Patents

Literature

100 results about "Tar yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

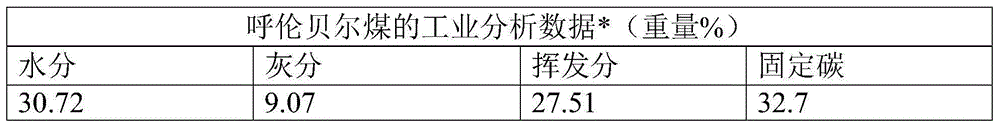

The yield of tar from various petroleums is 15–30 percent based on the petroleum. The main components of tar are oil not distilled during the fractionation of petroleum, petroleum resins, solid asphaltic substances (asphaltenes. carbenes, and carboids), and substances of an acidic nature (asphaltogenic acids and their anhydrides).

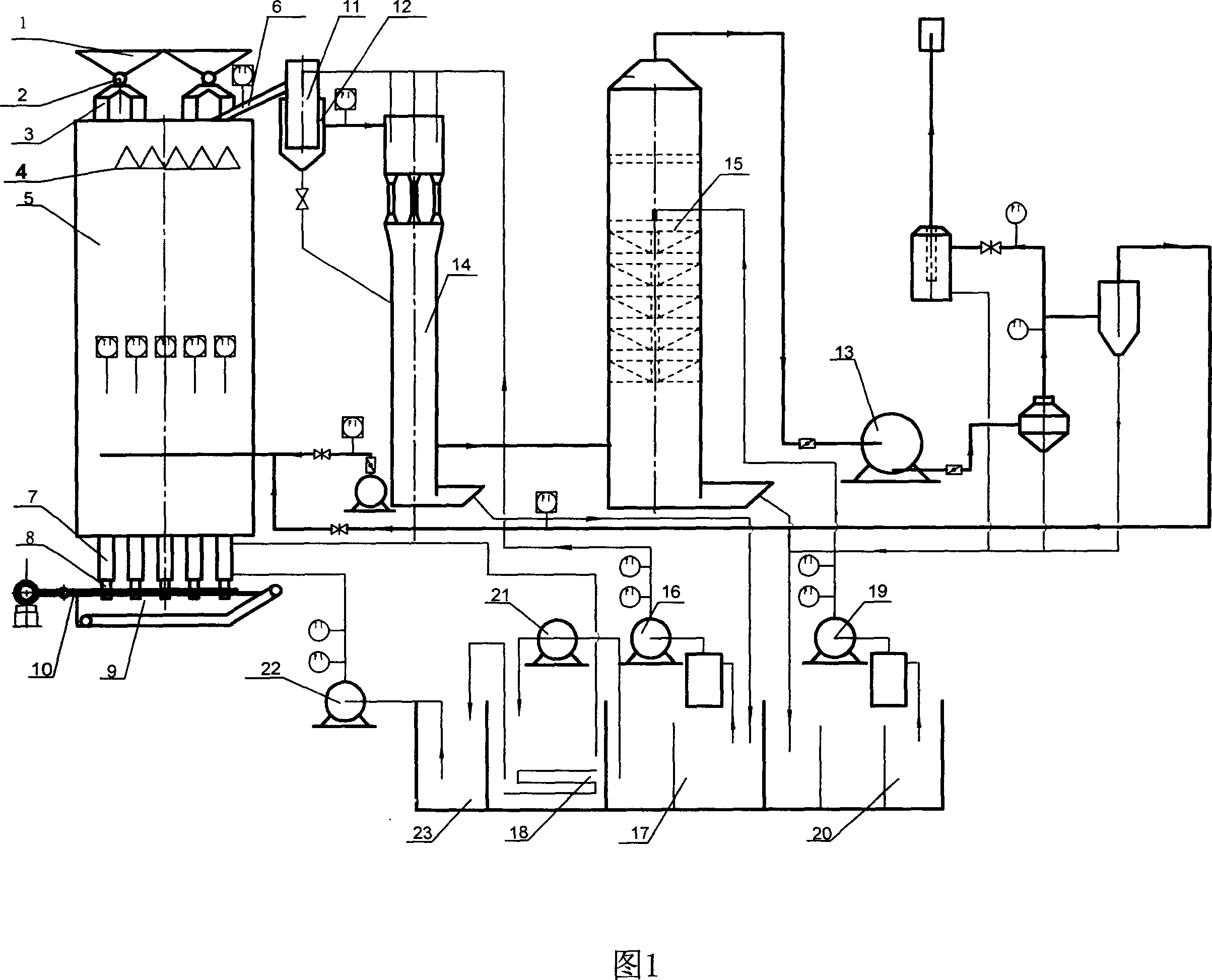

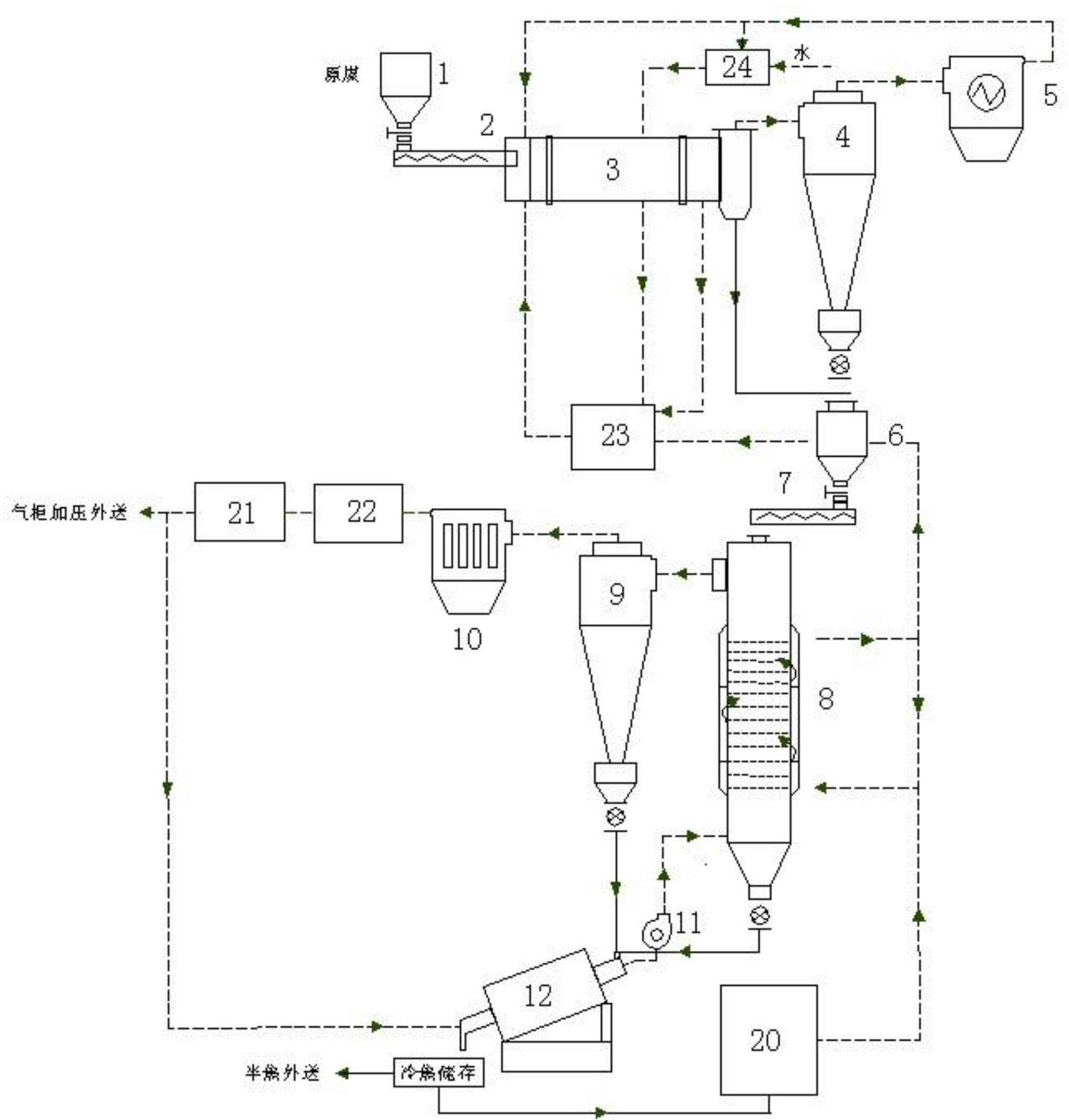

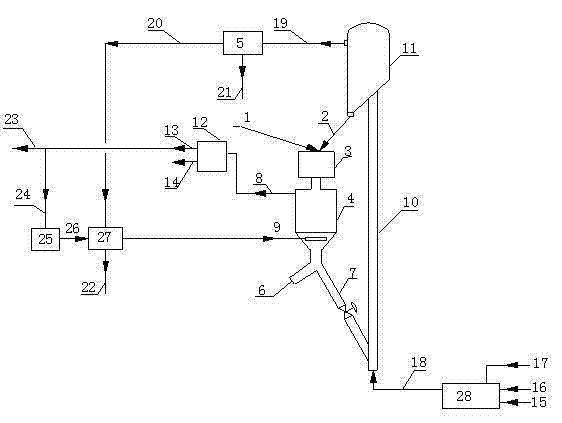

Low-temperature coal carbonization manufacturing technique

ActiveCN1966612AGive full play to the maximum capacityIncrease productionIndirect heating destructive distillationTemperature controlCarbonization

The invention disclosed a low temperature coal dry distillating process which includes the following steps: choosing the material coal; the coal goes through coal cup, roller, and assistant coalbox to get into collecting umbrella and being separated; pre-heating the coal in the drying stage; dry-distillating at 100-550DEG C for about 4h, the temperature of heating region is 700-800DEG C to decrease the content of semi-coal to less than 6%; cooling the semi-coal through the water-cooling jacket box. The heat in the stove is all absorbed by the coal in the invention. It needs less time to dry distillate the coal and it's quite direct and simple. The invention adopts big containing space, the heating gas is provided uniformly to the bottom of the stove so the stove throughput is 3 times more than the traditional stove; it can heat the material more uniformly and it need less temperature control; the tar yield has been increased and the recovery rate has been increased from less than 50% to 80% or more.

Owner:SHAANXI SHENMU SAN JIANG COAL CHEM

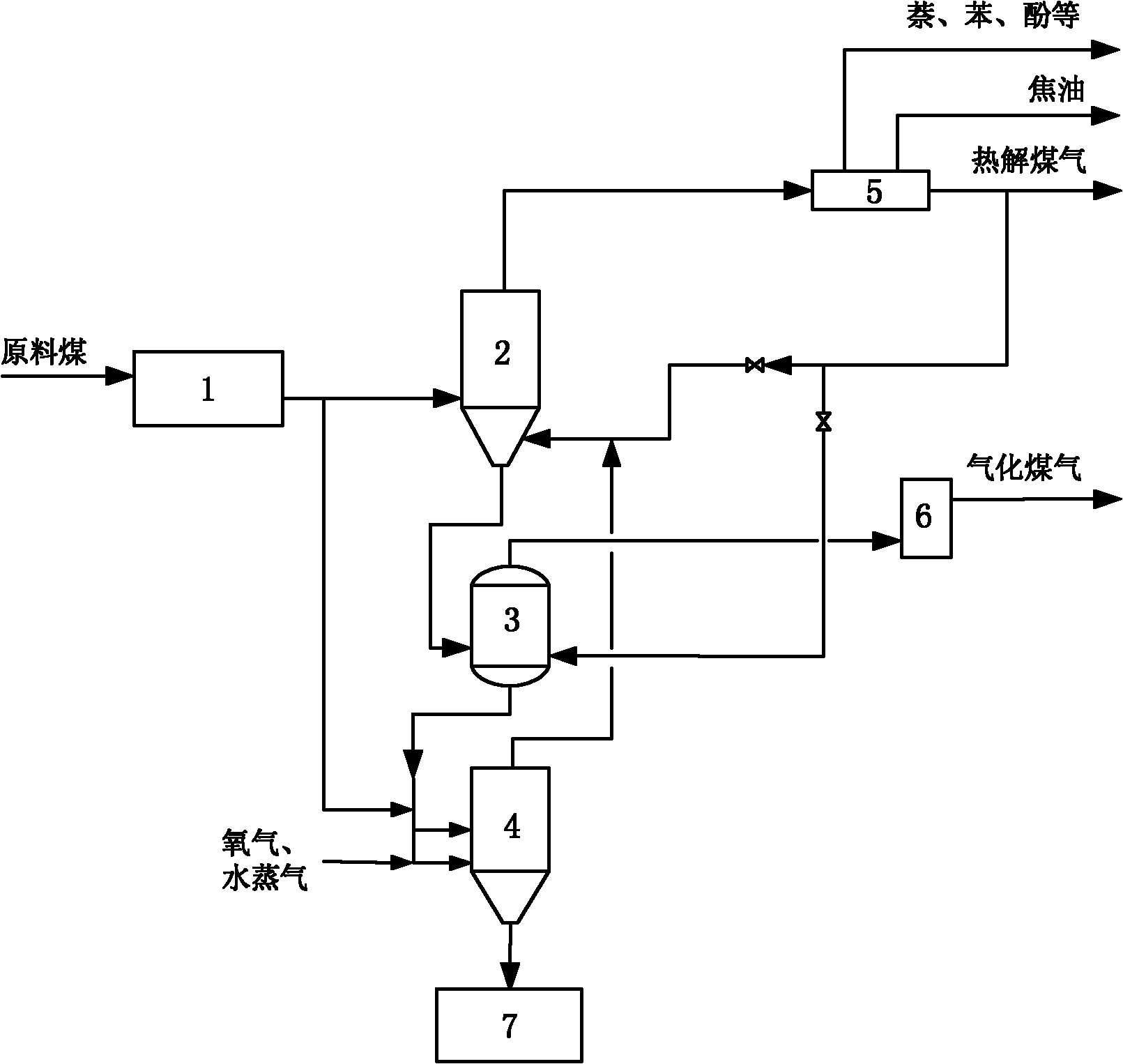

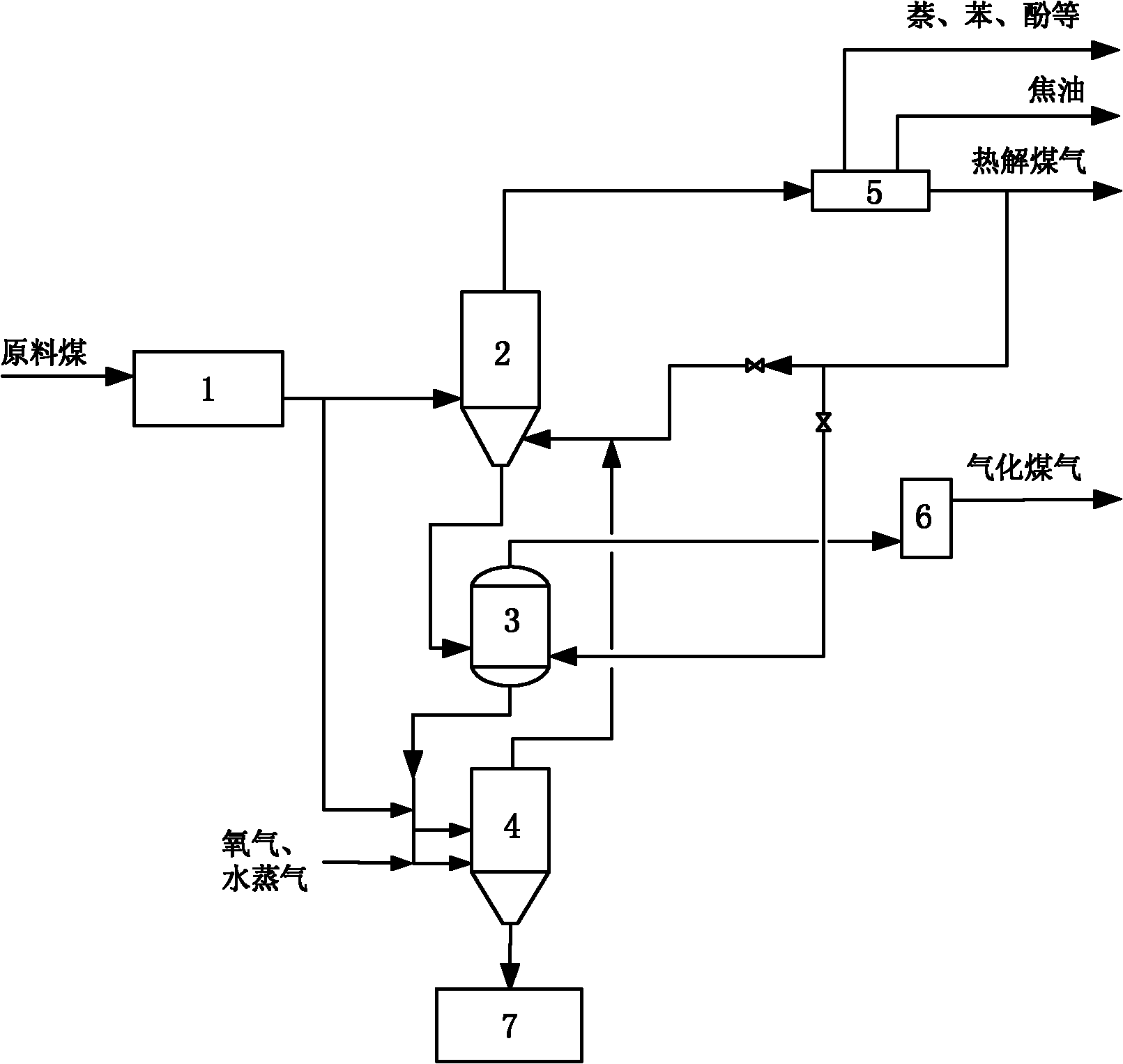

Method for coal hydrogenation pyrolysis and gasification coupling

ActiveCN102061182AFully extractedHigh yieldDirect heating destructive distillationGasification processes detailsWater vaporGas phase

The invention discloses a method for coal hydrogenation pyrolysis and gasification coupling, comprising the steps of: drying and preheating raw material coal with granularity less than or equal to 2mm in a coal drying and preheating system; putting 60-80% of the dried and preheated raw material coal in a coal hydrogenation pyrolysis furnace to carry out coal hydrogenation pyrolysis; putting a pyrolyzed gas-phase product in a pyrolyzed gas purification and separation system to carry out separation; putting all the semicoke generated by the coal hydrogenation pyrolysis furnace in a coke hydrogenation gasification furnace to carry out hydrogenation gasification; putting a gasified gas-phase product in a gasified gas purification and separation system; and causing 20-40% of the dried and preheated raw material coal and high-temperature coke granules from the coke hydrogenation gasification furnace to enter a hydrogen-rich generator from upper and lower paths under the combined action of oxygen and a water vapor mixed gasification agent so as to carry out gasification reaction. The coal hydrogenation pyrolysis, semicoke hydrogenation gasification and coke granule hydrogen production are combined; therefore, the tar yield and the light component content are effectively improved and methane-rich pyrolyzed gas, gasified gas and coal chemical products such as naphthalene, benzene, phenol and the like with high added value can be obtained.

Owner:北京锦泰诚瑞科技发展有限公司

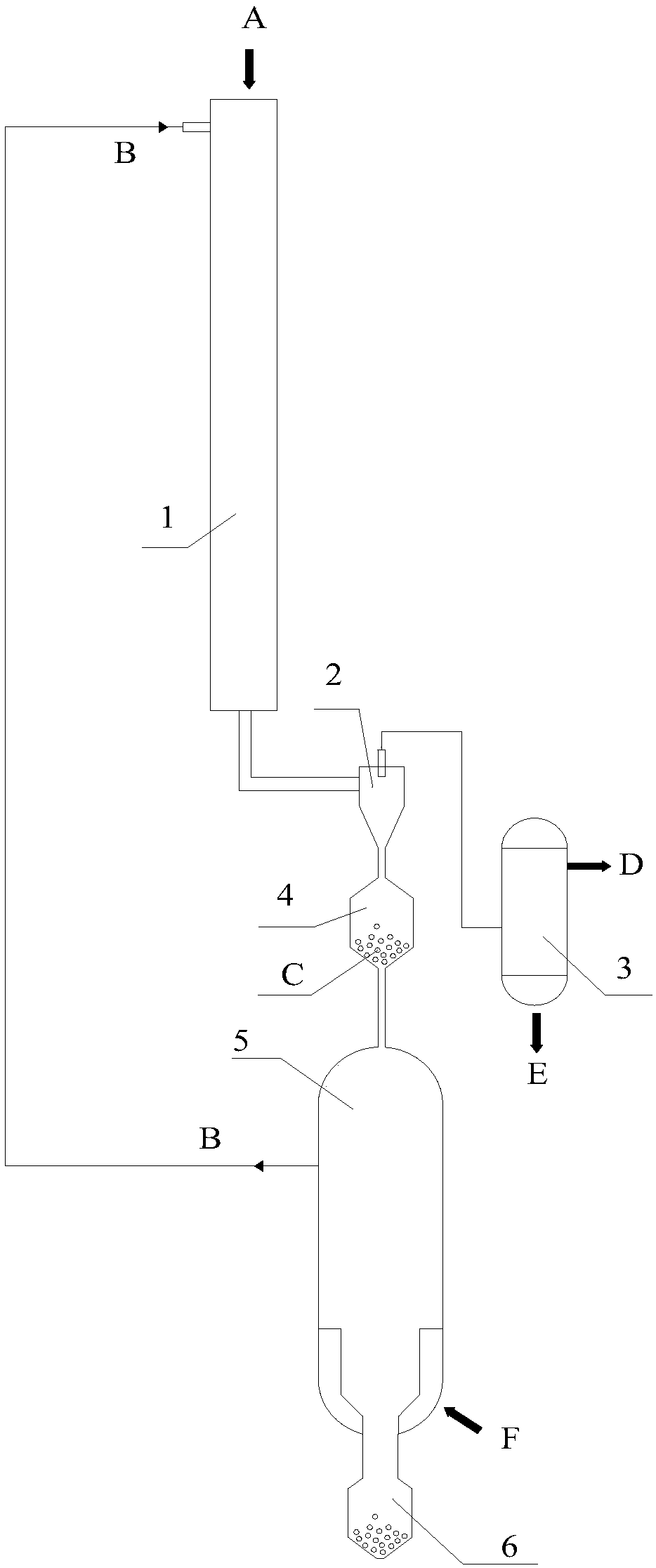

Apparatus for preparing synthesis gas based on dual fluidized bed biomass gasification and preparation method thereof

InactiveCN102977927AReduce outputHigh calorific valueBulk chemical productionGranular/pulverulent flues gasificationCycloneGas phase

The present invention discloses an apparatus for preparing synthesis gas based on dual fluidized bed biomass gasification, including a hopper, a dryer, a screw feeder, a pyrolysis fluidized bed, a reforming fluidized bed, a reforming cyclone separator, a calcination fluidized bed, a calcination cyclone separator, a first U-shaped refeeder, a second U-shaped refeeder and a third U-shaped refeeder. The method of the apparatus for preparing synthesis gas includes: feeding biomass into the hopper, feeding the dried biomass to the pyrolysis fluidized bed, pyrolyzing and gasifying, and feeding carbon residue into the calcination fluidized bed. In the calcination fluidized bed, the coke in solid residue is combusted with oxygen to decompose calcium carbonate. The products of gas phase and solid phase are separated by the calcination cyclone separator. The heat-carrying agent calcium oxide is fed into the reforming fluidized bed. The pyrolysis gas carries calcium oxide to increase to promote catalytic cracking of tar. The reformed gas is obtained by reforming the pyrolysis gas. The synthesis gas is obtained from a synthesis gas outlet. The apparatus for preparing synthesis gas can reduce the tar yield, and improve the synthesis gas heat value ?and gasification efficiency.

Owner:SOUTHEAST UNIV

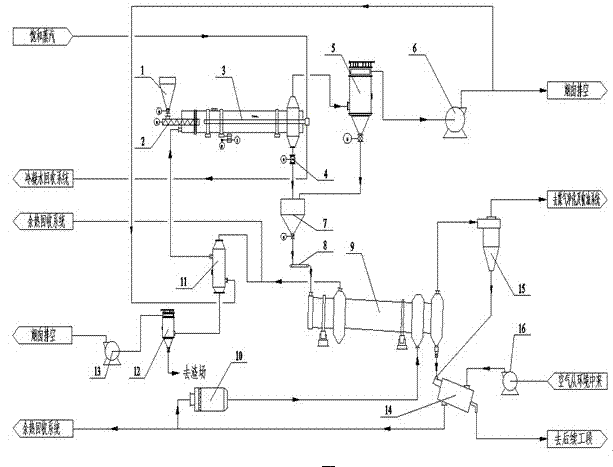

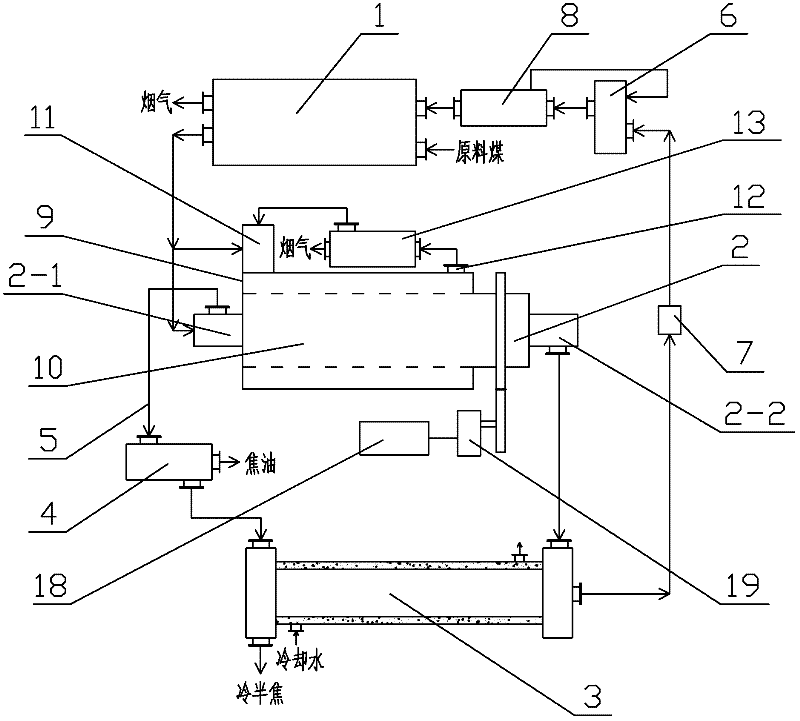

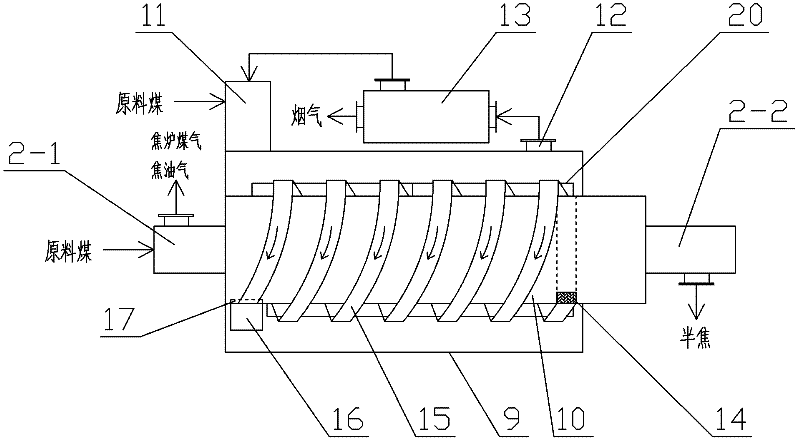

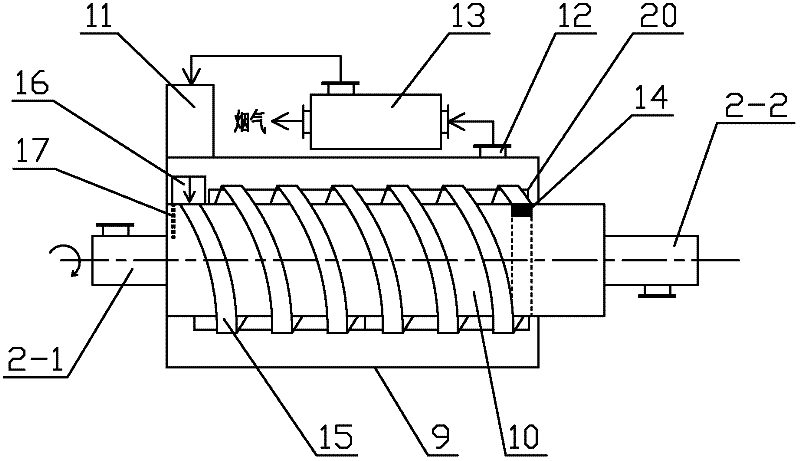

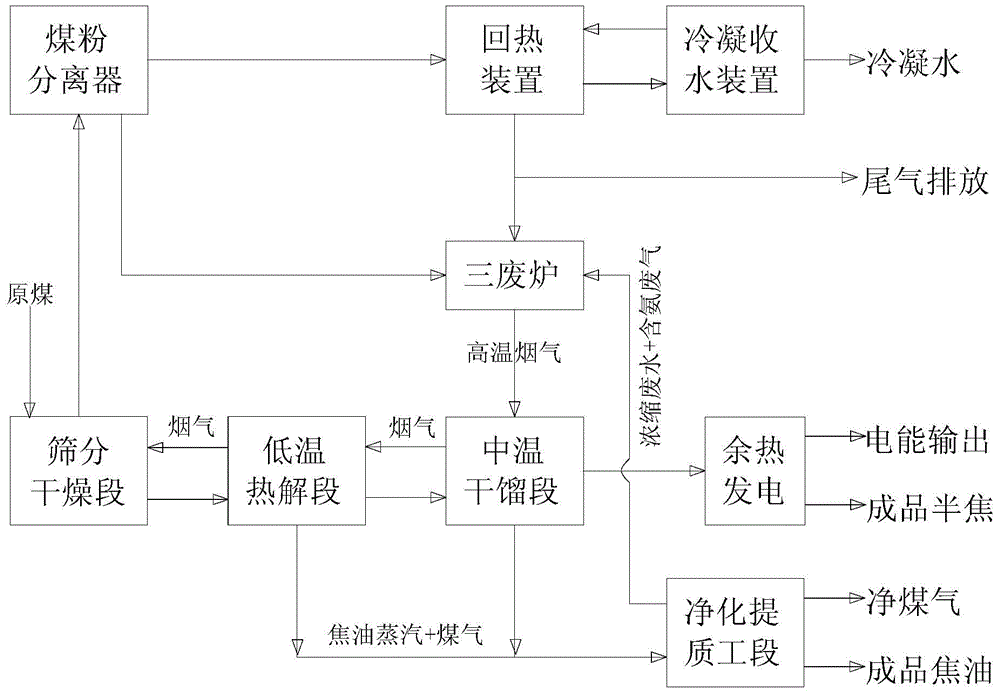

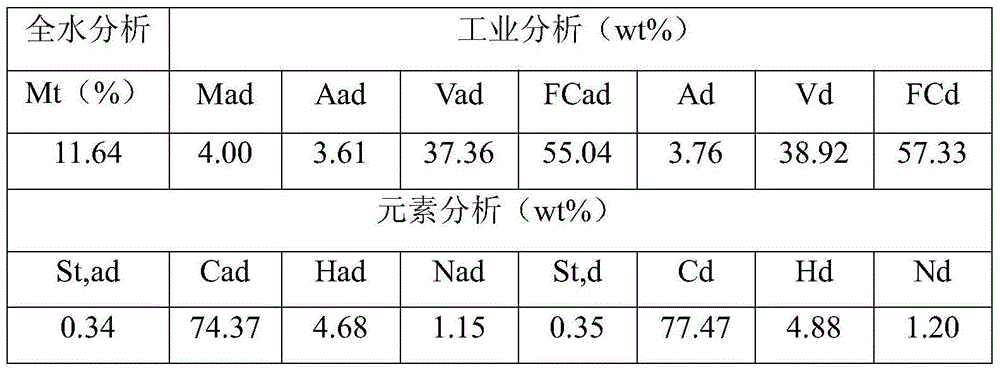

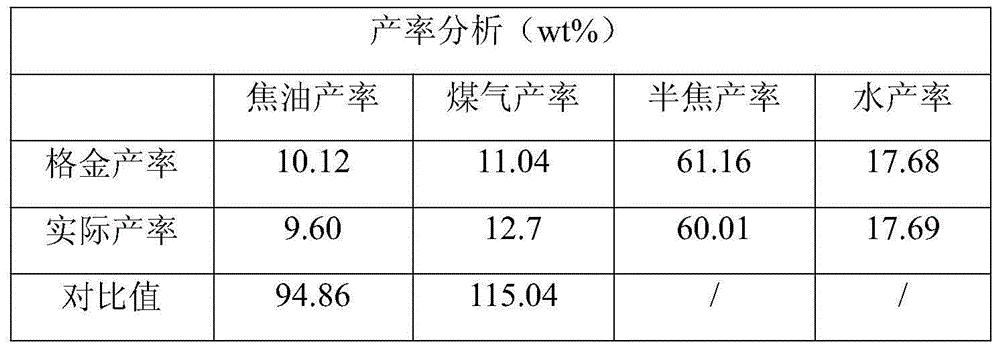

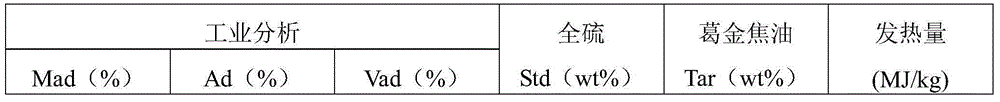

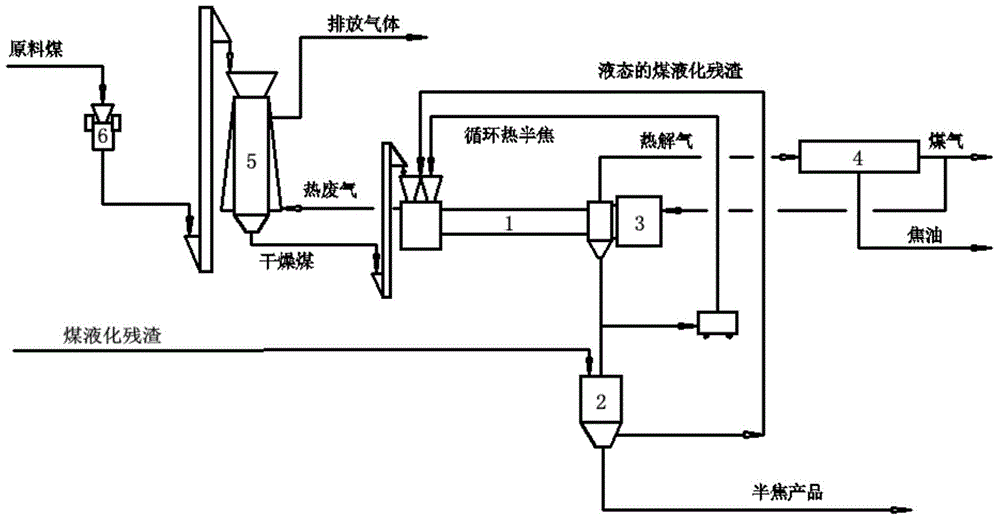

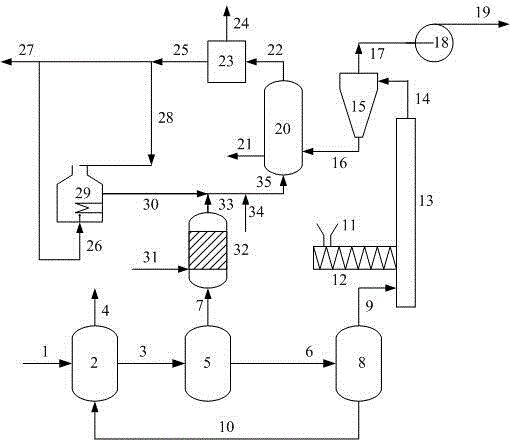

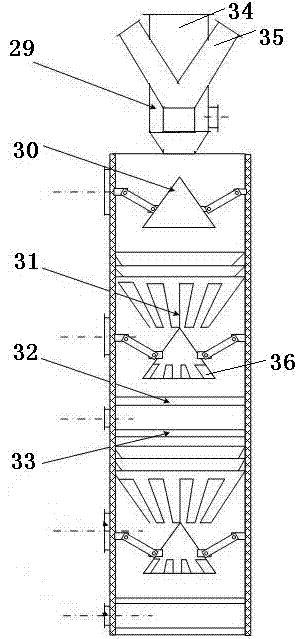

Drying and dry distillation combined quality improving process and system for low rank coal

The invention discloses a drying and dry distillation combined quality improving process and a drying and dry distillation combined quality improving system for low rank coal, which are used for overcoming the defects existing in the prior art and are particularly suitable for drying and dry distillation combined quality improvement of brown coal with high water content or other low rank coal such as long flame coal, non-caking coal or weakly caking coal, gas coal and the like. In the process, a combined quality improving method in which a steam revolving drier for drying and a multi-pipe revolving low-temperature dry distiller for dry distillation are provided is adopted, so that the problems of large coking wastewater handling capacity, large coal gas handling capacity and the like existing in a pure dry distillation process are solved. The drying and multi-pipe revolving low-temperature dry distillation combined quality improving process provided by the invention has the advantages of high energy utilization ratio, safe and stable systems, small dry distillation gas handling capacity, small coking wastewater handling capacity, high tar yield, high coal gas heat value and the like.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

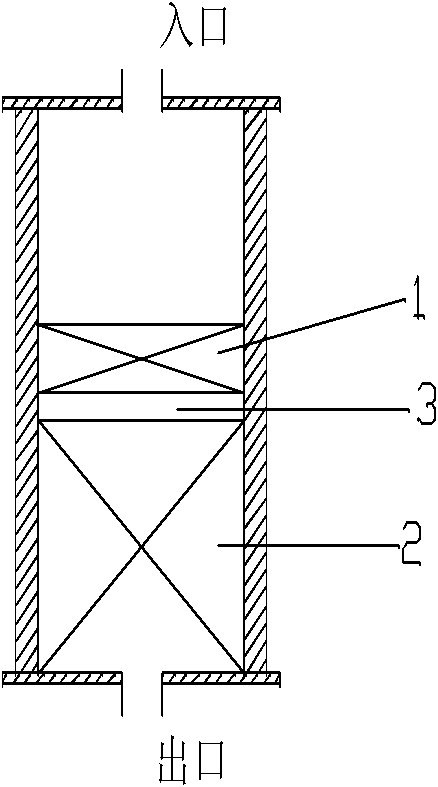

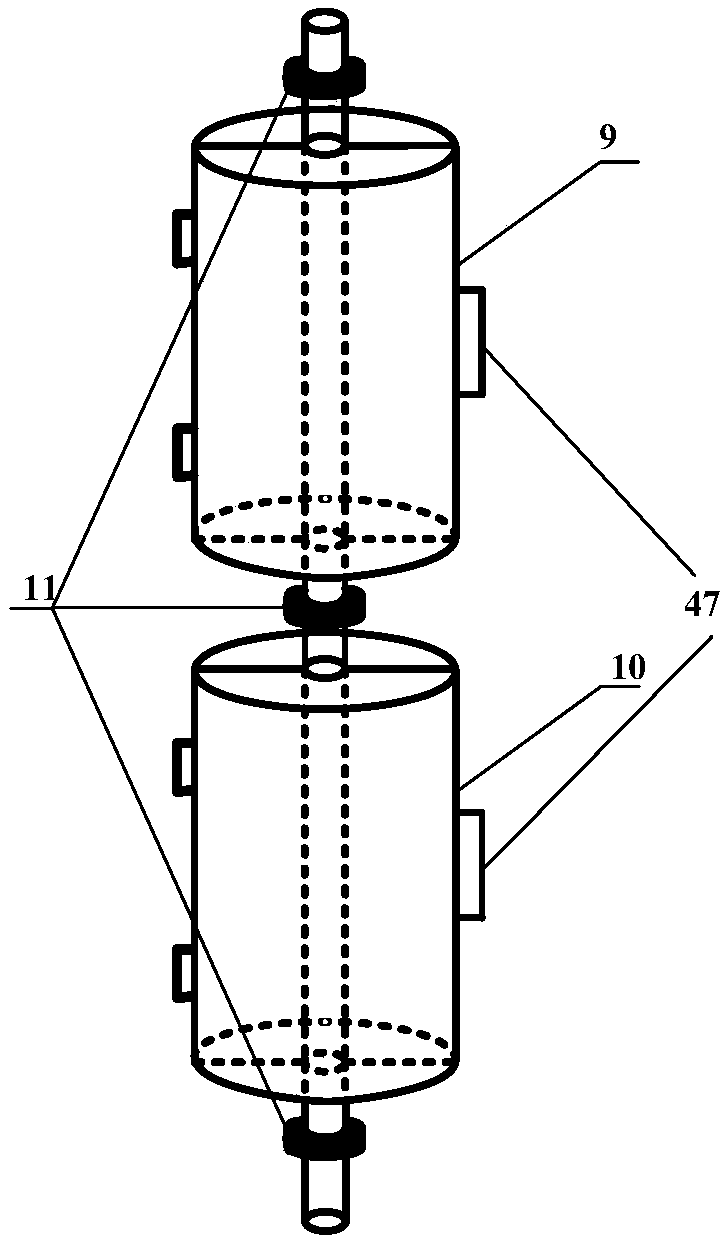

Method for increasing tar yield of coalite pyrolysis with methane as reaction gas

ActiveCN1664069AReduce the cost of hydropyrolysisEasy to recycleLiquid hydrocarbon mixture productionEnergy technologyHydrogen

The invention belongs to energy technology field and provides a method for increasing coking yield in coal pyrolytic and coking process. The method comprises employing methane as reacting gas and adding adequate oxidant, mixing them and introducing them to the pyrolytic reactor, which comprises two layers, the middle layer is separated by gas grid plate, activating the methane by catalyst, and introducing it to the coal layer, pyrolising and charring the coal. The invention is characterized in that it employs the methane instead of pure hydrogen gas as reacting gas, which can deduce the pyrolising cost; the coking yield is higher than that of employing hydrogen gas in the same condition; the char coal yield is equal to that of in the inert atmosphere but higher than that of employing hydrogen gas; the catalyst and coal do not mix directly, which is suitable for recovering.

Owner:DALIAN UNIV OF TECH

Coal horizontal rotation dry distillation process and equipment

InactiveCN102504848AAchieve cycleGuaranteed uptimeCoke quenchingInternal combustion piston enginesTarCoke oven gas

The invention discloses coal horizontal rotation dry distillation equipment, which comprises a dryer and a horizontal rotation gas retort, wherein the dryer is used for drying and preheating the coal; the horizontal rotation gas retort is communicated with the discharge hole of the dryer and is used for performing dry distillation and thermolysis on the coal; the horizontal rotation gas retort comprises a feeding section, a dry distillation section and discharge section; the discharge hole of the discharge section is communicated with a feeding hole arranged at one end of a carbocoal cooler; and a light pipeline which is used for performing cracking on coke-oven gas and tar gas and is filled with a catalyst is arranged between an exhaust port which is arranged on the feeding section and is used for discharging the coke-oven gas and the tar gas which are generated by dry distillation themolysis and the suction port of a coal gas desulfuration filter. Moreover, the invention also provides a process for performing horizontal dry distillation on the coal by utilizing the equipment. In the process, the waste heat of generated gas fume and carbocoal is reasonably utilized, and the heat use ratio is high. Compared with carbocoal produced by a traditional method, the carbocoal produced by the process does not contain water and has high quality and wide application, and the produced tar has high yield and high quality.

Owner:CHANGAN UNIV

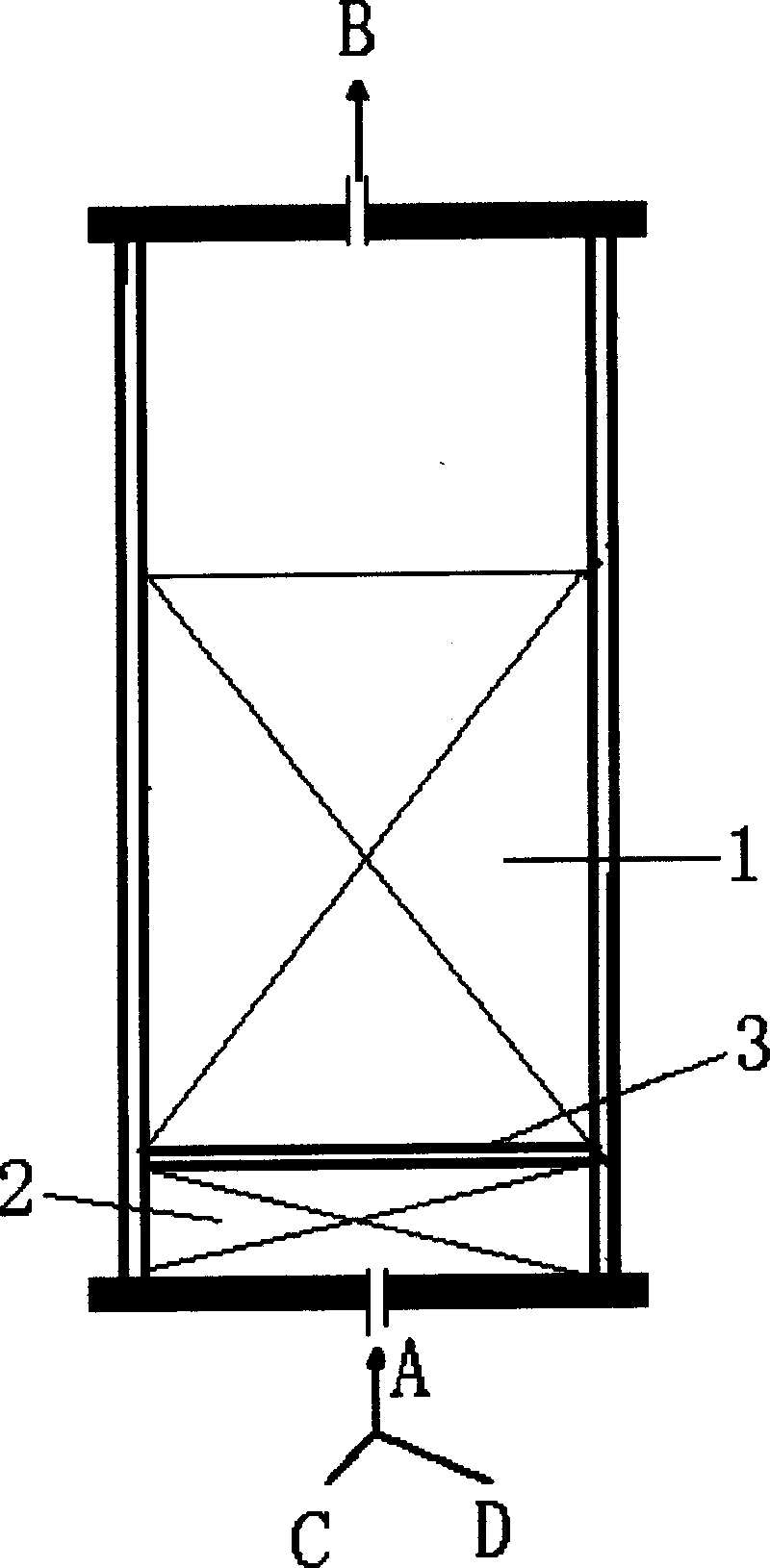

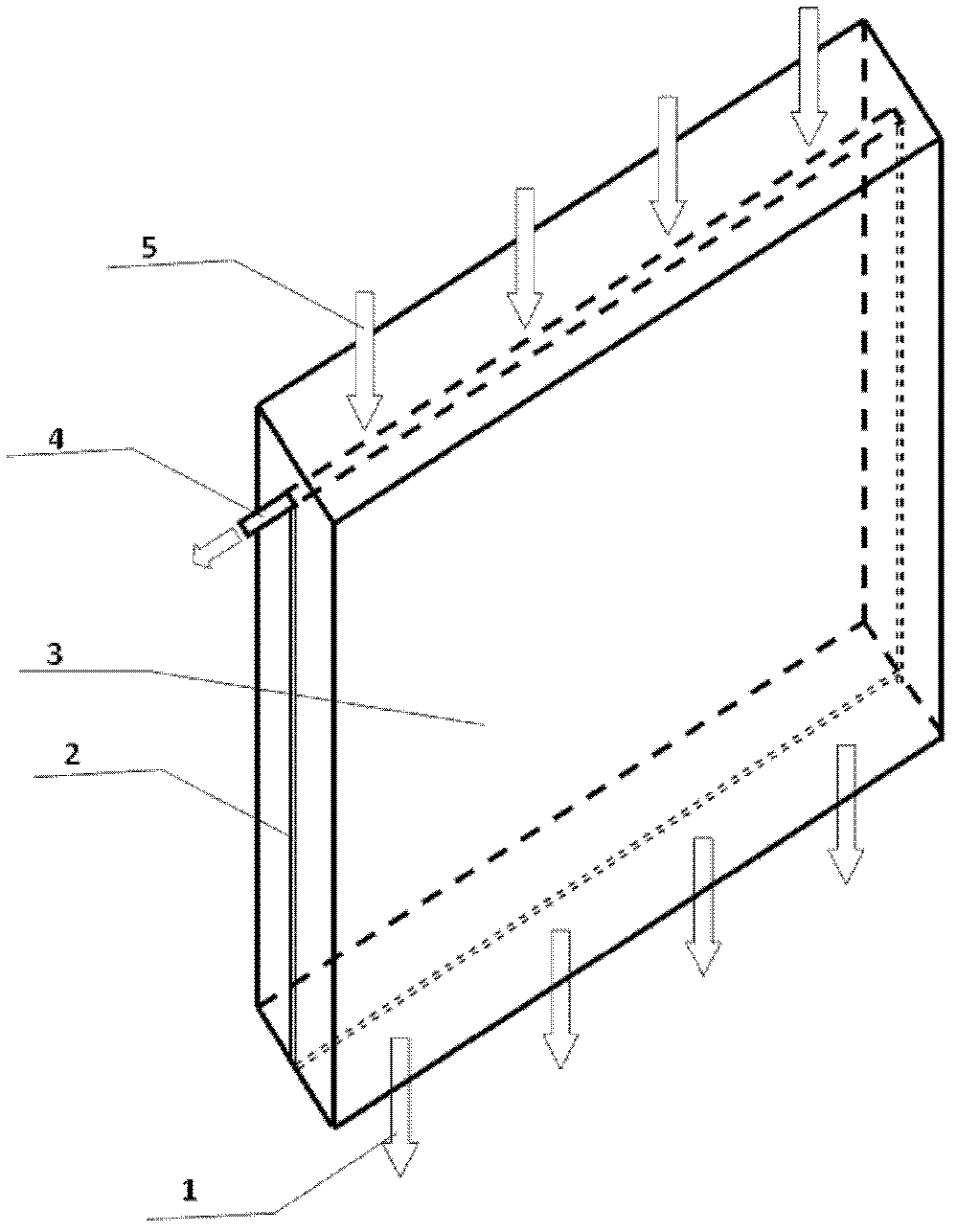

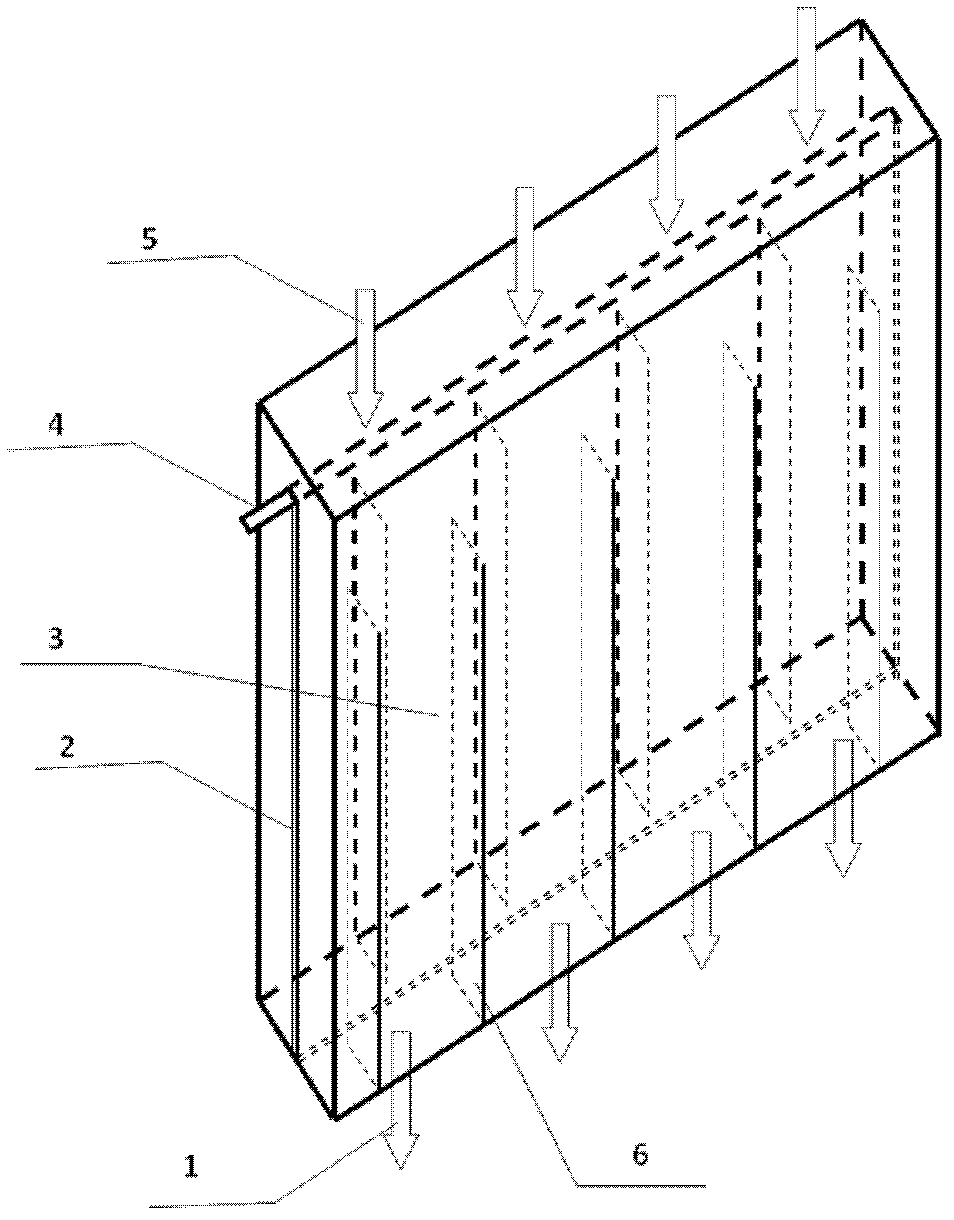

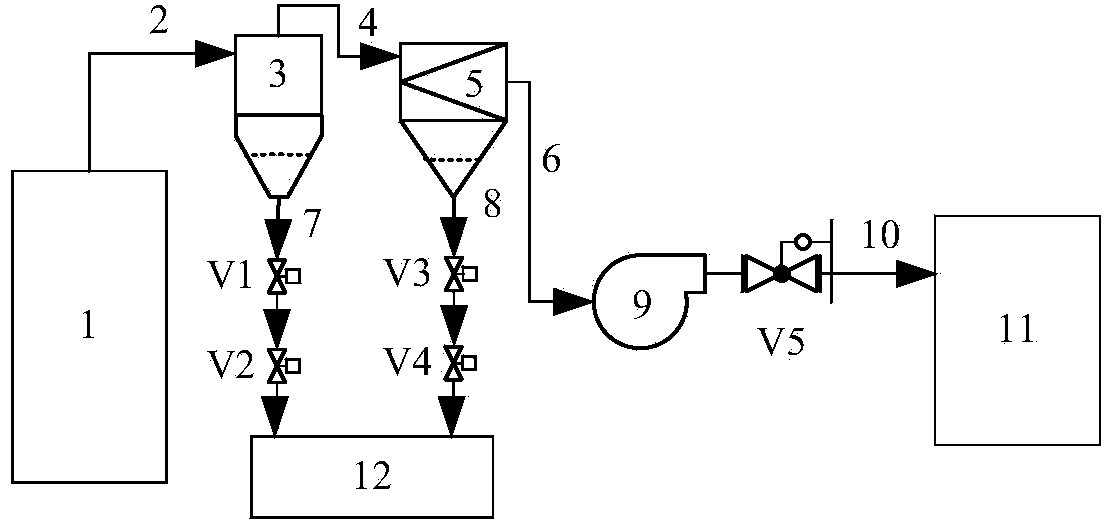

Dry distillation device for coal with wide particle size distribution and method

ActiveCN102703097AHigh yieldImprove qualityIndirect and direct heating destructive distillationSpecial form destructive distillationCombustionGas phase

The invention relates to the technical field of coal chemical industry, in particular to a dry distillation device for coal with wide particle size distribution and a method. The dry distillation device for coal with wide particle size distribution, provided by the invention, comprises a semi-coke outlet (1), a combustion heating chamber (3), a coal feed port (5) and a pyrolysis gas discharge pipe (4); two layers of partition plates are also arranged in the dry distillation device; a pyrolysis gas channel (2) is formed between the two layers of partition plates; and pores are formed in the partition plates to form a gas flow path from a fuel bed to the pyrolysis gas channel (2). In the dry distillation device for coal, provided by the invention, an inner component with good heat transfer performance and made from high-temperature resistant material also can be arranged therein, thus the heat transfer of a heating wall on the fuel bed and in the fuel bed is enhanced. In the invention, the pyrolysis gas channel is added into the dry distillation reaction device, so that the gas-phase product generated in the coal dry distillation process can overflow in time; and due to the inner component, the heat transfer and mass transfer effects are improved, the secondary reaction is reduced, and the tar yield and quality are further improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

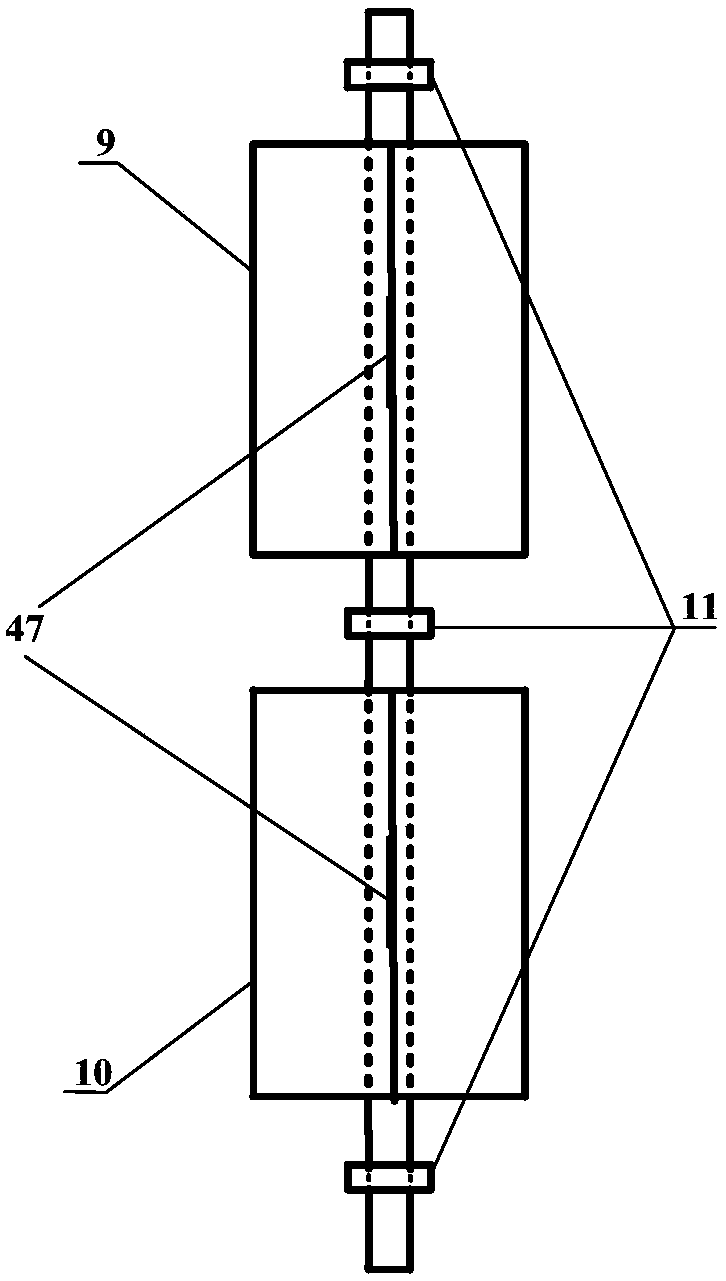

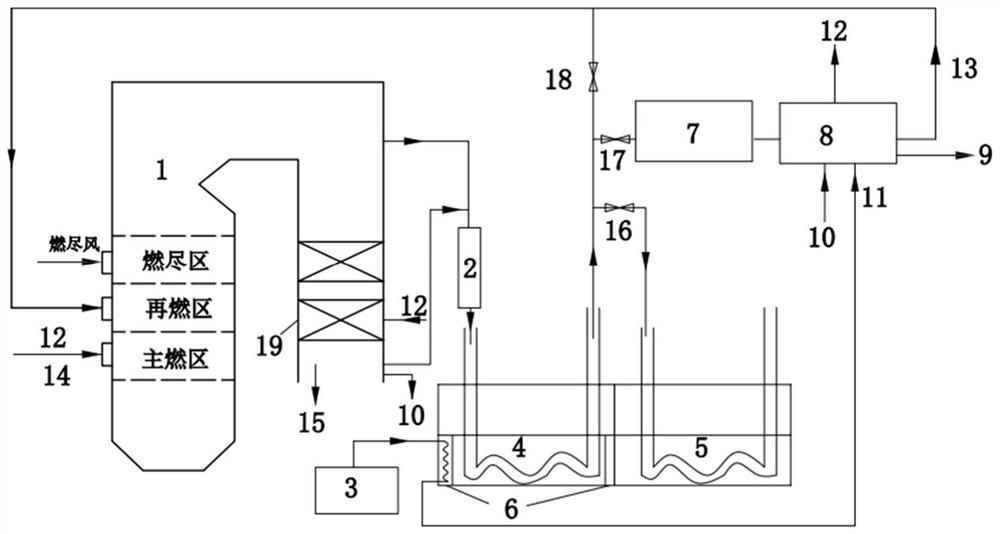

Method for increasing tar yield by coupling aromatization of hydrocarbons with coal pyrolysis

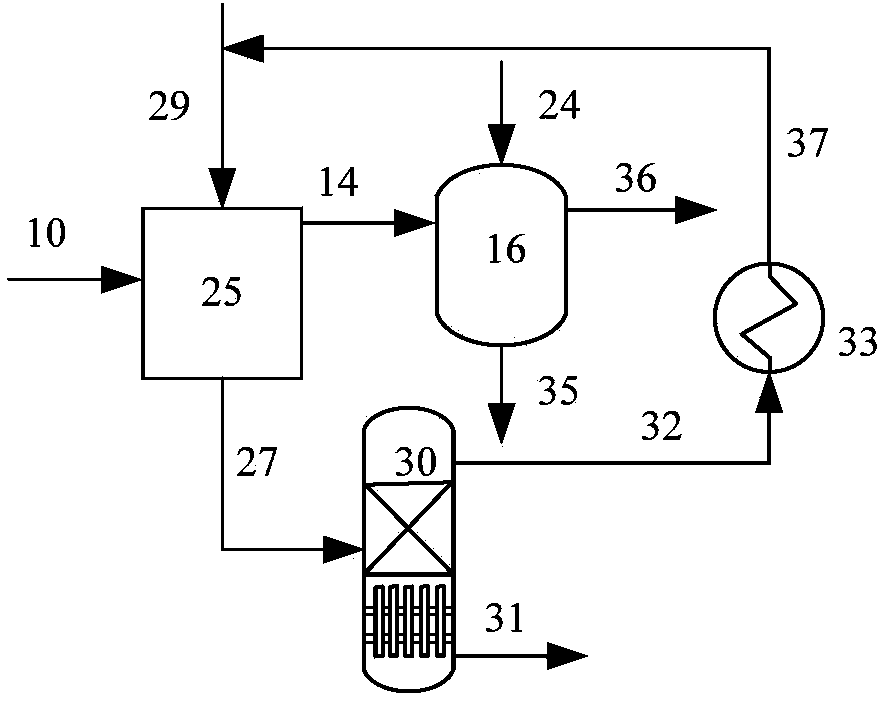

ActiveCN102161904AHigh yieldReduce the cost of hydropyrolysisLiquid hydrocarbon mixture productionHydrogenVapor–liquid separator

The utility model provides a method for increasing tar yield by coupling aromatization of hydrocarbons with coal pyrolysis. According to the method, hydrocarbon components taken as pyrolysis atmosphere are fed into a pyrolysis reactor through an inlet, activated by load-type metal catalysts and subjected to the aromatization, and then enter a coal pyrolysis layer for coupling pyrolysis with coal; and the reaction conditions are as follows: the temperature ranges from 300 DEG C to 1000 DEG C, the pressure ranges from 0.1 MPa to 3.0 MPa, the gas hourly space velocity ranges from 60 mL / g / h to 48000 mL / g / h, and the temperature is maintained constant for 0 minutes to 240 minutes. The method adopts hydrocarbons as the pyrolysis atmosphere instead of pure hydrogen gas for the pyrolysis, and increases the tar yield by coupling aromatization of hydrocarbons with coal pyrolysis. In the process, the cost of hydropyrolysis is reduced while the yield of tar is higher than the yield of tar produced by hydropyrolysis under the same conditions. Besides, the catalysts are not mixed with coal, and thus the catalysts are easy to be recycled and used repeatedly.

Owner:DALIAN UNIV OF TECH

Method for preparing tar, coal gas and semi-coke by virtue of pyrolysis of bituminous coal

InactiveCN104531187AMaximize oil productionIncrease productionEnergy inputSpecial form destructive distillationSocial benefitsThree stage

The invention discloses a method for preparing tar, coal gas and semi-coke by virtue of pyrolysis of low-rank coal. The method comprises the following steps of processing pulverized raw material coal as in a three-stage manner, namely, a screening drying stage as the first stage, a low-temperature pyrolysis stage as the second stage and a medium-temperature pyrolysis stage as the third stage, wherein in the first stage, most moisture in the raw material coal is removed, the pulverized coal having the size of below 1mm is screened by wind power and used as a combustion raw material of a three-waste furnace for providing a heat source for a system, dust having the size of below 50 microns in the system is almost removed so that the pre-dust removal effect is achieved and the content of the dust in the end product coal tar is greatly reduced; during the second stage, the reaction temperature is controlled to be about 550-570 DEG C, and thus the highest tar yield is ensured; during the third stage, the reaction temperature is controlled to be about 690-710 DEG C the yield of the coal gas is increased. The products have the advantages of good quality, high yield, energy conservation and environment friendliness and the method has good economic and social benefits and is worthy in popularization and application.

Owner:CHENGDU HOT NEW ENERGY TECH

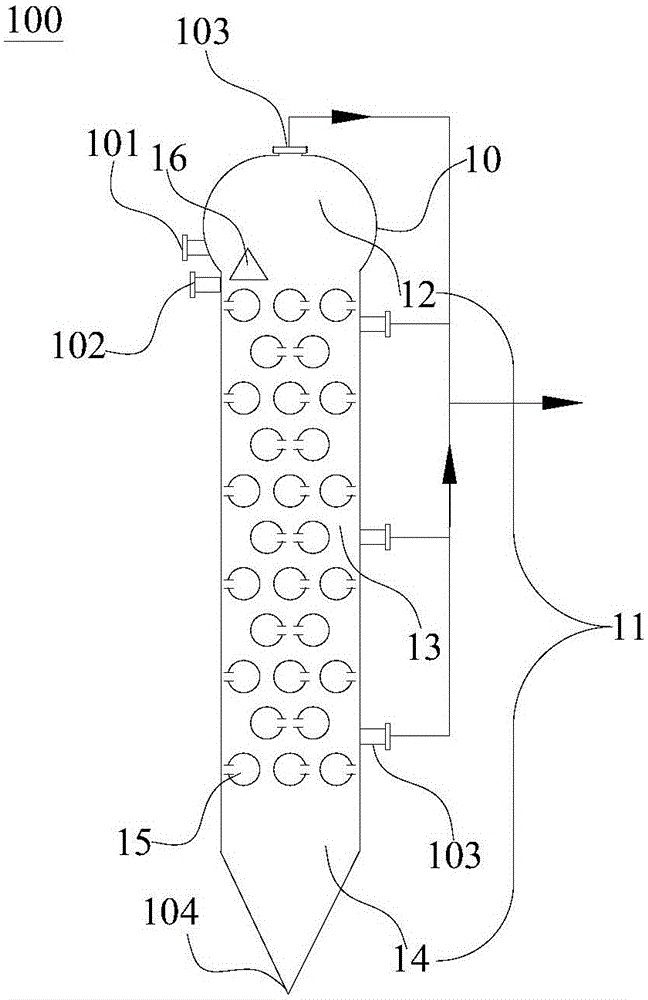

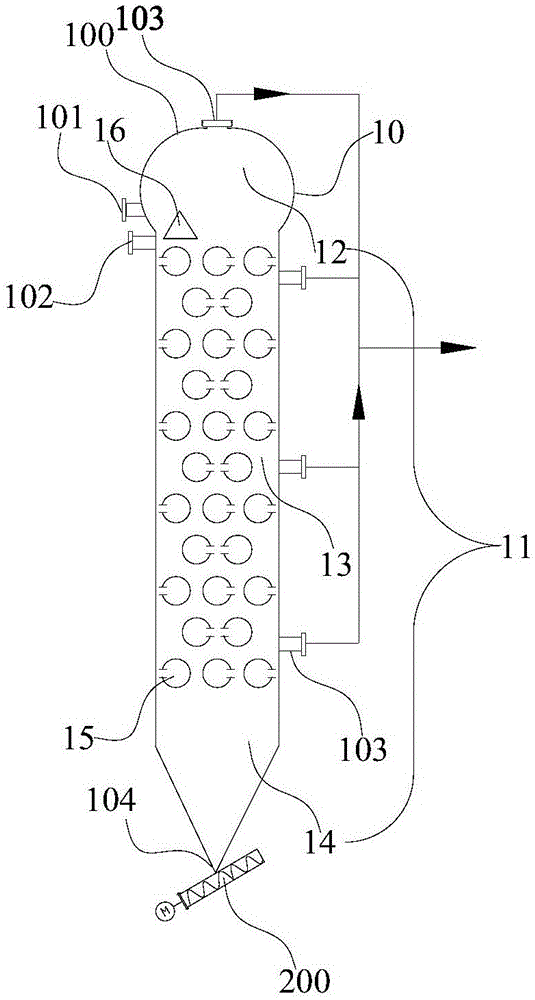

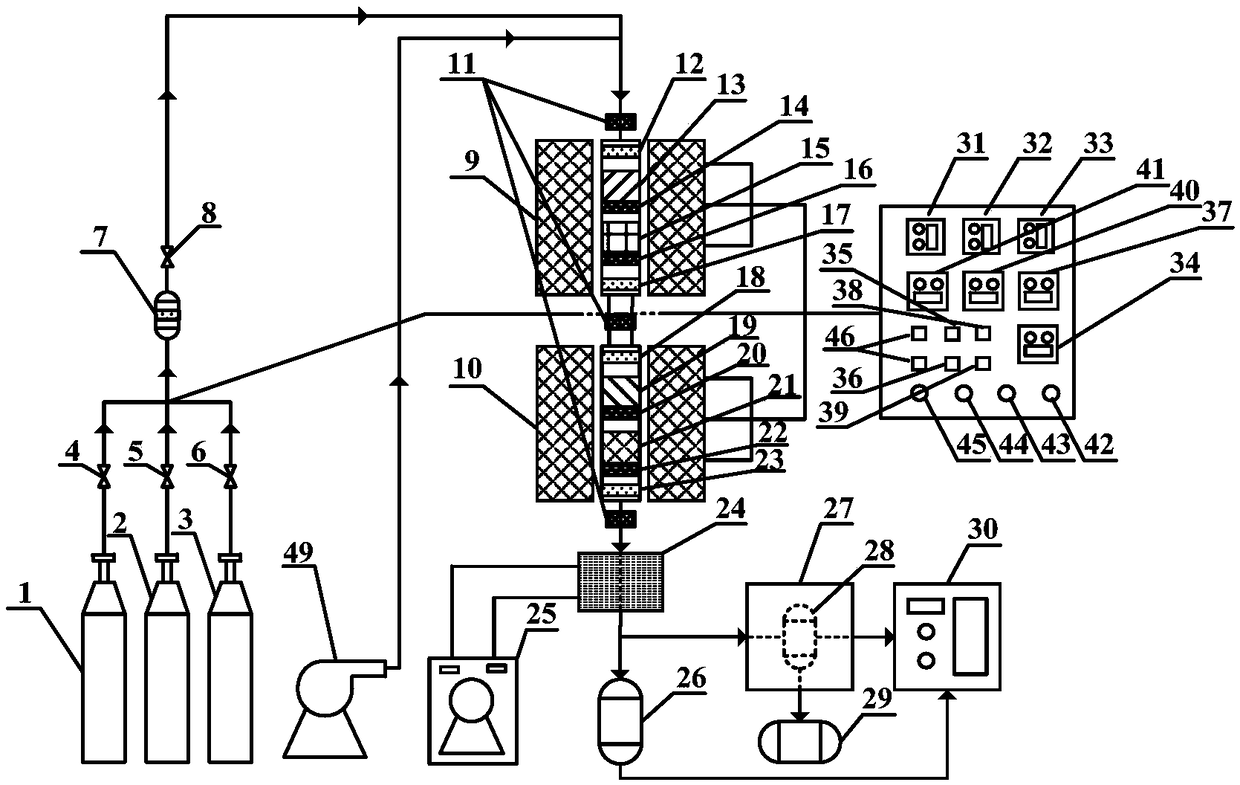

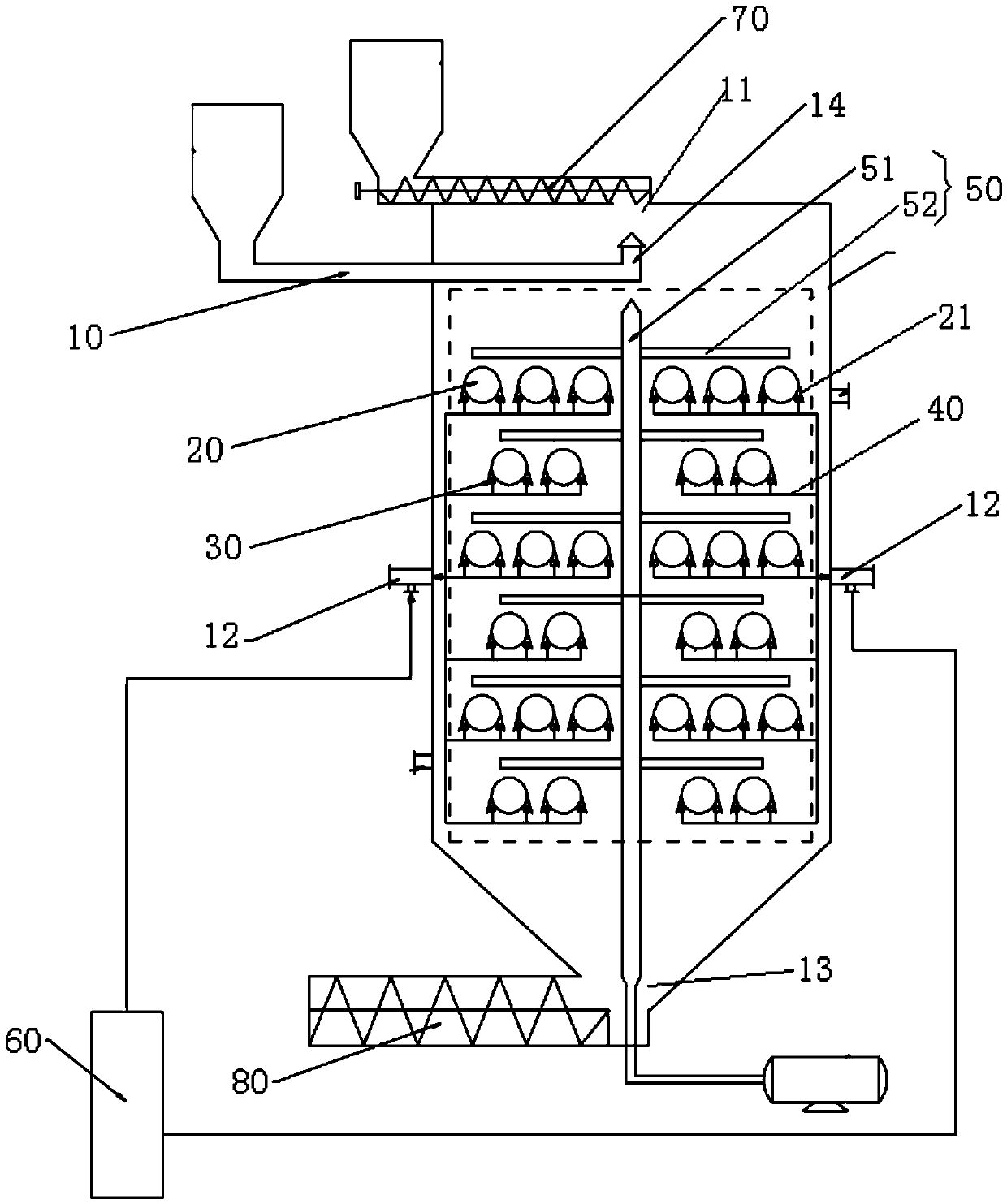

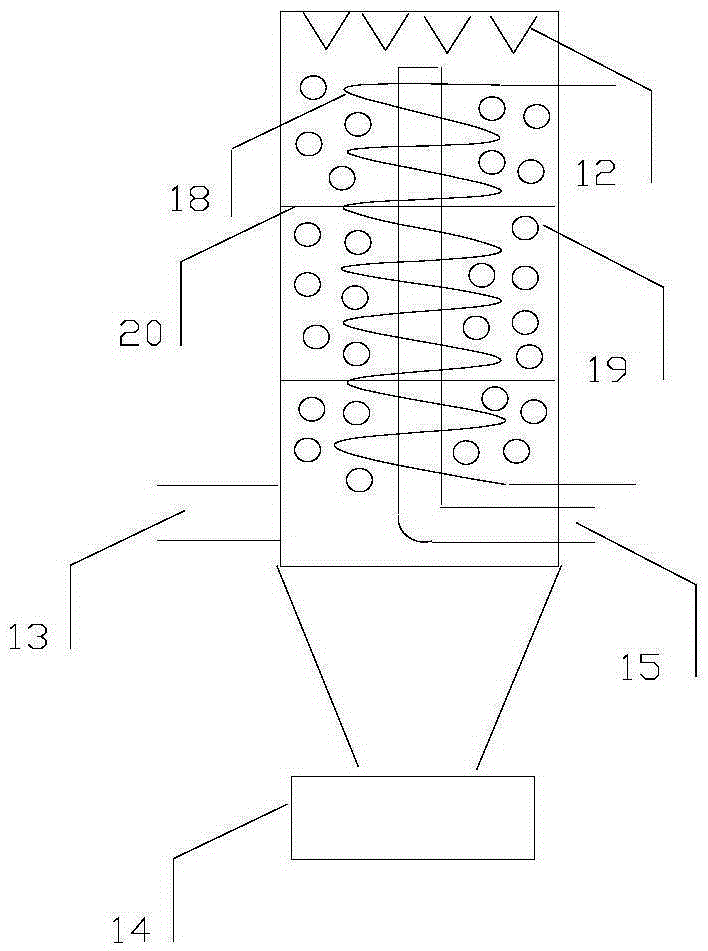

Flash pyrolysis reaction device

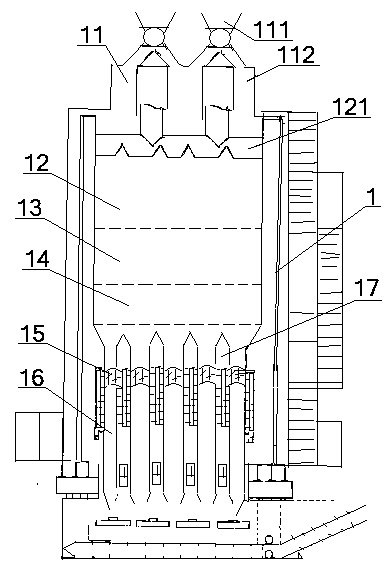

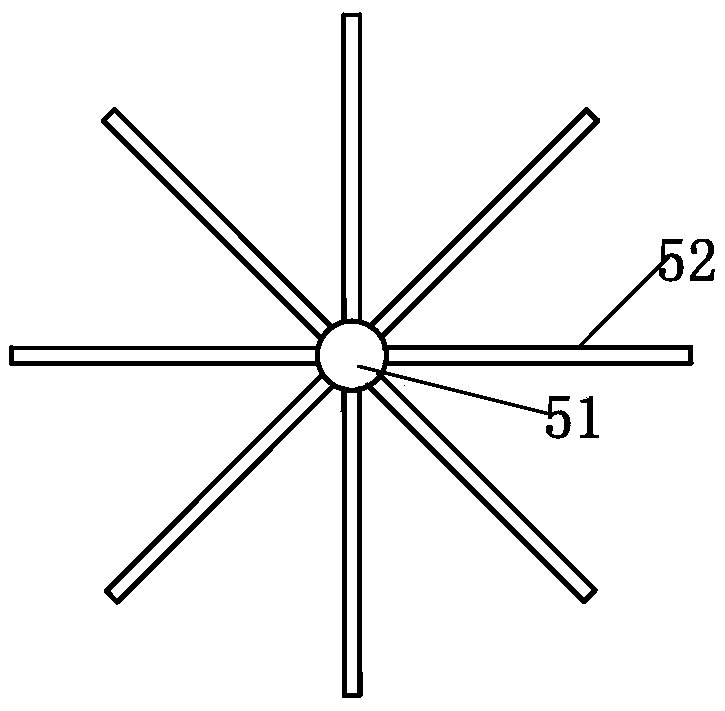

ActiveCN105154119AEvenly dispersedImprove running stabilityIndirect heating destructive distillationSpecial form destructive distillationDistributorStorage type

The invention discloses a flash pyrolysis reaction device. The flash pyrolysis reaction device comprises a reactor, multiple layers of heat storage type radiant tubes, a distributor, a material inlet, a distribution gas inlet, multiple pyrolysis gas outlets and a semicoke outlet. The reactor comprises a reactor body, and a reaction space is defined in the reactor body and forms a dispersion zone, a pyrolysis zone and a discharge zone from top to bottom. The multiple layers of heat storage type radiant tubes are distributed at intervals in the pyrolysis zone in the height direction of the reactor body, and each layer of heat storage type radiant tubes comprises multiple heat storage type radiant tubes distributed at intervals in the horizontal direction. The material inlet is located in the position, above the distributor, in the dispersion area. The distribution gas inlet is located in the dispersion zone and communicated with the distributor so that materials in the distributor can be conveniently blown out through distribution gas to enter the dispersion zone and then evenly fall into the pyrolysis zone. The multiple pyrolysis gas outlets are formed in the dispersion zone and / or the pyrolysis zone. The semicoke outlet is formed in the discharge zone. The device can significantly increase the tar yield and greatly simplify the flash pyrolysis reaction technological process.

Owner:SHENWU TECH GRP CO LTD

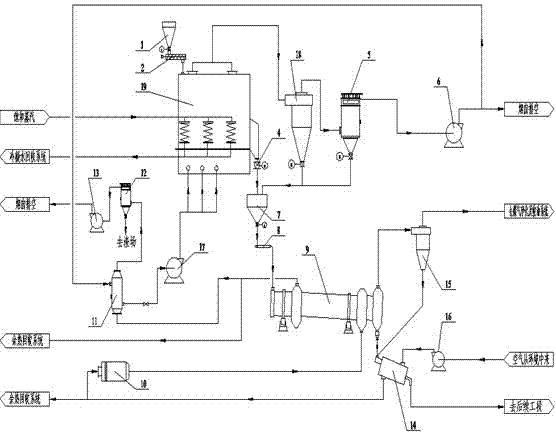

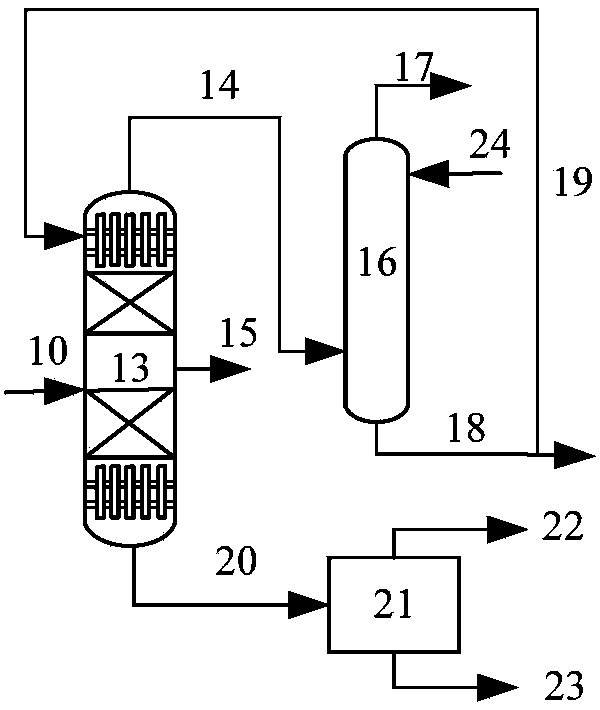

Novel external heating type lignite pyrolysis quality increasing system and process

ActiveCN102643703AHigh thermal efficiencyReduce entrainmentSolid fuelsCooling chamberSuperheated steam

The invention relates to an external heating type lignite pyrolysis quality increasing system and process. The feed port of a pyrolysis oven is connected with the discharge port of a drier, and the discharge port of the pyrolysis oven is connected with a semi-coke cooling chamber; the discharge port of the semi-coke cooling chamber is connected with a burner and a finished product area; the tail gas outlet of the pyrolysis oven is sequentially connected with a dust collection device, a tar collection and desulfuration device; the tail gas outlet of a desulfurizer is connected with the semi-coke cooling chamber and a gas holder, and the tail gas port of the semi-coke cooling chamber is connected with the pyrolysis oven through a high-temperature coal gas booster fan; the smoke inlet of a heat exchanger built in the pyrolysis oven is connected with the smoke outlet of the burner, and the smoke outlet of the heat exchanger is connected with a waste pan; the steam outlet of the waste pan is connected with the steam inlet of the drier; the water inlet of the waste pan is connected with the condensate water outlet of the drier; the tail gas outlet of the drier is connected with the steam inlet of the drier and waste heat recovery device through the dust collection device. According to the system and the process provided by the invention, a superheated steam drying process and an external heating type fluid bed pyrolysis method are utilized to increase the quality, and the thermal efficiency, the tar yield and the calorific value of gas are improved; the sulfur content of semi-coke and waste water treatment amount are reduced; the comprehensive utilization level of resources is high; and large-scale production can be realized.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

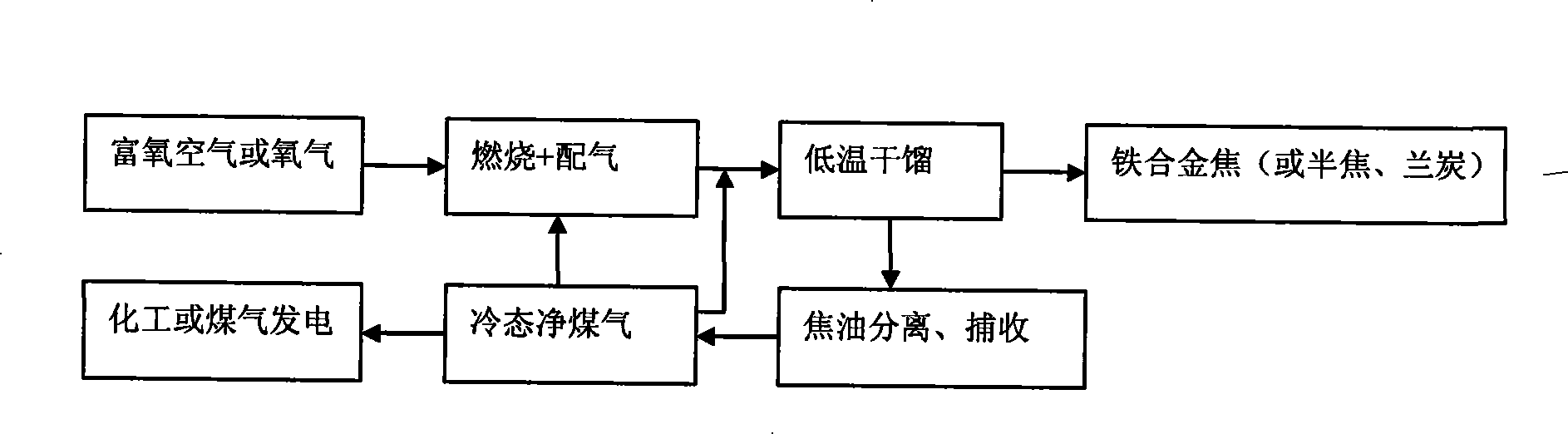

Coal gas internal heating low-temperature cracking process

The invention discloses a coal-gas internal-heat retorting method, which comprises leading oxygen-enriched or pure oxygen to produce high-temperature discharge gas with burning gas in a burner outside of a furnace to be basal heat resource which is needed by coal carbonization, mixing high-temperature discharge gas which is produced with cold coal gas which is produced in the restoring process after removing coke tar, preparing high-temperature circulation gas whose temperature is 680-810 DEG C, drumming high-temperature circulation gas into an internal heating type coal gas retort, heating coal in the furnace in non oxidation or weak oxidation, and achieving none combustion cycle of cycle part gas. The method which is utilized can effectively lower nitrogen content in coal gas, improve heat value of coal gas, improve coke tar yield, and improve semi-coke quality.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

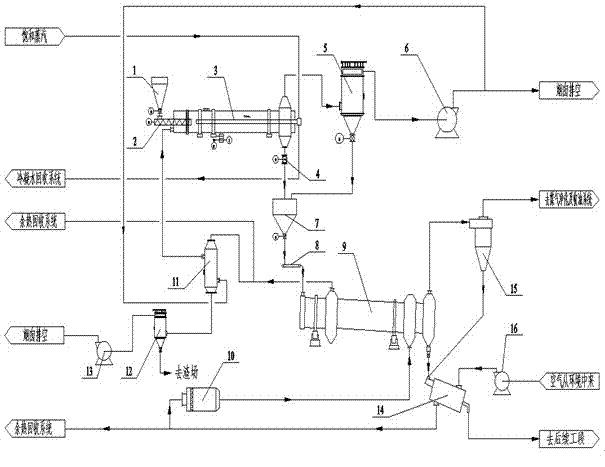

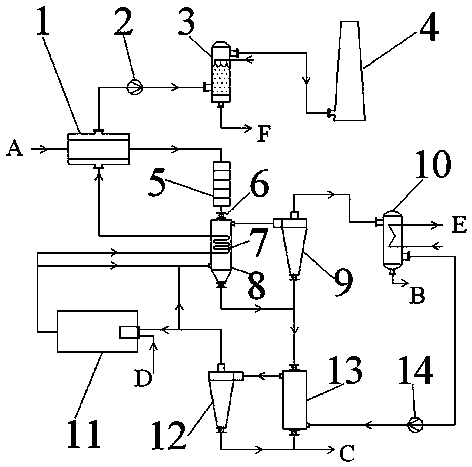

Device and process for improving productivity of oil and gas and efficiently recovering oil and gas

InactiveCN104046370AHigh yieldAvoid damageSpecial form destructive distillationGas purification by non-gaseous materials condensationProcess engineeringEngineering

The invention discloses a device and a process for improving productivity of oil and gas and efficiently recovering oil and gas. The device comprises a pyrolyzing furnace, a high-temperature dust catcher, an efficient filter, a high-temperature fan and an oil-gas recovery system which are sequentially connected, wherein a coarse powder coke outlet of the high-temperature dust catcher and a fine powder coke outlet of the efficient filter are respectively connected with a powder coke utilization system through a valve; high-temperature raw coke oven gas produced by the pyrolyzing furnace is subjected to preliminary dust removal by the high-temperature dust catcher and deep dust removal by the efficient filter, then is fed into the oil-gas recovery system by the high-temperature fan so that oil and gas are recycled; and powder coke filtered out of the high-temperature raw coke oven gas is fed into the powder coke utilization system; and the high-temperature fan is located between the pyrolyzing dust catcher and the oil-gas recovery system to ensure negative-pressure pyrolysis conditions and meet gas dust-removal demands, and moreover the high-temperature fan is also taken as a power source of the oil-gas recovery system; and under the negative-pressure pyrolysis conditions, effects of high tar yield and good quality are achieved, and the best process for oil-gas recovery is satisfied.

Owner:SHAANXI COAL & CHEM TECH INST

Coal pyrolysis system and pyrolysis method

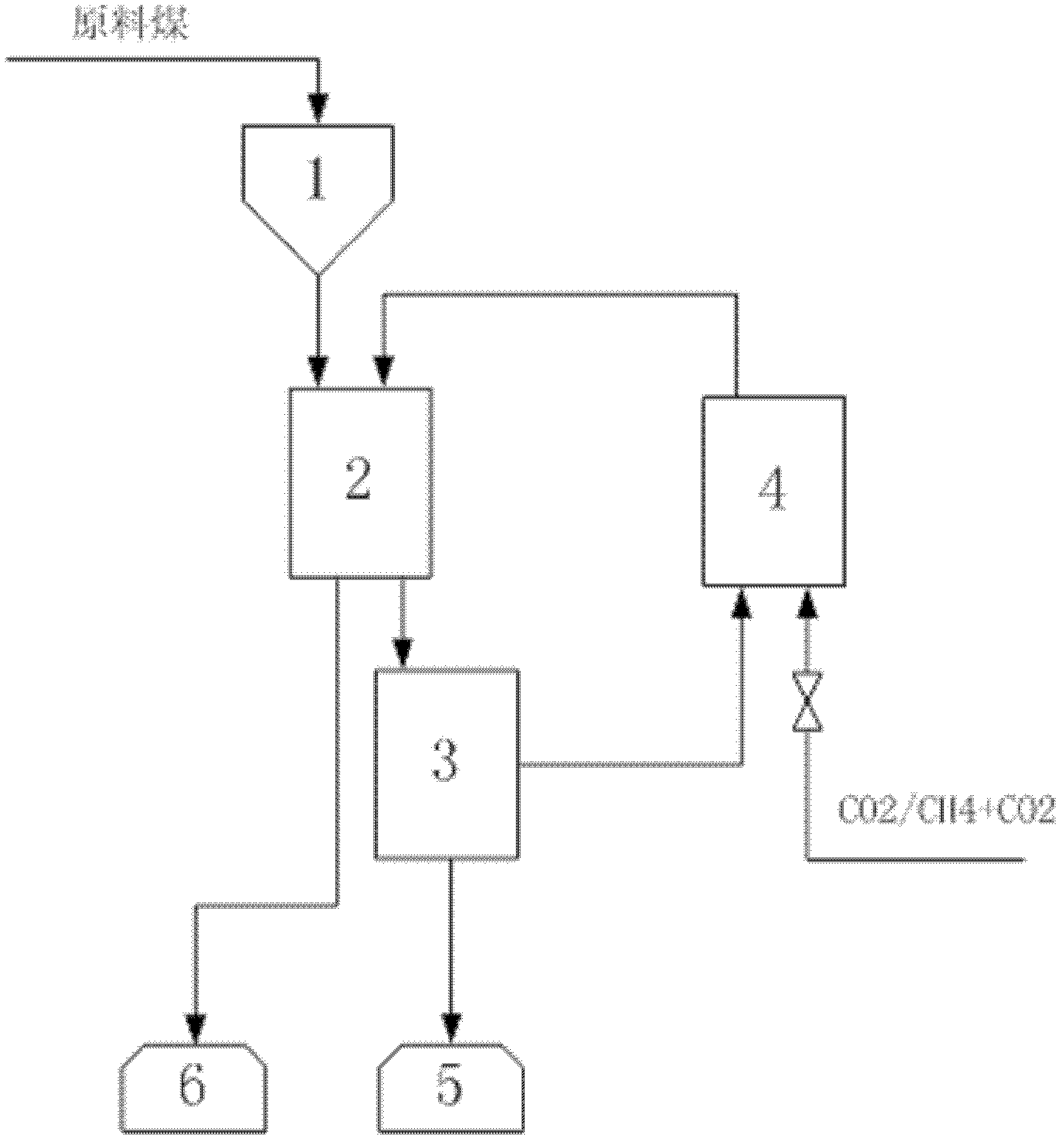

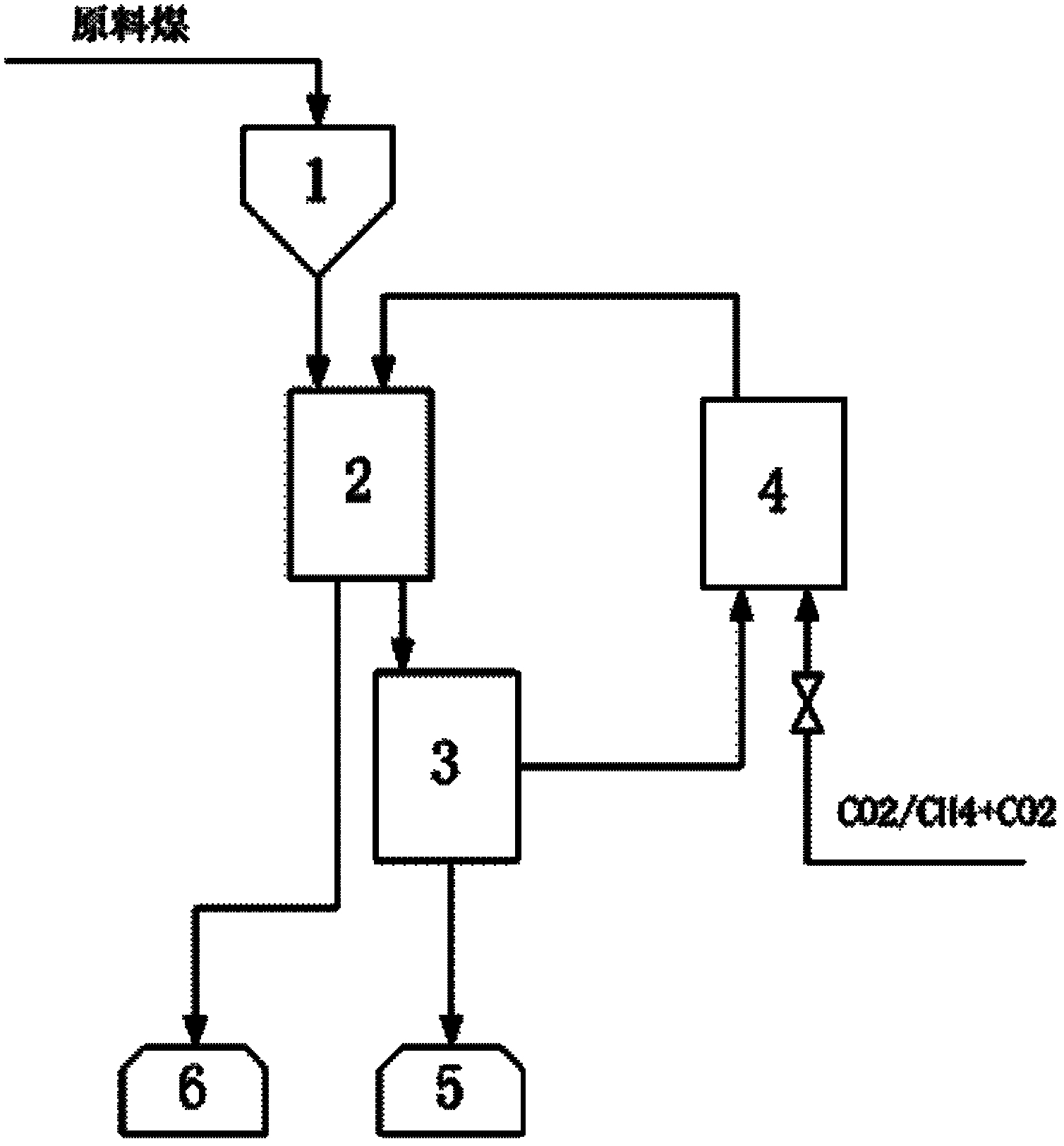

InactiveCN102559226ALow investment costLower pyrolysis costsCoke ovensGas purification by non-gaseous materials condensationHydrogenBiological activation

The invention provides a coal pyrolysis system and pyrolysis method for improving tar yield. The coal pyrolysis system comprises a coal pyrolysis reactor, a coal drying and preheating system connected with the coal pyrolysis reactor and a gas catalytic activation system for activating the coal pyrolysis reaction gas, wherein the gas outlet of the gas catalytic activation system is communicated with the coal pyrolysis reactor. According to the coal pyrolysis system and pyrolysis method, the yield of tar from the coal pyrolysis is improved by carrying out catalytic activation on the reaction gas; the circulating coal pyrolysis gas or the coal pyrolysis gas supplemented with carbon dioxide or a mixture of carbon dioxide and methane is used as the coal pyrolysis reaction gas after catalytic activation, thus the gas generated by the coal pyrolysis is sufficiently utilized, a great amount of hydrogen is not needed to be added to be used as the reaction gas, and the coal pyrolysis cost is lowered.

Owner:SHENWU TECH GRP CO LTD

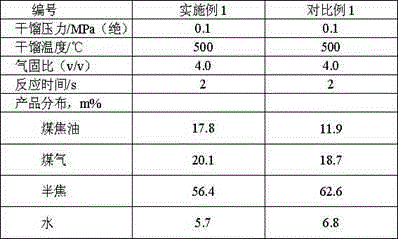

Low-quality fuel pyrolysis process

ActiveCN103980920AHigh thermal efficiencyImprove effective utilizationCoke quenchingDirect heating destructive distillationTar yieldGas blending

The invention discloses a low-quality fuel pyrolysis process. The process comprises the following steps: by mutually combining a coke dry quenching technology and a fluidized bed pyrolysis technology, mixing coke quenching gas absorbing semi-coke heat with a part of high-temperature flue gas to be used as a fluidizing medium, returning cooled fluidized gas to a coke dry quenching furnace to be used as the coke quenching gas, and using the high-temperature flue gas obtained after burning pyrolysis gas as a system heat source. The low-quality fuel pyrolysis process adopts the fluidized bed rapid pyrolysis technology, and effectively absorbs the waste heat of high-temperature semi-coke and improves the heat efficiency of a system at the same time; moreover, the fluidizing medium and a coke quenching medium of the system are coupled for use so as to ensure the tar yield, reduce the coke quenching cost, and achieve the synchronous production of tar and the semi-coke by using the fluidized bed technology.

Owner:吉林省利用厚生能源科技有限公司

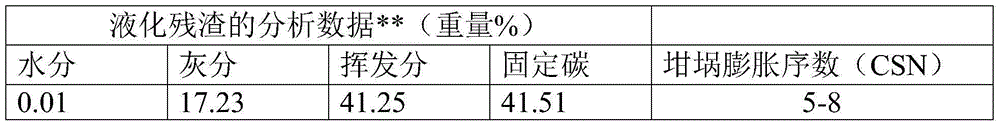

Method and device for preparing semi-coke

ActiveCN105295965AReduce powder cokeHigh yieldDirect heating destructive distillationEnergy inputCo pyrolysisTar yield

The invention discloses a method and a device for preparing semi-coke. The method comprises the following steps: under the condition of co-pyrolysis reaction, mixing hot liquefied residues with dry coal, and carrying out co-pyrolysis so as to obtain hot semi-coke and pyrolysis gas, wherein the liquefied residues are substances generated by direct liquefaction of coal, and the temperature of the co-pyrolysis is 450 to 650 DEG C. The method provided by the invention can reduce the content of powder coke generated in the process of preparing the semi-coke, thereby increasing long-period stable operation of a pyrolysis system; meanwhile, obtained coal gas and tar have high yield and good quality.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Directed catalytic cracking device and method

PendingCN108913179AHigh yieldImprove qualityBiofuelsLiquid hydrocarbon mixture productionTarDistributor

The invention discloses a directed catalytic cracking device and method. A reaction atmosphere in a reaction tube of an upper stage furnace is laid to a catalyst bed through a first gas distributor toactivate reaction gas, the reaction atmosphere generates free radicals under the action of a catalyst, the free radicals contact with free radicals produced by pyrolysis of the raw materials in a rawmaterial bed, a gaseous product is laid to a catalyst A bed through a third gas distributor, the catalyst A bed catalytically cracks the gaseous product of pyrolysis, the catalytic cracking product is fed into a catalyst B bed and is subjected to type-selective catalysis, and the type-selective catalysis product is fed into a condensation device and is condensed to form liquid tar. The device combines pyrolysis of coal, biomass and the like, a tar yield increasing process and orientation control of a product distribution process, simplifies the overall processes, is environmentally friendly,reduces the energy consumption cost, improves the production efficiency, is suitable for large-scale production and is suitable for industrial promotion and application.

Owner:NORTHWEST UNIV(CN)

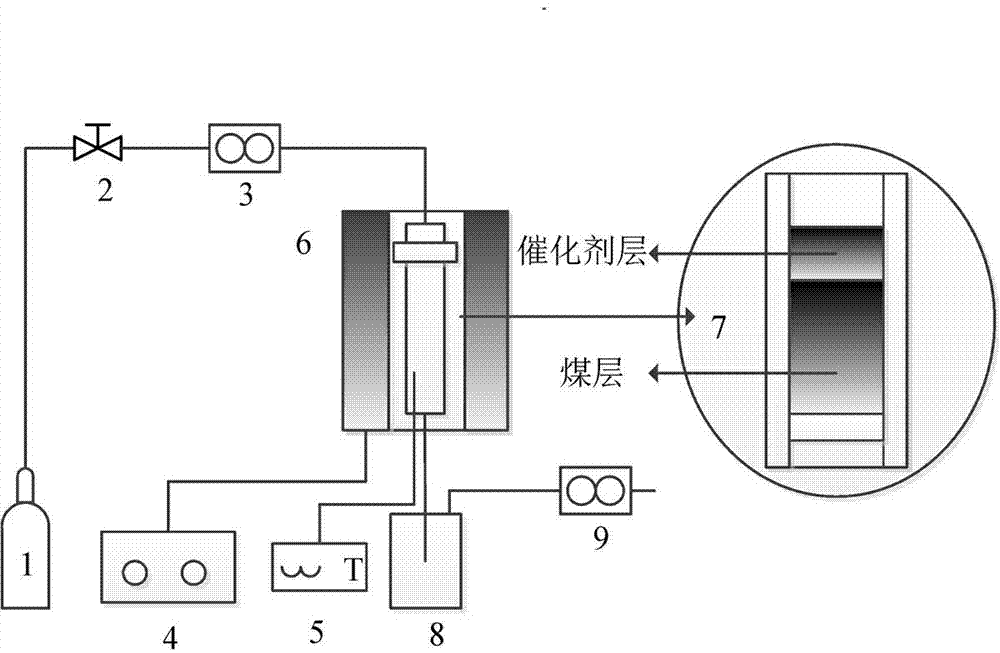

Method for increasing coal pyrolysis tar yield by return catalytic conversion of pyrolysis gas

The invention provides a method for promoting bituminous coal pyrolysis and increasing a tar yield by catalytic conversion of pyrolysis gas generated by coal pyrolysis. In the invention, the pyrolysis gas generated by coal pyrolysis is used as reaction gas; in the coal pyrolysis process, the pyrolysis gas passes through a catalyst layer at first so as to carry out catalytic gasification reaction under the action of a catalyst, so that a gas flow containing methane is generated; and then, the gas flow enters a coal seam so as to carry out pyrolysis of a coal sample under the reaction gas. According to the invention, the catalyst is a nickel-containing catalyst; reforming reaction of CO, CO2 and CH4 can be carried out under the catalysis of nickel; an intermediate body generated in the reforming process can be used for stably pyrolyzing generated macromolecular radicals, so that the tar yield is increased; because the pyrolysis gas is used as the reaction gas, the cost due to addition of gases, such as hydrogen and methane, in the pyrolysis process can be reduced; simultaneously, the pyrolysis gas generated by coal pyrolysis is also recycled; the coal tar yield is also higher than the tar yield in N2 atmosphere under same conditions; and furthermore, due to layering in the pyrolysis process, the catalyst can be recycled.

Owner:SHIHEZI UNIVERSITY

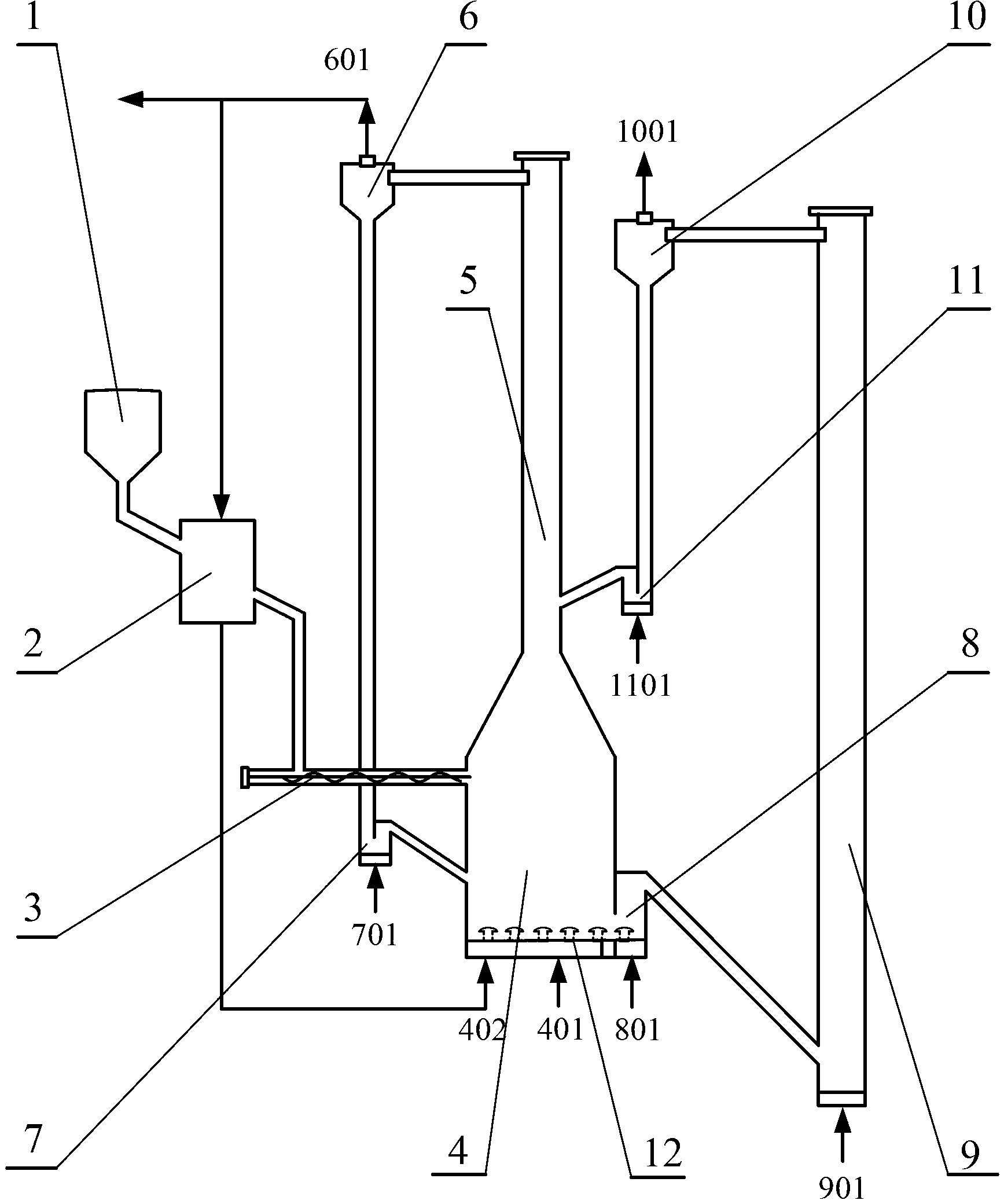

Downer-fixed bed pyrolysis-gasification integrated method and device

ActiveCN109652103AReduce energy consumptionLow costDirect heating destructive distillationChemical industryFixed bedProcess engineering

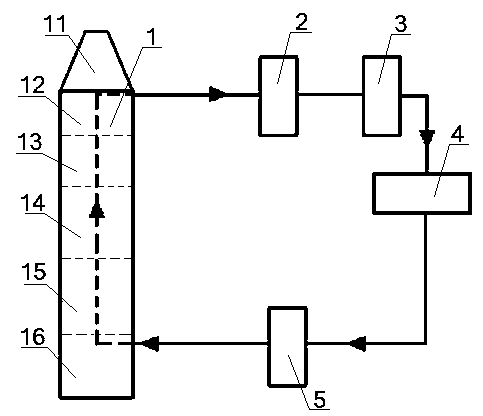

The invention relates to a downer-fixed bed pyrolysis-gasification integrated method and device, and the problems that in the prior art, the tar yield is low, the heat transfer efficiency is low, andlow-rank coal is difficult to utilize are mainly solved. A downer pyrolysis furnace and a fixed bed gasification furnace are combined, and the method comprises: raw materials are added from the upperpart of a downer pyrolysis furnace and heated by a gasified product gas from the fixed bed gasification furnace, a pyrolysis reaction is performed, and a pyrolysis gas, tar and coal coke are generated; by separation, a mixed gas of the gasified product gas and the pyrolysis gas is sent to a condensing device for rapid cooling, wherein a condensable gas is cooled to form the tar, and a non-condensable gas is further purified and treated; the coal coke is sent into the fixed bed gasification furnace for gasification reaction to generate a gasified product gas, the high-temperature gasified product gas is sent into a downer pyrolysis furnace to be used as a heat source and a pyrolysis medium required by pyrolysis to carry out pyrolysis reaction, the energy consumption of the whole circulatingsystem is reduced, and the method can be applied to the technical field of coal chemical industry.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing semicoke and tar by virtue of co-pyrolysis of organic waste and coal

The invention provides a method for preparing semicoke and tar by virtue of co-pyrolysis of organic waste and coal. The method comprises the steps of firstly, mixing the organic waste with the coal to form a mixture and drying and preheating the mixture, secondly, orderly performing low-temperature carbonization at 450-650 DEG C and medium temperature carbonization at 650-800 DEG C on the preheated material to obtain low-volatile semicoke and gas, next, recovering the semicoke and the tar, and finally, purifying the gas. The method for preparing the semicoke and the tar by virtue of co-pyrolysis of the organic waste and the coal has the advantages that the tar yield, the resource utilization efficiency of waste rubber and waste plastics and the quality of the semicoke can be obviously improved, and the effects of economic efficiency, environmental friendliness and low production cost can be achieved, based on the principle that the pyrolysis final temperature of the waste rubber and the waste plastics is lower than that of the coal under the same working condition, so that the gas generated by the pyrolysis of the organic waste and the waste is recovered and purified together.

Owner:陈卫

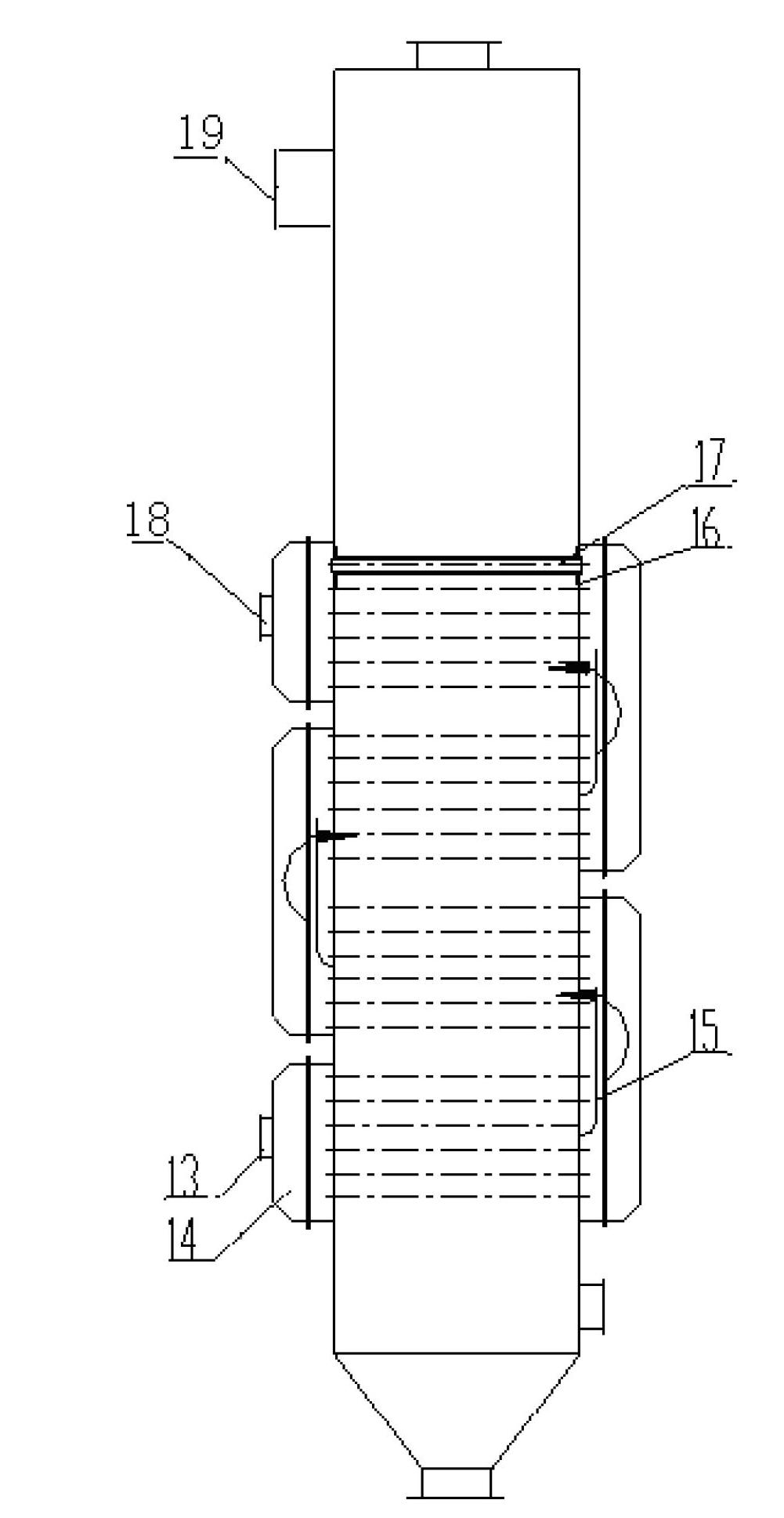

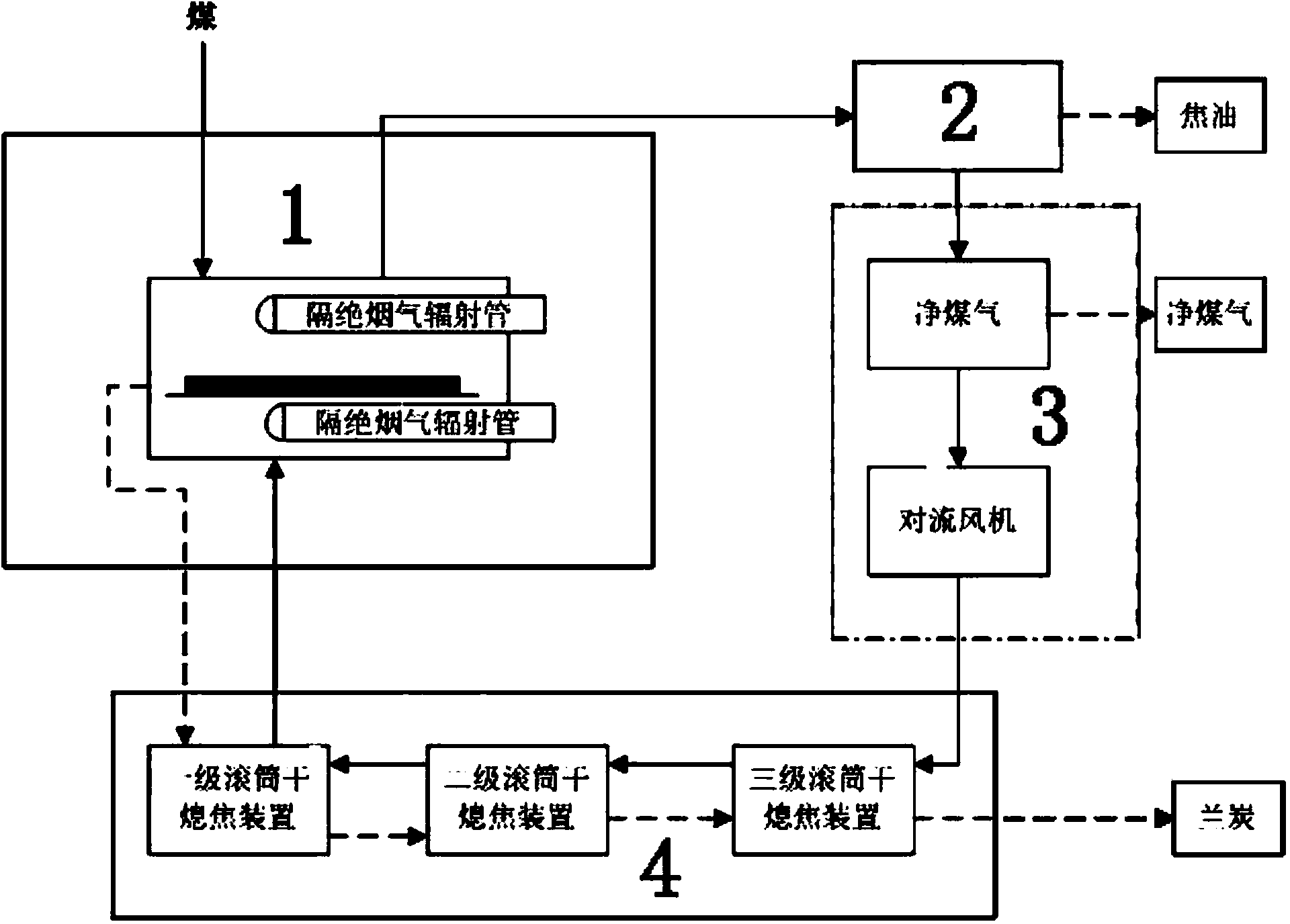

Coal low-temperature carbonization system and method

ActiveCN104178186AQuick take outShort staySpecial form destructive distillationTrappingCarbonization

The invention provides a coal low-temperature carbonization system and method. The system comprises a revolving bed carbonization unit, a raw gas washing unit, a tar trapping unit, a gas convection unit and a gas dry quenching unit, wherein the revolving bed carbonization unit is sequentially connected with the raw gas washing unit, tar trapping unit, gas convection unit and gas dry quenching unit. The system and method shorten the oil-gas retention time in the furnace, reduce the secondary cracking reaction and enhance the tar yield.

Owner:SHENWU TECH GRP CO LTD

Method for increasing tar yield in hydropyrolysis of coal by using ferric ammonium salt

InactiveCN102757807AHigh yieldSimple processLiquid hydrocarbon mixture productionPtru catalystPhysical chemistry

The invention relates to the technical field of hydropyrolysis of coal, in particular to a method for increasing tar yield in hydropyrolysis of coal by using a ferric ammonium salt. The method is carried out according to the following steps of: (1) adding a catalyst by an immersion method: (1) uniformly mixing coal, a ferric ammonium salt catalyst (in term of ferrum) and distilled water according to a mass ratio of 100:1:150-100:7:300; keeping a mixture at a constant temperature of 30-80 DEG C for 8-16 h; and mechanically stirring the mixture at a stirring speed of 100-300 r / min during keeping the mixture at the constant temperature; the method for increasing the tar yield in the hydropyrolysis of the coal by using the ferric ammonium salt, provided by the invention, has the advantage of simple and easy process; the cheap ferric ammonium salt catalyst is adopted as the catalyst in the hydropyrolysis of the coal; and as the ferric ammonium salt is adopted as the catalyst in the hydropyrolysis of the coal in the process, the tar yield of the method can be greatly increased when compared with the hydropyrolysis of the coal, in which the catalyst is not added.

Owner:XINJIANG UNIVERSITY

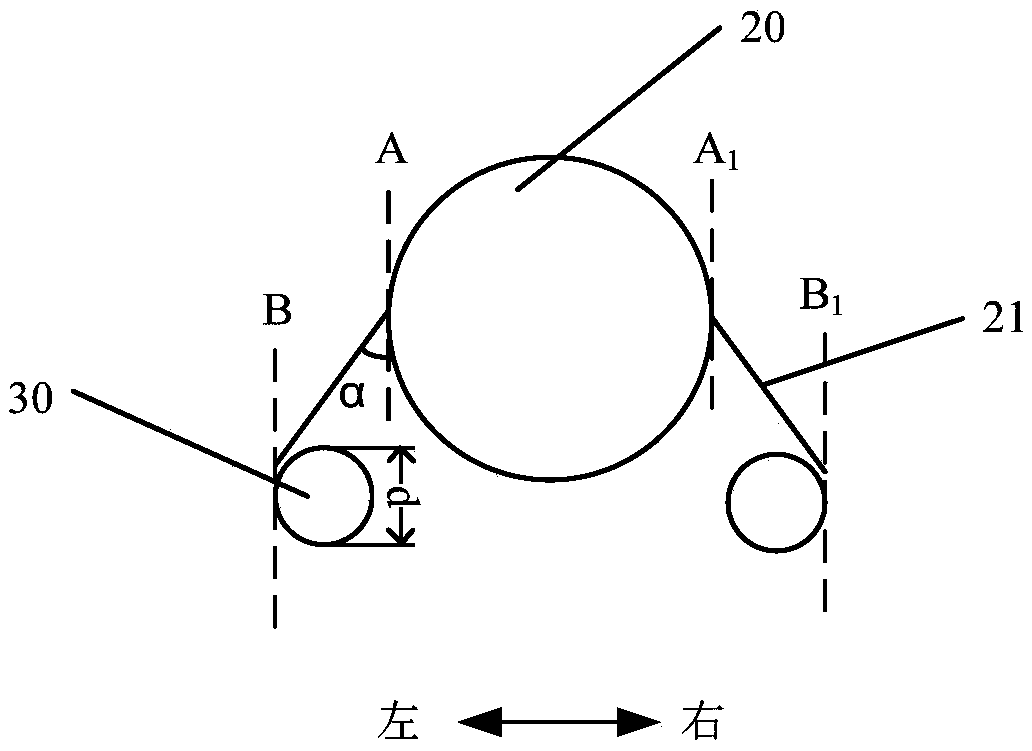

Downer rapid catalytic pyrolysis reactor

ActiveCN105505423AAvoid cokingAvoid affecting heat transfer efficiencyIndirect heating destructive distillationLiquid hydrocarbon mixture productionCatalytic pyrolysisProcess engineering

The invention provides a downer rapid catalytic pyrolysis reactor. The reactor is provided with a material inlet, oil gas outlets and a semi-tar outlet; the semi-tar outlet is formed in the bottom of the reactor, the material inlet is formed in the center of the top of the reactor, and the oil gas outlets are formed in the side wall of the reactor. The reactor further comprises a catalyst conveying pipe, radiant tubes, oil gas output pipes, gas collection pipes and a stirring device, wherein the catalyst conveying pipe extends into the reactor through the side wall of the reactor; the radiant tubes are arranged into multiple layers in the height direction of the reactor; the oil gas output pipes are arranged into multiple layers in the height direction of the reactor, and multiple oil gas output pipes which are parallel to one another in the horizontal direction are arranged on each layer; the oil gas output pipes are communicated with the gas collection pipes, and the gas collection pipes are communicated with the oil gas outlets; the stirring device comprises a stirring shaft and multiple stirring rods connected to the stirring shaft. By means of the downer rapid catalytic pyrolysis reactor, pyrolysis efficiency can be improved, and the tar yield can be raised.

Owner:SHENWU TECH GRP CO LTD

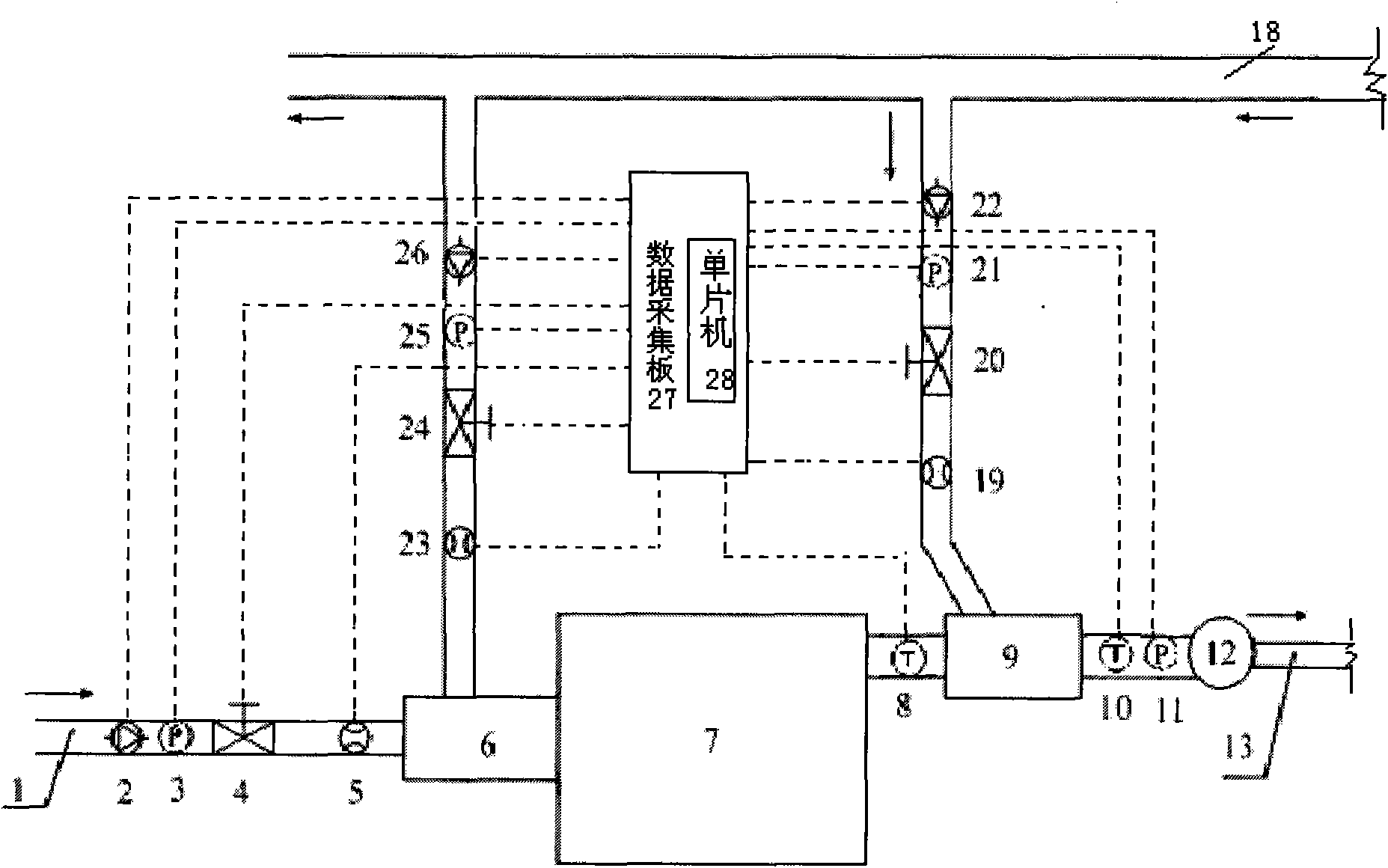

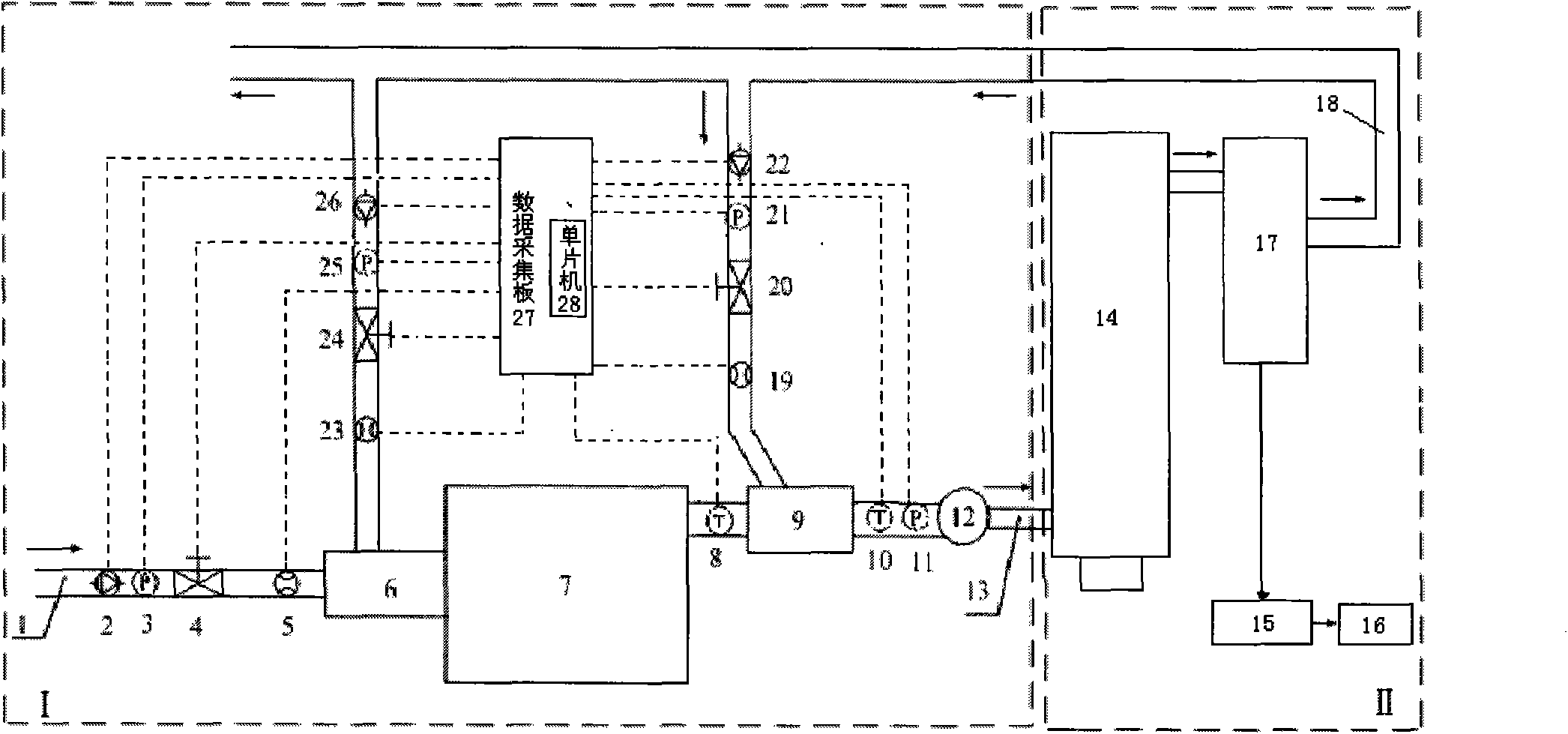

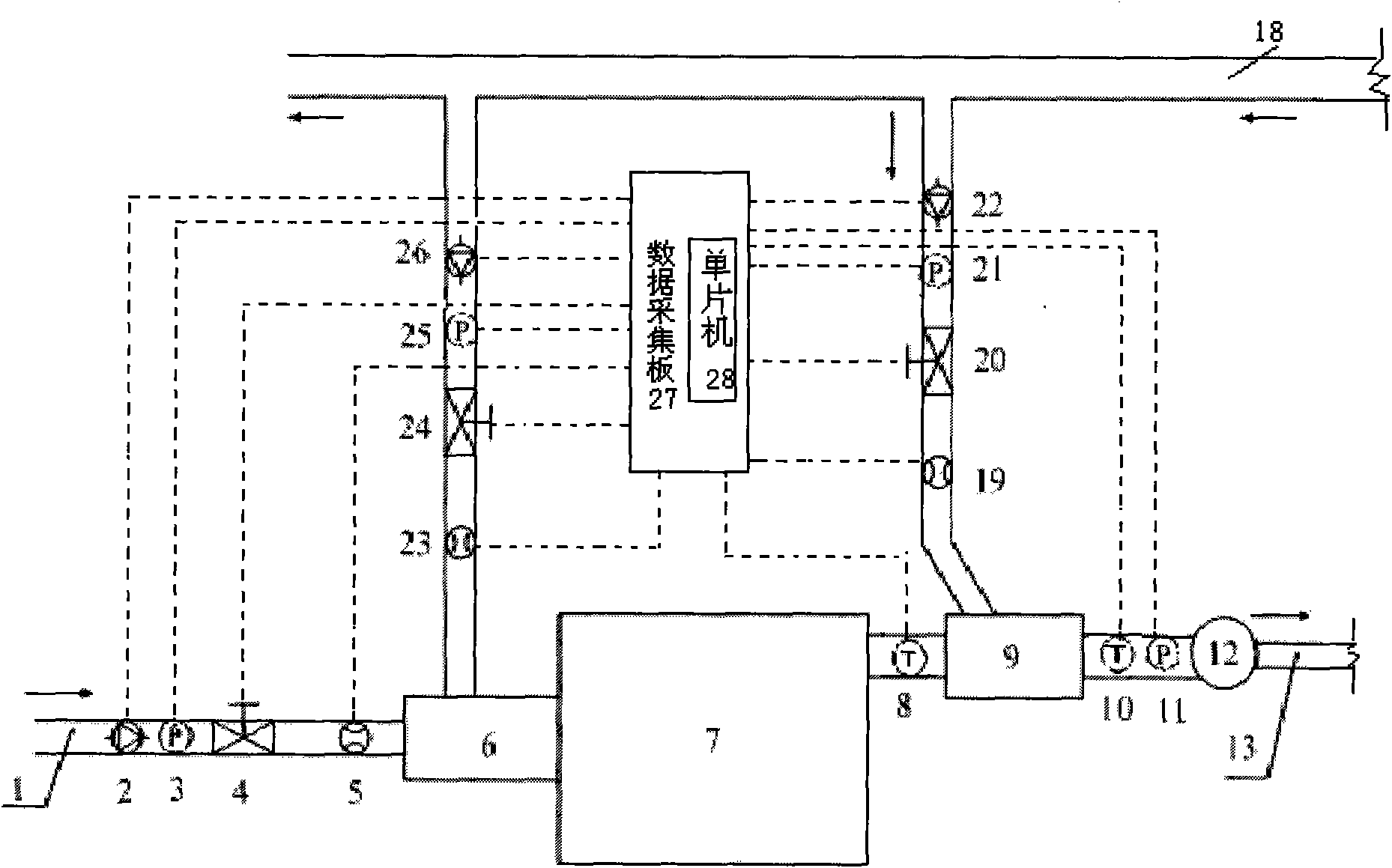

Dry distillation medium generating system for internal heat type low-temperature dry distillation and automatic control method

InactiveCN101818070ATake advantage ofImprove heat utilization efficiencyProgramme controlCombustible gas coke oven heatingCombustion chamberAutomatic control

The invention discloses a dry distillation medium generating system for internal heat type low-temperature dry distillation. The system comprises a combustor, a mixed combustion chamber and a fuel gas pipeline, wherein the input end of the combustor is connected with the fuel gas pipeline and also connected with an oxygen-enriched air or oxygen pipeline, and the output end of the combustor is connected with the mixed combustion chamber; the output end of the mixed combustion chamber is connected with a gas mixing chamber; the input end of the gas mixing chamber is connected with the fuel gas pipeline; the oxygen-enriched air or oxygen pipeline connected to the input end of the combustor is provided with a first pressurization fan, a first pressure measurement instrument, a first control valve and a first flow measurement instrument in order; and the fuel gas pipeline connected to the input end of the combustor is provided with a second pressurization fan, a second pressure measurementinstrument, a second control valve and a second flow measurement instrument in order. The system has the advantages of ensuring part of the fuel gas in a closed cycle, improving quality, reducing three-waste emission and improving tar yield so as to easily realize co-production among enterprises and comprehensive utilization of the fuel gas.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Method for increasing yield of pyrolytic tar of lignite and improving quality of pyrolytic tar of lignite through pretreating lignite by using acidic ionic liquid

ActiveCN103923680AHigh yieldImprove qualitySpecial form destructive distillationOrganic solventCoal tar

The invention discloses a method for increasing the yield of pyrolytic tar and improving the quality of the pyrolytic tar through pretreating lignite by using an acidic ionic liquid under a mild condition, belonging to the technical field of comprehensive utilization of lignite. The method comprises the steps of selecting an acidic ionic liquid capable of efficiently damaging a weak bonding structure in lignite, adding lignite powder and the acidic ionic liquid into a reaction kettle, and pretreating under a mild condition; then, washing the acidic ionic liquid by using water or an organic solvent, then, drying a coal sample, and recycling the organic solvent and the acidic ionic liquid. Compared with raw coal which is pretreated by using the acidic ionic liquid, the pretreated lignite is pyrolyzed, so that the pyrolytic tar of the lignite is high in yield and remarkably improved in quality. The method is simple in process, clean in process and high in tar yield; in addition, the acidic ionic liquid is low in dosage and easy to recycle.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

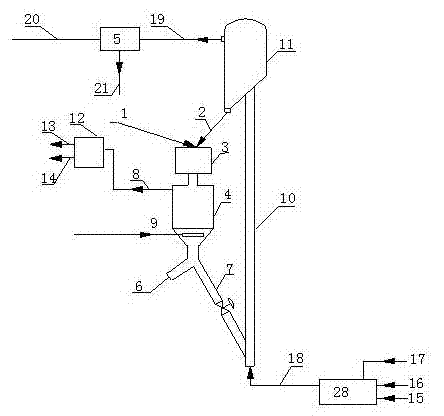

Coal carbonization and coal catalytic cracking combined technological method

ActiveCN105647552AAdvantages of combination processImprove utilization efficiencyDirect heating destructive distillationTreatment with plural serial stages onlyHeat carrierFlue gas

The invention discloses a coal carbonization and catalytic cracking combined technological method. feed coal is crushed and sieved, and then enters a preheating dryer, feed coal is dried and dewatered by catalytic cracking second regenerator flue gas and then enters a fluidized bed carbonization reactor, a mixture of catalytic cracking second regenerator flue gas burning produced high temperature flue gas, water and heated cyclic coal gas is taken as a heat carrier, under the conditions of 0.1-0.4MPa (absolute) and 500-750DEG C, pyrolytic reaction is carried out to generate coal gas, tar and semicoke. After gasification, the volume content of added water in the heat carrier is 1-20v%, preferably 3-10v%. The method organically combines coal chemical industry with petroleum refining technology, not only increases the tar yield, improves the calorific value of coal gas, but also realizes high efficiency cascaded utilization of energy.

Owner:CHINA PETROLEUM & CHEM CORP +1

Oil-rich coal in-situ pyrolysis and carbon capture coupling system

ActiveCN113738325AReduce inputReduce consumptionConstructionsOther gas emission reduction technologiesAir preheaterPower station

The invention discloses an oil-rich coal in-situ pyrolysis and carbon capture coupling system. The oil-rich coal in-situ pyrolysis and carbon capture coupling system comprises a power station oxygen-rich combustion boiler, a compressor, an air separation device, a heat exchanger, a gas-liquid separation device and a boiler air preheater. In order to solve the problem that fuel with high tar yield such as oil-rich coal is easy to decompose to generate oil gas after being heated, flue gas at the tail of an oxygen-enriched combustion power station boiler is adopted to heat an underground coal seam, so that in-situ pyrolysis oil extraction of coal is realized, and gradient utilization of energy in the in-situ coal pyrolysis process is completed. Oil generated in the pyrolysis process is extracted, other substances are fully utilized, and carbon dioxide is captured. The process of inputting the fuel and outputting electric energy and the oil in the whole system is achieved, and pollutants and the carbon dioxide are not discharged. According to the oil-rich coal in-situ pyrolysis and carbon capture coupling system, in the in-situ pyrolysis process, clean and efficient utilization of the oil-rich coal is achieved, and the goal of energy carbon neutralization is promoted.

Owner:XI AN JIAOTONG UNIV

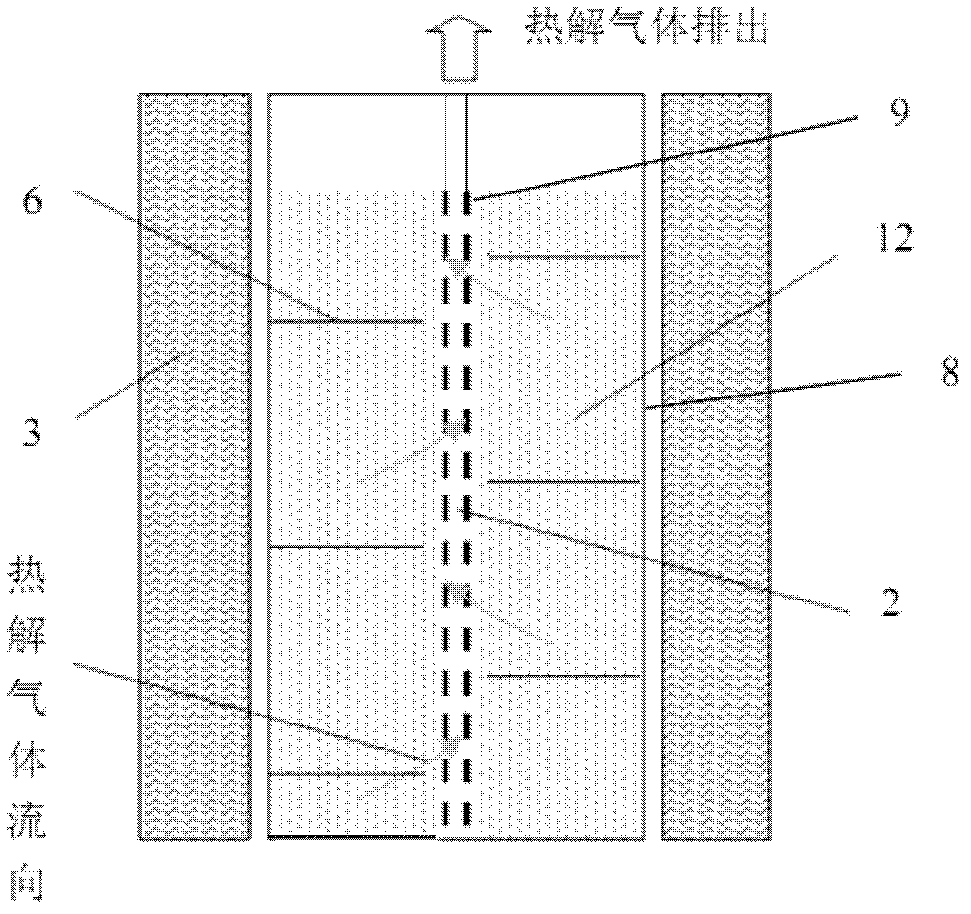

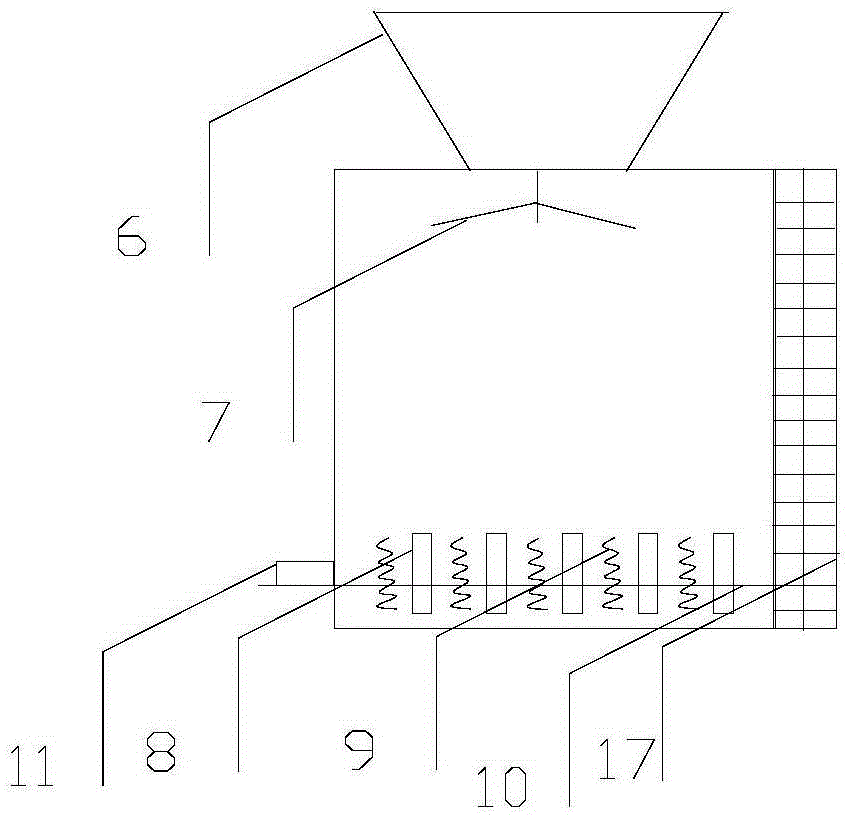

Coal solid heat carrier pyrolysis method and system for guide type stripping reinforced oil gas accelerated introduction

InactiveCN102786966AReduced responseEvenly mixedDirect heating destructive distillationEnergy inputHeat carrierProcess engineering

The invention discloses a coal solid heat carrier pyrolysis method and a system for guide type stripping reinforced oil gas accelerated introduction. In the process that powder particles flow in a mix apparatus, the segmentation, diversion and remixing effects of a mixed element can be used for reaching the purpose of uniform mixing of the solid materials. A pyrolysis reaction is generated in a moving-bed reactor, stripping gas is introduced into a distributor and is combined with a pyrolysis gas gas collection device by intersecting to realize partial lowering and accelerated introduction of oil gas, oil gas polymerization and secondary cracking reaction can be minimized, and the coal pyrolysis tar yield can be enhanced.

Owner:DALIAN UNIV OF TECH +2

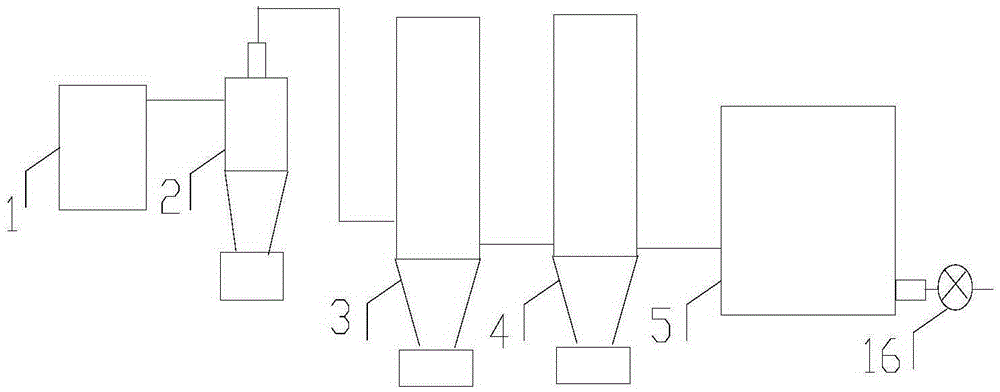

Device and method for improving tar yield by pyrolysis of low-rank coal

ActiveCN105295968APromote escapeHigh yieldSpecial form destructive distillationProcess engineeringEngineering

The invention provides a device and a method for improving tar yield by pyrolysis of low-rank coal. The device comprises a pyrolysis furnace, a cyclone separator, a first tar condensing tower, a second tar condensing tower and a vacuum pump which are sequentially connected from left to right, wherein the top of the pyrolysis furnace is provided with a coal hopper, a plurality of furnace walls are arranged in the pyrolysis furnace, a spiral tar remover is arranged between adjacent furnace walls, a pyrolysis gas inlet is formed in one side of the bottom of the first tar condensing tower, a tar collecting slot is formed right below the bottom of the first tar condensing tower, and a pyrolysis gas outlet is formed in the other side of the bottom of the first tar condensing tower. Under the conditions of negative pressure and pyrolysis of sweeping gas, along with the reducing of pressure in the pyrolysis process, the tar yield is increased, and the proportion of acid compounds (mainly phenolic compounds) in the components of coal tar is increased. The yield of the coal tar in the coal pyrolysis process can be obviously increased, and coal pyrolysis temperature is reduced. Meanwhile, the possibility of secondary reaction of the separated-out coal tar in the pyrolysis process is reduced.

Owner:NORTHWEST UNIV(CN)

Coke for gasification and preparation method thereof

InactiveCN104745211AIncrease productivityCrude benzene yield increasedCoke quenchingSolid fuelsBenzeneTar yield

The invention relates to a coke for gasification and a preparation method thereof, for solving the problems of a low tar yield, a low crude benzene yield and a low coal gas yield of the existing coal gasification. The coke for gasification disclosed by the invention is mainly composed of combustible volatiles, ash, M40 and water; the preparation method comprises the following steps: 1, crushing and mixing; and 2, coking. The coke for gasification and the preparation method thereof disclosed by the invention are used for coal gas production adopting a manner of coke gasification.

Owner:QITAIHE BAOTAILONG COAL CHEM IND

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com