Patents

Literature

534 results about "Ultrashort pulse laser" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An ultrashort pulse laser is a laser that emits ultrashort pulses of light, generally of the order of femtoseconds to ten picoseconds. They are also known as ultrafast lasers owing to the speed at which pulses "turn on" and "off"—not to be confused with the speed at which light propagates, which is determined by the properties of the medium (and has an upper limit), particularly its index of refraction, and can vary as a function of field intensity (i.e. self-phase modulation) and wavelength (chromatic dispersion).

Transparent material processing with an ultrashort pulse laser

InactiveUS20100025387A1Reduce quality problemsPoor precisionSemiconductor/solid-state device manufacturingFine working devicesLight beamOptoelectronics

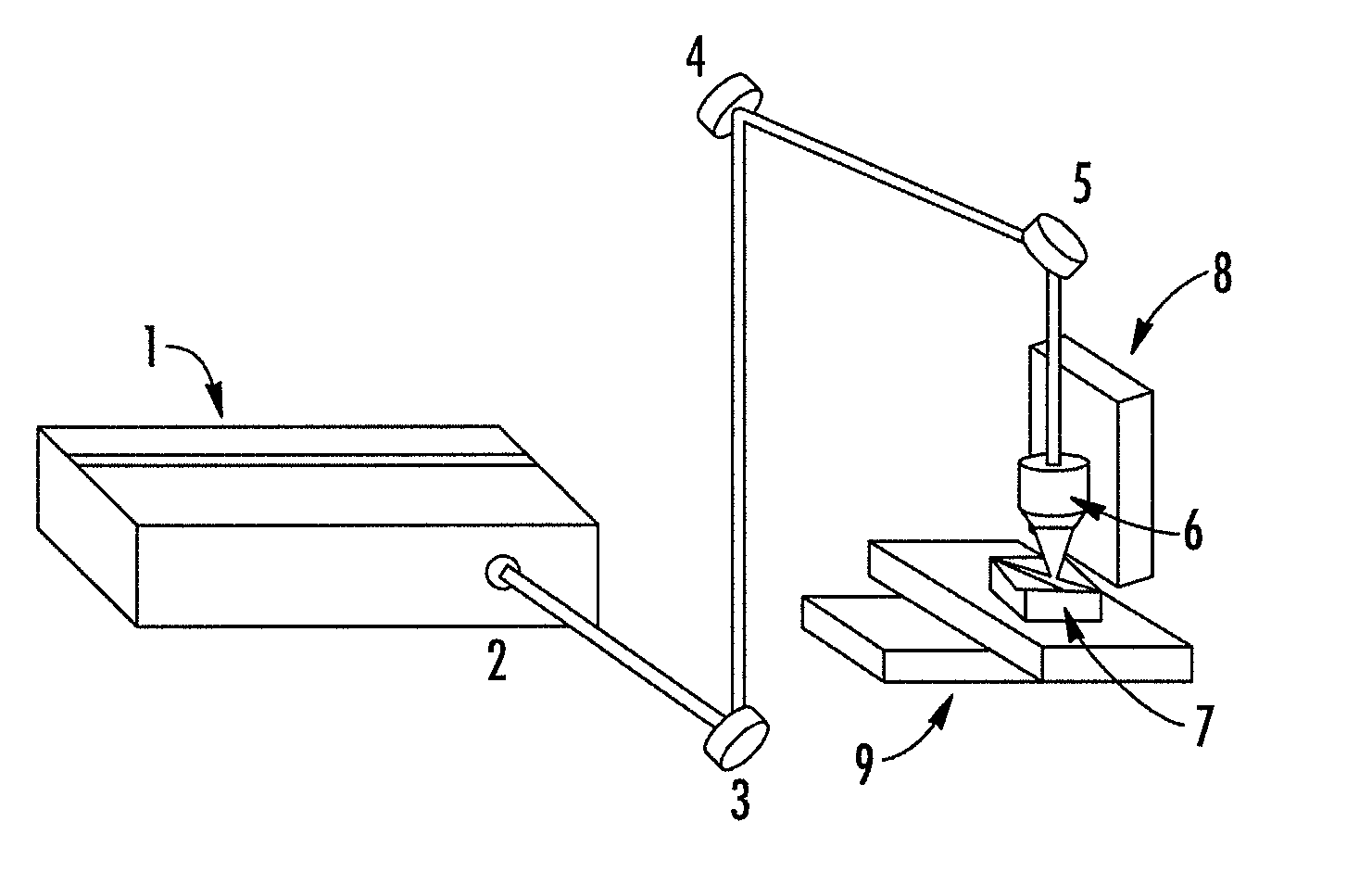

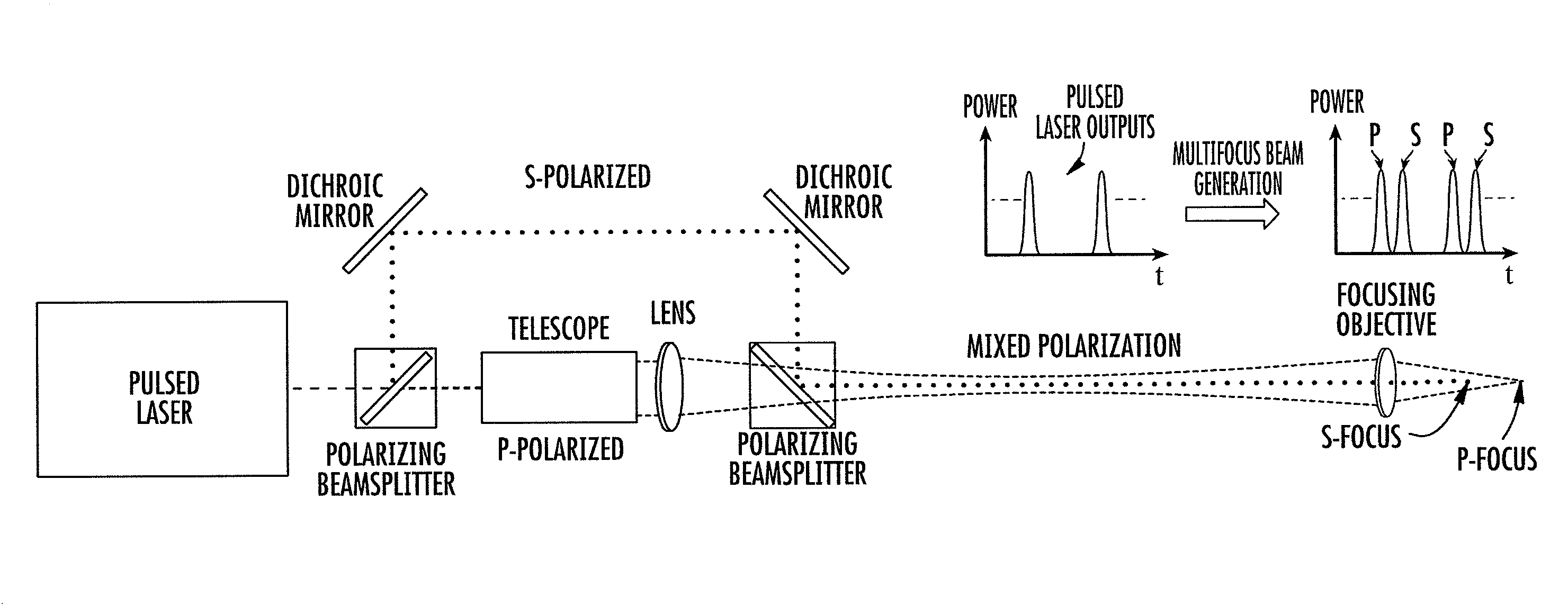

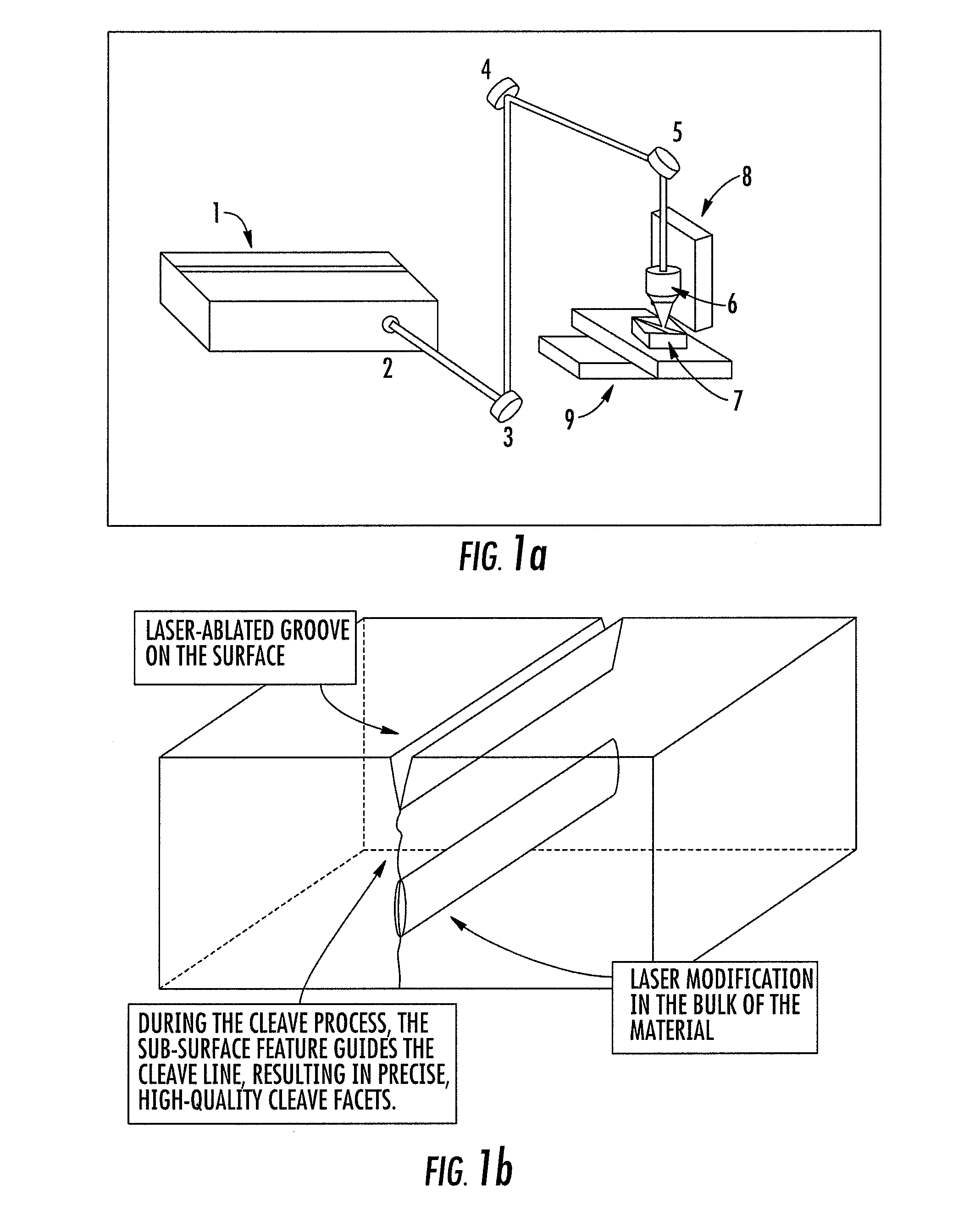

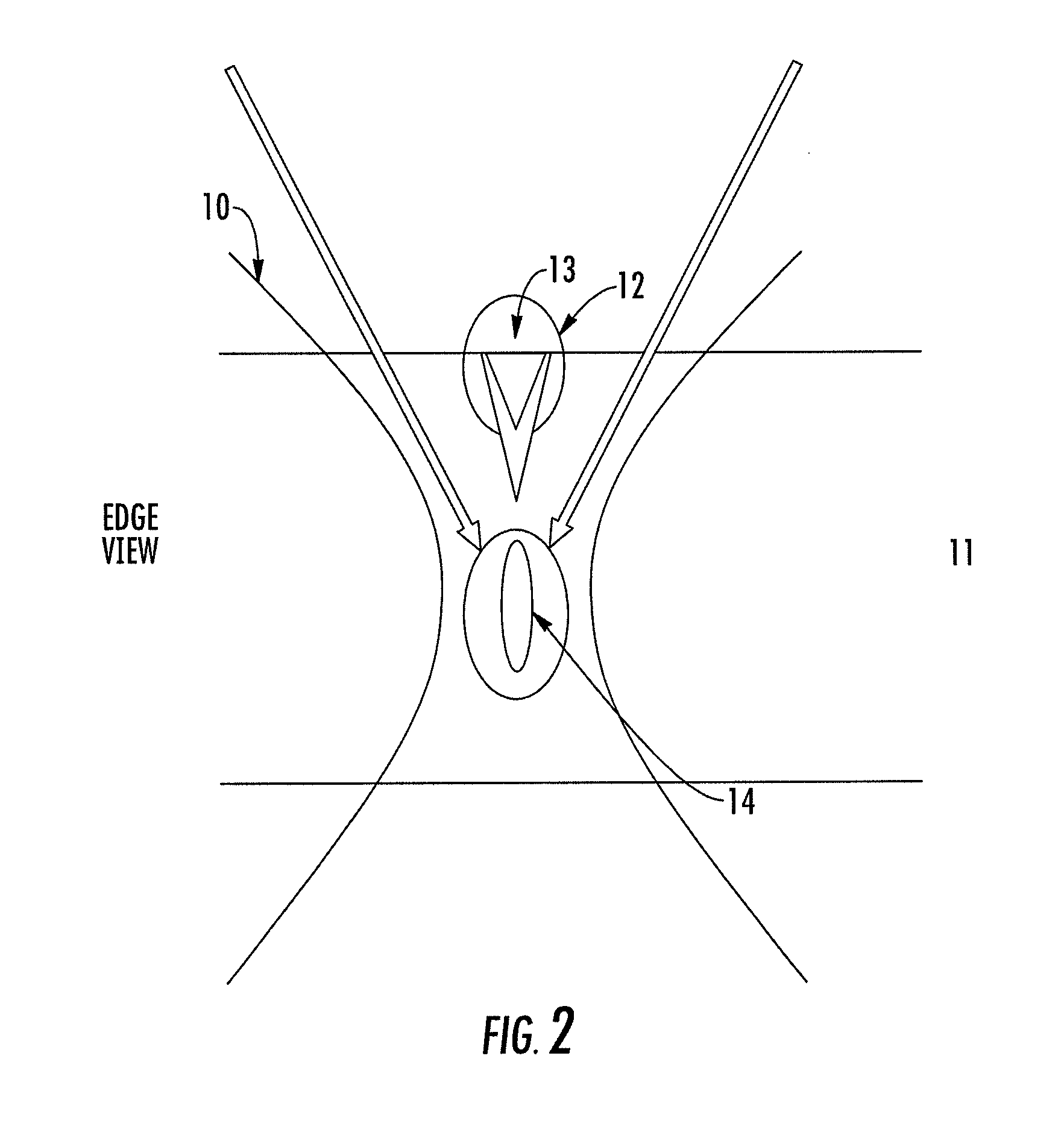

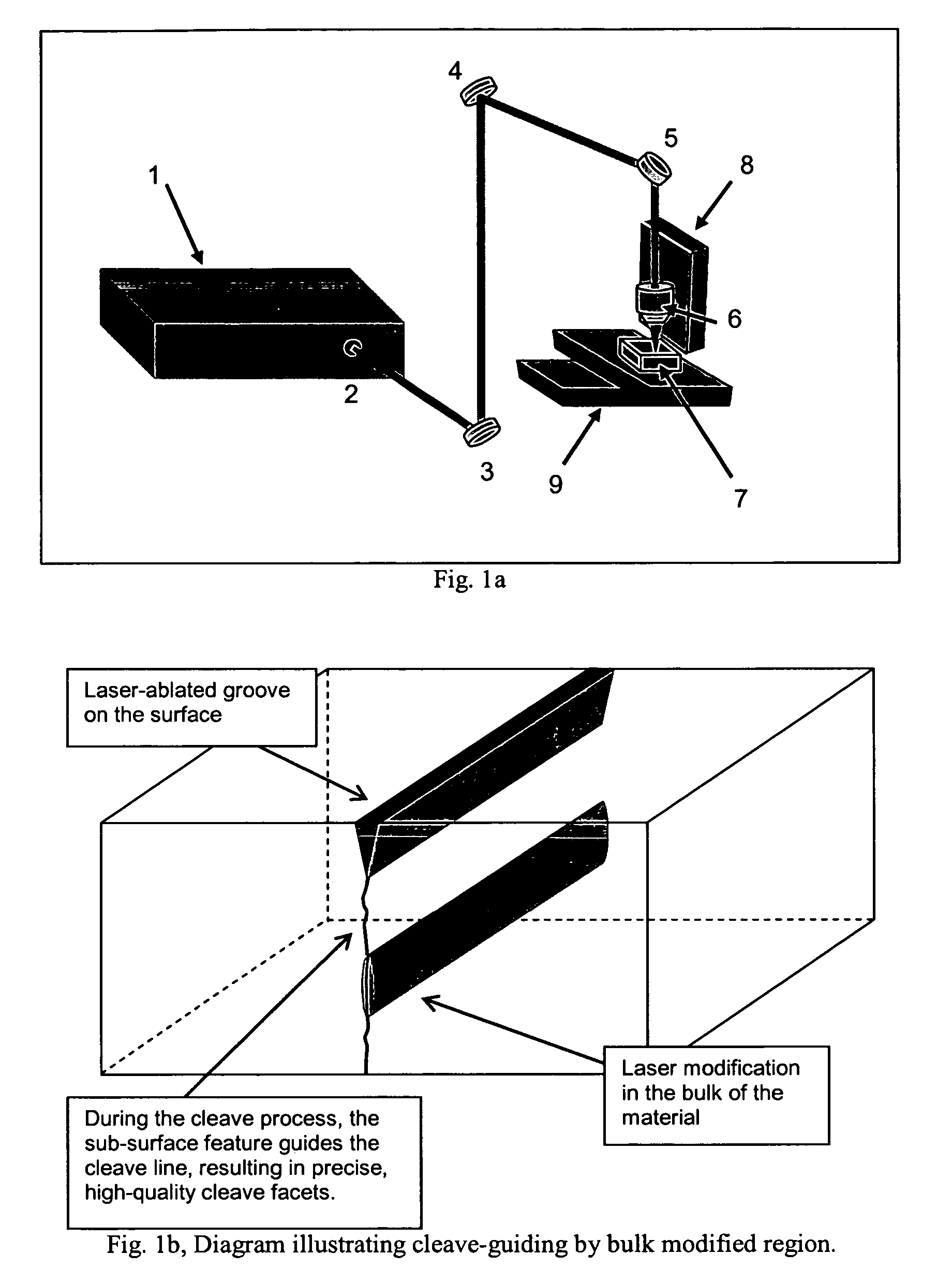

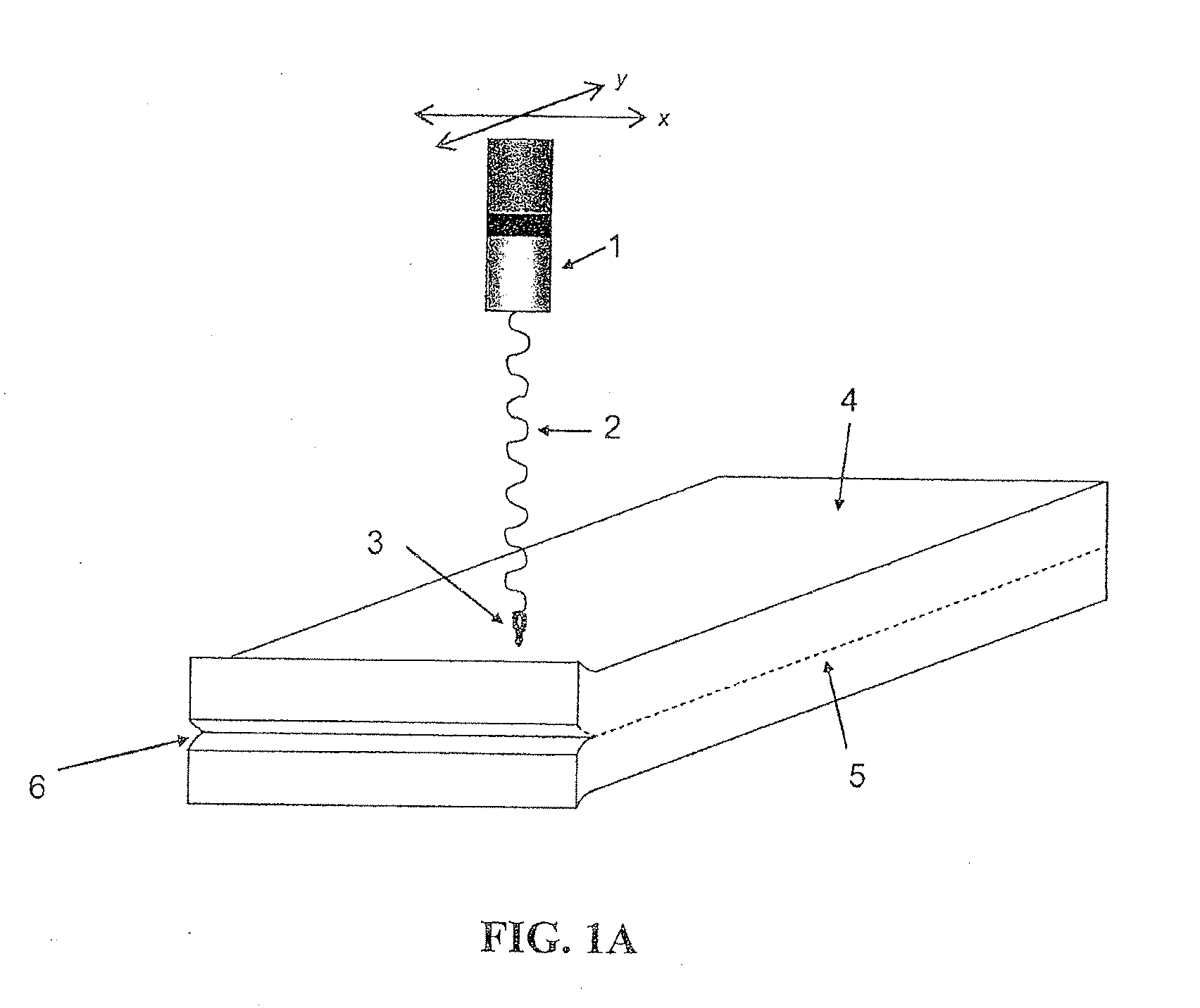

Methods, devices, and systems for ultrashort pulse laser processing of optically transparent materials are disclosed, with example applications in scribing, marking, welding, and joining. For example, ultrashort laser pulses create scribe features with one pass of the laser beam across the material, with at least one of the scribe features being formed below the surface of the material. Slightly modifying the ultrashort pulse laser processing conditions produces sub-surface marks. When properly arranged, these marks are clearly visible with correctly aligned illumination. Reflective marks may also be formed with control of laser parameters. A transparent material other than glass may be utilized. A method for welding transparent materials uses ultrashort laser pulses to create a bond through localized heating. In some embodiments of transparent material processing, a multifocus beam generator simultaneously forms multiple beam waists spaced depthwise relative to the transparent material, thereby increasing processing speed.

Owner:IMRA AMERICA

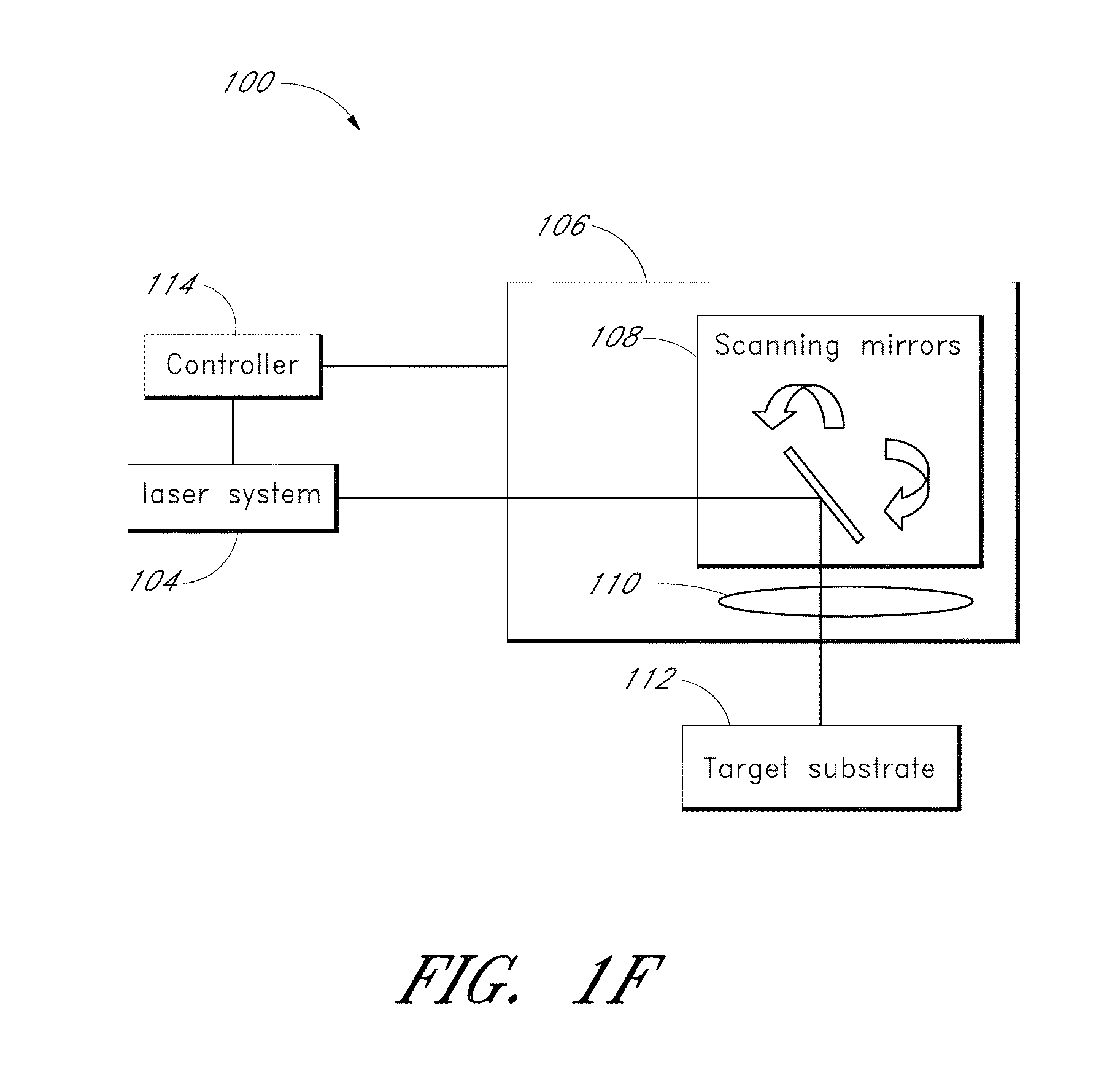

Laser-based material processing methods and systems

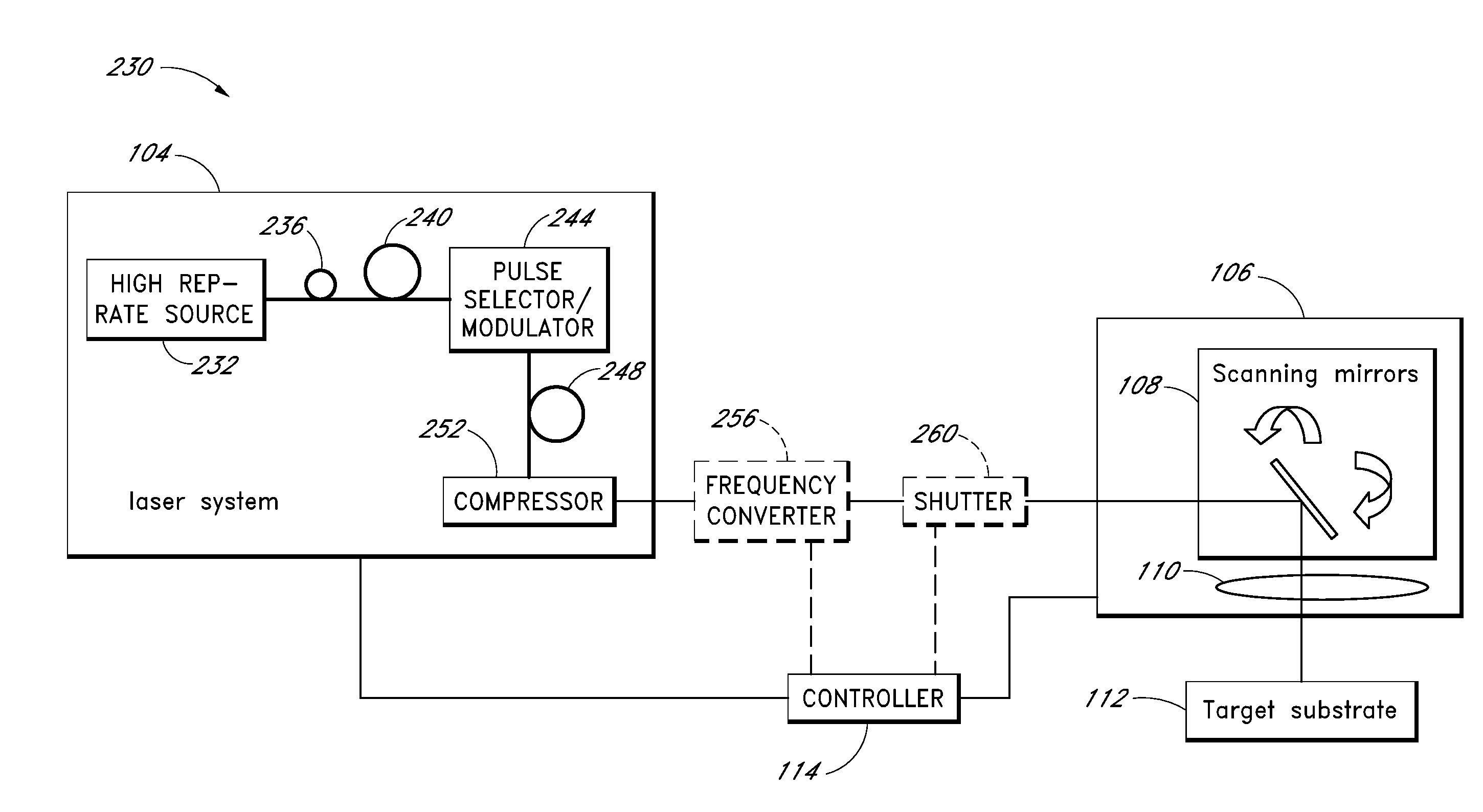

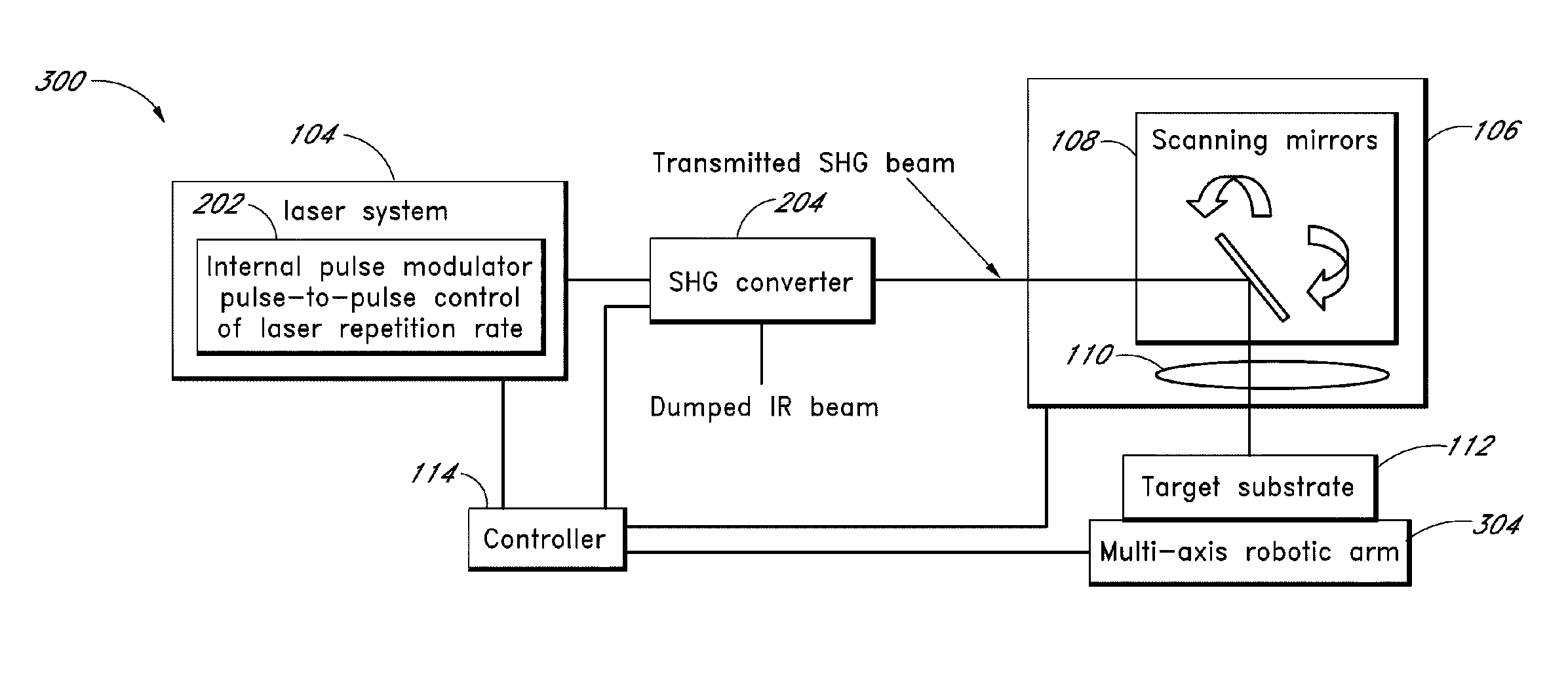

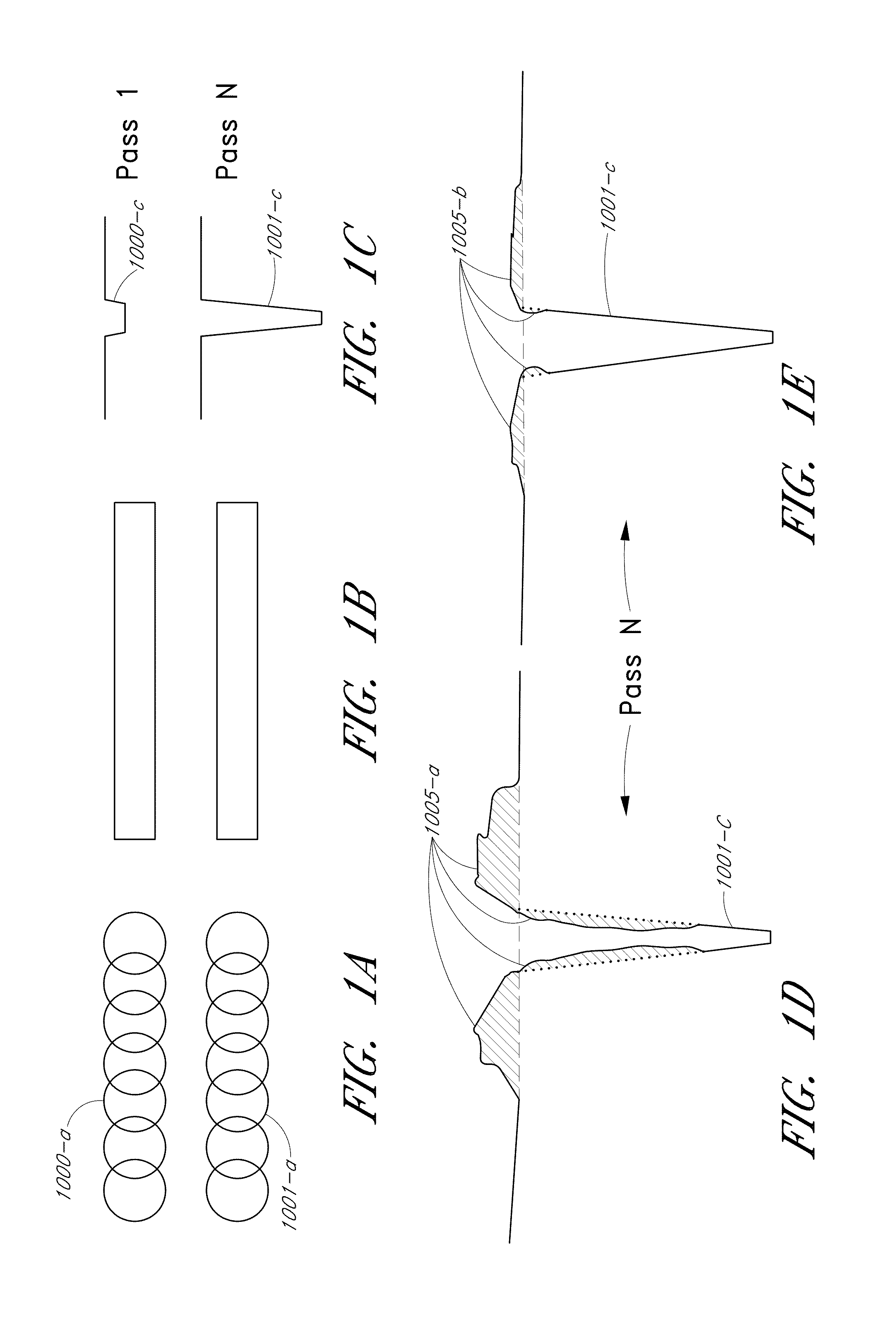

ActiveUS20100197116A1Efficient removalAvoid accumulationSemiconductor/solid-state device manufacturingWelding/soldering/cutting articlesDielectricMaterials processing

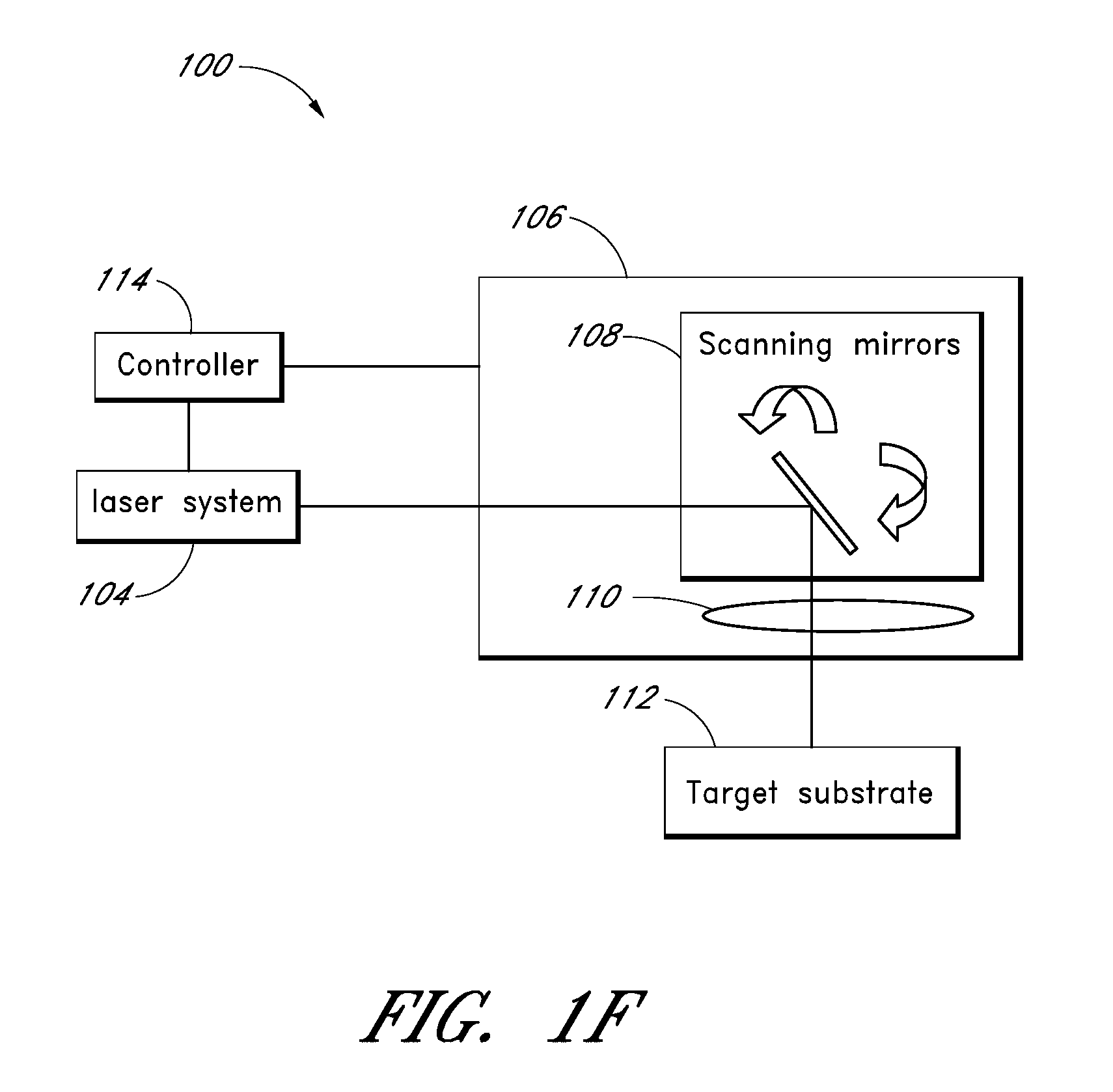

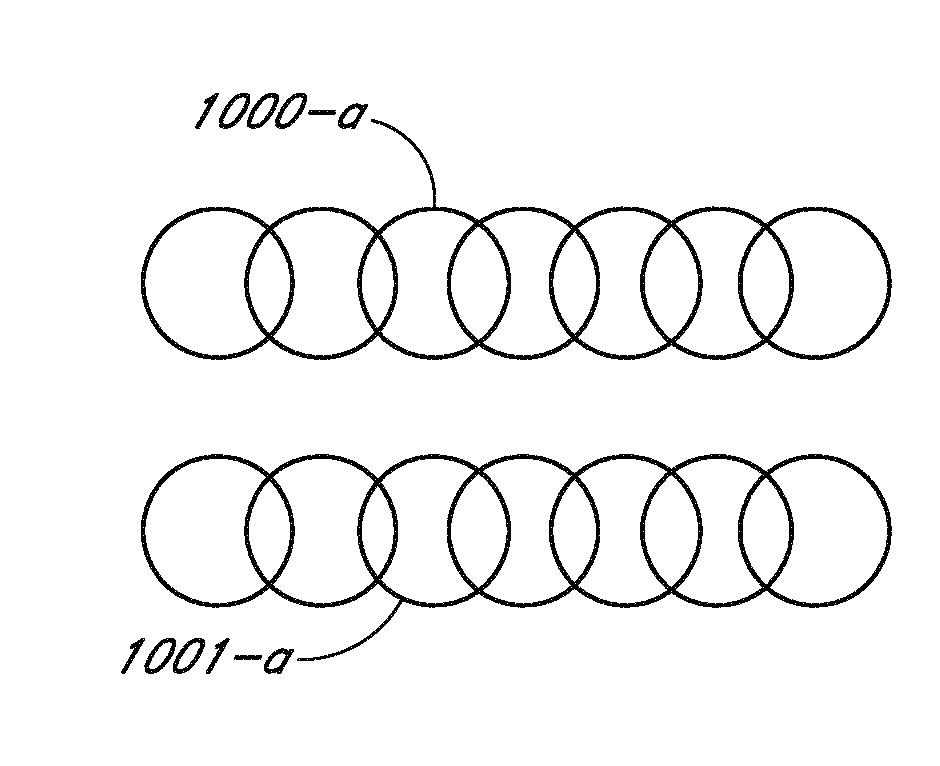

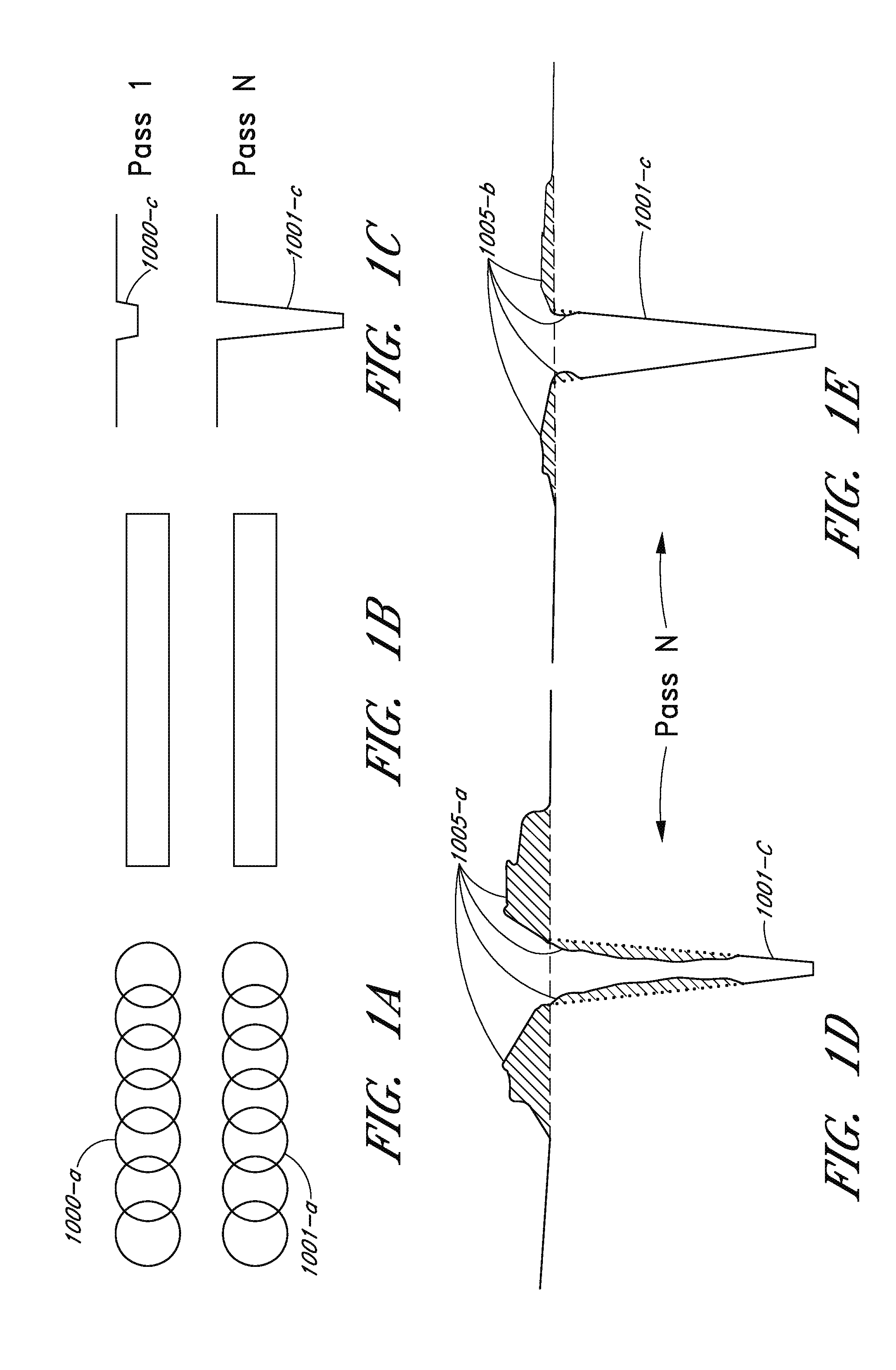

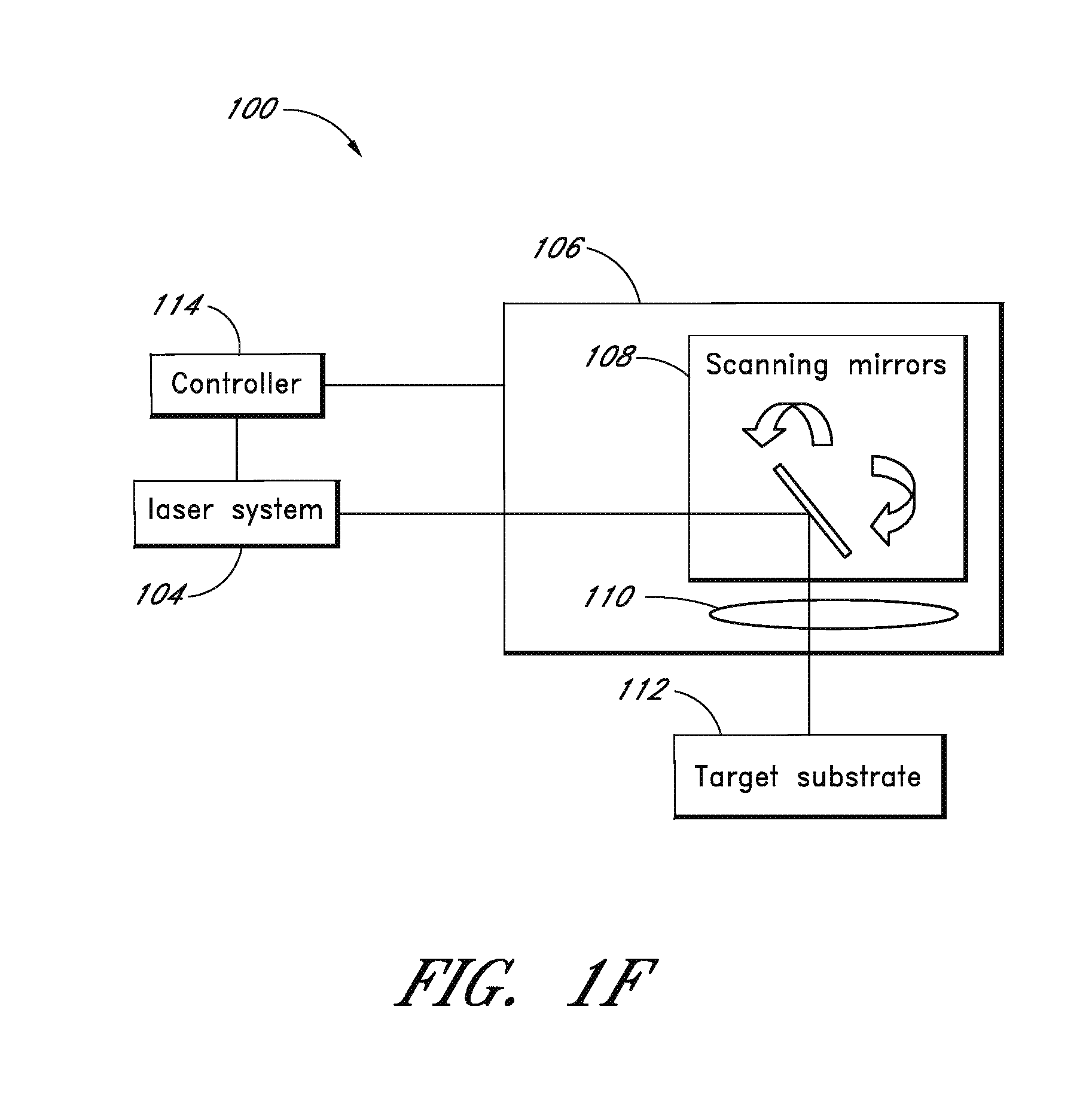

Various embodiments may be used for laser-based modification of target material of a workpiece while advantageously achieving improvements in processing throughput and / or quality. Embodiments of a method of processing may include focusing and directing laser pulses to a region of the workpiece at a pulse repetition rate sufficiently high so that material is efficiently removed from the region and a quantity of unwanted material within the region, proximate to the region, or both is reduced relative to a quantity obtainable at a lower repetition rate. In at least one embodiment, an ultrashort pulse laser system may include at least one of a fiber amplifier or fiber laser. Various embodiments are suitable for at least one of dicing, cutting, scribing, and forming features on or within a semiconductor substrate. Workpiece materials may also include metals, inorganic or organic dielectrics, or any material to be micromachined with femtosecond and / or picosecond pulses, and in some embodiments with pulse widths up to a few nanoseconds.

Owner:IMRA AMERICA

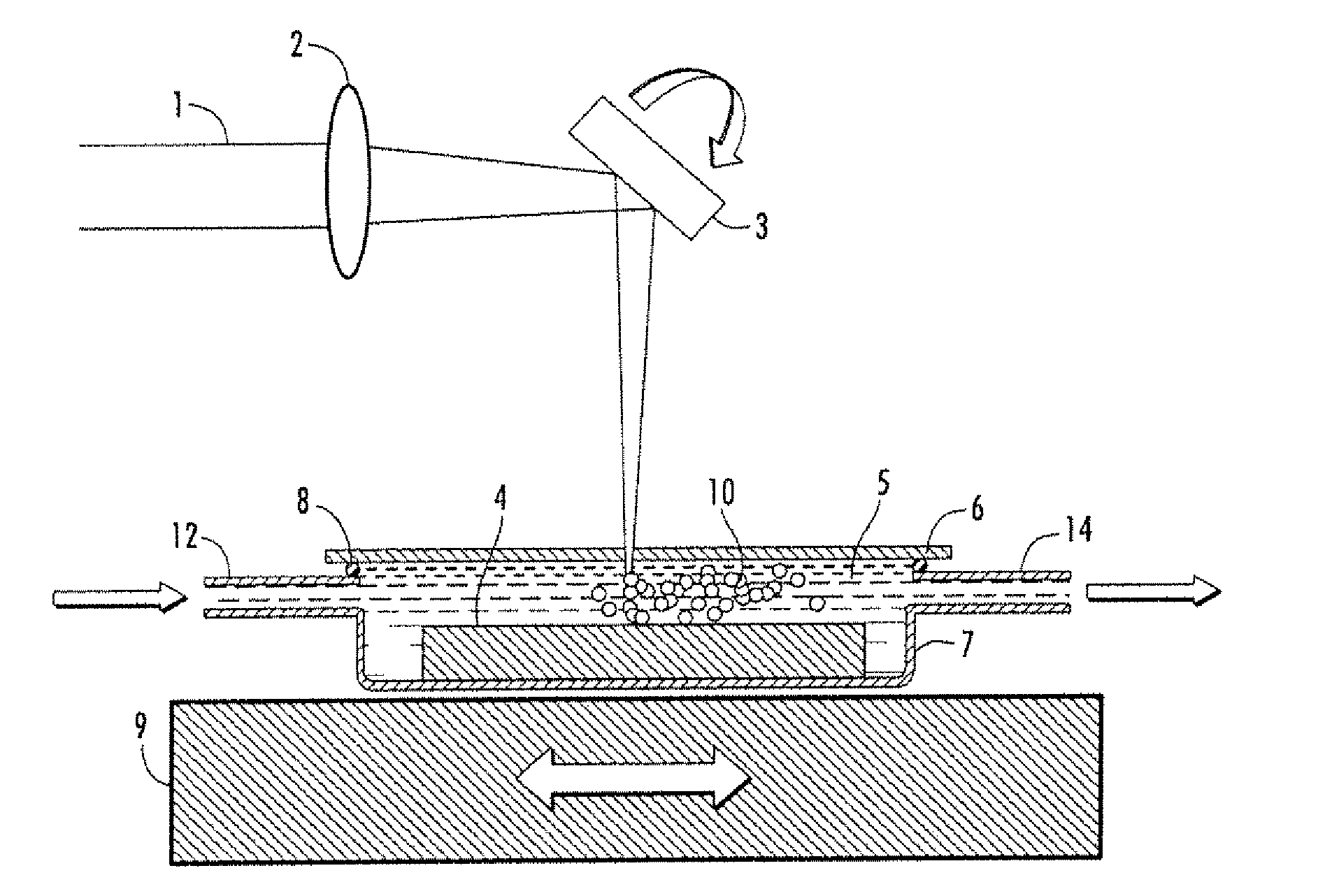

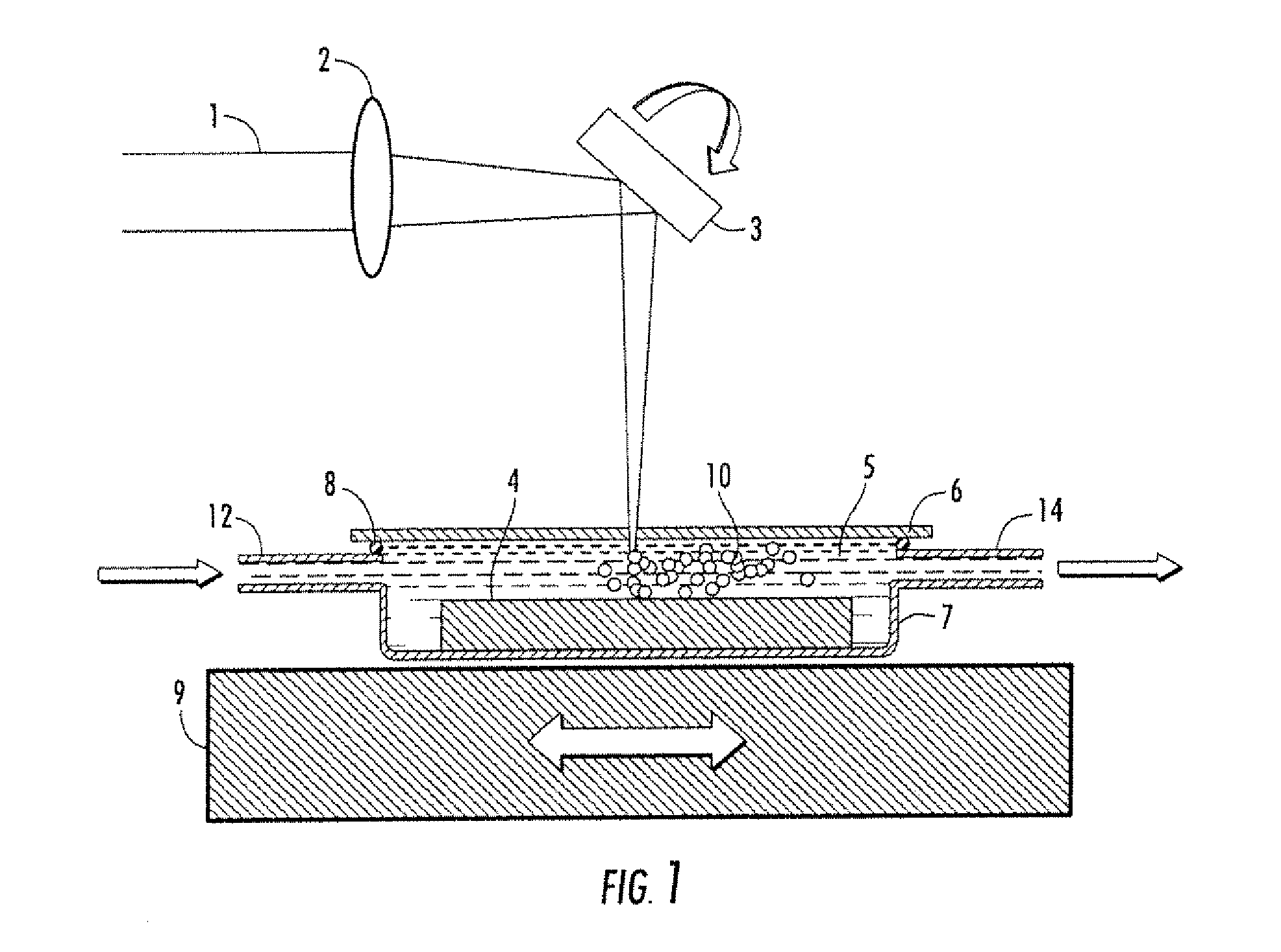

Transparent material processing with an ultrashort pulse laser

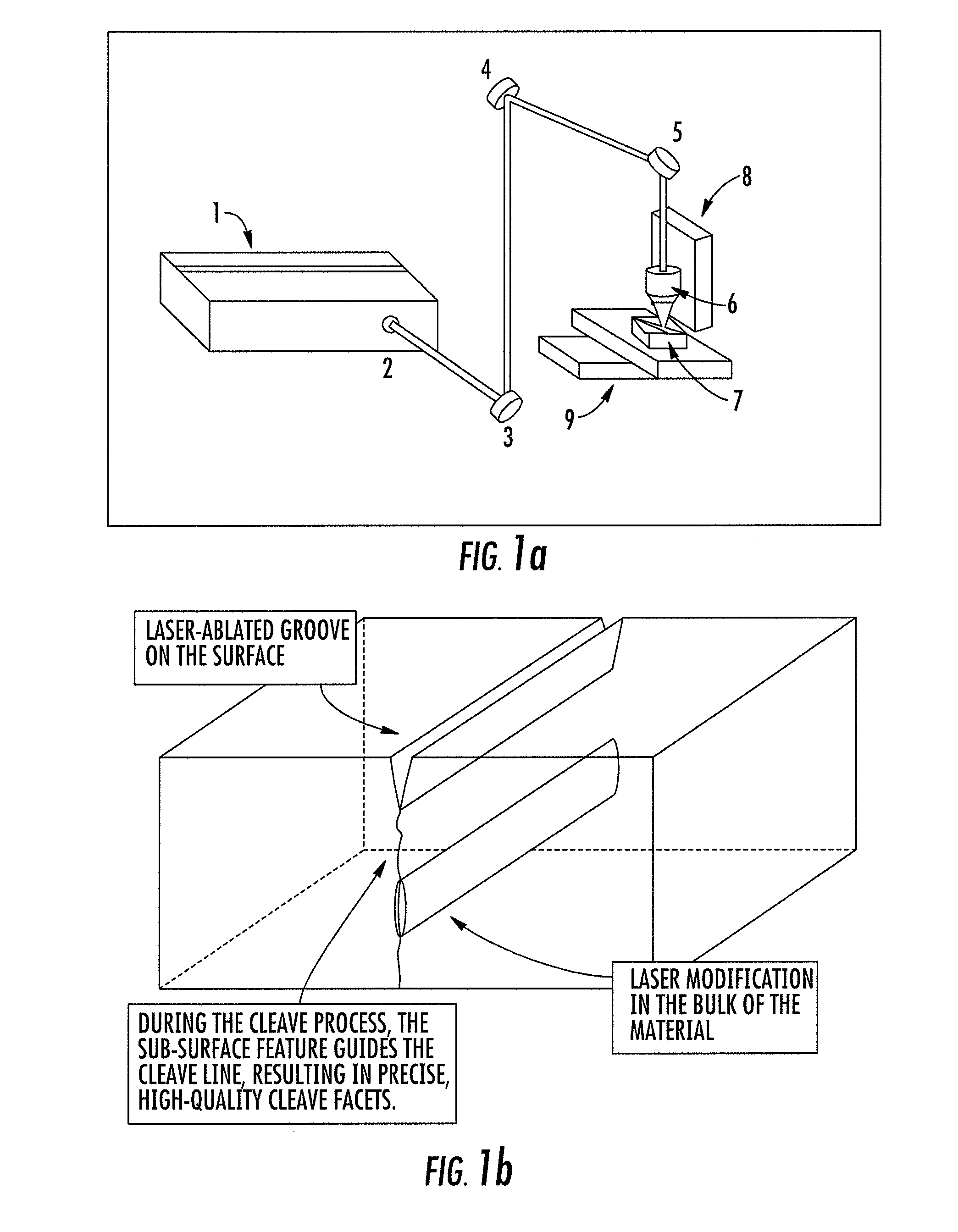

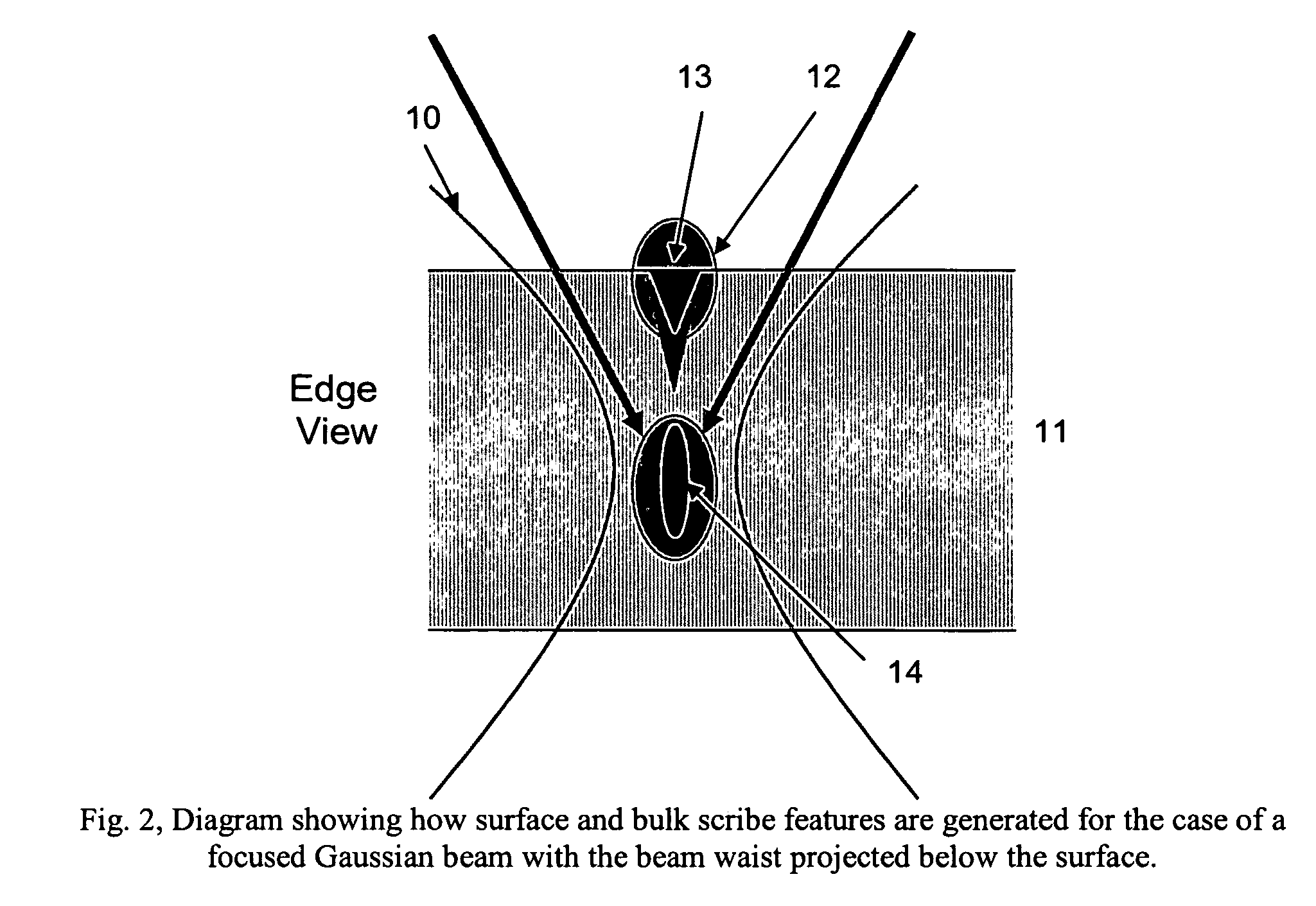

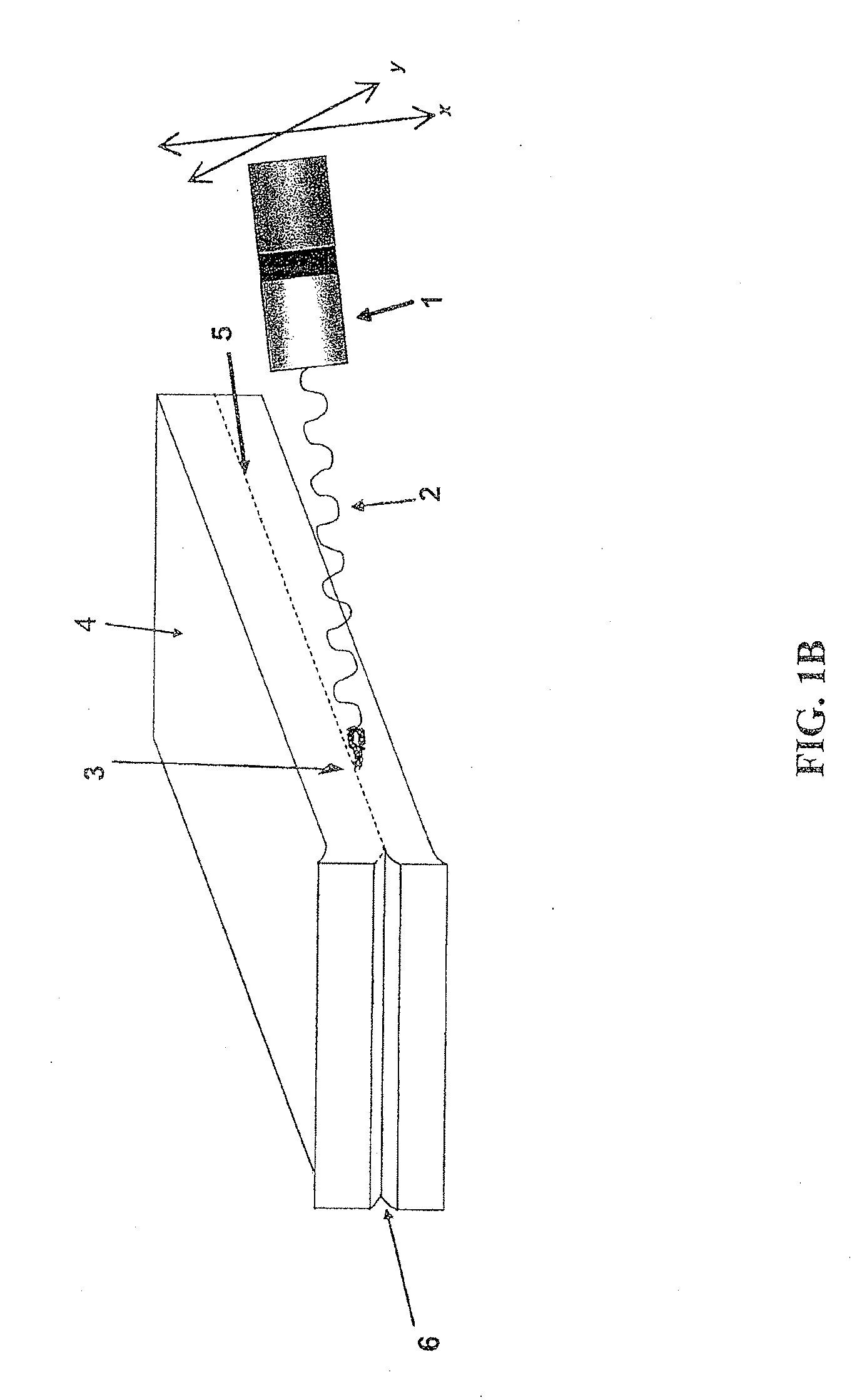

InactiveUS20070051706A1Reduce quality problemsPoor precisionFixed microstructural devicesThin material handlingHigh energyNonlinear absorption

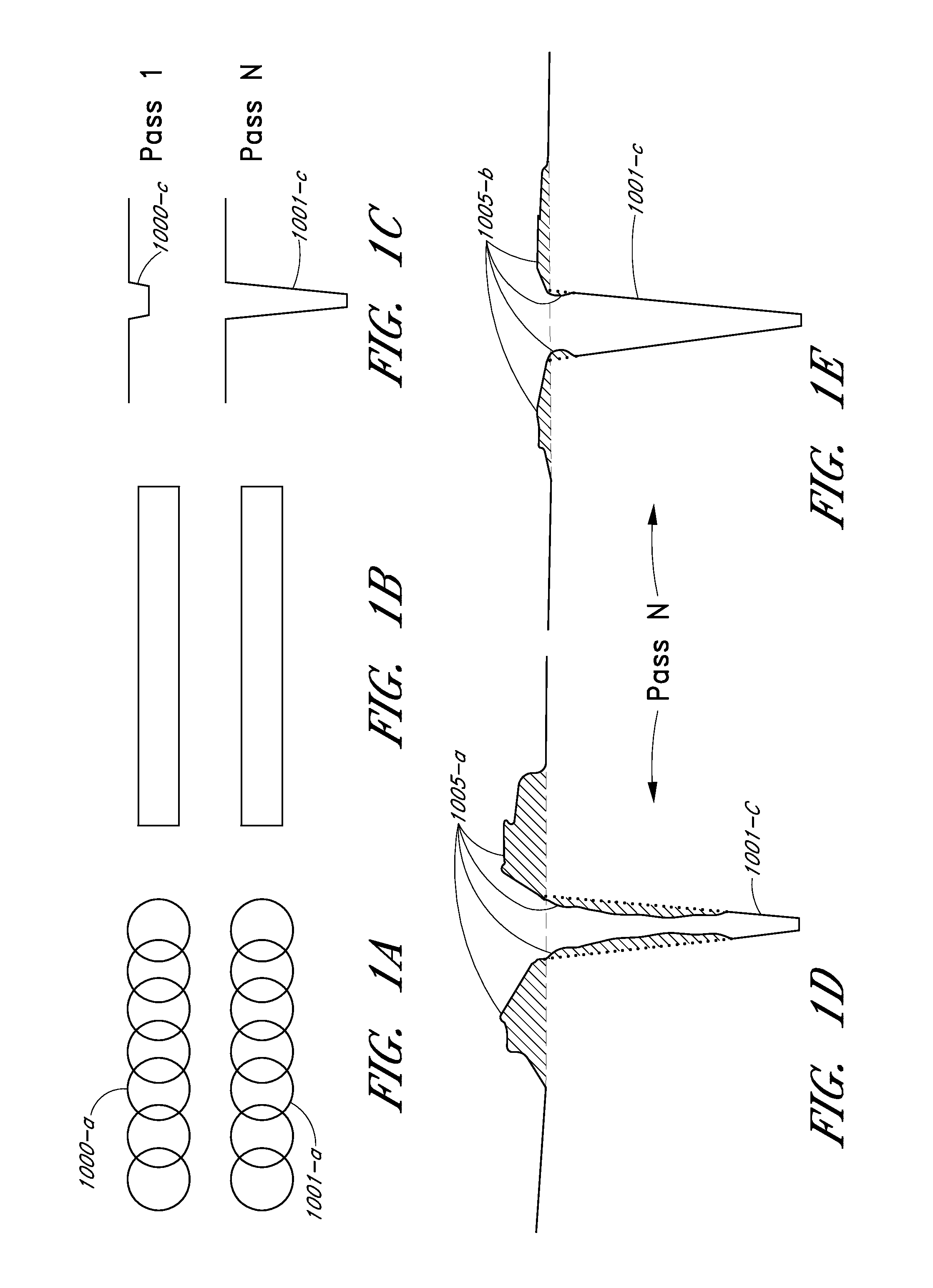

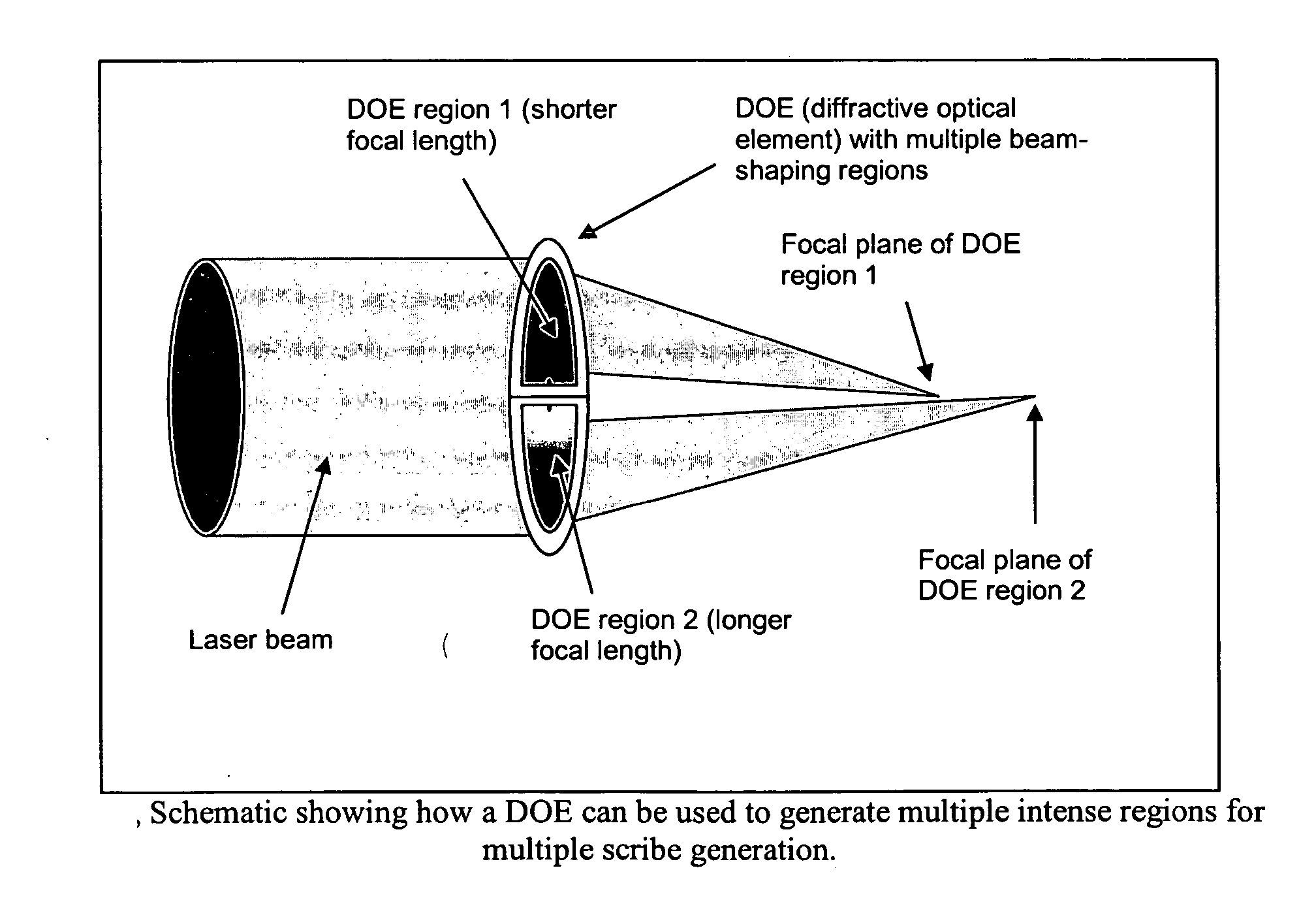

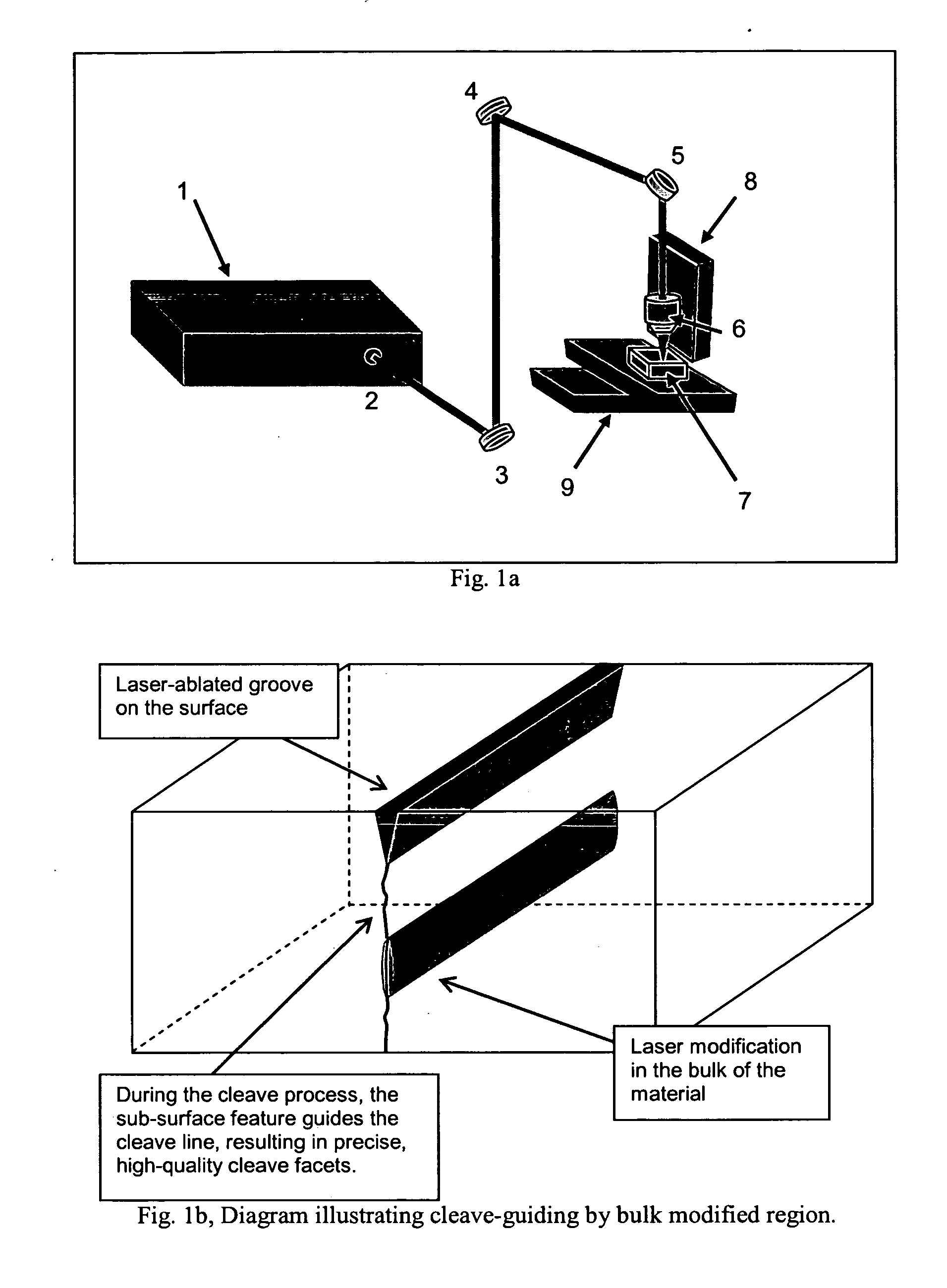

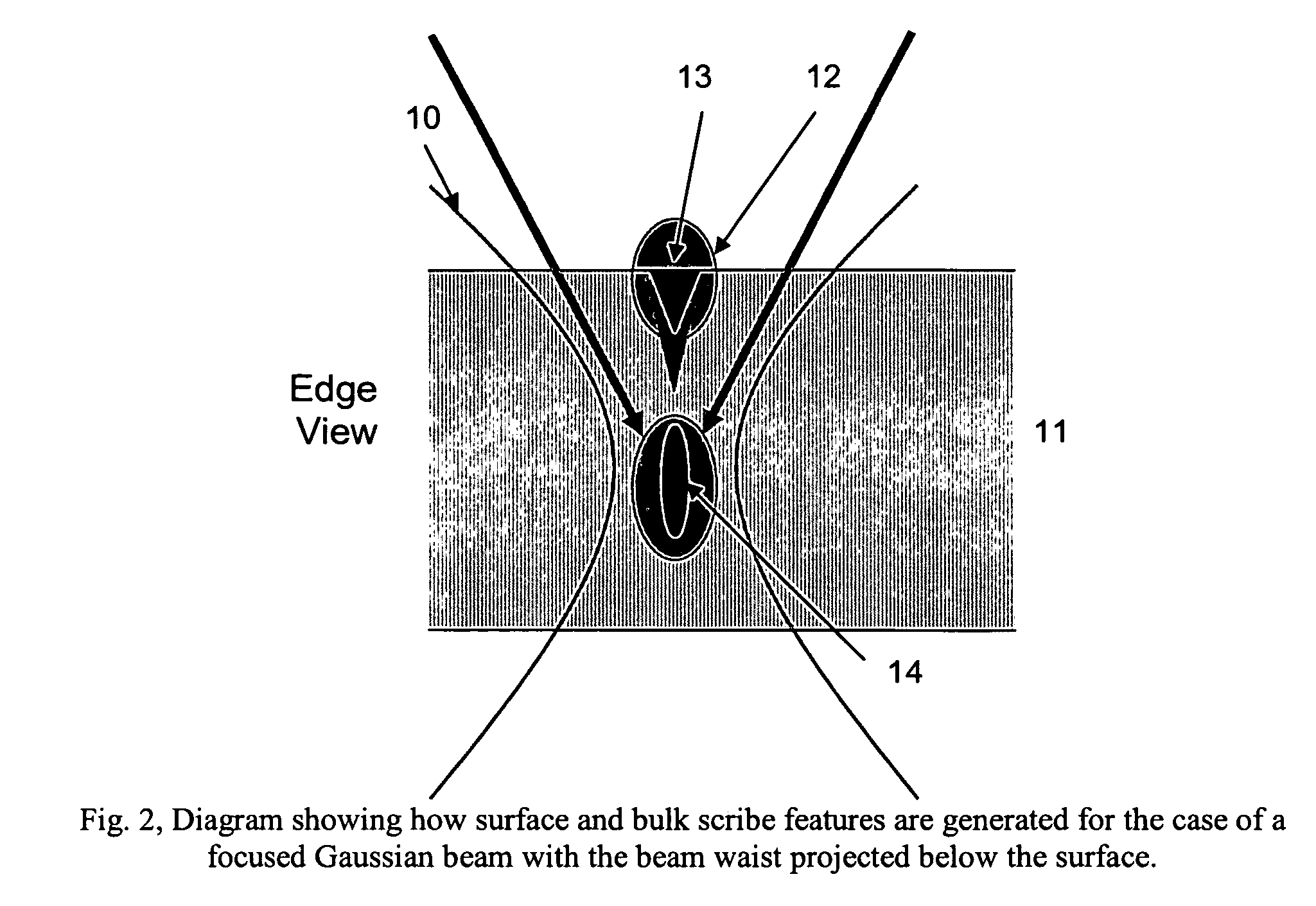

Methods for ultrashort pulse laser processing of optically transparent materials. A method for scribing transparent materials uses ultrashort laser pulses to create multiple scribe features with a single pass of the laser beam across the material, with at least one of the scribe features being formed below the surface of the material. This enables clean breaking of transparent materials at a higher speed than conventional techniques. Slightly modifying the ultrashort pulse laser processing conditions produces sub-surface marks. When properly arranged, these marks are clearly visible with side-illumination and not clearly visible without side-illumination. In addition, a method for welding transparent materials uses ultrashort laser pulses to create a bond through localized heating. The ultrashort pulse duration causes nonlinear absorption of the laser radiation, and the high repetition rate of the laser causes pulse-to-pulse accumulation of heat within the materials. The laser is focused near the interface of the materials, generating a high energy fluence at the region to be welded. This minimizes damage to the rest of the material and enables fine weld lines.

Owner:IMRA AMERICA

Laser-based material processing apparatus and methods

ActiveUS20110240617A1Efficient processingEliminate expensive processing stepGlass severing apparatusWelding/soldering/cutting articlesHeat-affected zoneErbium lasers

Various embodiments may be used for laser-based modification of target material of a workpiece while advantageously achieving improvements in processing throughput and / or quality. Embodiments of a method of processing may include focusing and directing laser pulses to a region of the workpiece at a pulse width sufficiently short so that material is efficiently removed by nonlinear optical absorption from the region and a quantity of heat affected zone and thermal stress on the material within the region, proximate to the region, or both is reduced relative to a quantity obtainable using a laser with longer pulses. In at least one embodiment, an ultrashort pulse laser system may include at least one of a fiber amplifier or fiber laser. Various embodiments are suitable for at least one of dicing, cutting, scribing, and forming features on or within a composite material.

Owner:IMRA AMERICA

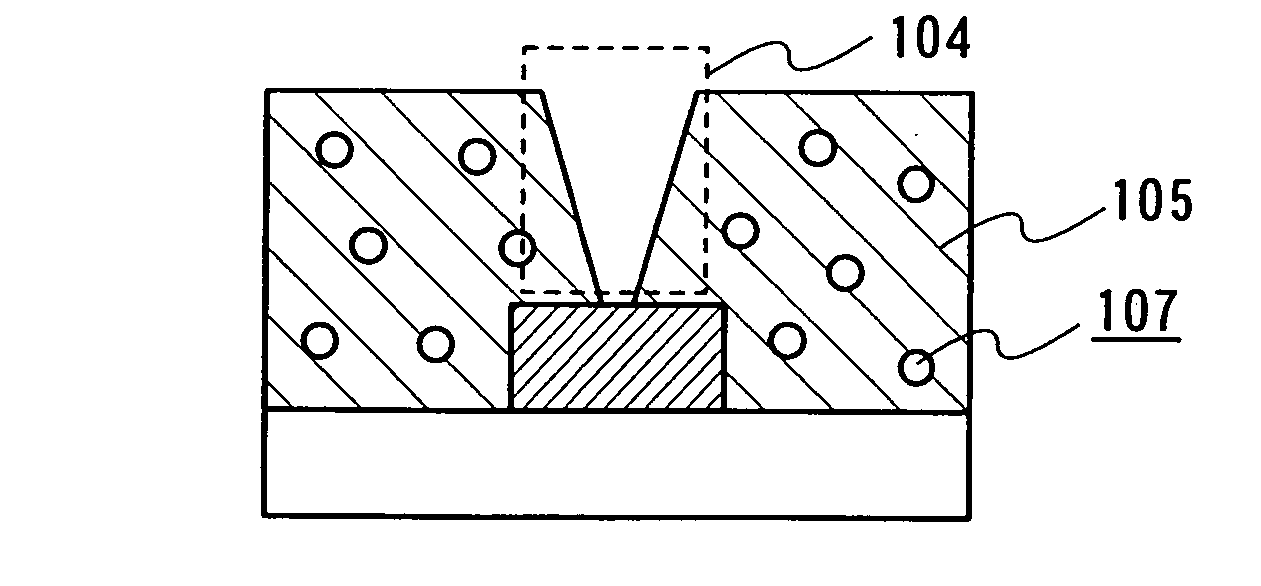

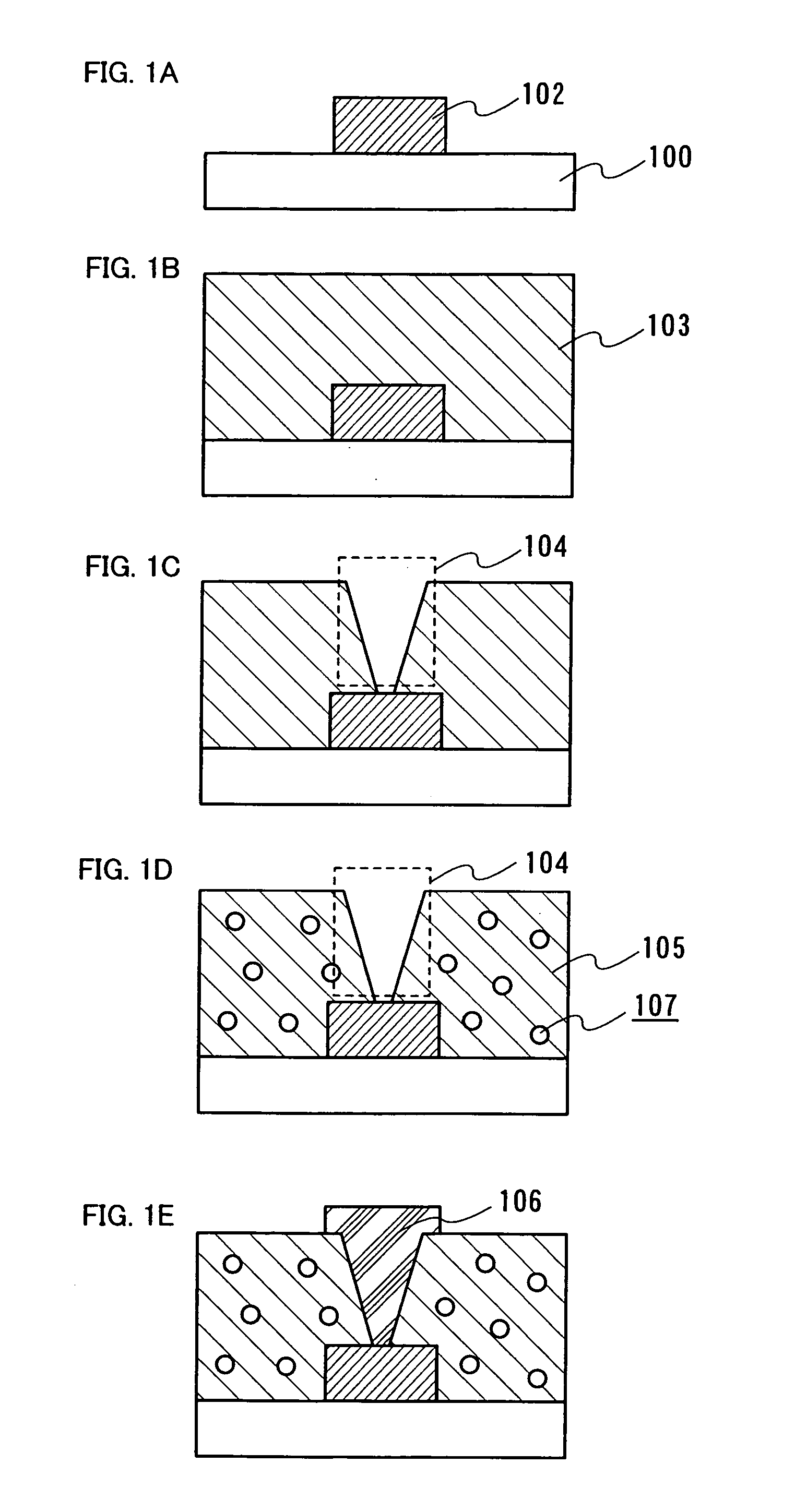

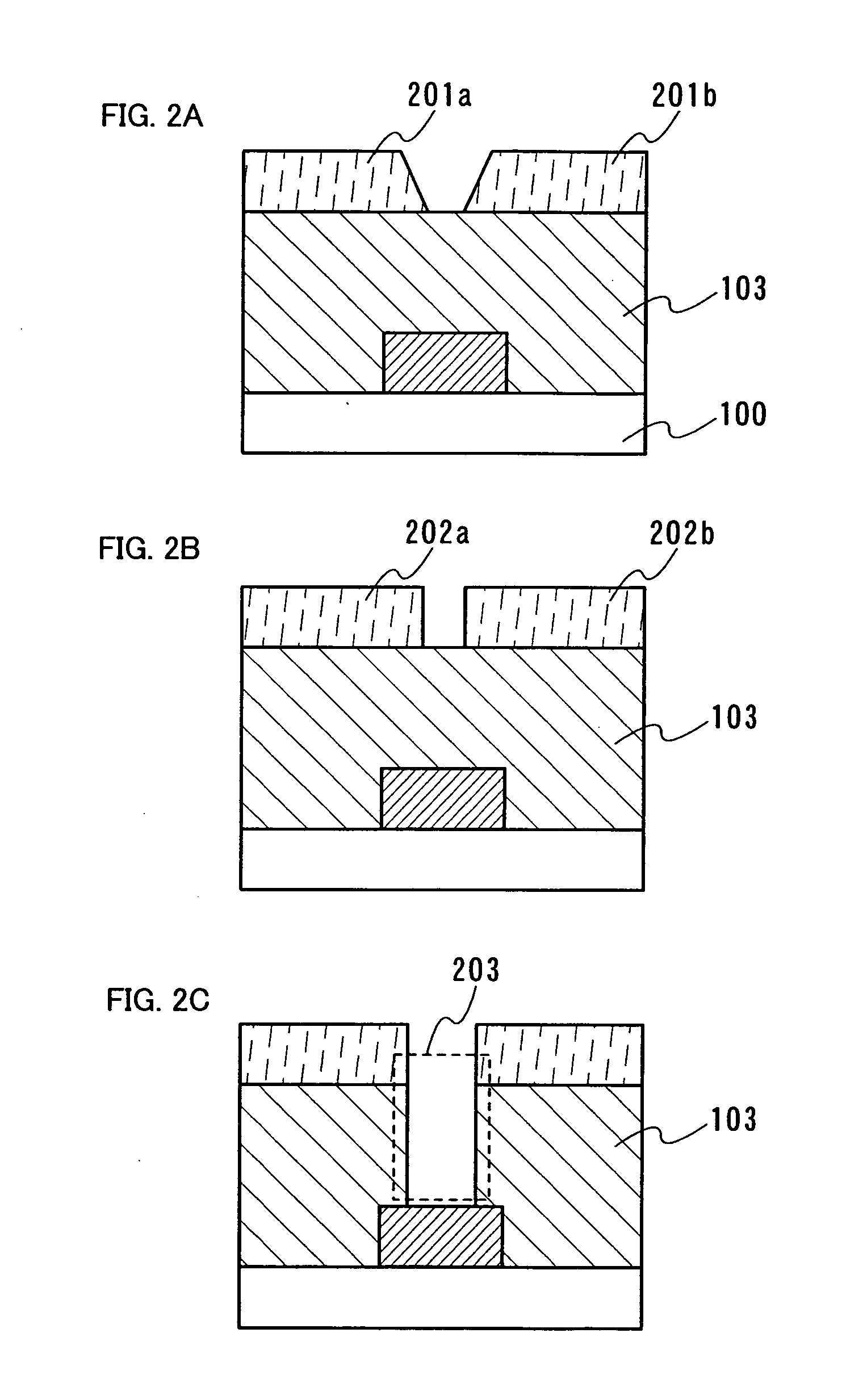

Manufacturing method of insulating film and semiconductor device

InactiveUS20060116000A1Adhesiveness reducedReduce layeringPorous dielectricsSemiconductor/solid-state device detailsUltrashort pulse laserLaser beams

The invention provides a manufacturing method of an insulating film having a plurality of pores, as well as a manufacturing method of a highly integrated semiconductor device with high yield. According to the invention, a porous insulating film is formed by forming a plurality of pores in an interlayer insulating film using a laser beam, which results in lower dielectric constant of the interlayer insulating film. In addition, a composition containing conductive particles is discharged onto the porous insulating film by a droplet discharge method typified by an ink jet printing method, and then baked to form a wire. As the laser beam, an ultrashort pulse laser beam is preferably used.

Owner:SEMICON ENERGY LAB CO LTD

Transparent material processing with an ultrashort pulse laser

InactiveUS9138913B2Reduce quality problemsPoor precisionAircraft componentsSemiconductor/solid-state device manufacturingLight beamLight reflection

Methods, devices, and systems for ultrashort pulse laser processing of optically transparent materials are presented, with example applications in scribing, marking, welding, and joining. For example, ultrashort laser pulses create multiple scribe features with one pass of the laser beam across the material, with at least one of the scribe features being formed below the surface of the material. Slightly modifying the ultrashort pulse laser processing conditions produces different types of sub-surface marks. When properly arranged, these marks are clearly visible with correctly aligned illumination through either light scattering or light reflection and nearly invisible without illumination. Transparent material other than glass may be utilized. A method for welding transparent materials uses ultrashort laser pulses to create a bond through localized heating. In some embodiments of transparent material processing, a multifocus beam generator simultaneously forms multiple beam waists spaced depthwise relative to the transparent material, thereby increasing processing speed.

Owner:IMRA AMERICA

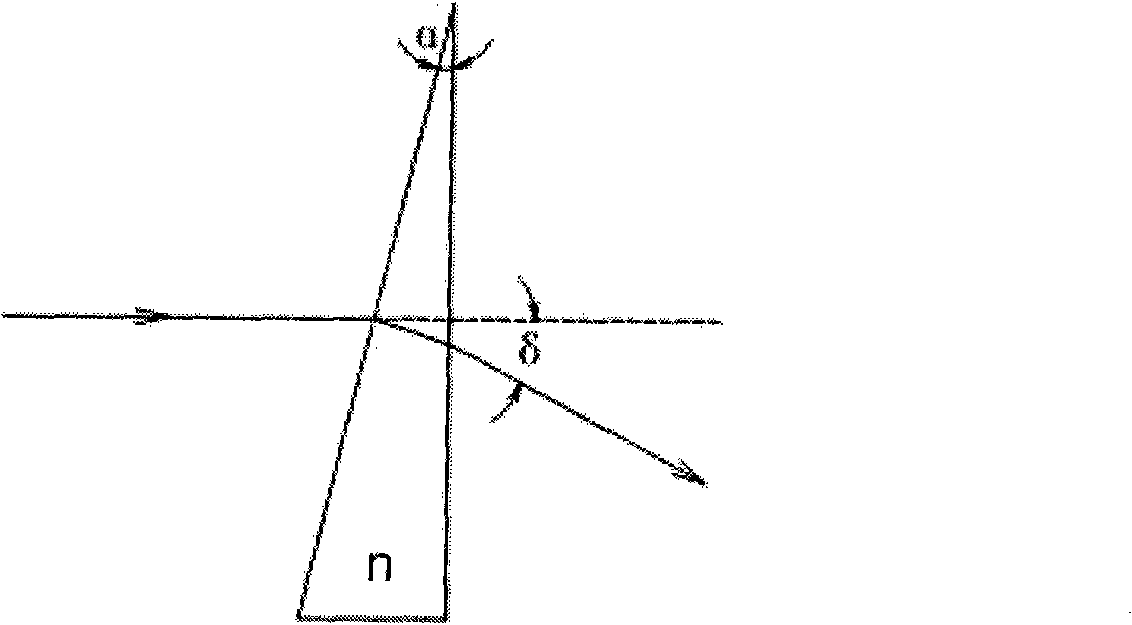

Laser processing method and laser processing apparatus

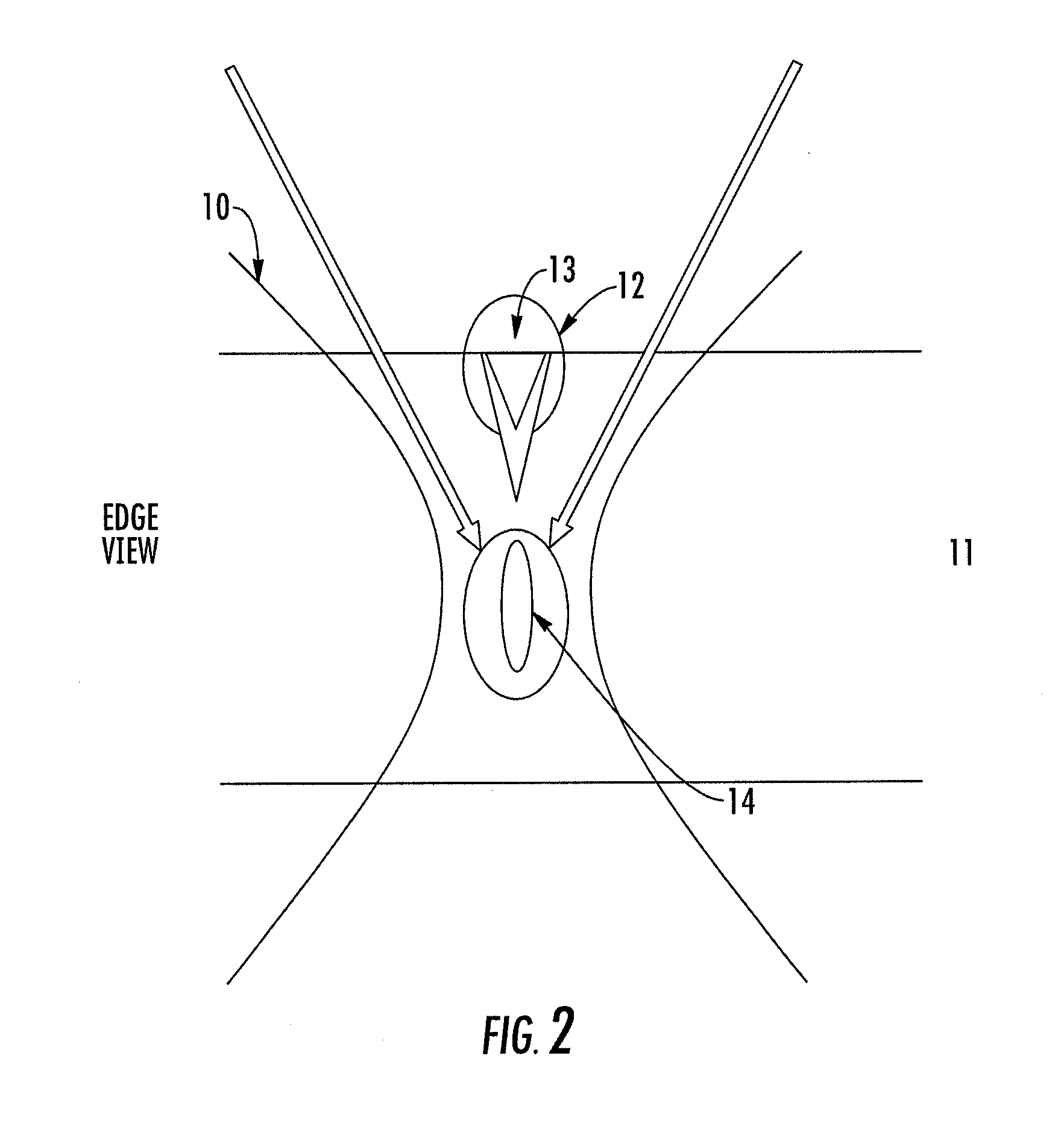

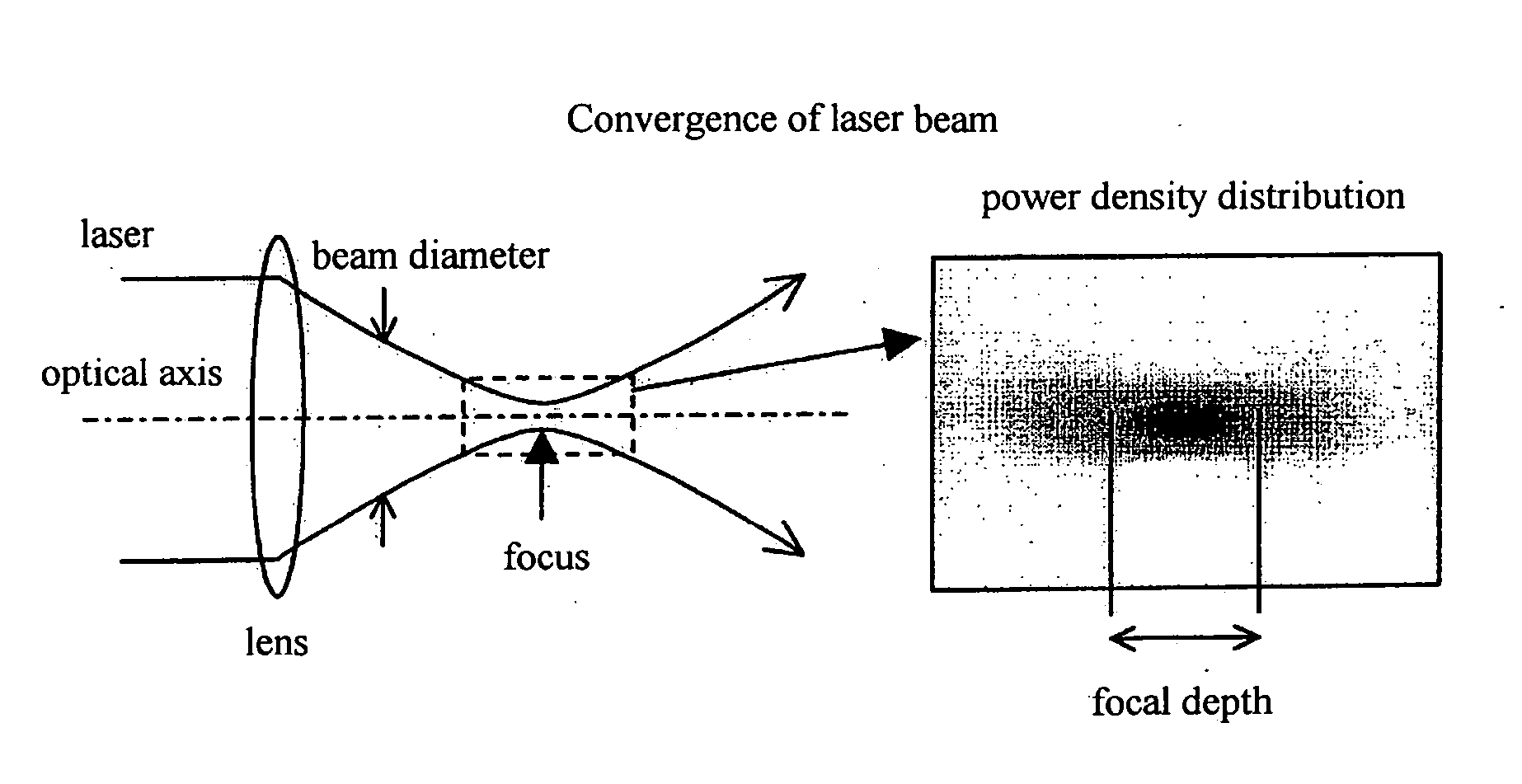

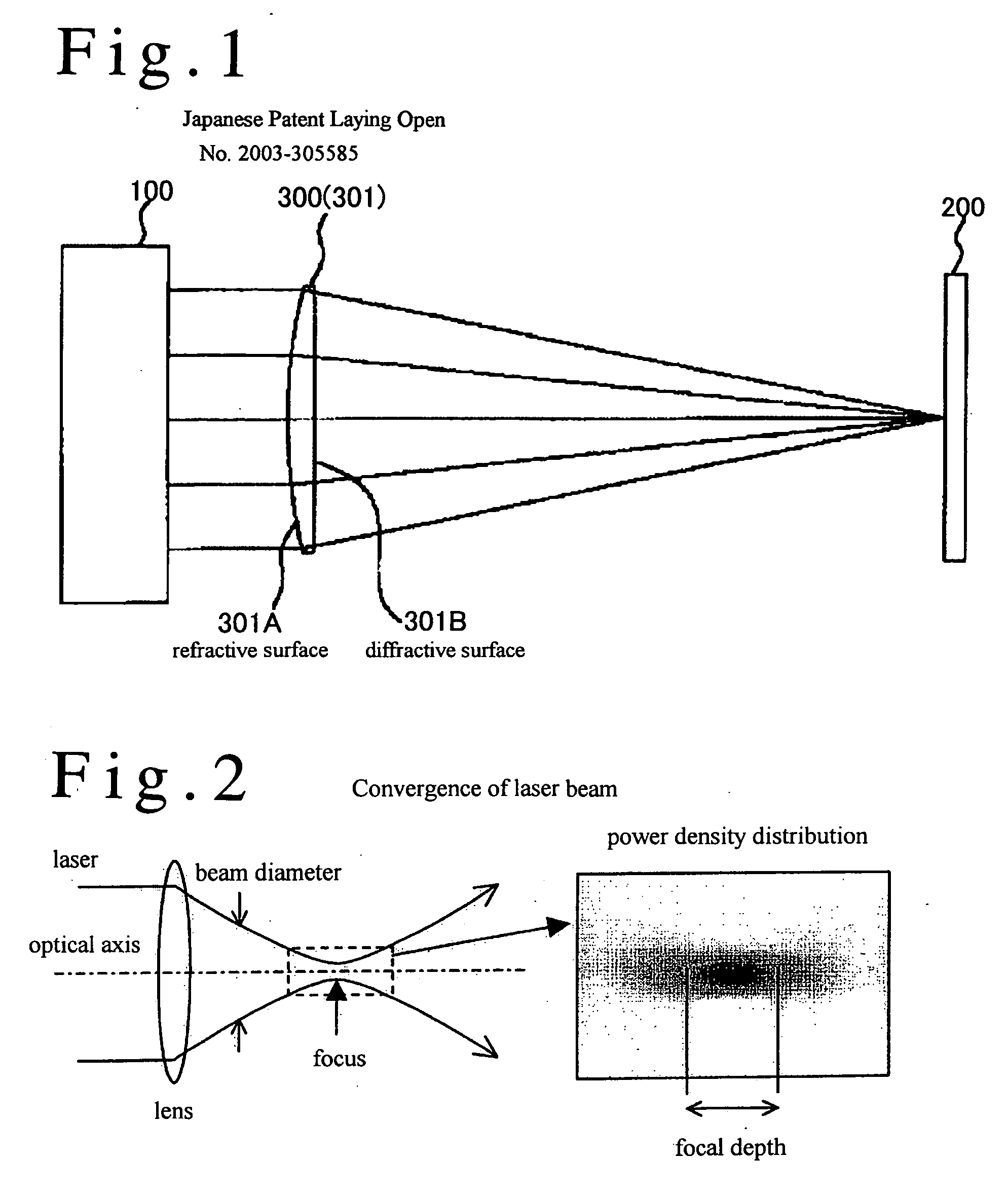

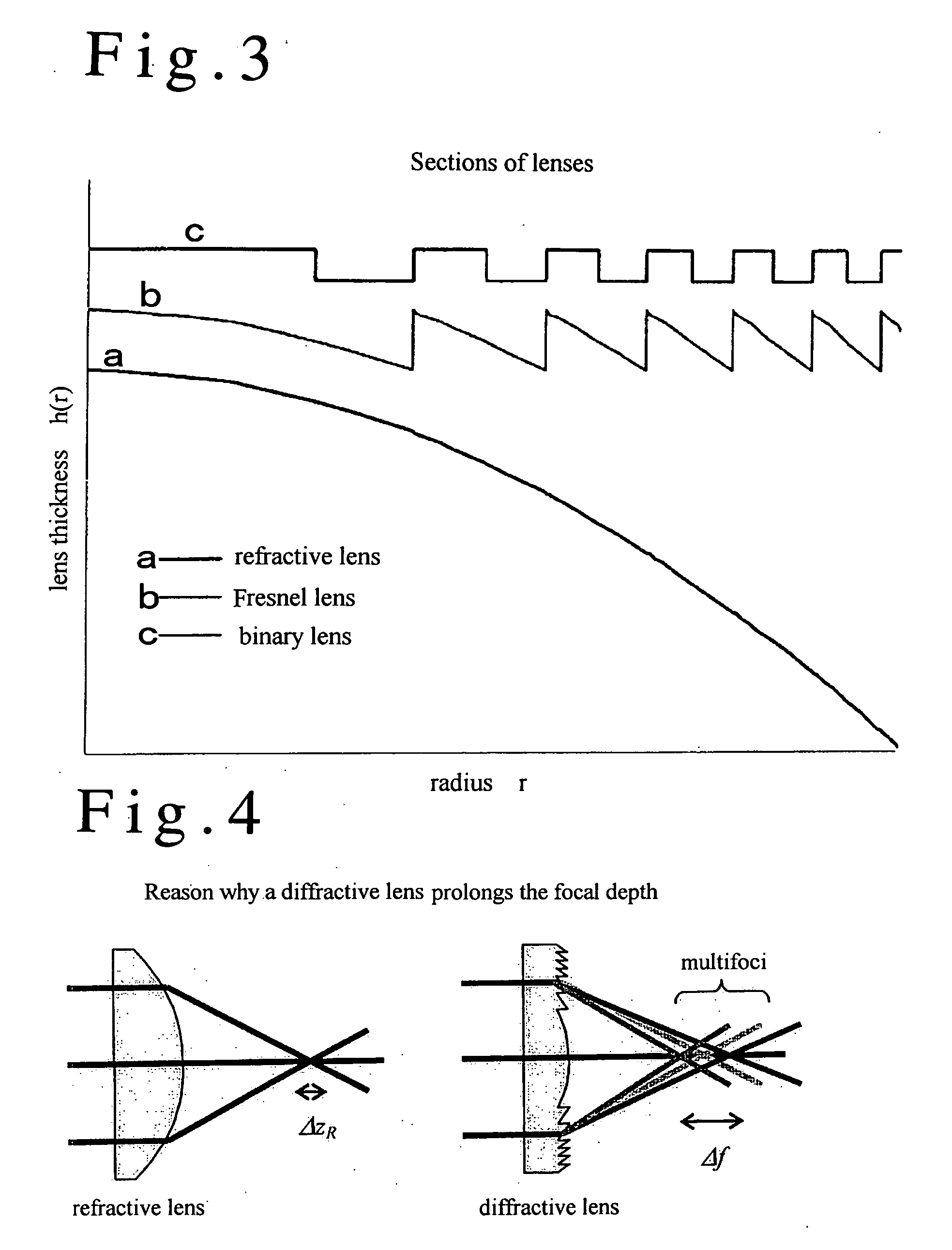

InactiveUS20060109874A1Lengthens focal depthFocal depth is very shallowLaser detailsDiffraction gratingsLaser processingBeam diameter

Ultrashort pulse laser processing bores, welds or cuts objects (work pieces) by converging ultrashort laser pulses by a lens on the objects (work pieces) positioned at the focus and heating small spots or narrow lines on the objects (work pieces). Shortage of a focal depth of the lens prevents the ultrashort pulse laser processing from positioning the object (a work piece) and forming a deep, constant-diameter cylindrical hole. Z-parameter is defined to be Z=2fcΔt / Δi2, where Δt is a FWHM pulse width of the ultrashort pulse laser, Δi is a FWHM beam diameter of the ultrashort pulse, f is a focal length of the lens and c is the light velocity in vacuum. Selection of an optical system including a diffraction-type lens which gives the Z-parameter less than 1 (Z<1) prolongs the focal depth. Expansion of the focal depth facilitates the positioning of objects (work pieces) and enables the ultrashort pulse laser apparatus to bore a deep, constant-diameter cylindrical hole.

Owner:SUMITOMO ELECTRIC IND LTD

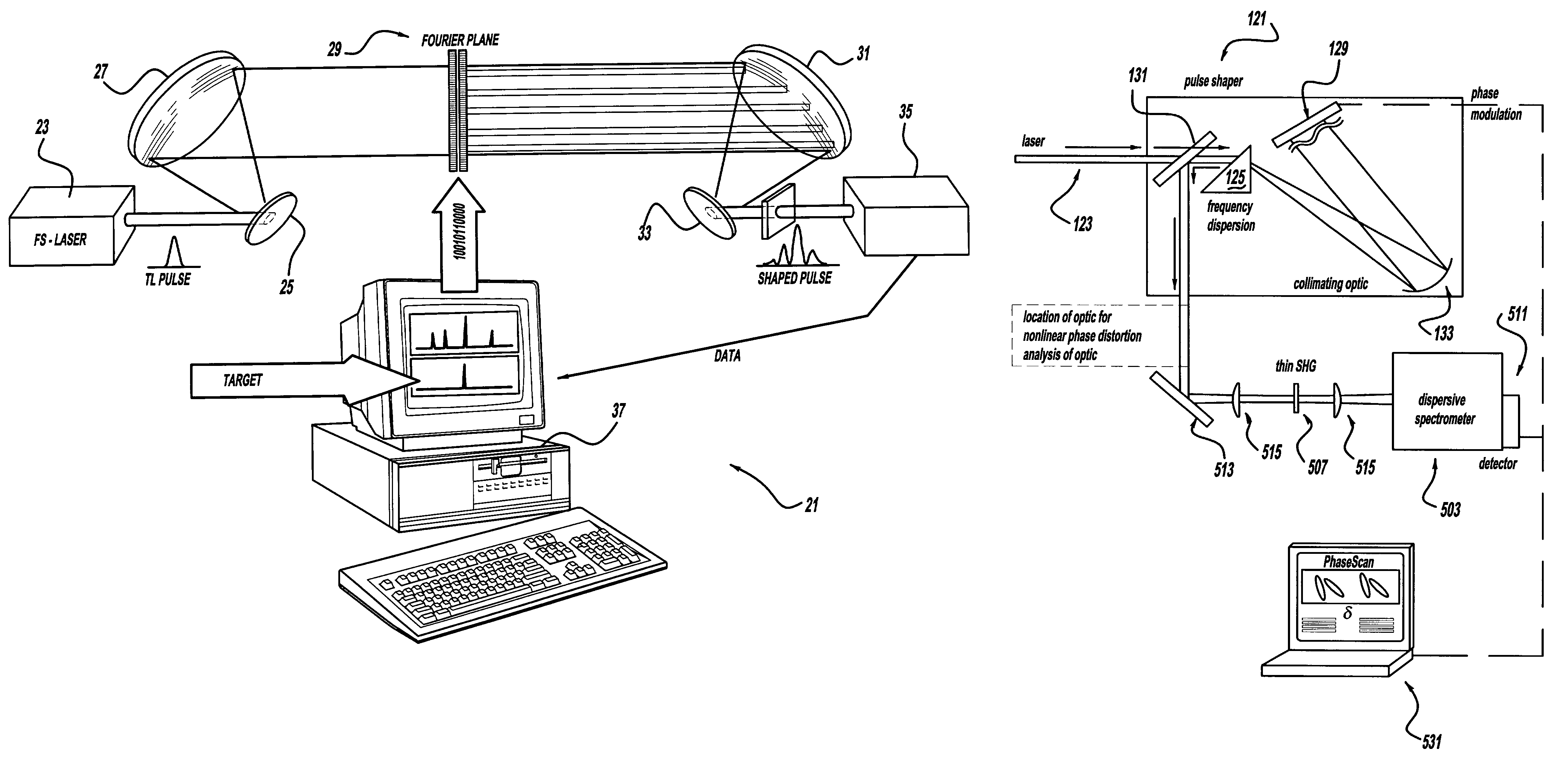

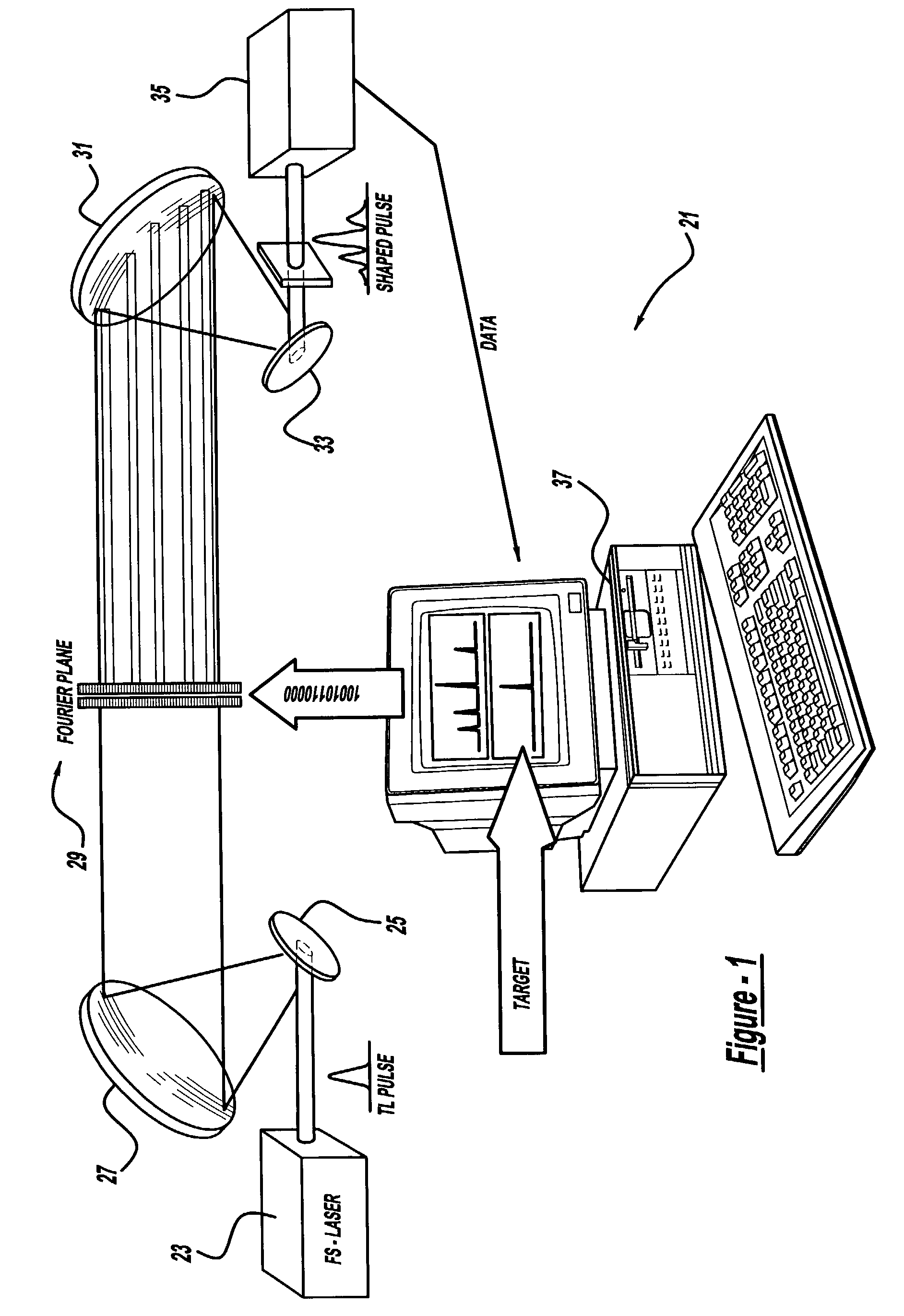

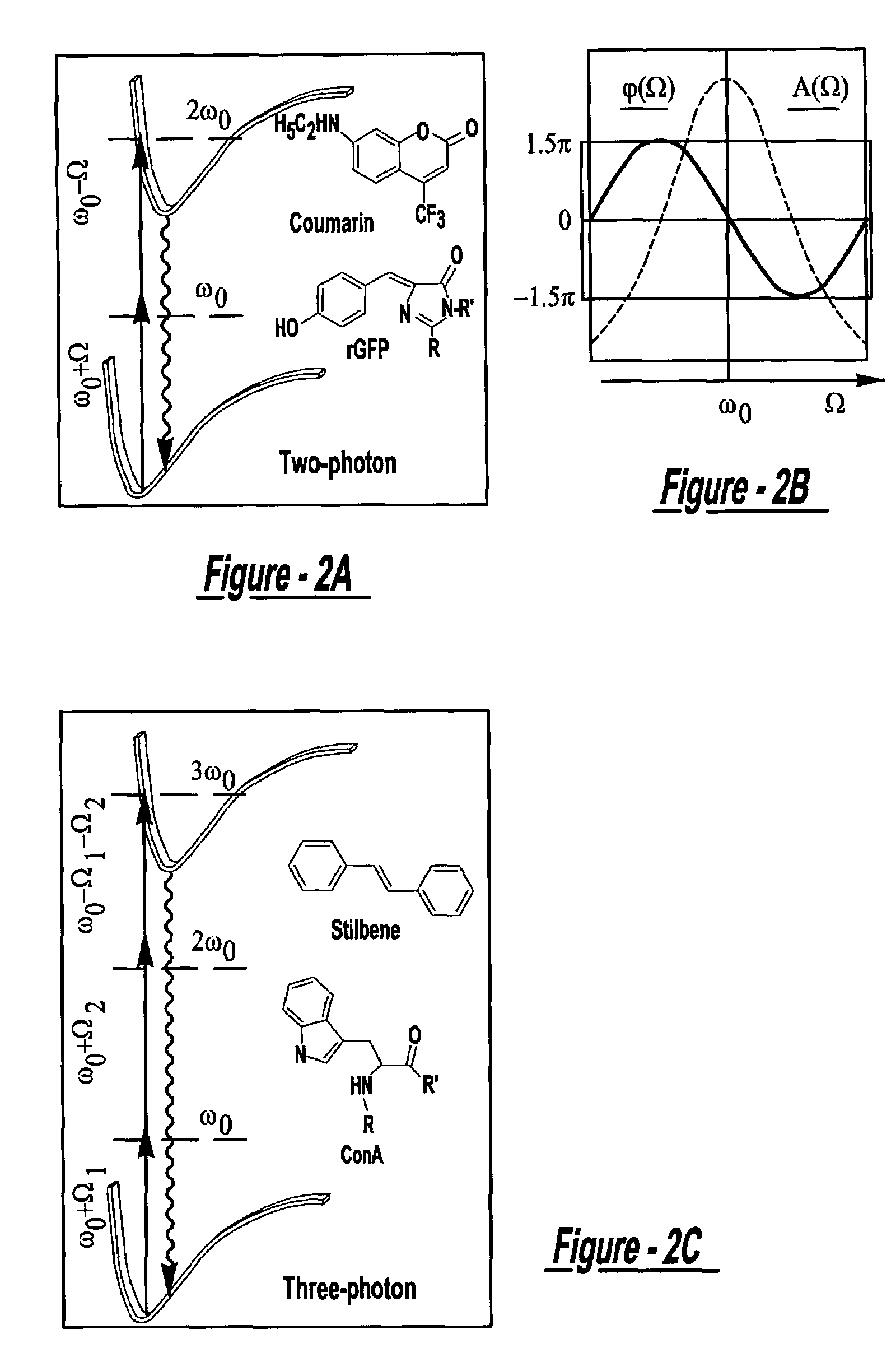

Laser system using ultrashort laser pulses

ActiveUS7450618B2Easy to set upEasy to useLaser detailsMaterial analysis by optical meansFemto second laserCharacterization test

A laser system using ultrashort laser pulses is provided. In another aspect of the present invention, the system includes a laser, pulse shaper and detection device. A further aspect of the present invention employs a femtosecond laser and a spectrometer. Still another aspect of the present invention uses a laser beam pulse, a pulse shaper and a SHG crystal. In yet another aspect of the present invention, a multiphoton intrapulse interference phase scan system and method characterize the spectral phase of femtosecond laser pulses. Fiber optic communication systems, photodynamic therapy and pulse characterization tests use the laser system with additional aspects of the present invention.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

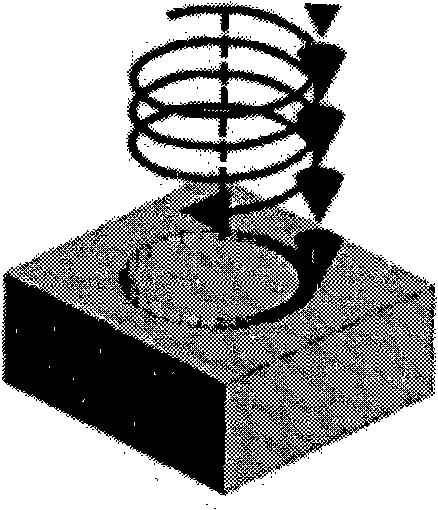

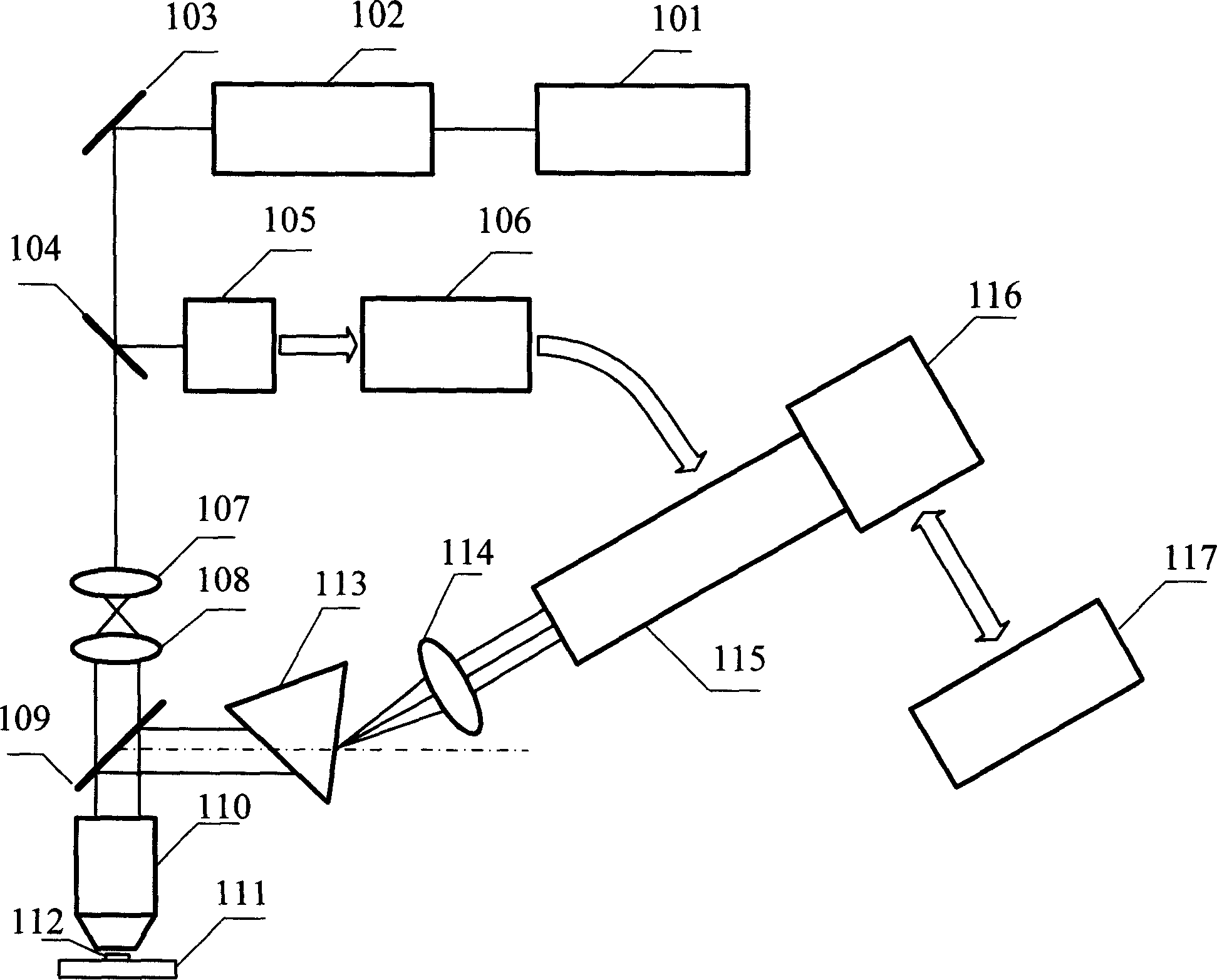

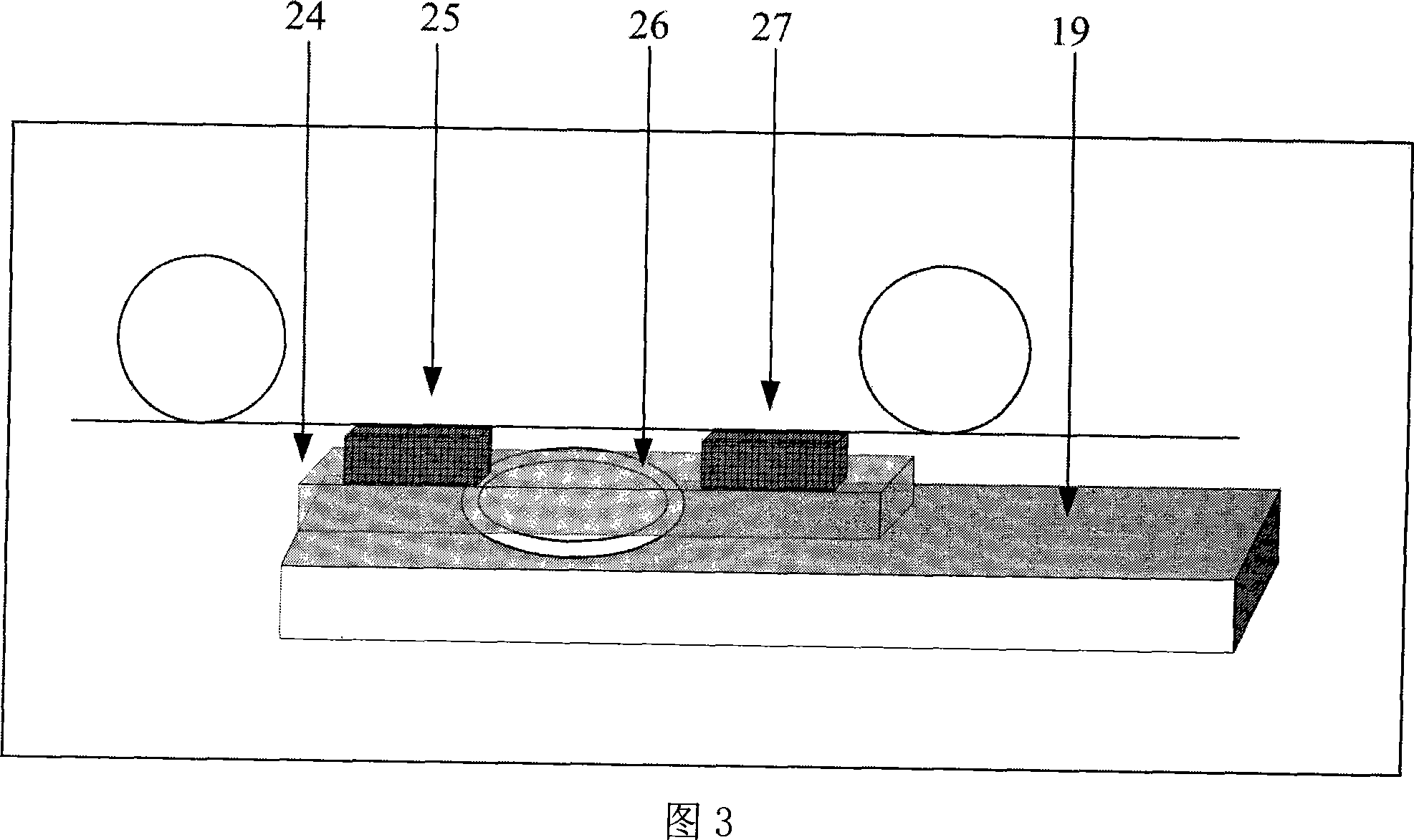

Laser micropore processor of rotating double-optical wedge

InactiveCN101670486ASmall heat affected zoneHigh precisionLaser beam welding apparatusBeam expanderHeat-affected zone

The invention discloses a laser micropore processor of a rotating double-optical wedge, comprising an ultrashort pulse laser output system consisting of a laser, a beam expander and a laser transmission system, a beam deflection system of the double-optical wedge consisting of two optical wedges, a bearing rotary mechanism of the double-optical wedge and a control system, a laser focusing system consisting of a laser focus lamp and a focuser and an adsorption location displacement system of workpieces and a computer system consisting of an installation mechanism of the workpieces and a two-dimensional displacement platform. The invention selects the DPSS laser with high-quality beam and uses the laser focusing system reaching or approaching the diffraction limit to obtain the fine focusesbeams, and then uses double-optical wedge to process the micropore in the situation of high speed revolution, therefore the invention reduces the heat affected zone of the edge of an aperture and improves caliber precision and work efficiency.

Owner:SHANGHAI INST OF LASER TECH

Transparent material processing with an ultrashort pulse laser

InactiveUS7626138B2Reduce quality problemsPoor precisionFixed microstructural devicesThin material handlingHigh energyNonlinear absorption

Methods for ultrashort pulse laser processing of optically transparent materials. A method for scribing transparent materials uses ultrashort laser pulses to create multiple scribe features with a single pass of the laser beam across the material, with at least one of the scribe features being formed below the surface of the material. This enables clean breaking of transparent materials at a higher speed than conventional techniques. Slightly modifying the ultrashort pulse laser processing conditions produces sub-surface marks. When properly arranged, these marks are clearly visible with side-illumination and not clearly visible without side-illumination. In addition, a method for welding transparent materials uses ultrashort laser pulses to create a bond through localized heating. The ultrashort pulse duration causes nonlinear absorption of the laser radiation, and the high repetition rate of the laser causes pulse-to-pulse accumulation of heat within the materials. The laser is focused near the interface of the materials, generating a high energy fluence at the region to be welded. This minimizes damage to the rest of the material and enables fine weld lines.

Owner:IMRA AMERICA

Laser-based material processing methods and systems

ActiveUS8158493B2Avoid insufficient heatingAvoid layeringSemiconductor/solid-state device manufacturingWelding/soldering/cutting articlesDielectricPicosecond

Various embodiments may be used for laser-based modification of target material of a workpiece while advantageously achieving improvements in processing throughput and / or quality. Embodiments of a method of processing may include focusing and directing laser pulses to a region of the workpiece at a pulse repetition rate sufficiently high so that material is efficiently removed from the region and a quantity of unwanted material within the region, proximate to the region, or both is reduced relative to a quantity obtainable at a lower repetition rate. Embodiments of an ultrashort pulse laser system may include at least one of a fiber amplifier or fiber laser. Various embodiments are suitable for at least one of dicing, cutting, scribing, and forming features on or within a semiconductor substrate. Workpiece materials may also include metals, inorganic or organic dielectrics, or any material to be micromachined with femtosecond, picosecond, and / or nanosecond pulses.

Owner:IMRA AMERICA

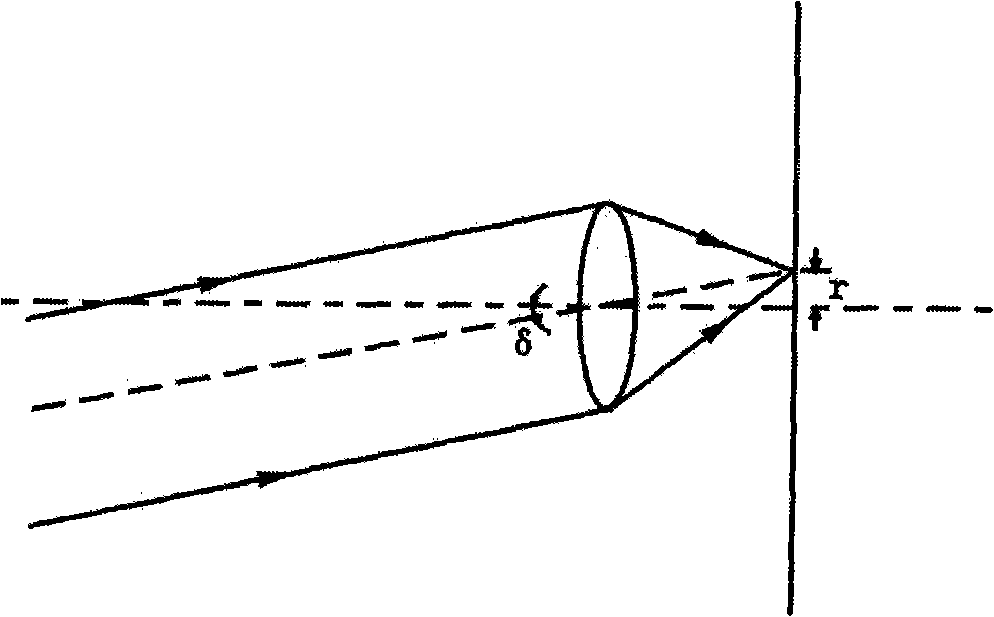

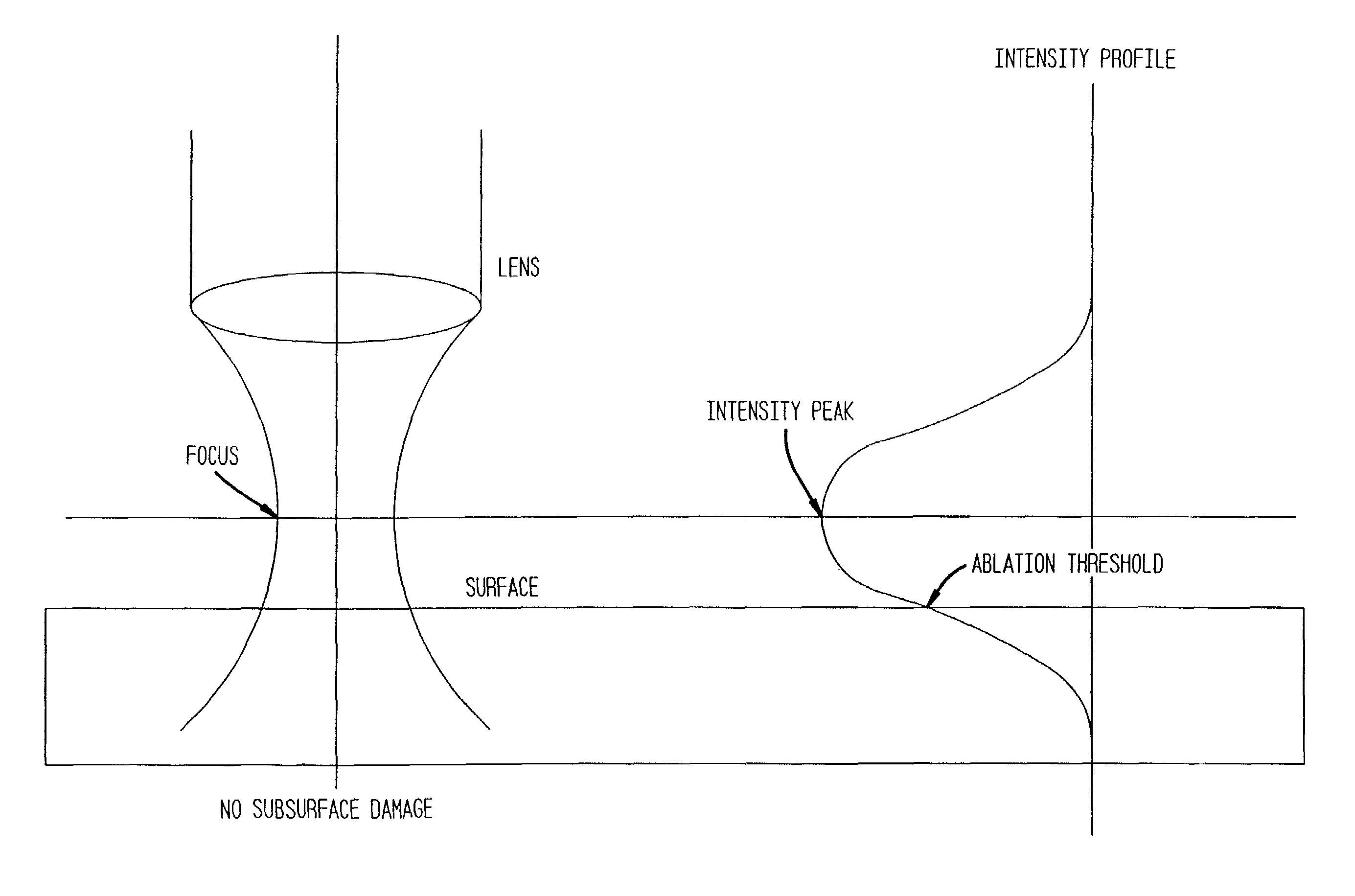

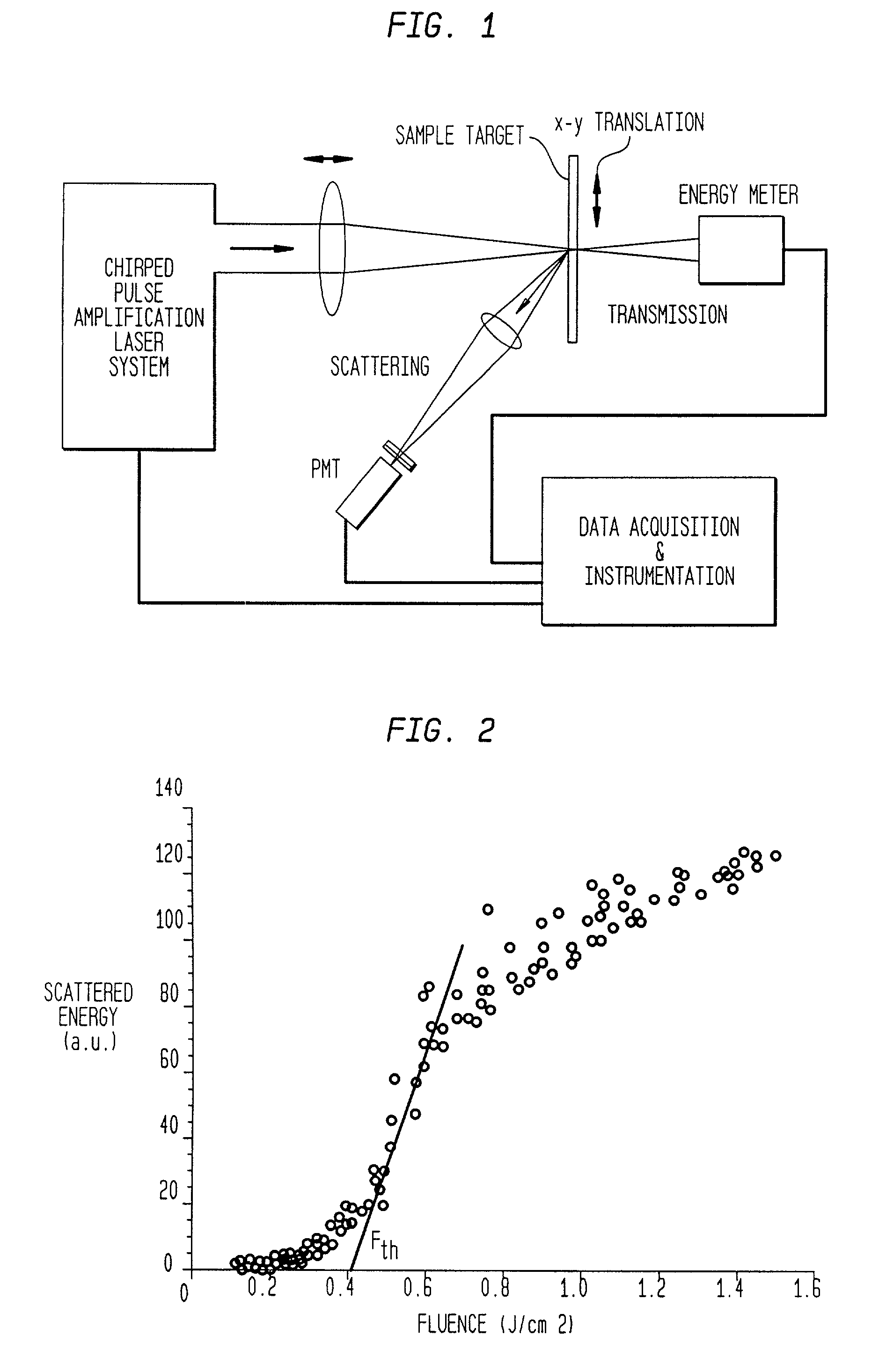

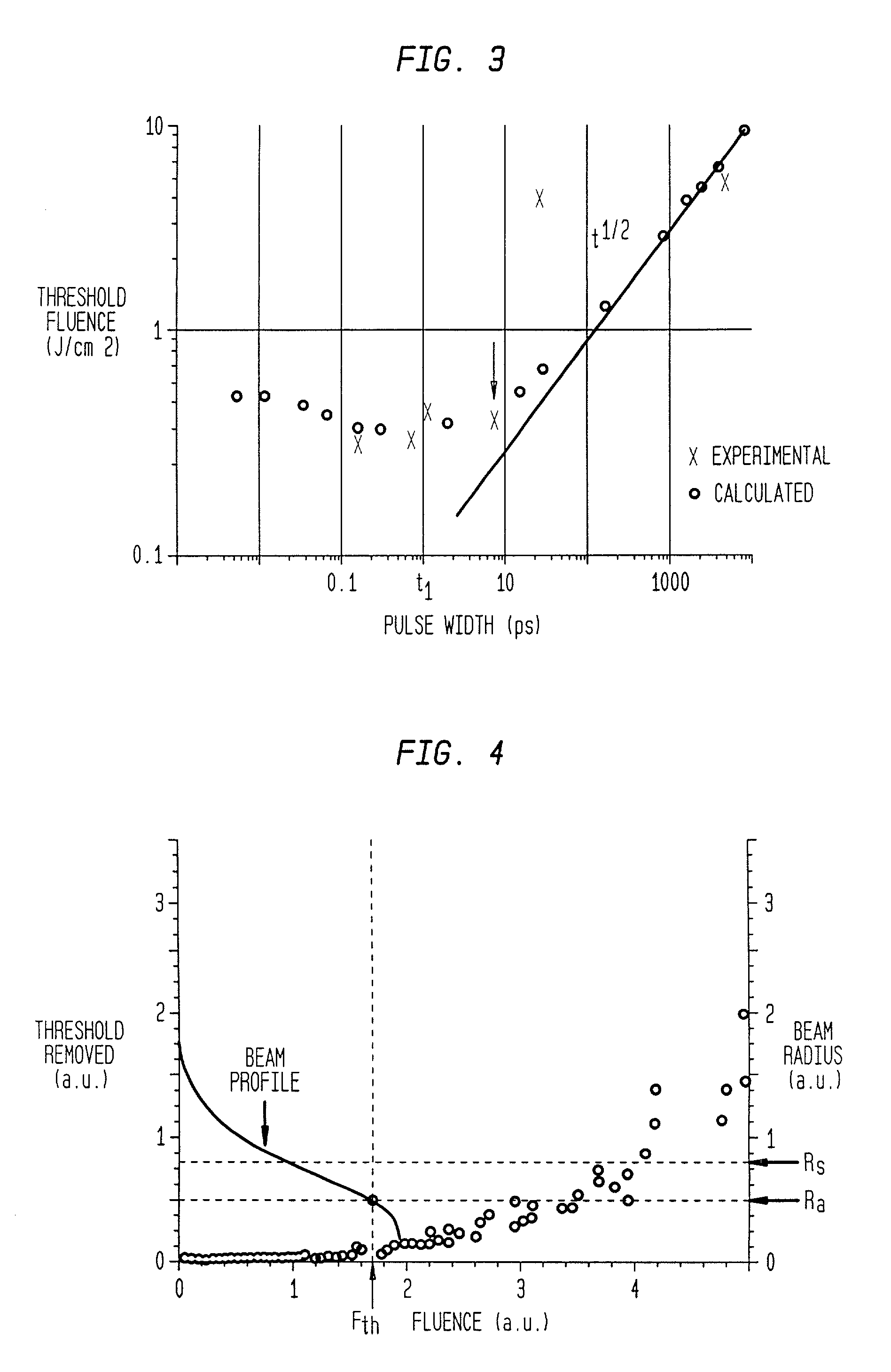

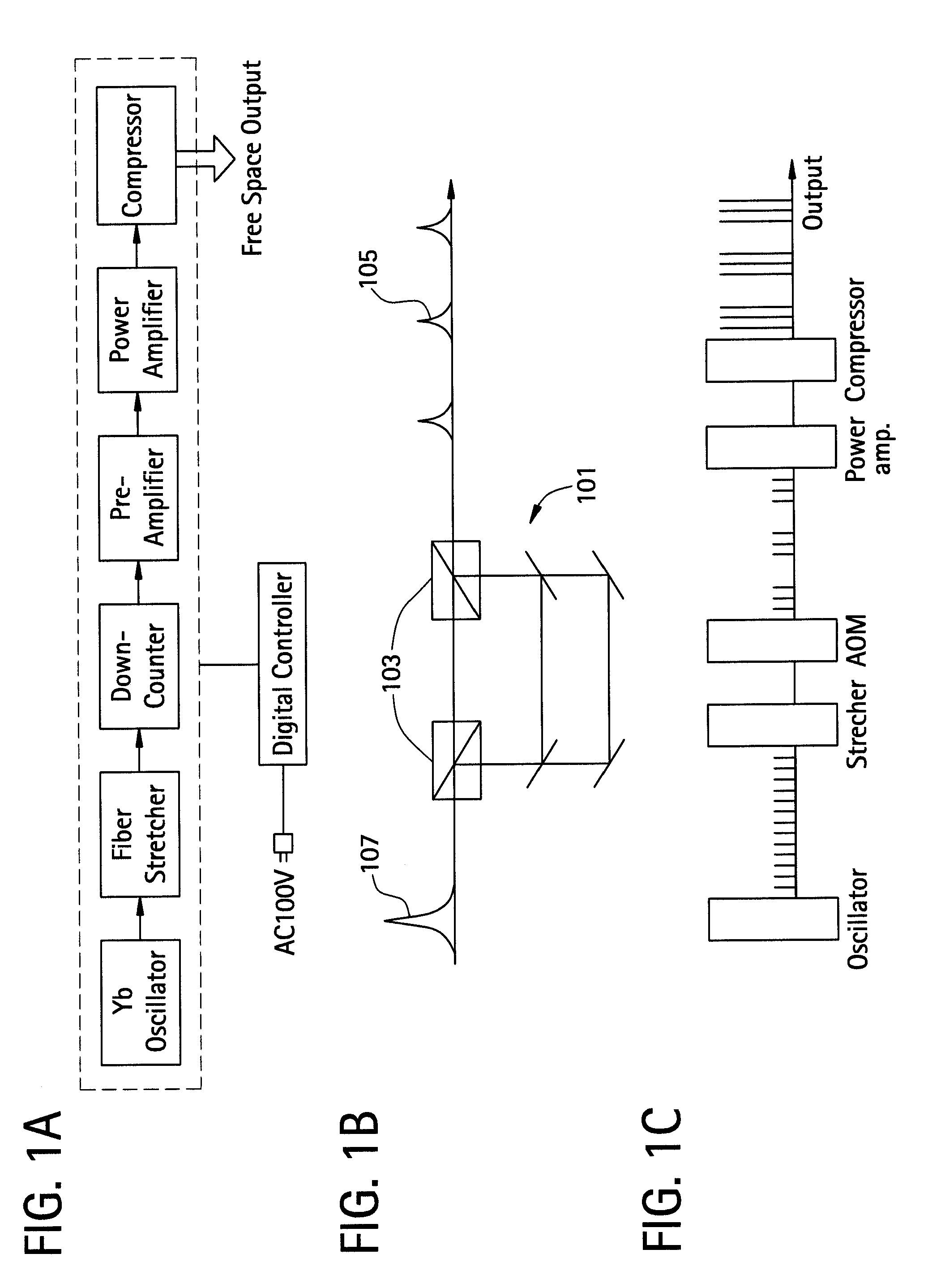

Method for minimizing sample damage during the ablation of material using a focused ultrashort pulsed laser beam

In one aspect the invention provides a method for laser induced breakdown of a material with a pulsed laser beam where the material is characterized by a relationship of fluence breakdown threshold (Fth) versus laser beam pulse width (T) that exhibits an abrupt, rapid, and distinct change or at least a clearly detectable and distinct change in slope at a predetermined laser pulse width value. The method comprises generating a beam of laser pulses in which each pulse has a pulse width equal to or less than the predetermined laser pulse width value. The beam is focused above the surface of a material where laser induced breakdown is desired. The region of least confusion (minimum beam waist or average spot size) is above the surface of the material in which laser induced breakdown is desired since the intensity of the beam falls off in the forward direction, preferably the region of the beam at or within the surface is between the region of least confusion and sufficient to remove material and the minimum intensity necessary for laser induced breakdown of the material to be removed, most preferably the region of minimum intensity is disposed at the surface of the material to be removed. The beam may be used in combination with a mask in the beam path. The beam or mask may be moved in the x, y, and Z directions to produce desired features. The technique can produce features smaller than the spot size and Rayleigh range due to enhanced damage threshold accuracy in the short pulse regime.

Owner:GLOBALFOUNDRIES U S INC

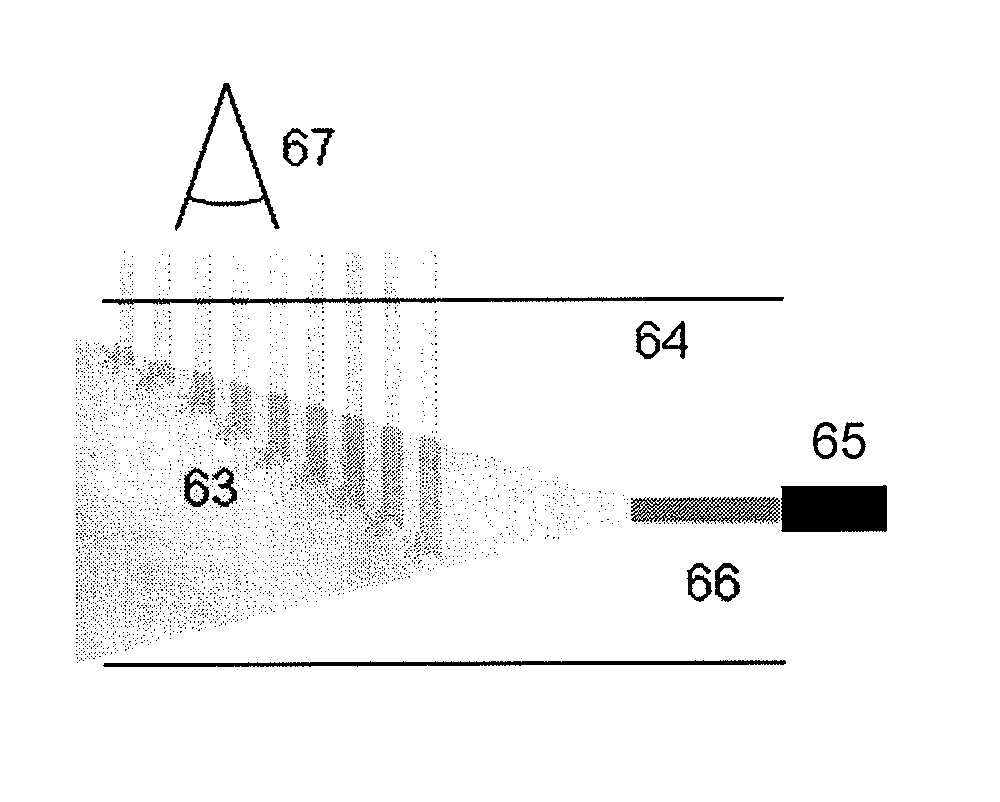

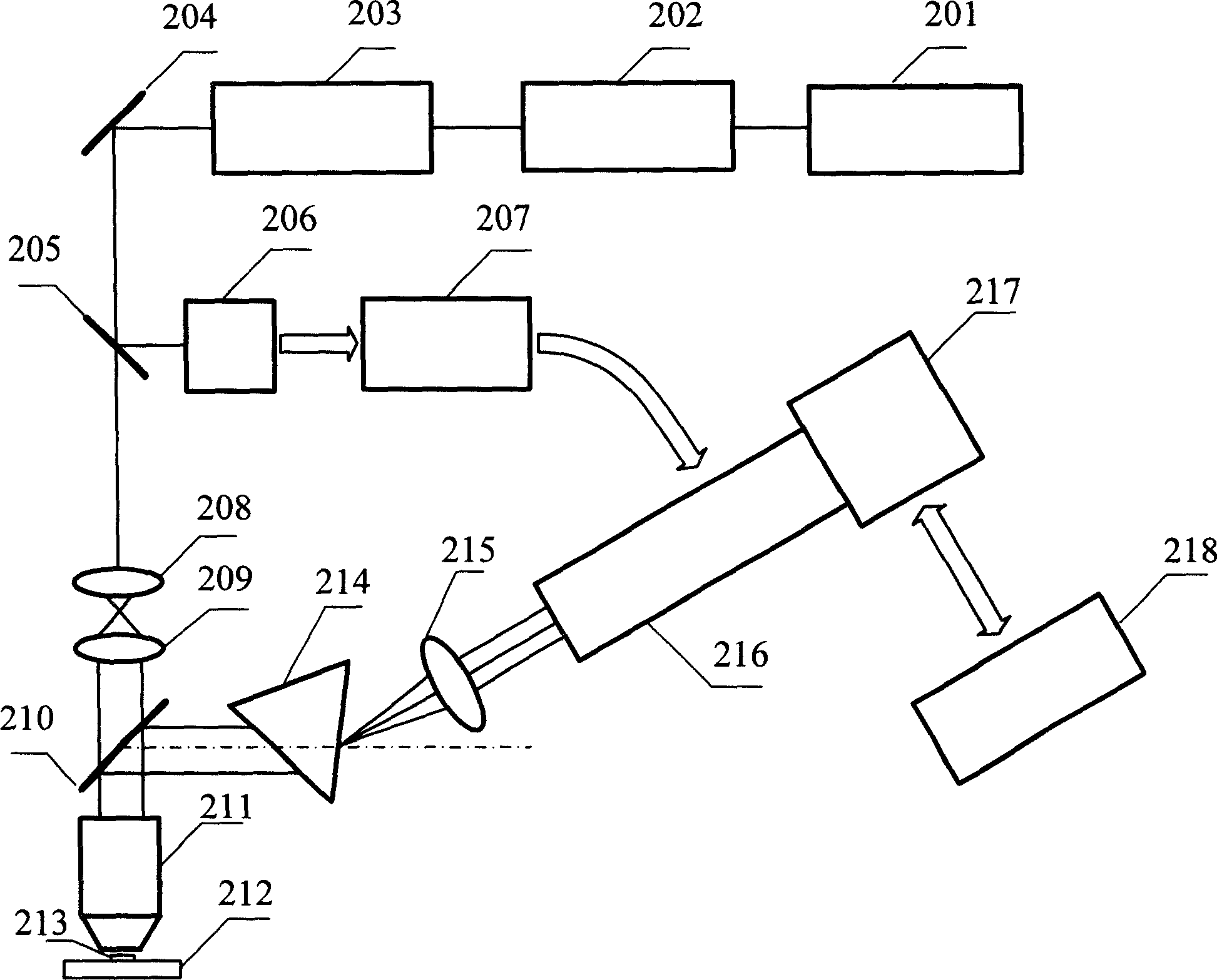

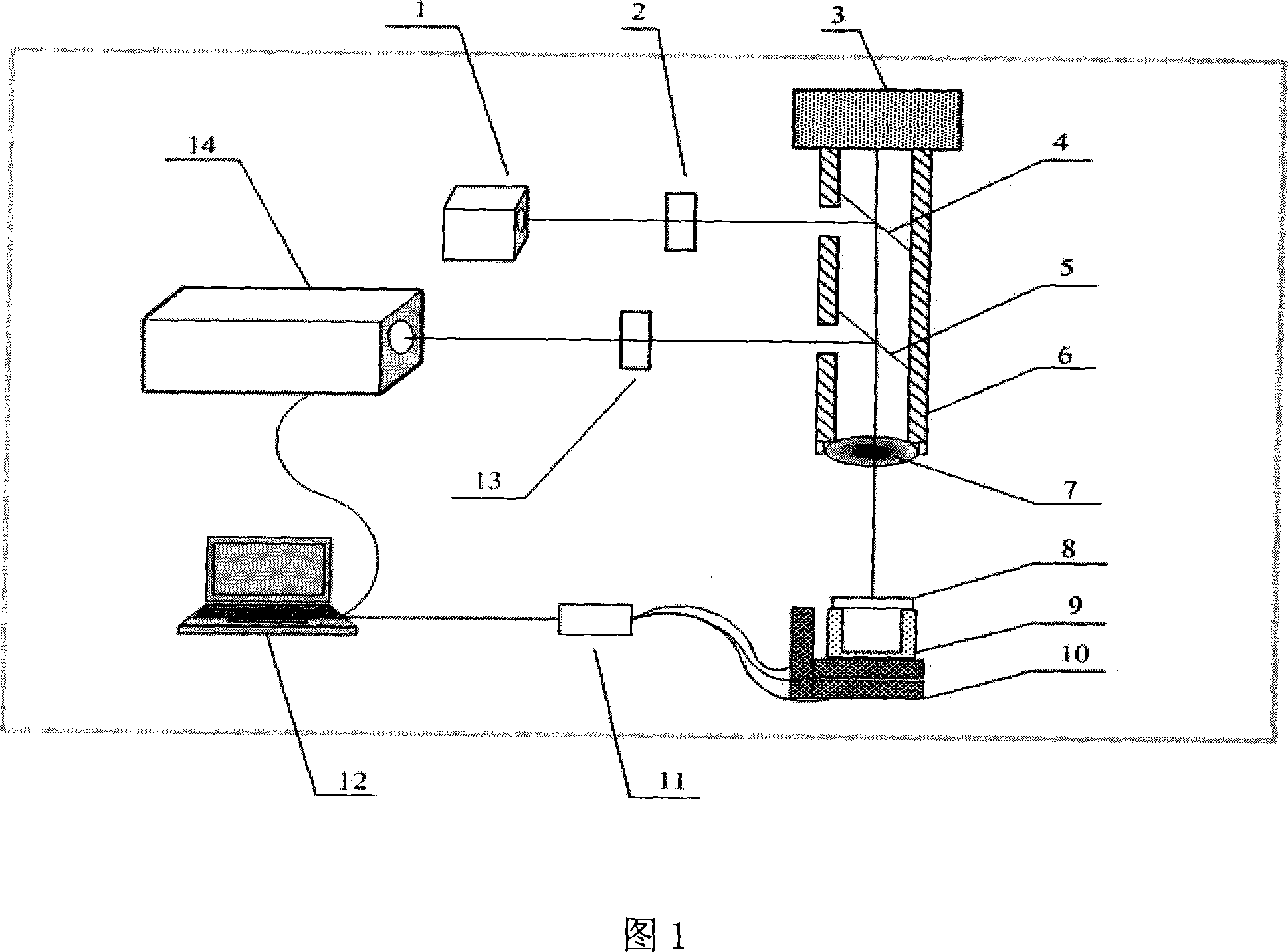

Time resolution fluorescence spectral measuring and image forming method and its device

InactiveCN1912587ADifferent temporal resolutionsAchieving high-sensitivity detectionFluorescence/phosphorescencePhotocathodePicosecond

A method of using picosecond scan camera to simultaneously obtain fluorescent light spectrum and fluorescent lifetime of sample includes focusing blue violet light emitted by laser on sample by objective to excite sample single photon, collecting fluorescent from sample then splitting it and focusing it to be image on photoelectric cathode of picosecond scan camera, setting dispersion direction of fluorescent to be the same as slit direction of said camera but to be vertical to scan direction in order to measure out fluorescent lifetime of different light spectrum simultaneously under coaction of scan circuit and image intensifier deflection system.

Owner:SHENZHEN UNIV

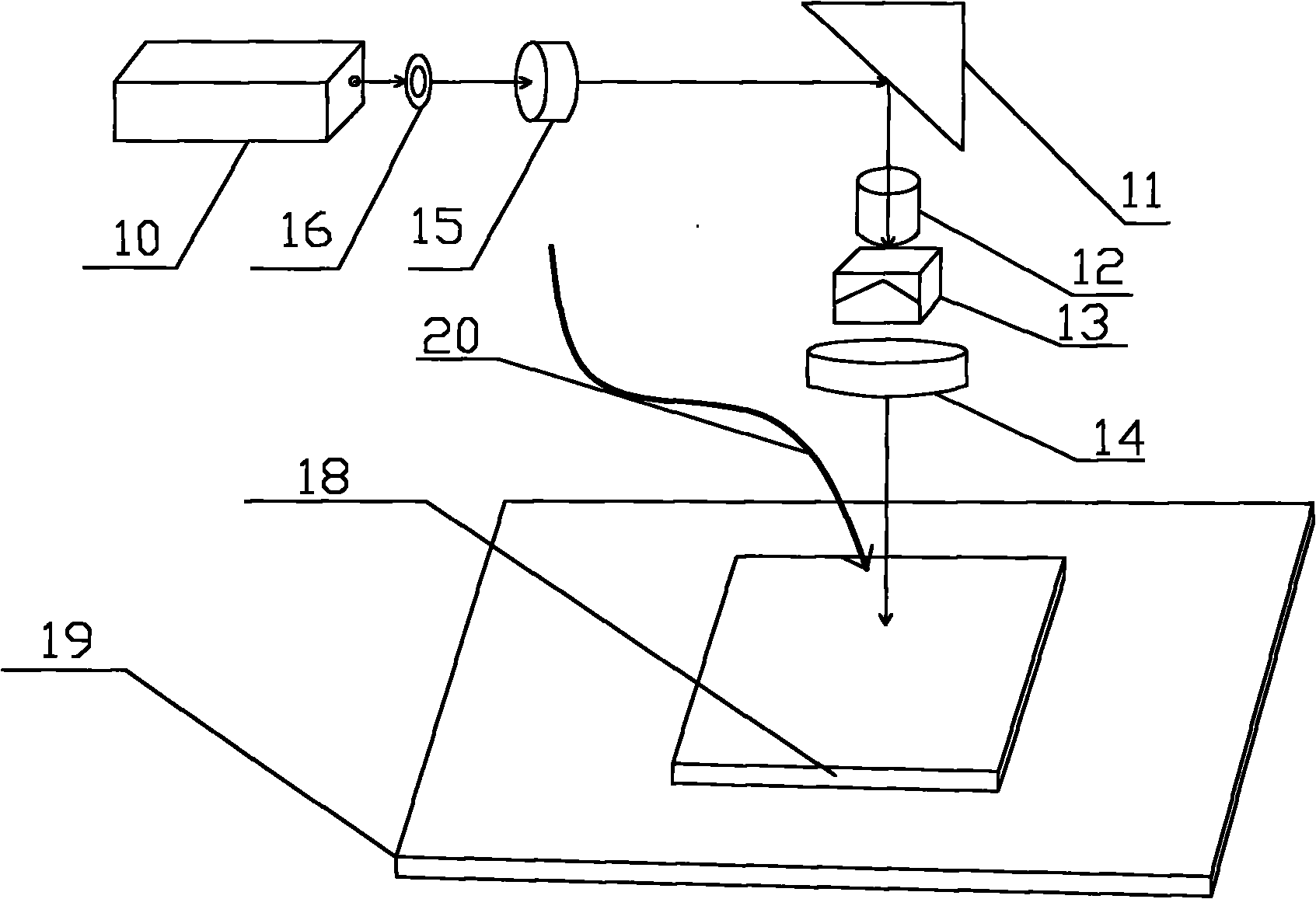

Device and method for abnormally cutting toughened glass by ultra-short pulse laser

InactiveCN102248302AImprove smoothnessImprove cutting efficiencyLaser beam welding apparatusBeam expanderSlag

The invention relates to a device and method for abnormally cutting a toughened glass by ultra-short pulse laser. An output end of an ultra-short pulse laser apparatus is provided with an optical gate, an output end of the optical gate is provided with a beam expander, an output end of the beam expander is provided with a 45-degree holophote, an output end of the 45-degree holophote is provided with a three-dimensional (3D) dynamical focusing system, an output end of the 3D dynamical focusing system is provided with a telecentric field lens which is arranged facing to a platform above which a blowing device is arranged. When the ultra-short pulse laser device is used to cut, a heating device is used for heating the glass; the ultra-short pulse laser is focused in the glass by the 3D dynamical focusing system to abnormally scan the glass along with the laser, and the whole processing procedure is in helical processing; a suction dust-collecting device at the bottom of the platform is used for collecting the scanned glass slag; and the blowing device on the platform is used for blowing the slag and dust particles processed on the surface of the glass. The abnormal graph processing to the toughened glass is a processing form with smooth cutting surface and high cutting efficiency.

Owner:SUZHOU DELPHI LASER

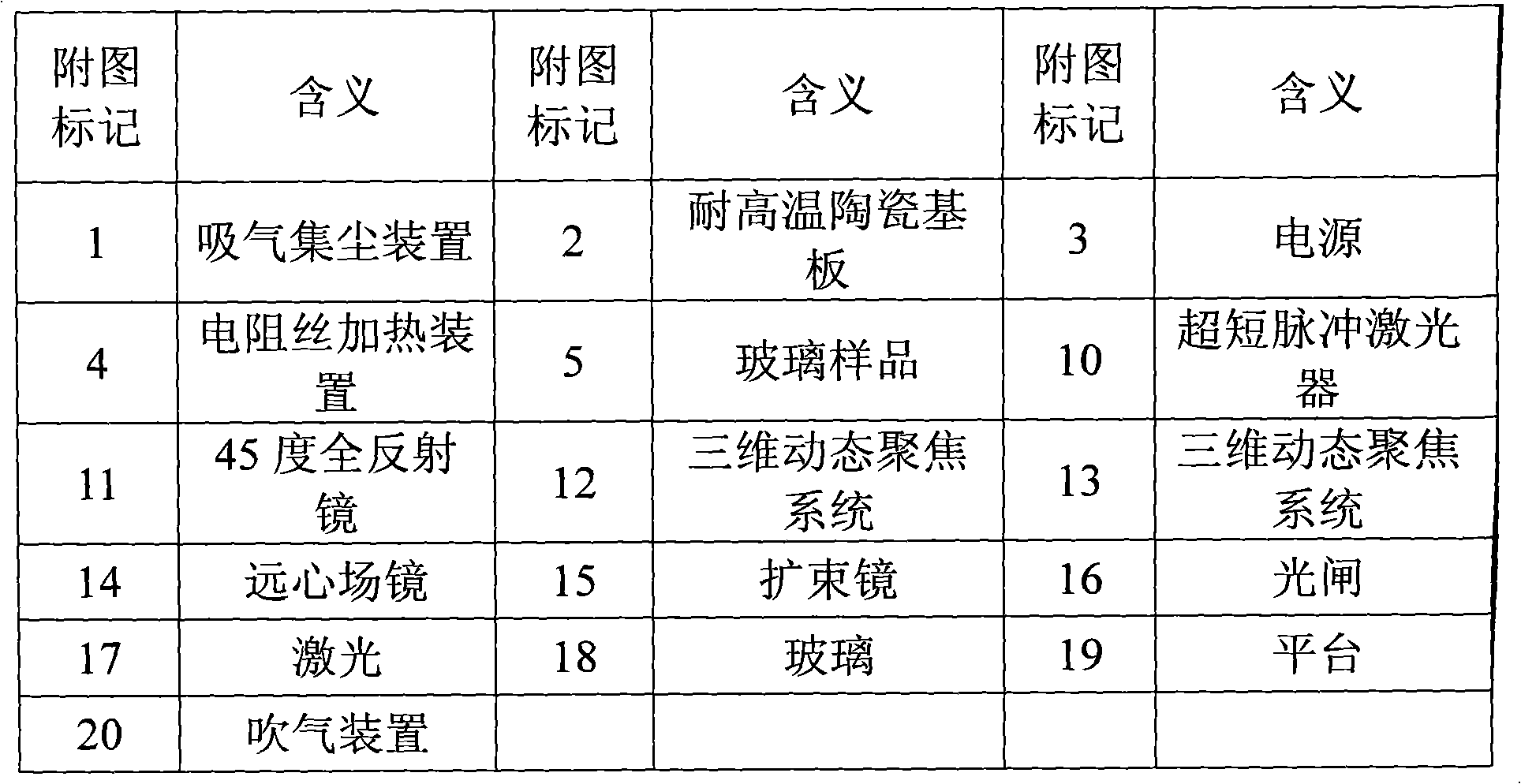

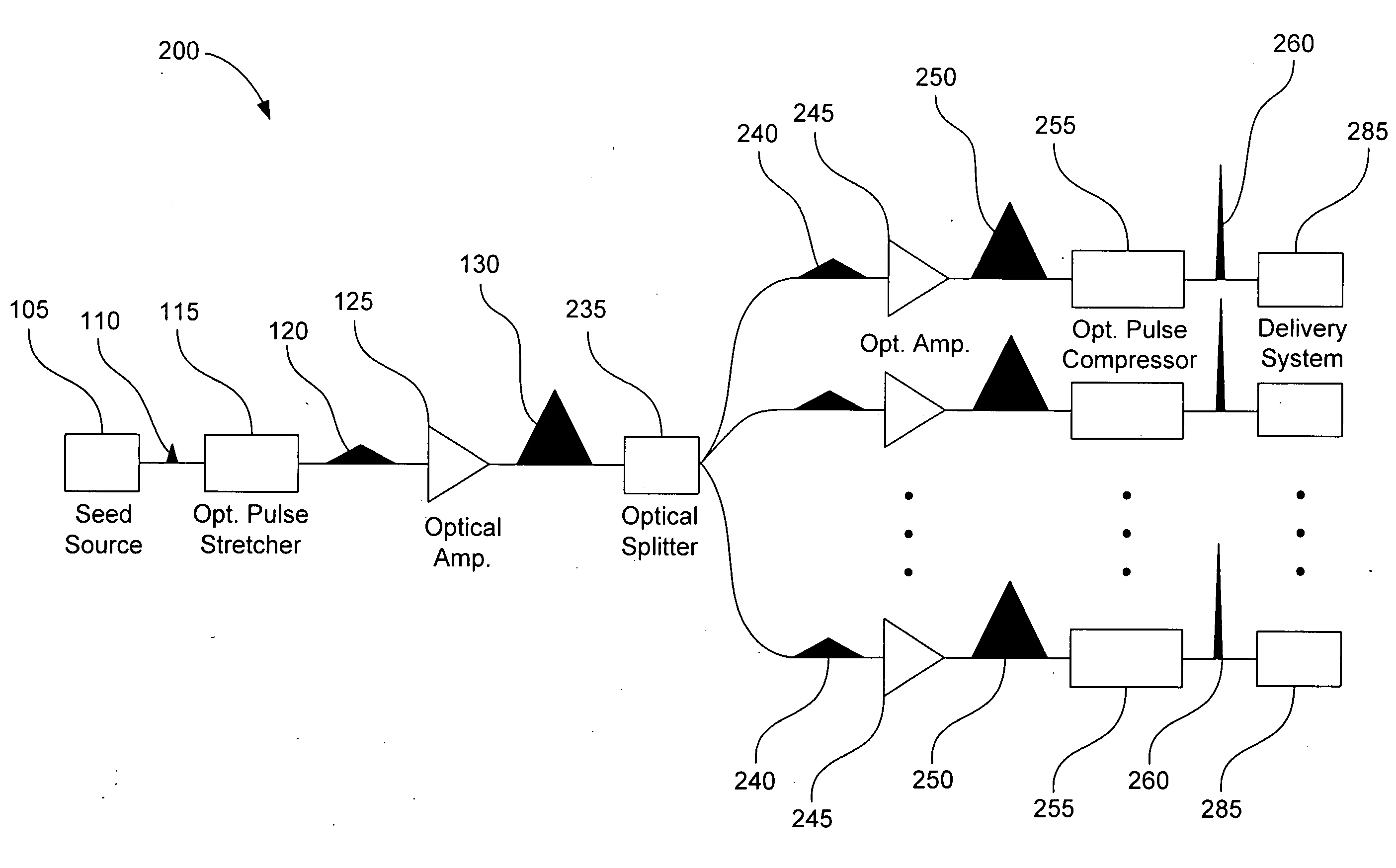

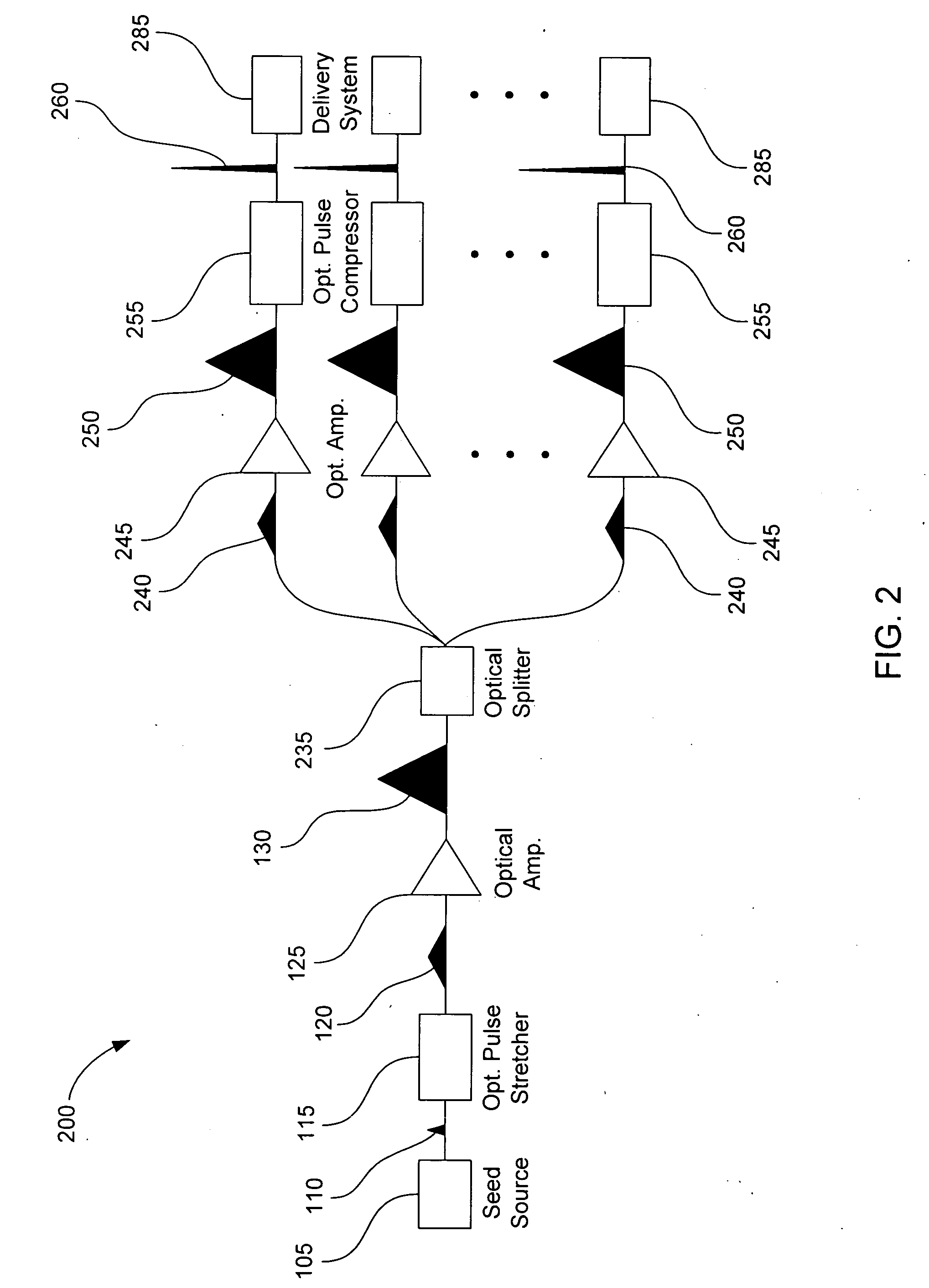

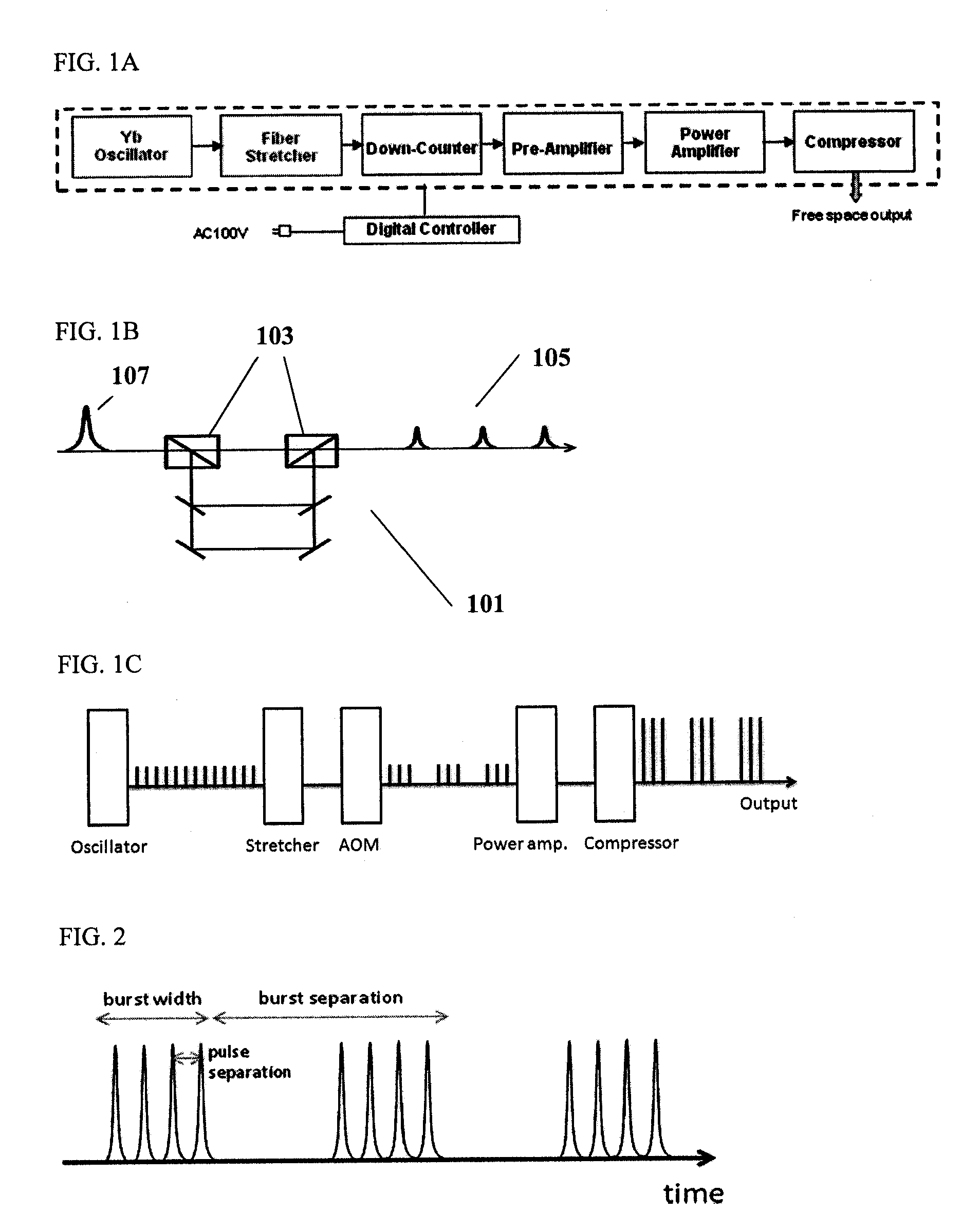

High average power ultra-short pulsed laser based on an optical amplification system

The present invention includes an apparatus and the method to scale the average power from high power ultra-short pulsed lasers, while at the same time addressing the issue of effective beam delivery and ablation, by use of an optical amplification system.

Owner:RAYDIANCE

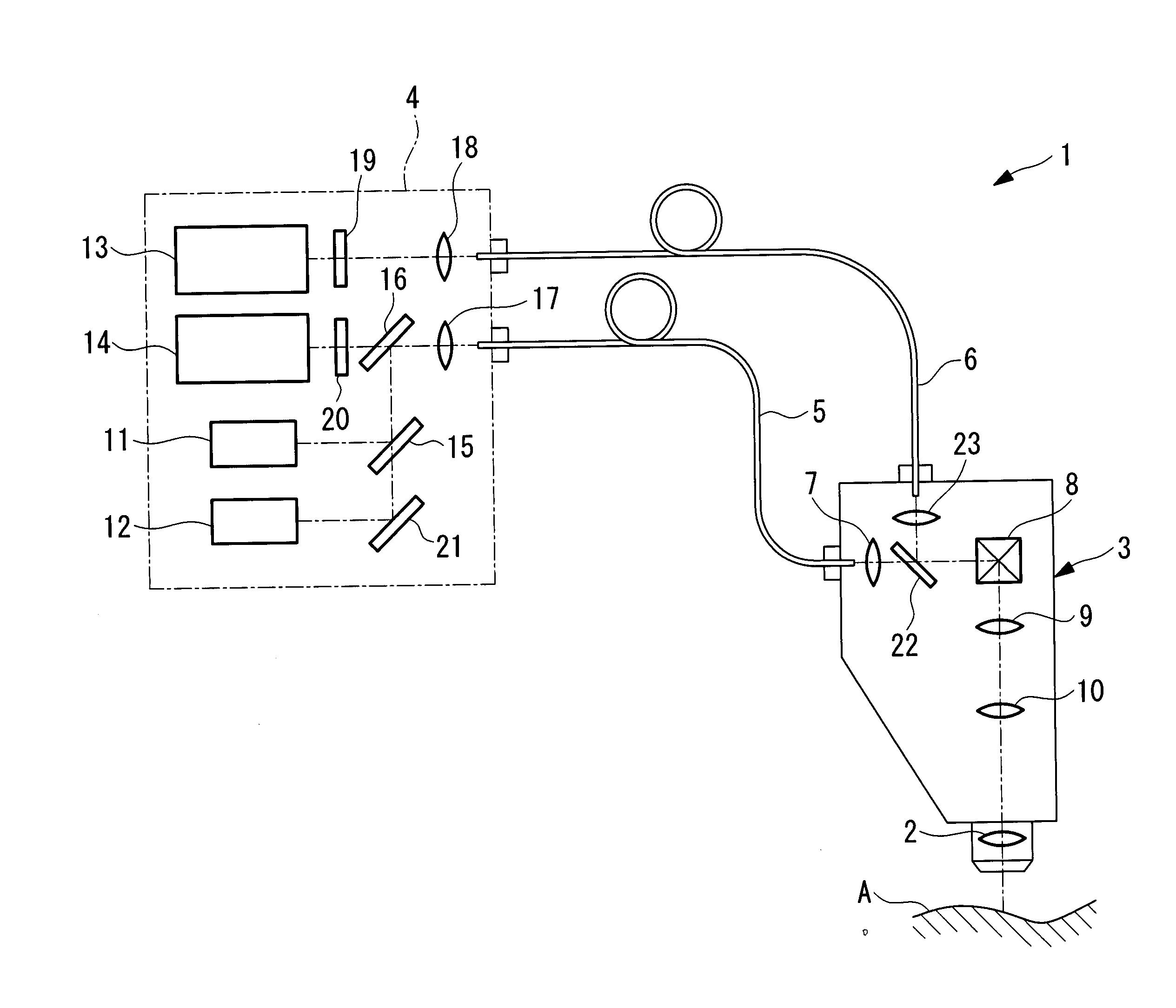

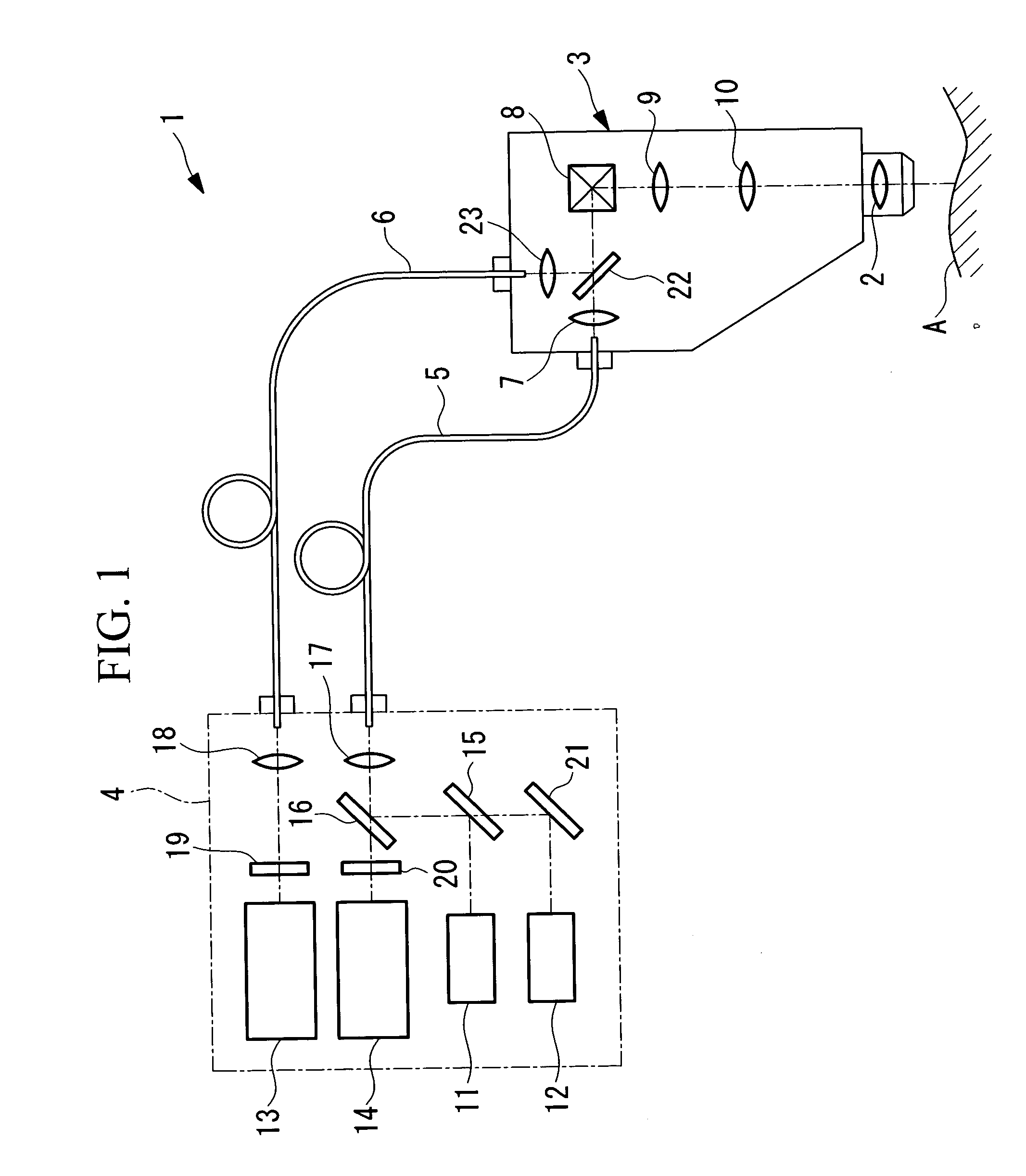

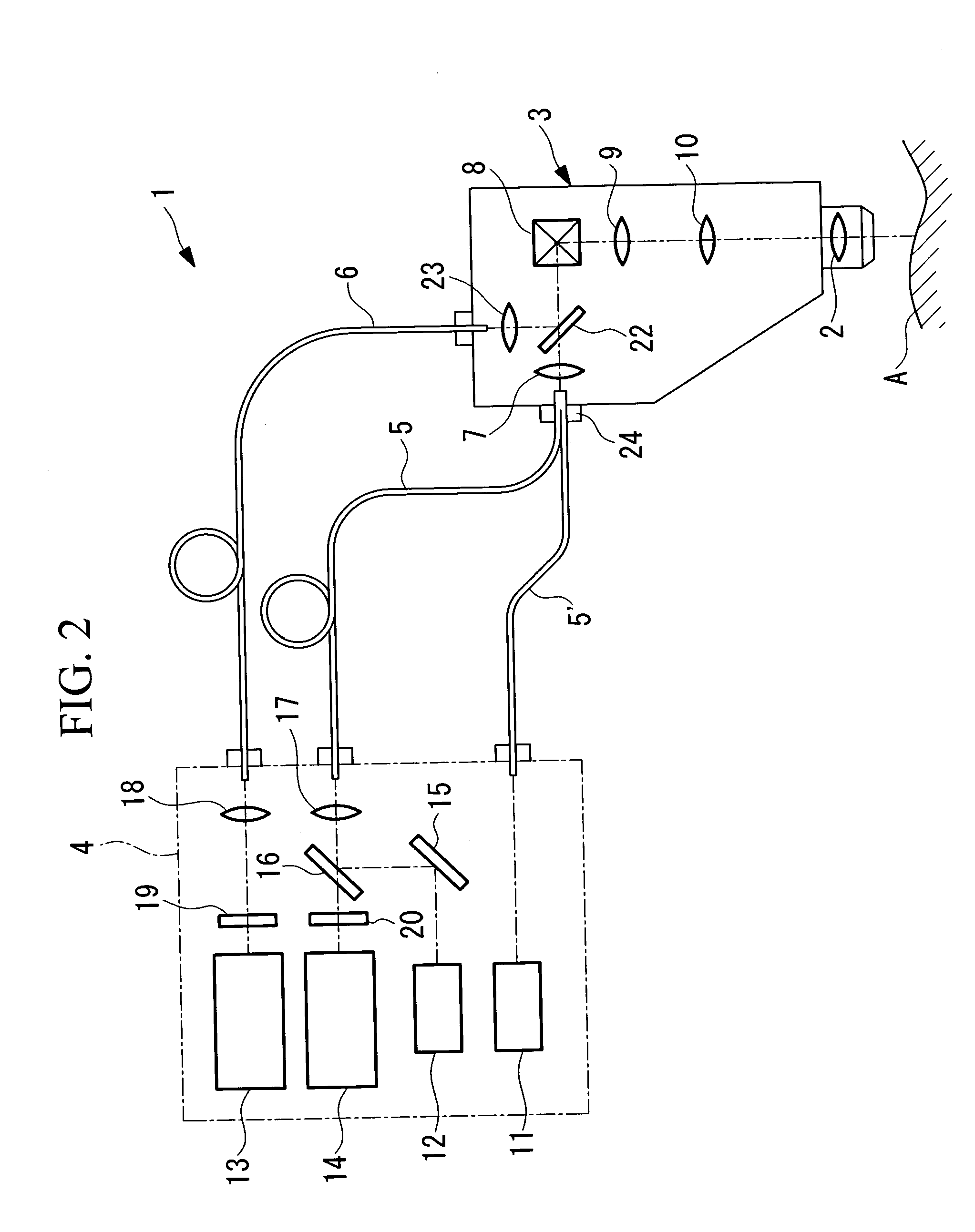

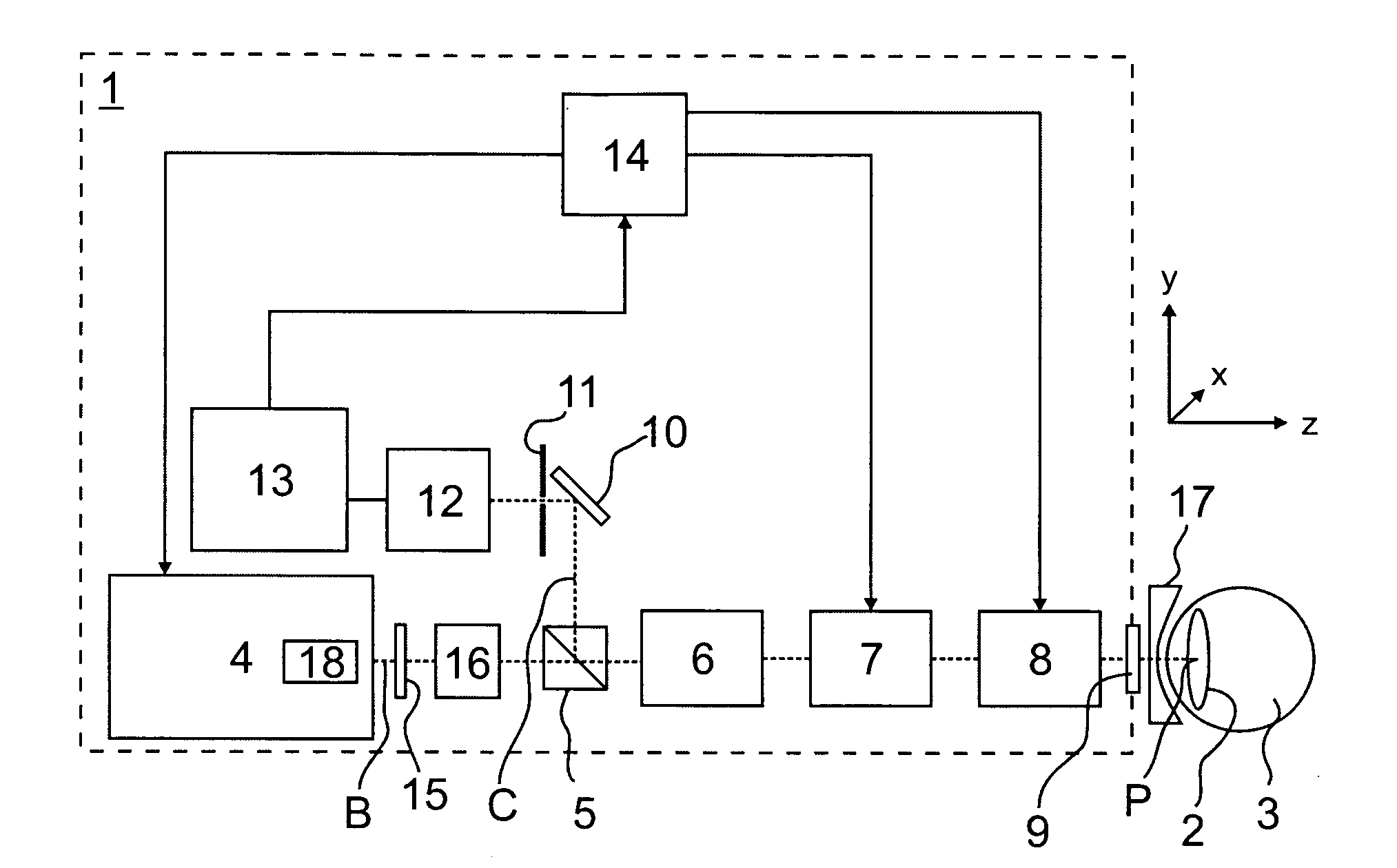

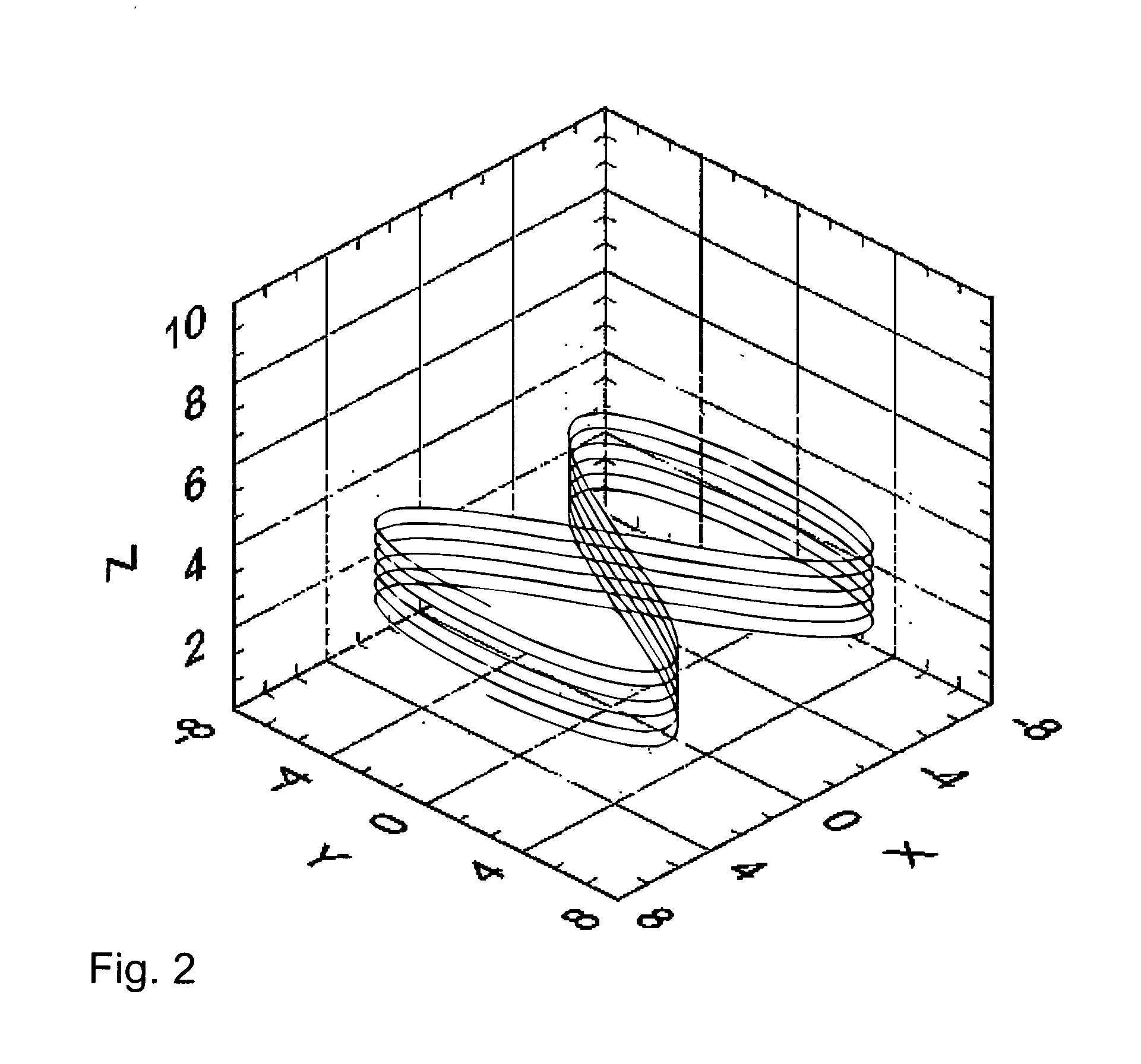

Laser-scanning examination apparatus

InactiveUS20060017920A1Reduce lossesCompact configurationRadiation pyrometrySpectrum investigationLaser scanningLaser light

The invention reduces the loss of fluorescence intensity obtained from a specimen to acquire clear fluorescence images when irradiating the specimen with ultrashort-pulse laser light produced by a laser light source. The invention provides a laser-scanning examination apparatus including a laser light source for producing ultrashort-pulse laser light; a laser light source for producing continuous-wave laser light; a measurement head including an optical scanning unit for scanning the laser light on a specimen and an objective optical system; an imaging unit for detecting return light from the specimen in response to the ultrashort-pulse laser light; and an imaging unit for detecting return light from the specimen in response to the continuous-wave laser light. The laser light sources and one imaging unit are connected to the measurement head by an optical fiber, and the other imaging unit is connected to the measurement head by another optical fiber with a larger core diameter.

Owner:OLYMPUS CORP

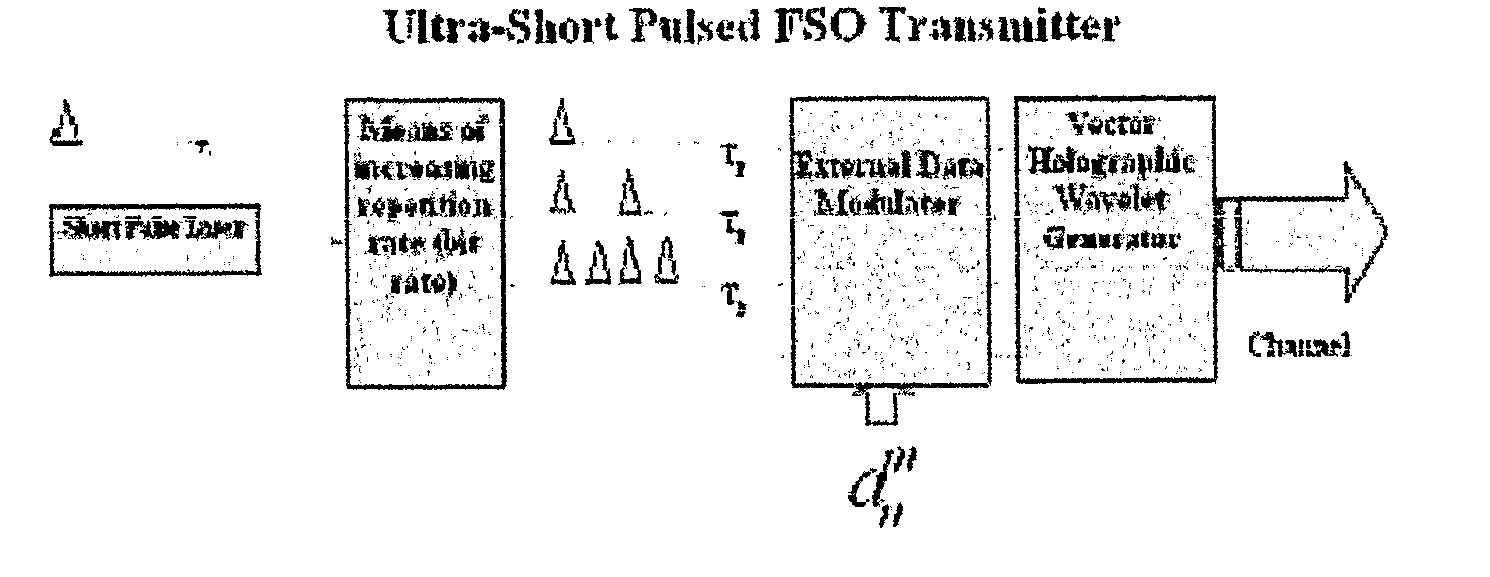

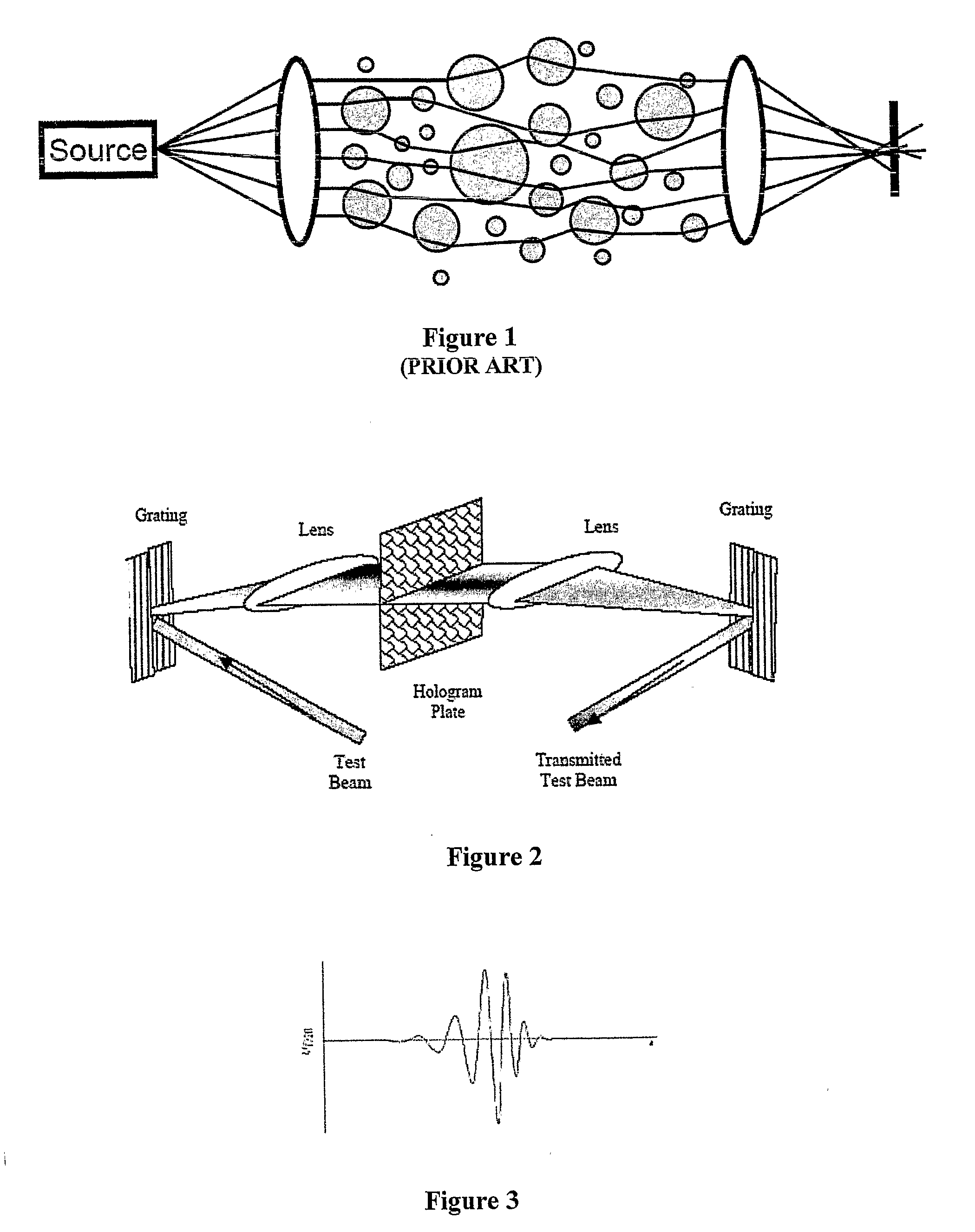

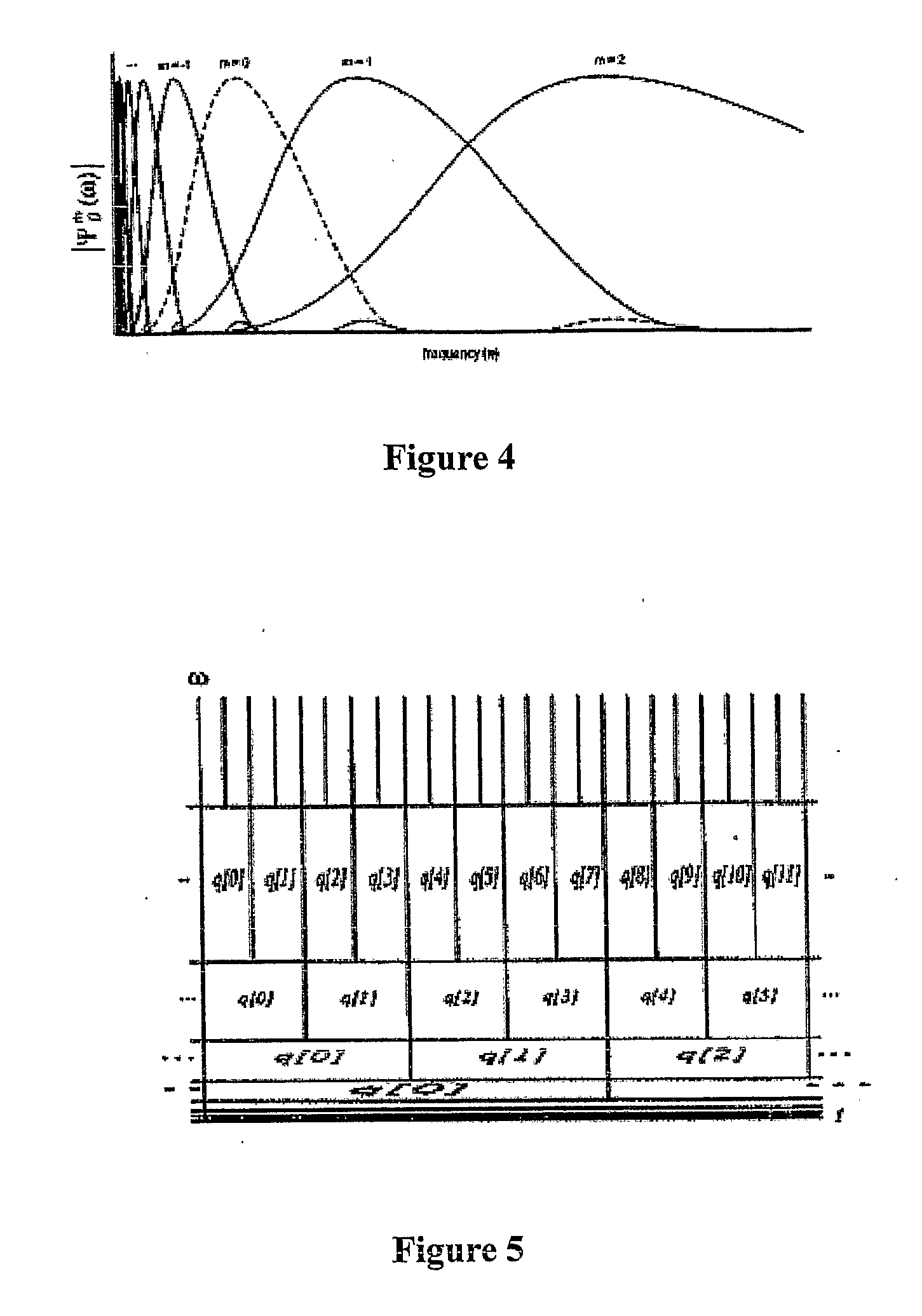

Optical Wireless Communications Using Ultra Short Light Pulses and Pulse Shaping

InactiveUS20070242955A1Improve combat capabilityReduce impactElectromagnetic transmissionTransceiverWireless transceiver

An optical, wavelet-based fractal modulation of ultra-short light pulses is used as part of a high-bandwidth communications system. The preferred embodiment utilizes the scheme as part of a hybrid wireless optical and RF transmission system for broadband communications among fixed and / or mobile platforms. An ultra-short pulse laser, high-power WDM-ARRAY laser or high-power incoherent light sources may be used. Computer-generated hologram techniques are employed in designing the optical transceiver subsystems for spectral encoding and decoding of wavelet patterns. Part of the design goal is to select a diversity receiver Field-of-View (FOV) in a way that the effects of scintillation are reduced by as much as possible. Compared to existing optical wireless systems, the invention offers a much higher average transmission bit rate and a much smaller bit error rate outage value, thus enabling highly available FSO links. Wireless transceiver will be capable of communications with nearly line-of-sight FSO links and will be more tolerant to shadowing. Also, the optical medium is designed to be more secure than counterparts against any intrusion.

Owner:PENN STATE RES FOUND

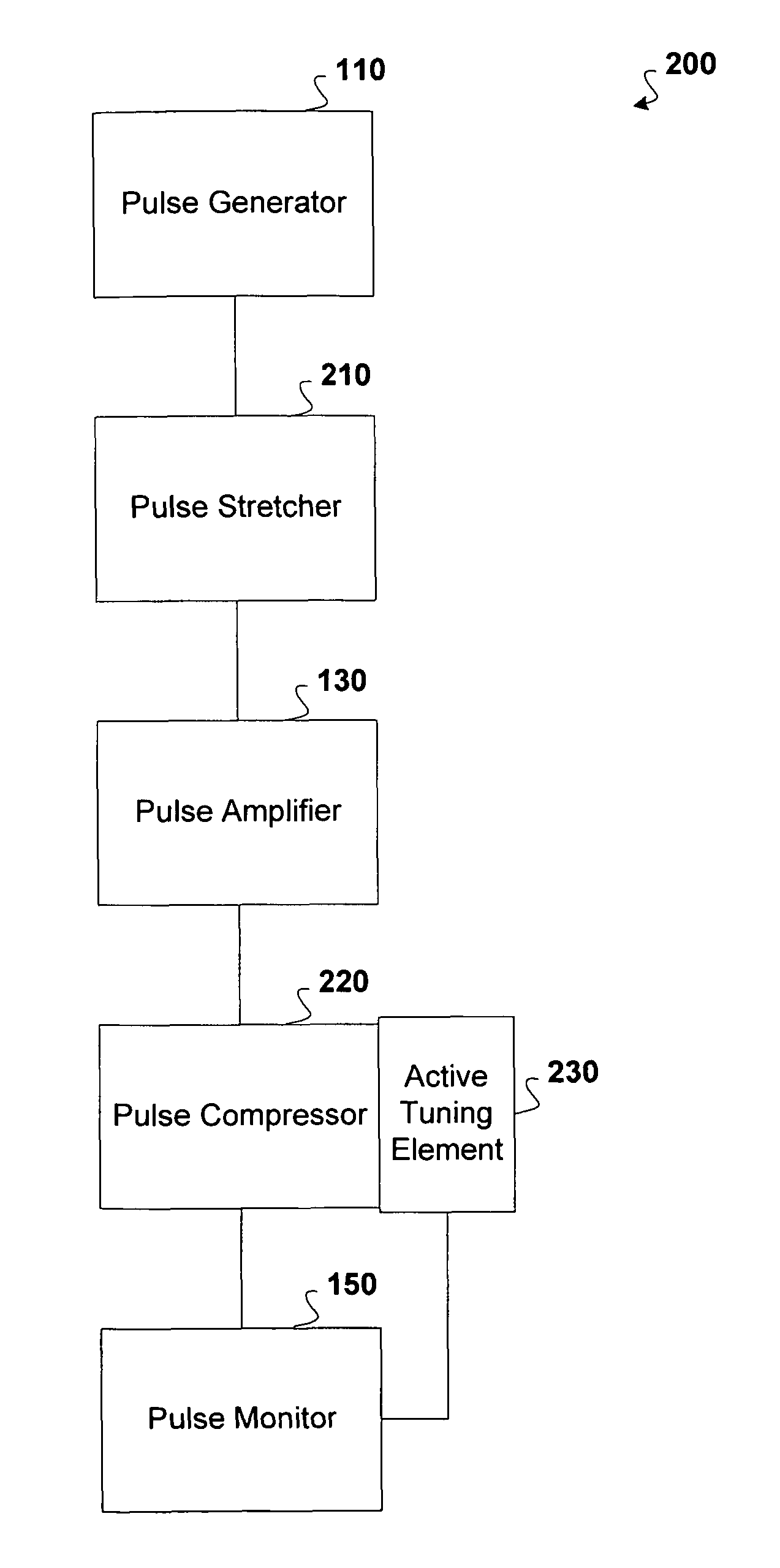

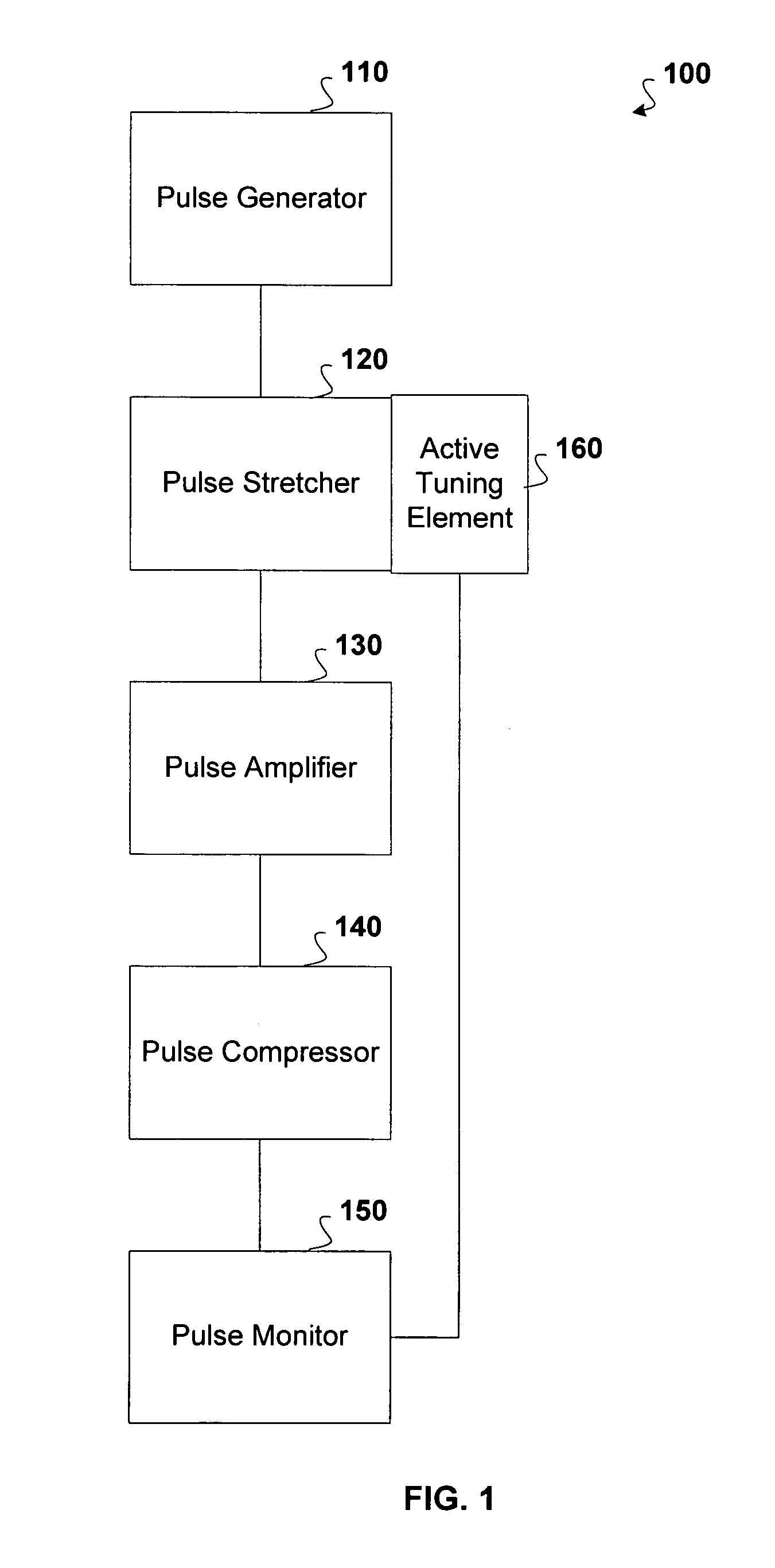

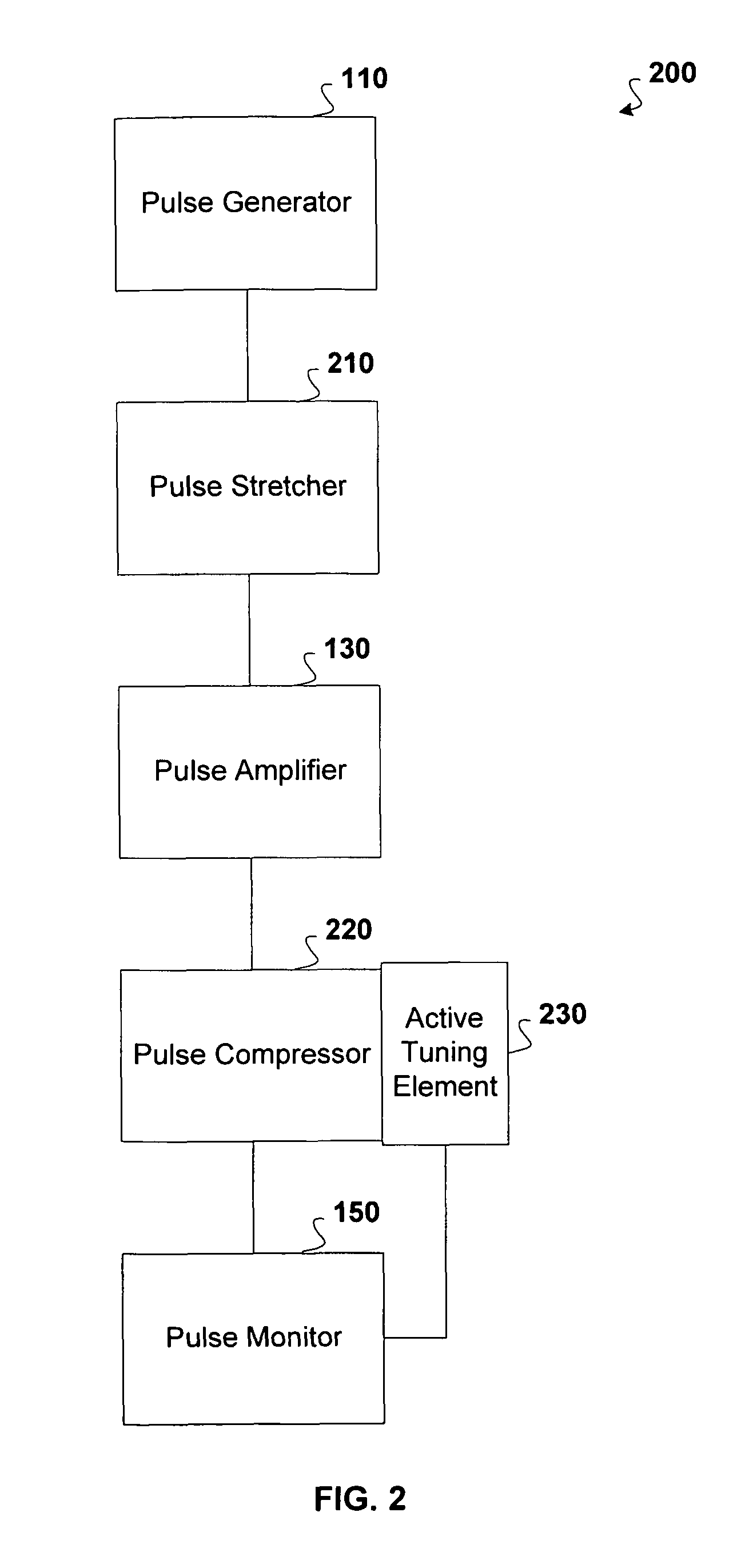

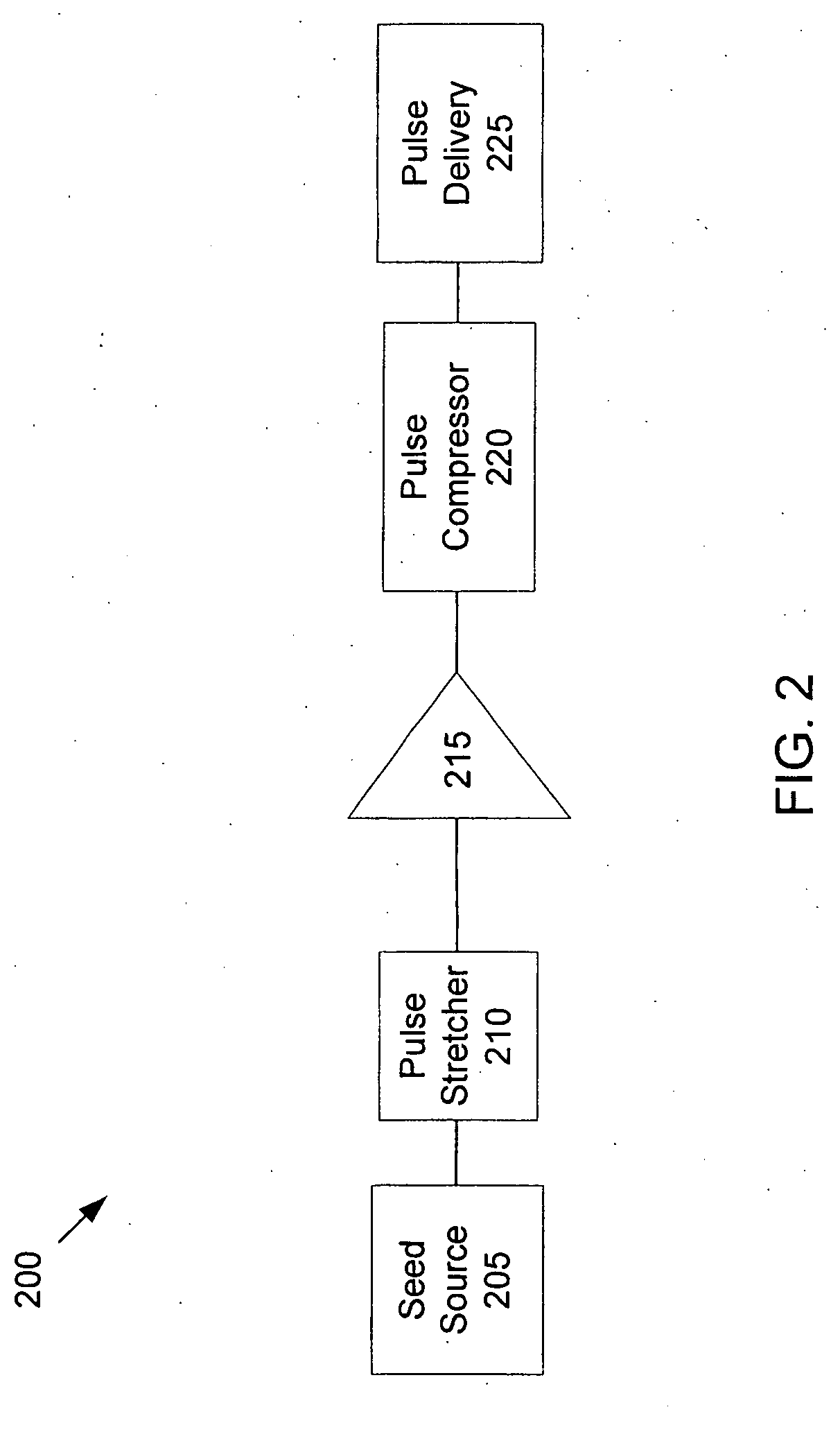

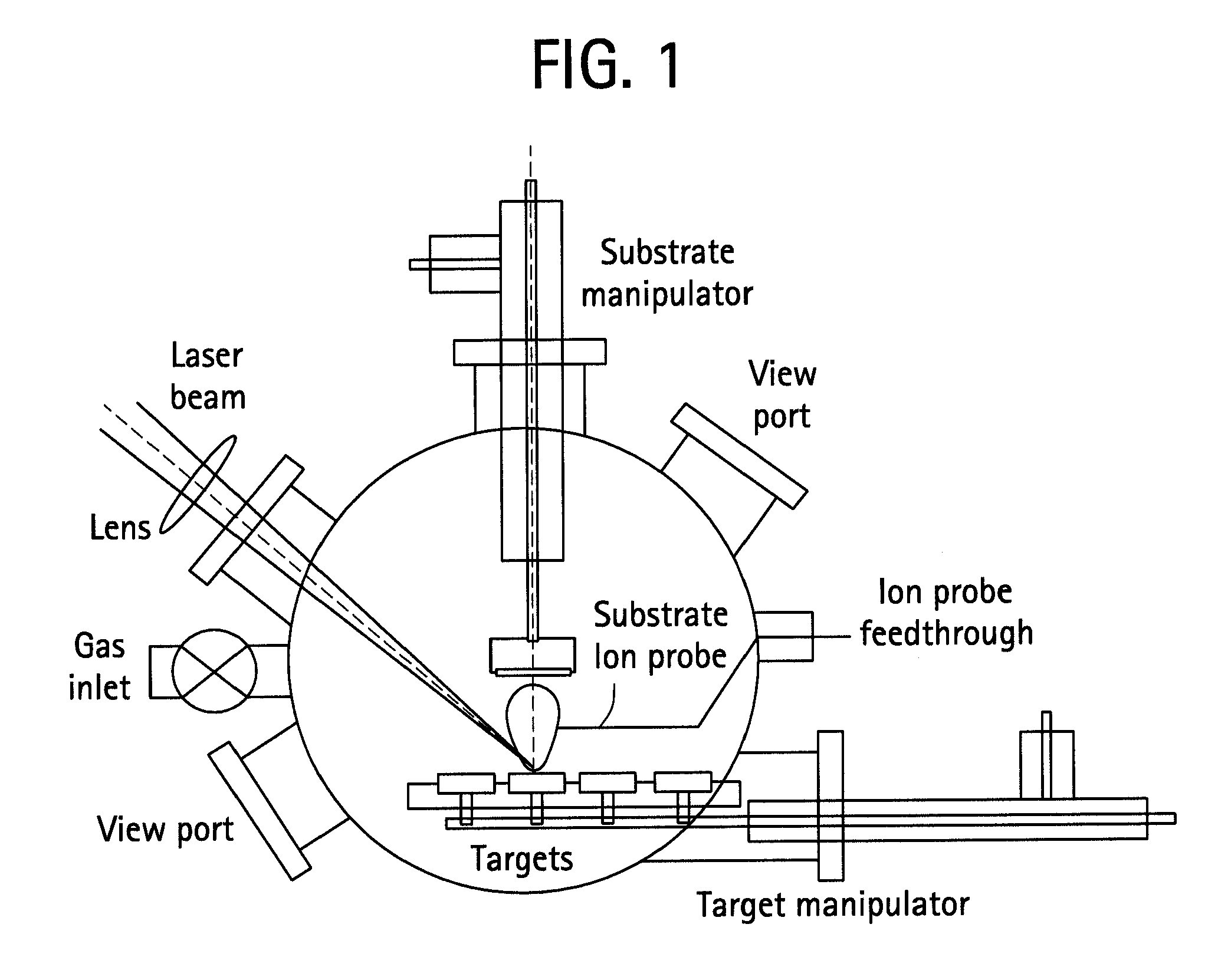

Active tuning of temporal dispersion in an ultrashort pulse laser system

InactiveUS7822347B1Decrease temporal width of output pulseLaser detailsElectromagnetic transmittersChirped pulse amplificationEngineering

A chirped pulse amplification (CPA) system and method is described wherein the dispersion of the system is tuned by actively tuning one or more system components, for example, using a temperature or strain gradient, or using actinic radiation. In other embodiments, an additional element, such as a modulator, is added to the CPA system to actively to tune the pulse. A pulse monitor is added to the system to measure an output pulse and provide feedback to one or more active tuning elements.

Owner:COHERENT INC

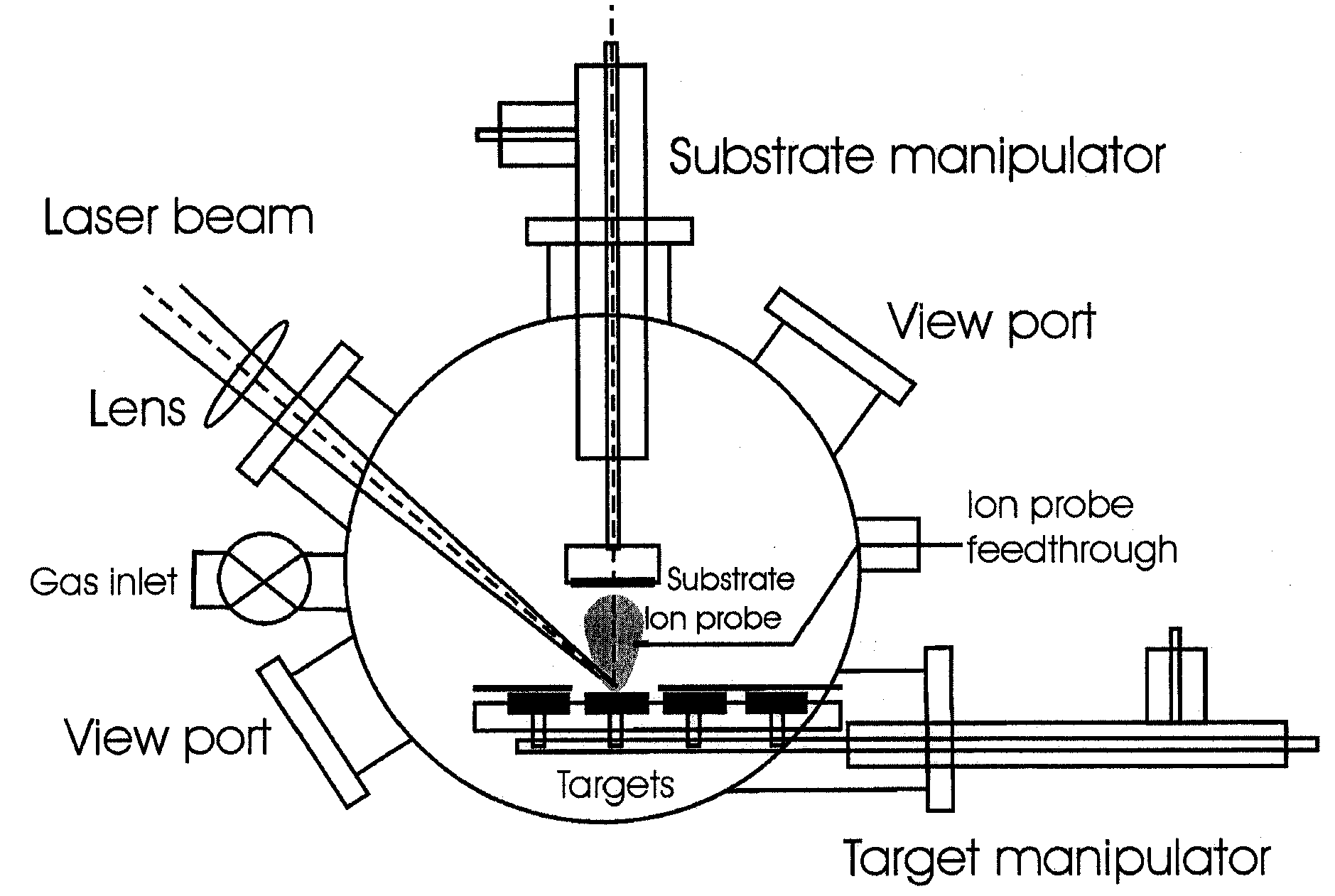

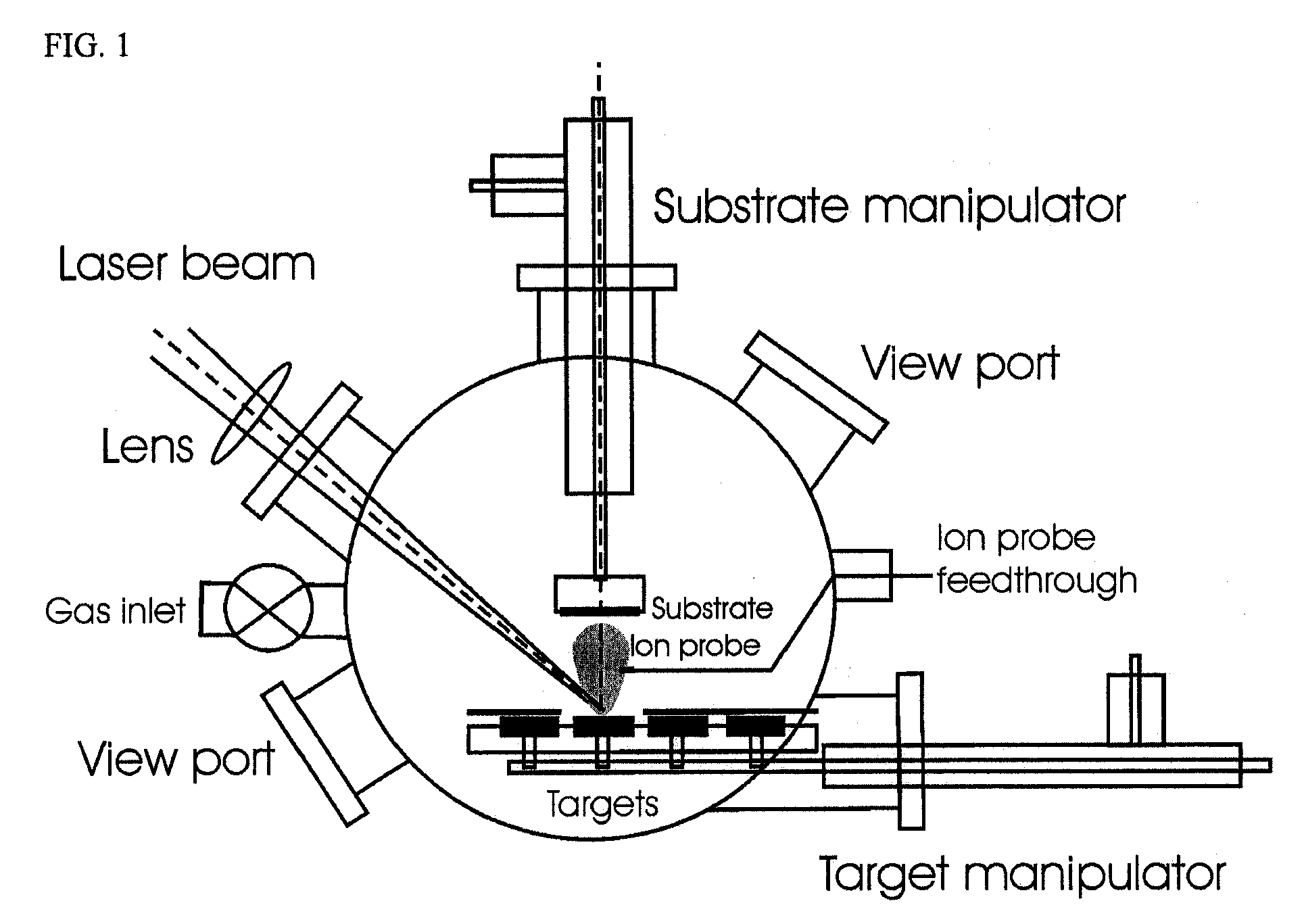

Method For Fabricating Thin Films

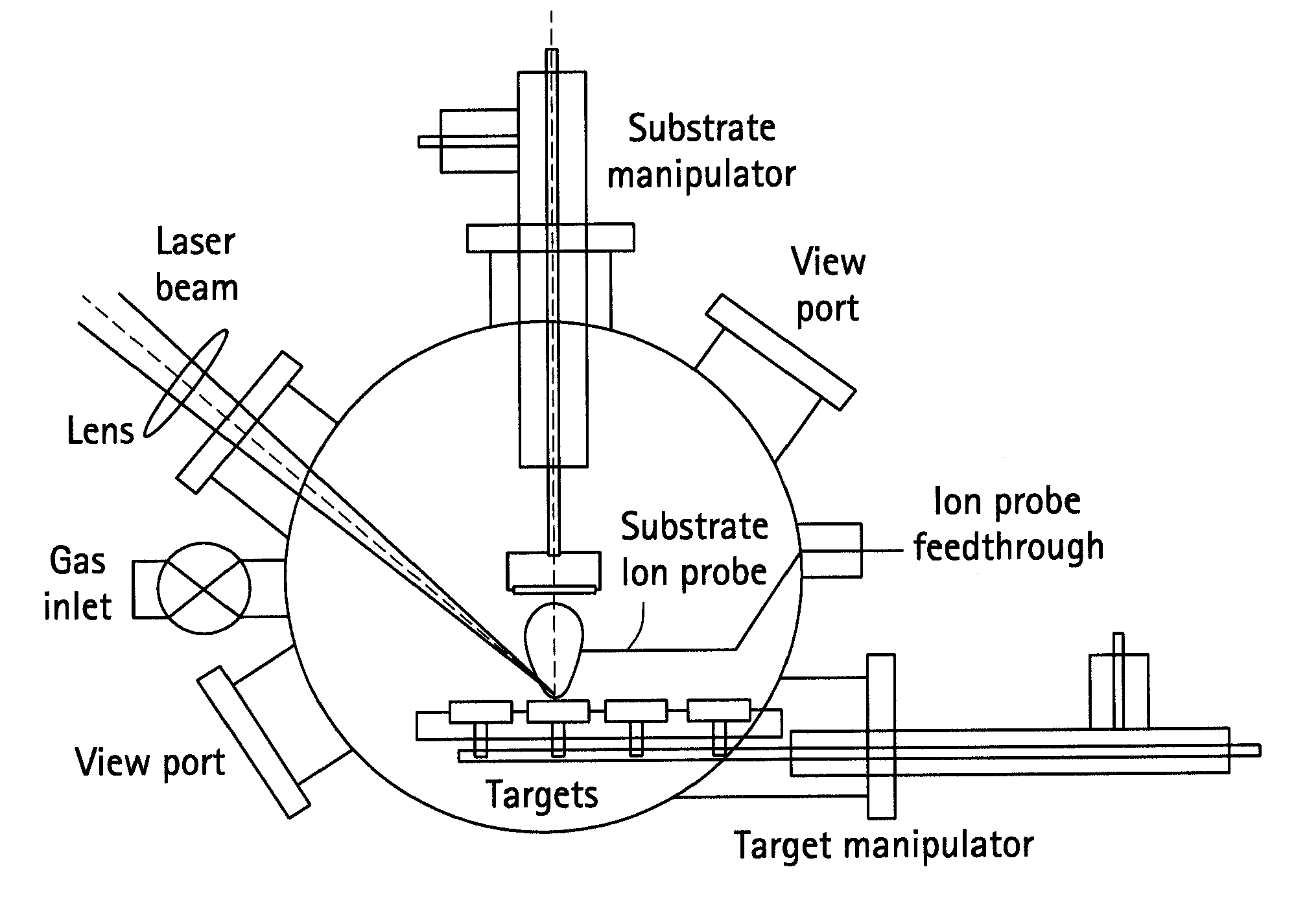

InactiveUS20090246530A1Small particle sizeEasily realizedLiquid surface applicatorsElectric discharge heatingSheet filmAlloy

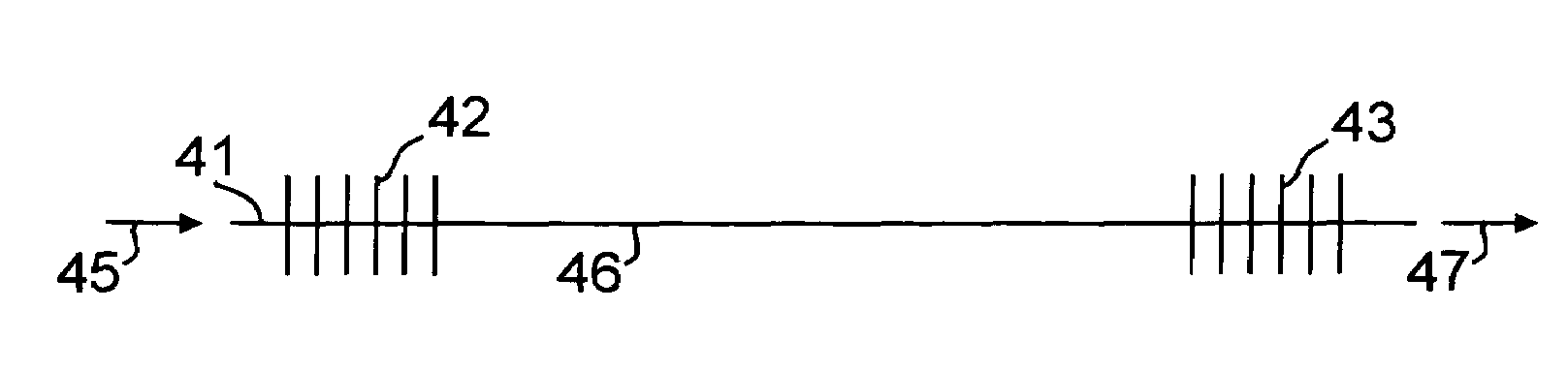

A method of pulsed laser deposition (PLD) capable of continuously tuning formed-film morphology from that of a nanoparticle aggregate to a smooth thin film free of particles and droplets. The materials that can be synthesized using various embodiments of the invention include, but are not limited to, metals, alloys, metal oxides, and semiconductors. In various embodiments a ‘burst’ mode of ultrashort pulsed laser ablation and deposition is provided. Tuning of the film morphology is achieved by controlling the burst-mode parameters such as the number of pulses and the time-spacing between the pulses within each burst, the burst repetition rate, and the laser fluence. The system includes an ultrashort pulsed laser, an optical system for delivering a focused onto the target surface with an appropriate energy density, and a vacuum chamber in which the target and the substrate are installed and background gases and their pressures are appropriately adjusted.

Owner:IMRA AMERICA

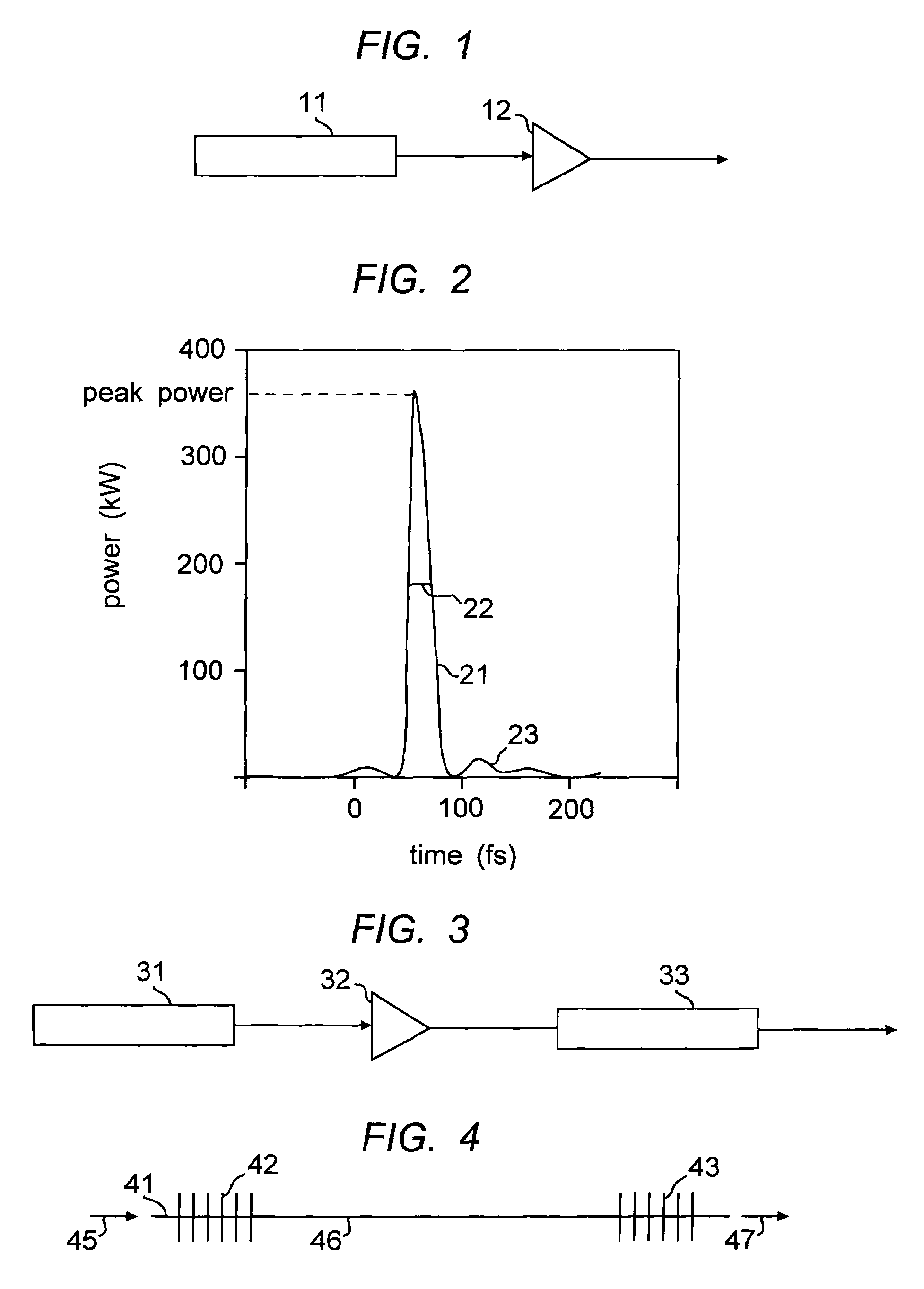

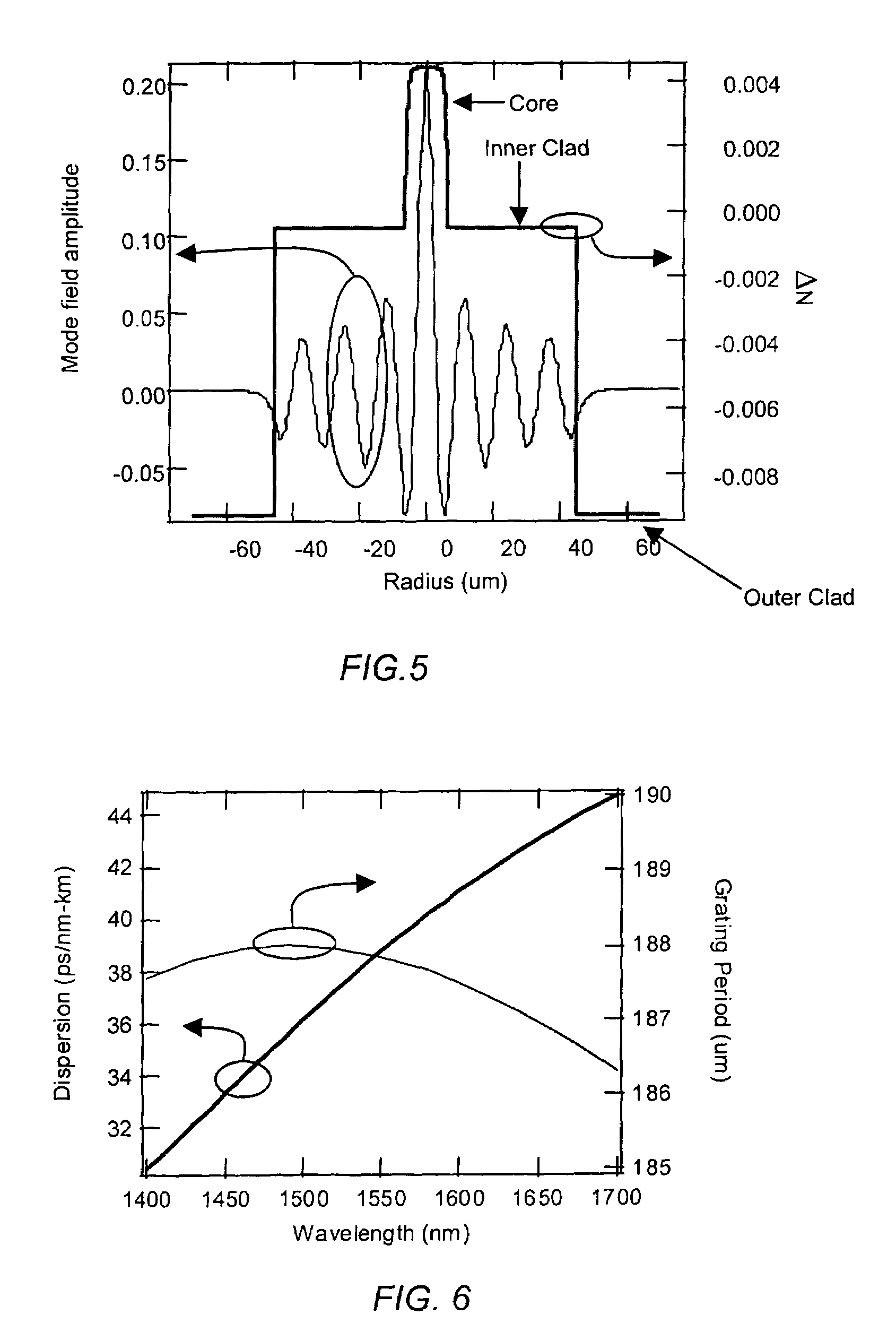

Short pulse lasers using large mode area fibers and higher order modes

ActiveUS7228029B1Reduce distortion problemsQuality improvementLaser using scattering effectsOptical fibre with multilayer core/claddingUltrashort pulse laserDistortion

The specification describes an optical fiber device for propagating and recompressing high energy, ultrashort pulses with minimal distortions due to nonlinearity. The device is based on propagation in a higher order mode (HOM) of a few-moded fiber. Coupling into the HOM may be accomplished using long-period gratings. Features of the HOM fiber mode that are useful for high quality pulse compression include large effective area, high dispersion and low dispersion slope. In a preferred case the long period gratings go through a turn-around point (TAP) at the wavelength of operation.

Owner:FURAKAWA ELECTRIC NORTH AMERICA INC

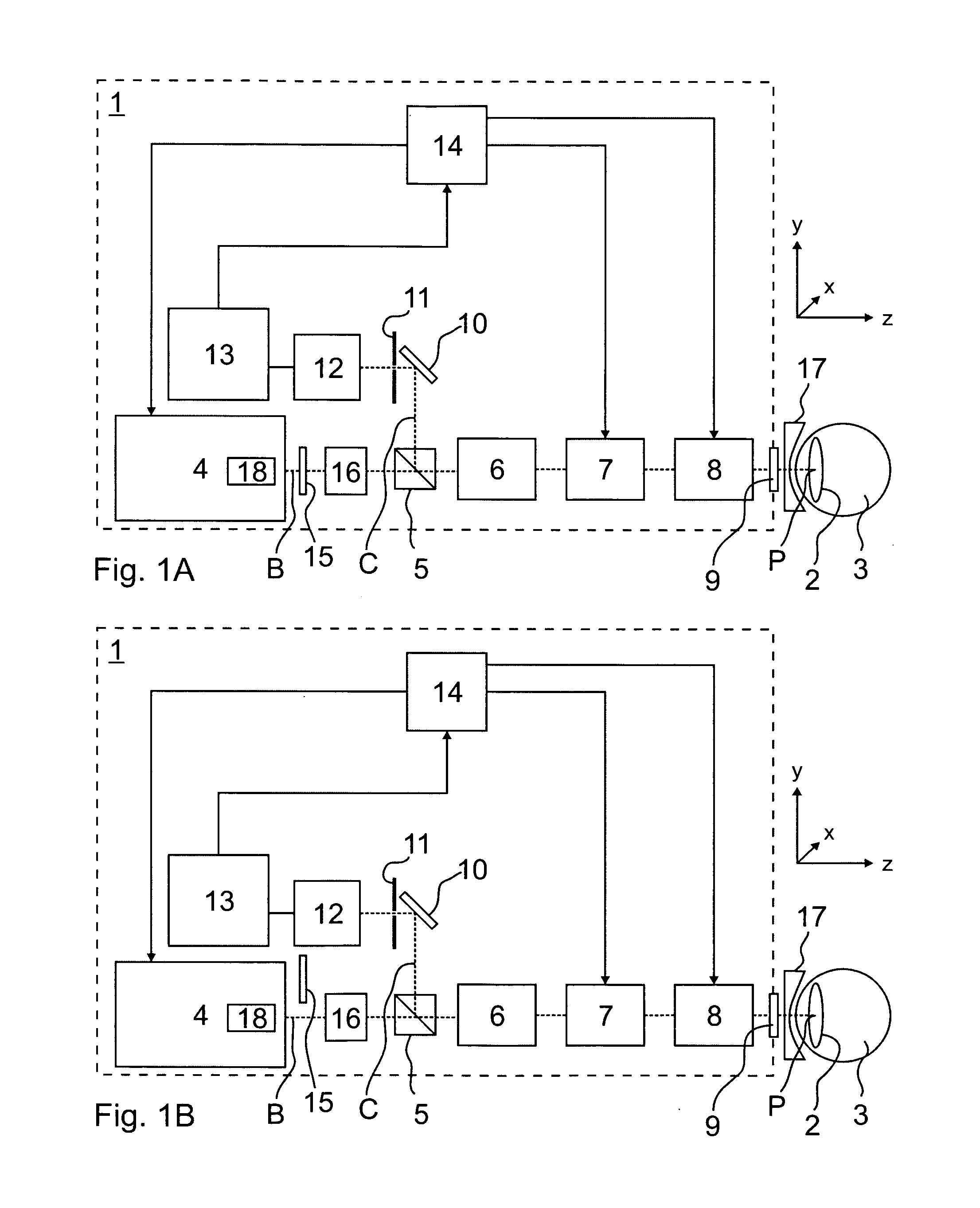

Ophthalmologic laser system

ActiveUS20120016352A1Interference minimizationReduce radiation exposureLaser surgerySurgical instrument detailsLens crystallineUltra short pulse

An ophthalmological laser system for photodisruptive irradiation of ocular tissue, including a crystalline lens or a cornea. The system includes an ultra-short pulse laser, the radiation of which is focusable as illumination light via an illumination beam path including a scanner unit and focusing optics. A control unit is programmed to execute determining irradiation control data for photodisruptions at irradiation points in an interior of the ocular tissue distributed three-dimensionally and non-equidistantly to create at least one predetermined target incision. The laser system then irradiates the ocular tissue according to the determined irradiation control data.

Owner:CARL ZEISS MEDITEC AG

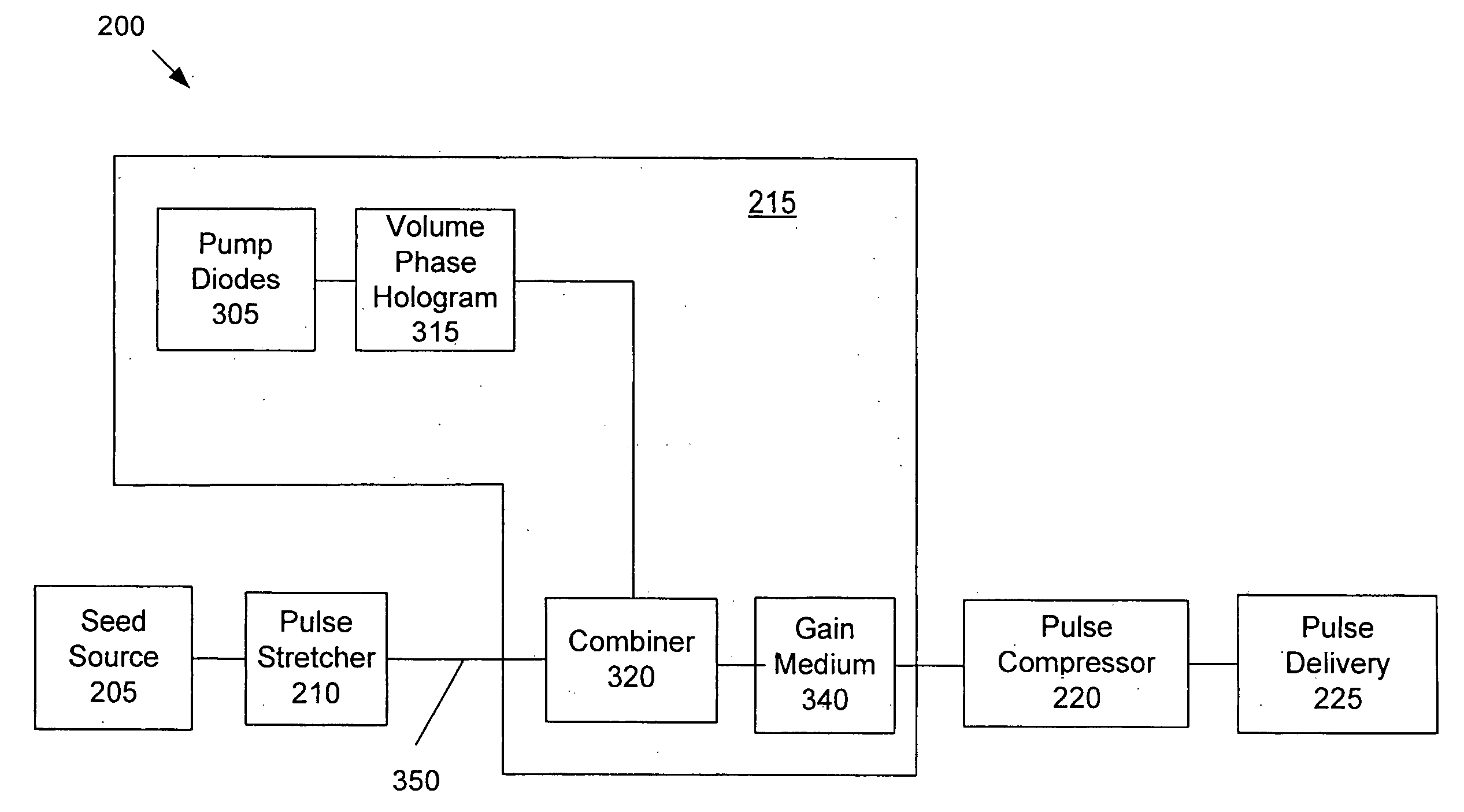

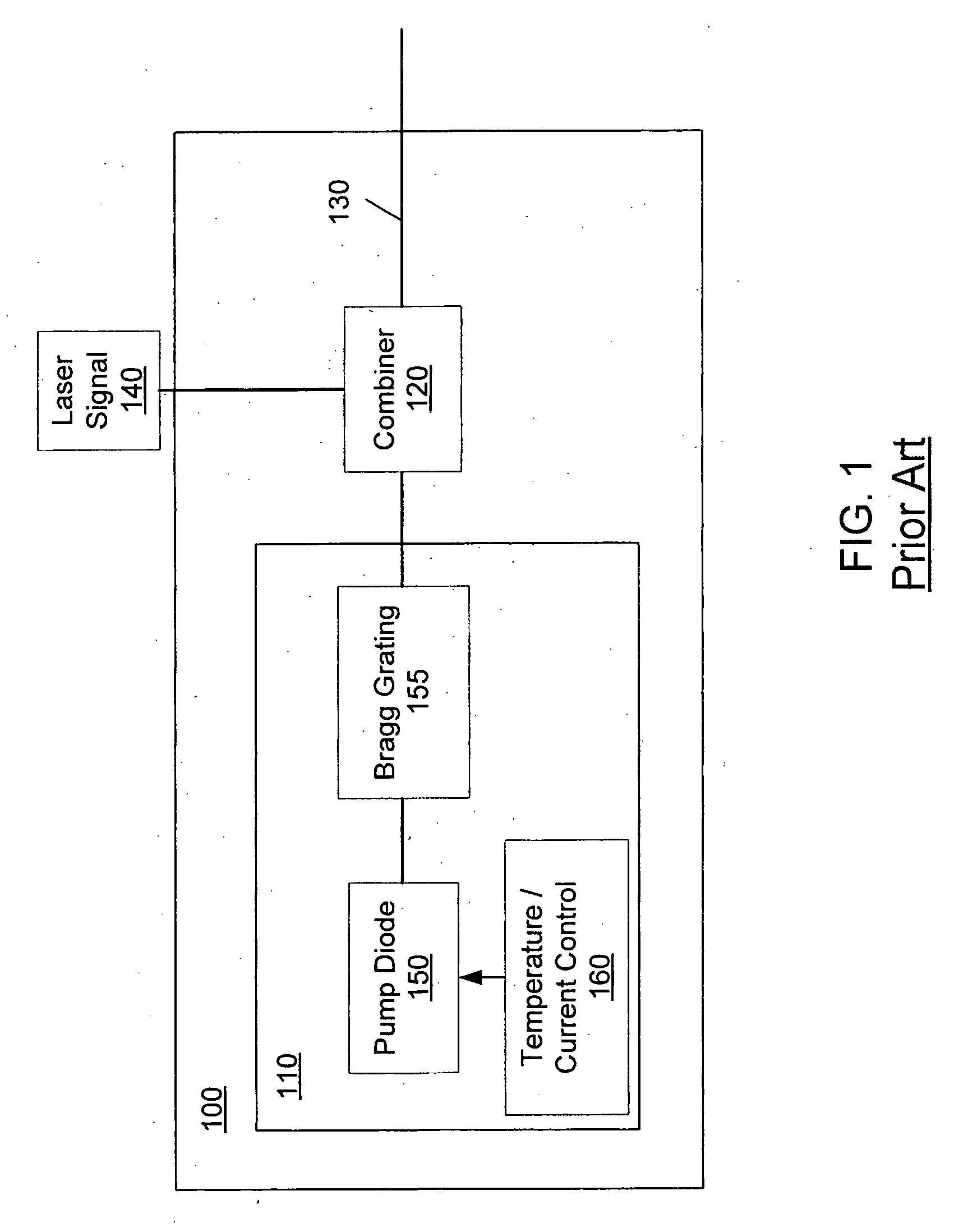

Wavelength-stabilized pump diodes for pumping gain media in an ultrashort pulsed laser system

ActiveUS20070064304A1Improve power efficiencyHigh peak powerLaser detailsSemiconductor lasersNonlinear distortionRare earth ions

In an optical amplifier, passively wavelength-stabilized pump diodes generate pumping light to excite a gain medium (e.g., rare-earth-ion doped optical fiber or solid-state optical amplifier) near an absorption peak of the gain medium. The gain medium amplifies a pulsed laser signal coupled into the gain medium to a high peak power with minimal non-linear distortion. The gain medium may include a portion configured to receive the pumping light and another portion configured to amplify the pulsed laser signal. A volume phase hologram device may passively wavelength stabilize the pump diodes by reflecting a portion of the pumping light back to the pump diodes. Passively wavelength-stabilizing the pump diodes improves power efficiency of the optical amplifier.

Owner:COHERENT INC

Production of fine particles of functional ceramic by using pulsed laser

InactiveUS20110193025A1Synthetic resin layered productsCellulosic plastic layered productsPhosphorColloid

A method of forming nanometer sized fine particles of functional ceramic from a bulk functional ceramic, particularly fine particles of phosphorous ceramics from a bulk phosphor material is disclosed. The method relies on irradiation of a bulk phosphorous ceramic in a liquid with an ultrashort-pulsed-laser-fragmentation beam to thereby form nanometer sized particles of the phosphorous ceramic. The method is unique in that the generated particles retain the chemical and crystalline properties of the bulk phosphorous ceramic. The generated solutions are stable colloids from which the particles can be isolated or used as is.

Owner:IMRA AMERICA

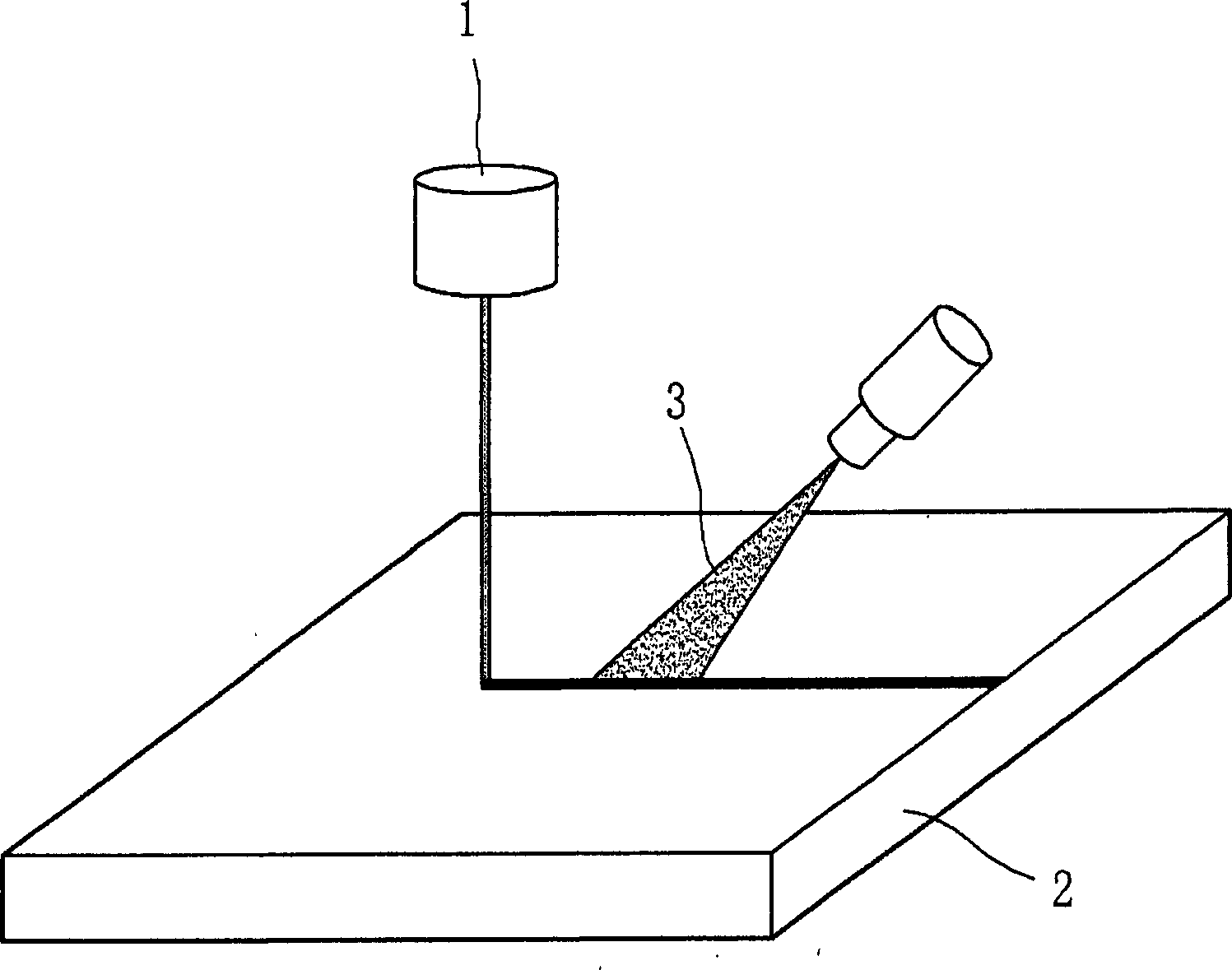

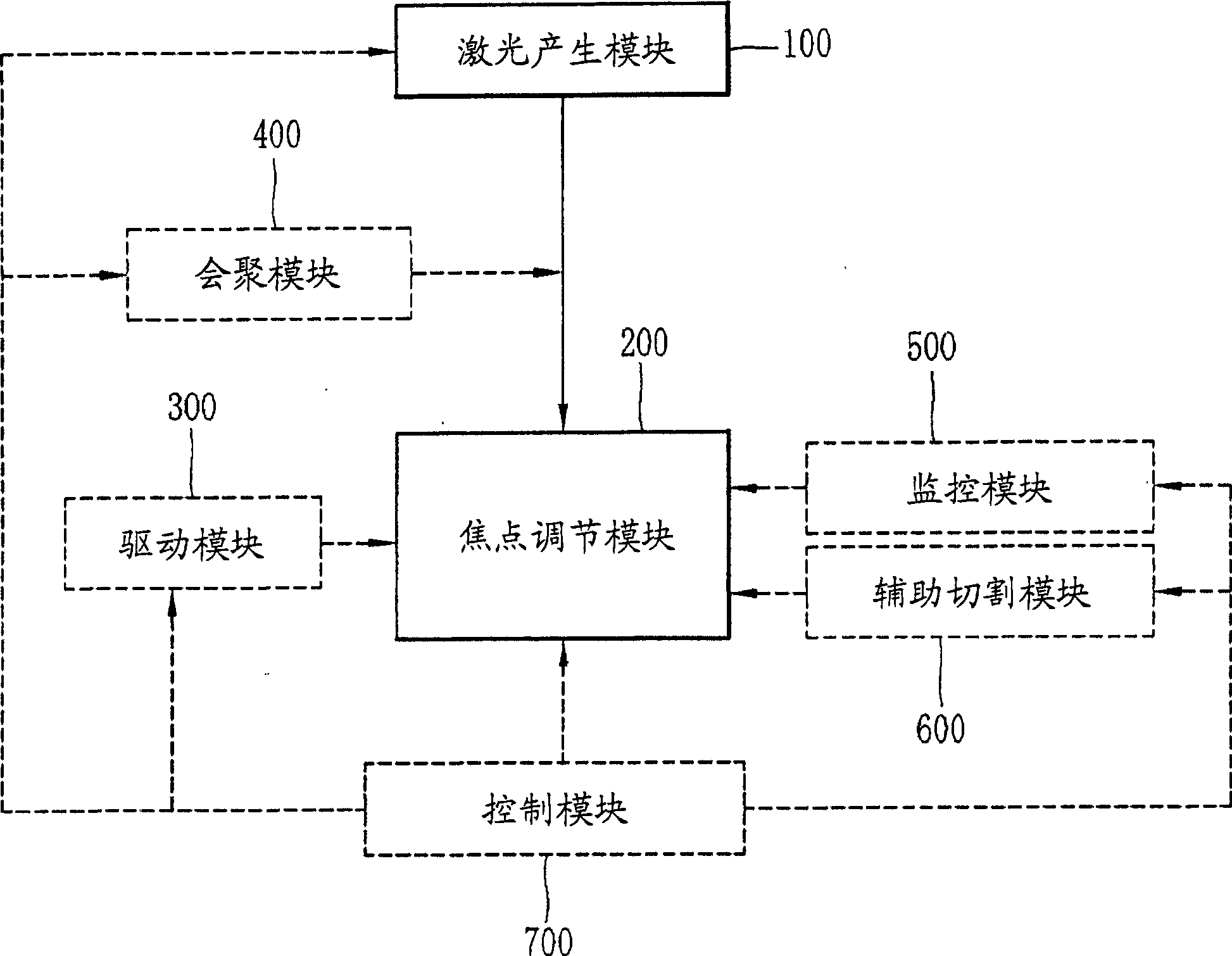

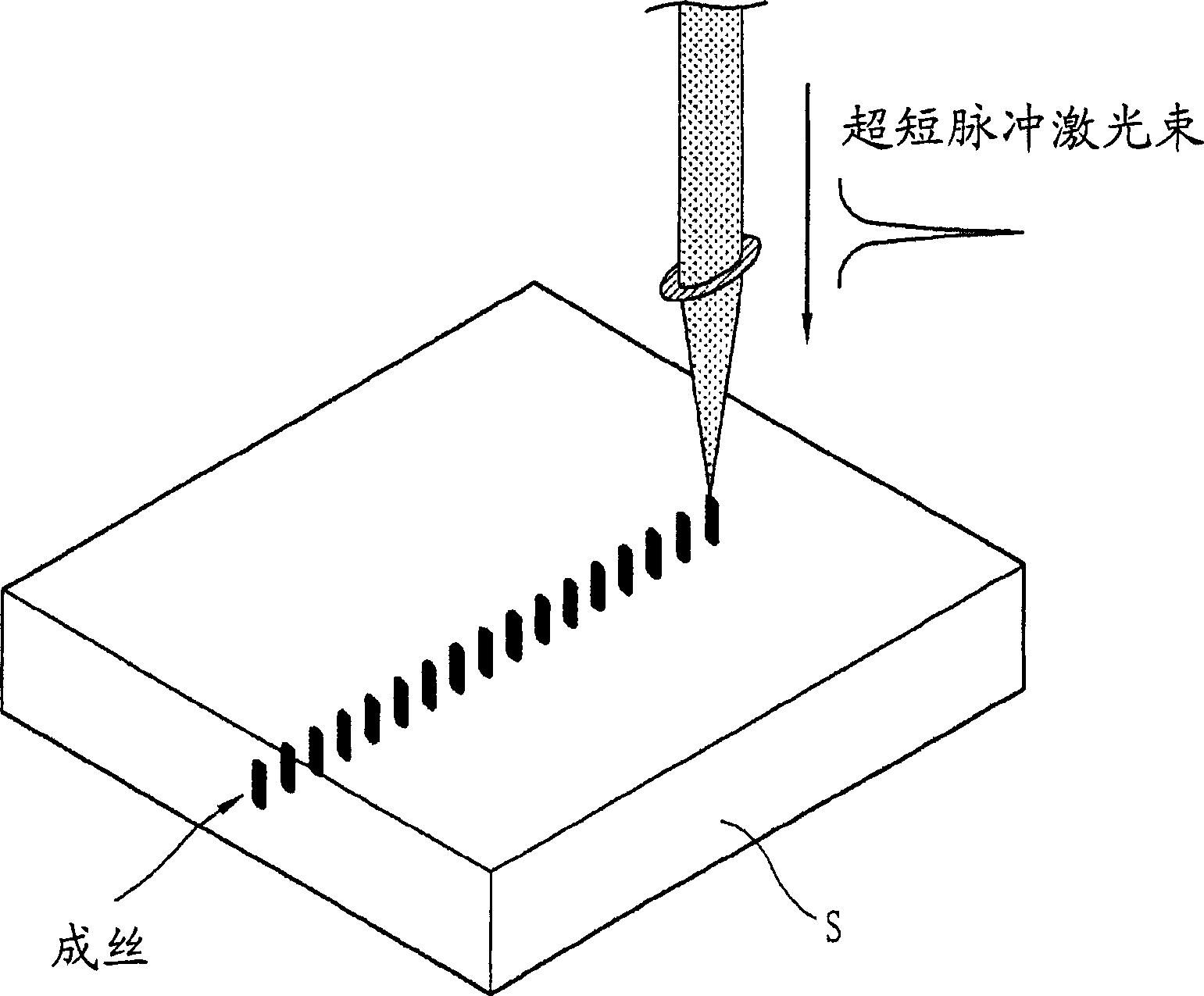

A cutter for substrate using microwaves laser beam and method thereof

InactiveCN101391860AHigh precisionAvoid heat damageSemiconductor/solid-state device manufacturingGlass severing apparatusMicrowaveDisplay device

The invention relates to a substrate cutting device by using ultrashort pulse laser bean and a cutting method thereof. Ultrashort pulse laser from FS to PS is used, complex per / post procedures are simplified as far as possible unrelated to substrate characteristic of glass or transparent material, wherein the substrate characteristic of glass or transparent material is a little different according to use and property of displays, thereby preventing unwanted cutting, gaps or damage, and minimizing defect rate. The substrate cutting device by using ultrashort pulse laser bean comprises a laser generating unit which generates ultrasonic pulse laser bean; a focus adjusting unit for adjustment to focus the ultrashort pulse laser bean on the internal of the substrate to be cut, which guides internal filament forming phenomenon to form a cutting groove in the substrate by focusing the ultrashort pulse laser bean on the internal of the substrate and radiating along the desired cutting path. Substrates of diversified displays can be quickly cut with high precision by simple procedure without generation of damage and gaps.

Owner:RAINBOW SUN

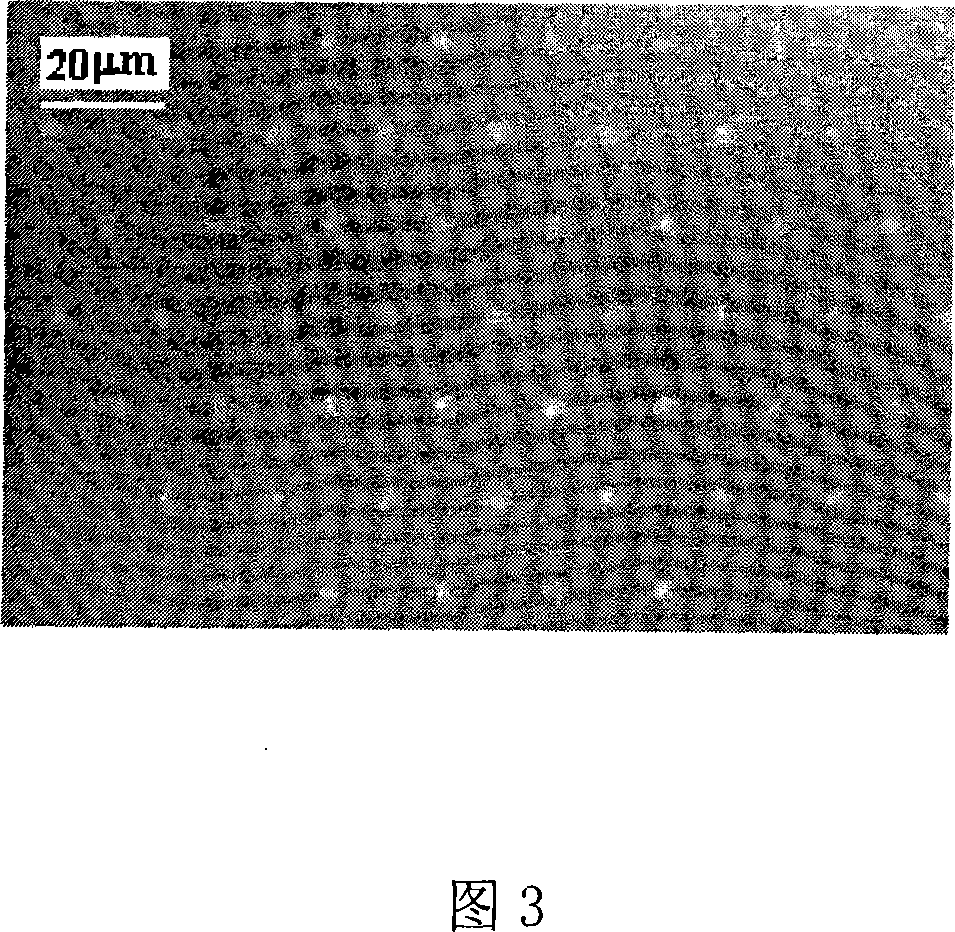

Method for fabricating thin films

A method of ultrashort pulsed laser deposition (PLD) capable of continuously tuning formed-film morphology from that of a nanoparticle aggregate to a smooth thin film completely free of particles and droplets. The materials that can be synthesized using various embodiments of the invention include, but are not limited to, metals, alloys, metal oxides, and semiconductors. A ‘burst’ mode of ultrashort pulsed laser ablation and deposition is provided, where each ‘burst’ contains a train of laser pulses. Tuning of the film morphology is achieved by controlling the burst-mode parameters such as the number of pulses and the time-spacing between the pulses within each burst, the burst repetition rate, and the laser fluence. The system includes an ultrashort pulsed laser, an optical setup for delivering the laser beam such that the beam is focused onto the target surface with an appropriate average energy density (fluence), and a vacuum chamber in which the target and the substrate are installed and background gases and their pressures are appropriately adjusted.

Owner:IMRA AMERICA

Ultrashort pulse laser applications

The invention relates to methods of processing biological tissue using an ultrashort pulse (USP) laser. In one embodiment, the invention relates to a method of separating transverse layers or portions of a biological tissue using USP laser. In an alternative embodiment, the invention relates to a method of cutting biological tissue using USP laser. In another embodiment, the invention relates to a method of removing unwanted material from the surface of a biological tissue comprising application of the USP laser to the tissue surface.

Owner:GUO ZHIXIONG +3

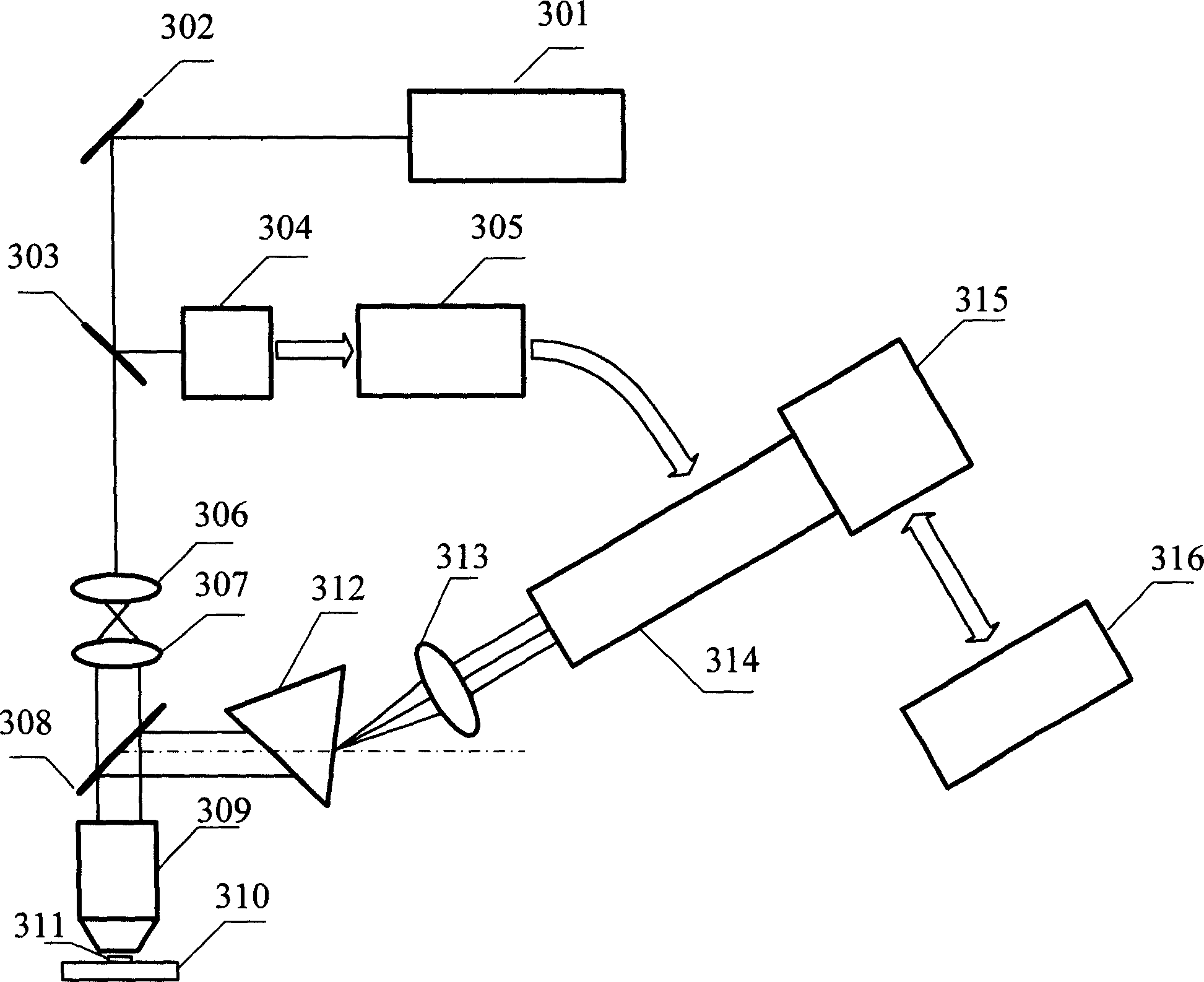

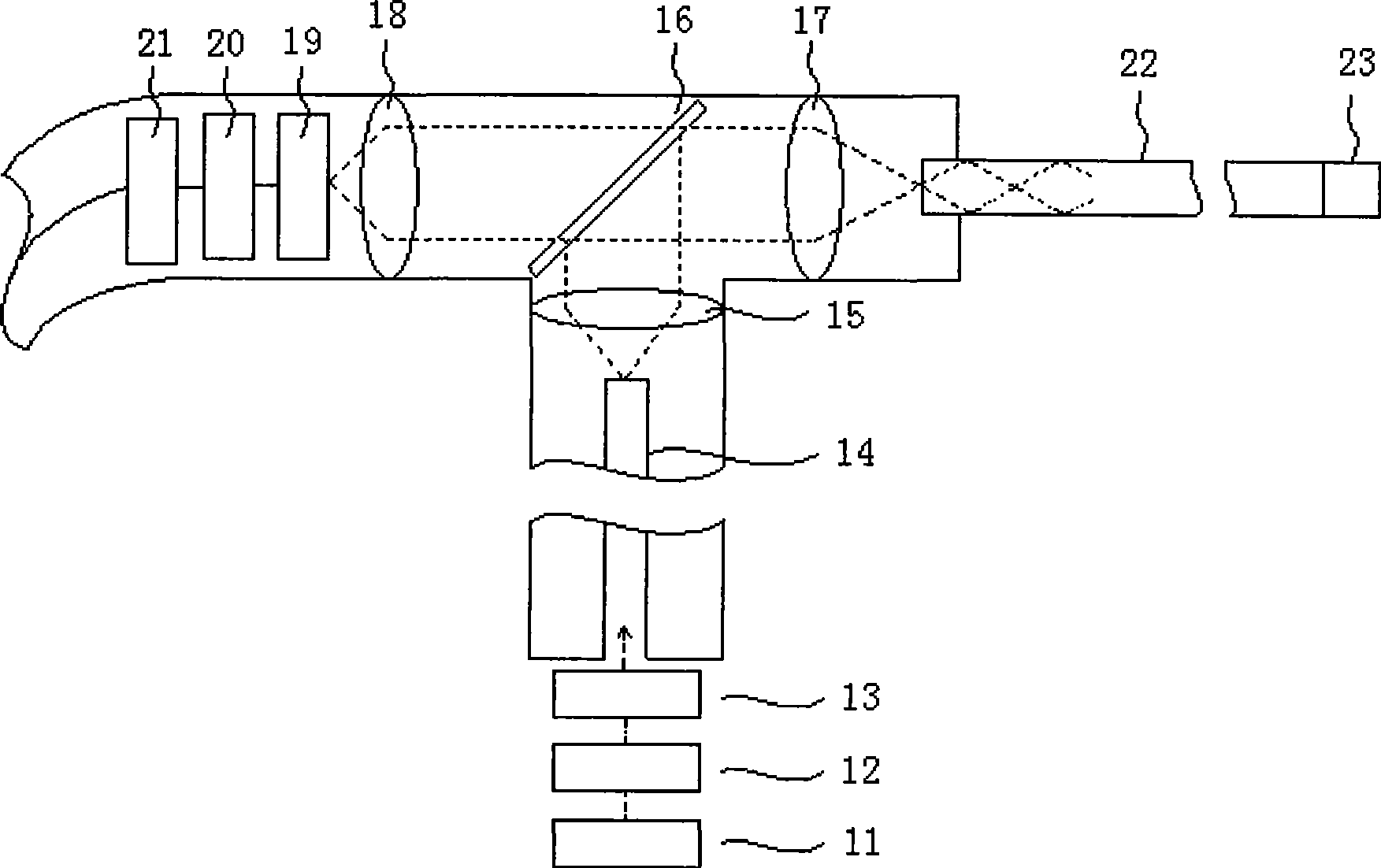

Method and apparatus for producing fibre-optical FP sensor by ultrashort pulse laser fine machining

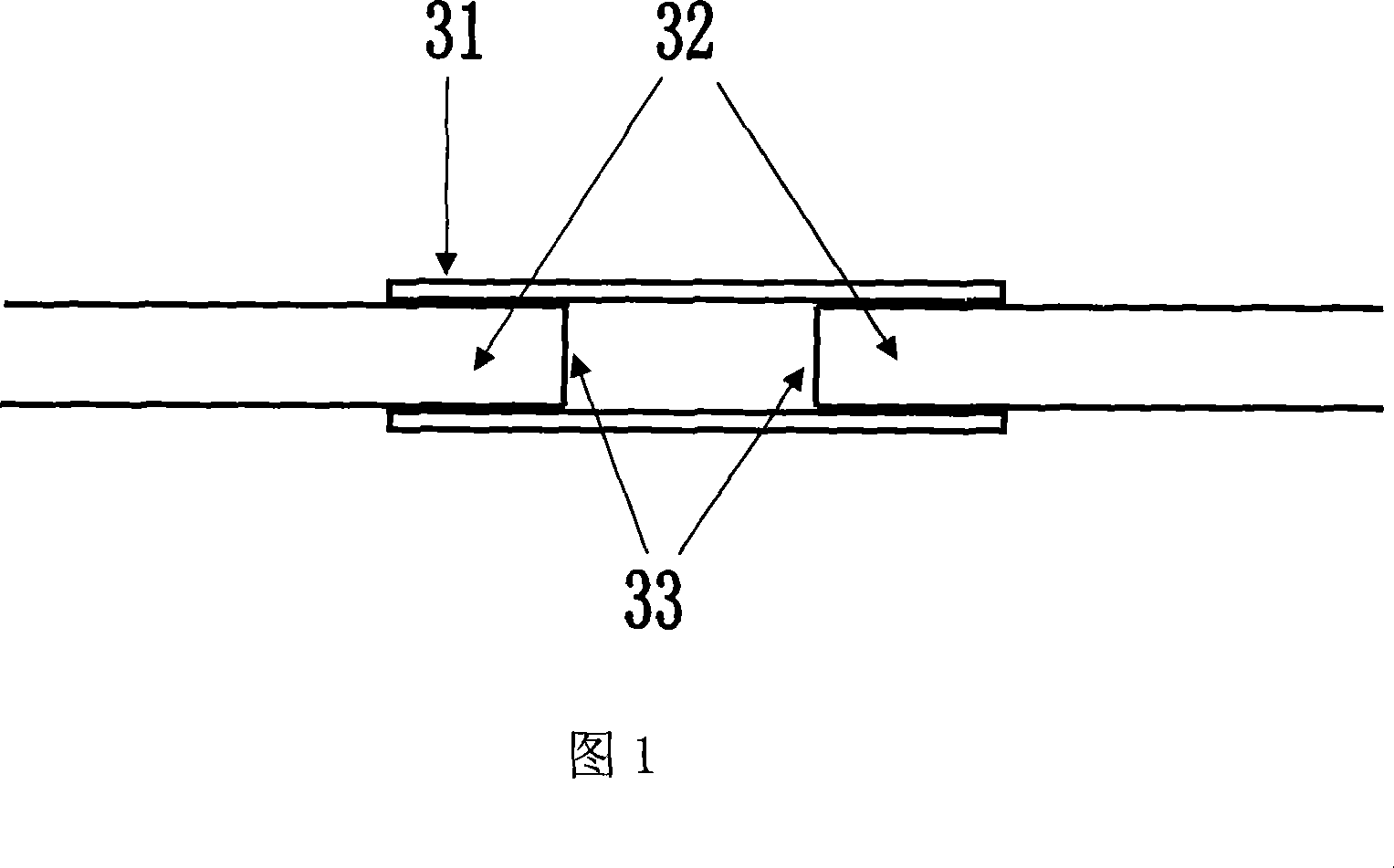

InactiveCN101028670AImprove sensor sensitivityGood compatibilityLaser beam welding apparatusCcd cameraUltrashort pulse laser

An ultra-short pulse laser micromachining technology for preparing F-P sensor of optical fiber features that the ultra-short pulse laser beam is fully reflected by a full-reflecting mirror, then focused by a focusing system and finally used to machine an F-P cavity on an optical fiber to generate an F-P sensor, and the machined image and it position on optical fiber are reflected via a half-mirror to a CCD camera and then transmitted to a monitor. Its apparatus is also disclosed.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Single-optical fiber multiphoton fluorescence scanning endoscope

InactiveCN101485558AEnables early screeningImprove the detection rateEndoscopesDiagnostics using fluorescence emissionCancer cellAcousto-optics

The invention relates to a single-fiber multi-photon fluorescent scanning endoscope, applied in early screening and diagnosis of various mucosa cancers of human body. A single mode fiber is carried inside an endoscope system to enter a human body and guide extracorporeal ultrashort pulse laser into intracorporeal target cell, and an acousto-optic deflector is adopted to carry out laser deflexion in two orthogonal directions; moreover, the endoscope adopts a piezocrystal to perform fine adjustment on the focus of the lens group so as to adjust fluorescence excitation depth, and adopts a multi-photon fluorescent imaging mechanism to eliminate confocal pinholes; therefore, the endoscope reduces the process difficulty of making acousto-optic deflexion scanning front end and also overcomes mechanical inertia of devices adopting micromechanics to realize deflexion scanning so as to ensure convenient integrated molding and miniaturization of an entire scanning imaging tail end. The system provided by the invention can carry out cell morphologic analysis on suspect cancer cells at low cost during routine endoscope examination.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

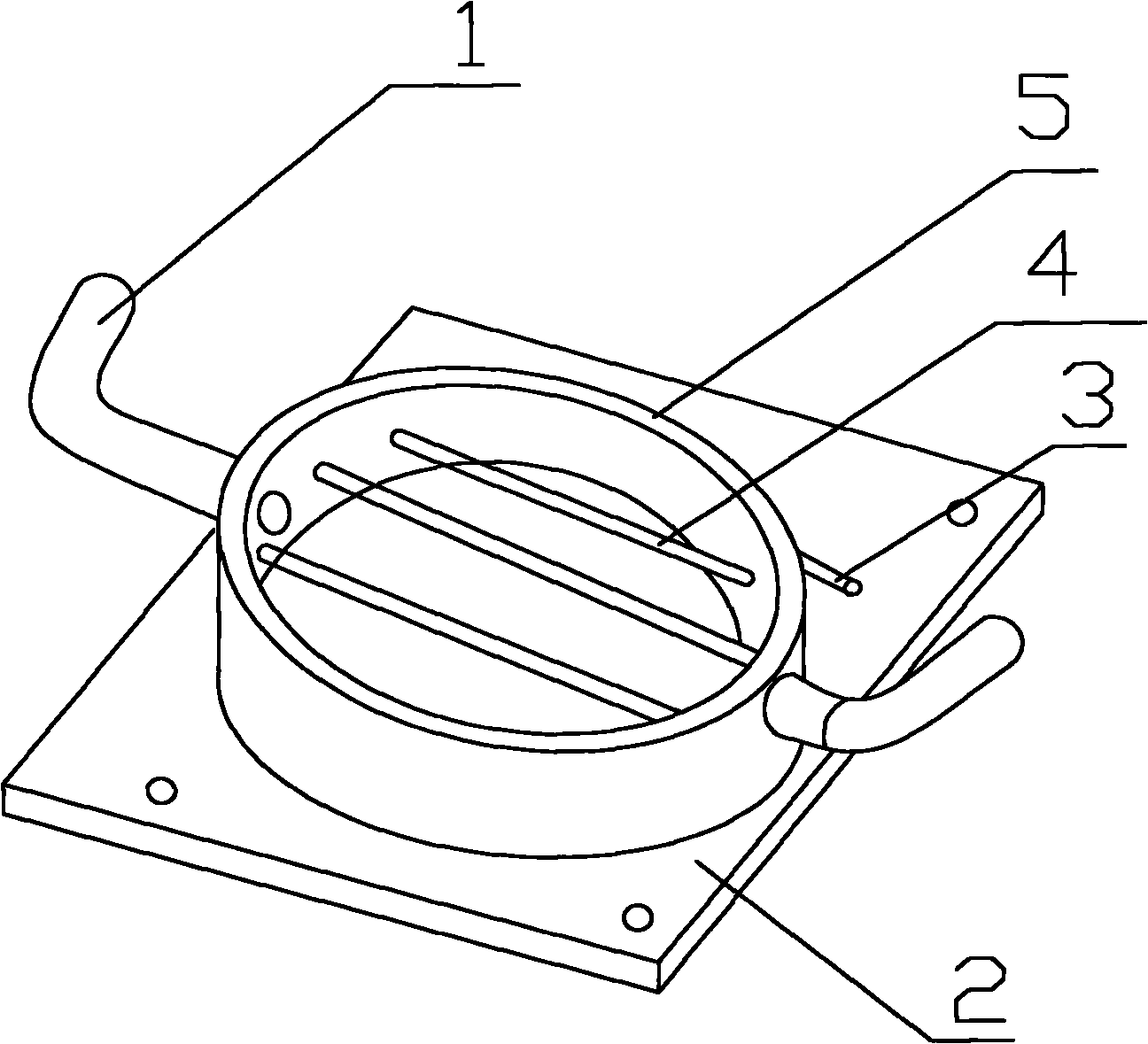

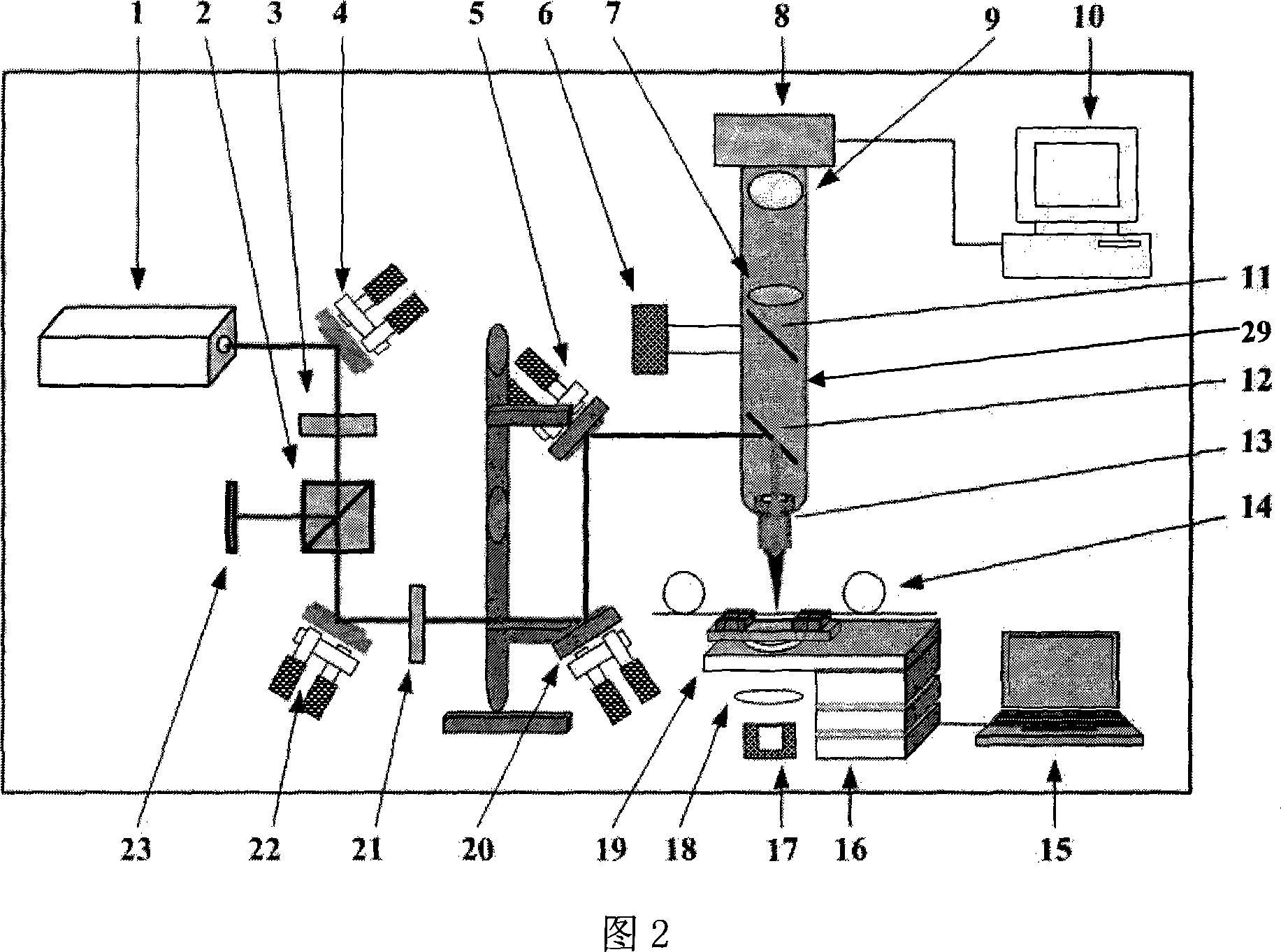

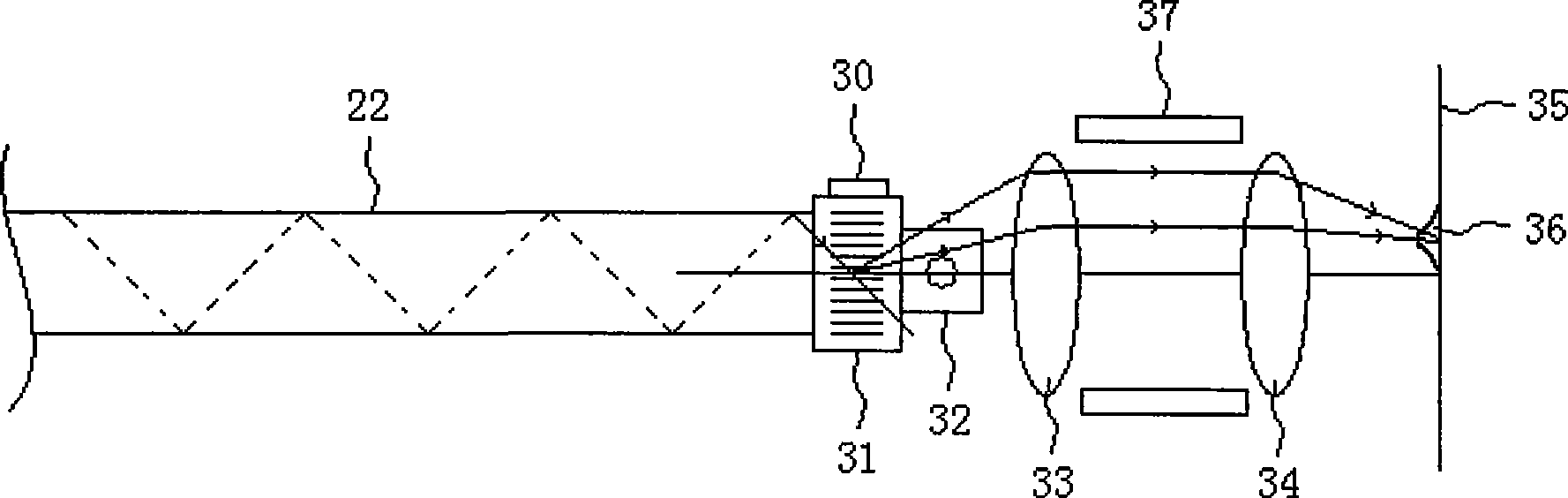

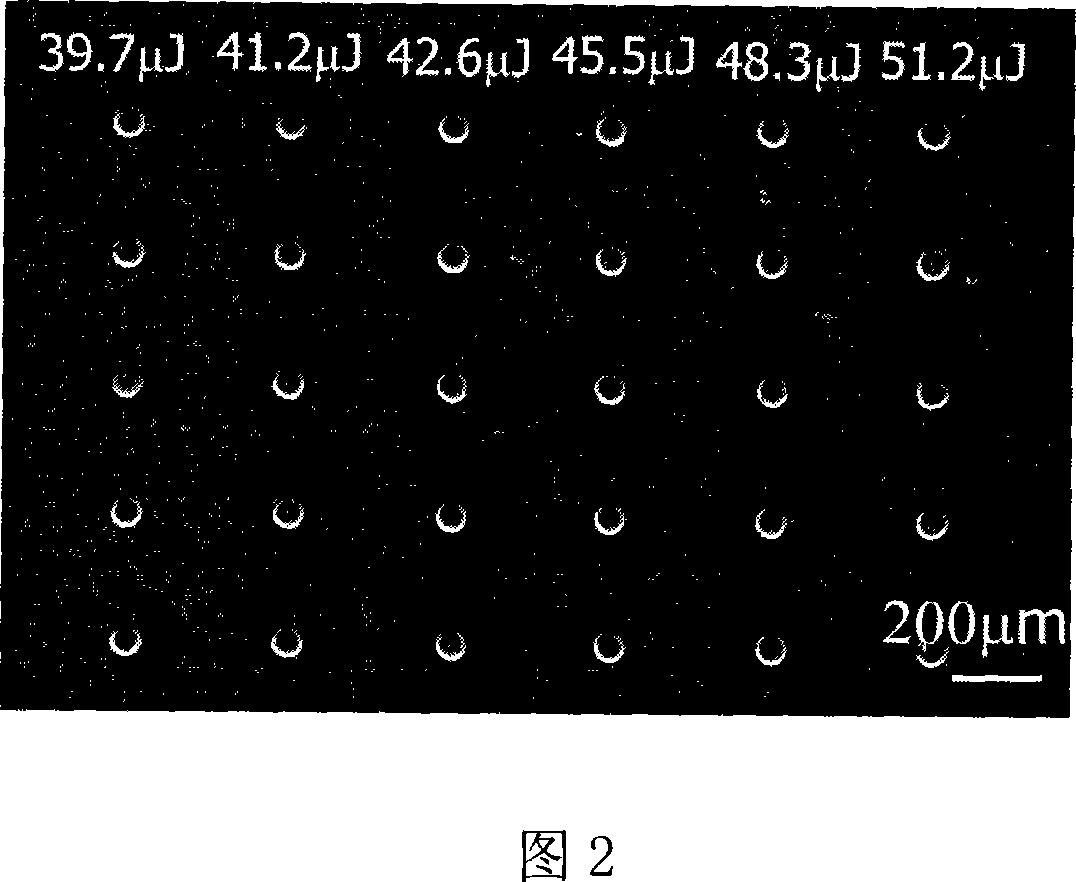

Method and apparatus for ultrashort pulse laser parallel fine machining

InactiveCN101028671AImprove processing efficiencyPrevent sputtering and contaminationLaser beam welding apparatusLaser processingOptoelectronics

A parallel ultra-short pulse laser micromachining technology is characterized by that an ultra-short pulse laser beam passes through a microlense array to become multiple divergent ultra-short pulse laser beams, which are then focused onto a focal plane on a workpiece by a focusing system for micromachining on it. Its apparatus is also disclosed.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

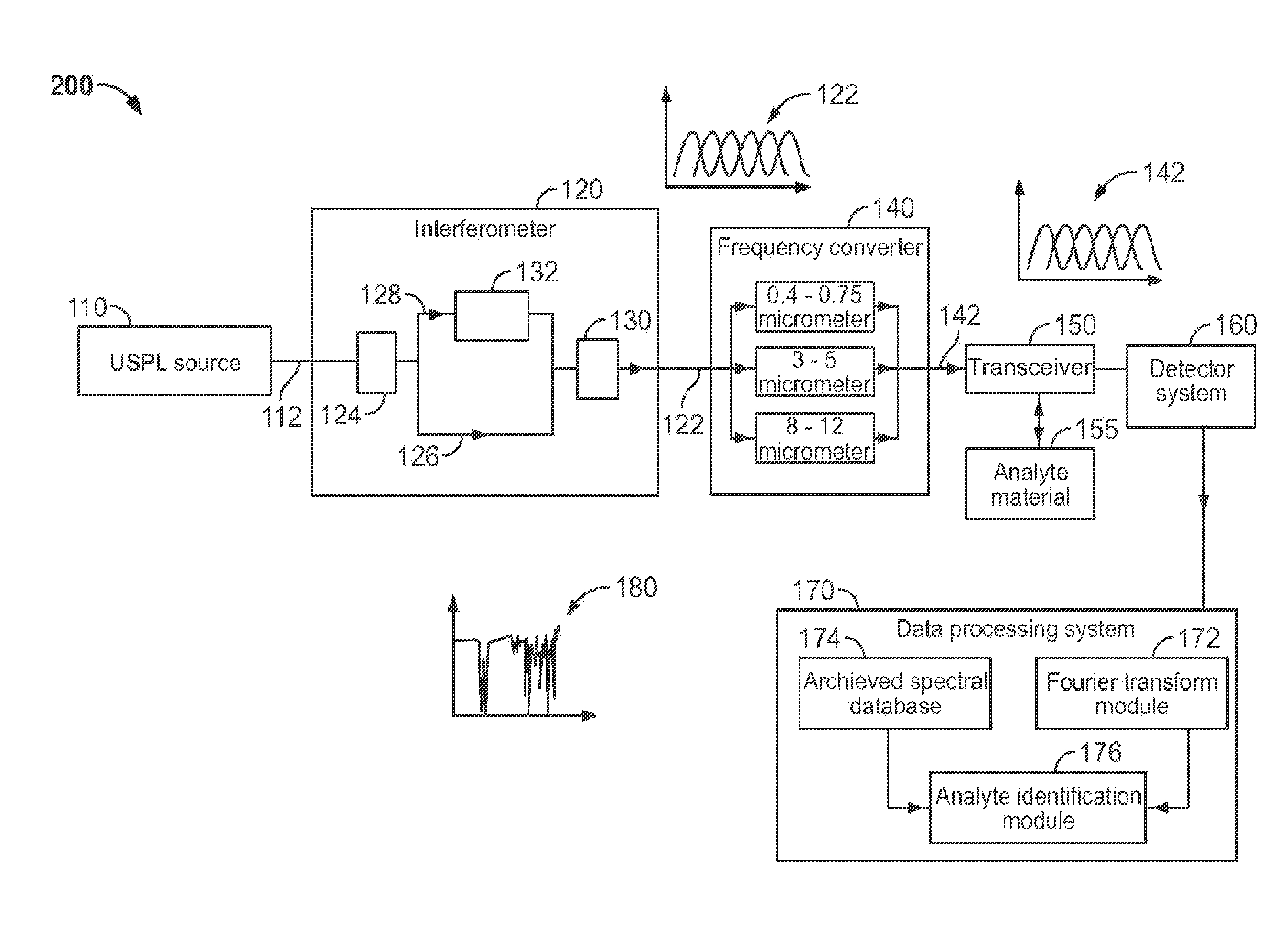

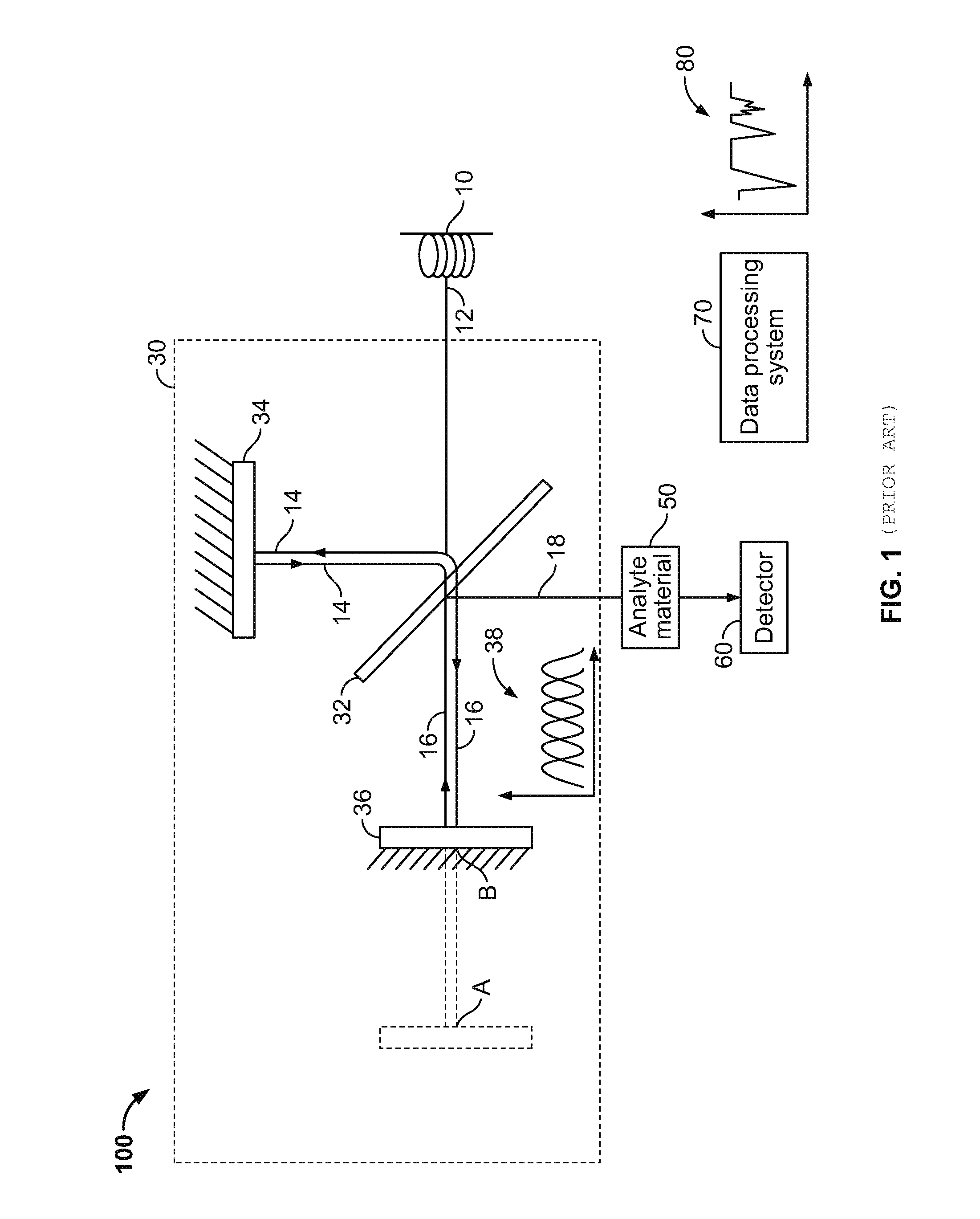

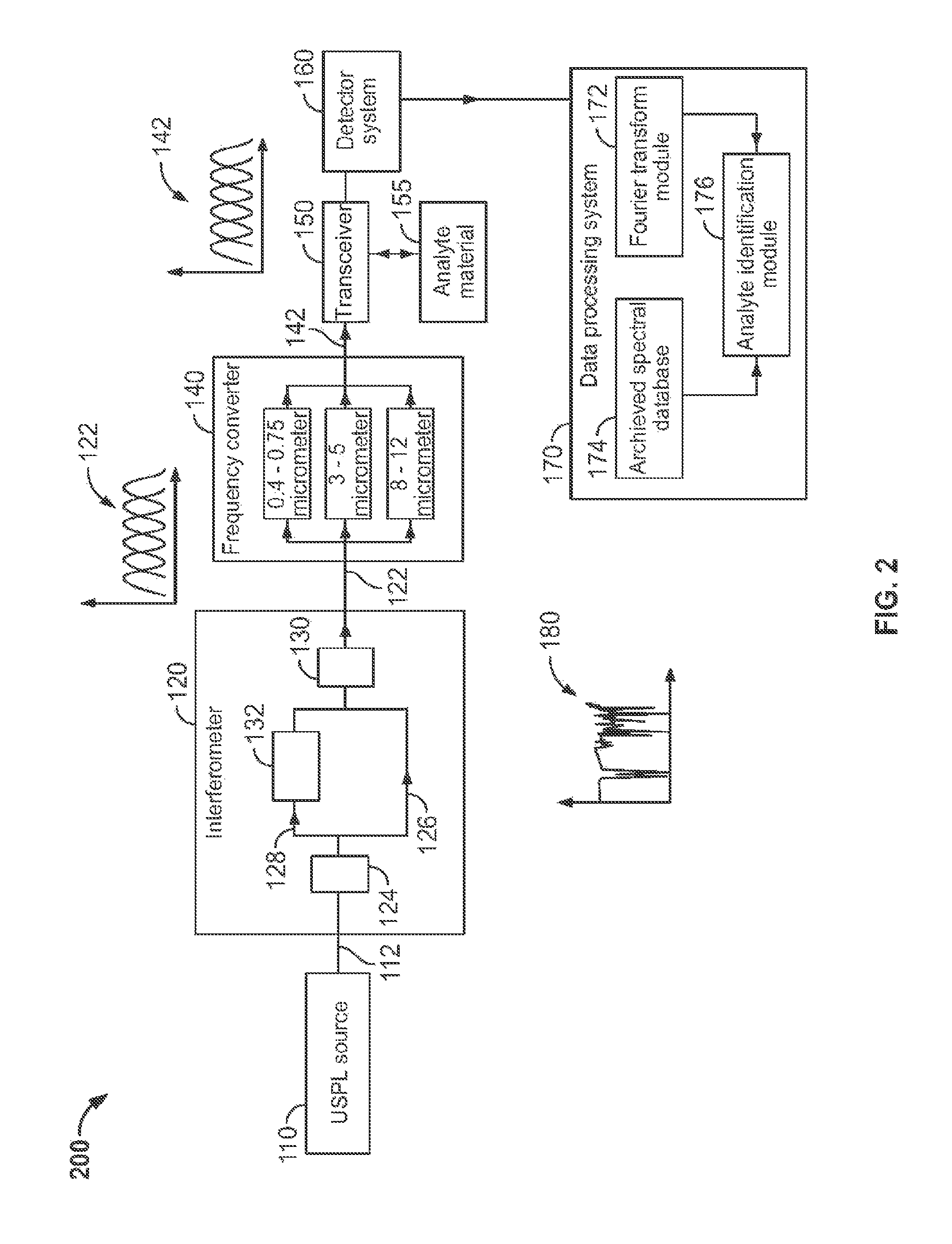

Spectrometer for identifying analyte materials

A spectrometer for identifying an analyte material. One embodiment of the spectrometer includes a single ultrashort pulsed laser (USPL) source, a fiber interferometer, a frequency converter and a transceiver. The USPL source is configured to generate a laser beam. The interferometer is operatively coupled to the USPL source, and is configured to split the laser beam into a first laser beam and a second laser beam, providing a variable difference in lengths between the paths of the first laser beam and the second laser beam. The spectrometer then electronically scans the variable-path second laser beam over the first laser beam to generate interferogram patterns. The frequency converter is configured to receive the interferogram patterns from the interferometer, and perform a frequency conversion of the interferogram patterns to form an output beam. The transceiver is configured to transmit the output beam and to receive radiation from the analyte material. The radiation is thereafter used to identify the analyte material.

Owner:SYSTEM PLANNING CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com