DEG C; after the coke is completely pushed to the repaired oven, cooling the oven temperature to between 850 and 900 DEG C, and controlling the temperature of the oven head to between 800 and 850 DEG C; when cooling, putting an insulating brick retaining wall in the coke side direction on the coke side 1m away a repair section from a large cover port of the oven top; when the repaired oven is cooled to between 800 and 850 DEG C, ensuring that the temperature of the wall is above 700 DEG C; cleaning the damaged surface; replacing a silicon brick by using a mullite high-aluminum clay brick; and arranging an oven door on the machine side, and opening the oven door on the machine side when the temperature is raised to 1,100 DEG C to observe the repair effect. The process can fully avoid the problem of cracking during repairing the brick, realizes the maintenance of coke oven production under an abnormal working condition, and prolongs the service life of the coke oven.

Owner:NANJING IRON & STEEL CO LTD

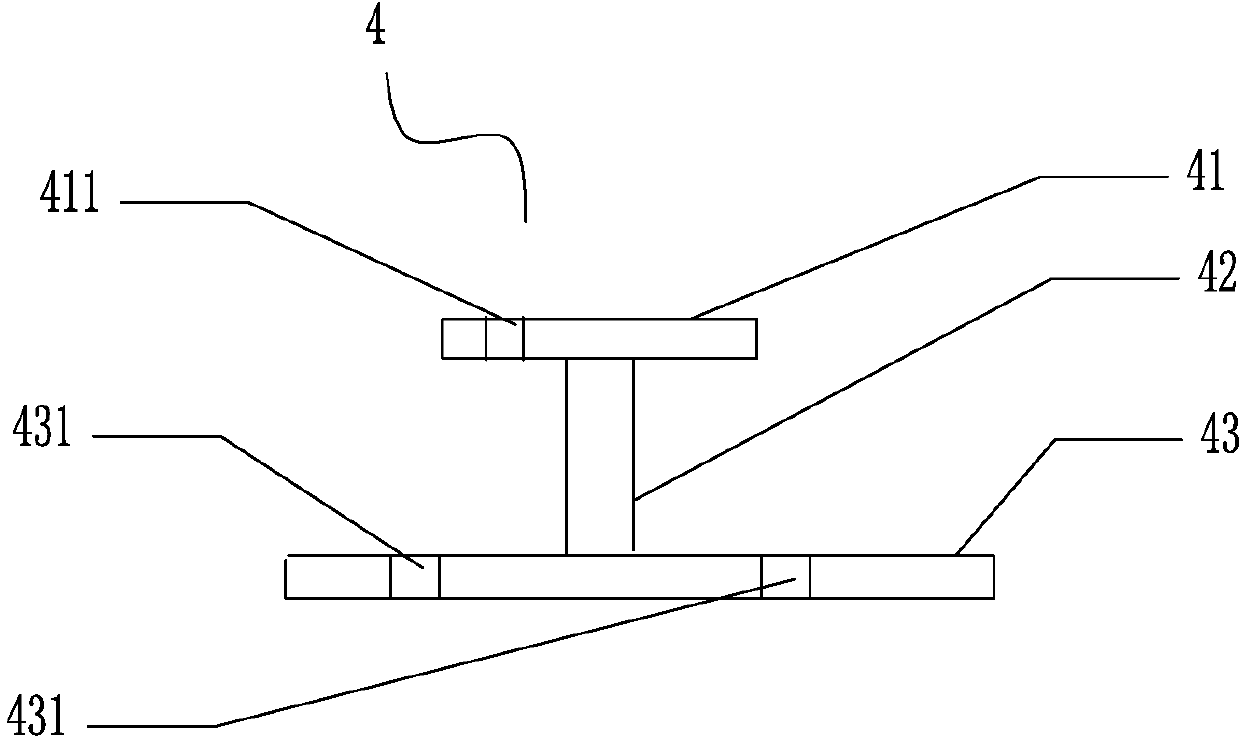

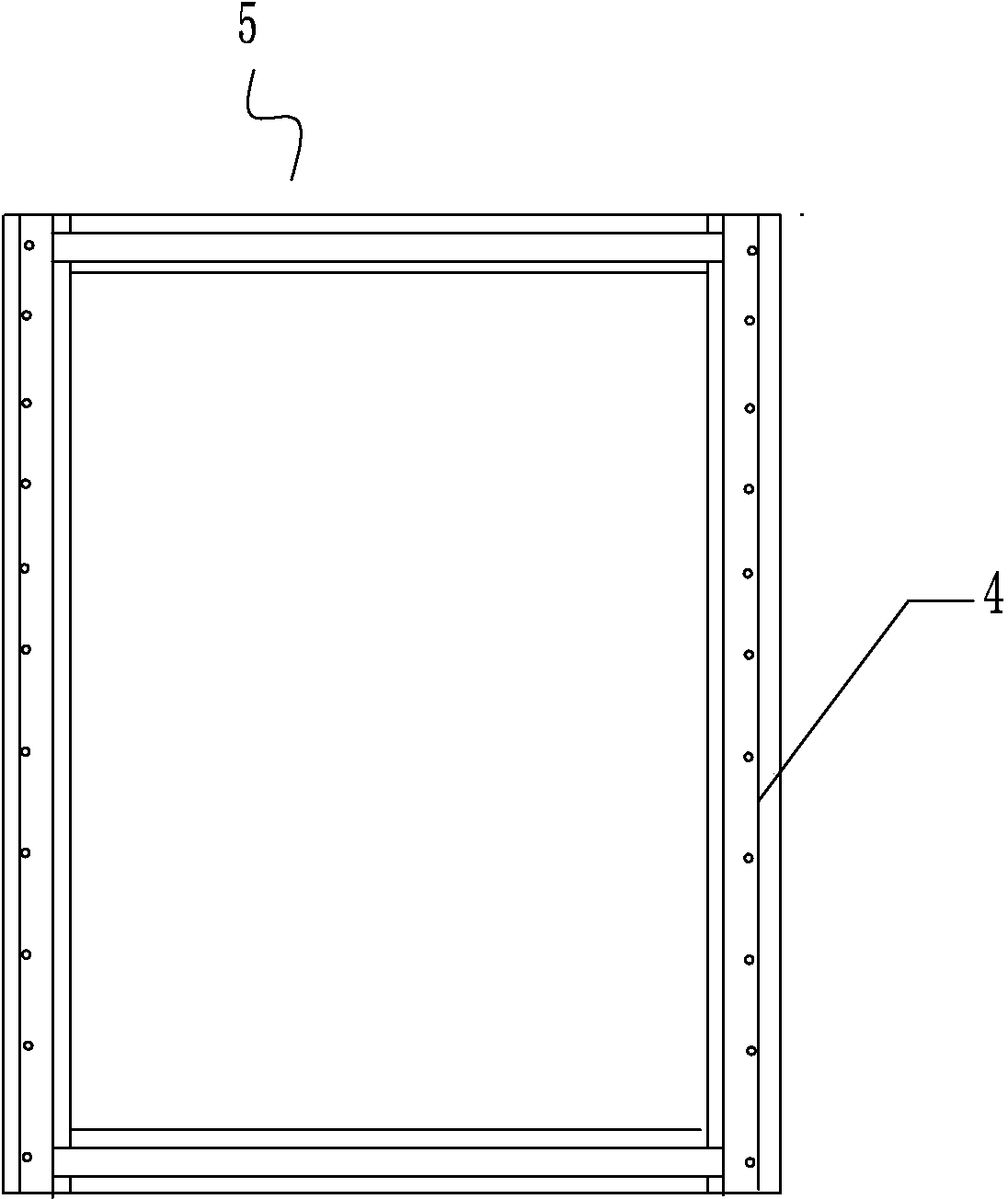

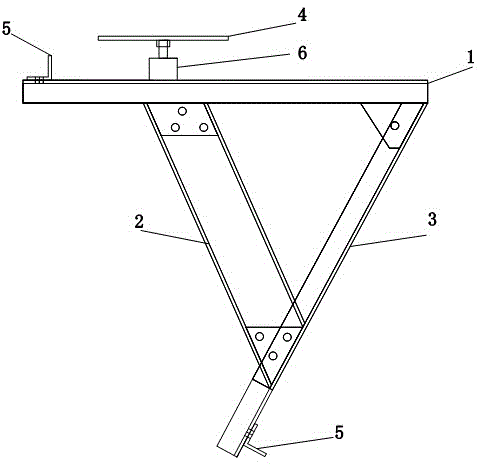

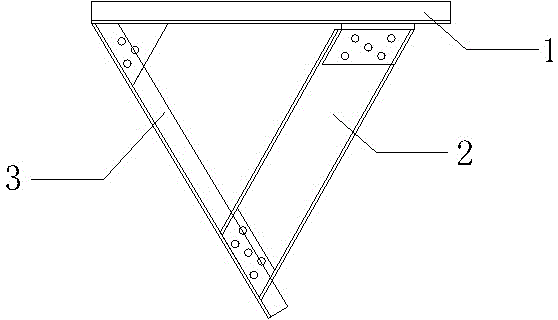

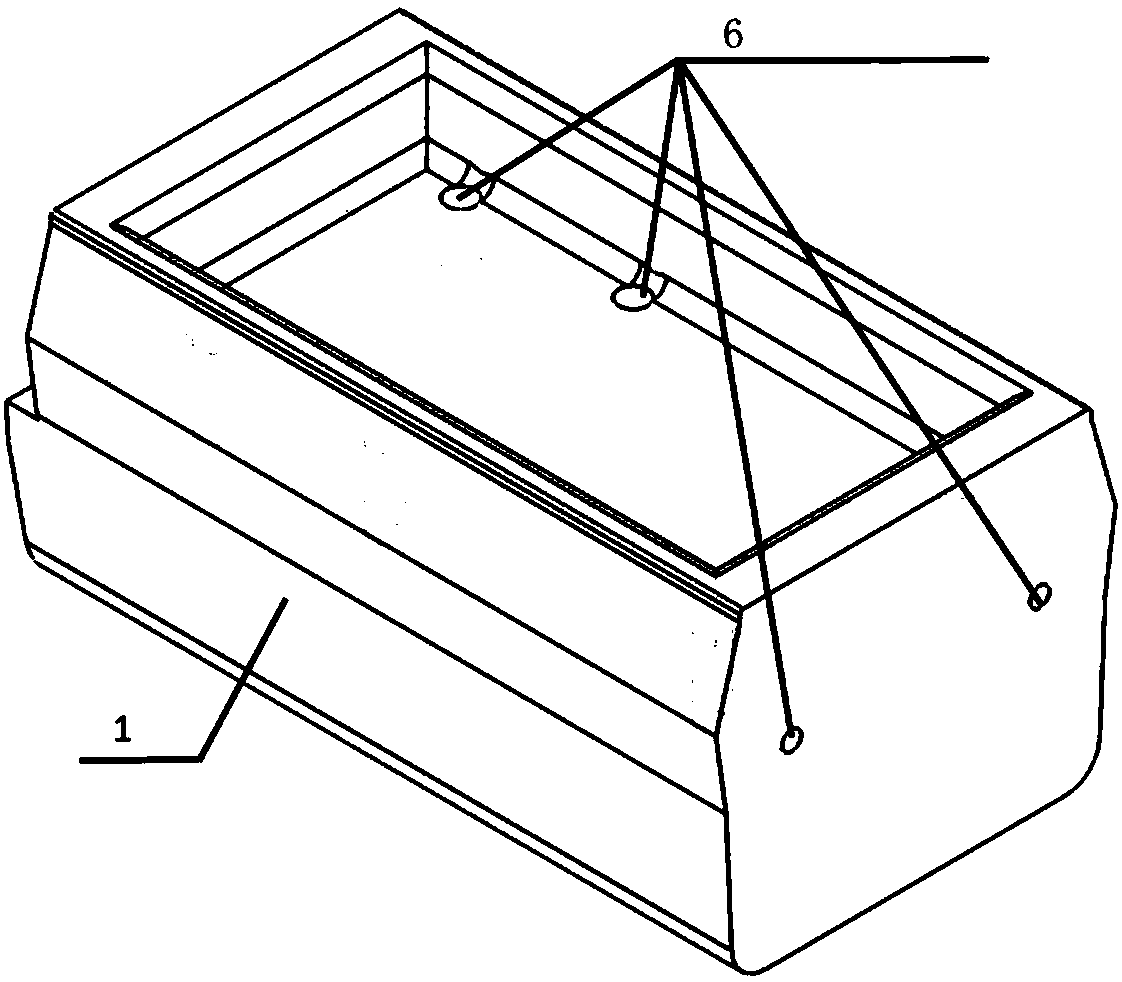

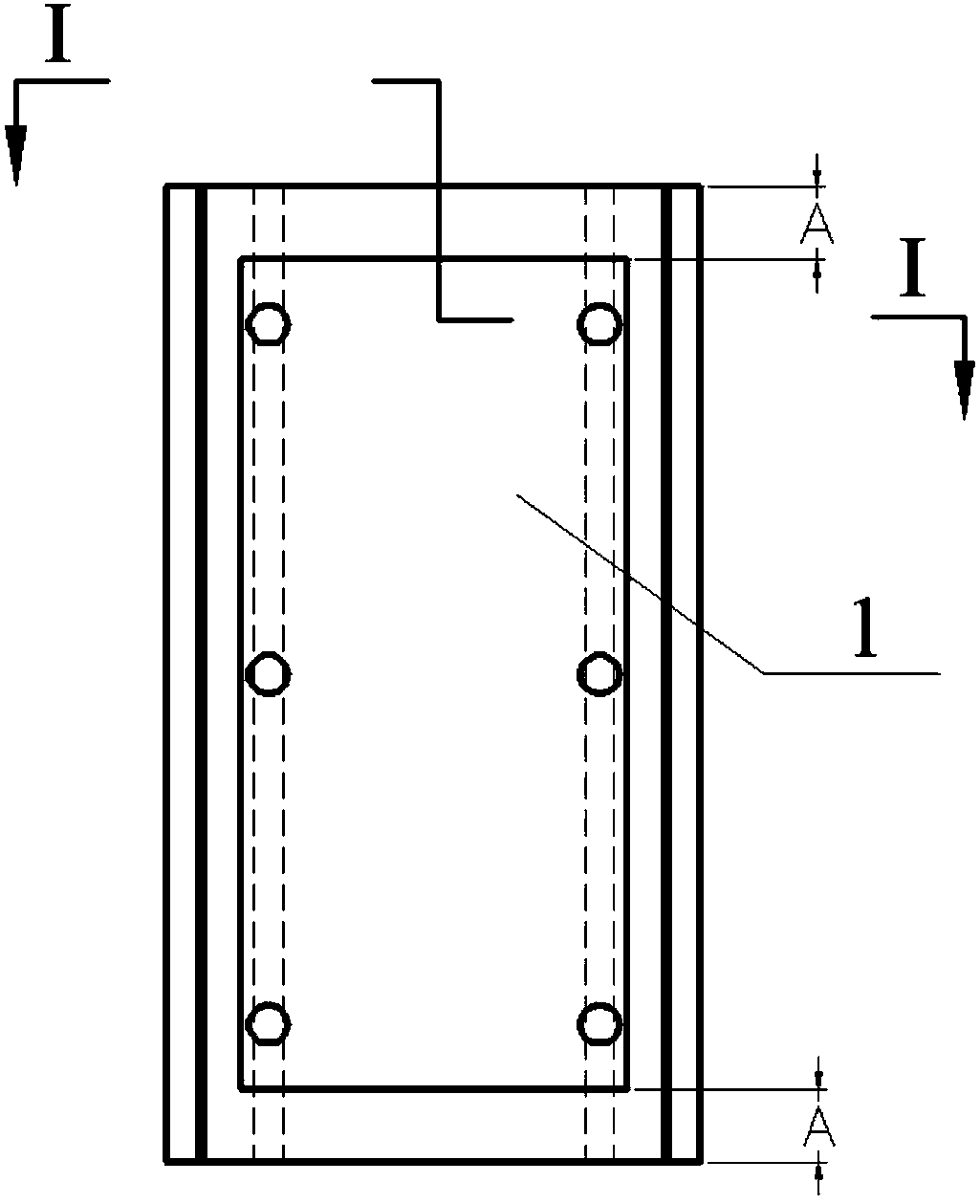

False corbel bracket and using method thereof during examining and repairing corbel bricks in dry quenching chute

ActiveCN104560065ASimple structureEasy to manufactureCoke quenchingCoke oven brickworkBrickRefractory

The invention relates to a false corbel bracket. The false corbel bracket comprises a bearing beam (1), a support member (2) and a chute opening contact member (3). The corbel bracket is characterized in that the bearing beam (1) is a steel beam horizontally arranged, screw holes are respectively formed in both ends of the support member (2), and a screw hole is formed in one end of the chute opening contact member (3), so that the chute opening contact member (3) is in bolt connection with the bearing beam (1) through a bolt; a stiffened plate with a screw hole is fixedly welded to the lower part of the other end of the chute opening contact member (3), so that the chute opening contact member (3) is in bolt connection with the support member (2) through a bolt; a screw hole is formed in the other end part of the chute opening contact member (3), so that the chute opening contact member (3) is in bolt connection with angle steel (5) through bolts; therefore, the false corbel bracket is formed through overlapping of the support member (2) and the chute opening contact member (3) below the bearing beam (1) in a Y shape. The false corbel bracket and the using method thereof during examining and repairing corbel bricks in a dry quenching chute, disclosed by the invention, have the advantages that the false corbel bracket is simple in structure, is convenient to manufacture, and the bricks on a corbel are supported to ensure that the bricks do not collapse and to ensure that in a replacing process of the corbel bricks, the structure of fireproof materials of a furnace body is not damaged.

Owner:MCC5 GROUP CORP SHANGHAI

7.63m coke oven upper spanning hole masonry method

The invention discloses a masonry method for cross-over holes on a coke oven of 7.63m, including the coke oven of 7.63m and the cross-over holes on the oven. The holes comprise an upper layer and a lower layer, and an interlayer is arranged between the cross-over holes of the upper layer and the lower layer and provided with two through holes, the cross-over holes of the two layers form mutually communicating channels by the through holes of the interlayer, the interlayer divides the cross-over hole of the upper layer into five areas, which are respectively the area above the right middle of the interlayer and four areas at two sides of the through holes of the interlayer, the whole area above the right middle of the interlayer is the masonry with silica brick, and the upper cross-over hole is completely plugged, waste gas is prevented from flowing to adjacent flame paths; the four areas at two sides of the through holes of the interlayer adopt the refractory materials with little density and the property of heat insulation for masonry and blockage. The masonry method of the invention limits hot waste gas to flow on the upper part of a combustion chamber, takes advantage of the heat insulation property of the refractory materials to stop heat transfer, effectively prevents the temperature of the top space of the coke oven from rising and further lowers the temperature of the top of the coke oven and the consumption of gas.

Owner:武汉钢铁有限公司

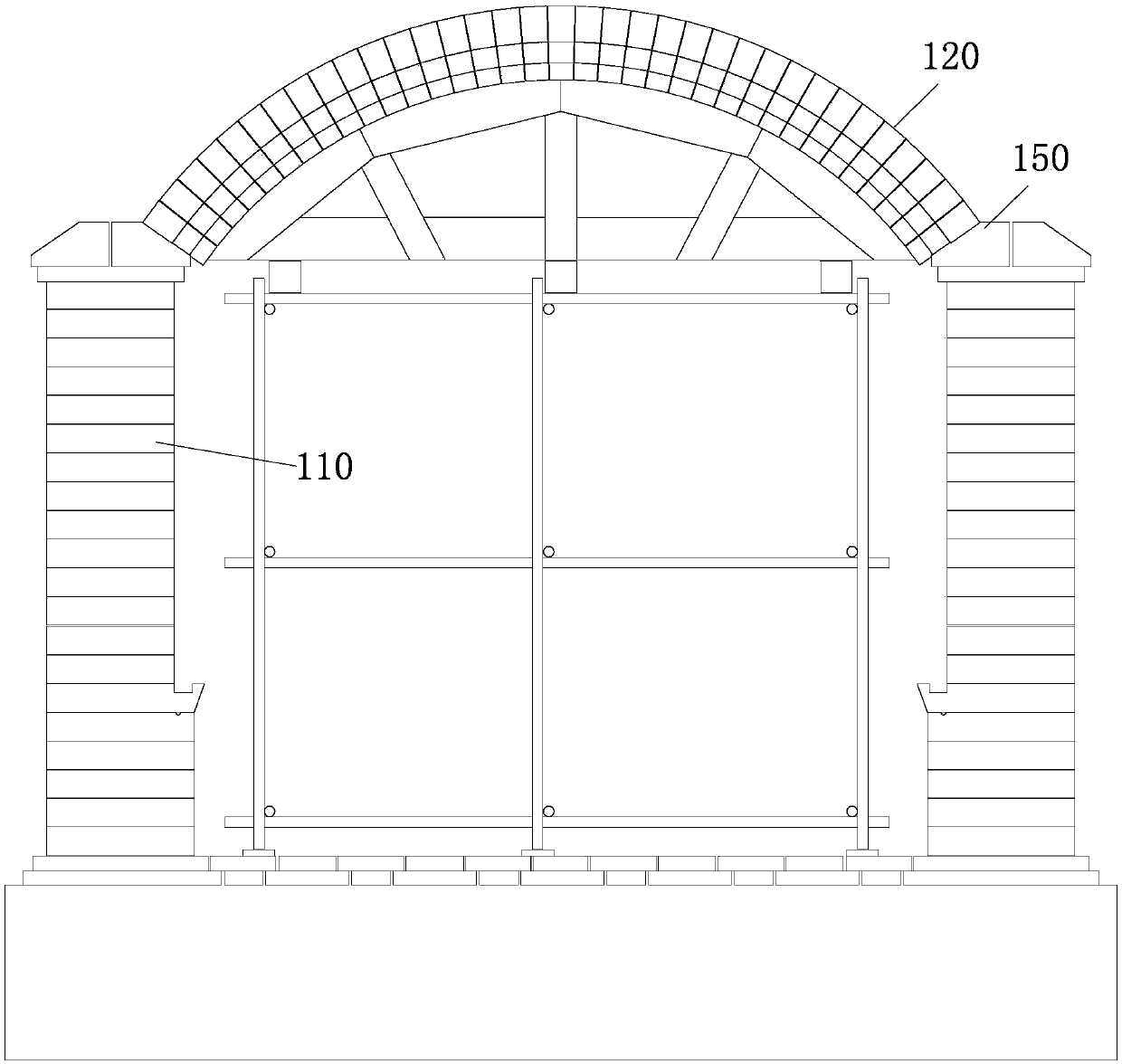

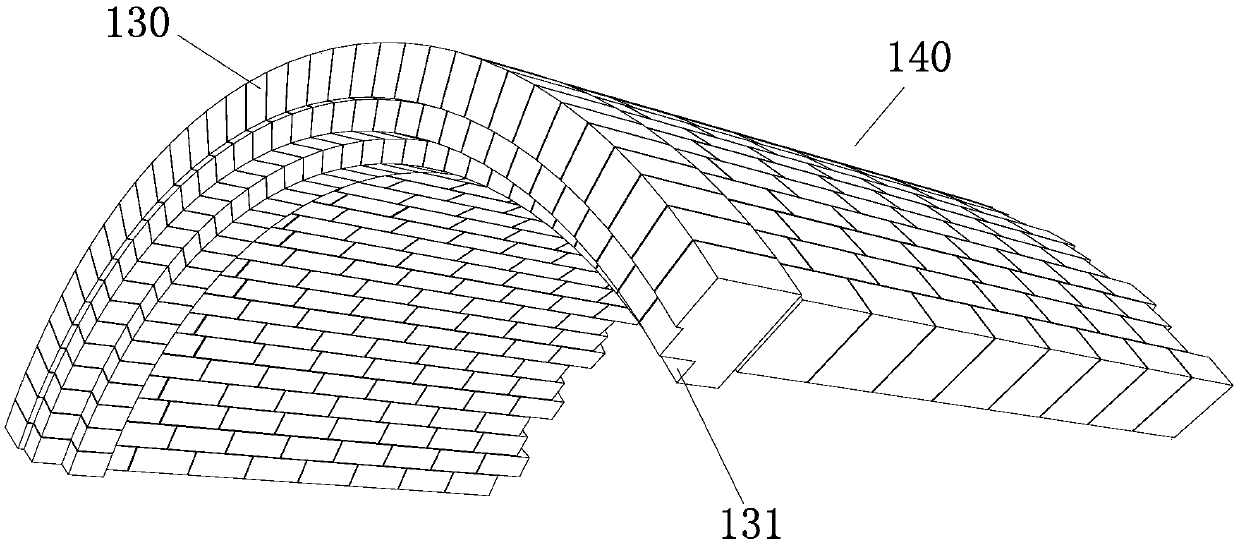

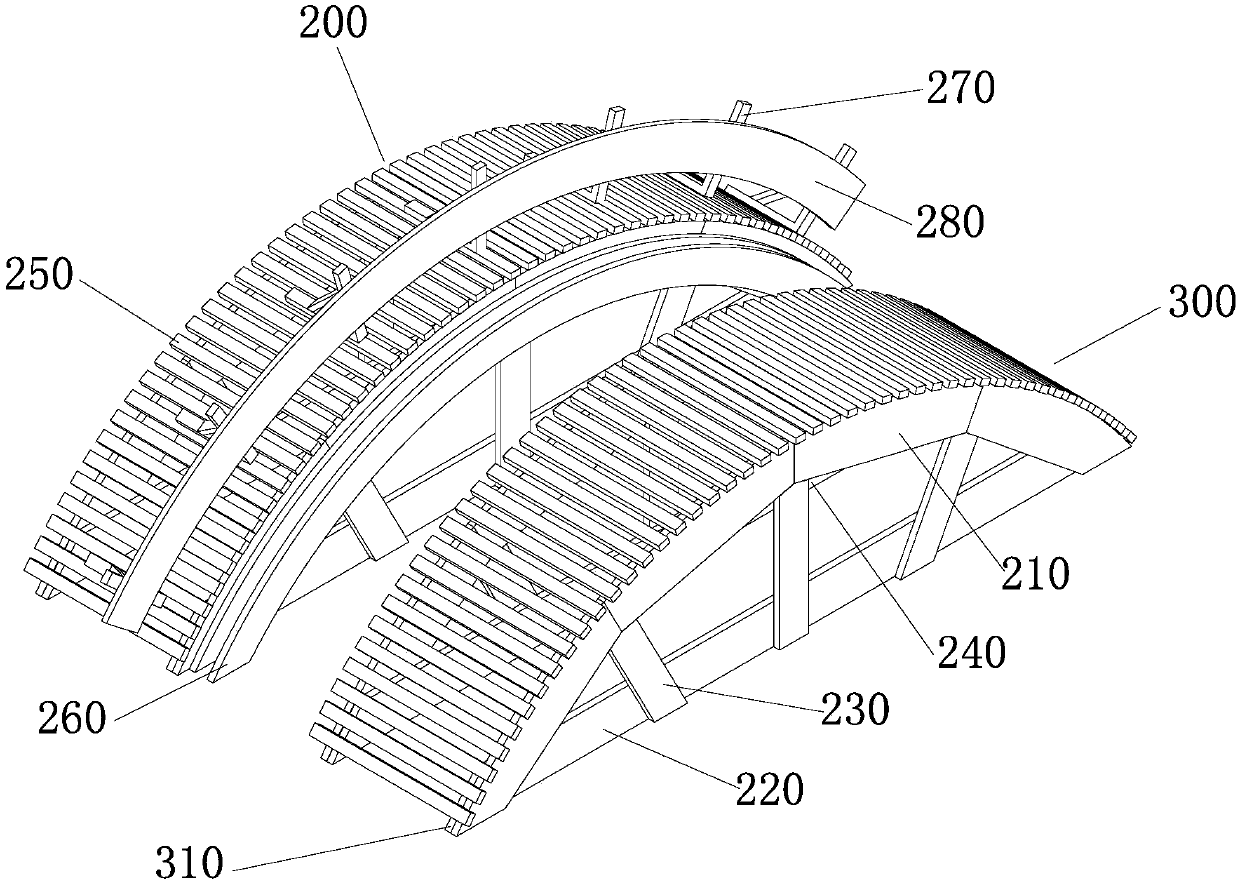

Furnace opening vault laying control device and method for heat recovery coke furnace

The invention relates to a furnace opening vault laying control device for a heat recovery coke furnace. The device comprises a furnace opening outer side arch body, a hearth arch body and a supporter, a boss bed mould is arranged on the side, close to the hearth arch body, of the furnace opening outer side arch body, and the upper surface of the boss bed mould supports the bottom surfaces of furnace opening bricks; the boss bed mould and an arch body strip of the furnace opening outer side arch body form a staggered platform structure, and the staggered platform structure is matched with bosses at the lowest ends of the furnace opening bricks; a limit bracket is arranged on the arch body strip of the furnace opening outer side arch body, an arc limit plate is installed on the inner side of the limit bracket, and the inner side surface of the limit plate closely fits the front surfaces of the furnace opening bricks; the supporter comprises a first supporting base and a second supporting base which are arranged at the two ends, in the laying process, the first supporting base is supported on the reverse surfaces of the furnace opening bricks, and the second supporting base is supported on the hearth arch body. According to the device, it can be ensured that in the process of laying the furnace opening bricks, the front surfaces of the furnace opening bricks are perpendicular, after the process of laying the furnace opening bricks, in the process of laying other vault bricks, the vault of the furnace opening bricks is kept stable, and the deflection phenomenon cannot occur.

Owner:CHINA FIRST METALLURGICAL GROUP

Down-adjusted 7m coke oven regenerative chamber constructing method

InactiveCN104927882AImprove working environmentCreate pollutionCoke oven brickworkBrickArchitectural engineering

The invention discloses a down-adjusted 7m coke oven regenerative chamber constructing method. The method comprises the following steps: firstly, alternately constructing main wall, single wall, small flue lining bricks and grating bricks of a small flue construction section according to construction section and construction order; and then, alternately constructing main wall, single wall, down-adjusted hole adjusting bricks, checker bricks, partition and enclosing wall of a regenerative chamber construction section according to construction section and construction order until reaching the top of a regenerative chamber. Therefore, the constructing method can expand a construction working surface, guarantee constructing quality, facilitate quality inspection, improve working efficiency, improve the working environment of workers and avoid dust pollution to the environment.

Owner:MCC TIANGONG GROUP

Coke oven reconstruction

InactiveCN101225312AGood dimensional stabilityNegligible thermal expansionFurnace componentsCoke oven brickworkEngineeringCoke oven

A new, faster and more efficient process to replace heating walls and ceilings in coke oven batteries. Thus, when replaced, at least one heating wall is constructed of thermally stable non-expanding large size modular cast modules from end to end and the ceiling adjacent the heating wall is constructed of thermally stable non-expanding large modular cast blocks.

Owner:VANOCUR REFRACTORIES LLC

An energy-saving door lining brick for a coke oven

The invention relates to a door structure of a coke oven, and particularly relates to an energy-saving door lining brick for a coke oven. The door lining brick includes a lining brick main body, a glaze surface, a web and fastening members. The lining brick main body is provided with at least one concave type hollow structure, and is provided with fastening member connecting holes. The glaze surface is hung on the external surface, in contact with coke, of the lining brick main body. The wed covers the concave type hollow structure. The upper surface of the lining brick main body is in close contact with the web. The web and the lining brick main body are fastened through the fastening members so that the concave type hollow structure becomes a sealed cavity. The bottom of the web is coated with a coating. Heat-reflecting coating having high reflectivity is adopted by the coating. The lining brick is a fire-resistant precast block lining brick, and has a height of 500-2000 mm. The lining bricks are arranged into a row up and down and are tightly mounted inside an oven door frame. The lining brick can greatly reduce the present oven door thickness, reduce the temperature of the external wall of an oven door, reduce heat loss and save energy.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com