Thermal storage system

a technology of thermal storage and storage systems, applied in the direction of heat collector mounting/support, lighting and heating apparatus, greenhouse gas reduction, etc., can solve the problems of high capital costs, limited success of thermal storage systems, uncompetitive energy production costs, etc., and achieve the effect of low temperature rang

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

[0062]FIG. 7B is a schematic of a solar energy conversion system that absorbs the solar energy delivered by concentrator 26 from exit aperture 118 shown in FIG. 6 and converts it into electricity. This embodiment is a combined cycle electricity generation system which uses both a Brayton gas turbine cycle, and a Clausius-Rankine water / steam cycle. This embodiment is more efficient at energy conversion but adds additional cost for the steam cycle elements. The additional elements are boiler heat exchanger 94 that is heated with the exhaust gas from heat engine 84, steam turbine 96, second electricity generator 98, condensor heat exchanger 100, and water pump 102. Ambient heat exchanger 88 is probably not needed or can be much simpler for this combined cycle system.

[0063]A particular advantage of the use of a combined cycle system with a high temperature concentrating solar system is the improved thermal capacity of sensible heat storage system 82. The thermal storage capacity of ther...

first embodiment

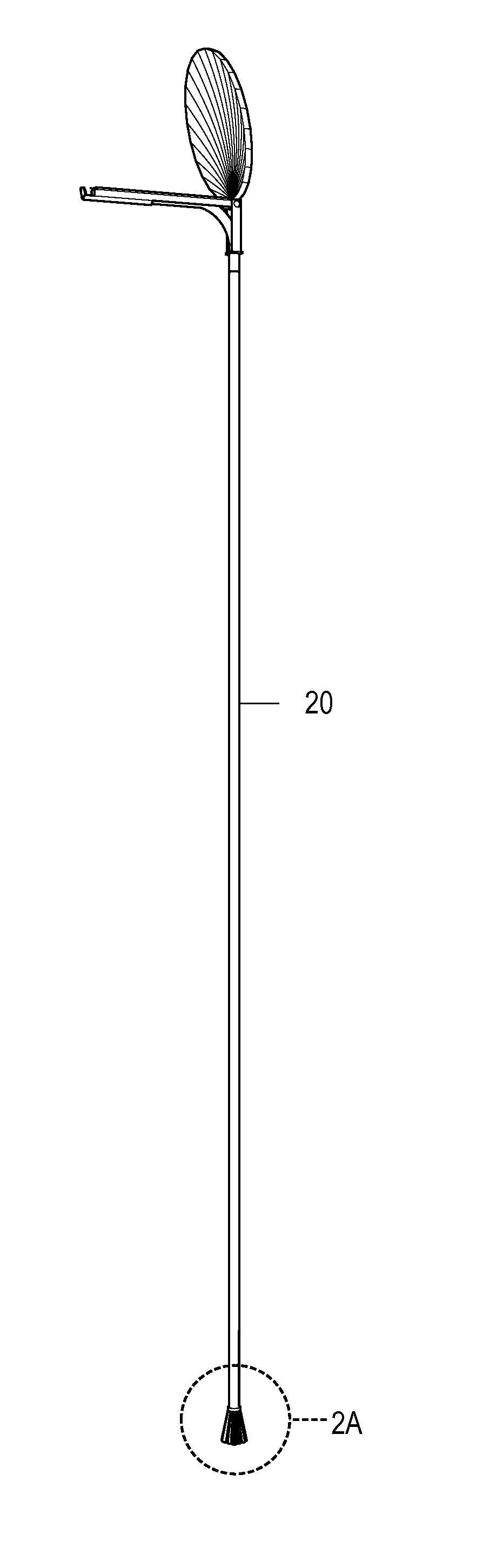

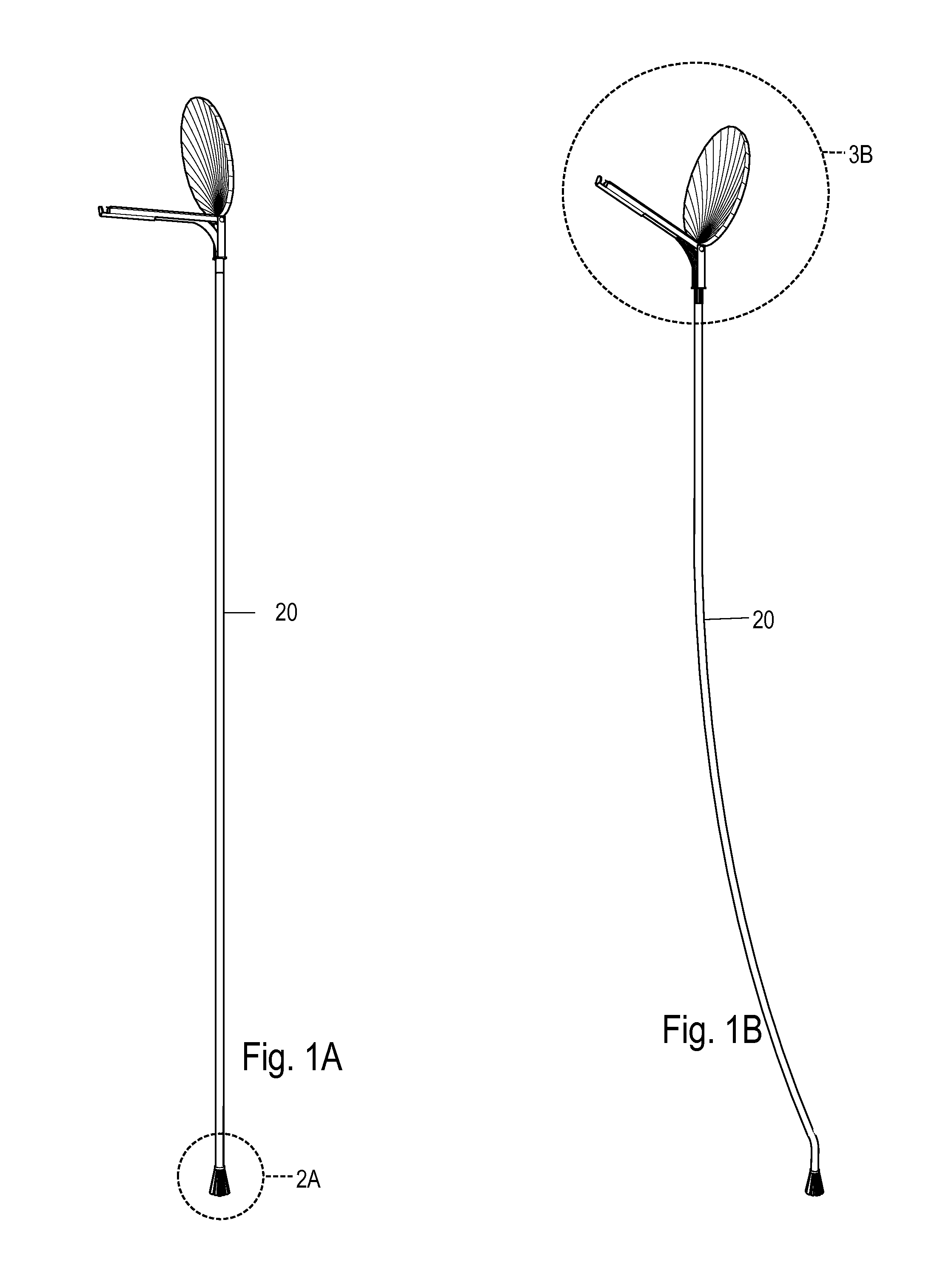

[0067]FIGS. 1A and 1B are perspective views of two positions of a solar concentrator energy system of a It consists of the following:

1) A large, buoyant, segmented, reflecting, parabolic, mirror concentrator, and collimator assembly detailed in FIG. 3B.

2) A flexible hollow buoyant light pipe 20.

3) A ground based foundation, anchor, optical concentrator and receiver assembly detailed in FIG. 2A.

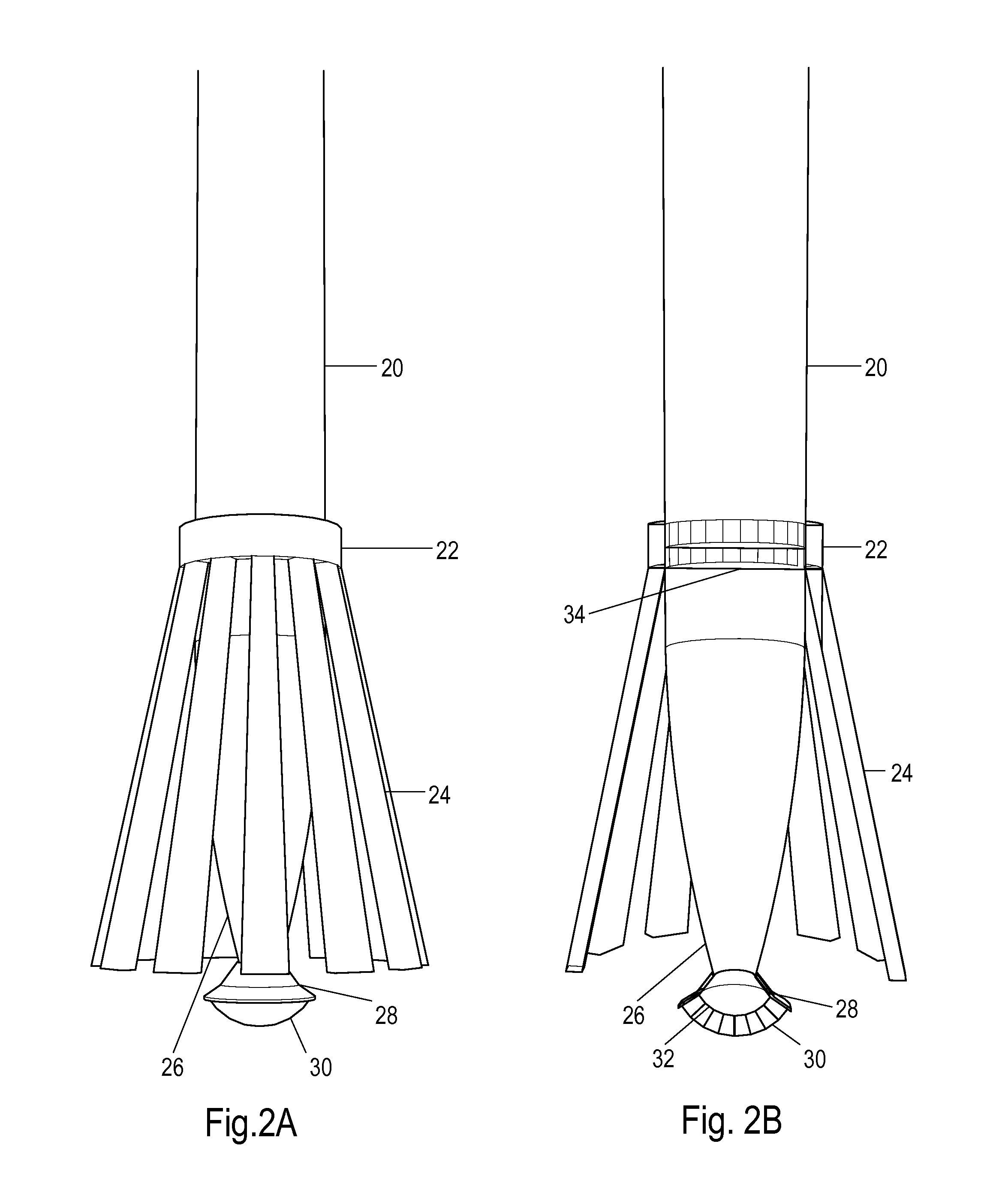

[0068]FIG. 2A and FIG. 2B show the ground structures of a first embodiment in more detail. Light pipe 20 is attached to anchor ring 22 which is supported by foundation legs 24. Light pipe 20 is a hollow buoyant tube which exerts a considerable vertical upward force on this anchor structure. Transparent membrane 34 is fabricated from polyethylene terephthalate (PET) or other similar transparent film and contains the pressurized gas within the light pipe 20. As is typical for inflated structures the gauge pressure is quite low, only a small fraction of an atmosphere. The section of the light pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com