Patents

Literature

354results about "Porous dielectrics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

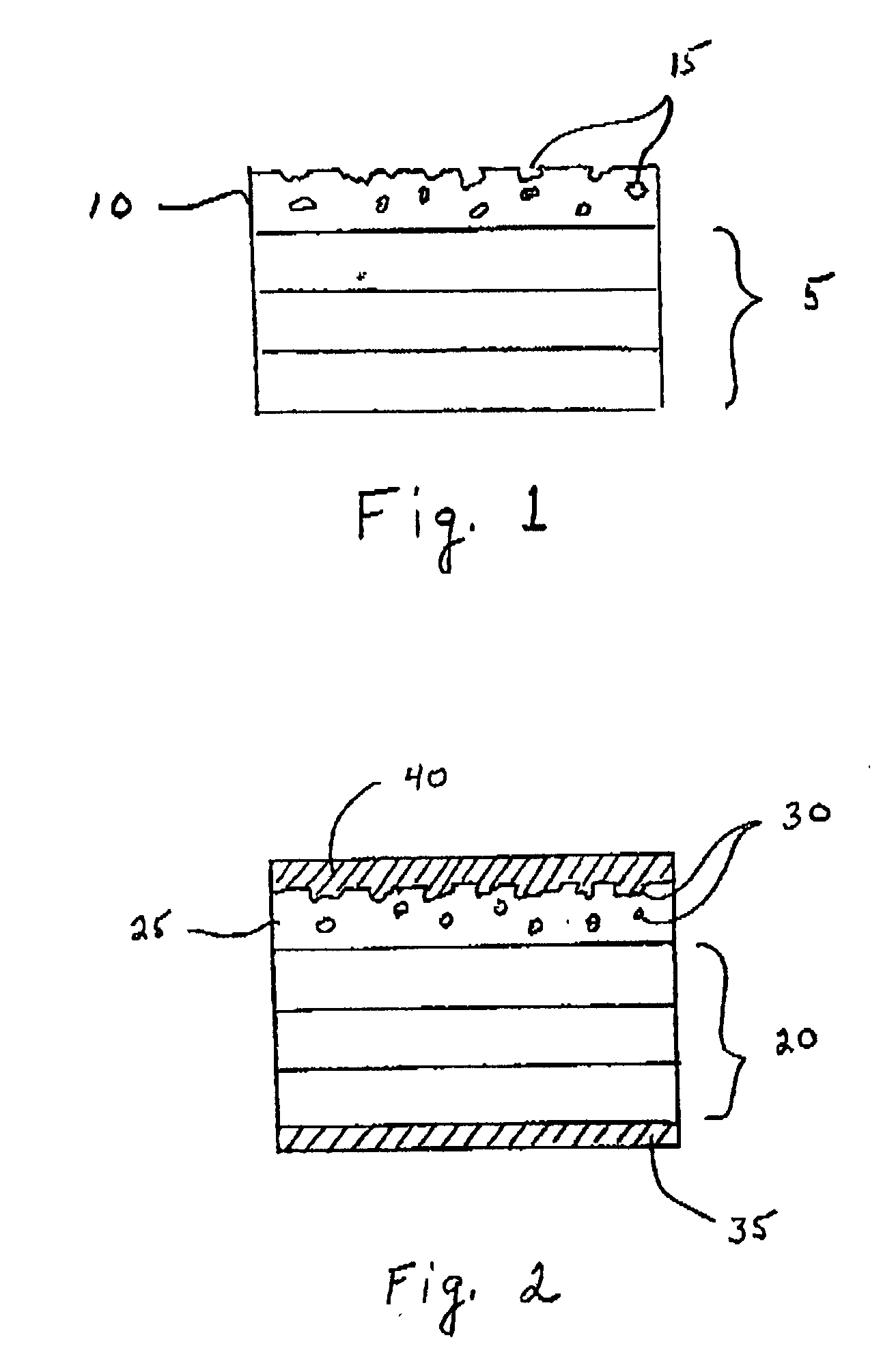

Printable electrical conductors

An electrical conductor formed from one or more metallic inks. The electrical conductor comprises a network of interconnected metallic nodes. Each node comprises a metallic composition, e.g., one or more metals or alloys. The network defines a plurality of pores having an average pore volume of less than about 10,000,000 nm3. The electrical conductors advantageously have a high degree of conductivity, e.g., a resistivity of not greater than about 10× the resistivity of the (bulk) metallic composition, which forms the individual nodes.

Owner:CABOT CORP

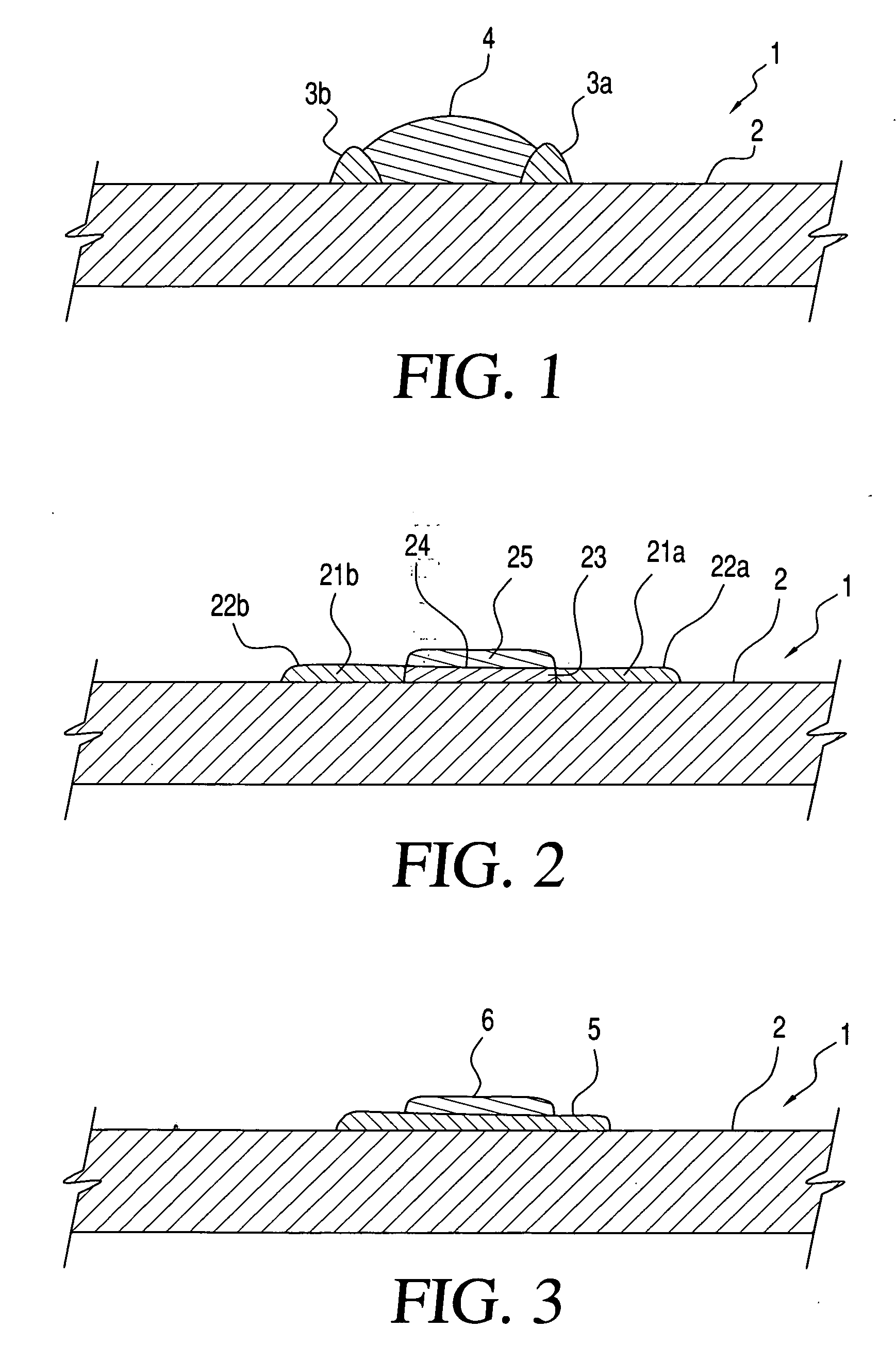

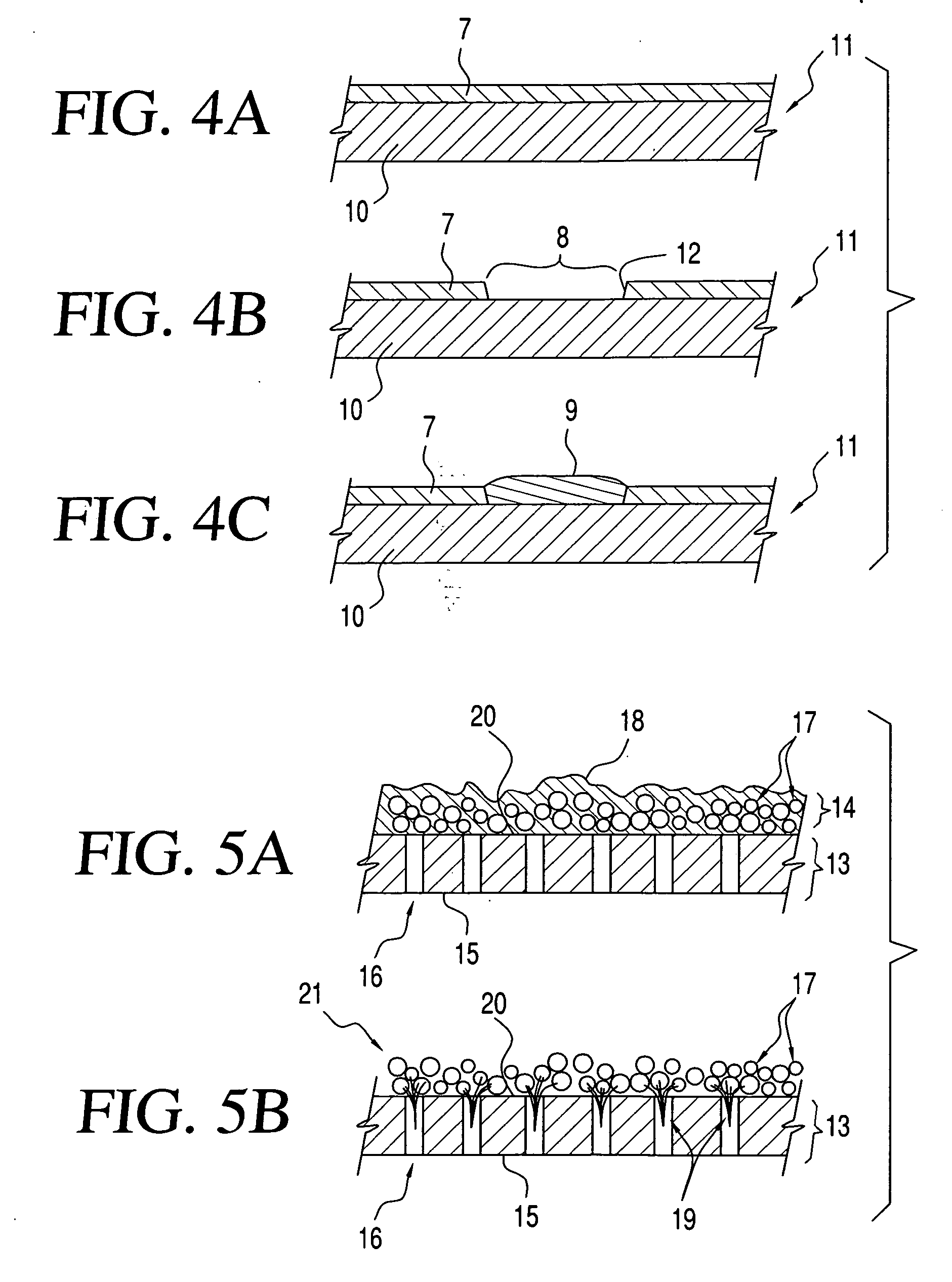

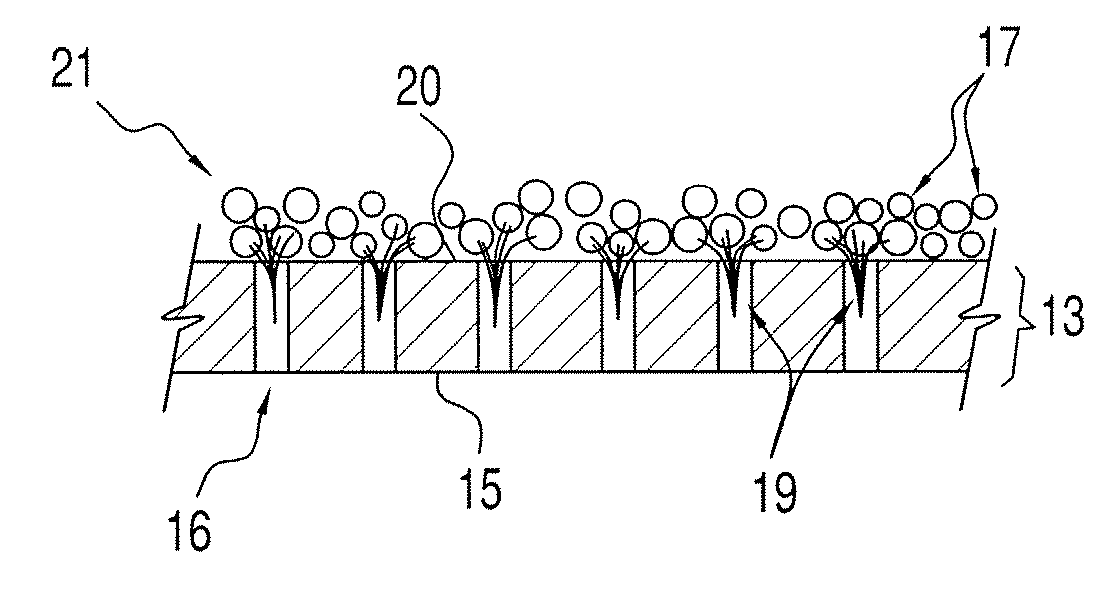

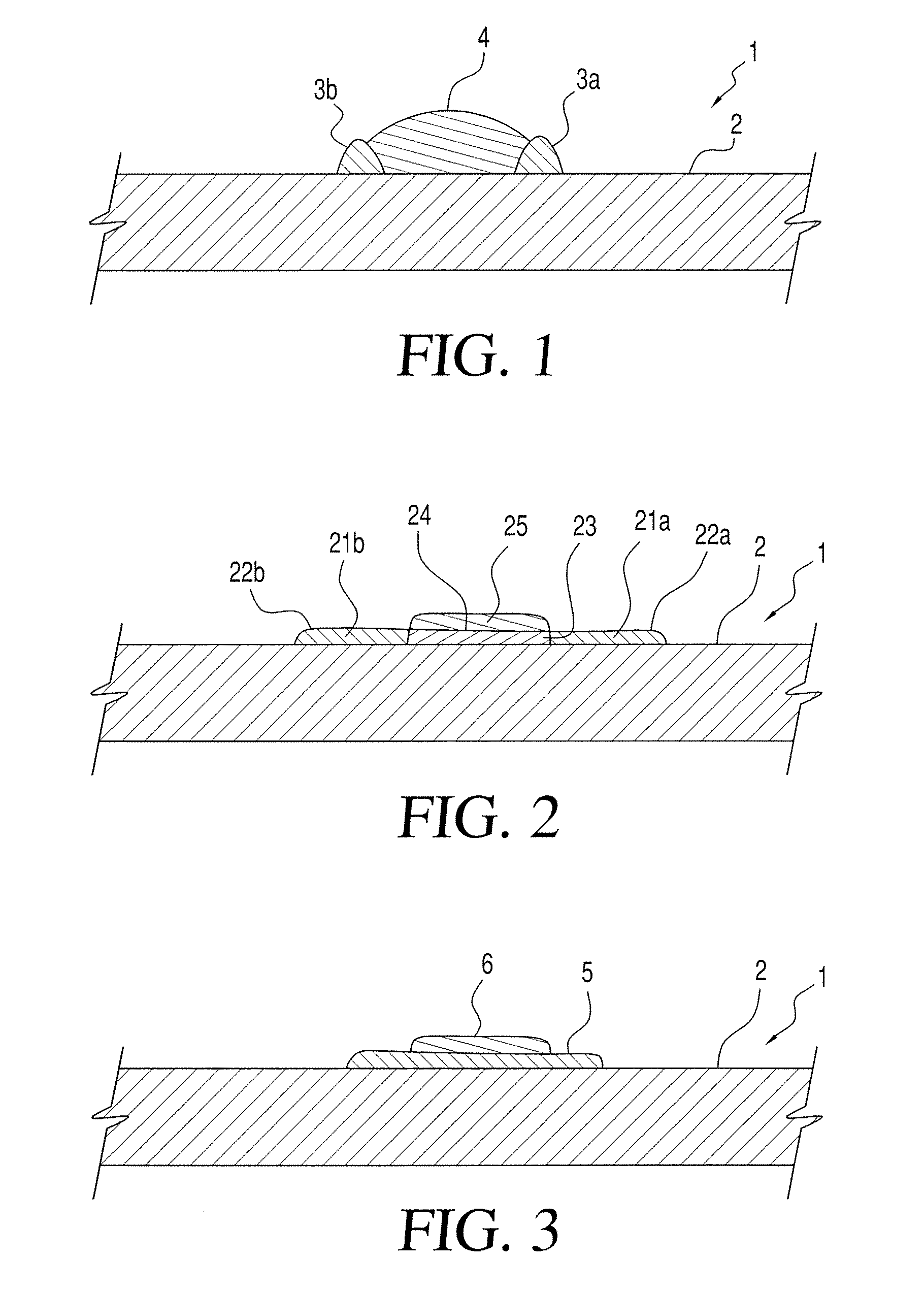

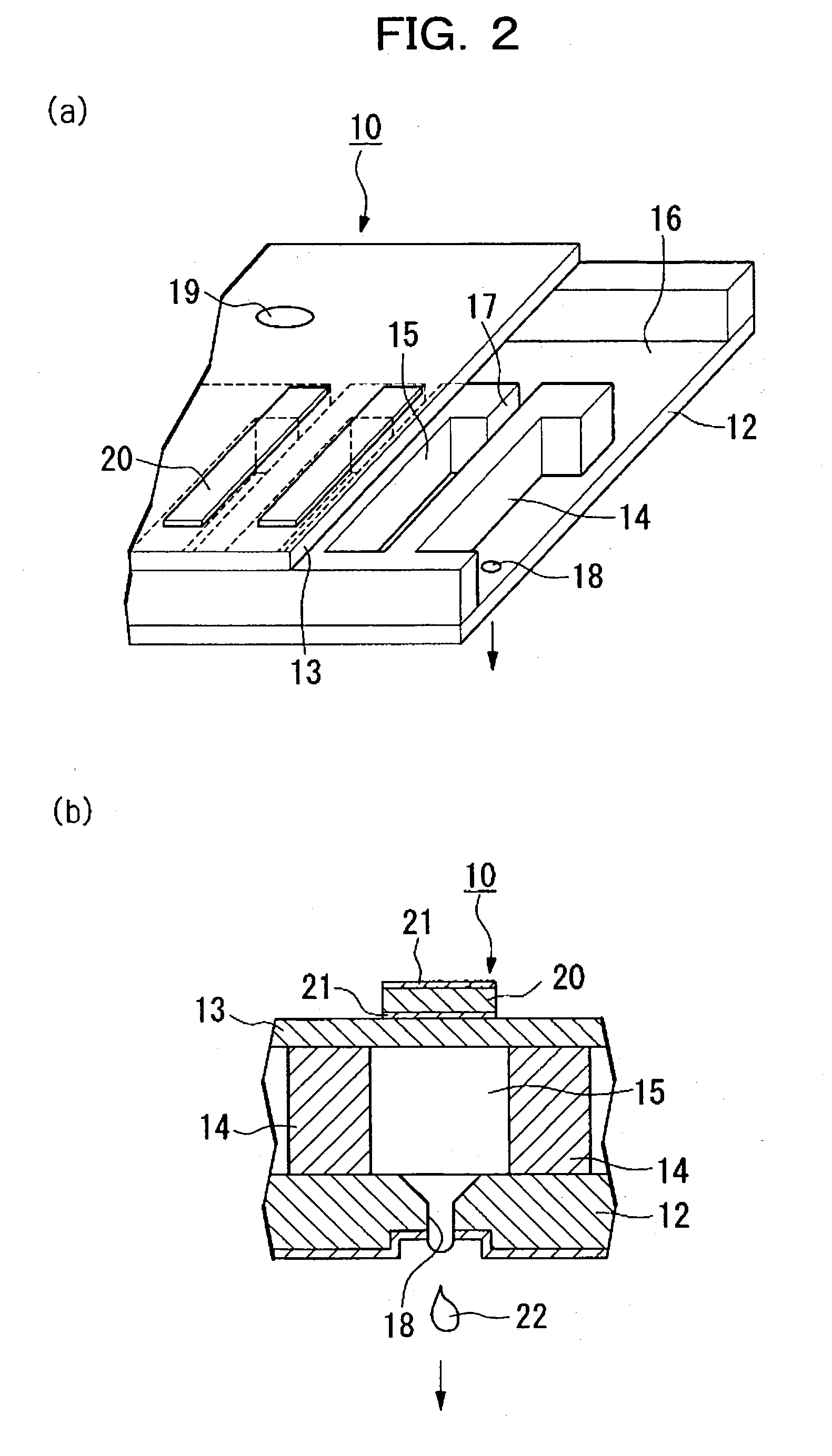

Conductive layer pattern and method for forming the same, wiring board, electronic device, electronic appliances and noncontact card medium

InactiveUS20030213614A1Eliminate effectiveQuality improvementPorous dielectricsConductive layers on insulating-supportsConductive materialsEngineering

Owner:SEIKO EPSON CORP

Manufacturing method of insulating film and semiconductor device

InactiveUS20060116000A1Adhesiveness reducedReduce layeringPorous dielectricsSemiconductor/solid-state device detailsUltrashort pulse laserLaser beams

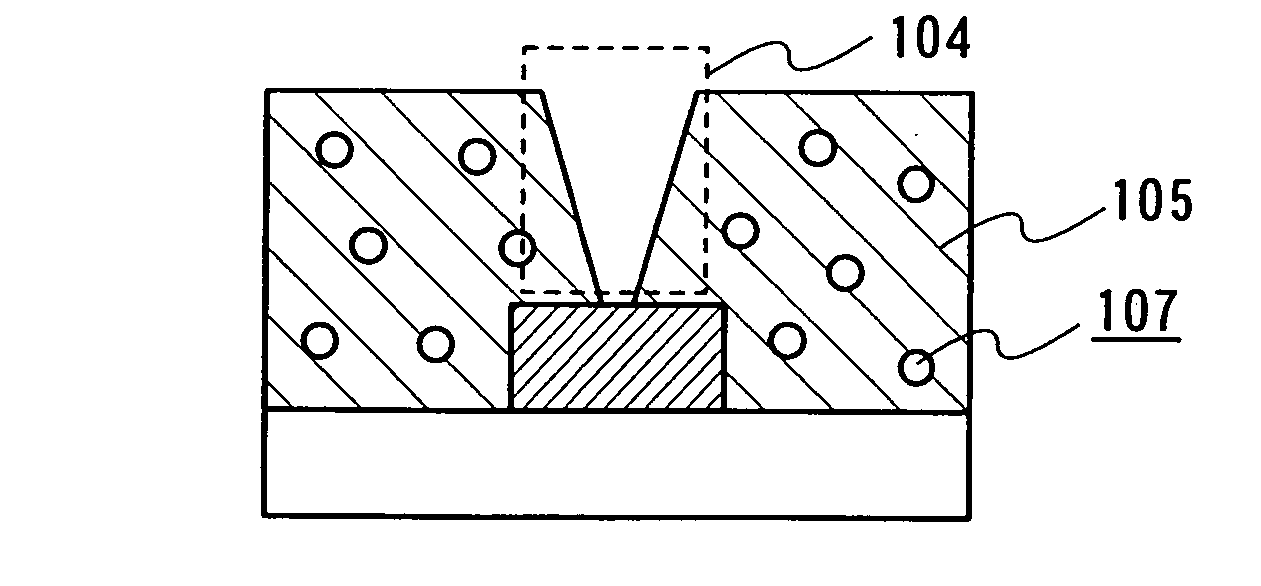

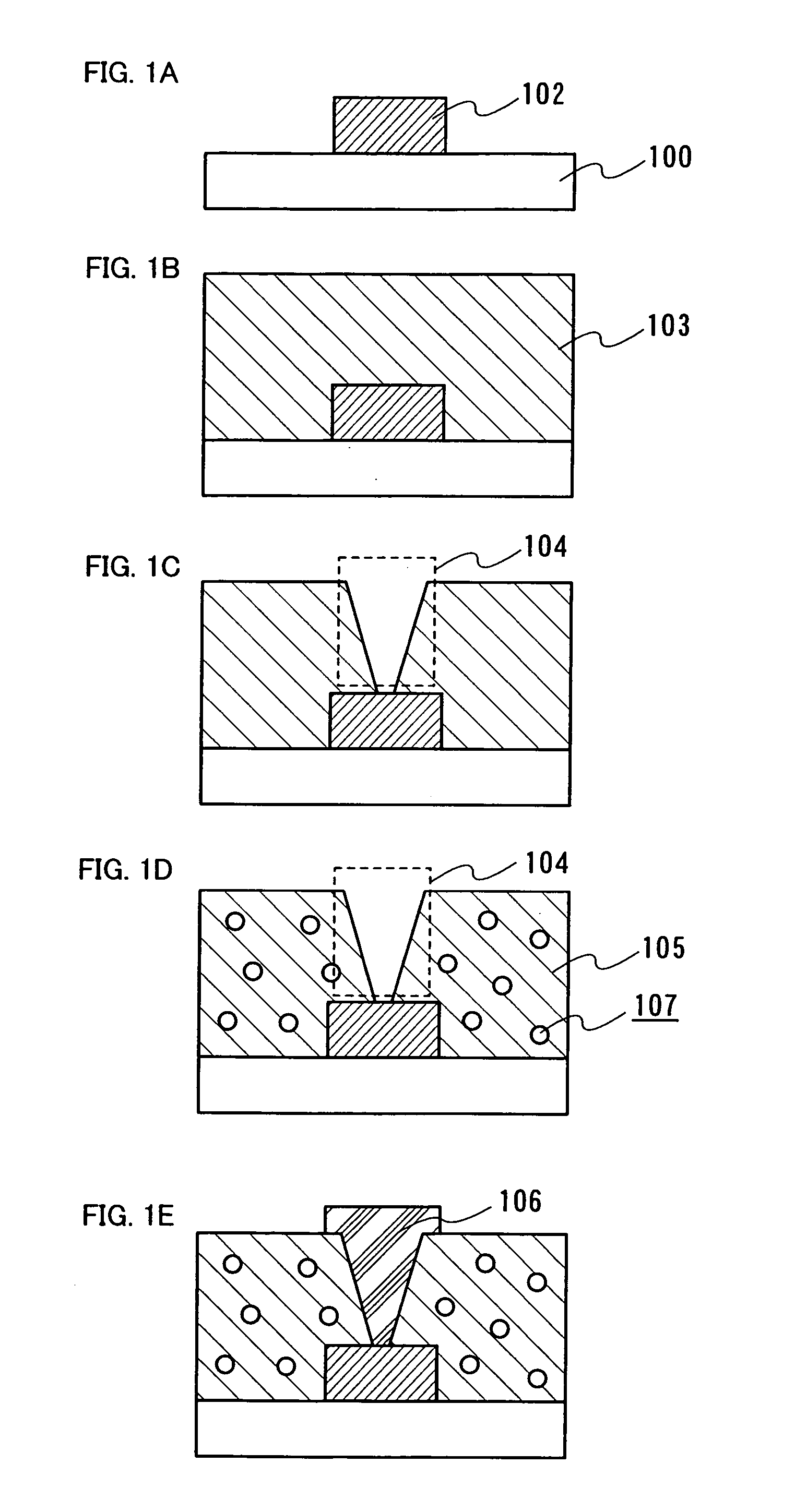

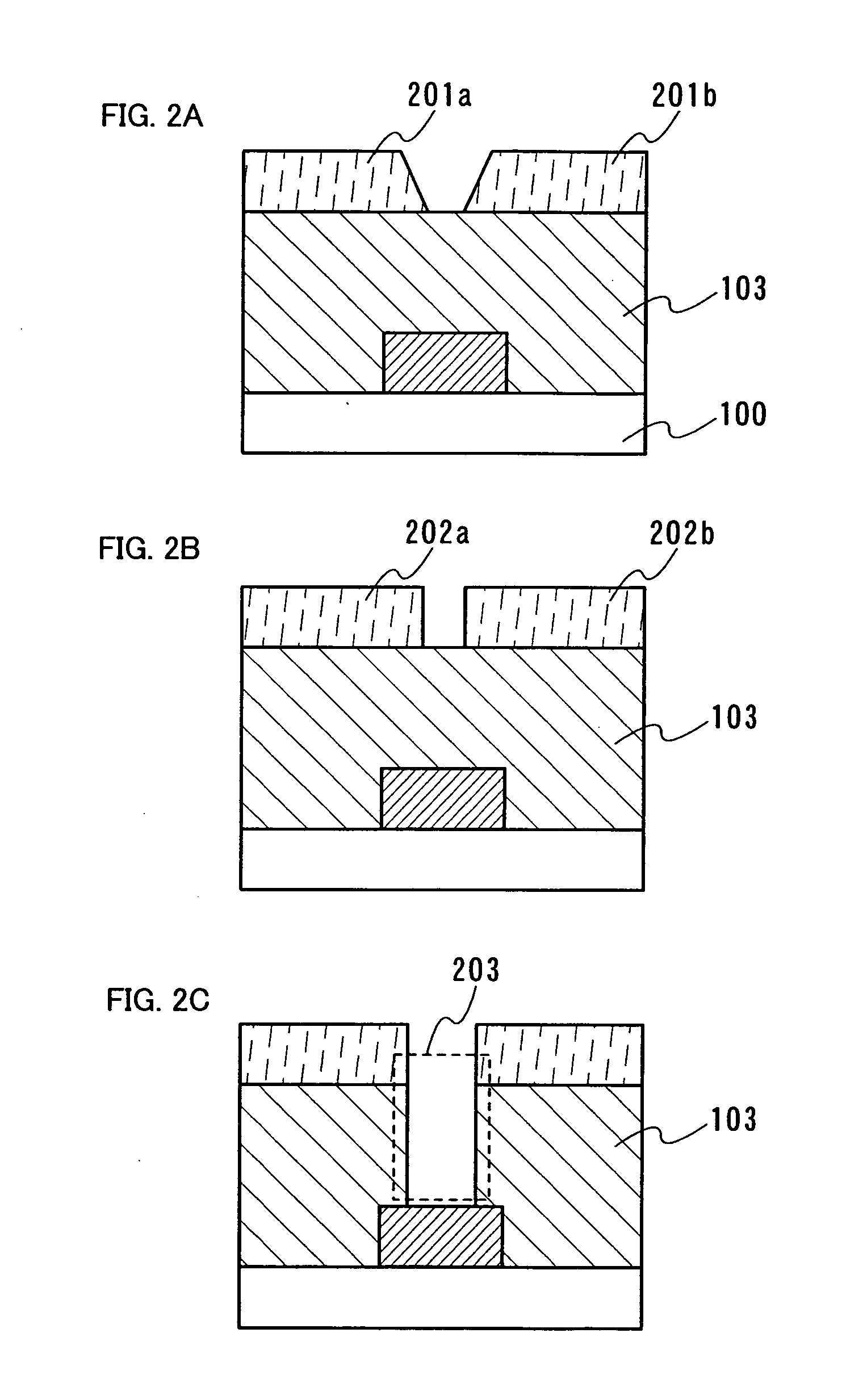

The invention provides a manufacturing method of an insulating film having a plurality of pores, as well as a manufacturing method of a highly integrated semiconductor device with high yield. According to the invention, a porous insulating film is formed by forming a plurality of pores in an interlayer insulating film using a laser beam, which results in lower dielectric constant of the interlayer insulating film. In addition, a composition containing conductive particles is discharged onto the porous insulating film by a droplet discharge method typified by an ink jet printing method, and then baked to form a wire. As the laser beam, an ultrashort pulse laser beam is preferably used.

Owner:SEMICON ENERGY LAB CO LTD

Thermally vanishing material, transfer sheet using the same, and method for forming pattern

InactiveUS20050276934A1Low production costSimple patternPorous dielectricsConductive layers on insulating-supportsOxygen atomAdditive ingredient

Provided is a heat-decaying material that hardly deteriorates and decomposed at ordinary service temperatures, but decays within a short period of time when heated at relatively low temperatures. This comprises a polyoxyalkylene resin as the principal ingredient thereof, and has an oxygen atom content of from 15 to 55% by mass. When heated at a predetermined temperature falling between 150 and 350° C., at least 95% by mass of the material decays within 10 minutes. The heat-decaying material has many applications for production of porous materials, conductive particles transfer sheets, transfer sheets for circuit formation, pattern formation, etc.

Owner:SEKISUI CHEM CO LTD

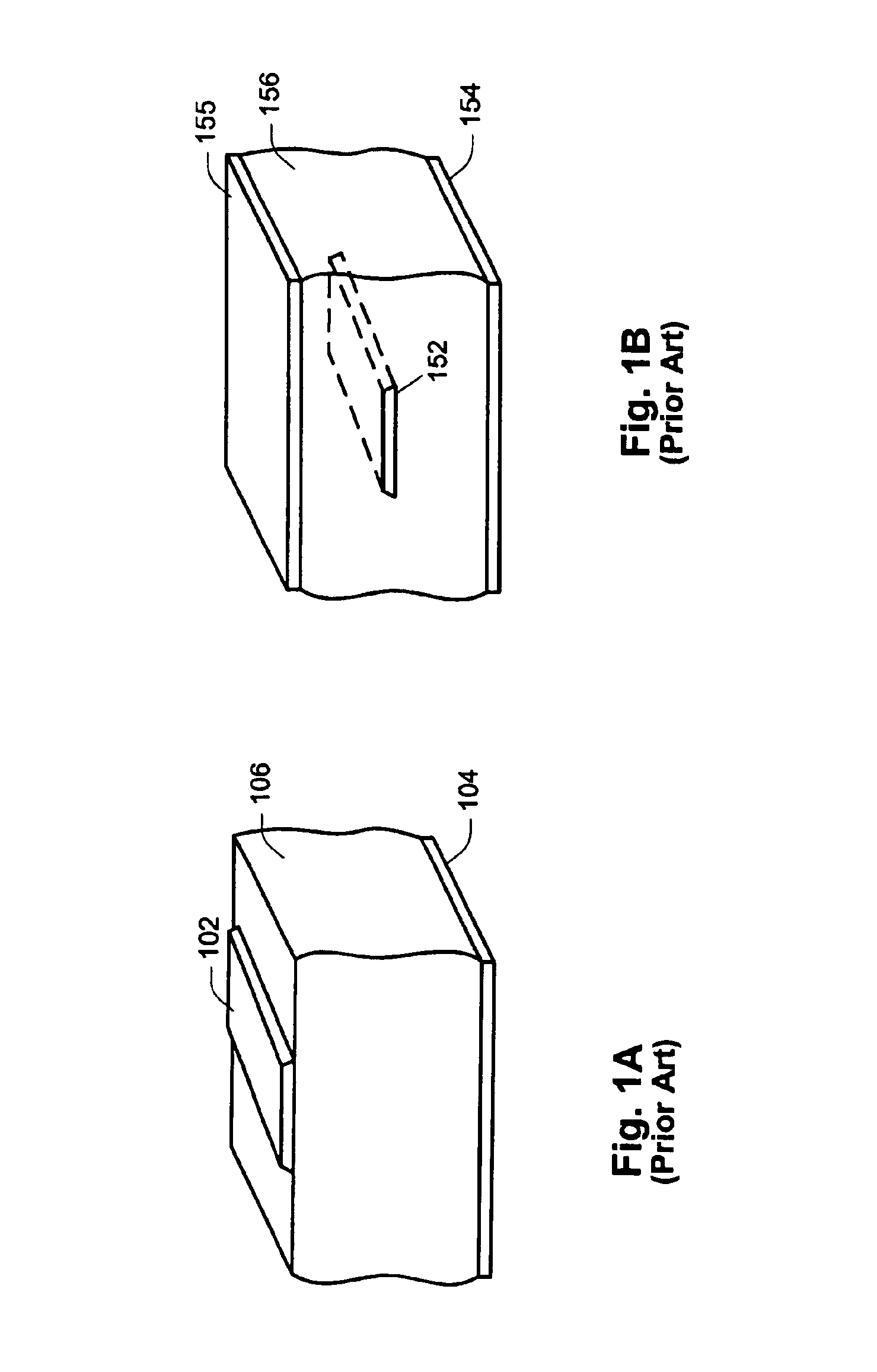

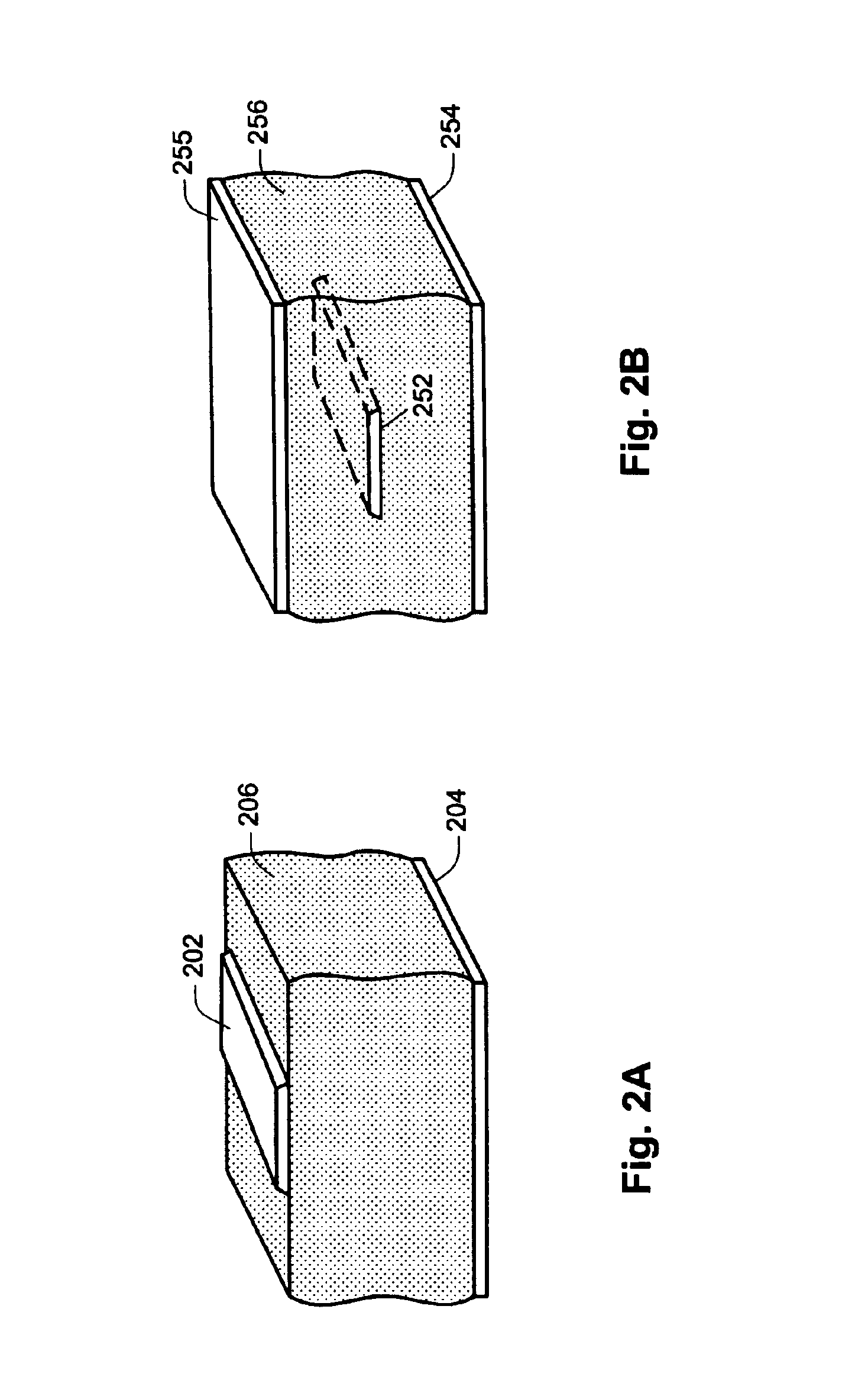

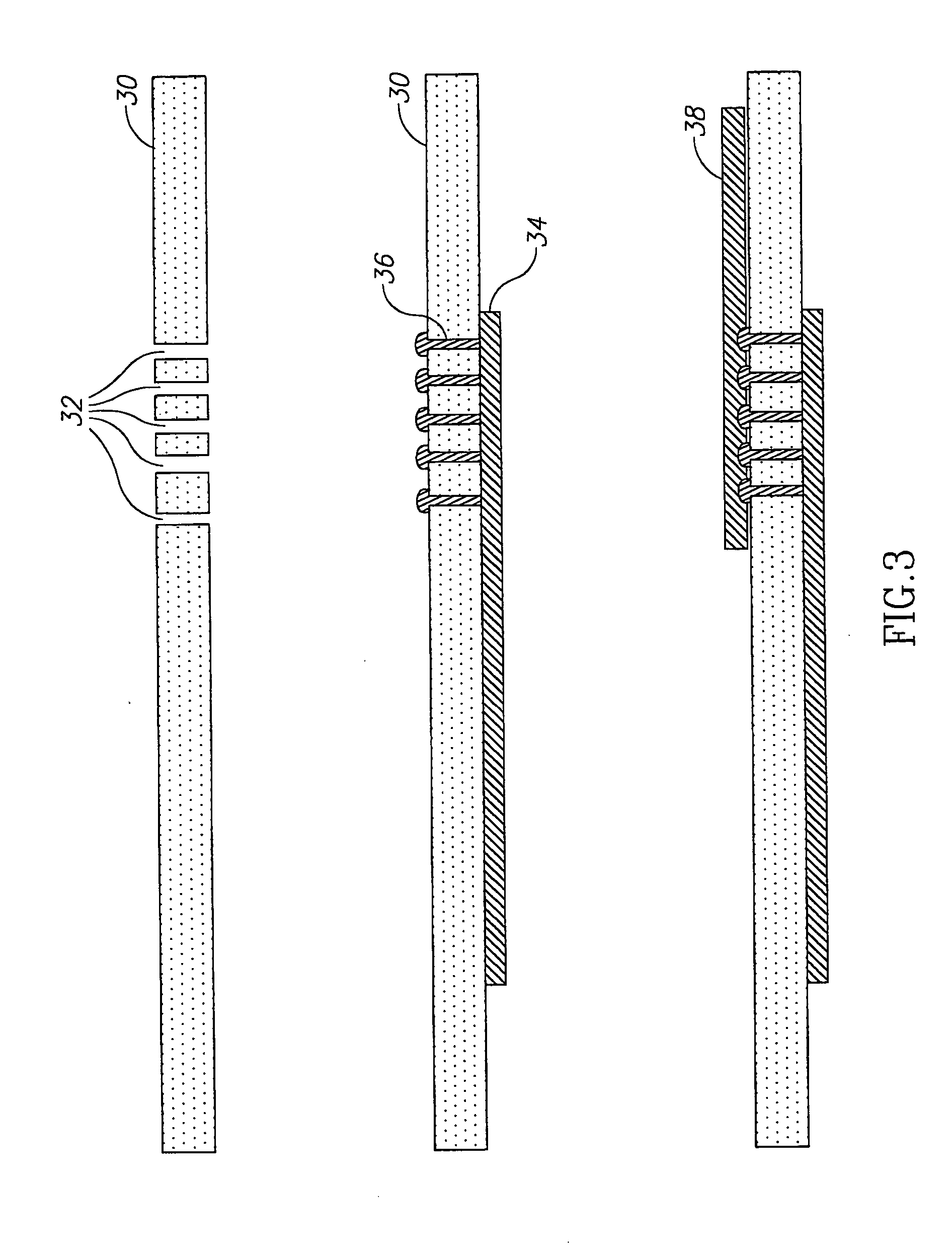

Flex-circuit-based high speed transmission line

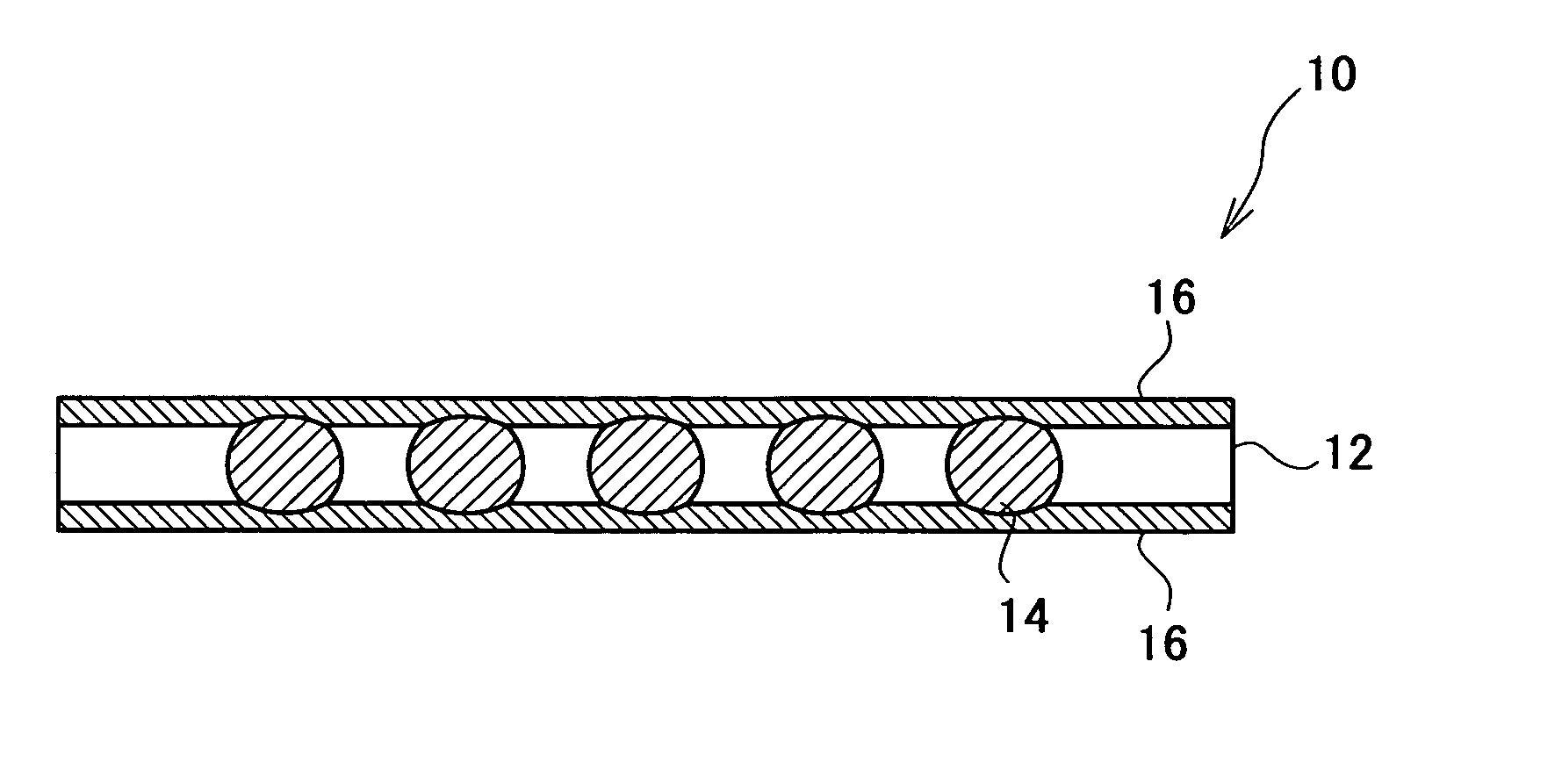

InactiveUS6888427B2Low dielectric constantImprove performancePorous dielectricsHigh frequency circuit adaptationsInter layerFlexible circuits

A transmission line circuit is described which includes a conductive plane, a plurality of signal traces, and an intermediate layer between the conductive plane and the signal traces. The intermediate layer maintains a substantially constant separation between the conductive plane and the signal traces. At least a portion of the intermediate layer comprises air. The signal traces and the conductive plane form transmission lines.

Owner:XANDEX

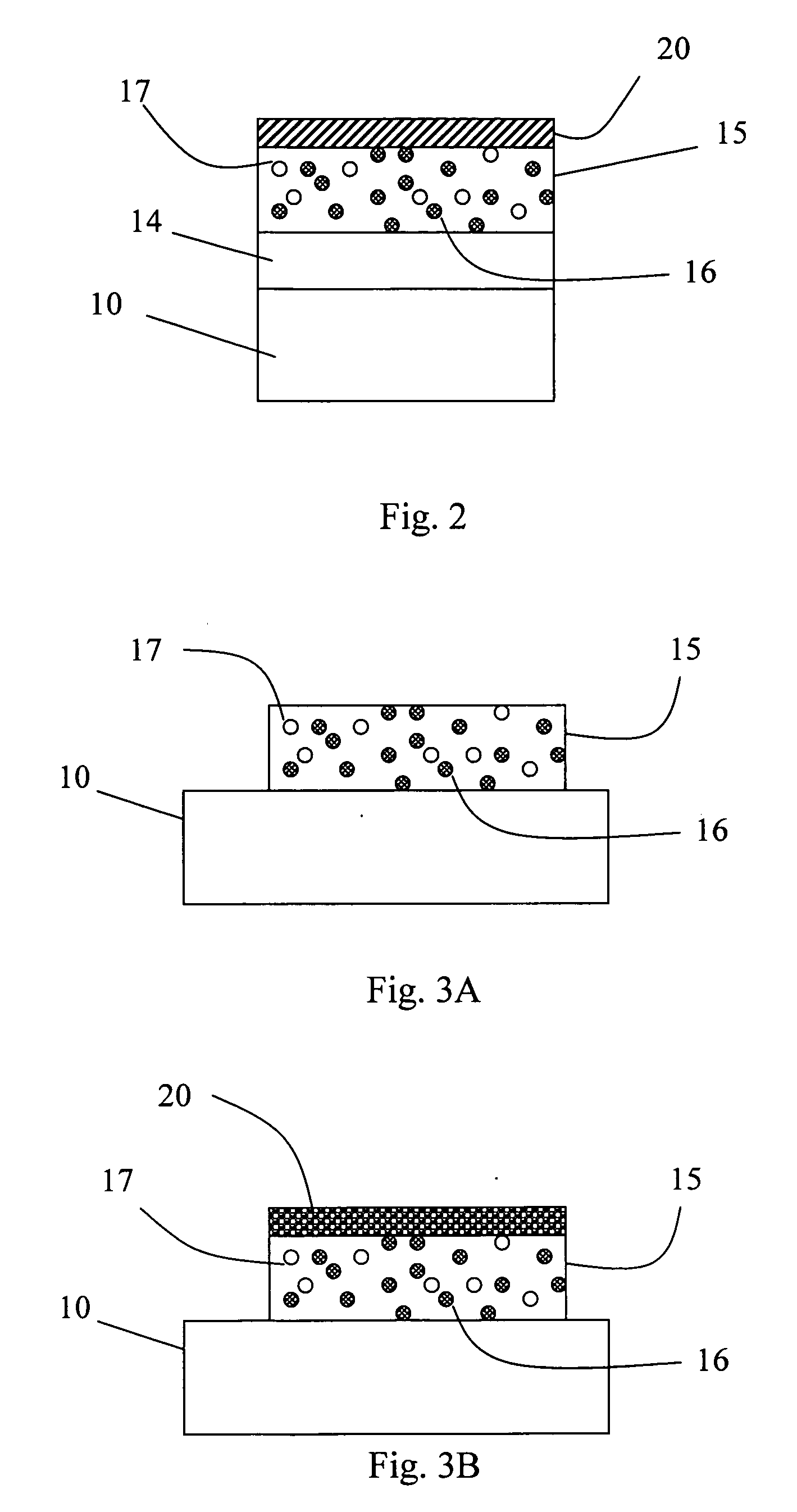

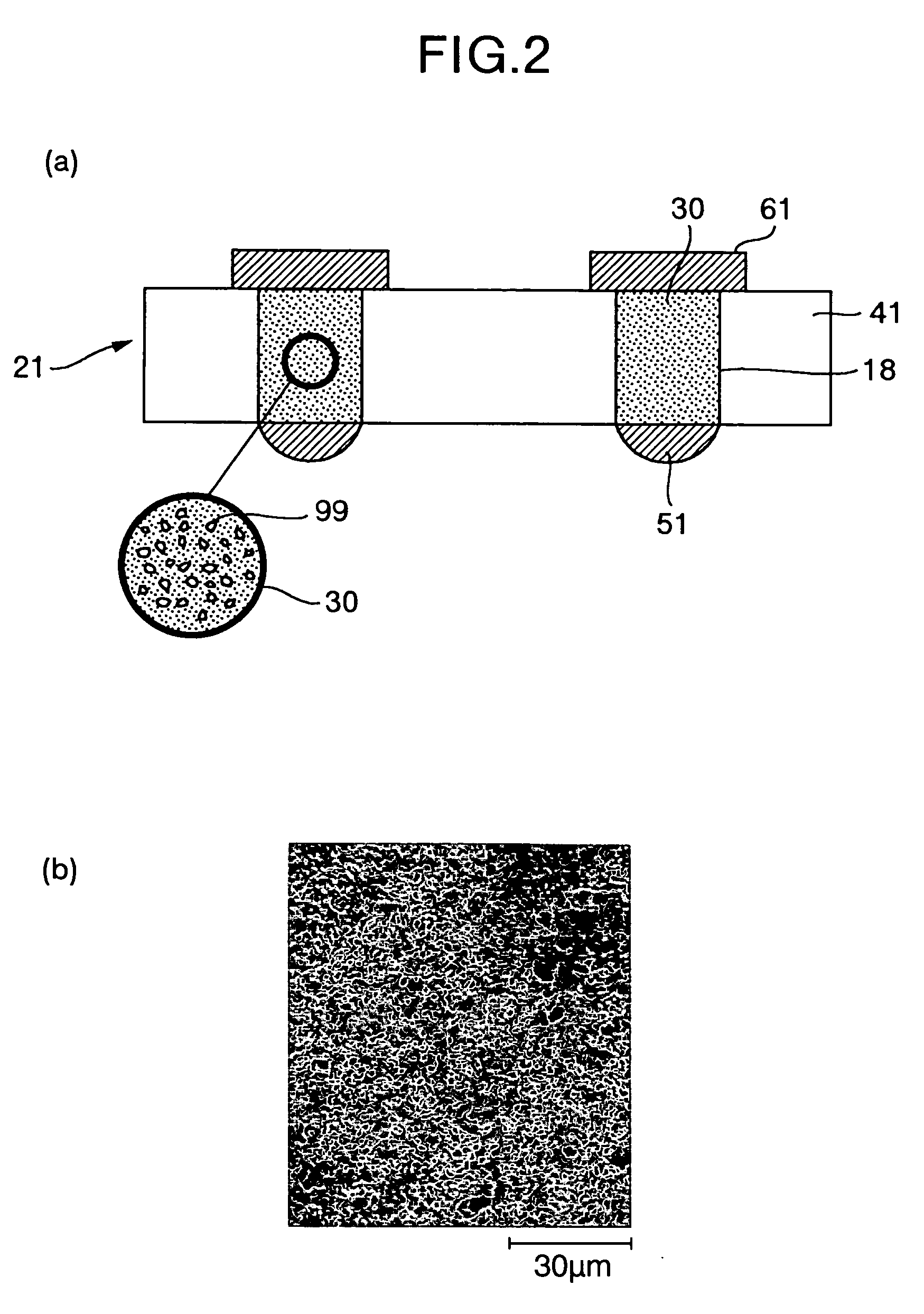

Bonding Material for Semiconductor Devices

ActiveUS20130134591A1Improve reliabilityFew voidPorous dielectricsLayered productsMetallurgyInternal bond

A semiconductor device is provided which has internal bonds which do not melt at the time of mounting on a substrate. A bonding material is used for internal bonding of the semiconductor device. The bonding material is obtained by filling the pores of a porous metal body having a mesh-like structure and covering the surface thereof with Sn or an Sn-based solder alloy.

Owner:SENJU METAL IND CO LTD

Metal-foil-clad composite ceramic board and process for the production thereof

InactiveUS6113730APorous dielectricsSemiconductor/solid-state device detailsPorosityComposite ceramic

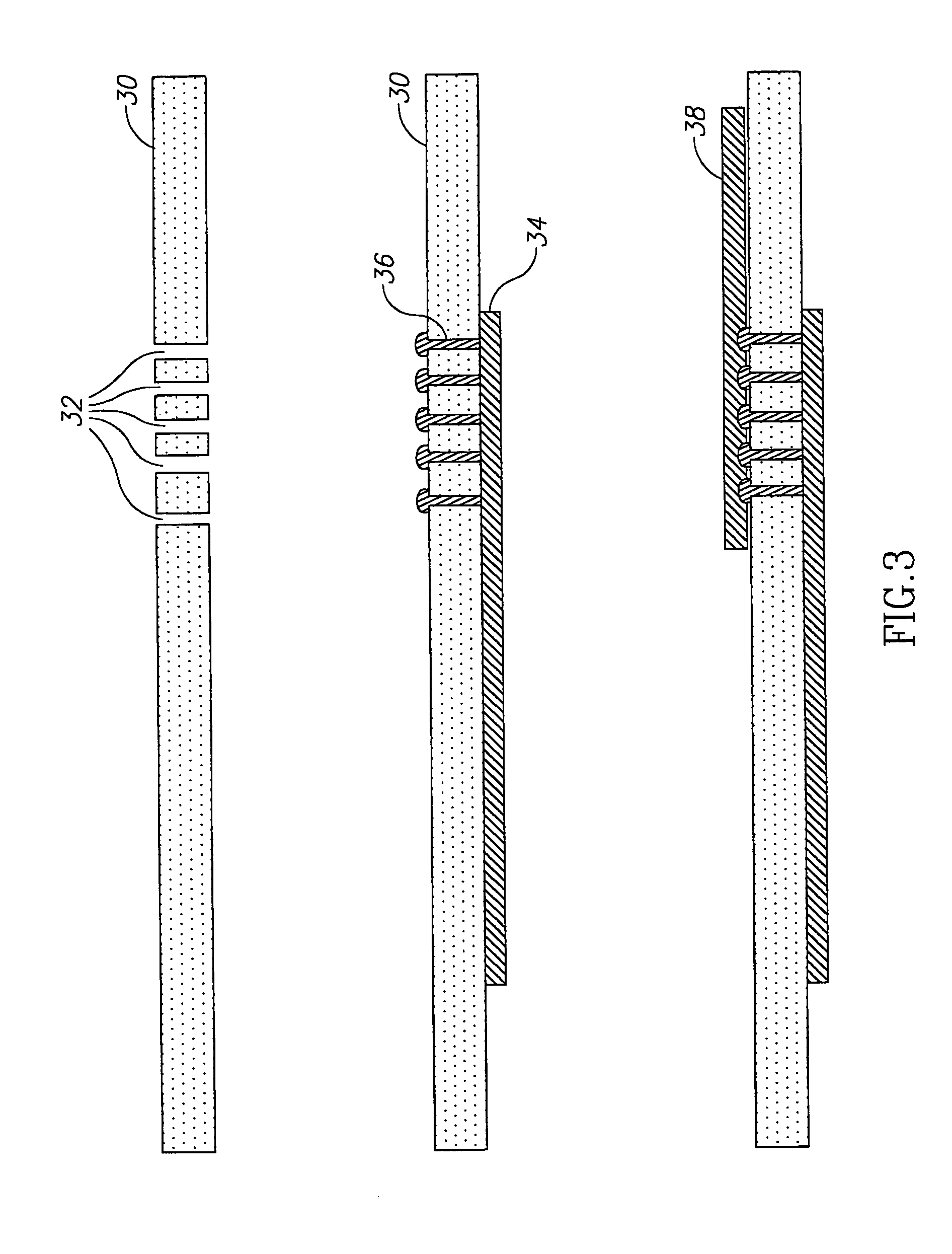

A metal-foil-clad composite ceramic board produced by impregnating a sintered substrate (II) of an inorganic continuously porous sintered body (I) having a true porosity of 12 to 50% and an open porosity of at least 10%, with a thermosetting resin (R) under vacuum, to form a resin-imprgnated sintered substrate (IIR), stacking a metal foil on the resin-impregnated sintered substrate (IIR) and press-forming the resultant laminate, wherein the stacked metal foil has a 10-point average surface roughness Rz of 10 mu m or less, and the resin-impregnated sintered substrate (IIR) and the metal foil have substantially no adhesive layer therebetween or have an adhesive layer having a thickness of 10 mu m or less therebetween.

Owner:MITSUBISHI GAS CHEM CO INC

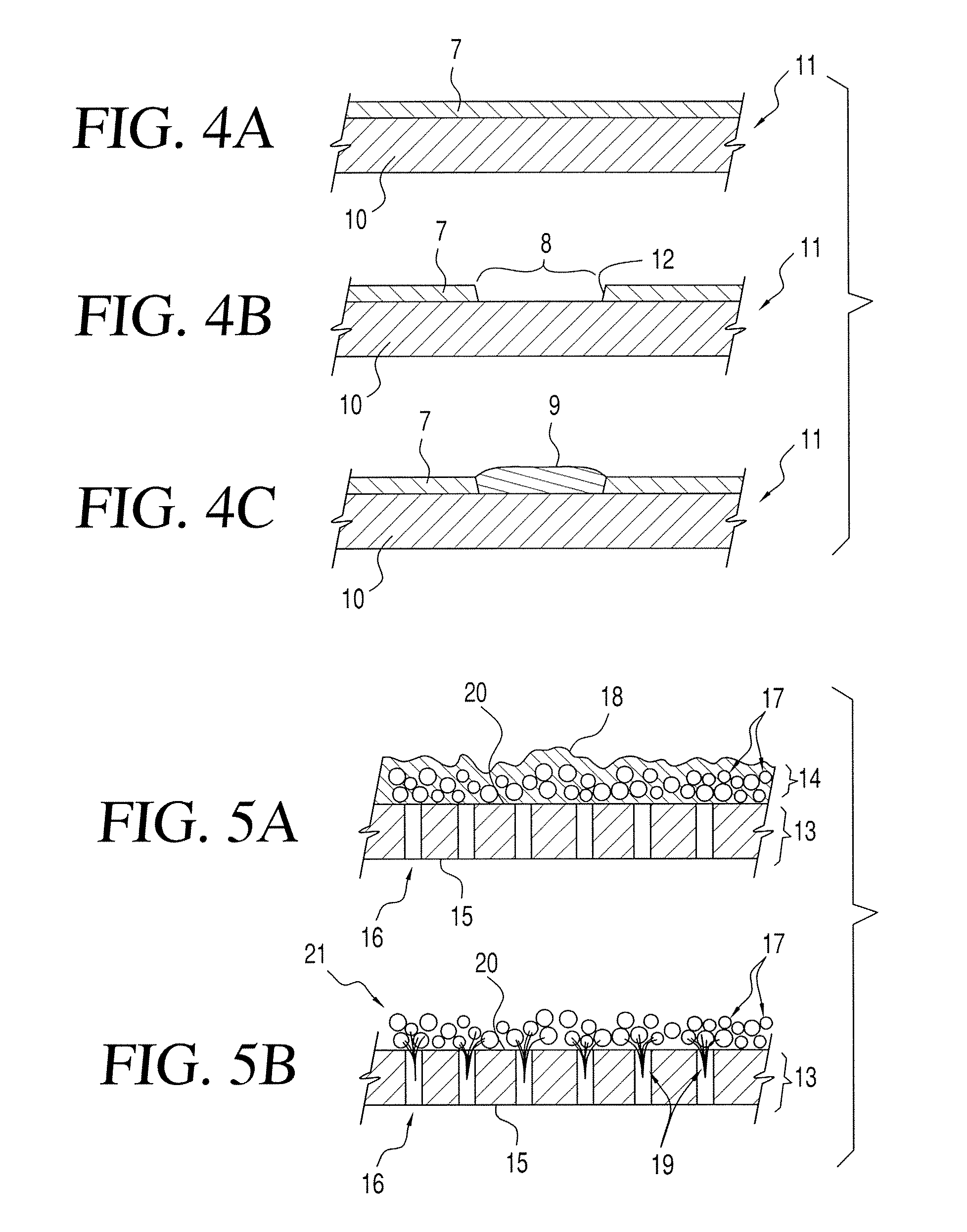

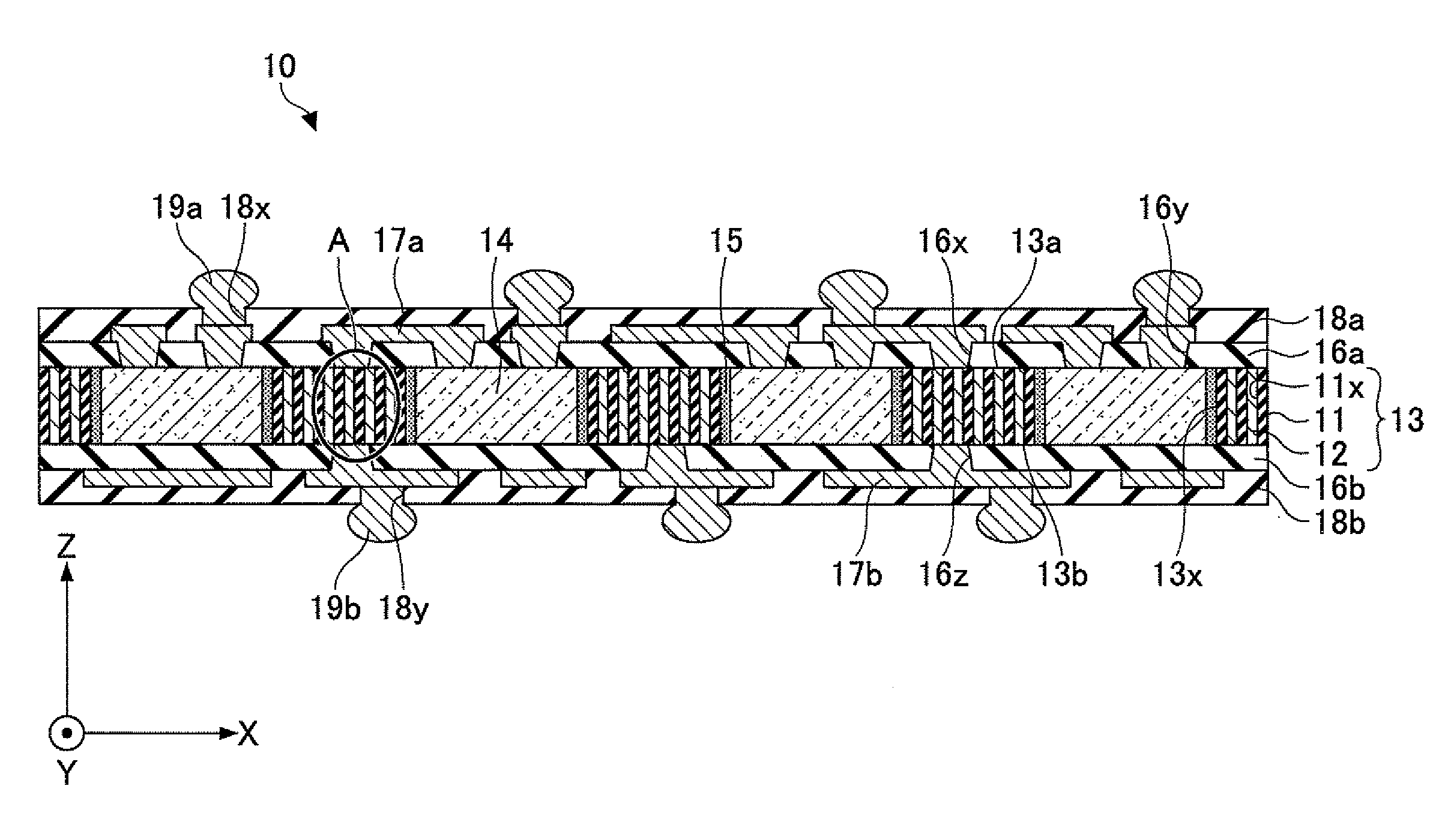

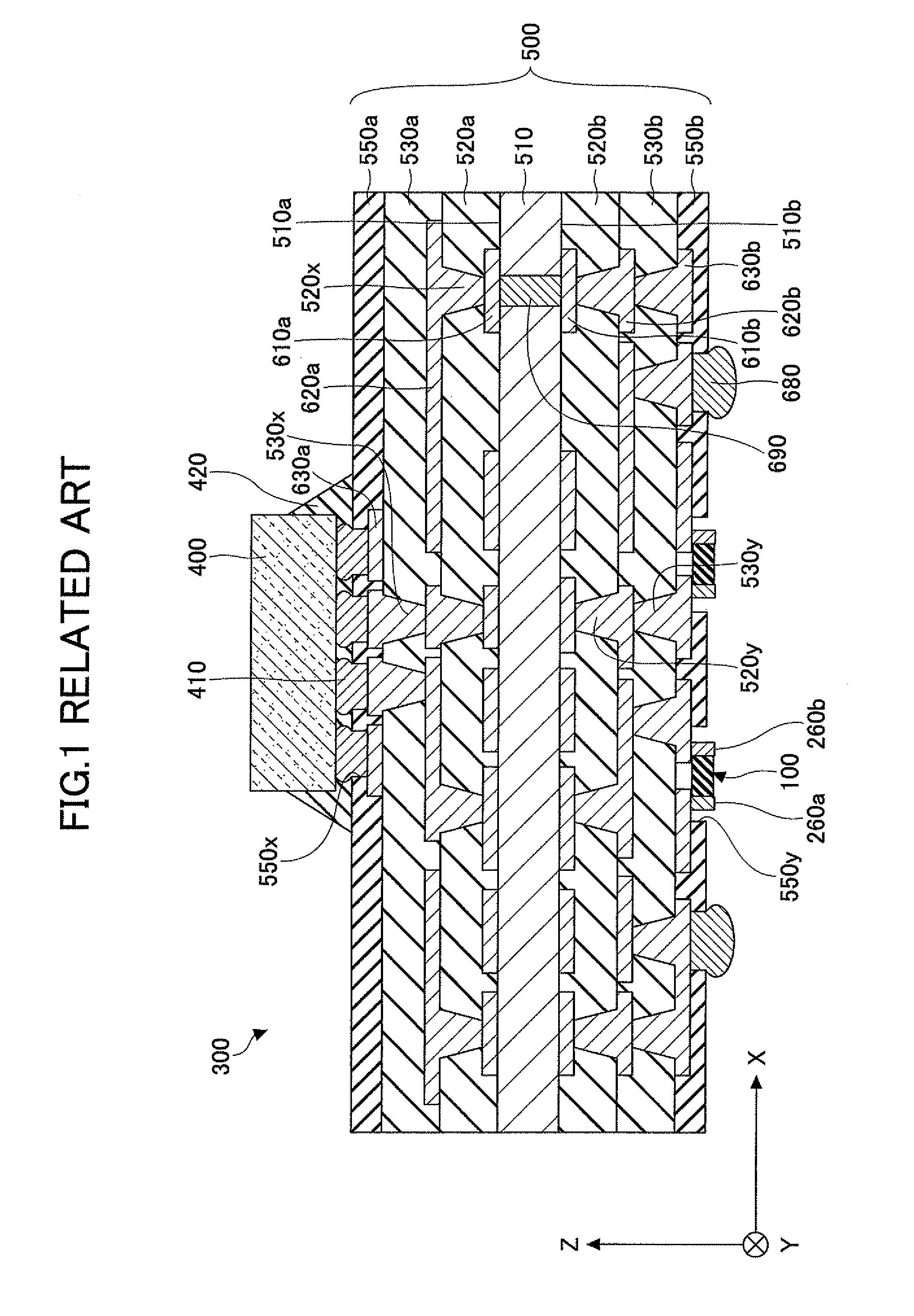

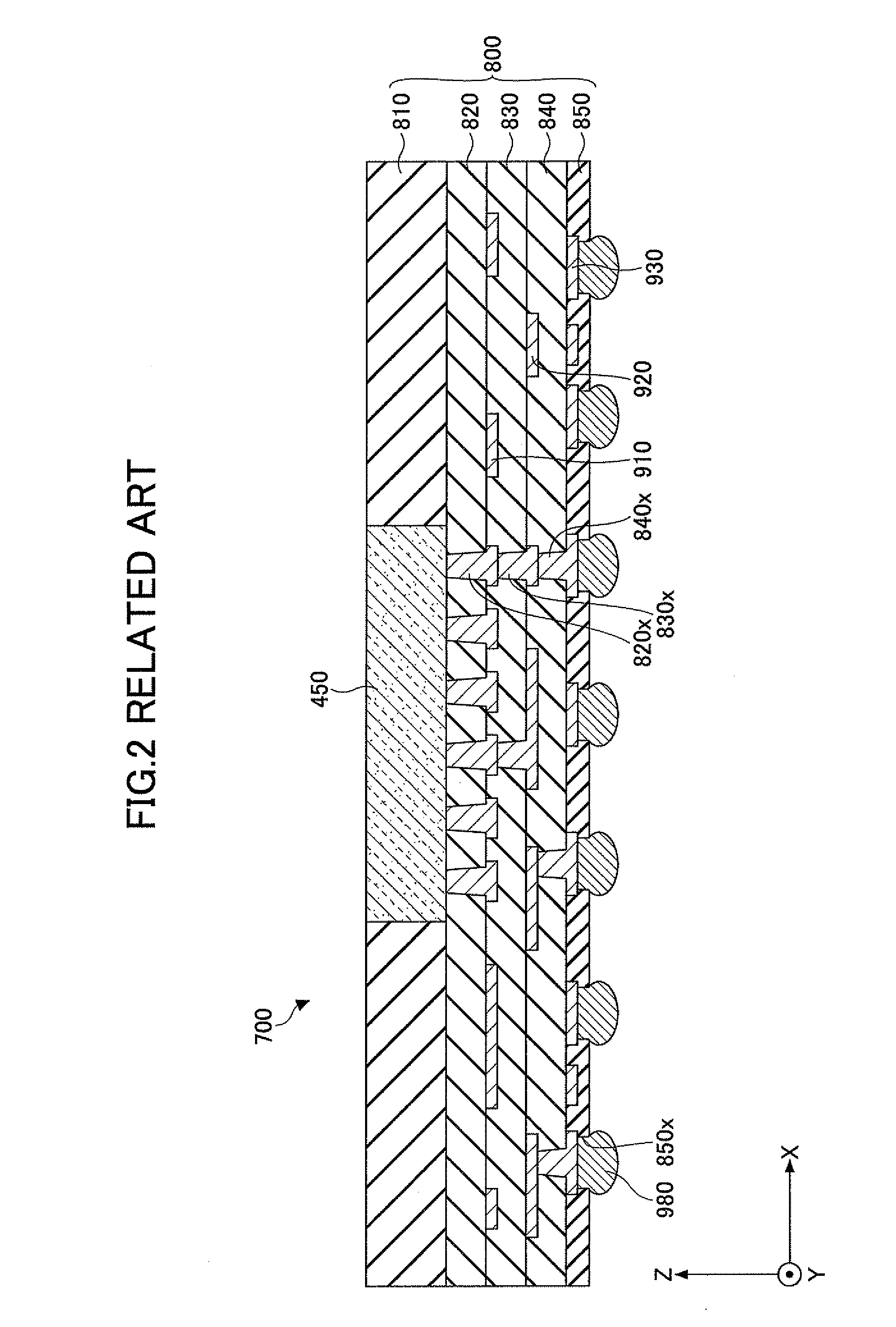

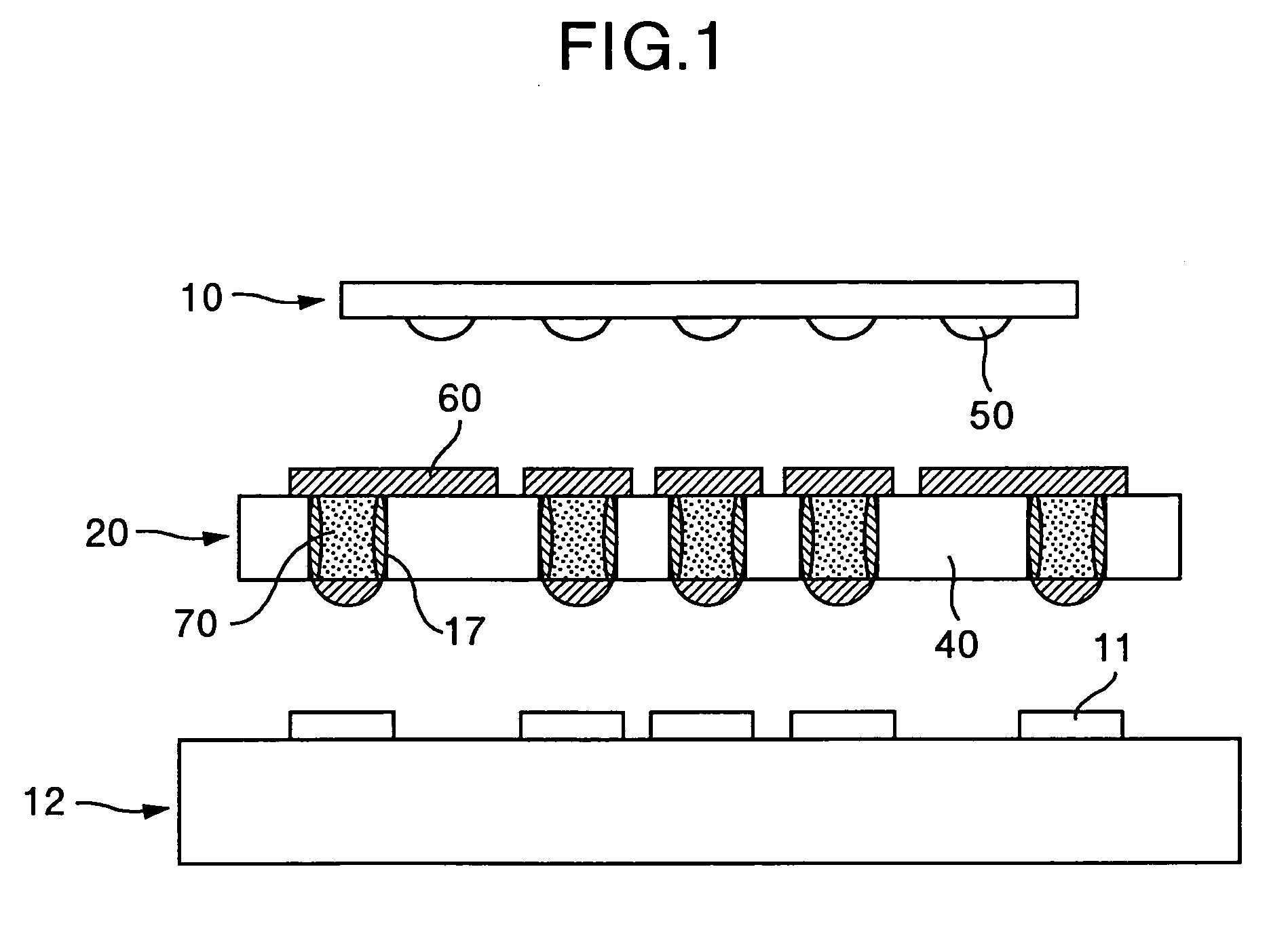

Semiconductor device and method of manufacturing semiconductor device

ActiveUS20110012266A1The connection is tight and firmHigh-density fabricationPorous dielectricsSemiconductor/solid-state device detailsElectrical conductorSemiconductor chip

In a semiconductor device, a substrate includes a plurality of line conductors which penetrate the substrate from a top surface to a bottom surface of the substrate. A semiconductor chip is secured in a hole of the substrate. A first insulating layer is formed on the top surfaces of the substrate and the semiconductor chip. A first wiring layer is formed on the first insulating layer and electrically connected via through holes of the first insulating layer to the semiconductor chip and some line conductors exposed to one of the through holes. A second insulating layer is formed on the bottom surfaces of the substrate and the semiconductor chip. A second wiring layer is formed on the second insulating layer and electrically connected via a through hole of the second insulating layer to some line conductors exposed to the through hole.

Owner:SHINKO ELECTRIC IND CO LTD

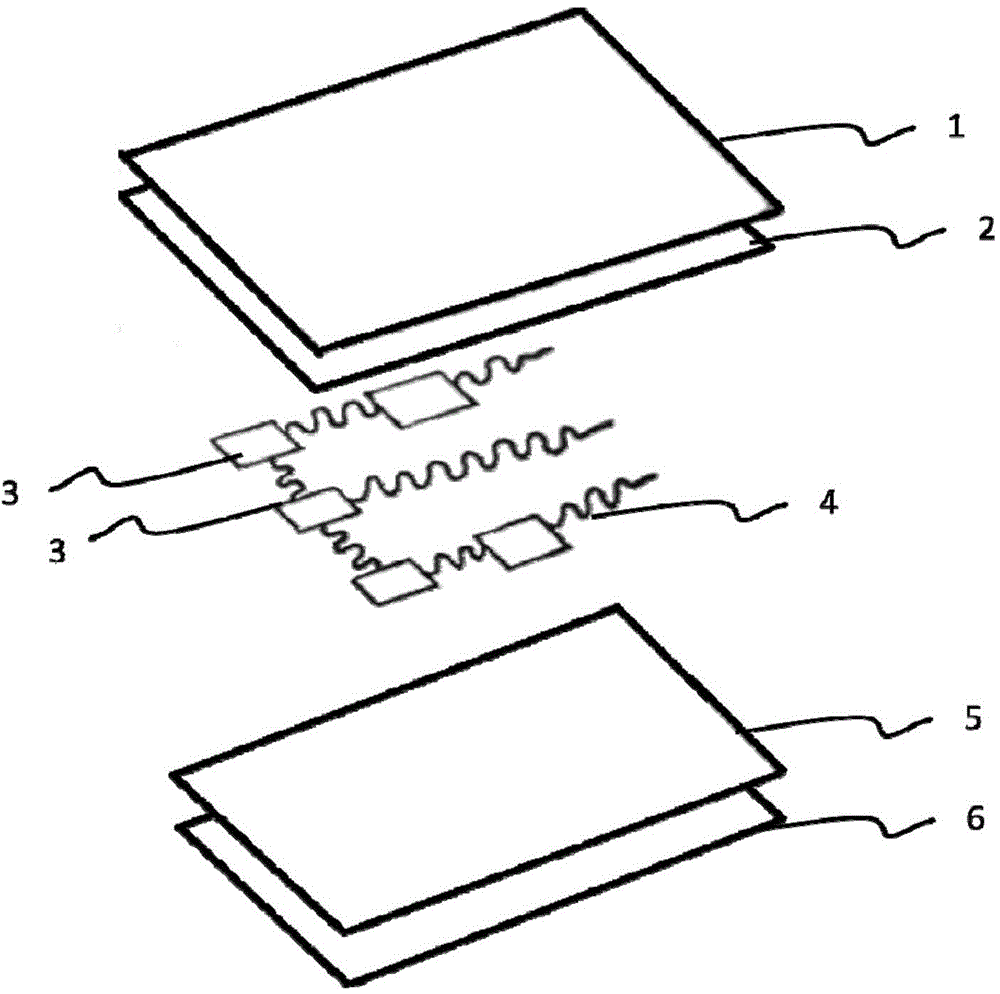

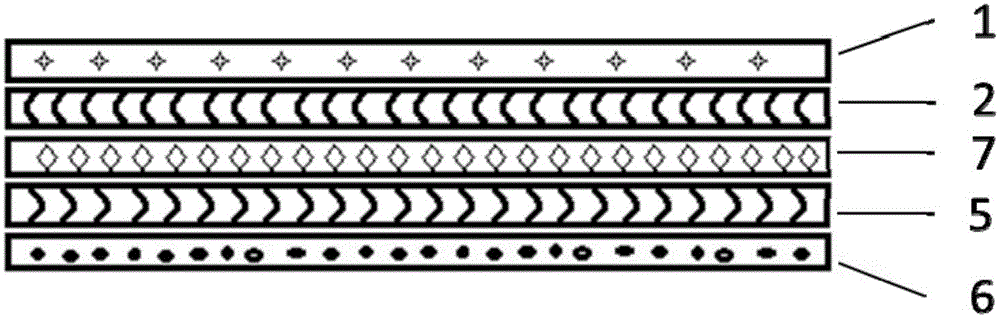

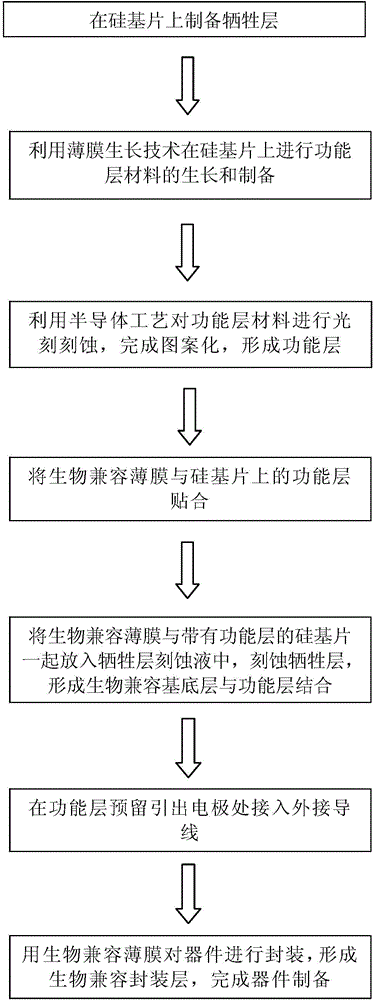

Flexible and extendable electronic device based on biocompatible films and manufacturing method

ActiveCN104523227AAvoid rednessAvoid reactionPorous dielectricsCircuit bendability/stretchabilityExtensibilityBiocompatibility Testing

The invention relates to a flexible and extendable electronic device based on biocompatible films and a manufacturing method, and belongs to the technical field of flexible and extendable electronic devices. The flexible and extendable electronic device is technically characterized in that the biocompatible films are used as an encapsulation layer and a substrate layer of the flexible and extendable electronic device, a bonding layer used for enhancing the boundary strength between the encapsulation layer and a functional layer can be further arranged between the encapsulation layer and the functional layer, and an adhesive layer used for enhancing the adhesive force of the device with the surface of an object to be tested is arranged underneath the substrate layer; the functional layer is of a flexible and extendable structure. In the manufacturing process of the flexible and extendable electronic device, a transfer printing technology based on a solution is mainly adopted to achieve integration of the functional layer and a flexible substrate. The flexible and extendable electronic device structurally keeps and even improves flexibility and extensibility. Meanwhile, compatibility features such as waterproofness, breathability and low allergenicity of the flexible and extendable electronic device allow the flexible and extendable electronic device to normally work on the surface of a human body for more than 24 hours without causing a foreign body feeling and discomfort, and skin soaking or rubefaction or other anaphylactic reactions caused by poor biocompatibility can be avoided.

Owner:浙江智柔科技有限公司

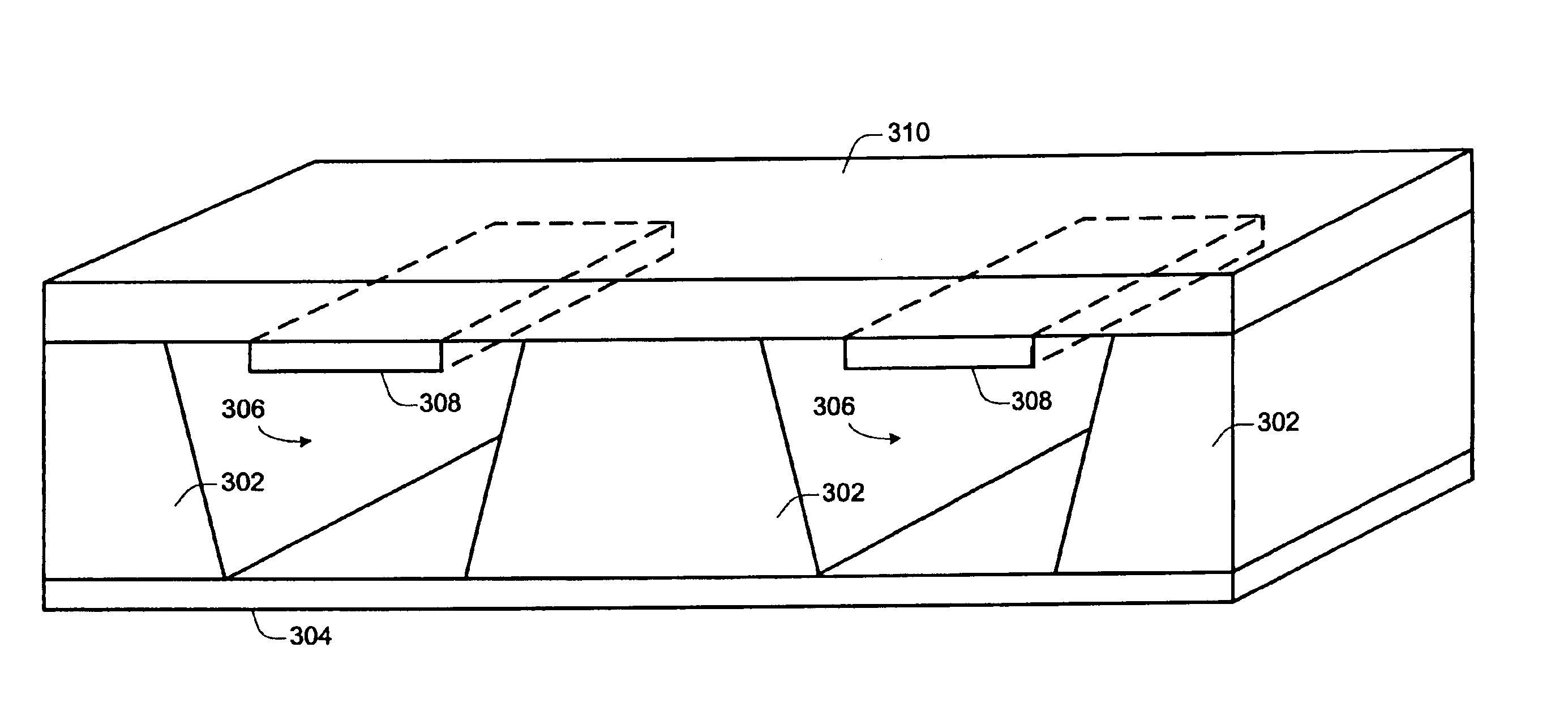

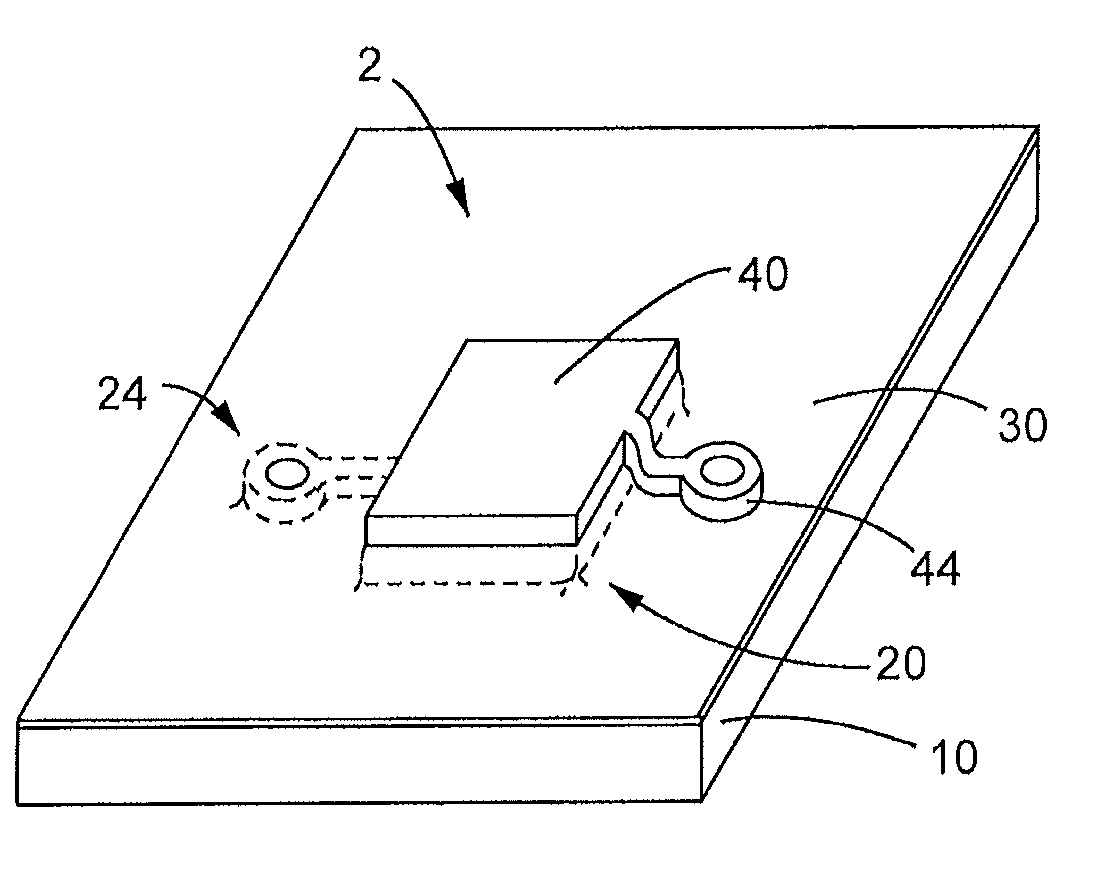

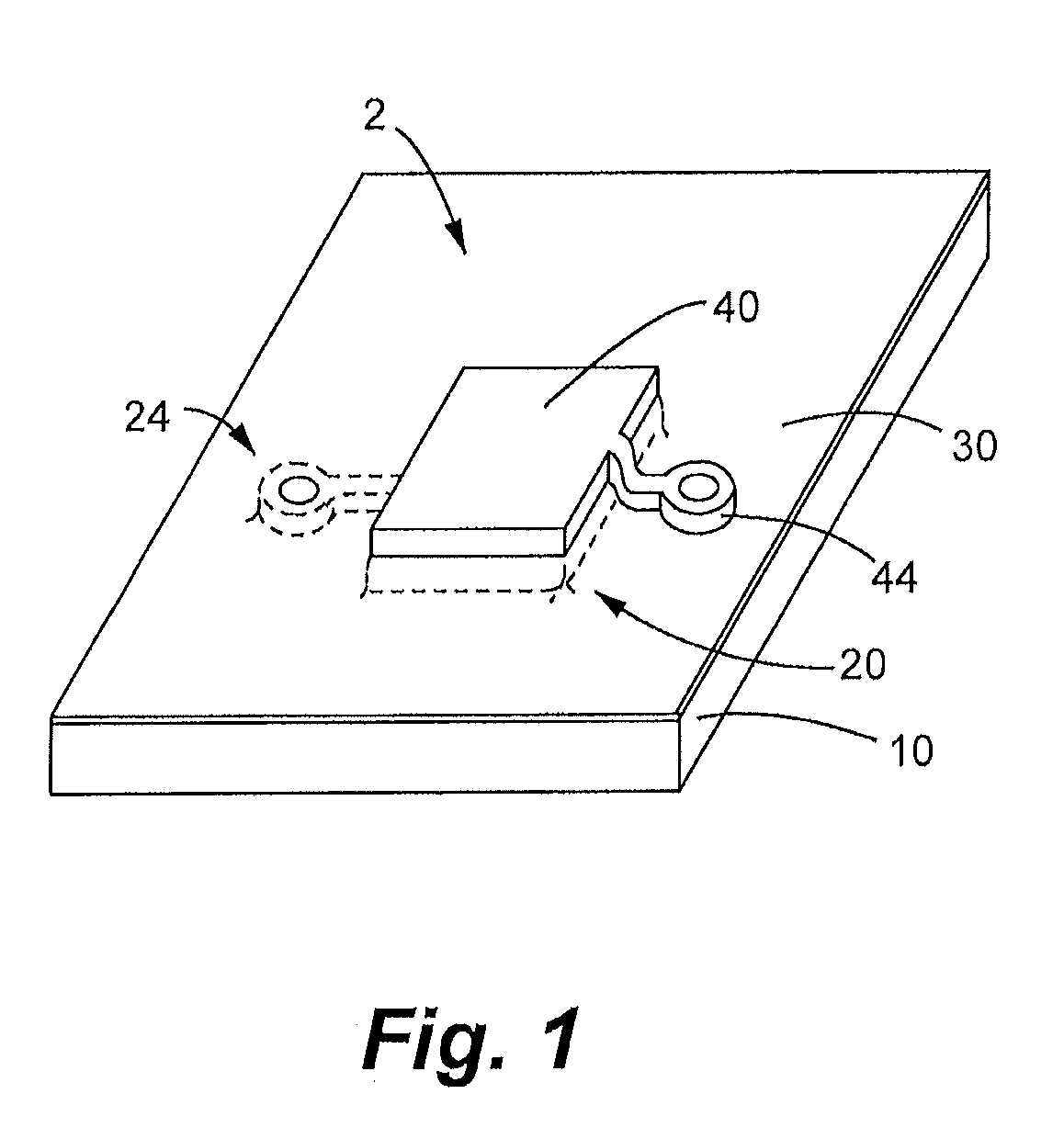

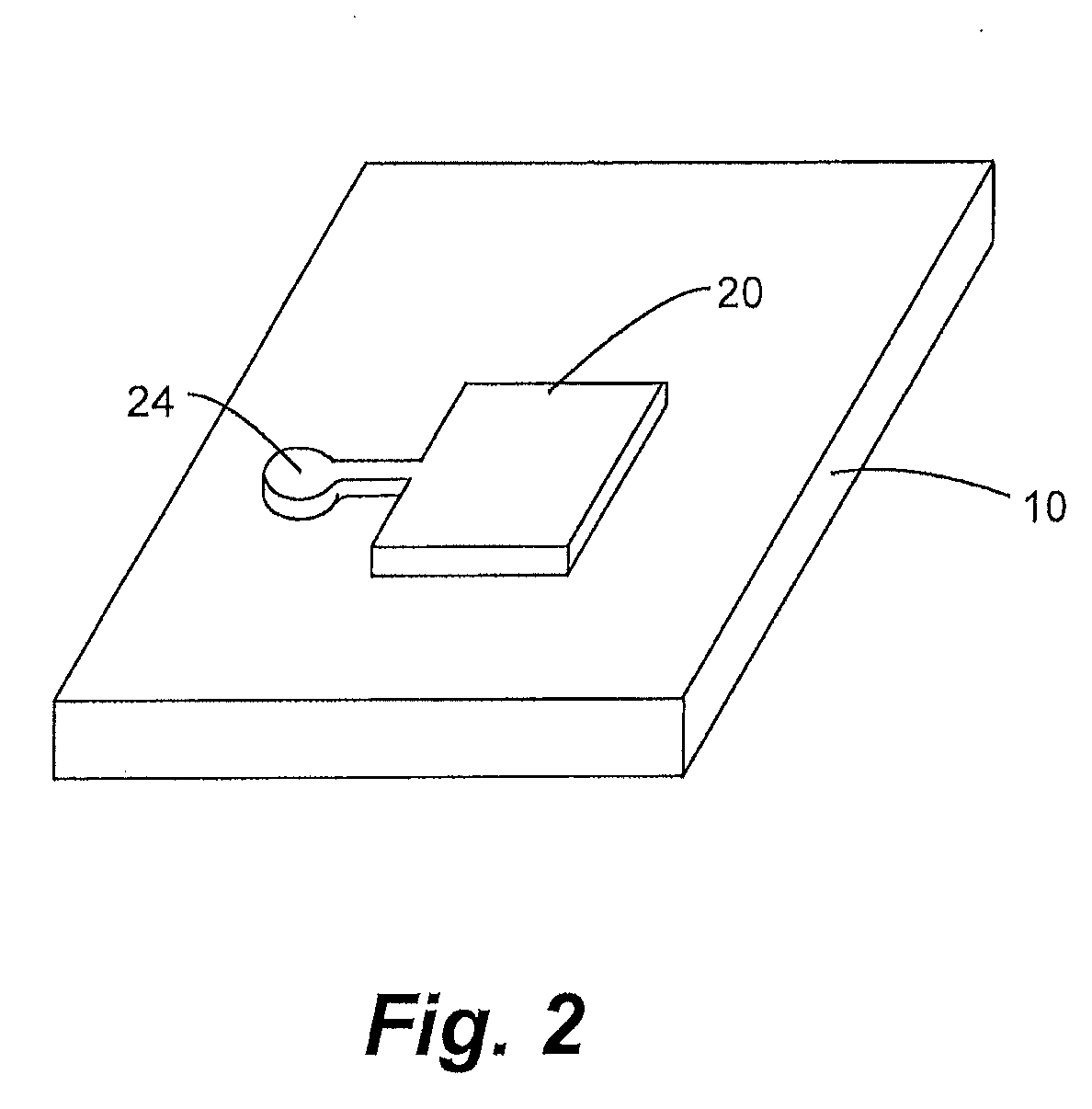

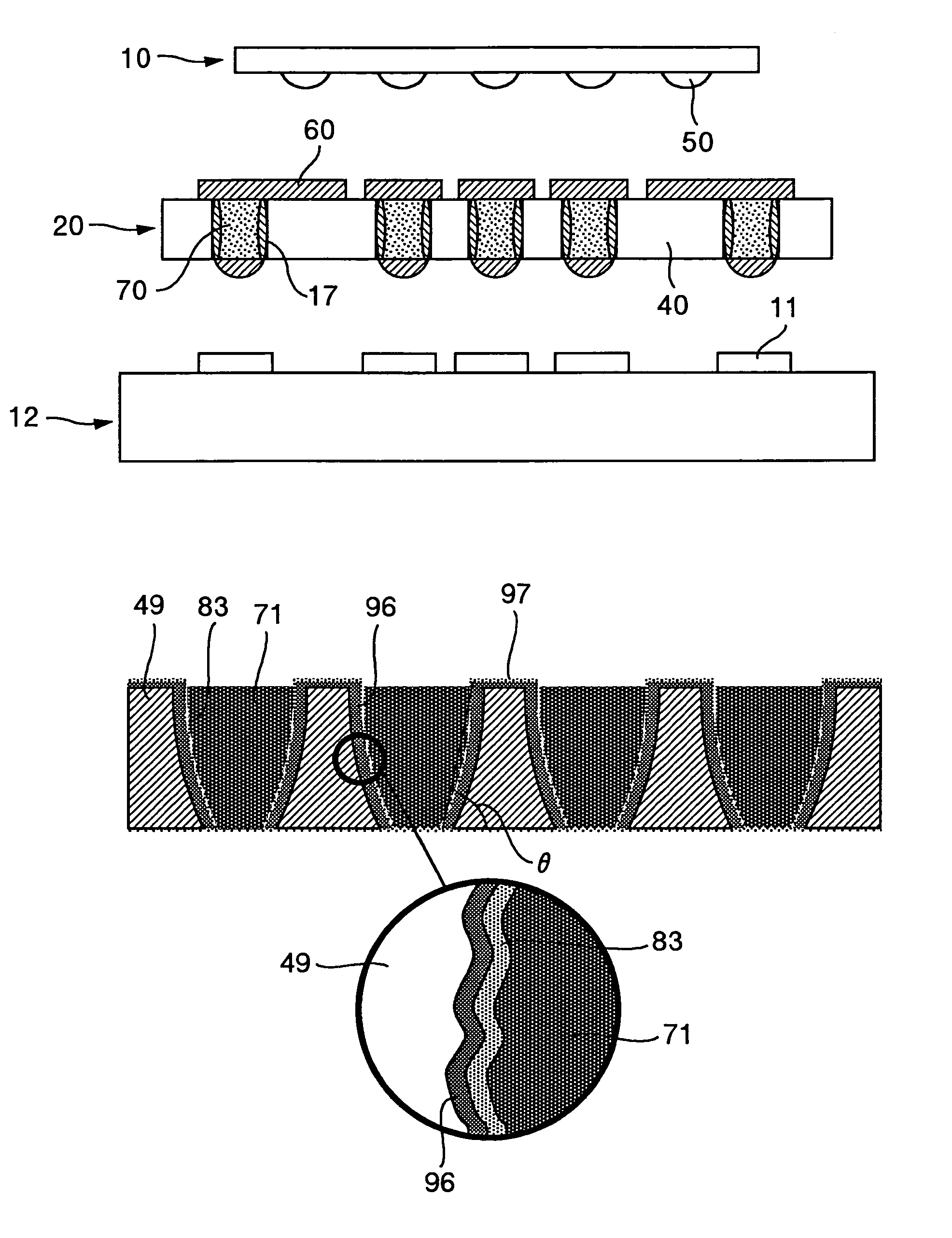

Processing low dielectric constant materials for high speed electronics

InactiveUS6297459B1Easy to fillEqually distributedPorous dielectricsInsulating substrate metal adhesion improvementPorous layerPrinted circuit board

A low dielectric constant printed circuit board includes: a low dielectric constant porous polymer layer having holes therethrough, the porous layer having pores; and a patterned metallization layer over surfaces of the low dielectric constant porous polymer layer and surfaces of the holes, the patterned metallization layer not significantly protruding into the pores of the porous layer.

Owner:SABIC INNOVATIVE PLASTICS IP BV

Dielectric structure

InactiveUS20030128496A1Increase surface areaImprove adhesionPorous dielectricsAnti-noise capacitorsDielectric structureCapacitor

Dielectric structures particularly suitable for use in capacitors and having a textured surface are provided, together with methods of forming these structures. Such dielectric structures show increased adhesion of subsequently applied conductive layers.

Owner:SHIPLEY CO LLC

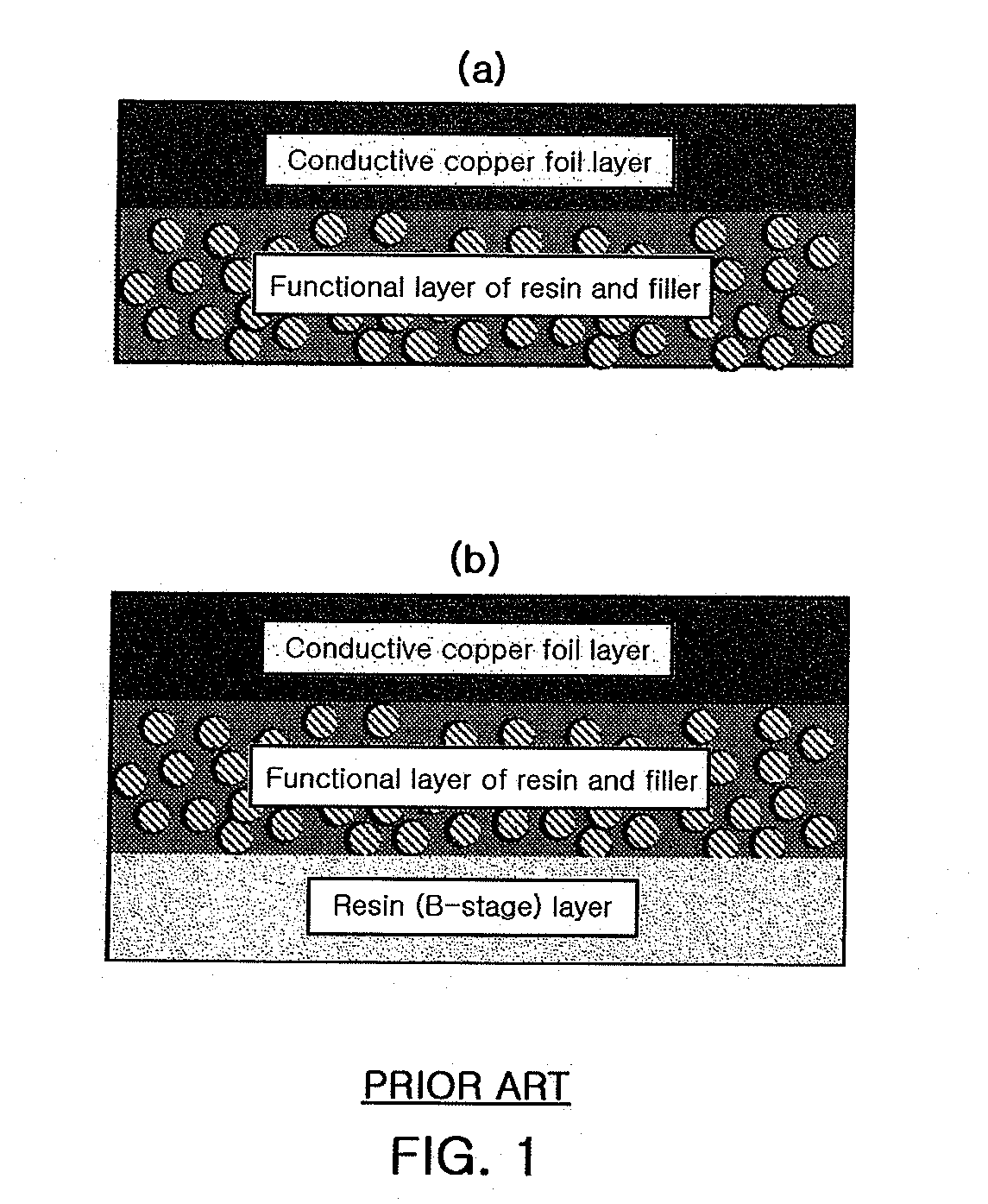

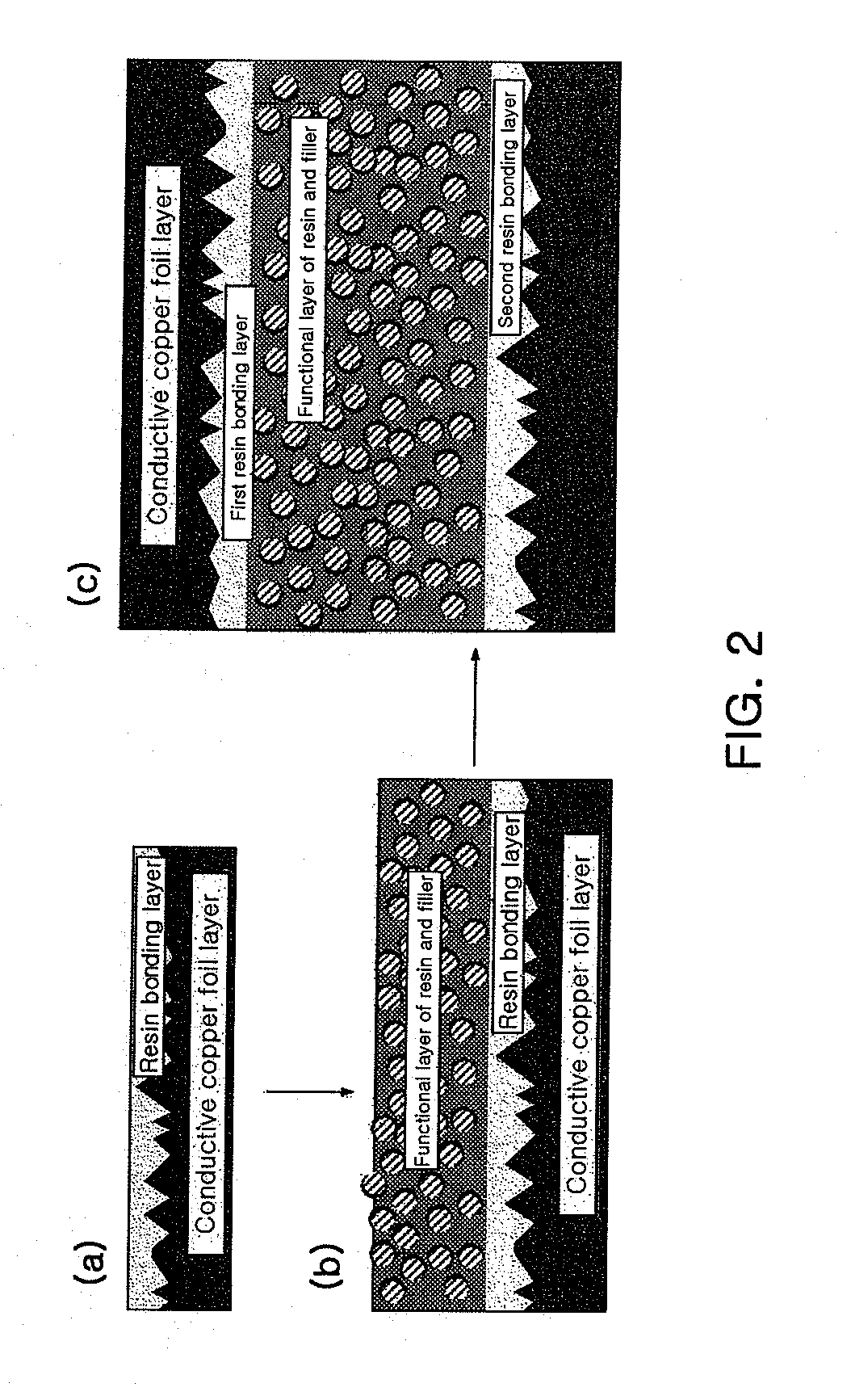

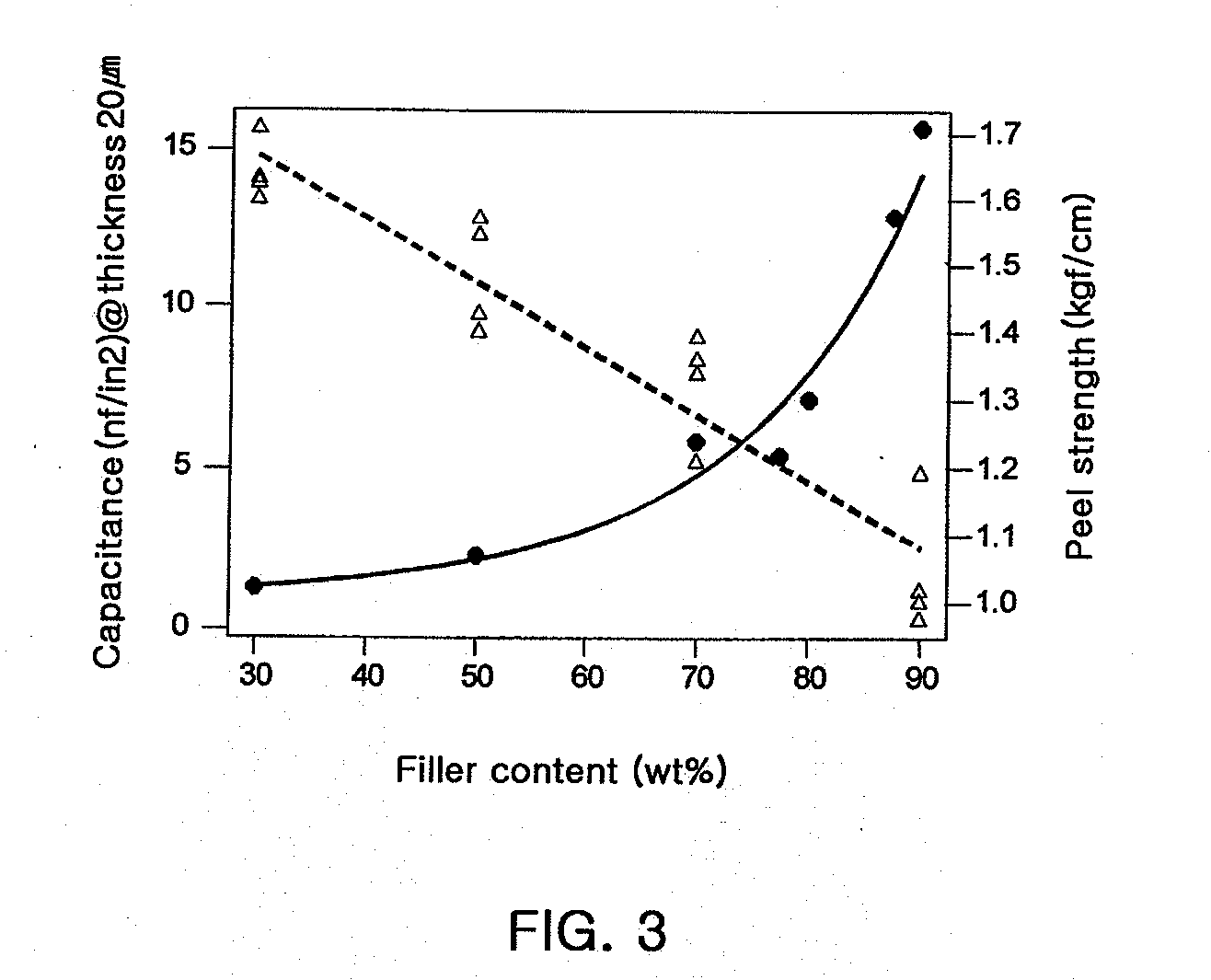

Printed circuit board material for embedded passive devices and preparing method thereof

InactiveUS20070148421A1Excellent electromagnetic property and reliabilityExcellent in dielectric and magnetic property and adhesion strengthPorous dielectricsPrinted capacitor incorporationCopper foilResin bonding

A printed circuit board material for embedded passive devices, which has excellent electromagnetic properties and reliability is provided. The invention provides a printed circuit board material comprises: a conductive copper foil layer; a resin bonding layer formed on the conductive layer and including above 70-100 vol % of resin and 0-30 vol % of filler; and a functional layer formed on the resin bonding layer and including resin and filler. The printed circuit board material has the resin bonding layer interposed between the copper foil layer and the functional layer. Thus, even when the content of fillers in the functional layer is increased, the adhesion strength between the conductive layer and the functional layer is ensured without deteriorating the properties of the functional layer, such as dielectric and magnetic properties.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

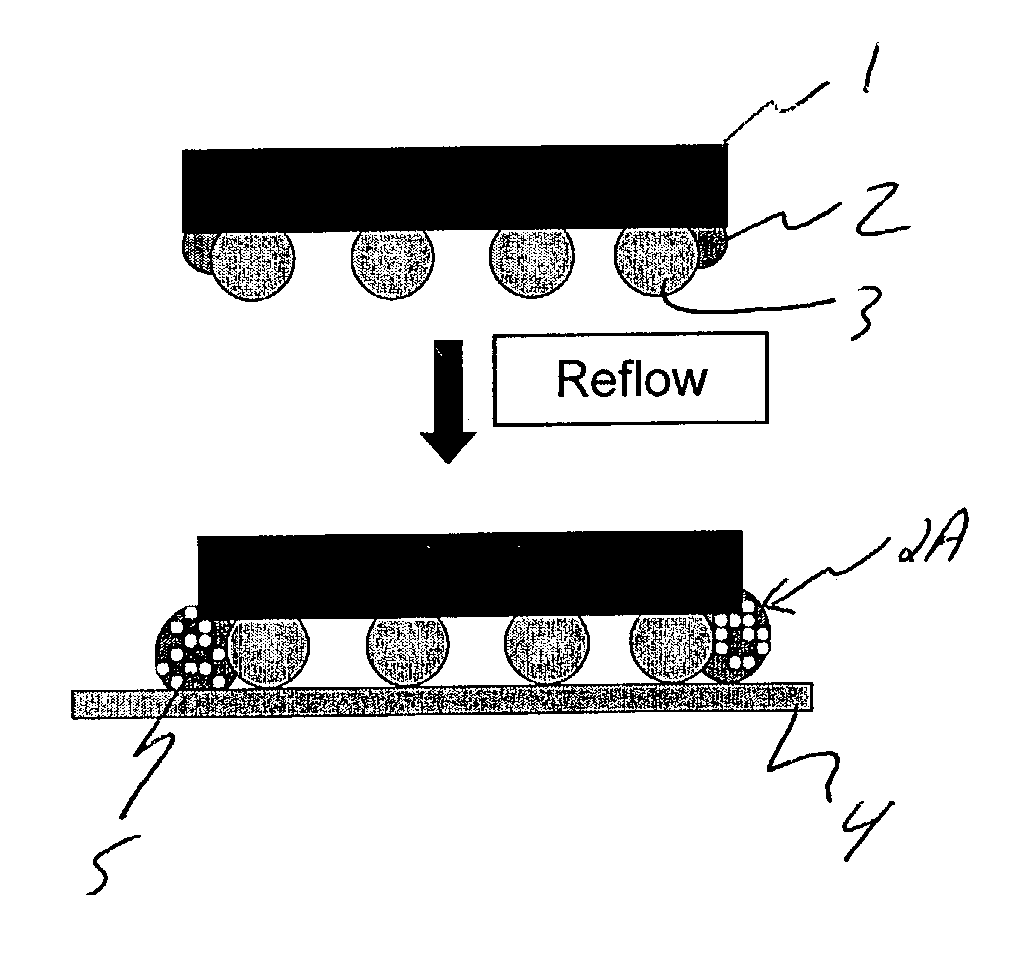

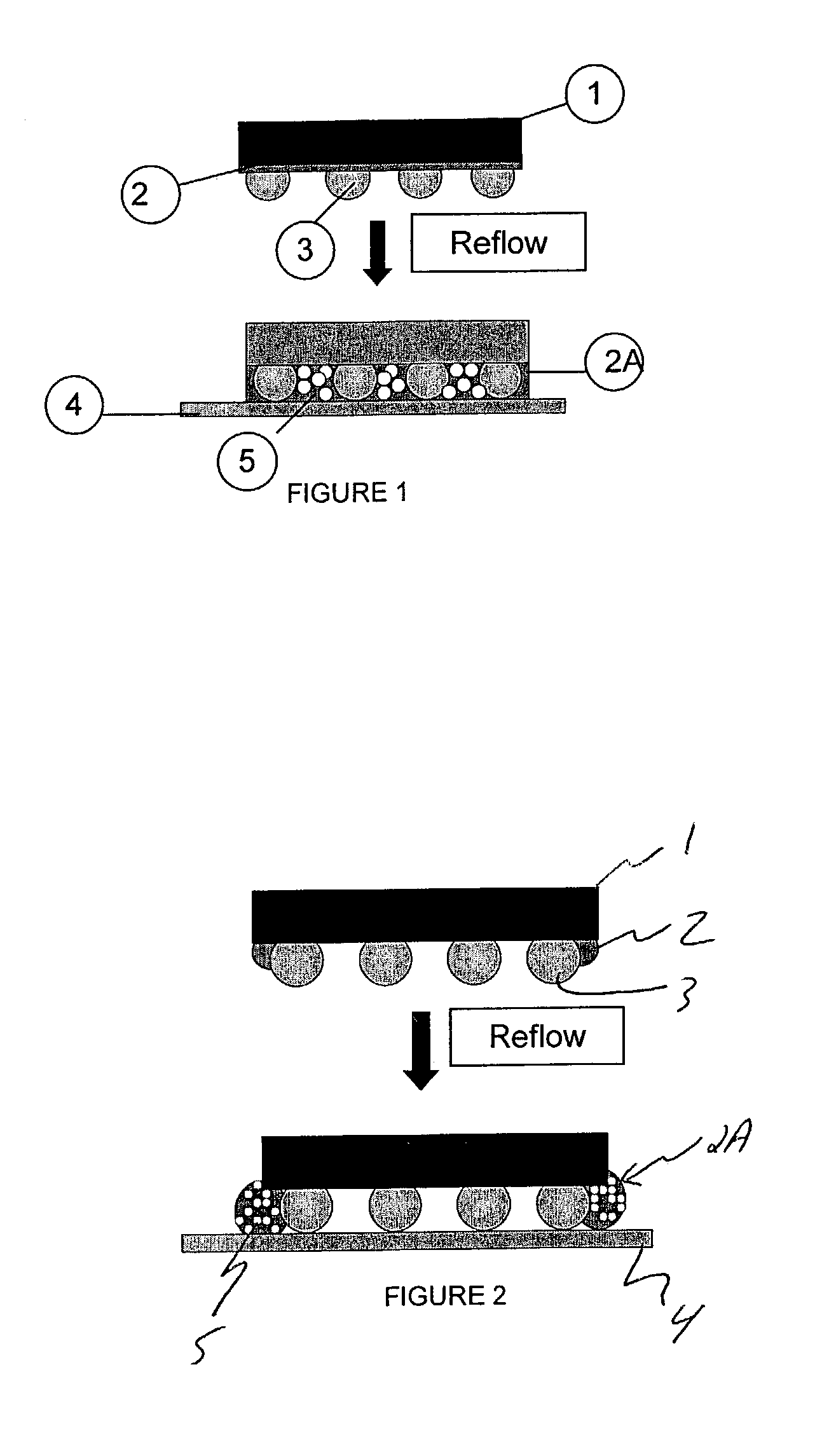

Method of using pre-applied underfill encapsulant

InactiveUS7047633B2Increase contactEliminate needPorous dielectricsPrinted circuit assemblingEpoxyThermoplastic

The invention relates to a method for utilizing one or more B-stageable or pre-formed underfill encapsulant compositions in the application of electronic components, most commonly chip scale packages (CSP's) to substrates. One such composition comprises a thermoplastic resin system comprising a phenoxy resin, an expandable polymer sphere or thermosetting composition, optionally an epoxy resin such as higher molecular weight epoxy resin, a solvent, an imidazole-anhydride catalyst or comparable latent catalyst, and optionally, fluxing agents and / or wetting agents. The underfill encapsulant may be B-stageable to provide a coating on the substrate or component that is smooth and non-tacky. In an alternative embodiment, the underfill encapsulant is a pre-formed film. In both embodiments the expandable filler material expands upon the application of higher temperatures to form a closed-cell foam structure in the desired portion of the assembly. The method of applying the underfill application of the underfill to a component or substrate, attachment of the component and substrate, and heating of the assembly to a temperature sufficient to cause the expandable thermoplastic or thermosetting composition to foam. A second pre-applied underfill composition containing an epoxy resin, an anhydride curing agent, and catalyst may also be applied, either separately or in conjunction with the foamable underfill. The second composition acts as a pressure sensitive adhesive and may be applied selectively to parts of the CSP, for example to the solder bumps. The pressure sensitive adhesive property of the composition provides sufficient tack in order to hold the electronic assembly together during the assembly process.

Owner:HENKEL KGAA

Plating method

InactiveUS20060182881A1Porous dielectricsLiquid/solution decomposition chemical coatingMetal depositionInorganic chemistry

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

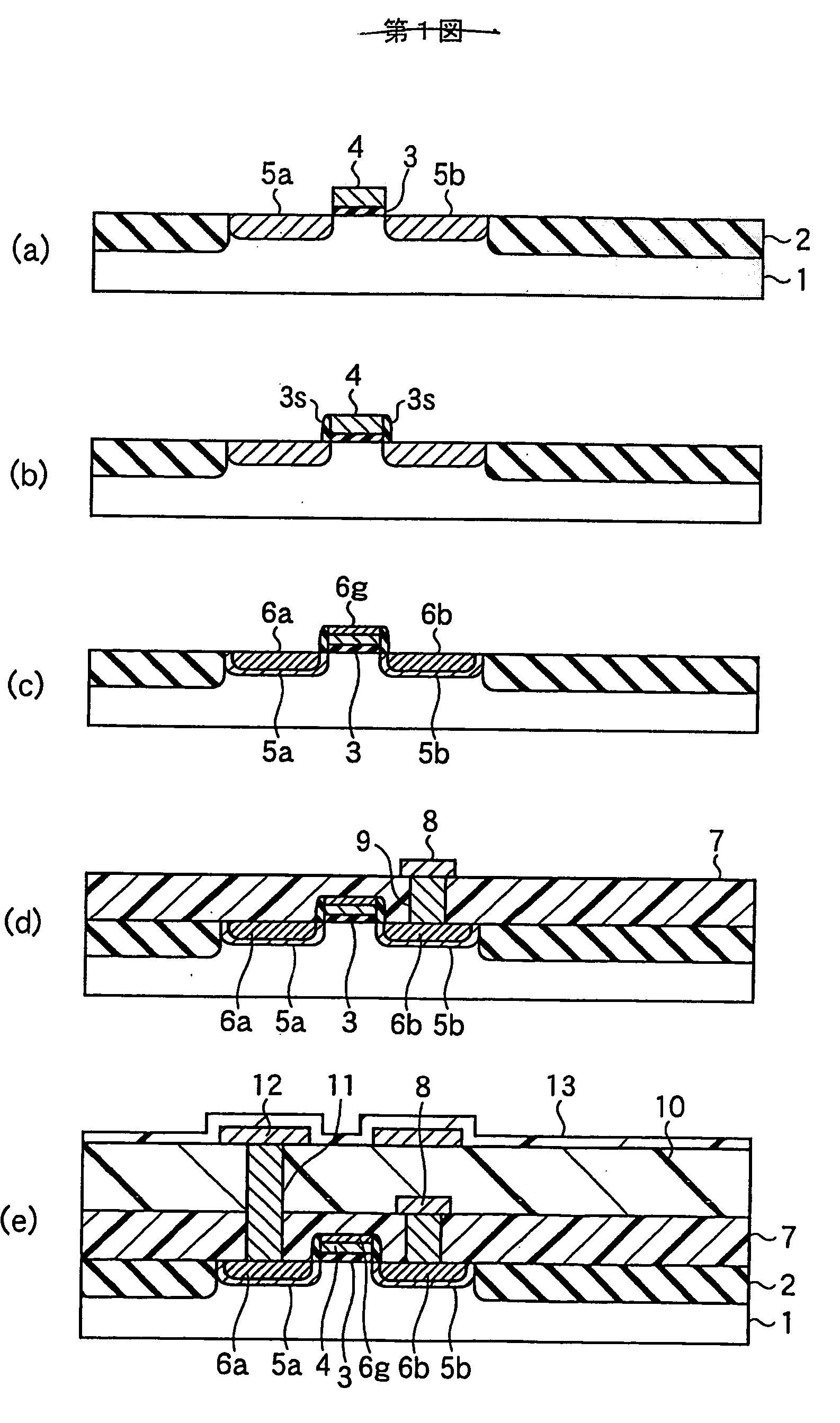

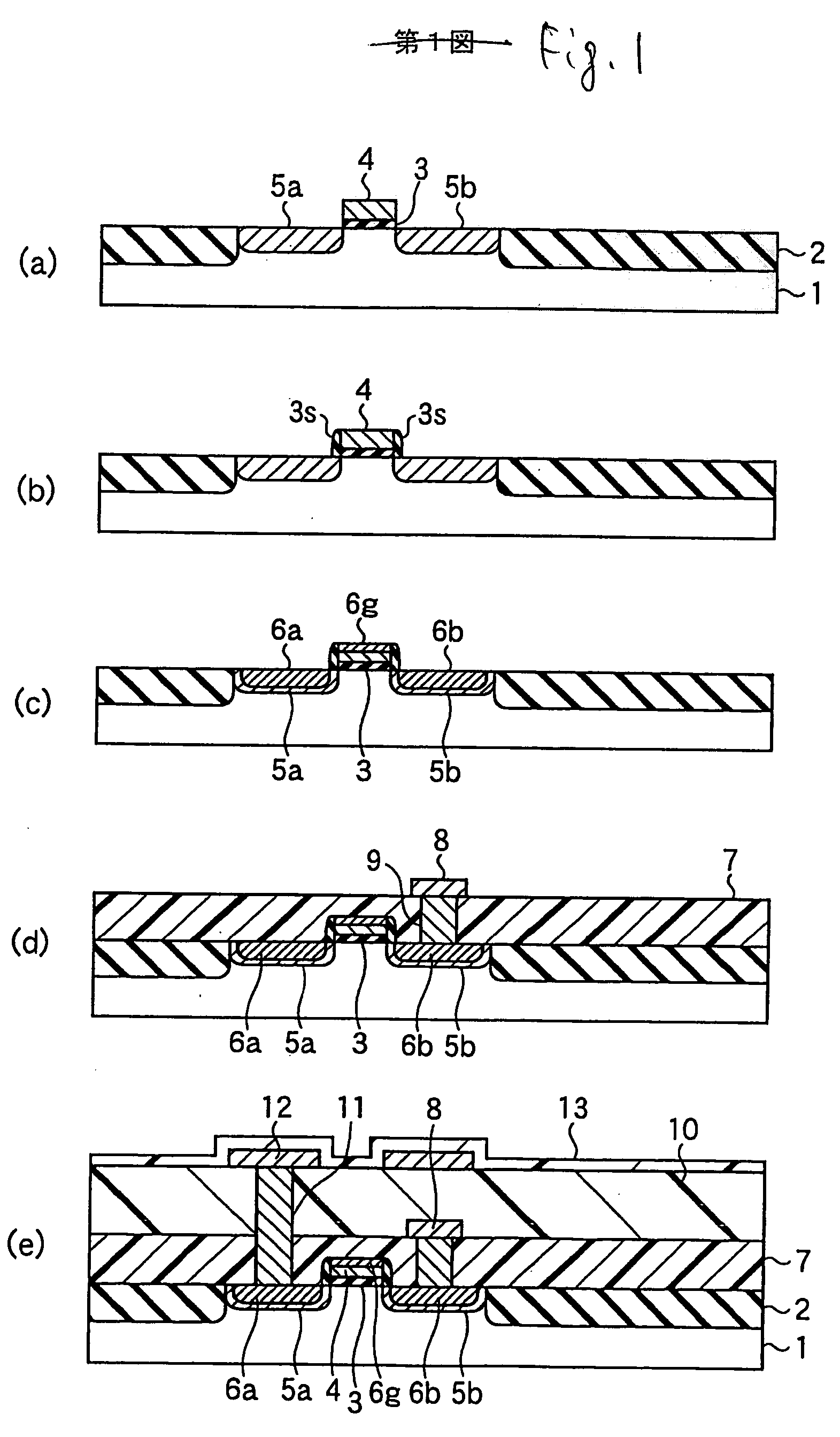

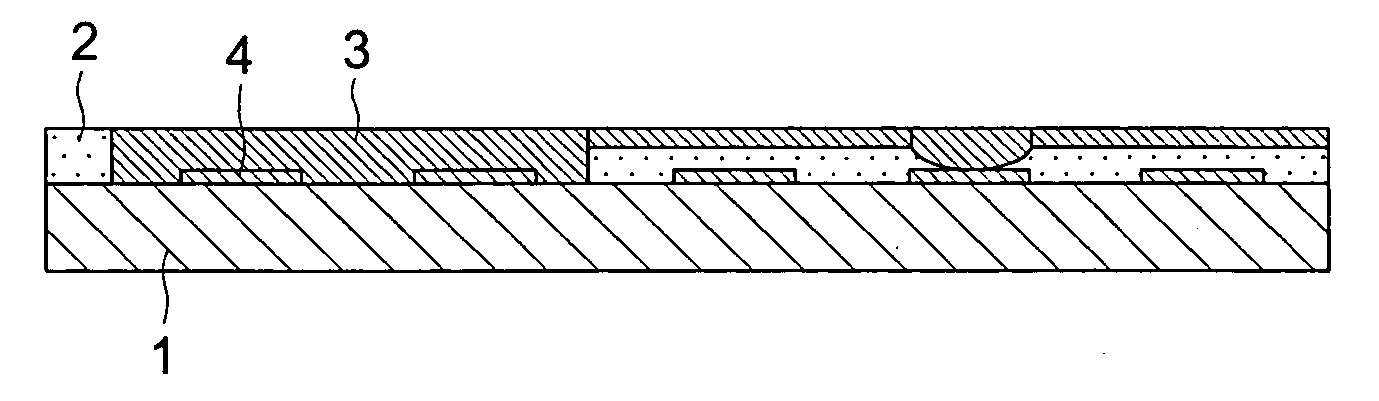

Electrical circuit, thin film transistor, method for manufacturing electric circuit and method for manufactturing thin film transistor

InactiveUS20060006378A1Simply and quickly formedSimply and quickly formingTransistorPorous dielectricsConductive polymerEngineering

An electrical circuit containing a substrate having thereon a receptive layer, wherein the receptive layer has a conductive polymer impregnated in the receptive layer, and a method for forming the electrical circuit.

Owner:FLEX DISPLAY SOLUTIONS LLC

Atomic layer deposition process for manufacture of battery electrodes, capacitors, resistors, and catalyzers

InactiveUS20100123993A1No leaksReduced series resistancePorous dielectricsSolid electrolytic capacitorsMulti materialMacroscopic scale

The present disclosure relates generally to the field of sequential surface chemistry. More specifically, it relates to products and methods for manufacturing products using Atomic Layer Deposition (“ALD”) to depose one or more materials onto a surface. ALD is an emerging variant of Chemical Vapor Deposition (“CVD”) technology with capability for high-quality film deposition at low pressures and temperatures, which may produce defect-free films, on a macroscopic scale, at any given thickness. The present disclosure includes, in varying embodiments, methods of manufacturing microelectronic assemblies and components such as battery electrodes, capacitors, resistors, catalyzers and PCB assemblies by ALD, and the products manufactured by those methods.

Owner:LAOR CONSULTING +1

Wiring glass substrate for connecting a semiconductor chip to a printed wiring substrate and a semiconductor module having the wiring glass substrate

InactiveUS7183650B2Lower resistanceComposition ratio is notPorous dielectricsSemiconductor/solid-state device detailsSemiconductor chipConductive materials

Owner:RENESAS TECH CORP

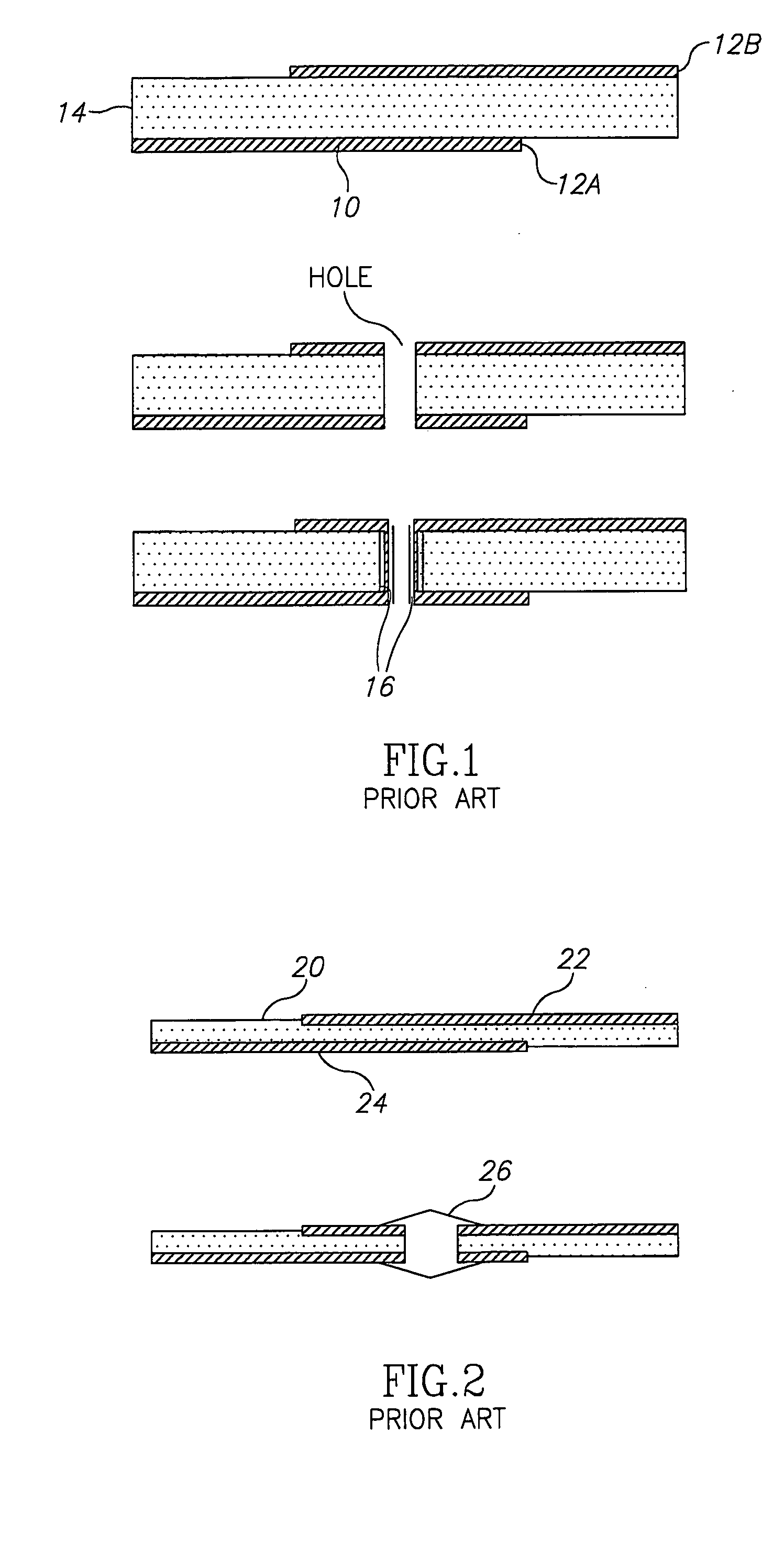

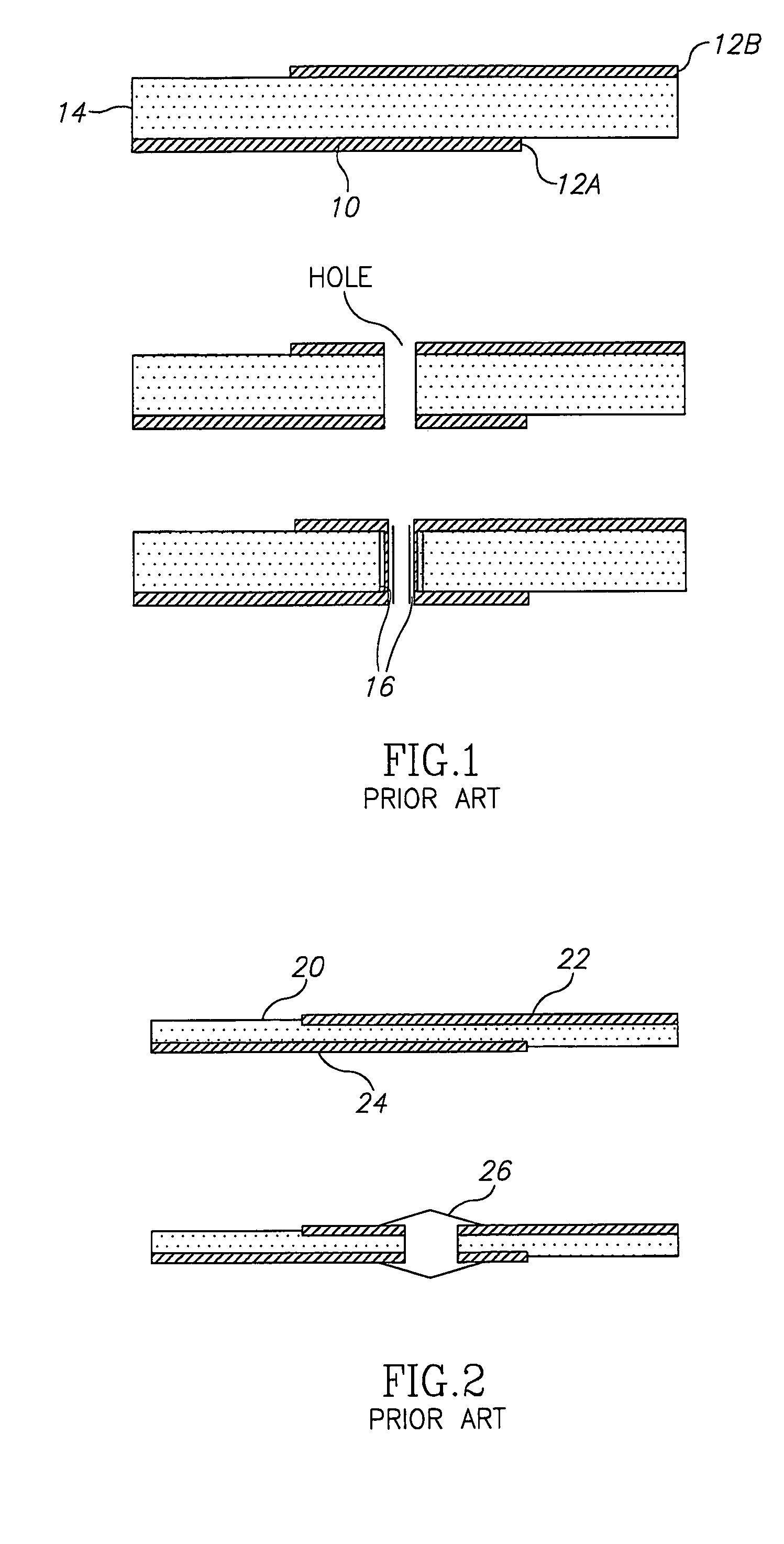

Flexible printed circuits with many tiny holes

InactiveUS20050217895A1Connection formPorous dielectricsContact surface shape/structureElectrical connectionEngineering

A board that may include for example a first conductive area on a first side and a second conductive area on a second side of such board. The board may be fitted with a plurality of holes that may for example open or end on both such first side and such second side of such board. A conductive material in the form of for example a liquid or gel may be applied or for example painted onto one or both sides of such board so that such material may for example substantially fill some or all of such holes and may establish a connection through which an electric current may pass from for example the first conductive area to the second conductive area. A switch having for example a board with a plurality of holes running through such board from a first side to a second side. A conductive material may for example be applied to such board so that such material substantially fills for example two or more of such holes and may be capable of forming an electrical connection between a conductive area on a first side of such board and a conductive area on a second side of such board. A method of forcing a conductive liquid into a plurality of holes in a board so that the liquid forms for example a connection capable of carrying a current between a conductive area on a first side of such board and a conductive area of a second side of such board.

Owner:MAHARSHAK ARIE +2

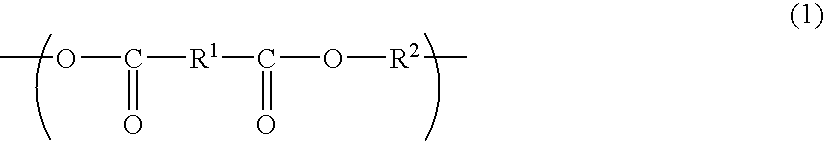

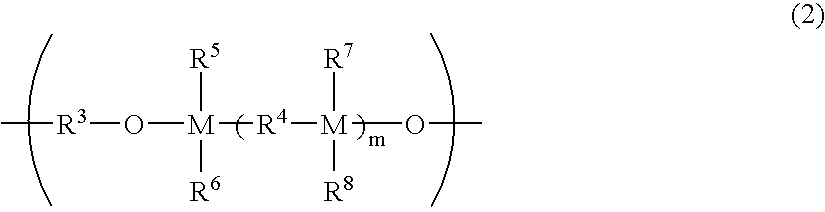

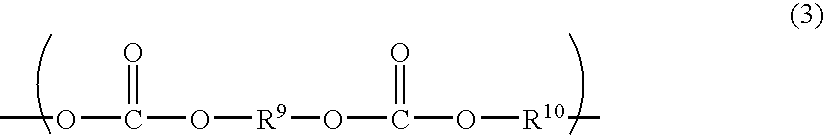

Composition having permitivity being radiation-sensitively changeable and method for forming permitivity pattern

InactiveUS20040005506A1High strengthProcess stabilityPorous dielectricsPhotography auxillary processesRadiation sensitivityDielectric permittivity

A radiation sensitive dielectric constant changing composition comprising (A) a decomposable compound, (B) a nondecomposable compound, (C) a radiation sensitive decomposer and (D) a stabilizer. The composition allows its dielectric constant to be changed by a simple method, has a sufficiently large difference between its changed dielectric constant and its original dielectric constant and can provide a dielectric constant pattern and an optical material which are stable regardless of their use conditions.

Owner:JSR CORPORATIOON

Method for producing porous polyimide resin and porous polymide resin

InactiveUS7022377B2Avoid cloggingSimple structurePorous dielectricsHigh frequency circuit adaptationsHeat resistanceSolvent

A method of producing porous polyimide resin that enables pores to be formed in a precursor of polyimide resin, with its form of microphase-separated structure wherein a dispersive compound is dispersed in the precursor of polyimide resin being kept unchanged, so as to provide significantly reduced dielectric constant and also provide improvement in mechanical strength and heat resistance, and the porous polyimide resin produced in the same producing method. A coating comprising porous polyimide resin is formed by applying resin solution comprising a precursor of polyimide resin and a dispersive compound and then drying a solvent, to form a coating in which the dispersive compound is dispersed in the precursor of polyimide resin; extracting the dispersive compound from the coating for removal to make the precursor of the polyimide resin porous; and imidizing the coating after preheated in a temperature range of 190–250° C.

Owner:NITTO DENKO CORP

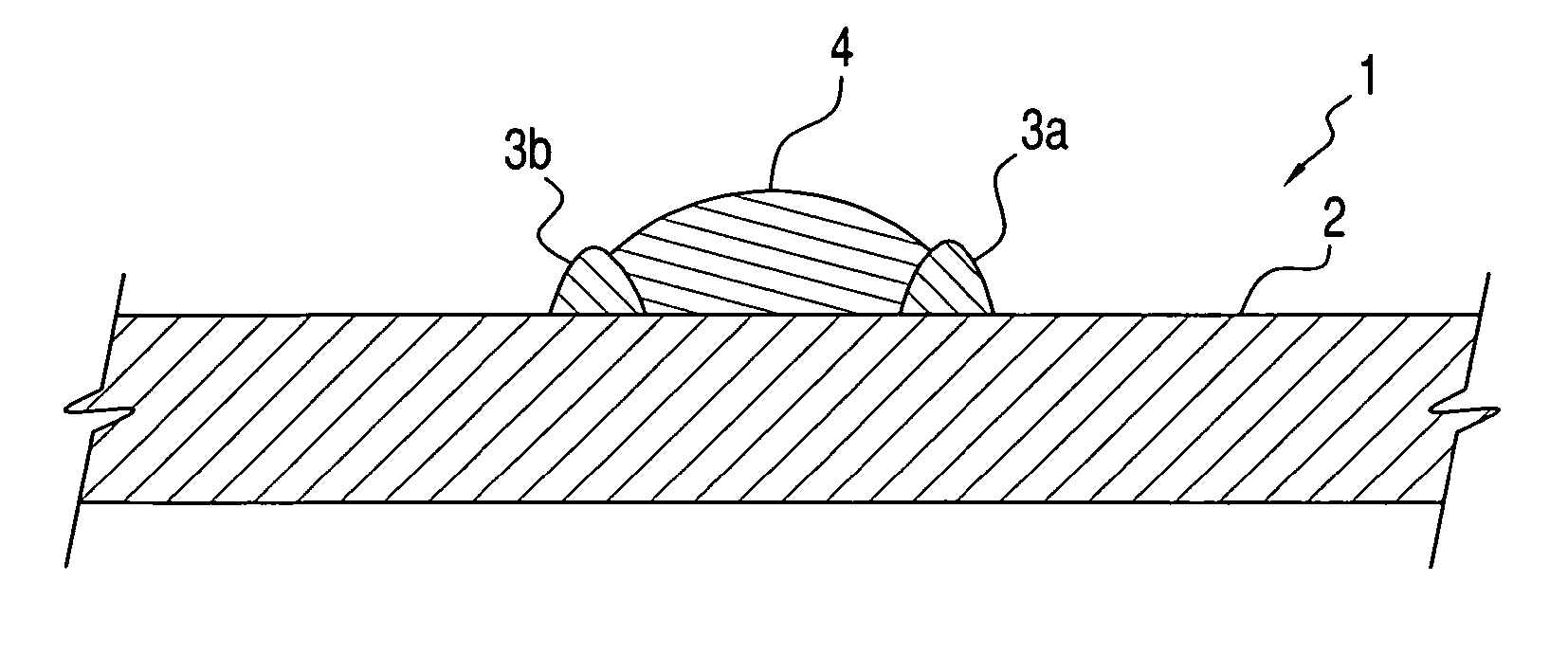

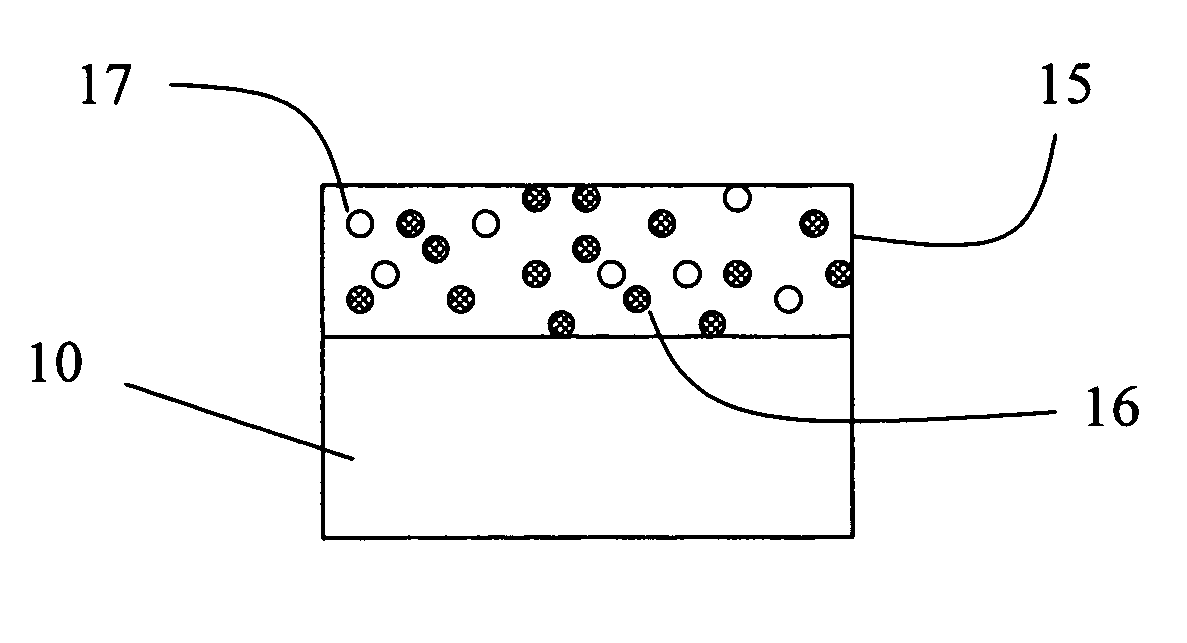

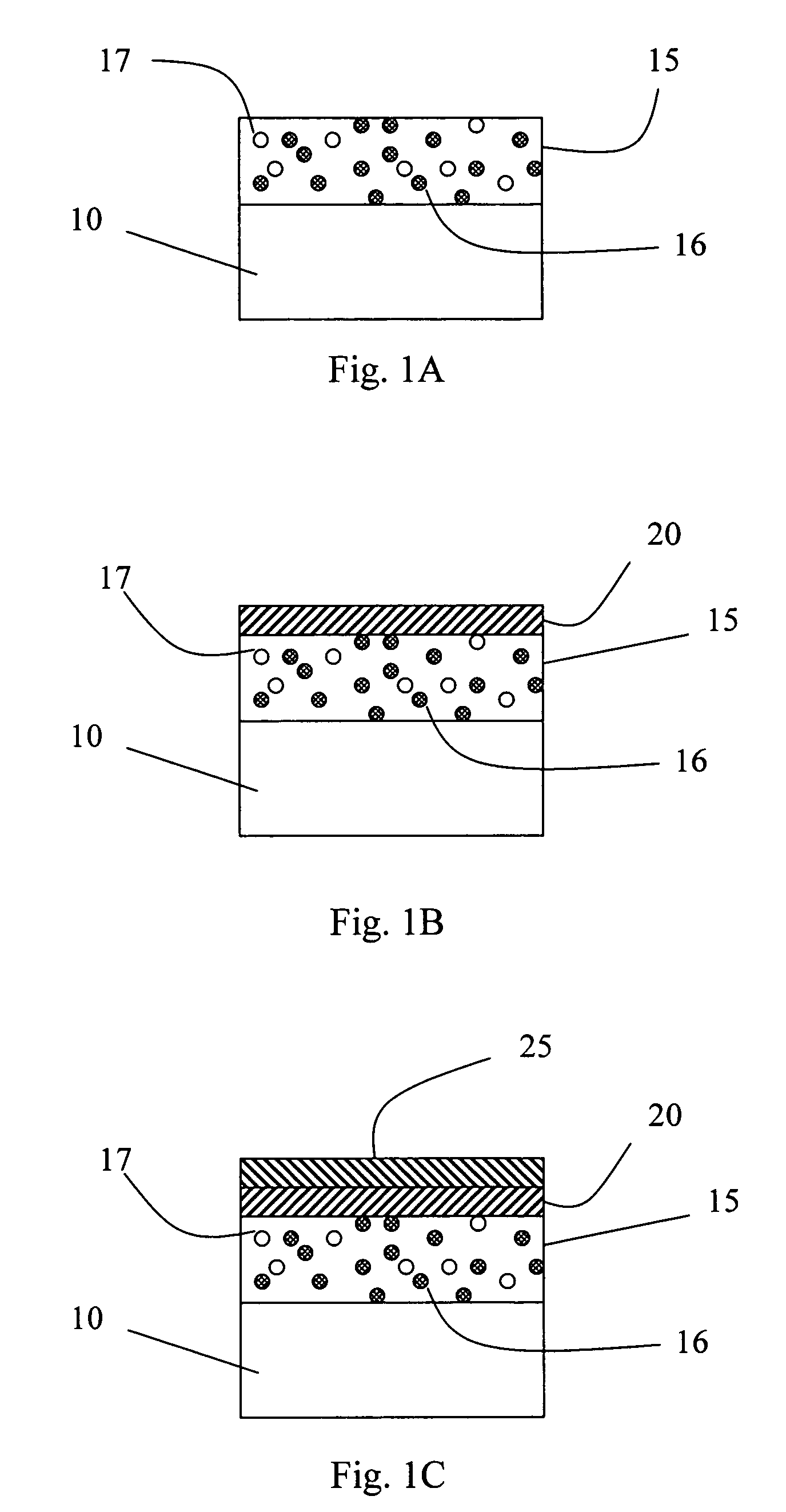

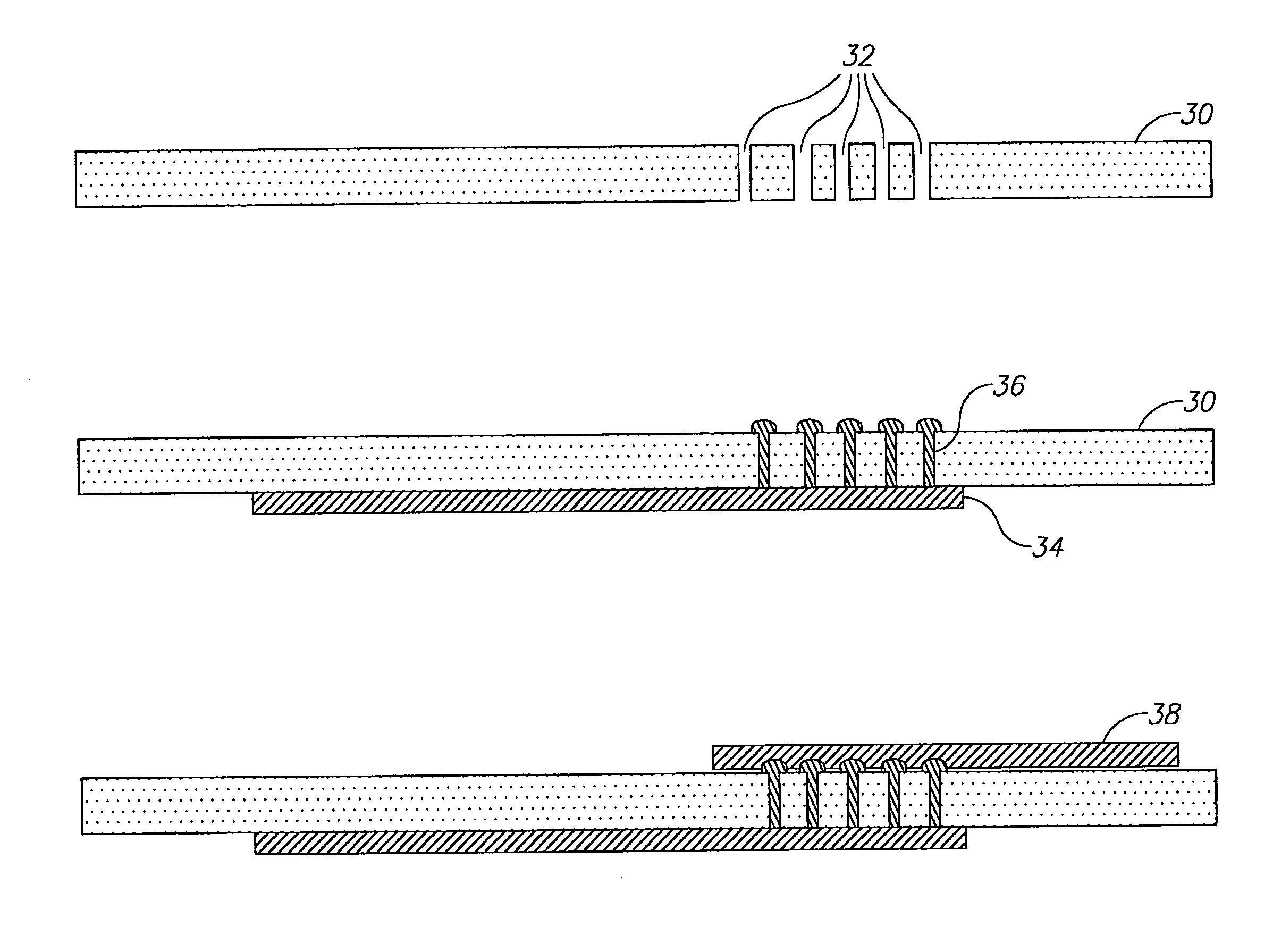

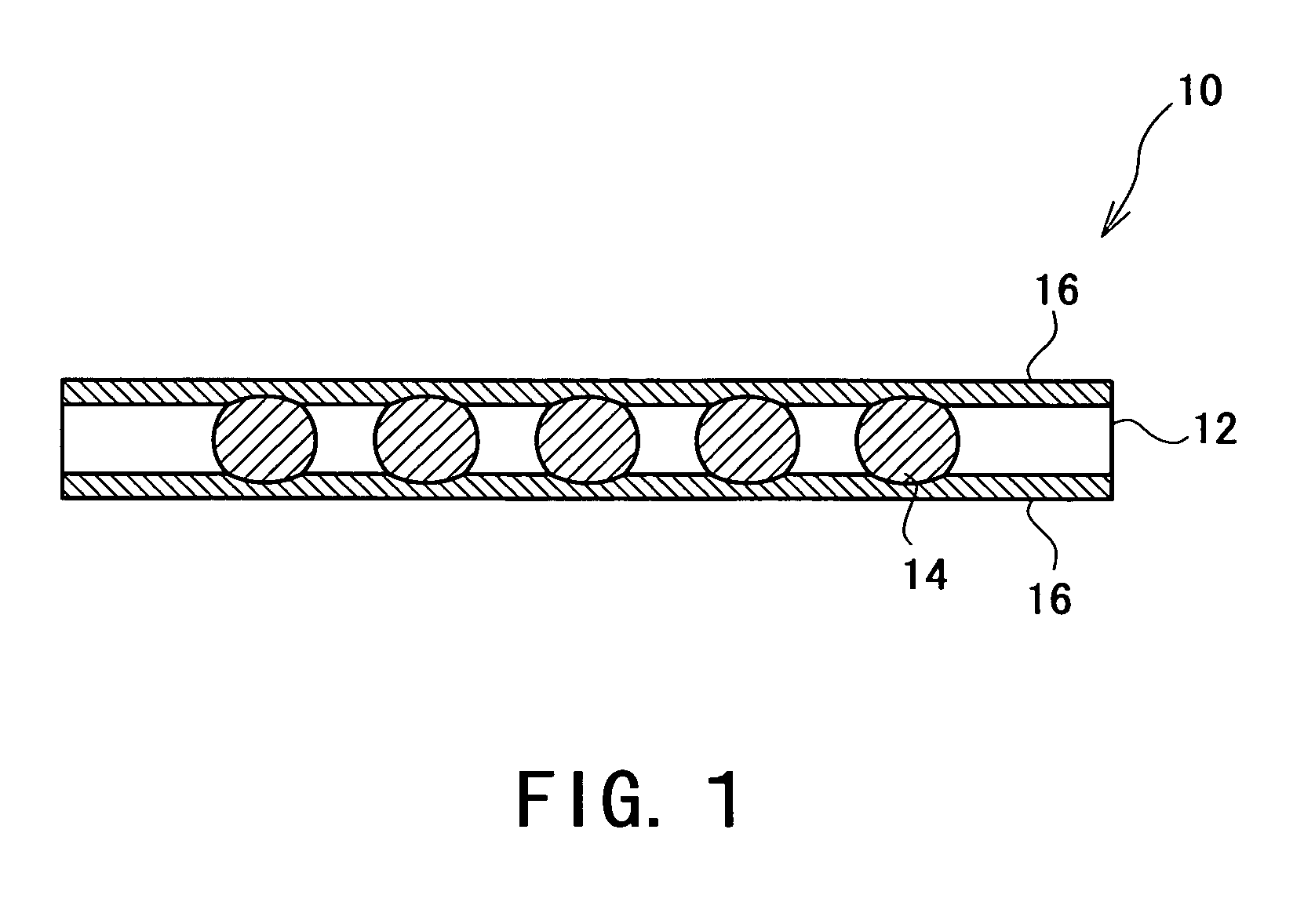

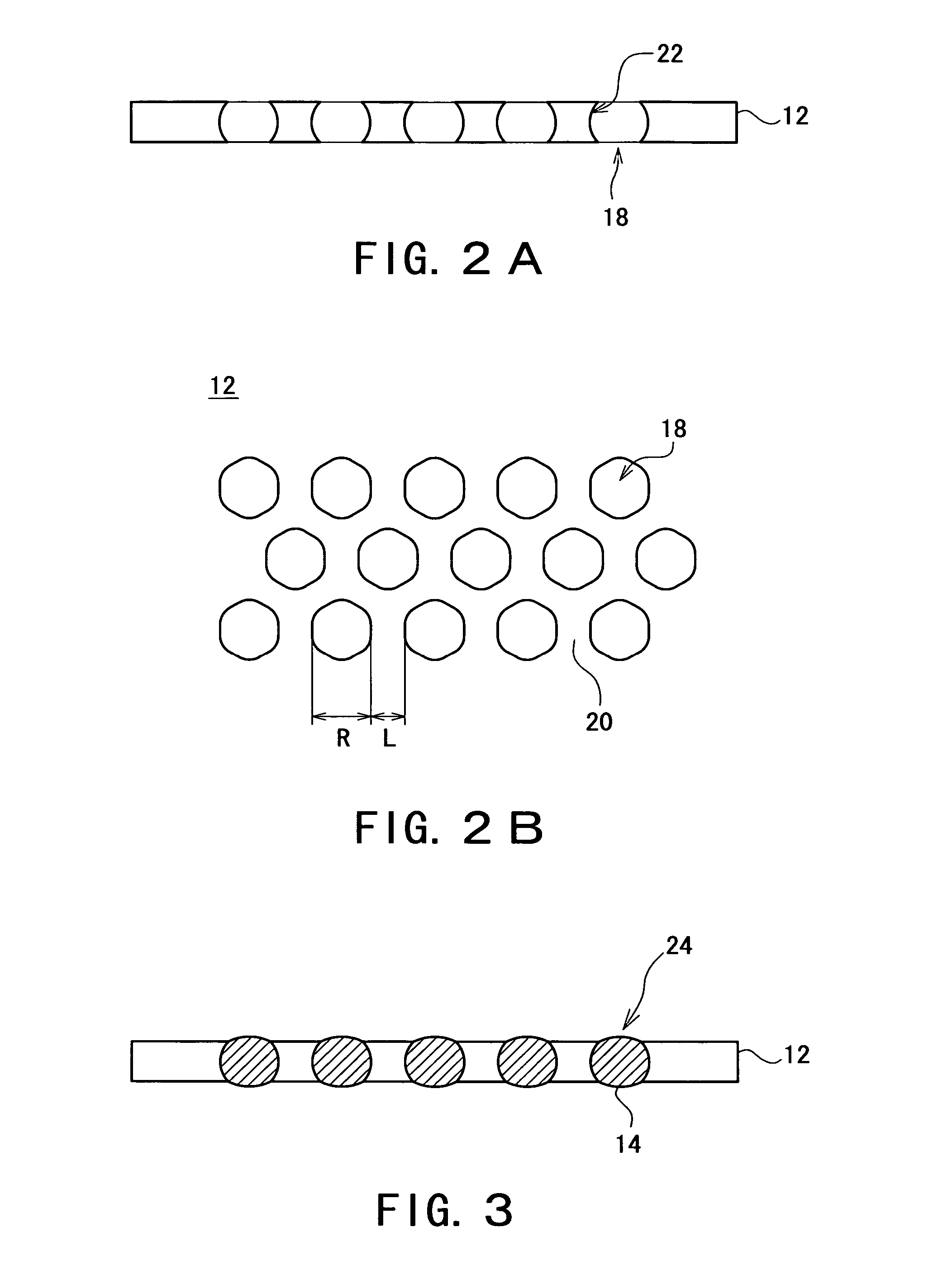

Anisotropic Conductive Film and a Method of Manufacturing the Same

InactiveUS20070212521A1Improve reliabilityImprove adhesionPorous dielectricsPrinted circuit assemblingAnisotropic conductive filmOrganic solvent

To provide an anisotropic conductive film which can respond to increasing pitch reduction of connection targets while maintaining connection reliability, and can be manufactured at a lower cost than conventional, and to provide a method of manufacturing the same. The anisotropic conductive film is provided with a porous film consisting of polymer, having numerous holes penetrating in a film thickness direction, the holes being in a honeycomb arrangement and having inner wall surfaces which curve outwards, a conductive material that fills the holes in the porous film, and an adhesive layer coated on both surfaces of the porous film. The porous film is formed by leaving a supporting substrate on which cast is a polymer solution where a polymer is dissolved in a hydrophobic, volatile organic solvent, under high humidity conditions.

Owner:SUMITOMO RIKO CO LTD

Flexible printed circuits with many tiny holes

InactiveUS7291795B2Porous dielectricsContact surface shape/structureElectrical connectionConductive materials

A switch or circuit board having a first conductive area on a first side of the board, a second conductive area on a second side of the board, several tiny holes running through the board from the first side to the second side, and a conductive material substantially filling the holes by capillary force, where the conductive material forms an electrical connection between the first conductive area and the second conductive area.

Owner:MAHARSHAK ARIE +2

Mesoporous silica/fluorinated polymer composite material

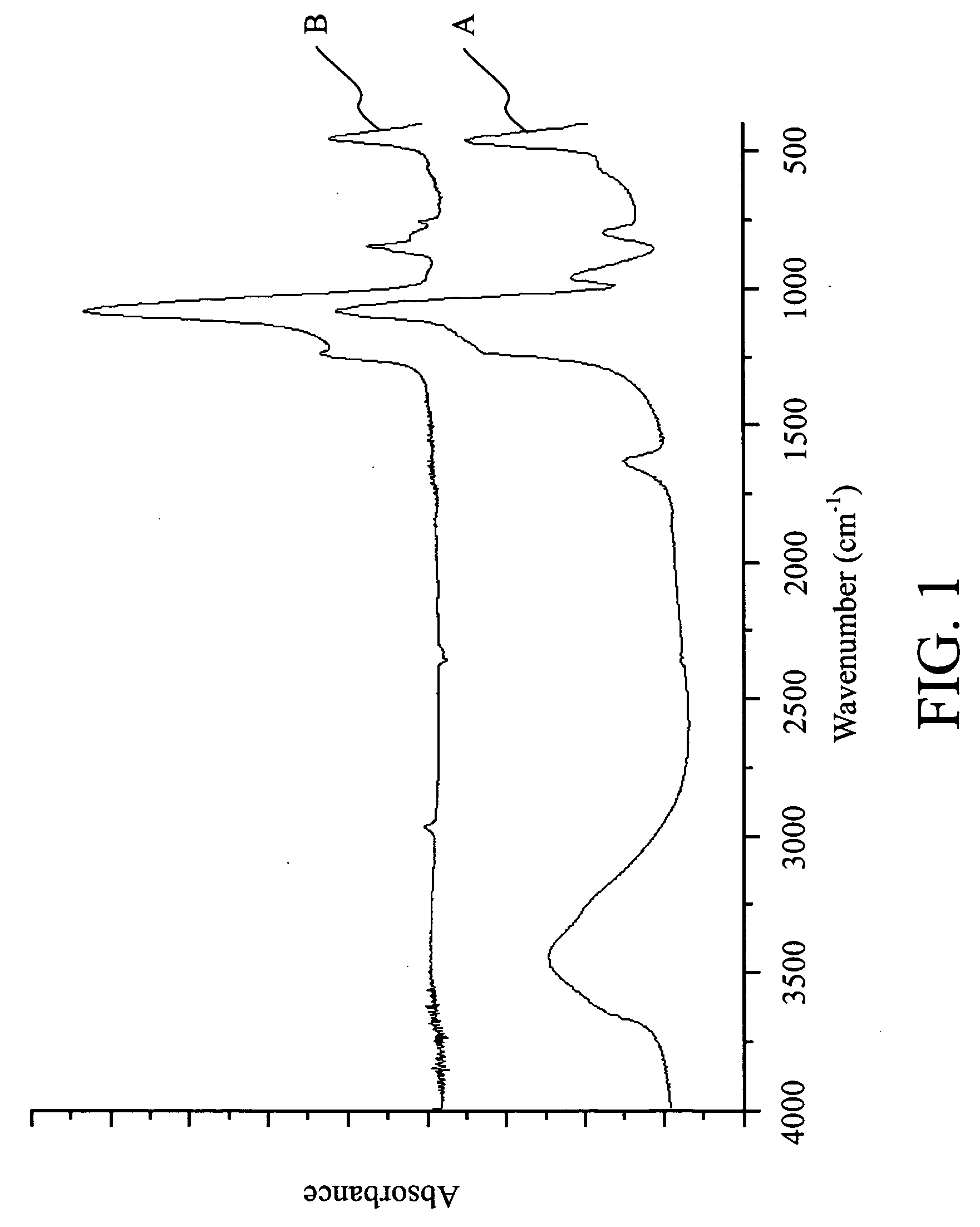

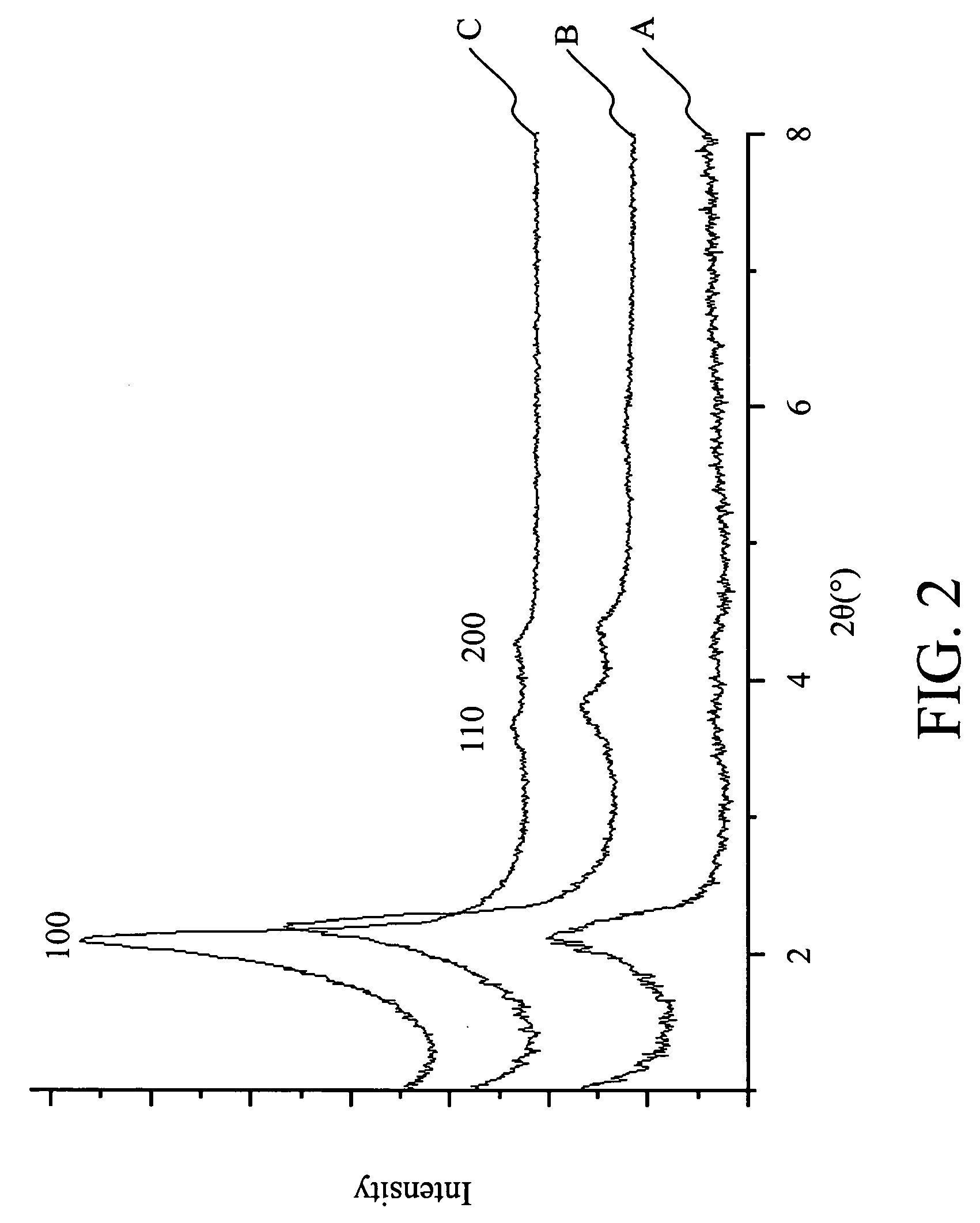

A mesoporous silica / fluorinated polymer composite material. Made up of hydrophobic modified mesoporous silica with a pore size of 0.1 to 50 nm and a fluorinated polymer, to provide Dk<4, Df<0.04, and CTE<60 ppm, the material is suitable for use in printed circuit boards or substrates in high frequency applications.

Owner:CHUNG YUAN CHRISTIAN UNIVERSITY

Printed circuit board, antenna, wireless communication device and manufacturing methods thereof

InactiveUS20130088406A1Low dielectric lossReduce the impactPorous dielectricsAntenna arraysElectrical conductorBroadband

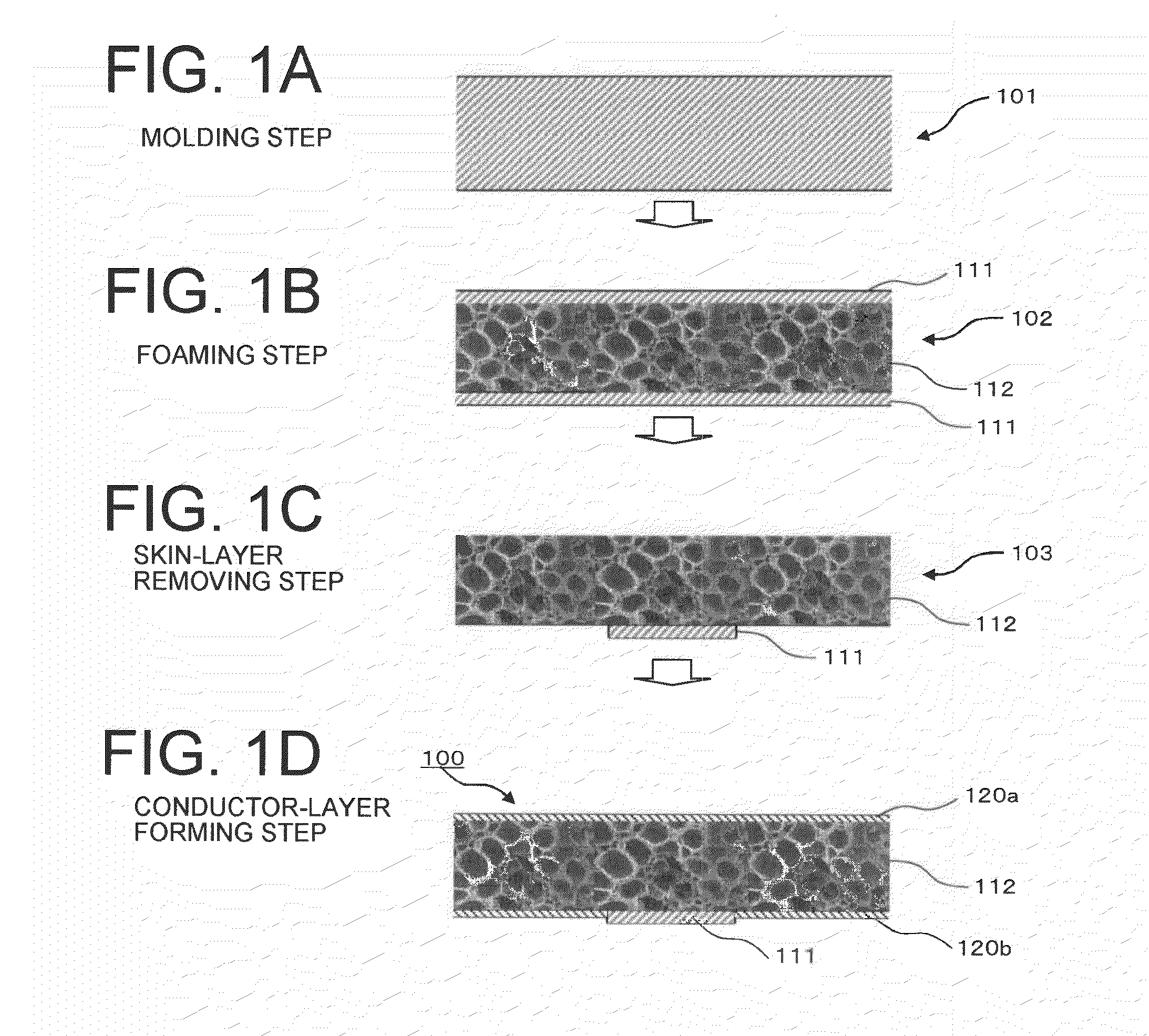

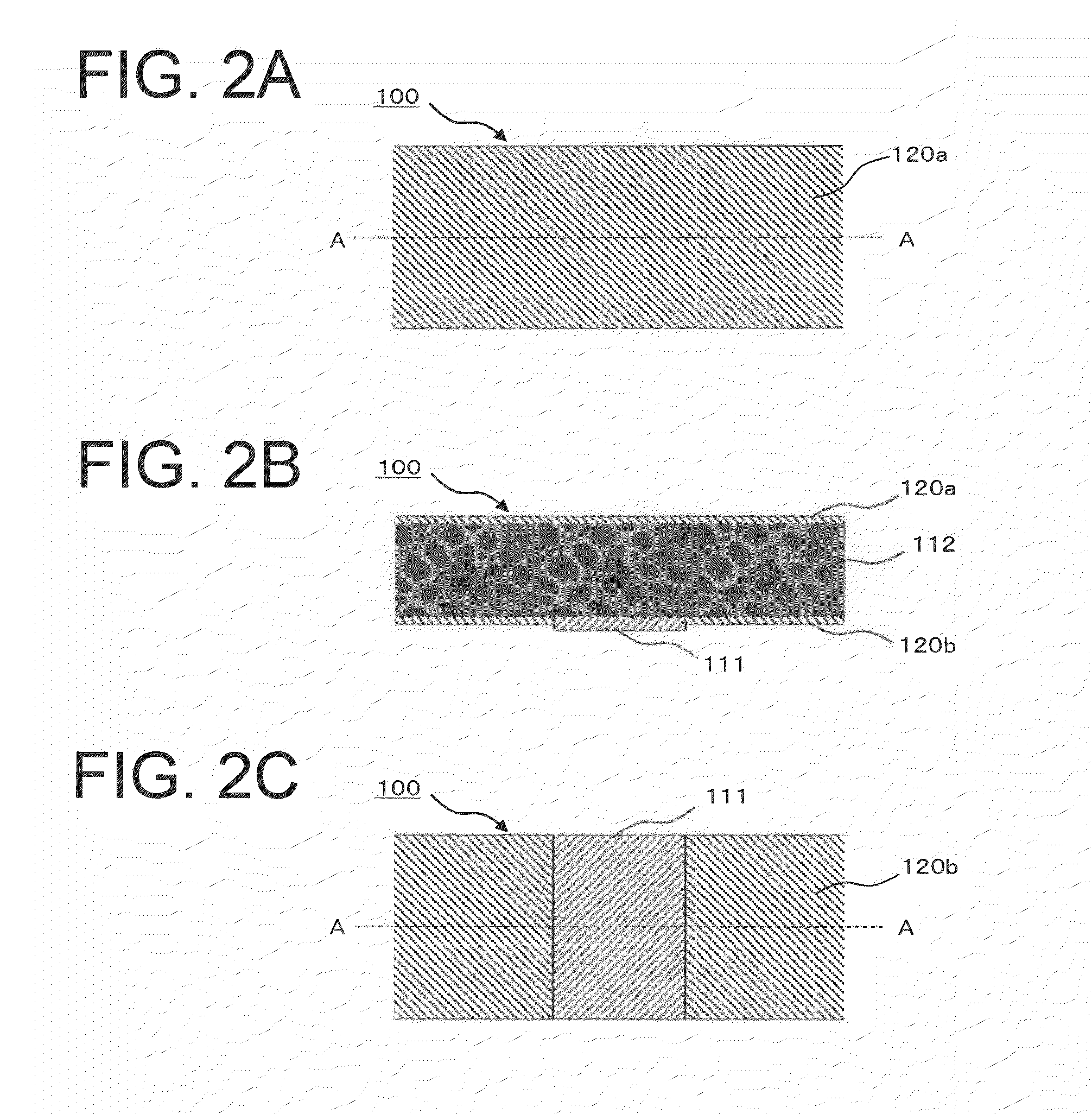

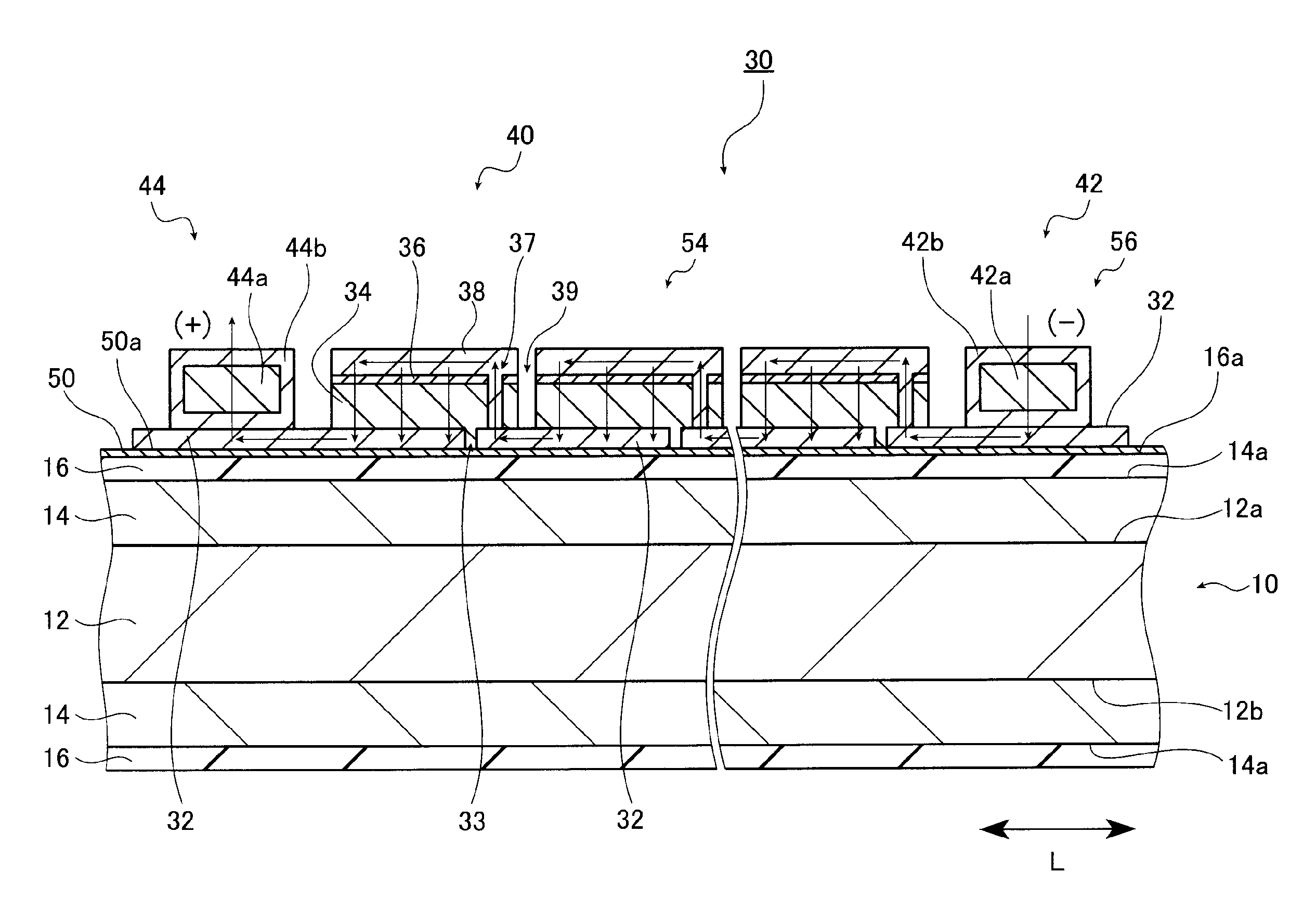

Low-loss printed circuit boards, low-loss wide-band antennas, and manufacturing methods thereof are provided by using a resin as a board material. A resin material (101) having a predetermined shape is prepared in a molding step, and the resin material (101) is foamed in a foaming step. As a result, a skin layer (111) and a foamed part (112) are formed. Since the skin layer (111) does not allow close contact of plating, the skin layer (111) is removed in the shape of a conductor pattern in a skin-layer removing step to expose the foamed part (112) in the interior. Electroless plating is carried out in a conductor-layer forming step; and, as a result, plating is brought into close contact with the foamed part (112) having an anchor effect, and a conductor layer (120) is formed.

Owner:FURUKAWA ELECTRIC CO LTD

Metal substrate with insulation layer and manufacturing method thereof, semiconductor device and manufacturing method thereof, solar cell and manufacturing method thereof, electronic circuit and manufacturing method thereof, and light-emitting element and manufacturing method thereof

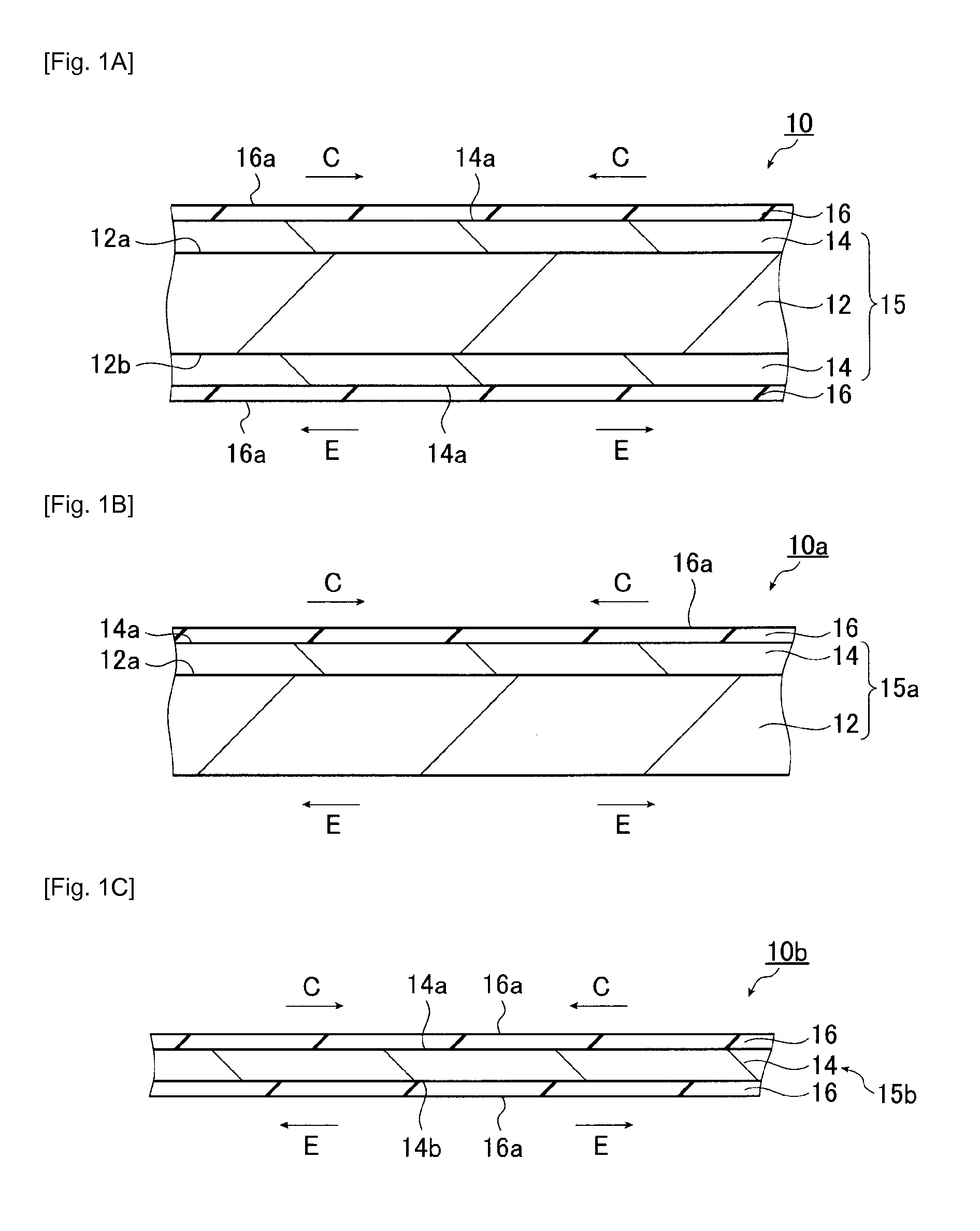

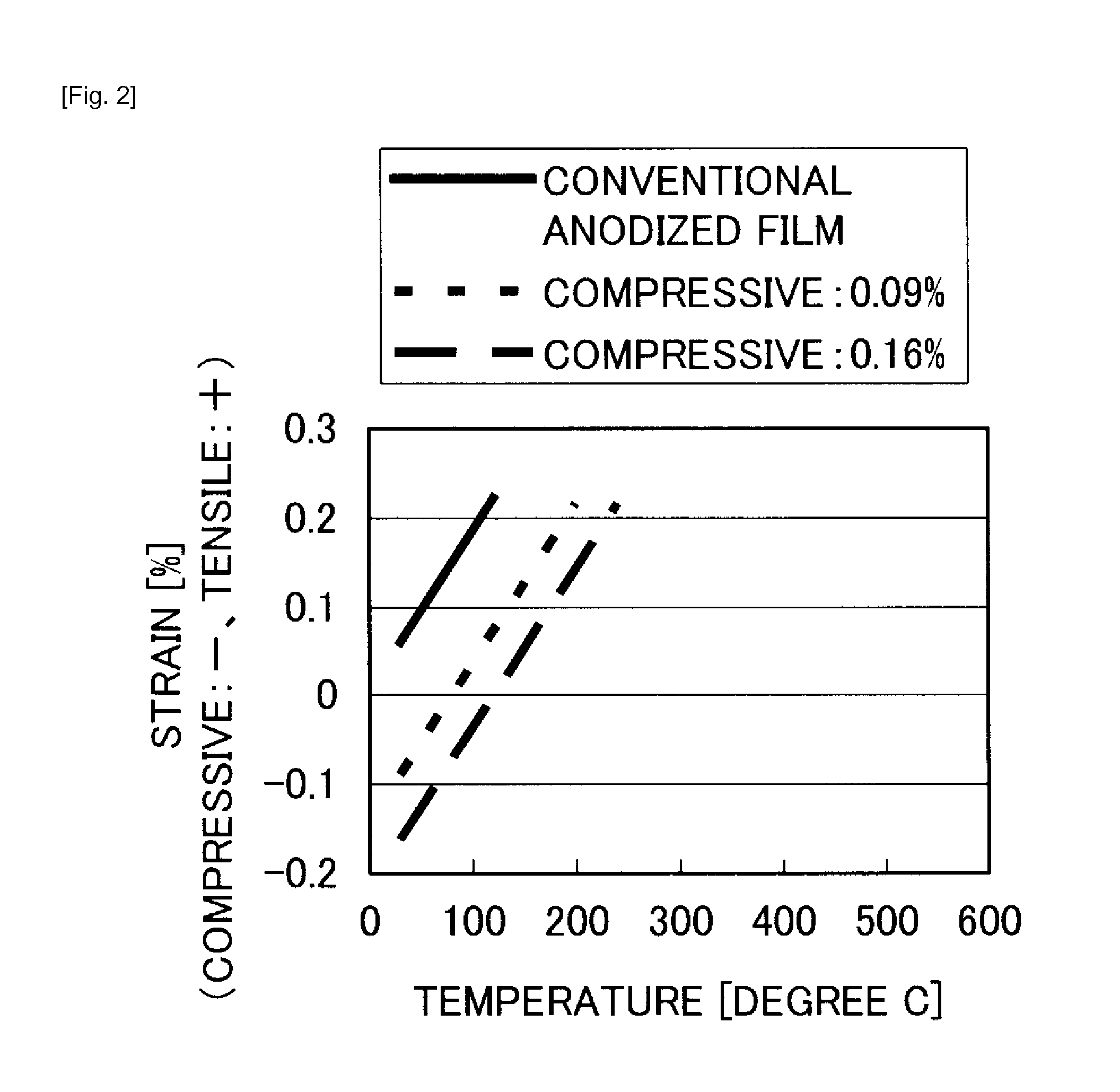

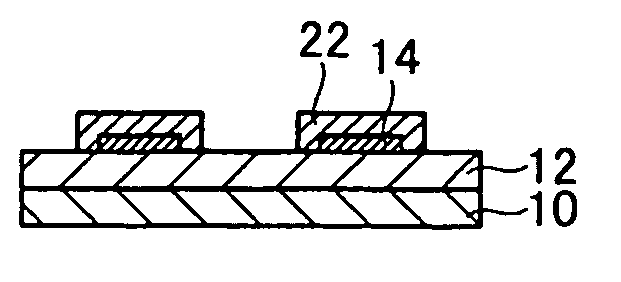

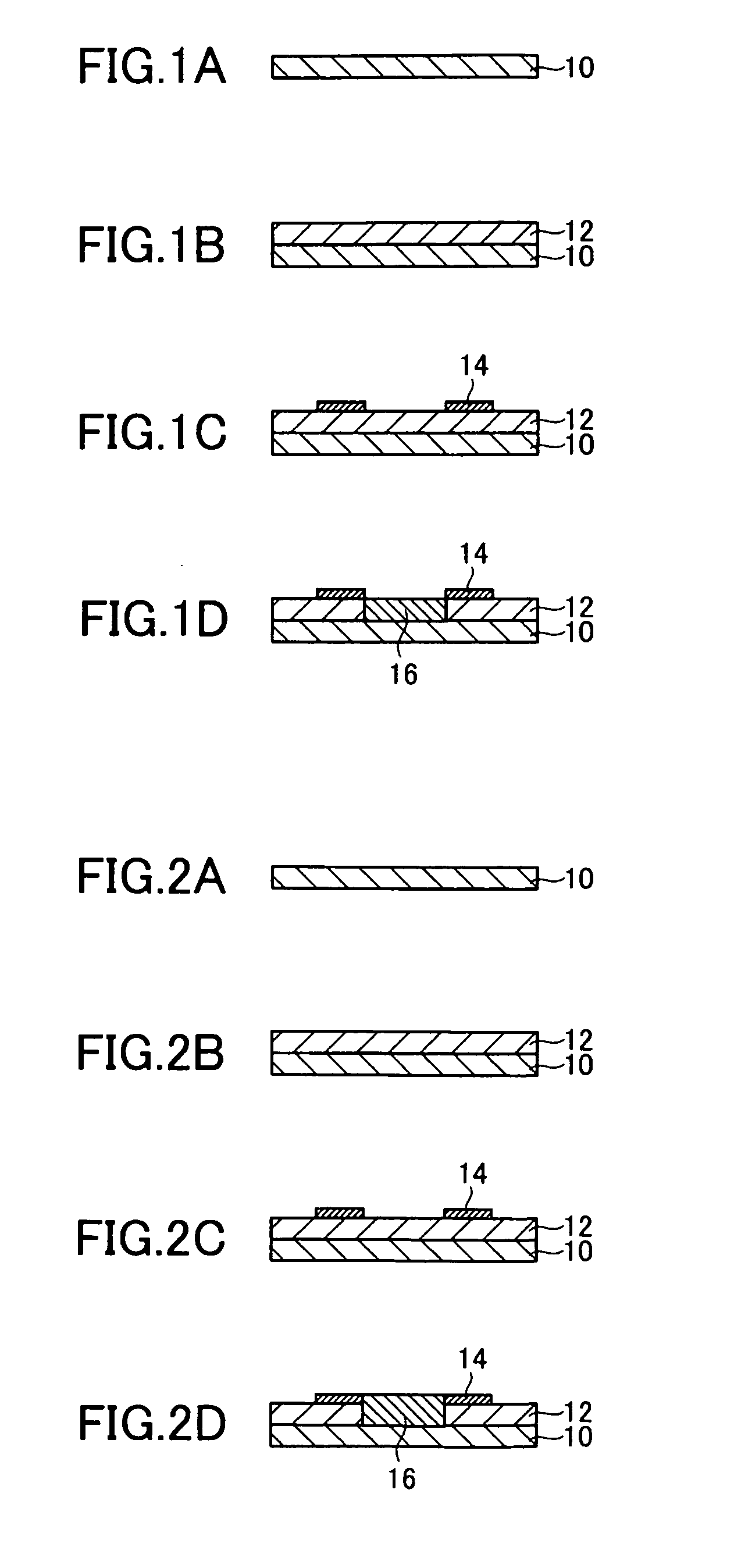

InactiveUS20120273034A1Improve crack resistanceImprove insulation performancePorous dielectricsAnodisationInsulation layerMicrometer

A metal substrate with an insulation layer includes a metal substrate having at least an aluminum base and an insulation layer formed on said aluminum base of said metal substrate. The insulation layer is a porous type anodized film of aluminum. The anodized film includes a barrier layer portion and a porous layer portion, and at least the porous layer portion has compressive strain at room temperature. a magnitude of the strain ranges from 0.005% to 0.25%. The anodized film has a thickness of 3 micrometers to 20 micrometers.

Owner:FUJIFILM CORP

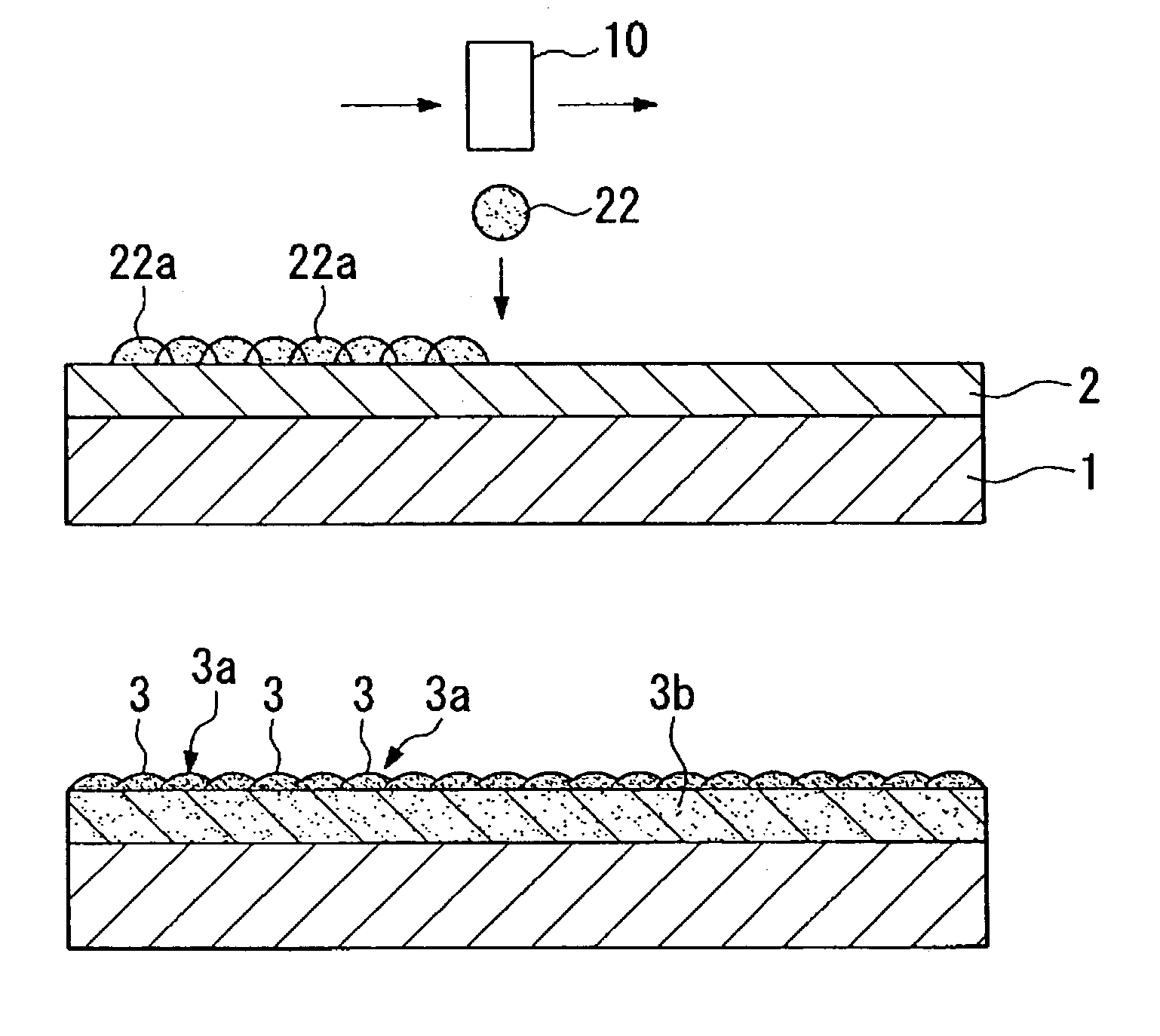

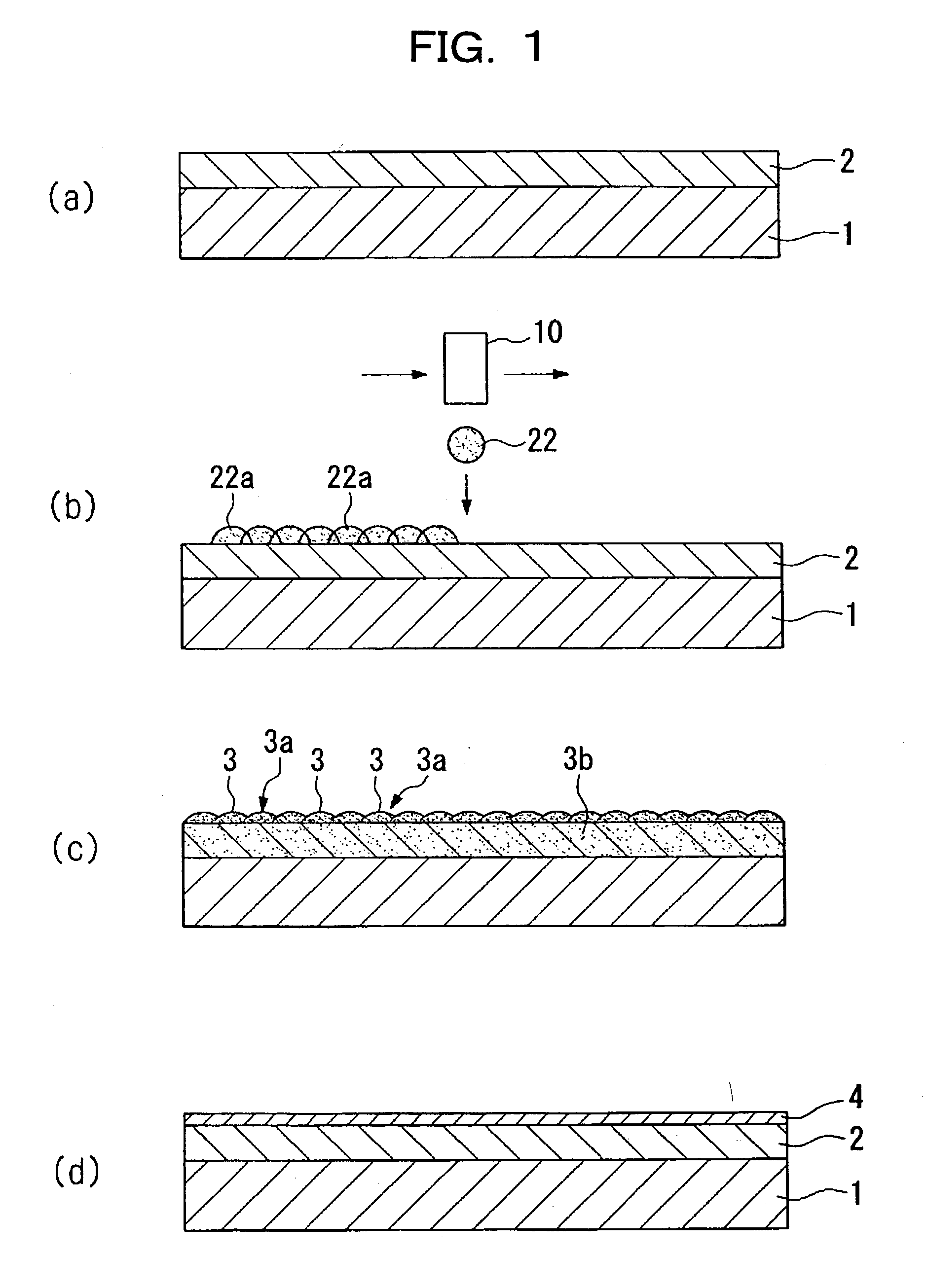

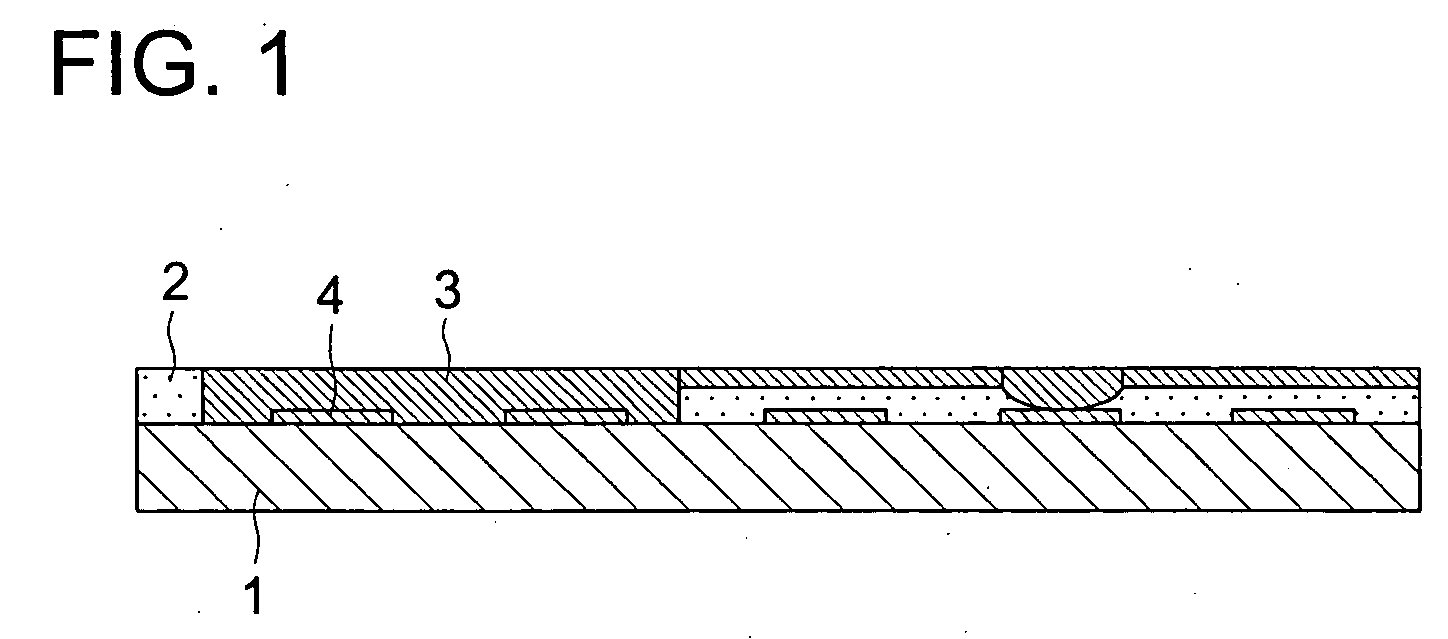

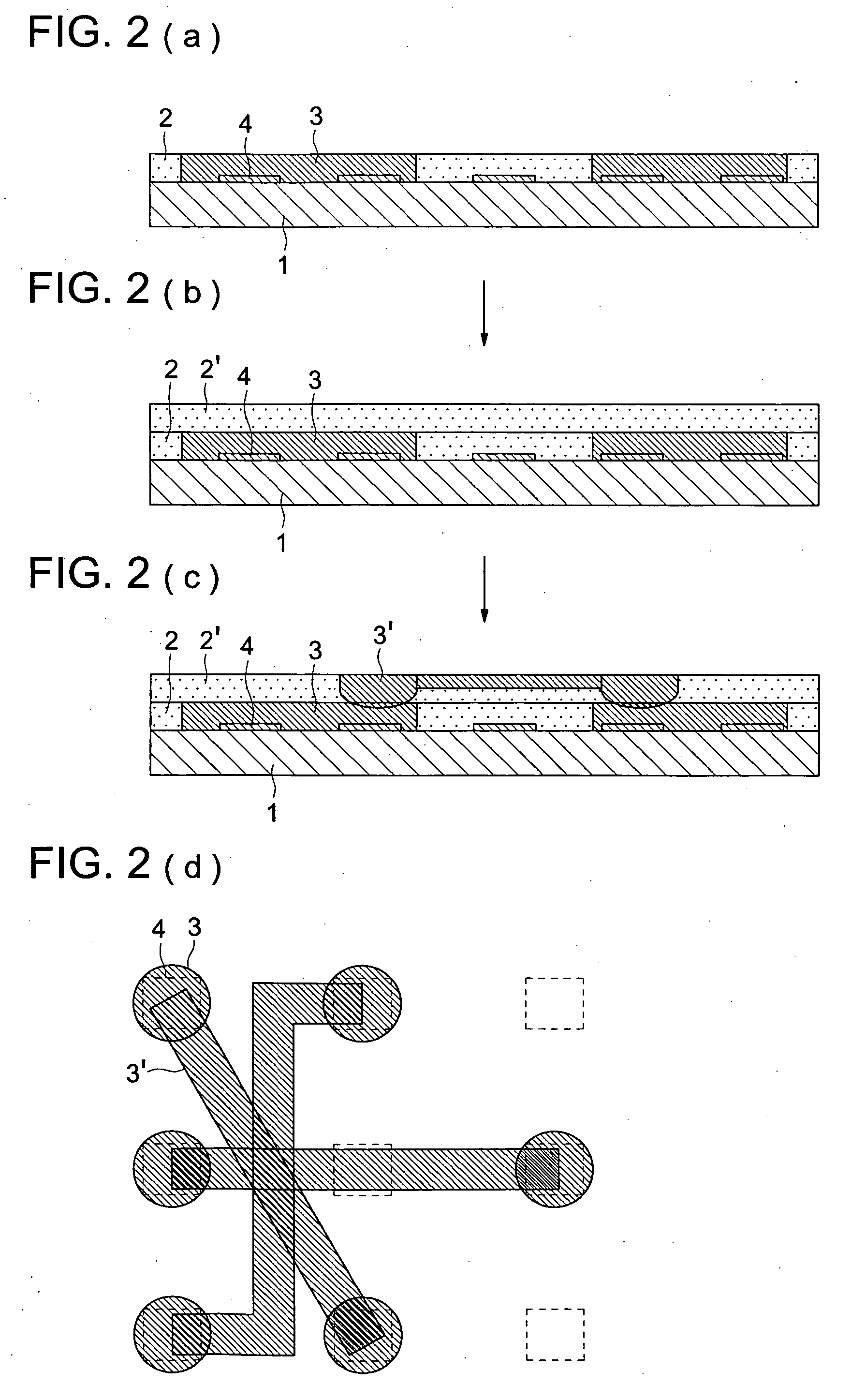

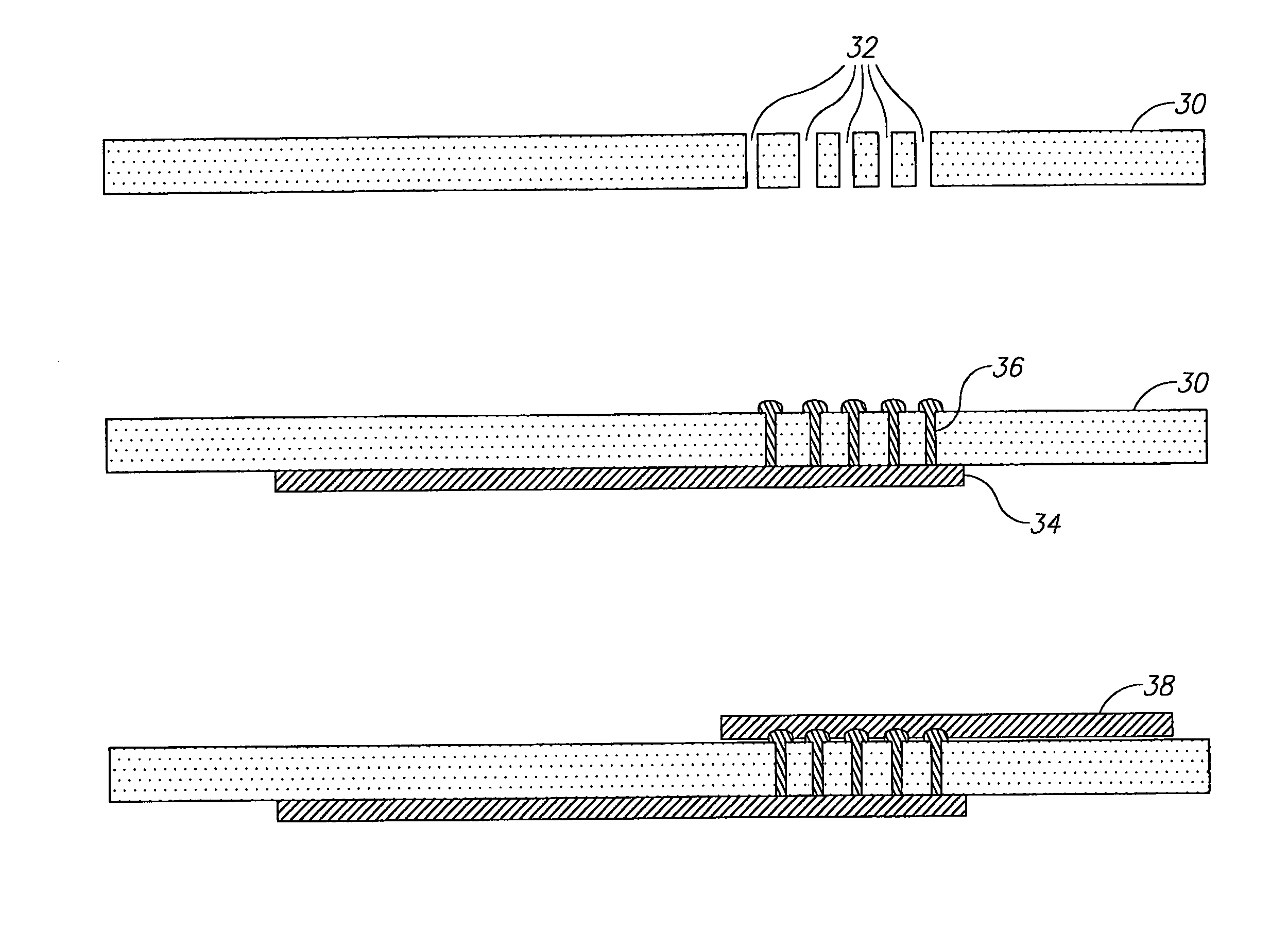

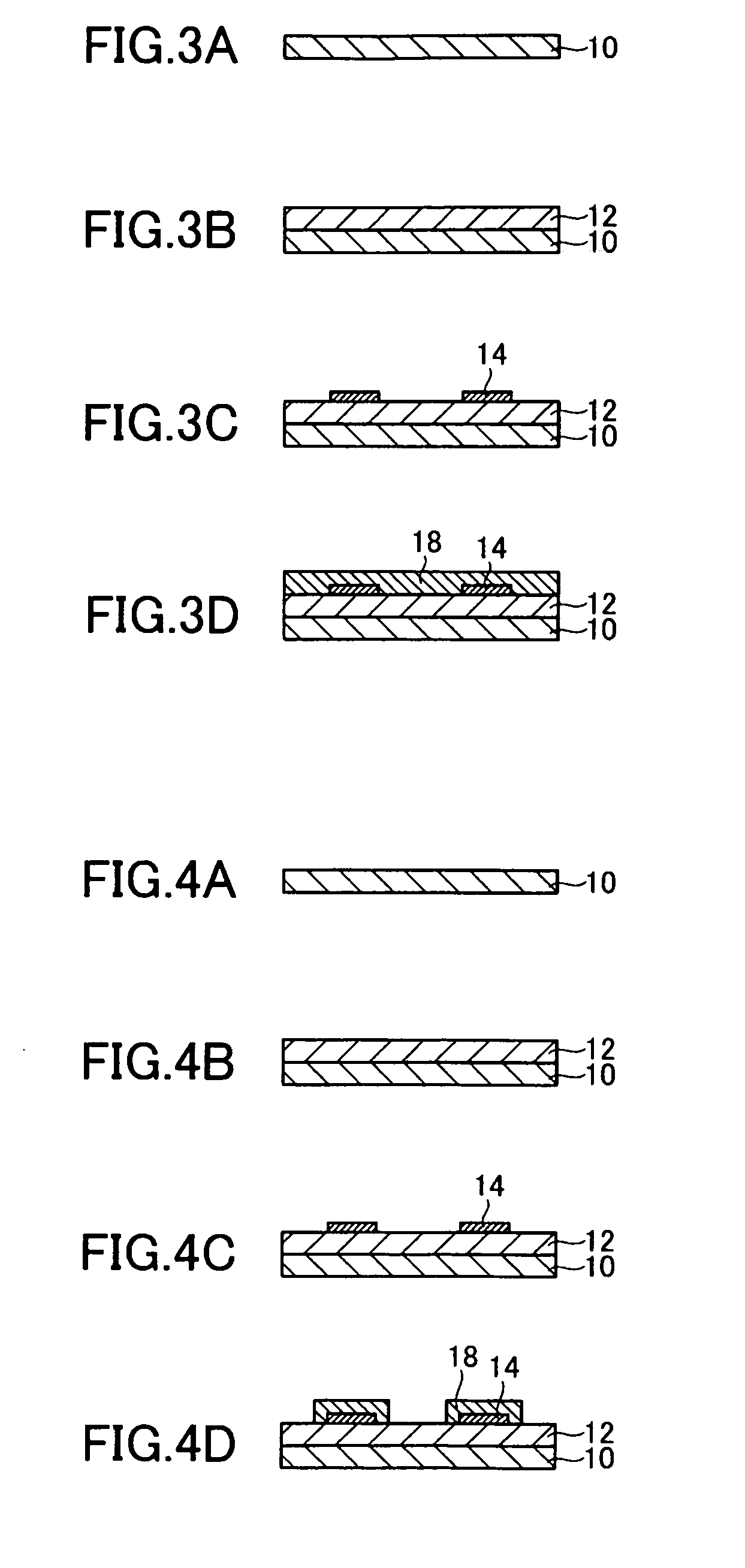

Method of forming wiring board and wiring board obtained

ActiveUS20100078208A1Improve reliabilityInhibit migrationPorous dielectricsDielectric materialsEngineeringMetal

A method of forming a wiring board comprises: a step of forming a receptive layer having a porous structure on a substrate; a step of forming wiring portions in a desired conductive pattern on a surface of the receptive layer by ejecting a colloidal metal solution for drawing by an ink-jet system based on image date of the conductive pattern; and a step of performing a migration-proof treatment on at least part of the receptive layer exposed between mutually adjacent wiring portions.

Owner:FUJIFILM CORP

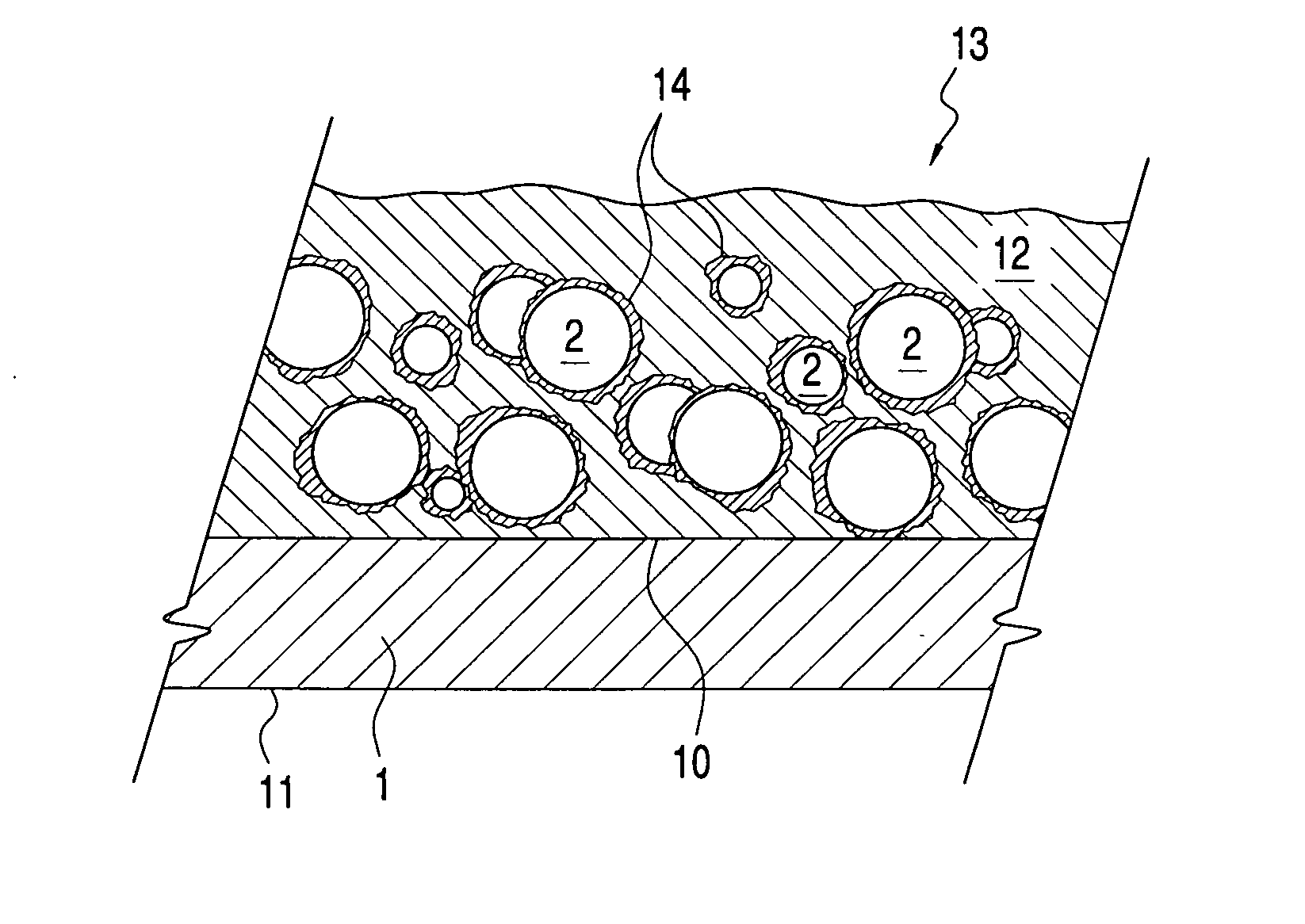

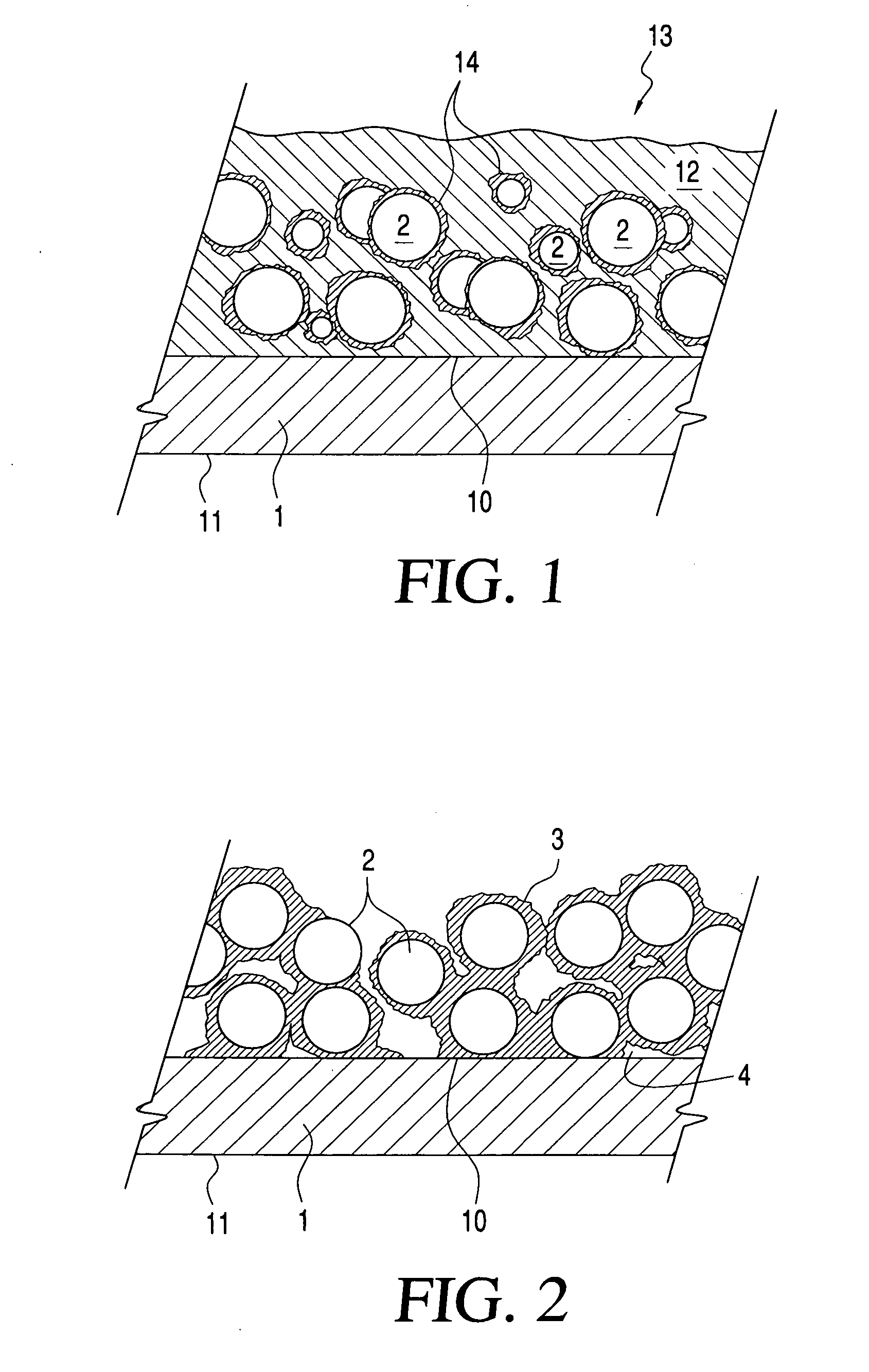

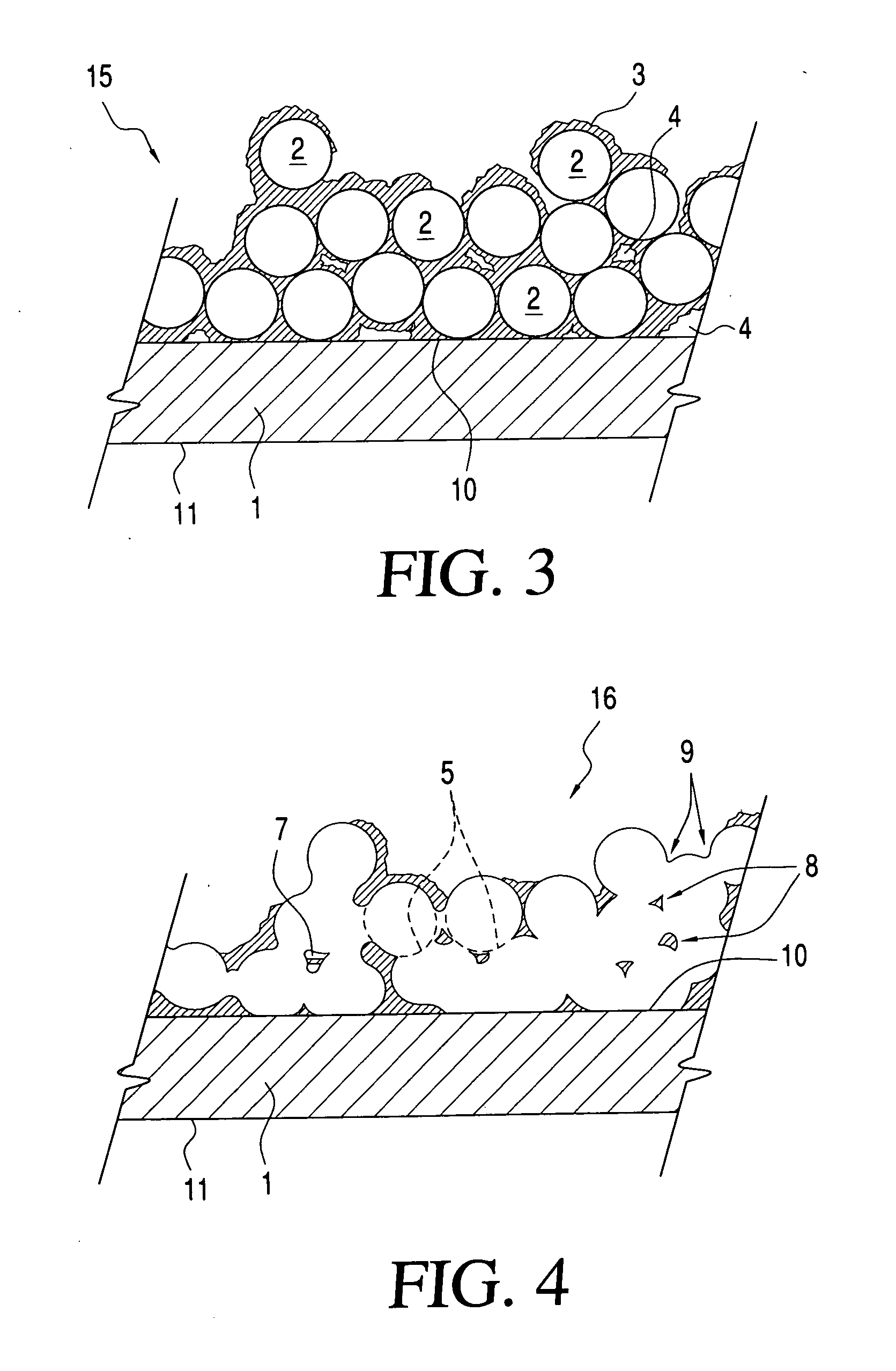

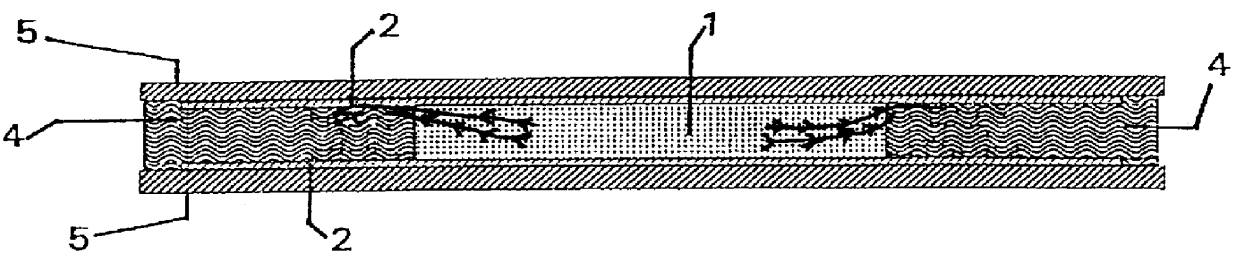

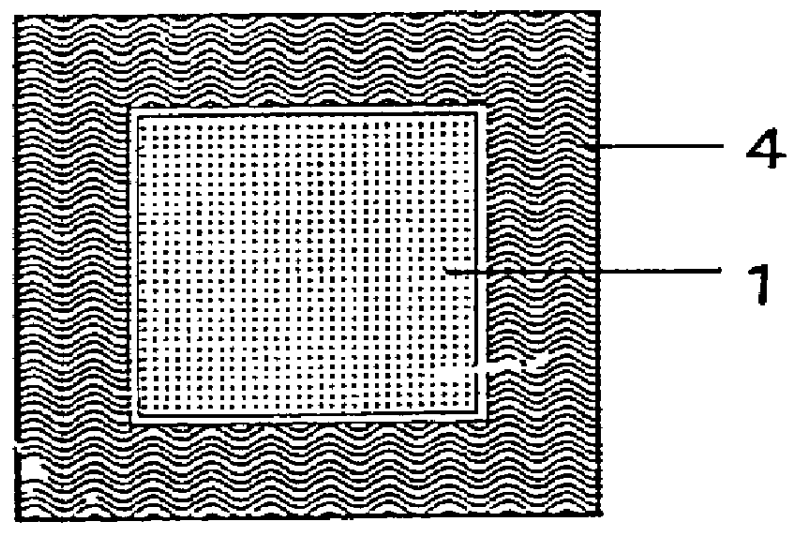

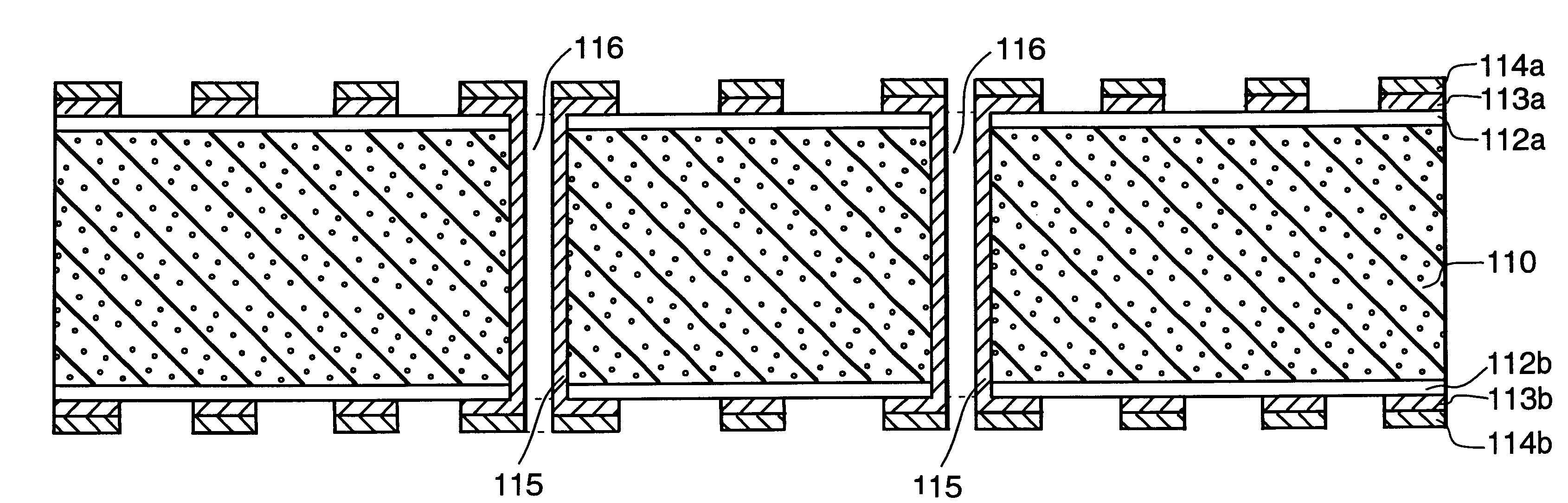

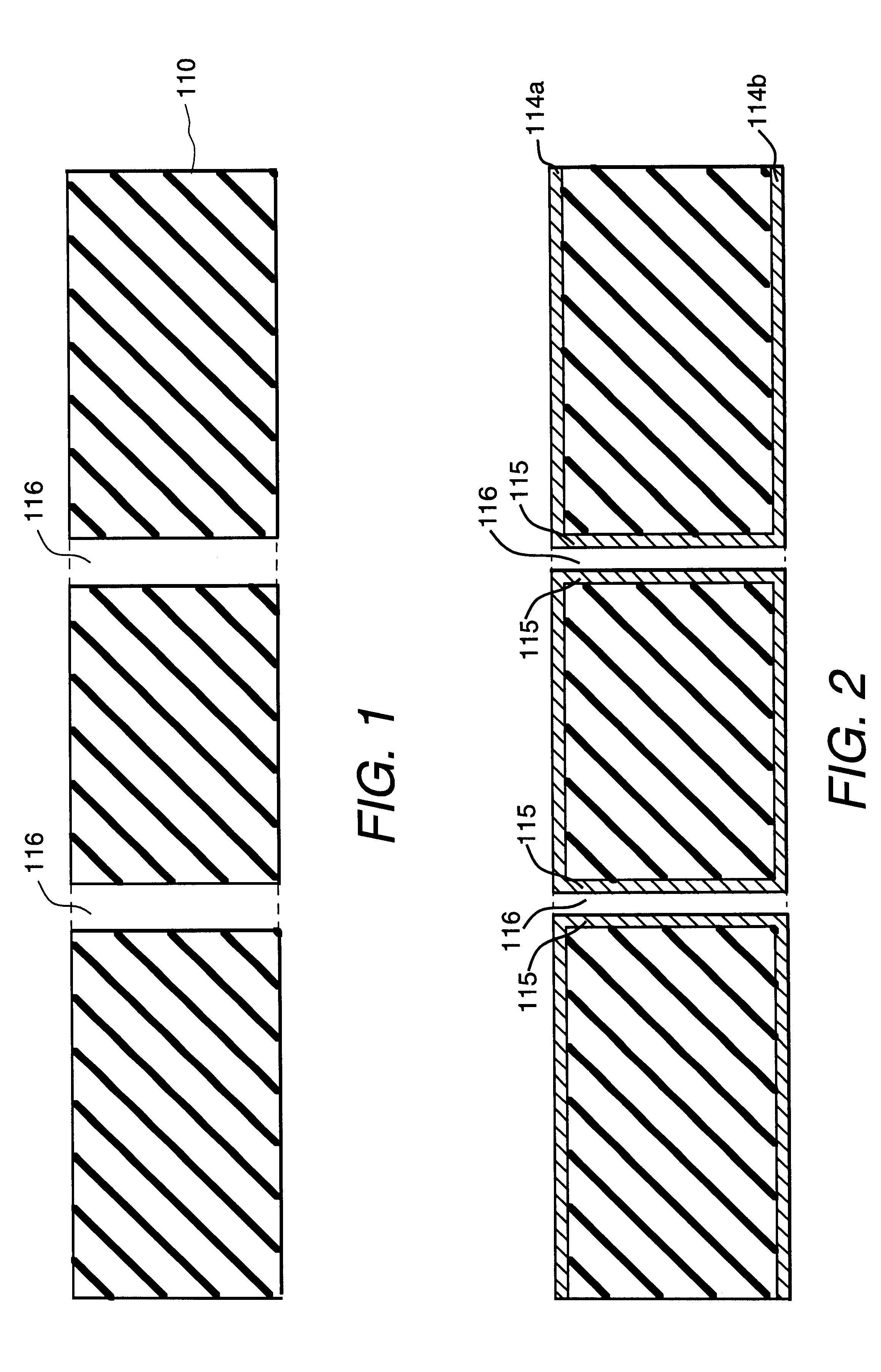

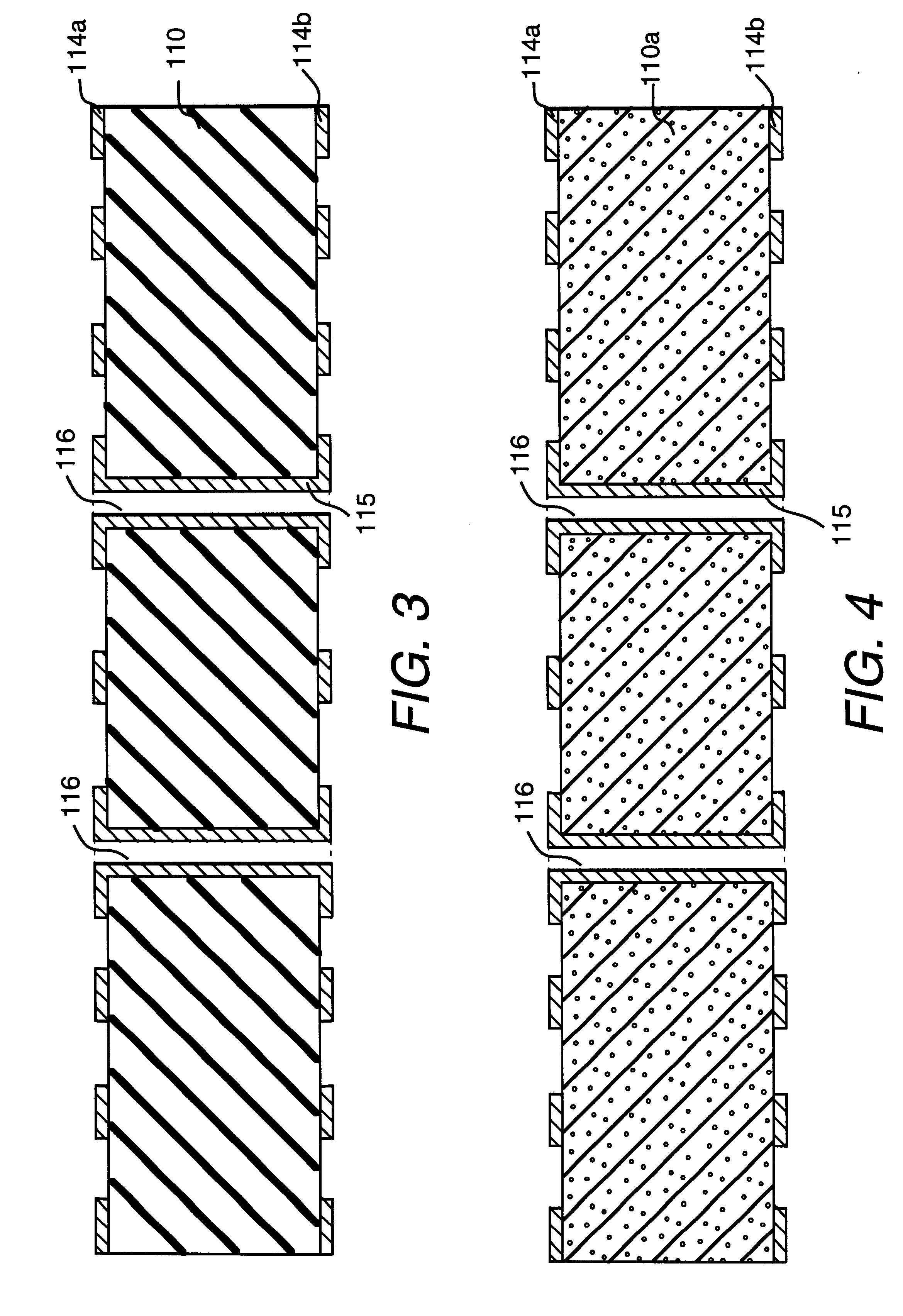

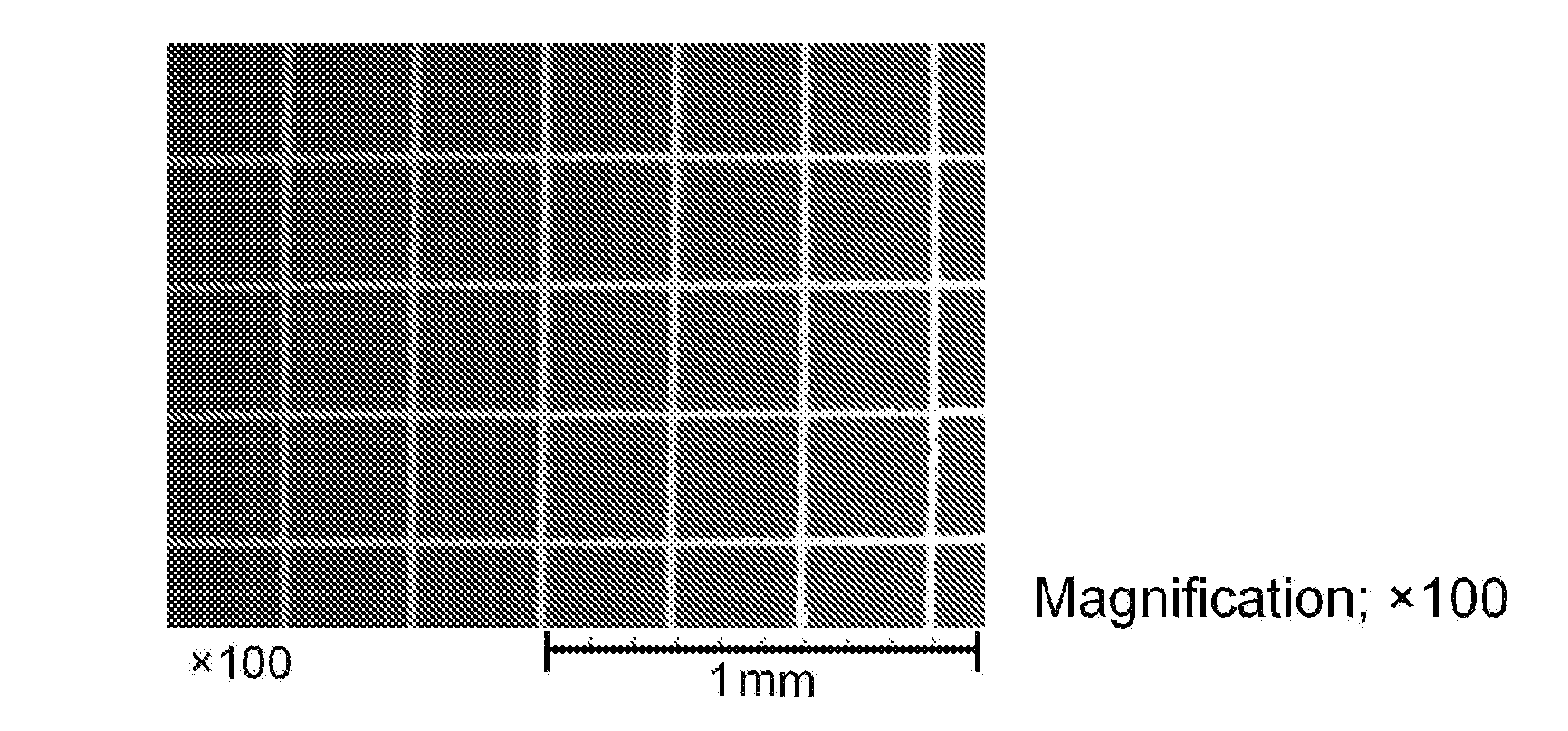

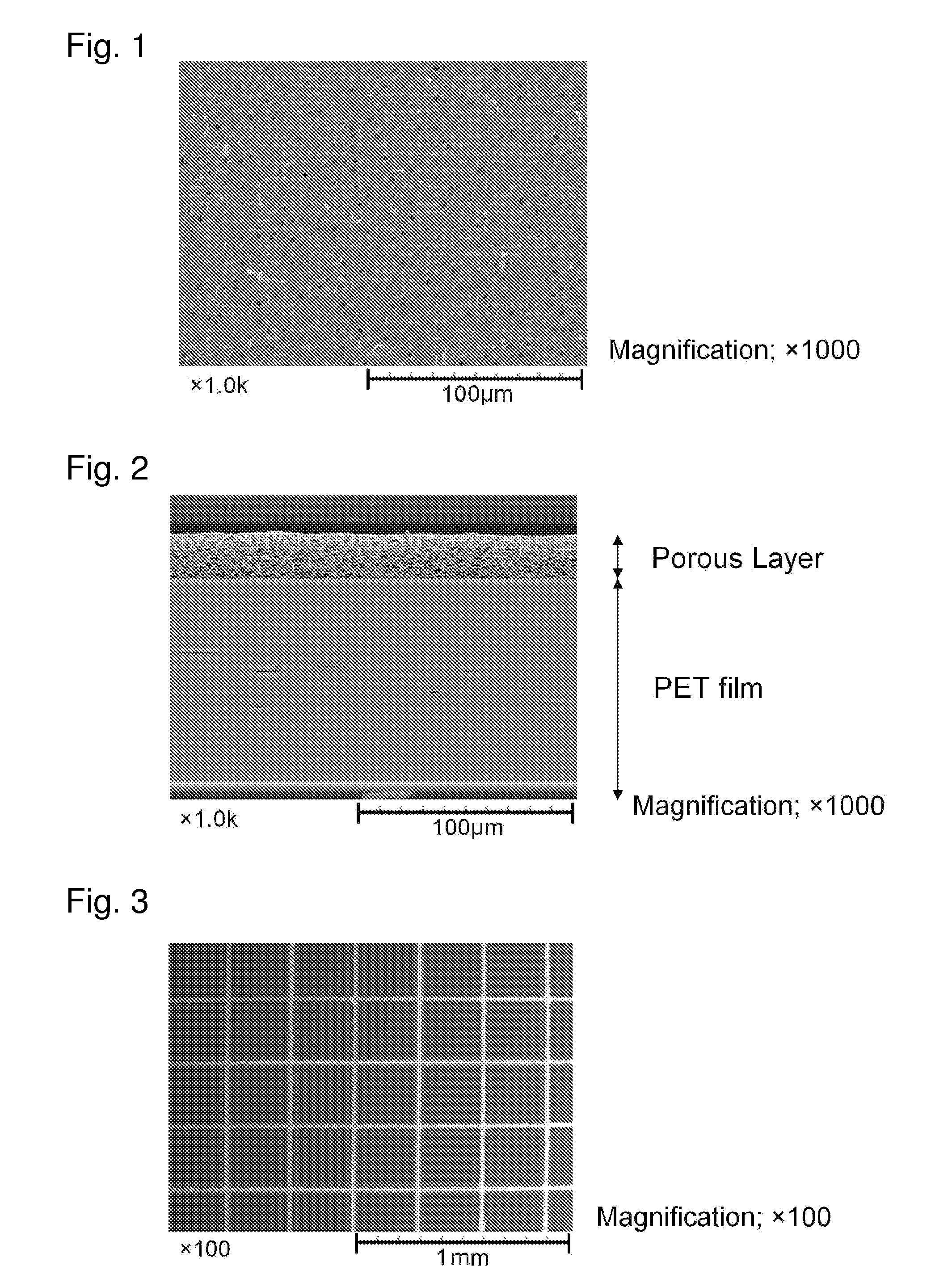

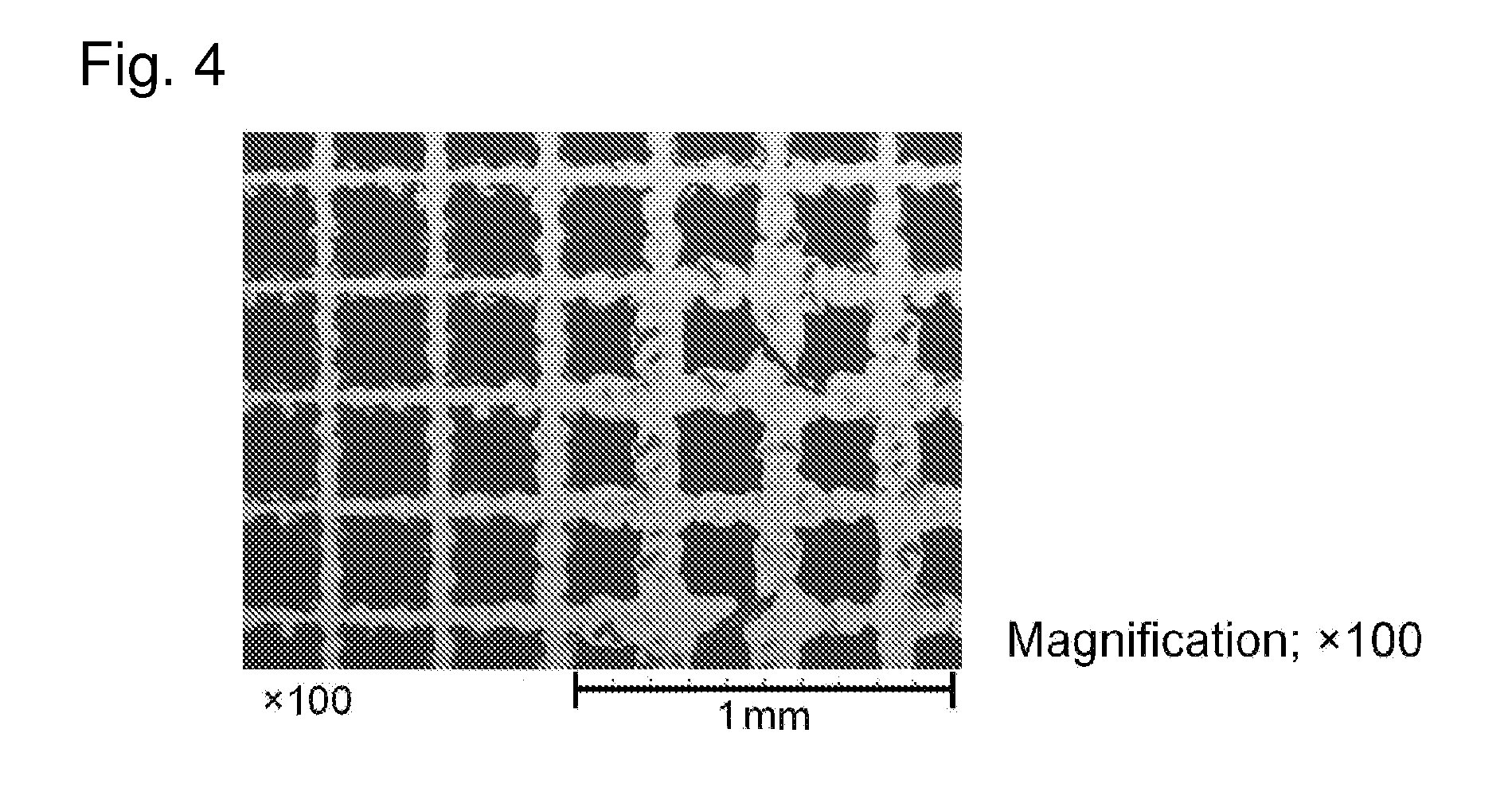

Layered product having porous layer and functional layered product made with the same

InactiveUS20110081527A1High strengthGood flexibilityPorous dielectricsLamination ancillary operationsPorous layerConductive materials

The present invention provides a layered product having a porous layer made mainly of a polymer on a base, and a process for producing the same; and a functional layered product wherein a pattern of a functional material, such as an conductive material, is formed onto a light-transmitting base using the layered product having the porous layer, and a process for producing the functional layered product. A layered product comprising a base and a porous layer on at least one surface of the base, wherein the porous layer is constituted of a composition containing a polymer as a main component, the porous layer has micropores having an average pore diameter of 0.01 to 10 μm, and has a porosity of 30 to 85%, the composition constituting the porous layer has a glass transition temperature of 20° C. or higher, and the porous layer is a layer which is convertible to a transparent layer by a heat treatment through disappearance of the micropores. A conductive pattern is formed on the porous layer surface of the layered product, and then the resultant layered product is subjected to a heat treatment to cause the micropores in the porous layer to disappear, thereby converting the porous layer to a transparent layer.

Owner:DAICEL CHEM IND LTD

Deposition fabrication using inkjet technology

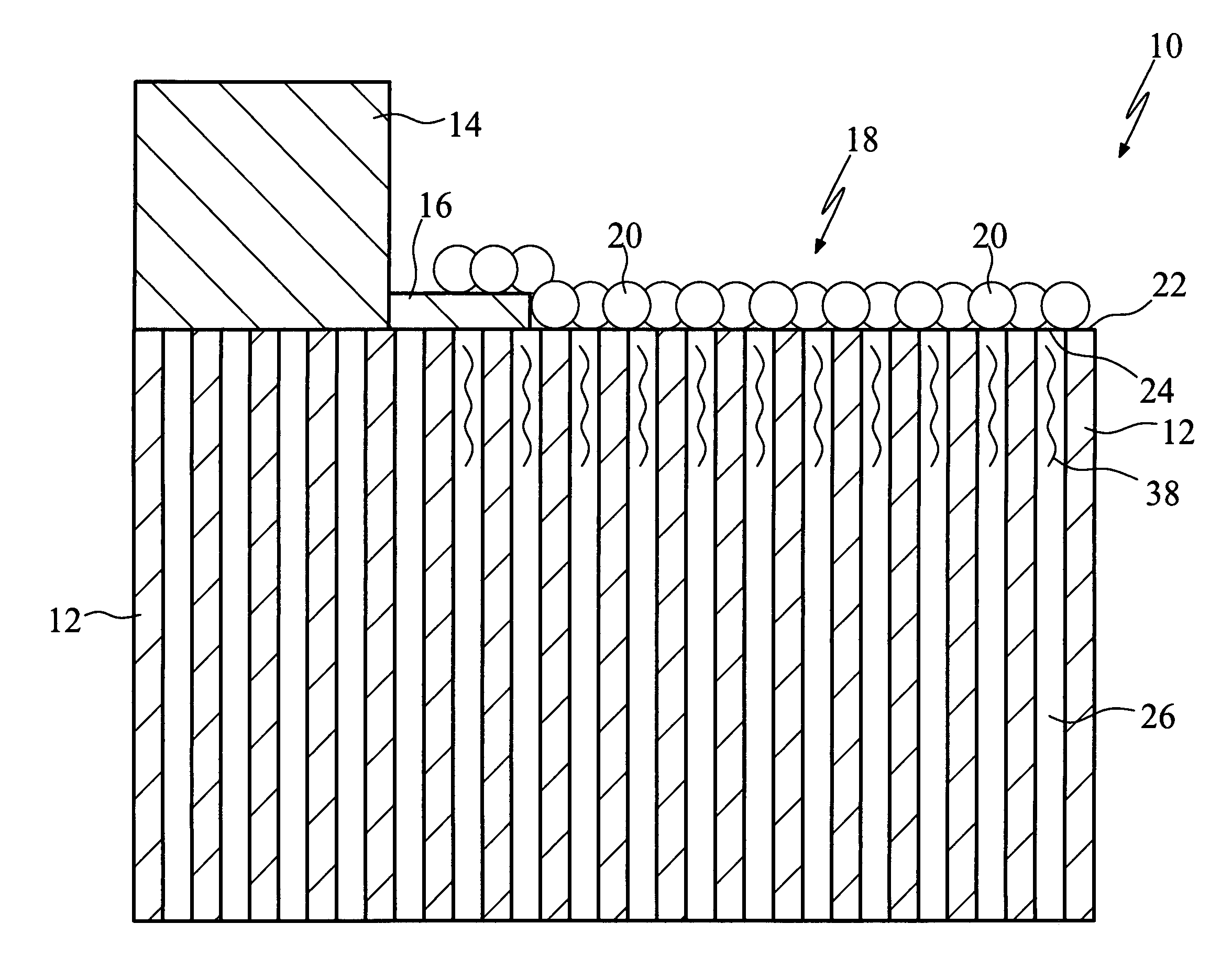

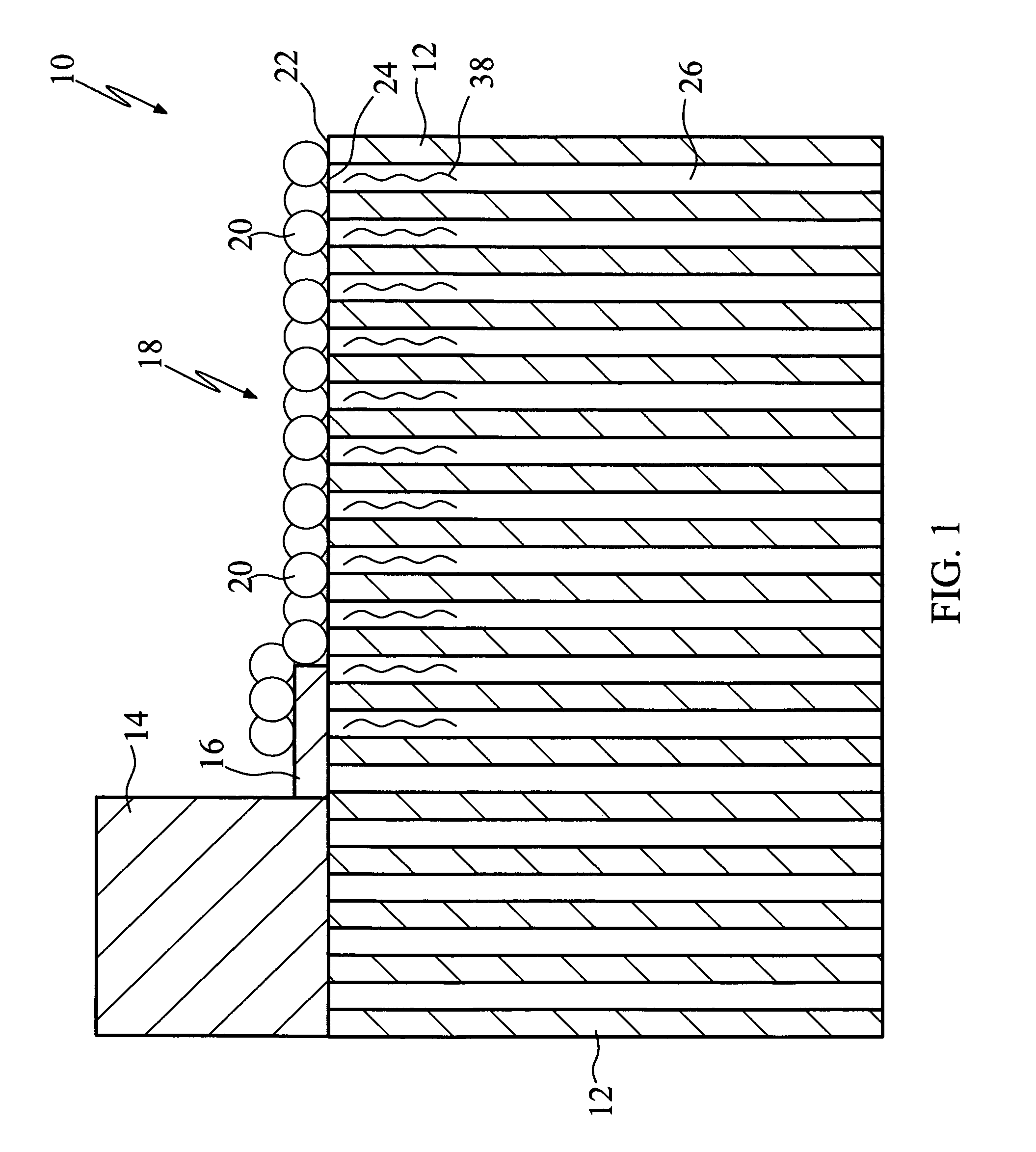

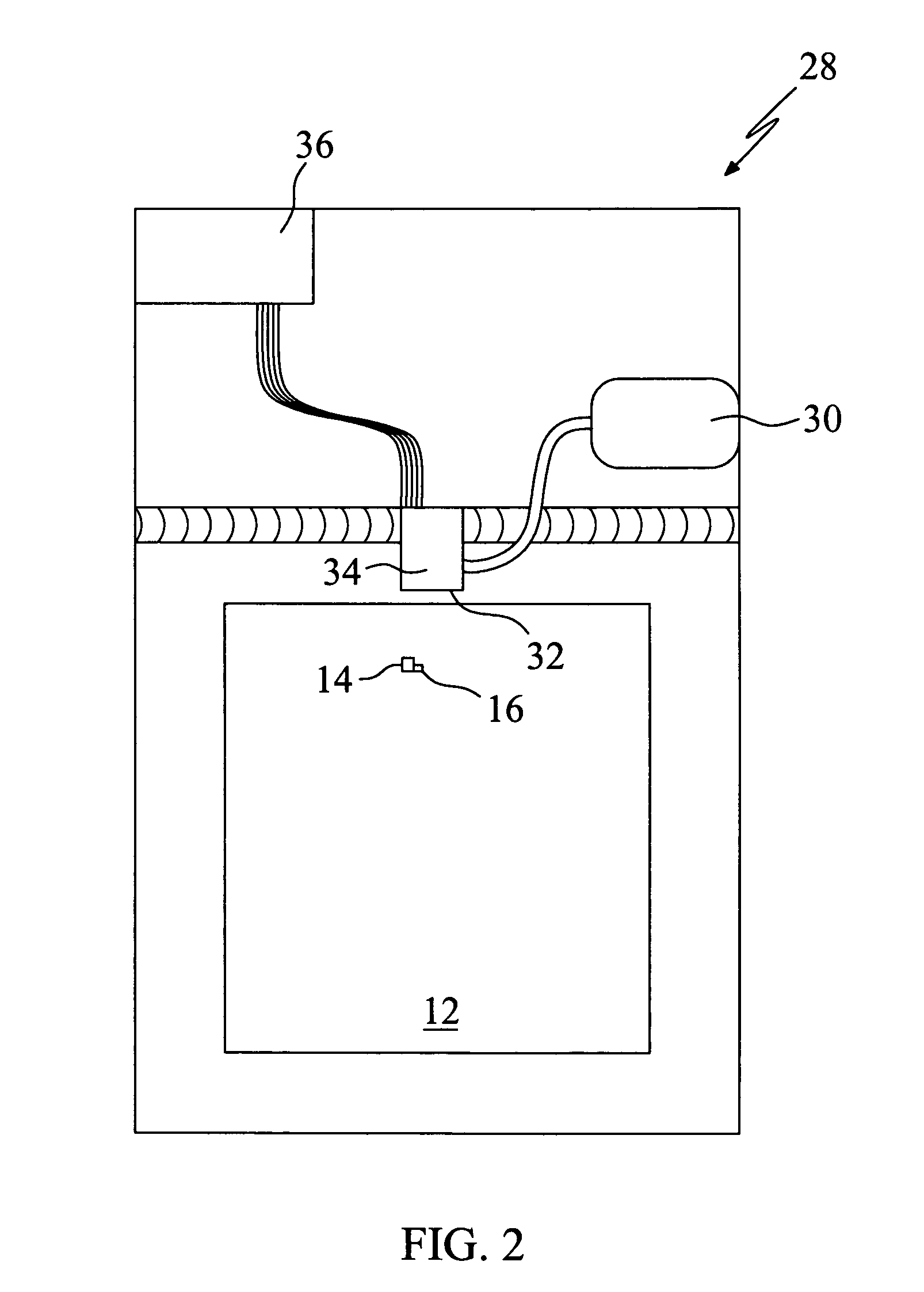

ActiveUS7055756B2Great precision and densityReduce areaPorous dielectricsPrinted circuit manufactureOptoelectronicsSlurry

A method of fabricating an RFID antenna, the method comprising: (a) depositing a slurry upon a substrate in a predetermined pattern, the substrate including a plurality of micropores operative to drain a fluid component of the slurry from the surface of the substrate, while maintaining conductive particles of the slurry on a surface of the substrate; and (b) drying the conductive particles to secure the conductive particles upon a surface of the substrate and provide a conductive antenna. The invention also includes an RFID tag comprising: (a) a substrate including a plurality of micropores; (b) a microchip; and (c) an RFID antenna in electrical communication with the microchip and contacting the substrate, the RFID antenna comprising conductive particles deposited upon the substrate by ejecting a slurry from an inkjet printer.

Owner:LEXMARK INT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com