Device and method for denitrifying flue gas of coking furnace

A desulfurization device and denitrification technology, applied in the field of coke oven flue gas denitrification, can solve the problems of high operating cost and unsatisfactory operating conditions of SCR, and achieve the effects of no waste liquid discharge, little influence of chimney suction, and large thermal gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

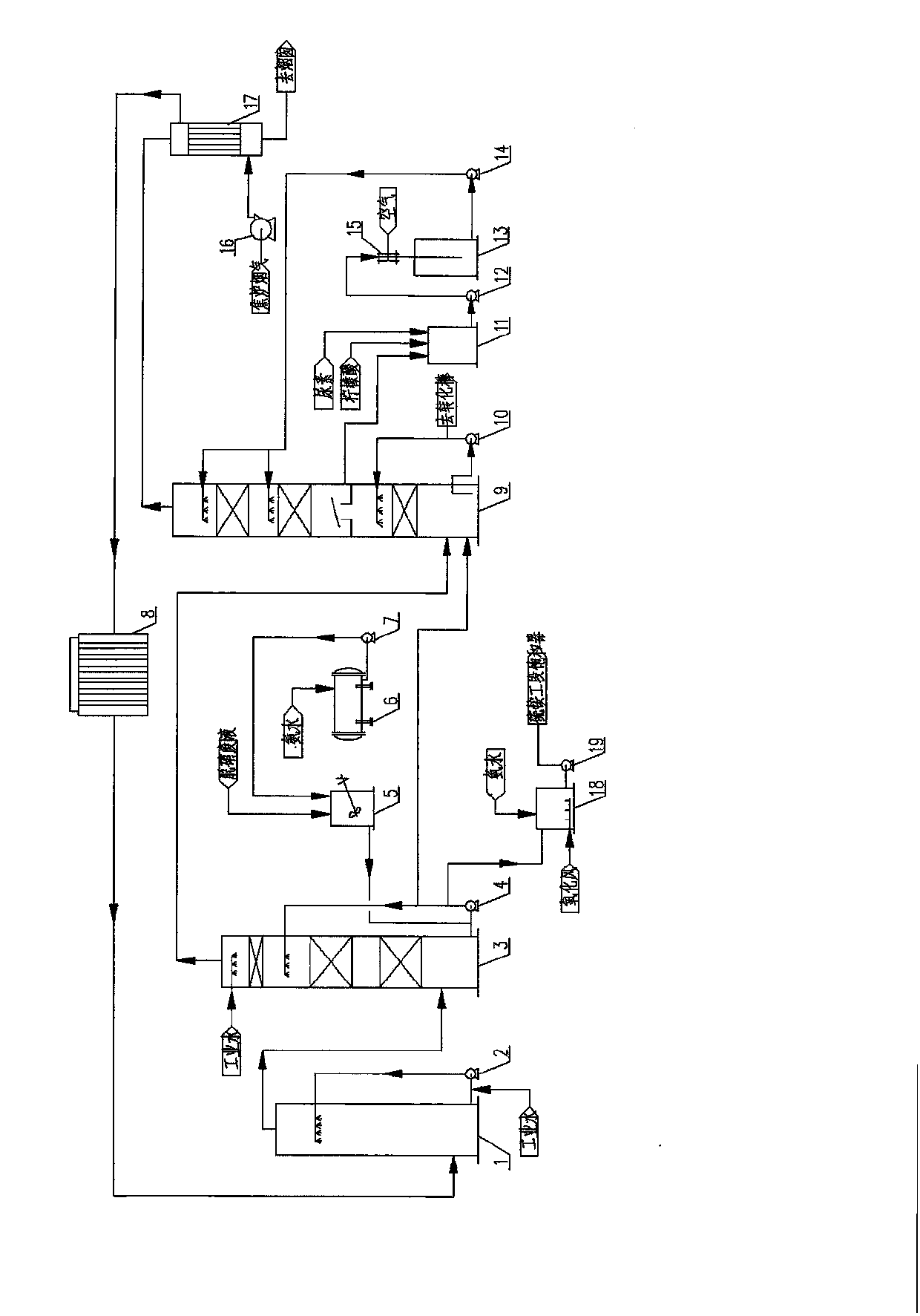

[0076] A. The coke oven flue gas is cooled three times:

[0077] After the coke oven flue gas at a temperature of 258°C enters the heat exchanger 17 through the induced draft fan 16, it exchanges heat with the purified flue gas from the denitrification tower 9 in the heat exchanger 17. The purified flue gas is heated to a higher temperature, and the coke oven smoke After the gas is cooled once, the temperature drops to 181°C, and then the purified flue gas enters the chimney to be discharged. After cooling, the coke oven flue gas enters the waste heat boiler 8 for heat exchange and cooling with soft water. After the second cooling, the temperature of the coke oven flue gas drops to 82°C , the coke oven flue gas from the waste heat boiler 8 enters the cooling and humidifying tower 1, and the coke oven flue gas is circulated and sprayed with industrial water for three times for cooling through the humidification pump 2, and the temperature of the coke oven flue gas drops to 71°C....

Embodiment 2

[0087] A. The coke oven flue gas is cooled three times:

[0088] After the coke oven flue gas with a temperature of 264°C enters the heat exchanger 17 through the induced draft fan 16, it exchanges heat with the purified flue gas from the denitrification tower 9 in the heat exchanger 17. The purified flue gas is heated to a higher temperature, and the coke oven smoke After the gas is cooled once, the temperature drops to 186°C, and then the purified flue gas enters the chimney to be discharged. After cooling, the coke oven flue gas enters the waste heat boiler 8 for heat exchange and cooling with soft water. After the second cooling, the temperature of the coke oven flue gas drops to 85°C , the coke oven flue gas from the waste heat boiler 8 enters the cooling and humidifying tower 1, and the coke oven flue gas is circulated and sprayed with industrial water for three times for cooling through the humidification pump 2, and the temperature of the coke oven flue gas drops to 74°...

Embodiment 3

[0098] A. The coke oven flue gas is cooled three times:

[0099] After the coke oven flue gas at a temperature of 271°C enters the heat exchanger 17 through the induced draft fan 16, it exchanges heat with the purified flue gas from the denitrification tower 9 in the heat exchanger 17. The purified flue gas is heated and the temperature of the coke oven flue gas After the gas is cooled once, the temperature drops to 189°C, and then the purified flue gas enters the chimney to be discharged. After cooling, the coke oven flue gas enters the waste heat boiler 8 for heat exchange and cooling with soft water. After the second cooling, the temperature of the coke oven flue gas drops to 89°C , the coke oven flue gas from the waste heat boiler 8 enters the cooling and humidifying tower 1, and the coke oven flue gas is circulated and sprayed with industrial water for three times for cooling through the humidification pump 2, and the temperature of the coke oven flue gas drops to 77°C. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com