Patents

Literature

634results about How to "Reduce exhaust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

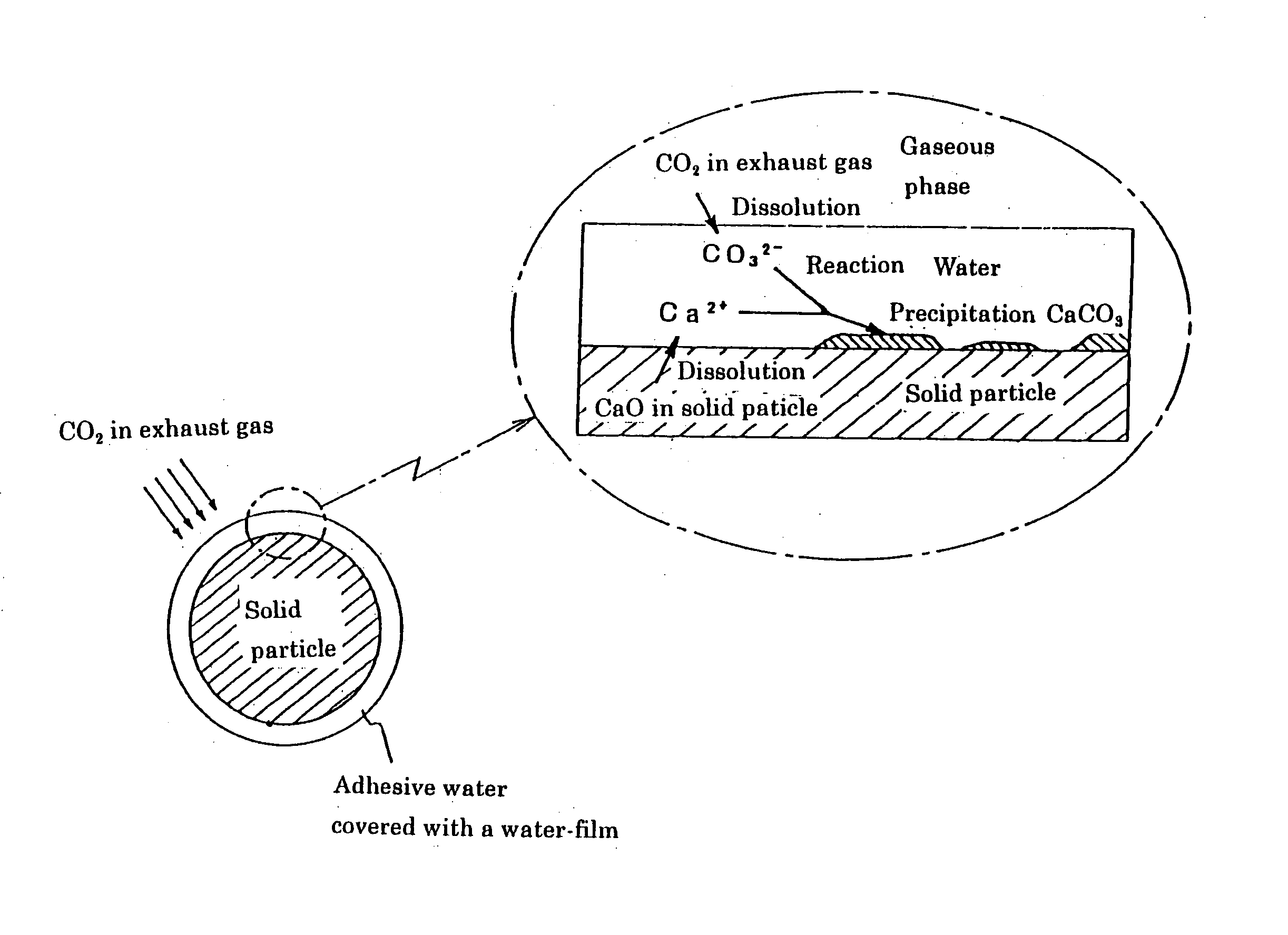

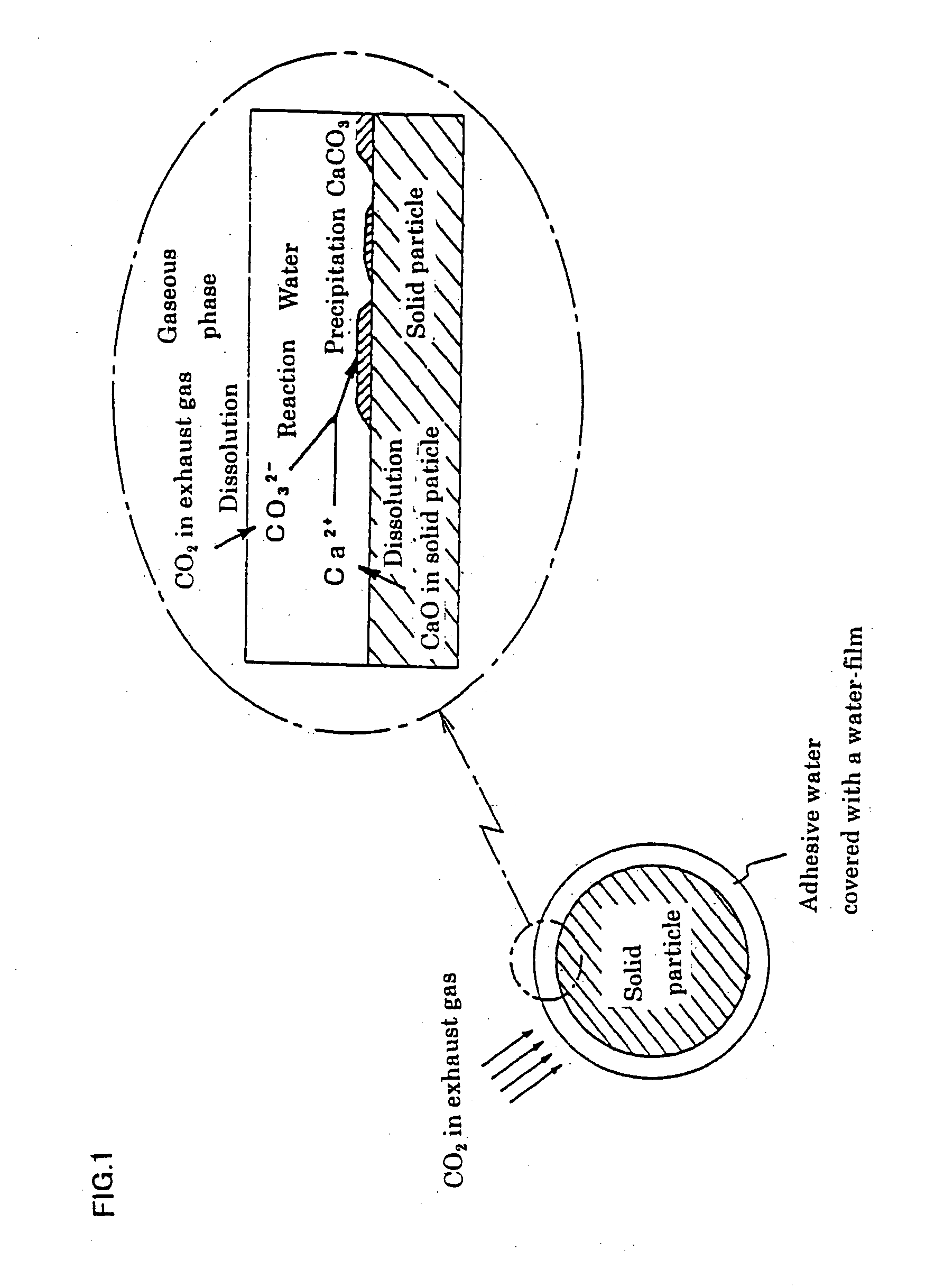

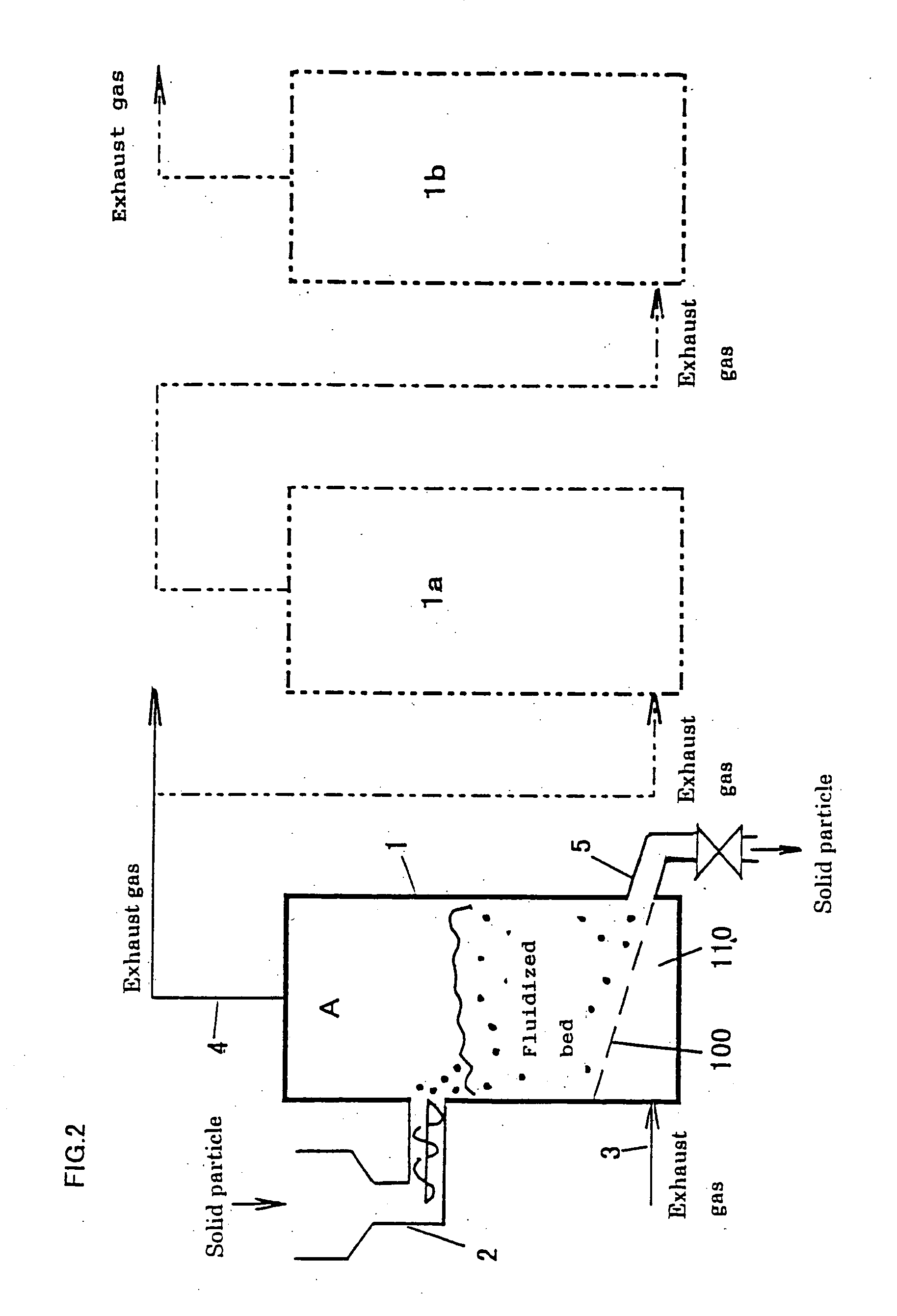

Method for reducing exhaust carbon dioxide

InactiveUS20050036932A1Efficient removalReduce exhaustCalcium/strontium/barium carbonatesWater resource protectionExhaust fumesEnvironmental engineering

A method for effectively absorbing and removing CO2 in an exhaust gas generated during an industrial process for reducing the amount of CO2 that is exhausted into the atmosphere. The exhaust gas containing CO2 is blown into an agglomerate of solid particles containing CaO and / or Ca(OH)2 so that the CO2 is in contact with the agglomerate for fixing the CO2 in the exhaust gas as CaCO3, thereby reducing the CO2 concentration in the exhaust gas. Preferably, the solid particles contain water, and more preferably, the solid particles contain surface adhesive water.

Owner:JFE STEEL CORP

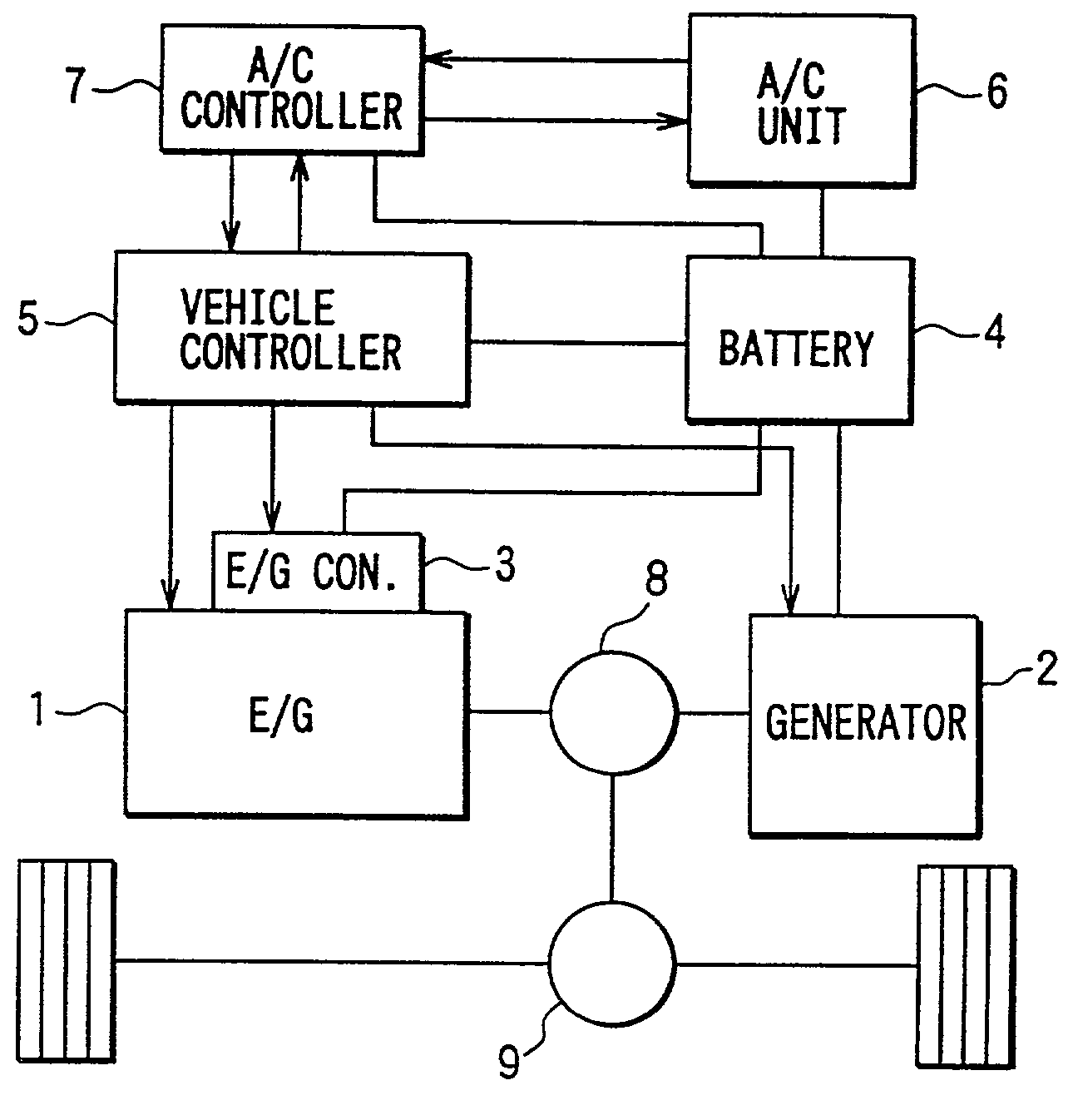

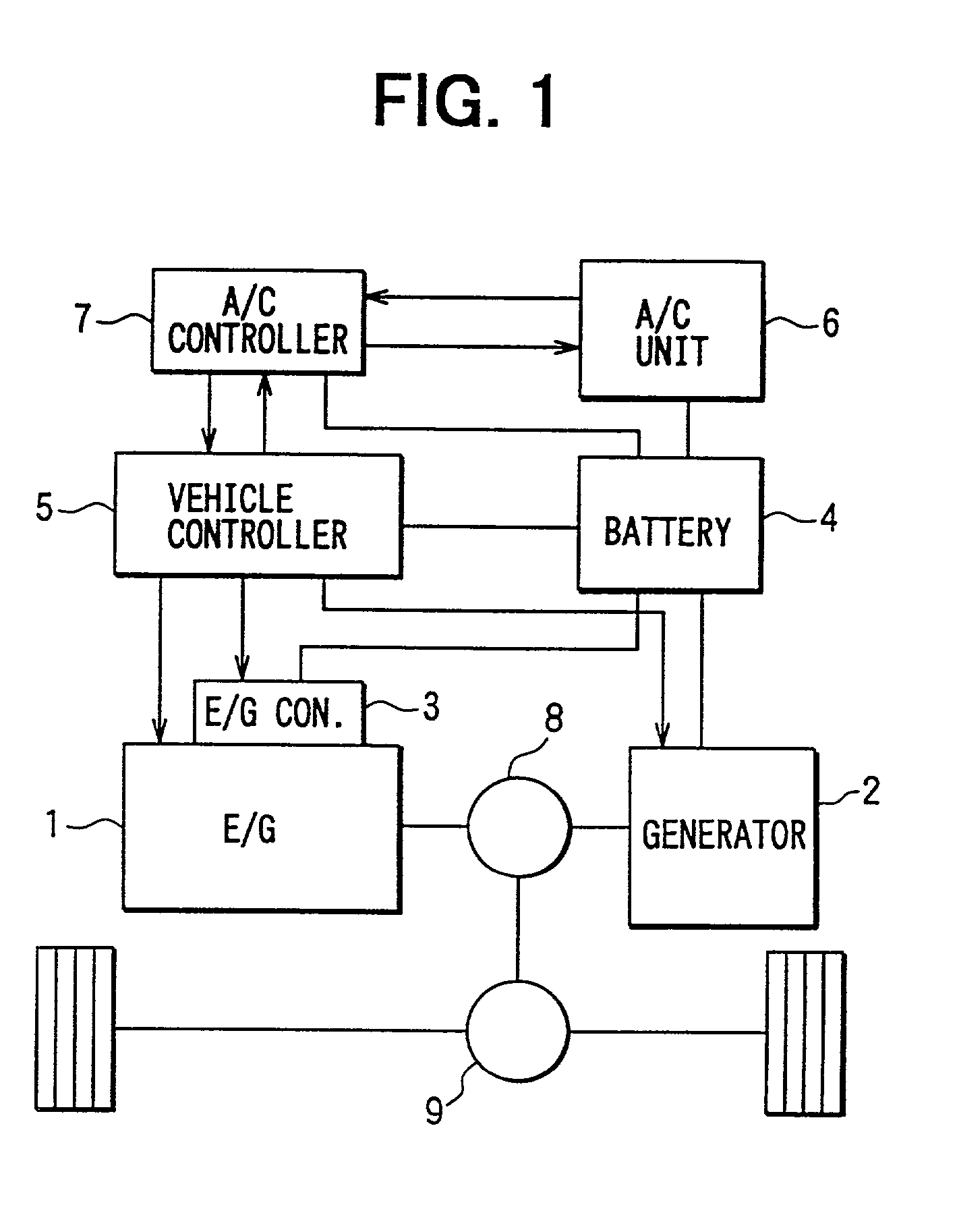

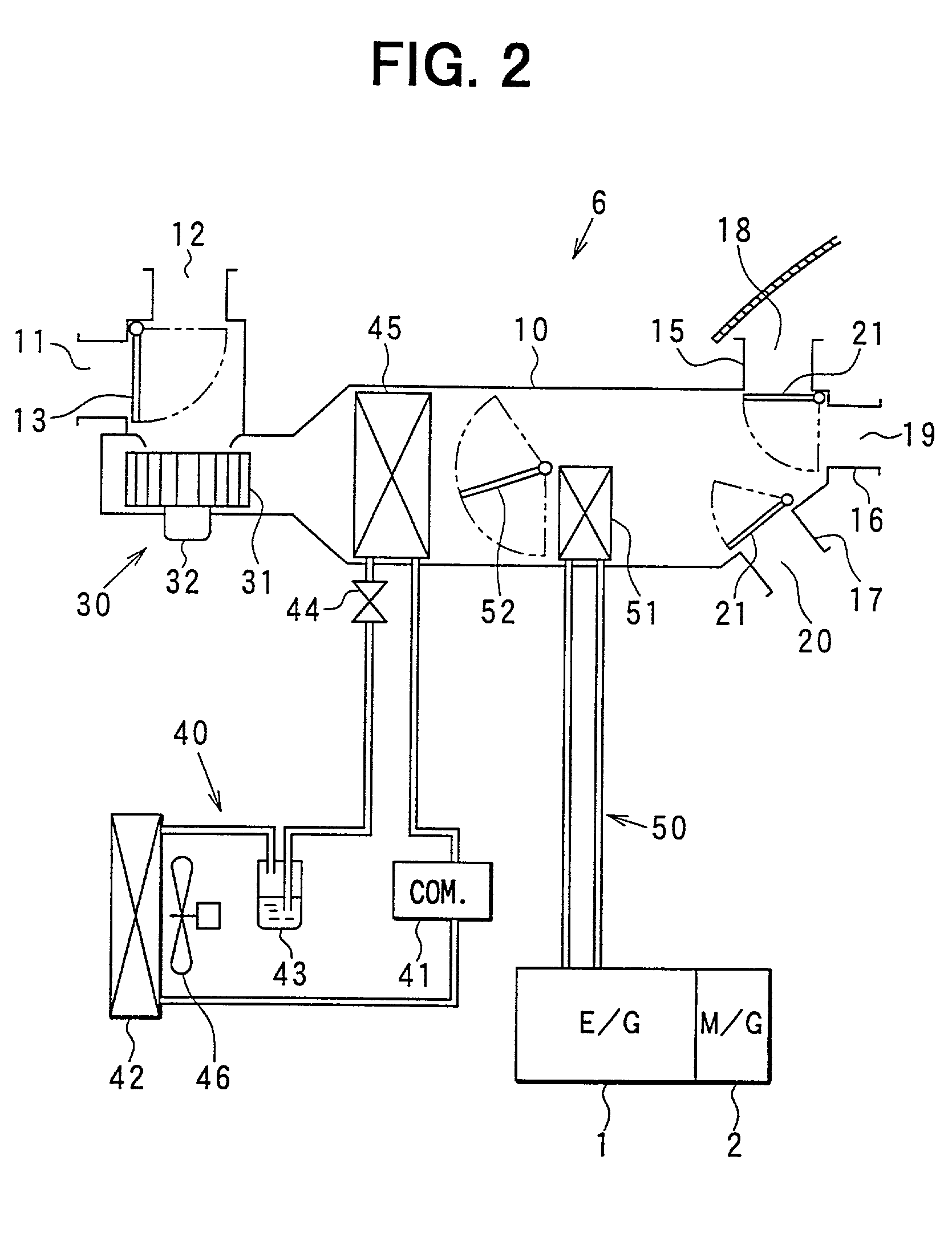

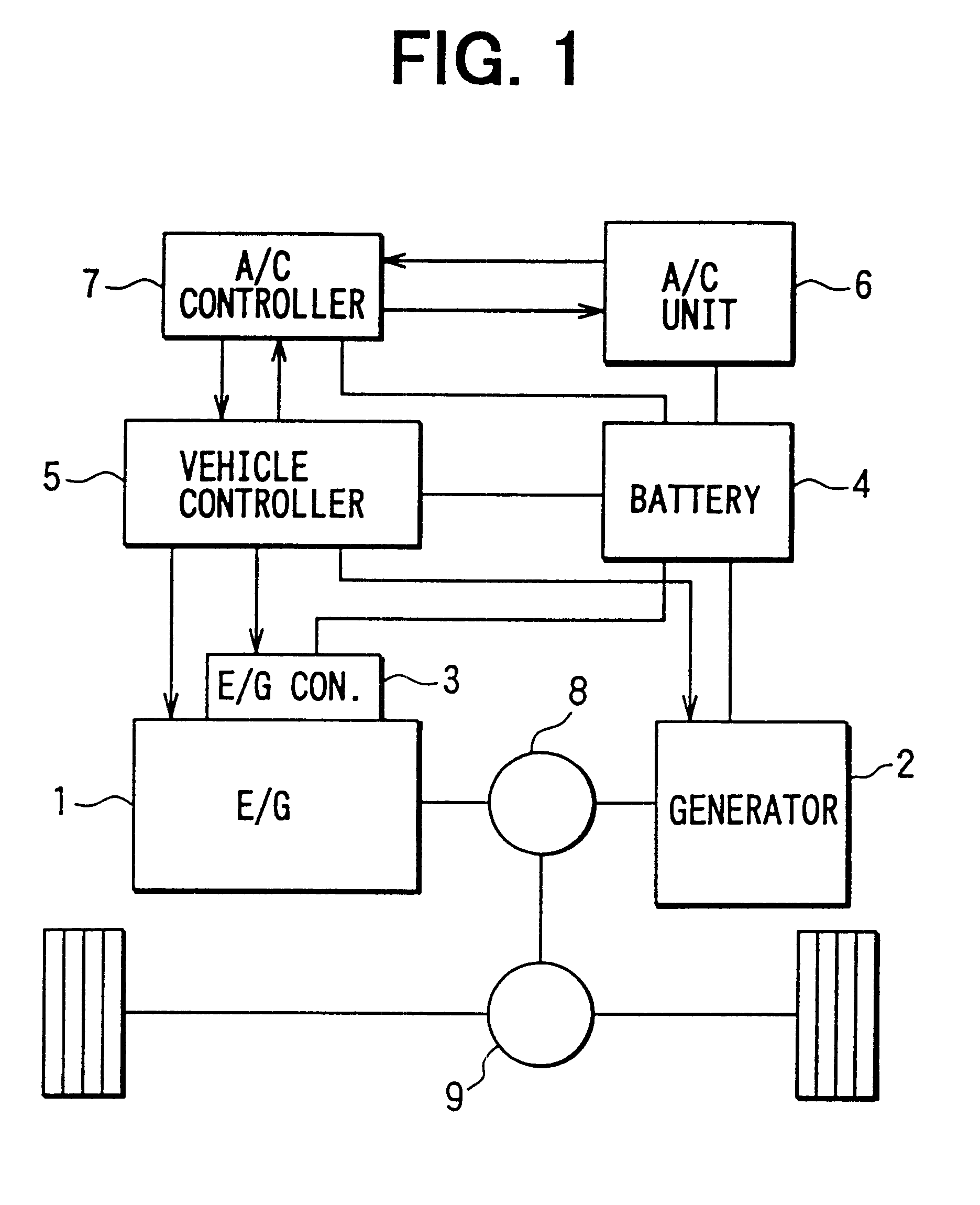

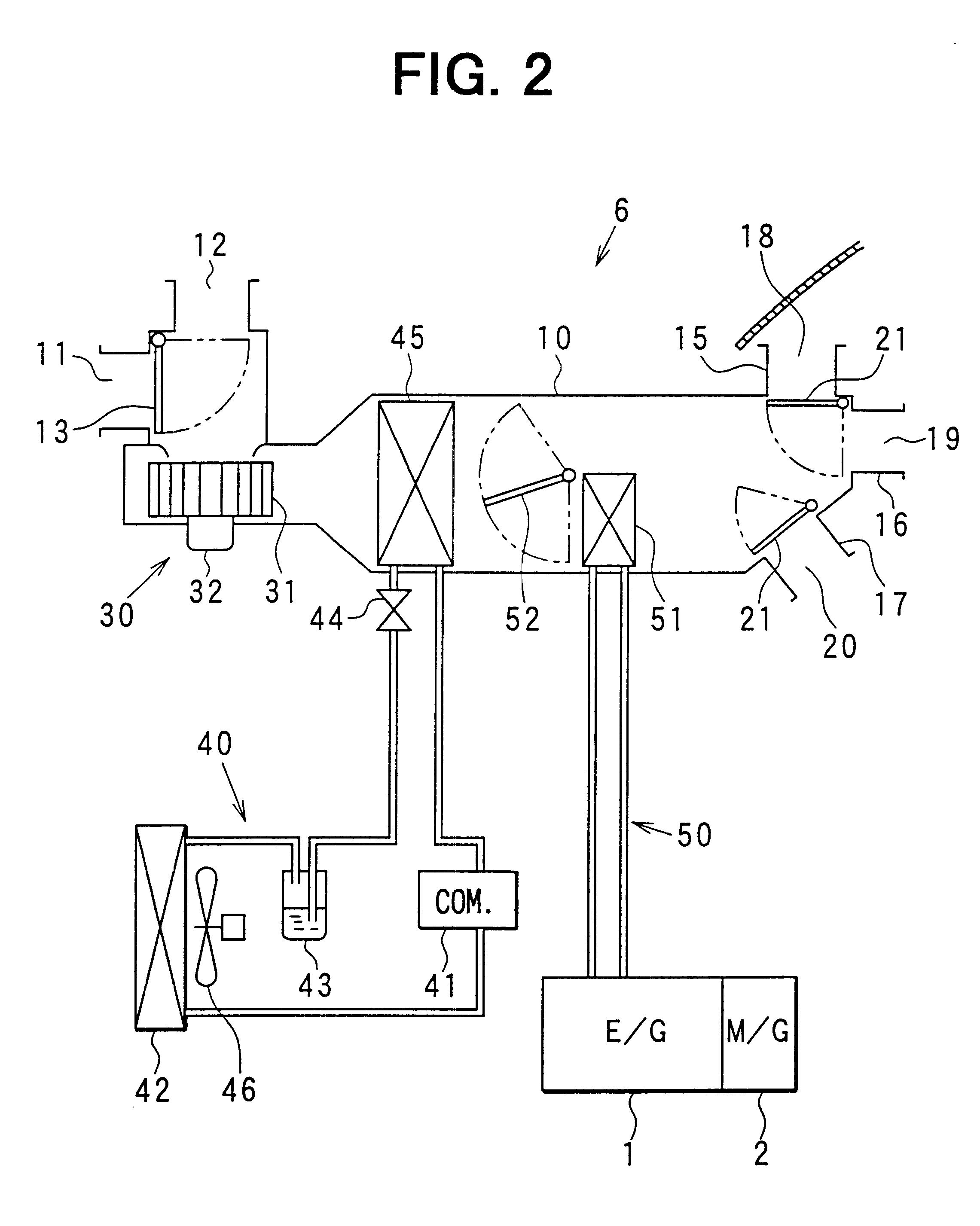

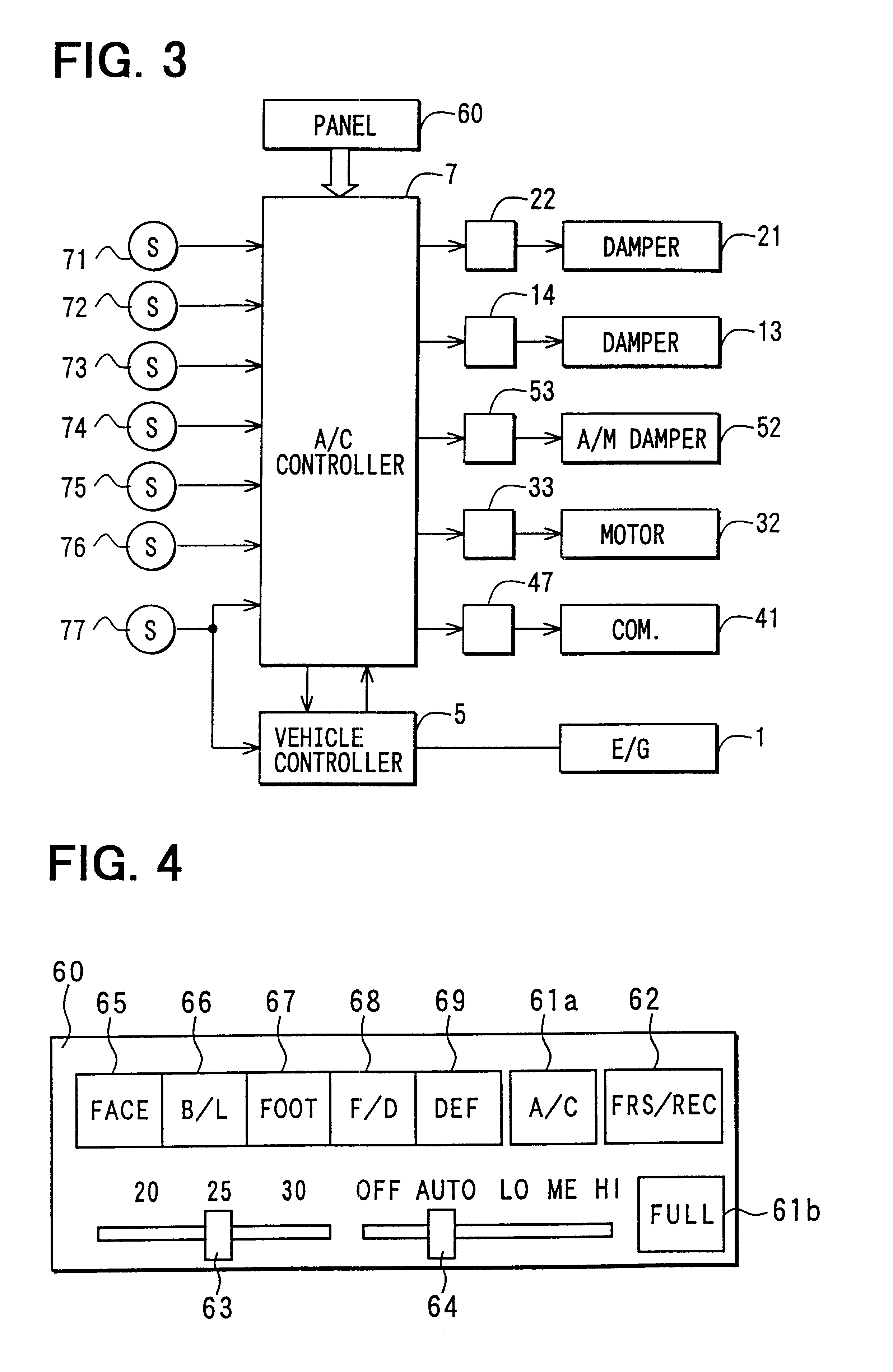

Air conditioner for hybrid vehicle

InactiveUS20020084769A1Less frequentReduce exhaustAir-treating devicesBatteries circuit arrangementsElectrical batteryHybrid vehicle

In an air conditioner for a hybrid vehicle, when a residual charging degree of a battery becomes equal to or lower than a target degree, the electrical motor generator is driven by a vehicle engine so that the battery is charged through the electrical motor generator. When the engine is driven, the target degree of the battery is set higher than that when the engine is stopped so that a charging operation tends to be required while the engine is driven. Accordingly, the frequency for starting the engine only for charging the battery is reduced.

Owner:DENSO CORP

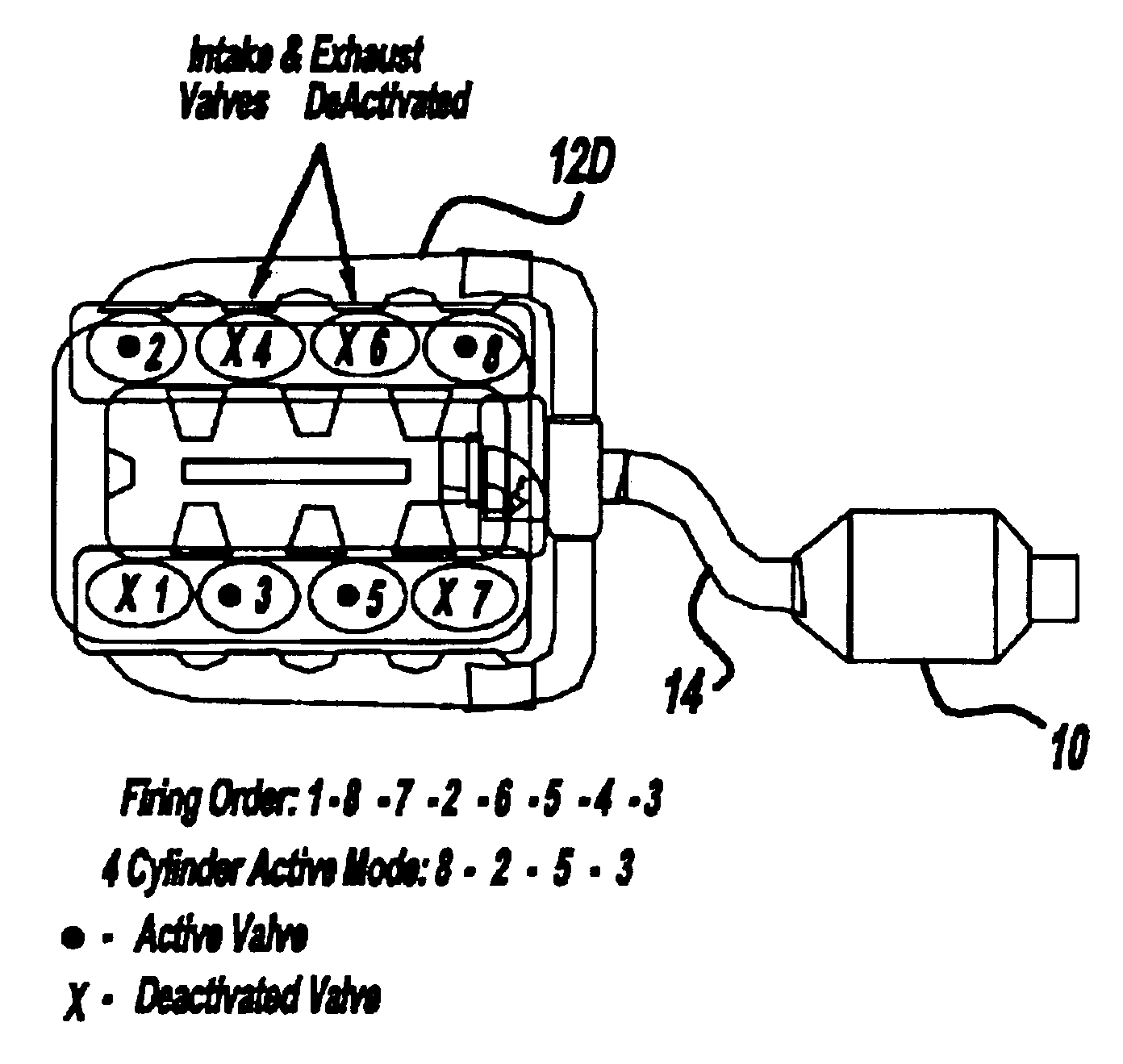

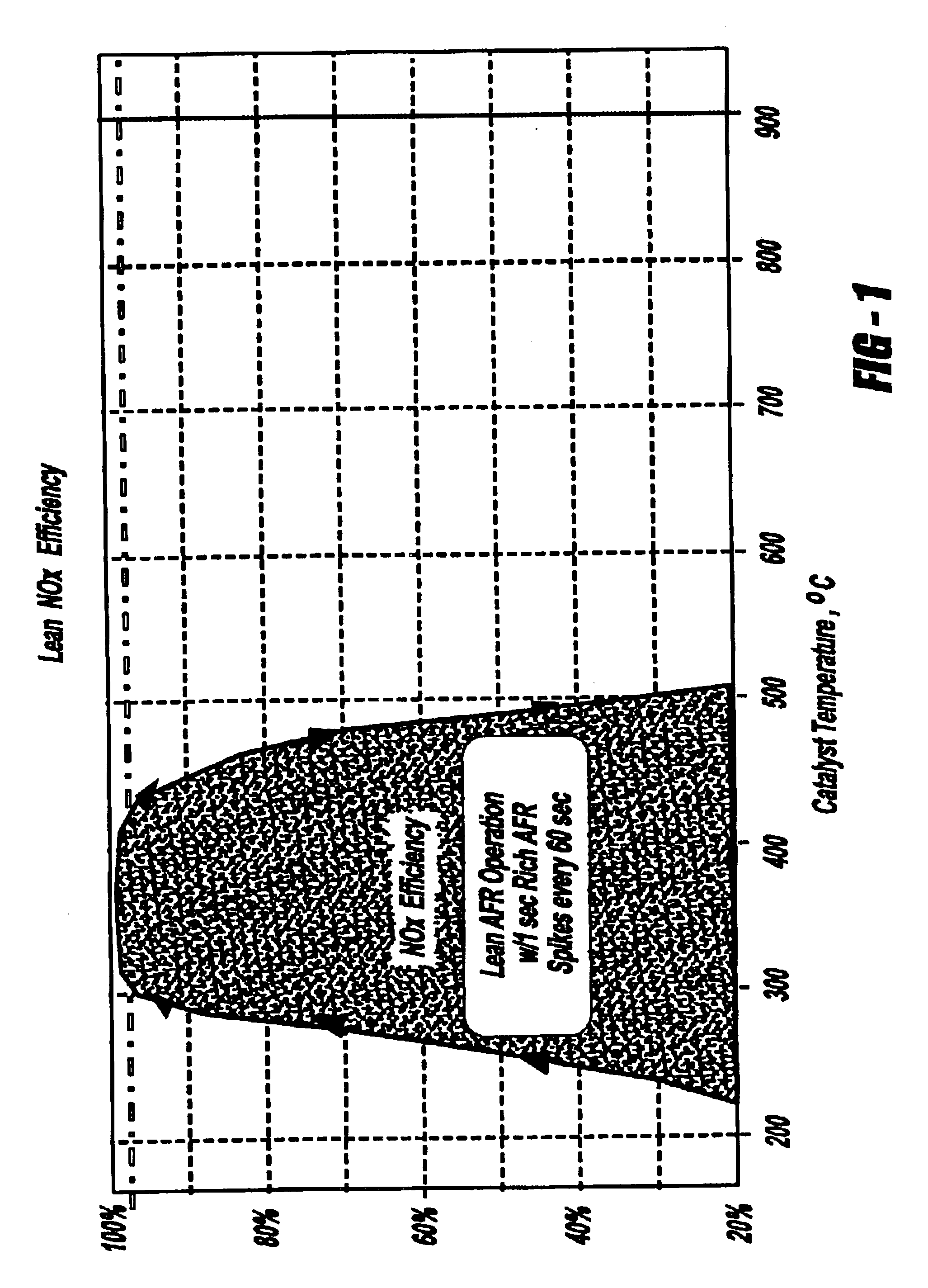

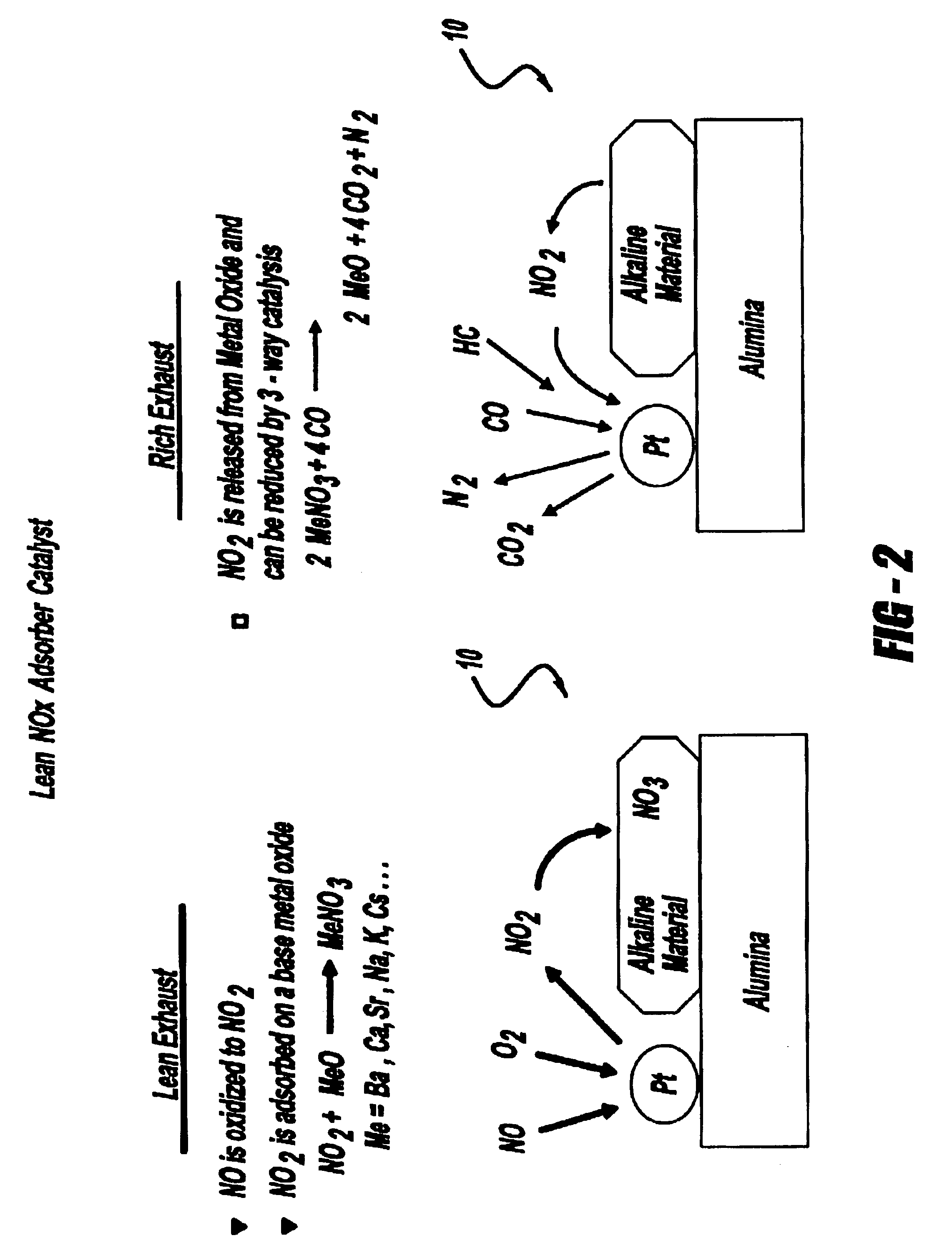

Exhaust emission aftertreatment

InactiveUS6857264B2Raise temperatureImprove utilityElectrical controlNon-fuel substance addition to fuelExhaust gasExhaust fumes

An engine control system in a vehicle including a variable displacement internal combustion engine, a controller for controlling the displacement of the variable displacement internal combustion engine, and where the controller operates the variable displacement internal combustion engine in a partially displaced operating mode upon startup to increase exhaust gas temperature.

Owner:GM GLOBAL TECH OPERATIONS LLC

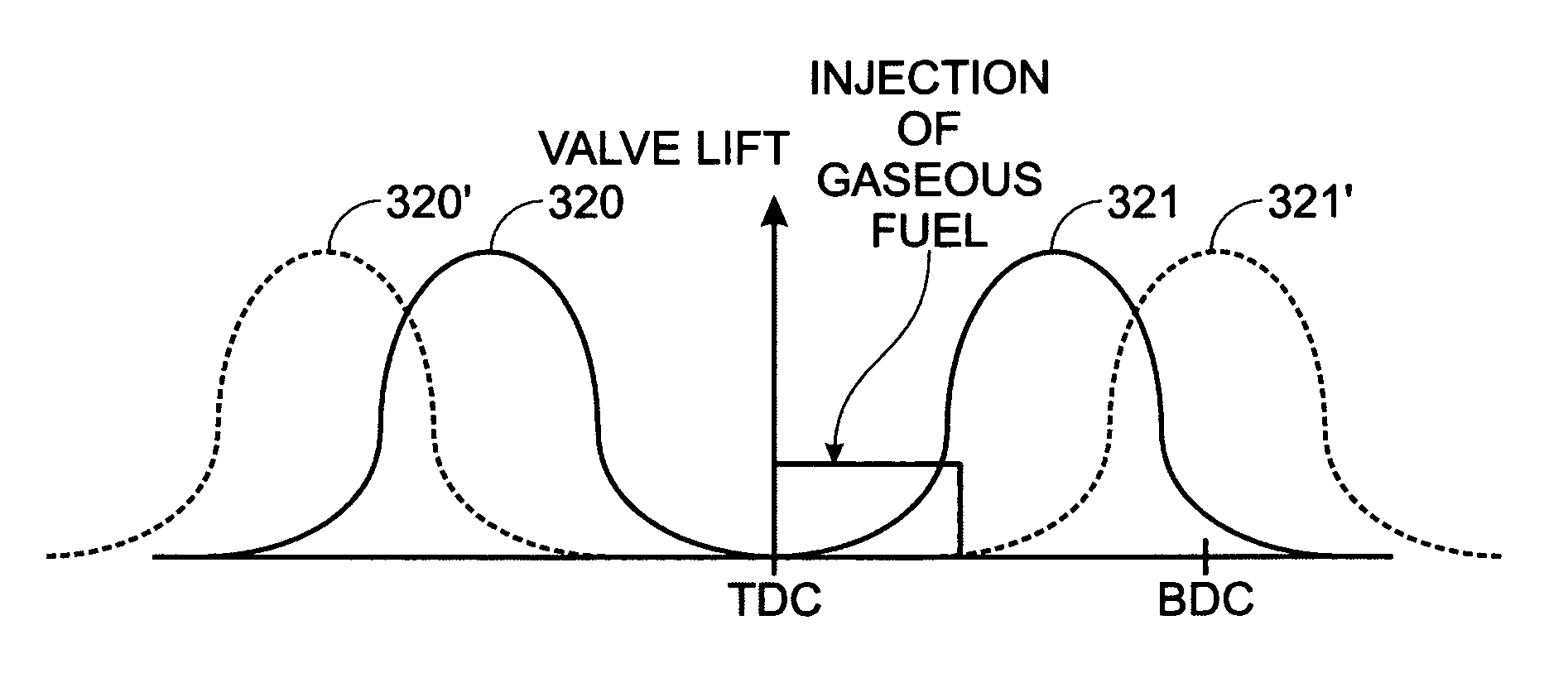

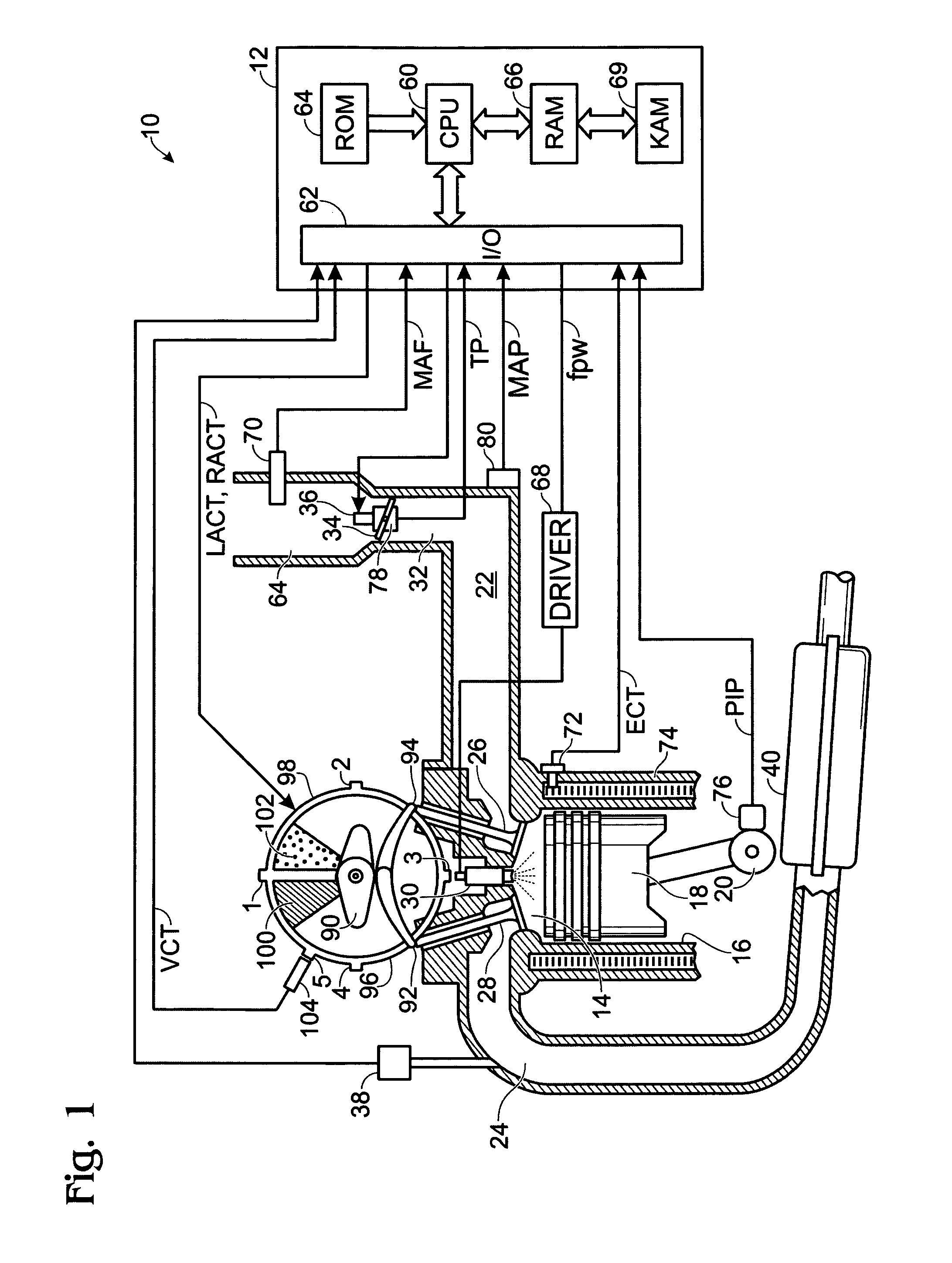

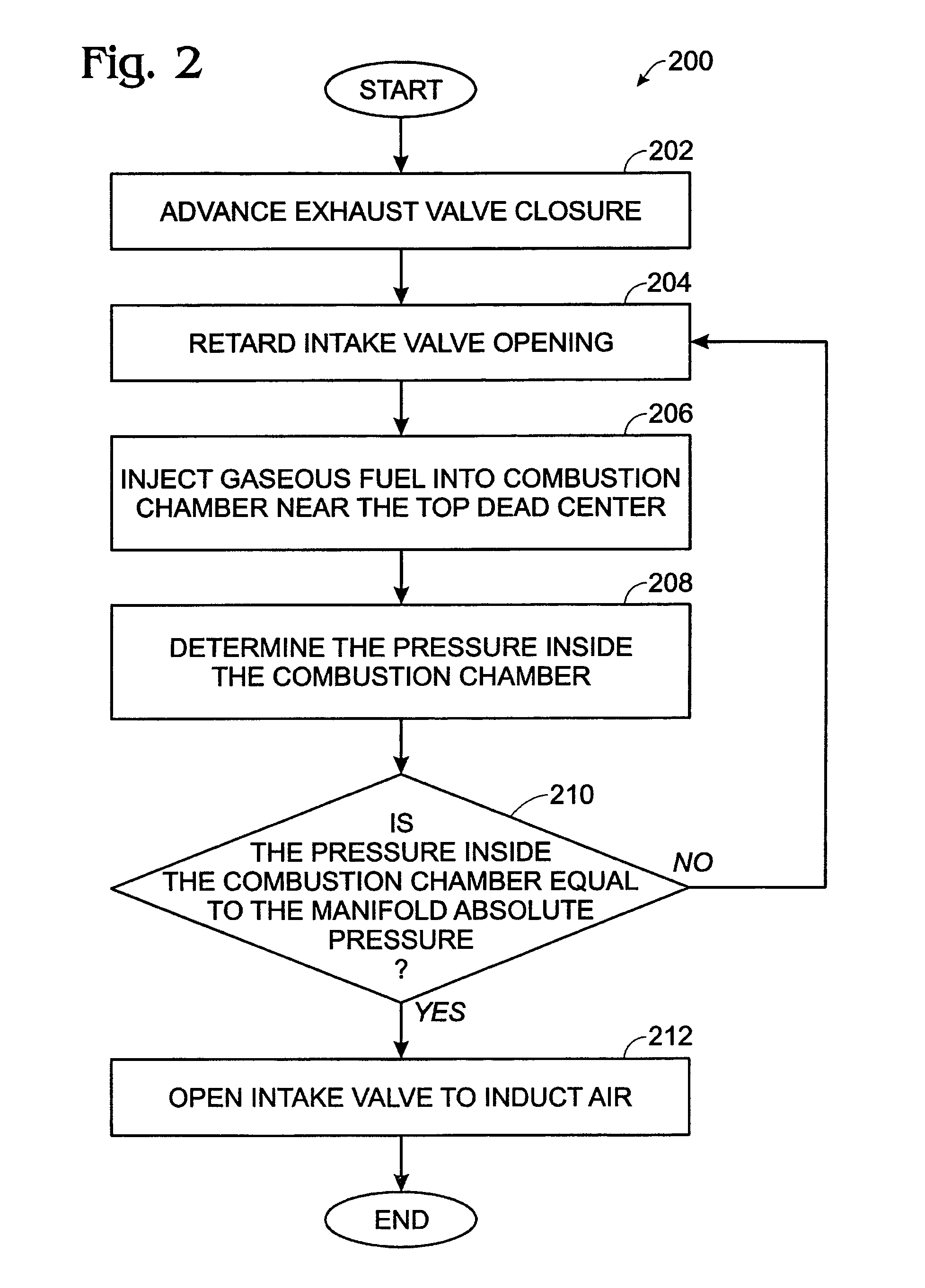

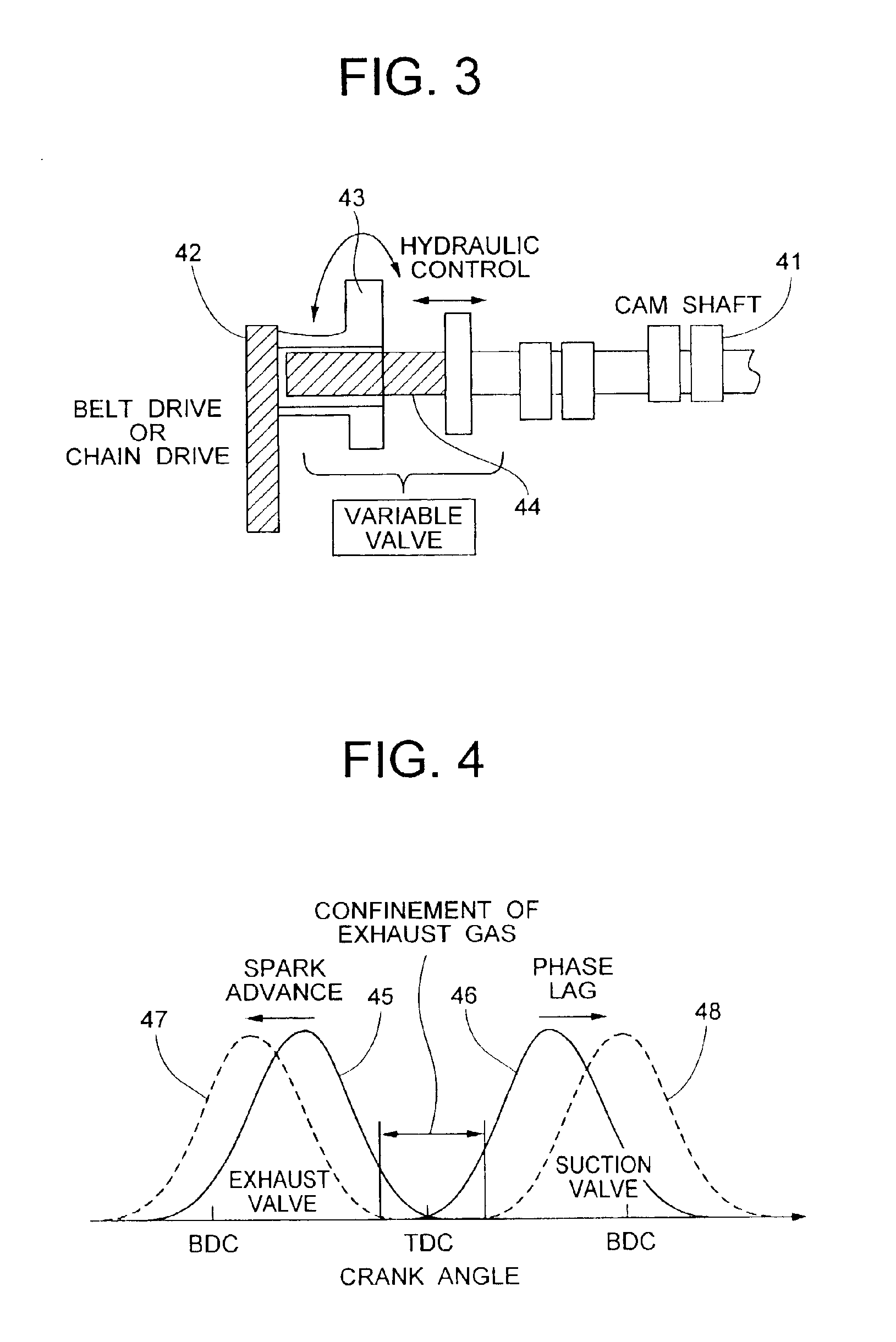

System and method for direct injection of gaseous fuel into internal combustion engine

InactiveUS7117830B1Reduce exhaustReduce volumeValve arrangementsElectrical controlExhaust valveTop dead center

A method for an engine capable of burning gaseous fuel, the engine also including a combustion chamber, at least one intake valve, and at least one exhaust valve, an injector to directly inject pressurized gaseous fuel into the combustion chamber, and a variable valve timing system coupled to the intake valves and exhaust valves, the method comprising closing the exhaust valve before top dead center of piston position to increase combustion chamber pressure achieved at top dead center and to trap exhaust gas in the cylinder; and starting injection of a gaseous fuel directly into the combustion chamber after the exhaust valve is closed and before the intake valve is opened.

Owner:FORD GLOBAL TECH LLC

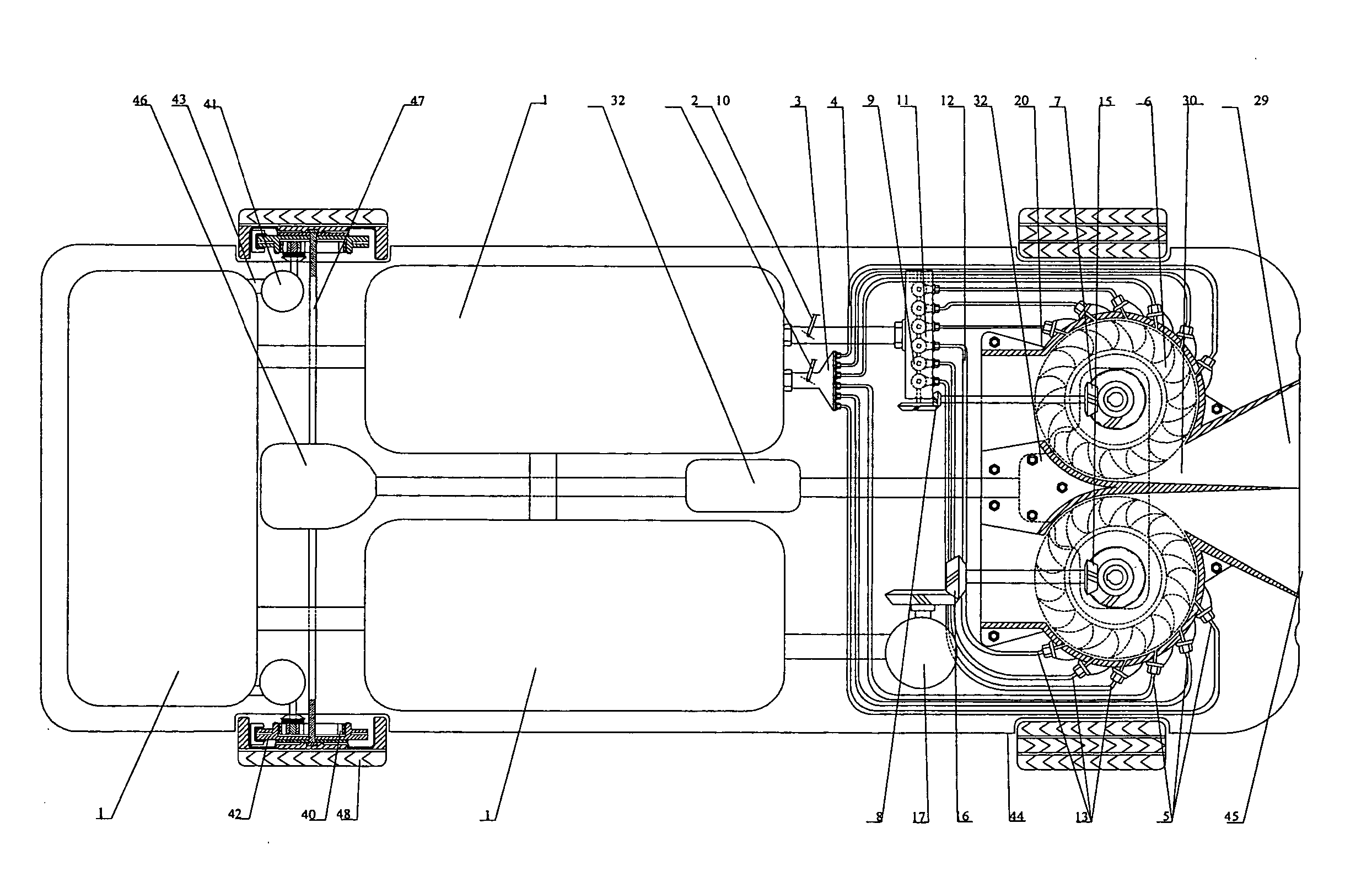

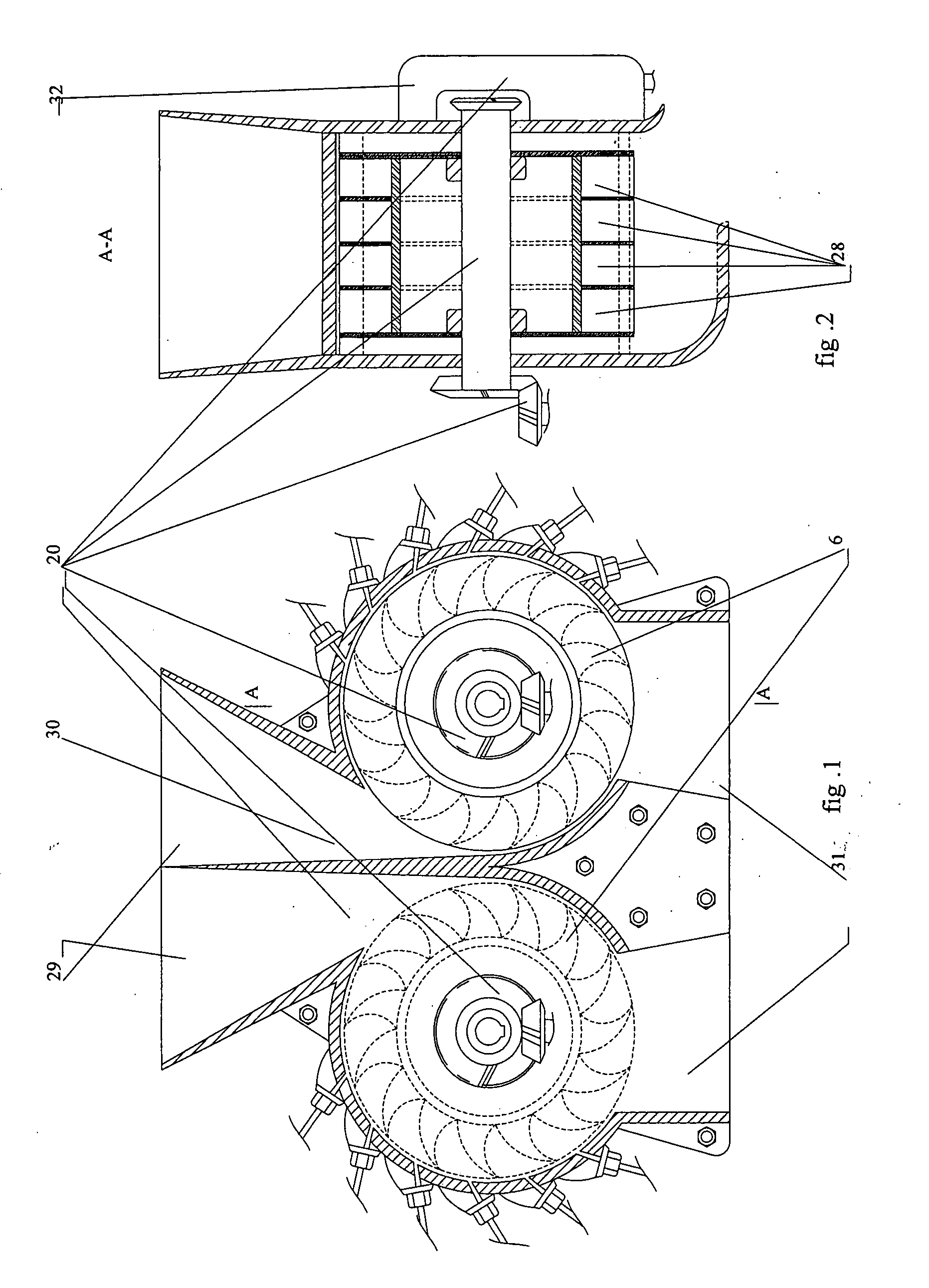

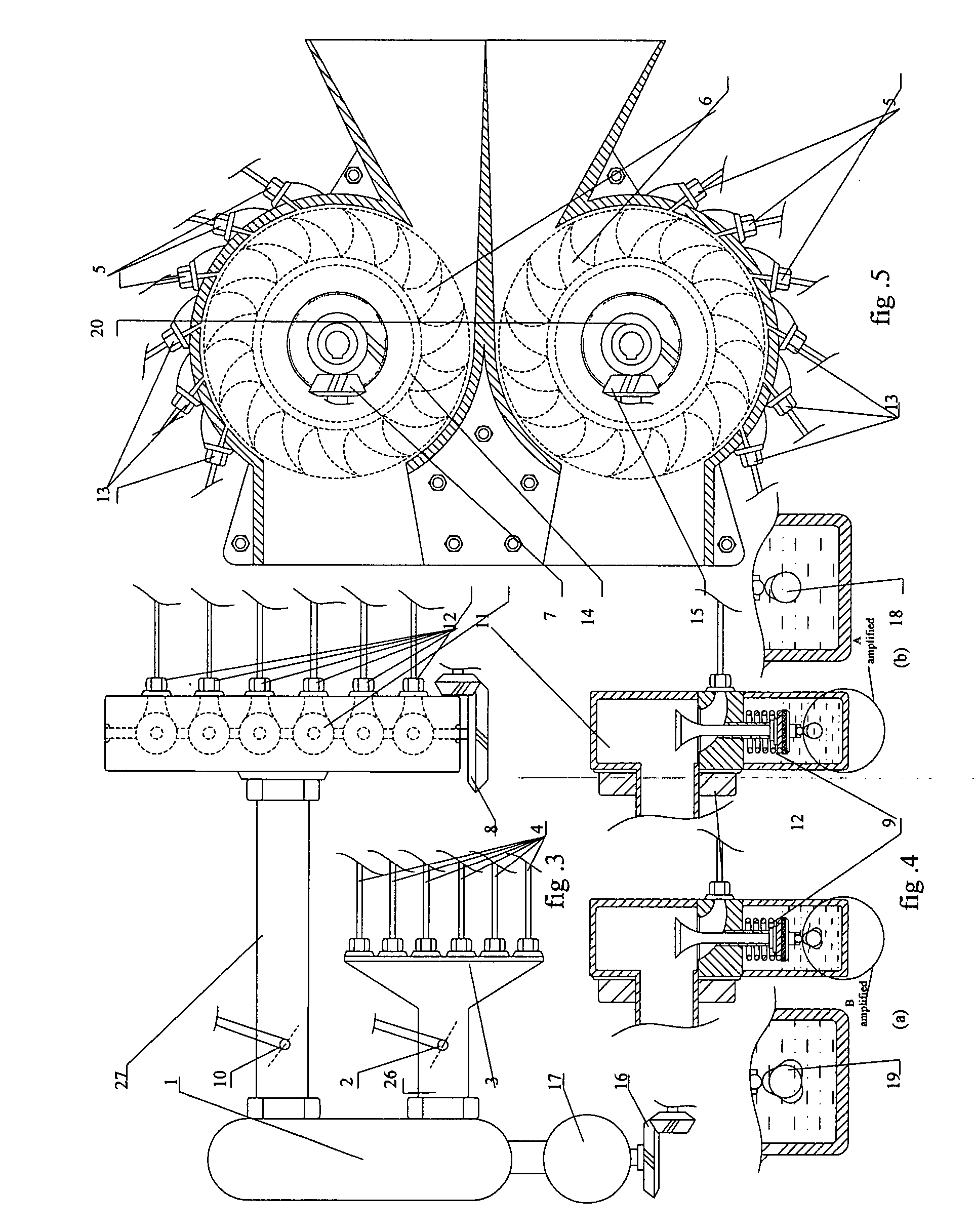

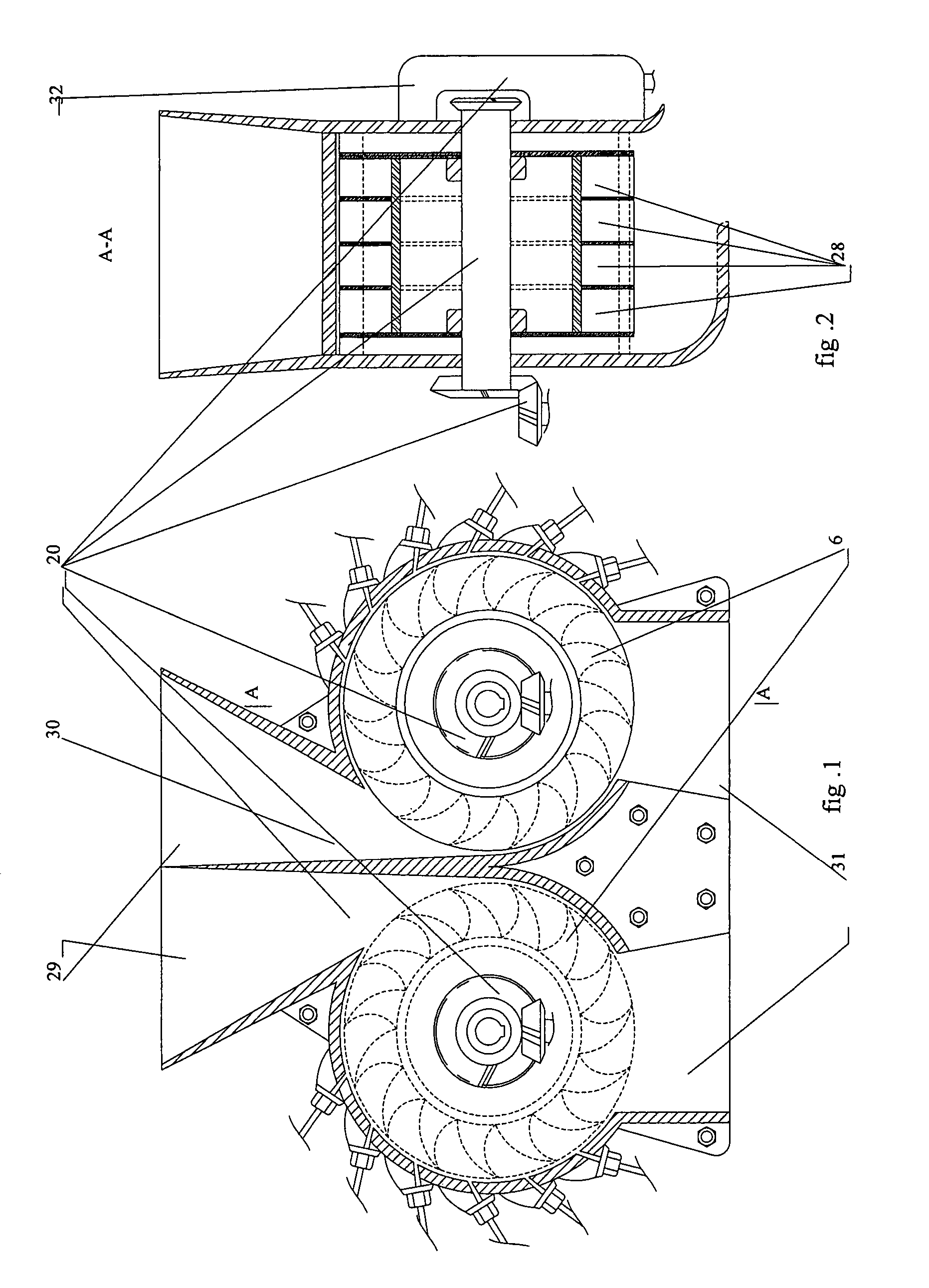

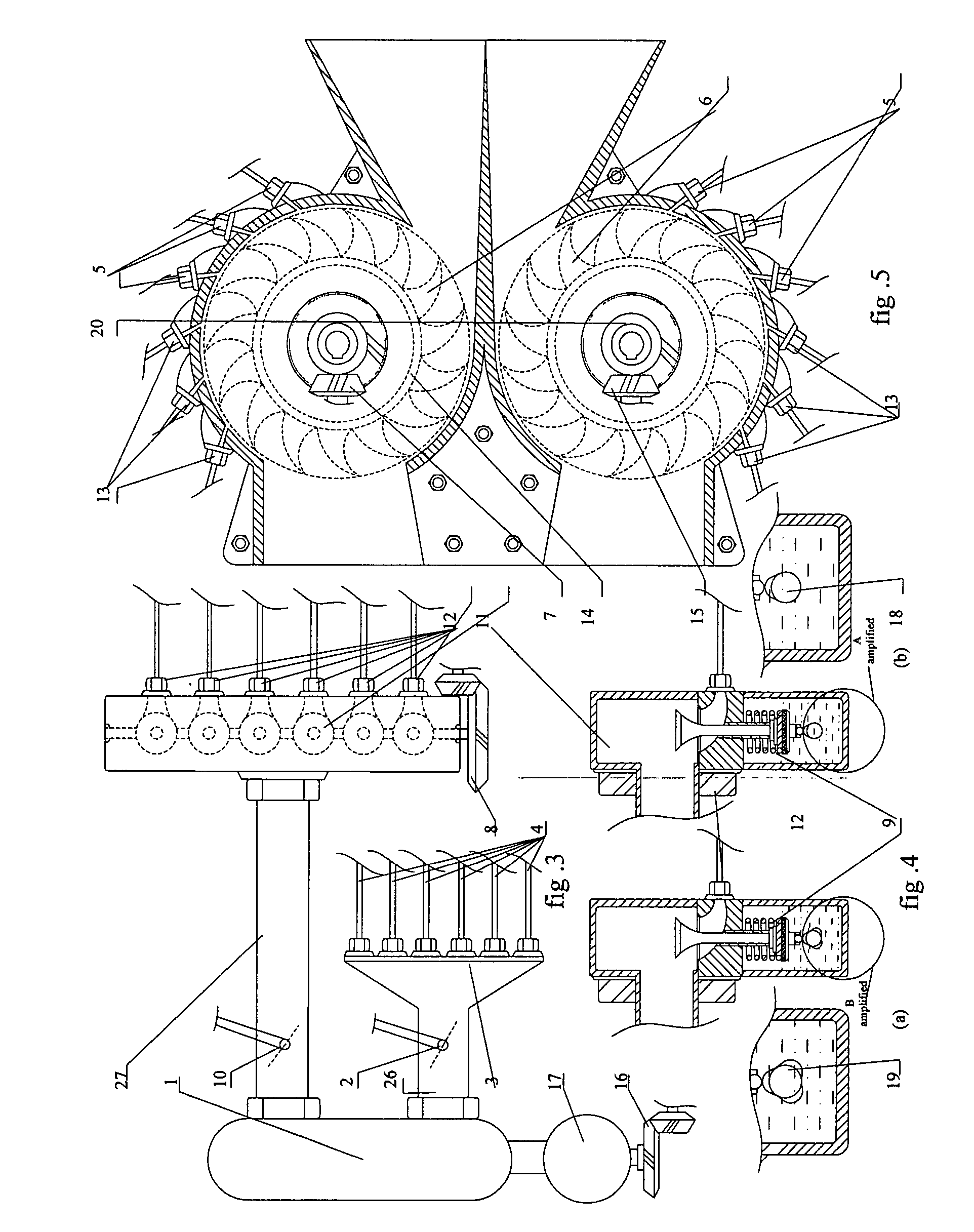

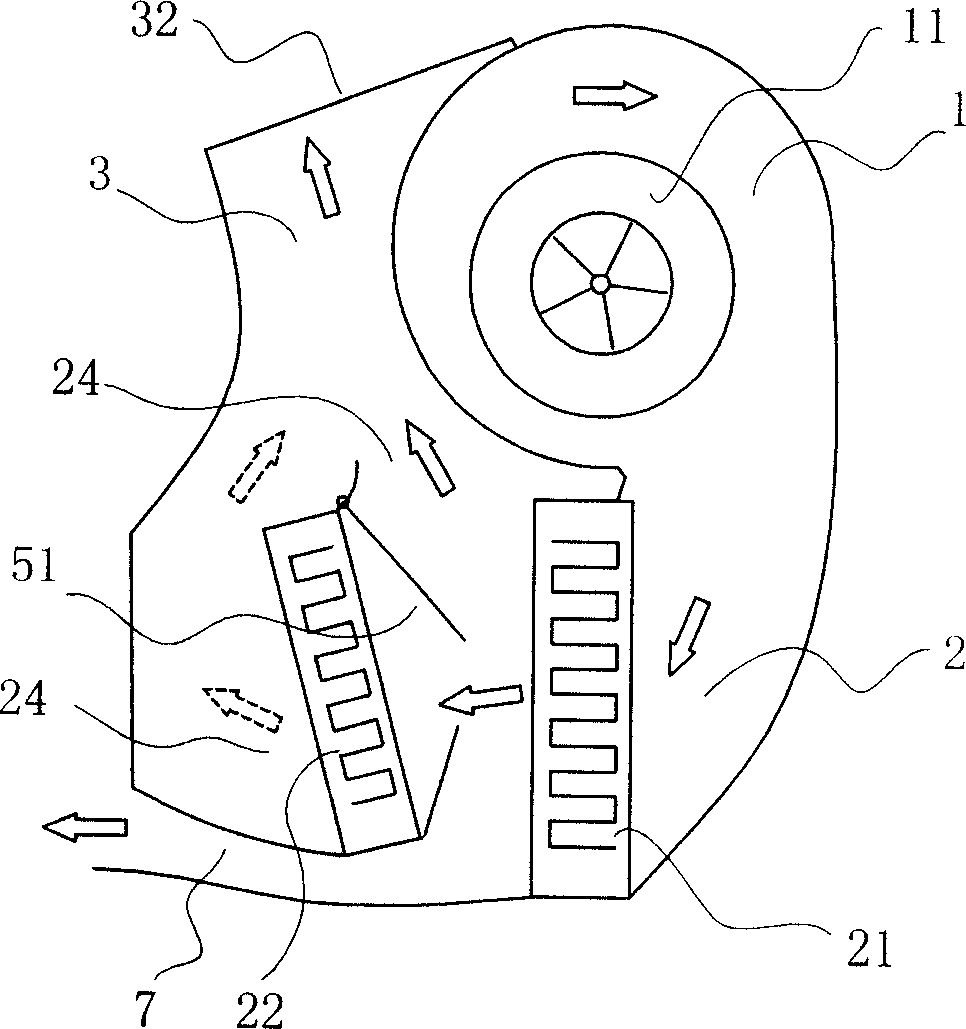

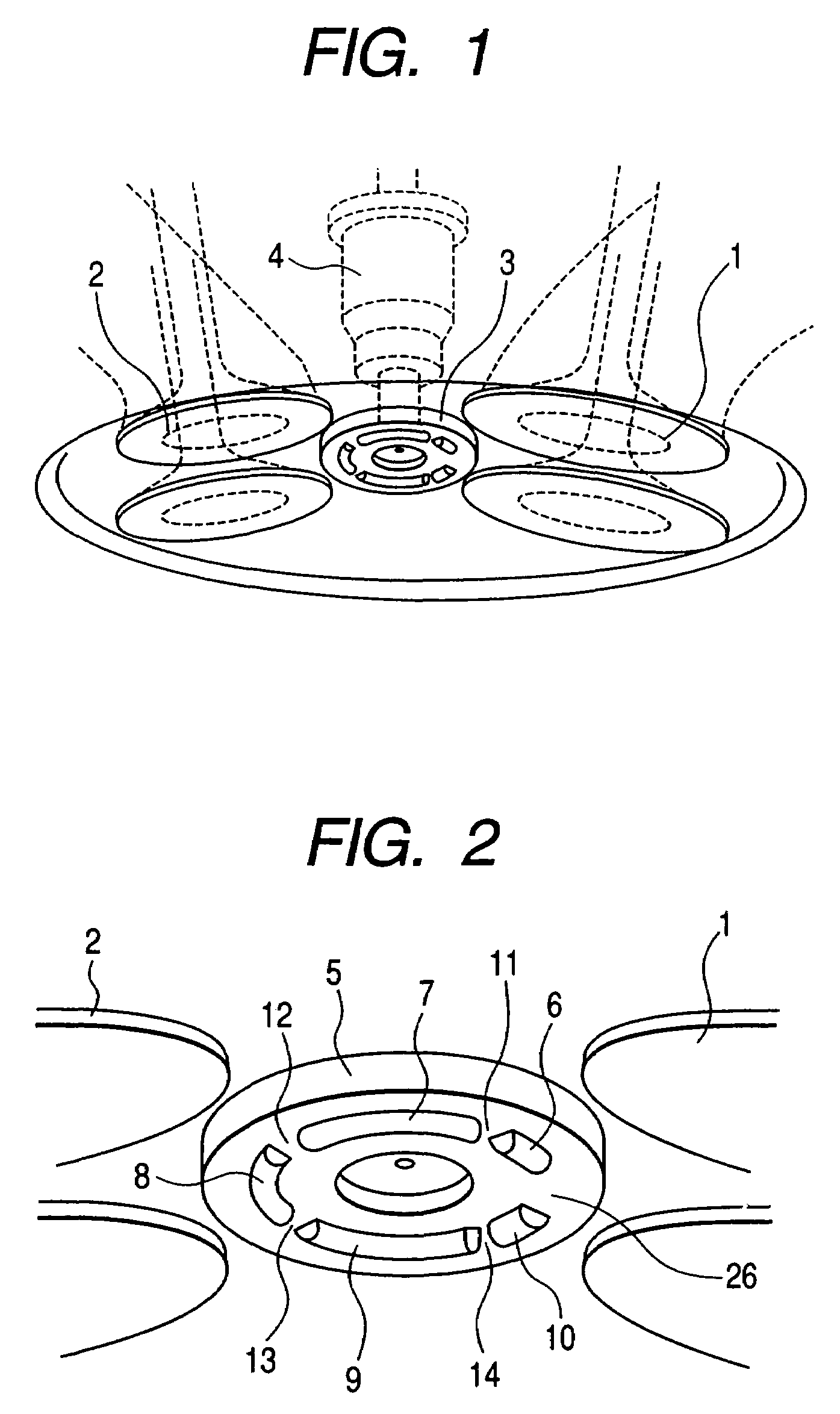

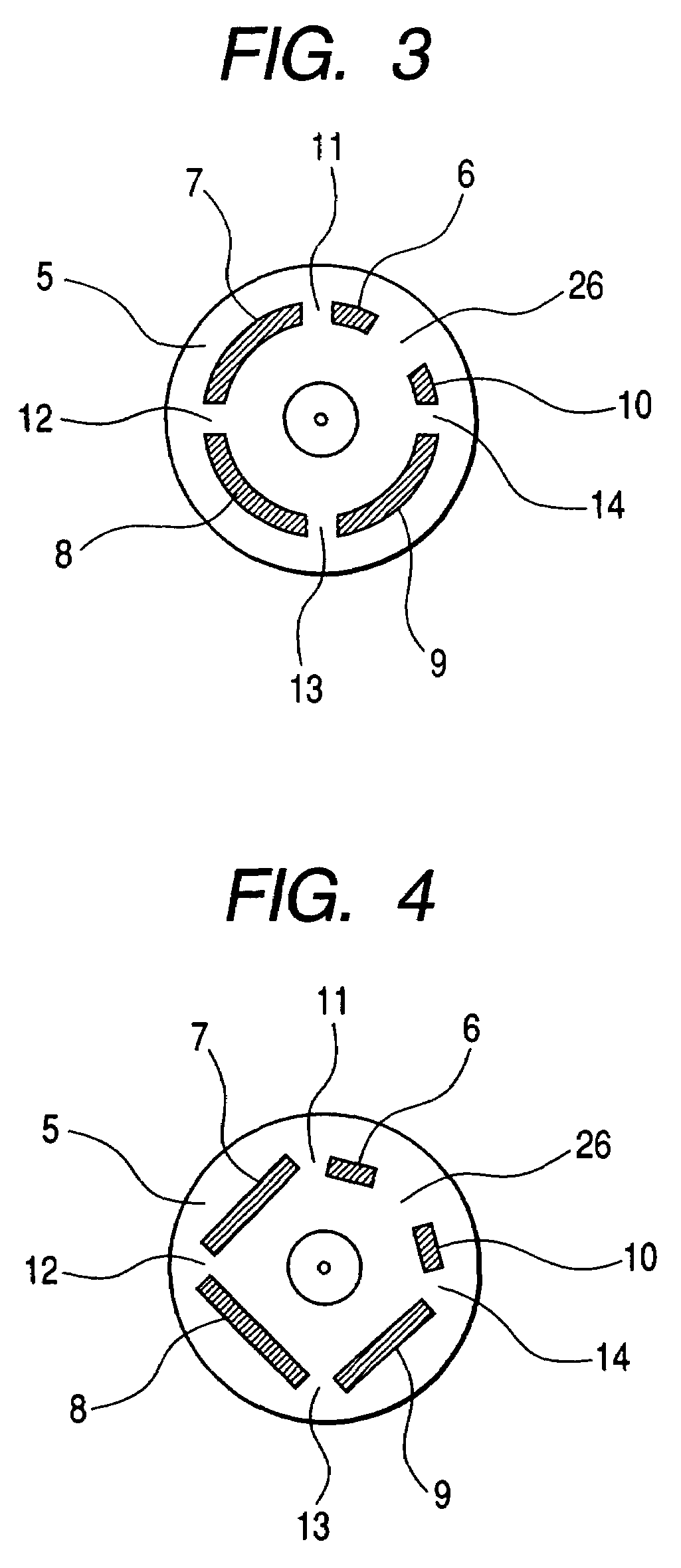

Wind-powered pneumatic engine and a motor vehicle equipped with the engine

InactiveUS20070284155A1Improve energy efficiencyIncrease profitAuxillary drivesWind motor controlEngineeringEnergy expenditure

A wind-powered pneumatic engine including one or more impeller chambers and one or more impellers disposed in the impeller chambers is provided. One or more air inlets for receiving external wind resistance airflow are disposed on the impeller chambers, and the external wind resistance airflow entering the air inlets drives the impellers to operate to generate power output. The wind-powered pneumatic engine further includes an air-jet system for jetting HPCA into the impeller chambers, and the internal high-pressure compressed air jetted by the air-jet system in conjunction with the external wind resistance airflow entering the air inlets drives the impellers to operate to generate power output. In the present invention, the external resistance airflow around a motor vehicle moving at a speed is converted into power for use, which greatly reduces energy consumption and improves the moving speed of a motor vehicle. A motor vehicle equipped with wind-powered pneumatic engine is also provided.

Owner:CONG YANG

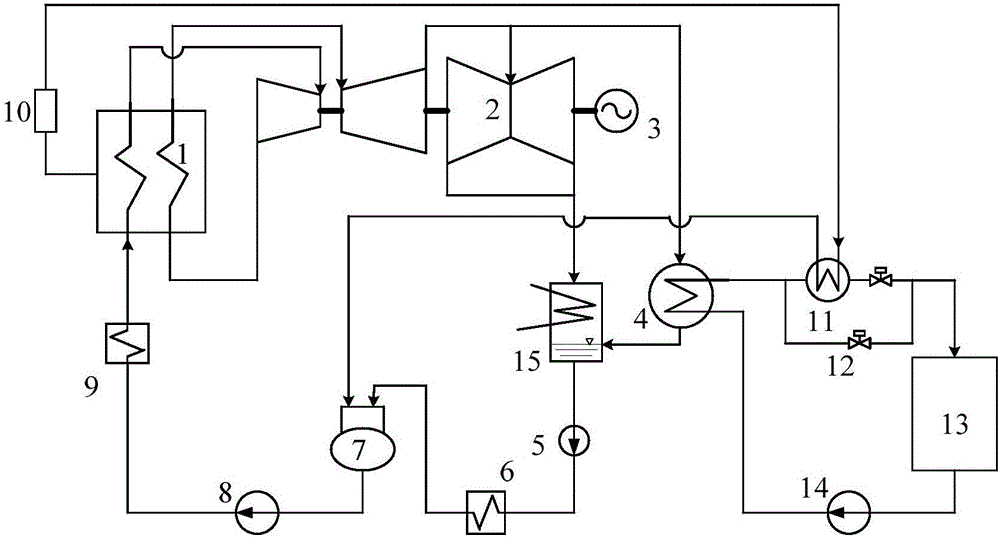

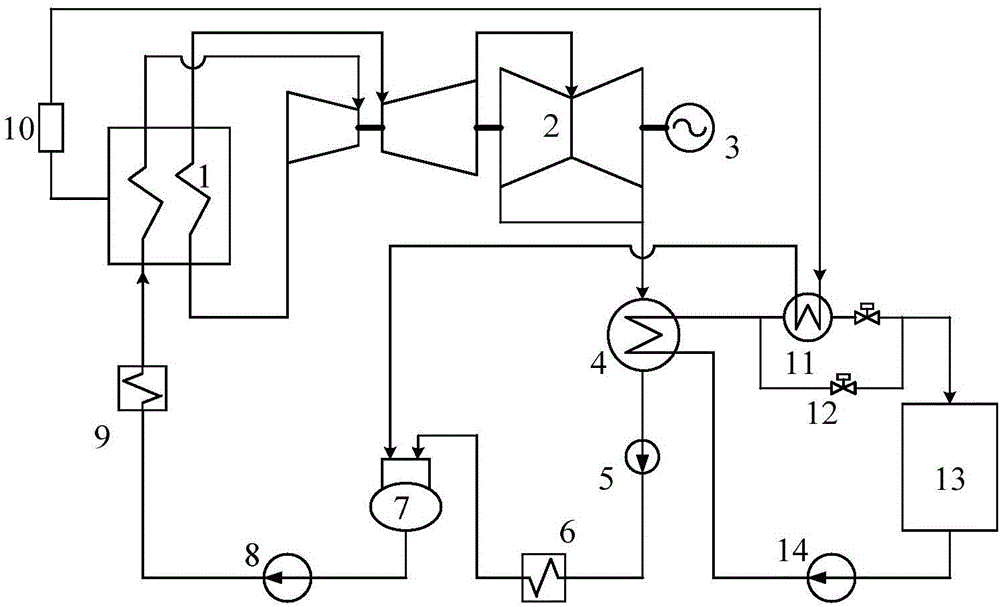

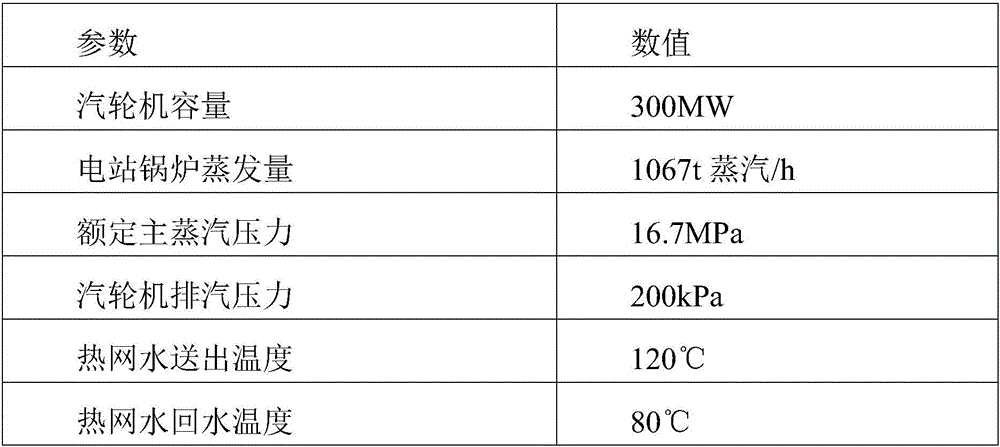

Thermoelectric decoupling heating system extracting steam from utility boiler

InactiveCN106194296AAchieve thermoelectric decouplingCapable of peak regulationSteam engine plantsEngineeringHigh pressure

The invention discloses a thermoelectric decoupling heating system extracting steam from a utility boiler. A steam condensing heat exchanger is mainly adopted for heating return water of a heating network, a steam extraction heater is then additionally arranged behind the steam condensing heat exchanger, and heat source steam of the steam extraction heater is extracted from an overheating section or a reheating section of the utility boiler. When a turbine power generation system is under the high load, exhaust steam of a turbine or steam extracted from a medium-pressure cylinder and low-pressure cylinder communicating pipe of the turbine is completely adopted to be condensed in the steam condensing heat exchanger to release heat to heat the water of the heating network, when the load of the turbine power generation system is reduced and the heating capability of the steam condensing heat exchanger is insufficient, high-pressure steam is extracted from the utility boiler, subjected to pressure reduction and sent to the steam extraction heater, the water of the heating network is further heated, and therefore it is ensured that the heating capability is not reduced under the low power generation load. According to the thermoelectric decoupling heating system extracting the steam from the utility boiler, thermoelectric decoupling of a heating power plant can be achieved, it is ensured that the heating capability under the low power generation load is not reduced, in addition, decreasing of the temperature of tail smoke of the utility boiler under the low load can be relieved, and it is ensured that a boiler denitration system works normally.

Owner:HUANENG POWER INT INC +1

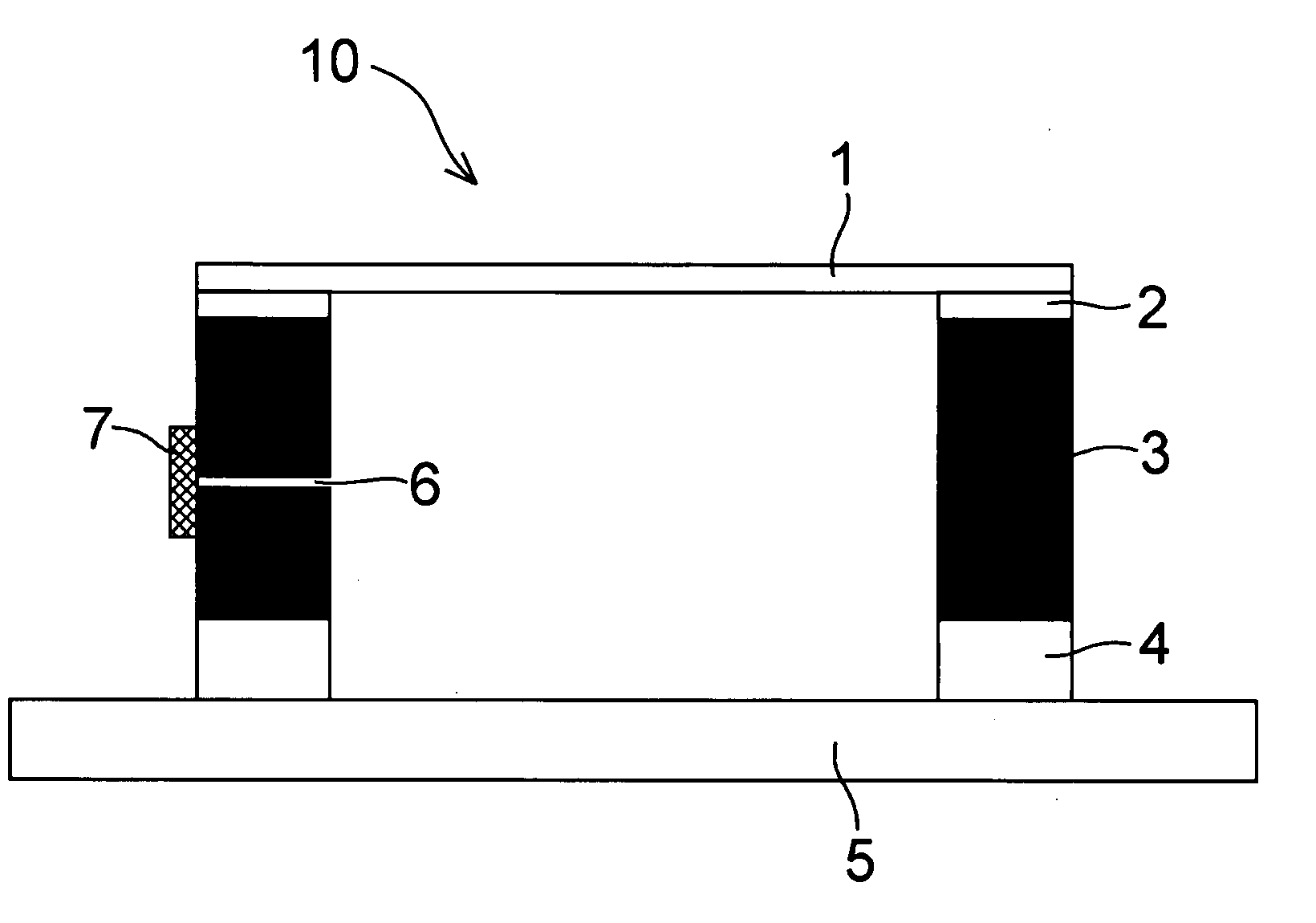

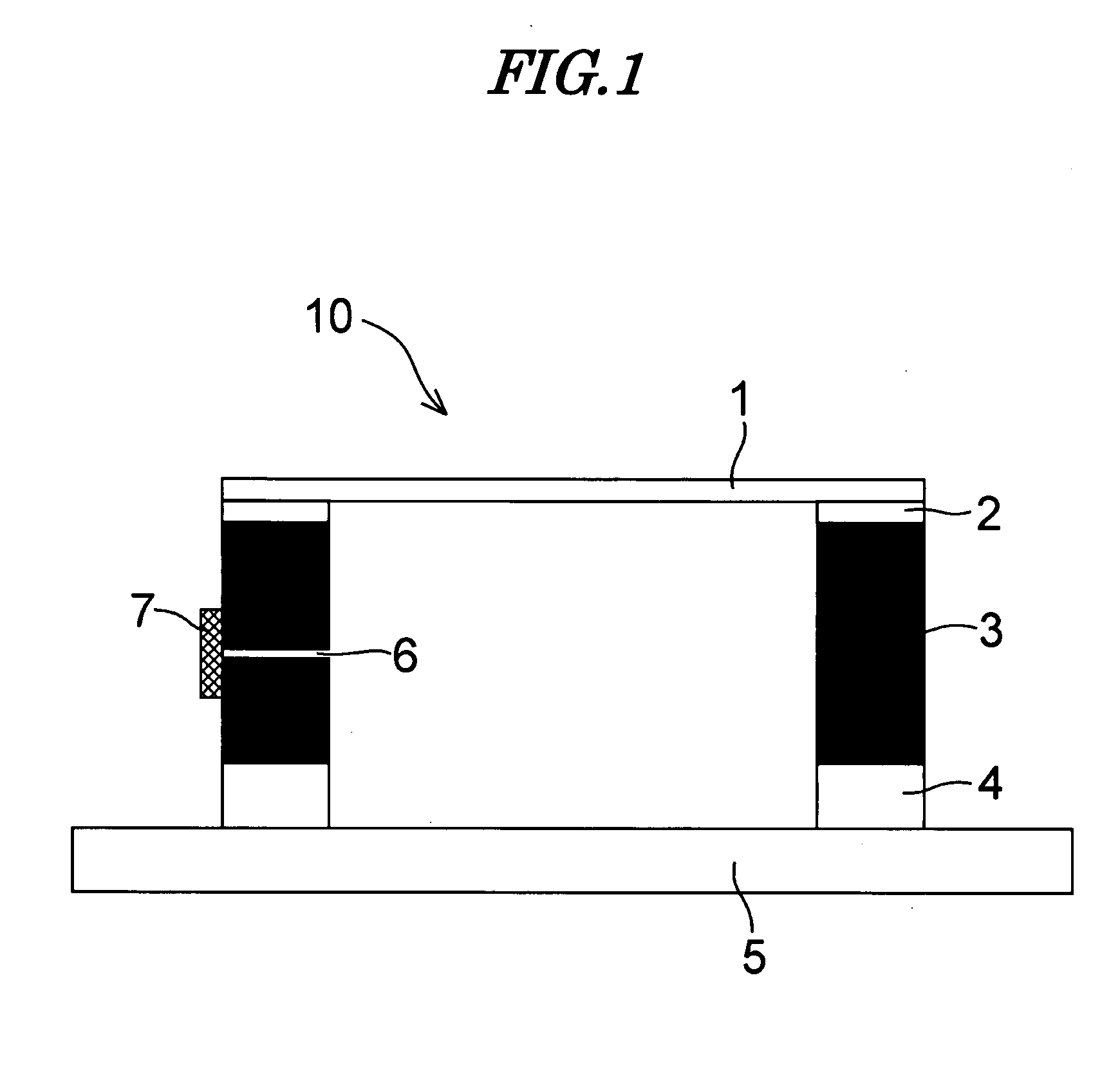

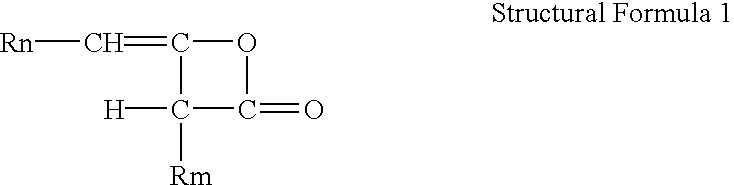

Pellicle

InactiveUS20070292775A1Reduce the amount requiredReduce exhaustPhotomechanical apparatusOriginals for photomechanical treatmentPolymer coatingsPellicle membrane

A pellicle is provided that includes an aluminum alloy pellicle frame having a polymer coating on the surface and a pellicle film stretched over the pellicle frame. There is also provided a process for producing the pellicle in which the polymer coating is an electrodeposition-coated film, the process including a step of roughening the surface of the aluminum alloy pellicle frame by sandblasting, a step of etching the surface of the pellicle frame with an alkali solution, a step of electrodeposition coating the pellicle frame, and a step of stretching the pellicle film over the pellicle frame.

Owner:SHIN ETSU CHEM IND CO LTD

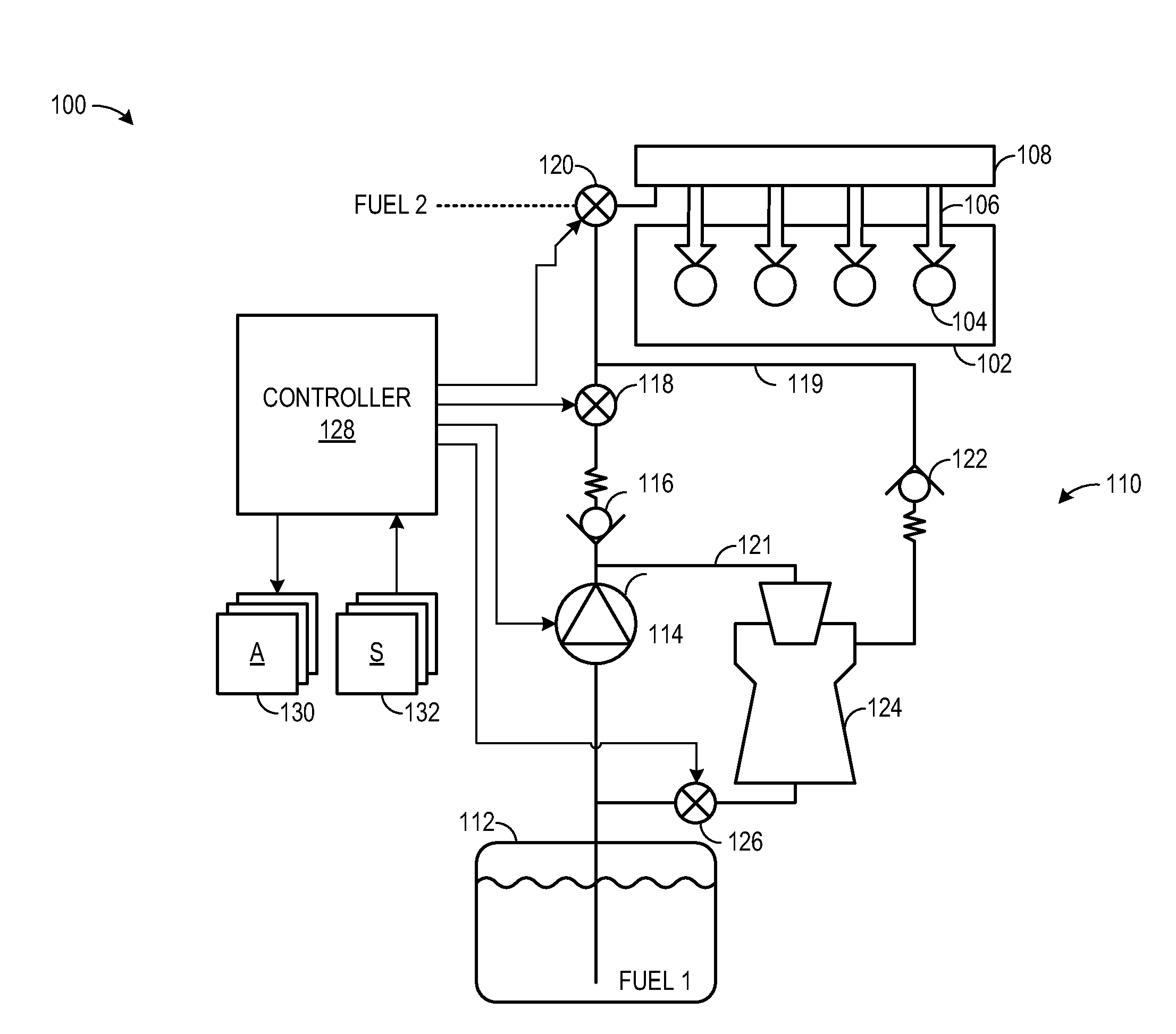

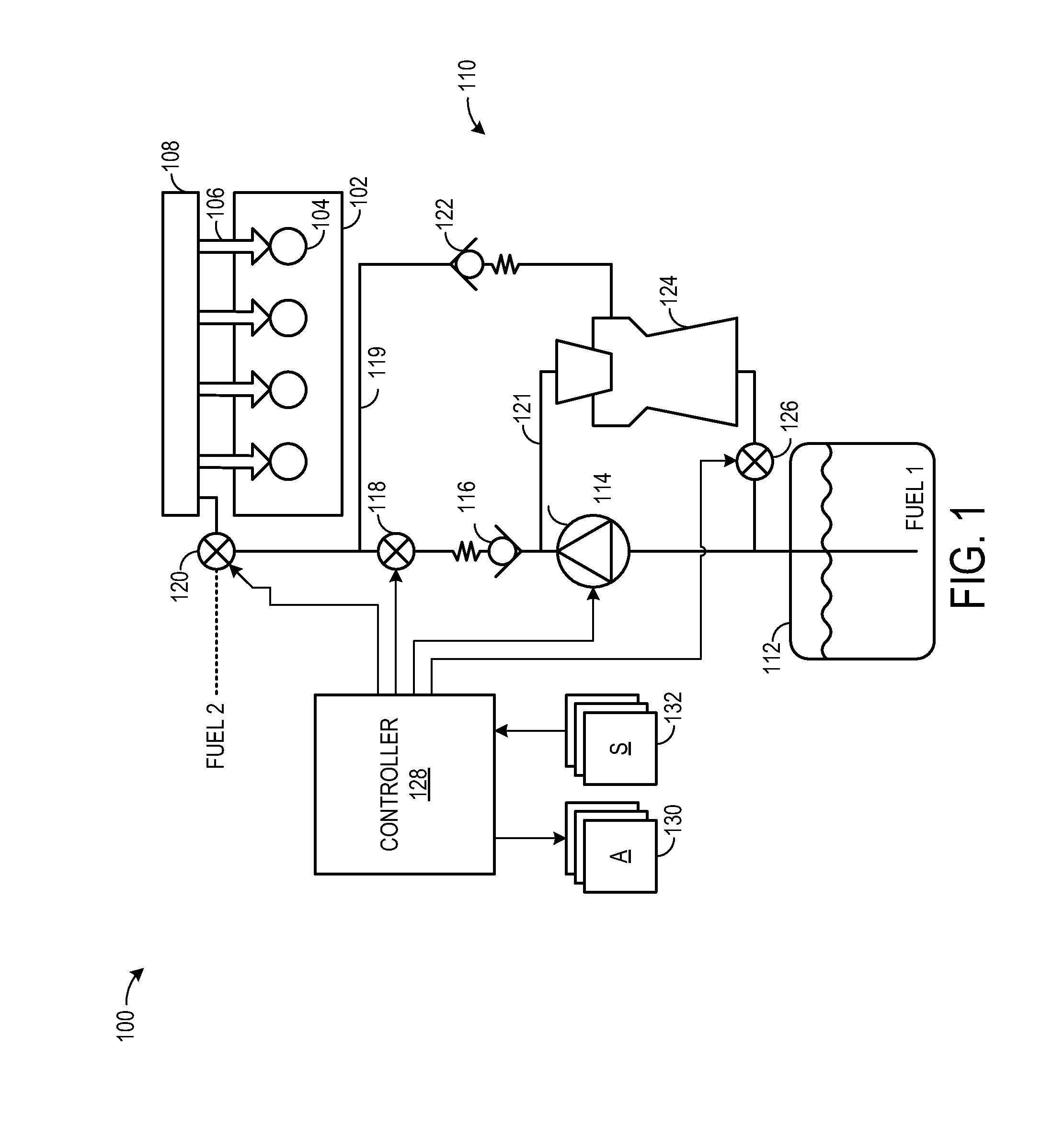

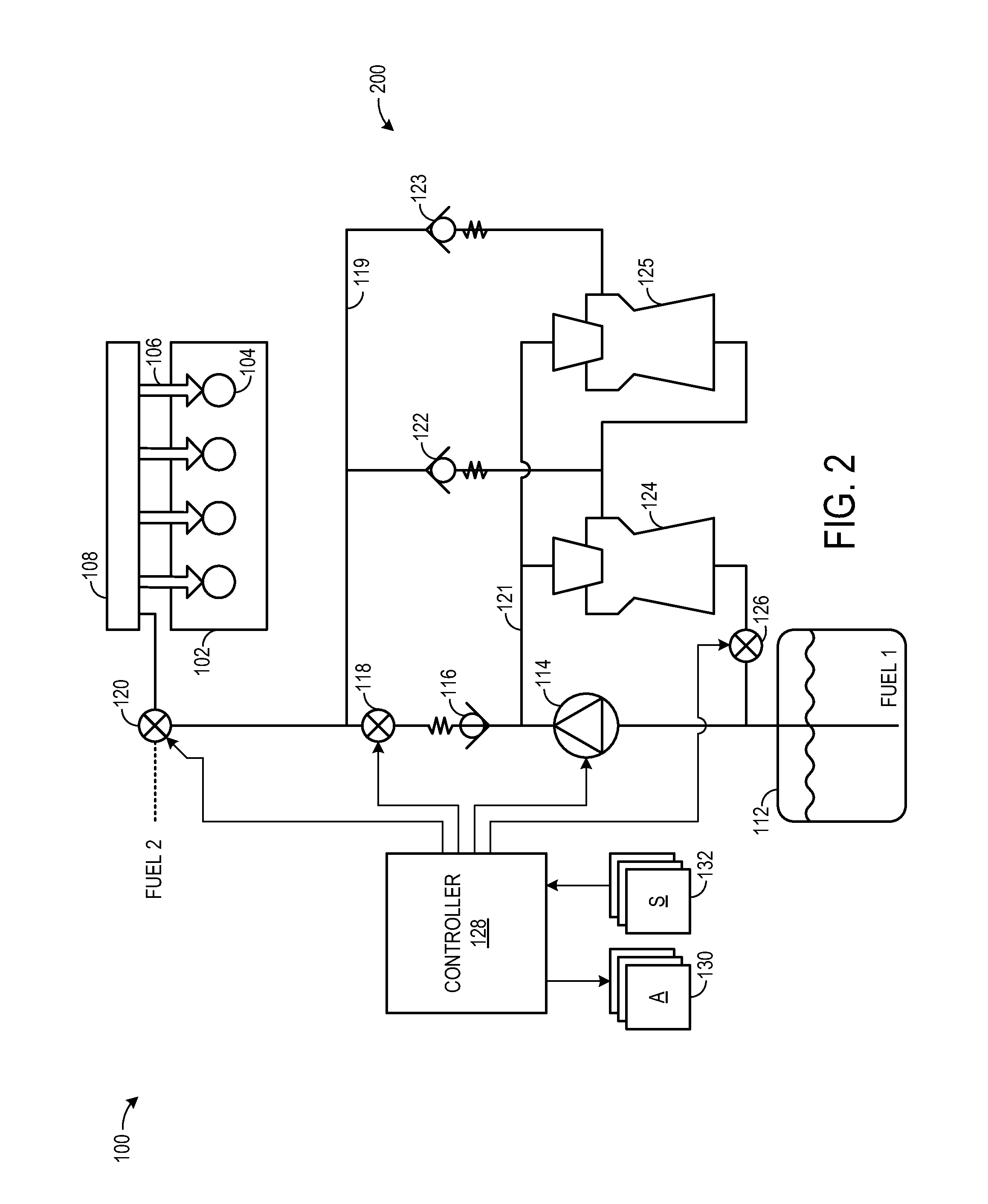

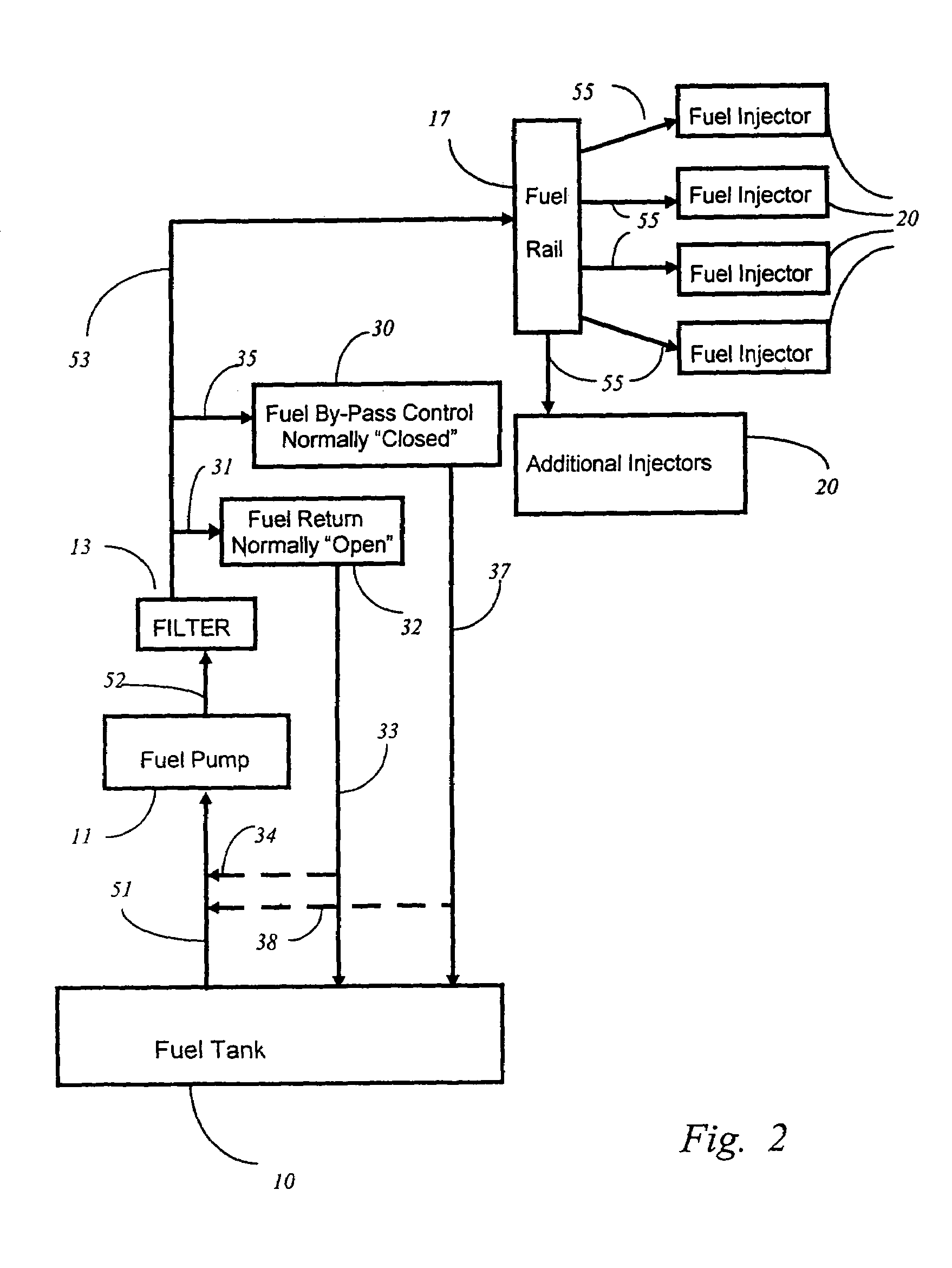

Approach for controlling fuel flow with alternative fuels

ActiveUS20110168133A1Reduced air displacementIncreased massAnalogue computers for vehiclesCoolant flow controlAutomotive engineeringAlternative fuels

Fuel is evacuated from a fuel rail by directing liquid fuel from the fuel rail to a fuel tank and then by directing gaseous fuel from the fuel rail to a fuel vapor canister.

Owner:FORD GLOBAL TECH LLC

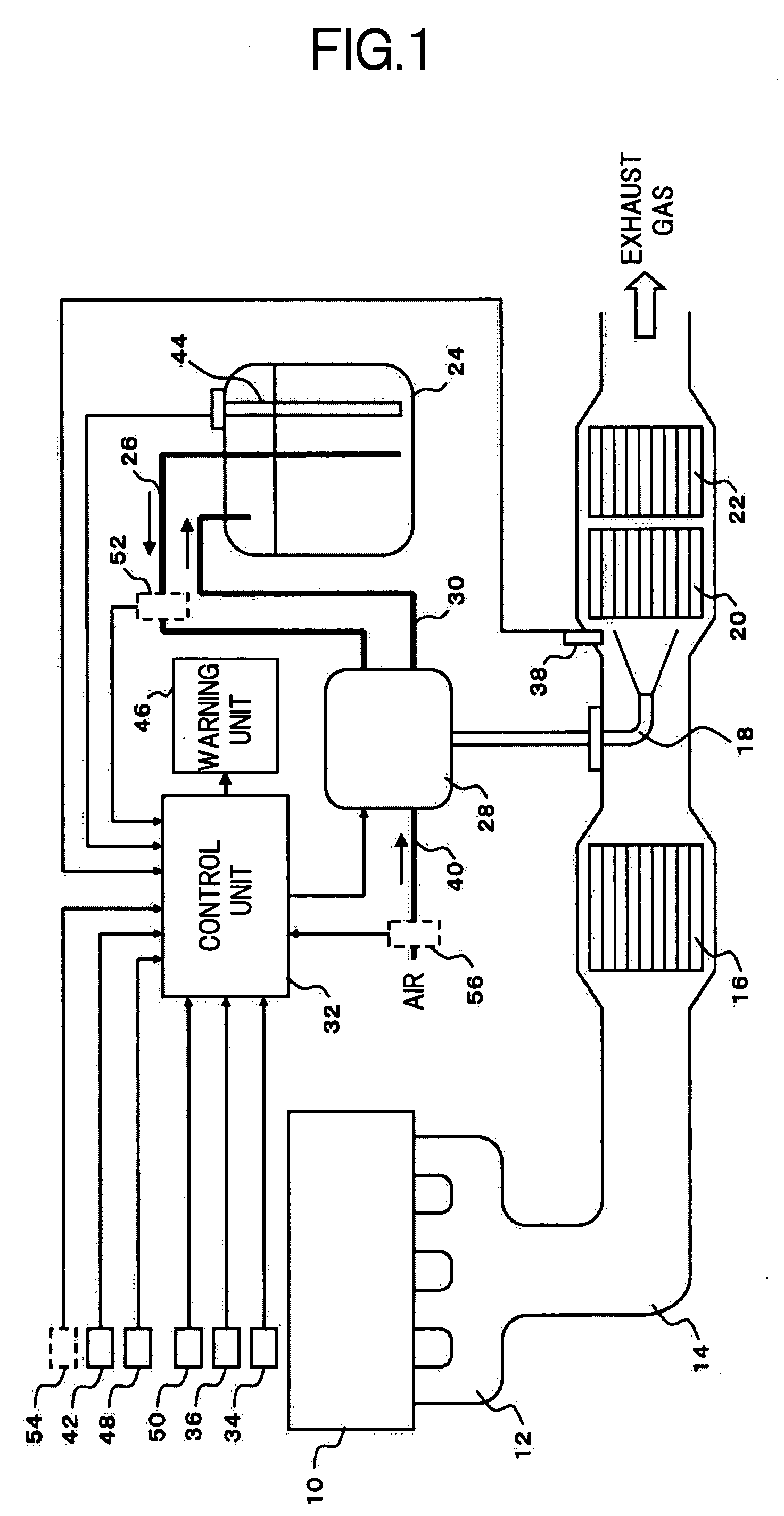

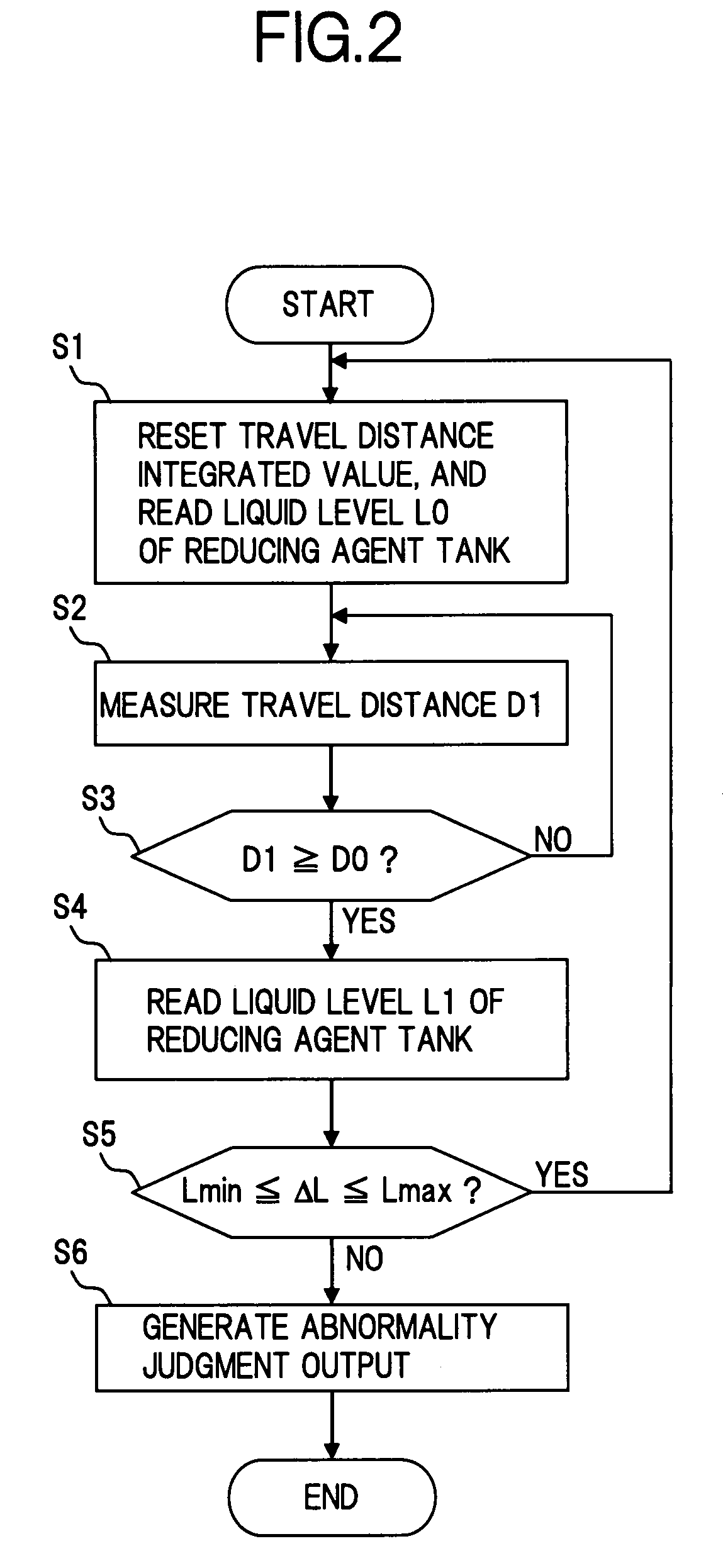

Apparatus for judging condition of injection of reducing agent incorporated in exhaust gas purification system

InactiveUS20070266703A1Increase in NOxReduce exhaustNitrous oxide captureCombination devicesRunning timeContinuous monitoring

In relation to an exhaust gas purification system that mixes a liquid reducing agent with air and injection-supplies this mixture into an exhaust gas flowing on an upstream side of a reduction catalyst (20) to thereby effect reduction purification of NOx in exhaust gas, a technical attention is directed to the relation of respective elements of; the travel distance, the fuel consumption, the air consumption, or the running time and the like, and the liquid reducing agent consumption, to constitute a configuration such that a continual monitor as to whether the injection condition of liquid reducing agent is normal or abnormal is executed by judging whether or not the amount of liquid reducing agent consumed for a predetermined travel distance, a predetermined fuel consumption, a predetermined air consumption, or a predetermined running time, is within a predetermined range.

Owner:NISSAN DIESEL MOTOR CO

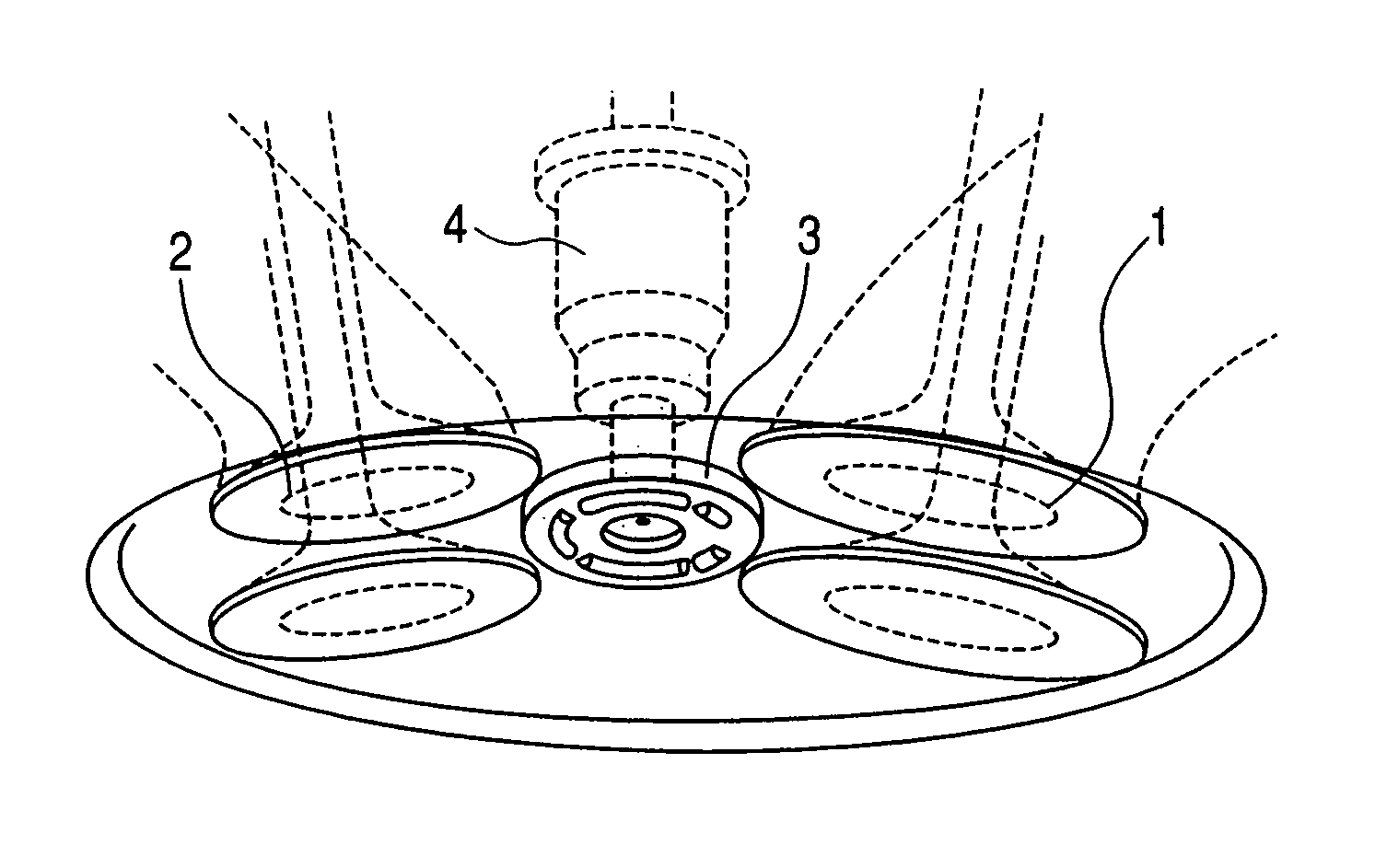

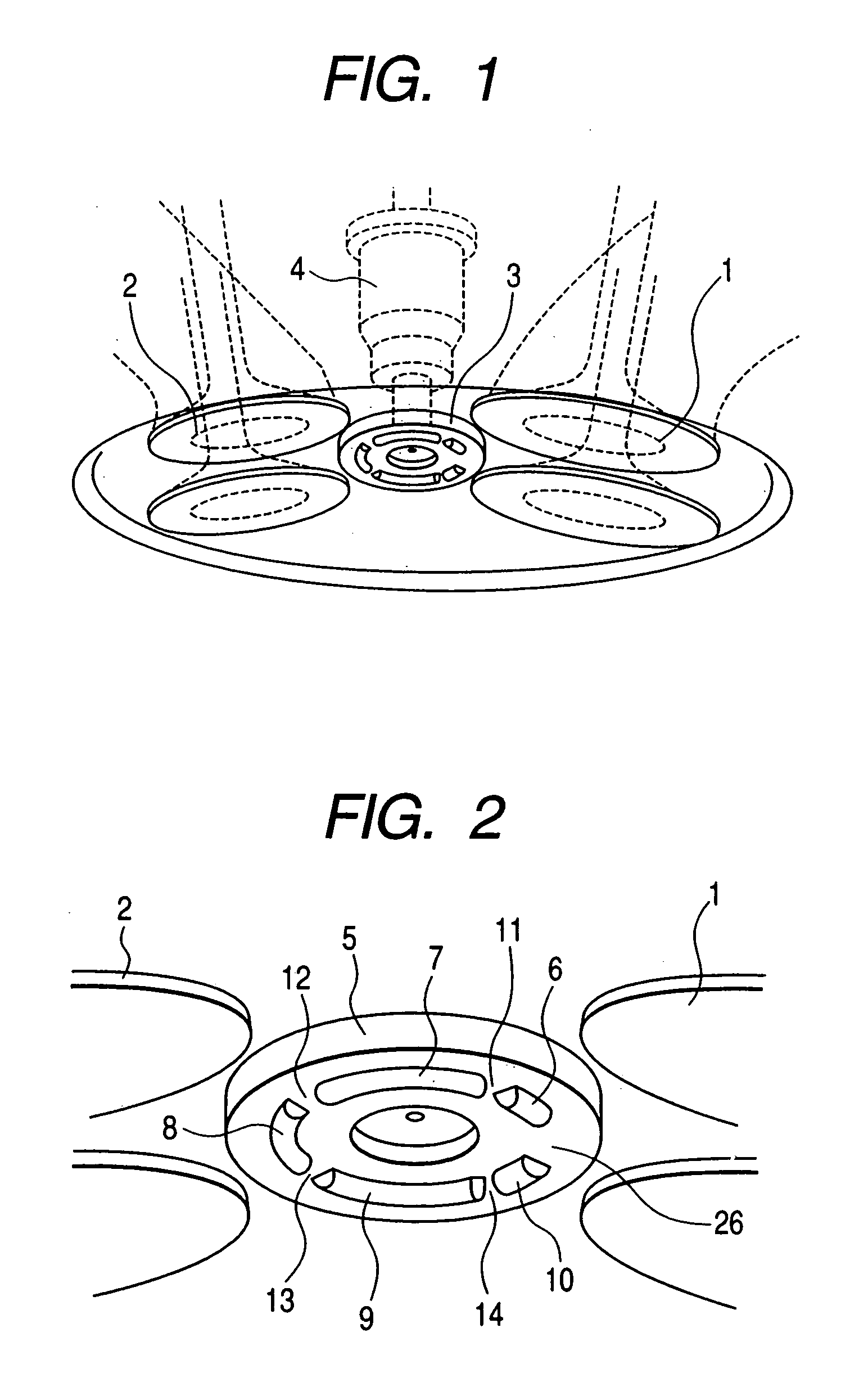

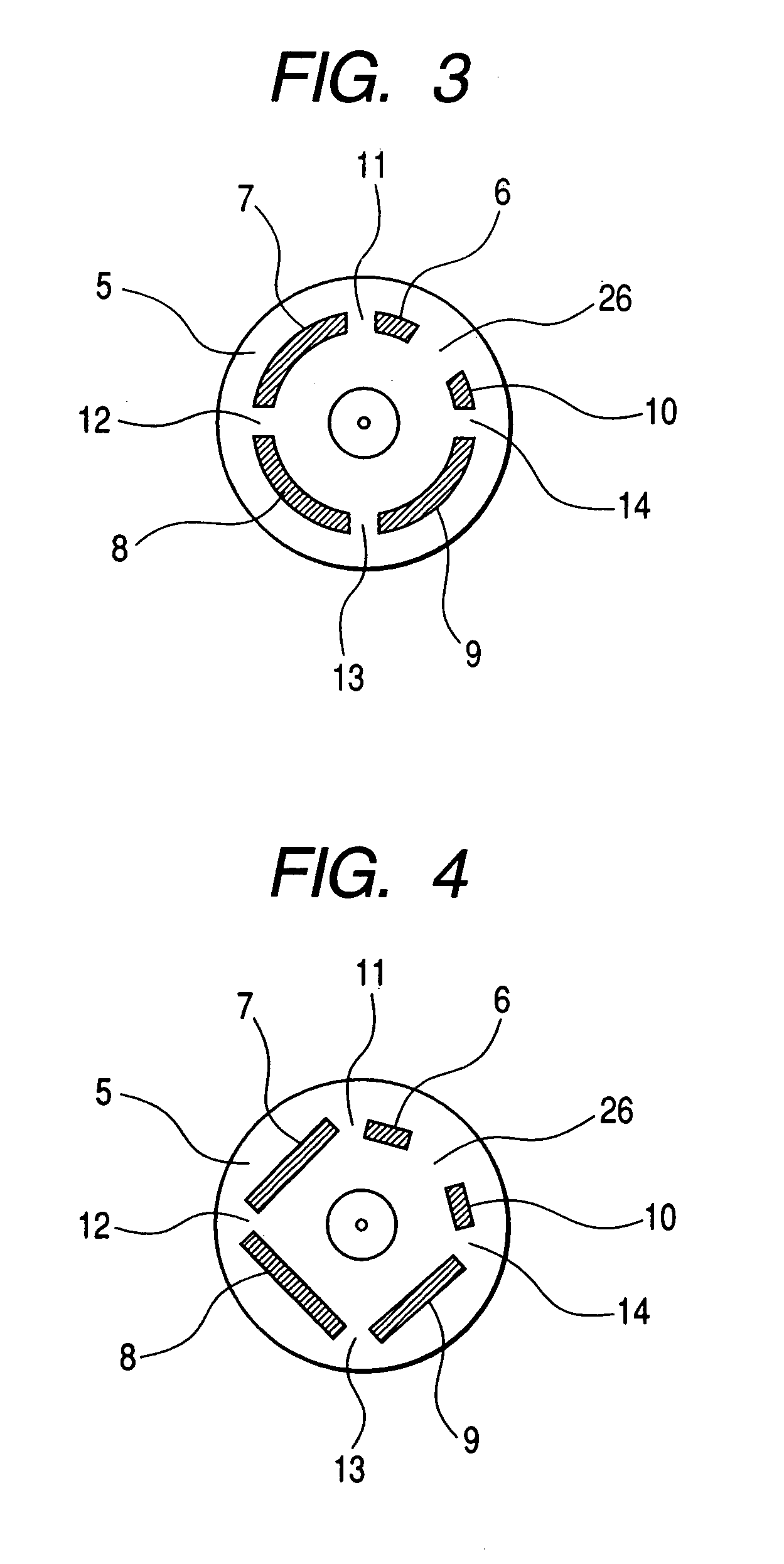

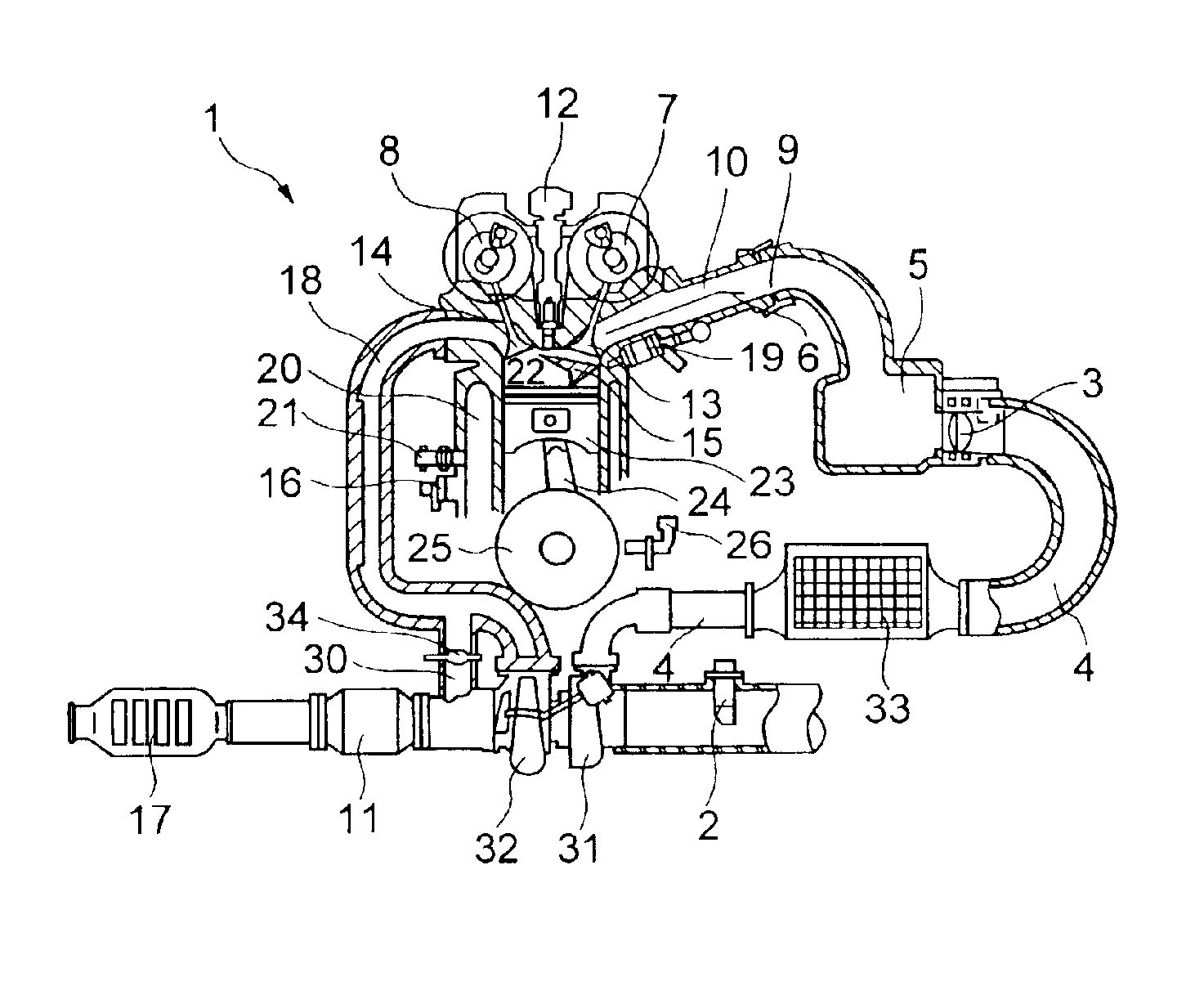

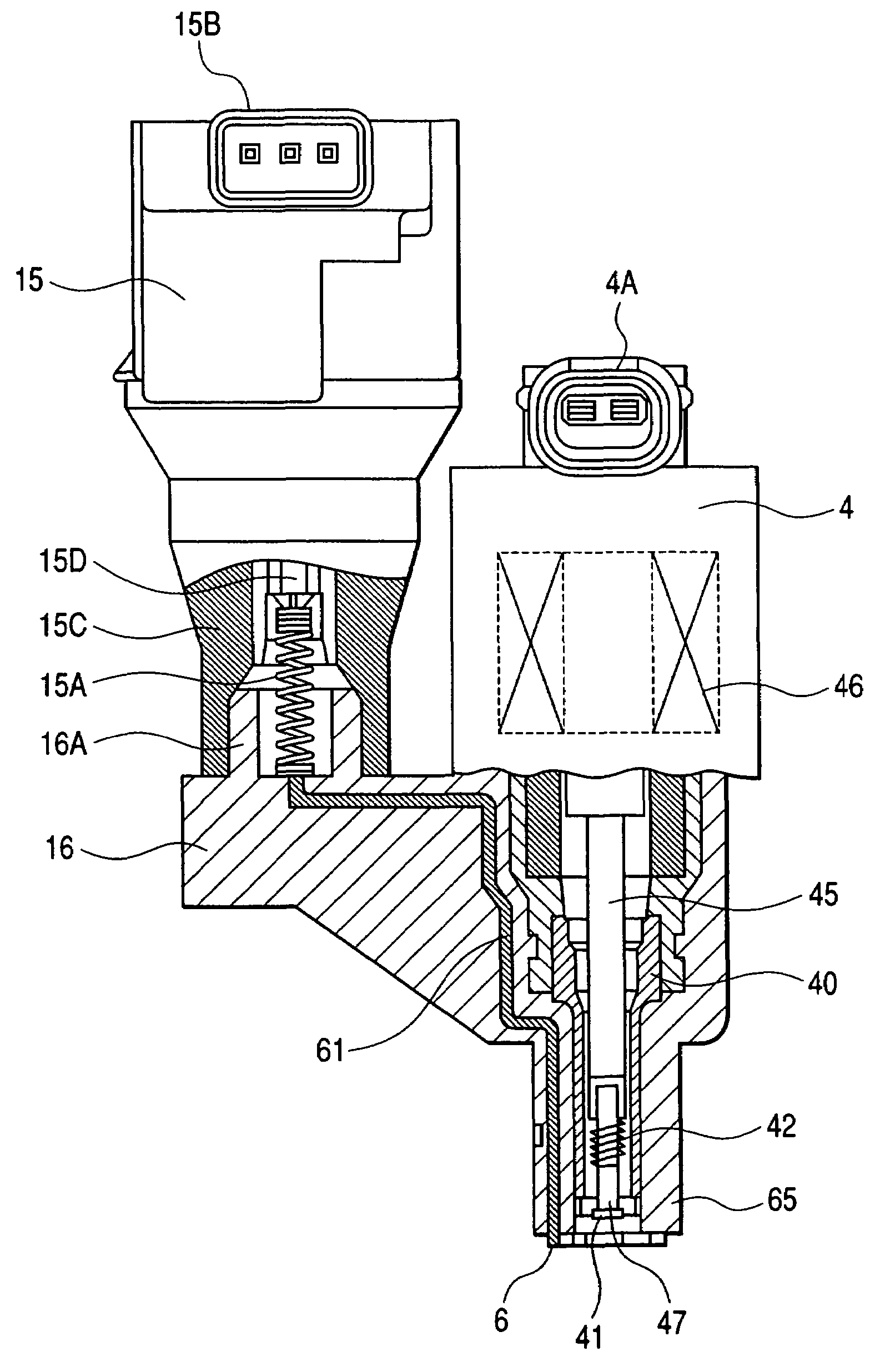

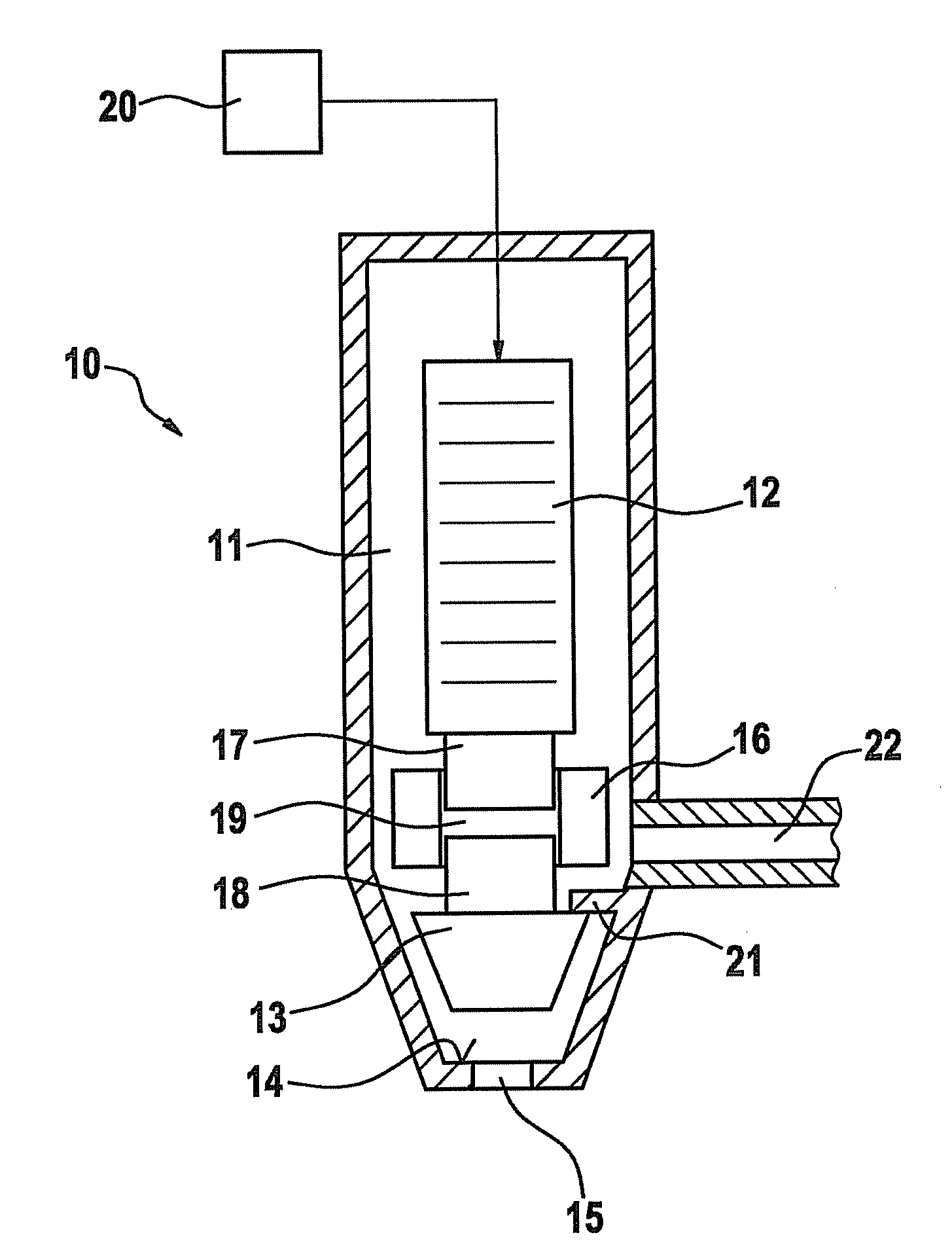

Spark ignition device and internal combustion engine with the same

InactiveUS20060102140A1Spread of fire be improveCombustion speed be increaseSparking plugsInternal combustion piston enginesIgnition coilInjector

A plurality of spark electrodes are disposed in an arc shape on the surface or so as to be projected from the surface of an insulating member formed on a part of the wall face of a combustion chamber, and are formed so as to be in series electrically via discharging gaps. A spark plug is provided integrally with an injector, and the spark plug and the ignition coil are integrated. The three members are constructed as an integral unit, thereby improving installability to an engine.

Owner:HITACHI LTD

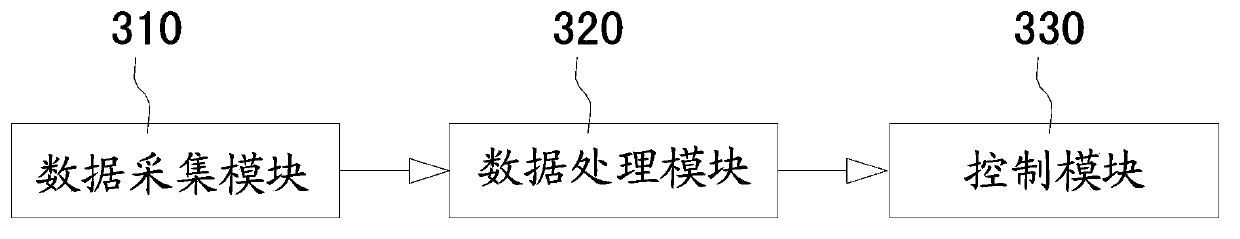

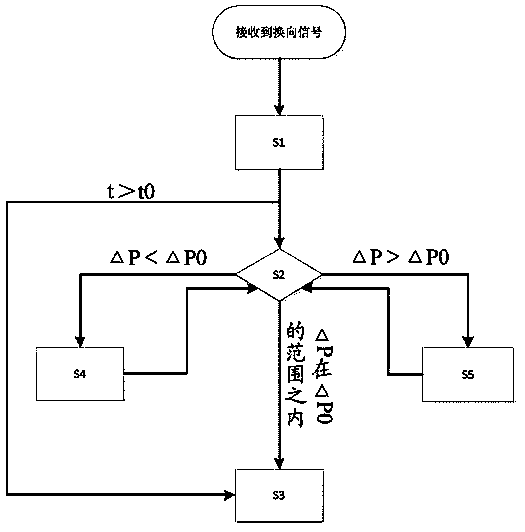

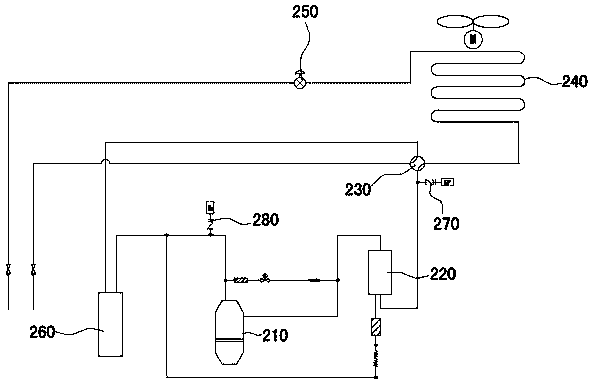

Control method of air-conditioning system and air-conditioning system

ActiveCN103968494AEffective control of differential pressureGuaranteed commutation reliabilitySpace heating and ventilation safety systemsLighting and heating apparatusFour-way valveEngineering

The invention discloses a control method of an air-conditioning system and the air-conditioning system. The control method comprises the following steps: 1, when receiving a signal of a switch four-way valve, respectively detecting pressure values (P1 and P2) of an outlet and an inlet of a compressor; 2, calculating the pressure difference delta P of (P1 and P2), judging whether delta P is within the range of preset pressure different delta P0 or not, if delta P is within the range of delta P0, controlling the four-way valve to perform steering action, if delta P is less than delta P0, controlling the compressor to increase the exhaust amount, if delta P is greater than delta P0, controlling the compressor to reduce the exhaust amount. Through the adoption of the control method disclosed by the invention, the pressure difference of the four-way valve when steering is effectively controlled, the reliability of the four-way valve in steering is ensured, and moreover relatively great instantaneous noise caused by too large pressure difference is reduced when the four-way valve steers.

Owner:GREE ELECTRIC APPLIANCES INC

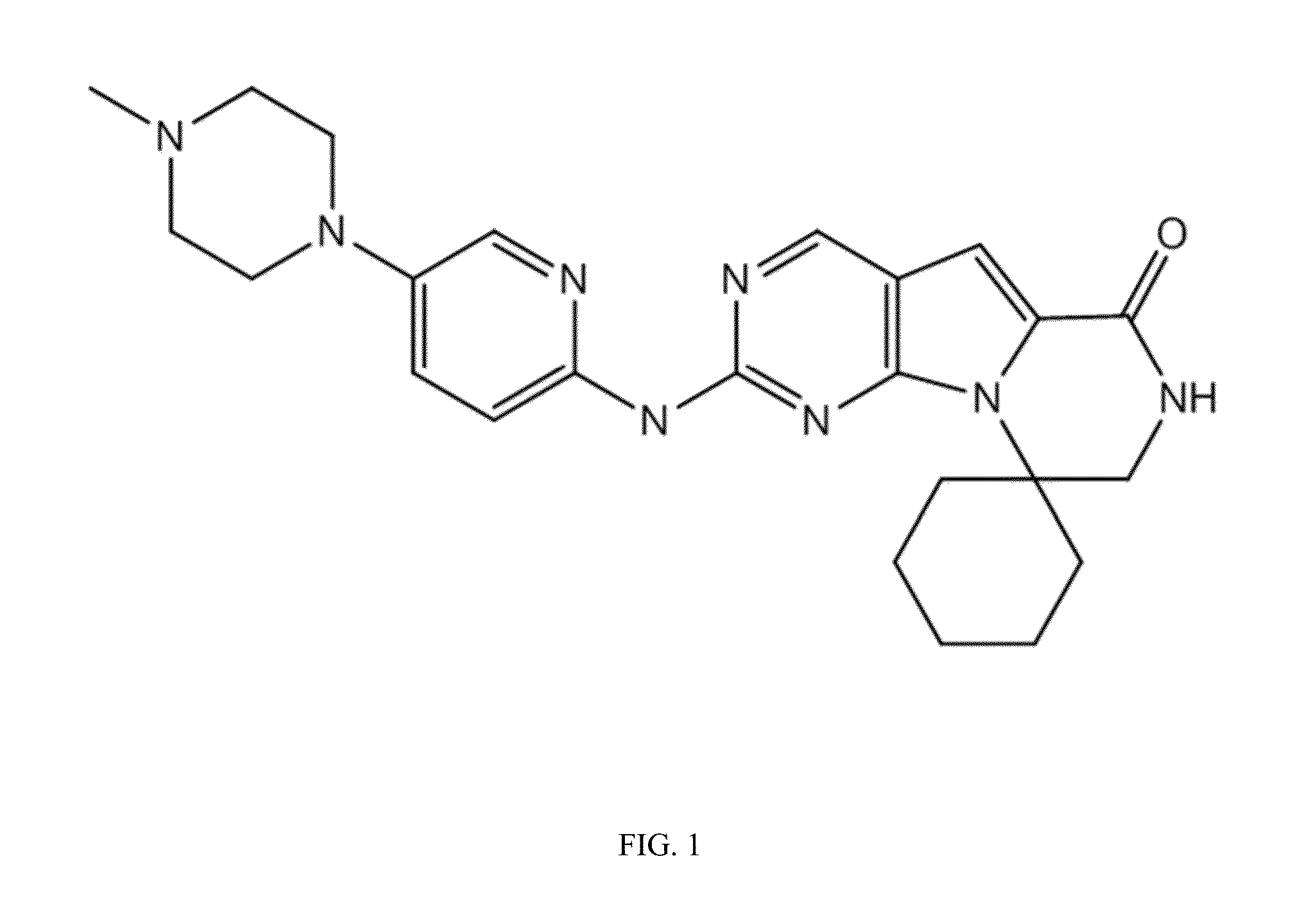

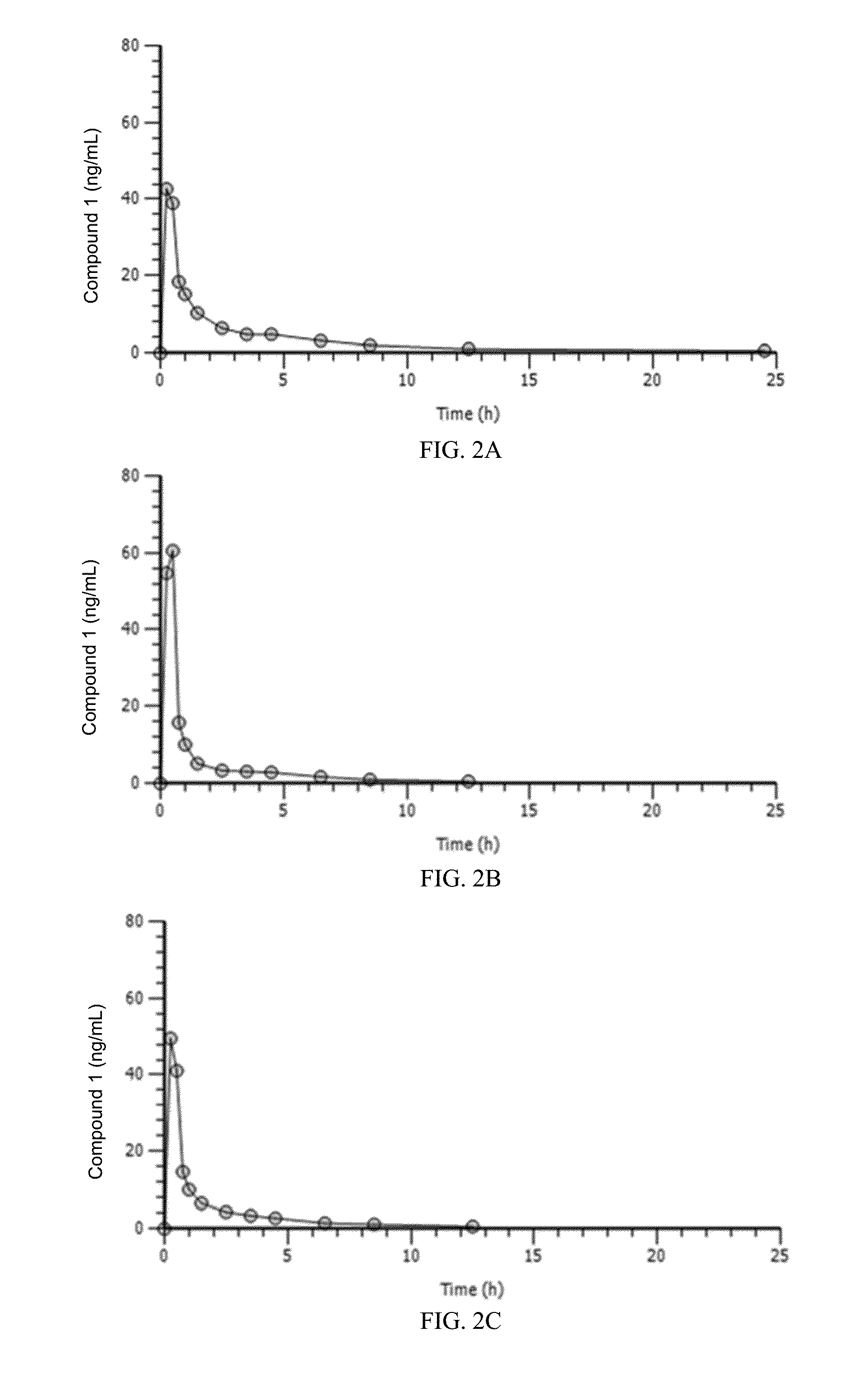

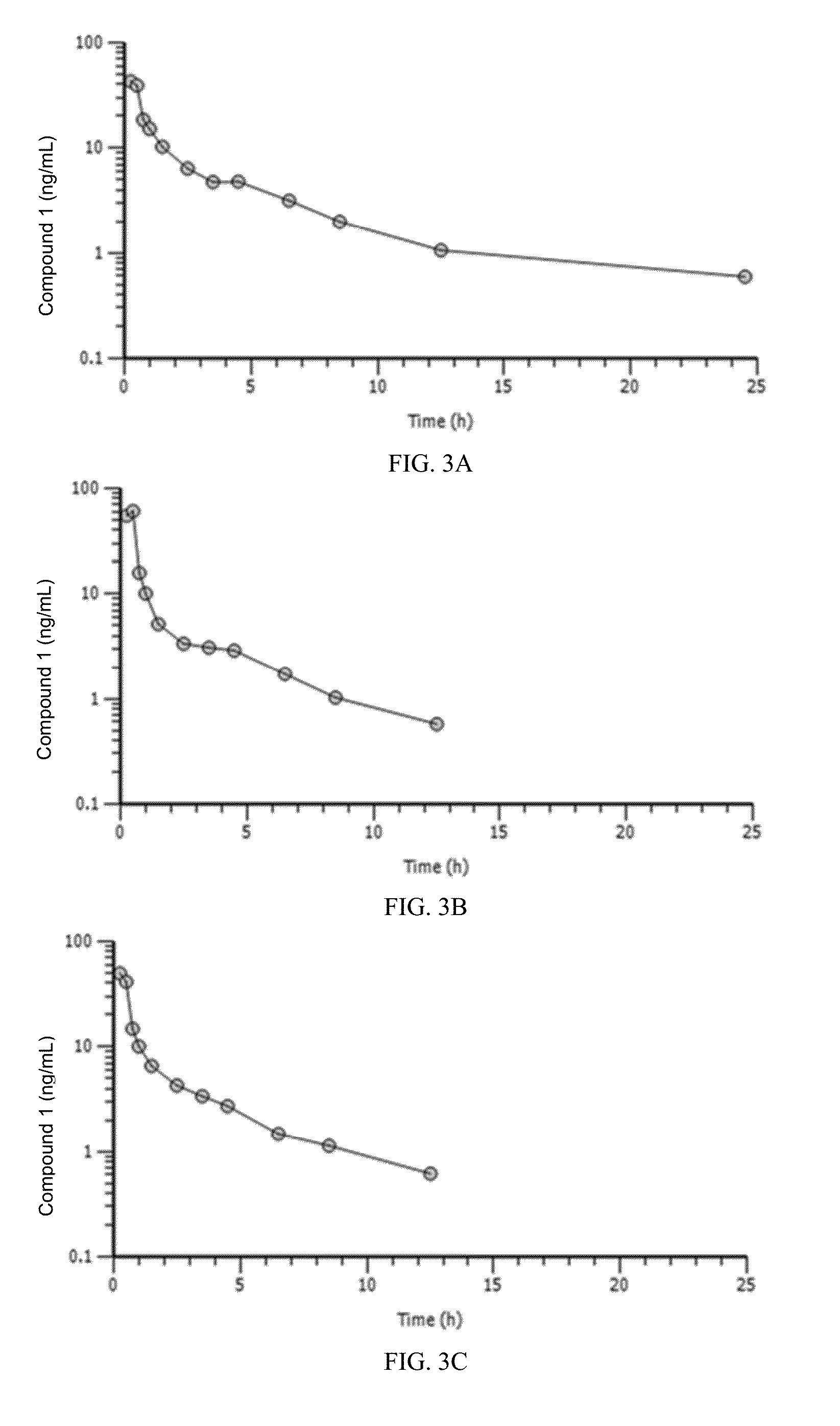

CDK4/6 Inhibitor Dosage Formulations For The Protection Of Hematopoietic Stem And Progenitor Cells During Chemotherapy

InactiveUS20160220569A1Reduction in therapeutically effective doseFaster hematopoietic recoveryPowder deliveryOrganic active ingredientsProgenitorDNA

This invention is in the area of dosage formulations and methods of administering a CDK4 / 6 inhibitor for the transient protection of healthy cells, and in particular hematopoietic stem and progenitor cells (HSPC), from damage associated with DNA damaging chemotherapeutic agents in subjects undergoing DNA damaging chemotherapeutic therapies for the treatment of proliferative disorders. In one aspect, improved protection of healthy cells is disclosed using a dosage that provides desirable pharmacokinetic and pharmacodynamic characteristics, including AUC, Tmax, Cmax, dosage-corrected AUC, and dosage-corrected Cmax. In another aspect, a method of treating a subject undergoing chemotherapy for the treatment of a CDK 4 / 6-replication independent cellular proliferation disorder by administering Compound 1 is provided.

Owner:G1 THERAPEUTICS INC

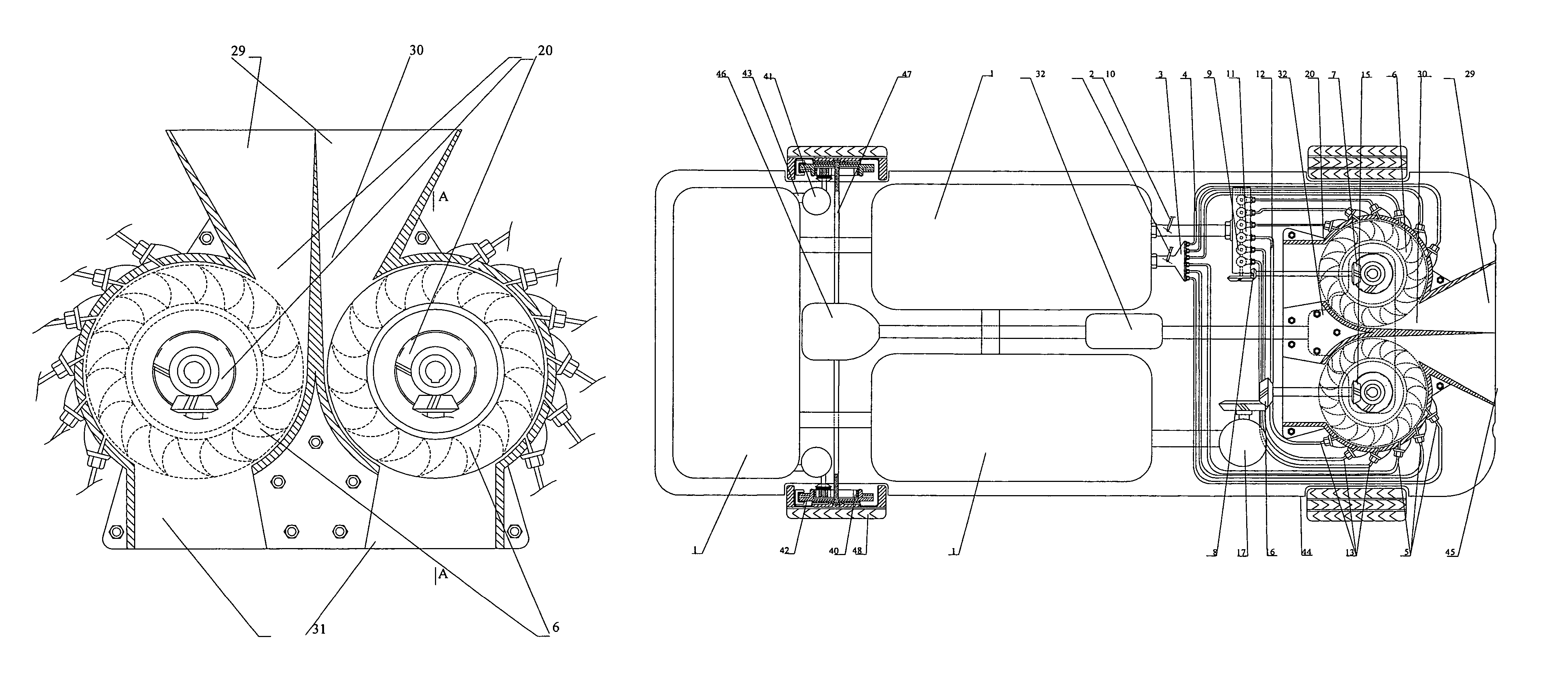

Wind-powered pneumatic engine and a motor vehicle equipped with the engine

InactiveUS7641005B2Improve overall utilizationShorten speedAuxillary drivesWind motor controlEngineeringHigh pressure

A wind-powered pneumatic engine including one or more impeller chambers and one or more impellers disposed in the impeller chambers is provided. One or more air inlets for receiving external wind resistance airflow are disposed on the impeller chambers, and the external wind resistance airflow entering the air inlets drives the impellers to operate to generate power output. The wind-powered pneumatic engine further includes an air-jet system for jetting HPCA into the impeller chambers, and the internal high-pressure compressed air jetted by the air-jet system in conjunction with the external wind resistance airflow entering the air inlets drives the impellers to operate to generate power output. In the present invention, the external resistance airflow around a motor vehicle moving at a speed is converted into power for use, which greatly reduces energy consumption and improves the moving speed of a motor vehicle. A motor vehicle equipped with wind-powered pneumatic engine is also provided.

Owner:CONG YANG

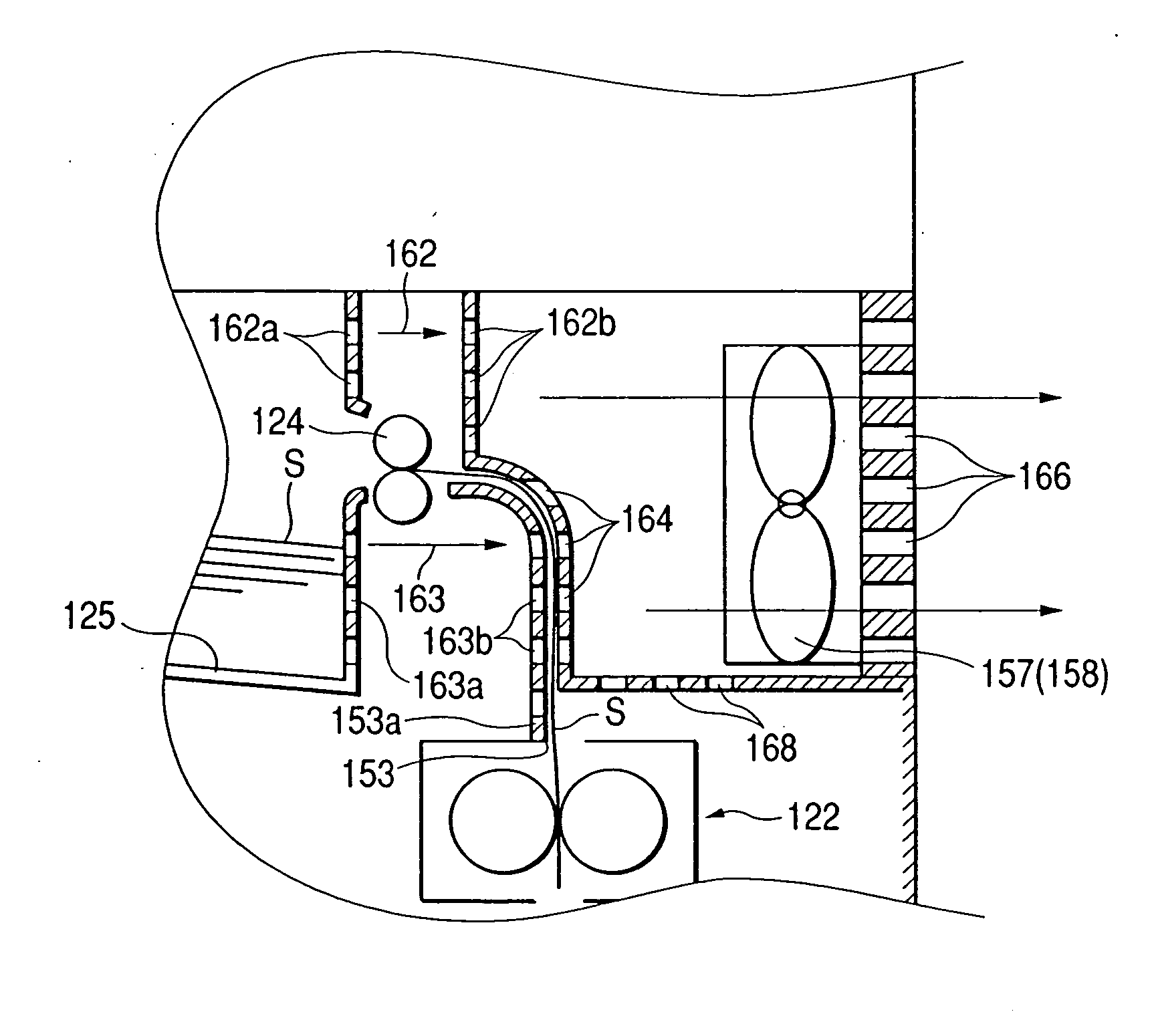

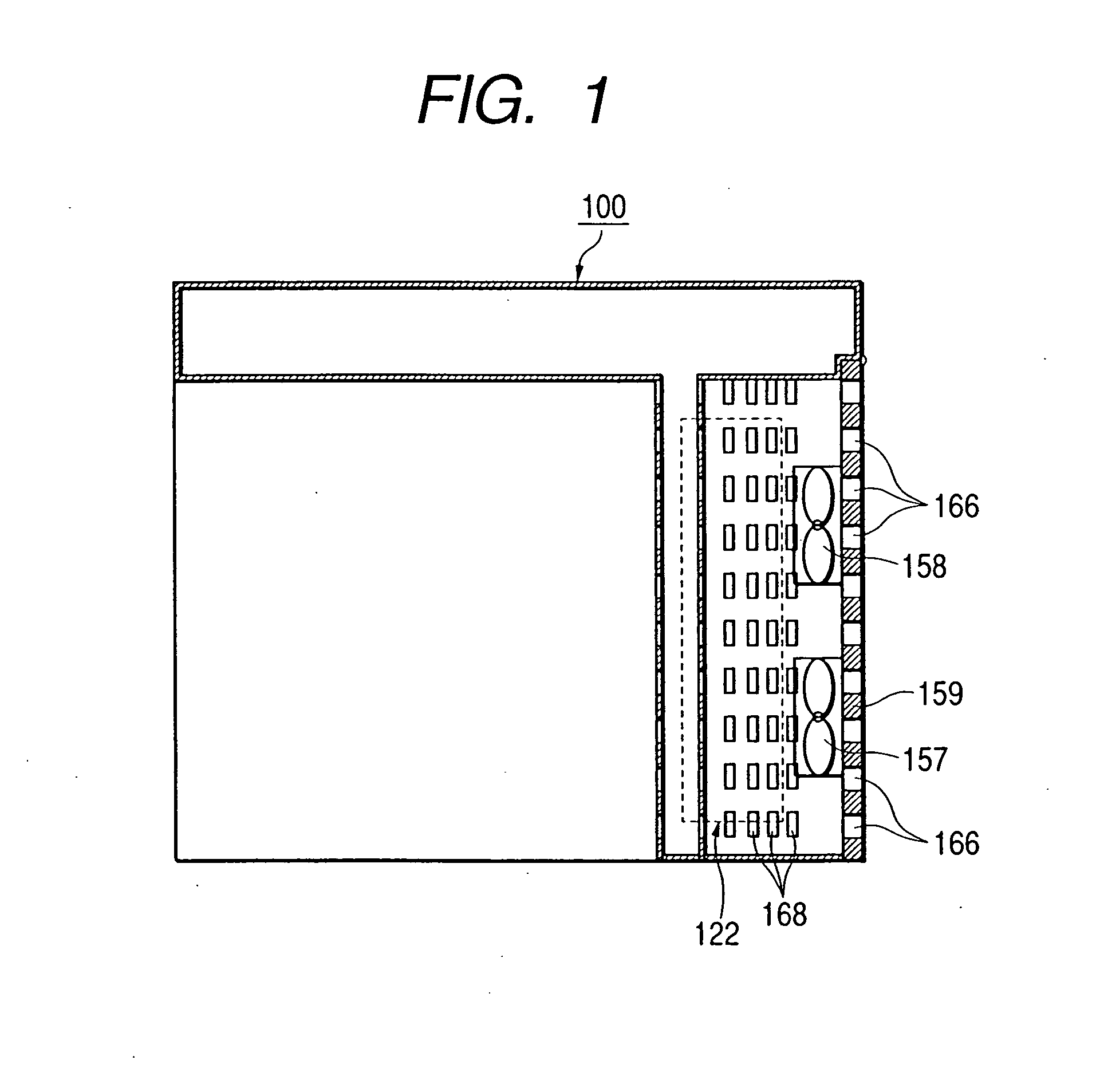

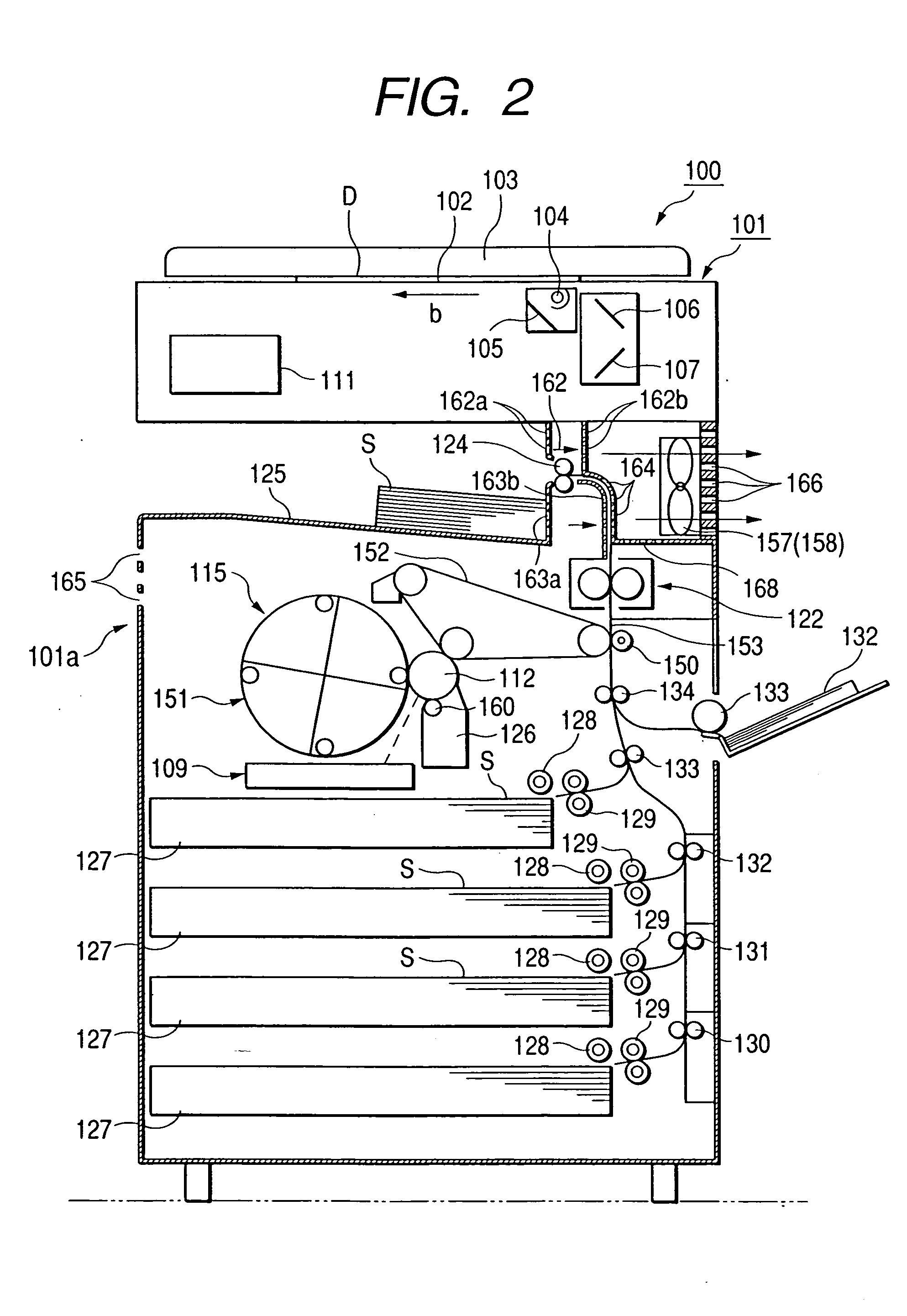

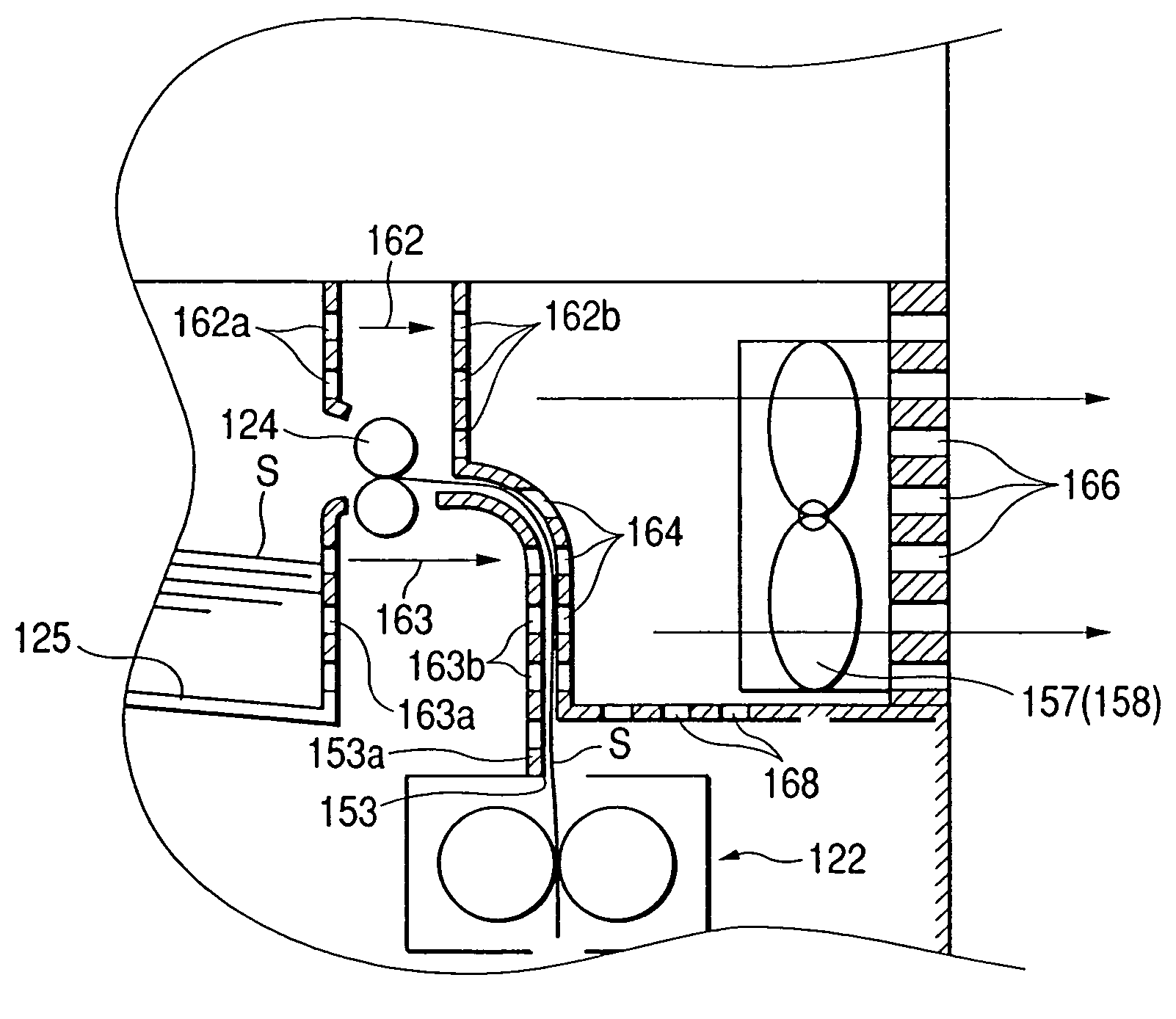

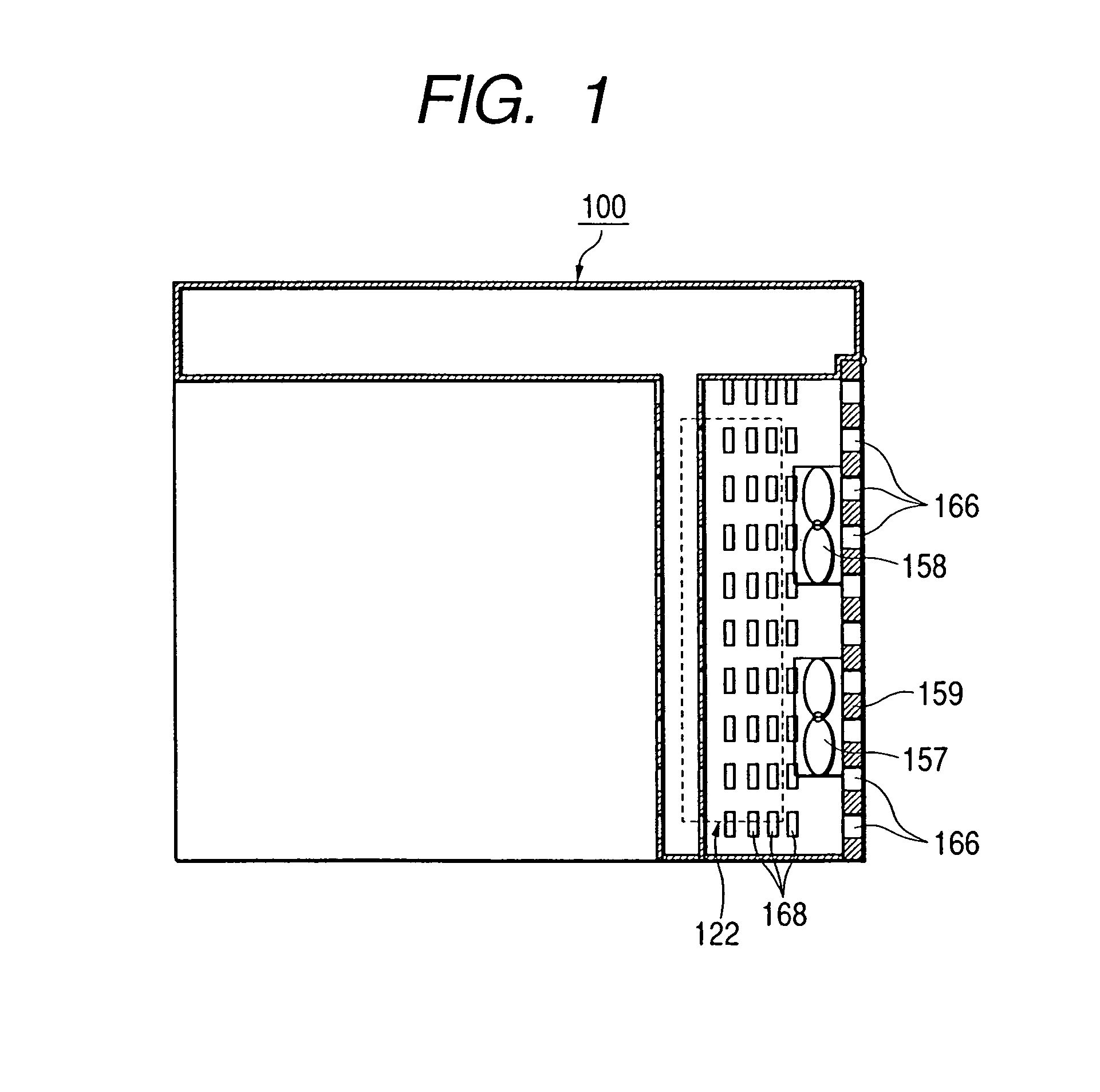

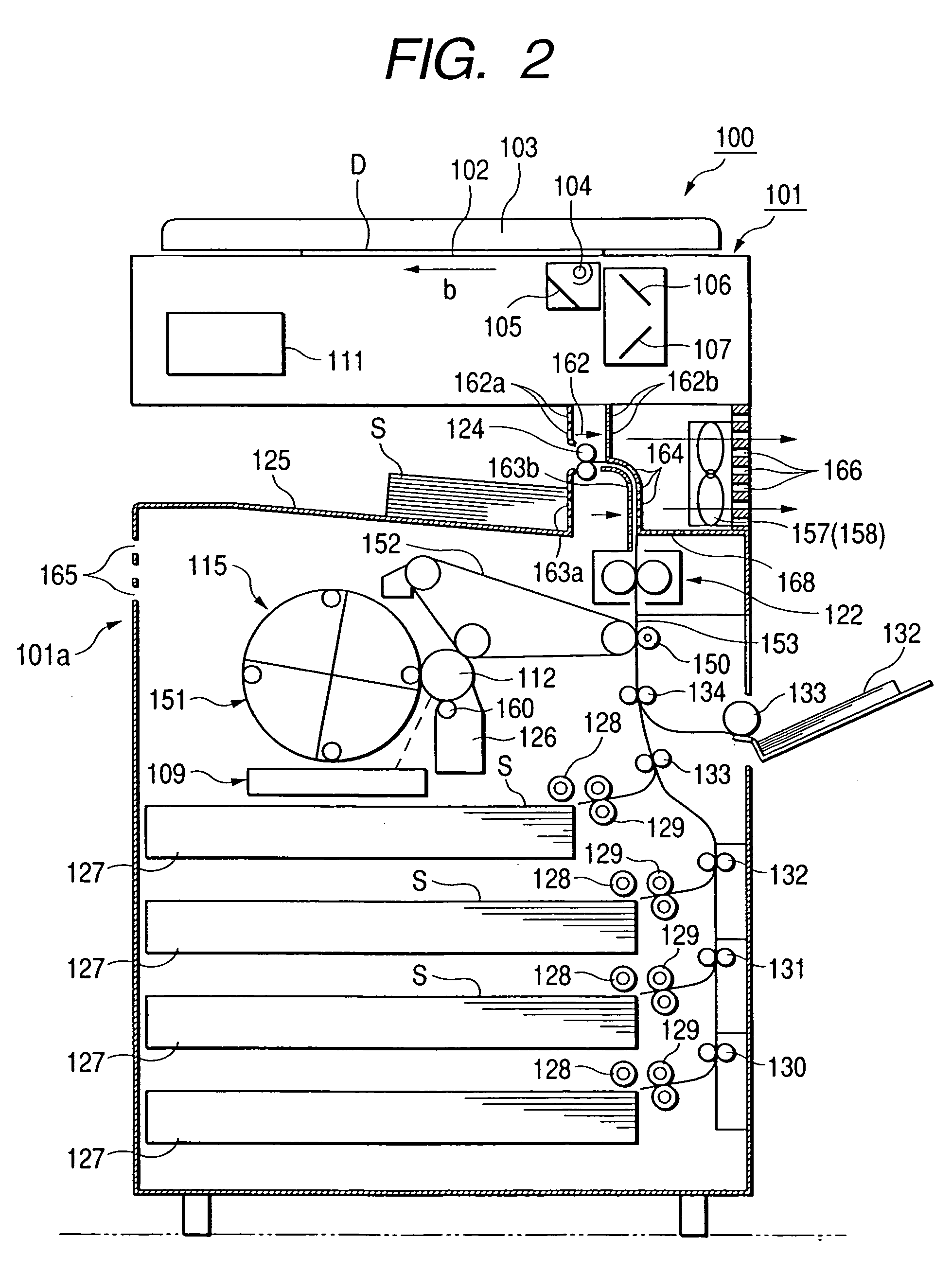

Dielectric film forming method

InactiveUS20050074255A1Exhaust heatReduce exhaustElectrographic process apparatusHigh heatElectrical and Electronics engineering

A copying machine 100 is provided with an image forming portion 115 for forming a toner image on a sheet, a fixing device 122 for applying heat to the sheet to fix the toner image on the sheet, a delivery portion 125 on which the sheet is delivered and stacked, heat exhausting fans 157 and 158 provided in the vicinity of the fixing device 122 and the delivery portion 125 for exhausting air in the surroundings of those 122, 125 from the right side 101b of the main body 101. There is provided air vents 162, 163 and 164 between the fixing device 122 and the heat exhausting fans 157, 158 and between the delivery portion 125 and the heat exhausting fans 157 and 158. Thus, heat of the fixing device 122 is exhausted to avoid the delivered sheet adhesion caused by the high temperature.

Owner:CANON KK

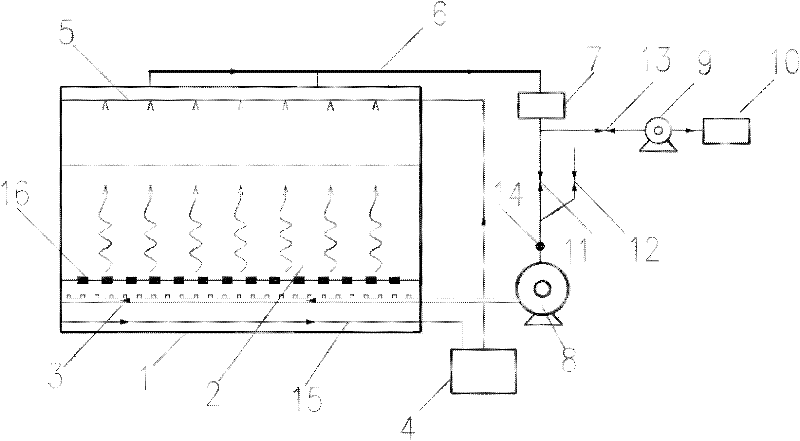

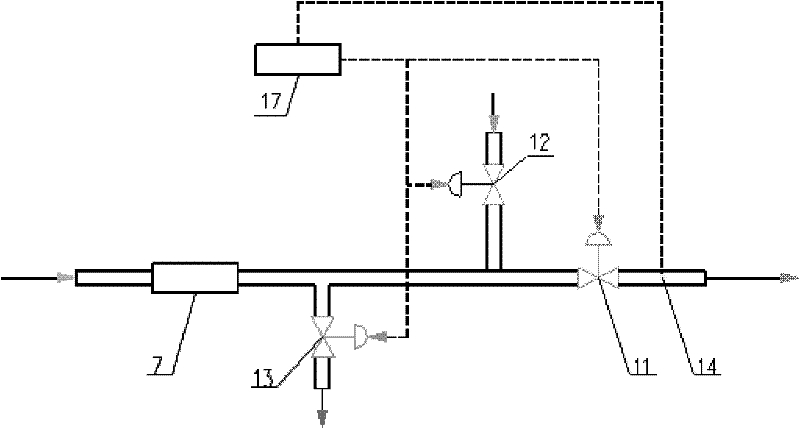

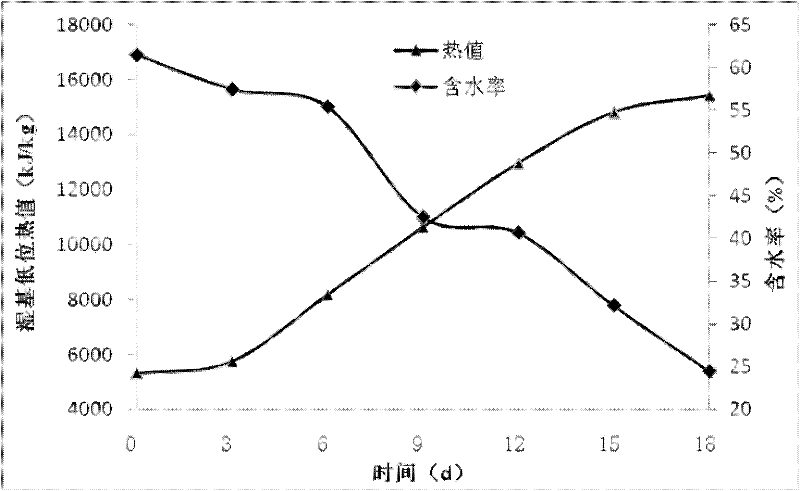

Method and apparatus for controlling secondary pollutants in biodrying of mixed domestic waste

The invention relates to a method and apparatus for controlling secondary pollutants in biodrying of mixed domestic waste. The method comprises the following steps: (1) simple pretreatment; (2) stacking; (3) biodrying of waste; (4) back spraying of leachate; (5) drying, reflux and concentrated treatment of tail gas. The apparatus comprises a sealed reactor, a leachate collector, a ventilating system and a tail gas treating device, wherein, the leachate collector is respectively connected with a leachate collecting pipe and a spray pipe in the reactor through pipelines, the tail gas treating device comprises a tail gas recovering pipe, a drying box, a tail gas treating fan and a purifying means, the tail gas recovering pipe is connected with the drying box, the drying box is respectively connected with a ventilating fan and the tail gas treating fan, and the tail gas treating fan is connected with the purifying means through a pipeline. According to the invention, the leachate does not need to be treated individually; tail gas is collected in a totally enclosed environment, and the amount of tail gas to be treated is small; a low heating value of obtained dried waste is increased by 100%; the invention is widely applicable to mixed waste with high water content and enables resource values of burning and sorting of domestic waste to be improved.

Owner:CHINA URBAN CONSTR DESIGN & RES INST CO LTD

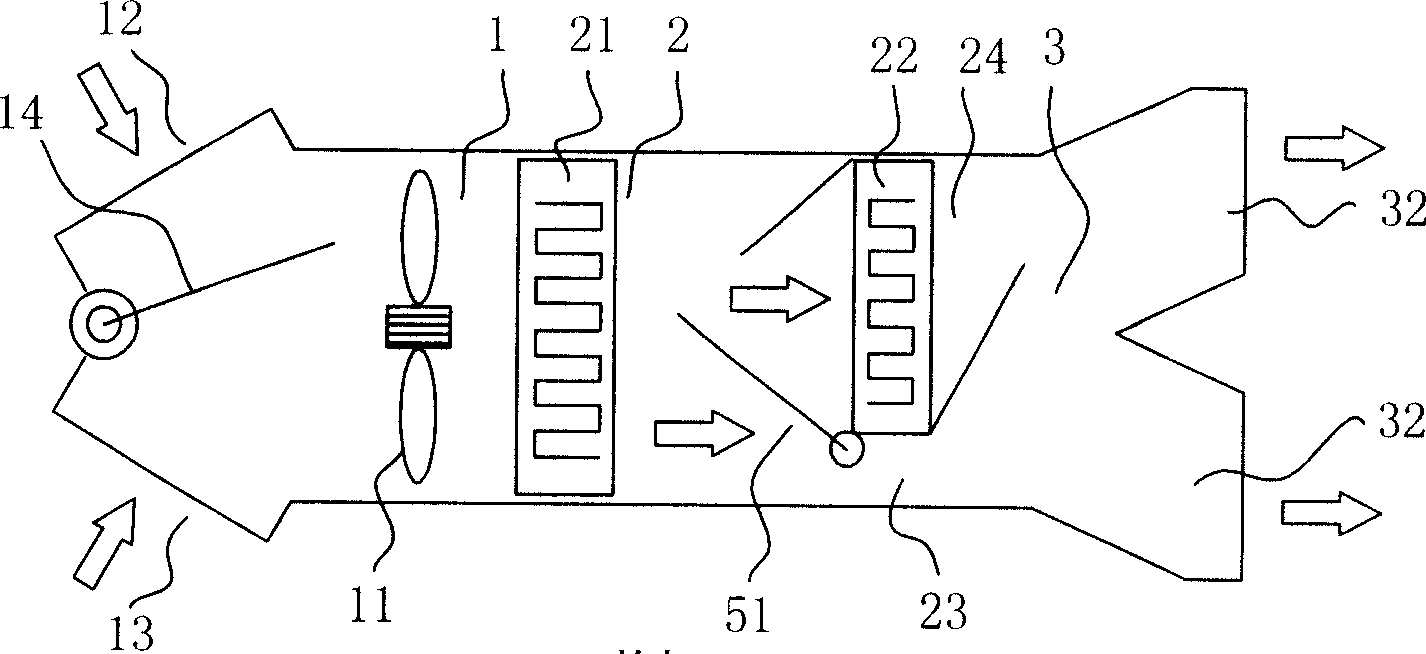

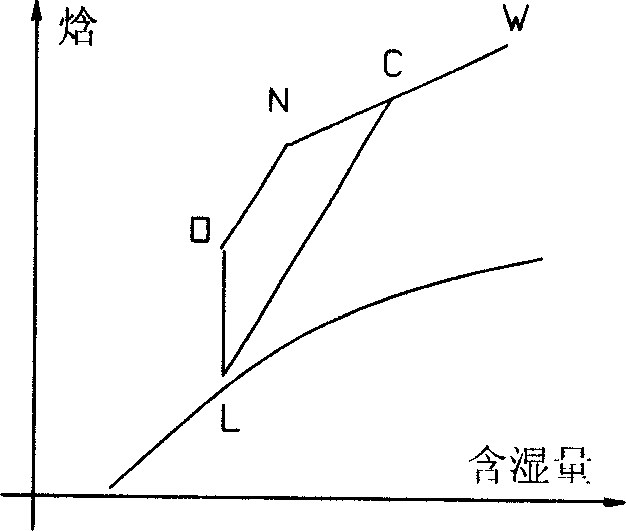

Air return temperature regulating sedan air conditioner

InactiveCN1900613AReduce volumeReduce lossAir-treating devicesLighting and heating apparatusFresh airEngineering

The invention related to air condition of saloon car, especially to air return thermoregulated air condition of saloon car. The air condition includes air intake dual duct, refrigeration air duct, and air out duct. A blower fan is setup in the air intake dual duct. Air inlet of air intake dual duct is composed of fresh air inlet, air return inlet, and regulating door for fresh air setup between the fresh air inlet and the air return inlet. Evaporator of air conditioning unit is setup in the refrigeration air duct. Characters are that conduction through air duct insulated from refrigeration air duct is added between the air intake dual duct and air out duct. Air outlet of the conduction through air duct, and air outlet of the refrigeration air duct are led to the air out duct. The invention is in favor of reducing energy consumption caused by heating blast of air condition repeatedly.

Owner:FUJIAN UNIV OF TECH

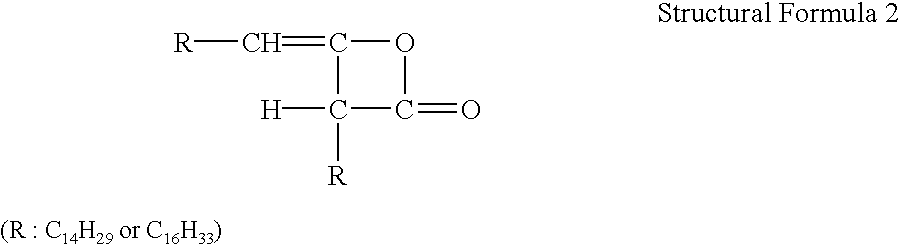

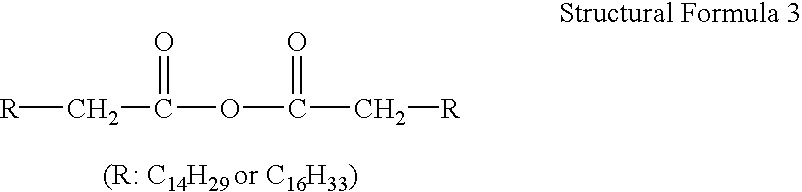

Filter medium for air filter and method for its production

InactiveUS20030145569A1High water-repellencyHigh strengthSynthetic resin layered productsLoose filtering material filtersFiberAir filter

A filter medium for an air filter, characterized in that it comprises a filter material having a glass fiber as its primary component and an alkyl ketene dimer adhered to the surface of the glass fiber; and a method for producing the filter medium which comprises a step of subjecting a dispersed slurry of a raw material fiber to a wet papermaking to form a wet paper, a step of immersing the wet paper in an aqueous dispersion or solution of the dimer or a liquid mixture of the dimer and a binder resin, or applying or spraying any of the above-mentioned liquids to the wet paper, to thereby allow the dimer to adhere onto the surface of the glass fiber, and a step of drying the resultant wet paper having the dimer adhered thereto. The filter medium exhibits a reduced amount of an out gas generated when it is used with ventilation and also exhibits high water-repellency and satisfactory strength in various applications such as air conditioning of a building and semiconductor manufacturing.

Owner:HOKUETSU KK

Image forming apparatus with heat exhausting means for exhausting air from around a fixing unit and a delivery tray

A copying machine 100 is provided with an image forming portion 115 for forming a toner image on a sheet, a fixing device 122 for applying heat to the sheet to fix the toner image on the sheet, a delivery portion 125 on which the sheet is delivered and stacked, heat exhausting fans 157 and 158 provided in the vicinity of the fixing device 122 and the delivery portion 125 for exhausting air in the surroundings of those 122, 125 from the right side 101b of the main body 101. There is provided air vents 162, 163 and 164 between the fixing device 122 and the heat exhausting fans 157, 158 and between the delivery portion 125 and the heat exhausting fans 157 and 158. Thus, heat of the fixing device 122 is exhausted to avoid the delivered sheet adhesion caused by the high temperature.

Owner:CANON KK

Air conditioner for hybrid vehicle

InactiveUS6515448B2Less frequentReduce exhaustAir-treating devicesBatteries circuit arrangementsElectrical batteryHybrid vehicle

In an air conditioner for a hybrid vehicle, when a residual charging degree of a battery becomes equal to or lower than a target degree, the electrical motor generator is driven by a vehicle engine so that the battery is charged through the electrical motor generator. When the engine is driven, the target degree of the battery is set higher than that when the engine is stopped so that a charging operation tends to be required while the engines driven. Accordingly, the frequency for starting the engine only for charging the battery is reduced.

Owner:DENSO CORP

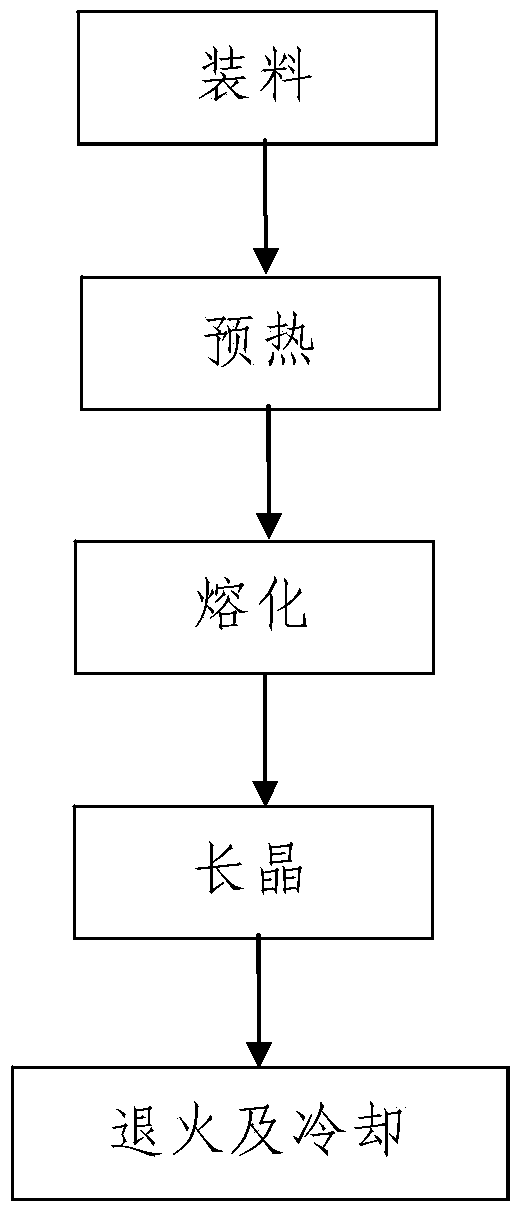

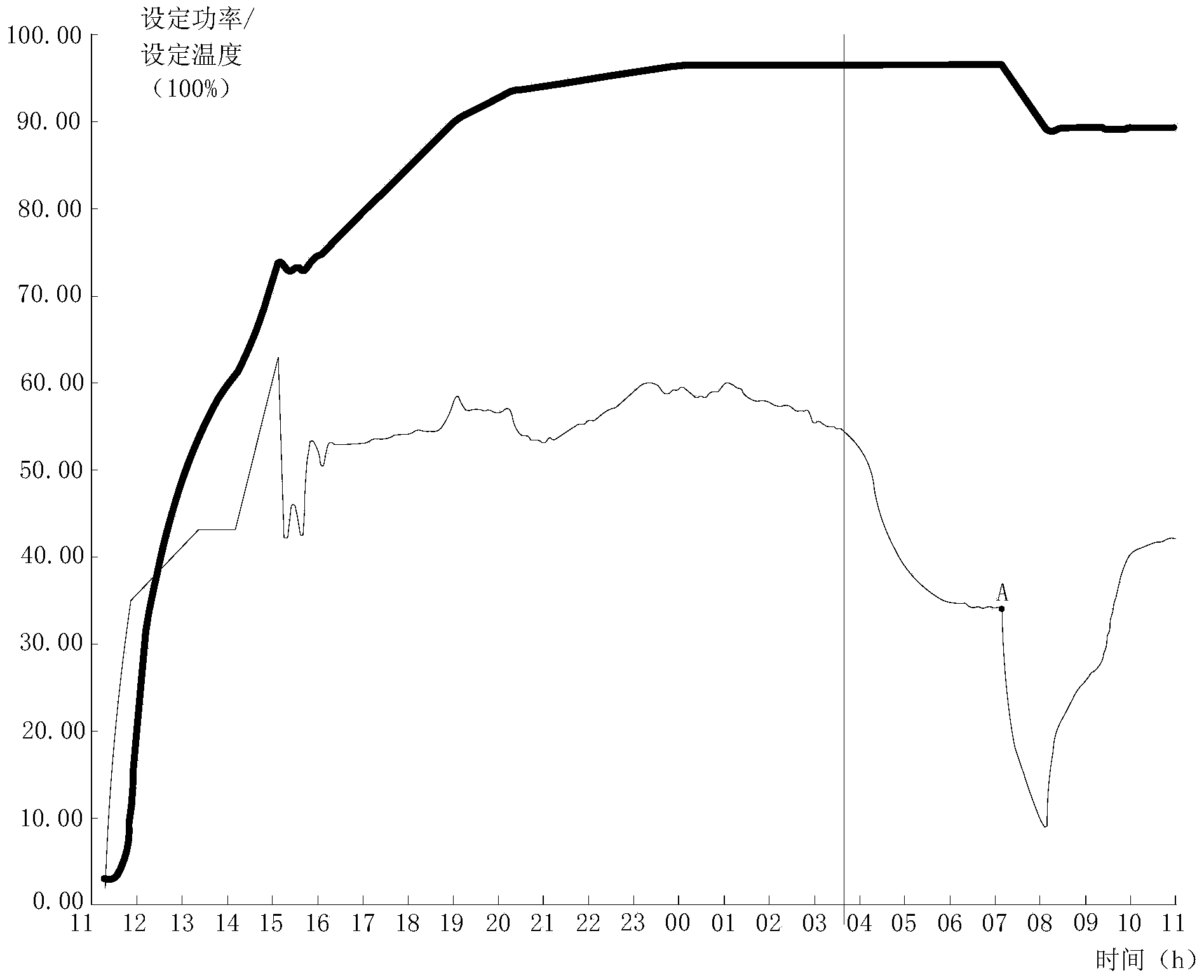

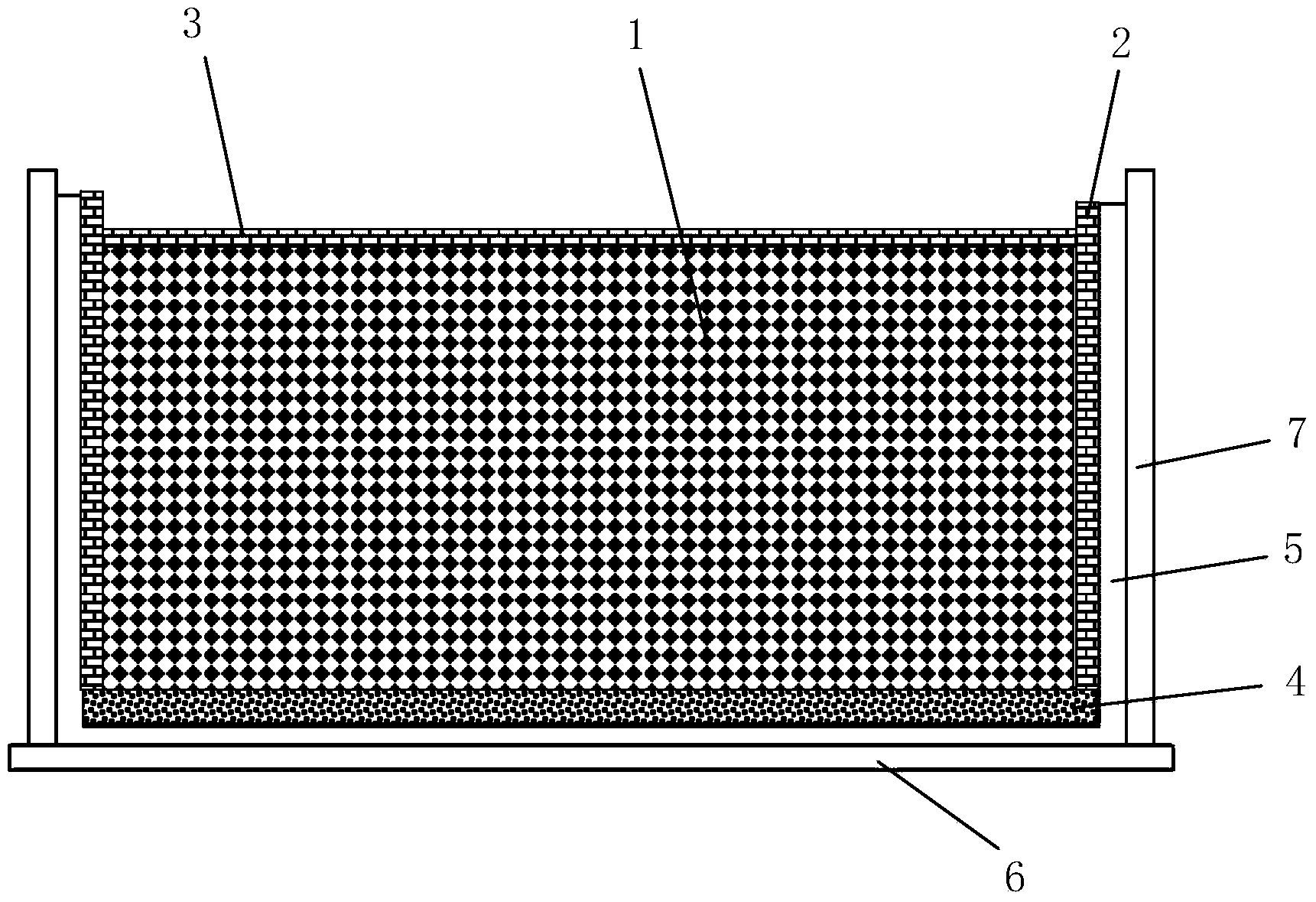

Ingot casting method of granular polysilicon

InactiveCN103741215AReasonable designThe process steps are simplePolycrystalline material growthSingle crystal growth detailsPolycrystalline siliconRise time

The invention discloses an ingot casting method of granular polysilicon. The method comprises the following steps: firstly, charging: putting the granular polysilicon into a crucible as silicon ingot casting materials; secondly, preheating; thirdly, melting, wherein the melting process comprises the following steps: step 1, carrying out heat preservation; steps 2 to 5, heating and implementing pressurization; step 6, raising temperature for the first time and keeping pressure, namely raising the temperature to T3 which is equal to 1450 DEG C; step 7, raising the temperature for the second time and keeping the pressure, namely raising the temperature to T4 which is equal to 1500 DEG C; step 8, raising the temperature for the third time and keeping the pressure, namely raising the temperature to T5 which is equal to 1550 DEG C, wherein temperature rise times from the step 6 to step 8 are all 260 to 300 minutes; step 9, carrying out heat preservation; step 10, continuously carrying out the heat preservation; fourthly, growing crystals; fifthly, annealing and cooling. The method disclosed by the invention is simple in steps, reasonable in design, convenient in realization, easily mastered, and good in use effect. Furthermore, ingot casting products with high conversion efficiency can be manufactured by using the low- cost granular polysilicon, thereby achieving the purposes of reducing wastes and lowering cost.

Owner:XIAN HUAJING ELECTRONICS TECH

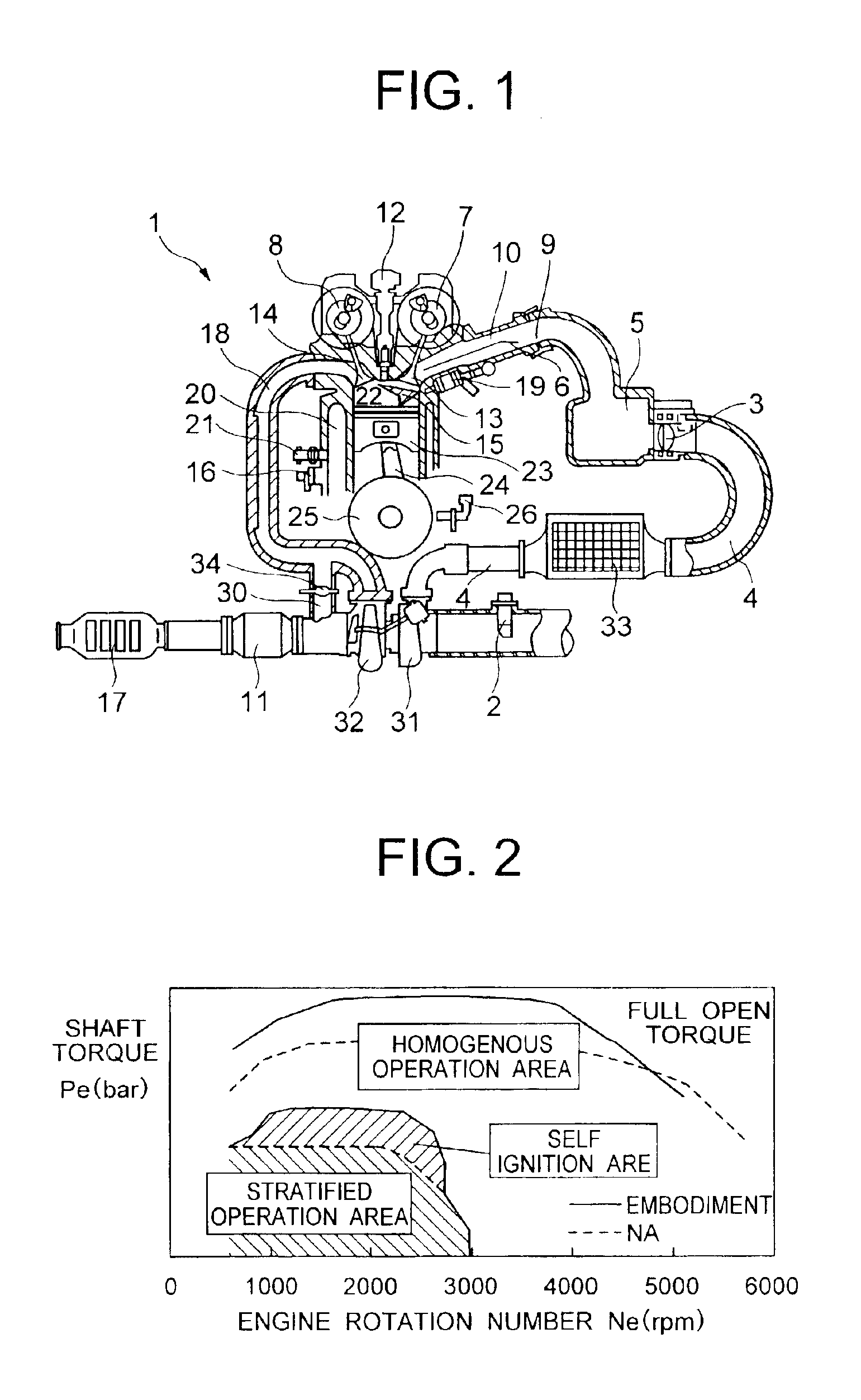

Method of controlling direct gasoline injection type internal combustion engine with turbocharger and direct gasoline injection type internal combustion engine with turbocharger

InactiveUS6880518B2Reduce decreaseReduce exhaustValve arrangementsElectrical controlTop dead centerTurbocharger

A first object of the invention is to reduce an exhaust gas in a lean burn area which is expanded by a supercharging, in a direct gasoline injection type internal combustion engine provided with a turbocharger. A second object of the invention is to prevent a knocking and a misfire at a time of self ignition combustion. The invention is used for the direct gasoline injection type internal combustion engine provided with the turbocharger. In order to achieve the first object, a combustion mode is switched from a stratified combustion mode to a self ignition combustion mode at a time when a suction pressure of the engine is equal to or more than an atmospheric pressure. Further, in order to achieve the second object, an ignition timing is set to a range between a top dead center and 10 degrees after the top dead center (0 to 10 (ATDC)) at a time of operating an engine in accordance with a self ignition combustion mode.

Owner:HITACHI LTD

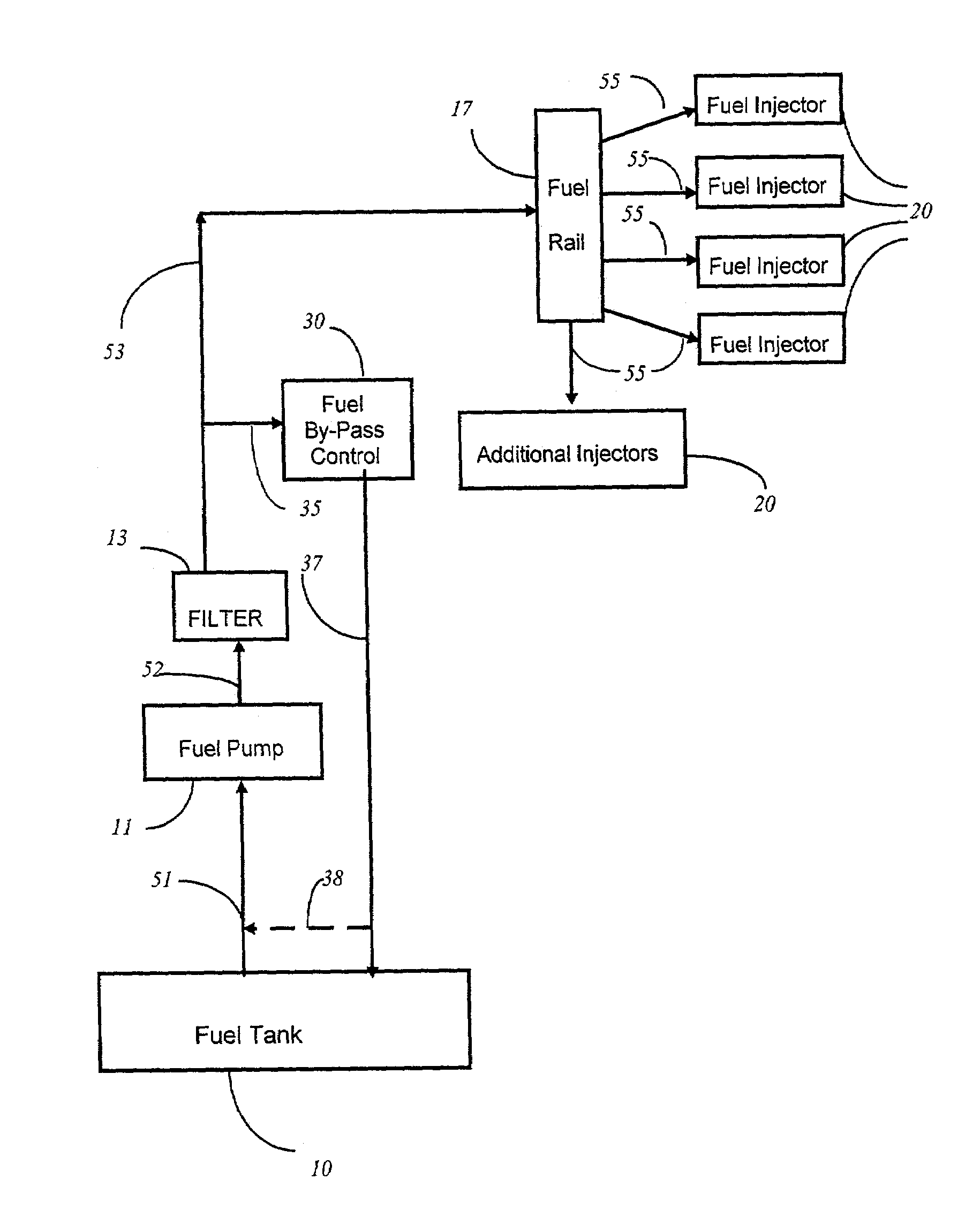

Constant-speed multi-pressure fuel injection system for improved dynamic range in internal combustion engine

ActiveUS7318414B2Avoid excess fuelAvoid pressure built-upElectrical controlLow-pressure fuel injectionExternal combustion engineFuel tank

A fuel injection system operates under a substantially constant pump speed and creates multi-pressure levels by diverting the fuel flow. Fuel pressure can be switched from one steady pressure level to another level on-demand instantly. This superimposes and overlaps typical fuel injection events in the linear operating ranges under different pressure levels, significantly increasing the fuel injection dynamic range. Lower fuel injection when idle or during city driving reduces fuel consumption per mile traveled and reduces exhaust emission that causes smog in metropolitan areas. The system delivers additional power to the engine instantly at peak load on-demand, reduces idle speed with the engine running smoothly, does not change fuel tank temperature, and may enhance the life of the fuel pump.

Owner:TMC FUEL INJECTION SYST

Spark ignition device and internal combustion engine with the same

InactiveUS7228840B2Reduce exhaustIncrease fuel consumptionSparking plugsInternal combustion piston enginesCombustion chamberIgnition coil

A plurality of spark electrodes are disposed in an arc shape on the surface or so as to be projected from the surface of an insulating member formed on a part of the wall face of a combustion chamber, and are formed so as to be in series electrically via discharging gaps.A spark plug is provided integrally with an injector, and the spark plug and the ignition coil are integrated. The three members are constructed as an integral unit, thereby improving installability to an engine.

Owner:HITACHI LTD

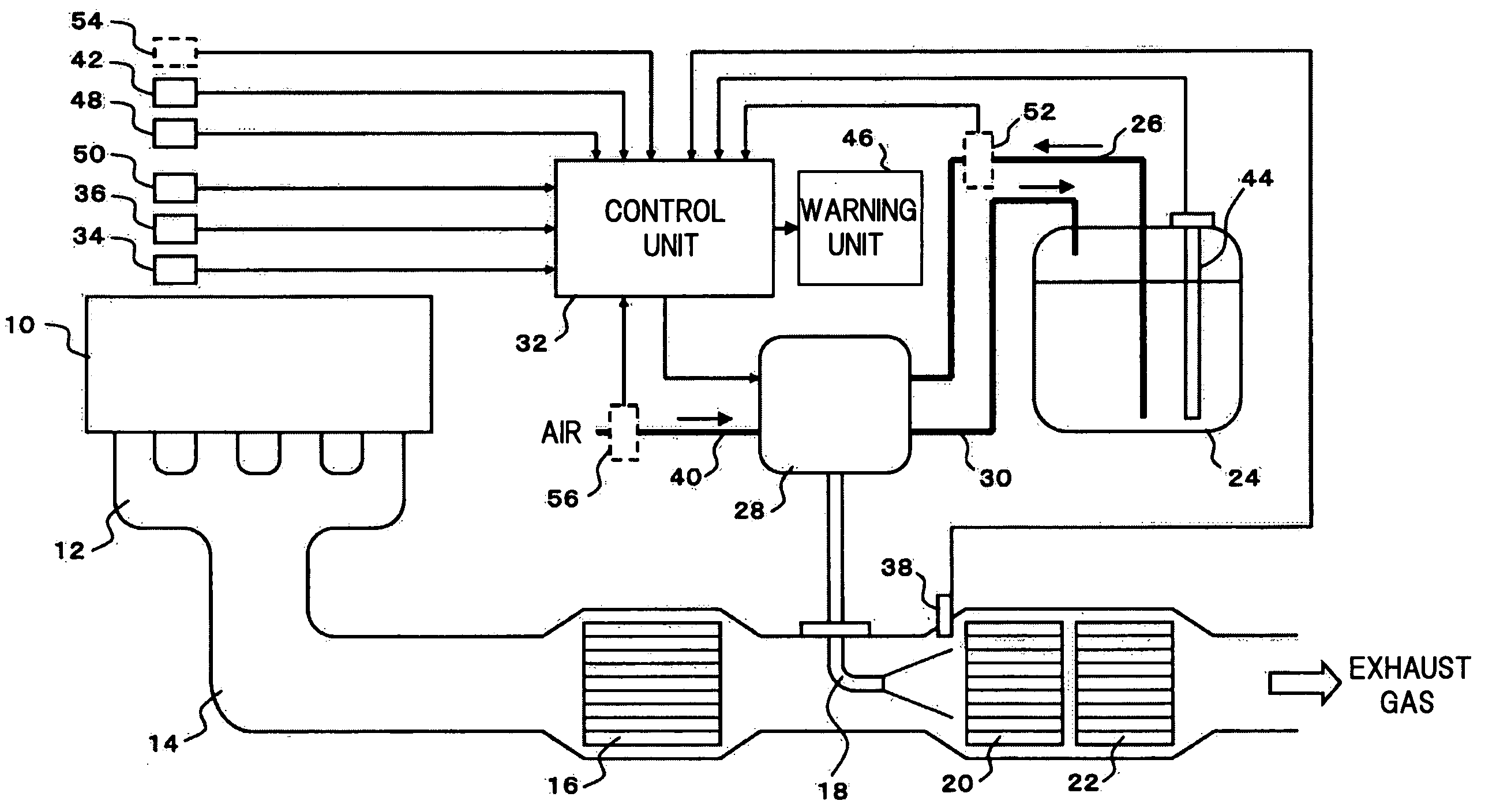

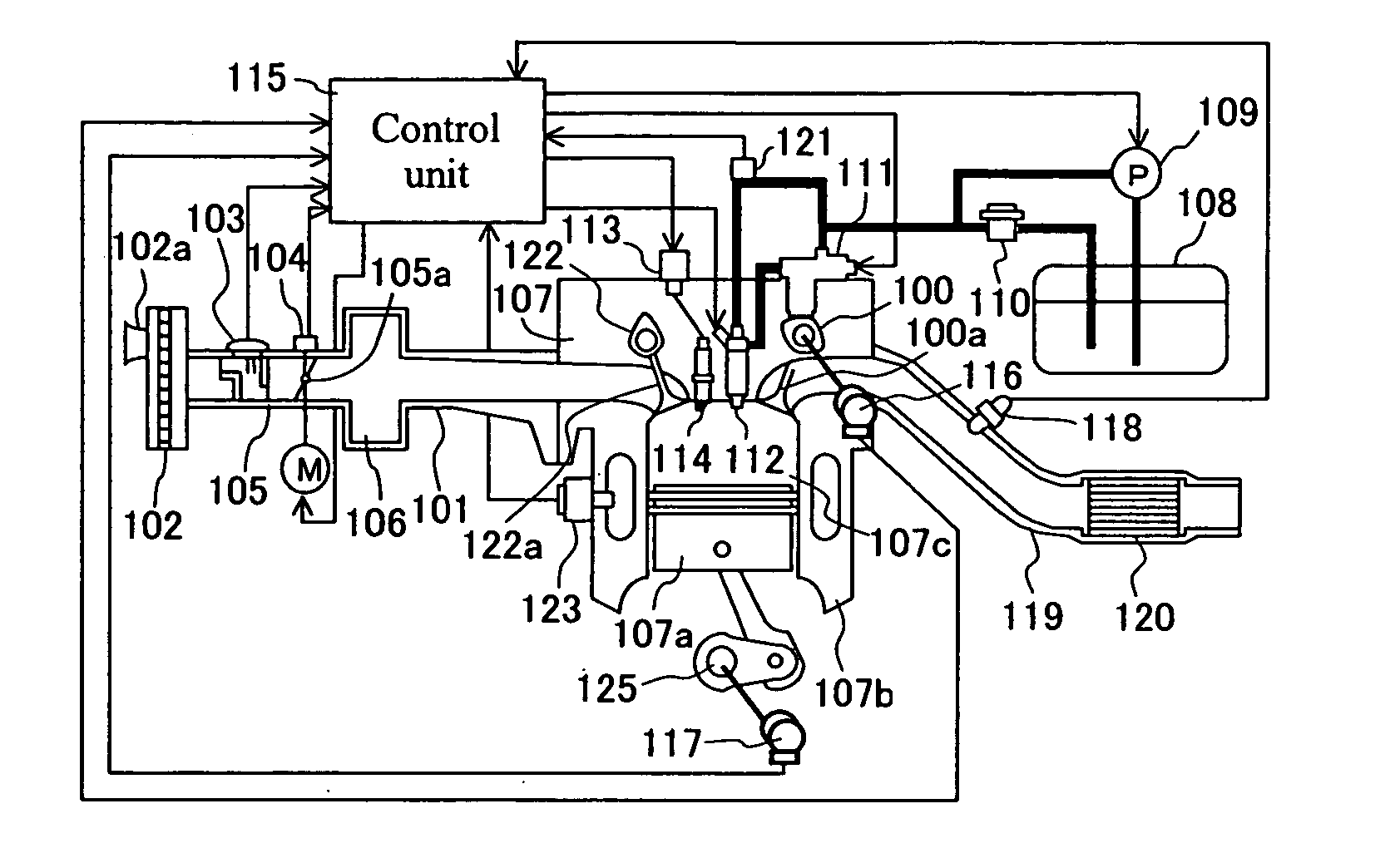

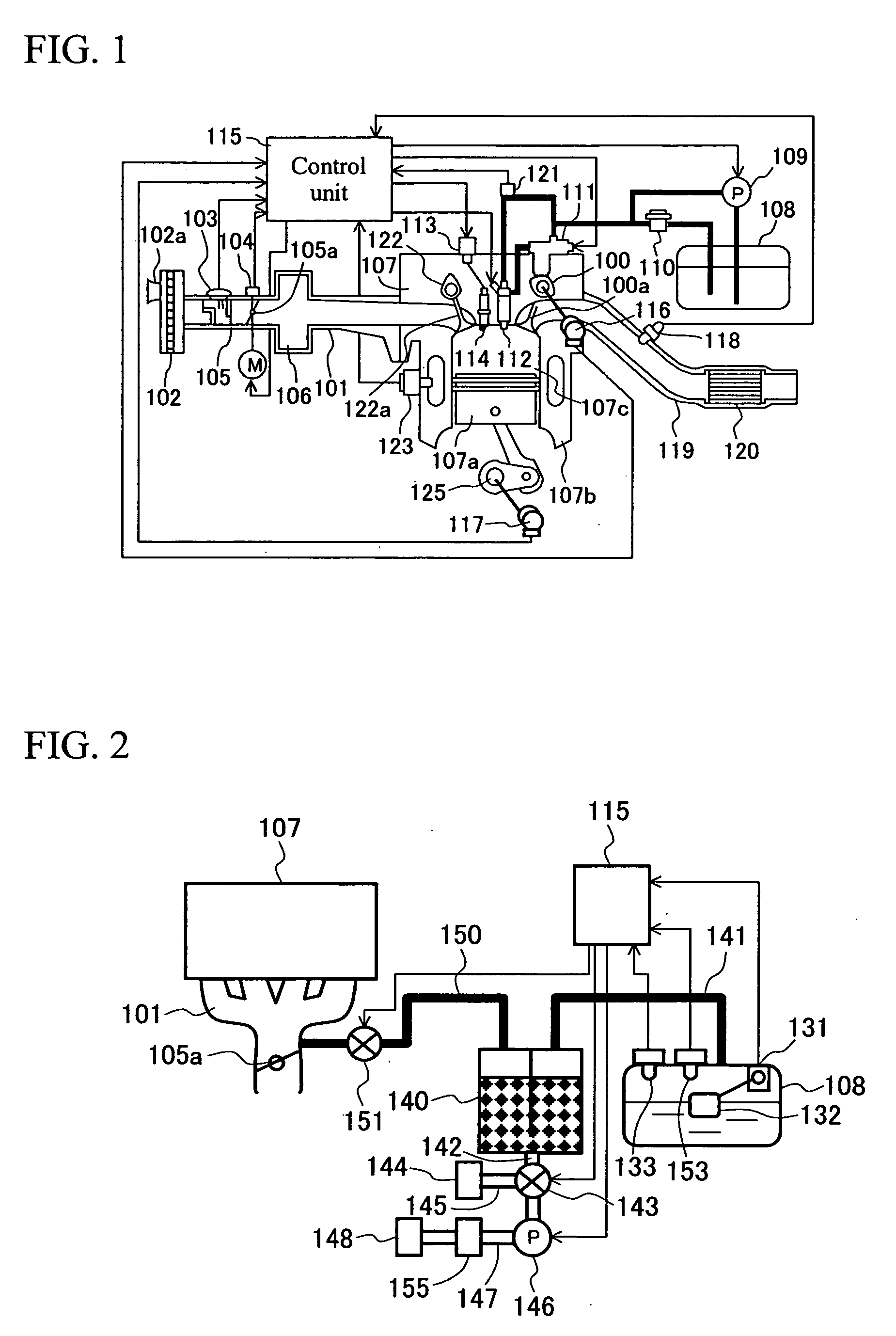

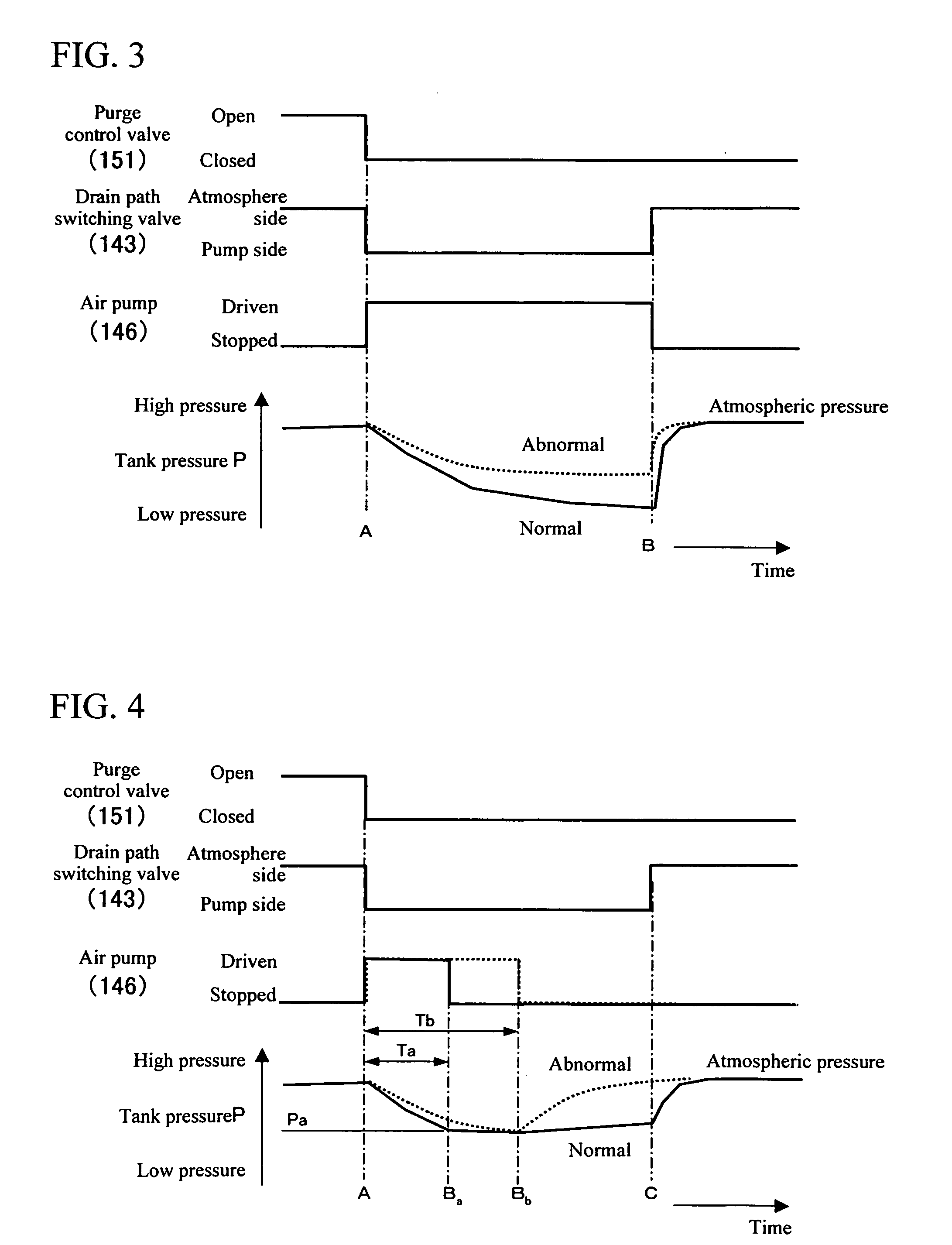

Device and method for diagnosing evaporation leak, and control device of internal combustion engine

InactiveUS20060144370A1Shorten diagnostic timeImprove stabilityInternal-combustion engine testingDetection of fluid at leakage pointAtmospheric airEvaporation

Pressure detection means detects the pressure of an evaporation purge system that includes a fuel tank and a communicating tube, which connects a canister for adsorbing and retaining fuel vapor to an intake pipe. Shutout means shuts out the evaporation purge system from atmospheric air. A pump is driven for pressurization or depressurization purposes while the shutout means shuts out the evaporation purge system from atmospheric air. The pump is stopped when the pressure detected by the pressure detection means reaches a predetermined level. A leak judgment is formulated in accordance with pump drive time and a pressure change after pump stoppage.

Owner:HITACHI LTD

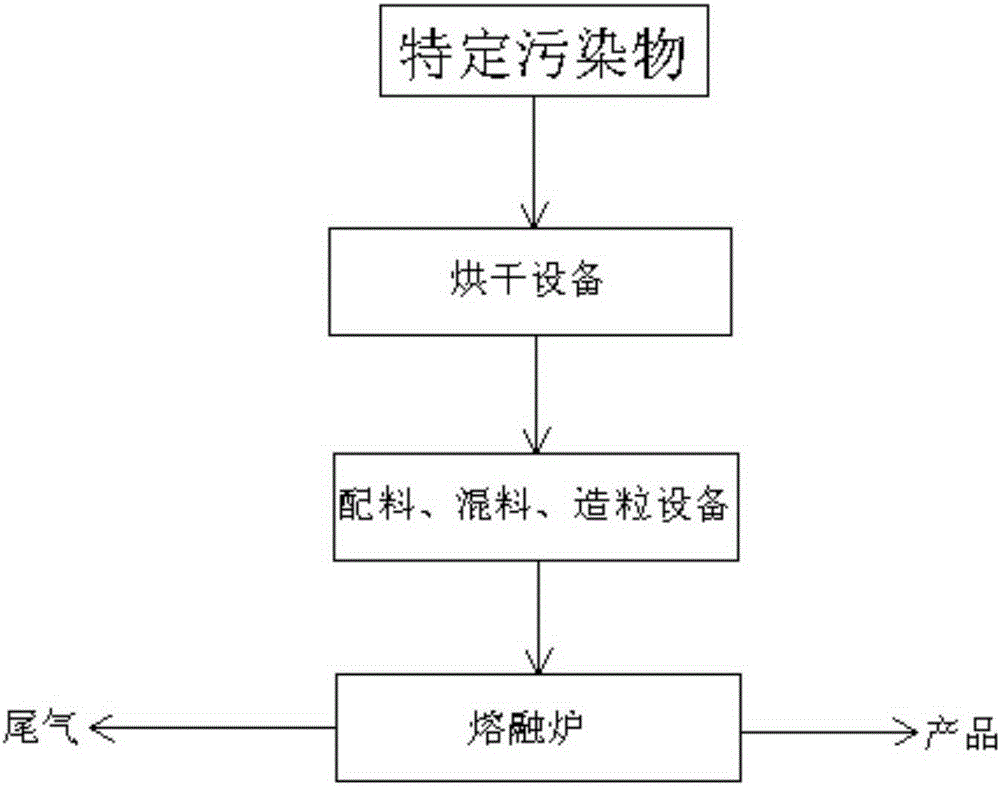

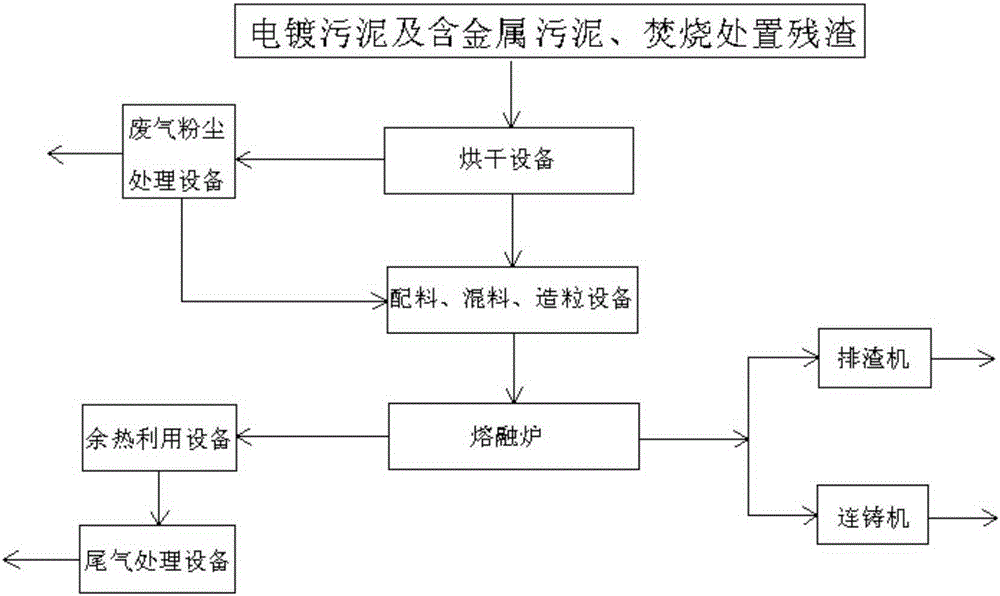

Method for treating specific pollutants through high-temperature melting technology

InactiveCN105344698AReduce operating costsResourcefulSolid waste disposalTransportation and packagingSludgeSlag

The invention provides a method for treating specific pollutants through a high-temperature melting technology. The specific pollutants comprise electroplating sludge, sludge containing metal and / or incineration disposal residues. The method comprises the steps that pretreatment is carried out, wherein the specific pollutants are pretreated, the water content of the specific pollutants is reduced to be 10 wt% or lower, and dry specific pollutant materials are obtained; burdening, blending and granulating are carried out, wherein regulating components are added as needed, mixed and granulated, and a granulated mixture is obtained; melting is carried out, wherein the granulated mixture is melted at the melting temperature ranging from 1,200 DEG C to 1,800 DEG C; and products are obtained, wherein the melted metal is settled on the lower layer and is discharged to obtain a metal alloy, and slag and a small part of metal float above the melted metal and are discharged to obtain glassy-state slag. After the specific pollutants are treated through the method, harmless and pollution-free resource materials can be obtained, and the method can be used for resource recycling, and is good in economic benefit and beneficial to commercial popularization.

Owner:SHANGHAI LVCHENG ENVIRONMENTAL PROTECTION TECH

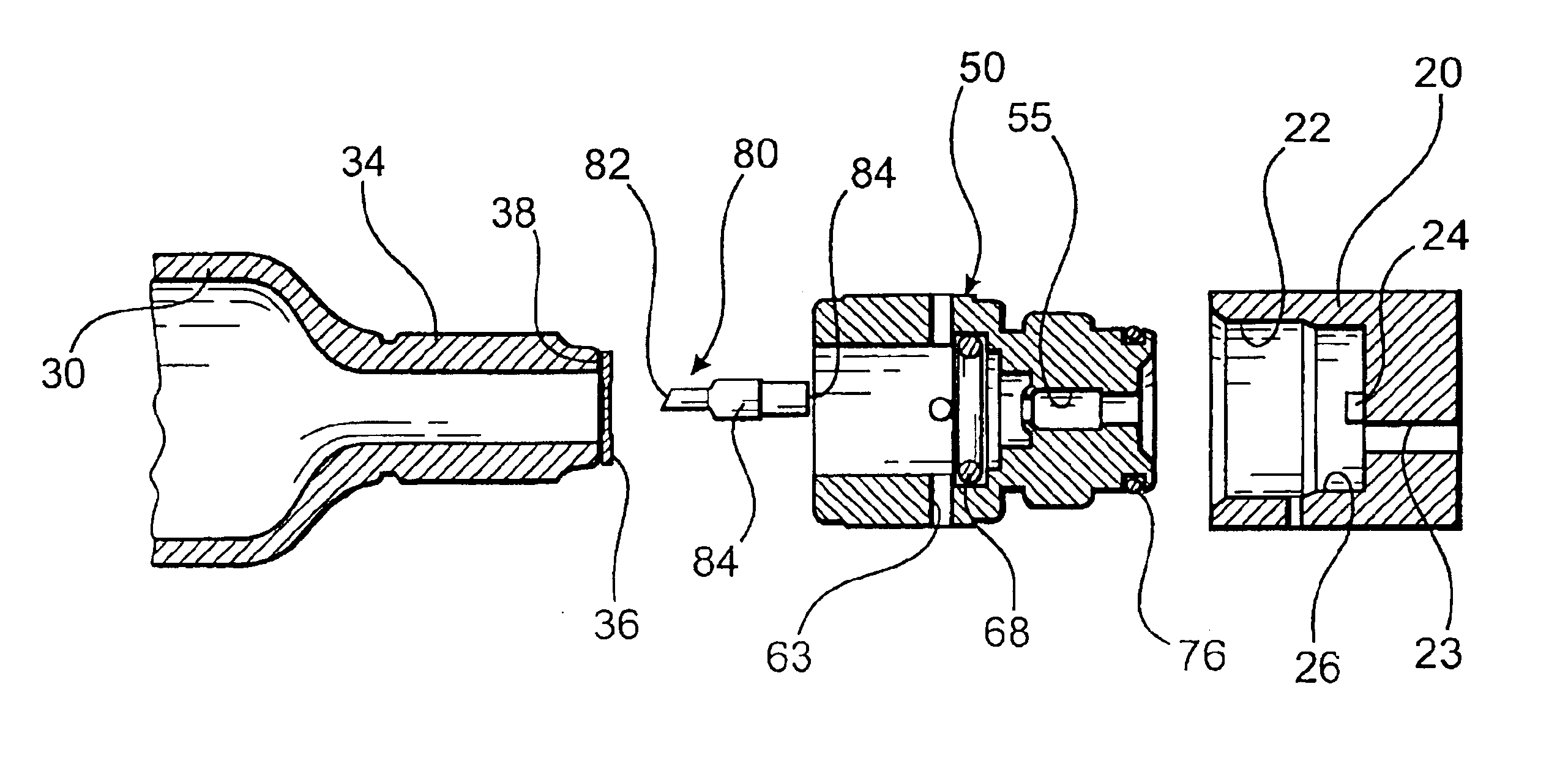

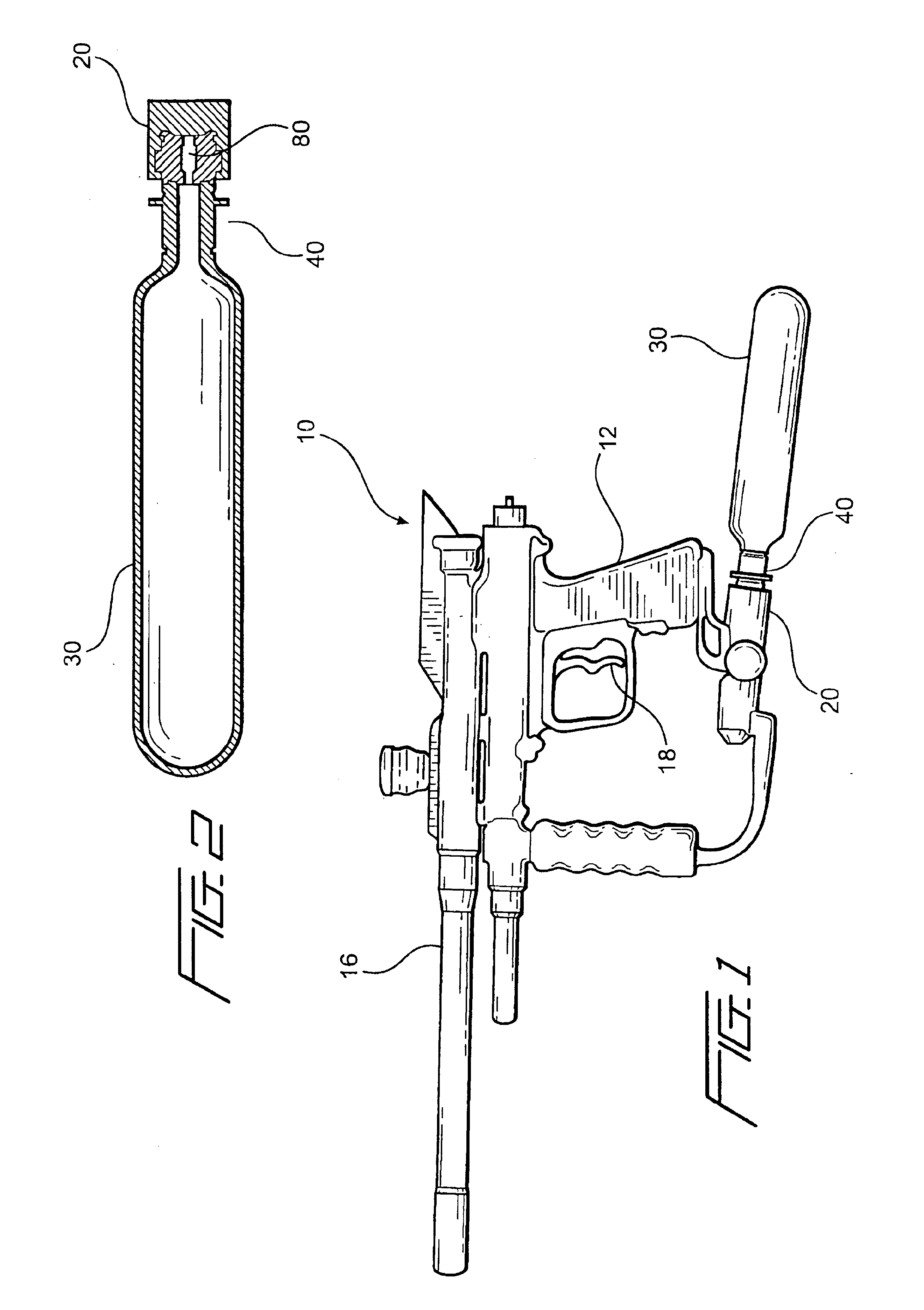

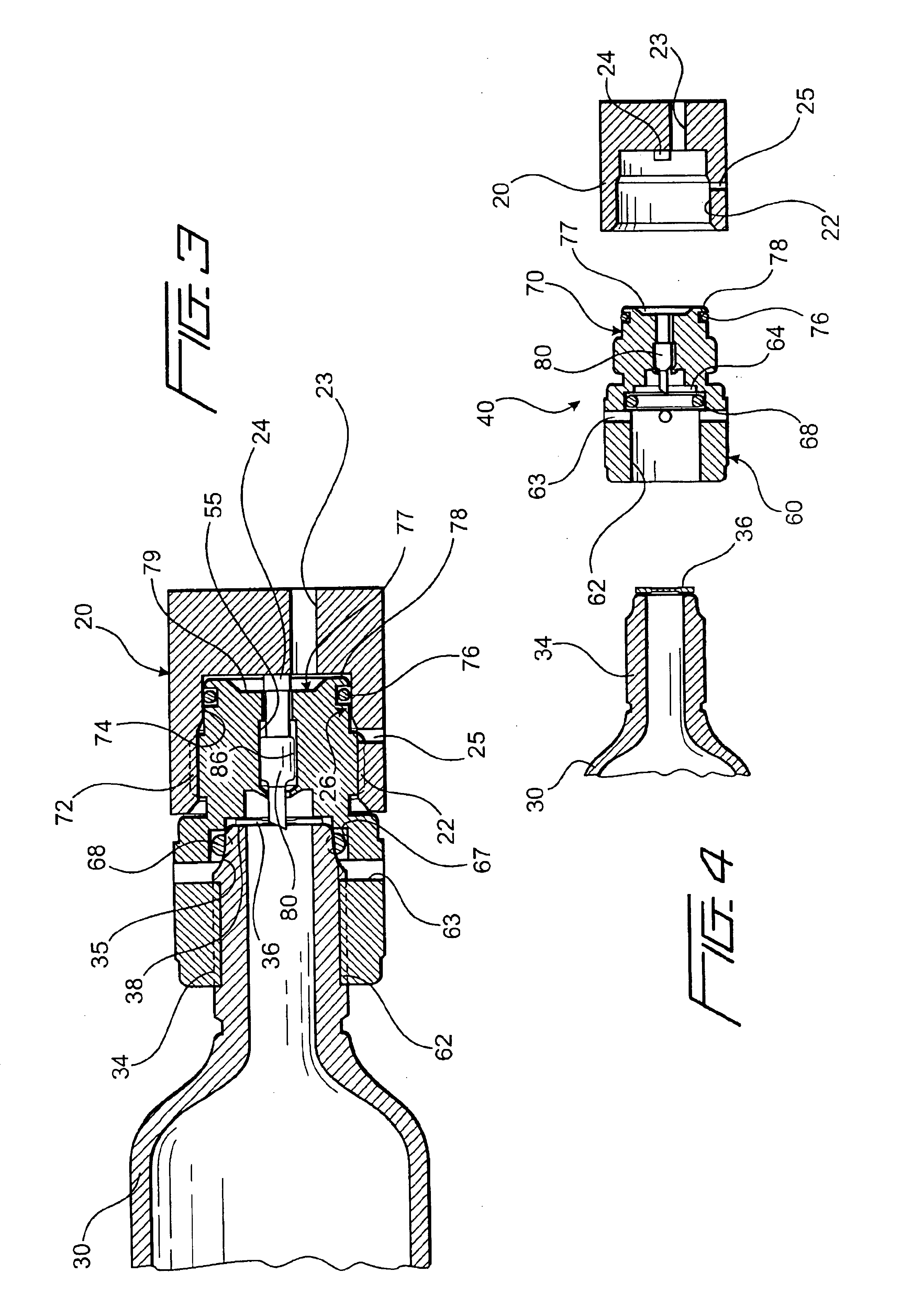

Adapter assembly with floating pin for operably connecting pressurized bottle to a paintball marker

InactiveUS6941938B2Reduce exhaustEqualizing valvesLiquid transferring devicesBottleBiomedical engineering

An adapter assembly for releasably interconnecting a pressurized bottle with a paintball marker, wherein the adapter assembly includes a piercing pin moveable between retracted position and an extended position. The adapter assembly includes an internally threaded female socket for releasably engaging the pressurized bottle, and an externally threaded male head for releasably engaging a corresponding female connector on the paintball marker. The spacing of the threaded connections and the travel of the piercing pin are selected such that the piercing pin punctures a frangible seal of the pressurized bottle subsequent to fluid interconnection of both the pressurized bottle and the paintball marker with the adapter assembly.

Owner:CROSMAN CORP

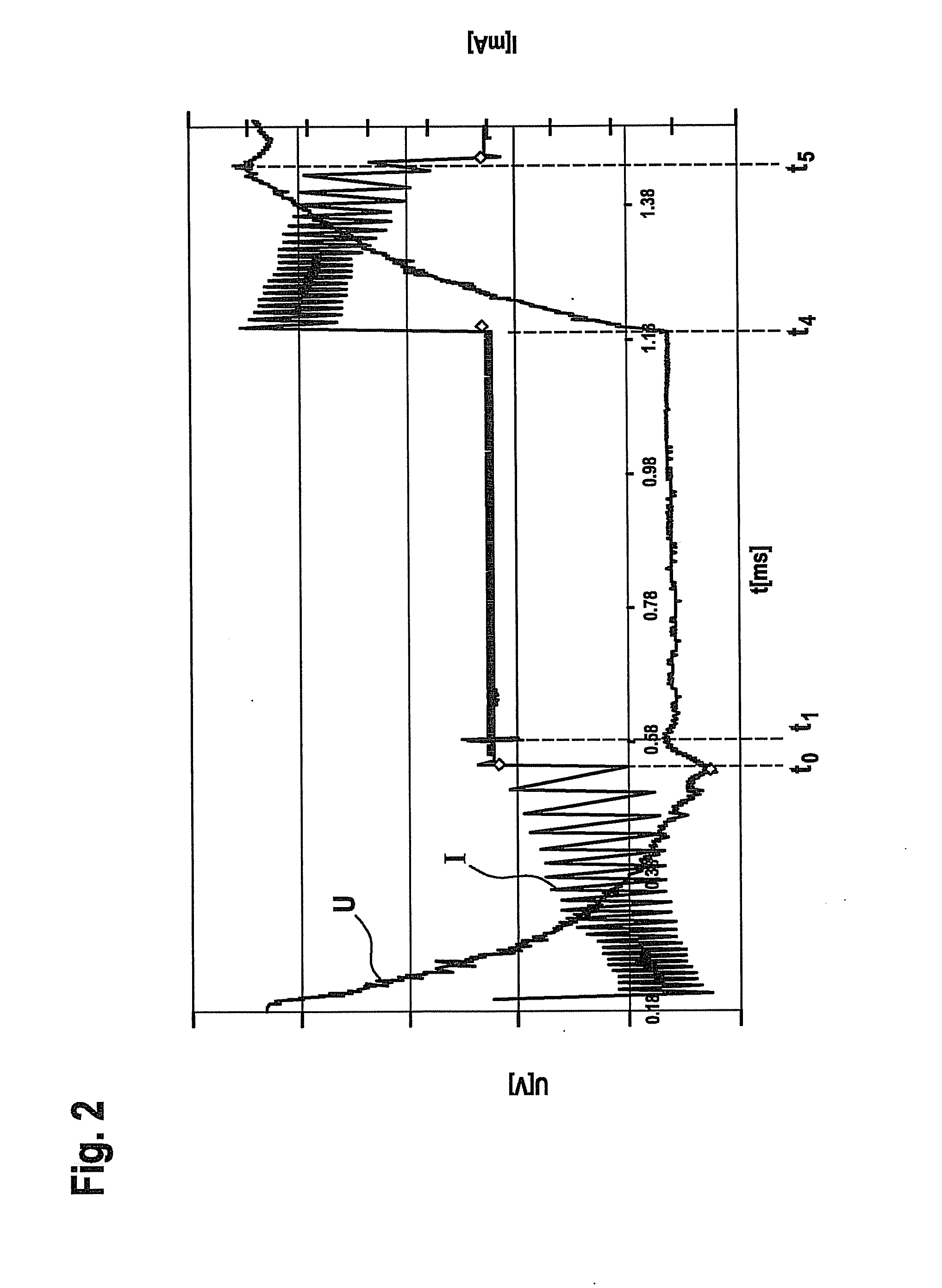

Method for manufacturing ceramic of multi-layer structure

ActiveCN106116688ATight outer surfaceHigh light chromaCeramic materials productionCeramicwareWork in processCeramic tiles

The invention provides a method for manufacturing ceramic of a multi-layer structure. The method includes the following steps that a common ceramic brick material is used for manufacturing surface blank, a foamed ceramic bottom blank material is used for preparing foamed ceramic bottom blank, the surface blank and the foamed ceramic bottom blank are pressed into multiple layers in a spaced mode, the uppermost layer of a tile serves as the surface blank, and after the surface blank is dried, a semi-finished product is obtained; the semi-finished product is colored and subjected to one-time cofiring to form a ceramic tile of the multi-layer structure where the foamed ceramic bottom blank layer and the non-porous surface blank layer coexist. The ceramic tile of the multi-layer structure has the advantages that the ceramic tile is light and convenient to attach, the surface blank is compact, and photochromism is high.

Owner:XINLAILI CERAMIC DEV CO LTD

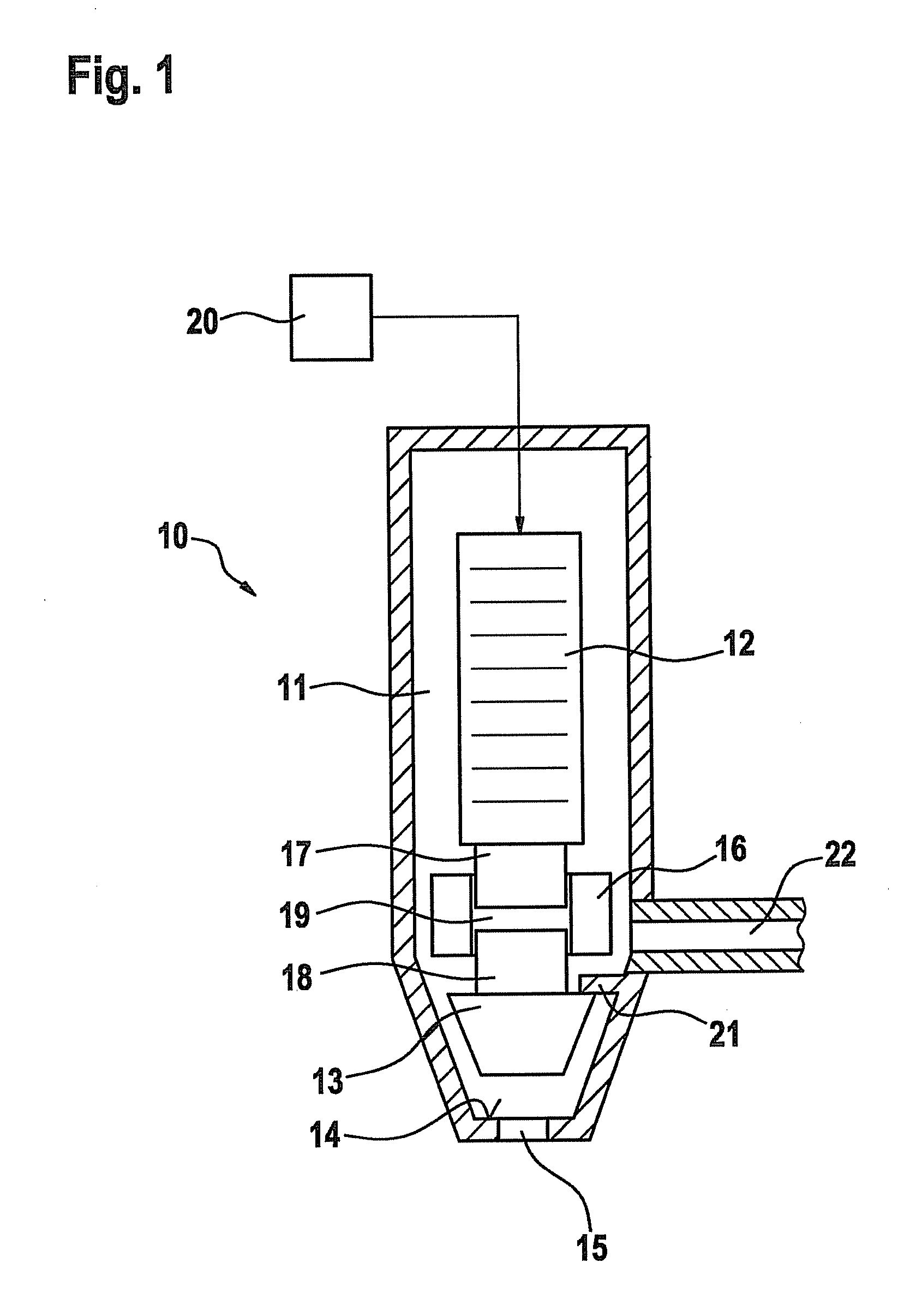

Fuel injection system and method for ascertaining a needle stroke stop in a fuel injector

InactiveUS20100059021A1TimelyEasy to detectElectrical controlFuel injection apparatusCorrelation coefficientElectricity

In fuel injection system having at least one fuel injector and a control unit for triggering the injector, each injector has a piezoelectric actuator, a nozzle element having at least one nozzle opening and at least one movable nozzle needle for selectively closing and opening the at least one nozzle opening, a hydraulic coupling element, which is connected between the piezoelectric actuator and the nozzle needle, and at least one stroke stop, against which the nozzle needle rests in its completely open and / or completely closed position. To be better able to ascertain when the stroke stop is reached in such injectors, the needle stroke stop is ascertained during an energization pause of the piezoelectric actuator by analyzing a voltage signal applied to the piezoelectric actuator. Oscillations of the voltage signal during the energization pause are preferably analyzed. To this end, regression lines are drawn through the voltage characteristic, a correlation coefficient of the regression lines to the voltage characteristic is ascertained and a needle stroke stop is detected on the basis of the correlation coefficient.

Owner:ROBERT BOSCH GMBH

Method for preparing composite interlayer coating film on surface of engineering plastics

ActiveCN102152541AReduce consumptionAnti-corrosionVacuum evaporation coatingPretreated surfacesWater savingMetallurgy

The invention discloses a method for preparing a composite interlayer coating film on the surface of engineering plastics, relates to a method for obtaining a metal composite layer on the surface of the engineering plastics and provides a method for preparing a composite interlayer coating film on the surface of engineering plastics, which can improve the function and the quality of metal-coated plastic products, reduce the production cost and is water-saving and environment-friendly because any aqueous solution is not needed in the whole processing flow. The method comprises the following steps of cleaning plastic blanks in a dry method, activating the plastic blanks, putting the activated plastic blanks into a PVD (Physical Vapor Deposition) furnace, plating a metal base film layer on the activated plastic blanks, spraying and plating an organic coating to the plastic blanks after plasma activation is carried out on the plastic blanks plated with metal base film layer, and finally putting the plastic blanks into PVD furnace to be plated with a metal facial film layer in order to obtain metalized engineering plastic products. The method is suitable for industries, such as bathroom accessories, electron, appliances, automobiles, and the like.

Owner:XIAMEN RUNNER IND CORP

Method for carrying out full dry method composite film plating on metal surface

InactiveCN102758176AHard and smooth surfaceReduce consumptionVacuum evaporation coatingSputtering coatingComposite filmCyanide

The invention discloses a method for carrying out full dry method composite film plating on a metal surface, and relates to a treatment method of the metal surface. The invention provides a method for carrying out full dry method composite film plating on metal surface capable of obtaining a highly bright metal appearance through only a layer of PVD (Physical Vapor Deposition) plated metal film and finish without spraying a primer. The method comprises the following steps: mechanically polishing and cleaning a metal blank; plating a metal film on the cleaned metal blank; organically spraying the obtained sample and solidifying at high temperature to obtain a product. After test, the obtained metalized metal product has the advantages of antisepsis, corrosion resistance, weather resistance, temperature resistance and colorful property, the surface is hard and smooth, and is comparable to the quality of the conventional hydroelectric plating metal product, roughening, activating and washing processes in the conventional hydroelectric plating are removed, no any harmful electroplating liquid medicine is added, in particular, toxic hexavalent chromium and cyanide are not used, meanwhile, the process has less metal consumption and few waste gas, and is completely free of wastewater discharge and low in cost, and the method is suitable for bathroom, electronics, electrical appliance and automobile industries.

Owner:NINGBO RUNNER INDAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com