Patents

Literature

406 results about "Coke burner" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

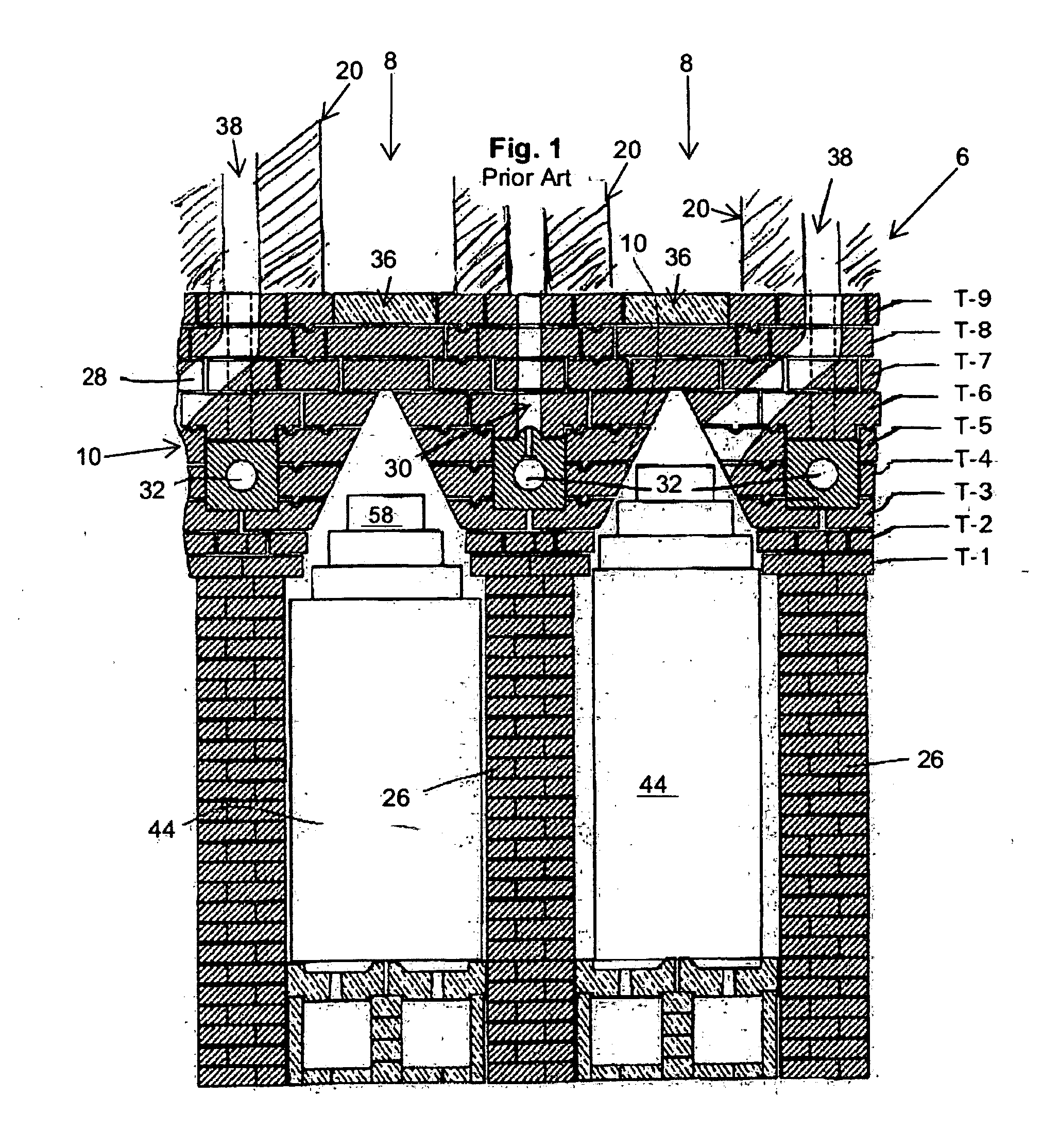

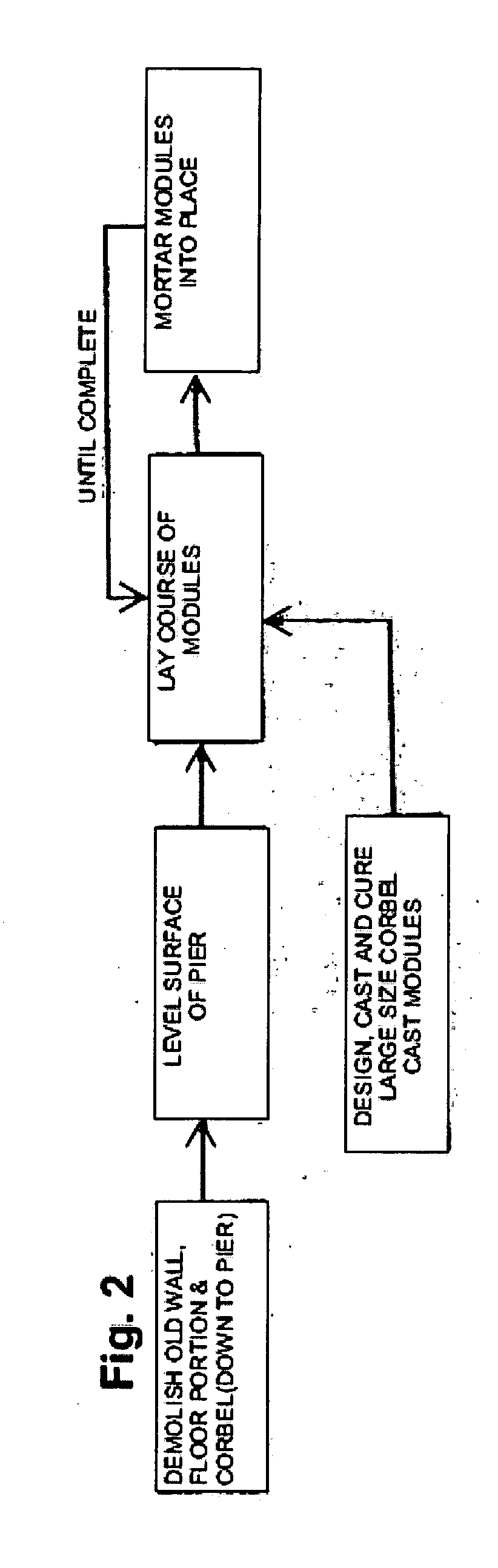

Corbel repairs of coke ovens

ActiveUS8266853B2Cost-effective constructionSave significant amountFurnace componentsFloorsEngineeringCoke oven

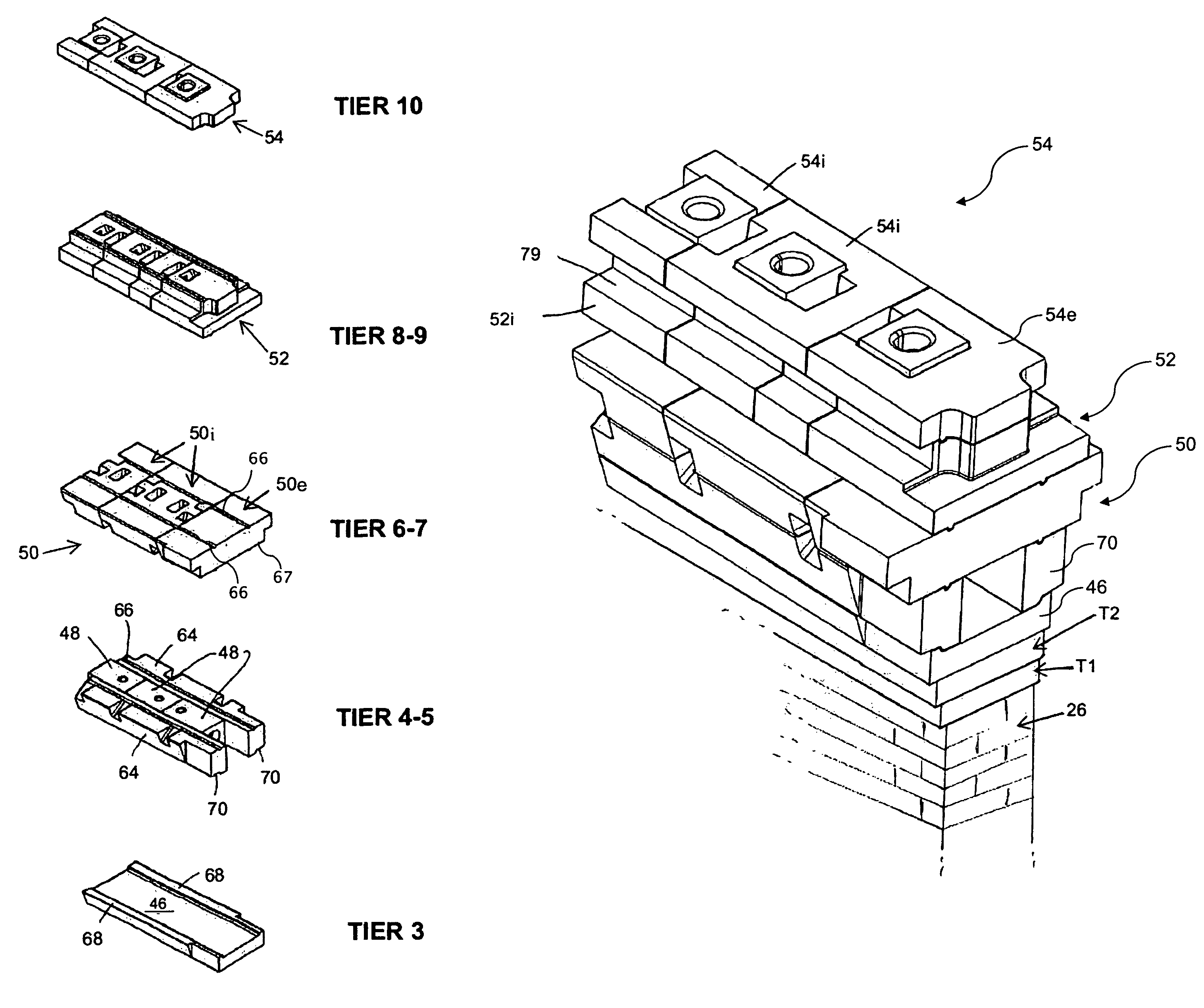

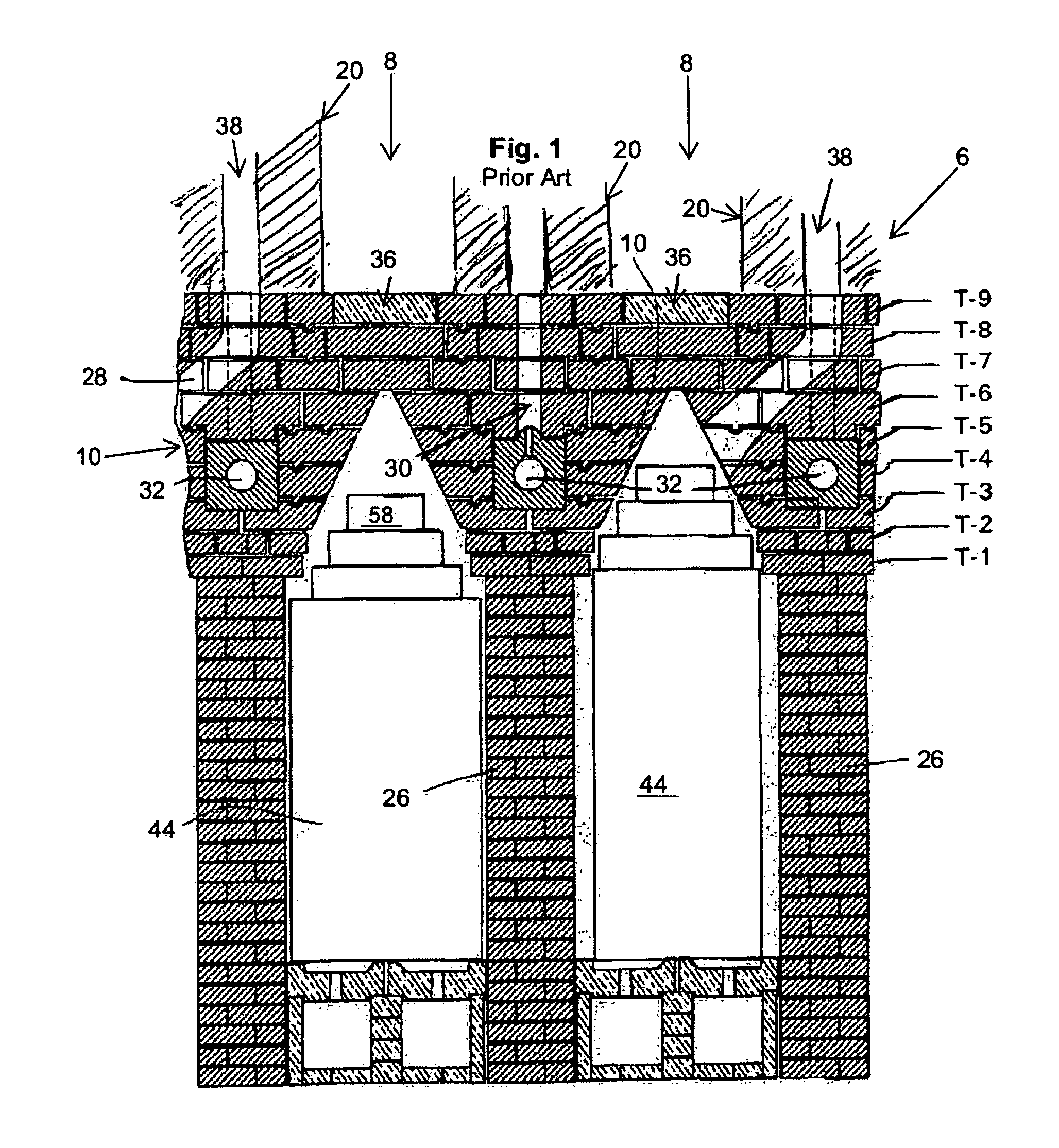

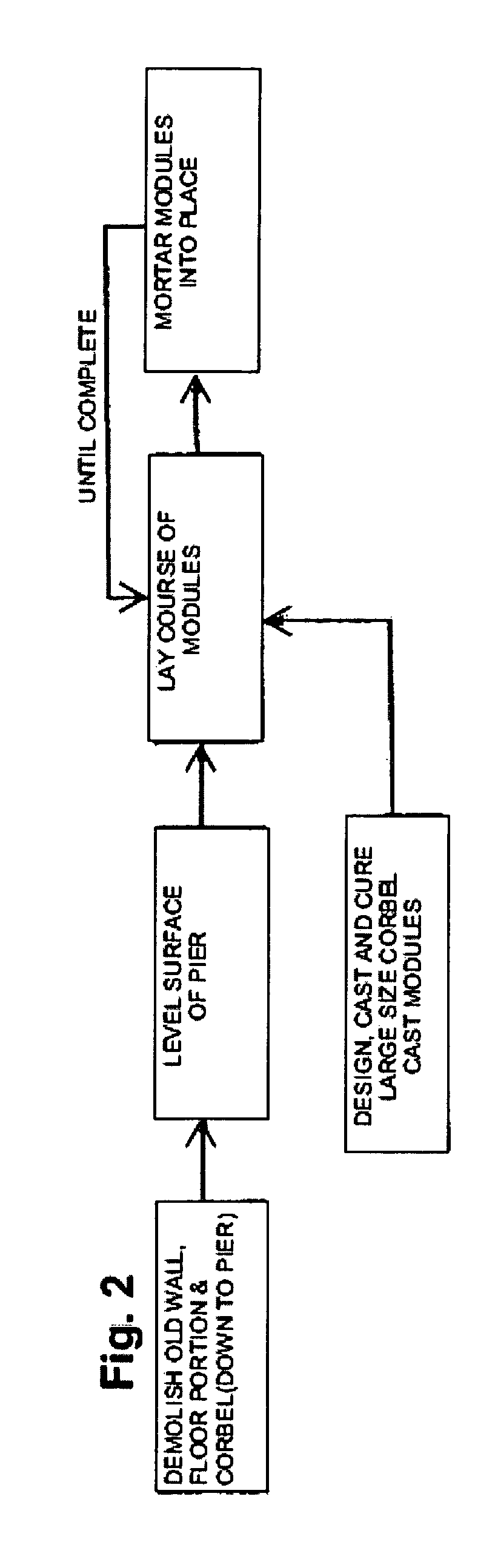

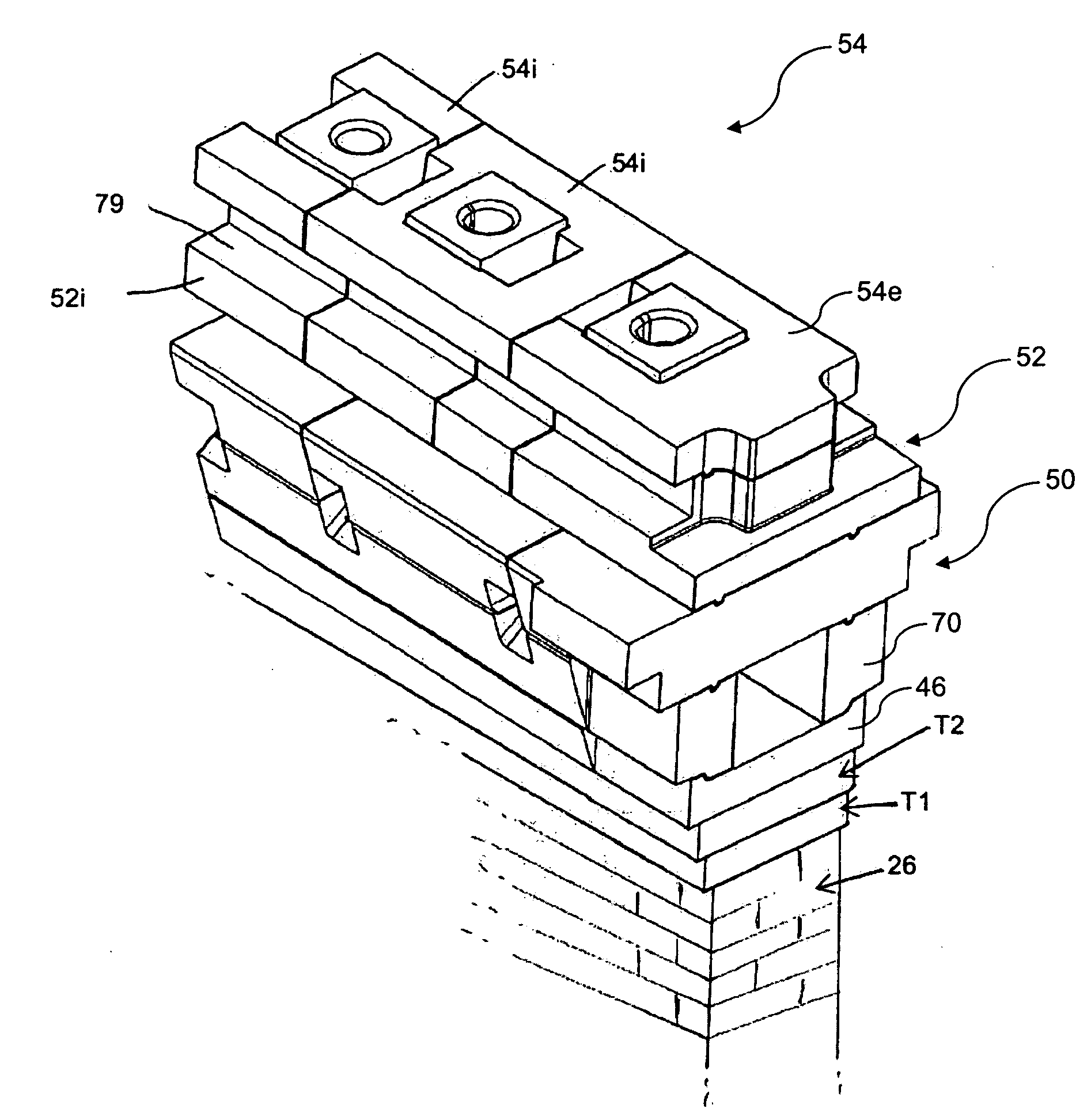

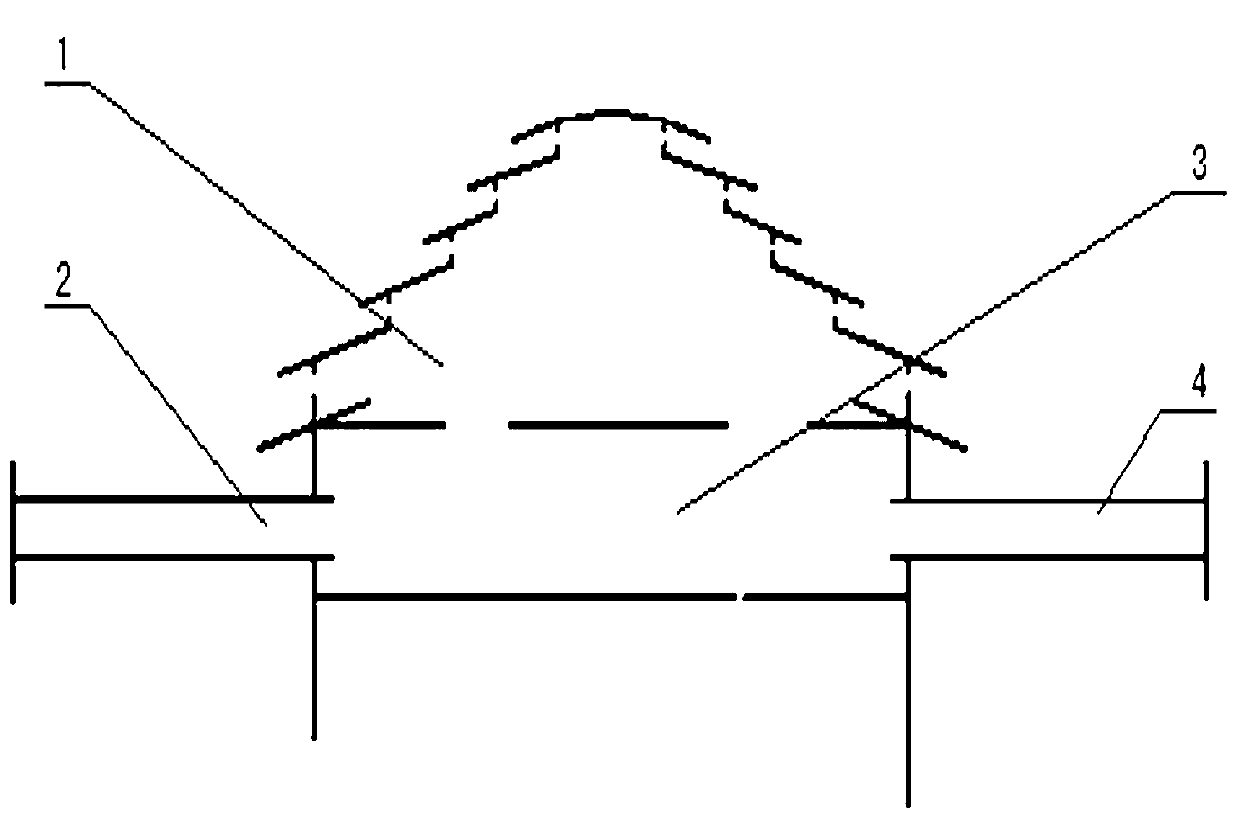

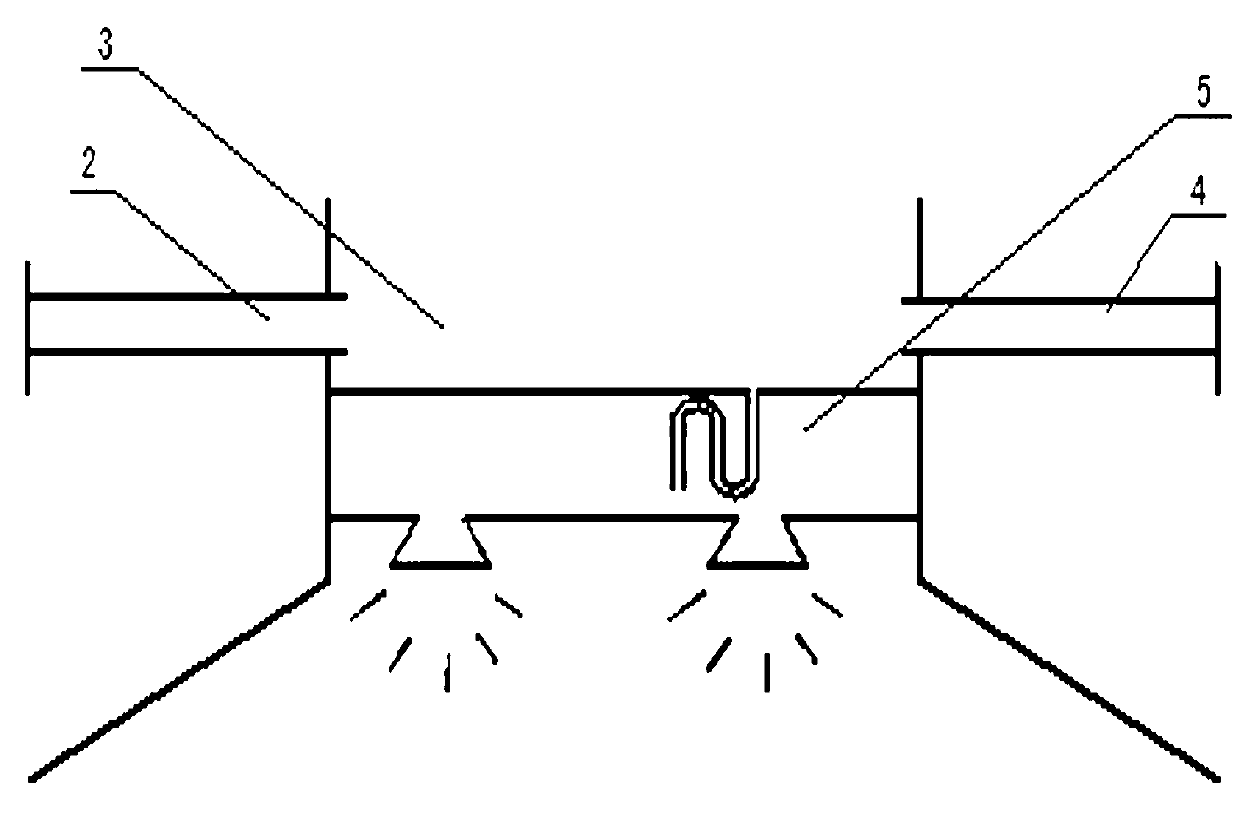

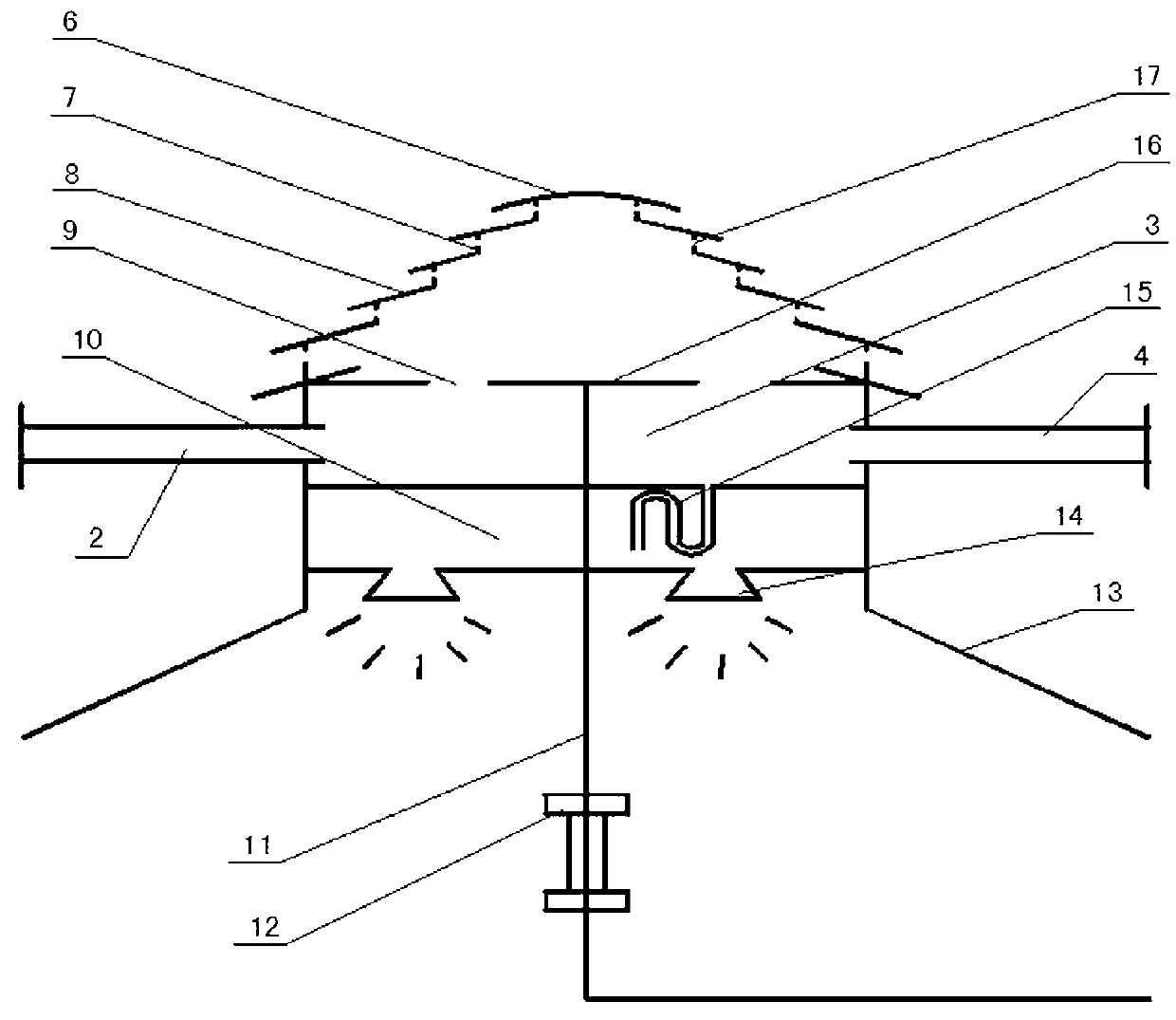

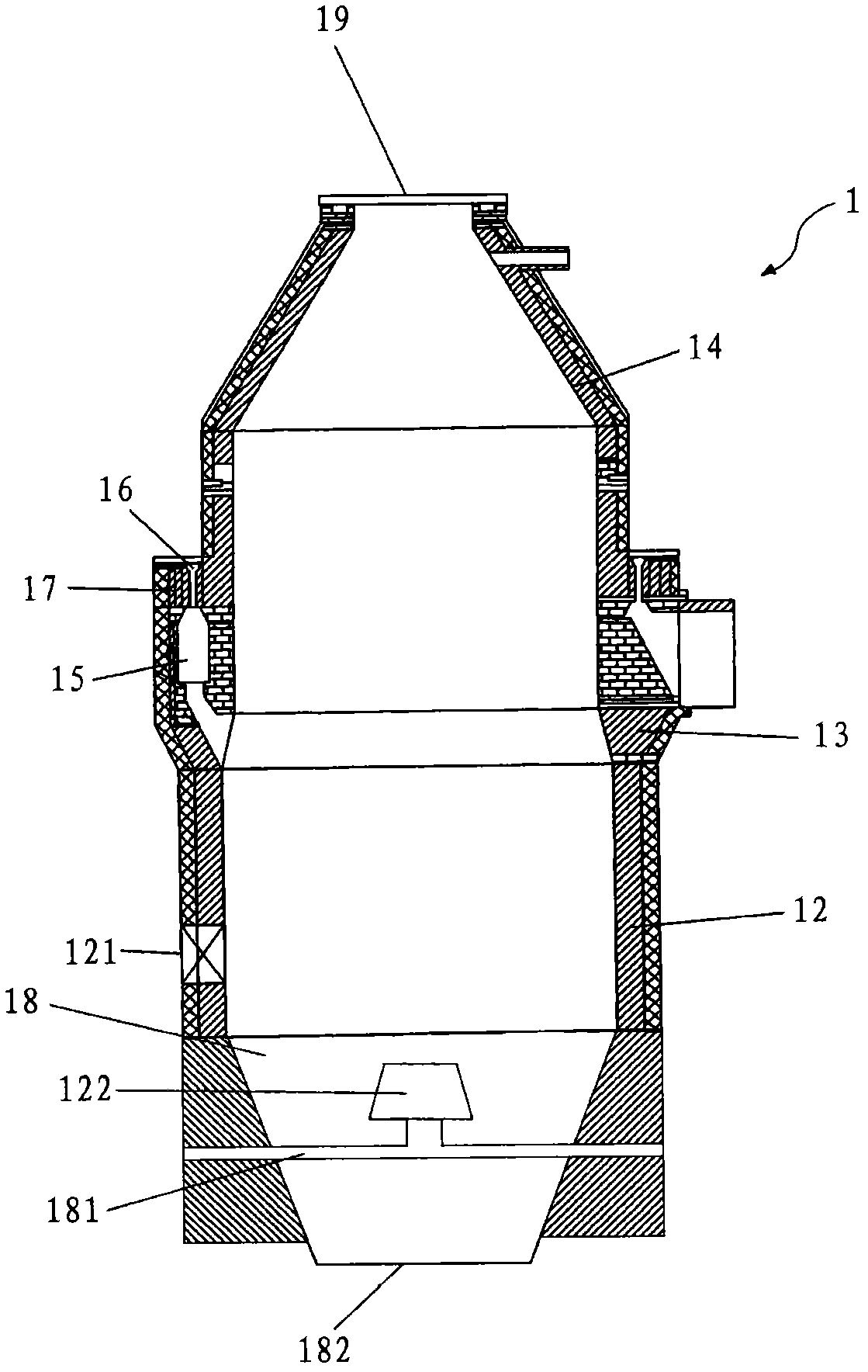

An improved corbel includes a first tier having first blocks and a second tier having second blocks. Each of the first blocks includes a first aperture extending through the block from a first surface to a back surface and a second aperture formed through a top surface of the block, extending into the first aperture. The first blocks are arranged on a substantially planar surface to align the respective first apertures to define a first passageway. Each of the second blocks includes a third aperture extending through the second block from a top surface to a bottom surface. The second blocks are disposed above the first tier to align the third aperture of each of the second blocks with the second aperture of the first blocks to form a second passageway.

Owner:VANOCUR REFRACTORIES LLC

Corbel repairs of coke ovens

ActiveUS20100287871A1Cost-effective constructionSave significant amountFurnace componentsWallsEngineeringCoke oven

An improved corbel includes a first tier having first blocks and a second tier having second blocks. Each of the first blocks includes a first aperture extending through the block from a first surface to a back surface and a second aperture formed through a top surface of the block, extending into the first aperture. The first blocks are arranged on a substantially planar surface to align the respective first apertures to define a first passageway. Each of the second blocks includes a third aperture extending through the second block from a top surface to a bottom surface. The second blocks are disposed above the first tier to align the third aperture of each of the second blocks with the second aperture of the first blocks to form a second passageway.

Owner:VANOCUR REFRACTORIES LLC

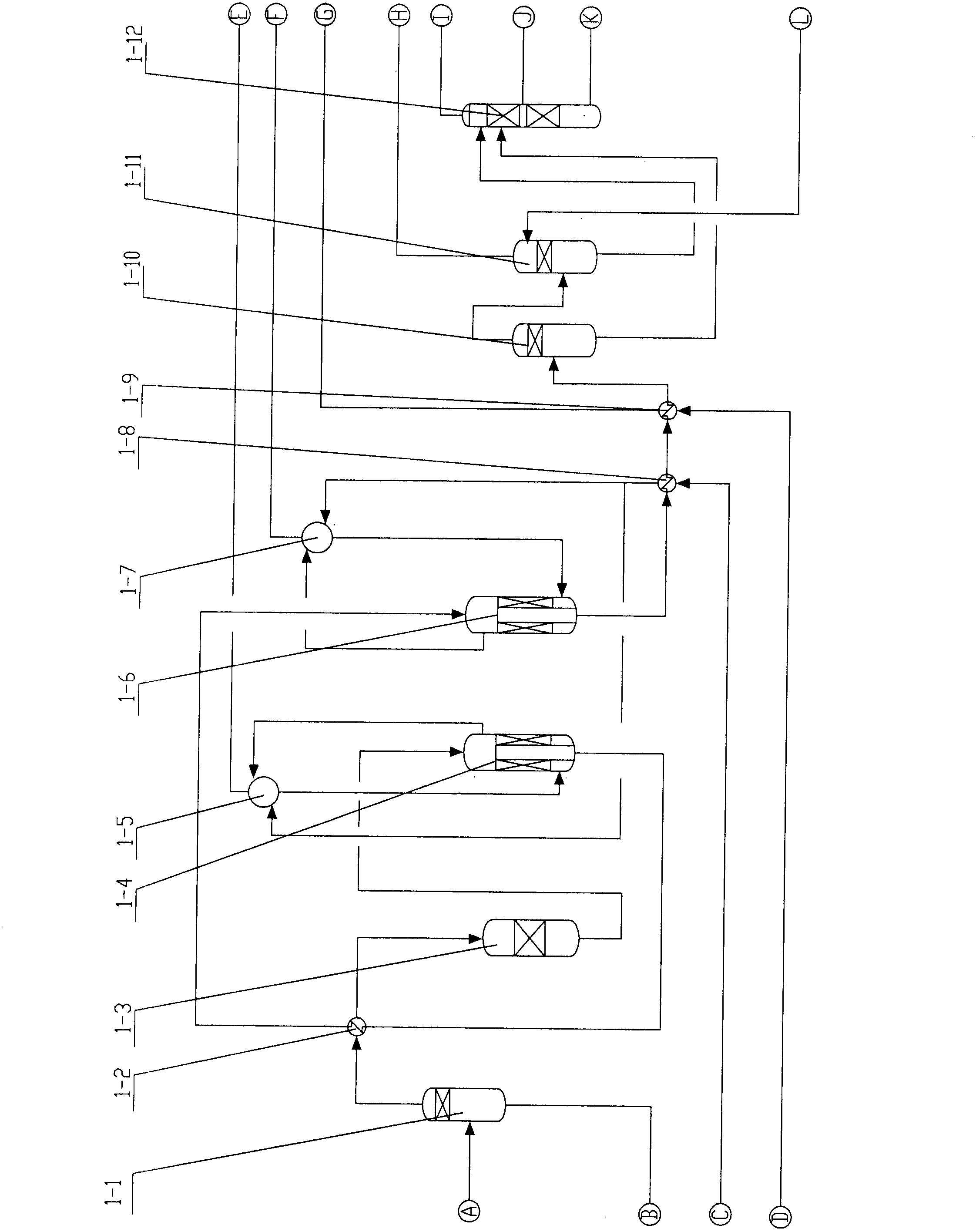

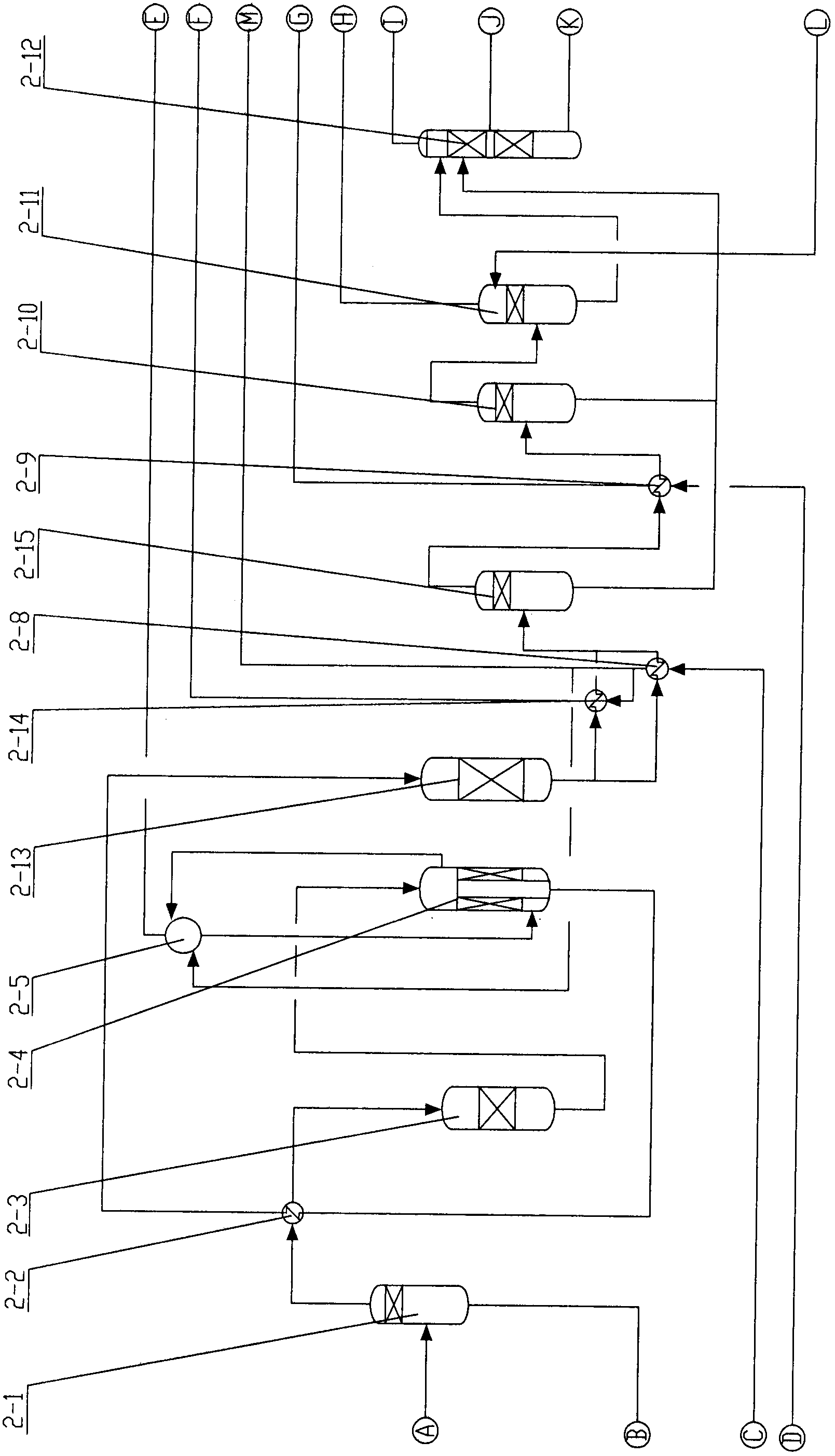

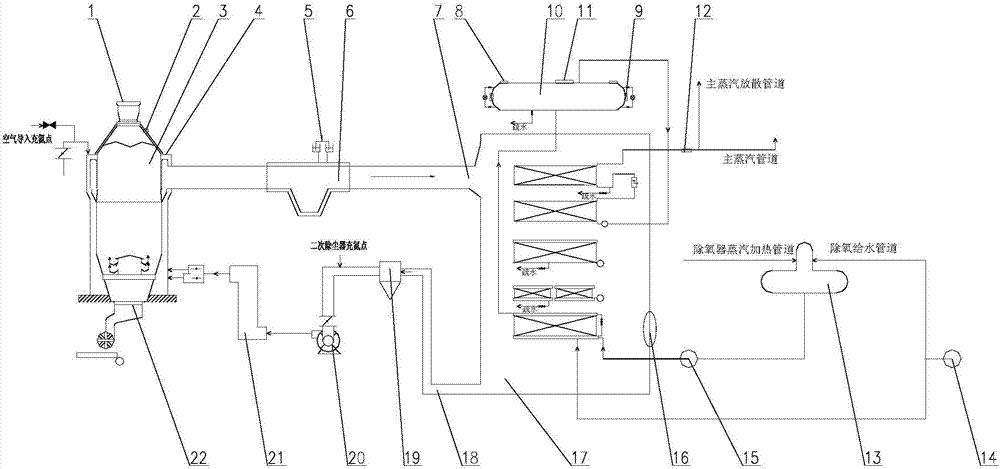

Water heat-transfer shift process for by-product high-grade steam energy-saving deep conversion

ActiveCN102701149AGuaranteed service lifeEliminate "dew point corrosion"HydrogenChemical recyclingComing outThermal energy

The invention relates to a water heat-transfer shift process for by-product high-grade steam energy-saving deep conversion. According to the process, a primary water heat-transfer shift converter and a secondary shift converter are adopted, CO in feed gas reacts with H2O to generate H2 and CO2 under the catalysis of a Co-Mo (copper-zinc) catalyst, and CO in shift gas coming out of a shift system is less than or equal to 0.1% (dry basis). In the process, CO is subject to deep conversion, the feed gas (containing water gas, semi-water gas, natural gas conversion gas or coke-oven gas conversion gas) utilization rate is high, the shift catalyst is not overheated, and the catalyst has a long service life; meanwhile, by-product saturated steam with the pressure of 0.5 to 9.0 MPa is generated, sensible heat and latent heat in the shift gas are further recovered by deoxygenated water and desalted water, low-grade heat energy is converted into high-grade heat energy, cooling water consumption is reduced, the temperature of` the shift gas coming out of a process system is lower than or equal to 40 DEG C, equipment is few, the flow is short, the investment is small, and the resistance is low (less than or equal to 0.05MPa).

Owner:NANJING DUNXIAN CHEM TECH

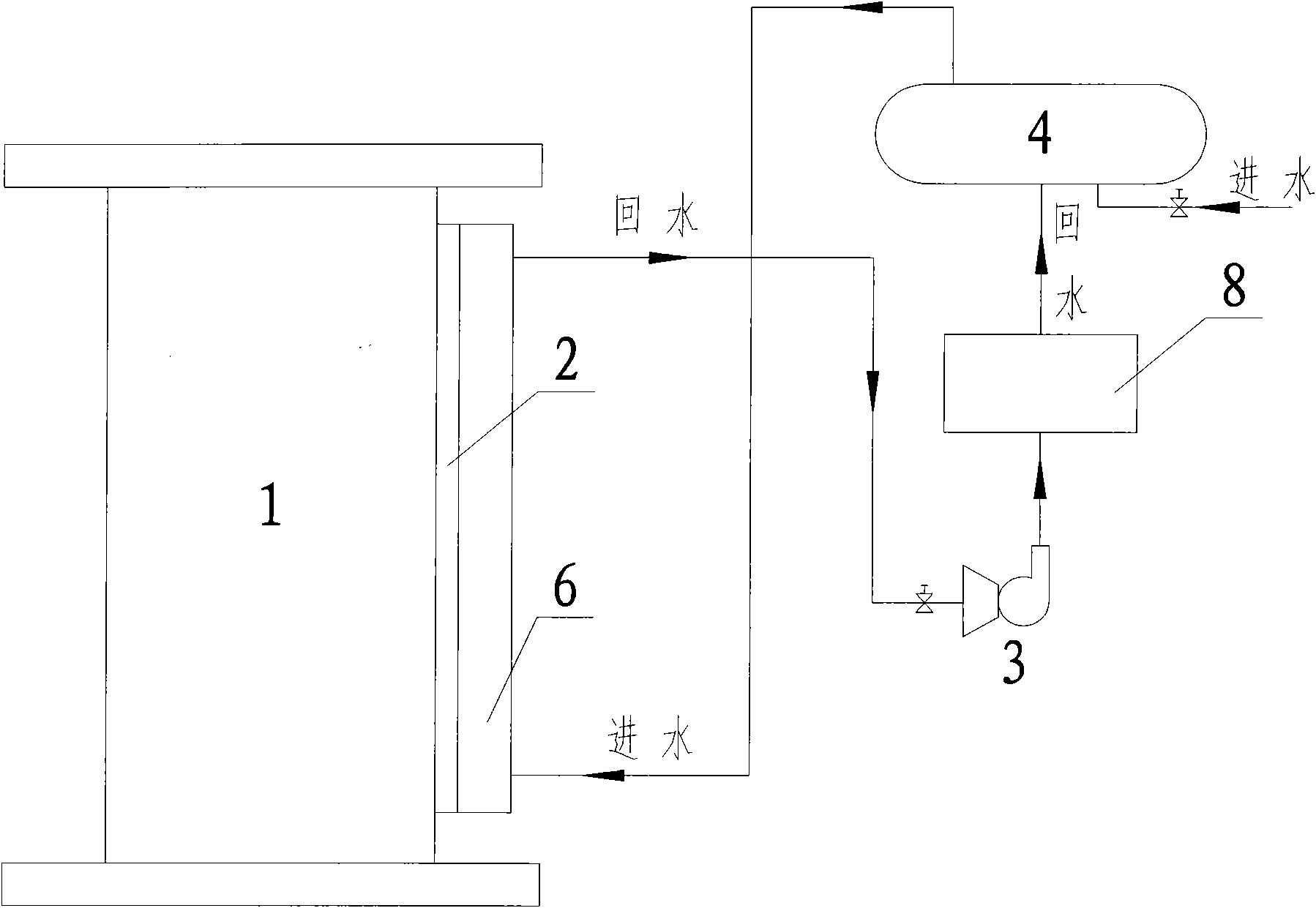

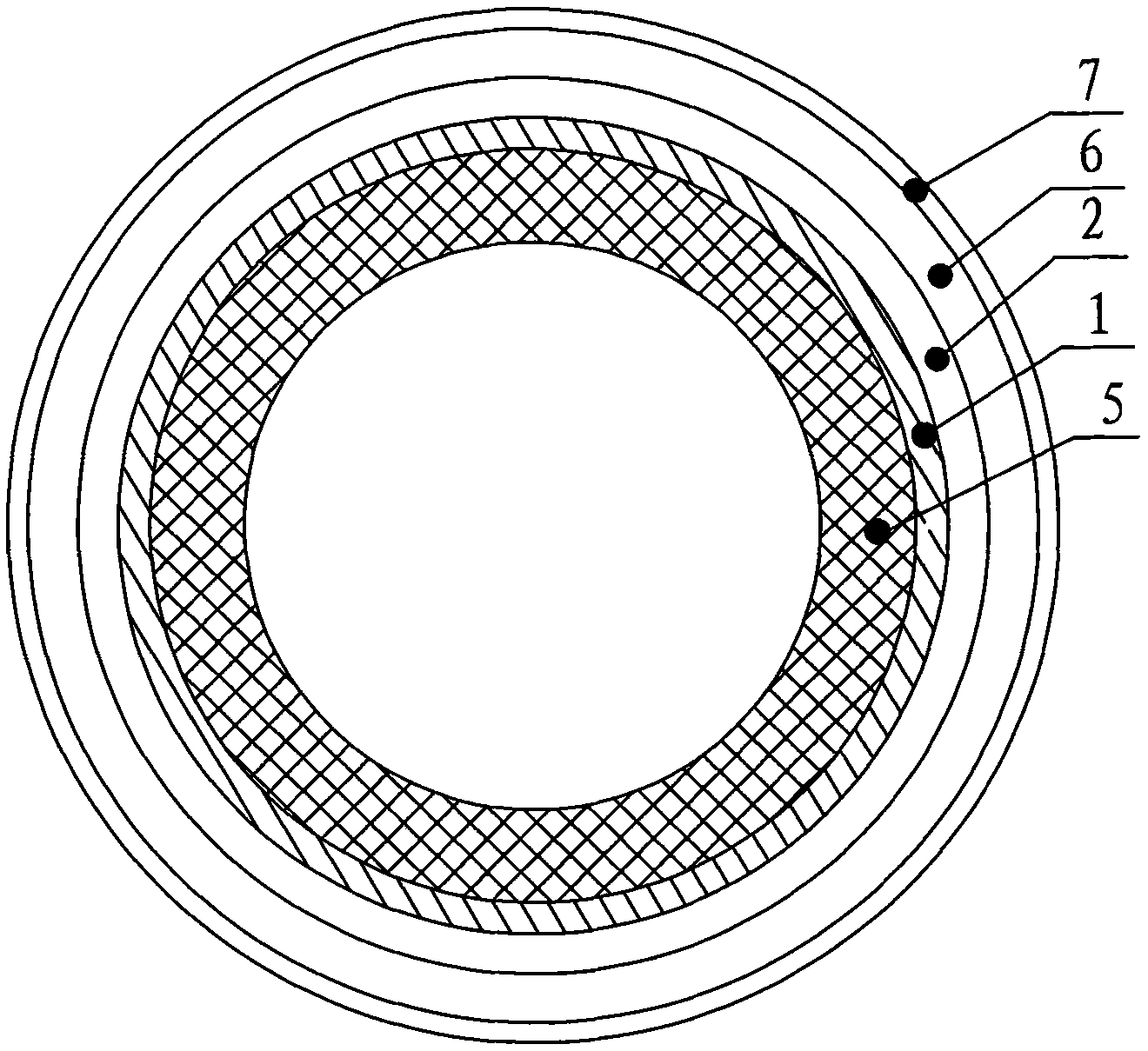

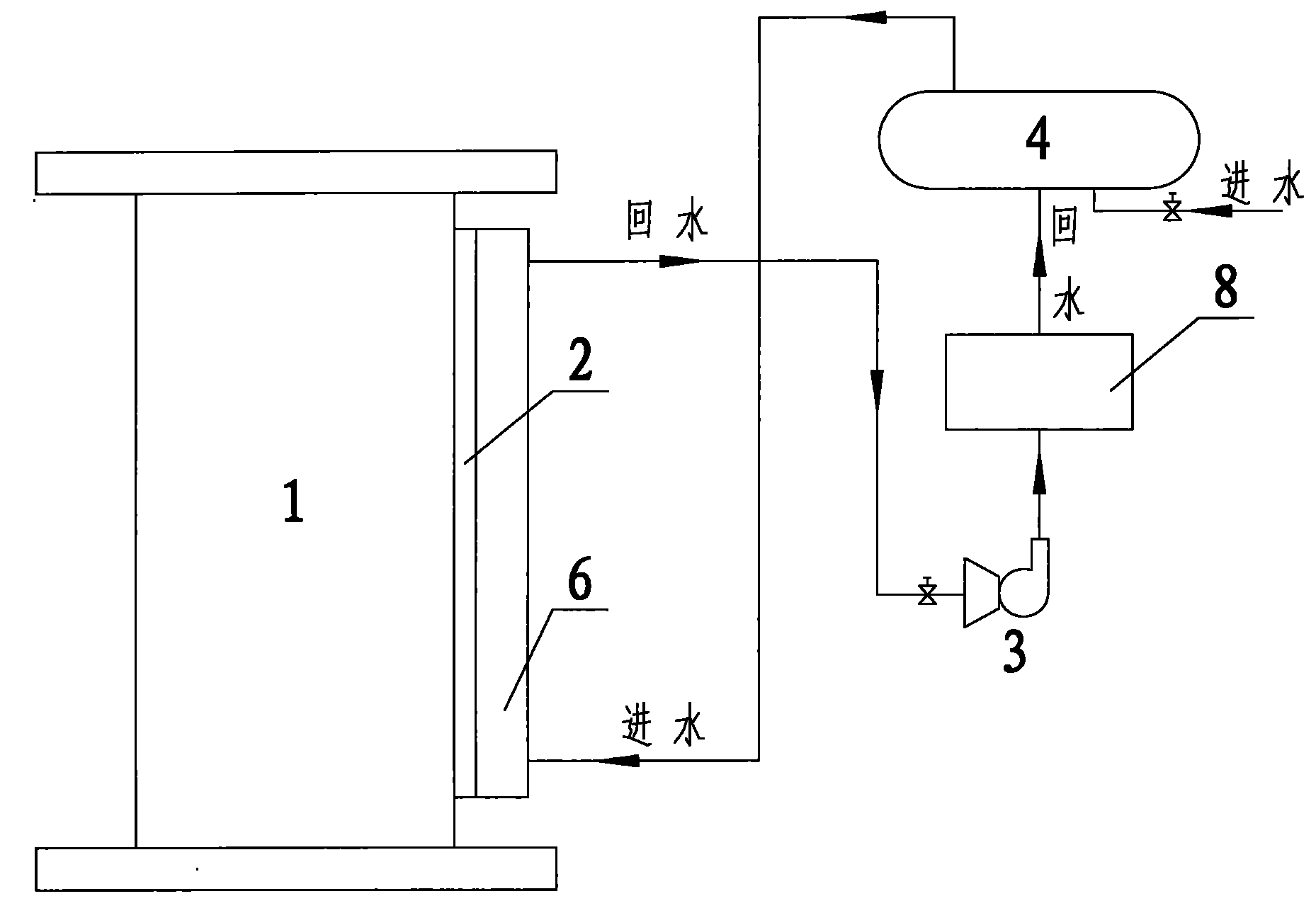

Method and device for recovering waste heat of coke oven crude gas

InactiveCN101888200ASolve the problem of recovering the waste heat of coke oven waste gasOther heat production devicesEnergy inputBrickCooling channel

The invention relates a method and a device for recovering the waste heat of a coke oven crude gas. In the method, the refractory lining bricks of a riser are improved by using silicon carbide refractory lining bricks, a semiconductor temperature difference power generation module is arranged on the outer wall of the riser so as to use the coke oven crude gas in the riser as the heat source of a semiconductor temperature difference power generator, the riser serves as the heat collector of for semiconductor temperature difference power generation, and the waste heat recovery of the coke oven crude gas in the riser is realized. The method and the device of the invention have the advantages that: 1) the problem of recovering the waste heat of the coke oven crude gas in a coking process is solved; and 2) when the method and the device are used, the waste heat carried by the coke oven crude gas can be recovered for generating power and cooling hot water flowing out from a channel and for civil or industrial heating, cooling and heat production for saving energy and improving energy efficiency.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP +3

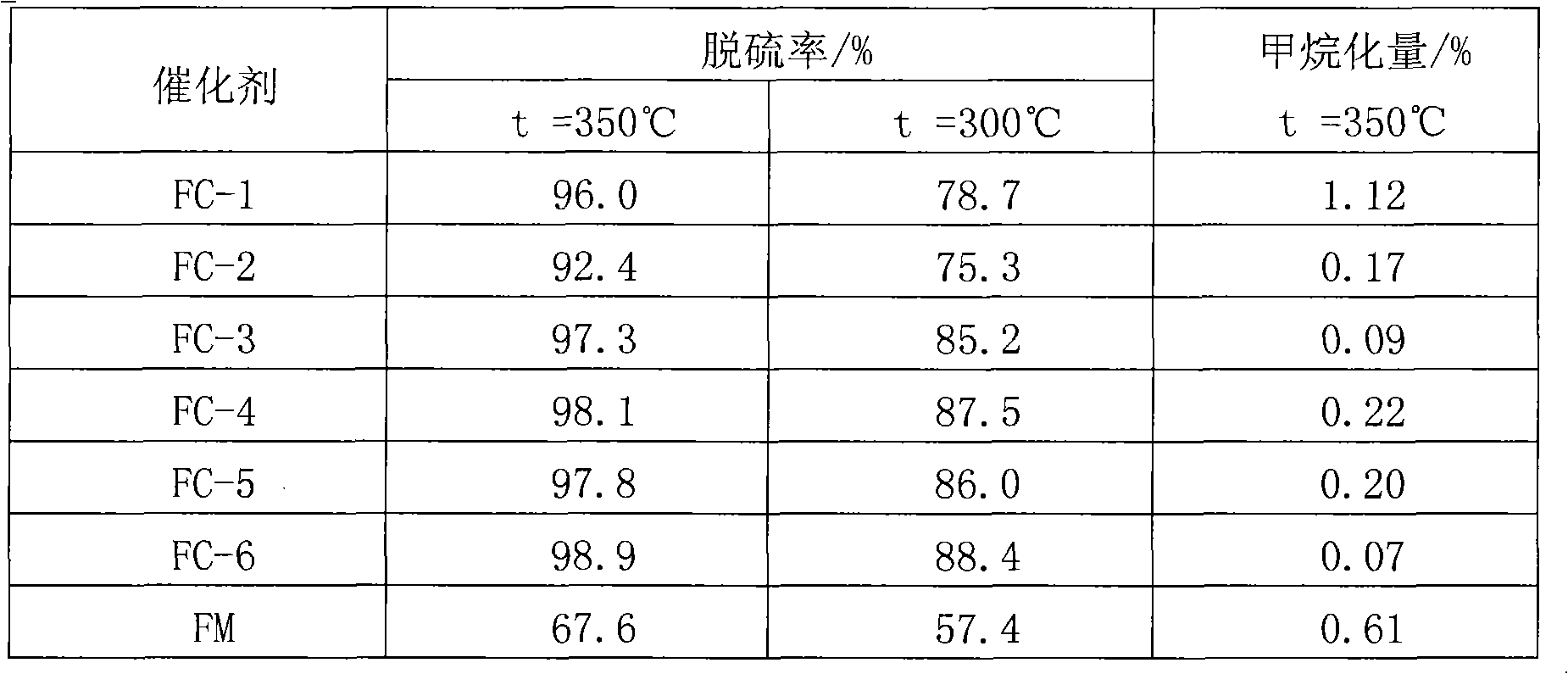

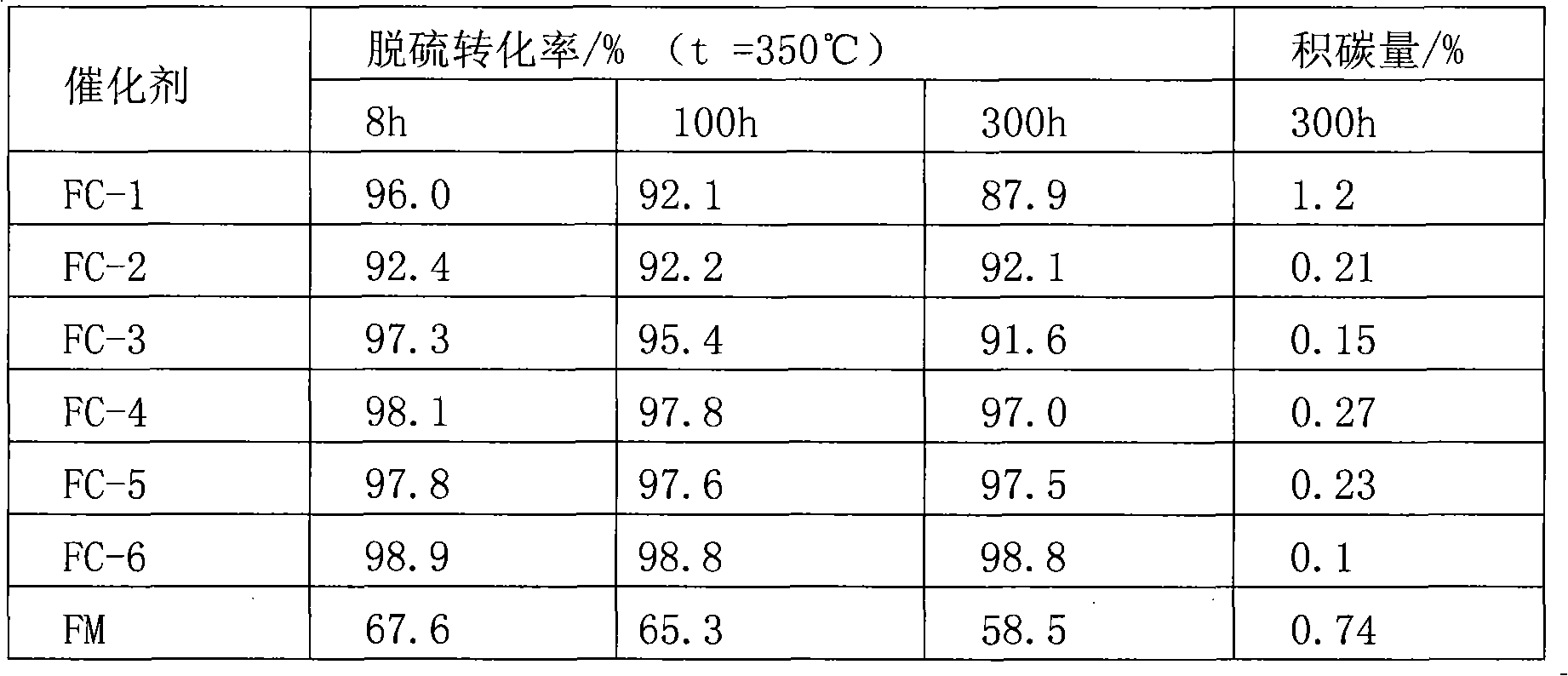

Coking oven gas hydrodesulfurization catalyst and method for preparing same

ActiveCN101797508AEvenly distributedIncrease profitGas purification by catalytic conversionMetal/metal-oxides/metal-hydroxide catalystsHydrodesulfurizationMethanation

The invention discloses coking oven gas hydrodesulfurization catalyst and a method for preparing the same. The coking oven gas hydrodesulfurization catalyst is prepared by loading active components on the carrier of Gamma-Al2O3 with the immersion method. The active components comprises iron oxide, molybdenum oxide and cobalt oxide, wherein the weight of the iron oxide is 2-10 percent of the totalweight of the coking oven gas hydrodesulfurization catalyst, the weight of the molybdenum oxide is 5-20 percent of the total weight of the coking oven gas hydrodesulfurization catalyst, the weight ofthe cobalt oxide is 0.1-5 percent of the total weight of the coking oven gas hydrodesulfurization catalyst, and the balance is Gamma-Al2O3. The coking oven gas hydrodesulfurization catalyst has the characteristic of high hydrodesulfurization activity, less methanation reaction and CO disproportionation reaction and good thermal stability, etc.

Owner:WUHAN KELIN FINE CHEM

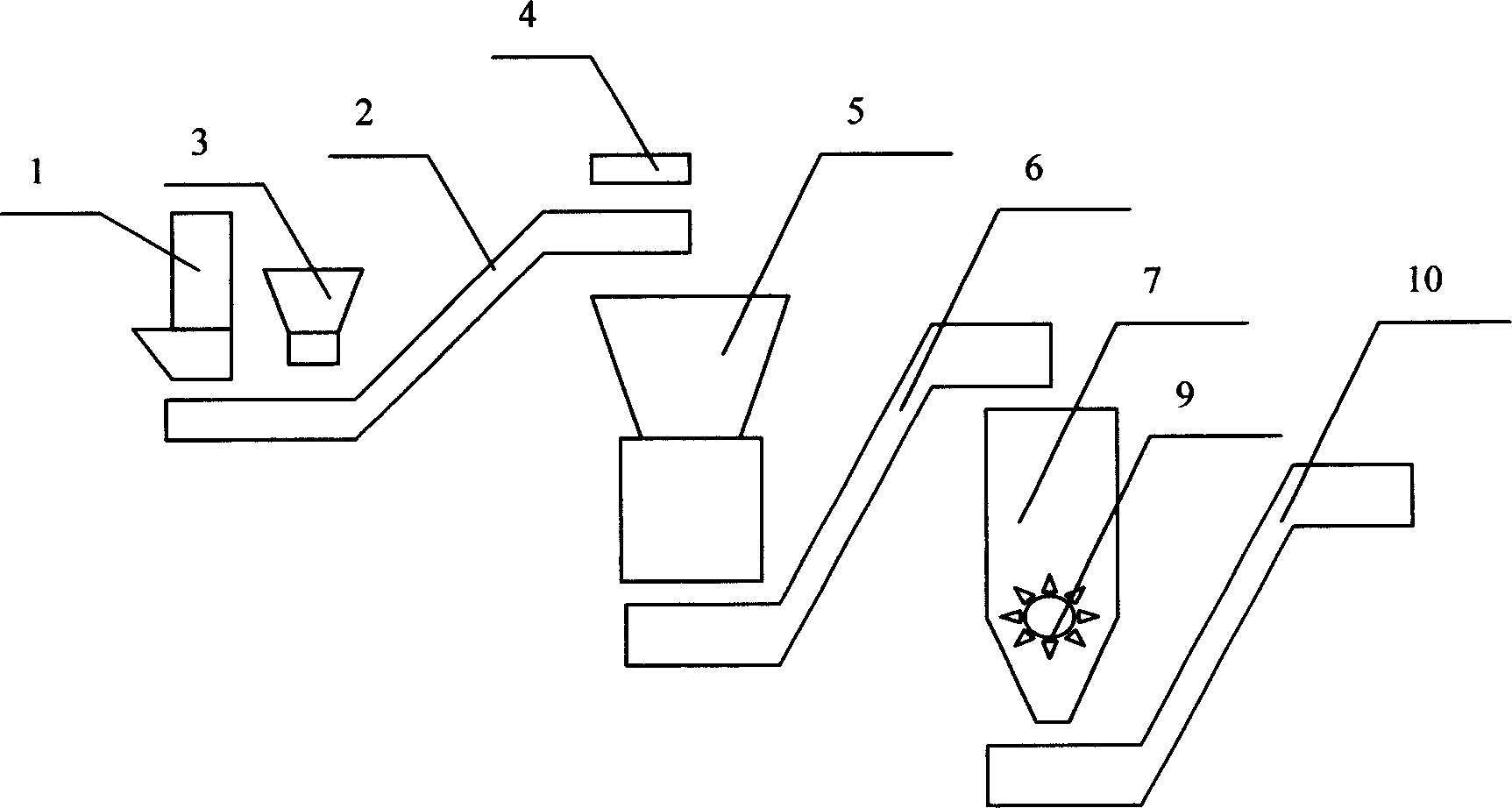

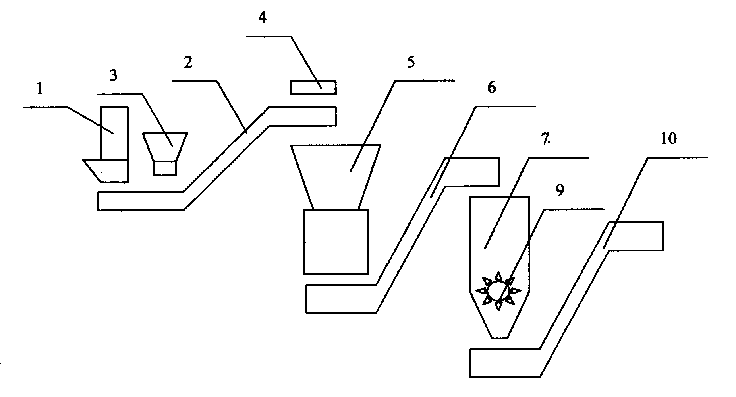

Method and system for improving metallurgical coke strength by utilizing waste plastics

The present invention relates to a method for raising strength of metallurgical coke and its system. Said invention adopts traditional coking process and equipment, and adds waste plastics in the course of coking process, and is characterized by that after the waste plastics and additive are processed, they are added into coking furnace to implement co-coking with coking coal, at the same time of that the waste plastics are charred at high temp., and converted into coke, tar and gas the coke quality can be improved, crushing strength of coke M40 can be raised, abrasive resistance index of coke M10 is reduced, coke reactivity CPI is reduced and coke postreaction strength can be raised. Said system includes waste plastics processing system, additive and waste plastics mixing system, waste plastics and additive mixture and coking coal mixing system and traditional coking system.

Owner:SHOUGANG CORPORATION

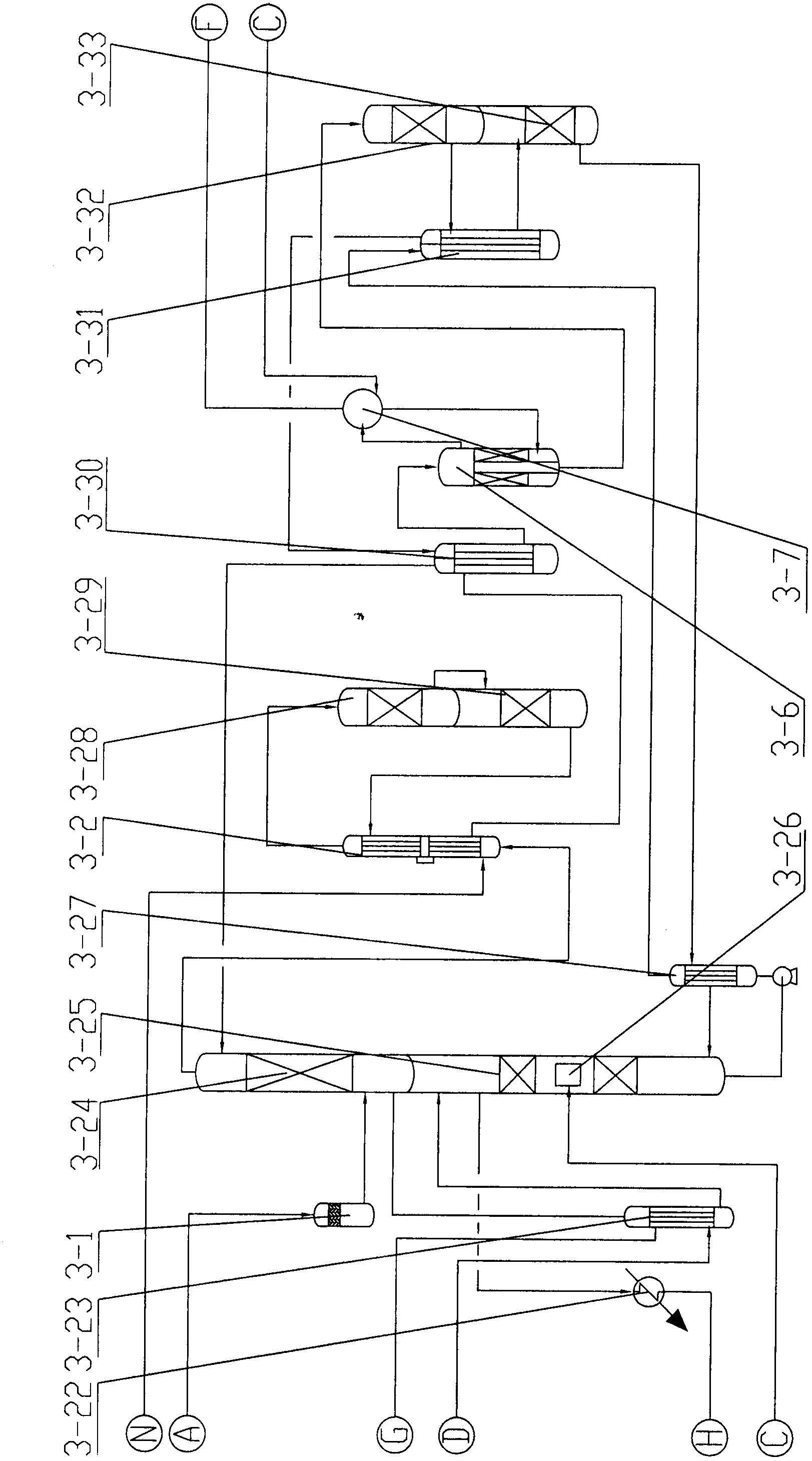

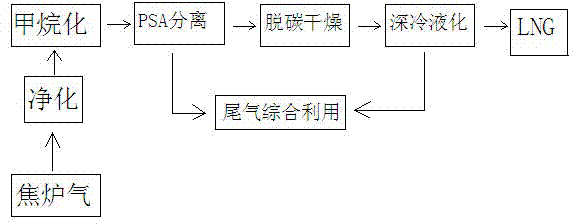

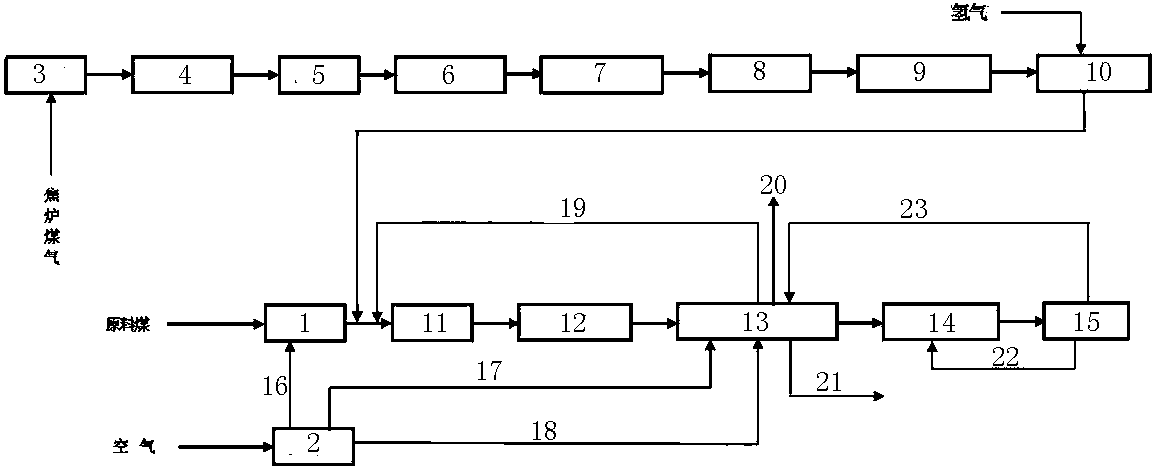

Method of combined production of methanol and liquefied natural gas in coking plant

InactiveCN104119975ASimple processEasy to operateHydrogen separationOrganic compound preparationSyngasThermodynamics

The invention belongs to the technical field of comprehensive coke-oven gas utilization, and particularly relates to a method of combined production of methanol and liquefied natural gas (LNG) in a coking plant. Coke-oven gas is subjected to temperature swing adsorption (TSA), desulphurization, vacuum pressure swing adsorption (VPSA), and other purifying treatment, and is subjected to cryogenic liquidation separation to obtain a liquefied natural gas (LNG) product. The main component of the non-liquefied part is (CO+H2), and is adopted as methanol synthesis gas used for producing methanol, wherein the insufficient carbon component based on the H2is supplied by continuous oxygen-rich gas production from chopped coke having a size of 7-24 mm by a normal-pressure gasifier. The method achieves direct utilization of CH4 that is one of the main components of the coke-oven gas, the (CO+H2) are directly used for methanol synthesis, and the insufficient carbon source is supplied by a normal-pressure gasifier adopting the chopped coke produced by the coking plant as a gas production raw material, and therefore intermolecular conversion and other main energy-consumption sections and high-investment devices are reduced, the whole process is simplified, the comprehensive energy consumption for producing the methanol and the liquefied natural gas (LNG) is low, the whole economic benefit of coking enterprises is increased, and the investment is saved.

Owner:COAL BRANCH YANZHOU MINING GRP

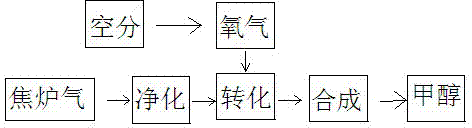

Superhigh-thermal conductivity silica brick for coke oven charing chamber furnace wall and preparation method thereof

The invention discloses a superhigh-thermal conductivity silica brick for a coke oven charing chamber furnace wall and a preparation method thereof. The superhigh-thermal conductivity silica brick comprises, by weight, 60-70% of crystalline silica, 10-20% of fused silica, 3-20% of waste silica bricks, 1-15% of Si3N4, 1-4% of an additive, 6.9-9.5% of a binder and 0.1-0.3% of a water reducer. The preparation method comprises the following steps of carrying out wet-grinding blending on the raw materials with the above ratio, carrying out mechanical pressing molding and carrying out drying roasting to obtain the superhigh-thermal conductivity silica brick. The superhigh-thermal conductivity silica brick has thermal conductivity of 2.50-2.60w / m.k improved by more than 25% than the traditional silica brick thermal conductivity and has obvious energy saving and emission reduction effects.

Owner:REFRACTORY MATERIAL OF SINOSTEEL CORP +1

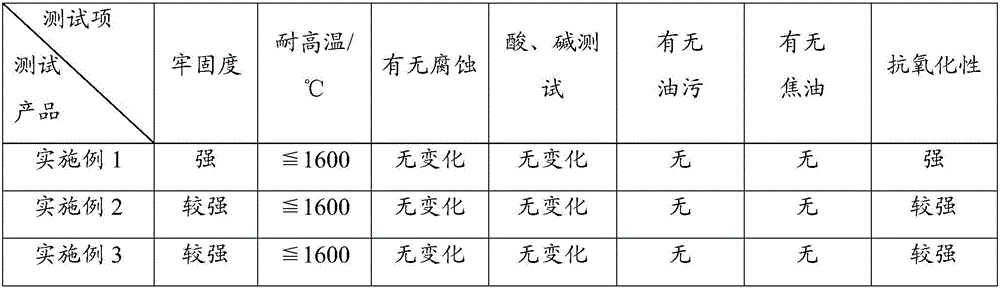

High-temperature-resistant and corrosion-resistant nano self-cleaning coating and preparation method and application thereof

InactiveCN106543779AGood super slippery effectImprove heat transfer effectFireproof paintsAntifouling/underwater paintsSilanesOxidation resistant

The invention discloses a high-temperature-resistant and corrosion-resistant nano self-cleaning coating and a preparation method and application thereof. The high-temperature-resistant and corrosion-resistant nano self-cleaning coating is prepared from, by weight, 5-8 parts of nano silicon dioxide, 3-5 parts of nano zirconium dioxide, 6-10 parts of nano-scale ceramic powder, 5-7 parts of nano titanium dioxide, 1-3 parts of nano silicon nitride, 1-3 parts of nano iron oxide, 1-3 parts of nano magnesium oxide, 3-5 parts of triphenyl phosphate, 6-10 parts of absolute ethyl alcohol, 1-3 parts of amino silane and 30-70 parts of water. The nano self-cleaning coating has excellent fastness, is resistant to high temperature, corrosion, acid and alkali, prevents oil contaminations and tar sagging and has oxidation resistance and other properties, the super-thinning and lubricating effect of CSH is excellent, and the nano self-cleaning coating is applied to a coke oven ascension pipe heat exchanger, so that a coke oven ascension pipe is non-coking, the heat exchanging effect of the heat exchanger is good, and the production capacity is improved.

Owner:江苏龙冶节能科技有限公司

Glaze for furnace door lining brick of coke furnace and application method thereof

Owner:WUHAN UNIV OF SCI & TECH +1

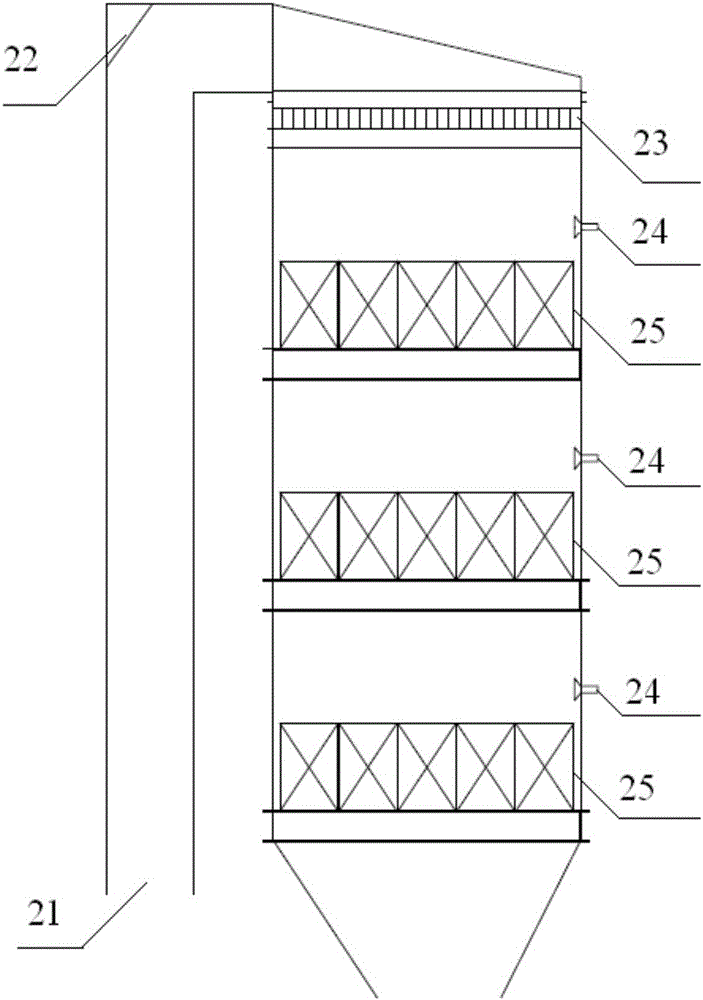

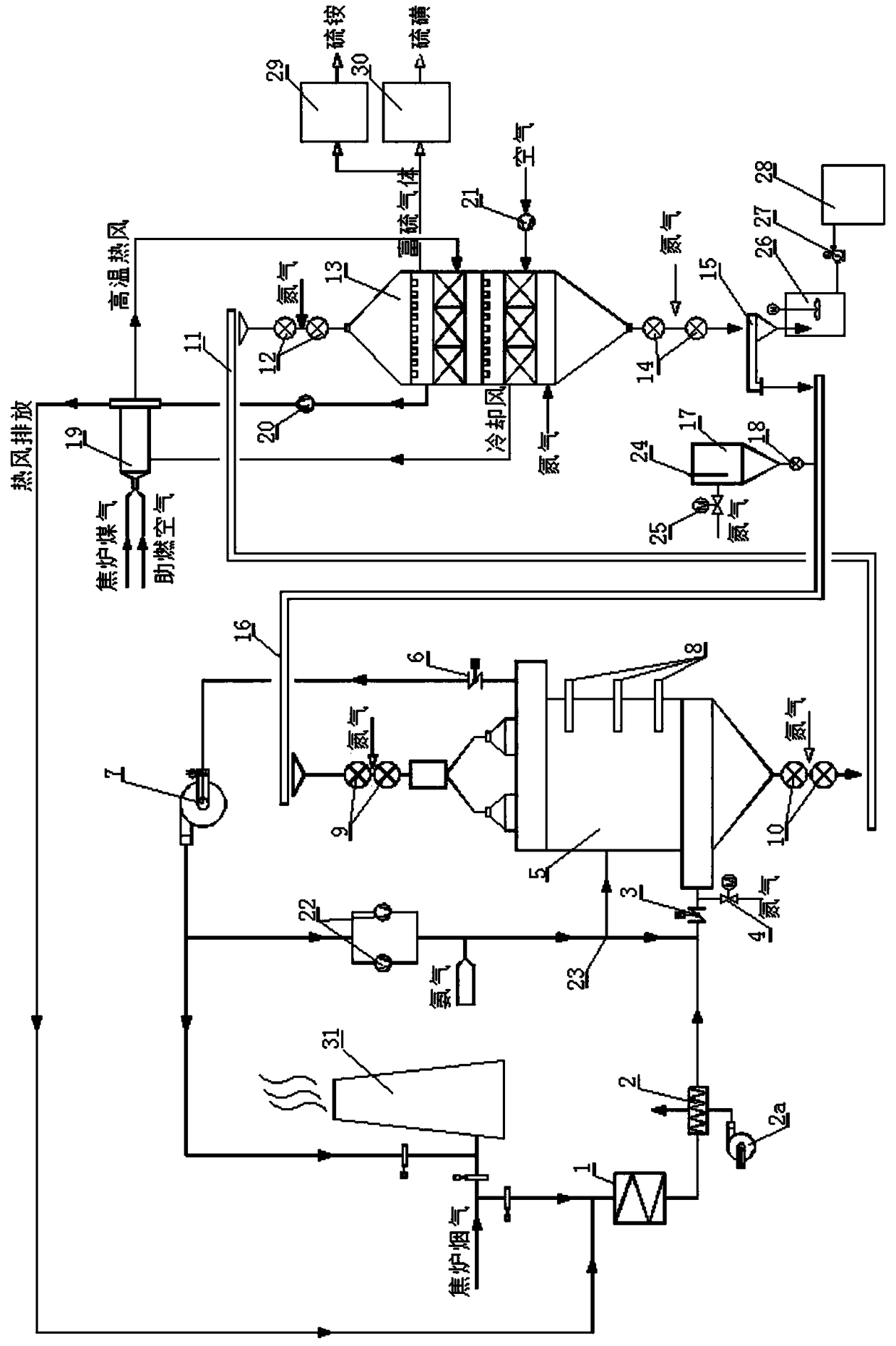

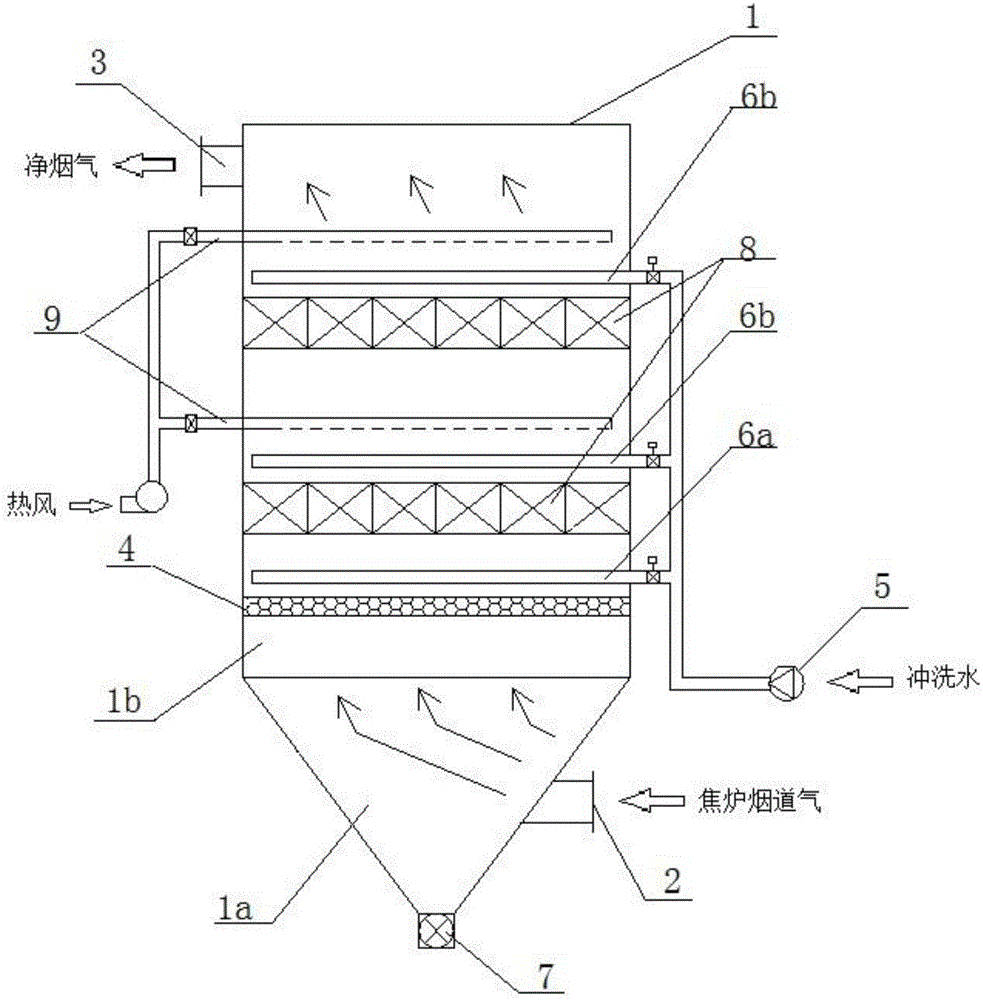

Coke oven flue gas multi-pollutant dry purification device and process

InactiveCN107854997AAvoid waste heat to maximize utilizationGuaranteed safe operationDispersed particle separationSteam generation using hot heat carriersPtru catalystFlue gas

The invention relates to a coke oven flue gas multi-pollutant dry purification device. The device consists of an evaporator I, a desulfurizer adding apparatus, a cloth bag dust collector, and a mediumand low temperature SCR denitration reactor. The evaporator I is a heat pipe type evaporator, the desulfurizer adding apparatus is connected to a desulfurizer grinding and conveying system, and the desulfurizer grinding and conveying system consists of a desulfurizer powder bin, a Roots blower and a desulfurizer pulverizer. The cloth bag dust collector includes a filter bag chamber, the filter bag chamber includes a dust remover ash hopper, a dust remover middle box and a purified air chamber that are disposed from the bottom up in order, the dust remover middle box is internally equipped with a tubesheet, a filter bag is disposed on the tubesheet, and a pulse dust-cleaning apparatus is disposed above the filter bag. An air outlet of the cloth bag dust collector is connected to an air inlet of the medium and low temperature SCR denitration reactor, an air inlet pipeline of the medium and low temperature SCR denitration reactor is internally equipped with an ammonia injection grid anda guide plate II, and a flue gas current equalizer, a catalyst reservation layer and a catalyst layer are disposed below the guide plate II in order.

Owner:ANHUI WEIDA ENVIRONMENTAL PROTECTION TECH

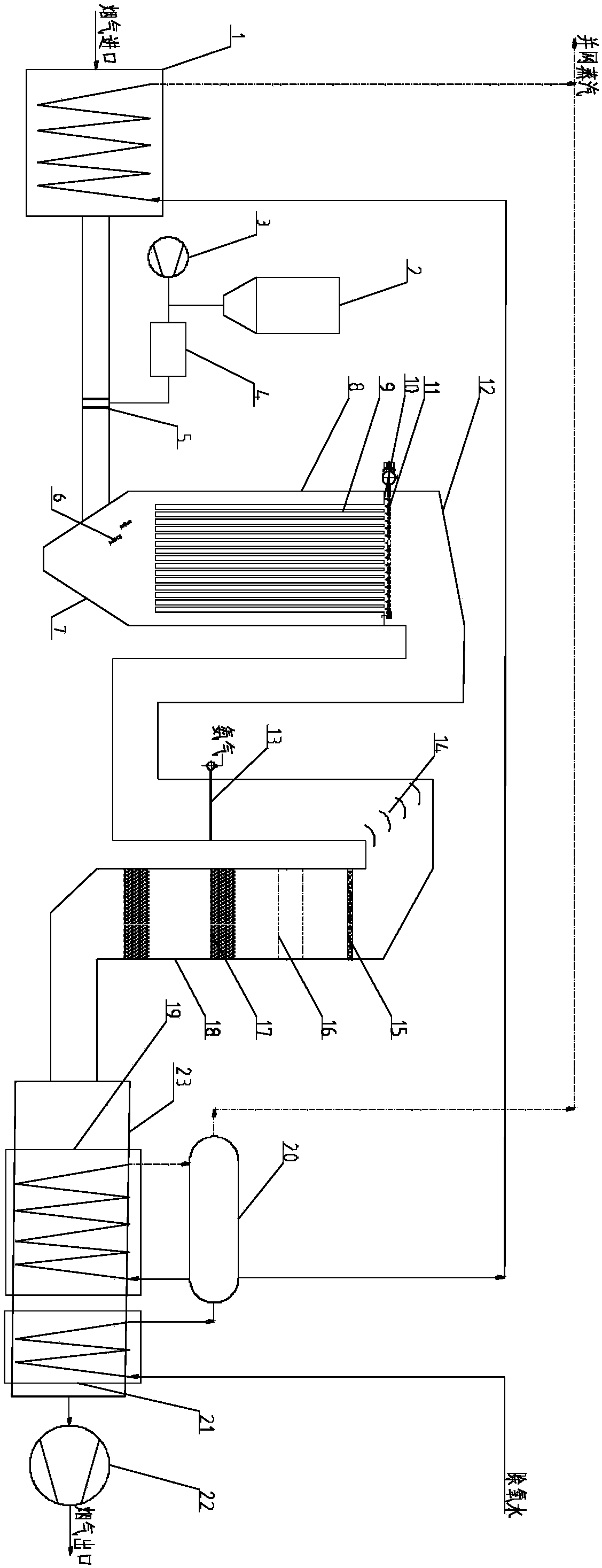

Method for preparing coke by using direct coal-liquefied residue

ActiveCN103436280AHigh beta-resin contentHigh softening pointWorking-up pitch/asphalt/bitumen by selective extractionWorking-up pitch/asphalt/bitumen by chemical meansCoal briquetteCoke burner

The invention discloses a method for preparing coke by using direct coal-liquefied residue. The method comprises the following steps: S1, orderly carrying out primary hot melt-extraction, primary solid-liquid separation and polymeric modification on the direct coal-liquefied residue, so as to obtain coal-liquefied modified asphalt; S2, mixing the coal-liquefied modified asphalt with cleaned coal for coking, crushing, tamping and pressing into a cake, so as to obtain a coal briquette; and S3, conveying the coal cake to a coke burner to heat and insulate heat in isolated air, and then cooling and screening to obtain the coke. The coal-liquefied modified asphalt which is obtained from the direct coal-liquefied residue in manners of hot melt-extraction, solid-liquid separation and polymeric modification is applied to a tamping coking process, so that the coke of which all indexes achieve the first national metallurgical coke standard is obtained; the yield of qualified products can be up to over 82%.

Owner:CHNA ENERGY INVESTMENT CORP LTD +3

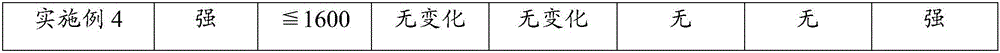

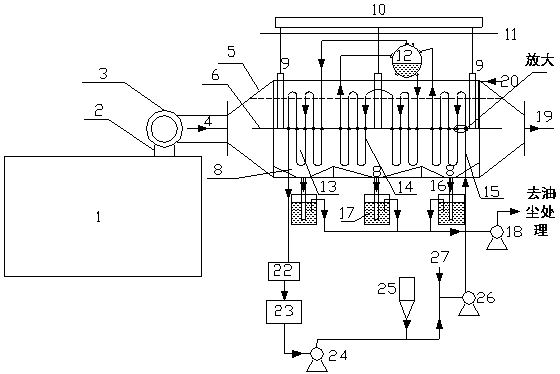

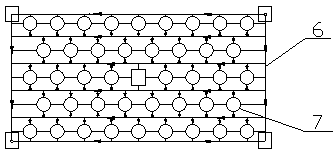

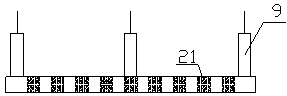

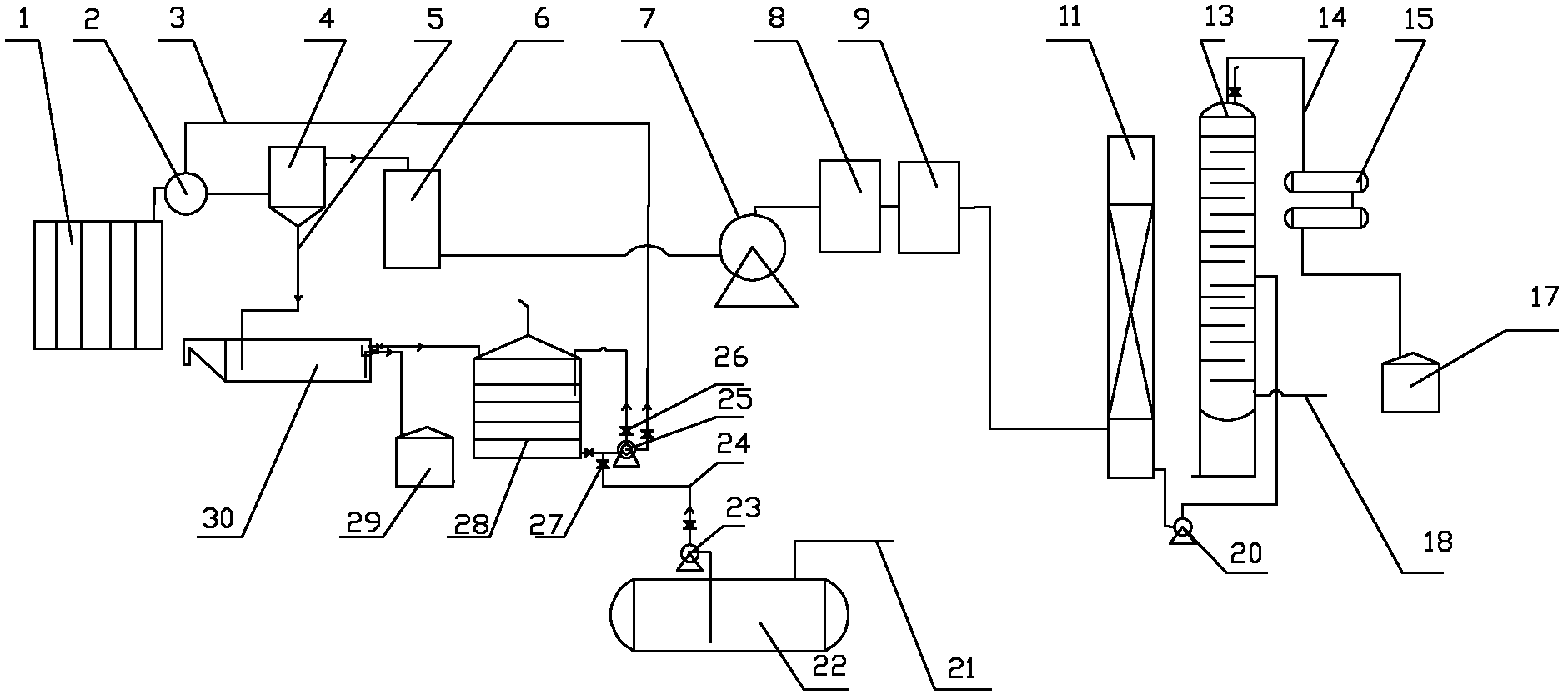

High-temperature raw gas waste heat and tar recovery device and recovery method therefor

InactiveCN104031658AReduce lossesImprove work efficiencyEnergy inputSteam superheatersSuperheaterCondensate pump

The invention discloses a high-temperature raw gas waste heat and tar recovery device and a recovery method therefor. The recovery device is characterized in that a tar recovery device is arranged in a high-temperature raw gas waste heat recovery device, and the high-temperature raw gas waste heat recovery device and the tar recovery device are integrated for continuous recovery. The recovery method comprises the following steps: directly introducing high-temperature raw gas at the top of a coking furnace into a heat exchanger through a collection pipe, exchanging heat with heat exchange pipes of a coal saver, an evaporator and an overheater, and discharging the raw gas subjected to heat exchange; generating overheat steam by cooling water subjected to heat exchange through the coal saver, the evaporator, the overheater and a steam pocket to drive a steam turbine to generate power; and removing oxygen from condensed water through a condensate pump and an oxygen remover, and recycling the condensed water subjected to oxygen removal together with tap water. The recovery device is simple in structure and continuous in operation, the water consumption is greatly reduced, the wastewater discharge is reduced, and waste heat and tar in the high-temperature raw gas are efficiently recovered.

Owner:TAIYUAN UNIV OF TECH

Device and method for denitrifying flue gas of coking furnace

ActiveCN104190220ALittle effect on suctionNo emissionsDispersed particle separationIncreasing energy efficiencyThermodynamicsPtru catalyst

The invention discloses a device and method for denitrifying flue gas of a coking furnace by using citric acid as a catalyst. The device comprises a cooling device, a desulfurization device and a denitration device. The method for denitrifying flue gas of the coking furnace by using the device comprises the following steps of cooling the flue gas of the coking furnace three times; desulfurizing the flue gas of the coking furnace; carrying out first-stage denitration on the flue gas of the coking furnace; carrying out second-stage denitration on the flue gas of the coking furnace; and discharging the purified flue gas. The method disclosed by the invention is safe, reliable, high in denitration and absorption efficiencies, little in influences to the suction force of a chimney, free of waste liquid discharge and capable of reducing the operation cost at the desulfurization stage; the obtained product does not contain poisonous ammonium sulphate; and the contents of SO2, NO and NO2 in the discharged flue gas are far lower than the national flue gas discharge standard.

Owner:鹤岗市征楠煤化工有限公司

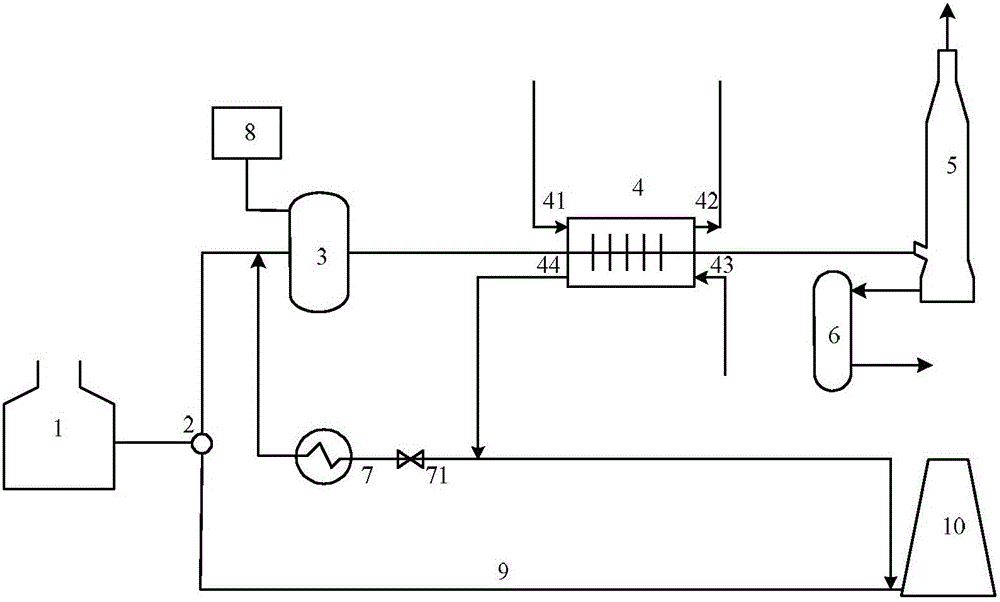

Gas-liquid two-phase distributor and coke quenching furnace using the same

InactiveCN103131435AAvoid pollutionAvoid wastingCoke quenchingCombustible gas productionPhysical chemistryCoke burner

Disclosed are a gas-liquid two-phase distributor and a coke quenching furnace using the same. The gas-liquid two-phase distributor is arranged in the coke quenching furnace. The gas-liquid two-phase distributor is formed by communication of a gas distribution tower and a liquid distribution disc through a gas-liquid separation tank, and is supported in the middle of the coke quenching furnace through a support rod fixed on the inner wall of the coke quenching furnace. The gas-liquid two-phase distributor is small in resistance and large in flow, and enables a gas-liquid even distribution area to be formed in the coke quenching furnace. The coke quenching furnace utilizes gas-liquid two-phase distribution, multi-step quenching and mixed cooling medium circulation quenching, and is high in quenching efficiency, strong in processing capacity, and wide in application range.

Owner:TAIYUAN UNIV OF TECH

Fine ferric oxide desulfurizing agent and preparation method and application method thereof

ActiveCN106268219AHigh precisionHigh sulfur capacityDispersed particle separationSodium BentoniteCopper sulfate

The invention discloses a fine ferric oxide desulfurizing agent and a preparation method and an application method thereof. The fine ferric oxide desulfurizing agent is prepared from ferrous sulfate septihydrate, calcium hydroxide, copper sulfate pentahydrate, sodium hydroxide, bentonite and sodium carboxymethylcellulose through mixing, strip extrusion and drying, and comprises, by mass, 57%-68% of ferrous sulfate septihydrate, 18%-25% of calcium hydroxide, 3%-8% of copper sulfate pentahydrate, 6.5%-18% of sodium hydroxide, 3%-10% of bentonite and 1%-3% of sodium carboxymethylcellulose. The fine ferric oxide desulfurizing agent is applied to removal of natural gas, coke-oven gas, oil field gas, synthesis gas, methane, carbon dioxide and organic sulfur such as H2S, COS and mercaptan in liquid hydrocarbon feed gas under the normal-temperature anaerobic condition and is high in desulfurization precision and sulfur capacity. The environment-friendly fine ferric oxide desulfurizing agent is prepared without washing and filtering, and the preparation method has the advantages of simple production technology, low equipment investment and maintenance cost and suitability for large-scale industrial production.

Owner:HUNAN HUANDA ENVIRONMENTAL PROTECTION

Fine desulfurization agent of zinc oxide as well as preparation and application methods thereof

ActiveCN102961959AEasy to produceProduction and preparation process safetyDispersed particle separationCombustible gas purificationSodium BentoniteRefinery

The invention relates to a fine desulfurization agent of zinc oxide as well as preparation and application methods thereof. The fine desulfurization agent is prepared by the following steps of: carrying out mixing and strip extruding on activated zinc oxide, high aluminum powder, bentonite, calcium hydroxide and sodium carboxymethylcellulose, drying the materials at 120 DEG C, and roasting the materials at 500 to 650 DEG C. The initial mass percentage composition of the fine desulfurization agent is that the activated zinc oxide accounts for 62.5%-86%, and a mixture of the high aluminum powder, the bentonite, the calcium hydroxide and the sodium carboxymethylcellulose accounts for the balance; and the mixture comprises the following components according to mass percentage: 17%-32% of the high aluminum powder, 17%-22% of the bentonite, 13%-44% of the calcium hydroxide and 10%-47% of the sodium carboxymethylcellulose. The fine desulfurization agent is applied to purification of H2S in coke-oven gas, refinery dry gas, natural gas, synthesis gas, carbon dioxide, liquefied petroleum gas and liquid hydrocarbon feed gas in a range from a room temperature to 400 DEG C, and can be used for partially removing COS (carbon oxide sulfide) and sulfur alcohol in a range from 200 to 400 DEG C; and the H2S content at an outlet is less than or equal to 0.03 ppm, and the removing rates of the COS and the sulfur alcohol are more than or equal to 50%.

Owner:HUNAN HUANDA ENVIRONMENTAL PROTECTION

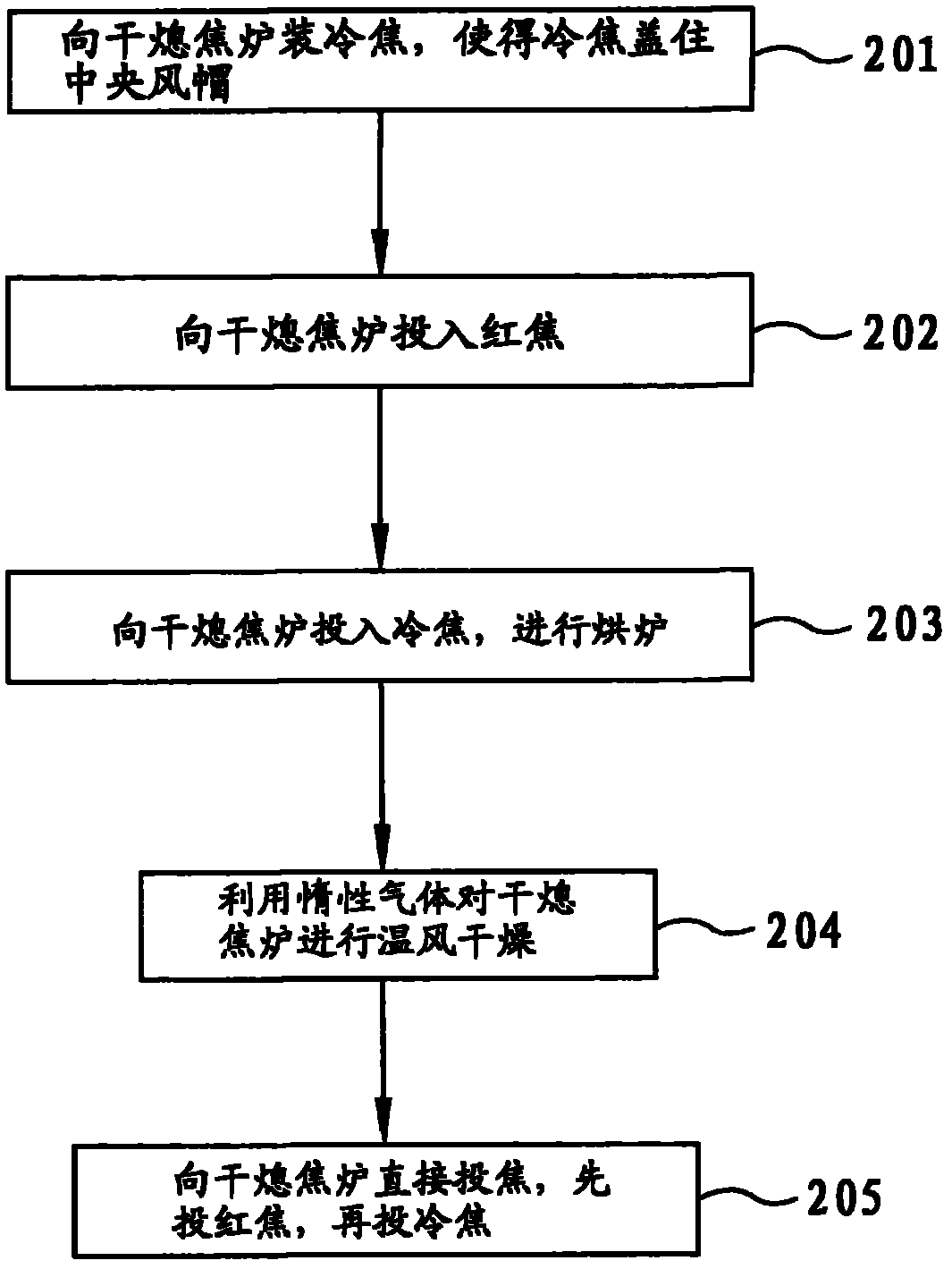

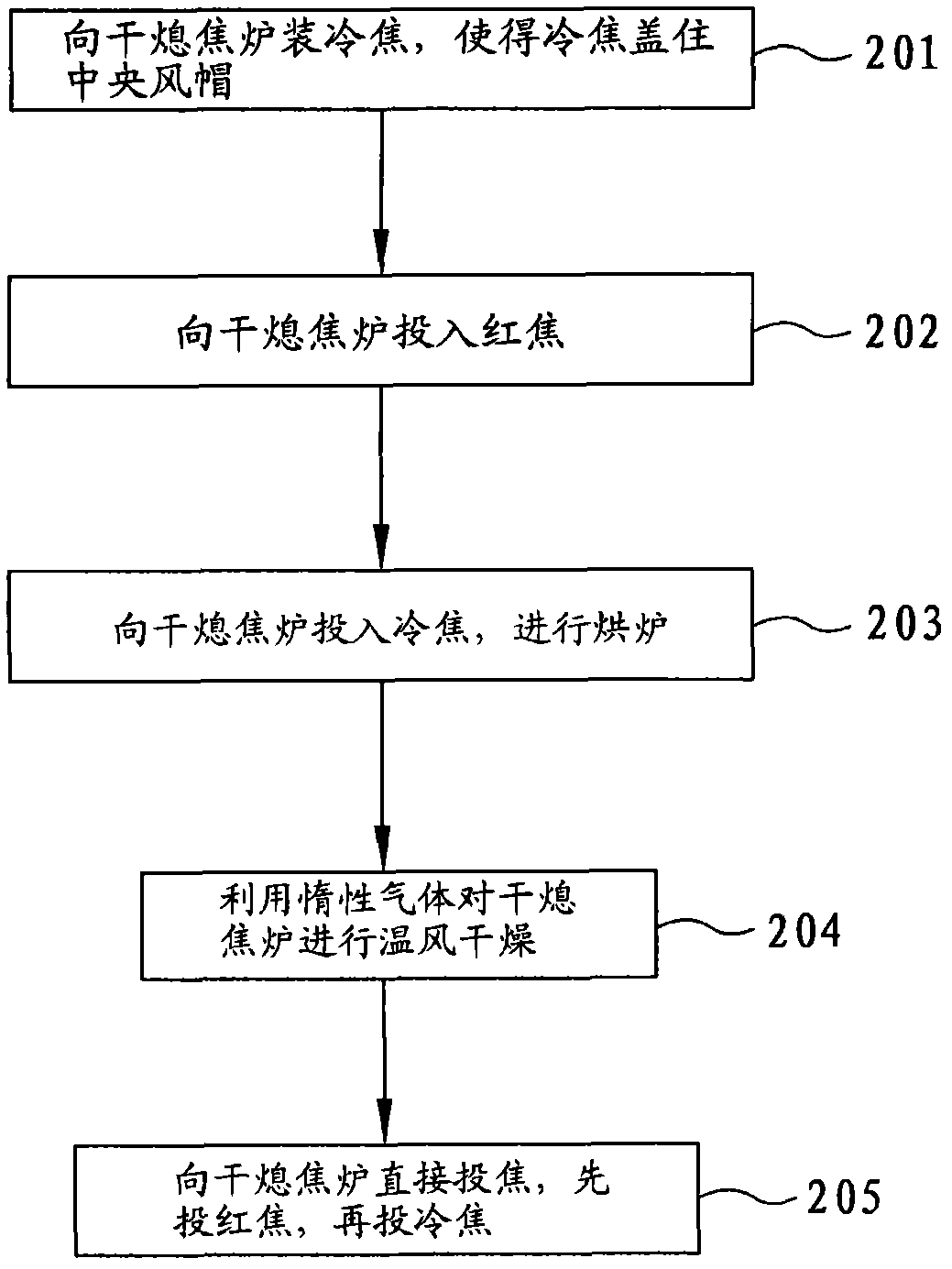

Method for raising temperature in coke dry quenching furnace

The invention discloses a method for raising the temperature in a coke dry quenching furnace, which comprises the following steps: a, filling cold coke into the coke dry quenching furnace, pilling the cold coke in a concave shape and allowing the cold coke to cover a central hood; b, filling red-hot coke into the coke dry quenching furnace, and allowing the red-hot coke to cover the cold coke in the step a; c, filling cold coke into the coke dry quenching furnace, allowing the cold coke to cover the red-hot coke in the step b and drying the coke dry quenching furnace; d, introducing inert gas into the coke dry quenching furnace and drying the coke dry quenching furnace with warm wind; and e, directly filling coke into the coke dry quenching furnace. In the step e, the red-hot coke is filled into the coke dry quenching furnace first and covers the cold coke in the step c, and then the cold coke is filled into the coke dry quenching furnace and covers the red-hot coke in the step e. And when the method disclosed by the invention is used, the furnace drying quality and construction period are both guaranteed.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

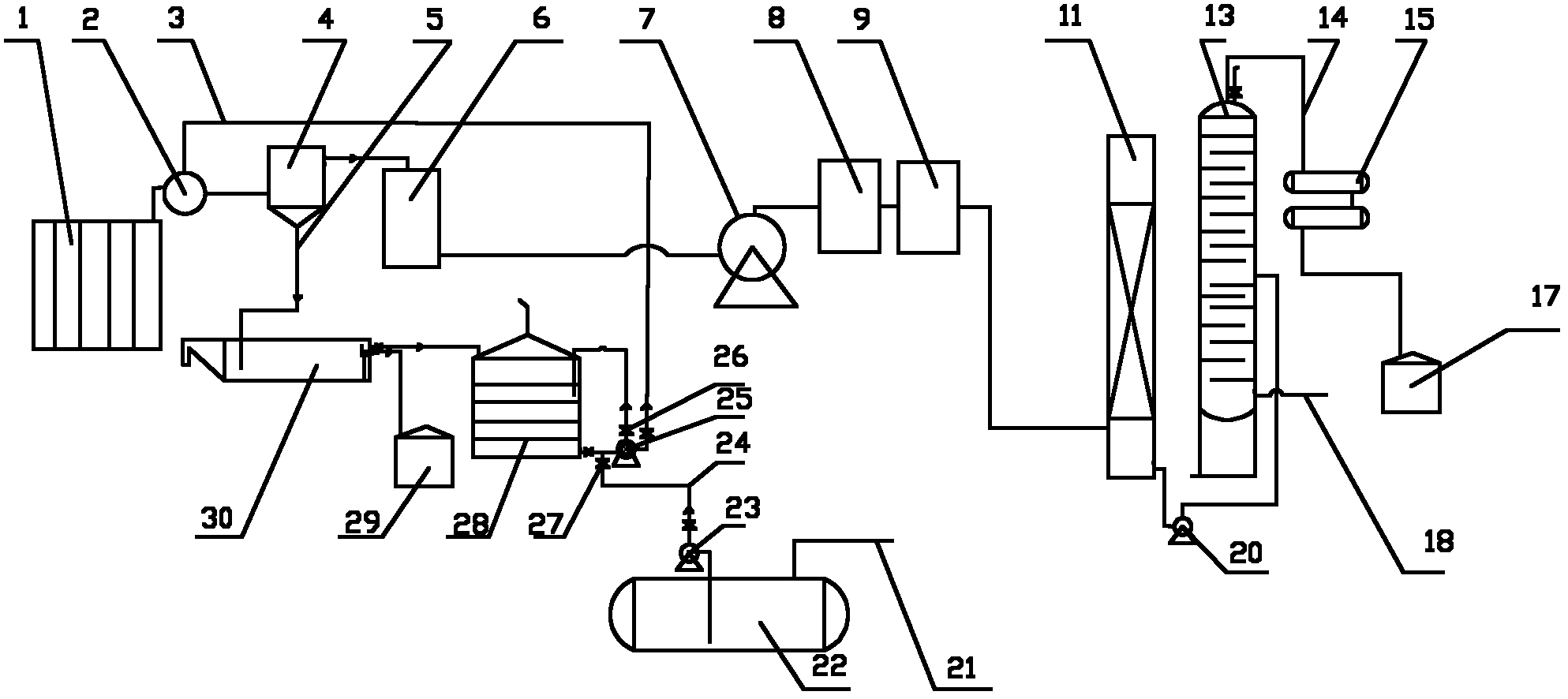

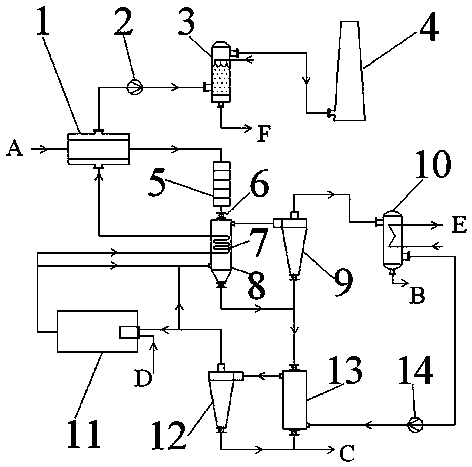

System and process for utilizing coke oven flue gas desulfurization and denitrification waste heat

InactiveCN105797581AReasonable process arrangementImprove economyGas treatmentCoke ovensSoot blowerSulfide

The invention provides a system and process for utilizing coke oven flue gas desulfurization and denitrification waste heat. The process includes: allowing flue gas to enter an SCR denitrification reactor to react with the reducing agent, allowing the flue gas after the reaction to enter a waste heat boiler module for heat exchanging, controlling the module to allow the temperature of the flue gas to be 160-180 DEG C, allowing the flue gas to enter a magnesium desulfurization module for desulfurization, and discharging, wherein the SCR denitrification reactor is connected with an inlet flue, a guide plate is arranged at the turning part of the flue, a rectifying grating is arranged on the upper portion in an SCR denitrification reactor shell, a catalyst layer is arranged below the rectifying grating, and a steam soot blower is arranged between the rectifying grating and the catalyst layer; the catalyst is a vanadium-titanium-based catalyst and / or a rare-earth-system low-temperature catalyst; volume velocity is controlled to be 5000-8000m<3> / m<3>. H, and flue gas speed is controlled to be 3-10m / s; the waste heat boiler module is a heat pipe waste heat boiler. The process has the advantages that the nitrogen oxide and sulfide in the coke oven flue gas are removed successfully, the flue gas waste heat is utilized to the maximum extent, and the economy of the system is increased.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

Refractory binder

The invention relates to the technical field of refractory materials, and specifically relates to a binding material of a high temperature furnace body such as a coke oven and the like. The refractory binder is composed of the following raw materials (by weight): 45-55 parts of sintered corundum, 35-45 parts of silica sol, 4-8 parts of sodium tripolyphosphate and 15-27 parts of calcium aluminate cement. The refractory binder provided by the invention has good bonding effect and is not easy to fall off.

Owner:YIXING JICHUANG NEW MATERIAL TECH CO LTD

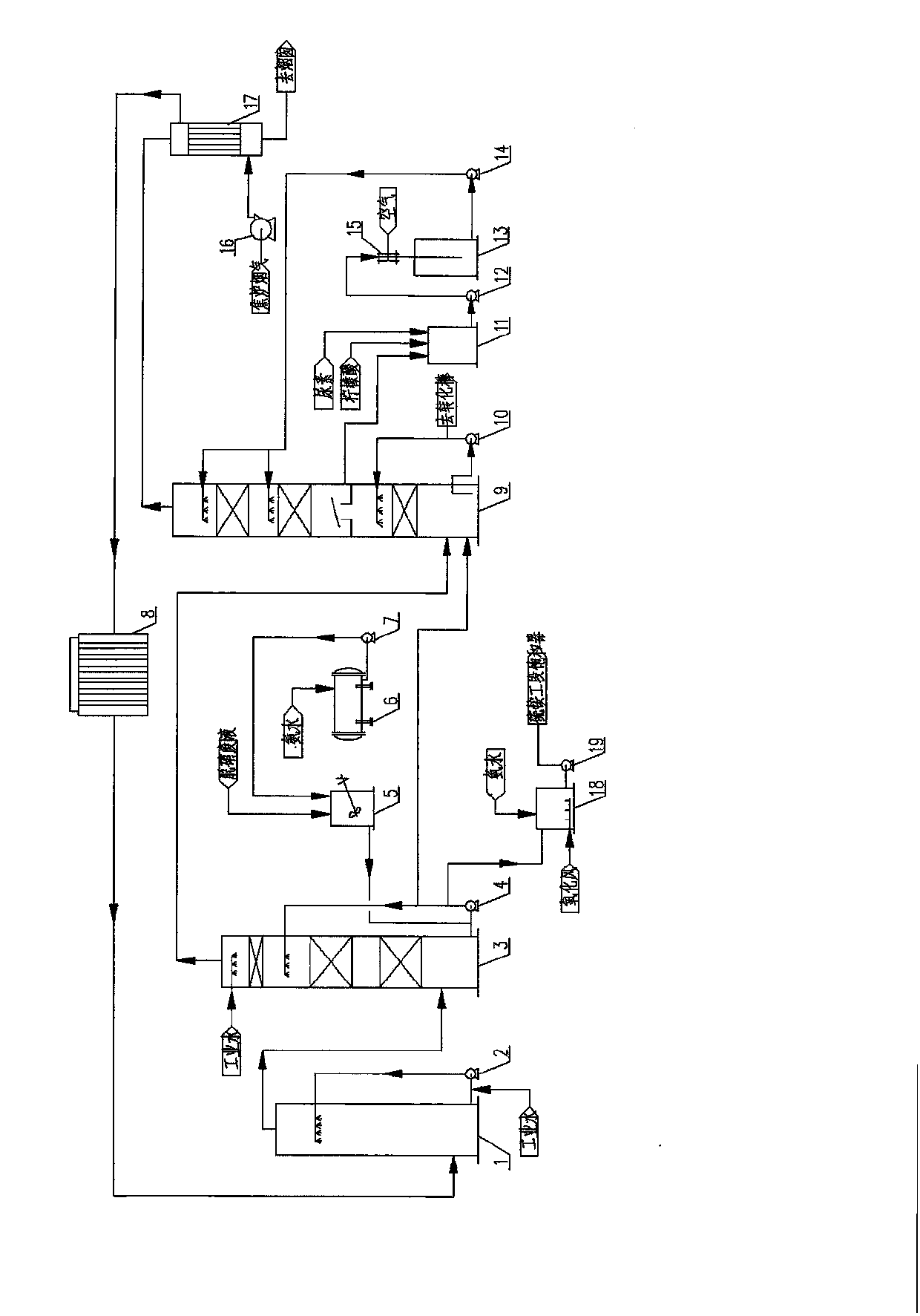

Process and system for activated-carbon desulfurization and denitration of coke oven flue gas and comprehensive utilization of byproducts

PendingCN109432980ASmall footprintNo potential hazardGas treatmentDispersed particle separationSorbentNitrogen gas

The invention relates to a process and a system for activated-carbon desulfurization and denitration of coke oven flue gas and comprehensive utilization of byproducts. The activated carbon is adoptedas a desulfurization adsorbent and a denitration catalyst of the coke oven flue gas, sulfur-rich gas generated by desulfurization is sent to a chemical production process of a coking plant for producing sulfur or ammonium sulfate, and powdered activated carbon which cannot be recycled is sent to a sewage treatment process of the coking plant as a high-efficiency adsorbent of coking wastewater, sothat the byproducts from activated-carbon desulfurization and denitration of the coke oven flue gas are recycled. Real desulfurization and denitration integration is realized, requirements of desulfurization and denitration indexes are met, and the activated carbon is environmentally friendly; the sulfur-rich gas generated by desulfurization is sent to the chemical production process of the cokingplant for producing sulfur or ammonium sulfate; ammonia is used as a reducing agent in activated carbon denitration, and the generated products are nitrogen and water, which can be directly discharged with flue gas; the worn powdered activated carbon is sent to the sewage treatment process of the coking plant as the high-efficiency adsorbent of the coking wastewater, and thus, comprehensive utilization of the desulfurization and denitration by-products of the coke oven flue gas is realized.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

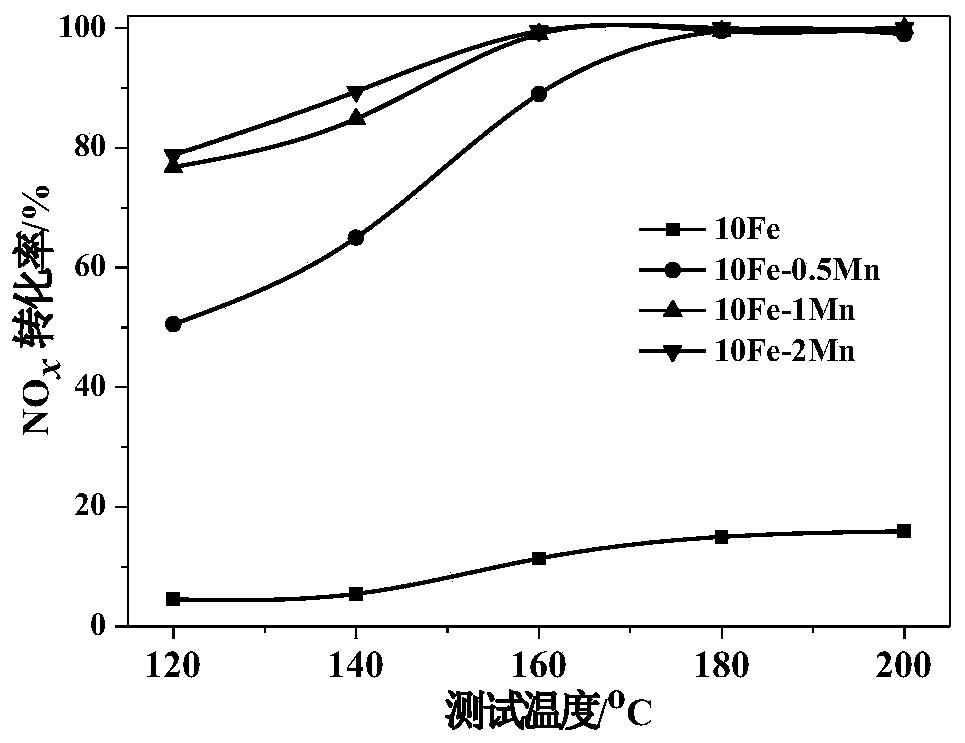

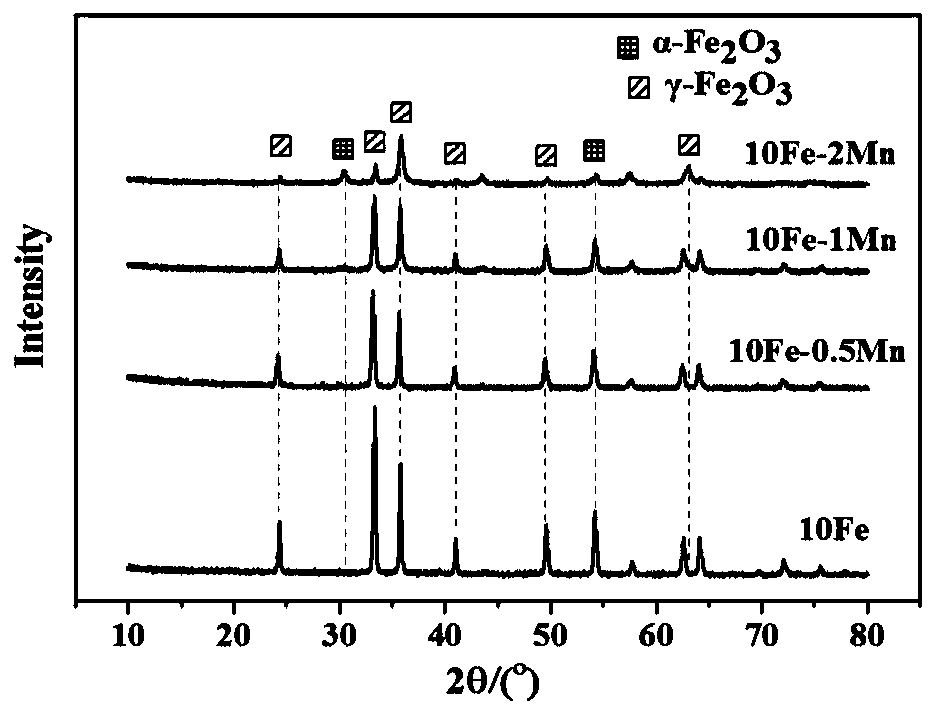

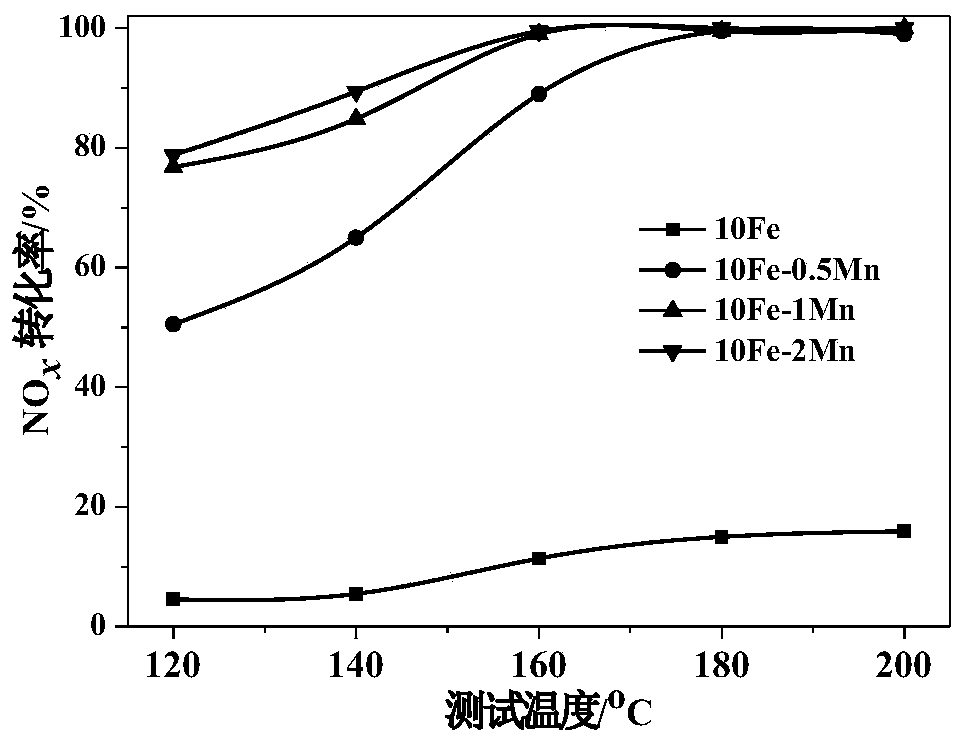

Bimetal ferromanganese low-temperature catalyst for selective catalytic reduction (SCR) denitration as well as preparation method and application of catalyst

InactiveCN109999829AGood synergistic performanceGood denitrification effect at low temperature (120~200°C)Gas treatmentDispersed particle separationEnvironmental resistanceWater baths

The invention discloses a bimetal ferromanganese low-temperature catalyst for selective catalytic reduction (SCR) denitration as well as a preparation method and application of the catalyst, and belongs to the fields of atmospheric pollution control technology and environment-friendly catalytic materials. The catalyst for the SCR denitration is prepared by adopting Fe(NO3)3, Mn(NO3)2 and citric acid reagents as main raw materials and adopting a sol-gel method. The catalyst is obtained by the steps of performing magnetic stirring in a water bath, performing drying treatment and performing roasting in an air atmosphere, the catalyst uses MnOx and FeOx as active components, wherein a mass ratio of component element Mn to component element Fe to a carbon source in the catalyst is (0.05-0.2):(0.8-1.2):(0.5-2), and the catalyst has an operating temperature of 120-200 DEG C. According to the technical solution provided by the invention, the method provided by the invention can significantly improve the denitration effect of the catalyst at a low temperature and facilitates prolonging the service life of the catalyst; and the catalyst provided by the invention has better stability of denitration efficiency at low temperature, and is suitable for promotion and applications in low-temperature SCR denitrification of sintering flue gas or coke oven flue gas.

Owner:CHANGZHOU UNIV

High thermal shock abrasive brick for dry quenched coke oven chute pillar and manufacture method

The present invention discloses one kind of abrasive brick with high thermal shock resistance for use in dry quenching coke oven and its making process. The abrasive brick is made with the materials including silicon carbide 62-80 wt%, silicon nitride 17-35 wt%, inorganic adhesive 0.4-3 wt%, lanthanide oxide 0.1-0.8 wt% and ferric oxide impurity less than 1.0 wt%, and has high thermal shock stability and normal temperature pressure strength higher than 120 MPa. The making process includes the steps of mixing all the materials, pressing at 75-125 N / sq mm pressure to form adobe, stoving the adobe at 100-300 deg.c and final sintering in a kiln at 1380-1420 deg.c under the protection of nitrogen. The abrasive brick with high thermal shock resistance has long service life.

Owner:武汉钢铁有限公司

Coke dry quenching furnace castable used for in-suit generation of aluminium nitride, and preparation method thereof

ActiveCN105237001ARealize multiple utilizationStrong medium and high temperature strengthAl powderPtru catalyst

The invention relates to a coke dry quenching furnace castable used for in-suit generation of aluminium nitride, and a preparation method thereof. According to the preparation method, 45 to 65wt% of mullite, 15 to 35wt% of silicon carbide, 2 to 8wt% of aluminum powder, 0 to 5wt% of aluminium-silicon alloy powder, 0 to 2wt% of silicon powder, 4 to 6wt% of alpha-aluminium oxide micro powder, 2 to 4wt% of silicon micro powder, and 4 to 6wt% of calcium aluminate cement are taken as raw materials, a catalyst with an amount accounting for 0.1 to 0.3wt% of the amount of the raw materials, an anti-hydration agent with an amount accounting for 0.2 to 0.5wt% of the amount of the raw materials, and a water reducing agent with an amount accounting for 0.1 to 0.3wt% of the amount of the raw materials are taken as additives; aluminum powder, aluminium-silicon powder, the catalyst, and the anti-hydration agent are subjected to pre-mixing so as to obtain a premixed material; the premixed material, the water reducing agent, and the other raw materials are mixed and stirred to be uniform so as to realize in-suit generation of the aluminium nitride coke dry quenching furnace castable. The coke dry quenching furnace castable is excellent in middle temperature and high temperature mechanical properties, wear resistance, and thermal shock stability, is long in service life, is friendly to the environment, and is capable of saving energy, and is suitable for coke dry quenching furnace chute stand columns.

Owner:WUHAN UNIV OF SCI & TECH +1

System and method for treating benzene-contained separating water of coking benzol

ActiveCN102634381ASolve pollutionNo secondary pollutionFatty/oily/floating substances removal devicesCombustible gas purificationBenzeneWater treatment system

The invention belongs to the technical field of purifying coke oven gas, and relates to a system and method for treating benzene-contained separating water of coking benzol. The method comprises the following steps that: benzene-contained and oil-contained separating water which is separated in a benzol production process is fed to an inlet pipeline of a circulating ammonia pump through a pipeline; the benzene-contained and oil-contained separating water reaches the circulating ammonia pump through an inlet of the circulating ammonia pump; raw coke oven gas reaches a gas collecting pipe of a coke oven for spraying by pressurizing the circulating ammonia pump; heat exchange is carried out on the raw coke oven gas in the gas collecting pipe at a temperature of 780-850 DEG C; benzene matter is separated from water so as to rapidly volatilize to mix with gas due to heating effects of the raw coke oven gas at a high temperature, and enters a next benzene washing process with gas; the separating water in which the benzene is removed is mixed with an ammonia tar system; and finally, ammonia enters an ammonia vaporizing system for treatment and oil matter enters a tar system. According tothe invention, the treatment efficiency of the benzene-contained separating water is high and the treatment speed of the benzene-contained separating water is high. Meanwhile, the conventional equipment and device in coking can be sufficiently used, so that the operation cost is low, the operation field conditions is improved, and the yield of chemical product of benzol is increased.

Owner:NANJING IRON & STEEL CO LTD

Method for replacing safety valve of boiler drum of coke drying quenching boiler

ActiveCN107366895AShorten the timeShorten incident handling timeCoke quenchingSteam boilersCold airOperation mode

The invention discloses a method for replacing a safety valve of a boiler drum of a coke drying quenching boiler. According to the method, nitrogen gas is introduced into gas pipelines of a coke drying quenching furnace and a boiler, cold water cooling is performed in a water jacketing operation mode, meanwhile, the temperature of the coke drying quenching boiler is reduced quickly in a mode of making cold air enter from a manhole of the boiler and exhausting the cold air from an opening of the coke quenching furnace by utilizing gas buoyancy, and finally, the safety valve of the boiler drum of the boiler is replaced quickly; compared with the prior art, the method has the following beneficial effects that: (1) the time that the boiler drum of the boiler satisfies safety valve replacing conditions is shortened, and the conditions required for replacing the safety valve of the boiler drum of the boiler are satisfied within eight hours; and (2) the accident handling time can be shortened and the production loss can be reduced by the method.

Owner:ANGANG STEEL CO LTD

Method and device for co-production of synthetic ammonia and LNC (liquefied natural gas) by coke gas

ActiveCN103588221AIncrease profitShort processGaseous fuelsCombustible gas purificationAmmonia productionCoke oven

The invention provides a method for co-production of synthetic ammonia and LNC (liquefied natural gas) by coke gas, which is high in raw material utilization ratio. The method comprises the steps as follows: semi-water gas and purified coke gas are mixed and fed into a conversion unit, and then enters a low-temperature methanol washing unit for purification treatment; purified gas after purification treatment enters a two-in-one cooling box consisting of a liquid nitrogen washing unit and a cryogenic device, is further purified in the two-in-one cooling box and is configured into pure synthesis gas finally, and a ratio of H2 to N3 in the pure synthesis gas is 3:1; and the pure synthesis gas enters a synthetic ammonia unit to generate synthetic ammonia, and exhausted gas generated by the synthetic ammonia unit returns the two-in-one cooling box device to generate an LNG product. According to the method for co-production of synthetic ammonia and the LNC by the coke gas, methane in the purified coke gas and the semi-water gas and methane in the exhausted gas generated during the synthetic ammonia production process are separated out to produce the LNG, then residual available gas is utilized to produce synthetic ammonia, and the method has the advantages of short technological process and high virgin gas utilization ratio.

Owner:SHANXI YANGMEI FENGXI FERTILIZER IND GRPCO

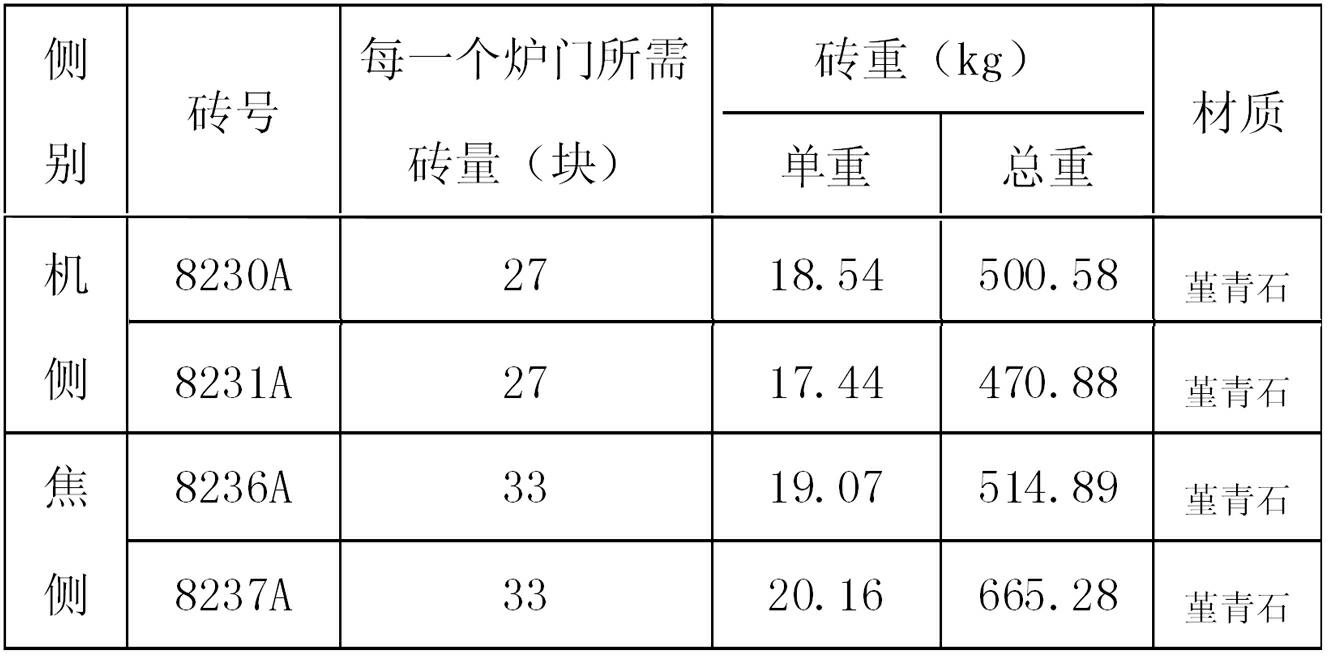

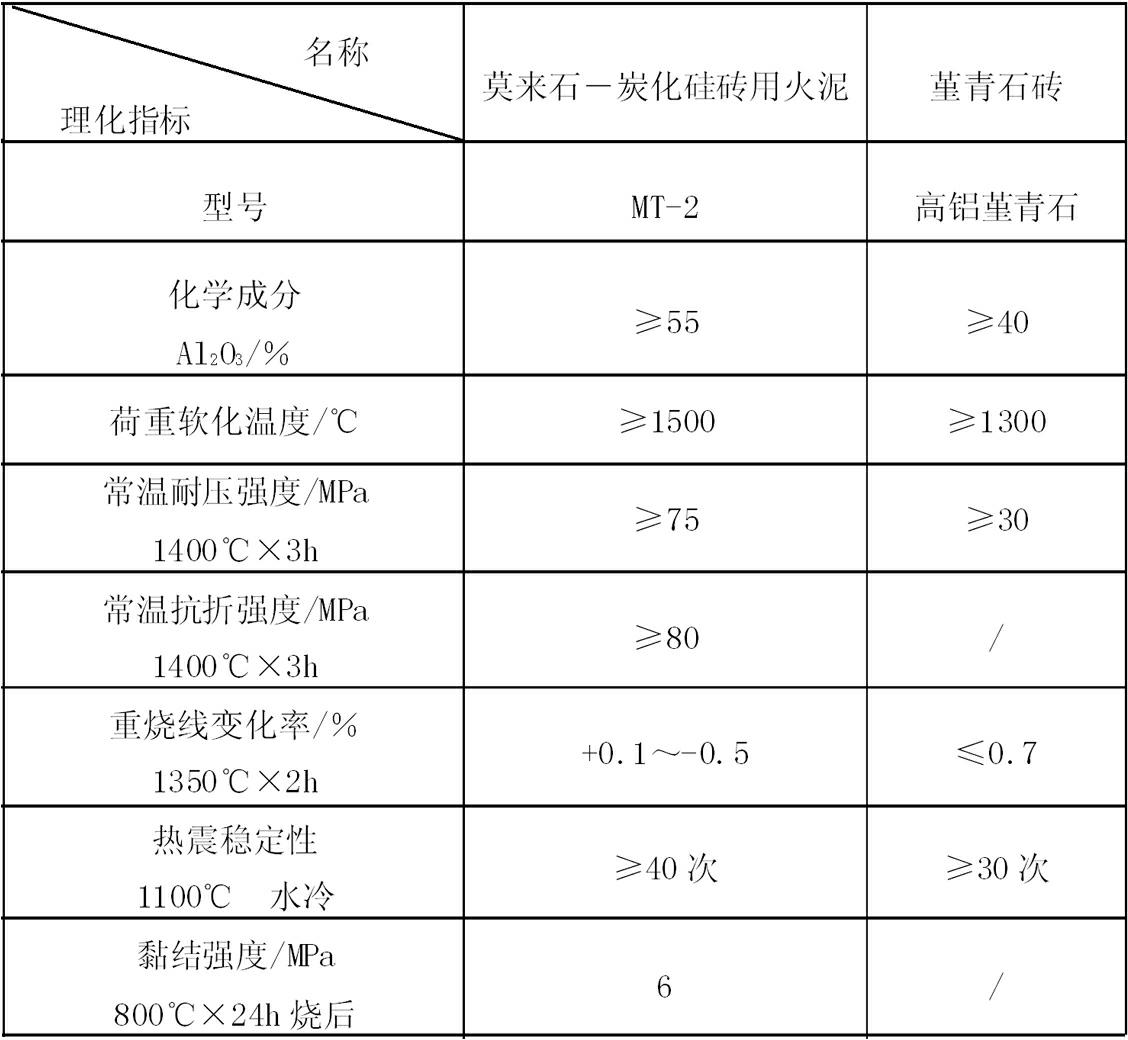

Coke oven door lining brick repairing process

ActiveCN102676181ALow costReduce labor intensityBrickwork leakage repair/preventionCoke oven doors/closuresAluminateBrick

The invention relates to a coke oven door lining brick repairing process, comprising the following steps of: cleaning a damaged surface; preparing the damaged part to be repaired into a pitted surface with steel chisel for connection with a repaired material; preparing an oven door lining brick repairing material; evenly pouring a layer of sparse mortar prepared from aluminate cement and water on the damaged surface and filling repairing materials; spraying a layer of aluminate cement on the surface; and immediately trowelling the repairing surface with a cutter to ensure a smoothed repairing surface. By using a corbel special repairing material remained after dry quenching during annual overhaul, new oven door lining bricks are not required, thereby avoiding wasting resources and reducing the cost; the damaged oven door lining brick does not need to be removed, thereby reducing the labour intensity and shortening the operation time; the whole repairing process only consumes 1-1.5h; and by using the oven door repaired by the invention, the service life is prolonged.

Owner:SGIS SONGSHAN CO LTD

Low-quality fuel pyrolysis process

ActiveCN103980920AHigh thermal efficiencyImprove effective utilizationCoke quenchingDirect heating destructive distillationTar yieldGas blending

The invention discloses a low-quality fuel pyrolysis process. The process comprises the following steps: by mutually combining a coke dry quenching technology and a fluidized bed pyrolysis technology, mixing coke quenching gas absorbing semi-coke heat with a part of high-temperature flue gas to be used as a fluidizing medium, returning cooled fluidized gas to a coke dry quenching furnace to be used as the coke quenching gas, and using the high-temperature flue gas obtained after burning pyrolysis gas as a system heat source. The low-quality fuel pyrolysis process adopts the fluidized bed rapid pyrolysis technology, and effectively absorbs the waste heat of high-temperature semi-coke and improves the heat efficiency of a system at the same time; moreover, the fluidizing medium and a coke quenching medium of the system are coupled for use so as to ensure the tar yield, reduce the coke quenching cost, and achieve the synchronous production of tar and the semi-coke by using the fluidized bed technology.

Owner:吉林省利用厚生能源科技有限公司

Anti-blocking blocking-relieving method and apparatus for coke oven flue gas SCR (selective catalytic reduction) denitration catalyst

InactiveCN106215696AAvoid cloggingAvoid inactivationDispersed particle filtrationTransportation and packagingFlue gasCoke oven

The invention relates to an anti-blocking blocking-relieving method and apparatus for coke oven flue gas SCR (selective catalytic reduction) denitration catalyst. One side of a lower ash bucket of a denitration reactor is provided with a flue gas inlet, the other side of the top end of an upper straight barrel is provided with a purified flue gas outlet, a metal strainer and multiple layers of denitration catalyst are arranged in the upper straight barrel sequentially from bottom to top, a first flushing pipe is arranged above the metal strainer, a second flushing pipe and a heating air pipe are arranged above each layer of denitration catalyst, the first flushing pipe and the second flushing pipes are connected with an external flushing water supply device through a pressure pump after being communicated, the heating air pipes are connected with an external heating device after being communicated, and the bottom of the lower ash bucket is provided with a drain valve. The metal strainer is disposed at the front of the denitration catalyst to intercept ammonia salts and sticky particles in the coke oven flue gas and prevent blocking of the denitration catalyst; the flushing pipes are arranged above the denitration catalyst to flush blockage; therefore, efficient denitration of the denitration catalyst is guaranteed, and the life of the denitration catalyst is extended.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com