Patents

Literature

142results about "Rocking grate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

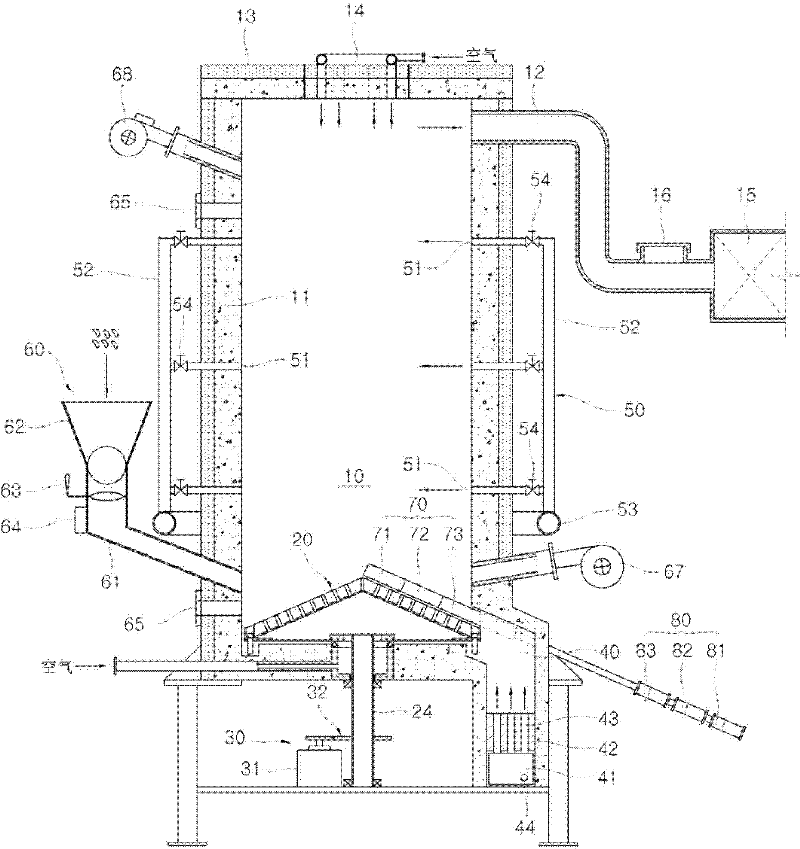

Efficient burning furnace with rotary fluidization grate

InactiveCN101532667ATurn overWith self-cleaning functionRevolving grateRocking grateCombustion systemFlue gas

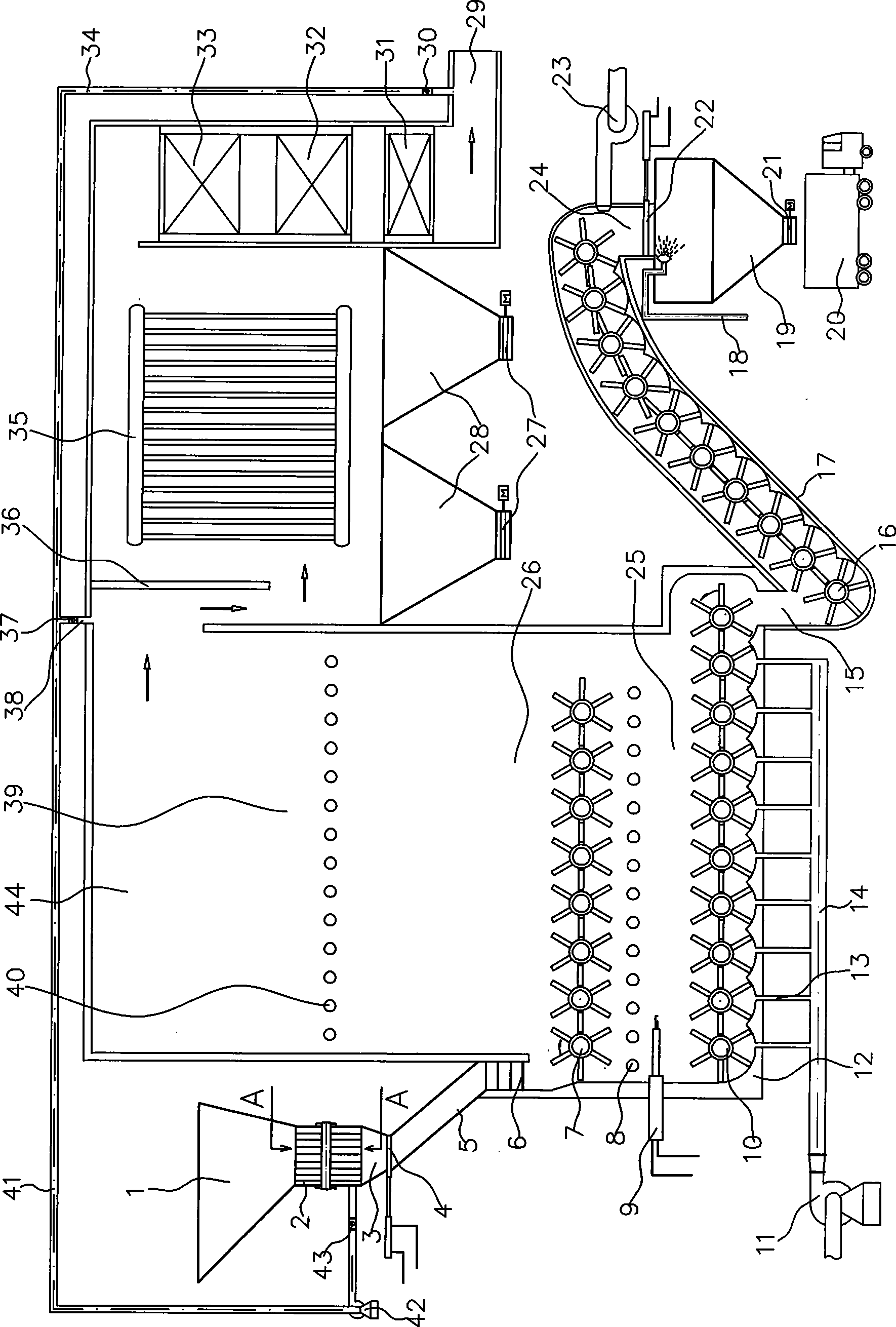

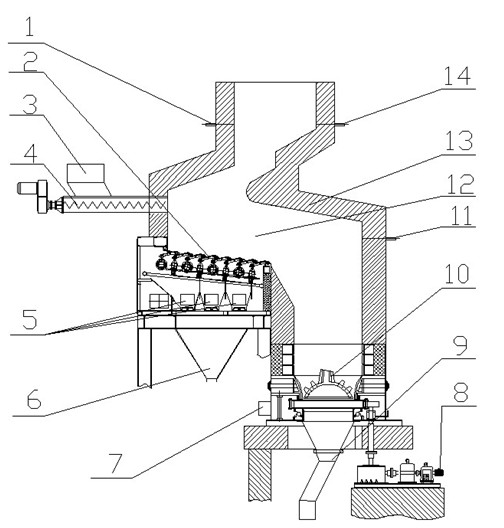

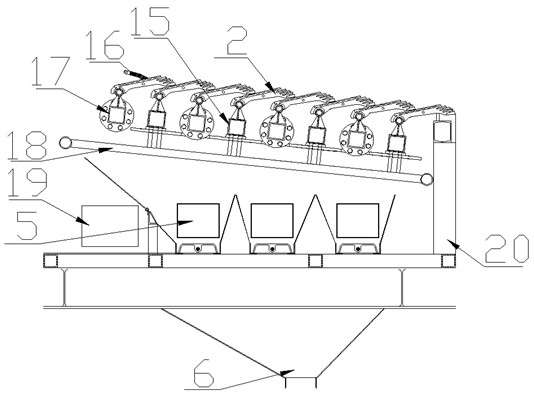

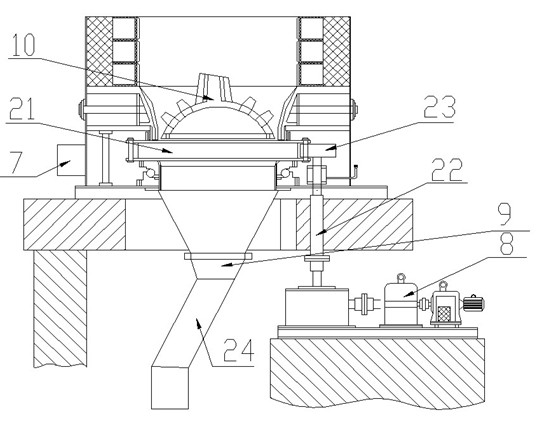

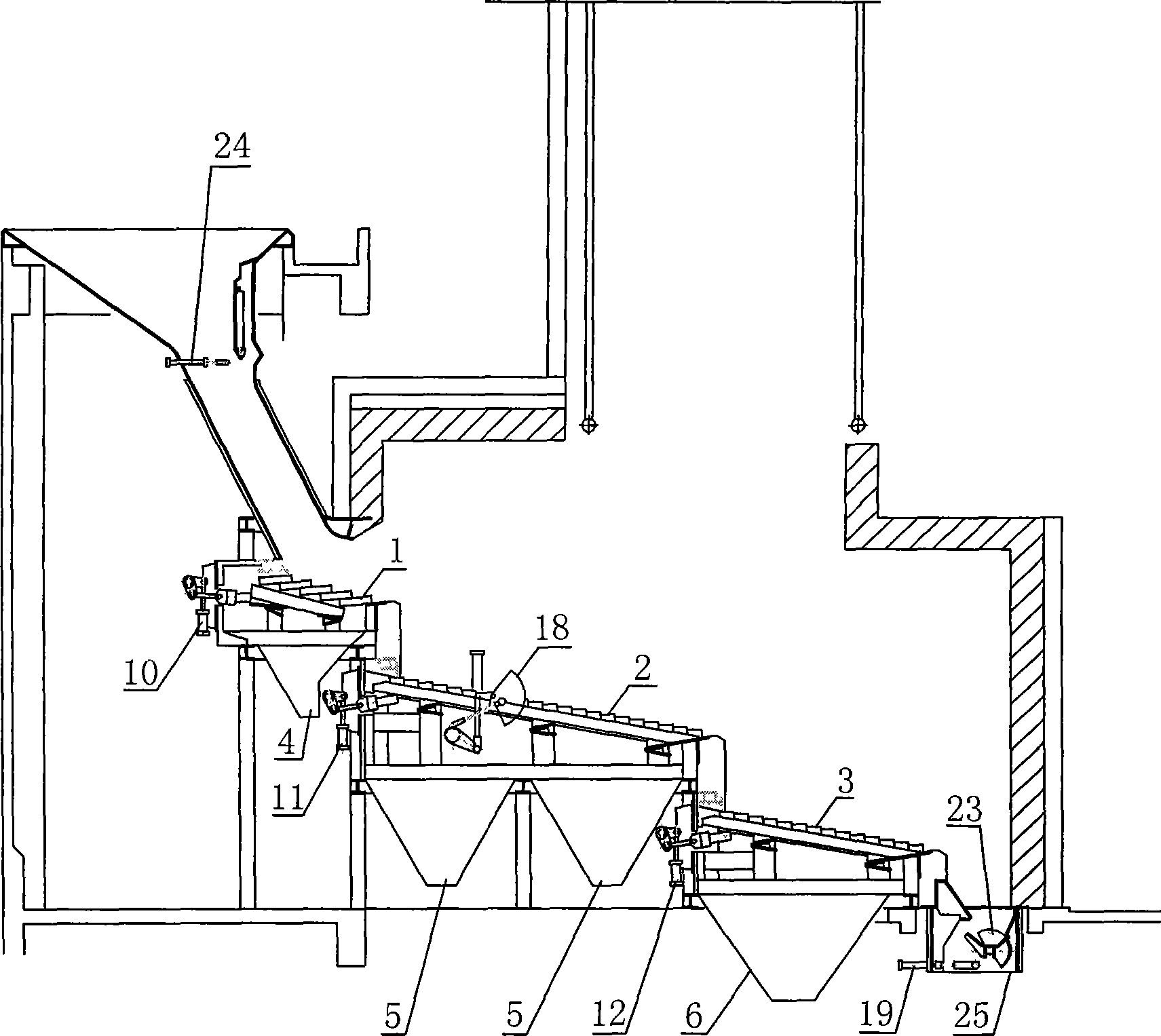

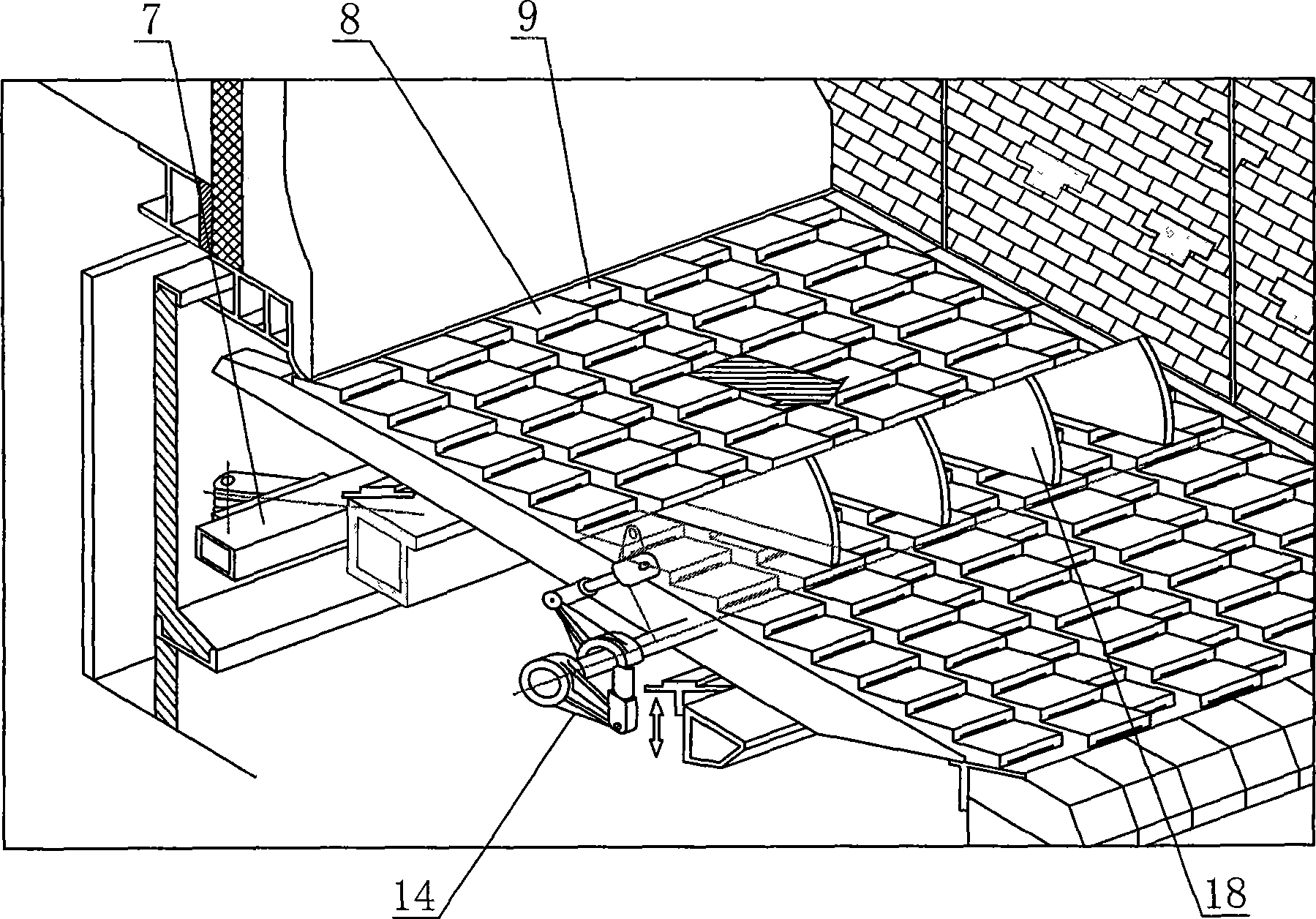

The invention relates to an efficient burning furnace with a rotary fluidization grate. The burning furnace with the rotary fluidization grate consists of a feeding system, a burning system and a slagging system; moreover, a waste heat boiler and a flue gas treatment system are connected with the burning furnace to form a complete garbage burning and generating system. The feeding system consists of a feeding hopper, a pre-drying conveying device, an aggregate bin, a chute and a charge distributor. The feeding hopper is a receiving opening for feeding garbage into the burning furnace and is arranged in a garbage storage pit close to one side of the burning furnace. An outlet of the feeding hopper is connected with an inlet of the pre-drying conveying device. A material level switch is arranged in the feeding hopper, and gives an alarm to prompt an operator to feed materials when the material level is lower than a set value so as to ensure that the hopper is not empty. The outlet of the hopper can be selectively provided with a feeding device. The burning furnace has the advantages of high burning speed, high burning efficiency, high slag burning degree, easy control, lower energy consumption, low pollution, low cost and investment conservation, and is applicable to domestic garbage with low thermal value and high moisture; and the garbage does not need to be pretreated.

Owner:新乡锅炉制造有限公司

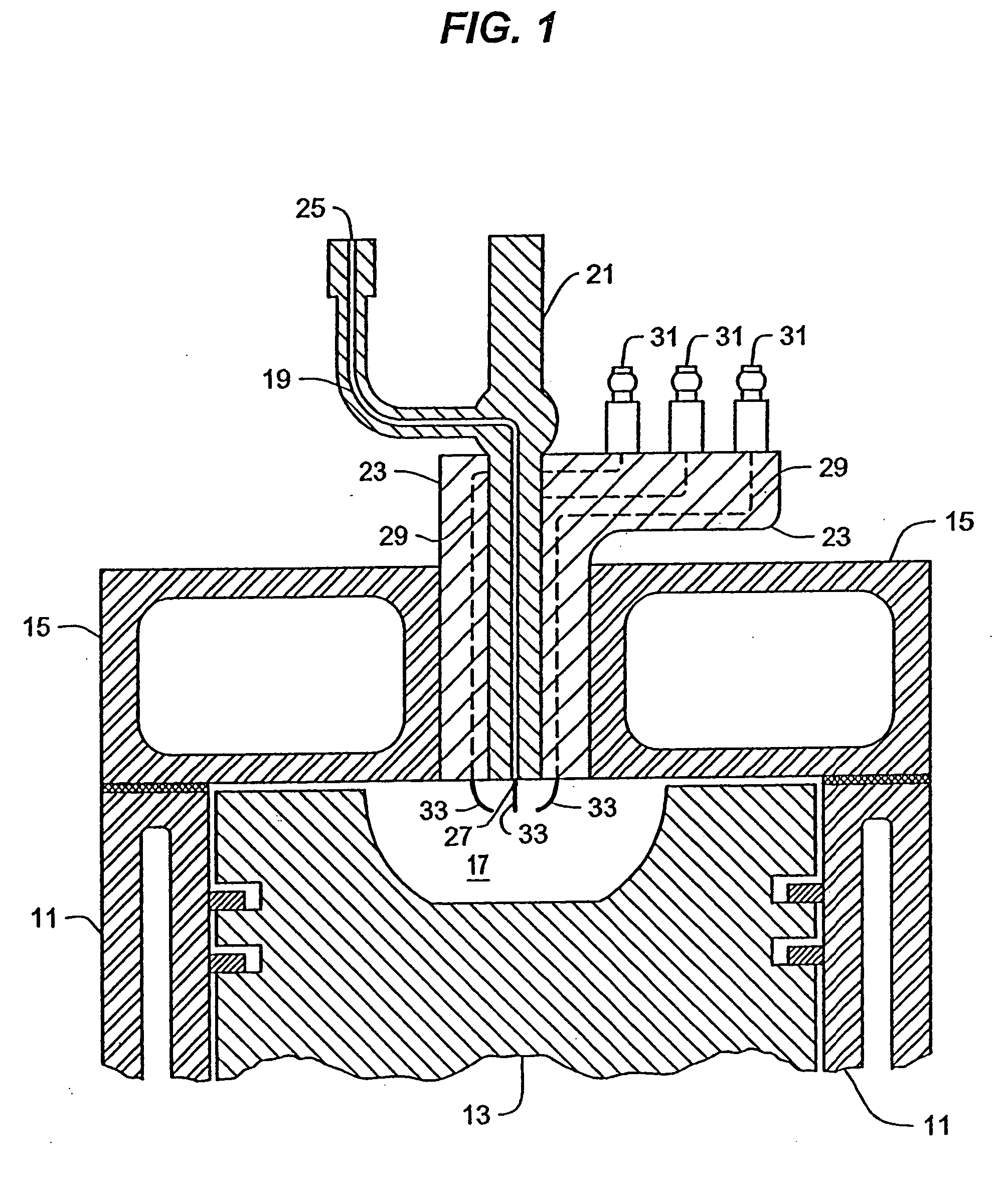

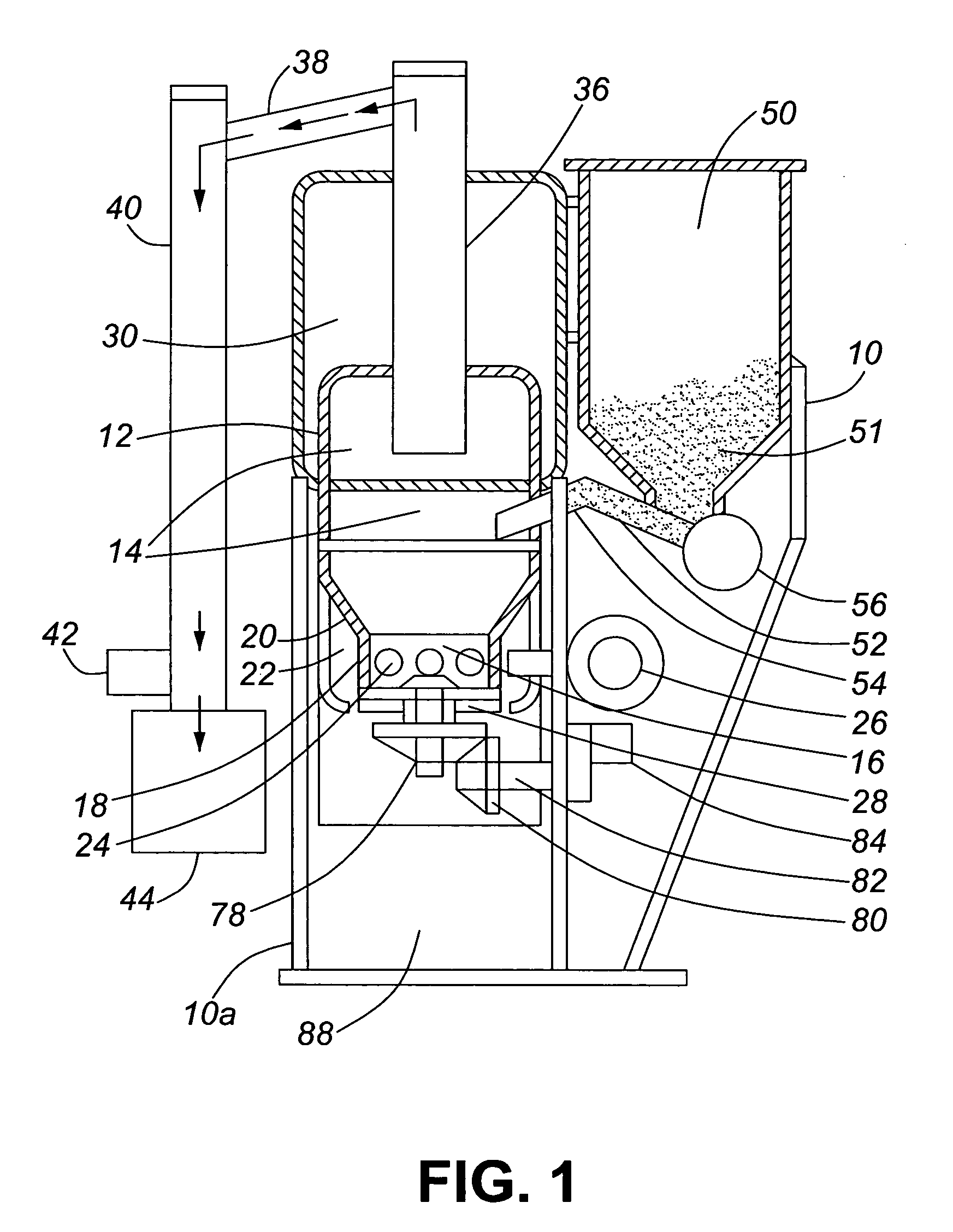

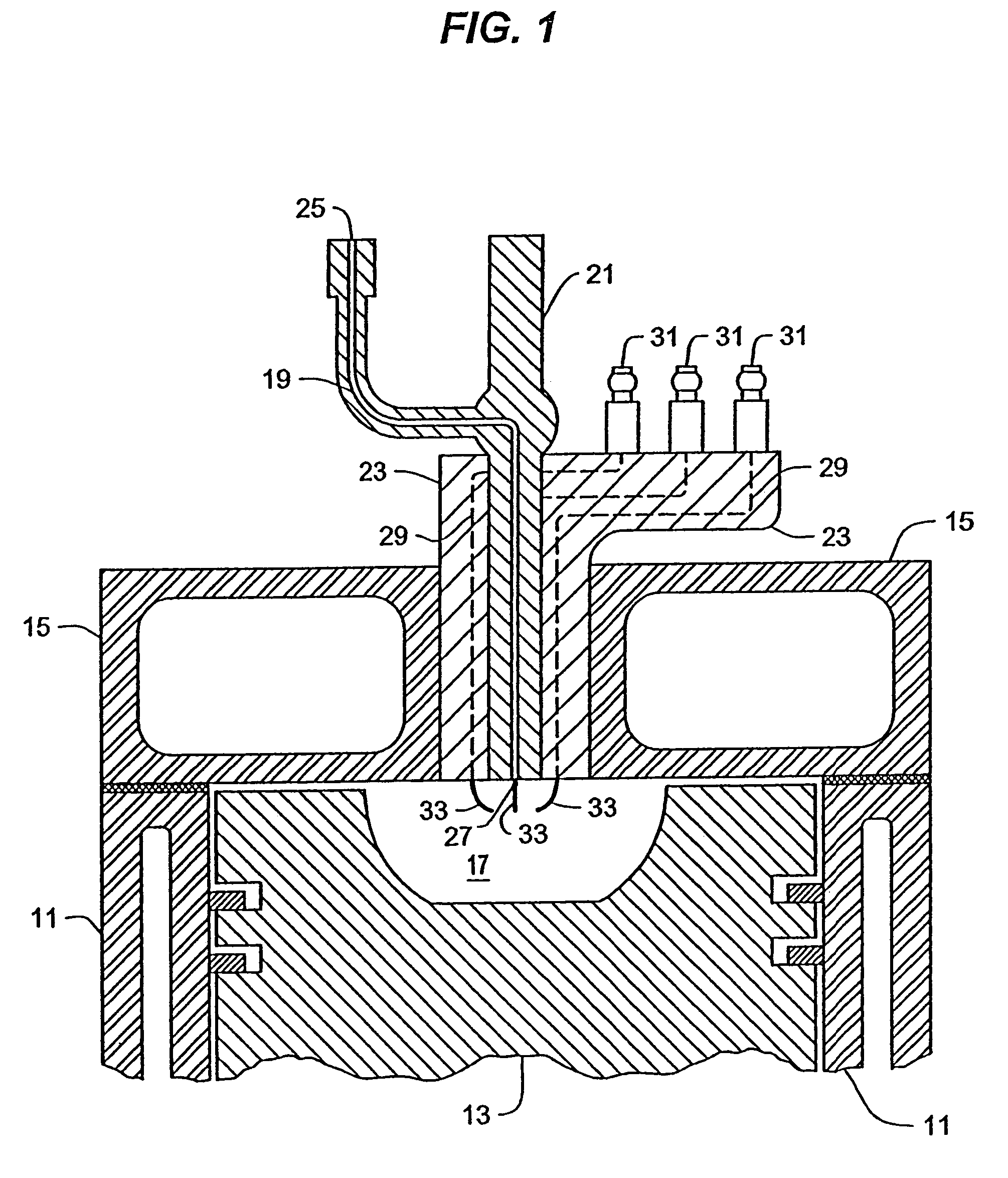

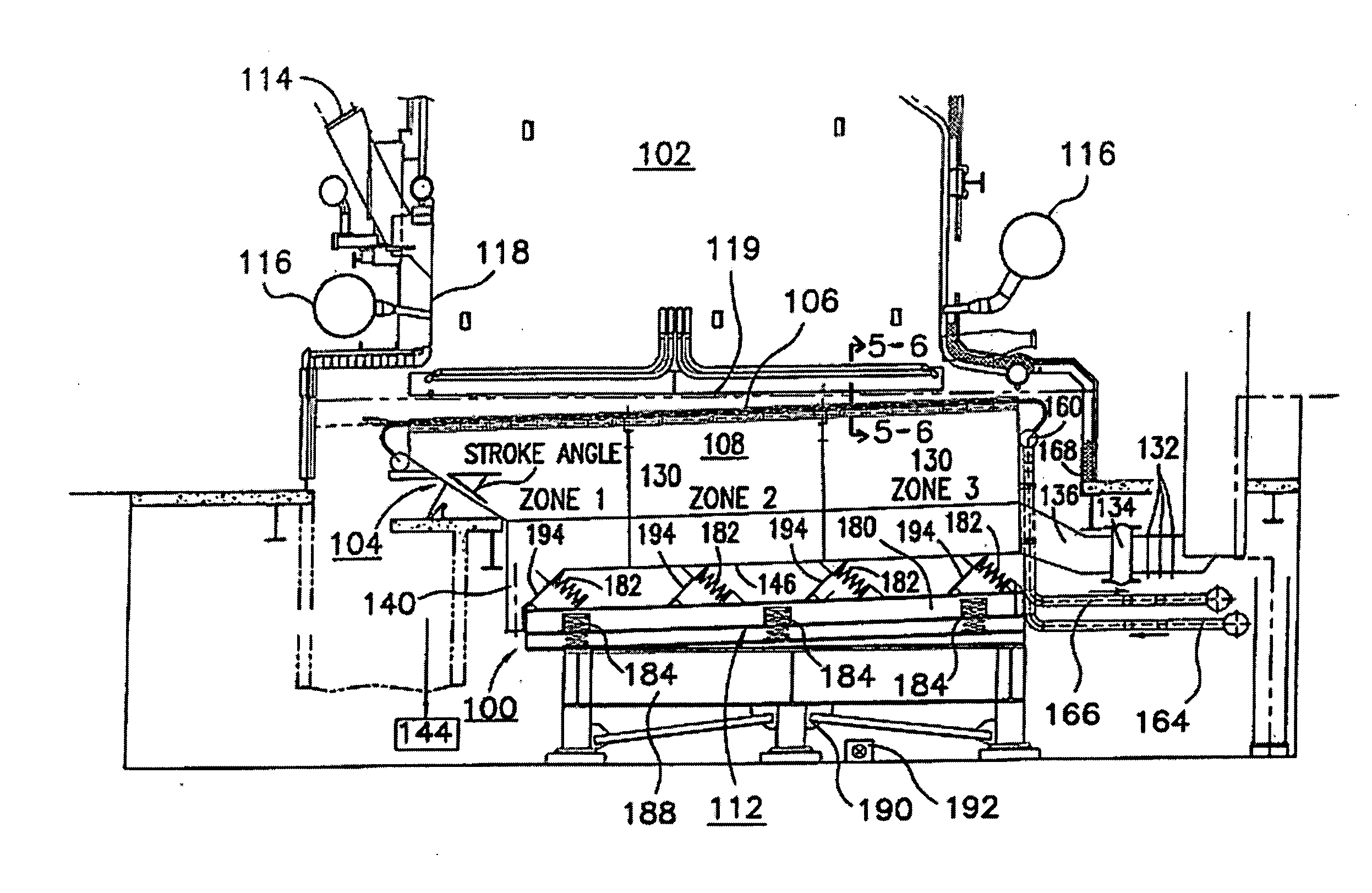

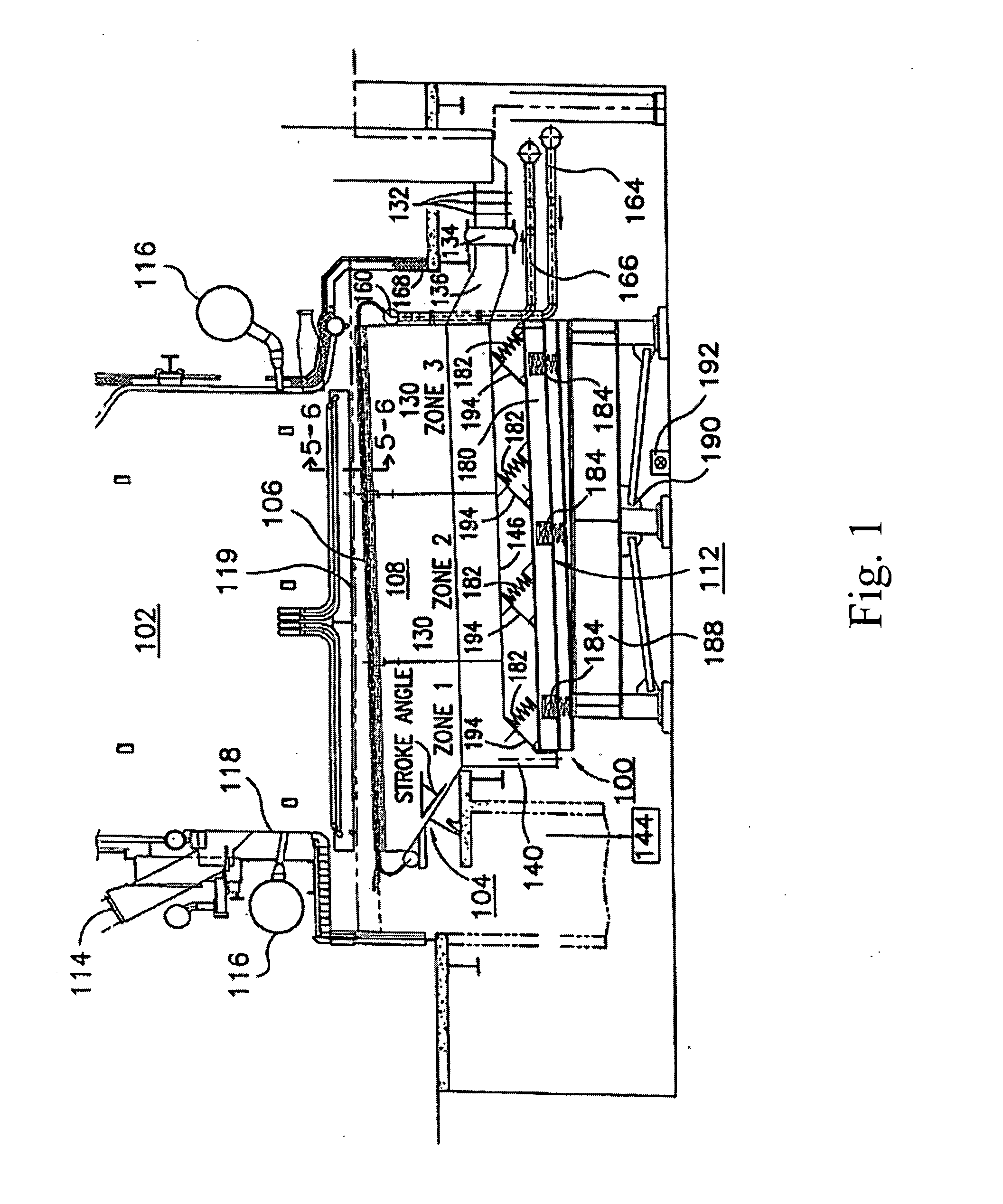

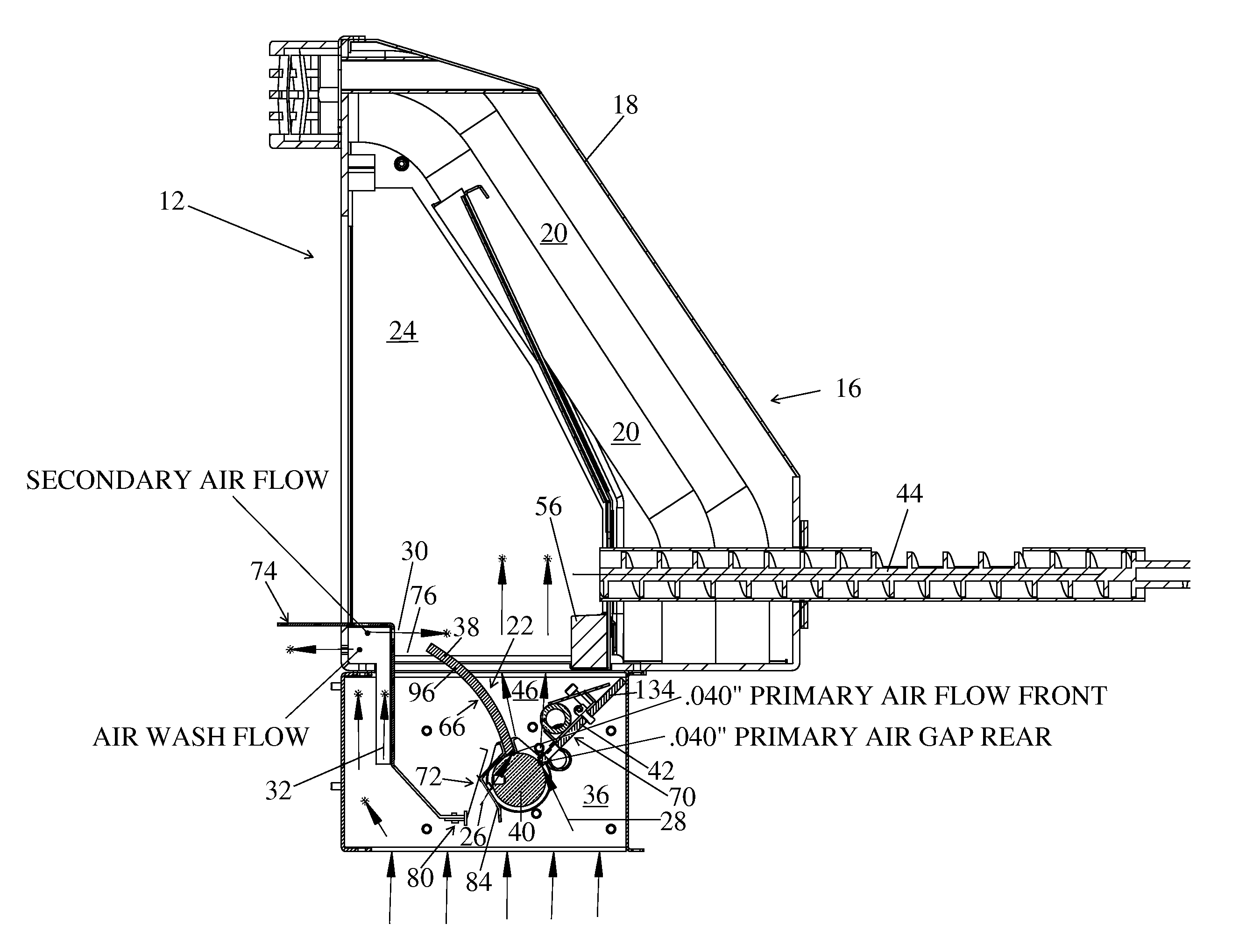

Furnace using plasma ignition system for hydrocarbon combustion

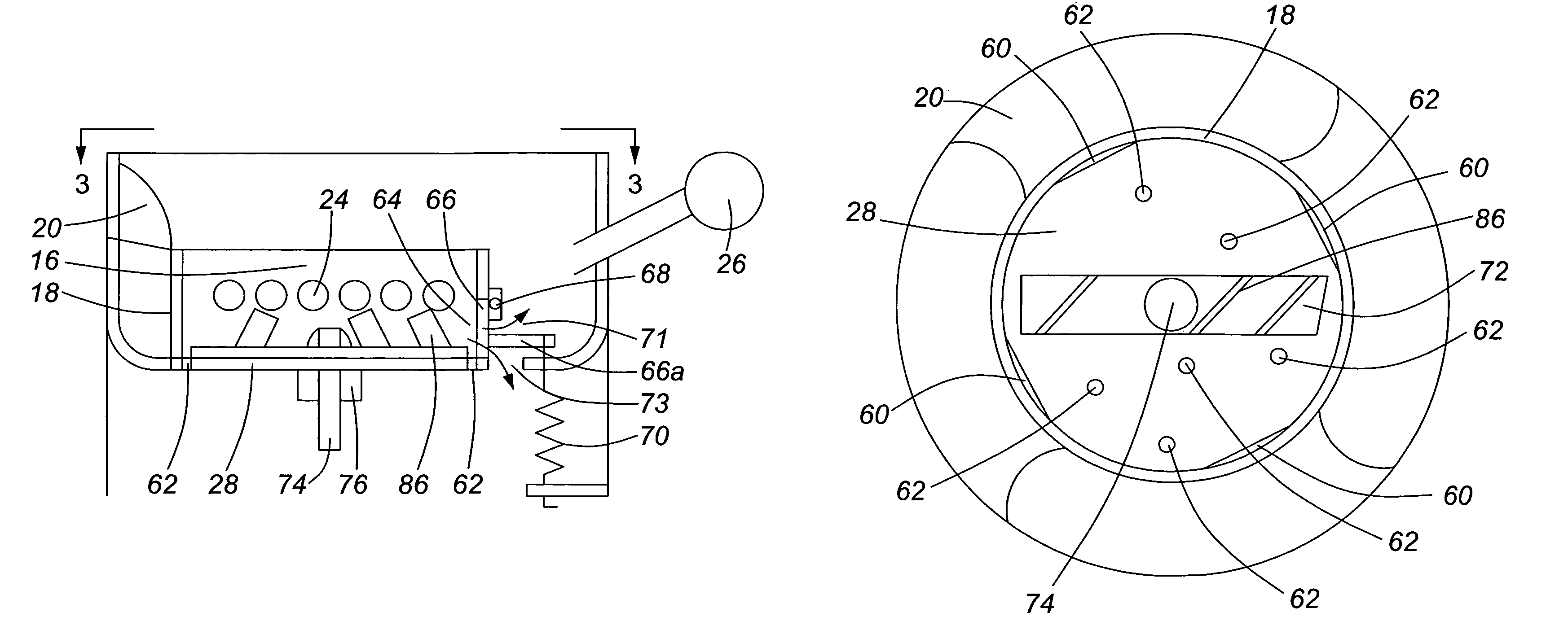

InactiveUS20050208446A1Improve fuel efficiencyMany timesBurnersInternal combustion piston enginesCombustorFuel efficiency

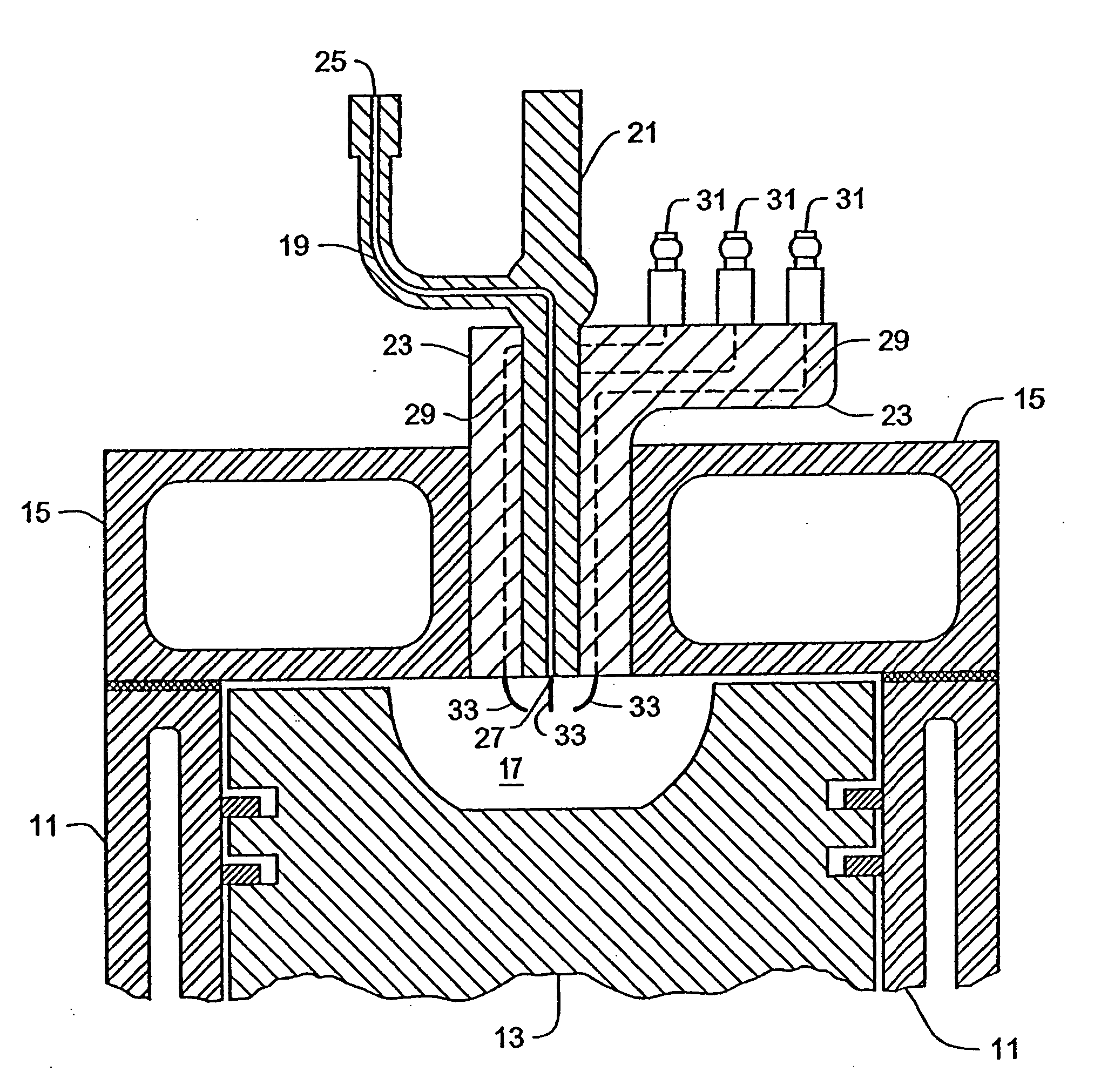

An apparatus and method for the creation, placement and control of an area of electrical ionization within an internal combustion engine combustion chamber or a fuel burner for a furnace is disclosed. A furnace includes a fuel source, a fuel burner, a plasma nozzle and igniter assembly, and the associated housing and flue structures. The plasma nozzle and igniter assembly is arranged so that the fuel sprayed out from the nozzle into the combustion area passes through or in close proximity to the area of plasma ionization. A fuel burner equipped with this electrical ionization device has its fuel efficiency enhanced by the complete and immediate combustion of substantially all of the fuel that passes through the area of plasma ionization. Exhaust gas recirculation using this system is also disclosed.

Owner:JAYNE MICHAEL E

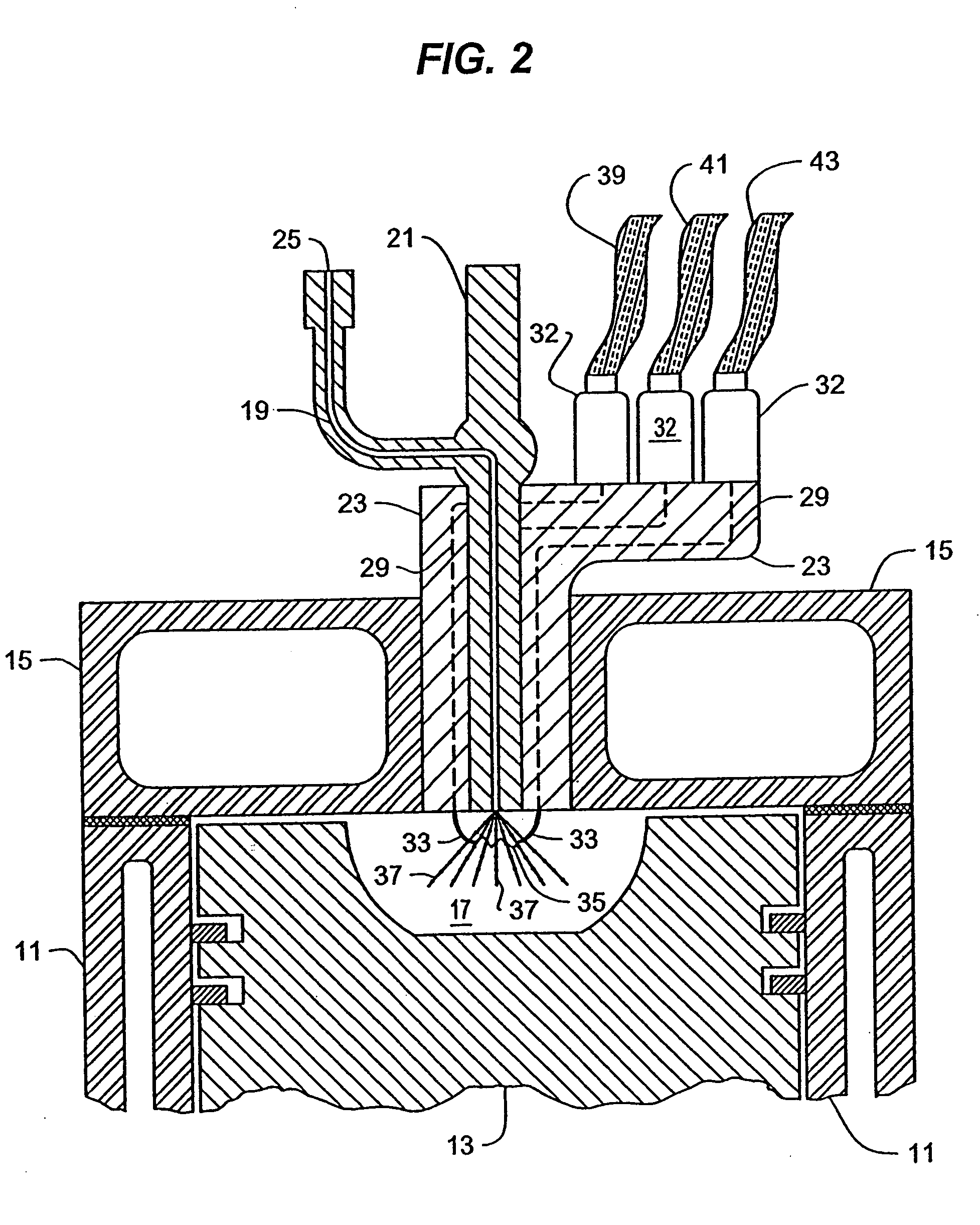

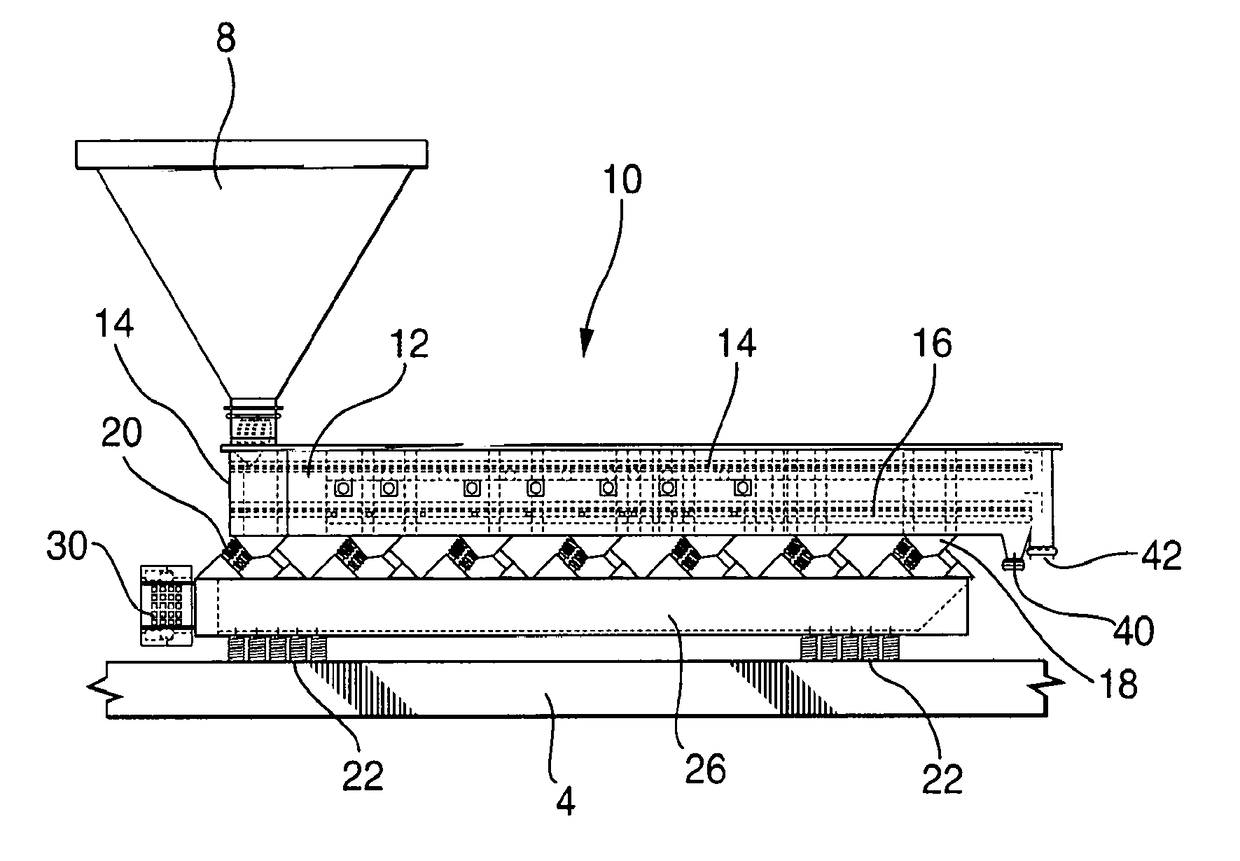

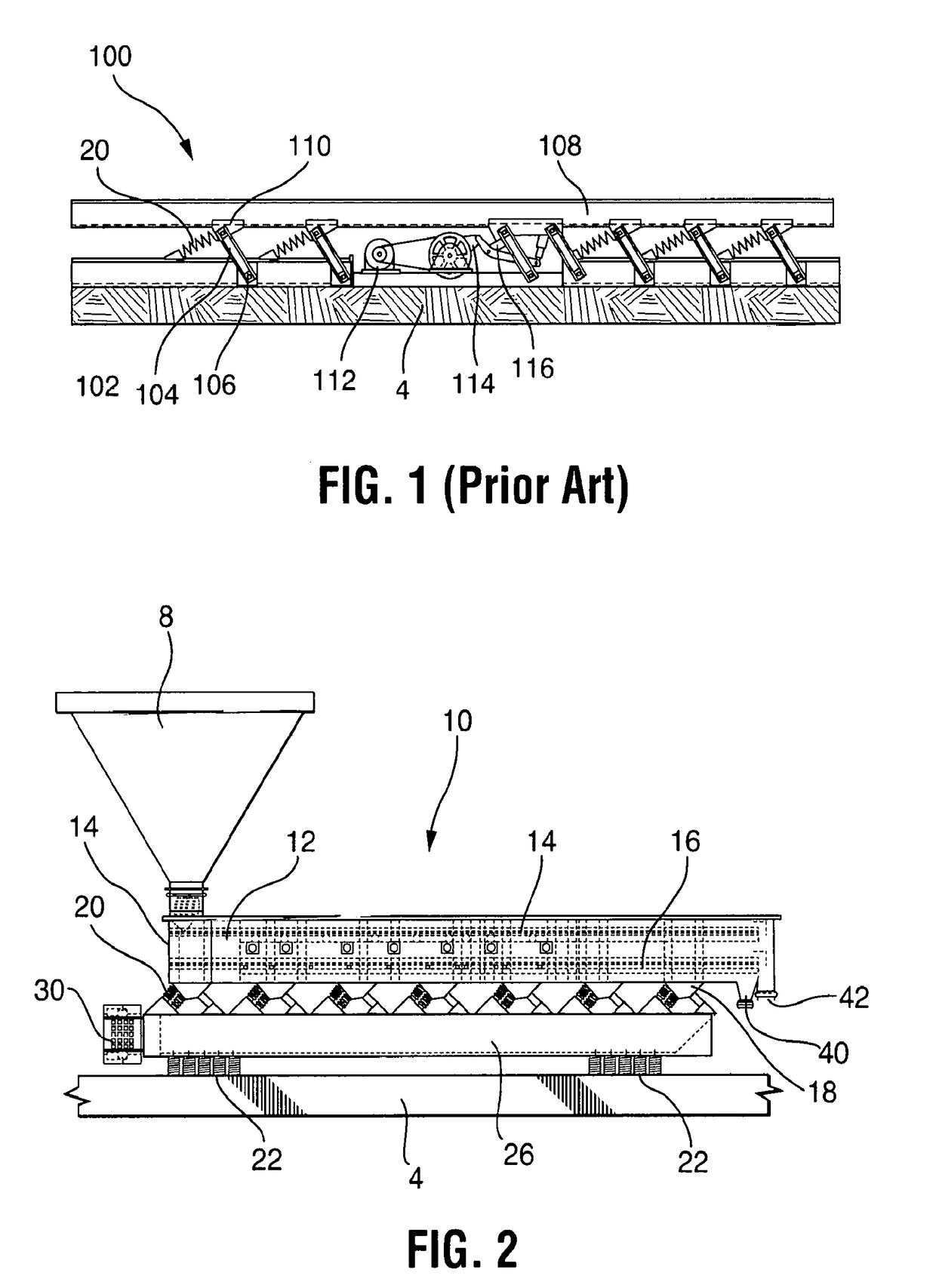

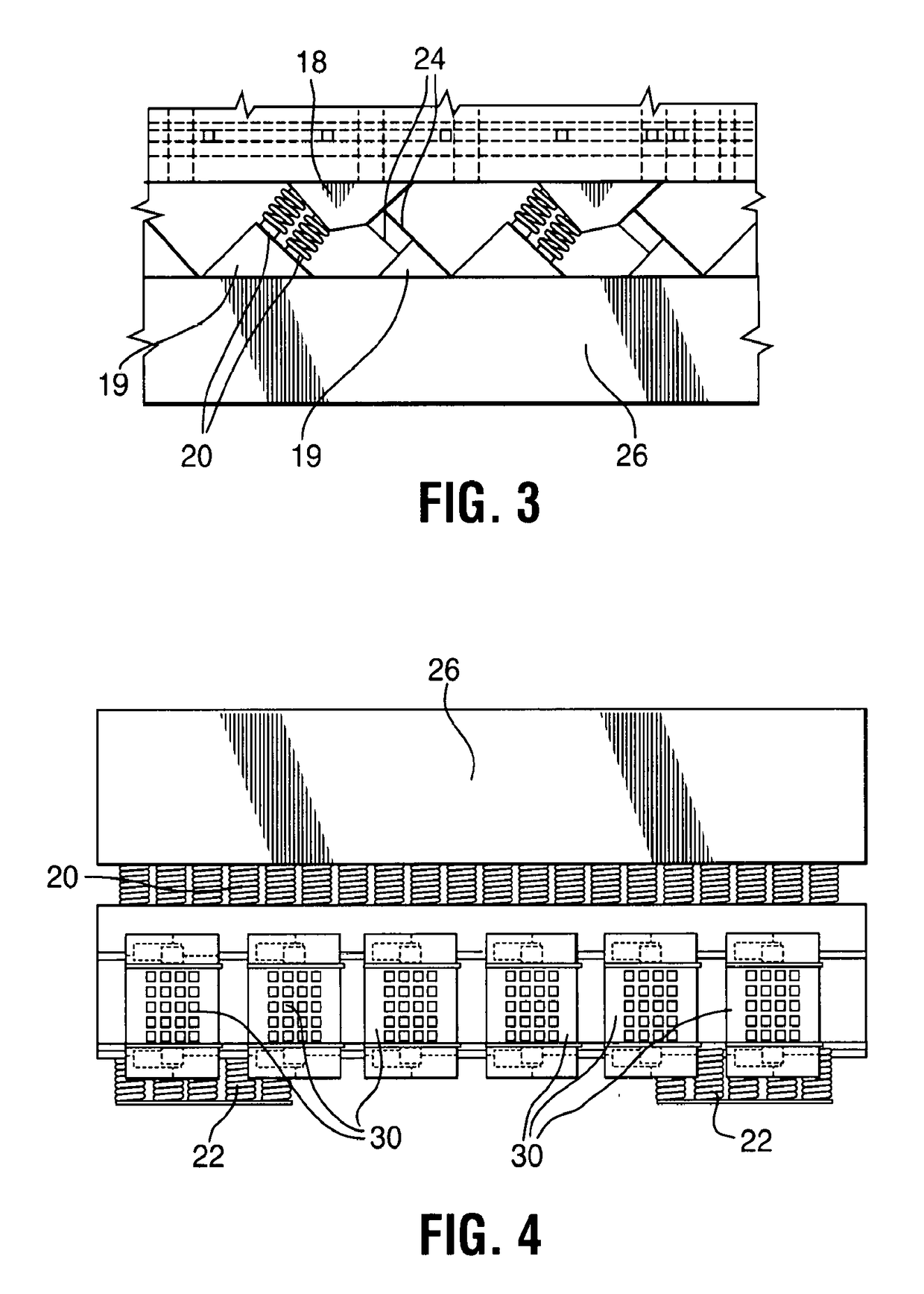

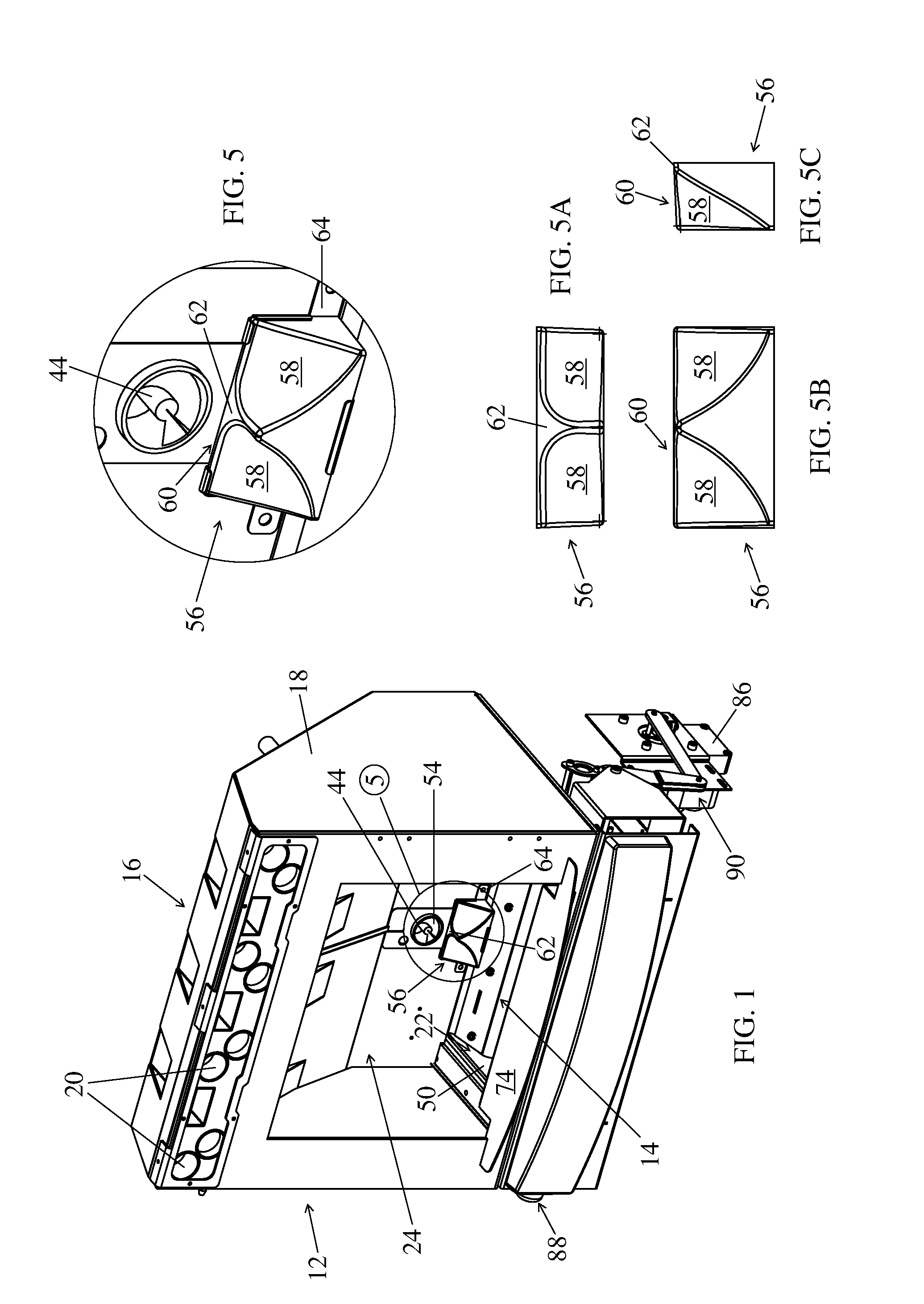

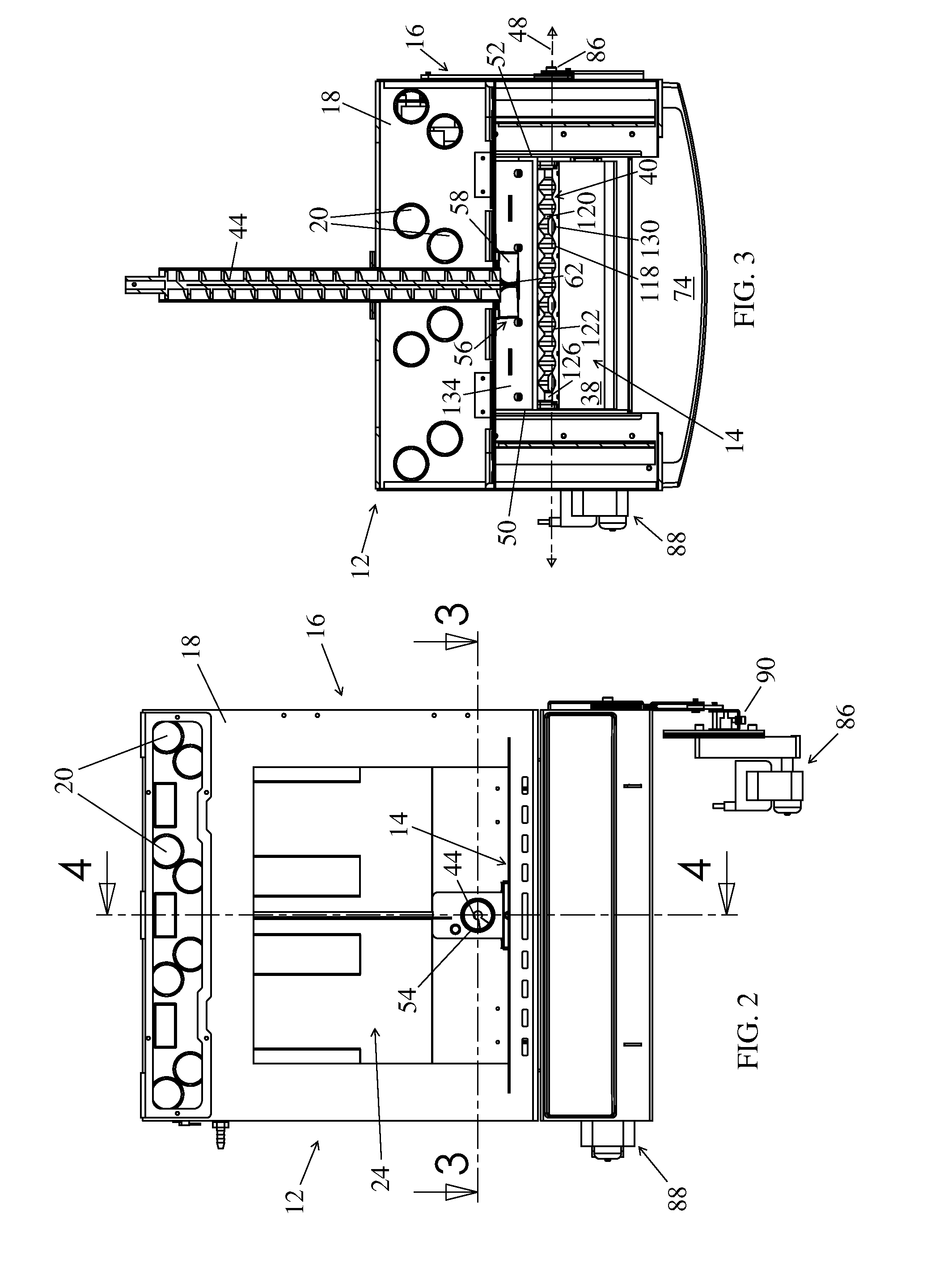

Vibrating screening feeder and method of use

InactiveUS20180193880A1Eliminate residueRugged performance characteristicSievingScreeningEngineeringMoisture

A vibrating screen feed conveying apparatus for conveying and separating sticky “moisture laden bulk solids” which are sticky and wet flowing onto a vibrating screening feeder and into a hopper. The apparatus includes a bed on which material is conveyed, a longitudinal counterbalance supported on a plurality of isolation springs, a plurality of inclined drive springs extending between the bed and the longitudinal counterbalance, and a plurality of stabilizers for controlling movement of the drive springs along their central axes. A plurality of vibratory motors, each having rotatable eccentric weights are attached to the rear end of the longitudinal counterbalance. The eccentric weights rotate in phase with one another to vibrate the bed at a vibration frequency.

Owner:KINERGY

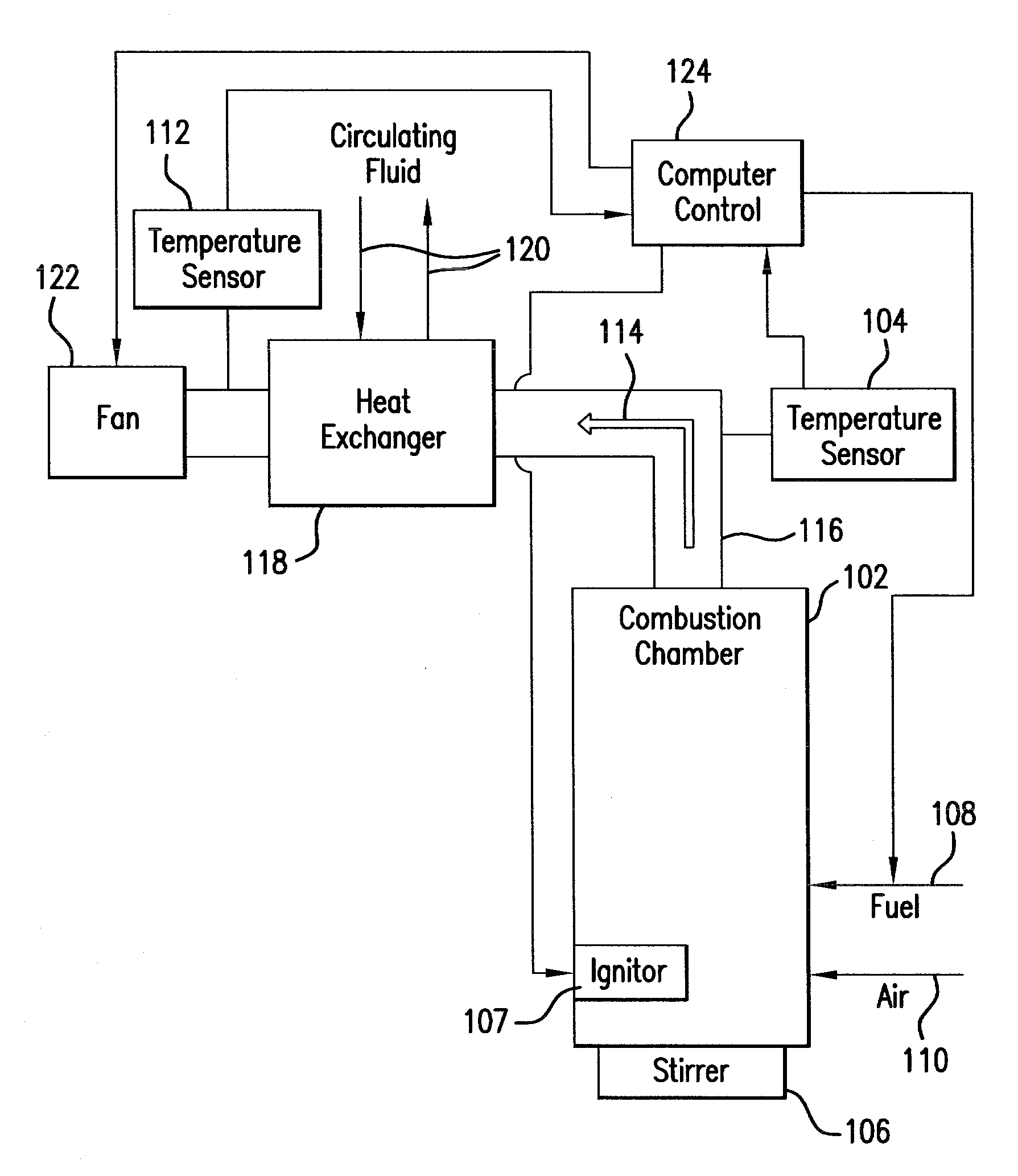

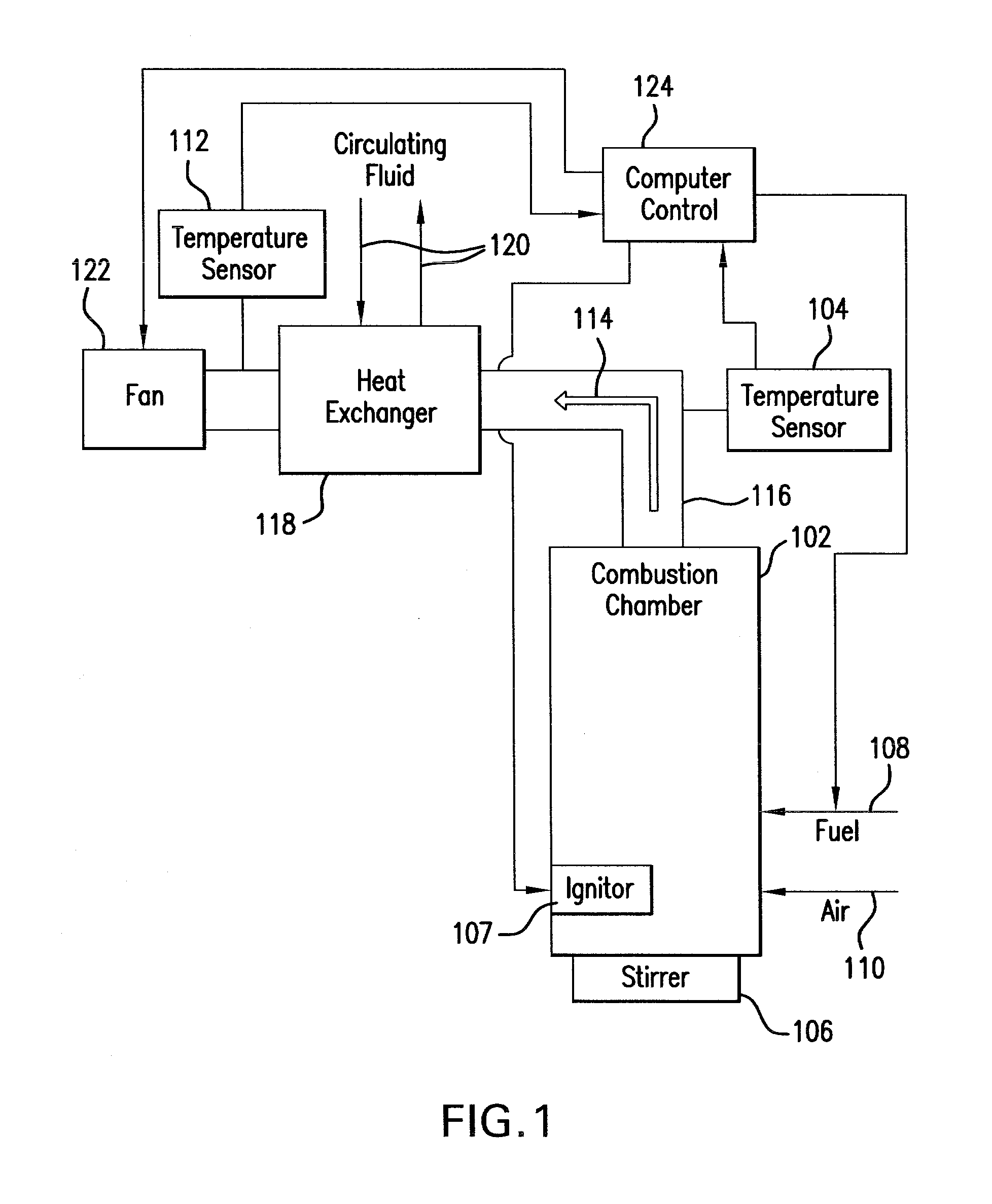

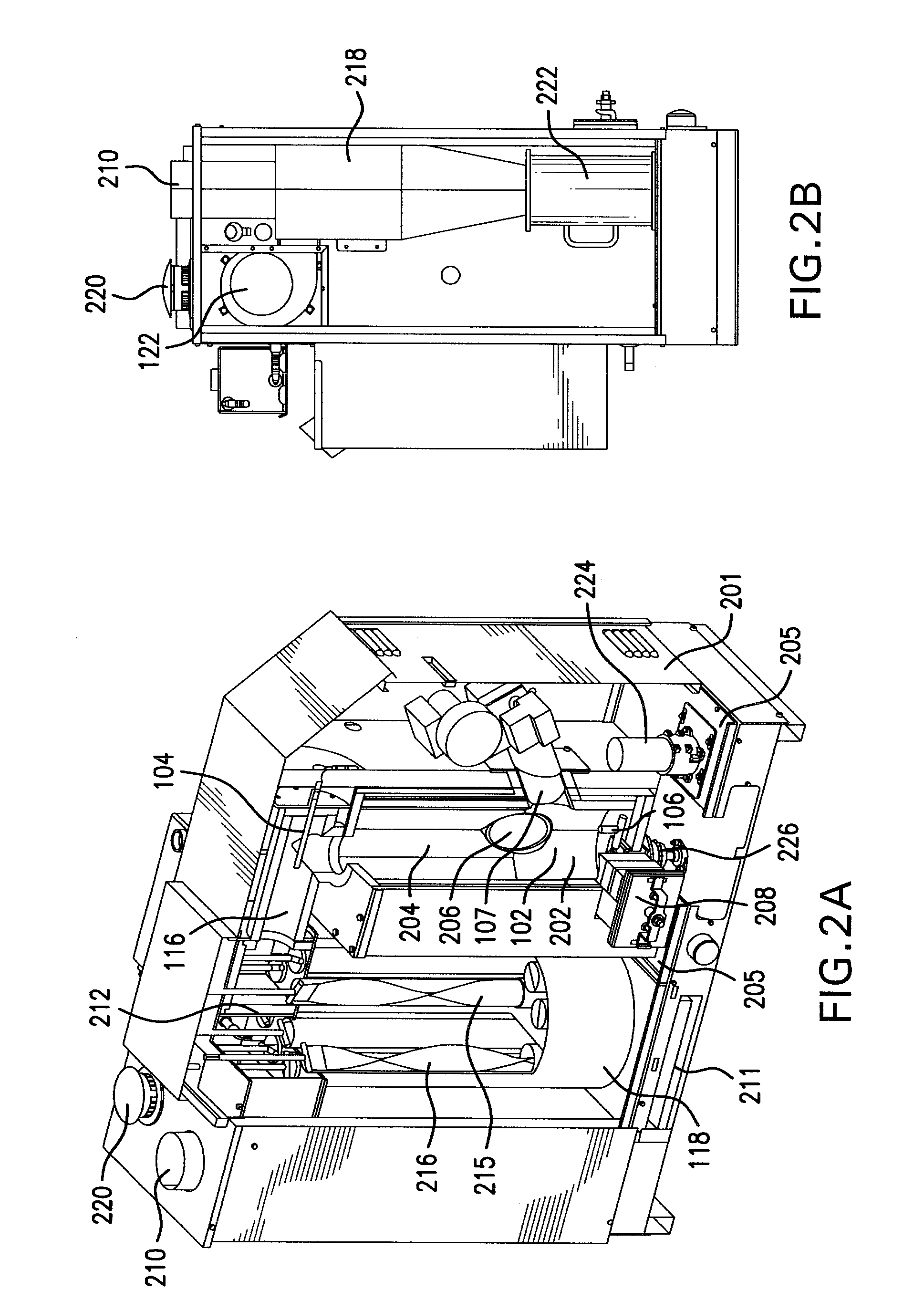

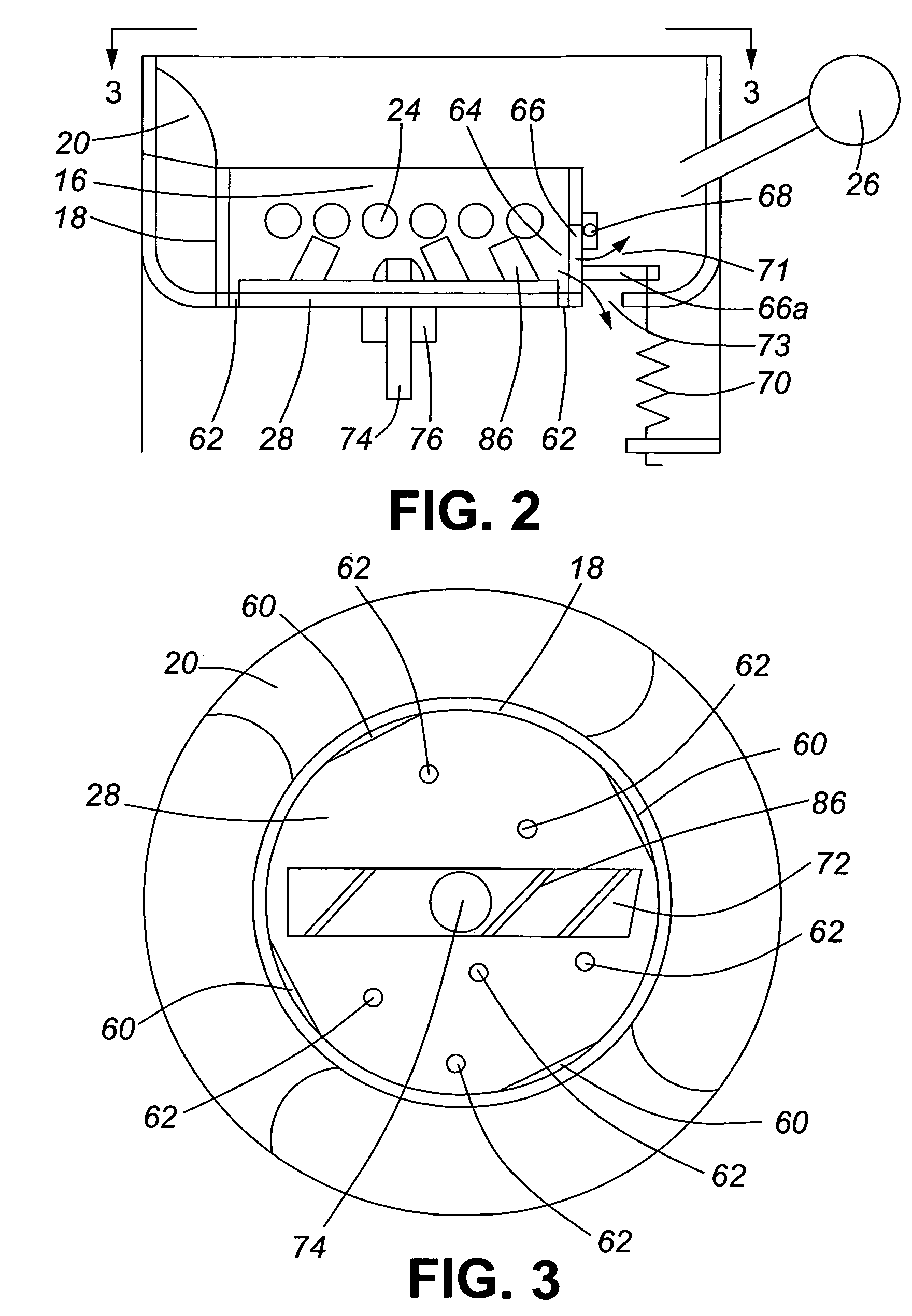

Non-catalytic biomass fuel burner and method

The present invention relates to a non-catalytic biomass burner that may be used to burn a variety of fuel types at high efficiencies. The burner may include a cylindrical combustion chamber with an auxiliary igniter to heat the fuel in the combustion chamber until desirable combustion temperatures are reached. Fuel may be added to the chamber via a fuel feed assembly, and the rate of fuel addition to the chamber by the fuel feed assembly may be controlled by a computer. A fan located on the distal side of a flue pipe from the chamber may also be provided that pulls air into the chamber through one or more air inlets that are designed to encourage cyclonic air and exhaust flow in the chamber. Methods are further provided for controlling the manner of operation of the burner by a computer that may be instructed by a computer program code.

Owner:LASKOWSKI SCOTT +3

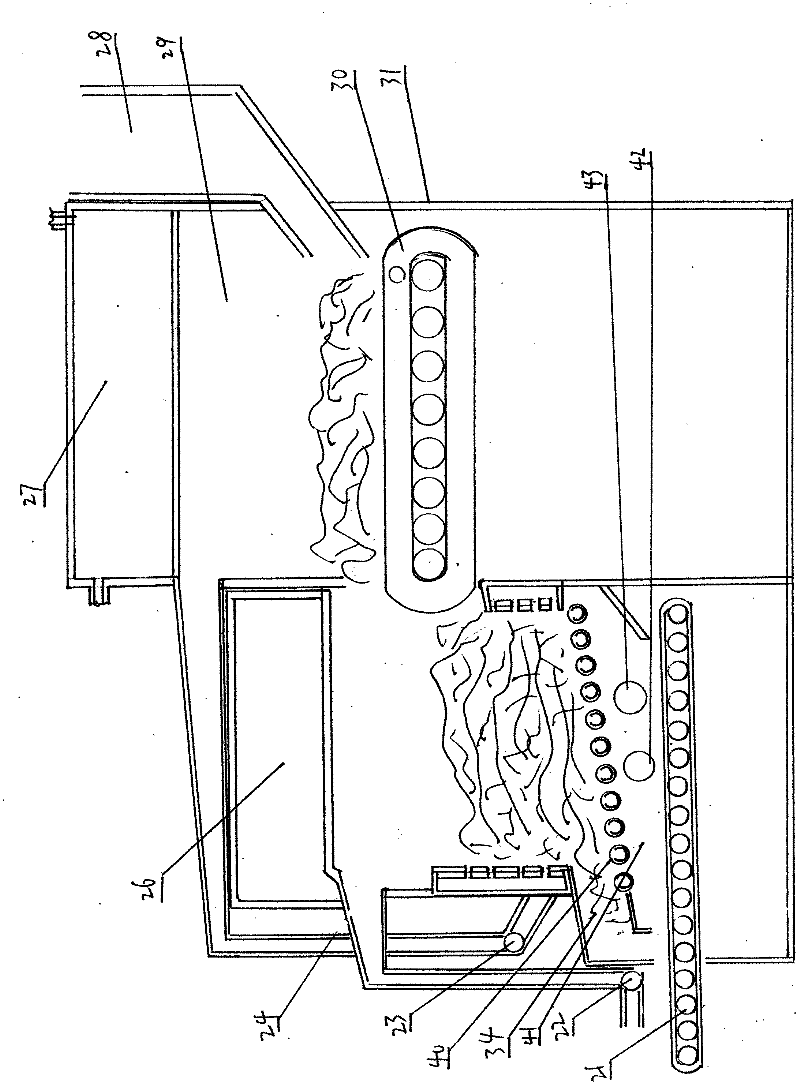

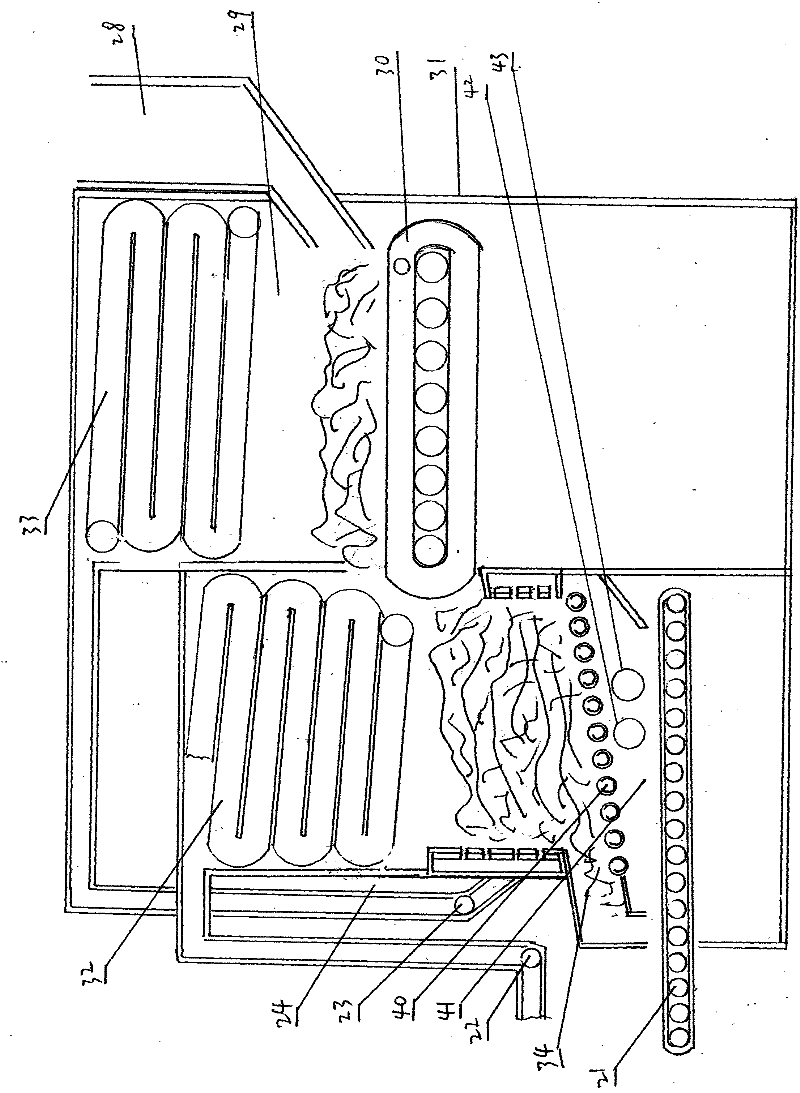

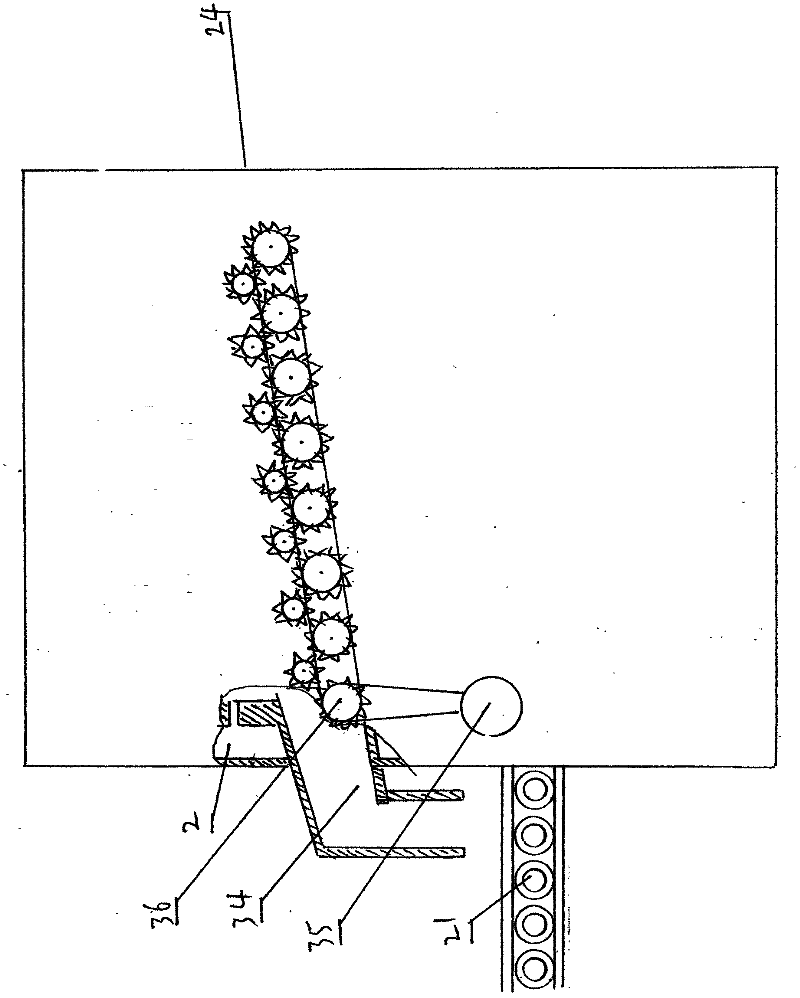

Novel high-efficiency vaporizing combustion compound furnace grate device with slag disintegrating function

ActiveCN102588950APromote precipitationAchieve emissionsChemical industryRevolving grateSlagEngineering

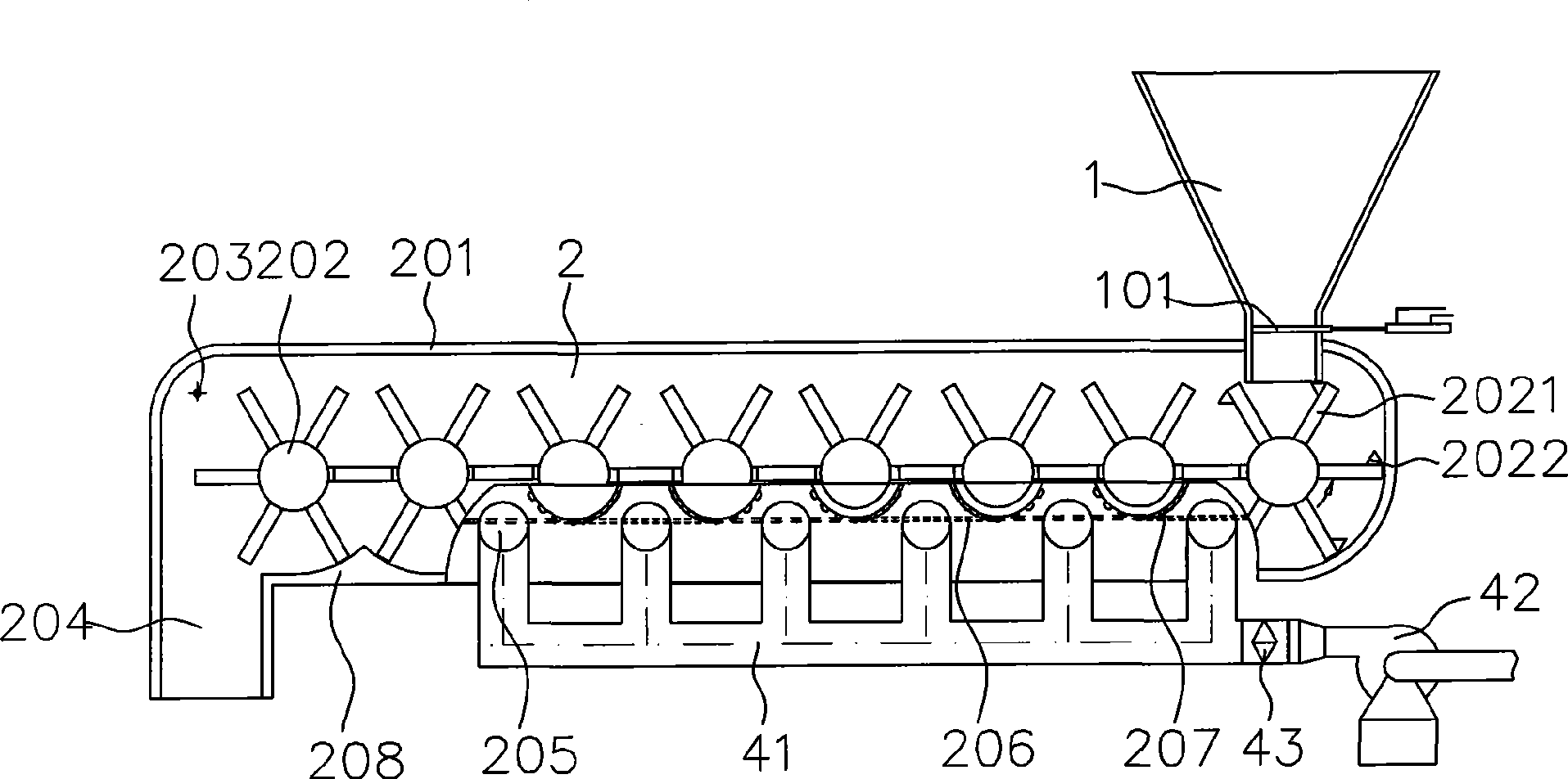

The invention discloses a novel high-efficiency vaporizing combustion compound furnace grate device with a slag disintegrating function. The traditional incinerator has the disadvantages of lower heat efficiency and high repairing and maintenance cost of a furnace grate due to poor fuel mixture and insufficient combustion. The novel high-efficiency vaporizing combustion compound furnace grate device with the slag disintegrating function adopts a two-section compound structure, wherein on the front section of a reciprocating type furnace grate, wastes are dried, vaporized and partially burned; and the unburned parts fall on a back-end rotary furnace grate device to be extruded, crushed and fully mixed to be burned completely. The reciprocating type furnace grate adopts a multi-air-port segmental air distribution way for reasonable air distribution; the heat radiation on the furnace grate is increased due to a long back arch, thereby facilitating the firing of wastes with low heat values. The novel high-efficiency vaporizing combustion compound furnace grate device with the slag disintegrating function is adopted to effectively improve the disadvantages of poor mixing effect and low burn-off rate of the traditional furnace grate incineration device, and meanwhile, the area of a furnace grate bar with high temperature resistance can be reduced, and the investment is reduced.

Owner:ZHEJIANG UNIV

Burner for combustion of fuel in pellet or granular form

A burner for fuel in pellet or granular form in which the fuel has a high ash content, for example grass or hay pellets in which the ash content is 5% or more. The burner has a combustion chamber with a grate at its lower end, into which fuel and air are fed, the combustion chamber having a hot gas outlet for exhausting combustion gases. The grate is provided with a rotary member having upstanding vanes which is adapted to continually move ash or clinker on the grate through outlet apertures spaced around the grate. The grate is a generally planar, horizontal surface which is imperforate apart from the outlet apertures; air inlet ports are arranged in a circumferential wall surrounding the grate.

Owner:SWANSON HAROLD ANGUS

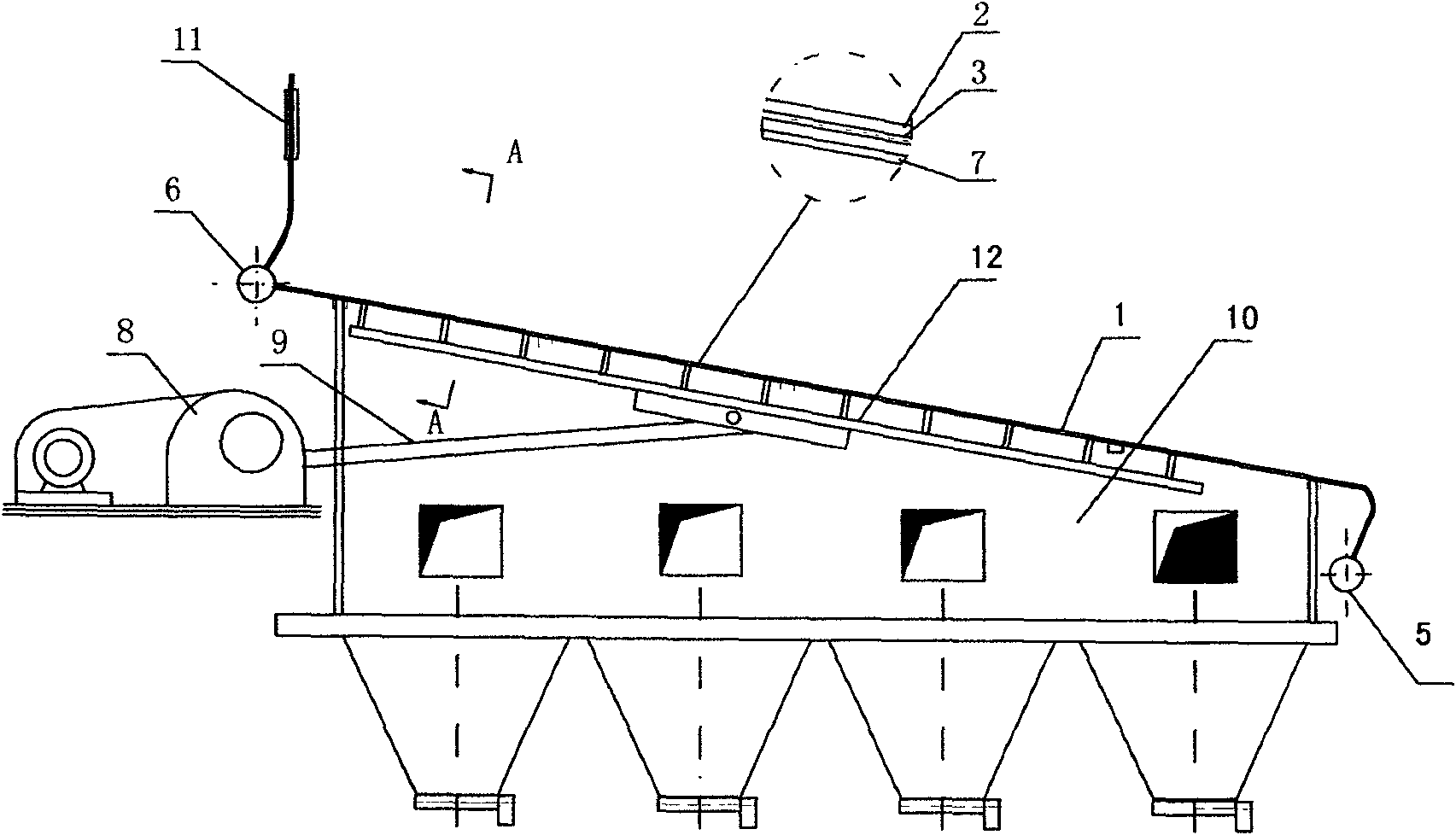

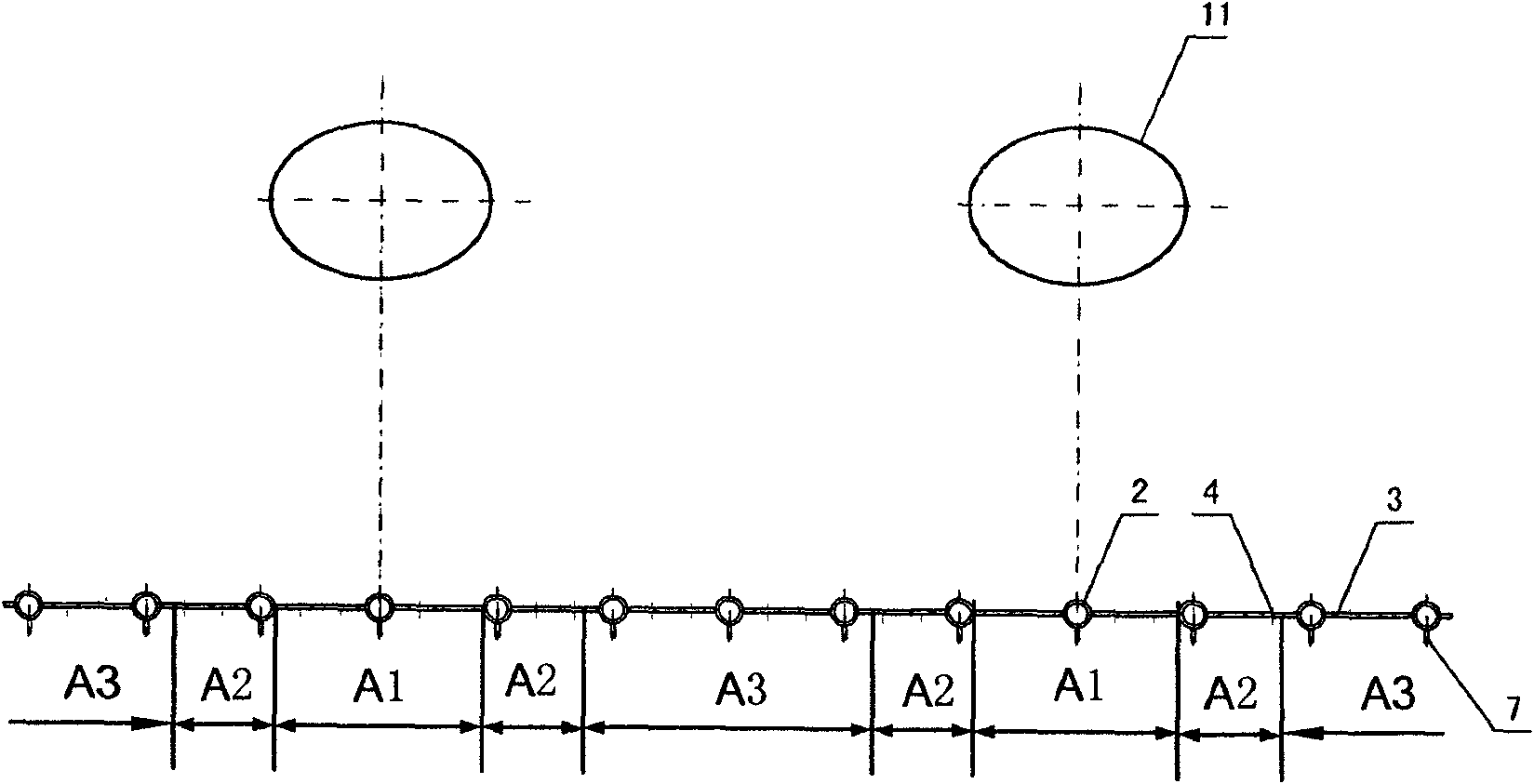

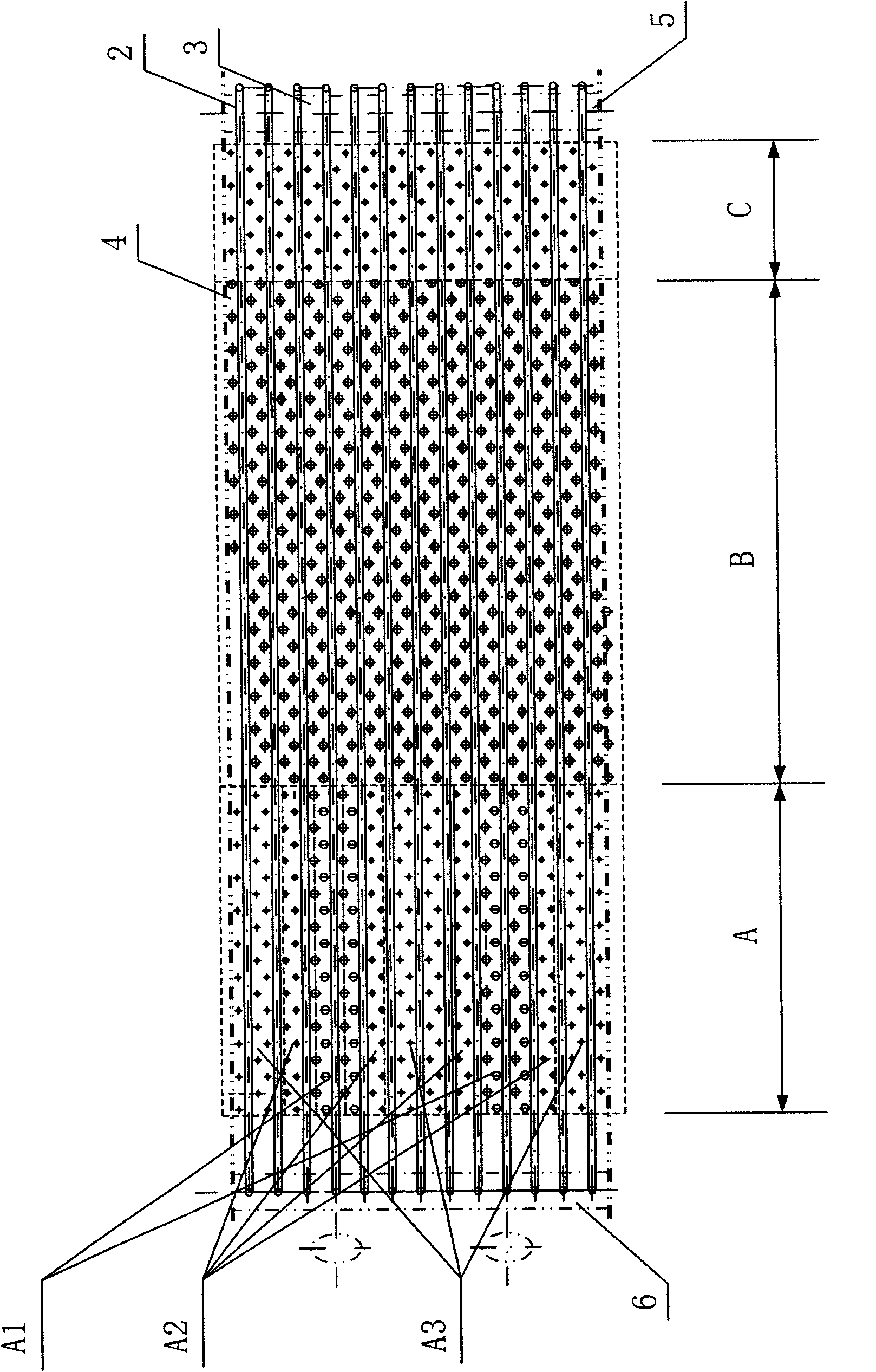

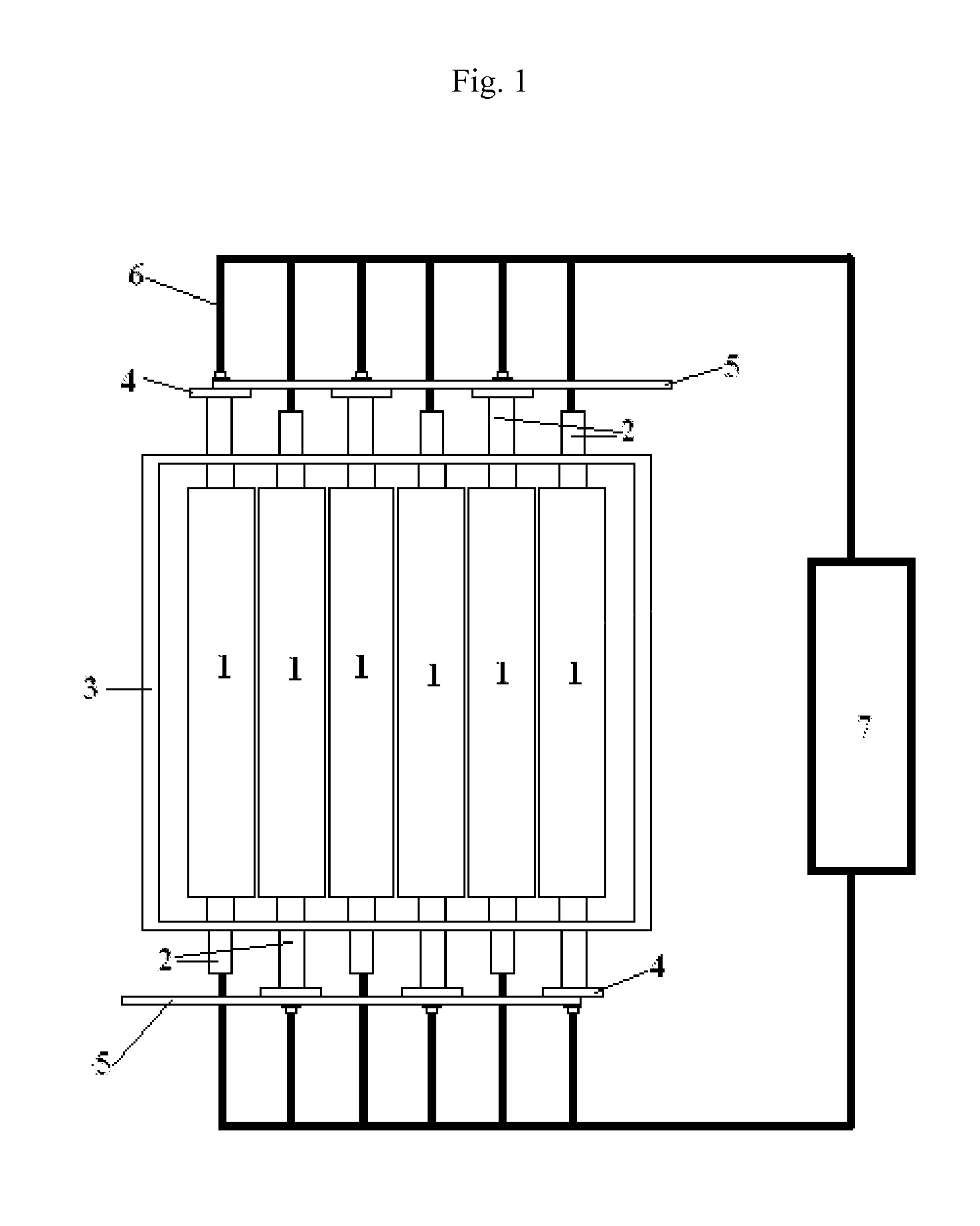

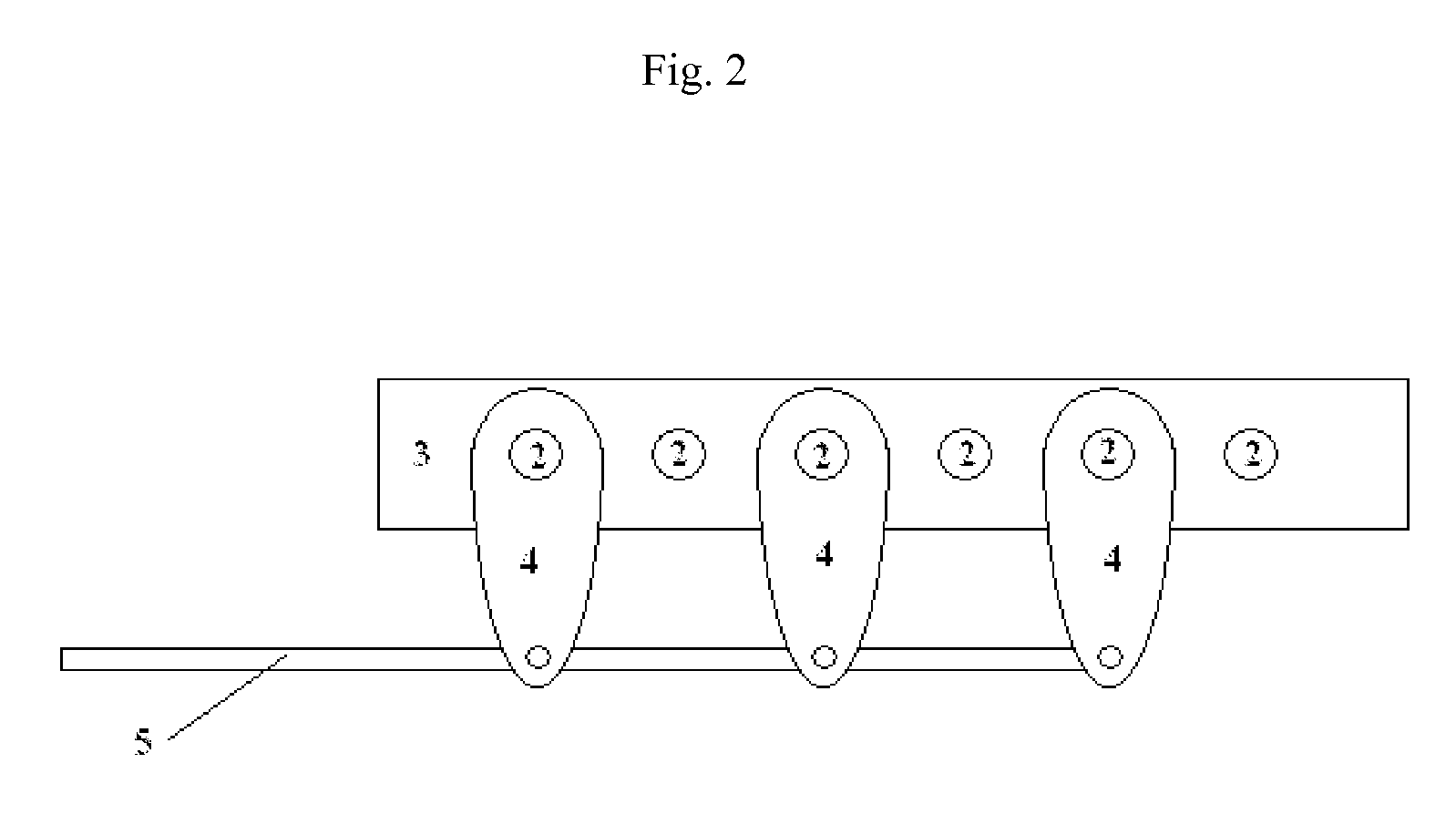

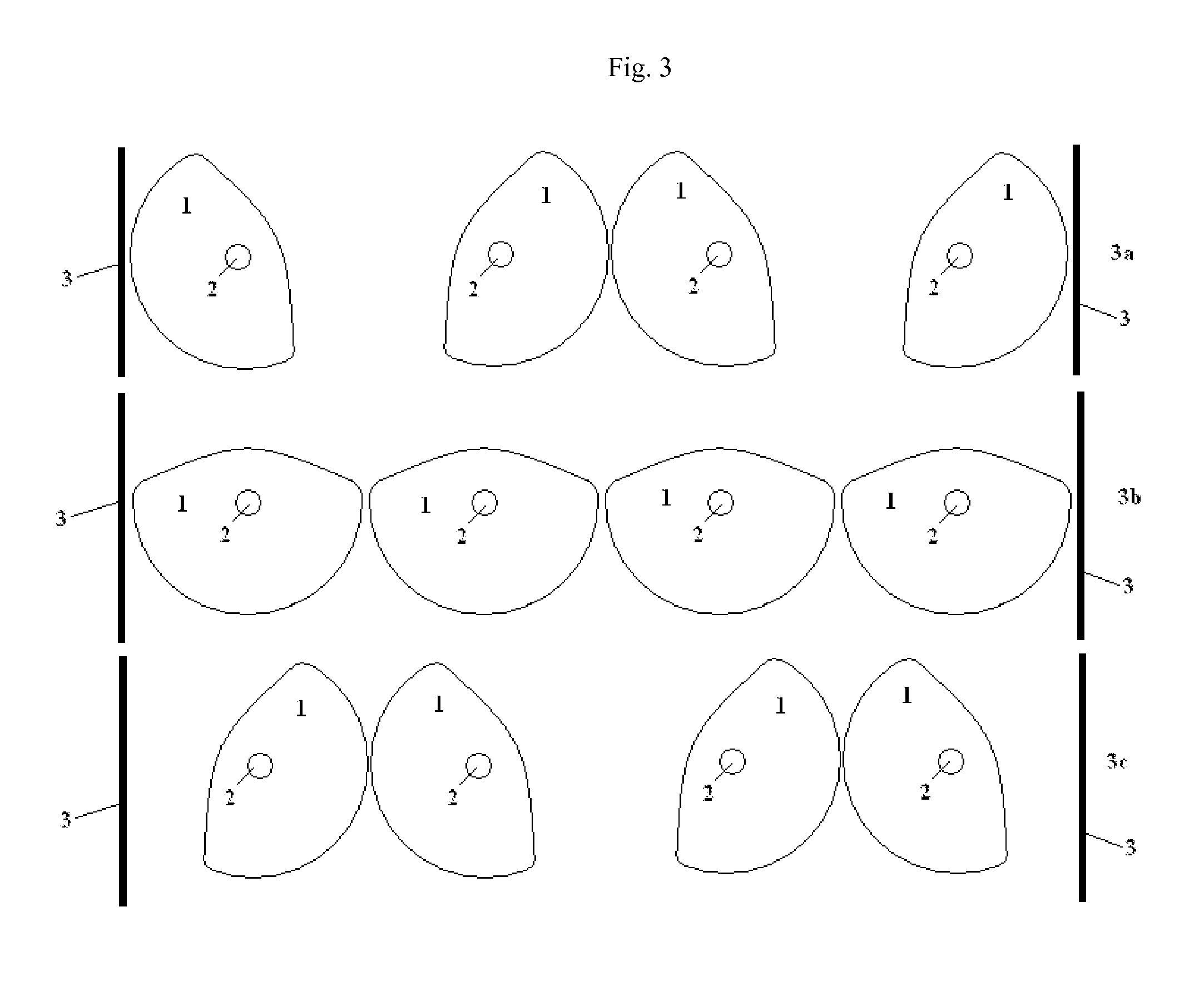

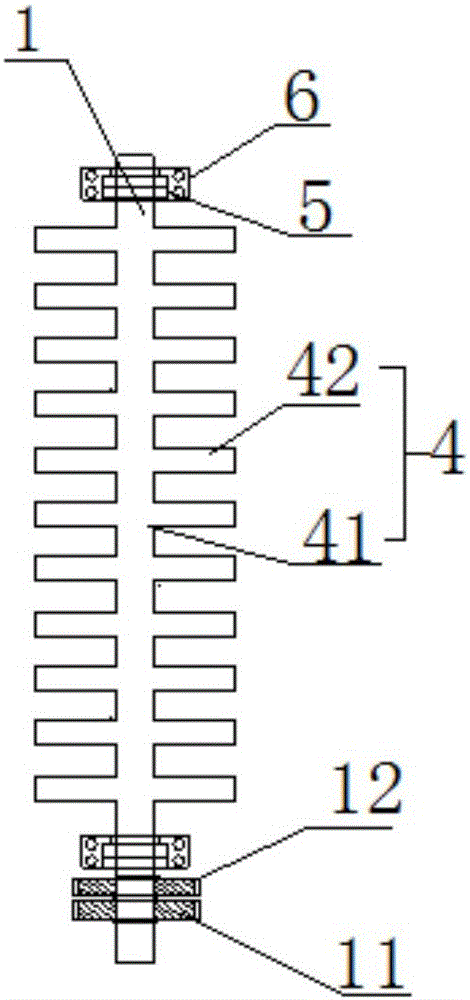

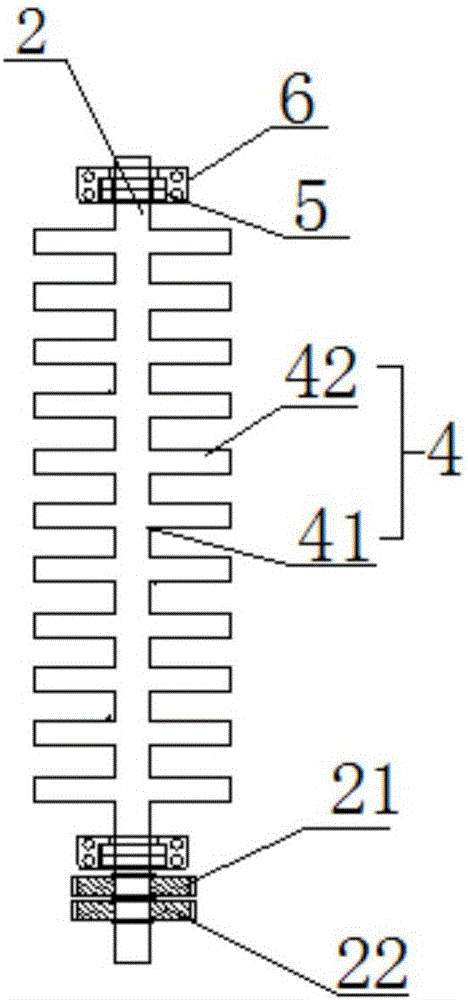

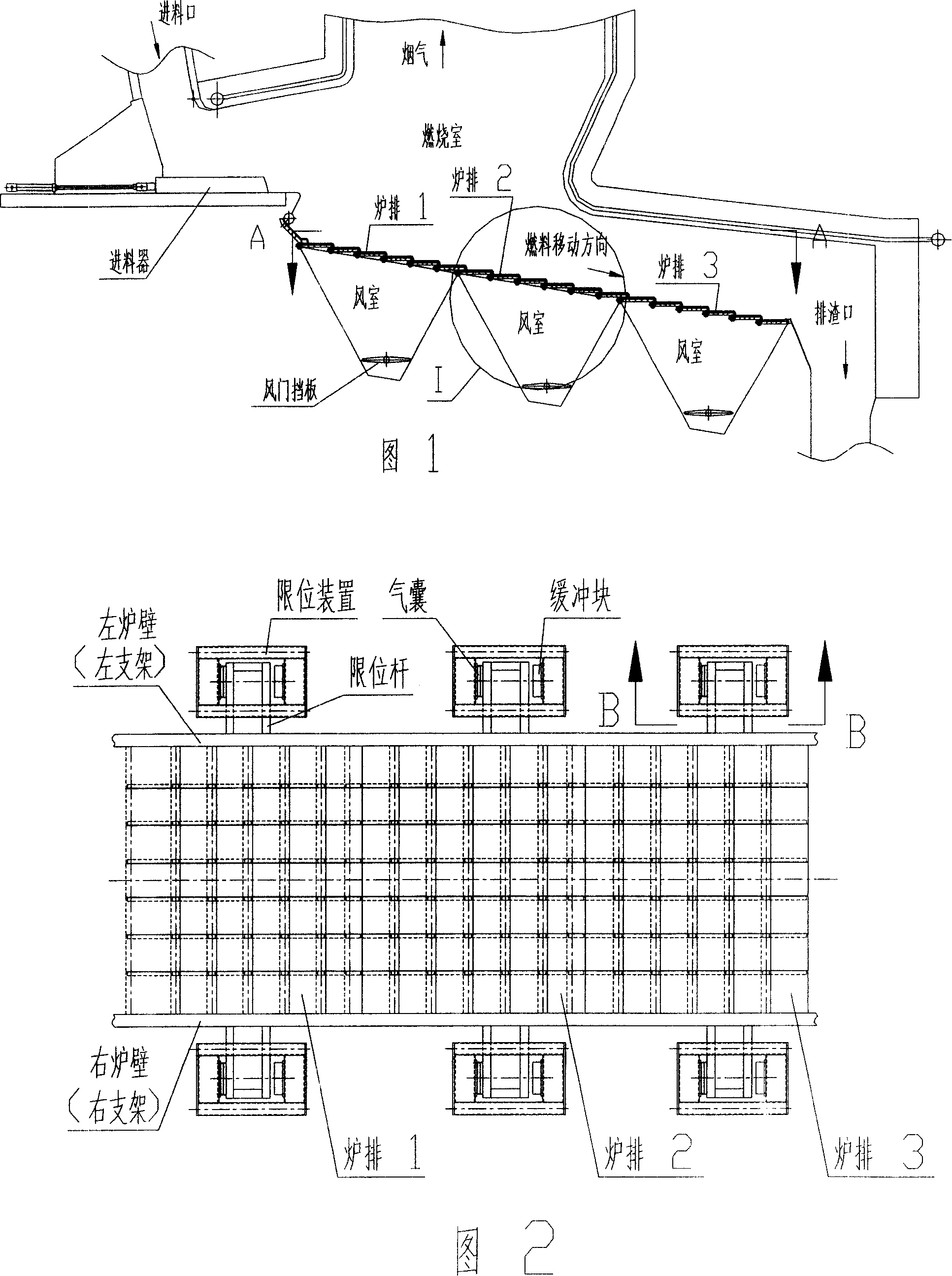

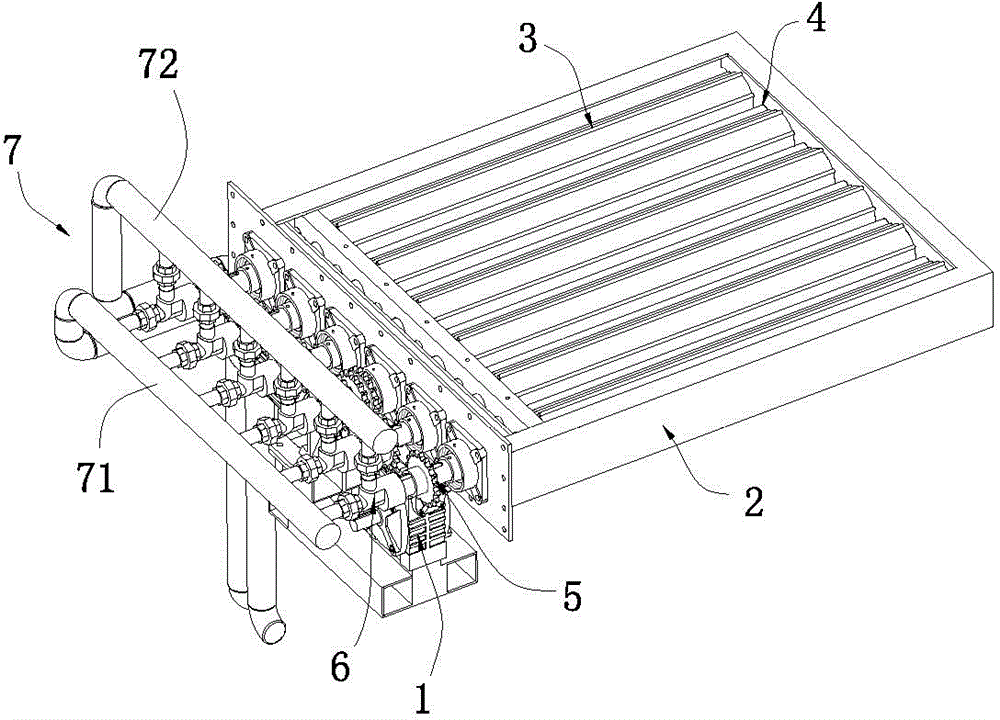

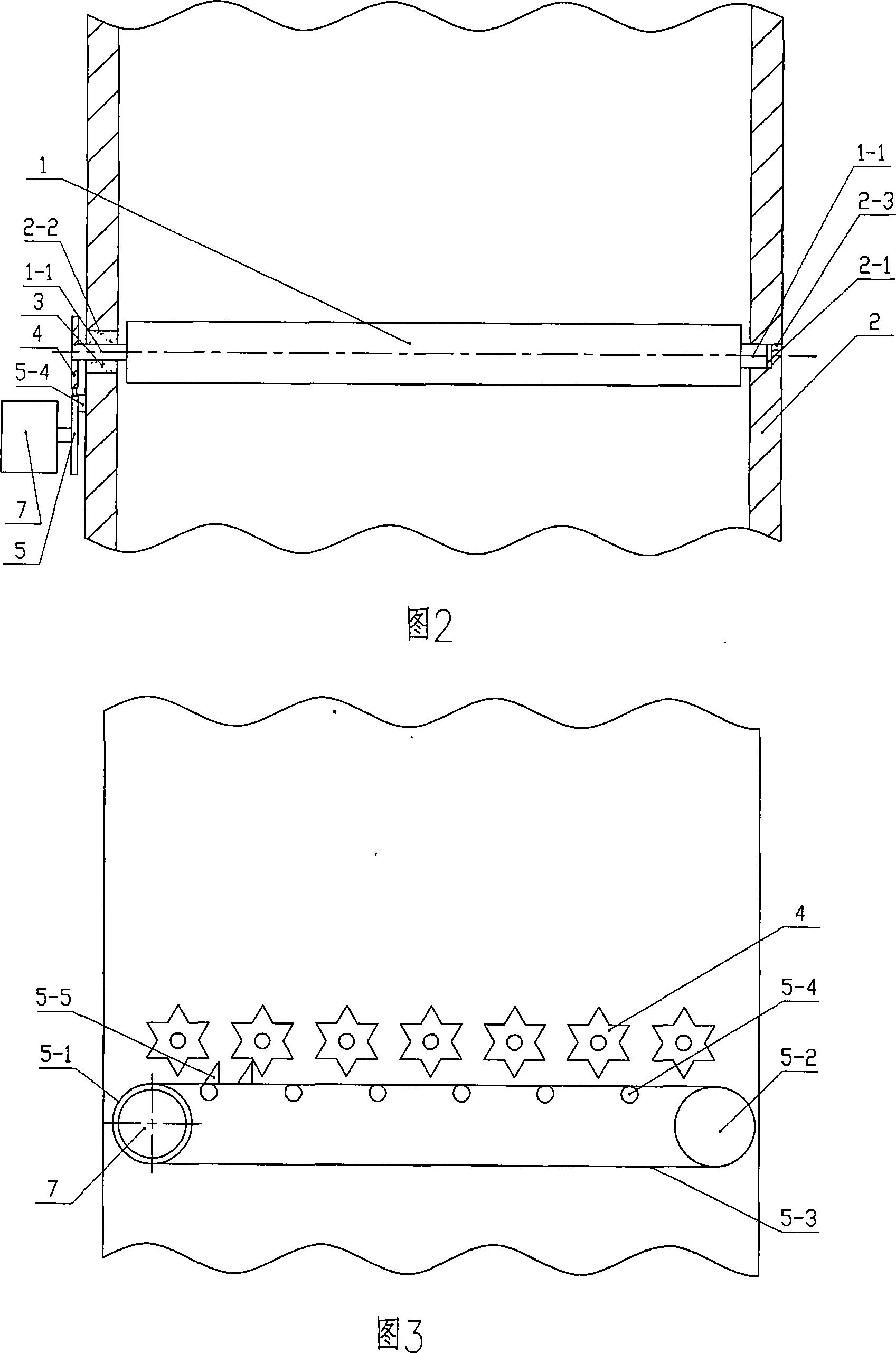

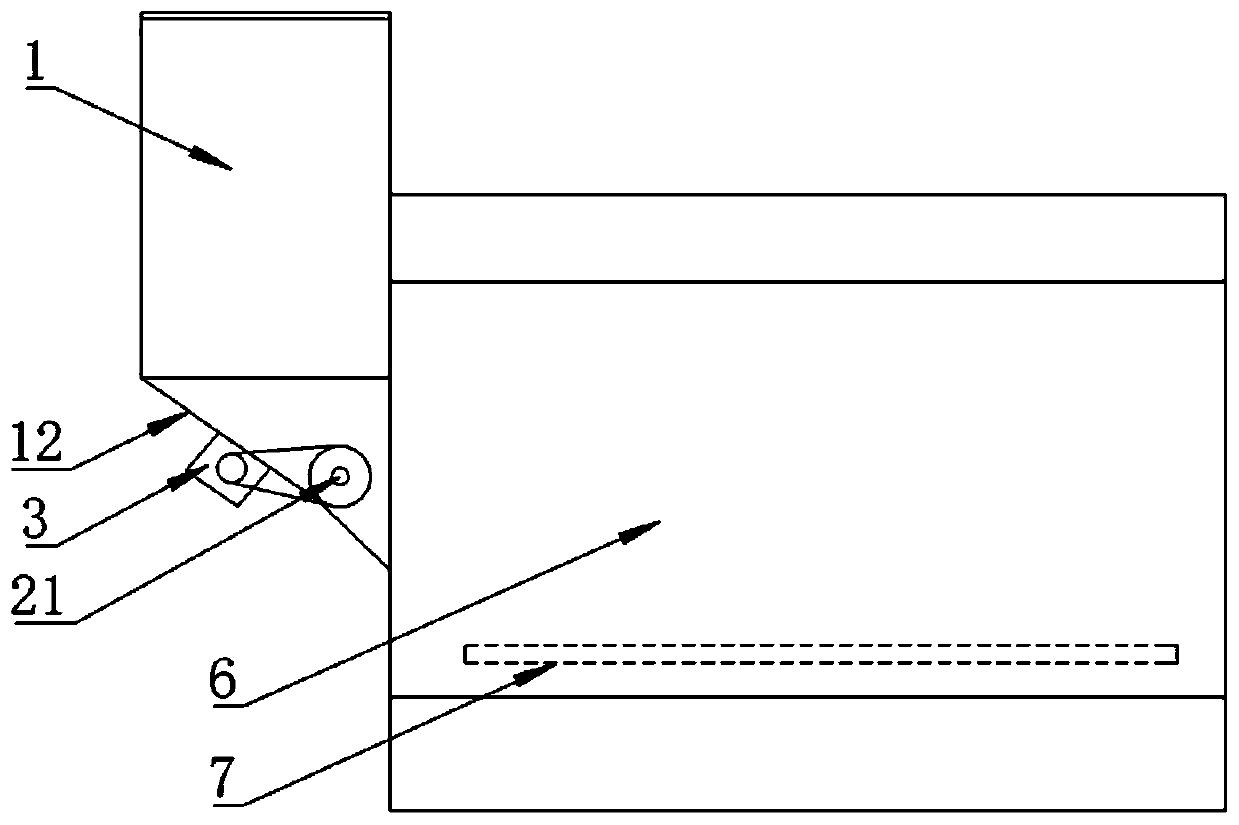

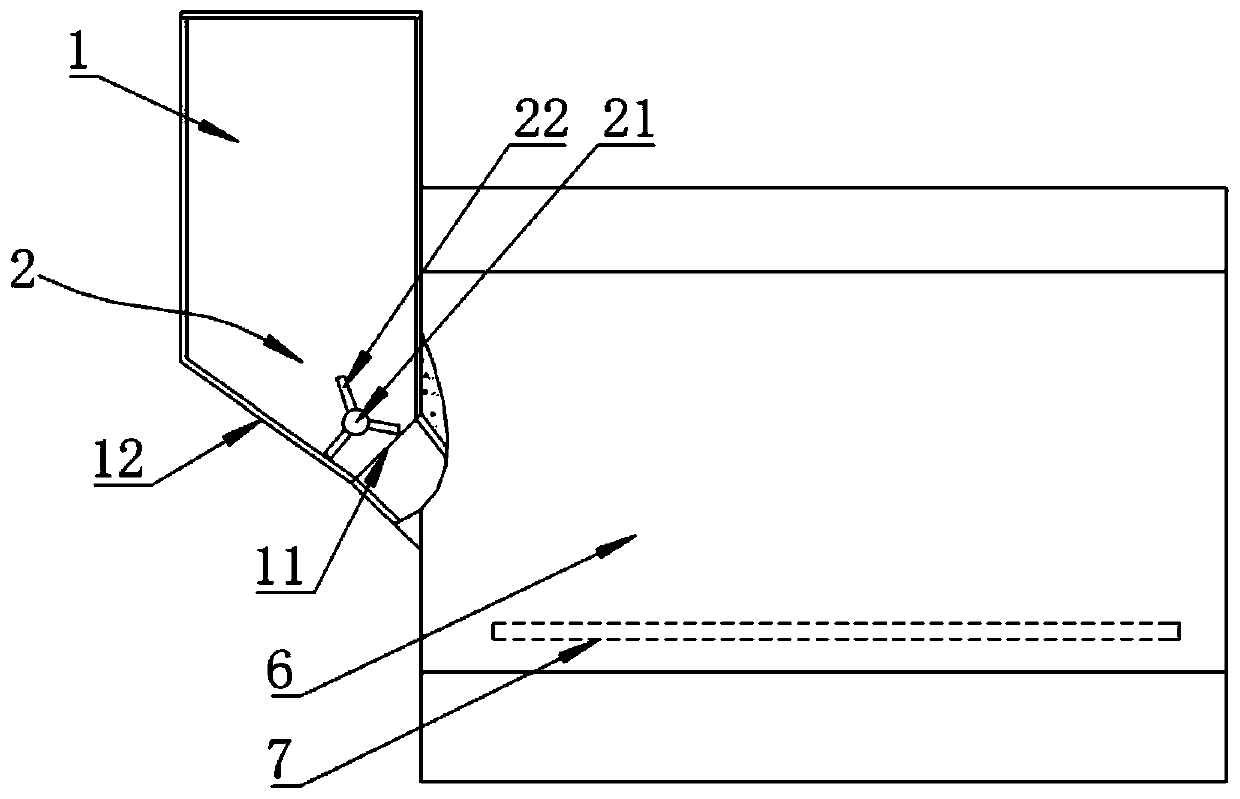

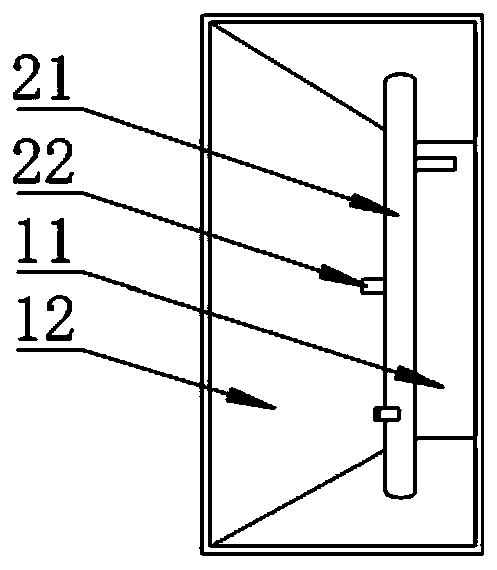

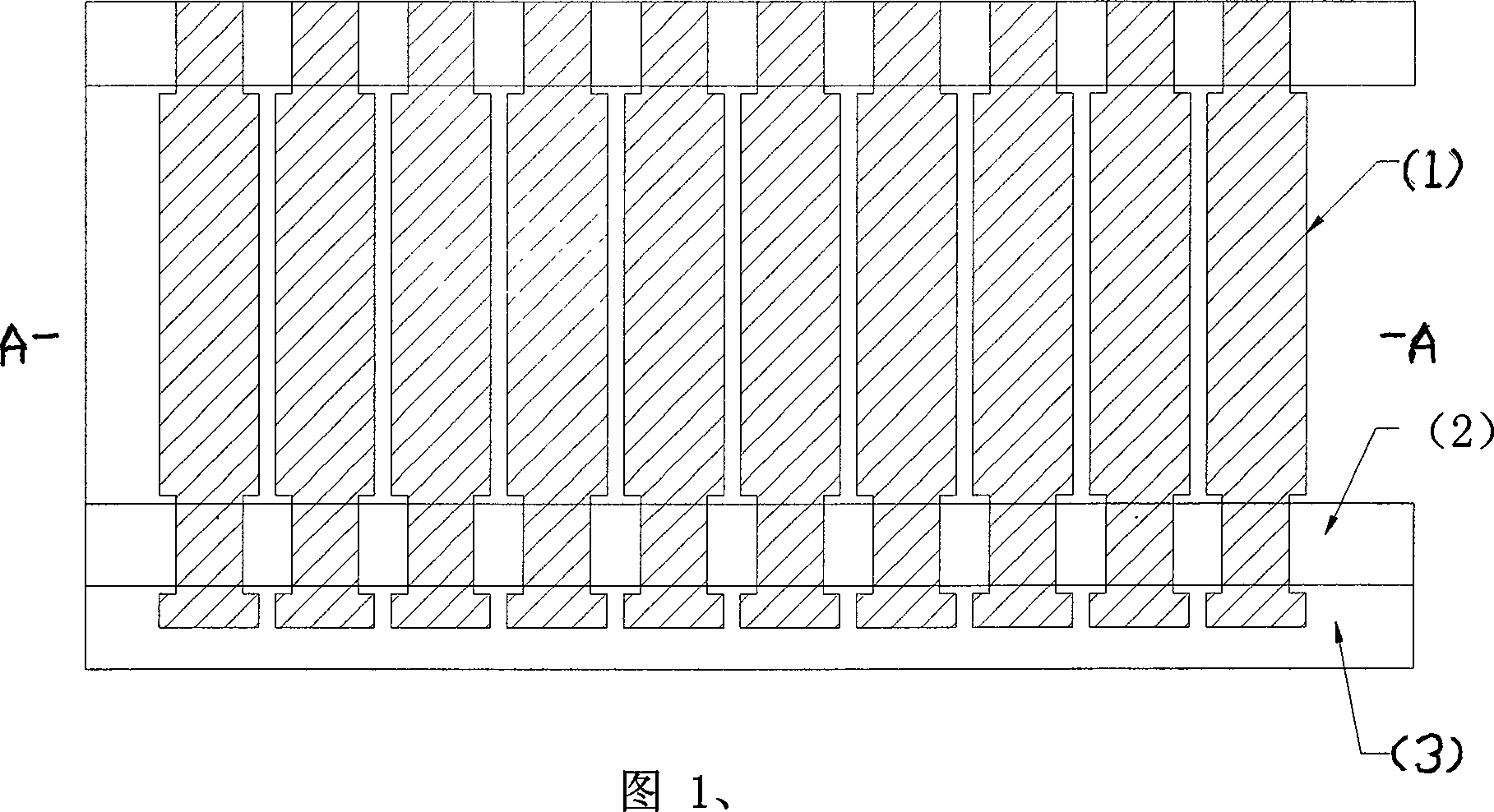

Bidirectional non-uniform matching air distributing water-cooled vibration grate of biomass direct-combustion boiler

InactiveCN101625126ASimple structureWide adaptabilityHollow bar grateRevolving grateDirect combustionEngineering

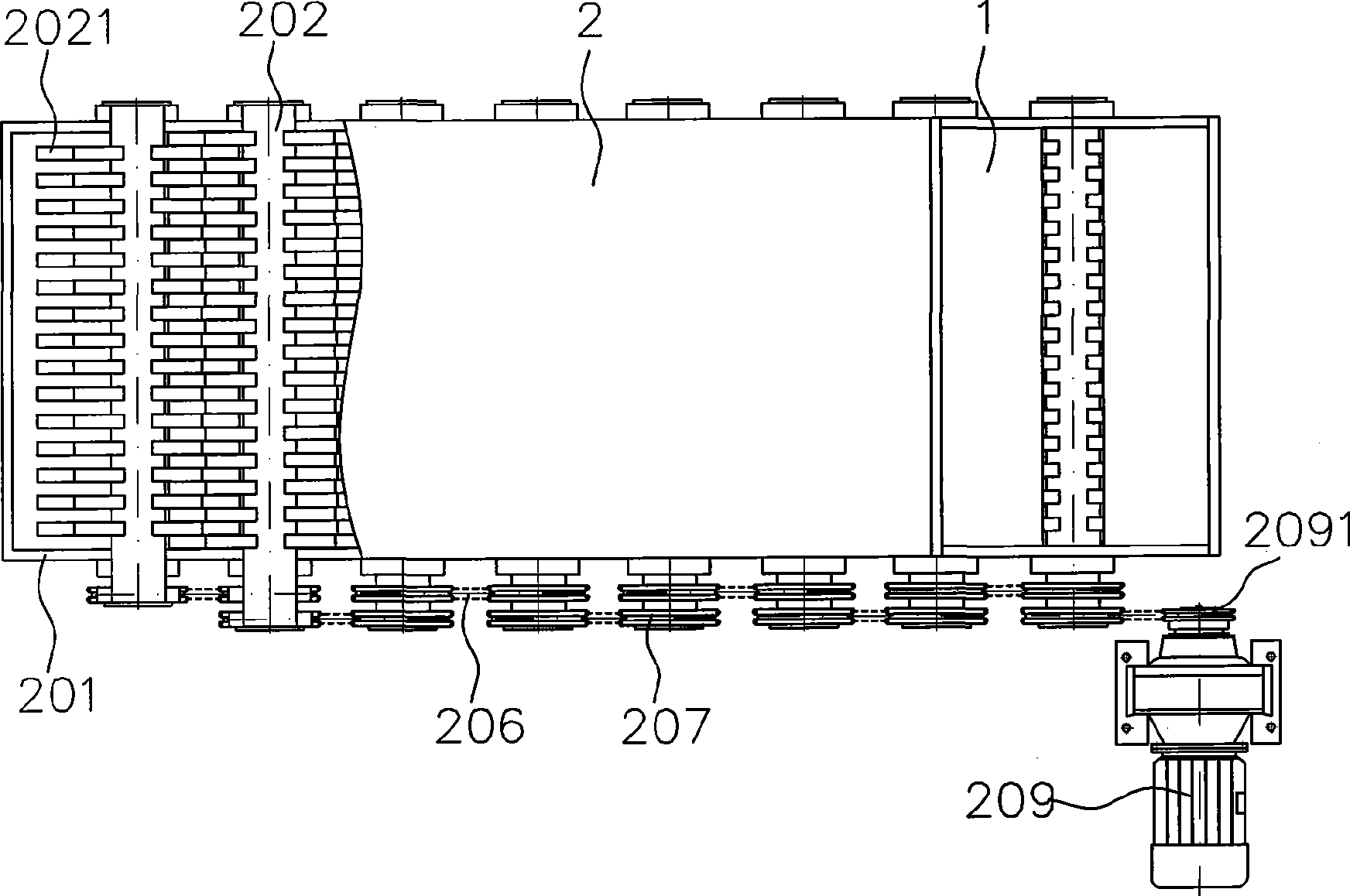

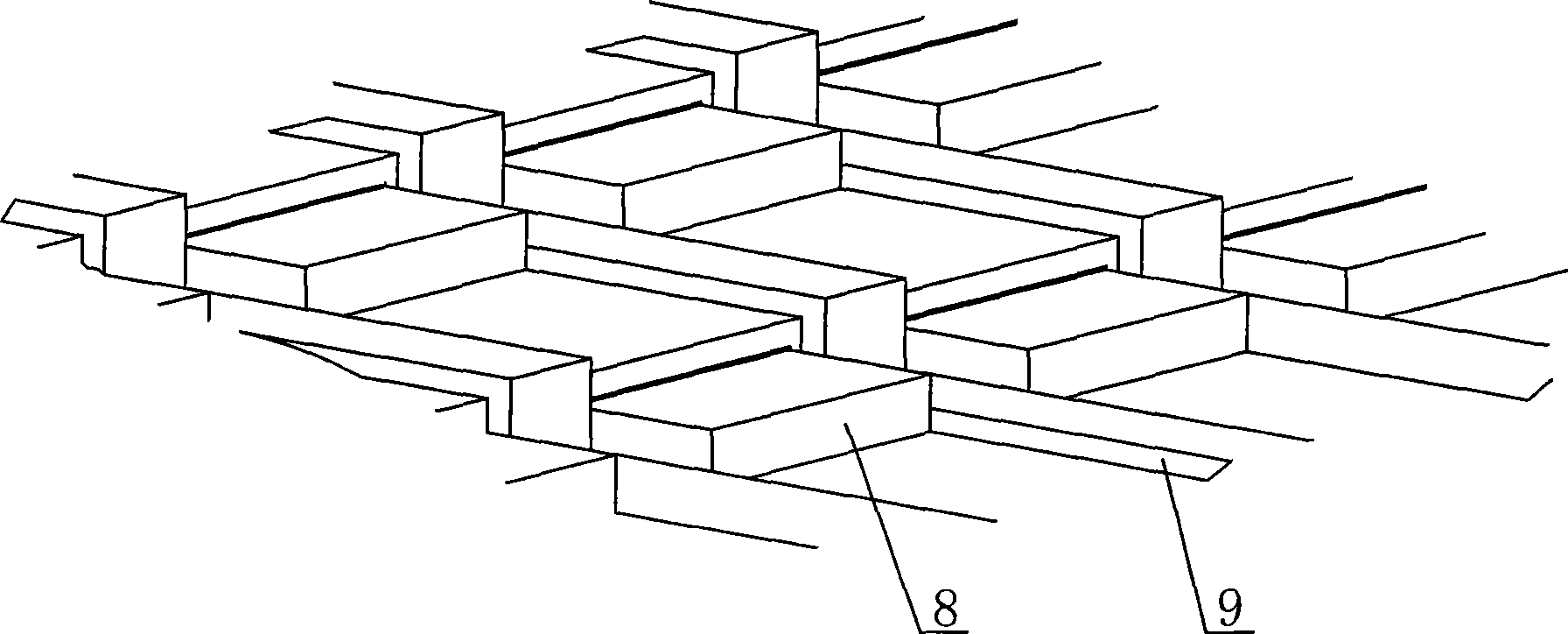

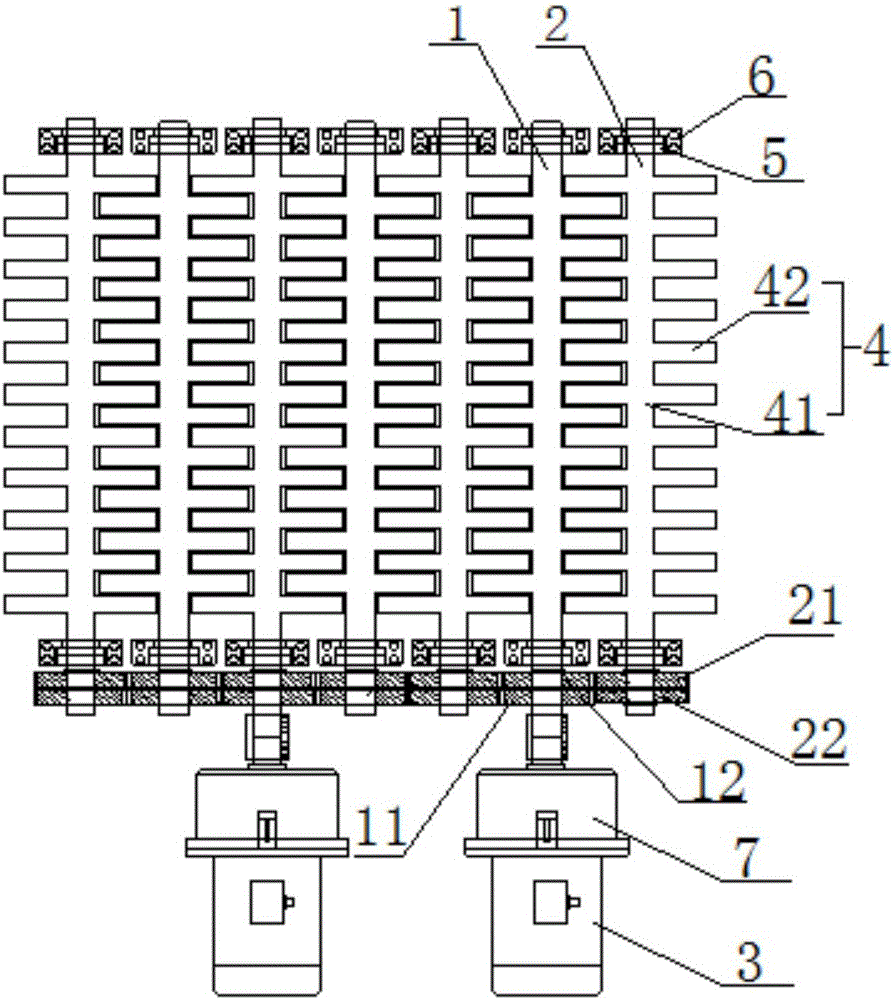

The invention relates to a bidirectional non-uniform matching air distributing water-cooled vibration grate of a biomass direct-combustion boiler, comprising a grate (1) formed by arranging a plurality of inclined water-cooled pipes (2) in parallel at predetermined intervals, wherein the grate (1) is fixed on a support frame (12); an air chamber (10) is arranged below the support frame (12); a discharge hole (13) is arranged below the air chamber (10); the water-cooled pipes (2) are connected with each other by a membrane (3) which is provided with an air inlet hole (4); an inlet end of the water-cooled pipe (2) is connected with an inlet collection tank (5); an outlet end of the water-cooled pipe (2) is connected with an inlet collection tank (6); and a driving device (8) is connected with the support frame (12) at the lower part of the grate (1) through a connecting rod (9) to provide vibration for the grate (1). A drying initial combustion zone, a primary combustion zone and an after-combustion zone are divided in the moving direction of biomass with different aperture ratios for each zone. In addition, the drying initial combustion zone is divided into three sub-zones according to the feeding amount of biomass with larger aperture ratio closer to the sub-zone of a feeding inlet.

Owner:SOUTHEAST UNIV

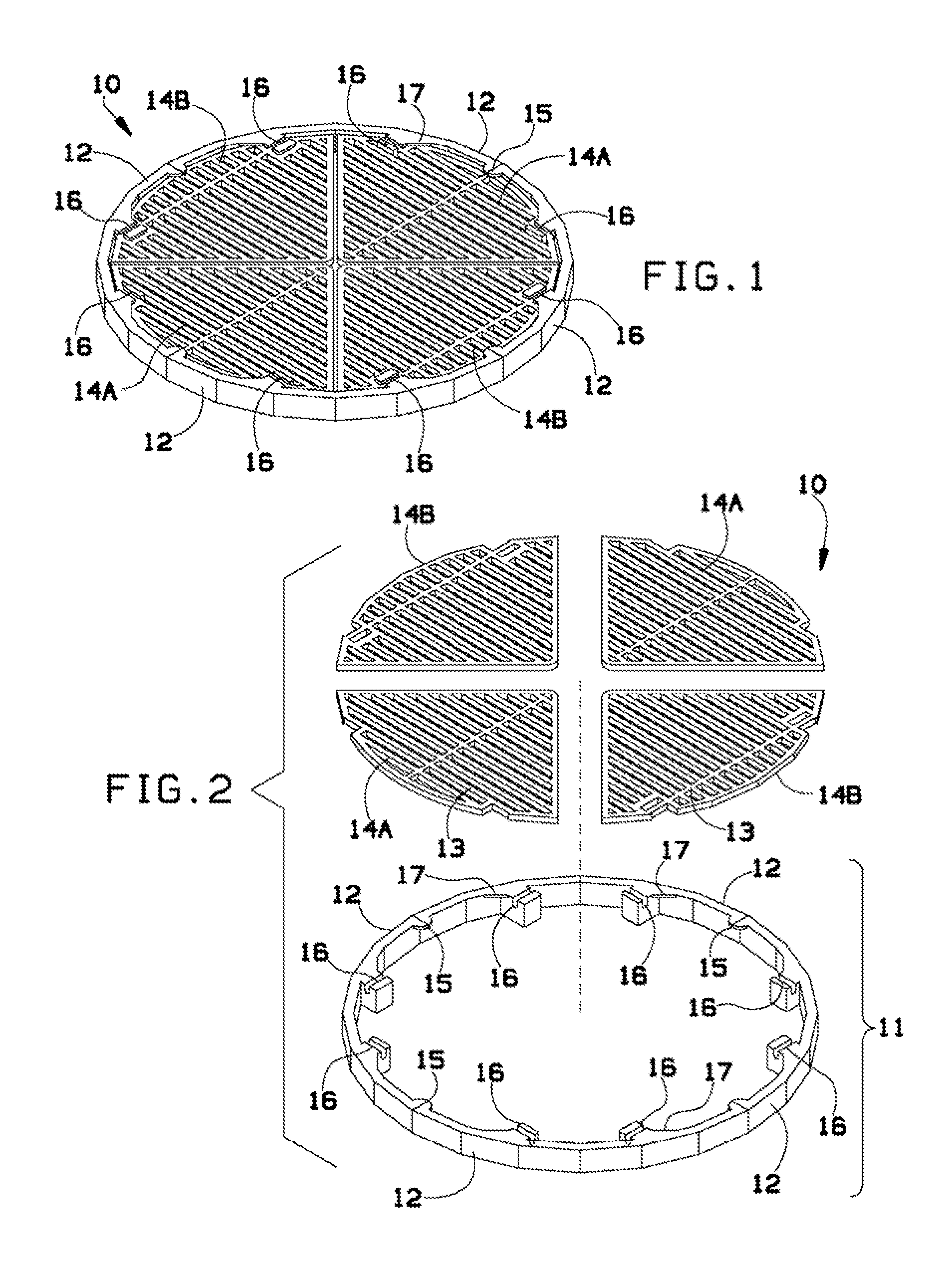

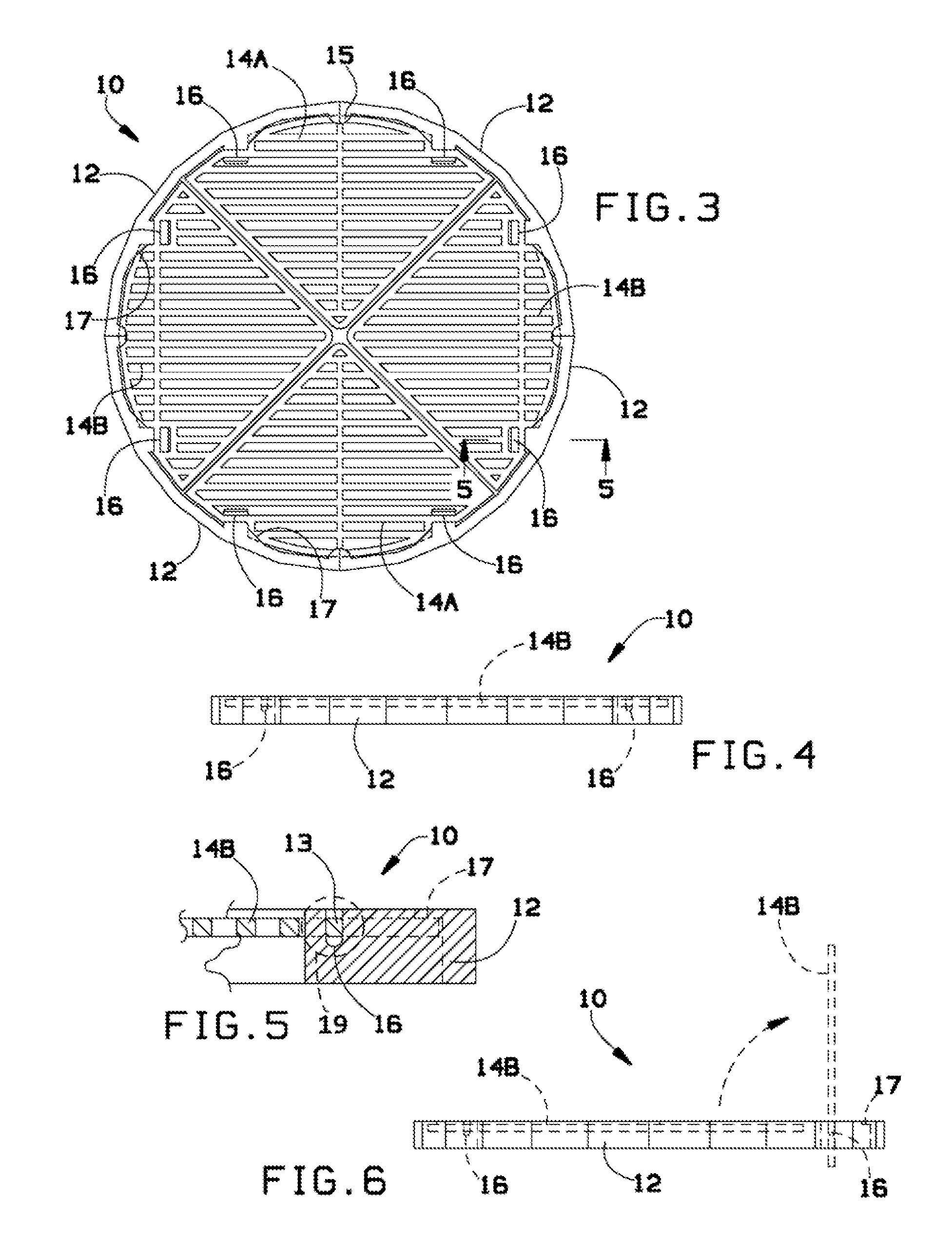

Modular-hinged grilling grate system

A modular-hinged grilling grate system may include a modular outer support structure and at least one attachable swivel grill grate section.

Owner:BURKLE ROLF

Grate for high temperature gasification systems

An improved active grate consisting of at least two elongated rockers positioned parallel to one and another, each rocker having a lower surface and an upper surface and configured to rotate back and forth about their longitudinal axis. Each individual rocker is further configured to rotate in the opposite direction of the adjacent rockers such that any pair of adjacent rockers alternately forms a void allowing material to pass through active grate when rotating in one direction into a first position, and closes the void when rotated in the opposite direction in a second position. The active grate finds particular utility in a combined gasification / vitrification waste treatment system, where it is used to pass partially oxidized materials from a gasification chamber to a vitrification chamber. The rockers include a coolant loop through the longitudinal axis of the rockers.

Owner:INENTEC

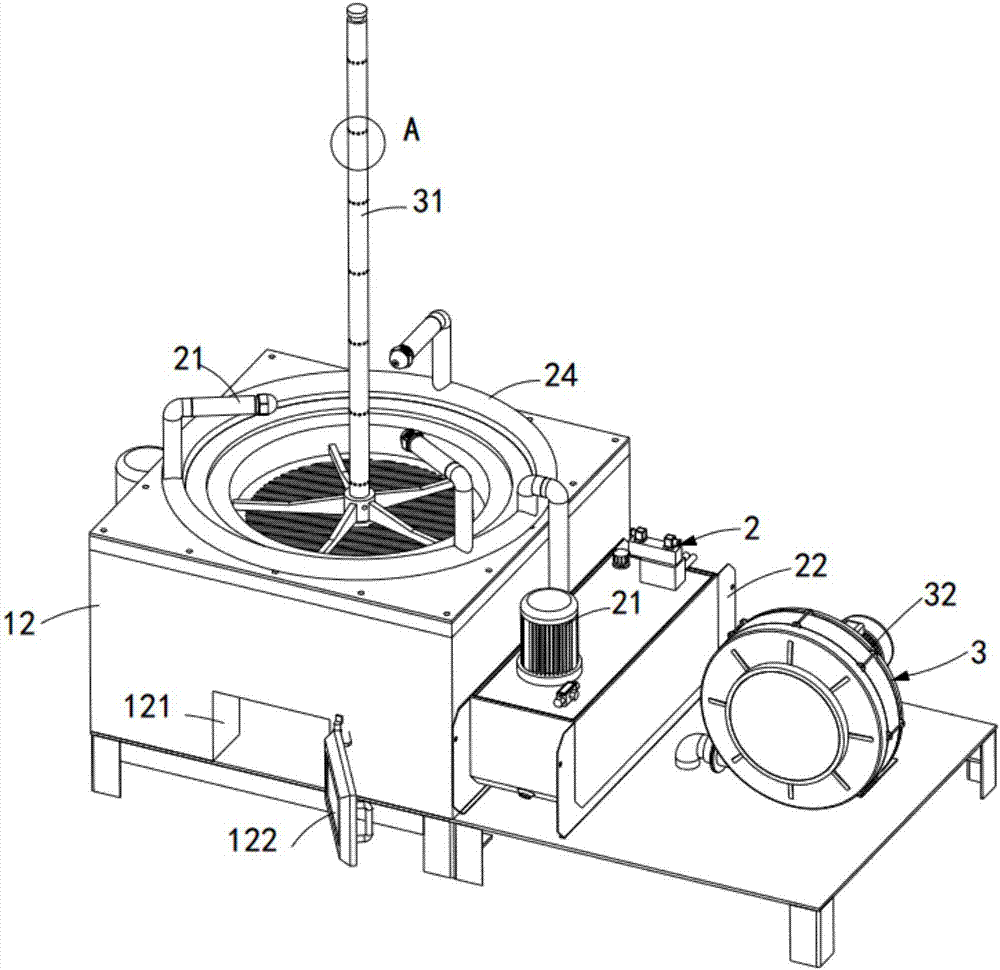

Novel rotary air-cooled grate system for biomass boiler

The invention discloses a novel rotary air-cooled grate system for a biomass boiler, which comprises a rotating shaft (1), a grate chassis (4), a chassis bracket (5), a grate (6), a primary air duct (7), an air duct bracket (8), a wind deflector (9), a belt pulley (10), a belt (11) and a motor (12). The novel rotary air-cooled grate system for the biomass boiler is characterized in that the rotating shaft (1) rotates to drive the grate (6) to rotate; and air enters the primary air duct (7) through the wind deflector (9) and is uniformly blown towards the grate (6), so that the fuel on the grate is combusted. The novel rotary air-cooled grate system for the biomass boiler has the advantages that firslty, a variable-speed gear can be manually adjusted, so that the grate is low and uniform in rotating speed, and the fuel is uniformly arranged on the grate and is fully combusted; secondly, the shaft and the bearing are cooled by the air, and the self-temperature is effectively reduced, so that the primary air temperature is raised, and the fuel is conveniently combusted; and thirdly, the air supply temperature is changed through the wind deflector, so that the primary air is uniformly blown to the grate; and therefore, the grate is cooled, and the phenomenon that the biomass ash drops on the bearing so as to damage the shaft and accessories is avoided.

Owner:JIANGSU YUANTONG AGRI MACHINERY TECH

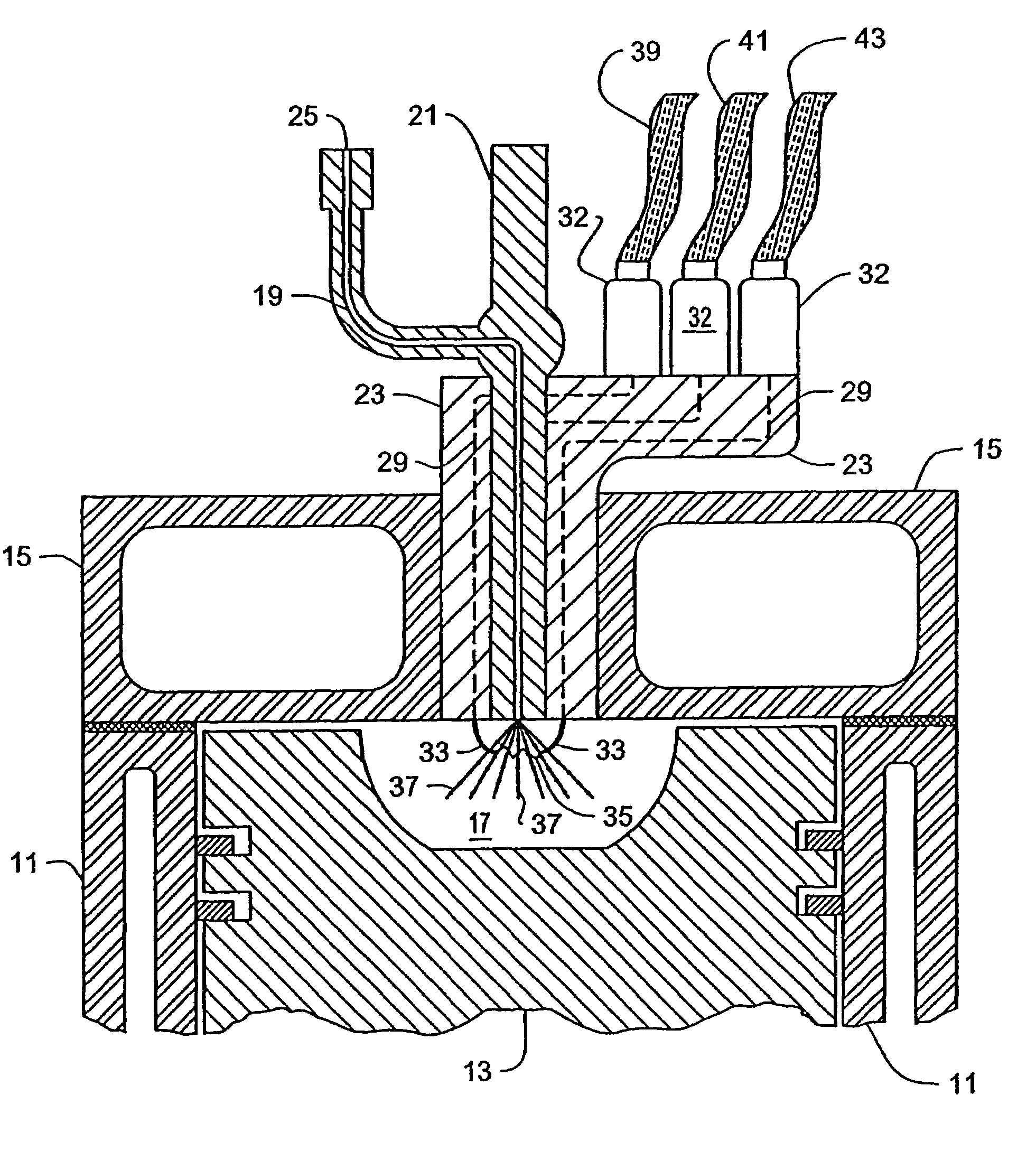

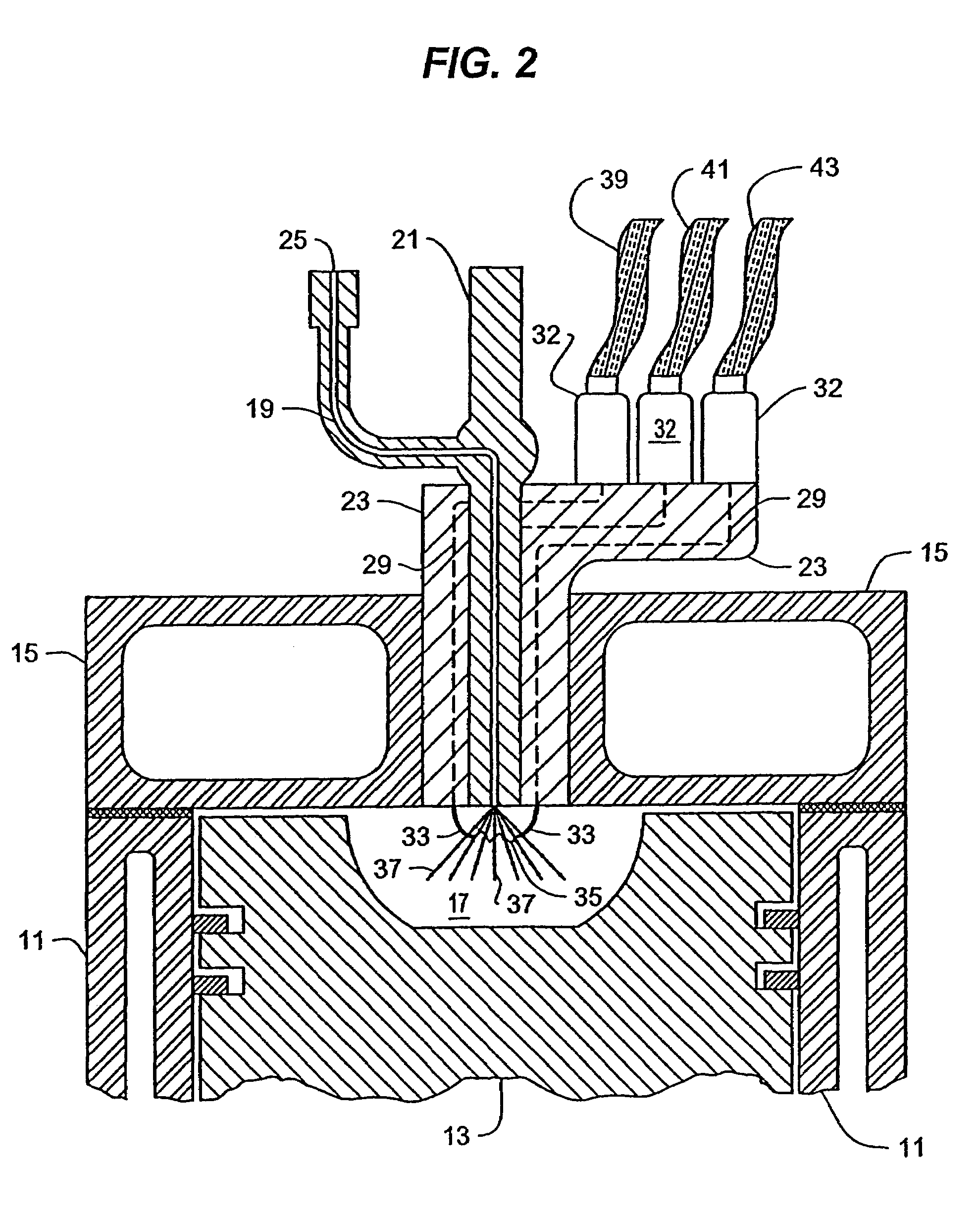

Furnace using plasma ignition system for hydrocarbon combustion

InactiveUS7435082B2Promote combustionImprove efficiencyBurnersInternal combustion piston enginesCombustorFuel efficiency

An apparatus and method for the creation, placement and control of an area of electrical ionization within an internal combustion engine combustion chamber or a fuel burner for a furnace is disclosed. A furnace includes a fuel source, a fuel burner, a plasma nozzle and igniter assembly, and the associated housing and flue structures. The plasma nozzle and igniter assembly is arranged so that the fuel sprayed out from the nozzle into the combustion area passes through or in close proximity to the area of plasma ionization. A fuel burner equipped with this electrical ionization device has its fuel efficiency enhanced by the complete and immediate combustion of substantially all of the fuel that passes through the area of plasma ionization. Exhaust gas recirculation using this system is also disclosed.

Owner:JAYNE MICHAEL E

Modular-hinged grilling grate system

A modular-hinged grilling grate system may include a modular outer support structure and at least one attachable swivel grill grate section.

Owner:BURKLE ROLF

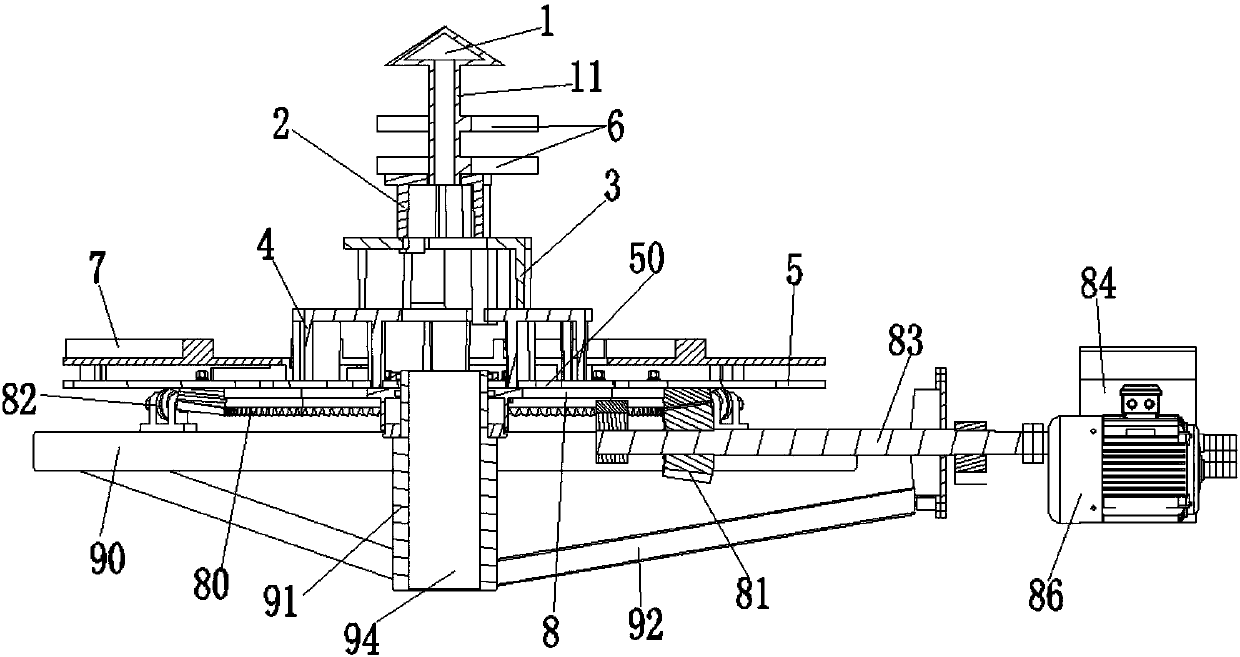

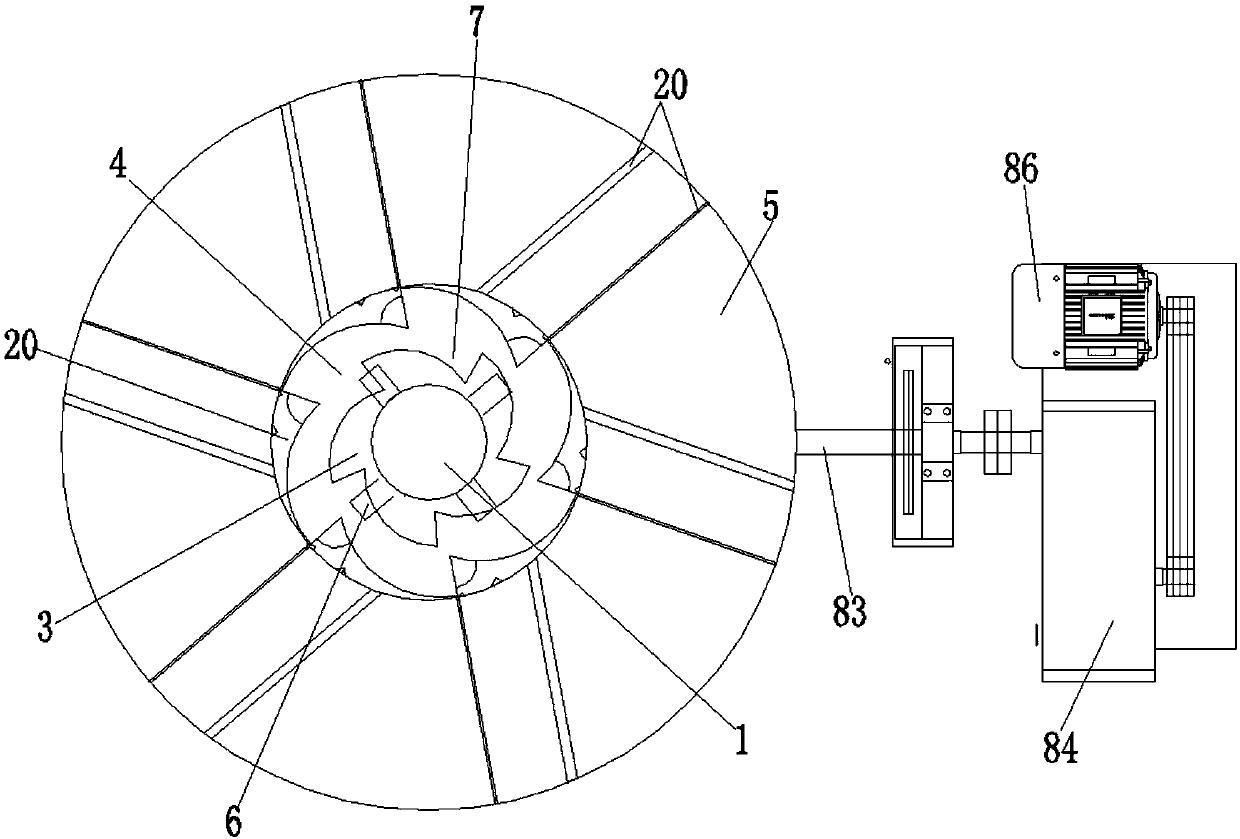

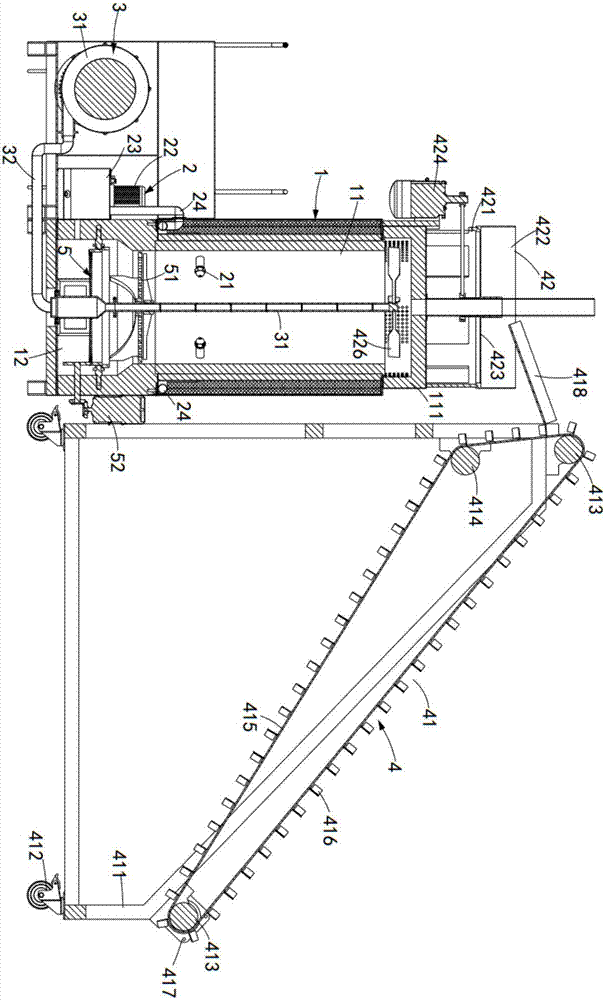

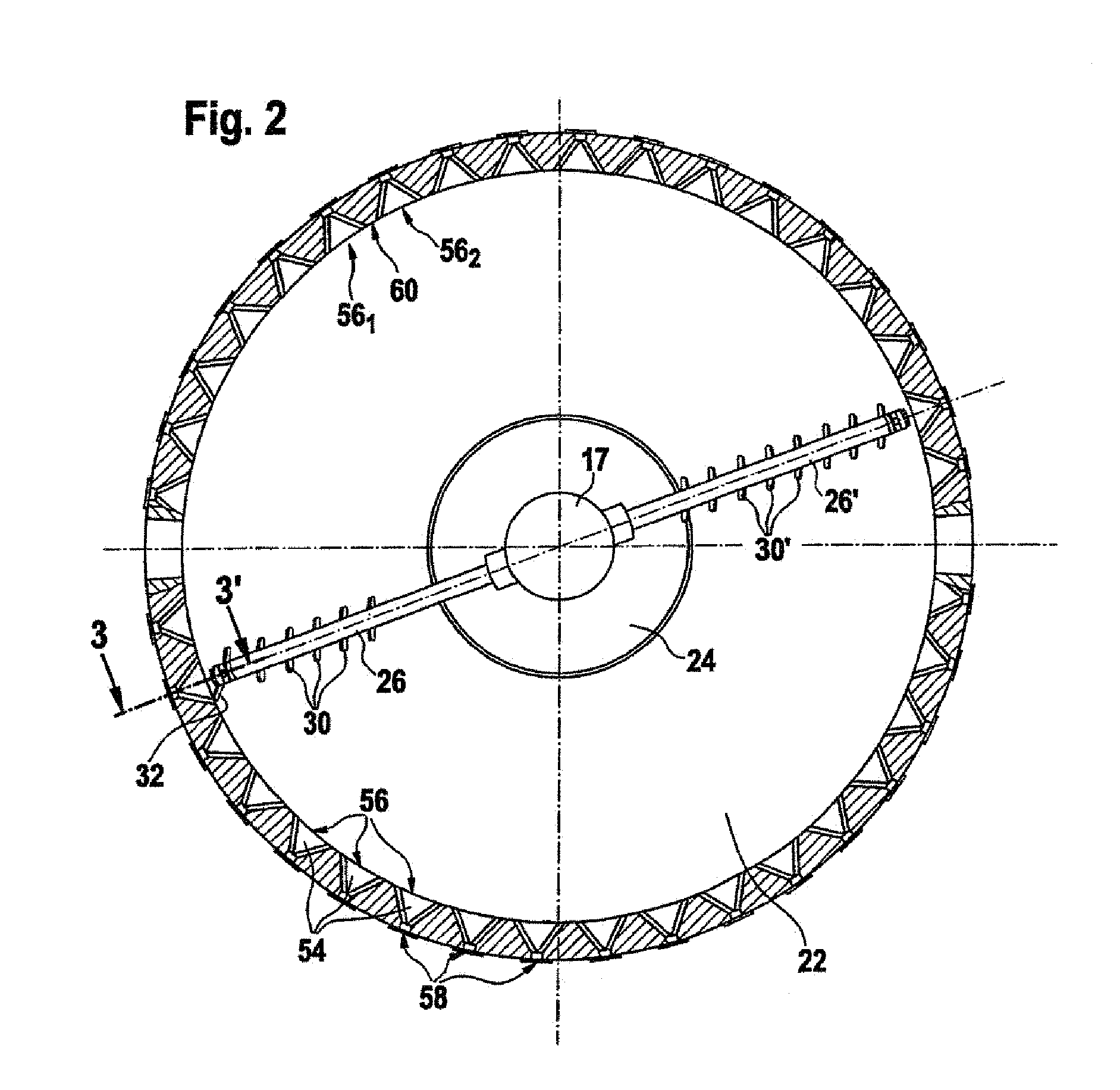

Rotary fire grate of vertical pyrolysis gasification furnace

PendingCN107893998AFull pyrolysis gasification incinerationRevolving grateRocking grateCombustionSlag

The invention discloses a rotary fire grate of a vertical pyrolysis gasification furnace. The rotary fire grate of the vertical pyrolysis gasification furnace comprises a cone cap, a small fire grate,a medium fire grate, a large fire grate and a fire grate plate connected in sequence from top to bottom, wherein the cone cap is axially provided with an integrally molded cone cap cylinder; at leasttwo layers of stirring shafts are arranged on the outer side of the cone cap cylinder; multiple scrapers are arranged on the upper surface of the fire grate plate in the peripheral direction; the fire grate plate is provided with a slag discharge hole; and a rotating plate is arranged on the lower surface of the fire grate plate, and is arranged on a fixed frame through a bearing. The rotary firegrate of the vertical pyrolysis gasification furnace further comprises a rotating mechanism for driving the rotating plate to rotate; the rotating mechanism comprises a gear row on the rotating plate, a gear, a support wheel and a transmission shaft; the gear row is driven to rotate by the gear on the transmission shaft to realize the process of a rotating mechanism easily driving the rotating plate to rotate; massive lagging hard matters of the rotary fire grate are repeatedly stirred, extruded and crushed; and combustion assisting air is fed from a gap between the slag discharge hole and the fire grate to fully mix with garbage materials so as to realize full pyrolysis, gasification and incineration of materials.

Owner:福建汇鑫环保科技股份有限公司

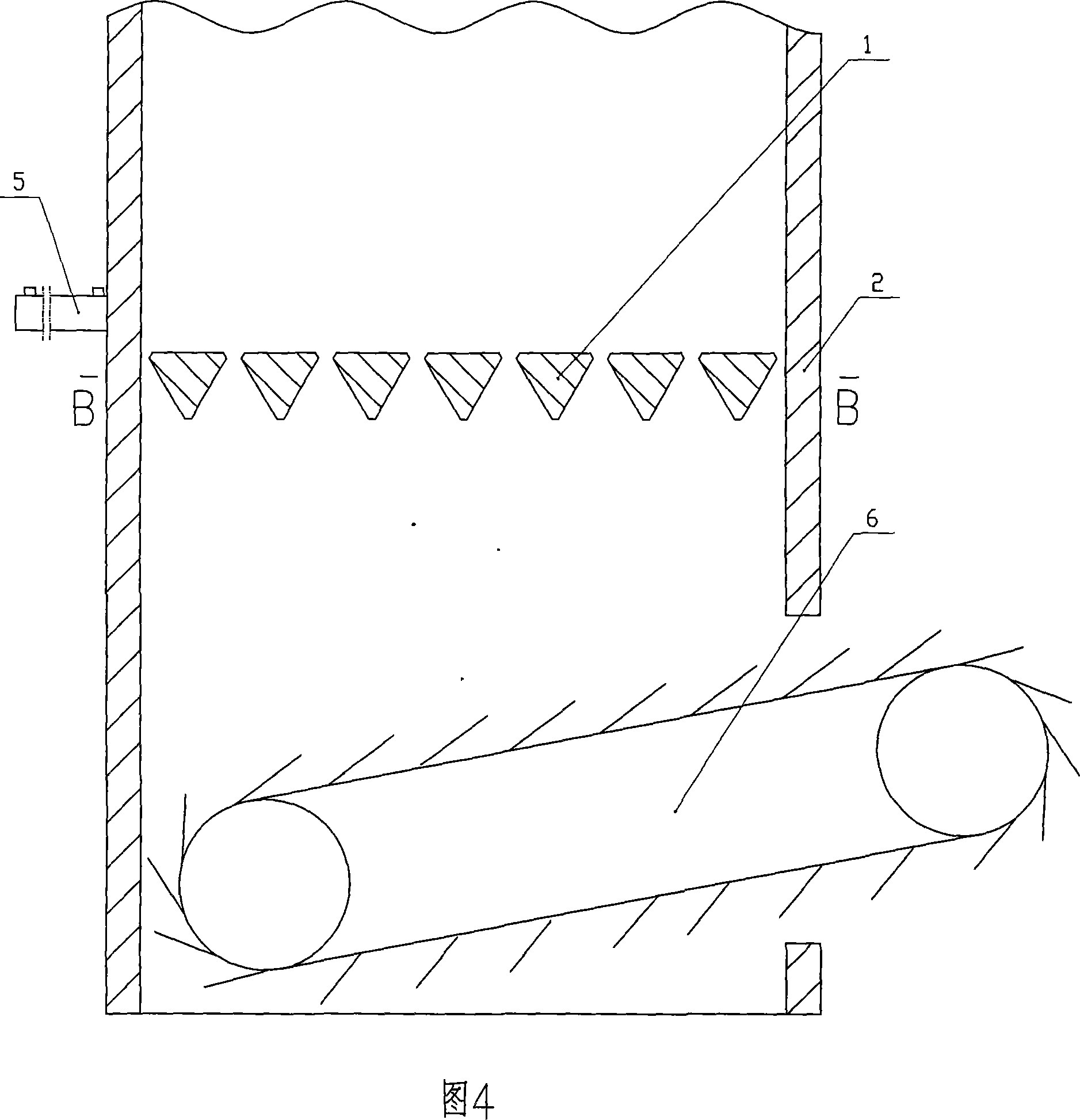

Oscillating type pushing mechanical grate

The invention discloses a rocking type direct pushing mechanical grate, which consists of three sections of grates having falling head with each other, including a drying grate, a combustion grate and a post-combustion grate, wherein each section of the grate is arranged into a downward sloping stepped type movable grate arrangement and a fixed grate arrangement through fire grate segments which are in a mutually-staggered form, and a movable support frame under each movable grate arrangement is fixedly connected with a hydraulic piston; and the combustion grate is provided with a cutting blender consisting of a plurality of sector cutting blades which are evenly arranged on a link mechanism and a driven shaft, and the tail of the combustion grate is provided with a turning type full combustion device consisting of an oil pressure piston, a driving shaft, a driving rod, the driven shaft, and a turning mechanism on the driven shaft. The rocking type direct pushing mechanical grate solves the problem that in the prior art rubbishes cannot be burnt completely, improves the combustion efficiency of the rubbishes in an incinerator, and has the advantages of adaptability to complex components of municipal wastes in China, simple structure, convenient maintenance and few malfunctions.

Owner:ANHUI SHENGYUN ENVIRONMENT PROTECTION GRP CO LTD

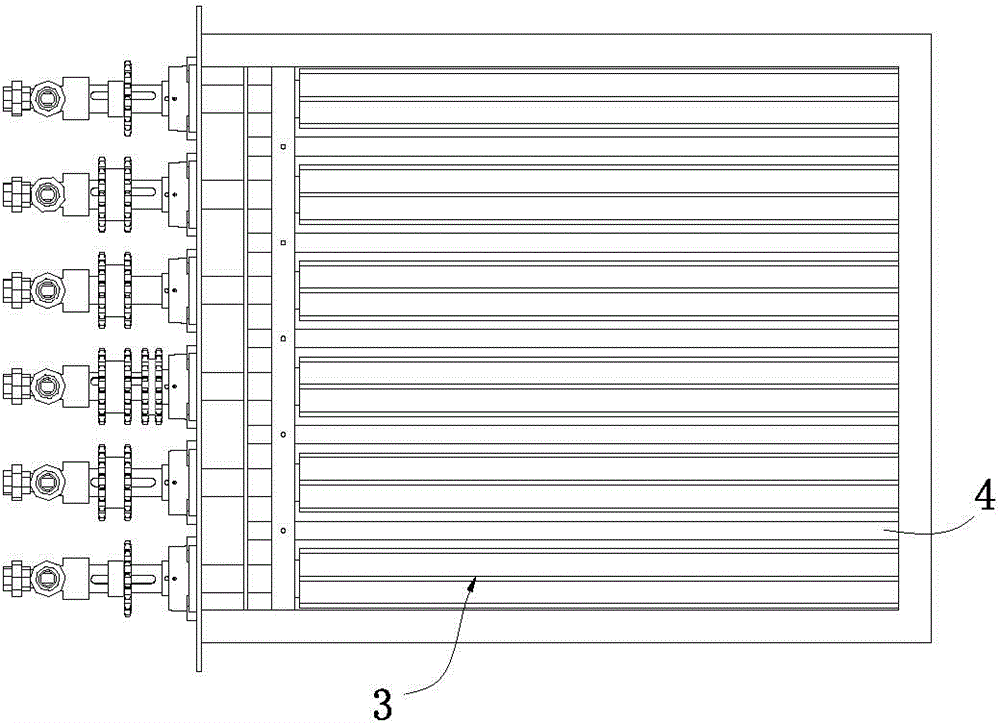

Rotary fire grate

PendingCN106705079ASmall form factorSave burning spaceRevolving grateRocking grateSpelunkingCombustion

The invention discloses a rotary fire grate. The rotary fire grate comprises installing bases, shaft plate sets A, shaft plate sets B and drive motors connected with the shaft plate sets A and the shaft plate sets B correspondingly. Tooth-shaped shaft plates of the shaft plate sets A and the shaft plate set B are distributed at intervals. The two ends of all the tooth-shaped shaft plates are connected to the corresponding installing bases in a pivoted mode. The tooth-shaped shaft plates are composed of rotary shafts and tooth-shaped plate bodies distributed in the axial directions of the corresponding rotary shafts symmetrically in an arrayed mode. A gear is fixed to the tooth-shaped shaft plate rotary shaft of each shaft plate set, and the tooth-shaped shaft plate rotary shaft of each shaft plate set is movably sleeved with a transition gear, wherein the gear is in engaged transmission with the transition gear. According to the rotary fire grate, stove ash and slag deposited after fuel combustion are timely cleared away, the single set of drive motors are used for repeatedly driving the tooth-shaped shaft plates to horizontally rotate around the corresponding shafts to form part of neutral positions, the phenomenon that integral fuel caving is caused and consequentially heat imbalance in a furnace is caused is avoided, and continuous operation of the combustion furnace is guaranteed through intermittent and intervallic rotation of the tooth-shaped shaft plates and timed instantaneous slag-discharging; and the space occupied by the fire grate is small during the static status or operating status of the fire grate, the overall appearance size of the combustion furance is compressed, and a combustion space in the combustion furnace is saved.

Owner:潘汉祥

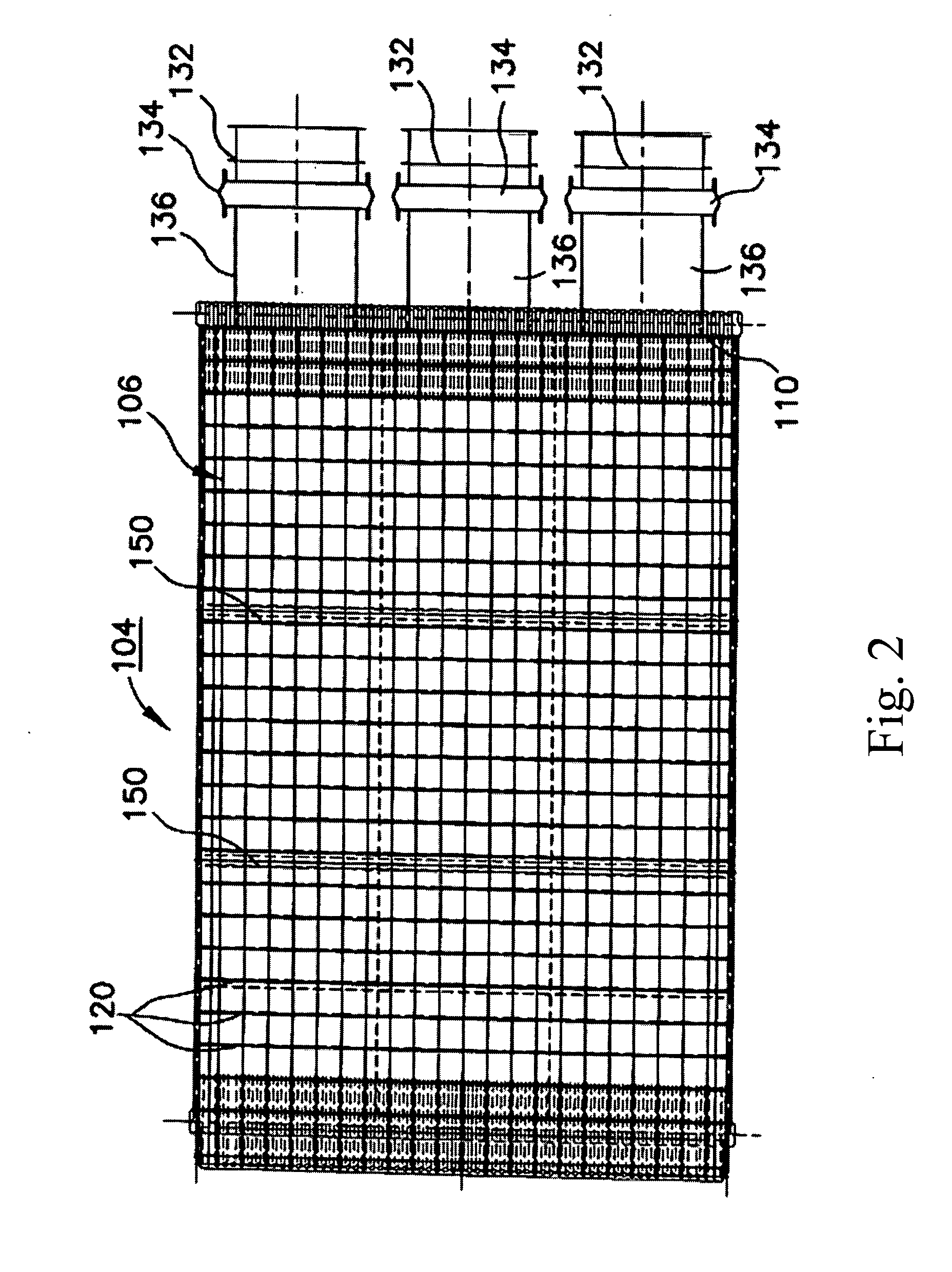

Grating system and sidewall seal arrangement for oscillating grate stoker

InactiveUS20080276843A1Obstruct passageGood vibration isolationSievingSolid bar grateGratingCombustion

The invention includes a grate system for a boiler. The grate system includes a grate unit and a side header guard. The grate unit supports fuel during combustion thereof, and has an upper surface, a lower surface, and upturned lateral edges. The side header guard is arranged along a side wall of the boiler and has upwardly and downwardly projecting fin portions. The upwardly projecting fin portion is adapted and configured to extend over and protect the boiler side wall from abrasion by fuel. The downwardly projecting fin portion is adapted and configured to extend over the upturned lateral edge of the grate unit, inhibiting passage of fuel therebetween.

Owner:RILEY STOKER

Compound combustion boiler

The invention provides a compound combustion boiler. By the boiler, fuel is fully combusted, pollution emission is avoided, and energy is saved and consumption is reduced in the using process; and the boiler is provided with at least one three-dimensional hearth and at least one directional combustion-supporting air-cooled revolving grate hearth, and is characterized in that: a slag discharging outlet of the boiler is provided with a directional combustion-supporting air-cooled revolving grate compound hearth with an assembly slag discharging plate or slag discharging teeth; a revolving grate is arranged at the bottom of the compound hearth; the outer end of the revolving grate is assembled with the slag discharging plate or slag discharging teeth; a flue gas return chamber is formed below the grate; a flue gas return fan is arranged outside the flue gas return chamber; a fan is arranged outside the compound hearth; and flue gas discharged by the boiler circularly enters the flue gas return chamber at the bottom of the directional combustion-supporting air-cooled revolving grate compound hearth through the flue gas return fan, and is mixed with air, subjected to secondary combustion by the boiler at high temperature, and discharged into the atmosphere through a flue gas discharging pipe, a flue gas discharging fan and a flue gas discharging chimney.

Owner:海宁市袁花镇工业投资有限公司

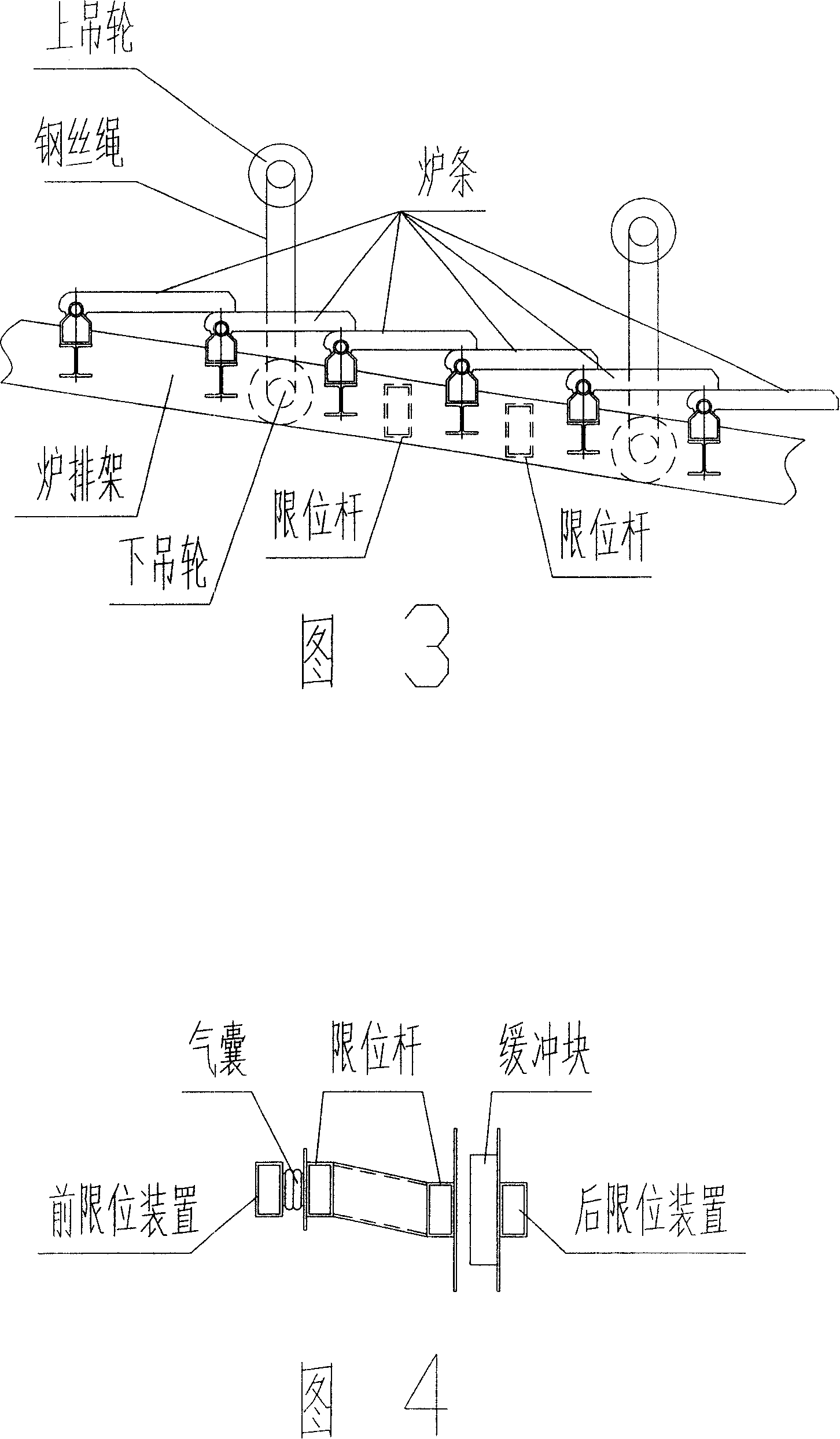

Vibrating high burn-out grate

InactiveCN101149152AReduce gapImprove combustion efficiencyRevolving grateTravelling grateCombustion chamberSlag

This invention is a vibrating high burnout grate. The fire bar is fixed at the grate surface. The grate is suspended on the furnace wall through steel wire and can move a little backwards. The air chamber in vibration device provides driving force for grate to move. The anterior end of grate is material feeding opening. The posterior end is slag-off opening. The superior end is combustion chamber. The inferior end is air chamber. This invention has high combustion efficiency and long life span.

Owner:刘沪滨

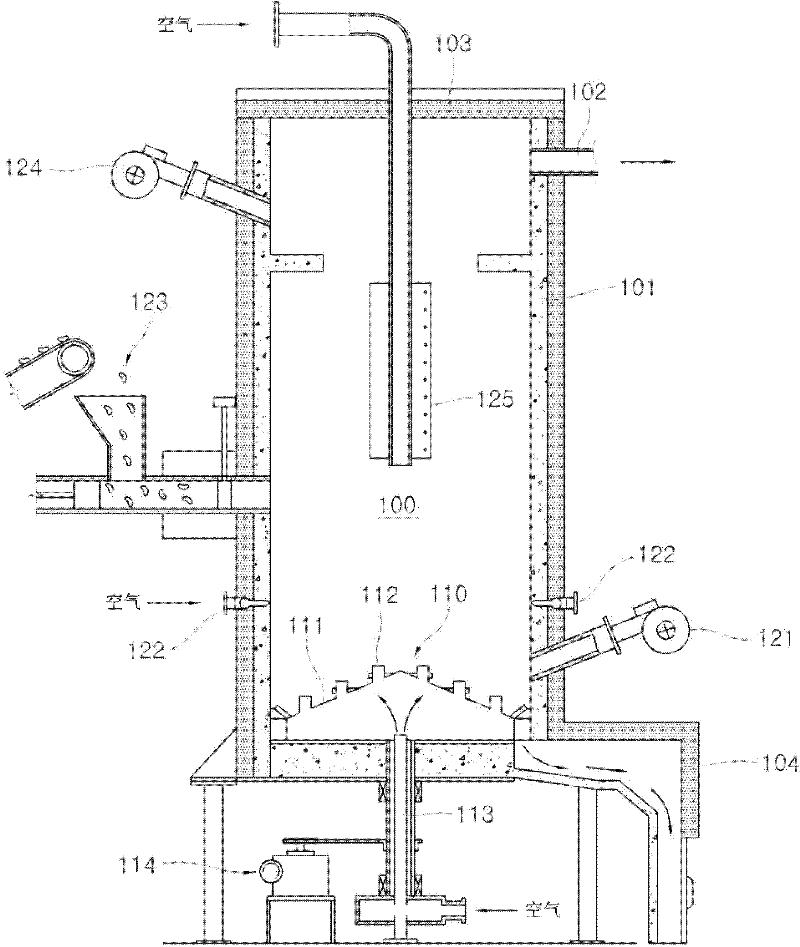

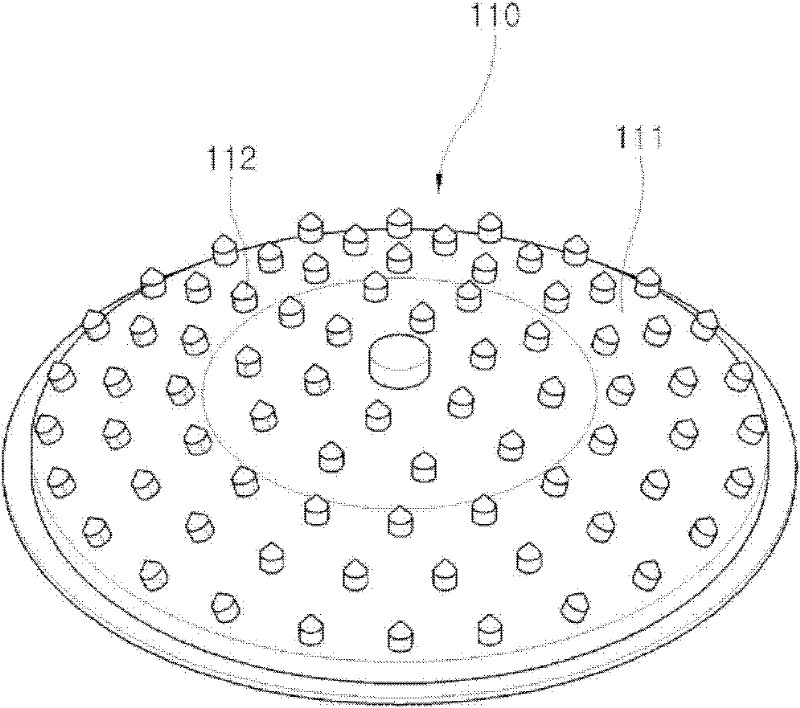

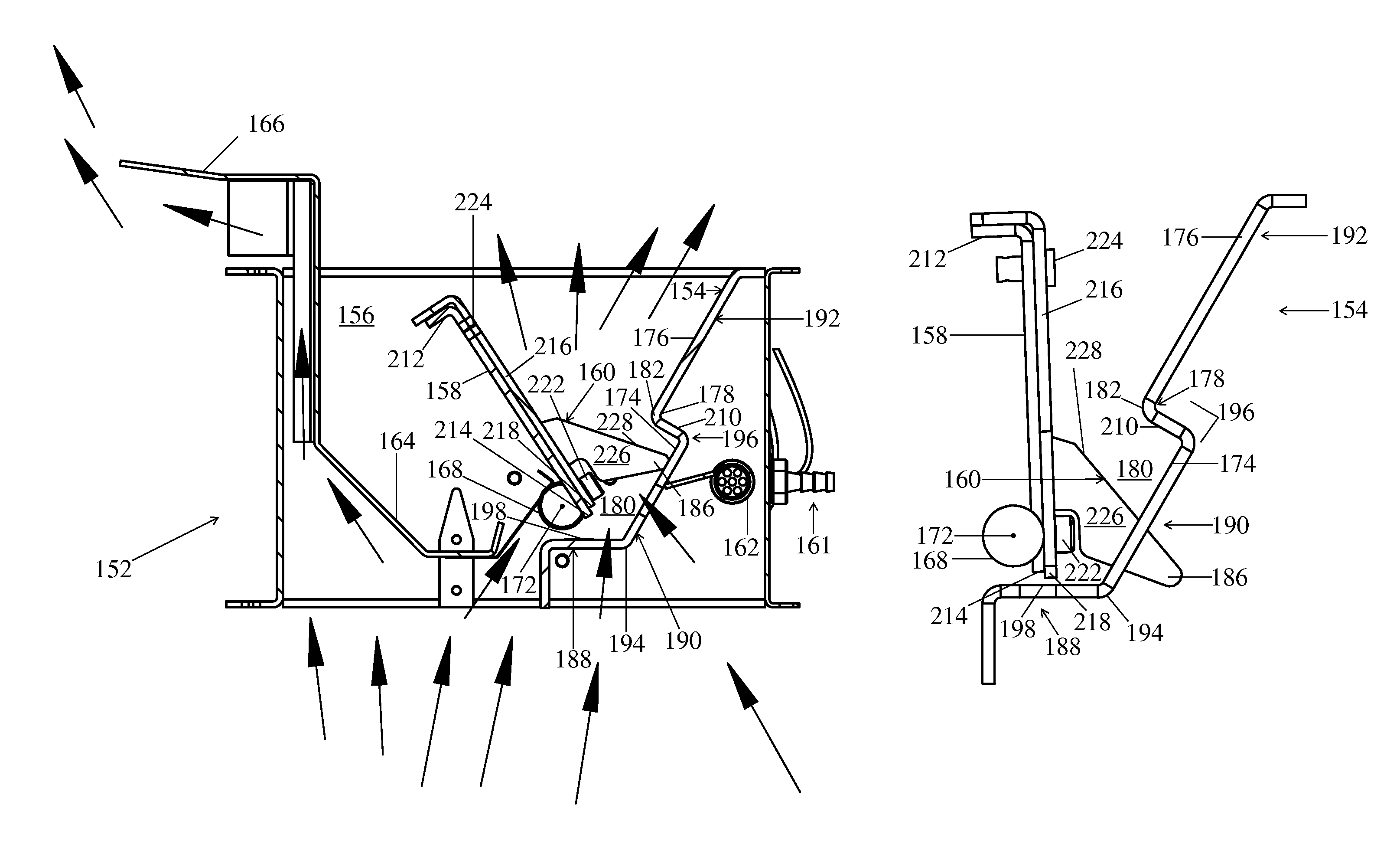

Heat recovery incinerator using combustible waste as fuel

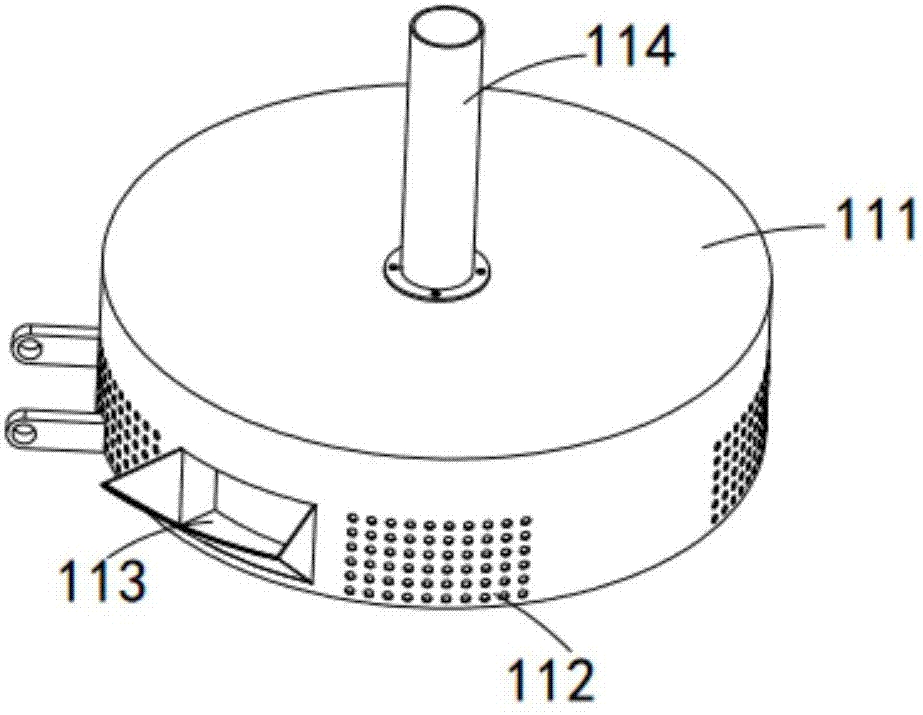

InactiveCN102292598AExtend your lifeAvoid corrosionRevolving grateRocking grateForeign matterCombustion chamber

Disclosed is a heat recovery incinerator using combustible waste as fuel. The heat recovery incinerator can protect the combustion plate and the second oxygen supply pipe installed in the combustion chamber so that they will not be damaged by the high temperature of the combustion chamber and the combustion exhaust gas. Thermal deformation and corrosion occur, thereby prolonging the life, and preventing the problem of reducing the performance of the internal structure due to the adhesion of foreign matter on the inner wall surface of the combustion chamber; and, performing complete combustion on the combustion exhaust gas generated during fuel combustion to make the exhaust gas The harmful substances contained are minimized, so that air pollution can be prevented. The heat recovery incinerator using combustible waste as fuel according to the present invention comprises: a combustion chamber surrounded by a wall made of a refractory and heat-resistant material layer; a combustion plate rotatably arranged on the side of the combustion chamber The lower part is for placing fuel for combustion. The above-mentioned combustion plate includes: a conical turntable made of alloy steel, a plurality of nozzles protruding from the upper surface of the turntable, and the plurality of nozzles inject combustion air in a certain direction; a rotating shaft is connected to the central lower part of the turntable, The turntable is supported in a rotatable manner; the air manifold is arranged at the lower part of the turntable to supply combustion air to the interior of the turntable; the heat-resistant and fire-resistant cover member covers the upper surface of the turntable to the protruding height of the nozzle to avoid Avoid protruding the nozzles to the side of the combustion chamber while exposing the upper surface of the turntable.

Owner:李钟弼

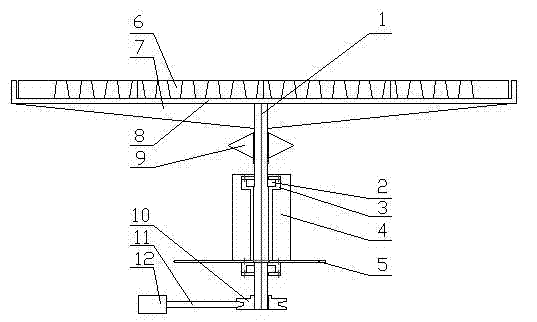

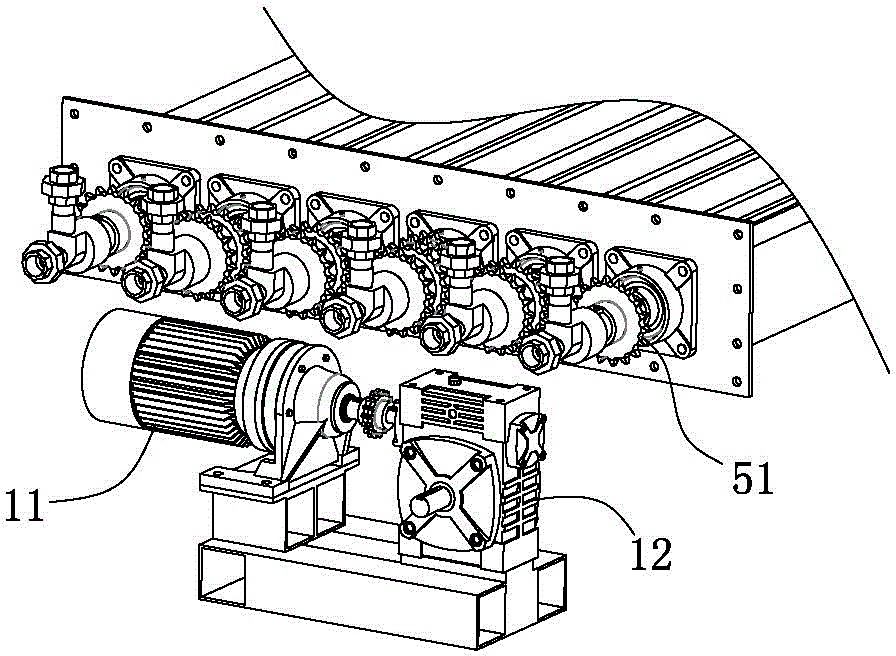

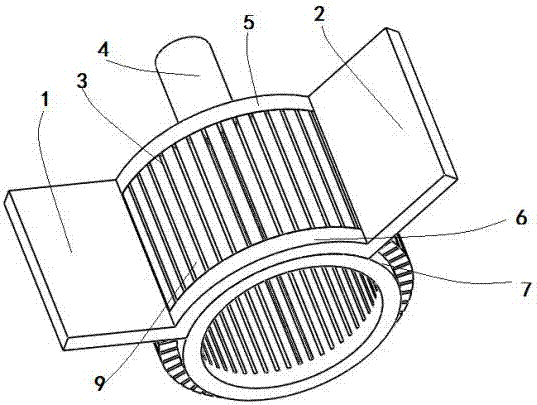

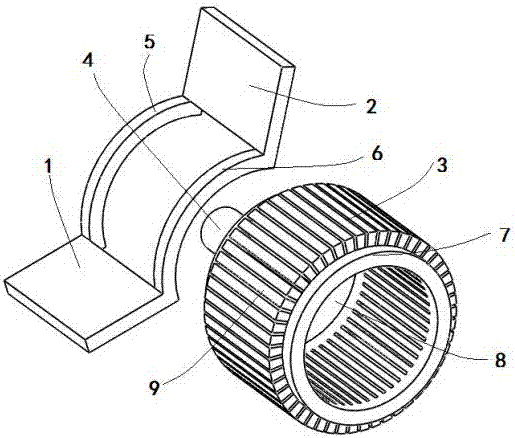

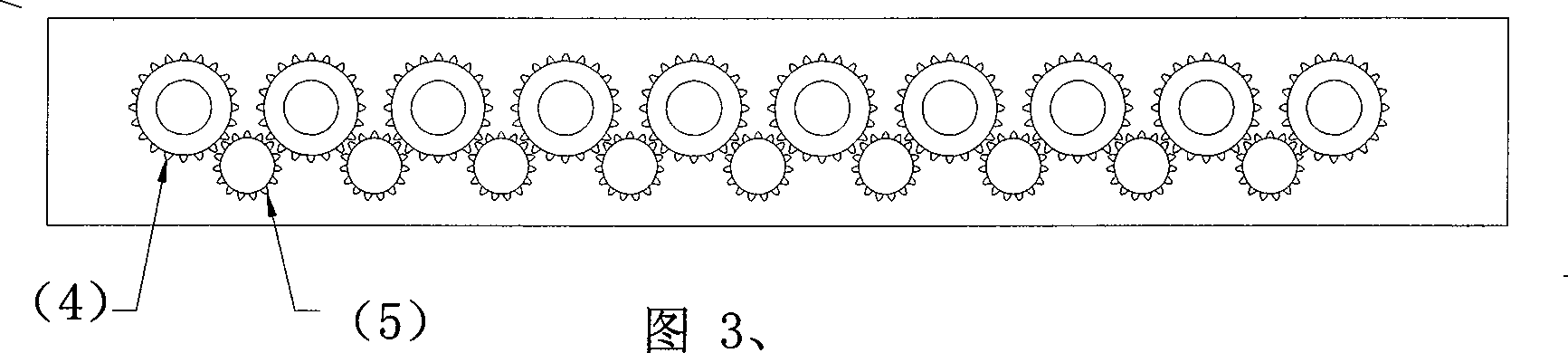

Rotary type water-cooled fire grate

InactiveCN103953935ABurn fullyWon't burn outRevolving grateRocking grateElectric machineThrough transmission

The invention discloses a rotary type water-cooled fire grate, which comprises a drive device, an installation frame, a plurality of large rotary discharge pipes and small fixed tier poles, wherein the large rotary discharge pipes are arranged on the installation frame in parallel at intervals; one small fixed tier pole is arranged between each two adjacent large rotary discharge pipes; the drive device is connected with all the large rotary discharge pipes through transmission components. The rotary type water-cooled fire grate is ingenious and reasonable in structural design; the large rotary discharge pipes are arranged in parallel at intervals, and one small fixed tier pole capable of forming a certain barrier is arranged between each two adjacent large rotary discharge pipes, so that air leakage can be prevented, fuel can be fully combusted, meanwhile, wind energy can be utilized maximally, the large rotary discharge pipes are linked synchronously, the deslagging effect is good, and the application range is wide; in addition, water cooling is adopted for protection, the service life is long, and the rotary speed and the working time of a motor can be controlled through a controller, so that the rotary type water-cooled fire grate can meet the work requirements under different conditions, is simple, easy and convenient to operate, is high in degree of automation, and is beneficial to be popularized and applied widely.

Owner:佛山市凯沃森环保科技有限公司

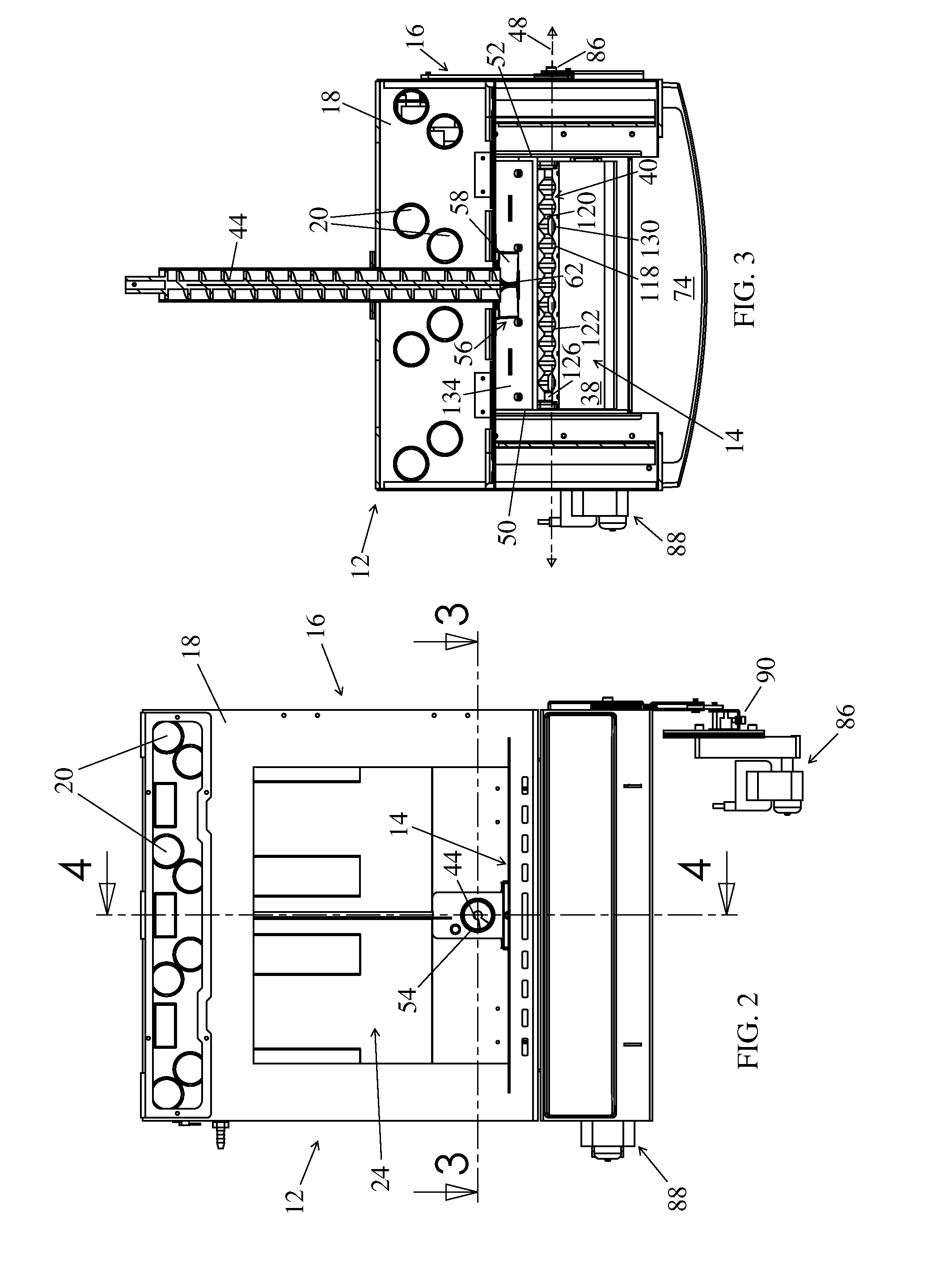

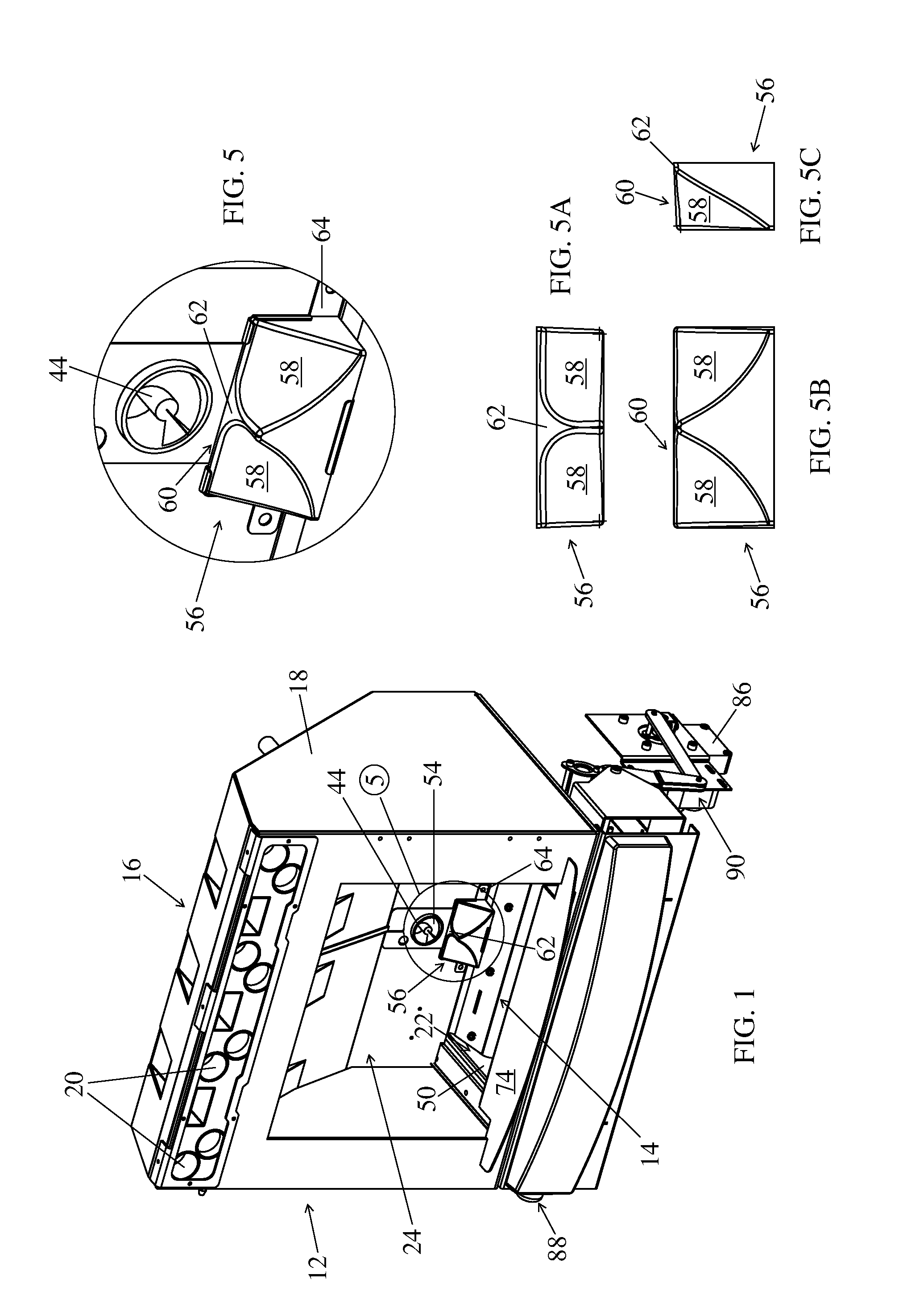

Apparatus for combustion of biofuels

InactiveUS8210110B2Avoid excess smokingReadily and efficiently converts pelletized, minimally processedSolid bar grateRevolving grateCombustionBiofuel

An apparatus for combustion of biomass is provided. The apparatus generally includes opposingly paired sidewalls, a fixed panel traversing the opposingly paired sidewalls, an actuatable panel opposite the fixed panel, and a fuel platform supported by a panel of either of the panels. A portion of the fuel platform is reversibly receivable through a portion of a panel opposite the panel supporting the fuel platform in furtherance of fuel conditioning upon actuation of the actuatable panel.

Owner:HESTIA HEATING PRODS

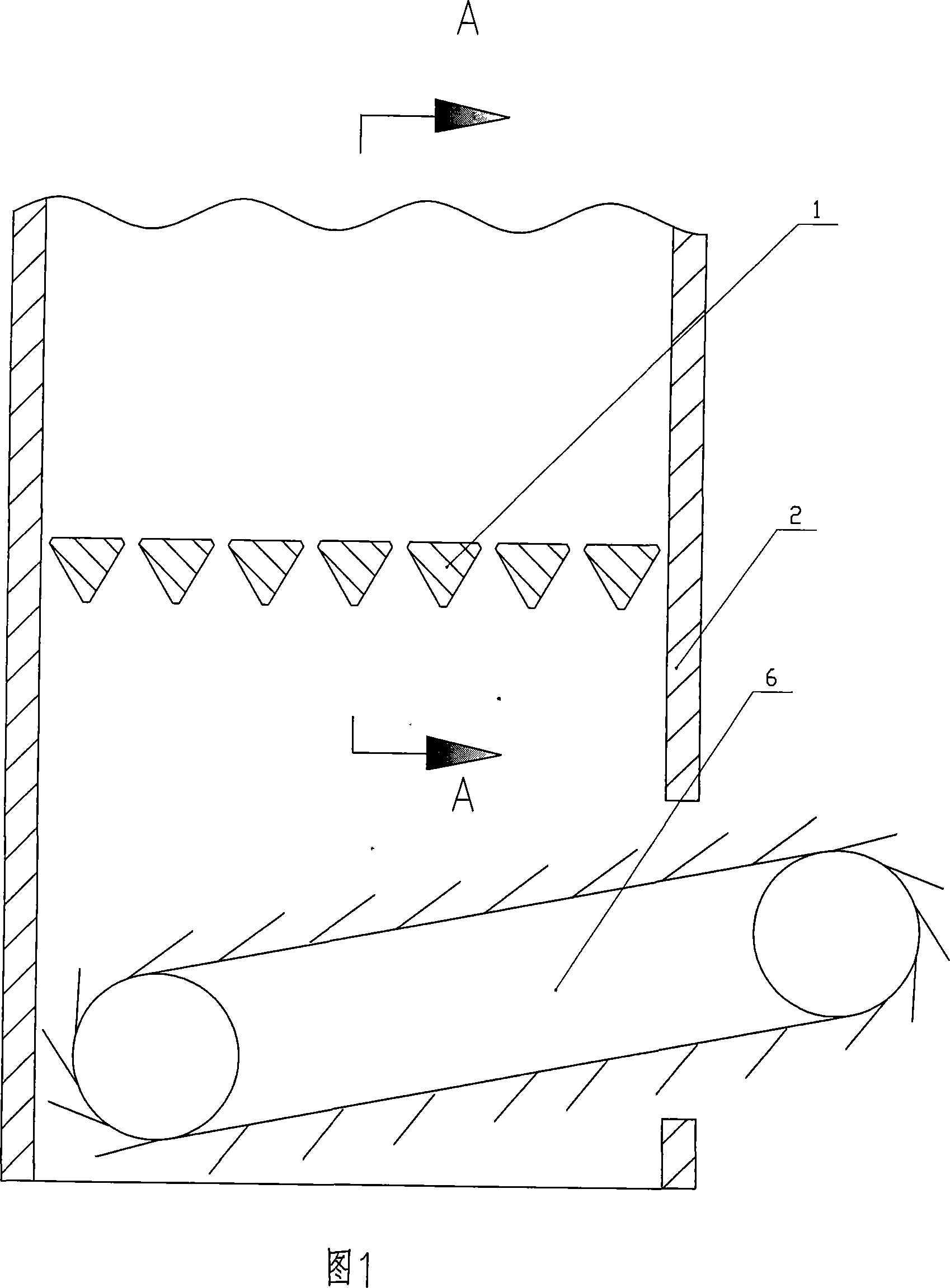

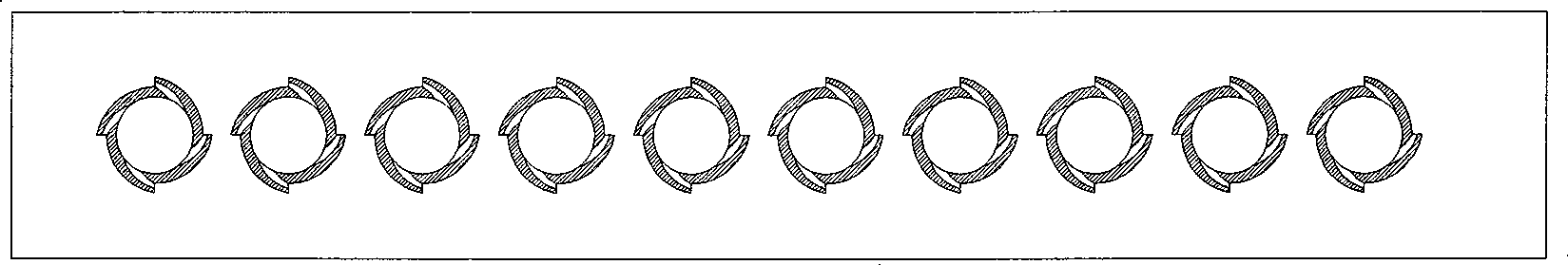

Triangle roll-over type moving grate

InactiveCN101144621ASimple structureLess prone to failureRevolving grateRocking grateEdge surfaceEngineering

The invention relates to the turn over type fire grate technology field, in particular to a triangular turn over type moving fire grate, and has a plurality of parallelly arranged fire bars. The main bodies of the fire bars are triangular prisms, chamfering or rounding is at the edge angles of the main bodies of the fire bars, axle heads concentric with the fire bars are at the two ends of the fire bars, the fire bars are rotatively connected with a furnace body through the axle heads at the two ends, axle heads at one ends of the fire bars stretch out of the furnace body, rotating plates are fixedly installed at the ends of the axle heads outside the furnace body, a rotating plate driving mechanism driving the intermittent rotation of the rotating plates is also arranged outside the furnace body, and when the rotating plate driving mechanism is in the non-working state, each fire bar has an edge surface being parallel to the connecting line of the axle center of each fire bar. The invention solves the technical problems that the existing moving fire grate structure can not enable the fuel to be fully burned, the moving fire grate is easy to fail, and the service quantity is large, etc., the invention has simple structure, and can realize automatic deslagging under the condition of not shutting down the furnace, not stopping the fire, and not opening the furnace door, the fuel is fully burned, the failure is uneasy to happen, as well as the maintenance is convenient.

Owner:江苏福昌环保科技集团有限公司

Apparatus for combustion of biofuels

InactiveUS20090272302A1Avoid excess smokingEnsure complete combustionRevolving grateSolid fuel combustionCombustionBiofuel

An apparatus for combustion of biomass is provided. The apparatus generally includes opposingly paired sidewalls, a fixed panel traversing the opposingly paired sidewalls, an actuatable panel opposite the fixed panel, and a fuel platform supported by a panel of either of the panels. A portion of the fuel platform is reversibly receivable through a portion of a panel opposite the panel supporting the fuel platform in furtherance of fuel conditioning upon actuation of the actuatable panel.

Owner:HESTIA HEATING PRODS

Automatic feeding and ash removing incinerator

InactiveCN107448951ASolve the problem of polluted airResolve Insufficient CombustionRevolving grateRocking grateLitterEnvironmental engineering

The invention provides an automatic feeding and ash cleaning incinerator, aiming to solve the technical problems of environmental pollution caused by smoke and dust entering the air with hot air and incomplete combustion of garbage in the furnace body during the process of incinerating garbage in the incinerator, including the furnace body, oil injection Mechanism, air injection mechanism, automatic feeding mechanism and automatic ash cleaning mechanism, by using the flame air curtain formed by the combustion of gas and fuel oil in the air injection pipe to block the ashes and dust after incineration of garbage, so that the ashes and dust are deposited downward on the The bottom of the furnace body, and through the relative movement between the rotating grate and the fork to move the garbage, so that the garbage can be burned more fully, and at the same time, the ashes can be deposited into the ash storage area smoothly, and the waste incineration process can be achieved. Burn fully.

Owner:CHANGXING CAZENOVE FUNANCE IND CO LTD

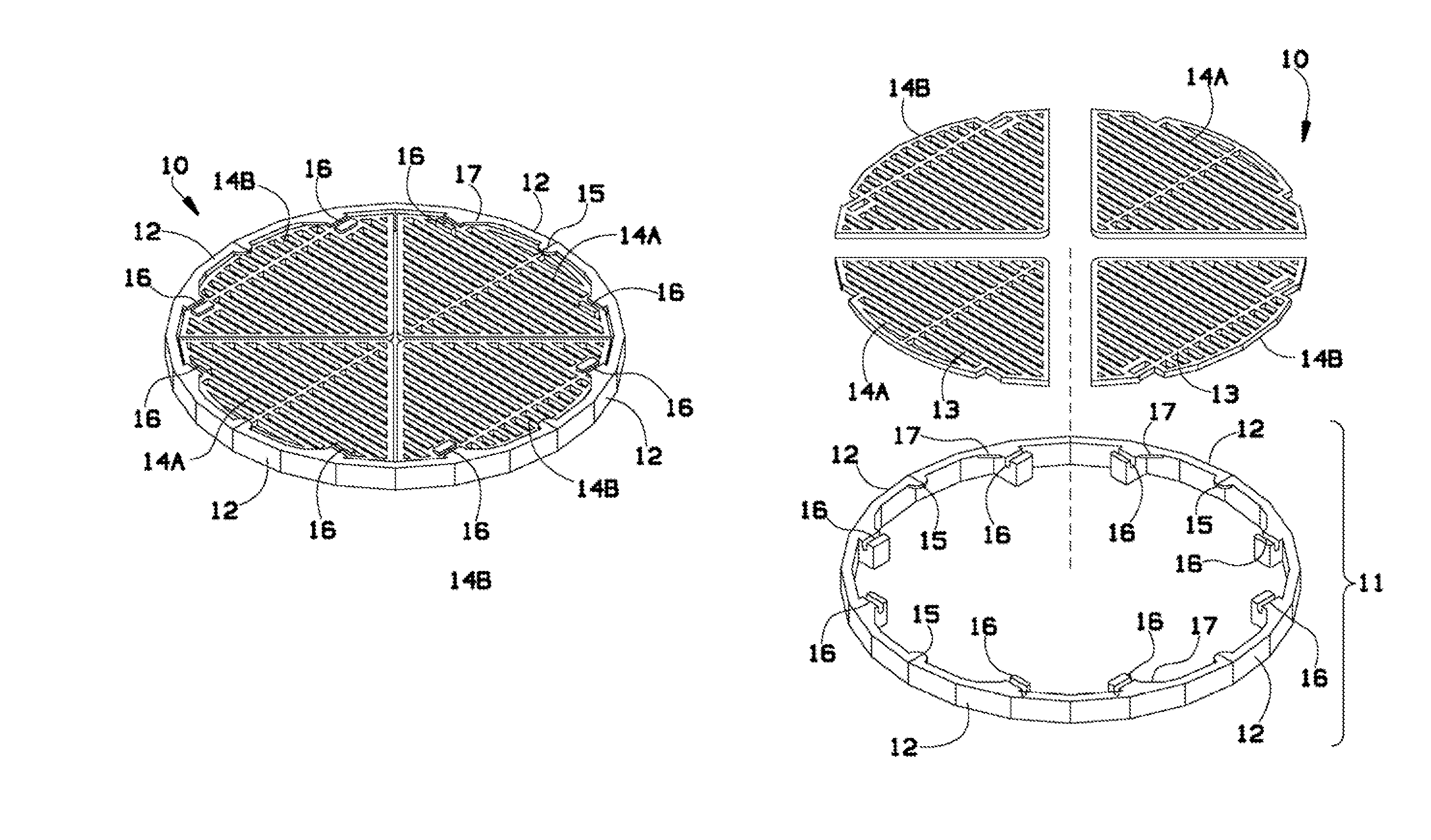

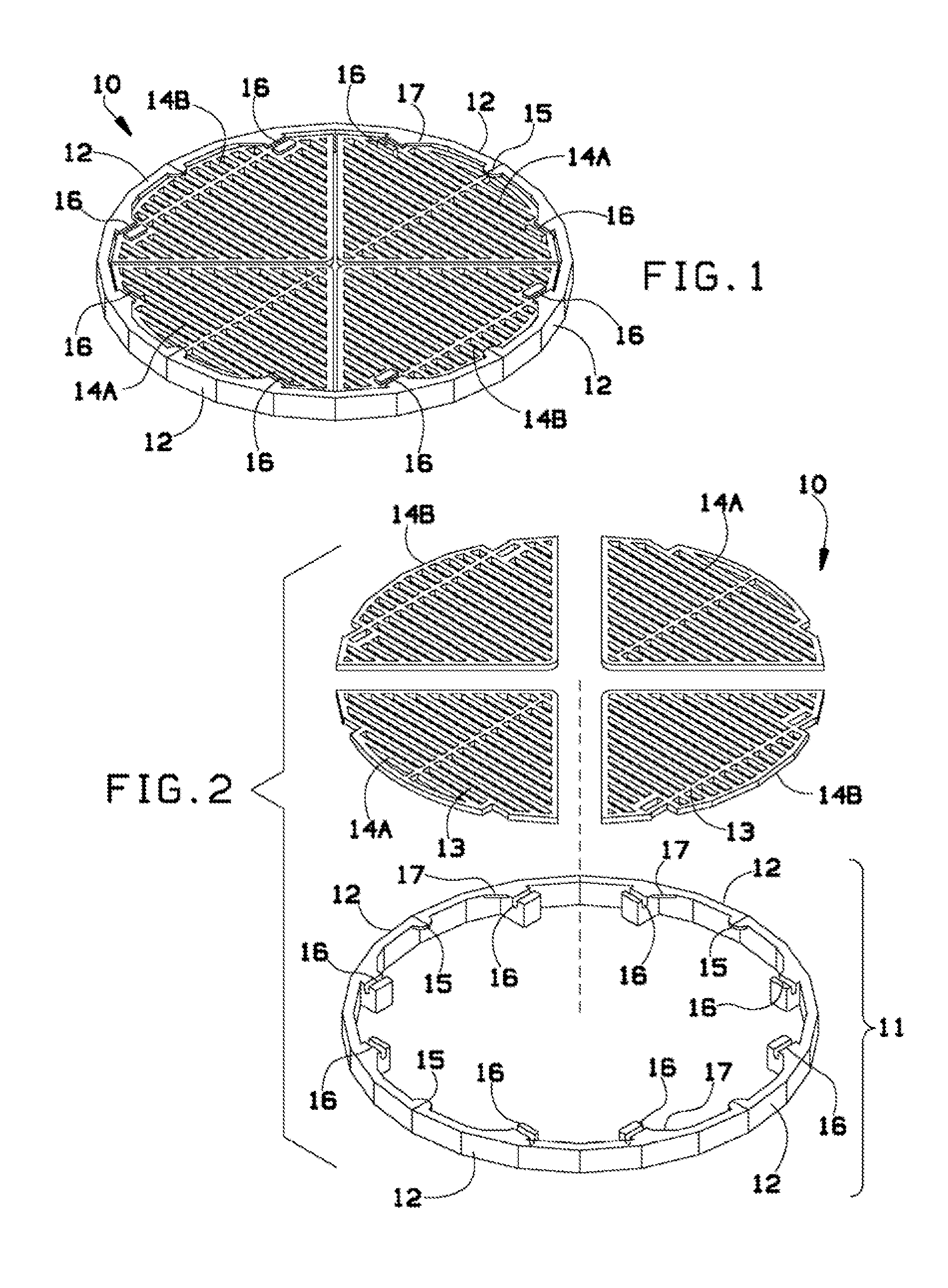

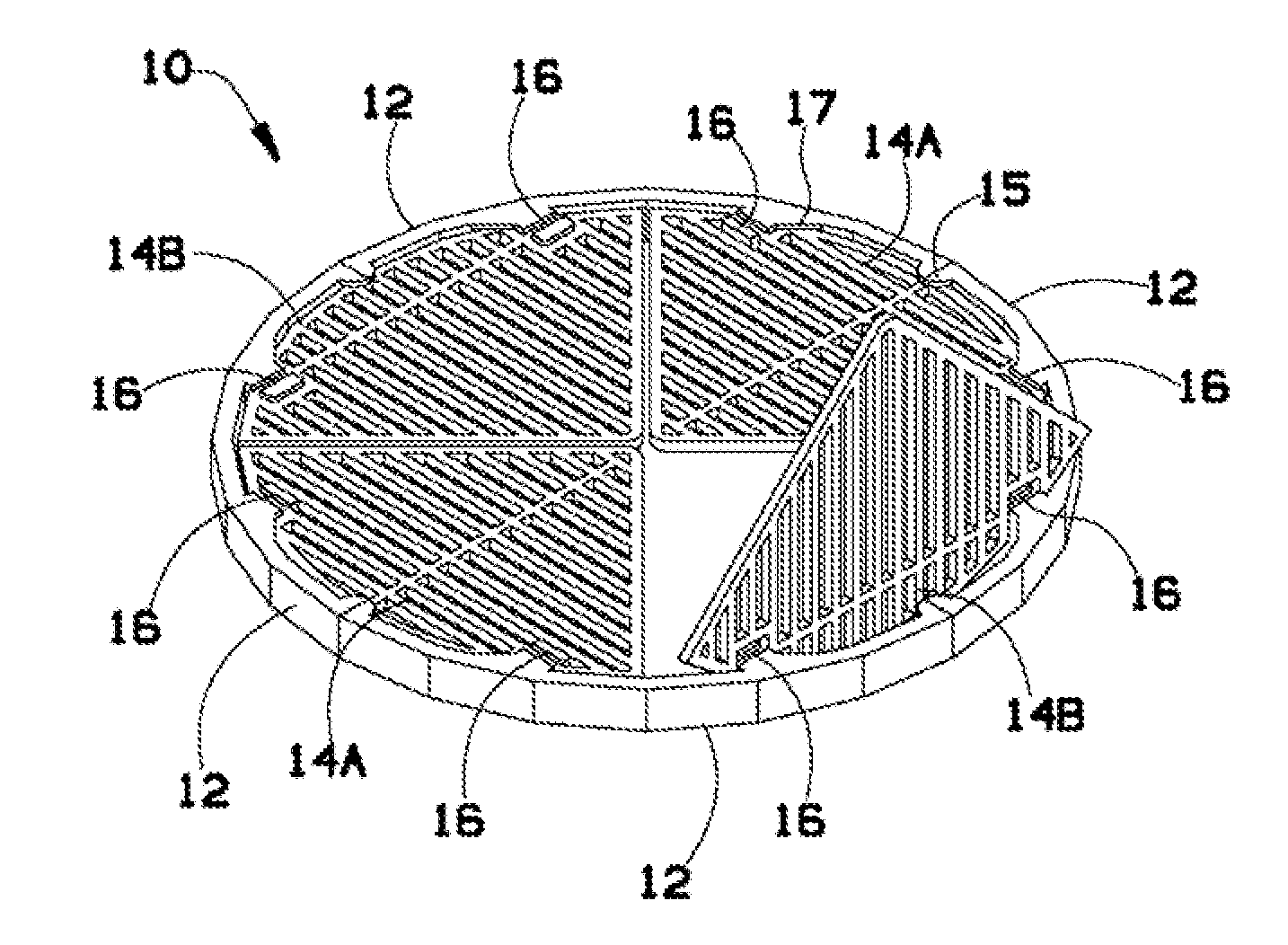

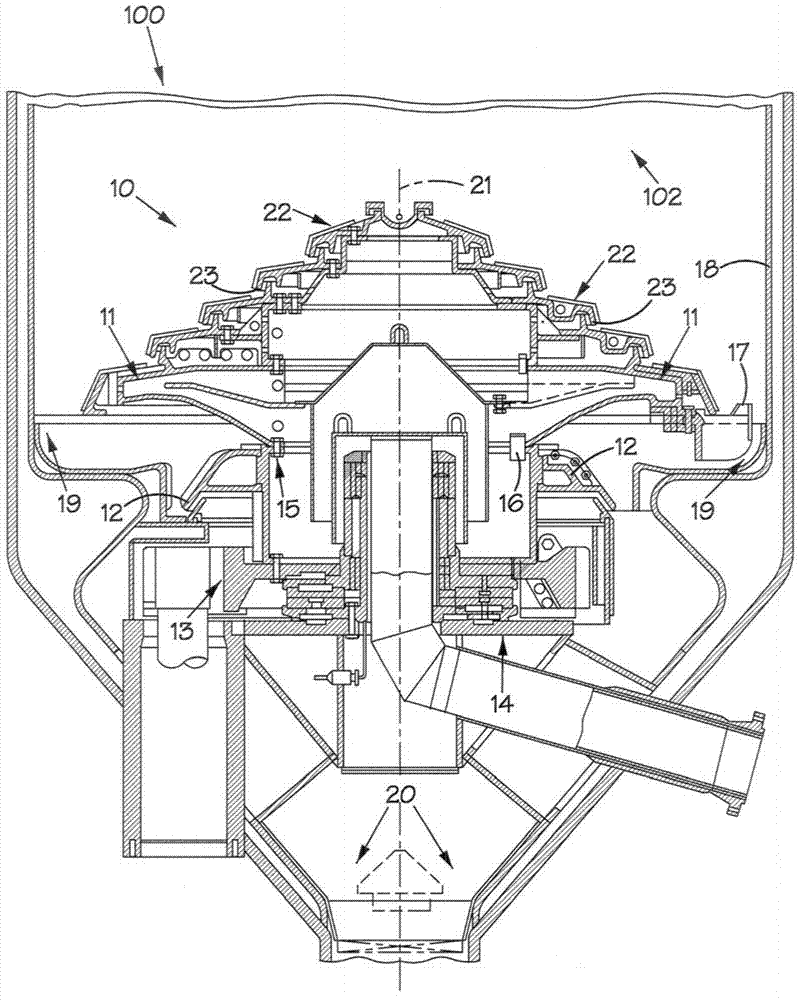

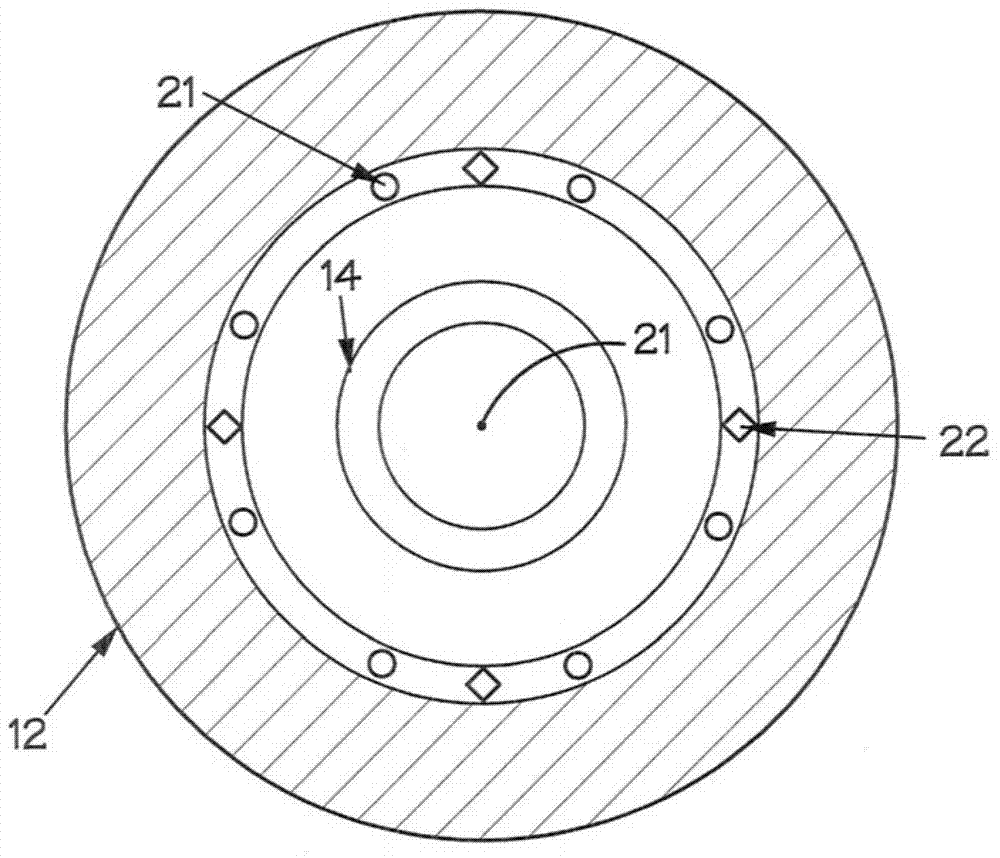

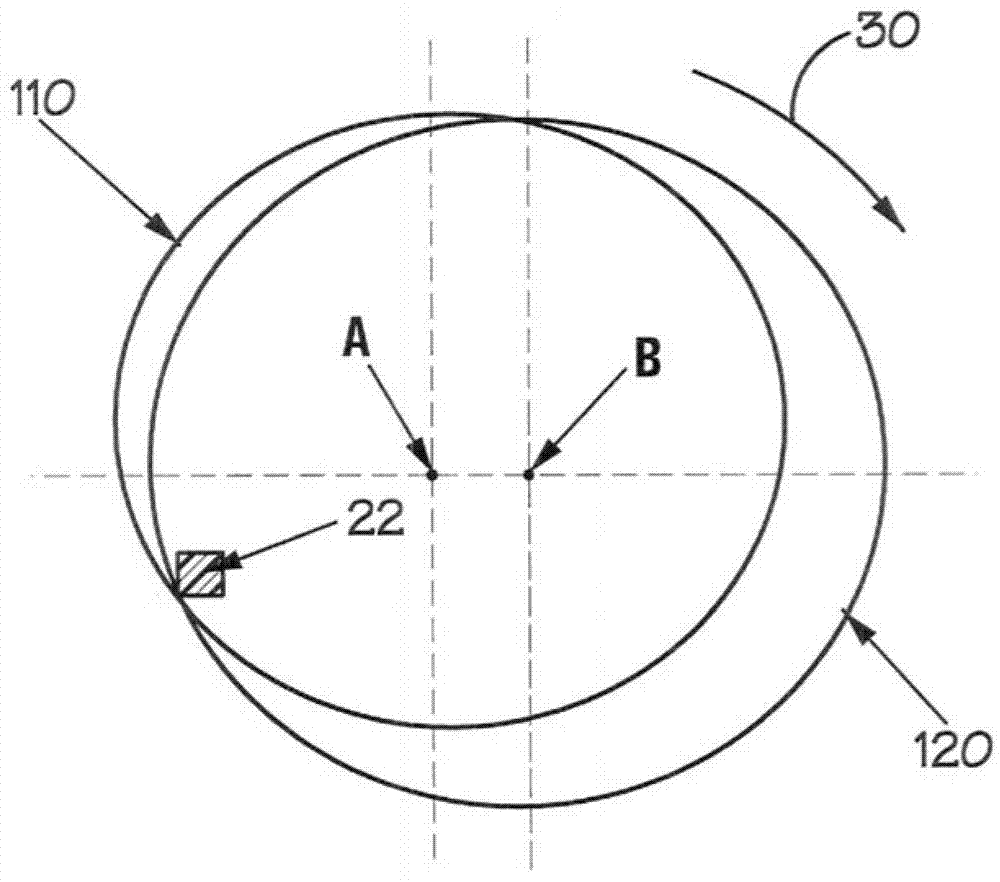

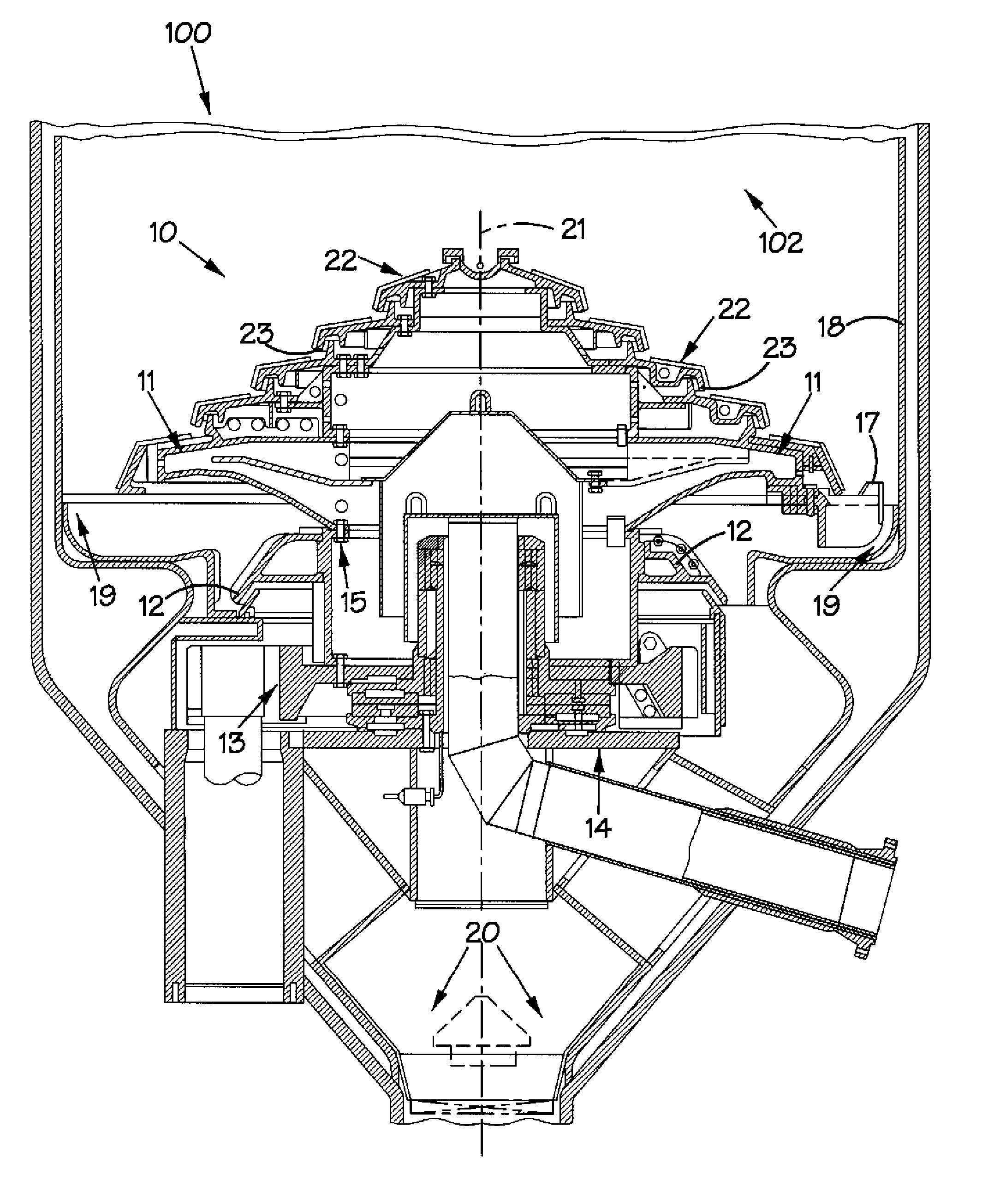

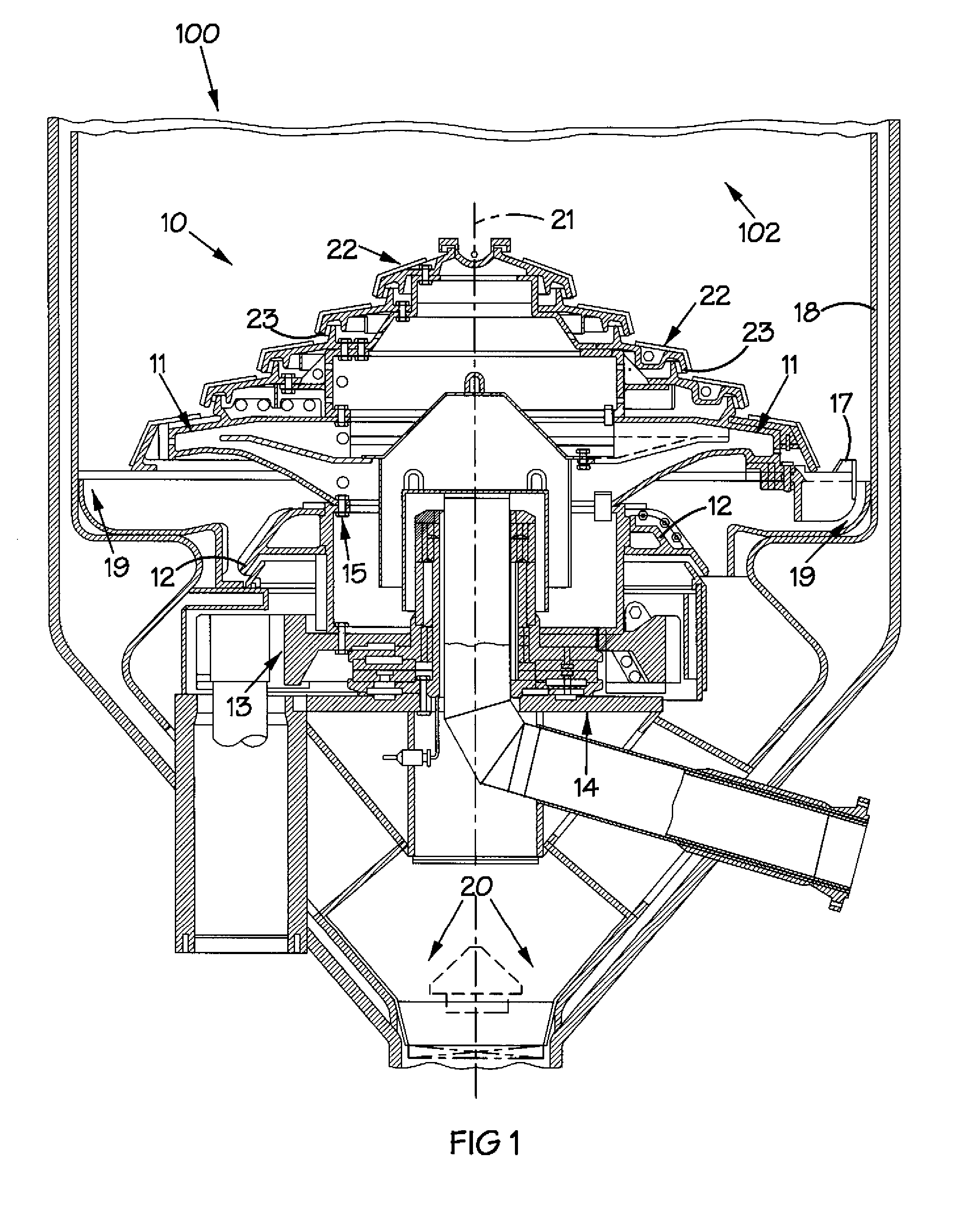

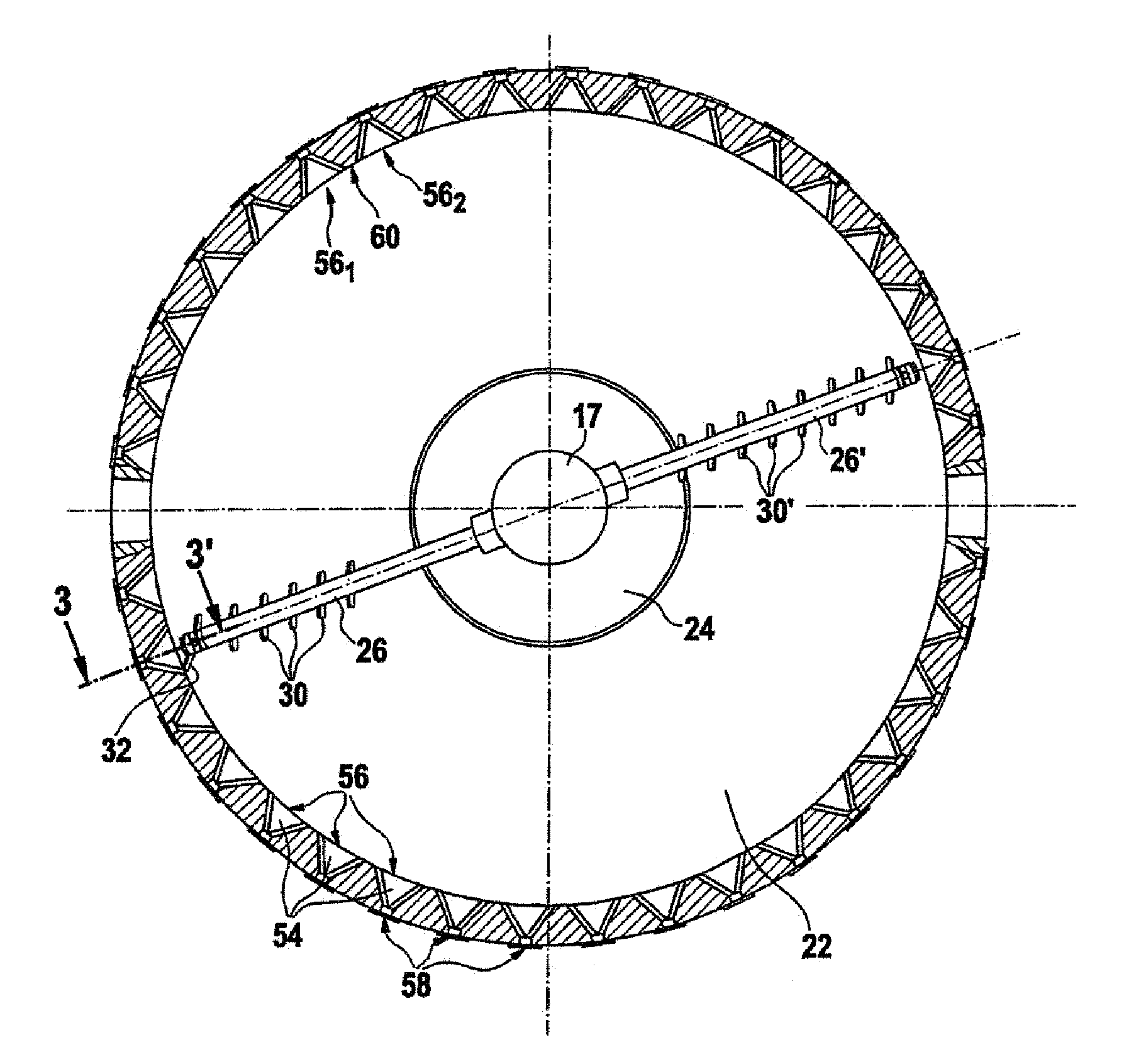

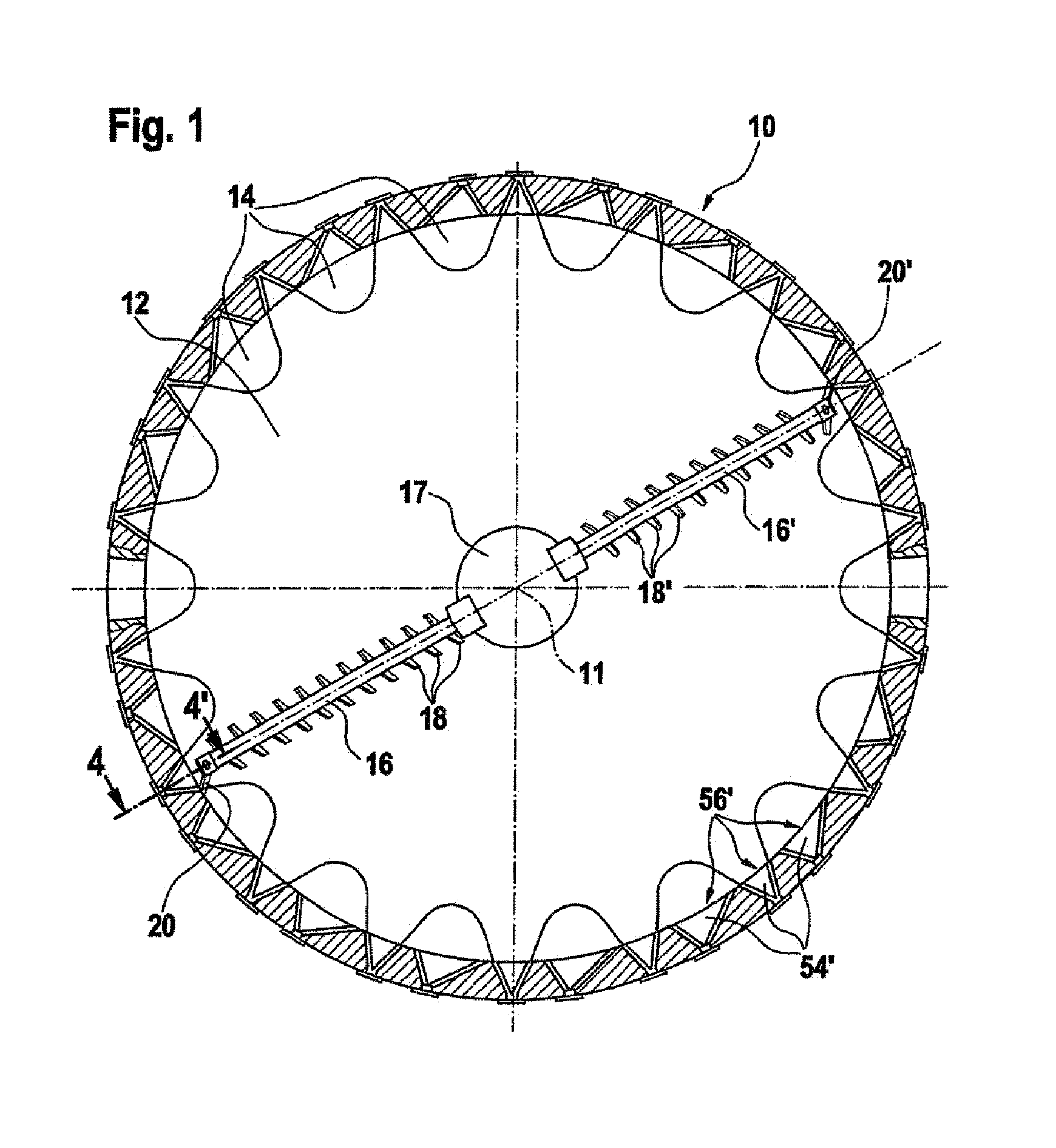

Gasification of carbonaceous material

The present invention relates to GASIFICATION OF a CARBONACEOUS MATERIAL, and discloses a grate assembly 10 for a gasifier for gasifying carbonaceous material producing ash includes an upper rotatable grate component 11 and a lower rotatable support structure 12 fastened to the upper rotatable grate component by a plurality of removable fasteners 15 acting to prevent vertical displacement of the upper rotatable grate component and the lower rotatable support structure. The lower rotatable support structure is configured to be drivingly rotated about a common vertical axis of rotation 21 shared with the upper rotatable grate component. The assembly 10 further includes at least two key torque transmitters 16 spaced angularly relative to the common axis of rotation and engaging the upper rotatable grate component and the lower rotatable support structure to transfer torque from the lower rotatable support structure to the upper rotatable grate component when the lower rotatable support structure is driven.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

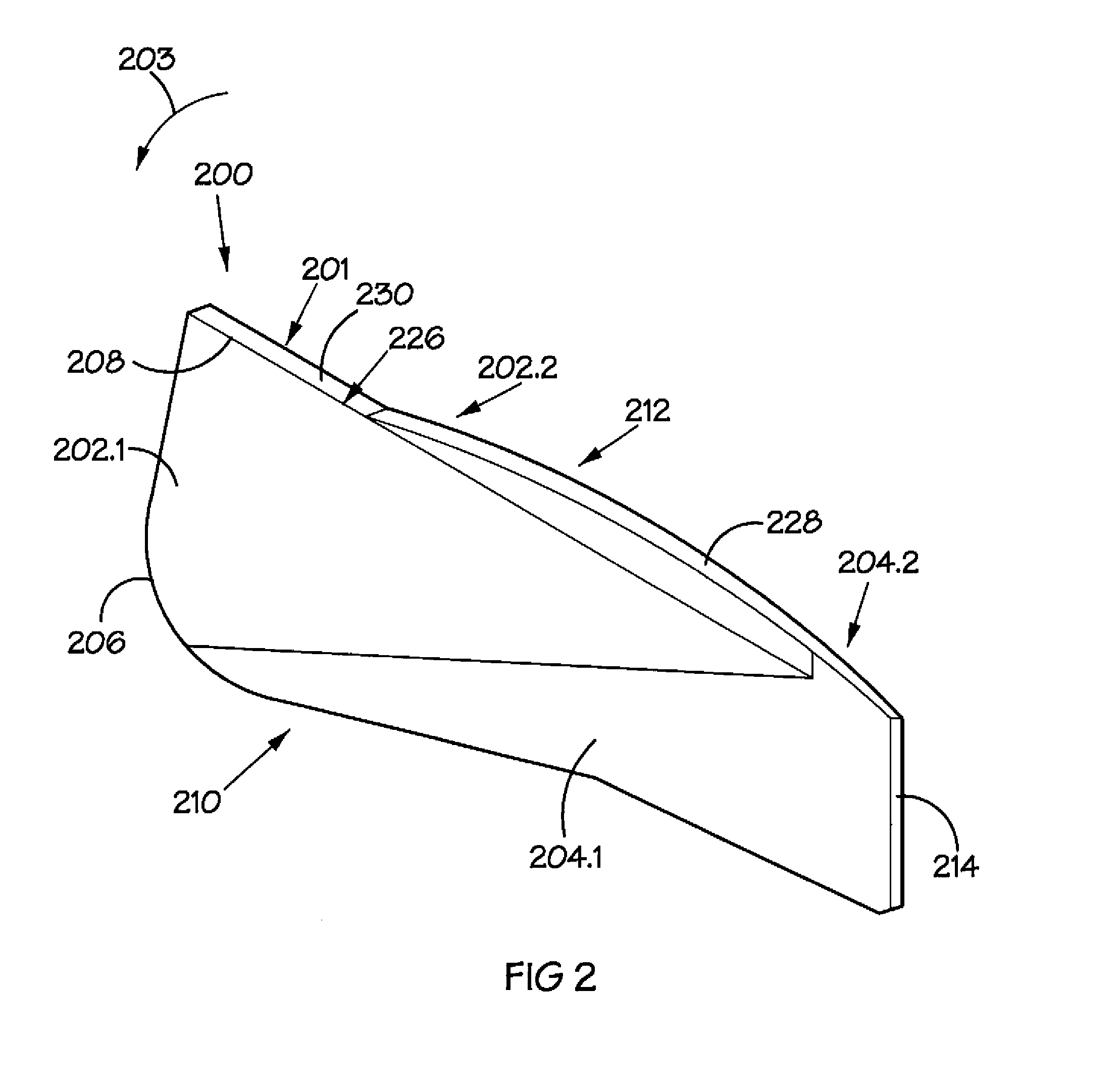

Rotary plough for gasifiers

A solids handling equipment rotary plough (200) includes an elongate metal body (201) with a leading face (210) and a trailing face (212). The body (201) is configured to be mounted to a rotary component for rotation about an axis of rotation at least in one direction which is an operative forward direction such that the leading face (210) leads the trailing face (212). At least the leading face (210) has at least two major operatively upwardly and outwardly extending surfaces (202.1, 204.1) which are not coplanar. A first major surface (202.1) is angled operatively rearwardly and upwardly relative to the forward direction of rotation at an angle of at least 1° to the vertical. A second major surface (204.1) is angled operatively forwardly and outwardly at an angle of at least 1° relative to a radius of a circle described in use by the rotary plough (200) when rotating in the operative forward direction.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

Multiple-hearth furnace

The inventive multi-level furnace comprises a furnace wall delimiting a cylindrical space having a vertical axis, a plurality of beds defining the levels inside said cylindrical space and at least one scraping arm which is provided with a wall scraper and associated with the bed in such a way that it is rotatable about the vertical axis of the furnace. During scraping arm rotation, said wall scraper defines a scraped area on the internal surface of the furnace wall which comprises a plurality of wall cavities forming a row of access openings in the scraped area, thereby making it possible to avoid the formation of a hardened crust adhered to the internal surface of the furnace wall and to develop braking shocks in the scraping arm.

Owner:PAUL WURTH SA

Biomass fuel feeding device and biomass fuel furnace

PendingCN110594772AIncrease activity spaceLess squeezeRevolving grateRocking grateRadial planeBiomass fuels

The invention provides a biomass fuel feeding device and a biomass fuel furnace, and belongs to the field of furnace tools. The biomass fuel feeding device comprises a hopper and a raking assembly, wherein the bottom of the hopper is provided with a discharging port, the side portion of the hopper is provided with a material guide inclined wall which is arranged at an included angle with the vertical direction and extends to the discharging port, the raking assembly comprises a rotating shaft arranged in the hopper and a plurality of shifting rods arranged at intervals along the axial direction of the rotating shaft, each shifting rod is arranged along the radial direction of the rotating shaft, the projection of every two adjacent shifting rods in the radial plane of the rotating shaft isarranged at an included angle, and the shifting rods are used for shifting the biomass fuel on the material guide inclined wall towards the discharging port. The biomass fuel furnace comprises the above biomass fuel feeding device. According to the biomass fuel feeding device and the biomass fuel furnace, only a small amount of biomass fuel is in contact with the small-size shifting rods, so thatthe situations that biomass fuel is crushed and biomass fuel sticks the shifting rods are avoided, the adjacent shifting rods are not inserted into the biomass fuel at the same time, and the biomassfuel is prevented from being crushed.

Owner:正信德(北京)国际环保有限公司

Novel biomass burner rotary fire grate

InactiveCN106918047AReduce cloggingImprove work efficiencyRevolving grateRocking grateSlagAgricultural engineering

The invention discloses a novel biomass burner rotary fire grate, which comprises a left baffle plate, a right baffle plate, strip-shaped holes, a rotating shaft, a back baffle plate, a front baffle plate, a round cylinder, a round plate and a bearing cylinder and is characterized in that the round cylinder is arranged in front of the bearing cylinder; the front baffle plate is arranged above the round cylinder; the left baffle plate is arranged at the left side of the front baffle plate; the right baffle plate is arranged at the right side of the front baffle plate; the round plate is fixed behind the carrying tube; the rotating shaft is fixed on the back side surface of the round plate; the back baffle plate is fixed above the round plate; a plurality of strip-shaped holes are uniformly distributed in the carrying tube. The novel biomass burner rotary fire grate has the advantages that the integrated design structure is simple; the culture concept of the existing conventional fire grate is broken; a rotatable novel fire grate is used; the blockage caused by material slag in the biomass burner operation process is reduced; the work efficiency of the burner is improved; the investment cost is saved; good market prospects are realized.

Owner:ANHUI JIUNENG INFORMATION TECH

Shaft-rotating coal stirring boiler

InactiveCN101457927AEasy to manufactureEasy transferRevolving grateSolid fuel combustionFluidized bedProcess engineering

The invention provides a pivot coal spreading boiler, belonging to an industrial boiler. The boiler combines the advantages of a grate furnace, a double-layered grate furnace, a coal tossing furnace and a chain furnace such as mechanical coal transportation, uniform fire coal spreading, multizone and multimode burning, sufficient burning, inferior coal adaptability, high heating efficiency, fast load adjustment and the like; and overcomes the defects of the furnaces. The invention has the characteristics of high efficiency, energy saving, environmental protection, and the like, and is very practical. The structure of the boiler comprises a pivot coal spreading horizontal boiler and a pivot coal spreading fluidized bed furnace and is composed by the combination of pivot coal spreading grates and general grates or a fluidized bed; and the pivot coal spreading grate comprises a fin arris, a pivot tube and vents. The best characteristic of the pivot coal spreading boiler is that the pivot coal spreading grate has functions of fire coal transporting, grinding and spreading; the boiler is provided with an upper grate layer and a lower grate layer with multiple burning modes such as grate firing, float firing, boiling and the like, the heating efficiency is high and the application range of the coal variety is wide; the rotating speed of the grate is adjustable, thus changing the coal supply quantity and adapting to the load change; furthermore, the rotation and production are simple, assembly is simple and fast and replacement is convenient and fast.

Owner:袁吉增

Popular searches

Incinerator apparatus Electric spark igniters Combustion using gaseous and pulverulent fuel Combustion using liquid and pulverulent fuel Fuel injection apparatus Combustion using lump and gaseous fuel Combustion using lump and liquid fuel Combustion using liquid and gaseous fuel Combustion using lump and pulverulent fuel Ignition sparking plugs

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com