Patents

Literature

925 results about "Counter flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Counter-flow (also referred as contra-flow) is the movement of cultures from one place to another brought by mobile subjects (migrants) that can have a positive or negative impact or effect on society. It is no longer from “the west to the rest,” but a two way movement.

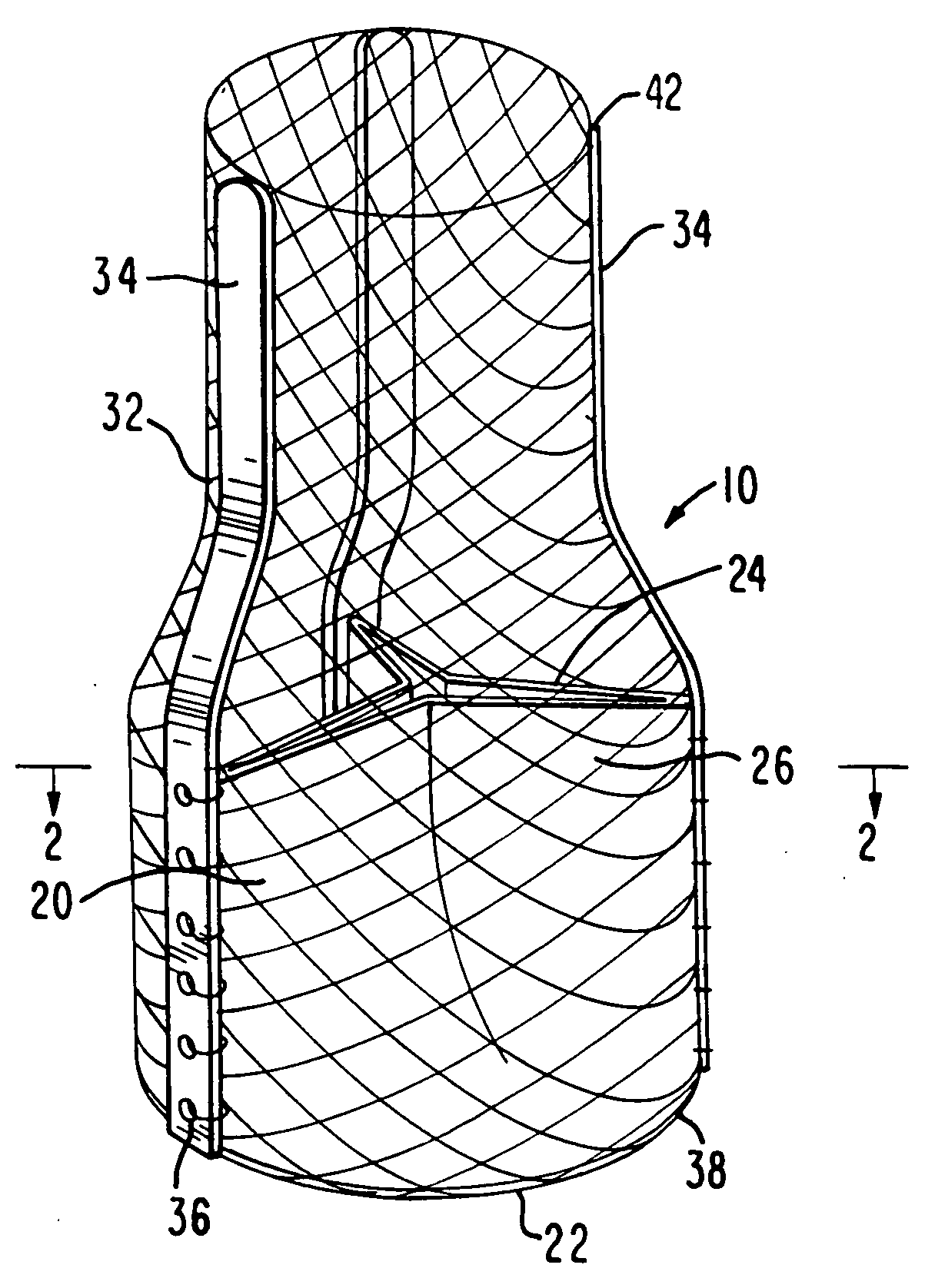

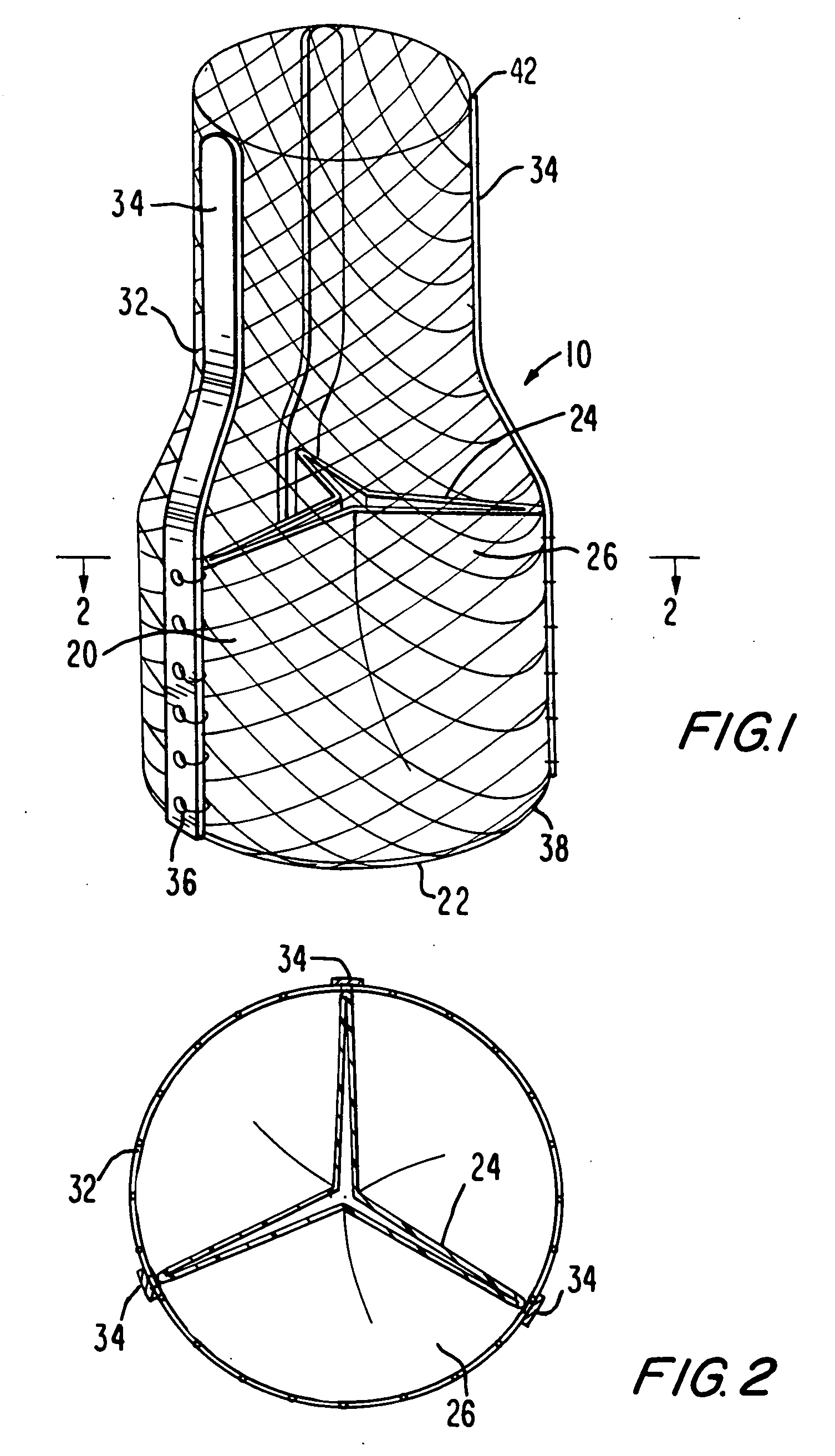

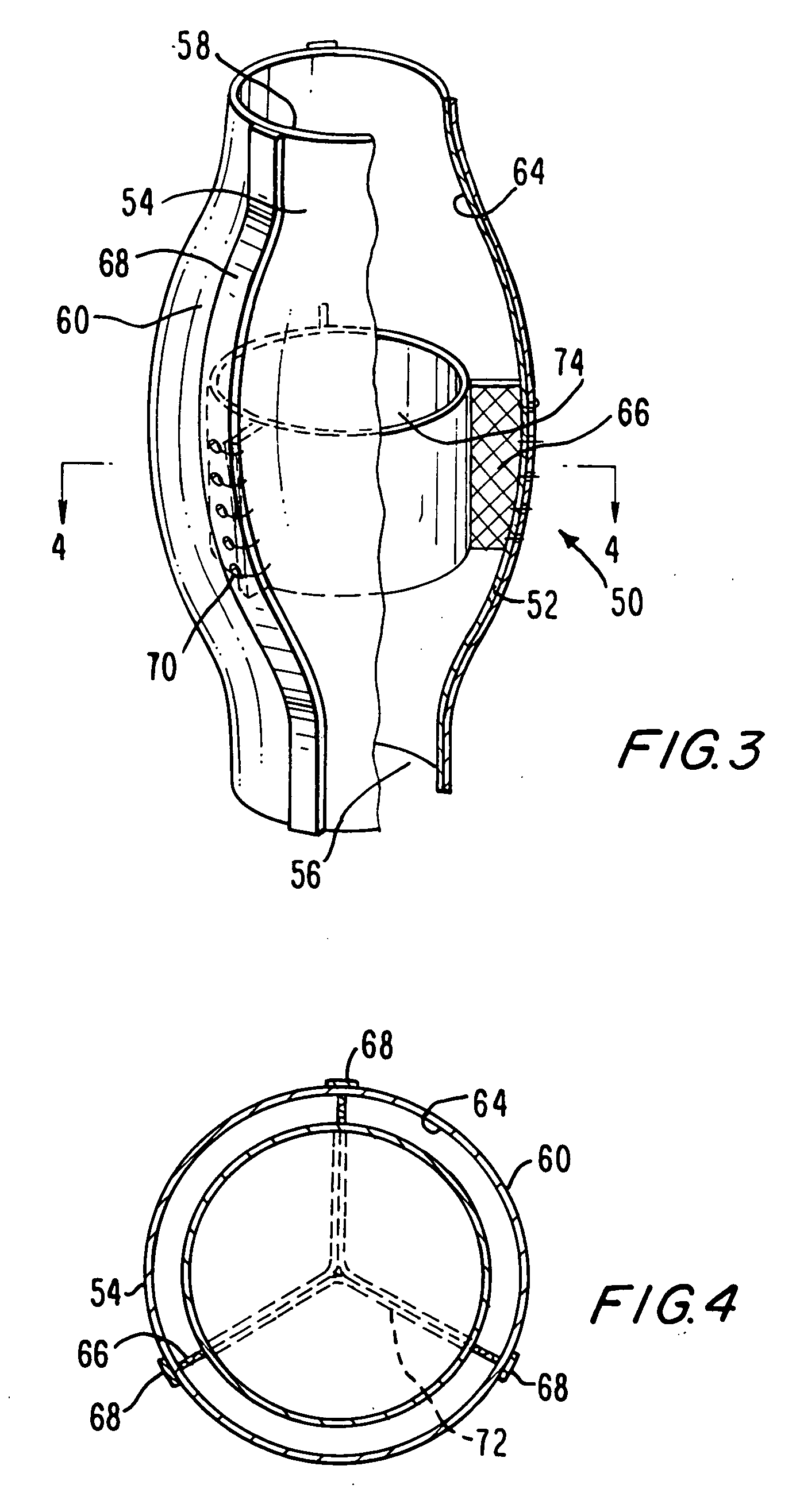

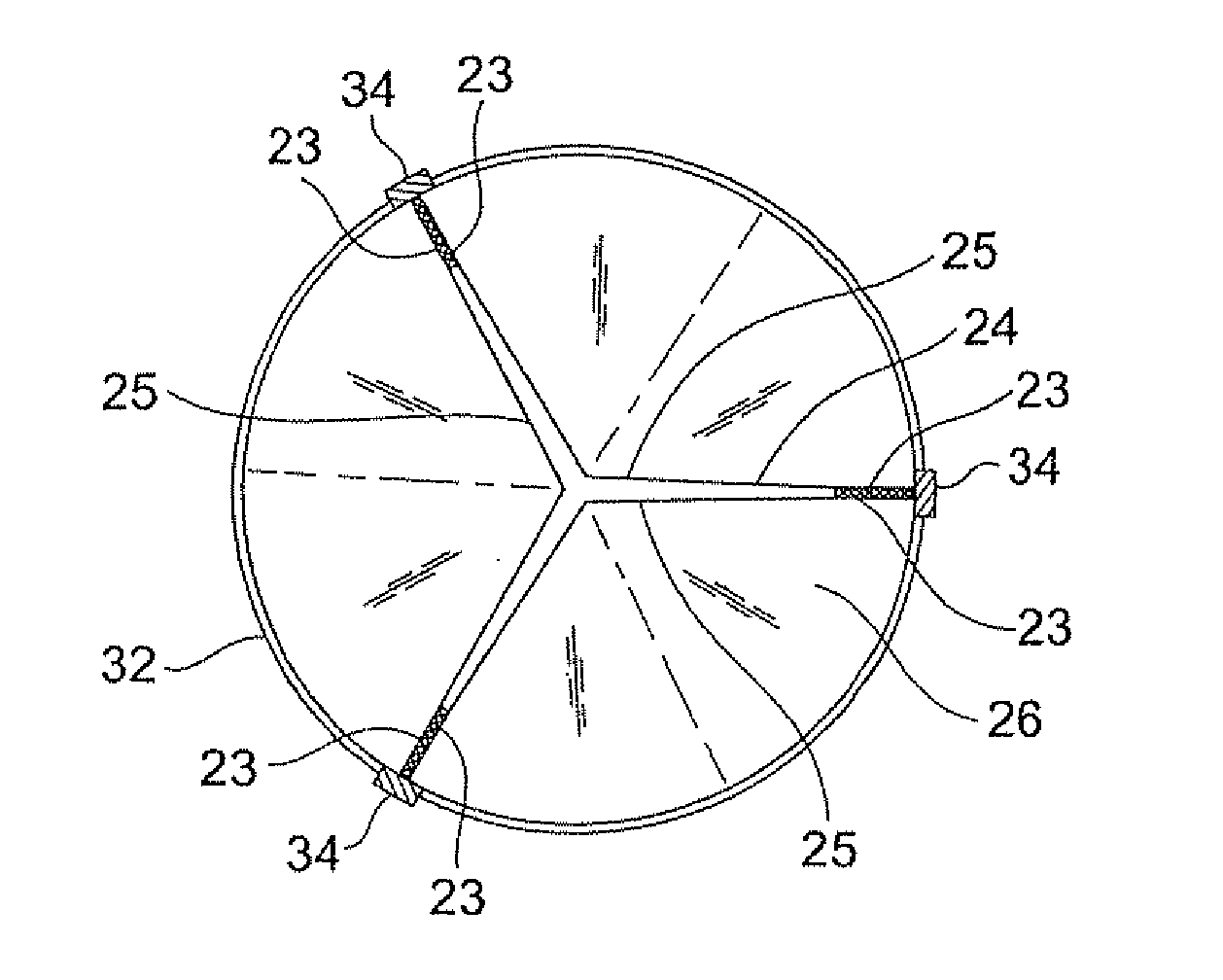

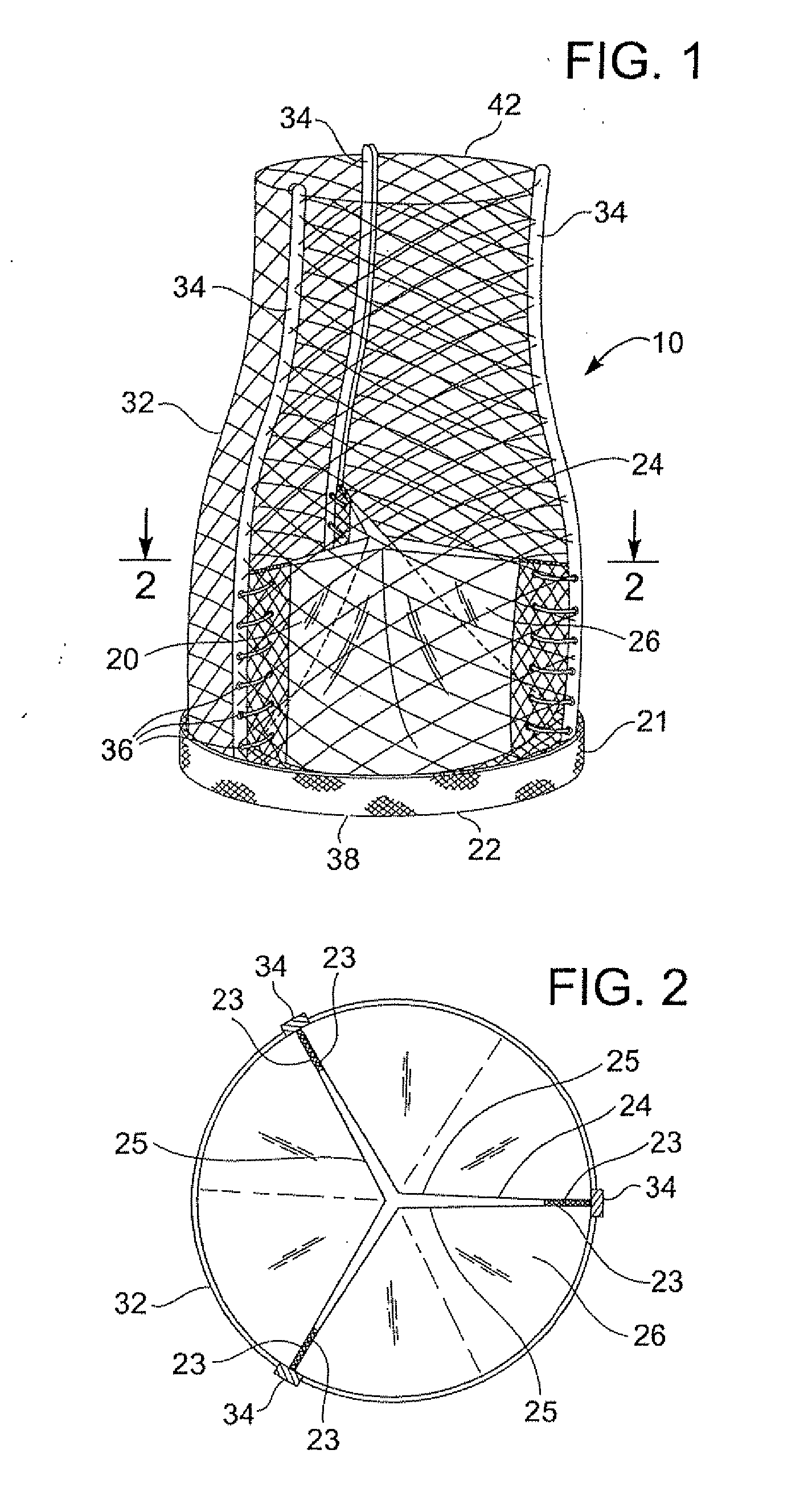

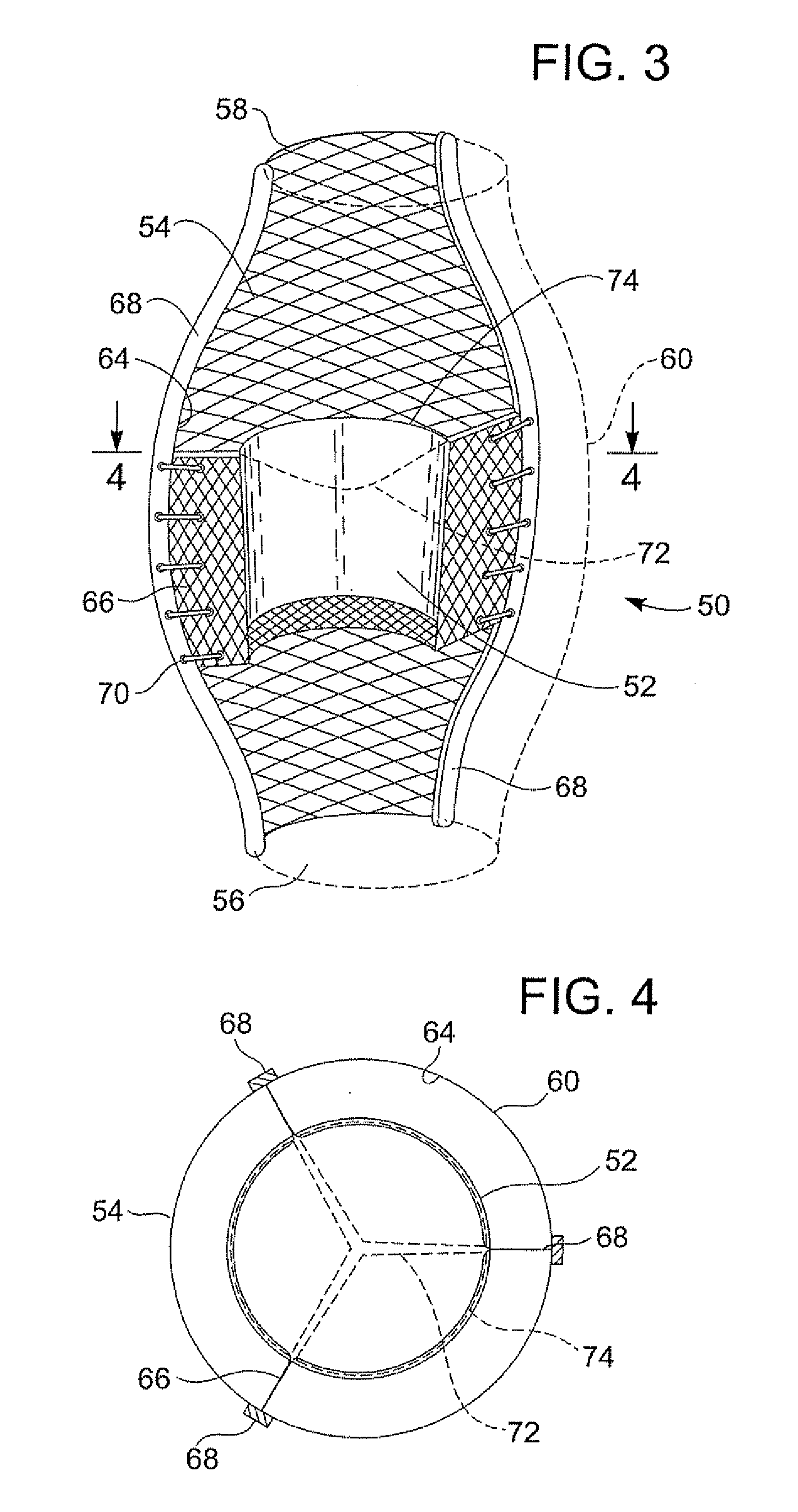

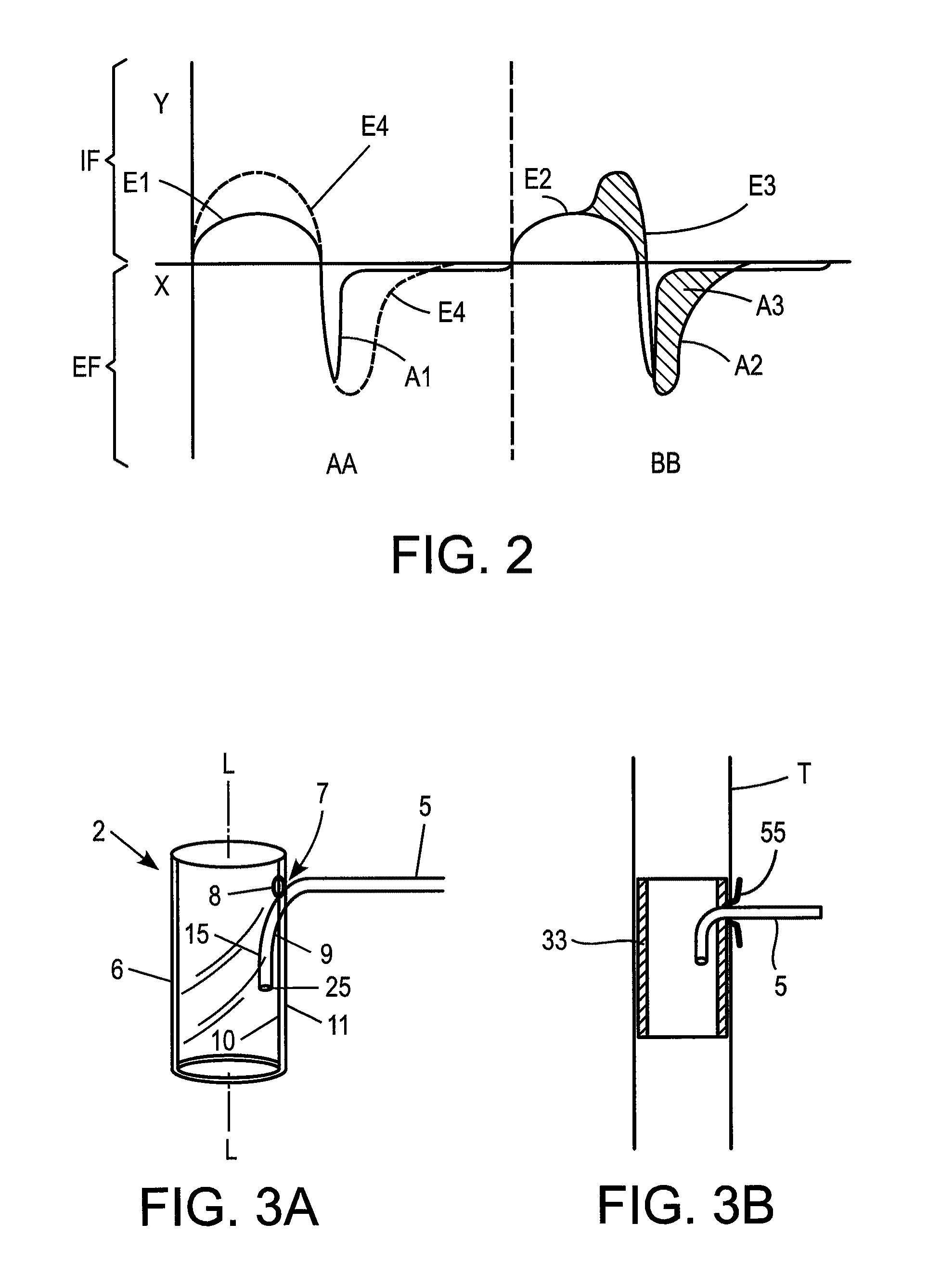

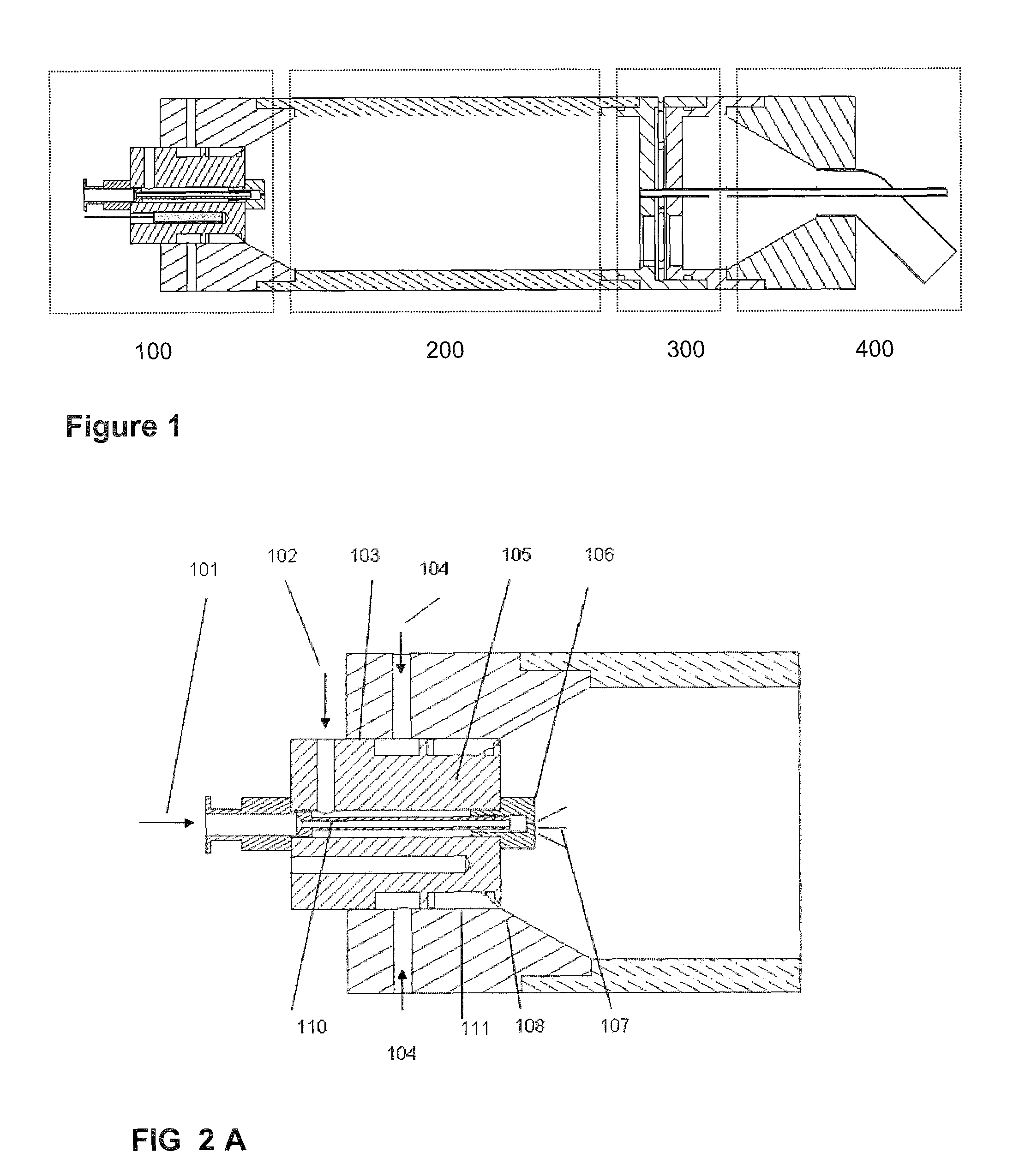

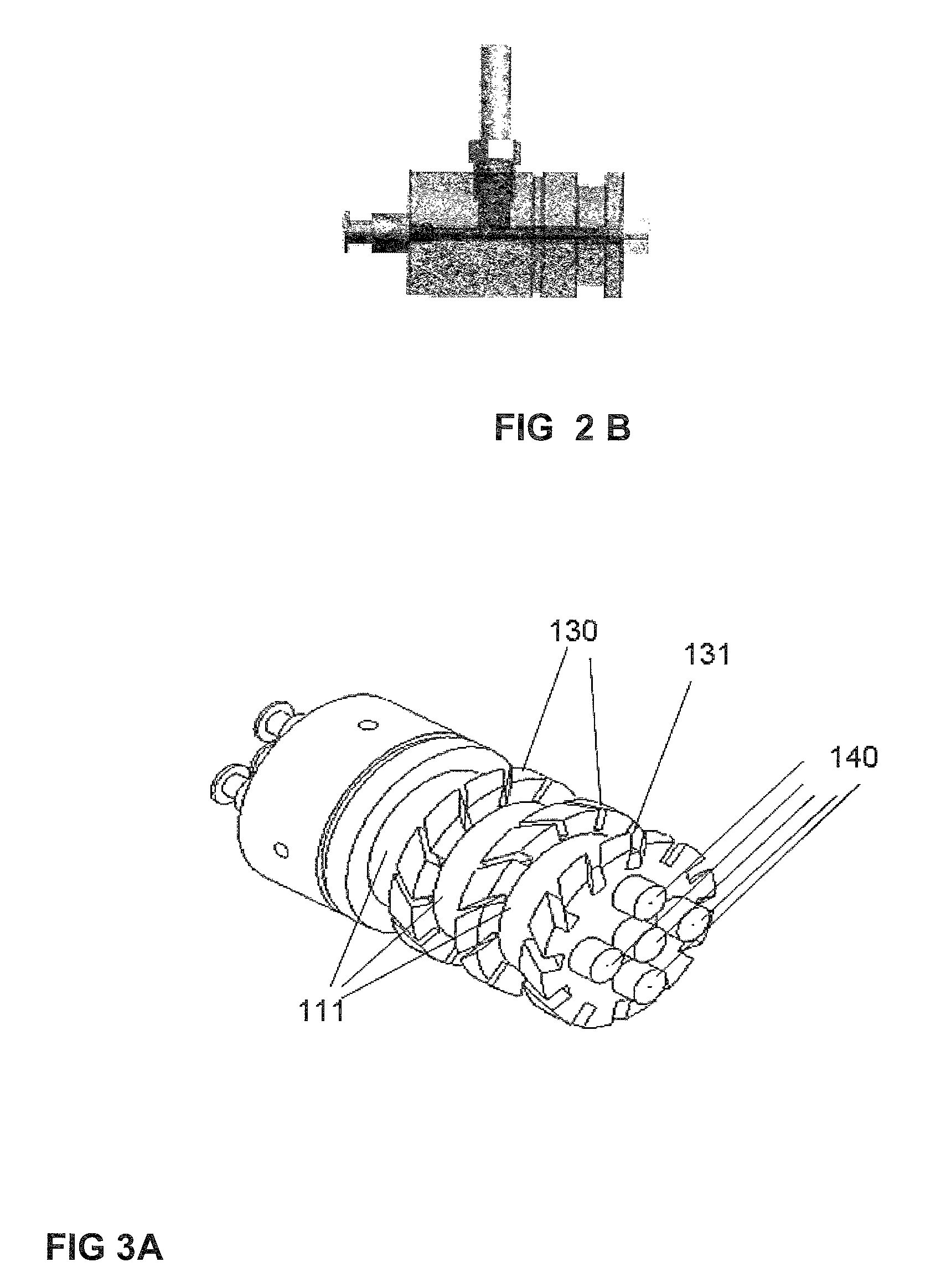

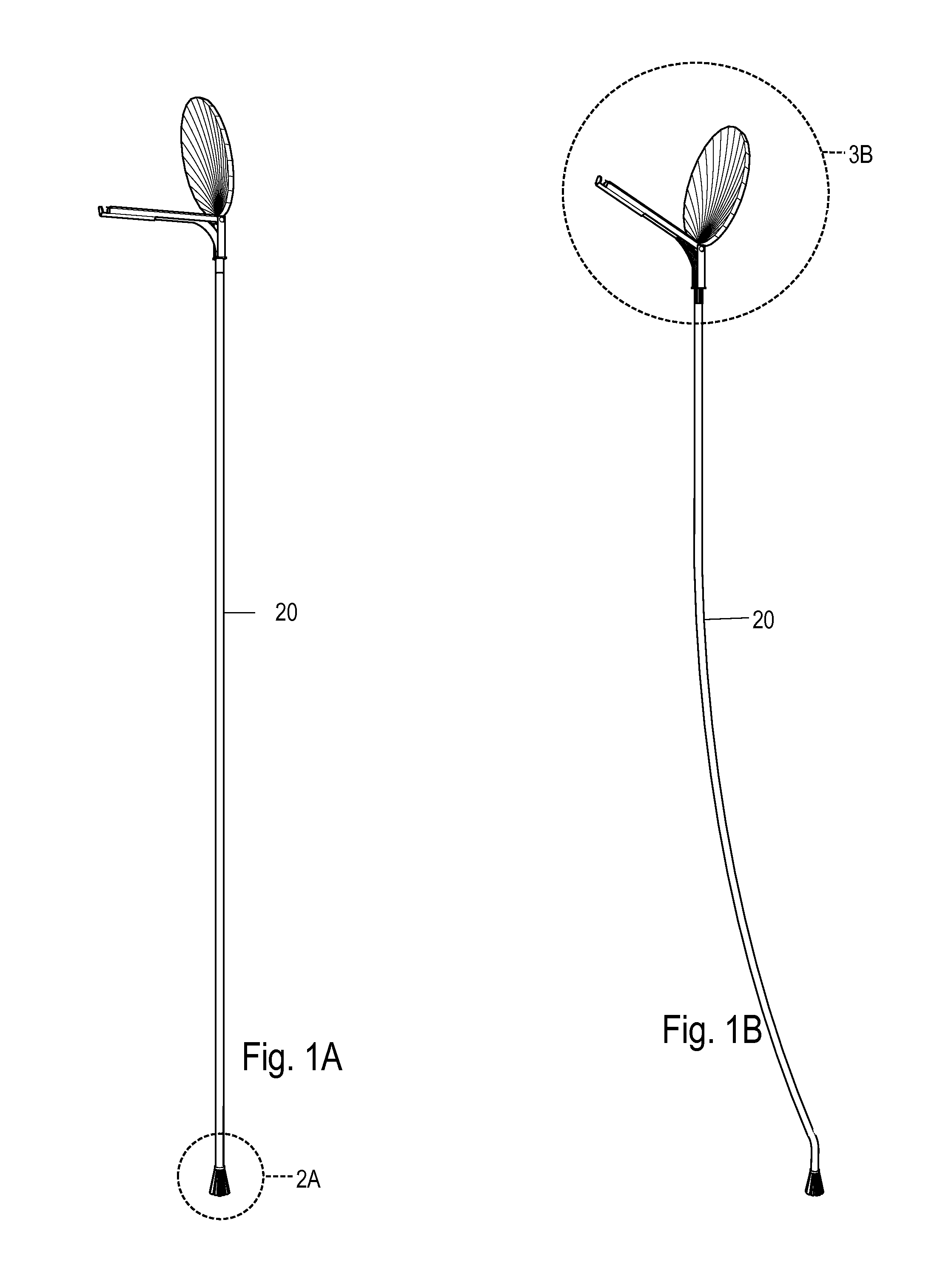

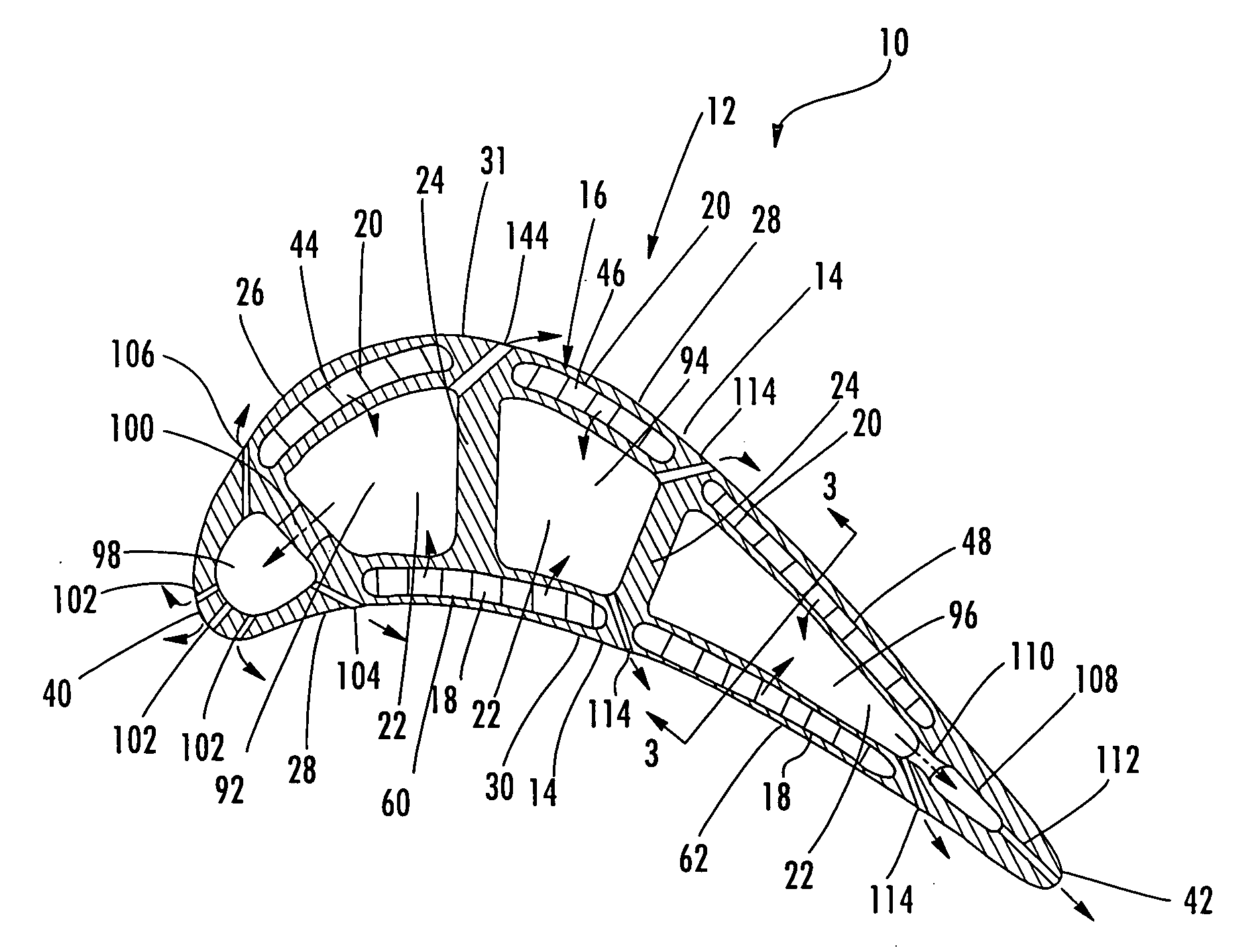

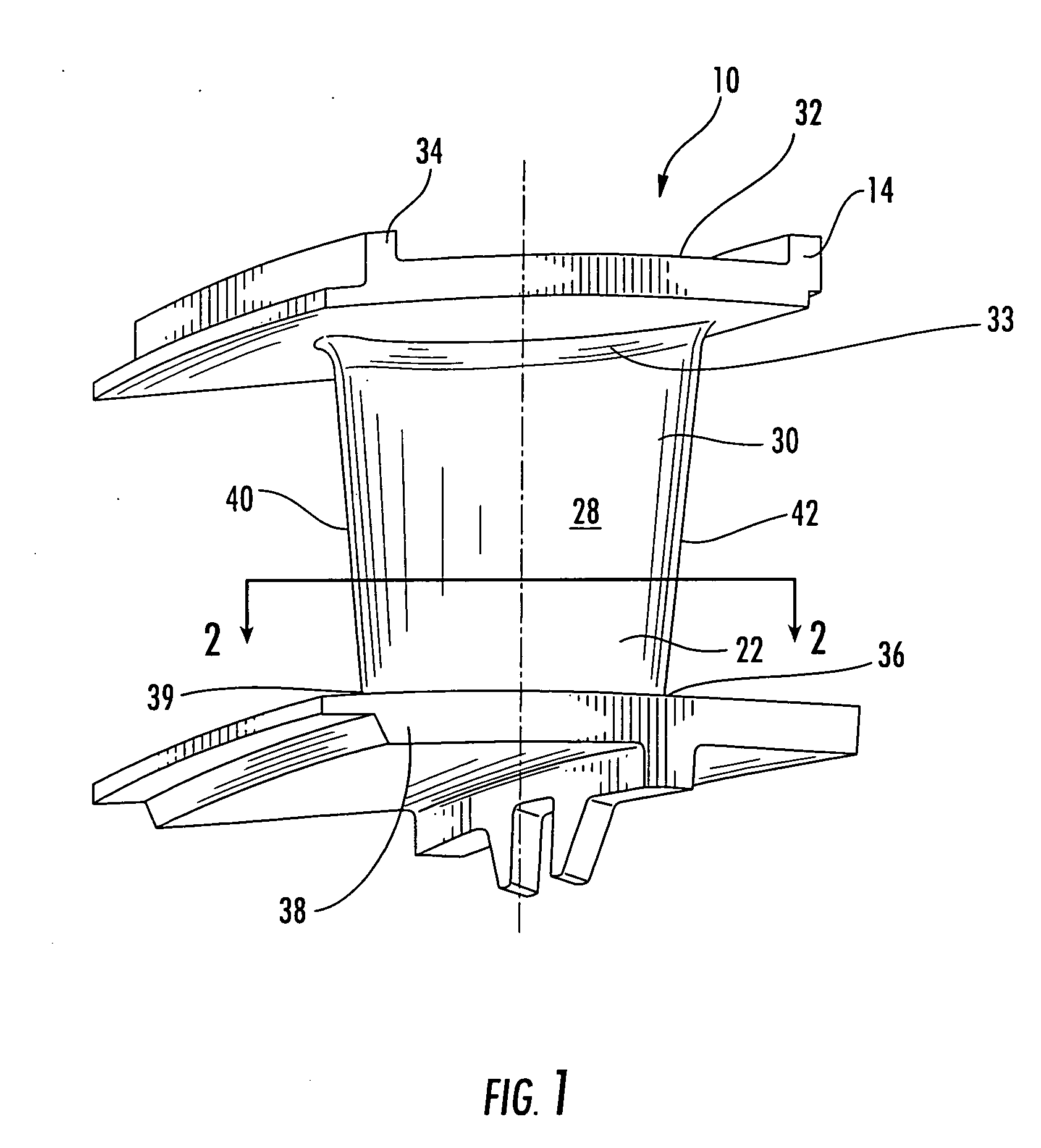

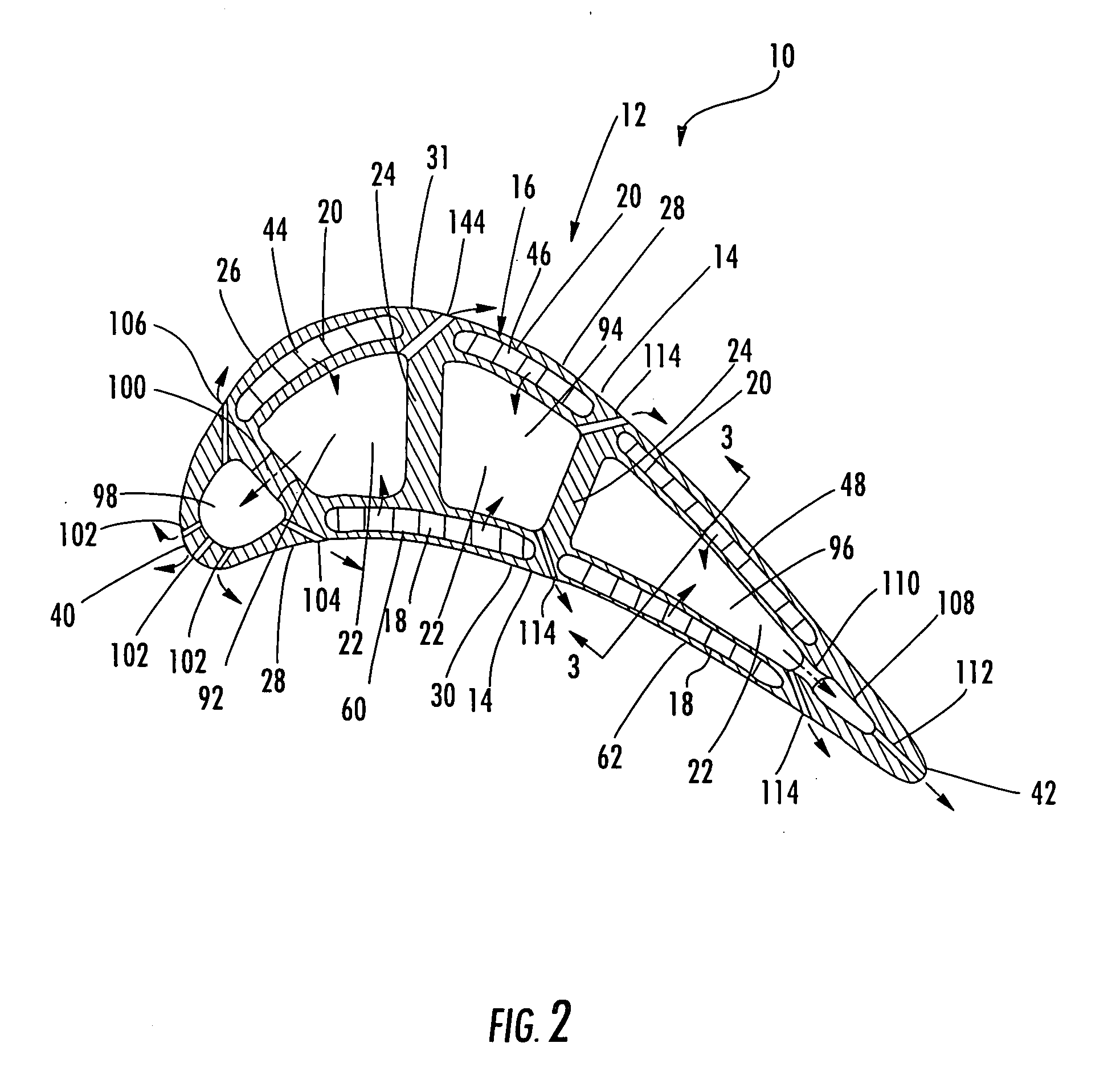

Implantable prosthetic valve with non-laminar flow

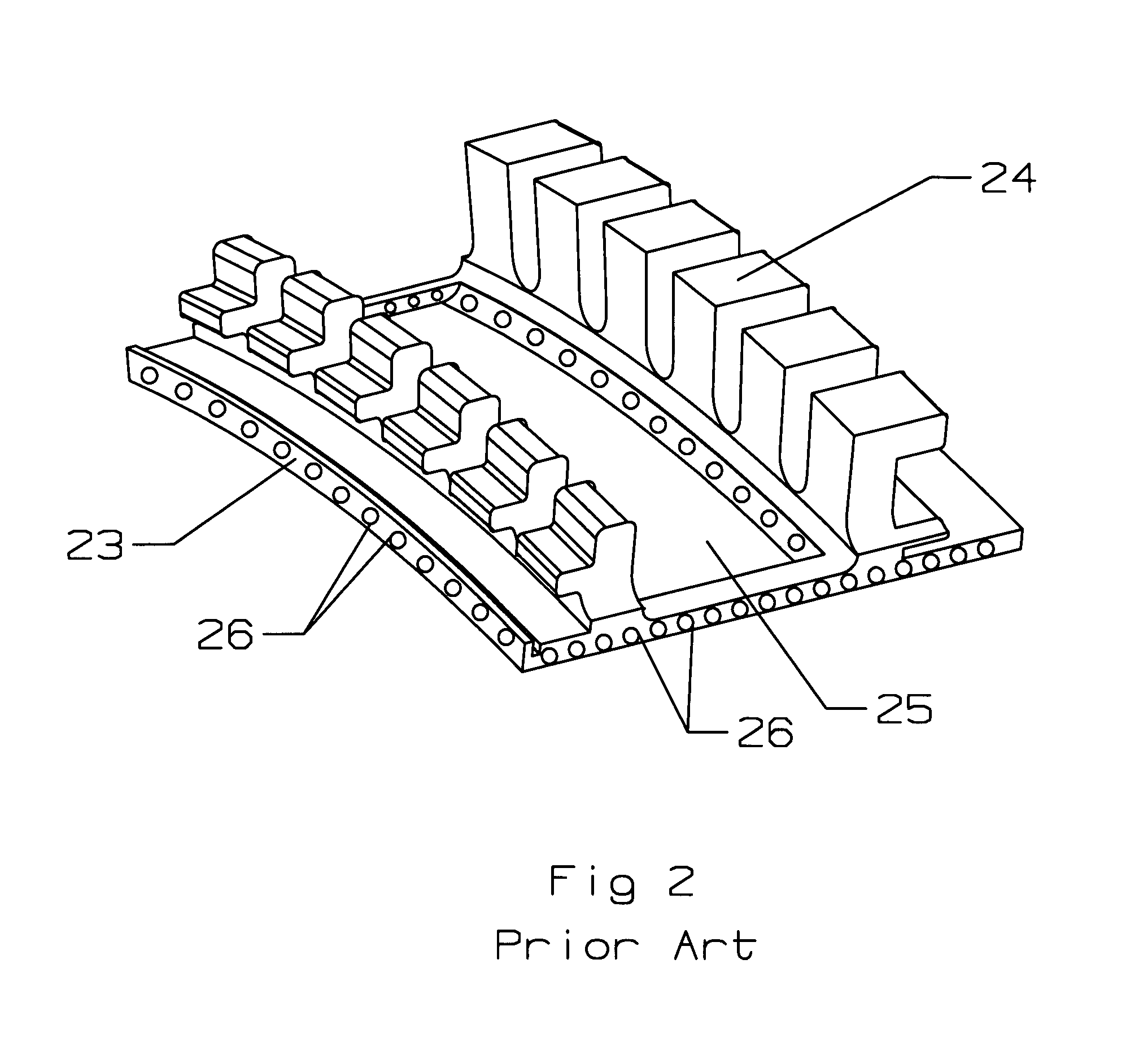

InactiveUS20050075725A1Prevent backflowEasy to trackStentsBalloon catheterCounter flowInsertion stent

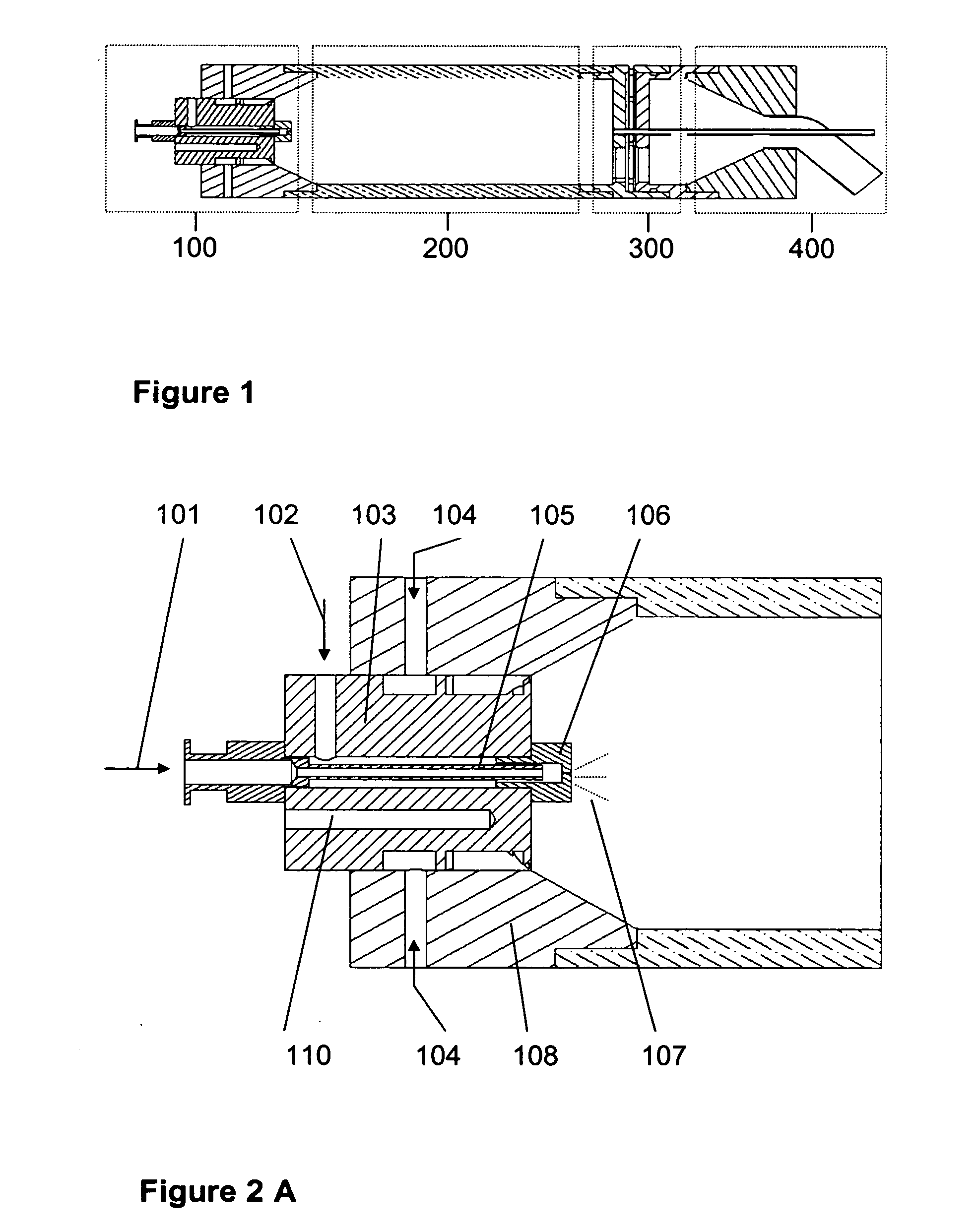

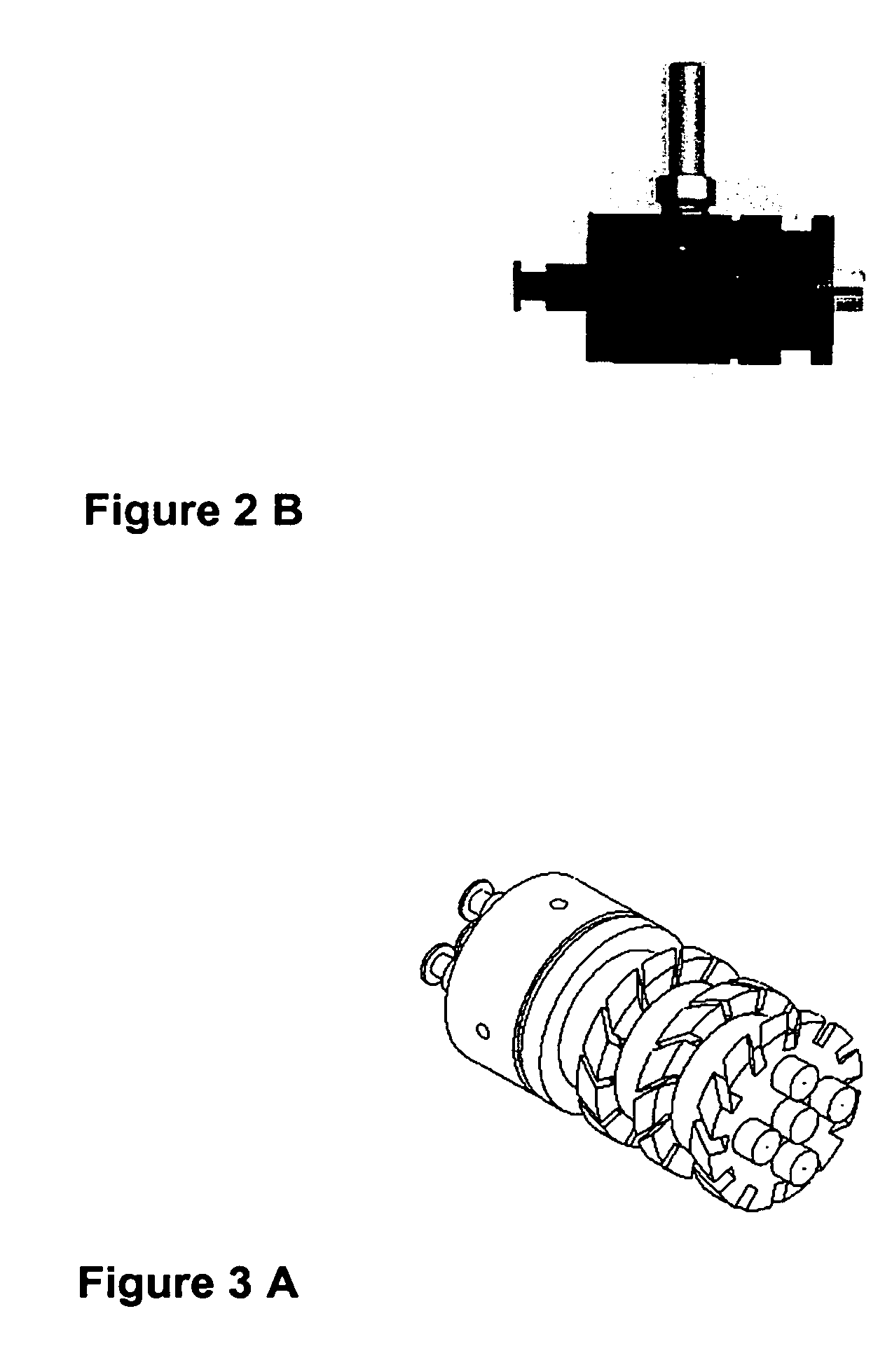

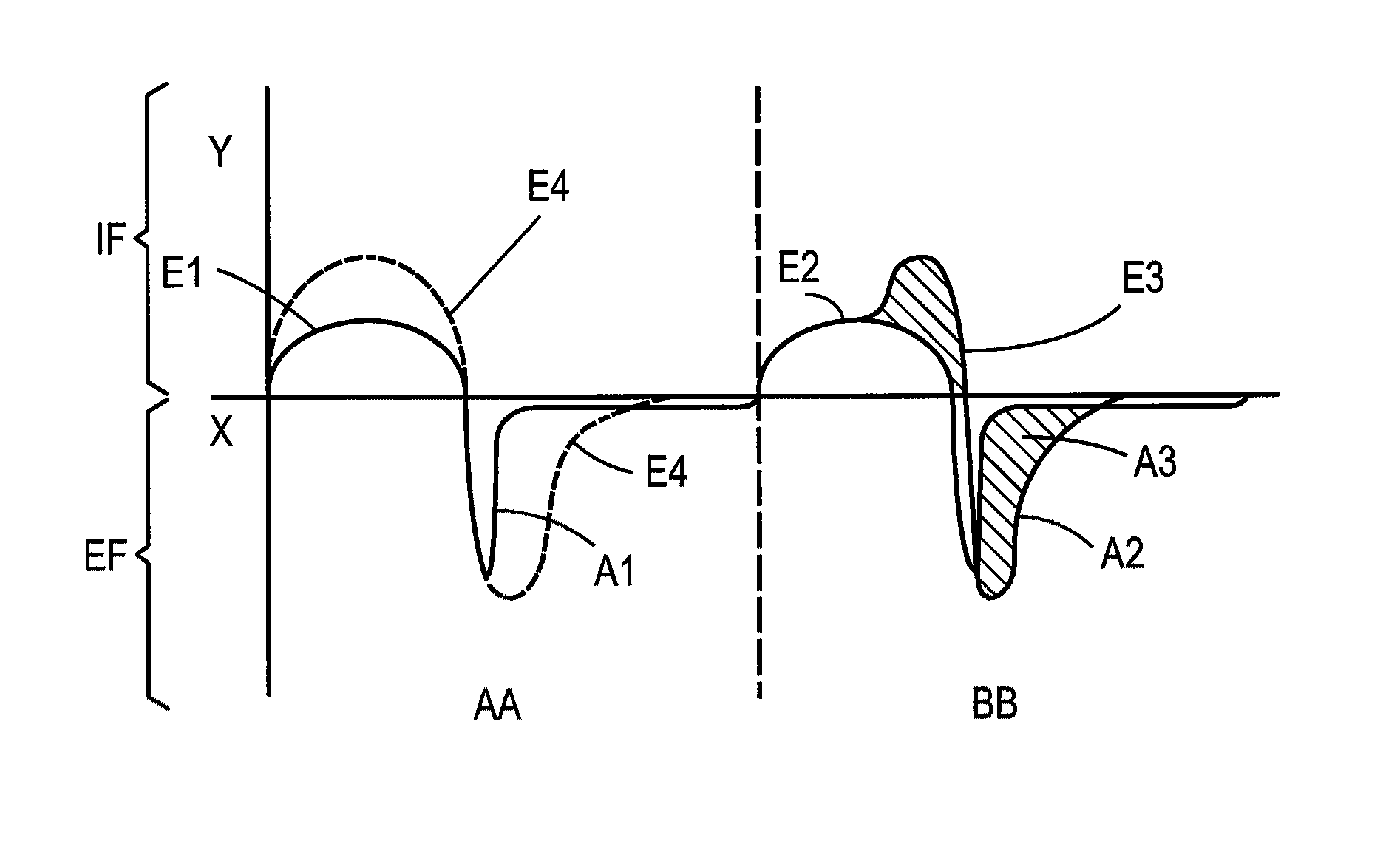

A valve prosthesis device is disclosed suitable for implantation in body ducts. The device comprises a support stent, comprised of a deployable construction adapted to be initially crimped in a narrow configuration suitable for catheterization through the body duct to a target location and adapted to be deployed by exerting substantially radial forces from within by means of a deployment device to a deployed state in the target location, and a valve assembly comprising a flexible conduit having an inlet end and an outlet, made of pliant material attached to the support beams providing collapsible slack portions of the conduit at the outlet. The support stent is provided with a plurality of longitudinally rigid support beams of fixed length. When flow is allowed to pass through the valve prosthesis device from the inlet to the outlet, the valve assembly is kept in an open position, whereas a reverse flow is prevented as the collapsible slack portions of the valve assembly collapse inwardly providing blockage to the reverse flow. The device is configured so that retrograde flow will be altered from laminar flow and directed towards the leaflets to effect closing.

Owner:EDWARDS LIFESCIENCES CORP

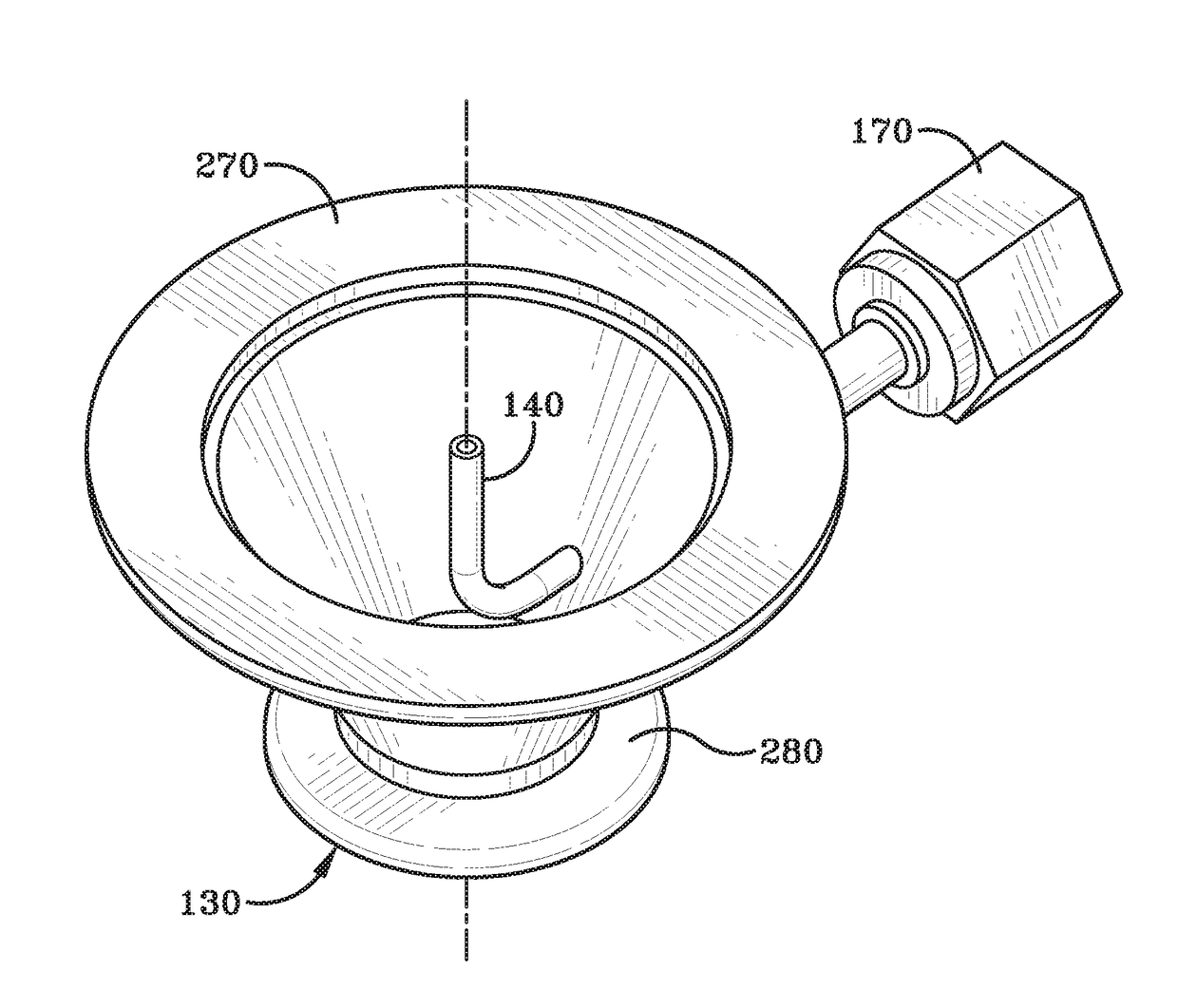

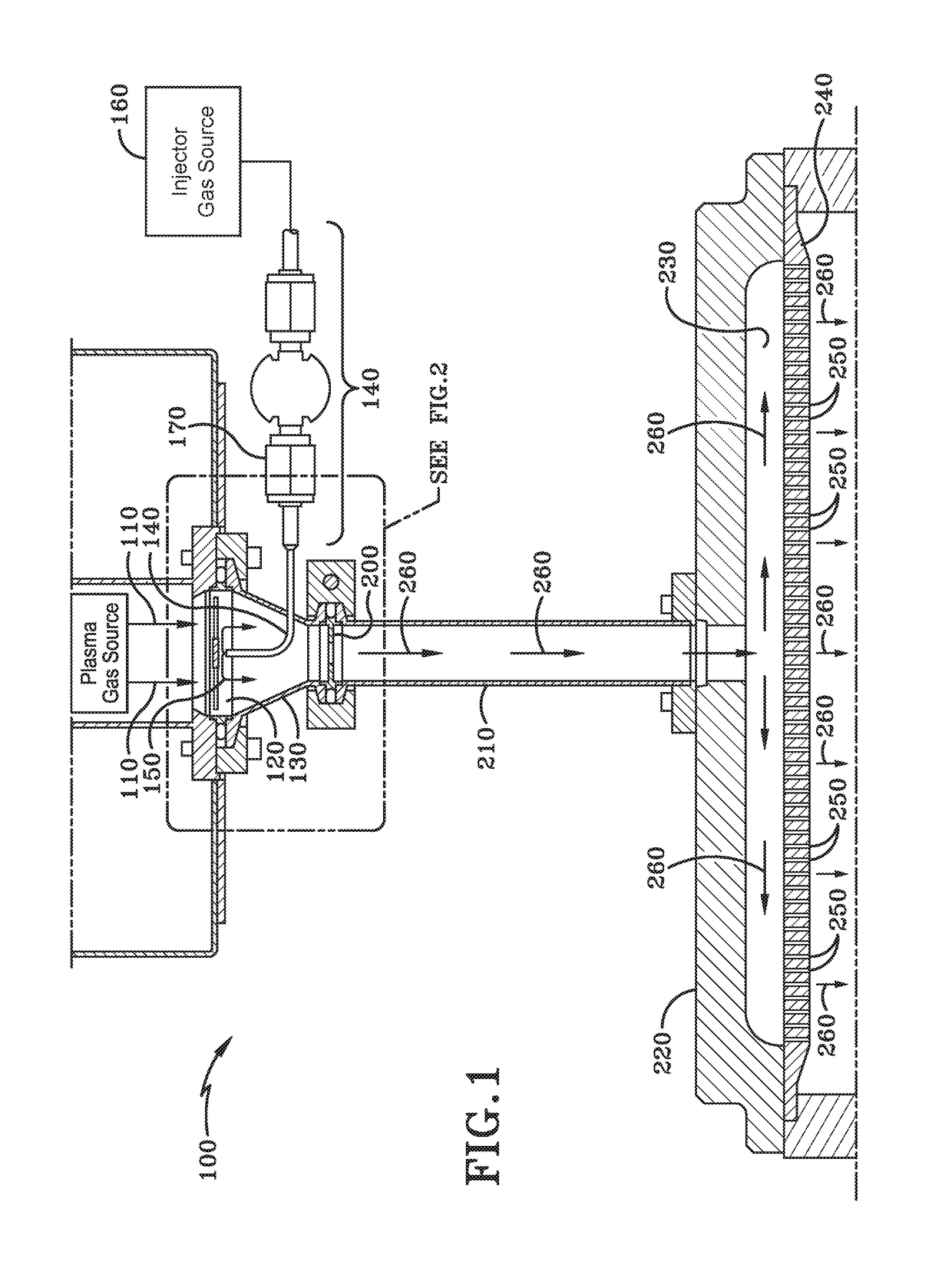

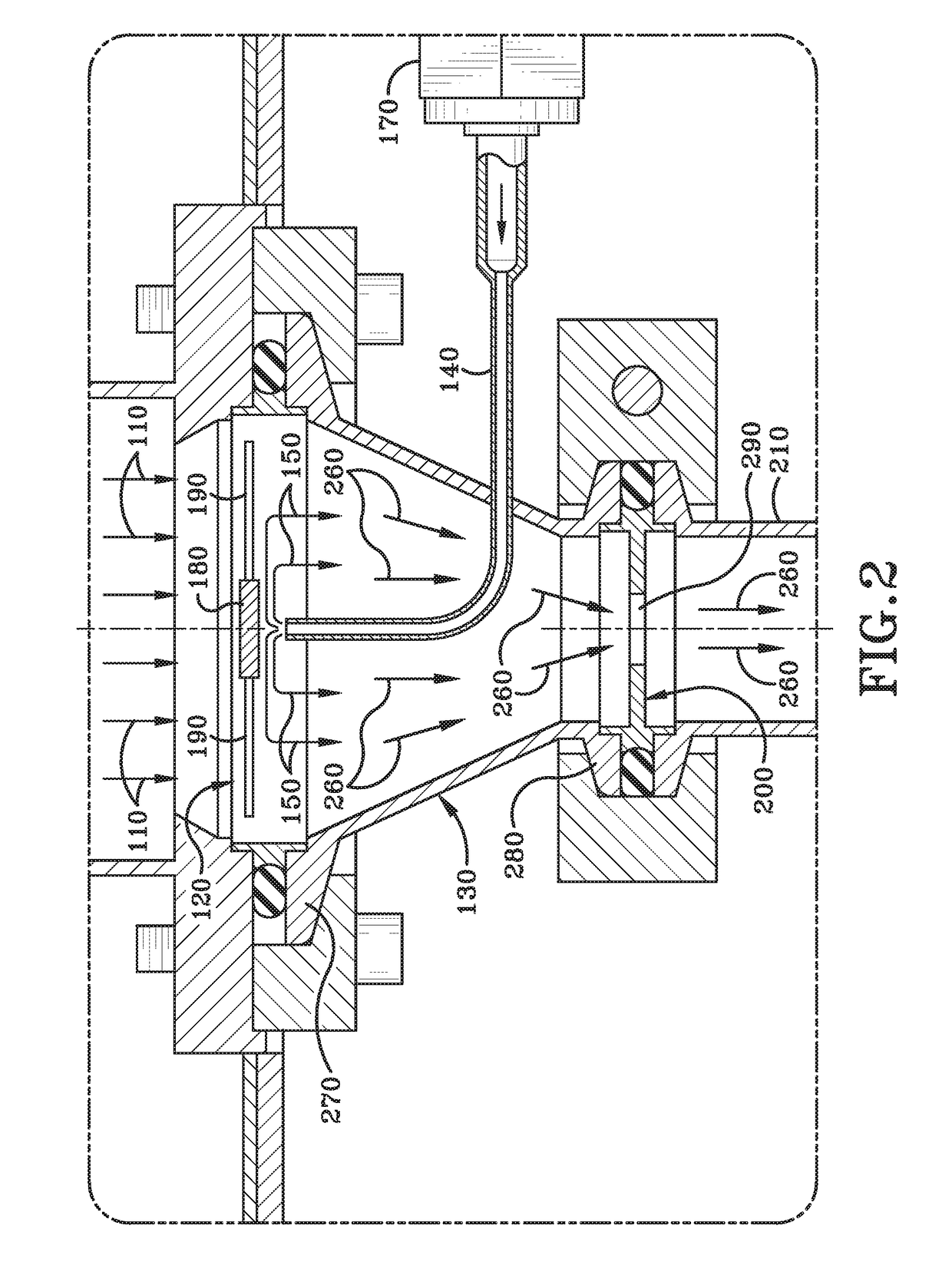

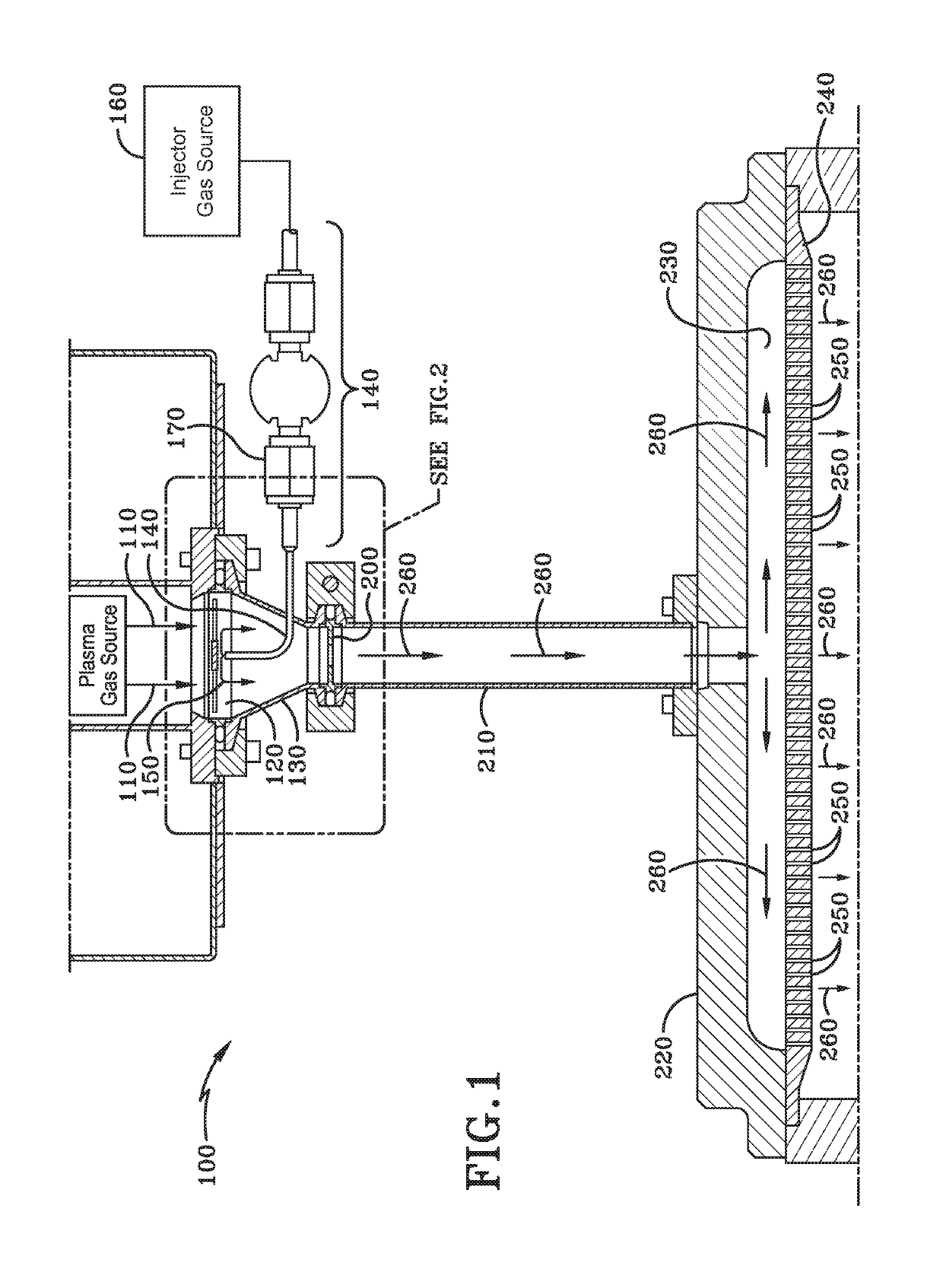

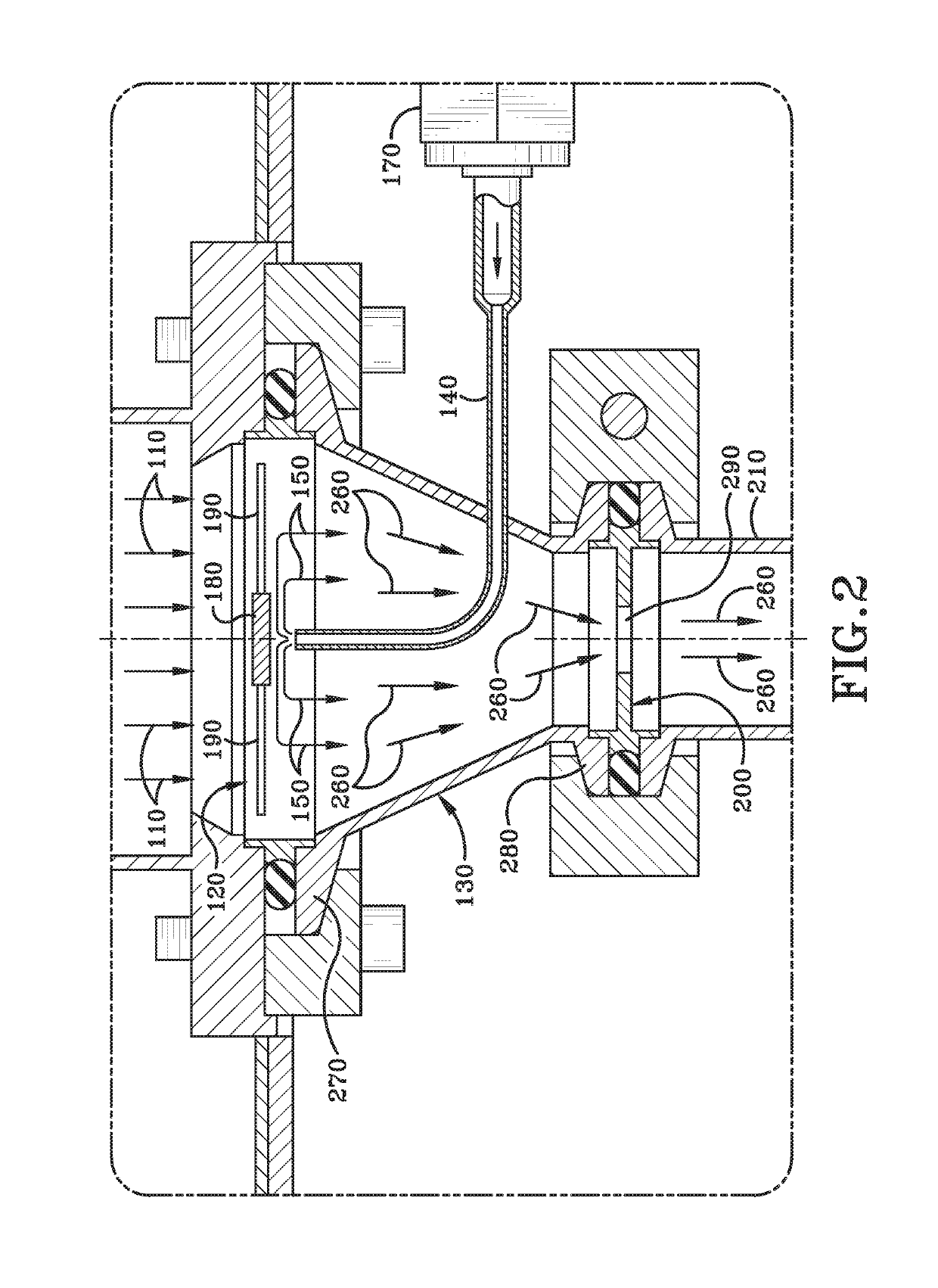

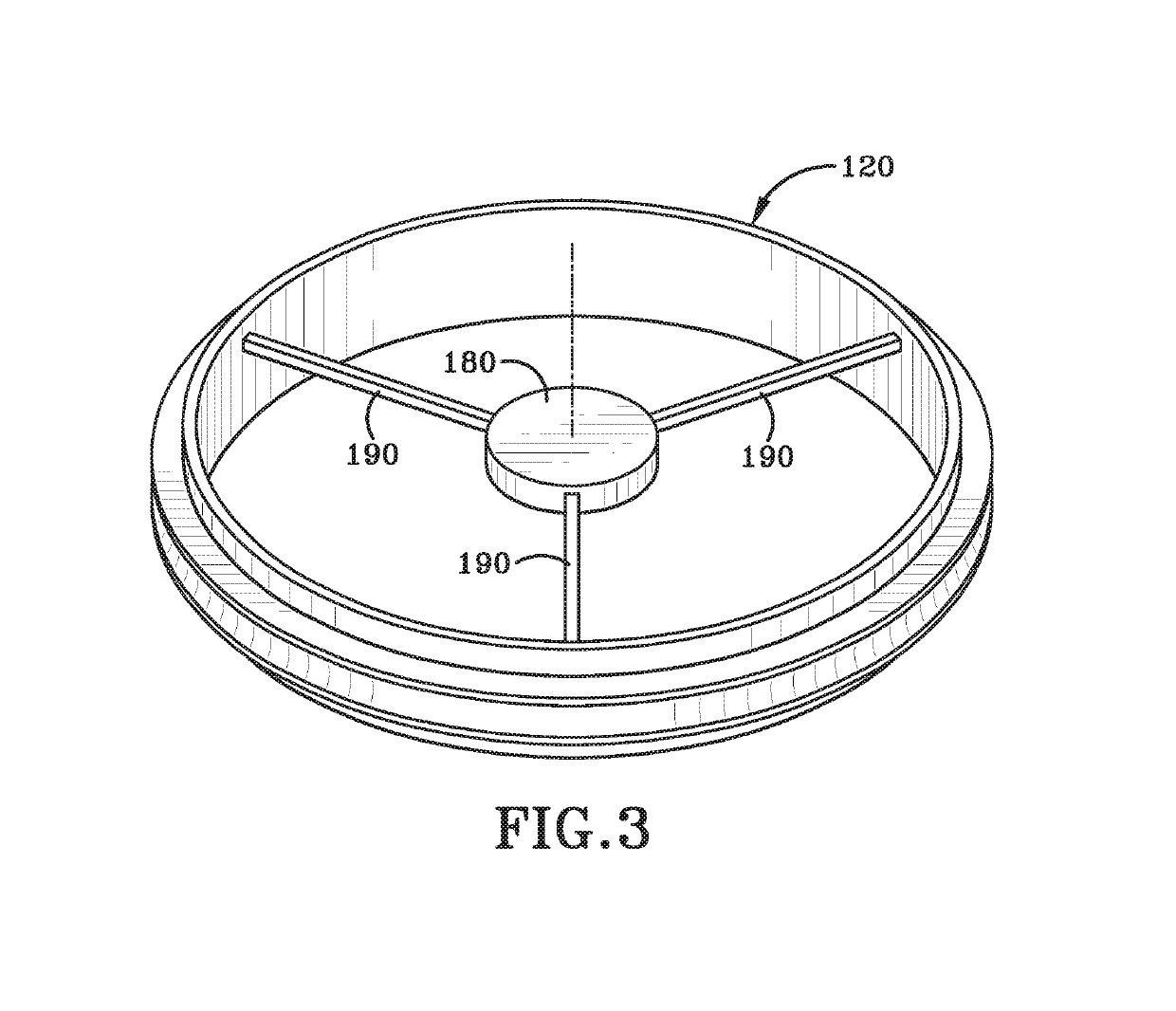

Counter flow mixer for process chamber

A counterflow mixing device for a process chamber is disclosed, comprising an injection tube that introduces a fluid in a manner counter to a flow of a post-plasma gas mixture traveling downward from a plasma source. The invention allows for proper mixing of the fluid as well as avoiding recombination of generated ions and radicals.

Owner:ASM IP HLDG BV

Counter flow mixer for process chamber

Owner:ASM IP HLDG BV

Implantable prosthetic valve with non-laminar flow

Owner:EDWARDS LIFESCIENCES CORP

Aerosol processing and inhalation method and system for high dose rate aerosol drug delivery

ActiveUS20070144514A1Increase dose rateRisk minimizationRespiratorsLiquid surface applicatorsSolvent vaporCounter flow

A method and system is disclosed which is capable of delivering at a high dose rate, respirable solid aerosols derived from aqueous- or nonaqueous-based solutions containing the desired therapeutic agent(s). The method and system comprises the integration of an aerosol generator, an aerosol evaporator, an aerosol concentrator, and an aerosol flow regulator. The aerosol generator generates 10-30 μm droplets, with a narrow size distribution. The aerosol jet is arrested by a coaxial counter-flow heated air jet, and evaporated rapidly by annular swirling heated air. Most of the air, together with the unwanted solvent vapor, is removed from the aerosol stream during the process of aerosol concentration. The output aerosol carries the dry particles to be inhaled by the patient. The respiratory-governed control of aerosol fluid generation system delivers fluid containing the test agent of interest (drug or toxin) to the aerosol generator throughout inhalation.

Owner:KAER BIOTHERAPEUTICS CORP

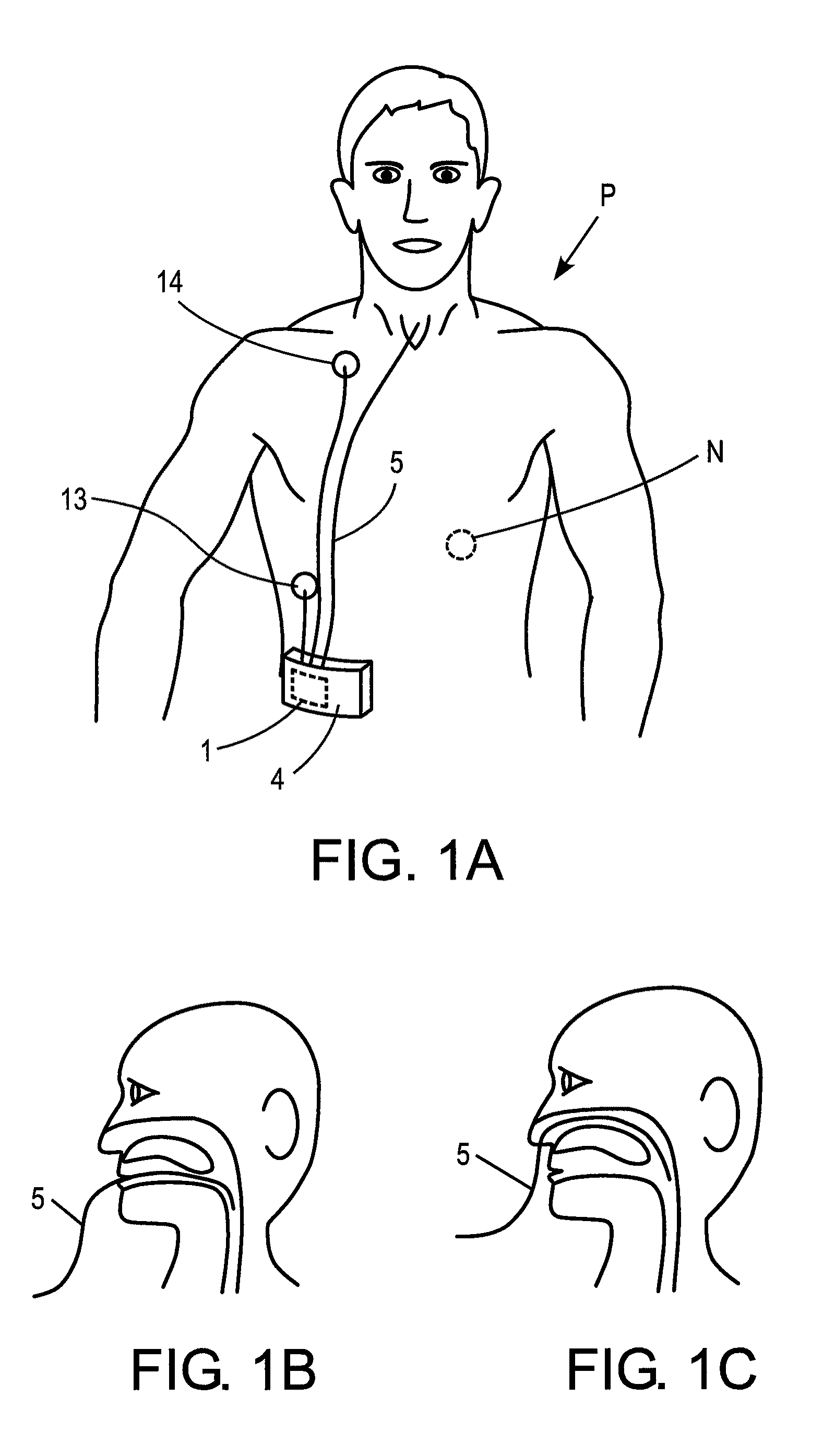

Systems, methods and apparatus for respiratory support of a patient

ActiveUS7533670B1Improve the quality of lifeEfficient way of supporting the respiration of a patientTracheal tubesOperating means/releasing devices for valvesCounter flowOxygen

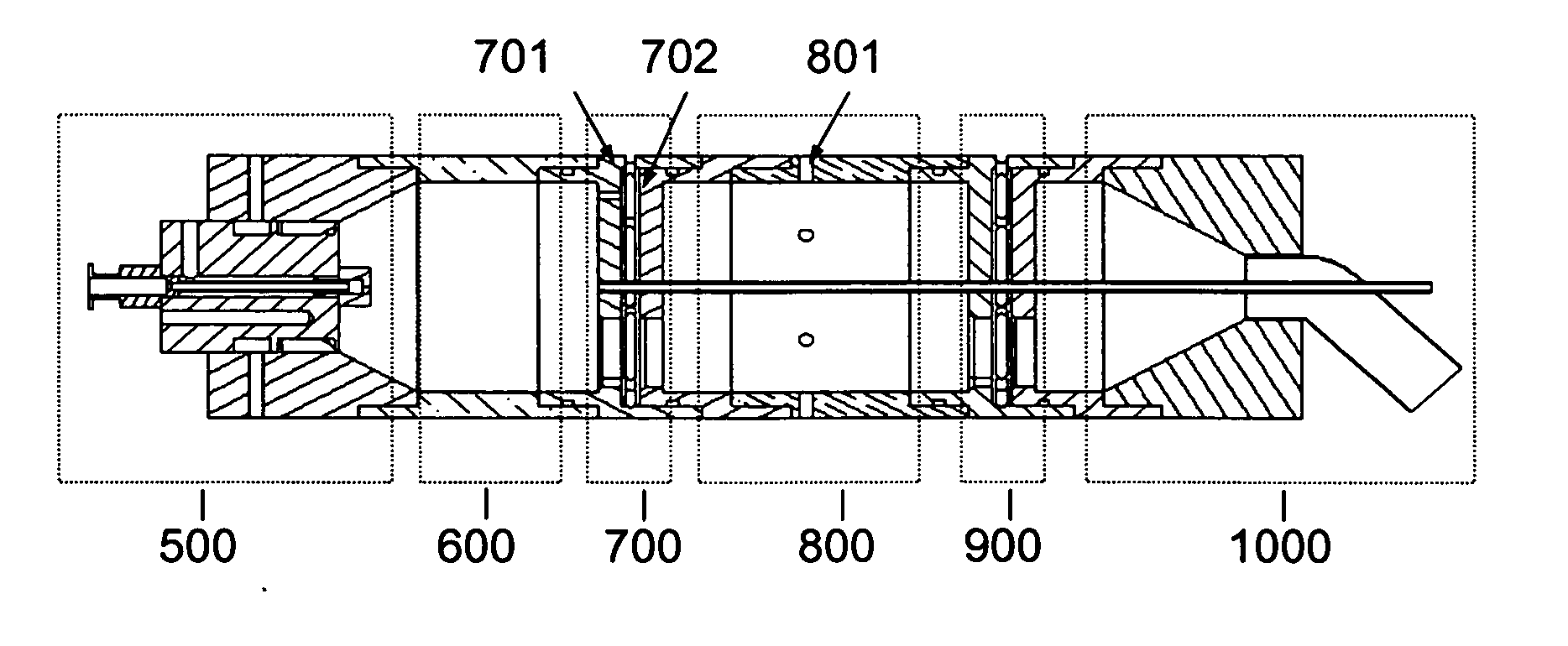

Spontaneous respiration is detected by sensors. An additional amount of oxygen is administered to the lungs via a jet gas current at the end of an inhalation procedure. Breathing volume, absorption of oxygen during inhalation, and clearance of carbon dioxide during exhalation are improved. If required, the exhalation procedure of the patient can be arrested or slowed by a countercurrent to avoid a collapse of the respiration paths. An apparatus including an oxygen pump can be connected to an oxygen source and includes a tracheal prosthesis that can be connected via a catheter. The respiration detections sensors are connected to a control unit for activating the oxygen pump. The tracheal prosthesis includes a tubular support body with a connection for the catheter, and the sensors are associated with the support body. The tracheal prosthesis and jet catheter are dimensioned so the patient can freely breathe and speak without restriction.

Owner:BREATHE TECHNOLOGIES INC

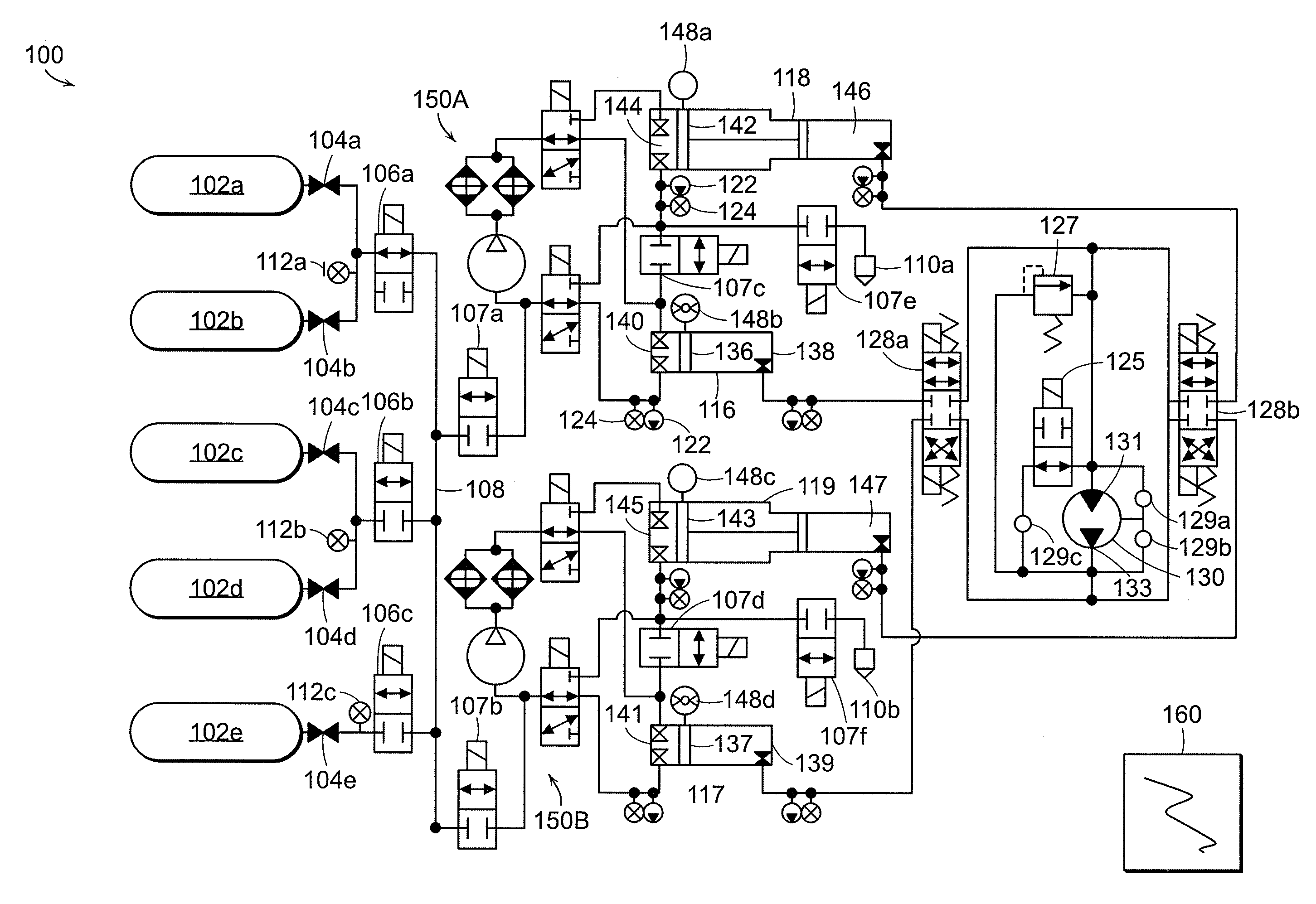

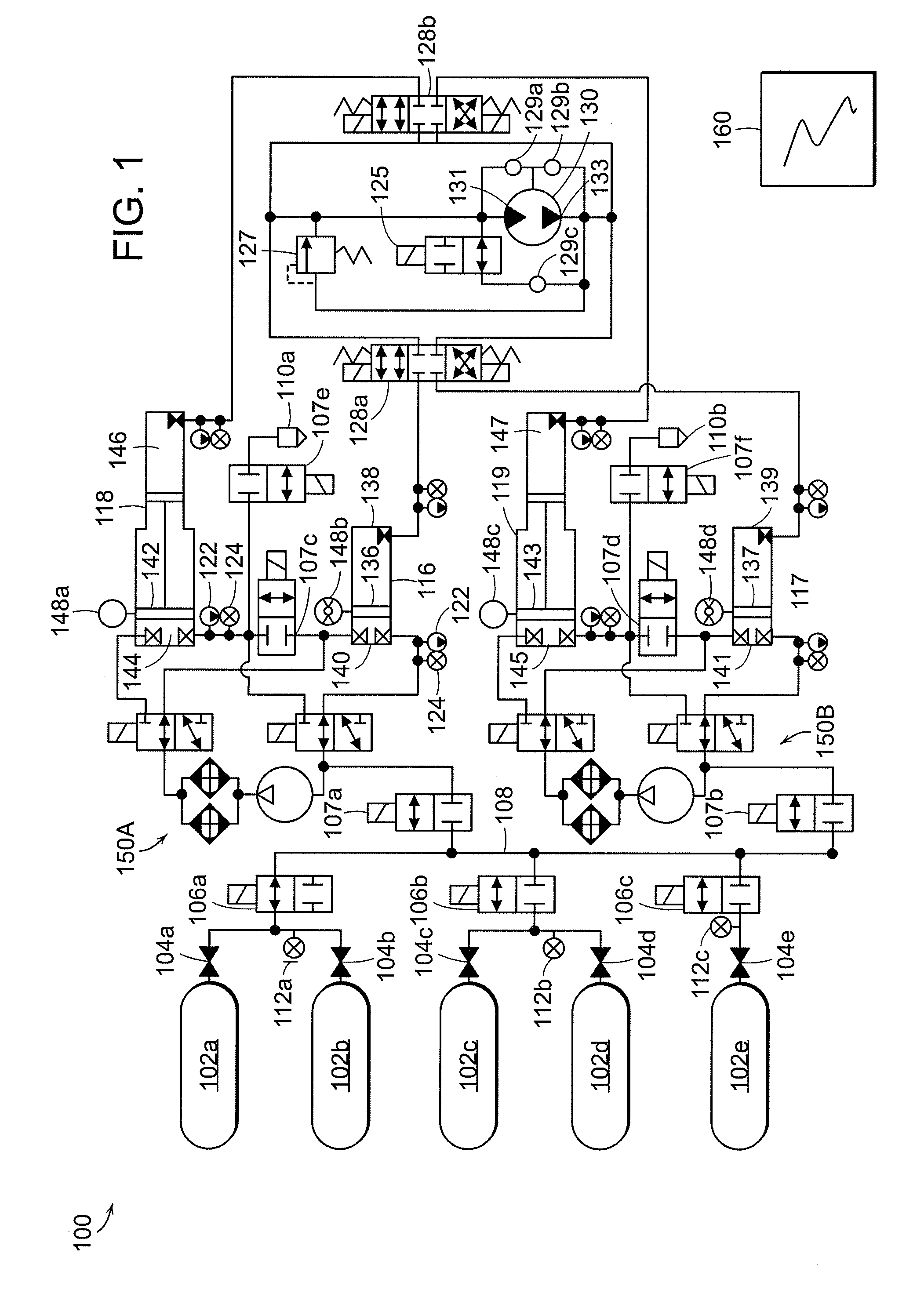

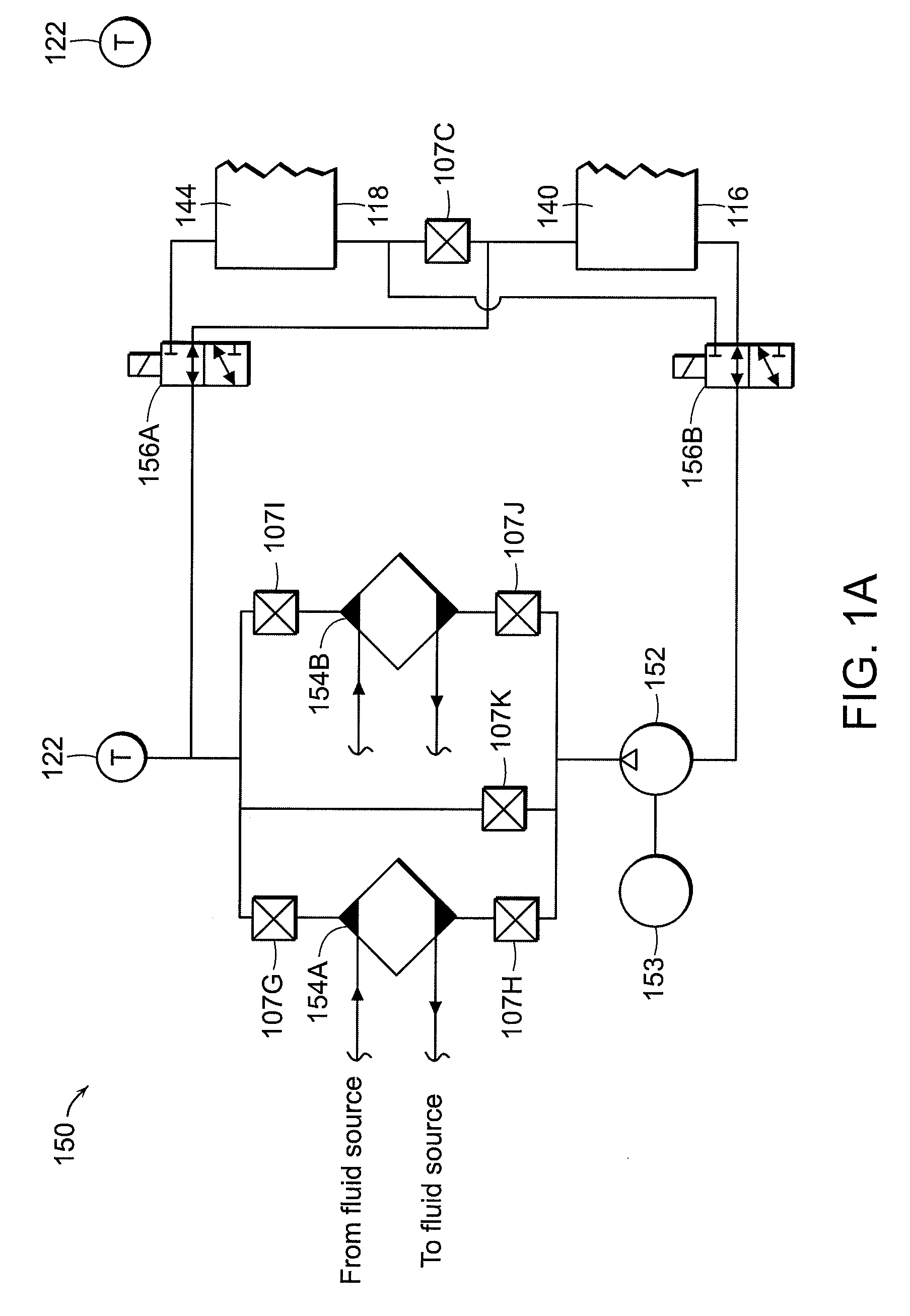

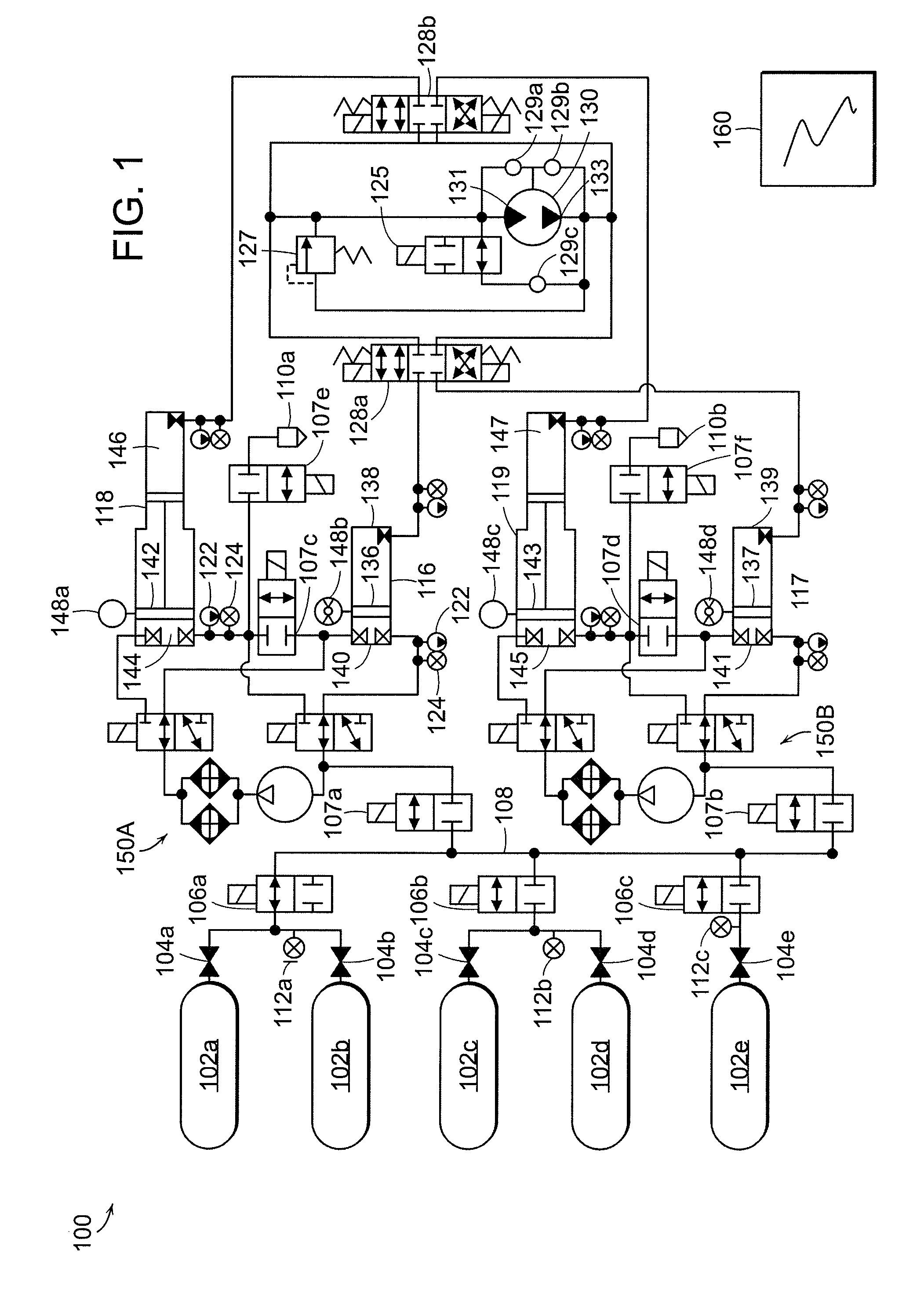

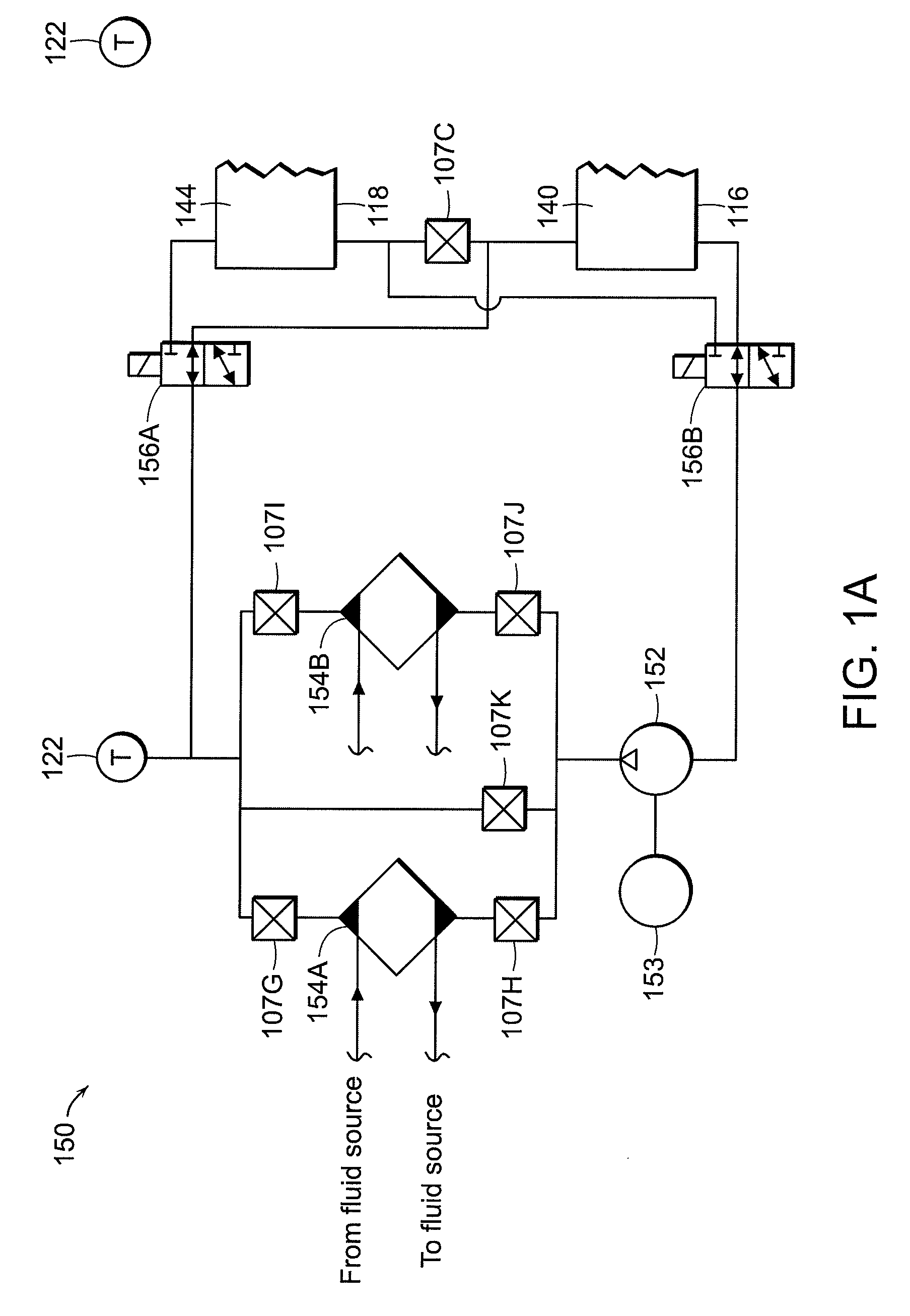

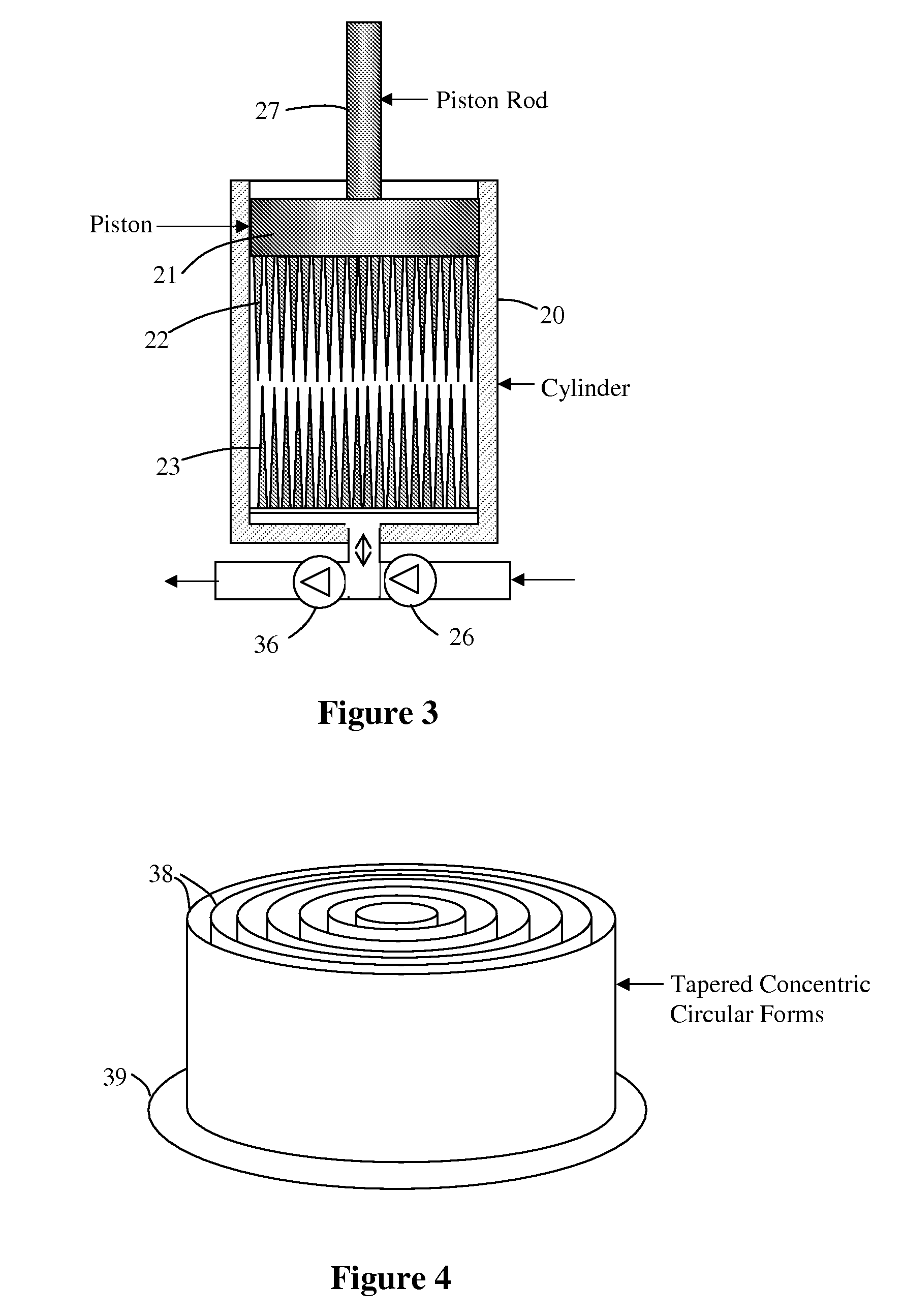

System and Method for Rapid Isothermal Gas Expansion and Compression for Energy Storage

InactiveUS20090301089A1Overcome disadvantagesInhibit migrationElectrical storage systemFluid couplingsCounter flowEngineering

The invention relates to systems and methods for rapidly and isothermally expanding gas in a cylinder. The cylinder is used in a staged hydraulic-pneumatic energy conversion system and includes a gas chamber (pneumatic side) and a fluid chamber (hydraulic side) and a piston or other mechanism that separates the gas chamber and fluid chamber while allowing the transfer of force / pressure between each opposing chamber. The gas chamber of the cylinder includes ports that are coupled to a heat transfer subassembly that circulates gas from the pneumatic side and exchanges its heat with a counter flow of ambient temperature fluid from a reservoir or other source.

Owner:SUSTAINX

System and method for rapid isothermal gas expansion and compression for energy storage

InactiveUS7802426B2Overcome disadvantagesInhibit migrationElectrical storage systemServomotorsCounter flowEngineering

The invention relates to systems and methods for rapidly and isothermally expanding gas in a cylinder. The cylinder is used in a staged hydraulic-pneumatic energy conversion system and includes a gas chamber (pneumatic side) and a fluid chamber (hydraulic side) and a piston or other mechanism that separates the gas chamber and fluid chamber while allowing the transfer of force / pressure between each opposing chamber. The gas chamber of the cylinder includes ports that are coupled to a heat transfer subassembly that circulates gas from the pneumatic side and exchanges its heat with a counter flow of ambient temperature fluid from a reservoir or other source.

Owner:SUSTAINX

Apparatus and method for selecting a flow mixture

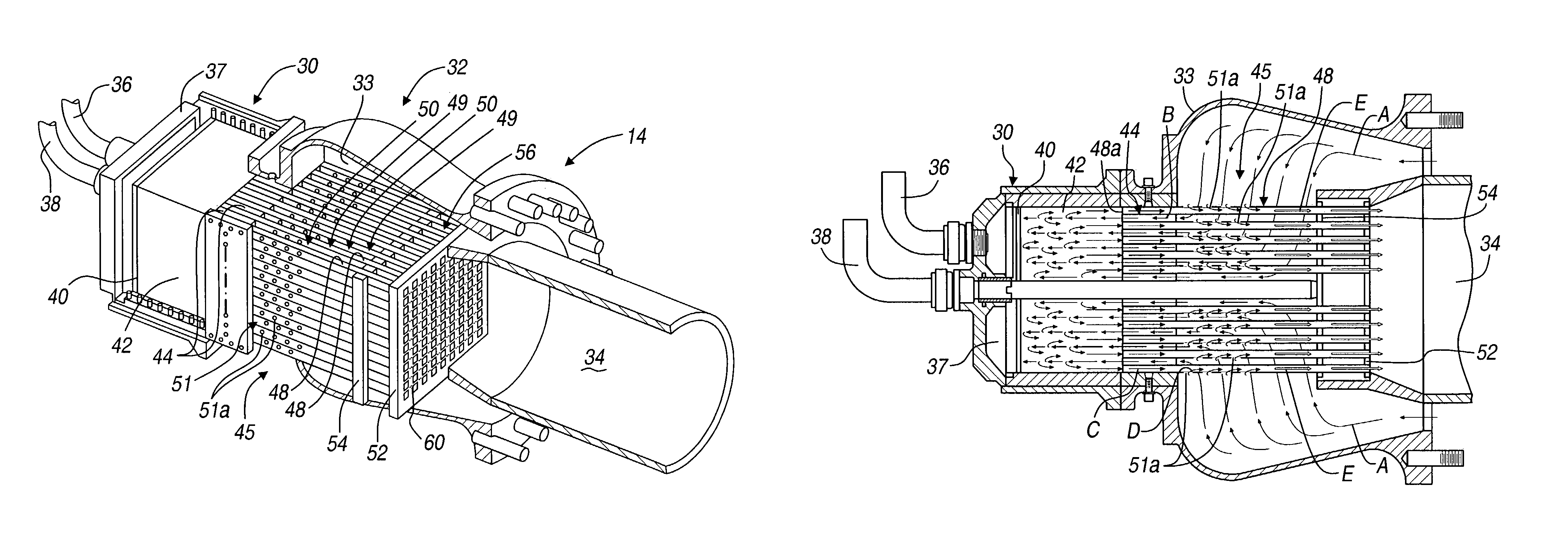

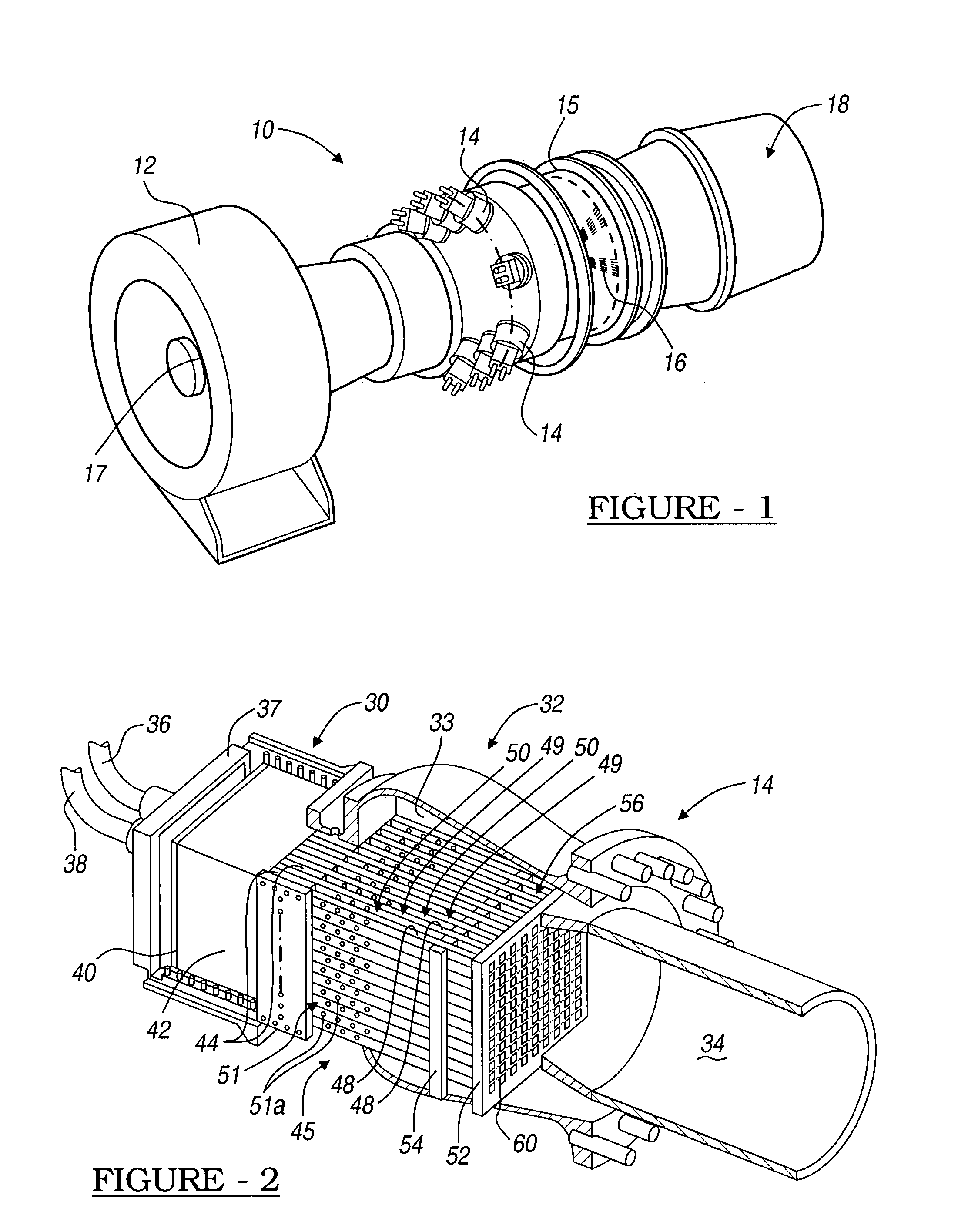

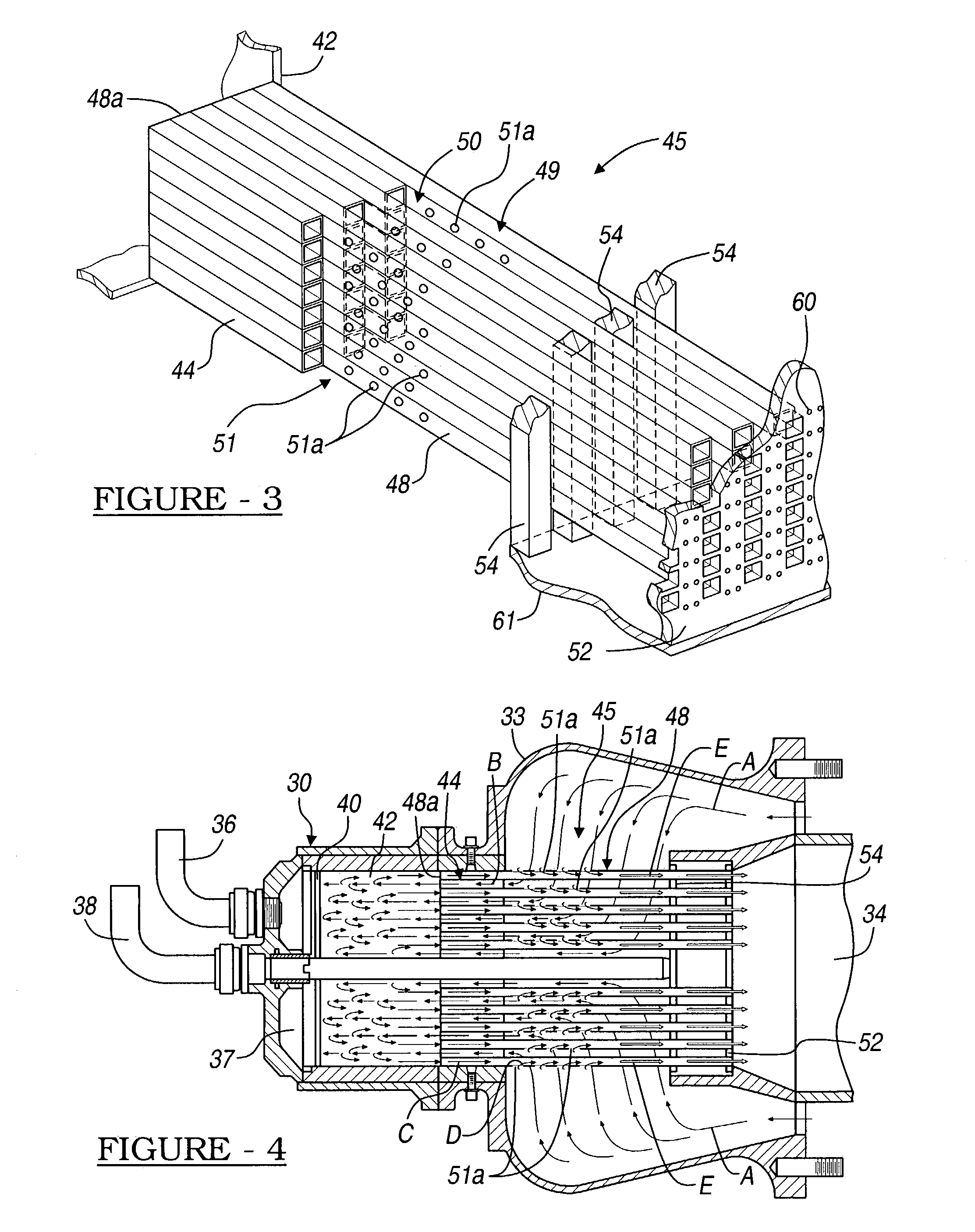

InactiveUS7007486B2Turbine/propulsion fuel supply systemsContinuous combustion chamberCounter flowChemical species

A counter-flow system for use in a turbine for selecting various mixtures of fluids for use with the system. The system may be used for a combustor for a gas powered turbine which employs a heat exchanger to combust a fuel without the emission of undesired chemical species. A gas powered turbine requires expanding gases to power the turbine blades. Fuel is combusted to produce the required gases. An oxidizer is introduced into the counter-flow system in a first direction before a first portion of fuel is introduced into the oxidizer. The fuel and oxidizer mixture is then flowed through a second pathway wherein the fuel and oxidizer mixture obtains a selected amount of thermal energy. Moreover, in a second pathway an equivalence ratio of the fuel and oxidizer mixture may be altered from the original fuel and oxidizer mixture.

Owner:UNITED TECH CORP +1

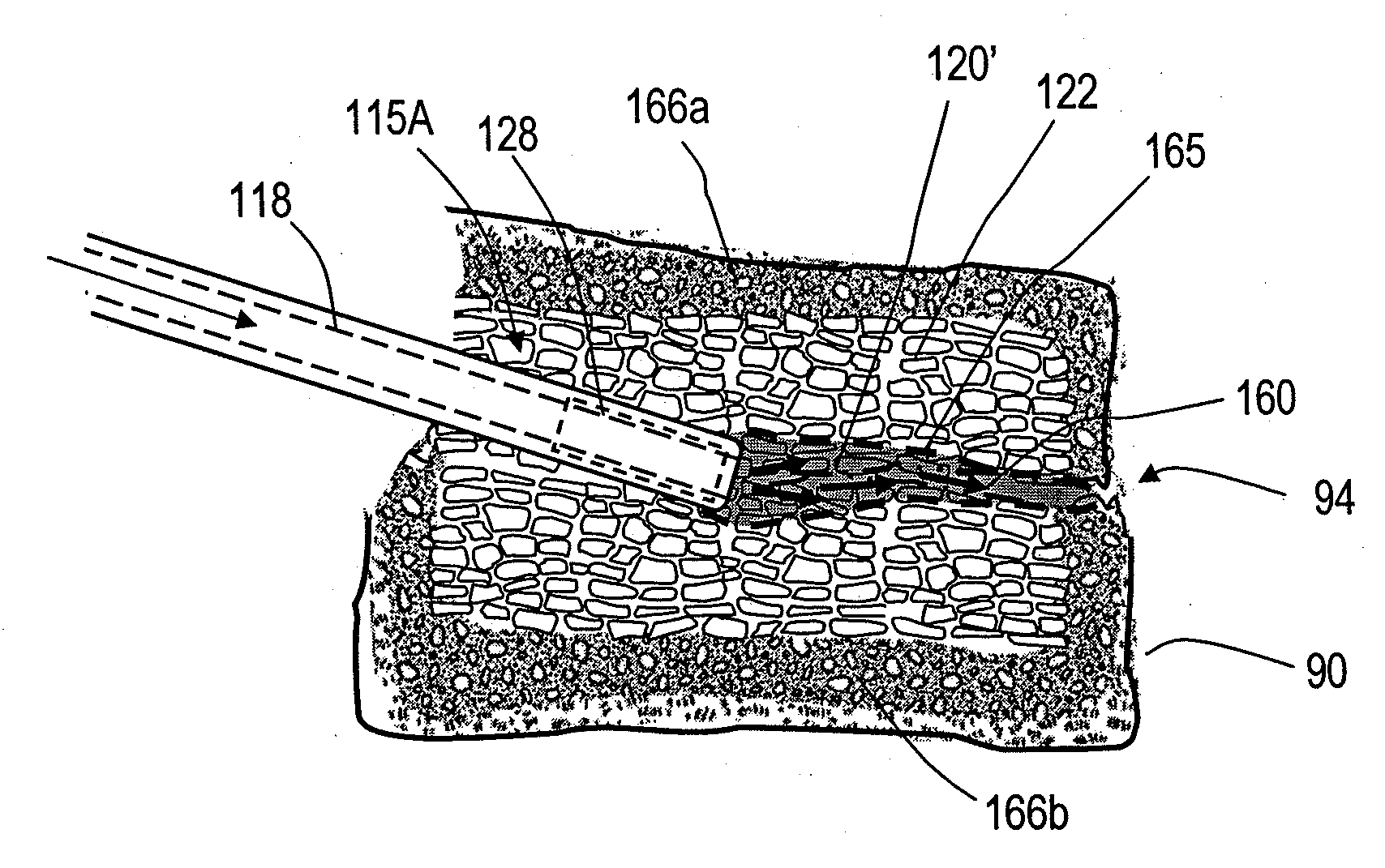

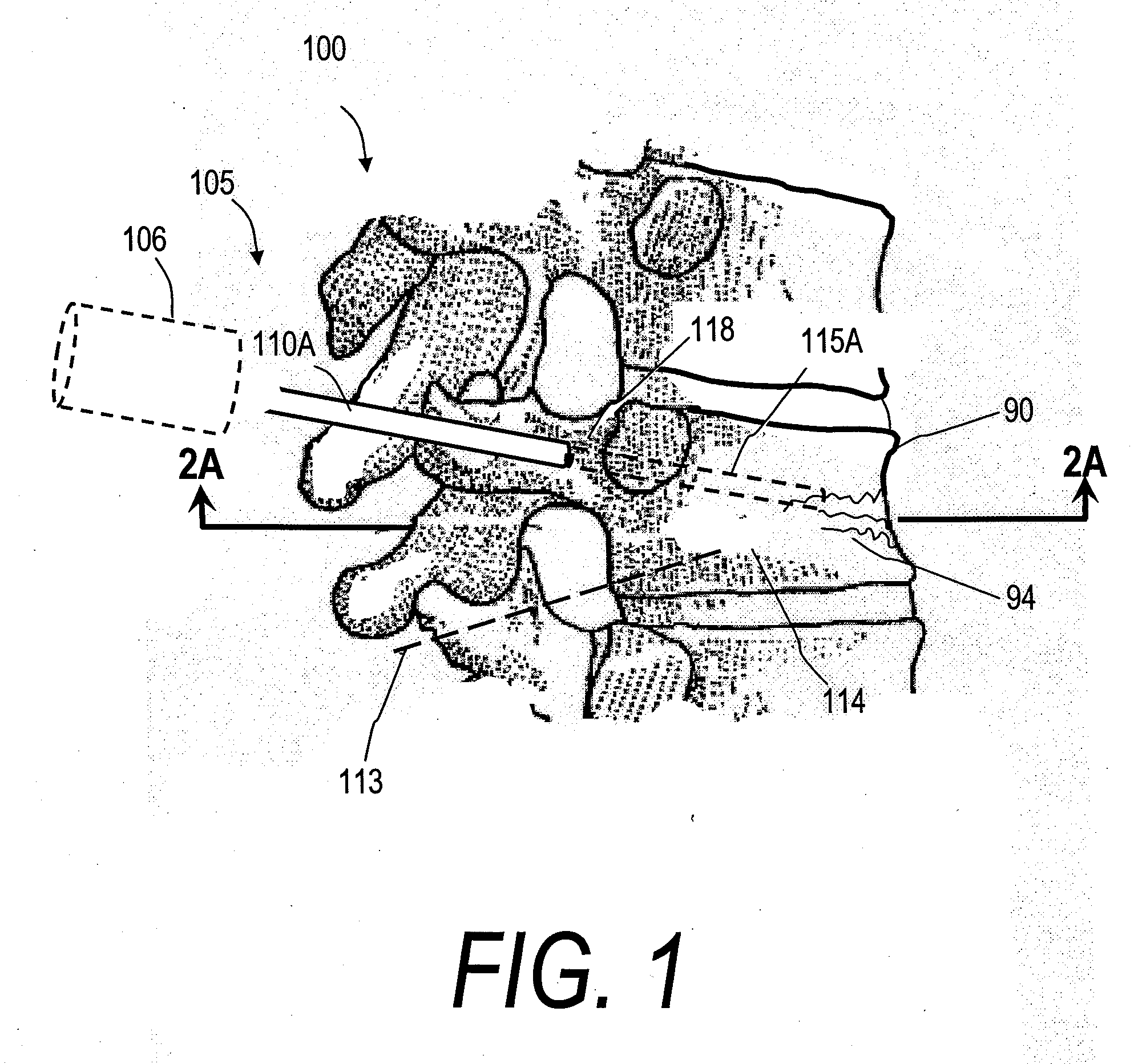

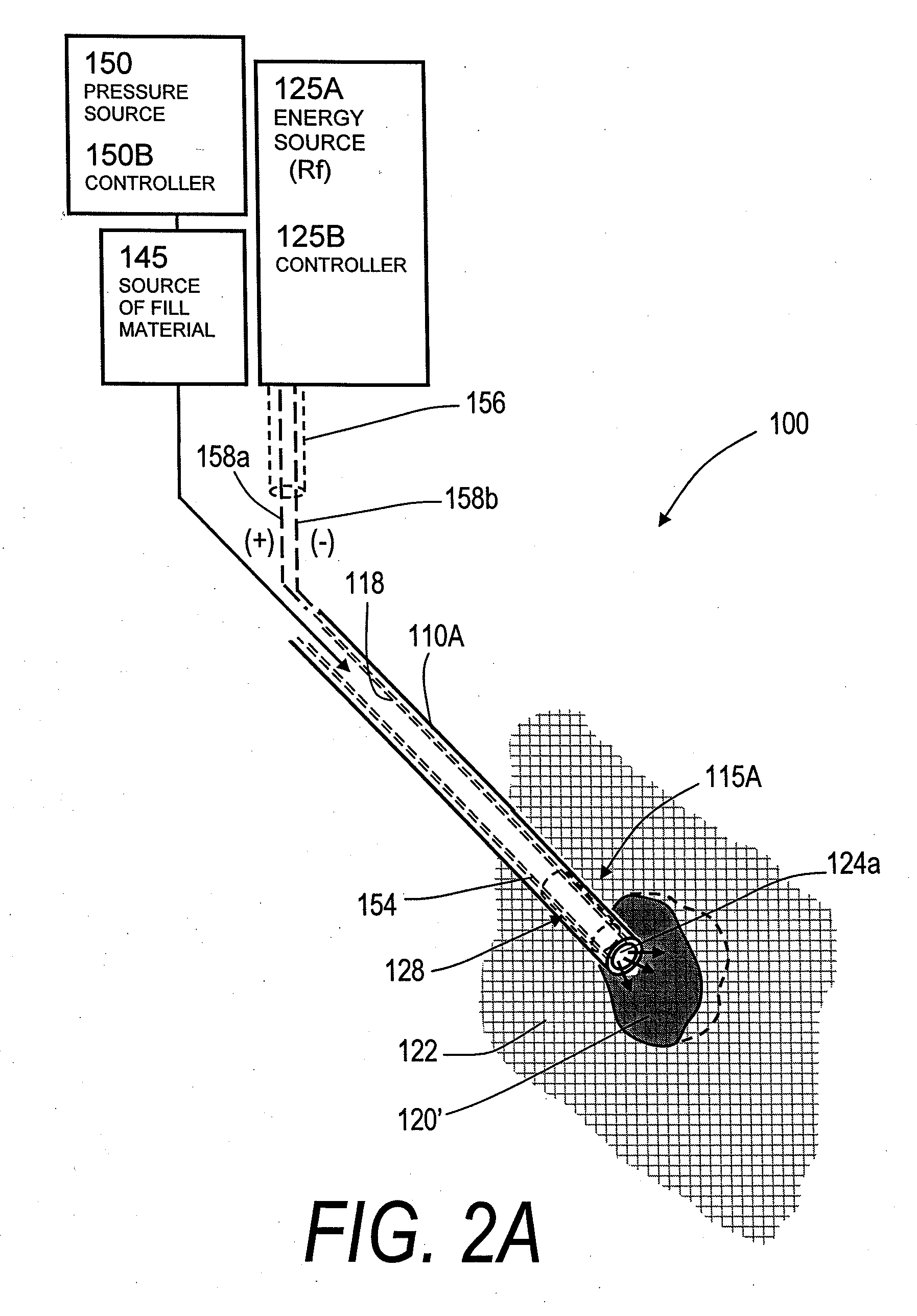

Systems for sensing retrograde flows of bone fill material

InactiveUS20070118144A1Inhibit migrationReduction procedureDiagnosticsSpinal implantsCounter flowFilling materials

The present invention relates in certain embodiments to medical devices, systems and methods for use in osteoplasty procedures, such as vertebral compression fractures. One device for delivering a bone fill material to a bone, such as a vertebra, includes an elongated sleeve configured for introduction into a bone, the elongated sleeve having an opening to allow a flow of bone fill material therethrough into the bone. The device also includes at least one sensor disposed on an exterior surface of the sleeve, the sensor being configured to sense a retrograde flow of bone fill material about the sleeve and proximate the at least one sensor. One system for treating a bone includes such a device and a controller configured to receive signals from the sensor and controls at least one parameter of bone fill material flow into the bone based at least in part on said signals.

Owner:DFINE INC

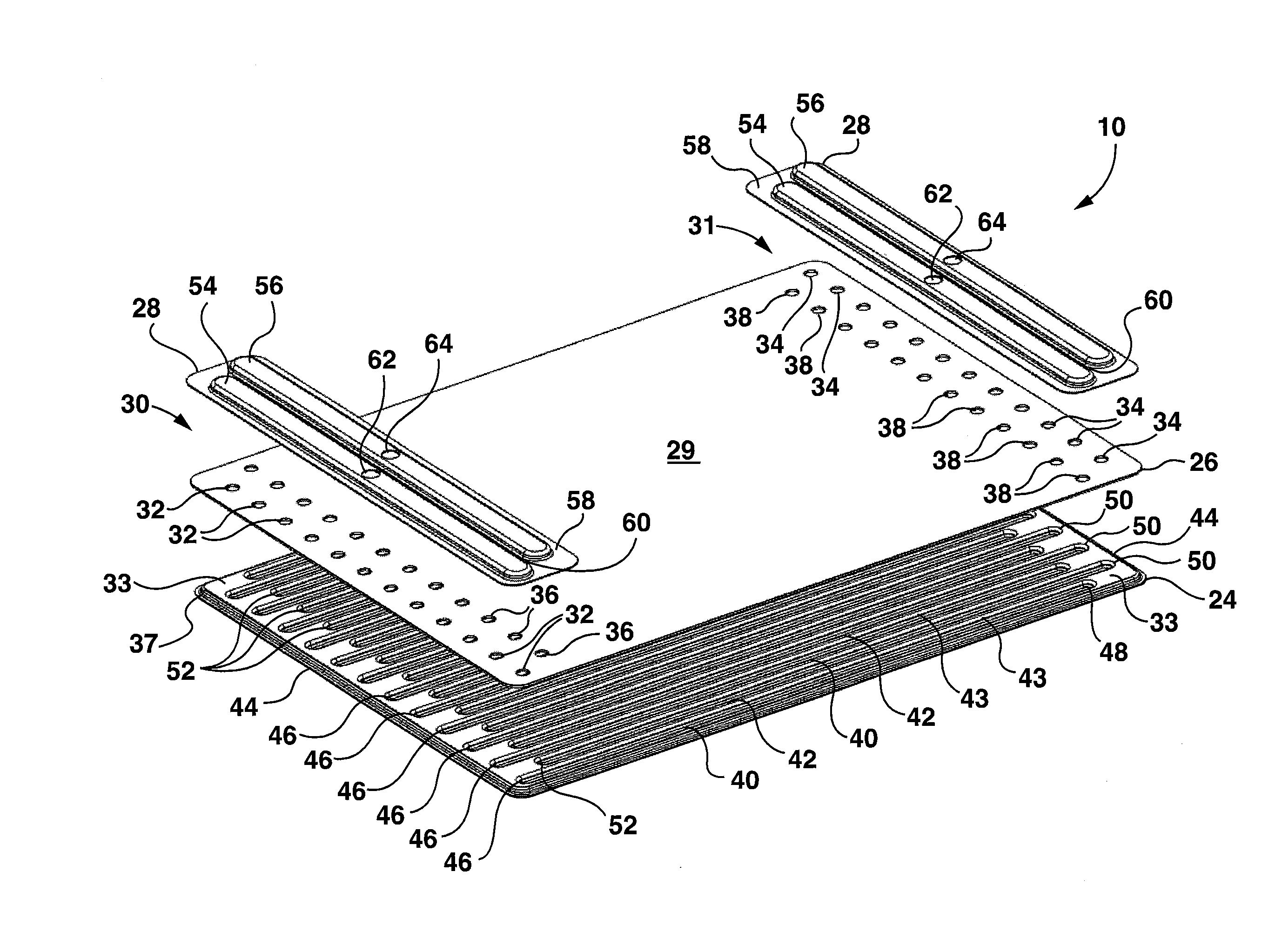

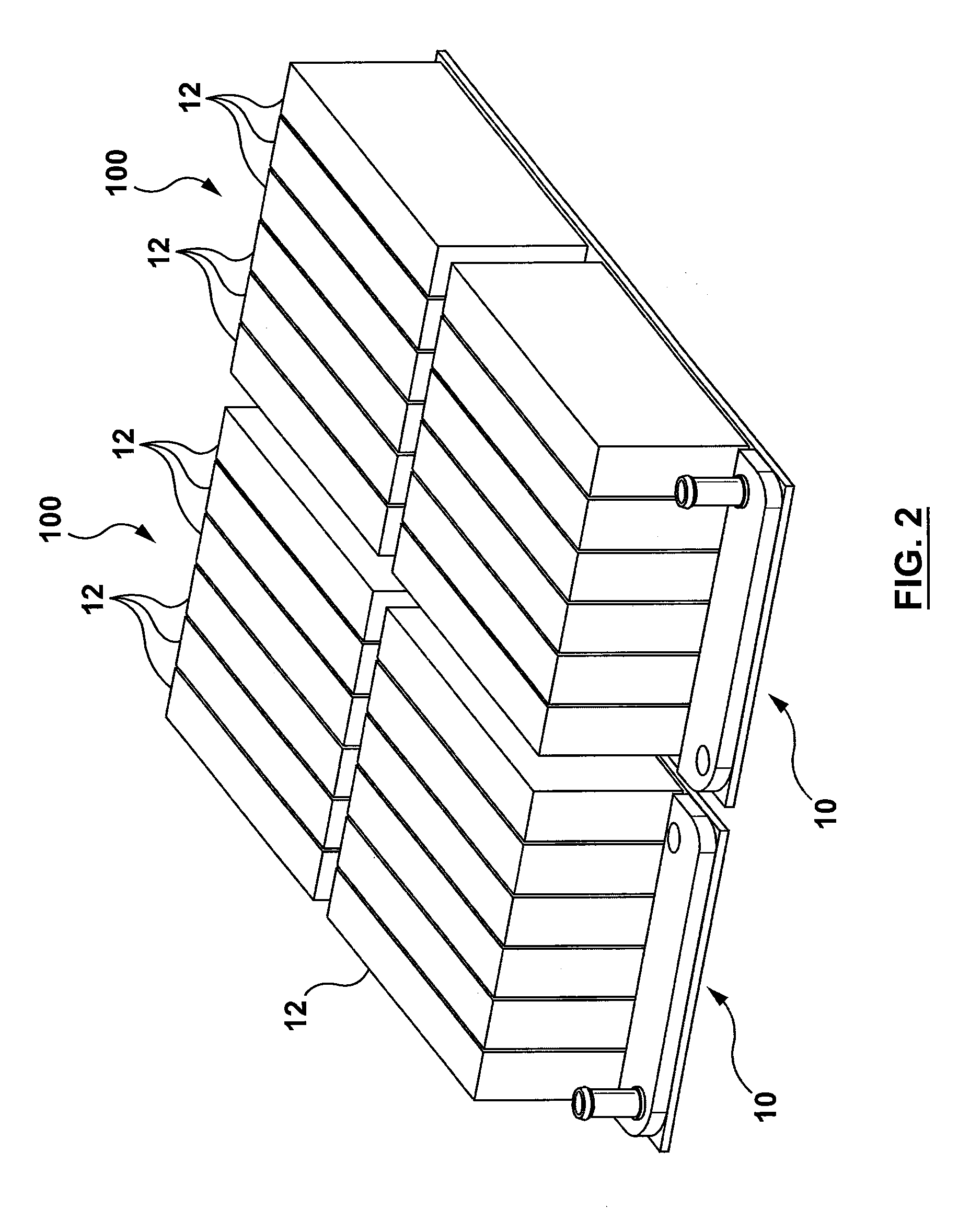

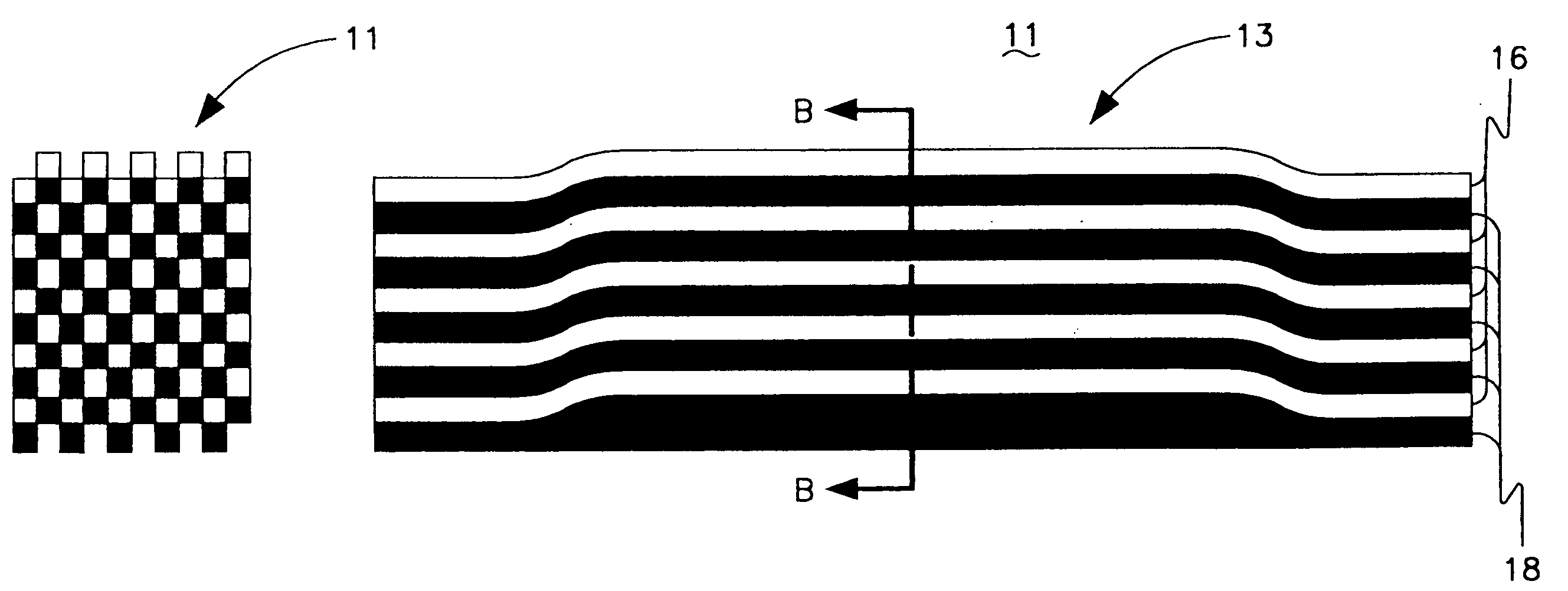

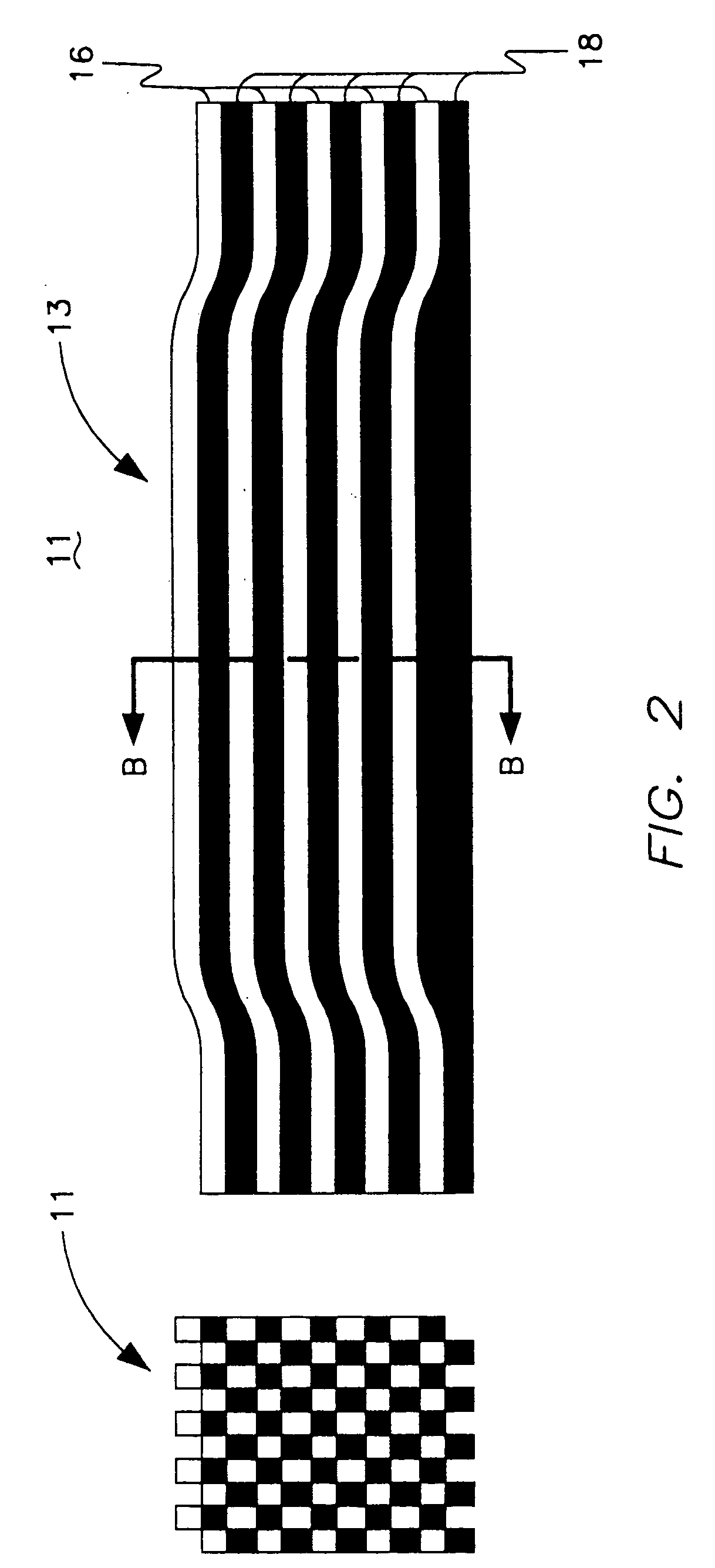

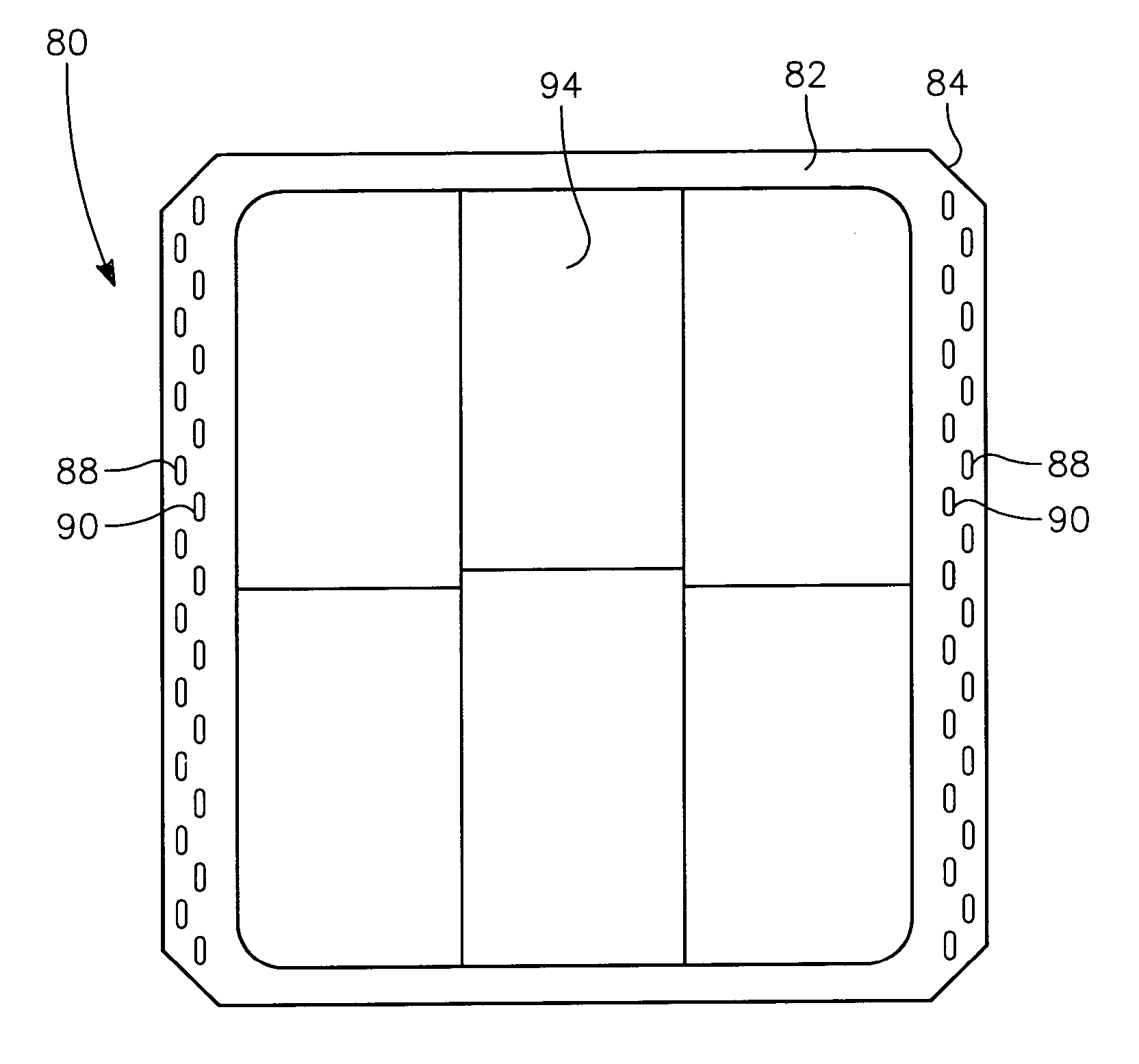

Counter-Flow Heat Exchanger for Battery Thermal Management Applications

A heat exchanger for thermal management of battery units made-up of plurality of battery cells or battery cell containers housing one or more battery cells is disclosed. The heat exchanger has a main body portion defining at least one primary heat transfer surface for surface-to-surface contact with a corresponding surface of at least one of the battery cells or containers. A plurality of alternating first and second fluid flow passages are formed within the main body portion each defining a flow direction, the flow direction through the first fluid flow passages being generally opposite to the flow direction through the second fluid flow passages providing a counter-flow heat exchanger. In some embodiments the heat exchanger has a two pairs of inlet and outlet manifolds, the heat exchanger providing a single-pass, counter-flow arrangement. In other embodiments the first and second fluid flow passages are interconnected by turn portions forming a U-flow, counter-flow heat exchanger.

Owner:DANA CANADA CORP

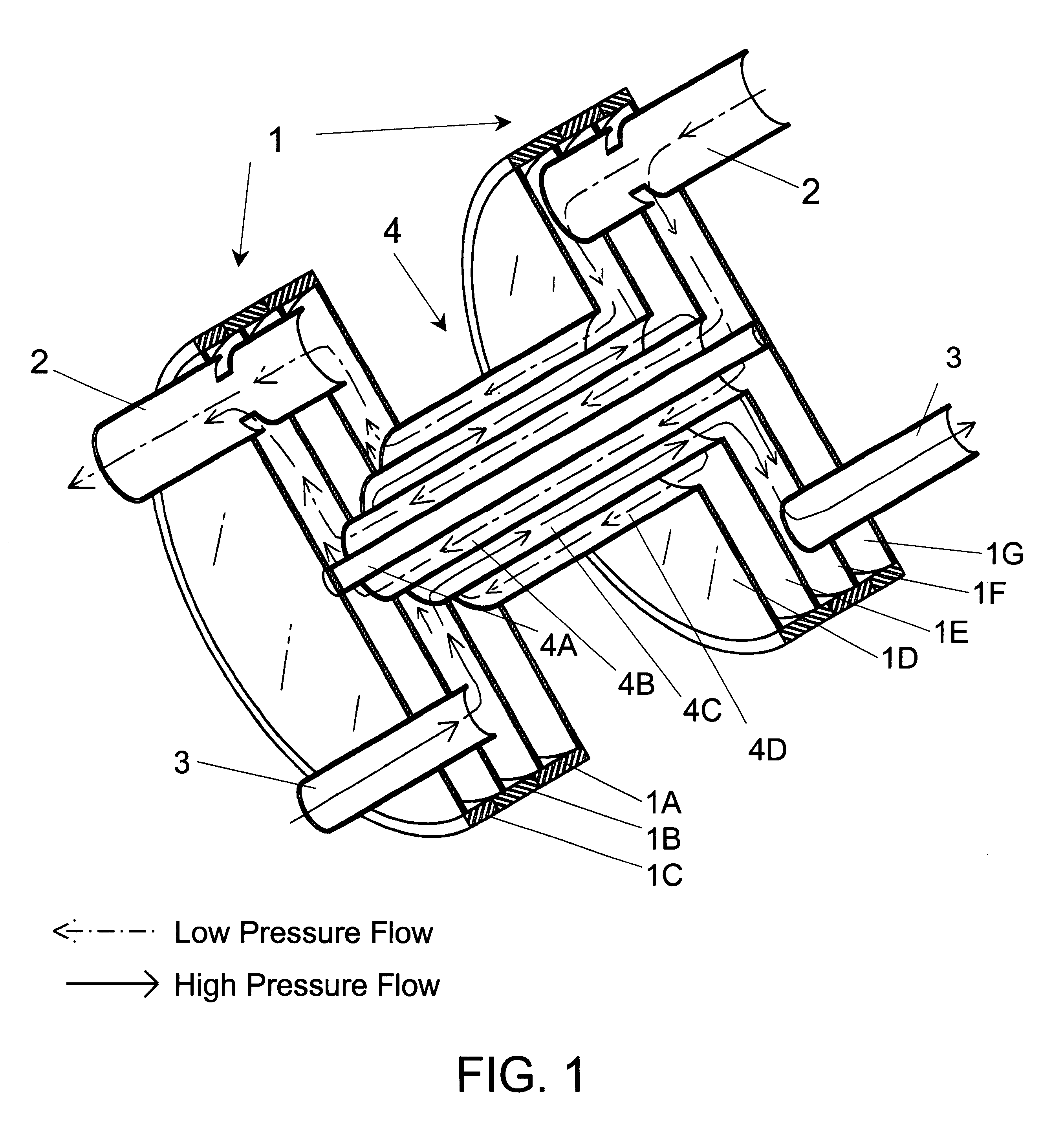

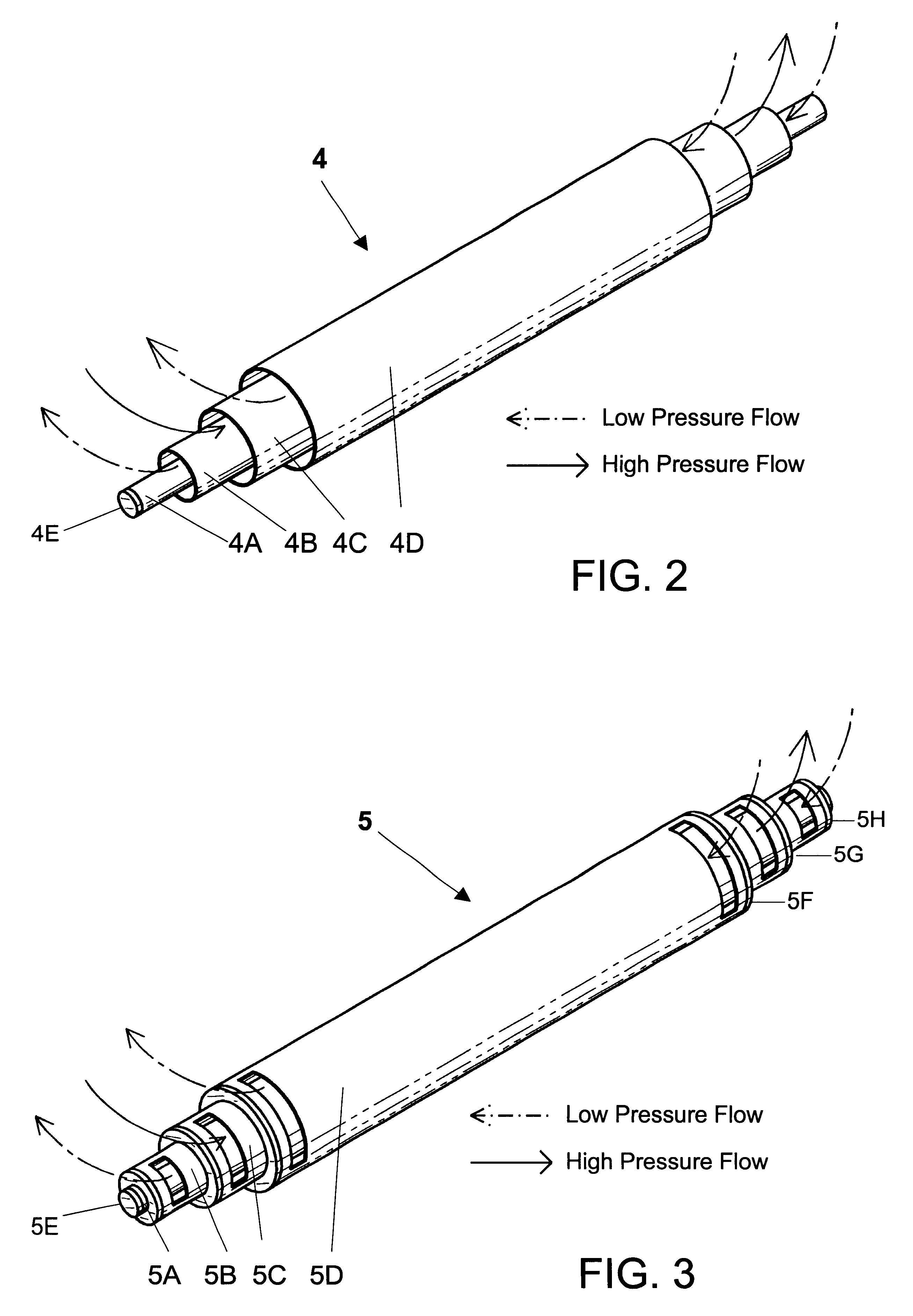

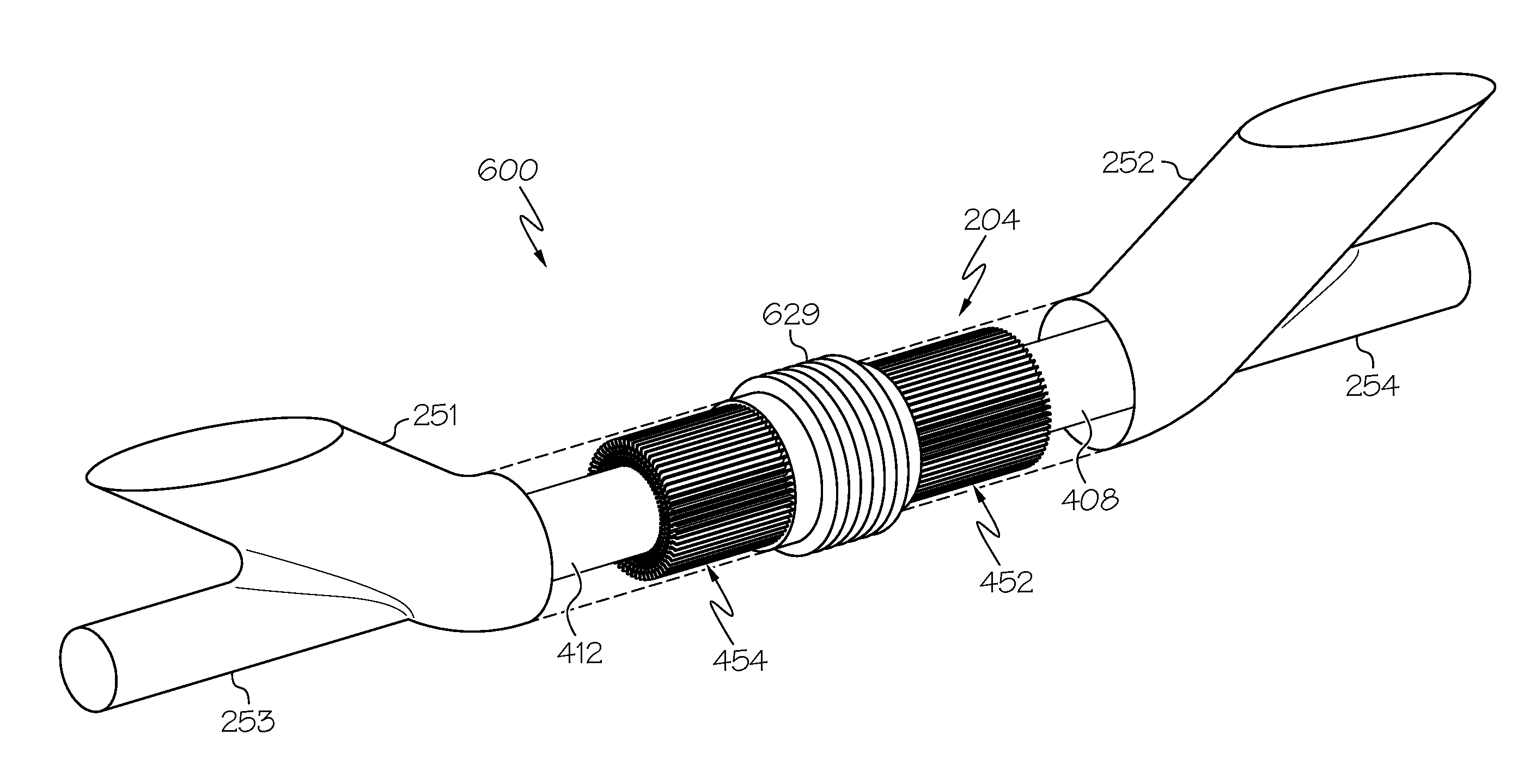

Annular flow concentric tube recuperator

InactiveUS6390185B1Minimal effectivenessNegligible reduction in effectivenessRecuperative heat exchangersStationary tubular conduit assembliesCounter flowVolumetric Mass Density

An annular flow concentric tube heat exchanger for heating two counter flowing fluid streams has been devised. Although capable of heating gases or liquids, the primary purpose of the invention is to function as an improved recuperator for recovering exhaust heat from a Brayton Cycle gas turbine engine, Ericsson Cycle engine or similar recuperated engine. The basic element of the recuperator is a concentric tube assembly that, in the preferred embodiment, is comprised of four concentric tubes that enclose three concentric annular flow passages. The low pressure exhaust flows through the inner and outer annular passages while the high pressure compressor exit air flows through the annular passage that is between the two low pressure passages. The high and low pressure flows are in opposite directions to achieve the high effectiveness that is only available with a counterflow heat exchanger. Heat is transferred from the exhaust gas to the compressor air though the tube walls on each side of the high pressure passage. Two low pressure passages are provided for each high pressure air passage to compensate for the lower pressure (and therefore lower density) of the exhaust gas. Multiple concentric tube assemblies are used to make a recuperator. The tube assemblies terminate in header assemblies located at each end of the concentric tube assemblies. The headers are made of simple plates and rings that serve the dual function of structurally locating the concentric tube assemblies and directing the flow to the proper passage in the concentric tube assemblies. High and low pressure flow tubes provide flow passages connecting the recuperator to the engine compressor air and exhaust tubing respectively. The annular flow concentric tube recuperator can be easily made from commercial tubing with minimal special tooling and is capable of very high effectiveness with very low pressure drop.

Owner:PROE POWER SYST

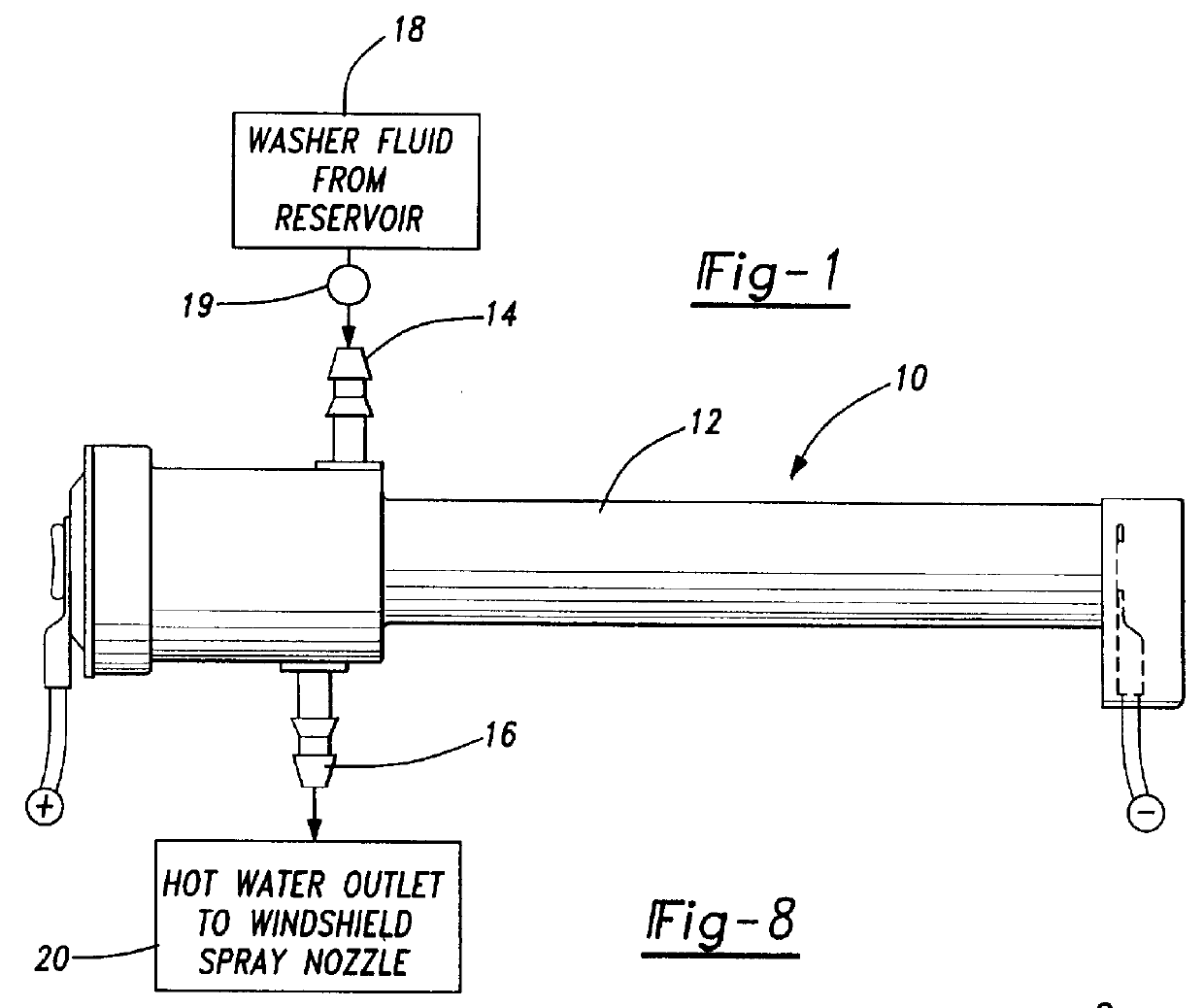

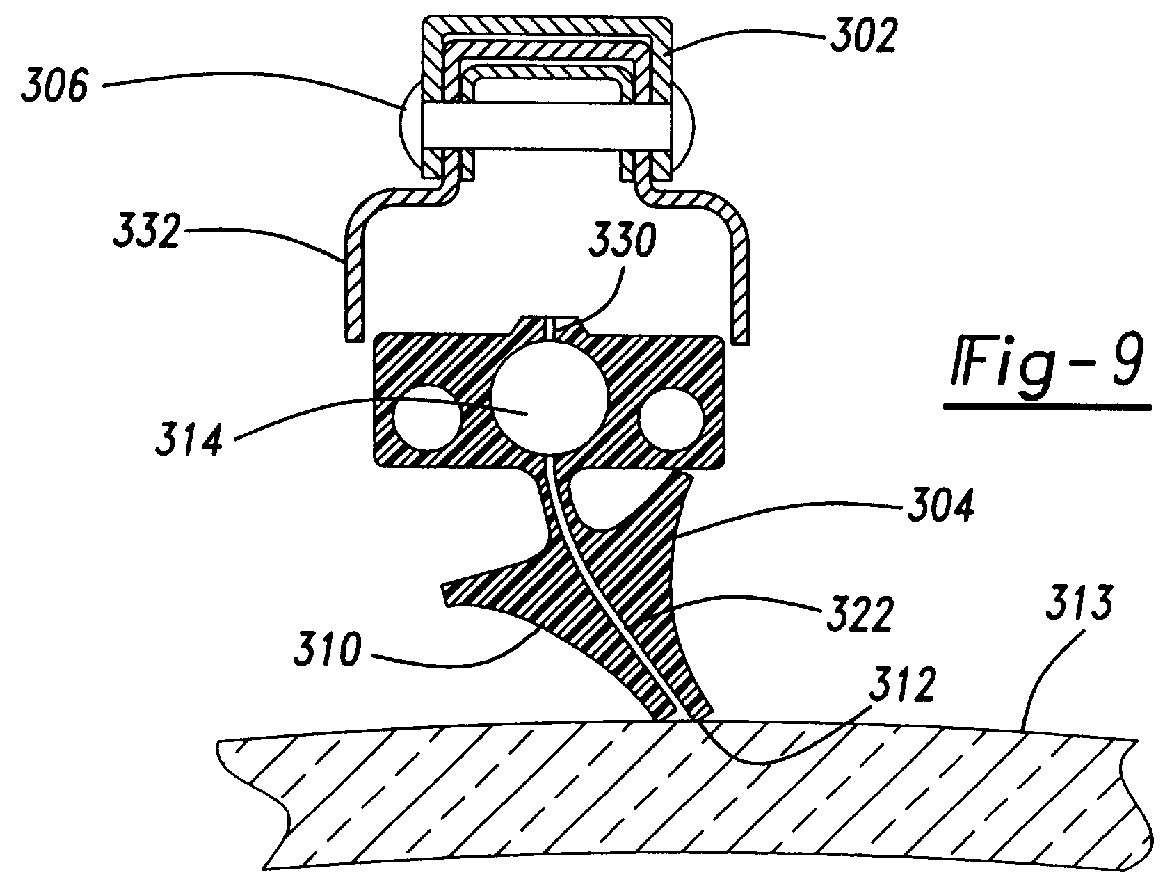

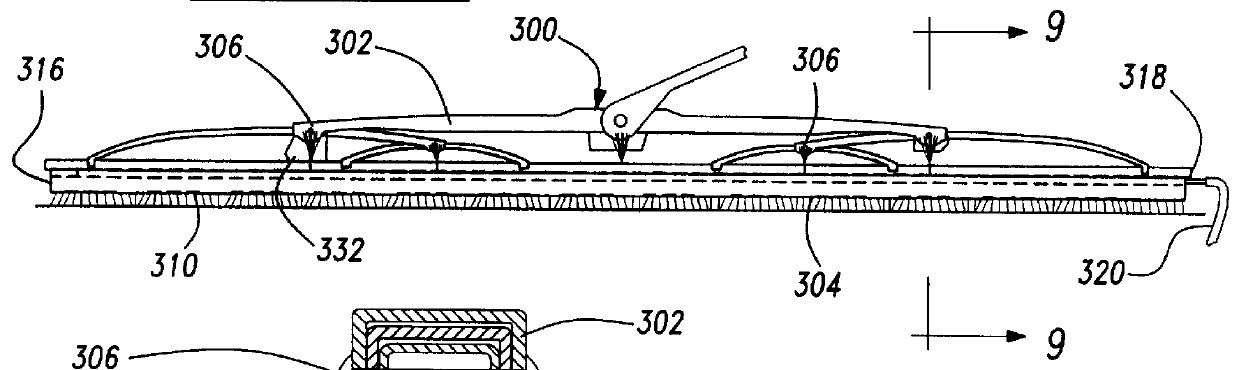

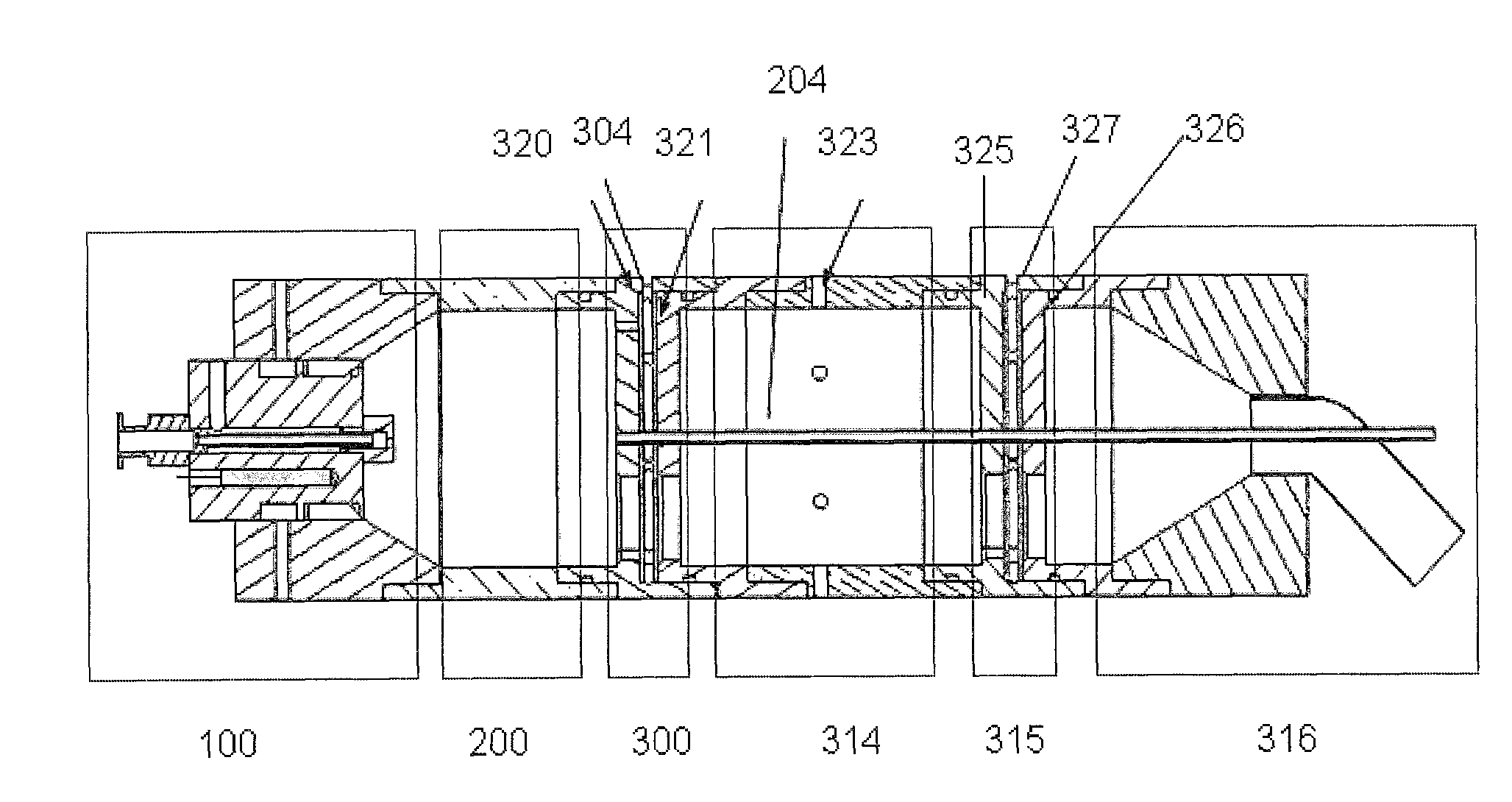

Windshield heated wiping system

InactiveUS6032324AEffectively doubling clean wiping life of the rubber bladeSpray nozzlesWindow cleanersCounter flowEngineering

A windshield wiper system for an automotive vehicle is disclosed in which the windshield wiper washer fluid is heated and delivered to the windshield through the rubber wiping element. In one embodiment, the windshield wiper fluid is heated to a substantial level of temperature and pressure within a sealed reservoir by the heat from the engine coolant system. In another embodiment, a tubular electrical high intensity heating element with turbulent counter flow is used to instantly heat the windshield wiper fluid, and the heating element is automatically electrically energized in response to fluid flow through the tubular heating element. In another embodiment electrical direct current vehicle power or selectively alternating current external power is used to heat fluid to a substantial level of temperature and pressure within a sealed insulated reservoir. A novel windshield wiper blade is also disclosed in which the wiper blade has a longitudinally elongated fluid chamber formed along its length. The fluid chamber is closed at one end and connected to the source of the washer fluid at its other end. A plurality of longitudinally aligned slits is formed through the wiper blade to the outlet edge to uniformly dispense the heated washing fluid downstream of wipe direction, and onto the vehicle windshield while one or more openings are also formed in the wiper blade to direct a portion of the heated washing fluid to the joints in the wiper support frame to remove ice binding the wiper frame flex joints. Additionally, the dual configuration of the blade edge is such that the second edge pair wears out sequentially to the first edge pair effectively doubling the clean wiping life of the blade.

Owner:LANSINGER JERE RASK

Aerosol processing and inhalation method and system for high dose rate aerosol drug delivery

ActiveUS7802569B2Risk minimizationIncrease dose rateRespiratorsDispersed particle separationCounter flowSolvent vapor

Owner:KAER BIOTHERAPEUTICS CORP

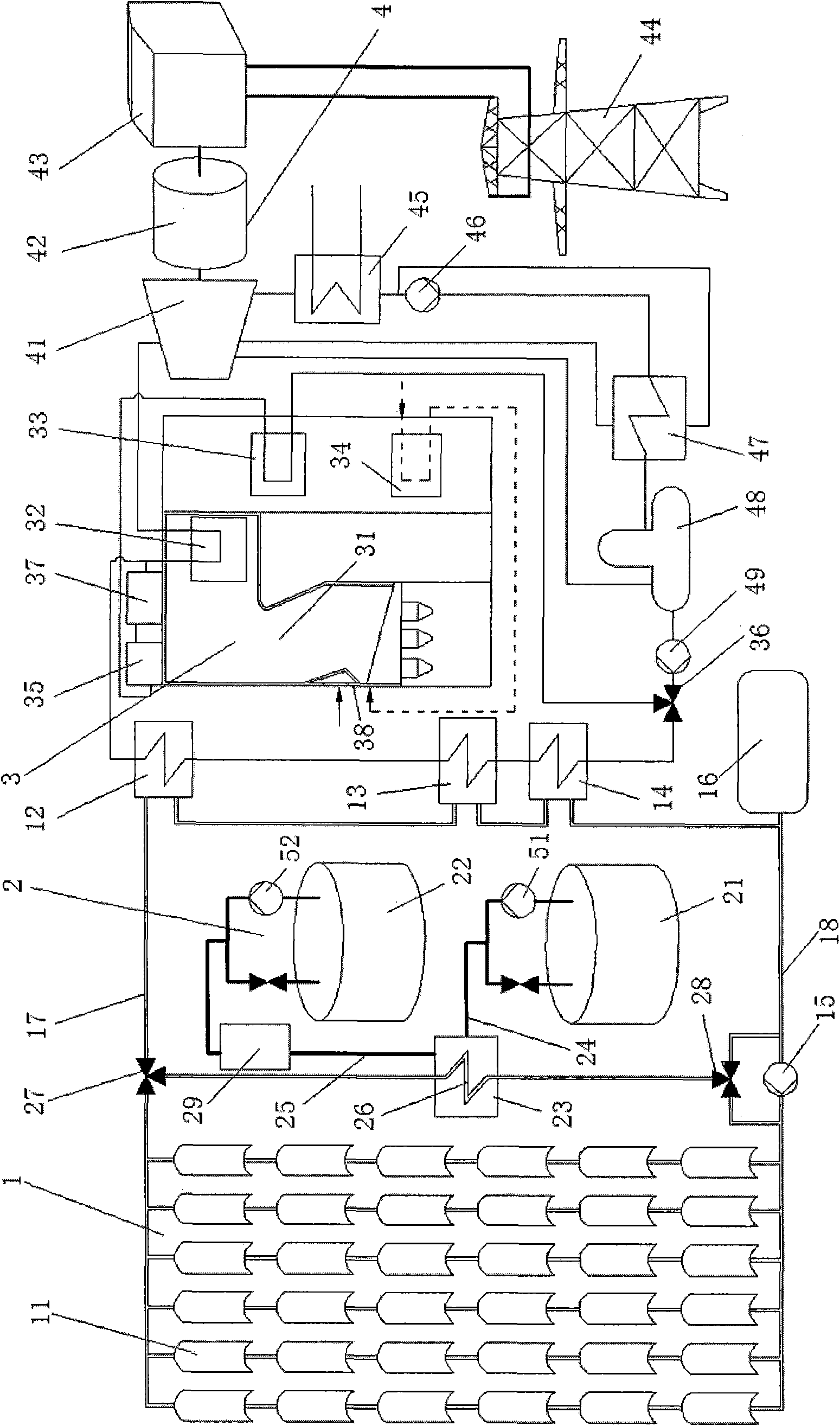

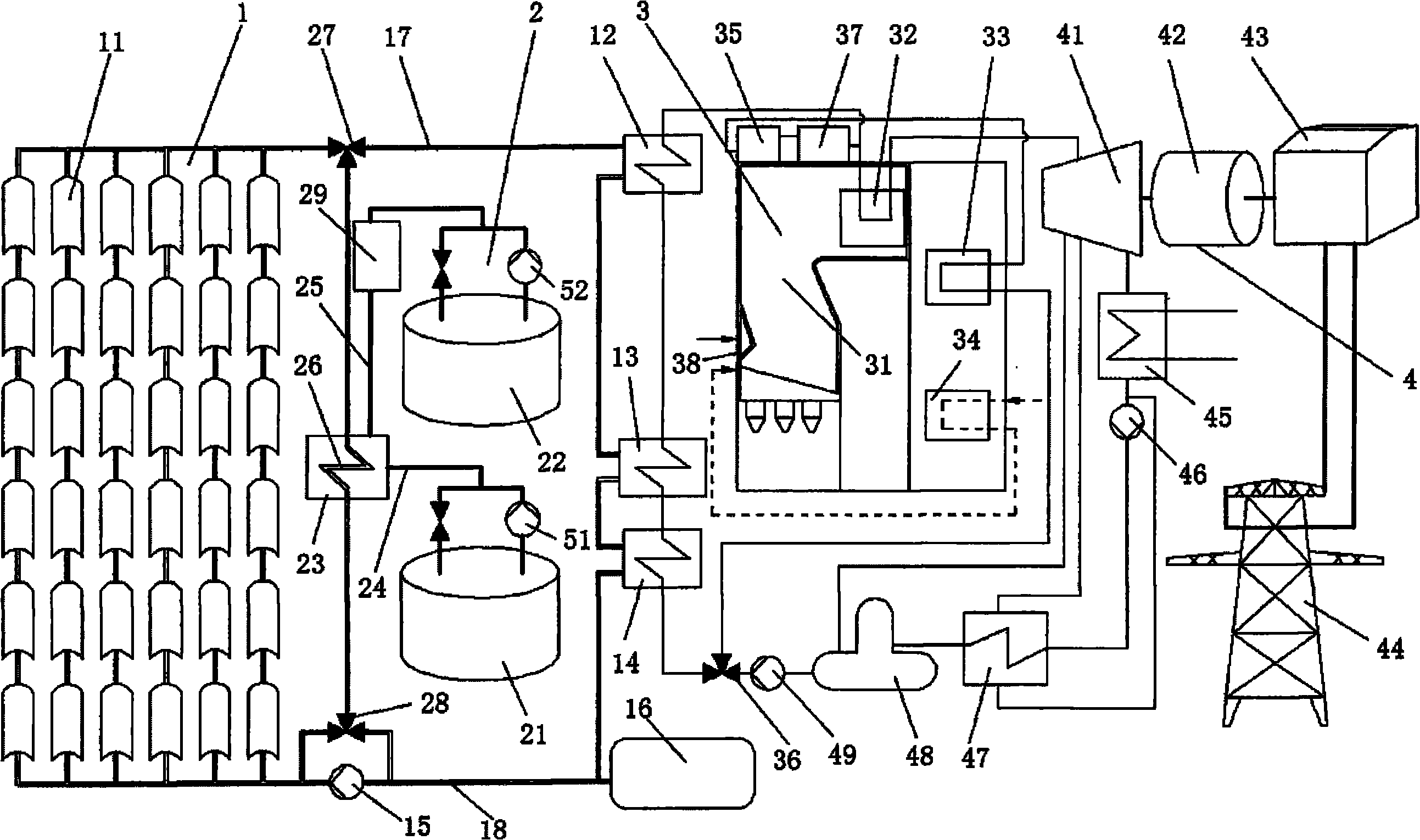

Method and system for combing solar energy thermal power generation with biomass power generation

ActiveCN101876299AReduce dosageReduce procurement costsSteam generation heating methodsFrom solar energyThermal energyCounter flow

The invention relates to a method and a system for combining solar energy thermal power generation with biomass power generation. When the method is used for generating electricity in the daytime (a fine day), one path of heat transfer oil heated in a heat collection field passes through a heat exchanger to ensure that counter-flow water is heated up into superheated steam at the temperature of between 360 and 380 DEG C; and the other path of the heat transfer oil heated in the heat collection field passes through the heat exchanger to heat up a fused salt so as to perform energy storage. The water heated in a water cooled wall of a biomass boiler is changed into steam which enters a steam header and a steam-water separator, then is heated to the temperature of between 535 and 545 DDEG C after being sent into a super-heater of the boiler together with the steam at the temperature of between 360 and 380 DEG C, and then is supplied to a steam turbine to drive a generator to finish the power generation process. During receiving electric valley adjustment, the biomass boiler maintains the minimum stable combustion state. The self power generation of the method and the system can be used for supplying electricity to an electric heater in a fused salt heat storage system to heat the fused salt and perform secondary energy storage for a fused salt heat tank. During the night, or when a solar energy condition is not good, the heat energy stored in the fused salt is released by the heat exchanger to generate electricity.

Owner:北京京仪集团有限公司

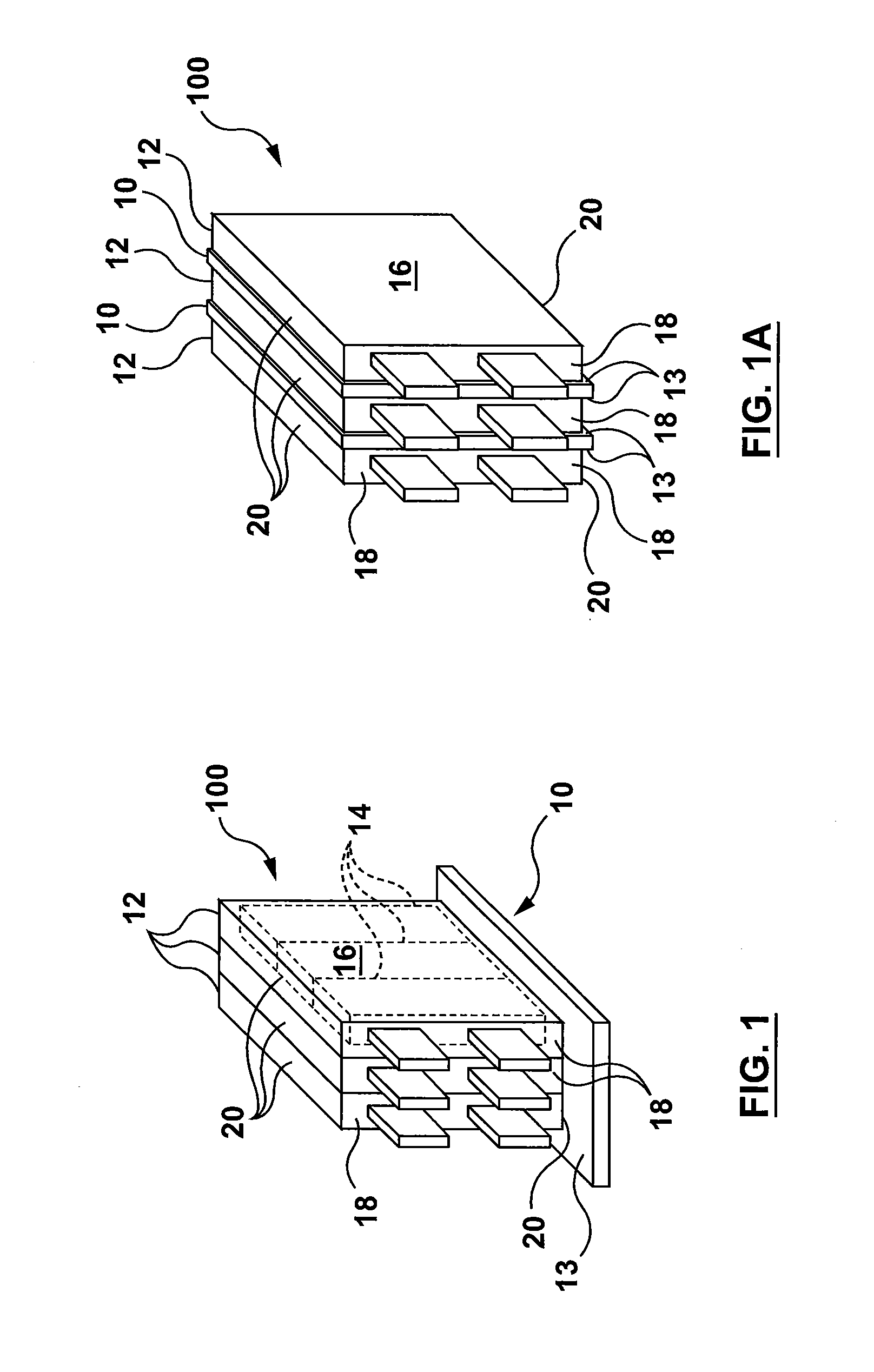

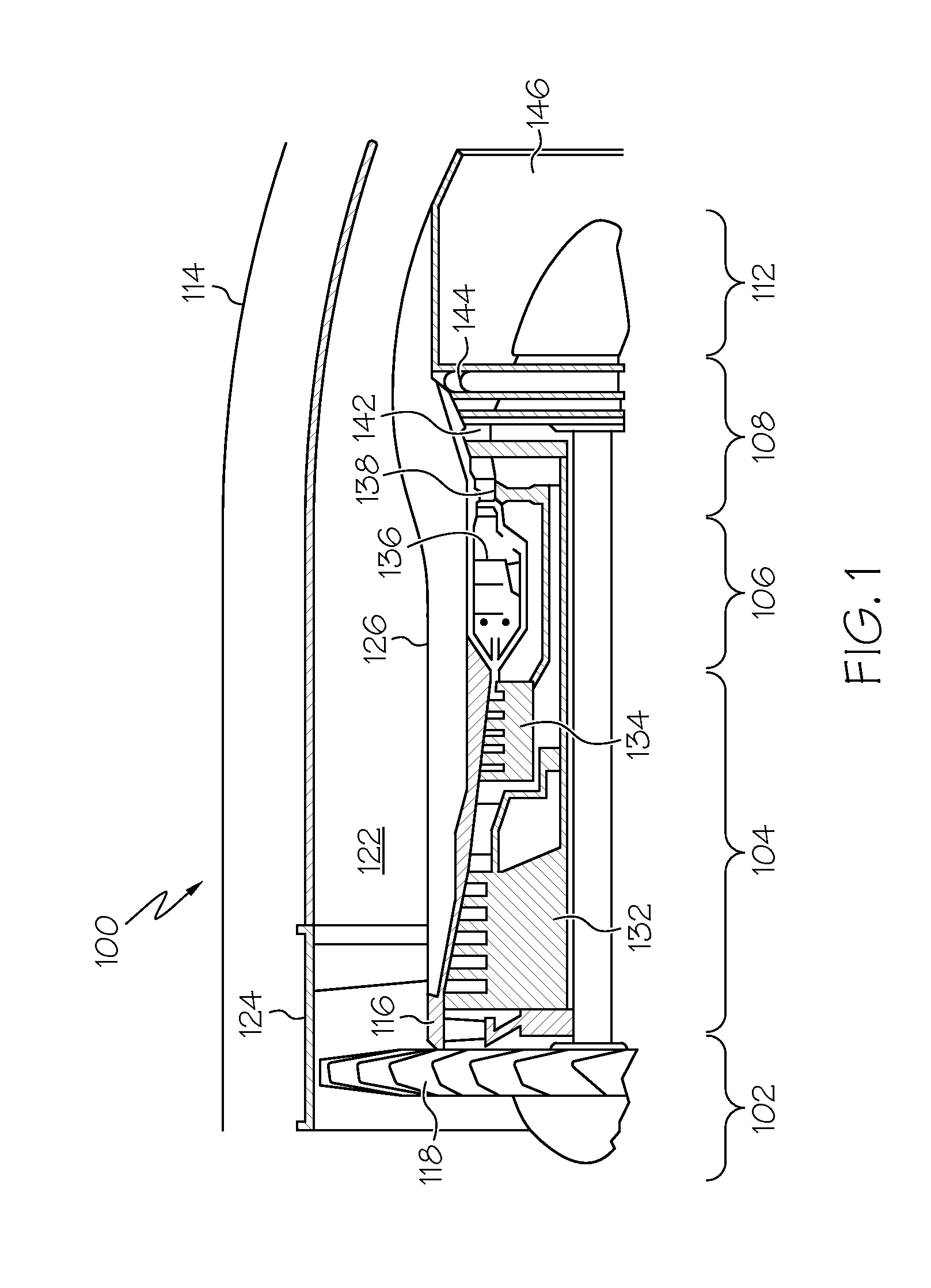

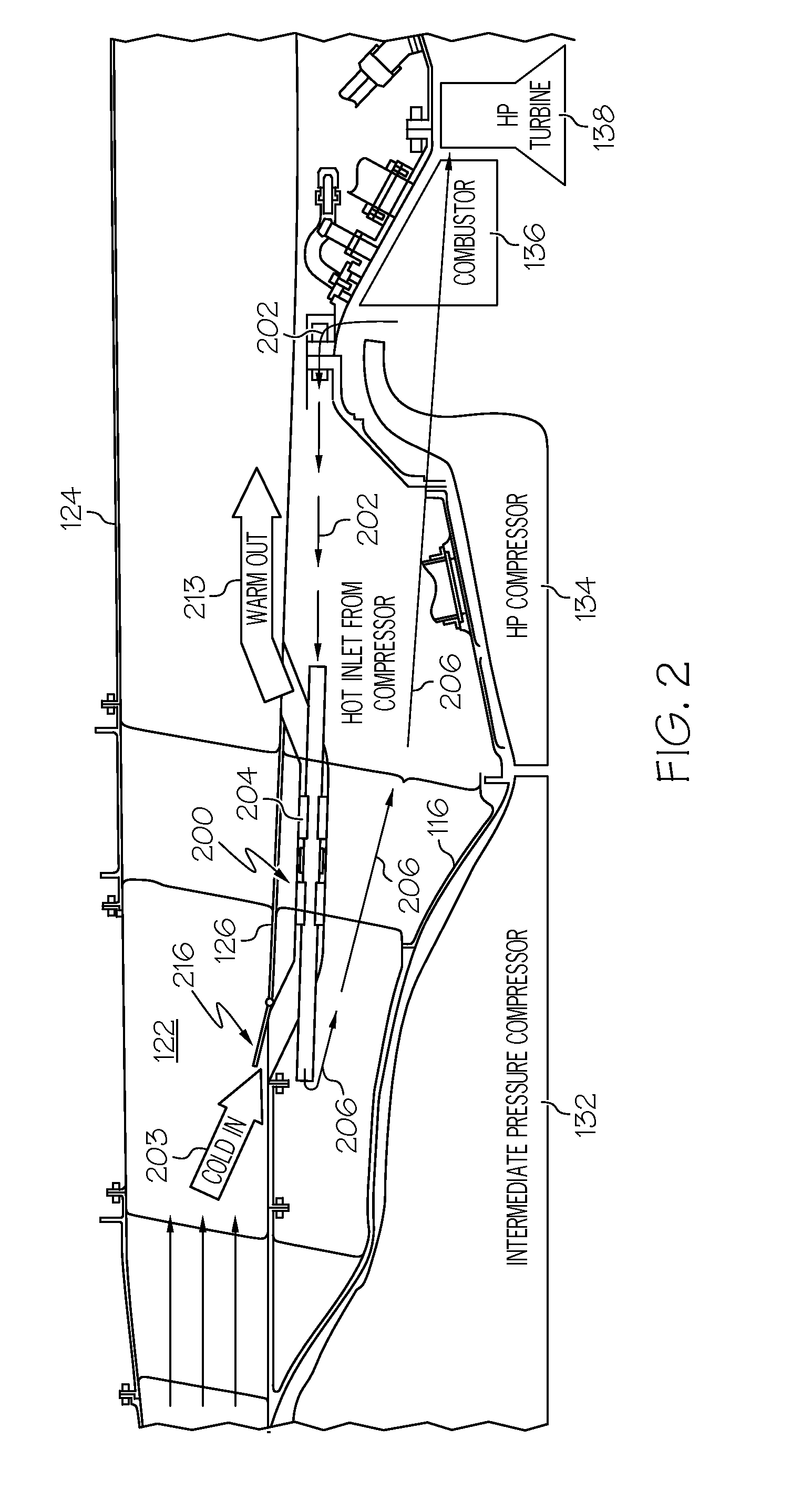

Counter-flow heat exchange systems

ActiveUS20150114611A1Safety devices for heat exchange apparatusTurbine/propulsion engine coolingCounter flowEngineering

A heat exchange system includes a tubular fan air inlet portion and a tubular cooled air outlet portion connected to a first end of a tubular mid portion. The heat exchange system further includes a tubular hot air inlet portion and a tubular recycled fan air outlet portion connected a second end of the mid portion. Still further, the heat exchange system includes an integrally-formed, compliant heat exchanger tube extending between the hot air inlet portion and the cooled air outlet portion within the mid portion to define a heat exchanger first flow passage within the heat exchanger tube and a second flow passage outside of the heat exchanger tube but within the tubular mid portion. Methods for fabricating such heat exchange systems are also provided.

Owner:HONEYWELL INT INC

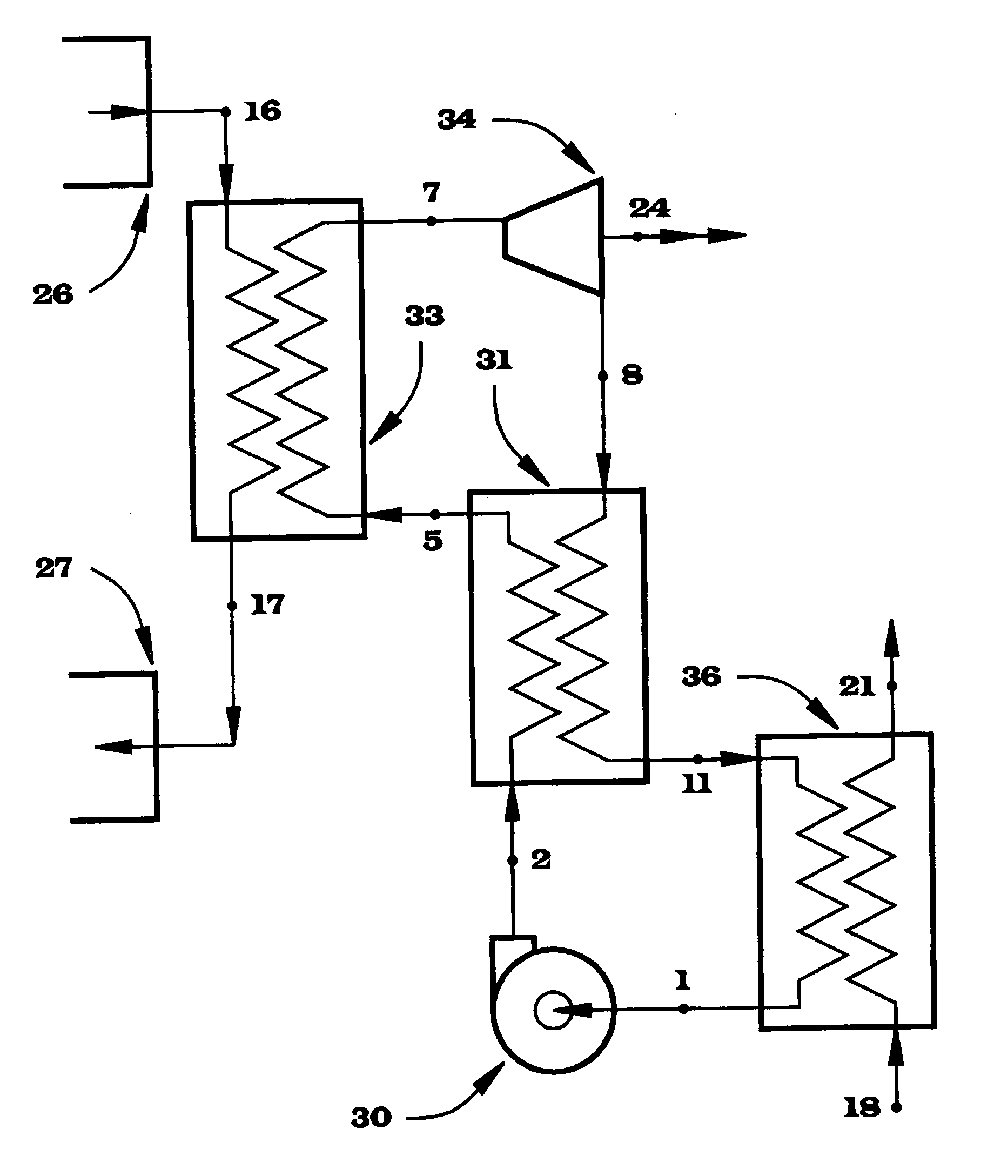

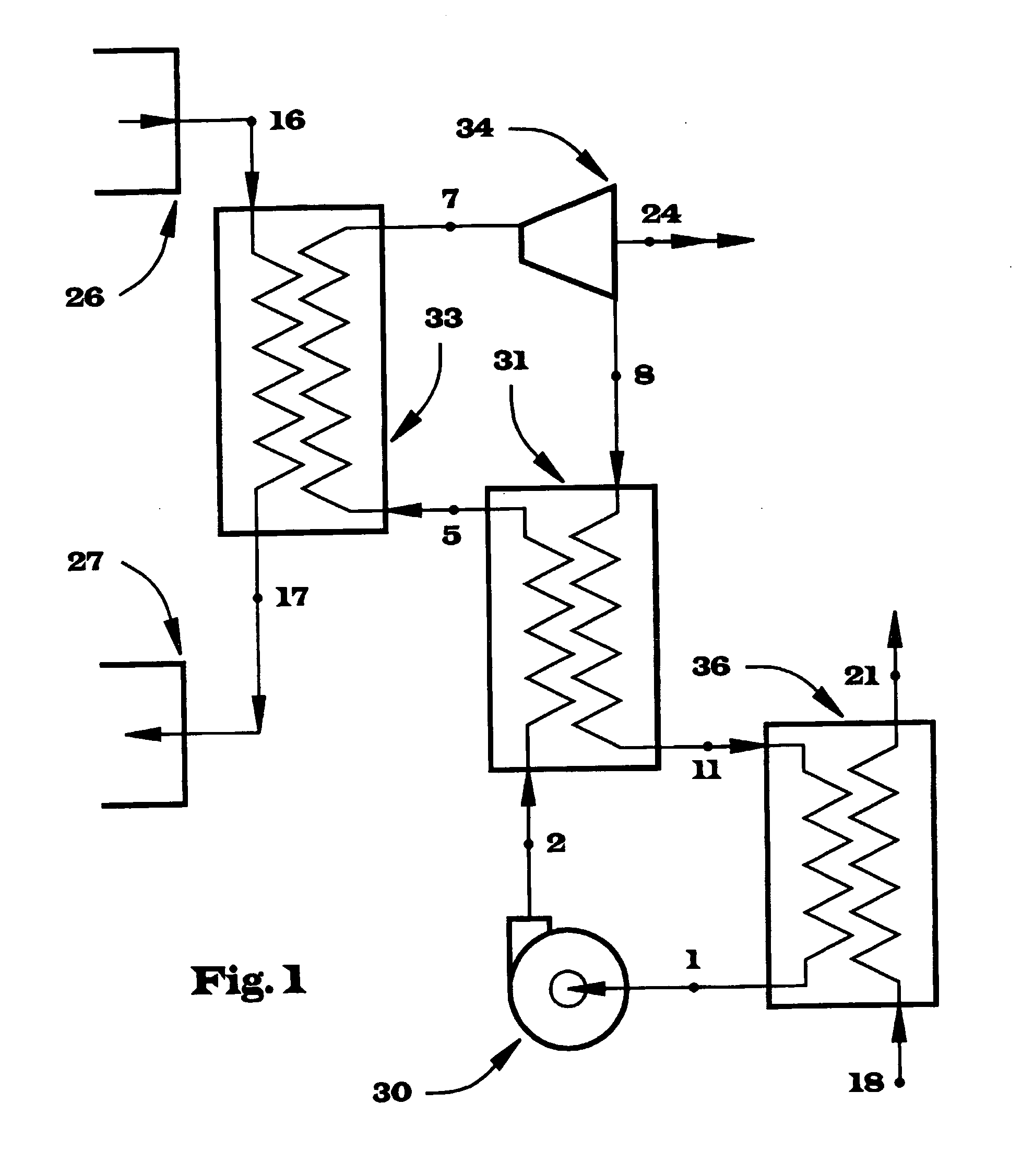

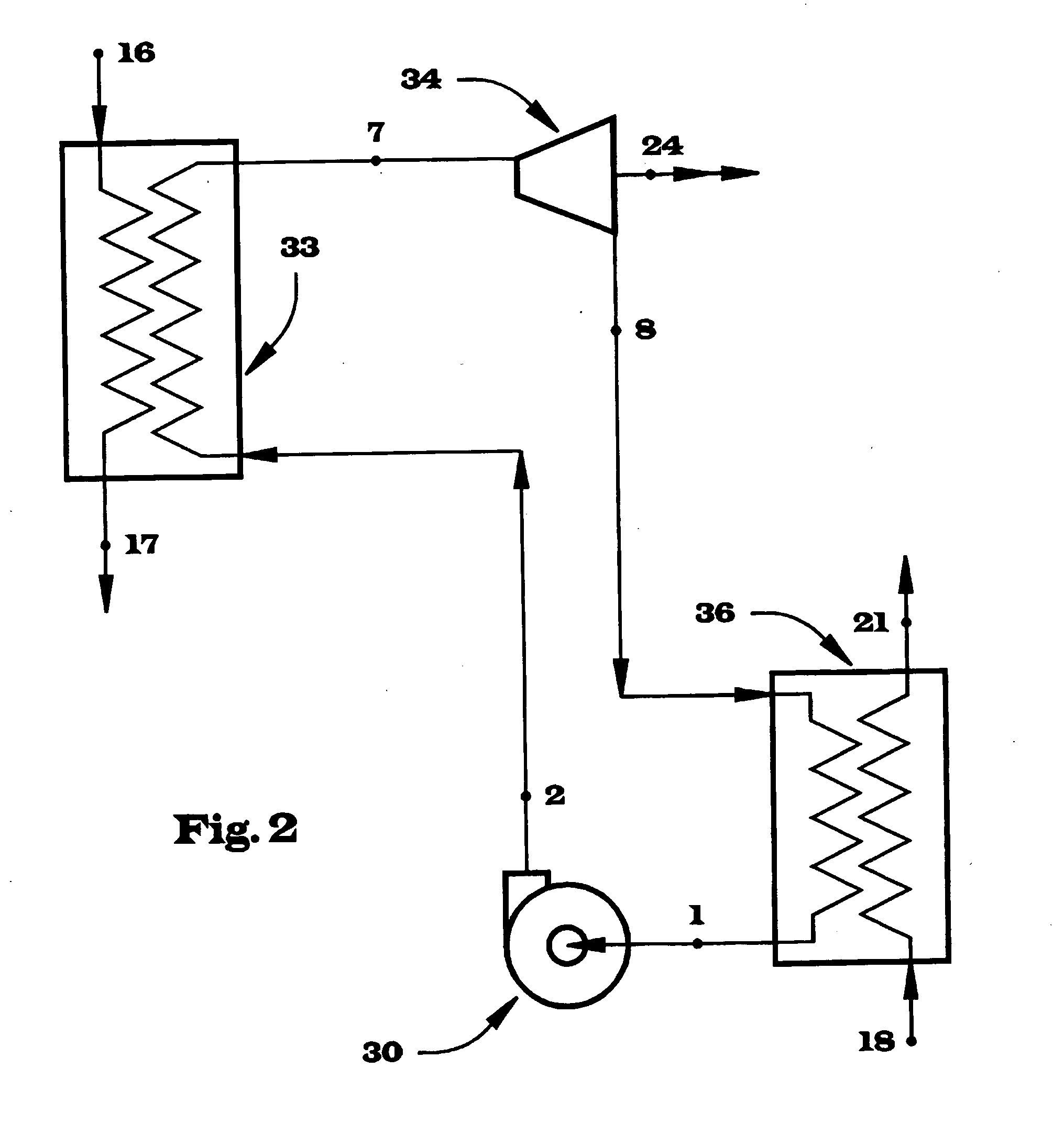

Method of converting energy

The invention provides a method of converting heat energy to a more usable form using a multi-component working fluid mixture that contains ammonia and water. The working fluid is operated in a thermodynamic cycle that includes liquid compression (30), vaporization (33), expansion through a turbine (34) and condensing (36). The multi-component fluid varies in temperature during phase change allowing for the use of counter-flow heat exchangers for the heater (33), cooler (36), recuperator and pre-heater (32). Significant recuperation is possible due to the temperature change during phase change. A pre-heater (32) can be applied to ensure only single-phase vapour exists within the heater. The invention can be used in conjunction with a biomass combustor or with waste flue gas from an existing industrial process. The coolant exits at a temperature sufficient to allow use in external heating applications or to minimize the size of external heat rejection equipment

Owner:SMITH & WESSON

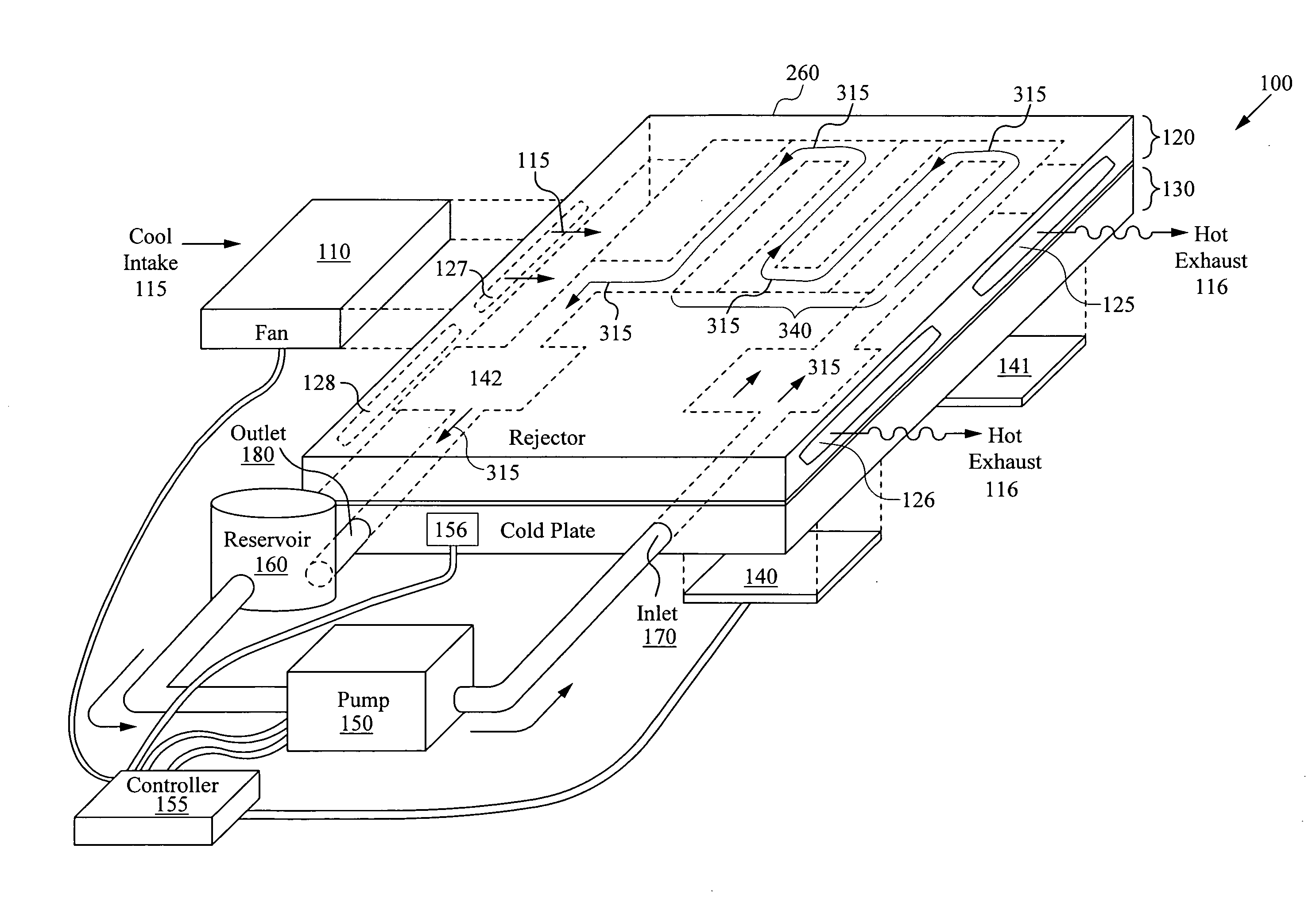

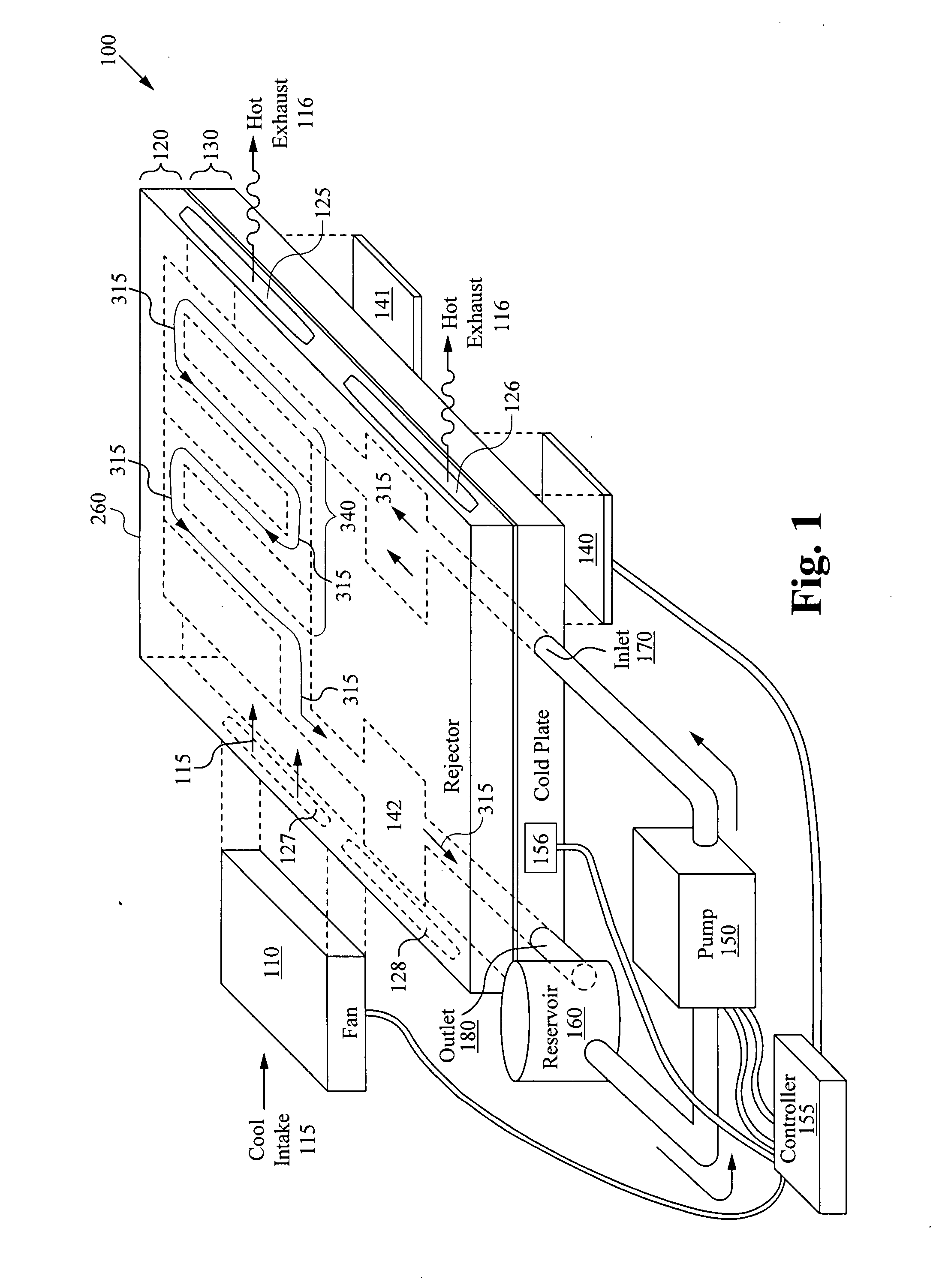

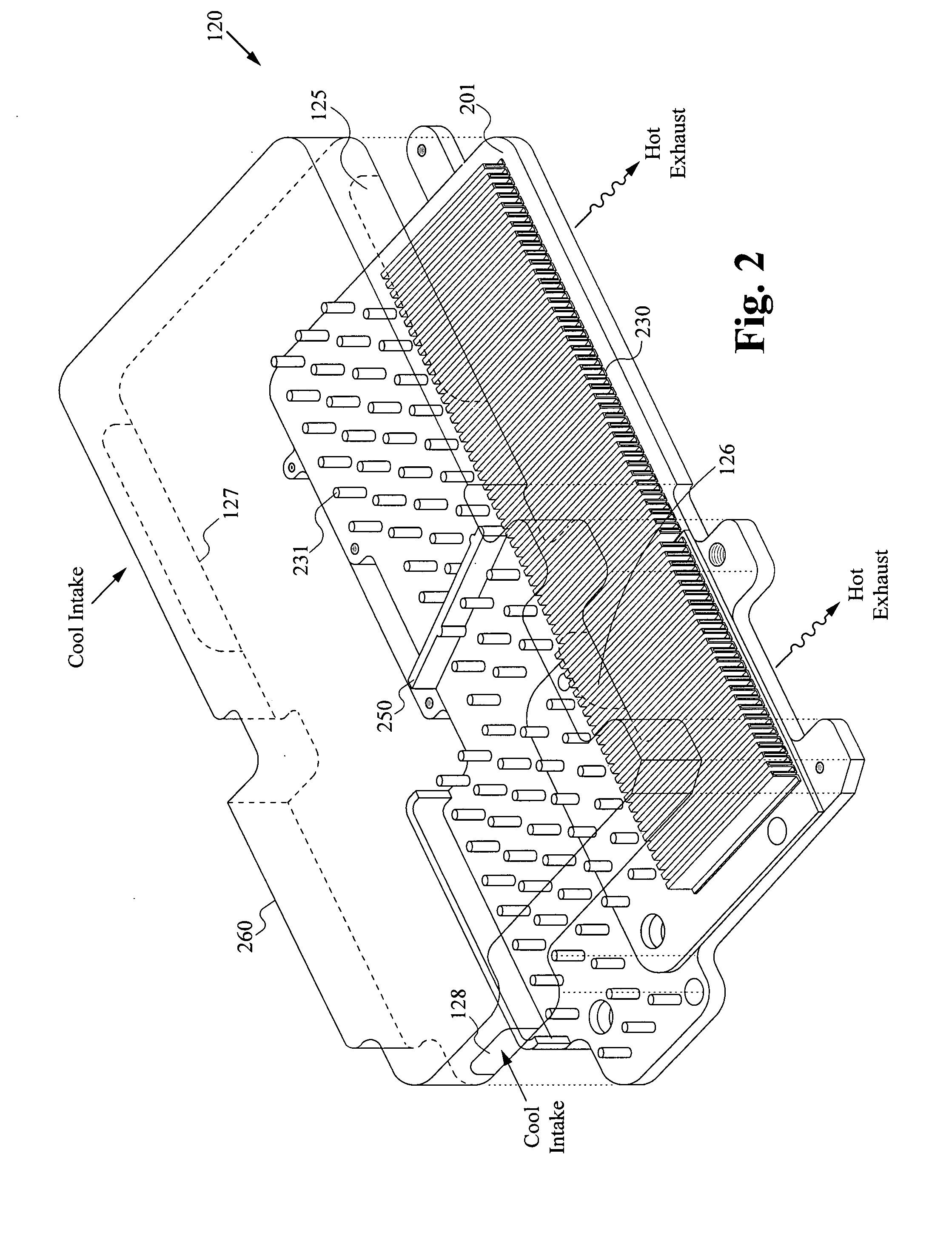

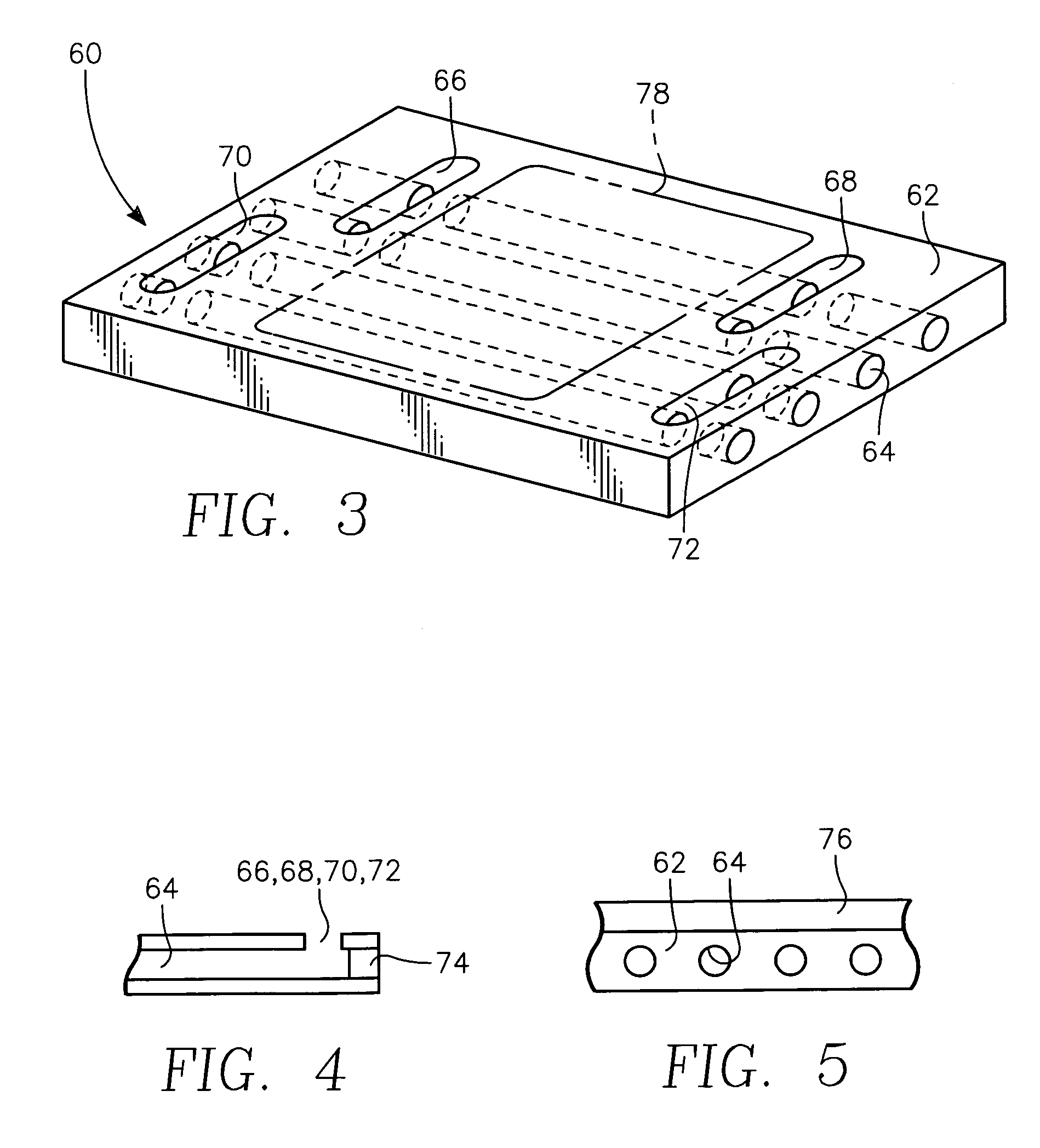

Integrated liquid to air conduction module

ActiveUS20070227708A1Increase the areaMaximizes timeSpace heating and ventilation safety systemsSpace heating and ventilation control systemsGraphic cardCounter flow

An integrated cooling system for cooling systems such as laptops or subsystems such as a graphics card is disclosed. An integrated cooling system includes a first layer having a contact area configured for coupling to a heat source, wherein the first layer has a fluid path passes adjacent to the contact area where the heat source is in thermal contact with first layer. Coupled to the first layer is a second layer to which a number of air fins are attached. The invention includes a pump that is connected to the fluid path forming a closed path for circulating a fluid through the first layer. Within the first layer, the fluid path will contain a plurality of fluid fins which control the flow of a fluid within the fluid path. Within the fluid path, a structure providing a double-counter flow adjacent to one or more electronic devices. Additionally the fluid path can include a microchannel plate structure. The system can include a includes a programmable controller connect the an air-mover, pump and temperature sensing device. A reservoir can be connected to the fluid path.

Owner:VERTIV CORP

Methods for dehydration of sugars

The invention includes a method of dehydration of a sugar using a dehydration catalyst and a co-catalyst within a reactor. A sugar is introduced and H2 is flowed through the reactor at a pressure of less than or equal to about 300 psig to convert at least some of the sugar into an anhydrosugar product. The invention includes a process for producing isosorbide. A starting material comprising sorbitol is flowed into a reactor. H2 is counter flowed through the reactor. The starting material is exposed to a catalyst in the presence of a co-catalyst which comprises at least one metal. The exposing is conducted at a hydrogen pressure of less than or equal to 300 psig within the reactor and the hydrogen removes at least some of any water present during the exposing and inhibits formation of colored byproducts.

Owner:BATTELLE MEMORIAL INST

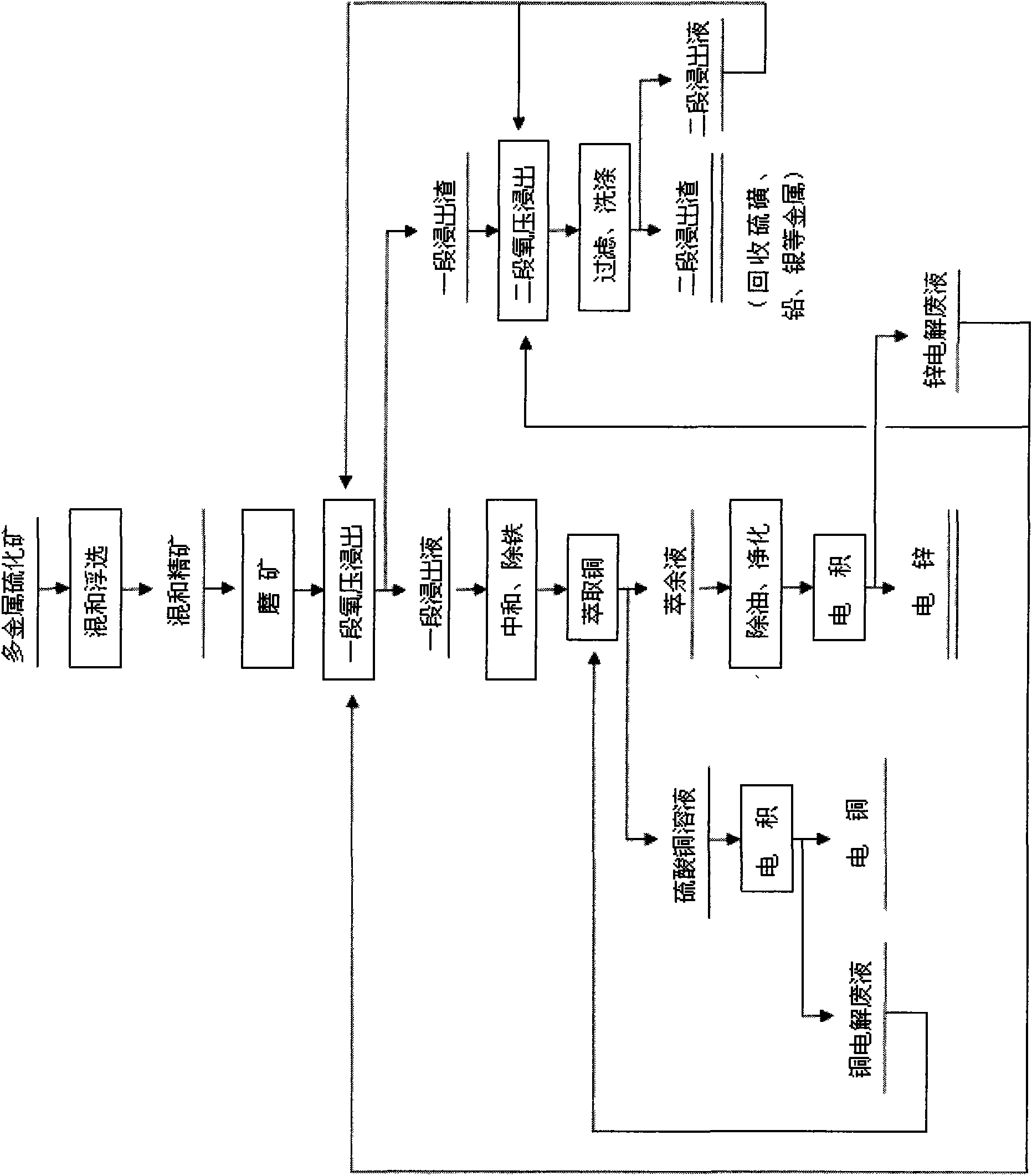

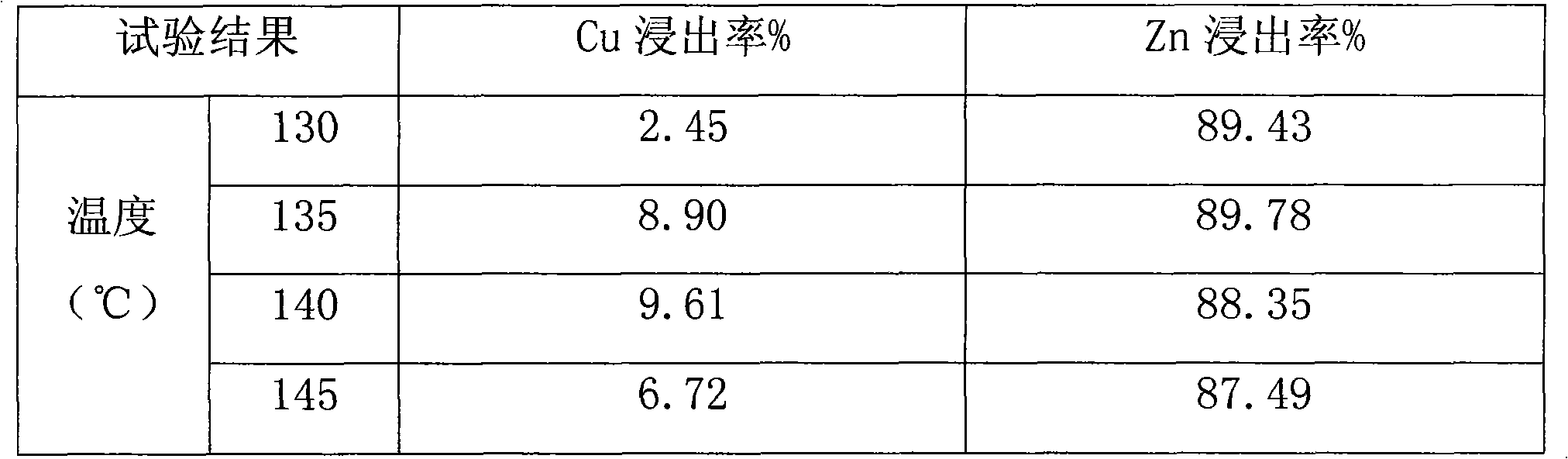

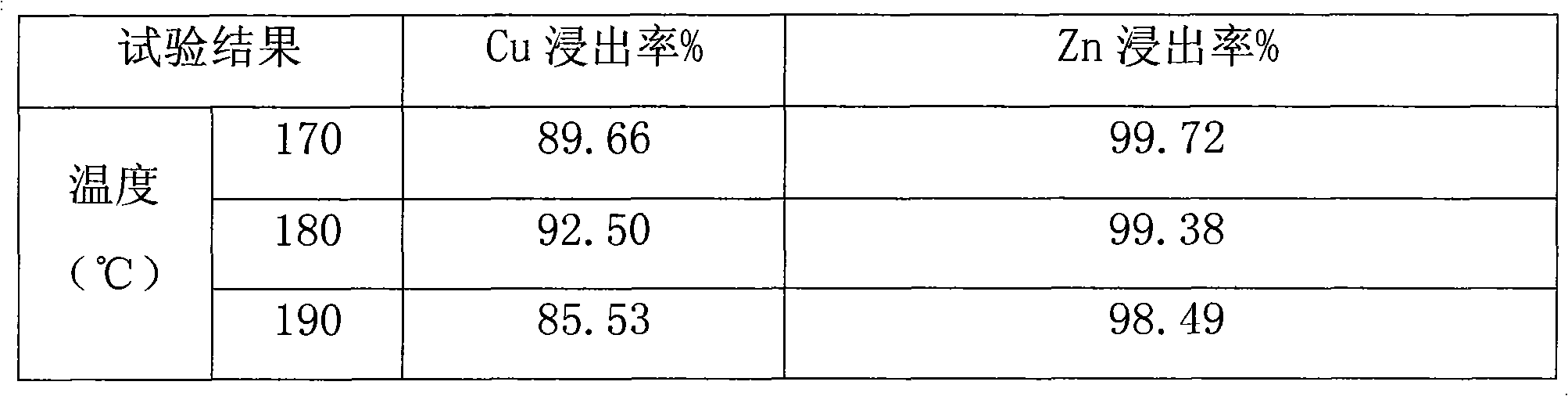

Comprehensive recovery method of complex polymetal sulphide ore containing copper, lead and zinc

InactiveCN101643857AHigh recovery rateSimple processSulfur preparation/purificationFlotationRecovery methodLead smelting

The invention discloses a comprehensive recovery method of complex polymetal sulphide ore containing copper, lead and zinc and adopts dressing-metallurgy combination method and hydrometallurgy-pyrometallurgy combination method to recover metals. The recovery method comprises the following steps: first performing bulk flotation to the complex polymetal sulphide ore, fine grinding the obtained concentrate, leaching by using two-step counter flow oxygen pressure leaching process, extracting and separating copper and zinc from the obtained leachate, electrodepositing the strip liquor of copper-loaded organic phase to obtain cathode copper, cleaning the obtained raffinate and electrodepositing to obtain cathode zinc; pressurizing leaching residue to perform flotation separation and obtain sulfur concentrate and lead silver residue, distilling sulfur concentrate to obtain sulfur; performing lead smelting process to lead silver residue to obtain electrolytic lead product and lead anodic slime; and comprehensively recovering noble metals such as gold, silver and the like from lead anodic slime. The method can greatly improve the metal recovery rate, resource utilization and the economic efficiency of mines and generate a lot of sulfur so as to obviously reduce the sulfur dioxide pollution to the atmosphere.

Owner:WESTERN MINING CO LTD

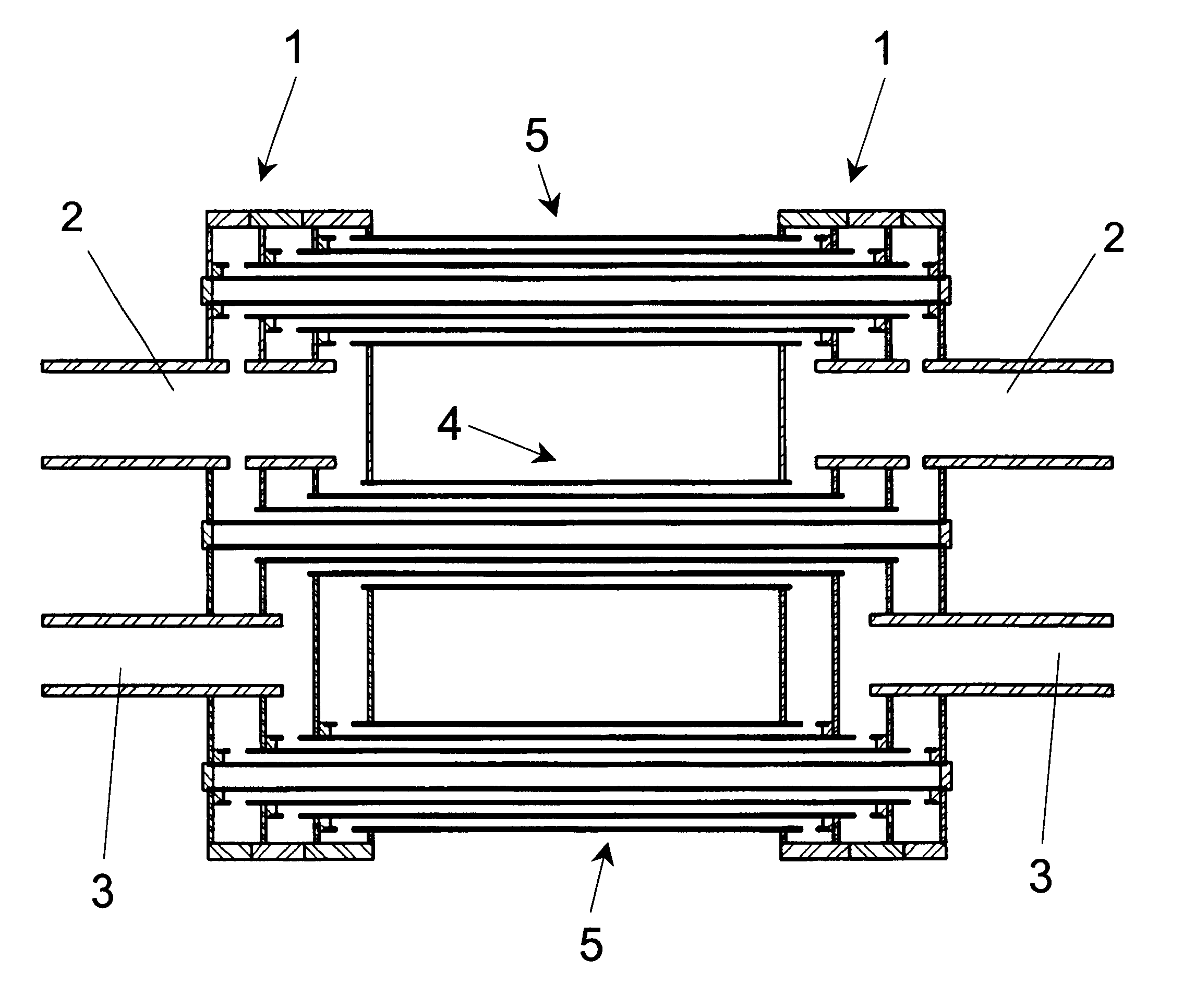

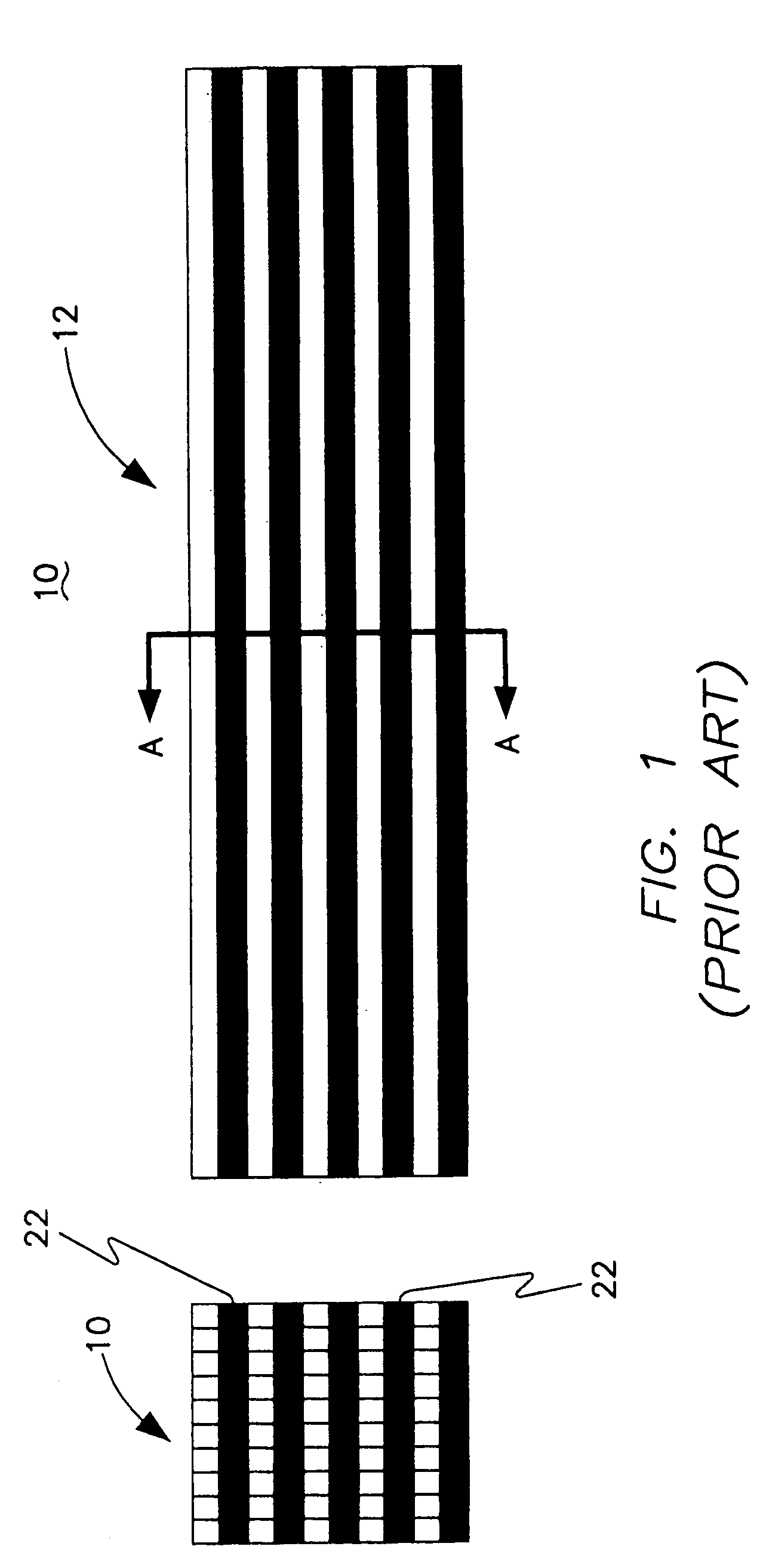

Compact counterflow heat exchanger

InactiveUS20050217837A1Heat exchanger casingsStationary tubular conduit assembliesCounter flowEngineering

A geometric arrangement of components in a compact counter-flow heat exchanger that allows for either an increase in effectiveness at a set mass, or a reduction in heat exchanger mass at a set effectiveness, or a combination of the two. The geometric arrangement can be achieved by either tube bending at the level of piece part manufacture and subsequent care during the tube stacking process, or by elastic deformation of the tube stack at the time of bonding.

Owner:UNITED TECH CORP

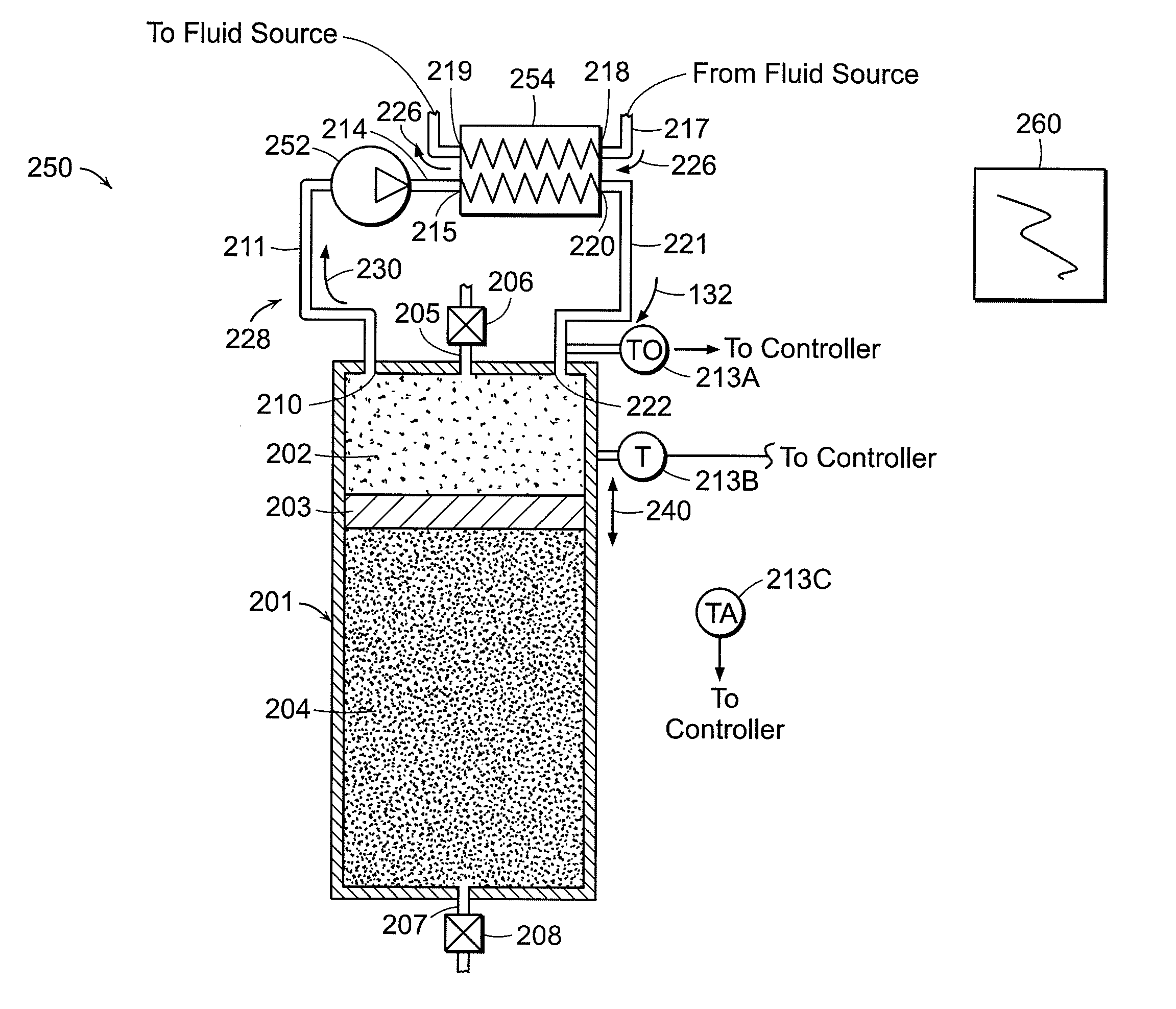

Thermal storage system

InactiveUS20120080161A1Lower temperature rangeSolar heating energySolar heat devicesThermal energyWorking fluid

Apparatus and method for efficiently storing thermal energy, in particular thermal energy transferred from a concentrated solar energy receiver. The apparatus consists of a collection of modular thin walled tube pressure vessels enclosing solid sensible heat thermal storage elements. The high temperature solid is separated from the thin wall by thermal insulation and two thin gaps that carry the cold in and cold out high-pressure working fluids. Hot in and hot out working fluids circulate in counter flow channels within the solid sensible heat thermal storage elements. The solar receiver can also be modular to match the thermal storage elements, facilitating manufacturing and on site assembly. The design enables scalable thermal storage and concurrent thermal charging and discharging with no circuit switching between charge and discharge.

Owner:KELLY EDMUND JOSEPH

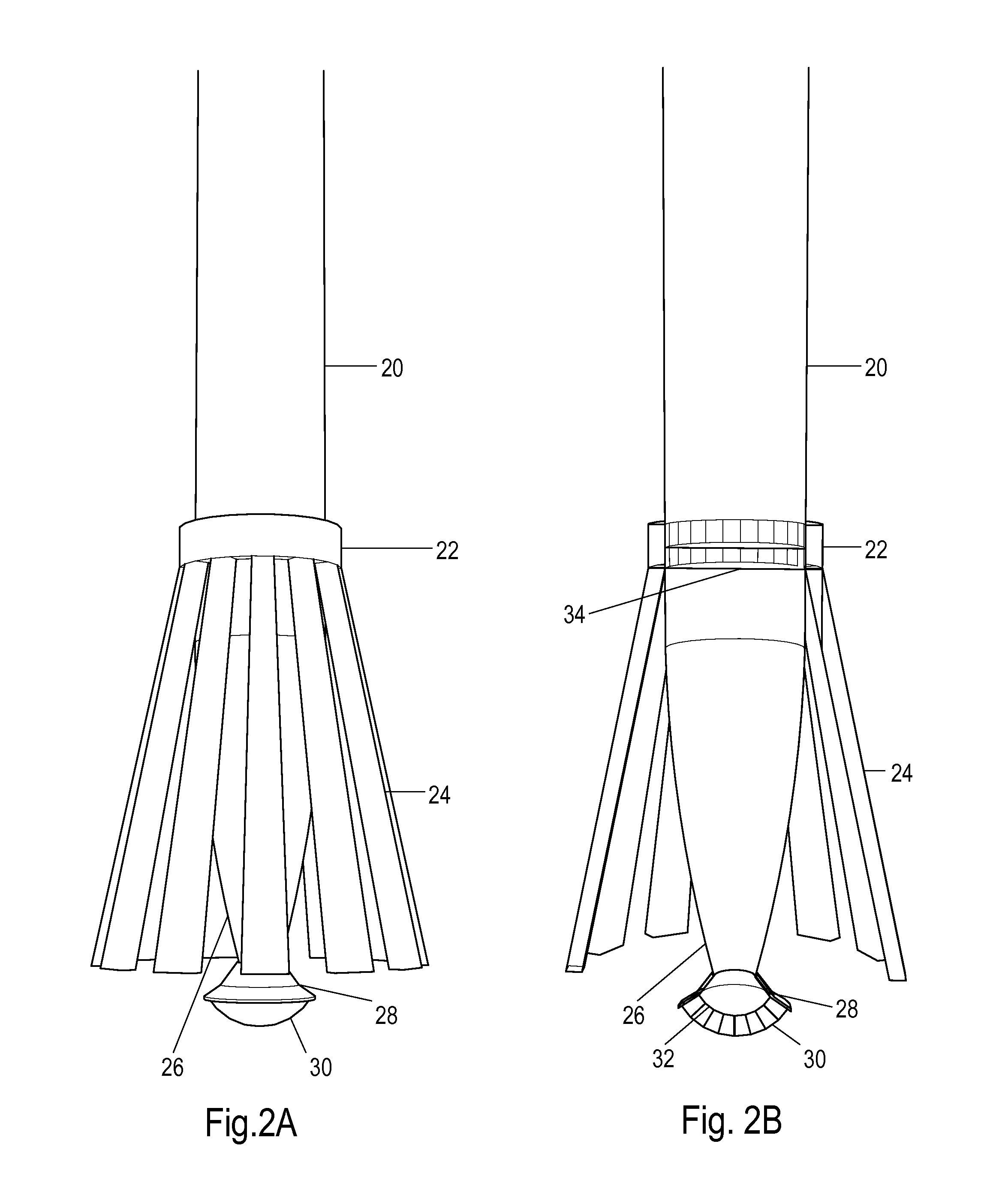

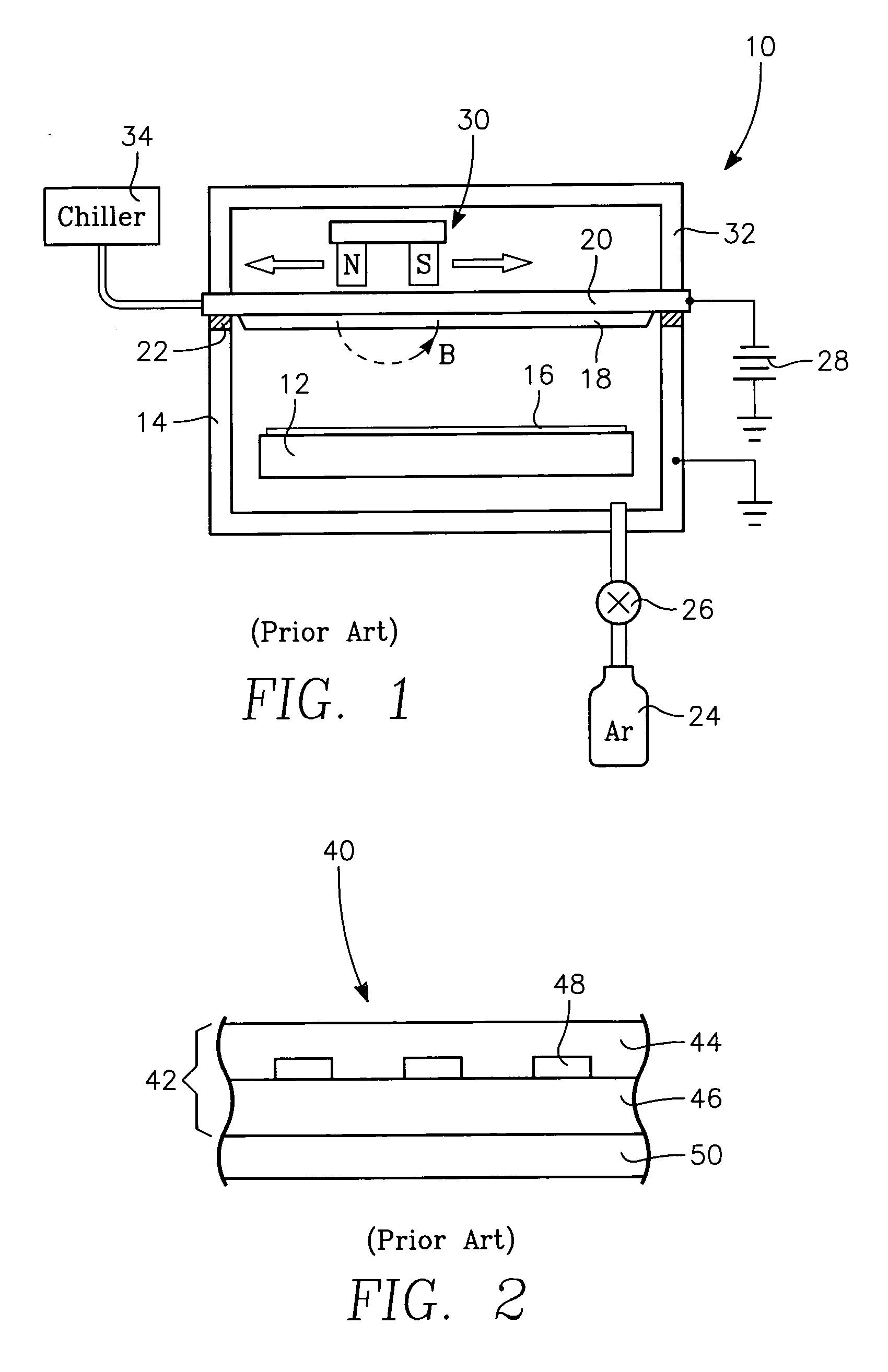

Controllable target cooling

InactiveUS20070023275A1Reduce temperature differenceCellsElectric discharge tubesCounter flowEngineering

A sputter target assembly particularly useful for a large panel plasma sputter reactor having a target assembly sealed both to the main processing chamber and a vacuum pumped chamber housing a moving magnetron. The target assembly to which target tiles are bonded includes an integral plate with parallel cooling holes drilled parallel to the principal faces. The ends of the holes may be sealed and vertically extending slots arranged in two staggered groups on each side and machined down to respective pairs of cooling holes on opposite sides of the backing plate in pairs. Four manifolds tubes are sealed to the four groups of slots and provide counter-flowing coolant paths.

Owner:APPLIED MATERIALS INC

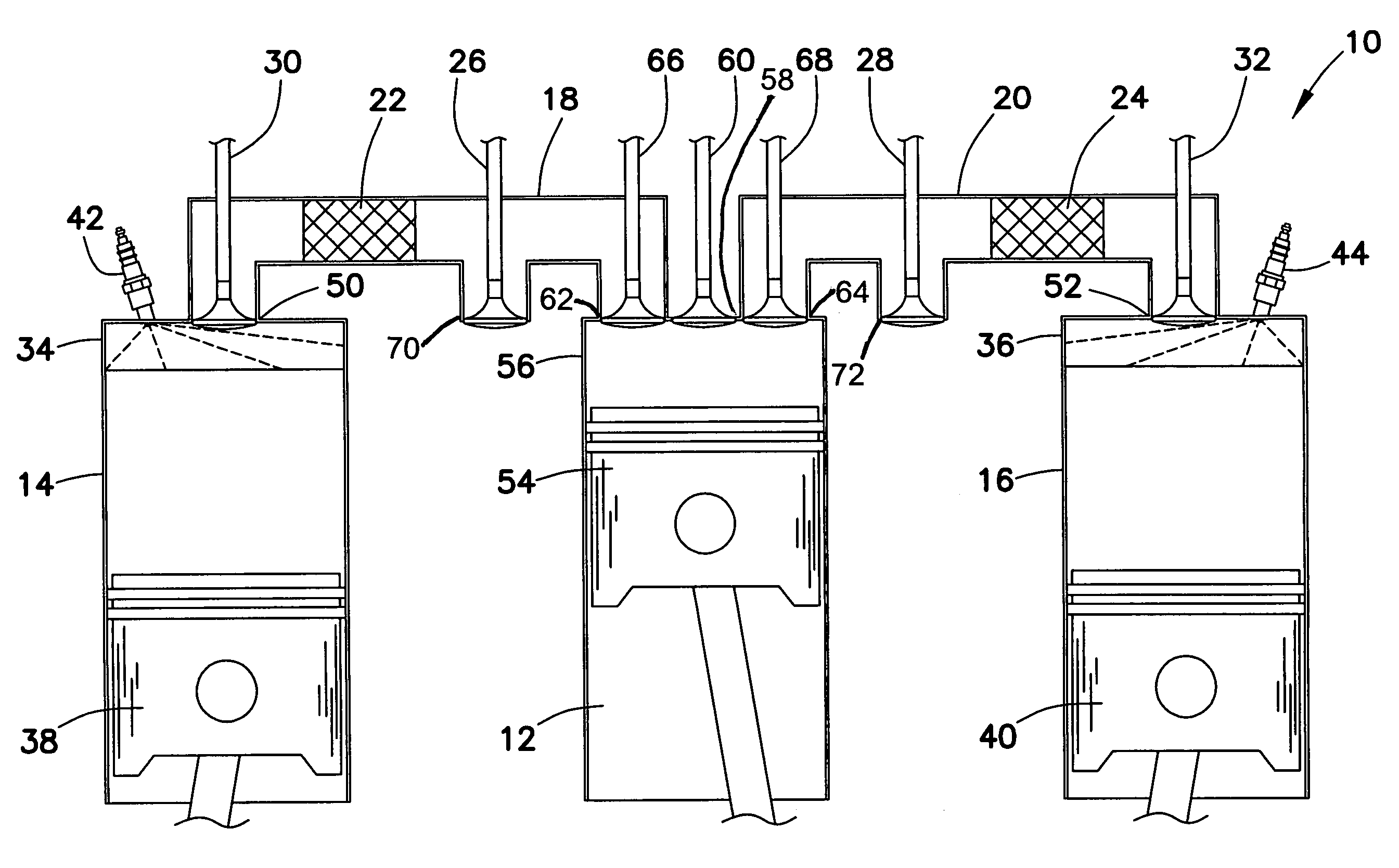

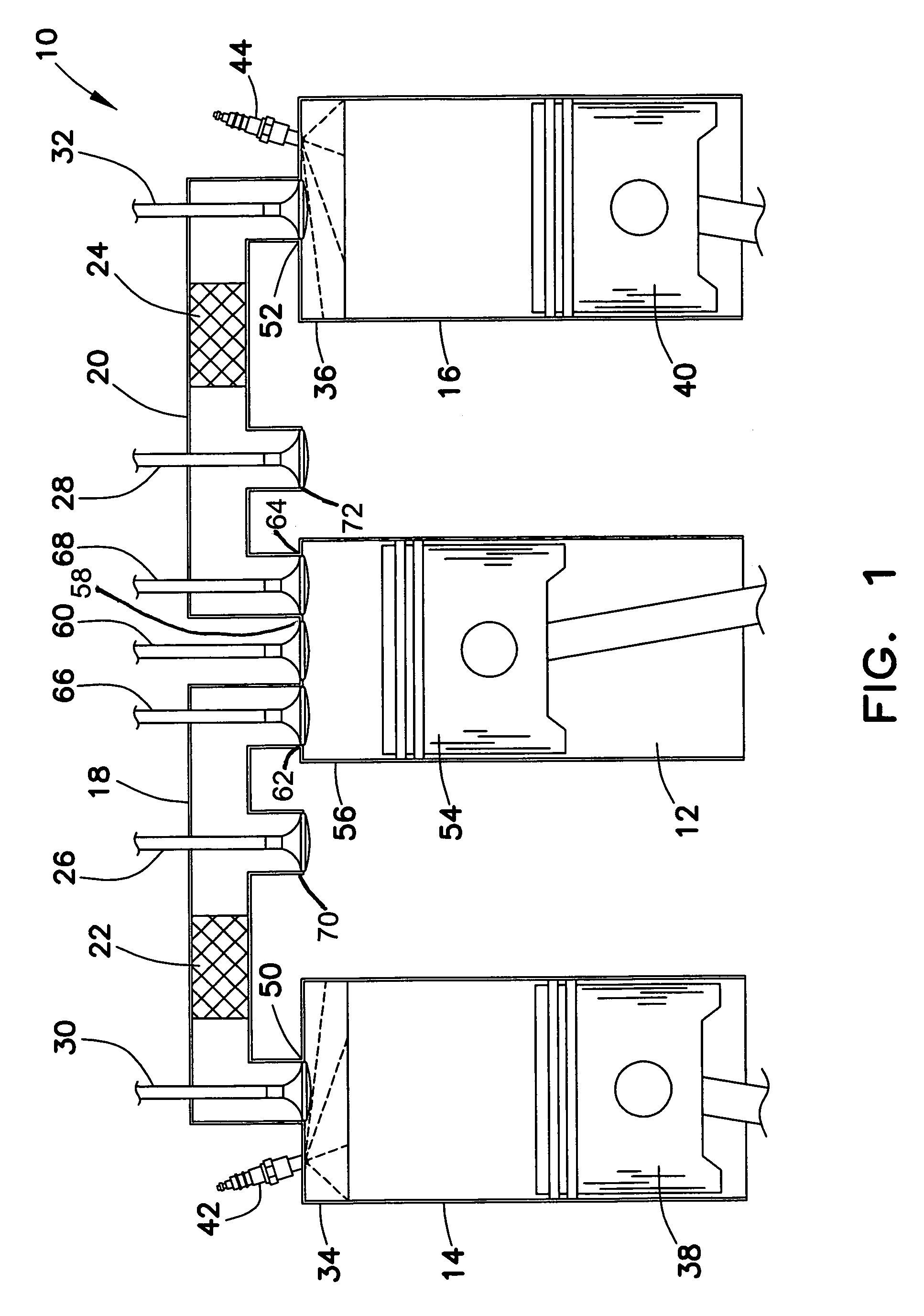

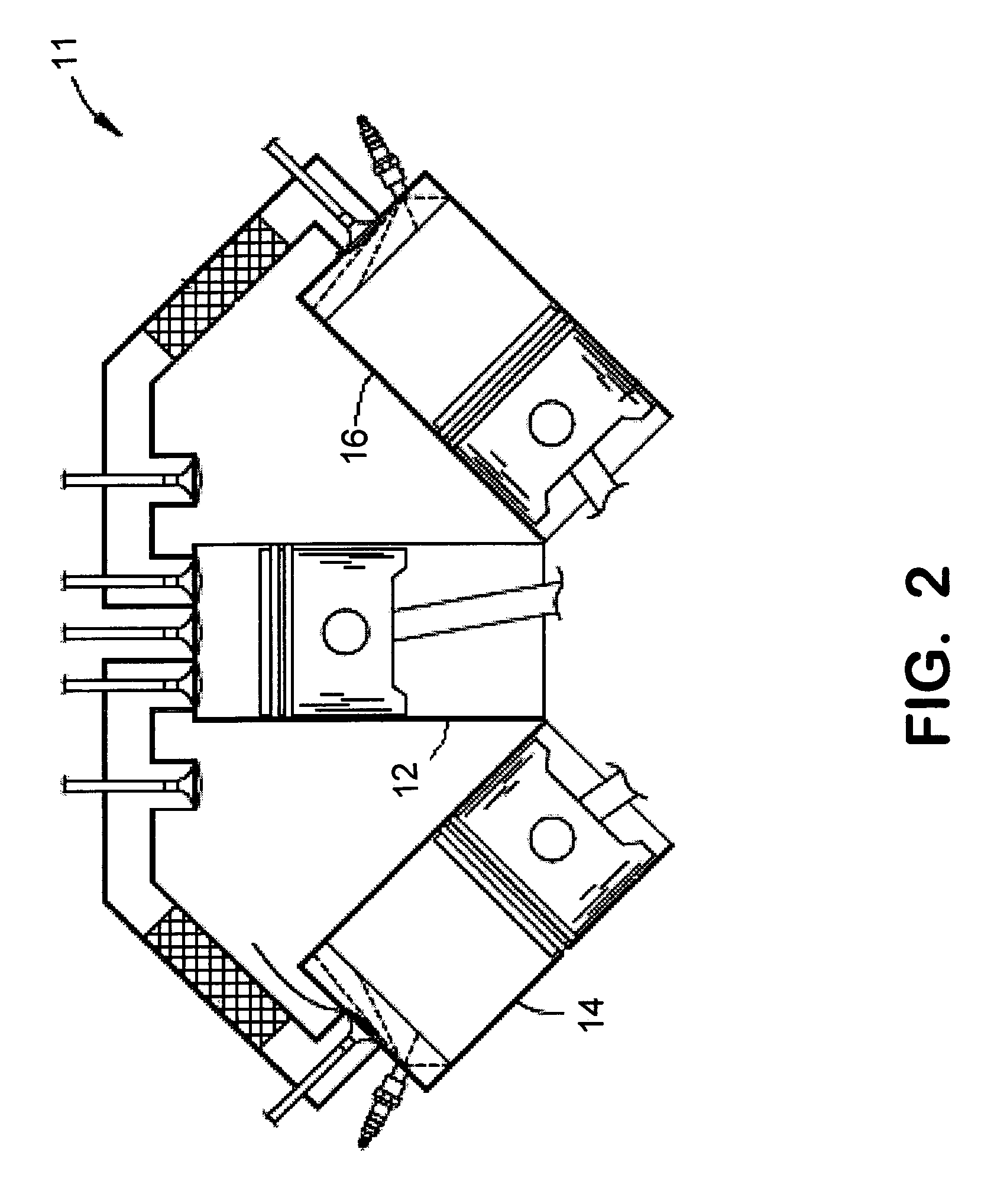

Thermal transfer internal combustion engine

A thermal transfer internal combustion engine with an air transfer cylinder located between a pair of power cylinders. The transfer cylinder has an intake valve and two transfer valves alternately feeding the two power cylinders. The power cylinders each contain a mono valve used for both intake and exhaust. Counter-flow manifolds connect the mono valves of the power cylinders to the transfer valves of the transfer cylinder. A regenerator with catalytic converter properties is located in each counter-flow manifold. The regenerator is heated by exhaust gases exiting the power cylinders, prior to exiting the engine through exhaust dump valves. Uncompressed intake air is pushed from the transfer cylinder through the regenerator where it is heated and delivered to the power cylinder for conventional processing. The heat recovery system provides high compression temperatures at low compression ratios, reducing engine fuel consumption.

Owner:WAIT IRVING S

Ventilation device

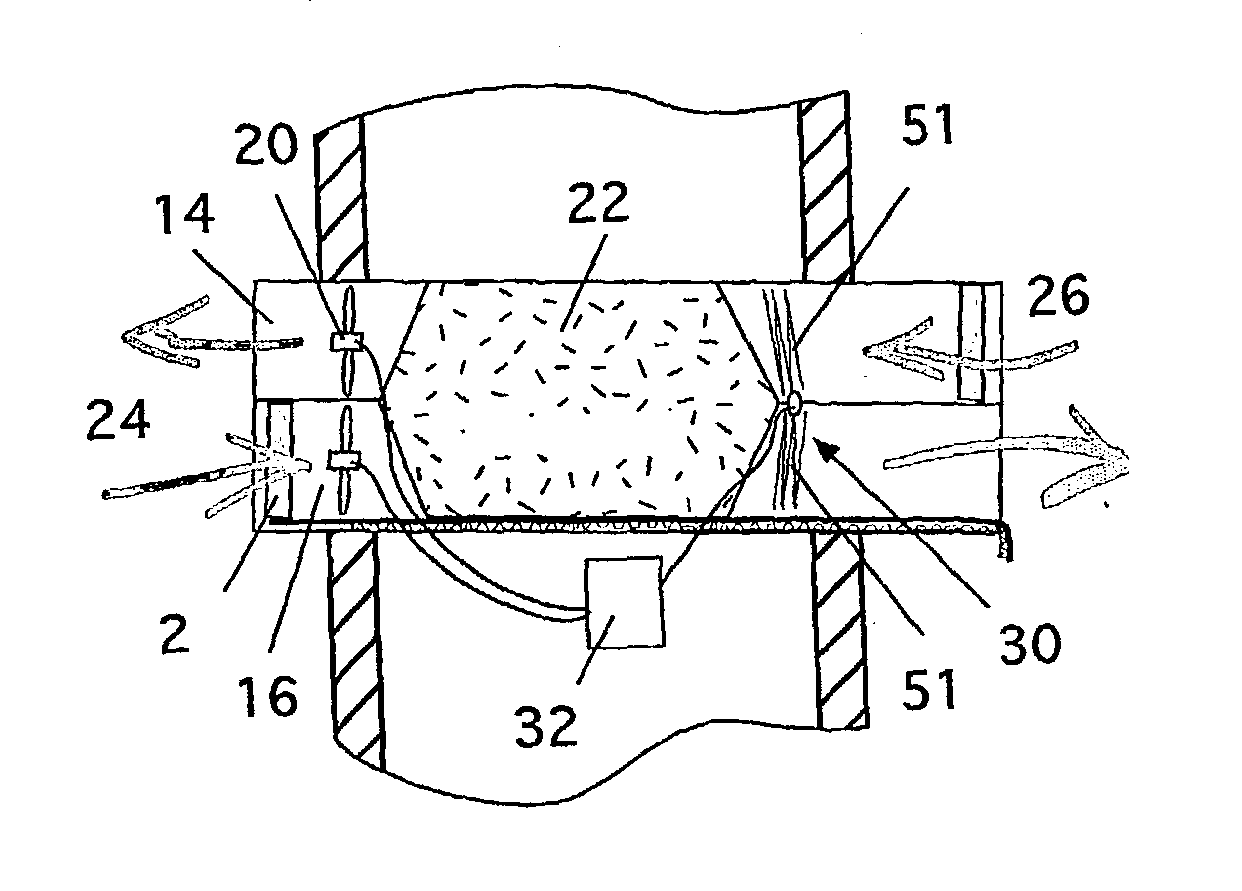

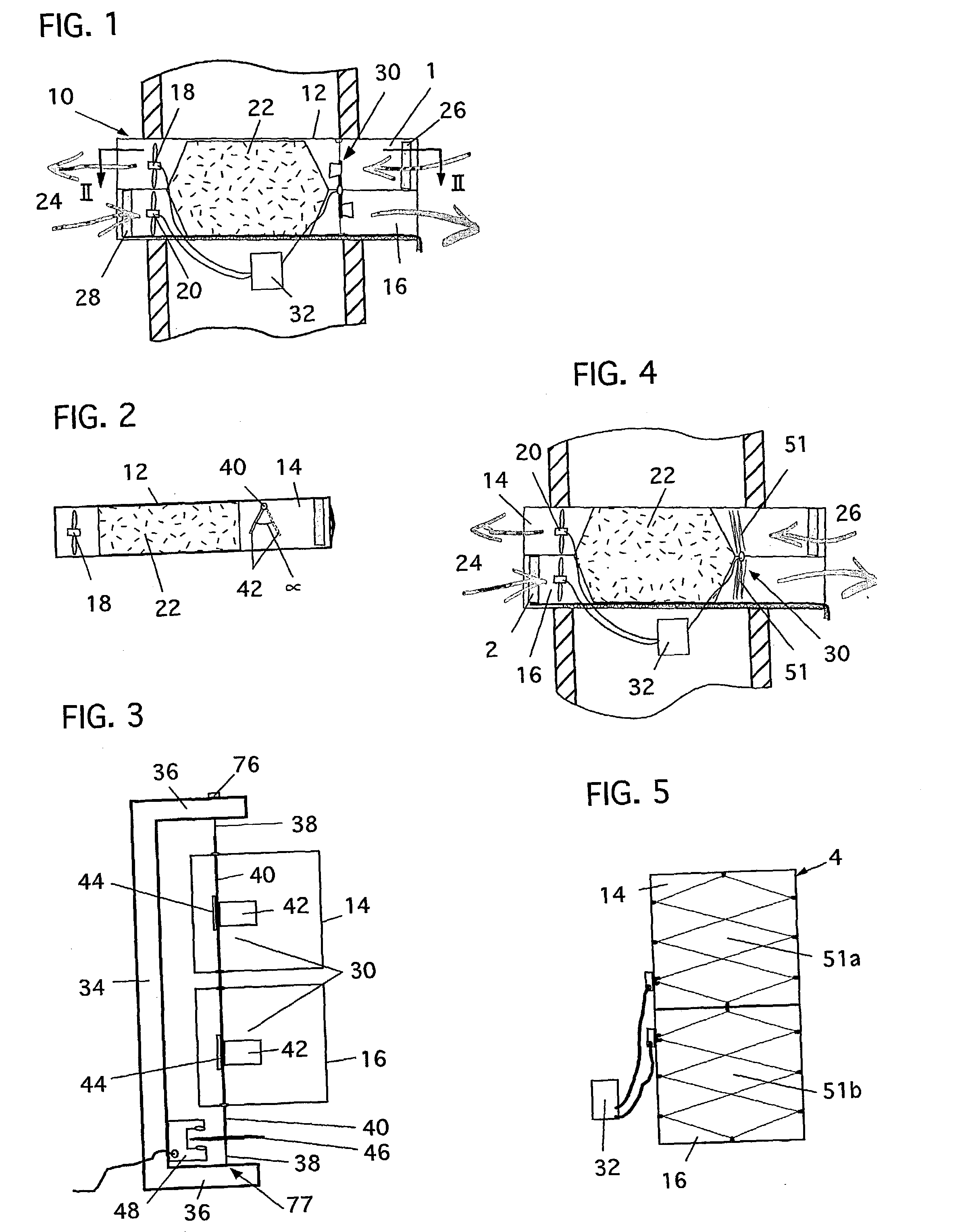

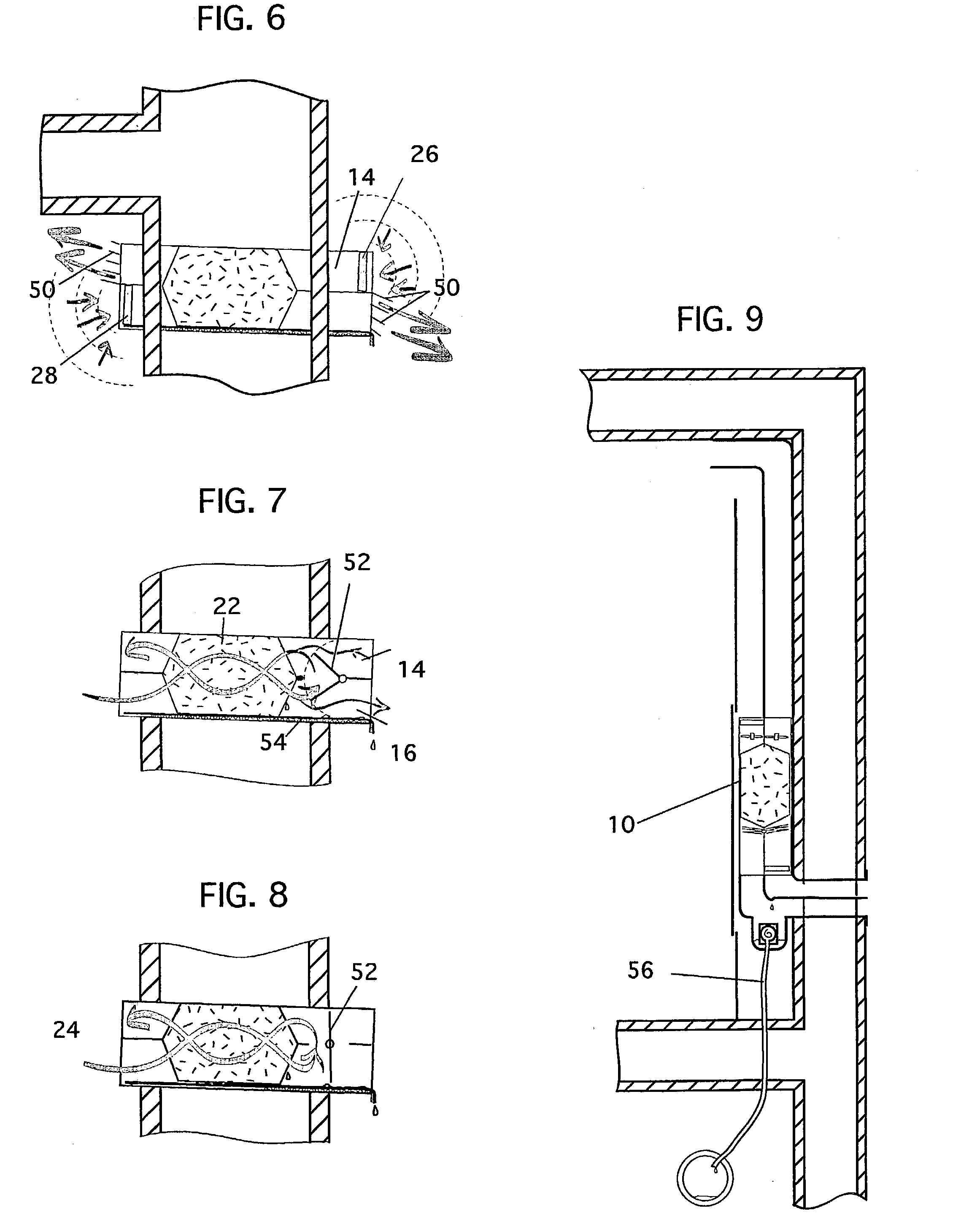

InactiveUS20030159802A1Reduced Power RequirementsReduce outputMechanical apparatusEfficient regulation technologiesCounter flowEngineering

The invention relates to a ventilation device for ventilation room by room and / or zone by zone and comprises: a) a device casing (12), which is provided in or adjacent an outer wall of a building or the like and which connects room air to outside air, b) a heat-exchange (22) of counter flow type, provided in the casing (12) and transferring heat from the outgoing and in-going airflows, respectively, c) two fans (18,20) arranged in said casing (12), of which one is connected to the ingoing air duct (14) of the heat-exchanger (22) and the other to the outgoing air duct (16) of the heat-exchanger (22), d) at least one sensor (30) for determination of the airflow's relative deviation in velocity from a neutral value of the airflows passing through each respective duct (14, 16), and e) a control means (32), which, depending on the values given by the sensor (30), is arranged to regulate the rotation speed of the fans (18, 20), for the purpose of substantially balancing the airflow, so that it is substantially equal for the ingoing and outgoing air.

Owner:STENEBY BENGT +1

Turbine airfoil with near wall inflow chambers

InactiveUS20100104419A1Improve cooling effectReduces stress inducing temperature gradientPump componentsBlade accessoriesCounter flowCooling chamber

A turbine airfoil usable in a turbine engine and having at least one cooling system. At least a portion of the cooling system may be positioned in an outer wall of the turbine airfoil for receiving cooling fluids from a cooling fluid supply source, passing those fluids through the chambers in the outer wall, and exhausting those fluids into central cooling fluids collection chambers. The outer wall may include a plurality of outer wall cooling chambers that may be configured to pass cooling fluids in a counter flow direction. The outer wall cooling chambers may include a plurality of ribs including a plurality of impingement orifices for increasing the cooling efficiency of the cooling system.

Owner:SIEMENS ENERGY INC

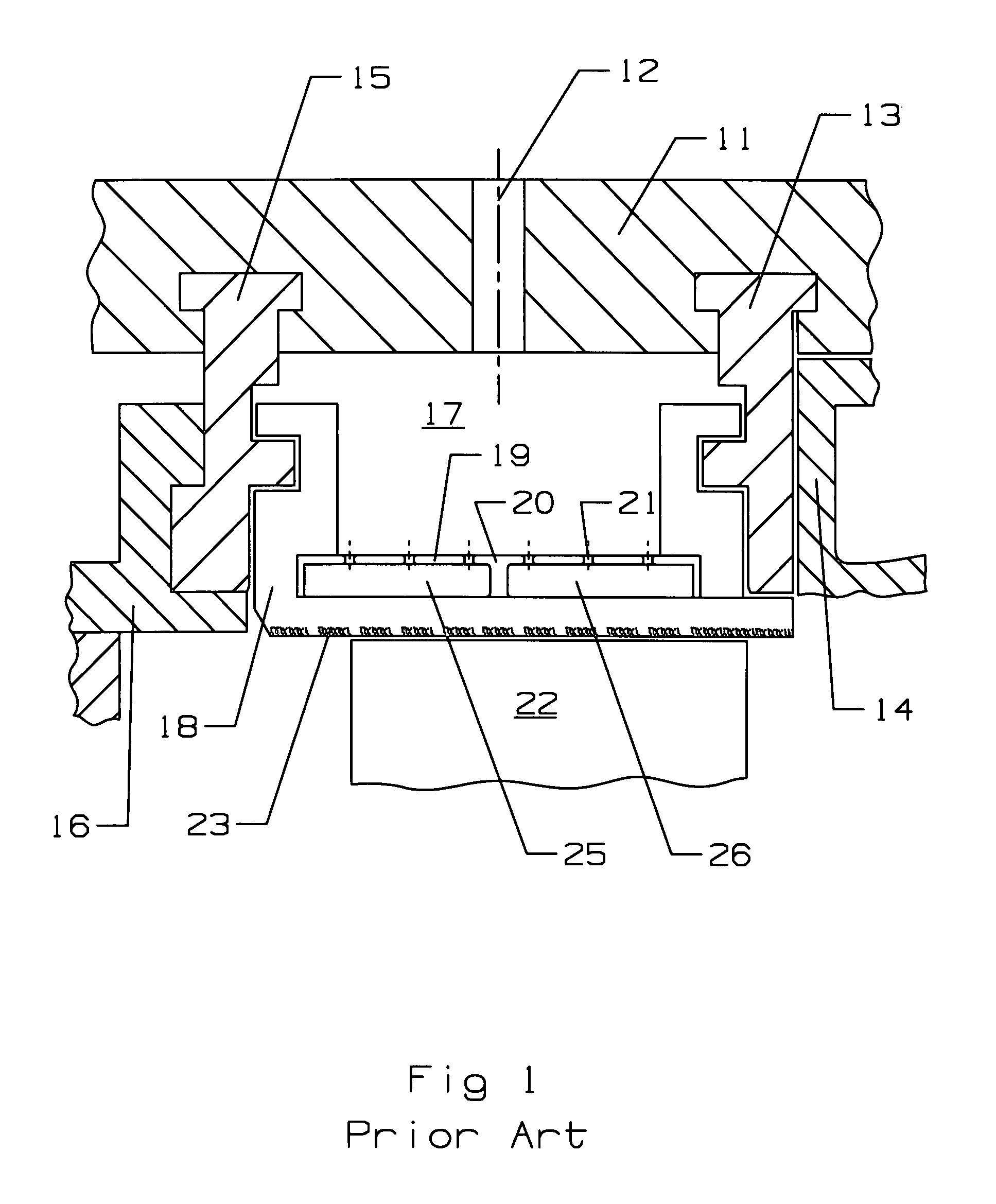

Turbine BOAS with edge cooling

A cooling hole having an inlet passage forming an inward spiral flow path and an outlet passage forming an outward spiral flow path in which the two paths are counter flowing in order to improve the heat transfer coefficient. The spiral cooling hole is used in a blade outer air seal (BOAS) for a turbine in which the edges of the shroud segments include a counter flowing micro serpentine flow cooling circuit with thin diffusion discharge cooling slots for the BOAS edges. The total BOAS cooling air is impingement from the BOAS cooling air manifold and metered through the impingement cooling holes to produce impingement cooling onto the backside of the BOAS. The spent cooling air is then channels into the multiple micro serpentine cooling flow circuits located around the four edges of the shroud segments. This cooling air then flows in a serpentine path through the horizontal serpentine flow channels and then discharged through the thin diffusion cooling slots as peripheral purge air for the mate faces as well as the spacing around the BOAS or shroud segments. Trip strips are used in the serpentine flow channels for the augmentation of internal heat transfer cooling capability. The micro serpentine flow cooling air circuits spaced around the four edges of the shroud segments are formed into the shroud segments during the casting process of the shroud segments.

Owner:FLORIDA TURBINE TECH

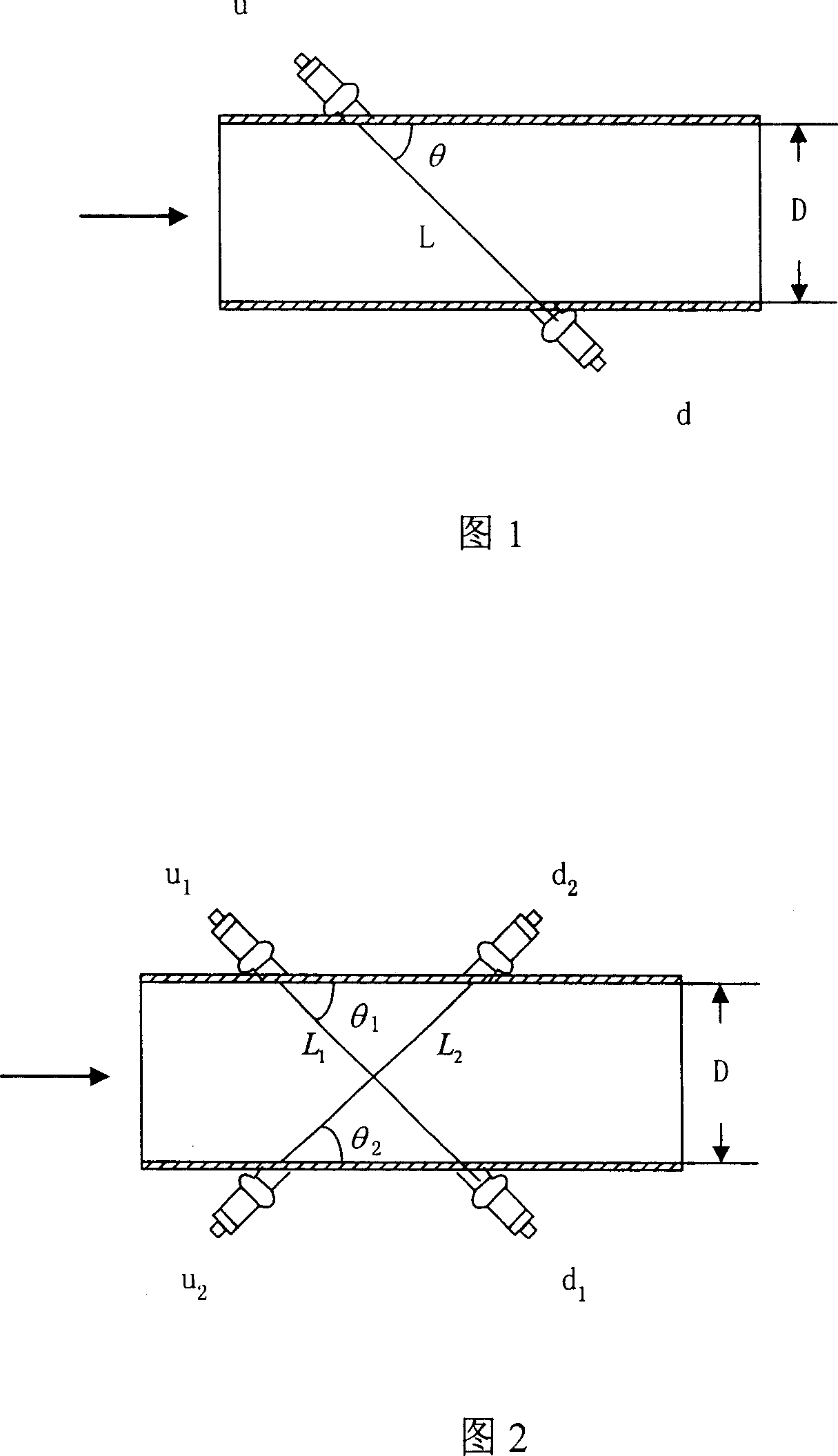

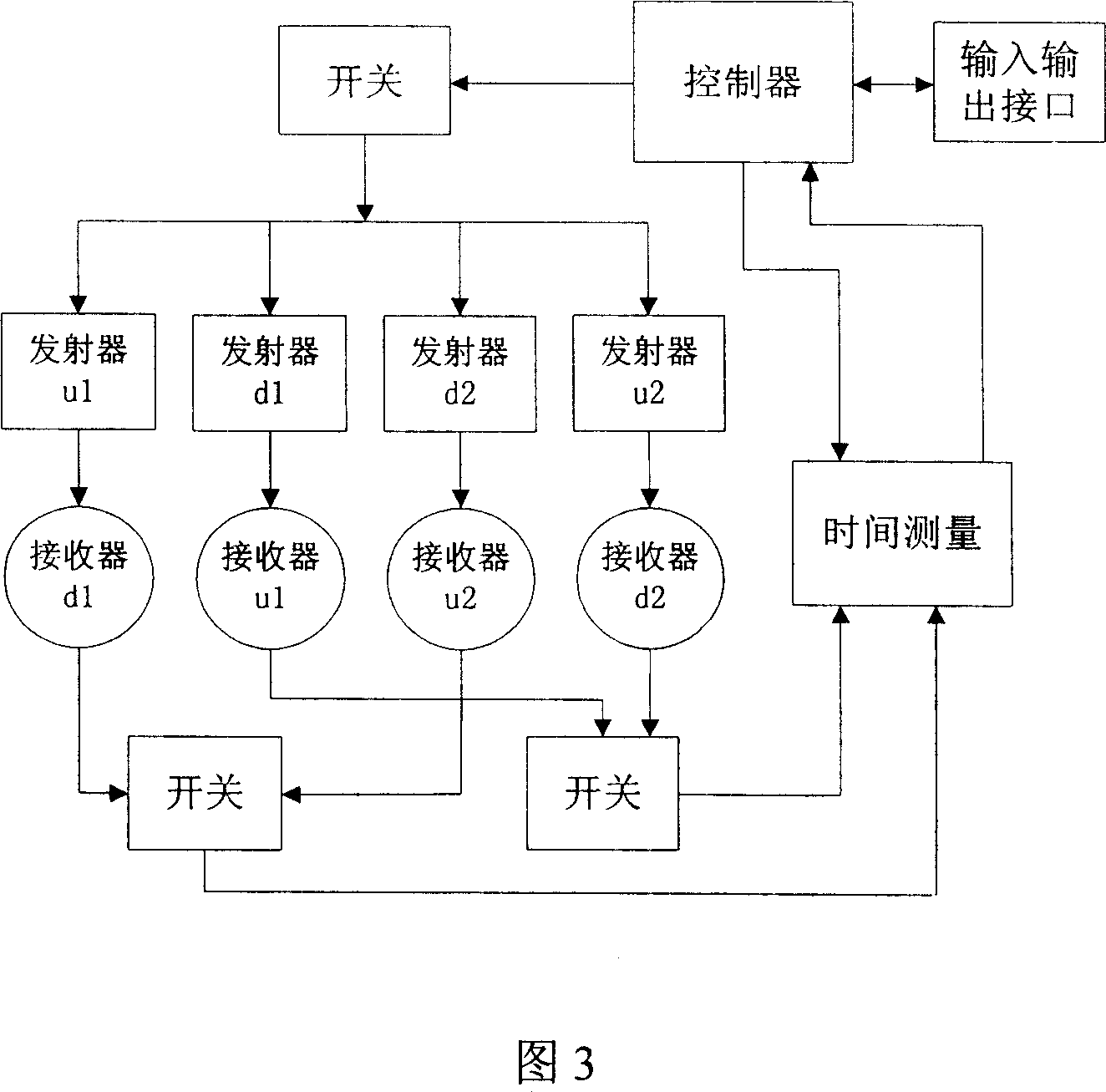

Detection method of time difference cross in use for ultrasonic flowmeter

A time difference cross detecting method of ultrasonic flow meter includes using two pairs of transverters as probe set to emit and receive signal, setting the first pair of transverters to be worked on forward flow mode and second pair of transverters to be worked on counter flow mode, emitting out ultrasonic ray simultaneously by probe set formed by two pairs of transverters to record thee time-differences, exchanging the working directions of two pairs of transverters and repeating above said emitting step to obtain another three time-differences.

Owner:CHINA JILIANG UNIV

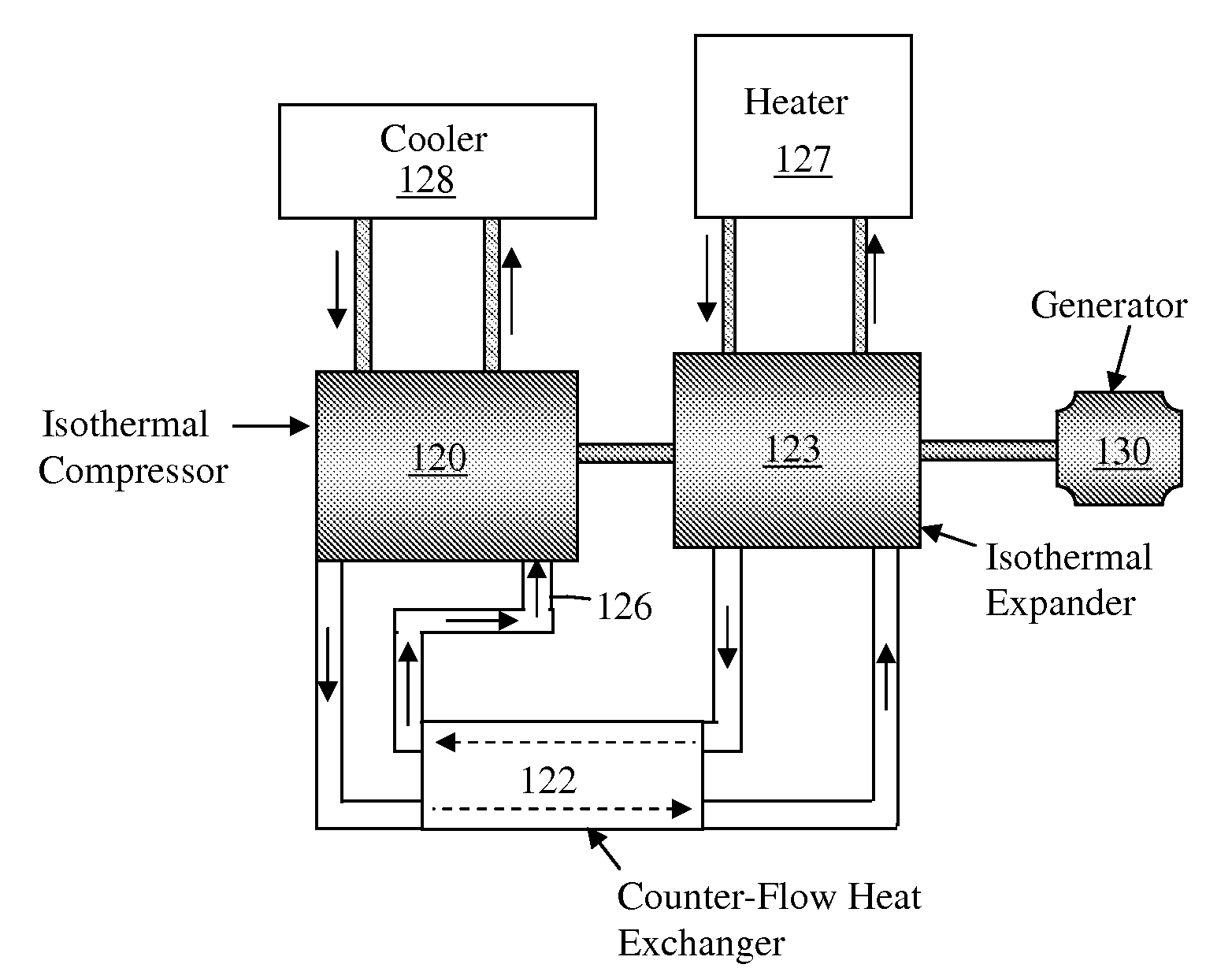

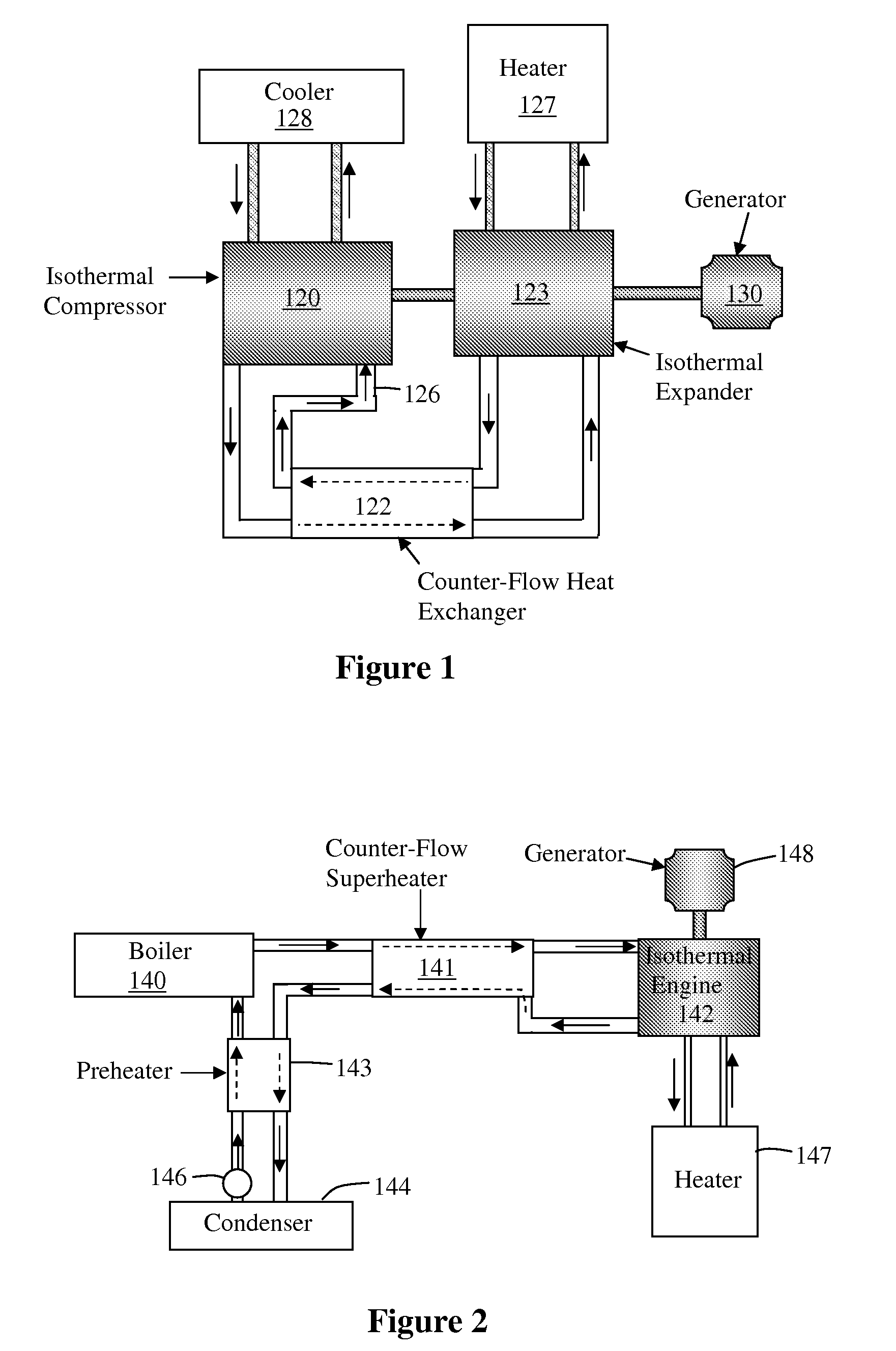

Isothermal power system

InactiveUS20090260361A1Increase in sizeMore energySteam engine plantsPlate heat exchangerCounter flow

This invention provides means for producing power by using isothermal compressors and isothermal expanders. One embodiment has an isothermal compressor that compresses air (or other gas), passes the air through a counter-flow heat exchanger, which heats the air, uses the heated air to drive an isothermal expander for power generation, and passes the expander exhaust back through the counter-flow heat exchanger to heat the input air to the expander. Another embodiment has a boiler that produces vapor that flows through a counter-flow heat exchanger to superheat the vapor. The vapor then flows through an isothermal expander for power generation. The exhaust from the isothermal expander flows back through the counter-flow heat exchanger to supply heat to super heat the vapor coming from the boiler. The description presents several devices that can perform at near isothermal conditions, including a modified Tesla turbine.

Owner:PRUEITT MELVIN L

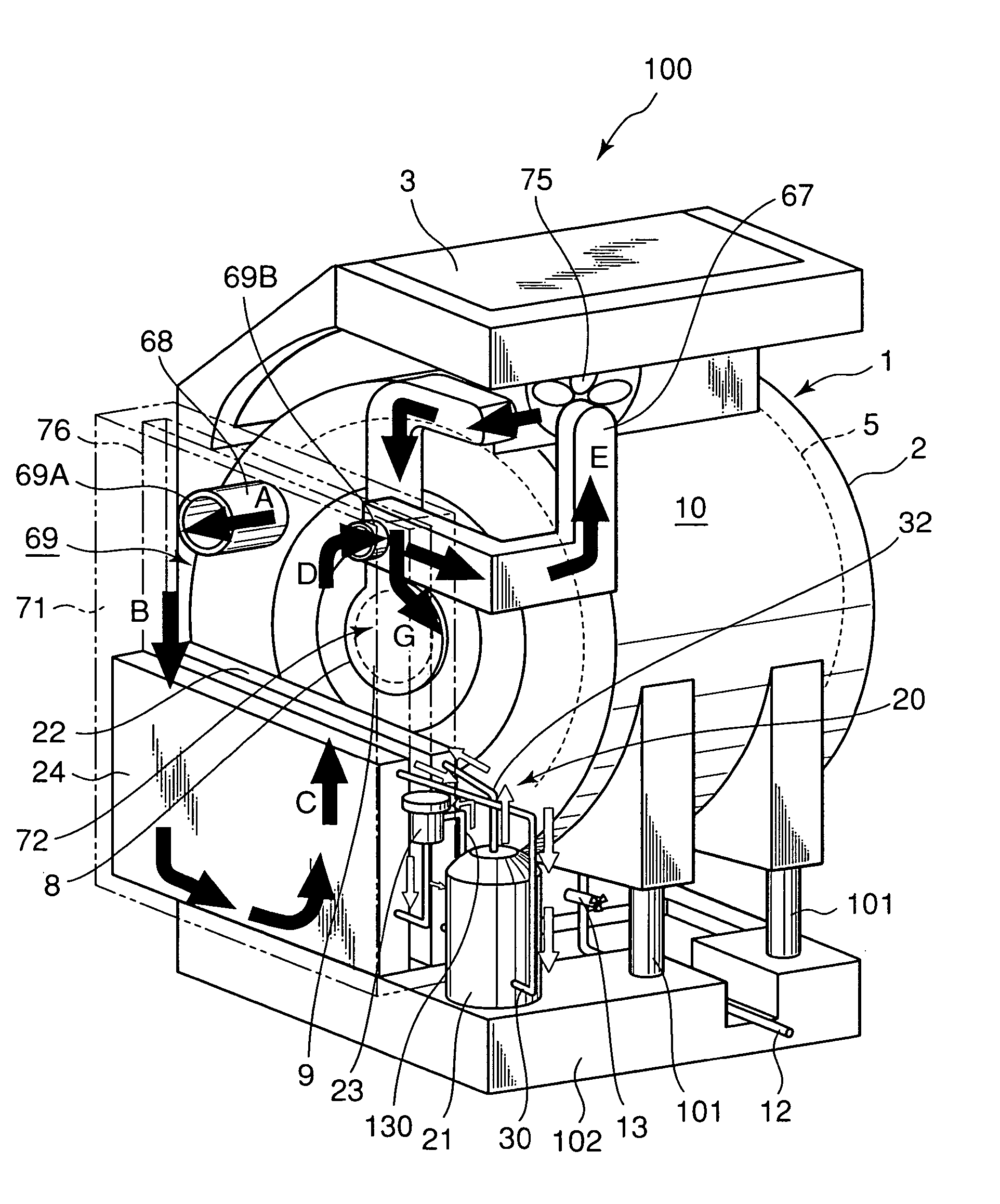

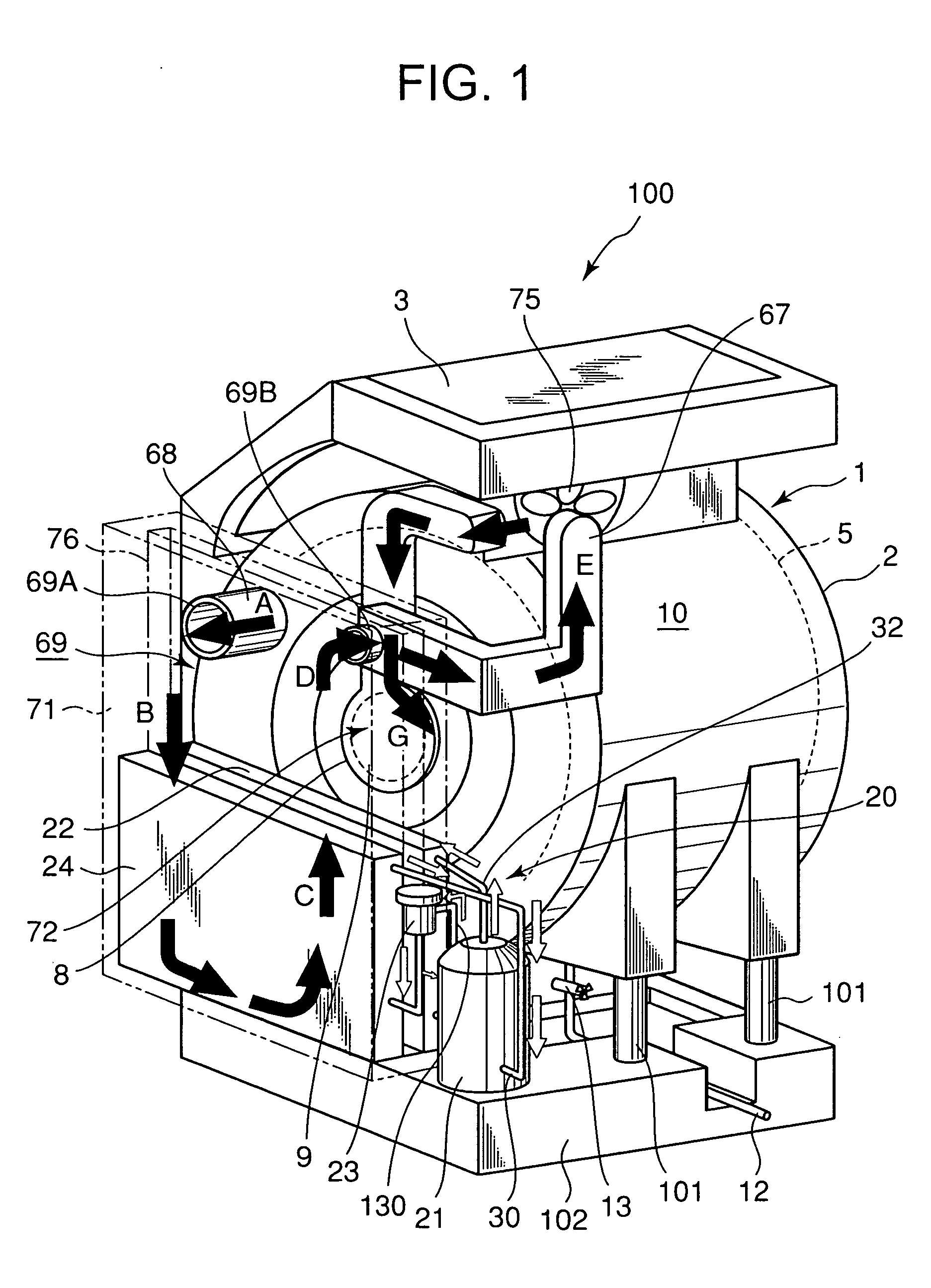

Drying machine

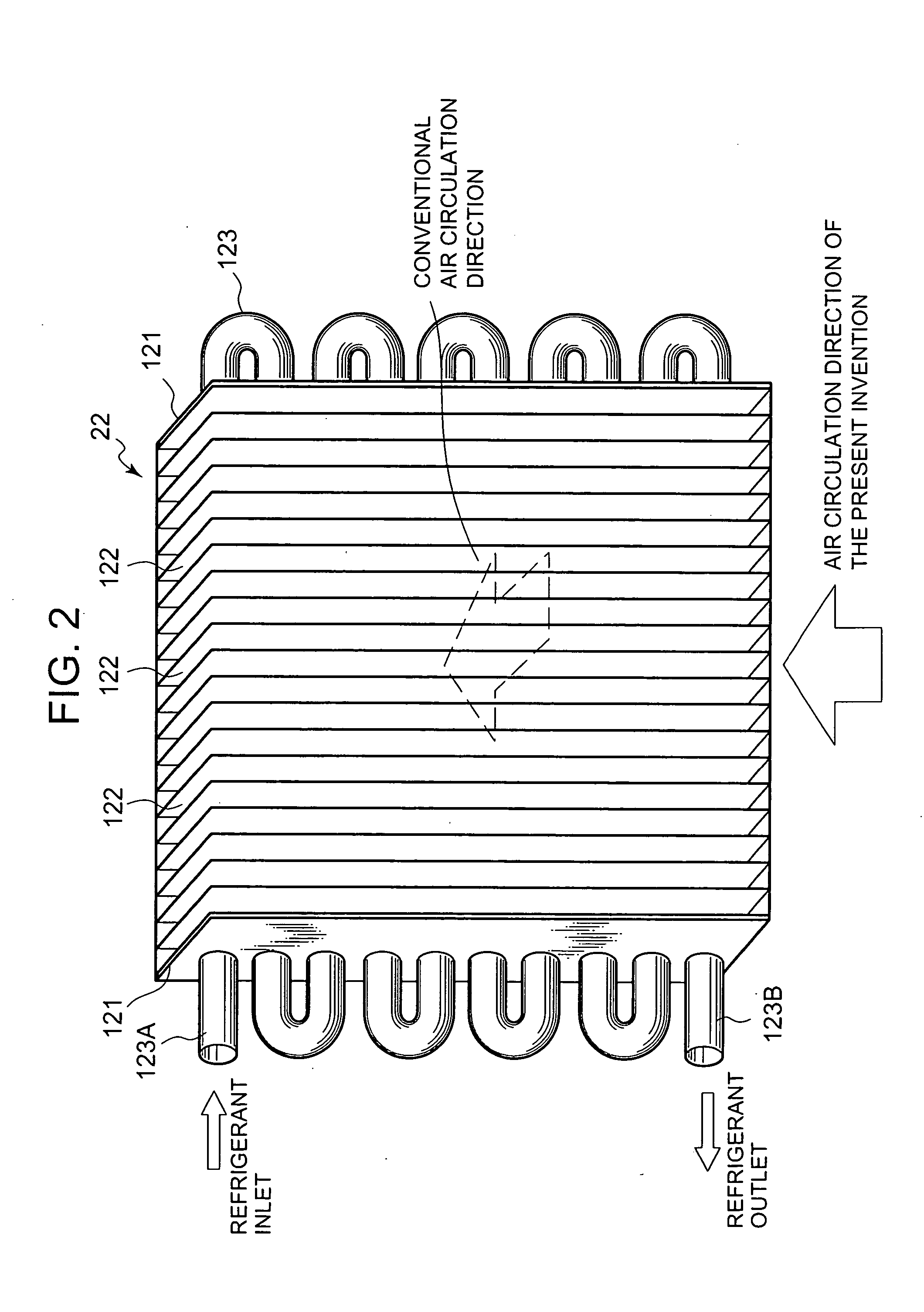

ActiveUS20050086827A1Efficient dryingGuaranteed heat exchange effectCompression machines with non-reversible cycleEvaporators/condensersCounter flowEngineering

A washing / drying machine has objects to shorten a time required for a washing operation, to improve a heat exchange capability in a radiator and an evaporator, and to shorten a drying time for things to be dried, and comprises: an accommodating chamber in which things to be washed (things to be dried) are accommodated and in which a drying operation of the things to be washed is performed; a refrigerant circuit in which a compressor, a gas cooler, a decompression device, an evaporator and the like are successively connected to one another in an annular form via a piping and in which carbon dioxide is used as a refrigerant and which has a supercritical pressure on a high pressure side thereof; and blower means for blowing air which has exchanged heat with the radiator into the accommodating chamber to allow the air passed through the accommodating chamber to exchange the heat with the evaporator, wherein the blower means constitutes a circulation direction of the air passed through the gas cooler, and that of the refrigerant flowing in the gas cooler in such a manner as to form a counter-flow, and constitutes a circulation direction of the air passed through the evaporator, and that of the refrigerant flowing in the evaporator in such a manner as to form a counter-flow.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com