Flue arch crown online opening pipe connecting method for smoke waste-heat utilization of coke oven

A flue gas waste heat and flue technology, applied in coking oven bricklaying operations, energy input, etc., can solve the problems of environmental pollution, waste of energy, etc., achieve reasonable production steps, high production efficiency, and overcome high temperature and negative pressure suction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

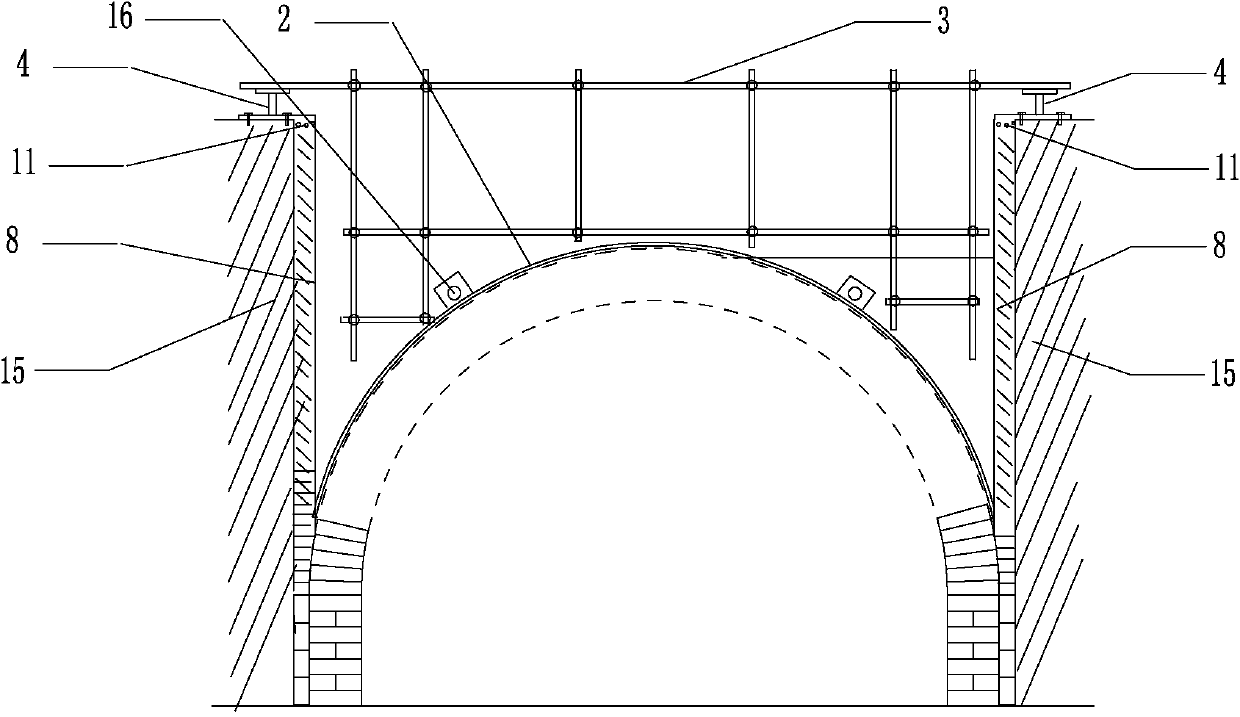

[0042] The flue vault online opening connection method for coke oven flue gas waste heat utilization of the present invention is characterized in that it comprises the following steps:

[0043] a. Flue concrete crushing and demolition

[0044] Lay out 3000mm×3200mm wires at the front and rear openings of the flue flap valve, use a drill breaker to drill holes at the corners of the sidelines, then use a concrete cutting chainsaw to cut the concrete, and finally use a crane to lift out the concrete as a whole ;

[0045] b. Clay refractory bricks are built in the gap between the flue vault 1 and the concrete 15

[0046] Determine the aperture of the flue vault according to the diameter of the outer flue pipe, 2400mm×2600mm. After cleaning the insulation bricks between the flue vault and the concrete gap, build a 230mm thick clay refractory brick on the flue vault to form a rectangular wellhead of 2400mm×2600mm;

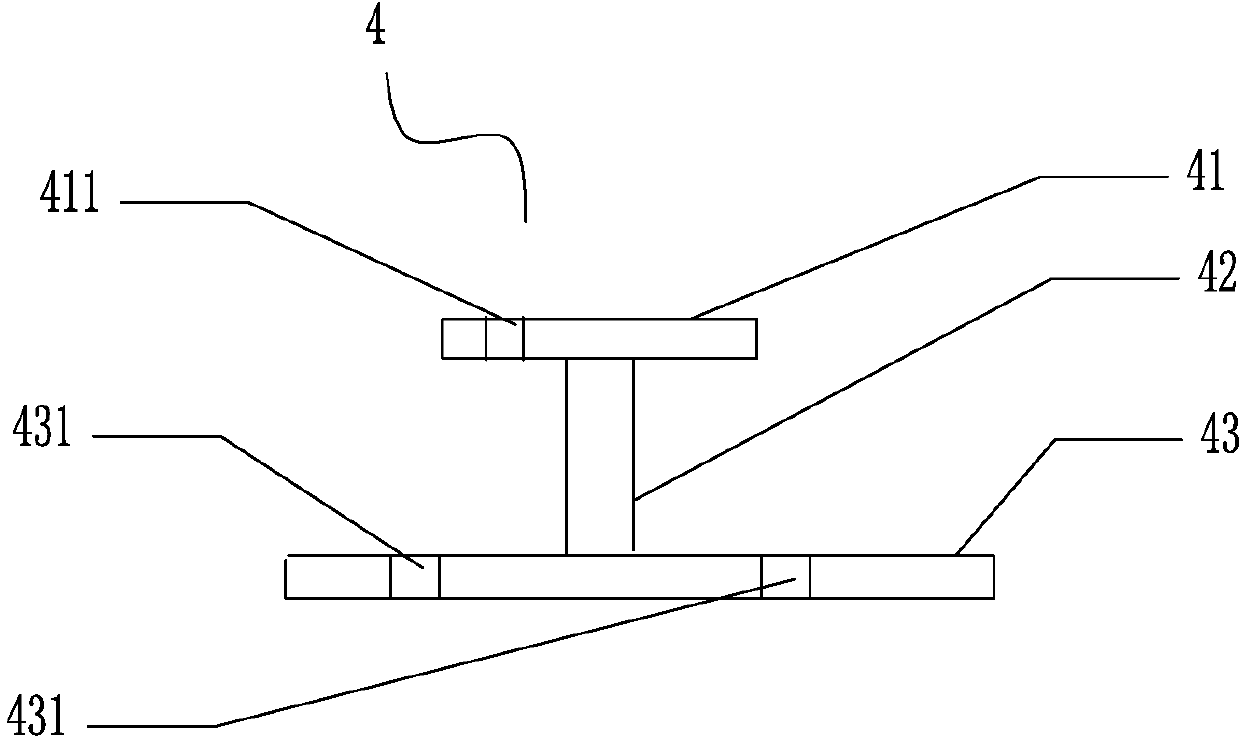

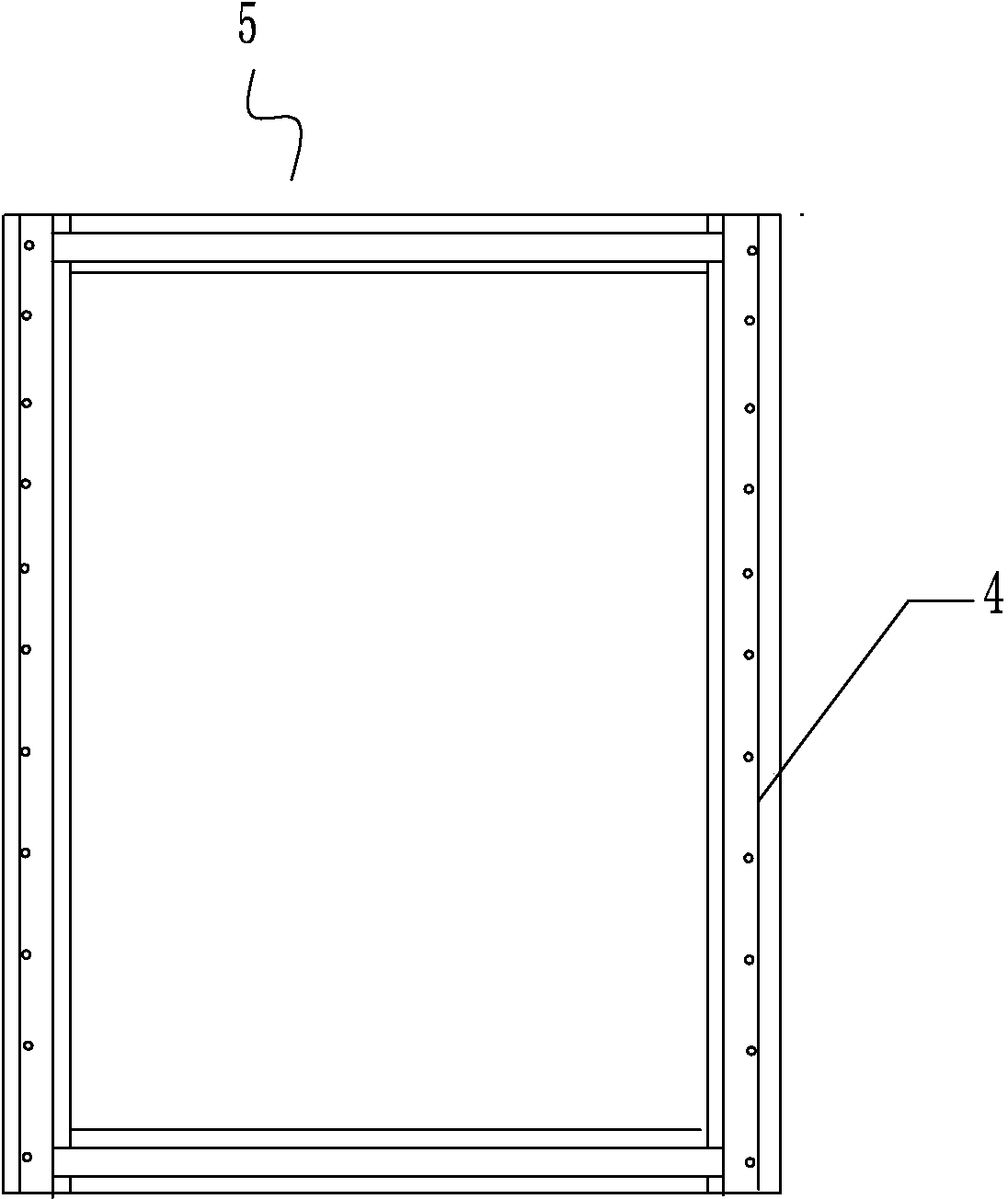

[0047] c. The manufacture and installation of the steel wellhead...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com