Low-quality fuel pyrolysis process

A low-quality fuel, pyrolysis technology, used in the petroleum industry, direct heating dry distillation, special forms of dry distillation, etc., can solve the problems of only burning off, not getting finished semi-coke, difficult to separate, etc., to improve thermal efficiency, improve Effective utilization and the effect of reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

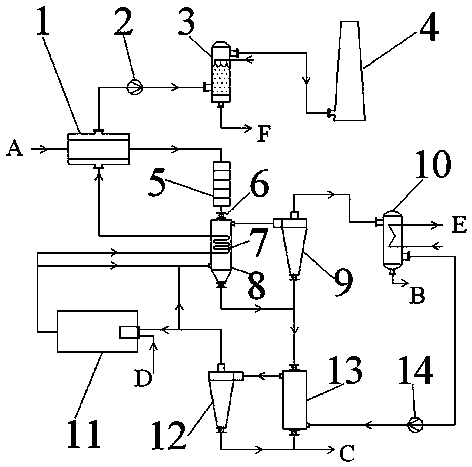

[0048] As attached figure 1 As shown, the elemental analysis of the dry ash-free base of lignite with a particle size of about 2mm and a water content of 37% is: C-70.5%, H-5.4%, O-22.2%, N-1.7%, S-0.2%, The high calorific value is 19.1MJ / kg. The lignite is indirectly heated by the high temperature flue gas with an inlet temperature of 530°C in the rotary drying furnace 1 to remove moisture to 5%, and then is sent to the electromagnetic vibrating feeder 5, and then sent to the gauge pressure through the discharge valve 6 In the 3kPa fluidized bed pyrolysis furnace 8, the heating surface of the inner heating tube bundle 7 is arranged in the fluidized bed pyrolysis furnace 8, and the high temperature flue gas of 810℃ flows through the inner heating tube bundle 7 to provide the lignite pyrolysis process Part of the heat required. The combustible gas produced during the pyrolysis process carries some solid particles out of the upper part of the fluidized bed pyrolysis furnace 8, ...

Embodiment 2

[0054] As attached figure 1 As shown, the elemental analysis of bituminous coal with a particle size of about 1mm and a water content of 12% is: C-76%, H-5.7%, O-17.3%, N-0.8%, S-0.2%, The high calorific value is 21.9MJ / kg. The bituminous coal is indirectly heated by high-temperature flue gas with an inlet temperature of 580°C in the rotary drying furnace 1 to remove moisture to 4%, and then sent to the electromagnetic vibrating feeder 5, and then sent to the gauge pressure through the discharge valve 6 In the 5kPa fluidized bed pyrolysis furnace 8, the heating surface of the inner heating tube bundle 7 is arranged in the fluidized bed pyrolysis furnace 8, and the high temperature flue gas at 850°C flows through the inner heating tube bundle 7 to provide the lignite pyrolysis process Part of the heat required. The combustible gas produced during the pyrolysis process carries some solid particles out of the upper part of the fluidized bed pyrolysis furnace 8, and then enters t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com