Patents

Literature

3146results about How to "Guaranteed yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for extracting and refining rutin

ActiveCN102718820AReduce pollutionGuaranteed withdrawal rateSugar derivativesSugar derivatives preparationAlkaline waterOrganic solvent

A method for extracting and refining rutin comprises the following steps of (1) extraction: smashing raw materials, adding organic solvent into the smashed raw materials, performing extraction for 2-4 times, mixing extracting solution and concentrating the mixed extracting solution to thick extract with organic solvent content smaller than or equal to 5wt%; (2) alkali dissolution-acid sediment: adding alkaline water into the thick extract, then heating the mixture and stirring, filtering the heated mixture, regulating pH of alkaline filtrate to be 3-4, standing, filtering, drying to obtain a rutin pure product; and (3) mother liquor treatment: enabling obtained acid mother liquor to penetrate through a chromatographic column filled with resin, after the acid mother liquor penetrates through the chromatographic column, firstly using deionized water to wash a column bed until outflow liquid is neutral and colorless, introducing eluent into the chromatographic column and collecting eluate until outflow liquid is colorless, concentrating the eluate to the volume which is 5-10% of the original volume in a pressure reduction mode, cooling the concentrated eluate to achieve crystallization, filtering, using the deionized water to elute a filter cake, and drying the eluted filter cake to obtain a mother liquor rutin product. The prepared rutin is high in yield and purity, and the quality of the rutin reaches the international standard.

Owner:湖南莱崔尔生物科技有限公司

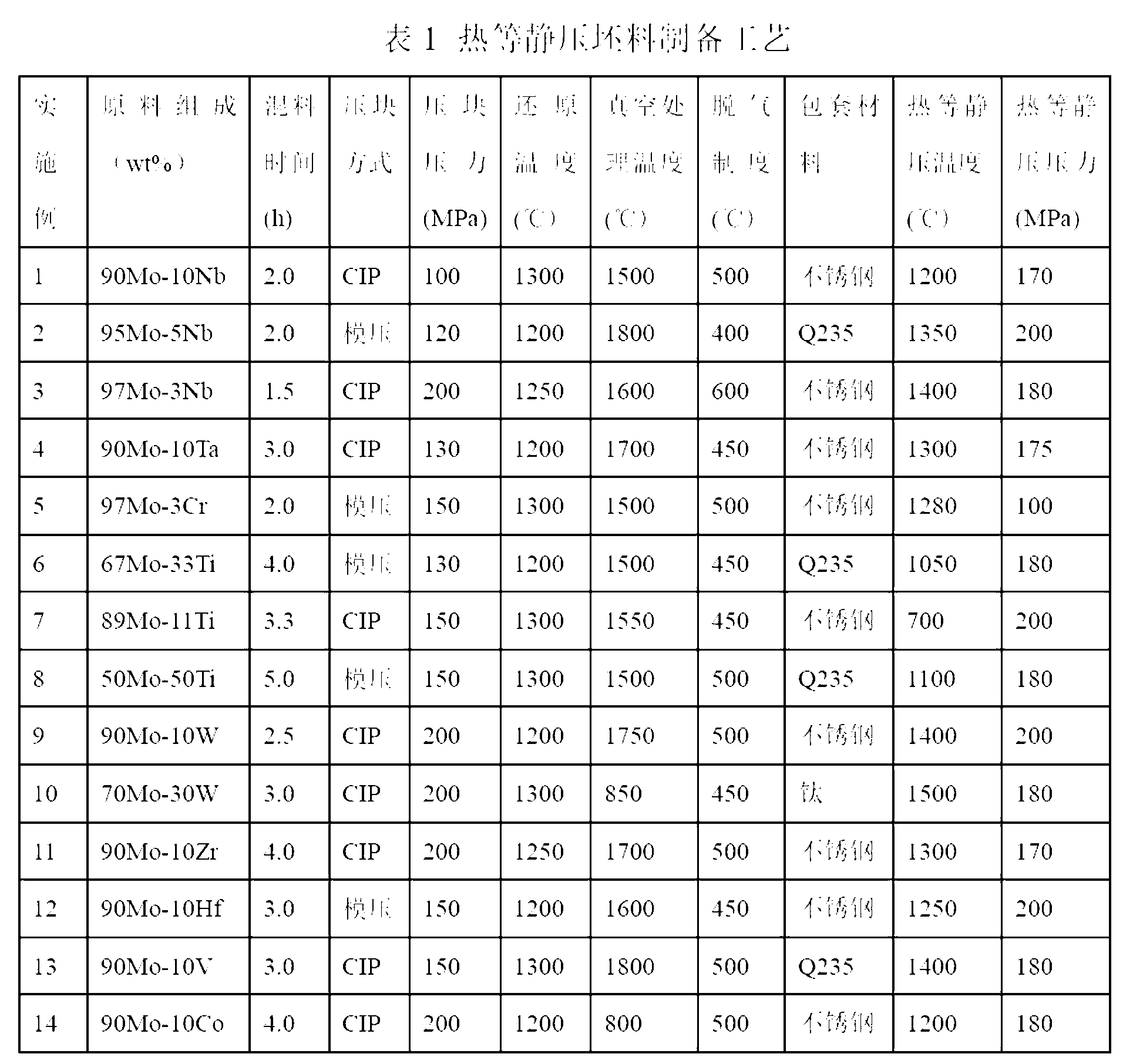

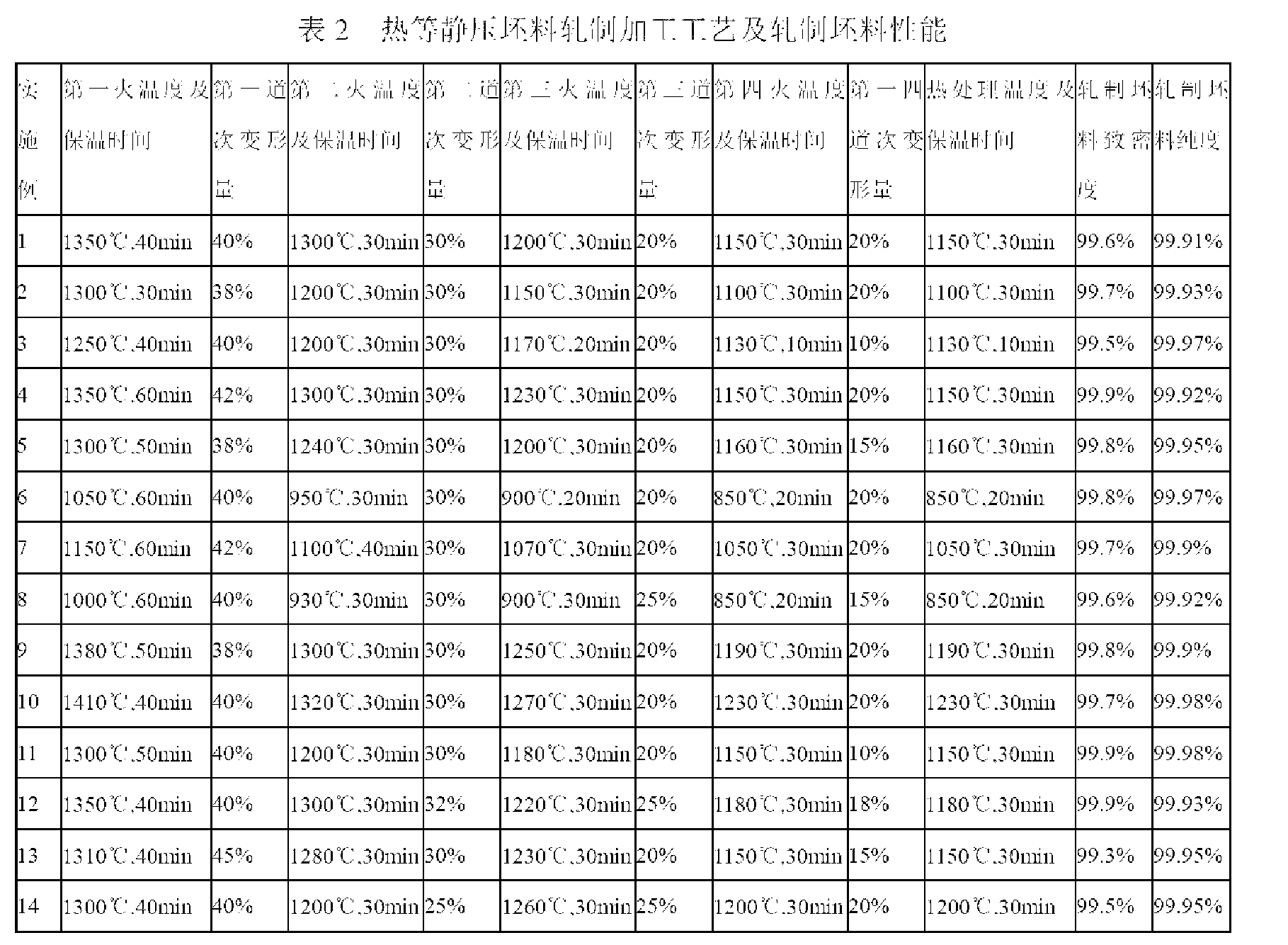

Method for mill processing of high-purity and high-density molybdenum alloy target

ActiveCN103302295AReduce processing costsShorten the processing cycleVacuum evaporation coatingSputtering coatingHigh densityProcessing cost

The invention relates to a method for mill processing of a high-purity and high-density molybdenum alloy target and belongs to the technical field of colored target preparation. The method comprises the technical steps of powder mixing, briquetting, presintering and reduction, vacuum treatment, shaping, hot isostatic pressing jacket processing, jacket charge, jacket degassing, sealing weld, hot isostatic pressing treatment, rolling with a jacket, and finish product processing. Due to the rolling with the jacket, the method solves the problems that active metal components are difficult to reduce after oxidized during deformation processing of a molybdenum alloy containing active metal, so that the deformation processing cannot be performed. Compared with a processing method of cutting into thin blanks with a large-thickness blank line, the processing cost can be lowered greatly, the processing cycle can be shortened greatly, and the production efficiency is improved.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

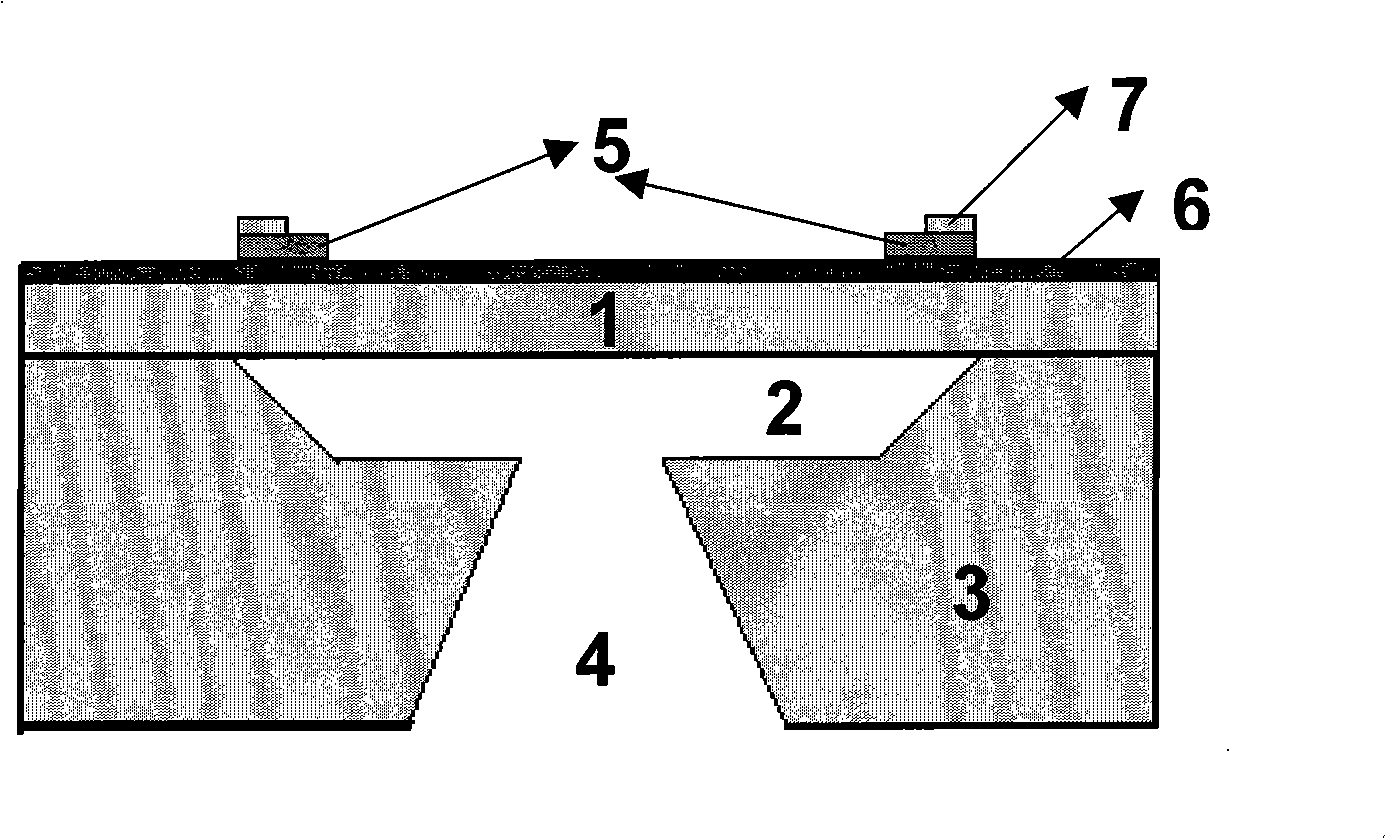

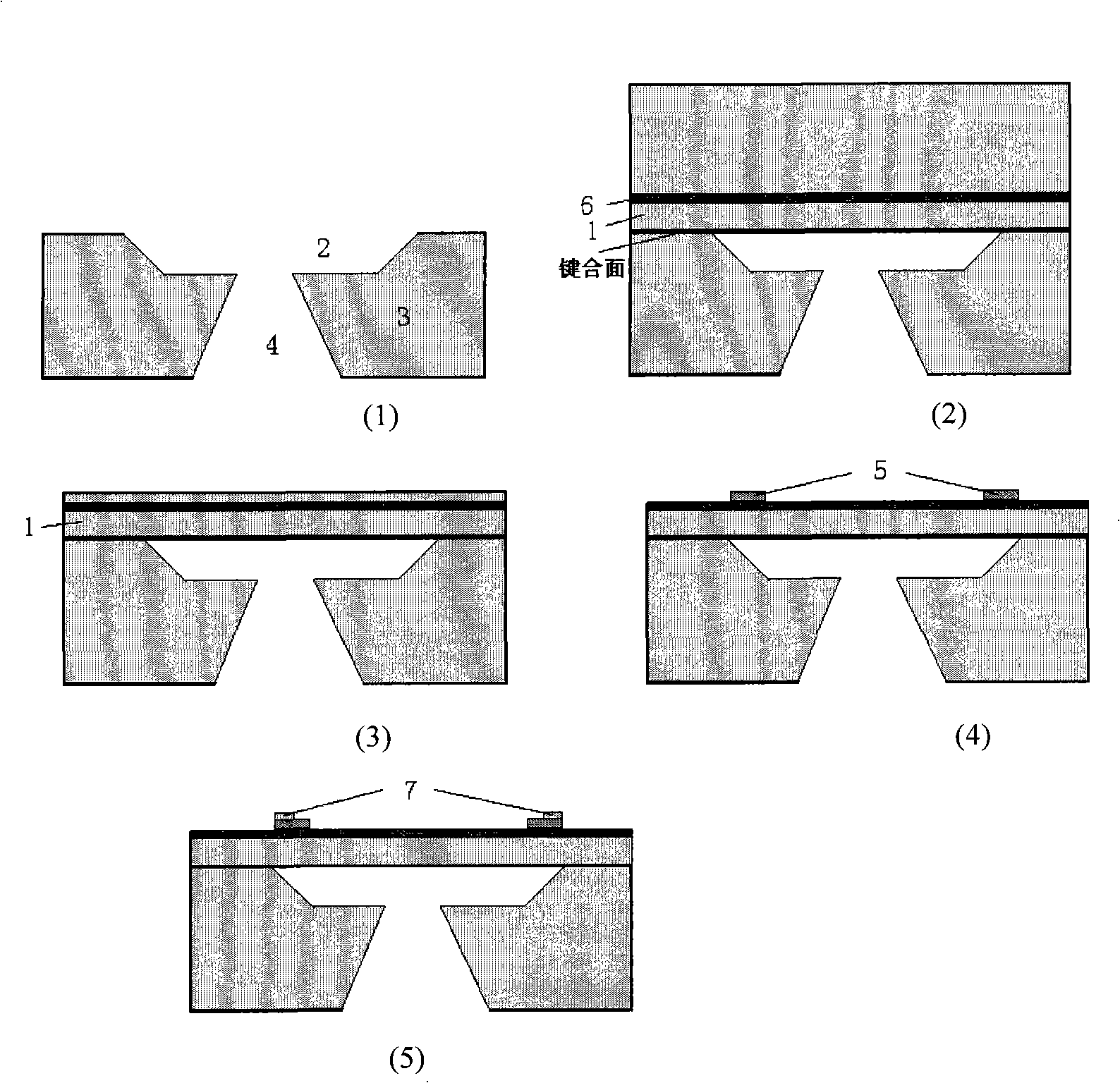

Si-Si bonding isolator upper silicon high-temperature pressure sensor chip and manufacture method

InactiveCN101266176AIncrease flexibilityReduce residual stressTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesPhysicsBuried oxide

The invention relates to a high-temperature press sensor of silicon-silicon-bonded-based silicon on an insulator (SOI) and a producing method, belonging to the field of sensor chip, characterized in that a shallow slot and a gas vent on a support silicon substrate are all formed through anisotropic etch; suitable depth of the shallow slot can be obtained by controlling etching time so as to accomplish over-voltage protection for the device; the support silicon substrate is bonded with an inverted SOI chip; a piezoresistor is produced on the top layer of silicon after reducing and polishing the back of the SOI chip. The device can operate normally at high temperature using SOI buried oxide layer for isolation of sensitive component and elastic component.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Manufacturing technique and device for composite board

ActiveCN103231216AQuality assuranceAchieve mass productionOther manufacturing equipments/toolsVacuum pumpingComposite slab

The invention discloses a manufacturing technique for a composite board and belongs to the technical field of composite metal strip rolling. The manufacturing technique comprises the following steps implemented successively: joint surface machining, end surface machining, press fit, blank assembly, vacuum pumping and inert gases filling, heating, hot rolling and verifying. By means of the manufacturing technique, the machining accuracy is improved, and volume production of carbon steel-stainless steel composite boards is achieved; simultaneously, air in a combination blank is replaced through vacuum pumping and inert gases filling, oxidization of interfaces of the combination blank is prevented in a subsequent heating process, a little of residual air between the composite interface and two layers of stainless steel interfaces can be squeezed into an air storage bag gradually along with the moving of a roller and the composite blank simultaneously, and the residual air is prevented from expelling a separating agent or oxidizing the composite interfaces, accordingly, the joint of the finished composite slab is improved effectively, and the quality of the composite slab is further improved.

Owner:山东易川新材料科技股份有限公司

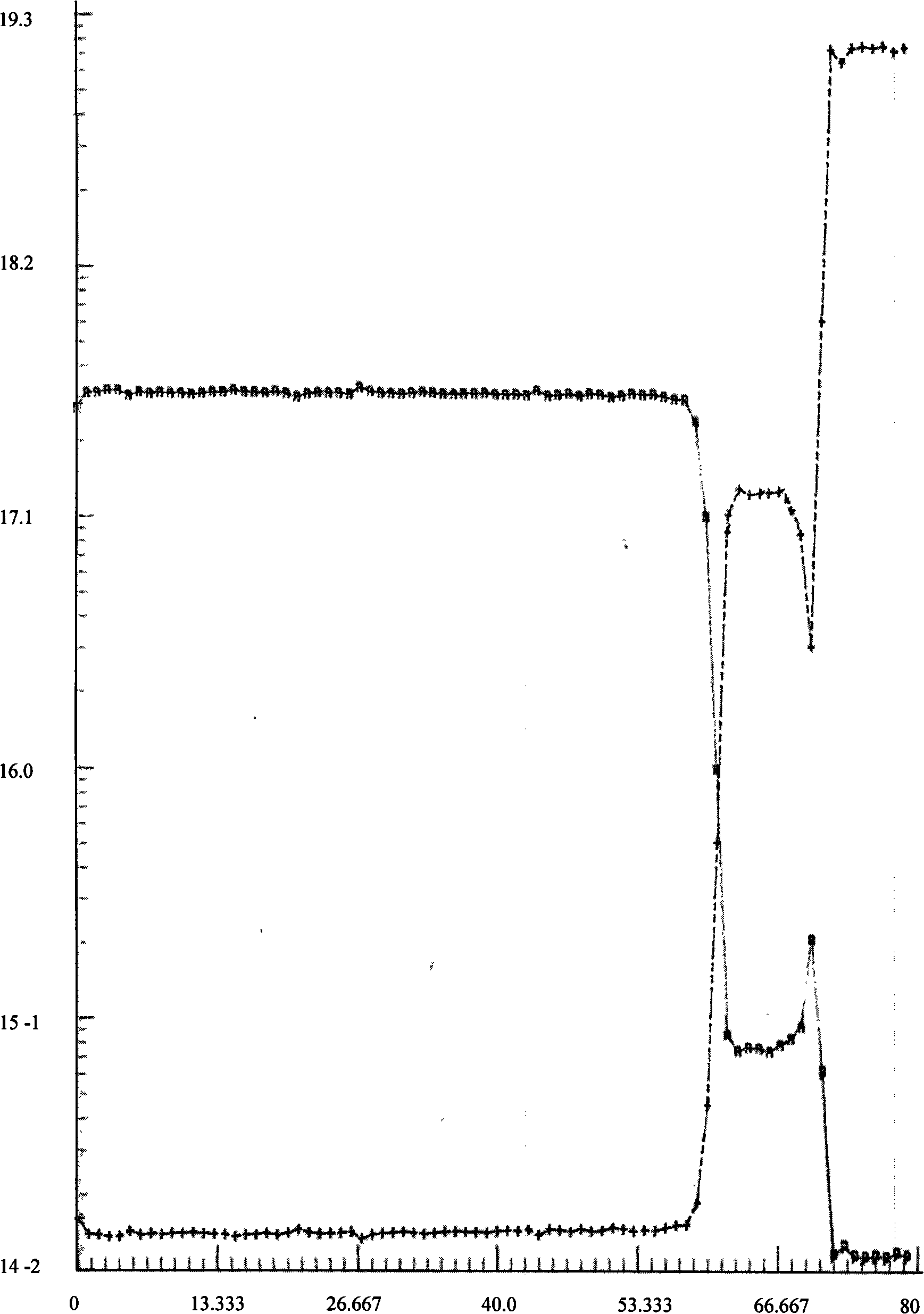

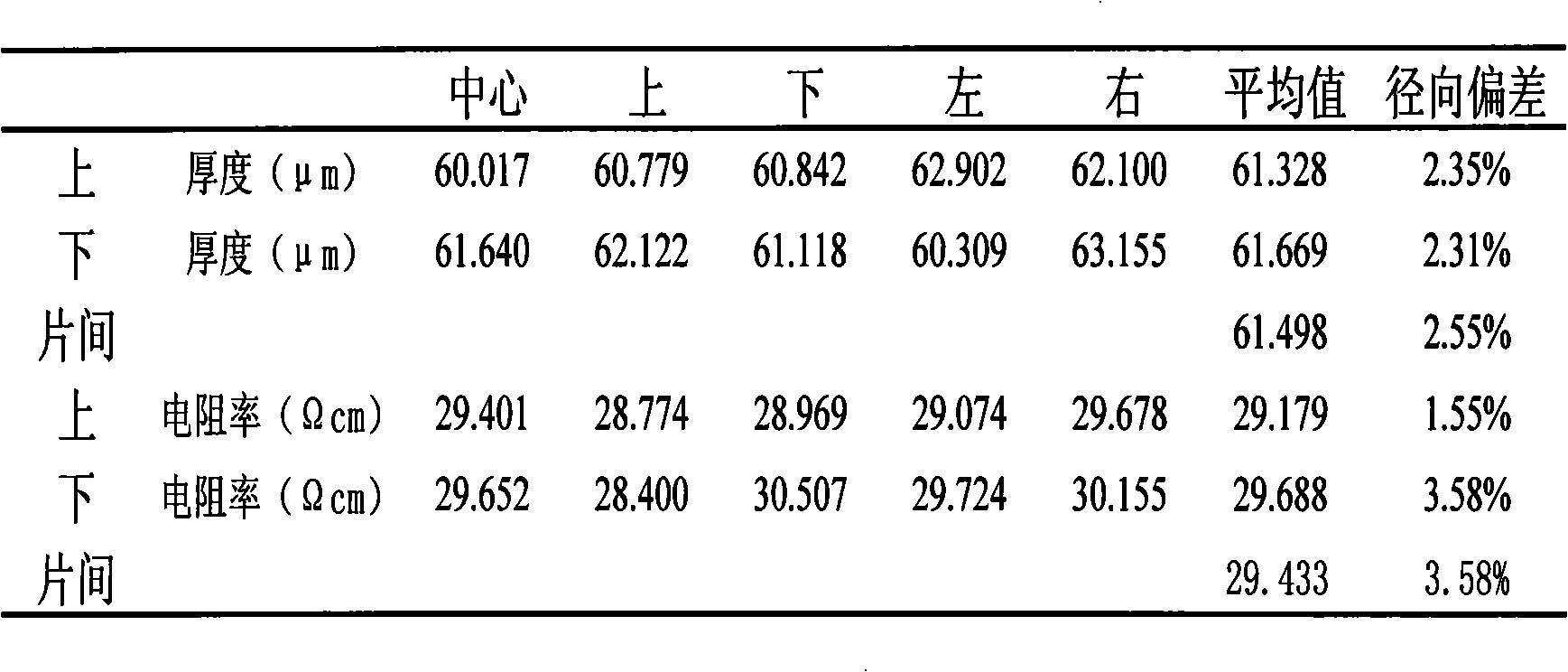

Method for manufacturing IGBT silicon epitaxial wafer

ActiveCN101256958AImprove uniformityGood repeatabilitySemiconductor/solid-state device manufacturingGrowth controlBoron

The present invention discloses a manufacturing method of IGBT silicon epitaxial wafer, the selecting P type of the heavily Boron-doped & 1t; 100 &g t; the polished piece, the electrical resistivity <= 0.02 Omega cm, the partial flatness <= 1.5 mm, the backing layer of oxide at side edge without the width <= 1mm; appropriate increasing polished time and improving the technique temperature, selecting appropriate HC1 flow quantity 8-10L at 1180 EDG C, polishing time 10 min, sweeping more than 10min by using high flow rate H2 after polishing; synthetic considering factors such as self-doping, crystal lattice quality, electric resistivity control and production efficiency, etc, selecting appropriate epitaxial process condition with double-layer, silicon source using ultra-pure trichlorosilane, first step developing temperature 1080-1100 EDG C, developing rate-controlling 0.8-1.0 Mu m, second step developing temperature 1120-1150 EDG C, developing rate-controlling 1.2-1.6 Mu m, the double-layer epitaxial growth controlled by different adulterate source accurately.

Owner:NANJING GUOSHENG ELECTRONICS

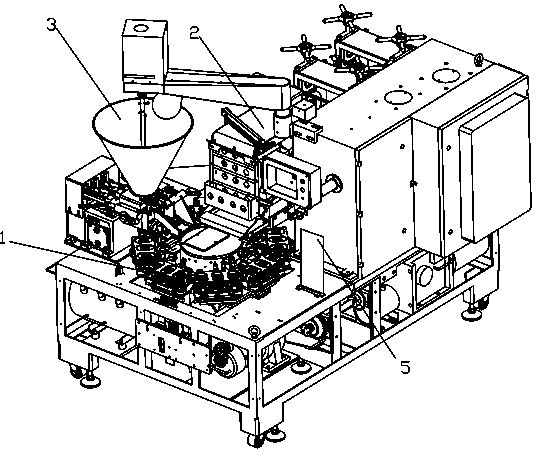

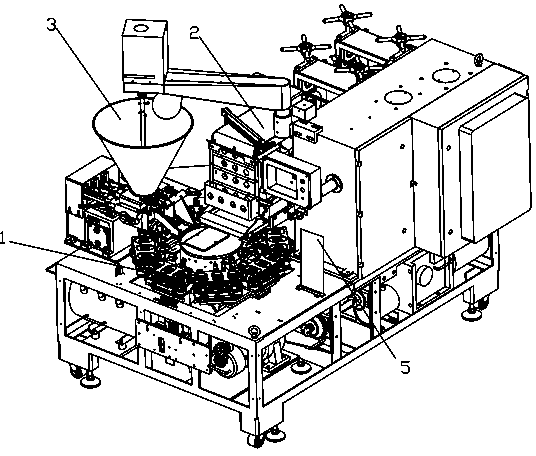

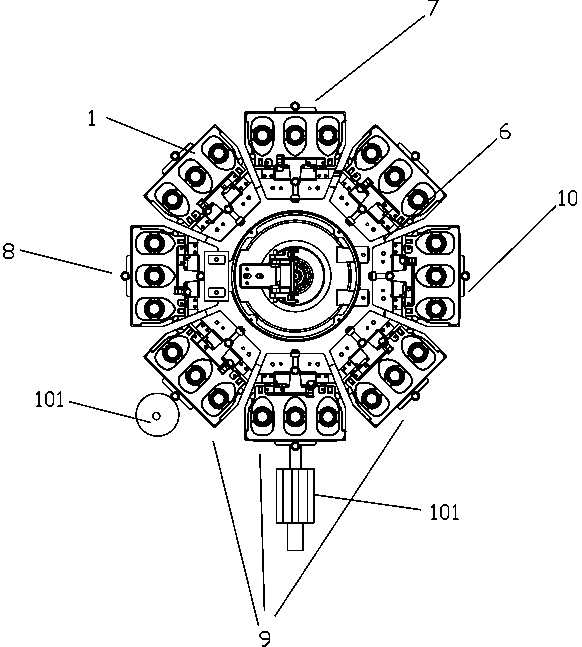

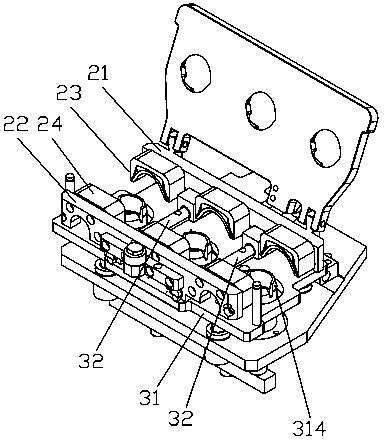

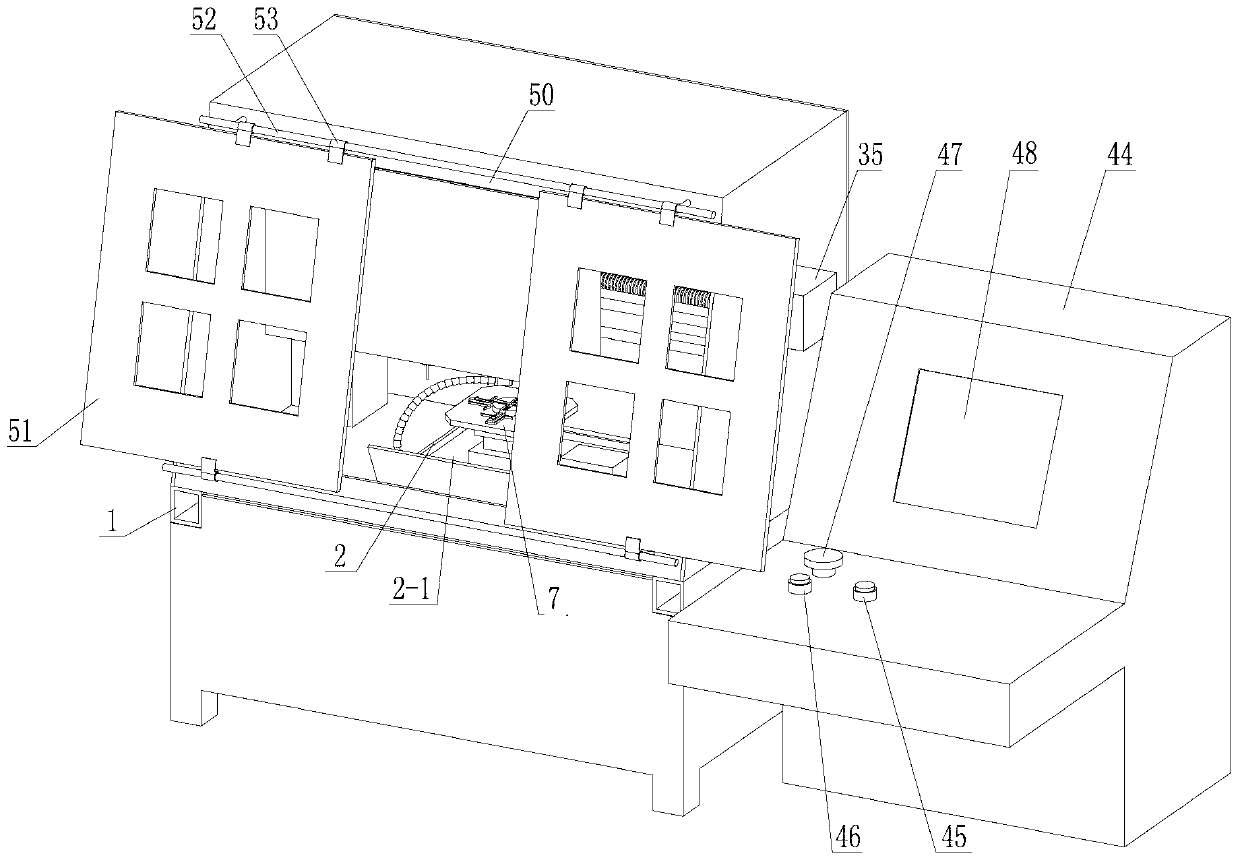

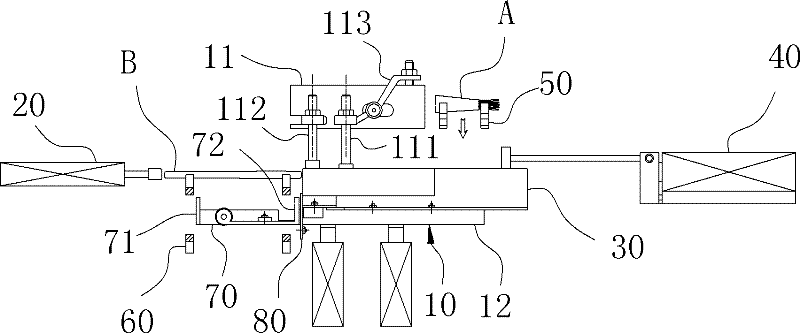

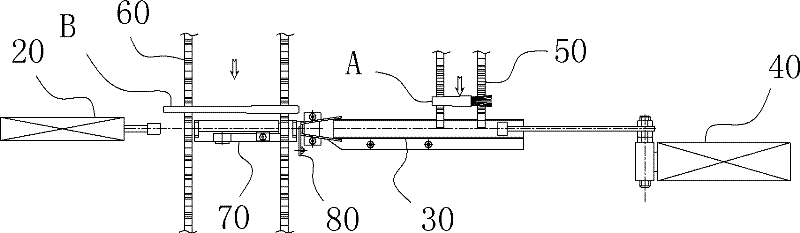

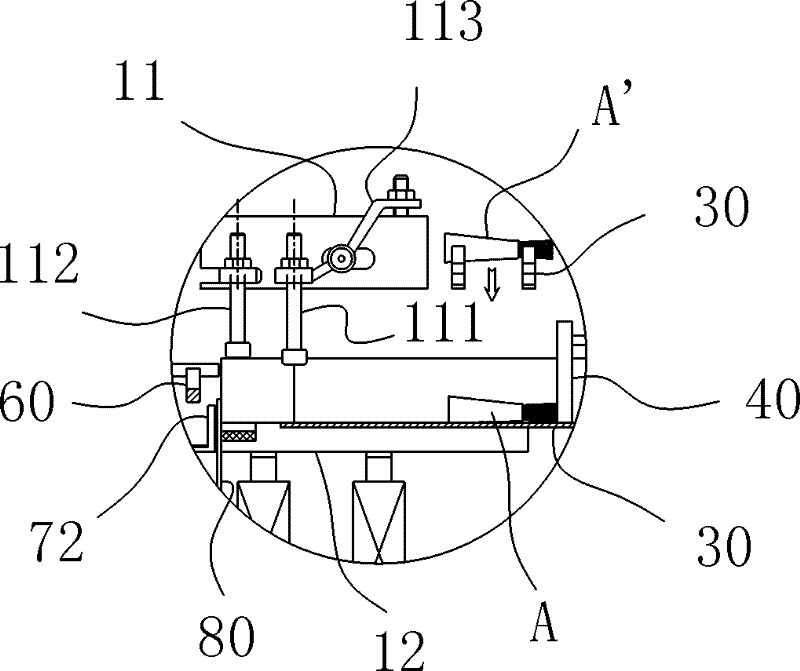

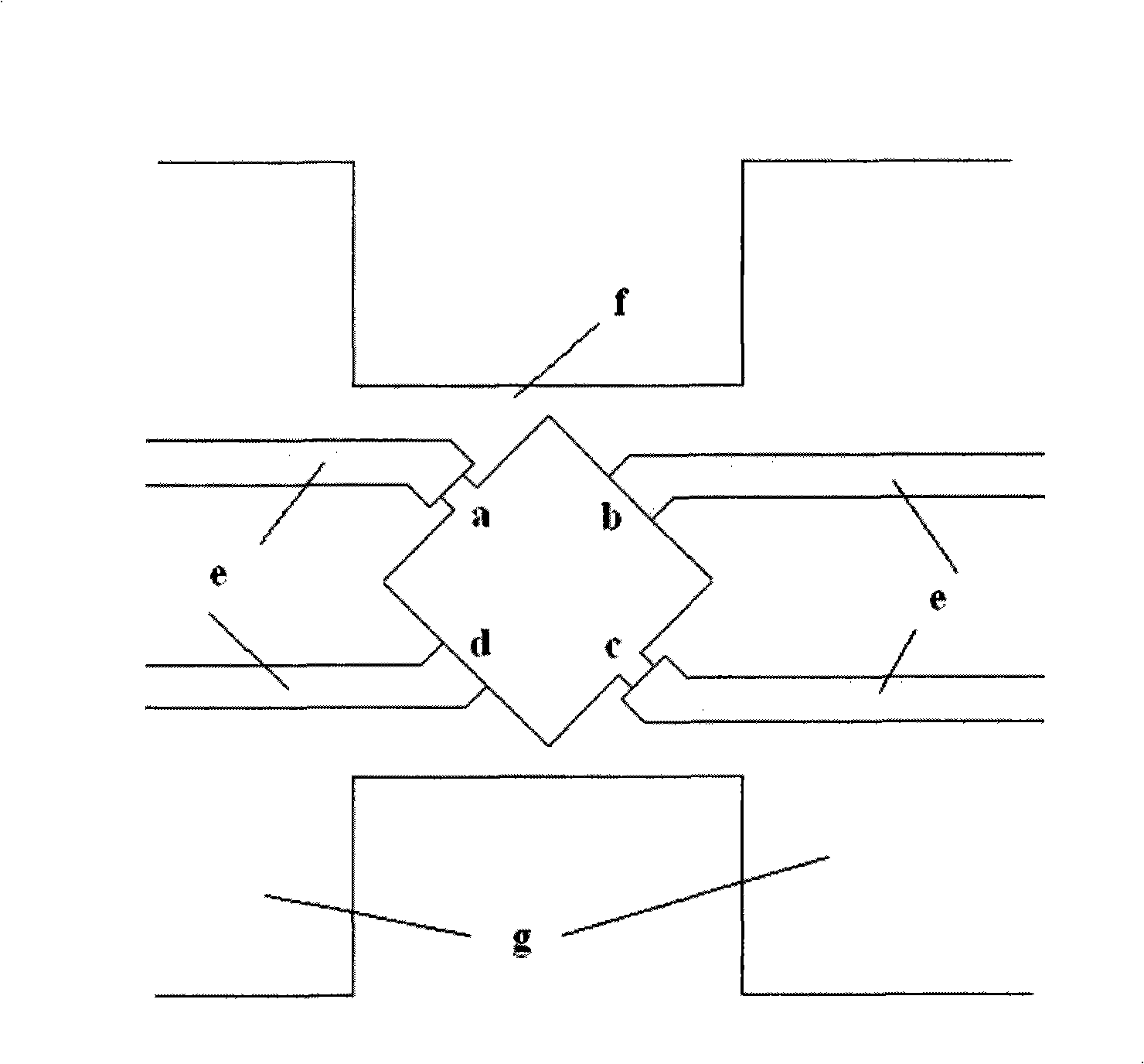

Farci food forming machine

The invention belongs to the technical field of food processing, and particularly relates to a farci food forming machine. The farci food forming machine comprises a stander and a flour wrapper transporting device, a stuffing feeding device, a flour wrapper receiving plate, a withdrawing device and an annular track arranged on the stander, wherein the flour wrapper transporting device, the stuffing feeding device and the withdrawing device are respectively and fixedly arranged on the flour receiving station, the stuffing injecting station and the withdrawing station of the annular track, the flour wrapper receiving plate capable of moving around the annular track is arranged on the annular track, a die assembly device is arranged under the flour wrapper receiving plate, the die assembly device of the farci food forming machine can provide a persistent press force when the farci food is processed, so that the compactness of the fit part of the flour wrapper of the farci food can be guaranteed, and the flour wrapper can not be opened after being pressed for a long time, so that the yield of the farci food can be guaranteed.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

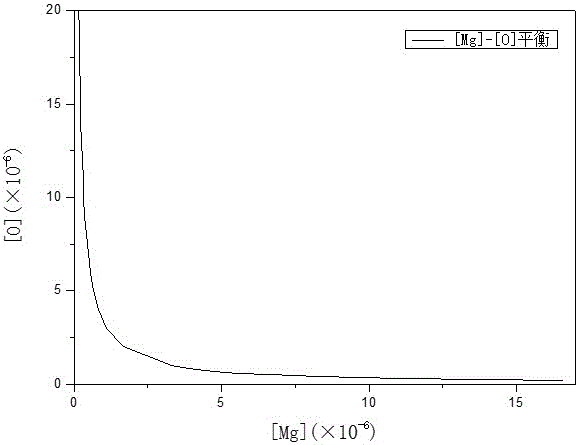

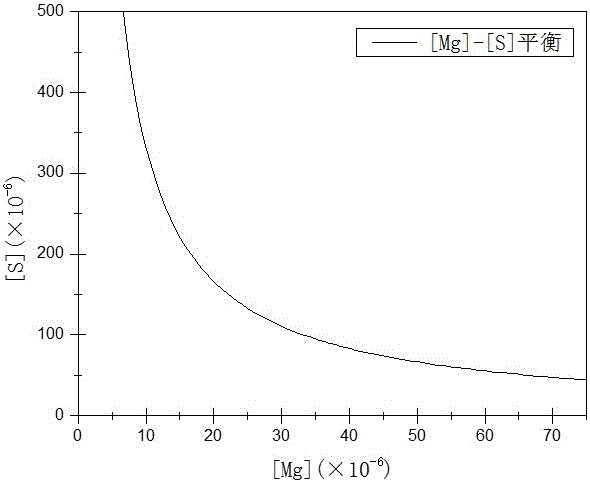

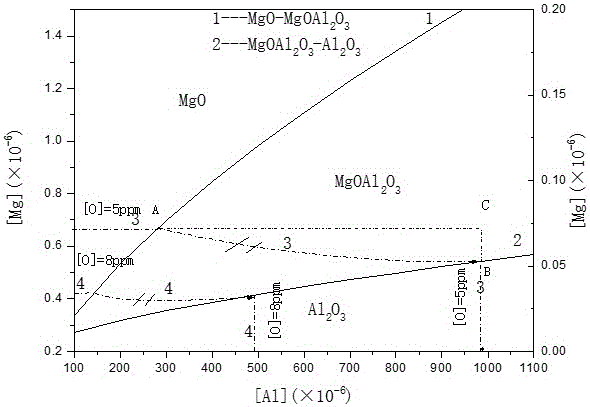

Magnesium, calcium and sulfur containing 20MnCr free-cutting gear steel and preparation method thereof

The invention discloses magnesium, calcium and sulfur containing 20MnCr free-cutting gear steel and a preparation method thereof. The steel is prepared from, by weight percent, 0.15%-0.25% of C, not larger than 0.12% of Si, 0.80%-1.50% of Mn, not larger than 0.035% of P, 0.02%-0.055% of S, 0.80%-1.30% of Cr, 0.015%-0.055% of Al, 0.004%-0.015% of N, 0.0006%-0.004% of Mg, 0.0006%-0.005% of Ca, not larger than 0.0025% of [O] and the balance iron and inevitable impurities. Composite modification is carried out on inclusion by adding a small quantity of calcium and magnesium elements in the refining process, and the composite inclusion with oxide (including multiple oxide) as a core is formed, wherein the core of the composite inclusion is wrapped by sulfide; splitting of the oxide to a steel substrate can be relieved, the anti-fatigue performance can be improved, and the transverse mechanical property of the steel can be improved; and the magnesium, calcium and sulfur containing 20MnCr free-cutting gear steel both good in mechanical performance and cutting performance is produced, and has large economic benefits.

Owner:SHANGHAI UNIV

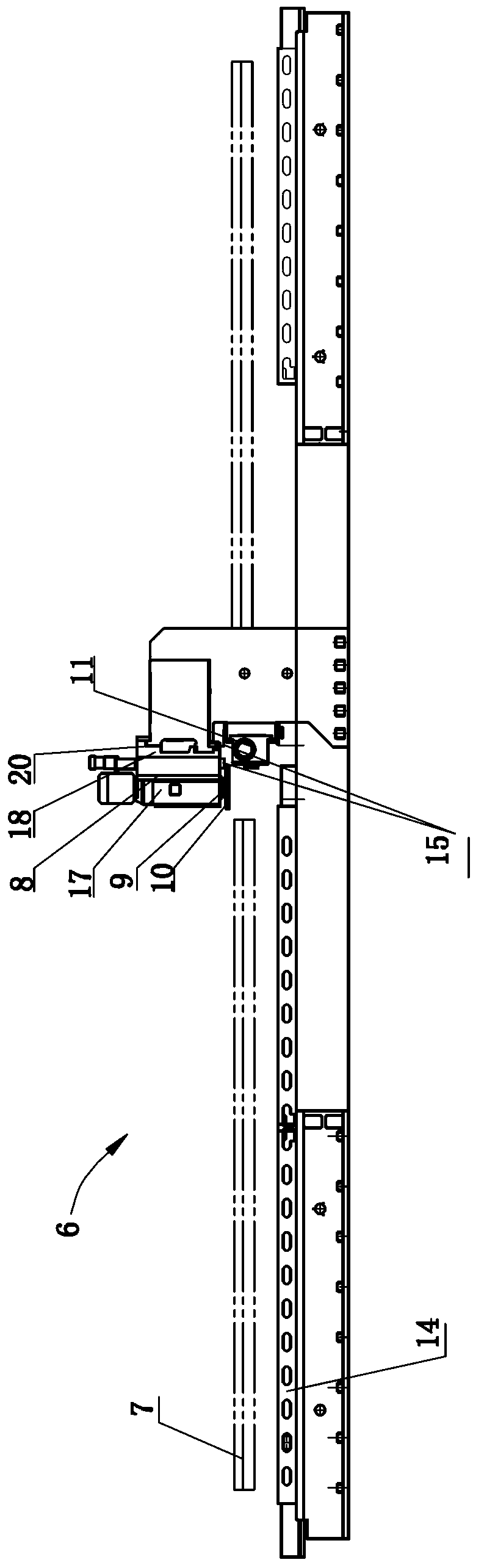

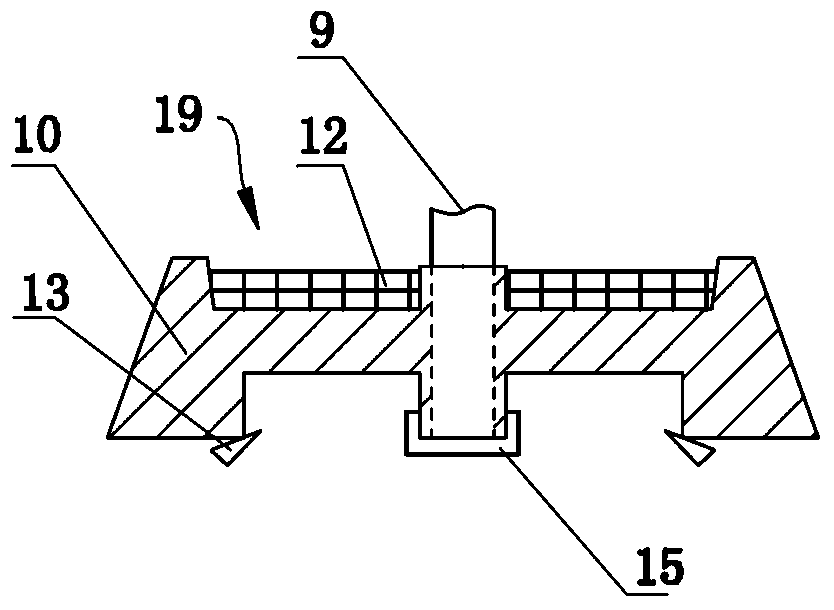

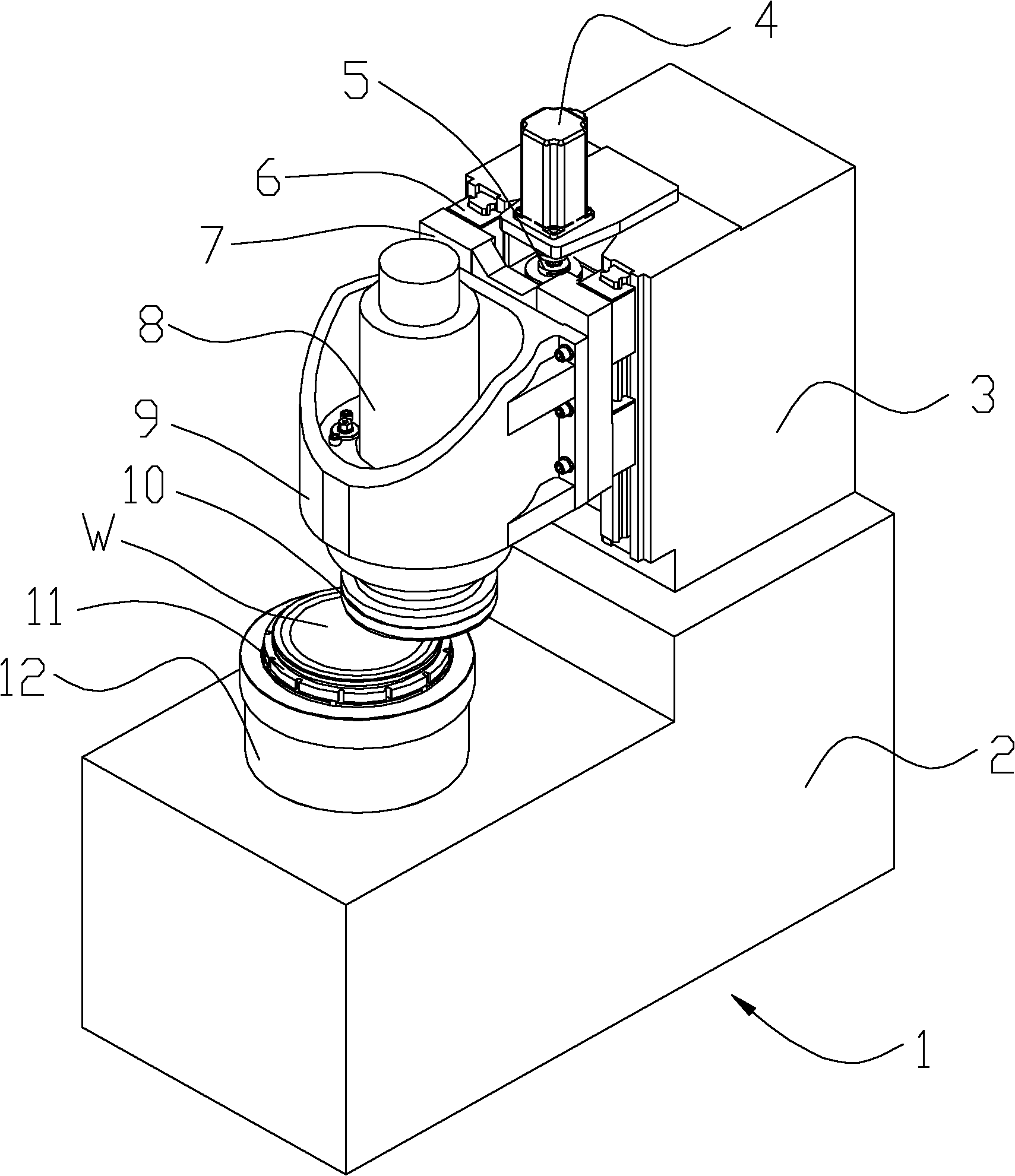

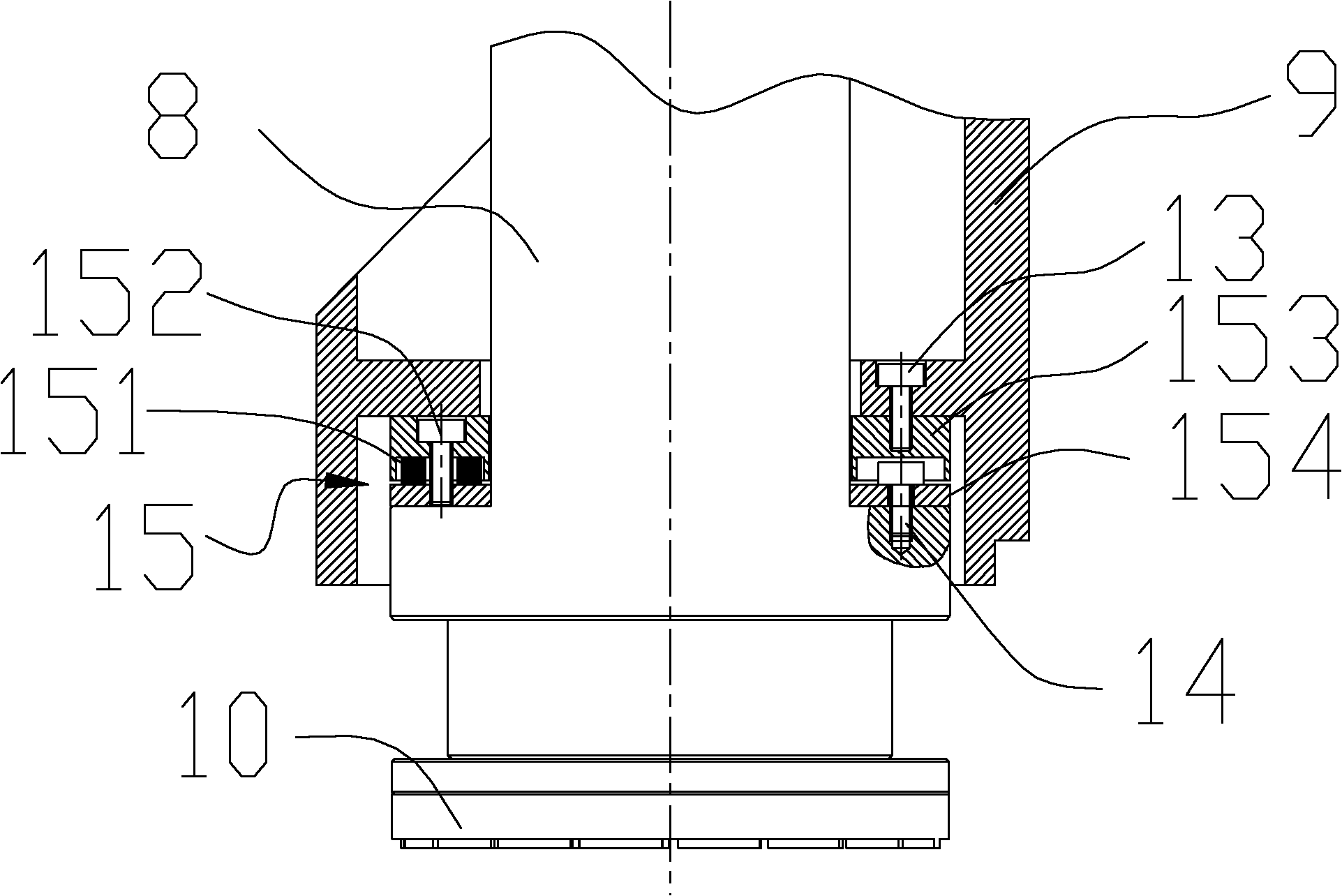

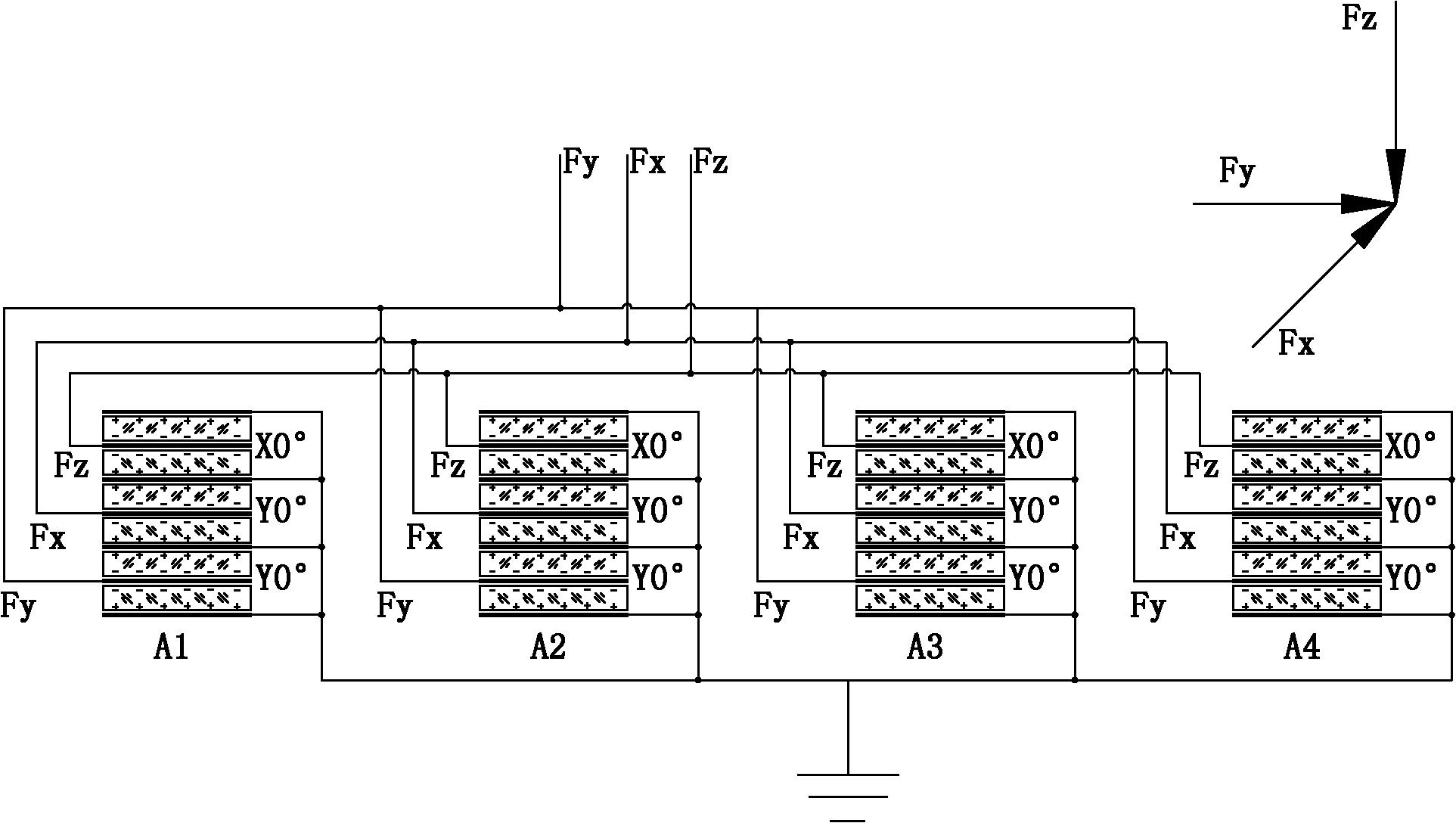

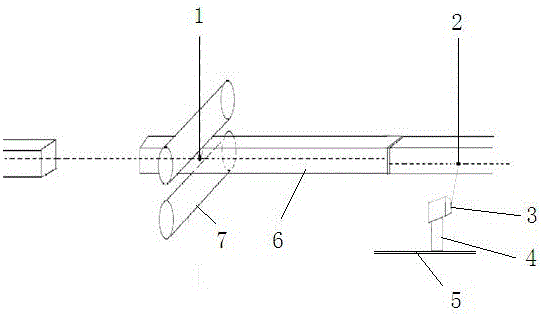

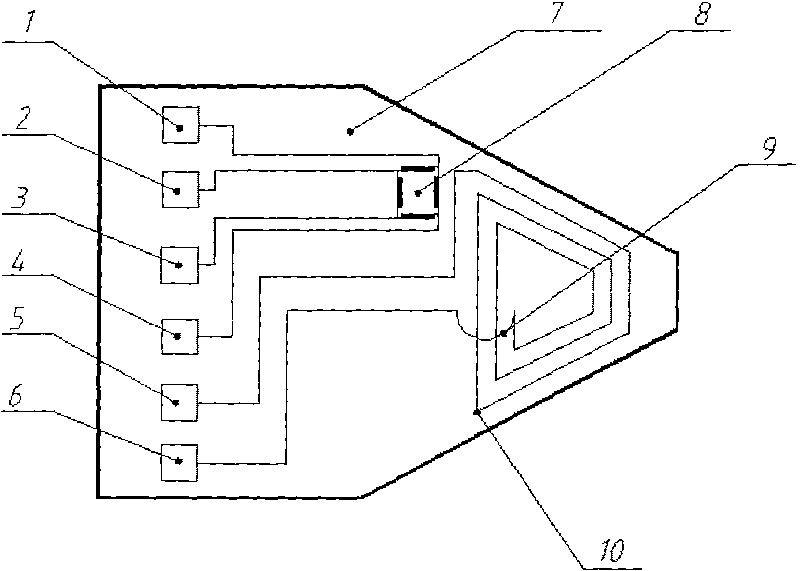

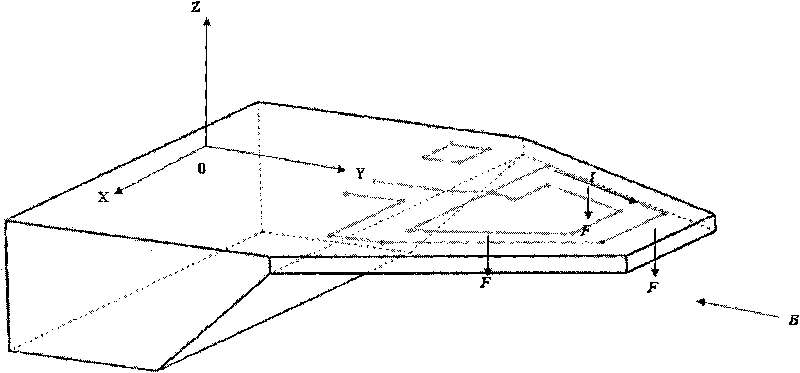

Semiconductor wafer grinding force on-line measurement device and force-controlling grinding method

ActiveCN102009387AImprove machining accuracyImprove processing qualityGrinding feed controlMeasurement deviceTangential force

The invention belongs to the ultraprecision machining field of the hard and brittle semiconductor crystalline materials and relates to a grinding force on-line measurement device used in the grinding process of the semiconductor wafer and a force-controlling grinding method. The invention discloses a semiconductor wafer grinding force on-line measurement device which is used as the feedback element of a grinding force adaptive control system. The grinding force measurement device adopts the piezoelectric measuring principle and contains a sensor part and a data processing unit, wherein the sensor part is used for the on-line measurement of the radial force Fr, the tangential force Ft and the axial force Fz; and the data processing unit is used to collect and analyze the grinding force data and perform feedback control to the feed speed and feed amount of the grinding wheel, thus the aim of on-line measurement can be achieved. The invention has the following advantages: the grinding force on-line measurement device has simple structure, and the modifications to the original equipment are less; the grinding force on-line measurement links are fewer, the response speed is fast, and the precision is high; and the grinding efficiency of the semiconductor wafer can be increased and the thickness of the damaged layer is reduced.

Owner:宁波知行半导体有限公司

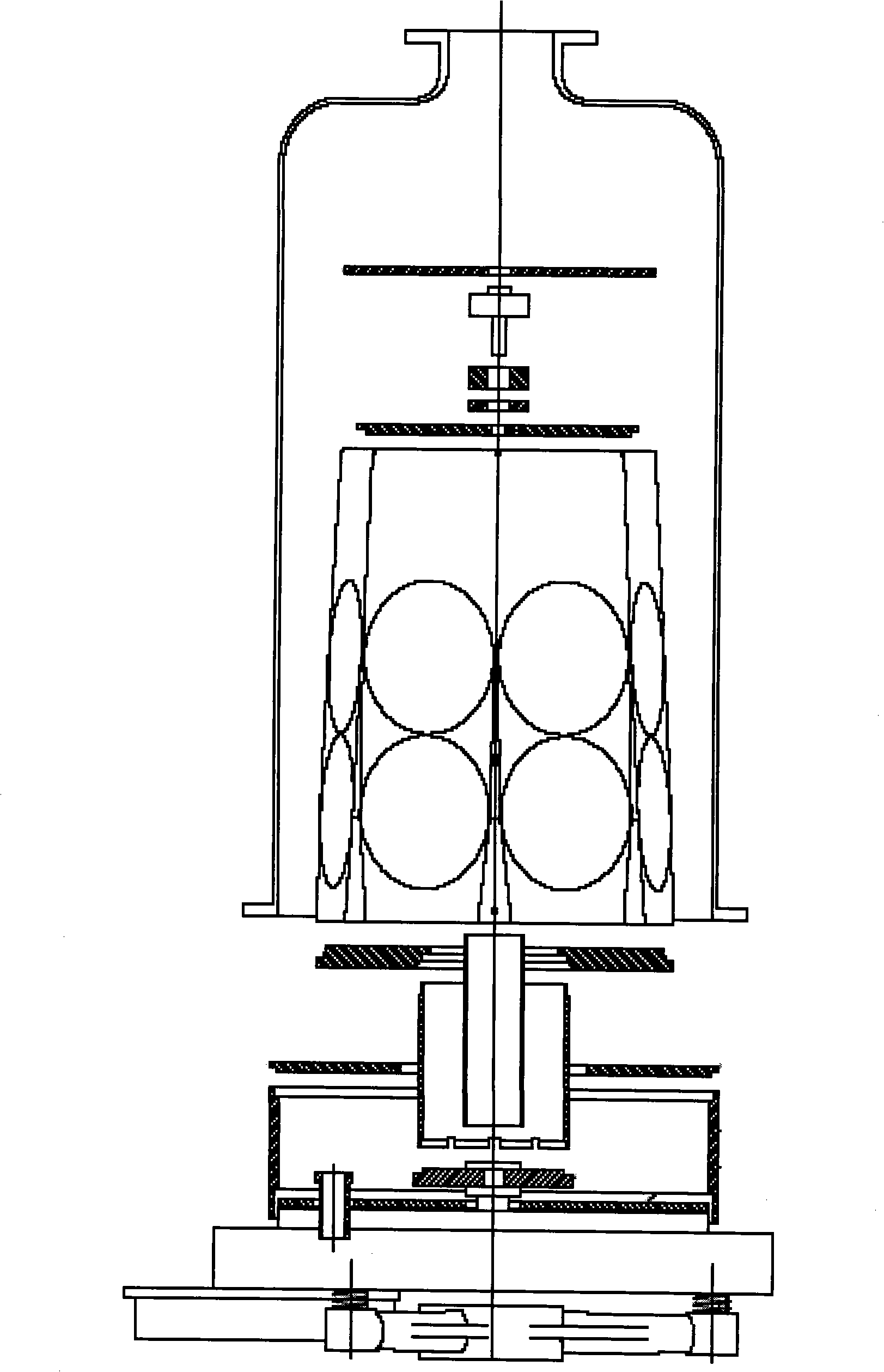

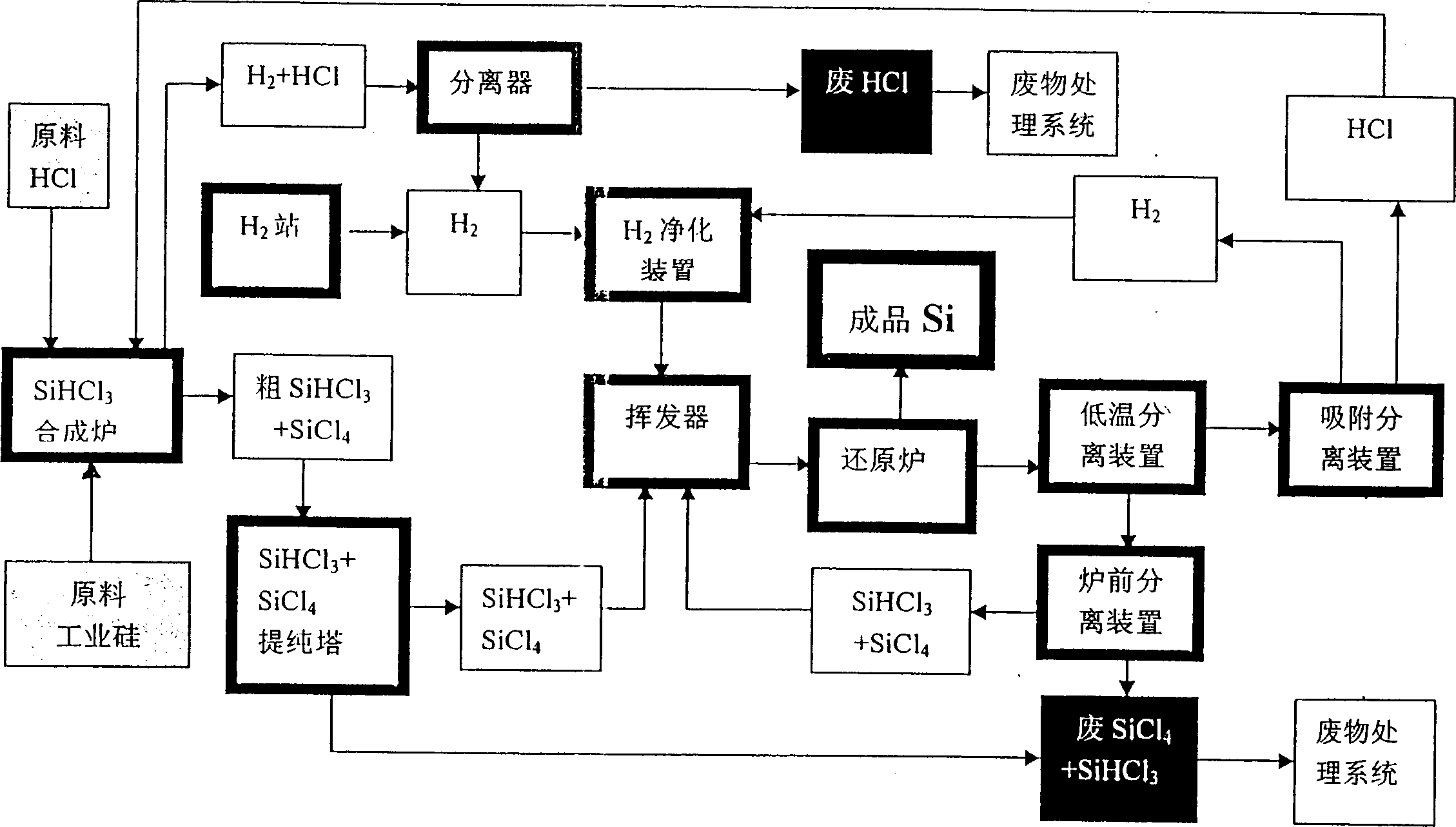

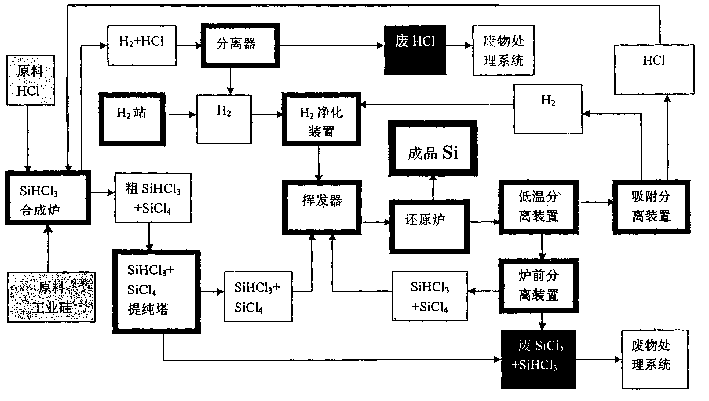

Method of producing polysilicon with mixed source of trichloro-hydrosilicon and silicon tetrachloride

The present invention, method of producing polysilicon with mixed source of trichloro-hydro silicon and silicon tetrachloride, is one completely new hydrogen reduction process of producing polysilicon. The trichloro-hydro silicon and silicon tetrachloride is first refined and purified to 9-10 nines under protective dry inert gas of 0.5-0.8 atm and the hydrogen is also refined to 5-6 nines. The material is then sprayed into hydrogen reduction furance is certain flow rate to result in silicon converting rate of 0.08% and H / Cl ratio of 0.15% of the reduction temperature is controlled in 1145-1155 deg.c, so that polysilicon is produced on the silicon rod inside the furnace. SiC14 and HCl produced in the production process is utilized fully and this results in high quality, high yield, low material consumption and low cost.

Owner:TONGJI UNIV

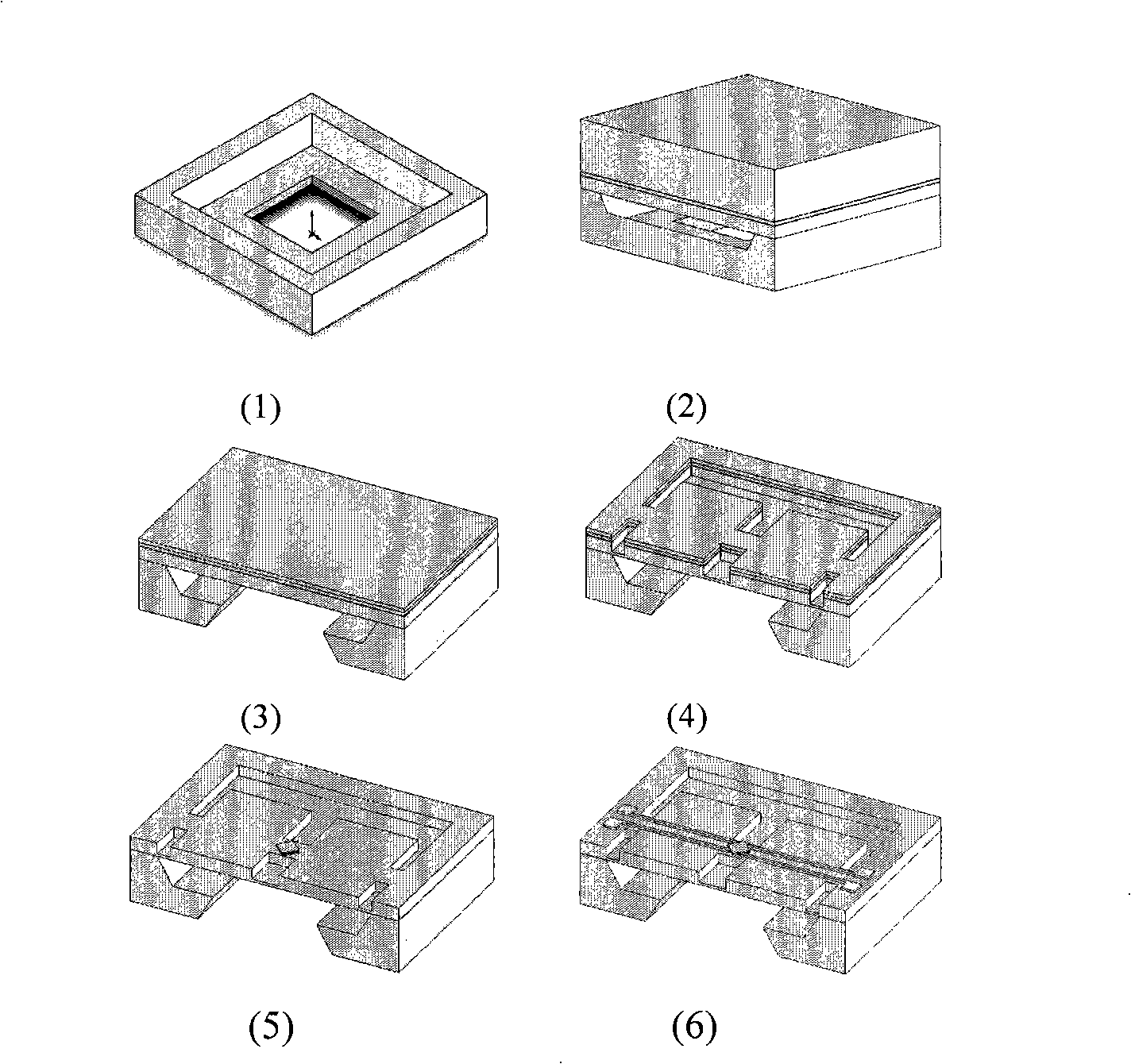

Stuffed food forming method

The invention belongs to the technical field of food processing and in particular relates to a stuffed food forming method. The stuffed food forming method comprises the following steps: 1, allowing a wrapper receiving plate to be positioned at a wrapper receiving station of an annular rail, and conveying the wrapper to the wrapper receiving plate at the wrapper receiving station through a wrapper conveying device; 2, moving the wrapper receiving plate and a die assembly device to a stuffing injection station on the annular rail, and injecting the stuffing on the surface of the wrapper through a stuffing injection device; 3, mutually closing die assembly blocks which are positioned on the die assembly device below the wrapper receiving plate and are opposite to each other, coating and forming stuffed foods, and continuously keeping the two closed die assembly blocks be in the state; and 4, simultaneously moving the wrapper receiving plate and the die assembly device to a taken-out station on the annular rail, so that the wrapper receiving plate is opened, and the die assembly blocks which are always positioned in a closed state are separated. According to the die assembly device in the method, continuous pressing force can be provided for the stuffed foods in the processing process, the tightness on the joint part of the wrapper of the stuffed foods can be guaranteed, the wrapper is not open after being pressed for a long time, and the forming rate of the stuffed foods is guaranteed.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

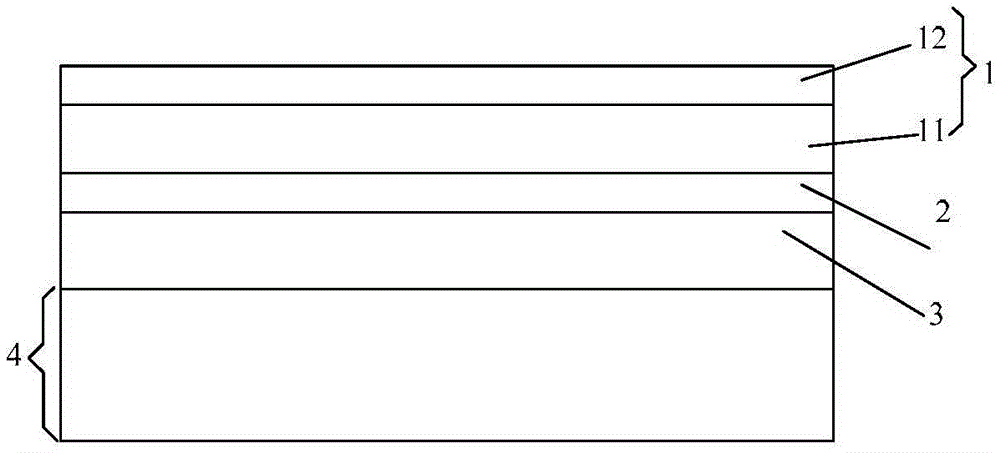

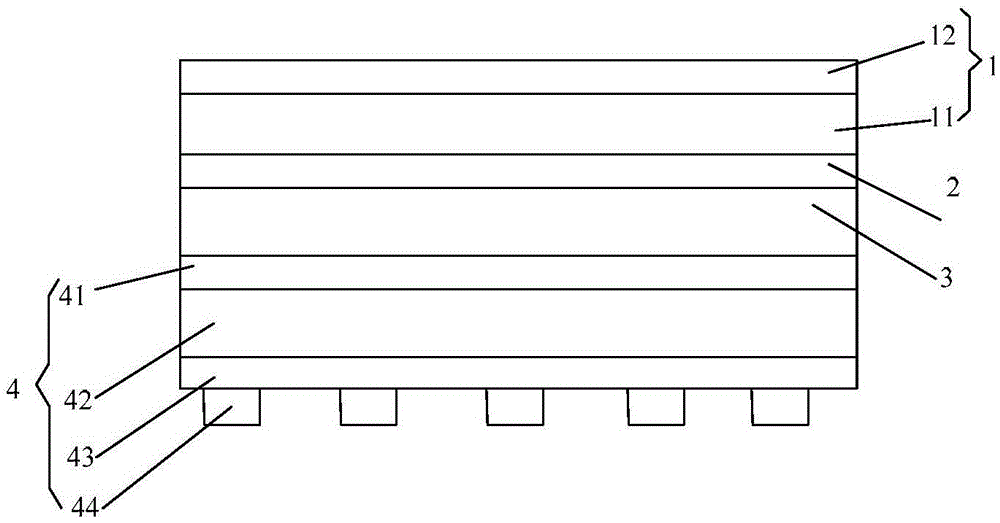

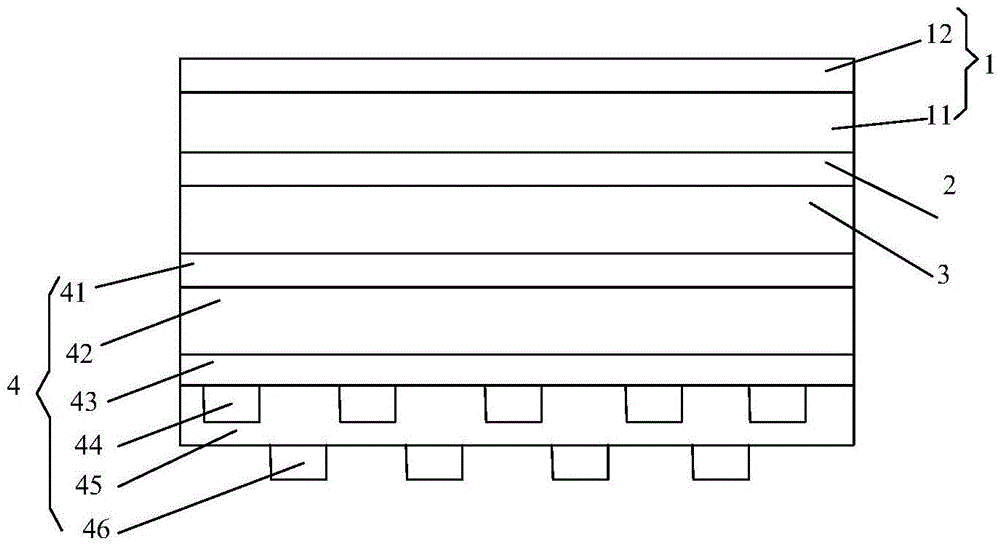

Comprehensive functional membrane, manufacturing method thereof, and OLED display panel

ActiveCN105655501AReduce thicknessSimple processSolid-state devicesSemiconductor/solid-state device manufacturingPolarizerLinear polarization

The invention provides a comprehensive functional membrane, a manufacturing method thereof, and an OLED display panel with the comprehensive functional membrane. The comprehensive functional membrane comprises a linear polarizer, a 1 / 4 wave plate and a touch membrane module with the obstructing function, wherein the linear polarizer comprises a linear polarization functional sheet layer and a hardening protecting layer arranged on the surface of one side of the linear polarization functional sheet layer, and the hardening strength of the hardening protecting layer is higher than the hardness 5H of a pencil; the 1 / 4 wave plate is arranged on the surface, far away from the hardening protecting layer, of the linear polarization functional sheet layer; the touch membrane module with the obstructing function is arranged on the surface, far away from the linear polarization functional sheet layer, of the 1 / 4 wave plate in a contact mode. The hardening strength of the hardening protecting layer of the linear polarizer is higher than the hardness 5H of a pencil, and therefore the hardening protecting layer can serve as a protective cap, a glass cover in the prior art is omitted, the thickness of the OLED display panel is reduced, and flexible packaging is achieved through the linear polarizer. The water-oxygen obstructing function, the touch function and the polarizing function are integrated, and therefore an adhering layer is omitted, the thickness of a packaging structure is reduced, the technological process is simplified, and the yield of finished products is guaranteed.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

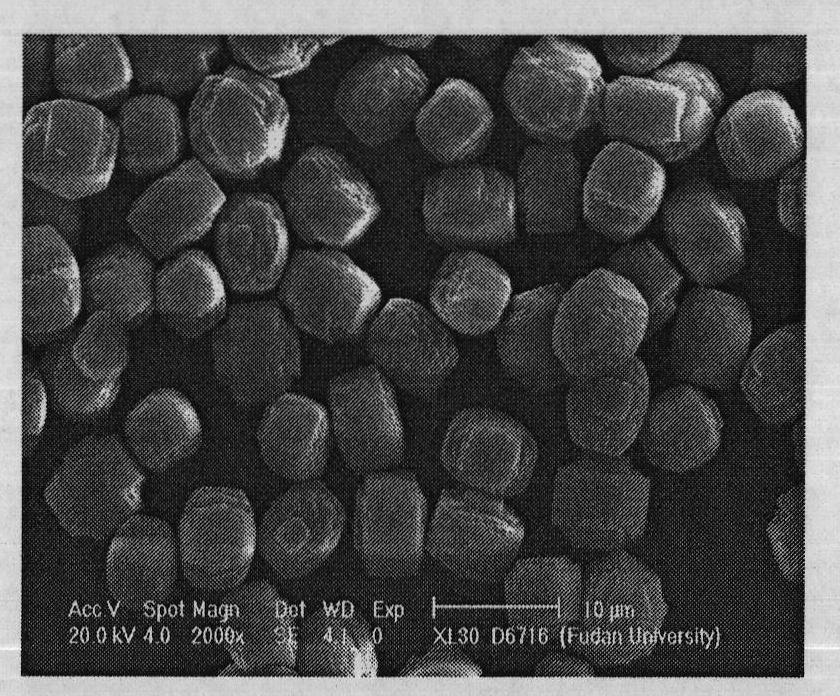

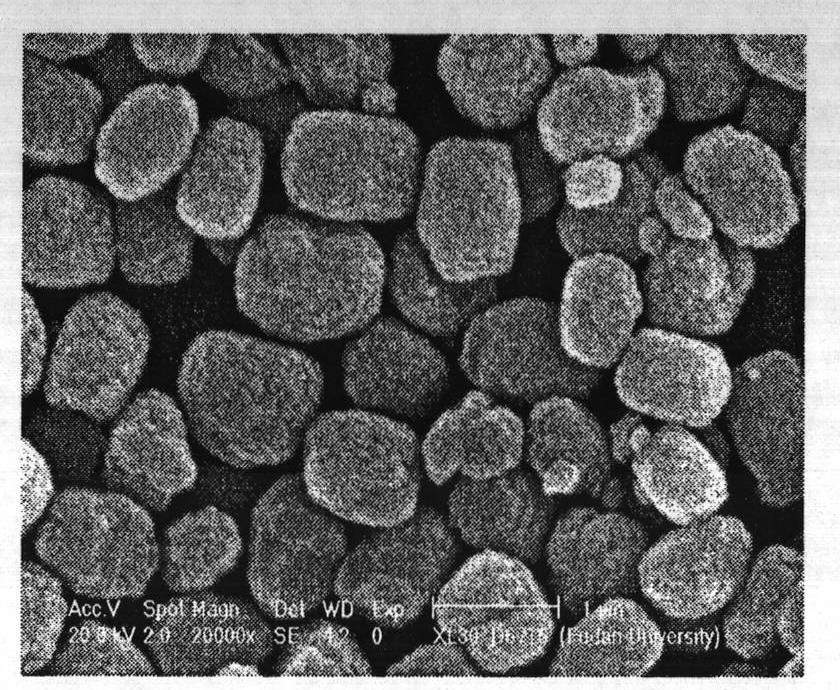

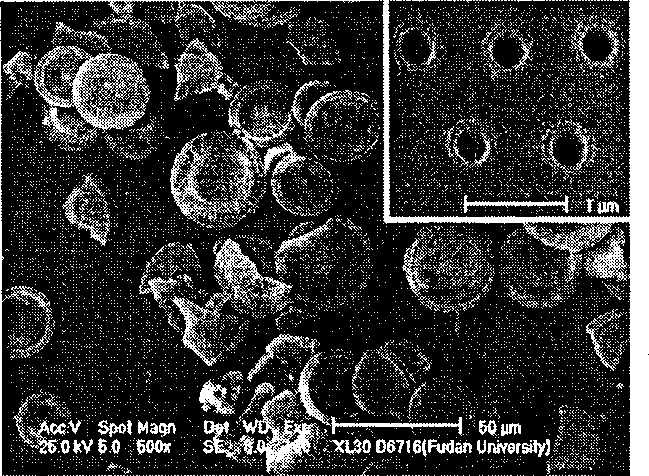

Method for adjusting surface hole diameter of ZSM-5 molecular sieve by surface dealuminizing and compensating silicon

InactiveCN101857243ASmall surface pore sizeMaintain skeleton structurePentasil aluminosilicate zeolitePore diameterFluosilicates

The invention belongs to the technical field of zeolite molecular sieves, in particular to a method for adjusting a surface hole diameter of a ZSM-5 molecular sieve by surface dealuminizing and compensating silicon. The invention accurately controls the surface hole diameter of the molecular sieve by using the treating measure of dealuminizing and compensating silicon on the ZSM-5 zeolite molecular sieve with ammonium fluosilicate solution. An ultrathin layer enriched with silicon is formed on the surface of the ZSM-5 zeolite molecular sieve treated by the method so that the hole caliber on the surface of the molecular sieve is shrunk. The ZSM-5 zeolite molecular sieves with different hole caliber shrinkage level can be selectively obtained by changing different treating conditions. The SM-5 zeolite molecular sieves modified by the method can be used for absorbing a mixture of three isomerides of P-, M-and O-Xylene.

Owner:FUDAN UNIV

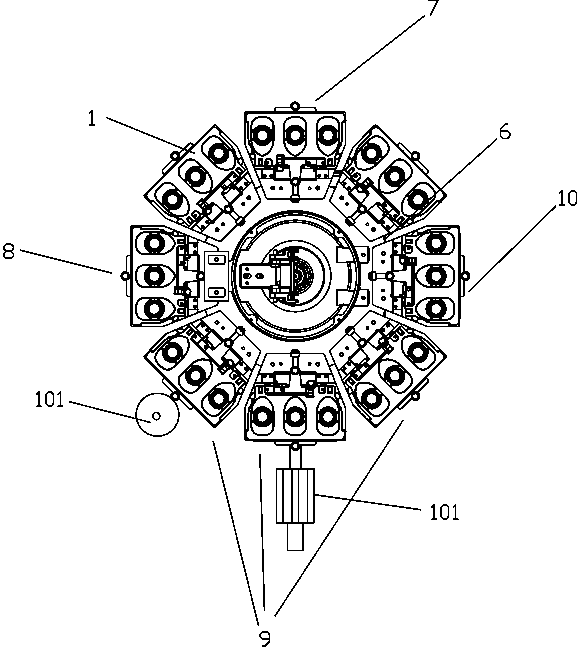

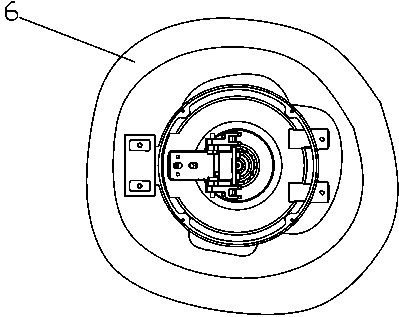

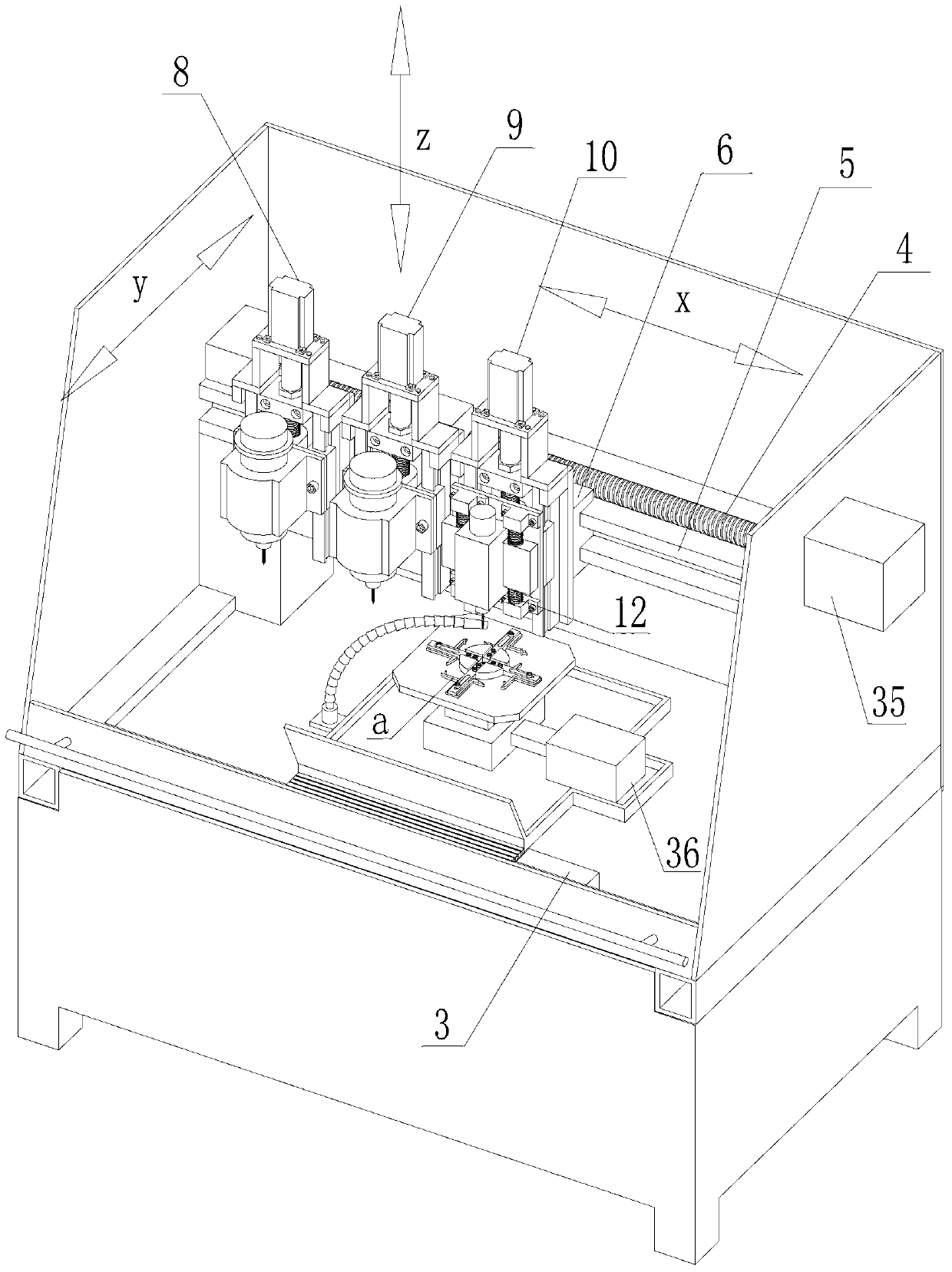

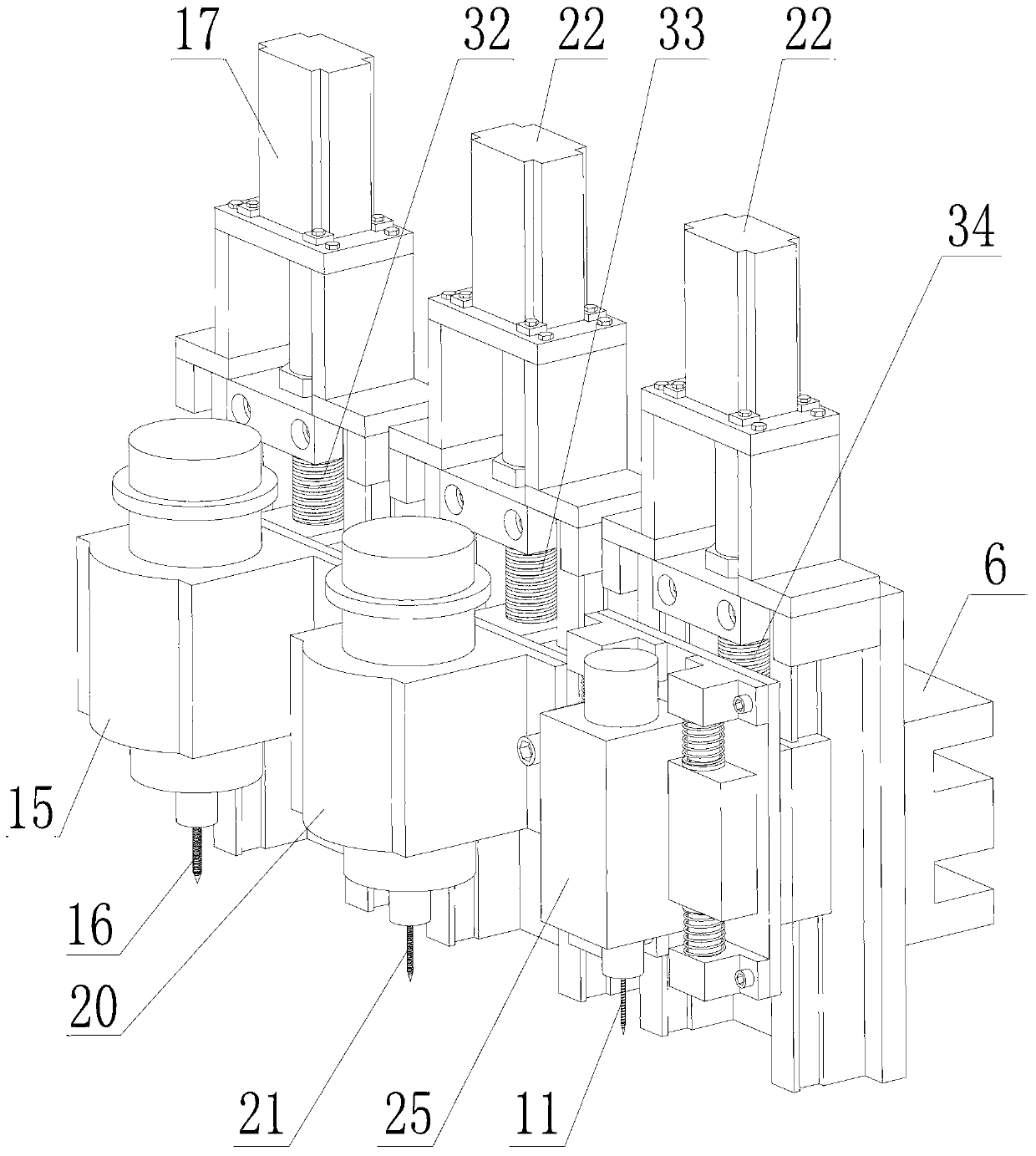

Multi-functional all-in-one automatic drilling and tapping machine tool

InactiveCN103341653AGuaranteed service lifeGuaranteed YieldThread cutting machinesBoring/drilling componentsEngineeringHardness

A multi-functional all-in-one automatic drilling and tapping machine tool comprises assemblies, mutually assembled in a reasonable mode, such as a machine frame, a working table, a concave table, an X-axis servo motor, a Y-axis servo motor, a driving lead screw, a transverse guide rail, a main sliding seat, a multi-workpiece-holder mechanism, a pre-drilling mechanism, a drilling mechanism, a tapping mechanism, a screw tap and a buffer mechanism. Through the reasonable arrangement, automatic micro hole pre-drilling machining, automatic micro hole drilling machining and automatic micro hole tapping machining are achieved through the multi-functional all-in-one automatic drilling and tapping machine tool, and a plurality of problems that at present, the ratio of finished products is low when high-hardness workpiece micro holes are drilled and tapped, the machining cost is too high, the labor intensity of workers is high and automatic machining is difficult to achieve are effectively solved. The multi-functional all-in-one automatic drilling and tapping machine tool is simplified in structure, can achieve all-in-one automatic machining for the high-hardness workpiece micro holes, is high in machining accuracy, low in cost and convenient to maintain, and deserves popularization.

Owner:LISHUI NANGUANG MEASURING & CUTTING

Lead-free environmental silicon brass alloy bar or alloy ingot and preparation method thereof

The invention relates to a lead-free environmental silicon brass alloy bar or alloy ingot and the alloy material comprises the following chemical elements by weight percent: 60%-70% of copper, 0.7%-3.0% of silicon, 0.15% or less of aluminium, 0.25% or less of lead, 0.5% or less of iron, 0.3% or less of tin, 0.1% or less of phosphorus, 0.2% or less of nickel, 0.25% or less of antimony and the balance zinc and unavoidable impurities. The lead content of the silicon brass alloy material of the invention is greatly reduced, which corresponds to the demand of environmental protection and health; the alloy material has good casting property and is applicable to casting, in particular to large-scale gravity casting so as to have broad application prospect in health fittings industry.

Owner:浙江天申铜业有限公司

Alumina supporter containing modified gamma zeolite and its preparation method

ActiveCN1765492ALowering the freezing pointReduce crackingMolecular sieve catalystsCatalyst activation/preparationIon exchangeMetal

The invention discloses an alumina support containing Y zeolite and relative preparing method. The carrier utilizes the Y zeolite and alumina as carriers, while the property of zeolite can be changed via changing the metallic positive ions between the VIB group and / or VIII group to adjust the acid distribution, especially the proportion of B acid and L acid. The invention can be used a carrier of hydro-treating catalyst to fraction prepare the winter cleaning diesel fuel from poor diesel fuel.

Owner:CHINA PETROLEUM & CHEM CORP +1

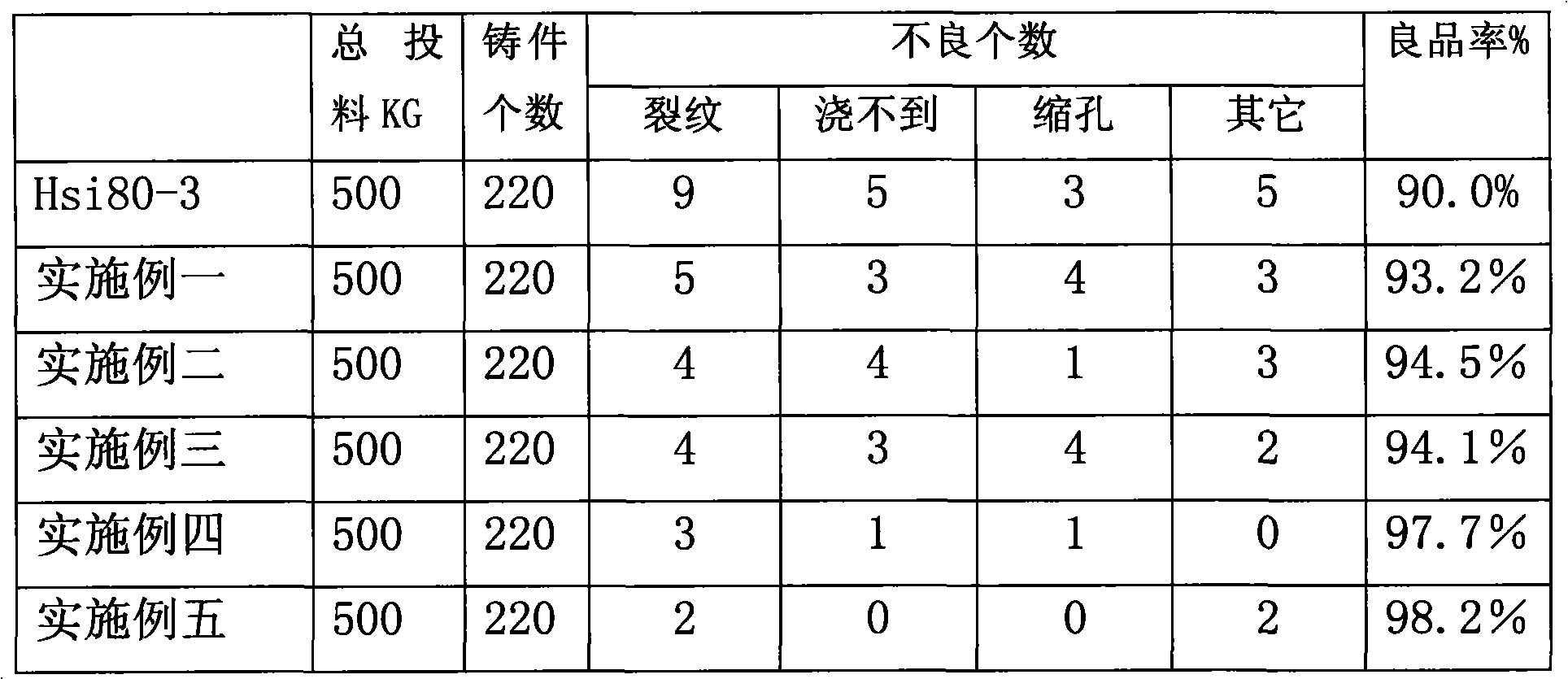

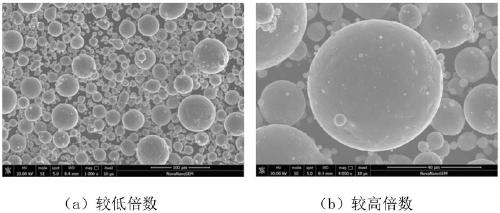

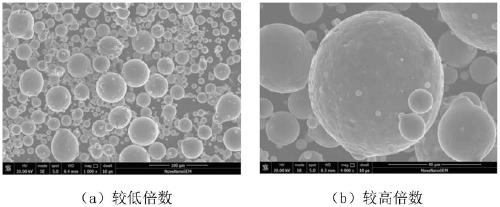

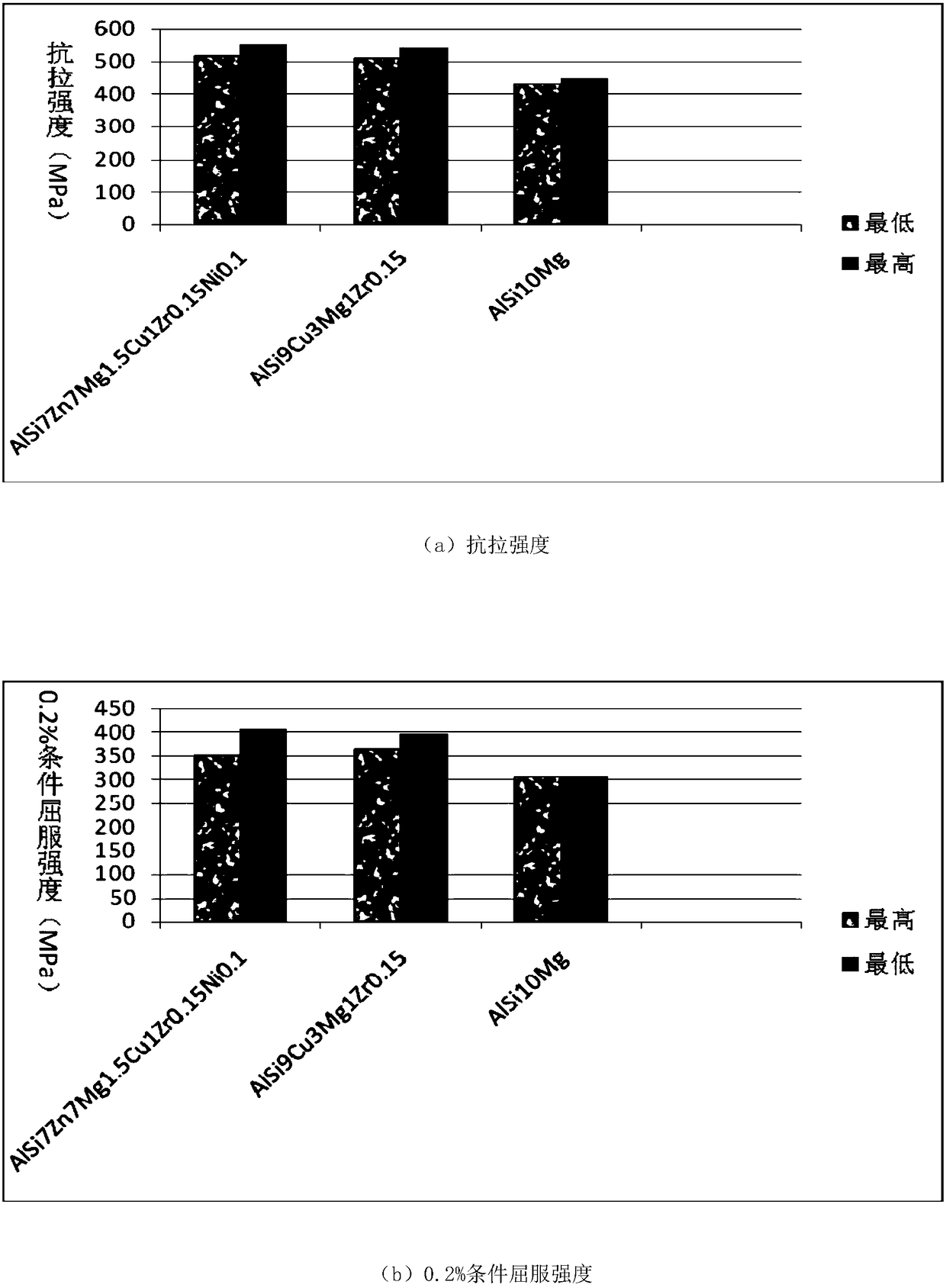

High-strength aluminum alloy for additive manufacturing and preparation method of high-strength aluminum alloy powder

ActiveCN109280820AGuaranteed yieldAvoid oxidation burnAdditive manufacturing apparatusTransportation and packagingTest sampleMedium frequency

The invention provides a high-strength aluminum alloy for additive manufacturing and a preparation method of high-strength aluminum alloy powder. The high-strength aluminum alloy powder is prepared byadopting a gas atomization process. The preparation method comprises the following steps of: firstly, melting an Al-Si-Zn-Cu-Mg-X alloy prefabricated ingot by adopting a medium frequency induction furnace, then powdering by adopting a supersonic speed gas atomization process, sieving and preparing powder of different specifications for additive manufacturing. A test sample obtained by adopting the high-strength aluminum alloy powder through additive manufacturing has compact texture without crack defects, the strength of extension exceeding 500MPa and the elongation exceeding 3%; the strengthperformance of the test sample is obviously superior to the strength performance of additive manufacturing test samples of AlSi10Mg, AlSi7Mg and AlSi12; and the performances of the test sample are also superior to the performances of additive manufacturing test samples of conventional 2000 series and 7000 series alloys. The alloy powder can be used for preparing aluminum alloy parts with compacttexture, complicated shapes and high strength in an additive manufacturing method to meet the requirements of use occasions on high specific strength and complicated shapes in the fields of aviation,spaceflight and automobiles.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

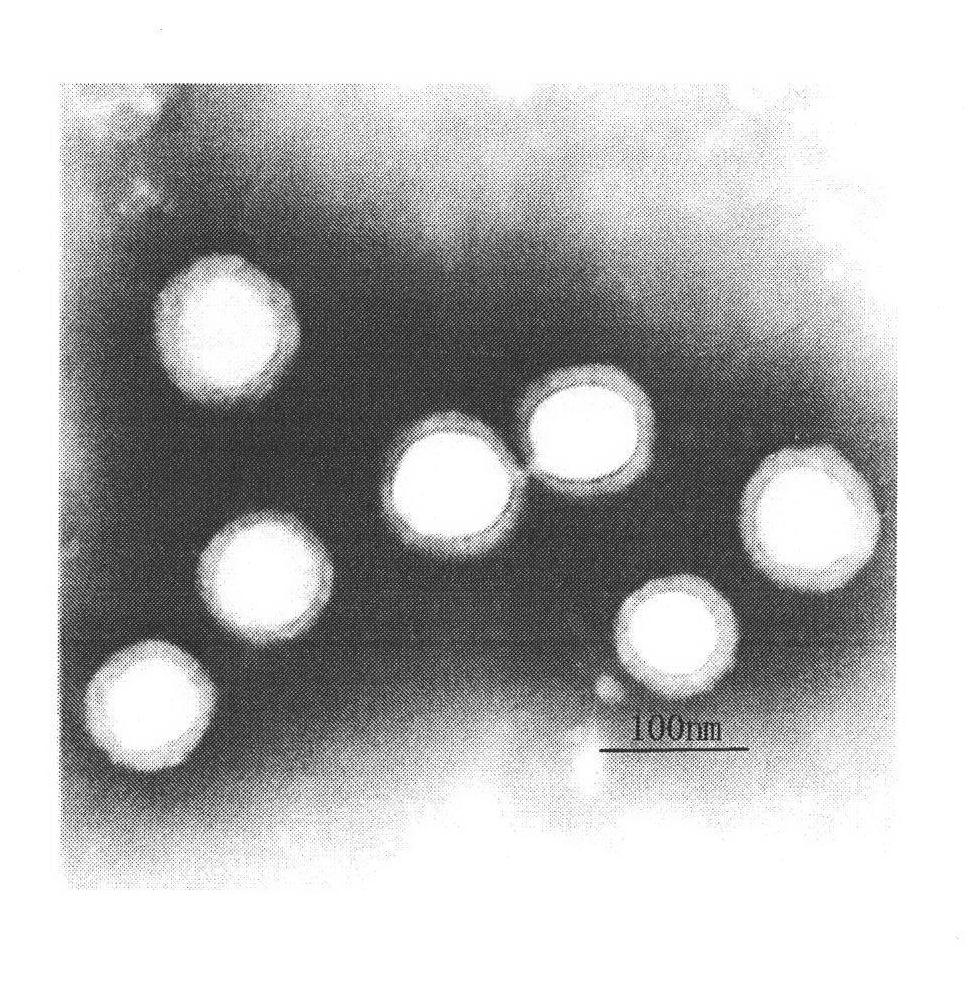

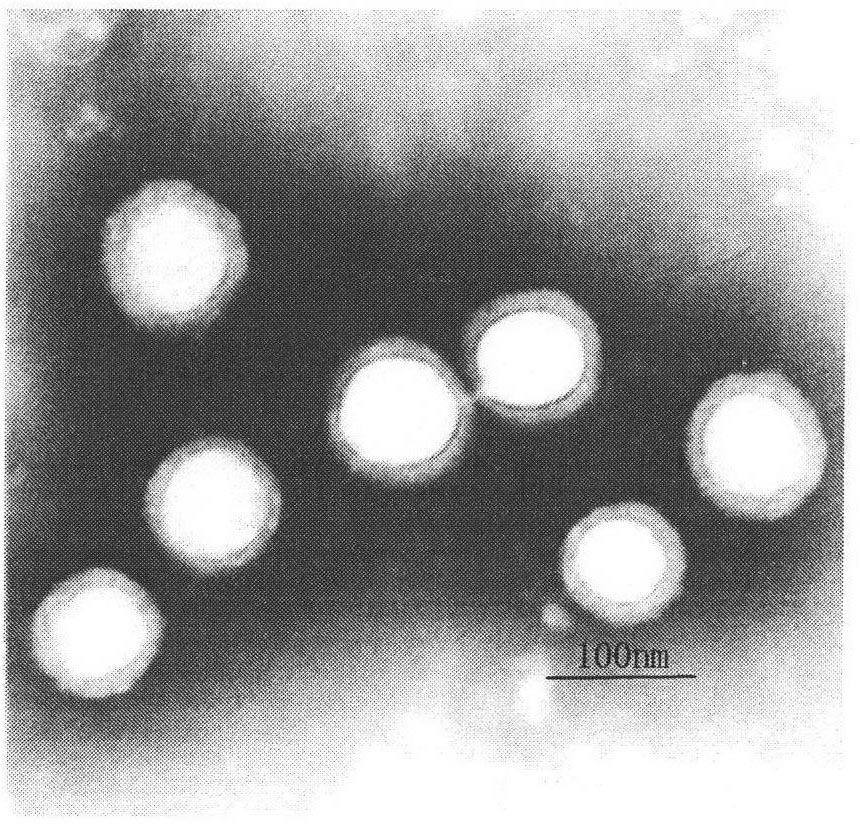

Preparation of nano silicone-acrylate core shell type composite latex for latex paints

InactiveCN101921360AThe polymerization process is stableGuaranteed yieldCoatingsChemistryWeather resistance

The invention relates to a preparation method of nano silicone-acrylate core shell type composite latex for latex paints. The preparation method solves the problem that latex paints prepared from the common latex is insufficient to meet the demands of people at the performance aspects of water resistance, weather resistance, pollution resistance and the like, and simultaneously reduces the restraint degrees of a region domain and a time and season domain for latex construction. In the preparation method, active organic silicon and acrylate monomers are mainly used as raw materials, and then the nano silicone-acrylate core shell type composite latex using polyacrylate as a core and using silicone-acrylate composite resin as a shell is synthesized by adopting a monomer pre-emulsifying process and a seed semi-continuous latex polymerization method, so that the preparation method has the advantages of stable polymerization process and convenient large-scale production. When used for preparing the latex paints of outer walls, the synthesized latex can greatly improve all performance of the latex paints, also solve the conflicts between the lowest film-forming temperature and film hardness and simultaneously realize the unification of the cost and the performance.

Owner:SHAANXI UNIV OF SCI & TECH

Plugging device of pen head and pen holder

InactiveCN102225674AGood production efficiencyStable working conditionPen repairingPackaging toiletriesEngineeringYield rate

The invention belongs to the field of pen manufacturing and in particular relates to a plugging device of a pen head and a pen holder. The plugging device comprises a clamping mechanism for fixing the pen head and a pen holder pushing mechanism for pushing the pen holder; the pen head and the pen holder are horizontally arranged in the pushing direction of the pen holder pushing mechanism when being assembled. By using the plugging device, the assembling quality and the production yield rate can be guaranteed while the plugging assembling efficiency of the pen head and the pen holder is improved; and the apparatus can run stably and reliably.

Owner:卫青山

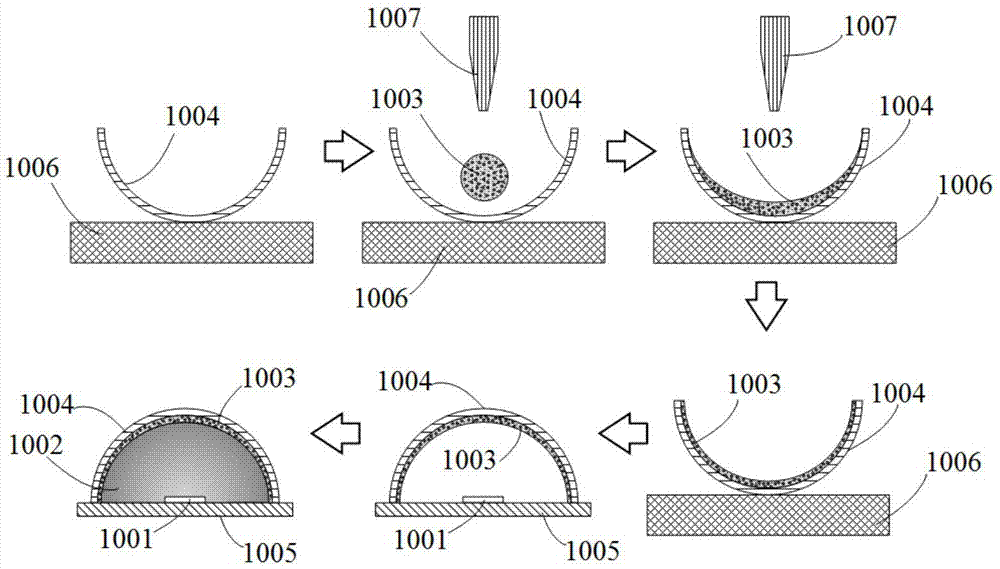

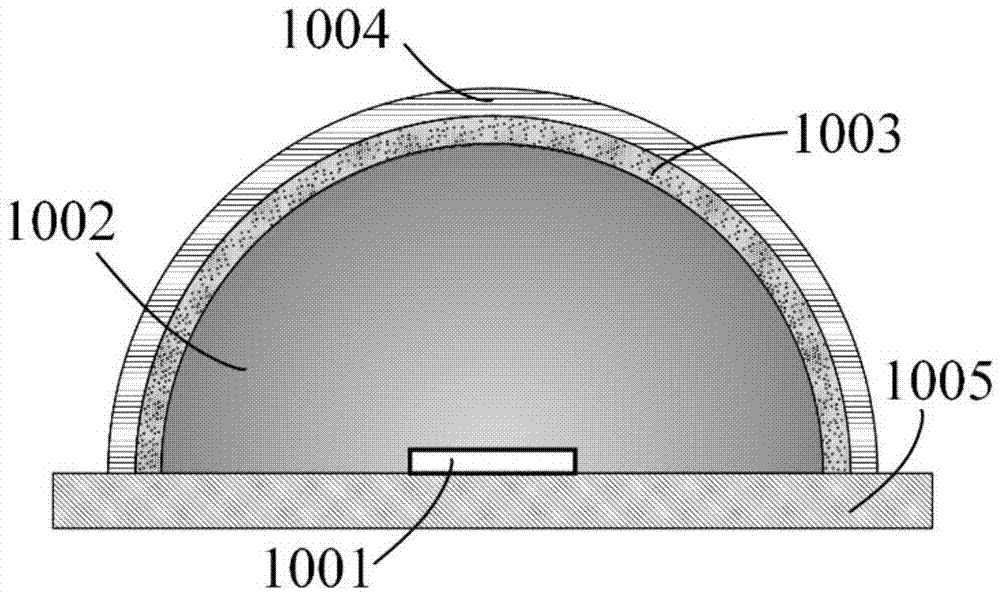

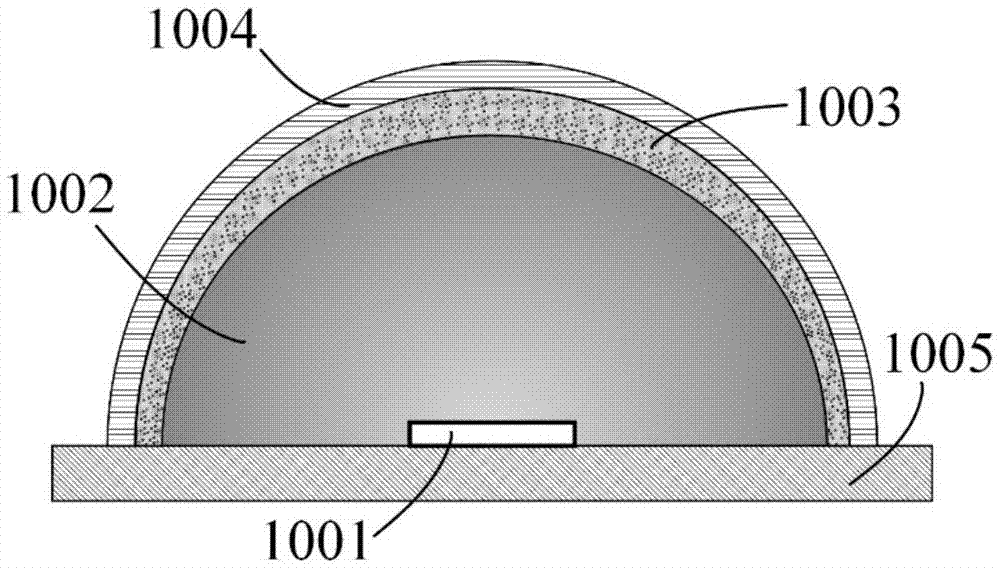

White light LED and preparation method thereof

InactiveCN105449078AImprove Optical ConsistencyAvoid wastingSemiconductor devicesQuantum dotRejection rate

The invention discloses a white light LED. The white light LED comprises a substrate, an LED chip and a transmitting shell, wherein the bottom of the LED chip is fixed on the surface of the substrate; the upper part of the LED chip is sleeved by the transmitting shell; a quantum dot thin film is adhered to the inner surface of the transmitting shell; and encapsulation glue is filled between the transmitting shell and the substrate. The invention furthermore discloses a preparation method of the white light LED. According to the white light LED and the preparation method, the operation method is simple, the cost is low, and the thickness, morphology and ingredients of the quantum dot thin film can be flexibly controlled, so that the optical consistency and space color uniformity of the white light quantum dot LED are improved; and the quantum dot thin film is prepared on a batch produced curved surface die, but not directly dispensed on the LED chip, so that the rejection rate of the quantum dot LED products is effectively decreased and the preparation method is suitable for the large-scale production of white light quantum dot LEDs.

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method for recovering high-purity yttrium europium from fluorescent powder scrap

The invention discloses a preparation method for recovering high-purity yttrium europium from fluorescent powder scrap, comprising the following steps: 1) dissolving fluorescent powder; 2) carrying out filter pressing on dissolved feed liquid to obtain rough europium by a plate frame; 3) removing zinc and iron from feed liquid rich with yttrium and zinc by N235; 4) putting YCL3 into HB extracting agent for secondary edulcoration to obtain fluorescent-grade 4N-5N YCL3, dewatering, carbonizing and oxidizing; 5) putting prepared rough EU and HA-extracted rough EU into a reaction vessel, and slowly adding zinc power in batches; 6) after reducing, adjusting pH value by ammonium chloride and ammonia water in place to prepare europium hydroxide; 7) preparing a europium hydroxide solution with certain concentration and pH value, transmitting to an HB agent system for reaction; 8) firing after washing; and 9) dewatering, carbonizing and oxidizing for 3-5 hours at the high temperature of about 1000 DEG C to obtain fluorescent-grade europium oxide, smashing, screening and packaging in vacuum. The invention has the advantages of reasonable technology, strong maneuverability and strong competitiveness.

Owner:赣州市永莱宝高新材料有限公司

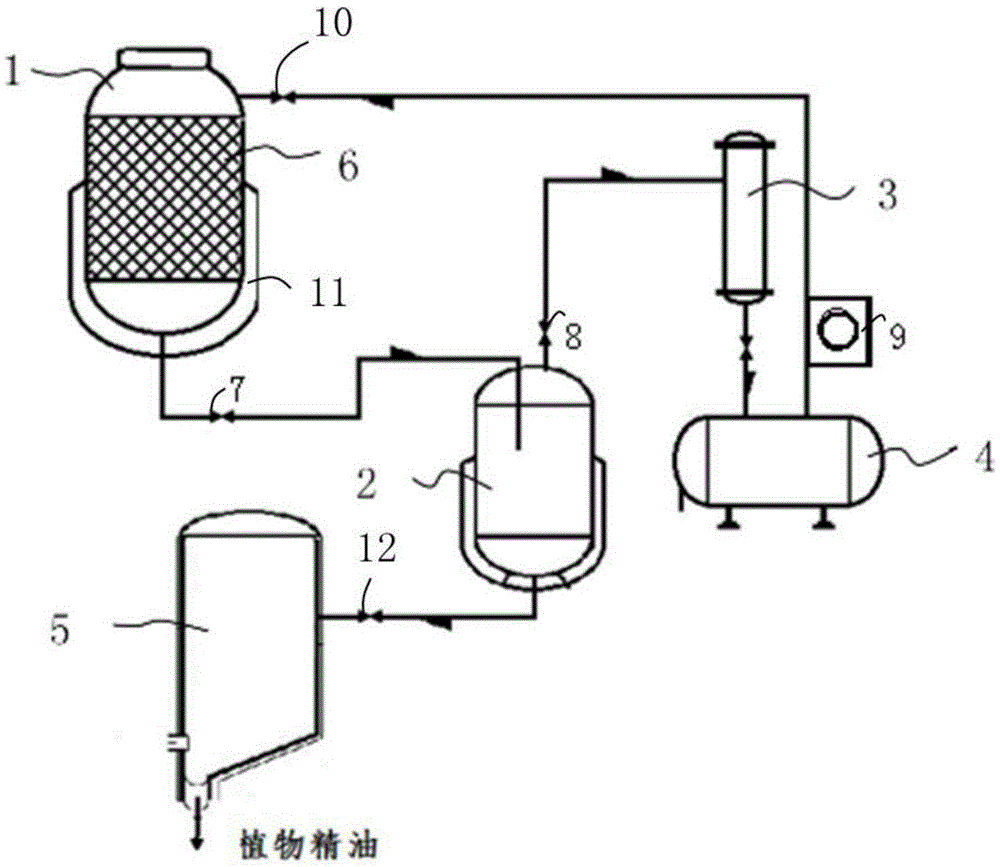

Microwave-assisted subcritical essential oil extracting method

InactiveCN105482897AUndamagedFast extraction rateEssential-oils/perfumesDistillation1,1,1,2-Tetrafluoroethane

The invention discloses a microwave-assisted subcritical essential oil extracting method. The microwave-assisted subcritical essential oil extracting method includes the steps that fresh plant tissues are frozen and then are smashed; 1,1,1,2-tetrafluoroethane is used as an extraction solvent and is led into the smashed plant tissues to perform microwave extraction; during microwave extraction, the extraction temperature is controlled to be 8-12 DEG C, the extraction pressure is controlled to be 0.8-6 Mpa, the microwave frequency is controlled to be 300-2400 MHZ, and the power is controlled to be 200-1200w; after a liquid phase in the system is separated out and microwave extraction is completed, the 1,1,1,2-tetrafluoroethane is recovered from the liquid phase, and the rest of the liquid phase is an essential oil stock solution; the essential oil stock solution is subjected to molecular distillation to obtain essential oil. By the adoption of the microwave-assisted subcritical essential oil extracting method, the essential oil free of any residual solvent can be obtained at lower temperature, the effective ingredients of the essential oil are not destroyed, and the natural quality of the essential oil can be kept to the most degree.

Owner:JIANGSU NAIQUE BIOLOGICAL ENG

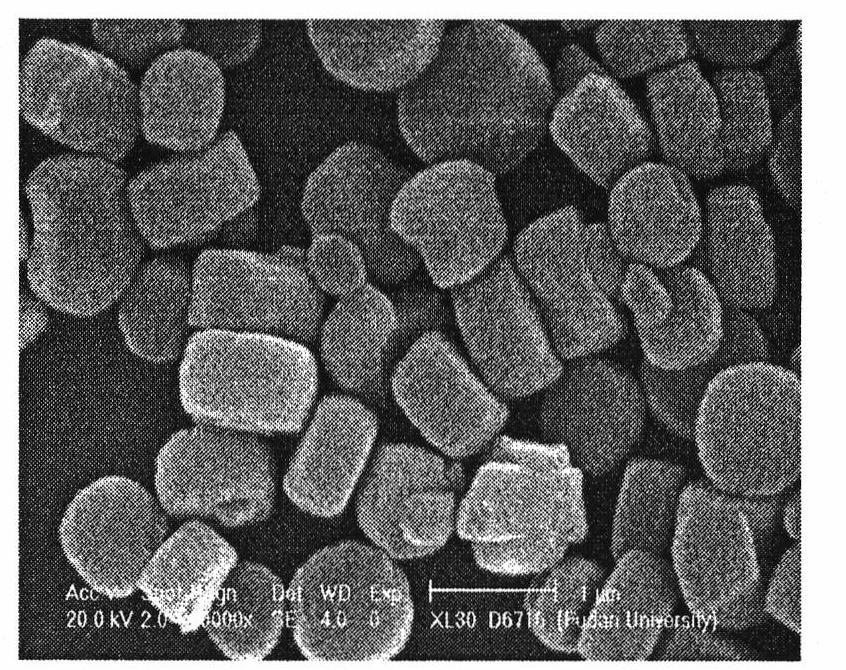

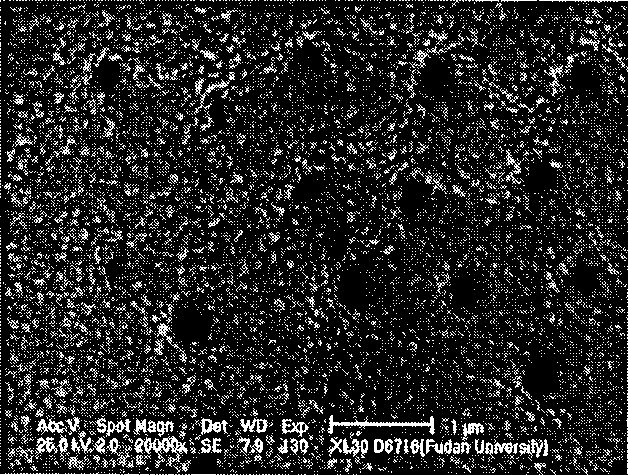

Process for preparing zeolite material with multi-class pore canal by zeolitizing diatomite

InactiveCN1346795AHigh zeolite contentUniformly enriched macroporous structureMolecular sieve catalystsAluminosilicate zeolite type-AMechanical stabilityColloid

A process for preparing zeolite with multi-class pore canal structure by zeolitizing diatomite features use of laminating technique and gas-solid crystal conversion technique. For the laminating technique, an electrostatic attraction is used to assemble the nano zeolite onto diatomite. For the gas-solid crystal conversion technique, the amorphous SiO2 is converted to zeolite without damage to the form and structure of diatomite. Its advantages are simple operation, high speed, rich macropores, environmentally friendly process and wide application range.

Owner:FUDAN UNIV

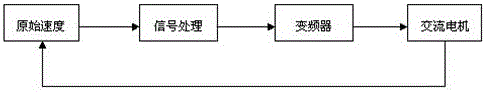

Device and method for shortening continuous tapping time interval of rolled steel production line

ActiveCN106670241ANo false signalAvoid sensor placement challengesRoll mill control devicesMetal rolling arrangementsProduction lineLow speed

The invention discloses a device and a method for shortening a continuous tapping time interval of a rolled steel production line, belongs to the technical field of rolled steel production line equipment and processes, and is used for shortening the continuous tapping time interval of the rolled steel production line. A heat metal detector is placed in front of a first rolling mill from the center line of a roller of the first rolling mill by a length of a whole section of steel blank; and steel tail signals monitored by the heat metal detector are used for replacing steel containing signals when engaging in the rolling mill. When the head part of the latter steel blank is rightly engaged in the first rolling mill, an alternating-current main motor of the first rolling mill starts to decelerate. The reasonable steel separation distance is guaranteed by dint of the continuously quickened rolling speed of a downstream frame, the low-speed continuous time and the low-speed rate setting. The safe steel separation is realized by using the first rolling mill as a steel separation point, so that the normal operation of subsequent key equipment is guaranteed, and the effects of shortening the steel blank rolling interval time, improving the production efficiency and largely reducing the energy consumption are achieved under the precondition of not influencing the production process.

Owner:张家口宣钢机电工程有限公司

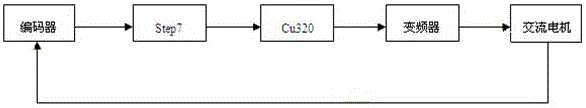

Ce-Zr-Al-based composite oxide rare earth oxygen-storage material and preparation method thereof

InactiveCN103084161AImprove high temperature anti-aging abilityHigh temperature anti-aging abilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAging resistanceCerium

The invention relates to a Ce-Zr-Al-based composite oxide rare earth oxygen-storage material and a preparation method thereof. The Ce-Zr-Al-based composite oxide rare earth oxygen-storage material is a composite oxide composed of cerium oxide, zirconium oxide, aluminum oxide and other rare earth oxides other than cerium oxide with a weight percentage of: 15-65% of cerium oxide, 12-55% of zirconium oxide, 5-50% of aluminum oxide, 4-10% of other rare earth oxides other than cerium oxide. Compared with conventional products, the interaction between alumina and Ce-Zr-based composite oxide is strengthened through the surface treatment for alumina, and the homogeneity between alumina and Ce-Zr-based composite oxide is adequately guaranteed. Through selection and compounding of a precipitant and controlling the precipitation end, the yield of the product is ensured. By adding a surface-treating agent, aperture and pore volume of the precipitate precursor are ensured to be large after firing, and high temperature aging resistance of the material is improved.

Owner:上海华明高纳稀土新材料有限公司

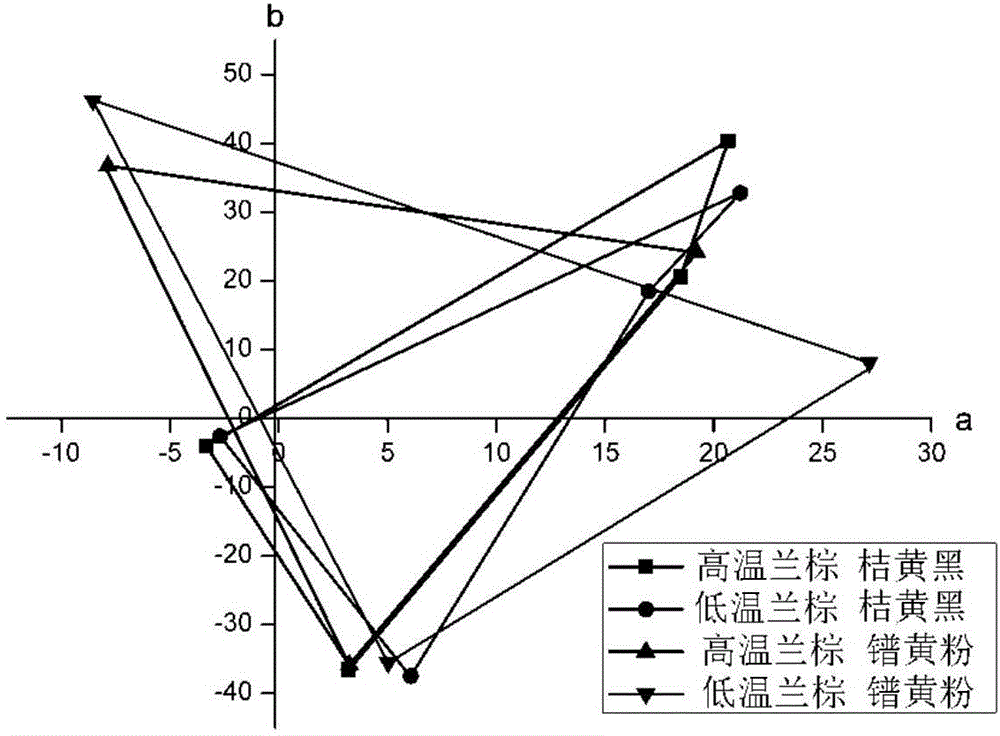

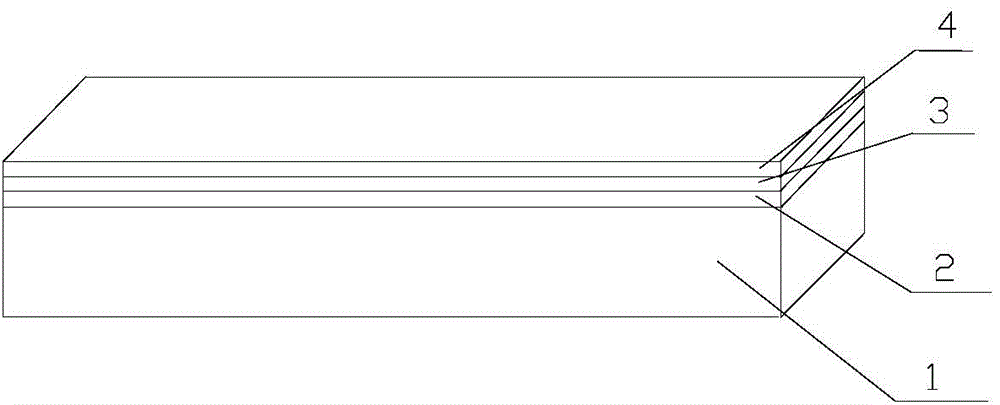

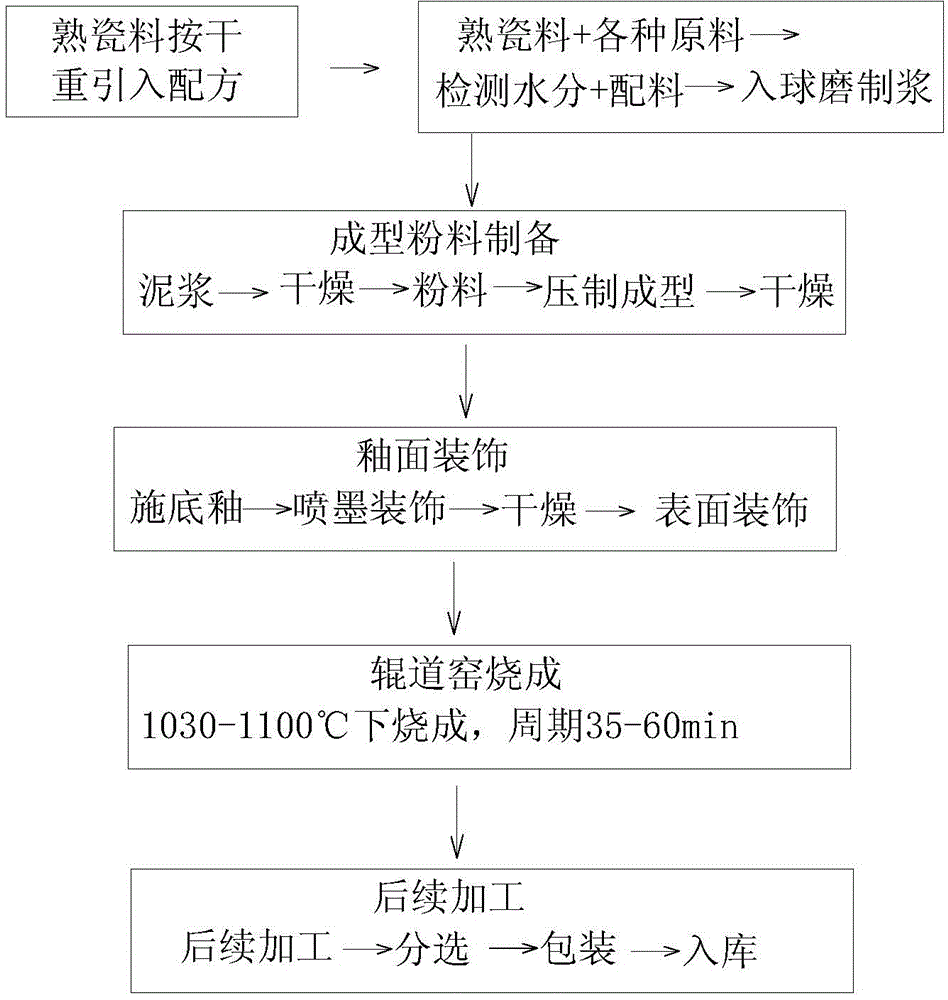

Wide-color-gamut inkjet glaze decorated ceramic floor tile and production process thereof

The invention relates to the technical field of ceramic tiles, and in particular relates to a wide-color-gamut inkjet glaze decorated ceramic floor tile and a production process thereof. A floor tile billet comprises the following components in parts by weight: 40-75 parts of a cooked porcelain material, 0-38 parts of porcelain stone, 20-30 parts of clay and 0-5 parts of a mineralizing agent; and a production method comprises the following steps: firstly performing conventional processes such as wet-process ball-milling, spray drying and dry-pressing molding on architectural ceramics to prepare a billet, by taking titanium series engobe as a ground glaze, combining engobe with a low-temperature ink-jet ink composition of interior wall tiles to perform inkjet decoration, and performing firing in a roller hearth kiln under the conditions that the firing temperature is 1030-1100 DEG C and the firing cycle is 35-60min to prepare a finished product, wherein the water absorption rate of the finished product is 0-3%, and the quality of the product can meet the national standard requirements. The wide-color-gamut inkjet glaze decorated ceramic floor tile disclosed by the invention has the beneficial effects that energy conservation and emission reduction can be achieved, and the firing temperature can be reduced by 50-100 DEG C compared with that of the same category of products; the technology bottleneck that titanium series opacified engobe can be yellowed when being applied in the floor tiles in a conventional high-temperature process can be effectively solved; and the color gamut range of an inkjet decorative layer of a glaze decorated ceramic tile can be significantly broadened.

Owner:JIANGXI HEMEI CERAMICS +1

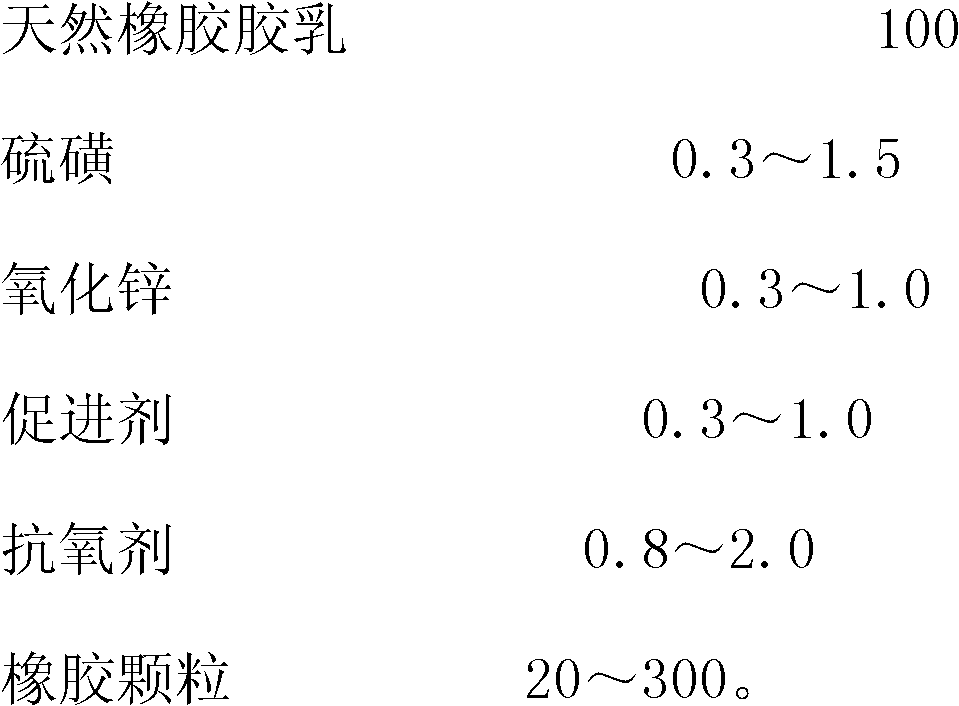

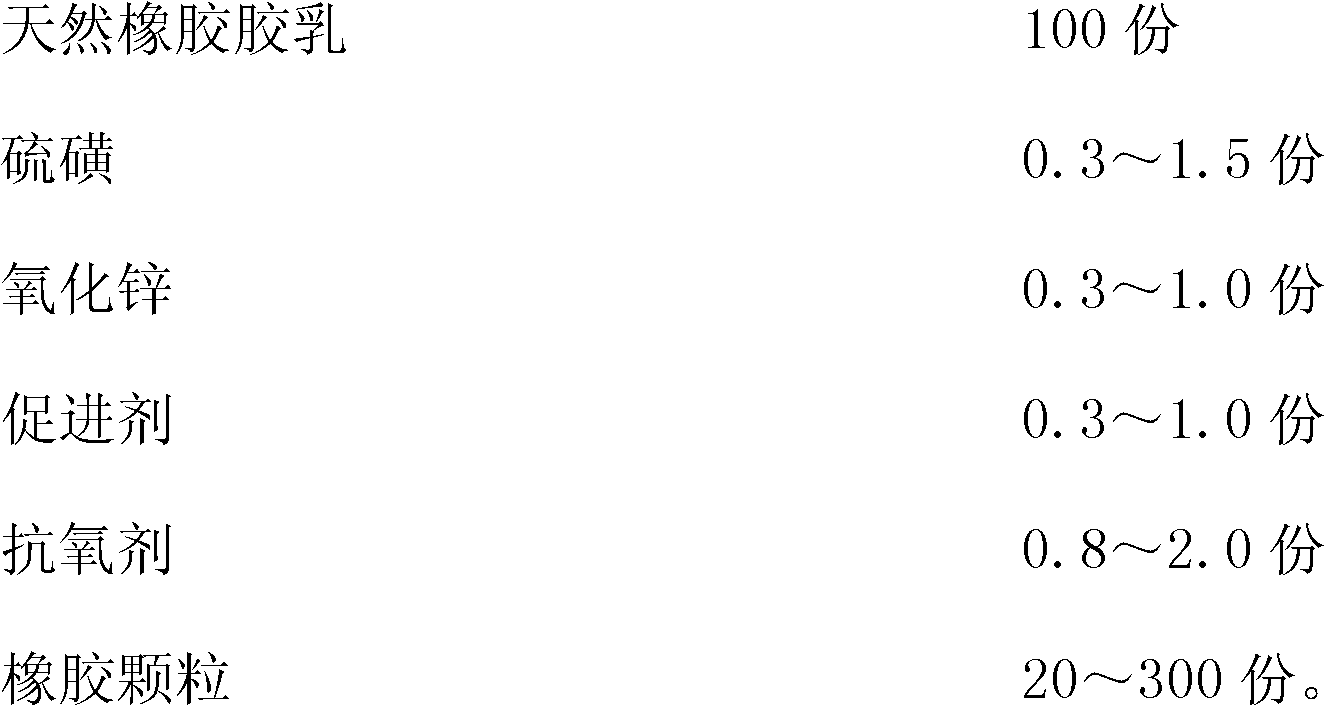

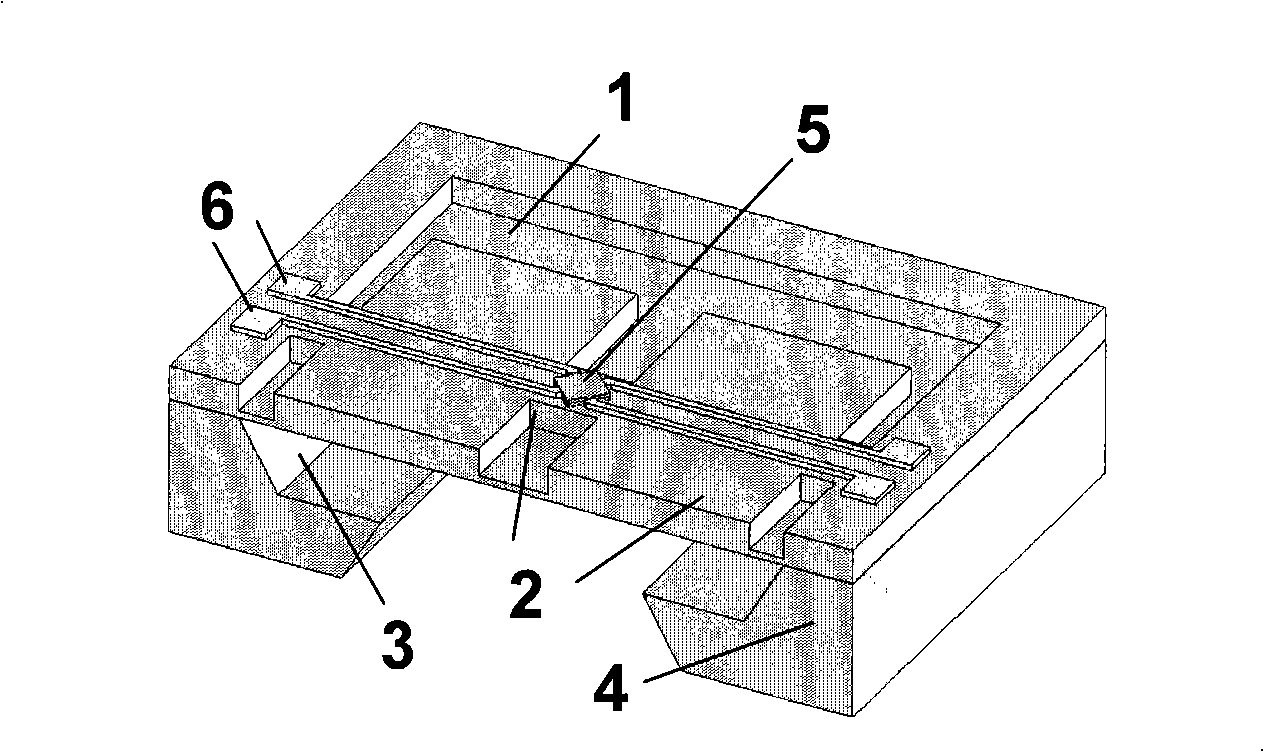

Antiskid rubber gloves and processing method thereof

InactiveCN102488340AIncrease coefficient of frictionImprove grip performanceCoatingsProtective garmentPolymer scienceSulfur

The invention discloses a pair of antiskid rubber gloves and a processing method thereof. Each antiskid rubber glove comprises rubber latex forming a glove body and antiskid rubber latex forming an antiskid layer, wherein the antiskid rubber latex consists of natural rubber latex, sulfur, zinc oxide, an accelerator, an antioxidant and rubber particles. According to the antiskid rubber gloves disclosed by the invention, rubber particles are arranged on the outer surfaces of the gloves in a processing course of the gloves so as to increase the friction coefficient of the gloves, enhance the catching power of the gloves and largely improve the antiskid effect of the gloves; in addition, the gloves have no special requirement on production moulds and equipment and only the traditional production mould is needed in a production process, therefore the production input is low and the production cost of enterprises can be reduced greatly. The gloves processed with the processing method disclosed by the invention have the advantages of good antiskid effect, capability of solving the problem that defective holes possibly appear on the gloves caused by mould bumps in the production process and high yield; and the processing method disclosed by the invention has the advantage of simple operation.

Owner:ZHENJIANG SUHUI LATEX PROD

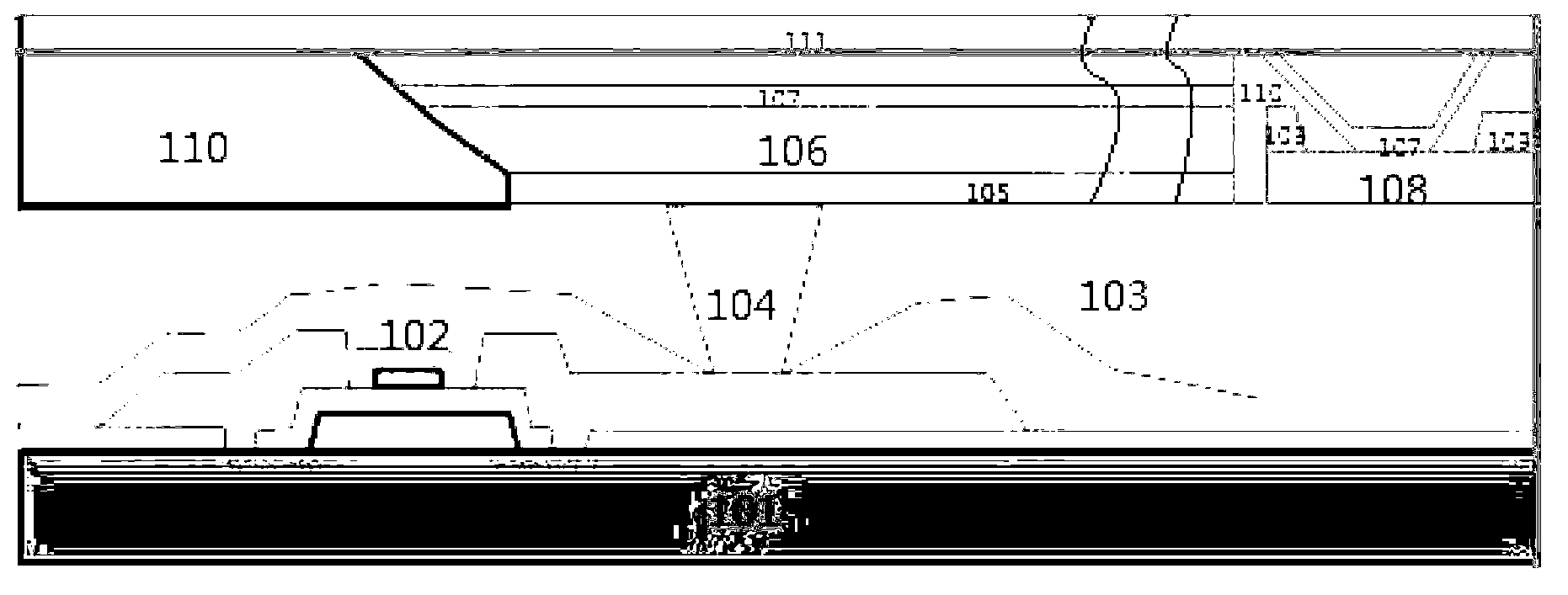

Silicon pressure transducer chip and method based on silicon-silicon linking and silicon-on-insulating layer

InactiveCN101271028AReduce residual stressImplement overvoltage protectionTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesLinearitySilicon on insulator

The invention relates to a pressure sensor chip based on silicon direction bonding and silicon on insulator and a manufacturing method thereof, and belongs to the field of sensor chips. The invention is characterized in that a shallow slot and a gas port on a supporting silicon wafer are formed through anisotropy corrosion, and appropriate shallow slot depth obtained by controlling the corrosion time can realize over pressure protection of parts. A silicon direct bonding technology bonds the supporting wafer and a reversed SOI wafer, realizes a beam-membrane structure on the SOI after lapping and polishing to improve the sensitivity and linearity of the parts; manufactures force sensing resistance elements on the processed beam; adopts the oxidation buried layer of the SOI to solve insulation and isolation of the sensing elements and elastic elements; and improves the long-termed reliability and adaptability under high temperature of the parts. The SOP high-sensitivity pressure sensor chip based on the bonding technology has the advantages of controllable process, excellent repeatability and high finished product rate.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

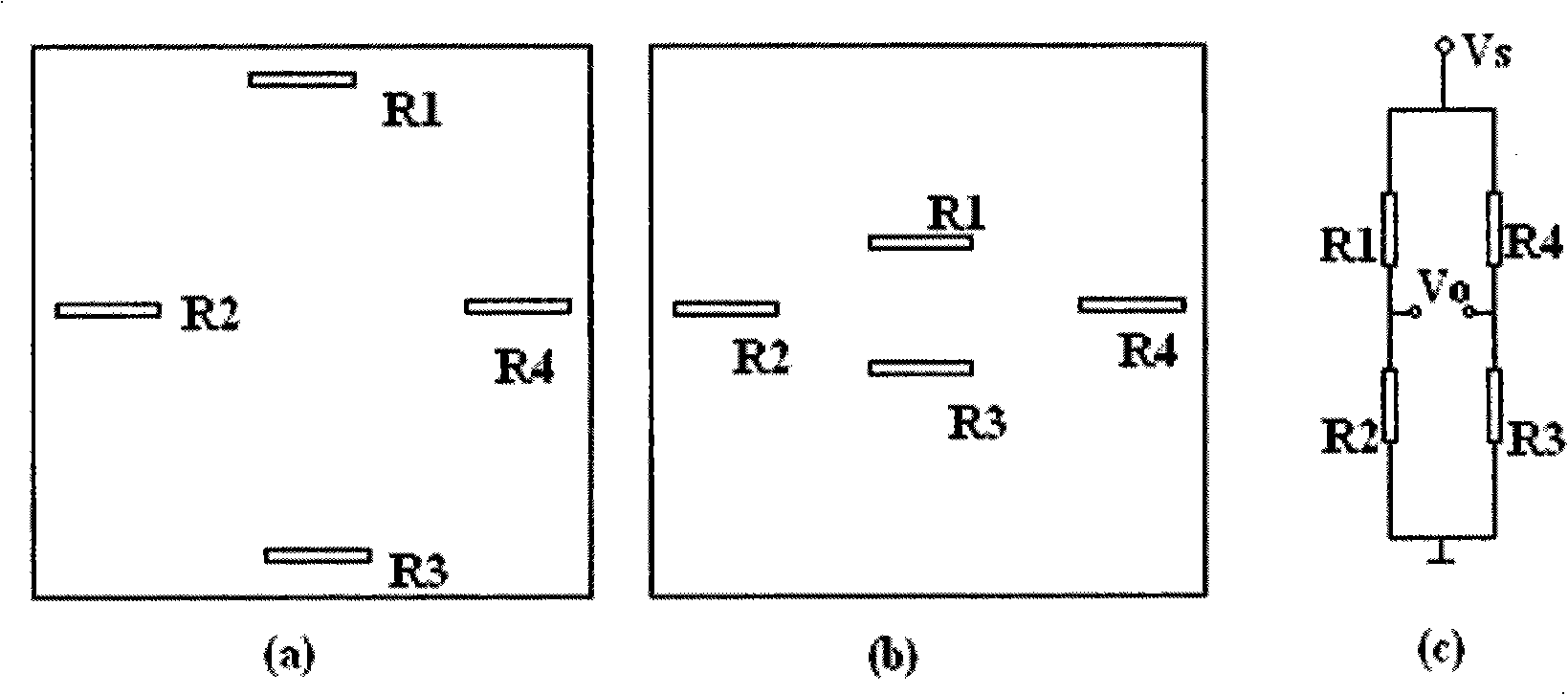

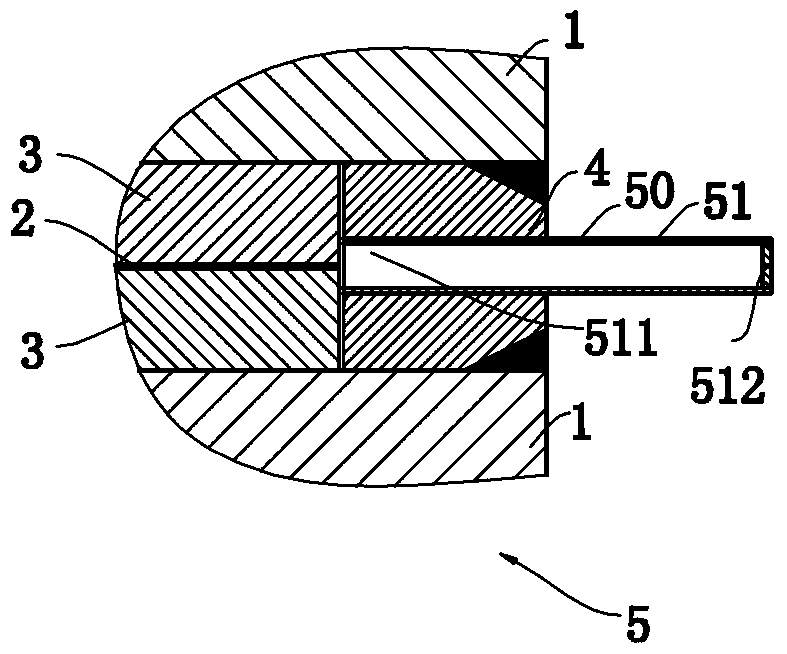

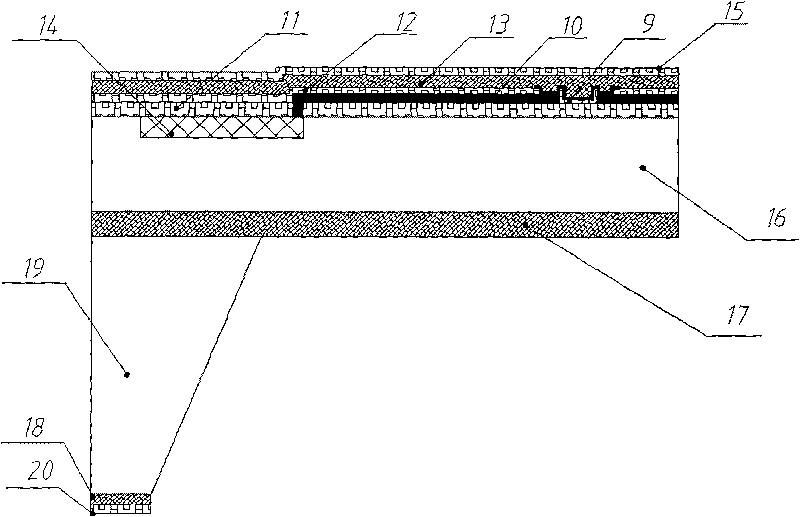

Density sensor chip based on micro electro mechanical system technology and preparation method thereof

InactiveCN101718667ASolve the shortcomings of low sensitivityGuaranteed YieldTelevision system detailsImpedence networksMicroelectromechanical systemsTemperature resistance

The invention discloses a cantilever beam type density sensor chip based on a micro electro mechanical system technology and a preparation method thereof. The chip adopts a trapezoid silicon micro cantilever beam structure based on a vibrating principle, a lead wire adopts a Ti-Pt-Au beam type lead wire, and a Ti-Pt-Au beam type fly wire is added. By adopting the trapezoid structure, the density sensor chip has the advantage of high sensitivity; by adopting the Ti-Pt-Au beam type lead wire, the density sensor chip has the advantages of corrosion resistance, high temperature resistance, low calorific value and the like compared with a traditional aluminum lead wire; and by adopting the Ti-Pt-Au fly wire, single input and single output of the lead wire are realized, thereby guaranteeing that currents inside the lead wire are equal everywhere, and further ensuring uniform distribution of magnetic field force in a whole MEMS vibrating cantilever beam chip after placing the lead wire into a magnetic field.

Owner:XI AN JIAOTONG UNIV

Active organic light-emitting diode (OLED) display device and manufacturing method thereof

ActiveCN103258968AImprove flatnessReduce contact resistanceSolid-state devicesSemiconductor/solid-state device manufacturingElectrical resistance and conductanceDisplay device

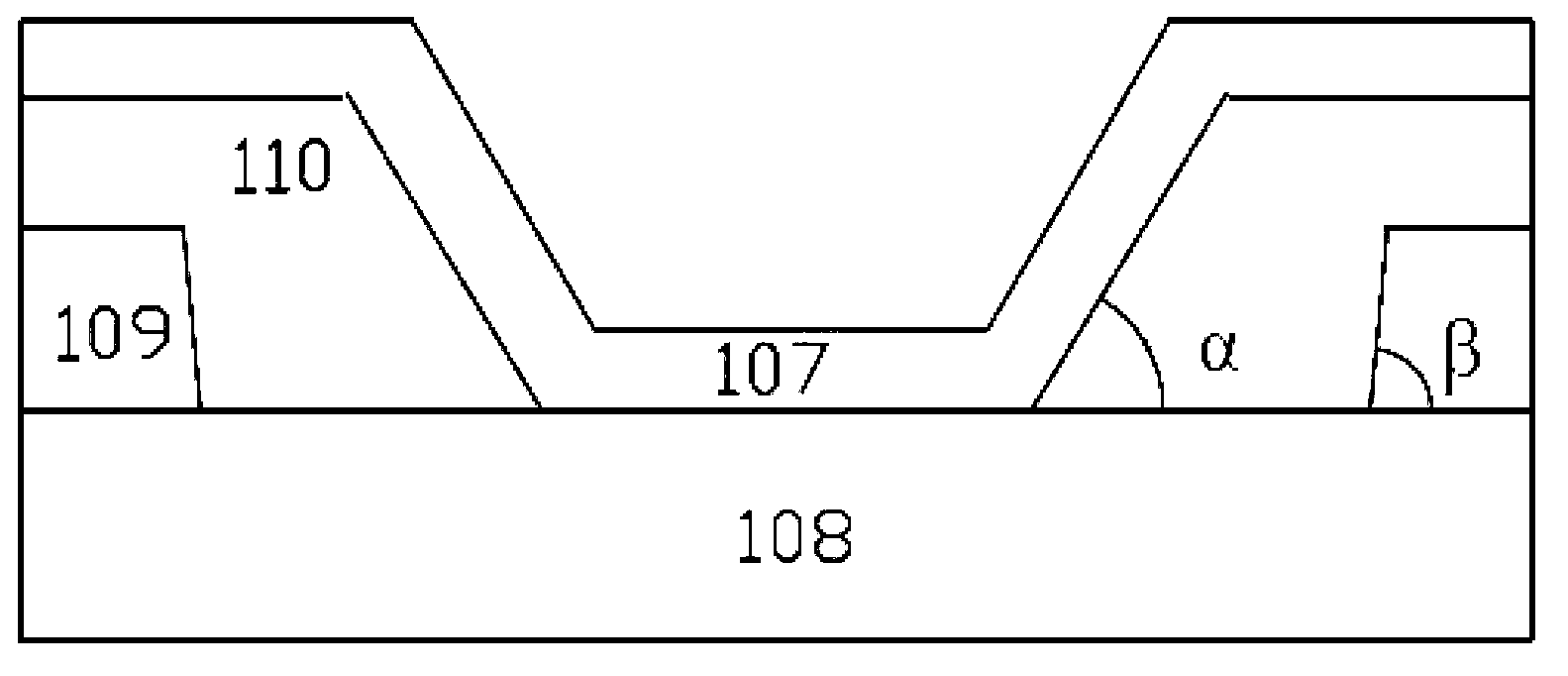

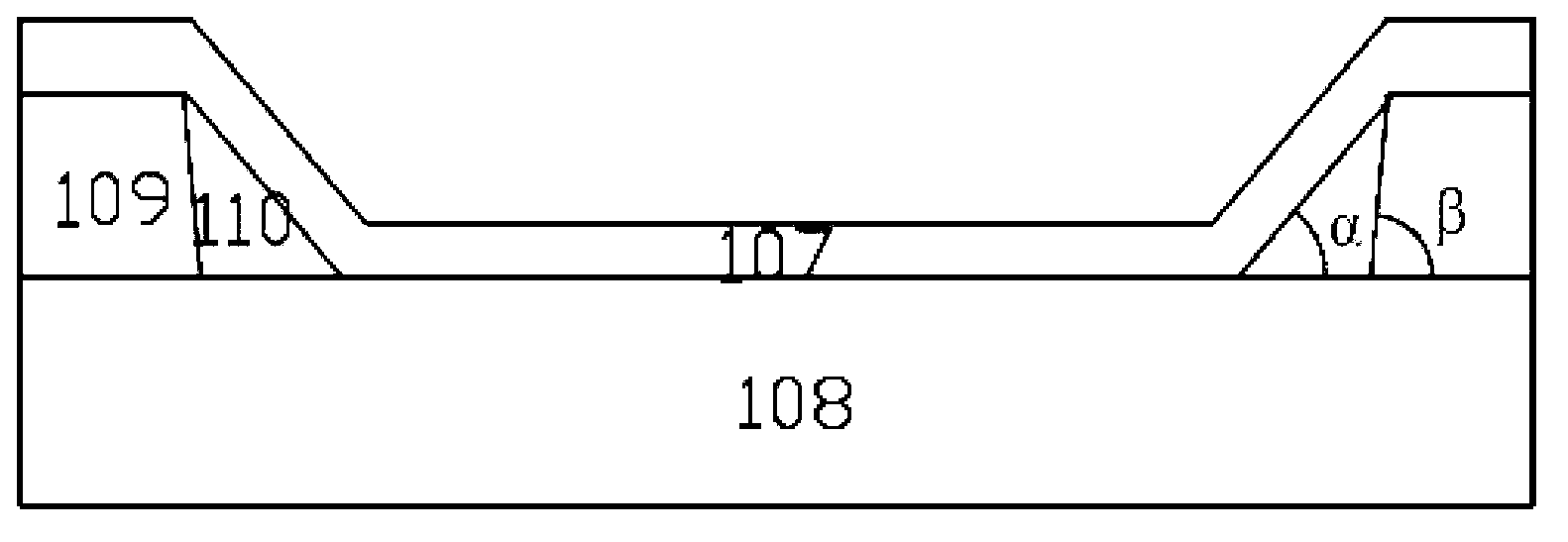

The invention provides an active organic light-emitting diode (OLED) display device and a manufacturing method thereof. The active OLED display device comprises a display area and a non-display area. The non-display area comprises a negative electrode power line, wherein an insulating layer is arranged on the negative electrode power line, a planarization layer further covers the insulating layer and extends to and covers the negative electrode power line, and a gradient included angle alpha formed by the planarization layer and the contact surface of the negative electrode power line is smaller than a gradient included angle beta formed by the insulating layer and the contact surface of the negative electrode power line, so transition is flatly and slowly formed from a negative electrode to the negative electrode power line, smoothness from the negative electrode to the contact area of the negative electrode power line is increased, and contact resistance is effectively reduced. The planarization layer covers a non-pixel area of a positive electrode, and the thickness of the planarization layer is larger than or equal to the sum of the thickness of the positive electrode, the thickness of an organic functional layer and the thickness of the negative electrode, so a pixel area can be protected against scratching, the rate of finished products of the display device is effectively guaranteed, a manufacturing process is simple, and the process is easy to achieve.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT

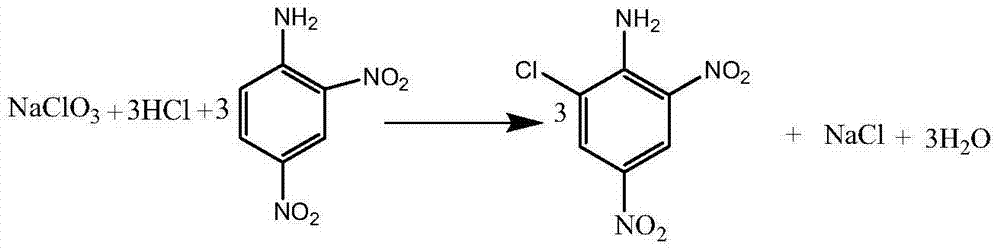

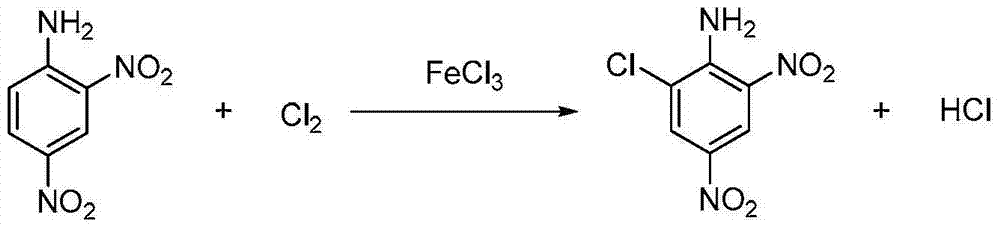

Clean production process of 6-chloro-2,4-dinitroaniline

ActiveCN103539680AFast responseLess side effectsOrganic compound preparationAmino compound preparationChemistryMother liquor

The invention discloses a clean production process of 6-chloro-2,4-dinitroaniline. The clean production process of 6-chloro-2,4-dinitroaniline comprises the following steps: 1, dispersing 2,4-dinitroaniline into hydrochloric acid solution for pulping, then introducing chlorine gas into the solution for reacting, and thus obtaining intermediate reaction solution; and 2, adding the intermediate reaction solution obtained in the step 1 into sodium chlorate solution for reacting, after the reaction is completed, processing the reaction solution to obtain the 6-chloro-2,4-dinitroaniline and mother solution, and returning the mother solution to the step 1 to serve as the hydrochloric acid solution. According to the production process, the chlorine gas and the sodium chlorate are sequentially employed as chloride agents for chlorinating in steps, so that the product purity and yield are improved and the cost of material is reduced; and the quantity of hydrochloric acid after the reaction is completed is kept stable basically, so that the mother solution is convenient to recycle for use and the pollution to environment is reduced.

Owner:浙江大井化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com