Patents

Literature

2649results about "Electric discharge heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

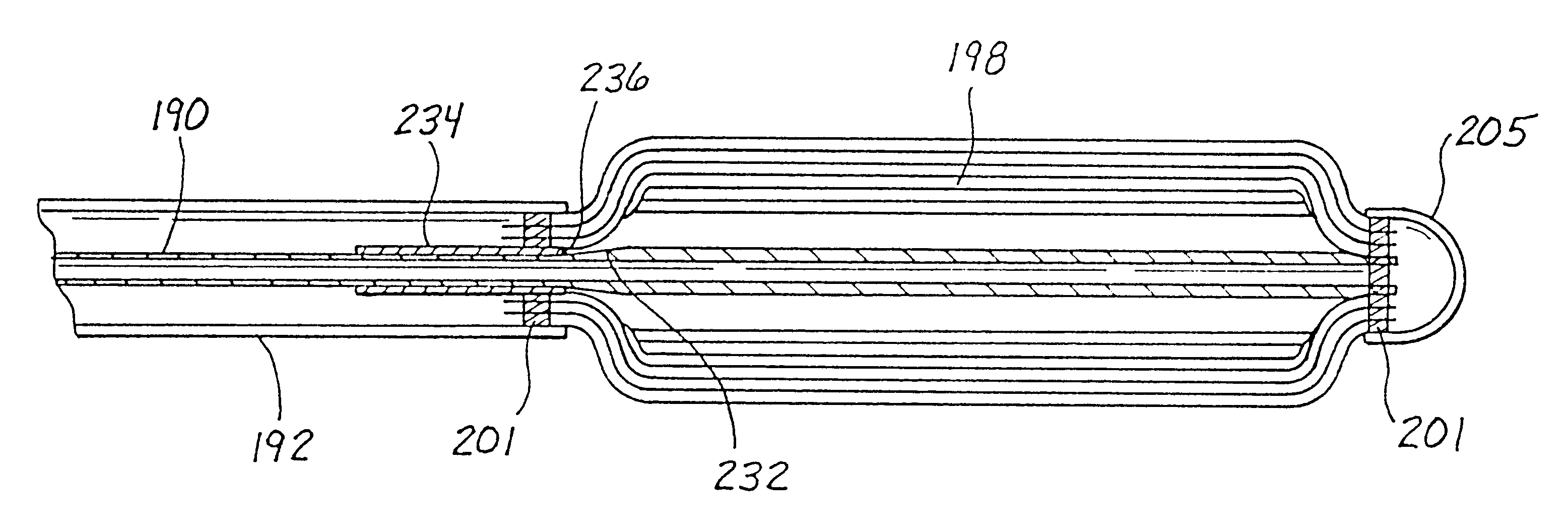

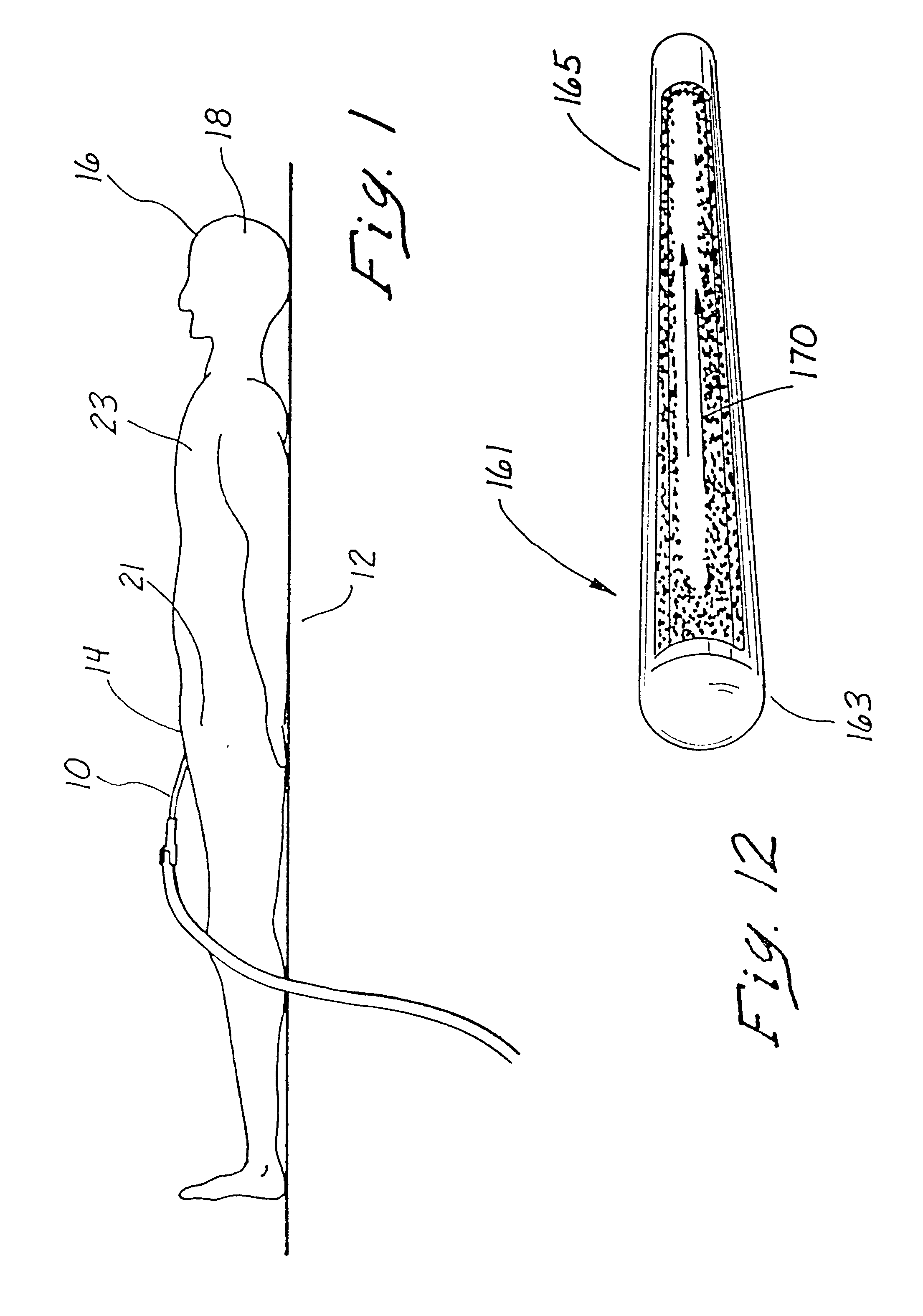

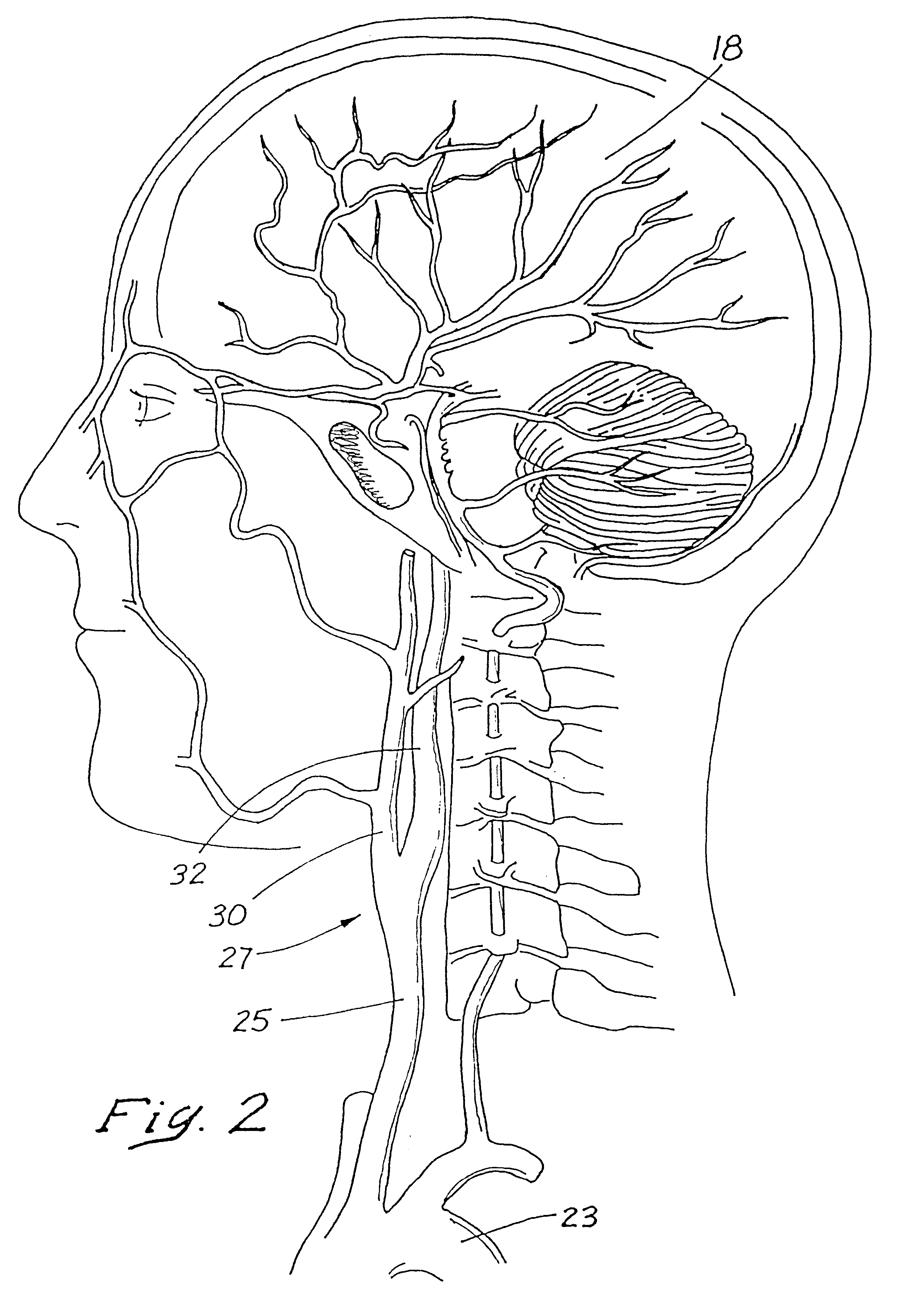

Indwelling heat exchange catheter and method of using same

A catheter is adapted to exchange heat with a body fluid, such as blood, flowing in a body conduit, such as a blood vessel. The catheter includes a shaft with a heat exchange region disposed at its distal end. This region may include hollow fibers which are adapted to receive a remotely cooled heat exchange fluid preferably flowing in a direction counter to that of the body fluid. The hollow fibers enhance the surface area of contact, as well as the mixing of both the heat exchange fluid and the body fluid. The catheter can be positioned to produce hypothermia in a selective area of the body or alternatively positioned to systemically cool the entire body system.

Owner:ZOLL CIRCULATION +1

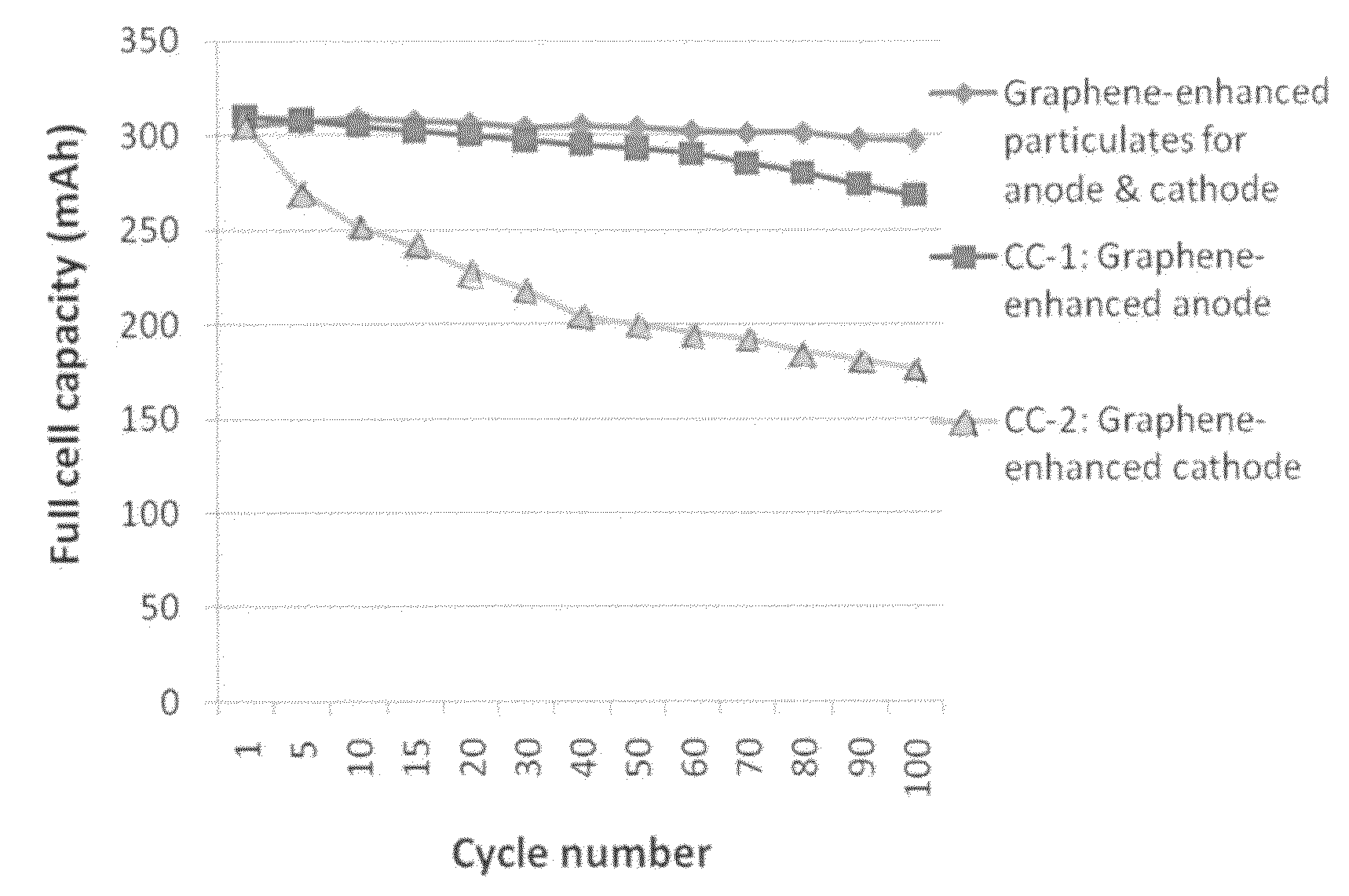

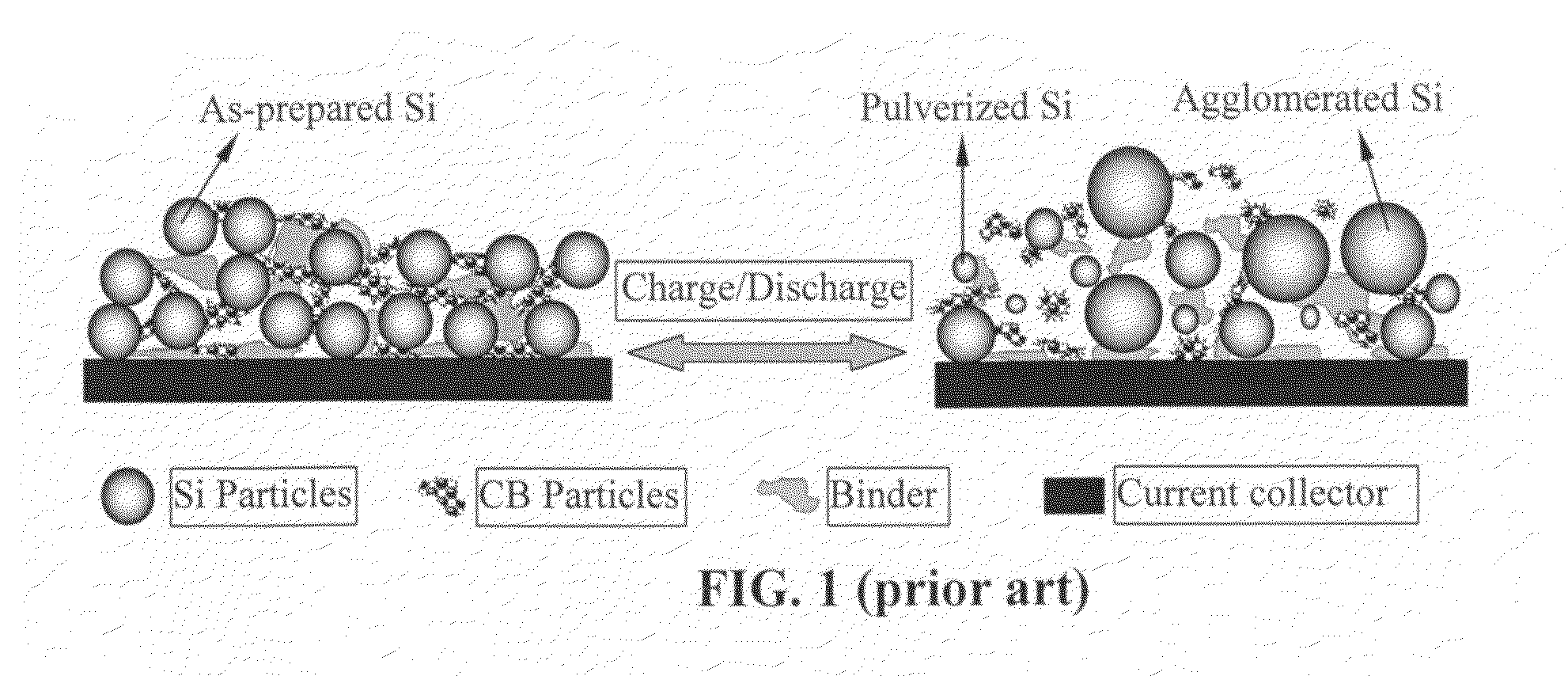

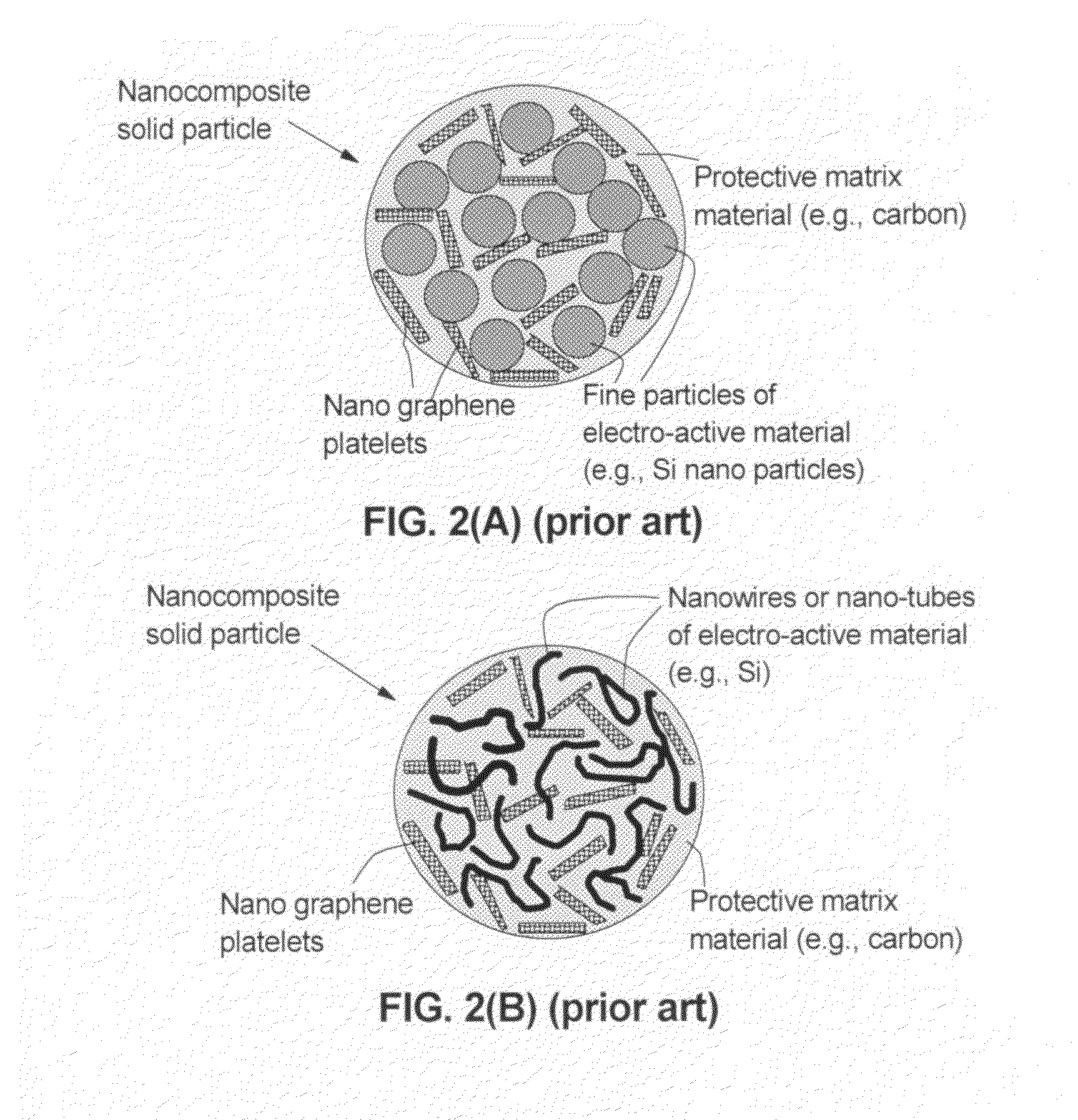

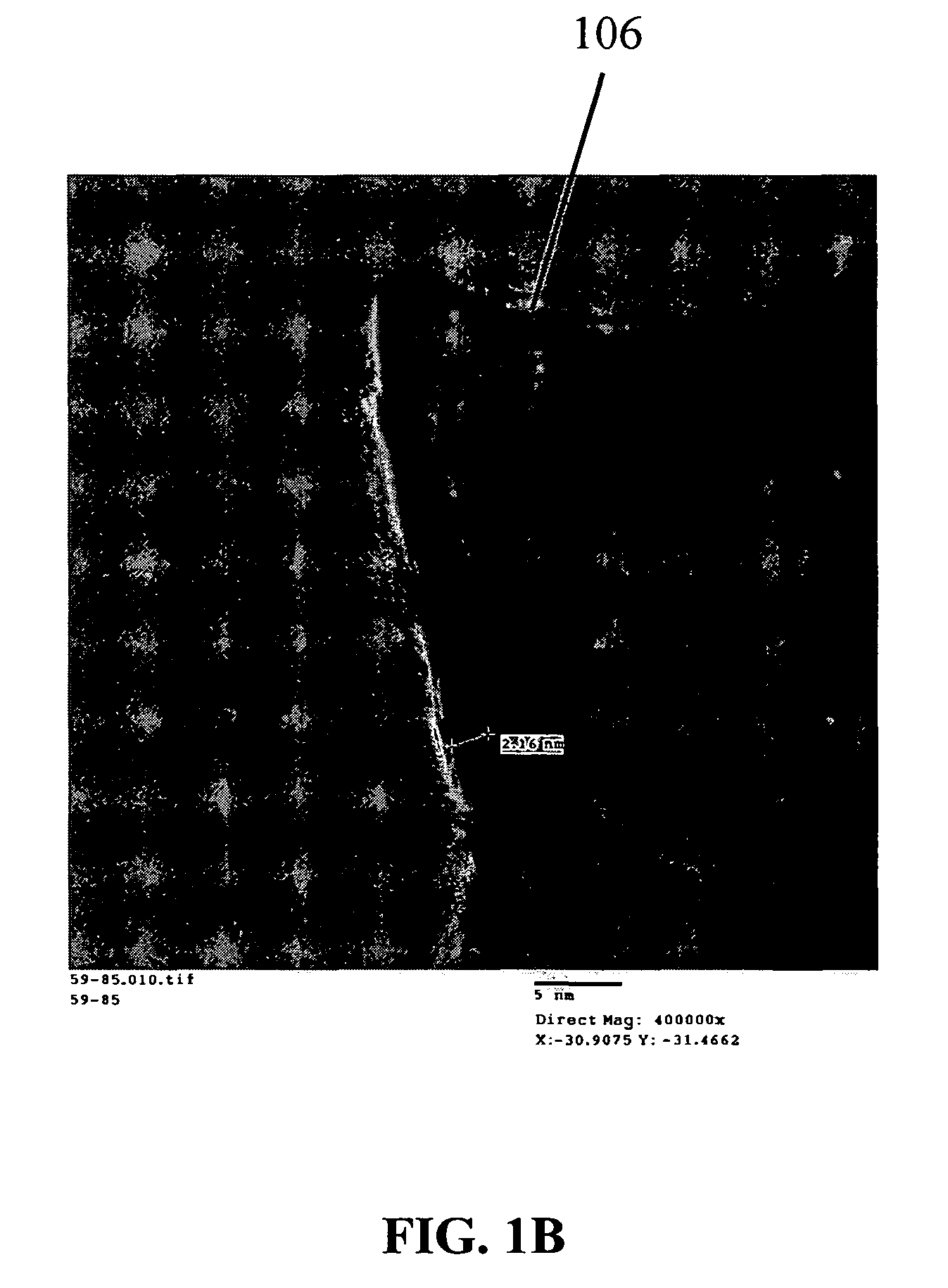

Graphene-enhanced anode particulates for lithium ion batteries

ActiveUS20120064409A1Enhanced Li-ion insertionIncrease capacityNon-metal conductorsMaterial nanotechnologyParticulatesMicroparticle

A nano graphene-enhanced particulate for use as a lithium-ion battery anode active material, wherein the particulate is formed of a single sheet of graphene or a plurality of graphene sheets and a plurality of fine anode active material particles with a size smaller than 10 μm. The graphene sheets and the particles are mutually bonded or agglomerated into the particulate with at least a graphene sheet embracing the anode active material particles. The amount of graphene is at least 0.01% by weight and the amount of the anode active material is at least 0.1% by weight, all based on the total weight of the particulate. A lithium-ion battery having an anode containing these graphene-enhanced particulates exhibits a stable charge and discharge cycling response, a high specific capacity per unit mass, a high first-cycle efficiency, a high capacity per electrode volume, and a long cycle life.

Owner:SAMSUNG ELECTRONICS CO LTD +1

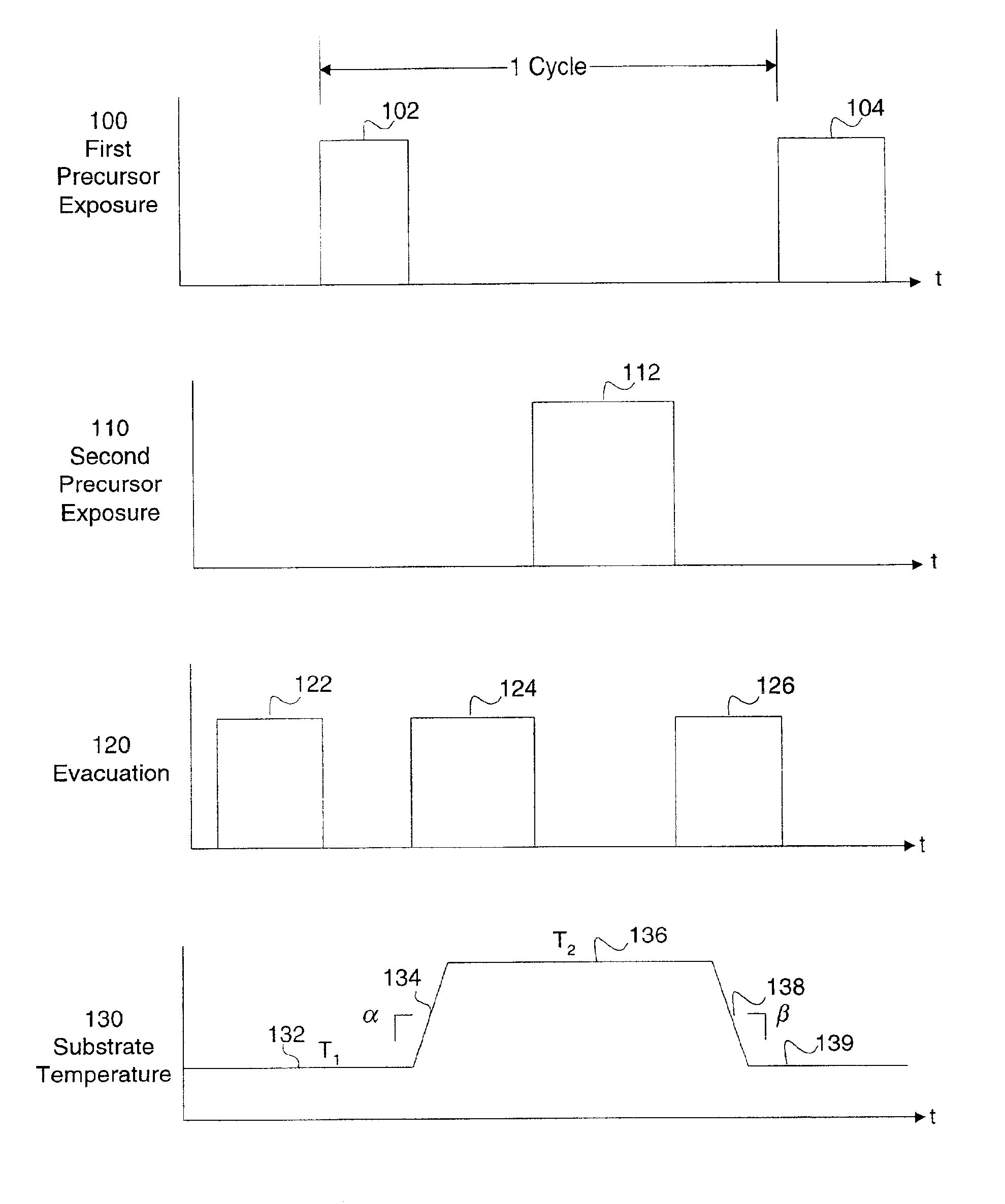

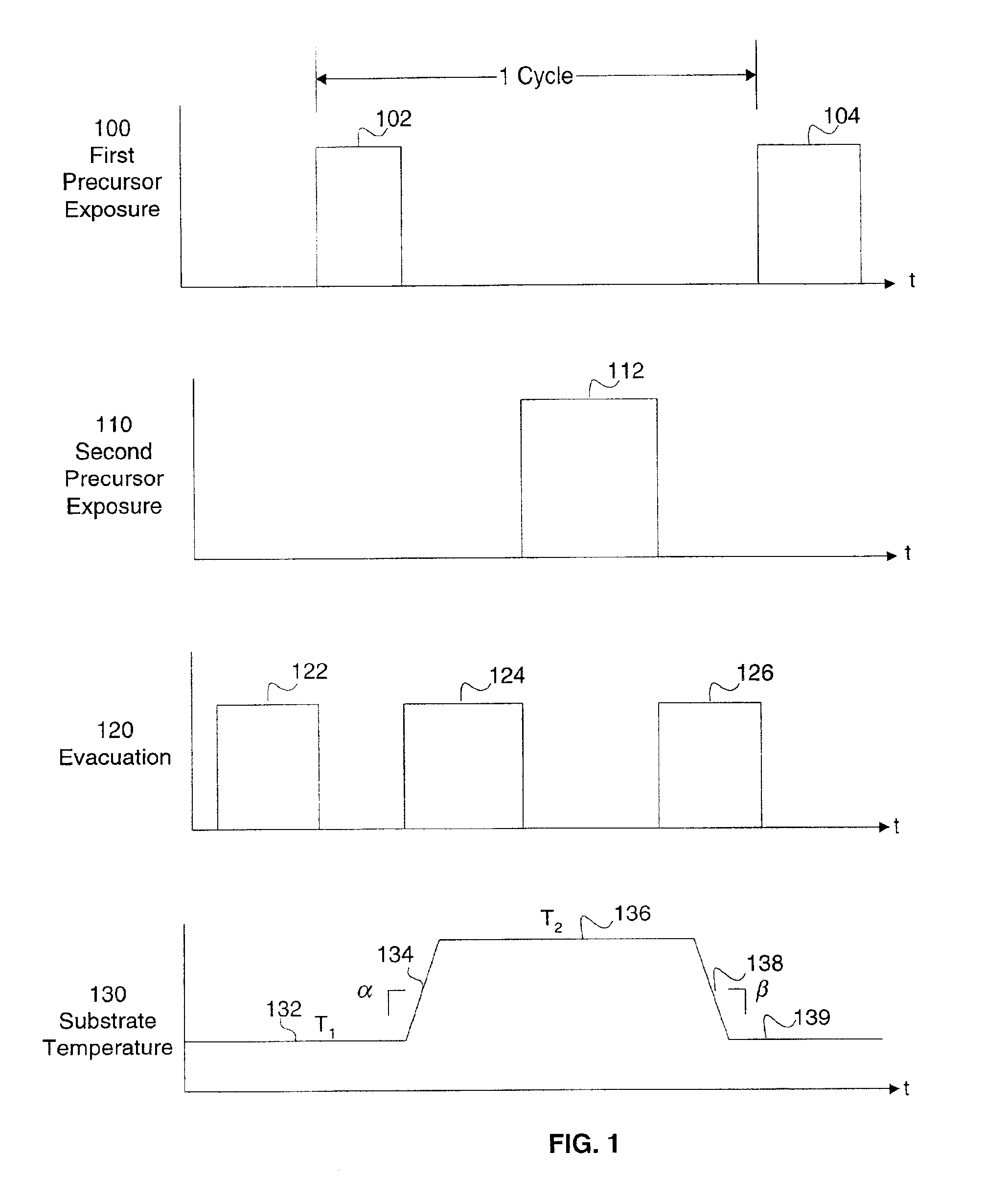

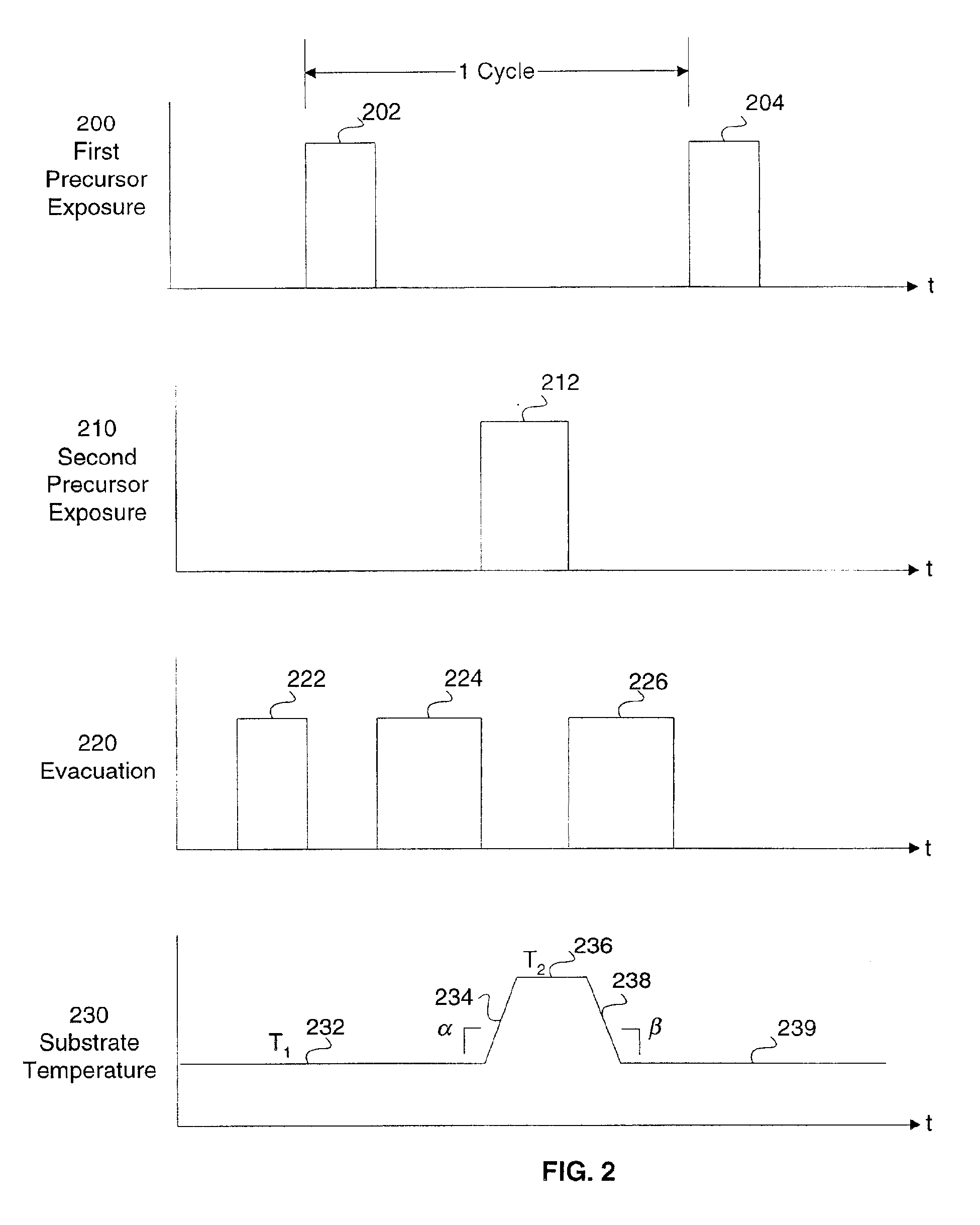

Method and apparatus for improved temperature control in atomic layer deposition

InactiveUS6878402B2Electric discharge heatingVacuum evaporation coatingTemperature controlThermal state

A system and method for that allows one part of an atomic layer deposition (ALD) process sequence to occur at a first temperature while allowing another part of the ALD process sequence to occur at a second temperature. In such a fashion, the first temperature can be chosen to be lower such that decomposition or desorption of the adsorbed first reactant does not occur, and the second temperature can be chosen to be higher such that comparably greater deposition rate and film purity can be achieved. Additionally, the invention relates to improved temperature control in ALD to switch between these two thermal states in rapid succession. It is emphasized that this abstract is provided to comply with rules requiring an abstract. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims.

Owner:NOVELLUS SYSTEMS

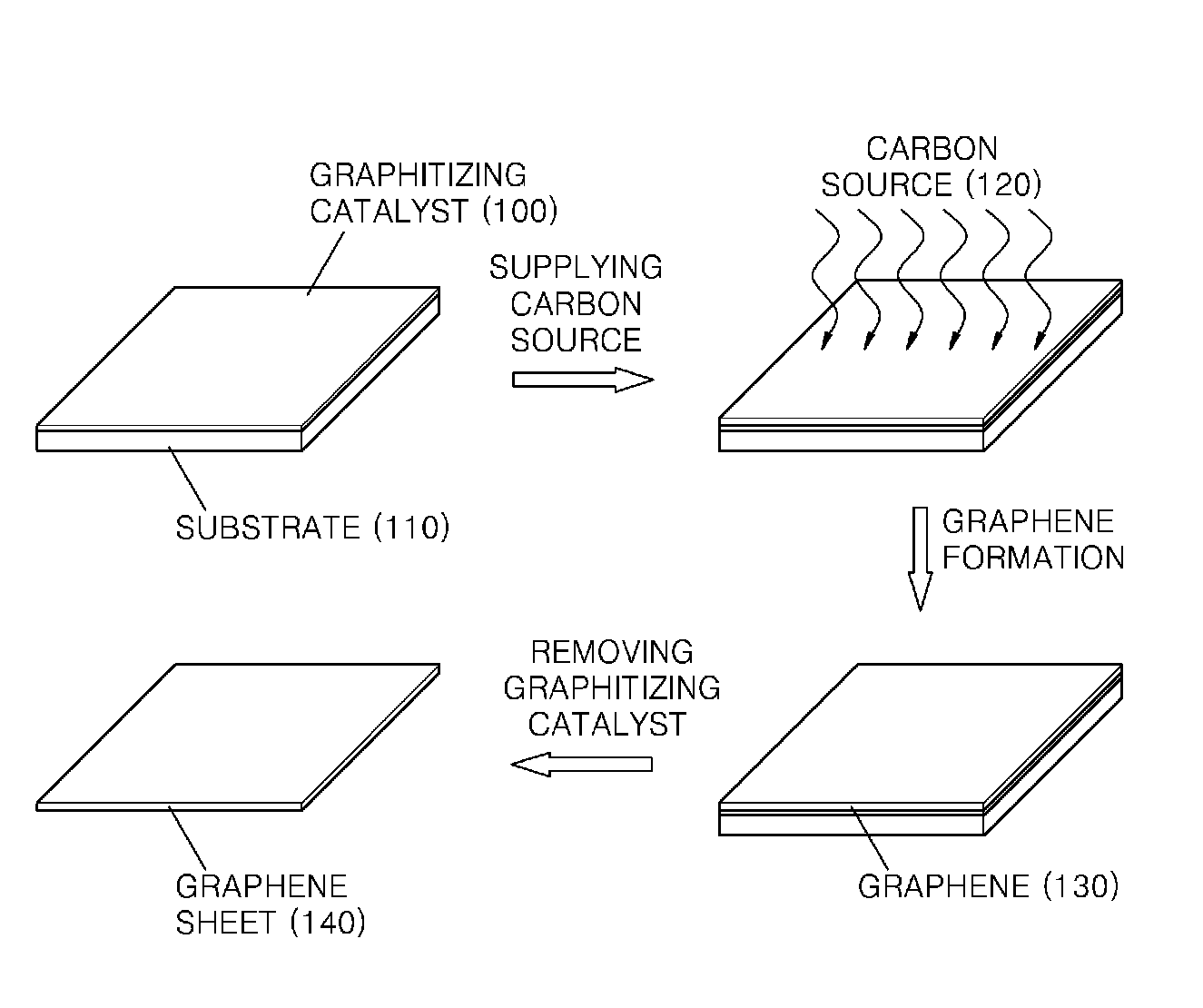

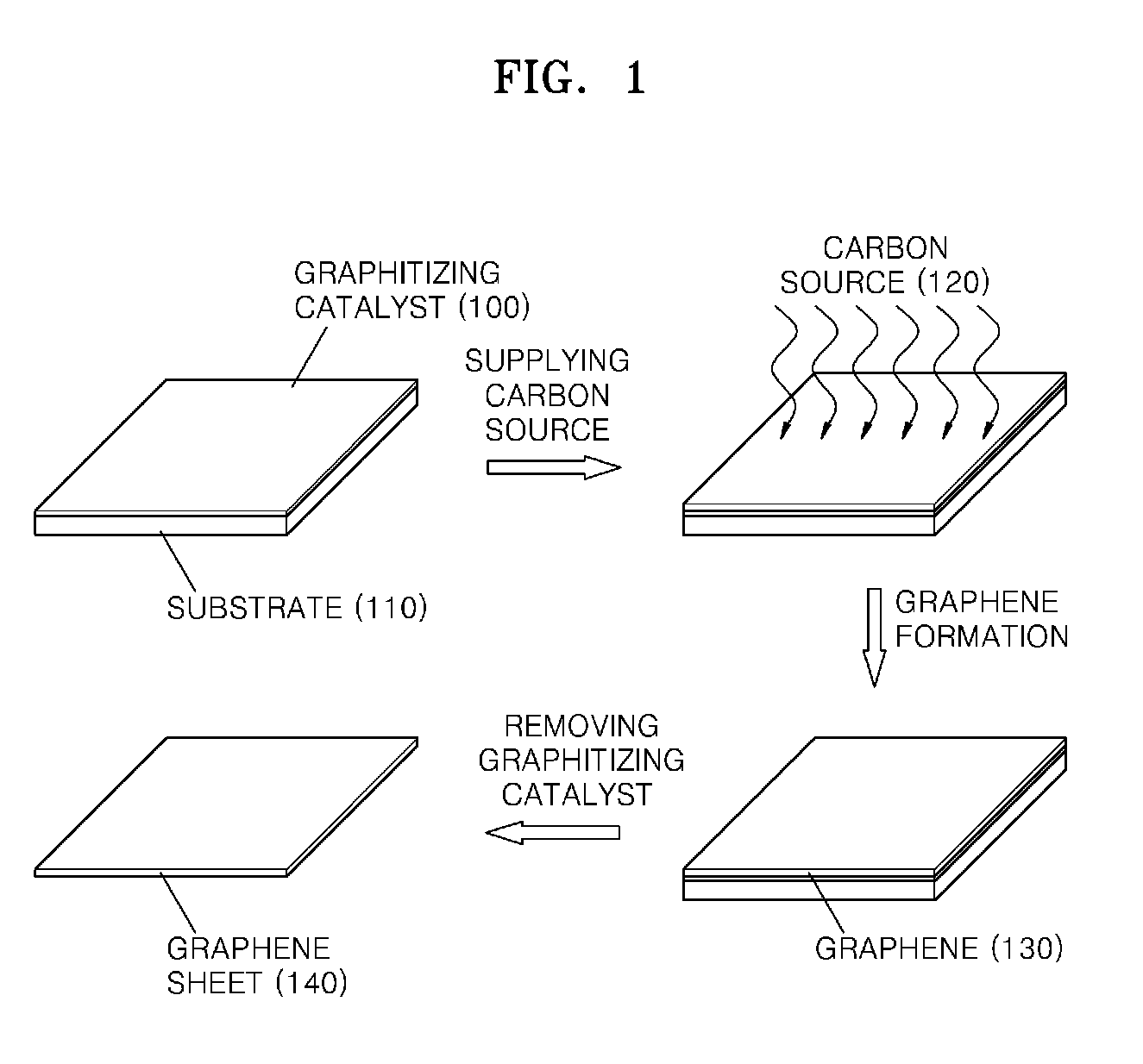

Graphene sheet and method of preparing the same

An economical method of preparing a large-sized graphene sheet having a desired thickness includes forming a film, the film comprising a graphitizing catalyst; heat-treating a gaseous carbon source in the presence of the graphitizing catalyst to form graphene; and cooling the graphene to form a graphene sheet. A graphene sheet prepared according to the disclosed method is also described.

Owner:SAMSUNG ELECTRONICS CO LTD

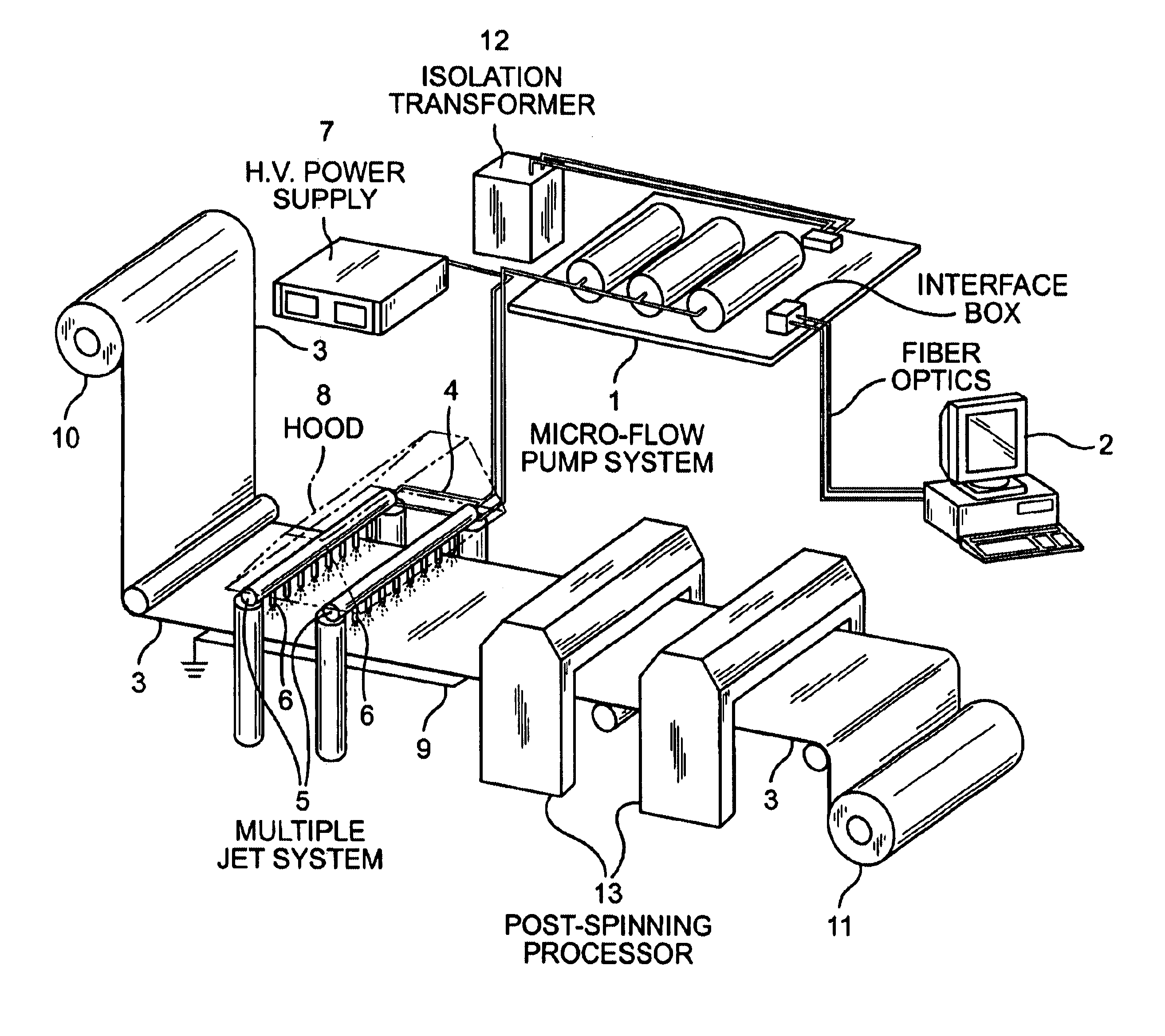

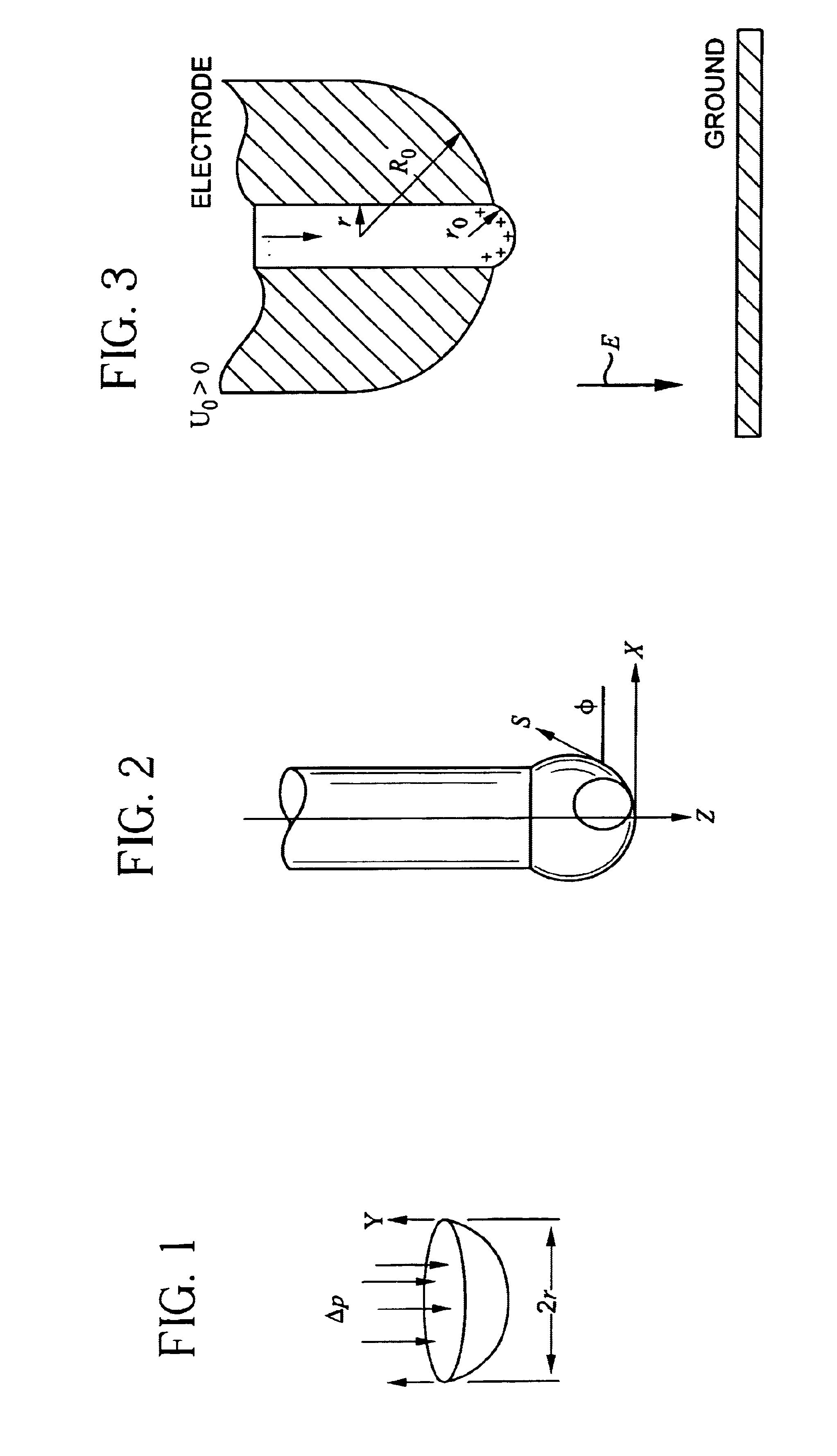

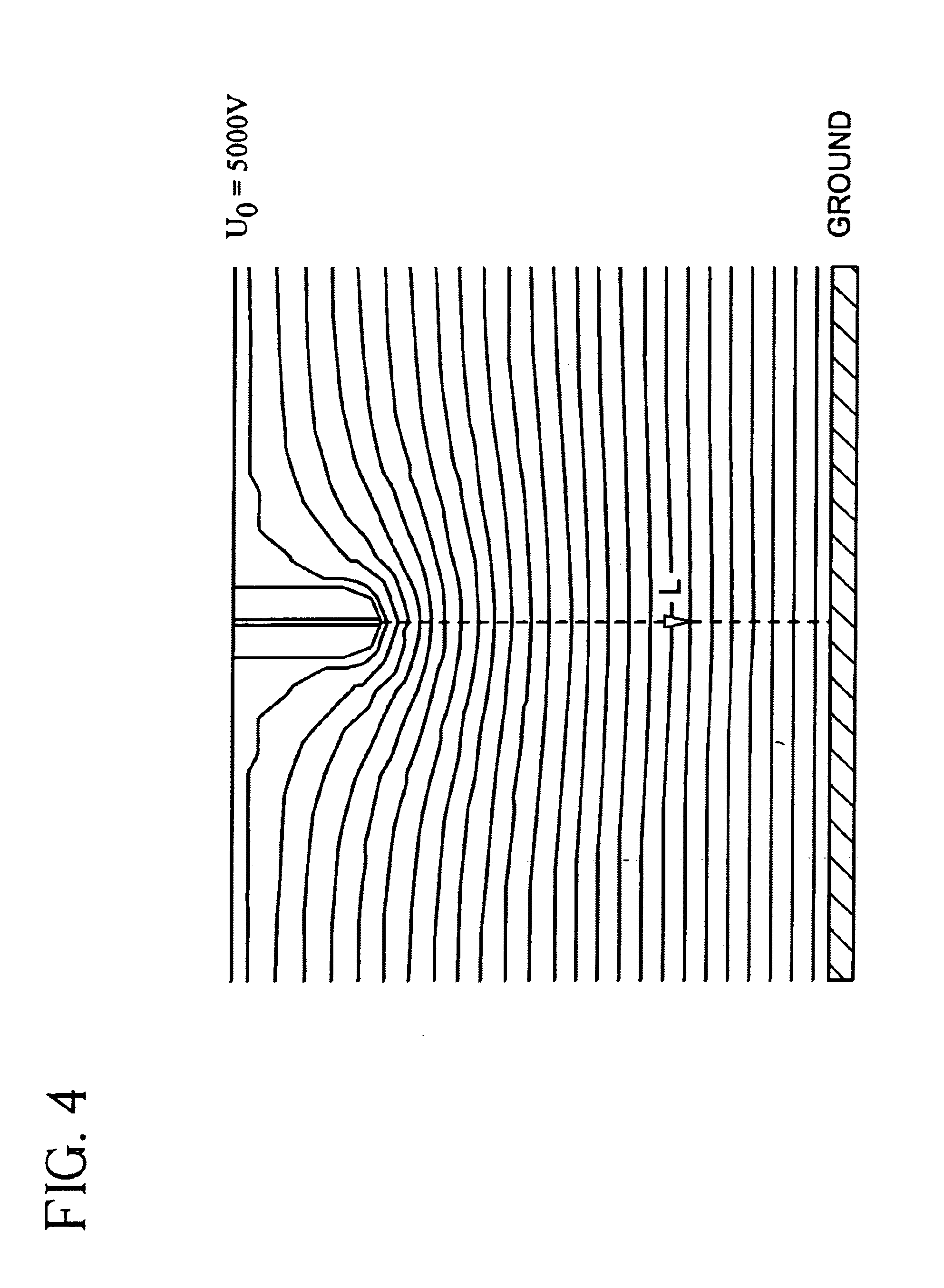

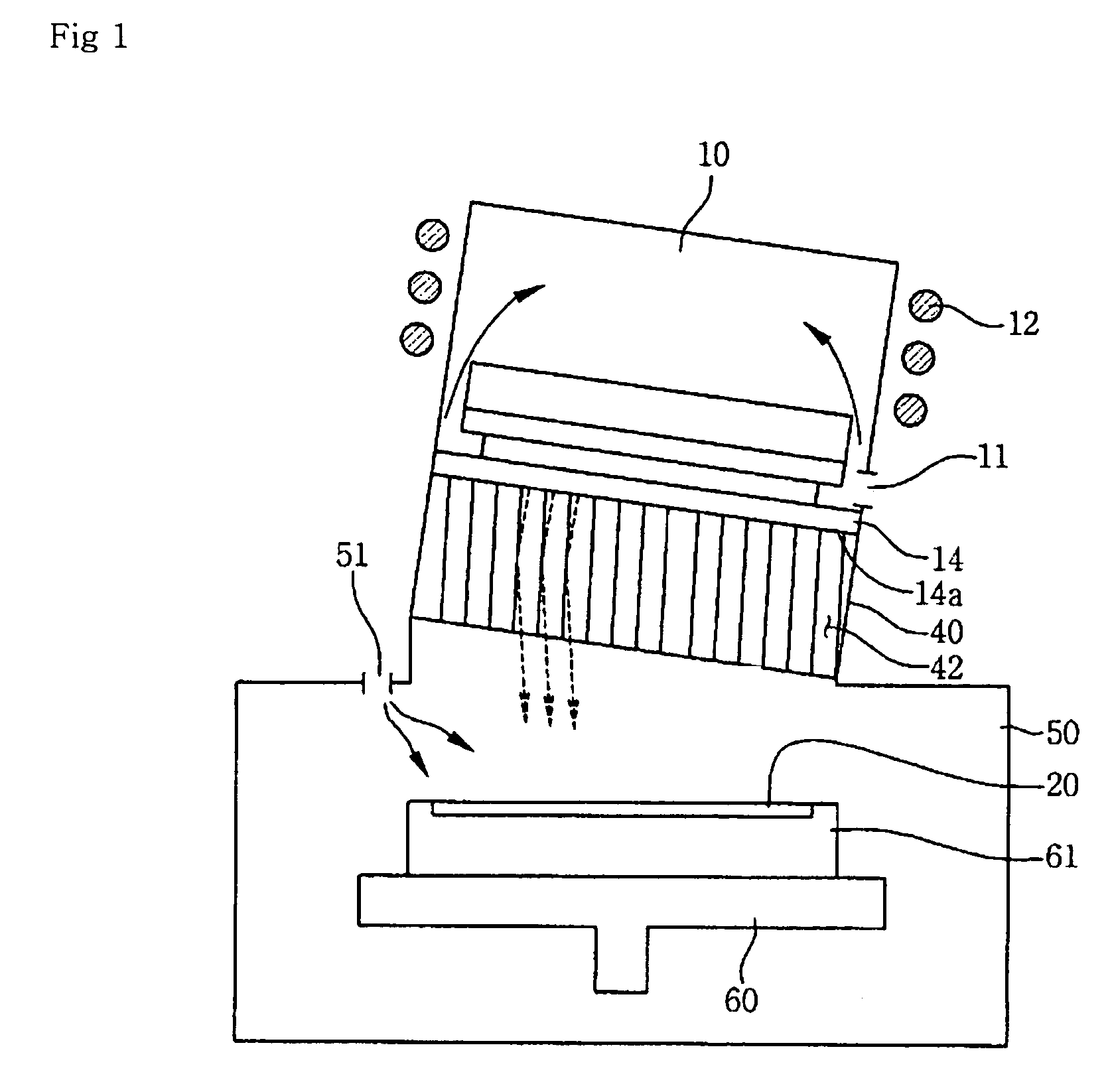

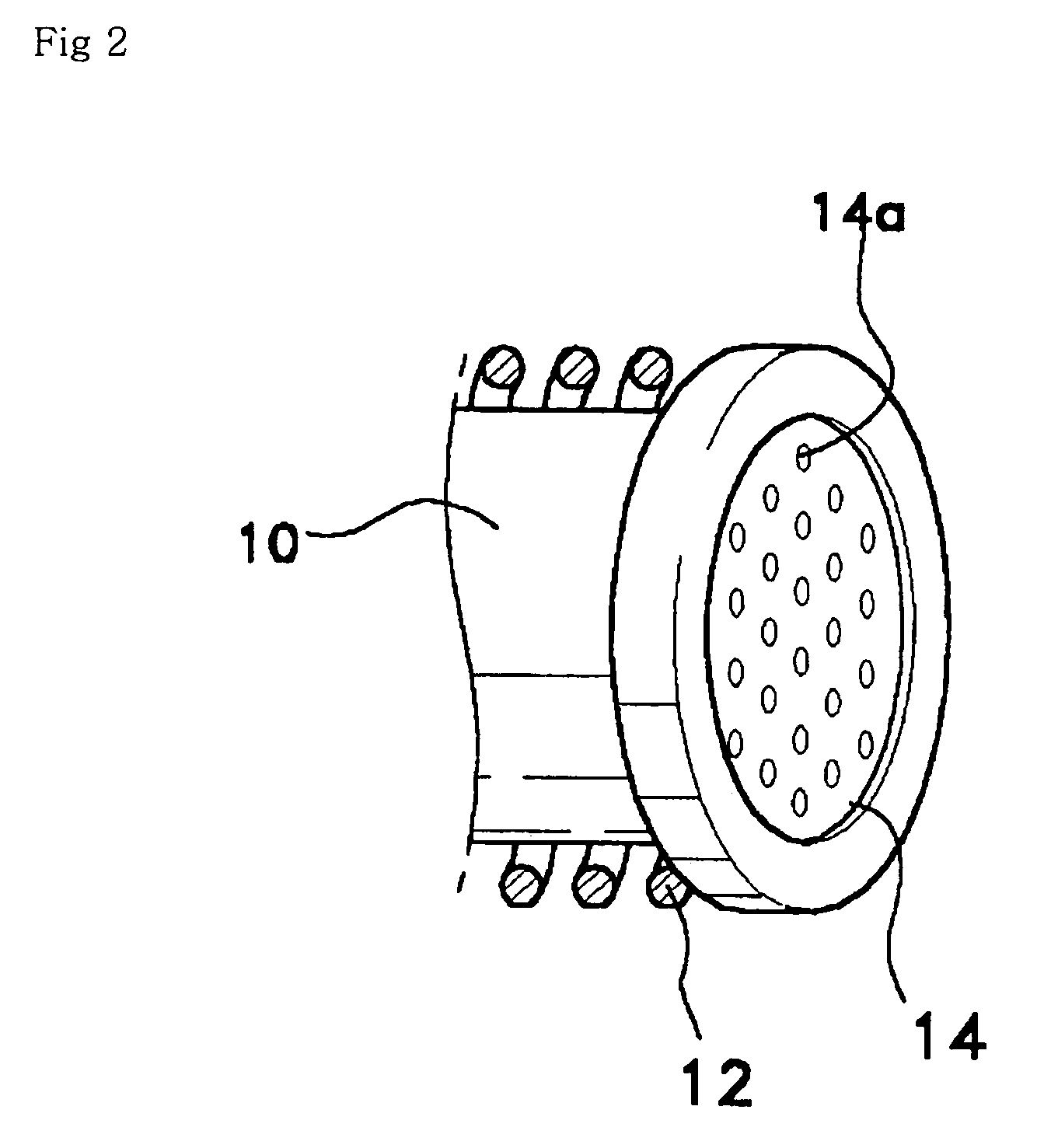

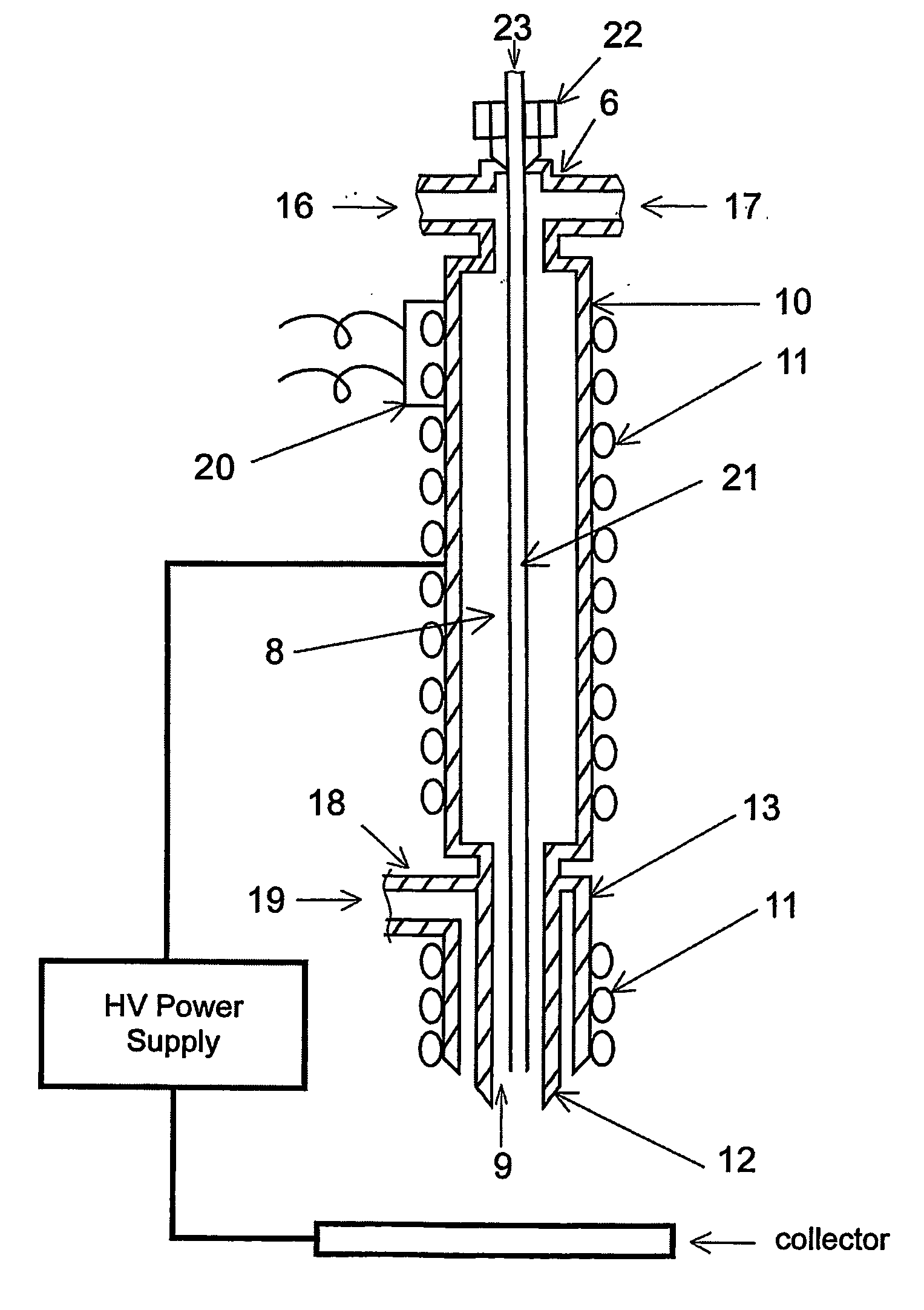

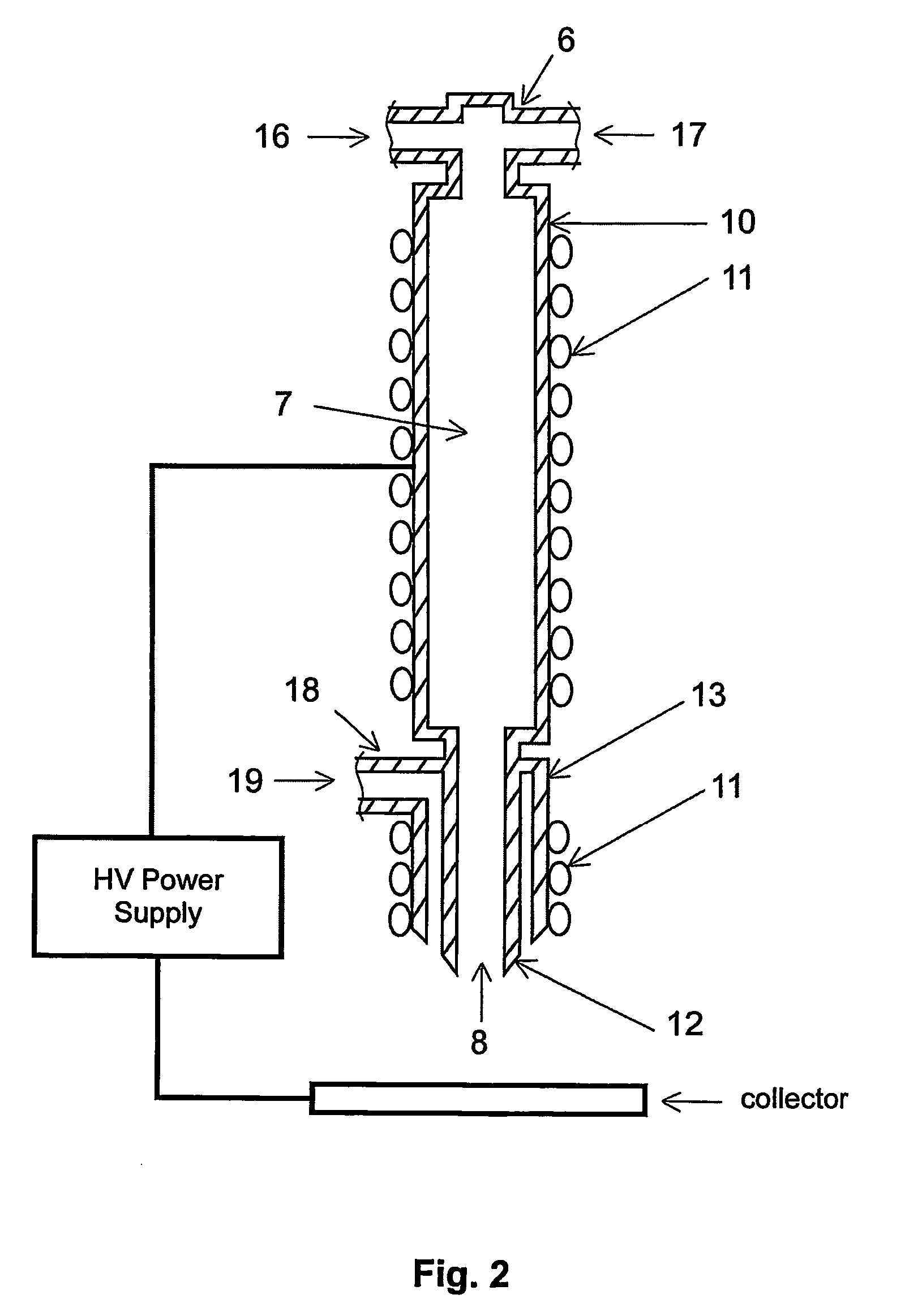

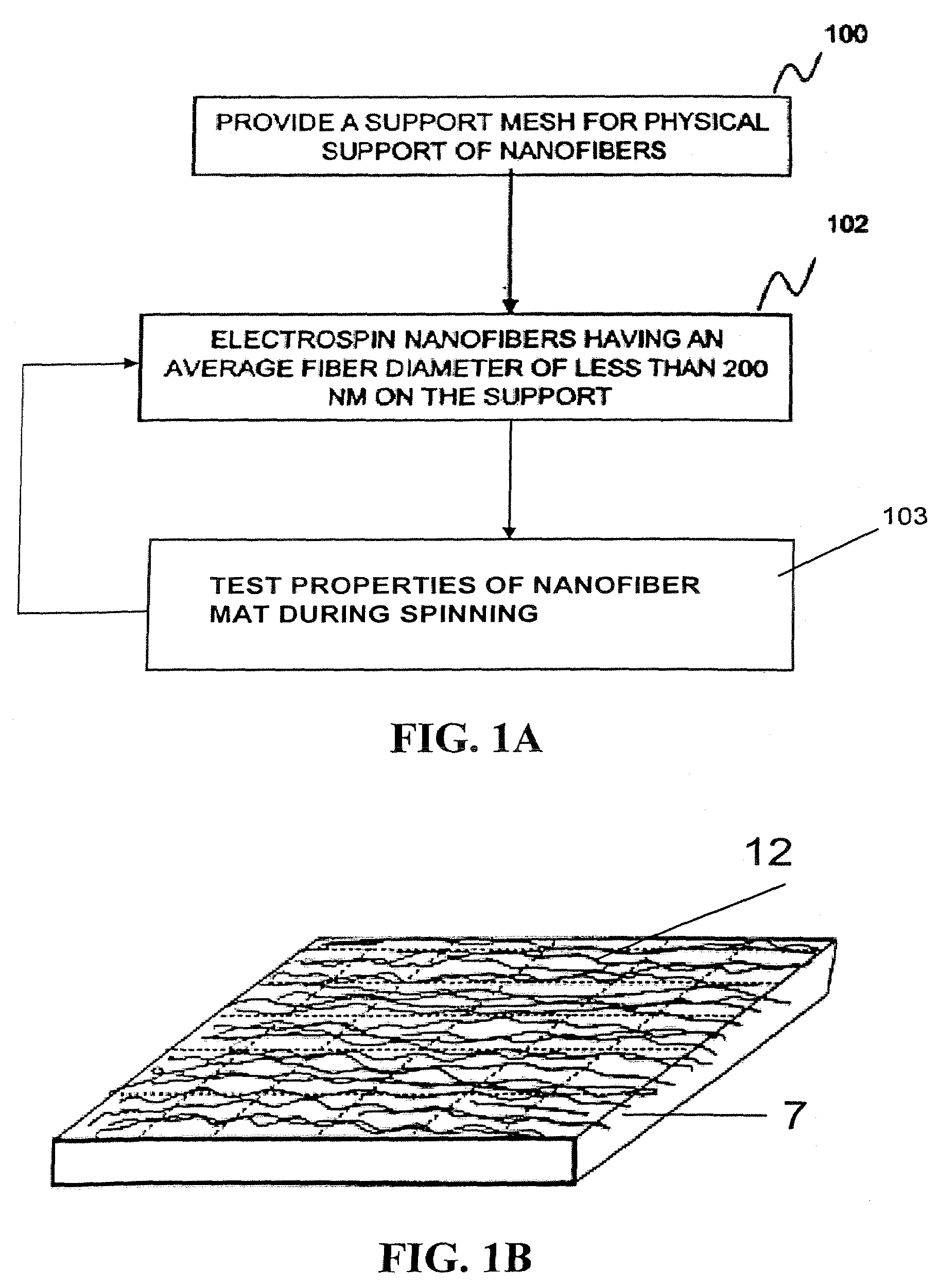

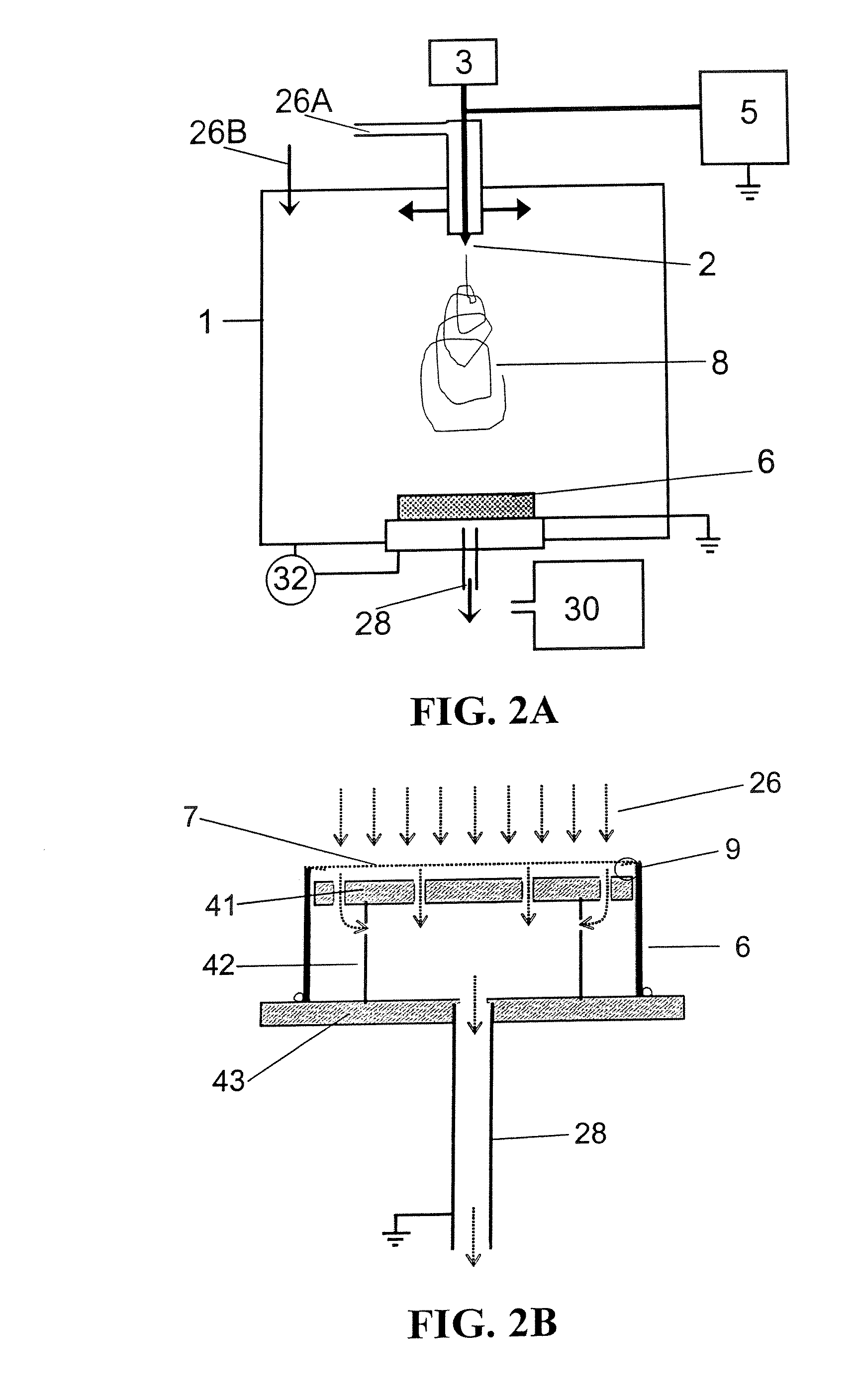

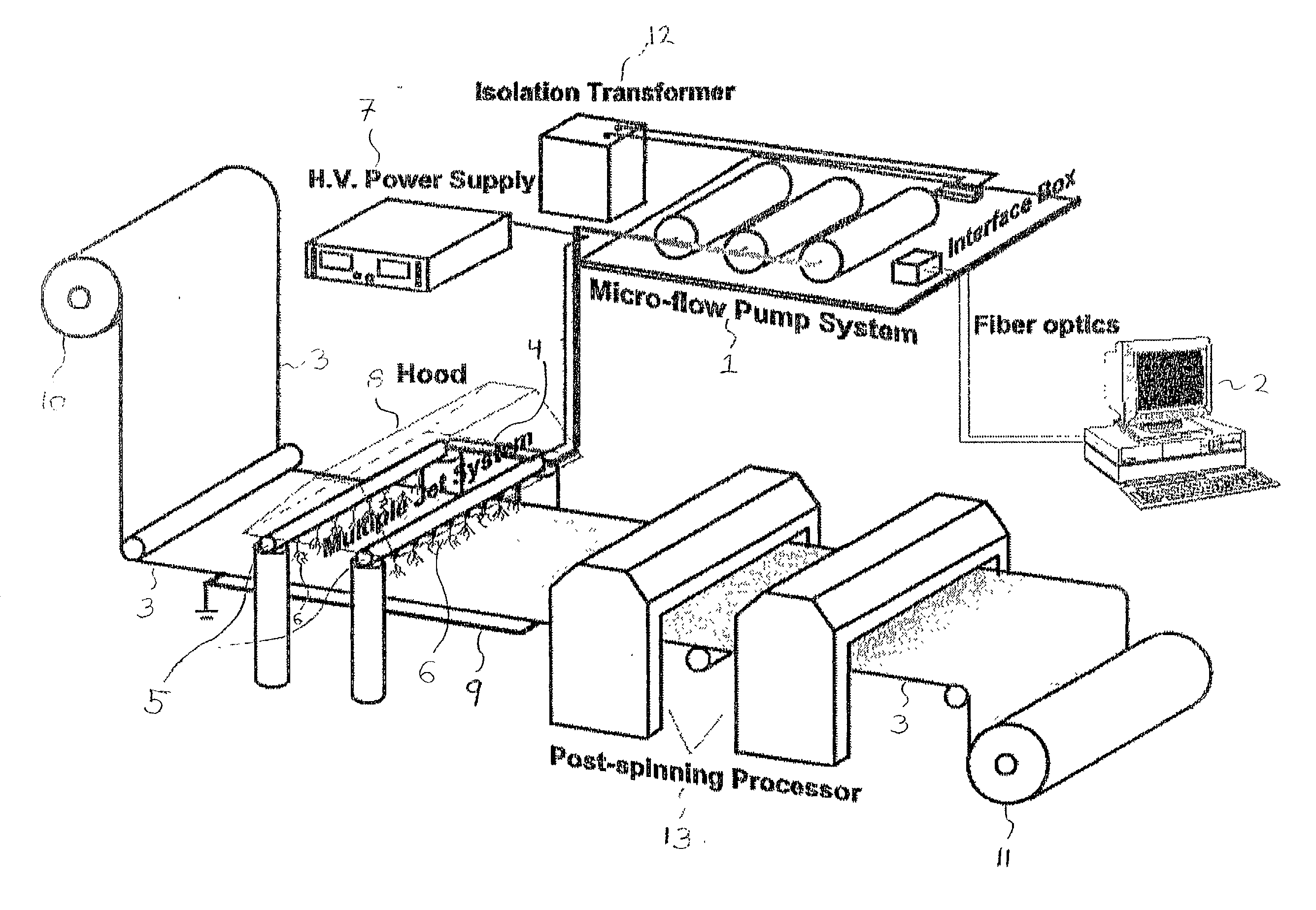

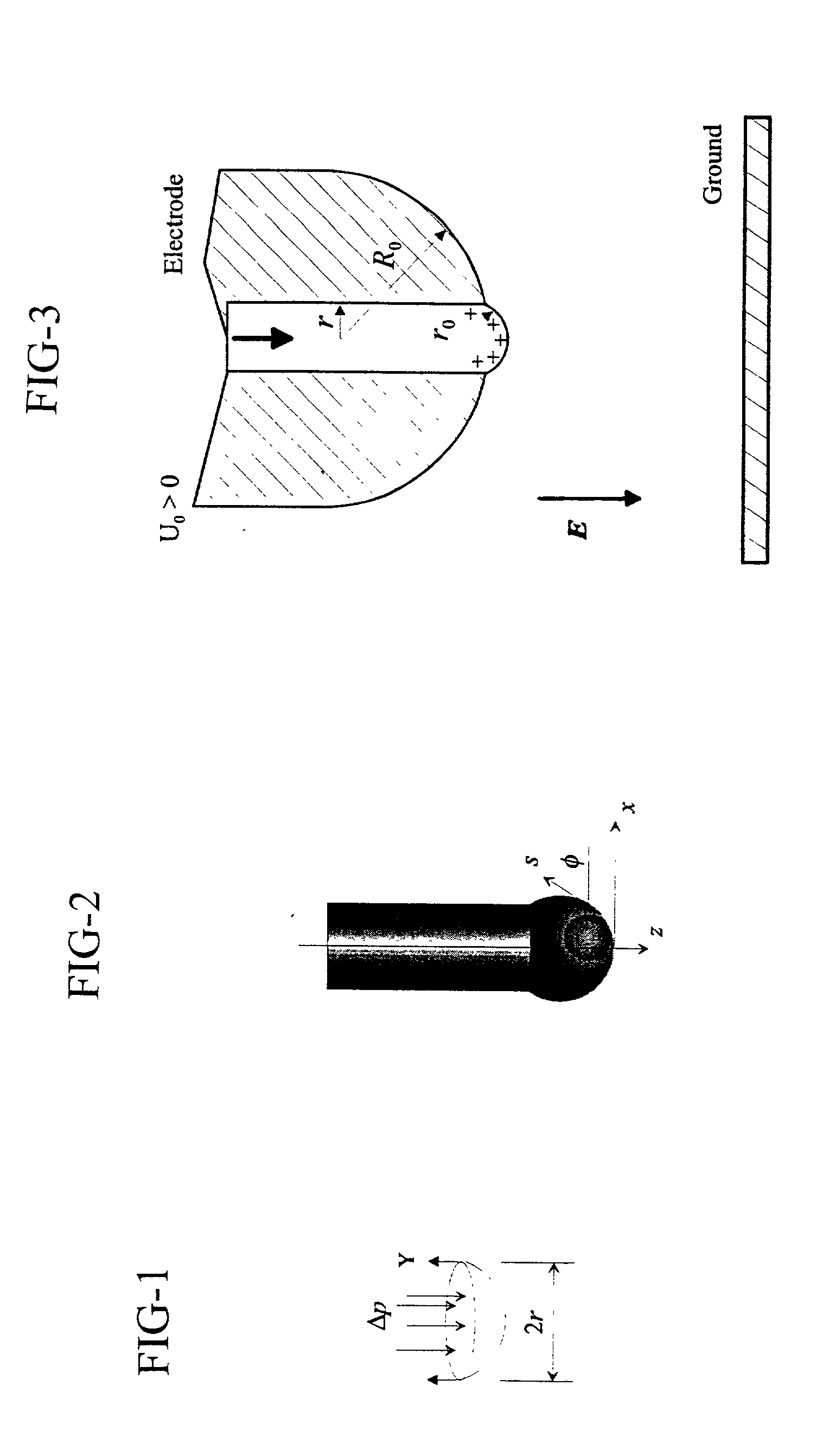

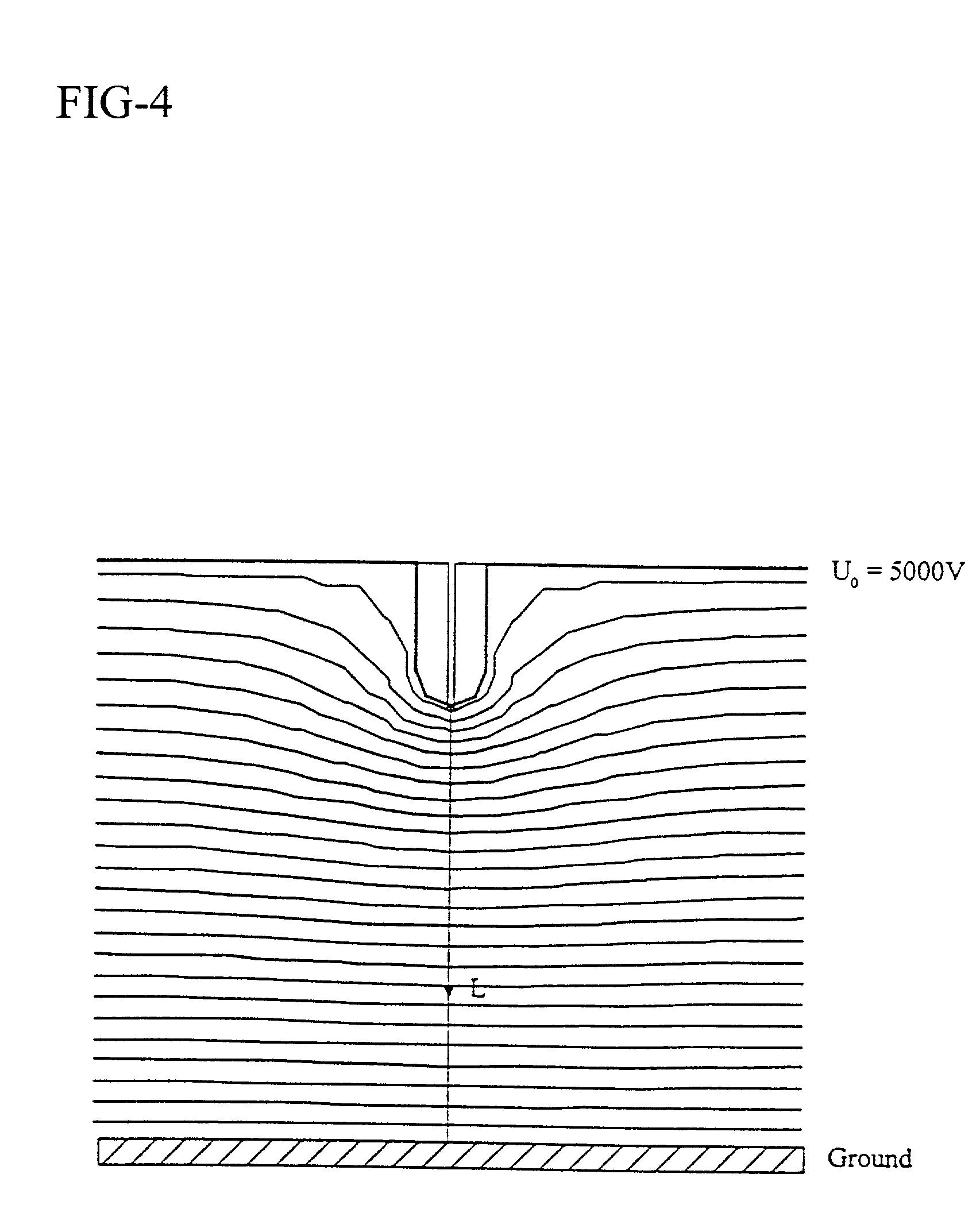

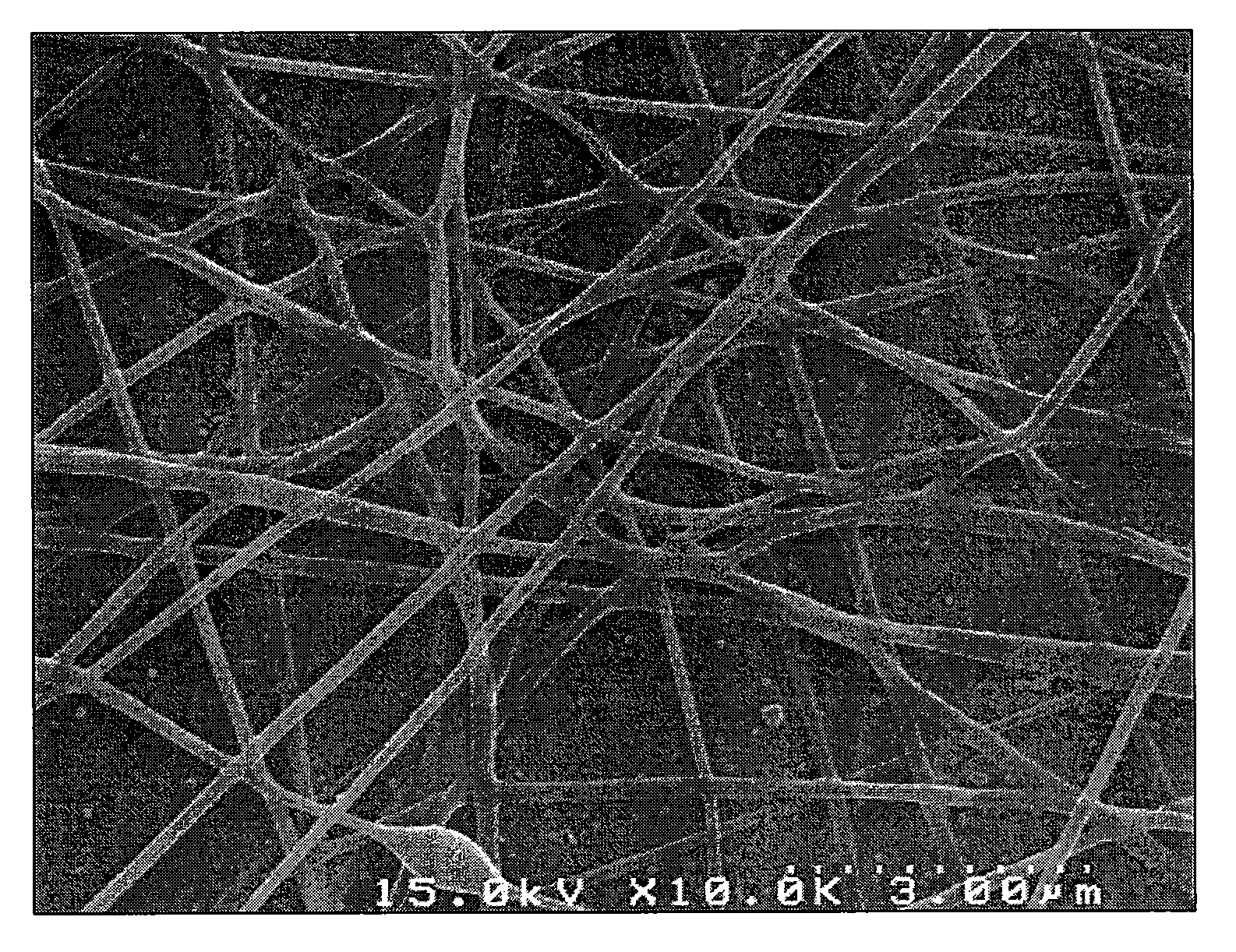

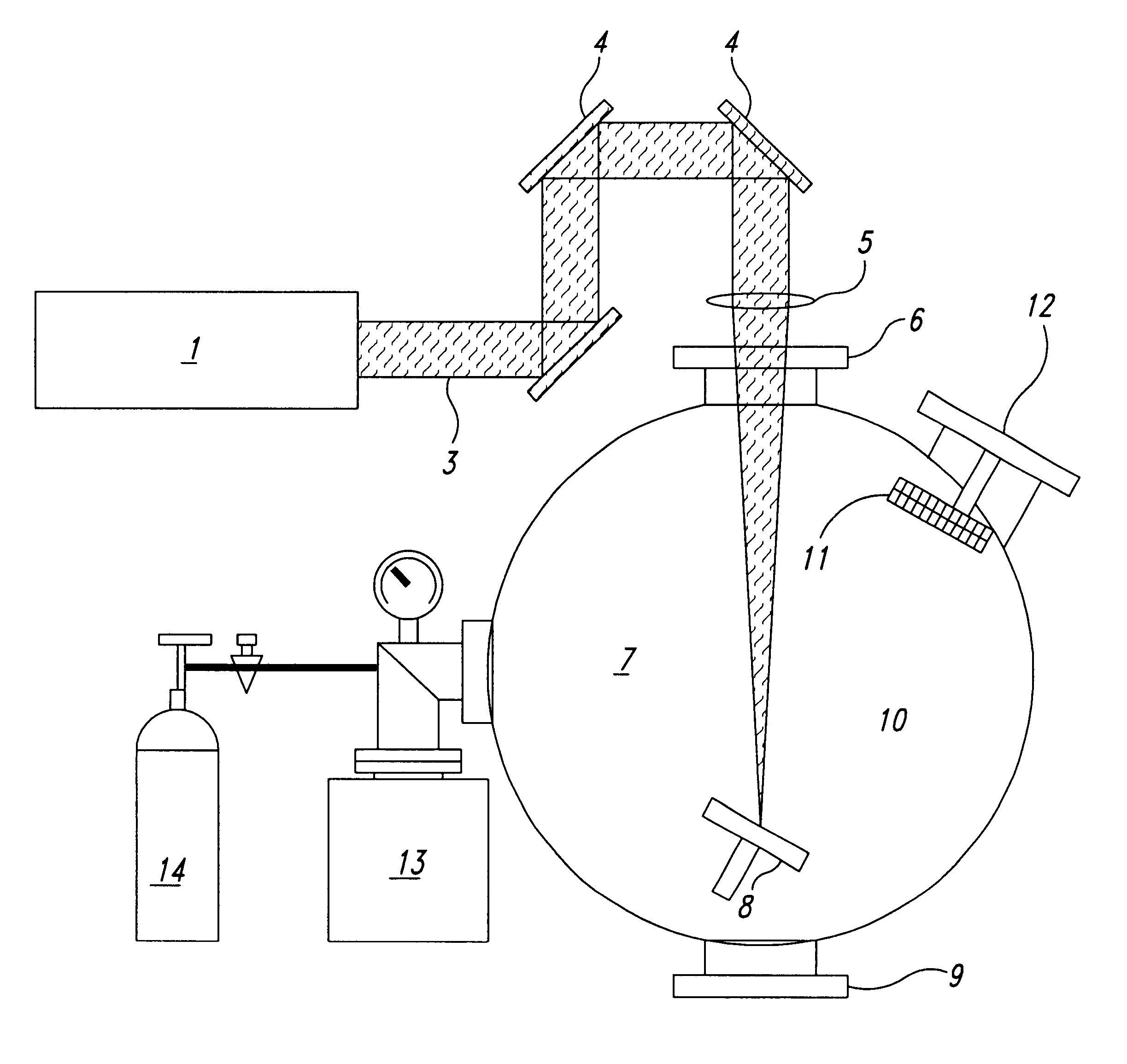

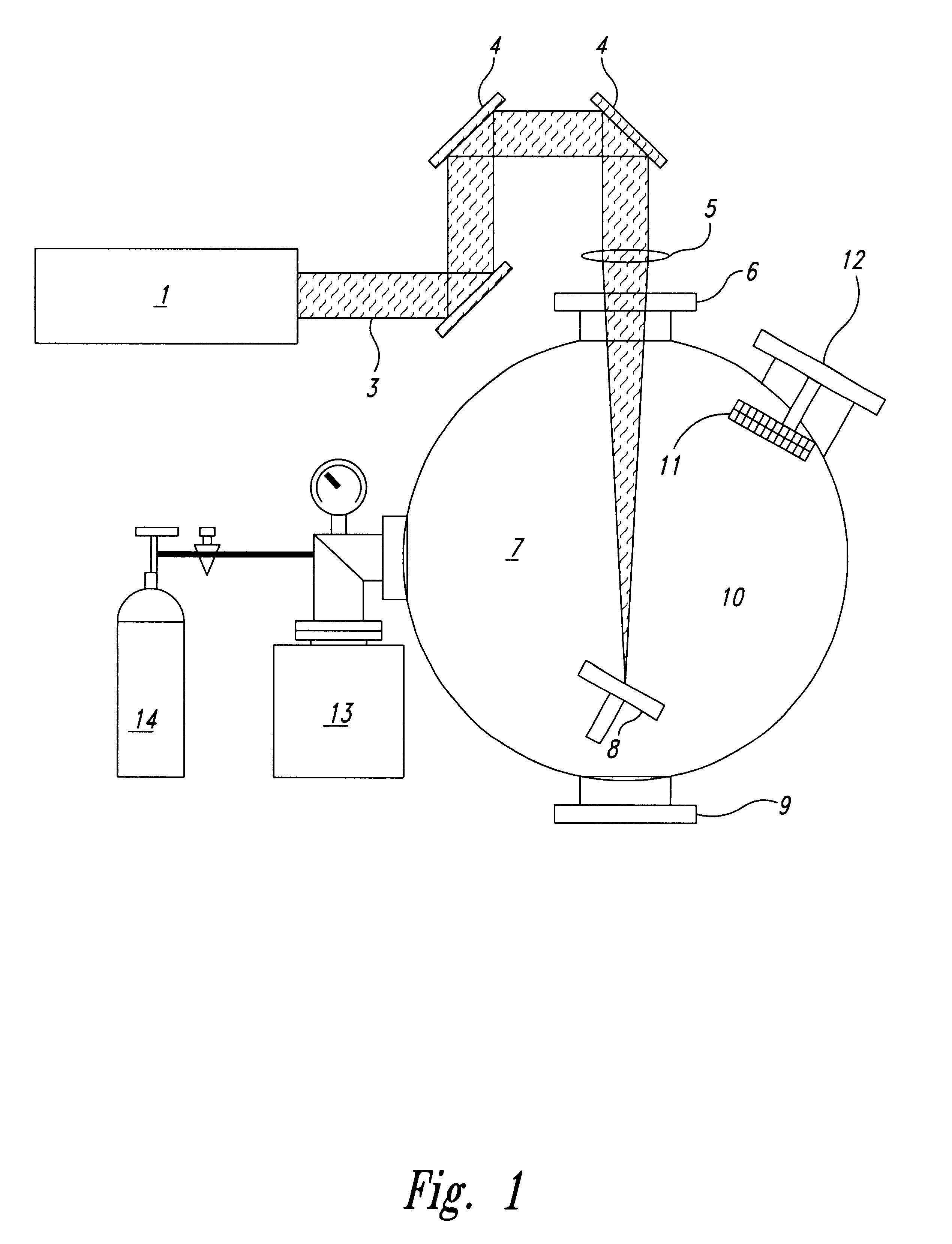

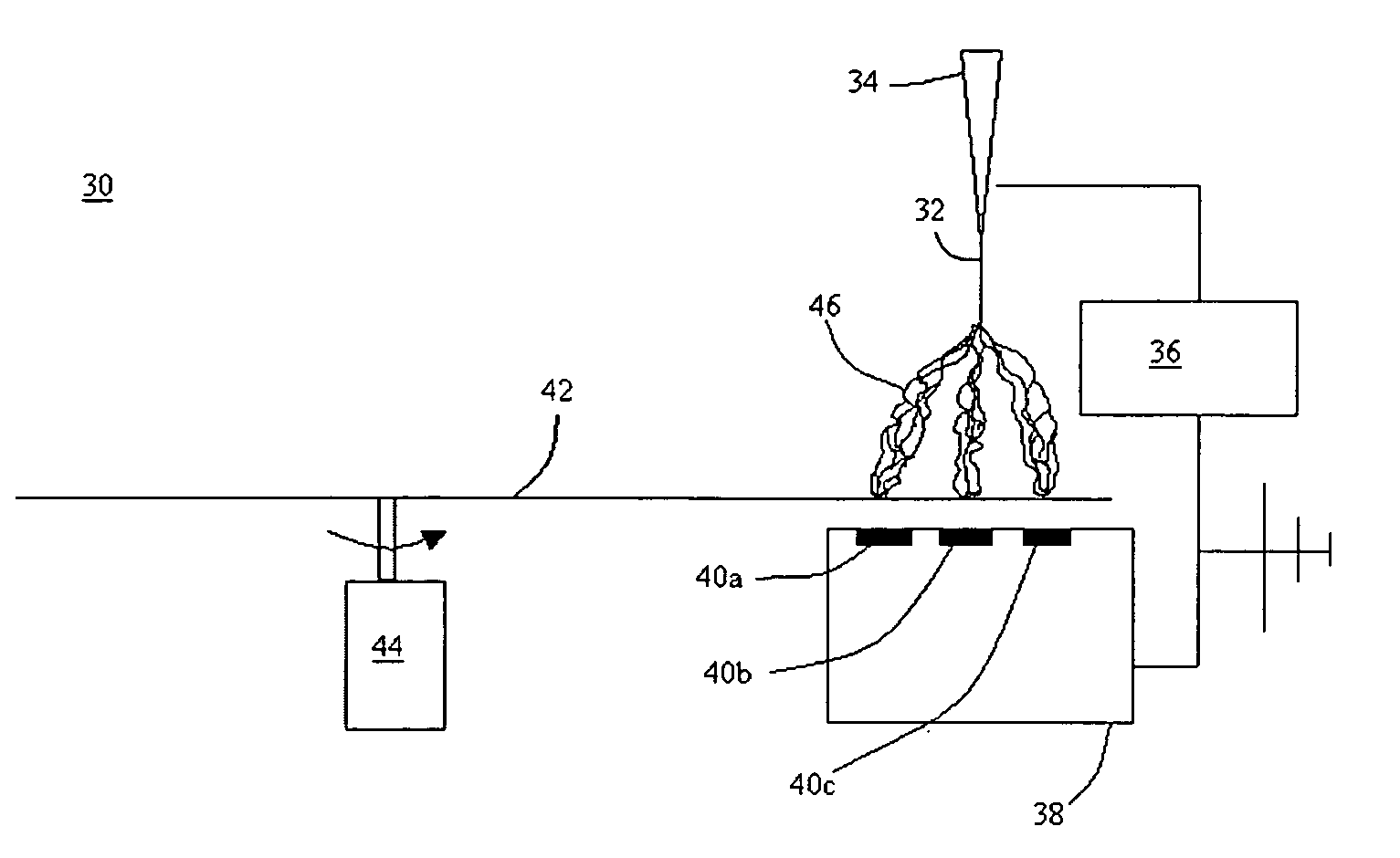

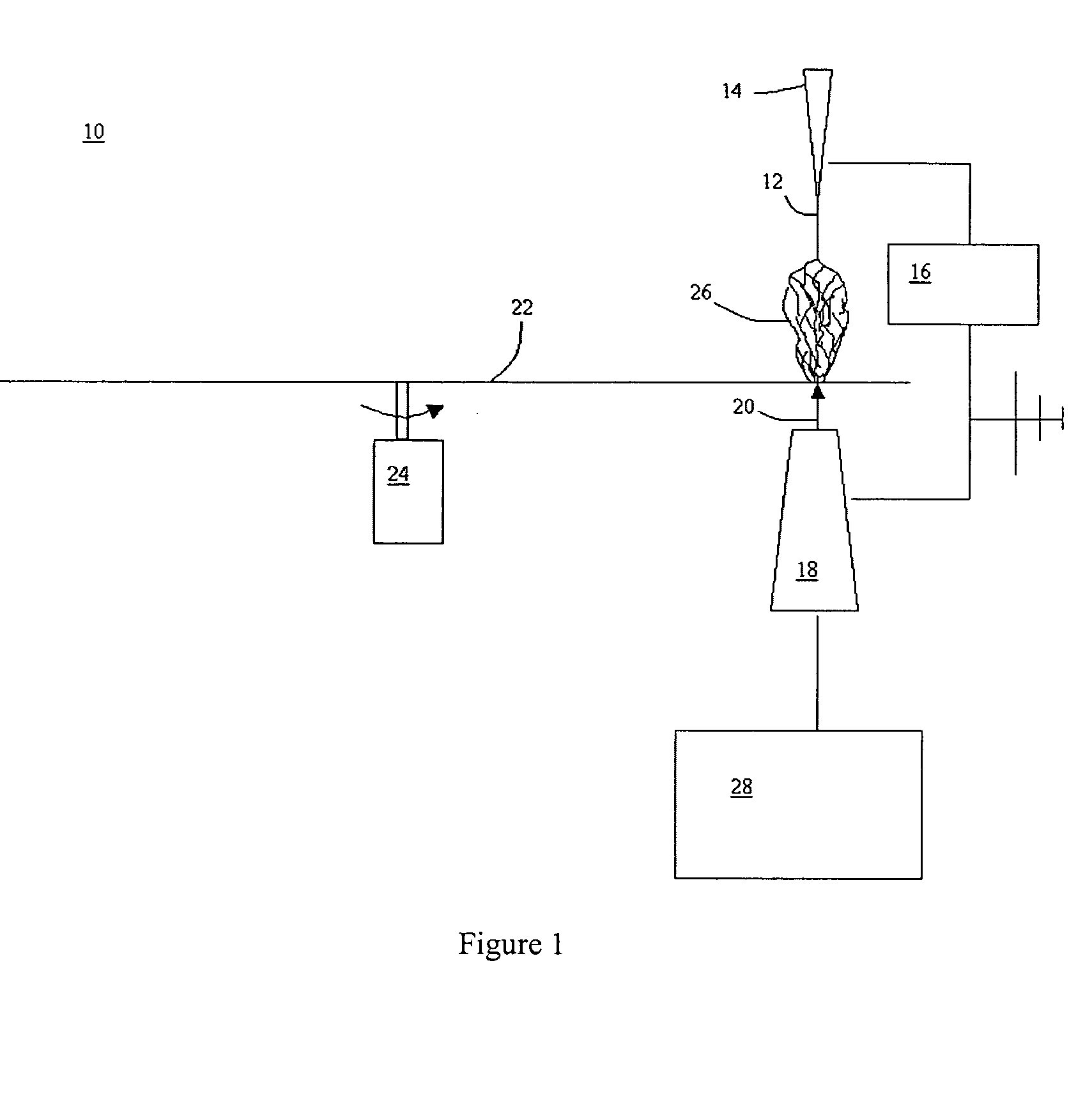

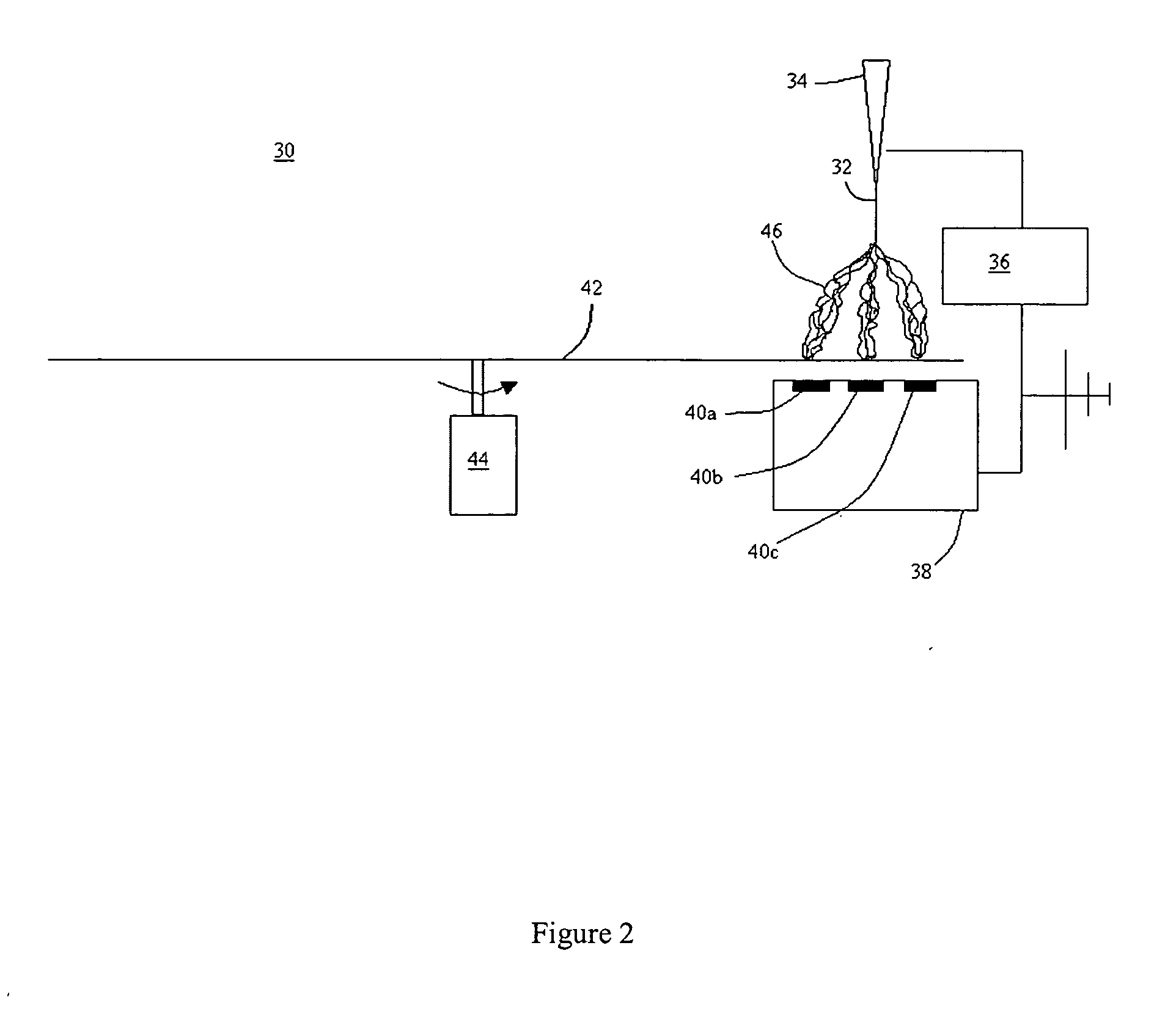

Apparatus and methods for electrospinning polymeric fibers and membranes

InactiveUS6713011B2Easy to controlLarge specific surface areaElectric discharge heatingConfectioneryFiberElectrospinning

An apparatus and method for electrospinning polymer fibers and membranes. The method includes electrospinning a polymer fiber from a conducting fluid in the presence of a first electric field established between a conducting fluid introduction device and a ground source and modifying the first electric field with a second electric field to form a jet stream of the conducting fluid. The method also includes electrically controlling the flow characteristics of the jet stream, forming a plurality of electrospinning jet streams and independently controlling the flow characteristics of at least one of the jet streams. The apparatus for electrospinning includes a conducting fluid introduction device containing a plurality of electrospinning spinnerets, a ground member positioned adjacent to the spinnerets, a support member disposed between the spinnerets and the ground member and movable to receive fibers formed from the conducting fluid, and a component for controlling the flow characteristics of conducting fluid from at least one spinneret independently from another spinneret.

Owner:RES FOUND THE

Atomic layer deposition apparatus using neutral beam and method of depositing atomic layer using the same

Owner:RES & BUSINESS FOUND SUNGKYUNKWAN UNIV

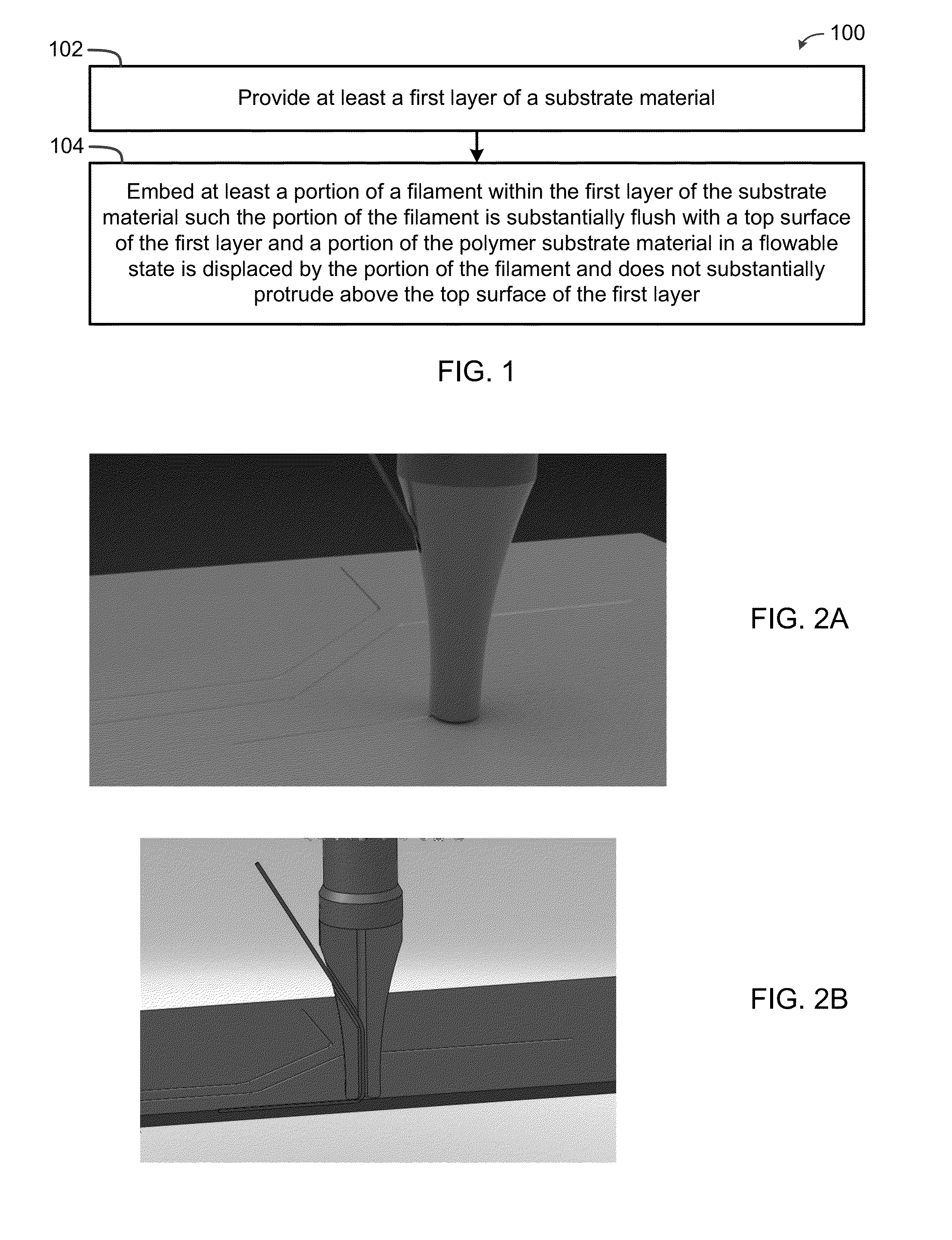

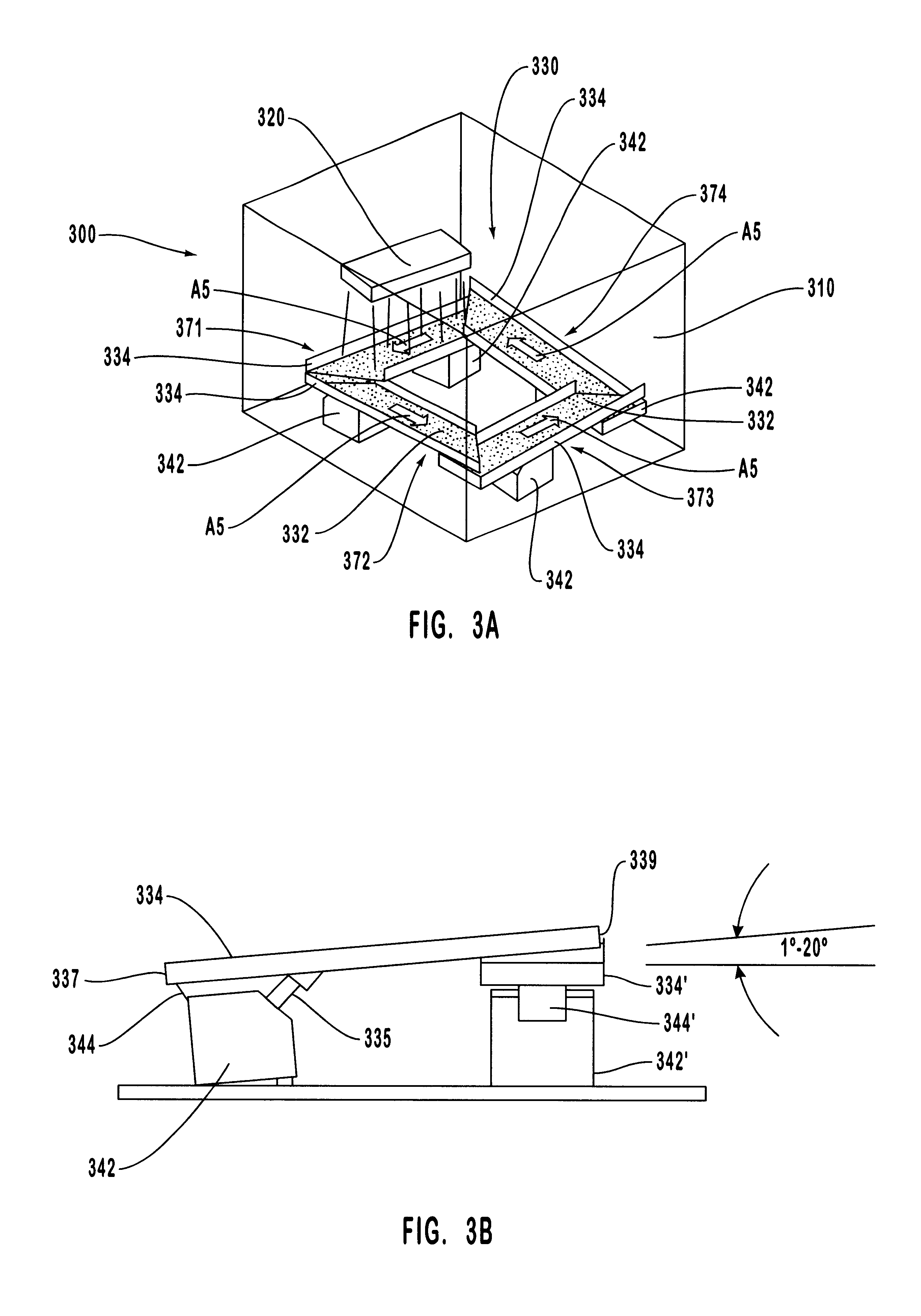

Methods and Systems For Embedding Filaments in 3D Structures, Structural Components, and Structural Electronic, Electromagnetic and Electromechanical Components/Devices

ActiveUS20140268604A1High mechanical strengthElectric discharge heatingCeramic shaping apparatusElectricityEngineering

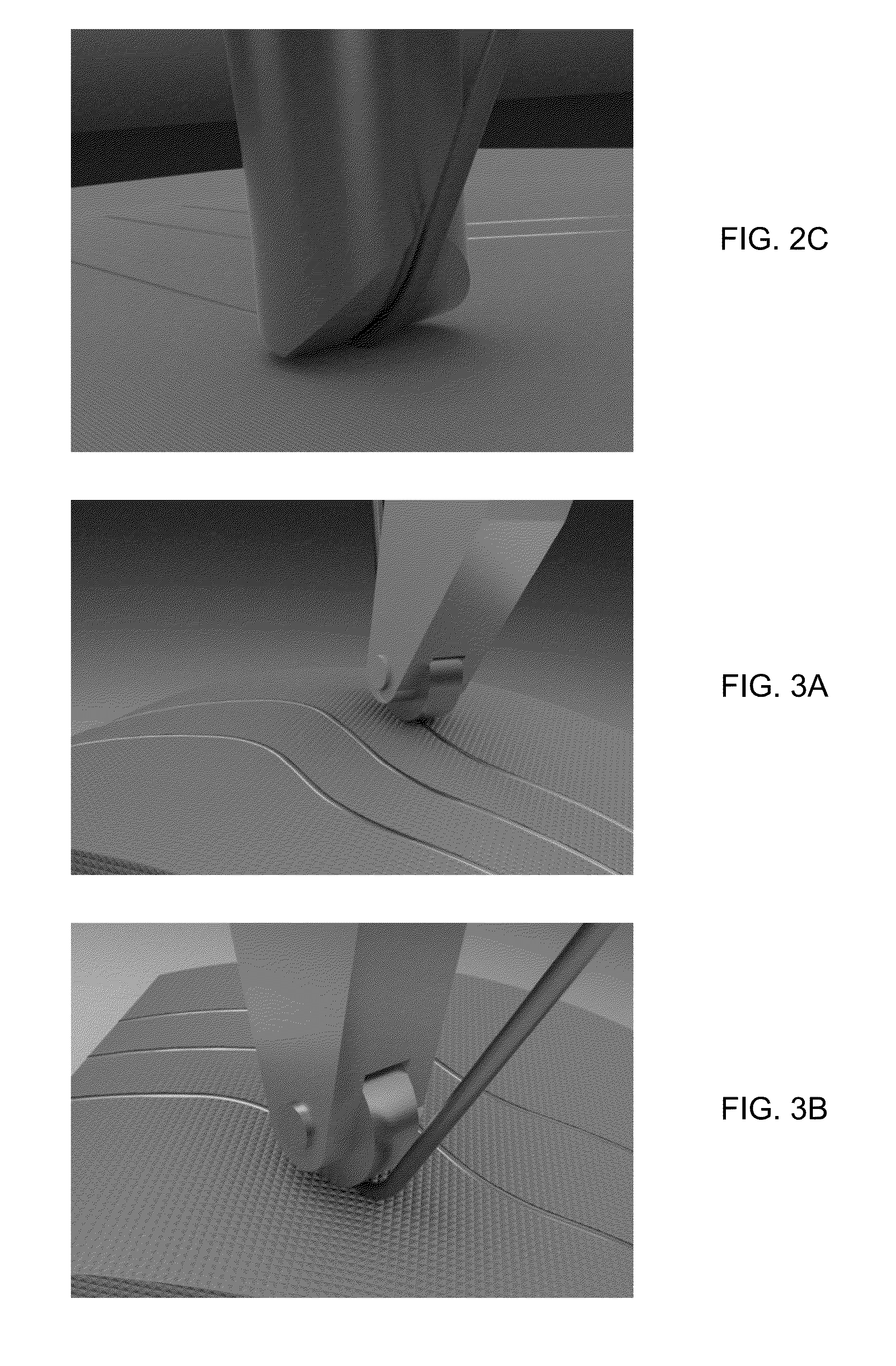

The present invention provides systems and methods for embedding a filament or filament mesh in a three-dimensional structure, structural component, or structural electronic, electromagnetic or electromechanical component / device by providing at least a first layer of a substrate material, and embedding at least a portion of a filament or filament mesh within the first layer of the substrate material such the portion of the filament or filament mesh is substantially flush with a top surface of the first layer and a substrate material in a flowable state is displaced by the portion of the filament and does not substantially protrude above the top surface of the first layer, allowing the continuation of an additive manufacturing process above the embedded filament or filament mesh. A method is provided for creating interlayer mechanical or electrical attachments or connections using filaments within a three-dimensional structure, structural component, or structural electronic, electromagnetic or electromechanical component / device.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

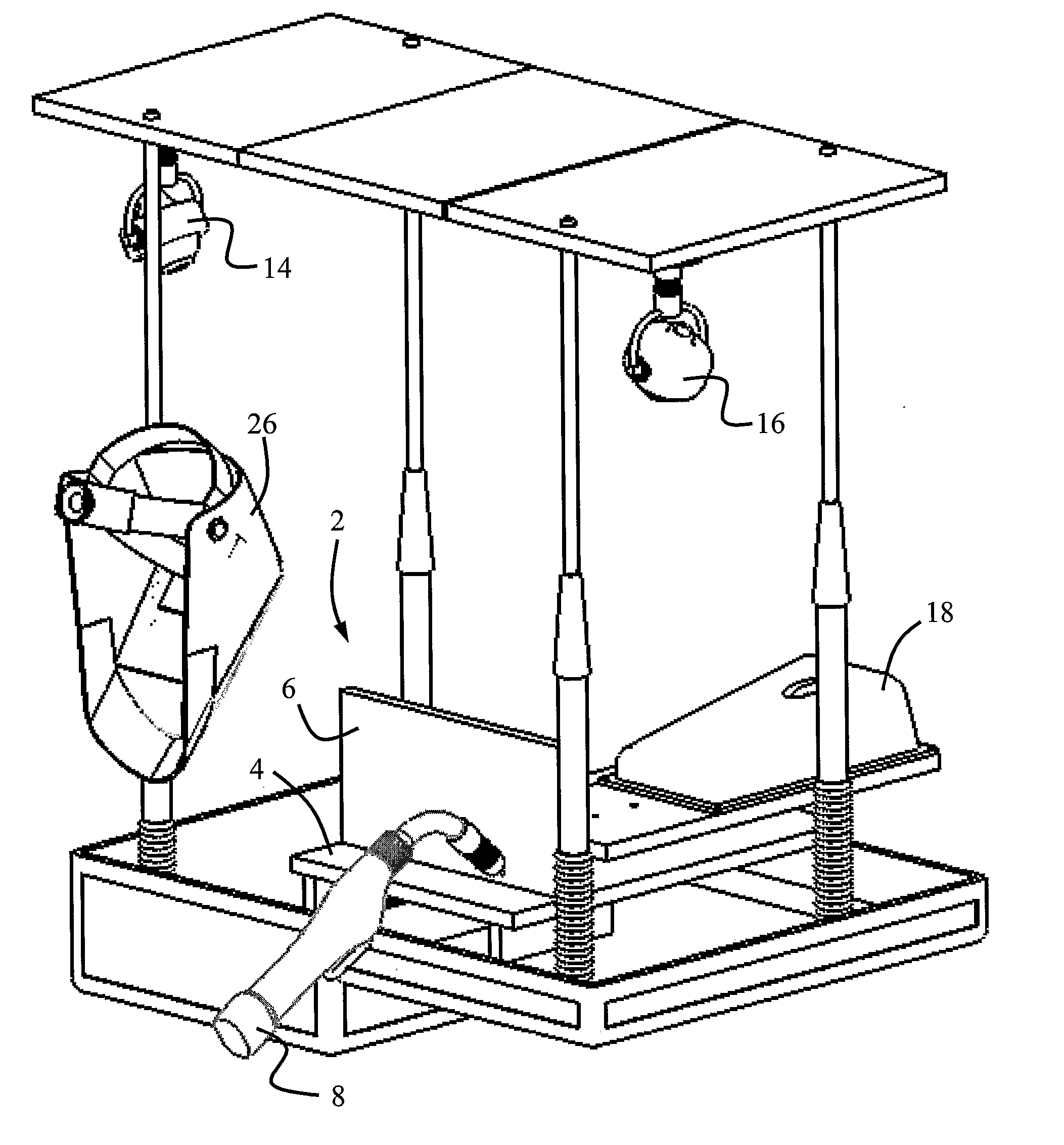

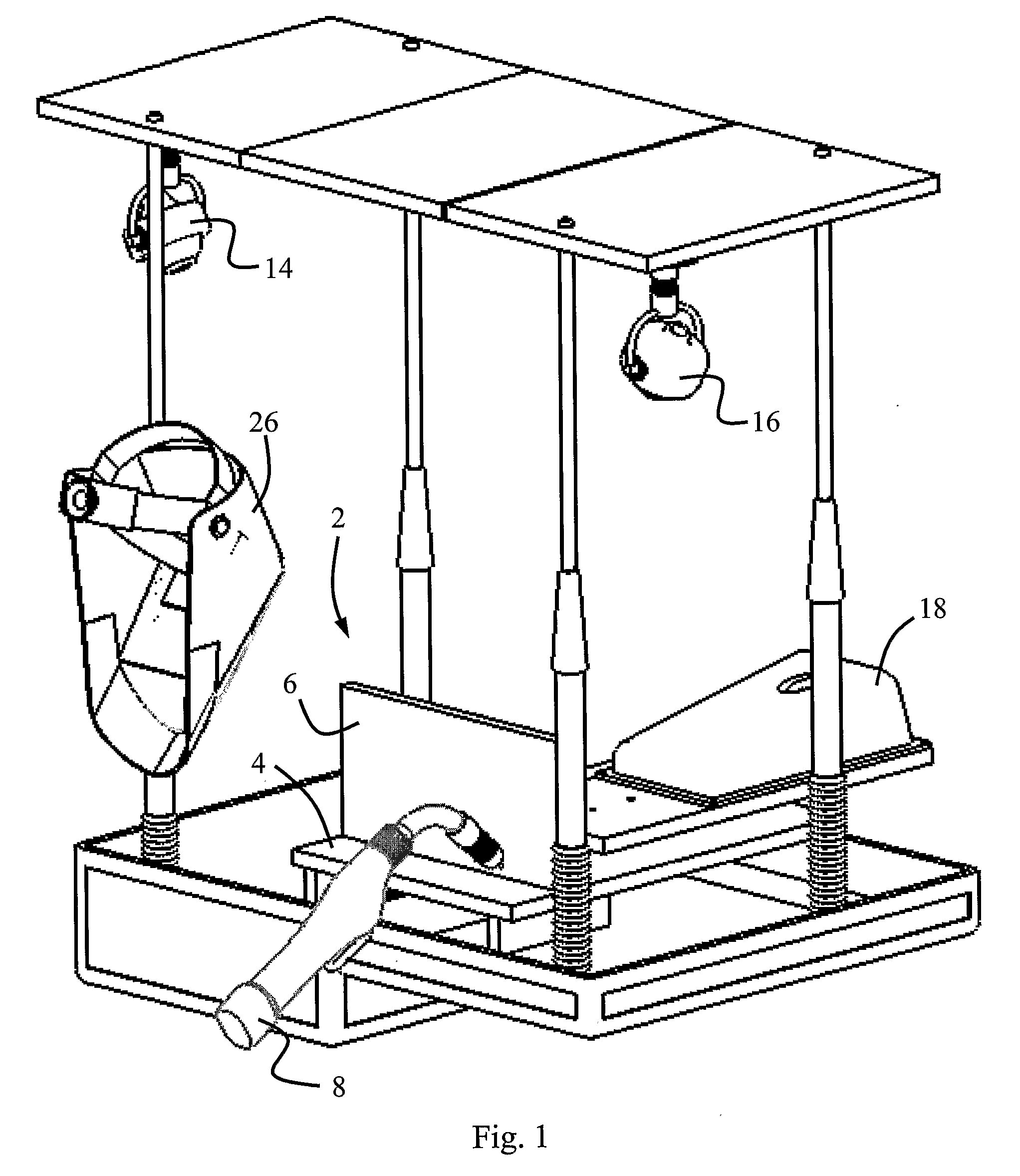

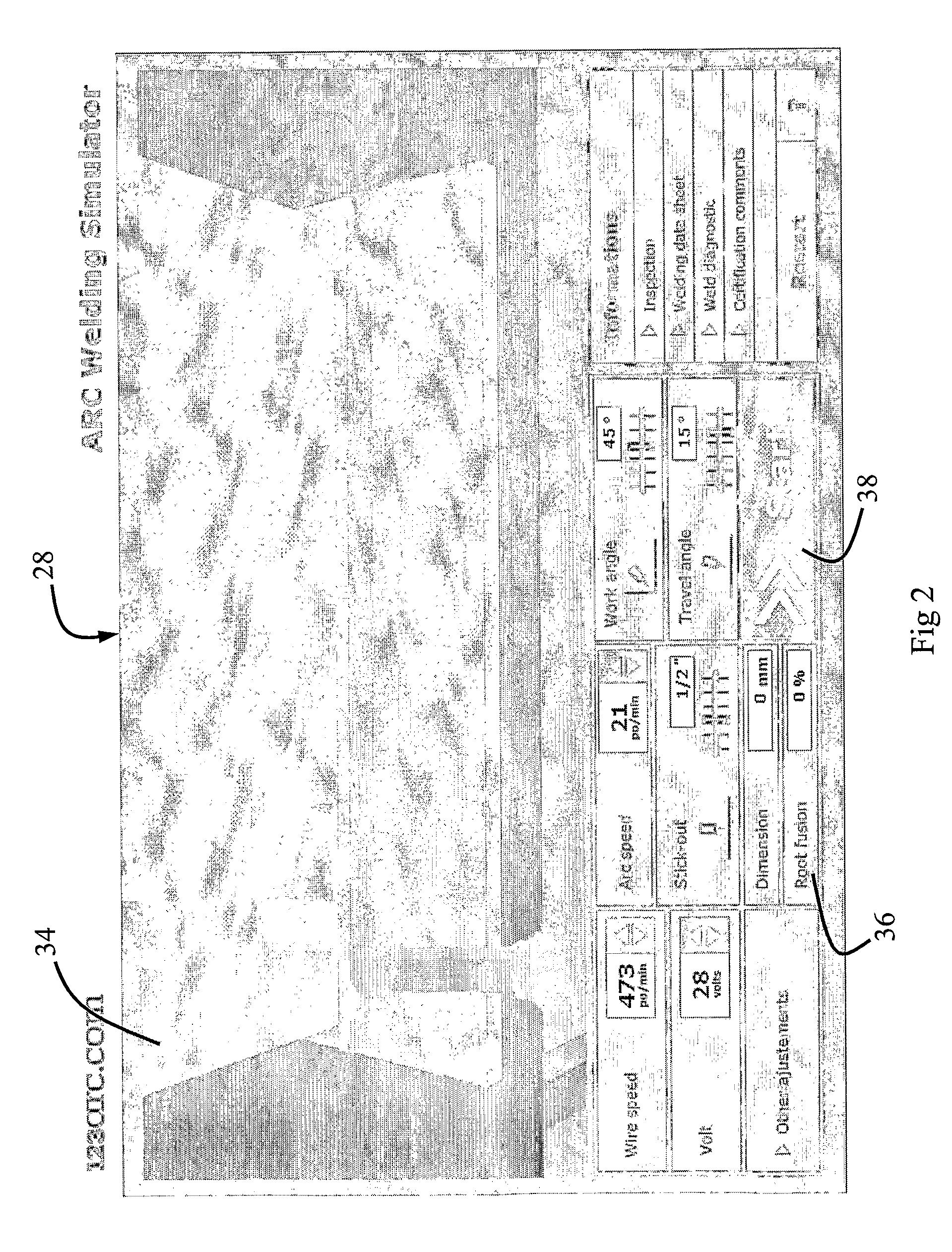

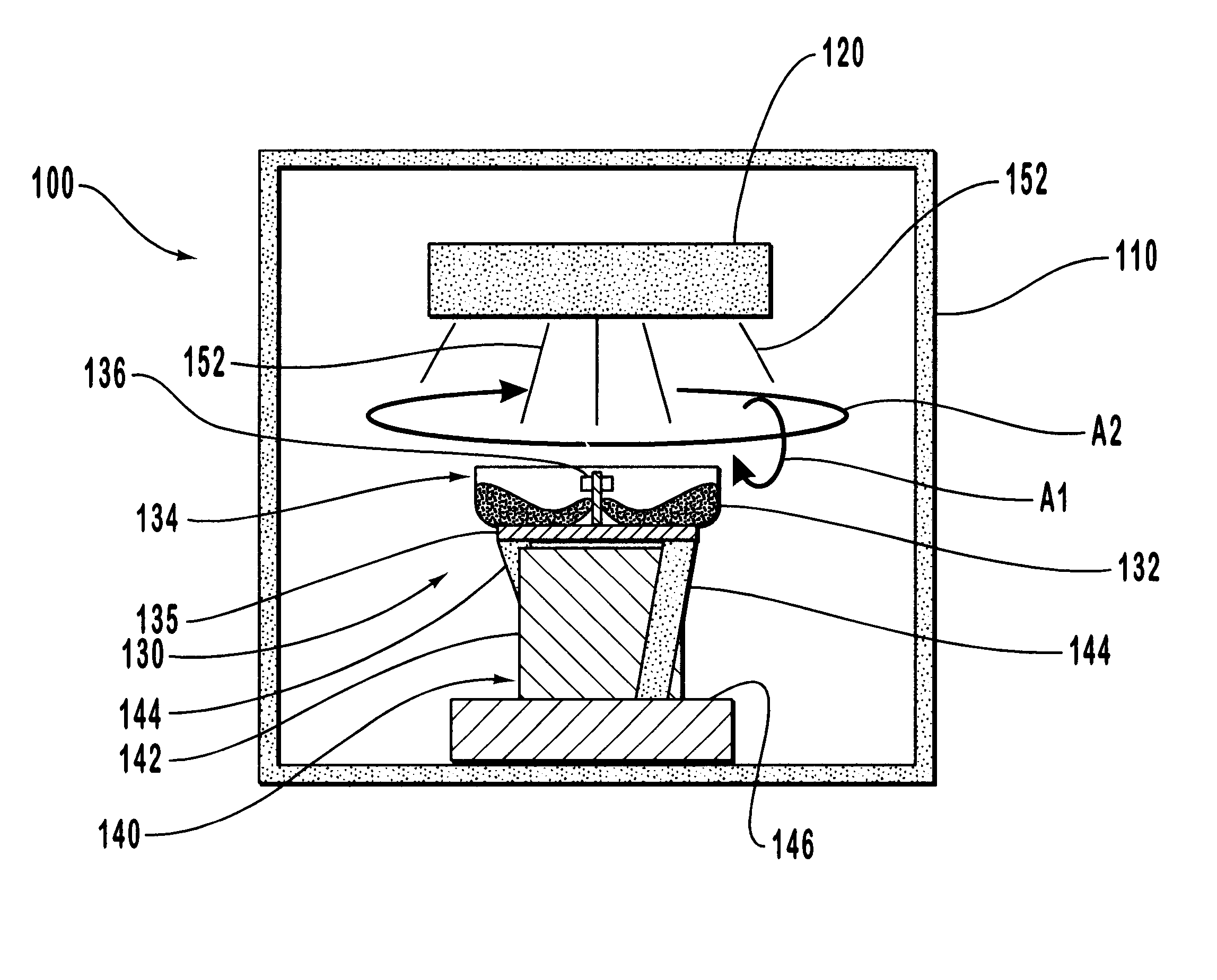

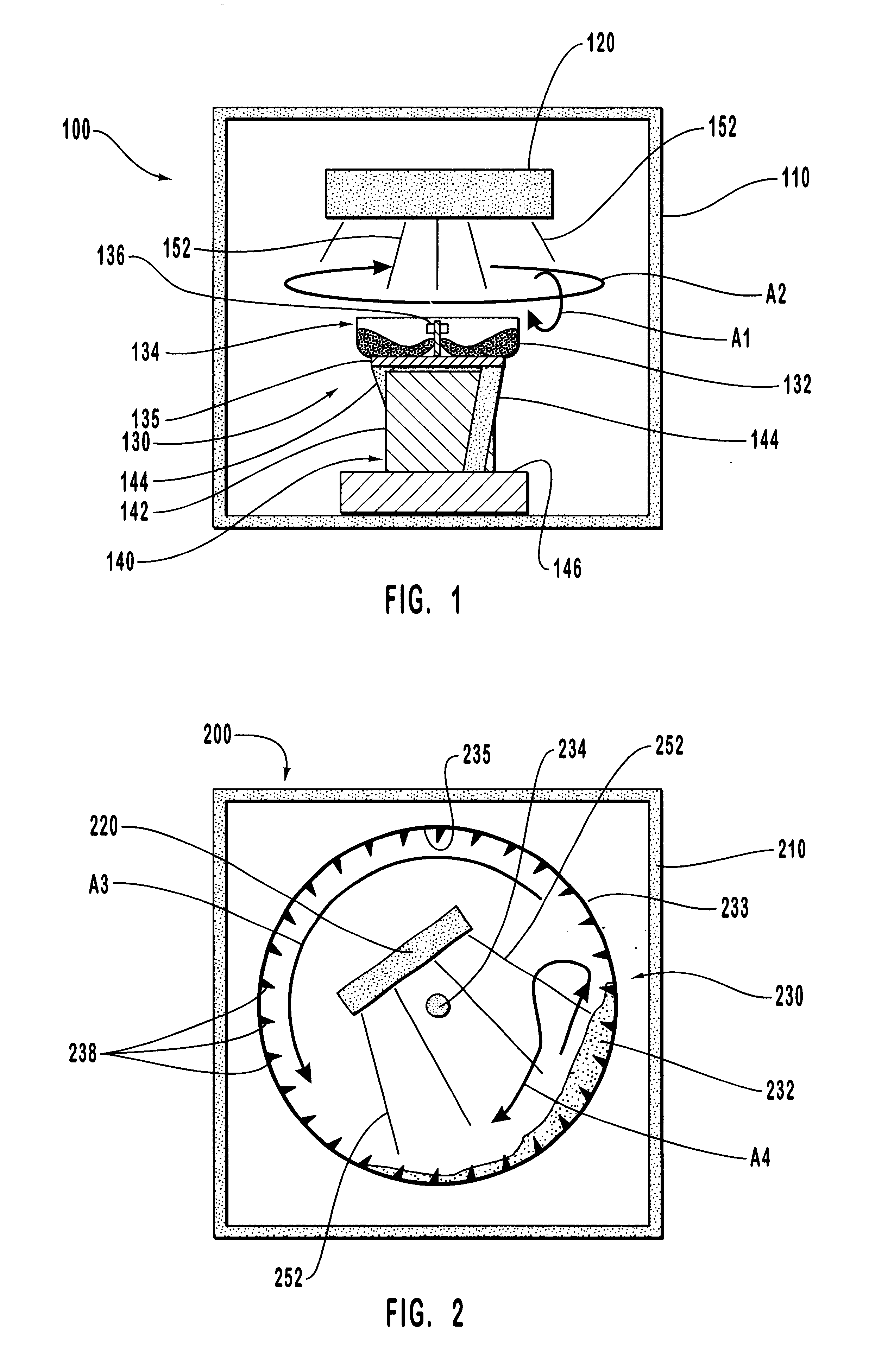

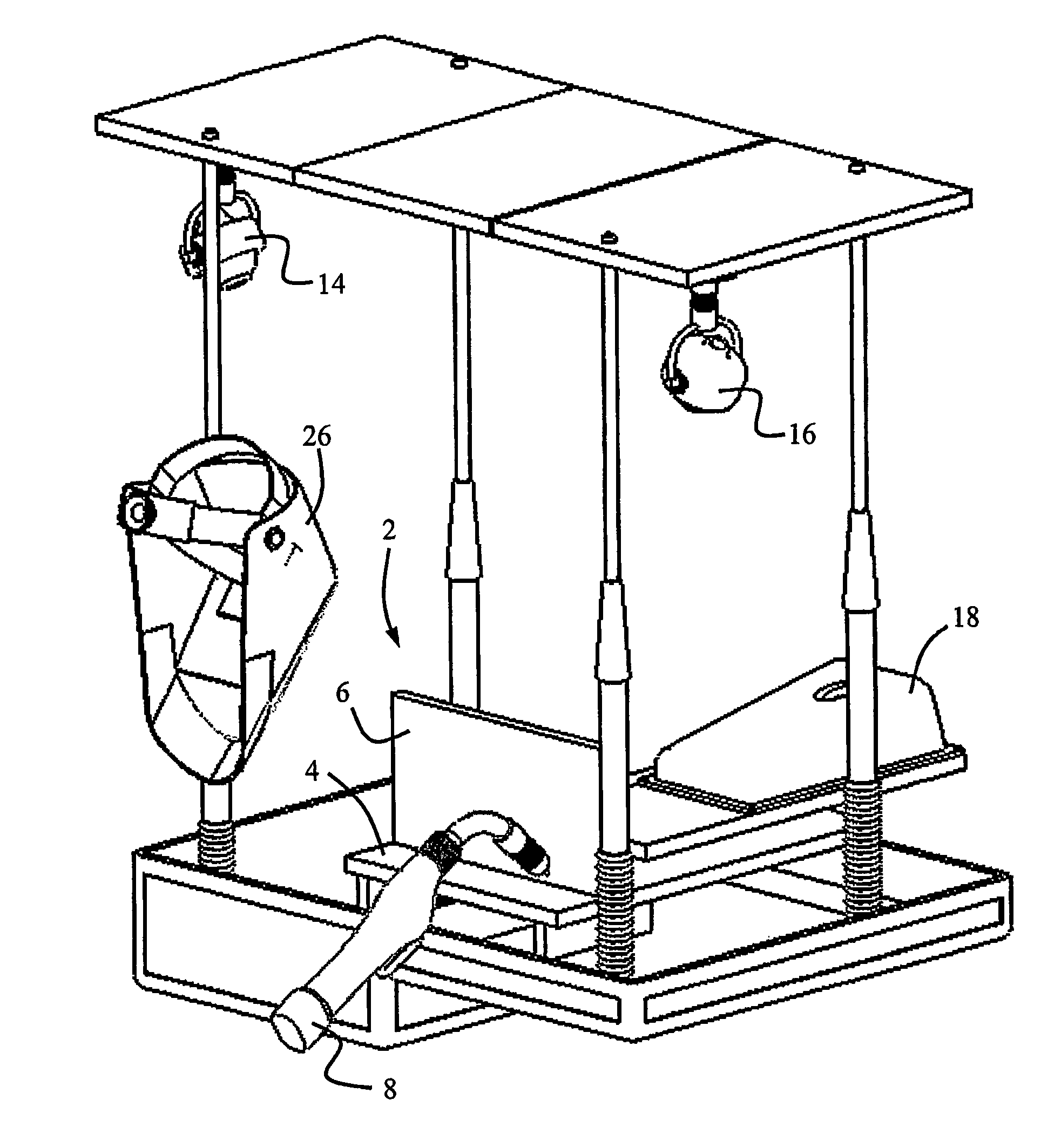

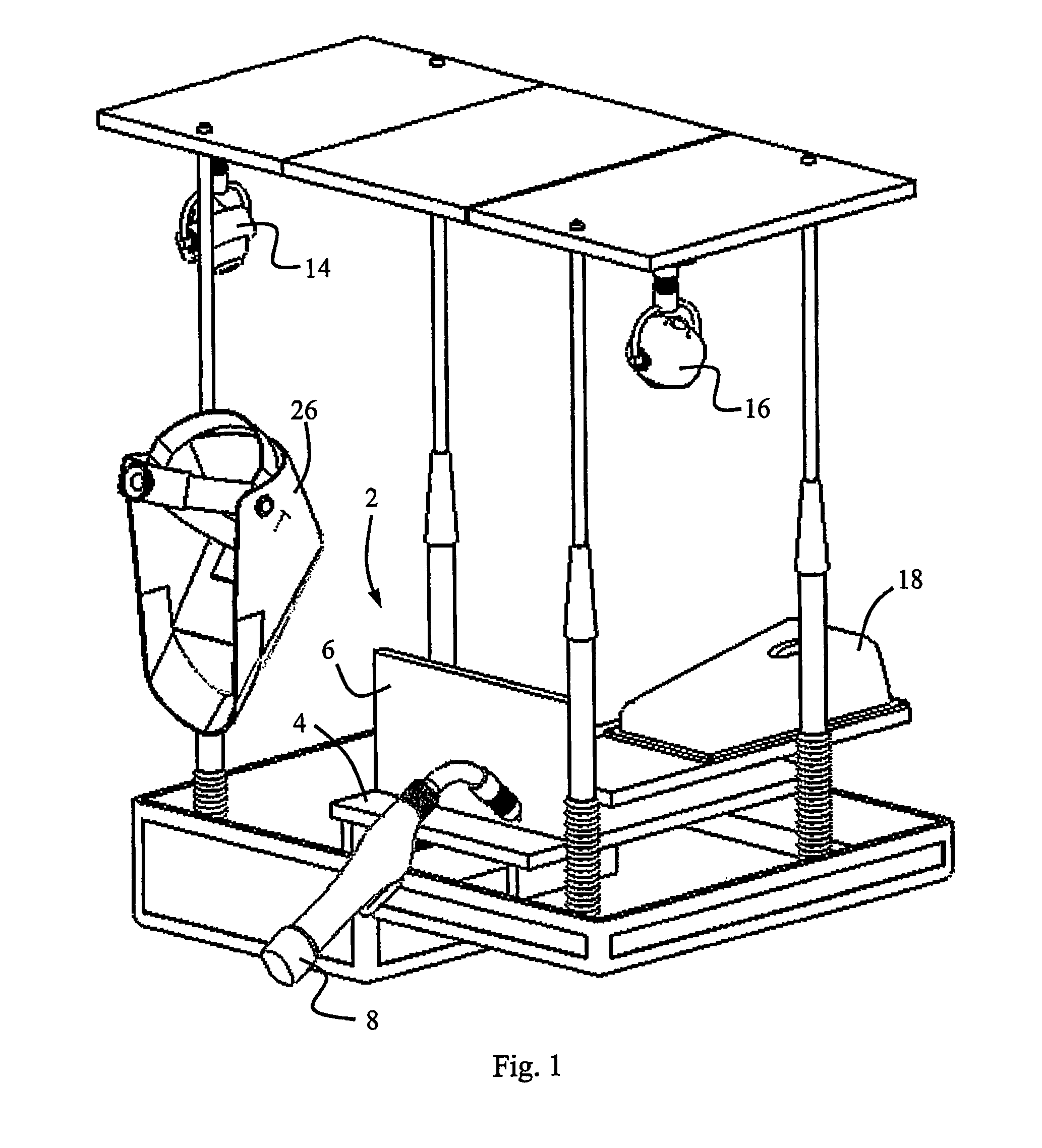

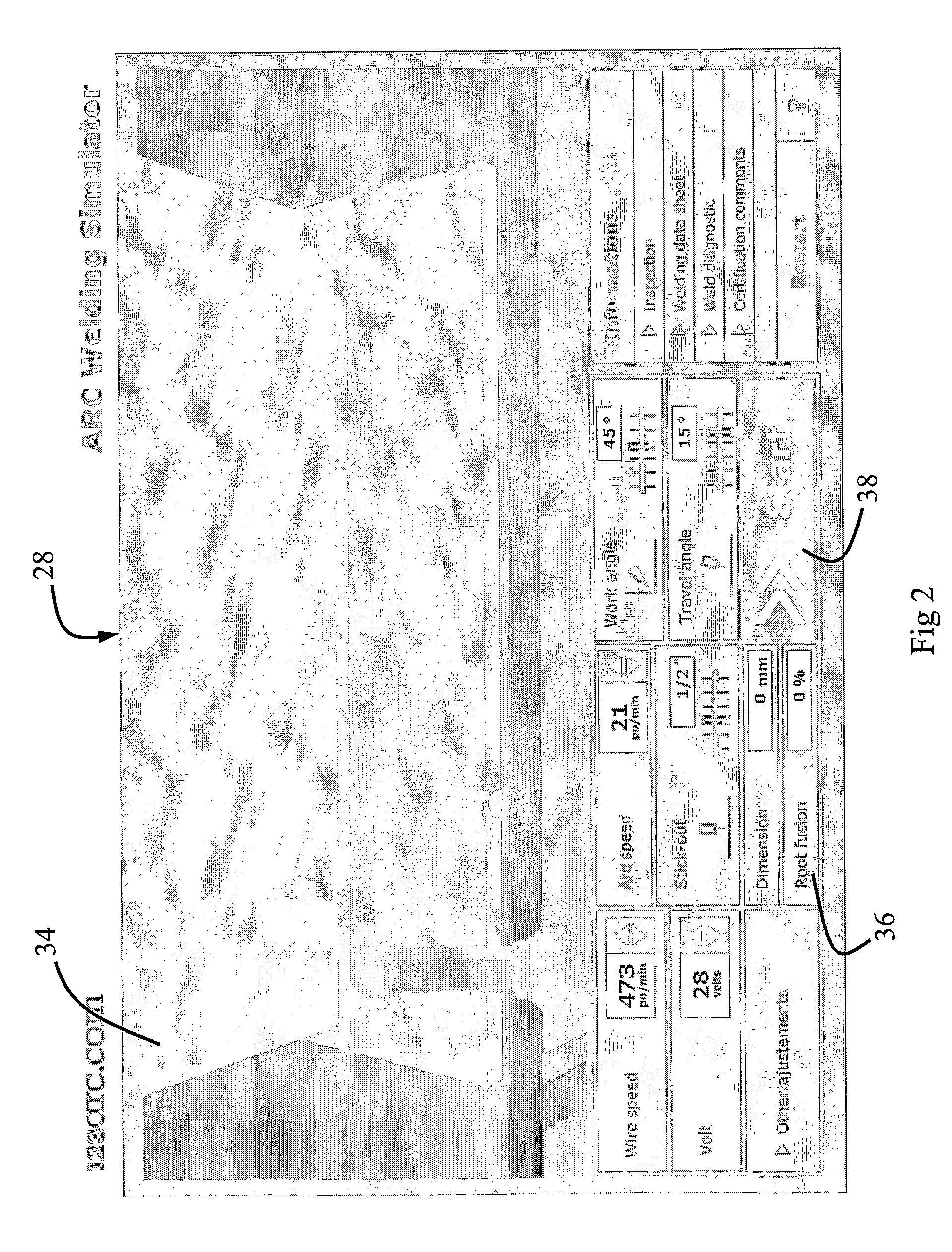

Body Motion Training and Qualification System and Method

InactiveUS20080038702A1Defective reproductionCosmonautic condition simulationsElectric discharge heatingSimulationDisplay device

The system allows training and qualification of a user performing a skill-related training exercise involving body motion in a workspace. A training environment is selected through a computer apparatus, and variables, parameters and controls of the training environment and the training exercise are adjusted. Use of an input device by the user is monitored. The 3D angles and spatial coordinates of reference points related to the input device are monitored through a detection device. A simulated 3D dynamic environment reflecting effects caused by actions performed by the user on objects is computed in real time as a function of the training environment selected. Images of the simulated 3D dynamic environment in real time are generated on a display device viewable by the user as a function of a computed organ of vision-object relation. Data indicative of the actions performed by the user and the effects of the actions are recorded and user qualification is set as a function of the recorded data.

Owner:123 CERTIFICATION

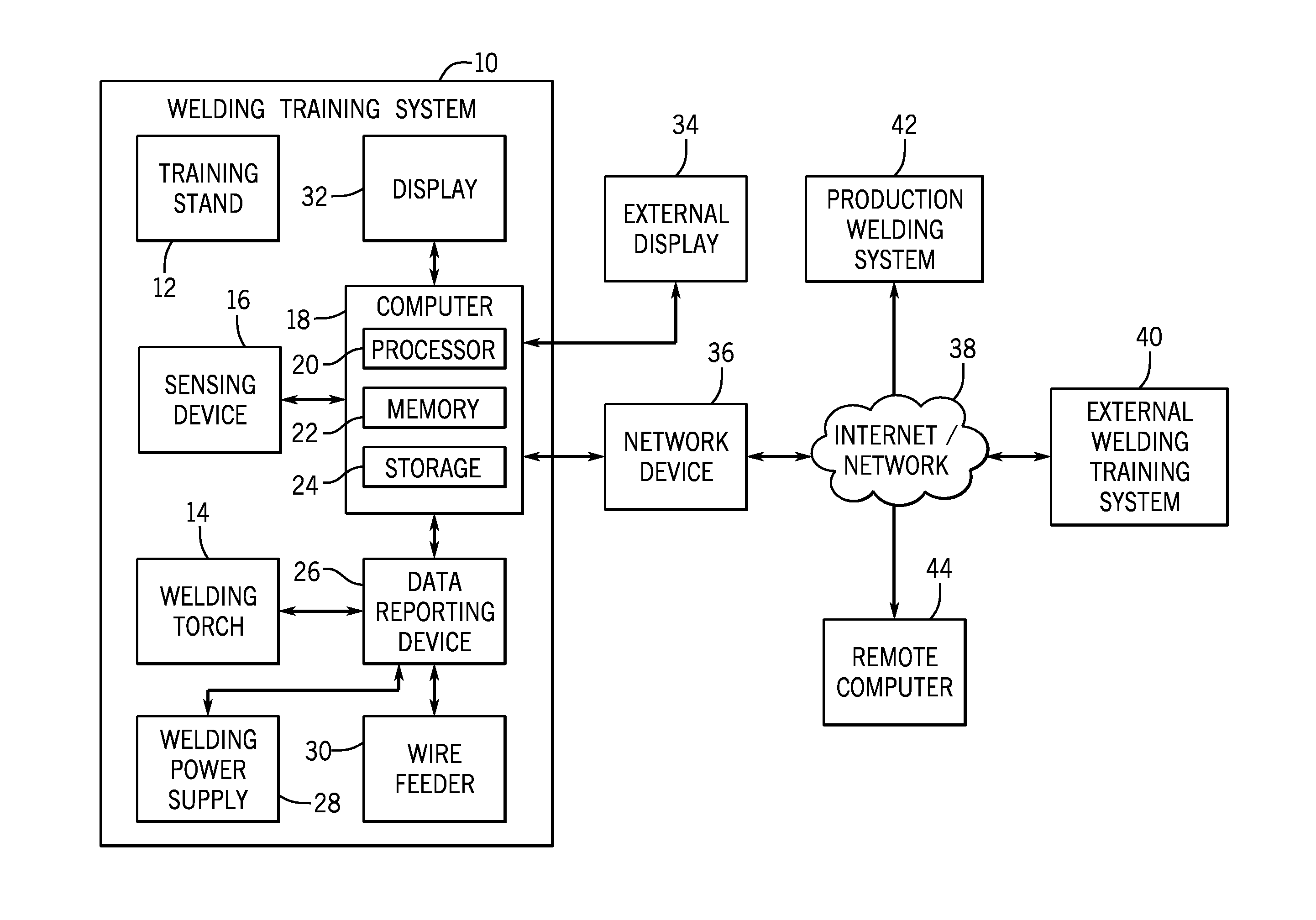

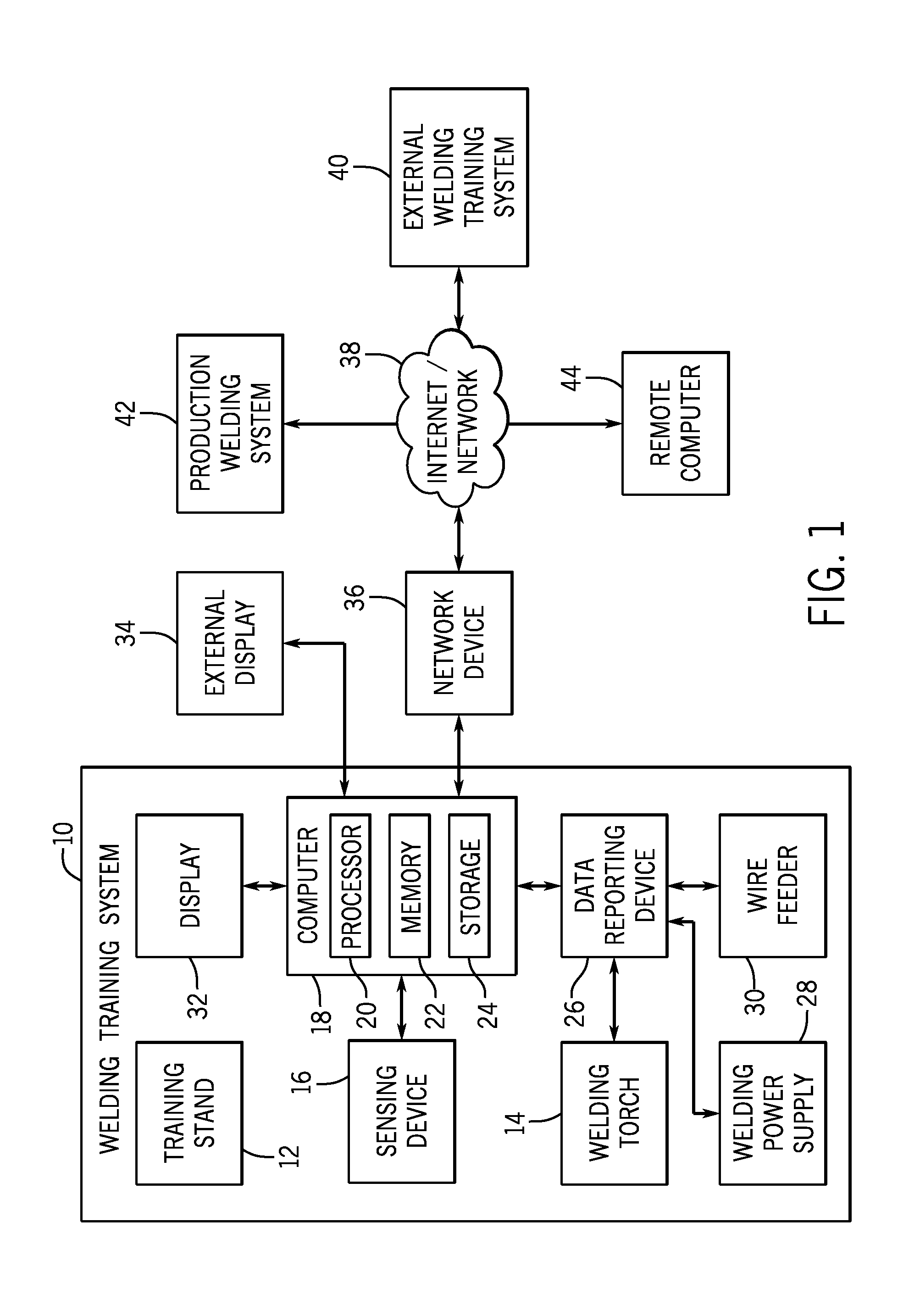

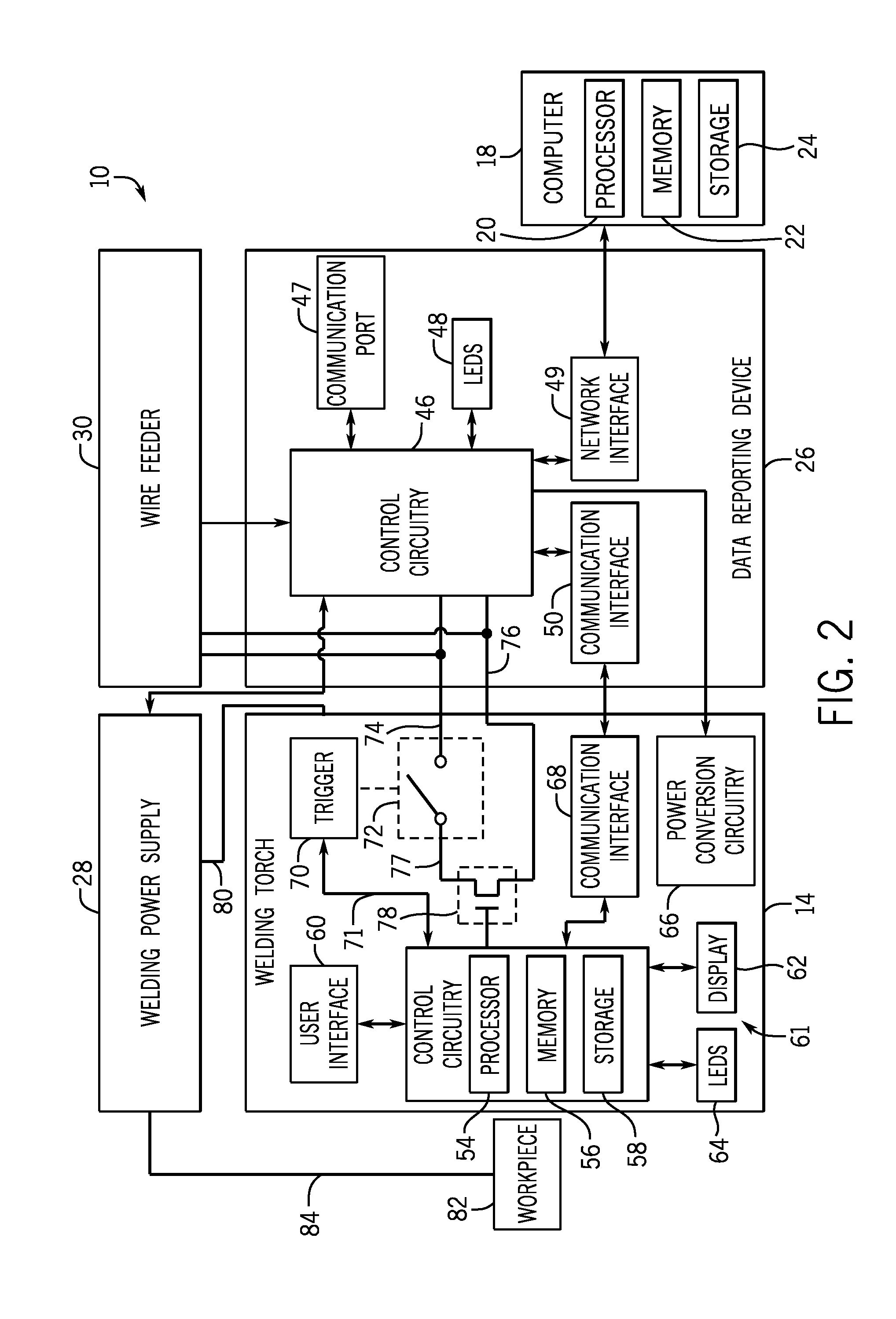

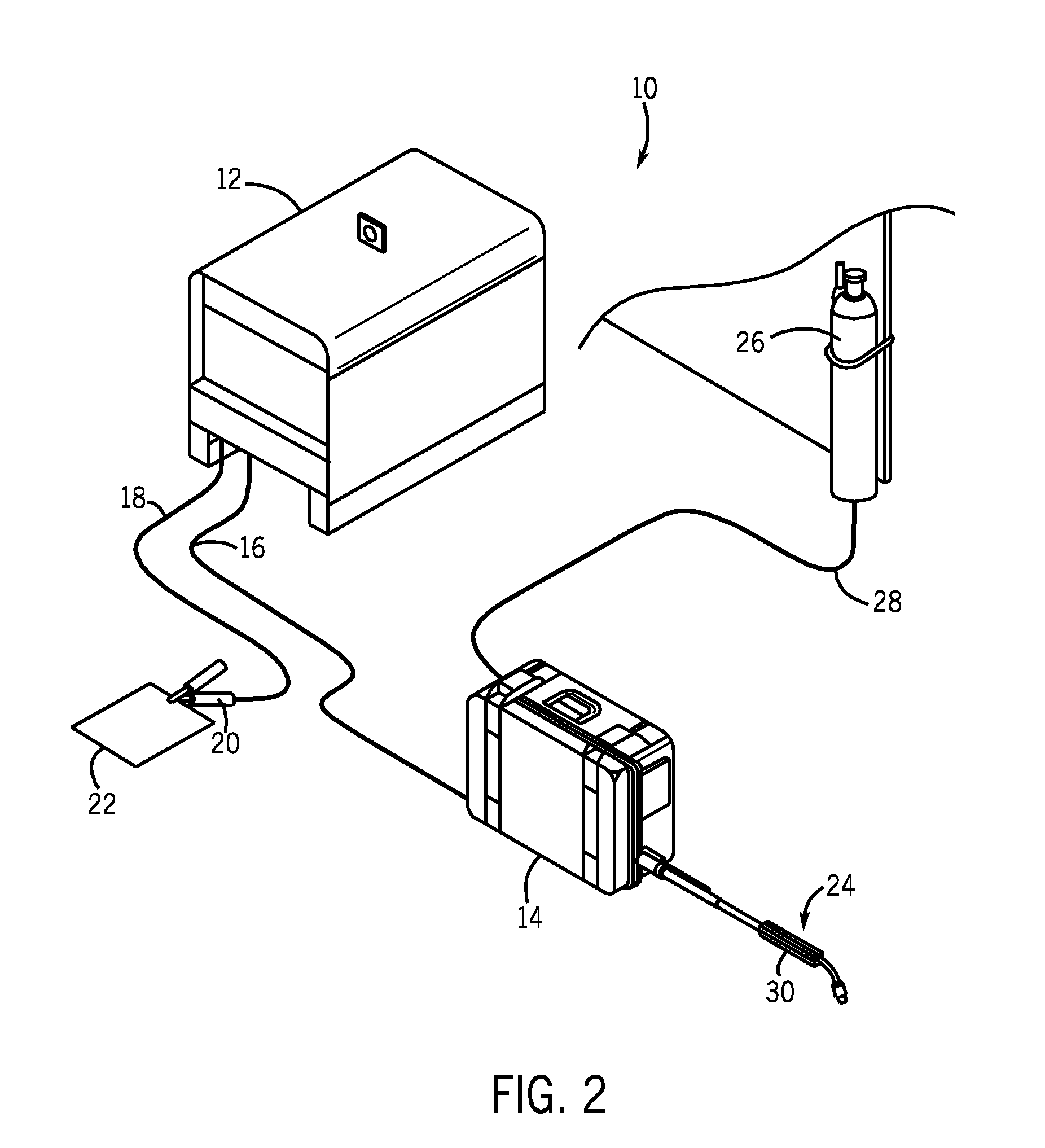

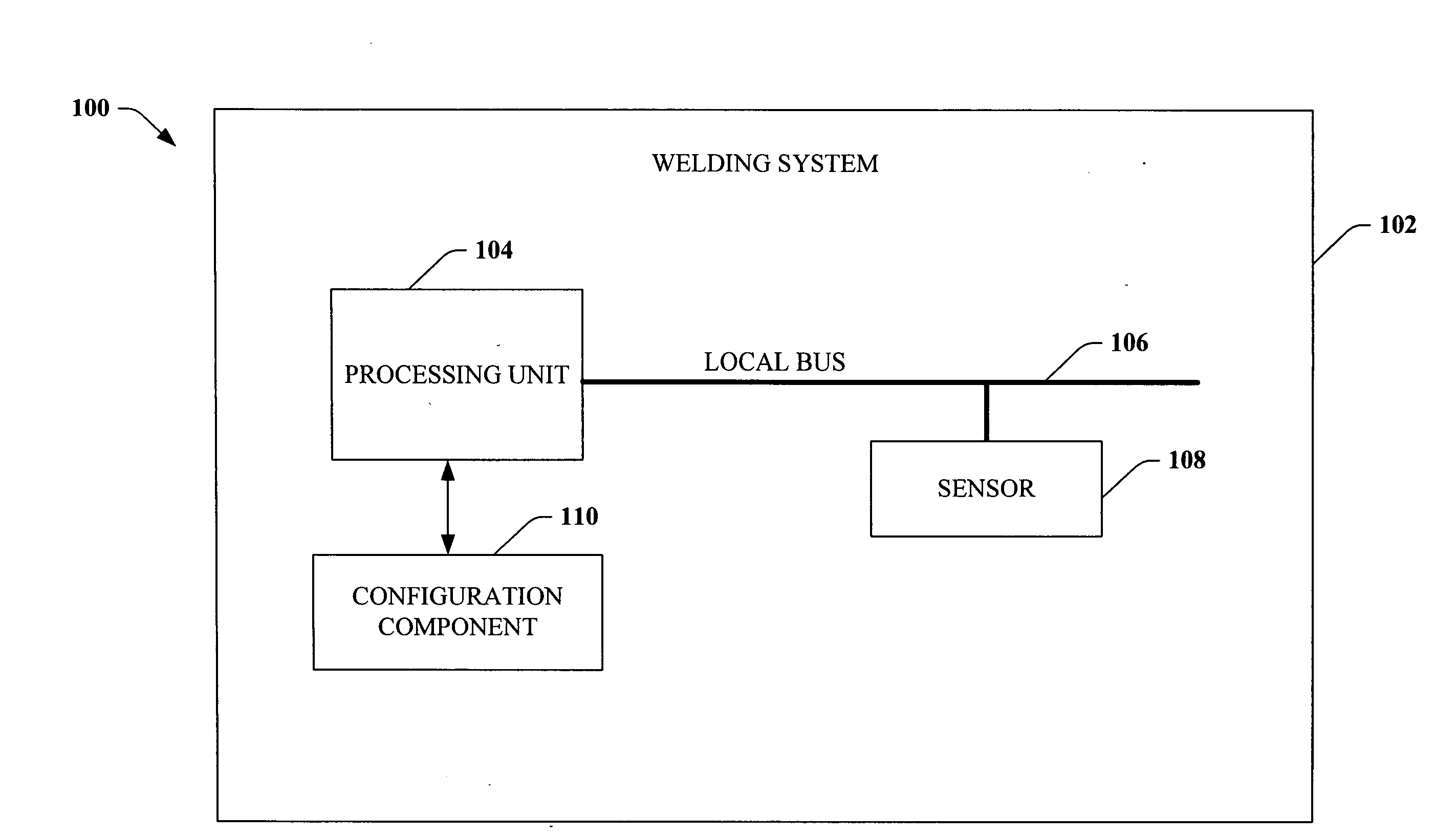

Welding training systems and devices

A welding tool includes a first handle and a second handle. The welding tool also includes a torch nozzle holder configured to hold a nozzle of a welding torch therein, and to block the nozzle from extending therethrough. The welding tool includes a blade assembly positioned a predetermined distance from the torch nozzle holder. The blade assembly is configured to cut welding wire extending through the blade assembly to calibrate wire stickout from the welding torch to the predetermined distance.

Owner:ILLINOIS TOOL WORKS INC

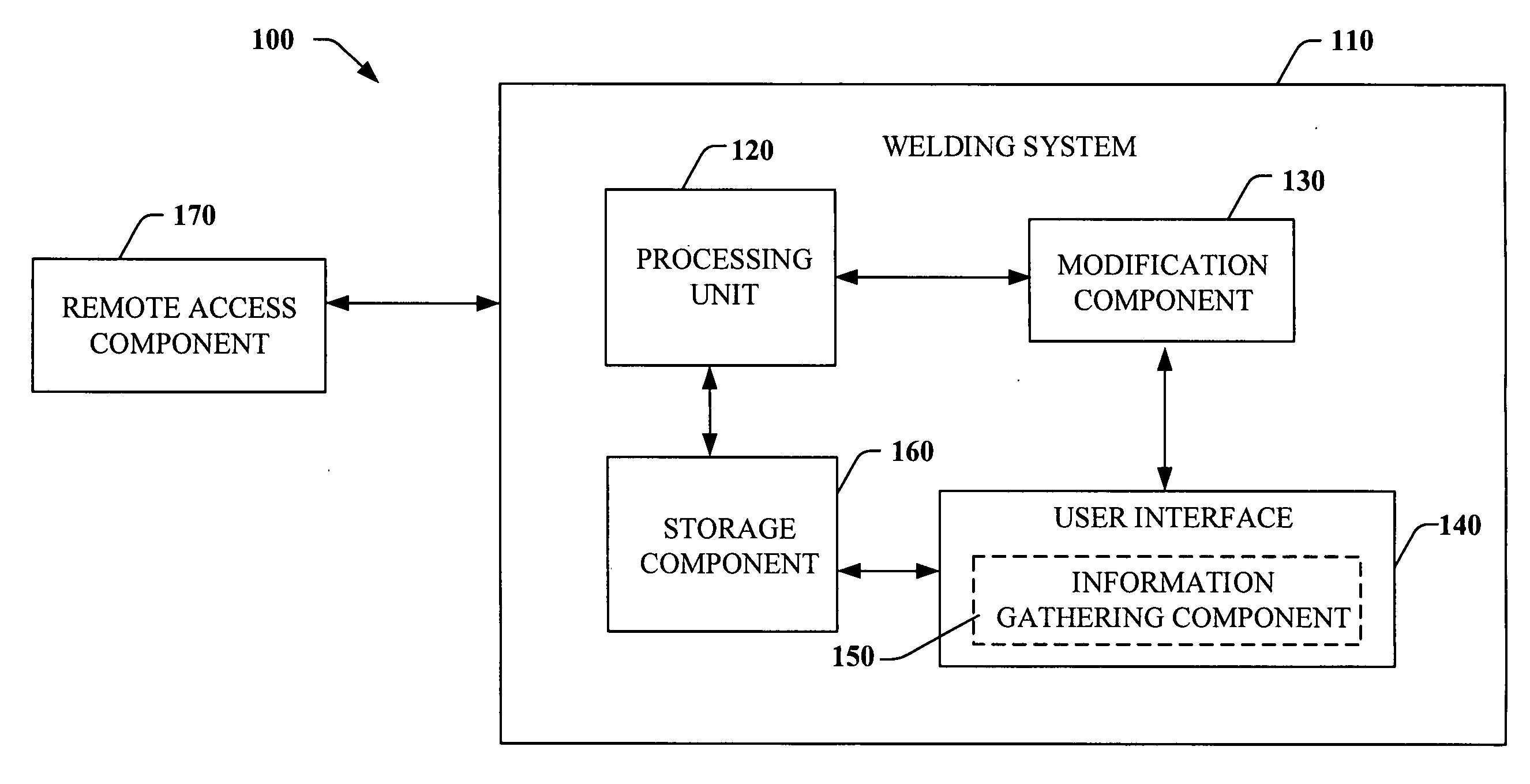

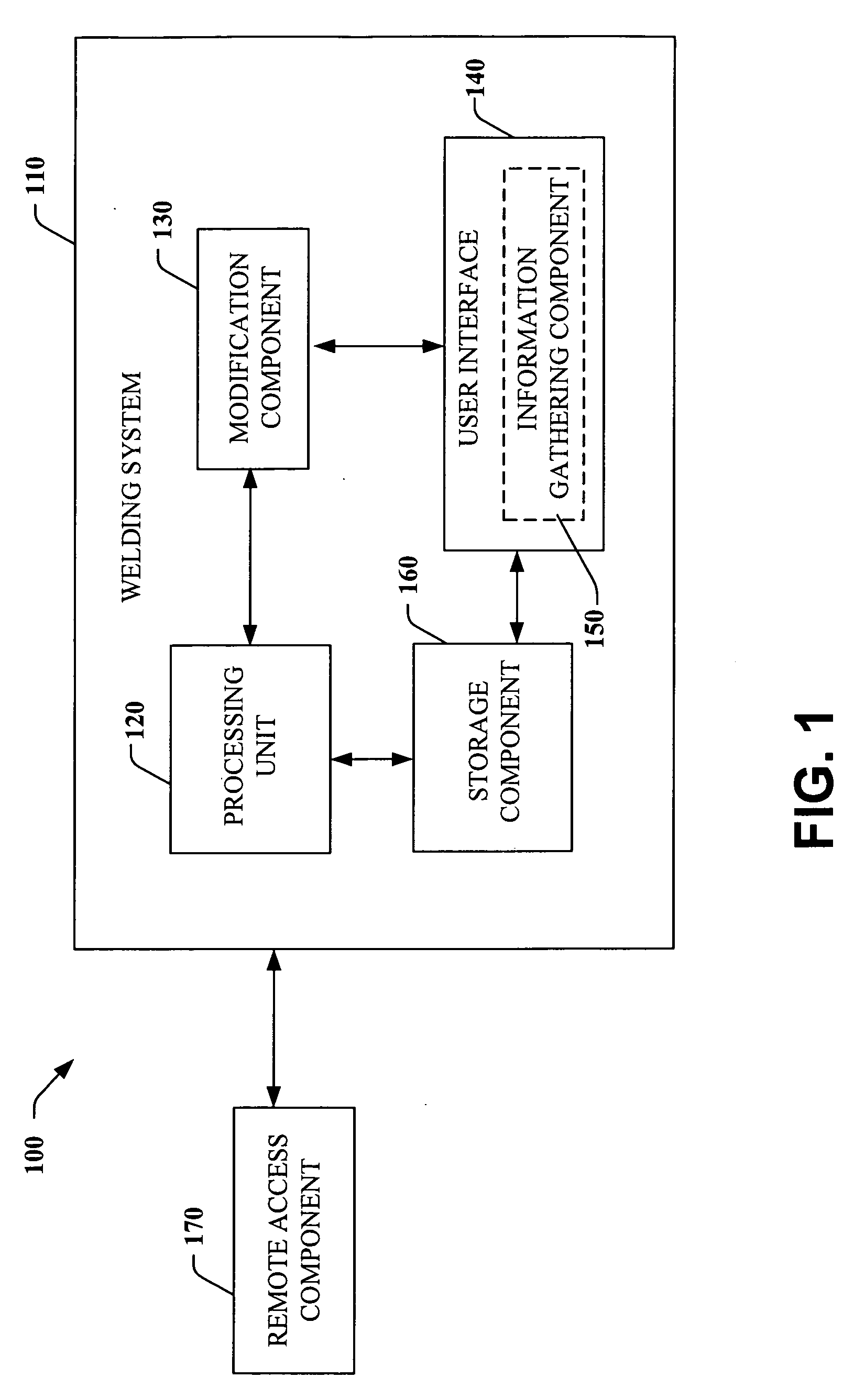

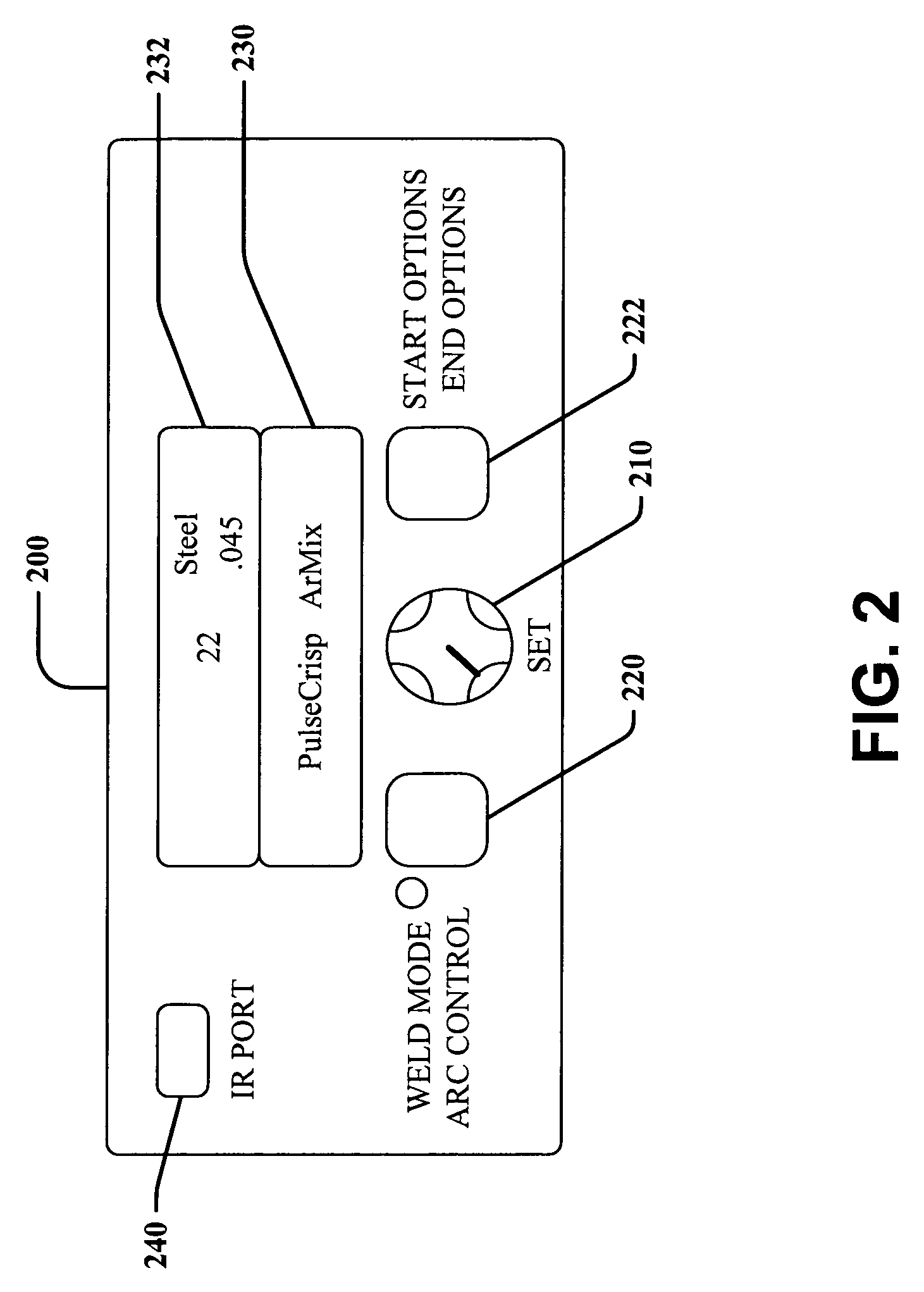

Comprehensive identification and designation of welding procedures

ActiveUS20060207980A1Easy selectionFacilitates namingElectric discharge heatingArc welding apparatusDefined ProcedureWaste management

System(s) and method(s) that facilitates comprehensive identification and designation of welding procedures. A configuration component facilitates configuring the welding system with respect to pre-defined procedures and / or parameters and facilitates naming of the configured welding system. A storage component that stores the configured welding system in a readily accessible memory location. A remote access component can facilitate remotely accessing the welding system, the configuration of the welding system alterable by way of the remote access component.

Owner:LINCOLN GLOBAL INC

Methods and apparatus for producing enhanced interference pigments

InactiveUS6241858B1Interference be notGood effectElectric discharge heatingPigment preparation by PVD/CVD methodsGas phaseVaporization

Methods and apparatus are provided for uniformly depositing a coating material from a vaporization source onto a powdered substrate material to form a thin coalescence film of the coating material that smoothly replicates the surface microstructure of the substrate material. The coating material is uniformly deposited on the substrate material to form optical interference pigment particles. The thin film enhances the hiding power and color gamut of the substrate material. Physical vapor deposition processes are used for depositing the film on the substrate material. The apparatus and systems employed in forming the coated particles utilize vibrating bed coaters, vibrating conveyor coaters, or coating towers. These allow the powdered substrate material to be uniformly exposed to the coating material vapor during the coating process.

Owner:JDS UNIPHASE CORP

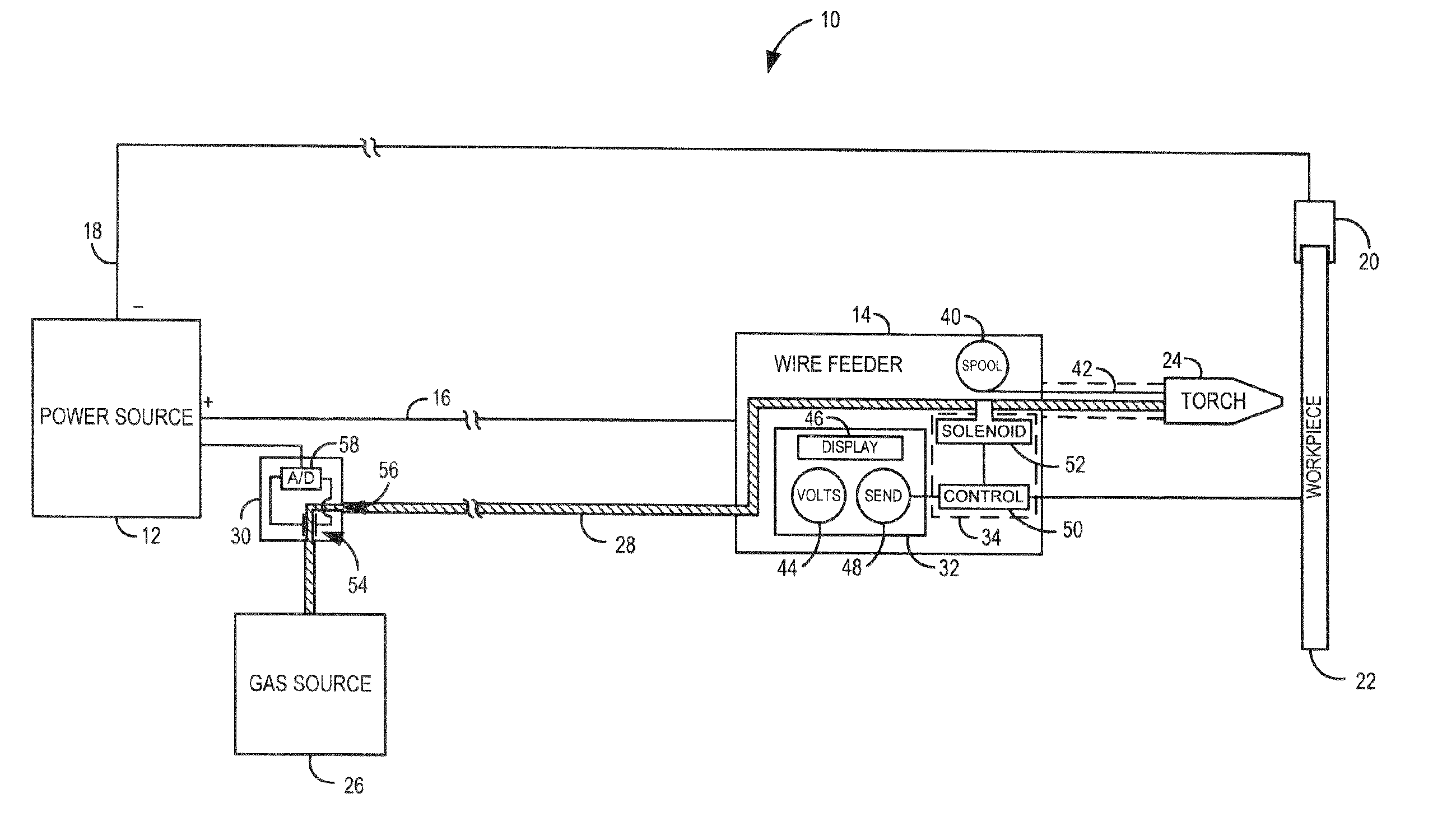

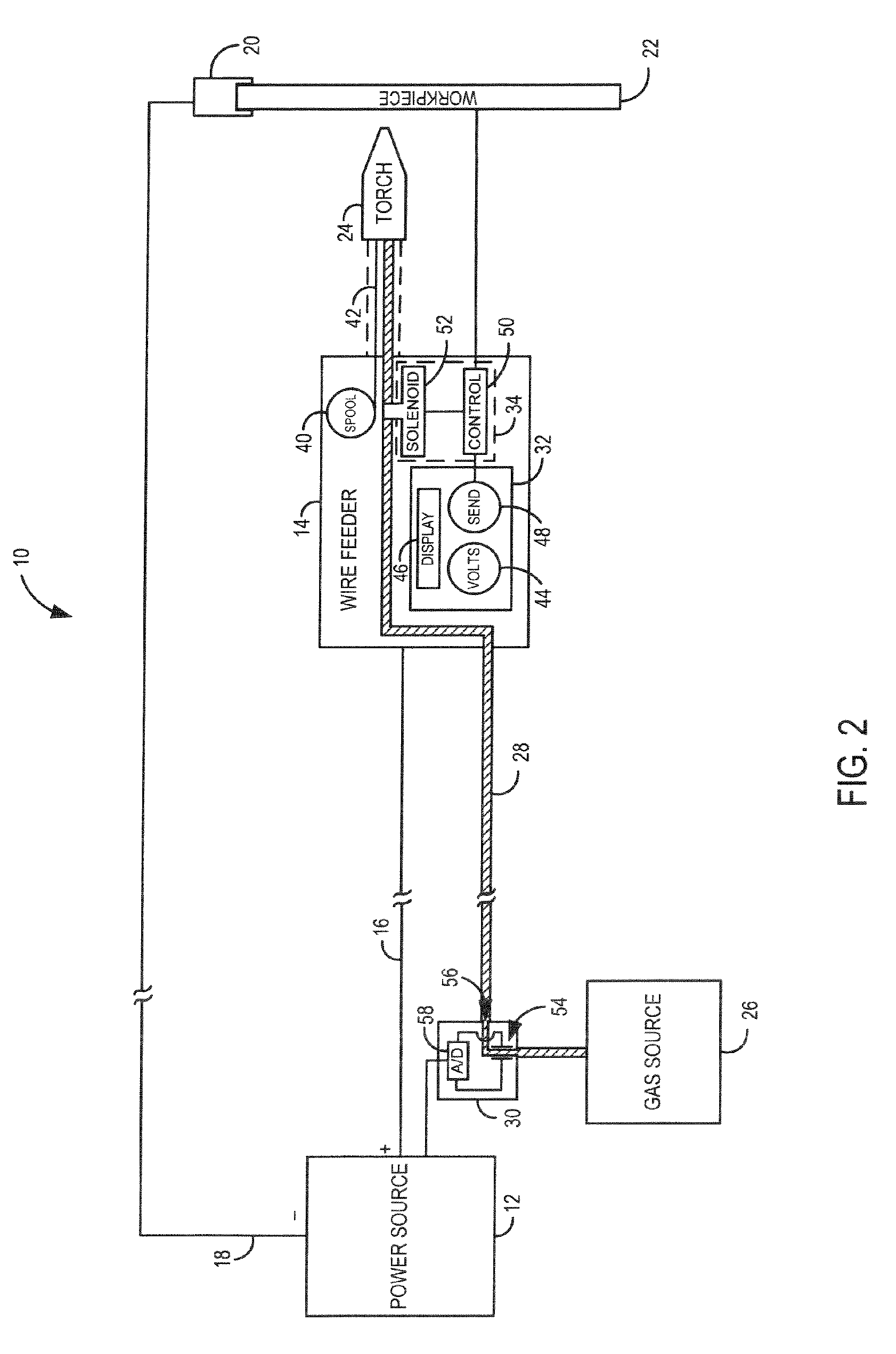

System and method for data communications over a gas hose in a welding-type application

ActiveUS20060213892A1Shielding gas supply/evacuation devicesElectric discharge heatingLine tubingCommunications system

The present invention includes a system and method of controlling a remotely located welding-type power source. A communications system includes a user interface to accept a user input at a portable location and a gas purging device to systematically purge pressurized gas from a gas line connecting the portable location to a remote location based on the user input. The communications system also includes a sensor to sense pressure changes in the gas line at the remote location and a processor configured to convert the sensed pressure changes to a representation of the user input.

Owner:ILLINOIS TOOL WORKS INC

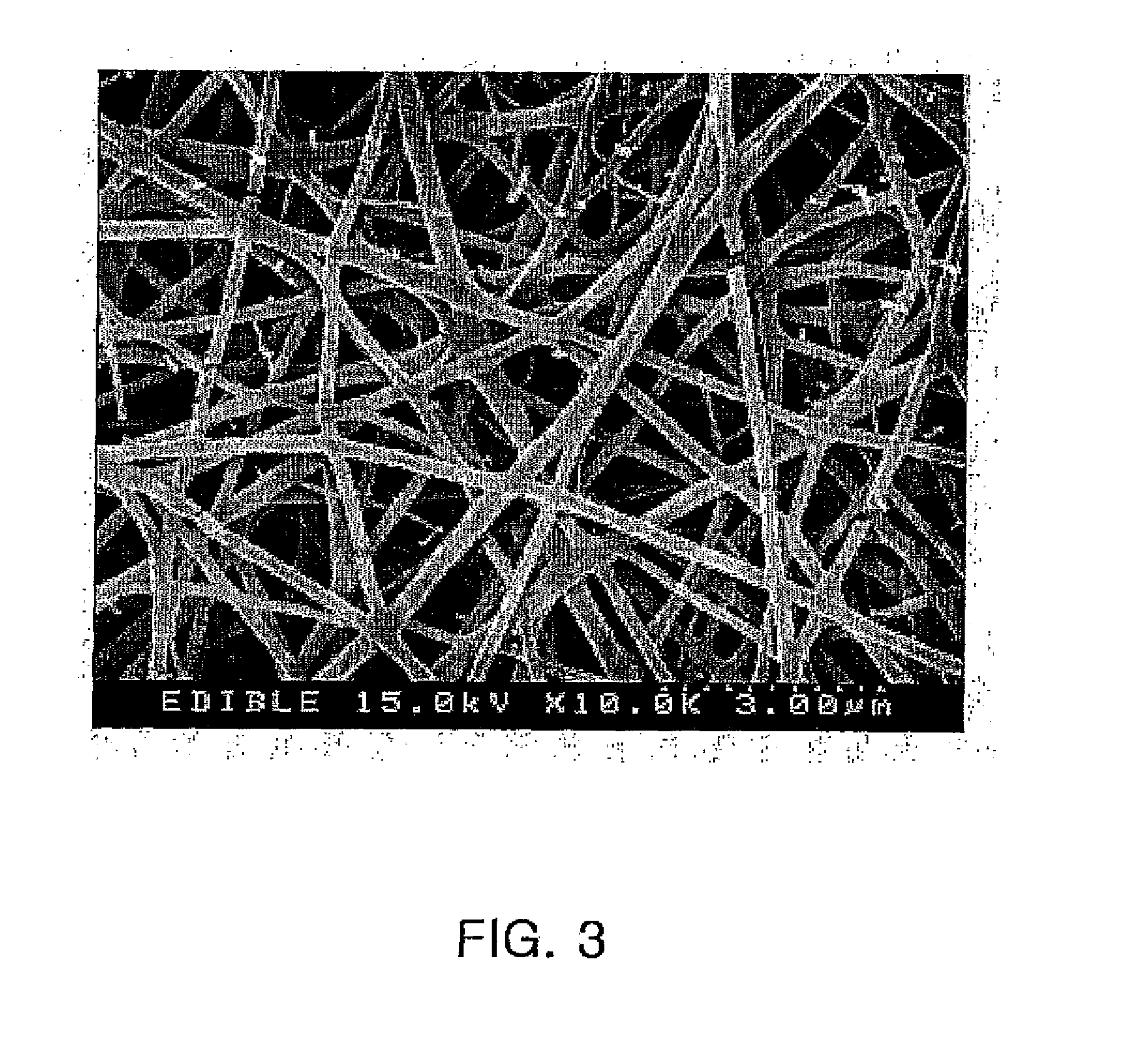

Nanofibers, and apparatus and methods for fabricating nanofibers by reactive electrospinning

ActiveUS20070018361A1Broaden applicationEasy to controlElectric discharge heatingInorganic material artificial filamentsFiberElectrospinning

Apparatus and methods for fabricating nanofibers by reactive electrospinning are described. An electrospinning process is coupled with an in-line reactor where chemical or photochemical reactions take place. This invention expands the application of the electrospinning and allows the production of nanofibers of crosslinked polymers and other new materials, such as gel nanofibers of ceramic precursors.

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE

Body motion training and qualification system and method

InactiveUS8512043B2Defective reproductionElectric discharge heatingGymnastic exercisingWorkspaceSimulation

The system allows training and qualification of a user performing a skill-related training exercise involving body motion in a workspace. A training environment is selected through a computer apparatus, and variables, parameters and controls of the training environment and the training exercise are adjusted. Use of an input device by the user is monitored. The 3D angles and spatial coordinates of reference points related to the input device are monitored through a detection device. A simulated 3D dynamic environment reflecting effects caused by actions performed by the user on objects is computed in real time as a function of the training environment selected. Images of the simulated 3D dynamic environment in real time are generated on a display device viewable by the user as a function of a computed organ of vision-object relation. Data indicative of the actions performed by the user and the effects of the actions are recorded and user qualification is set as a function of the recorded data.

Owner:123 CERTIFICATION

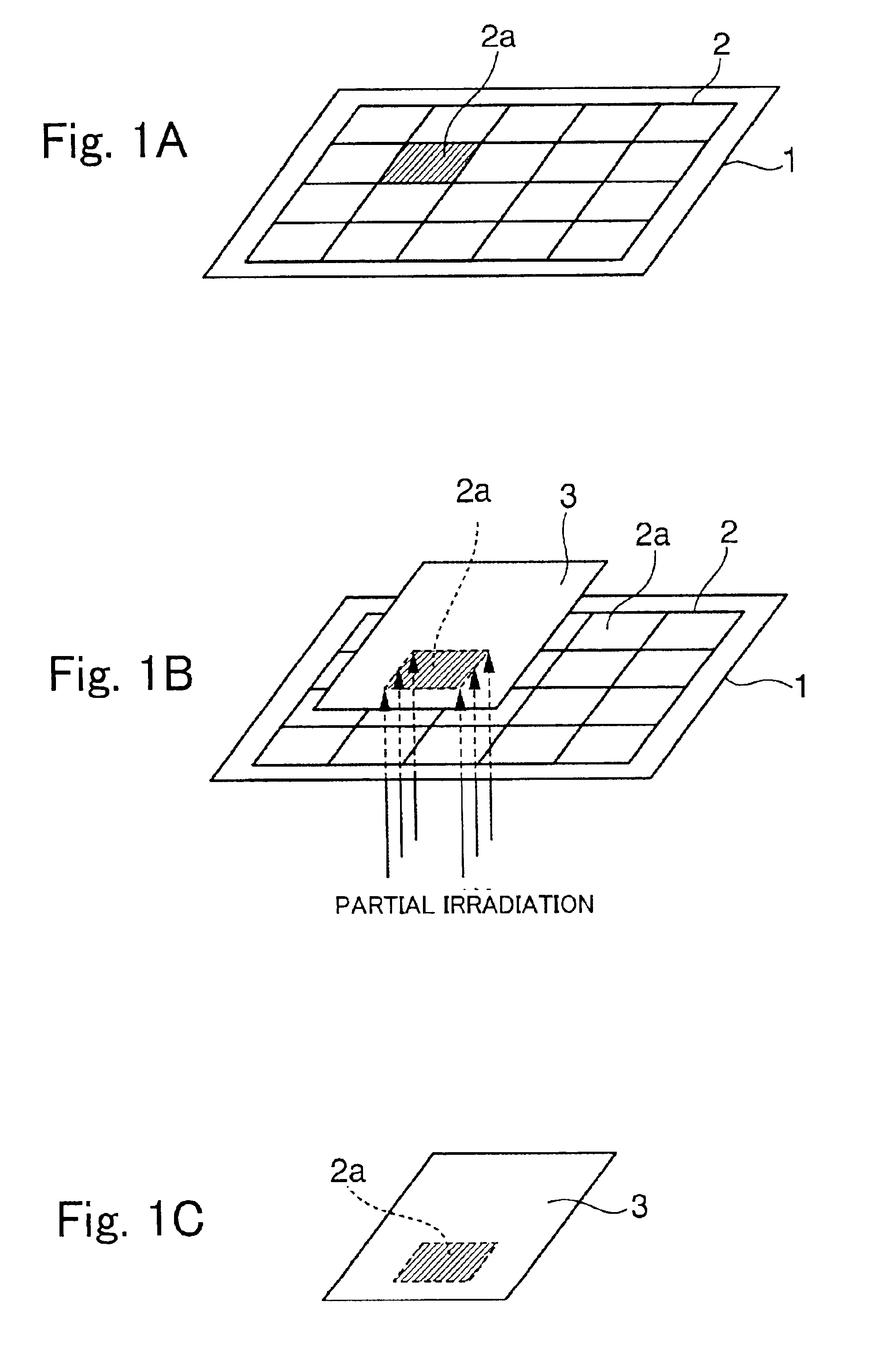

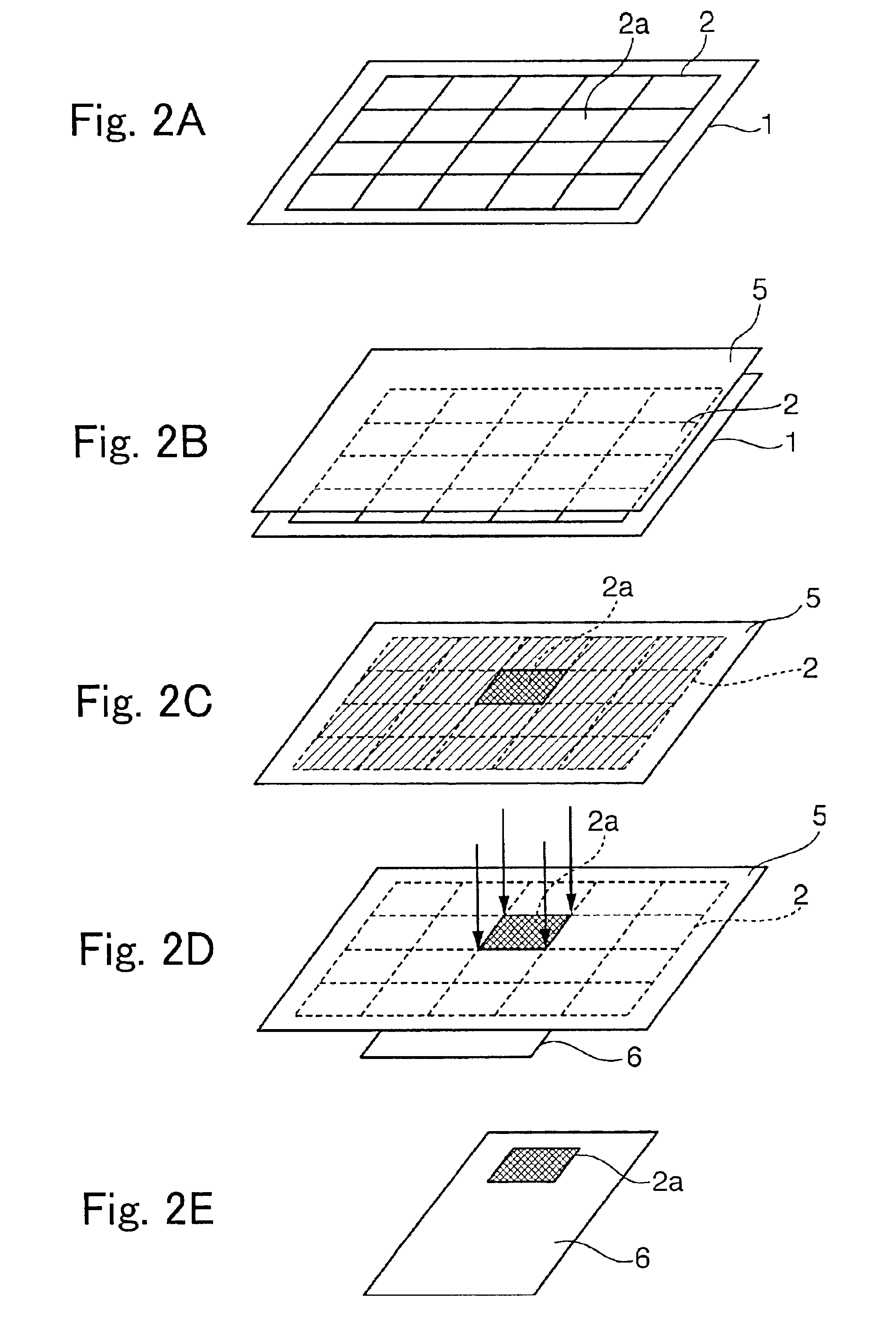

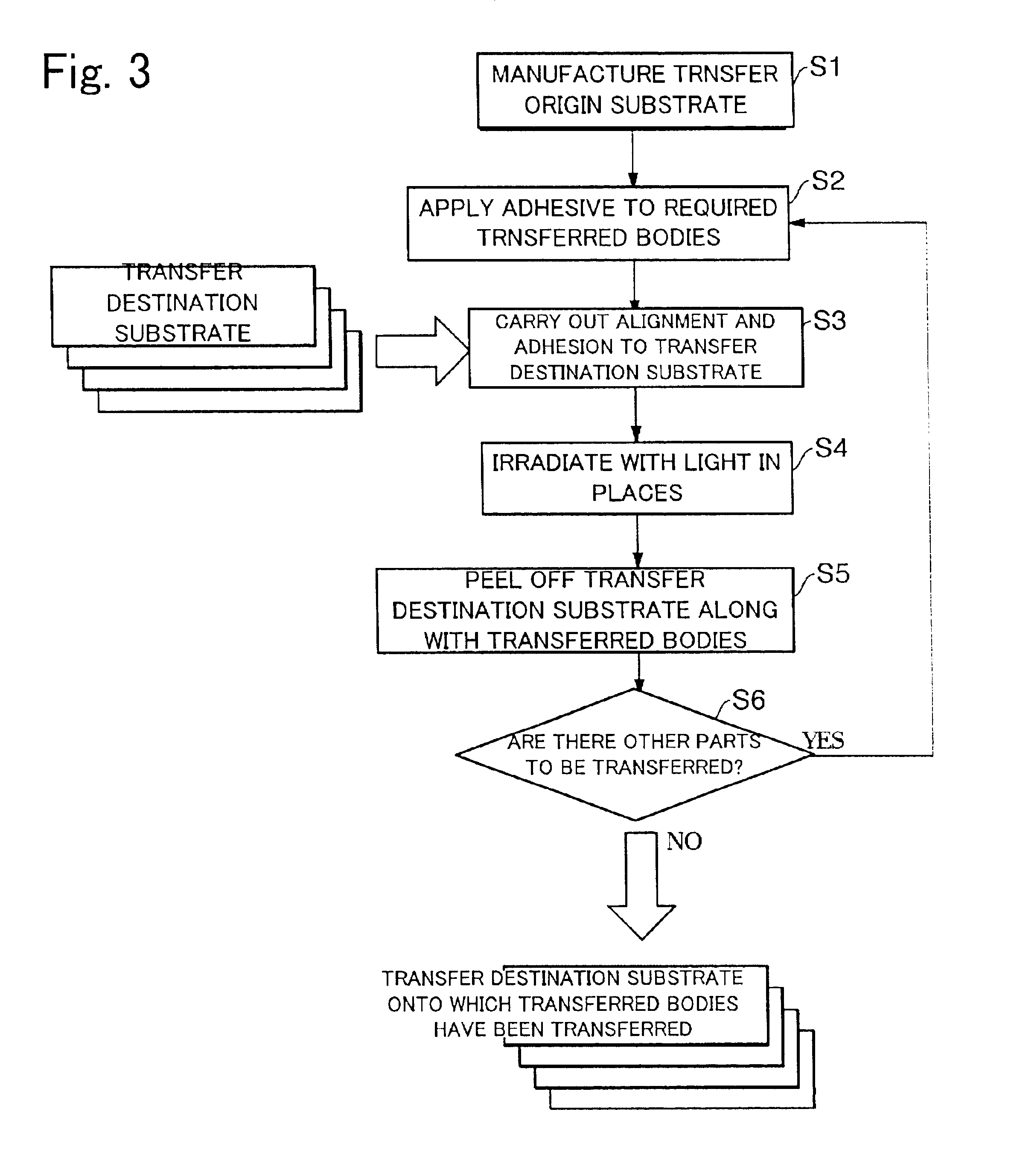

Transfer method, method of manufacturing thin film devices, method of manufacturing integrated circuits, circuit board and manufacturing method thereof, electro-optical apparatus and manufacturing method thereof, IC card, and electronic appliance

InactiveUS6887650B2Reduce material usageImprove area efficiencyMaterial nanotechnologyElectric discharge heatingIntegrated circuitElectronic equipment

Owner:SAMSUNG ELECTRONICS CO LTD

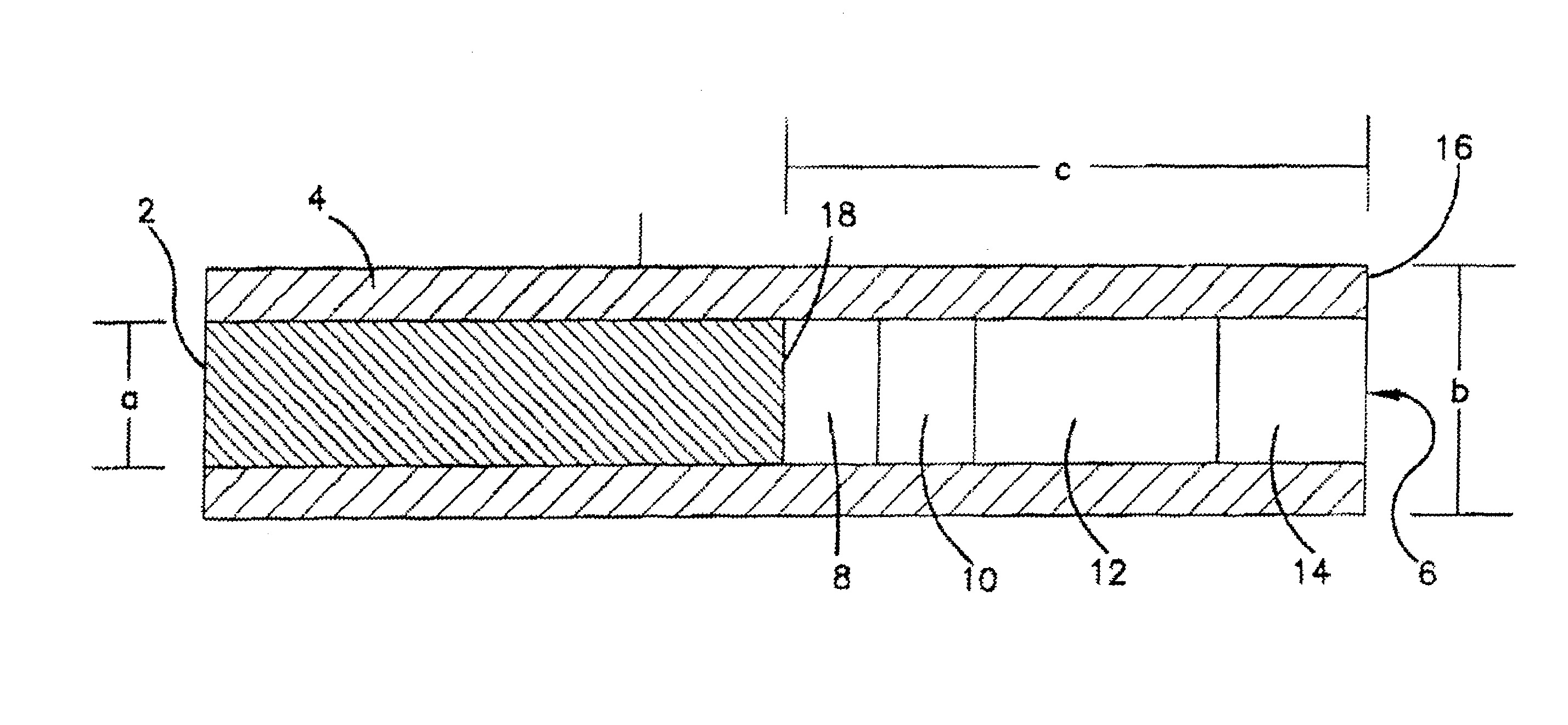

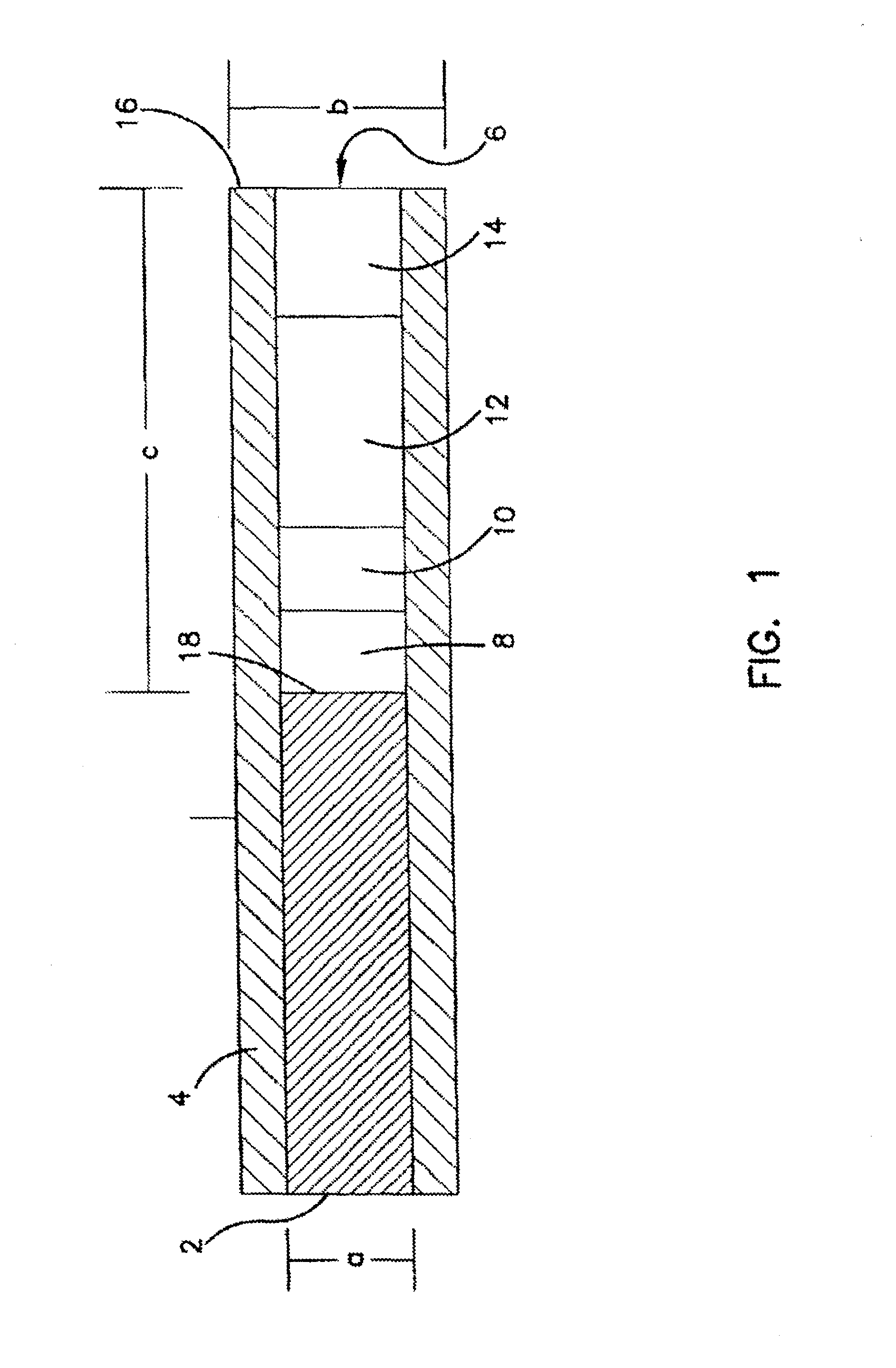

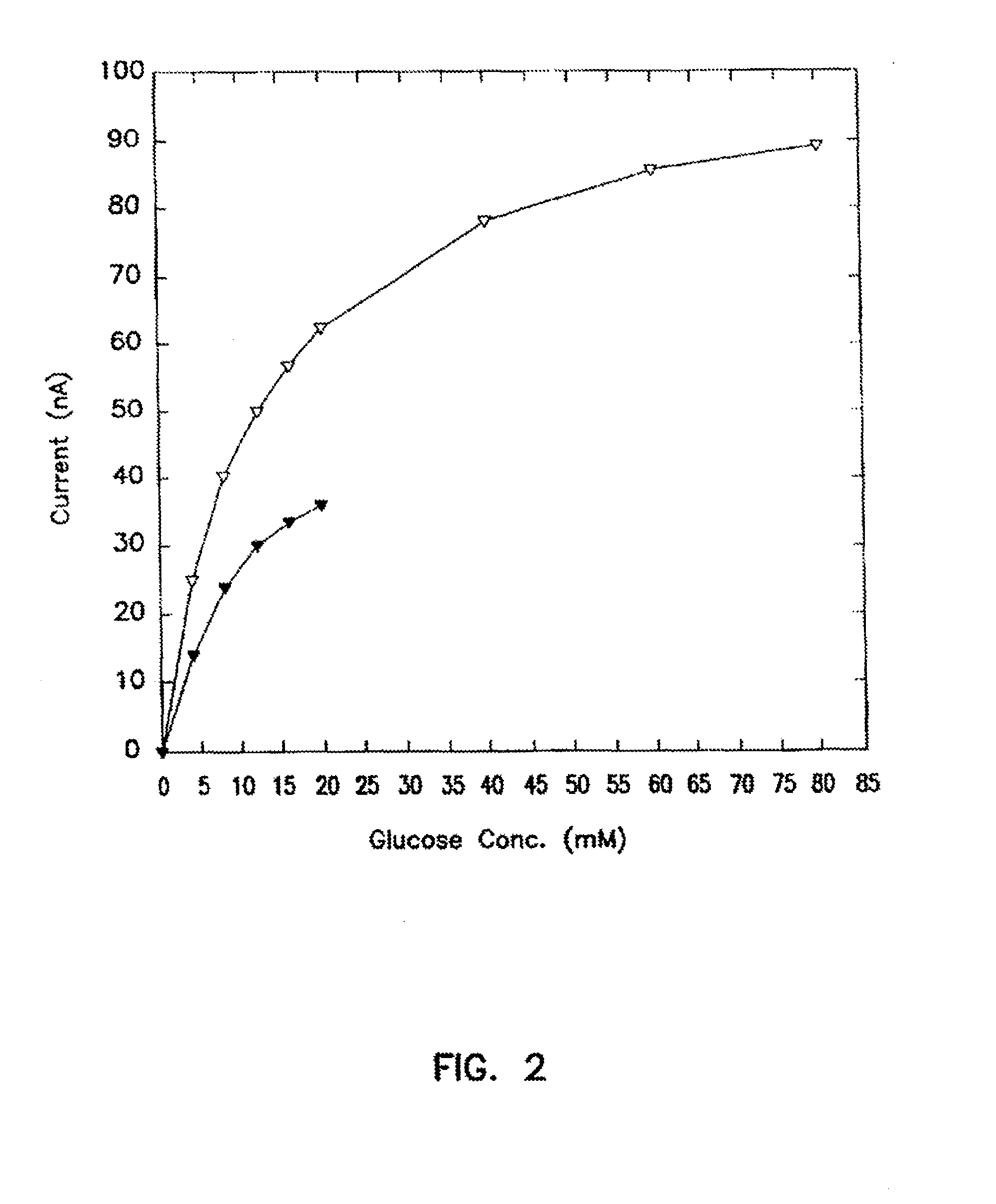

Subcutaneous glucose electrode

InactiveUS20080210557A1Reduce transportationAccurate measurementImmobilised enzymesBioreactor/fermenter combinationsPower flowConcentrations glucose

A small diameter flexible electrode designed for subcutaneous in vivo amperometric monitoring of glucose is described. The electrode is designed to allow “one-point” in vivo calibration, i.e., to have zero output current at zero glucose concentration, even in the presence of other electroreactive species of serum or blood. The electrode is preferably three or four-layered, with the layers serially deposited within a recess upon the tip of a polyamide insulated gold wire. A first glucose concentration-to-current transducing layer is overcoated with an electrically insulating and glucose flux limiting layer (second layer) on which, optionally, an immobilized interference-eliminating horseradish peroxidase based film is deposited (third layer). An outer (fourth) layer is biocompatible.

Owner:ABBOTT LAB INC

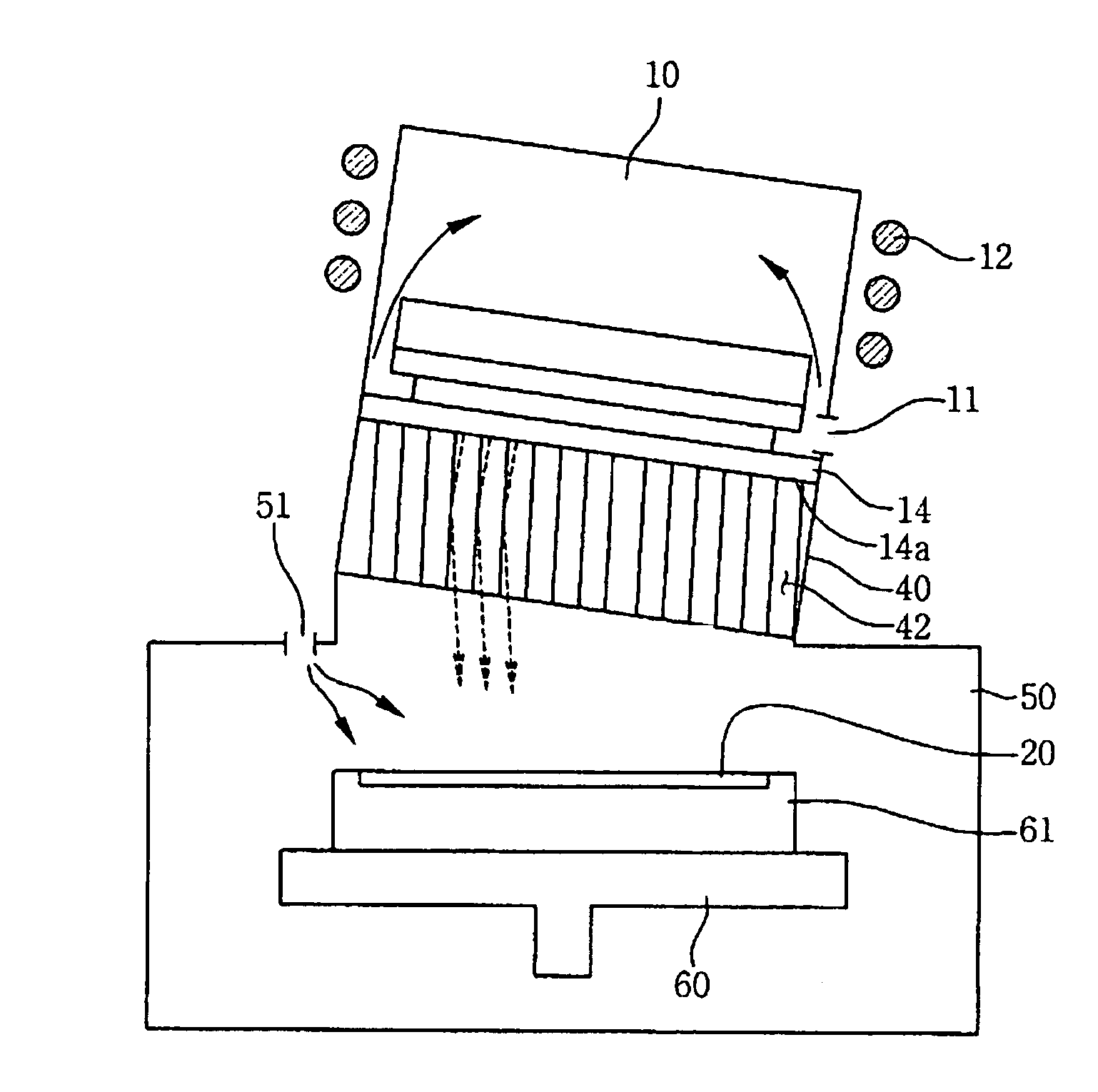

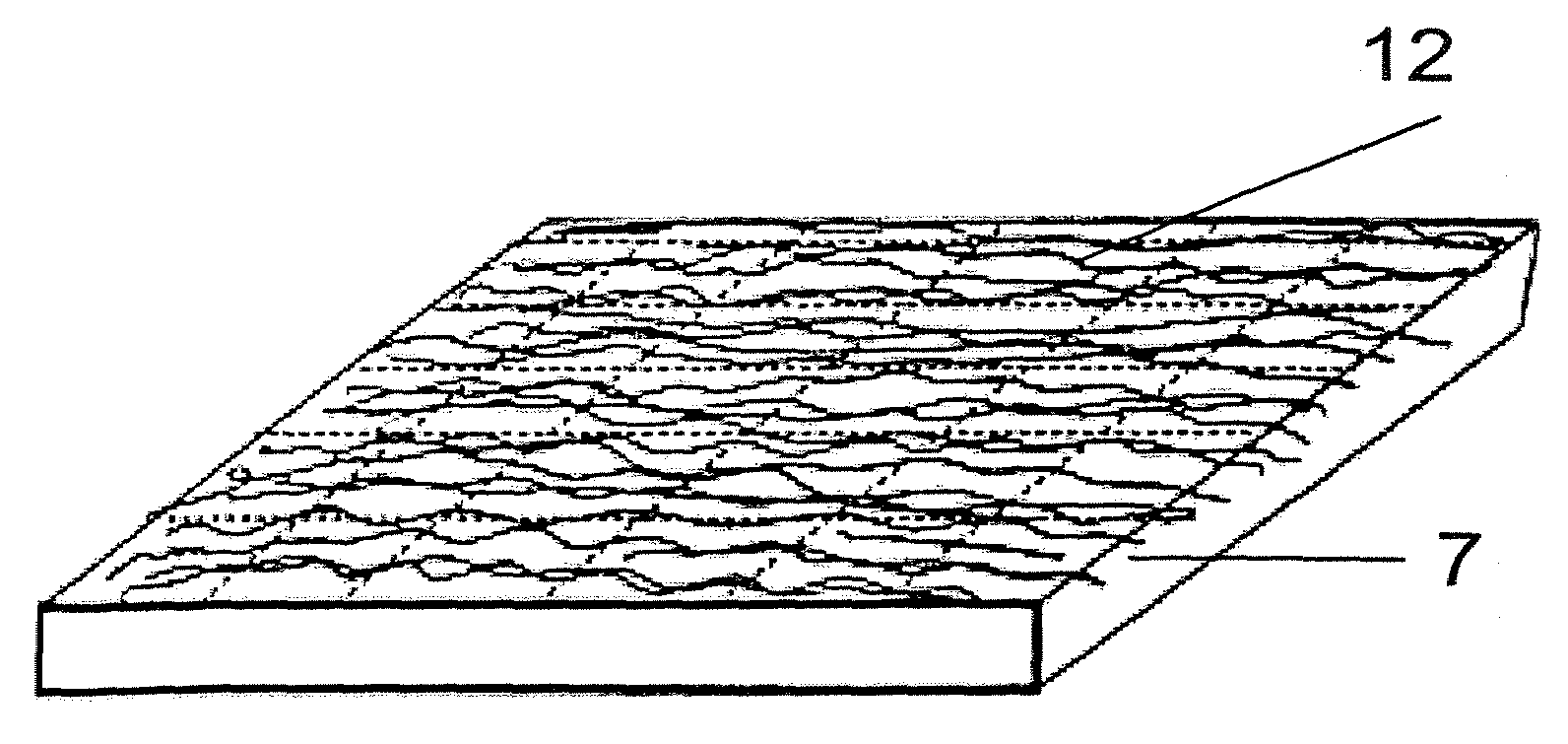

Particle filter system incorporating nanofibers

ActiveUS20080110342A1Electric discharge heatingFilament/thread formingElectric field modulationFiber

A filtration device including a filtration medium having a plurality of nanofibers of diameters less than 1 micron formed into a fiber mat in the presence of an abruptly varying electric field. The filtration device includes a support attached to the filtration medium and having openings for fluid flow therethrough. A device for making a filter material. The device includes an electrospinning element configured to electrospin a plurality of fibers from a tip of the electrospinning element, a collector opposed to the electrospinning element configured to collect electrospun fibers on a surface of the collector, and an electric field modulation device configured to abruptly vary an electric field at the collector at least once during electrospinning of the fibers. A method for making a filter material. The method provides a support having openings for fluid flow therethrough, electrospins nanofibers across an entirety of the openings, and abruptly varies an electric field at the collector at least once during electrospinning of the fibers.

Owner:RES TRIANGLE INST

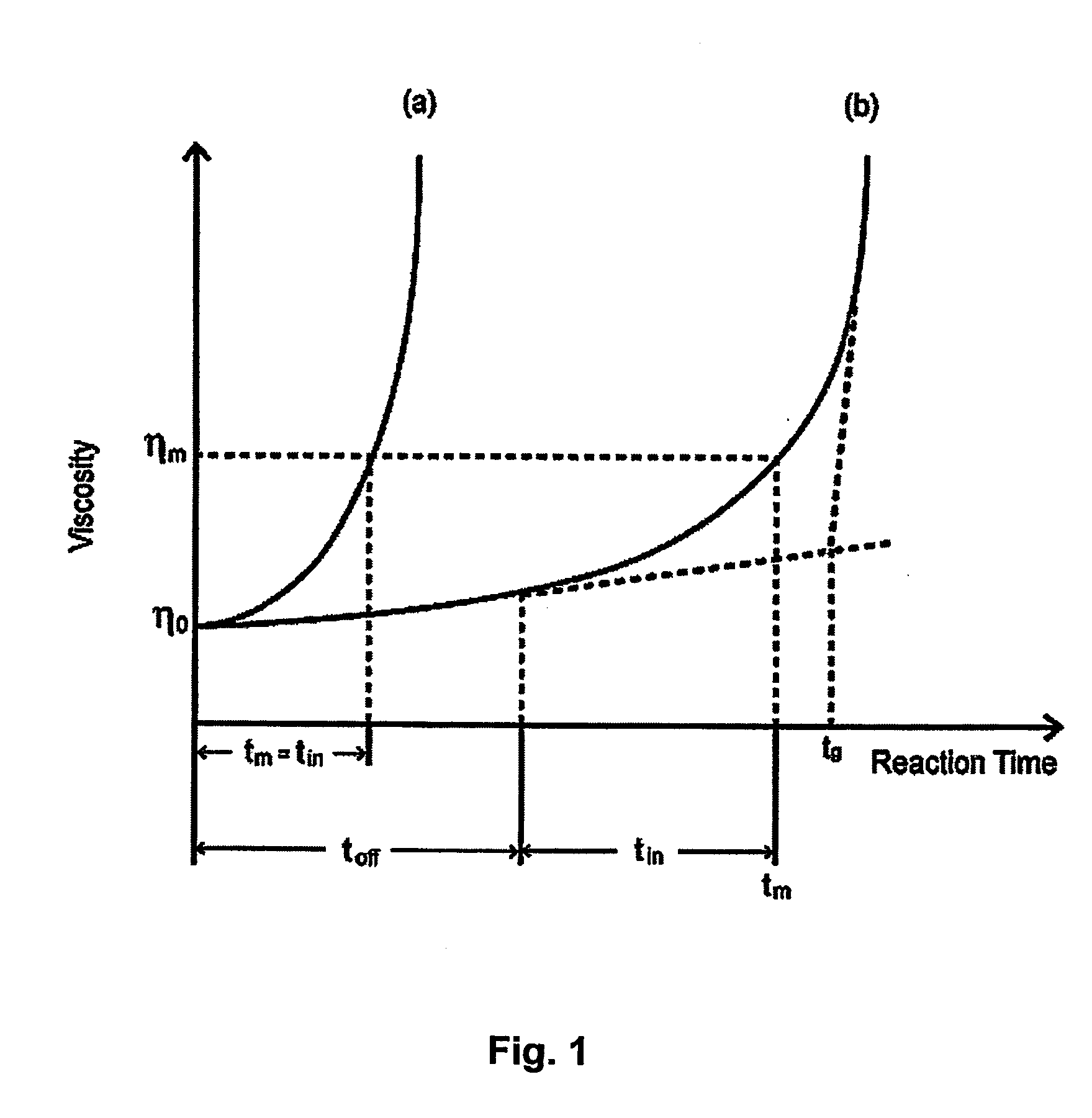

Process for production of surface-treated particulate water-absorbent resin

ActiveUS7201941B2Improve the level ofLittle cause gel blockingElectric discharge heatingVacuum evaporation coatingParticulatesReaction temperature

An object of the present invention is to provide an excellent process for production of a surface-treated particulate water-absorbent resin wherein the process adopts a surface-treatment process that can enhance the properties (which the water-absorbent resin is desired to have) to extremely high levels, and also can solve the prior problems in such as safety, and further can sufficiently carry out the treatment even at a reaction temperature near room temperature. As a means of achieving this object, the process according to the present invention for production of a surface-treated particulate water-absorbent resin is characterized by comprising the steps of: adding a treating liquid to a particulate water-absorbent resin as a base polymer, wherein the treating liquid contains a radically polymerizable compound; and then irradiating the particulate water-absorbent resin with active energy rays while fluidizing the particulate water-absorbent resin, thereby surface-treating it.

Owner:NIPPON SHOKUBAI CO LTD

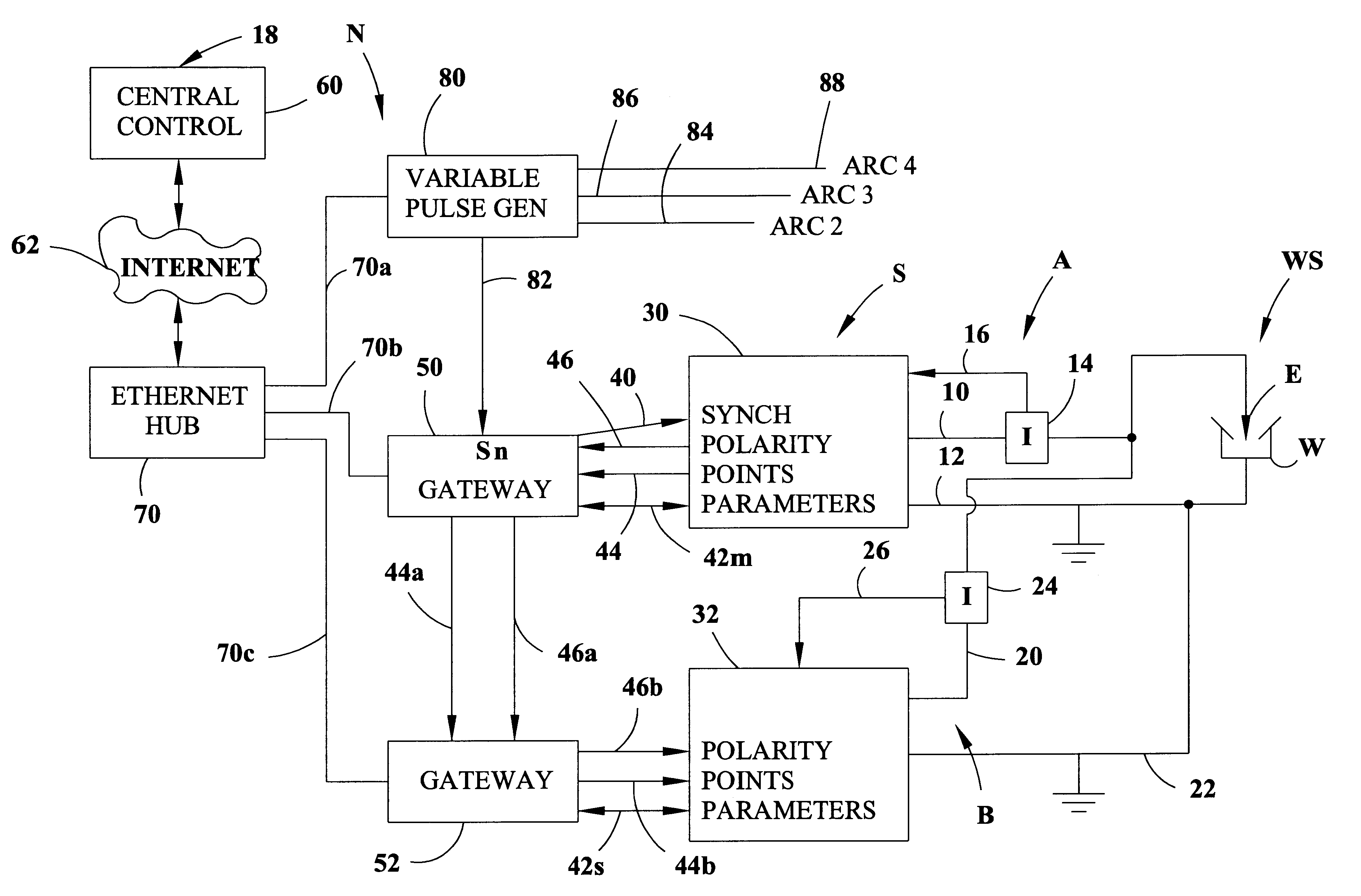

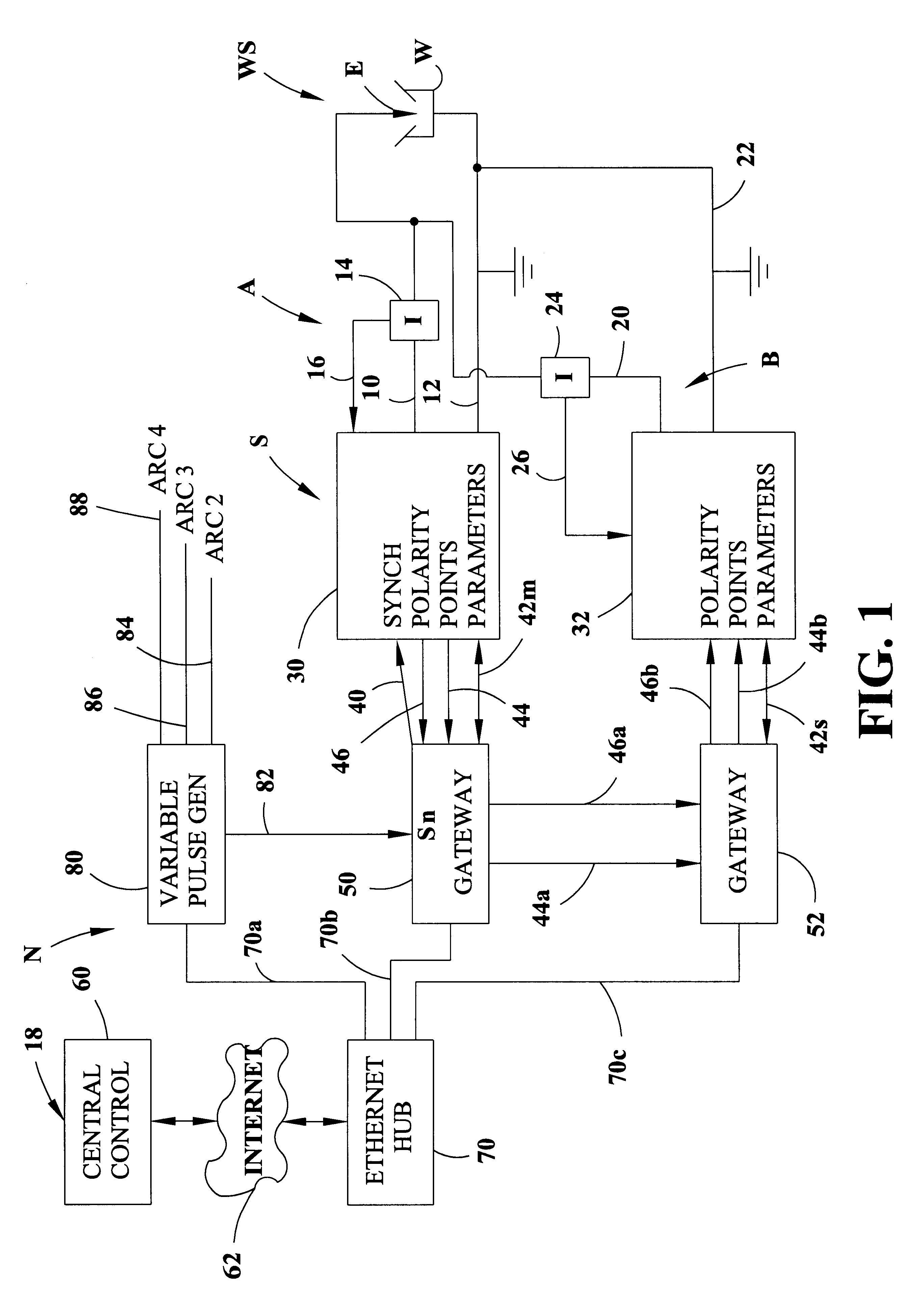

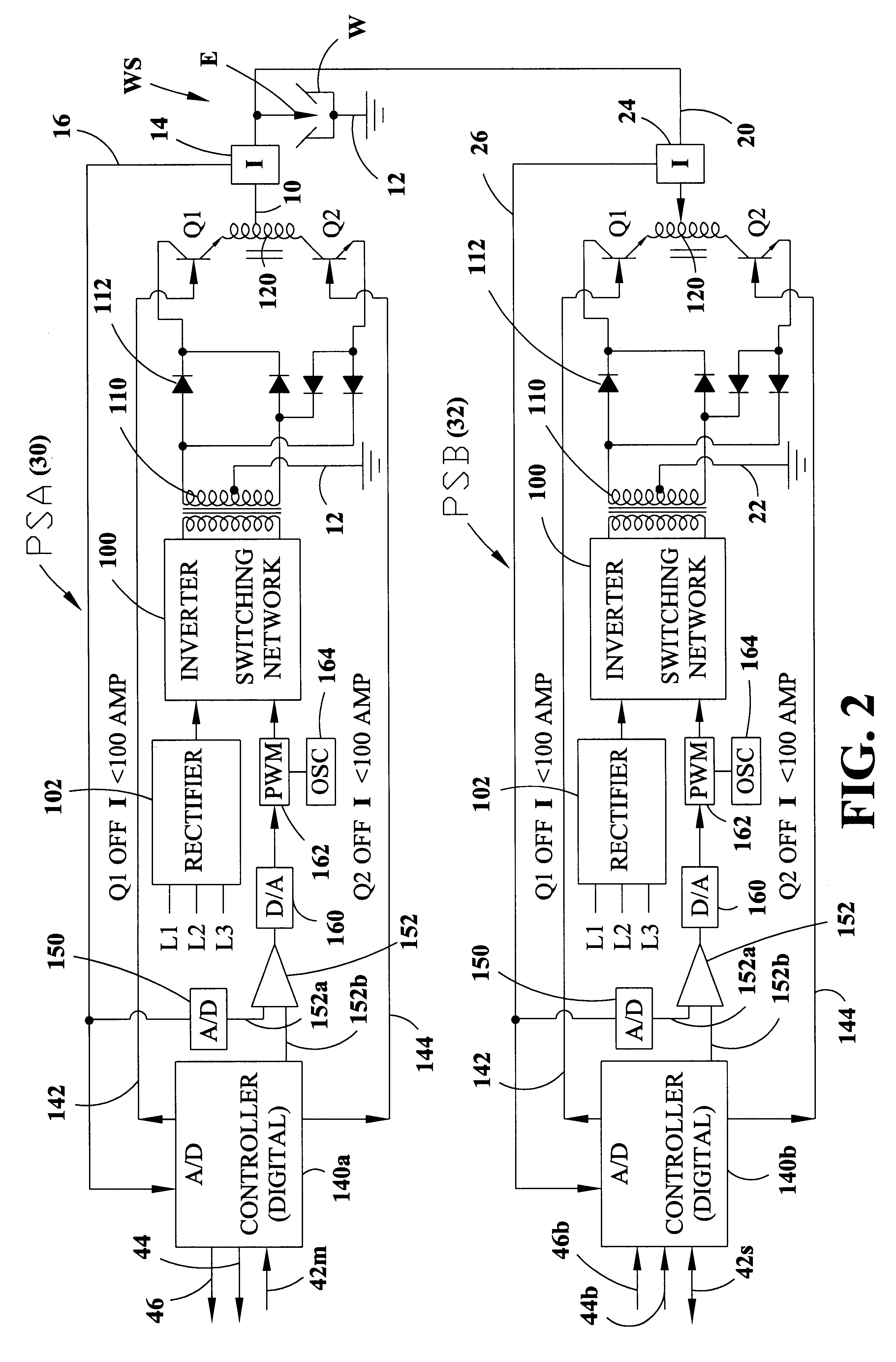

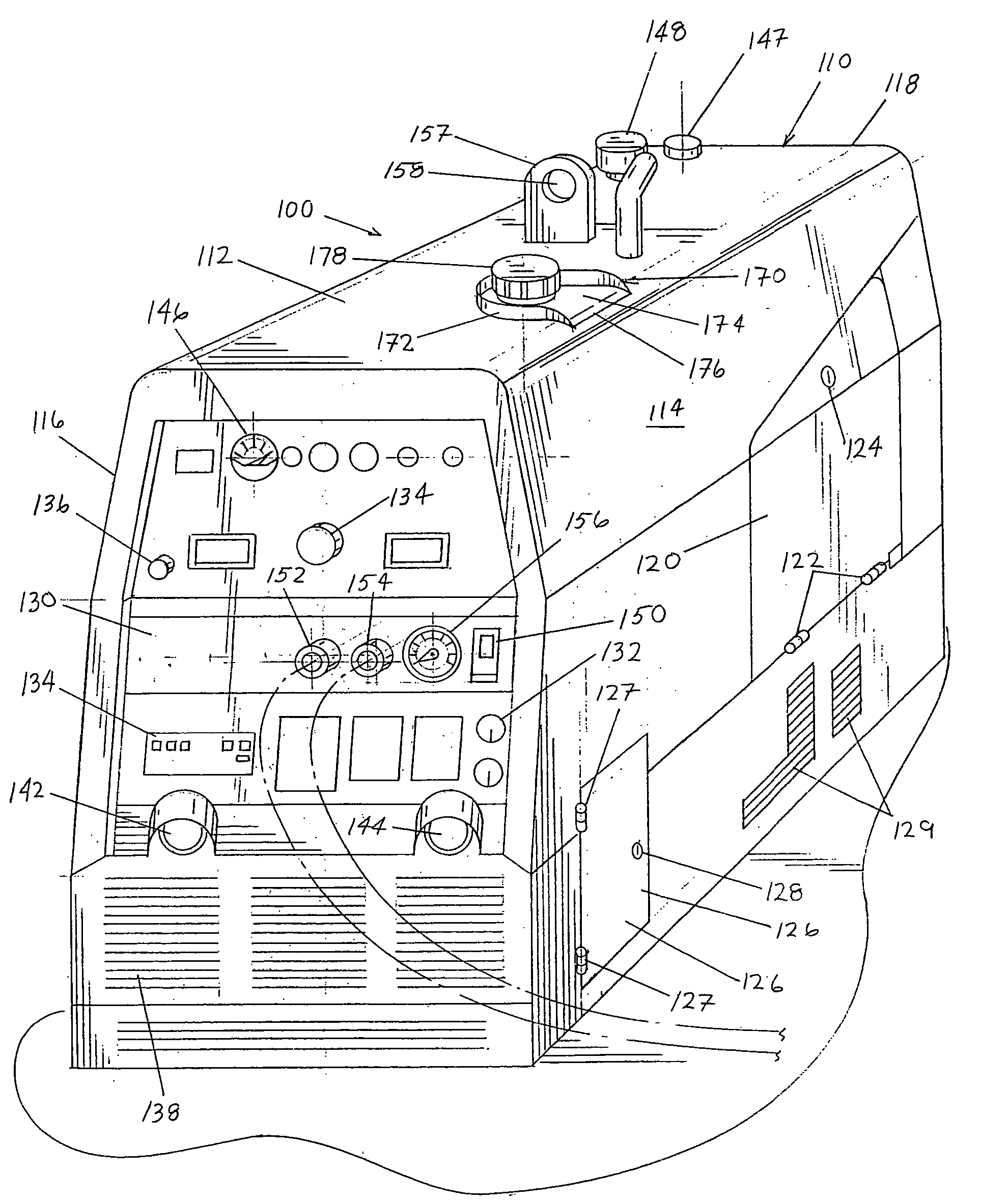

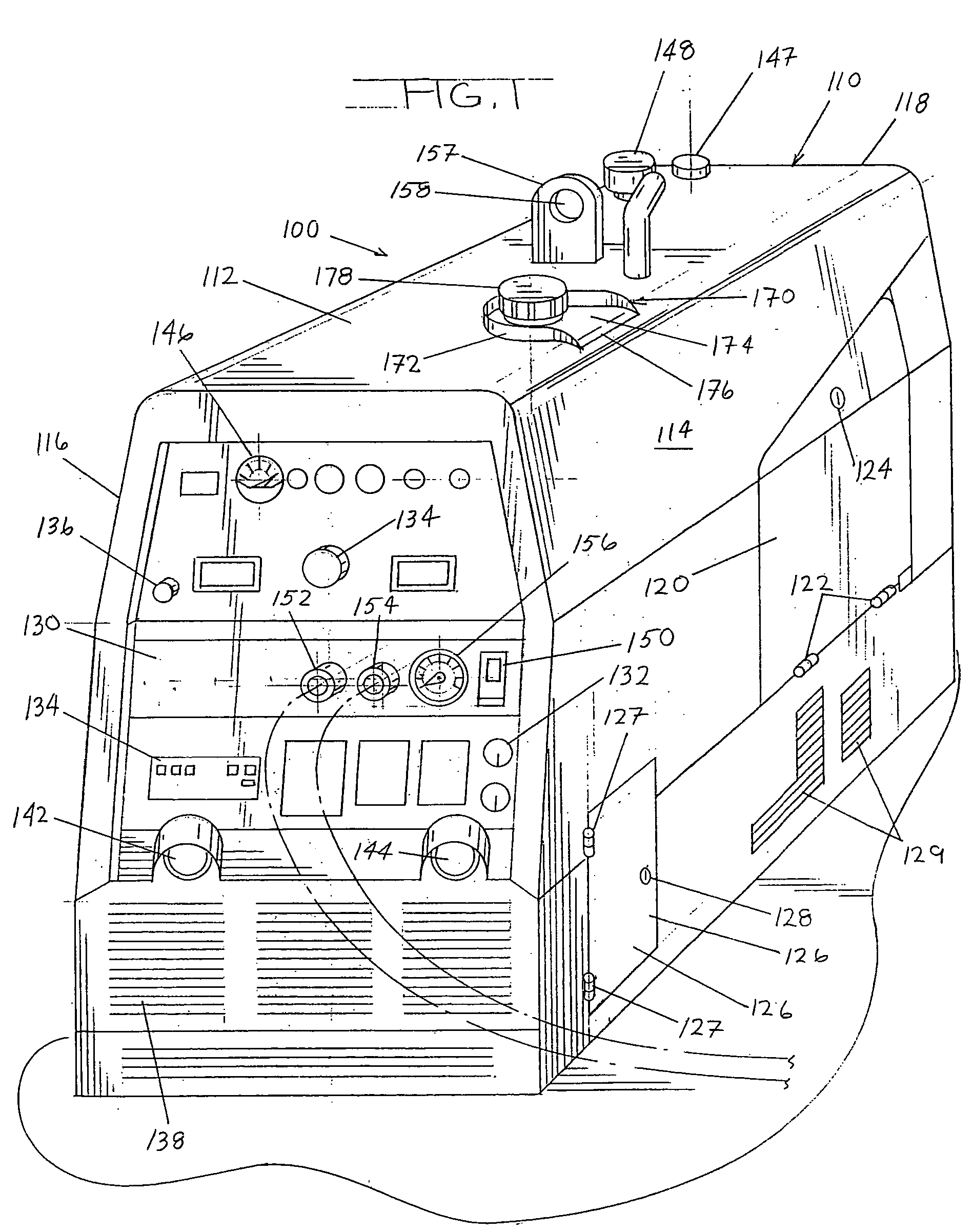

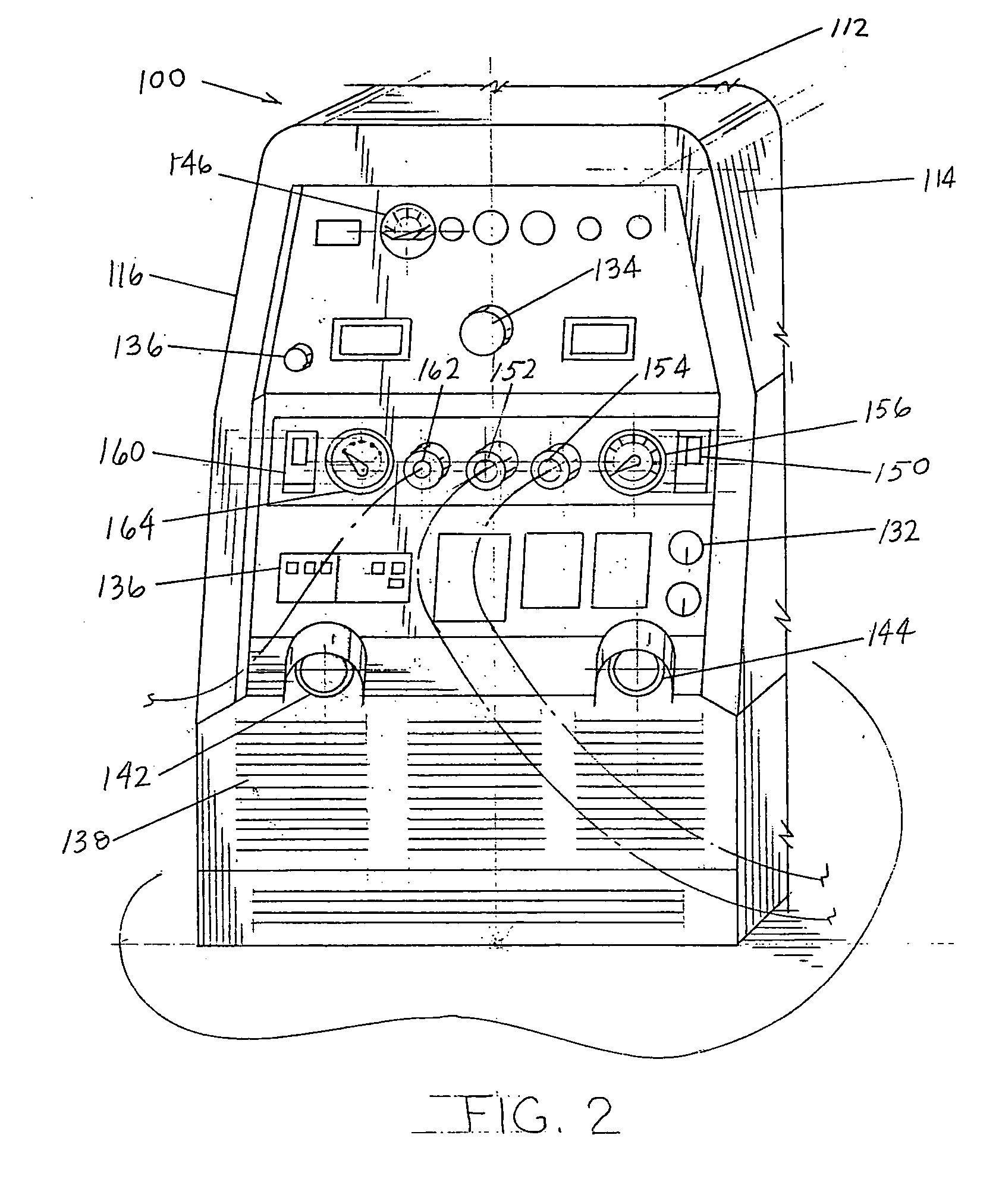

Electric arc welding system

InactiveUS6472634B1Prevent and reduce electrode interferenceLarge capacityElectric discharge heatingArc welding apparatusPower flowDigital interface

An electric arc welding system for creating an AC welding arc between an electrode and a workpiece wherein the system comprises a first controller for a first power supply to cause the first power supply to create an AC current between the electrode and workpiece by generating a switch signal or command with polarity reversing switching points in the first controller, with the first controller operated at first welding parameters in response to first power supply specific parameter signals to the first controller. The system has at least one slave controller for operating a slave power supply to create an AC current between the electrode and workpiece by reversing polarity of the AC current at switching points where the slave controller is operated at second welding parameters in response to second power supply specific parameter signals to the slave controller. An information network connected to the first controller and the slave controller and containing digital first and second power supply specific parameter signals for the first controller and the slave controller and a digital interface connects the first controller with the slave controller to control the switching points of said second power supply by the switch signal or command from the first controller.

Owner:LINCOLN GLOBAL INC

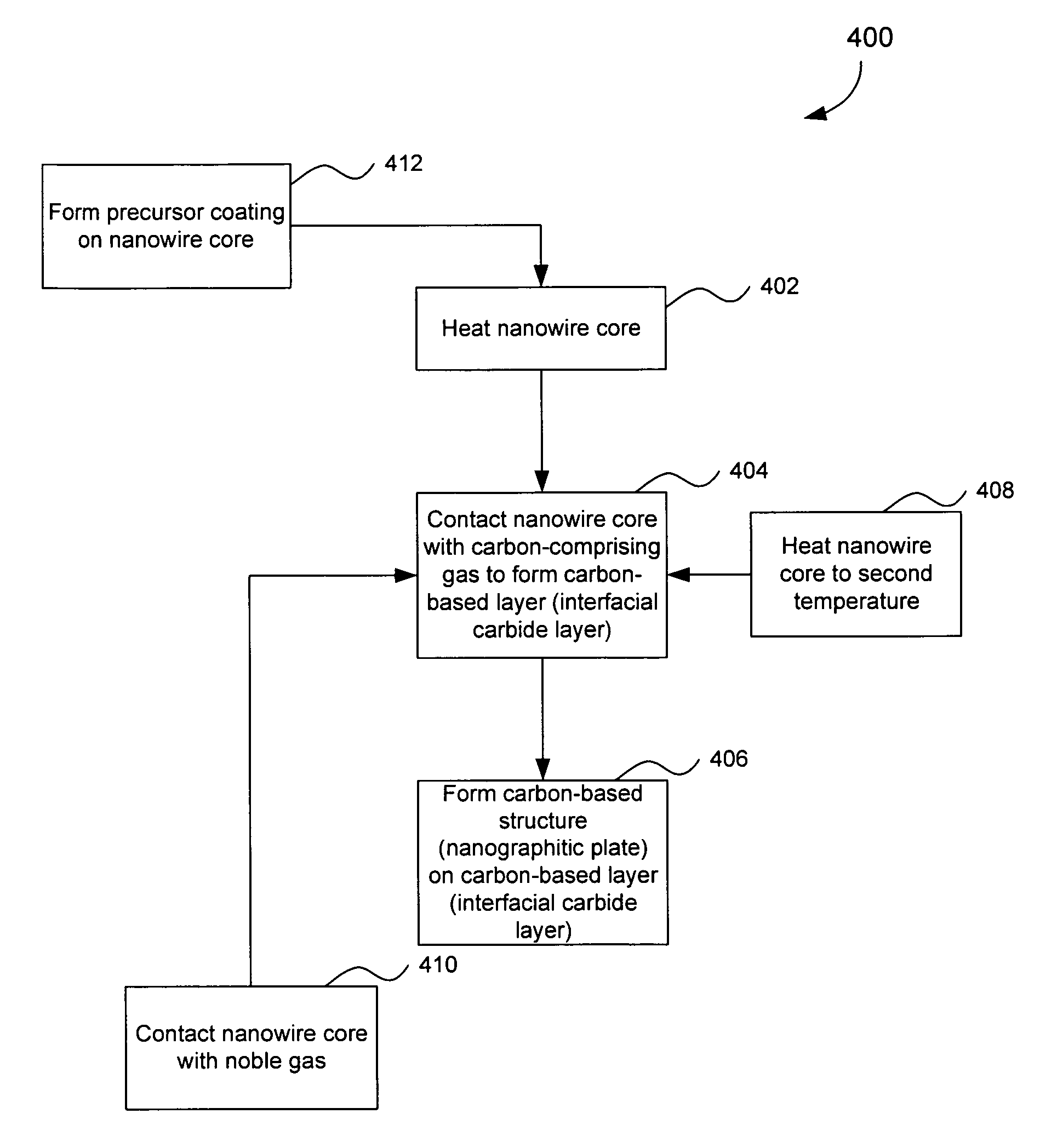

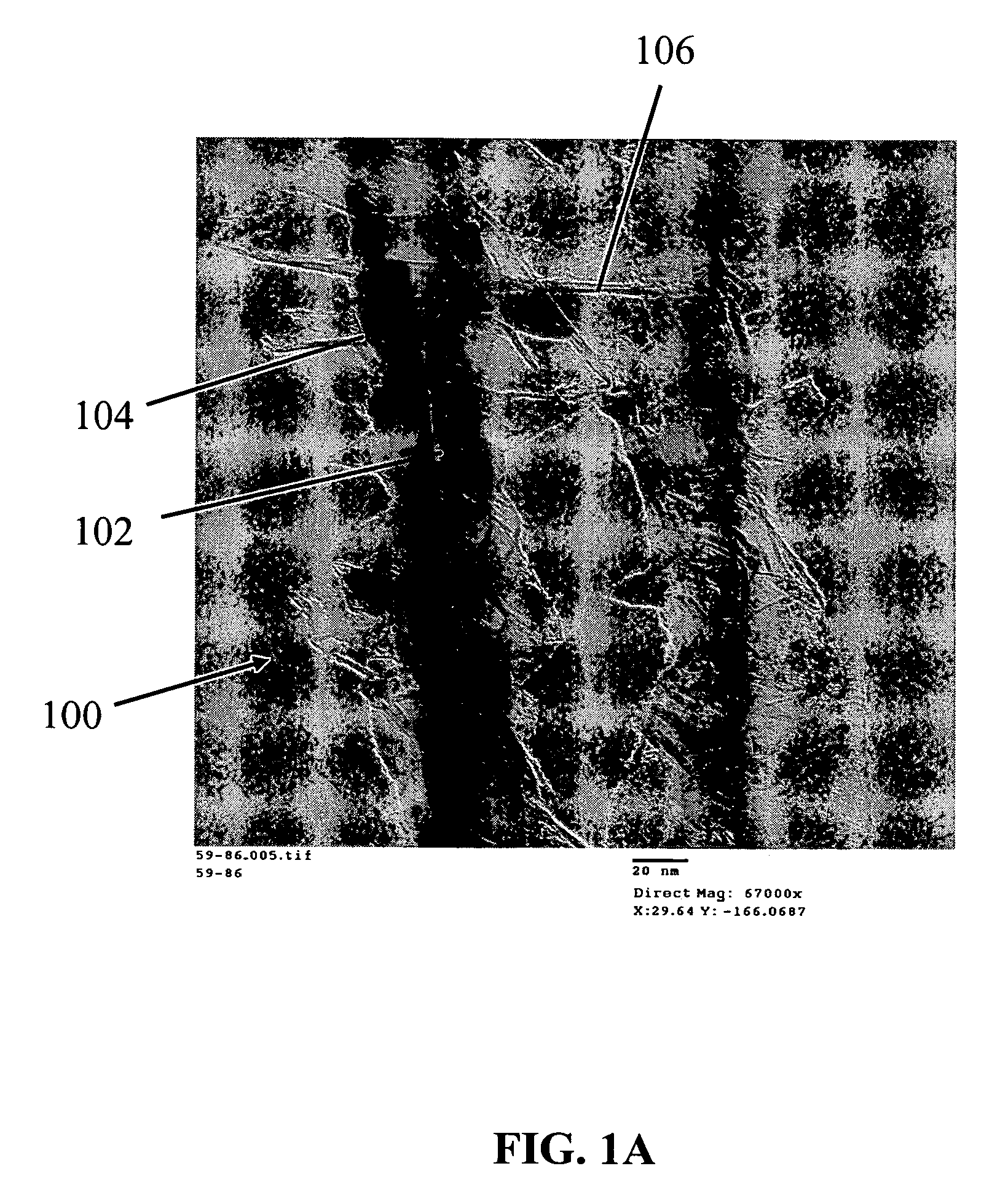

Nanowire structures comprising carbon

ActiveUS7939218B2High rateLow costElectric discharge heatingFuel cells groupingField emission deviceNanowire

The present invention is directed to nanowire structures and interconnected nanowire networks comprising such structures, as well as methods for their production. The nanowire structures comprise a nanowire core, a carbon-based layer, and in additional embodiments, carbon-based structures such as nanographitic plates consisting of graphenes formed on the nanowire cores, interconnecting the nanowire structures in the networks. The networks are porous structures that can be formed into membranes or particles. The nanowire structures and the networks formed using them are useful in catalyst and electrode applications, including fuel cells, as well as field emission devices, support substrates and chromatographic applications.

Owner:ONED MATERIAL INC

Apparatus and methods for electrospinning polymeric fibers and membranes

An apparatus and methods for electrospinning polymer fibers and membranes are described. The methods include in one aspect electrospinning a polymer fiber from a conducting fluid containing the polymer in the presence of a first electric field established between a conducting fluid introduction device and a ground source and modifying the first electric field with a second electric field to form a jet stream of the conducting fluid. In another aspect the methods include forming an electrospinning jet stream of the conducting fluid and electrically controlling the flow characteristics of the jet stream. In yet another aspect the methods include forming a plurality of electrospinning jet streams of the conducting fluid and independently controlling the flow characteristics of at least one of the jet streams. The apparatus for electrospinning includes a conducting fluid introduction device containing a plurality of electrospinning spinnerets for delivering the conducting fluid, a ground member positioned adjacent to the spinnerets, a support member disposed between the spinnerets and the ground member and movable to receive fibers formed from the conducting fluid, and a means for controlling the flow characteristics of conducting fluid from at least one spinneret independently from the flow characteristics of conducting fluid from another spinneret. An improved conducting fluid introduction device which includes a plurality of spinnerets, each for independently delivering a controlled quantity of conducting fluid at a controlled pressure or flow rate, the spinnerets being charged at an electric potential and being disposed relative to each other to normally interfere with the electric field produced by adjacent spinnerets, each of the spinnerets having a tip at which conducting fluid exits configured to have an electrostatic field strength at each tip stronger than the liquid surface tension at each of the tips is also described.

Owner:RES FOUND THE

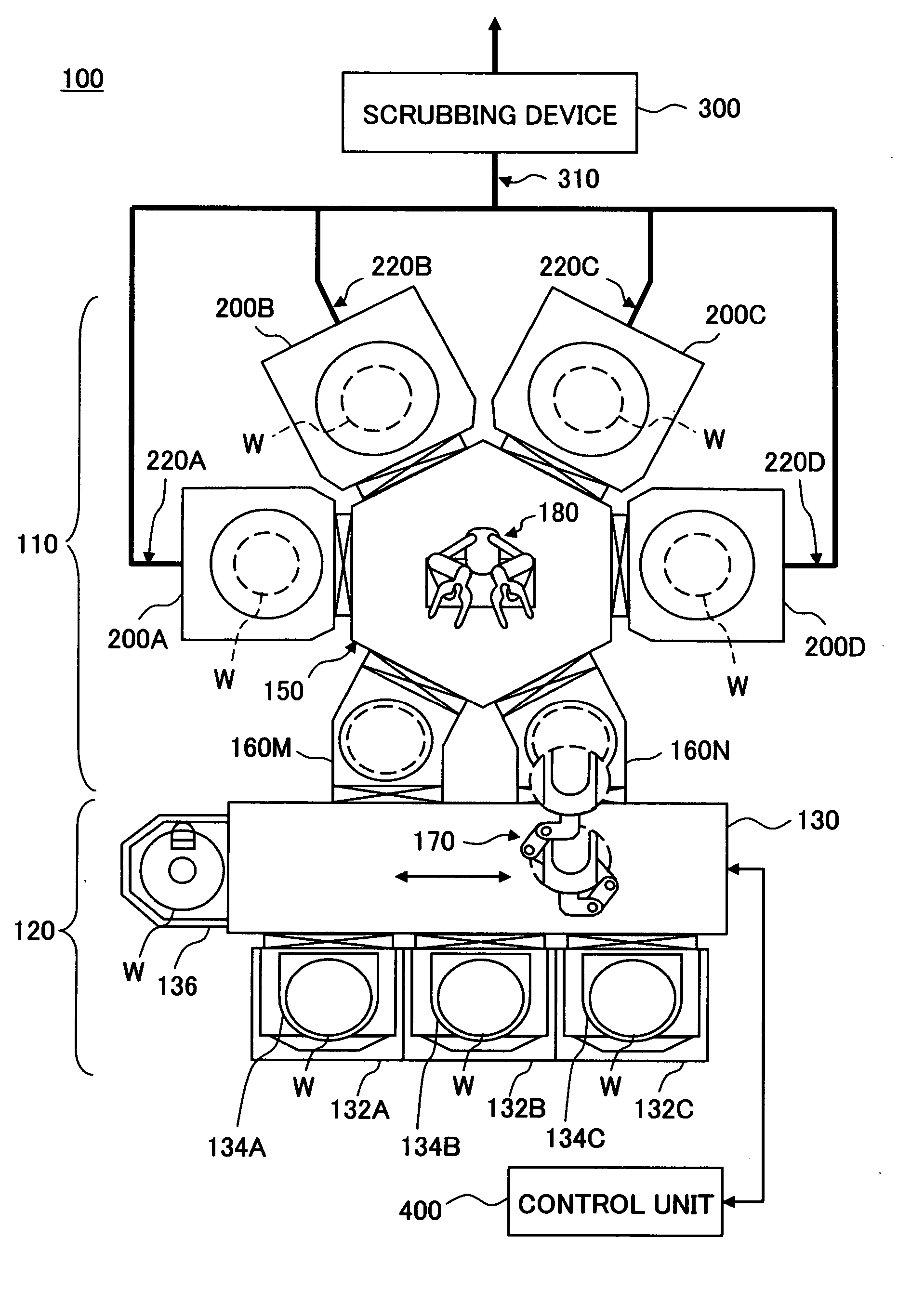

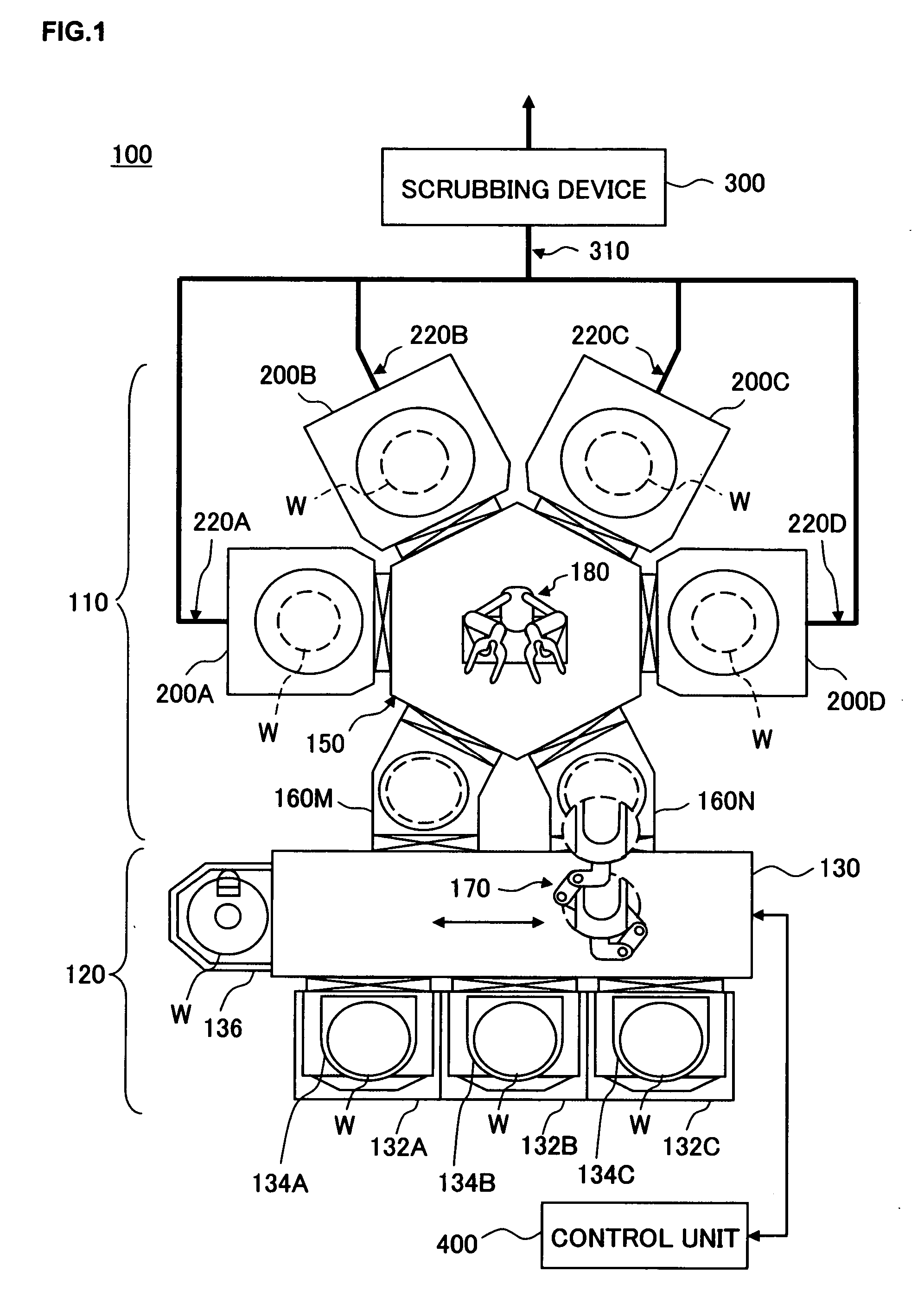

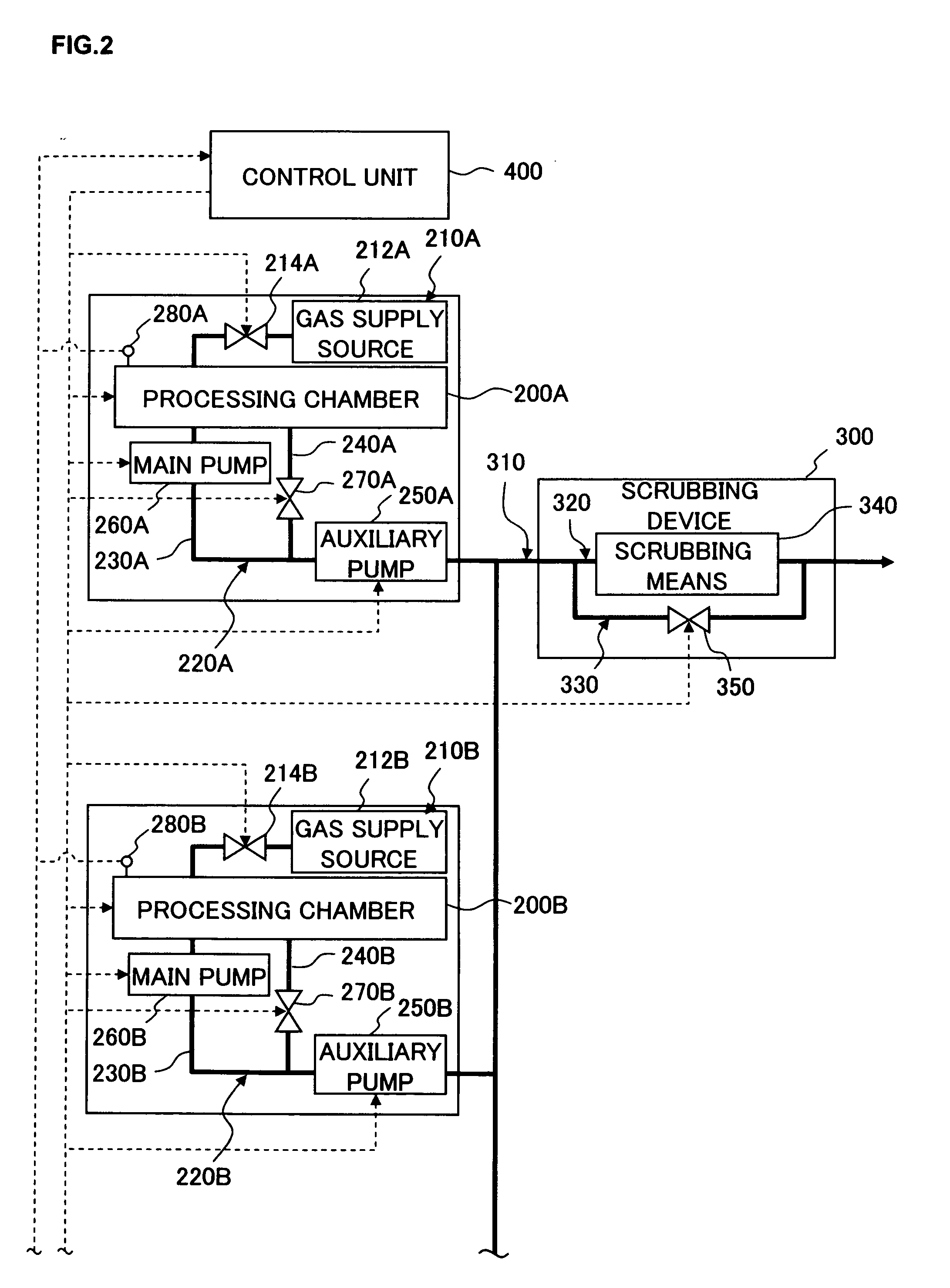

Substrate processing apparatus, control method adopted in substrate processing apparatus and program

InactiveUS20060176928A1Reduce responsibilityReduce placementElectric discharge heatingSemiconductor/solid-state device manufacturingEngineeringEmbedded system

A substrate processing apparatus according to the present invention comprises a plurality of processing chambers, discharge systems each provided in conjunction with one of the processing chambers and a common discharge system connected with the discharge systems of at least two processing chambers among the discharge systems provided in conjunction with the individual processing chambers. The common discharge allows a switch-over between a scrubbing common discharge system that discharges discharge gas from each processing chamber after scrubbing the discharge gas at a scrubbing means and a non-scrubbing common discharge system that directly discharges the discharge gas from the discharge system of the processing chamber without scrubbing at the scrubbing means. In this substrate processing apparatus, switch-over control is executed to select either the scrubbing common discharge system of the non-scrubbing common discharge system in correspondence to the type of processing executed in the processing chamber.

Owner:TOKYO ELECTRON LTD

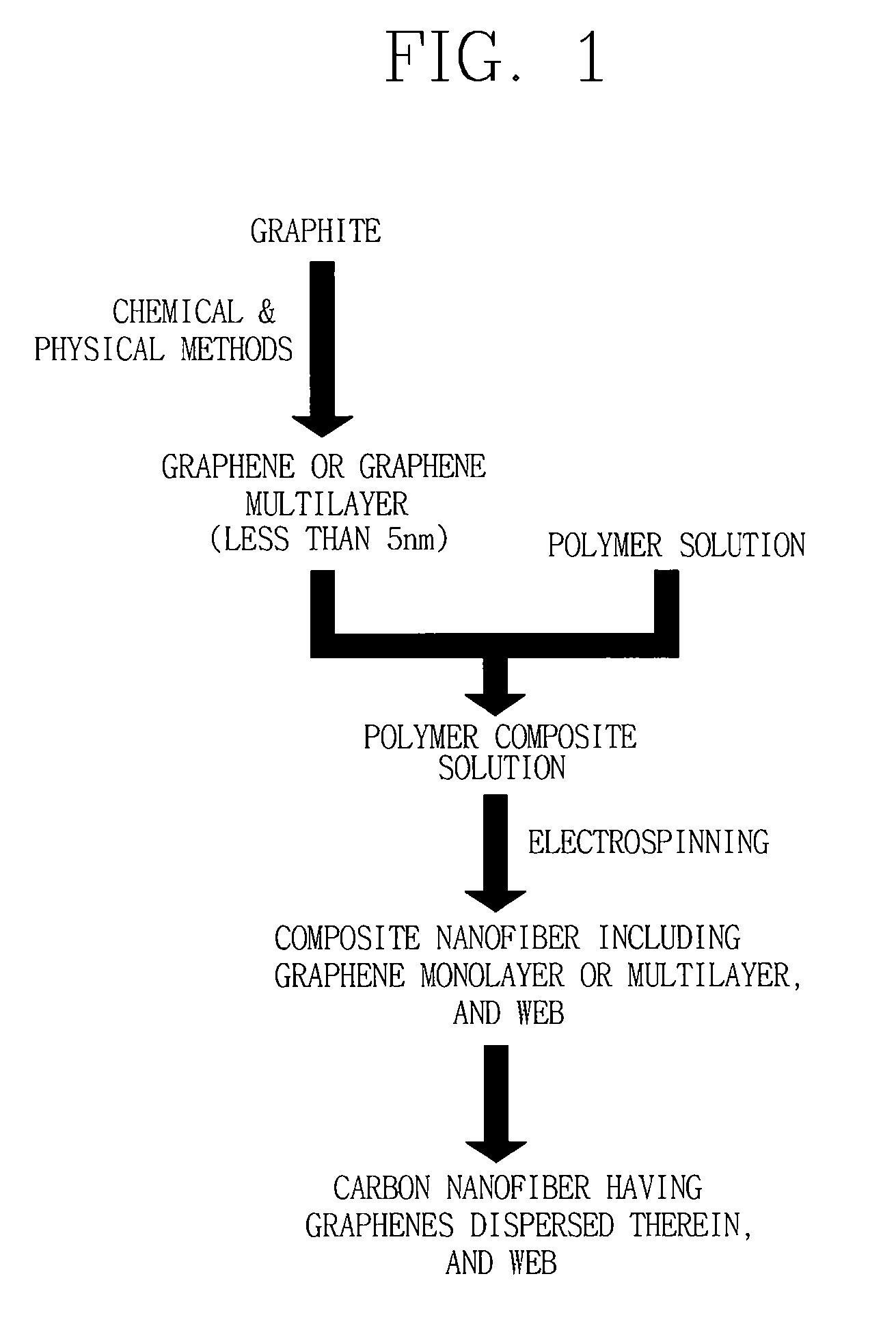

Graphene composite nanofiber and preparation method thereof

Disclosed are a graphene composite nanofiber and a preparation method thereof. The graphene composite nanofiber is produced by dispersing graphenes to at least one of a surface and inside of a polymer nanofiber or a carbon nanofiber having a diameter of 1˜1000 nm, and the graphenes include at least one type of monolayer graphenes, and multilayer graphenes having a thickness of 10 nm or less. The graphene composite nanofiber can be applied to various industrial fields, e.g., a light emitting display, a micro resonator, a transistor, a sensor, a transparent electrode, a fuel cell, a solar cell, a secondary cell, and a composite material, owing to a unique structure and property of graphene.

Owner:KOREA INST OF SCI & TECH

Method of deposition of thin films of amorphous and crystalline microstructures based on ultrafast pulsed laser deposition

InactiveUS6312768B1Improve surface qualityImprove efficiencyMaterial nanotechnologyElectric discharge heatingMacroscopic scaleCarbon nanotube

Powerful nanosecond-range lasers using low repetition rate pulsed laser deposition produce numerous macroscopic size particles and droplets, which embed in thin film coatings. This problem has been addressed by lowering the pulse energy, keeping the laser intensity optional for evaporation, so that significant numbers of the macroscopic particles and droplets are no longer present in the evaporated plume. The result is deposition of evaporated plume on a substrate to form thin film of very high surface quality. Preferably, the laser pulses have a repetition rate to produce a continuous flow of evaporated material at the substrate. Pulse-range is typically picosecond and femtosecond and repetition rate kilohertz to hundreds of megahertz. The process may be carried out in the presence of a buffer gas, which may be inert or reactive, and the increased vapour density and therefore the collision frequency between evaporated atoms leads to the formation of nanostructured materials of increasing interest, because of their peculiar structural, electronic and mechanical properties. One of these is carbon nanotubes, which is a new form of carbon belonging to the fullerene (C60) family. Carbon nanotubes are seamless, single or multishell co-axial cylindrical tubules with or without dome caps at the extremities. Typically diameters range from 1 nm to 50 nm with a length >1 mum. The electronic structure may be either metallic or semiconducting without any change in the chemical bonding or adding of dopant. In addition, the materials have application to a wide range of established thin film applications.

Owner:AUSTRALIEN NAT UNIV

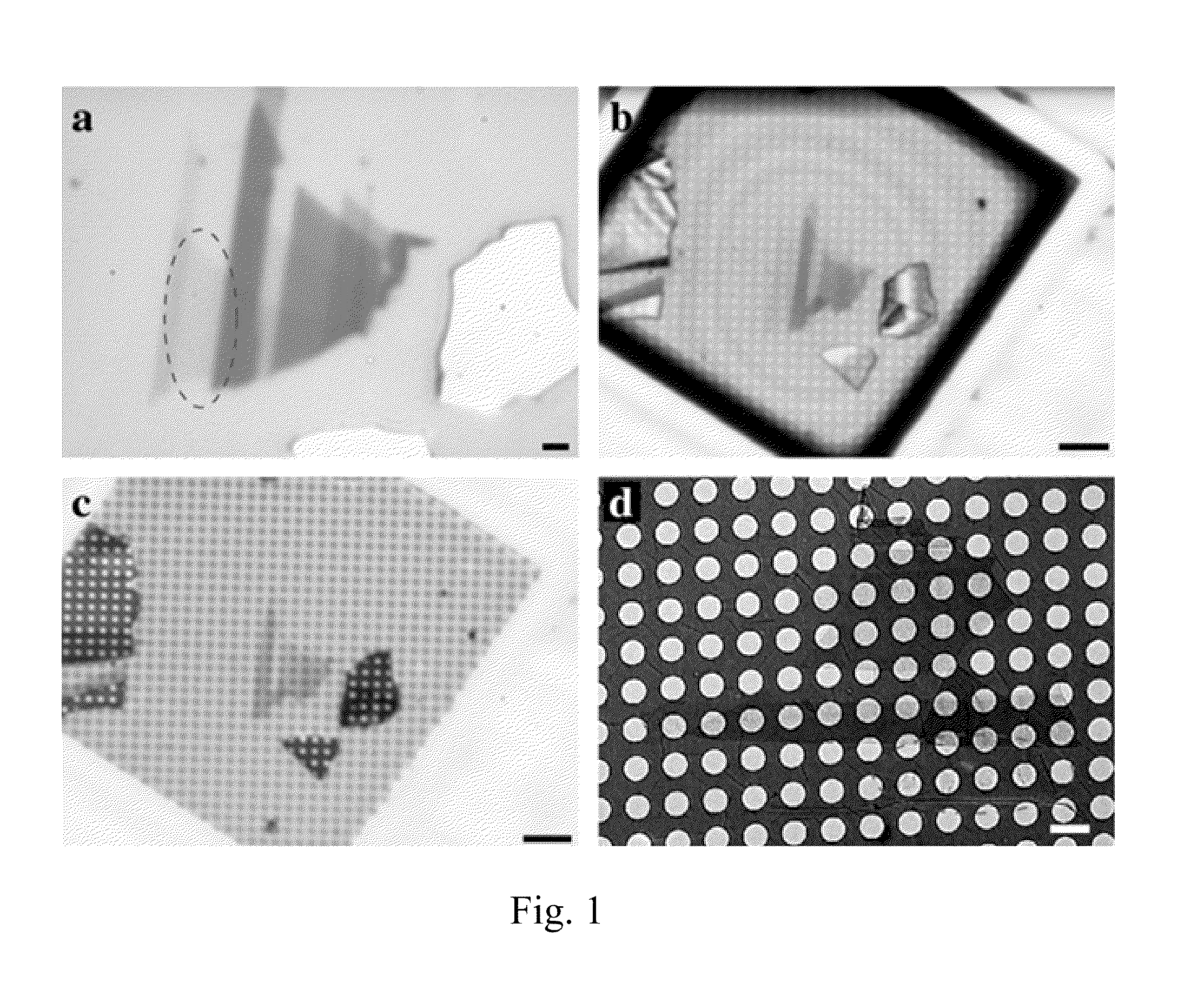

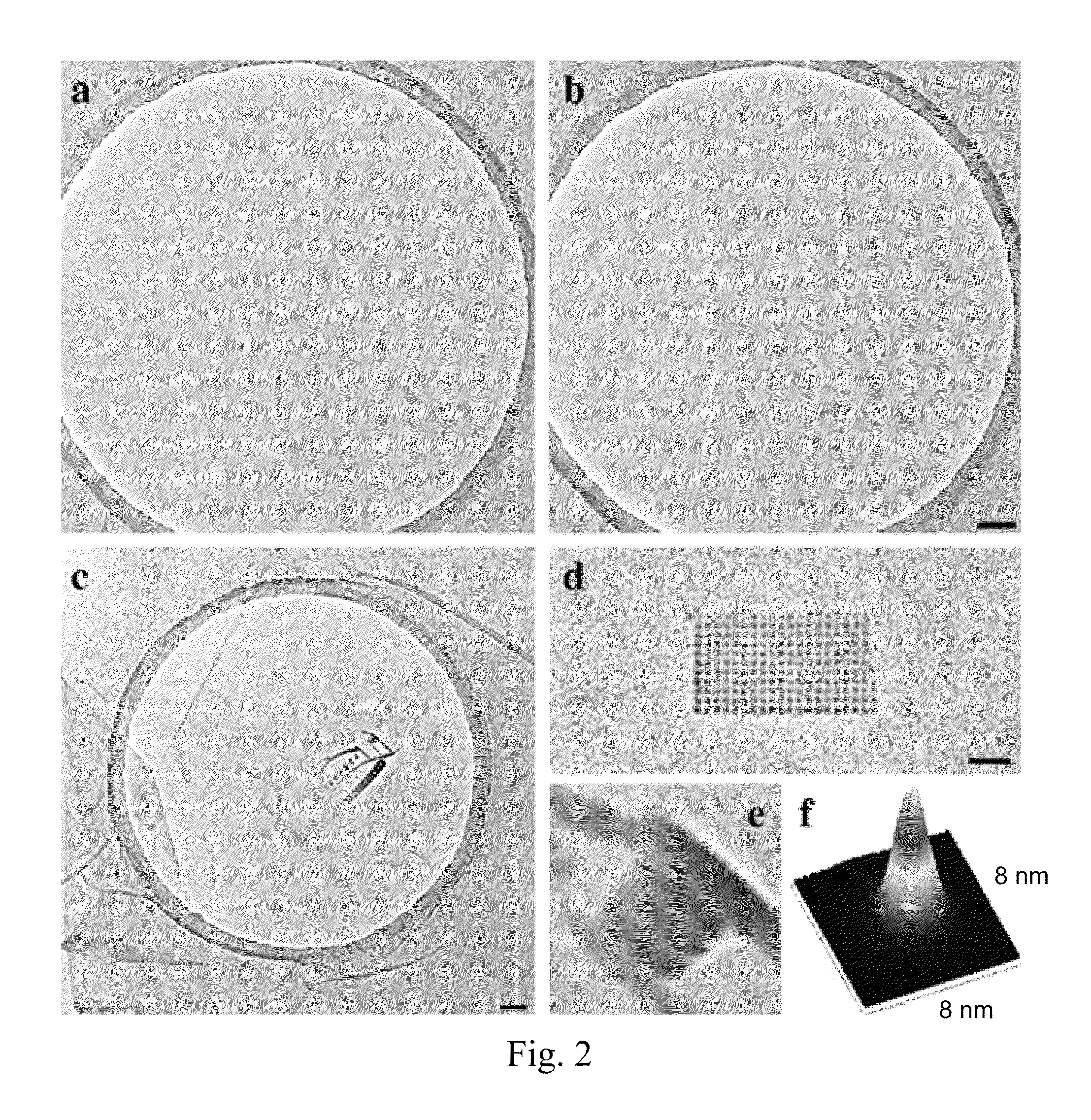

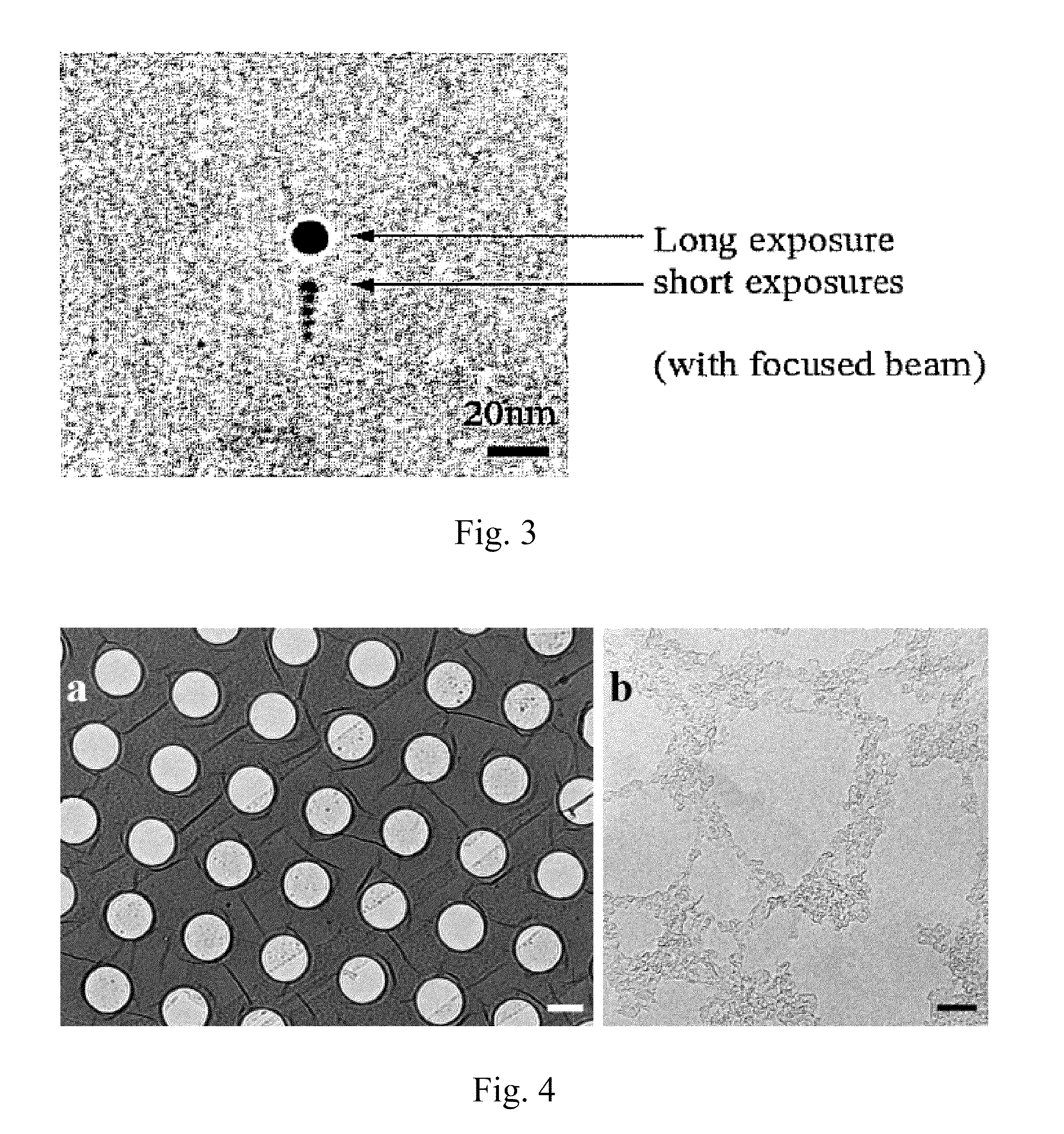

Graphene-based structure, method of suspending graphene membrane, and method of depositing material onto graphene membrane

An embodiment of a method of suspending a graphene membrane across a gap in a support structure includes attaching graphene to a substrate. A pre-fabricated support structure having the gap is attached to the graphene. The graphene and the pre-fabricated support structure are then separated from the substrate which leaves the graphene membrane suspended across the gap in the pre-fabricated support structure. An embodiment of a method of depositing material includes placing a support structure having a graphene membrane suspended across a gap under vacuum. A precursor is adsorbed to a surface of the graphene membrane. A portion of the graphene membrane is exposed to a focused electron beam which deposits a material from the precursor onto the graphene membrane. An embodiment of a graphene-based structure includes a support structure having a gap, a graphene membrane suspended across the gap, and a material deposited in a pattern on the graphene membrane.

Owner:RGT UNIV OF CALIFORNIA

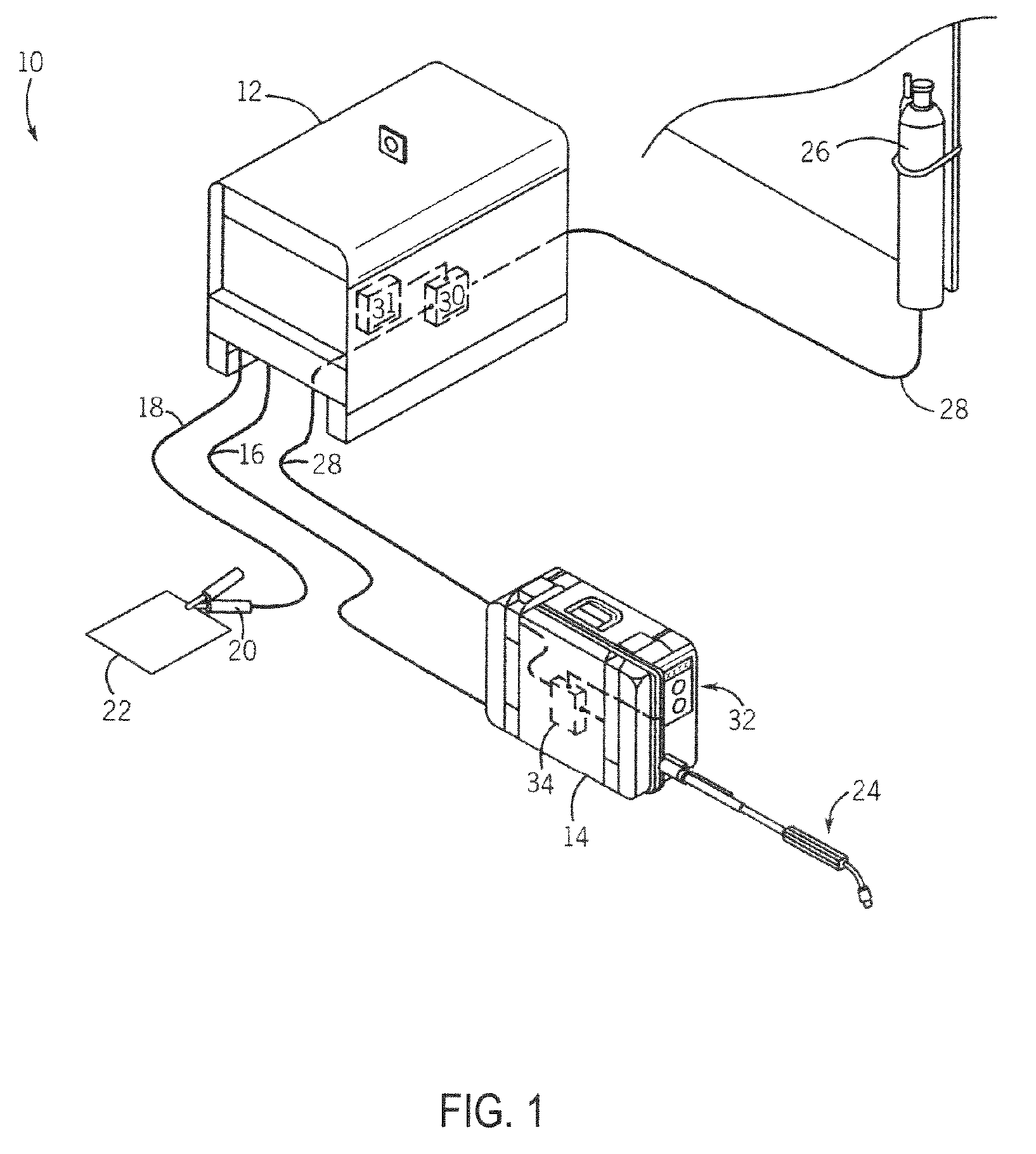

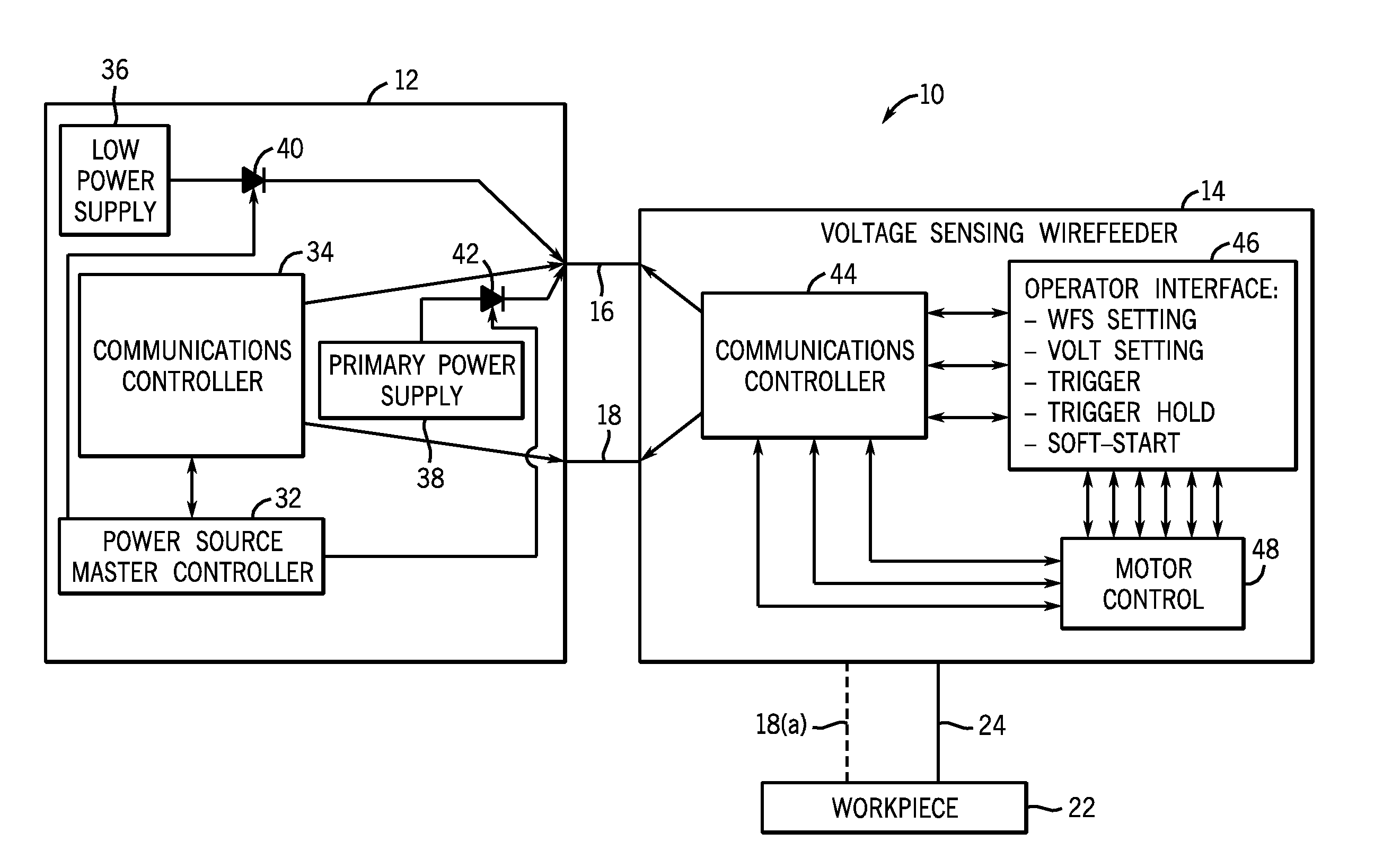

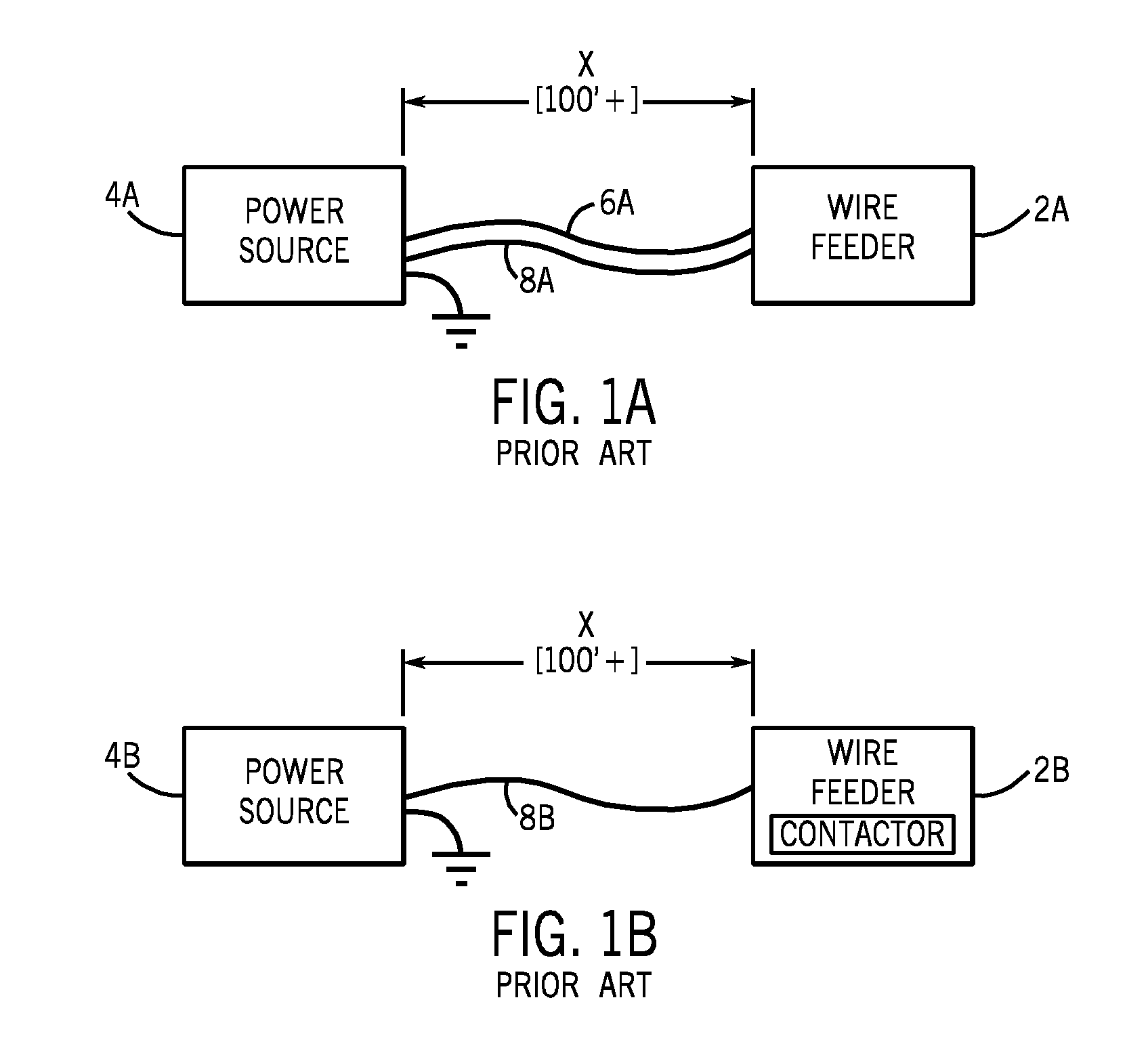

Remote wire feeder using binary phase shift keying to modulate communications of command/control signals to be transmitted over a weld cable

ActiveUS20060138113A1Overcomes drawbackElectric discharge heatingArc welding apparatusControl signalWelding power supply

The present invention is directed to a system and method of remotely controlling a welding machine with command signals transmitted to the welding power source across a weld cable connecting the power source to a remote device, such a wire feeder. A transmitter transmits the control commands containing desired welding operational parameters to a receiver disposed in the power source across a weld cable also designed to carry welding power from the power source to the wire feeder.

Owner:ILLINOIS TOOL WORKS INC

Patterned electrospinning

A polymer is directed from a source electrode into an electric field that drives the formation of electrospun fibers that are deposited onto a collecting surface to thereby form a patterned polymer structure. The collecting surface can be a counterelectrode or a collecting surface that is between the source electrode and a counterelectrode. Apparatus employed to conduct the method include an electrospinning source that directs polymer into an electric field formed by source and counterelectrodes. A collecting surface, such as the counterelectrode or a surface interposed between the source and counterelectrodes, collects electrospun fibers. Articles of manufacture formed by the method of apparatus include, for example, a structure of patterned electrospun fibers comprising multiple aggregations of polymeric electrospun fibers.

Owner:PHYSICAL SCI

Integrated engine welder and hydraulic pump

InactiveUS20060027547A1Easy to transportImproves ease of designElectric discharge heatingWelding coupling meansHydraulic pumpAir compressor

An integrated welder, generator and hydraulic unit that includes a housing that at least partially contains components of a welder, generator and a hydraulic pump. An engine, an electric current generator, and a hydraulic pump are at least partially mounted in the housing. The electric current generator is at least partially connected to the engine to be at least partially driven thereby. The hydraulic pump can be at least partially powered by the electric current generator or the fuel powered engine during the operation of the engine. The integrated welder, generator and hydraulic unit can also include an air compressor.

Owner:LINCOLN GLOBAL INC

Dissolvable Nano Web Porous Film and Method of Preparing the Same

InactiveUS20110250256A1Excellent in dissolvabilityImprove solubilityBiocideElectric discharge heatingSolubilityFiber

A dissolvable nano web porous film has a network structure and a large specific surface area. The network structure is formed by stacking nano fibers that have a thickness of 10˜50,000 nm. The nano fibers are formed of a composition comprising nano fiber forming polymer, a gelling agent, a plasticizer, an optional active component and an optional additive. A method of preparing a dissolvable nano web film comprises producing a polymer melt or solution formed of a composition that comprises a nano fiber forming polymer, a gelling agent, a plasticizer, an optional active component and additives, spinning the melt or solution to form a nano web porous film having nano webs stacked in a network structure, drying the nano web porous film, and stabilizing the nano web porous film. The porous film has a 5˜5000 times higher specific surface area and a 2˜20 times faster dissolving time than a conventional film. The dissolvable nano web porous film has excellent dissolvability and solubility.

Owner:GENIC

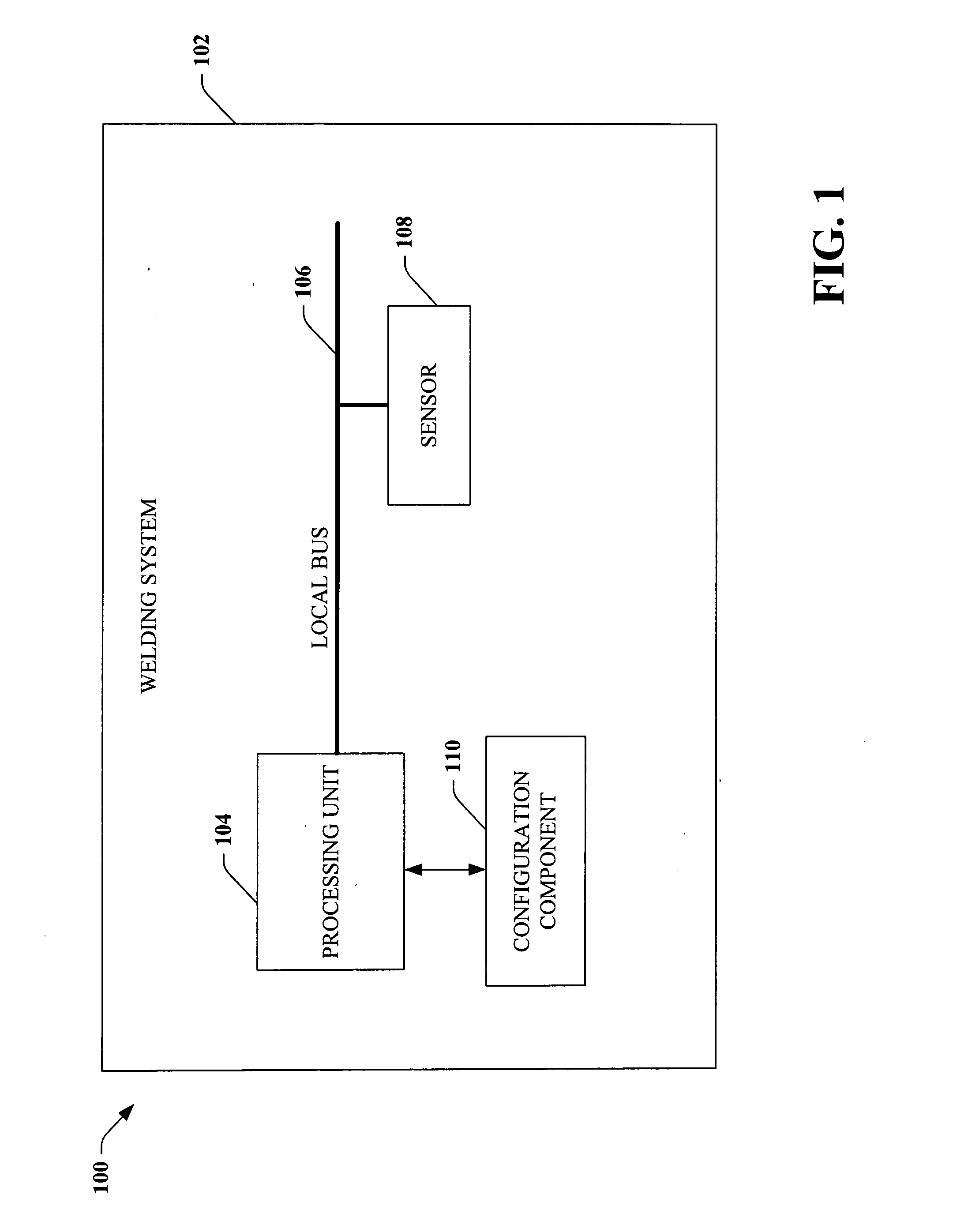

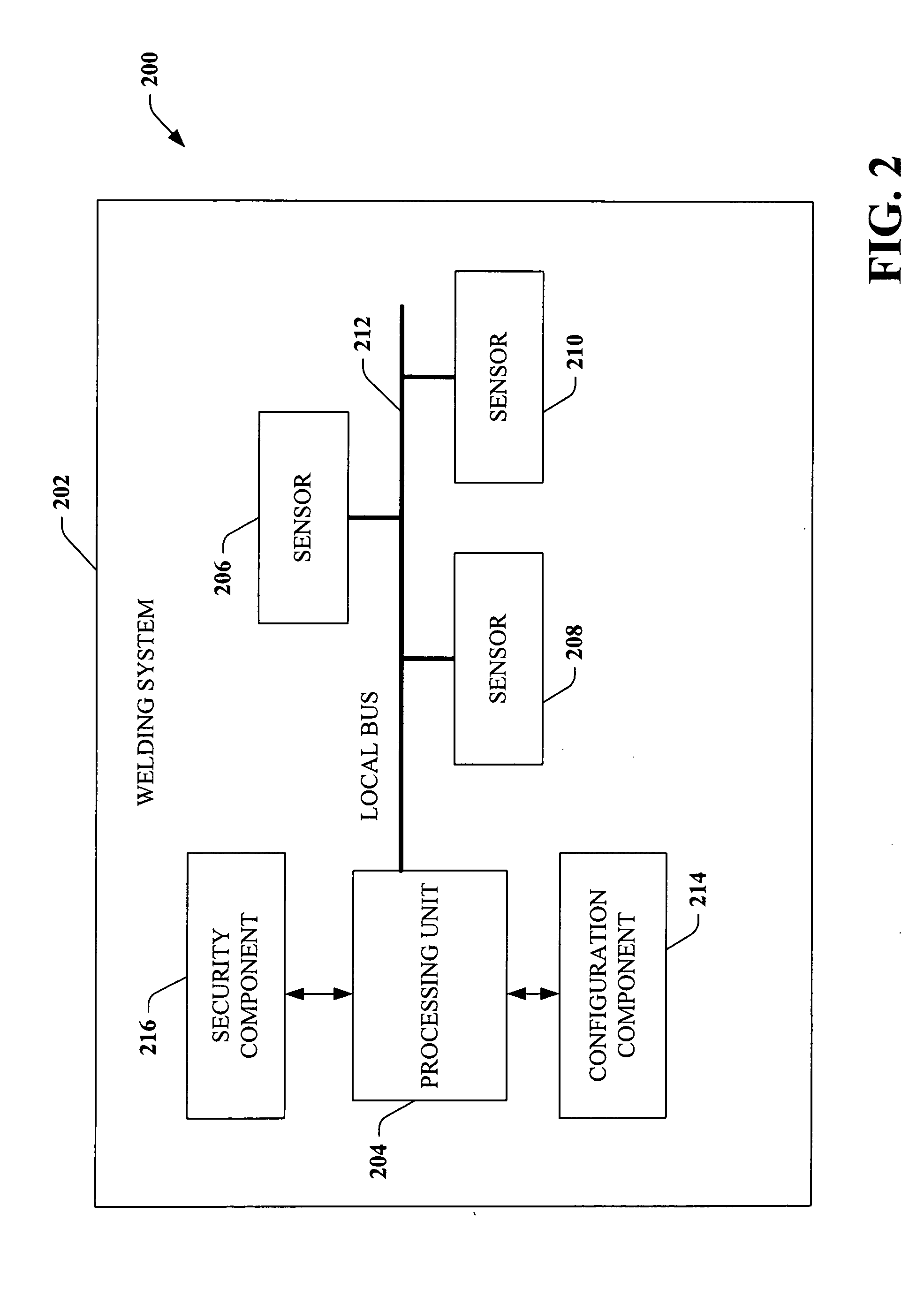

Integrating sensors over a digital link

ActiveUS20060163227A1Well formedReduce deficiencyElectric discharge heatingArc welding apparatusLocal busEmbedded system

A system that facilitates dynamic configuration of a welding system with respect to a sensor comprises a processing unit associated with the welding system. A configuration component facilitates configuring the welding system with respect to the sensor upon determining that the sensor is coupled to a local bus associated with the processing unit. A remote access component can facilitate remotely accessing the welding system, the configuration of the welding system alterable by way of the remote access component.

Owner:LINCOLN GLOBAL INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com