Low-condensing-pressure deep supercooling efficient dehumidifier

A technology of condensing pressure and deep subcooling, which is applied to compressors, refrigerators, compressors, etc. with multiple condensers. Compressor power consumption increases and other problems, to achieve the effect of improving evaporation heat absorption capacity and dehumidification capacity, ensuring integrity and effectiveness, and improving dehumidification energy efficiency ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

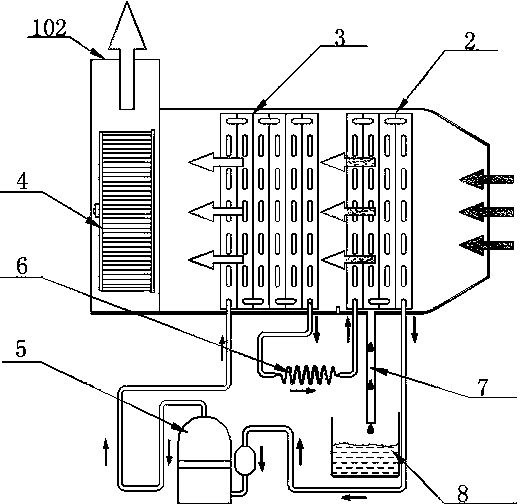

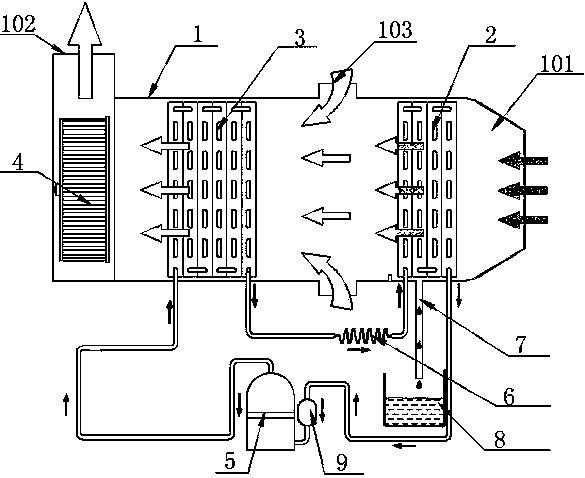

[0051] refer to figure 2 The low condensing pressure deep subcooling high-efficiency dehumidifier includes an air duct 1, a first fan 4 and a refrigeration dehumidification system, and the first fan 4 and the refrigeration dehumidification system are arranged in the air duct 1 side by side. Wherein, the air duct 1 has an air inlet 101 and an air outlet 102, and the first fan 4 is located at the air outlet 102 of the air duct 1; the first fan 4 is preferably a centrifugal fan, and of course other types of fans are also selected, which are not limited here.

[0052] In this embodiment, the refrigeration and dehumidification system includes an evaporator 2, a condenser 3, and a compressor 5, wherein both the evaporator 2 and the condenser 3 include bent pipes and fins arranged outside the bent pipes, wherein the fins can For aluminum fins, bent pipes can be copper pipes. The evaporator 2 and the condenser 3 are arranged side by side, and the evaporator 2 is close to the air inl...

Embodiment 2

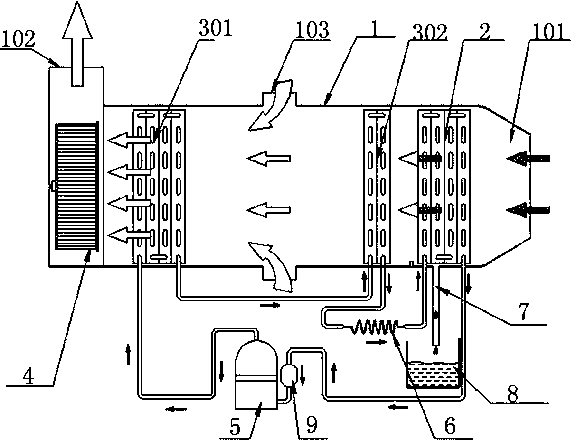

[0063] refer to image 3 , this embodiment is an improvement made on the basis of Embodiment 1. Specifically, in this embodiment, the refrigeration and dehumidification system includes two condensers, specifically a first condenser 301 and a second condenser 302 connected in series, the first condenser 301 and the second condenser 302 are arranged side by side, and the second A condenser 301 is close to the side of the first fan 4, a second condenser 302 is close to the side of the evaporator 2, and the bypass air passage 103 is located between the first condenser 301 and the second condenser 302; the second condenser Both ends of the pipeline in 302 are respectively connected to the pipelines in the first condenser 301 and the evaporator 2 , and the throttling device 6 is arranged on the pipeline between the second condenser 302 and the evaporator 2 .

[0064] In this embodiment, the heat release area of the first condenser 301 is larger than the heat release area of the...

Embodiment 3

[0072] refer to Figure 5 , this embodiment is an improvement made on the basis of the second embodiment. Specifically, a second fan 10 is also provided between the second condenser 302 and the bypass airflow channel 9. For other structures of the low condensing pressure deep subcooling and high-efficiency dehumidifier, refer to the description in Embodiment 2, which will not be repeated here. repeat.

[0073] In this embodiment, the present invention solves the problem of the second condenser 302 and the evaporator 2 compared with the bypass air passage 103 by adding a second fan 10 between the second condenser 302 and the bypass air passage 9 . The large wind resistance in the channel area helps to stabilize the ventilation volume of the second condenser 302 and the evaporator 2, and contributes to the air distribution of the bypass air channel 103, thereby stably increasing the air volume flowing through the condenser 301. Make its air volume reach more than 3 times of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com