Patents

Literature

3689 results about "Electric resistivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrical resistivity is a measure of a material’s property to oppose the flow of electric current. This is expressed in Ohm-meters (Ω⋅m).

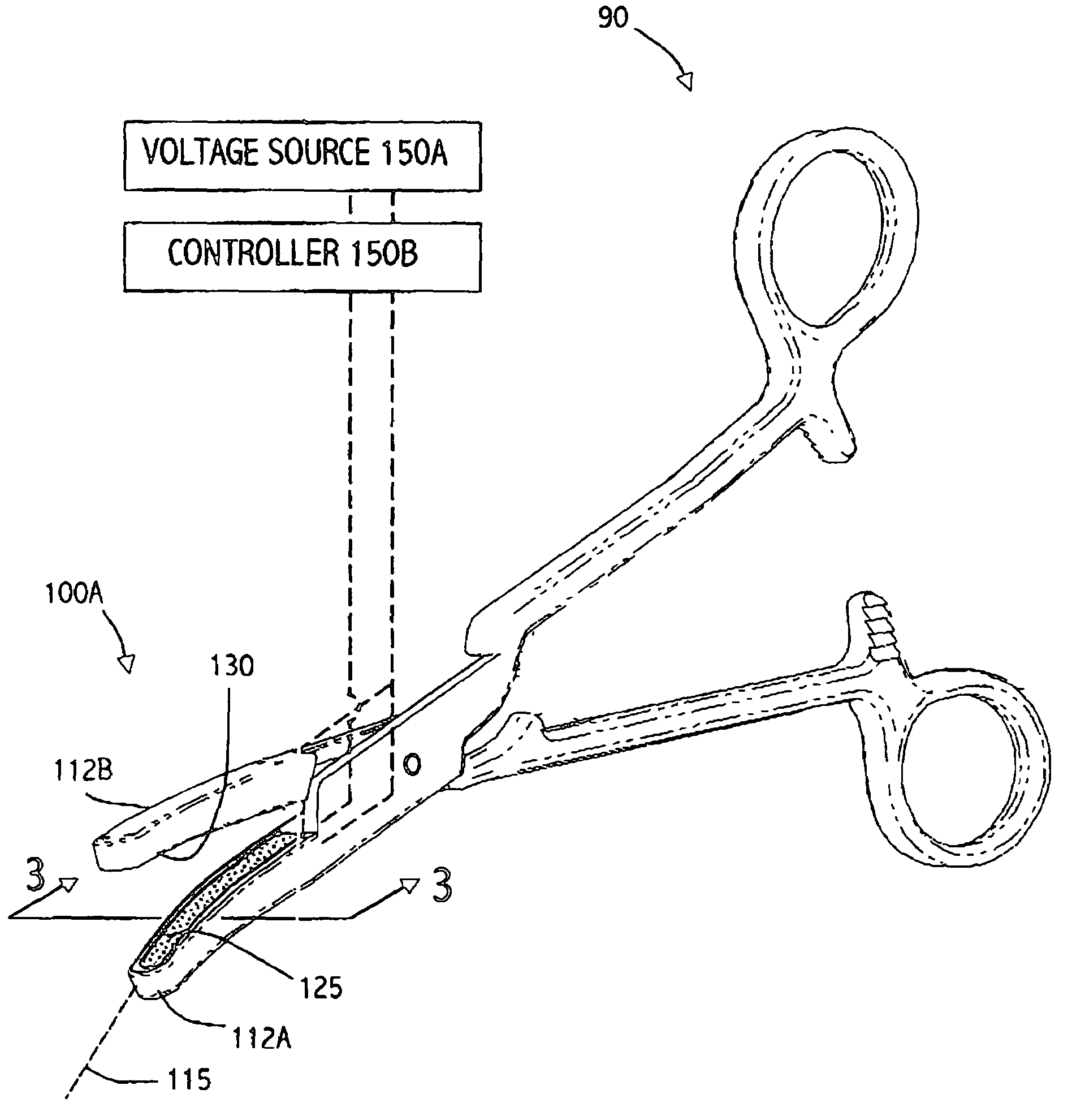

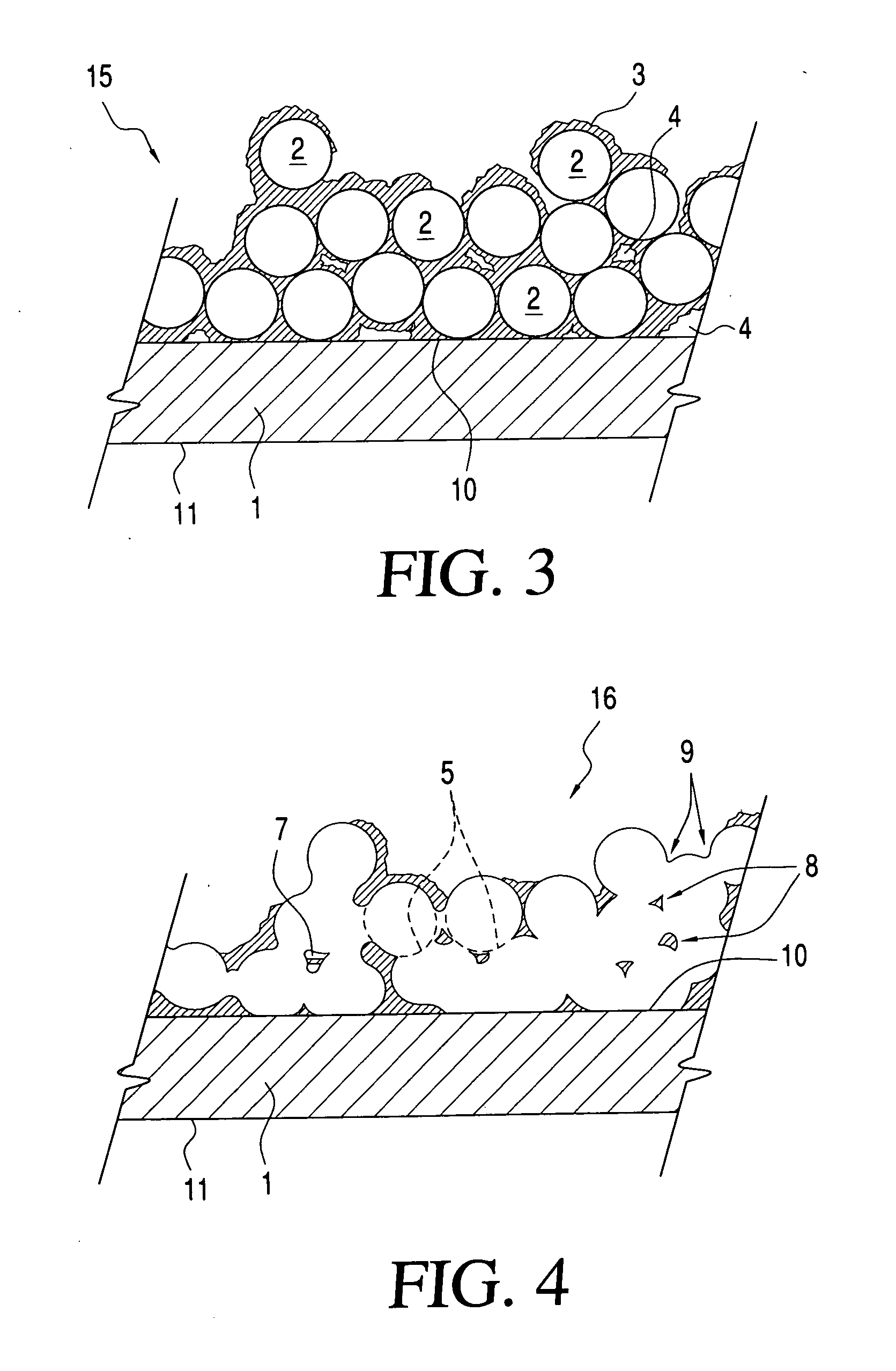

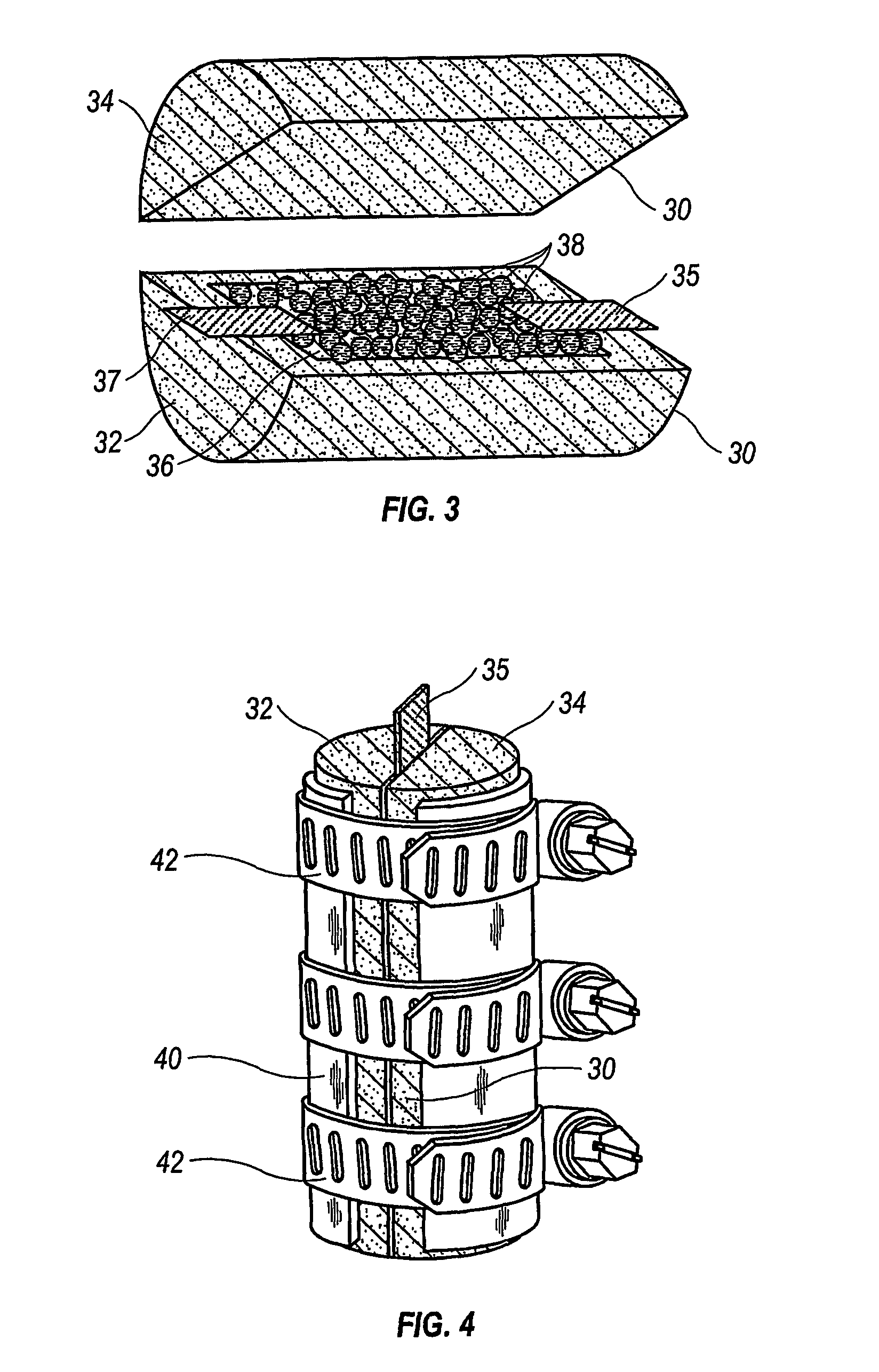

Electrosurgical probe and method of use

ActiveUS7169146B2Reduce the temperatureQuick changeSurgical instruments for heatingSurgical forcepsElectrical resistance and conductanceVolumetric Mass Density

An electrosurgical instrument that allows precise modulation of active Rf density in an engaged tissue volume. The working end of the instrument has a tissue-contacting surface of a conductive-resistive matrix that is variably resistive depending on its temperature. The matrix comprises a positive temperature coefficient (PTC) polymeric material hat exhibits very large increases in resistivity as any local portion increases beyond a selected temperature. In a method of use, the polymeric PTC material senses the temperature of engaged tissue in a manner akin to pixel-by-pixel sensing and thereby changes its resistance in a corresponding pixel-by-pixel manner. The instrument further carries cooling means to cause accelerated thermal relaxation of the PTC matrix during use to make the engagement surface highly responsive to temperature changes that in turn alter the matrix between being electrically conductive and electrically resistive.

Owner:ETHICON ENDO SURGERY INC

Electro-optic display and adhesive composition for use therein

InactiveUS6657772B2Non-macromolecular adhesive additivesStatic indicating devicesDisplay deviceElectric resistivity

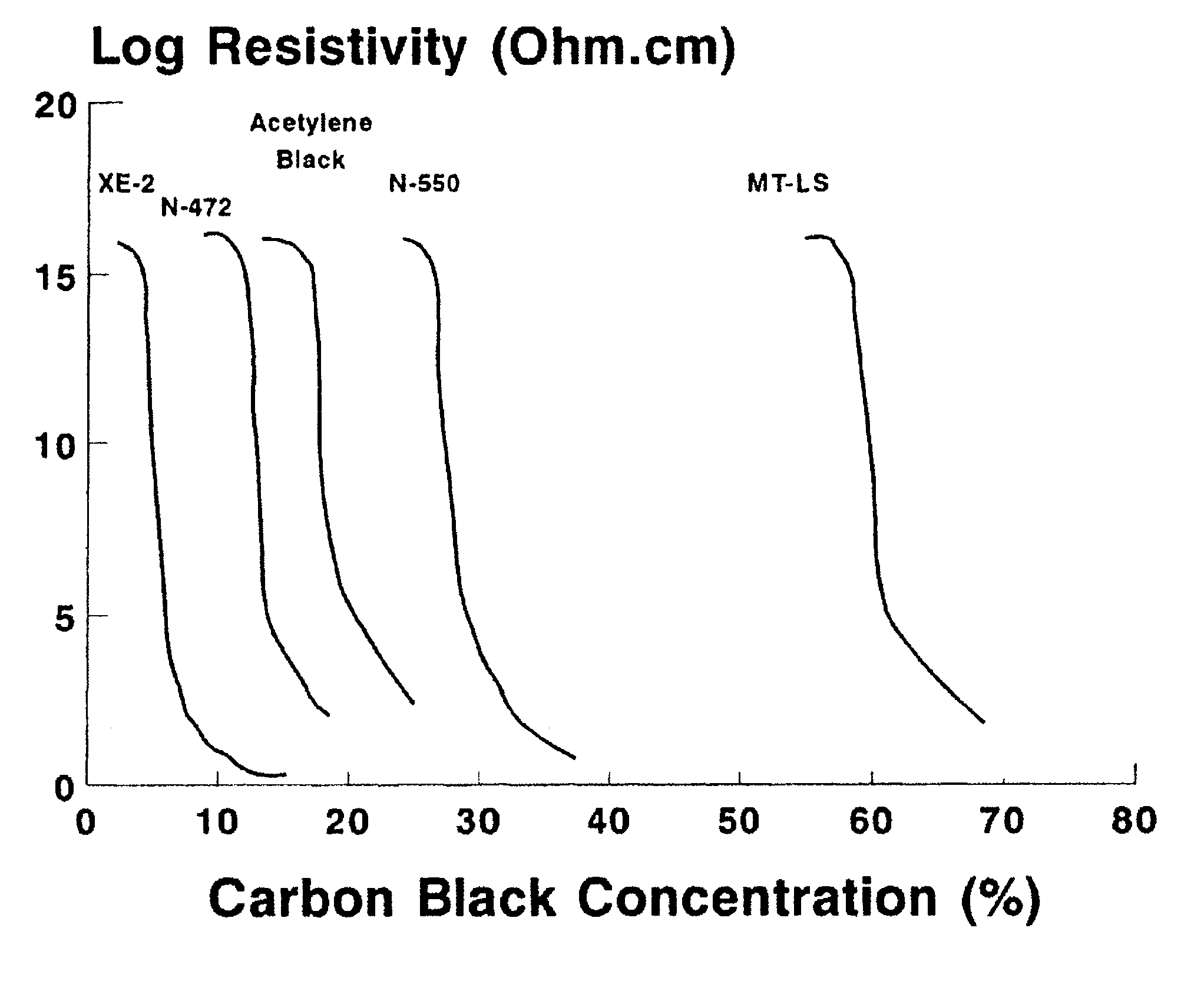

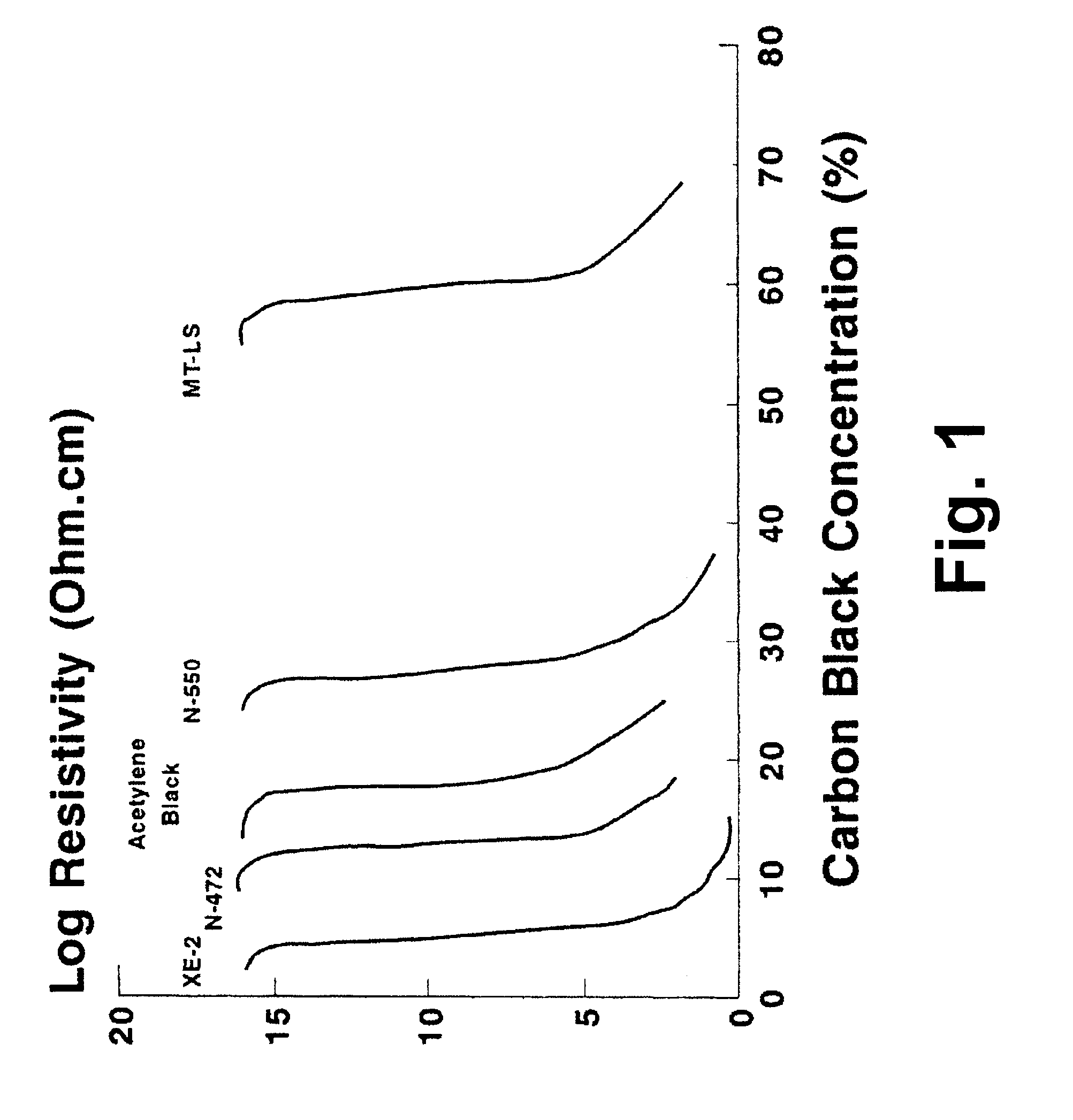

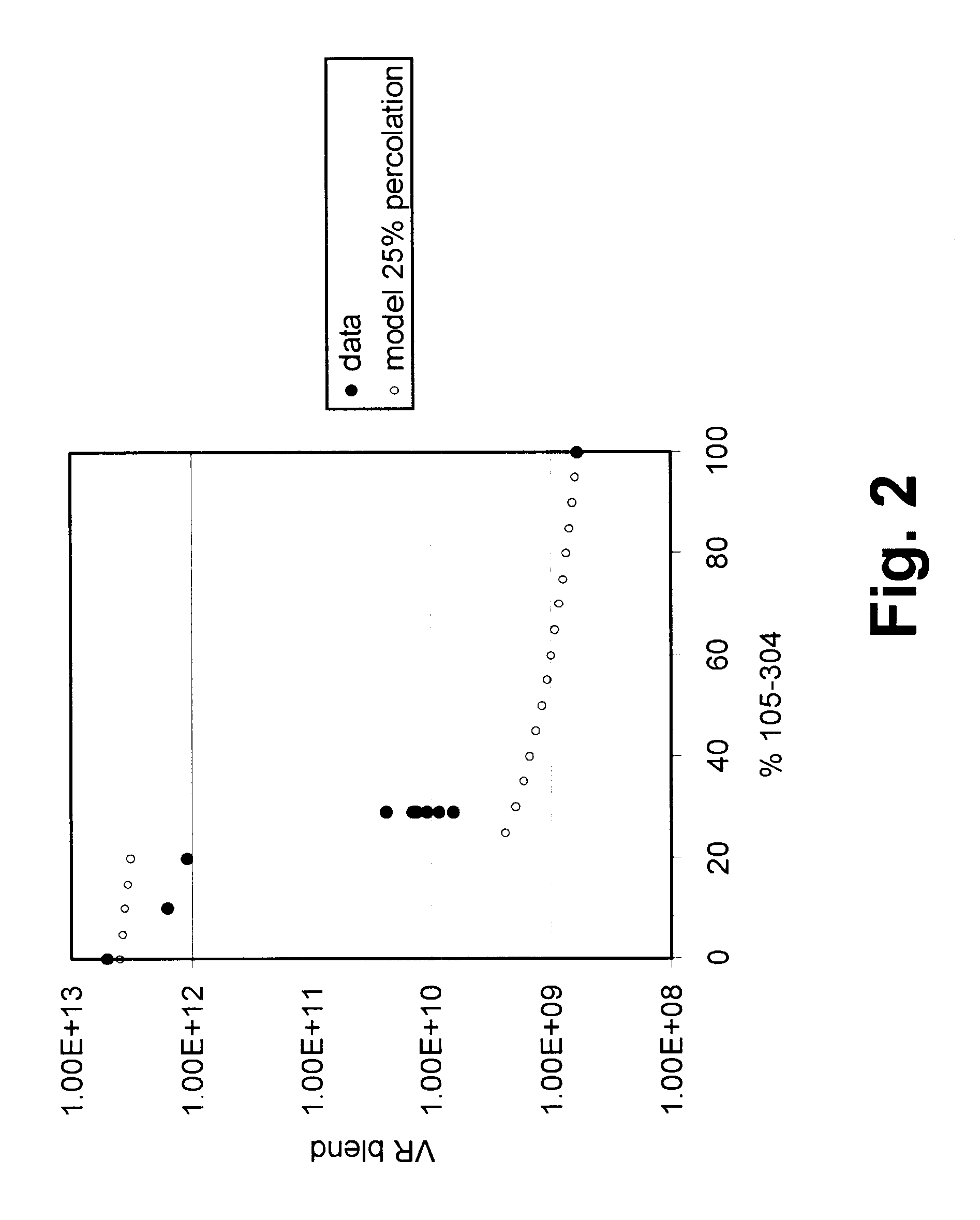

An electro-optic display comprises first and second substrates, and an adhesive layer and a layer of electro-optic material disposed between the first and second substrates. The adhesive layer has a volume resistivity in the range of about 10<9 >to about 10<11 >ohm cm and comprises a mixture of an adhesive material having a volume resistivity of at least about 5x10<11 >ohm cm and a filler having a volume resistivity not less than about 10<7 >ohm cm, the filler being present in the mixture in a proportion above its percolation threshold in the adhesive material.

Owner:E INK CORPORATION

Printable electrical conductors

An electrical conductor formed from one or more metallic inks. The electrical conductor comprises a network of interconnected metallic nodes. Each node comprises a metallic composition, e.g., one or more metals or alloys. The network defines a plurality of pores having an average pore volume of less than about 10,000,000 nm3. The electrical conductors advantageously have a high degree of conductivity, e.g., a resistivity of not greater than about 10× the resistivity of the (bulk) metallic composition, which forms the individual nodes.

Owner:CABOT CORP

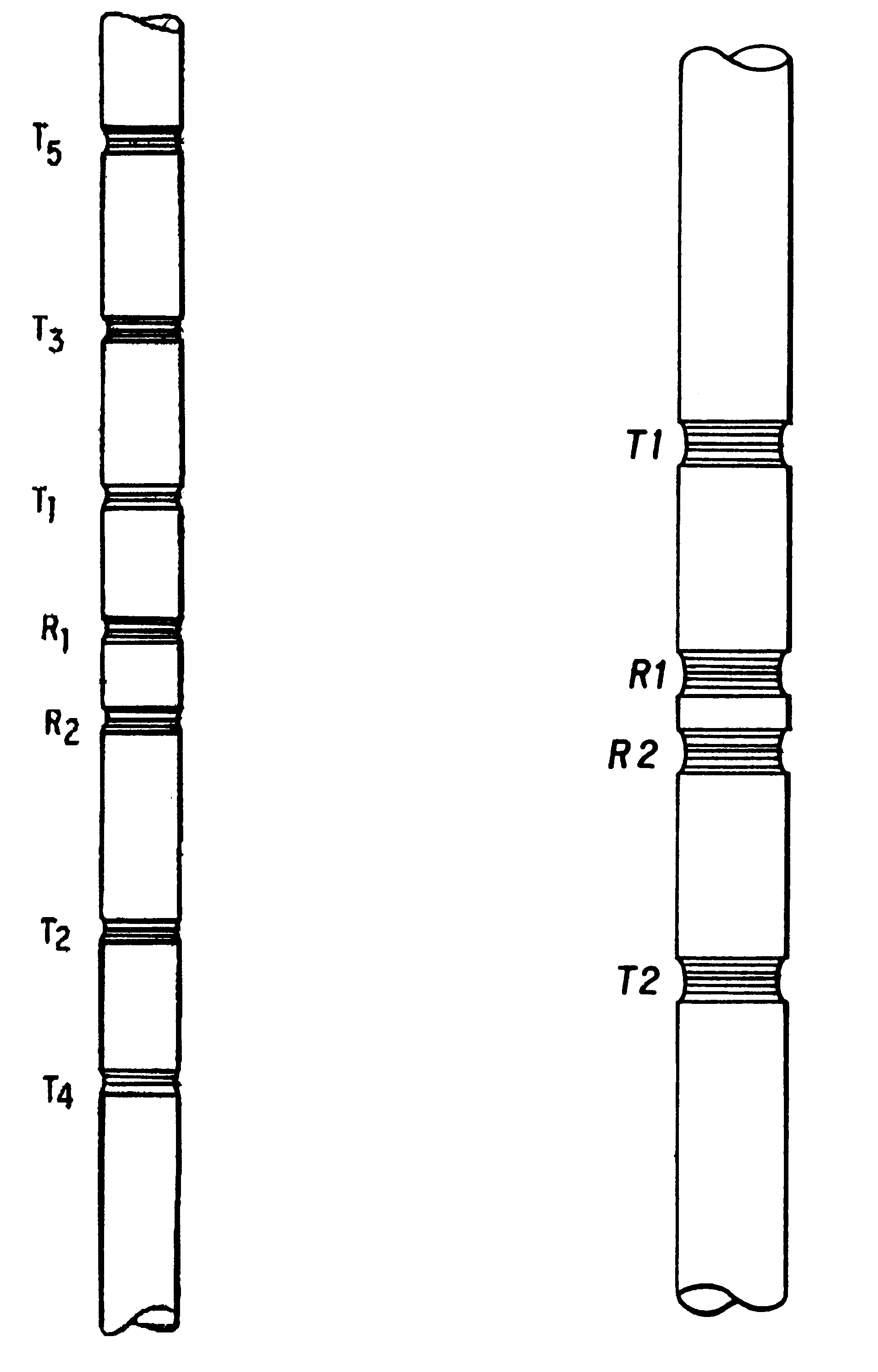

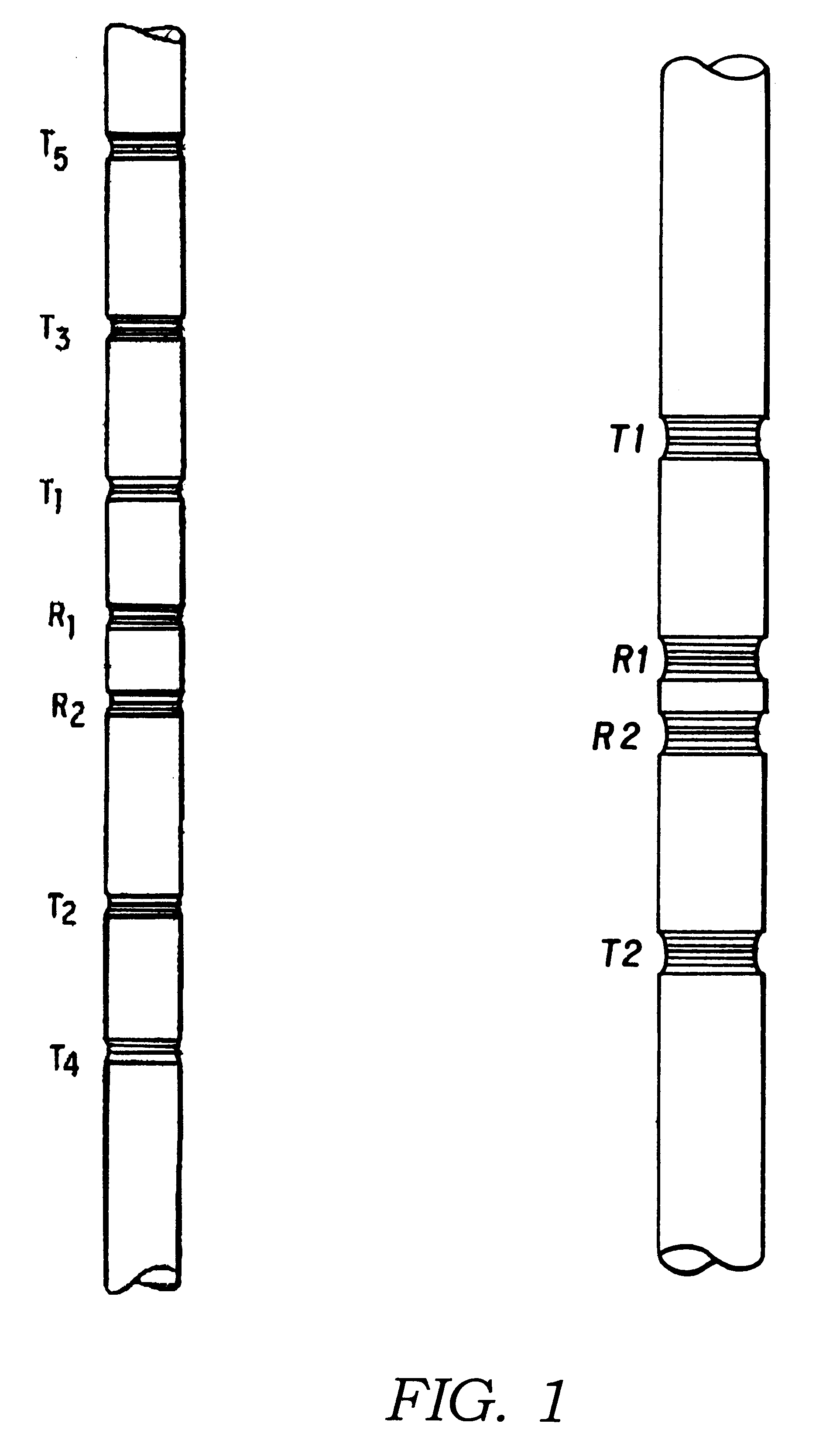

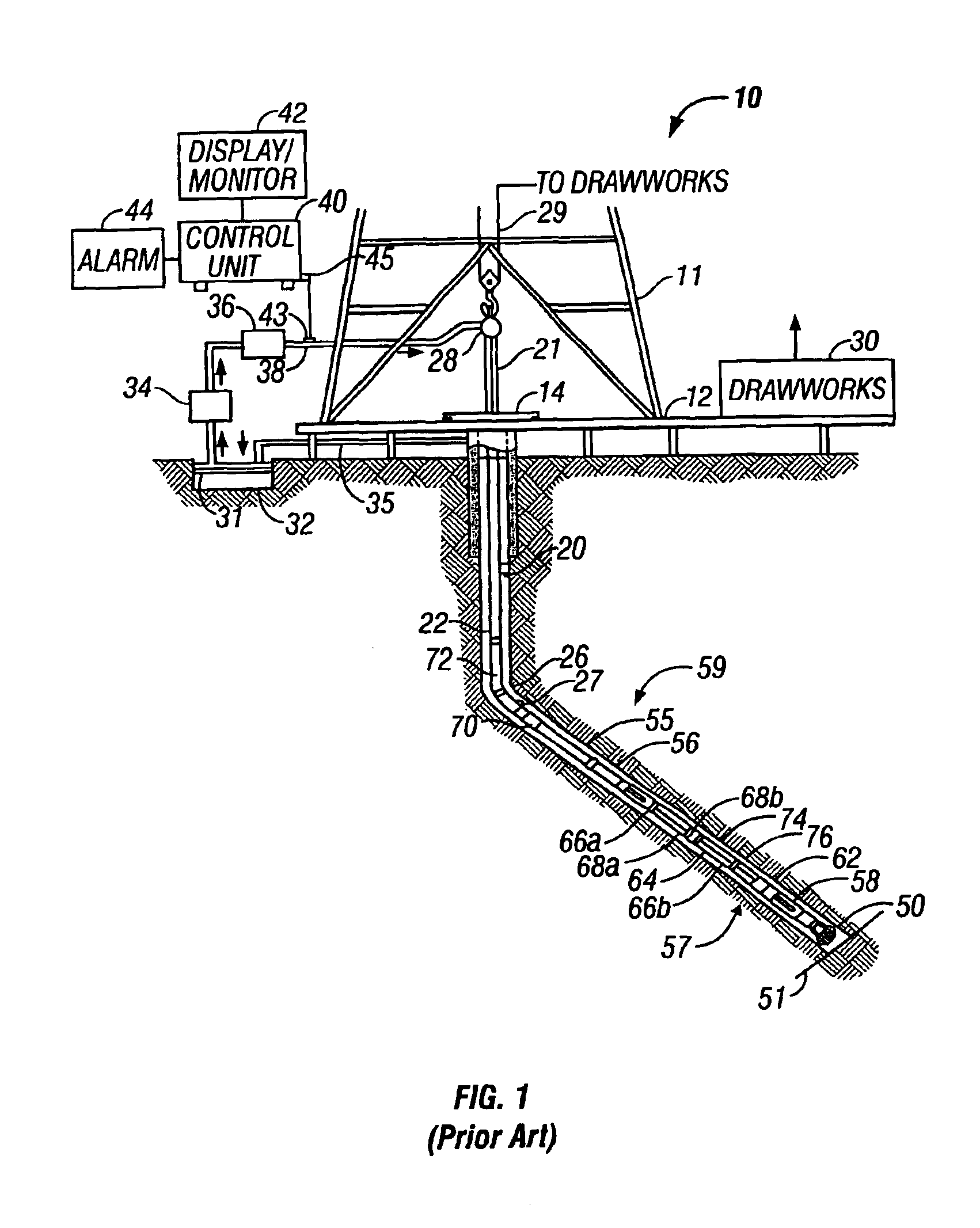

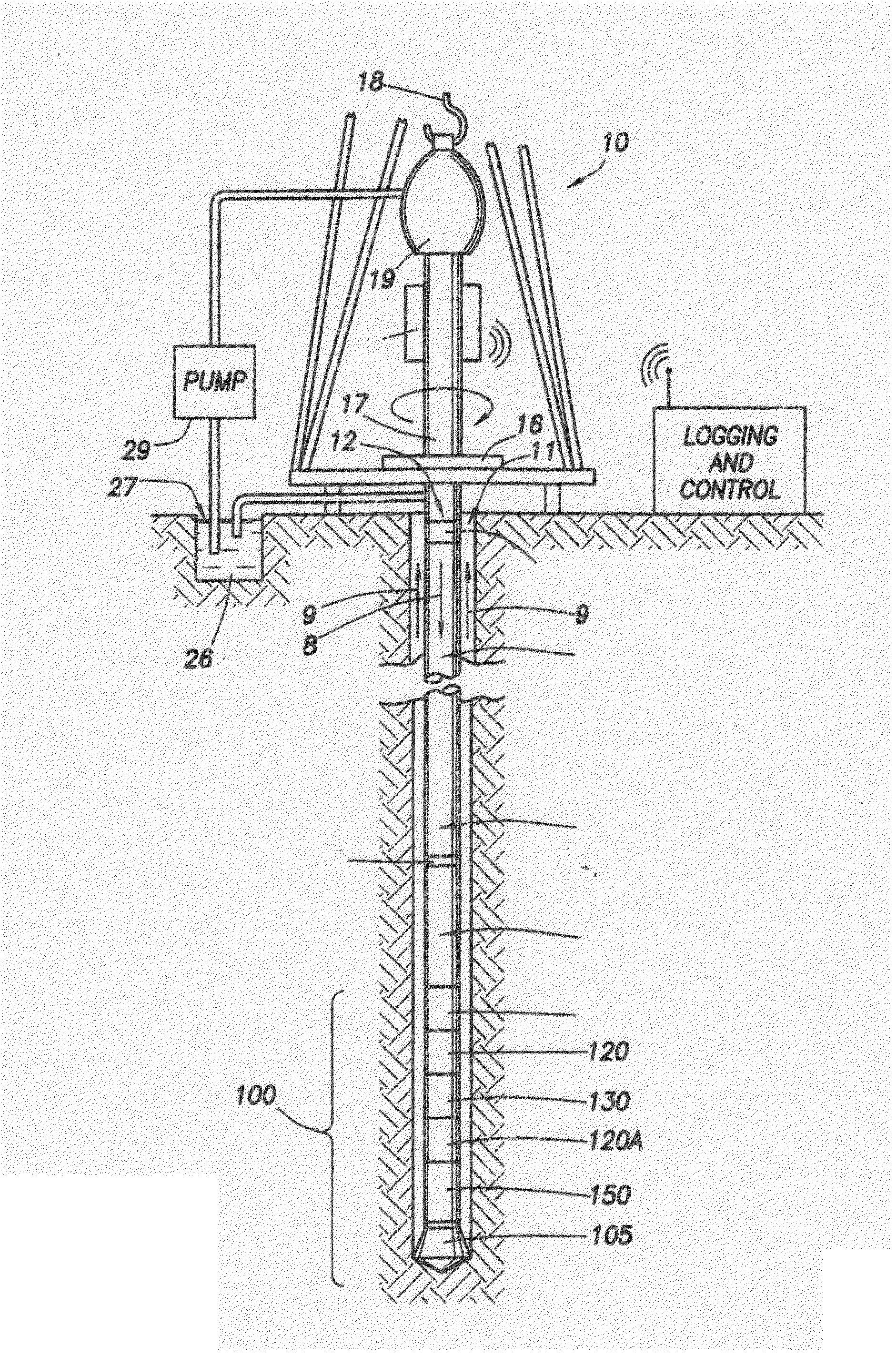

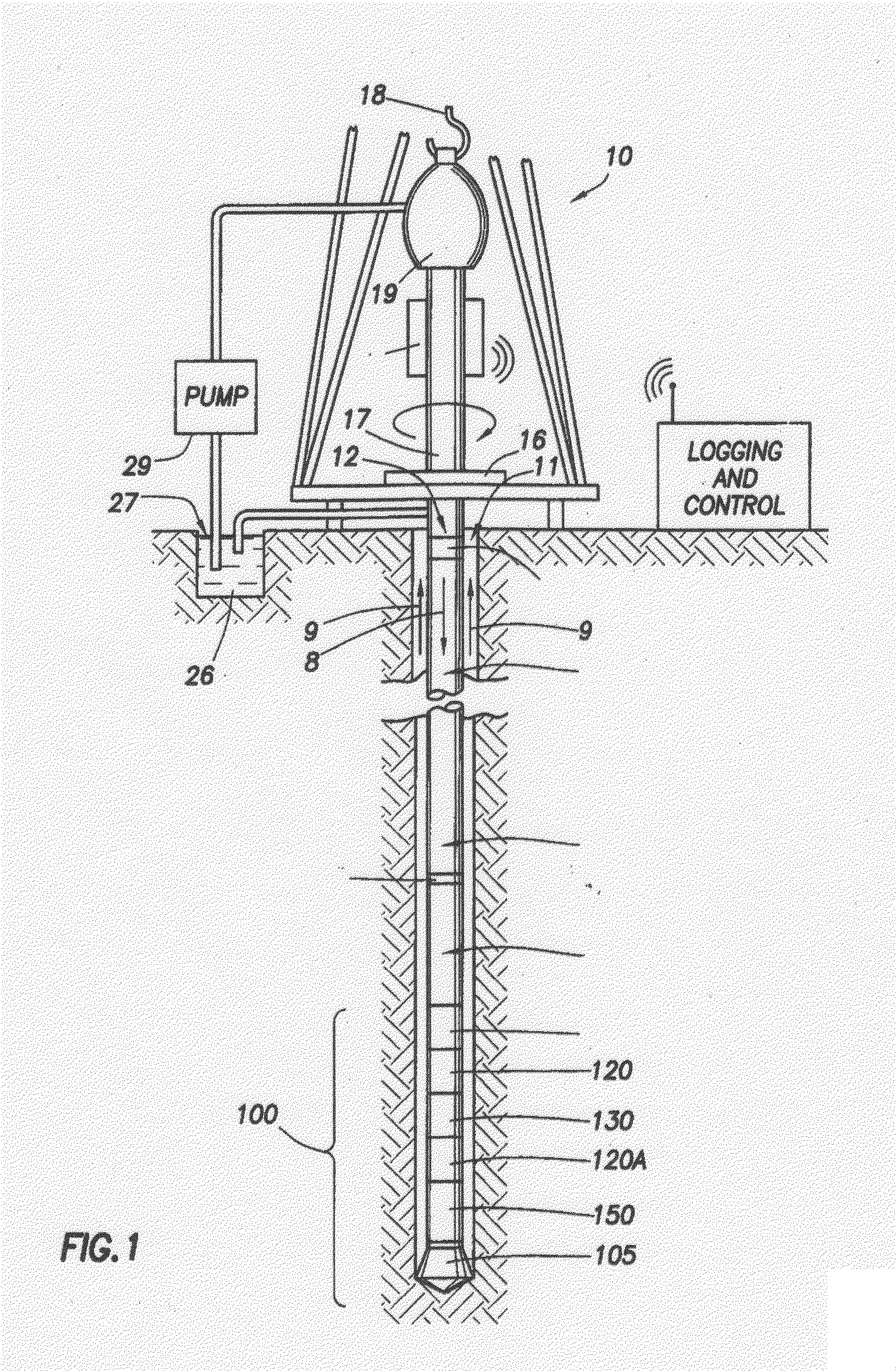

Electromagnetic wave resistivity tool having a tilted antenna for determining the horizontal and vertical resistivities and relative dip angle in anisotropic earth formations

InactiveUS6163155AElectric/magnetic detection for well-loggingSeismology for water-loggingTransmitter antennaHorizontal and vertical

This invention is directed to a downhole method and apparatus for simultaneously determining the horizontal resistivity, vertical resistivity, and relative dip angle for anisotropic earth formations. The present invention accomplishes this objective by using an antenna configuration in which a transmitter antenna and a receiver antenna are oriented in non-parallel planes such that the vertical resistivity and the relative dip angle are decoupled. Preferably, either the transmitter or the receiver is mounted in a conventional orientation in a first plane that is normal to the tool axis, and the other antenna is mounted in a second plane that is not parallel to the first plane. Although this invention is primarily intended for MWD or LWD applications, this invention is also applicable to wireline and possible other applications.

Owner:HALLIBURTON ENERGY SERVICES INC

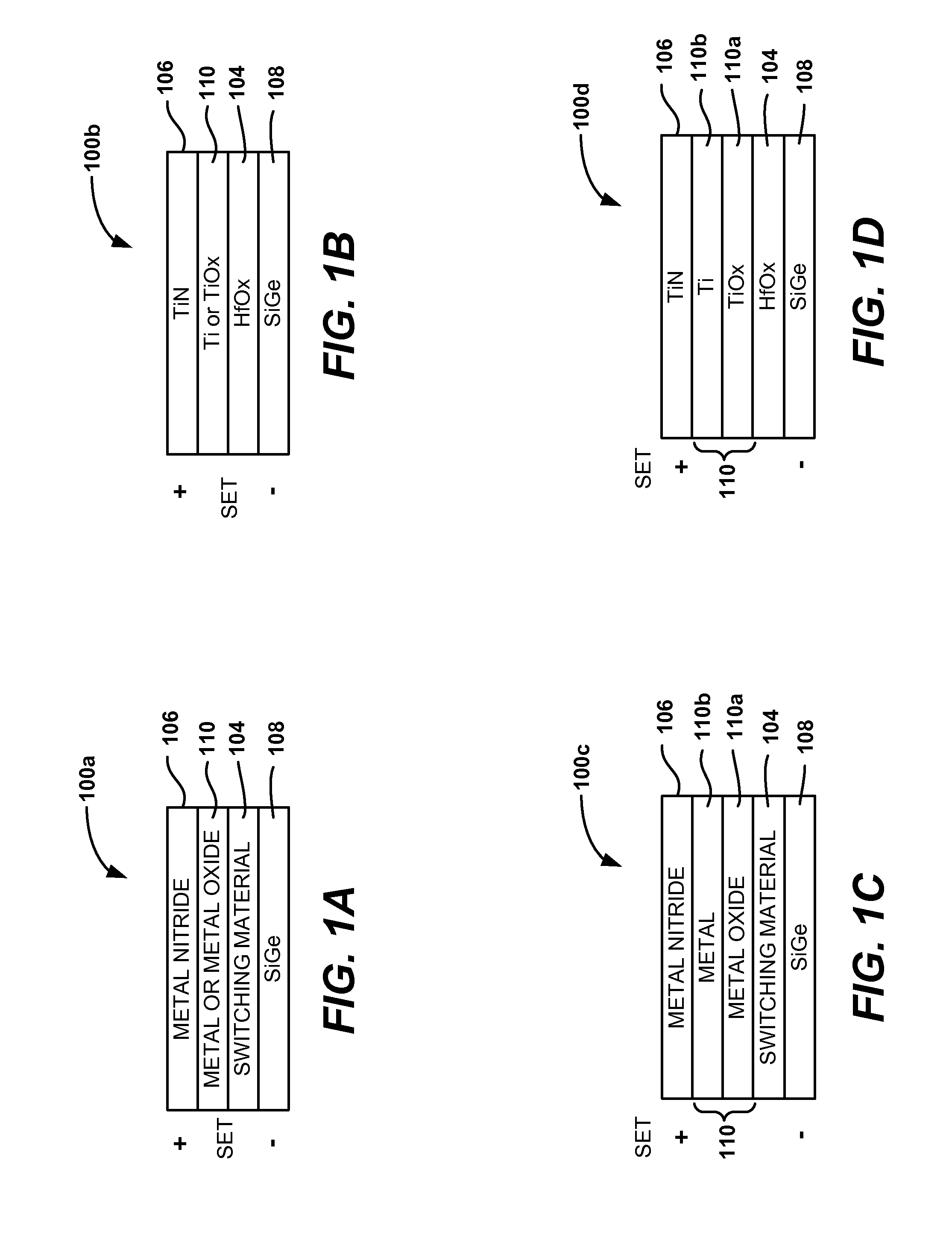

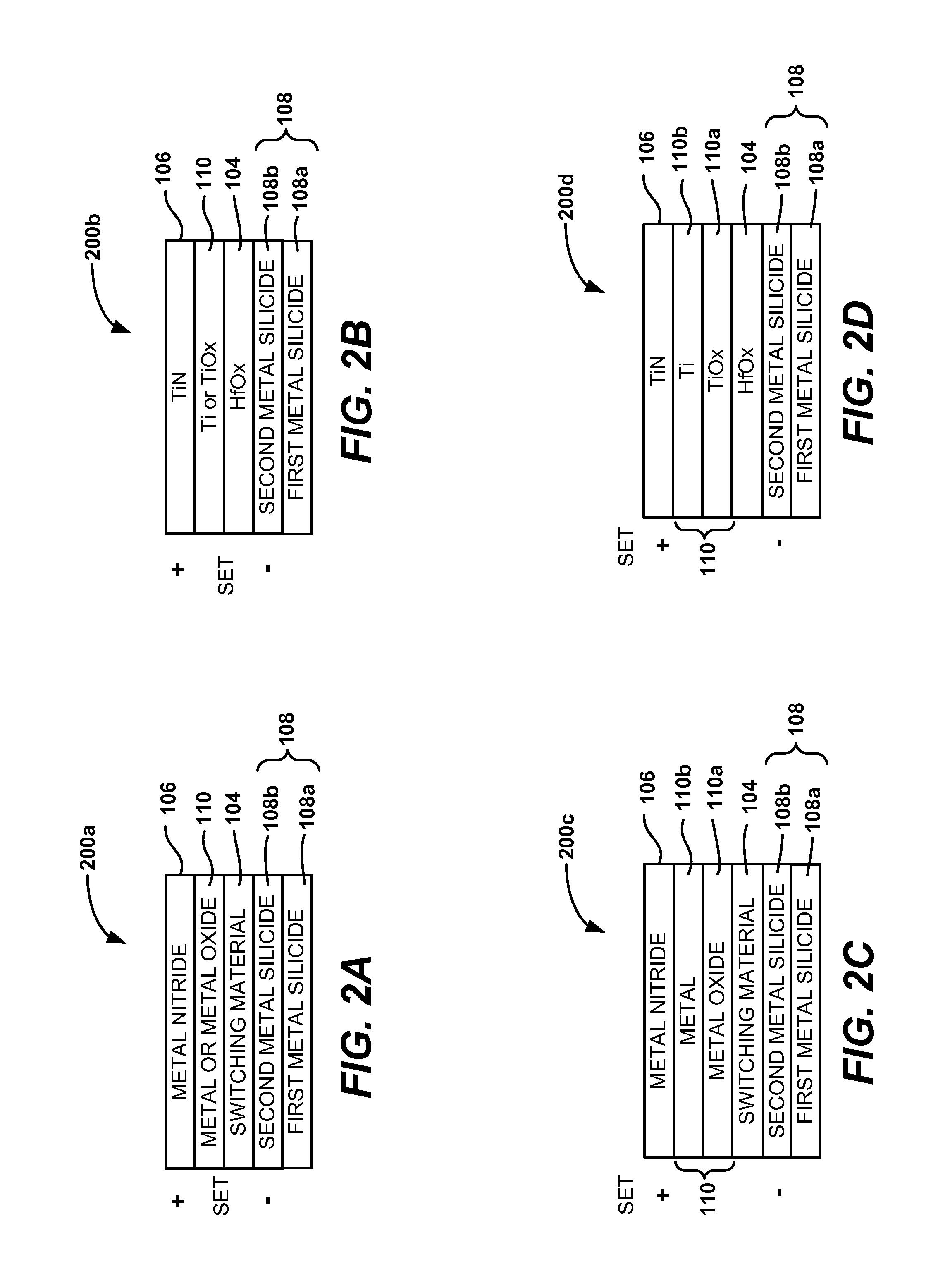

Bottom electrodes for use with metal oxide resistivity switching layers

ActiveUS20110227028A1Solid-state devicesSemiconductor/solid-state device manufacturingMetal silicideOptoelectronics

In a first aspect, an MIM stack is provided that includes (1) a first conductive layer comprising a first metal-silicide layer and a second metal-silicide layer; (2) a resistivity-switching layer comprising a metal oxide layer formed above the first conductive layer; and (3) a second conductive layer formed above the resistivity-switching layer. A memory cell may be formed from the MIM stack. Numerous other aspects are provided.

Owner:SANDISK TECH LLC

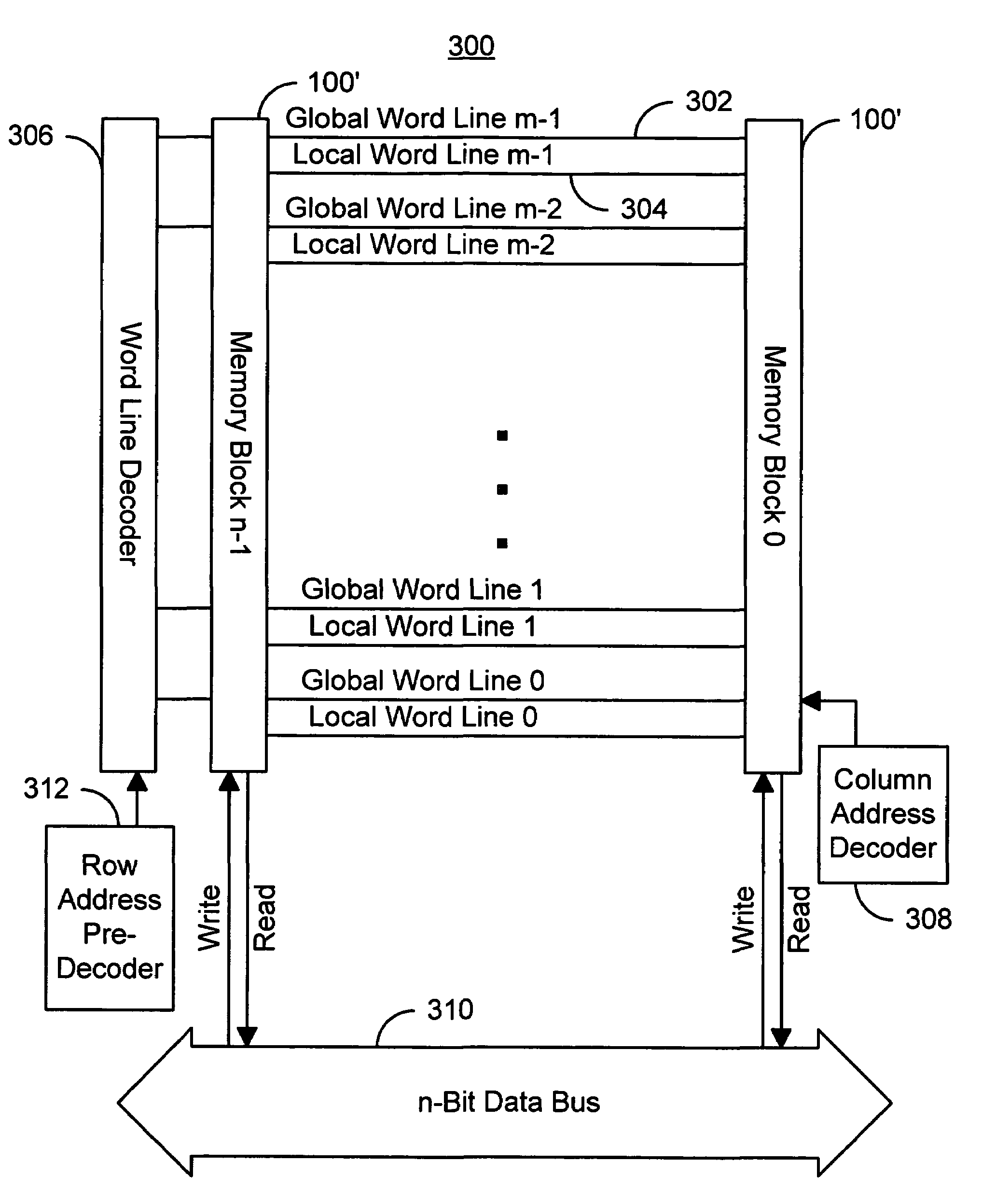

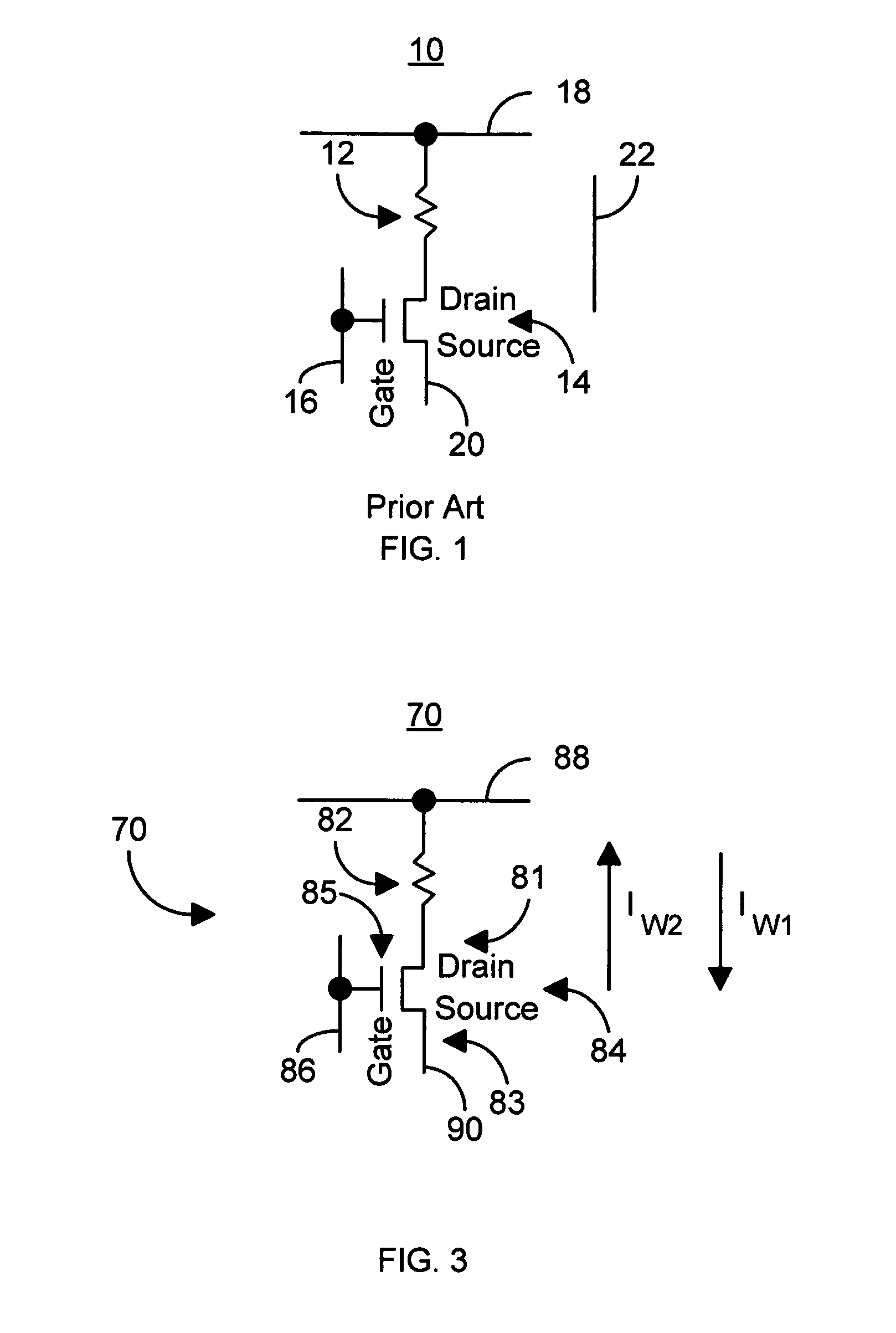

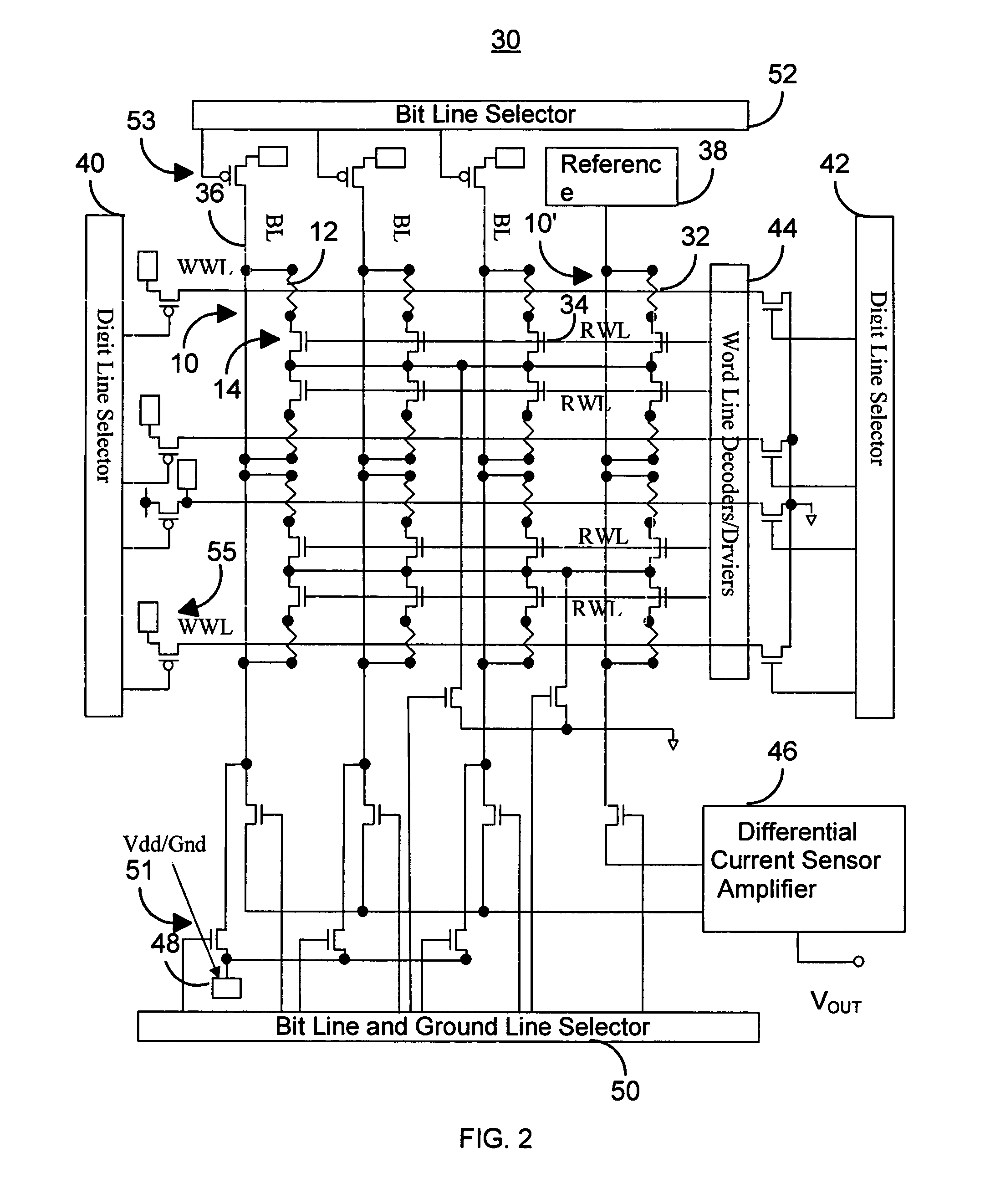

Method and system for providing a magnetic memory structure utilizing spin transfer

A method and system for providing a magnetic memory is described. The method and system include providing magnetic memory cells, local and global word lines, bit lines, and source lines. Each magnetic memory cell includes a magnetic element and a selection device connected with the magnetic element. The magnetic element is programmed by first and second write currents driven through the magnetic element in first and second directions. The local word lines are connected with the selection device of and have a first resistivity. Each global word line corresponds to a portion of the local word lines and has a resistivity lower than the first resistivity. The bit lines are connected with the magnetic element. The source lines are connected with the selection device. Each source line corresponds to a more than one of the magnetic memory cells and carries the first and second write currents.

Owner:RENESAS ELECTRONICS CORP +1

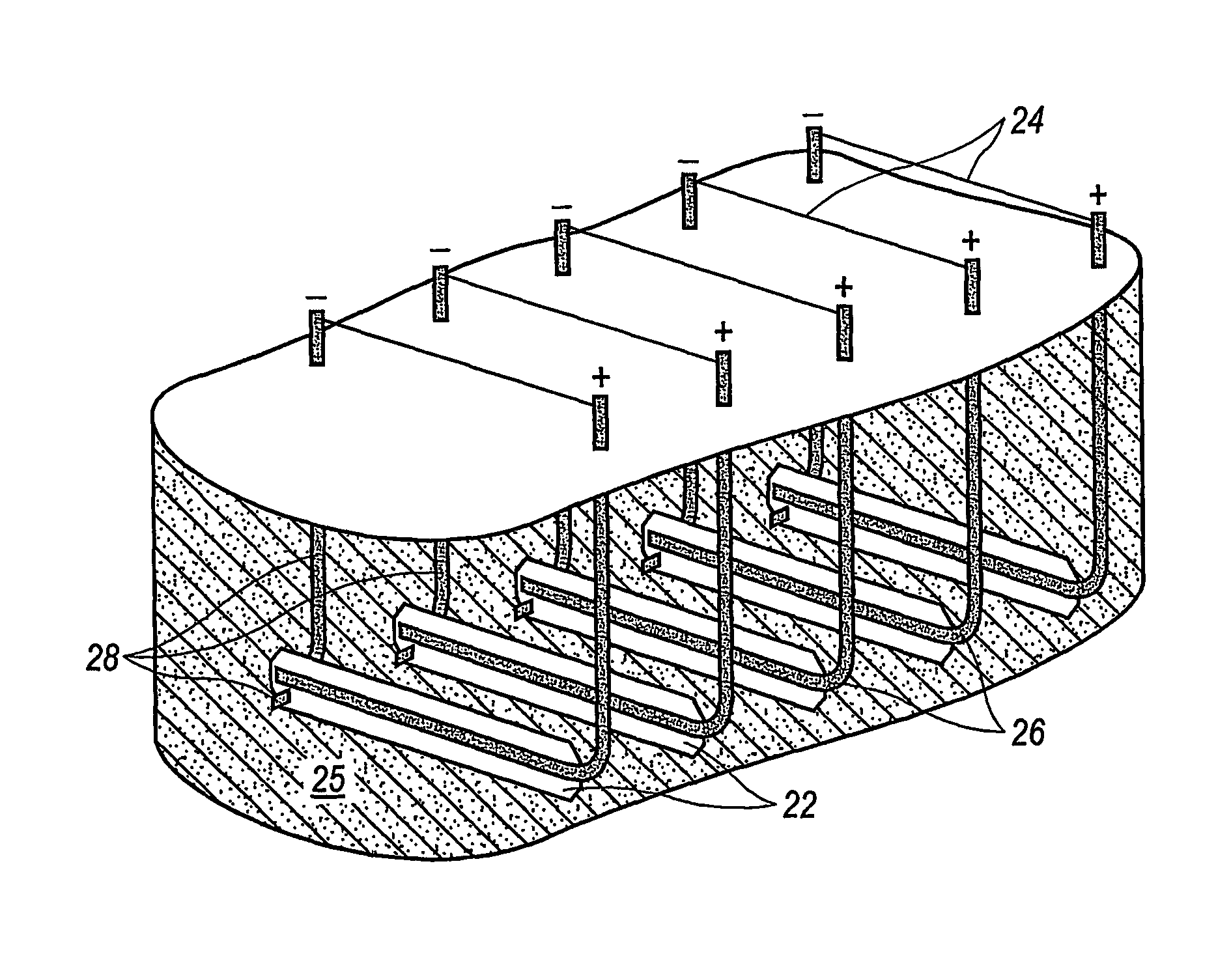

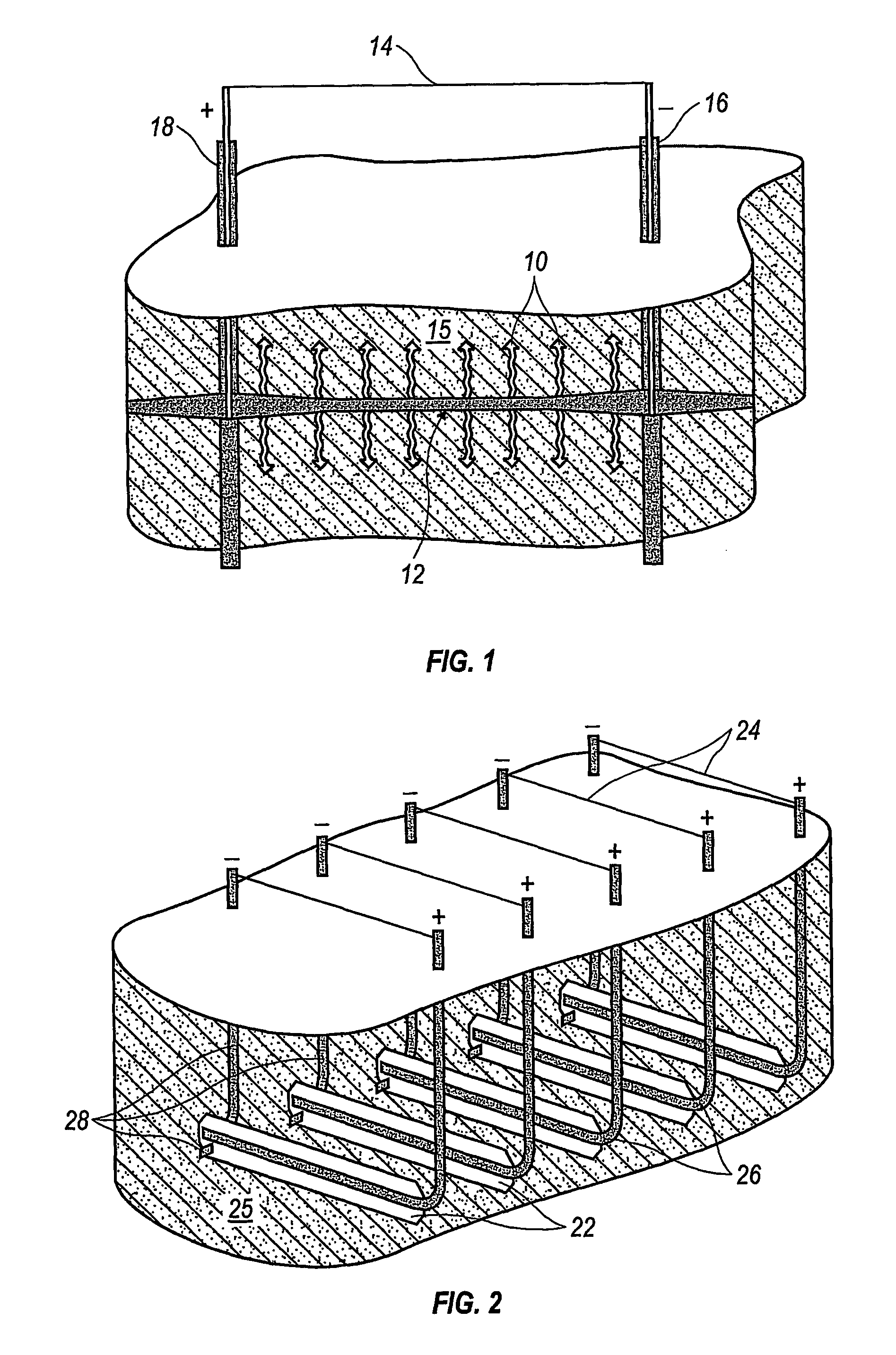

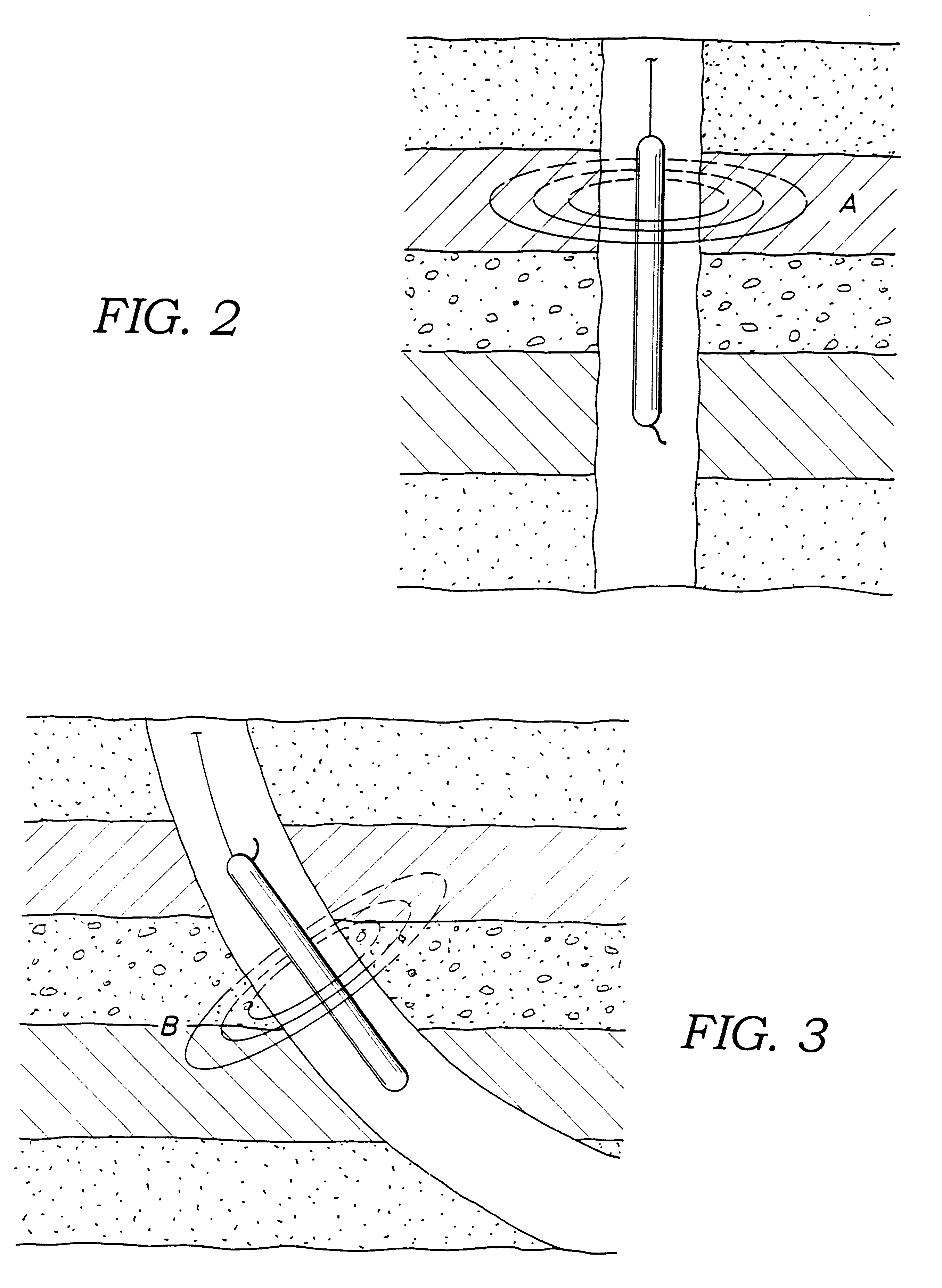

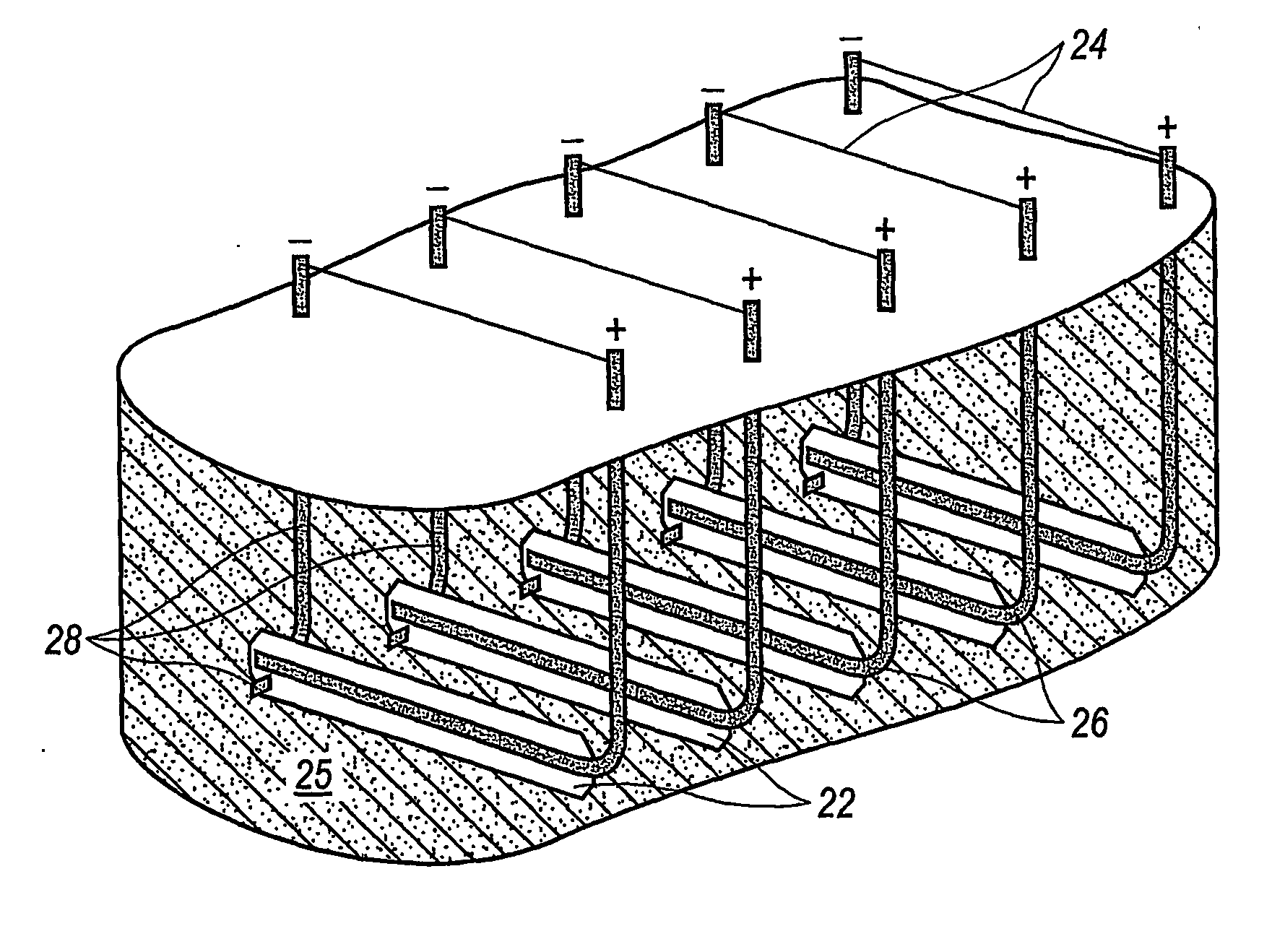

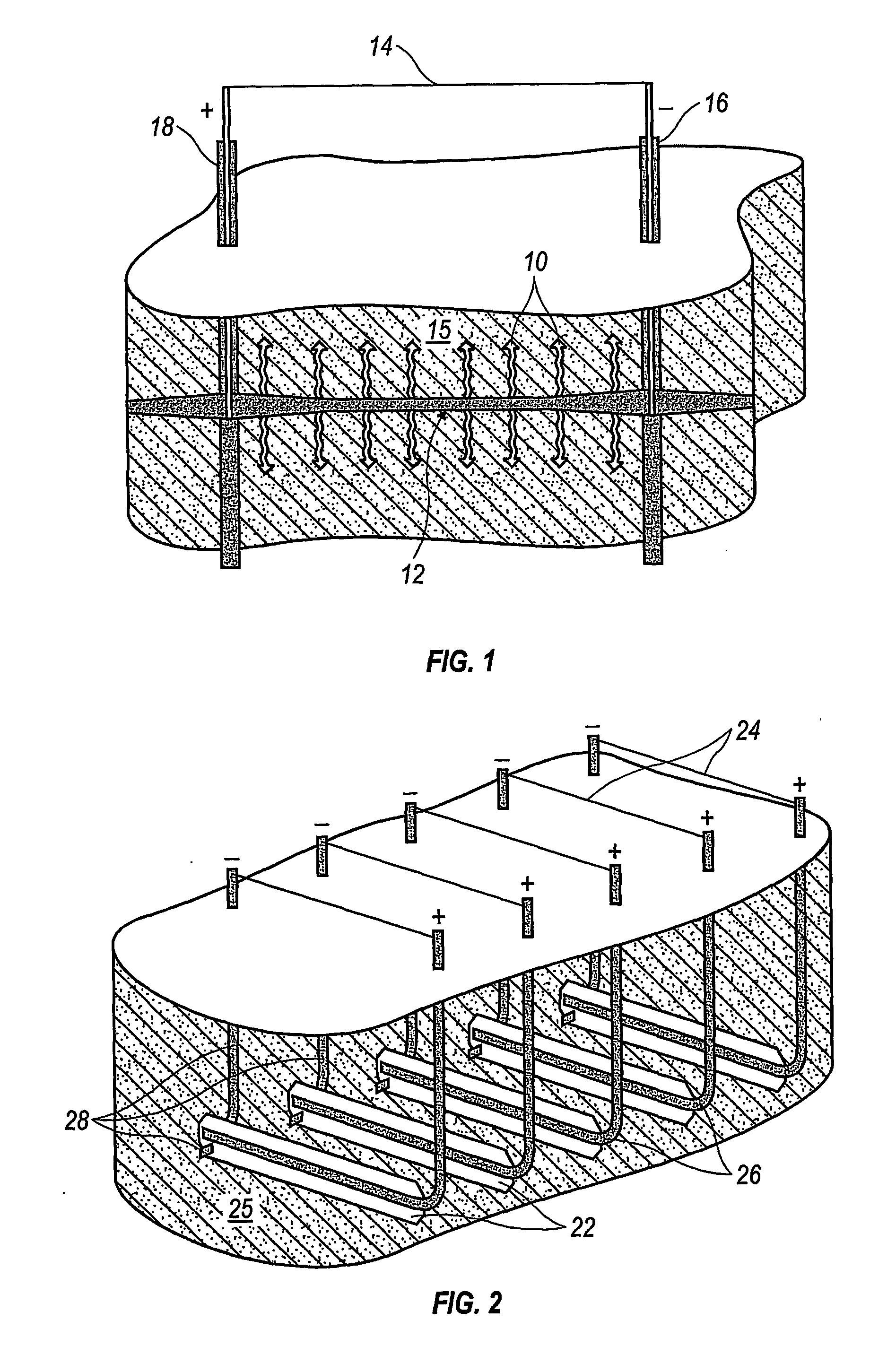

Methods of treating a subterranean formation to convert organic matter into producible hydrocarbons

ActiveUS7331385B2Low viscosityAvoid insufficient heatingFluid removalSoil organic matterConductive materials

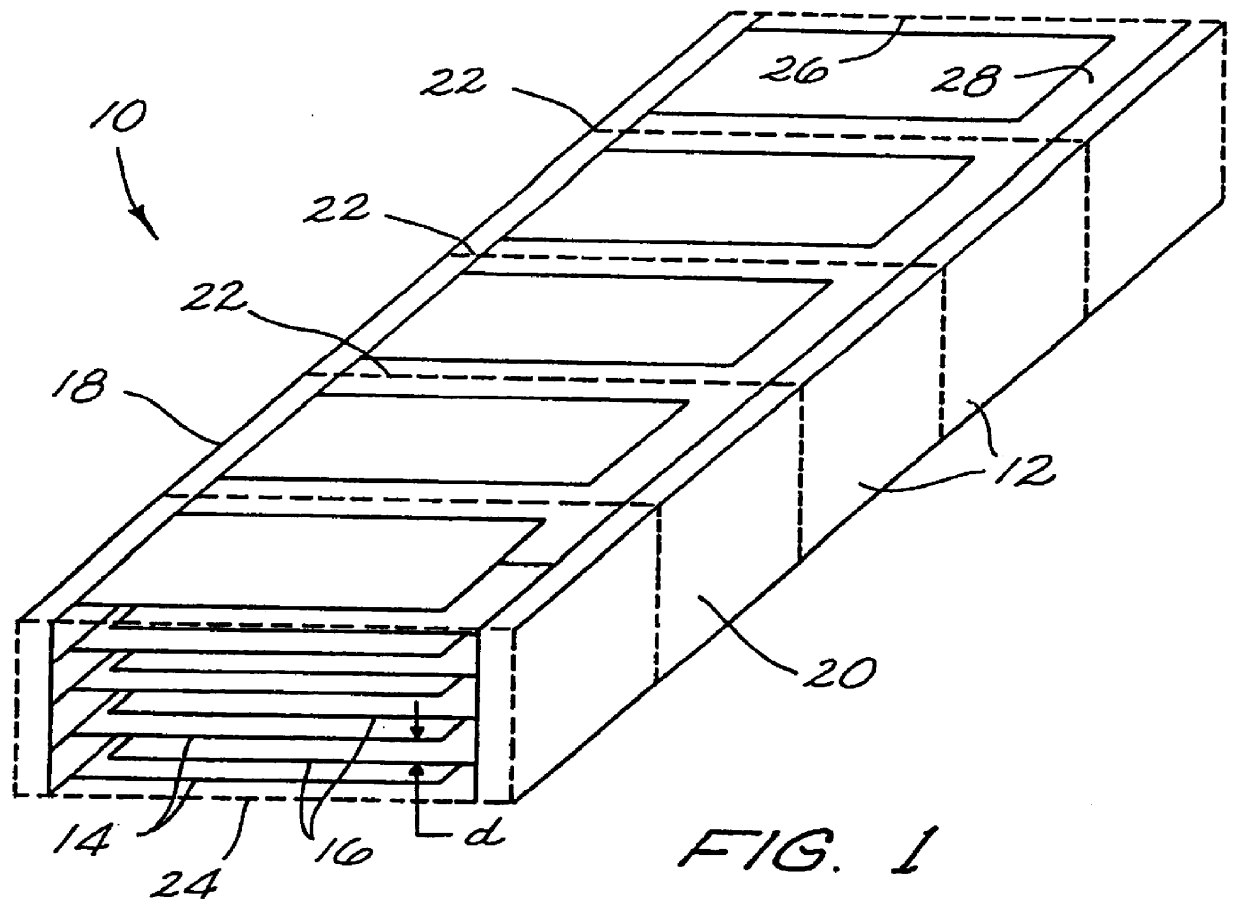

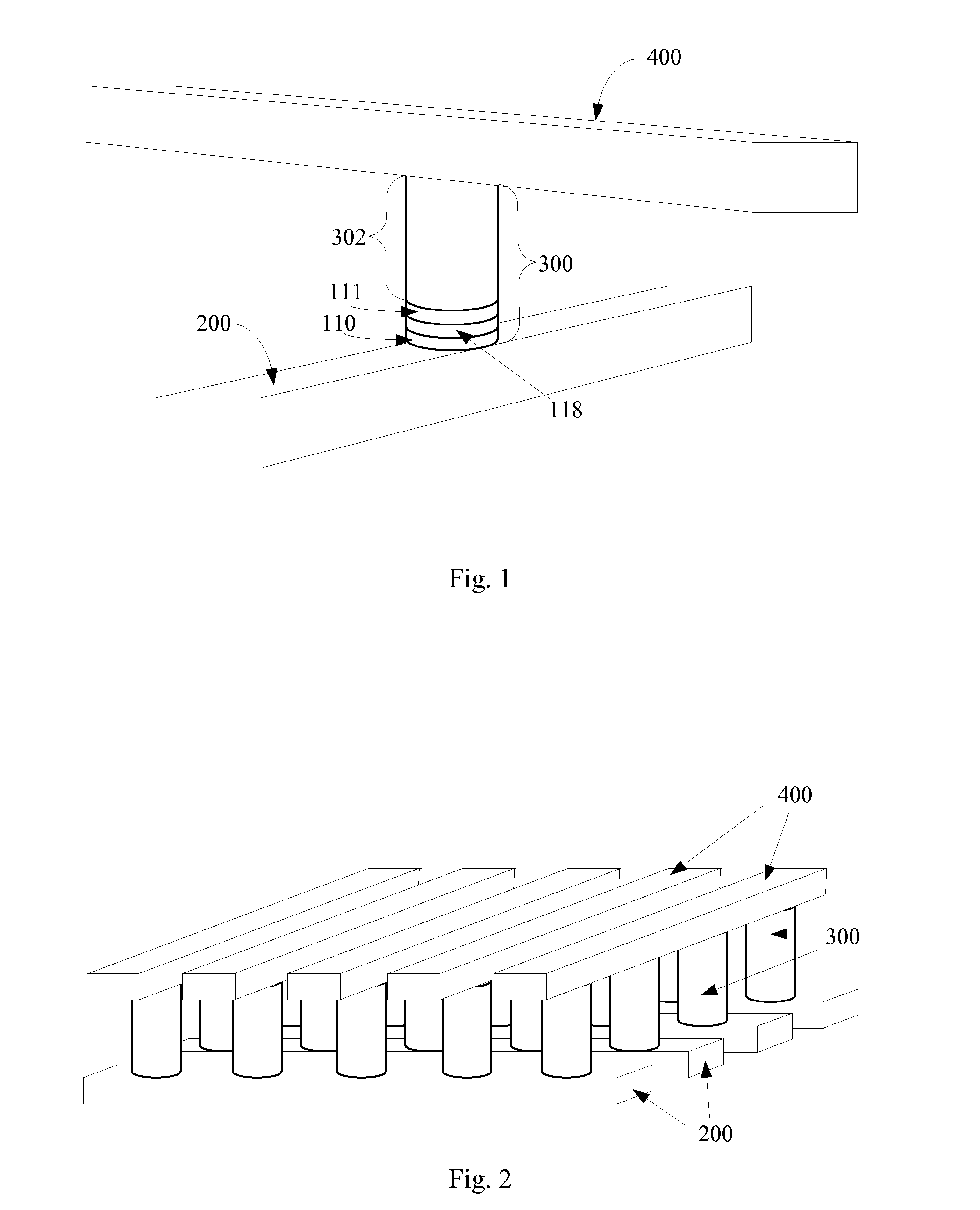

Methods are provided that include the steps of providing wells in a formation, establishing one or more fractures (12) in the formation, such that each fracture intersects at least one of the wells (16, 18), placing electrically conductive material in the fractures, and generating electric current through the fractures and through the material such that sufficient heat (10) is generated by electrical resistivity within the material to pyrolyze organic matter in the formation into producible hydrocarbons.

Owner:EXXONMOBIL UPSTREAM RES CO

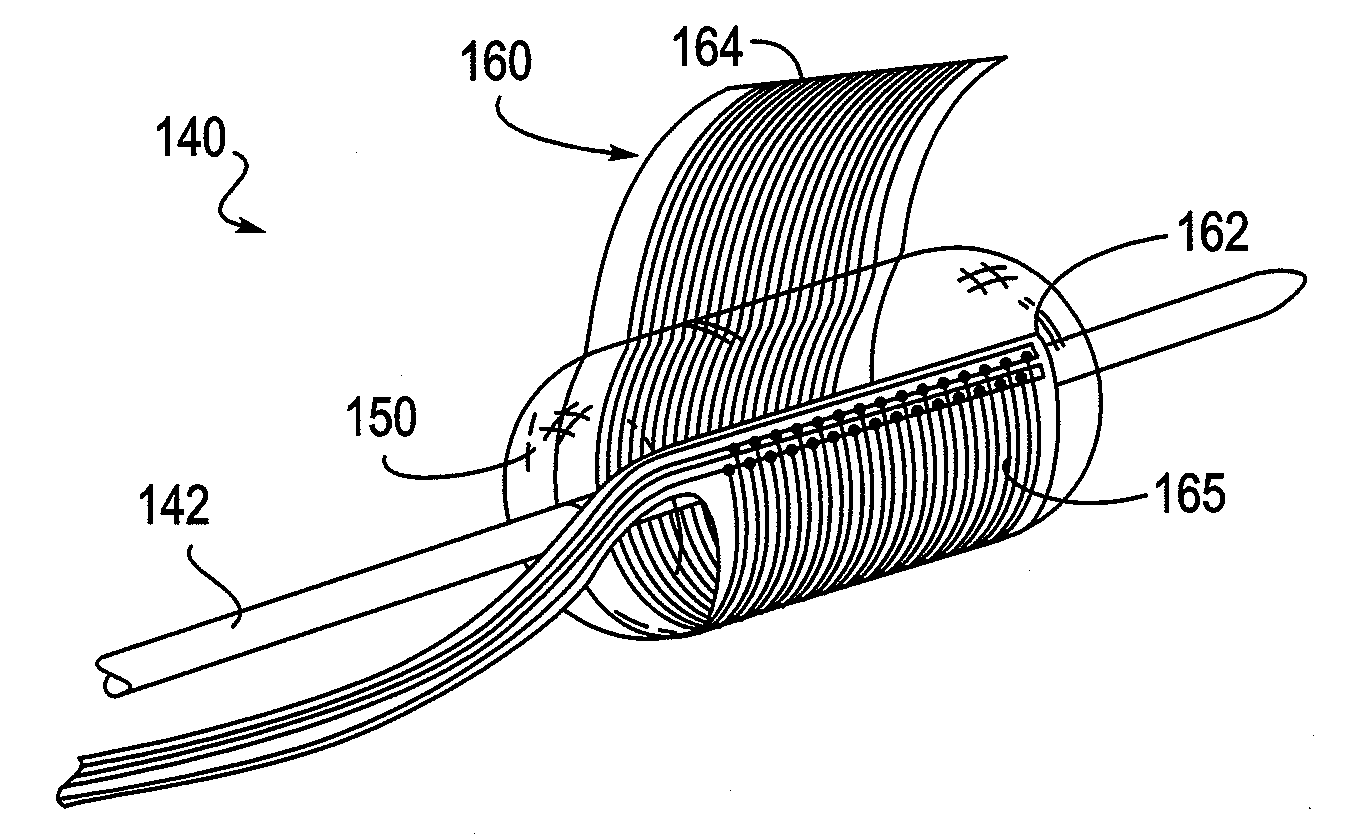

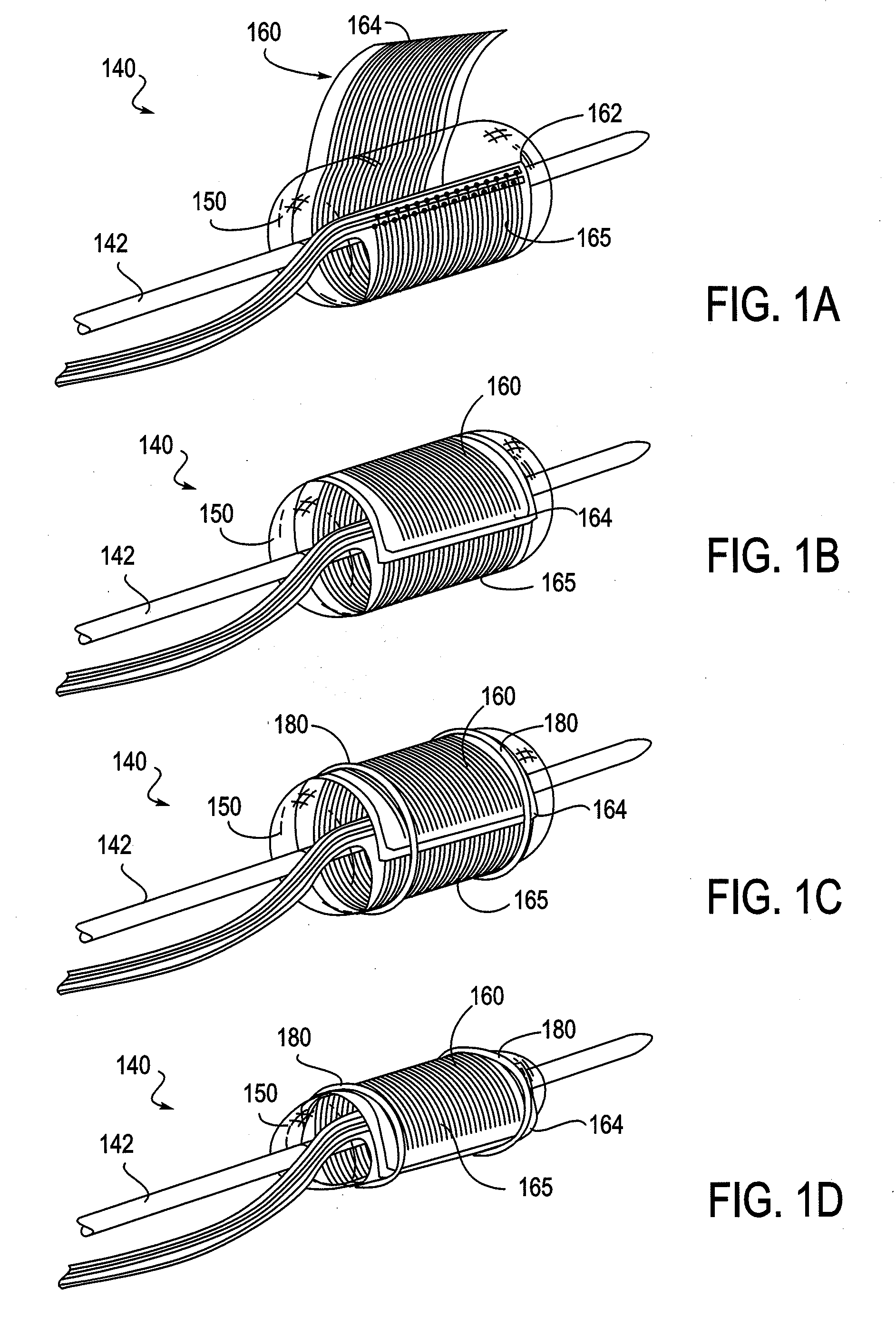

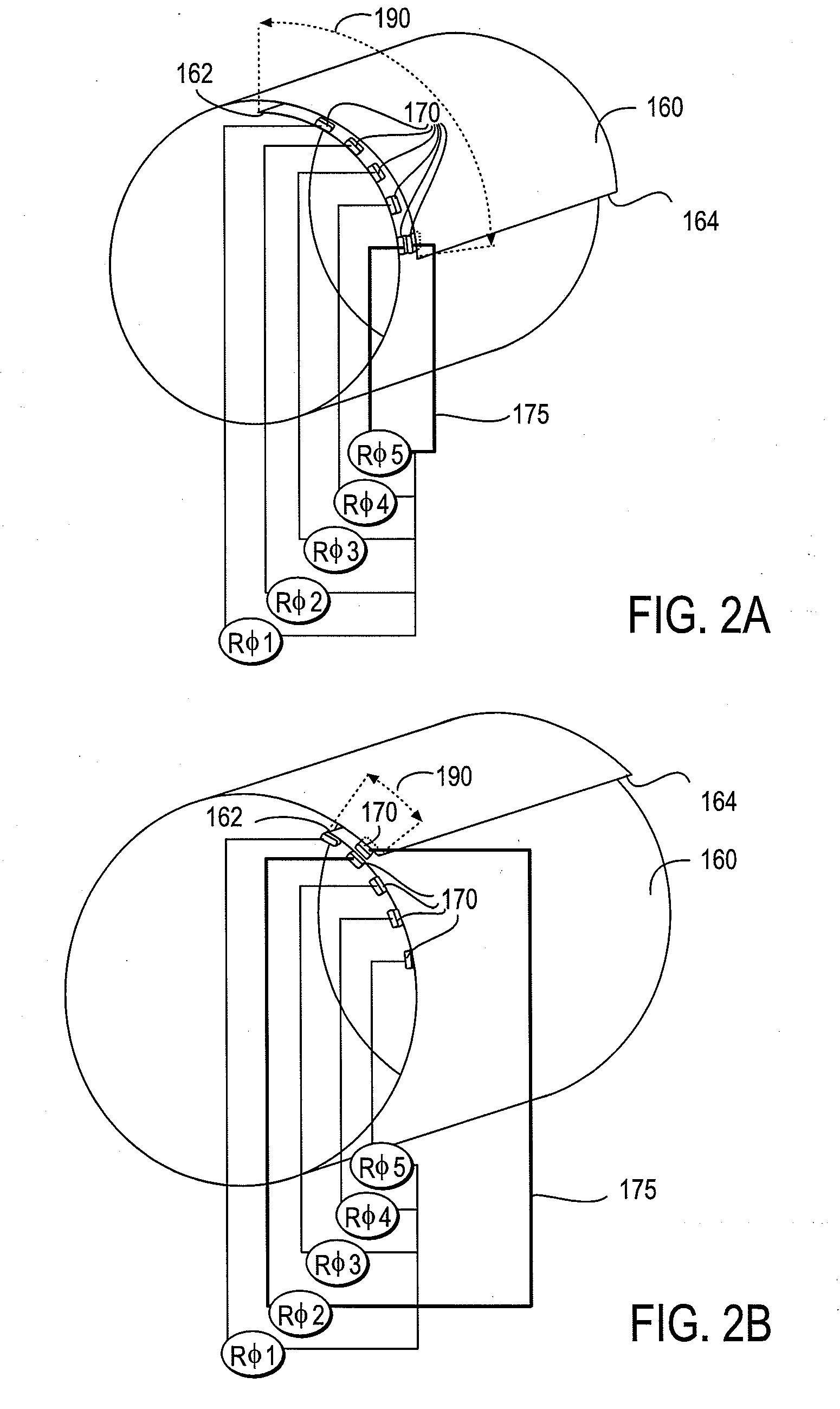

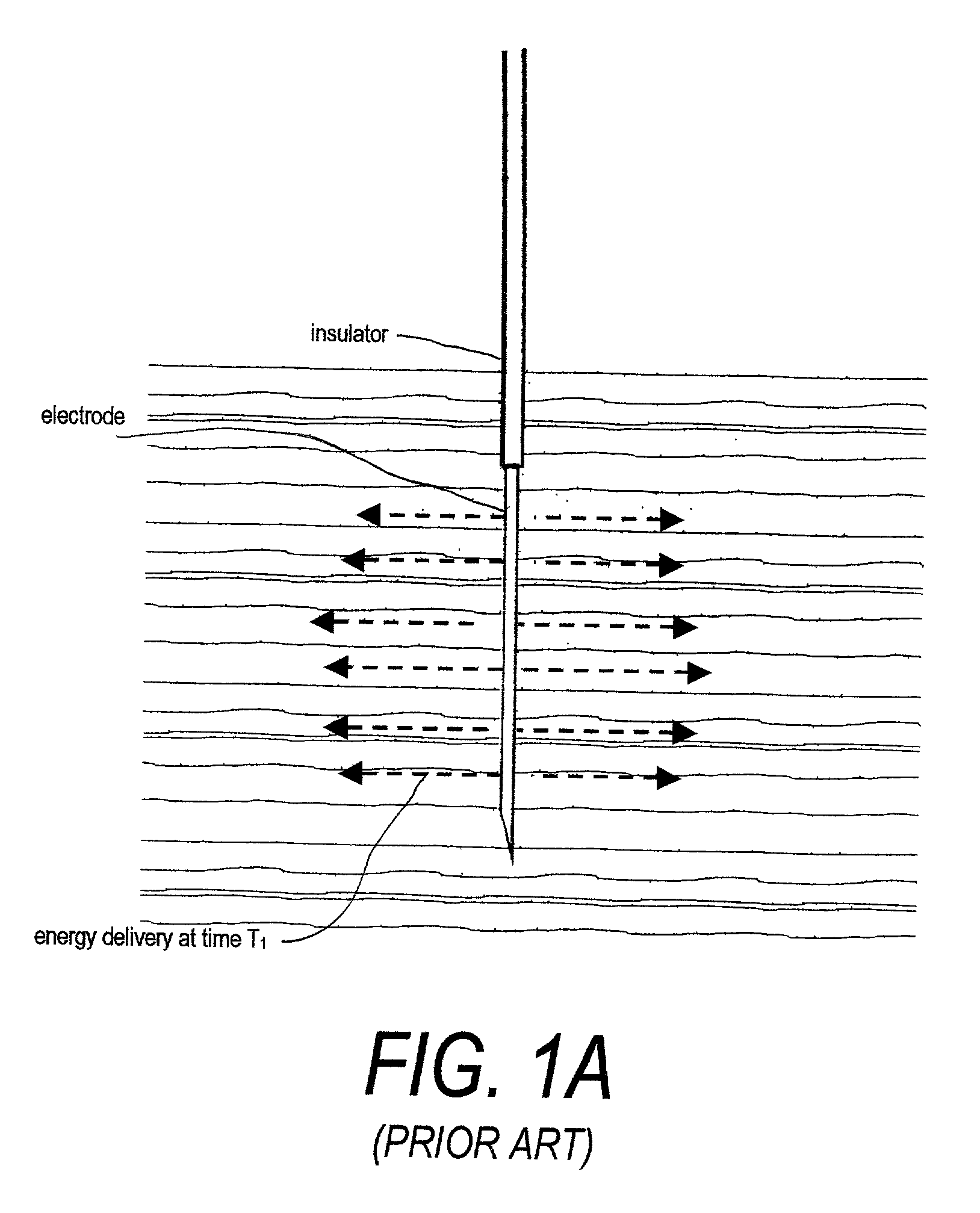

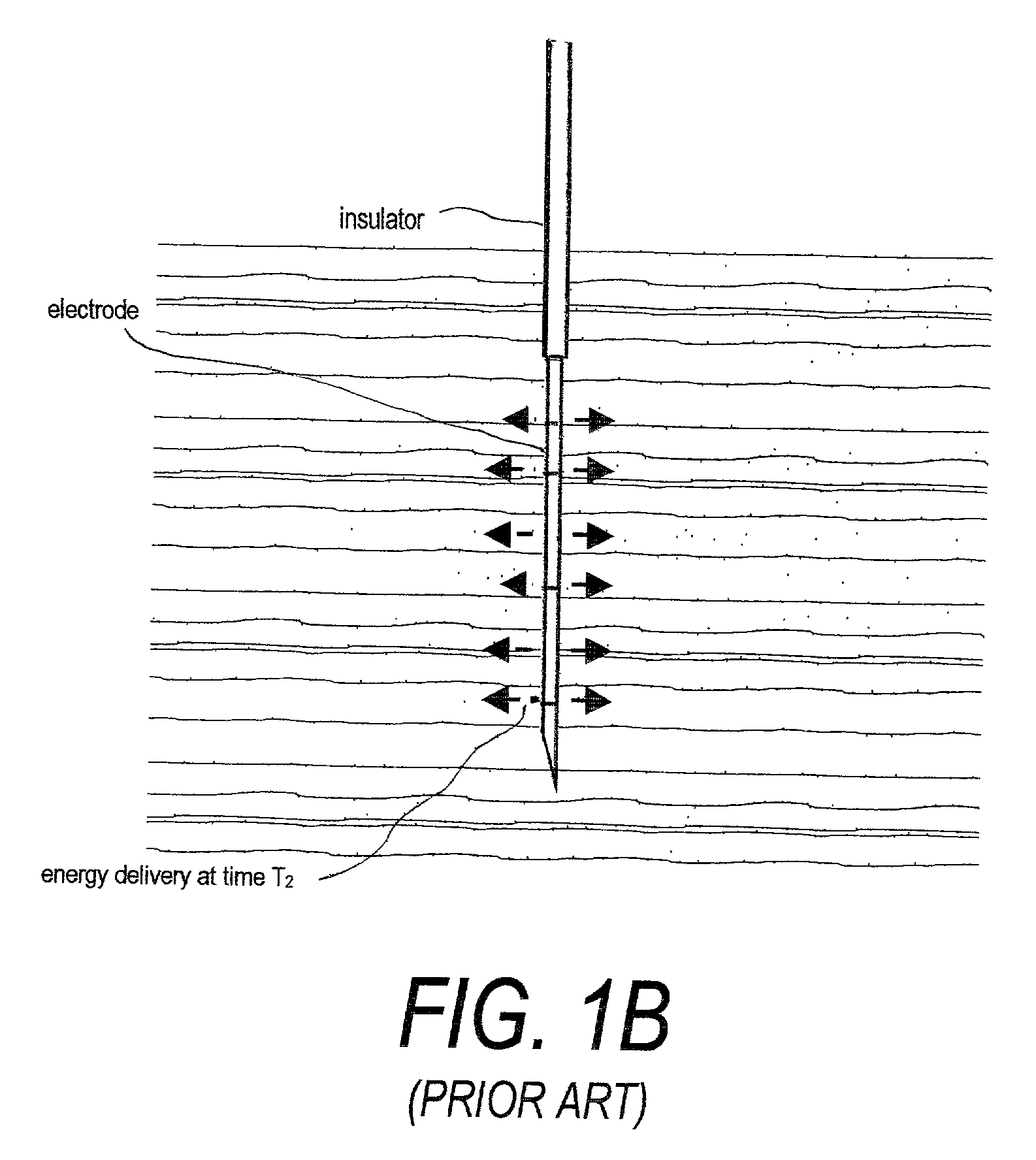

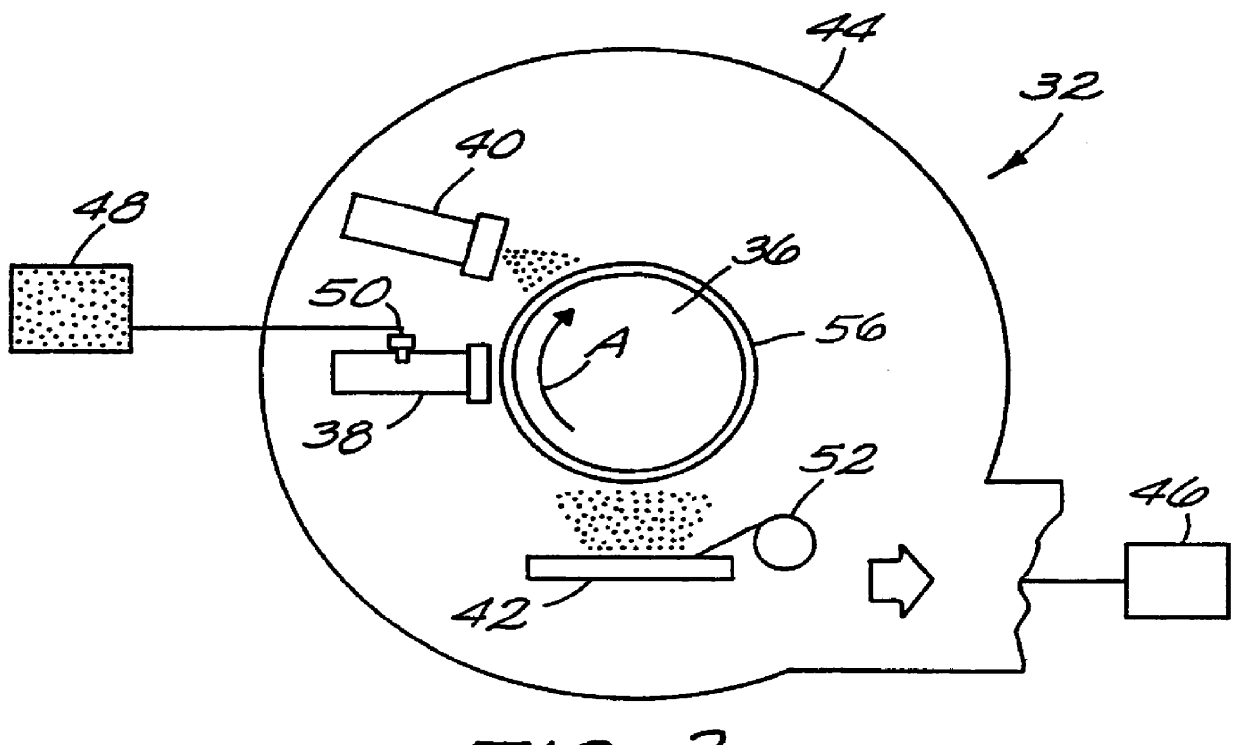

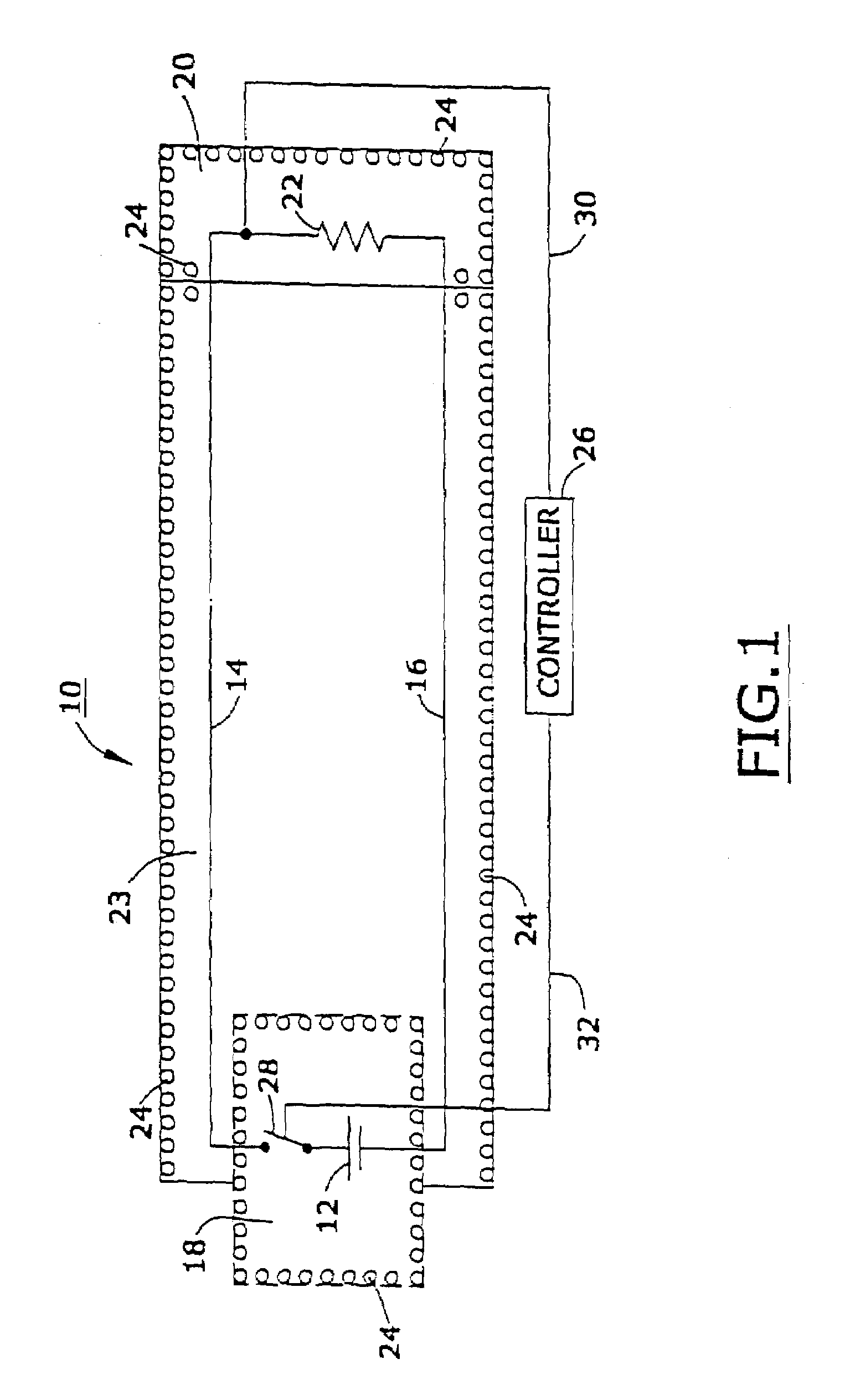

Electrical means to normalize ablational energy transmission to a luminal tissue surface of varying size

Methods and devices for measuring the size of a body lumen and a method for ablating tissue that uses the measurement to normalize delivery of ablational energy from an expandable operative element to a luminal target of varying circumference are provided. The method includes inserting into the lumen an expandable operative element having circuitry with resistivity or inductance that varies according to the circumference of the operative element, varying the expansion of the operative element with an expansion medium, measuring the resistivity of the circuitry, and relating the resistivity or inductance to a value for the circumference of the operative element. In some embodiments the sizing circuit includes a conductive elastomer wrapped around the operative element. Other embodiments of the method apply to operative elements that include an overlapping energy delivery element support in which the overlap varies inversely with respect to the state of expansion, and which is configured with sizing electrodes that sense the amount of the overlap.

Owner:TYCO HEALTHCARE GRP LP

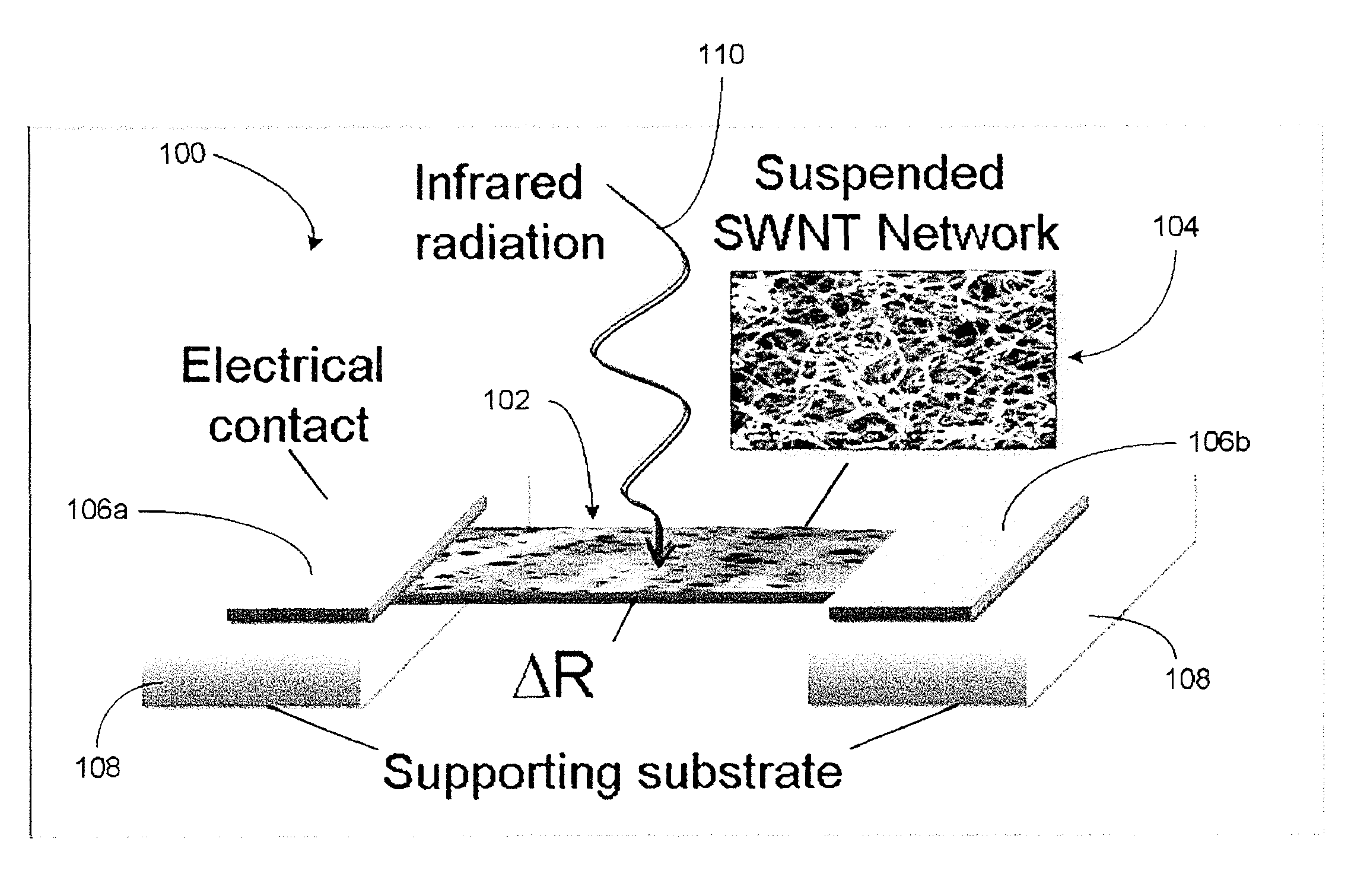

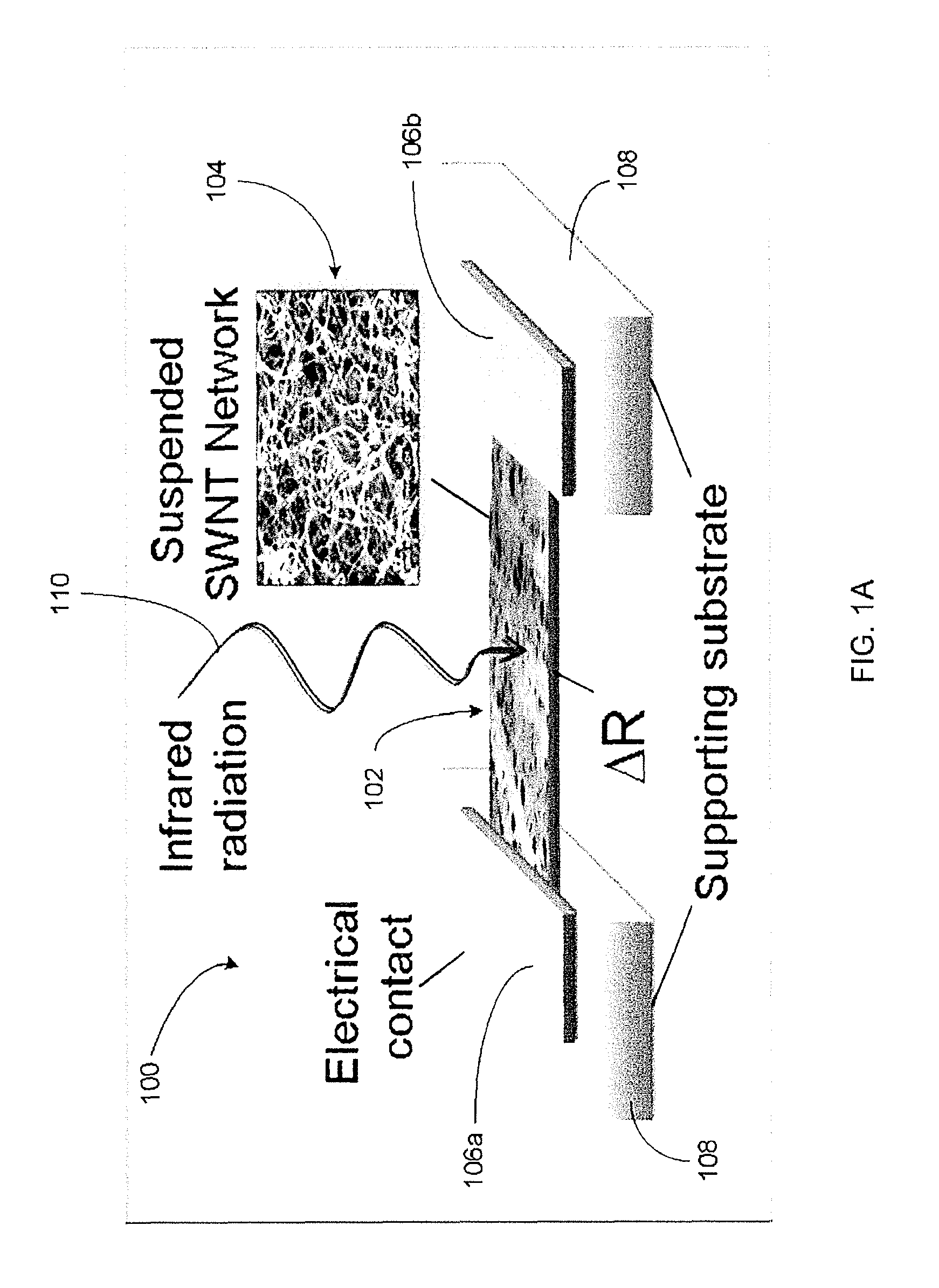

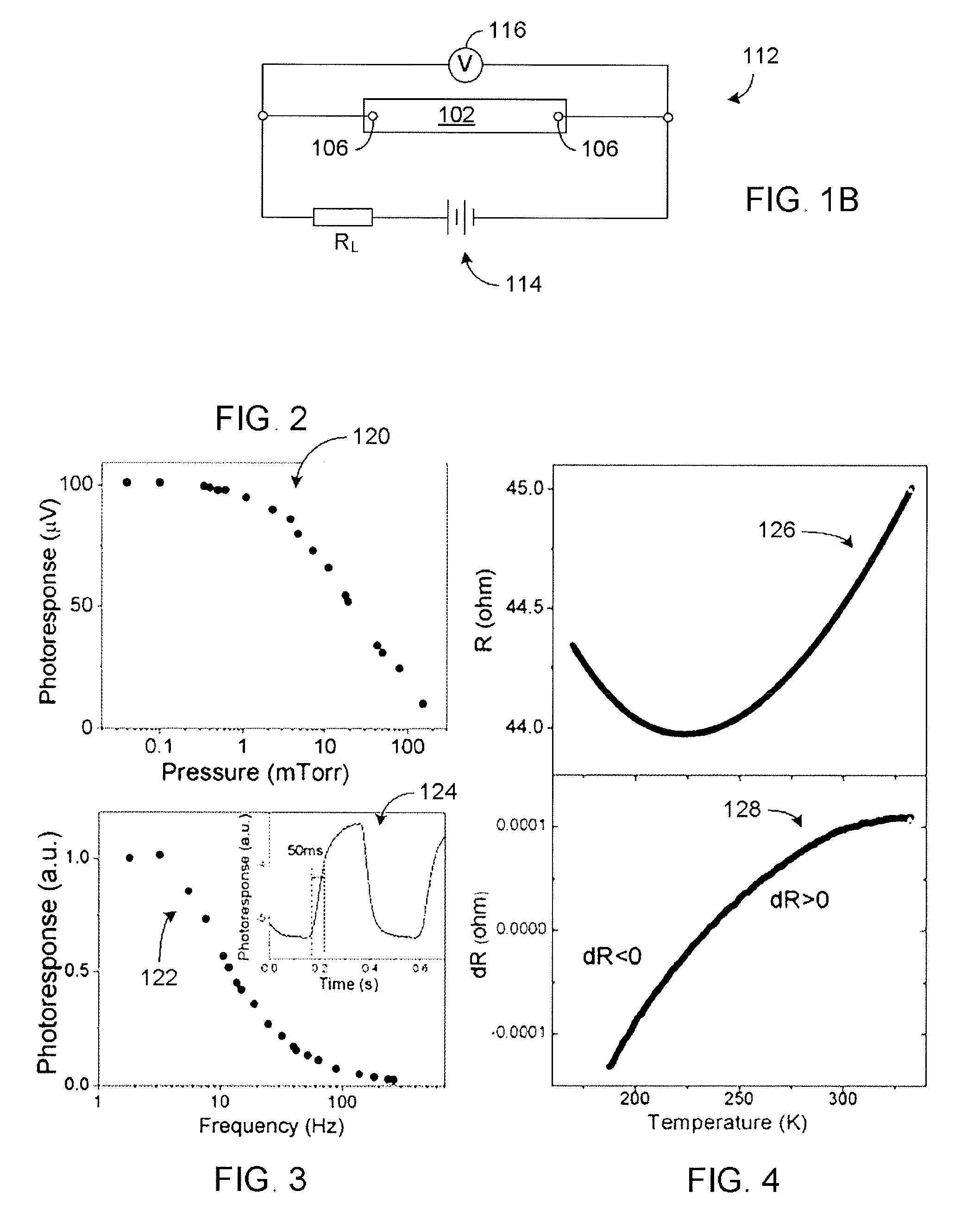

Carbon nanotube based detector

ActiveUS7723684B1Material analysis by optical meansPyrometry using electric radation detectorsSpectral responseCarbon nanotube

Systems and methods for designing and fabricating carbon nanotube based detectors are disclosed. In some embodiments, one or more sensor elements can be formed from a film of single-walled carbon nanotubes (SWNTs). Bolometric properties of such detectors are disclosed. In some embodiments, the film can be thermally isolated in various ways, such as suspending the film and providing a vacuum environment, to provide the bolometric properties. Various properties of the SWNT films, such as resistivity-dependence on temperature and spectral response, can be obtained by adjusting the dimension and / or composition of the film. Examples of SWNT film formation, detector element fabrication, and array fabrication are disclosed.

Owner:RGT UNIV OF CALIFORNIA

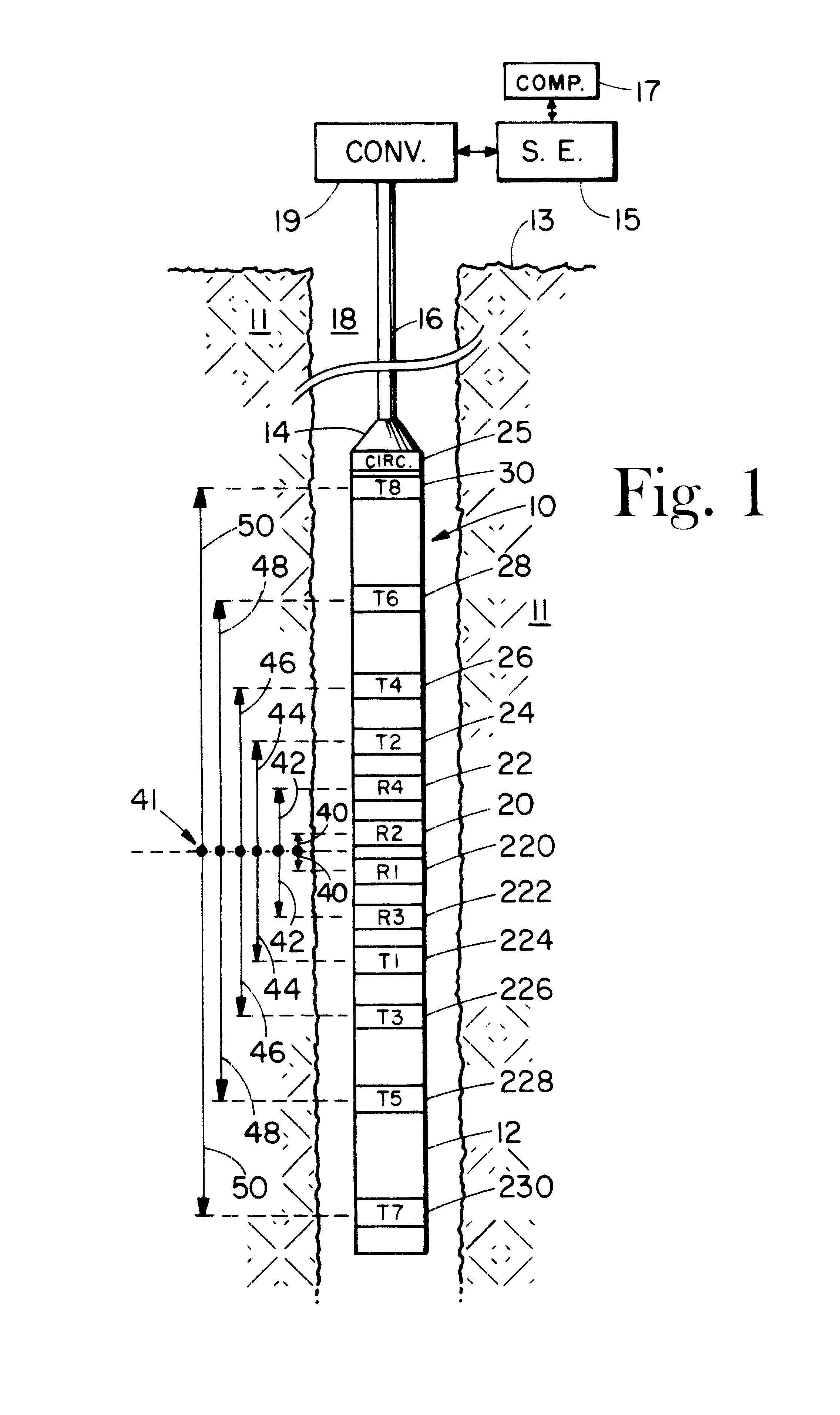

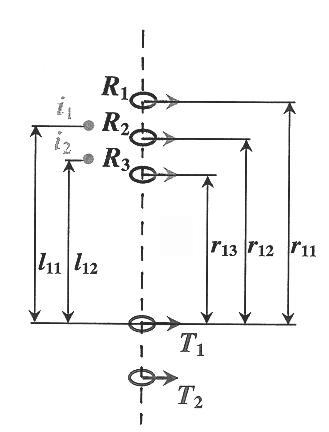

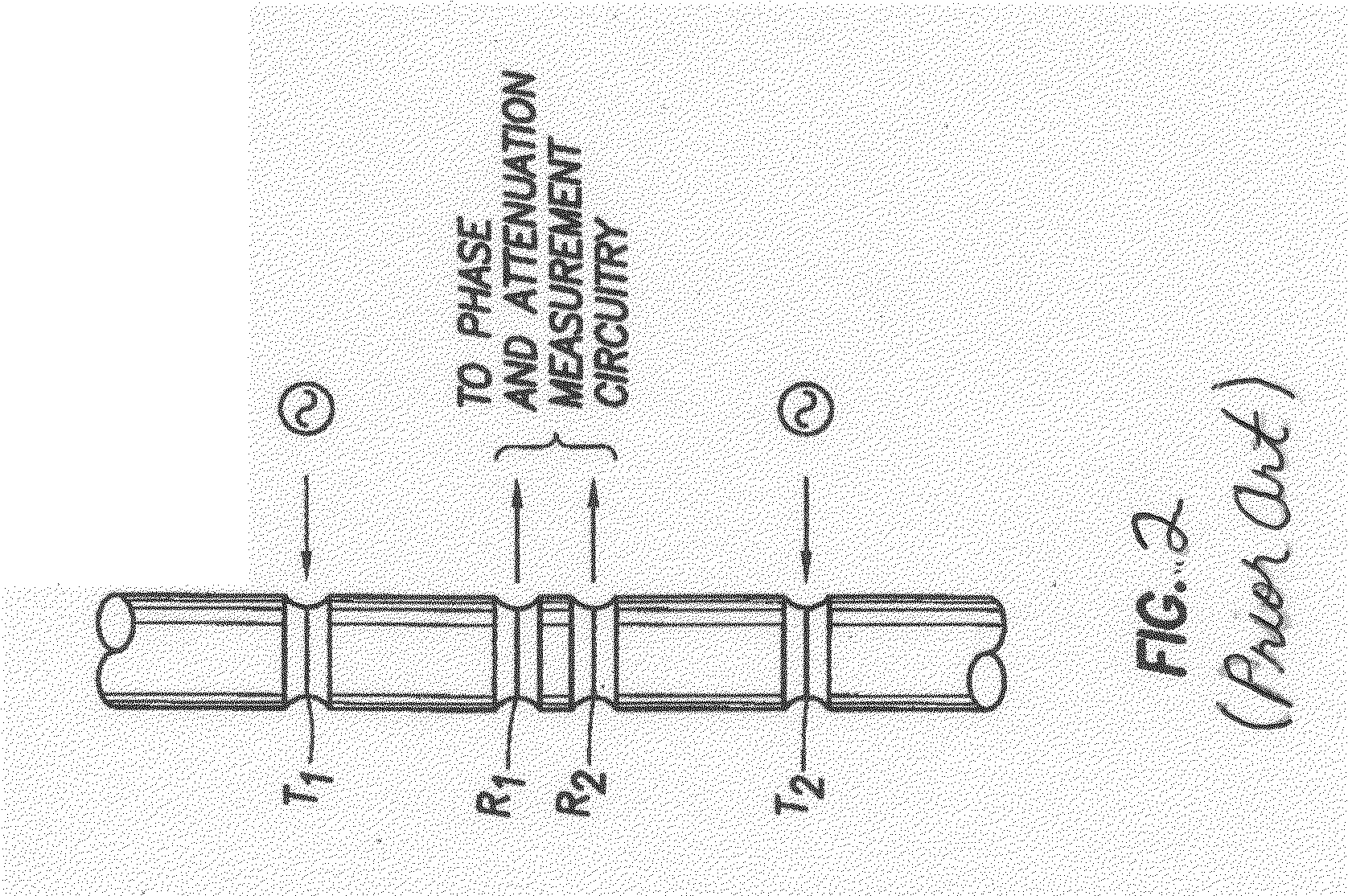

Method and apparatus for evaluating the resistivity of formations with high dip angles or high-contrast thin layers

InactiveUS6304086B1Electric/magnetic detection for well-loggingSeismology for water-loggingWell loggingThin layer

A method and apparatus for evaluating the resistivity of earth formations surrounding a borehole, particularly high-contrast thin-layer formations or at high dip angles. The method involves positioning a pair of transmitters and a pair of receivers within the borehole, the receivers or transmitters adhering to specific spacing limitations, alternately transmitting electromagnetic energy of a particular frequency and receiving voltage data associated with the transmitted energy. Multiple voltage data are acquired and a representation of a resistivity or conductivity profile is created from a formulated difference of the data from a particular depth and / or neighboring depths. The apparatus forms part of a well logging system including a well tool adapted to be moveable through a borehole. The apparatus being coupled to the well tool and adapted with means to input voltage data developed by the receivers disposed on the well tool. The apparatus further adapted with means for performing calculations to determine a conductivity profile and for recording the profile on an output record medium.

Owner:SCHLUMBERGER TECH CORP

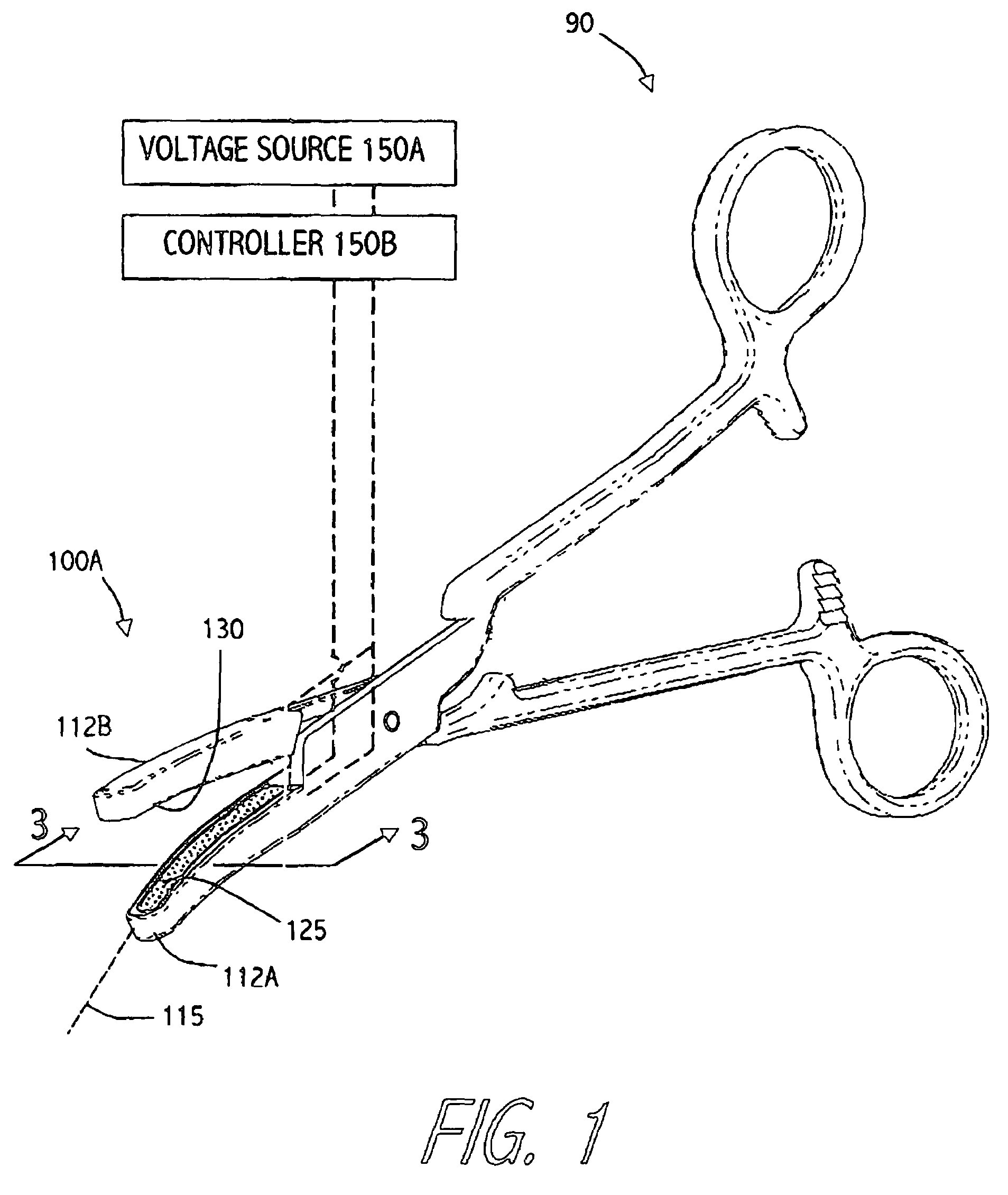

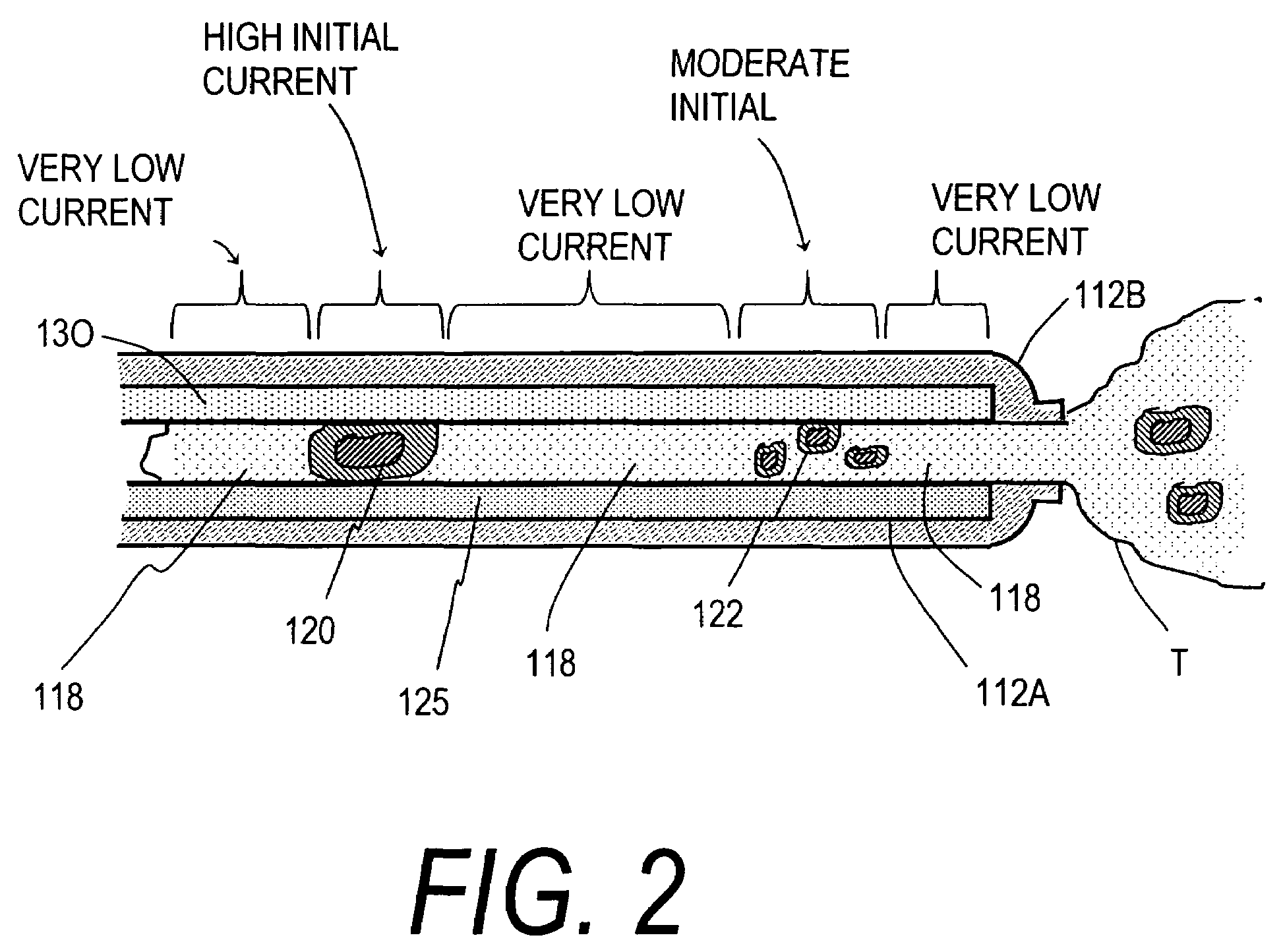

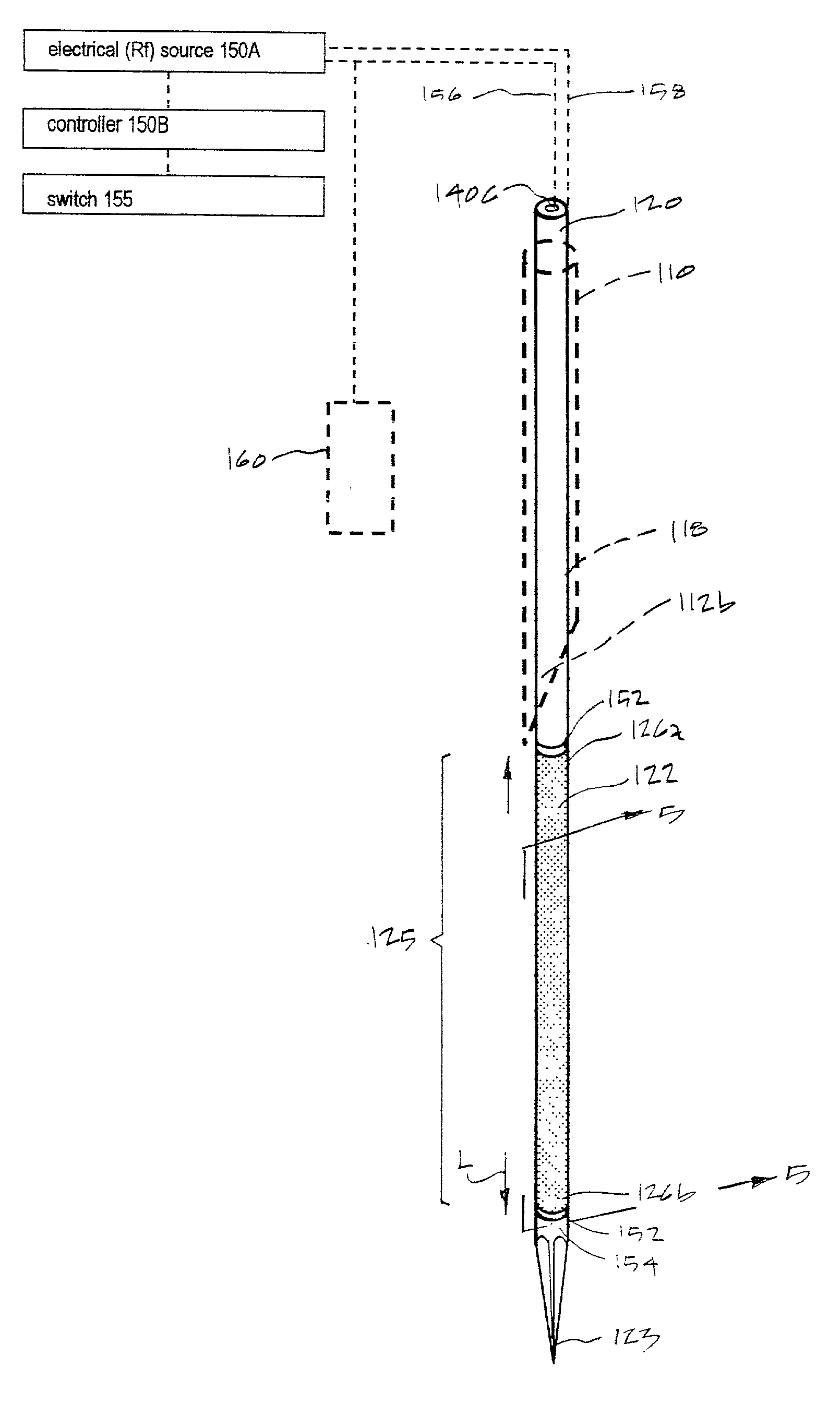

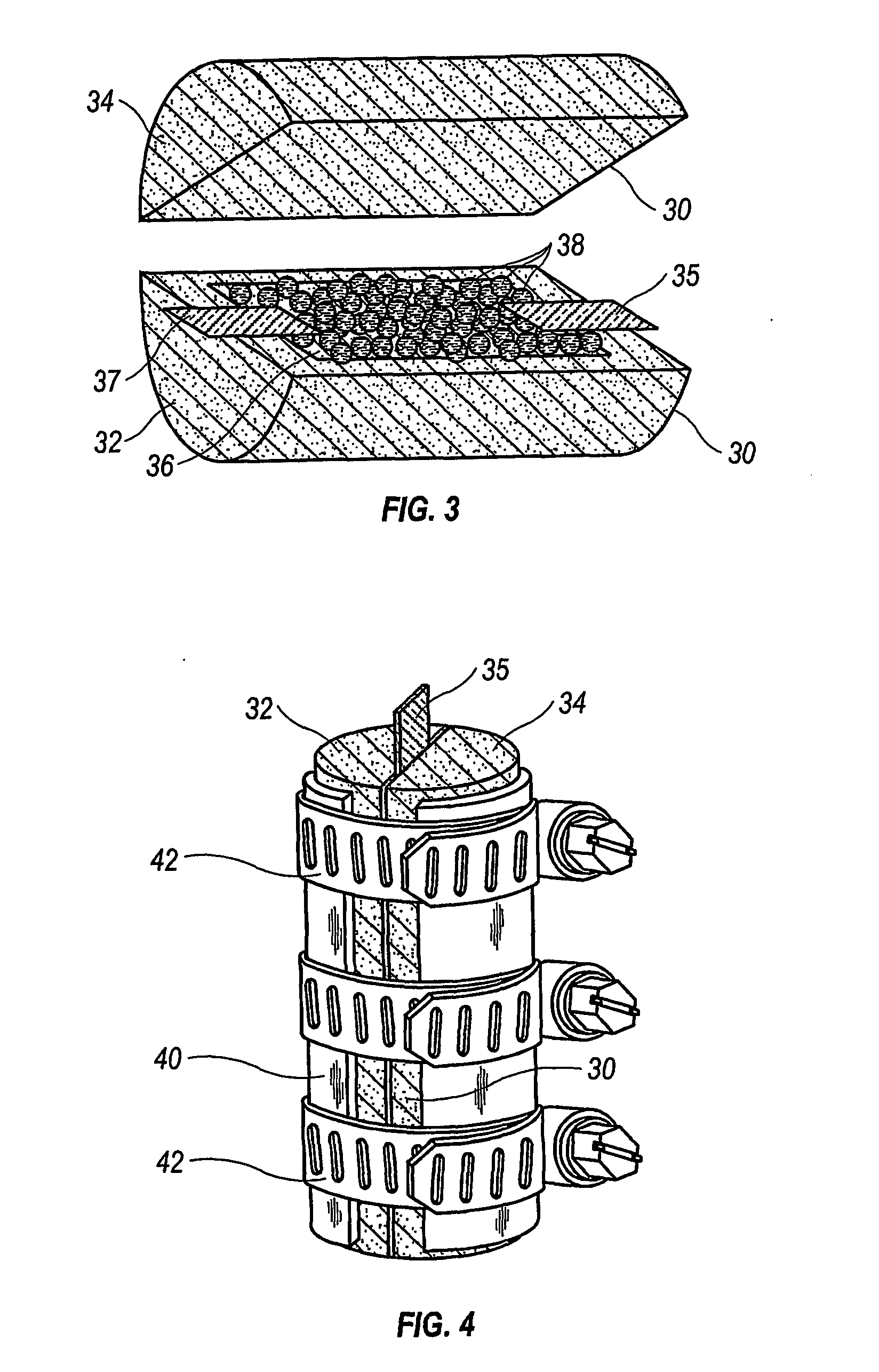

Electrosurgical working end for controlled energy delivery

InactiveUS20030078573A1Prevent any substantial dehydrationEnergy efficiencySurgical needlesSurgical instruments for heatingThermal energyConductive materials

An electrosurgical working end for instant and automatic modulation of active Rf density in a targeted tissue volume. The working end of the probe of the present invention defines a tissue-engagement plane that is adapted to contact the targeted tissue. The cross-section energy delivery apparatus comprises (i) a conductive surface engagement plane for tissue contact, (ii) a substrate comprising a medial conductive matrix of a temperature sensitive resistive material; and (iii) an inner or core conductive material (electrode) that is coupled to an Rf source and controller. Of particular interest, the medial conductive matrix comprises a positive temperature coefficient (PTC) that exhibits very large increases in resistivity as it increases beyond a selected temperature, which is described as a switching range. The PTC material is selected and fabricated to define a switching range that approximates a particular thermally-mediated therapy. In a method of use, it can be understood that the engagement plane will apply active Rf energy to the engaged the tissue temperature elevates the medial PTC conductive layer to its switching range. Thereafter, Rf current flow from the core conductive to the engagement surface will be instantly modulated to maintain tissue temperature at the switching range. Moreover, the conductive matrix effectively functions as a resistive electrode to thereafter passively conduct thermal energy to the engaged tissue above its switching range. Thus, the working end can modulate the energy application to tissue between active Rf heating and passive conductive heating of the targeted tissue to maintain a targeted temperature level.

Owner:SURGRX

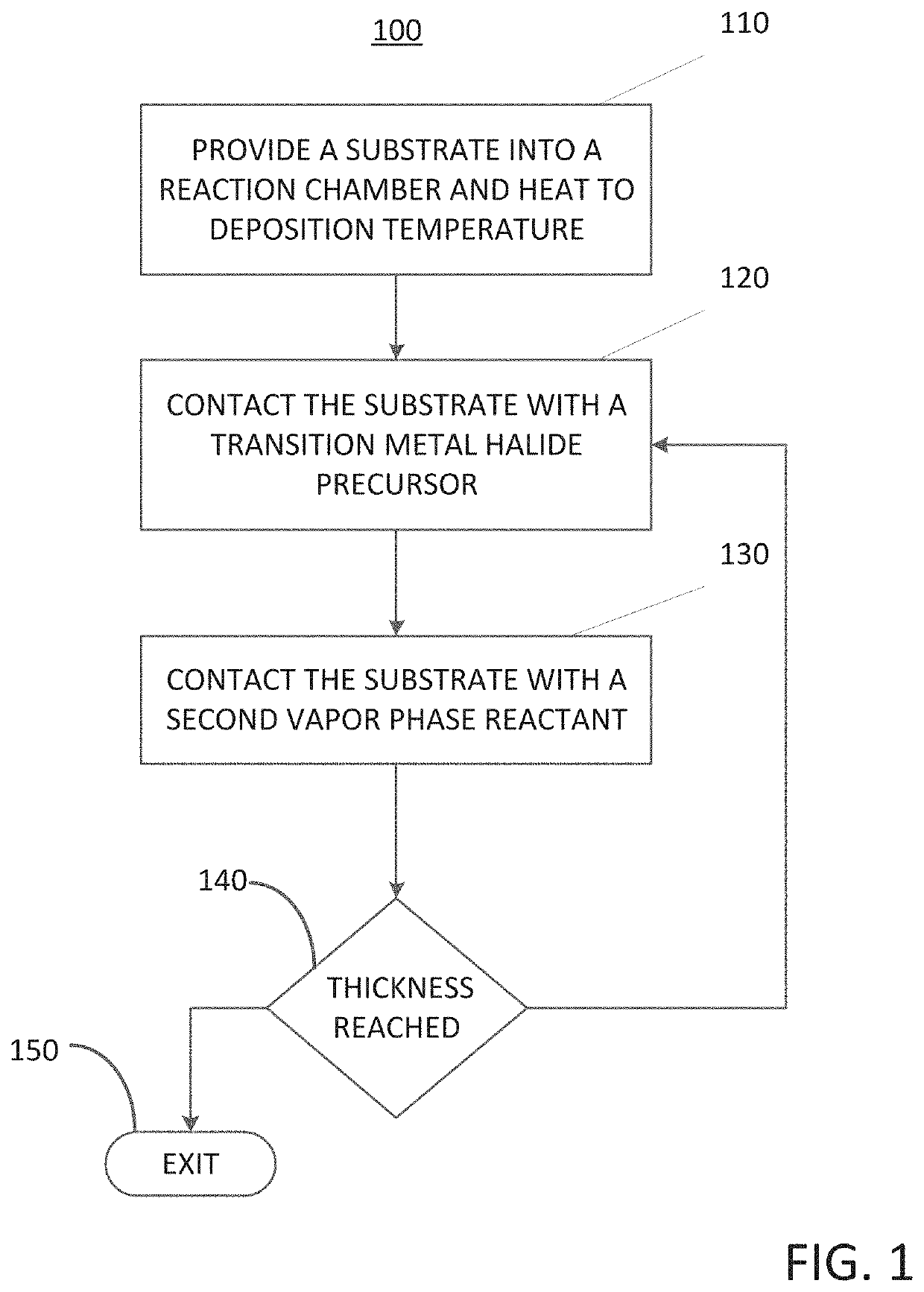

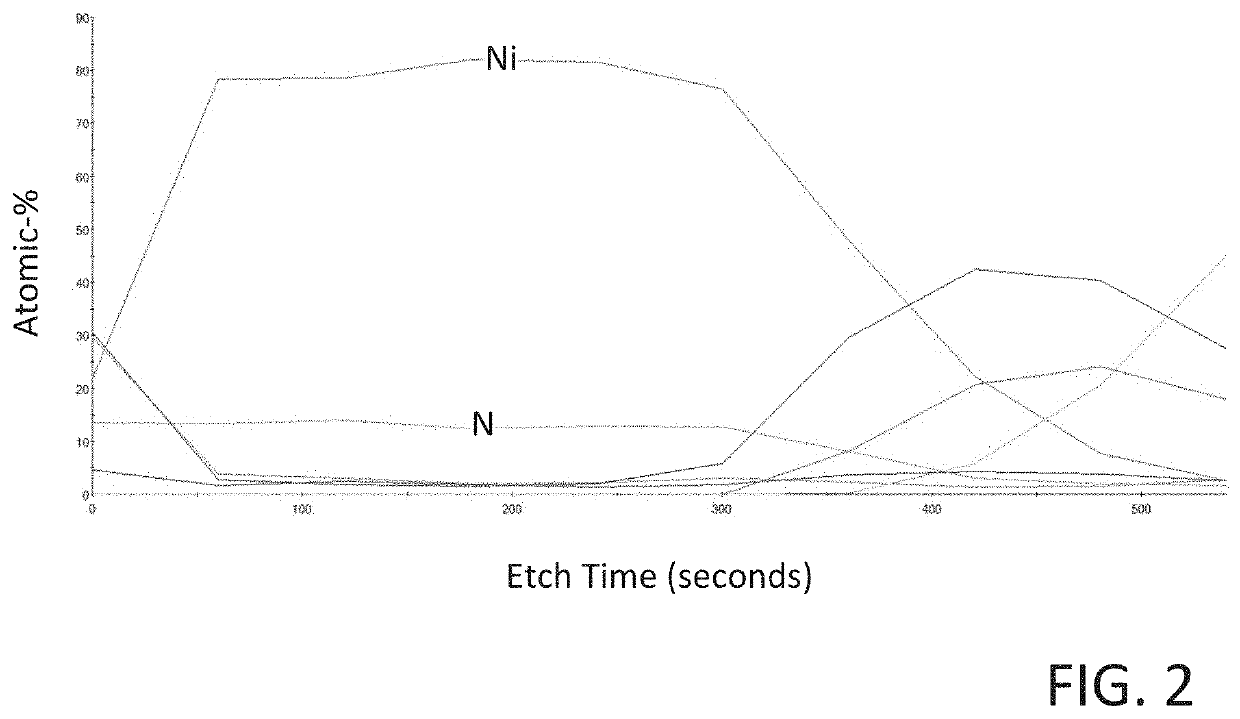

Methods of forming a transition metal containing film on a substrate by a cyclical deposition process

ActiveUS20200232096A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingDeposition processElectric resistivity

Methods of forming a transition metal containing film on a substrate by a cyclical deposition process are disclosed. The methods may include: contacting the substrate with a first vapor phase reactant comprising a transition metal halide compound comprising a bidentate nitrogen containing adduct ligand; and contacting the substrate with a second vapor phase reactant comprising a reducing agent precursor. The deposition methods may also include forming a transition metal containing film with an electrical resistivity of less than 50 μΩ-cm at a film thickness of less than 50 nanometers.

Owner:ASM IP HLDG BV

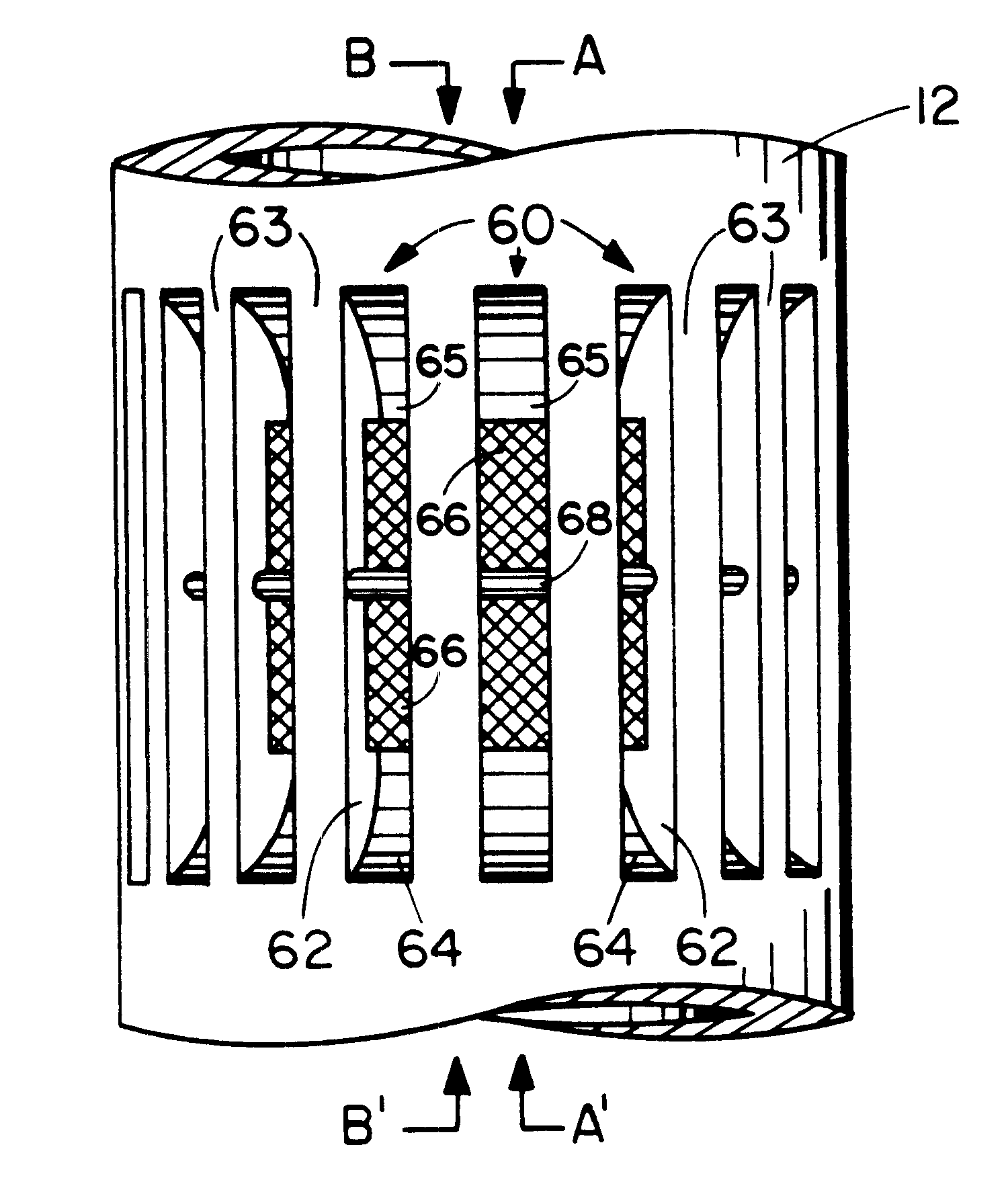

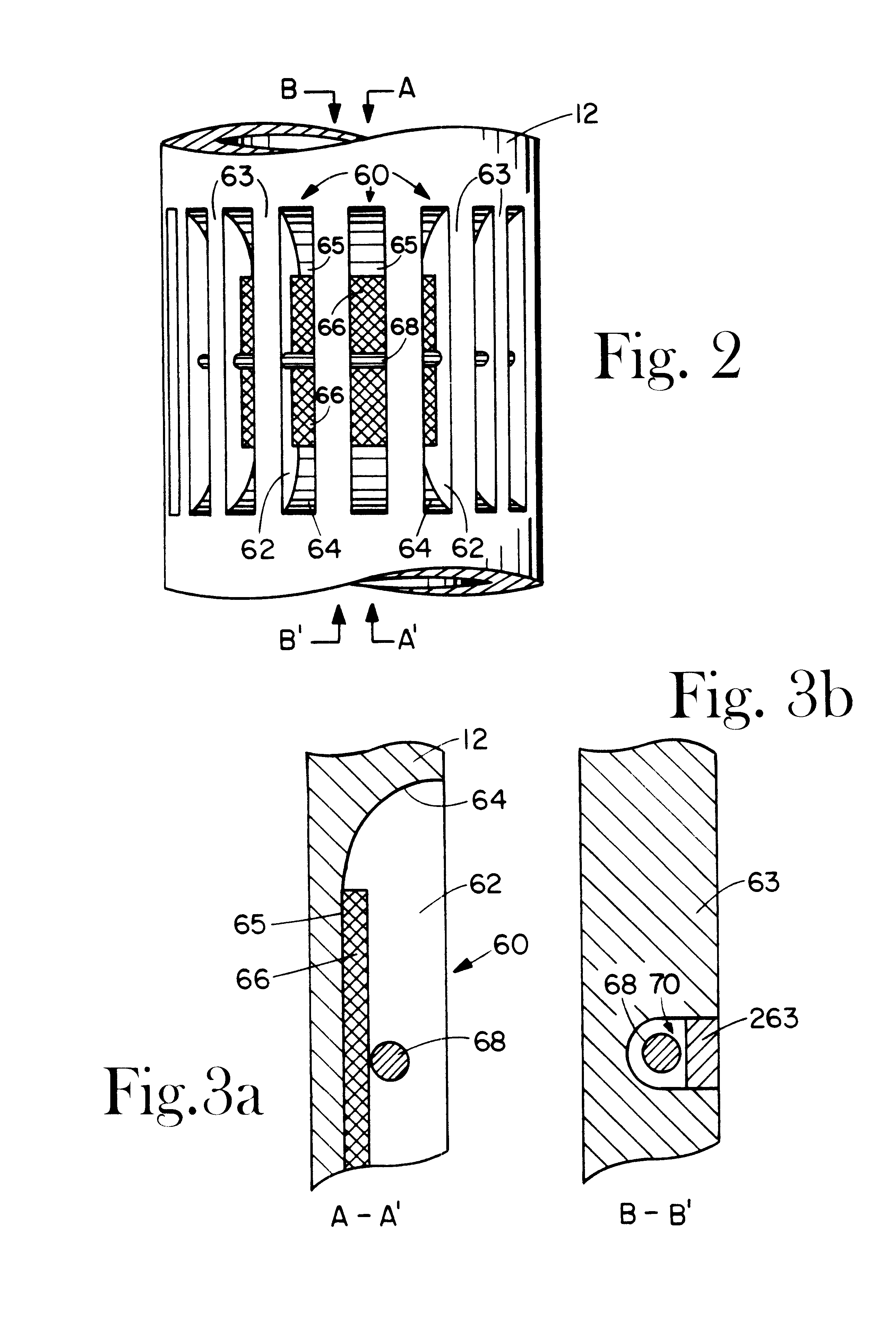

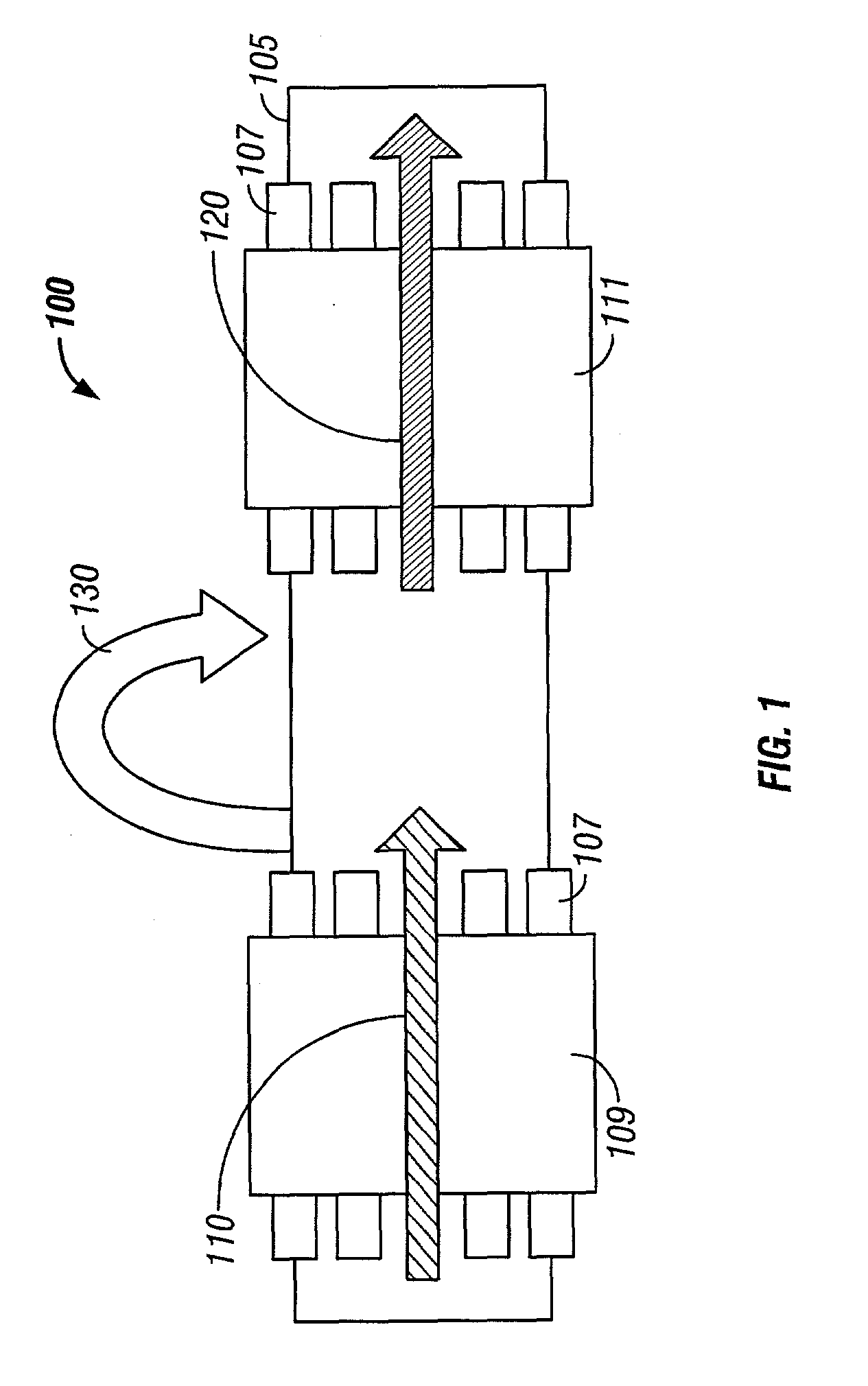

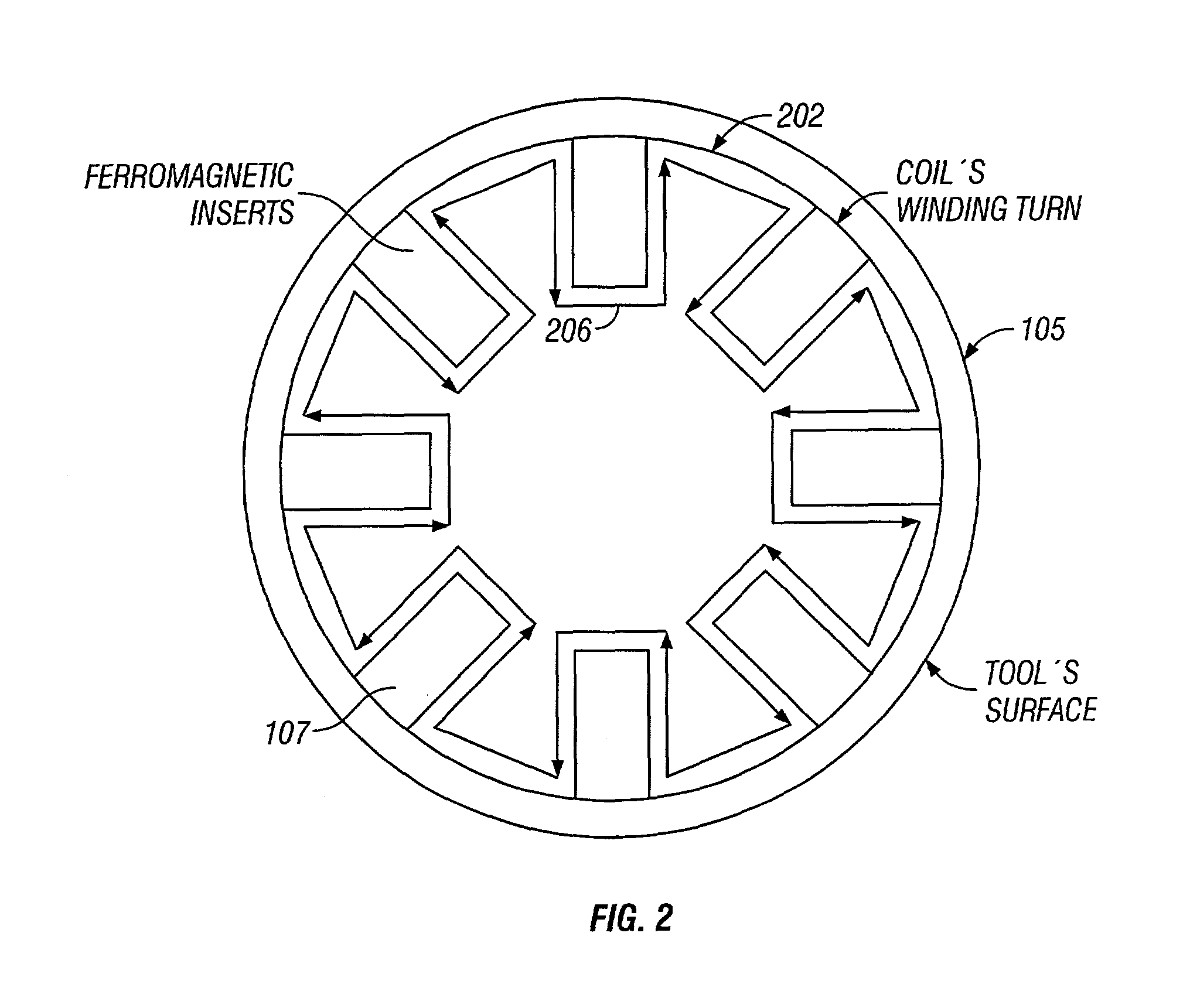

Well logging system for determining directional resistivity using multiple transmitter-receiver groups focused with magnetic reluctance material

InactiveUS6577129B1Improve antenna efficiencyHigh gainElectric/magnetic detection for well-loggingSubaqueous/subterranean adaptionWell loggingMagnetic reluctance

An electromagnetic wave propagation resistivity borehole logging system comprising multiple groups of electromagnetic transmitter-receiver arrays operating at three frequencies. The borehole logging tool component of the system employs eight transmitters and four receivers. The transmitters and receivers are disposed axially and symmetrically along the major axis of the tool to form four group pairs. Each group pair consists of a transmitter-receiver groups axially and symmetrically on opposing sides of a reference point on the tool. Each, transmitter-receiver group consists of one transmitter assembly and two receiver assemblies. Each transmitter-receiver group is operated at two of three operating frequencies which are 100 kHz, 400 kHz and 2 MHz. Some of the transmitter and receiver assemblies are fabricated to yield azimuthally focused resistivity measurements, and to yield vertical and horizontal resistivity in anisotropic dipping beds. The system can be embodied as a logging-while-drilling system or as a wireline logging system.

Owner:WEATHERFORD TECH HLDG LLC

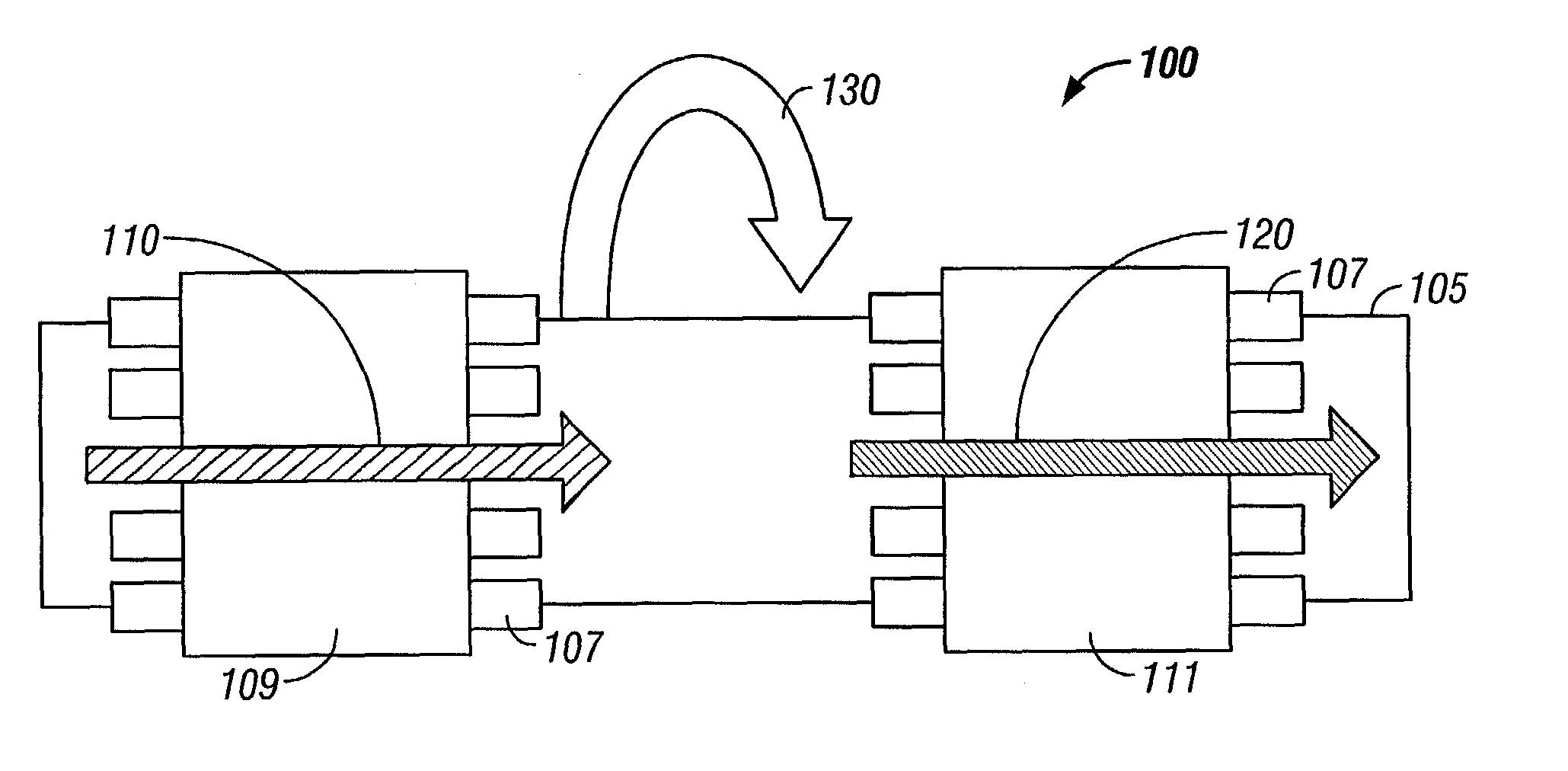

Method and apparatus for a multi-component induction instrument measuring system for geosteering and formation resistivity data interpretation in horizontal, vertical and deviated wells

InactiveUS20030076107A1Reduce the overall transmitter momentMinimize eddy currentElectric/magnetic detection for well-loggingSurveyGeosteeringWell logging

An improved induction tool for formation resistivity evaluations. The tool provides electromagnetic transmitters and sensors suitable for transmitting and receiving magnetic fields in radial directions that are orthogonal to the tool's longitudinal axis with minimal susceptibility to errors associated with parasitic eddy currents induced in the metal components surrounding the transmitter and receiver coils. Various transmitter receiver combinations are provided to select sensitivity to a desired reservoir formation properties, for example, different orientations xy, xz, yz, 20-40, 20-90, and combinations, such as, Symmetric-symmetric; Asymmetric-symmetric; and Asymmetric-asymmetric. Measurements made with a multi-component logging instrument when used in a substantially horizontal, vertical or deviated borehole in earth formations are diagnostic of the direction of resistive beds relative to the position of the borehole.

Owner:BAKER HUGHES INC

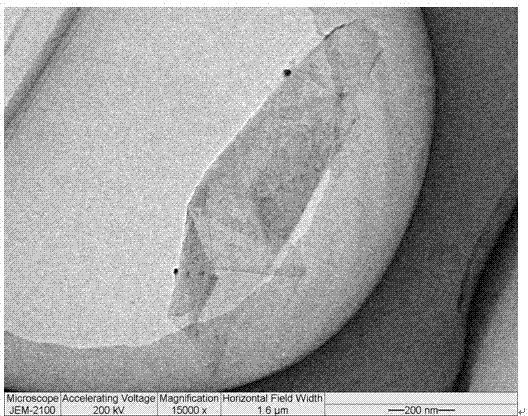

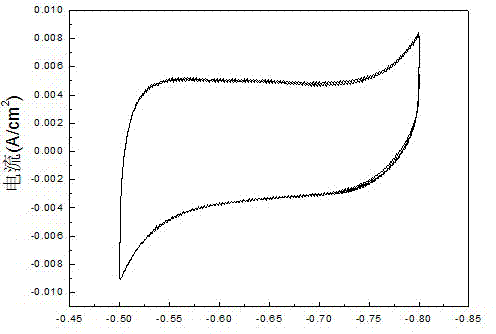

Graphene composite material and preparation method thereof

ActiveCN104495811ALarge specific surface areaImprove conductivityMaterial nanotechnologyPtru catalystElectrical battery

The invention relates to a graphene composite material and a preparation method thereof. The graphene composite material provided by the invention is characterized in that a graphene material plate fixed on a metallic matrix serves as a carrier, and the elementary substance and / or a compound are compounded on the graphene surface. Meanwhile, the invention also discloses a method for preparing the graphene composite material. The graphene composite material prepared by the invention is opened between graphene sheets and is compounded with a chemical substance under the condition that a space body structure is formed, and the obtained material has high conductivity, high specific surface area and excellent performance of low electrical resistivity between the sheets, and can be widely applied to the fields of energy storage materials such as lithium ion batteries, super-capacitors, super lead carbon batteries, super nickel-carbon electrodes, solar energy and fuel cells, the field of heat dissipation materials, the field of environment-friendly adsorbing materials, the field of sea water desalination materials, the field of photoelectric sensor materials, the biological relevance field, the field of catalyst materials and the fields of conductive ink and coating materials.

Owner:YANCHENG TEACHERS UNIV

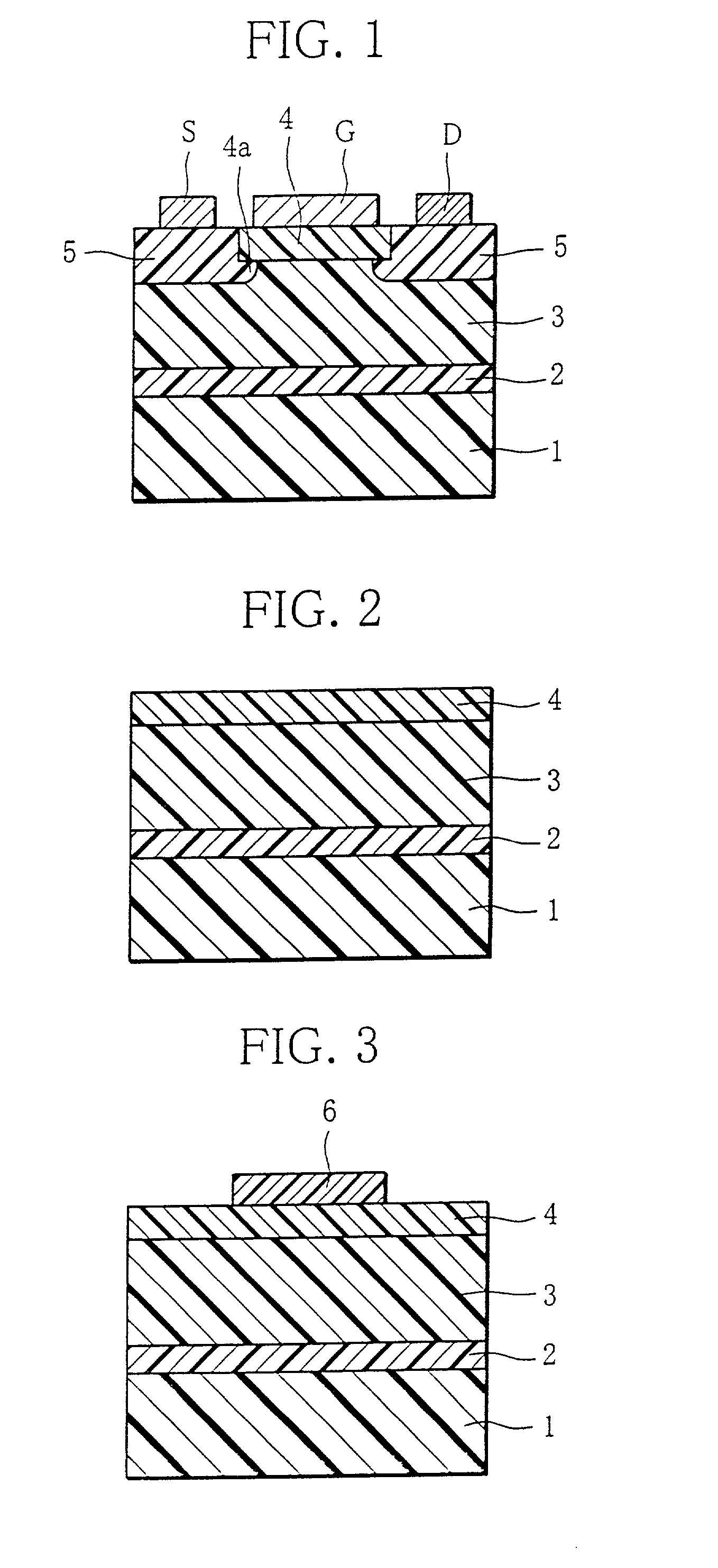

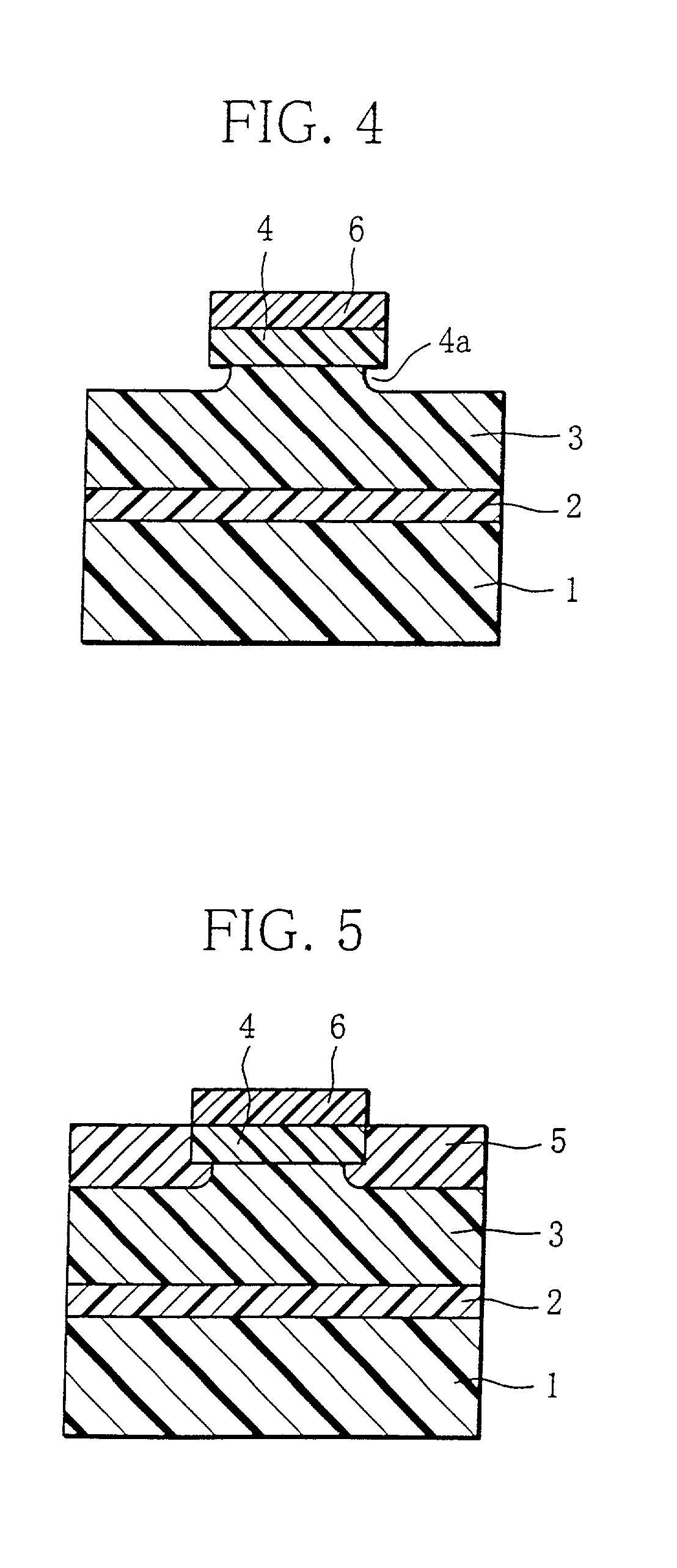

Manufacturing method for a semiconductor on insulator type substrate for radiofrequency applications

ActiveUS20140084290A1Semiconductor/solid-state device manufacturingSemiconductor devicesSemiconductorPolycrystalline silicon

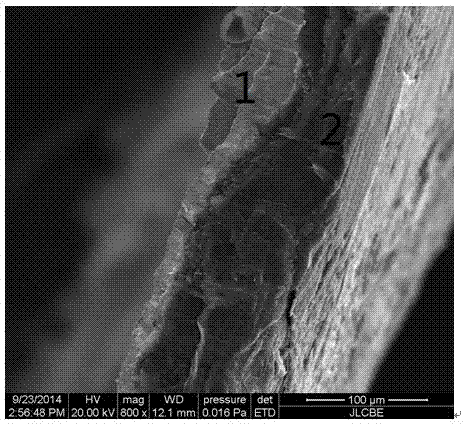

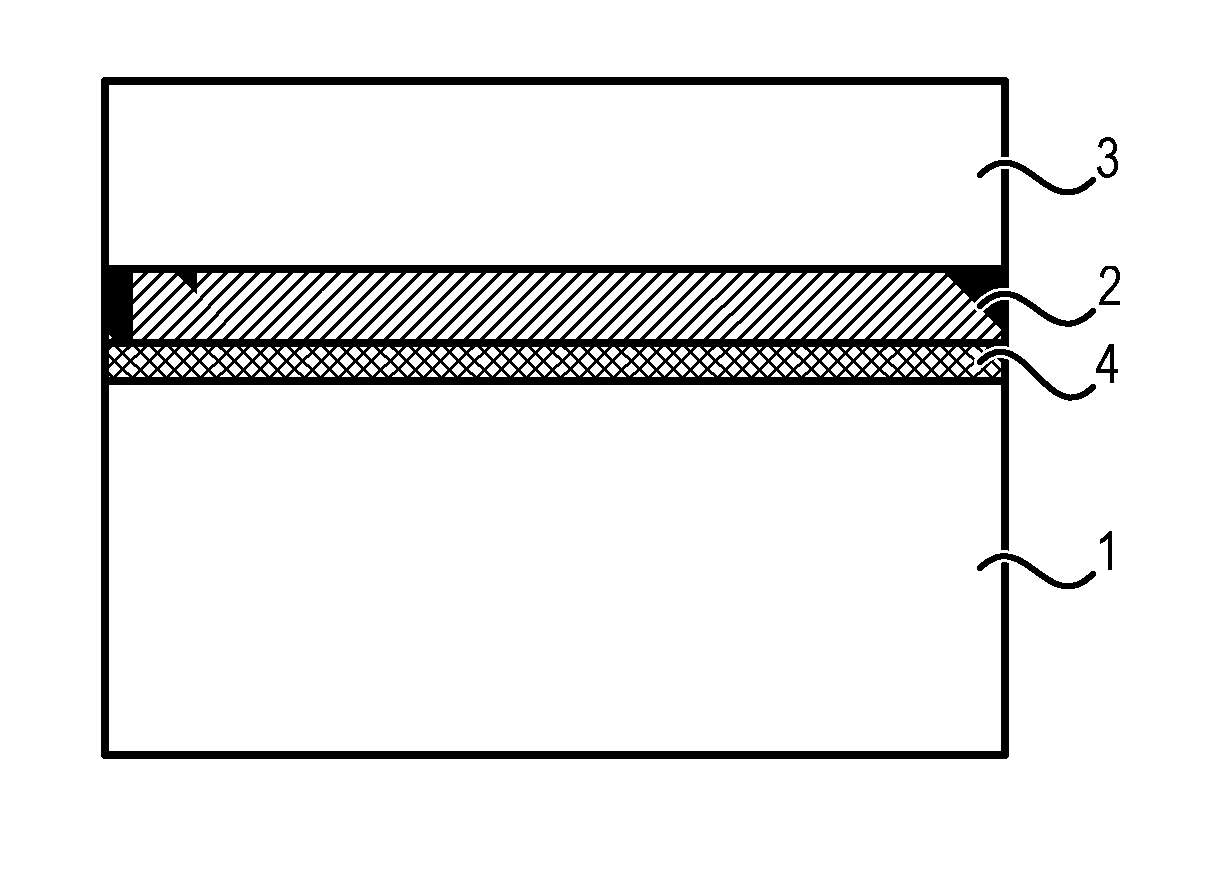

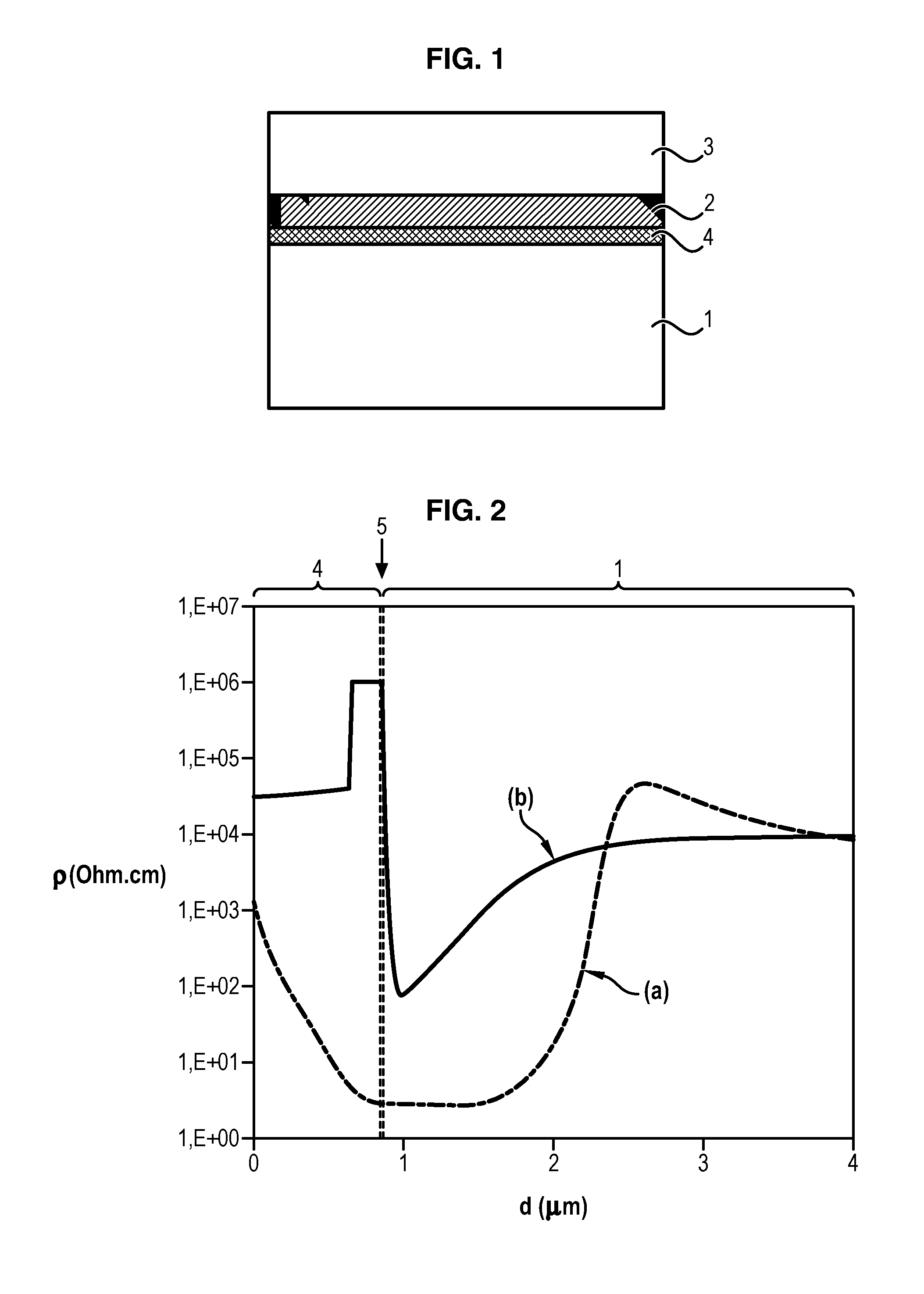

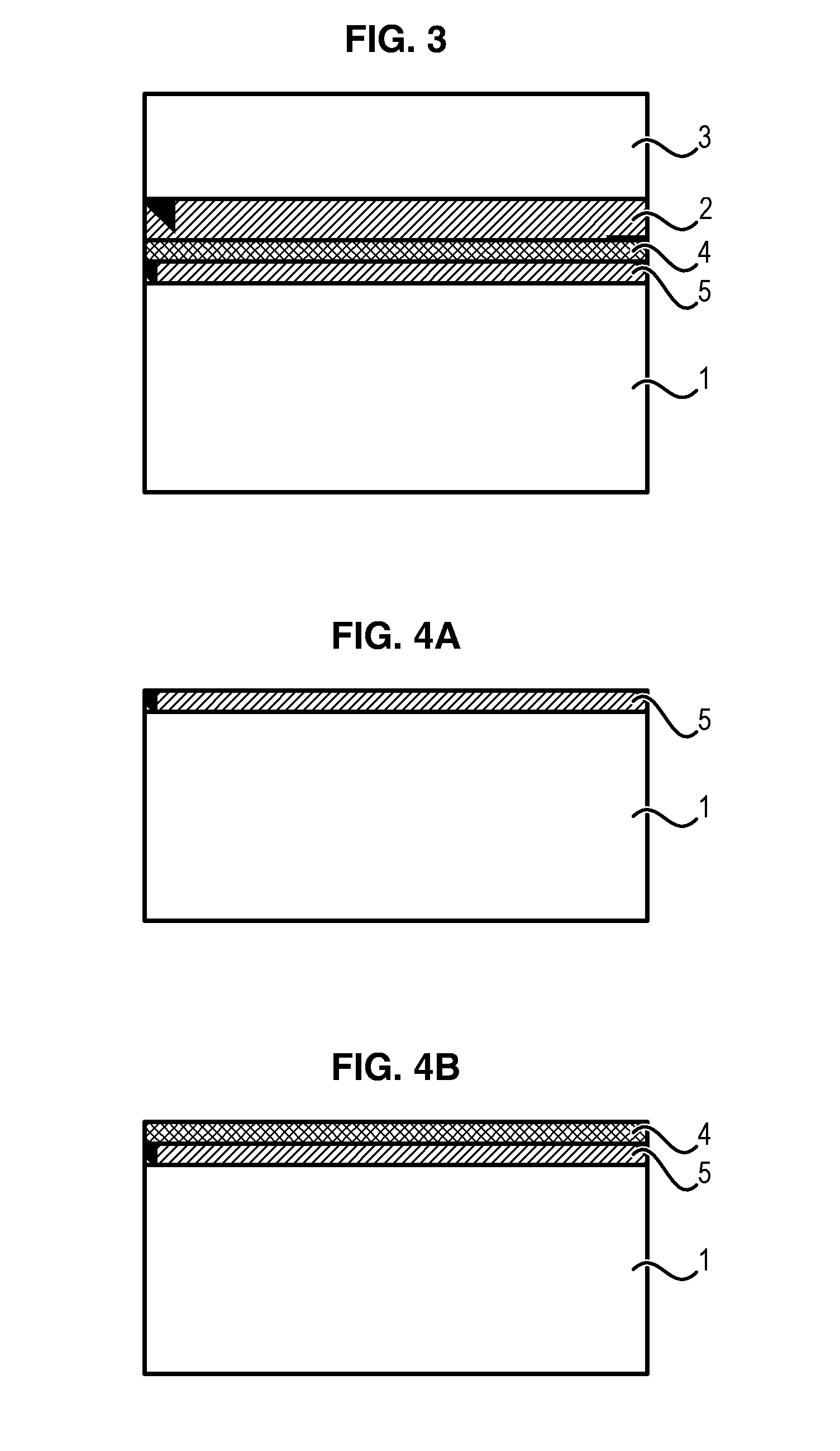

The invention relates to a method for manufacturing a semiconductor on insulator type substrate for radiofrequency applications, comprising the following steps in sequence: (a) provision of a silicon substrate (1) with an electrical resistivity of more than 500 Ohm·cm, (b) formation of a polycrystalline silicon layer (4) on said substrate (1), said method comprising a step between steps a) and b) to form a dielectric material layer (5), different from a native oxide layer, on the substrate (1), between 0.5 and 10 nm thick.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

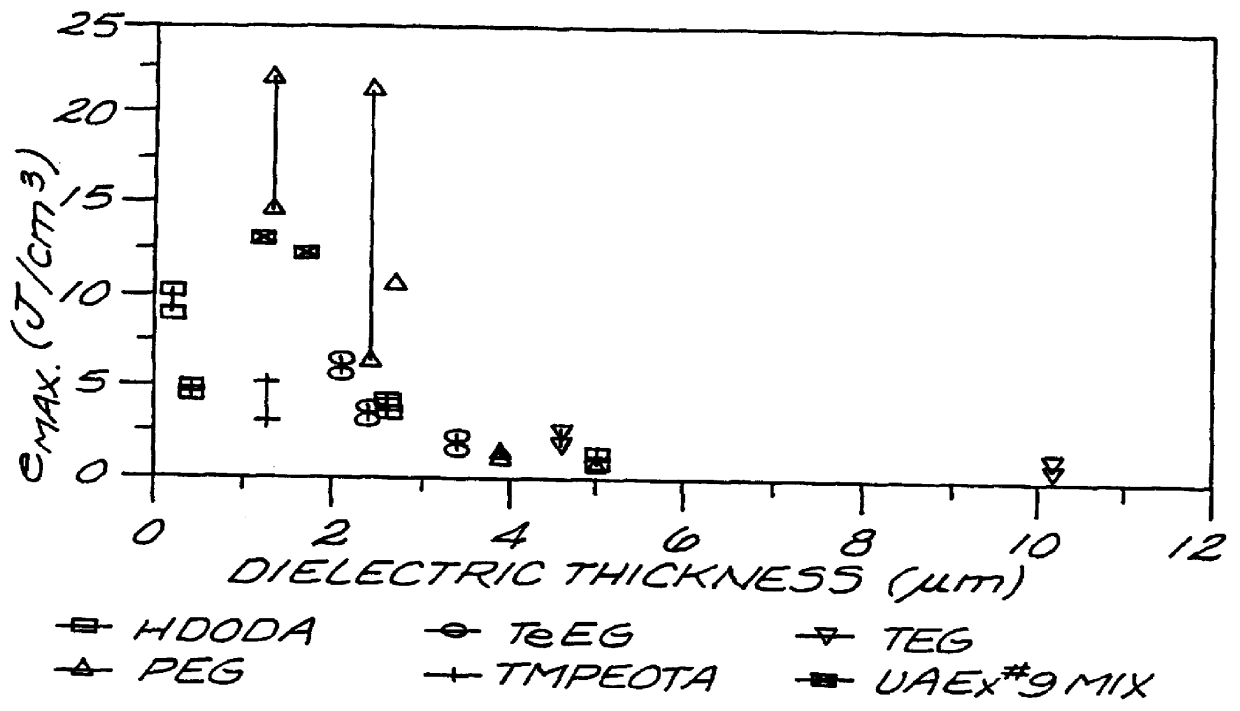

High energy density capacitor

A high energy density, high power density capacitor having an energy density of at least about 0.5 J / cm3 is provided. The capacitor comprises a plurality of interleaved metal electrode layers separated by a polymer layer. The interleaved metal electrode layers terminate at opposite ends in a solder termination strip. The high energy density aspect of the capacitors of the invention is achieved by at least one of the following features: (a) the dielectric thickness between the interleaved metal electrode layers is a maximum of about 5 mu m; (b) the polymer is designed with a high dielectric constant kappa of at least about 3.5; (c) the metal electrode layers within the polymer layer are recessed along edges orthogonal to the solder termination strips to prevent arcing between the metal electrode layers at the edges; and (d) the resistivity of the metal electrode layers is within the range of about 10 to 500 ohms per square, or a corresponding thickness of about 200 to 30 ANGSTROM .

Owner:SIGMA LAB OF ARIZONA

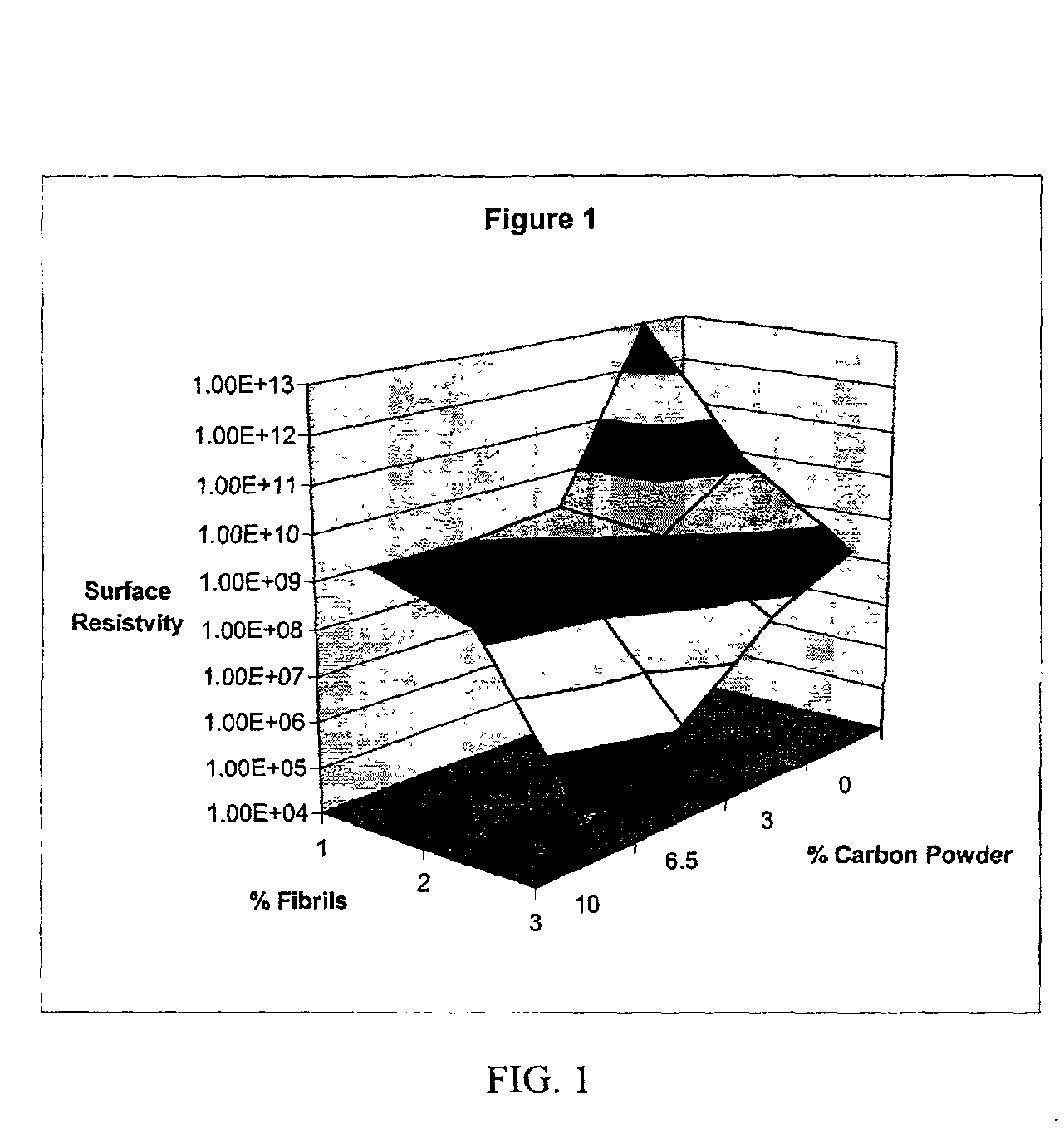

Conductive plastic compositions and method of manufacture thereof

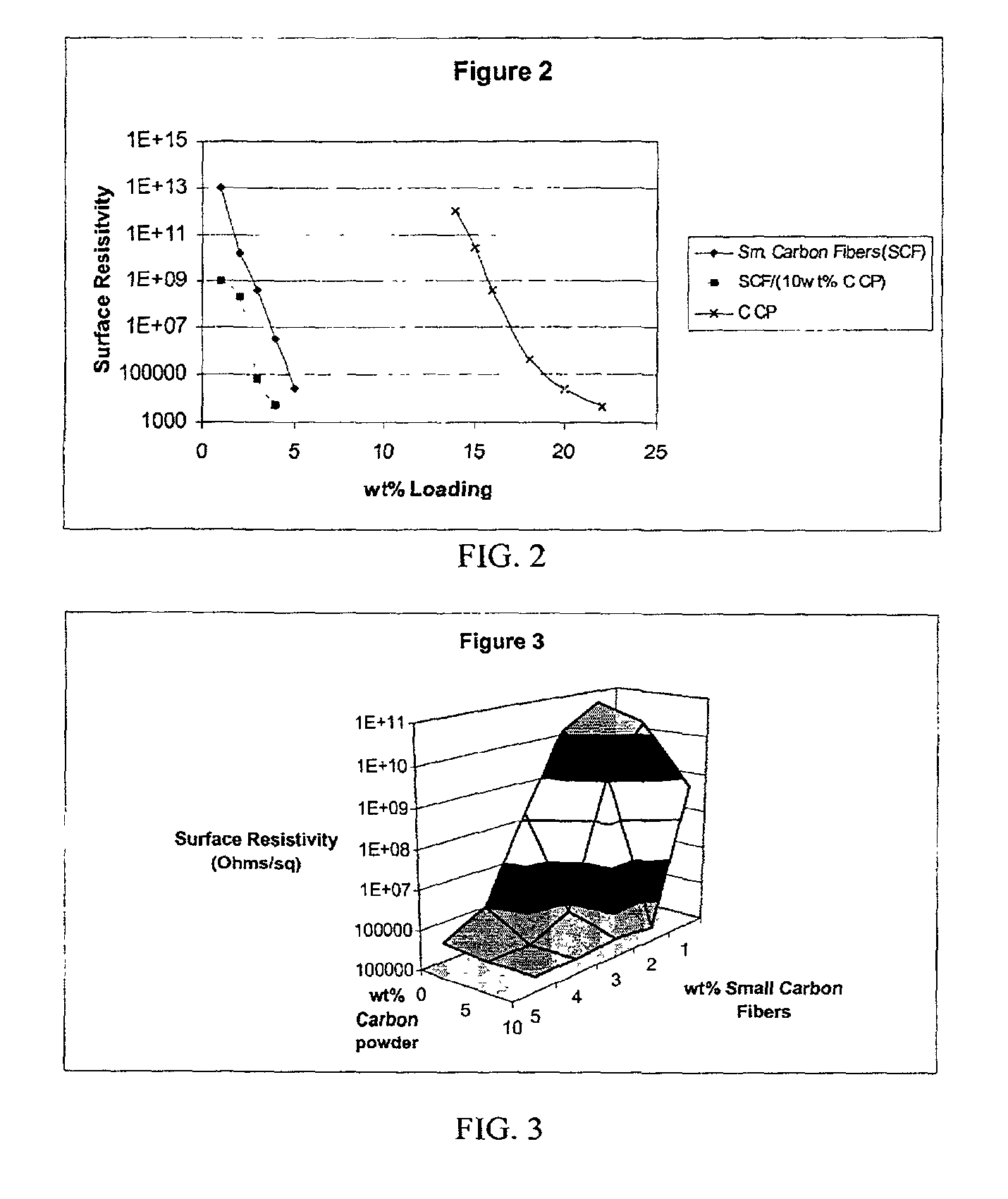

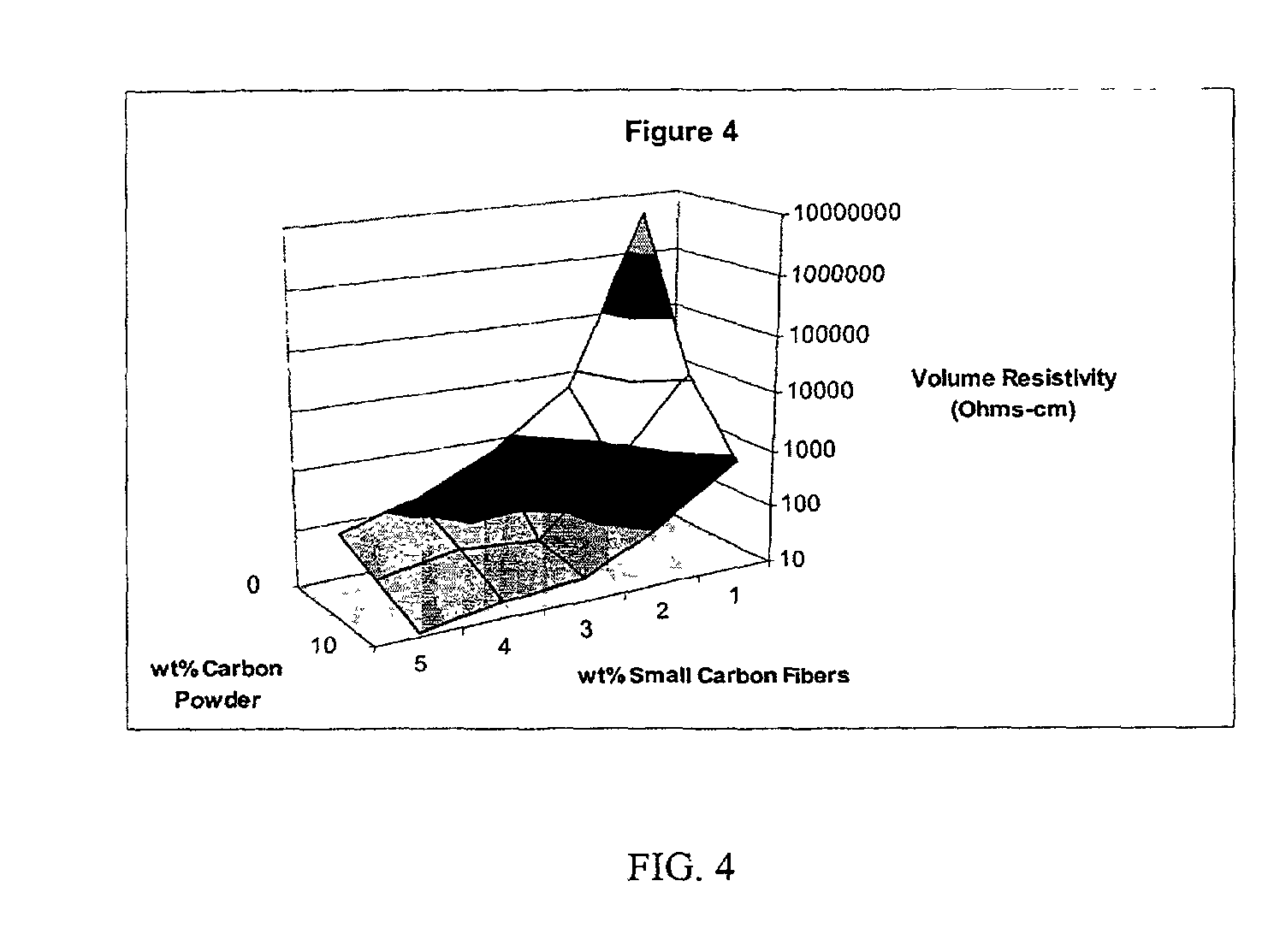

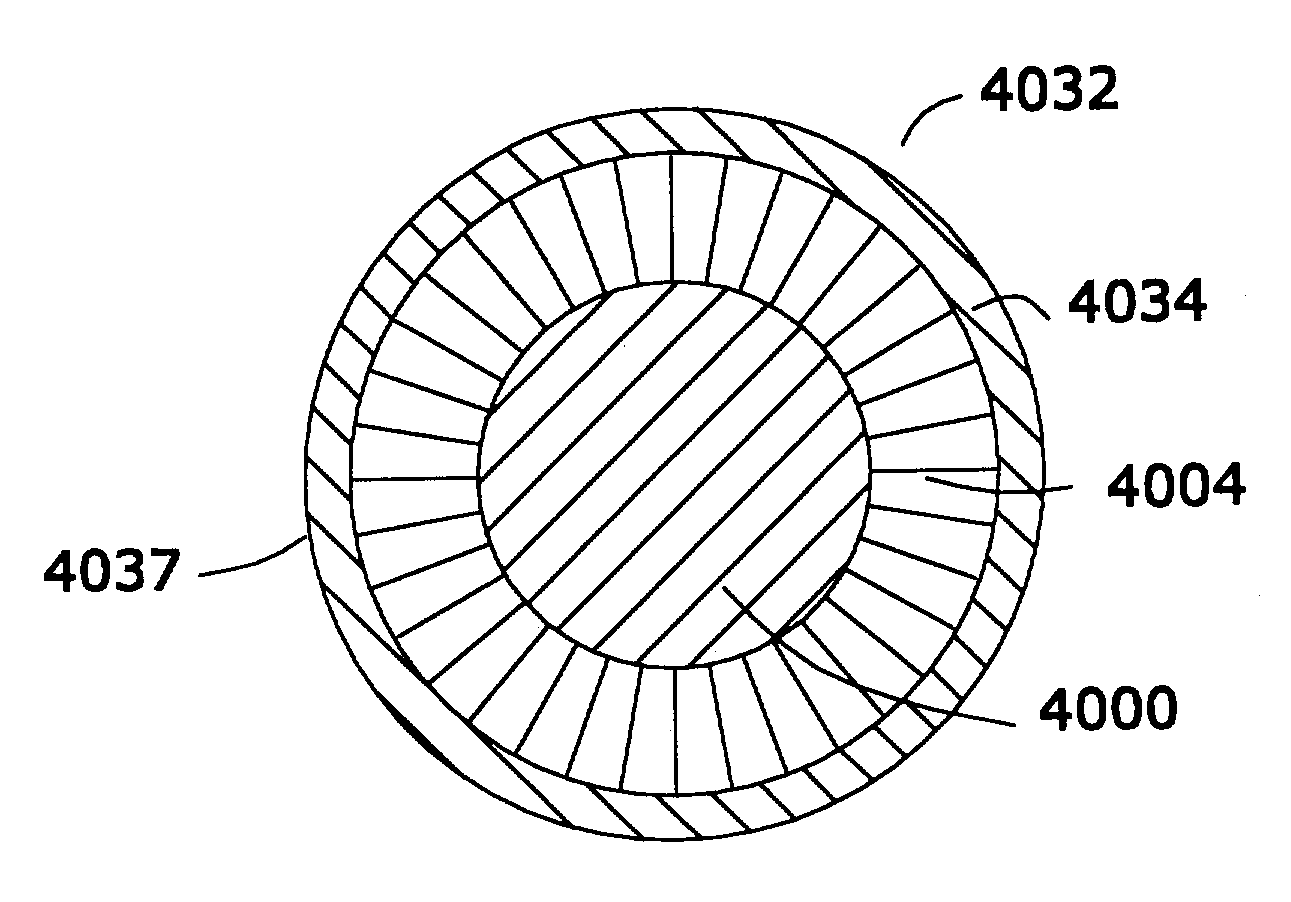

InactiveUS20020183438A1Reduce concentrationSame surface resistivitySpecial tyresNon-conductive material with dispersed conductive materialFiberCarbon fibers

An improved, conductive, polymeric composition comprises a polymeric resin; an electrically conductive filler system comprising small carbon fibers and either carbon powder or fibrous non-conductive filler or a combination of both. The amount of the conductive filler system utilized is dependent upon the desired electrical conductivity (surface and volume conductivity or resistivity) while preferably preserving intrinsic properties of the polymeric resin such as impact, flex modulus, class A finish, and the like. The conductive articles made from these compositions can therefore be used for electromagnetic shielding, electrostatic dissipation or antistatic purposes in packaging, electronic components, housings for electronic components and automotive housings.

Owner:SABIC GLOBAL TECH BV

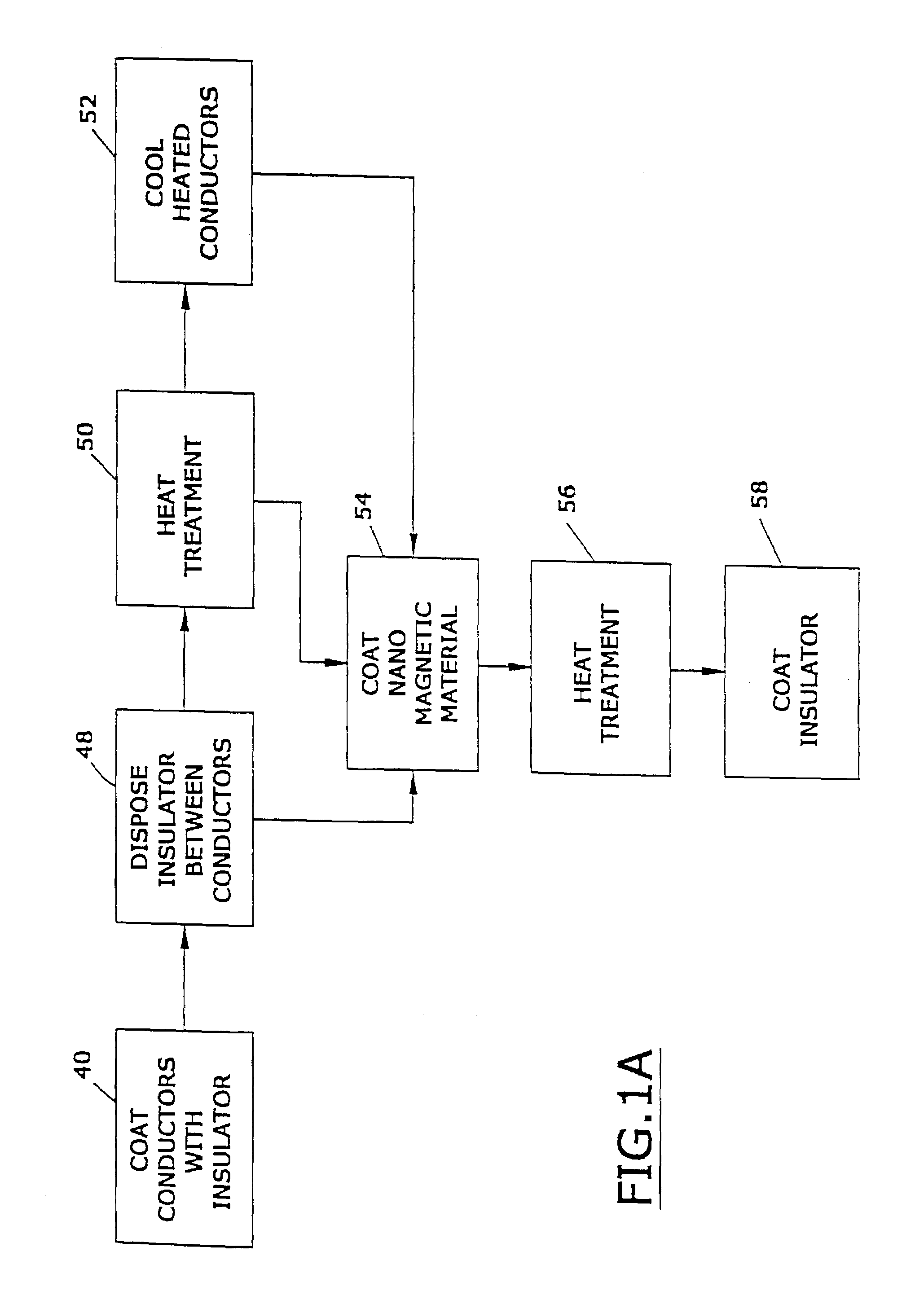

Implantable shielded medical device

An implantable device that contains a power source, a device for producing electrical signals, and a conductor assembly for communicating the electrical signals to biological matter. The conductor assembly contains of a conductor that is capable of being flexed at least about 15 degrees and that has a resistivity at 20 degrees Centigrade of from about 1 to about 100 micro ohm-centimeters. The conductor assembly also contains a magnetic shield located above the flexible conductor; the magnetic shield contains an antithrombogenic composition. The magnetic shield also contains a magnetic shielding material that has a magnetic shielding factor of at least about 0.5.

Owner:BIOPHAN TECH

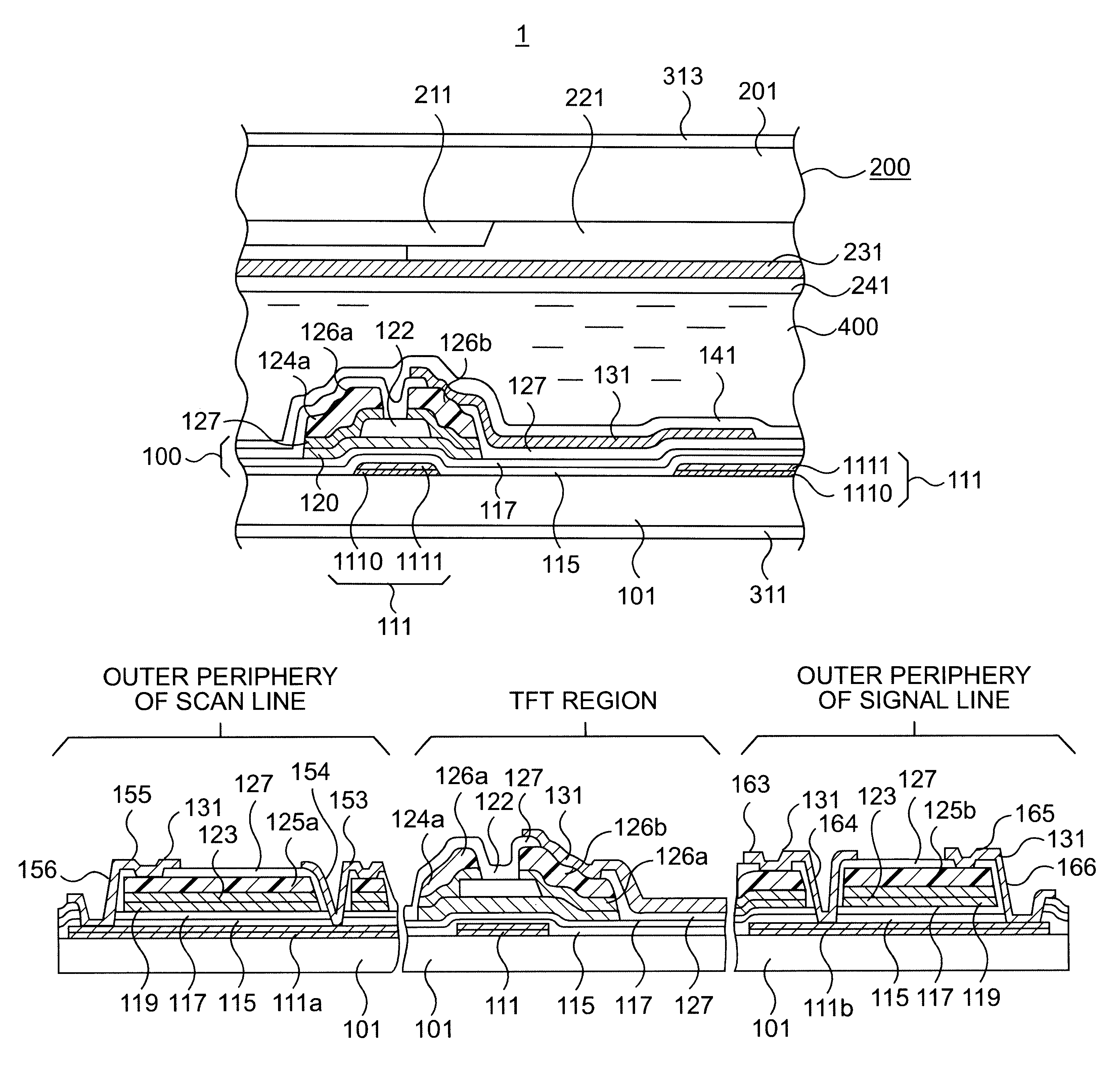

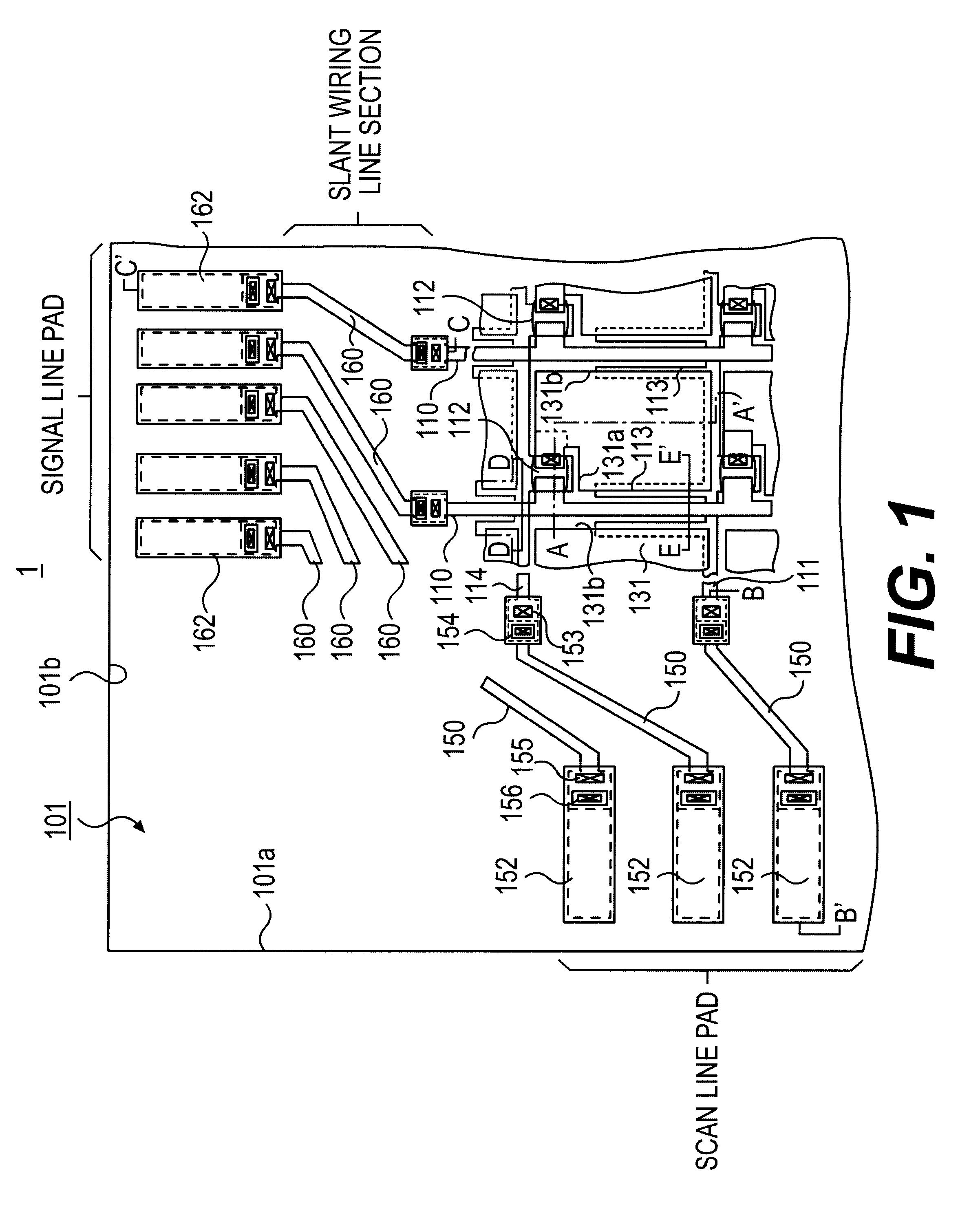

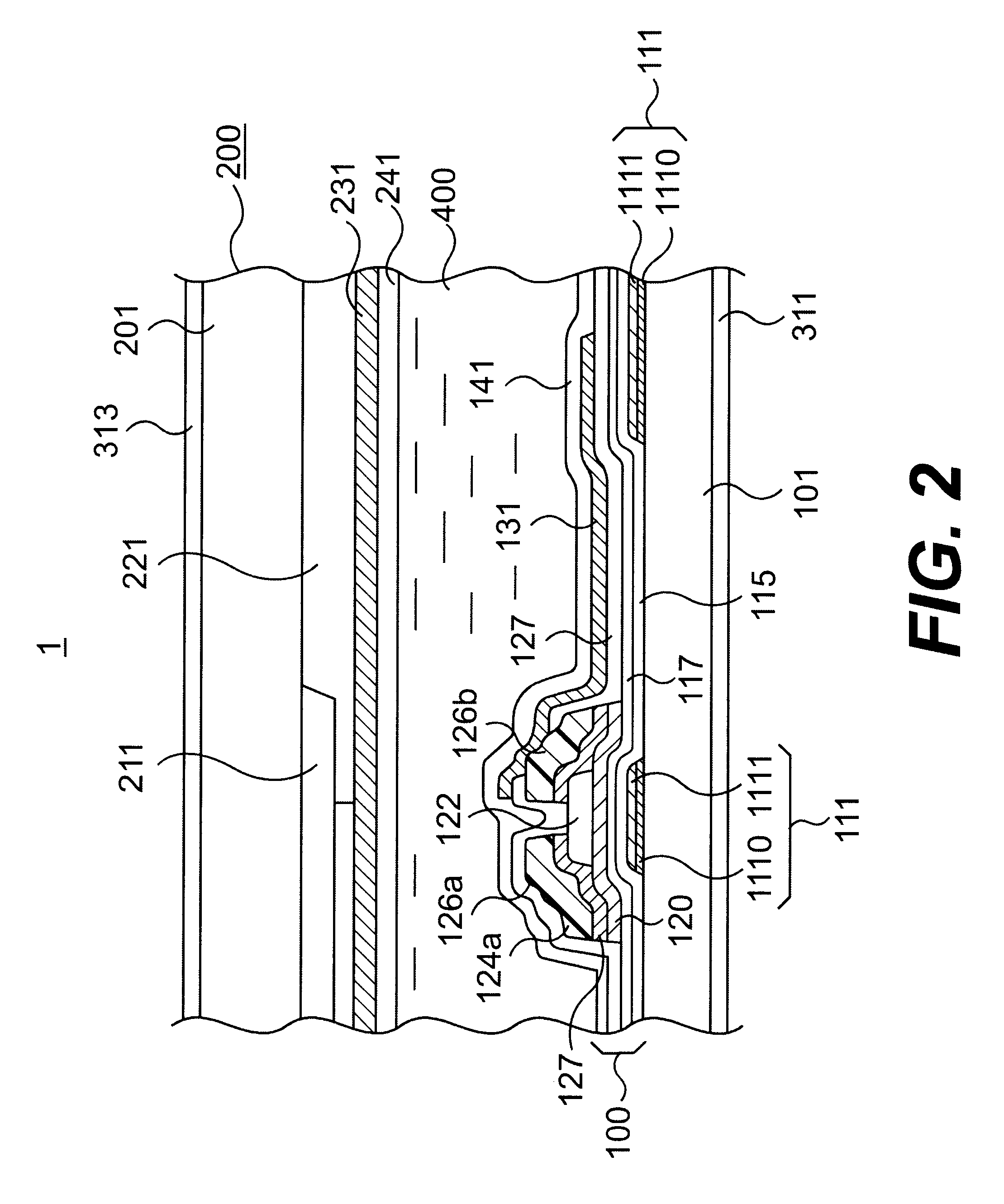

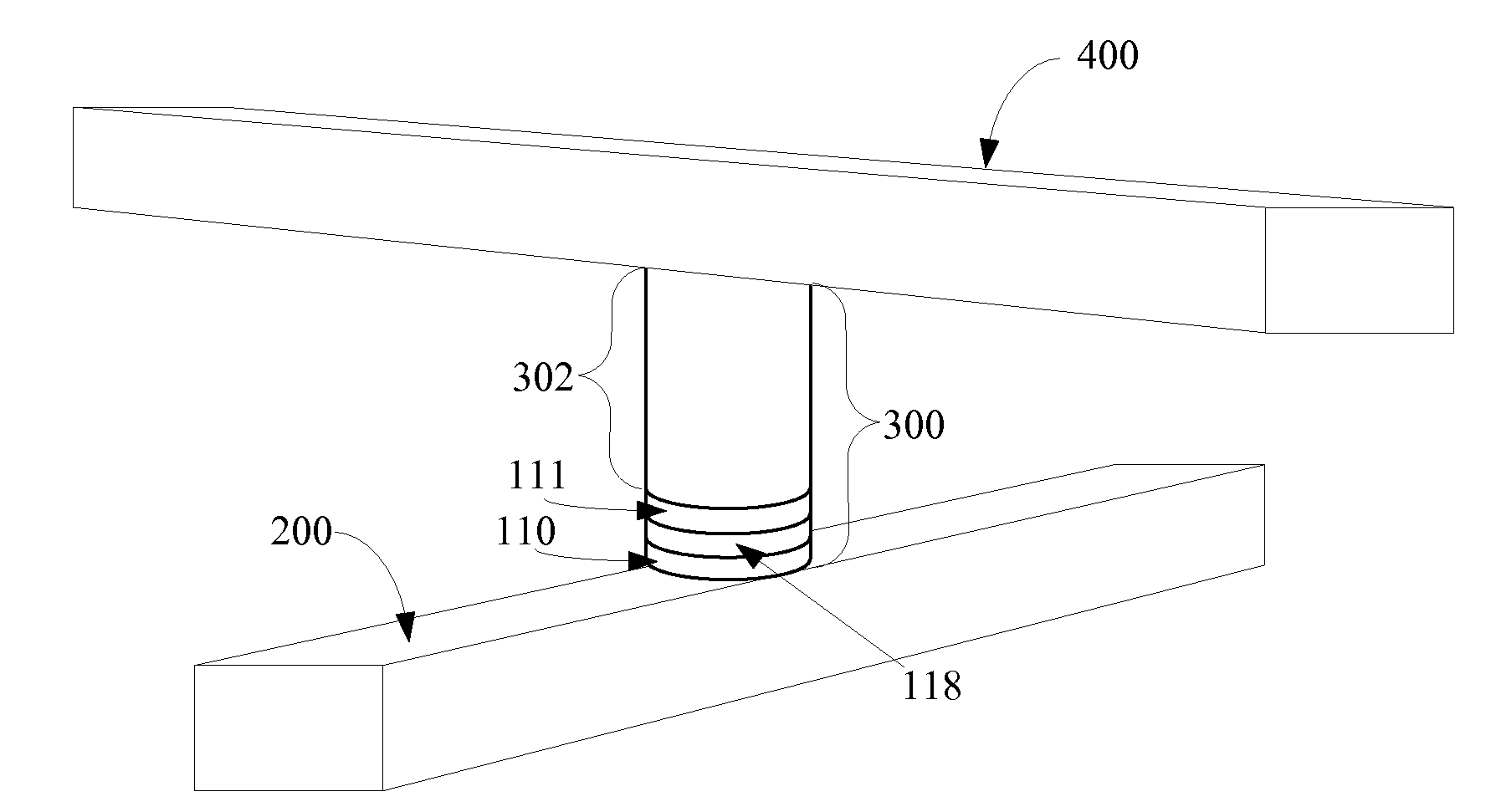

Method of manufacturing array substrate

InactiveUS6528357B2Reduce productionSolid-state devicesSemiconductor/solid-state device manufacturingOXALIC ACID DIHYDRATEDielectric

In the manufacturing method of array substrates for use in flat panel display devices including liquid crystal display (LCD) devices, it is aimed to prevent failure of interlayer dielectric film due to wiring deformation or the like while reducing the resistivity of wiring. It is also aimed to prevent corrosion of a metal wiring layer at the etching process and to thereby prevent deterioration of production yield due to corrosion. According to the method of the invention, to form scanning lines (111), an aluminum-neodymium alloy (Al-Nd) film (1110) is deposited in 300 nm thickness on the first hand, and then 50 nm thick Mo film (1110) is deposited thereon. Subsequently, gate insulator films (115 and 117) are formed by CVD processes at a substrate temperature of 350° C. Further, an etching process for forming pixel electrode (131) is carried out by HBr, HI, Oxalic acid or a mixture liquid containing at least one of these acids.

Owner:KK TOSHIBA

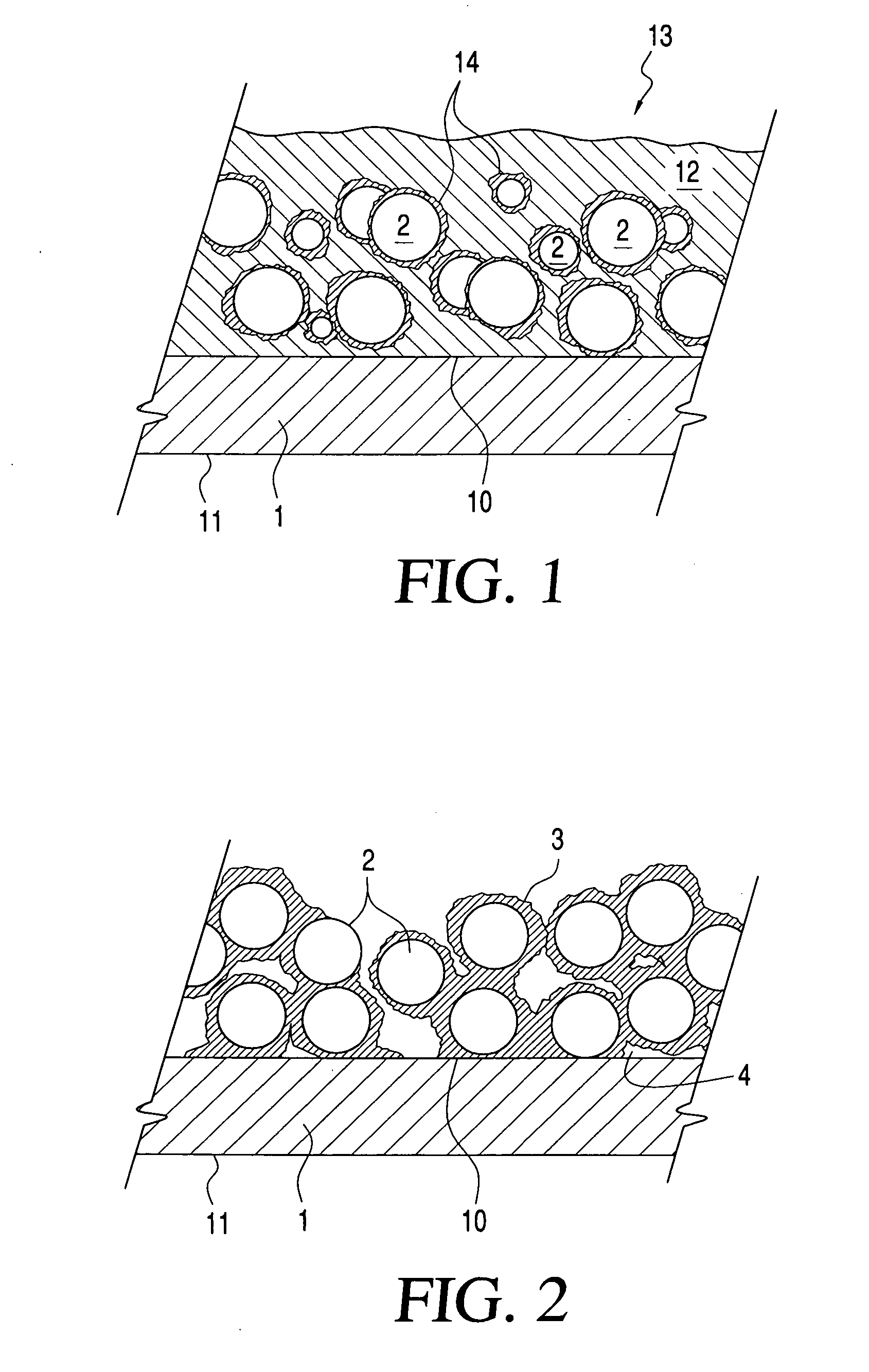

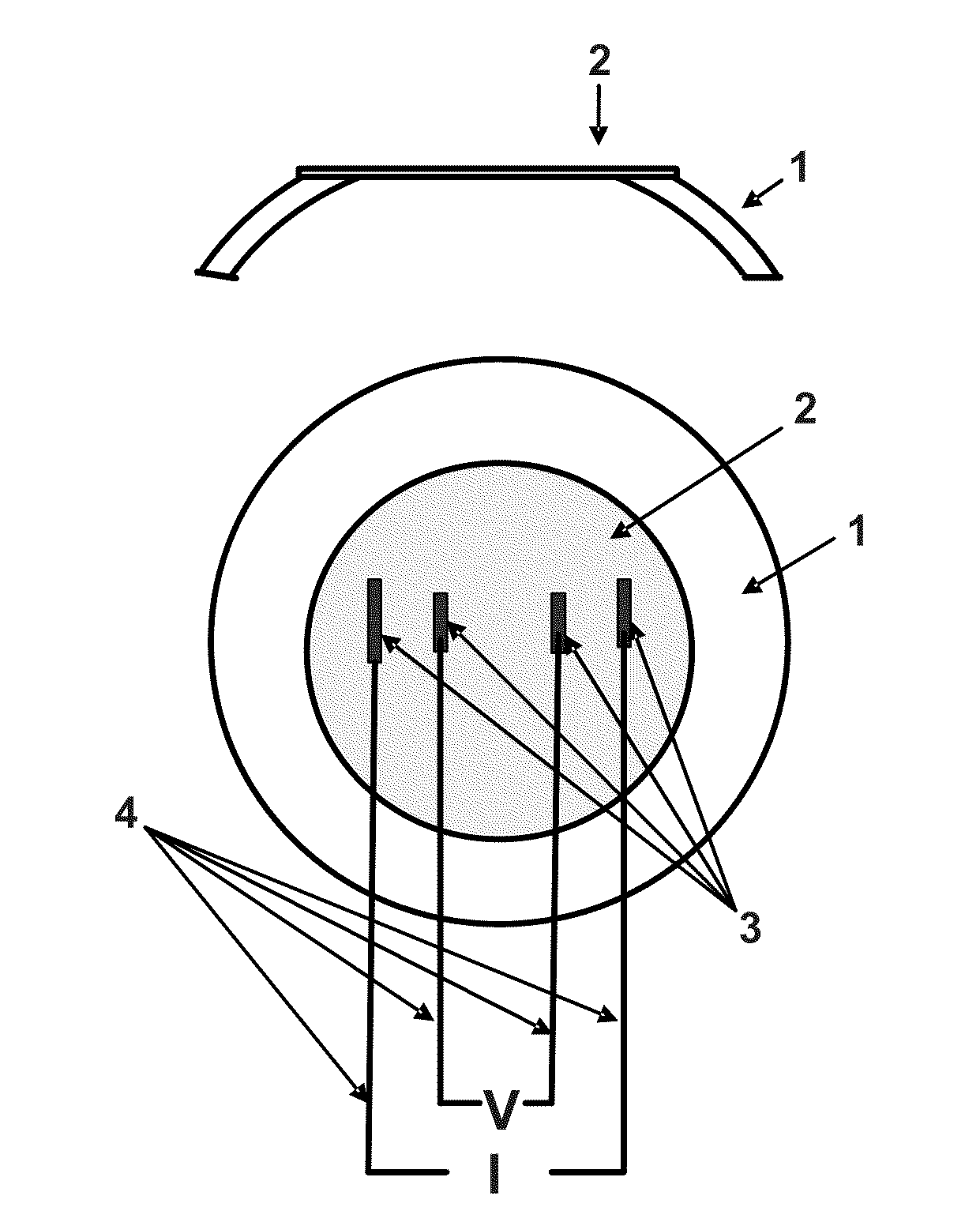

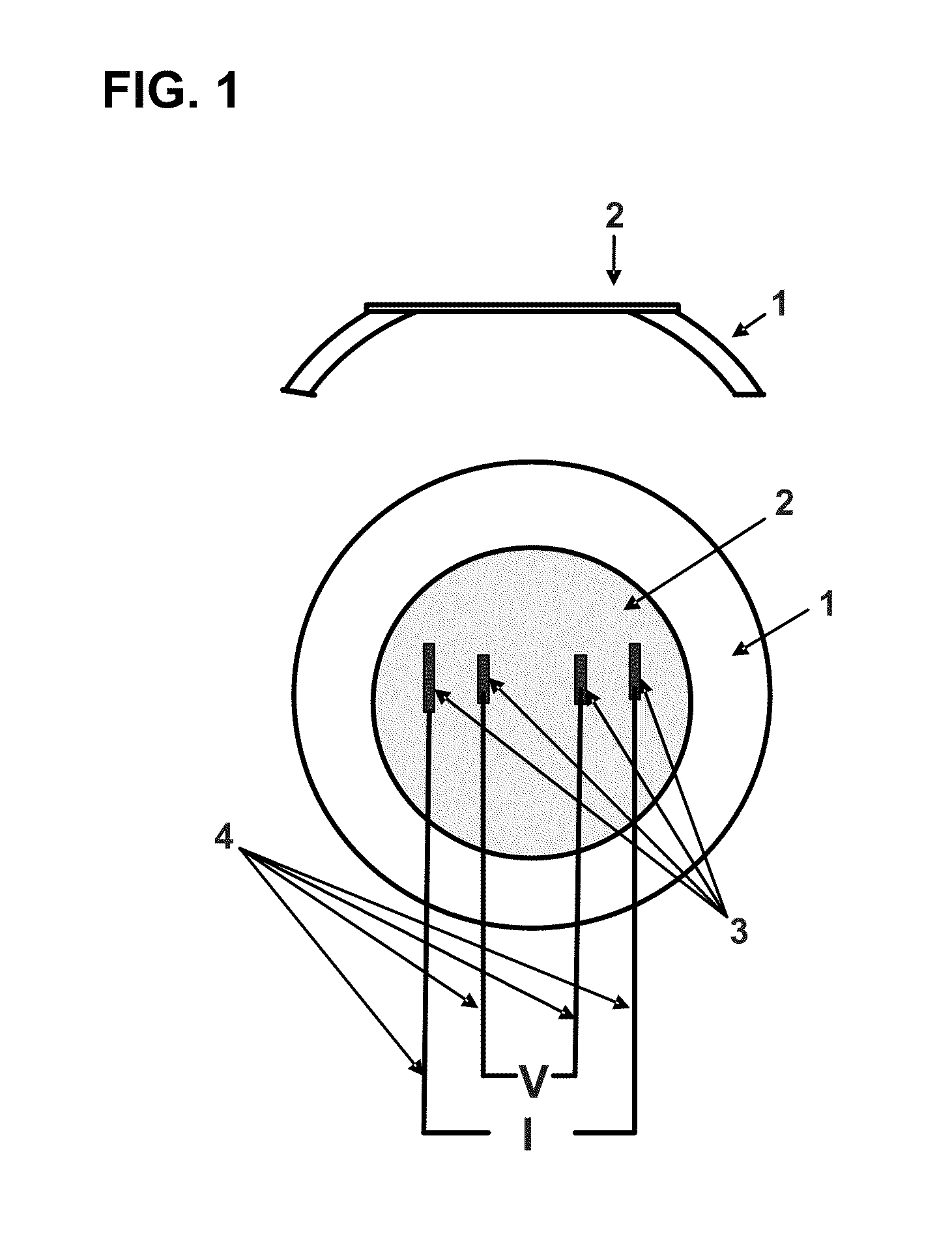

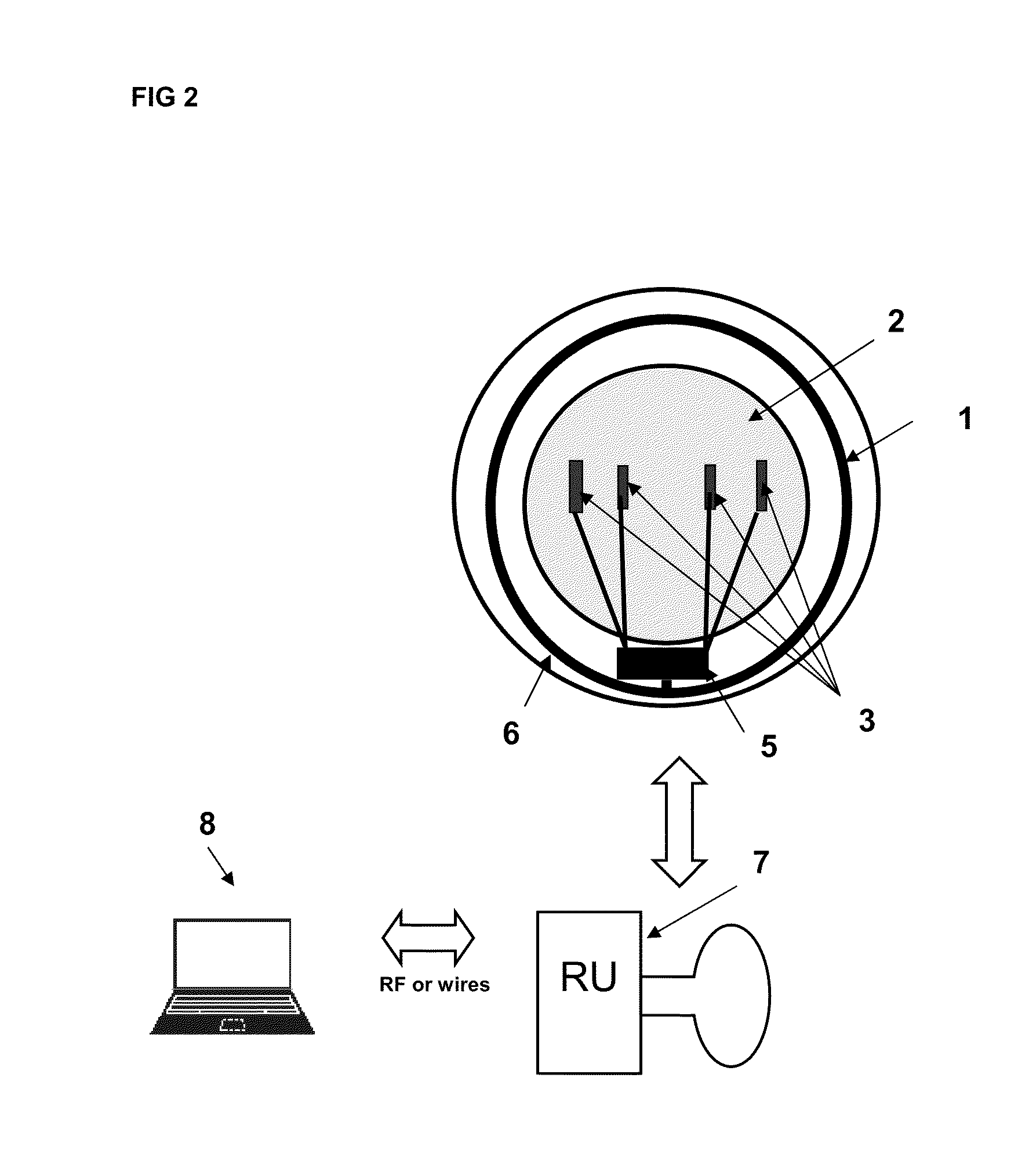

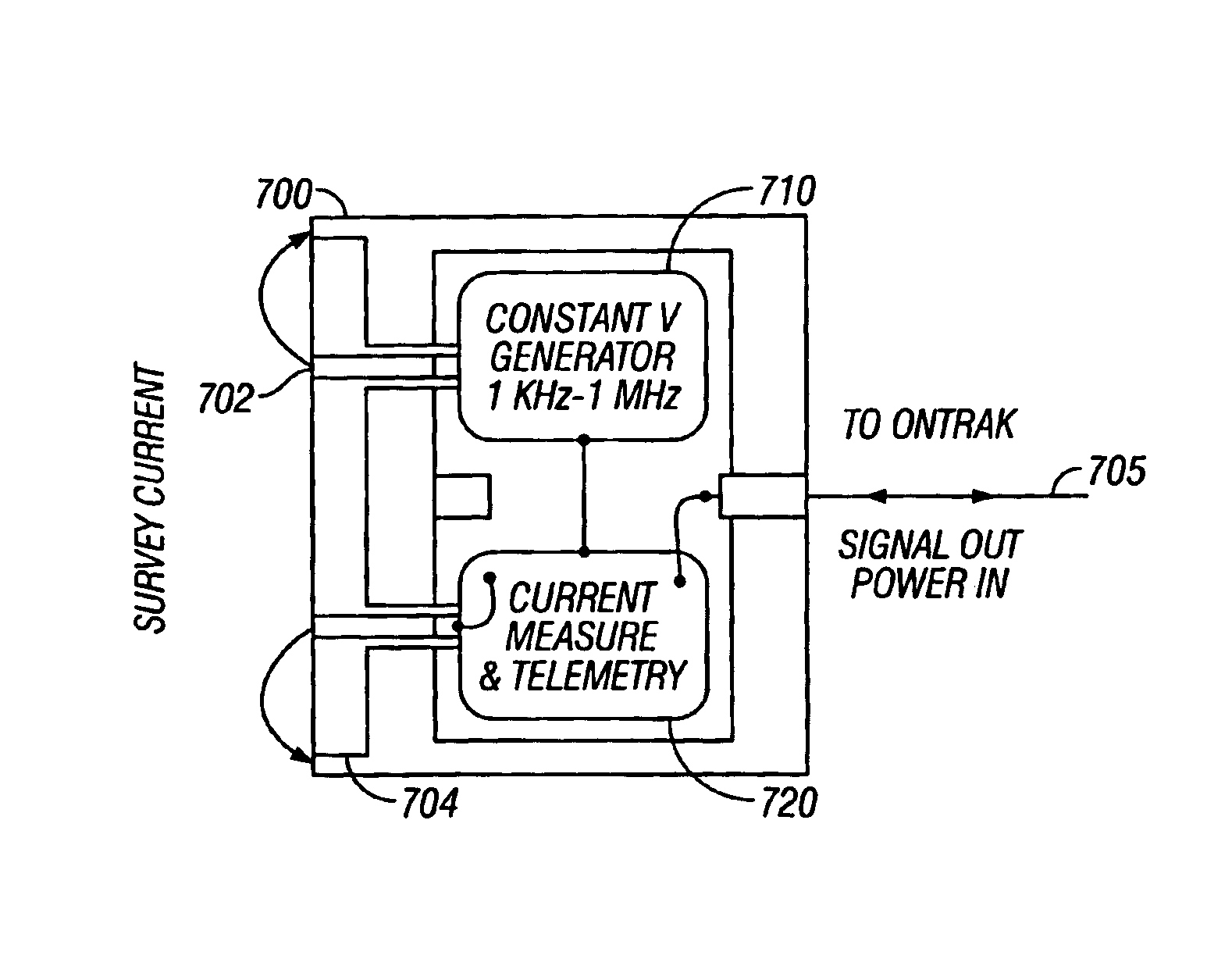

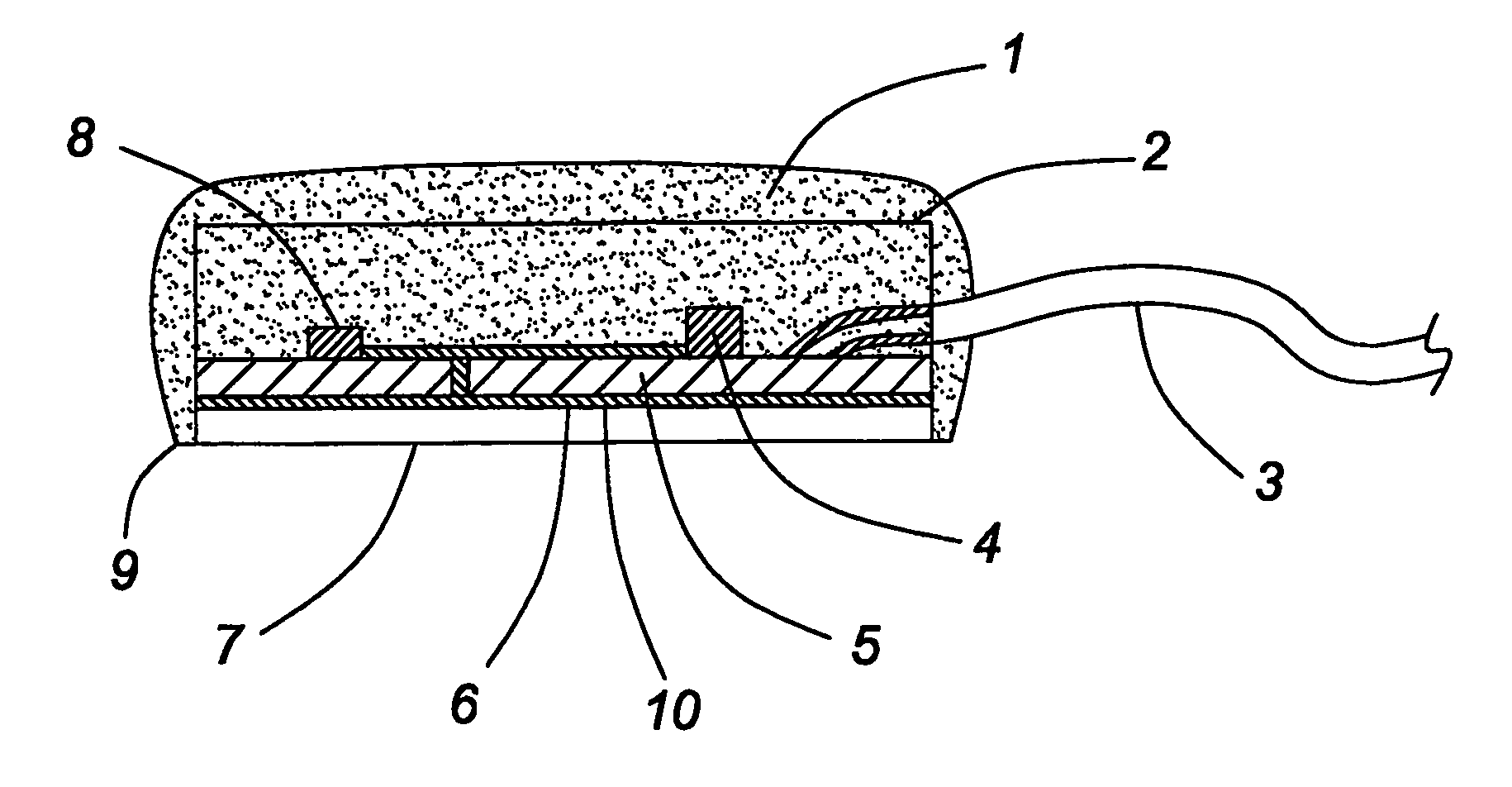

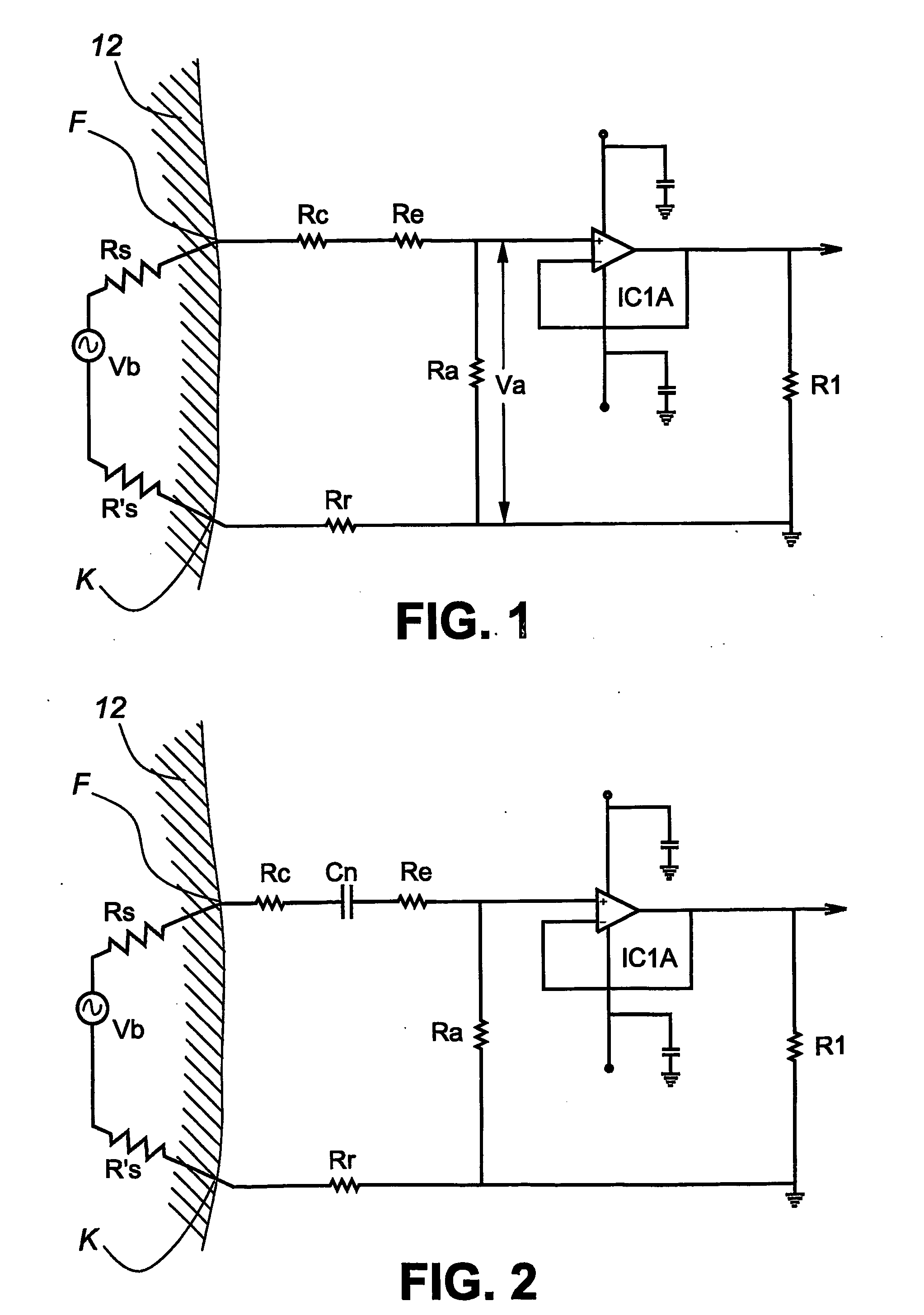

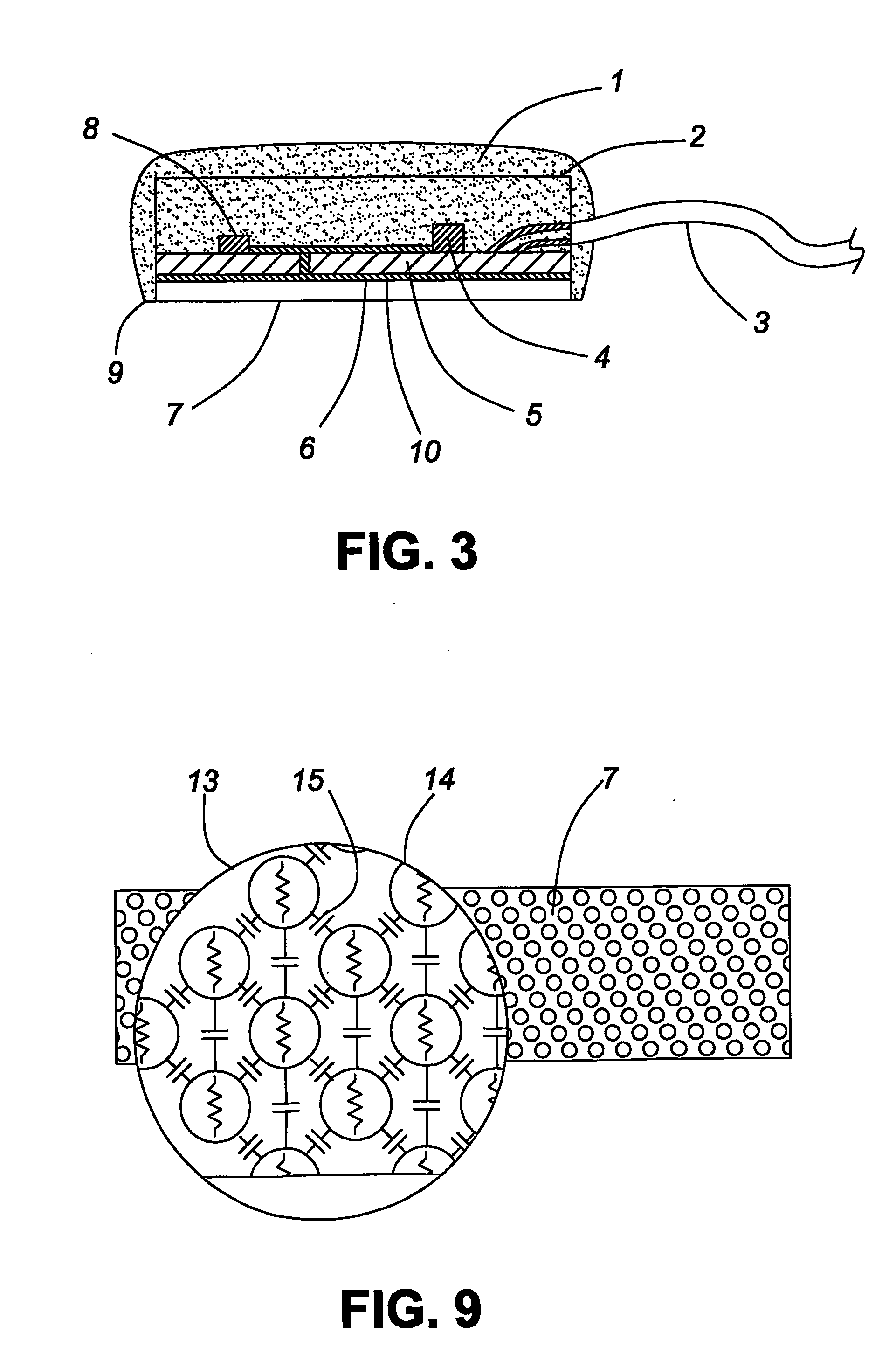

Sensor contact lens, system for the non-invasive monitoring of intraocular pressure and method for measuring same

The invention is characterized in that it comprises a truncated contact lens (1), whose truncation plane is parallel to the base of said contact lens, and a polymeric nanocomposite material (2) centrally disposed and attached to the perimeter of the truncated area, said material being sensitive to pressure changes, biocompatible and transparent, and including contact electrodes (3), and in that it also comprises means for transmitting IOP measurement data to an external system. The invention also relates to a method for measuring IOP using said lens comprising: i) placing said sensor contact lens in the eye to determine its intraocular pressure; ii) providing a direct current value between external electrodes; iii) ΔV measurement between internal electrodes; and iv) identifying whether the value obtained is outside the linear response, expressed in changes of resistivity, of the polymeric nanocomposite material. The invention also relates to a telemetry system comprising said lens.

Owner:CONSEJO SUPERIOR DE INVESTIGACIONES CIENTIFICAS (CSIC) +4

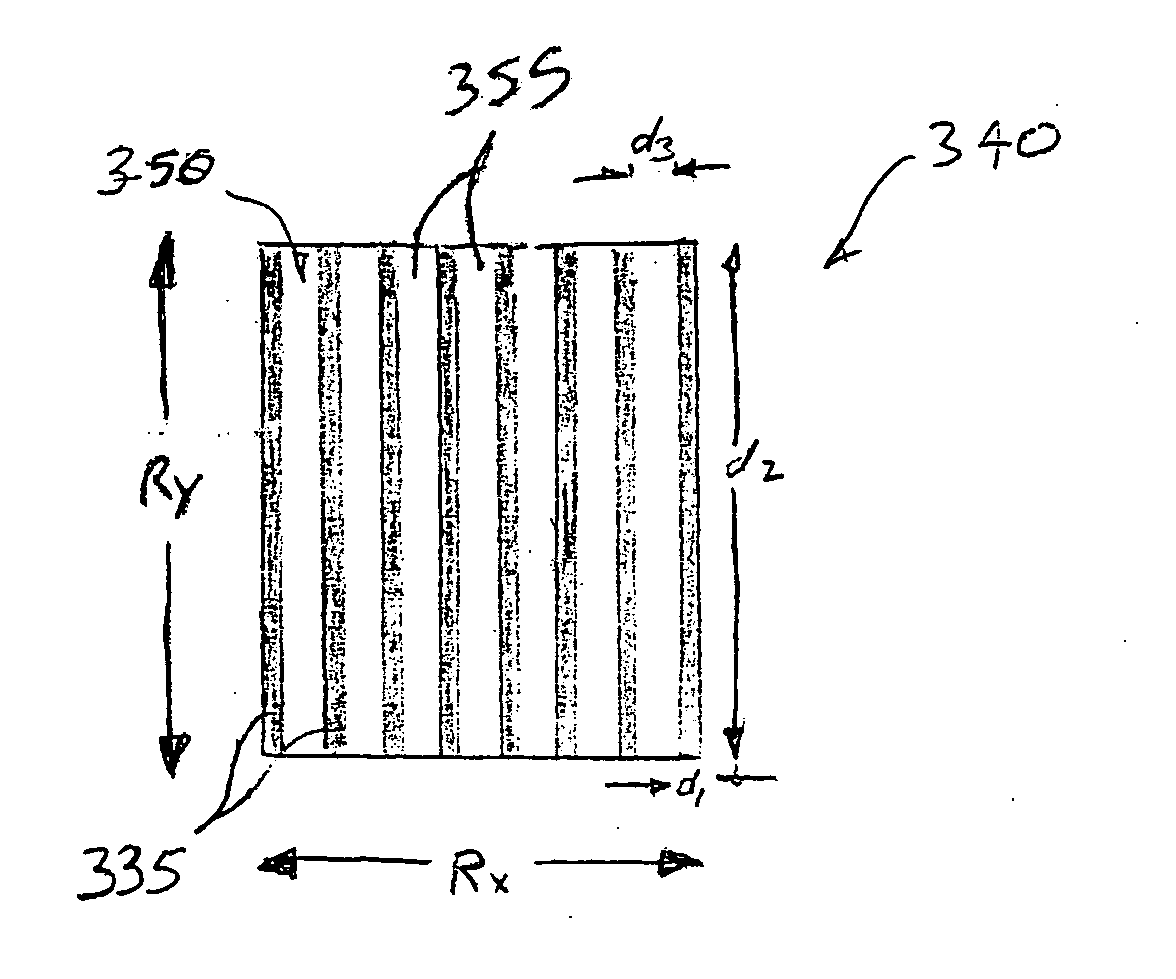

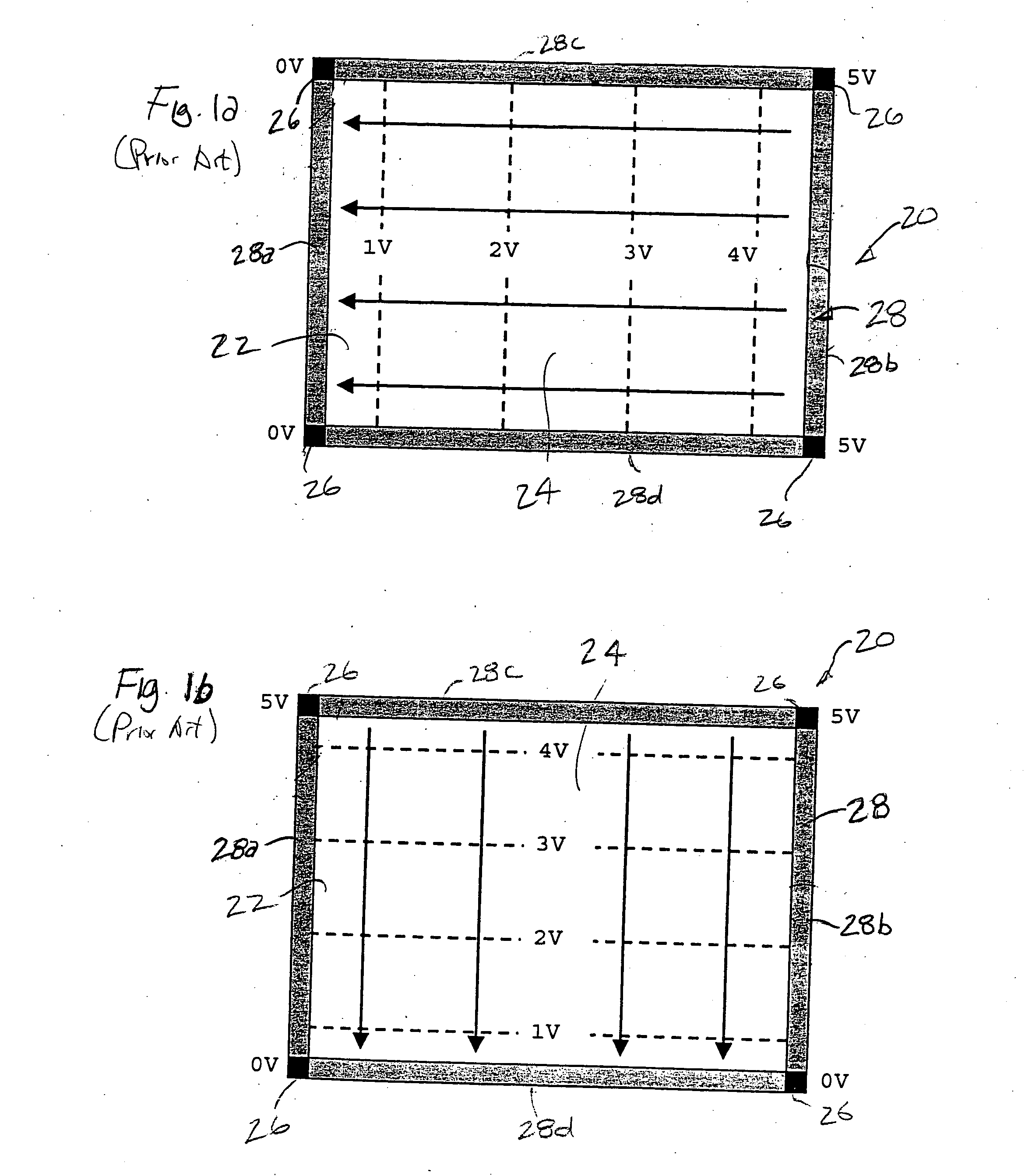

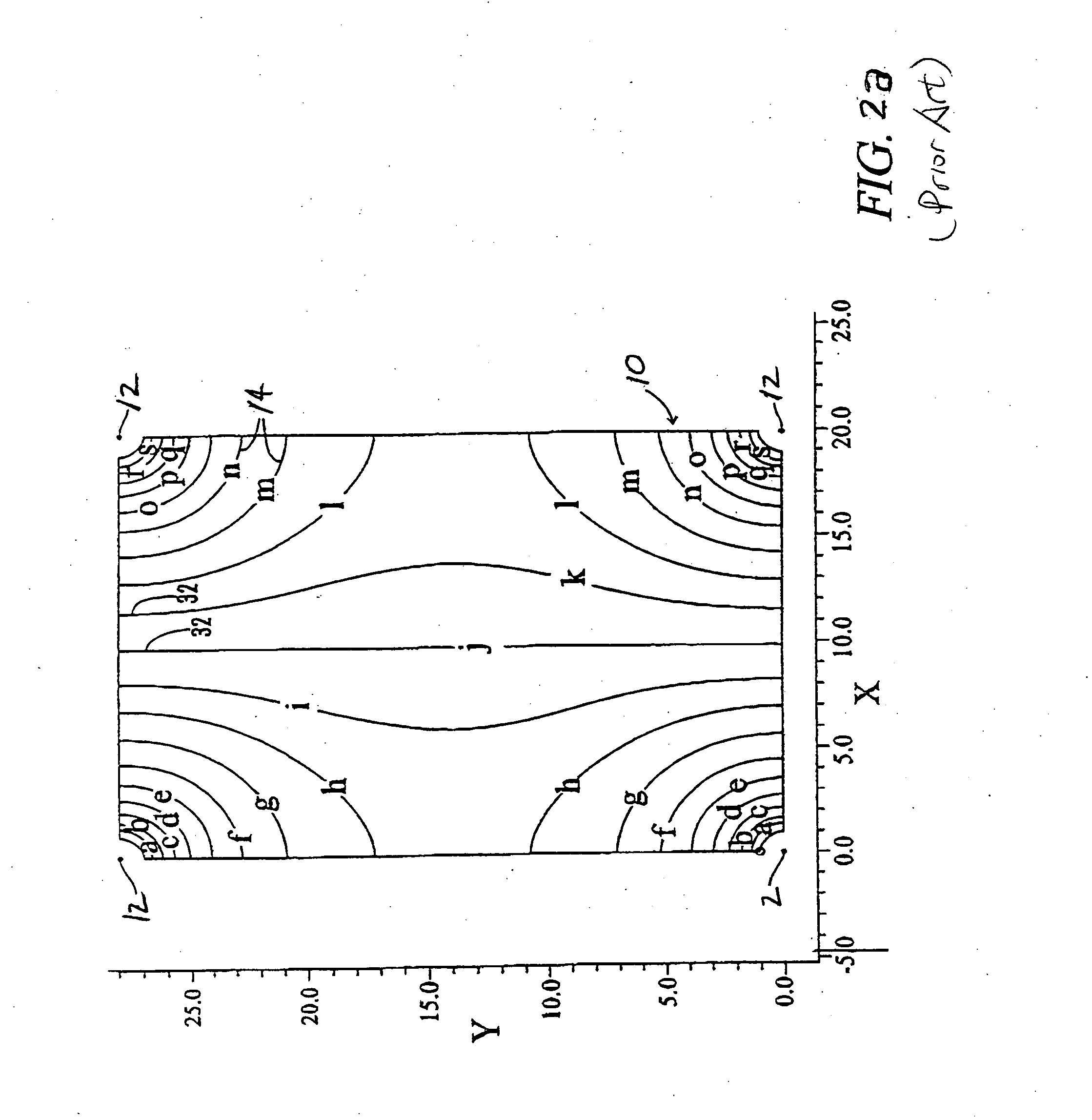

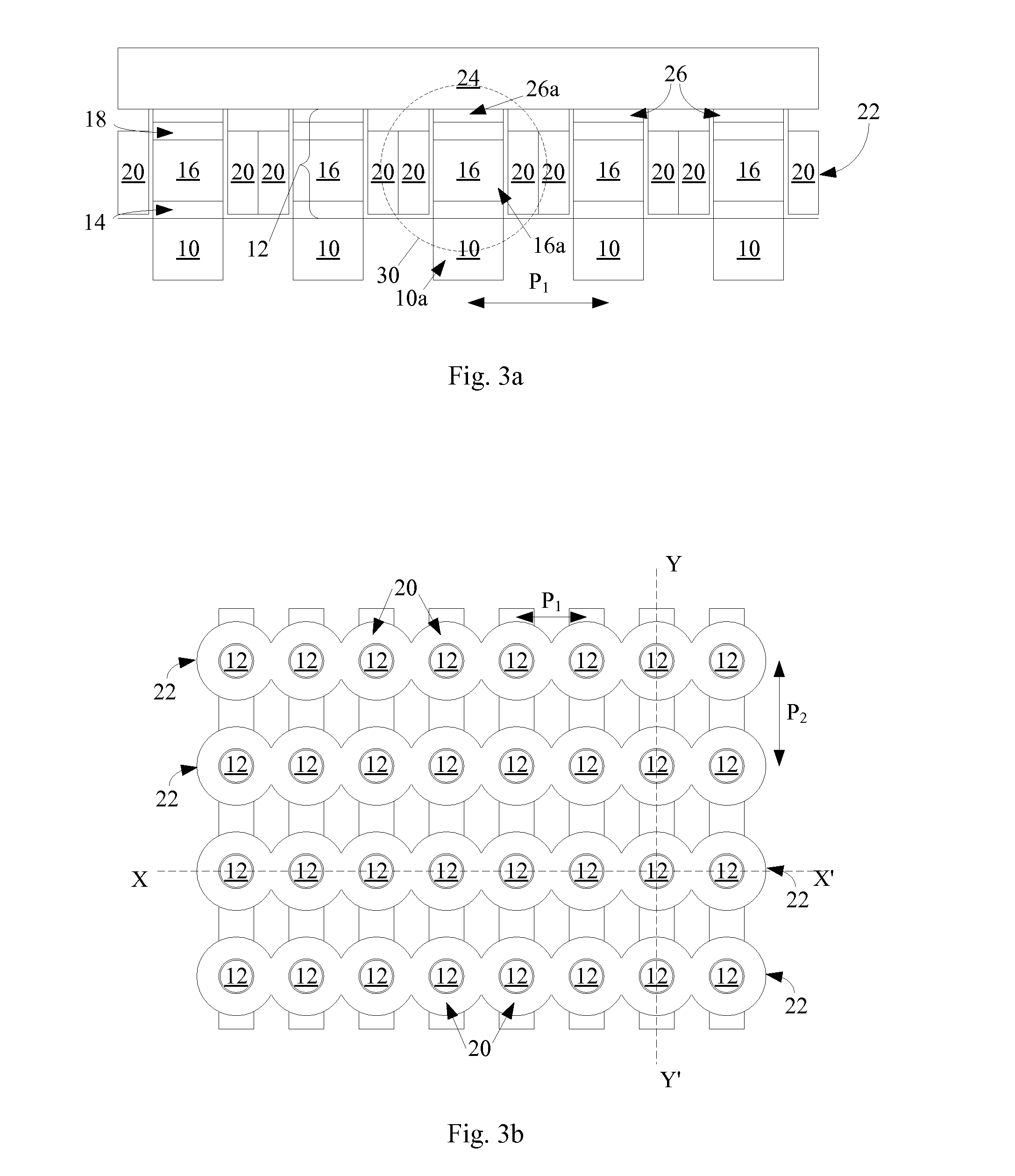

Touch sensor with non-uniform resistive band

InactiveUS20050012644A1Simple manufacturing processIncrease widthElectronic switchingInput/output processes for data processingElectrical resistance and conductanceEngineering

The present inventions are directed to touch sensors with improved topological equivalence between an equipotential space and a Cartesian space to which the equipotential space will be mapped. The touch sensor comprises a substrate with a touch region, and a set of electrodes that are electrically coupled to the touch region. The touch sensor further comprises a plurality of resistive band segments that frames the touch region. The electrodes are located between the resistive band segments. Each resistive band segment has a resistivity that is intermediate between the resistivity of the electrodes and the resistivity of the touch region, thereby providing a transition between the low resistivity electrodes and the high resistivity touch region, and improving the topological equivalence within the corners of the touch region. At least one of the band segments has a non-uniform linear resistance to provide further improvement to the topological equivalence.

Owner:ELO TOUCH SOLUTIONS INC

Formation resistivity measurement sensor contained onboard a drill bit (resistivity in bit)

A method and apparatus for obtaining a resistivity measurement of an earth formation surrounding a borehole in an MWD device uses an electrode for injecting current into the earth formation and an electrode for obtaining a responsive signal from the borehole. The electrodes are located on the drill bit arm or blade. Measured resistivity values are obtained at the location of the drill bit. Measurements can be taken in both oil-based mud and water-based mud environments. Maximum or minimum resistivity can be used to best represent the resistivity of the surrounding formation.

Owner:BAKER HUGHES INC

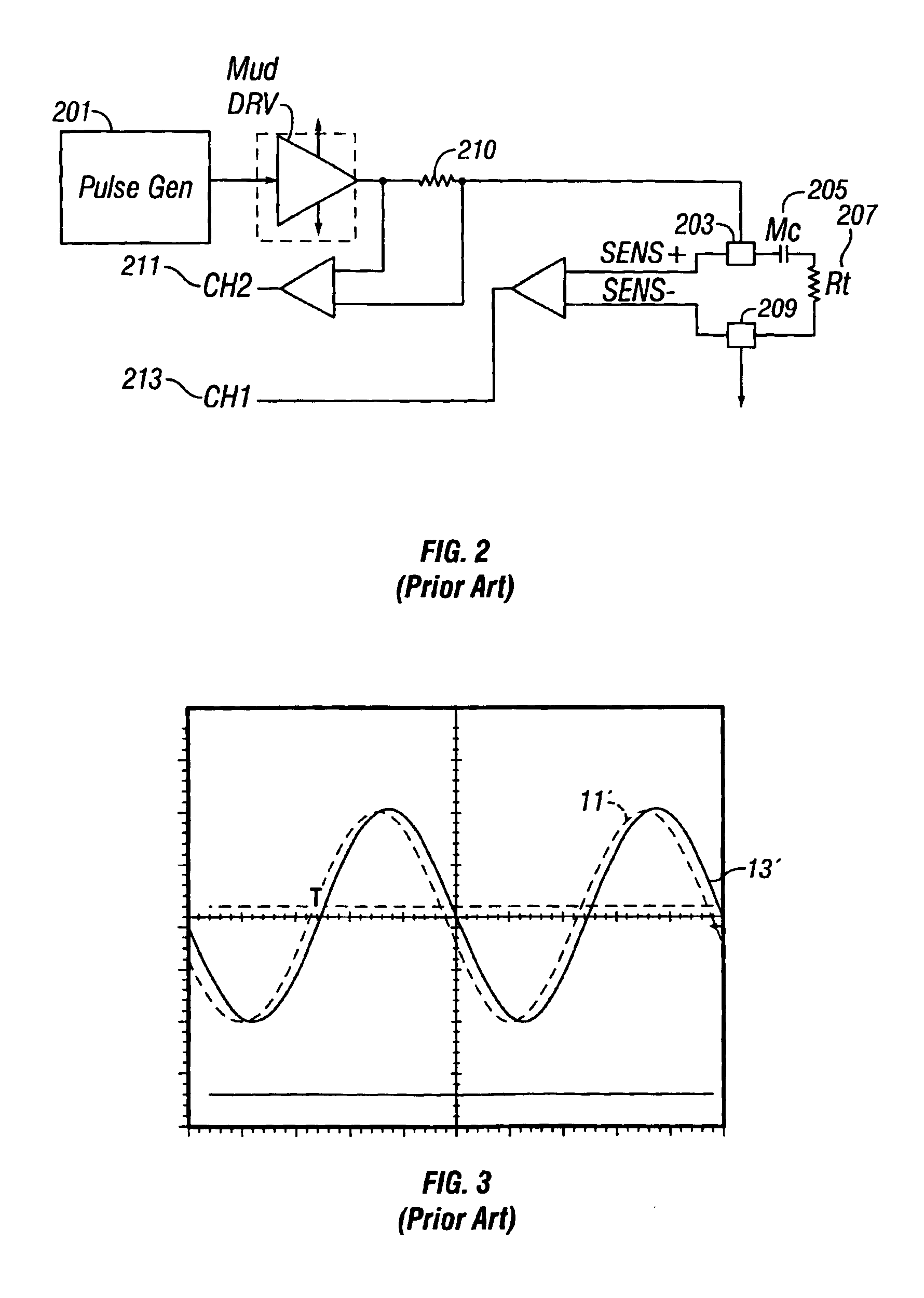

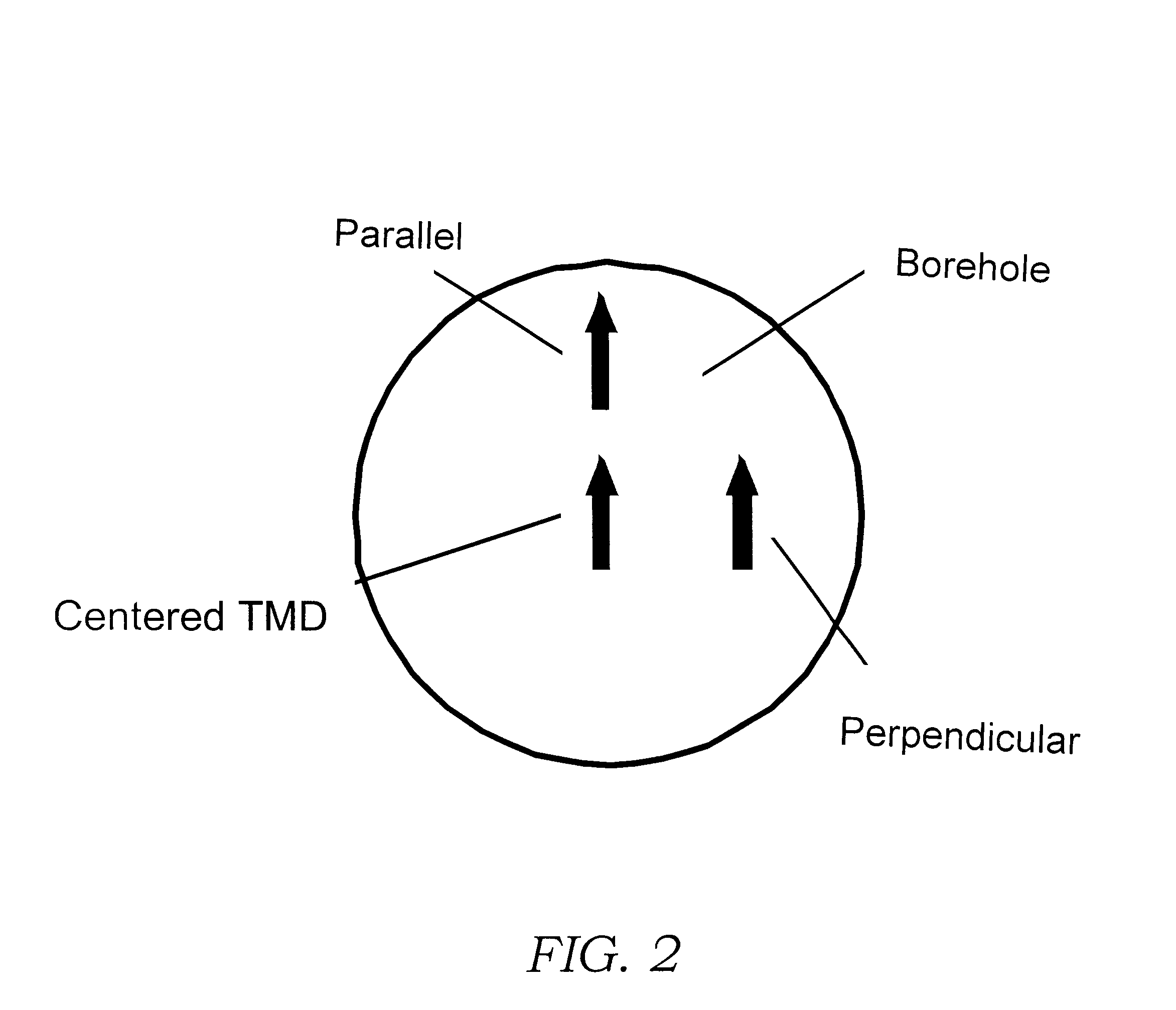

Multi-coil electromagnetic focusing methods and apparatus to reduce borehole eccentricity effects

InactiveUS6541979B2Electric/magnetic detection for well-loggingAcoustic wave reradiationElectrical resistance and conductanceCurrent sensor

Methods and apparatus are disclosed for canceling or eliminating borehole eccentricity effects on a formation resistivity measurement obtained with transmitter and / or receiver antennas which are substantially time varying magnetic dipoles with their dipole moments aligned at an angle to the axis of the borehole. Various apparatus are configured with a plurality of antennas having tilted or transverse magnetic dipole moments, at least one current sensor, means for conducting alternating current through one or more of the antennas, and means for calculating a scaling factor from signal measurements and for scaling the alternating current with the factor. One method includes scaling an alternating current and passing said current through one or more antennas to obtain the resistivity measurement. Another method includes calculating scaling factors based on spacings between antennas and / or current sensors disposed on an instrument and passing alternating currents scaled by said factors through one or more antennas to obtain the resistivity measurement. Another embodiment includes inputting a borehole fluid resistivity value to derive the formation resistivity.

Owner:SCHLUMBERGER TECH CORP

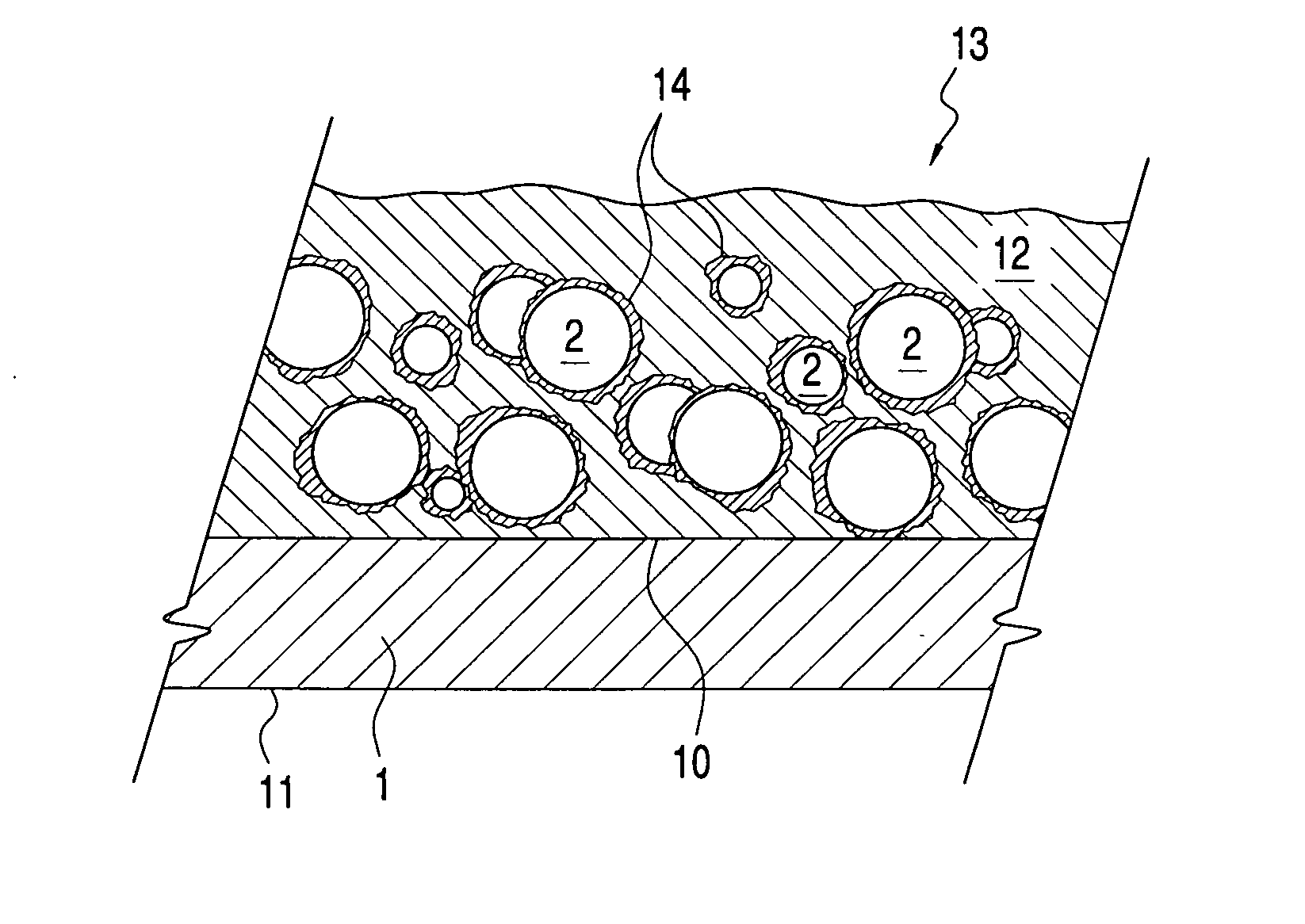

Methods of treating a subterranean formation to convert organic matter into producible hydrocarbons

ActiveUS20070000662A1Low viscosityAvoid insufficient heatingFluid removalConductive materialsOrganic matter

Methods are provided that include the steps of providing wells in a formation, establishing one or more fractures (12) in the formation, such that each fracture intersects at least one of the wells (16, 18), placing electrically conductive material in the fractures, and generating electric current through the fractures and through the material such that sufficient heat (10) is generated by electrical resistivity within the material to pyrolyze organic matter in the formation into producible hydrocarbons.

Owner:EXXONMOBIL UPSTREAM RES CO

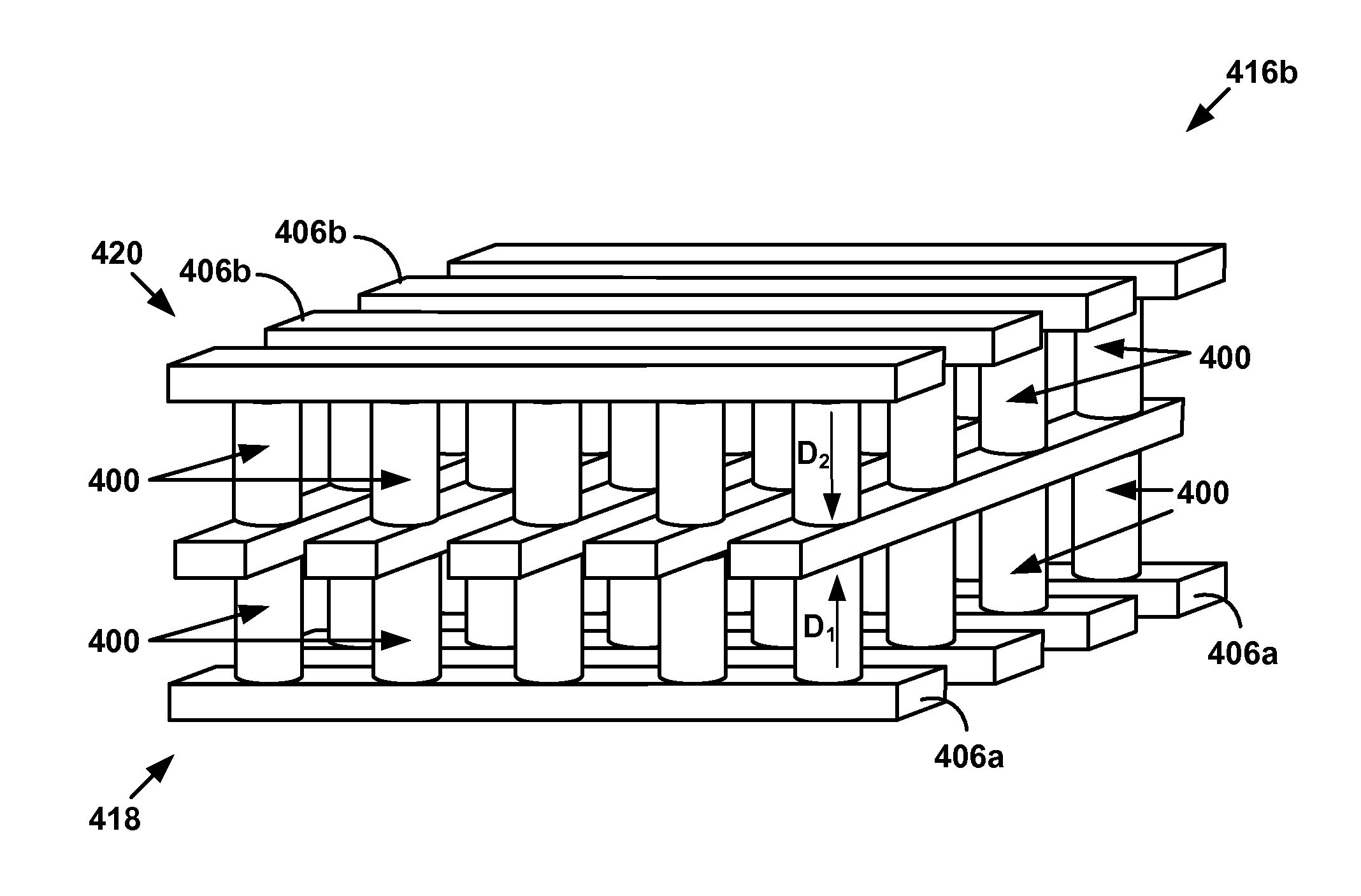

Method to form a memory cell comprising a carbon nanotube fabric element and a steering element

A method to form a rewriteable nonvolatile memory cell is disclosed, the cell comprising a steering element in series with a carbon nanotube fabric. The steering element is preferably a diode, but may also be a transistor. The carbon nanotube fabric reversibly changes resistivity when subjected to an appropriate electrical pulse. The different resistivity states of the carbon nanotube fabric can be sensed, and can correspond to distinct data states of the memory cell. A first memory level of such memory cells can be monolithically formed above a substrate, a second memory level monolithically formed above the first, and so on, forming a highly dense monolithic three dimensional memory array of stacked memory levels.

Owner:SANDISK TECH LLC

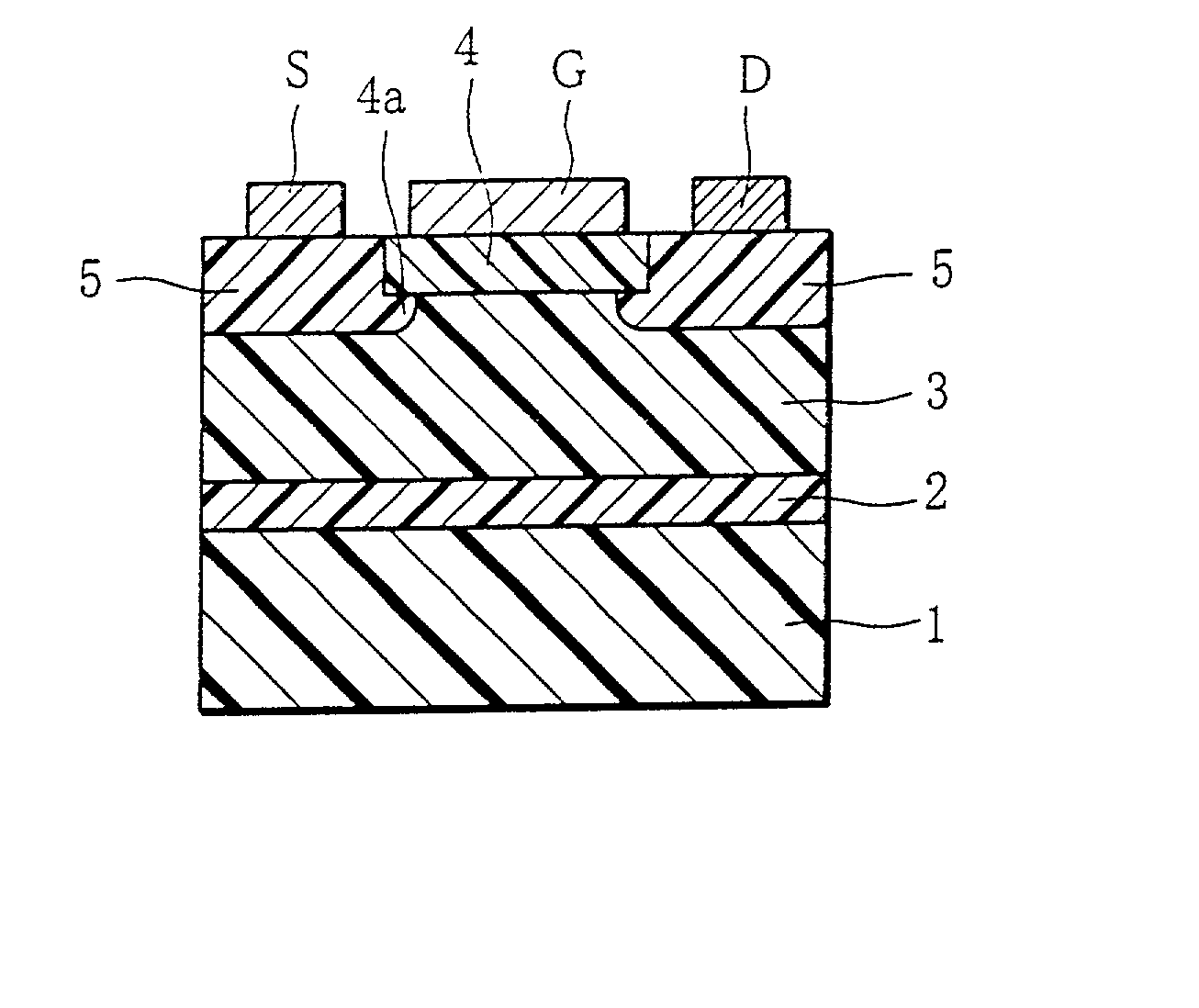

GaN-based high electron mobility transistor

InactiveUS20020079508A1Improve mobilityIncreased electrical resistivitySemiconductor/solid-state device manufacturingSemiconductor devicesHeterojunctionElectric resistivity

A GaN-based high electron mobility transistor (HEMT) has an undoped GaN layer where a two-dimensional electron gas layer is formed, the undoped GaN layer having a high electric resistivity enabling a pinch-off state to be obtained even when the gate bias voltage is 0 V. The GaN-based HEMT comprises a semi-insulating substrate on which a GaN buffer layer is formed. An undoped GaN layer is disposed on the GaN buffer layer and has an electric resistivity of not less than 1x106 OMEGA / cm2. An undoped AlGaN layer is disposed on the undoped GaN layer via a heterojunction such that an undercut portion is formed therebetween. An n-type GaN layer is further disposed in such a manner as to bury side portions of the undoped AlGaN layer and the undercut portion. The individual layers thus Ad form a layered structure. A gate electrode G is formed on the undoped AlGaN layer, and a source electrode S and a drain electrode D are formed on the n-type GaN layer.

Owner:FURUKAWA ELECTRIC CO LTD

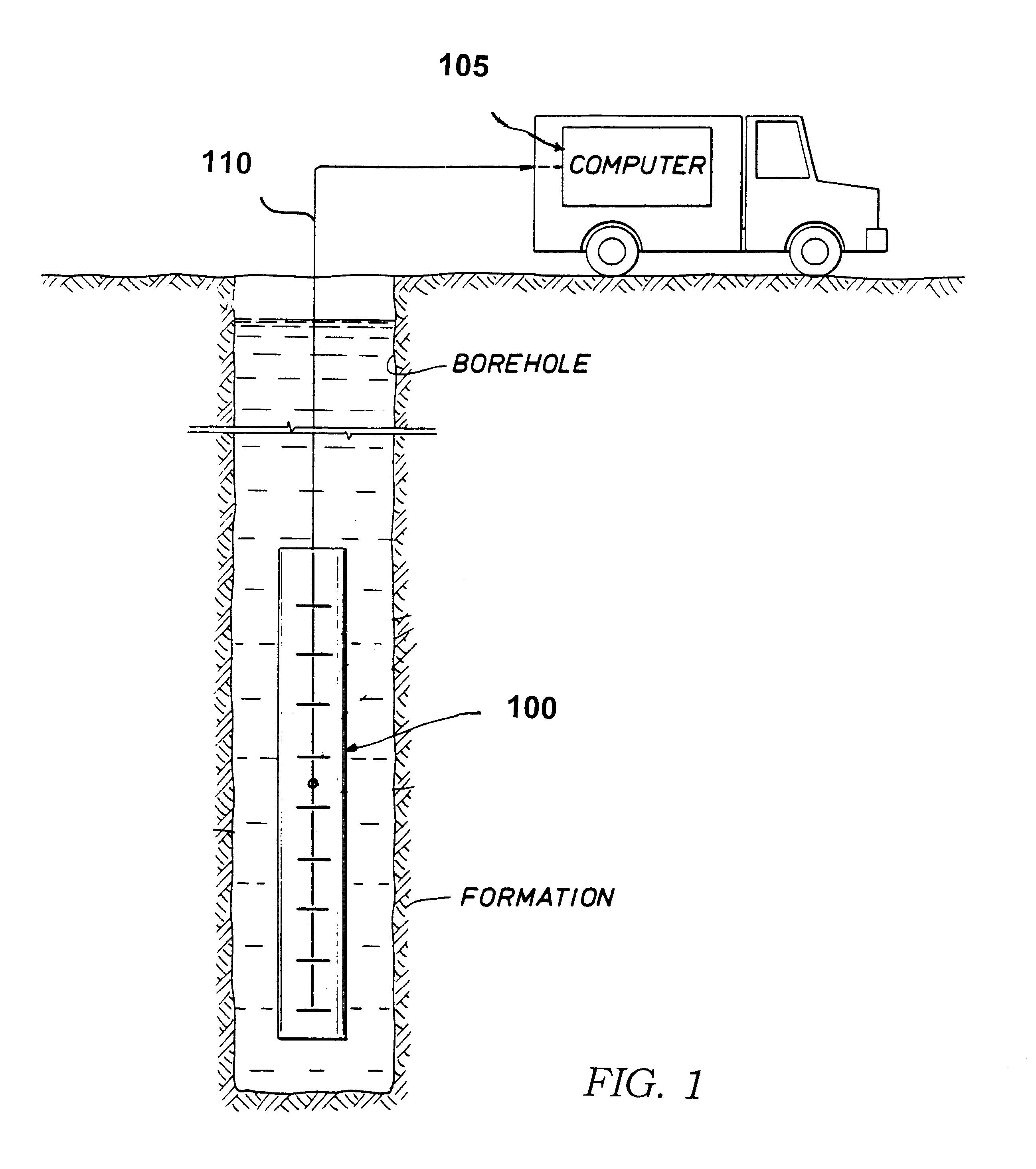

Directional resistivity measurement for well placement and formation evaluation

ActiveUS20110238312A1Electric/magnetic detection for well-loggingSeismology for water-loggingHarmonicWell placement

The present disclosure relates to a method to determine a formation property of a subsurface formation. A downhole logging tool having two or more antennas, at least two of the antennas having a transversely-sensitive element and an axially-sensitive element is provided. Azimuthally-sensitive measurements are obtained using the antennas of the downhole logging tool. The measurements are fitted to a Fourier series having Fourier coefficients that include channel gains, if any. A DC component, a first harmonic component, and a second harmonic component are determined from the Fourier series, a measurement type is determined using the DC component, the first harmonic component, and / or the second harmonic component, and the formation property of the subsurface formation is determined using the determined measurement type.

Owner:SCHLUMBERGER TECH CORP

Skin impedance matched biopotential electrode

InactiveUS20050177038A1Low output impedanceHigh input impedanceElectrocardiographySensorsEngineeringElectric resistivity

A bio-electrode for detecting heart signals and the like comprises a dry electode surface having an elevated resistivity to reduce the effect of polarization noise. The electrode is combined with a circuit having an external discharge resistor across which an output signal is obtained wherein the discharge resistor has a value which reduces the time constant of polarization noise to less than one second.

Owner:ADVANCED BIOELECTRIC CORP

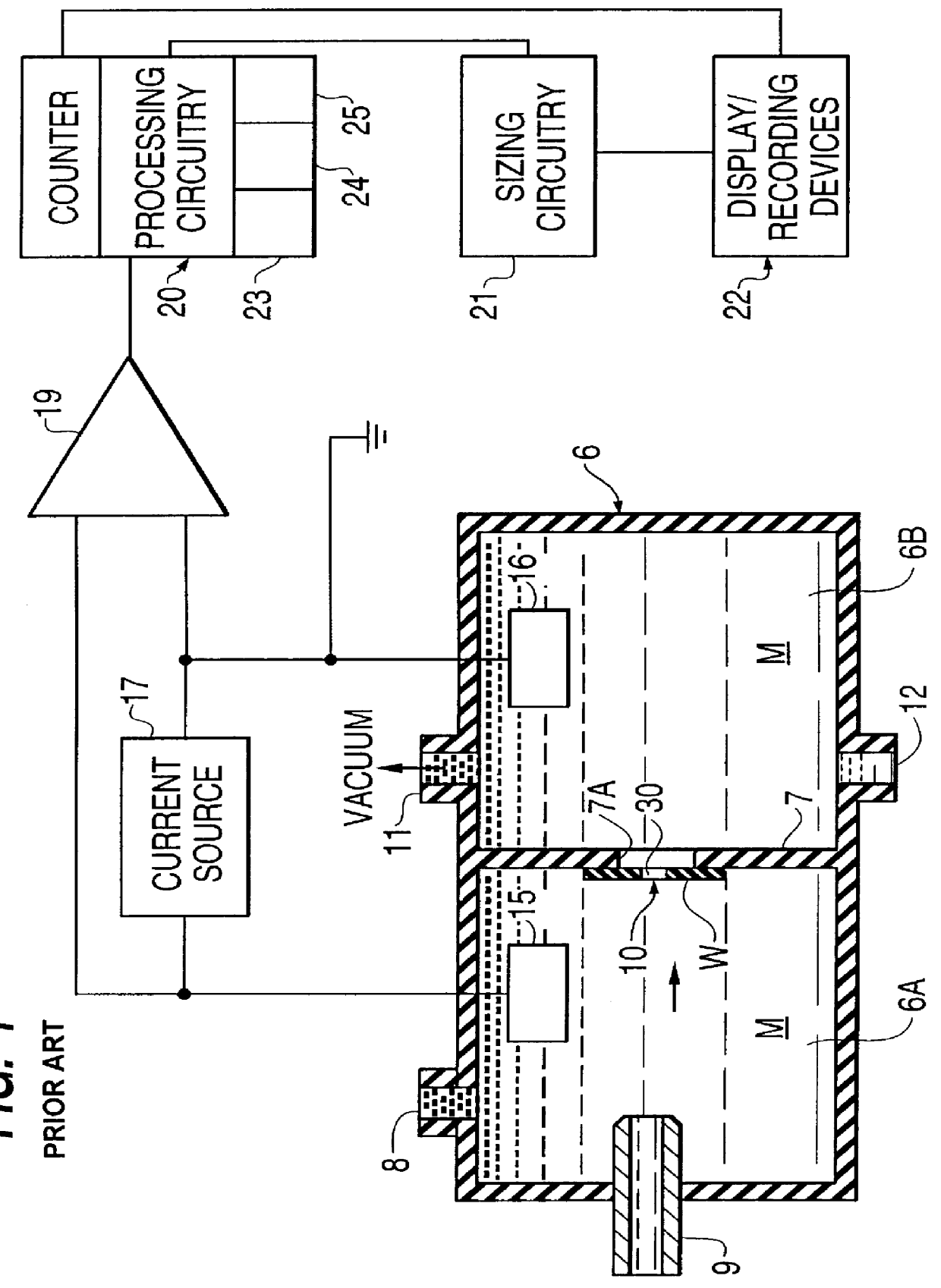

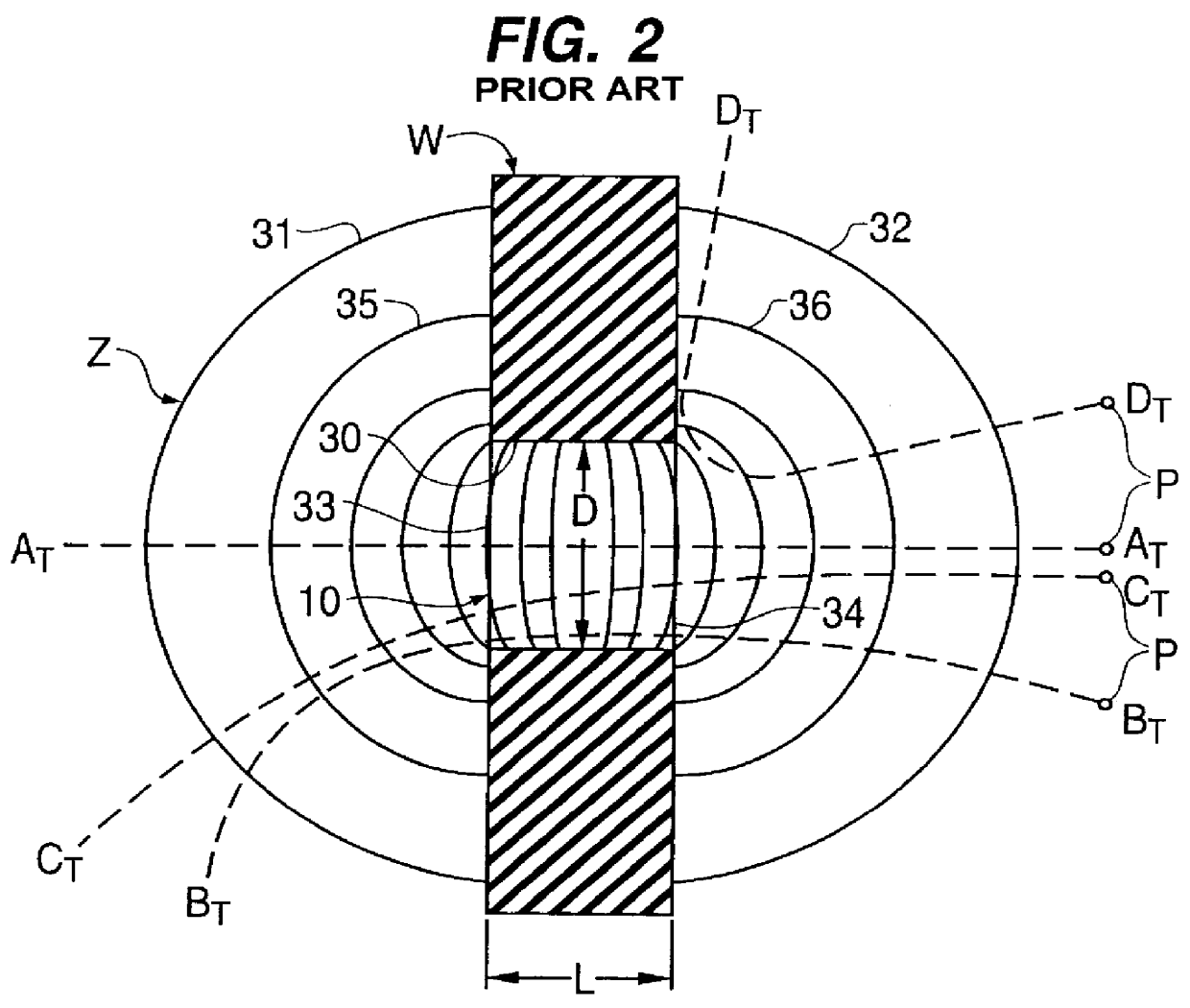

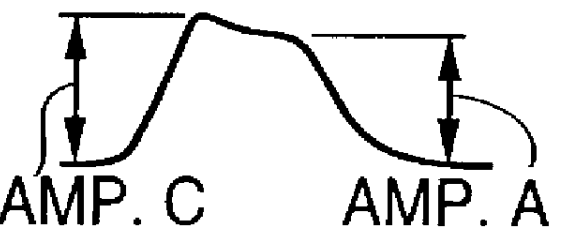

Method and apparatus for sensing and characterizing particles

InactiveUS6111398AIndividual particle analysisParticle suspension analysisLiquid mediumHigh resistivity

Apparatus for sensing and characterizing particles (e.g., blood cells or ceramic powders) suspended in a liquid medium comprises a conduit through which the particle suspension is caused to pass simultaneously with an electrical current. According to the invention, the interior wall of the conduit effectively varies in resistivity along the length of the conduit to define a delimited central region of high electrical resistivity which is smoothly contiguous on its opposing boundaries to uninsulated distal elements of lesser electrical resistivity. The delimited central region of the conduit functions as a Coulter volumeter conduit. The uninsulated distal elements of the conduit are made to have a dimension along the conduit wall which is at least equal to the axial extent of the effective ambit electric fields of a traditional Coulter volumeter conduit having a cross-sectional geometry identical to that of the delimited central region of high resistivity in the improved volumeter conduit. According to a preferred embodiment of the invention, the delimited central region of the improved volumeter conduit is defined by a traditional Coulter conduit wafer, i.e., a dielectric wafer containing a central circular conduit, and the distal elements of lesser resistivity are defined by uninsulated, electrically conductive, circular collars attached to opposite sides of the conduit wafer. The conduit in the conduit wafer and the openings in the conductive collars collectively form a hydrodynamically smooth volumeter conduit, in which the electric and hydrodynamic fields of the traditional volumeter conduit are advantageously amended in the manner above noted.

Owner:COULTER INTERNATIONAL CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com