Patents

Literature

1847 results about "Sensible heat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sensible heat is heat exchanged by a body or thermodynamic system in which the exchange of heat changes the temperature of the body or system, and some macroscopic variables of the body or system, but leaves unchanged certain other macroscopic variables of the body or system, such as volume or pressure.

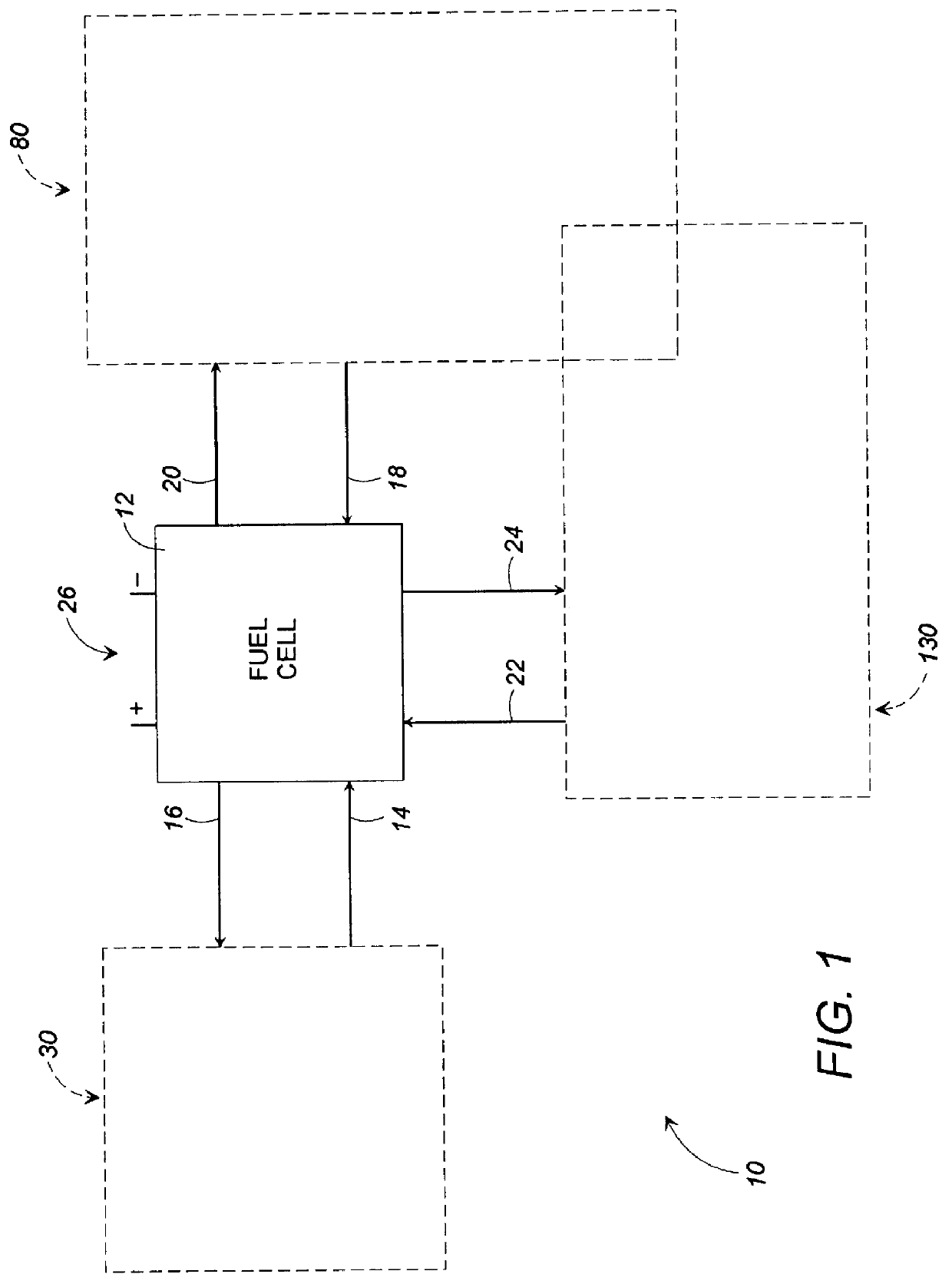

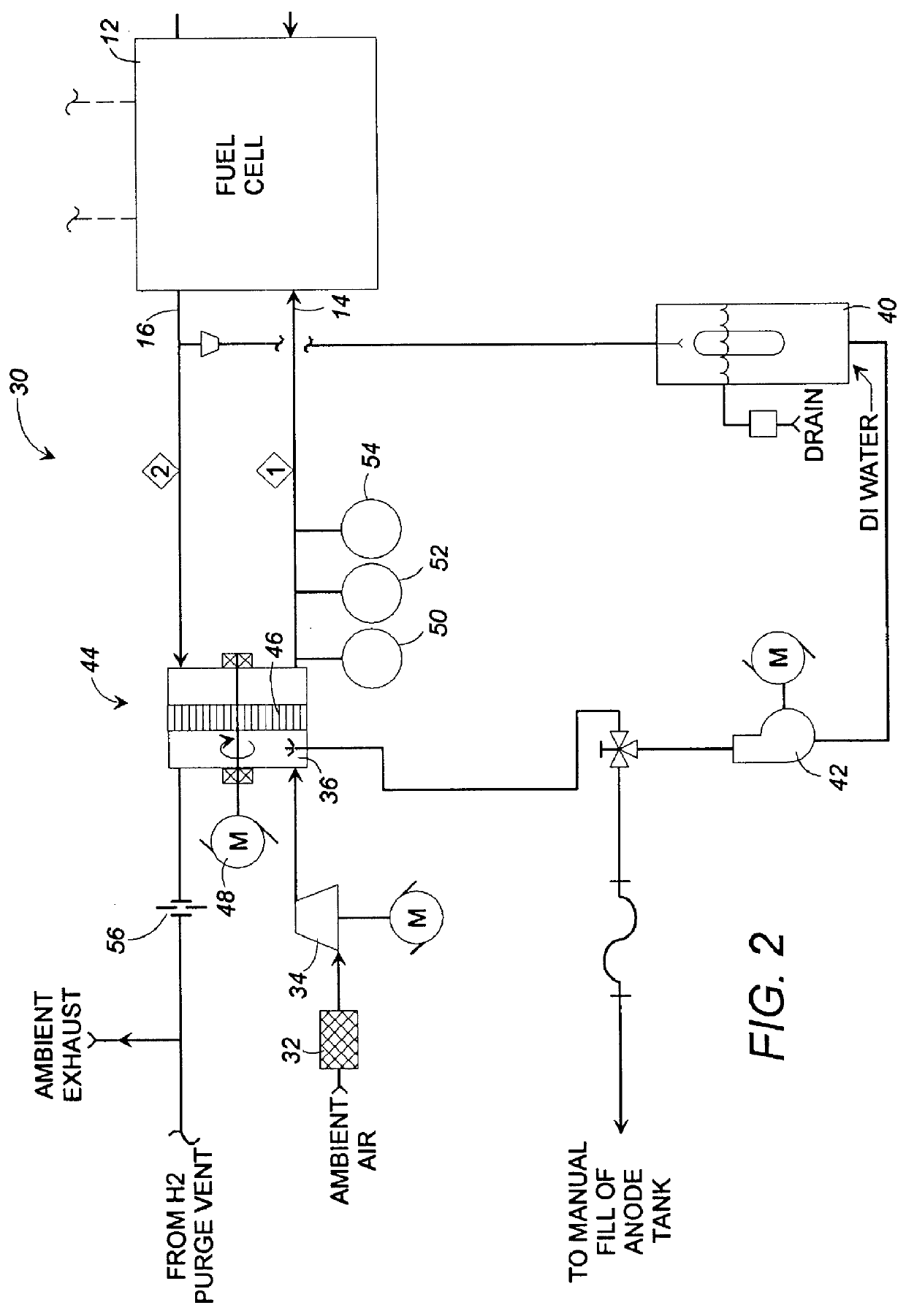

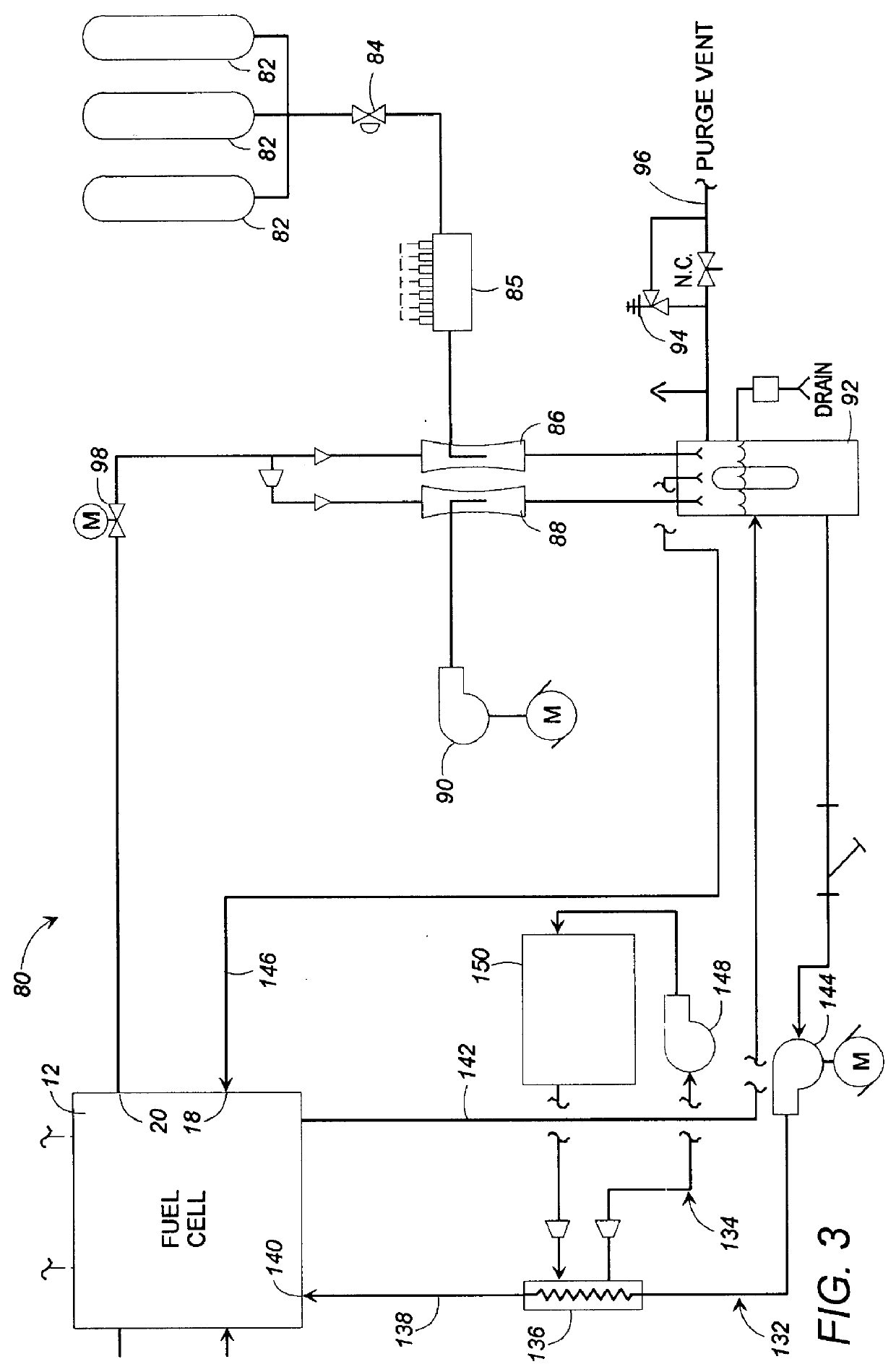

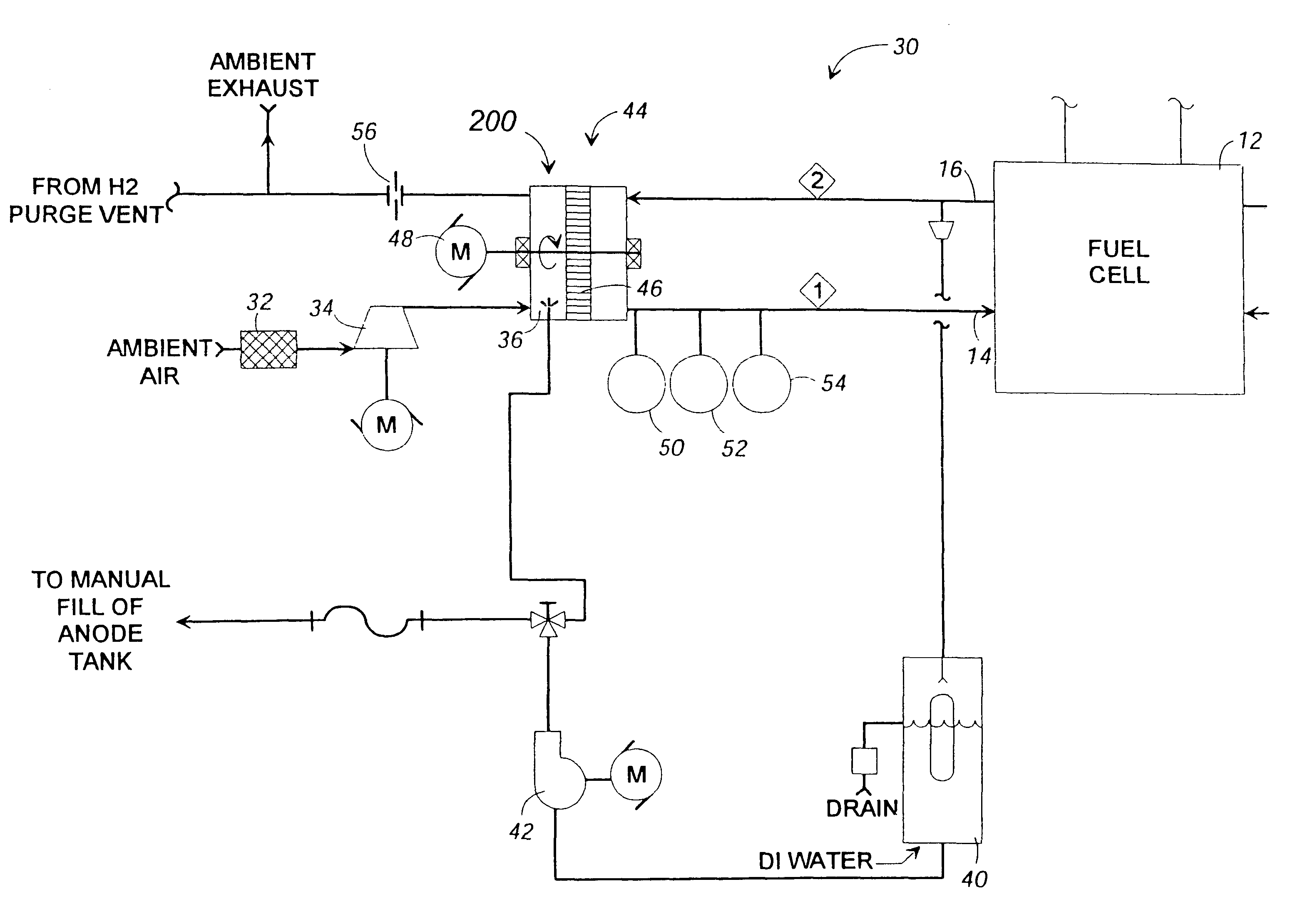

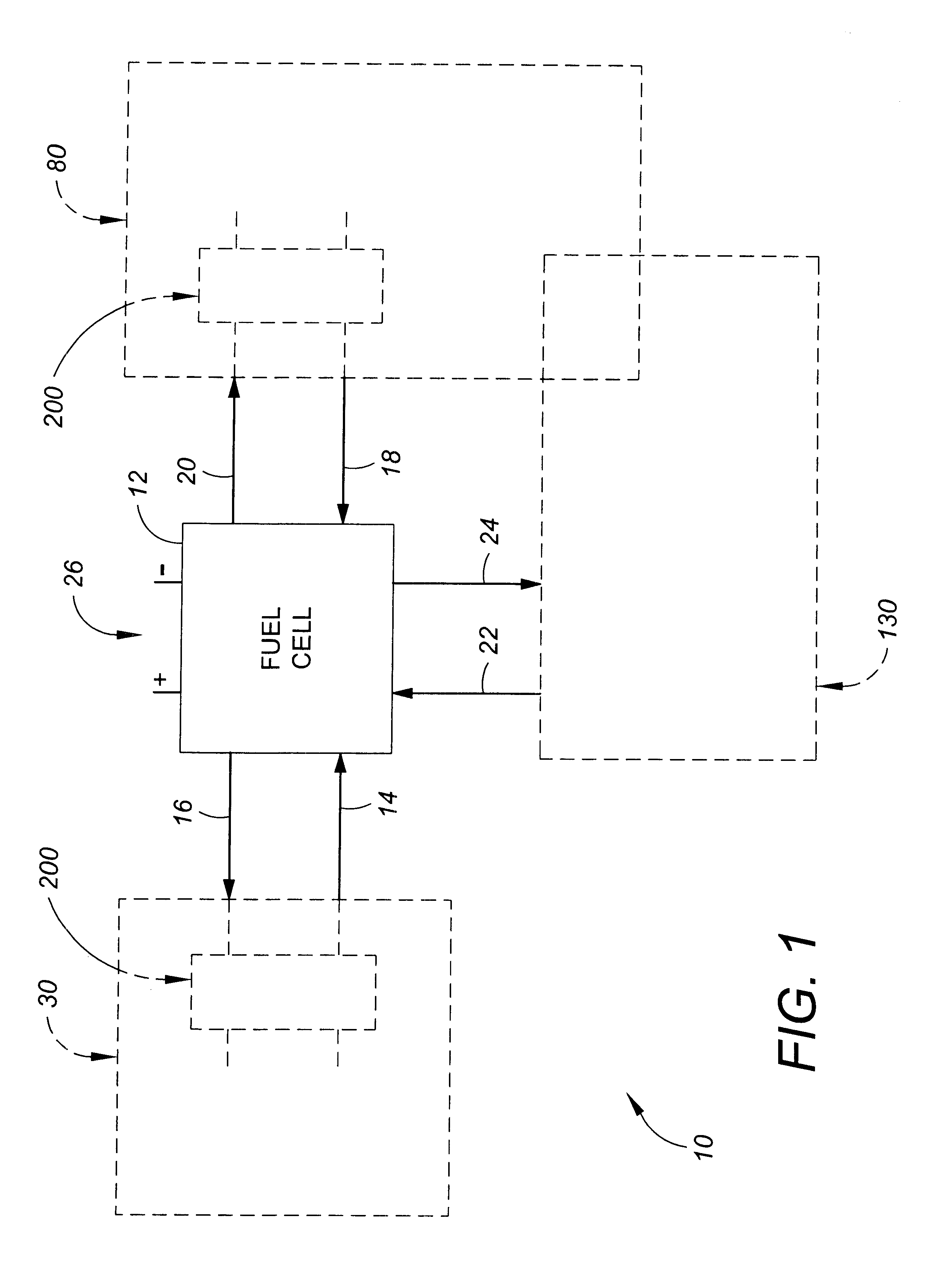

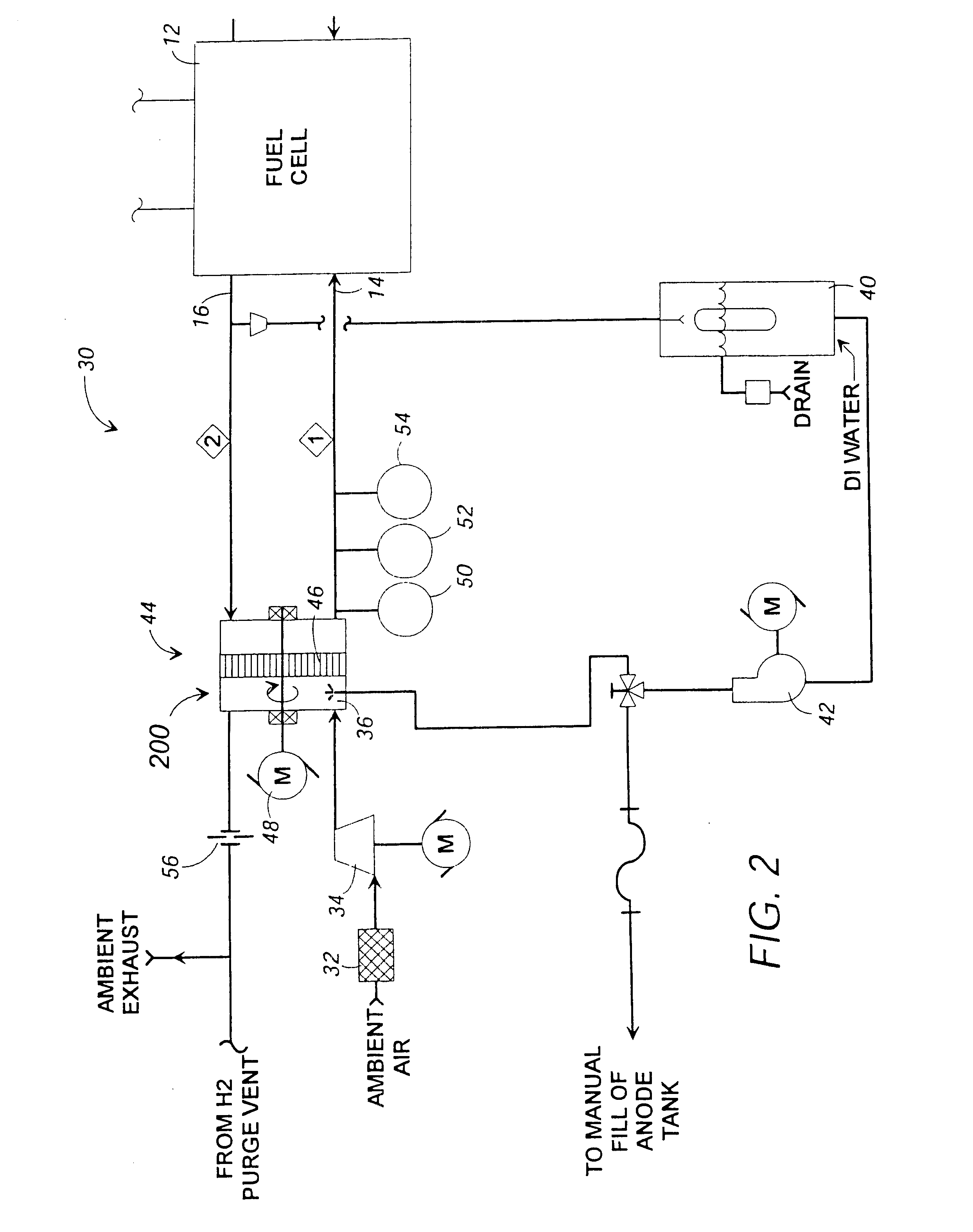

Fuel cell gas management system

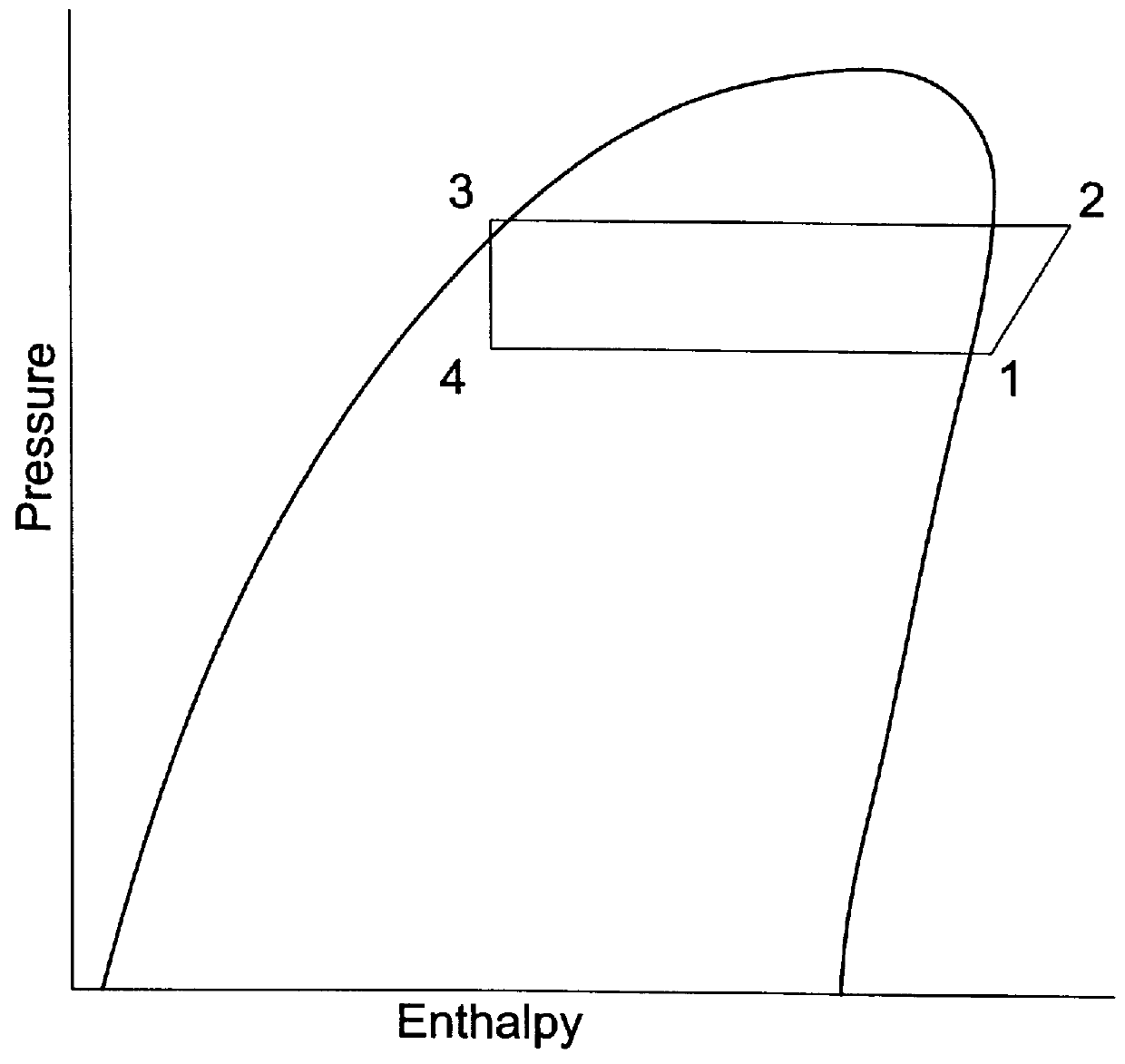

InactiveUS6013385AImprove battery efficiencyMinimize the possibilityFuel cell heat exchangeFuel cell controlIonEnthalpy

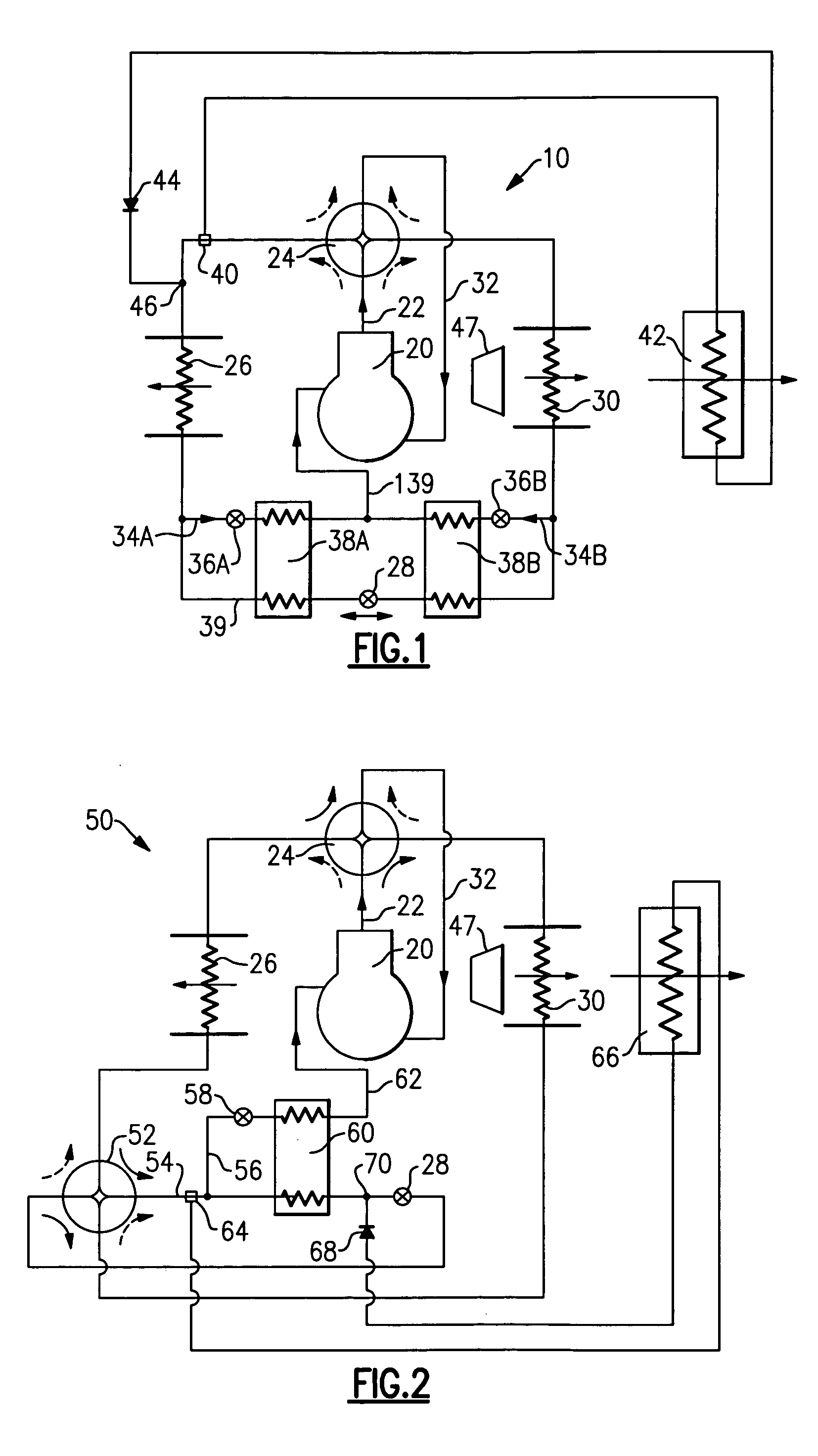

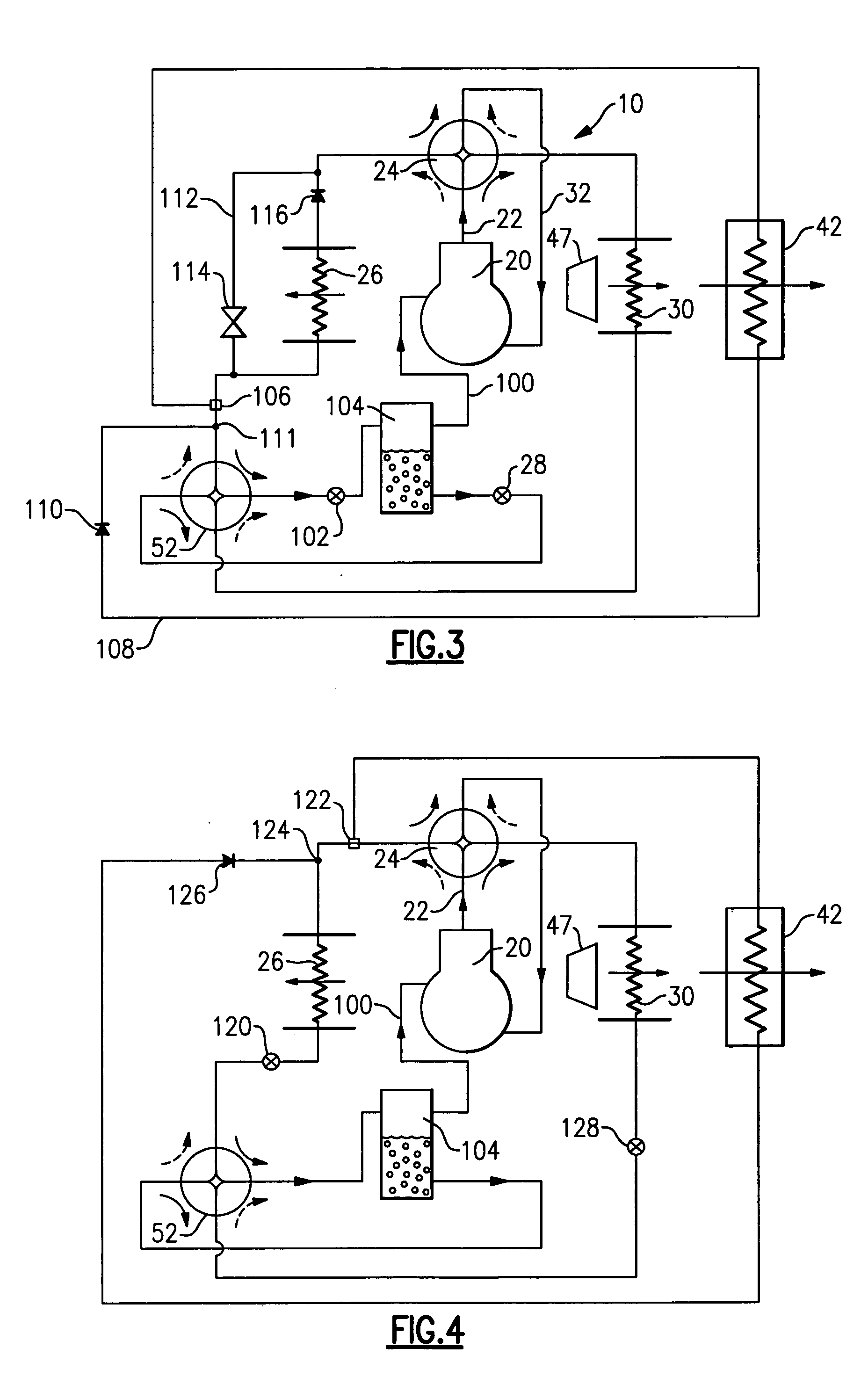

A fuel cell gas management system including a cathode humidification system for transferring latent and sensible heat from an exhaust stream to the cathode inlet stream of the fuel cell; an anode humidity retention system for maintaining the total enthalpy of the anode stream exiting the fuel cell equal to the total enthalpy of the anode inlet stream; and a cooling water management system having segregated deionized water and cooling water loops interconnected by means of a brazed plate heat exchanger.

Owner:EMPRISE TECH ASSOC

Fuel-cell engine stream conditioning system

A stream conditioning system for a fuel cell gas management system or fuel cell engine. The stream conditioning system manages species potential in at least one fuel cell reactant stream. A species transfer device is located in the path of at least one reactant stream of a fuel cell's inlet or outlet, which transfer device conditions that stream to improve the efficiency of the fuel cell. The species transfer device incorporates an exchange media and a sorbent. The fuel cell gas management system can include a cathode loop with the stream conditioning system transferring latent and sensible heat from an exhaust stream to the cathode inlet stream of the fuel cell; an anode humidity retention system for maintaining the total enthalpy of the anode stream exiting the fuel cell related to the total enthalpy of the anode inlet stream; and a cooling water management system having segregated deionized water and cooling water loops interconnected by means of a brazed plate heat exchanger.

Owner:EMPRISE TECH ASSOC

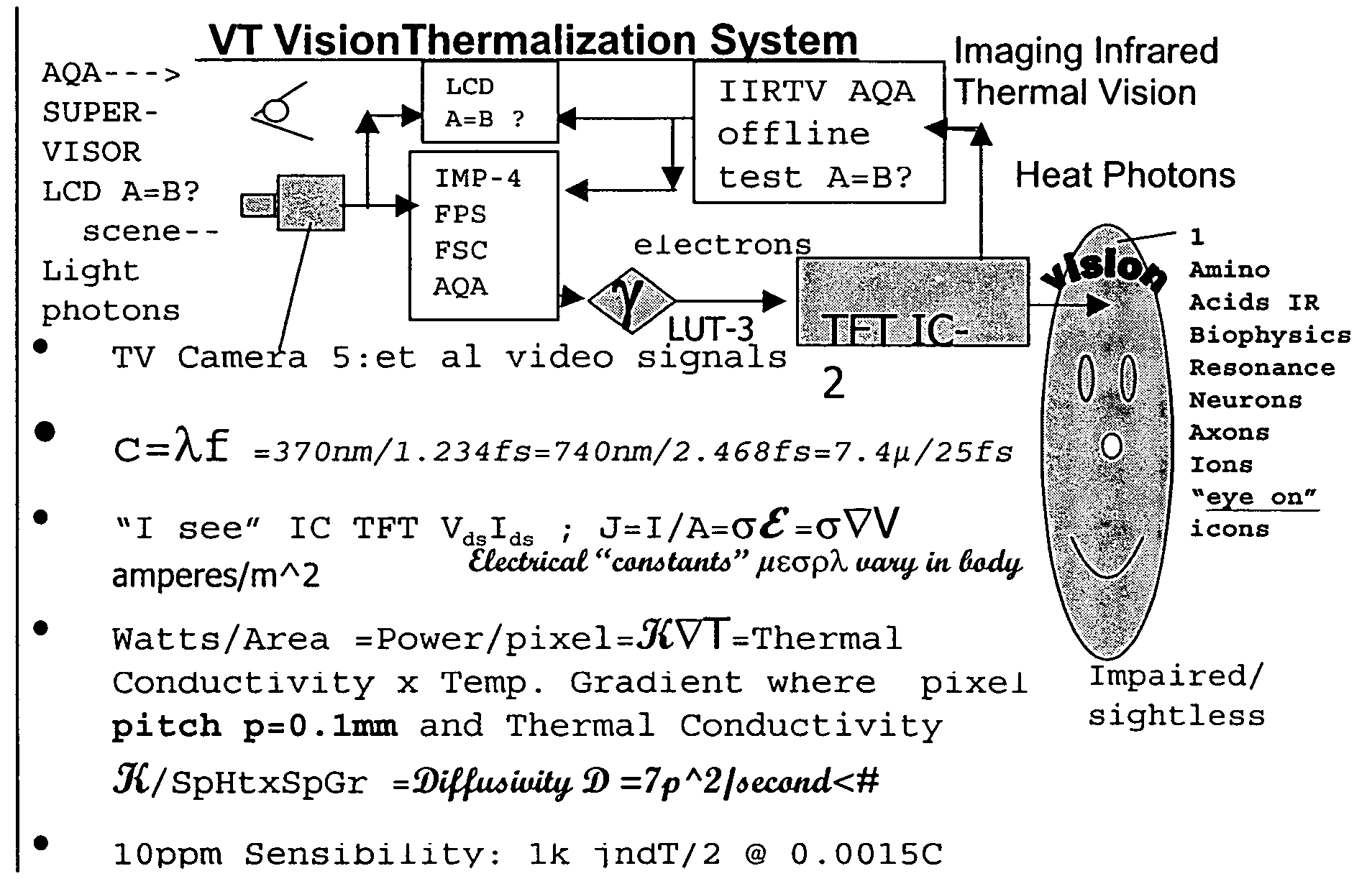

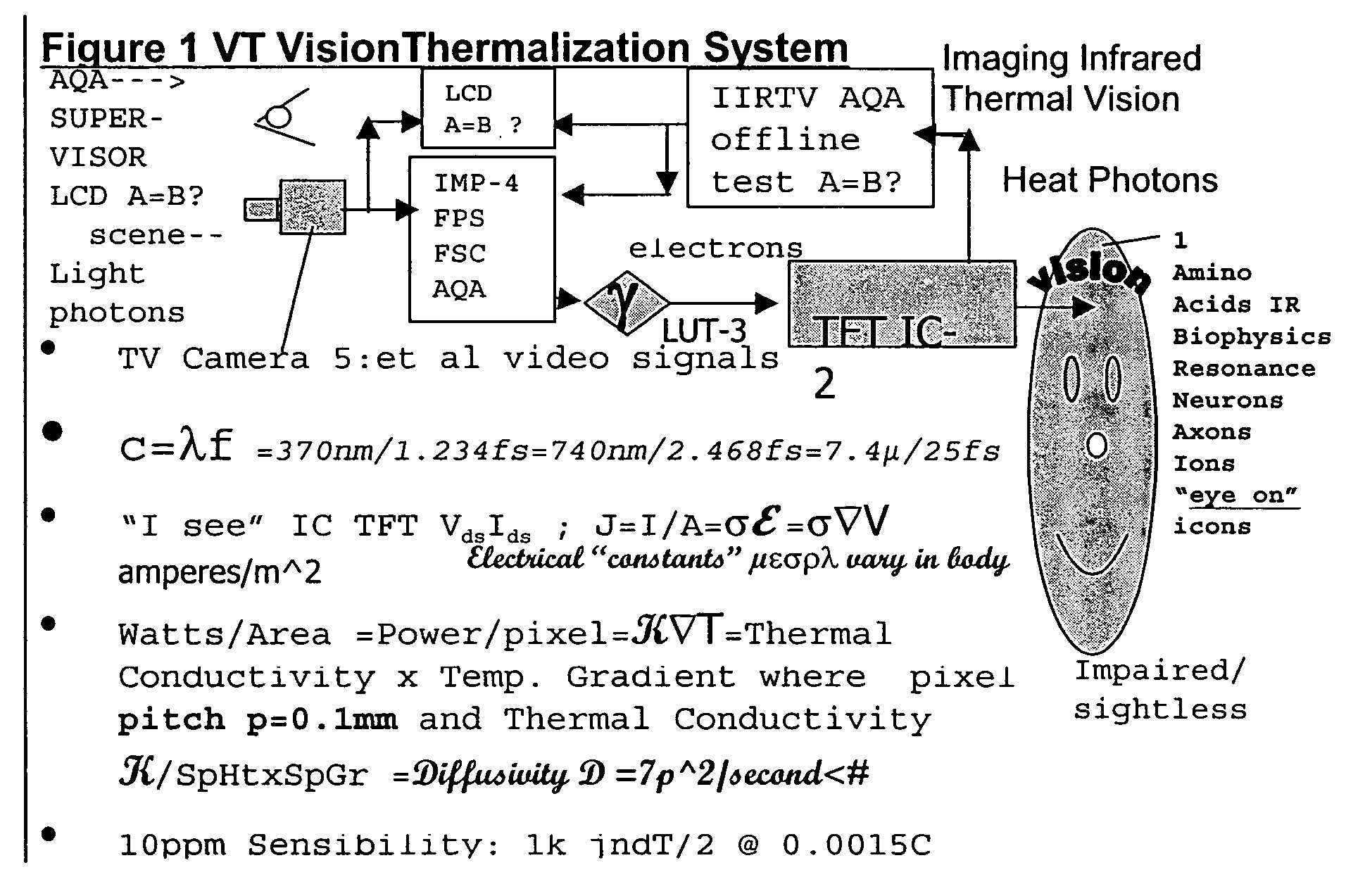

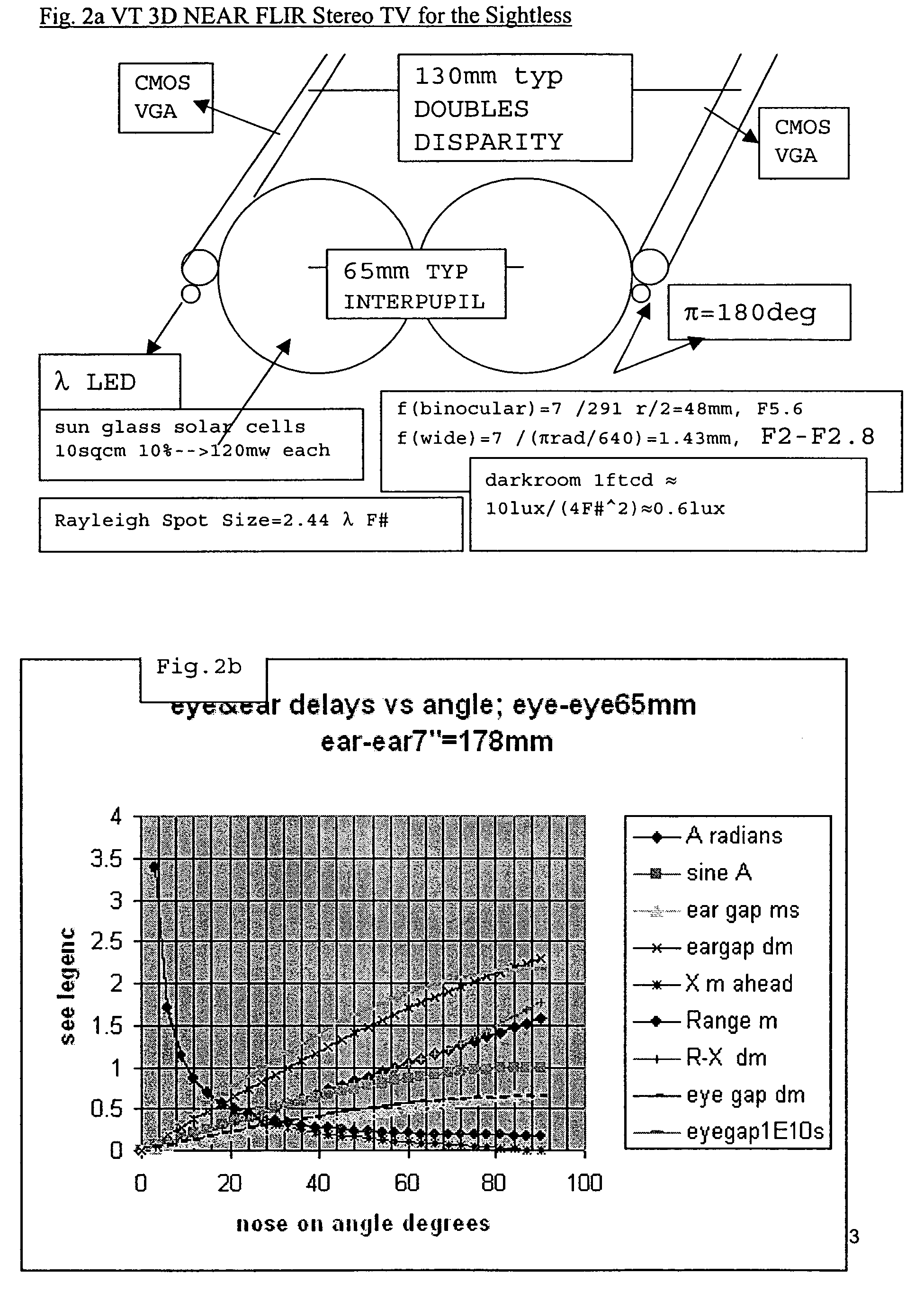

Vision thermalization for sightless and visually impaired

InactiveUS7843488B2Cost effectiveImprove efficiencyColor television detailsClosed circuit television systemsVisually impairedActive matrix

Owner:STAPLEVISION LLC

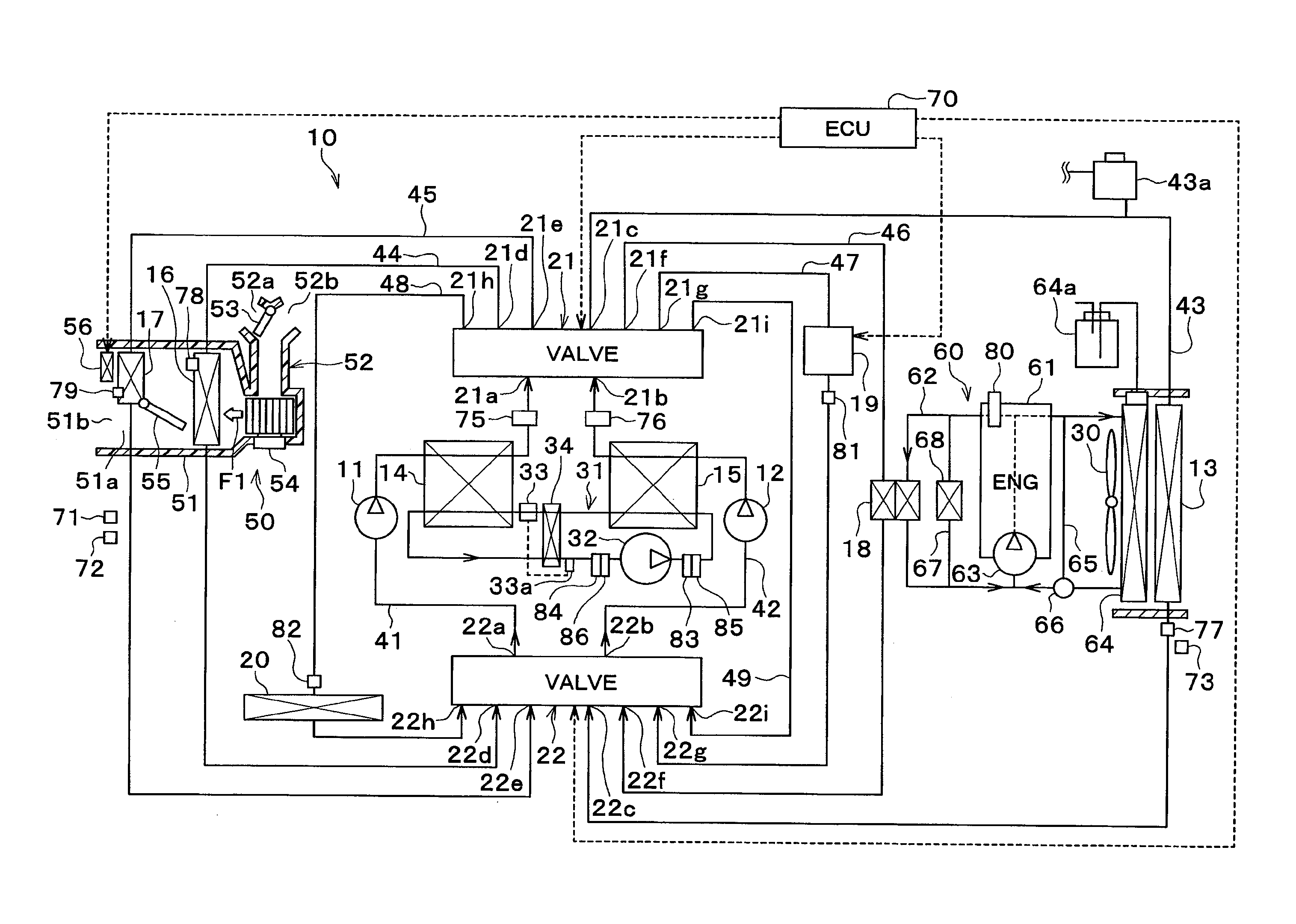

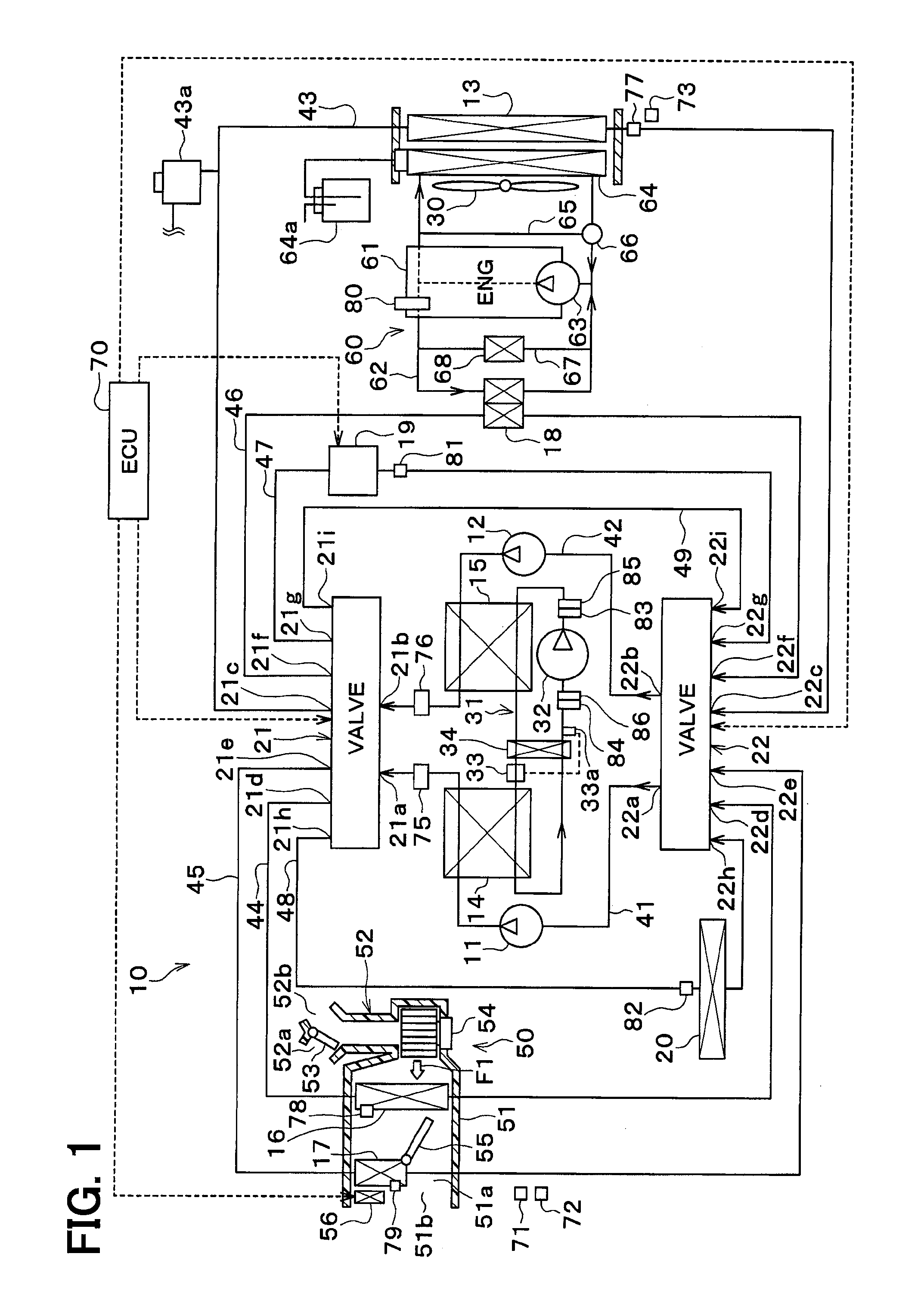

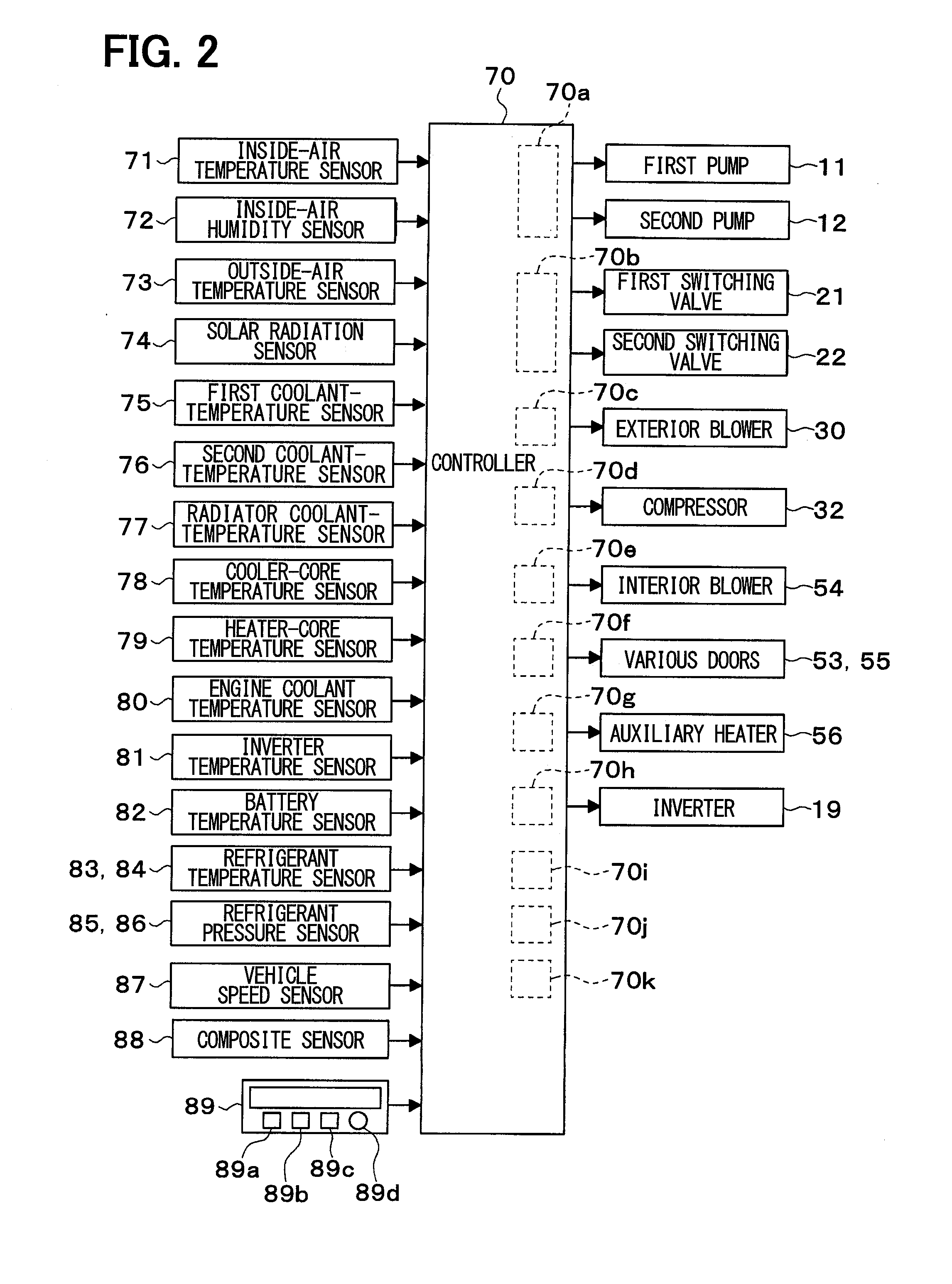

Air conditioner for vehicle

ActiveUS20160339767A1Reduced Power RequirementsSuppress fog on a window glassAir-treating devicesEvaporators/condensersEngineeringRefrigeration

An air conditioner for a vehicle includes a pump that draws and discharges a heat medium, a cooler core that exchanges sensible heat between the heat medium and ventilation air into a vehicle interior to cool and dehumidify the ventilation air, a heat-medium and outside-air heat exchanger that exchanges sensible heat between the heat medium and outside air, a compressor adapted to draw and discharge a refrigerant in a refrigeration cycle, a heat-medium cooling heat exchanger that cools the heat medium by exchanging heat between a low-pressure side refrigerant in the refrigeration cycle and the heat medium, and first and second switching valves that switch between a first dehumidification mode for circulation of the heat medium between the cooler core and the heat-medium cooling heat exchanger and a second dehumidification mode for circulation of the heat medium between the cooler core and the heat-medium and outside-air heat exchanger.

Owner:DENSO CORP

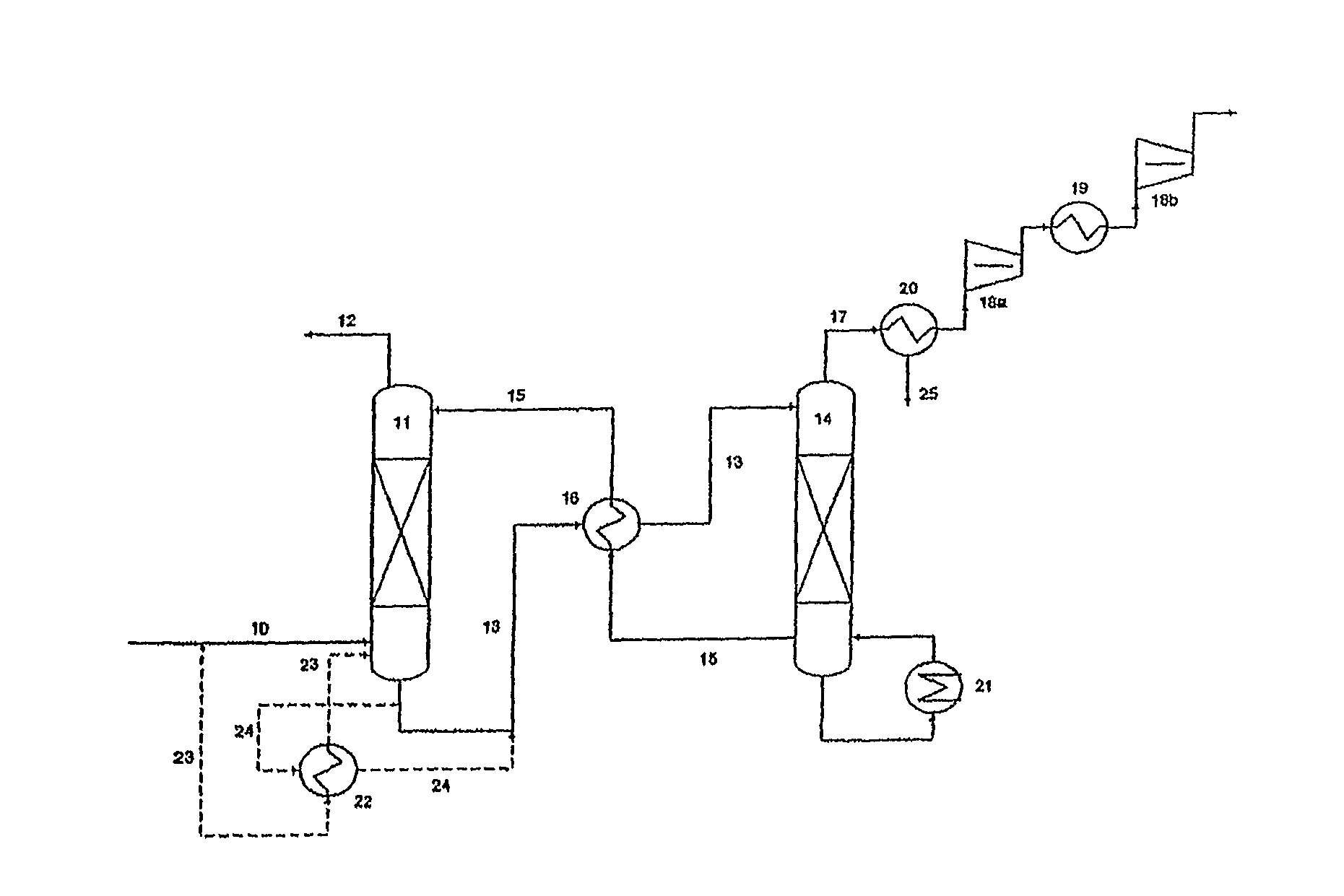

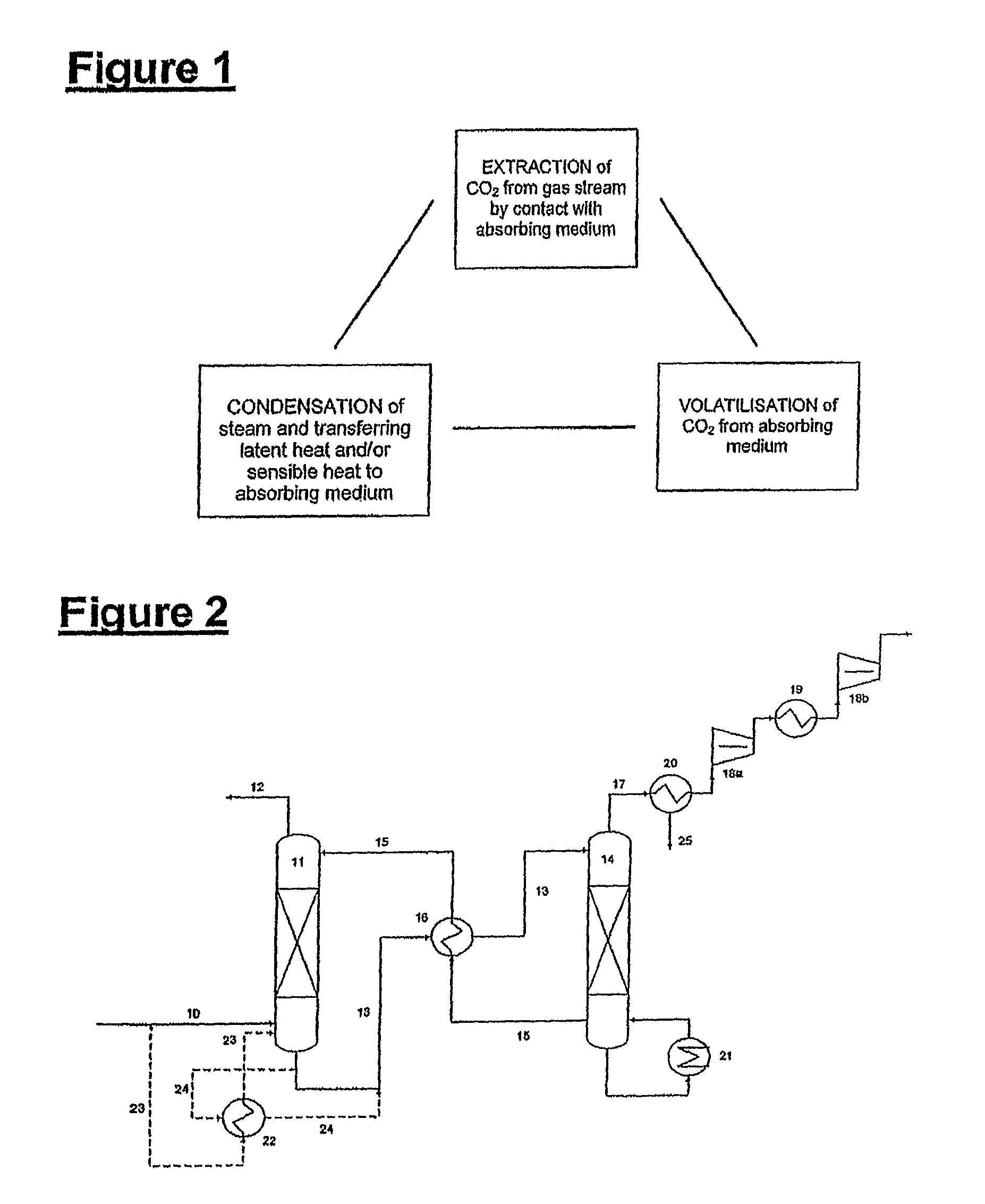

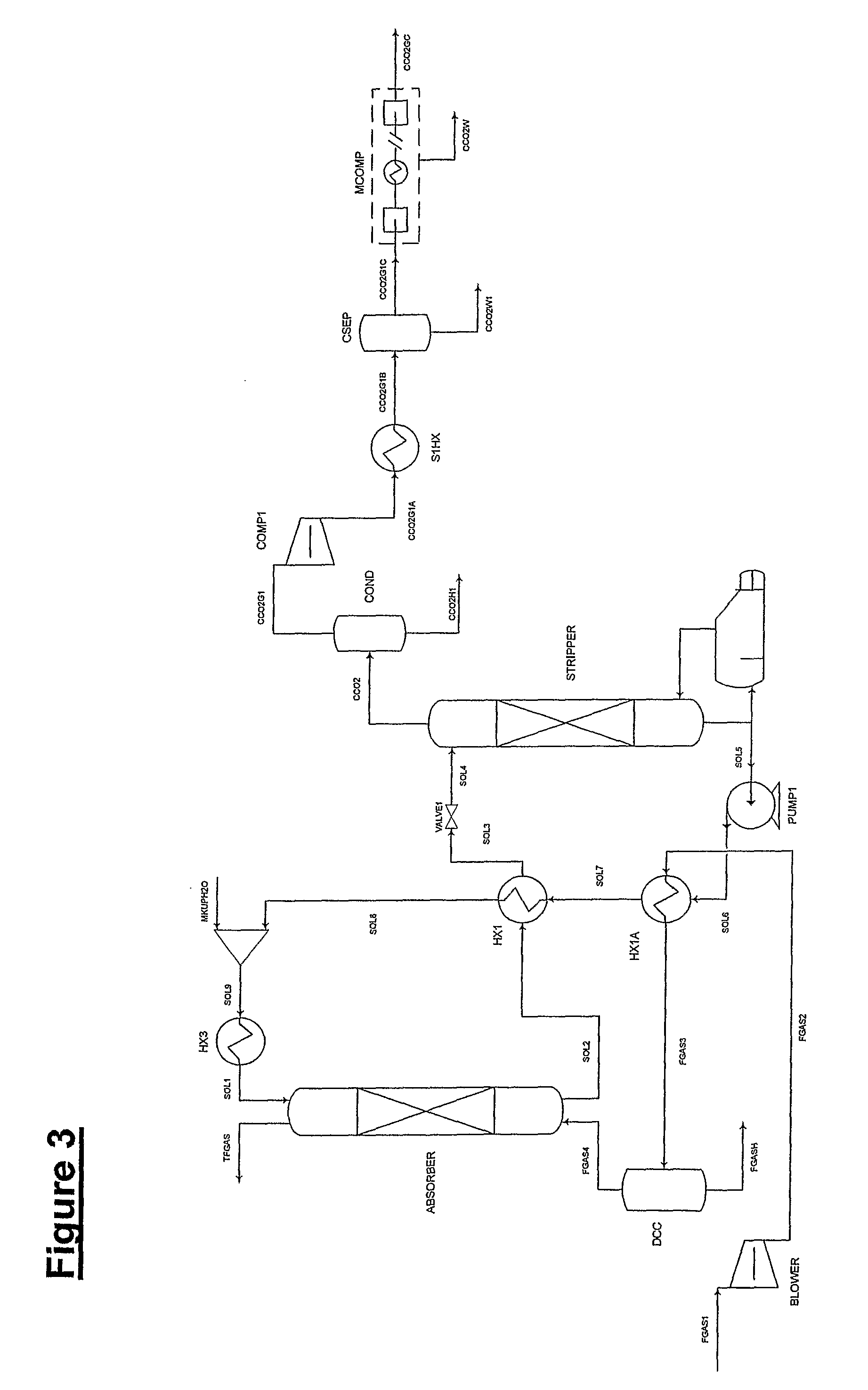

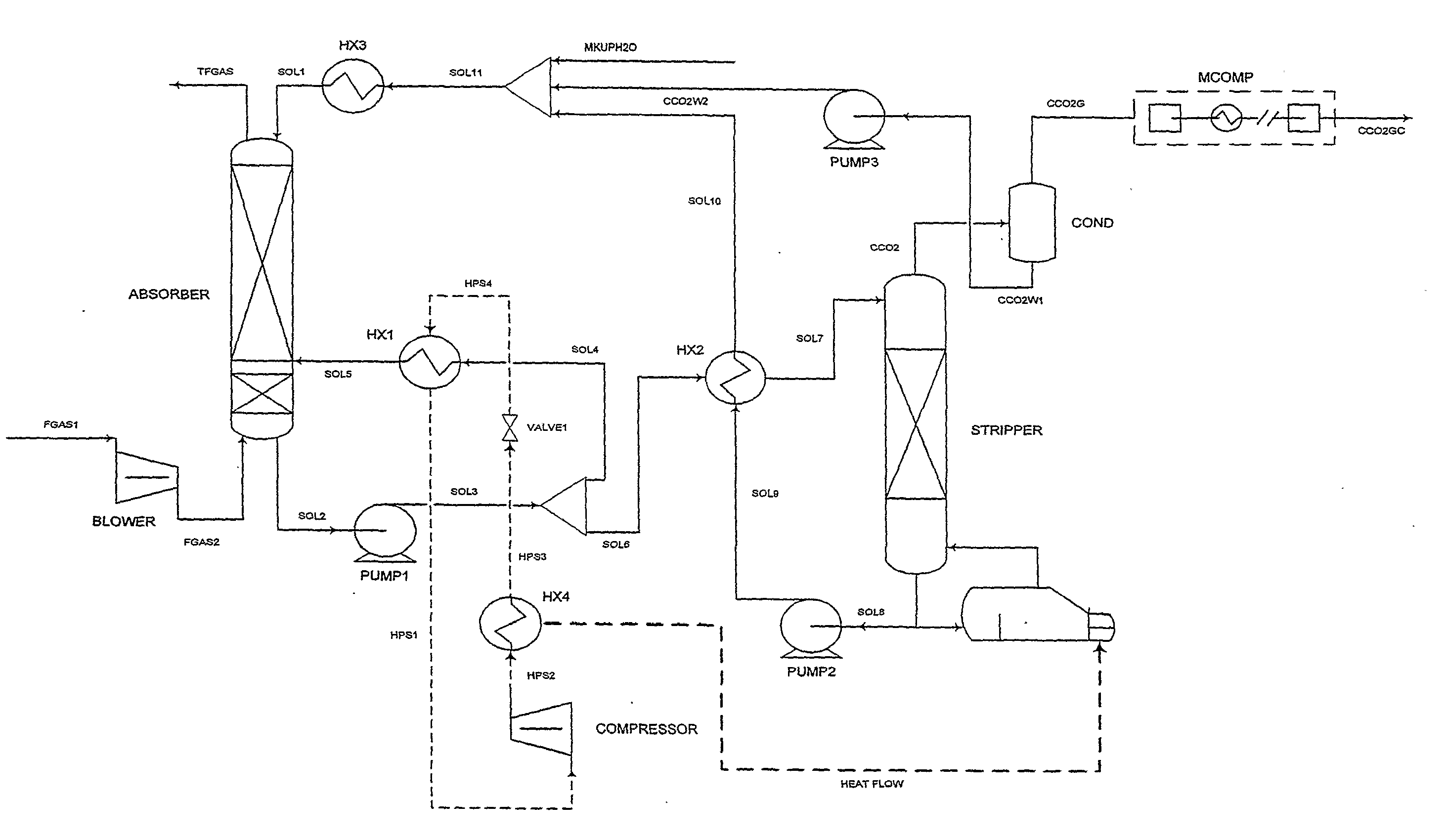

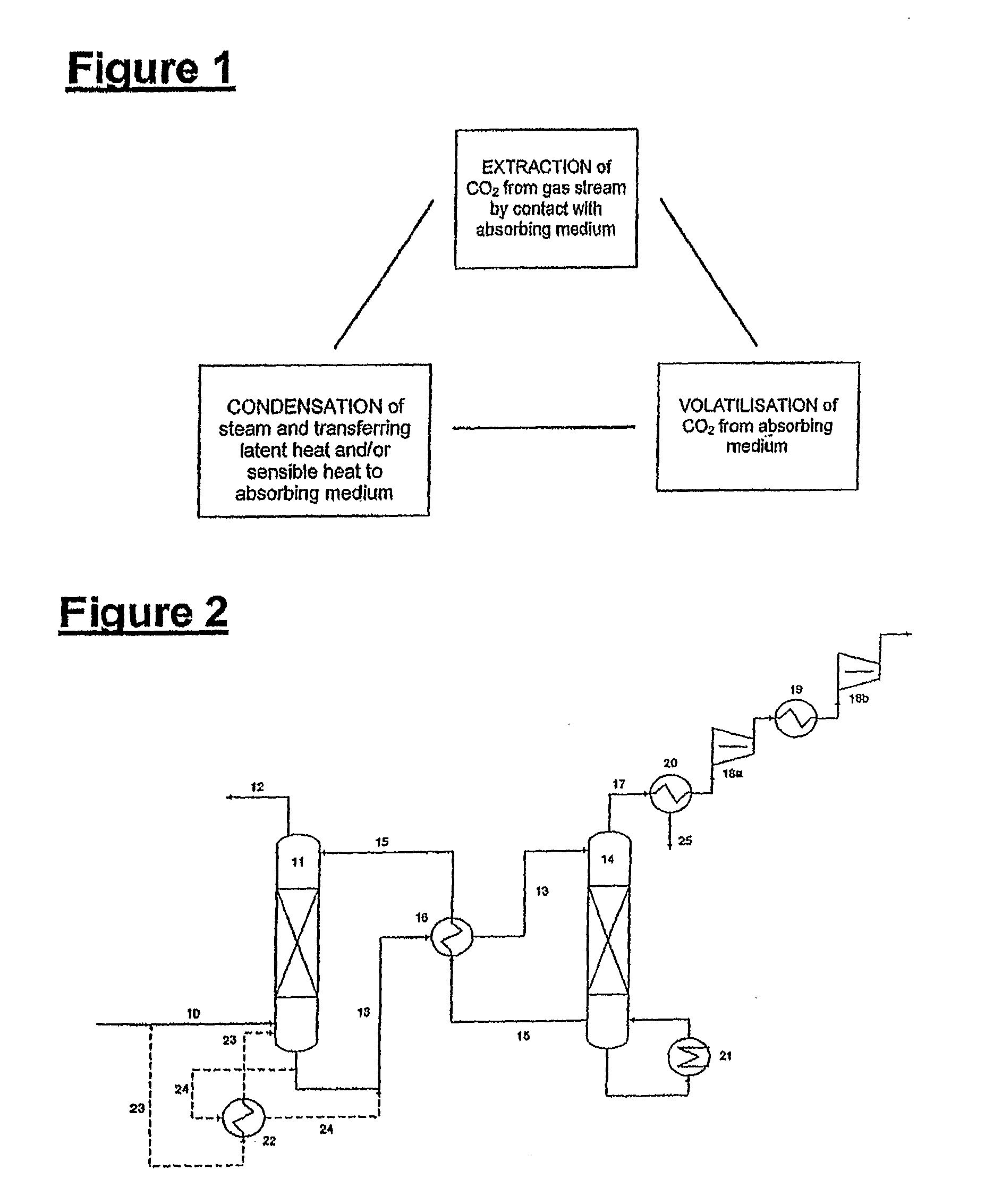

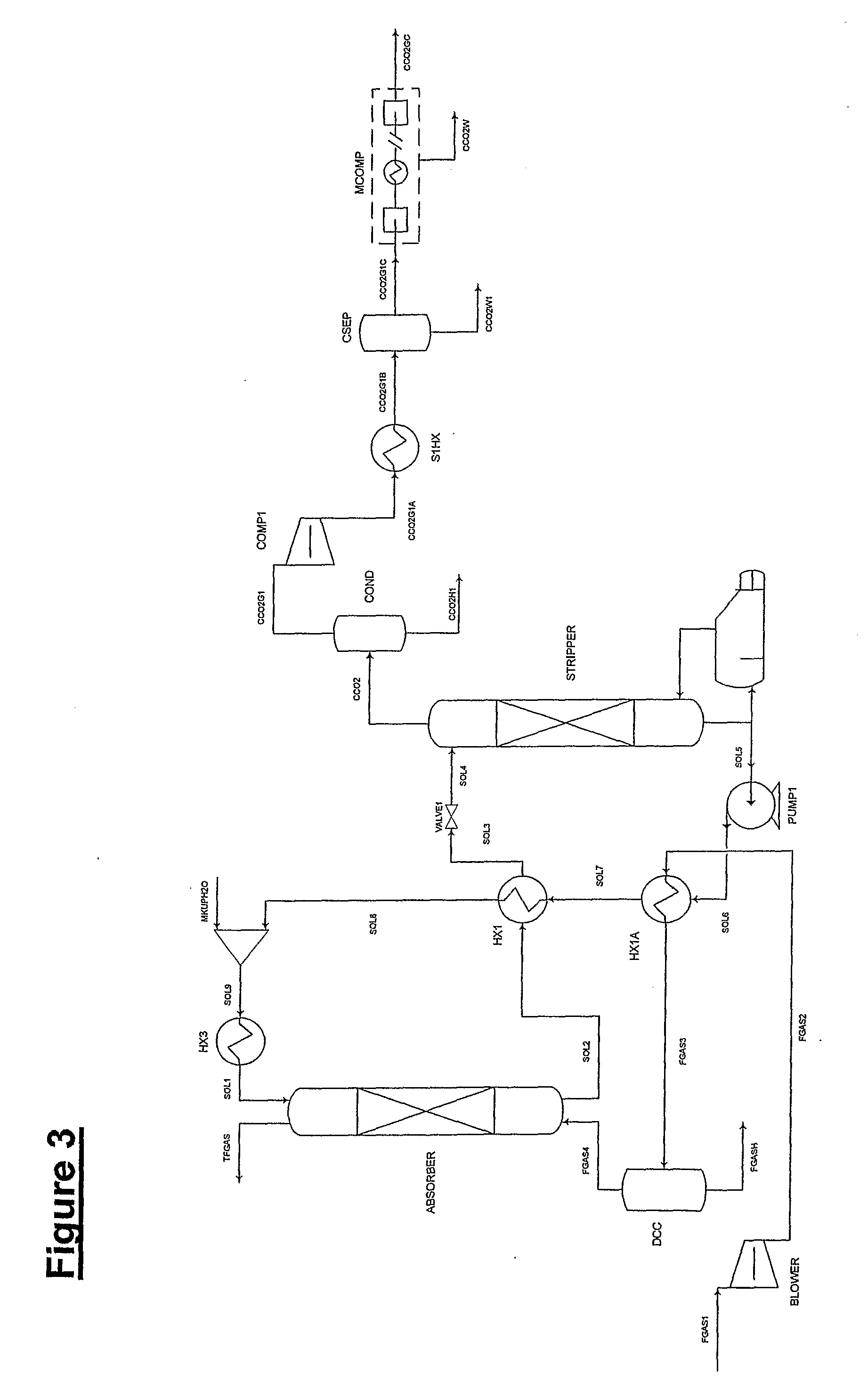

Plant and process for removing carbon dioxide from gas streams

ActiveUS7976803B2Minimizing overall energy requiredAssist in volatilizationFluidized bed combustionIndirect heat exchangersComponents of crude oilCoal

Owner:KC8 CAPTURE TECH LTD

Plant And Process For Removing Carbon Dioxide From Gas Streams

ActiveUS20080317651A1Minimizing overall energy requiredAssist in volatilizationExhaust apparatusDispersed particle separationBy-productChemistry

The present invention is based on the realization that the carbon dioxide component of industrial gas streams also containing steam can be processed so to utilize either as latent and / or sensible heat the heat available from the steam component to assist in separating carbon dioxide from the remainder of the gas stream. For example, flue gases produced by power stations burning brown coal, black coal or natural gas inherently contain a useful amount of energy that can be harnessed according to the present invention. According to particular preferred forms of the invention, nitrogen and sulphur constituent such as SOx and NOx, H2S and other nitrogen containing compounds may also be removed from the gas stream through direct contact with the absorbing medium and used to produce by-products such as fertiliser material.

Owner:KC8 CAPTURE TECH LTD

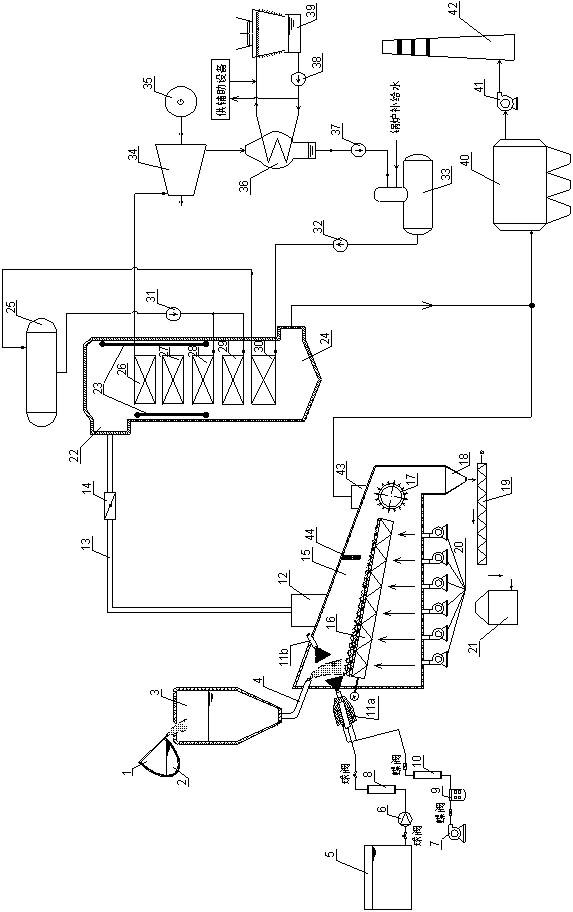

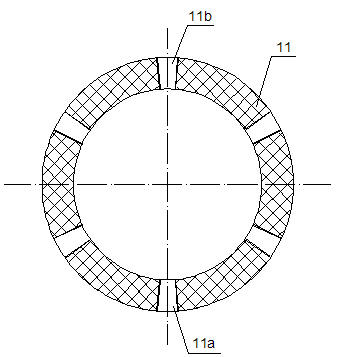

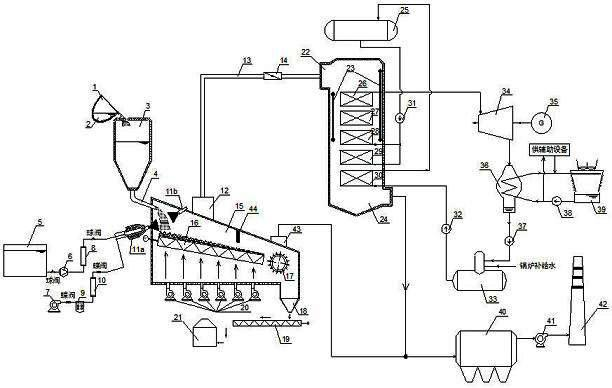

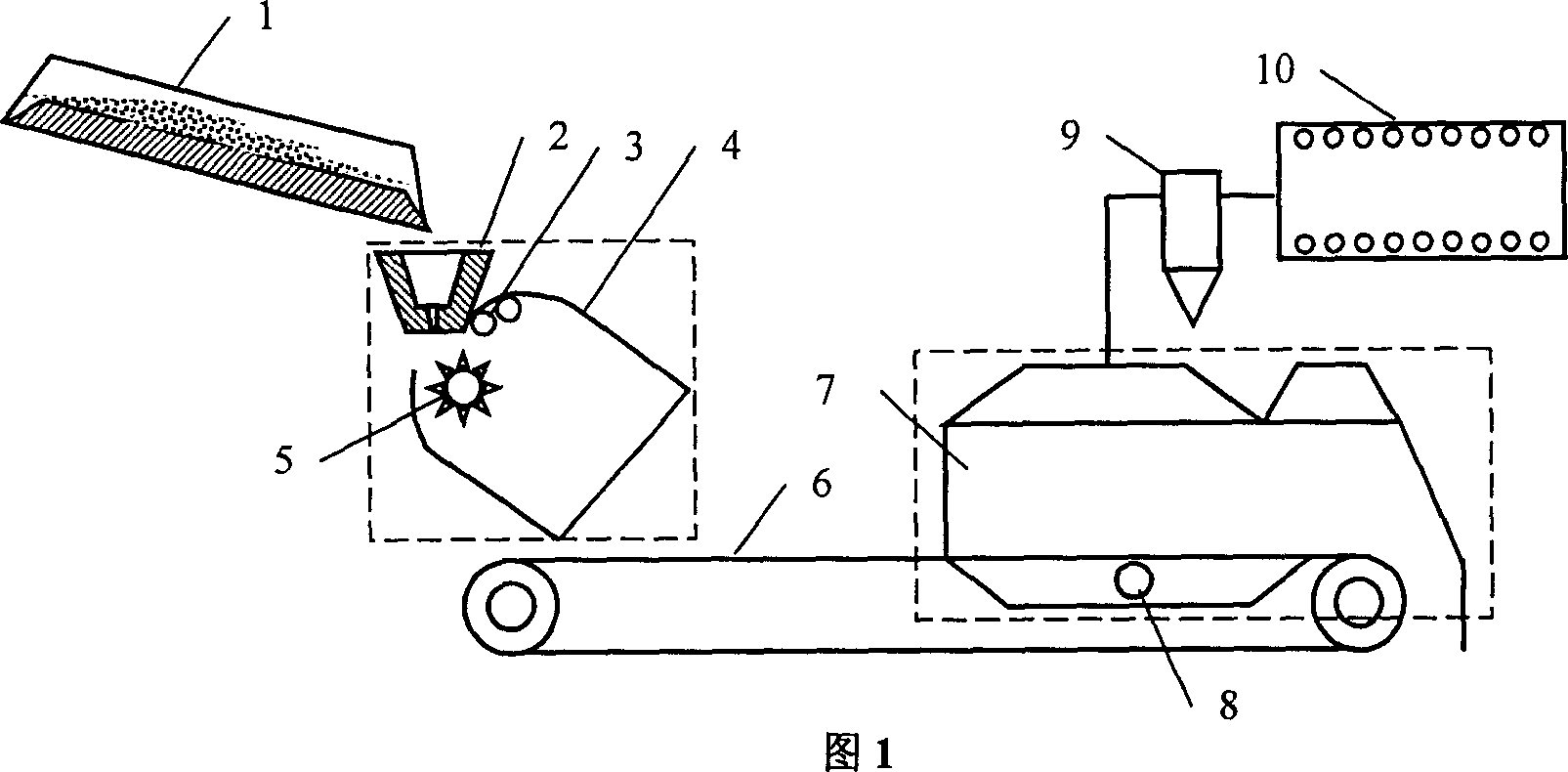

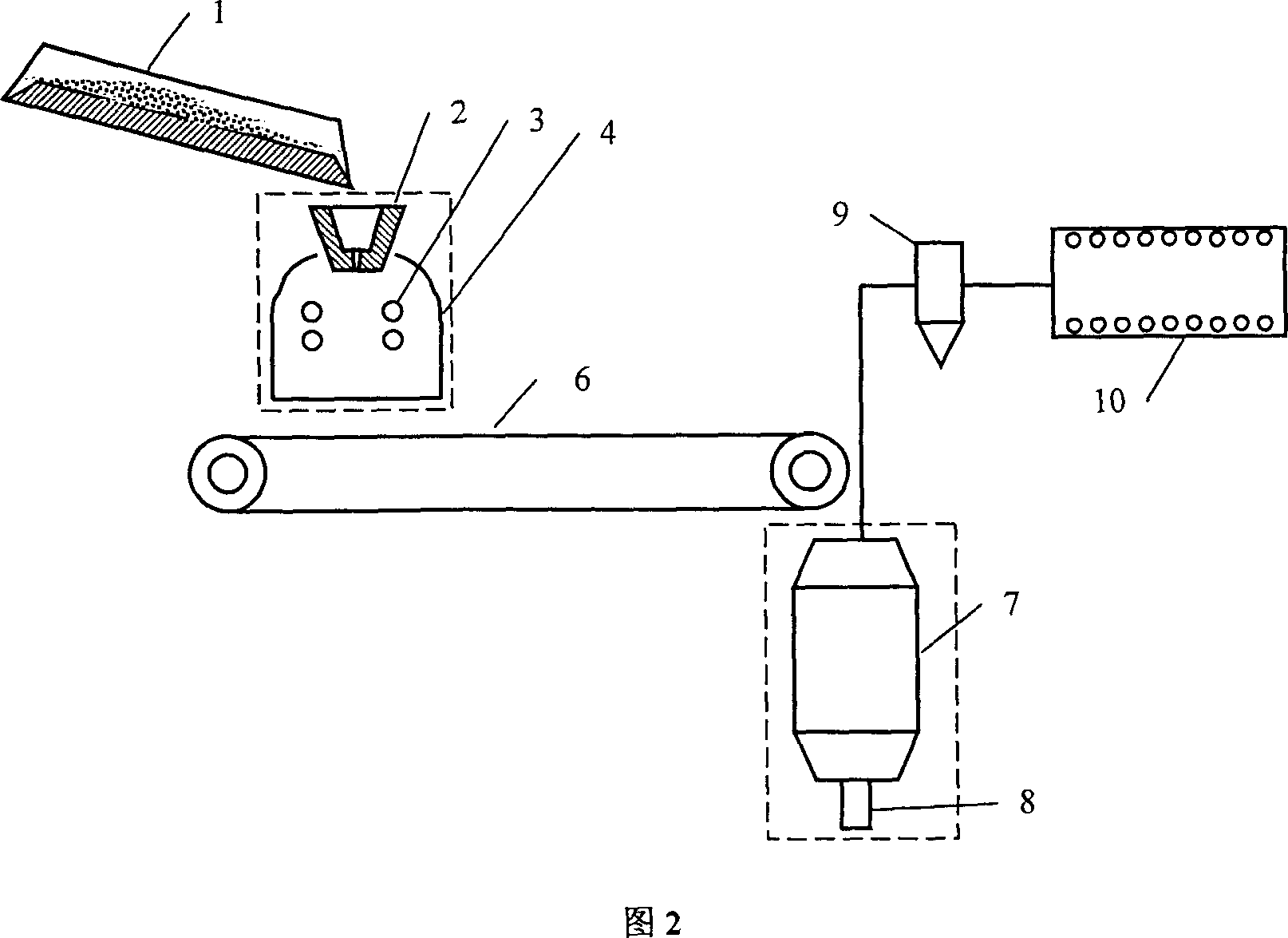

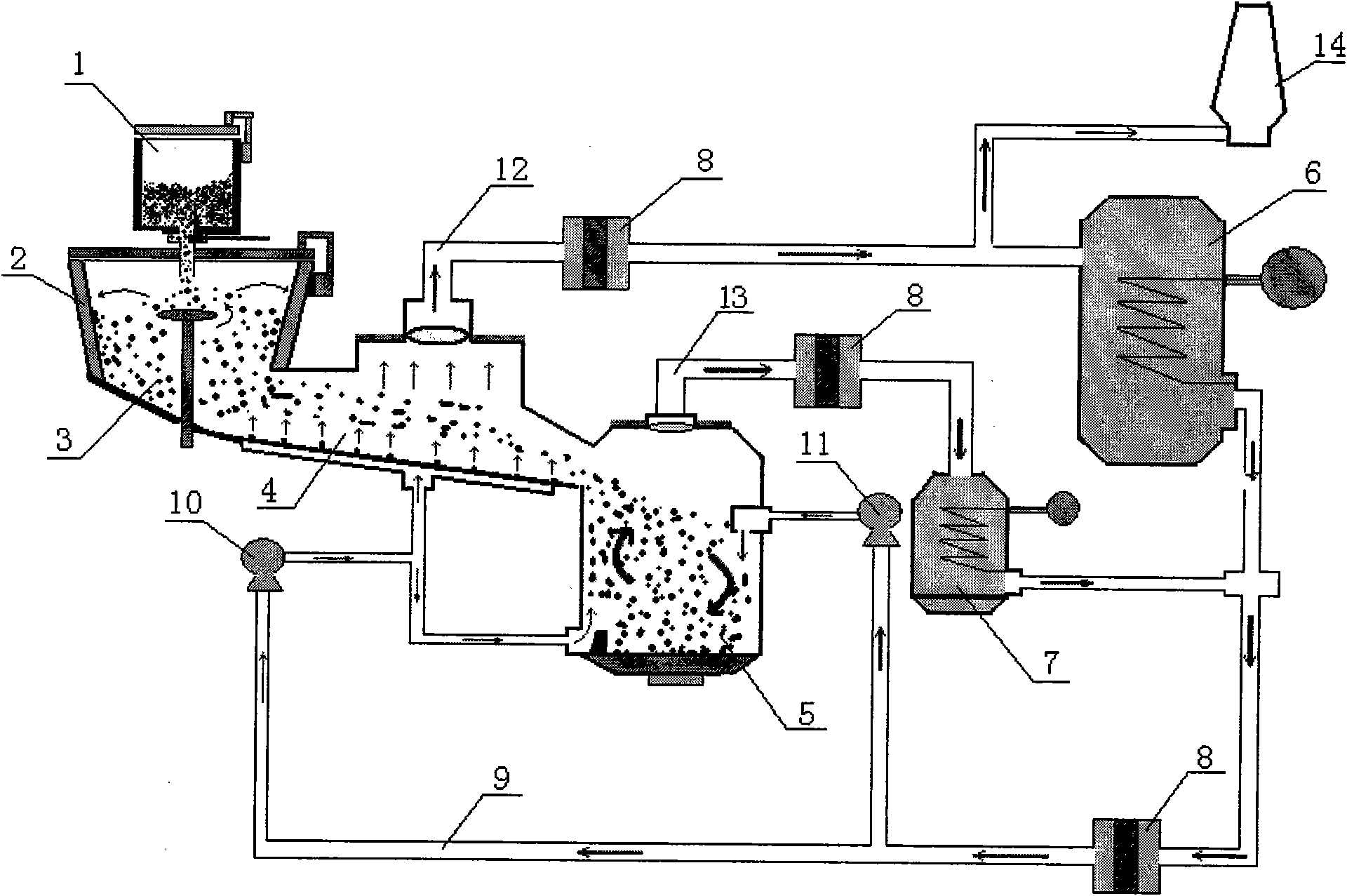

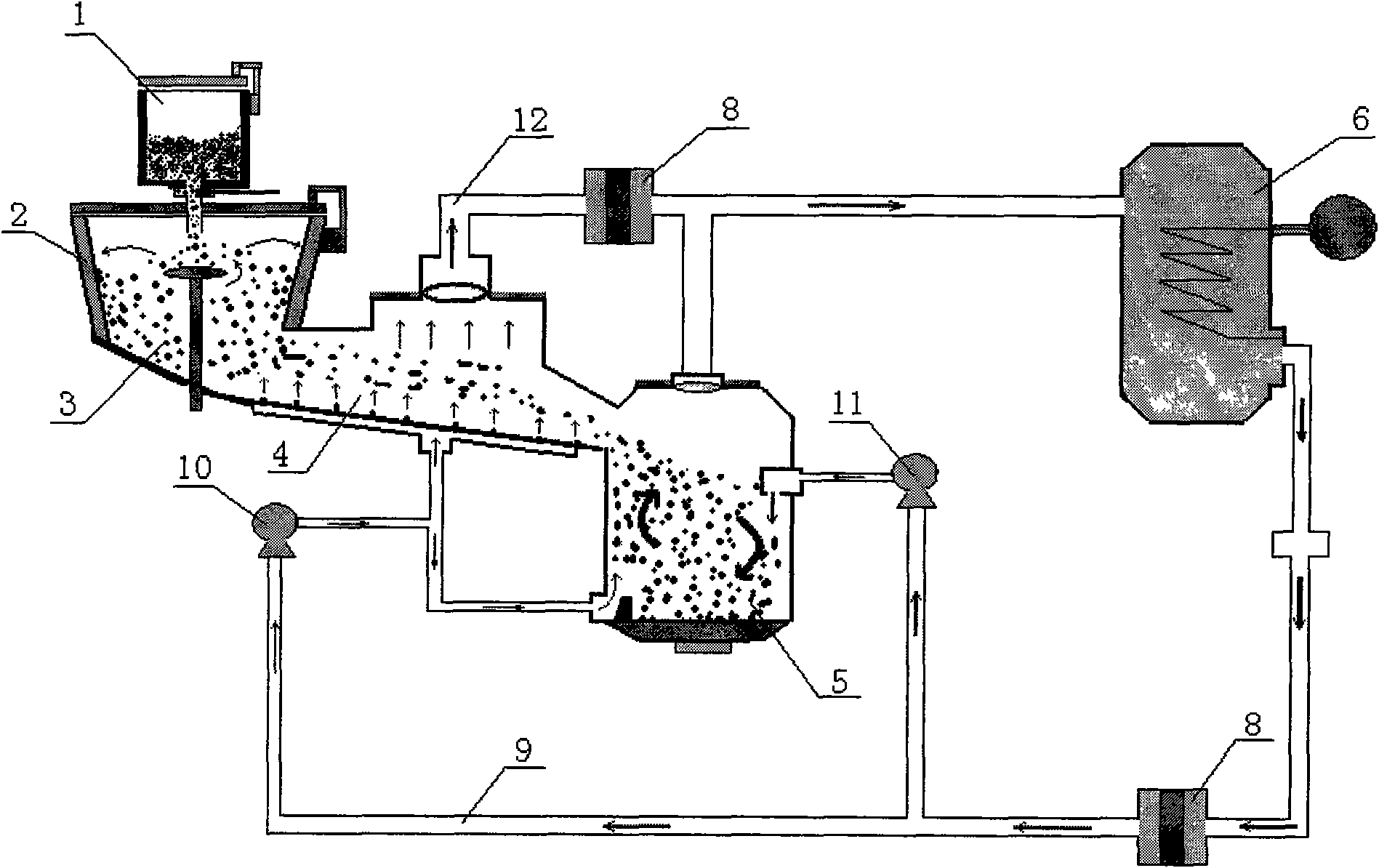

Melting furnace slag quenching dry type granulation and sensible heat recovery generating system and method using same

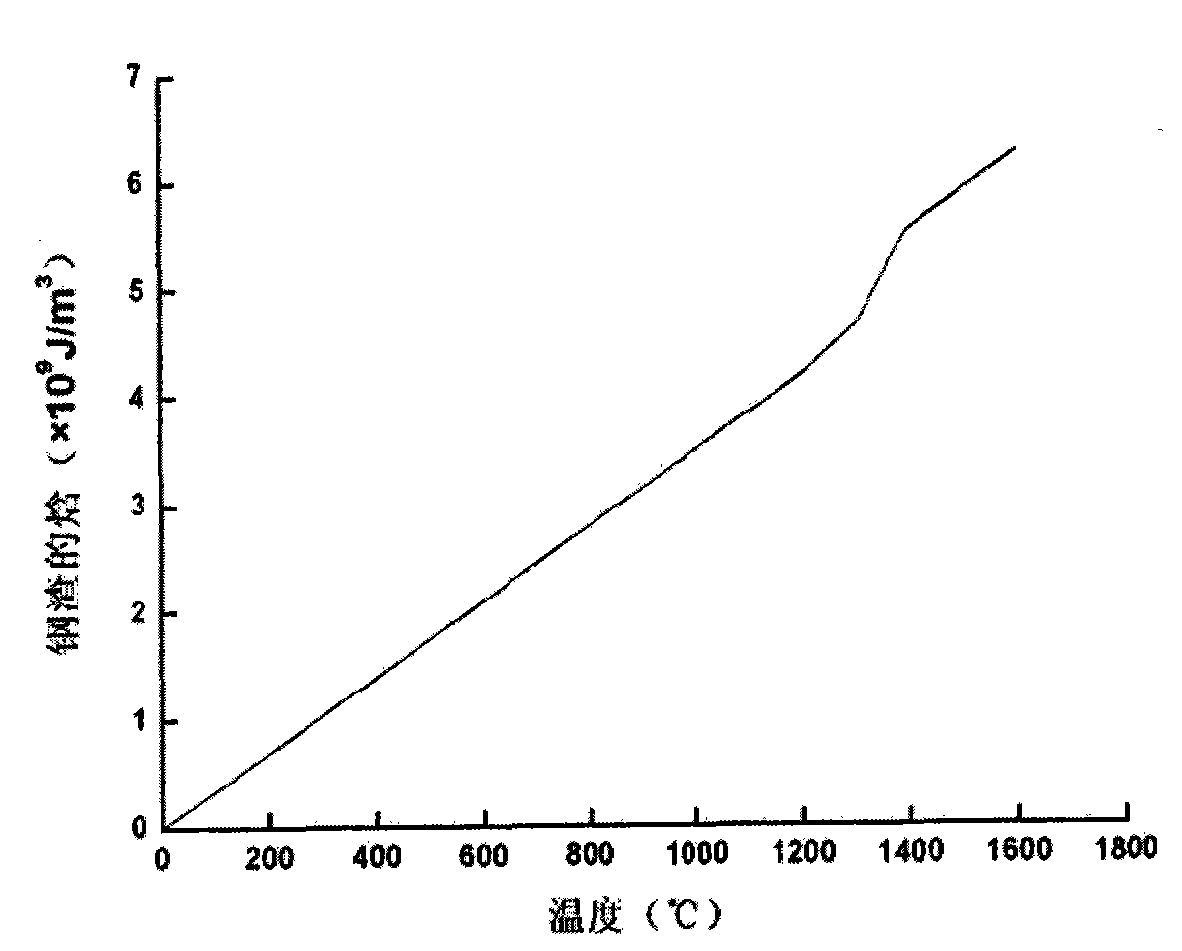

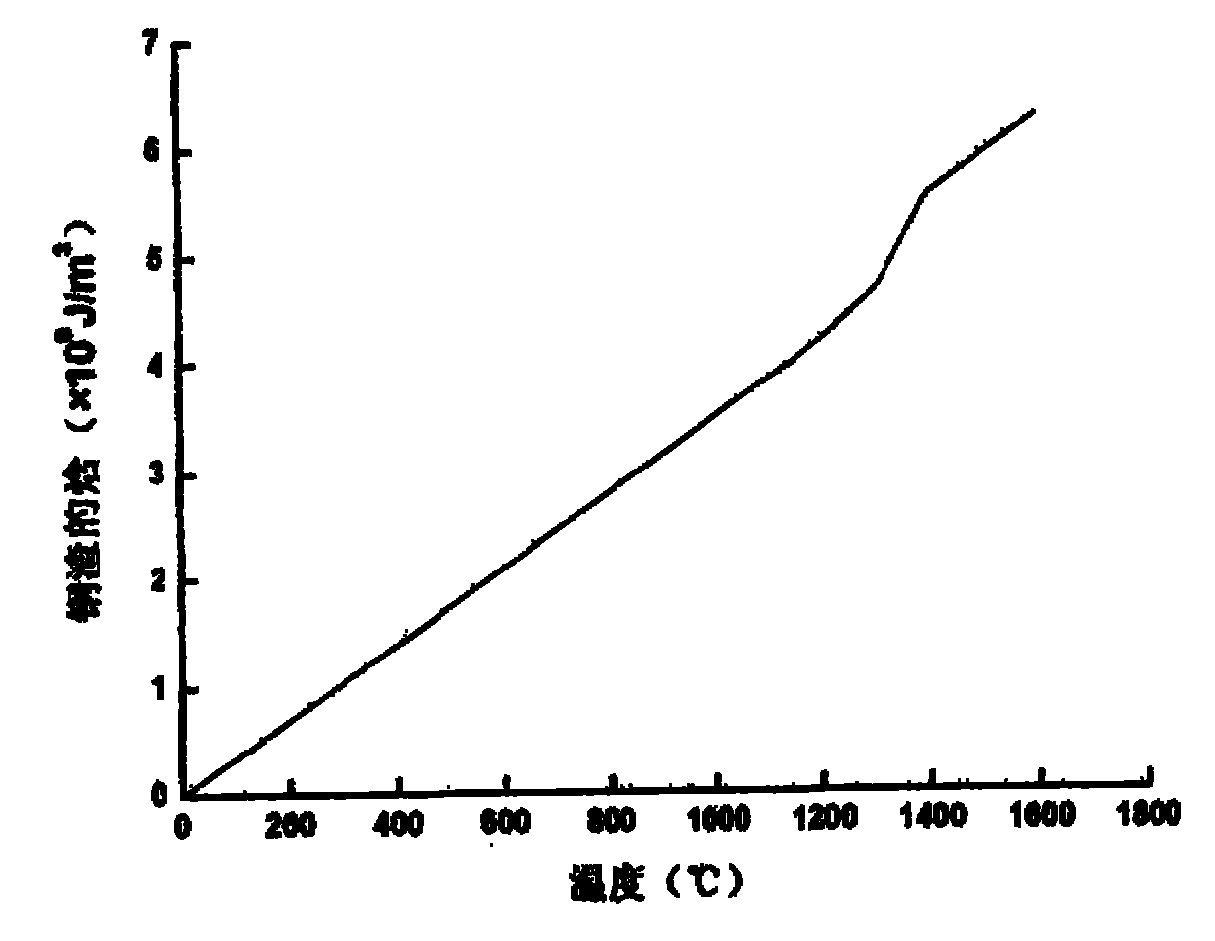

ActiveCN102433401AReduce cooling air volumeReduce power consumptionIncreasing energy efficiencyRecycling and recovery technologiesSlagHigh pressure water

The invention provides a melting furnace slag quenching dry type granulation and sensible heat recovery generating system and a method using the same and belongs to the technical field of steel metallurgy furnace slag treatment and complementary energy recovery. The melting furnace slag quenching dry type granulation and sensible heat recovery generating system provided by the invention comprisesa slag-receiving device, a high-pressure water-air pulverization furnace slag quenching and granulating device, a furnace slag slow-cooling device, a sensible heat recovery generating device and a waste gas purification treatment device. According to the invention, the melting furnace slag is quenched and granulated by utilizing the high-pressure water-air pulverization device, so that the melting furnace slag is rapidly cooled to be in a glassy state; and then through a water-cooled type vibration grid plate, the melting furnace slag in the glassy state is further subjected to heat exchange with cold air so as to facilitate the subsequent recovery of the sensible heat. By the system provided by the invention, the melting furnace slag is quenched and granulated, and the high-temperature sensible heat resource of the furnace slag is sufficiently recovered and is used for generation on the basis that the water activity quality of the furnace slag is not influenced.

Owner:NANJING KESEN KENEN ENVIRONMENT & ENERGY

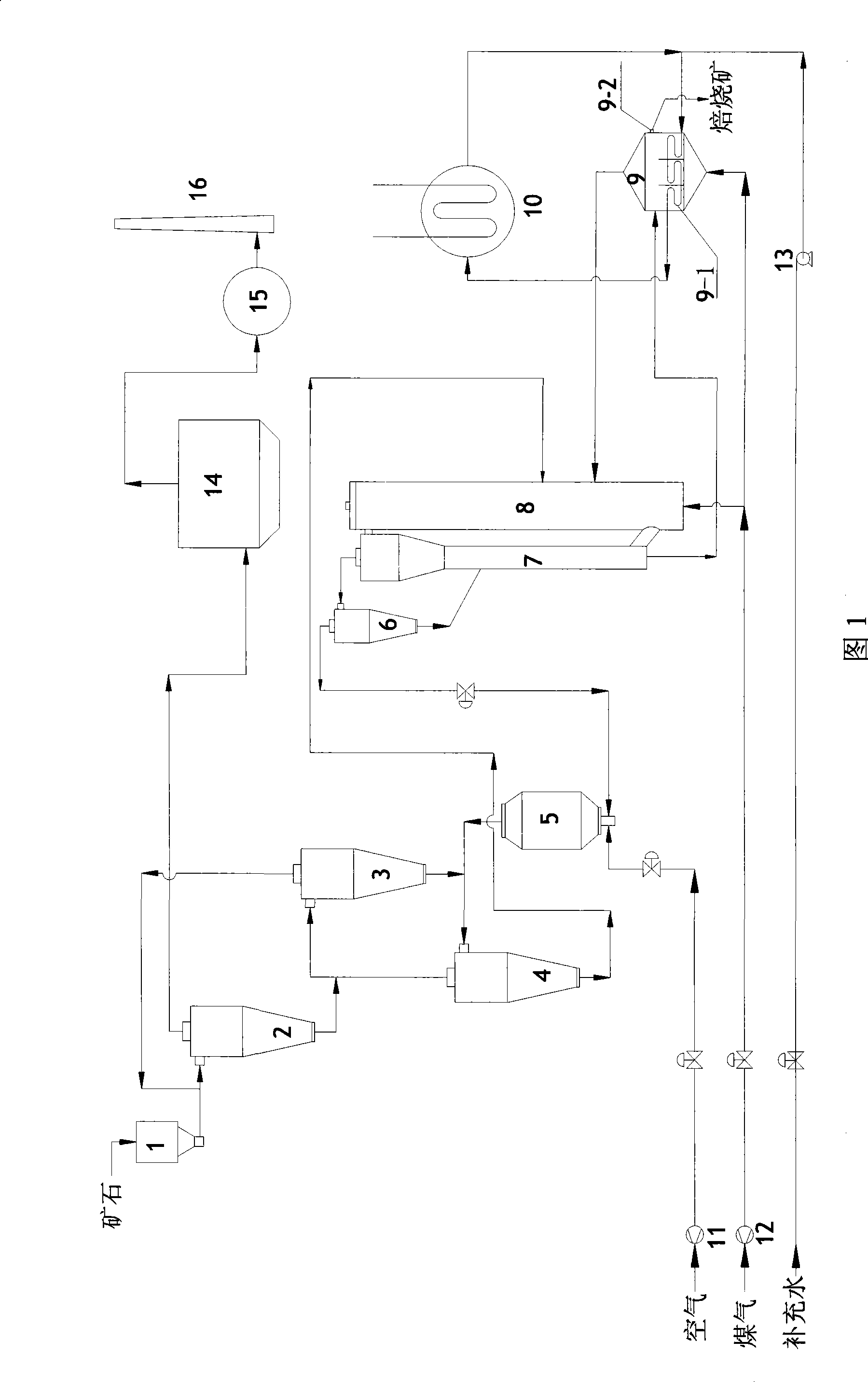

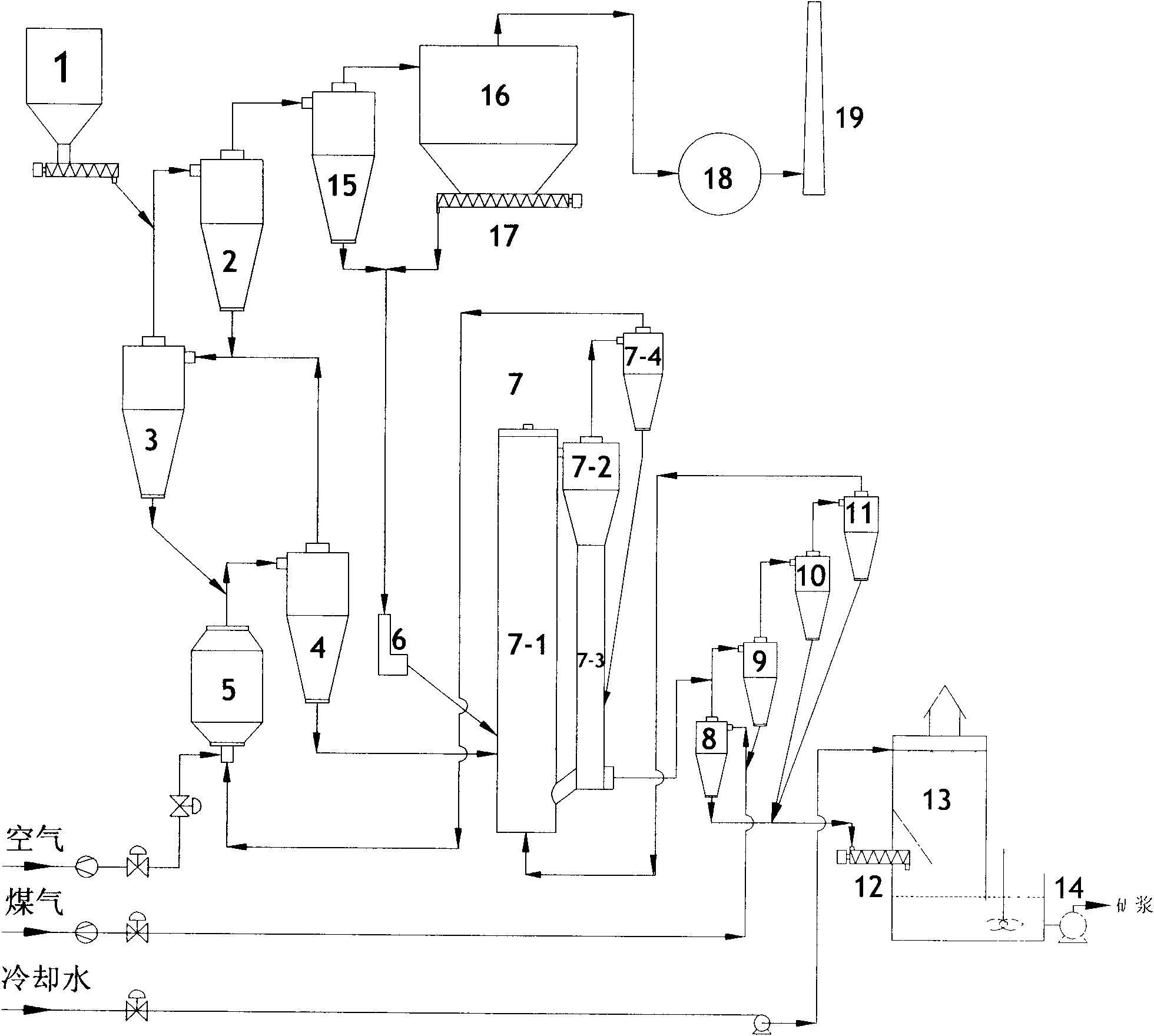

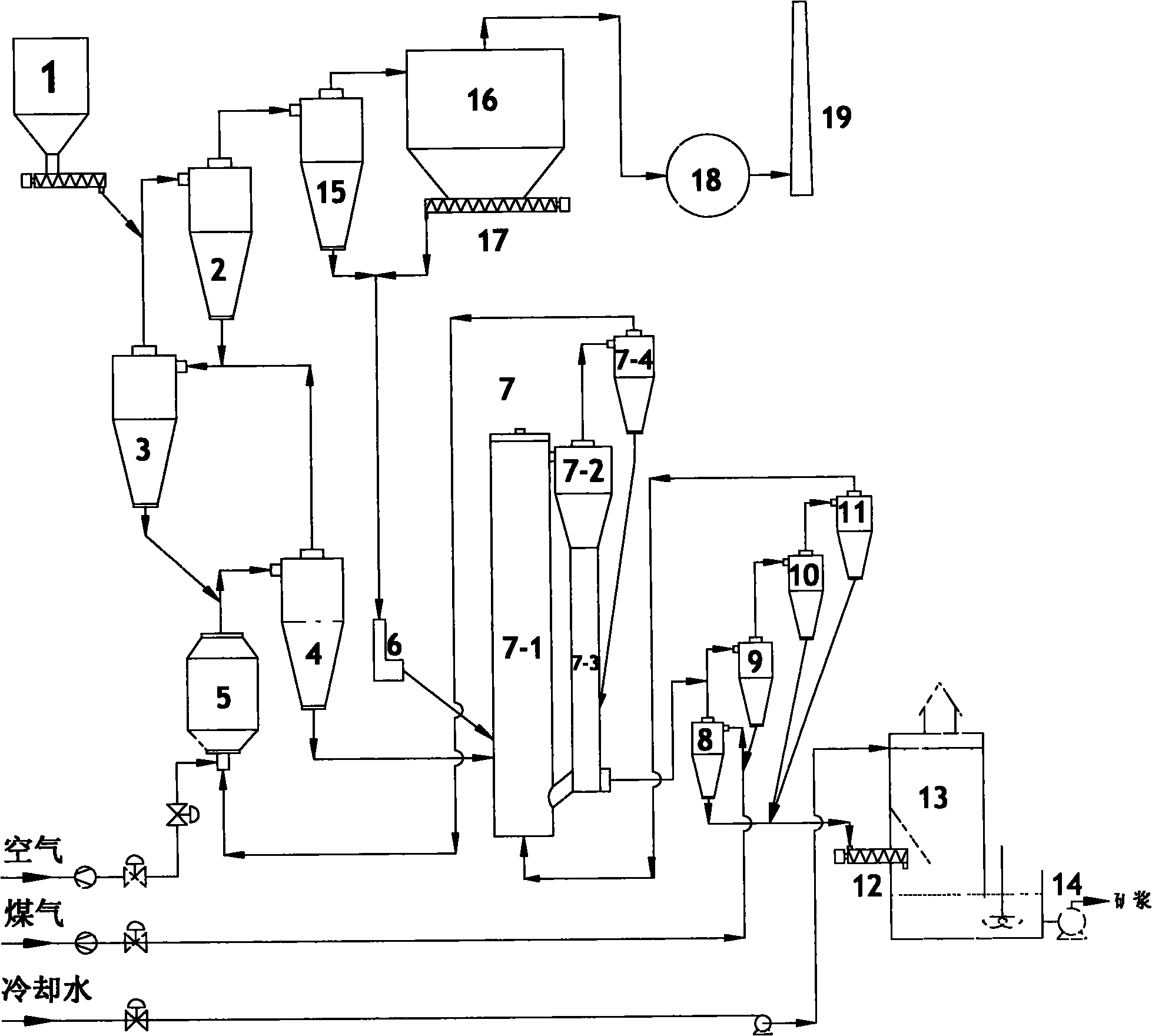

Magnetization roasting technique system for refractory iron ore powder and roasting technology

The invention belongs to the fields of chemical engineering and metallurgy and in particular relates to a process system which adopts a circulating fluid bed to carry out magnetization roasting on limonite, siderite, sedimentary hematite and other refractory iron ore powder bodies. The process system adopts a high-efficiency low-resistance reactor of the circulating fluid bed to carry out the magnetizing roasting to the iron ore powder body; firstly, roasted tail gas in a combustion chamber releases latent heat of unreacted reducing gas through combustion; secondly, the roasted tail gas exchanges heat with the cold iron ore powder body through a multilevel cyclone preheater to reclaim heat; and finally a fluidizing cooler is adopted to reclaim sensible heat of high-temperature roasting ore. The process system has the advantages of high magnetizing roasting efficiency and full heat reclaiming and utilization in the roasting process and the like, can reduce energy consumption of the refractory iron ore powder body in the process of magnetizing roasting and improve the economical efficiency of the refractory iron ore in the process of magnetizing roasting.

Owner:深圳市中科九台资源利用科技产业股份有限公司

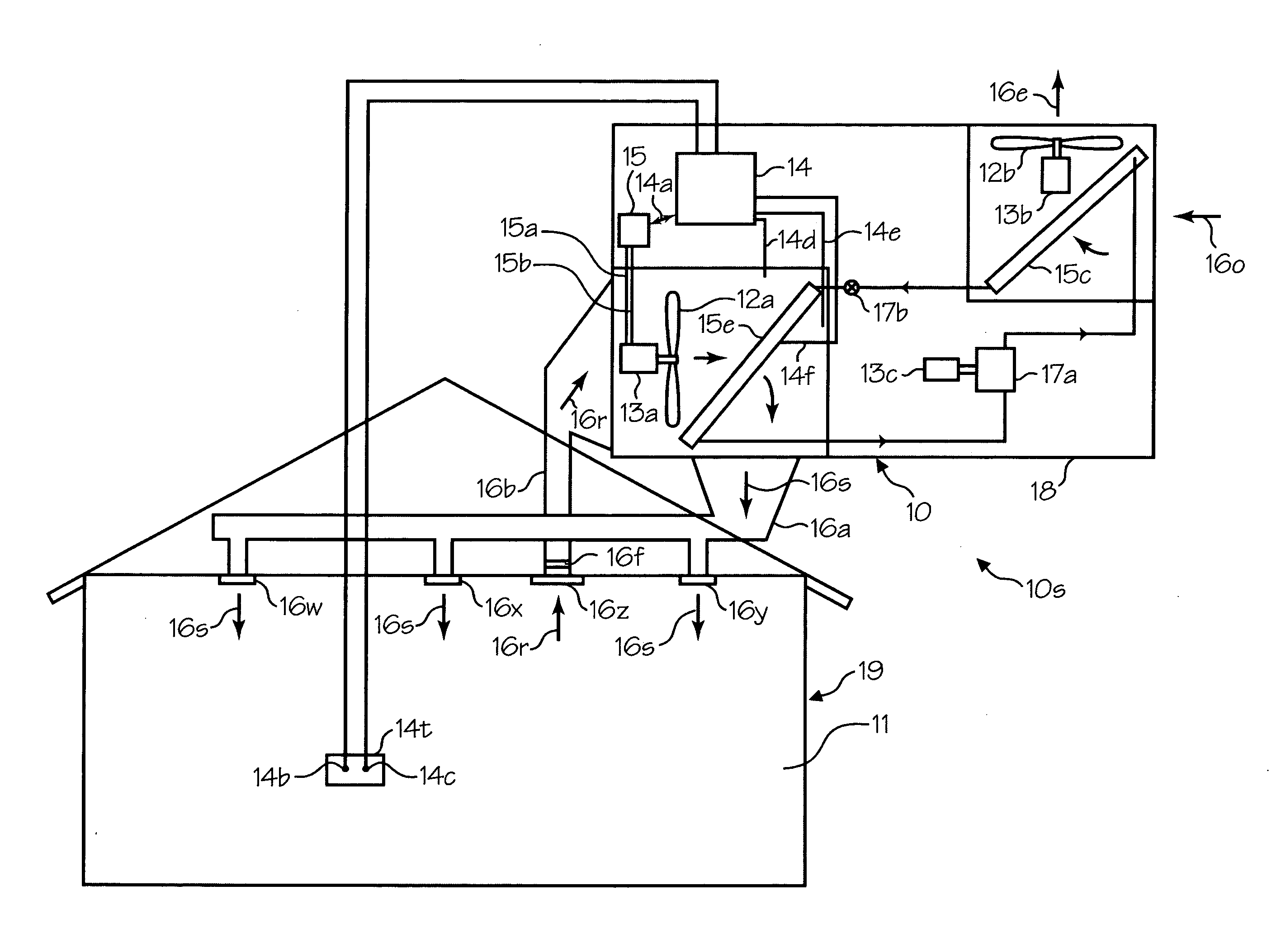

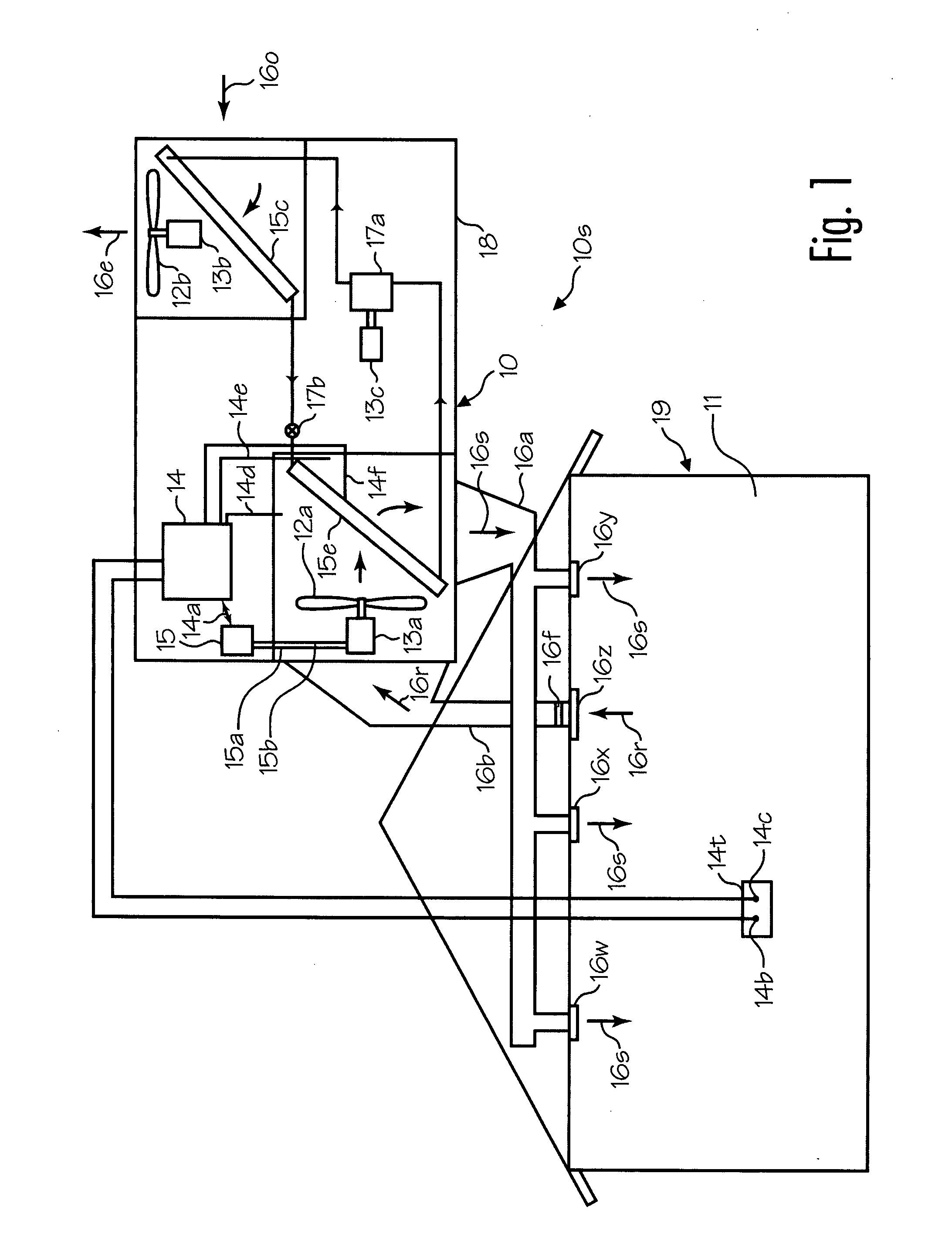

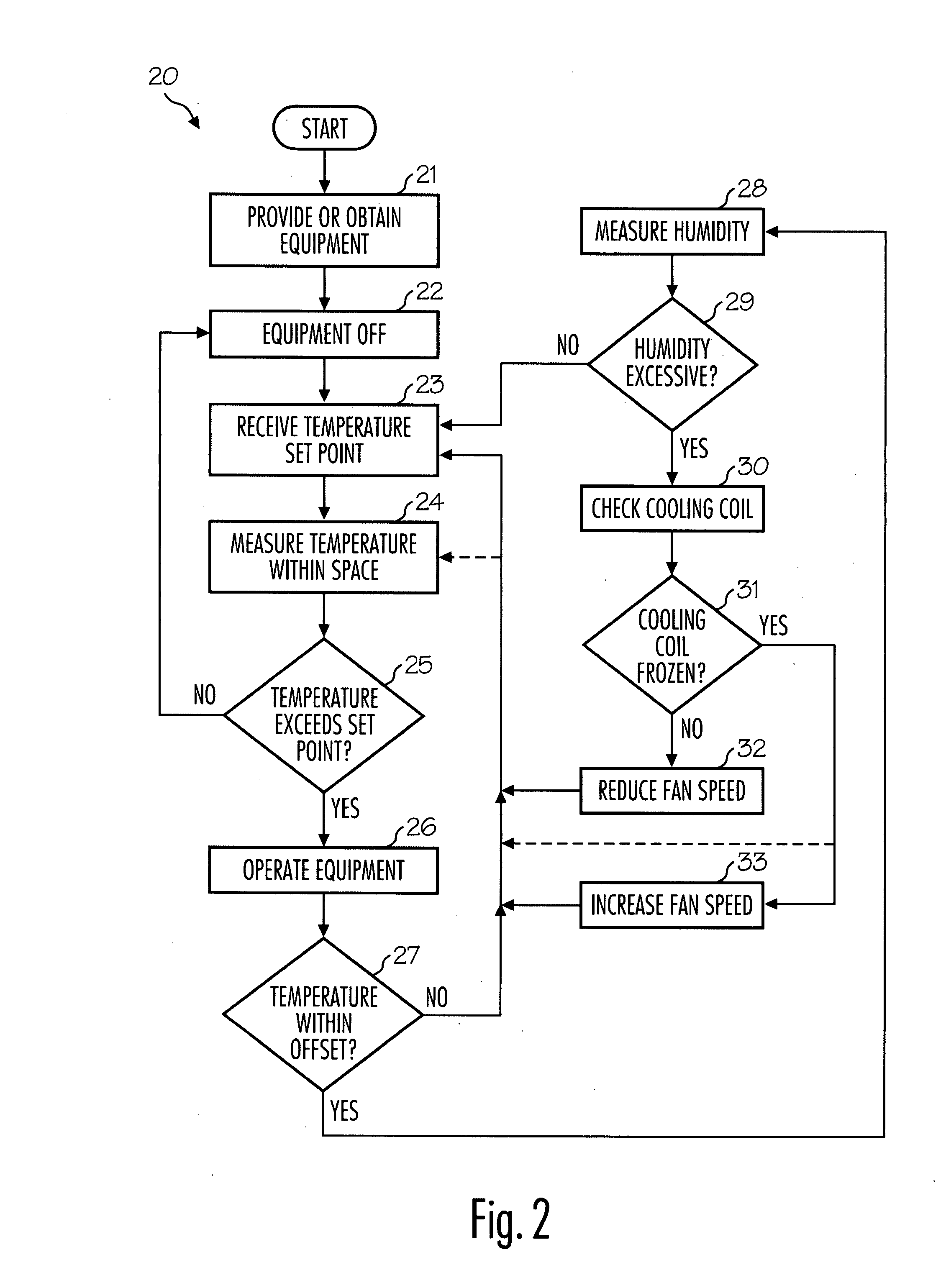

Humidity control and air conditioning

InactiveUS20080307803A1Shorten speedAvoid frostMechanical apparatusCompression machines with non-reversible cycleFrostCooling coil

Air conditioning systems that cool and dehumidify spaces within enclosures, buildings having such systems, and methods of controlling humidity within a space. Embodiments adjust speed of a blower or fan motor based on inputs from sensors within the system, using automated processes, to reduce airflow rates to provide for lower temperatures of the cooling coil and to increase the ratio of latent to sensible heat transfer. Fan speeds may be increased as appropriate to avoid frost formation on the cooling coil, to give priority to cooling when temperatures within the space are high, or periodically to provide for mixing within the space.

Owner:NORDYNE

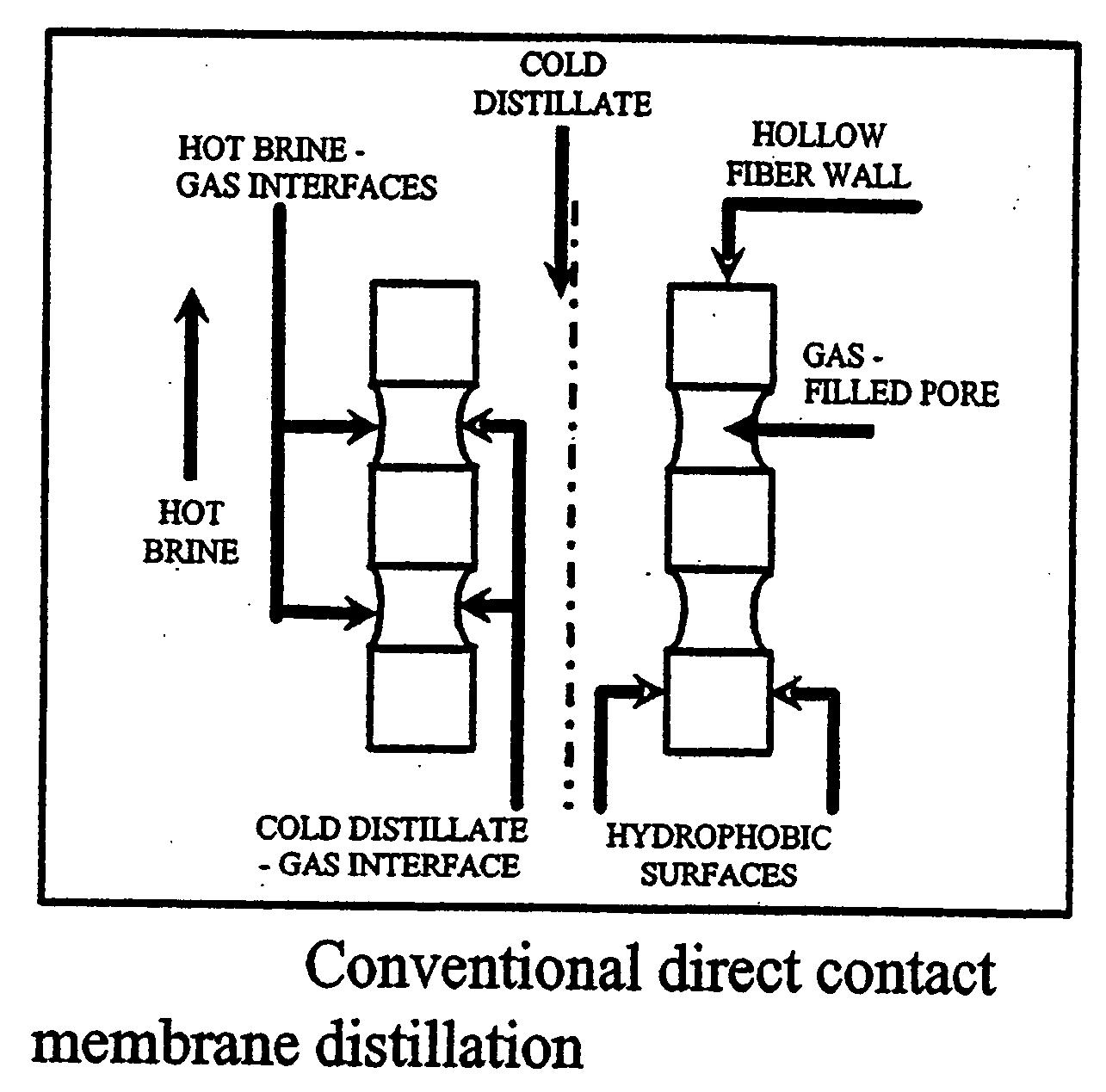

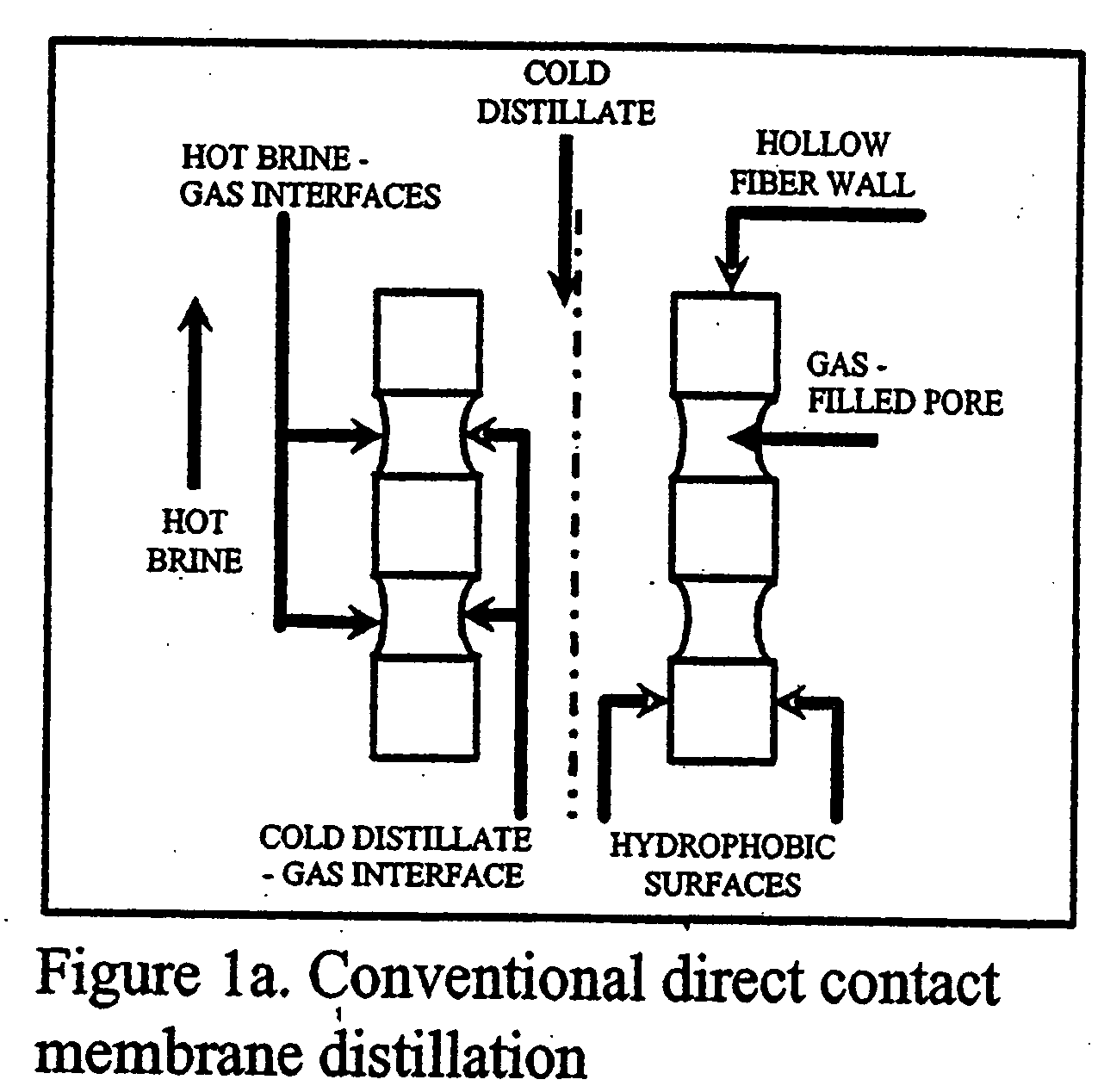

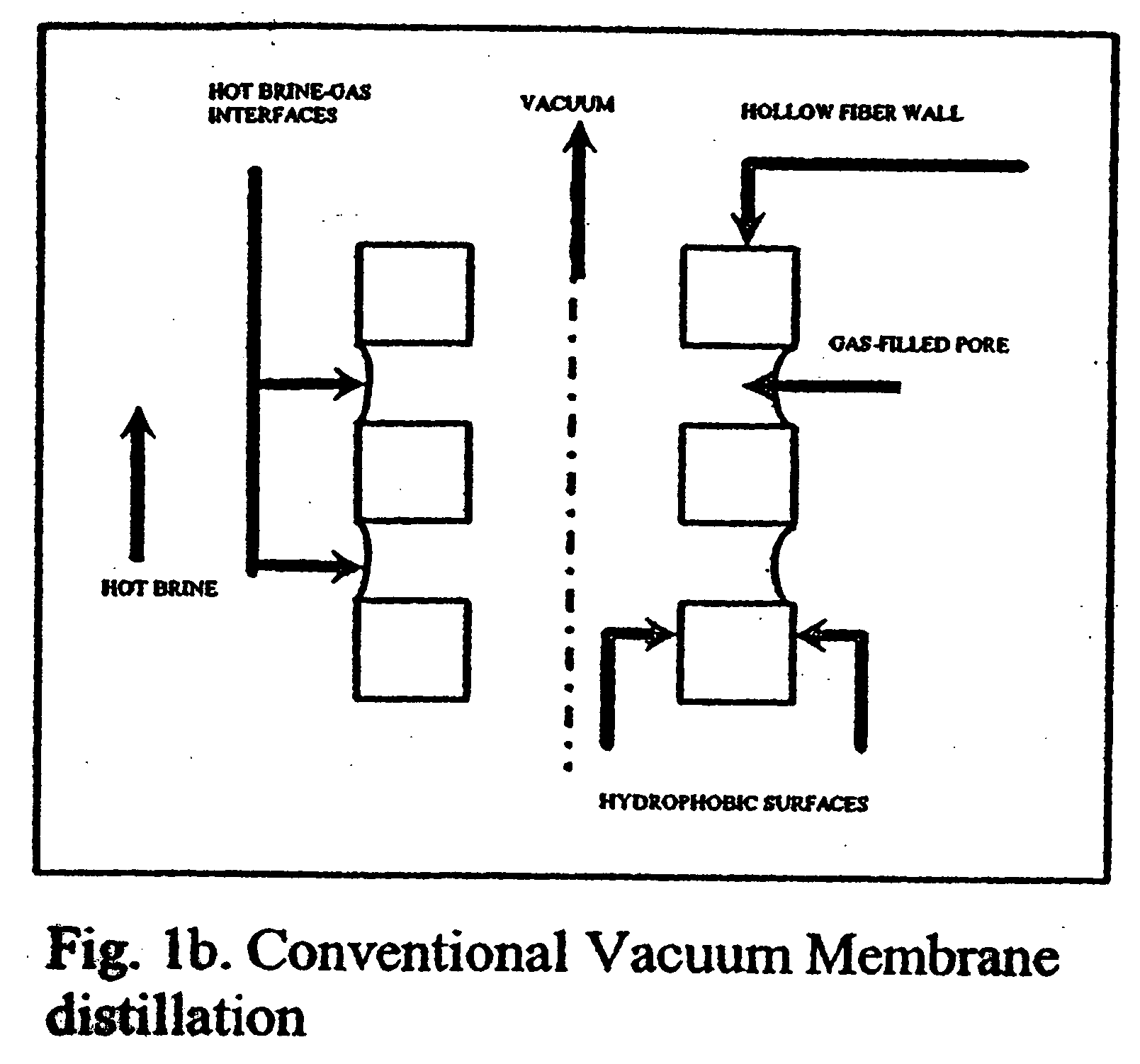

Devices and methods using direct contact membrane distillation and vacuum membrane distillation

ActiveUS20060076294A1Eliminate pore wettingReduce lossesGeneral water supply conservationSolid sorbent liquid separationFiberHollow fibre membrane

DCMD and VMD systems and methods for use in desalination applications are provided. The DCMD and VMD systems employ coated porous hydrophobic hollow fiber membranes. The coatings advantageously function to essentially eliminate pore wetting of the membrane, while permitting substantially unimpeded water vapor permeance through the fiber walls. The DCMD and VMD membranes are characterized by larger fiber bore diameters and wall thicknesses. The membranes substantially reduce the loss of brine sensible heat, e.g., heat loss via conductive heat flux through the membrane wall and the vapor space and, in exemplary embodiments, the brine-side heat transfer coefficient is dramatically enhanced by horizontal / vertical cross flow of brine over the outside surface of the coated fibers. Superior water vapor fluxes are achieved with the systems and methods.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

Thermal storage system

InactiveUS20120080161A1Lower temperature rangeSolar heating energySolar heat devicesThermal energyWorking fluid

Apparatus and method for efficiently storing thermal energy, in particular thermal energy transferred from a concentrated solar energy receiver. The apparatus consists of a collection of modular thin walled tube pressure vessels enclosing solid sensible heat thermal storage elements. The high temperature solid is separated from the thin wall by thermal insulation and two thin gaps that carry the cold in and cold out high-pressure working fluids. Hot in and hot out working fluids circulate in counter flow channels within the solid sensible heat thermal storage elements. The solar receiver can also be modular to match the thermal storage elements, facilitating manufacturing and on site assembly. The design enables scalable thermal storage and concurrent thermal charging and discharging with no circuit switching between charge and discharge.

Owner:KELLY EDMUND JOSEPH

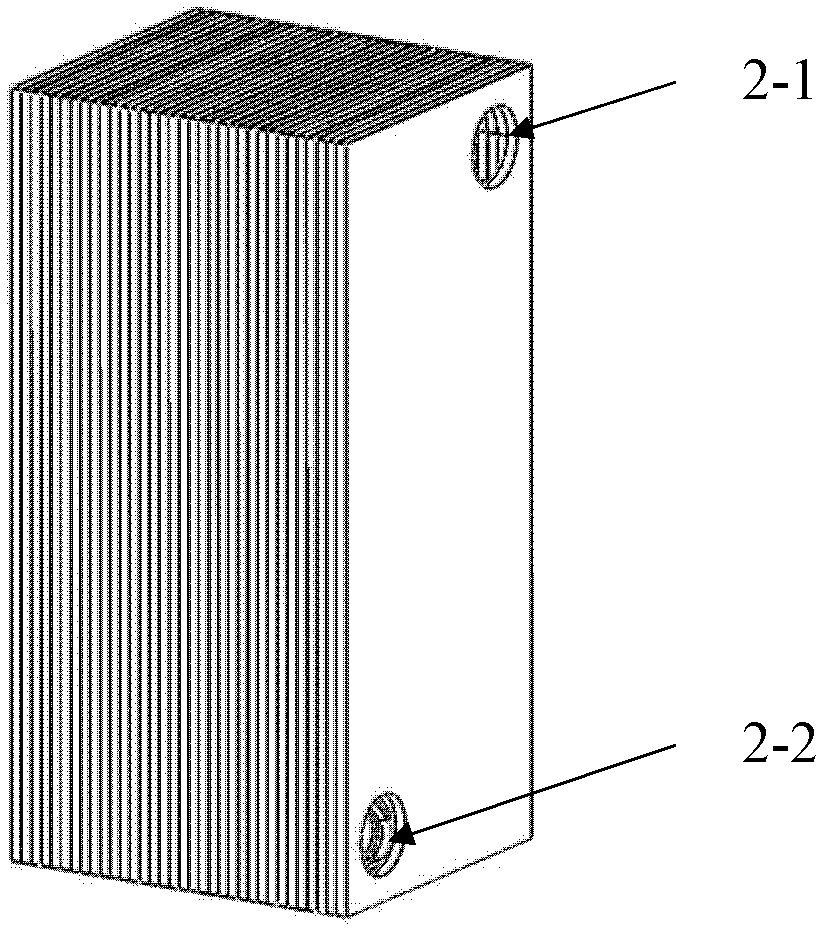

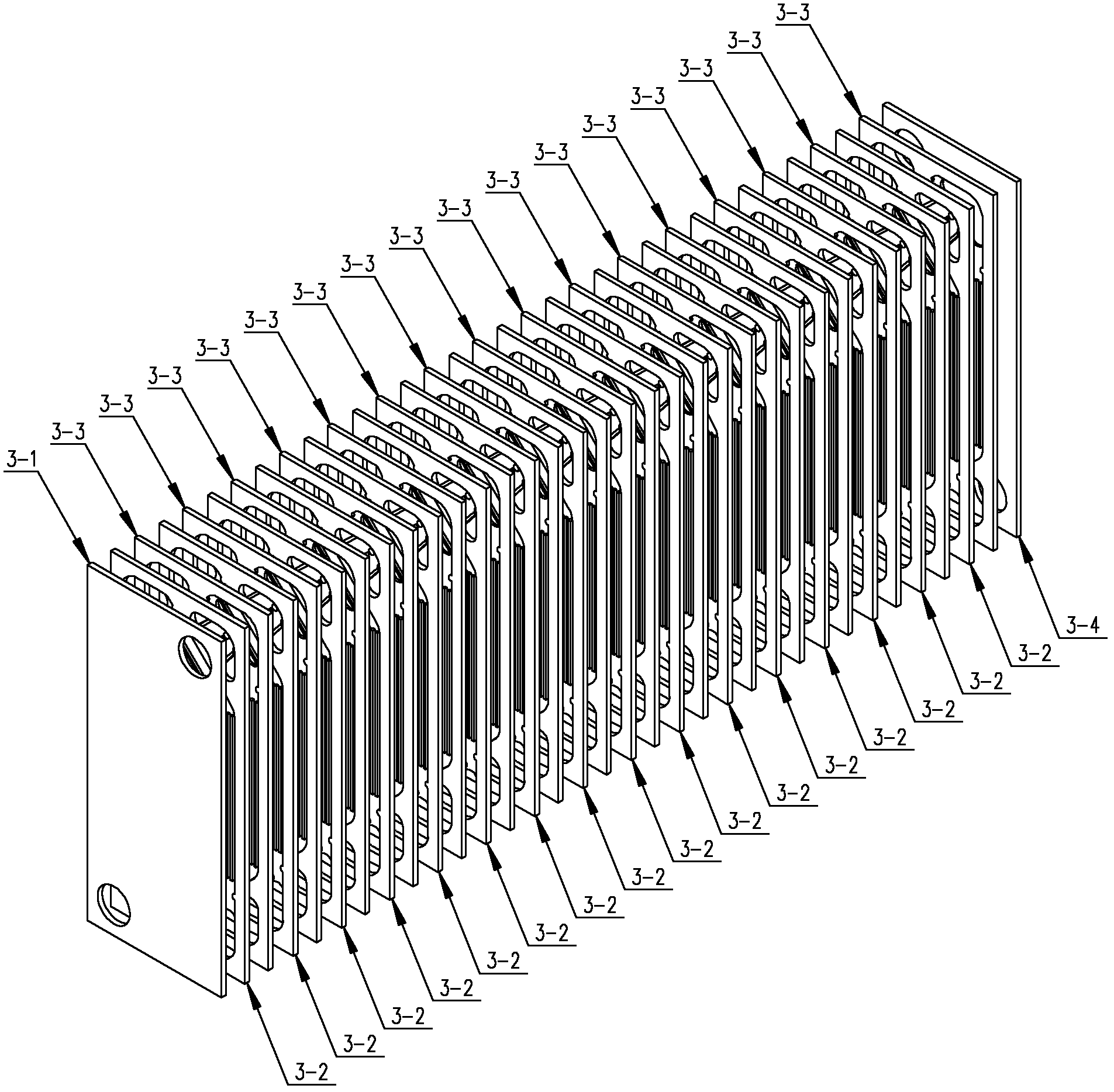

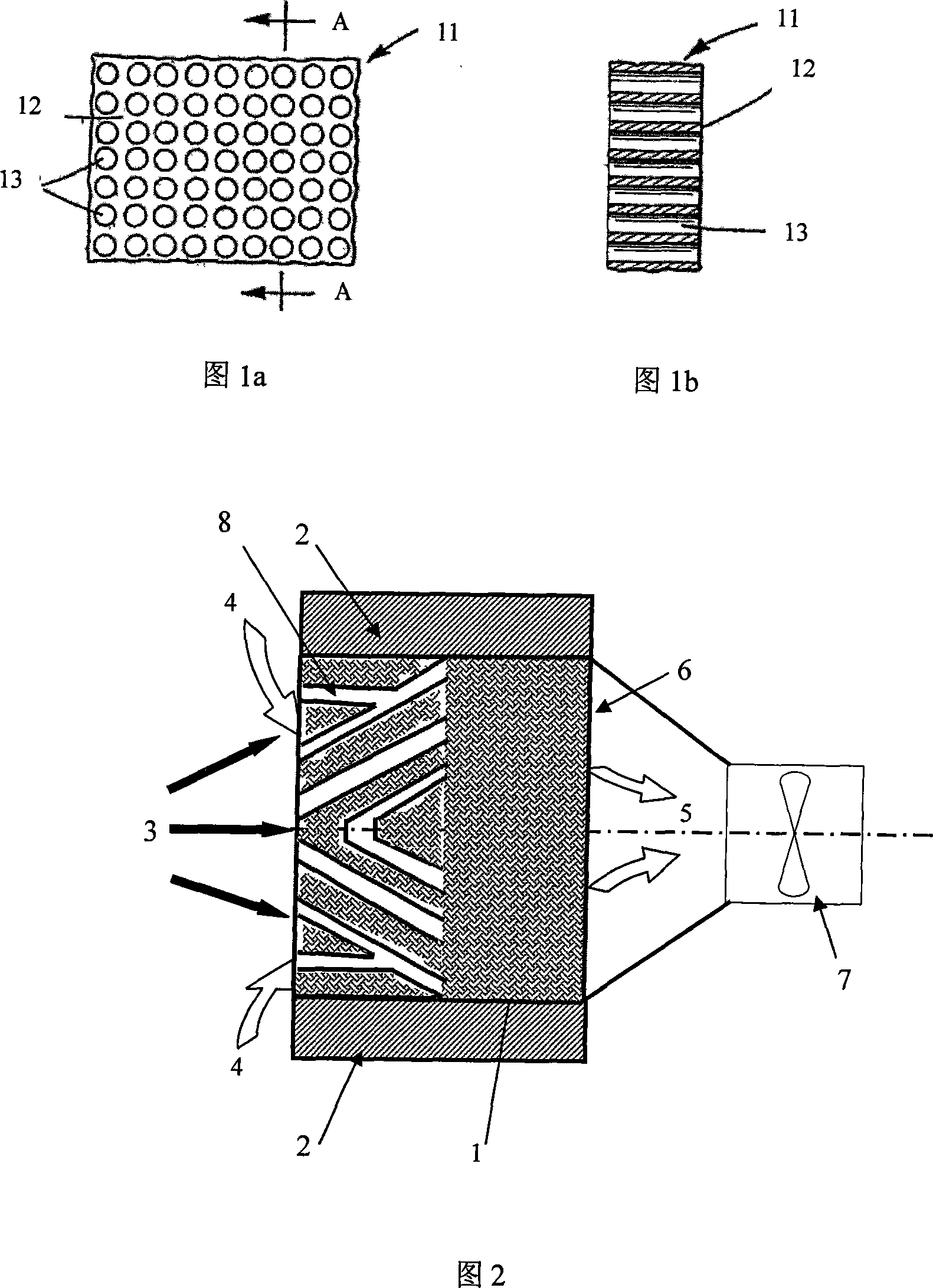

Miniature micro-channel plate-fin heat exchanger

ActiveCN102494547ALaminated elementsStationary plate conduit assembliesMiniaturizationMolecular level

The invention relates to a miniature heat exchanger with a plate-fin micro-channel structure, wherein the miniature heat exchanger can act as a novel sensible heat exchanger or a phase change heat exchanger which is compact in structure, small in volume, high in heat exchange efficiency and high in heat exchange density. According to the embodiment of the invention, the heat exchanger is composed of a plurality of layers of metal thin sheets; one surface of each layer of thin sheet is provided with a micro-channel structure through an etching method, and the other surface of each layer of thin sheet is of a plane structure; and the plane side of one metal thin sheet and the micro-channel side of another metal thin sheet are overlapped and pressed together, thus the plate-fin micro-channel structure is formed. According to the heat exchange quantity requirement, multiple layers of thin sheets are laminated, and molecular-level combination among metal layers can be formed through a vacuum diffusion welding method, thus all the thin sheets are connected into a whole, and a complete heat exchanger is formed. According to the invention, the miniaturization difficulties of the heat exchanger and a refrigerator device can be solved.

Owner:BEIHANG UNIV

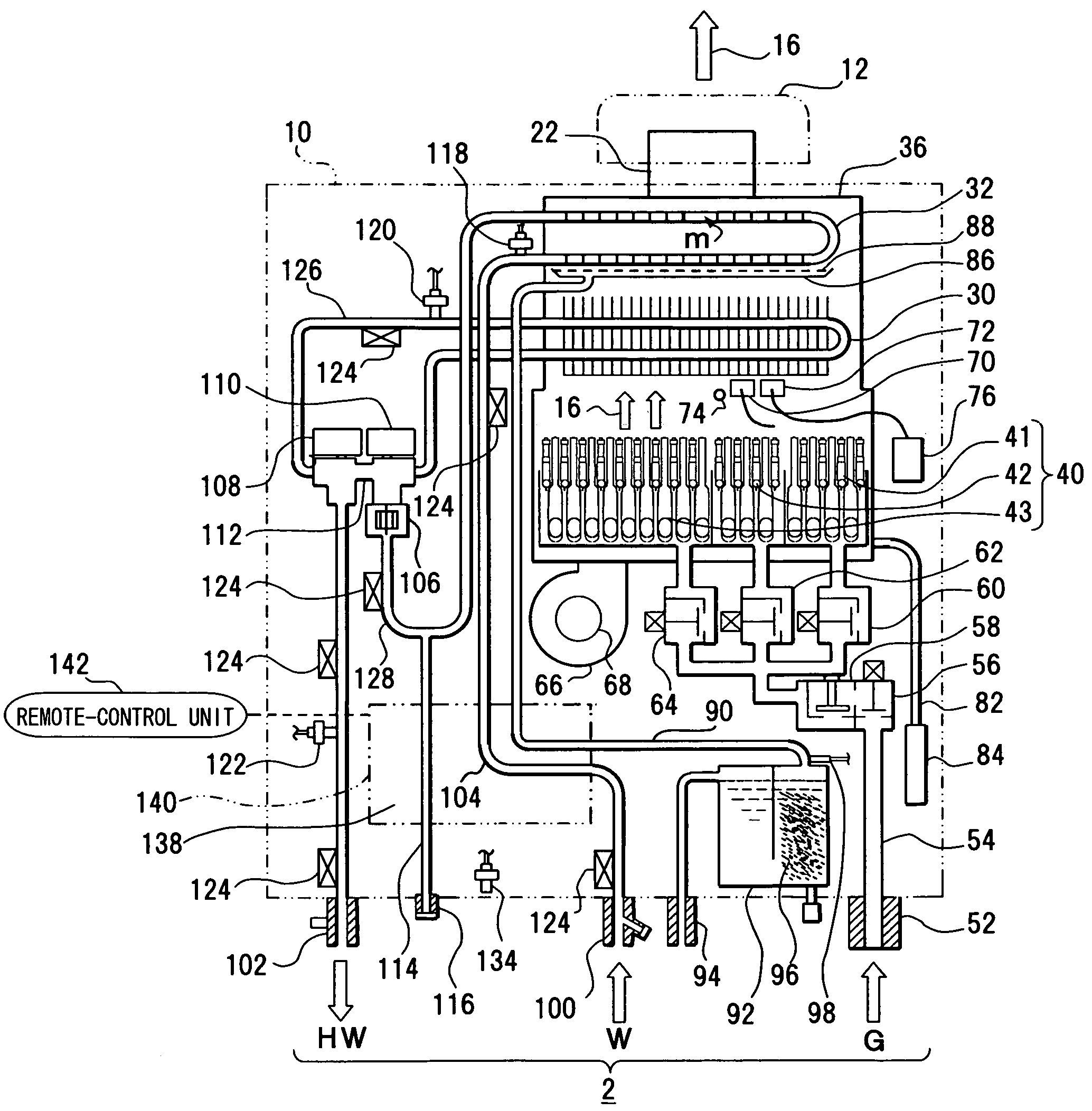

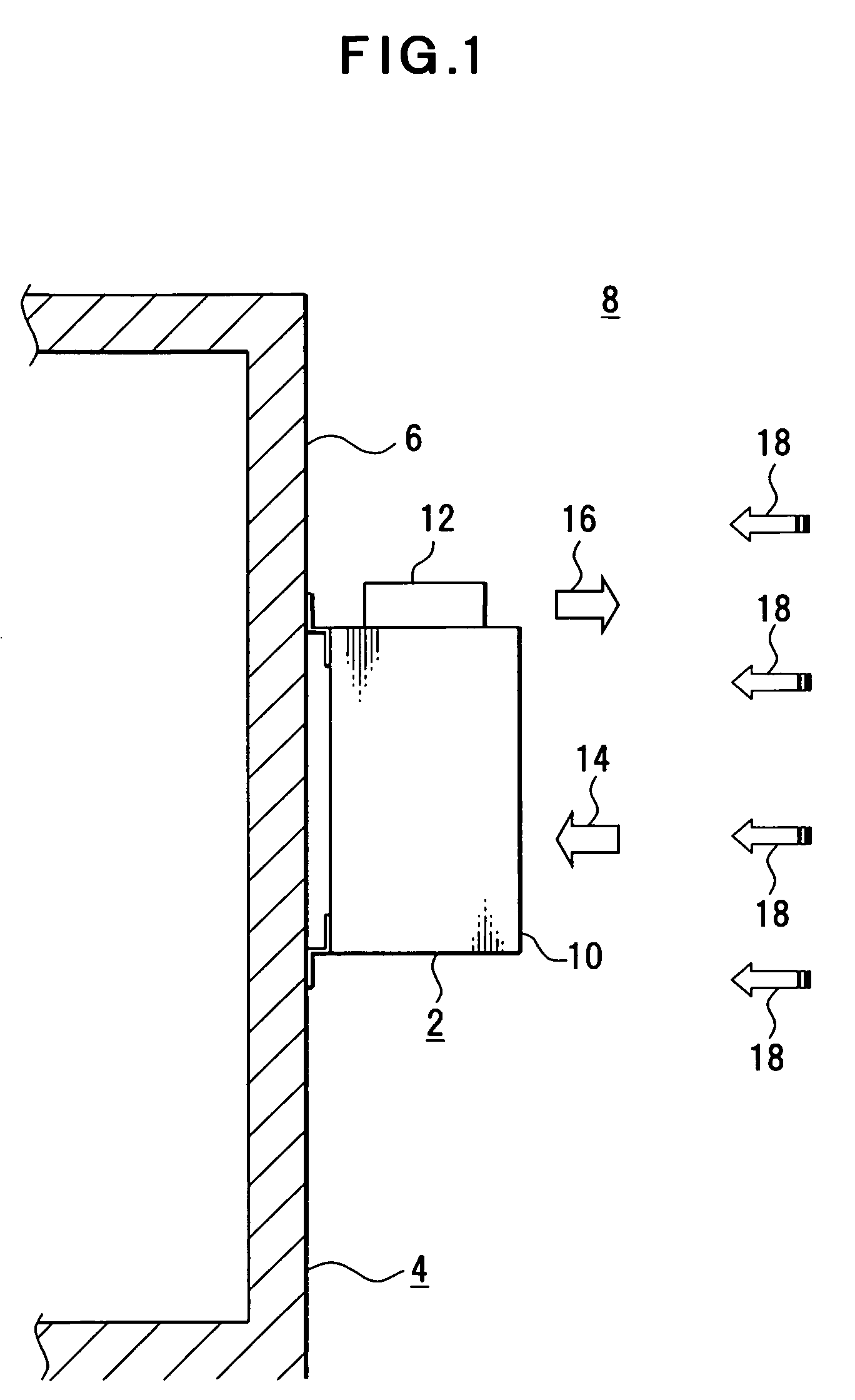

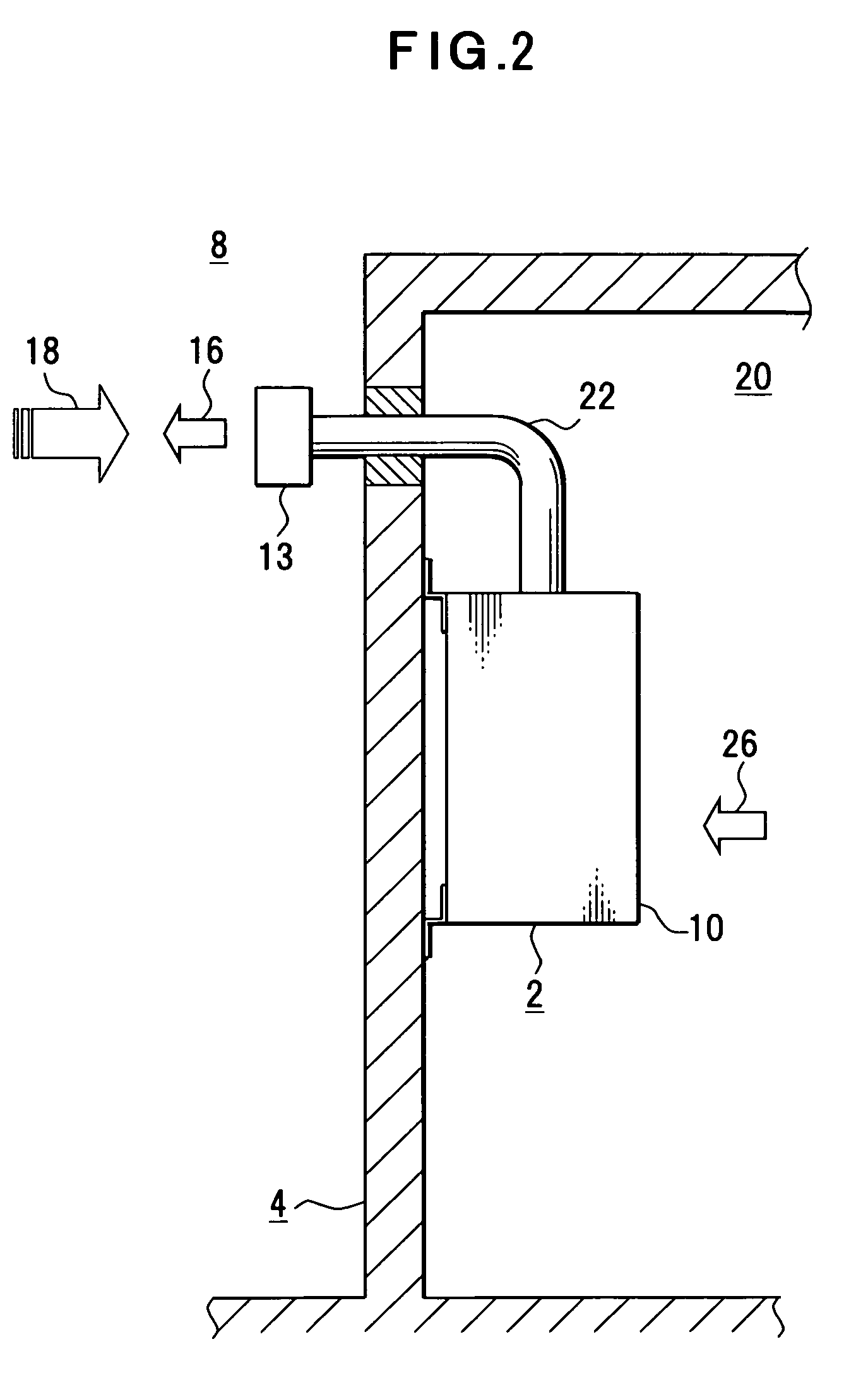

Hot-water supply apparatus, anti-freezing method thereof, and anti-freezing program thereof

ActiveUS7322532B2Function increaseAir-treating devicesVehicle heating/cooling devicesCombustionAnti freezing

A hot-water supply apparatus is an apparatus which has a primary heat exchanger absorbing sensible heat of combustion exhaust and a secondary heat exchanger absorbing latent heat of the combustion exhaust, and improves a freezing prevention function of the hot-water supply apparatus at a cold period. Further, this apparatus has a temperature detection means (temperature sensors) which detects a freezing prevention temperature, a combustion means (a burner group) which supplies combustion exhaust generated by combustion to the primary and secondary heat exchangers, an air supply means which supplies air to the combustion means, and a control means (a control unit) which makes the combustion means burn and drives the air supply means based on a detected temperature of the temperature detection means. When the temperature detection means detects the freezing prevention temperature, the combustion means is burned for a settled time to heat the primary heat exchanger, and the air supply means is driven to stream air from a side of the primary heat exchanger to the secondary heat exchanger for a given time after a combustion stop of the combustion means. By this, a side of the secondary heat exchanger is heated by remaining heat of the side of the primary heat exchanger.

Owner:PURPOSE CO LTD

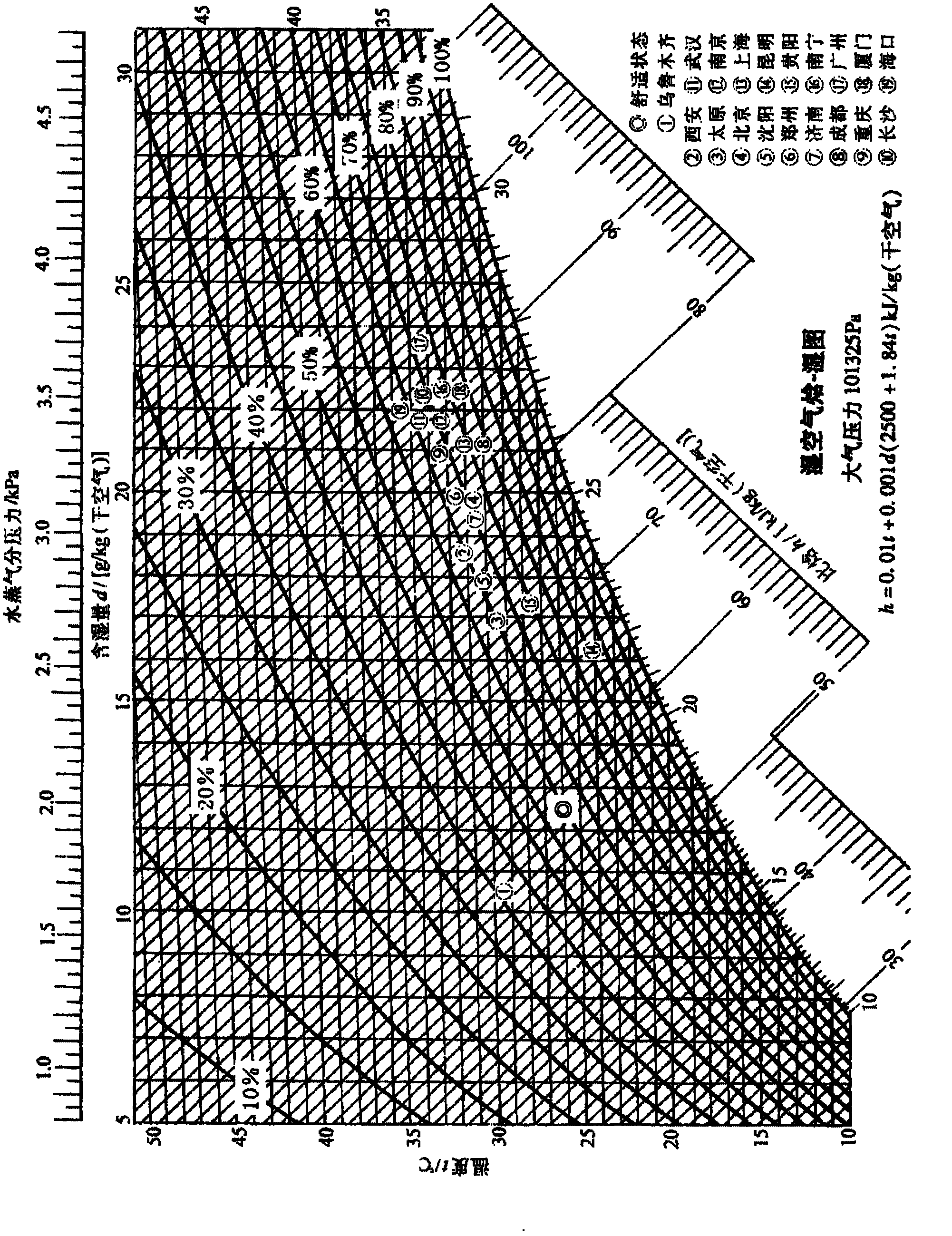

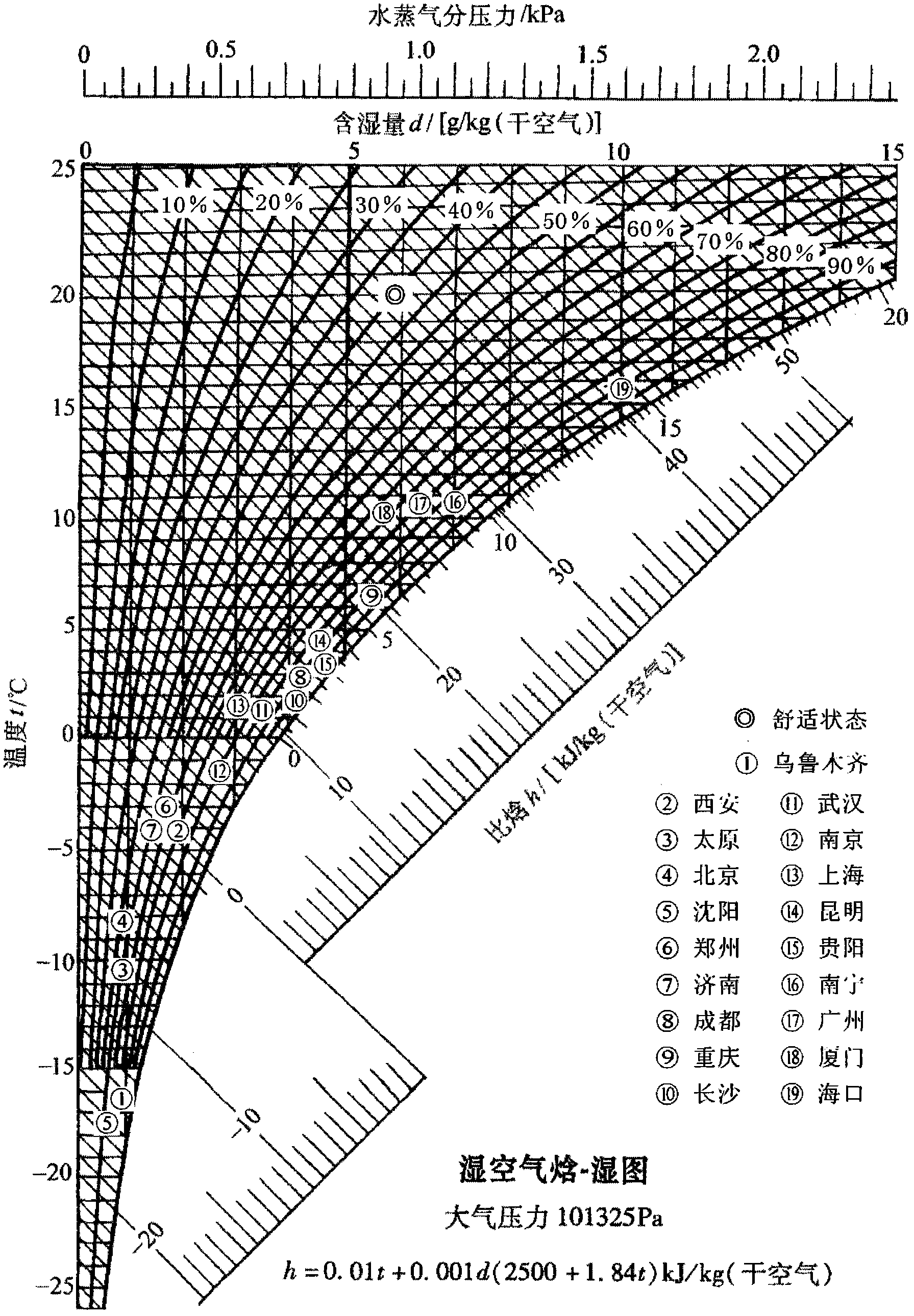

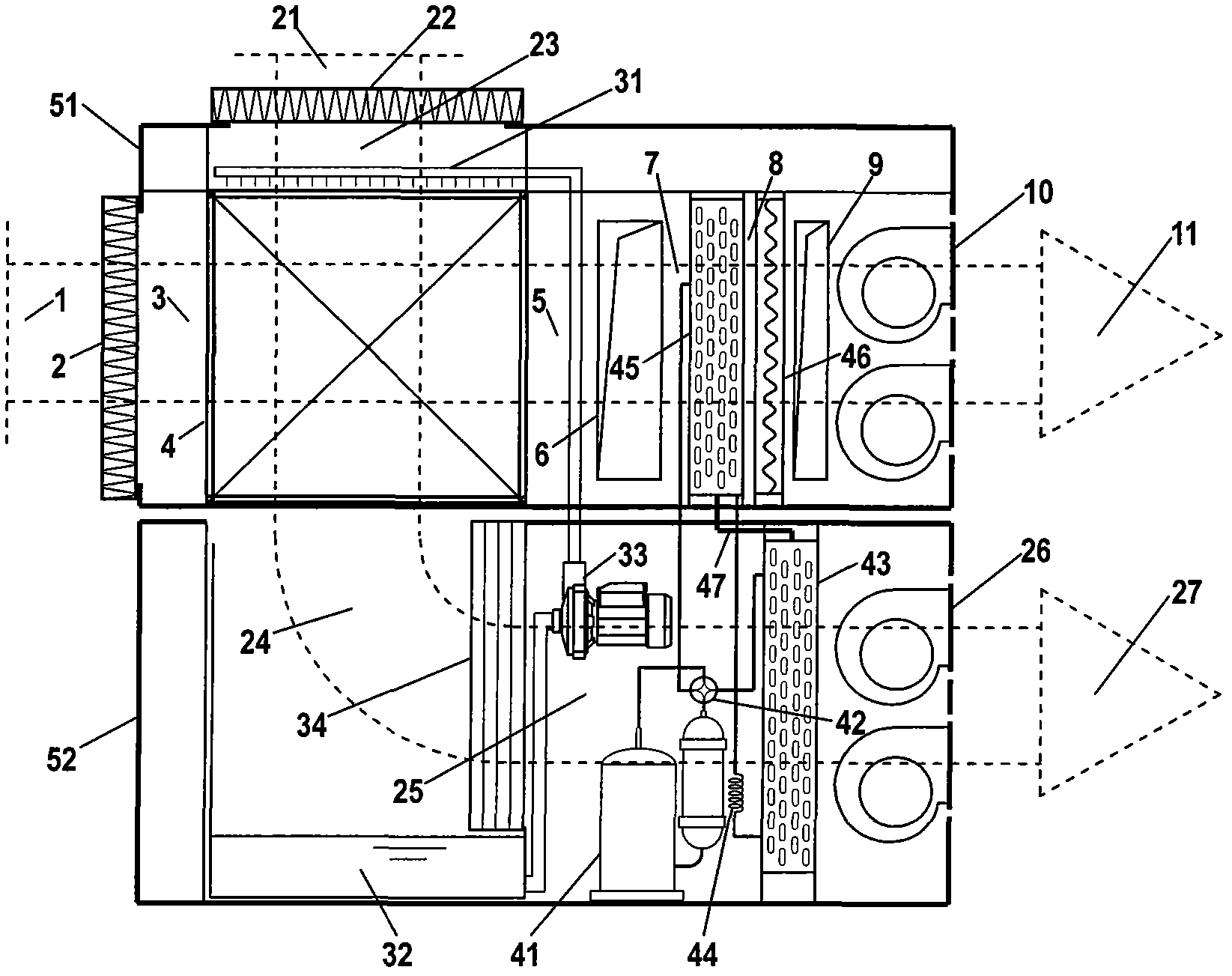

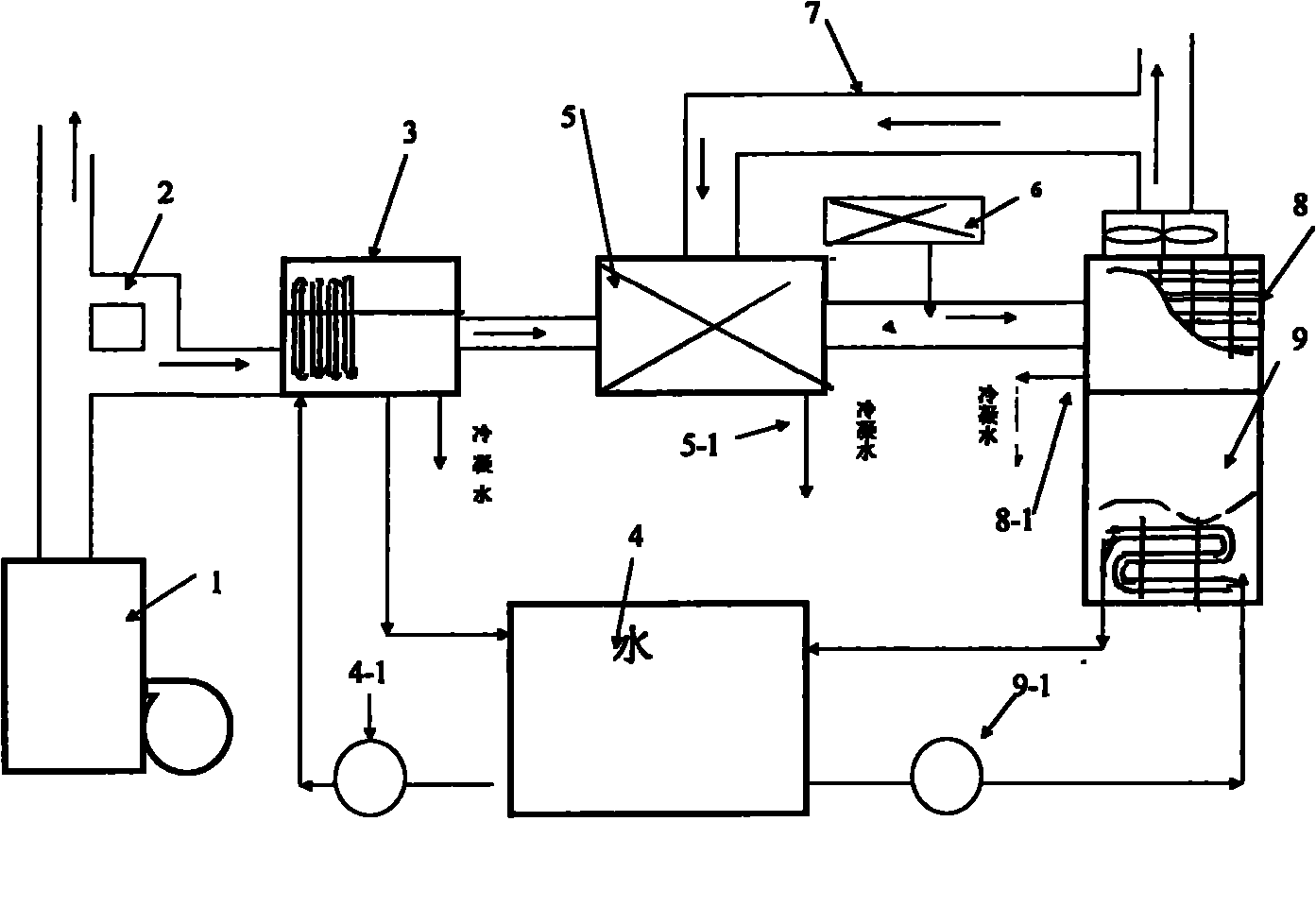

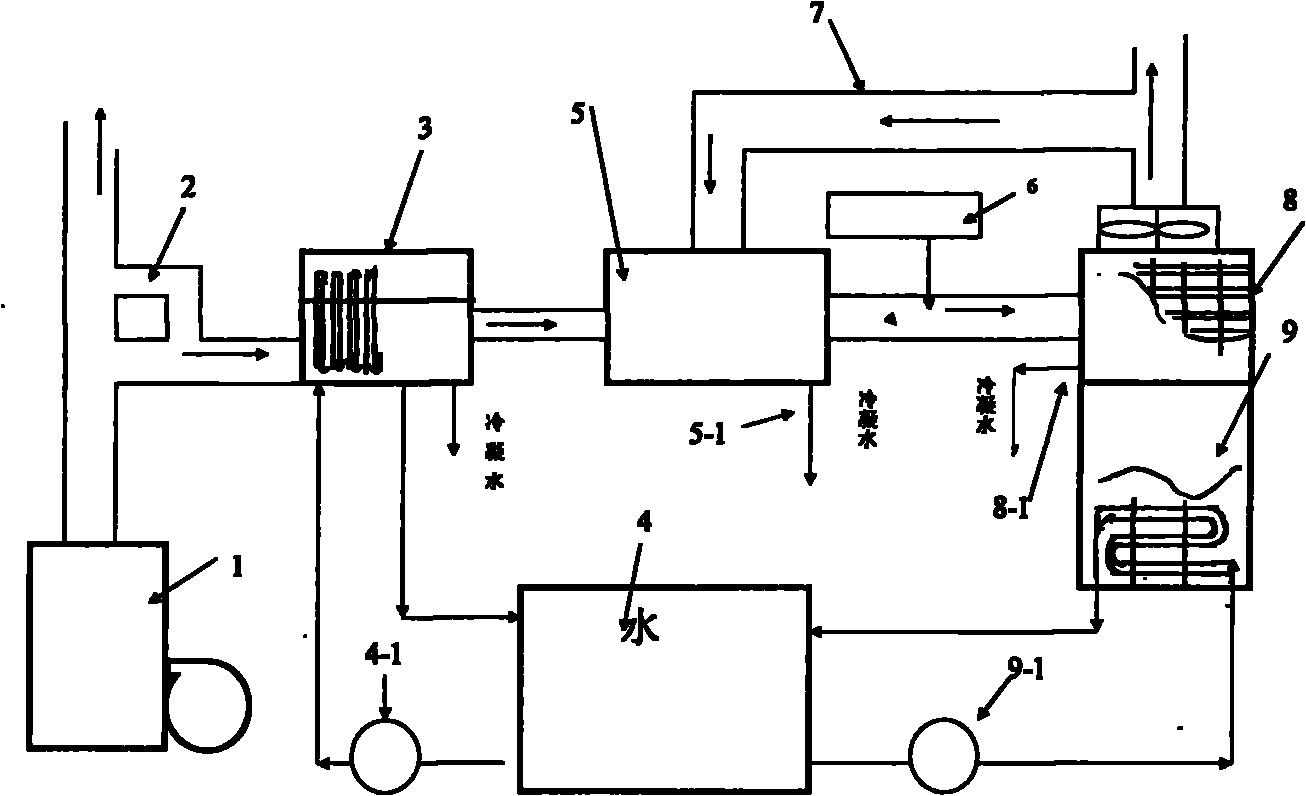

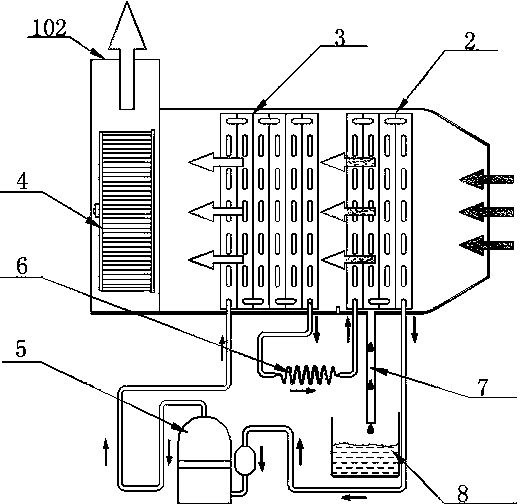

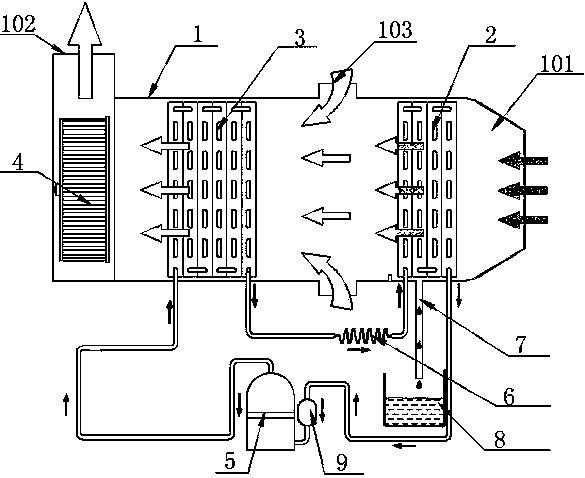

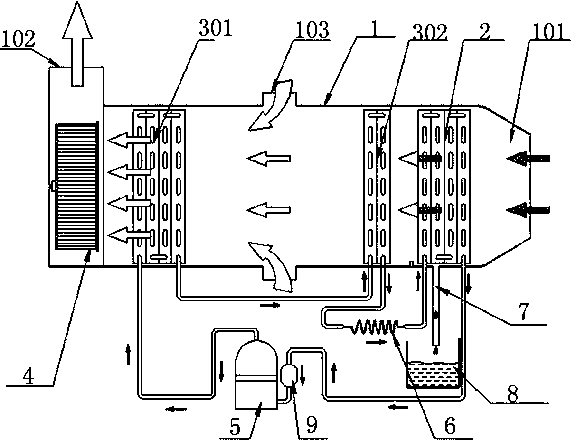

Fresh air conditioner

InactiveCN102425822AHuge latent heat ratioAvoid waterway hazardsEnergy recovery in ventilation and heatingLighting and heating apparatusIndoor air qualityFresh air

The invention relates to the field of heating ventilation air conditioners, in particular to an improved air treatment method and a fresh air conditioner device. The invention improves the problems of traditional fresh air treatment and air conditioners and particularly emphasizes that a plate-type air-air heat exchanger and indirect water evaporative cooling are used for recycling energy of sensible heat and latent heat in air exhaust in the fresh air treatment process of damp and hot regions in summer and condensed water is directly evaporated on an evaporator to improve the working condition of a compressor. Under the condition of quantificationally supplying outdoor fresh air, the energy efficiency ratio of the fresh air conditioner is increased, the thermal pollution, damp pollution and noise pollution of the fresh air conditioner to environments are reduced, the indoor air quality is improved, and meanwhile, the fresh air conditioner provides the manufacture, installation and using convenience for a local region all-air central air conditioner. The fresh air conditioner provided by the invention and a design and manufacture method of the fresh air conditioner are applicable throughout the year in various regions, particularly in the damp and hot regions; and the fresh air system provides controlled, comfortable and healthy air environments for indoor activity space of people and air conditioner environments for technology for processing, storage and the like.

Owner:张洪

Flue gas total-heat recovery device of gas boiler

ActiveCN101769594AEmission reductionImprove protectionEnergy efficient heating/coolingAir heatersPlate fin heat exchangerAir temperature

The invention relates to a flue gas total-heat recovery device of a gas boiler, belonging to the thermotechnical field. In the invention, the temperature of the flue gas exhausted by the gas boiler can be reduced to lower than 40 DEG C by a gas-water heat exchanger and a mixing cooler, then the cooled flue gas is directly supplied for an air-source heat pump water heater for generating the hot water, and the sensible heat and the latent heat in the flue gas can be totally recovered. Most CO2 and NOx in the flue gas can be absorbed by condensed water in the cooling process, thereby reducing the emission of harmful gas. The device comprises the gas-water heat exchanger, the mixing cooler and the heat pump water heater and is characterized in that the flue gas at 150-200 DEG C is cooled to lower than 90 DEG C by the gas-water heat exchanger and then can be cooled to lower than 40 DEG C in the mixing cooler, and the cooled flue gas can serve as heat source to directly enter an evaporator of the air-source heat pump water heater for heat exchange. The invention solves the problems of frosting and low efficiency of the air-source heat pump water heater due to low temperature in winter in the North while recovering the residual heat of the flue gas of the gas boiler at the same time; meanwhile, the emission of the harmful gas in the flue gas of the gas boiler can be reduced, thereby realizing energy saving and emission reduction.

Owner:北京浩特沃特广告有限公司

Blast-furnace cement sensible heat recovery system and its production process

InactiveCN1920380AReduce focal ratioRaise the hot air temperatureOther heat production devicesBlast furnace componentsSlagProduct gas

The invention relates to a blast furnace slag heat recycle system and relative production, wherein it is formed by cooling-breaking, gas-slag heat exchanger, and left-heat boiler units; the slag outlet has cooling-braking unit which will cool the slag to the solidify point 1200-1300Deg. C, to be broken into the slag particles whose diameter is less than 100mm; the transmitter is connected to the gas-slag heat exchanger to heat the air to 700-800Deg. C; the slag will be cooled under 150Deg. C; the heated air will be transmitted to the left-heat boiler; the water of heating tube of boiler will adsorb the heat of gas, to generate the steam whose pressure at 0.3-0.4MPa and temperature at 260-350Deg. C. The invention can improve the energy recycle efficiency more than 70%, to reduce the energy consumption of steel production, reduce the consumption of cooling water, and reduce the environment pollution.

Owner:ANGANG STEEL CO LTD +1

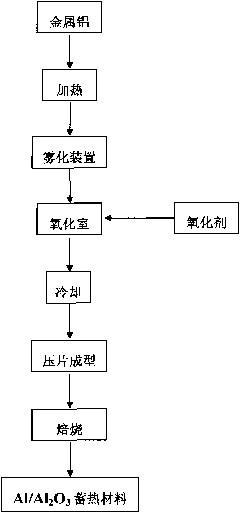

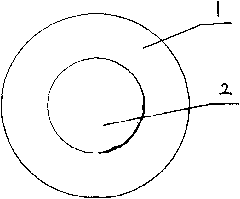

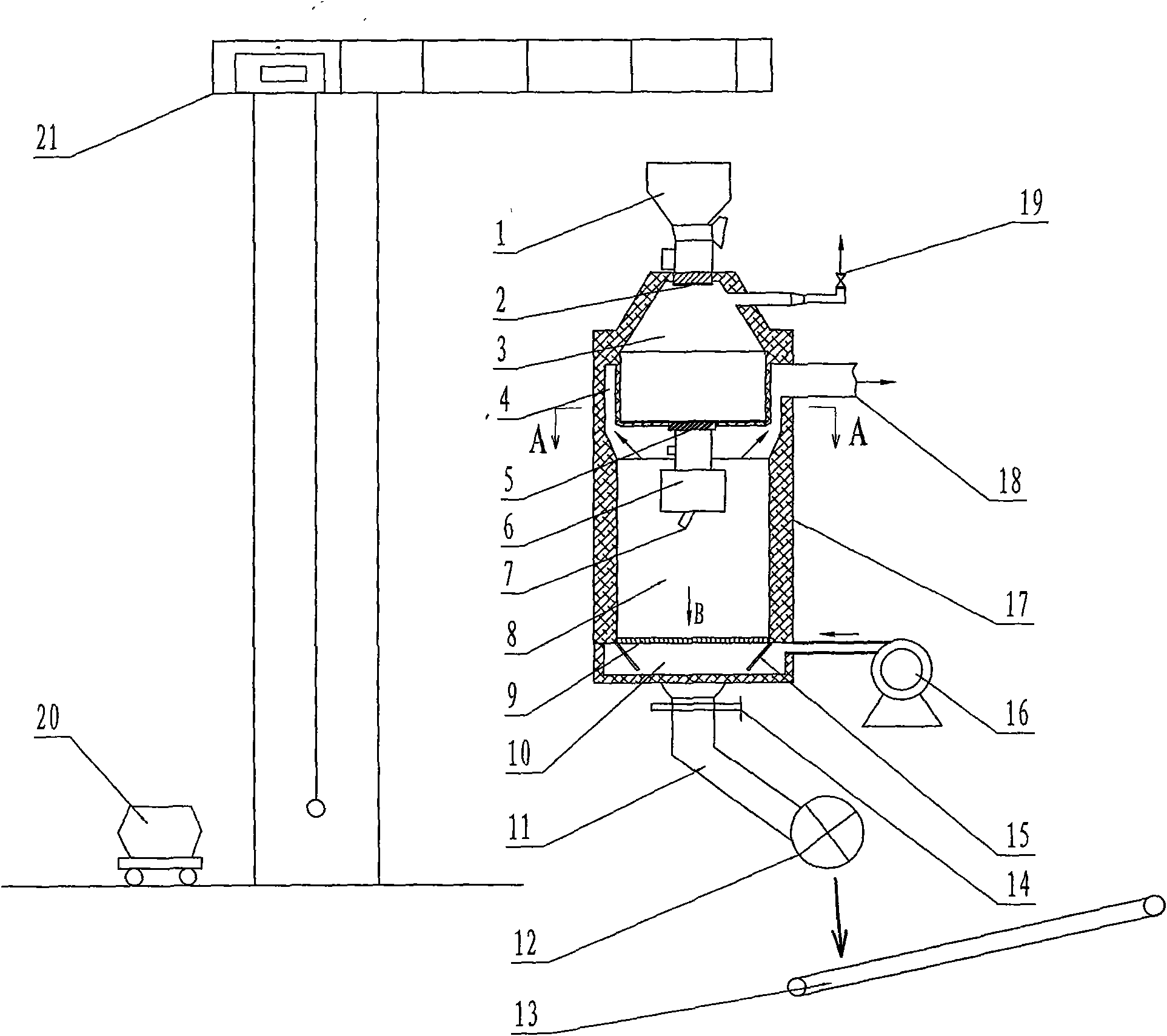

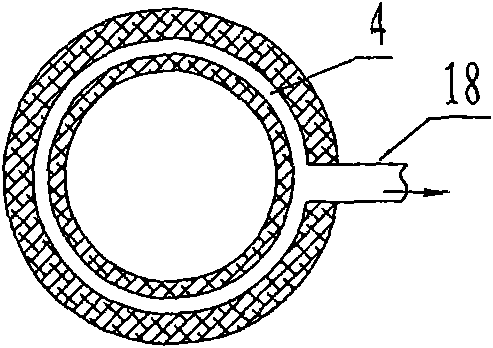

Al/Al2O3 heat storage material and preparation method thereof

The invention discloses an Al / Al2O3 heat storage material and a preparation method thereof. Aluminum oxide serves as a base material; and a spherical metallic aluminum 'core' is enclosed by a layer of aluminum oxide 'enclosure'. In the process of heat storage, metallic aluminum can absorb heat to be changed from a solid state to a liquid state and the temperature of the metallic aluminum rises; at the same time, the external aluminum oxide layer also can absorb the heat, so that the temperature of the external aluminum oxide layer rises; and in the process of heat transfer, the liquid metallic aluminum releases both hidden heat and sensible heat and the aluminum oxide enclosure releases the sensible heat. The preparation process of the Al / Al2O3 heat storage material is obviously different from a conventional method, and comprises the following steps of: atomizing the liquid metallic aluminum (above 660 DEG C) into tiny particles with an atomizing device; and cooling the tiny liquid metallic aluminum particles in an oxidizing atmosphere and oxidizing the external aluminum oxide layer to form the Al / Al2O3 phase-change heat storage material taking the metallic aluminum as the 'core' and taking aluminum oxide as the 'enclosure', wherein the oxidizing atmosphere may adopt oxygen, water vapor, carbon dioxide or air diluted by an inert gas. The preparation method is simple and easy to realize large-scale production.

Owner:KUNMING UNIV OF SCI & TECH

Vertical sinter ore cooling machine capable of efficiently recycling sensible heat of sinter ores

InactiveCN101576351AReduce heat transfer temperature differenceRaise the gradeIncreasing energy efficiencyHandling discharged materialGas solidMaterials science

The invention discloses a vertical sinter ore cooling machine capable of efficiently recycling the sensible heat of sinter ores, which pertains to the technical field of sintering equipment and is used for preventing air leak in the cooling course of sinter ores and effectively recycling the sensible heat of the sinter ores. The technical proposal of the invention is that: the cooling machine consists of a feeding part, a cooling part and a conveying part; the cooling part comprises a vertical closed body, a hot wind pipeline, a blower, as well as a hopper, an upper sealing valve, a pre-storing chamber, a lower sealing valve, a heat exchanging chamber, a wind distributing board, an isopiestic wind chamber and a discharging channel which are in sequence arranged on the body from top to bottom; an annular wind chamber is arranged between the pre-storing chamber and the heat exchanging chamber; the annular wind chamber is communicated with the hot wind pipeline; the isopiestic wind chamber is communicated with the blower; and wind shields and ore falling openings are distributed evenly on the wind distributing board . The vertical sinter ore cooling machine has the following advantages of: 1. an air leak rate near to 0; 2. improved gas-solid heat exchange efficiency of the cooling machine; 3. raised quality of the recycled hot air; and 4. being beneficial to increasing the utilization rate of exhaust-heat boilers. Based on the advantages, the vertical sinter ore cooling machine is expected to be used commonly as an upgraded replacement of the existing sinter cooling machine.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Molten blast furnace slag sensible heat recovery method and device

InactiveCN101660014ASave energyRecycling and recovery technologiesProcess efficiency improvementRecovery methodThermal energy

The invention relates to the field of energy recovery utilization and in particular to a molten blast furnace slag sensible heat recovery method and a device; the method is characterized in that: themolten blast furnace slag carries out a first heat recovery in a granulator, and then a second heat recovery is carried out by a vibrated bed, and then a third heat recovery is carried out in a fluidized bed, and the reclaimed heat energy is reutilized or converted in a hot air or power generating way; the realization steps are that: 1) the molten blast furnace slag is arranged in the granulator for granulation; 2) the blast furnace slag granules carry out heat exchange in the vibrated bed; 3) the blast furnace slag granules carry out heat exchange in the fluidized bed; 4) after heat exchangeis carried out, the heat is used for power generation from air or is directly utilized in a hot wind way. The method has the beneficial effects that: the sensible heat of the molten blast furnace slagis utilized respectively in a way of waste heat stream power generation and in a way of blast furnace hot wind, compared with the existing water quenching method, 1.0-1.2t of fresh water can be savedwhen processing 1t of molten slag, and sulfides H2S and SO2 are not produced, and energy equivalent to 47kg of standard coal is saved.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

Low-condensing-pressure deep supercooling efficient dehumidifier

ActiveCN104019574AReduce condensing pressureReduce power consumptionCompression machines with several condensersBusiness efficiencyThermal bridge

The invention provides a low-condensing-pressure deep supercooling efficient dehumidifier. The low-condensing-pressure deep supercooling efficient dehumidifier comprises an air flue, a first draught fan and a refrigerating and dehumidifying system. The refrigerating and dehumidifying system comprises an evaporator, a first condenser, a second condenser, a compressor and a throttling device. According to the low-condensing-pressure deep supercooling efficient dehumidifier, a bypass airflow channel is additionally arranged in the air flue between the first condenser and the second condenser, so that the ventilation quantity of the first condenser is increased, and the condensing pressure of refrigerating fluid gas in the condensers is reduced; the first condenser is used for heat release and cooling of a sensible heat portion of the overheated refrigerating fluid gas and heat release, condensation and liquefaction of the refrigerating fluid gas, and the second condenser is used for cooling and supercooling of refrigerating fluid; since a finned thermal bridge between the first condenser and the second condenser is disconnected, the supercooling degree of the refrigerating fluid at the tail end of the second condenser is improved, the vaporization ratio of the refrigerating fluid in the throttling device can be lowered, the evaporation and heat absorption capacity of the refrigerating fluid in the evaporator is improved, and the energy efficiency ratio of the dehumidifier is increased substantially.

Owner:HANGZHOU PREAIR ELECTRICAL APPLIANCE IND

Magnetic roasting system and process for powder of refractory iron ore

The invention belongs to the fields of chemical industry and metallurgy and in particular relates to a magnetic roasting system and process for powder of a refractory iron ore such as limonite, siderite, deposited hematite and the like by using a circulating fluidized bed. The powder of the iron ore is magnetically roasted by using a circulating fluidized bed reactor; the latent heat of unreacted reductive gas in roasting tail gas is released through combustion in a combustion chamber firstly, and then, heat is recovered through the heat exchange between a multistage cyclone preheater and the powder of a cold iron ore; and the sensible heat of the powder of a high-temperature roasted iron ore is recovered in a way that cold coal gas and the powder of the high-temperature roasted iron exchange heat in a cyclone cooler. The magnetic roasting system and process have the advantages of high magnetic roasting efficiency, high heat utilization efficiency in the roasting process and the like and can be used for reducing the energy consumption in the magnetic roasting process of the powder of the refractory iron ore and improving the economical efficiency in the magnetic roasting process of the powder of the refractory iron ore.

Owner:深圳市中科九台资源利用科技产业股份有限公司

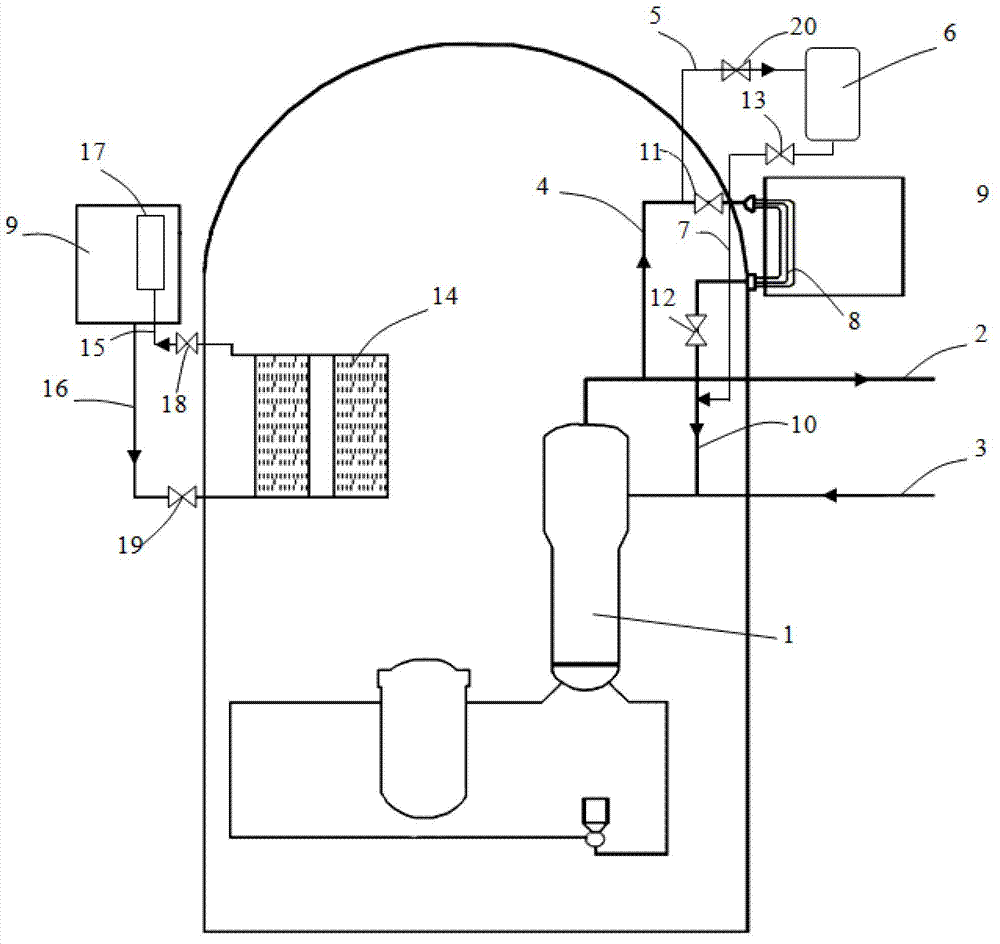

Passive heat removal device for dealing with station blackout accident

InactiveCN102867550AIntegrity guaranteedNo action requiredNuclear energy generationCooling arrangementRadioactive agentReactor design

The invention relates to reactor design technology, in particular to a passive heat removal device for dealing with a station blackout accident. The passive heat removal device structurally comprises a secondary side passive residual heat removal system and a passive containment heat export system, and the secondary side passive residual heat removal system is used for exporting residual heat of a reactor core and sensible heat of various devices of a reactor coolant system, so that a reactor is maintained to be in a safe shutdown state. The passive containment heat export system is used for exporting heat in a containment released by the reactor core so as to maintain integrity of the containment. The secondary side passive residual heat removal system and the passive containment heat export system share a hot water tank. The passive heat removal device for dealing with the station blackout accident is capable of exporting decay heat of the reactor core and heat in containment space released by the reactor core under the working condition of the station blackout accident, and melting probability of the reactor core and probability of radioactive substances released to the environment are evidently lowered.

Owner:CHINA NUCLEAR POWER ENG CO LTD

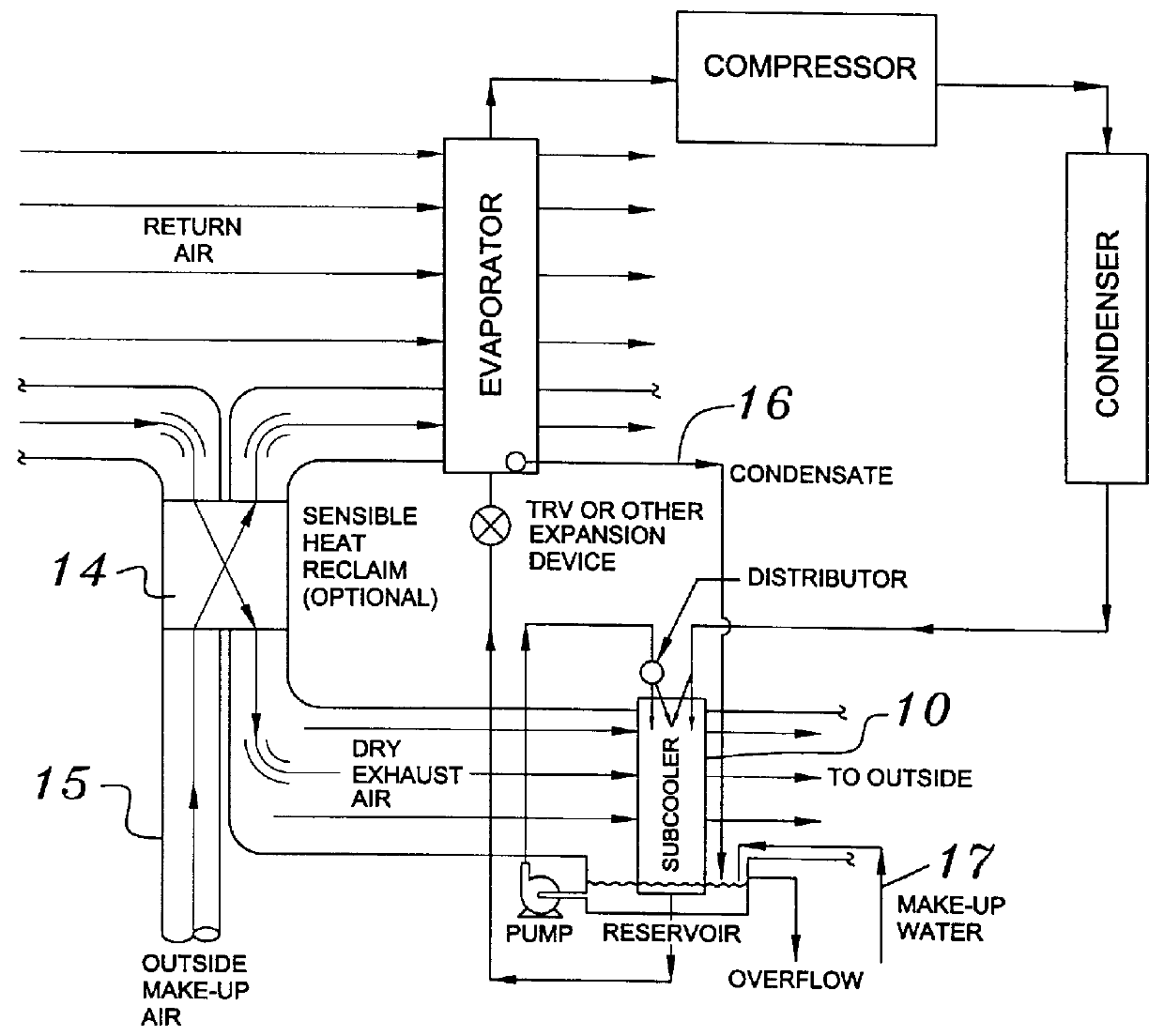

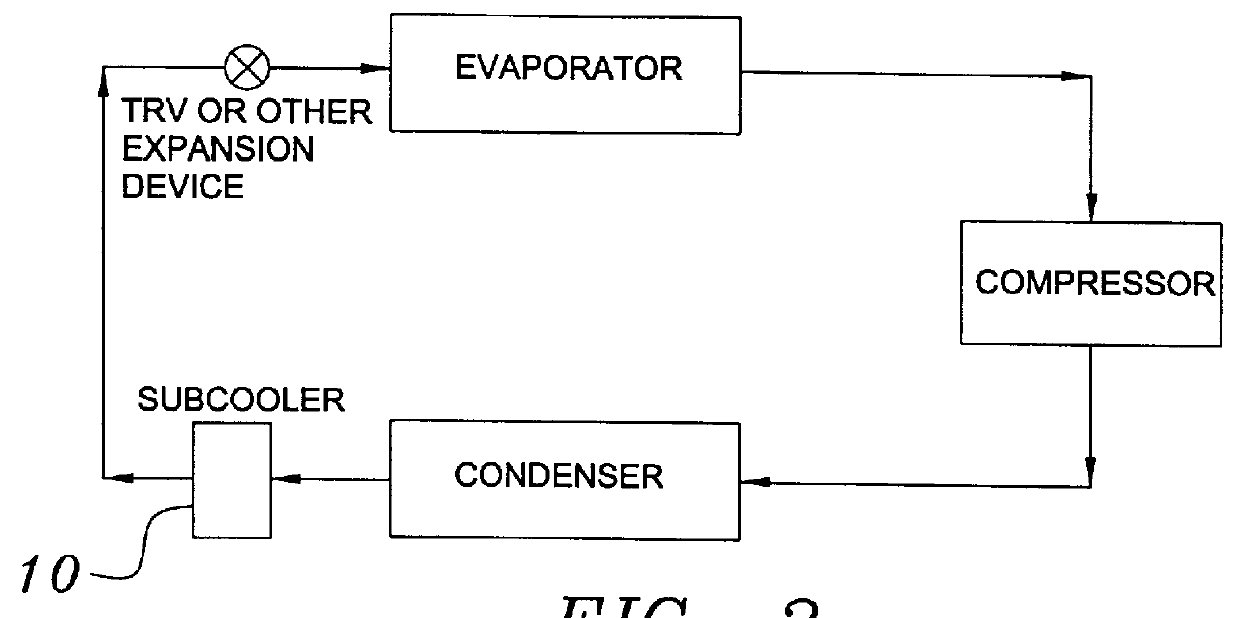

Building exhaust and air conditioner condenstate (and/or other water source) evaporative refrigerant subcool/precool system and method therefor

InactiveUS6070423AComprehensive understandingReduce the temperatureEnergy recovery in ventilation and heatingHeat recovery systemsWater wetIndoor air quality

First, a system for providing liquid refrigerant subcooling, subsequent to that subcooling accomplished by the primary condenser of an air conditioner or heat pump, by means of evaporative cooling utilizing the condensate water of said air conditioner or heat pump system and / or some other water supply to wet the surface of the subcool heat exchanger and then passing the cold, dry building exhaust air required for good indoor air quality across the wetted surface of the subcool heat exchanger. Said exhaust air could be used after first undergoing a sensible heat exchange with the incoming make up air. Said subcooling providing for an increased refrigeration capacity, and efficiency of the system. Secondly, a system for providing hot gas discharge refrigerant precooling before said hot gas passes into the primary condenser of an air conditioner or heat pump, by means of evaporative cooling utilizing the condensate water of said air conditioner or heat pump system and / or some other water supply to wet the surface of the precool heat exchanger and then passing the cold, dry building exhaust air required for good indoor air quality across the wetted surface of the precool heat exchanger. Said precooler providing lower power consumption of the compressor, lower head pressure, increased mass flow of the refrigerant and improved efficiency of the primary condenser of the air conditioning or heat pump system. Said exhaust air could be used after first undergoing a sensible heat exchange with the incoming make up air on either the subcooler or precooler. Finally, a combination subcooler and precooler system where the cold dry exhaust air is first used to evaporatively subcool the liquid refrigerant in the water wetted subcooler and then subsequently used to conductively cool the hot gas refrigerant passing through a dry surface precooler or alternately used to evaporatively cool the wetted surface of the precooler thereby evaporatively precooling the hot gas refrigerant passing through the precooler.

Owner:GLOBAL ENERGY & ENVIRONMENT RES INC +1

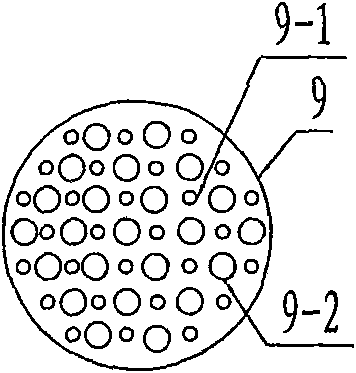

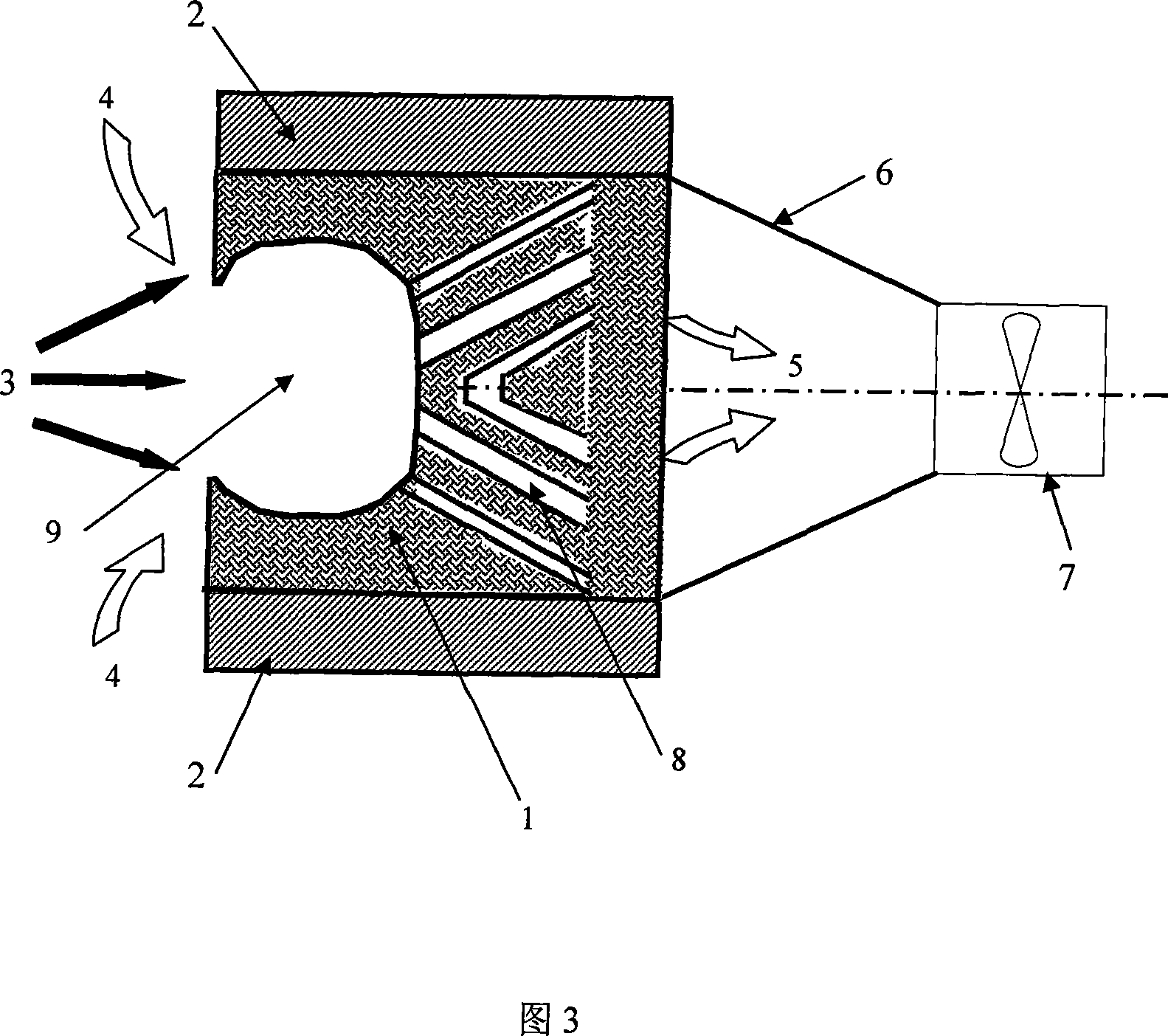

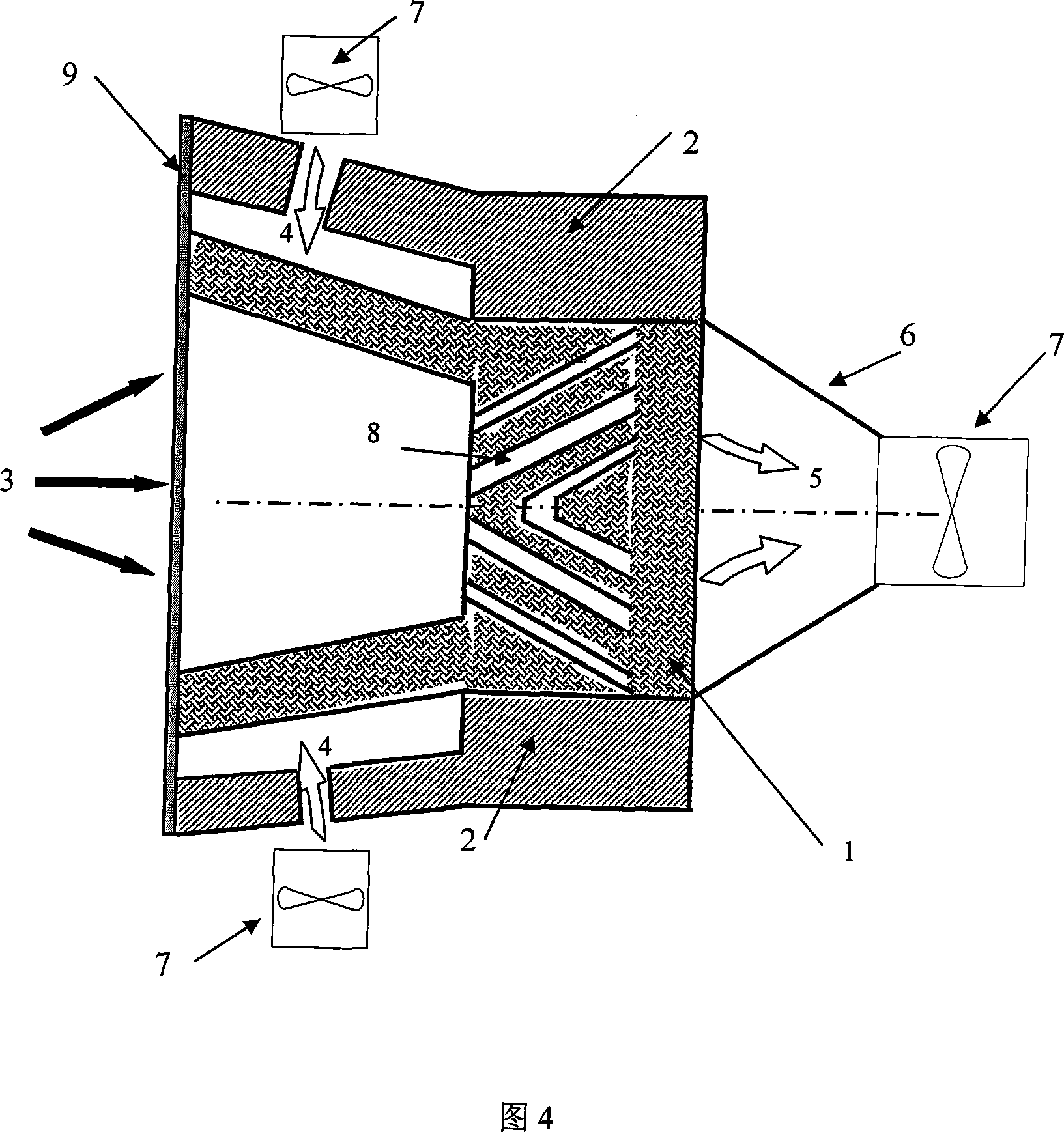

Silicon carbide foam ceramic solar energy air heat-absorbing device

InactiveCN101122425AImprove thermal conductivityFacilitate conductionSolar heating energySolar heat devicesCold airBlackbody cavity

A silicon carbide ceramic foam solar energy air heat absorber uses silicon carbide ceramic foam materials as solar energy absorber. The silicon carbide ceramic foam absorber is wrapped with an insulating layer (2). A radiant heat flux (3) projects onto the surface of the silicon carbide ceramic foam absorber (1) or into an artificial blackbody cavity (9) and is received by the silicon carbide ceramic foam absorber (1). Cold air (4) flows in from the side of the silicon carbide ceramic foam absorber (1) positive to the radiant heat flux (3). Hot air (5) is obtained through heat exchange of thecold air and the radiant heat flux. Or the cold air (4) flows in from the side of the silicon carbide ceramic foam absorber (1) positive to the radiant heat flux (3) or back to the radiant heat flux (3). The hot air (5) of 700 to 1300 DEG C is obtained through the heat exchange of the cold air and the radiant heat flux through a quartz window (10). The silicon carbide ceramic foam absorber (1) buries an air diversion channel (8) beforehand. The invention can effectively receive radiant heat and emit heat to the air and take advantage of self-sensible heat to store heat at the same time.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

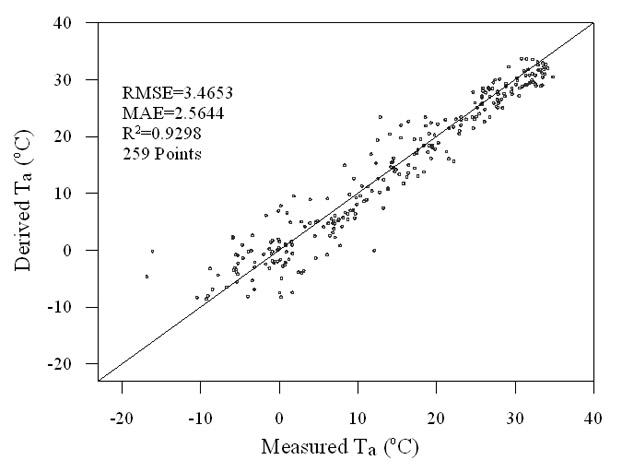

Remote sensing inversion method for land surface evapotranspiration of arid and semi-arid regions

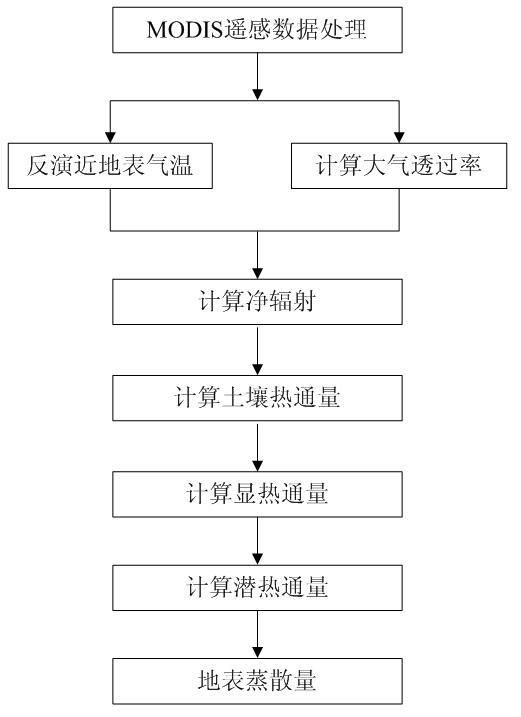

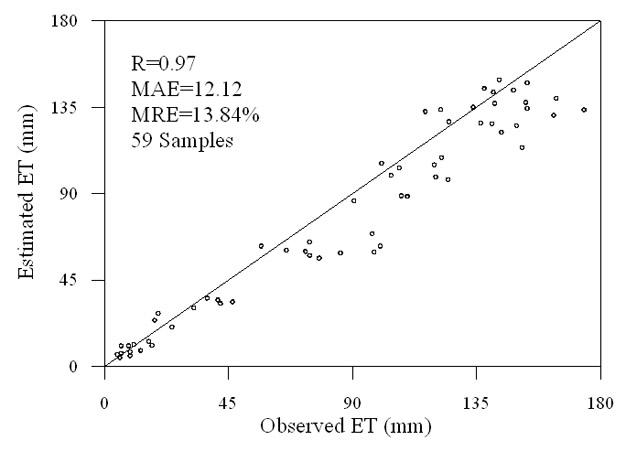

InactiveCN102253184AImprove applicabilityTargeted optimizationEarth material testingSensing dataHeat flux

The invention discloses a remote sensing inversion method for land surface evapotranspiration of arid and semi-arid regions. The method comprises the steps of: acquiring and processing EOS / MODISE (Earth Observing System / Moderate-resolution Imaging Spectroradiometer) remotely sensed data; performing the inversion of near-surface temperature and computing atmospheric transmittance; obtaining a land surface latent heat flux by solving a net radiation quantity, a soil heat flux and a sensible heat flux according to a land surface energy balance equation; and figuring out land surface evapotranspiration data according to the land surface latent heat flux. According to the invention, aiming at the characteristics of rare meteorological stations in the arid region of Northwest China, a near-surface temperature inversion model and an atmospheric transmittance model both based on remotely sensed data are established, and the temperature obtained by the remote sensing inversion is used for participating in the computation instead of the observed temperatures of the stations; therefore, requirements on meteorological and other observation data are reduced.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

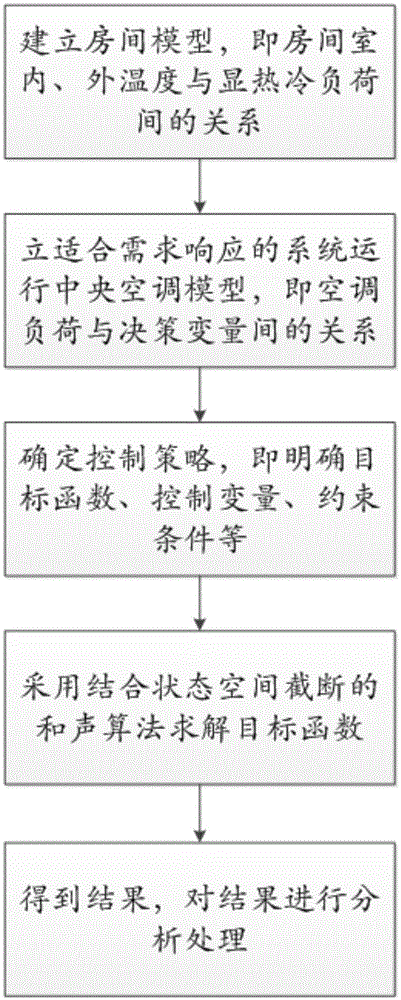

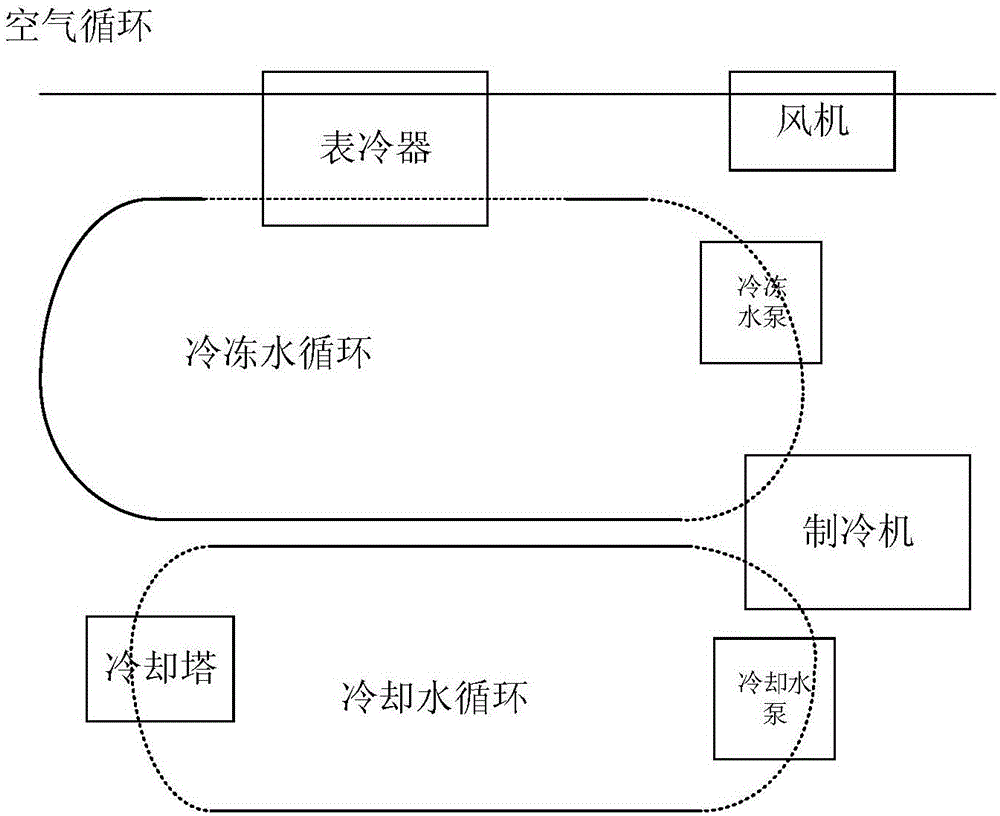

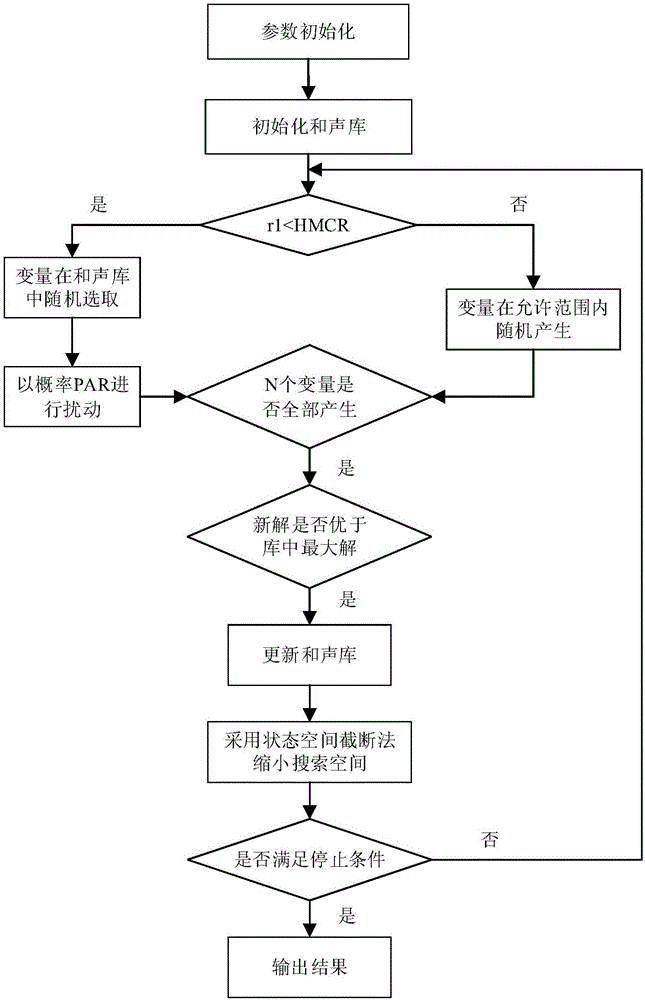

Central air-conditioning modeling and controlling strategy on basis of demand response

ActiveCN105004015AUniversalMechanical apparatusSpace heating and ventilation safety systemsHarmony searchSimulation

The invention discloses a central air-conditioning modeling and controlling strategy on the basis of demand response, which comprises the following steps of building a room model, namely the relation between the indoor temperature and outdoor temperature of the room and sensible heat cooling load; building a center air-conditioning model suitable for the system operation of the demand response, namely the relation between air conditioning load and a decision variable; determining a controlling strategy, namely making an objective function, a control variable, a constraint condition and the like clear; solving the objective function by adopting a harmony search algorithm combining with a state space truncation method; obtaining a result, and performing analysis and treatment on the result. According to the central air-conditioning modeling and controlling strategy on the basis of the demand response, through meticulously building the models, making the strategy of multiple control variables cooperative optimization clear, scientific theoretical support is provided for the central air-conditioning to participate in the system operation of the demand response.

Owner:SOUTHEAST UNIV

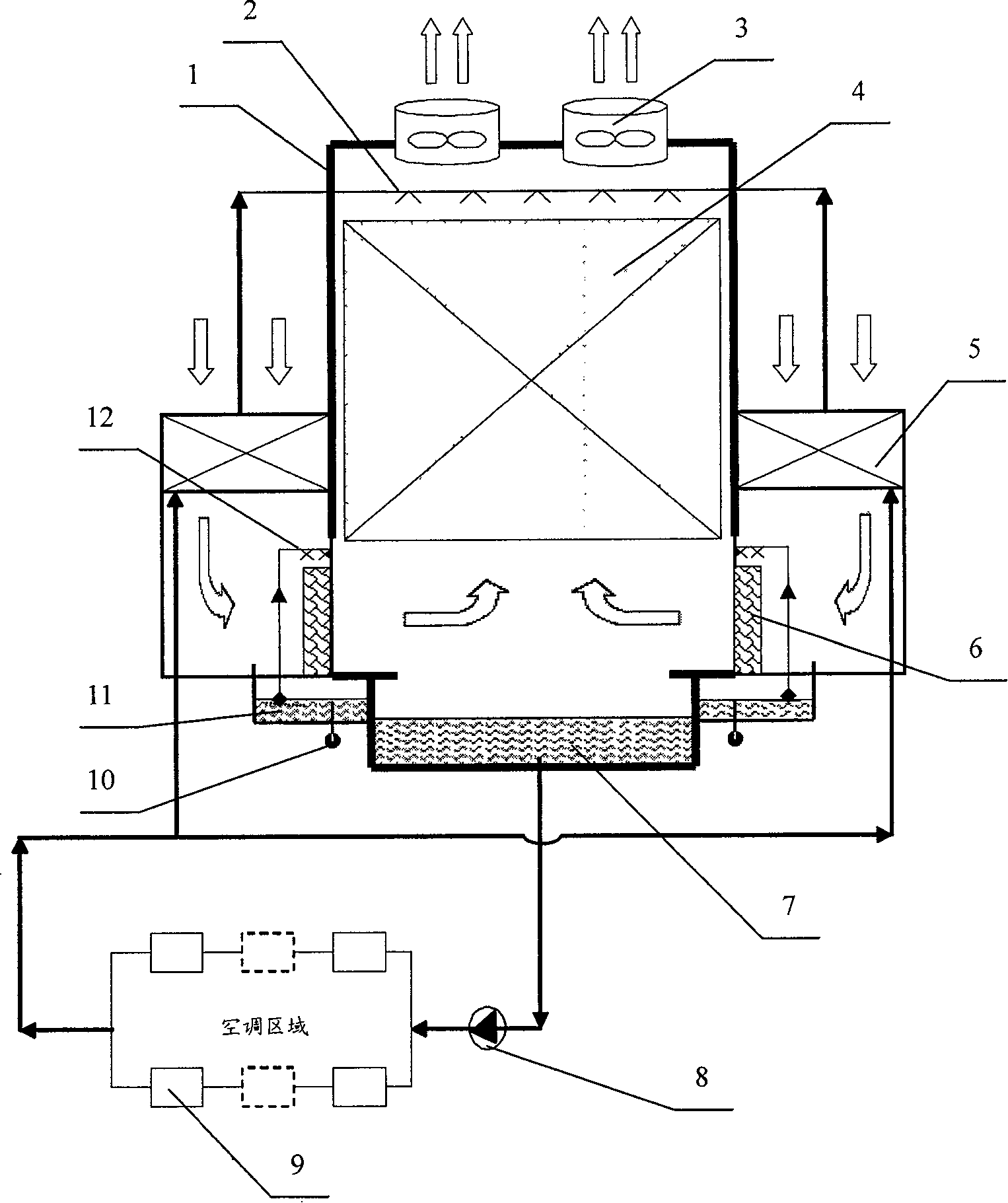

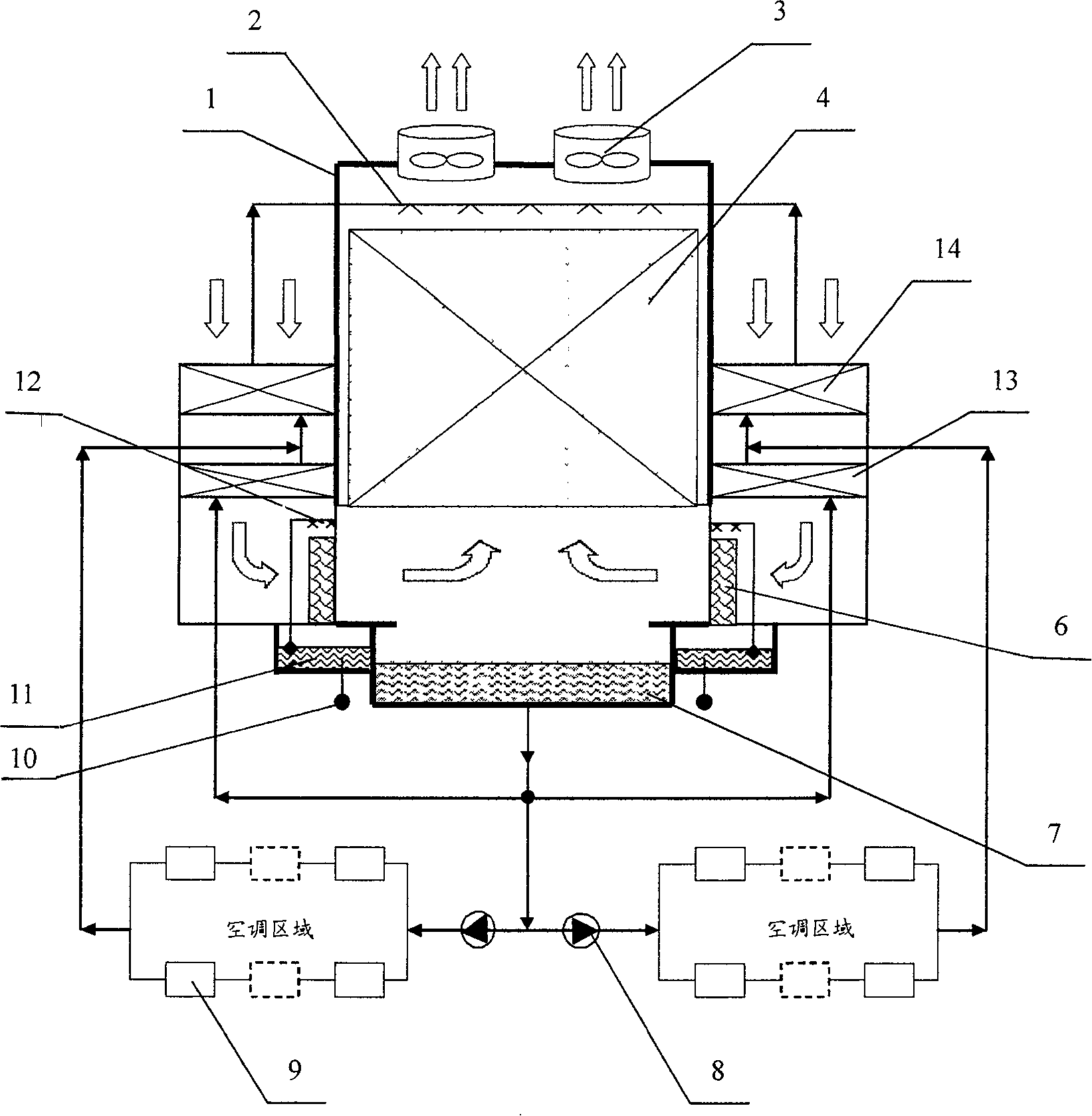

Evaporation regrigerating water chilling unit

ActiveCN101191646AEfficient use ofAchieve recyclingLighting and heating apparatusAir conditioning systemsWater storageHEAT/MOISTURE EXCHANGE

The present invention belongs to an improvement of an evaporative cooling cool supply device with dry air energy as power source, and in particular relates to an evaporative refrigeration water chilling unit. A spraying water distributor and a blower are arranged above a direct evaporative cooling heat exchanger; a water storage pool with a circulating water pump is arranged inside a casing on the lower part of the direct evaporative cooling heat exchanger; an air inlet of the casing is provided with a surface air cooler; a water inlet of the circulating water pump is connected with a water outlet at the bottom of the water storage pool through pipelines; a water outlet of the circulating water pump is connected with an indoor sensible heat cool supply terminal through pipelines; an outlet of the indoor sensible heat cool supply terminal is connected with the surface air cooler through pipelines; a water outlet of the surface air cooler is connected with a spraying water distributor through pipelines. The present invention can realize the effective utilization of the cold energy of cold water, reduces the irreversible loss of heat-moisture exchange, improves heat-moisture exchange efficiency, ensures that outlet water temperature can approach to the dew point temperature of inlet air, and improves the efficiency of utilizing dry air energy.

Owner:新疆绿色使者空气环境技术有限公司 +1

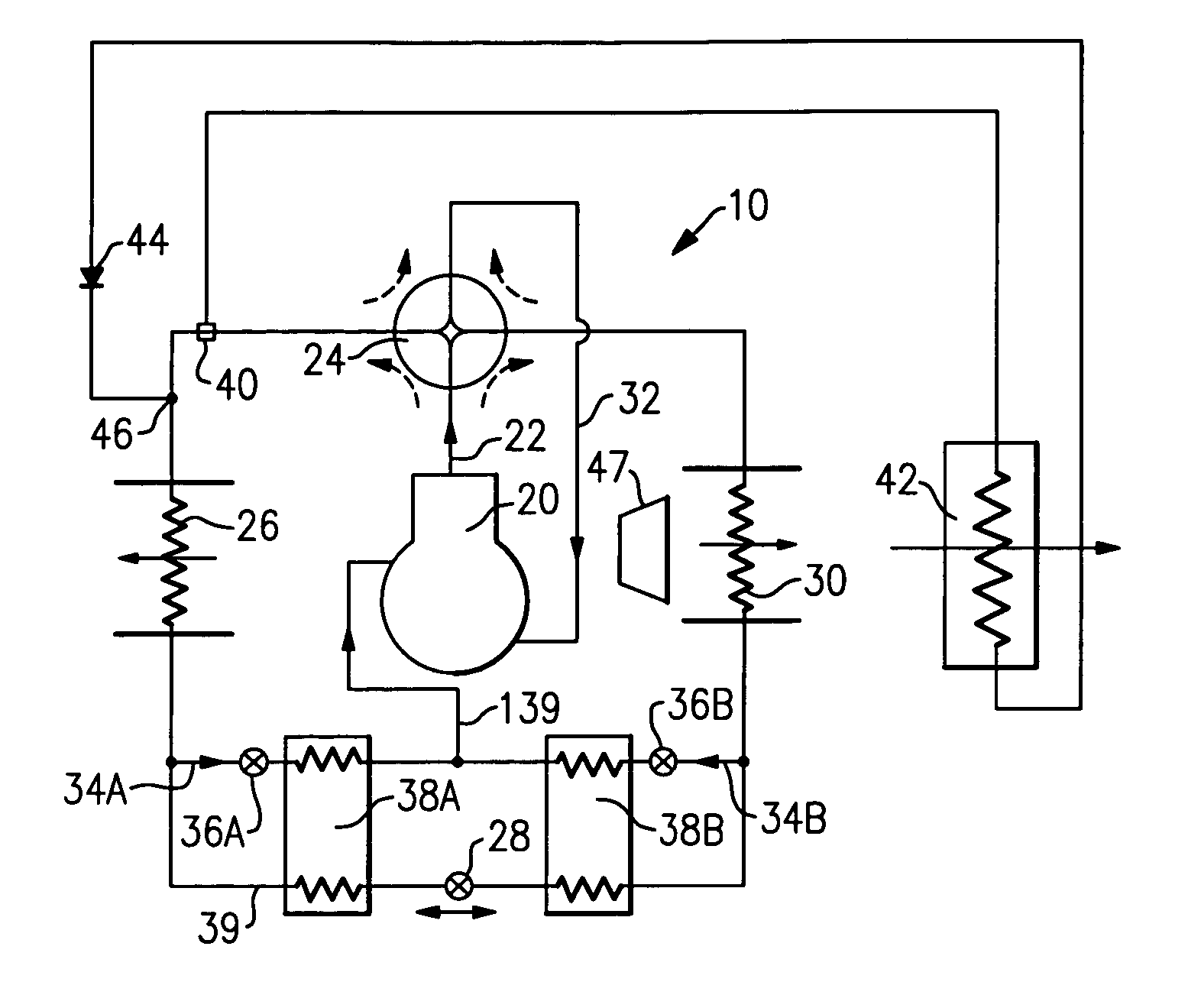

Heat pump with reheat and economizer functions

InactiveUS20060053823A1Improve performanceImprove comfortCompression machines with non-reversible cycleFluid circulation arrangementEngineeringEconomizer

A heat pump system operates in heating and cooling modes. The heat pump is provided with both a reheat function and economizer circuit. The economizer circuit provides augmented performance to the heat pump, while the reheat coil allows enhanced control over temperature and humidity of the air supplied to the conditioned space. A bypass line around an outdoor heat exchanger is also provided to achieve additional flexibility of control for a sensible heat ratio. Selective operation of the abovementioned components and subsystems allows precise control over system operation parameters and hence satisfaction of a wide spectrum of sensible and latent load demands and improved reliability.

Owner:CARRIER CORP

Energy-saving slag thermal insulator

InactiveCN101892332AImprove insulation effectLow raw material costRecycling and recovery technologiesChemical reactionSlag

The invention relates to an energy-saving slag thermal insulator, and belongs to the technical field of energy conservation, emission reduction and comprehensive utilization in the metallurgy industry. The thermal insulator comprises the following main chemical components in percentage by weight: 25 to 70 percent of SiO2, 1 to 25 percent of Al2O3, 1 to 40 percent of CaO, 0 to 20 percent of MgO, 0 to 10 percent of F<->, 0 to 10 percent of R2O (R is a monovalent metal ion), 0 to 10 percent of Fe2O3, 5 to 60 percent of fixed carbon with bulk density of 0.25 to 0.75g / cm<3>. The thermal insulator has high thermal insulation performance and can reduce the thermal loss of high-temperature slag; the thermal insulator contains a certain amount of fixed carbon, so heat generated in the chemical reaction of the fixed carbon can be used for further making up the thermal loss of the slag; meanwhile, the thermal insulator belongs to a silicon-aluminum material, and part or all of the thermal insulator can be dissolved in the slag finally so as to improve the chemical composition of the slag and reduce the melting point of the slag. The thermal insulator has the advantages of simple production process, low cost, and suitability for various processes for utilizing the sensible heat of the slag, increasing the fluidity of the slag or improving the performance of the slag.

Owner:UNIV OF SCI & TECH BEIJING

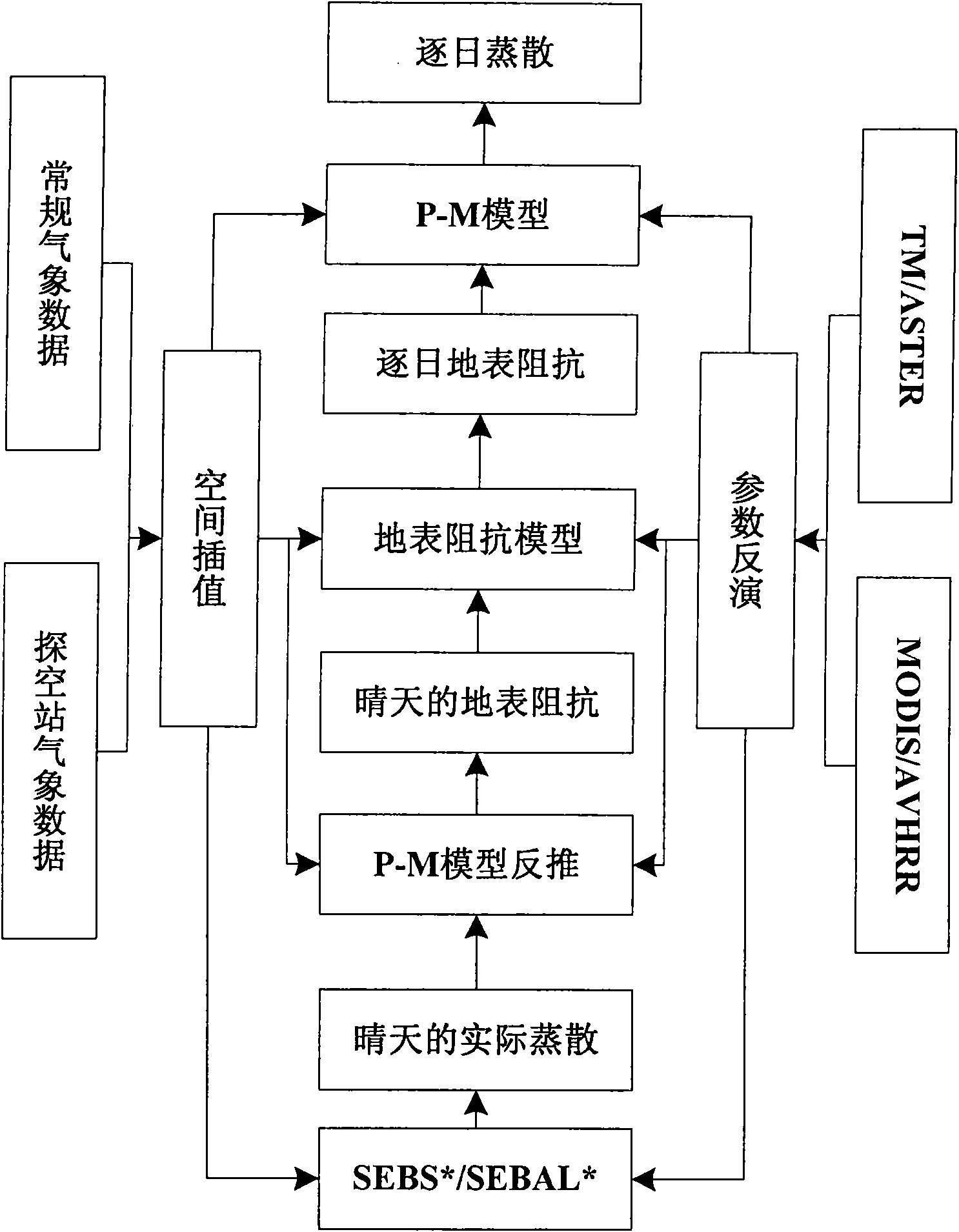

Method for monitoring regional evapotranspiration on the basis of remote sensing

InactiveCN101551459AHigh precisionImprove accuracyElectromagnetic wave reradiationICT adaptationEffective surfaceDown scaling

The invention provides a method for monitoring the regional evapotranspiration on the basis of remote sensing, comprising the following steps of: (1) obtaining the multi-temporal and multi-resolution satellite remote-sensing image data at a specific region; (2) carrying out remote sensing inversion to the key parameters on the ground surface; (3) calculating the impedance of each pixel during the exchanging process of the geogas energy by a remote-sensing geogas exchanging model, calculating the sensible heat flux used for heating the air above each pixel, calculating the latent heat energy by an energy remainder formula and inquiring into effective surface impedance; (4) establishing a surface impedance model in a daily dimension so as to obtain a daily ground surface impedance; and (5) working out the daily evapotranspiration by applying a P-M model repeatedly and carrying out time accumulation and dimension down-scaling, thus finally determining the regional ground surface evapotranspiration. According to the validation of the practical measurement at multi-regions, the method for monitoring the regional evapotranspiration is proved to be effective.

Owner:BEIJING WISEWATCH INFORMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com