Patents

Literature

798 results about "Biomass boiler" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and system for combing solar energy thermal power generation with biomass power generation

ActiveCN101876299AReduce dosageReduce procurement costsSteam generation heating methodsFrom solar energyThermal energyCounter flow

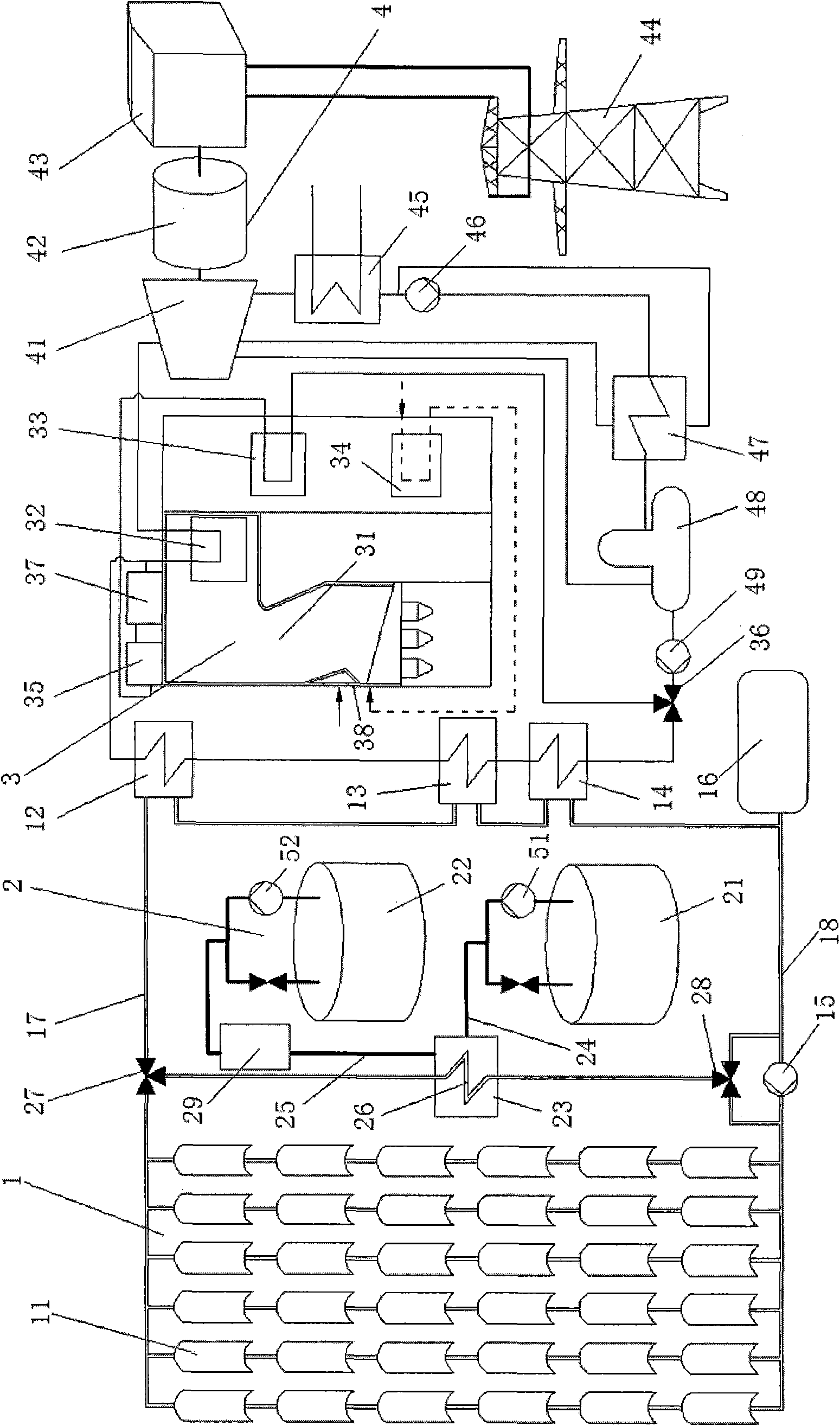

The invention relates to a method and a system for combining solar energy thermal power generation with biomass power generation. When the method is used for generating electricity in the daytime (a fine day), one path of heat transfer oil heated in a heat collection field passes through a heat exchanger to ensure that counter-flow water is heated up into superheated steam at the temperature of between 360 and 380 DEG C; and the other path of the heat transfer oil heated in the heat collection field passes through the heat exchanger to heat up a fused salt so as to perform energy storage. The water heated in a water cooled wall of a biomass boiler is changed into steam which enters a steam header and a steam-water separator, then is heated to the temperature of between 535 and 545 DDEG C after being sent into a super-heater of the boiler together with the steam at the temperature of between 360 and 380 DEG C, and then is supplied to a steam turbine to drive a generator to finish the power generation process. During receiving electric valley adjustment, the biomass boiler maintains the minimum stable combustion state. The self power generation of the method and the system can be used for supplying electricity to an electric heater in a fused salt heat storage system to heat the fused salt and perform secondary energy storage for a fused salt heat tank. During the night, or when a solar energy condition is not good, the heat energy stored in the fused salt is released by the heat exchanger to generate electricity.

Owner:北京京仪集团有限公司

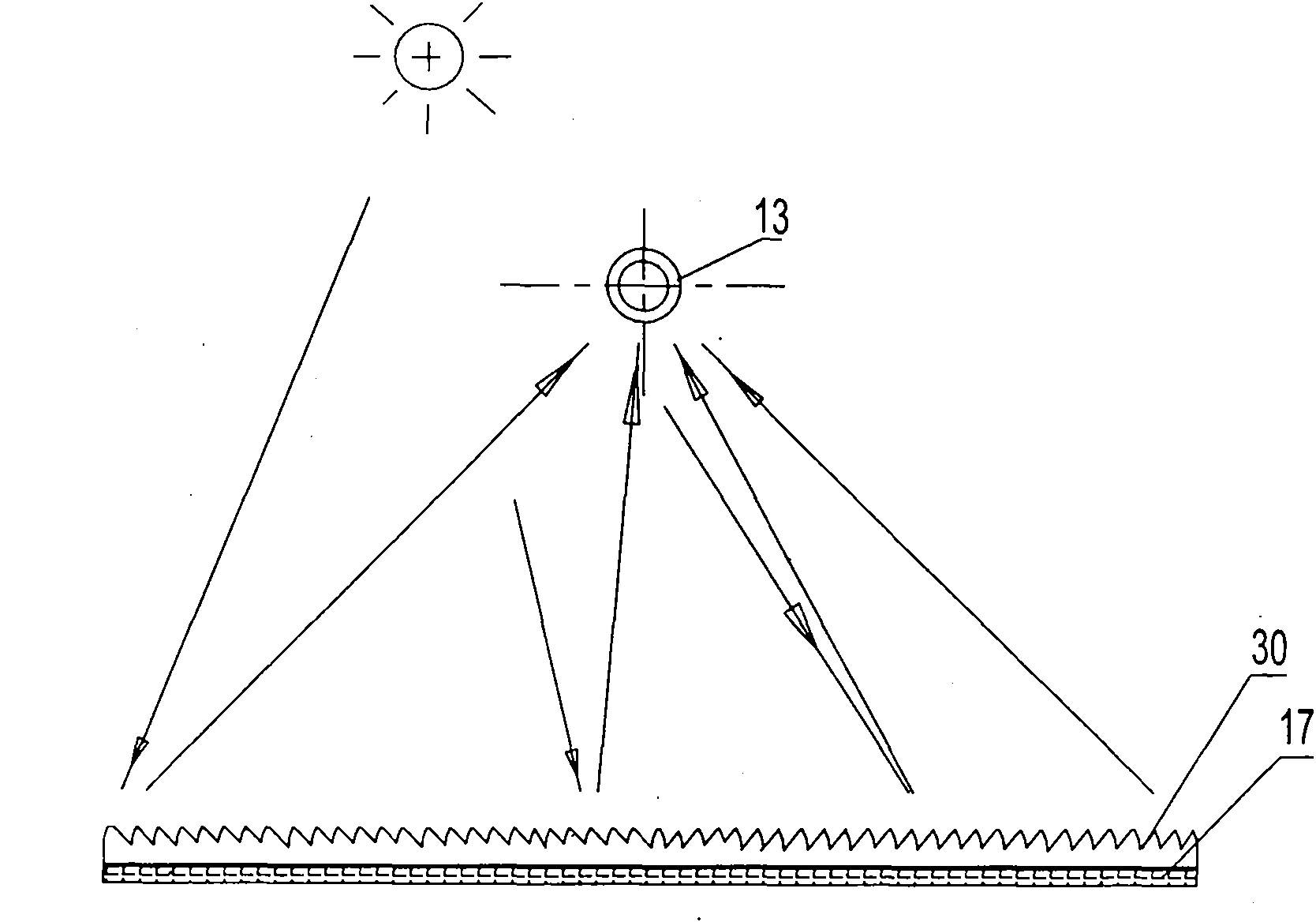

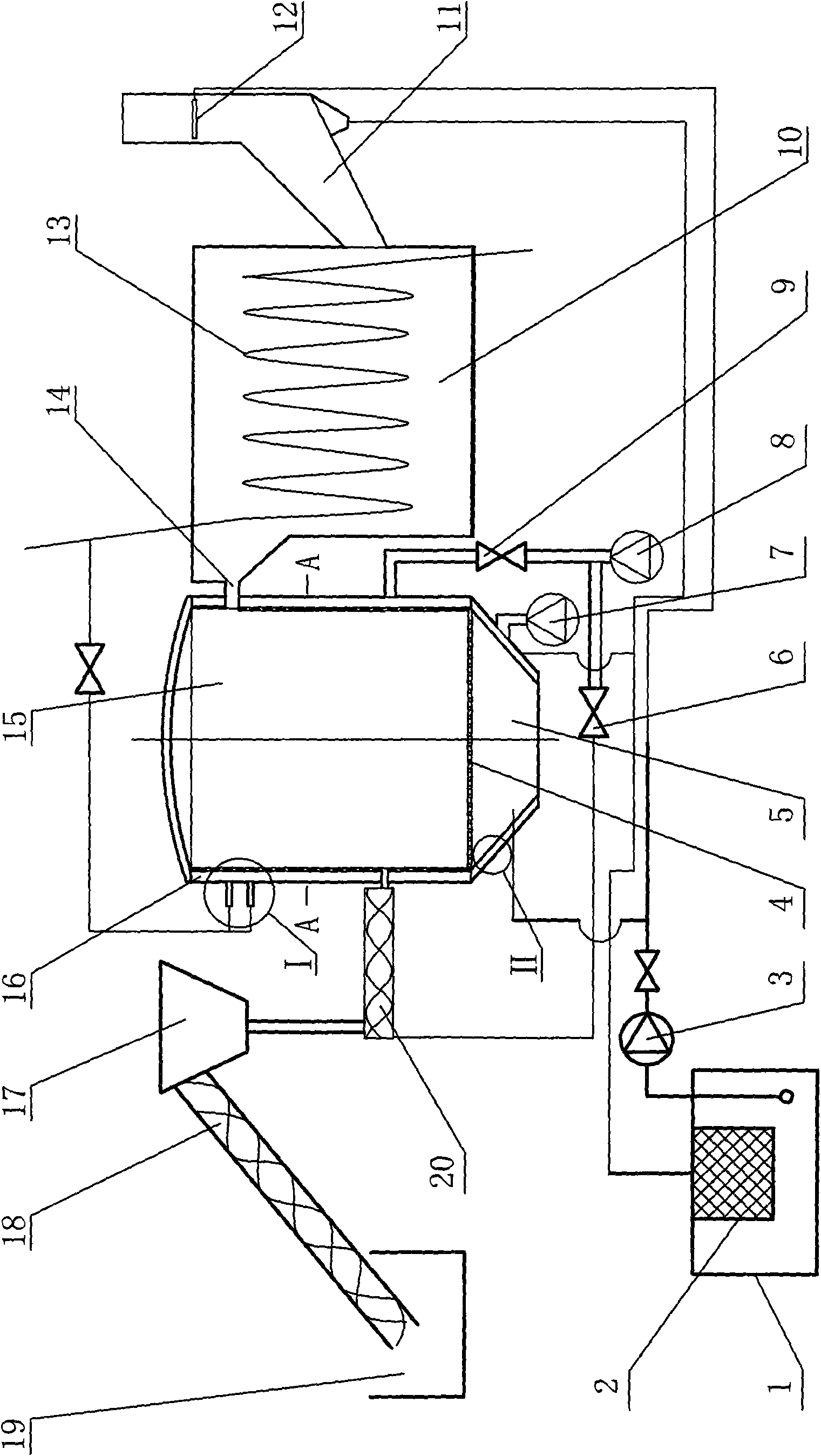

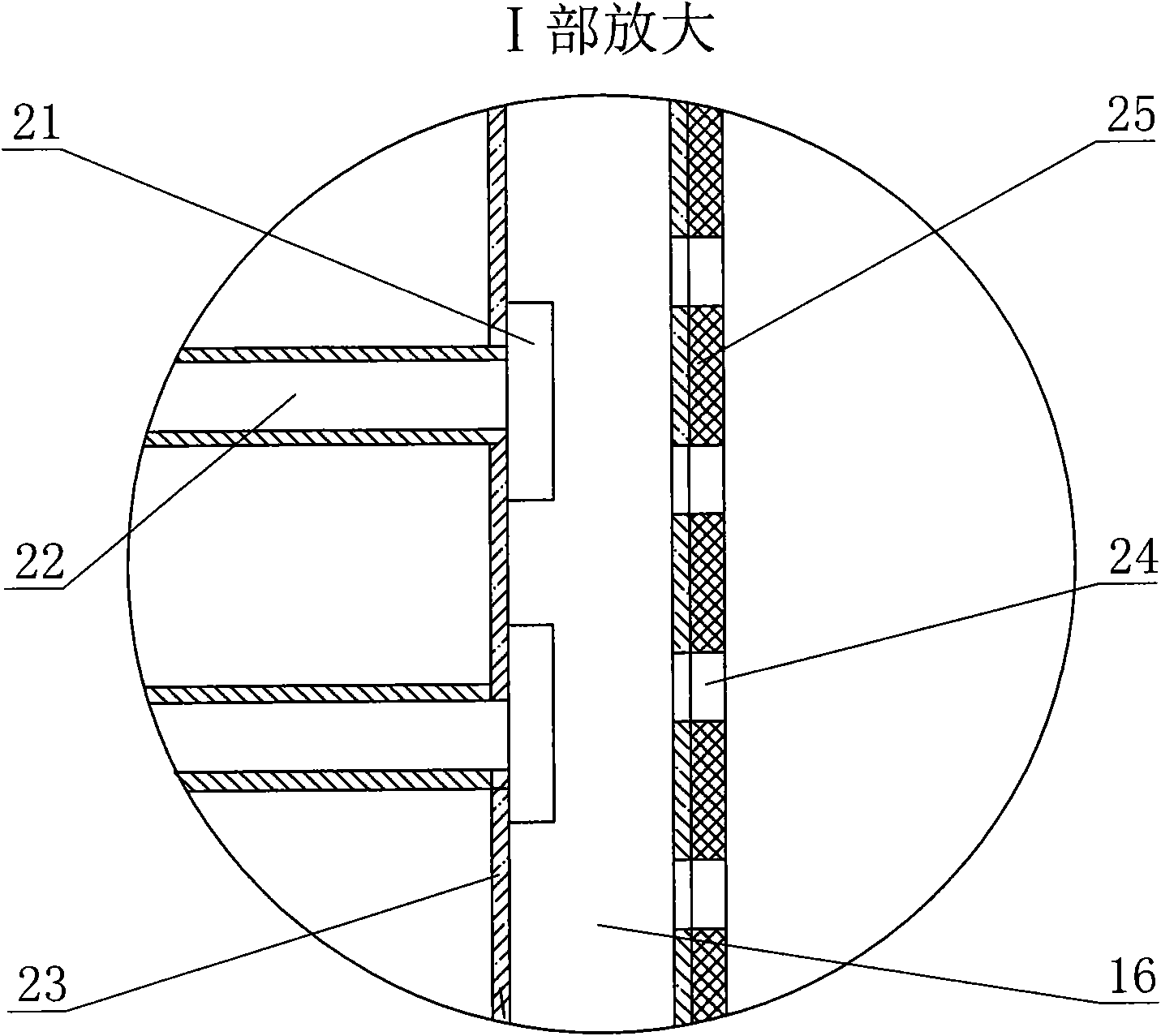

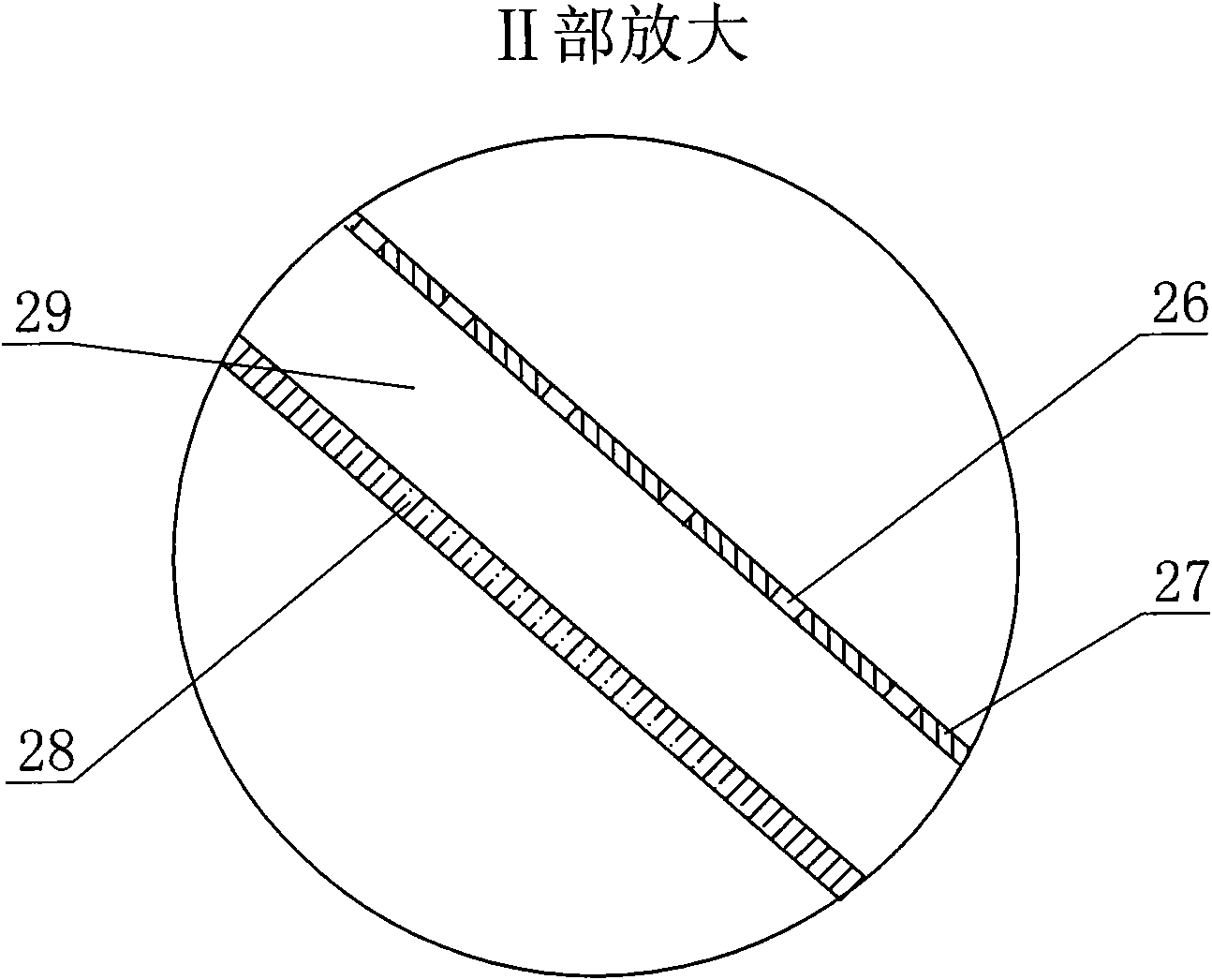

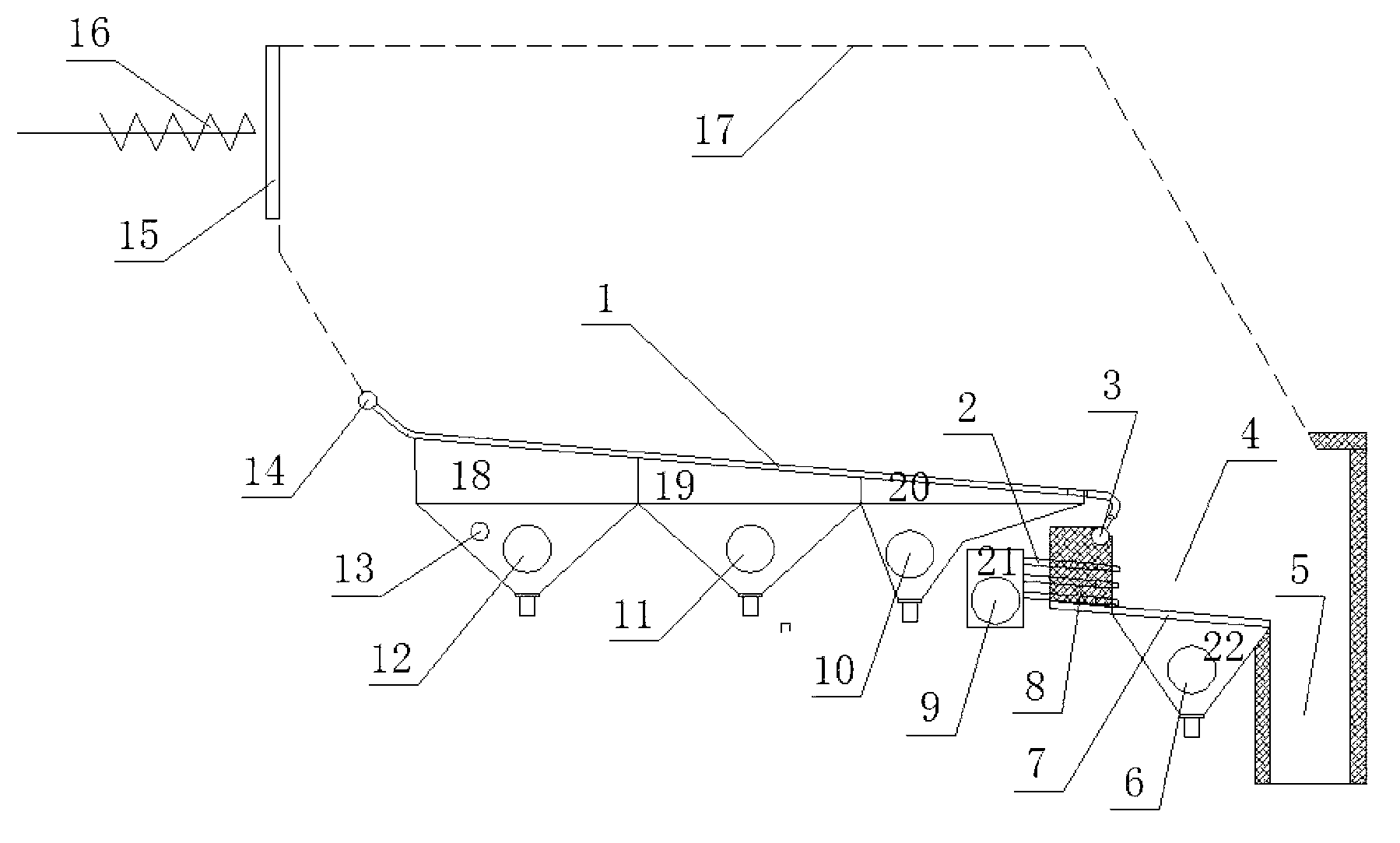

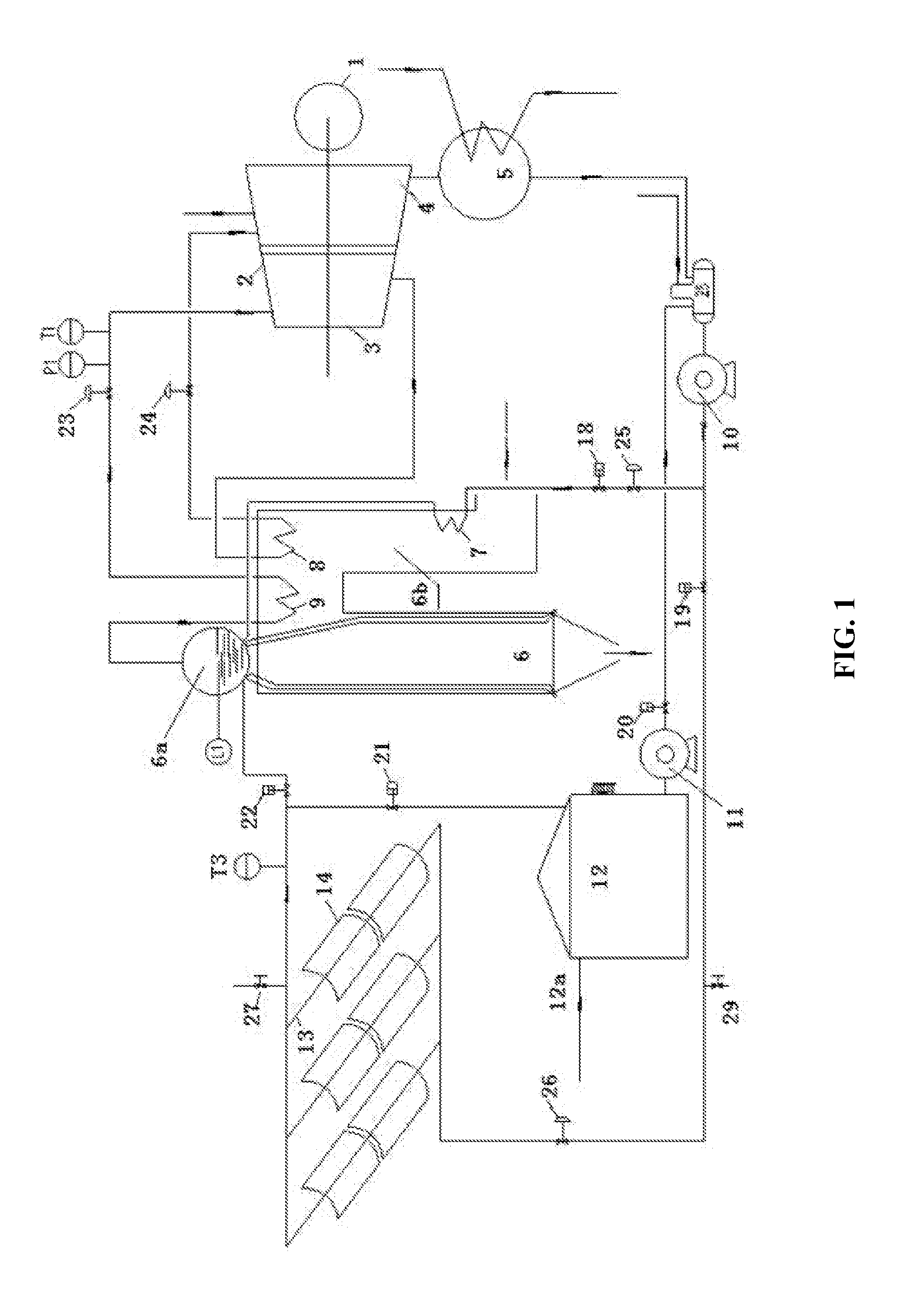

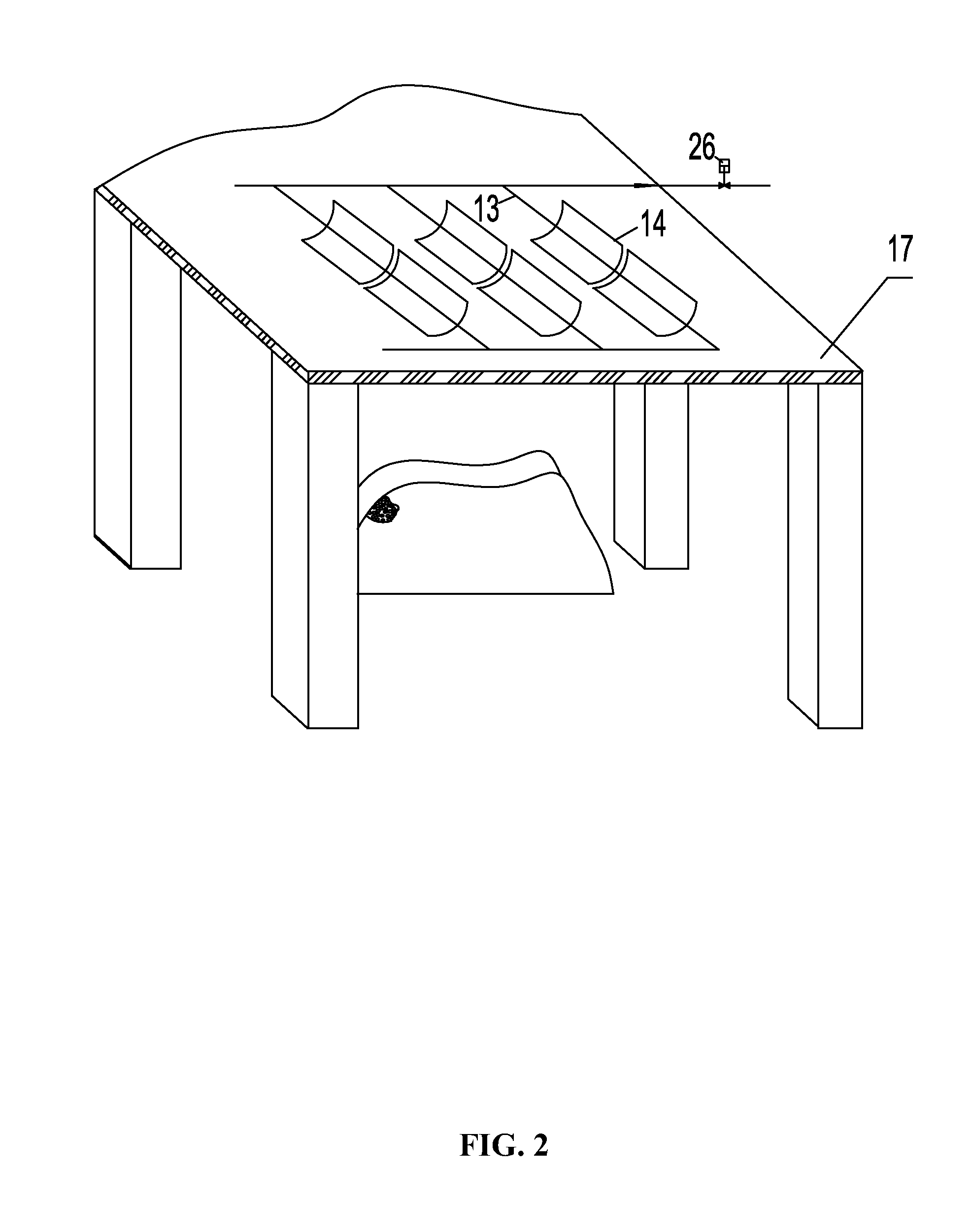

Solar power generation method and system taking biomass boiler as auxiliary heat source

ActiveCN101968041ASolve the problem of antifreeze in winterHigh thermal efficiencySolar heating energyFrom solar energyWater storage tankEngineering

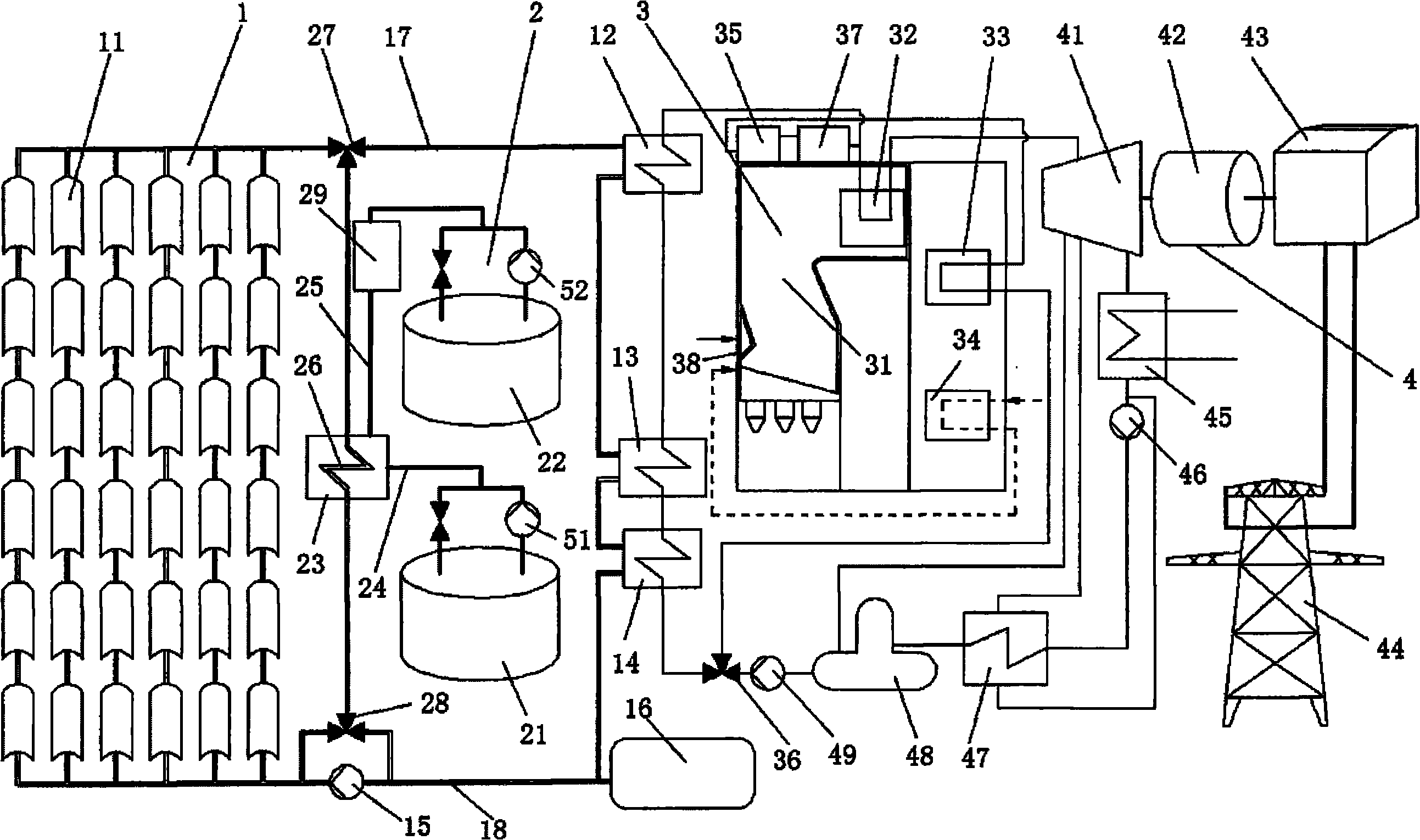

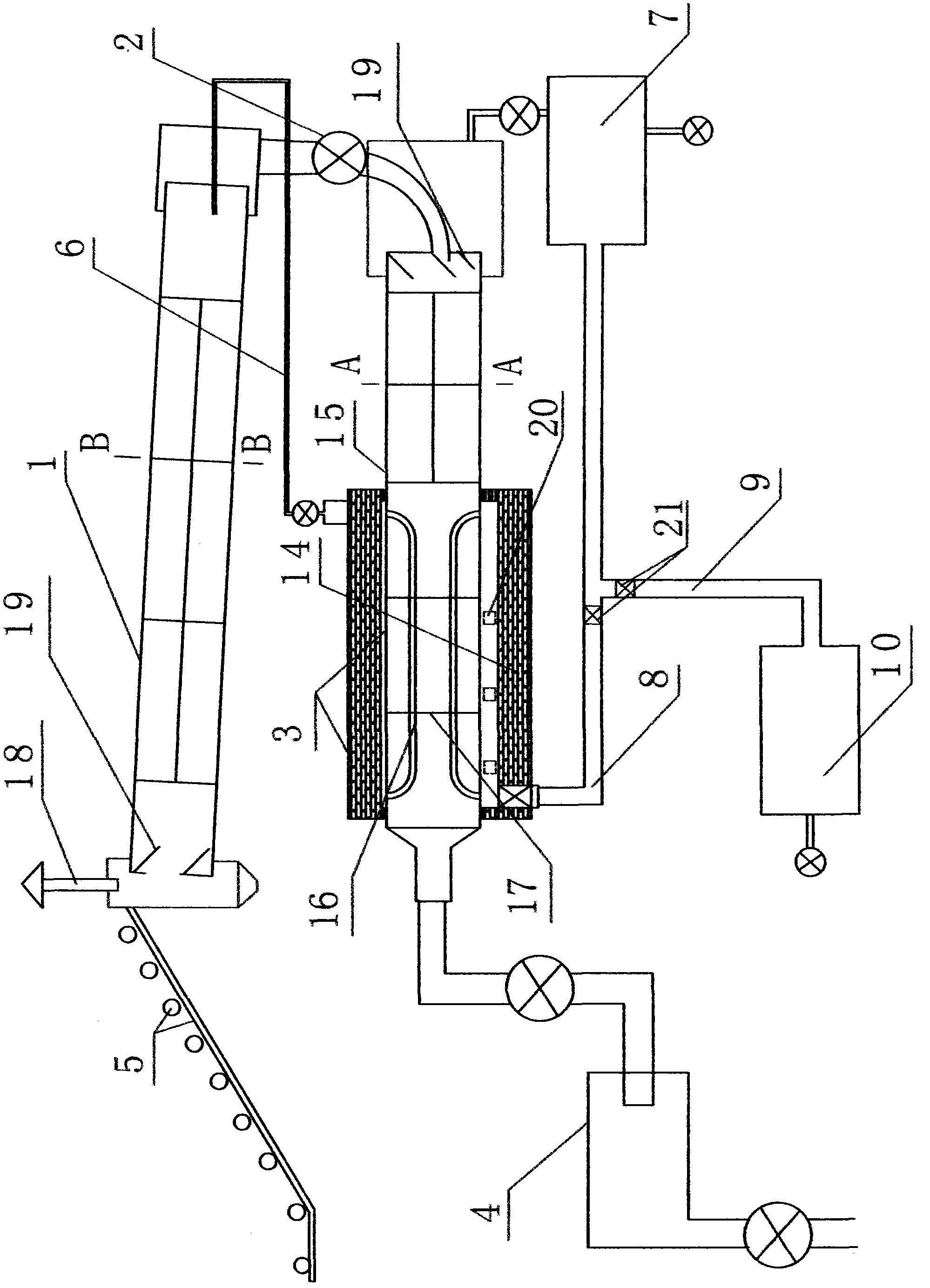

The invention discloses a solar power generation method and a solar power generation system taking a biomass boiler as an auxiliary heat source. The system comprises a solar condensation heat collecting device, a biomass boiler device and a steam turbine generator system, wherein the solar condensation heat collecting device takes water as a medium and is combined by adopting medium-pressure solar vacuum heat collecting pipes in a series-parallel matrix; the outlet of the solar condensation heat collecting device is communicated with the bottom of a steam pocket of the biomass boiler; and the steam outlet of the steam pocket of the biomass boiler is connected with a cylinder of a steam turbine generator. A de-aerator and a water supply pump are connected in series in the water inlet pipeline of the solar condensation heat collecting device. A steam re-heater is connected in series in the connected pipeline of the steam outlet of the steam pocket of the biomass boiler and the cylinder of the steam turbine generator; the steam re-heater is connected to the cylinder of the steam turbine generator; and the steam re-heater is placed in a flue of the biomass boiler. A water supply tank is a desalting water storage tank, and the desalting water storage tank is connected with the de-aerator through the water supply pump and connected with the outlet of the solar condensation heat collecting device through a first control valve.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

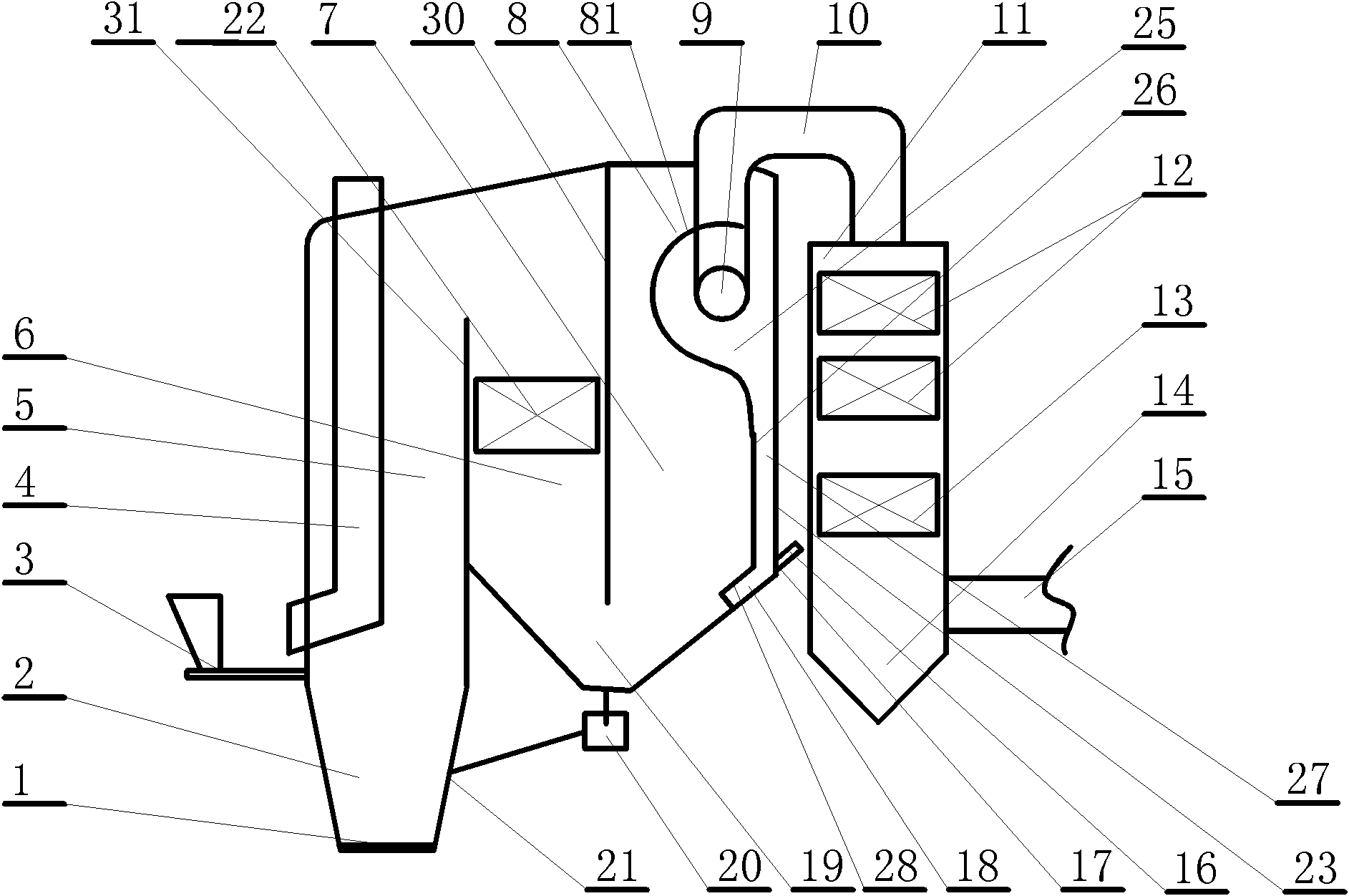

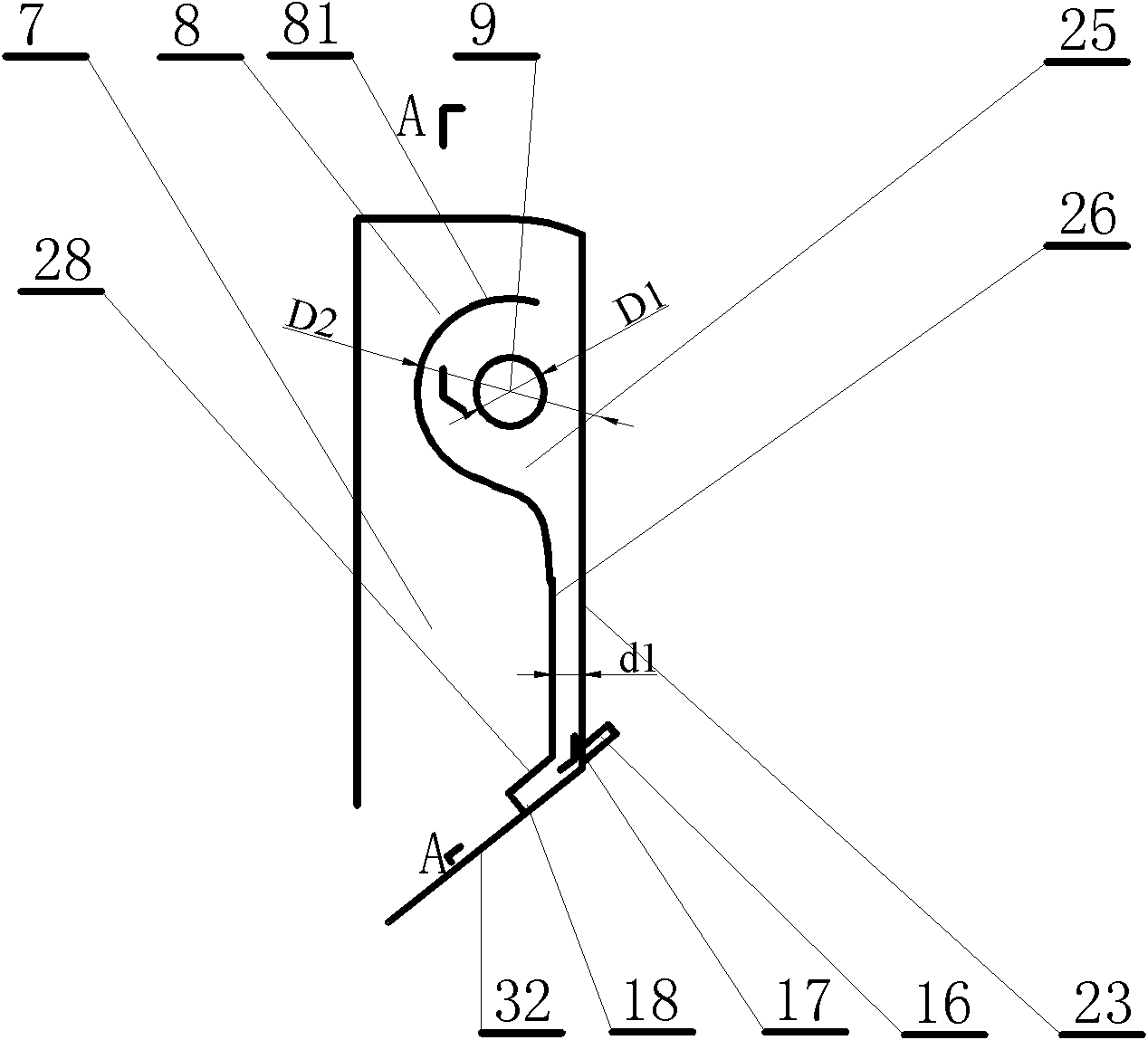

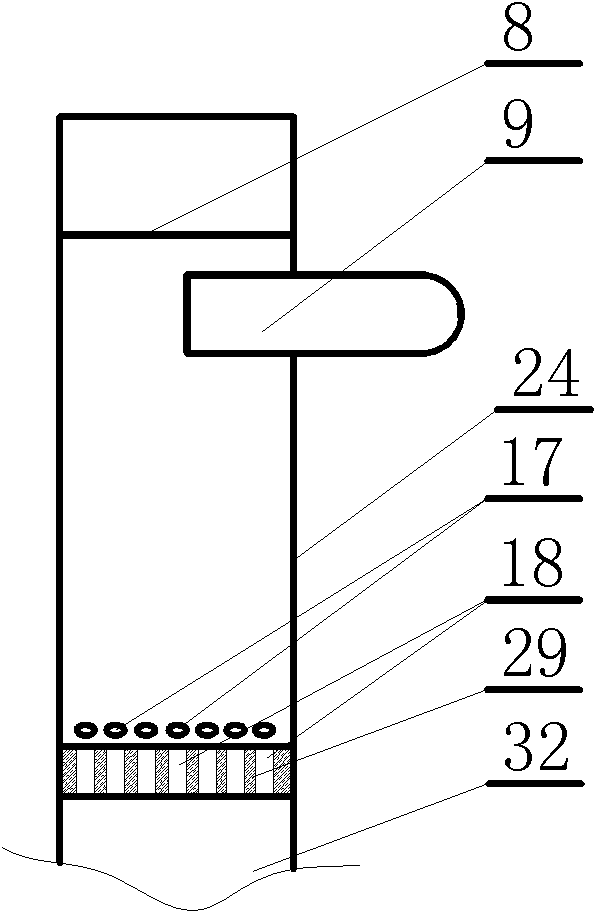

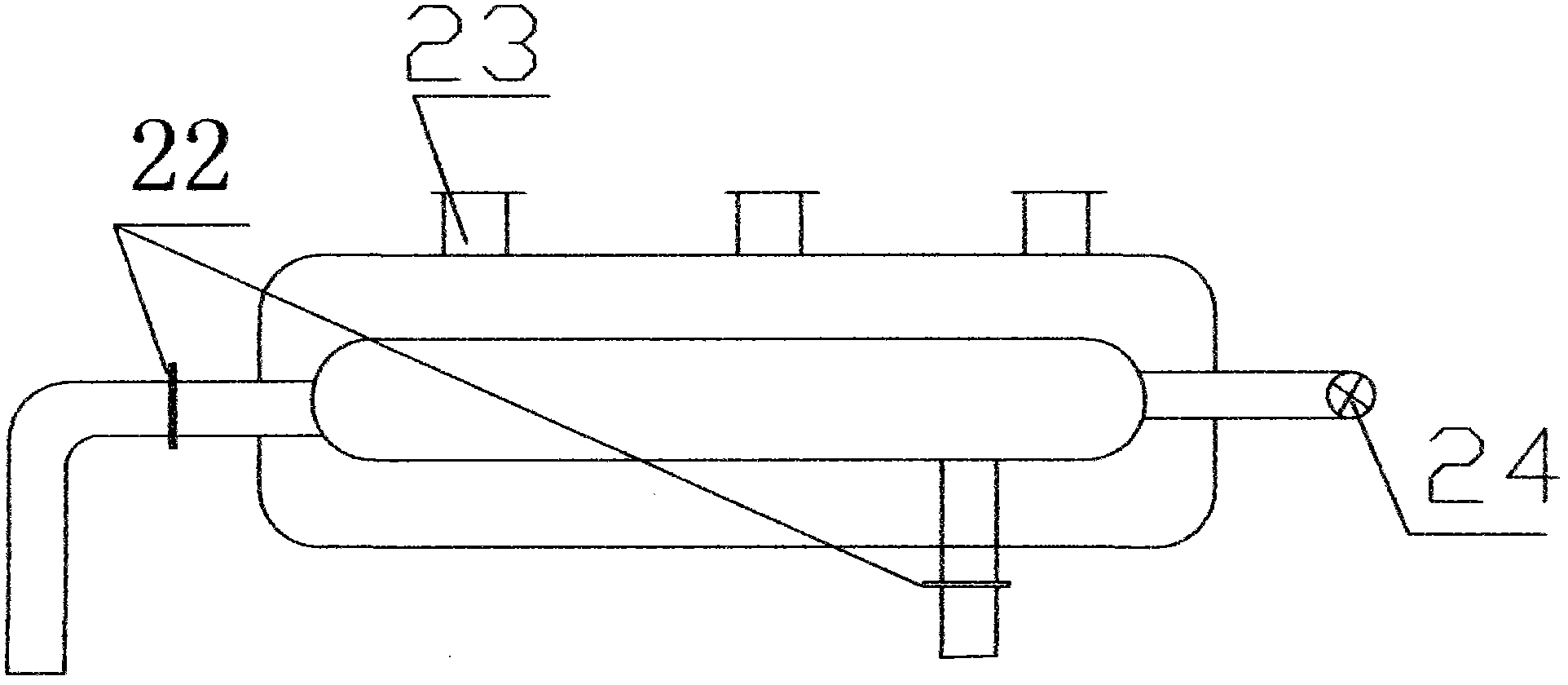

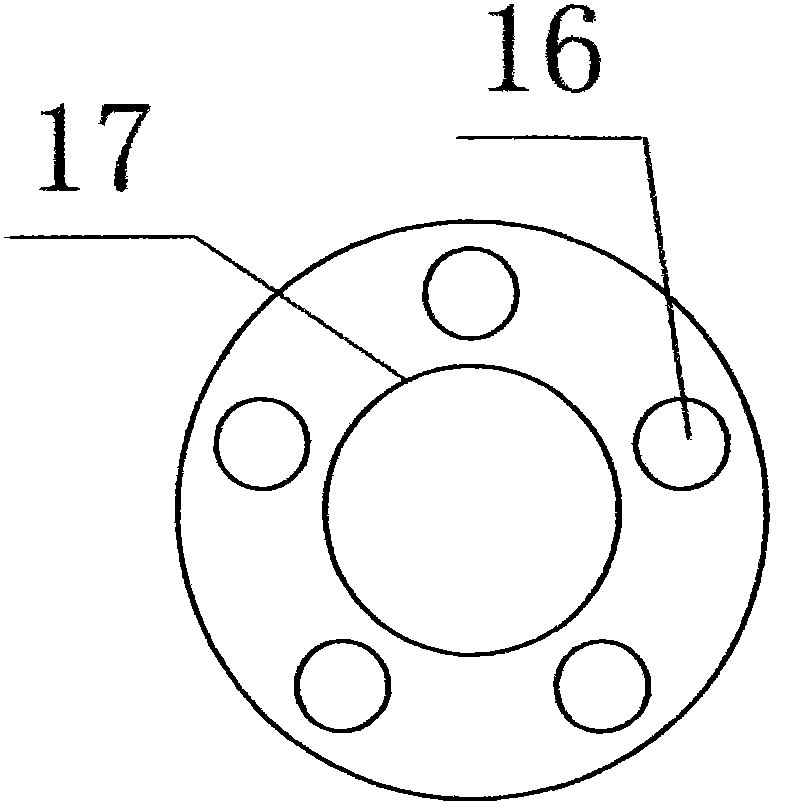

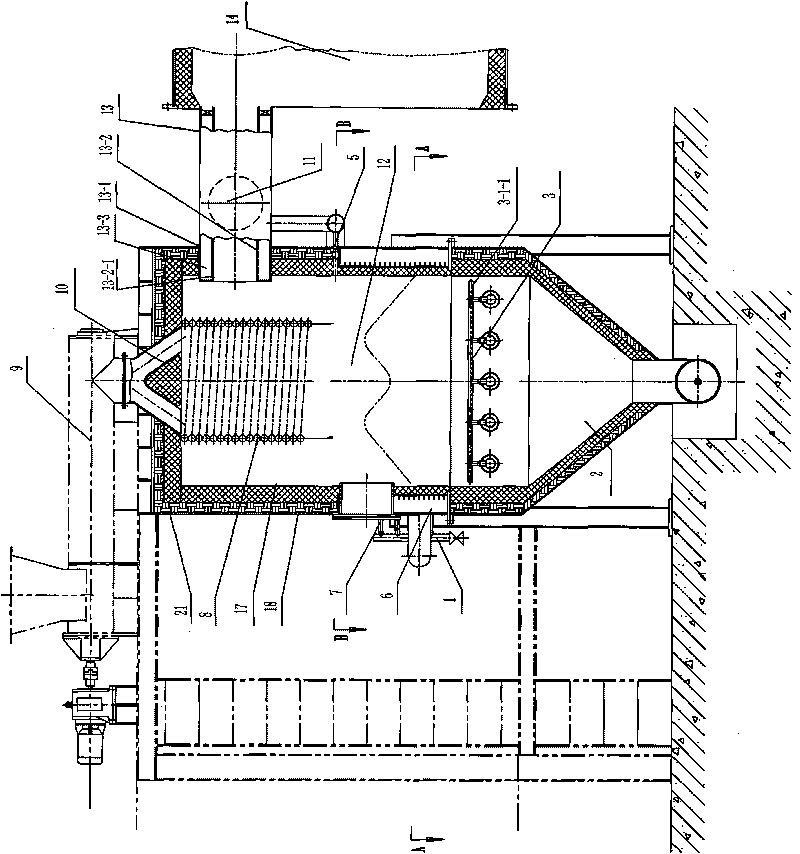

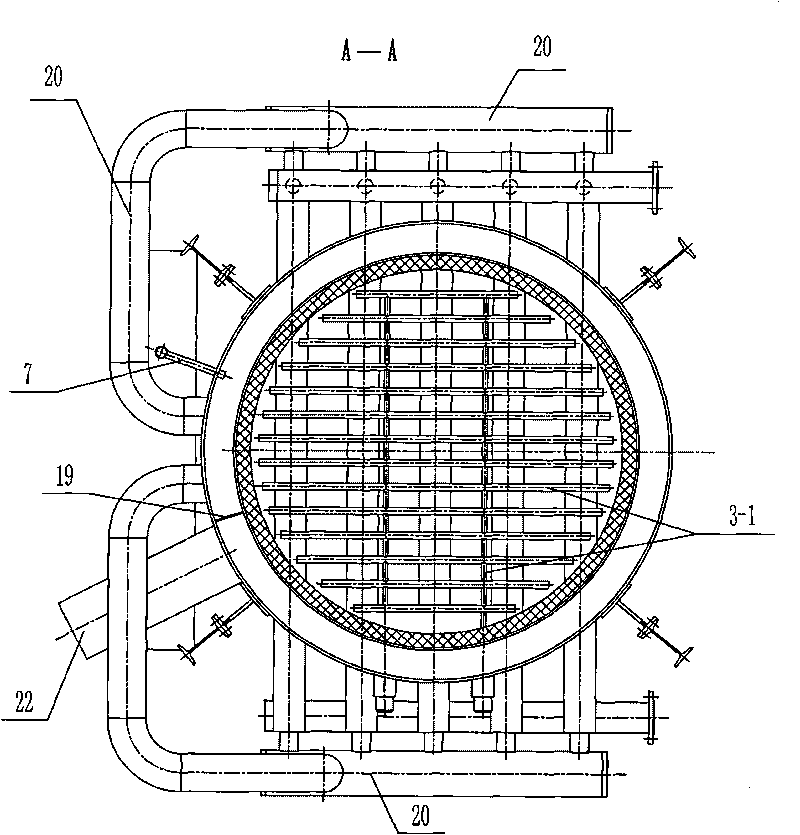

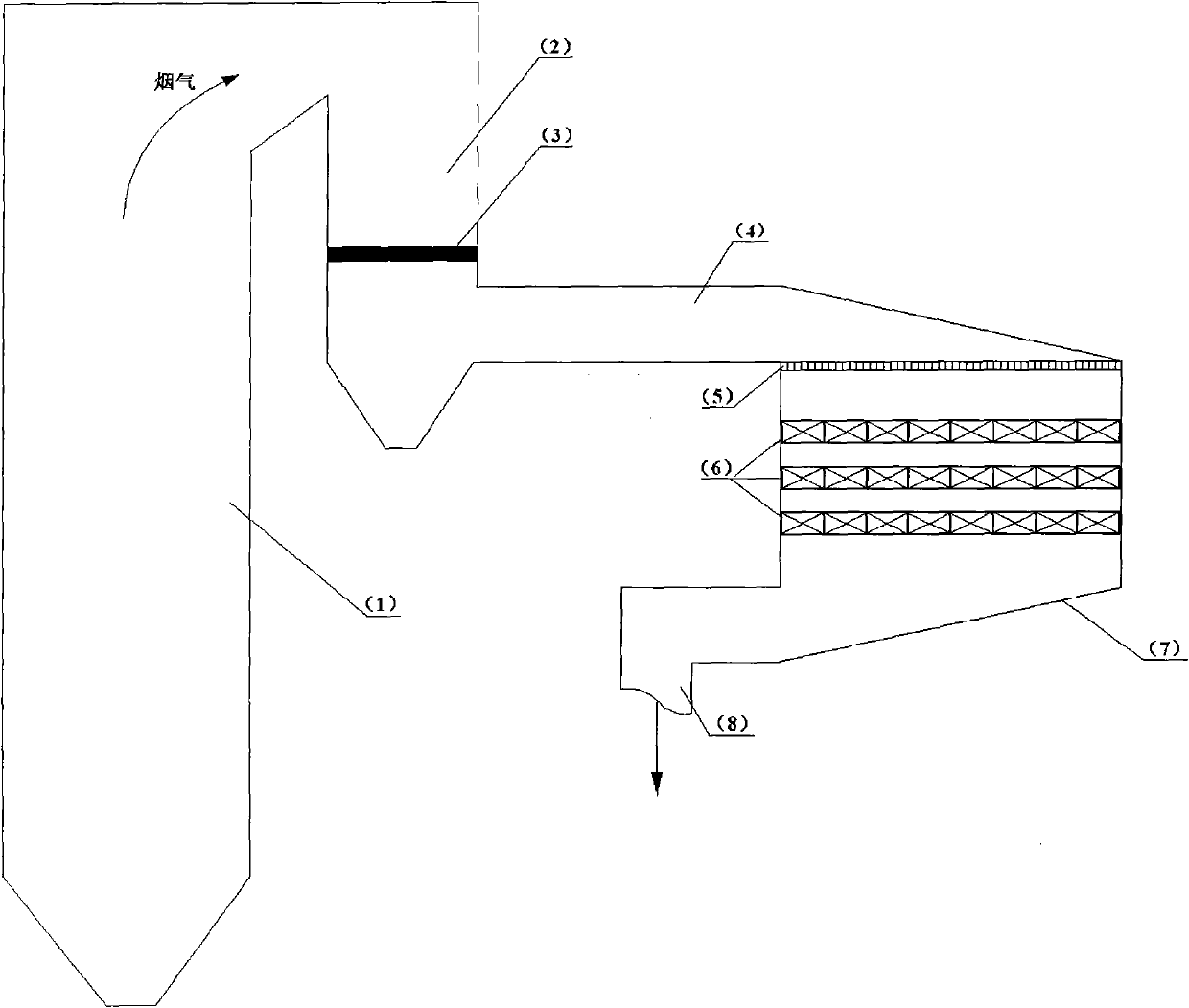

Horizontal type circulating fluidized bed boiler with horizontal cyclone separator

ActiveCN102537943ALow costReduce construction costsFluidized bed combustionReversed direction vortexCycloneCombustion chamber

The invention relates to a horizontal type circulating fluidized bed boiler with a horizontal cyclone separator, belonging to combustion equipment of inferior fuels such as inferior coal, solid waste, sludge or biomass and the like, and the horizontal type circulating fluidized bed boiler is particularly suitable for fluidized combustion of a biomass boiler with less ash content. The horizontal type circulating fluidized bed boiler consists of a main combustion chamber, a secondary combustion chamber, a burnout chamber and a tail gas flue, and a horizontal cyclone separator is arranged in the burnout chamber. The horizontal type circulating fluidized bed boiler in the invention changes a single-stage vertical circulating structure of a vertical circulating fluidized bed, can effectively reduce the height of a boiler and reduce the requirement for building height of a factory, meanwhile, the horizontal cyclone separator is integrated in the burnout chamber, the structure is more compact, thereby being beneficial to miniaturization of a circulating bed boiler and reducing the cost effectively. The horizontal type circulating fluidized bed boiler has all the advantages of a circulating fluidized bed and can combust fuels such as inferior coal, solid waste, municipal and industrial sludge, biomass and the like, has wide fuel adaptability and is high-efficiency combustion equipment with clean combustion, a compact structure and long service life.

Owner:TSINGHUA UNIV +1

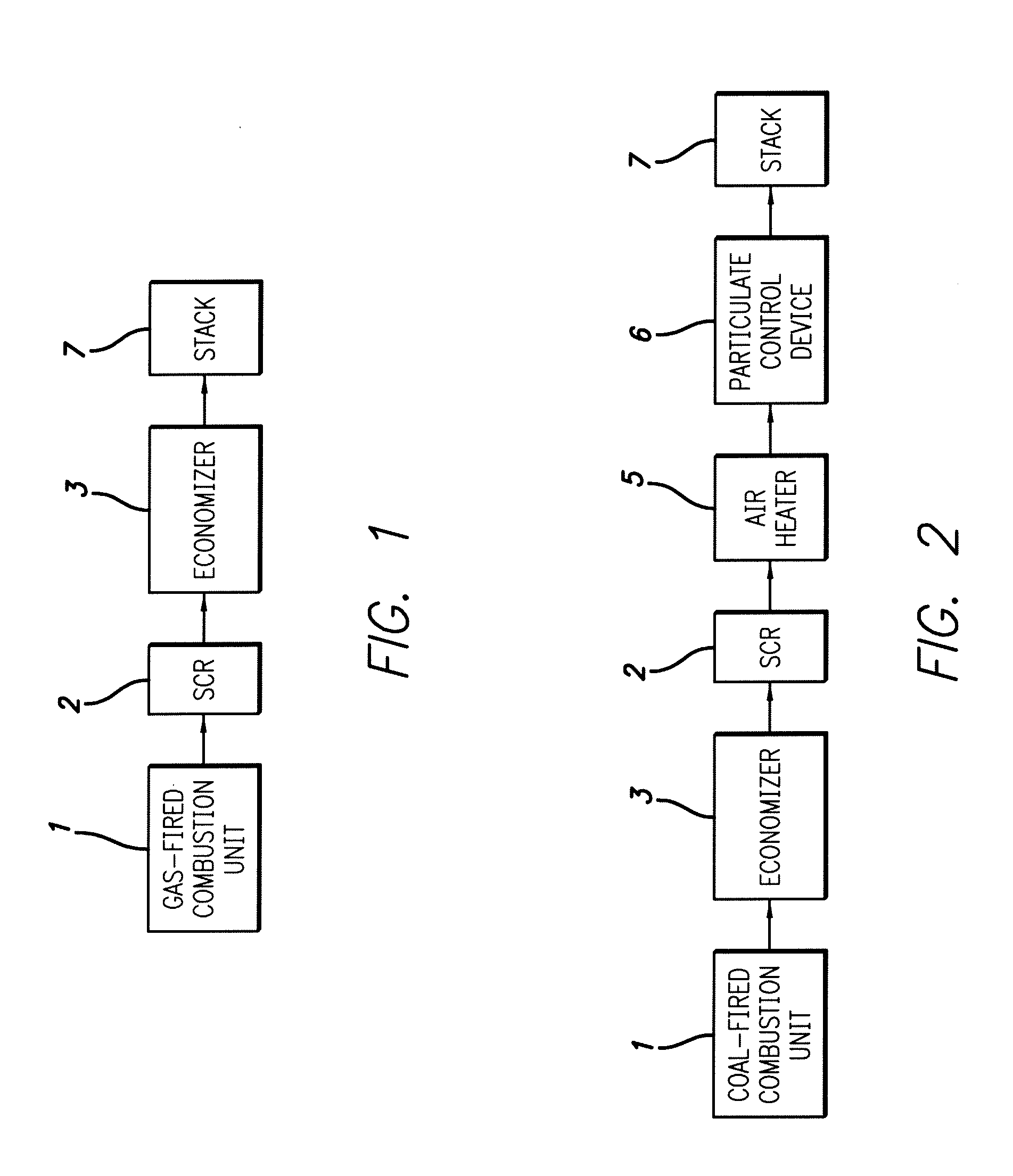

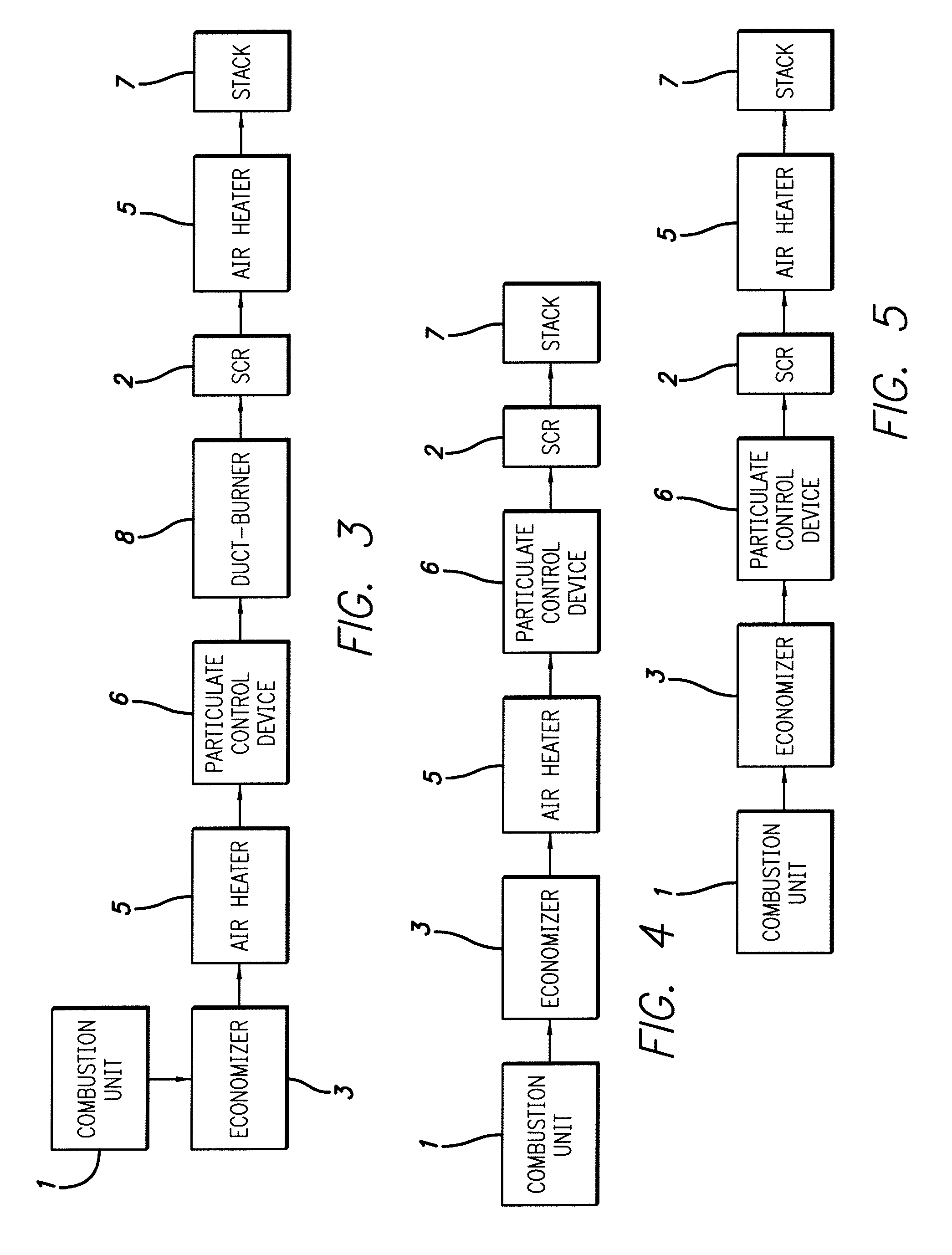

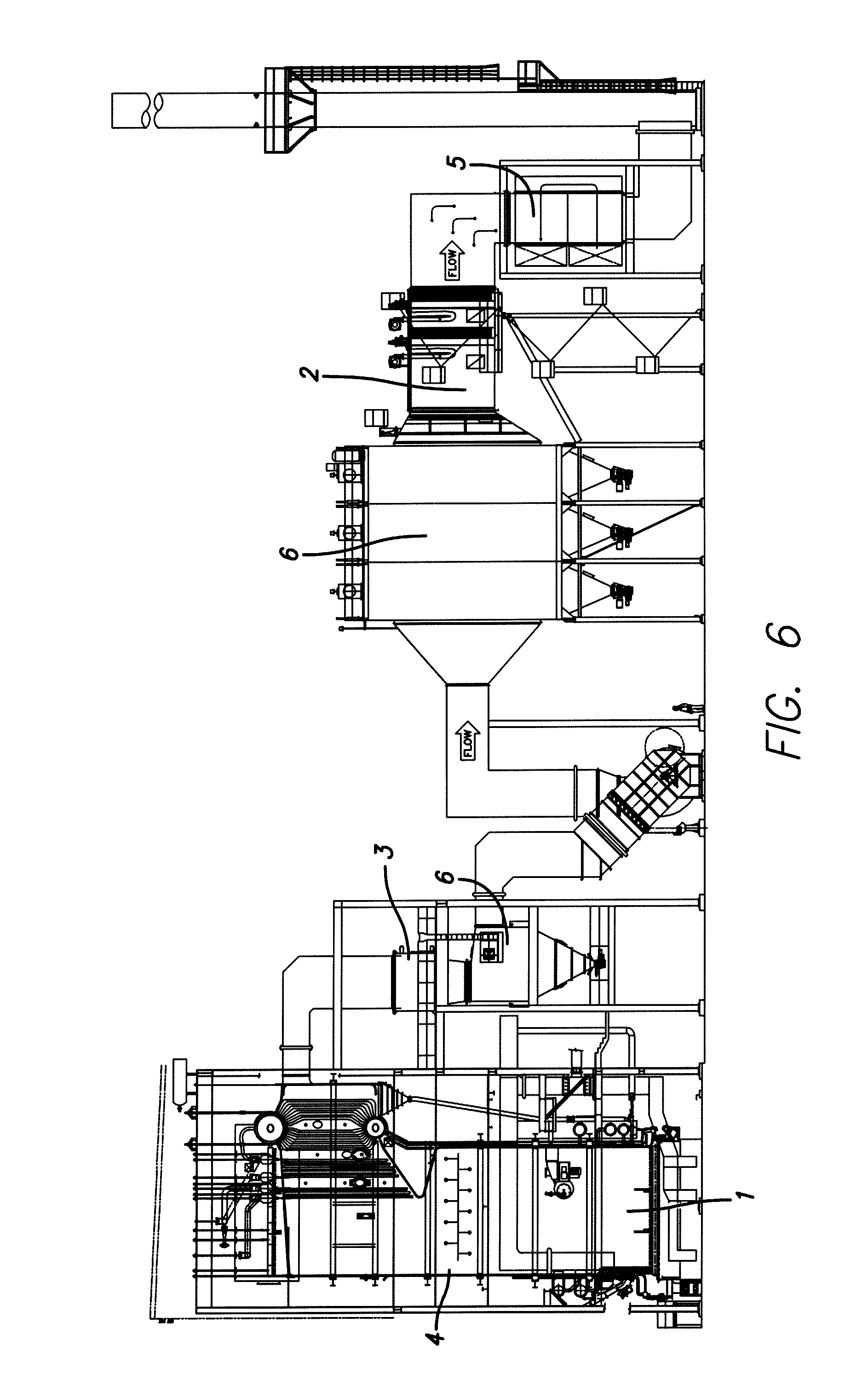

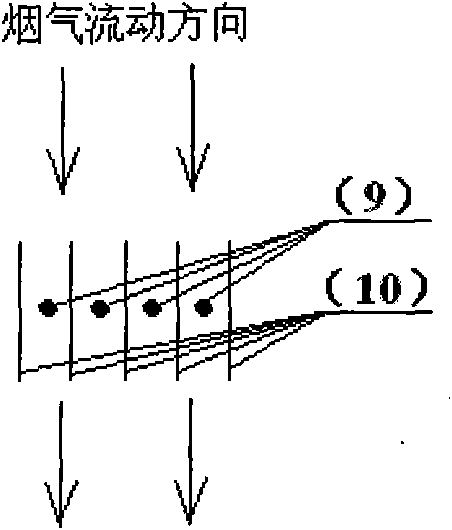

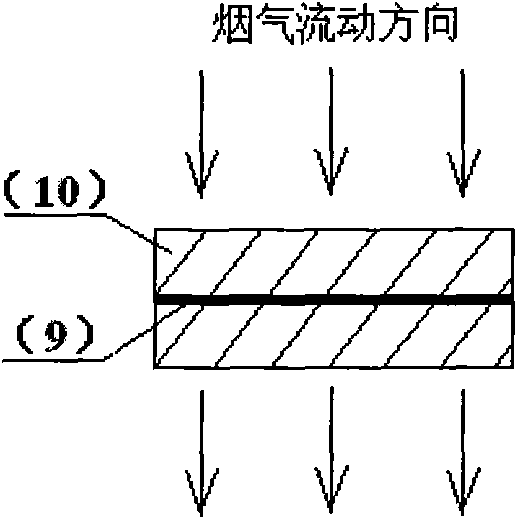

BIOMASS BOILER SCR NOx AND CO REDUCTION SYSTEM

InactiveUS20110311424A1High NOx control efficiencyWide temperature rangeCombination devicesNitrogen compoundsParticulatesFlue gas

A selective catalytic reduction system and method for reducing nitrogen oxide (NOx) emissions comprising a boiler producing flue gas emissions, a particulate control device receiving flue gas emissions from the boiler, a selective catalytic reduction unit (SCR) receiving flue gas emissions from the particulate control device and reducing nitrogen oxide (NOx) emissions, and a heat exchanger located downstream of the selective catalytic reduction unit (SCR) for removing heat from the flue gas for preheating at least one of boiler feed water and combustion air for the boiler.

Owner:2E ENVIRONMENTAL

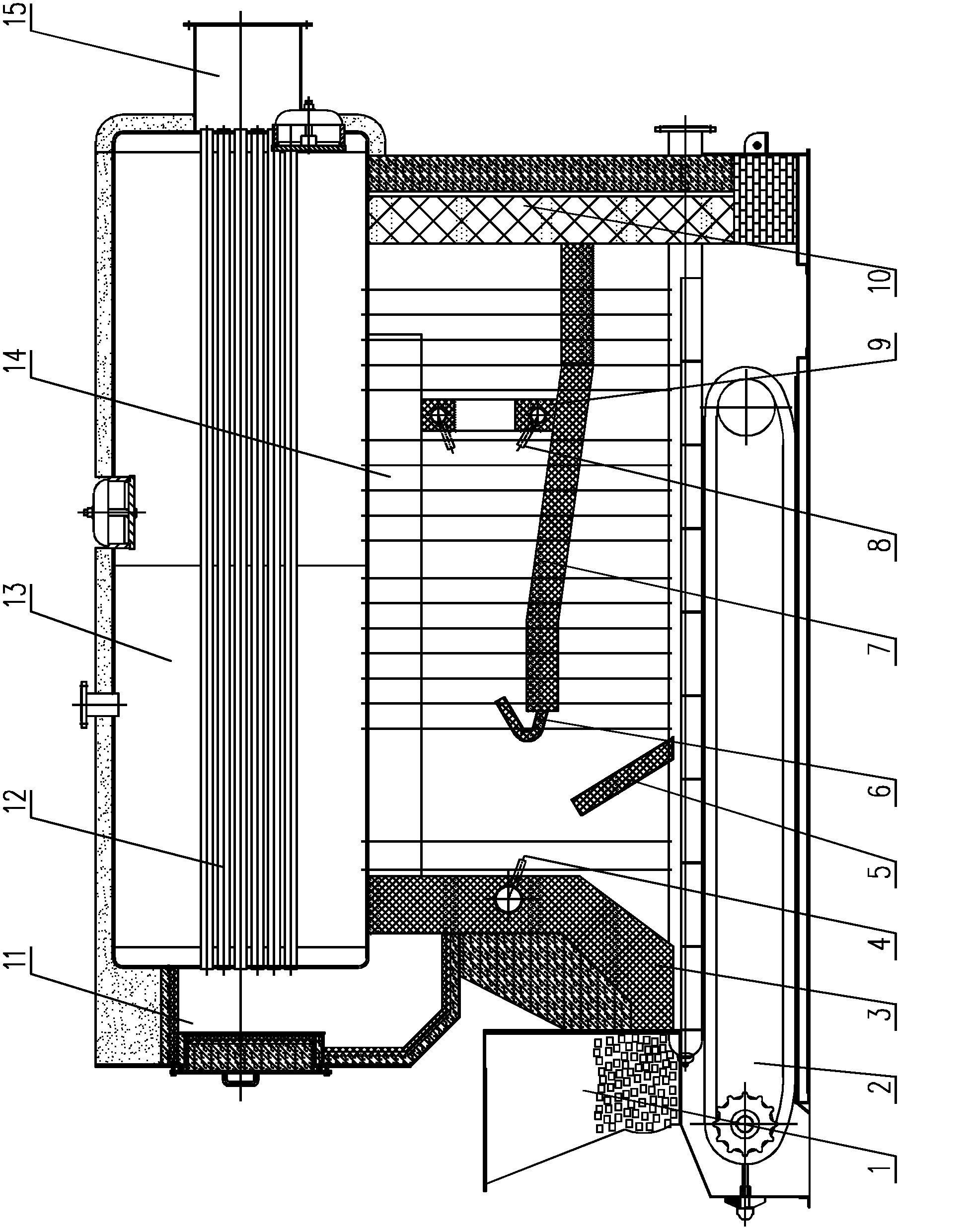

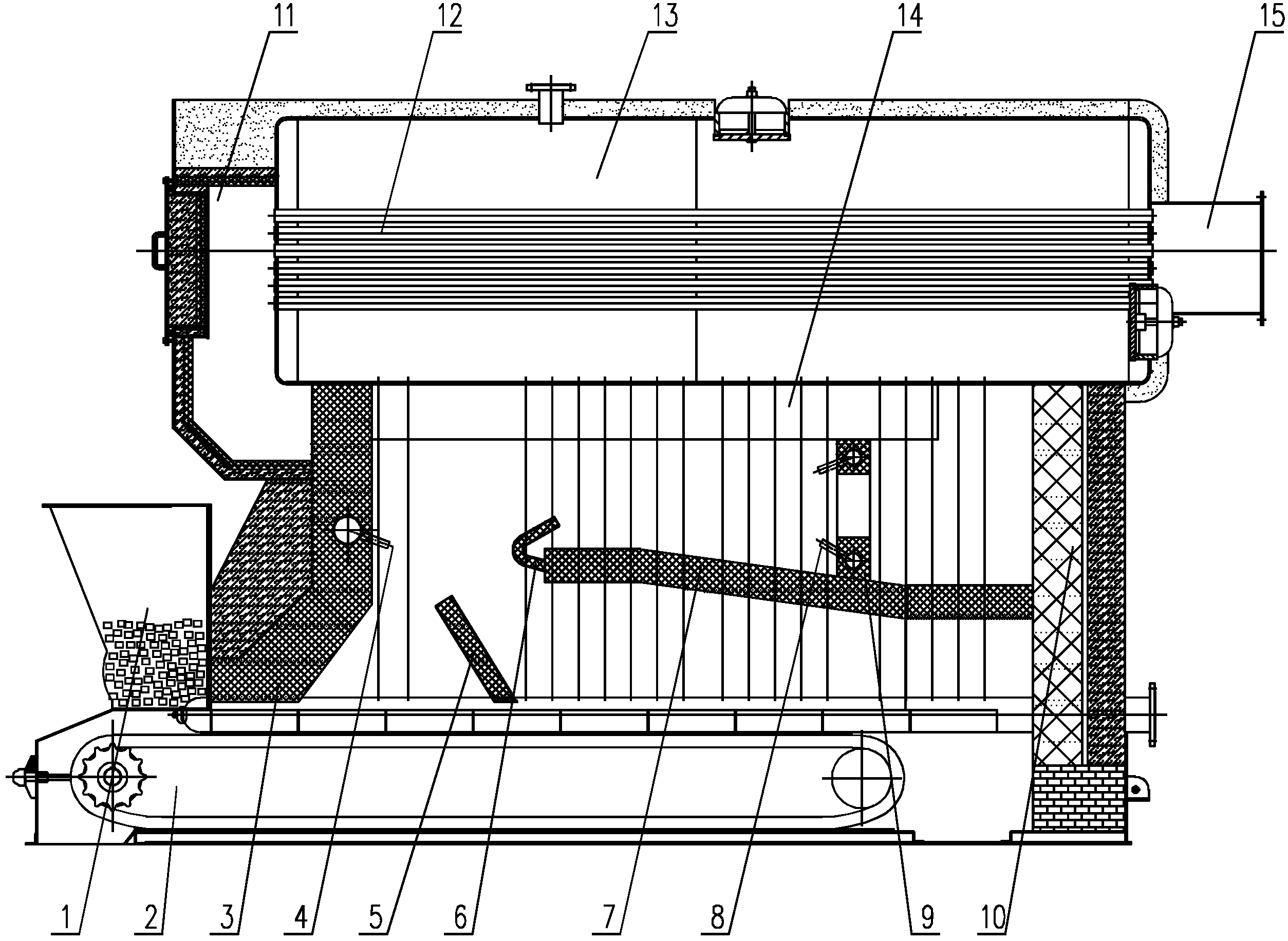

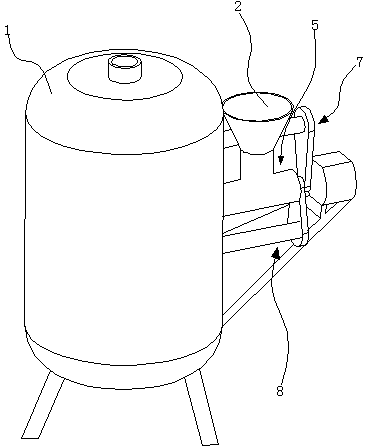

Continuous rotary biomass pyrolytic charring and boiler heat supply integrated equipment

ActiveCN102032553AImprove ergonomicsHigh thermal efficiencyDirect heating destructive distillationBiofuelsCombustion chamberEngineering

The invention discloses continuous rotary biomass pyrolytic charring and boiler heat supply integrated equipment. The equipment comprises raw material conveying equipment, a rotary drying furnace and a rotary charring furnace, and is characterized in that: the raw material conveying equipment is connected with the rotary drying furnace and connected with the rotary charring furnace through a star-like feeder; a material which is pyrolytically charred by the rotary charring furnace is discharged through a charred material outlet; the rotary charring furnace comprises a hearth and a rotary furnace; one path of high-temperature hot gas produced by combustion of an oxygen-containing combustion chamber is conveyed into the hearth of the rotary charring furnace through a flue to enter a charring section; the rotary furnace comprises a barrel, an inner heating tube and a baffle ring; one end head of the inner heating tube is fixed on the barrel wall on one side and passes through the baffle ring to be fixed on the barrel wall on the other side of the baffle ring; after the high-temperature hot gas passes through the hearth through the flue, certain high-temperature hot gas enters one end head of the inner heating tube, is discharged out of the other end head of the inner heating tube, enters a waste heat conveying pipe and is conveyed into the rotary drying furnace through an induced draught fan; and the high-temperature hot gas is conveyed into a biomass boiler through another flue. The equipment can improve the working efficiency of the rotary charring furnace.

Owner:FUJIAN TIANCHUANGLI BIOLOGICAL ENERGY EQUIP

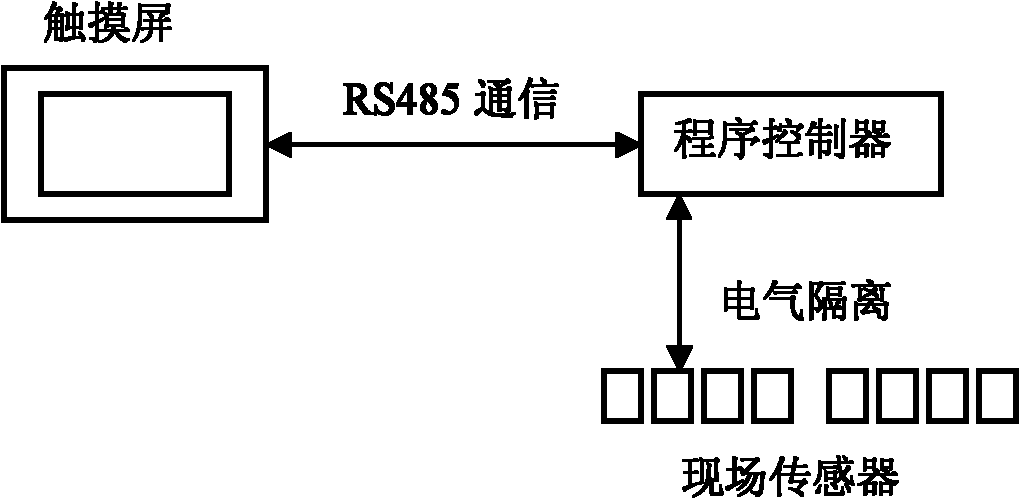

Control system and control method for biomass boiler combustion

The invention discloses a control system for biomass boiler combustion. The control system comprises a drum level information acquisition unit, a combustion control subsystem information acquisition unit, a signal transmission unit, a central control unit and an execution unit, wherein the drum level information acquisition unit and the combustion control subsystem information acquisition unit are used for acquiring information about a biomass boiler and sending the acquired information to the central control unit via the signal transmission unit; the central control unit sends a control signal to the execution unit after processing the acquired information; and the biomass boiler is kept always in an optimal combustion state via the control method of the central control unit, thereby saving energy and reducing pollution.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

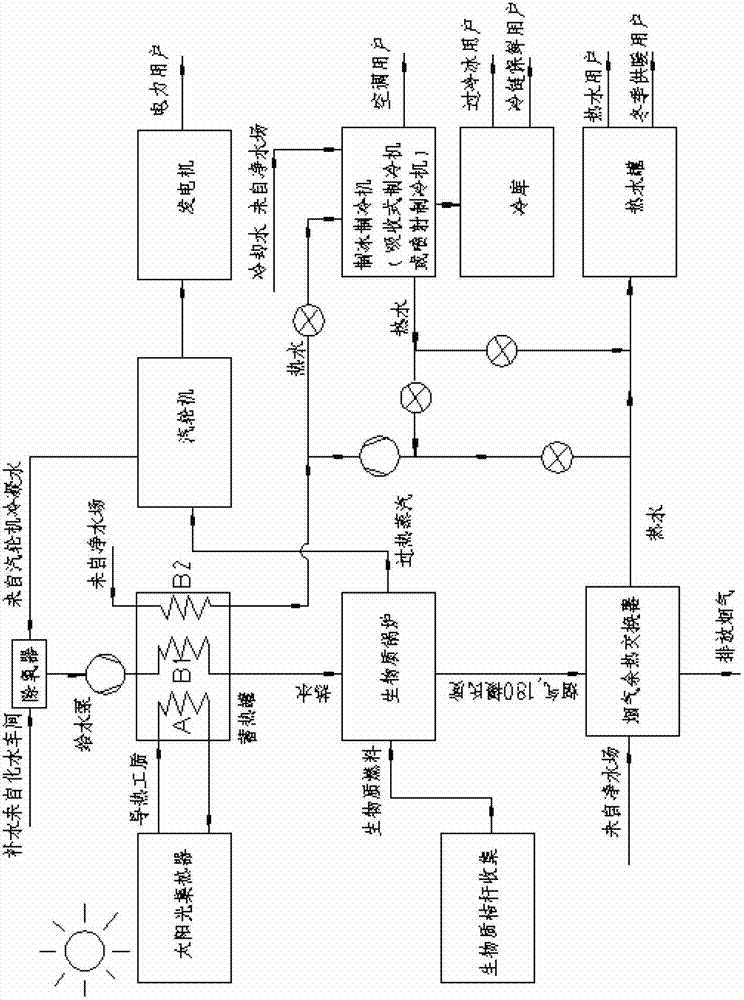

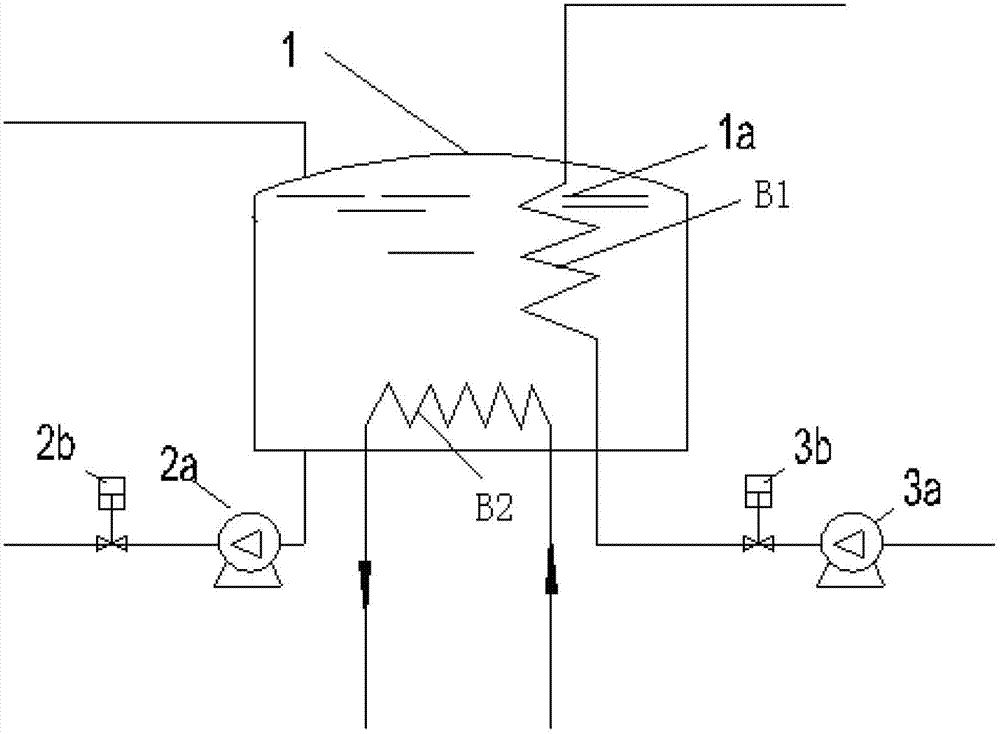

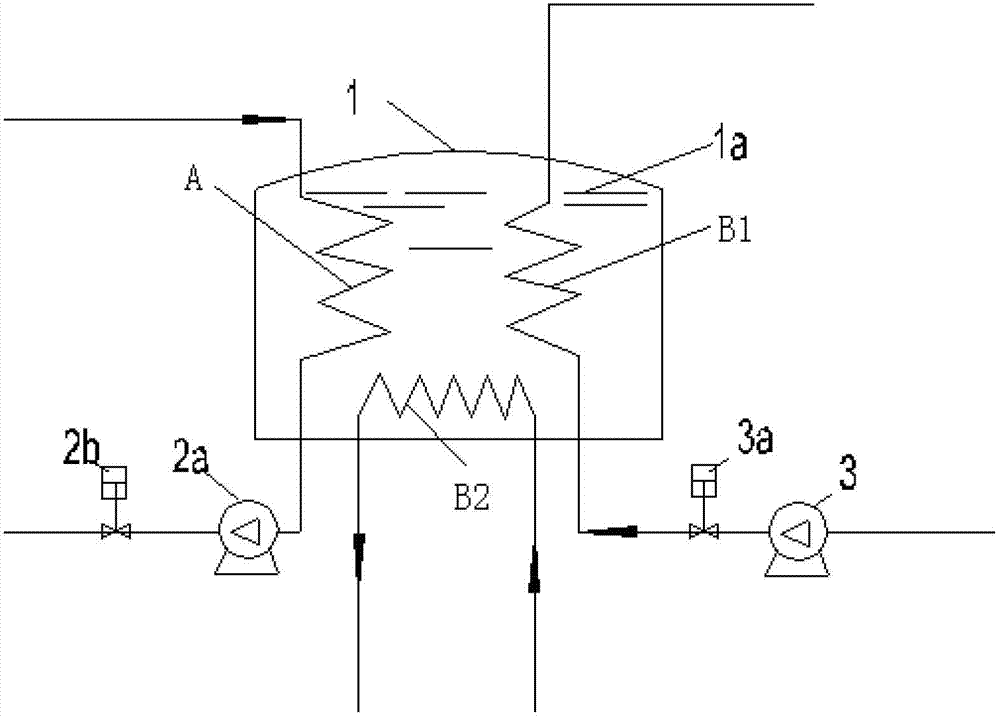

Thermal power system with complementation between solar energy and biomass energy

InactiveCN102967080AEnergy saving and environmental protection use energy modeSolve instabilitySolar heating energySpace heating and ventilationThermal energySolar light

The invention provides a thermal power system with complementation between solar energy and biomass energy. The thermal power system comprises a solar light condensing device, a solar heat storage kettle, a biomass heat power station, a combined refrigerating and icing device for intensive cooling, and a hot water system for intensive heating, wherein the solar light condensing device is connected with the solar heat storage kettle through a pipeline, the inlet of a first output heat exchanger B1 of the solar heat storage kettle is connected with the outlet of a water supply pump of a biomass boiler, and the outlet of the B1 is connected with the inlet of a water supply system of the biomass boiler; an inlet pipeline of a second output heat exchanger B2 of the solar heat storage kettle is connected with an output pipeline of a water purification plant, and the outlet of the B2 is connected with a heat input pipeline of the combined refrigerating and icing device; the heat input pipeline can supply heat for refrigerating and icing; and work cooling water of the combined refrigerating and icing device is connected to a hot water kettle of the heat supply system to intensively supply heat to users. The solar heat storage kettle is a two-medium or three-medium double-circulation heat storage kettle, and the heat storage medium is heat transfer oil and fused salt.

Owner:ZHONGYING CHANGJIANG INTERNATIONAL NEW ENERGY INVESTMENT CO LTD

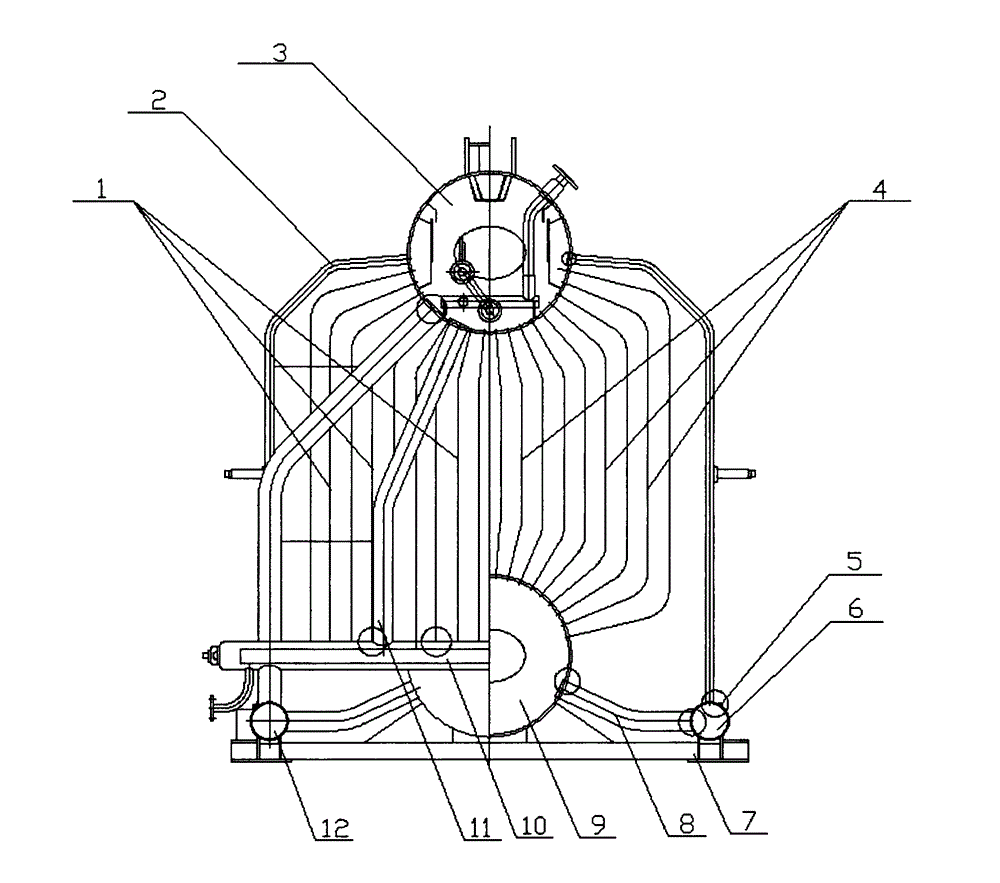

Biomass boiler

InactiveCN102913889ALess heat storageReduce lossesBoiler water tubesWater-tube boilersRefractoryPulp and paper industry

The invention relates to a biomass boiler. The biomass boiler comprises a base plate, an upper boiler, two lower boilers and a controller, wherein the two lower boilers are arranged end to end and connected with each other through a pipeline. The novel structure of the biomass boiler causes less heat accumulation of a furnace wall, so that construction for a thick furnace wall can be avoided when the biomass boiler is arranged, a refractory material can be saved or used fewer, the cost can be reduced, the arrangement cost can be reduced, and the arrangement complexity can be reduced. Therefore, the biomass boiler is simple in structure and convenient in use, can reduce the arrangement and complexity of a water-tube boiler can be effectively reduced, the boiler heat is prevented from losing, and the heat efficiency of the water-tube boiler can be improved.

Owner:青岛华泰锅炉热电设备有限公司

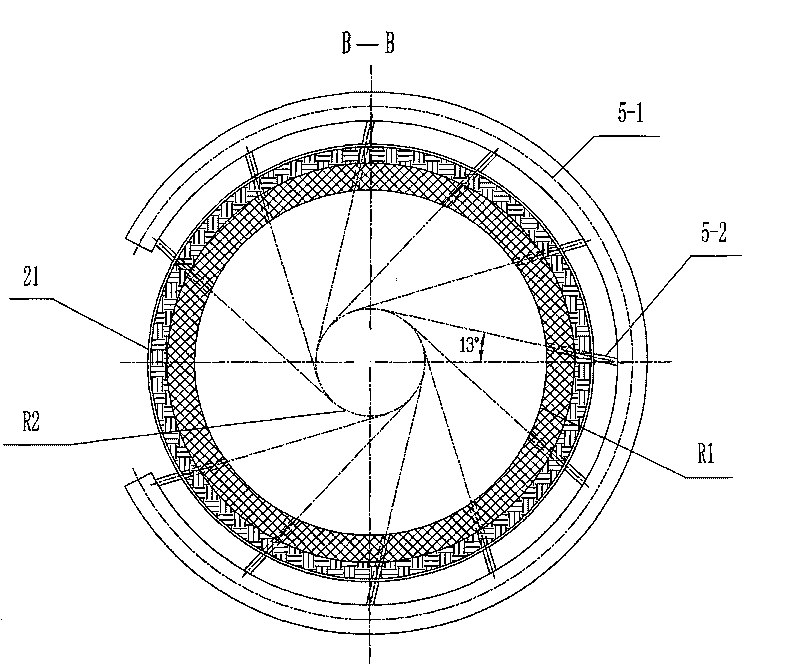

Biomass vaporizing combustion coupled type cyclone boiler

InactiveCN101625117ABurn fullyGuaranteed gasification effectChemical industrySolid fuel combustionCycloneCombustion chamber

The invention relates to a biomass vaporizing combustion coupled type cyclone boiler, solving the problems of low thermal efficiency, high tar content in vaporizing gas, easy scorification of a high-temperature heating surface and the like existing in the current biomass boiler, and comprising a jacketed type boiler body and a feeding device thereof, a primary air fan, a secondary air fan, a water circulating pump, an ash slurry pond and a flue water fog deduster. The invention has the technical points that the secondary air fan is connected with the jacket of the boiler body, and an atomizing nozzle is arranged on the inner side of an outer boiler wall; secondary air and water vapour tangential jet holes are distributed on the circumference of an inner boiler wall; one end of a small spiral feeder of the feeding device is connected with the inner cavity of a vaporizing combustion chamber, and the other end is connected with the secondary air fan by a feeding air valve; the vaporizing combustion chamber and a complete combustion chamber are communicated. The invention has reasonable structure design and stable operation and strengthens effects of heat transfer and fuel vaporization, which can increase the transformation efficiency of biomass energy and heat values of biomass fuel vaporizing products, and thus, the biomass fuel is completely and sufficiently burnt, thereby saving energy, increasing the heat efficiency of the boiler, protecting environment and reducing environmental pollution.

Owner:辽宁玺丰新能源科技有限公司

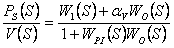

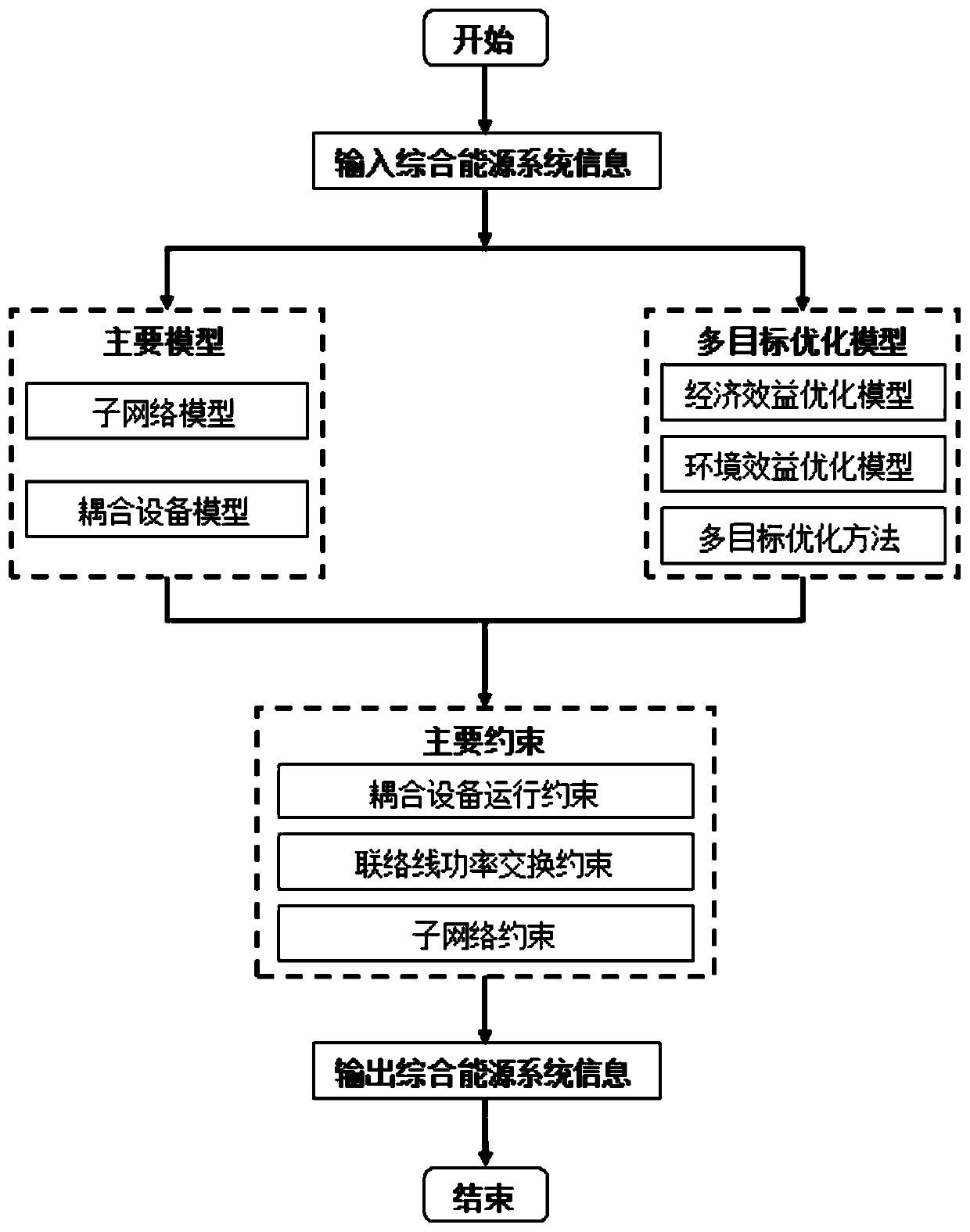

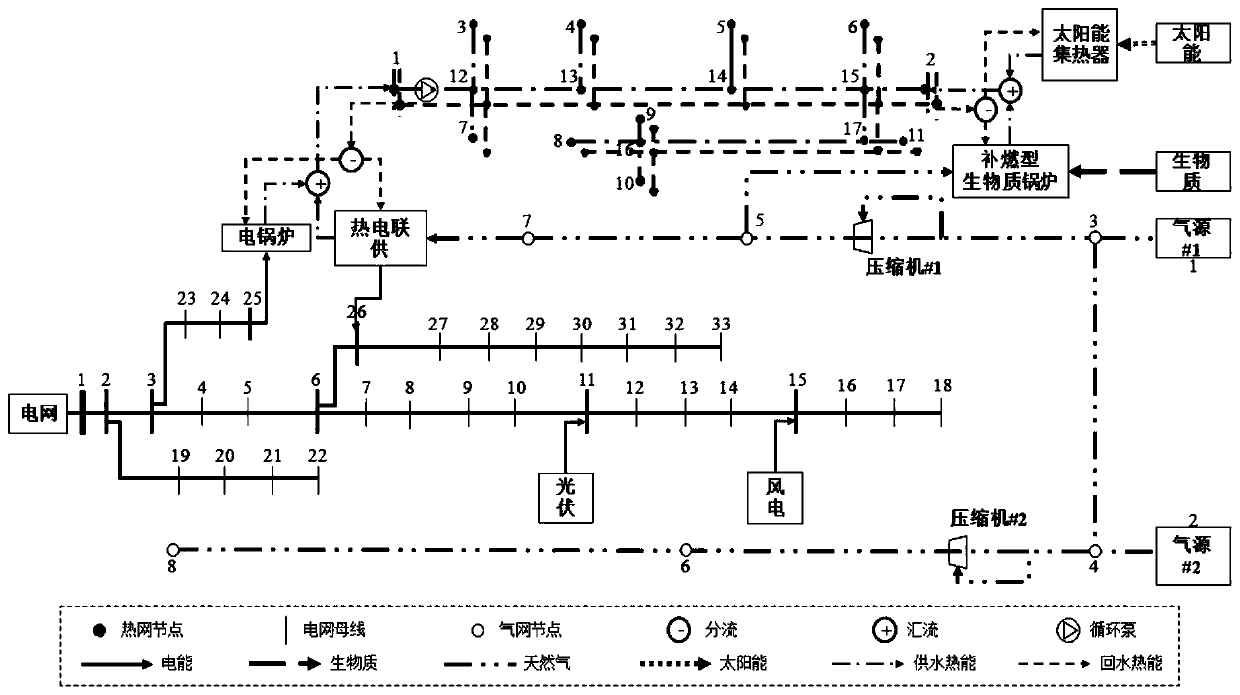

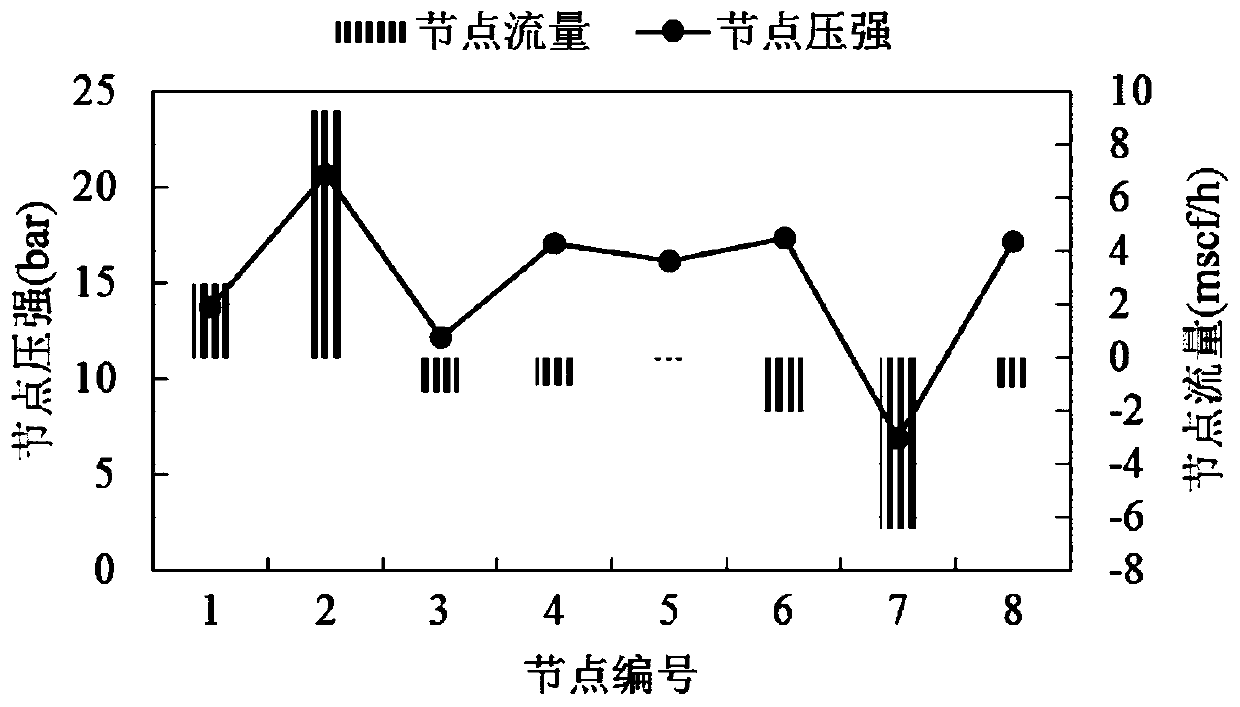

Comprehensive energy system multi-objective operation optimization method considering electric heating gas network

The invention provides a comprehensive energy system multi-objective operation optimization method considering an electric heating gas network. The comprehensive energy system multi-objective operation optimization method comprises the steps that a comprehensive energy system sub-network model comprising a natural gas network, a power network and a thermal network is established according to the obtained comprehensive energy system main information; then, an integrated energy system typical coupling equipment model comprising an electric boiler, a combined heat and power system, an afterburning type biomass boiler and a solar heat collector is established; secondly, on the basis of the maximization of the economic benefits and the environmental benefits, a multi-objective operation optimization model is established, and the comprehensive energy system operation constraint conditions including the coupling equipment operation constraints, the tie line power exchange constraints and thesub-network operation constraints, are set; and finally, the multi-objective operation optimization model is solved, and the main information of the comprehensive energy system is outputted. Accordingto the method, the effectiveness of the model and the method on the comprehensive energy system operation optimization is verified through the example analysis, and the reference can be provided forthe multi-objective operation optimization of the comprehensive energy system.

Owner:HOHAI UNIV

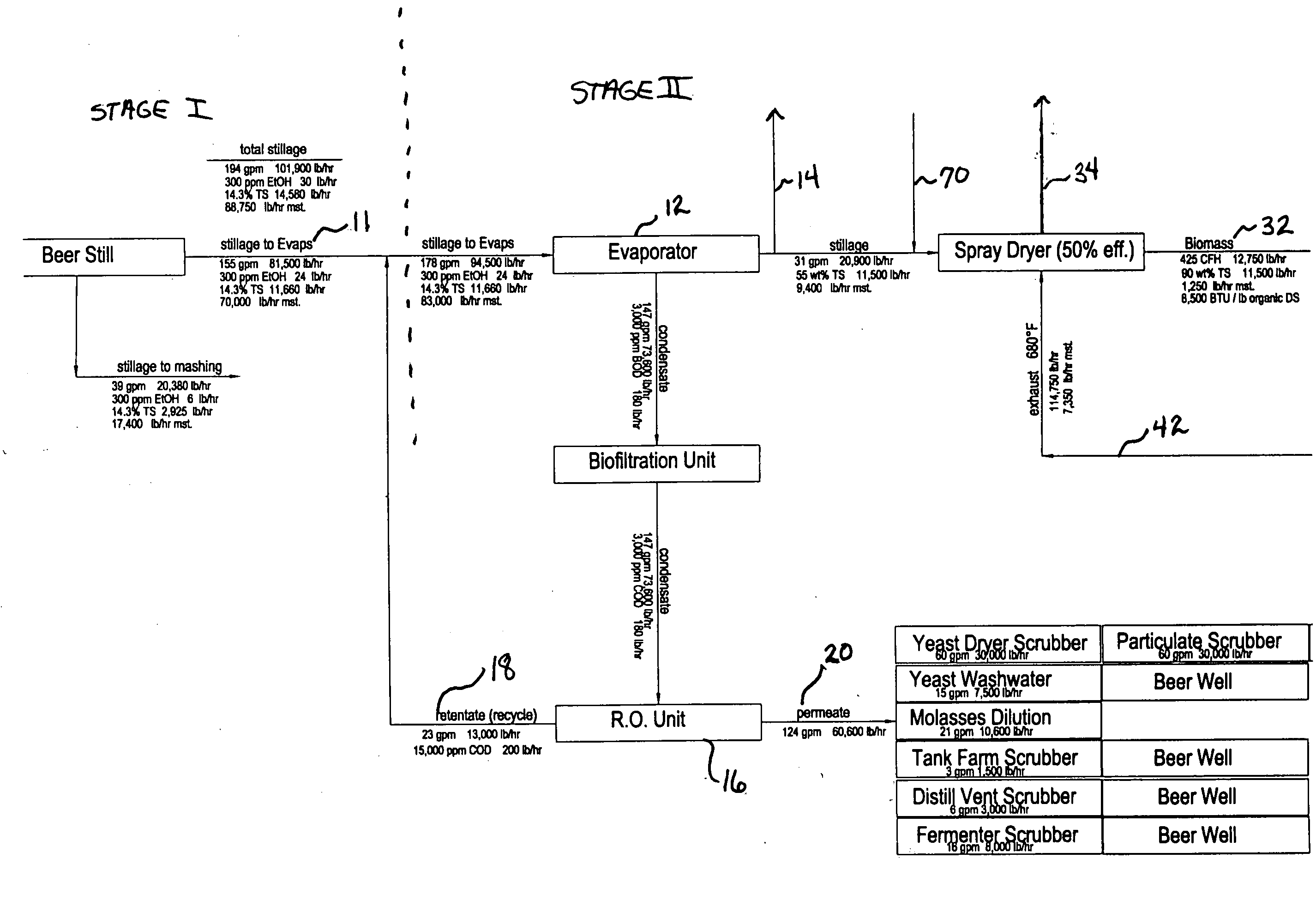

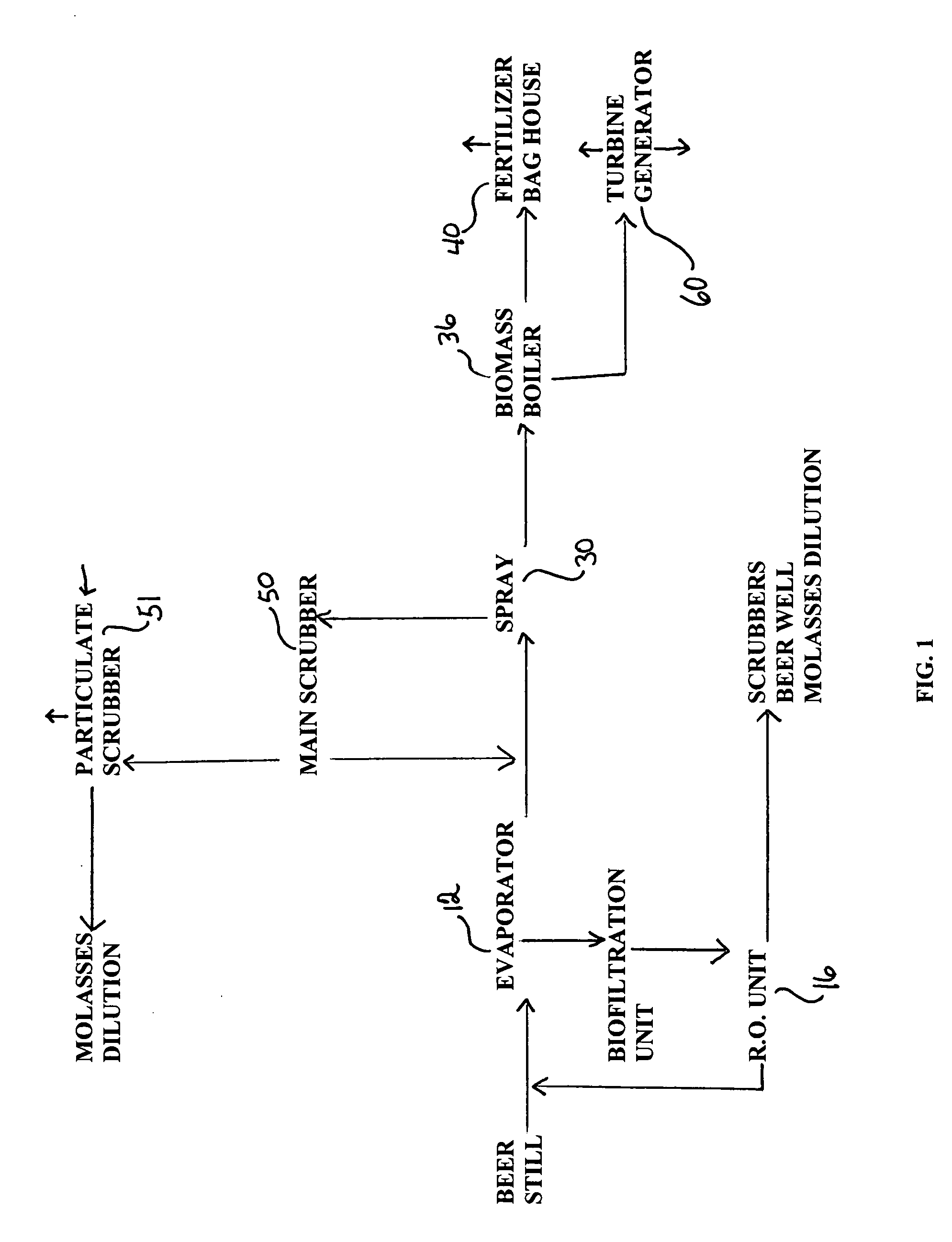

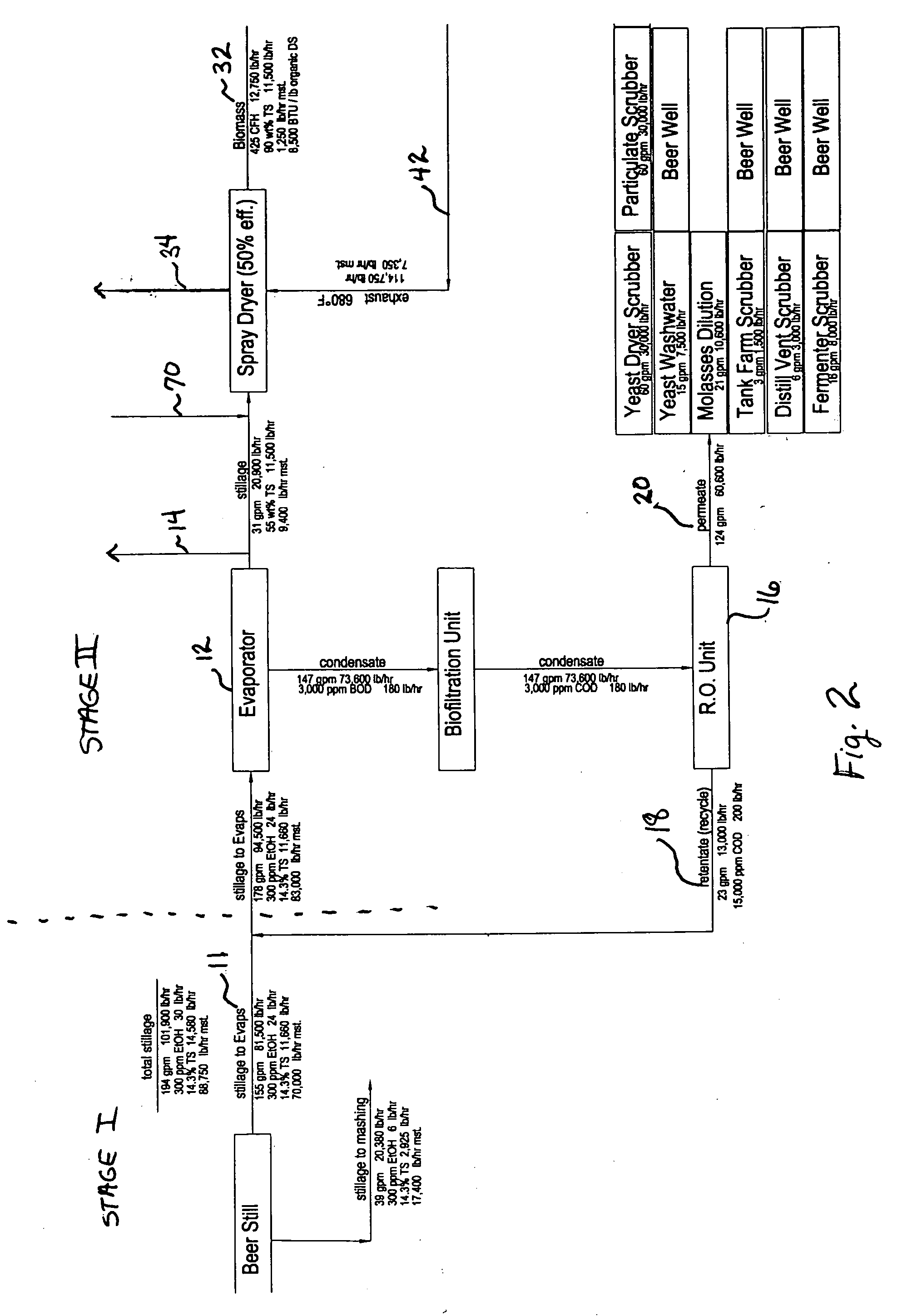

Process and apparatus for reusing energy recovered in alcohol production

A process for producing ethanol wherein stillage is recycled into the process as a source of heat and power. Specifically, stillage is spray dried and then combusted in a biomass boiler. Spray drier exhaust is exported to the main scrubber and employed to extract particulates. Flue gas from the boiler is used to produce high pressure steam and the cooled gas is recycled back to the spray dryer as a heat source. The high pressure steam is used by a turbine generator which in turn produces electric power and low pressure steam both of which are returned to the process. Ash remaining after combustion may be used as a fertilizer.

Owner:HEARTLAND RENEWABLE ENERGY

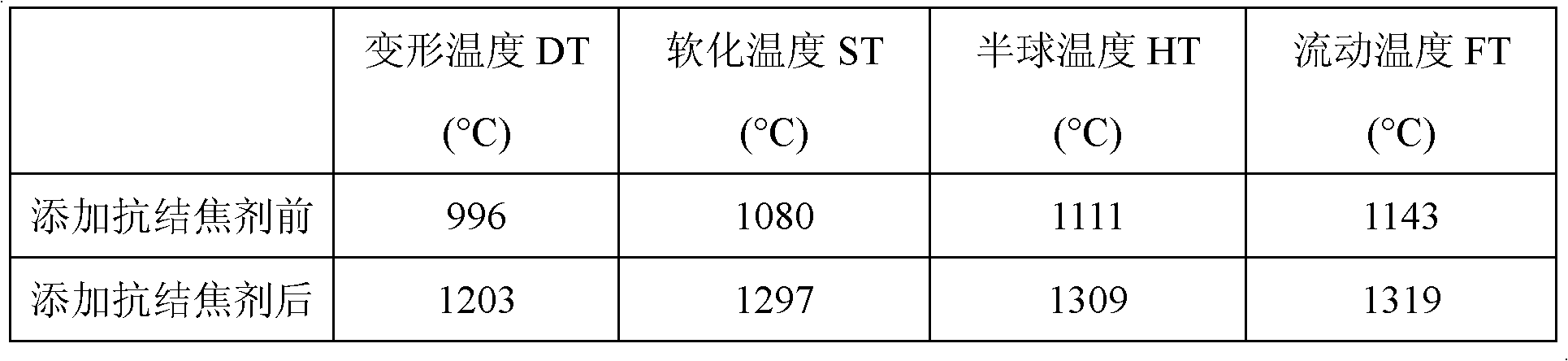

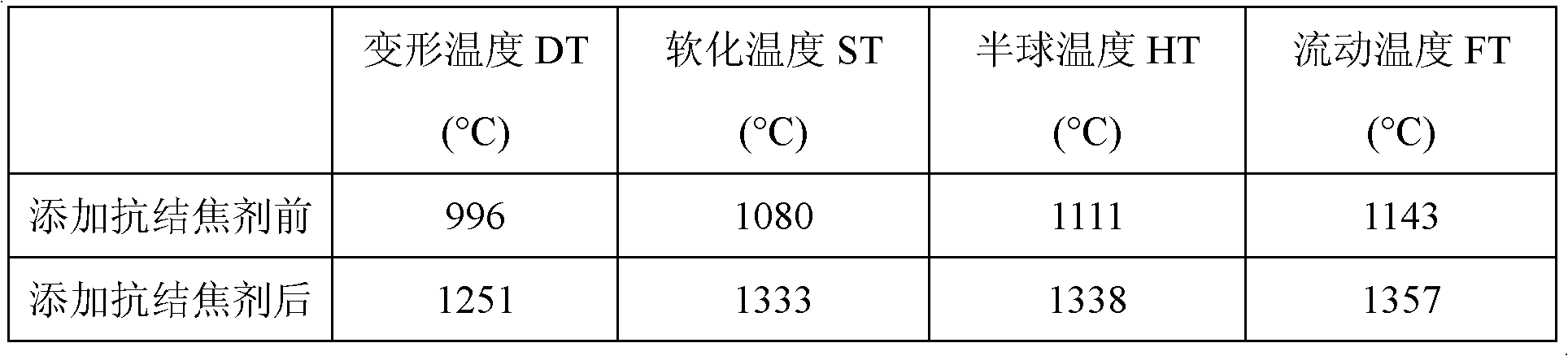

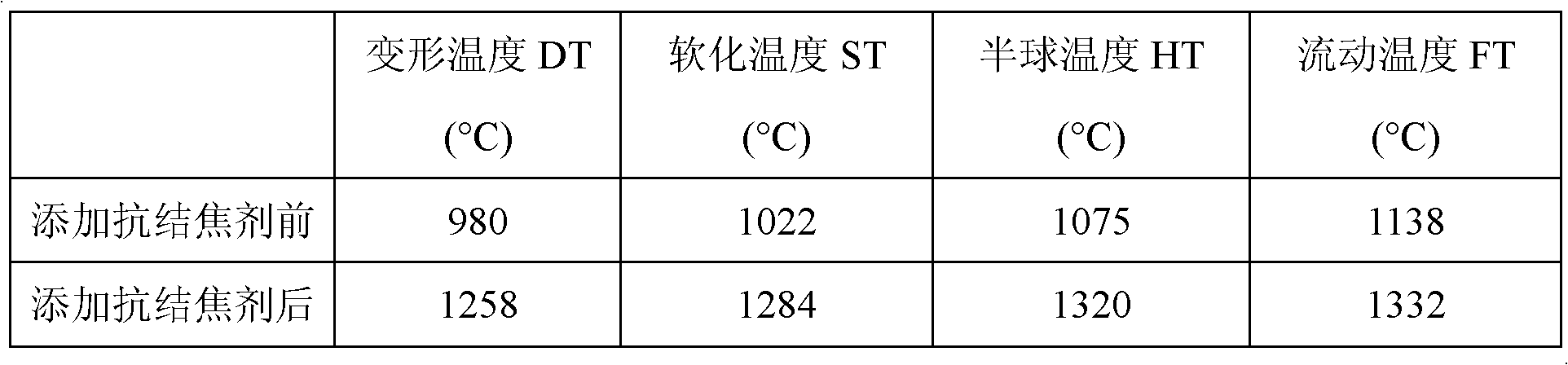

Biomass boiler anti-coking agent with porous membrane structure and preparation method thereof

ActiveCN102585963ARaise the ash melting temperatureHigh melting temperatureSolid fuelsFuel additivesFoaming agentSlag

The invention discloses a biomass boiler anti-coking agent with a porous membrane structure and a preparation method thereof. The anti-coking agent consists of magnesium oxide (MgO), kaolin, active aluminum oxide (Al2O3) and a foaming agent. The MgO, the kaolin and active Al2O3MgO form an MgO-kaolin-active Al2O3MgO matrix of the anti-coking agent, wherein percentage mass contents of the MgO, the kaolin and the active Al2O3 in the MgO-kaolin-active Al2O3MgO matrix are respectively 20%-60%, 25%-65% and 15%-30%. The percentage mass content of the foaming agent in the whole anti-coking agent is 20%-50%. The biomass anti-coking agent with the porous membrane structure is high in mechanical strength, stable in structure and large in poriness and specific surface area, and the reaction area between the anti-coking agent and alkali metal in biomass is increased. Micro-pores on the surface of the anti-coking agent have adsorption performance, alkali metal such as K and Na can be effectively adsorbed onto the surface of the anti-coking agent, high-melting-point matter is generated, and generation of slag of heat-transfer surface is reduced. The invention further provides the preparation method of the anti-coking agent.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

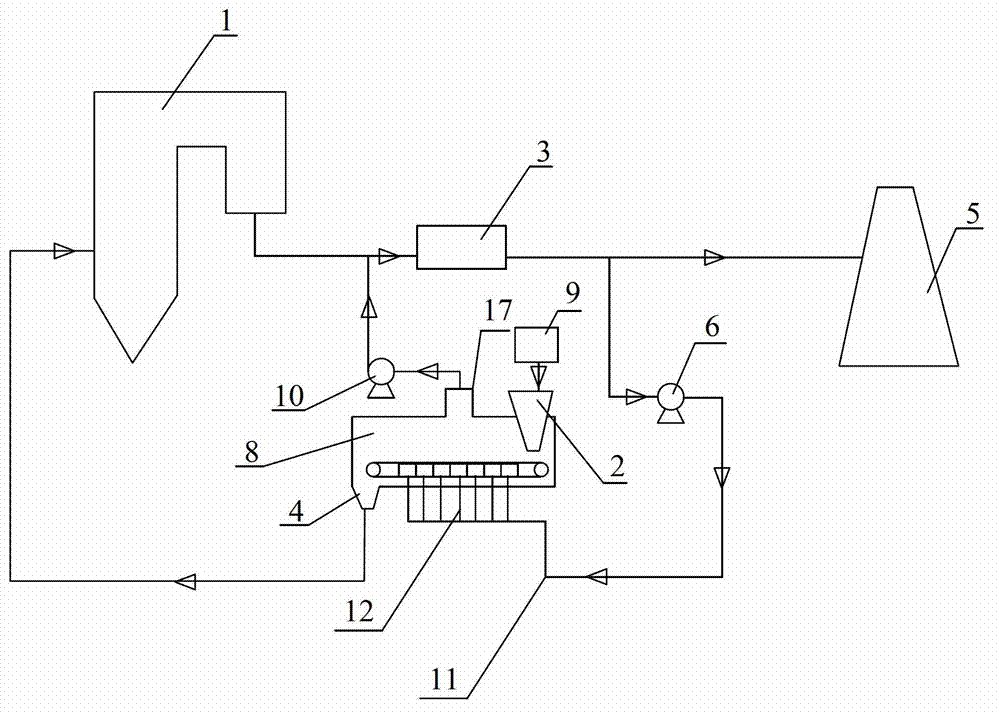

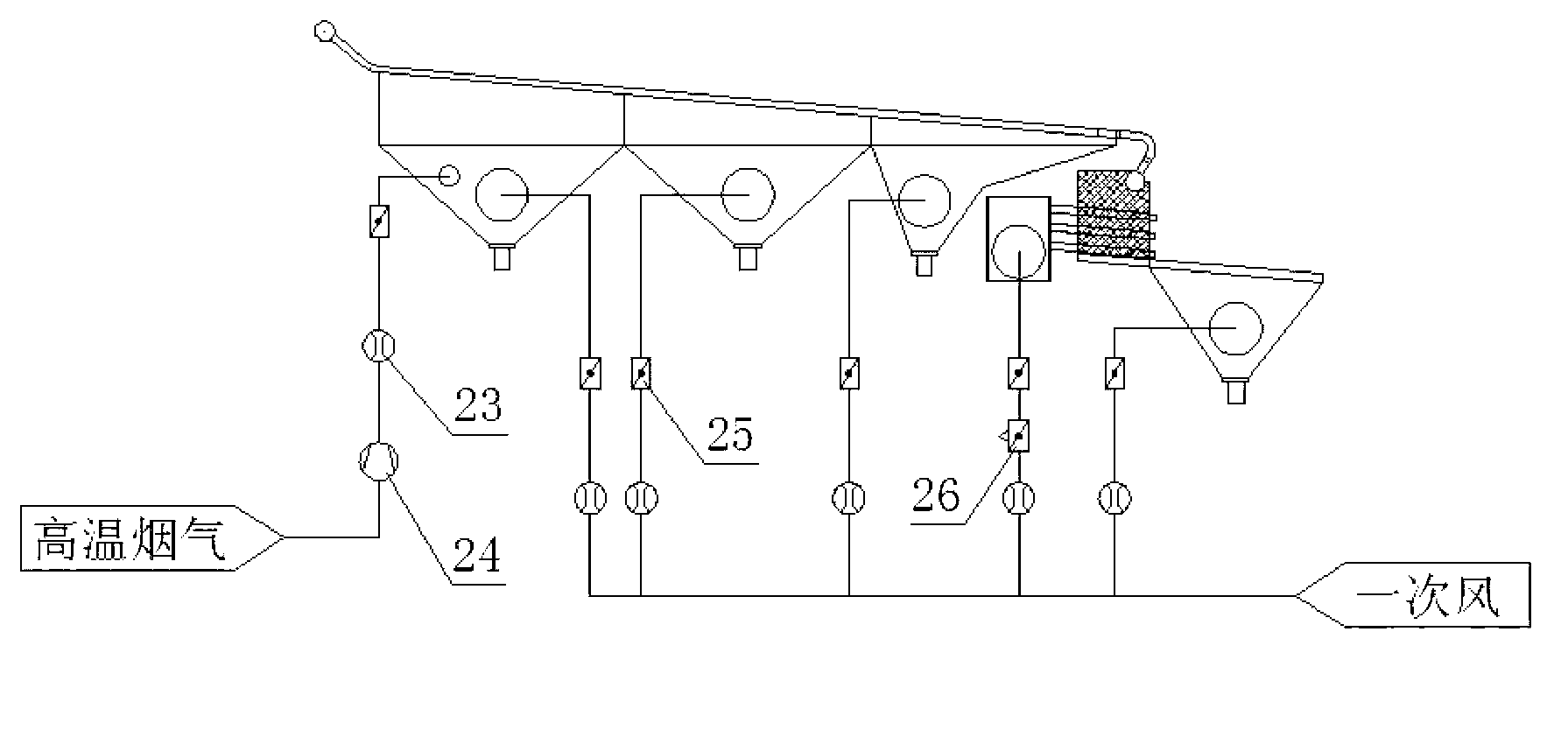

Method and device using biomass boiler smoke to dry biomass raw material

ActiveCN102954678AReduce trafficLow costDrying gas arrangementsHeating arrangementProcess engineeringBiomass boiler

The invention discloses a method and device using biomass boiler smoke to dry biomass raw material. The method comprises the following steps of guiding the biomass raw material to a belt conveyor in a drying chamber, carrying out dynamic conveying, guiding the biomass boiler smoke after being subjected to the dust removal treatment into the biomass raw material to carry out contact heat exchanging, and then removing part of moisture from the biomass raw material; carrying out dust removal treatment on the smoke after being subjected to the heat exchange, directly using the dried biomass raw material as the fuel of a biomass boiler, or storing the dried biomass material for standby. The device mainly consists of a smoke circulation system and the belt conveyor, wherein the smoke circulation system consists of a dust remover, the drying chamber, a booster fan, a draught fan and the like, and the belt conveyor is arranged in the drying chamber and is used for conveying the biomass raw material. The method and the device have the advantages that the structure is simple, the technology is economic, the drying effect is good, the size of the biomass boiler system can be effectively reduced, and the heat efficiency of the biomass boiler system is greatly improved.

Owner:SUNSHINE KAIDI NEW ENERGY GROUP CO LTD

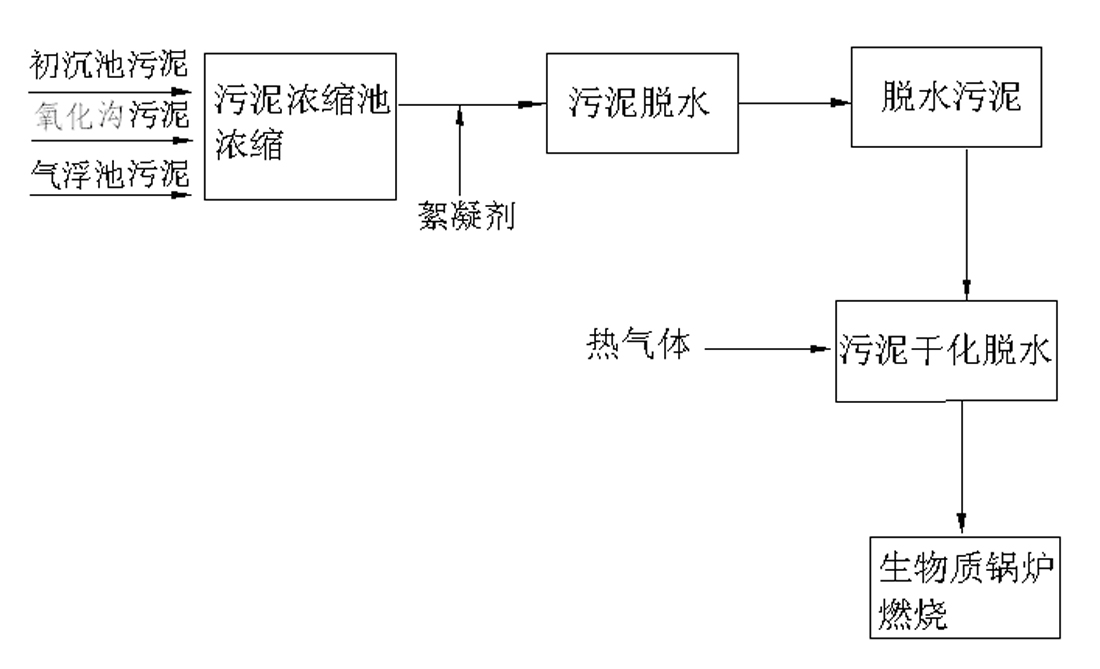

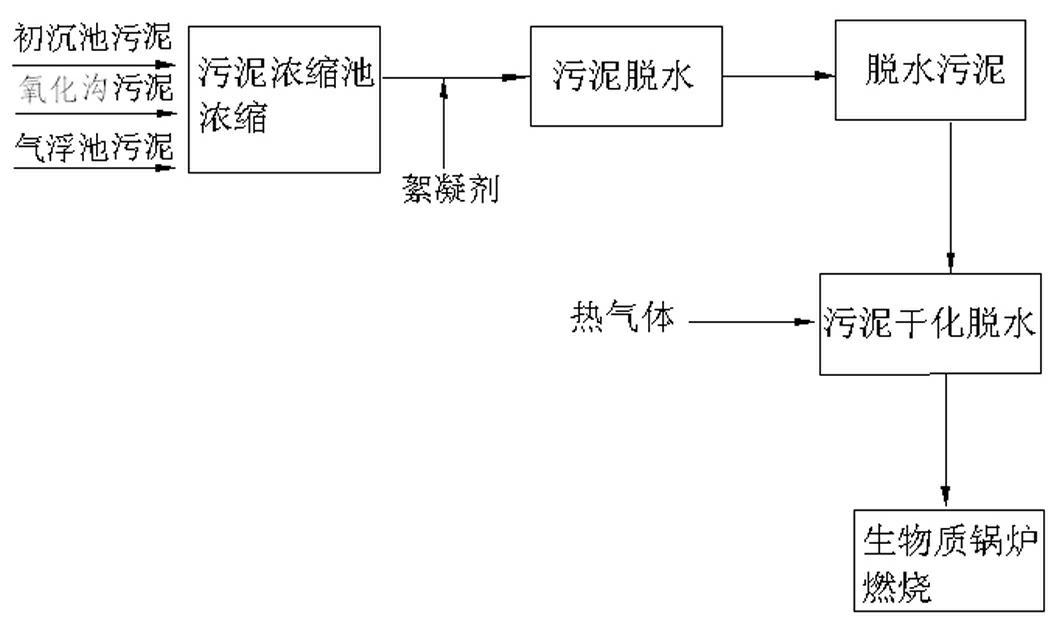

Method for harmlessly recycling sludge

ActiveCN102079615AReduce moisture contentConducive to maintaining spontaneous combustionSludge treatment by de-watering/drying/thickeningIncinerator apparatusSpontaneous combustionFluidized bed

The invention relates to a method for harmlessly recycling sludge, comprising the following steps of: concentrating and dehydrating the sludge with a moisture content of 94%-96% to ensure that the moisture content is reduced to 75%-85%; desiccating and dehydrating the concentrated and dehydrated sludge to ensure that the moisture content is reduced to be not higher than 60%; mixing the desiccated and dehydrated sludge with biomass waste; and delivering the mixture into a circulating fluidized-bed biomass boiler for burning. The method is beneficial to the maintaining of spontaneous combustion of the sludge and can be used for recovering heat energy produced in the combustion process of the sludge in the mean time, and therefore, costs of sludge transportation and landfill are saved, the heat energy produced in the combustion process of the sludge can be recovered to produce steam so as to save energy, and the secondary pollution to environment, caused by landfill, can be avoided.

Owner:湖南骏泰生物质发电有限责任公司

Biomass gasification boiler using air-steam as gasifying agent and coupling combustion method thereof

InactiveCN101737795ABurn fullyImprove gasification qualityChemical industryNon-combustible gases/liquids supplyCombustion chamberSlag

The invention provides a biomass gasification boiler using air-steam as a gasifying agent and a coupling combustion method thereof, belongs to the technical field of boiler combustion, and solves the problems of low heat efficiency, high tar content in gasified gases, easy slag bonding of a high-temperature heating surface and the like existing in the conventional biomass boiler. In the biomass gasification boiler of the invention, a baffle plate is arranged in a closed ring-shaped atomization cavity, an air inlet tube is communicated with the closed ring-shaped atomization cavity on the side of the baffle plate, a water inlet tube is communicated with the closed ring-shaped atomization cavity on the other side of the baffle plate by an atomization nozzle, and an outlet of a hot air-steam mixed pipeline is communicated with the closed ring-shaped atomization cavity between the baffle plate and the atomization nozzle. The method mainly comprises the following steps of: mixing hot air and steam to obtain a mixed gas serving as the gasifying agent, spraying the mixed gas in a gasifying combustion chamber by a spraying hole at the bottom part of a furnace grate to fully convert the biomass into the combustible gas, filling the generated hydrogen gas and carbon monoxide in a complete combustion chamber of a gas fired boiler for combustion with three times of air feeding. The biomass gasification boiler has the advantages of high heat efficiency, low tar content in the gasified gases, no slag bonding of the high-temperature heating surface and the like.

Owner:HARBIN INST OF TECH

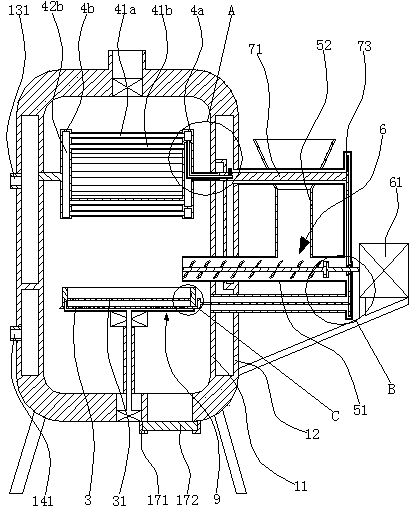

Biomass boiler capable of realizing combined combustion of synthesis gas and semicoke

ActiveCN101893234AReduce ash corrosionHigh thermal efficiencyChemical industrySolid fuel combustionCombustion chamberCombustor

The invention provides a biomass boiler capable of realizing combined combustion of synthesis gas and semicoke and relates to the biomass boiler. The biomass boiler aims to solve the problem that the conventional biomass boiler does not take the influences of semicoke yield on combustion efficiency into consideration and therefore causes increased heat loss due to imperfect combustion and reduces the heat efficiency of the biomass boiler. A semicoke combustor is arranged between a biomass vaporizing chamber and the main body of the boiler; the semicoke combustor is communicated with a hearth; one end of a synthesis gas outlet pipe is communicated with the inner cavity of the biomass vaporizing chamber through a synthesis gas outlet, and the other end of the synthesis gas outlet pipe is communicated with the hearth; a storage bin is arranged above the biomass vaporizing chamber and the semicoke combustor; a biomass fuel in the storage bin enters the biomass vaporizing chamber through a primary feeder; and the biomass fuel in the storage bin enters the semicoke combustor through a secondary feeder. The biomass boiler is suitable for combusting biomass fuels of various particle sizes and greatly improves combustion efficiency.

Owner:HARBIN INST OF TECH

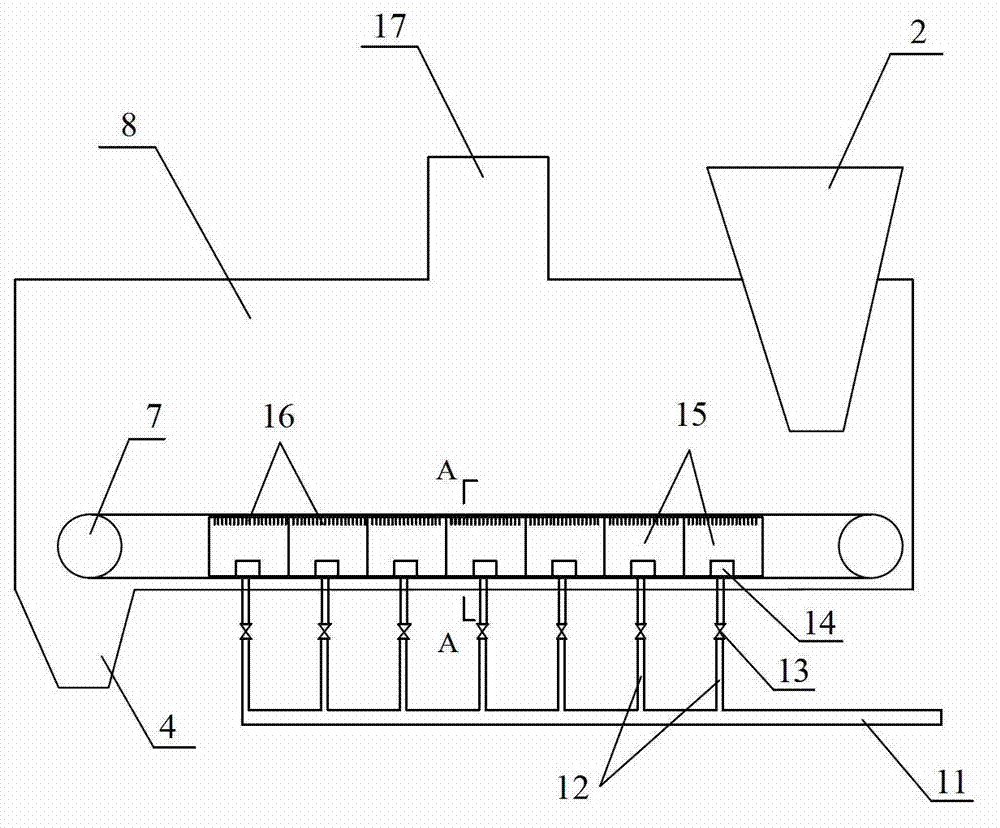

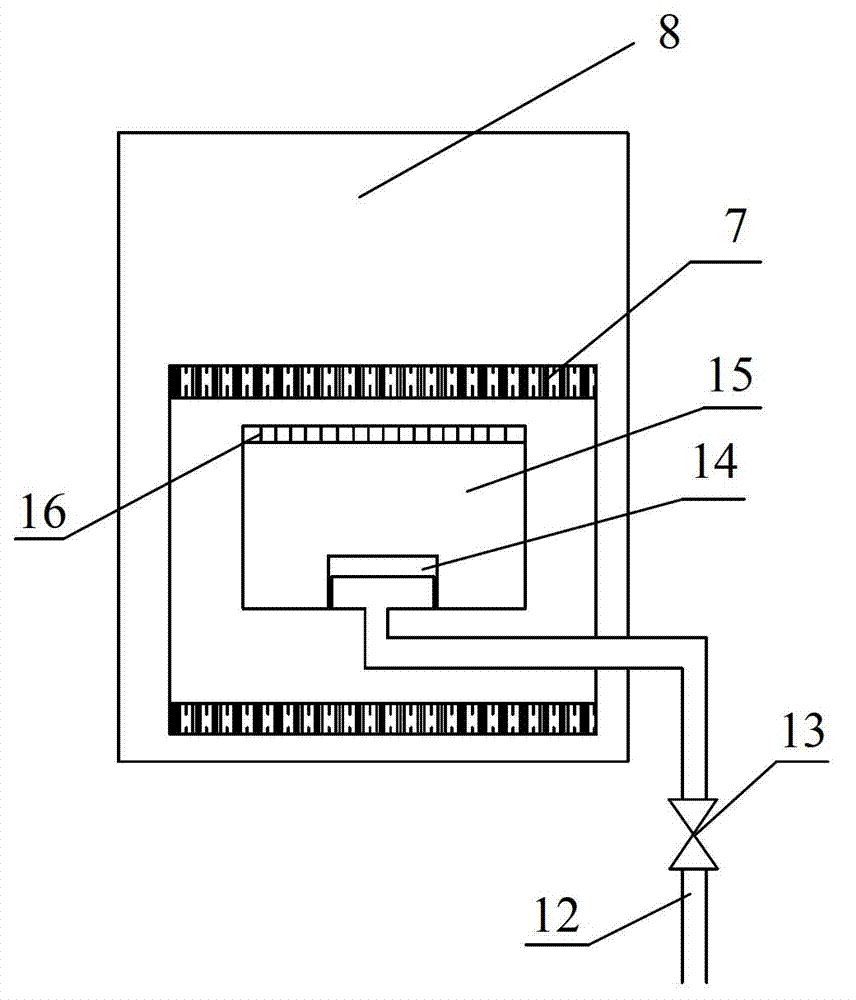

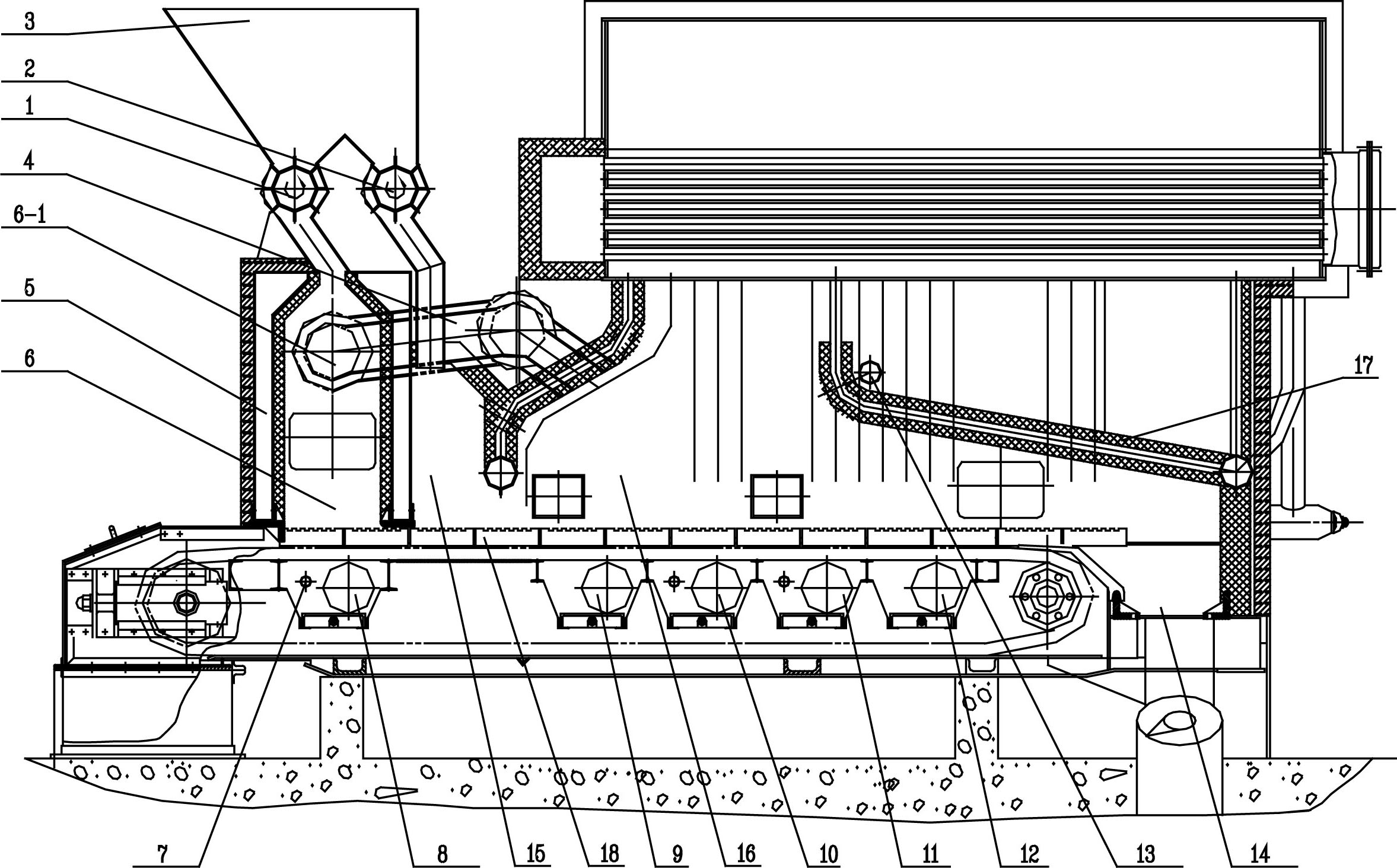

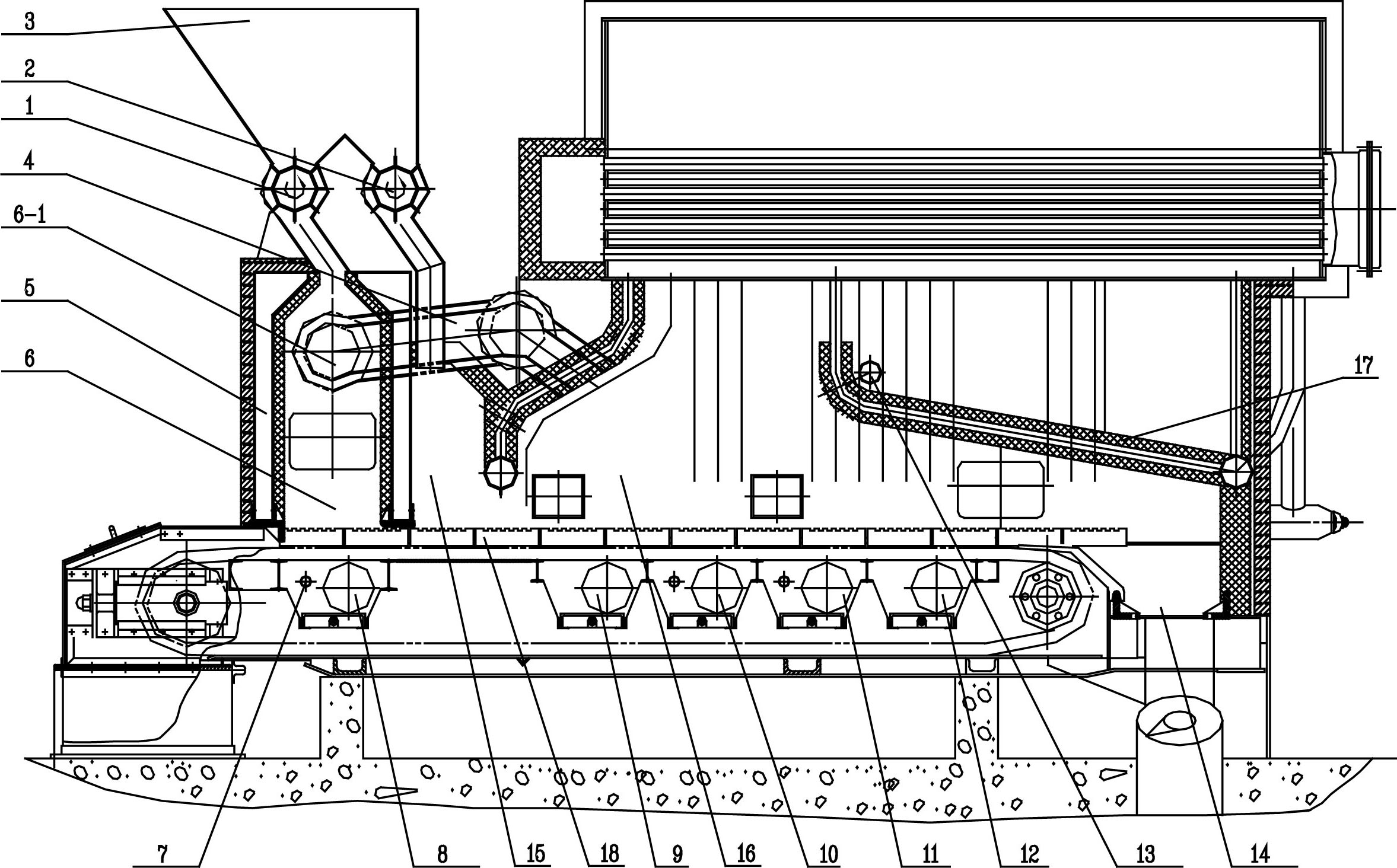

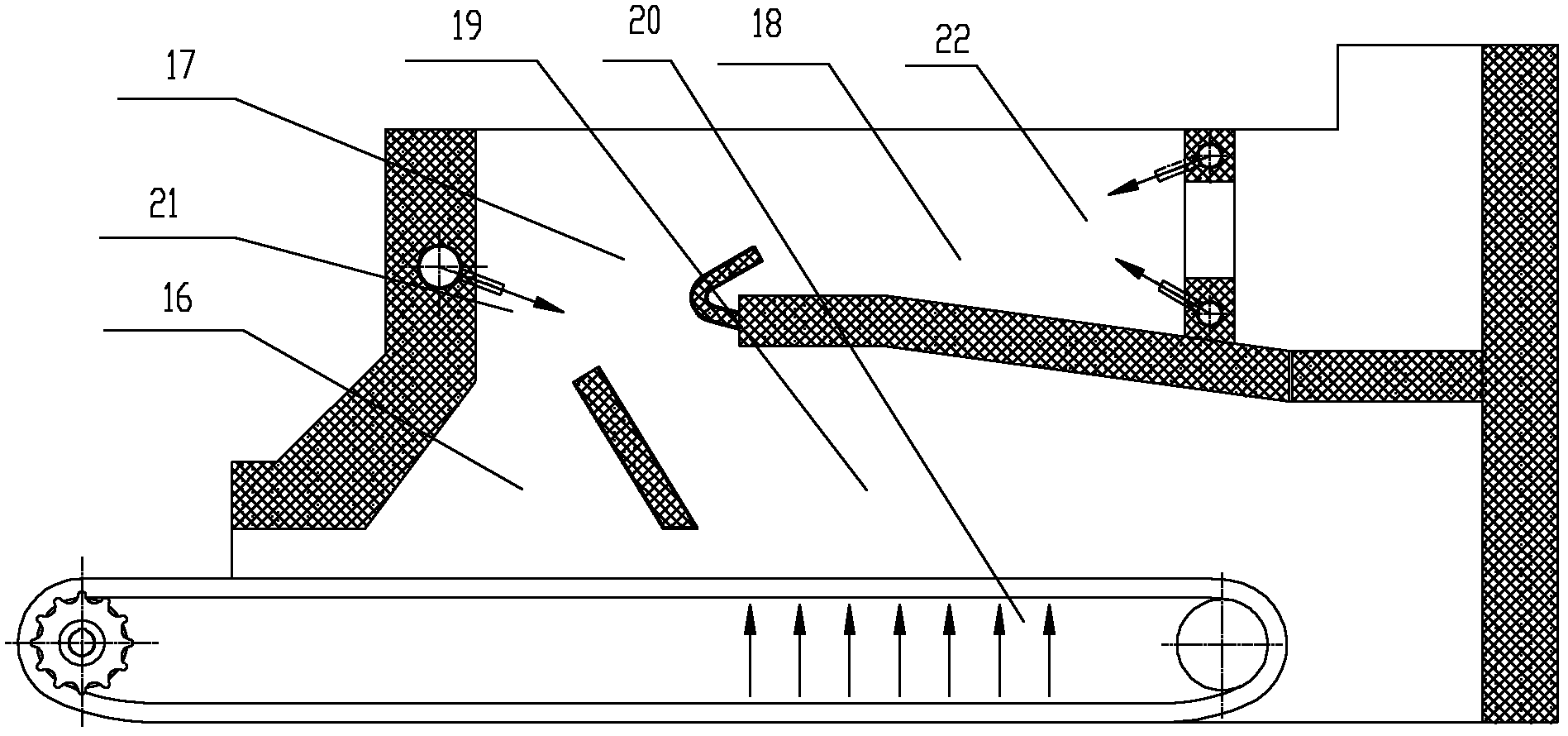

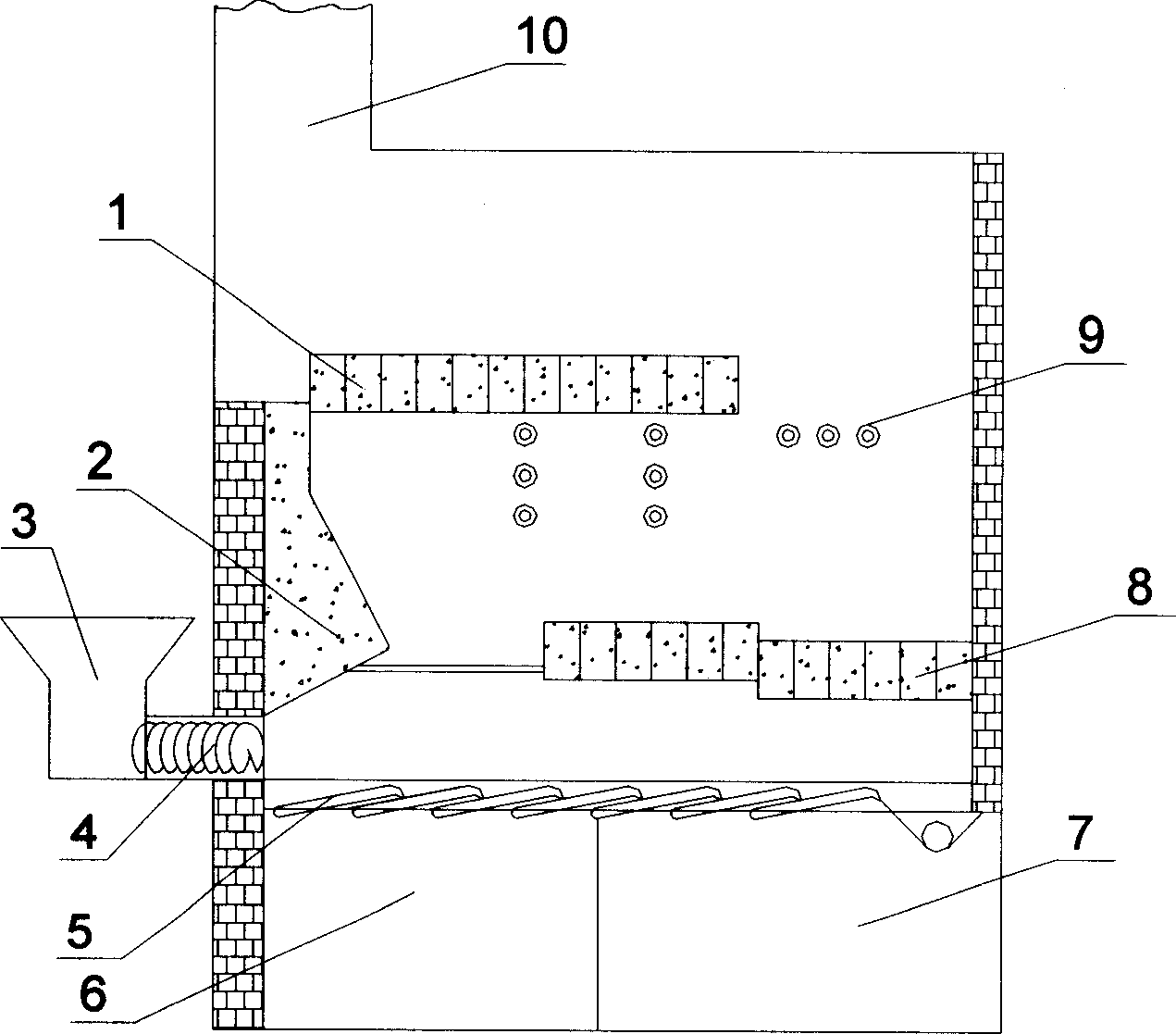

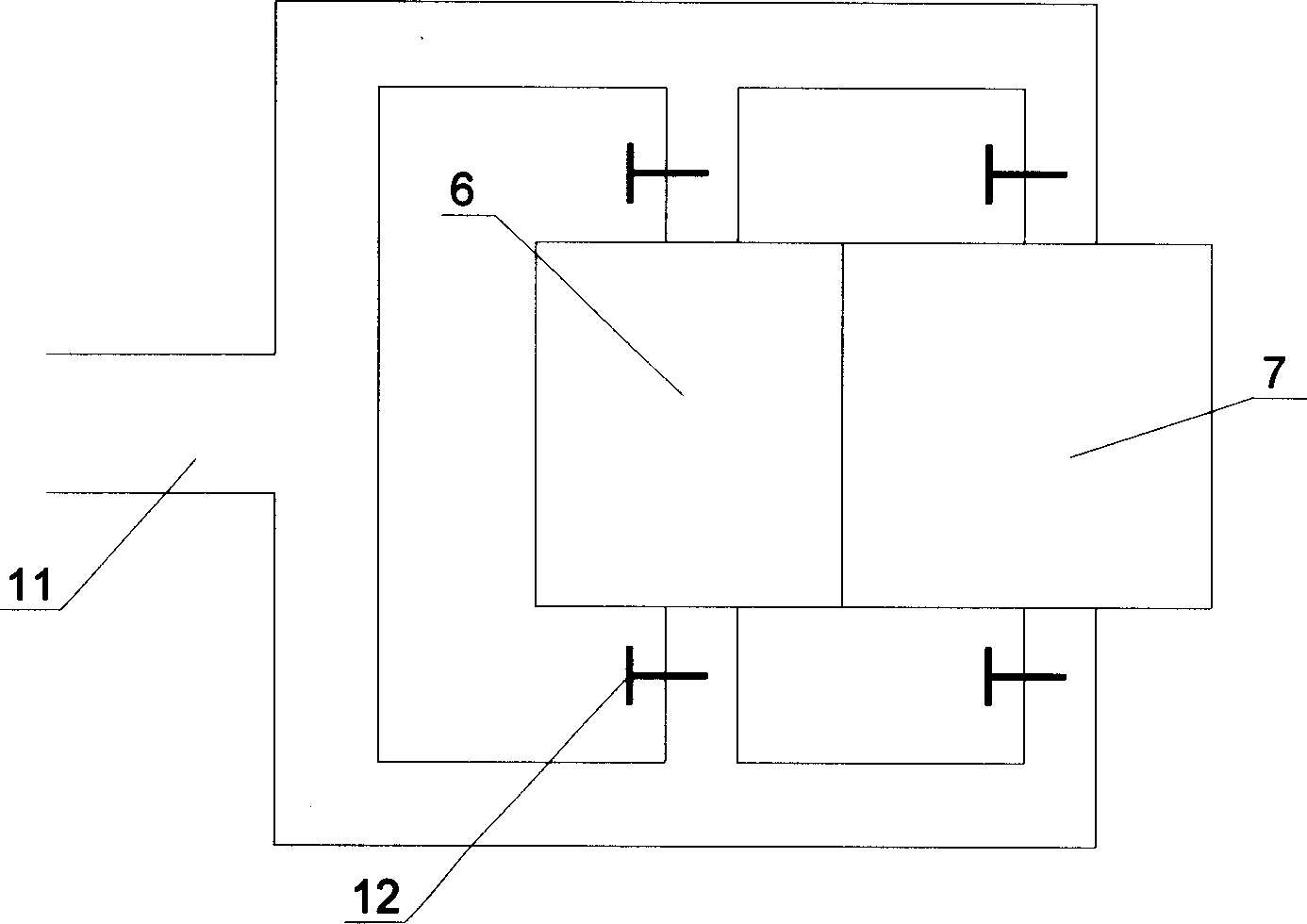

Efficient segmentation control combustion method and system for biomass boiler with charcoal combustion cell

InactiveCN103017145AEasy to removeIncrease the drying medium temperatureSolid fuel combustionCombustion apparatusSlagHearth

The invention discloses an efficient segmentation control combustion method and system for a biomass boiler with a charcoal combustion cell, and belongs to the technical field of the fire grate combustion of a biomass direct-combustion power generation boiler. A water cooling vibration fire grate is arranged on the bottom of a hearth; a smoke and air mixing box and a plurality of primary air bellows are arranged below the water cooling vibration fire grate; the charcoal combustion cell is arranged below the front end of the water cooling vibration fire grate; the bottom of the charcoal combustion cell is provided with a fixed fire grate; and the front end of the charcoal combustion cell is provided with a slag well. The external moisture of biomass fuel is removed in the drying area of the water cooling vibration fire grate; then, the biomass fuel is moved to the pyrolysis combustion area of the fire grate to generate a great quantity of volatile component to enter the hearth; when the volatile component of the biomass fuel is almost burnt, residual fixed carbon covered by ash is vibrated into the charcoal combustion cell; in the falling process, the residual fixed carbon covered by ash is overturned and collided to remove surface ash; oxygen is directly diffused to the surface of the charcoal to react with the charcoal; and the ash slag is blown into the slag well. According to the invention, the biomass fuels of different types and moistures can be subjected to efficient segmentation control combustion on the fire grate of the boiler.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

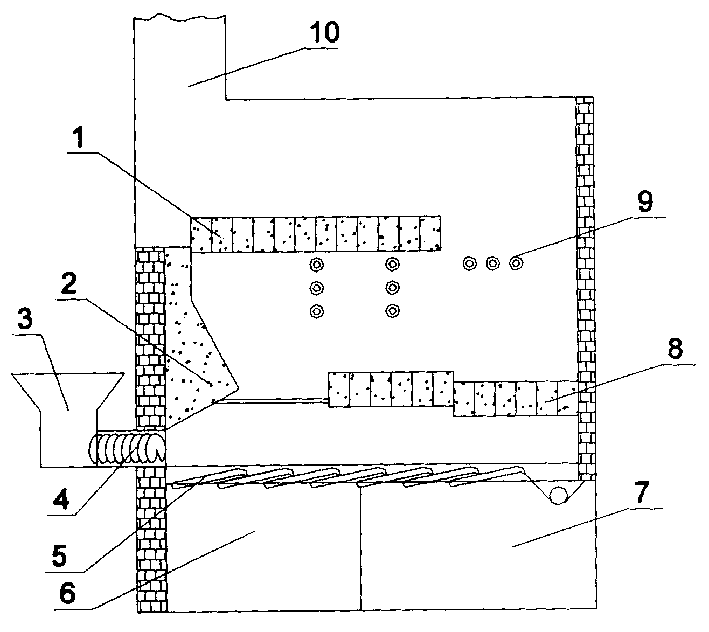

Biomass low-nitrogen direct combustion boiler

ActiveCN102252320ASolve high volatile contentSolve the problem of not being able to fully burnSolid fuel combustionAir/fuel supply for combustionLow nitrogenDirect combustion

The invention relates to a biomass low-nitrogen direct combustion boiler, comprising a hearth, wherein a boiler body is arranged on the upper part of the hearth, a hopper is arranged at a feeding port in the front of the hearth, a chain grate is arranged on the lower part of the hearth, a front smoke box and a rear smoke box are arranged at the front and the rear ends of the boiler body respectively, an isolating arch, a rear arch, a wing-shaped flue and a flue-gas-isolating wall are arranged inside a hearth cavity, a flue gas guide plate is arranged at the front end of the rear arch, the flue-gas-isolating wall is arranged on the upper part of the rear arch, a secondary air device is arranged on the front arch, and a tertiary air device is arranged on the flue-gas-isolating wall; and the hearth cavity is internally divided into a pyrolysis region, a layer combustion region, a re-combustion reduction region and a gasification combustion region. According to the invention, in accordance with the components and the combustion features of biomass fuel, efficient combustion of the fuel is realized by adopting the technologies of layer combustion and gasification coupling combustion, and ultralow emission of nitrogen oxides is realized by adopting the technologies of hierarchical air distribution, semi-coke reduction and re-combustion of pyrolysis products, therefore, the biomass boiler becomes a real energy-saving and environment-friendly product.

Owner:山东知周环境科技有限公司

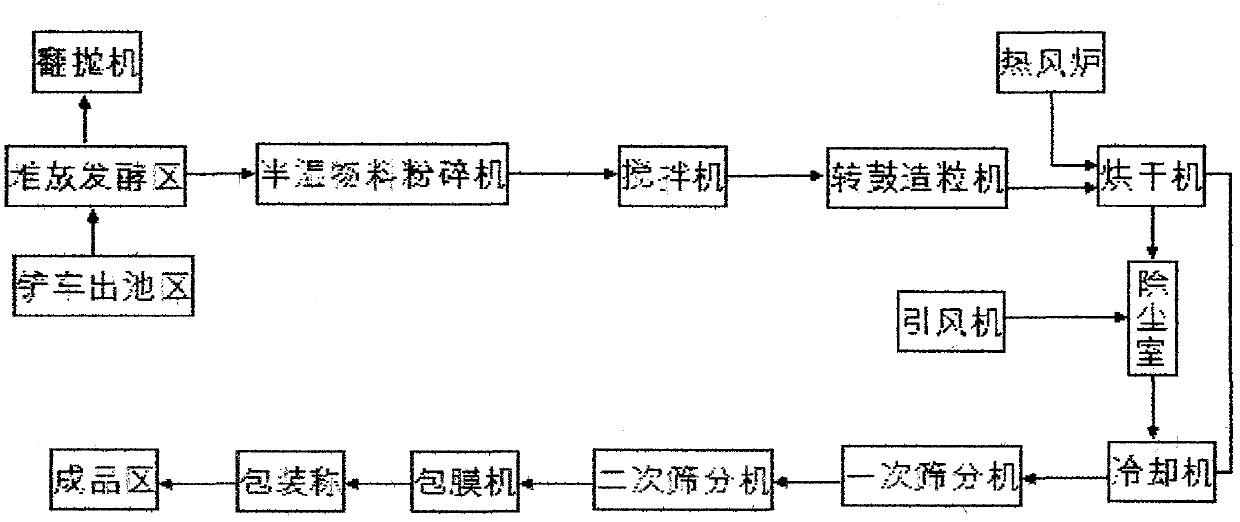

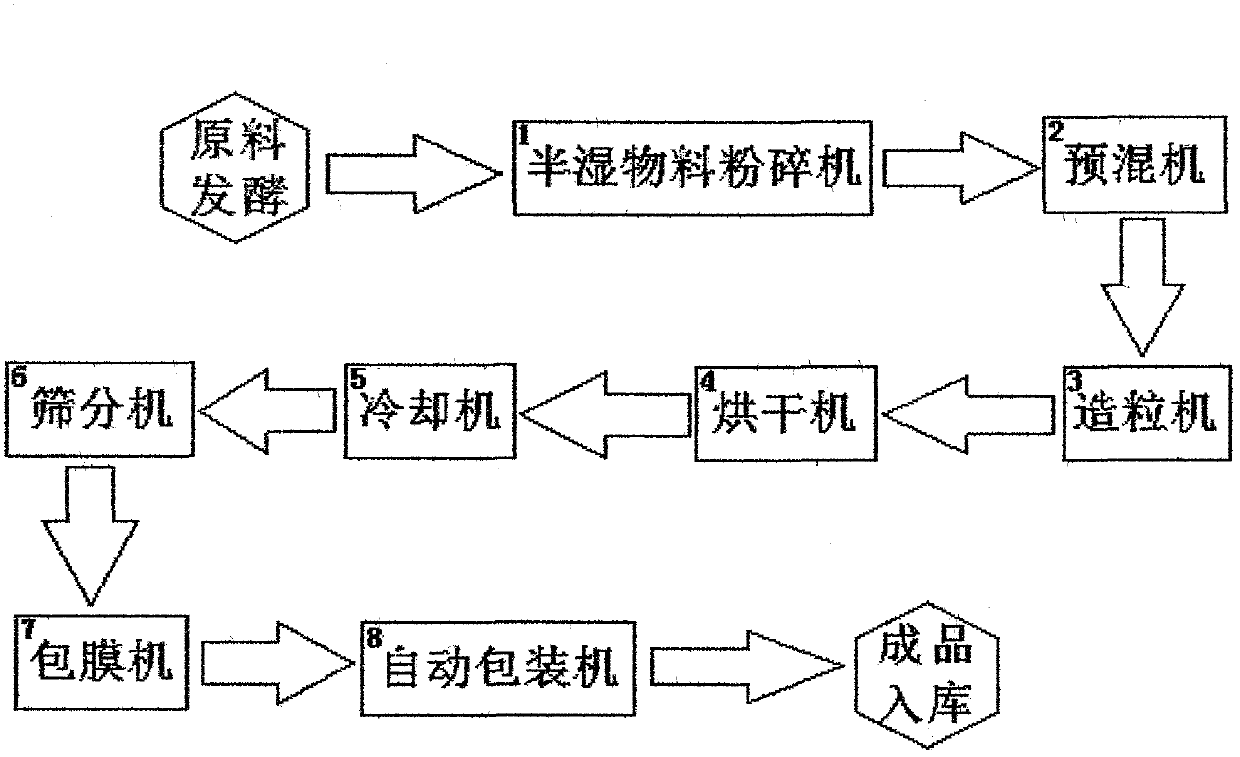

Production technology of biomass boiler ash organic fertilizer

InactiveCN103214295AWide range of usesLow costClimate change adaptationBioloigcal waste fertilisersEconomic benefitsEngineering

A production technology of a biomass boiler ash organic fertilizer employs biomass boiler pyrolysis ash as a main raw material, fermented animal night soil, household garbage, deadwood, rotten leave, slag and waste bacterial strains as auxiliary materials. The production technology comprises the following seven successive steps: stacking fermentation, material crushing, ingredient stirring, rotary drum granulation, drying, screening and package and storage. The production technology extensively utilizes biomass boiler ash to conduct efficient industrialization processing of organic fertilizer; and the produced organic fertilizer can return to the farmland to improve soil and facilitate strong growth of the crops. The invention has characteristics of wide purpose, low cost, no pollution and outstanding economic benefit, and is an ideal scheme with quite wide market prospect for biomass boiler ash to reenter into the biologic chain for recycling.

Owner:龚水明

Production method of biomass fuel

The invention discloses a production method of a biomass fuel, and relates to a production method of the biomass fuel with a low clinkering property. Crop straws, landscaping garbage, wood chips and other biomass are used as main raw materials, and are smashed and dried, then, an oxidizing agent and a slag-formation prevention agent are added, and the main raw materials, the oxidizing agent and the slag-formation prevention agent are mixed and pelletized, so that a biomass particle fuel can be obtained. The biomass fuel has the advantages that the combustion efficiency is high, and the slag formation is prevented, thereby being a high-grade fuel suitable for being used in cities of various scales and industrial boilers; the production method is safe, simple and convenient, can effectively improve the combustion performance of the biomass fuel, improves the operation efficiency of a biomass boiler, and greatly promotes the utilization effect of the biomass fuel.

Owner:NANKAI UNIV +2

Multiple-effect catalyst for synergistically purifying fume of biomass boiler and preparation method thereof

ActiveCN103752331AImprove purification efficiencyLow investment costPhysical/chemical process catalystsDispersed particle separationCeriumRare earth

The invention discloses a multiple-effect catalyst for synergistically purifying fume of a biomass boiler and a preparation method of the multiple-effect catalyst. According to the multiple-effect catalyst, noble metal is used as an active component, a mixture of aluminum oxide and an acidulated cerium-zirconium solid solution is used as a carrier, and barium oxide and light rare earth metal are used as additives. Under the action of the catalyst, NOx is selectively reduced into nitrogen through CO and hydrocarbon VOCs, the excessive CO and various VOCs are thoroughly oxidized to generate CO2 and water; by adopting the catalyst, the purification efficiency on NOx is higher than 95%, the purification efficiency on CO is higher than 90%, the purification efficiency on VOCs is higher than 85%, moreover, compared with combination of single pollutant control technique, the catalyst can simultaneously purify multiple pollutants, and the investment cost and the operation cost can be effectively lowered.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

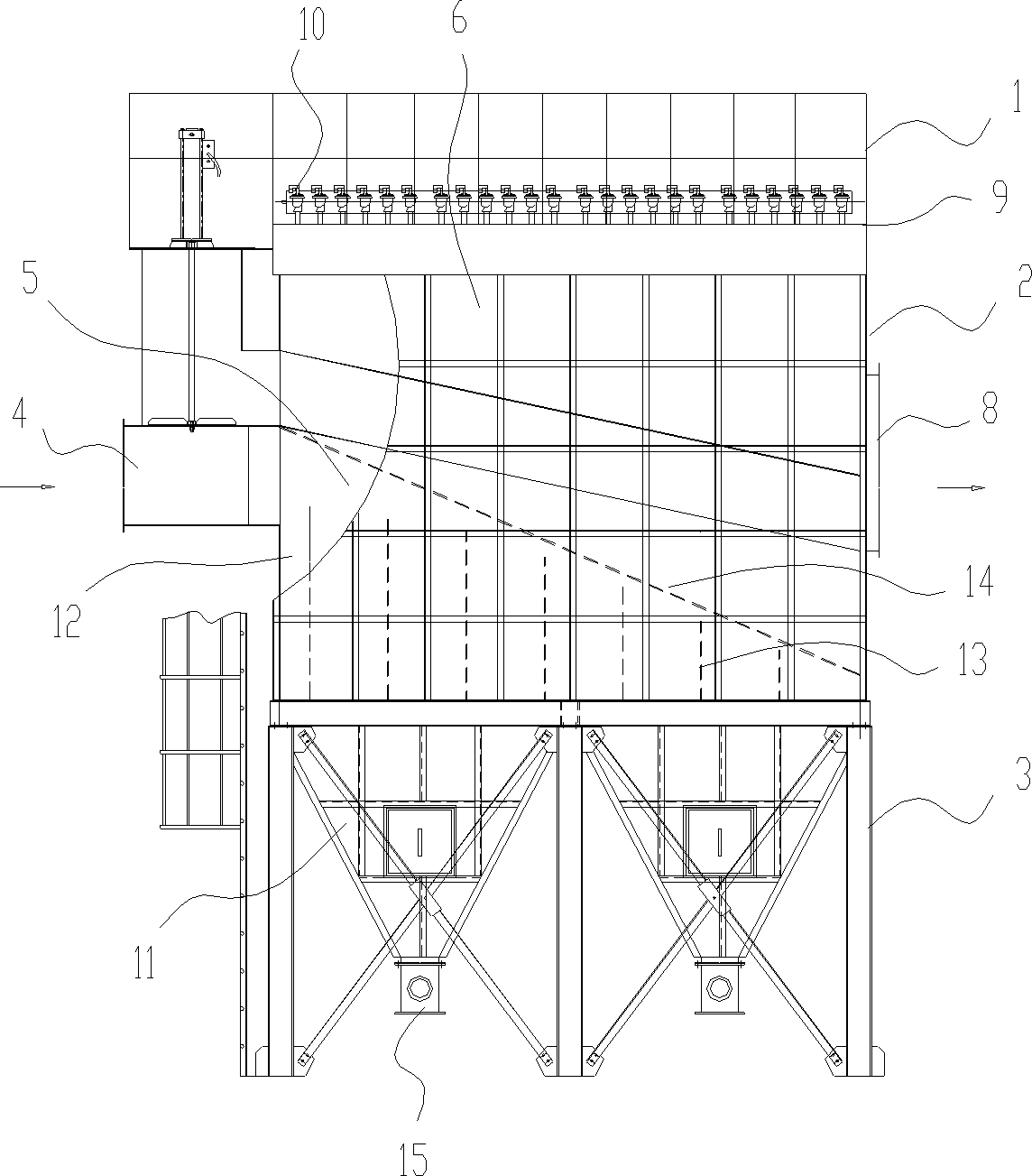

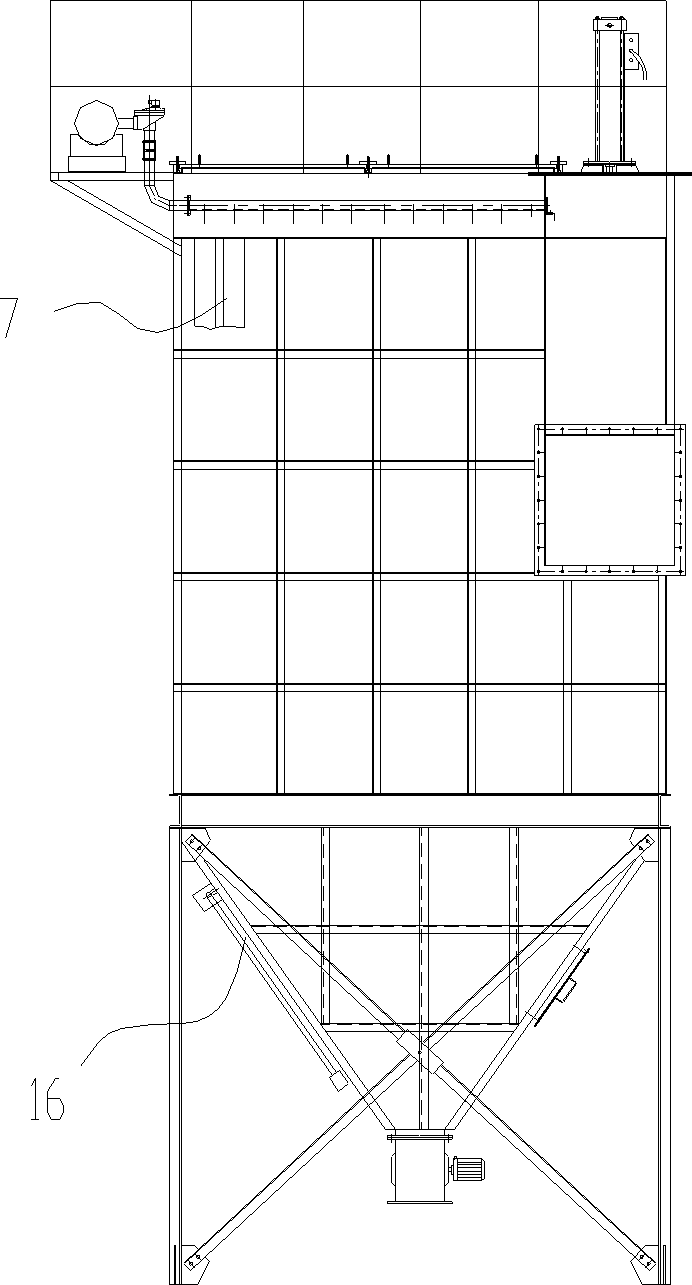

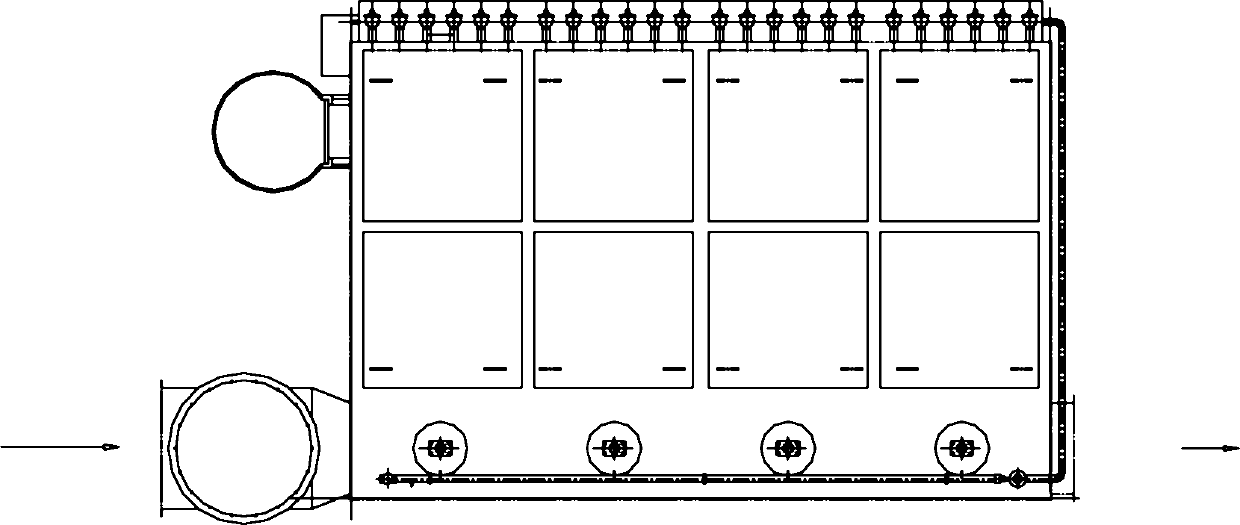

Biomass ash bag deduster

ActiveCN102553360ASolve the problem of difficult cleaningDispersed particle filtrationInlet channelEngineering

The invention discloses a biomass ash bag deduster, which contains an upper box, a central box and a lower box. An air inlet channel, which communicates with a dust-laden gas inlet, is arranged inside the central box. A plurality of bag cages which communicate with the air inlet channel are disposed in a spaced manner over the air inlet channel inside the central box. A filter bag is disposed inside each bag cage, which respectively communicates with a purified gas outlet through an outlet valve and communicates with a pulse valve disposed inside the upper box through a jet pipe. A dust hopper for ash discharge is arranged inside the lower box. Pulse-jet dust-cleaning is alternately carried out on an off-line compartment. The whole deduster is divided into a plurality of chambers (bag cages), which are connected with duct outlets through valves. When cleaning dust, the valve of one chamber is closed such that the chamber is off-line. Compress air is injected into the filter bag through a jet pipe by the pulse valve so as to finish dust removal by blowing. After the dust removal, the valve of the chamber is opened. Similarly, the chambers of the whole deduster undergo dust removal one by one. Therefore, the problem that it is difficult to remove dust during the biomass boiler operation is solved.

Owner:GUANGZHOU DEVOTION THERMAL TECH

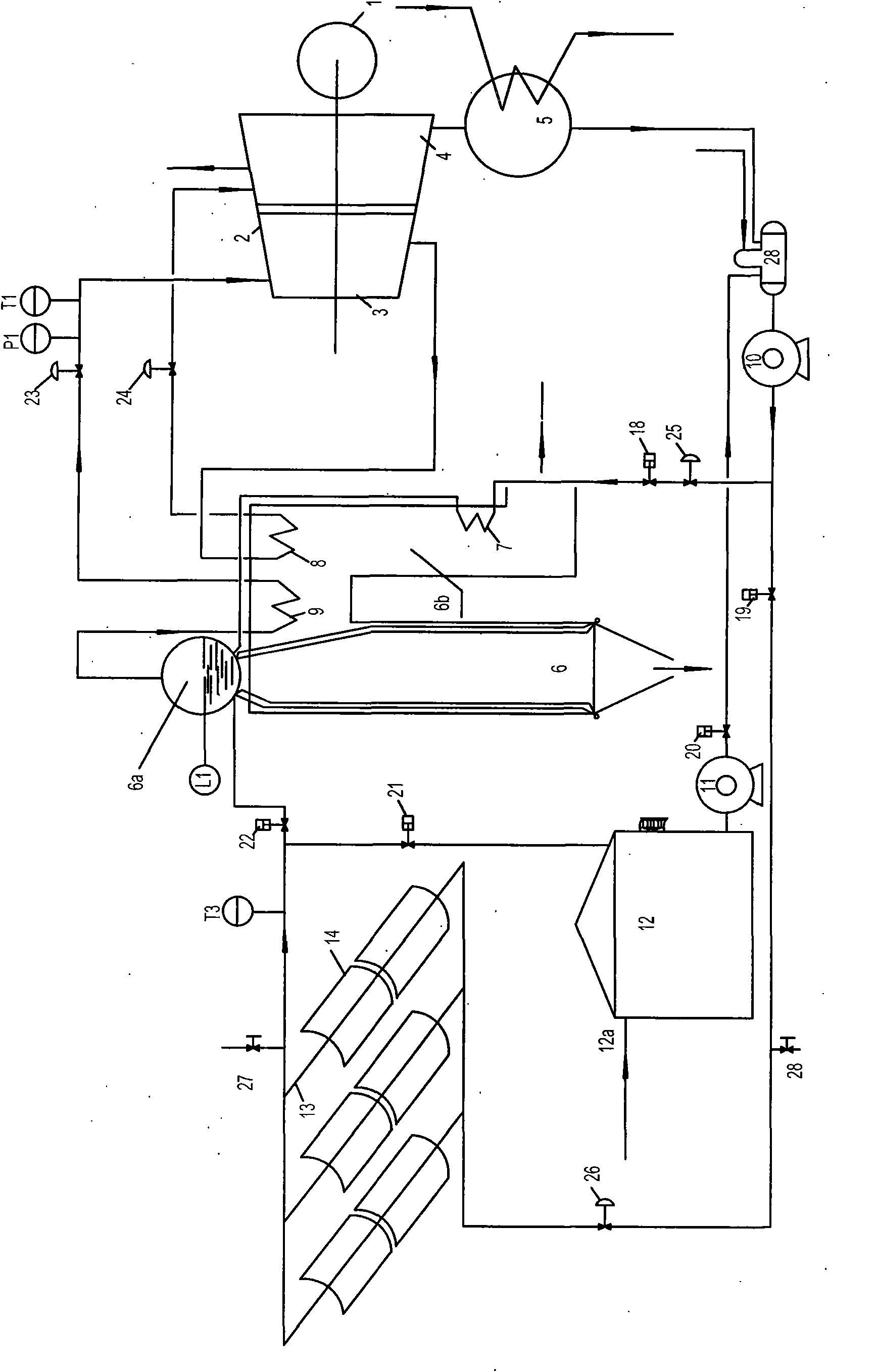

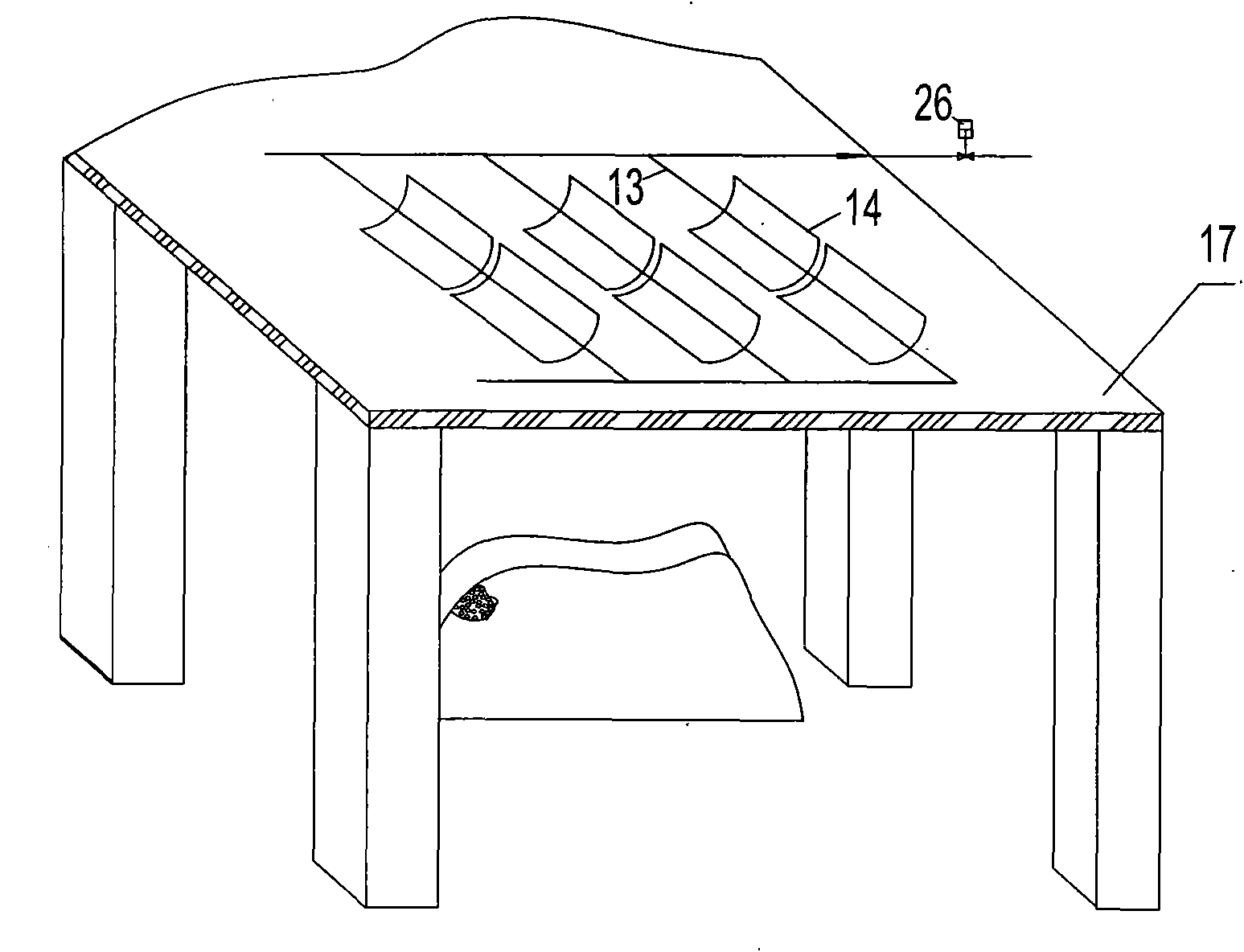

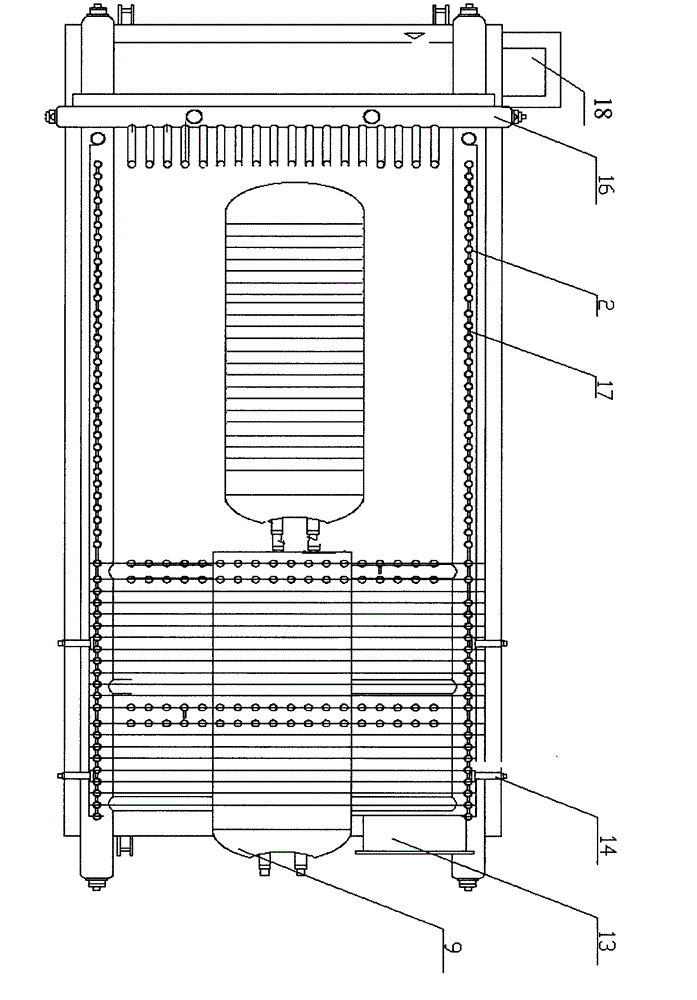

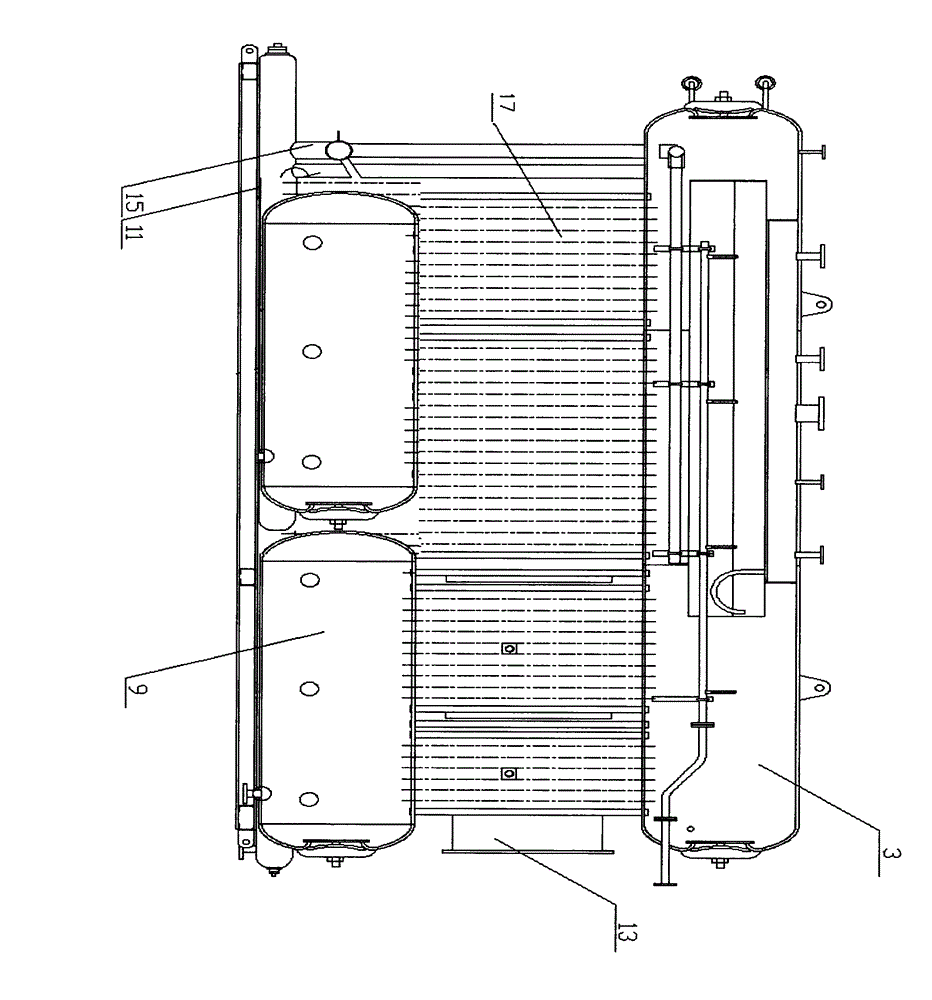

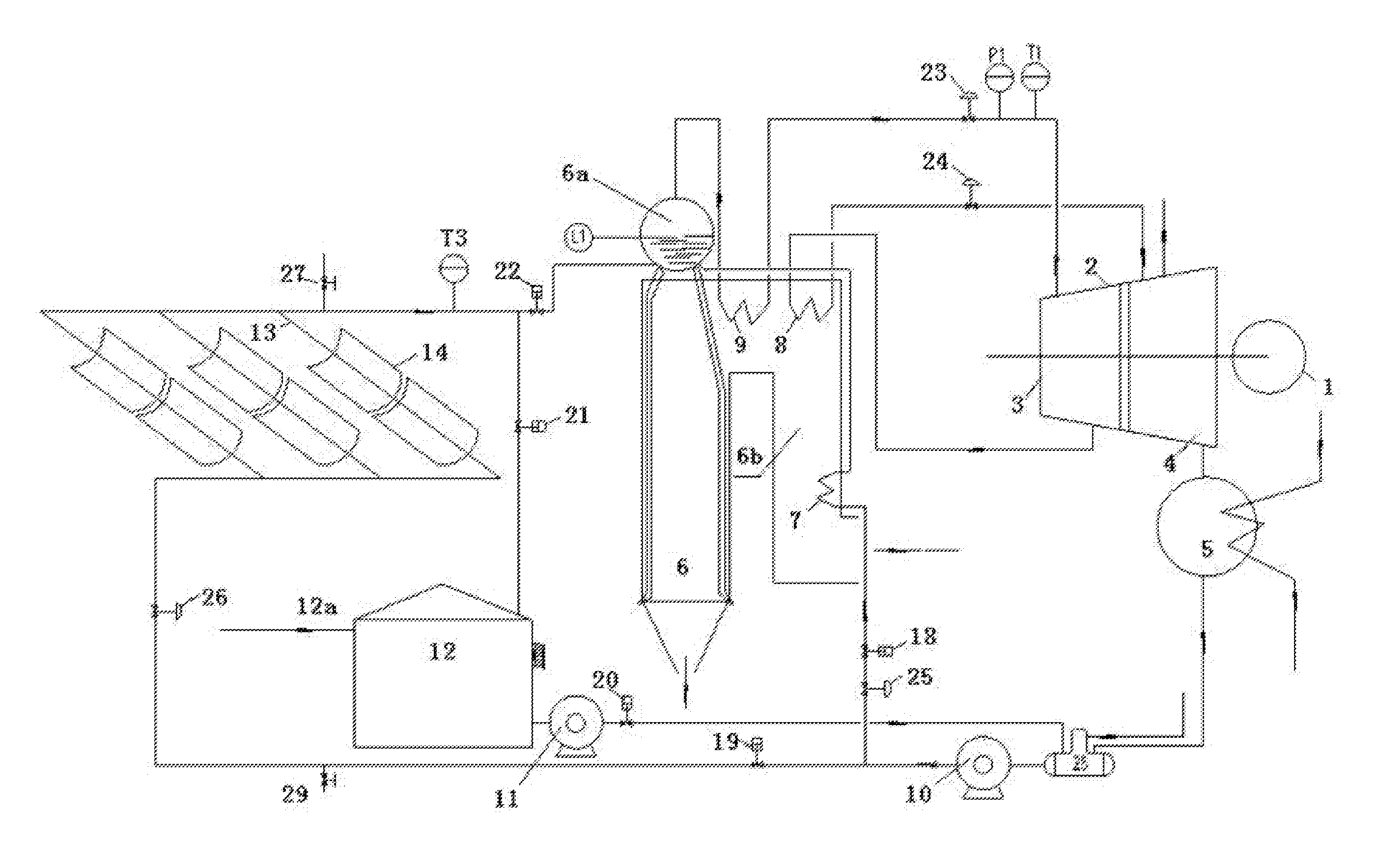

Method and system for power generation

InactiveUS20130219888A1Effectively solving instabilityImprove heating efficiencySolar heating energyAuxillary drivesEngineeringControl valves

A method of power generation, including: igniting a biomass boiler; starting a solar concentrating collector; measuring water temperature t3 at water outlet main of the solar concentrating collector; opening a second control valve arranged between the water outlet main and the boiler drum when t3 is greater or equal to 95° C.; closing the second control valve and the third control valve to prevent water in the solar collector tube from running and to maintain the water in a heat preserving and inactive state if the water temperature t3 decreases and t3 is less than 95° C.; turning the turbonator unit into a thermal power generation mode; opening a first control valve arranged between the water outlet main and a water supply tank if the water temperature t3 continues decreasing and when t3 is between 5 and 9° C.; and turning the turbonator unit into a biomass boiler power generation mode.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

Fe/pressed active carbon catalyst and preparation method thereof

InactiveCN101480614ASolve the catalytic activityAddressing Catalytic SelectivityHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsActivated carbonMinor metals

The invention discloses a catalytic conversion agent of tar in gas for a biomass boiler, which consists of the following ingredients by weight percent: 0.1% to 0.3% of Na2CO3, 0.1% to 0.3% of K2CO3, 0.1% to 1% of Fe3O4, 0.5% to 0.8% of NaCl, 0.5% to 0.8% of KCl, 0.3% to 0.5% of KOH, 0.3% to 0.5% of NaOH, 0.1 to 1% of Ni(NO3)2 6H2O, 0.1 to 1% of KNO3, 0.1 to 0.5% of Ce(NO3)3 6H2O, 20% to 46% of dry attapulgite powder and 46% to 75% of dry dolomite powder, wherein the dry dolomite powder is the dry powder with the grain size not less than 325 meshes, the water content less than 1% and the CaCO3 / MgCO3 ratio ranging from 1 to 1.5, and the dry attapulgite powder has the grain size not less than 325 meshes, the water content is less than 1%, the content of MgO is not less than 23% and the content of SiO2 is not more than 56%. By using the catalyst, tar in biomass gasified gas can be converted into combustible small molecules, so as to reduce the hazard caused by tar remarkably.

Owner:BEIJING UNIV OF CHEM TECH

Additional reductant-free smoke denitration device and method for combustion equipment

ActiveCN102000498AAchieve removalLow running costLighting and heating apparatusDispersed particle separationDirect-current dischargeHigh energy

The invention discloses an additional reductant-free smoke denitration device and method for combustion equipment. Smoke generated by a boiler flows through a coal economizer; a discharging device is distributed in an inlet connecting flue of the coal economizer or a denitration reactor; the discharging device adopts pulse discharge or direct current discharge; discharge voltage is controlled between critical coronal voltage and breakdown voltage; a high-energy electron e generated by discharging attacks a carbon dioxide molecule so that the carbon dioxide molecule is activated from a normal state to an activating state; the carbon dioxide molecule in the activating state is dissociated into CO and an active substance; part of CO2 is converted for producing CO by reacting; the smoke enters a denitration reactor through the inlet connecting flue of the denitration reactor and a rectifying device; NO and CO in the smoke react under the action of a catalyst bed layer in the denitration reactor and generate nontoxic N2 and CO2; and the reacting smoke is exhausted through an outlet connecting flue of the denitration reactor. The invention can be used for smoke denitration of a coal burning boiler, a gas burning boiler, an oil burning boiler, a biomass boiler, and the like and has the advantages of convenience for operation and obvious benefit.

Owner:ZHEJIANG UNIV

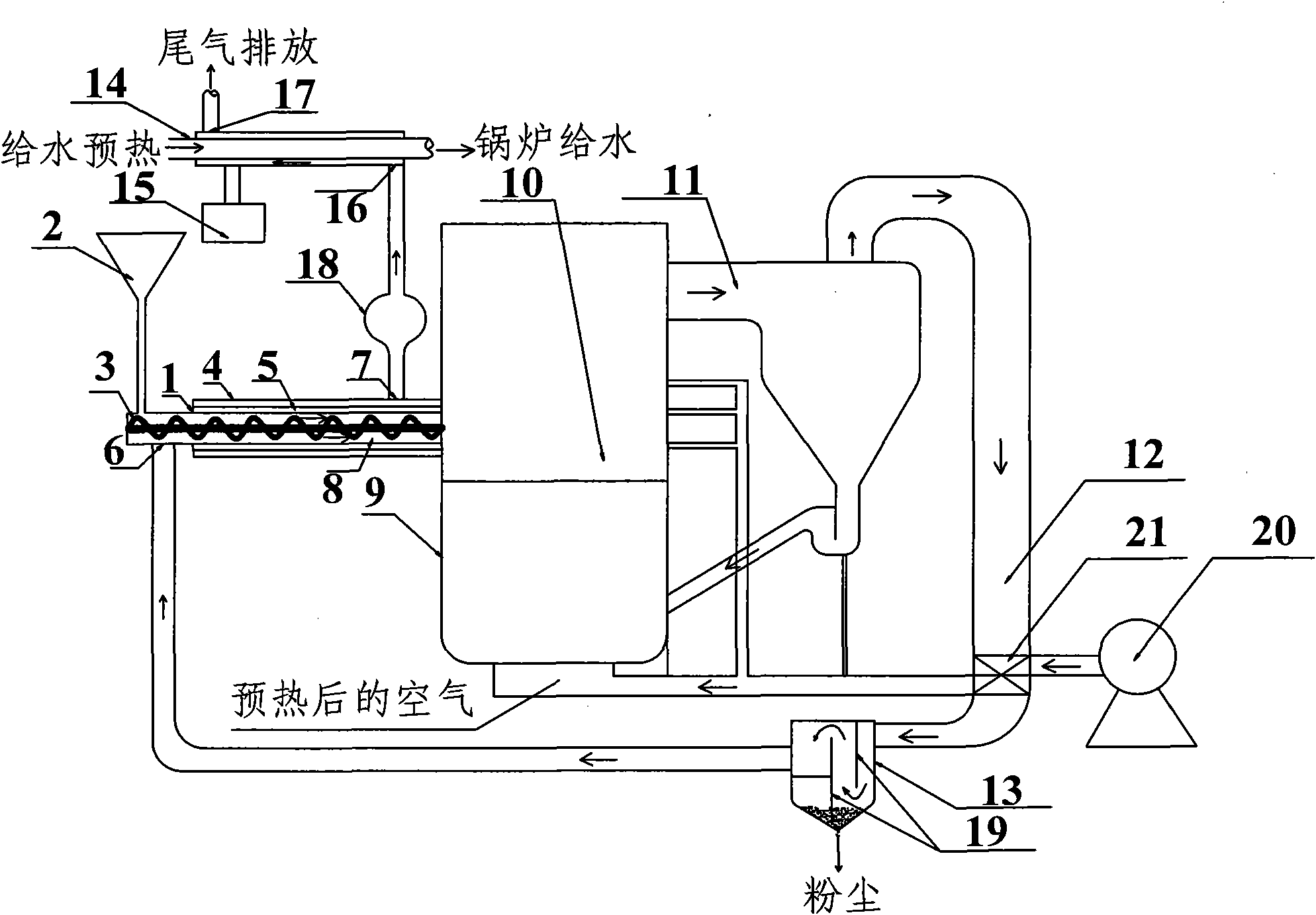

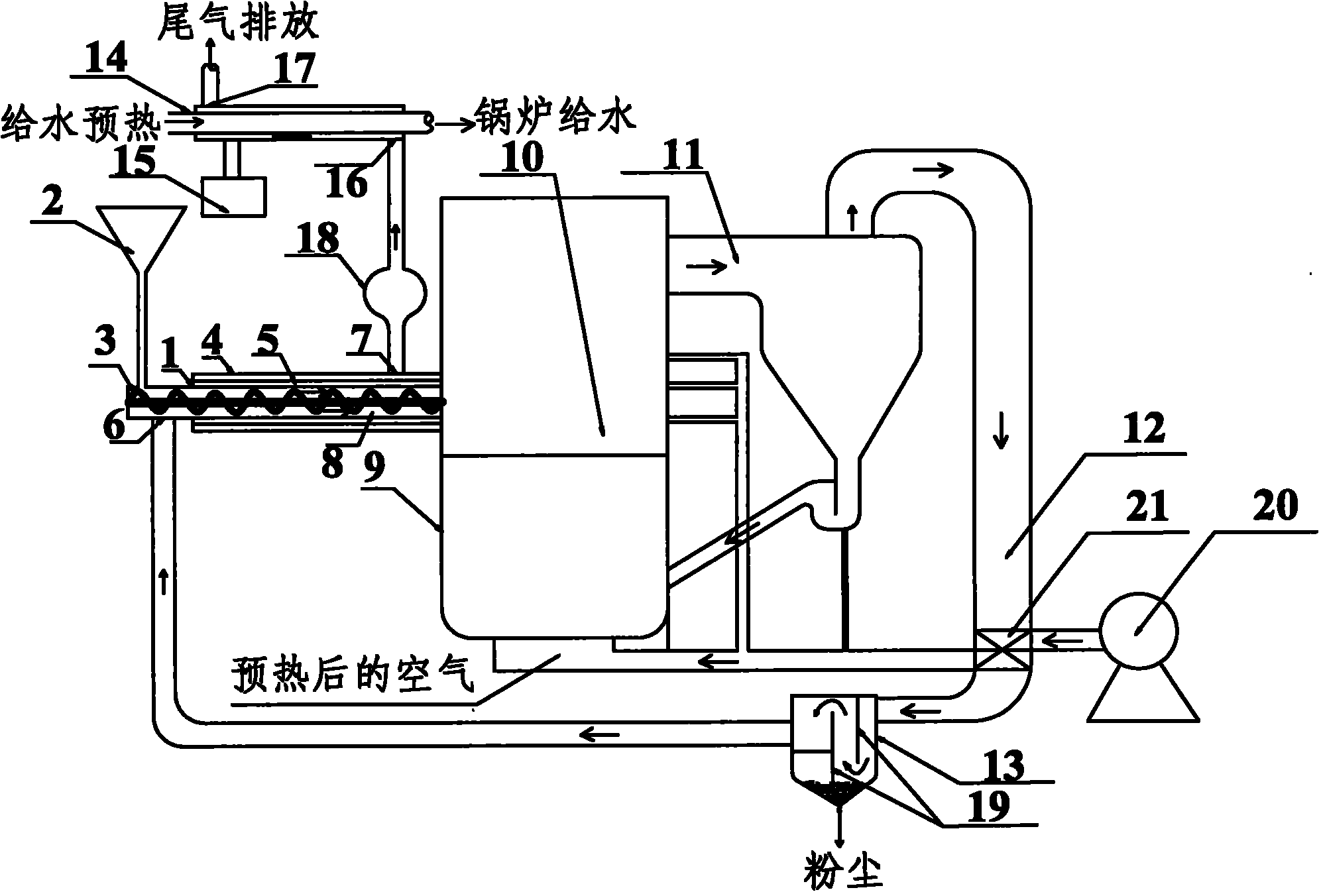

Biomass boiler system capable of saving energy and reducing emission

InactiveCN101975388AHigh efficiency, energy saving and environmental protectionRealize direct combustionSteam boilersFeed-water heatersAir preheaterCombustion chamber

The invention discloses a biomass boiler system capable of saving energy and reducing emission, comprising a dry feeding device, a boiler body, an air preheater and a water supplying preheater. The dry feeding device comprises a spiral feeder and a rotary drier, and the spiral feeder is arranged in the drying chamber in the rotary drier. The boiler body comprises a boiler furnace and a combustion chamber which are mutual connected, the material output end of the spiral feeder is arranged at the material inlet of the boiler furnace, and an exhaust gas outlet is arranged above the rotary drier. The top of the combustion chamber is connected with one end of the flue gas pipeline, the air preheater is arranged on the flue gas pipeline, the other end of the flue gas pipeline is connected with the inlet of a dust precipitation device, and the outlet of the dust precipitation device is connected with the exhaust gas inlet of the drying chamber. A mixing exhaust gas inlet is arranged on the lower side at one end of the water supplying preheater, an exhaust gas outlet is arranged on the upper side at the other end, and the exhaust gas outlet is connected with the mixing exhaust gas inlet. The system of the invention can recover 6 to 8% of the waste heat of the boiler flue gas, and has the advantages of energy saving, environmental protection, safety, and less requirements on the water content of the raw materials.

Owner:SOUTH CHINA UNIV OF TECH

Low nitrogen oxide biomass boiler with variable furnace arch structure

InactiveCN1488889ARich varietyAdapt to many types of biomassIncinerator apparatusFirebridgesLow nitrogenEngineering

The present invention relates to a low-nitrogen oxide biomass boiler with variable furnace arch structure, including front and rear zoned-air chambers, reciprocating grate, combined arch formed from front arch, rear arch and upper arch and zoned-air nozzles. The bottom portion of the boiler is equipped with front zone air chamber and rear zone air chamber to implement zoned-air distribution, and the reciprocating grate is arranged over the front and rear zound-air chambers, and in the interior of furnace cavity wall between upper arch and rear arch air inlaid several zoned-air nozzles whose inlets are connected with main air channel. Said boiler can extensively utilize biomass fuel, and can obtain good combustion effect.

Owner:SHANGHAI JIAO TONG UNIV

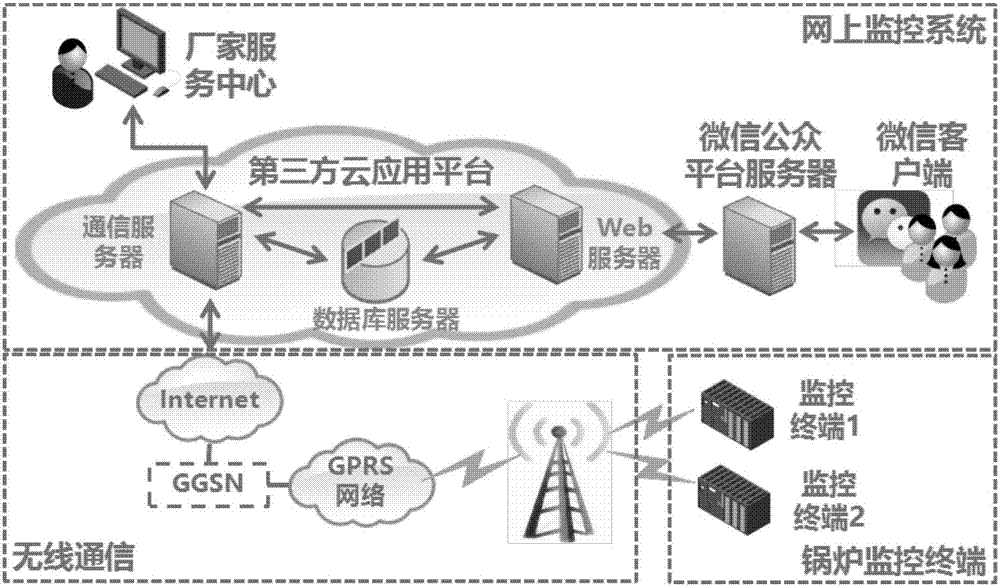

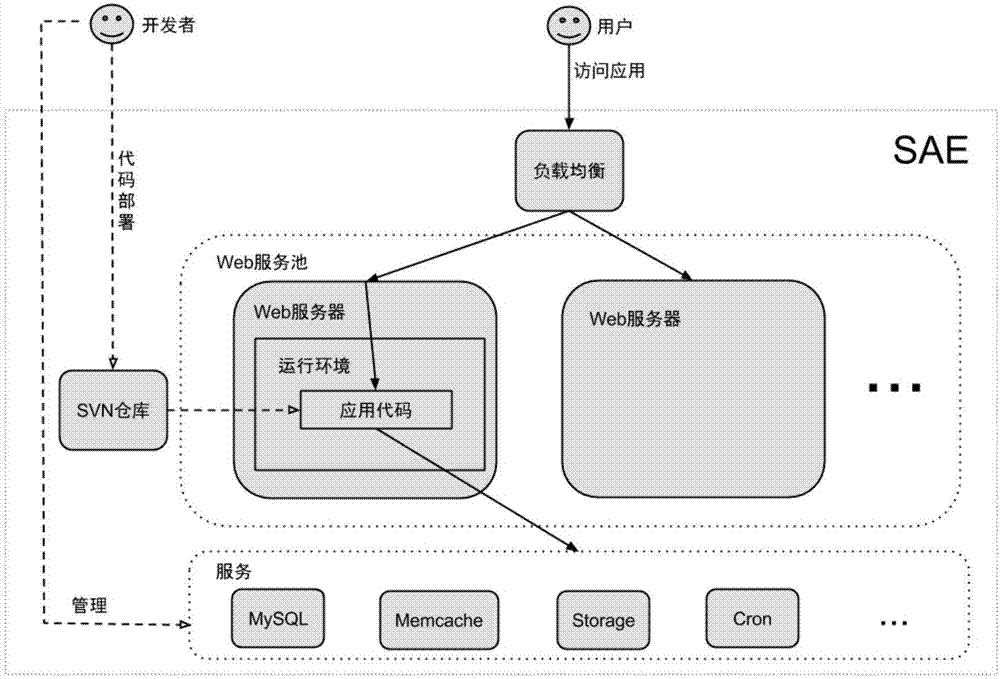

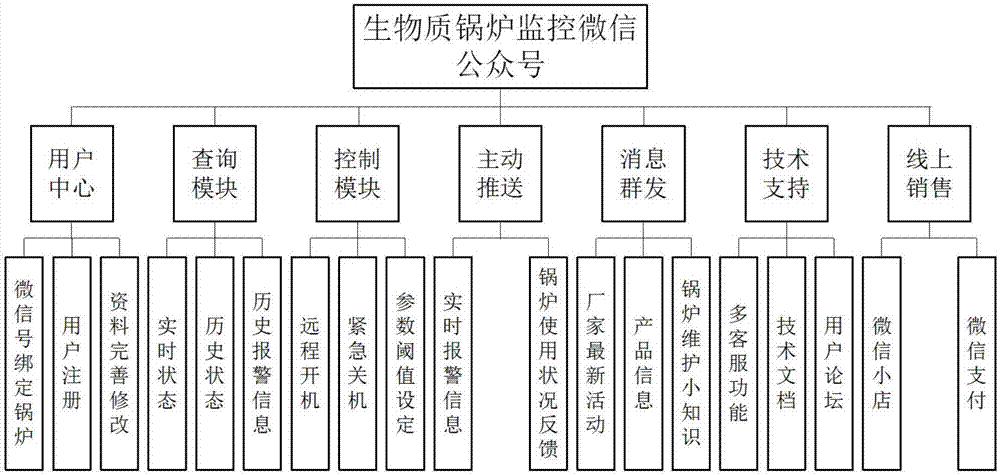

System and method for remote monitoring of biomass boiler based on Wechat and cloud application

The invention relates to a system and a method for the remote monitoring of a biomass boiler based on Wechat and a cloud application. The system consists of three parts, namely a boiler monitoring terminal, a wireless communication part and an on-line monitoring system, wherein the on-line monitoring system comprises a third-party cloud application platform, a factory service center, a Wechat public platform server and a Wechat client. The boiler monitoring terminal carries out GPRS wireless communication with the third-party cloud application platform. The third-party cloud application platform can carry out interaction with a factory monitoring center, also can carry out interaction with the Wechat client by using the Wechat public platform server as a medium, and is responsible for communication, data storage, Web request response and the like. Information, such as boiler state, historical data and real-time alarm, on the third-party cloud application platform, is provided by the Wechat public platform for user inquiry in the form of Wechat public number. Besides, the user also can send a control command to the boiler monitoring terminal through the Wechat public number on the Wechat client and can realize the functions of remotely turning on / off a boiler, adjusting parameter thresholds and the like.

Owner:ZHEJIANG UNIV

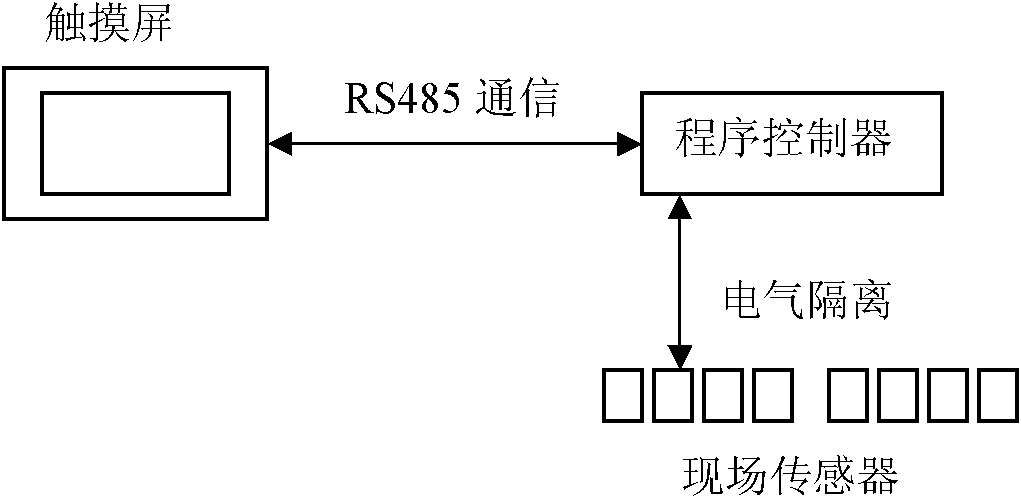

Biomass boiler control system

The invention discloses a biomass boiler control system. The system comprises a combustion chamber gas pressure sensor, a steam-pocket steam pressure sensor, a steam-pocket water level sensor and a program controller; and the program controller comprises a processing module, a storage module, a combustion chamber gas pressure sensing signal input module, a steam-pocket steam pressure sensing signal input module, a steam-pocket water level sensing signal input module, a combustion chamber gas pressure adjusting signal output module, a steam-pocket steam pressure adjusting signal output module and a steam-pocket water level adjusting signal output module. The automatic control of a biomass boiler is realized by the use of various sensors and the program controller. In particular, full combustion of biomass granules is ensured, the utilization rate of fuels is improved and the energy is saved by step control of different steam-pocket steam pressures; and in addition, alarm and emergency blowout treatment under various hazardous conditions are realized and safe production is ensured by the monitoring of the sensors.

Owner:GUANGZHOU DEVOTION THERMAL TECH

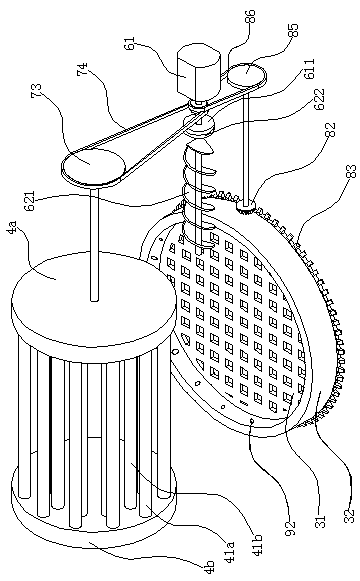

Biomass boiler

ActiveCN104034025AAvoid distributingAvoid burnsDamper arrangementSolid fuel combustionBiomass boilerFlue

The invention provides a biomass boiler, belongs to the technical field of boiler equipment and solves the problems that according to an existing biomass boiler, the flue is burnt incompletely and heating efficiency is low. The biomass boiler comprises a boiler body and a storage basin. The boiler body comprises an upper water storage cavity and a lower water storage cavity. A supporting disc is rotationally connected into the boiler body. A first rotary disc and a second rotary disc are rotationally connected into the boiler body, a first heat exchange tube and a second heat exchange tube are connected between the first rotary disc and the second rotary disc, the other end of the first heat exchange tube is communicated with the upper water storage cavity, and the other end of the second heat exchange tube is communicated with the lower water storage cavity. A material conveying mechanism is arranged between the storage basin and the boiler body. A first transmission mechanism is arranged between the first rotary disc and the material conveying mechanism, and a second transmission mechanism is arranged between the supporting disc and the material conveying mechanism. The supporting disc is further provided with a ventilation mechanism. The biomass boiler has the advantages that flue can be burnt completely, and heating efficiency is high.

Owner:丽水富特环保锅炉有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com