Patents

Literature

562 results about "Field emission device" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

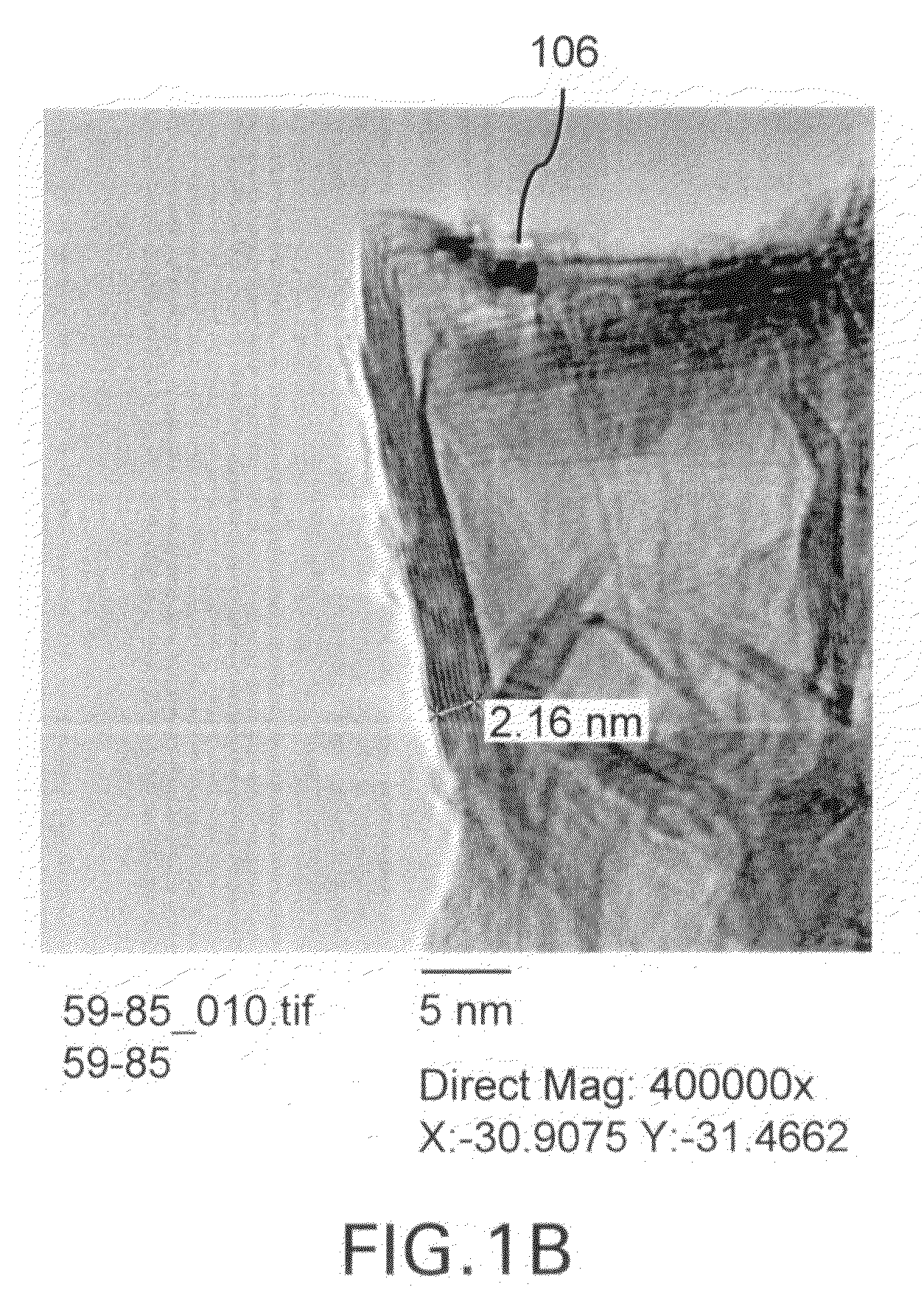

Nanowire structures comprising carbon

ActiveUS7939218B2High rateLow costElectric discharge heatingFuel cells groupingField emission deviceNanowire

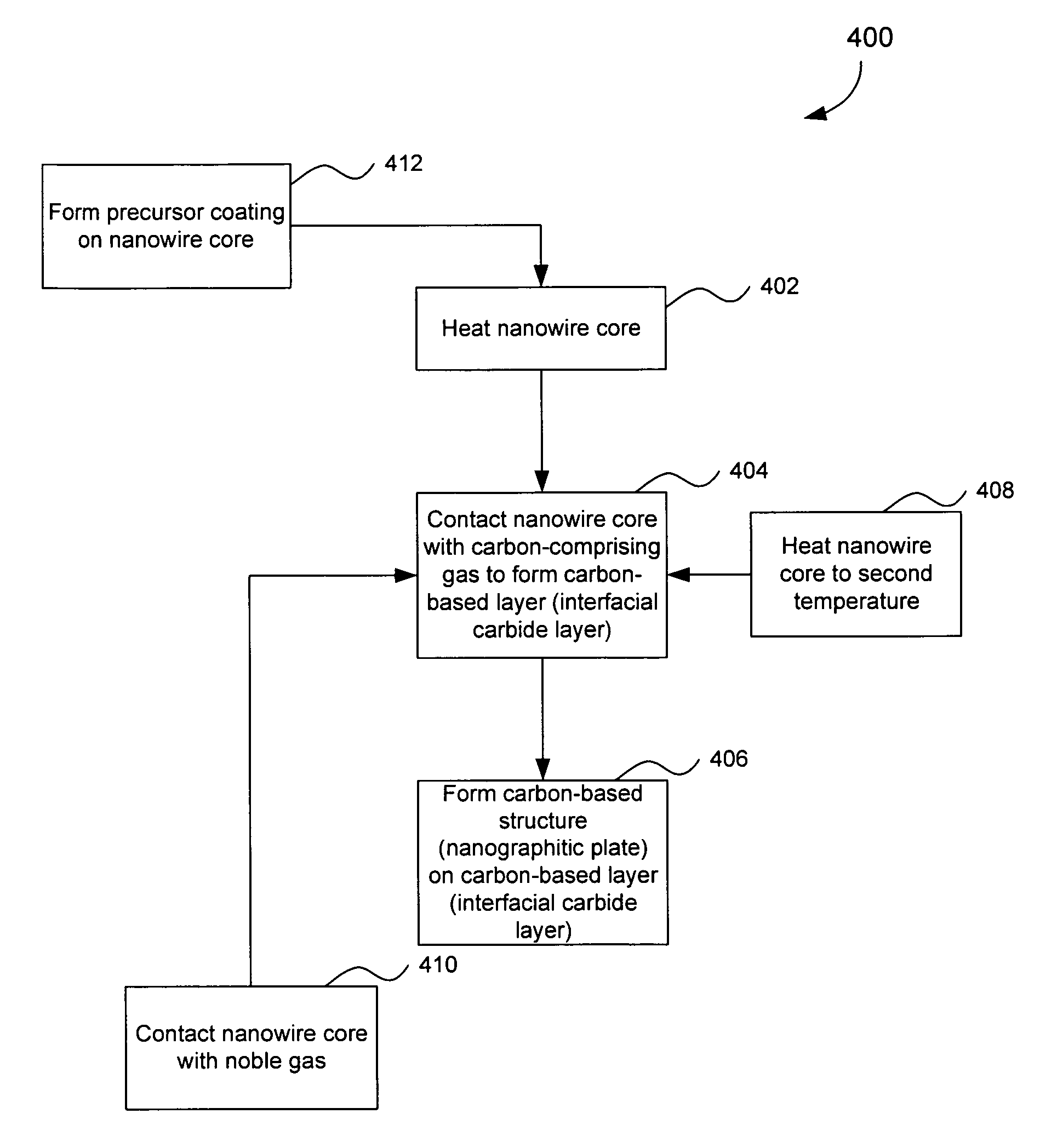

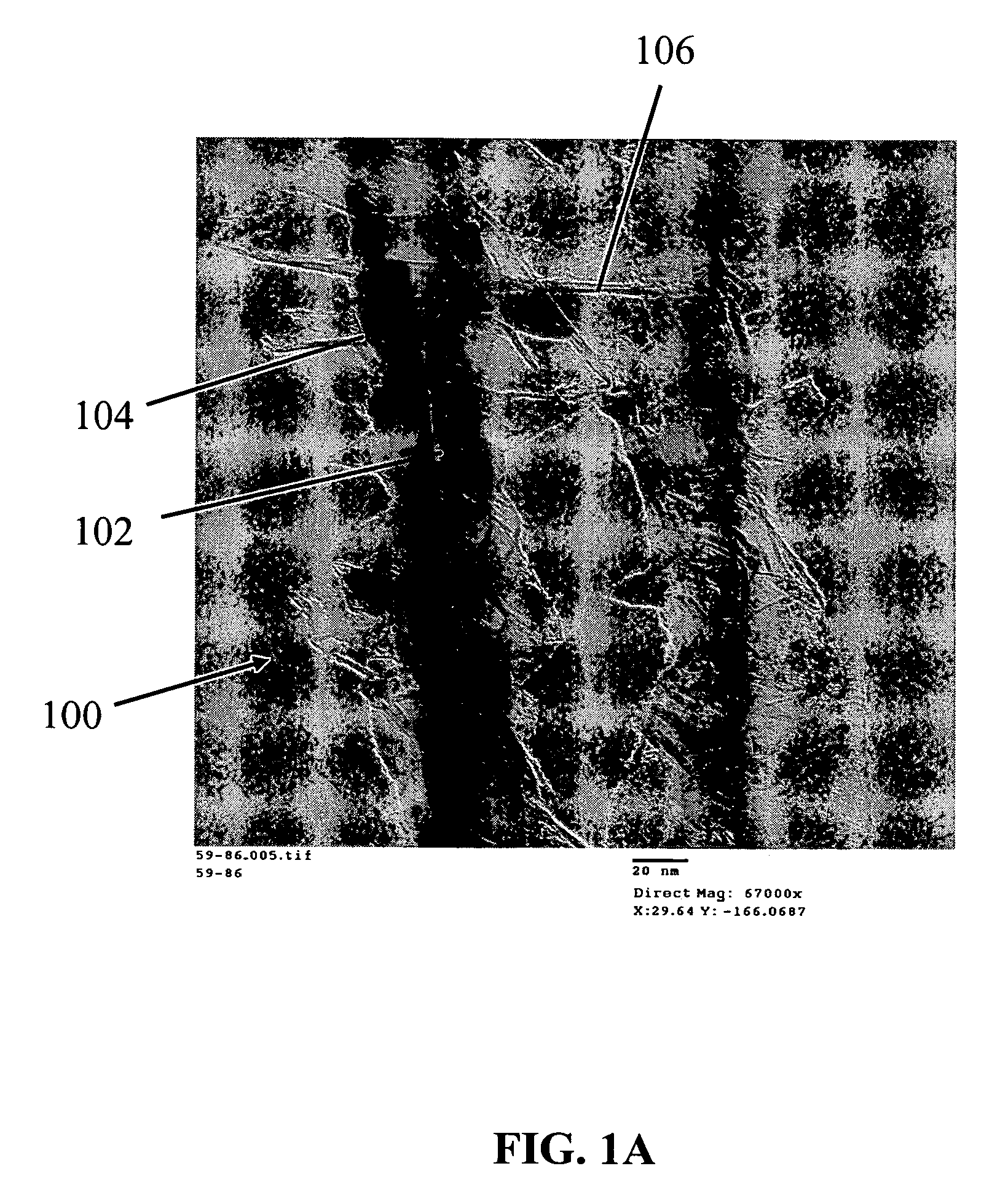

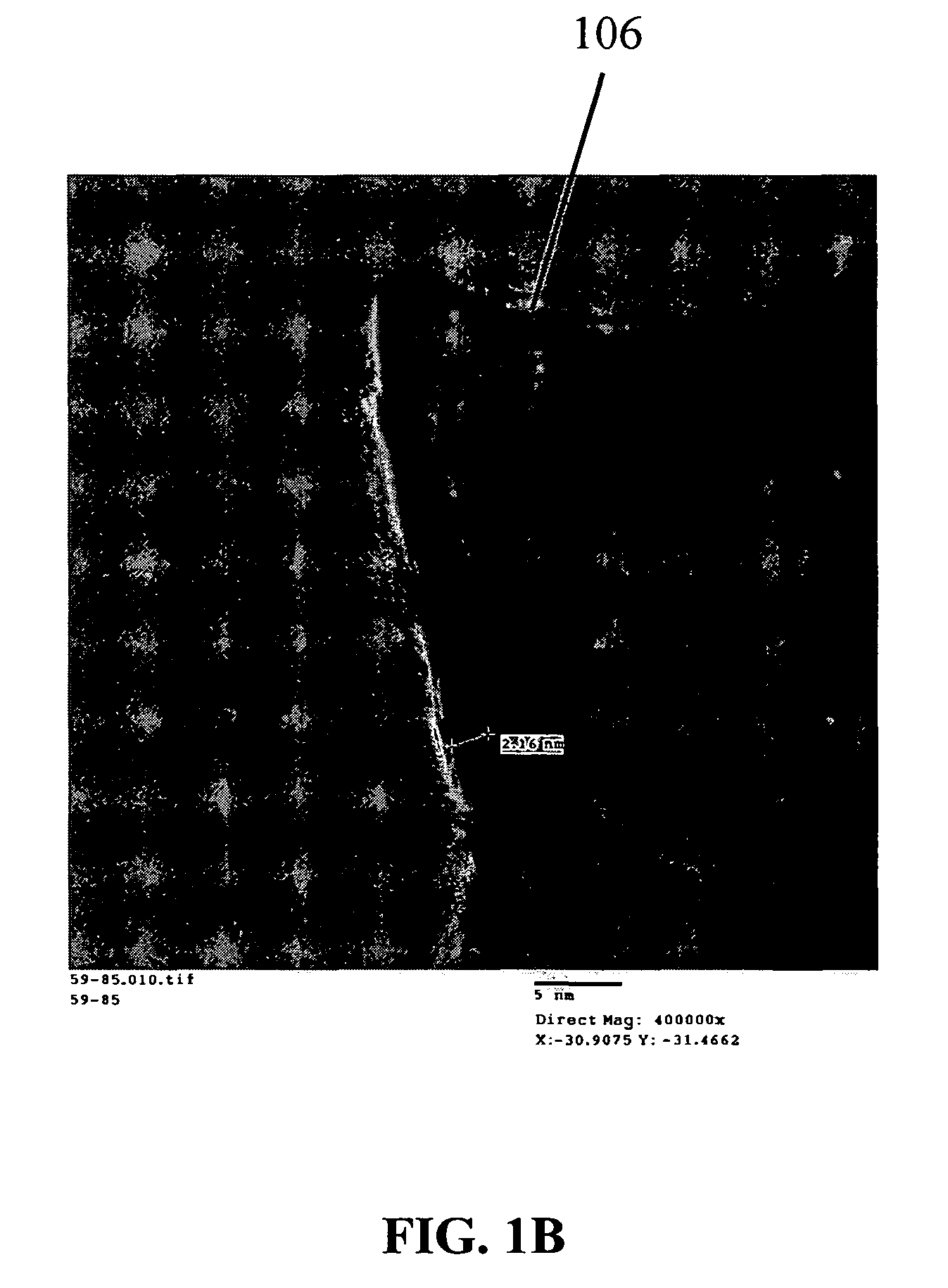

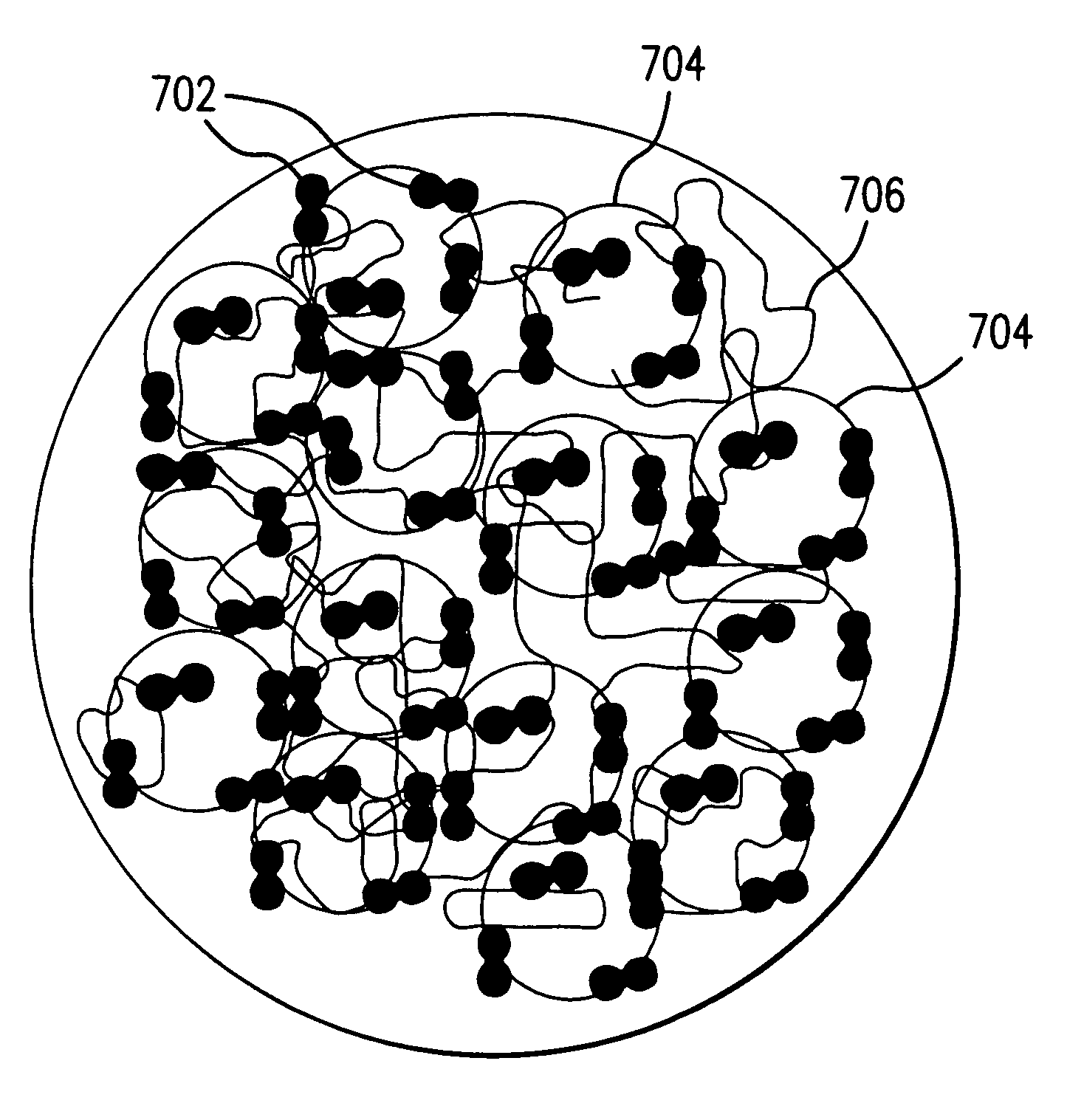

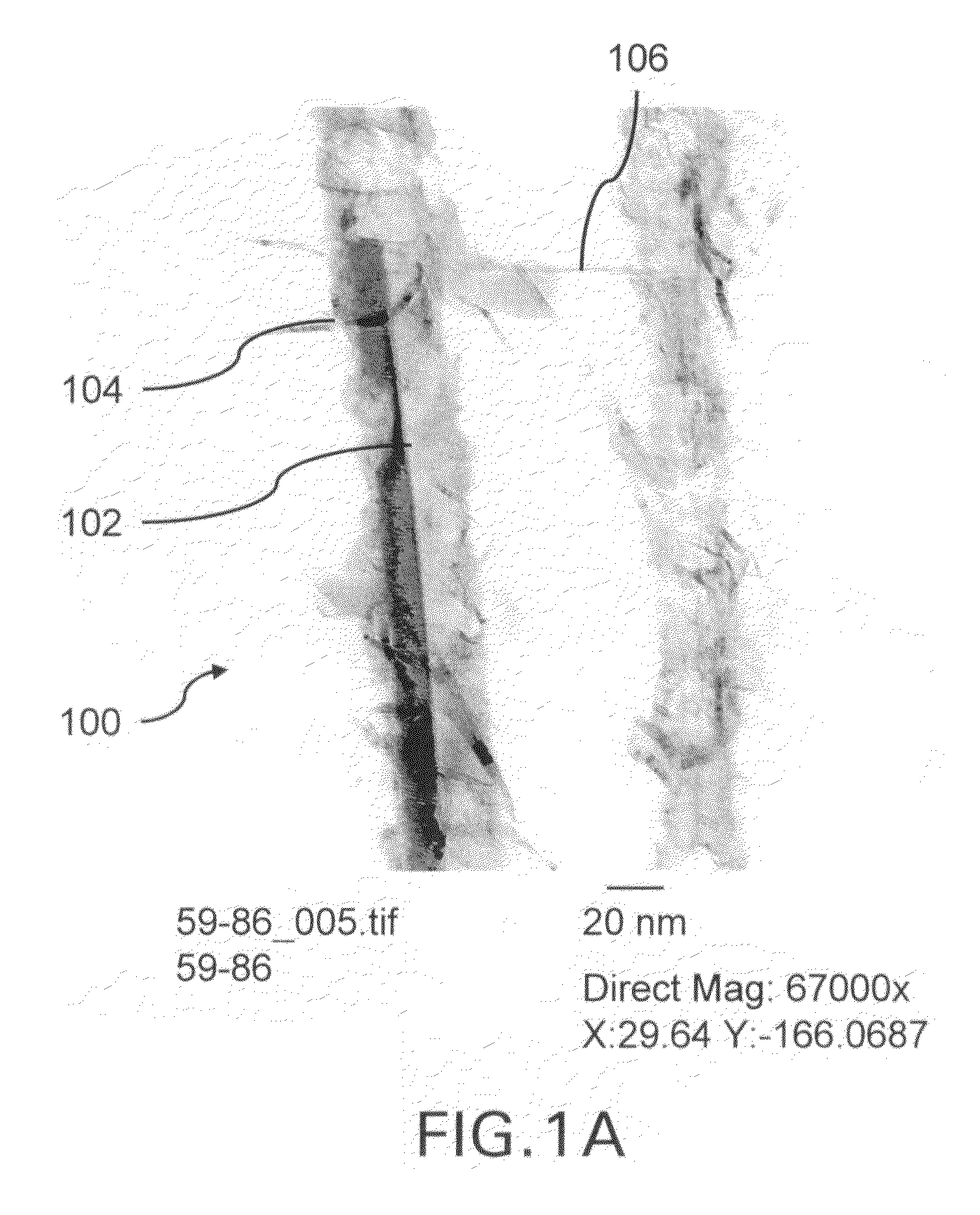

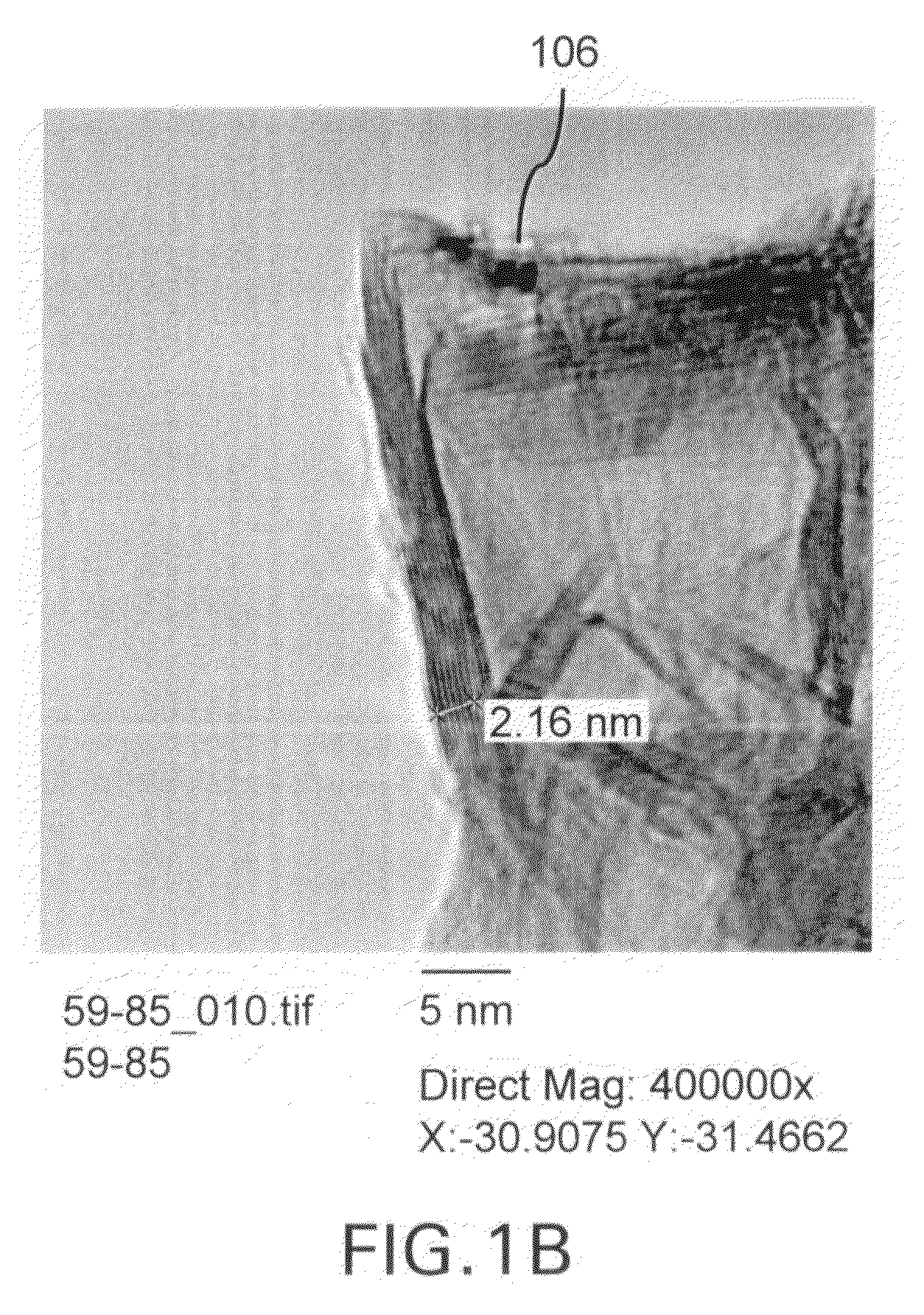

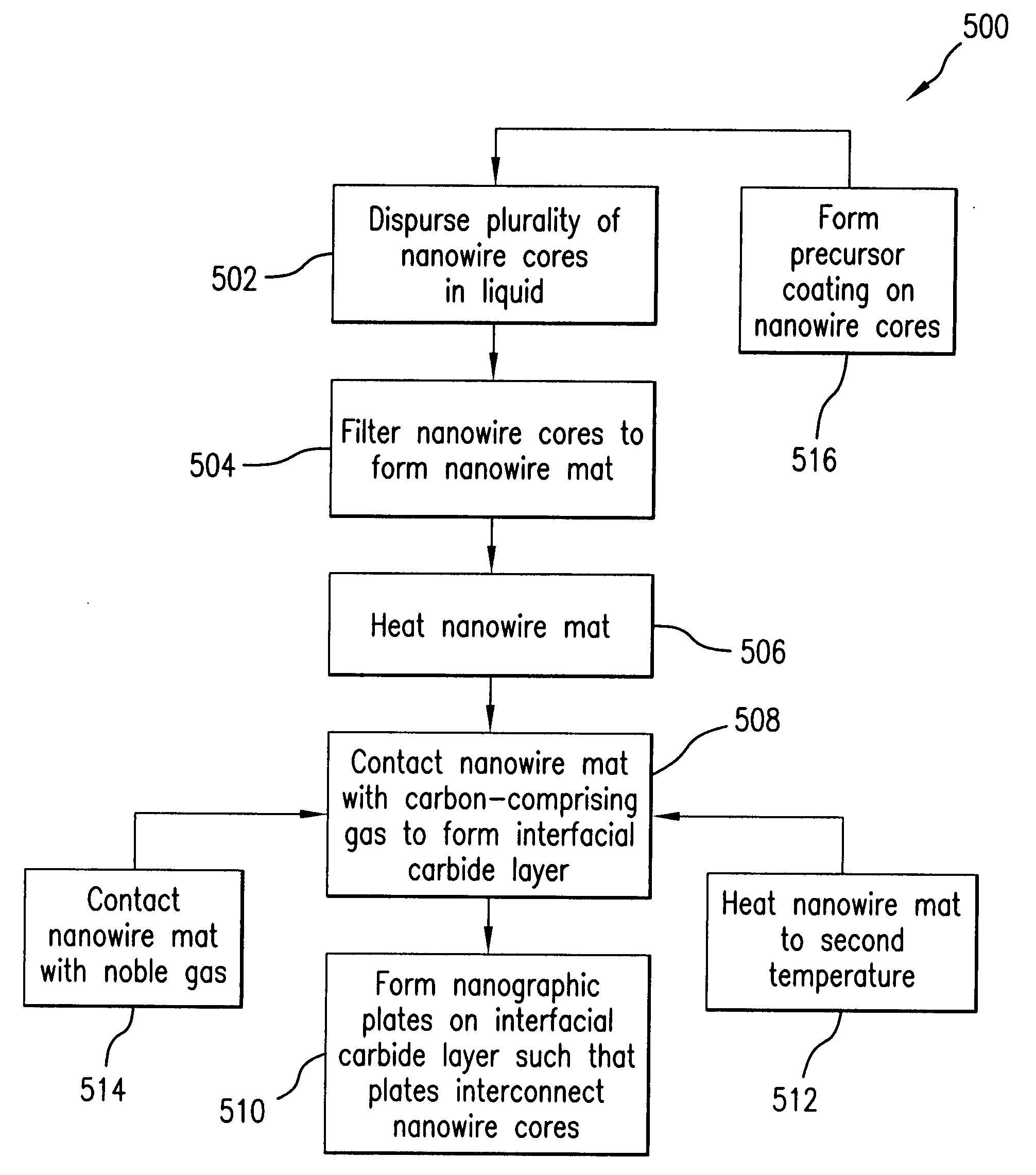

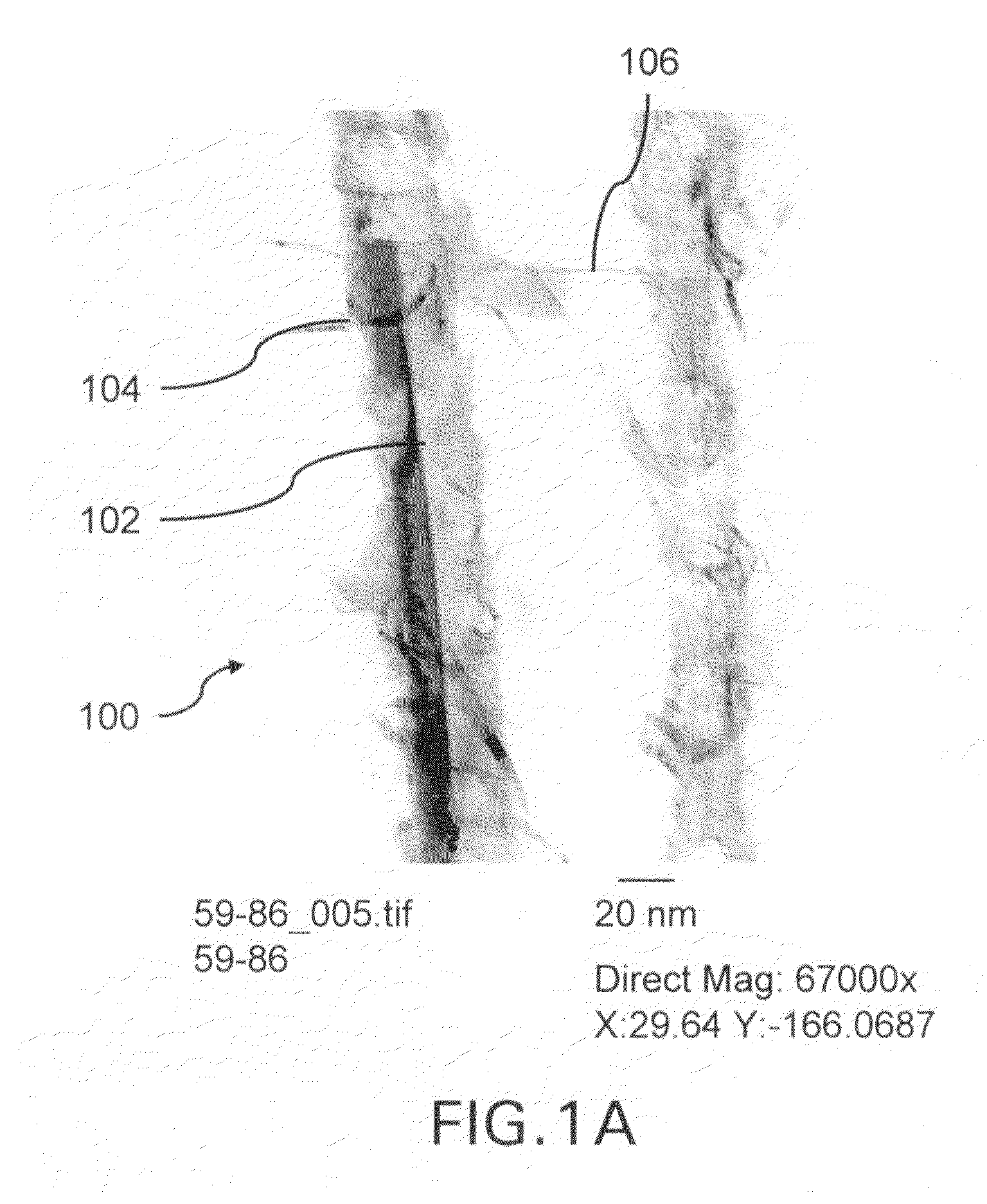

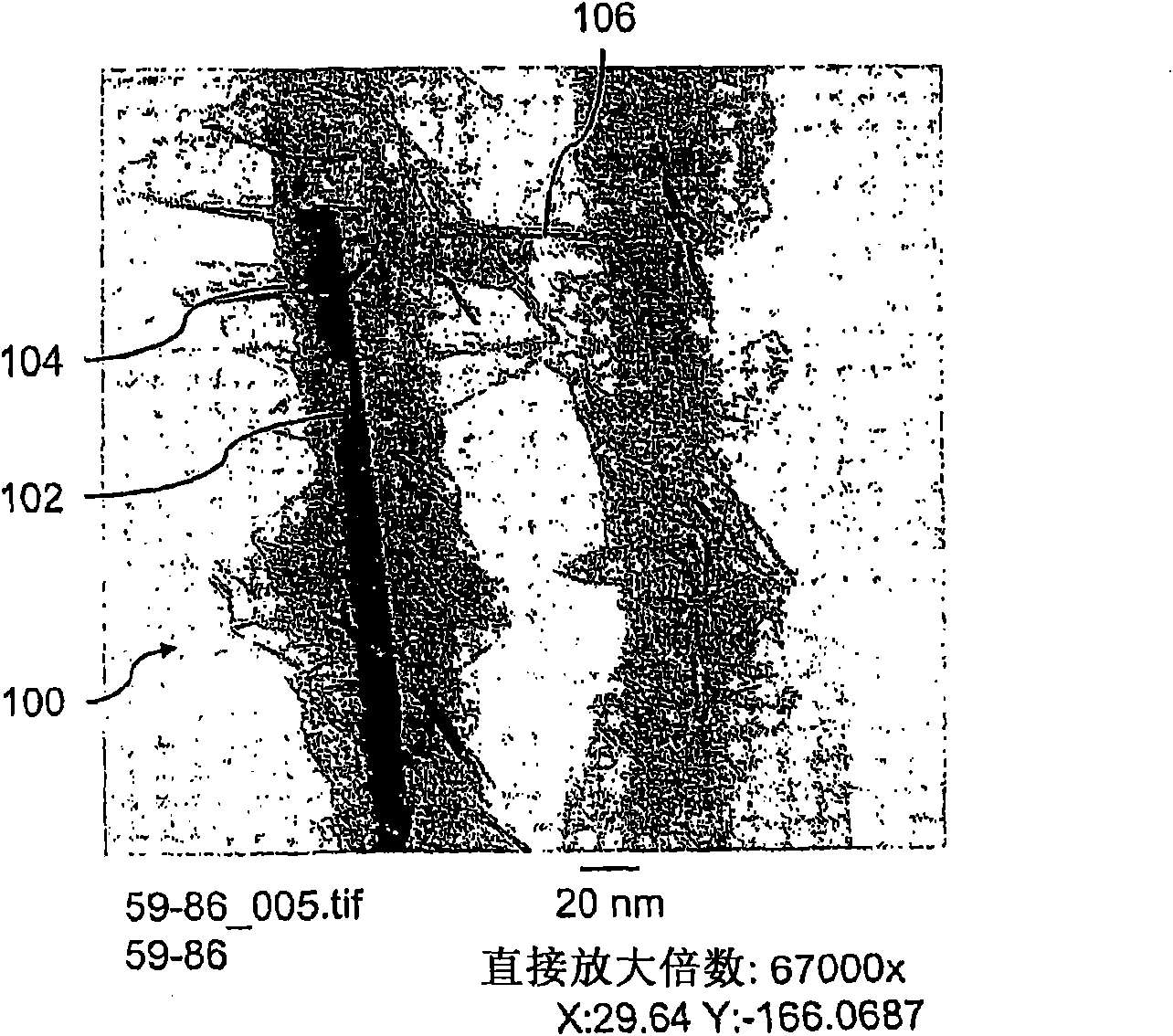

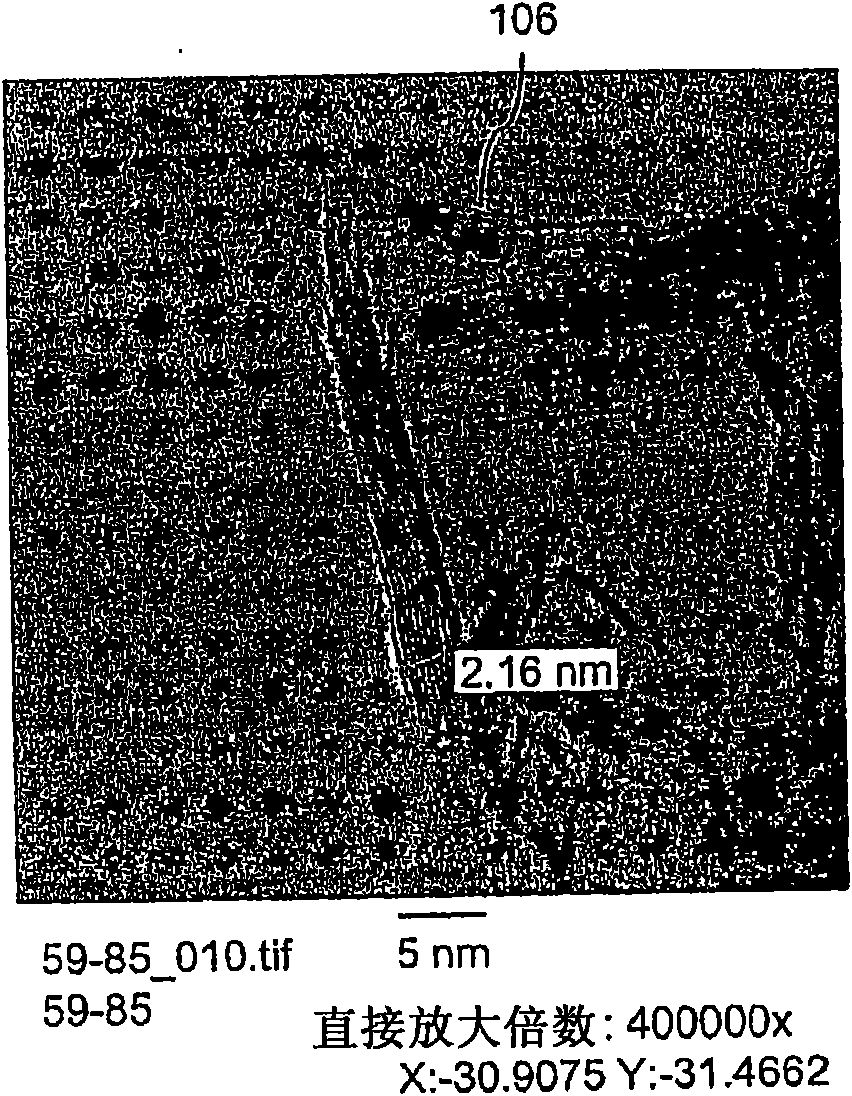

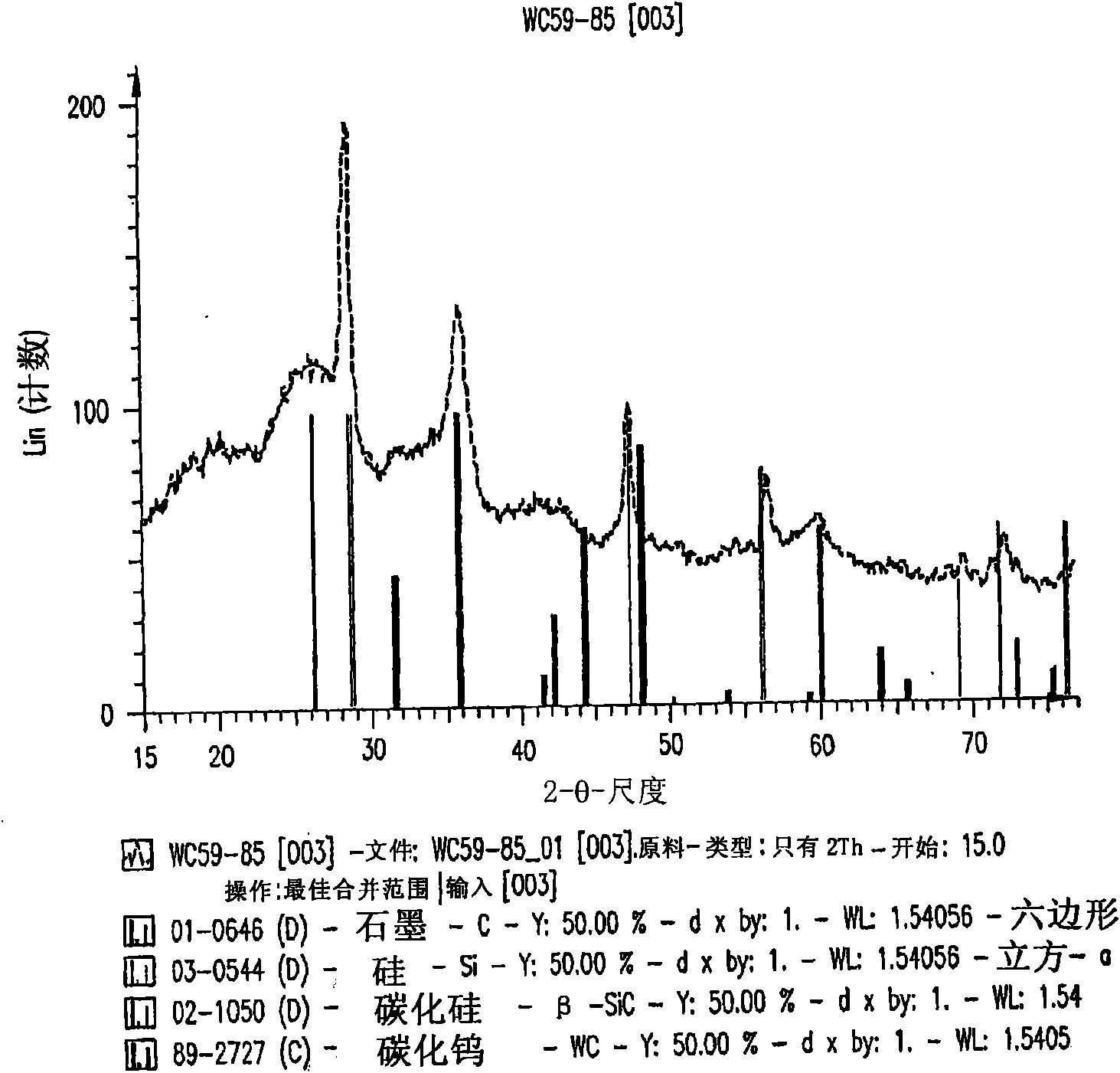

The present invention is directed to nanowire structures and interconnected nanowire networks comprising such structures, as well as methods for their production. The nanowire structures comprise a nanowire core, a carbon-based layer, and in additional embodiments, carbon-based structures such as nanographitic plates consisting of graphenes formed on the nanowire cores, interconnecting the nanowire structures in the networks. The networks are porous structures that can be formed into membranes or particles. The nanowire structures and the networks formed using them are useful in catalyst and electrode applications, including fuel cells, as well as field emission devices, support substrates and chromatographic applications.

Owner:ONED MATERIAL INC

Nanowire structures comprising carbon

ActiveUS7842432B2High rateLow costFinal product manufactureFuel cell auxillariesField emission deviceNanowire

The present invention is directed to nanowire structures and interconnected nanowire networks comprising such structures, as well as methods for their production. The nanowire structures comprise a nanowire core, a carbon-based layer, and in additional embodiments, carbon-based structures such as nanographitic plates consisting of graphenes formed on the nanowire cores, interconnecting the nanowire structures in the networks. The networks are porous structures that can be formed into membranes or particles. The nanowire structures and the networks formed using them are useful in catalyst and electrode applications, including fuel cells, as well as field emission devices, support substrates and chromatographic applications.

Owner:ONED MATERIAL INC

Nanowire structures comprising carbon

ActiveUS20080280169A1Low overall diffusion resistanceLow costFinal product manufactureFuel cell auxillariesField emission deviceFuel cells

The present invention is directed to nanowire structures and interconnected nanowire networks comprising such structures, as well as methods for their production. The nanowire structures comprise a nanowire core, a carbon-based layer, and in additional embodiments, carbon-based structures such as nanographitic plates consisting of graphenes formed on the nanowire cores, interconnecting the nanowire structures in the networks. The networks are porous structures that can be formed into membranes or particles. The nanowire structures and the networks formed using them are useful in catalyst and electrode applications, including fuel cells, as well as field emission devices, support substrates and chromatographic applications.

Owner:ONED MATERIAL INC

Field emission devices using modified carbon nanotubes

InactiveUS20030090190A1Accelerate emissionsReduce voltageNanostructure manufactureNanoinformaticsField emission deviceModified carbon

The present invention relates to a field emission device comprising an anode and a cathode, wherein said cathode includes carbon nanotubes nanotubes which have been subjected to energy, plasma, chemical, or mechanical treatment. The present invention also relates to a field emission cathode comprising carbon nanotubes which have been subject to such treatment. A method for treating the carbon nanotubes and for creating a field emission cathode is also disclosed. A field emission display device containing carbon nanotube which have been subject to such treatment is further disclosed.

Owner:HYPERION CATALYSIS INT

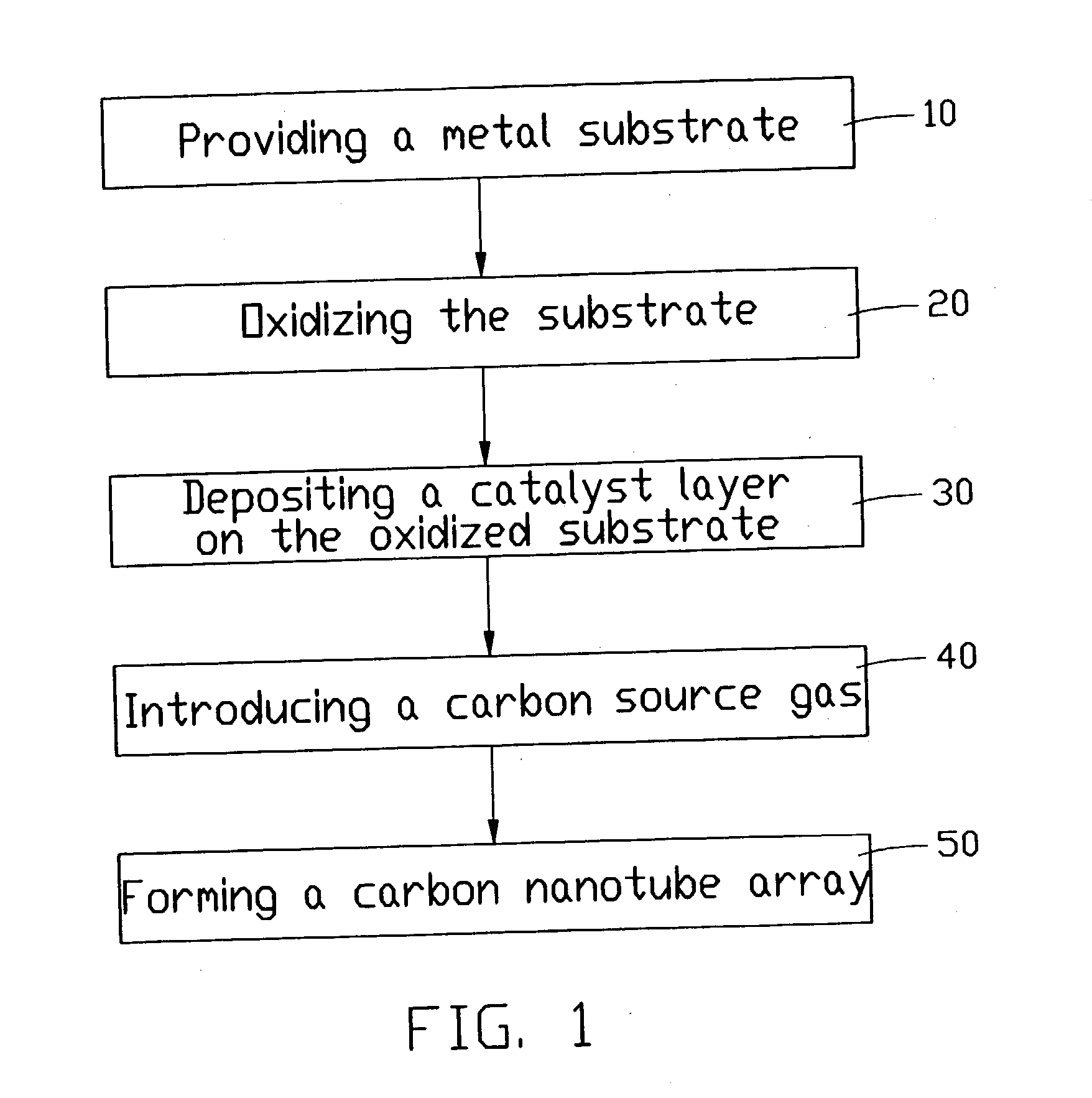

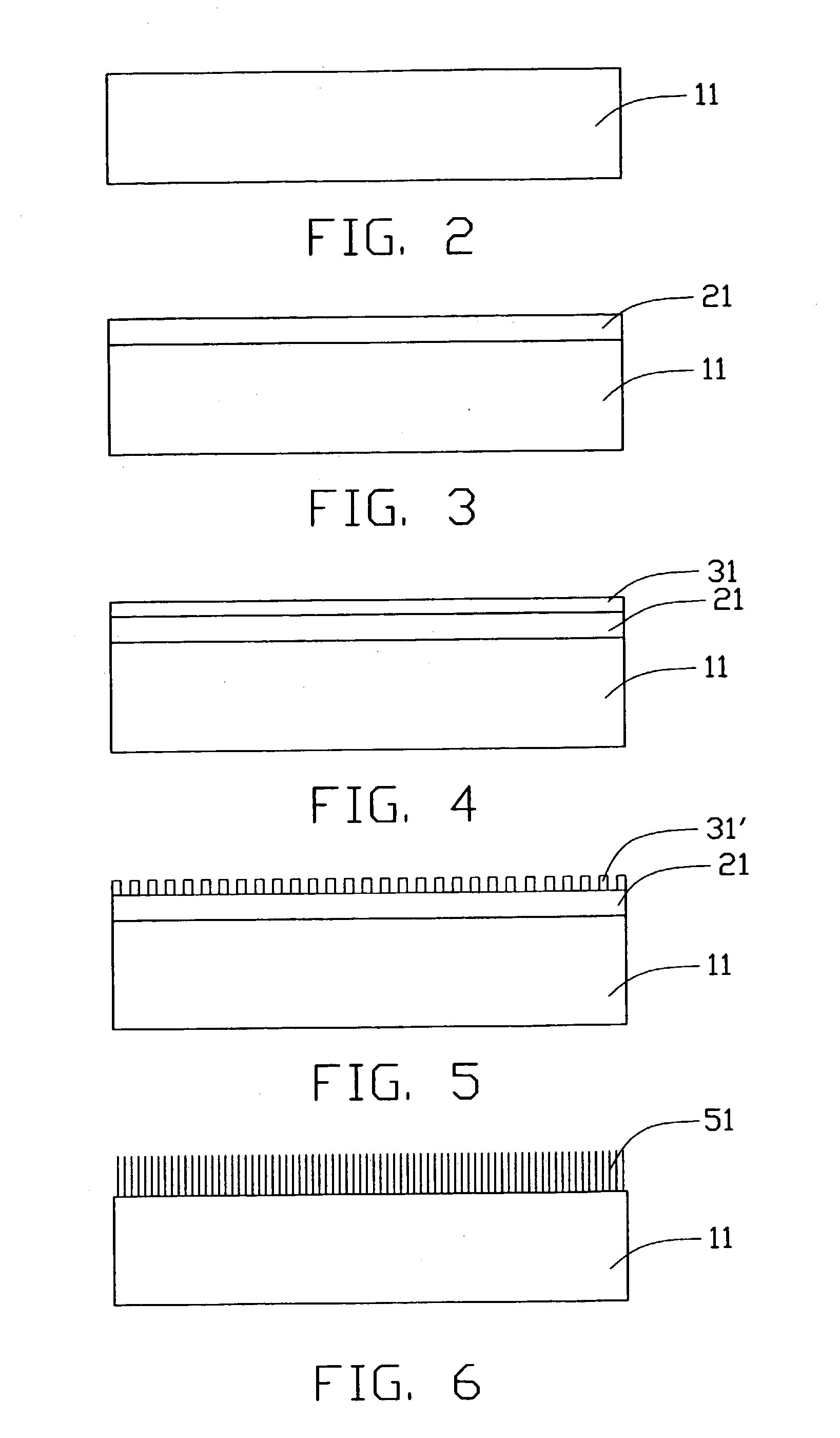

Carbon nanotube array and method for forming same

ActiveUS7160532B2Damage formationInhibition formationMaterial nanotechnologyFibre chemical featuresField emission deviceCarbon nanotube

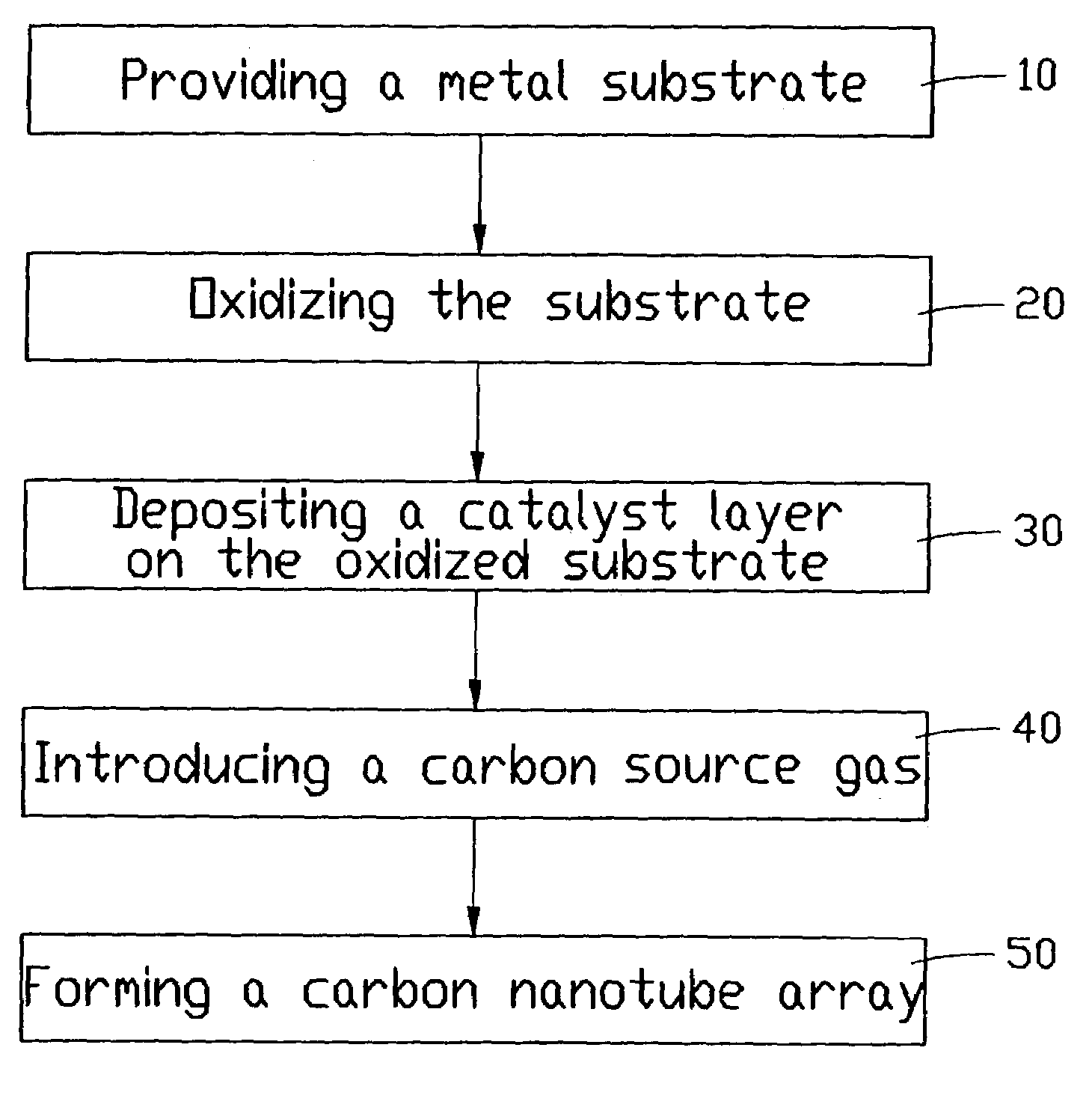

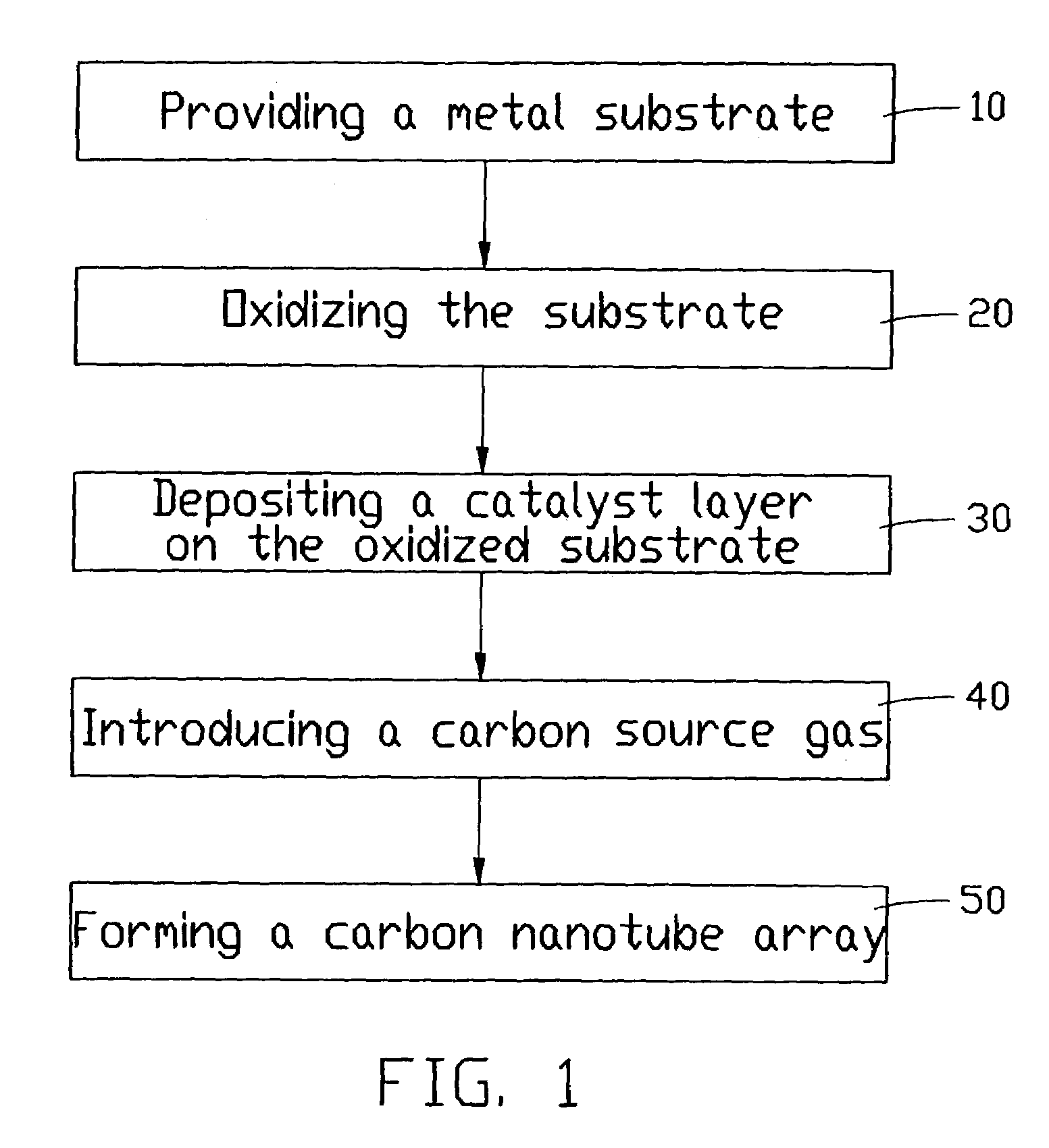

A method for forming a carbon nanotube array using a metal substrate includes the following steps: providing a metal substrate (11); oxidizing the metal substrate to form an oxidized layer (21) thereon; depositing a catalyst layer (31) on the oxidized layer; introducing a carbon source gas; and thus forming a carbon nanotube array (61) extending from the metal substrate. Generally, any metallic material can be used as the metal substrate. Various carbon nanotube arrays formed using various metal substrates can be incorporated into a wide variety of high power electronic device applications such as field emission devices (FEDs), electron guns, and so on. Carbon nanotubes formed using any of a variety of metal substrates are well aligned, and uniformly extend in a direction substantially perpendicular to the metal substrate.

Owner:TSINGHUA UNIV +1

Self-oriented bundles of carbon nanotubes and method of making same

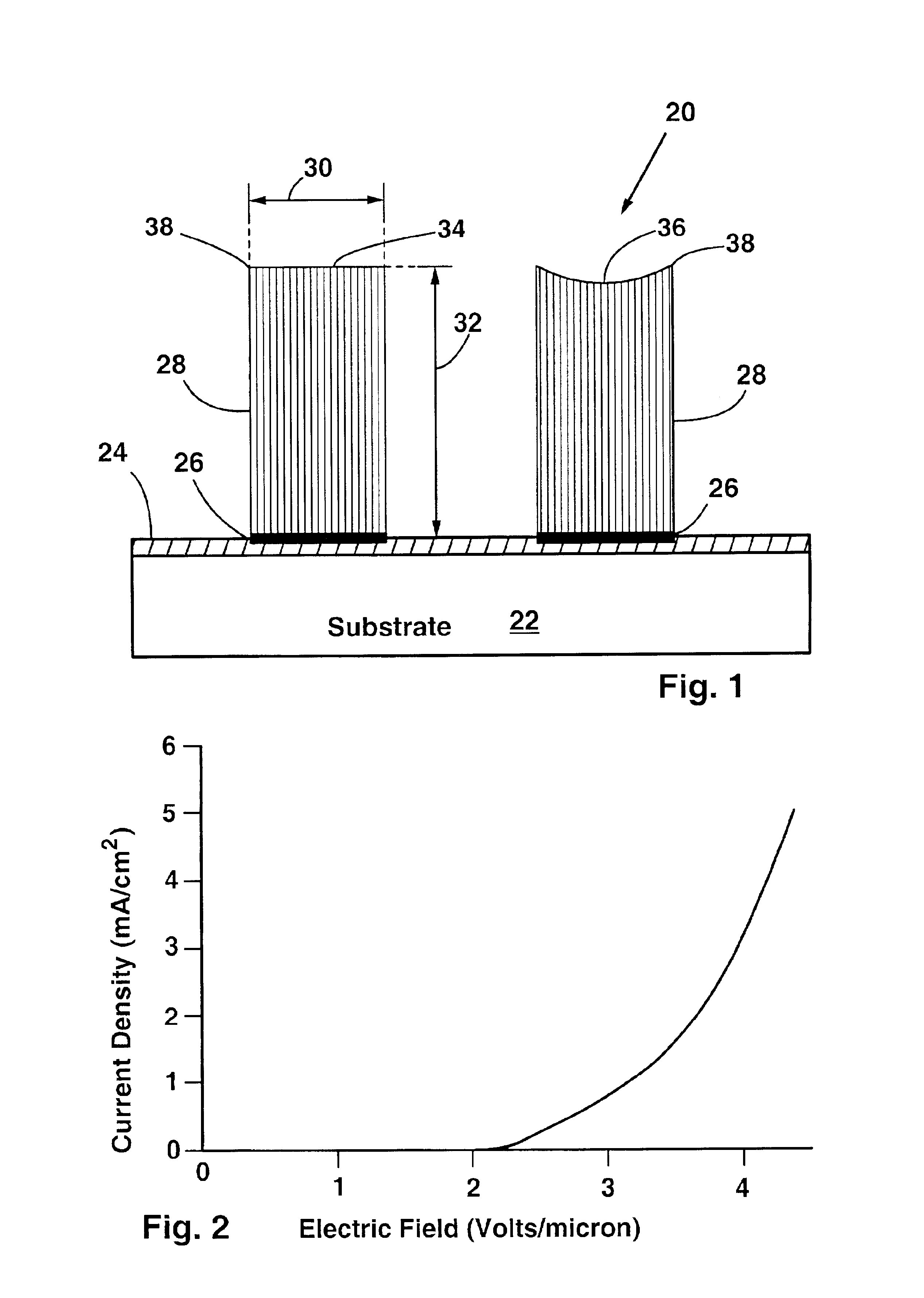

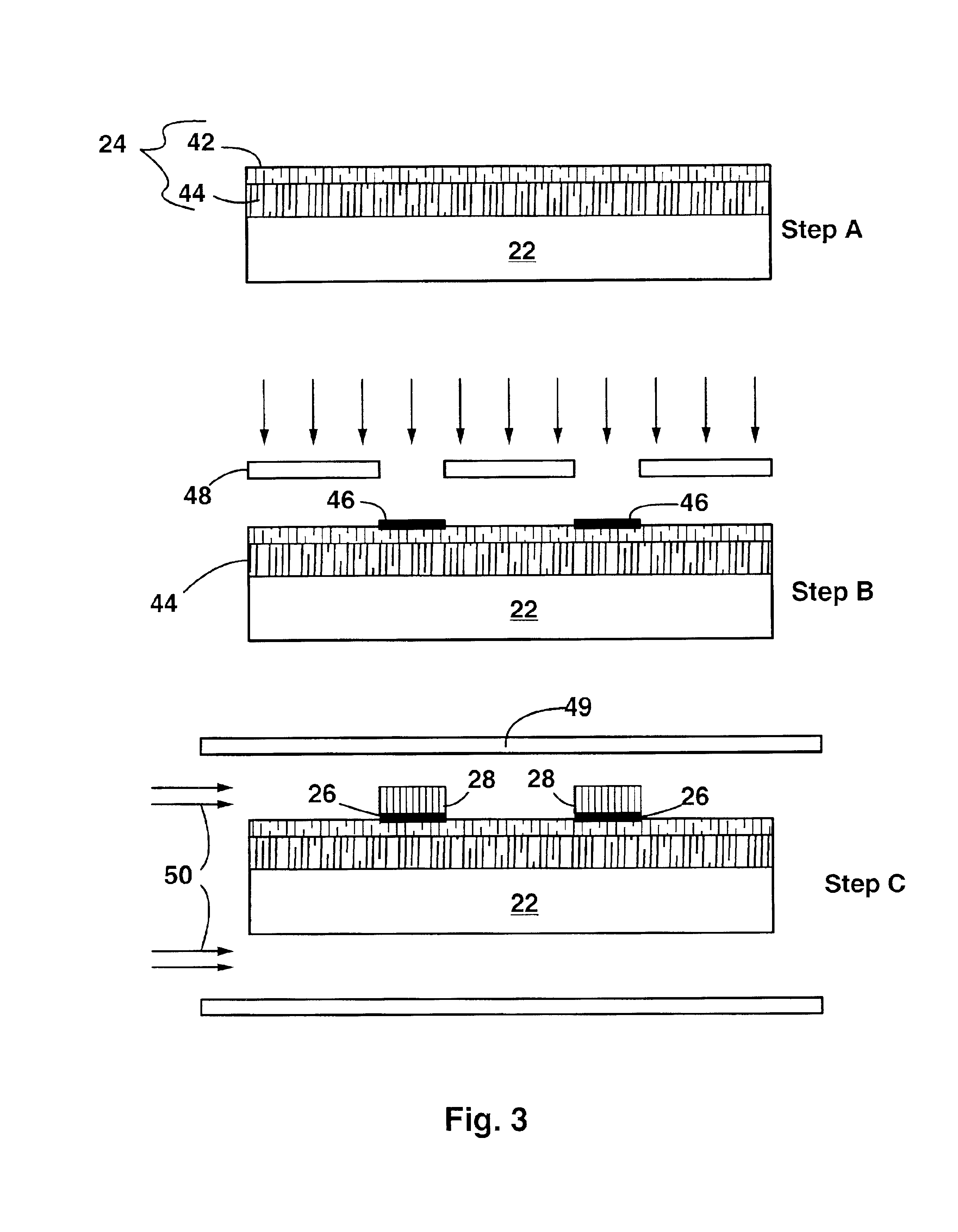

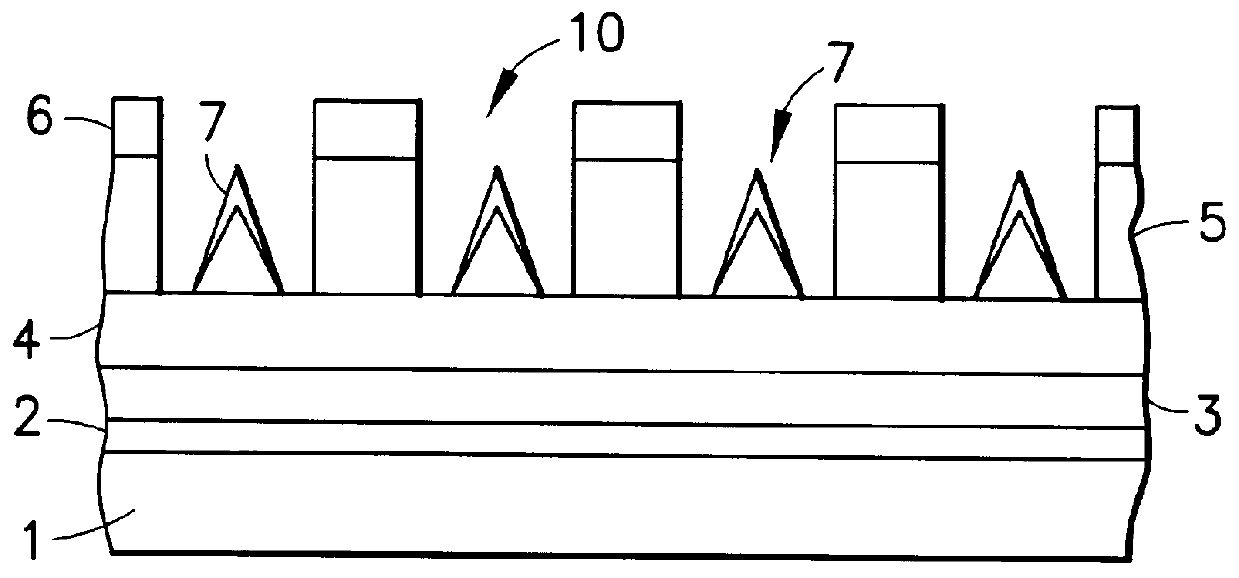

A field emission device having bundles of aligned parallel carbon nanotubes on a substrate. The carbon nanotubes are oriented perpendicular to the substrate. The carbon nanotube bundles may be up to 300 microns tall, for example. The bundles of carbon nanotubes extend only from regions of the substrate patterned with a catalyst material. Preferably, the catalyst material is iron oxide. The substrate is preferably porous silicon, as this produces the highest quality, most well-aligned nanotubes. Smooth, nonporous silicon or quartz can also be used as the substrate. The method of the invention starts with forming a porous layer on a silicon substrate by electrochemical etching. Then, a thin layer of iron is deposited on the porous layer in patterned regions. The iron is then oxidized into iron oxide, and then the substrate is exposed to ethylene gas at elevated temperature. The iron oxide catalyzes the formation of bundles of aligned parallel carbon nanotubes which grow perpendicular to the substrate surface. The height of the nanotube bundles above the substrate is determined by the duration of the catalysis step. The nanotube bundles only grow from the patterned regions.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

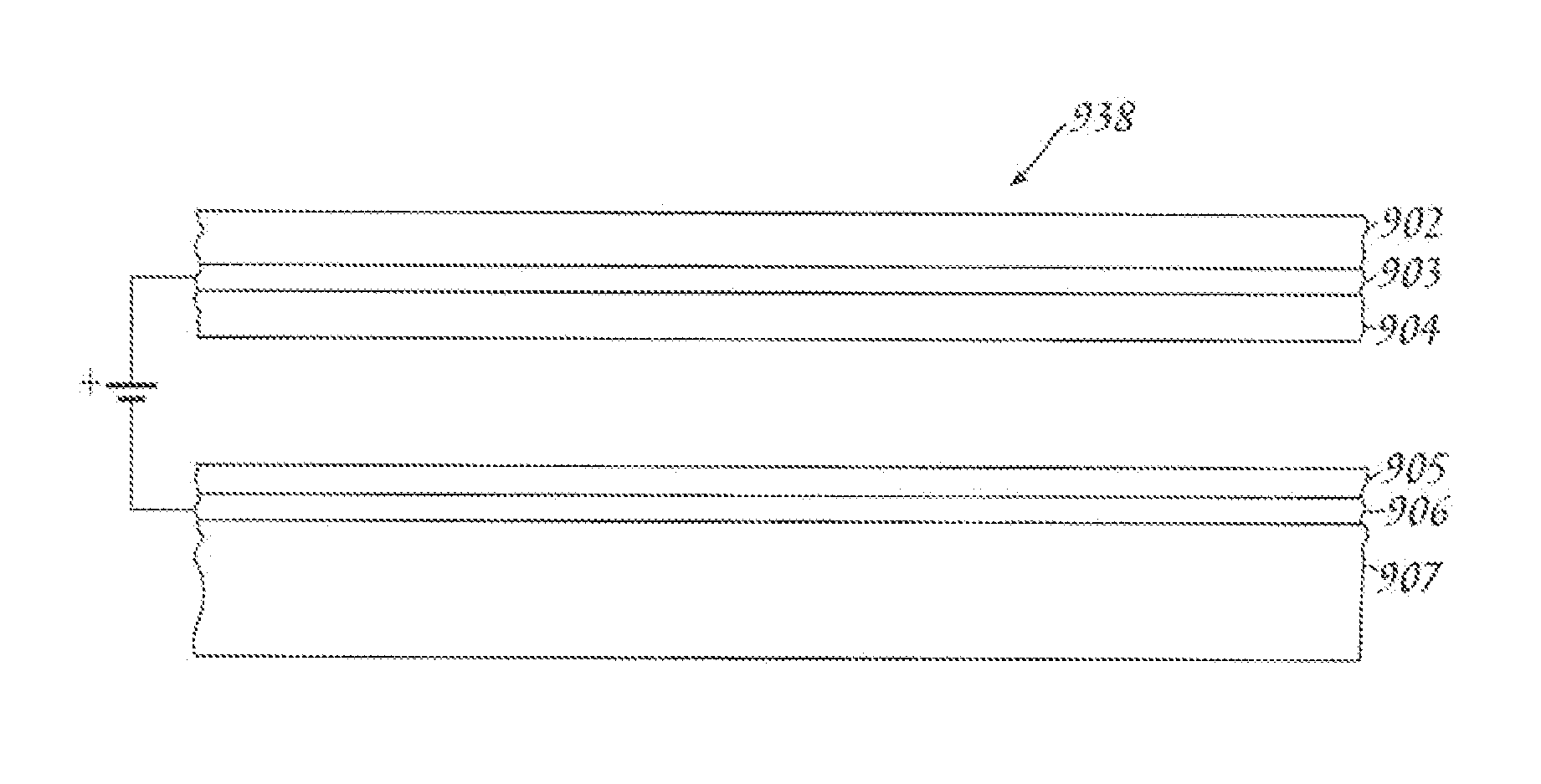

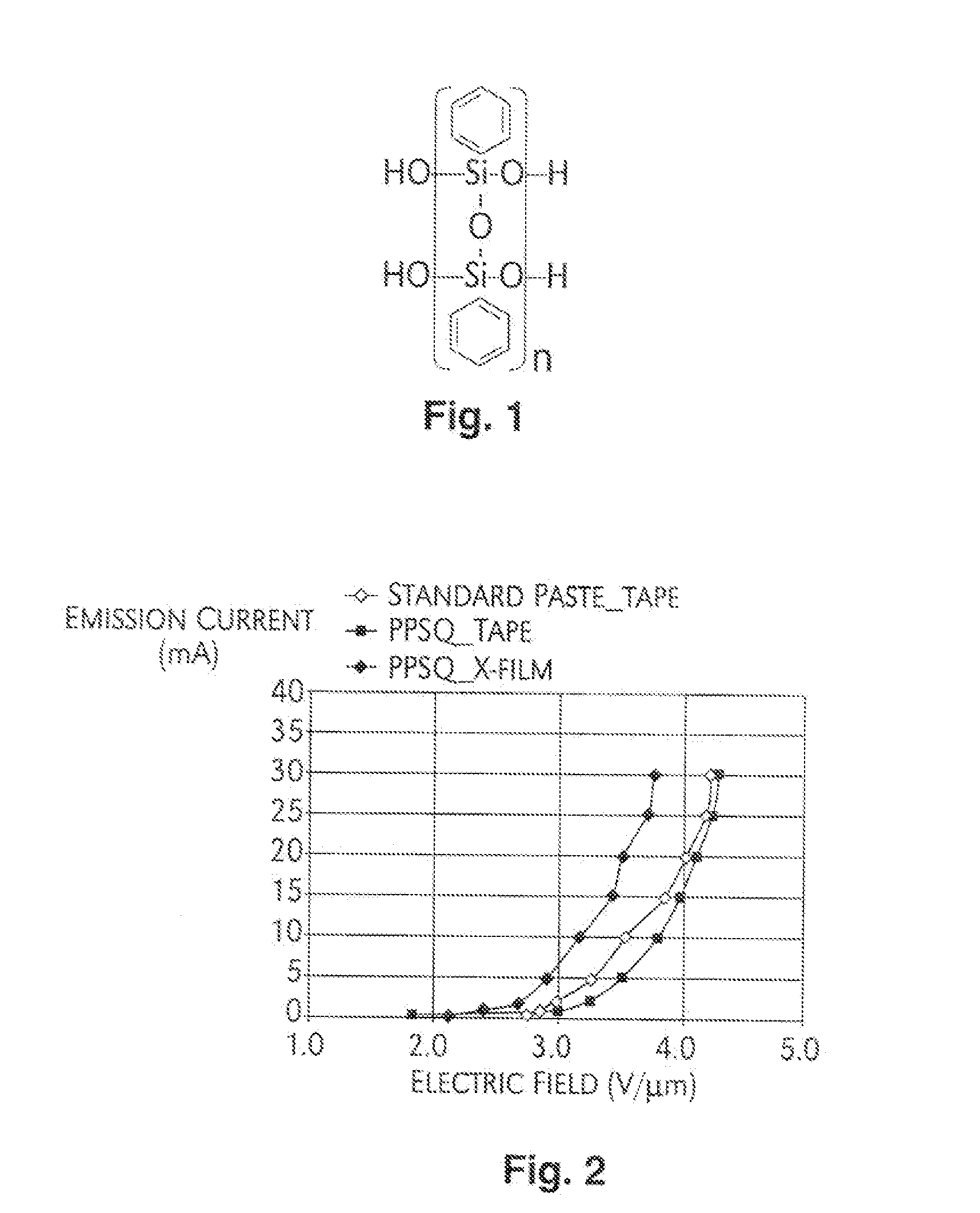

Curing binder material for carbon nanotube electron emission cathodes

InactiveUS20070262687A1Improve adhesionReduce exhaustMaterial nanotechnologyCathode ray/electron stream lampsField emission deviceBiological activation

A binder material, inorganic polymer, is used to formulate carbon nanotube pastes. This material can be cured at 200° C. and has a thermal-stability up to 500° C. Low-out gassing of this binder material makes it a good candidate for long life field emission devices. Due to better adhesion with this binder material, a strong adhesive peelable polymer from liquid form can be applied on the CNT cathode to achieve a uniform activation with even contact and pressure on the surface. The peelable polymer films may be used both as an activation layer and a mask layer to fabricate high-resolution patterned carbon nanotube cathodes for field emission devices using lithographic processes.

Owner:SAMSUNG ELECTRONICS CO LTD

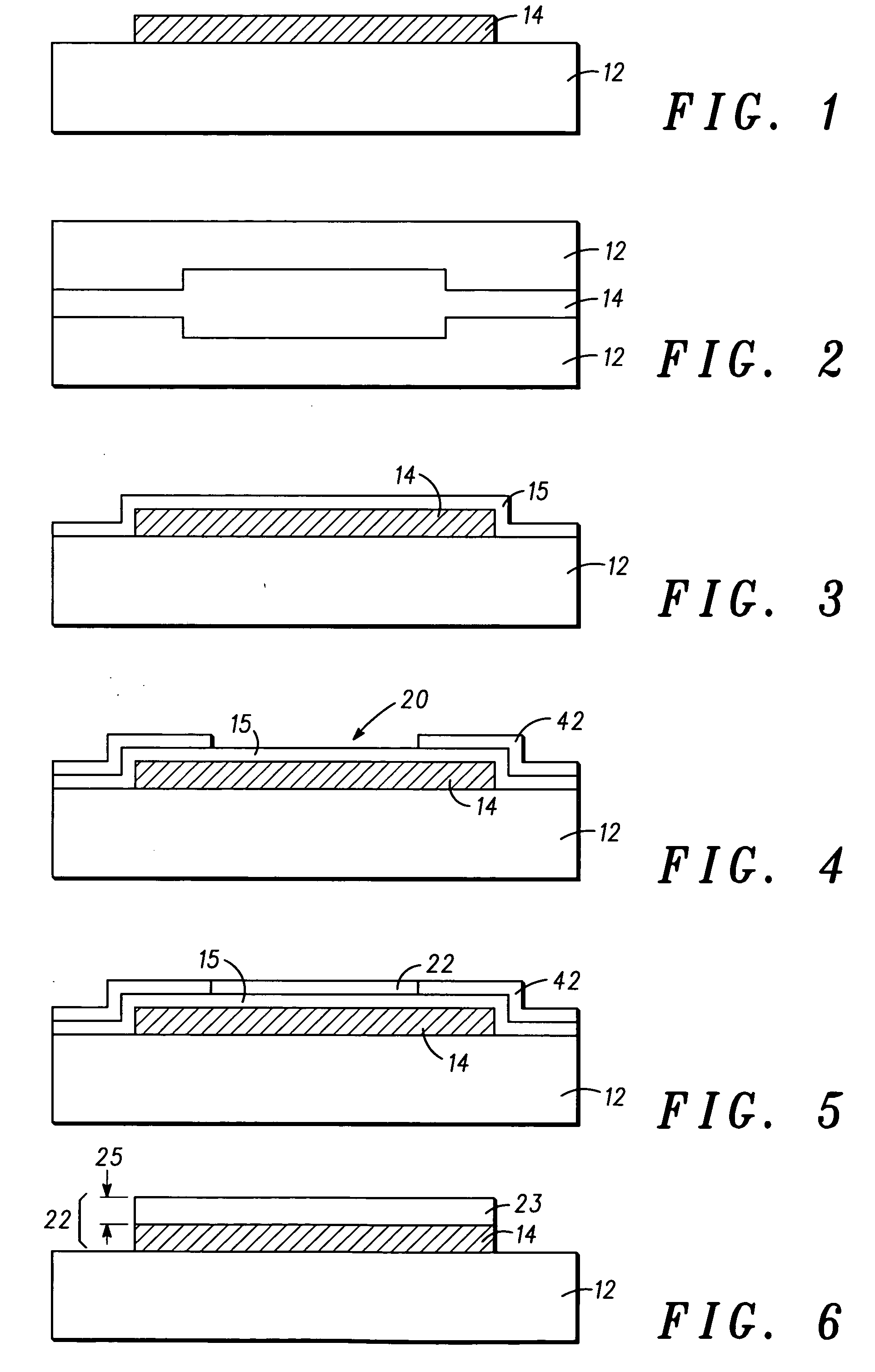

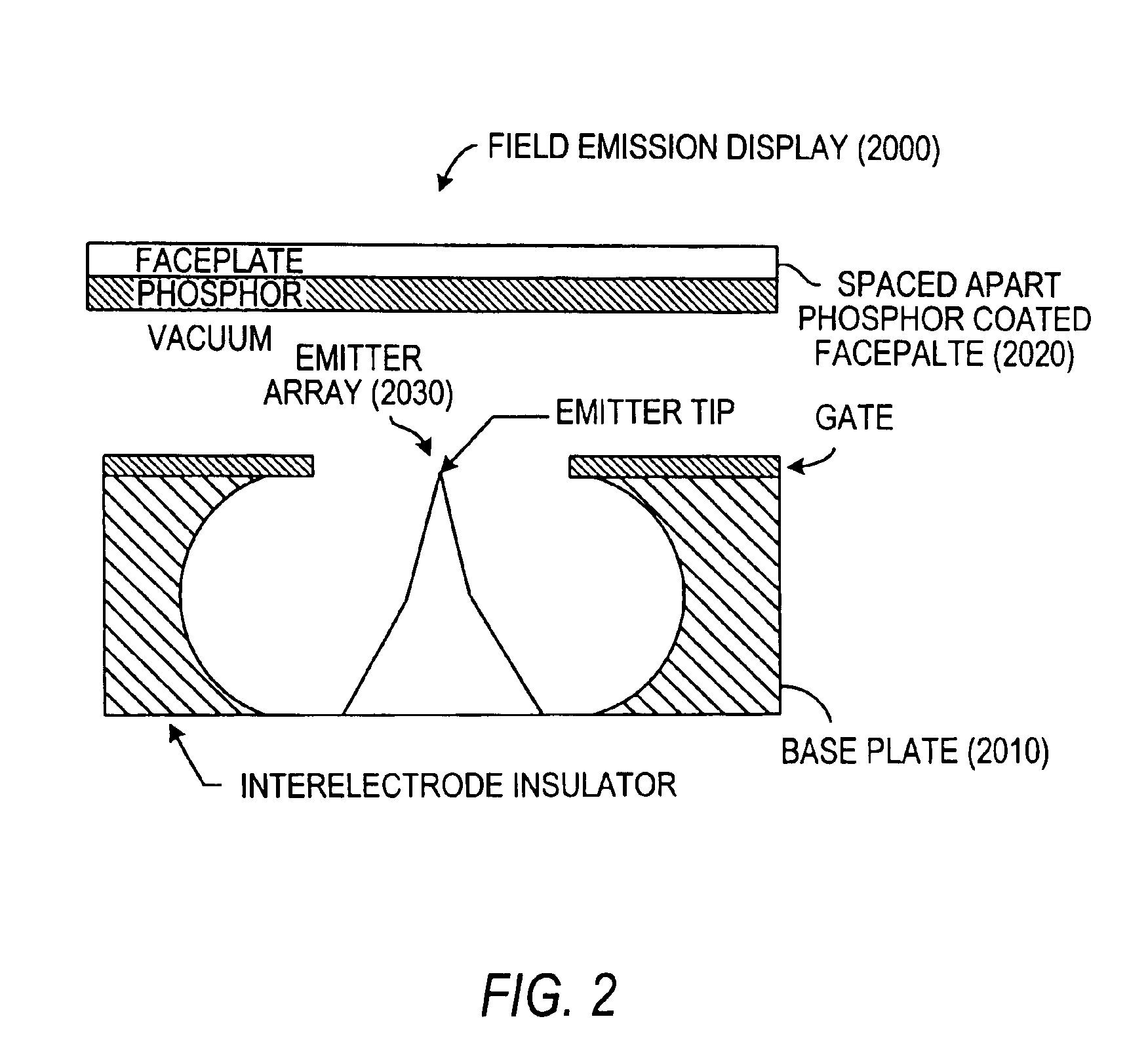

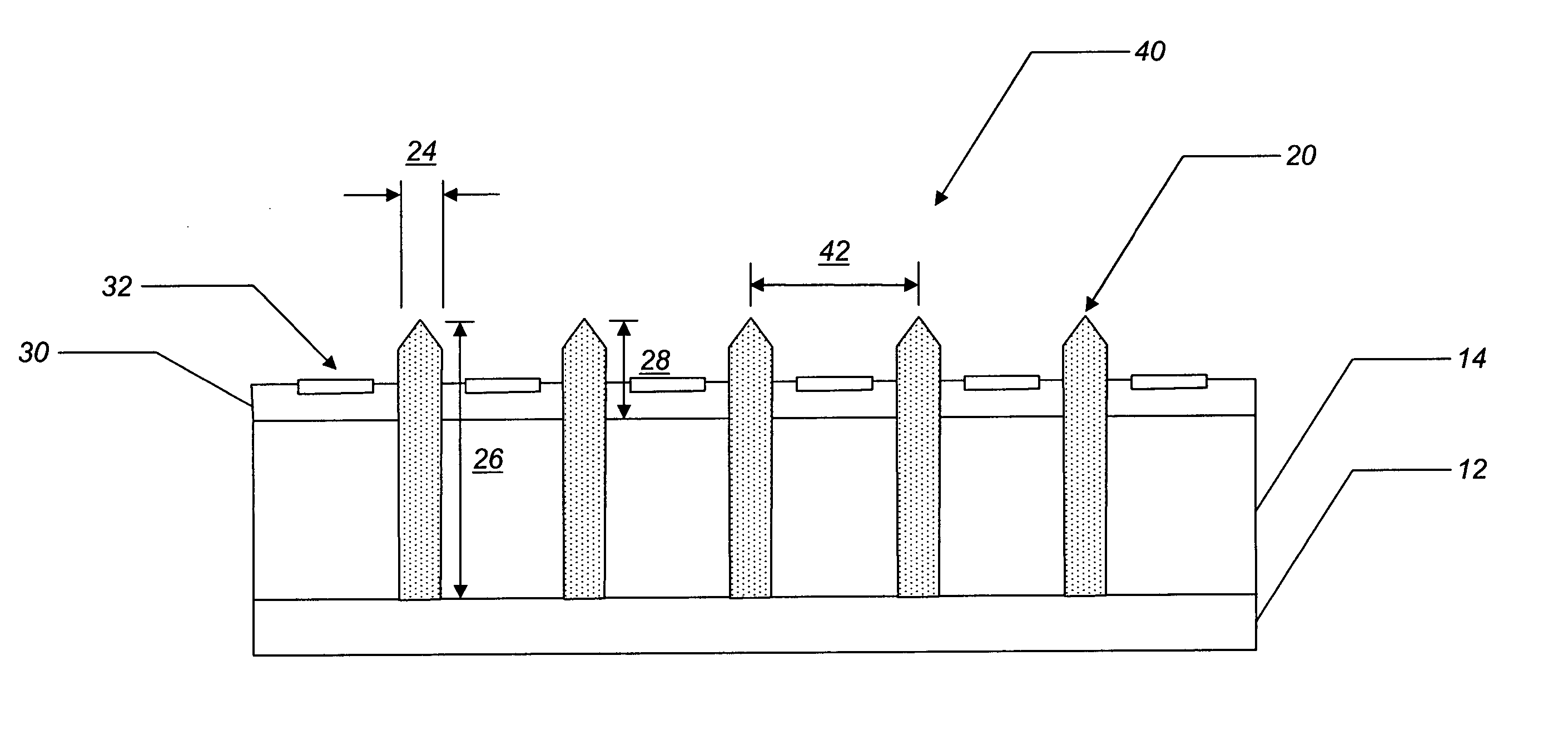

Field emission display and methods of forming a field emission display

A field emission device and method of forming a field emission device are provided in accordance with the present invention. The field emission device is comprised of a substrate (12) having a deformation temperature that is less than about six hundred and fifty degrees Celsius and a nano-supported catalyst (22) formed on the substrate (12) that has active catalytic particles that are less than about five hundred nanometers. The field emission device is also comprised of a nanotube (24) that is catalytically formed in situ on the nano-supported catalyst (22), which has a diameter that is less than about twenty nanometers.

Owner:MOTOROLA SOLUTIONS INC

Carbon nanotube array and method for forming same

ActiveUS20040101468A1Damage formationInhibition formationMaterial nanotechnologyLayered productsField emission deviceMetallic materials

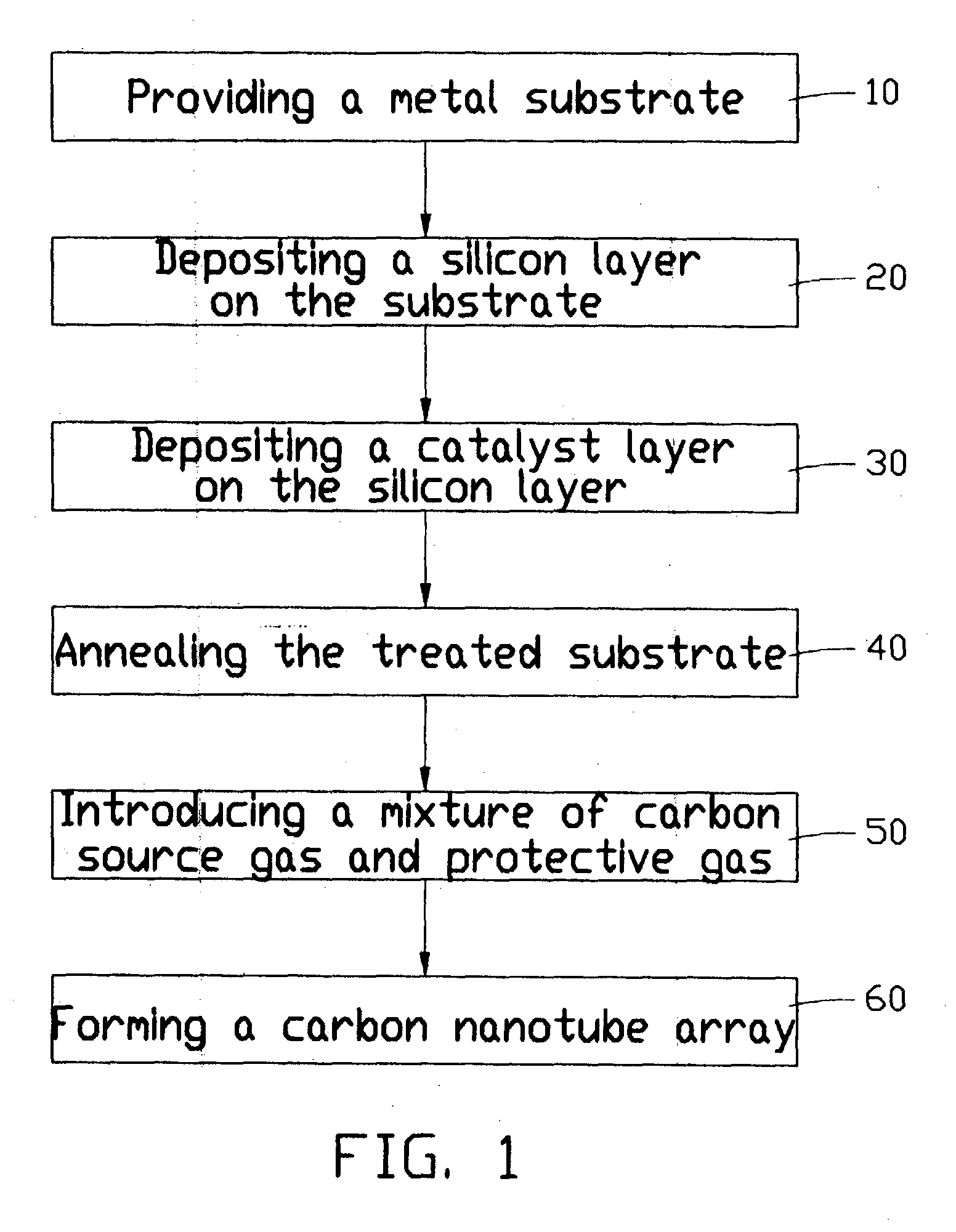

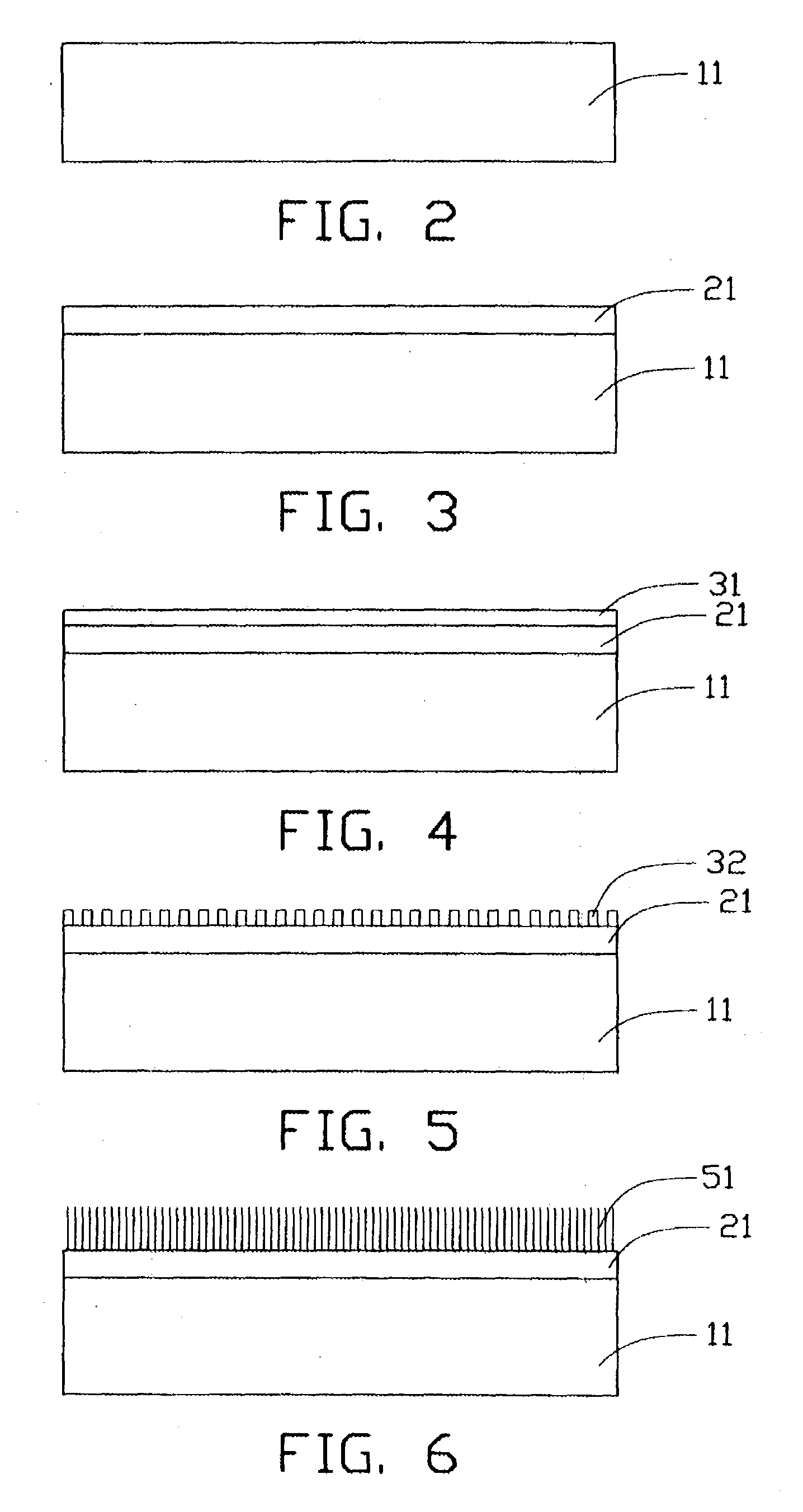

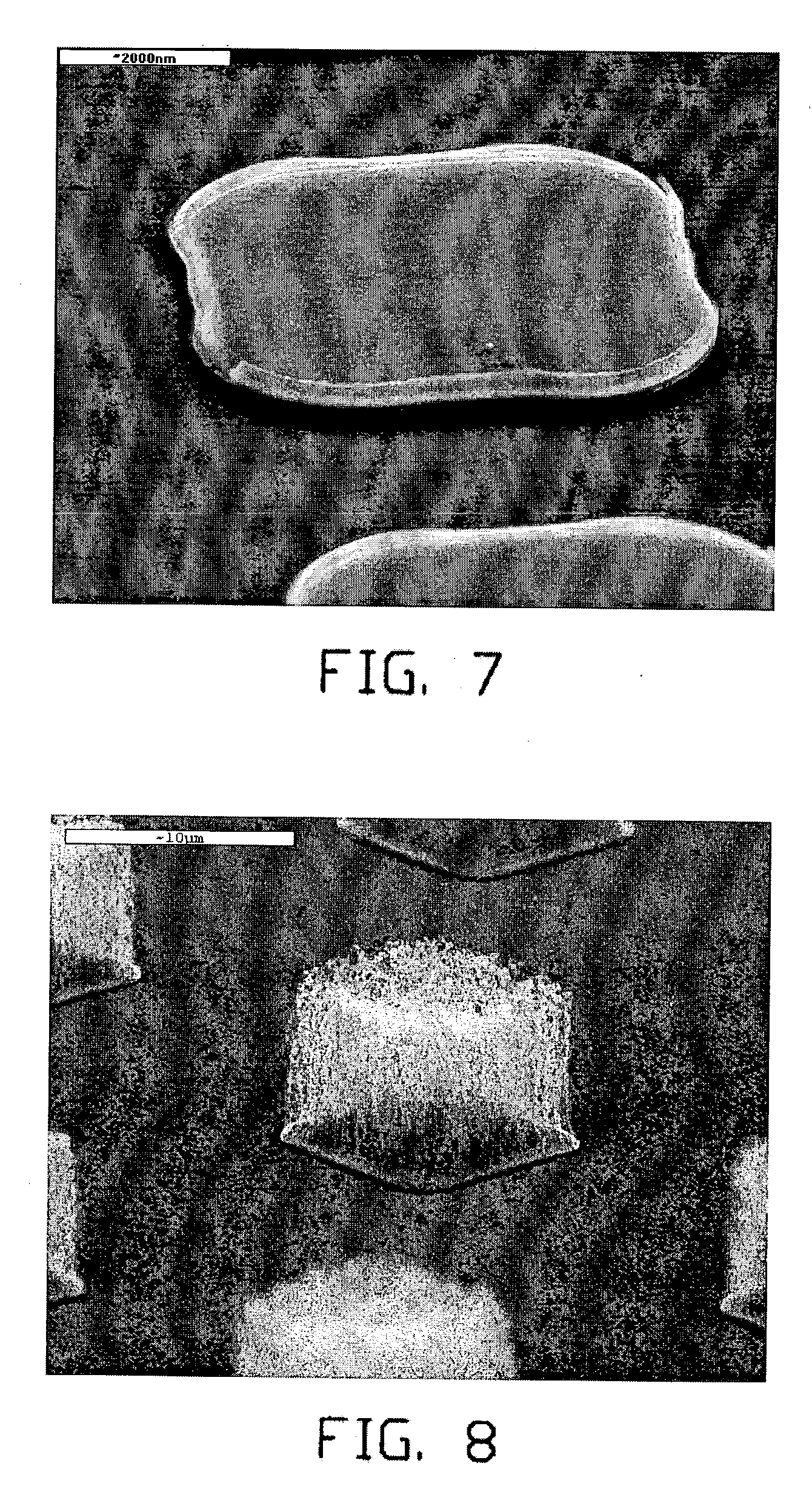

A method for forming a carbon nanotube array on a metal substrate includes the following steps: providing a metal substrate (11); depositing a silicon layer (21) on a surface of the metal substrate; depositing a catalyst layer (31) on the silicon layer; annealing the treated substrate; heating the treated substrate up to a predetermined temperature in flowing protective gas; introducing a carbon source gas for 5-30 minutes; and thus forming a carbon nanotube array (51) extending from the treated substrate. Generally, any metallic material can be used as the metal substrate. Various carbon nanotube arrays formed using various metal substrates can be incorporated into a wide variety of high power electronic device applications such as field emission devices (FEDs), electron guns, and so on. Carbon nanotubes formed using any of a variety of metal substrates are well aligned, and uniformly extend in a direction substantially perpendicular to the metal substrate.

Owner:TSINGHUA UNIV +1

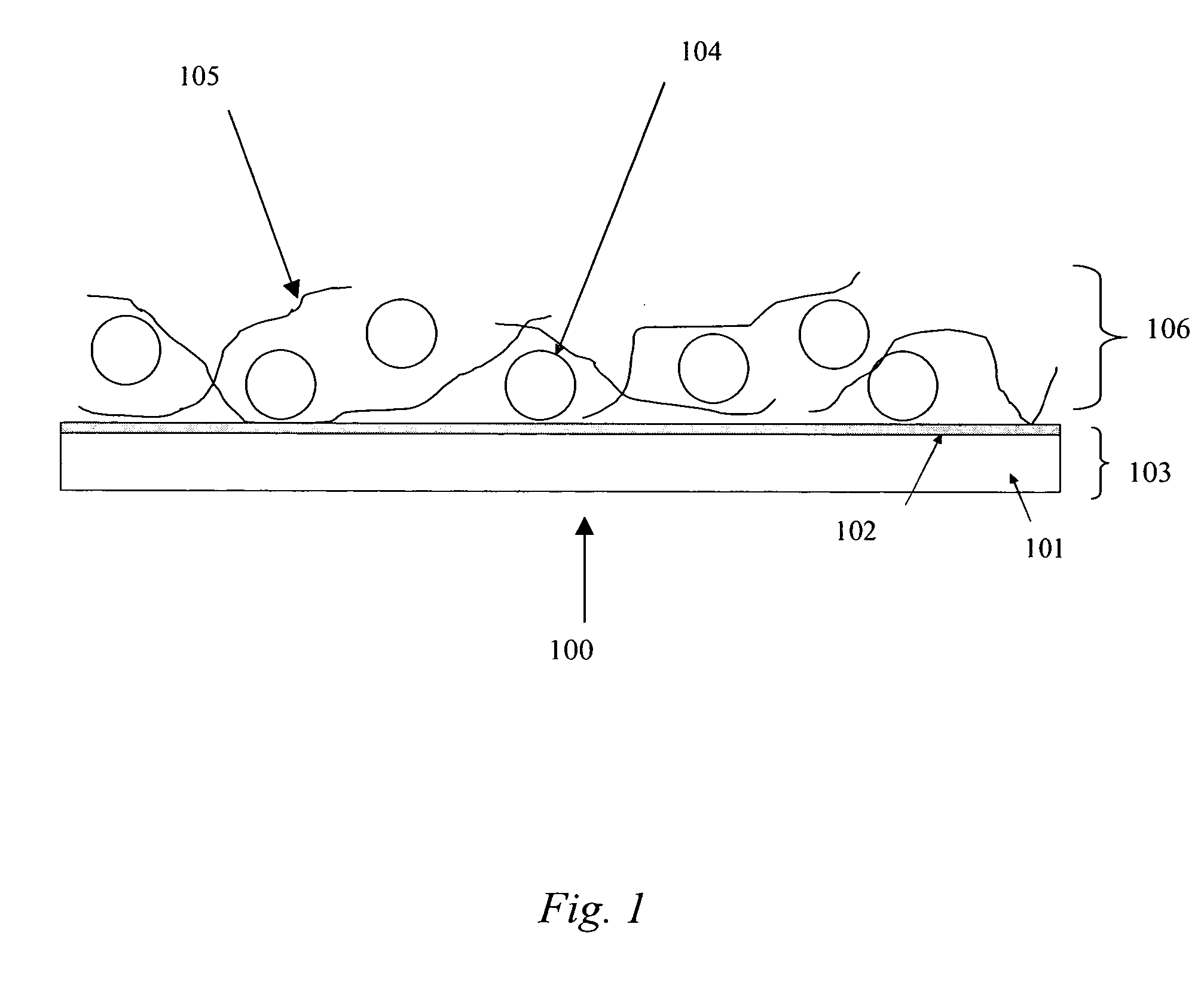

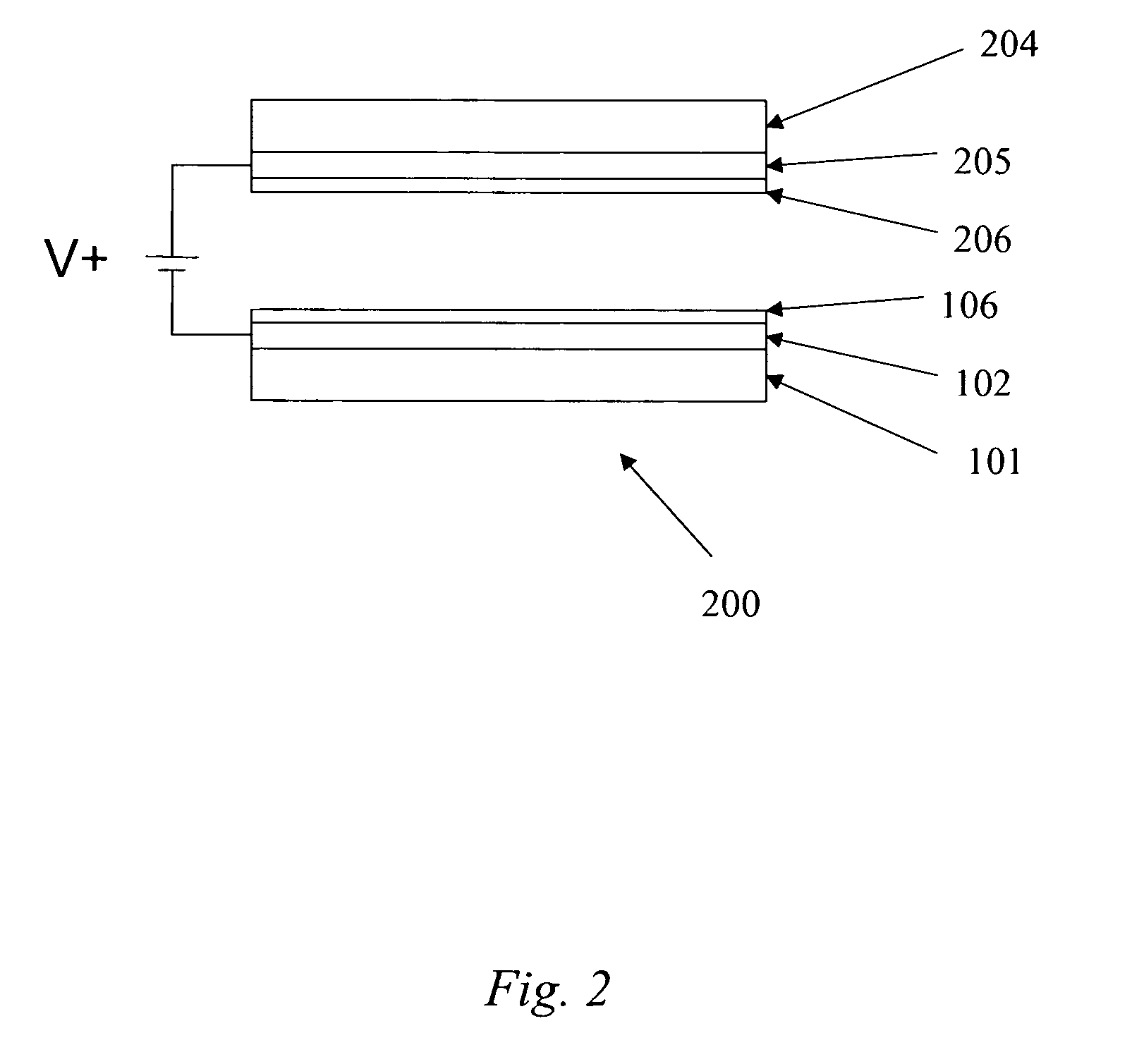

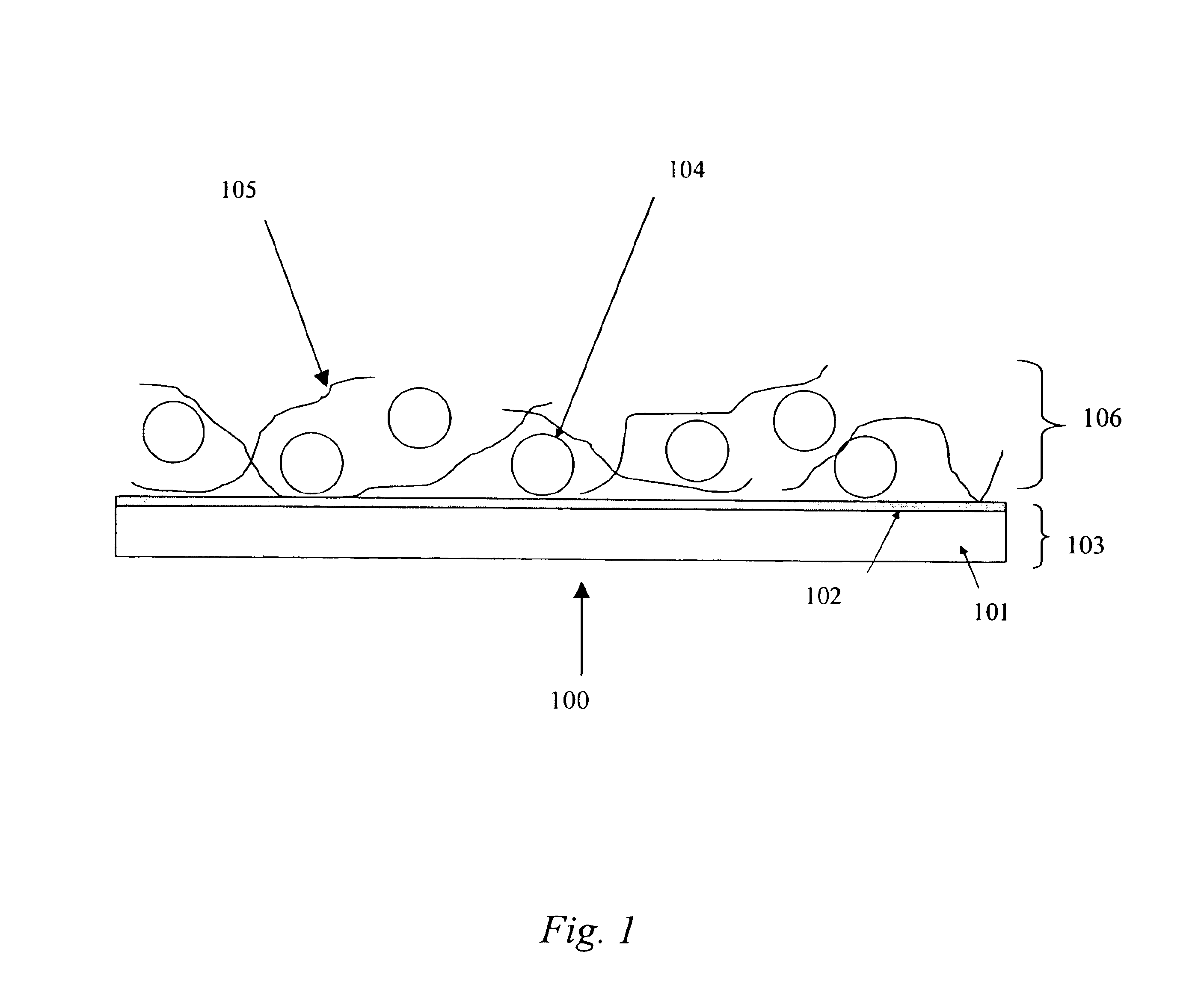

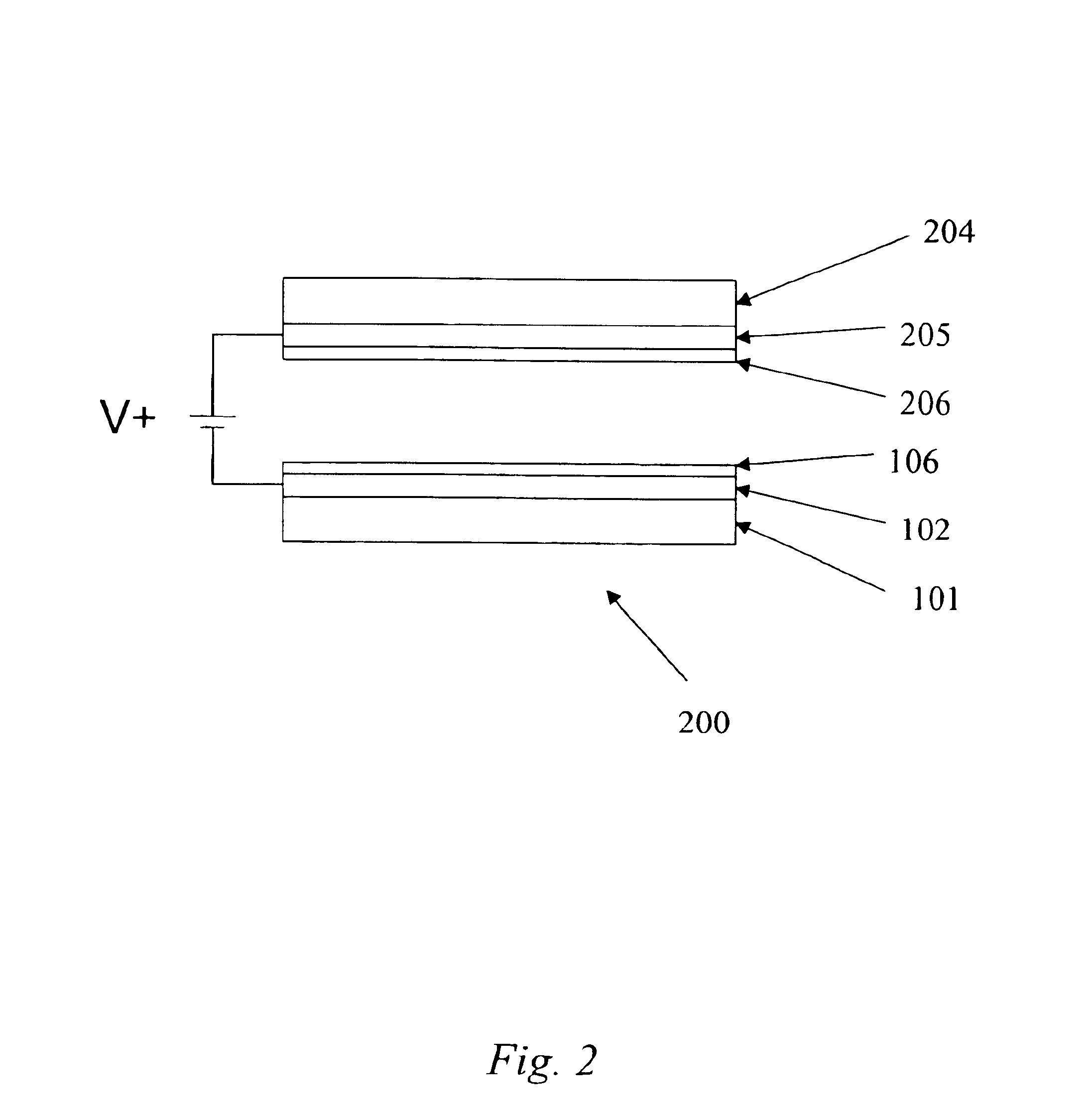

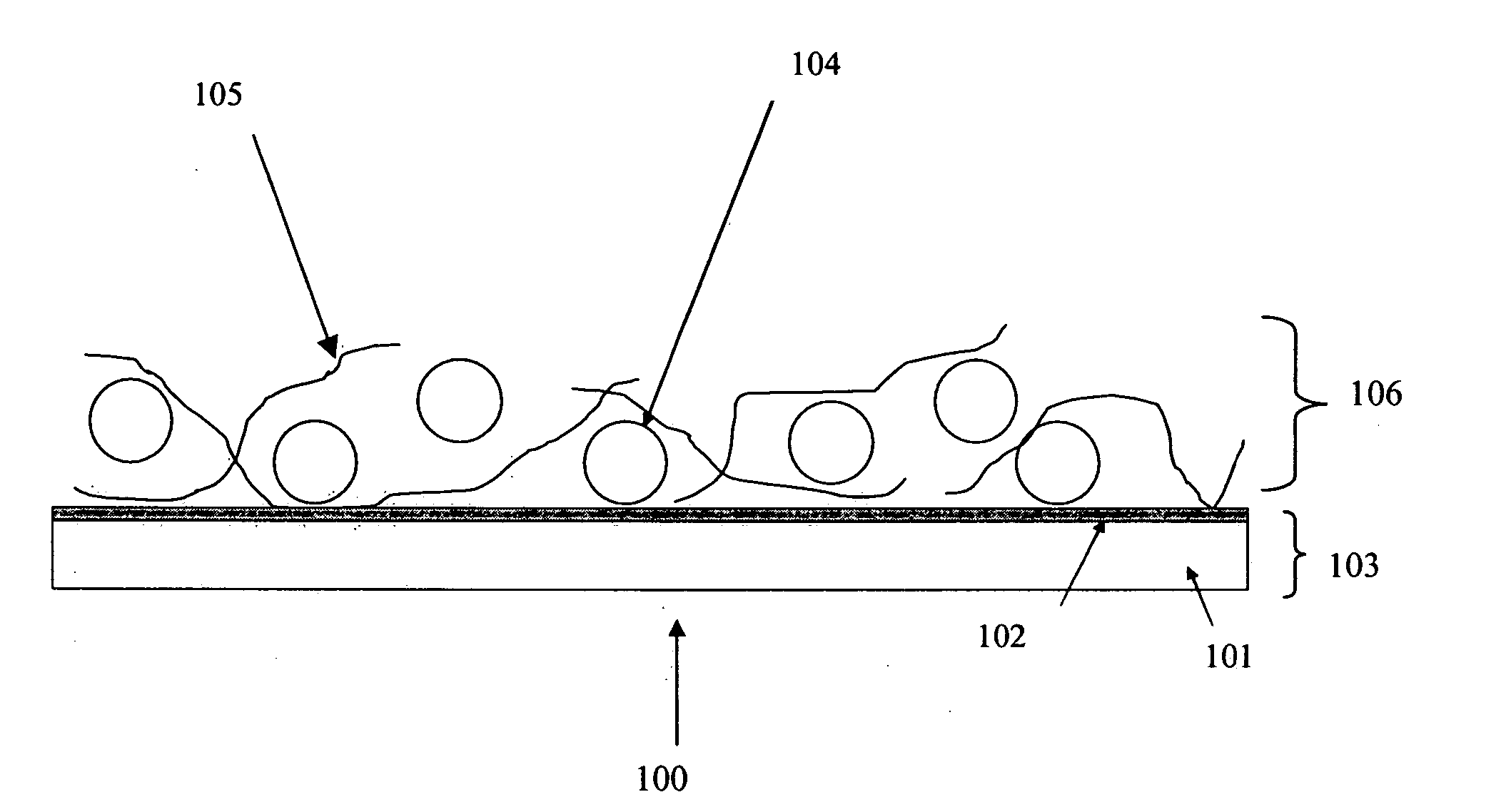

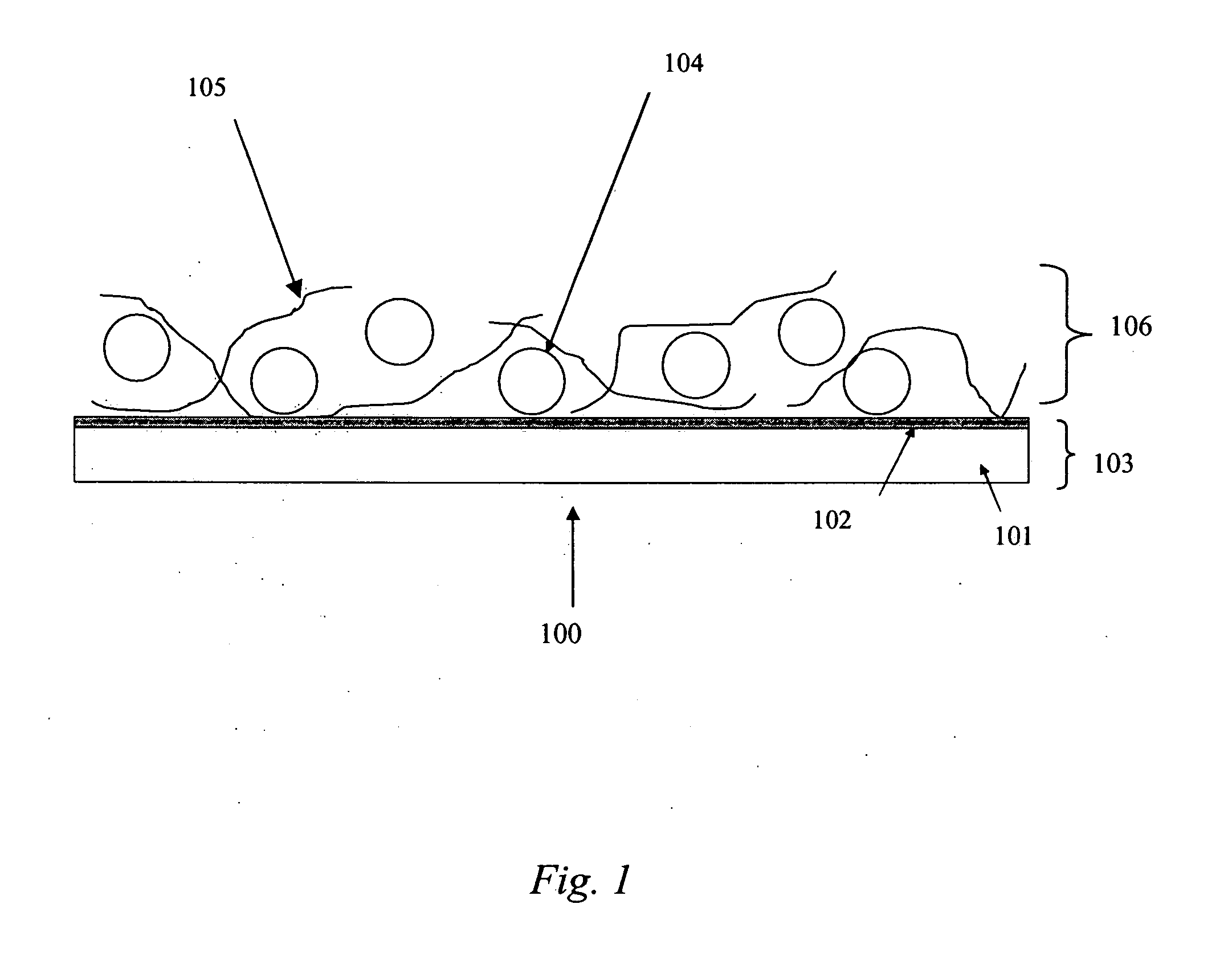

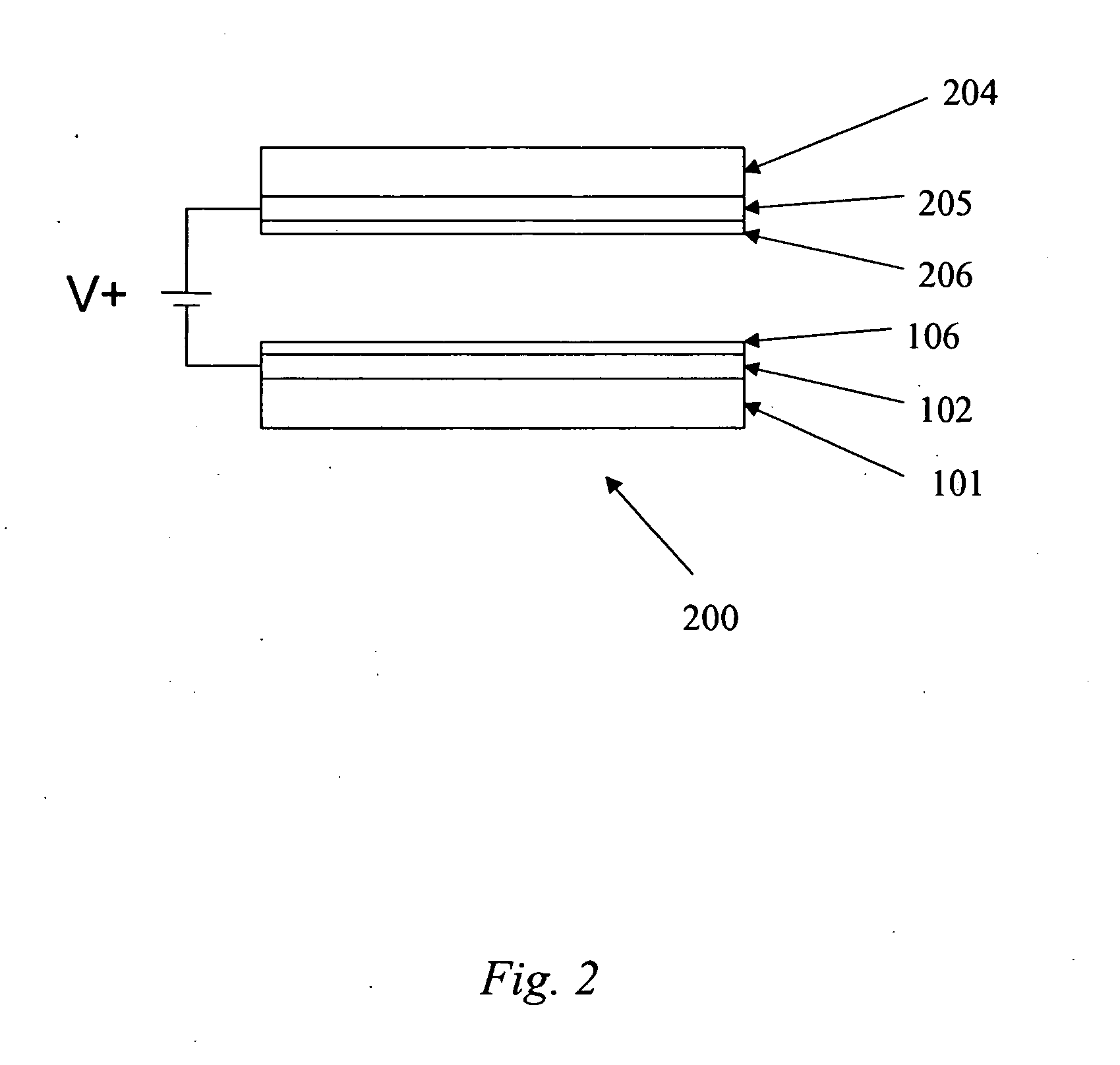

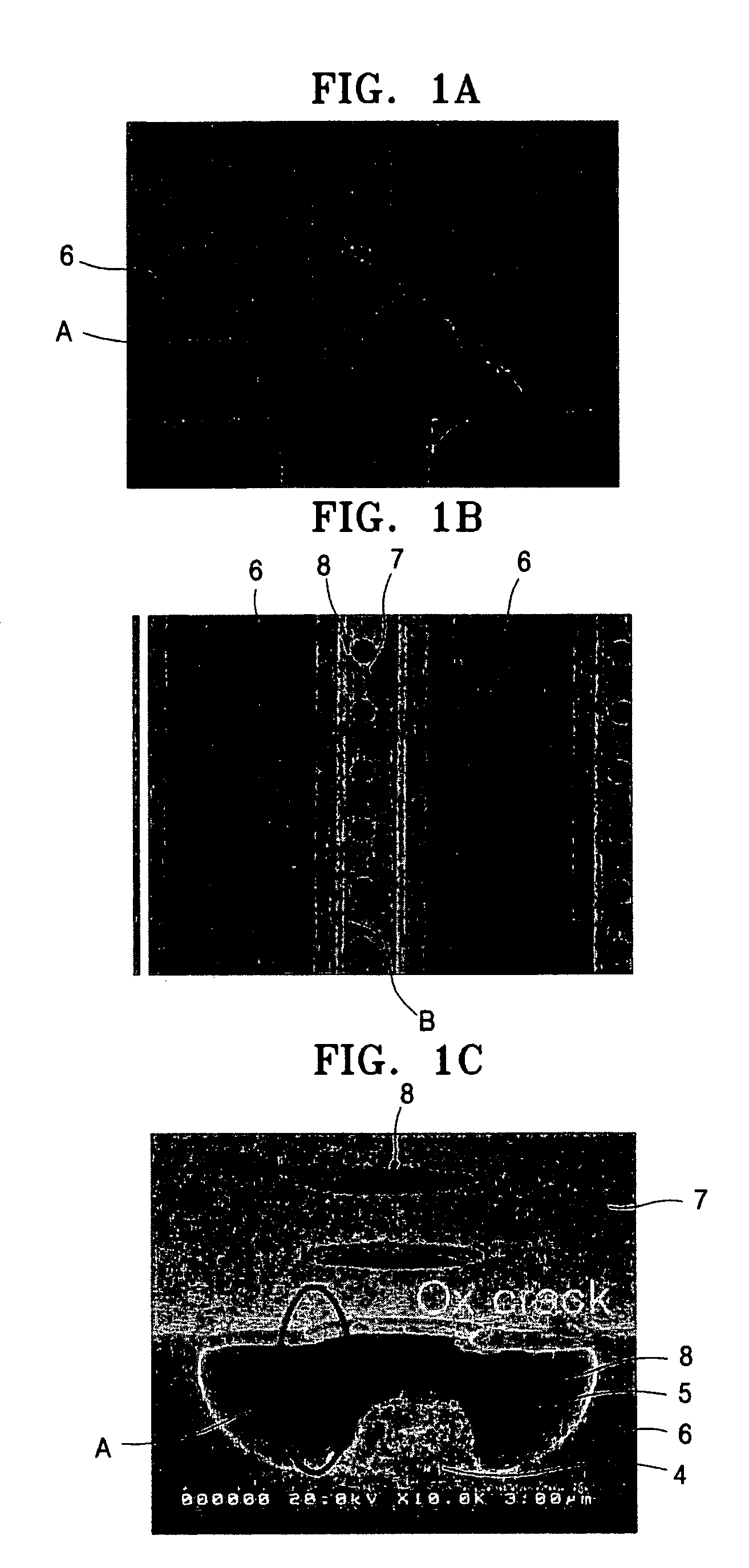

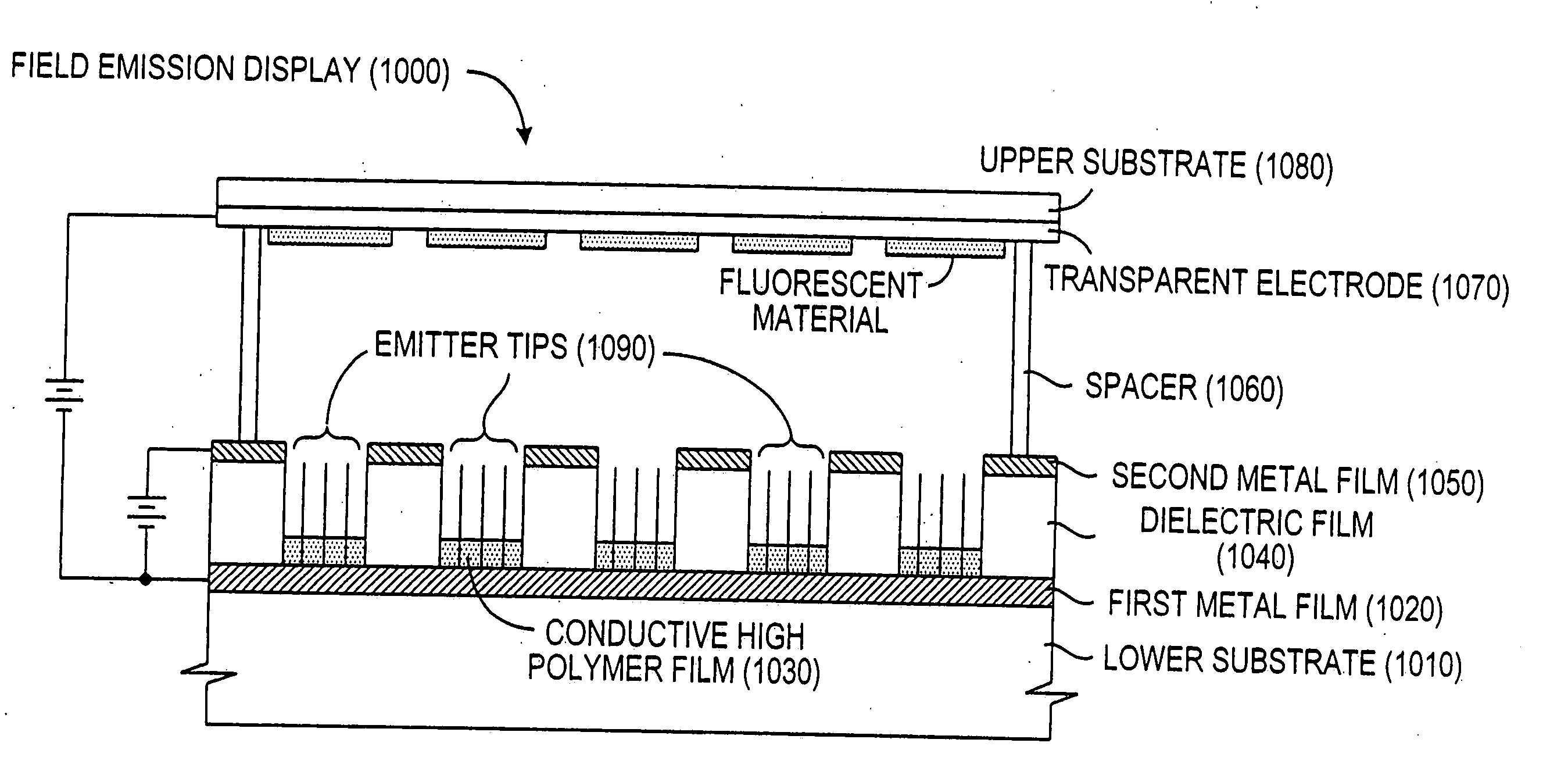

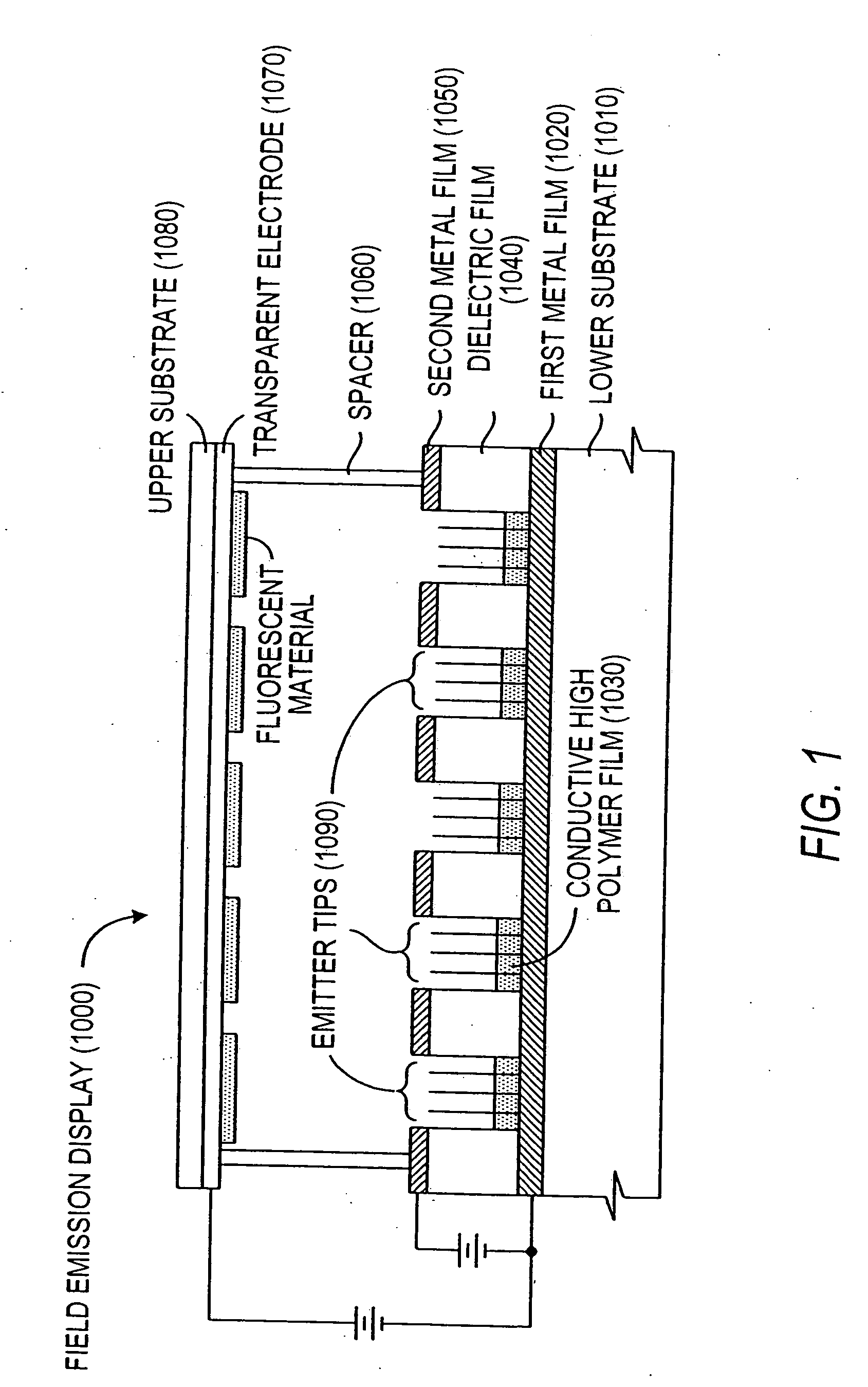

Enhanced field emission from carbon nanotubes mixed with particles

InactiveUS20040070326A1Discharge tube luminescnet screensNanoinformaticsField emission deviceCarbon nanotube

The present invention is directed toward cathodes and cathode materials comprising carbon nanotubes (CNTs) and particles. The present invention is also directed toward field emission devices comprising a cathode of the present invention, as well as methods for making these cathodes. In some embodiments, the cathode of the present invention is used in a field emission display. The invention also comprises a method of depositing a layer of CNTs and particles onto a substrate to form a cathode of the present invention, as well as a method of controlling the density of CNTs used in this mixed layer in an effort to optimize the field emission properties of the resulting layer for field emission display applications.

Owner:SAMSUNG ELECTRONICS CO LTD

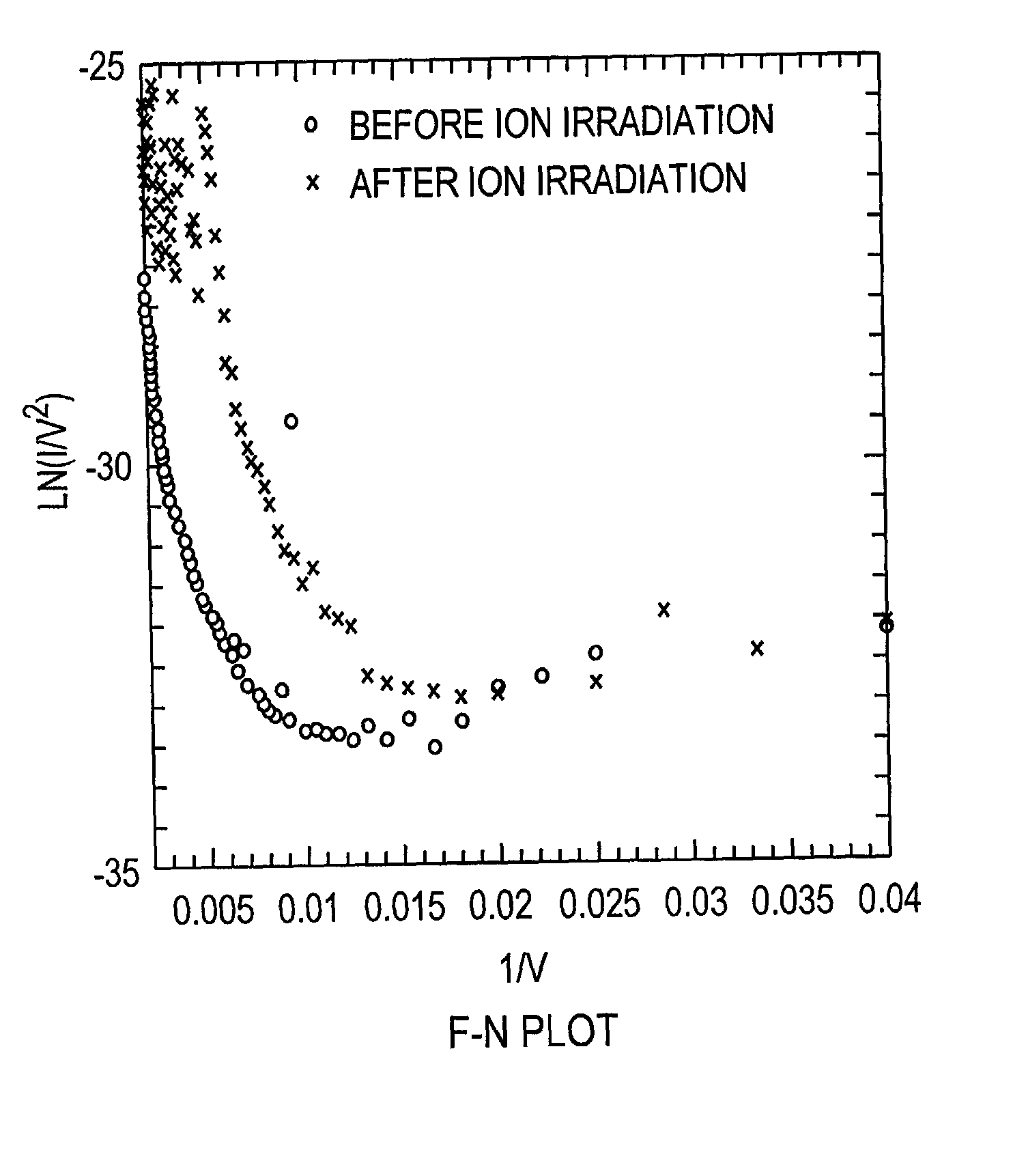

Field emission devices using ion bombarded carbon nanotubes

InactiveUS6911767B2Reduce voltageAccelerate emissionsCathode ray tubes/electron beam tubesNanoinformaticsField emission deviceOxygen

The present invention relates to a field emission device comprising an anode and a cathode, wherein said cathode includes carbon nanotubes which have been treated with an ion beam. The ion beam may be any ions, including gallium, hydrogen, helium, argon, carbon, oxygen, and xenon ions. The present invention also relates to a field emission cathode comprising carbon nanotubes, wherein the nanotubes have been treated with an ion beam. A method for treating the carbon nanotubes and for creating a field emission cathode is also disclosed. A field emission display device containing carbon nanotube which have been treated with an ion beam is further disclosed.

Owner:HYPERION CATALYSIS INT

Carbon nanotube array and method for forming same

ActiveUS20040184981A1Damage formationInhibition formationMaterial nanotechnologyFibre chemical featuresField emission deviceMetallic materials

A method for forming a carbon nanotube array using a metal substrate includes the following steps: providing a metal substrate (11); oxidizing the metal substrate to form an oxidized layer (21) thereon; depositing a catalyst layer (31) on the oxidized layer; introducing a carbon source gas; and thus forming a carbon nanotube array (61) extending from the metal substrate. Generally, any metallic material can be used as the metal substrate. Various carbon nanotube arrays formed using various metal substrates can be incorporated into a wide variety of high power electronic device applications such as field emission devices (FEDs), electron guns, and so on. Carbon nanotubes formed using any of a variety of metal substrates are well aligned, and uniformly extend in a direction substantially perpendicular to the metal substrate.

Owner:TSINGHUA UNIV +1

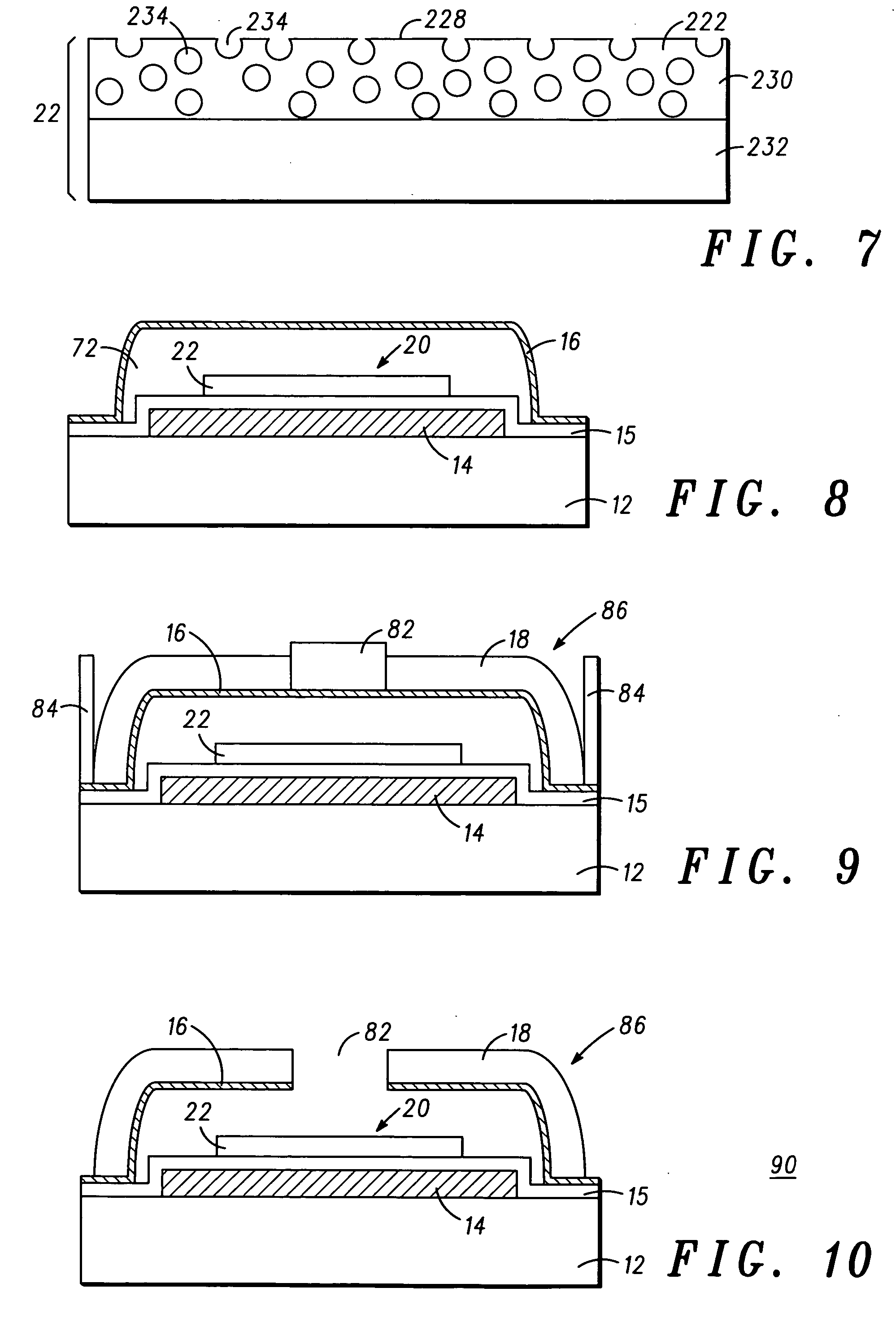

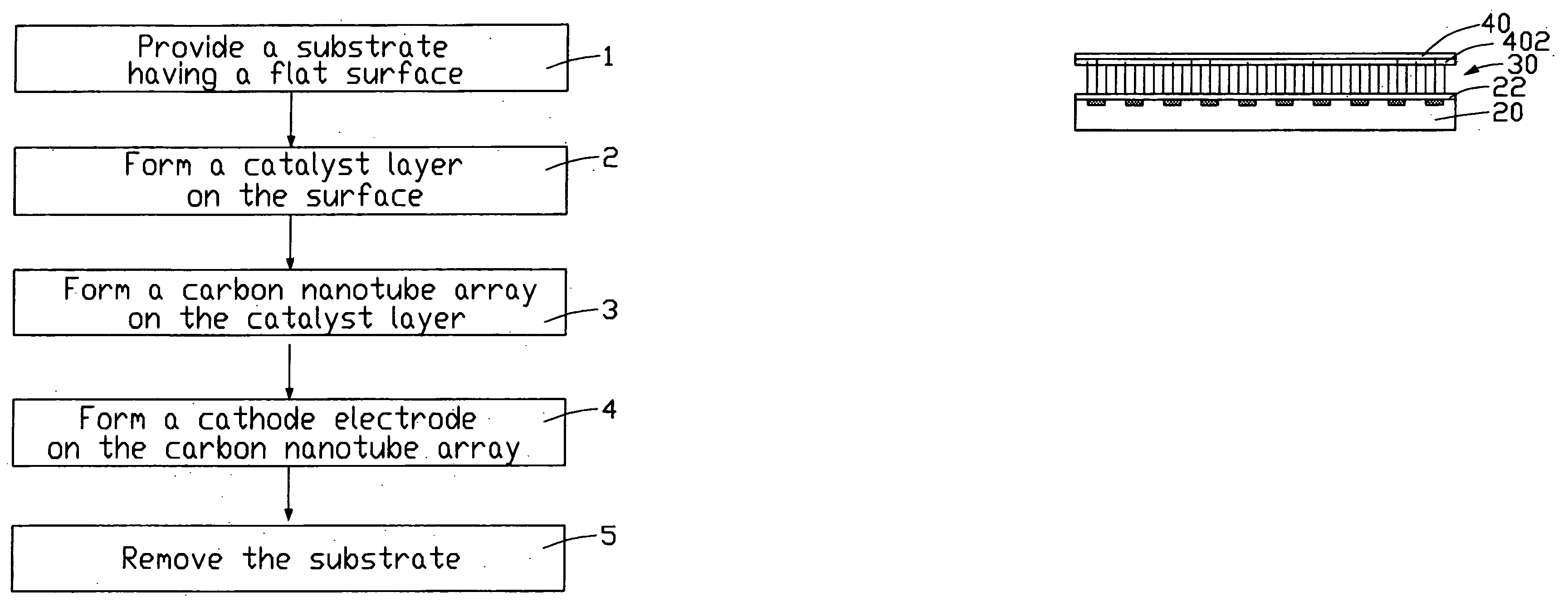

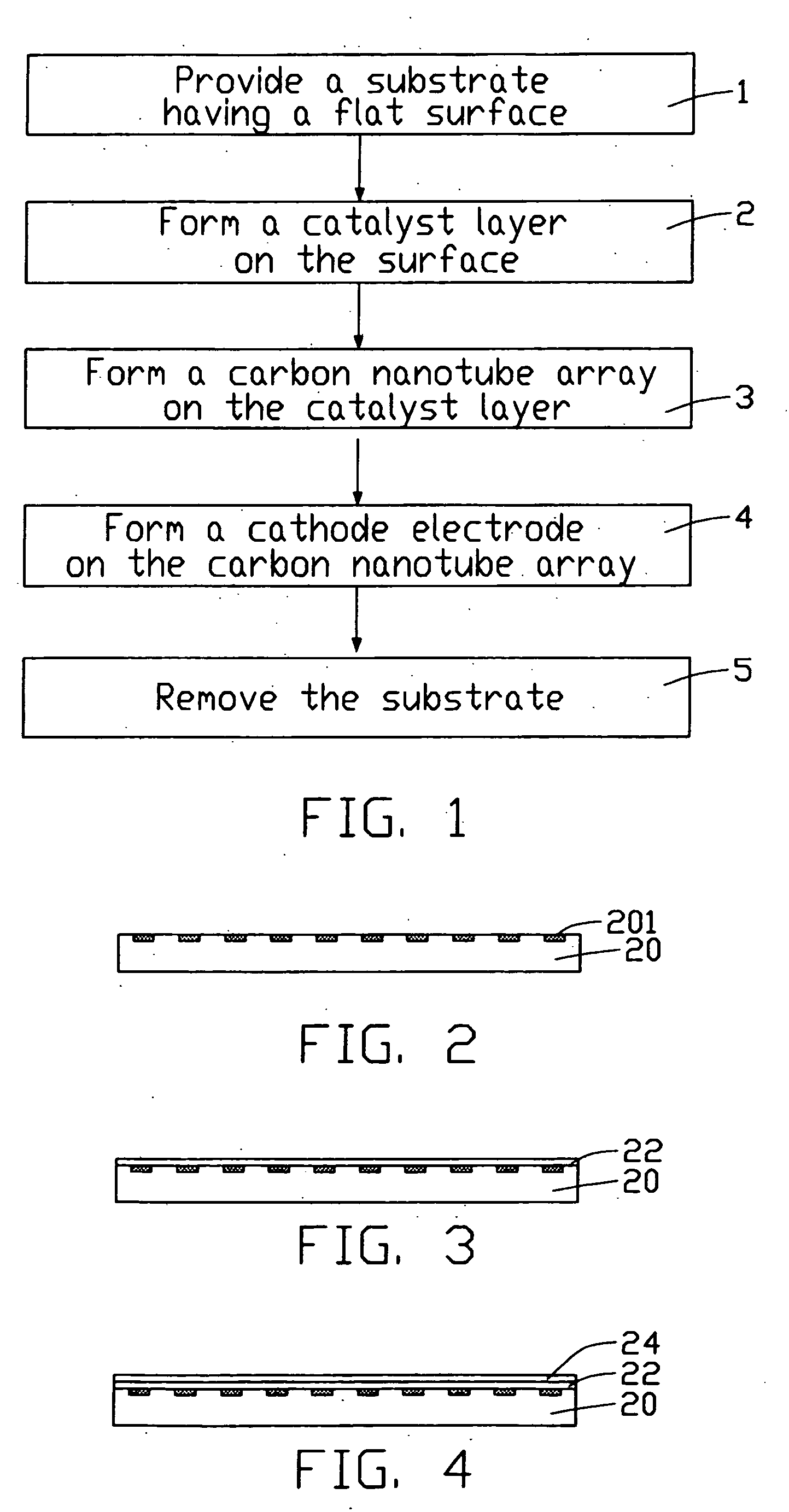

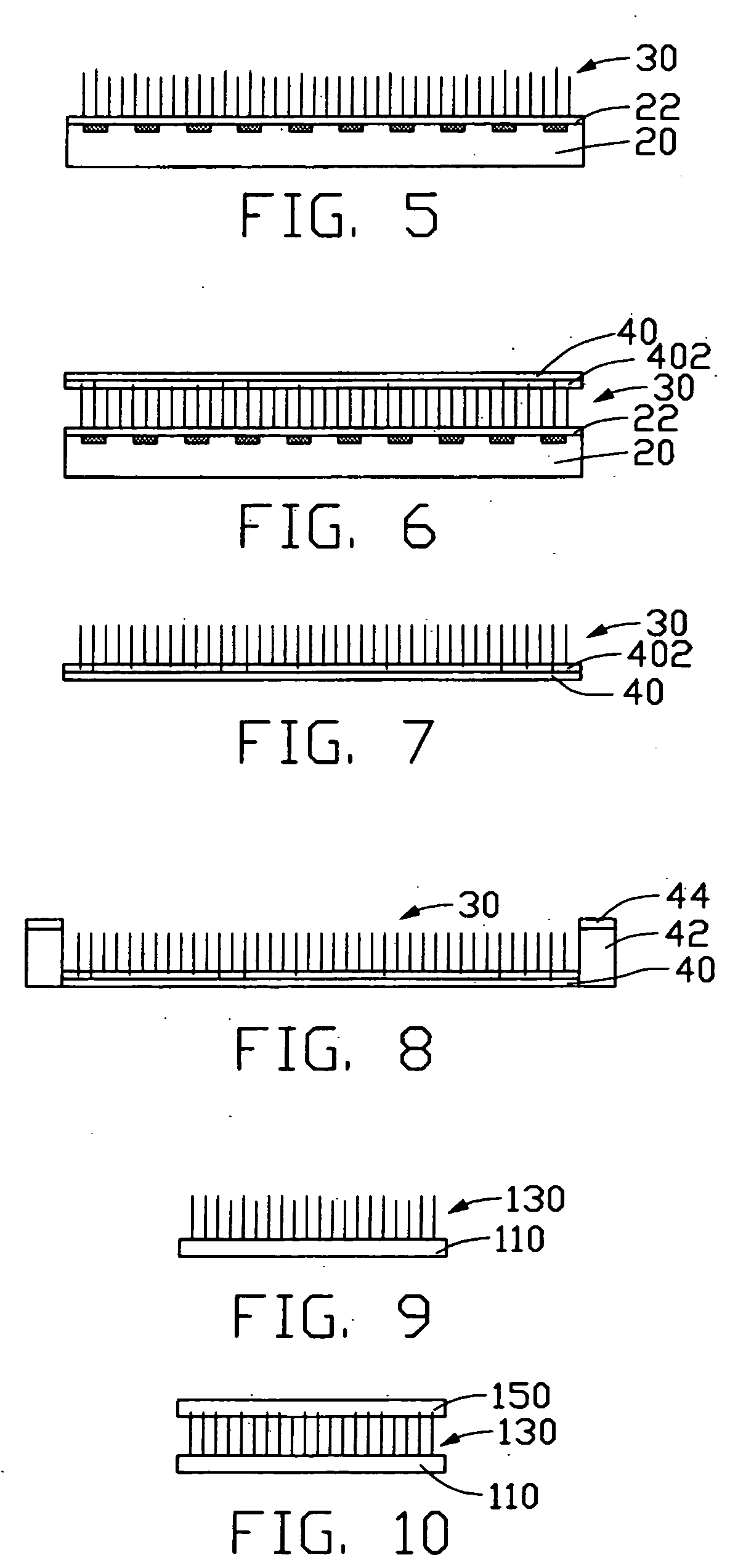

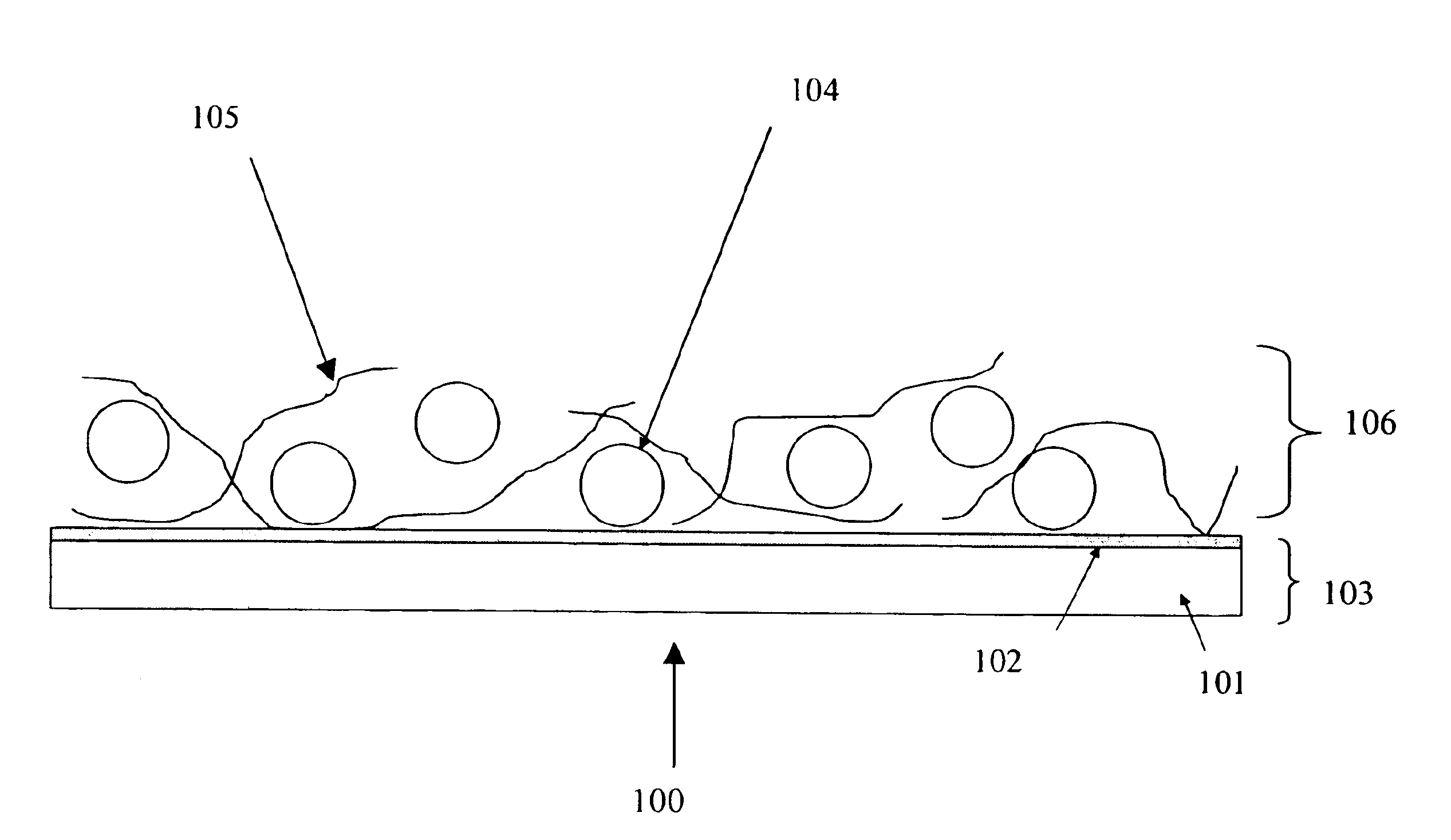

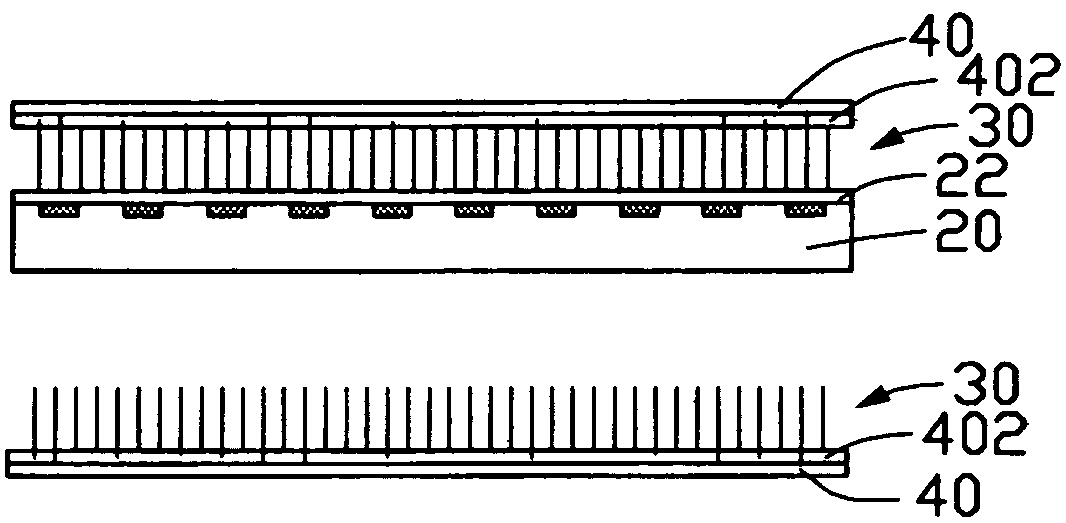

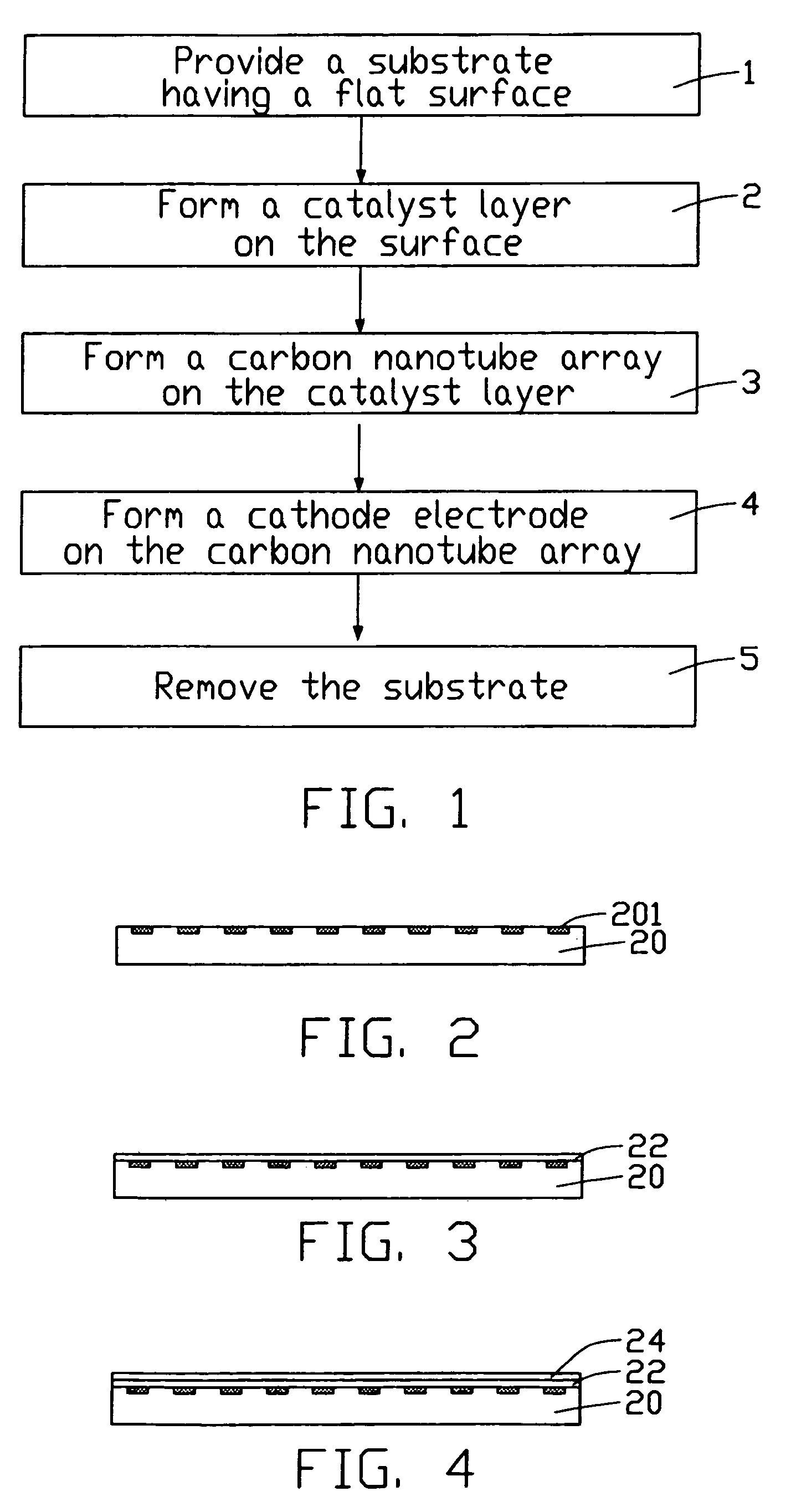

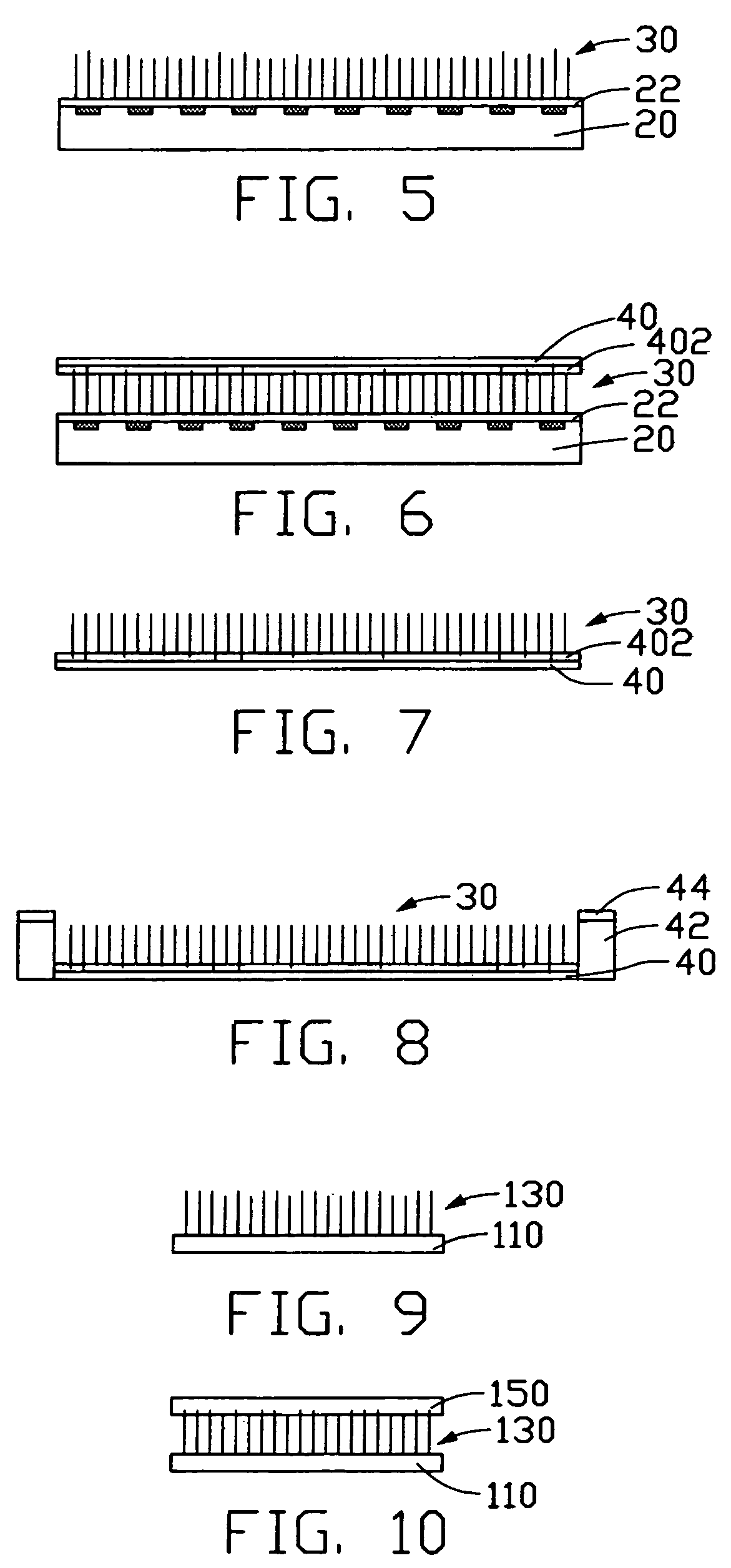

Method for making carbon nanotube-based field emission device

ActiveUS20040209385A1Surface cleaningEnhanced electron emission capabilityMaterial nanotechnologyElectric discharge tubesField emission deviceCarbon nanotube

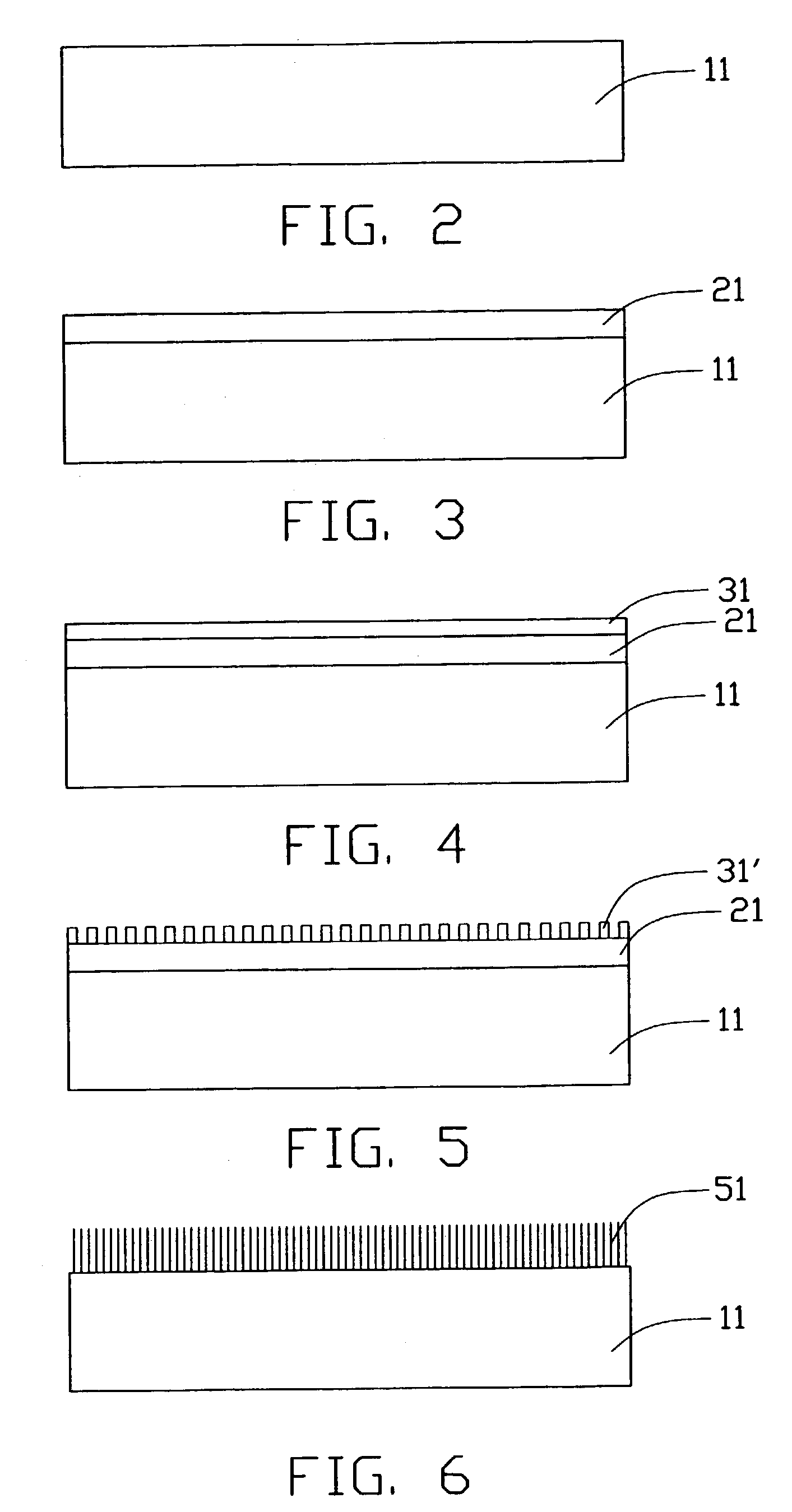

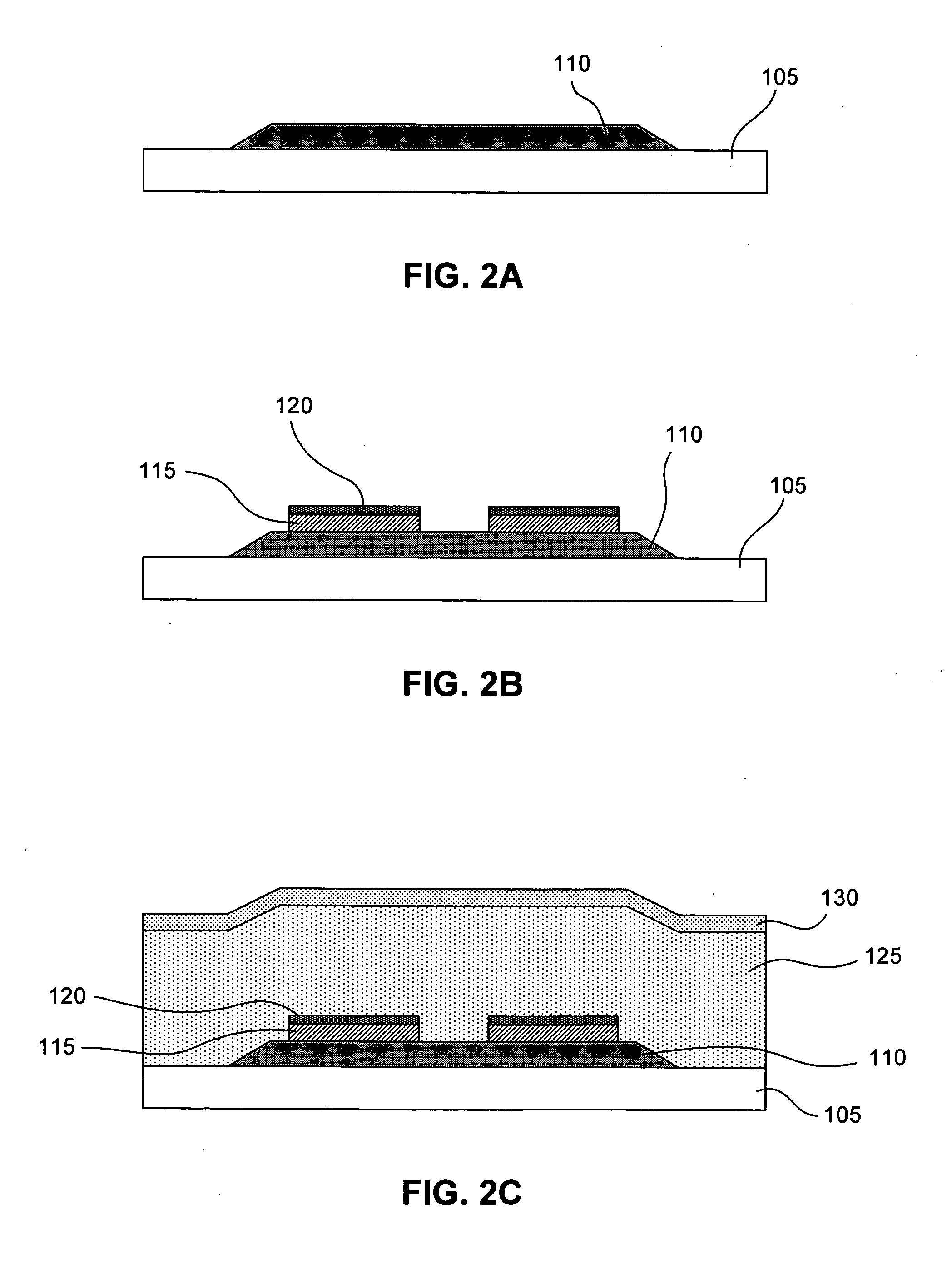

A preferred method for making a carbon nanotube-based field emission device in accordance with the invention includes the following steps: providing a substrate (22) with a surface; depositing a catalyst layer (24) on a predetermined area on the surface of the substrate; forming a carbon nanotube array (30) extending from the predetermined area; forming a cathode electrode (40) on top of the carbon nanotube array; and removing the substrate so as to expose the carbon nanotube array.

Owner:TSINGHUA UNIV +1

Enhanced field emission from carbon nanotubes mixed with particles

InactiveUS6798127B2Discharge tube luminescnet screensLamp incadescent bodiesField emission deviceCarbon nanotube

The present invention is directed toward cathodes and cathode materials comprising carbon nanotubes (CNTs) and particles. The present invention is also directed toward field emission devices comprising a cathode of the present invention, as well as methods for making these cathodes. In some embodiments, the cathode of the present invention is used in a field emission display. The invention also comprises a method of depositing a layer of CNTs and particles onto a substrate to form a cathode of the present invention, as well as a method of controlling the density of CNTs used in this mixed layer in an effort to optimize the field emission properties of the resulting layer for field emission display applications.

Owner:SAMSUNG ELECTRONICS CO LTD

Enhanced field emission from carbon nanotubes mixed with particles

ActiveUS20050001528A1Optimizing electron field emission performanceEmission reductionDischarge tube luminescnet screensNanoinformaticsField emission deviceCarbon nanotube

The present invention is directed toward cathodes and cathode materials comprising carbon nanotubes (CNTs) and particles. The present invention is also directed toward field emission devices comprising a cathode of the present invention, as well as methods for making these cathodes. In some embodiments, the cathode of the present invention is used in a field emission display. The invention also comprises a method of depositing a layer of CNTs and particles onto a substrate to form a cathode of the present invention, as well as a method of controlling the density of CNTs used in this mixed layer in an effort to optimize the field emission properties of the resulting layer for field emission display applications.

Owner:SAMSUNG ELECTRONICS CO LTD

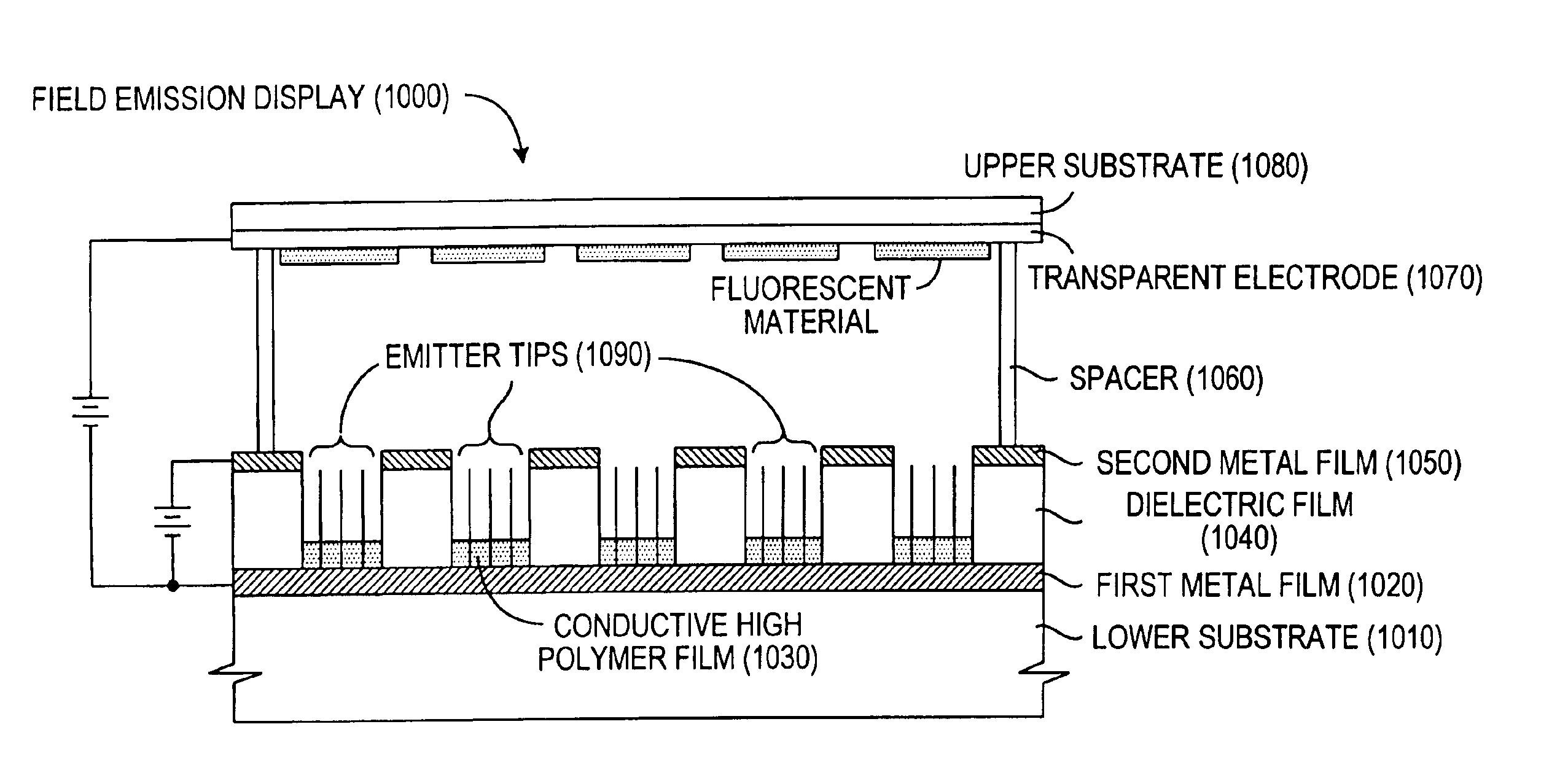

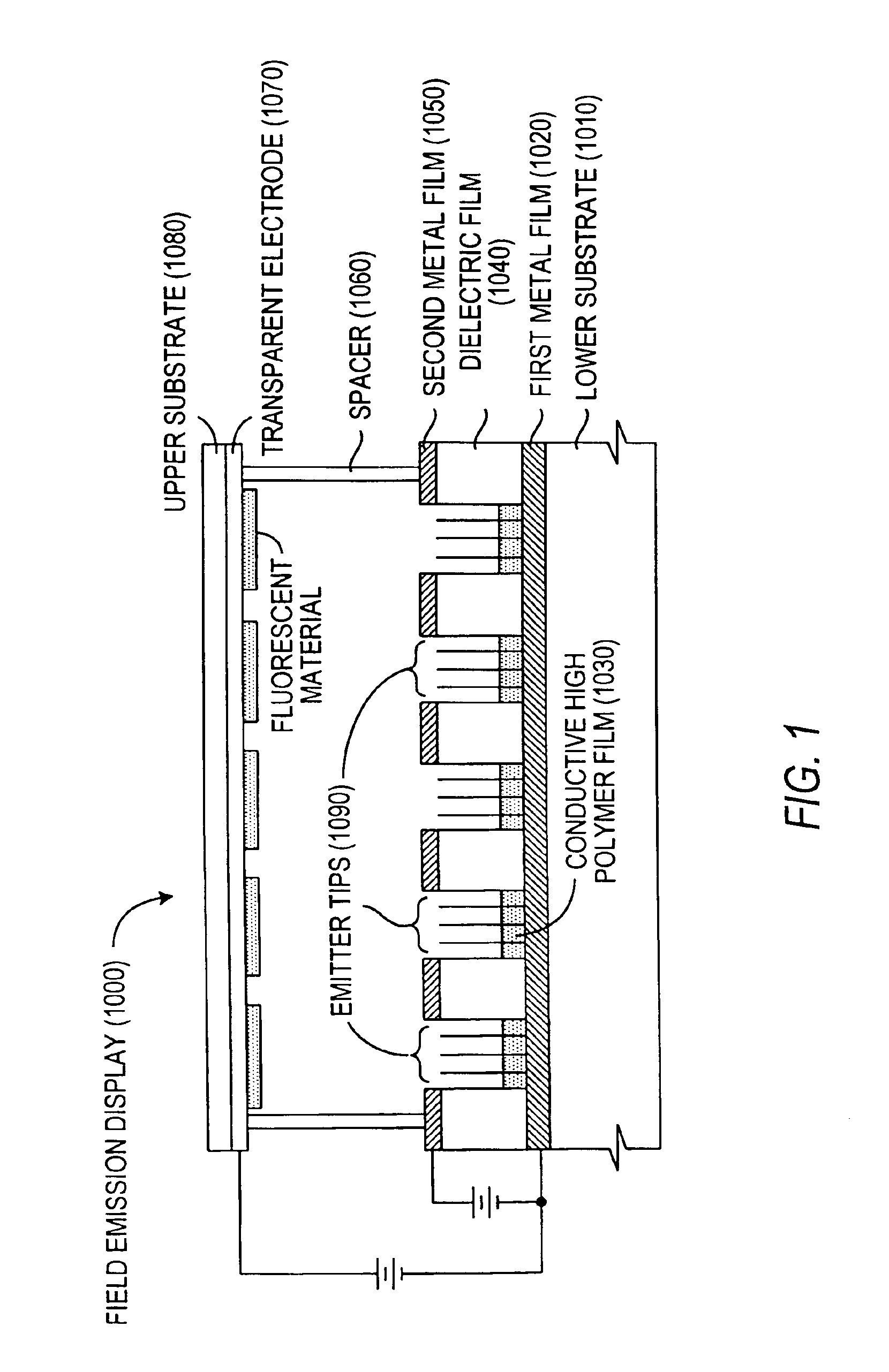

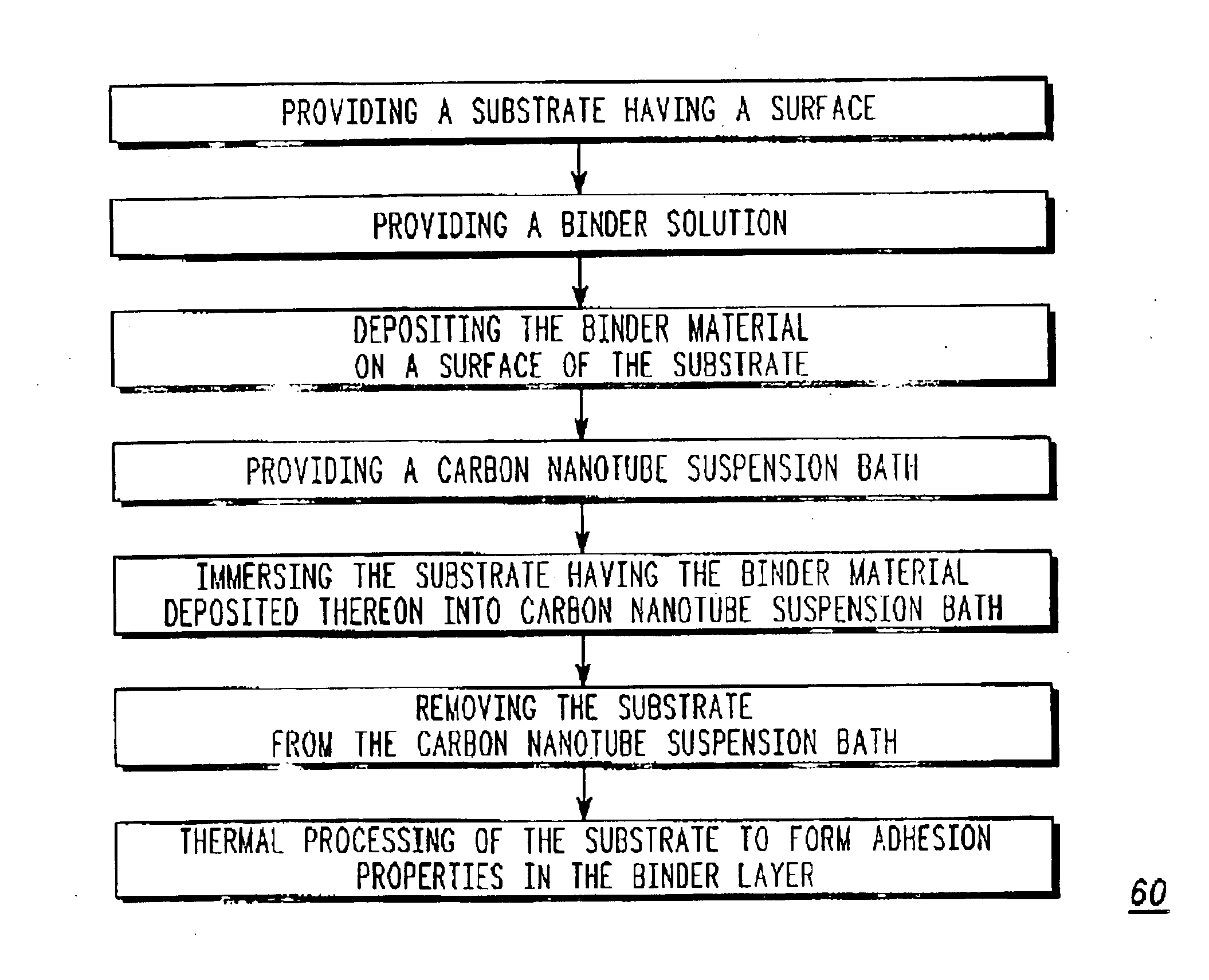

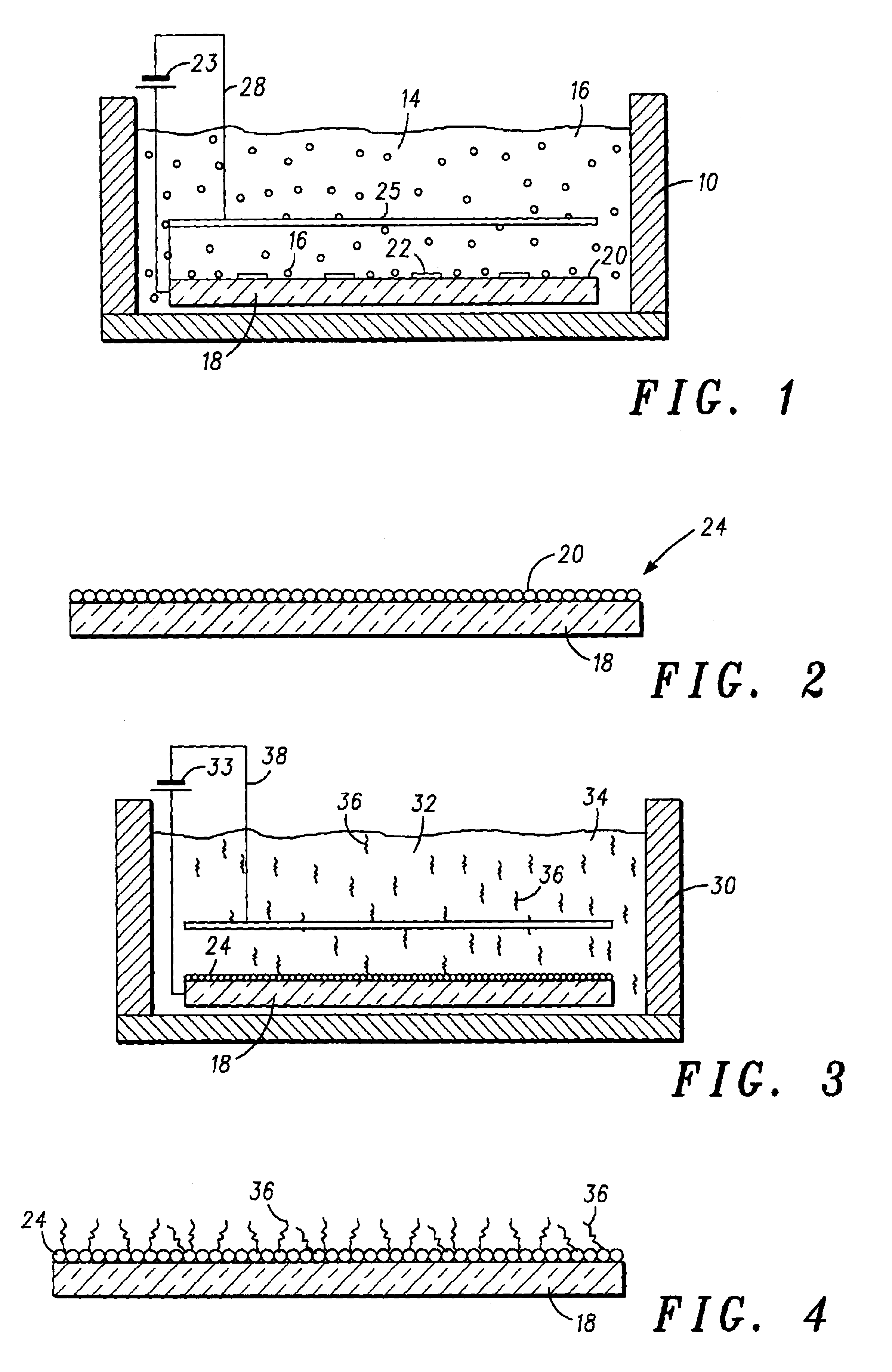

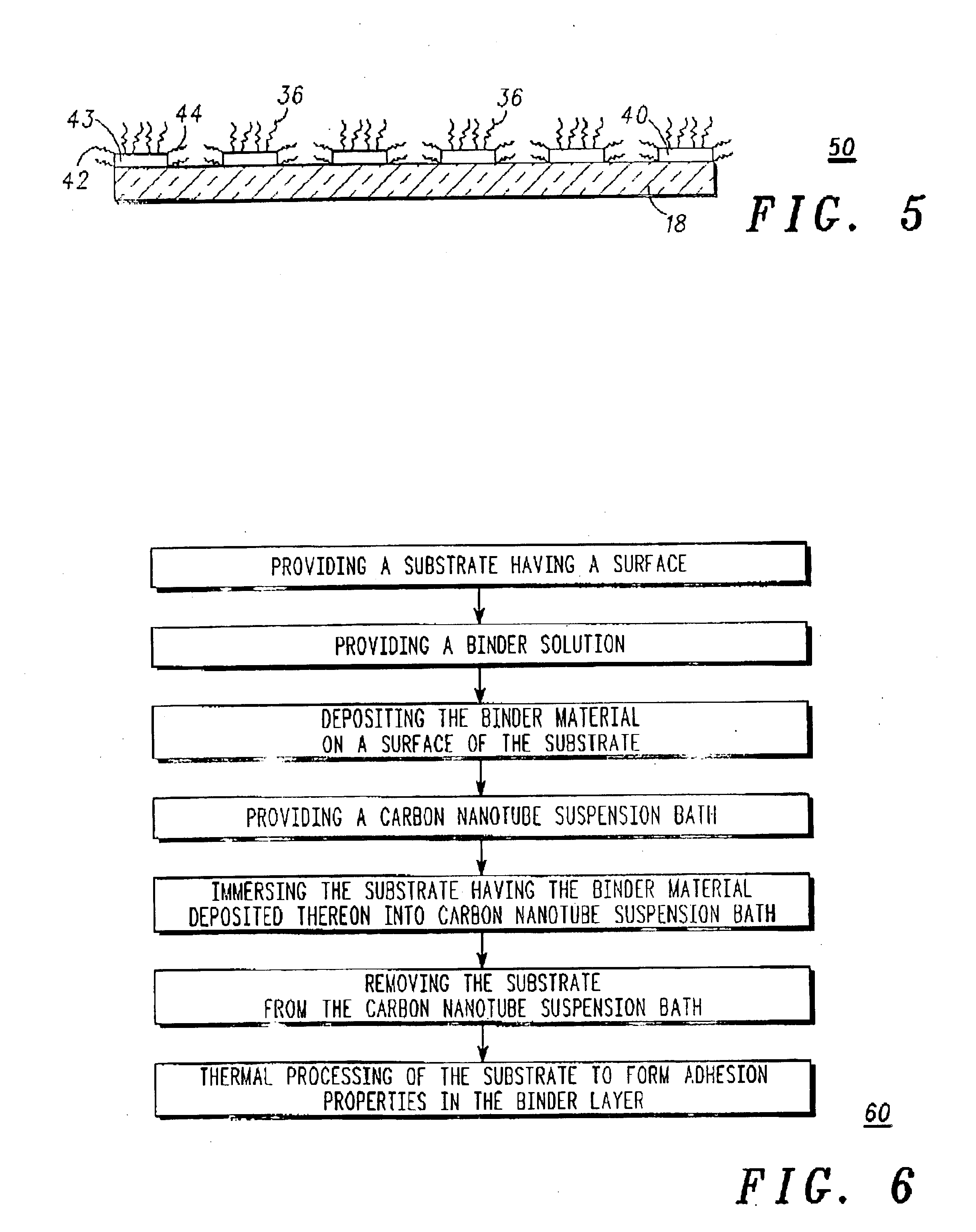

FED cathode structure using electrophoretic deposition and method of fabrication

InactiveUS6902658B2High densityVolume/mass flow measurementNanoinformaticsField emission deviceElectrophoresis

A method of fabricating a field emission device cathode using electrophoretic deposition of carbon nanotubes in which a separate step of depositing a binder material onto a substrate, is performed prior to carbon nanotube particle deposition. First, a binder layer is deposited on a substrate from a solution containing a binder material. The substrate having the binder material deposited thereon is then transferred into a carbon nanotube suspension bath allowing for coating of the carbon nanotube particles onto the substrate. Thermal processing of the coating transforms the binder layer properties which provides for the adhesion of the carbon nanotube particles to the binder material.

Owner:MOTOROLA SOLUTIONS INC

Field emission devices using ion bombarded carbon nanotubes

InactiveUS20030044519A1Easy to disassembleReduce voltageCathode ray tubes/electron beam tubesNanoinformaticsField emission deviceOxygen

The present invention relates to a field emission device comprising an anode and a cathode, wherein said cathode includes carbon nanotubes which have been treated with an ion beam. The ion beam may be any ions, including gallium, hydrogen, helium, argon, carbon, oxygen, and xenon ions. The present invention also relates to a field emission cathode comprising carbon nanotubes, wherein the nanotubes have been treated with an ion beam. A method for treating the carbon nanotubes and for creating a field emission cathode is also disclosed. A field emission display device containing carbon nanotube which have been treated with an ion beam is further disclosed.

Owner:HYPERION CATALYSIS INT

Cathode structure for field emission device

InactiveUS20060066217A1Avoid and reduce arcingReduce and eliminate electrical shortingDischarge tube luminescnet screensCathode ray tubes/electron beam tubesField emission deviceOptoelectronics

To avoid arcing and shorting within a field emission device, a bottom portion of a gate electrode is protected with an insulating material to avoid or reduce arcing among the electrodes and the electron emitters in the device. In a method for manufacturing such a field emission device, an emitter hole is formed through an insulating layer such that a portion of the gate electrode overhangs the hole and is protected on its underside by the insulating layer. The device can be used in display systems, such as CNT flat panel displays.

Owner:ARROW CAPITAL +1

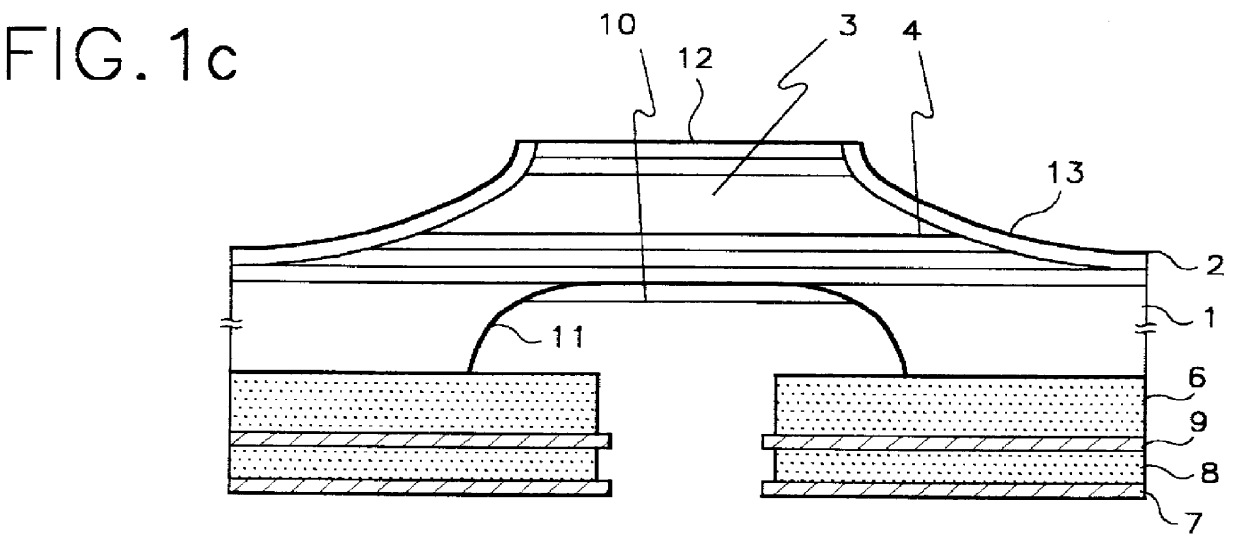

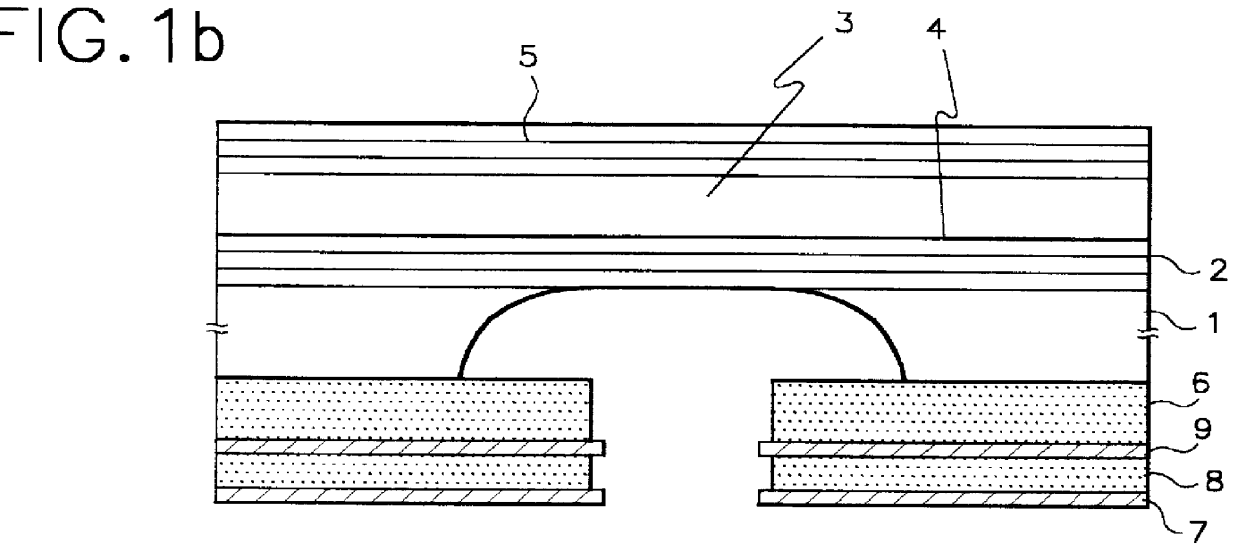

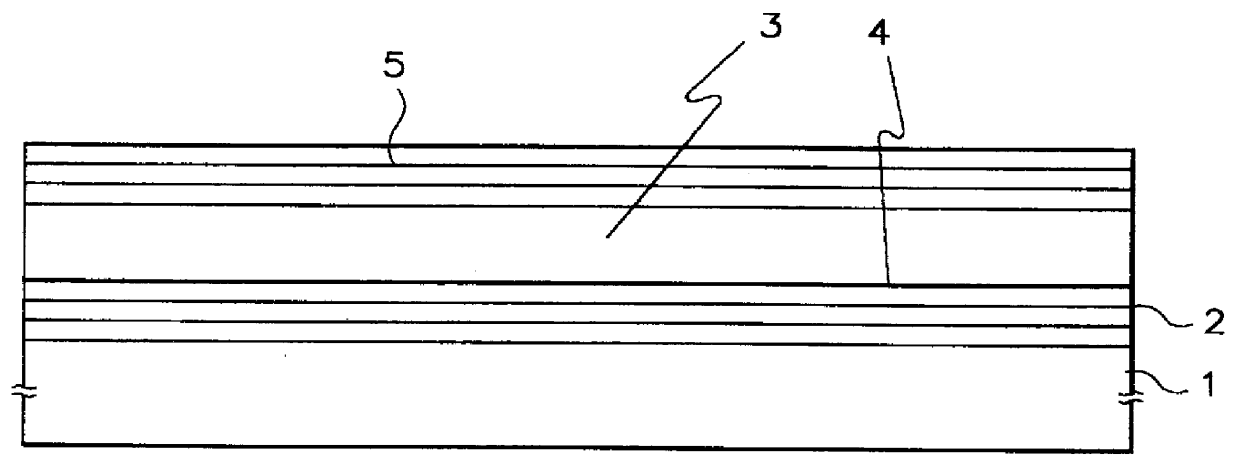

Short-wavelength optoelectronic device including field emission device and optical device and its fabricating method

InactiveUS6139760AEfficient productionHigh energyExcitation process/apparatusOptical articlesField emission deviceOpto electronic

Provided with a method of fabricating a 200-250 nm short-wavelength optoelectronic device, which has a combination of an optical device with a plurality of acceleration electrodes and a field emission device with a plurality of acceleration electrodes, from a semiconductor having a 5-6 eV energe band gap, based on a principle that an electron-hole pair is produced using a highly energetic electron which is injected from a field emission device, and short-wavelength photons are emitted when the electron recombines with the hole and confined in a quantum well to emit a light corresponding to the energy level of the quantum well, thereby eliminating the need of using dopants for forming n-p junctions in the semiconductor and achieving high efficiency in terms of energy because highly energetic electrons result in one or more electron-hole pairs.

Owner:ELECTRONICS & TELECOMM RES INST

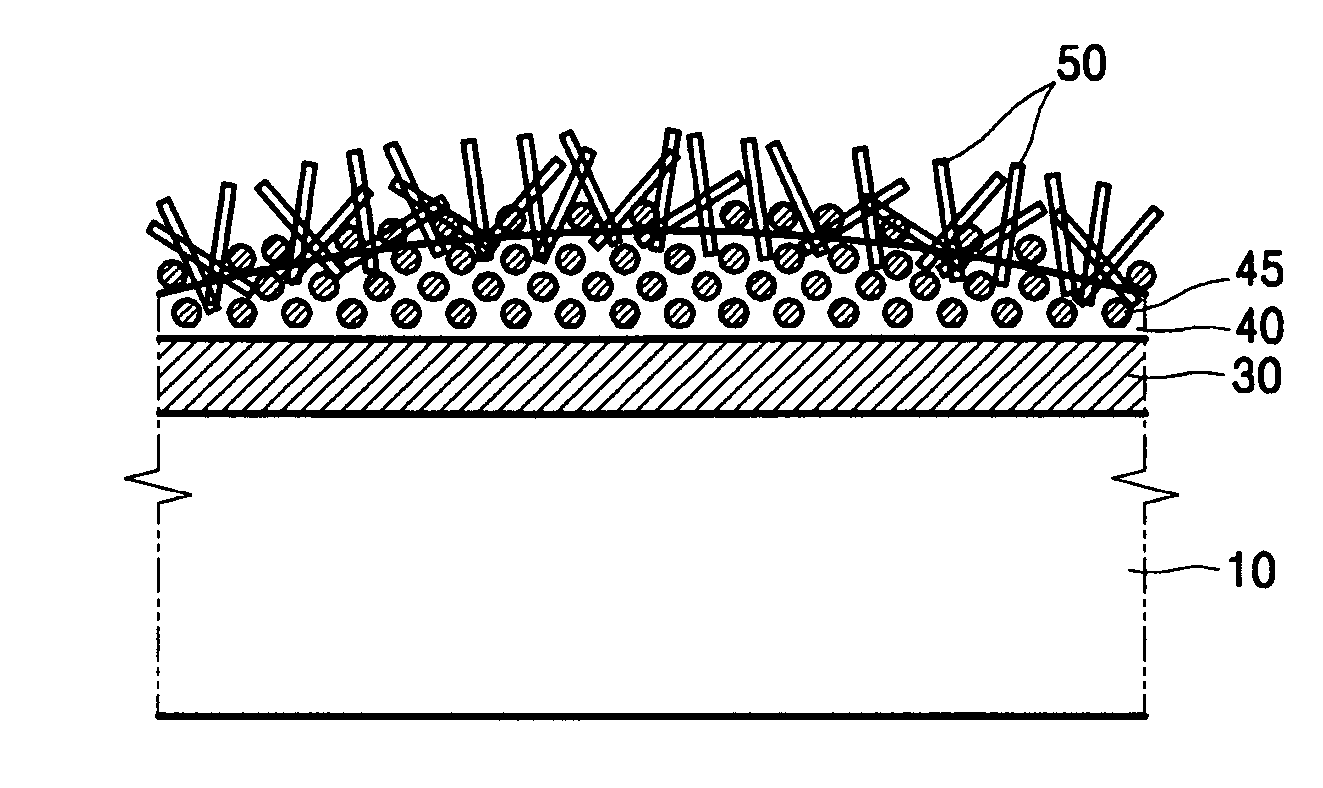

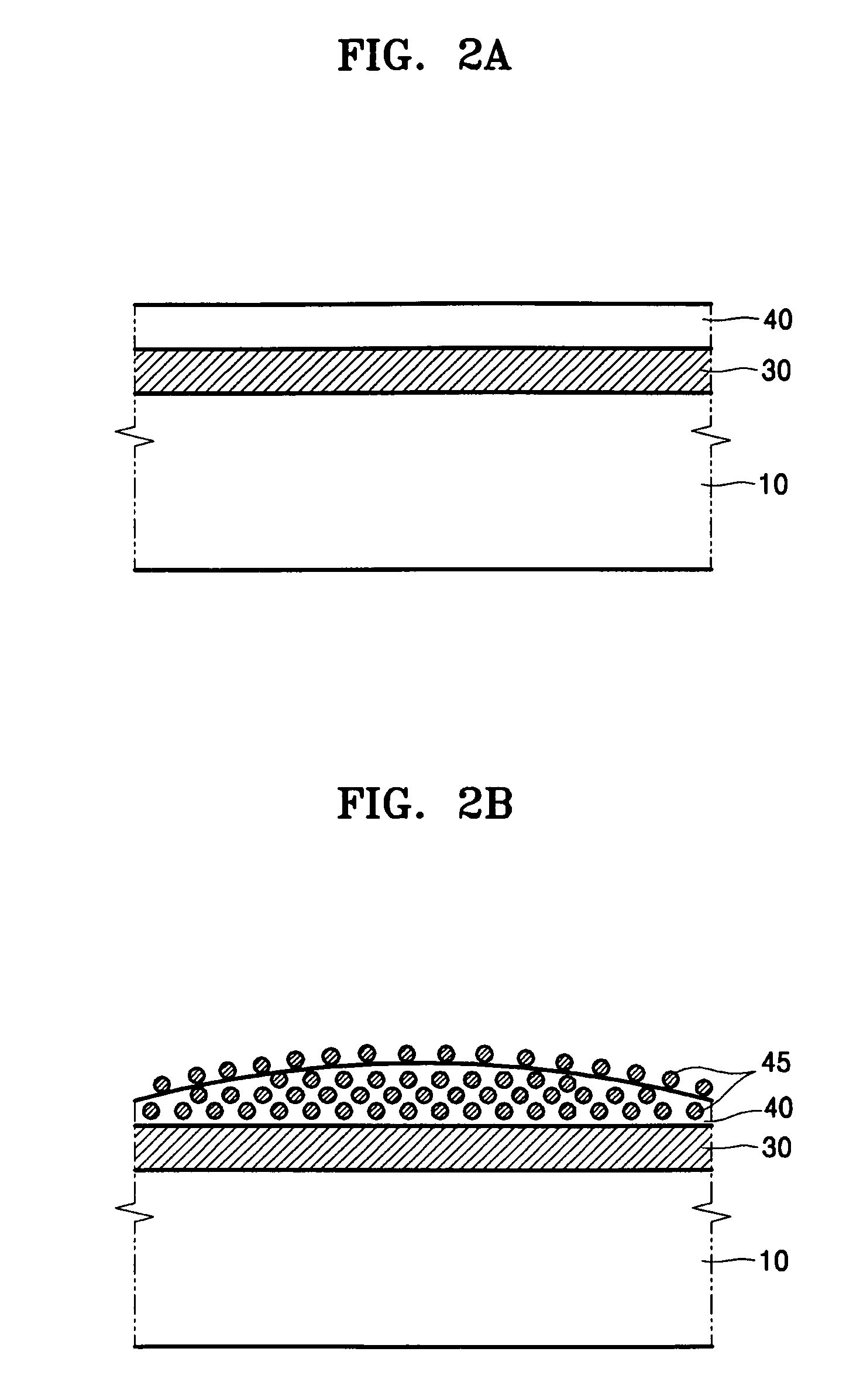

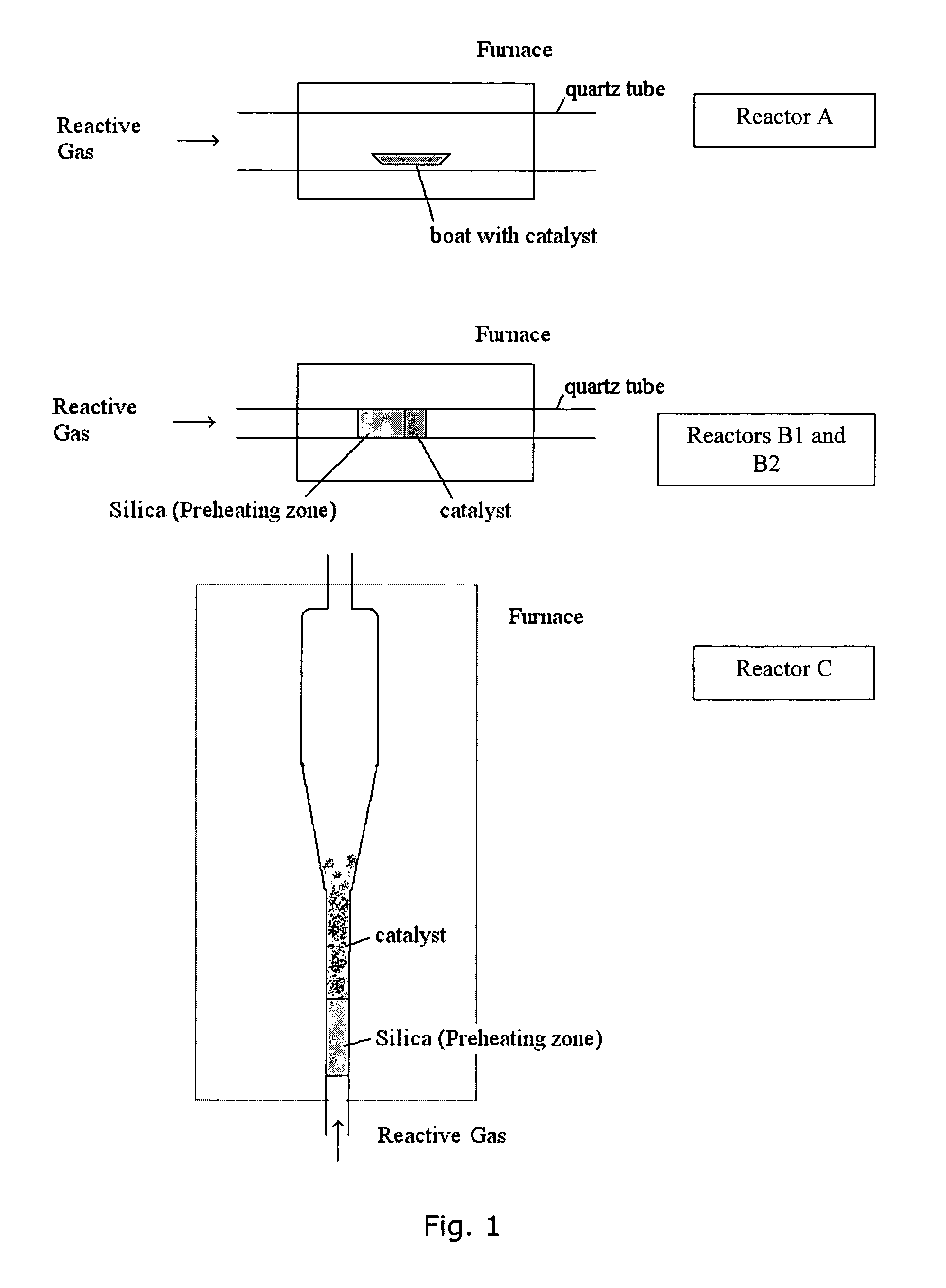

Method of growing carbon nanotubes and method of manufacturing field emission device using the same

InactiveUS7479052B2Superior field emission characteristicLow costMaterial nanotechnologyCarbon compoundsField emission deviceVolumetric Mass Density

Methods of growing carbon nanotubes and manufacturing a field emission device using the carbon nanotubes are provided. The method of growing carbon nanotubes includes the steps of preparing a substrate, forming a catalyst metal layer on the substrate to promote the growing of the carbon nanotubes, forming an amorphous carbon layer on the catalyst metal layer where the amorphous carbon layer partially covers the catalyst metal layer, and growing the carbon nanotubes from a surface of the catalyst metal layer. The carbon nanotubes are grown in a portion of the surface of the catalyst metal layer that is not covered by the amorphous carbon layer. In the method of growing carbon nanotubes, the carbon nanotubes are grow at a low temperature. A density of carbon nanotubes can be controlled to improve field emission characteristics of an emitter of a field emission device.

Owner:SAMSUNG SDI CO LTD

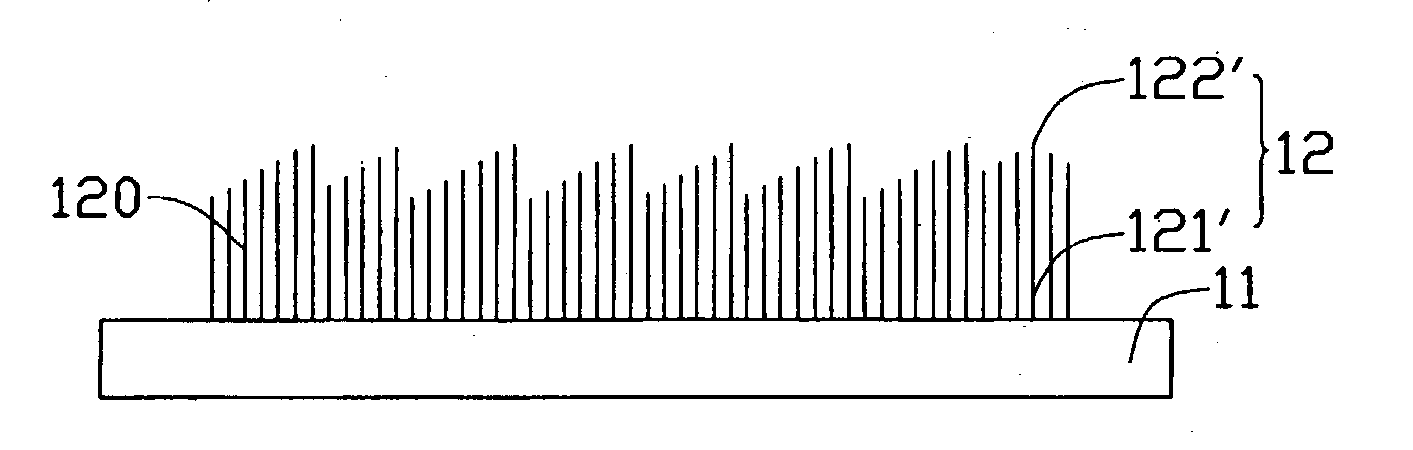

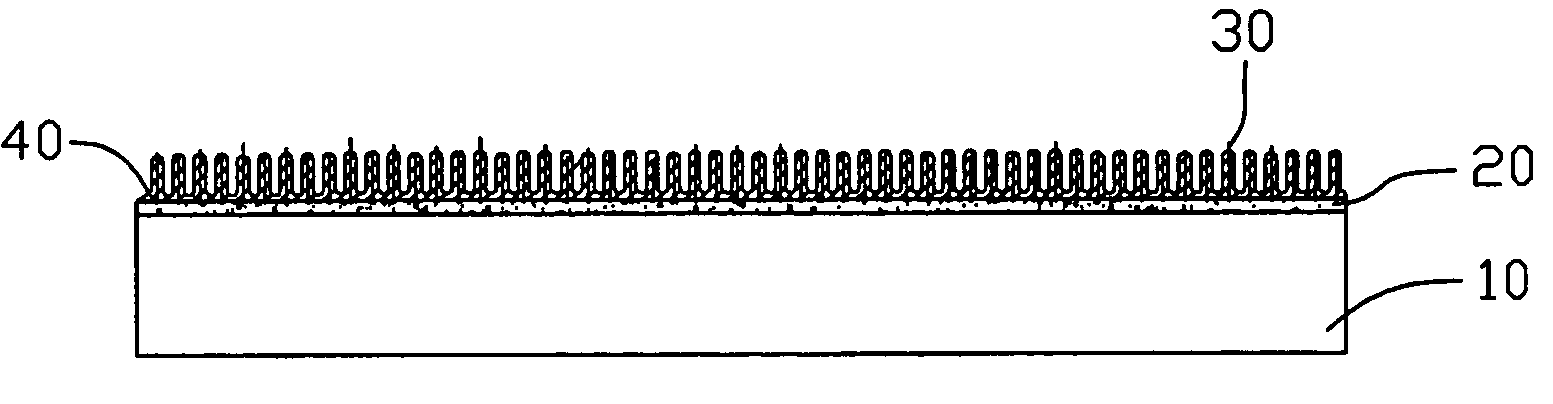

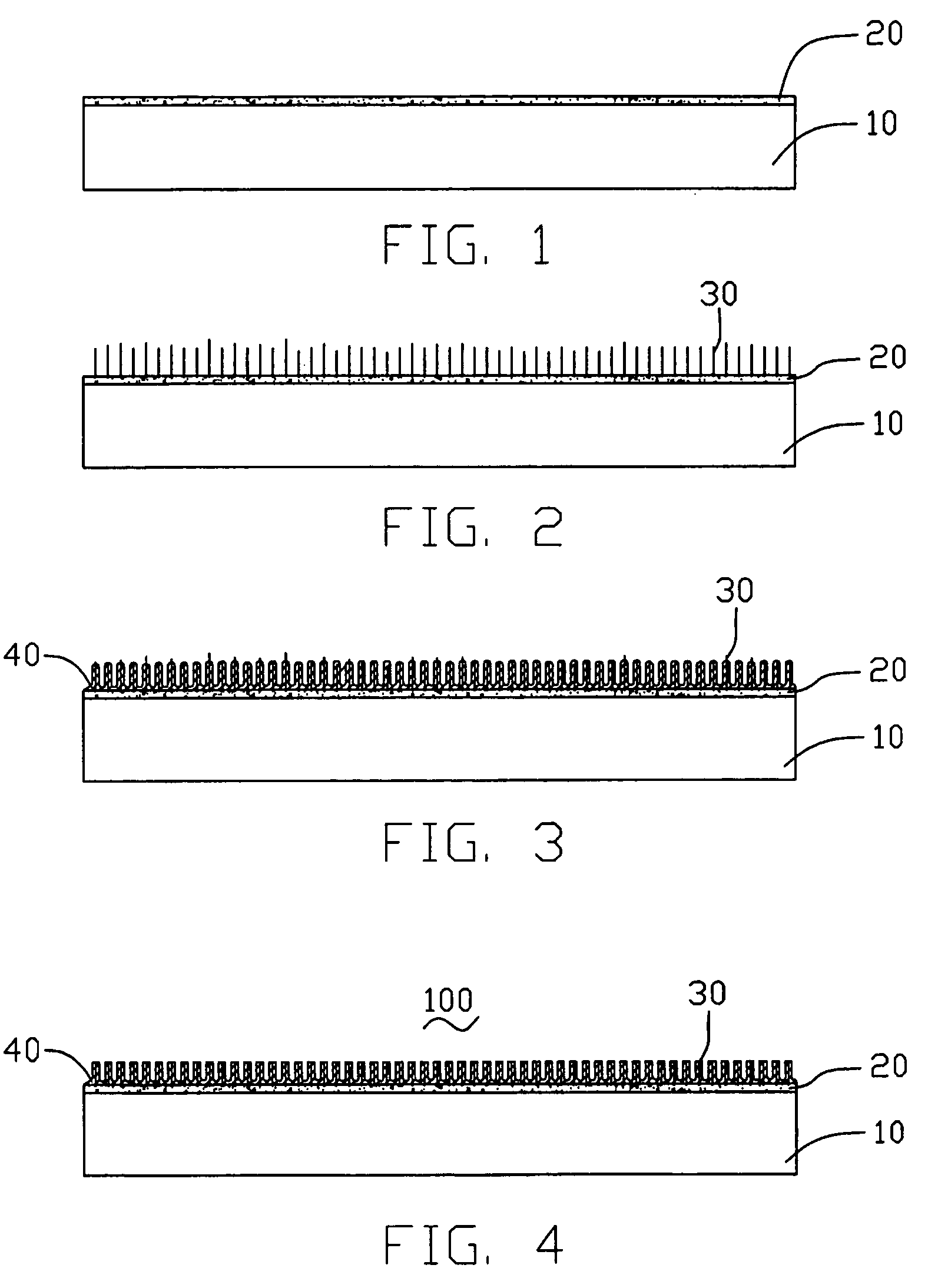

Field emission device

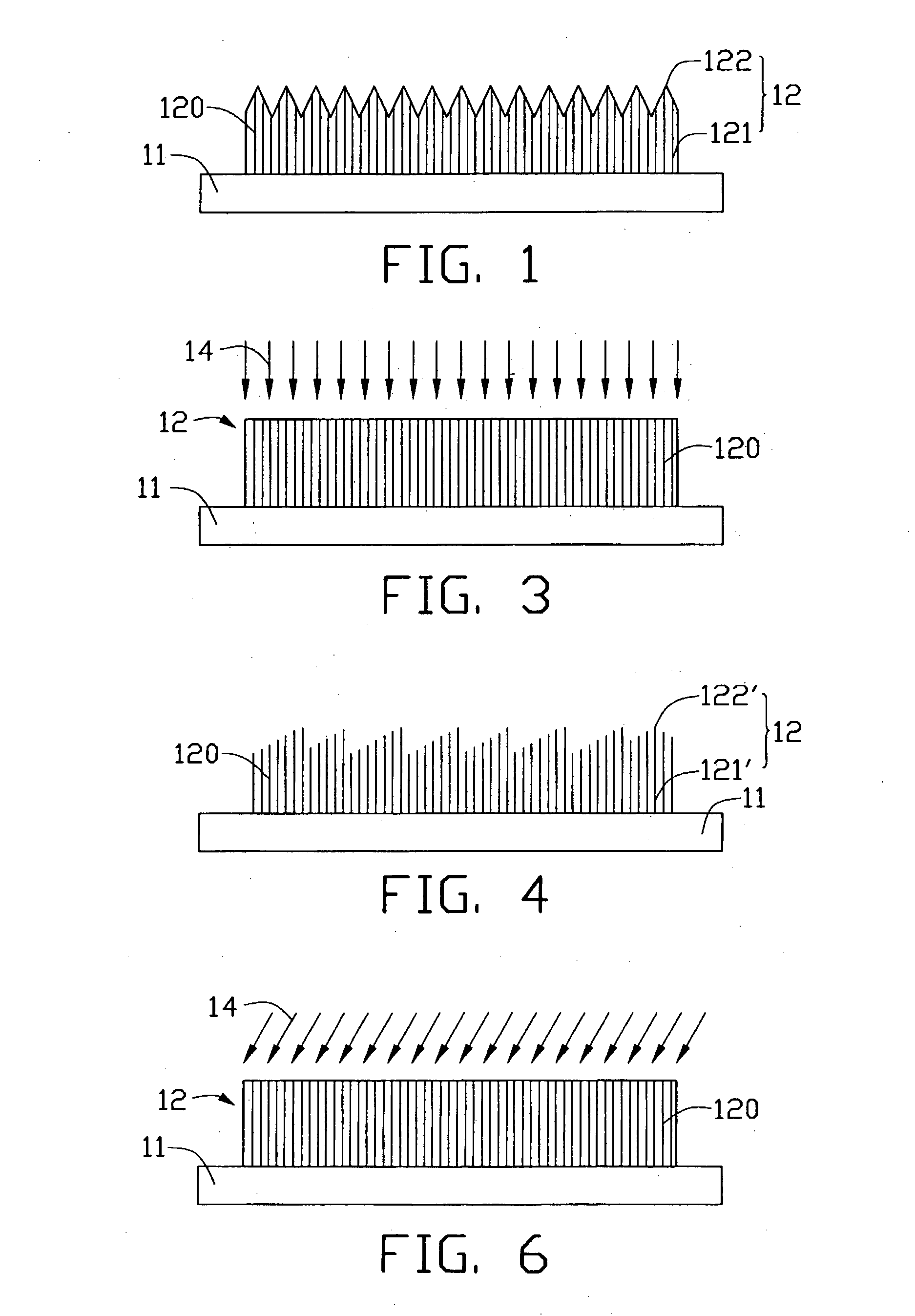

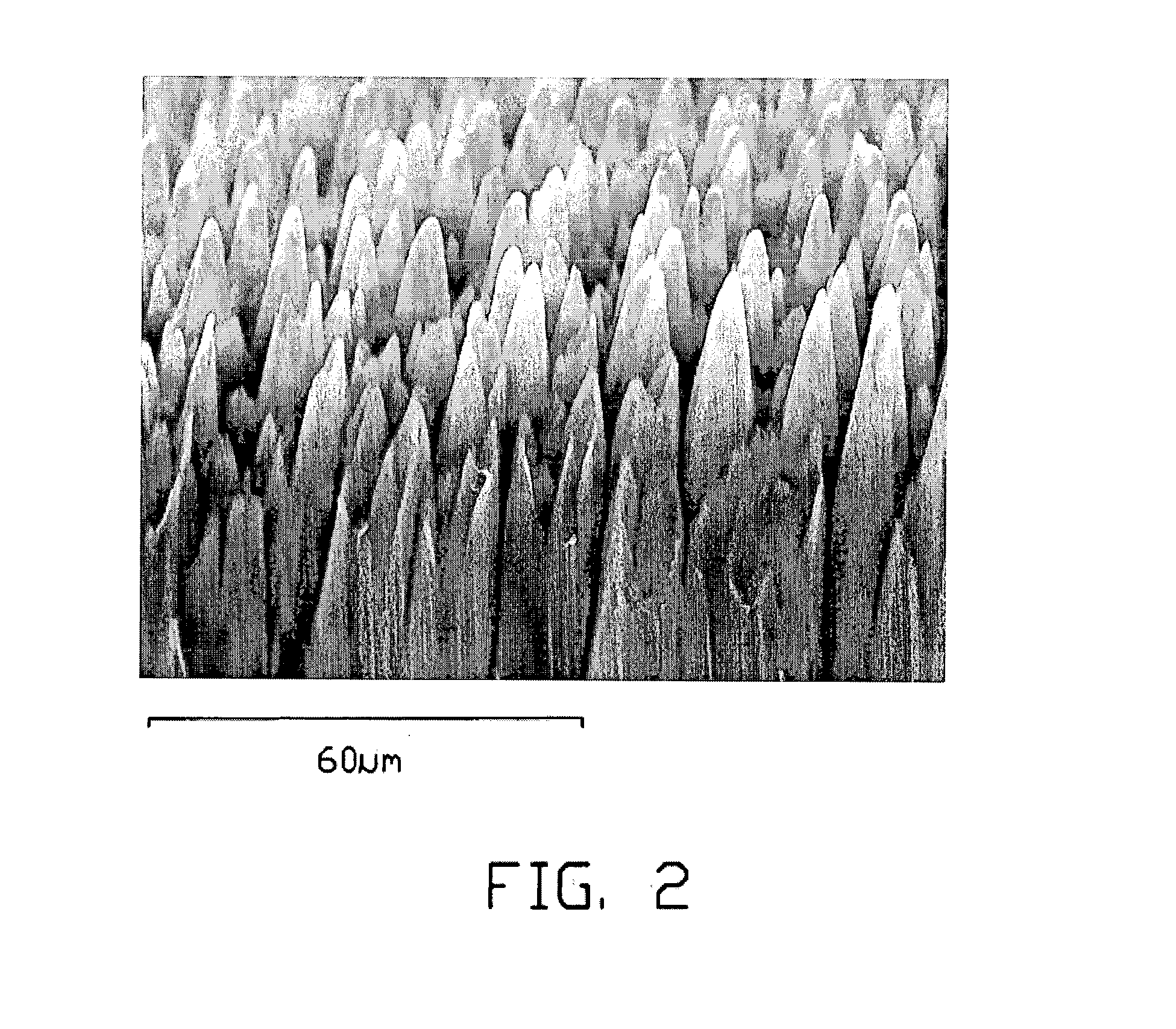

InactiveUS20040095050A1Lower threshold voltageMaterial nanotechnologyElectric discharge tubesField emission deviceMicrometer

A field emission device includes a substrate (11) and a carbon nanotube array (12) formed thereon. Carbon nanotubes (120) of the carbon nanotube array are parallel to each other and cooperatively form a plurality of substantially rod-shaped lower portions (121, 121') and a plurality of corresponding tapered tips (122, 122') above the lower portions. Each lower portion and tapered tips have a plurality of carbon nanotubes. Distances between adjacent tips are approximately uniform, and are more than one micrometer. Preferably, the distance is in the range from 1 to 30 micrometers. The field emission device with this structure has reduced shielding between adjacent carbon nanotubes and has decreased threshold voltage required for field emission by the carbon nanotubes. The field emission device also contributes to an improved field emission concentration and efficiency.

Owner:TSINGHUA UNIV +1

Method for depositing carbon nanotubes on a substrate of a field emission device using direct-contact transfer deposition

ActiveUS7357691B2Launch evenlyImprove flatnessMaterial nanotechnologyElectric discharge tubesField emission deviceCarbon nanotube

A preferred method for making a carbon nanotube-based field emission device in accordance with the invention includes the following steps: providing a substrate (22) with a surface; depositing a catalyst layer (24) on a predetermined area on the surface of the substrate; forming a carbon nanotube array (30) extending from the predetermined area; forming a cathode electrode (40) on top of the carbon nanotube array; and removing the substrate so as to expose the carbon nanotube array.

Owner:TSINGHUA UNIV +1

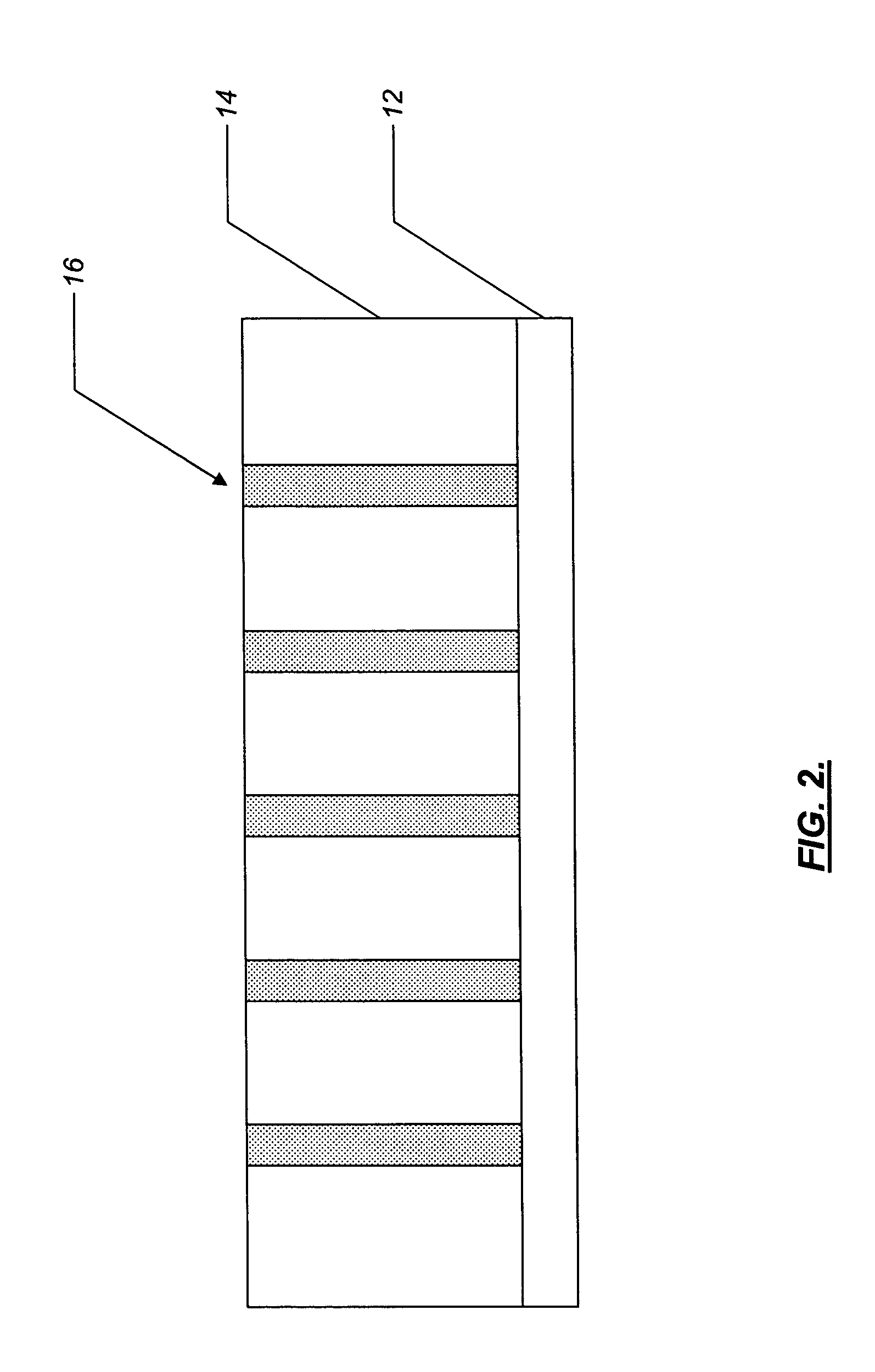

Self-aligned gated rod field emission device and associated method of fabrication

ActiveUS20050067935A1Discharge tube luminescnet screensLamp detailsCylindrical channelField emission device

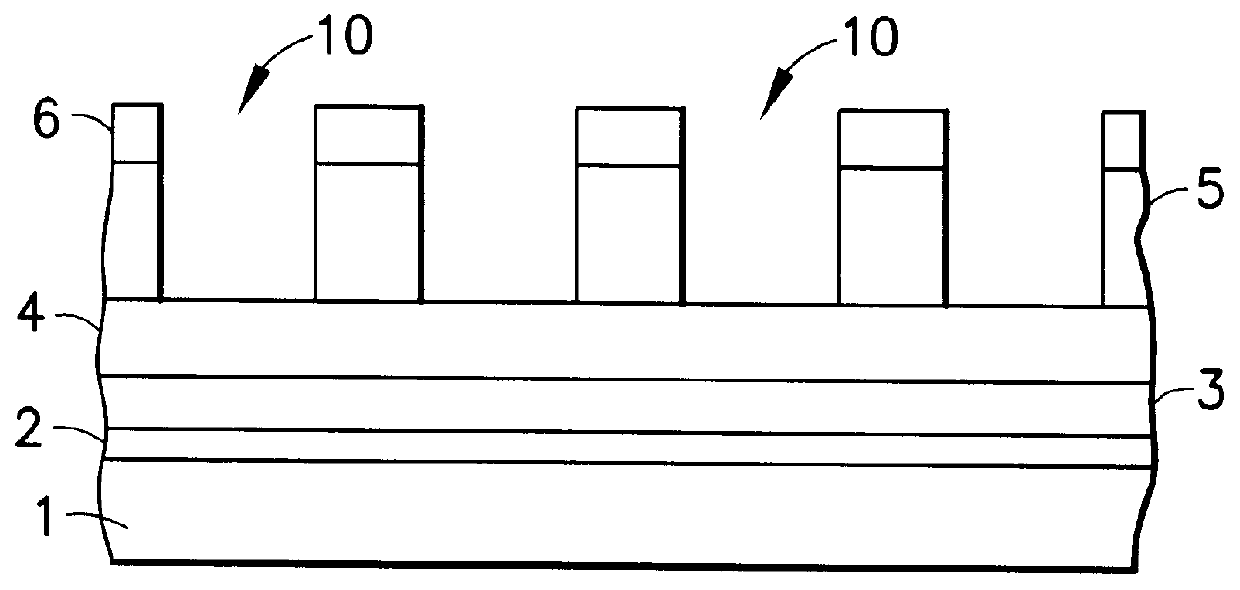

A self-aligned gated field emission device and an associated method of fabrication are described. The device includes a substrate and a porous layer disposed adjacent to the surface of the substrate, wherein the porous layer defines a plurality of substantially cylindrical channels, each of the plurality of substantially cylindrical channels aligned substantially parallel to one another and substantially perpendicular to the surface of the substrate. The device also includes a plurality of substantially rod-shaped structures disposed within at least a portion of the plurality of substantially cylindrical channels defined by the porous layer and adjacent to the surface of the substrate, wherein a portion of each of the plurality of substantially rod-shaped structures protrudes above the surface of the porous layer. The device further includes a gate dielectric layer disposed on the surface of the porous layer, wherein the gate dielectric layer is disposed between the plurality of substantially rod-shaped structures. The device still further includes a conductive layer selectively disposed on the surface of the gate dielectric layer, wherein the conductive layer is selectively disposed between the plurality of substantially rod-shaped structures.

Owner:GENERAL ELECTRIC CO

Nanowire structures comprising carbon

The present invention is directed to nanowire structures and interconnected nanowire networks comprising such structures, as well as methods for their production. The nanowire structures comprise a nanowire core, a carbon-based layer, and in additional embodiments, carbon-based structures such as nanographitic plates consisting of graphenes formed on the nanowire cores, interconnecting the nanowire structures in the networks. The networks are porous structures that can be formed into membranes or particles. The nanowire structures and the networks formed using them are useful in catalyst and electrode applications, including fuel cells, as well as field emission devices, support substrates and chromatographic applications.

Owner:ONED MATERIAL INC

Integrated circuit devices and methods employing amorphous silicon carbide resistor materials

InactiveUS6031250AReduce the temperatureLow implementation costSolid-state devicesSemiconductor/solid-state device manufacturingField emission deviceOxygen

Integrated circuits, including field emission devices, have a resistor element of amorphous SixC1-x wherein 0<x<1, and wherein the SixC1-x incorporates at least one impurity selected from the group consisting of hydrogen, halogens, nitrogen, oxygen, sulphur, selenium, transition metals, boron, aluminum, phosphorus, gallium, arsenic, lithium, beryllium, sodium and magnesium.

Owner:ENTEGRIS INC +1

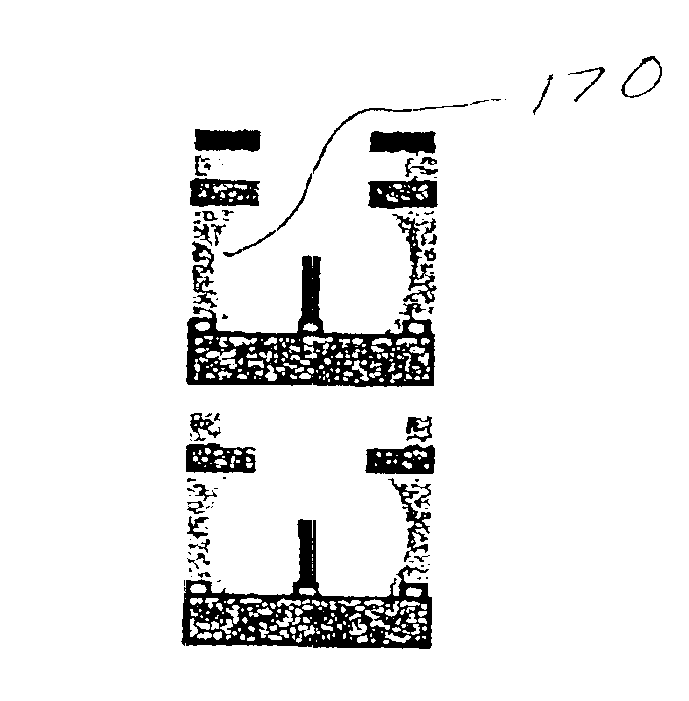

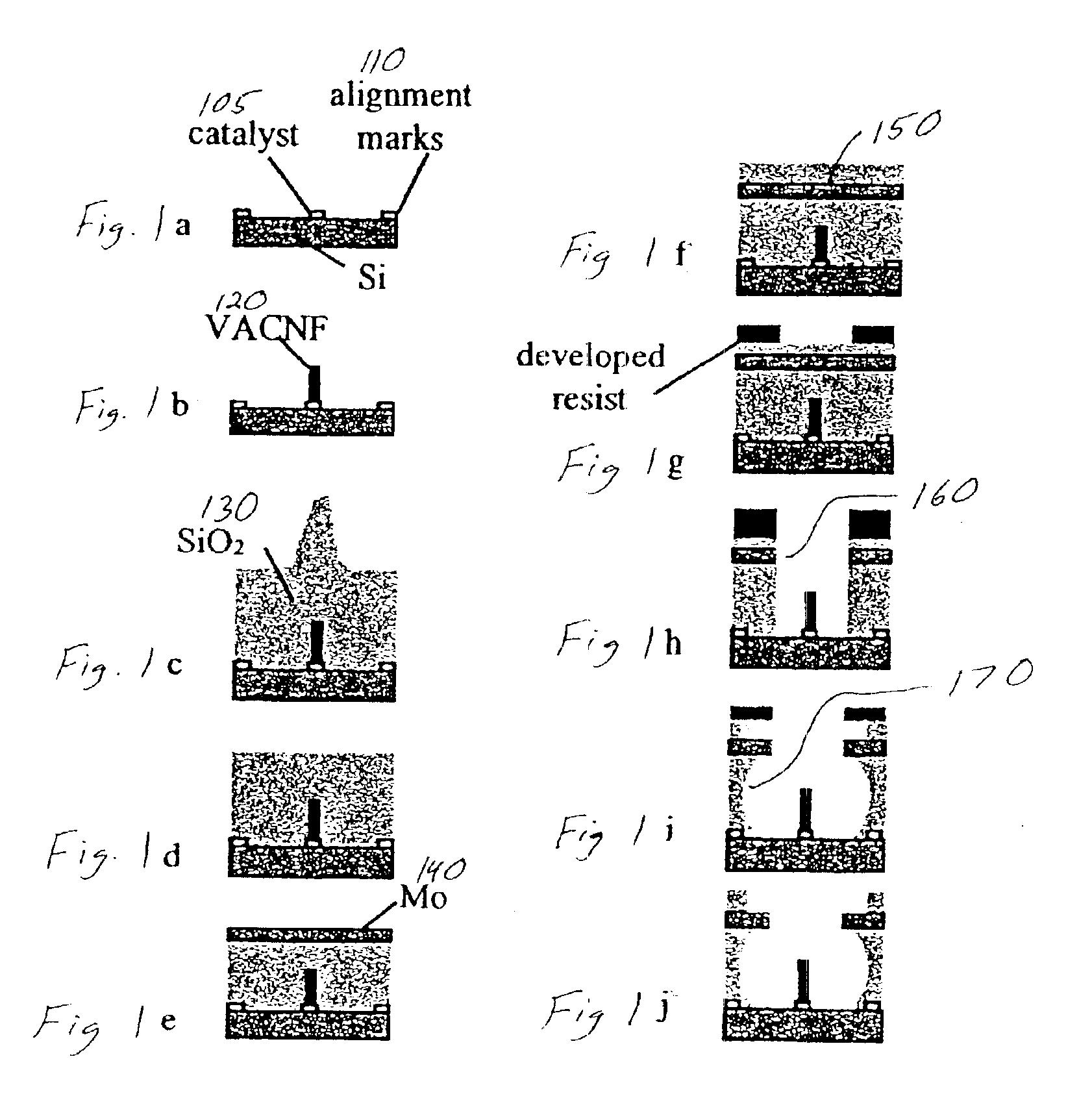

Gated fabrication of nanostructure field emission cathode material within a device

InactiveUS6858455B2Electric discharge tubesDecorative surface effectsField emission deviceDielectric

Gated field emission devices and systems and methods for their fabrication are described. A method includes growing a substantially vertically aligned carbon nanostructure, the substantially vertically aligned carbon nanostructure coupled to a substrate; covering at least a portion of the substantially vertically aligned carbon nanostructure with a dielectric; forming a gate, the gate coupled to the dielectric; and releasing the substantially vertically aligned carbon nanostructure by forming an aperture in the gate and removing a portion of the dielectric.

Owner:UT BATTELLE LLC

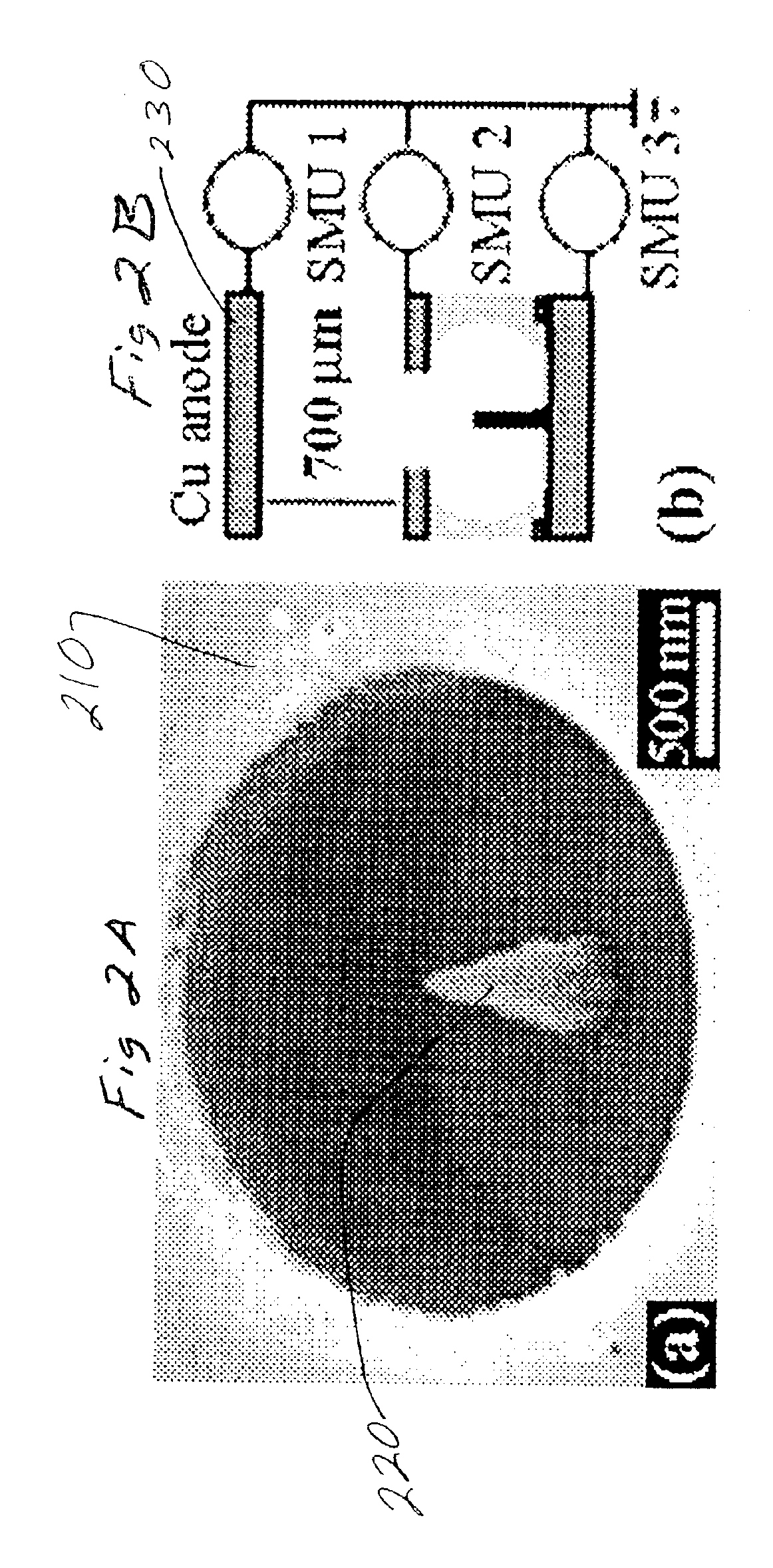

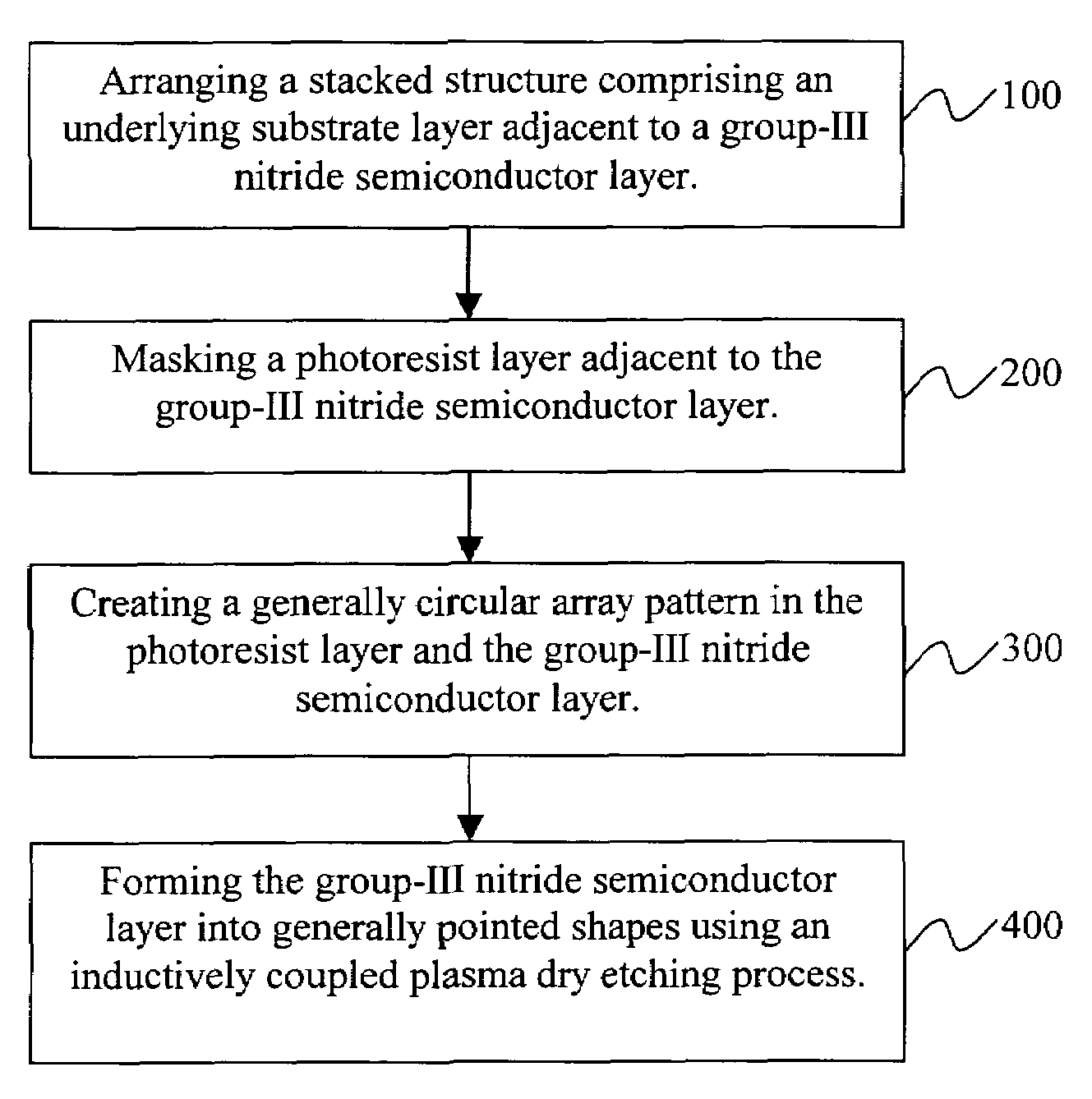

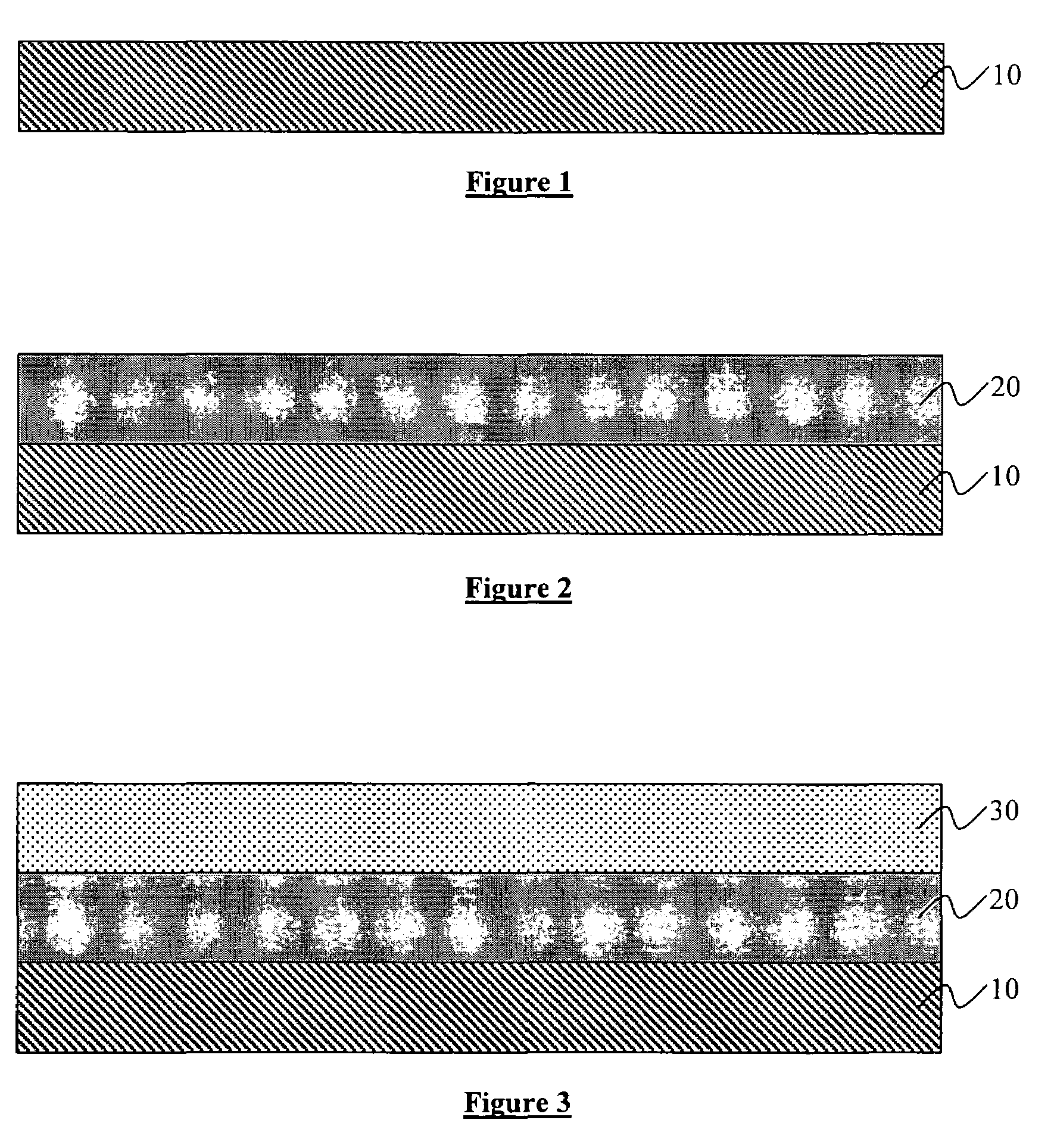

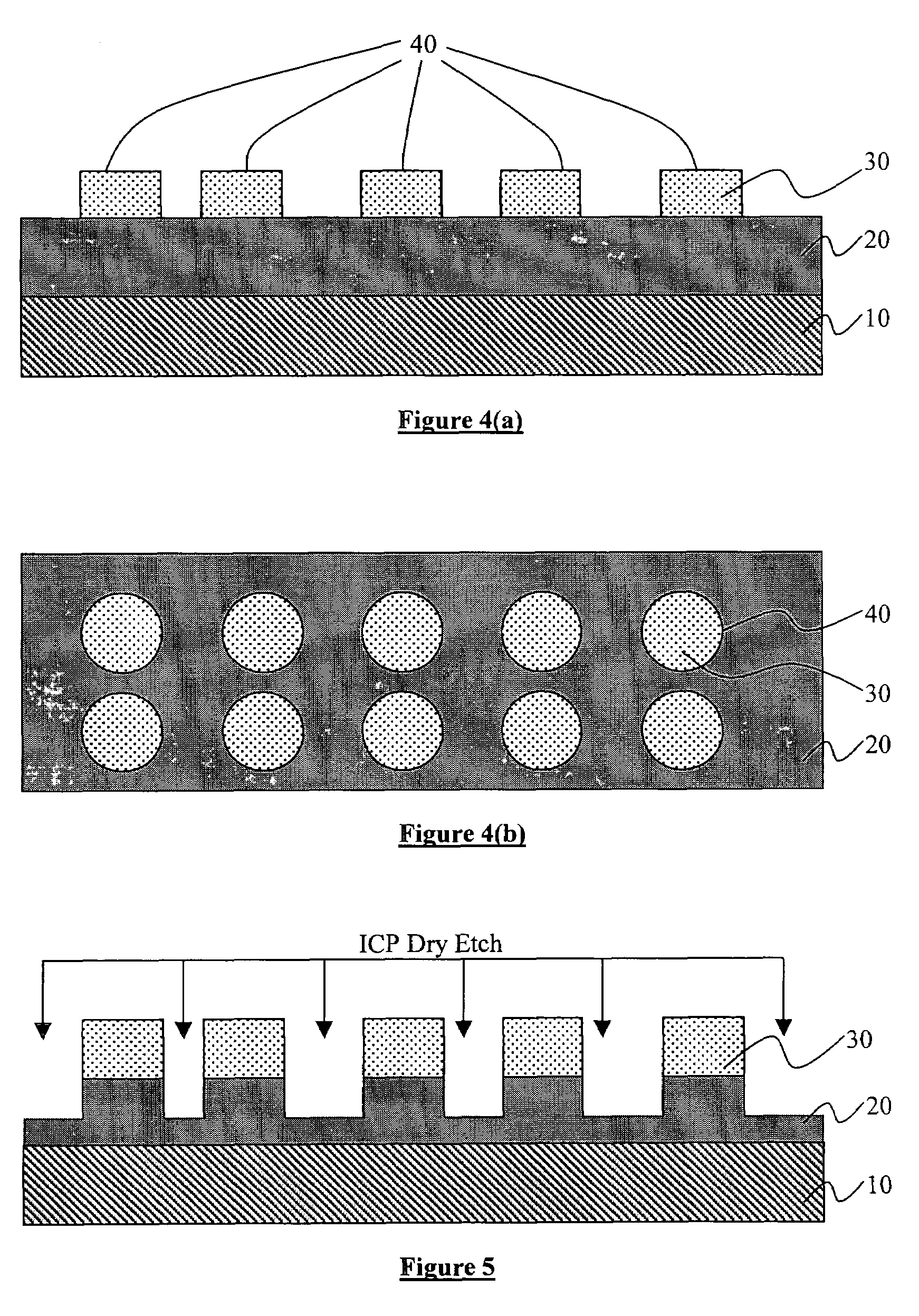

Method of fabricating sub-100 nanometer field emitter tips comprising group III-nitride semiconductors

InactiveUS6960526B1Fast and robust and cost-effective techniqueOpen quicklyElectric discharge tubesSemiconductor/solid-state device manufacturingField emission deviceInductively coupled plasma

A method of producing a field emission device includes laying a group III-nitride semiconductor layer over a substrate, placing a photoresist mask over the group III-nitride semiconductor layer, patterning a generally circular grid in the photoresist mask and the group III-nitride semiconductor layer, and forming the group III-nitride semiconductor layer into generally pointed tips using an inductively coupled plasma dry etching process, wherein the group III-nitride semiconductor layer comprises a group III-nitride semiconductor material having a low positive electron affinity or a even a negative electron affinity, wherein the inductively coupled plasma dry etching process selectively creates an anisotropic deep etch in the group III-nitride semiconductor layer, and wherein the inductively coupled plasma dry etching process creates an isotropic etch in the group III-nitride semiconductor layer. Preferably, the photoresist layer is approximately 1.7 microns in thickness, and the fabricated tips have a radius of curvature of less than 100 nanometers.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

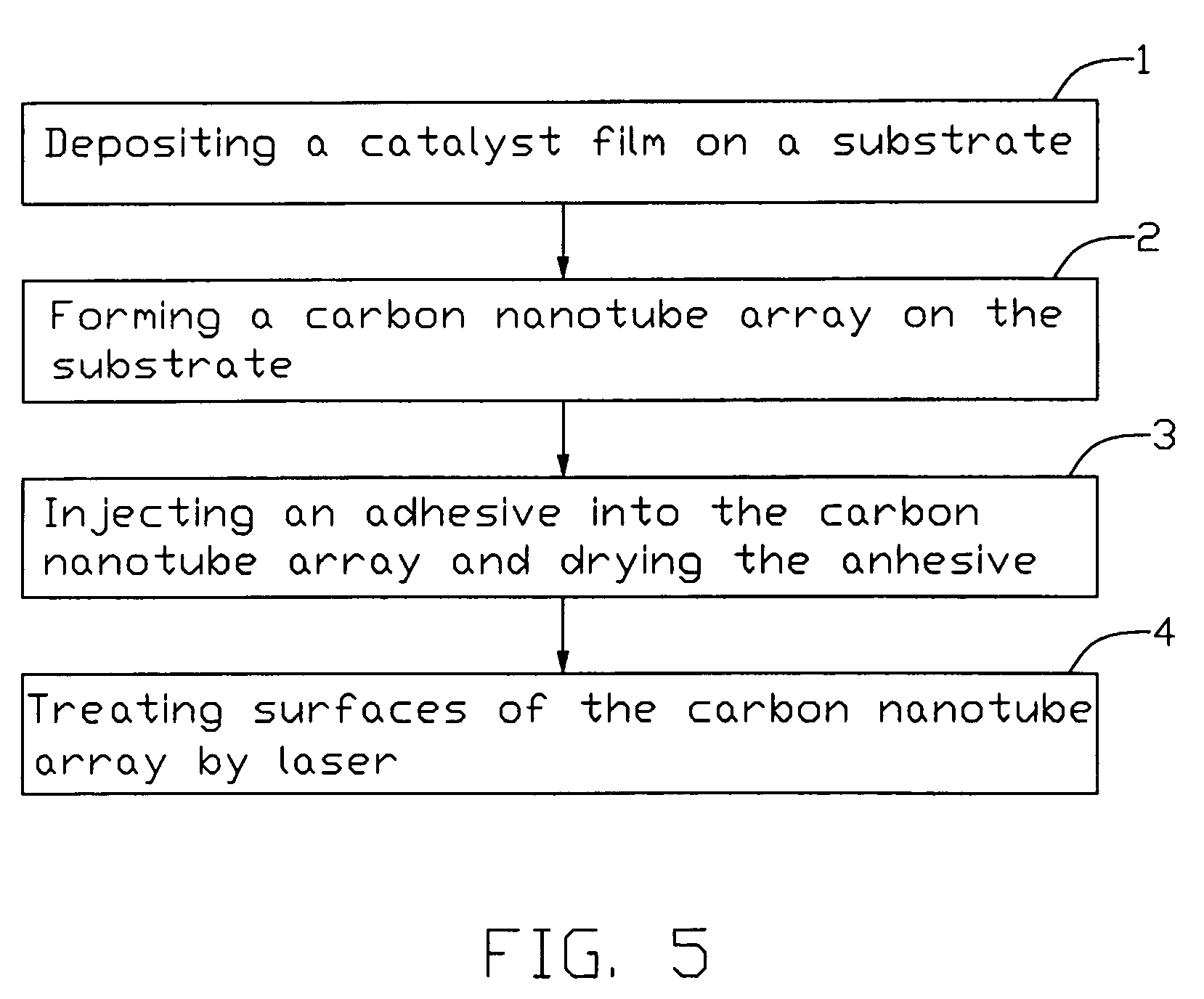

Method for manufacturing carbon nanotube field emission device

ActiveUS7448931B2Avoid separationReduced shieldingLiquid surface applicatorsDischarge tube luminescnet screensField emission deviceField emission current

A carbon nanotube field emission device (100) includes a substrate (10), and a carbon nanotube array (30) formed on and secured to the substrate. This avoids separation of the carbon nanotubes from the substrate by electric field force in a strong electric field. Tips of the carbon nanotubes are exposed. A method for manufacturing the carbon nanotube field emission device includes the steps of: (a) depositing a catalyst film (20) on a substrate; (b) forming a carbon nanotube array on the substrate; (c) injecting an adhesive into the carbon nanotube array, and drying the adhesive; and (d) treating surfaces of the carbon nanotube array by laser. The carbon nanotube field emission device has reduced shielding between adjacent carbon nanotubes, reduced threshold voltage, and increased field emission current.

Owner:HON HAI PRECISION IND CO LTD +1

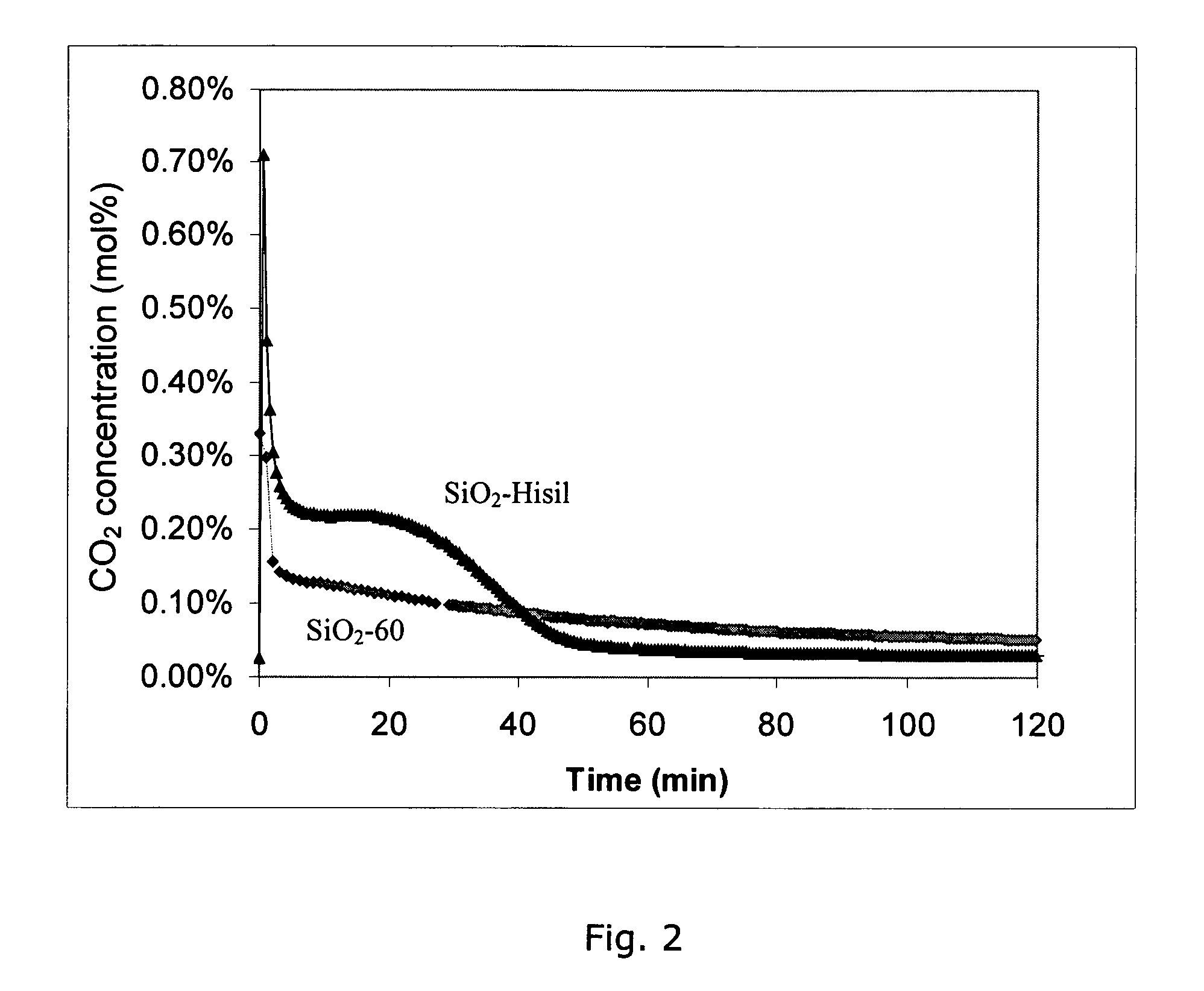

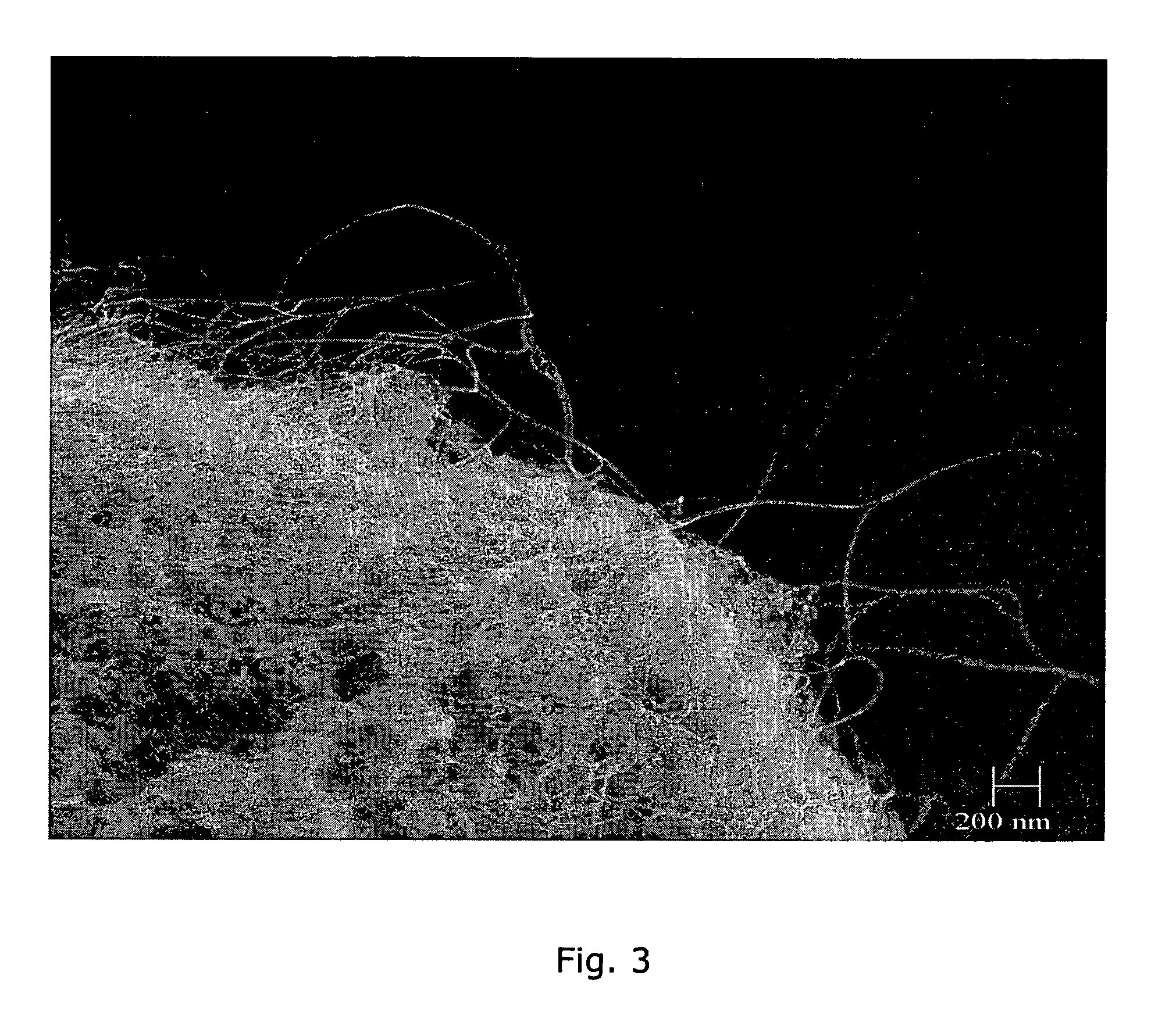

Single-walled carbon nanotube-ceramic composites and methods of use

InactiveUS7816709B2Material nanotechnologyIndividual molecule manipulationField emission deviceCeramic composite

Composites of single-walled carbon nanotubes (SWNTs) and a ceramic support (e.g., silica) comprising a small amount of catalytic metal, e.g., cobalt and molybdenum, are described. The particle comprising the metal and ceramic support is used as the catalyst for the production of the single-walled carbon nanotubes. The nanotube-ceramic composite thus produced can be used “as prepared” without further purification providing significant cost advantages. The nanotube-ceramic composite has also been shown to have improved properties versus those of purified carbon nanotubes in certain applications such as field emission devices. Use of precipitated and fumed silicas has resulted in nanotube-ceramic composites which may synergistically improve the properties of both the ceramic (e.g., silica) and the single-walled carbon nanotubes. Addition of these composites to polymers may improve their properties. These properties include thermal conductivity, thermal stability (tolerance to degradation), electrical conductivity, modification of crystallization kinetics, strength, elasticity modulus, fracture toughness, and other mechanical properties. Other nanotube-ceramic composites may be produced based on Al2O3, MgO and ZrO2, for example, which are suitable for a large variety of applications.

Owner:THE BOARD OF RGT UNIV OF OKLAHOMA

Field emission devices using modified carbon nanotubes

InactiveUS20050275331A1Reduce voltageAccelerate emissionsNanostructure manufactureNanoinformaticsField emission deviceModified carbon

The present invention relates to a field emission device comprising an anode and a cathode, wherein said cathode includes carbon nanotubes nanotubes which have been subjected to energy, plasma, chemical, or mechanical treatment. The present invention also relates to a field emission cathode comprising carbon nanotubes which have been subject to such treatment. A method for treating the carbon nanotubes and for creating a field emission cathode is also disclosed. A field emission display device containing carbon nanotube which have been subject to such treatment is further disclosed.

Owner:HYPERION CATALYSIS INT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com