Patents

Literature

5409results about How to "Dry fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqueous polyvinylidene fluoride composition

ActiveUS20100304270A1Dry fastUseful electrodeLiquid electrolytic capacitorsConductive materialInterconnectivityPolyvinylidene difluoride

The invention relates to an aqueous fluoropolymer, and preferably polyvinylidene fluoride (PVDF), composition for manufacturing electrodes for use in non-aqueous-type electrochemical devices, such as batteries and electric double layer capacitors. The composition contains aqueous PVDF binder, and one or more powdery electrode-forming materials. In one embodiment, the composition is free of fluorinated surfactant In another embodiment, one or more fugitive adhesion promoters are added. The electrode formed from the composition of the invention exhibits interconnectivity and irreversibility that is achieved from the use of aqueous PVDF binder.

Owner:ARKEMA INC

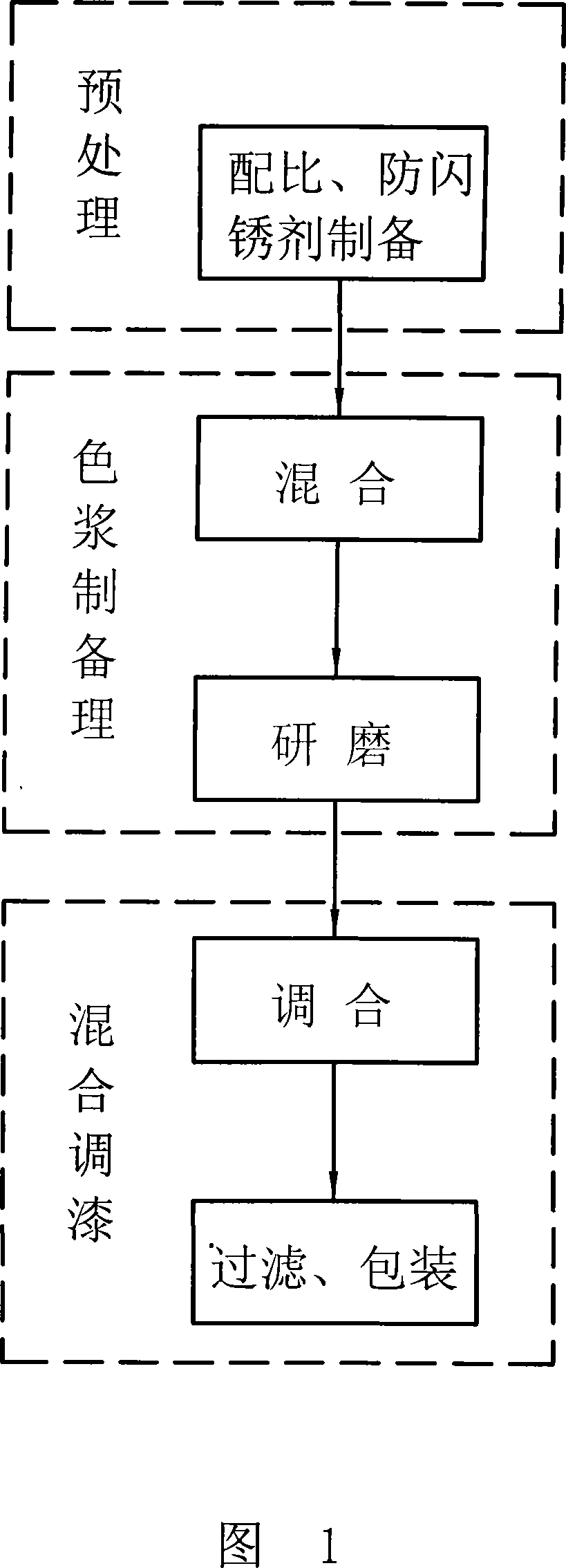

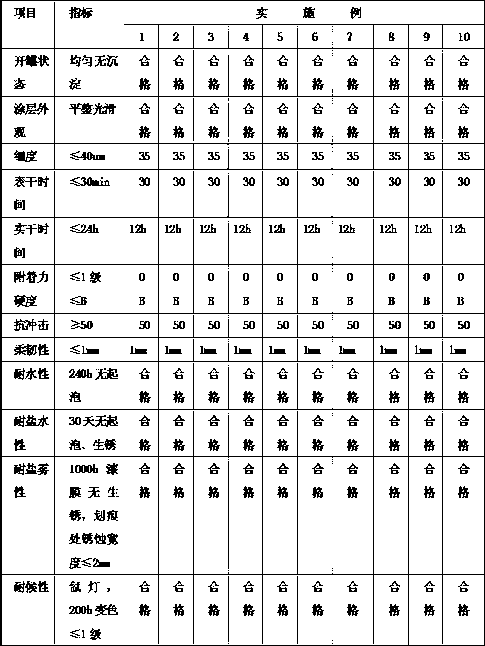

Water industrial antirust paint and preparation method thereof

InactiveCN101045843AHigh hardnessStrong adhesionAnti-corrosive paintsEmulsion paintsEpoxyALUMINUM PHOSPHATE

This invention relates to a aquosity industry anti-rust paint and its preparation method. According to weight it includes 8 to 11% aquosity acroleic acid modified epoxy, 33 to 40% acroleic acid latices, 0.1 to 0.3% defoamer, 0.05 to 0.15% wetting agent, 0.3 to 0.5% dispersant, 0.3 to 0.5% rust-resistant agent, 7.5 to 9% iron oxide red, 6 to 8% French chalk, 5 to 10% modified zinc phosphate, 2.5 to 10% trimerization aluminum phosphate, 3 to 3.5% precipitated baryte , 0.5 to 1% zinc oxide, 3 to 5% mica ferric oxide, alcohol ester twelve 1 to 2%, triethanolamine 1 to 2%, thickening agent 0.3 to 0.6%, preservative 0.05 to 0.1%, 5 to 20% de-ionized water, through pretreatment, color paste preparation and blending and adjusting to gain product.

Owner:邹磊

Reaction bonding type node sealant and preparation method thereof

ActiveCN102911638AImprove stabilityImprove bindingNon-macromolecular adhesive additivesOther chemical processesChemical LinkagePolyvinyl chloride

The invention provides a reaction bonding type node sealant and a preparation method thereof. The sealant comprises asphalt, modifiers, an emulsifier, a crosslinking agent, thickeners, a reinforcing agent and water. In the formula system, more appropriate modifiers are adopted compared with the prior art, so that a rubber asphalt mixture can achieve good emulsification effect, elasticity and strength of a sealing layer after drying are greatly improved, and the sealing effect can be good and lasting; the chemical linkage effect with concrete is formed by using the crosslinking agent, and bonding force with the concrete is improved; and a lot of thickeners are used for adjusting the stickness of the sealant system, so that the reaction bonding type node sealant can better adhere to the surface of a pentatricopeptide repeats (PPR) or polyvinyl chloride (PVC) pipe, and good sealing at positions where PPR or PVC water supply and drainage pipes are connected with base surfaces of concrete.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

Water-based intaglio ink equal to plate engraving ink and uses thereof

ActiveCN101284965AOptimizing physical fastnessNo pollutionInksOther printing apparatusScreen printingSolubility

The invention is equivalent to water soluble intaglio ink of plate engraving ink and / or equivalent to water-soluble screen printing ink of the ink, suitable for a gravure printing machine. The ink has the advantages of nontoxicity, tastelessness, nonflammable property, water solubility, non-environmental pollution and rapid drying; the printing effect of the obtained presswork is the same as or equivalent to the printing effect of the plate engraving presswork; the materialized firmness of the presswork is superior to the materialized firmness of the plate engraving presswork; the ink is low in printing cost and suitable for printing secure and confidential documents with deep printing lines, such as bank notes, securities, stamps, food packing, etc.

Owner:北京万垟防伪技术有限责任公司 +2

Modified emulsified asphalt waterproof sealant and preparation method thereof

InactiveCN102898850AImprove stabilityImprove bindingOther chemical processesBuilding insulationsBituminous waterproofingPolypropylene

The invention aims to provide a modified emulsified asphalt waterproof sealant and a preparation method thereof. The modified emulsified asphalt waterproof sealant comprises asphalt, a modifying agent, an emulsifying agent, a thickening agent and water. In a formula system of the modified emulsified asphalt waterproof sealant, more modifying agent in an appropriate amount is adopted than that of the prior art, so that a rubber-asphalt mixture can achieve a good emulsifying effect, the elasticity and strength of a dried sealing layer are greatly improved, and the sealing effect can be better and lasting; and a large amount of the thickening agent is used to adjust the appropriate viscosity of a modified emulsified asphalt waterproof sealant system, so that the modified emulsified asphalt waterproof sealant can be well adhered to the surface of a relatively smooth polypropylene random copolymer (PPR) or polyvinyl chloride (PVC) pipe to well seal the connection part of a PPR or PVC water supply and drainage pipe and a concrete base.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

Reaction bonding modified emulsified asphalt waterproof paint and preparation method thereof

ActiveCN102898947AImprove stabilityImprove bindingConjugated diene hydrocarbon coatingsChloropene polymer coatingsCross-linkBituminous waterproofing

The invention aims to provide a reaction bonding modified emulsified asphalt waterproof paint and a preparation method thereof. The reaction bonding modified emulsified asphalt waterproof paint comprises asphalt, a modifying agent, an emulsifying agent, a cross-linking agent and water. In the formula system of the reaction bonding modified emulsified asphalt waterproof paint, more modifying agents in an appropriate amount are adopted compared with the prior art, so that a rubber-asphalt mixture can achieve a good emulsifying effect, the elasticity and strength of a dried sealing layer are greatly improved, and the sealing effect can be better and lasting; and by using the cross-linking agent, a chemical coupling effect is achieved between the paint and concrete, so that the cohesive force of the concrete is promoted. The reaction bonding modified emulsified asphalt waterproof paint can be applied to waterproof construction of wall surfaces, roofs, roads, bridges and the like, and has a very high practical value.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

Acrylate micro-emulsion with high solid content, its preparation method and use

The invention refers to a high-solid content acrylate micro-latex, its making method and its application to carpentry dope. It adopts the technique of half-continuous starvation feeding, and is obtained by the polymerizing method of seed latex. It leads into cross-linking groups in the course of polymerization such as amidogen, acetoacetyl and amido, depends on the reaction of the groups of form film, gets painting film with cross-linking construction, and improves the water and solvent resistance of the painting film.

Owner:SOUTH CHINA UNIV OF TECH

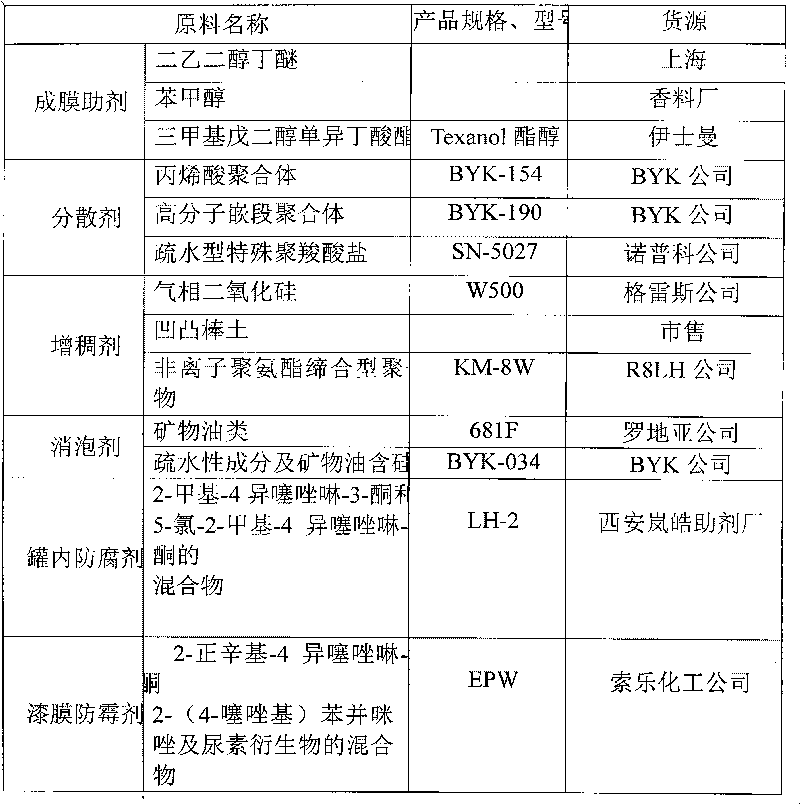

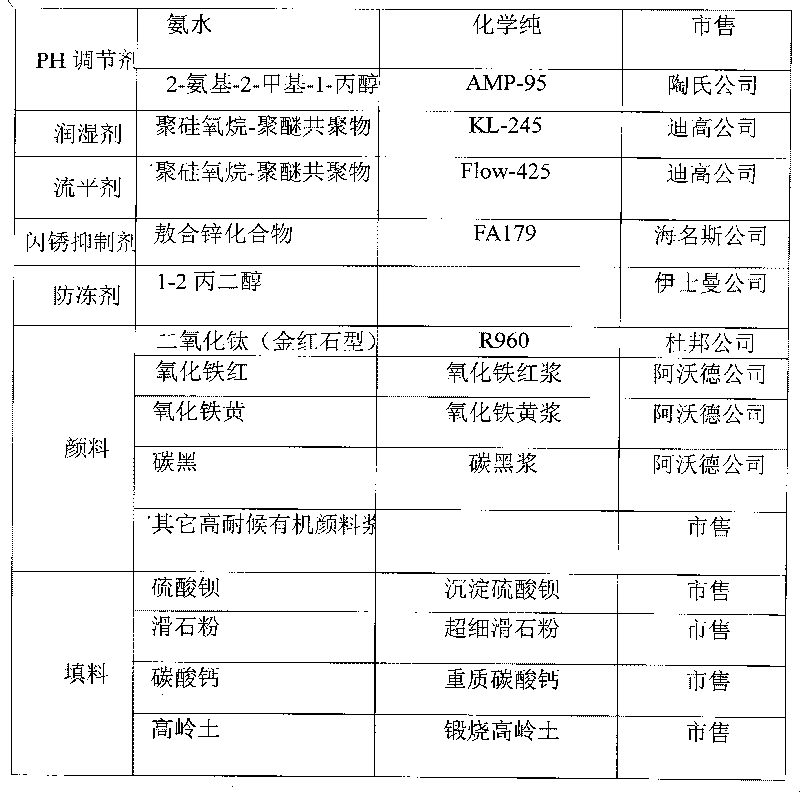

Aqueous high-performance monocomponent primer-topcoat anti-corrosion coating

The invention discloses an aqueous high-performance monocomponent primer-topcoat anti-corrosion coating, comprising aqueous modified acrylic acid emulsion, coloring pigment, antirust pigment, filling material, film forming auxiliary agent, thickening anti-settling agent, softened water, anti-flash rust agent, and auxiliary additive. The coating disclosed herein has excellent salt mist resistance, can resist salt mist for more than 1000h and resist weather for more than 200h, and has the characteristics of rapid drying, low content of VOC, no environmental pollution, and no harm to constructers' health. The coating disclosed therein is convenient for using, can be applied in high pressure airless spraying and ordinary air spraying, the thickness of single coating wet film can reach 200 mum without sagging or cracking, and the coating disclosed herein is widely suitable for anti-corrosion protection of locomotive, container, automobile, ship, bridge, iron tower, storage tank, pipeline and other steel structures.

Owner:中山大桥化工企业集团中山智亨实业发展有限公司

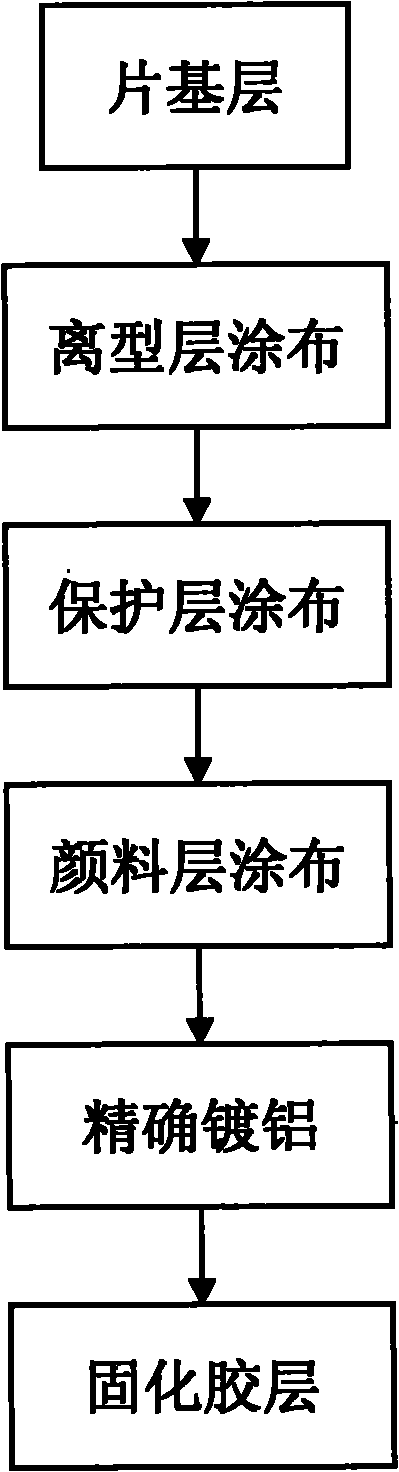

Production method of hot stamping foil

ActiveCN101879819ASolving Hot Stamping RequirementsEvenly paintedCoatingsThermographyPolyvinyl butyralHot stamping

The invention discloses a production method of hot stamping foil, which adopts six production process flows: release coating, protective layer coating, color layer coating, accurate aluminizing and curing glue layer coating. In the whole production process, water soluble glue, water soluble ink and water soluble gloss oil are used to realize the integrated production of the hot stamping foil, methacrylates and monomers which are emulsified and polymerized are mixed in a certain ratio, a dye leveler, thickener and the like are added in the mixture, the resulting product is coated and dried, polyvinyl butyral-based glue is coated, and the whole production of the hot stamping foil is finished. The hot stamping foil produced by the process has the characteristics of energy conservation, environmental protection and sanitation.

Owner:江苏卫星新材料股份有限公司

Concrete demoulding agent and preparation method thereof

ActiveCN105296122ADry fastGood demoulding qualityCeramic shaping apparatusLubricant compositionMaterials scienceDefoamer

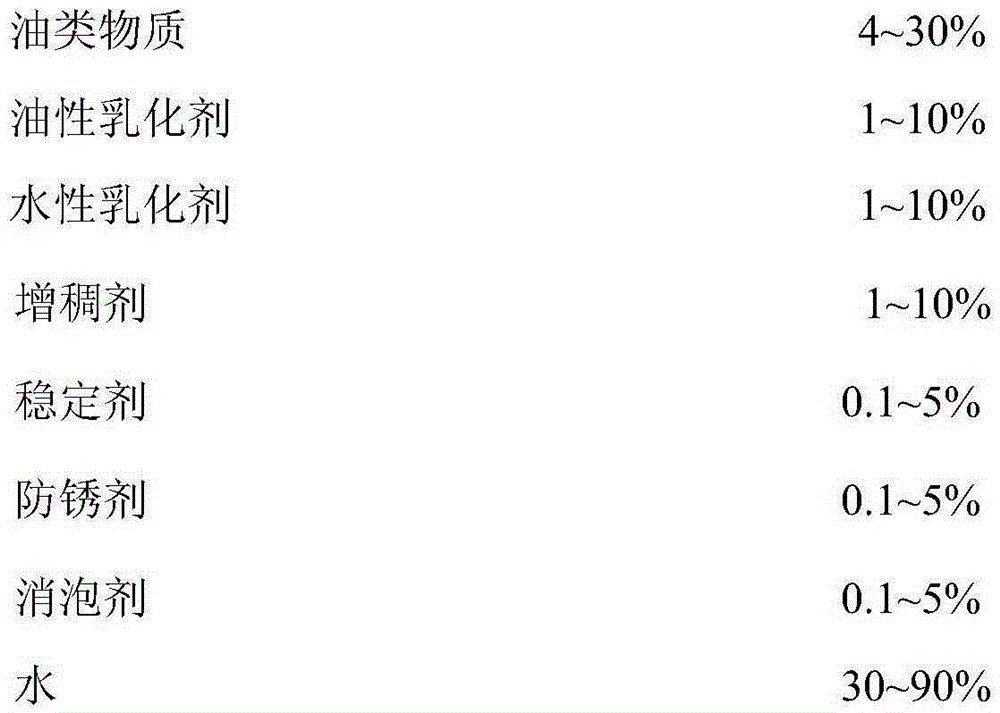

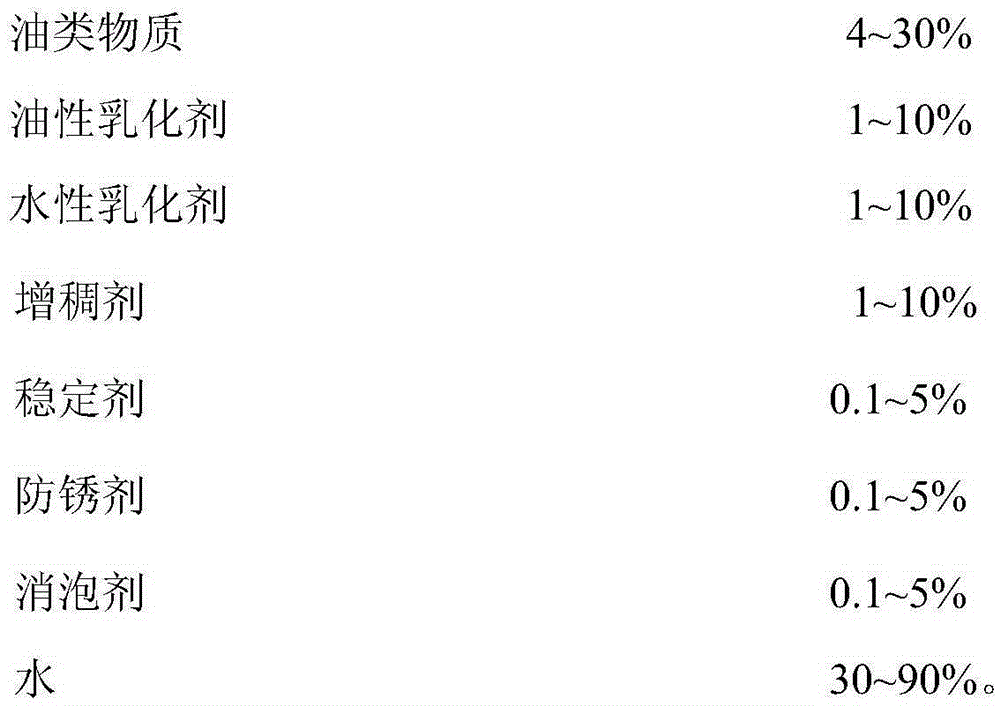

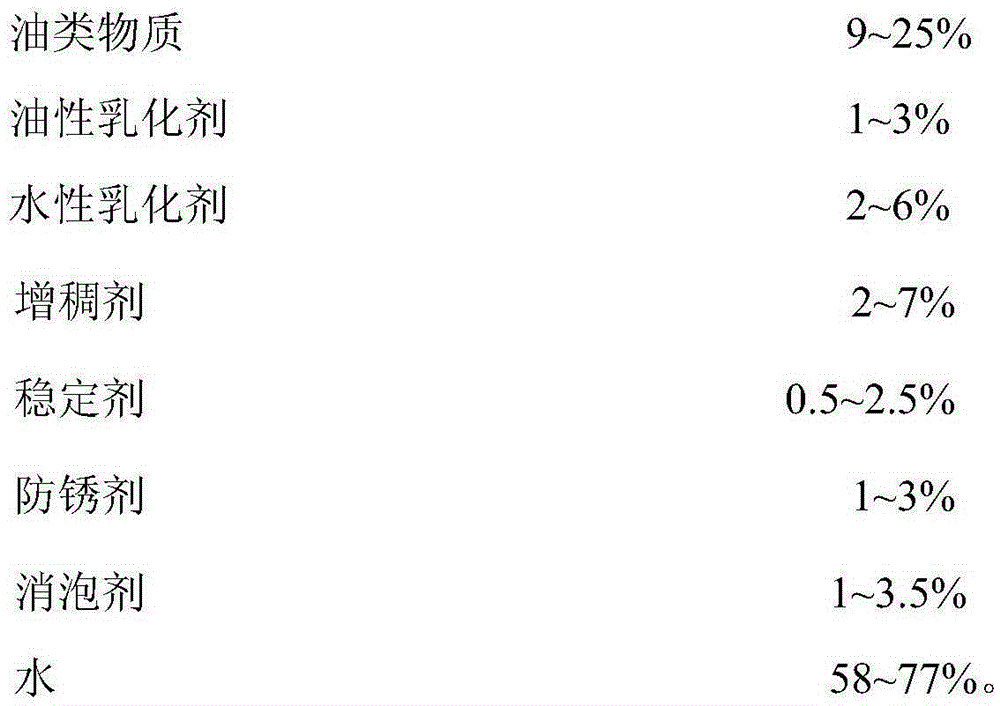

The invention discloses a concrete demoulding agent and a preparation method thereof. The demoulding agent is composed of the following raw materials in percentage by weight: 4 to 30% of oil substance, 1 to 10% of oily emulsifier, 1 to 10% of aqueous emulsifier, 1 to 10% of thickening agent, 0.1 to 5% of stabilizing agent, 0.1 to 5% of antirust agent, 0.1 to 5% of antifoaming agent, and 30 to 90% of water. The concrete demoulding agent has the advantages that the demoulding agent can be rapidly dried after film forming, the surface of moulded members is smooth and does not contain bubbles, the amount of residual ash in the mould is little, and the demoulding quality is good.

Owner:KZJ NEW MATERIALS GROUP CO LTD

Waterborne fluoropolymer composition

InactiveUS20120015246A1Dry fastUseful electrodeFinal product manufactureConductive materialIonVinylene carbonate

This invention relates to a waterborne fluoropolymer composition useful for the fabrication of Li-Ion-Battery (LIE) electrodes. The fluoropolymer composition contains an organic carbonate compound, which is more environmentally friendly than other fugitive adhesion promoters currently used in waterborne fluoropolymer binders. An especially useful organic carbonate compound is ethylene carbonate (EC) and vinylene carbonate (VC), which are solids at room temperature, and other carbonates which are liquid at room temperature such as propylene carbonate, methyl carbonate and ethyl carbonate. The composition of the invention is low cost, environmentally friendly, safer, and has enhanced performance compared to current compositions.

Owner:ARKEMA INC

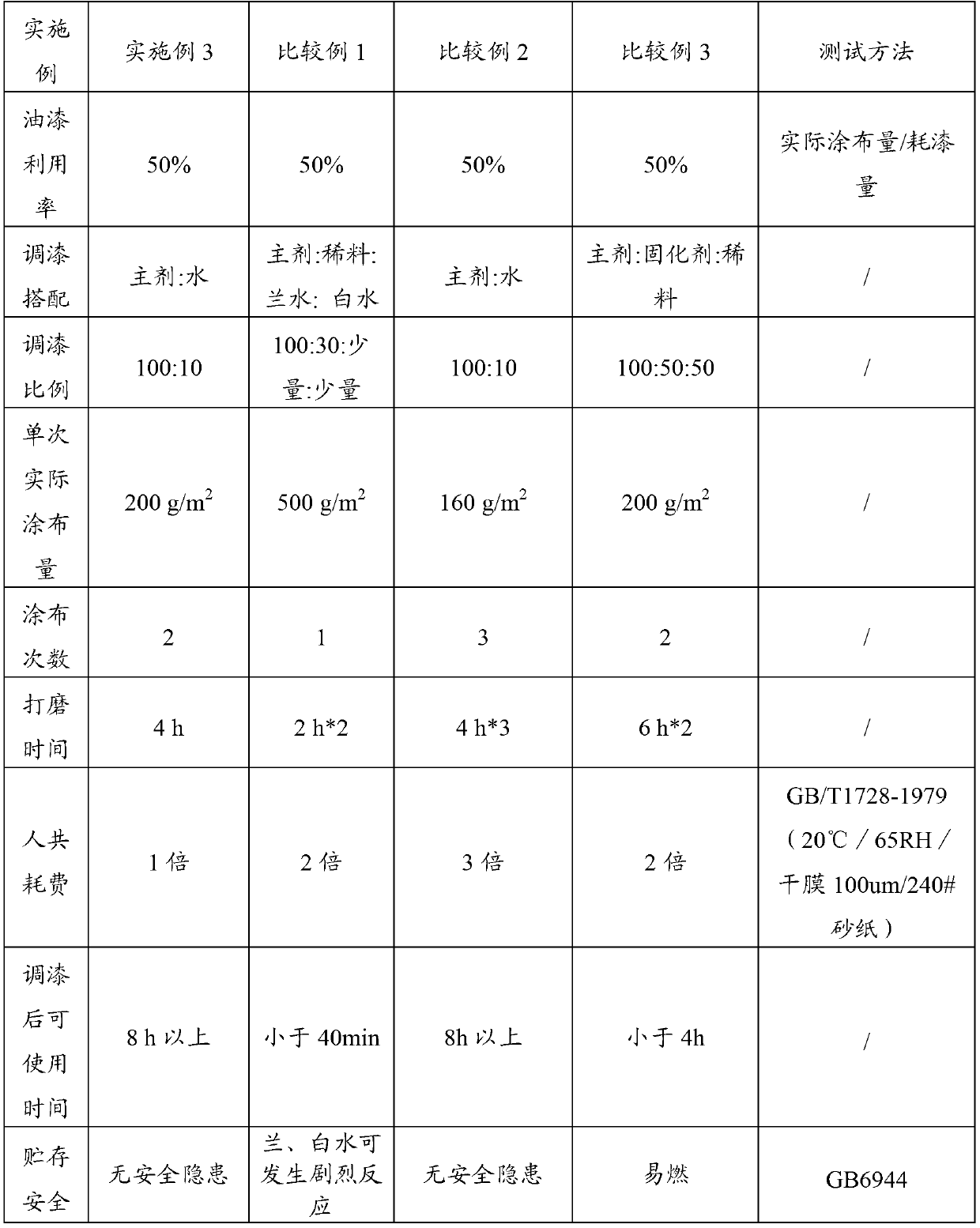

Water-based two-pack polyurethane preservative coating and preparation method thereof

ActiveCN101701128AHigh glossGood chemical resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedDipropylene glycol monomethyl ether acetate

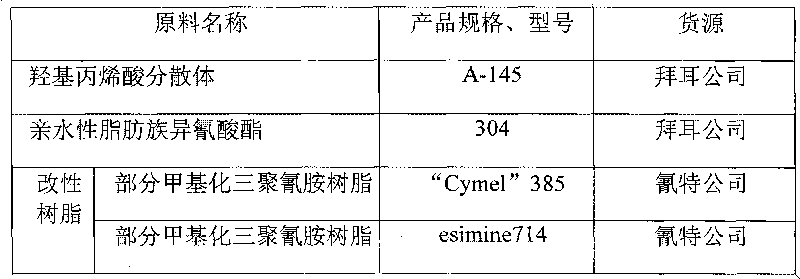

The invention relates to the preservative coating technology, in particular to a water-based two-pack polyurethane preservative coating and a preparation method thereof. The water-based two-pack polyurethane preservative coating comprises two parts, namely paint vehicle and curing agent, wherein the paint vehicle is prepared from water-based hydroxylated acrylic dispersion, modified resin, pigment, filler, additive and water, the curing agent part comprises hydrophilic aliphatic isocyanate, dodecyl ester and propylene glycol methyl ether acetate. When using the coating of the invention, the weight ratio of the paint vehicle to the curing agent is 74-85:15-26 and the coating can solve the defects of the existing preservative coating.

Owner:JIANGSU LANLING POLYMER MATERIAL CO LTD

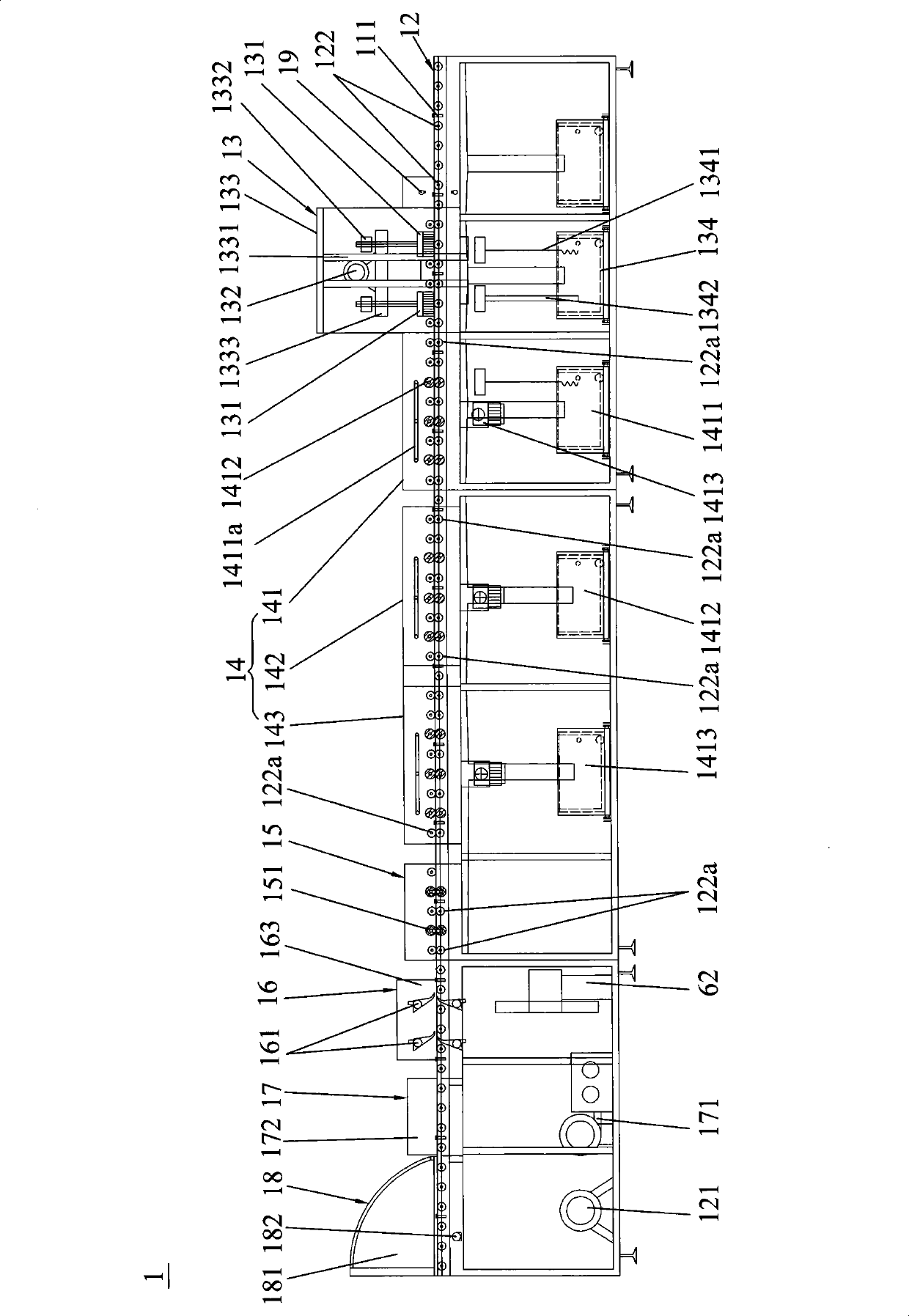

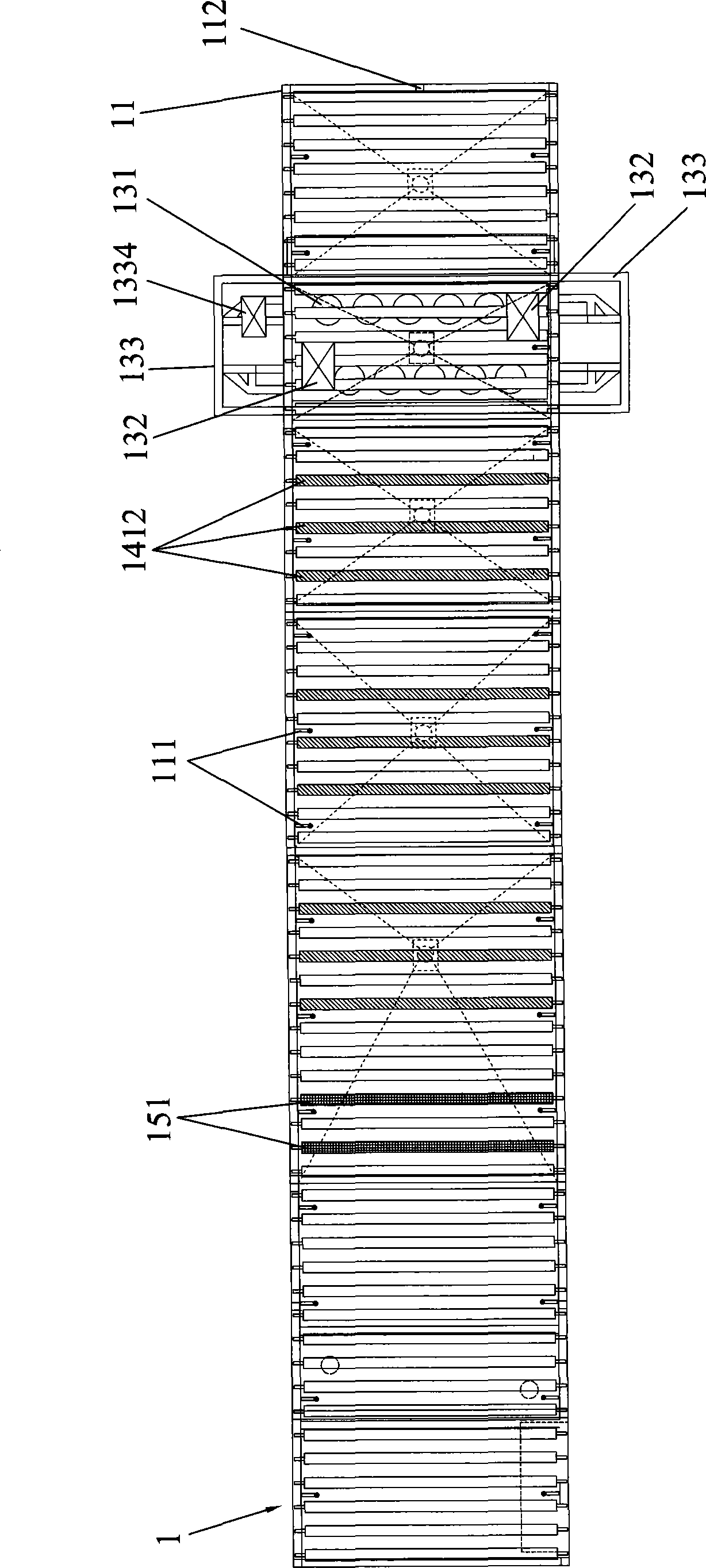

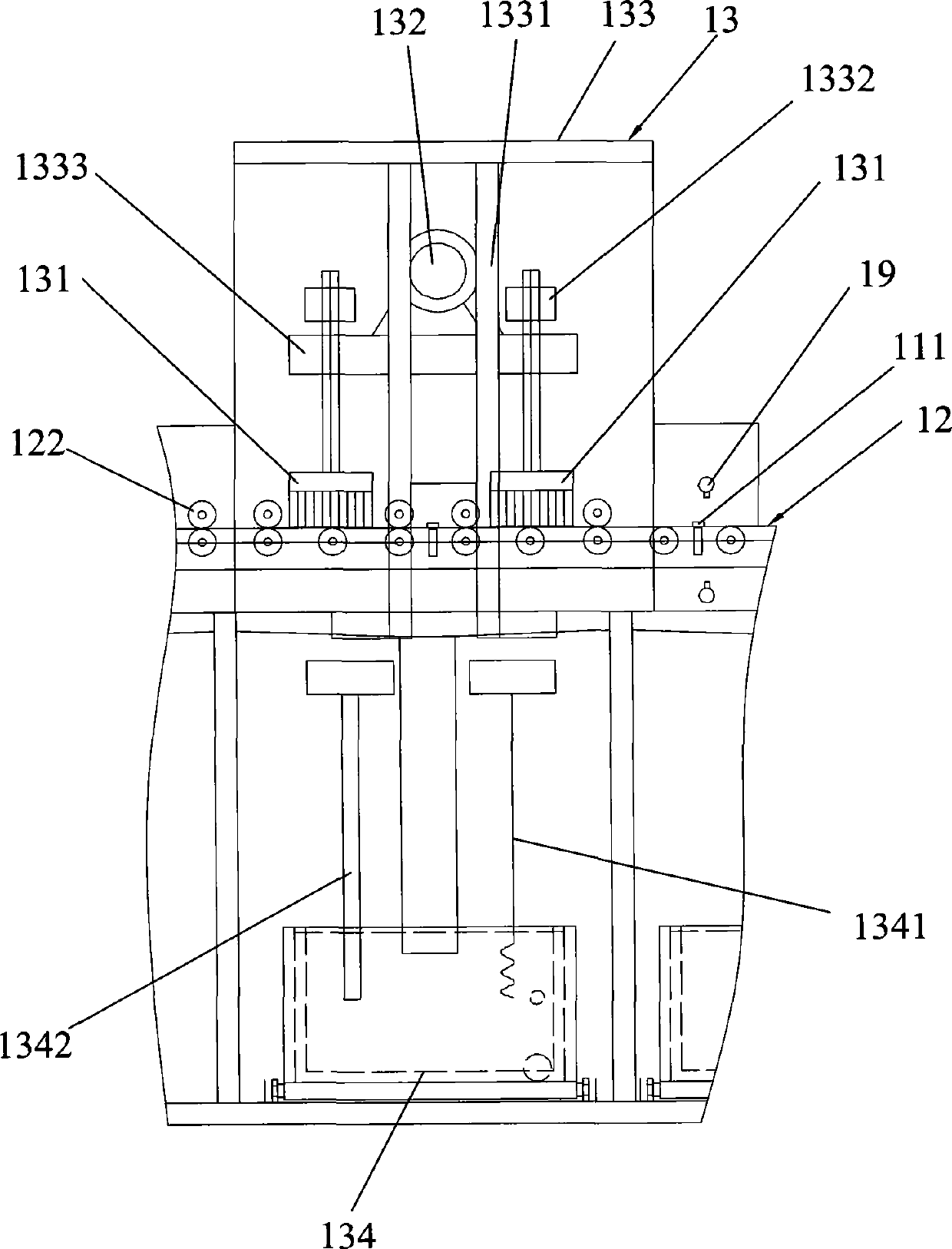

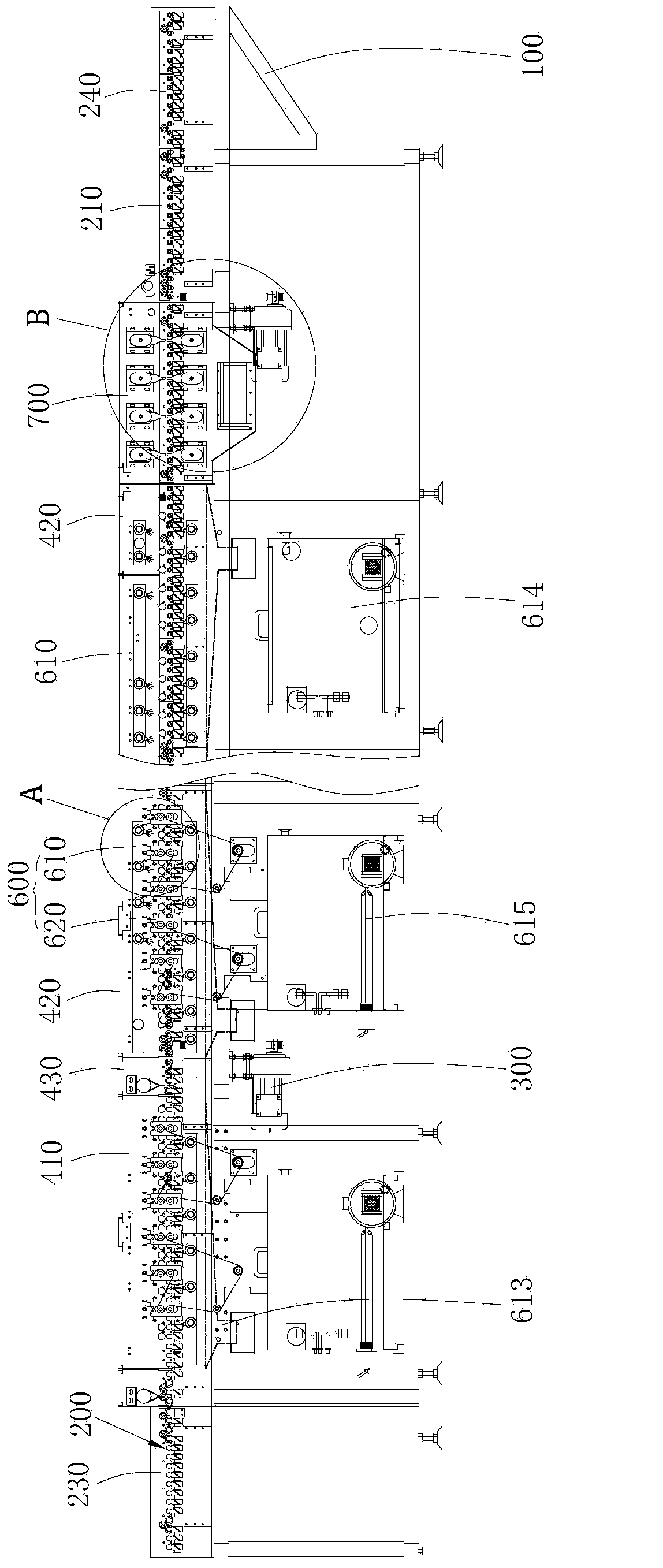

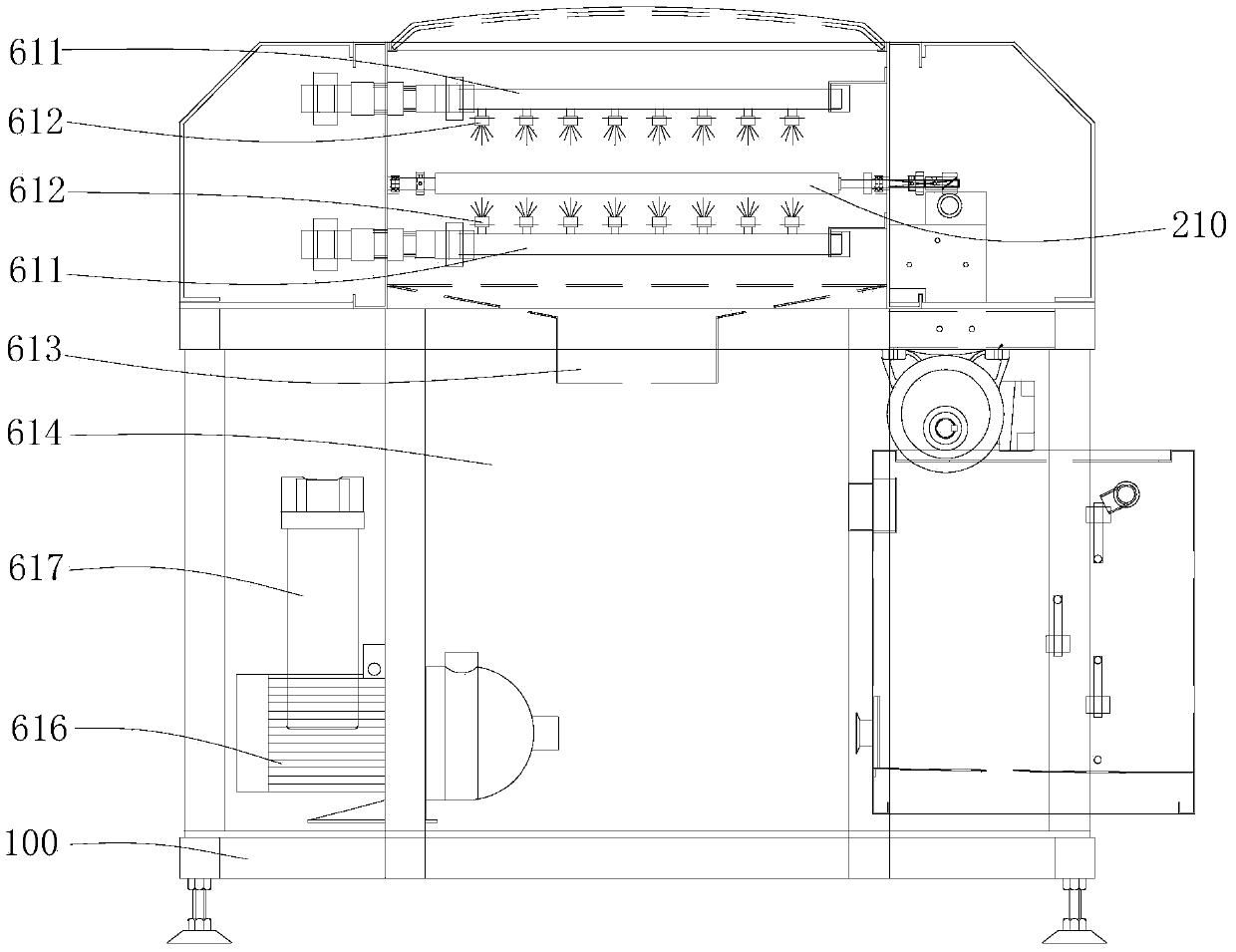

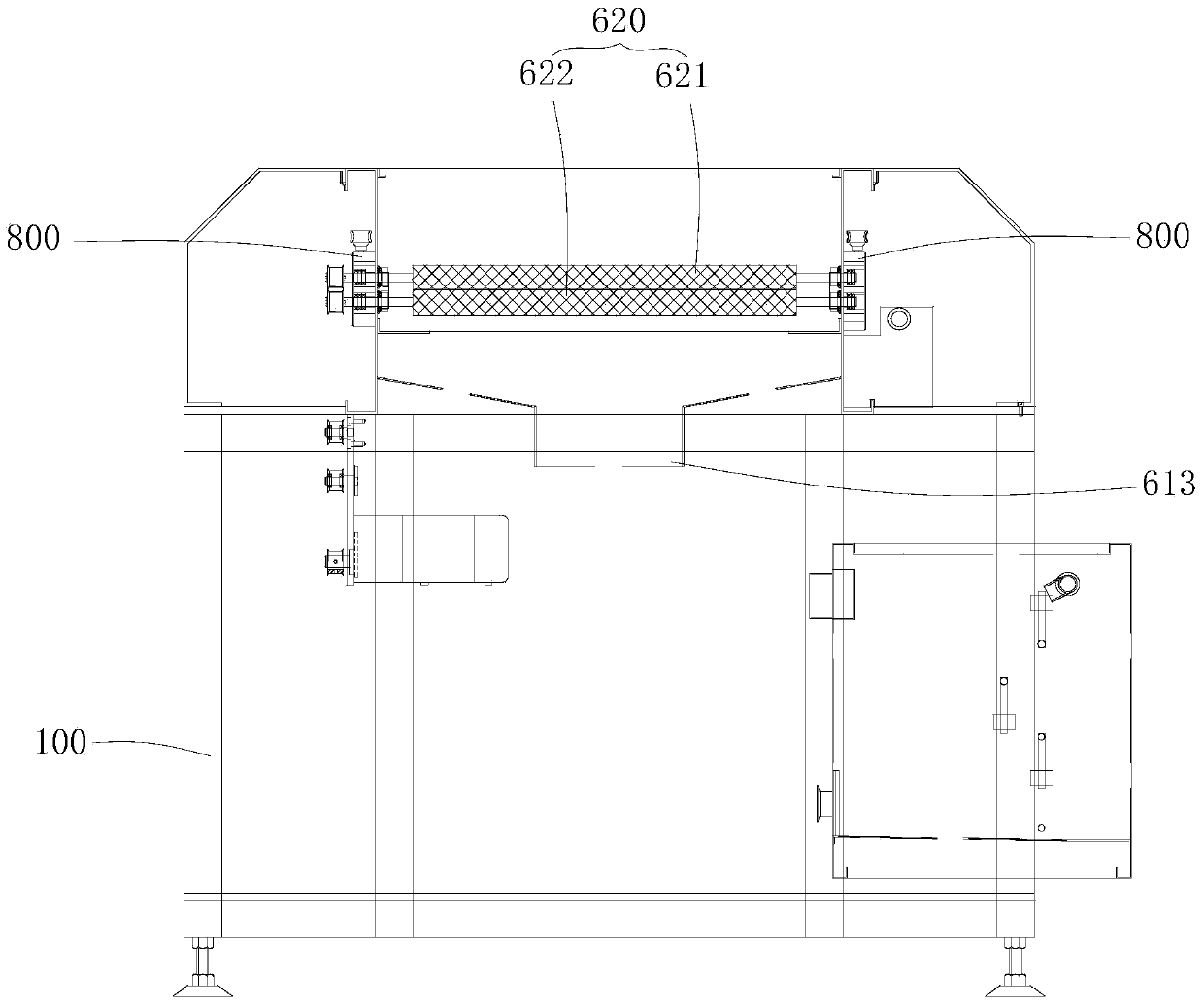

Glass-cleaning and drying device

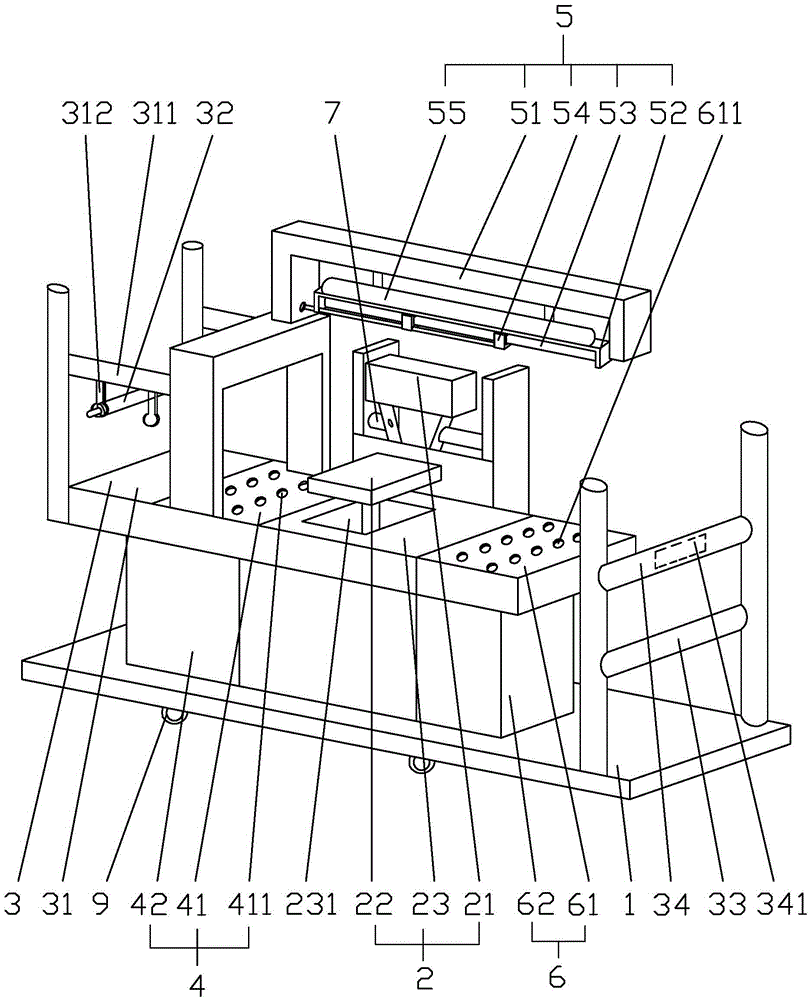

The invention provides a glass-cleaning and drying device suitable for cleaning and drying coated glass. The glass-cleaning and drying device comprises a stand, a conveying mechanism, a tray brush device, a brush device, a water-absorbing component, a drying device and a heat drying device. The conveying mechanism comprises a driving motor and a plurality of conveying rollers arranged in a line, wherein the driving motor drives the conveying rollers to convey coated glass; the tray brush device comprises a lifting mechanism, a plurality of tray brushes and a tray brush driving mechanism; the lifting driver of the lifting mechanism drives the tray brushes to move up and down relative to the coated glass; the tray brush driving mechanism drives the tray brushes to rotate; the clamped transmission roller group of the brush device is arranged between the tray brush device and the brush device for conveying the coated glass in a clamping mode and expelling moisture on the coated glass; the water-absorbing component comprises a water-absorbing roller group which comprises water-absorbing rollers with water absorption in vertical two-to-two correspondence; the drying device comprises air knives and a blower; and the air knives respectively face to the upper surface and the lower surface of the coated glass.

Owner:DONGGUAN ANWELL DIGITAL MASCH CO LTD

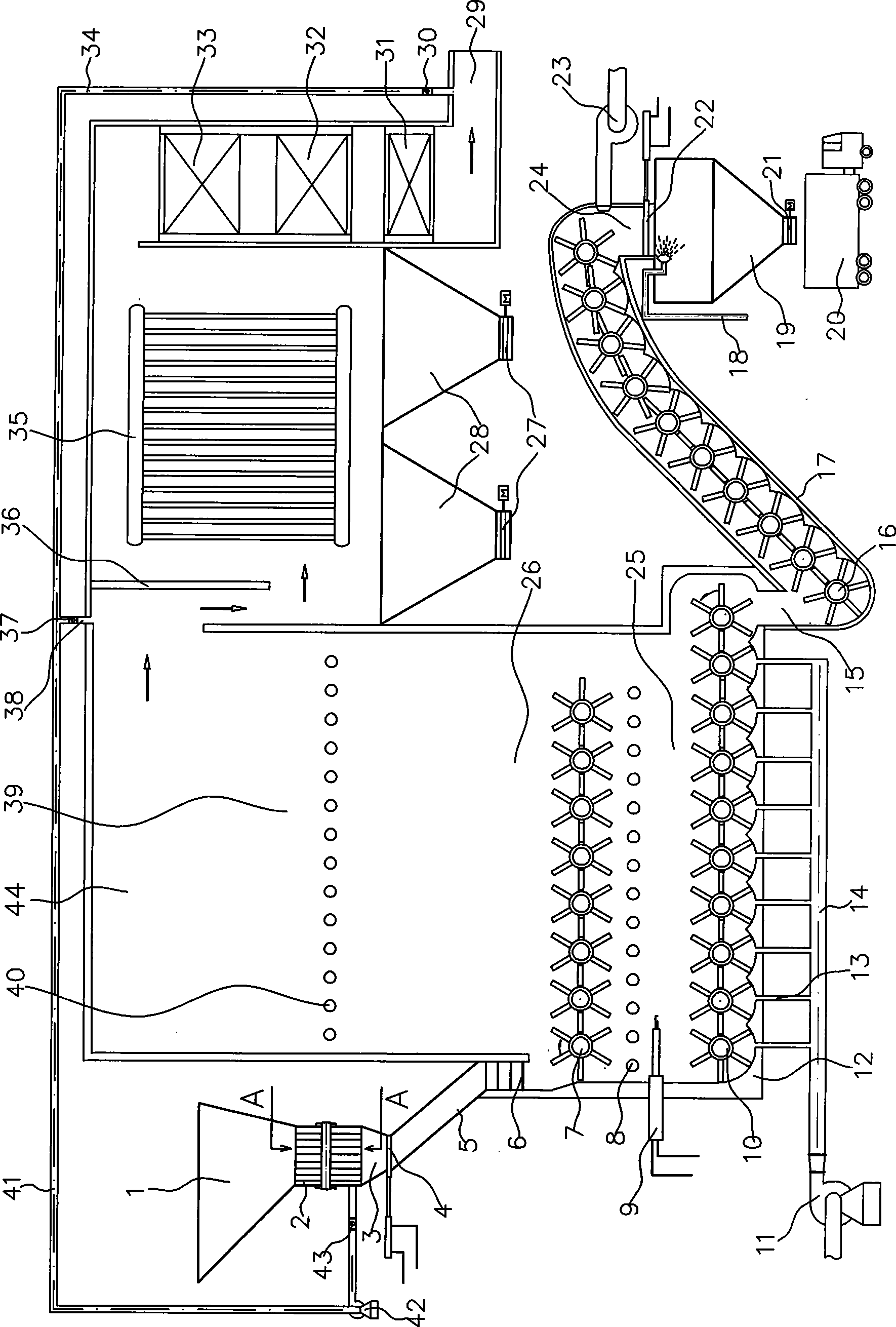

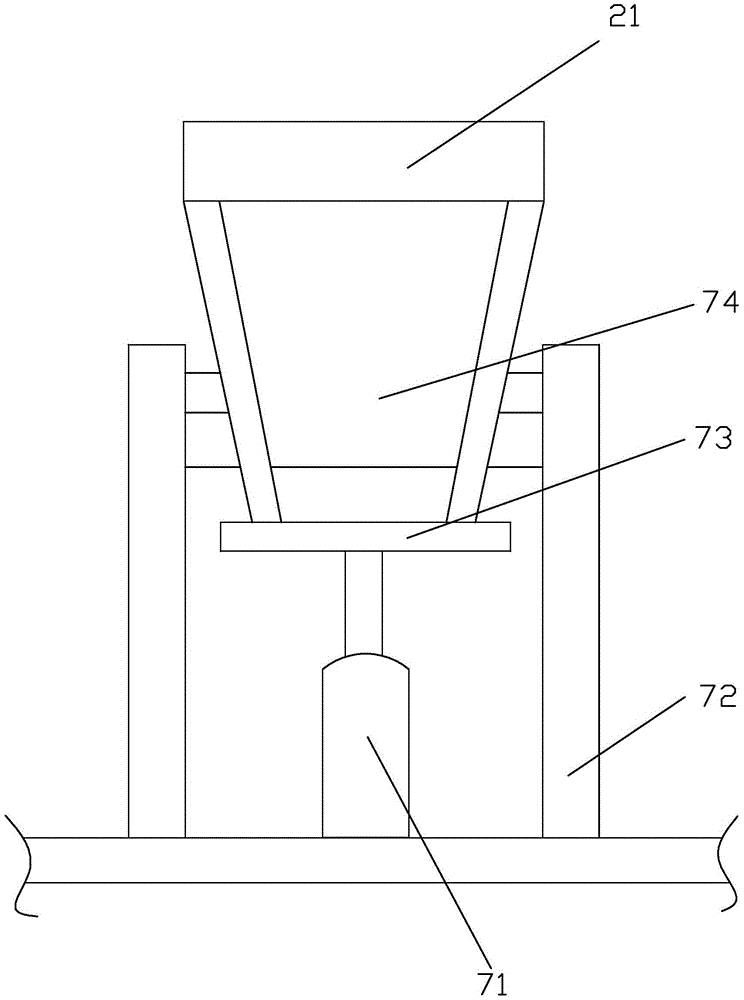

Efficient burning furnace with rotary fluidization grate

InactiveCN101532667ATurn overWith self-cleaning functionRevolving grateRocking grateCombustion systemFlue gas

The invention relates to an efficient burning furnace with a rotary fluidization grate. The burning furnace with the rotary fluidization grate consists of a feeding system, a burning system and a slagging system; moreover, a waste heat boiler and a flue gas treatment system are connected with the burning furnace to form a complete garbage burning and generating system. The feeding system consists of a feeding hopper, a pre-drying conveying device, an aggregate bin, a chute and a charge distributor. The feeding hopper is a receiving opening for feeding garbage into the burning furnace and is arranged in a garbage storage pit close to one side of the burning furnace. An outlet of the feeding hopper is connected with an inlet of the pre-drying conveying device. A material level switch is arranged in the feeding hopper, and gives an alarm to prompt an operator to feed materials when the material level is lower than a set value so as to ensure that the hopper is not empty. The outlet of the hopper can be selectively provided with a feeding device. The burning furnace has the advantages of high burning speed, high burning efficiency, high slag burning degree, easy control, lower energy consumption, low pollution, low cost and investment conservation, and is applicable to domestic garbage with low thermal value and high moisture; and the garbage does not need to be pretreated.

Owner:新乡锅炉制造有限公司

Nano composite hot melt type gage mark coating and preparation method thereof

InactiveCN1923929AExcellent wear resistanceImprove crack resistanceRosin coatingsTraffic signalsFiberAdjuvant

The invention discloses nanometer composite heat-fused reticle paint and preparing method, which comprises the following parts: 10-25% filming material, 3-8% dye, 40-70% filler, 0.5-4% specific reinforced material, 14-25% glass microball and 1-5% other adjuvants, wherein the specific reinforced material contains nanometer fiber, nanometer whisker, micrometer fiber, micrometer whisker. The preparing method comprises the following steps: pouring the filming material in the composite autoclave; adding adjuvant; stirring evenly; adding dye, filler, glass microball and specific reinforced material; stirring evenly; packing.

Owner:中科纳米涂料技术(苏州)有限公司

Cloth ironing machine

InactiveCN105463745AAvoid damageQuality improvementHeating/cooling textile fabricsTextile treatment by spraying/projectingEngineeringEnergy consumption

The invention mainly discloses a cloth ironing machine. The technical scheme is that the cloth ironing machine comprises a rack, an ironing mechanism, a conveying mechanism, a preheating mechanism, a sterilization mechanism and a drying mechanism, wherein the conveying mechanism comprises a putting table, cloth putting rollers and a cloth reeling roller, the putting table is provided with hanging rings, two ends of the cloth putting rollers are respectively hung on the hanging rings, one side of the cloth reeling roller is provided with a cooling roller, the ironing mechanism comprises an upper press mould, a lower press mould and an ironing table, the lower sides of the upper press mould and the lower press mould are respectively provided with a first transmission mechanism and a second transmission mechanism for driving the upper press mould and the lower press mould to be in force fit, the preheating mechanism comprises a preheating plate provided with steam holes and a water tank with an electric heater, the sterilization mechanism comprises a lamp base, a lamp holder and an ultraviolet tube with a cleaning device, the drying mechanism comprises a drying plate provided with air outlets and a warm air chamber provided with a warm air machine, and sliding wheels are arranged below the rack. The cloth ironing machine has the advantages of good ironing effect, shaping in one step, high work efficiency and less energy consumption.

Owner:SHENGZHOU YIHAI MOTOR PARTS FACTORY

Environment-friendly starch adhesive for cementing corrugated boards at low temperature and preparation method of environment-friendly starch adhesive

InactiveCN106085289ALess glueFacilitates quick dryingNon-macromolecular adhesive additivesStarch derivtive adhesivesChemistryAdhesive

The invention relates to an environment-friendly starch adhesive for cementing corrugated boards at a low temperature and a preparation method of the environment-friendly starch adhesive. The starch adhesive is prepared from the following raw materials in parts by weight: 15 to 30 parts of starch, 60 to 80 parts of water, 0.2 to 1 part of sodium hydroxide, 0.05 to 0.2 part of oxidizing agent, 0.1 to 0.5 part of cross-linking agent, 0.1 to 0.5 part of stabilizing agent, 2 to 10 parts of drier, 1 to 5 parts of reinforcing agent and 0.1 to 1 part of penetrating agent. Under the oxidation of the oxidizing agent, besides hydroxyl, groups such as carboxyl and carbonyl are added on molecular chains of the starch, so that the initial adhesion of the adhesive is improved, the cementing quantity is reduced, and the rapidness in drying is facilitated; by adding the penetrating agent, the adhesive can rapidly penetrate through paper and destroy fibers; by adding the cross-linking agent and the reinforcing agent, the adhesive can be instantaneously cross-linked to form a mass structure, the rapid dryness of the adhesive is facilitated, and the adhesive can also be cross-linked with groups on the paper fibers so as to increase the cementing strength and the water resistance of paper boards; and by adding the drier, the drying speed of the starch adhesive can be increased, so that the steam pressure of a paper machine is reduced.

Owner:明辉大秦(上海)环保科技股份有限公司

Photogravure ink equal to cut ink and its application

This invention relates to a photograghic intaglio printing ink which equals to carving intaglio printing ink. It can be used in photographic intaglio printer, and its outstanding feature is that the price of the printer is cheap, lithographic cost is low, and the post-treatment step of sewage during printing process is unneeded, so the sewage from carving intaglio printing ink printing process is eradicated completely and with no environmental pollution, and the printing ink is no waste and its non-offset performance is very good. It dries quickly, so it shortens the production cycle and saves the production buildings and land. The color of ink of its printing is of distinct hierachical structure and strong stereoscopic feeling. Its printing effect is the same as that of carving intaglio printings. The physicochemical fastness of its printing is superior to that of carving intaglio printings. Its printing cost is low.

Owner:北京万防伪技术有限责任

High-permeability liquid rubber spray coating

InactiveCN102329566AHigh bonding strengthImprove waterproof and anti-seepage performanceUnspecified rubber coatingsConjugated diene hydrocarbon coatingsPolymer scienceSpray coating

The invention discloses a high-permeability liquid rubber spray coating, and relates to the technical field of spray coatings. The high-permeability liquid rubber spray coating comprises a component A and a component B, wherein the component A is anionic liquid rubber asphalt emulsion; the component B is a coagulant solution; the component A has the solid content of liquid rubber asphalt emulsion of 50-75 weight percent, and comprises the following components in percentage by mass: 1 to 35 percent of rubber emulsion, 10 to 50 percent of asphalt emulsion, 0.01 to 2 percent of anionic dispersing agent, 0.01 to 2 percent of anionic surfactant, 0.1 to 10 percent of fatty alcohol-polyoxyethylene ether, 0.1 to 10 percent of alkali resistant wetting agent OEP-70 and 0.1 to 10 percent of alkali resistant wetting agent AEP; and the component B is an aqueous solution at the concentration of 3-18 percent, which is prepared by mixing calcium chloride and composite aluminum-iron polymer in percentage by mass. The wetting agents are added into the spray coating, and the coating has high permeability and wider application range.

Owner:DALIAN MEICHENTE TECH

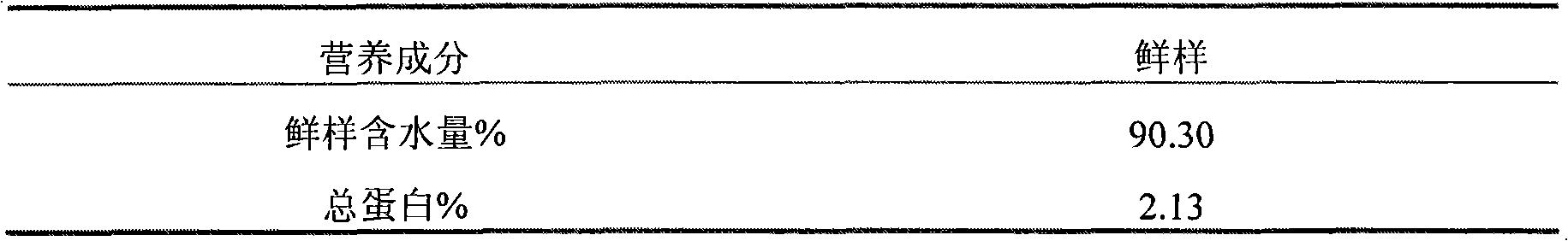

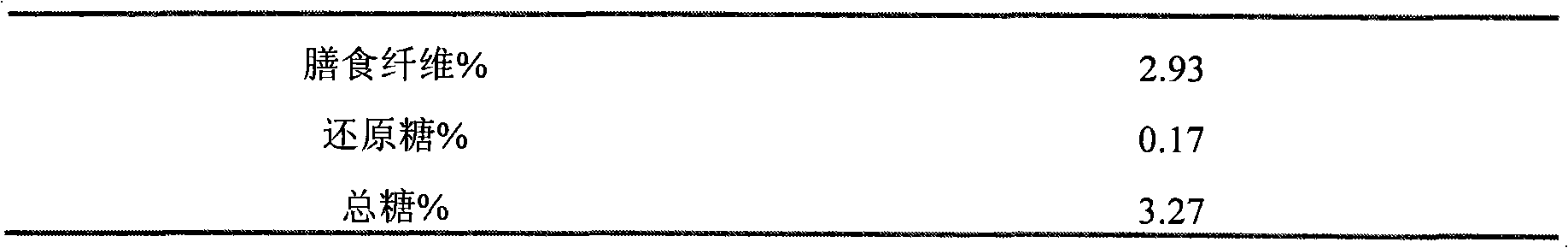

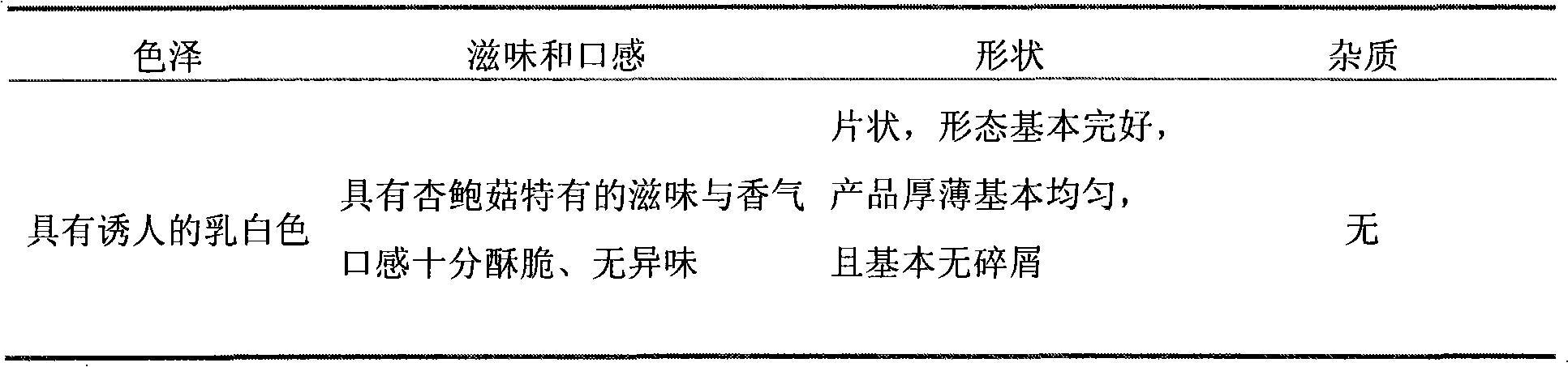

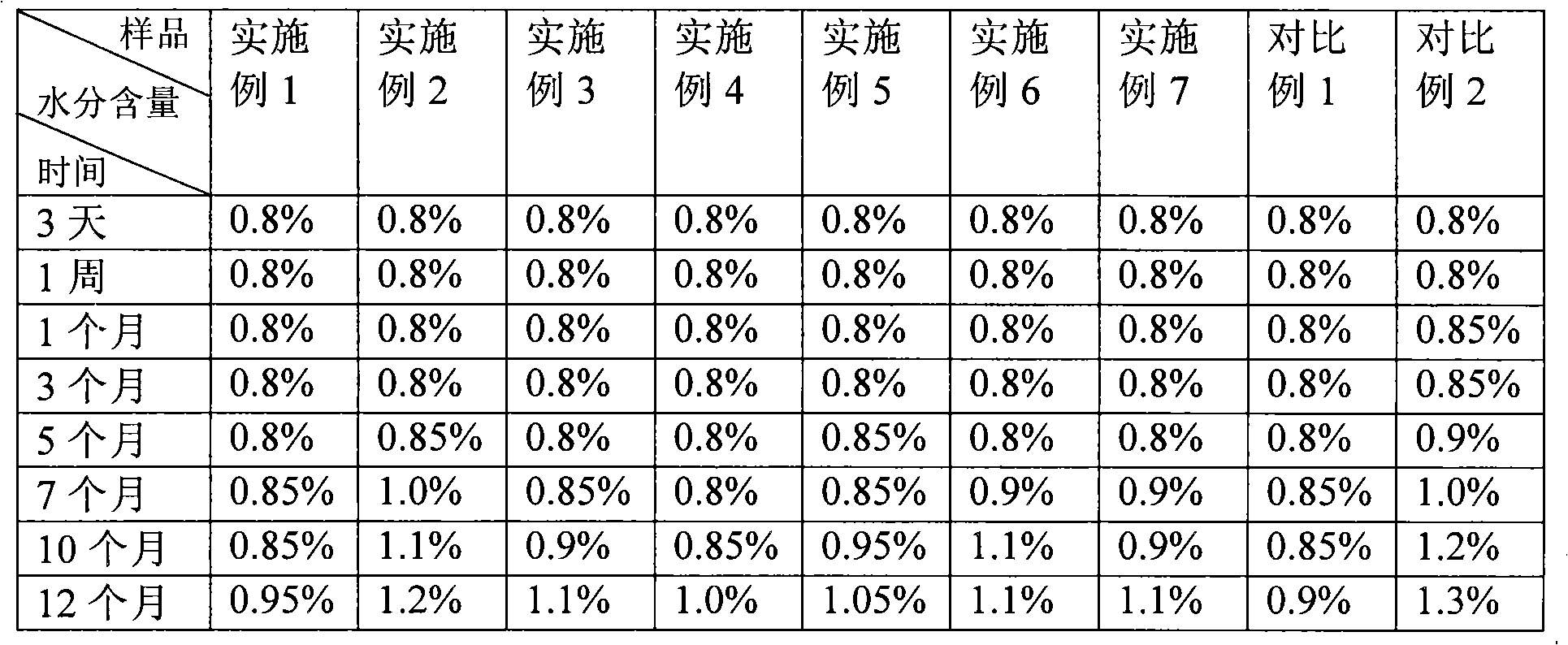

Puffed pleurotus eryngii chip production process and puffed pleurotus eryngii chip products

The invention relates to a puffed pleurotus eryngii chip production process and puffed pleurotus eryngii chip products, which belong to the field of agricultural product deep processing. The method for preparing puffed pleurotus eryngii chips is to perform vacuum and far-infrared combined vacuum microwave puffing of the pleurotus eryngii chips, wherein the vacuum and far-infrared combined vacuum microwave puffing is implemented by the following steps: placing fresh cut pleurotus eryngii chips in a cavity of a vacuum far-infrared dryer, and setting a drying temperature of 50 to 55 DEG C, setting a pressure upper limit of -0.085MPa, a pressure lower limit of -0.094MPa, a dehumidification time of 40 to 50 minutes and a drying time of 120 to 150 minutes; placing the materials in the cavity of a vacuum microwave dryer, and setting a microwave drying power of 4.0 to 5.5W / g, a vacuum degree of 0.085 to 0.095MPa and a drying time of 65 to 70 minutes; and obtaining the puffed pleurotus eryngii chips. In the invention, the whole drying process of the pleurotus eryngii is accomplished under vacuum and no food additive is added; and the pleurotus eryngii chip products are environmentally-friendly, have attractive color, crisp mouthfeel and high rehydration performance.

Owner:JIANGSU ACAD OF AGRI SCI

Chocolate composition for coating freezing beverage

ActiveCN101288434ARetain crisp textureCrisp texture maintainedFrozen sweetsMoisture resistanceXylitol

The invention provides a chocolate combination for coating frozen beverages; the combination includes 20-55 parts by weight of xylitol, 40-55 parts by weight of grease, 5-30 parts by weight of non-fat milk solids and 0.2-0.6 part by weight of emulsifier; the invention also provides a method for coating frozen beverages with the chocolate combination and the obtained frozen beverages with the coating prepared by the chocolate combination. Due to special formula adjustment of the invention, the formed chocolate coating can achieve excellent moisture resistance.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Water-based wood white primer as well as preparation method and use method thereof

ActiveCN103131284AHigh hardnessImprove adhesionAntifouling/underwater paintsPaints with biocidesWater basedLacquer

The invention relates to a water-based wood white primer as well as a preparation method and a use method thereof. The water-based wood white primer provided by the invention comprises the following components by weight: 15-35wt% of water-based resin, 0.2-0.6wt% of a defoaming agent, 0.5-1.5wt% of a wetting dispersant, 5-15wt% of titanium dioxide, 5-20wt% of talcum powder, 15-40wt% of coarse whiting, 0.2-0.8wt% of a thickening agent, 2-7wt% of a film-forming auxiliary agent, 0.1-0.4wt% of a substrate wetting agent, 0.1-0.4wt% of biocide mildewcide and 2-10wt% of water. The water-based wood white primer provided by the invention can be used together with solvent-based finishing paint, does not generate adverse film-painting defects, such as lifting, collapse and foaming adhesion, and has very low volatile content of VOC (Volatile Organic Compounds) and high value of environmental protection.

Owner:紫荆花制漆(成都)有限公司

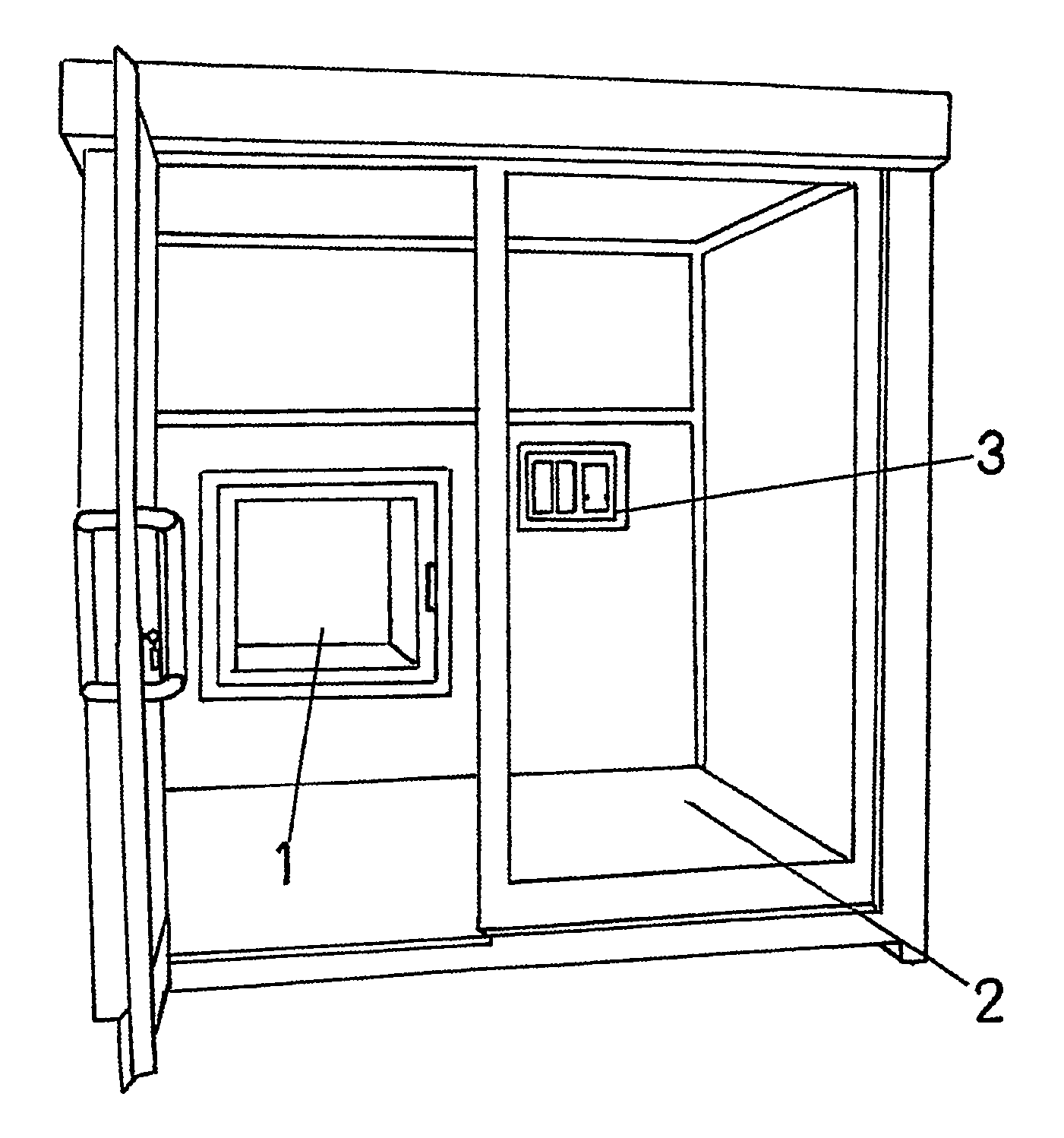

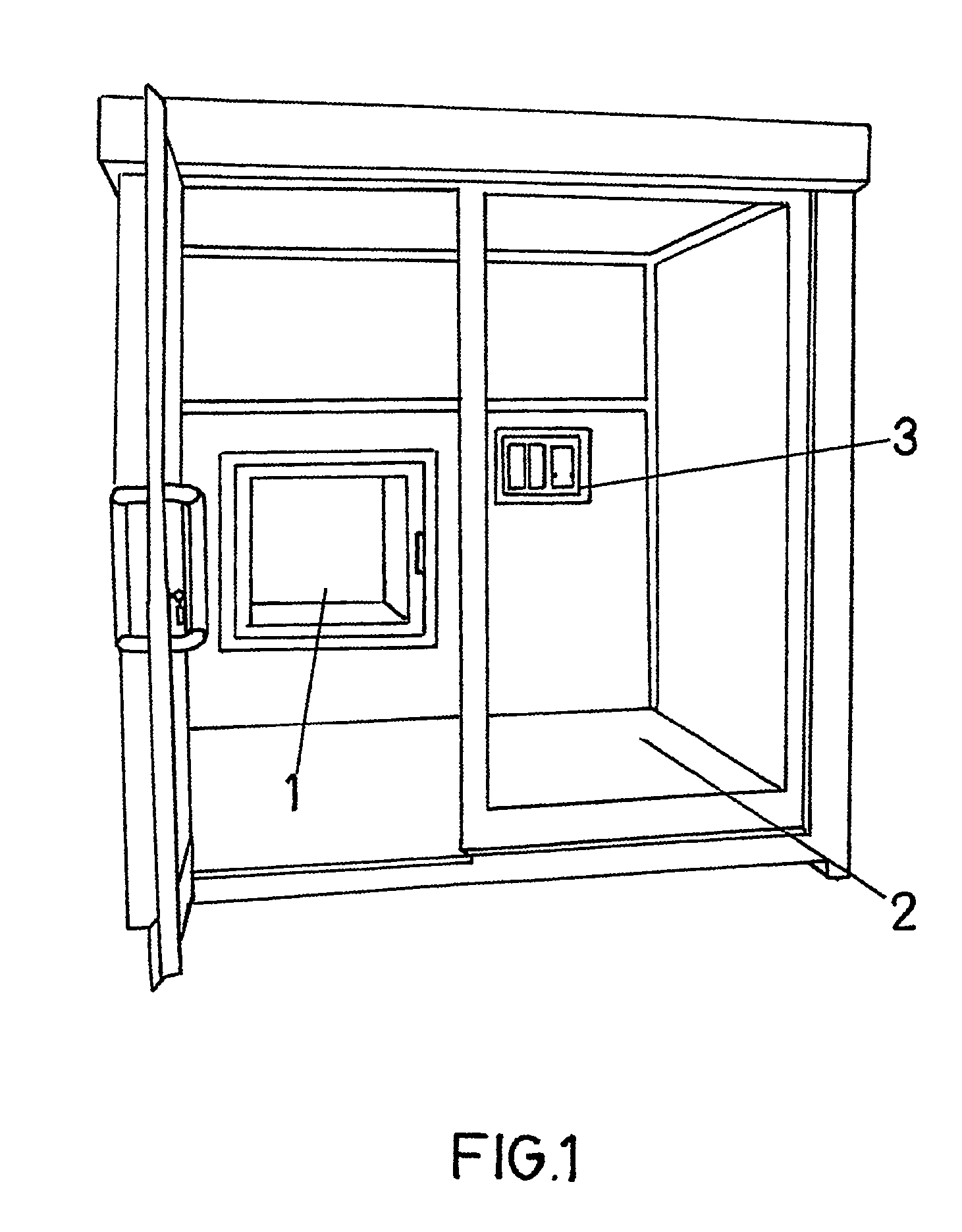

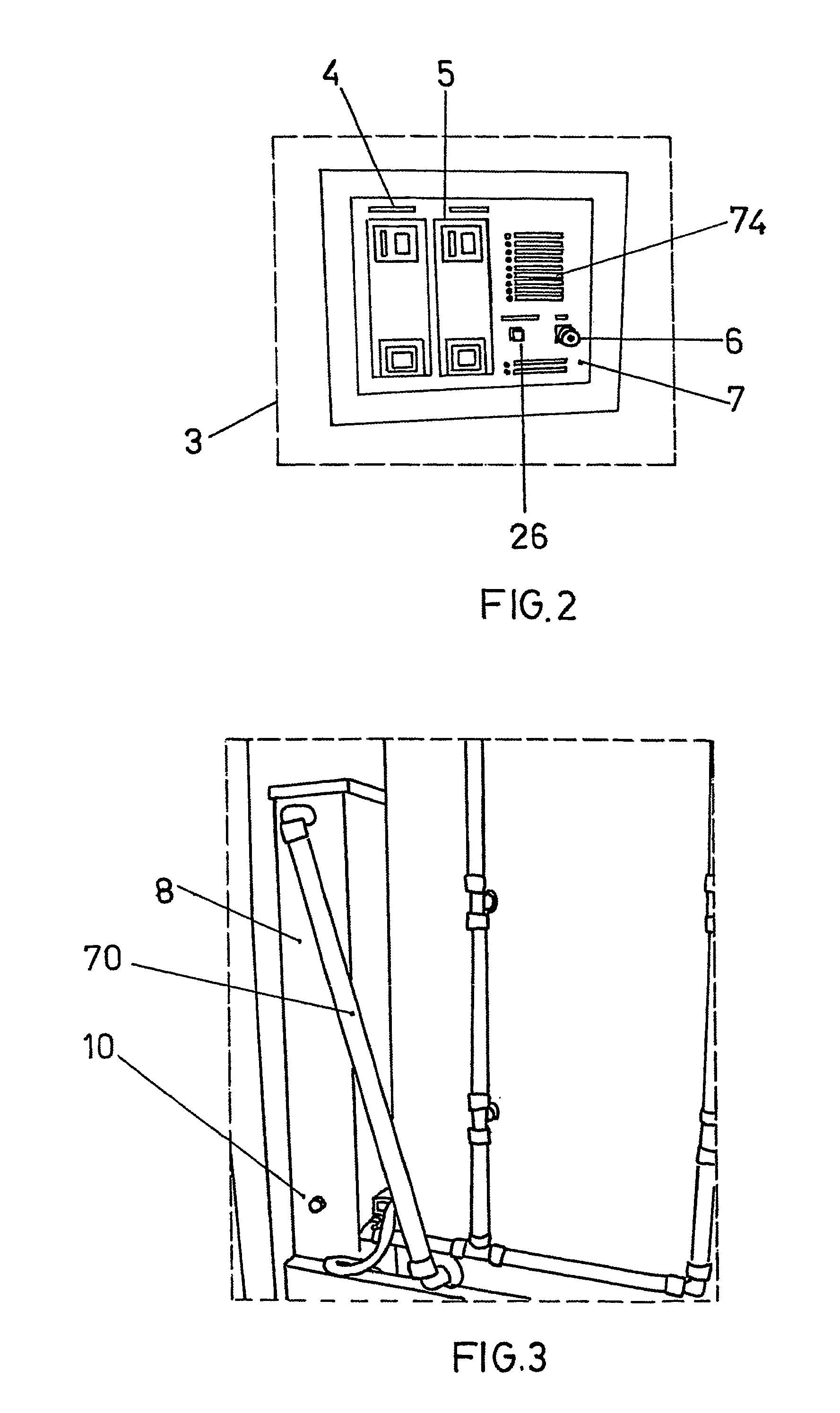

Station for preparing cleaning disinfecting delousing and hydromassaging animals

InactiveUS7011044B2Improve performancePreventing lime deposits on the circuit elementsOther apparatusGrooming devicesHydraulic circuitCleaning station

The invention relates to a cleaning station comprising a glass enclosure (2) in which the animals are prepared before and after washing. The glass enclosure (2) comprises the actual washing enclosure (1) and a control panel (3) which are controlled by a controller or PLC. According to the invention, the interior of the enclosure (1) is disinfected with each washing procedure. Moreover, the invention comprises: safety a mechanism for the hydraulic circuit and the electronics which are actuated when the door (72) of the enclosure (1) or the switchboard is opened, a frequency variator / converter which can be used to adjust the flow of air and water, and moisture and unpleasant odour extractors.

Owner:SEGURA JOBAL EDUARDO

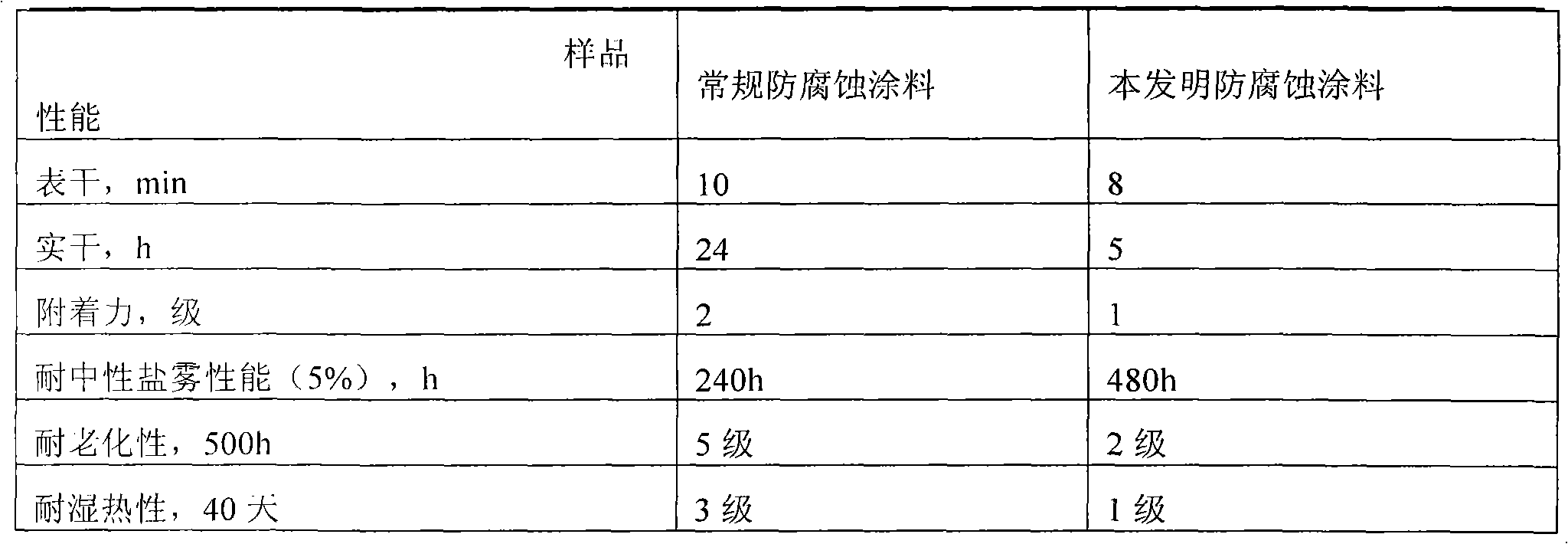

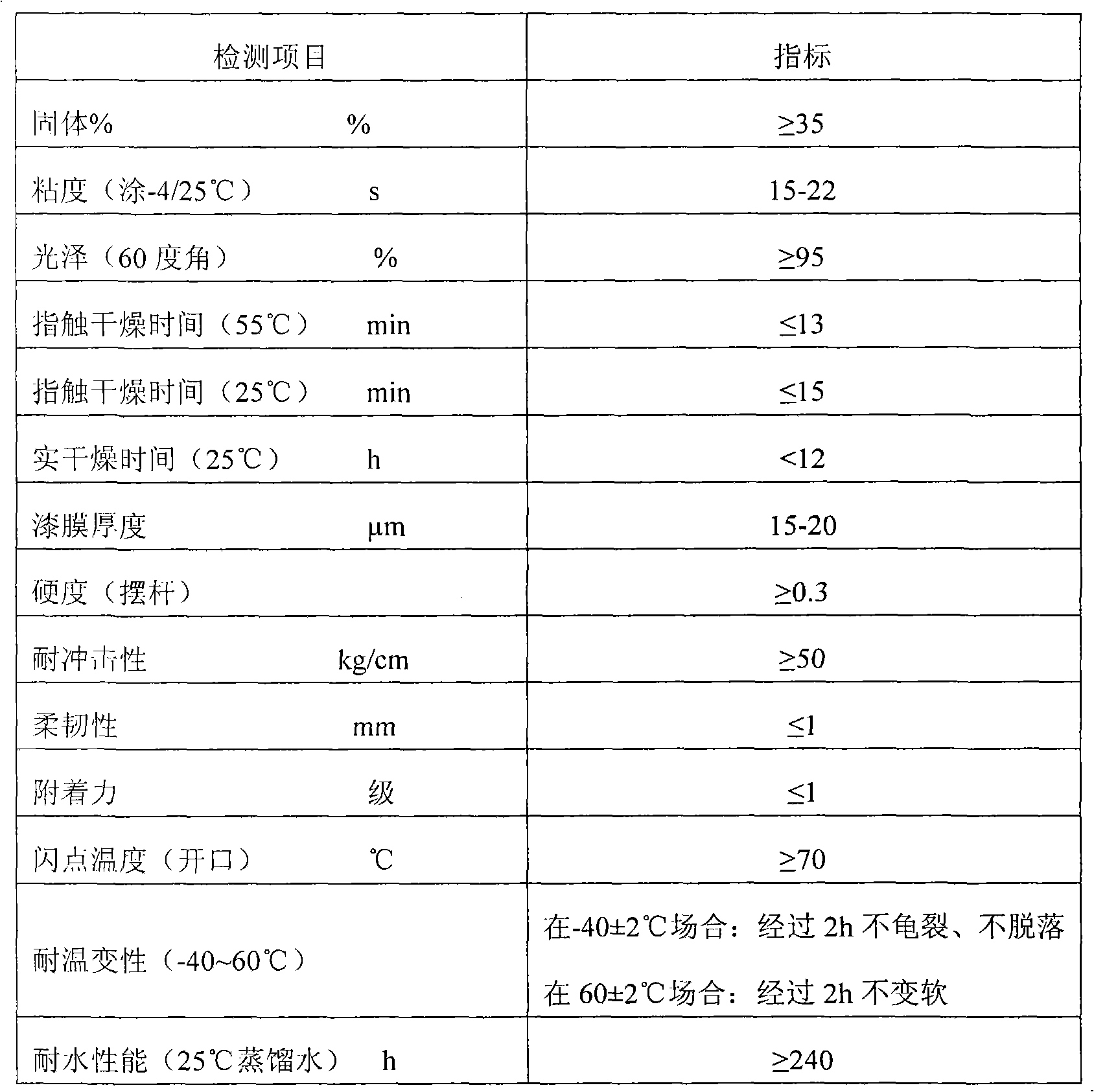

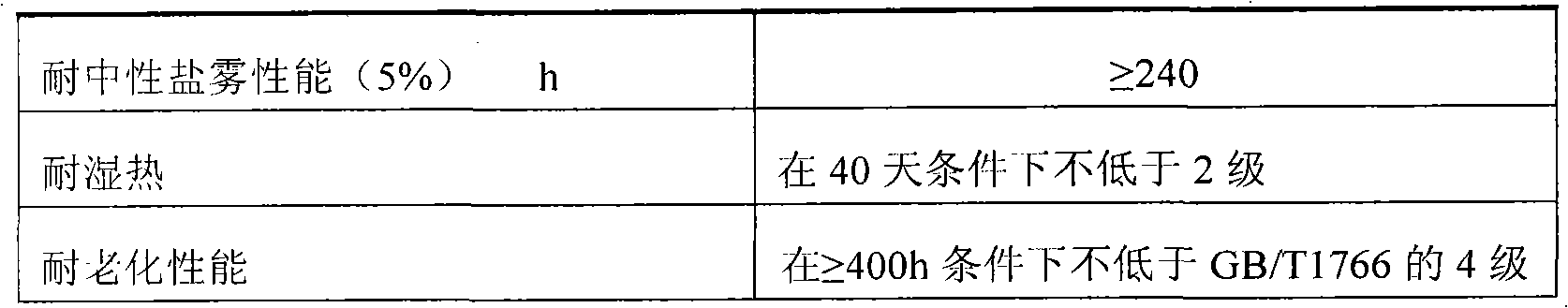

Anticorrosive paint for weather-resistant corrosion-resistant steel pipe outer wall

ActiveCN102120909AFast dryingDry fastGeneral water supply conservationAnti-corrosive paintsEpoxyWeather resistance

The invention relates to an anticorrosive paint for a weather-resistant corrosion-resistant steel pipe outer wall, which is prepared from 30-50 parts of alkyd resin, 2-5 parts of epoxy resin, 10-15 parts of terpene resin, 30-50 parts of hydrocarbon solvent, 3-8 parts of anticorrosive agent and 1-3 parts of drying agent. The paint provided by the invention can be applied by brushing, spraying, dipcoating, curtain coating or the like, and is naturally dried at normal temperature. The terpene resin adopted in the invention has high stability for oxygen, heat and light, and has excellent ageing resistance, so that the paint has excellent weather resistance. The rust inhibitor adopted in the invention can form a compact protective layer with high adhesive force on the surface of a steel pipe,and thus, prevents or slows the permeation of oxygen and water in the environment under the isolation action, thereby inhibiting the generation of corrosion microcells and performing a favorable anticorrosive protection function.

Owner:TIANJIN COLOROAD COATING & CHEM

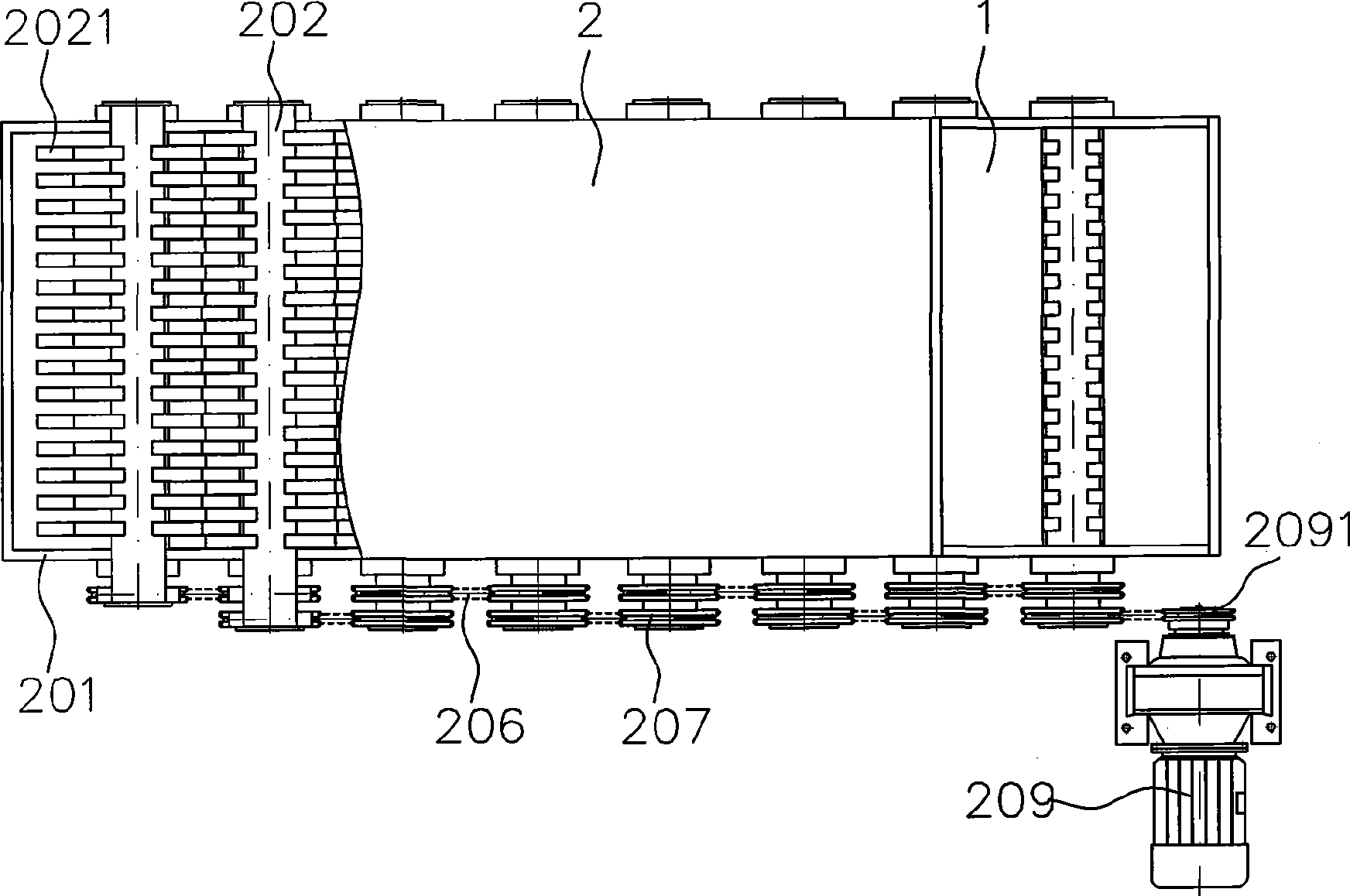

Cleaning machine

ActiveCN103990624AGood cleanlinessImprove efficiencyDrying gas arrangementsFlexible article cleaningDrive motorAir drying

The invention belongs to the field of mobile phone screen glass cleaning equipment, and discloses a cleaning machine. The cleaning machine comprises a machine frame and a plurality of conveying rubber rollers arranged on the machine frame to form a conveying channel. The machine frame is provided with a drive motor used for driving the conveying rubber rollers to rotate. One end of the conveying channel is the feeding end, the other end of the conveying channel is the discharging end, a cleaning area is formed between the feeding end and the discharging end, and the cleaning area is internally provided with a cleaning mechanism and a drying device. The cleaning mechanism comprises a spraying device and a brush assembly. The brush assembly comprises an upper brush shaft and a lower brush shaft which are arranged in parallel, the peripheral wall of the upper brush shaft and the peripheral wall of the lower brush shaft are covered with bristles, the two ends of the upper brush shaft and the two ends of the lower brush shaft are provided with brush adjusting mechanisms used for adjusting the length of a gap between the upper brush shaft and the lower brush shaft, and the drying device is connected with an air filter. The cleaning machine is high in cleaning efficiency and good in cleanliness, the brush adjusting mechanisms are arranged for adjustment to be carried out conveniently, positioning is accurate, glass screens with different thicknesses can be cleaned, and the drying device is high in air drying efficiency, and noise is low.

Owner:SHENZHEN HANDONG GLASS EQUIP MFG CO LTD

Quick-drying hydroxylated acrylic resin water dispersion and preparation method and use thereof

ActiveCN102161770AGood pigment wettingImprove performancePolyurea/polyurethane coatingsAcrylic resinPrepolymer

The invention relates to quick-drying hydroxylated acrylic resin water dispersion and a preparation method and use thereof, in particular to quick-drying aqueous automobile repair solid color paint prepared from the hydroxylated acrylic resin dispersion. The invention discloses a method for preparing the hydroxylated acrylic resin dispersion, which comprises: A, preparing a prepolymer of hydroxylated acrylic resin; and B, preparing aqueous prepolymer of the hydroxylated acrylic resin. And the invention also discloses a method for preparing quick-drying aqueous automobile repair solid color paint by using the dispersion. The coating of the quick-drying aqueous automobile repair solid color paint is accomplished at a low temperature or even at normal temperature, so the volatile organic compound (VOC) emission in a coating process of an automobile is reduced and energy conservation and emission reduction are realized. Thus, the quick-drying aqueous automobile repair solid color paint can be promoted and used easily.

Owner:广东绚缤材料科技有限公司

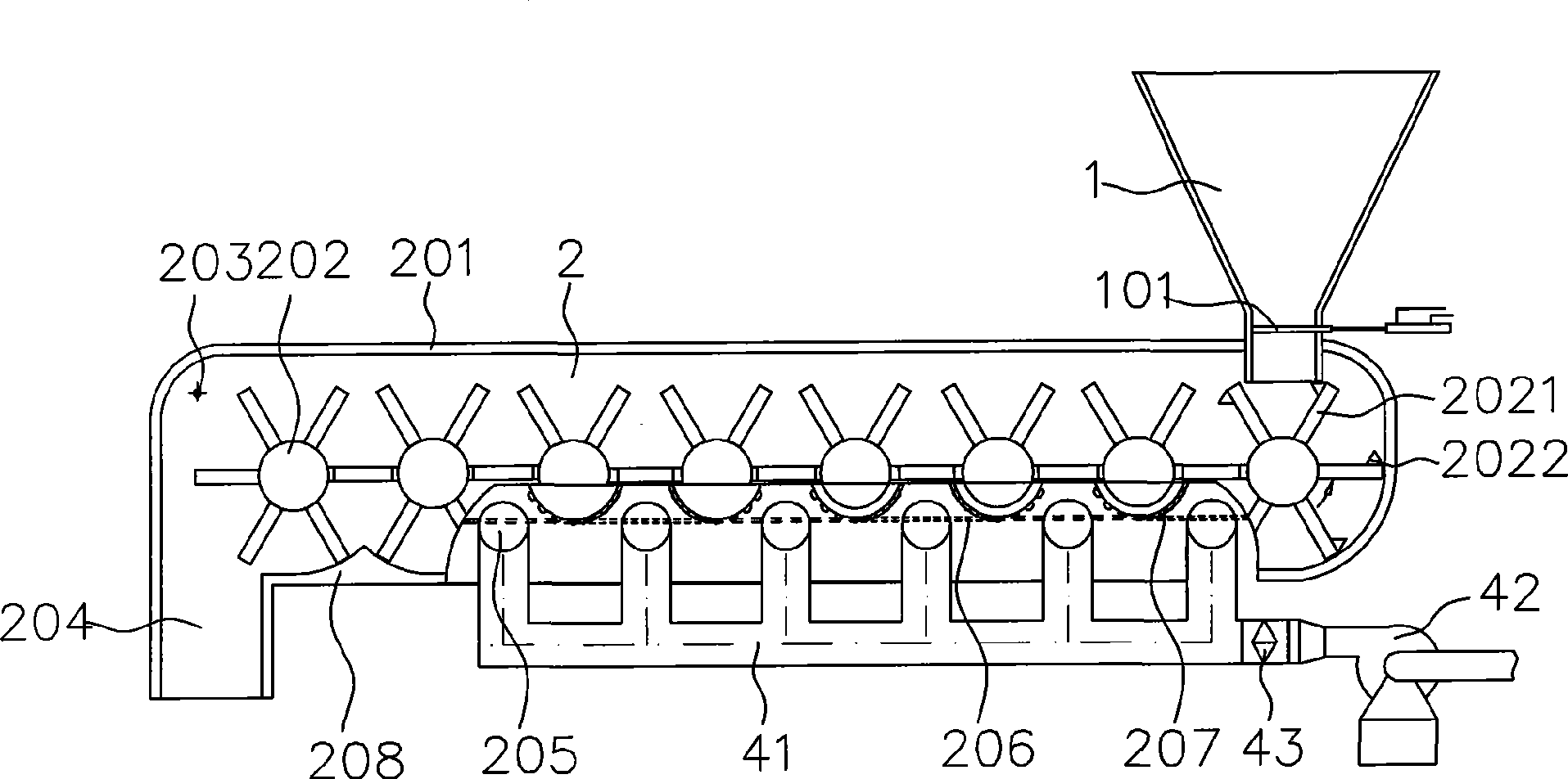

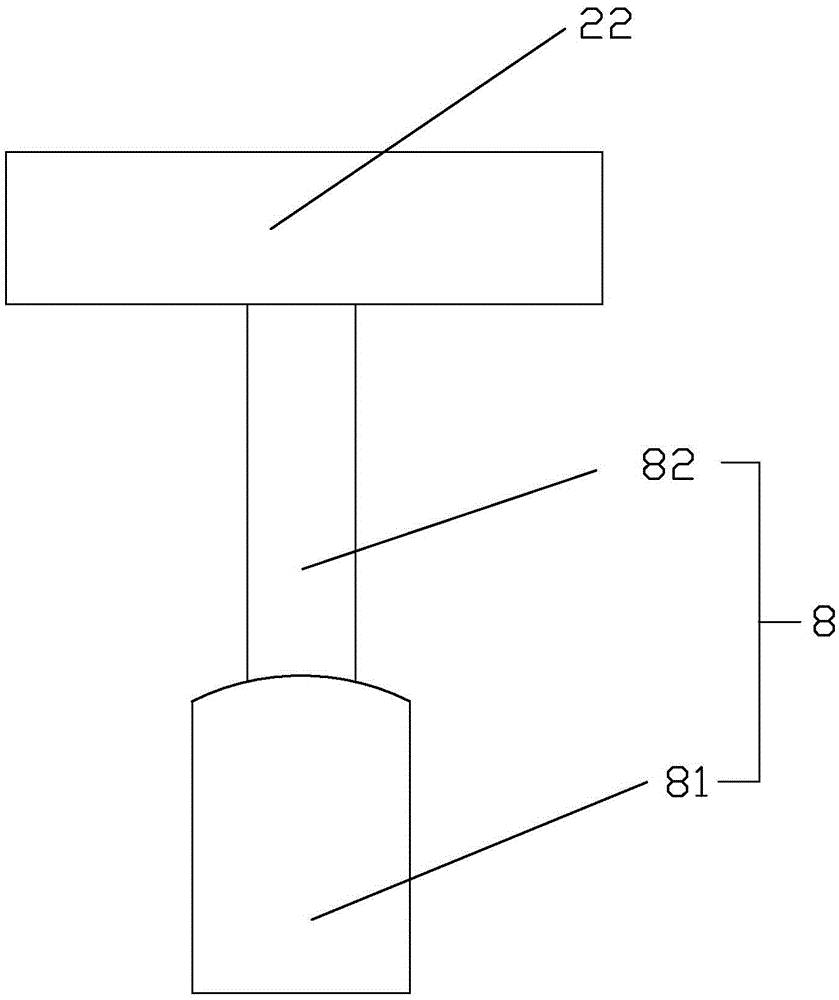

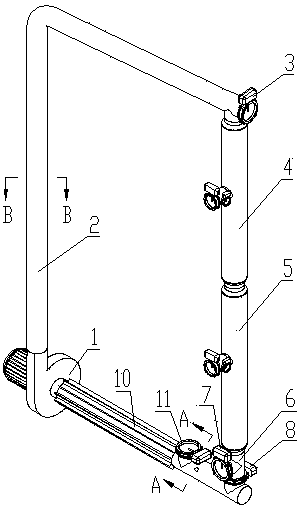

Circulating fluidized bed equipment and pine pollen production method thereof

InactiveCN103720725ADry fastSimple structureGas current separationDrying solid materials with heatFluidized bedPositive pressure

The invention discloses circulation fluidized bed equipment and a pin pollen production method thereof. The equipment forms a circulating passage by a fan (1), a positive pressure circulating pipe (2), a function branch and a negative pressure circulating pipe (10) according to a communication sequence of an outlet of the fan (1), the positive pressure circulating pipe (2), the functional branch, the negative pressure circulating pipe (10) and the inlet of the fan (1), wherein the functional branch is used for separating or screening material and gas, the material is formed into a fluidized state in the action of the fan (1) and circularly flows in the circulating passage at high speed, and is subjected to drying, impurity removing, sterilizing, screening, crushing, mixing, concentrating, evaporating, distilling and other process operations in the circularly flowing process.

Owner:KUNMING TEKANG TECH CO LTD

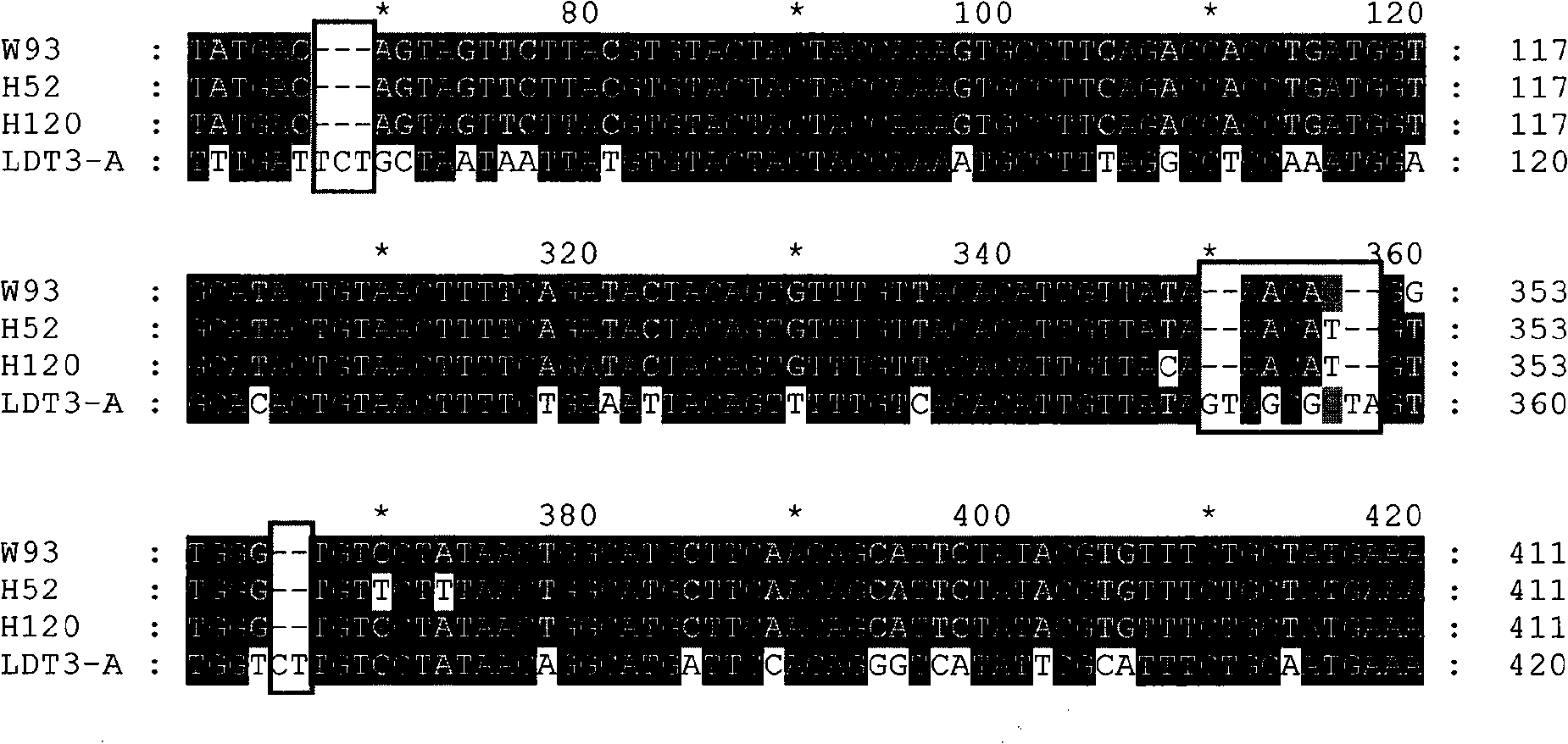

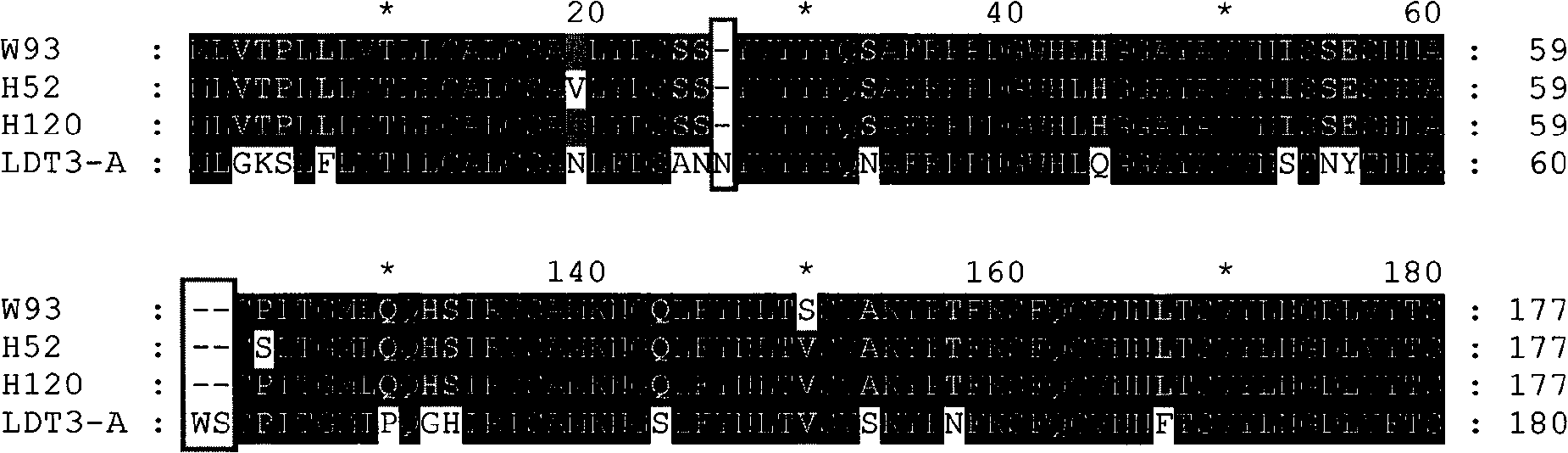

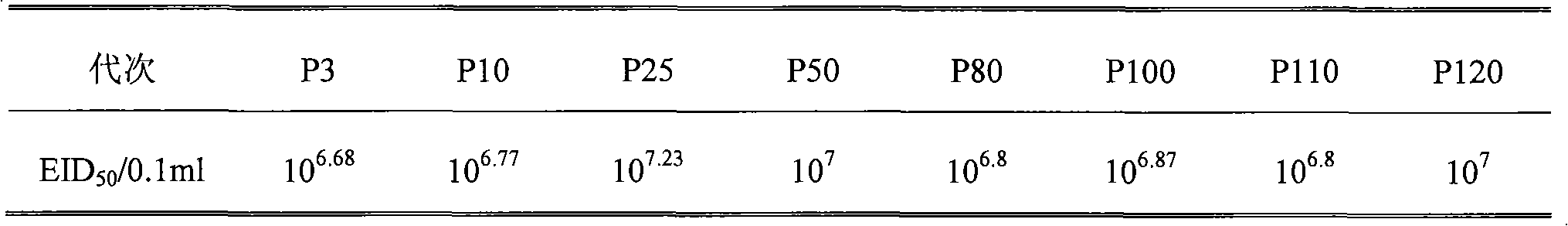

Chicken infectivity bronchitis virus attenuated vaccine strain and application thereof

ActiveCN101514334AImprove securityNo side effectsInactivation/attenuationMicroorganism based processesInfectious bronchitisMicroorganism

The invention discloses a infectivity bronchitis attenuated vaccine strain LDT3-A strain, and discloses application and application effect thereof in preventing and curing chicken infectivity bronchitis. The microorganism accession number of the attenuated vaccine strain is CGMCC-2902. The attenuated vaccine strain of the present invention has good safety and good immunization protection effect to the chicken infectivity bronchitis. The attenuated strain can be prepared into single vaccine or combined vaccine for preventing or curing infectivity bronchitis virus.

Owner:HARBIN VETERINARY RES INST CHINESE ACADEMY OF AGRI SCI +1

Foam concrete

The invention discloses a foam concrete, which comprises admixture, cementing material and chemical auxiliary agent, wherein the weight percentage of the admixture in the foam concrete is 25-40%, the weight percentage of the cementing material in the foam concrete is 45-75%, the weight percentage of the chemical auxiliary agent in the foam concrete is 5-25%, the cementing material comprises cement clinker, calcium oxide and bone gelatin powder, and the mass ratio of the three ingredients in the cementing material is 2: 2: 1. The invention further discloses a preparation method of the foam concrete. The preparation method comprises the following steps: foam technology, slurry processing, chemical auxiliary agent processing, mixing, shaping and curing. The foam concrete has the advantages that the cementing material is made of cement clinker, calcium oxide and bone gelatin powder and the use of a great amount of cement is avoided, so that the coal resources required for producing cement is reduced, which not only relieves the tension of energy utilization, but also can improve the compressive strength, leakage resistance, sound insulation effect of the foam concrete.

Owner:王寿光

Chocolate composition for coating the freezing beverage

The invention provides a chocolate composite coated on frozen drinks; based on the total weight of the composite, the composite comprises 8-20% of prebiotics, 15-28% of granulated sugar, 35-55% of grease, 5-20% of non-fat milk solid, as well as 0.3-0.5% of emulsifier. The invention also provides a method of coating the frozen drinks with the chocolate composite, and the obtained frozen drinks coated with the chocolate composite. The chocolate composite coated on frozen drinks comprises prebiotics and has the nutrition and health-care functions; moreover, through a special formula and an appropriate technique, the invention can solve the problem of hocolate grinding caused by the addition of prebiotics and enables the formed chocolate coating to taste crisp.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com