Patents

Literature

179results about How to "Improve ice production efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

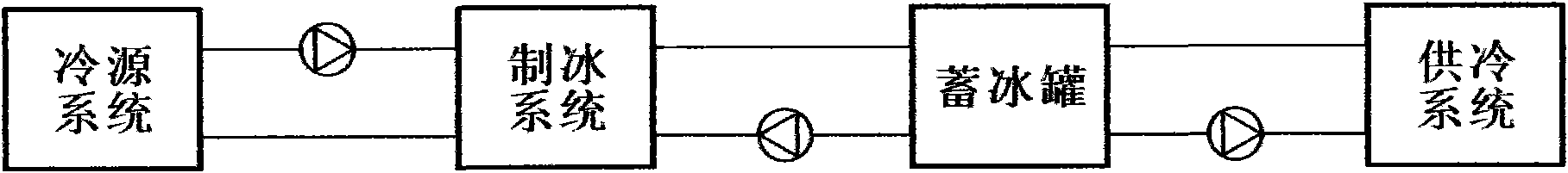

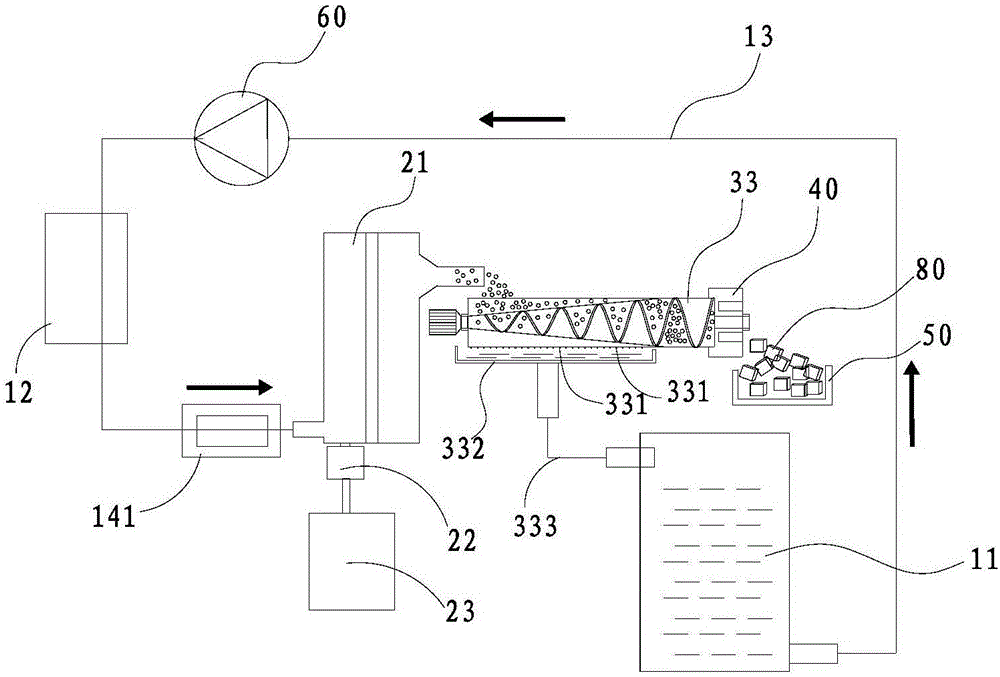

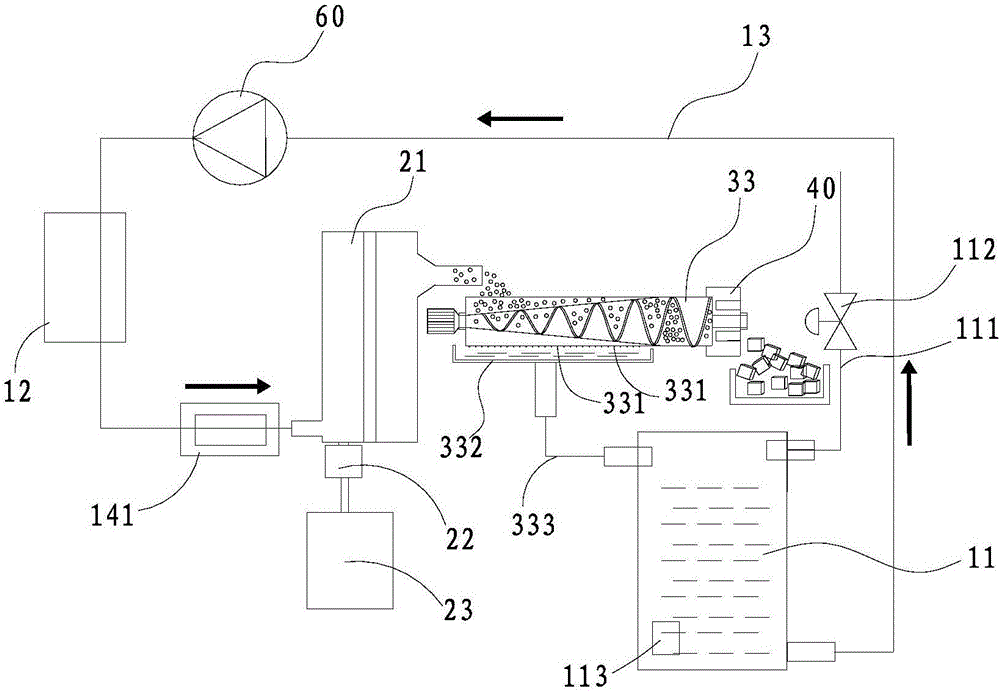

Central air-conditioning system of ice slurry cold storage

InactiveCN101629748ASimple structureIce storage tank requirements are lowLighting and heating apparatusAir conditioning systemsSlurryMotor power

The invention belongs to a central air-conditioning system, in particular to an energy-saving central air-conditioning system which uses ice slurry as an energy storage carrier for transferring the load of an electricity peak in the daytime to an electricity valley in the night. The central air-conditioning system mainly comprises a host refrigerating machine, a plate heat exchanger, an ice slurry generator, an ice storage tank, a water pump, a control system, and the like. The central air-conditioning system has the main functions of providing low-temperature water of about 1DEG C and low-temperature wind of about 15 DEG C, reducing the total installed capacity of the host refrigerating machine of a building, the diameter of a cold water pipe and the motor power of an end blower, balancing the power loads of the electricity peak and the electricity valley of a power system and reducing the operation cost of air conditioners, electrical capacity fees, initial cost, and the like by utilizing the power price difference between peak and valley power demand periods.

Owner:深圳力合节能技术有限公司 +2

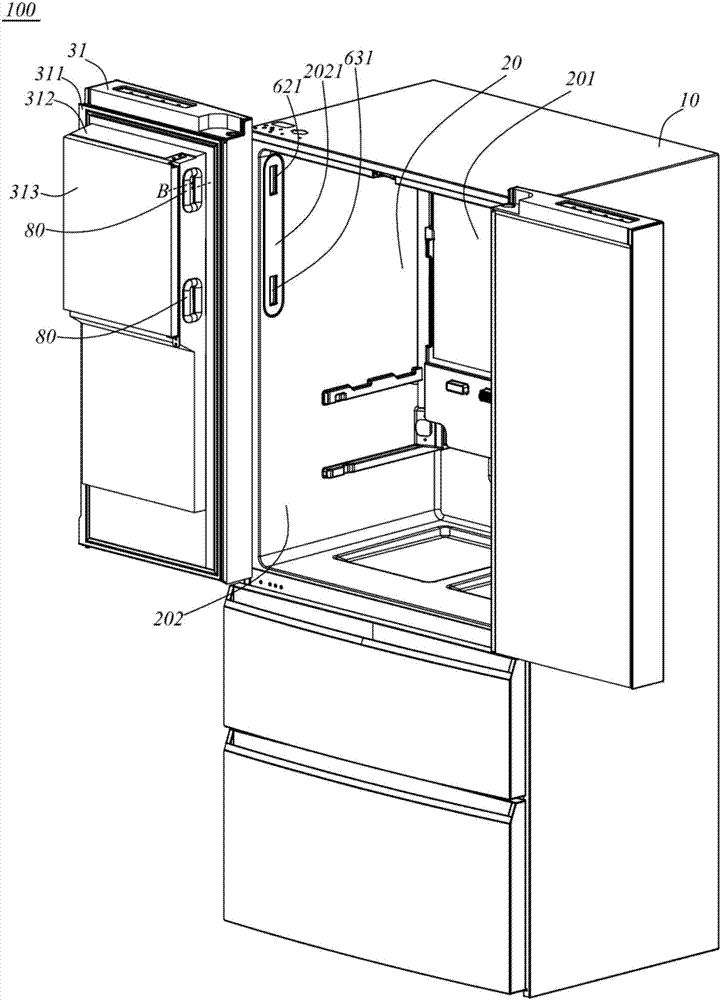

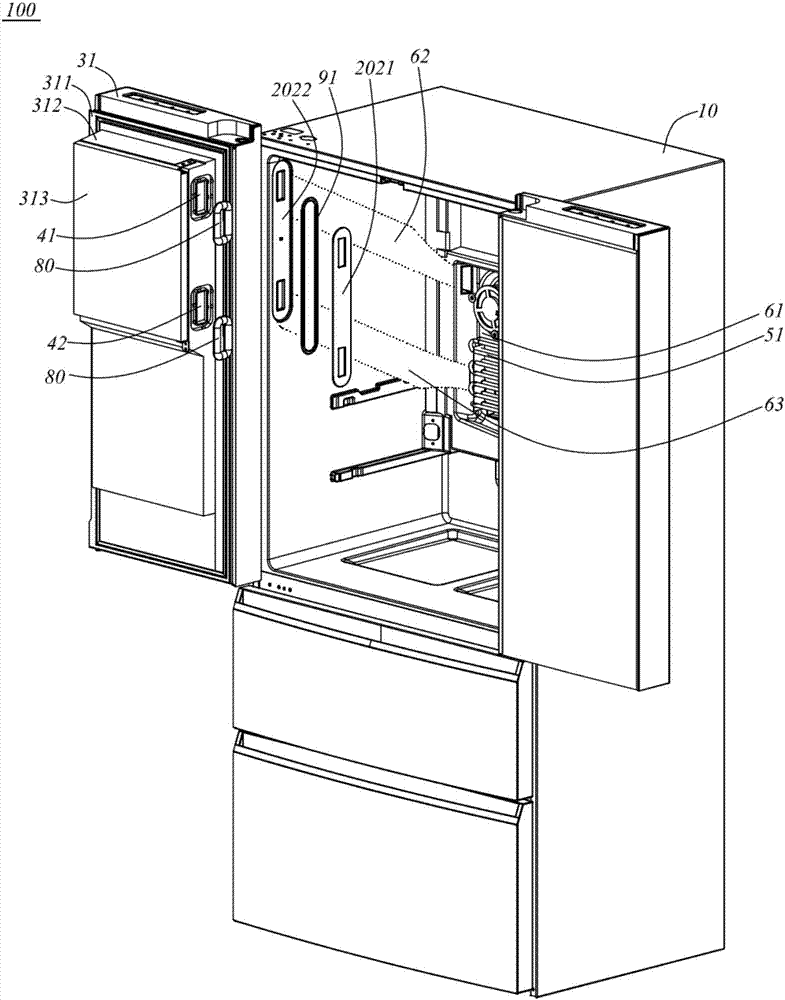

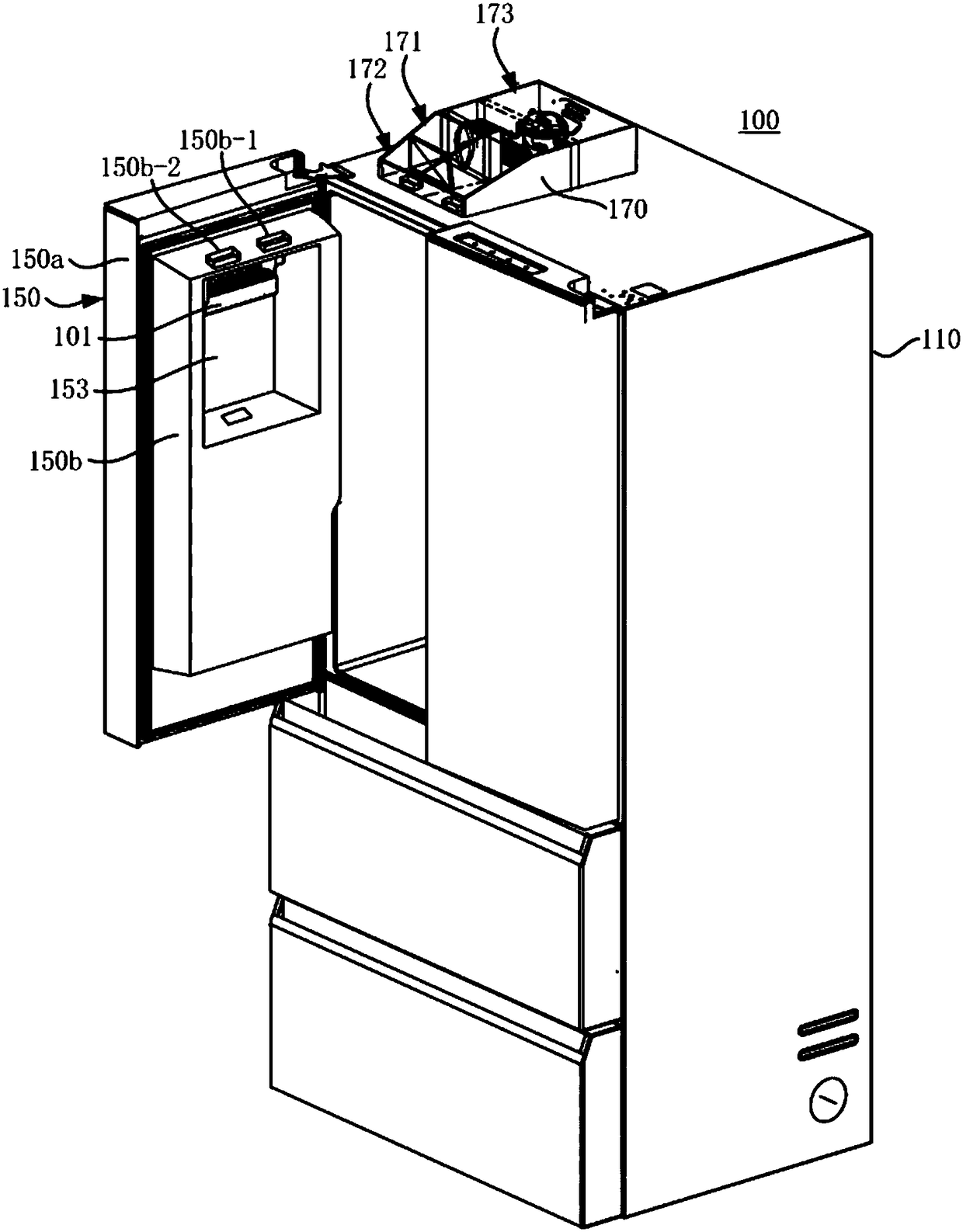

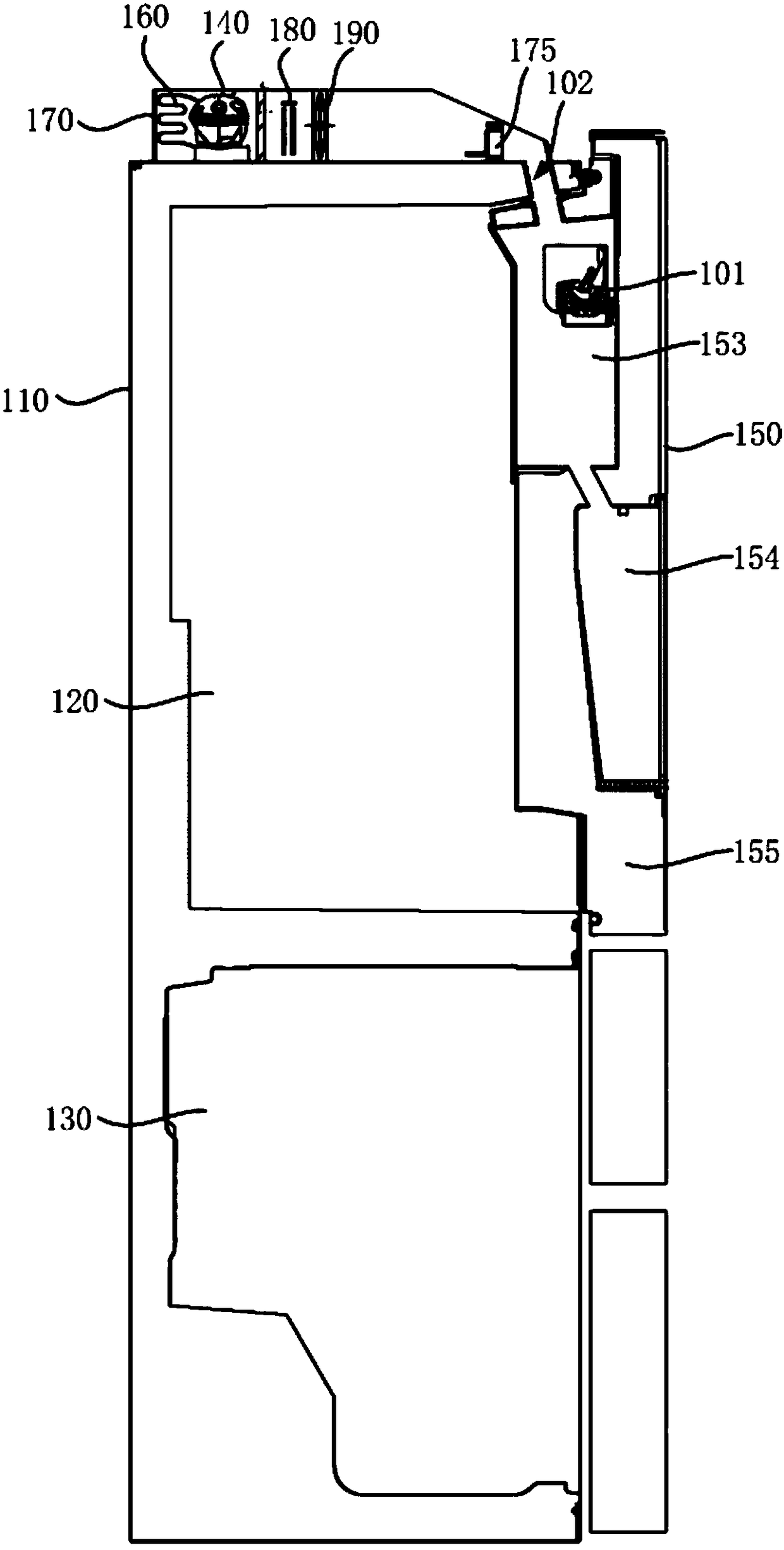

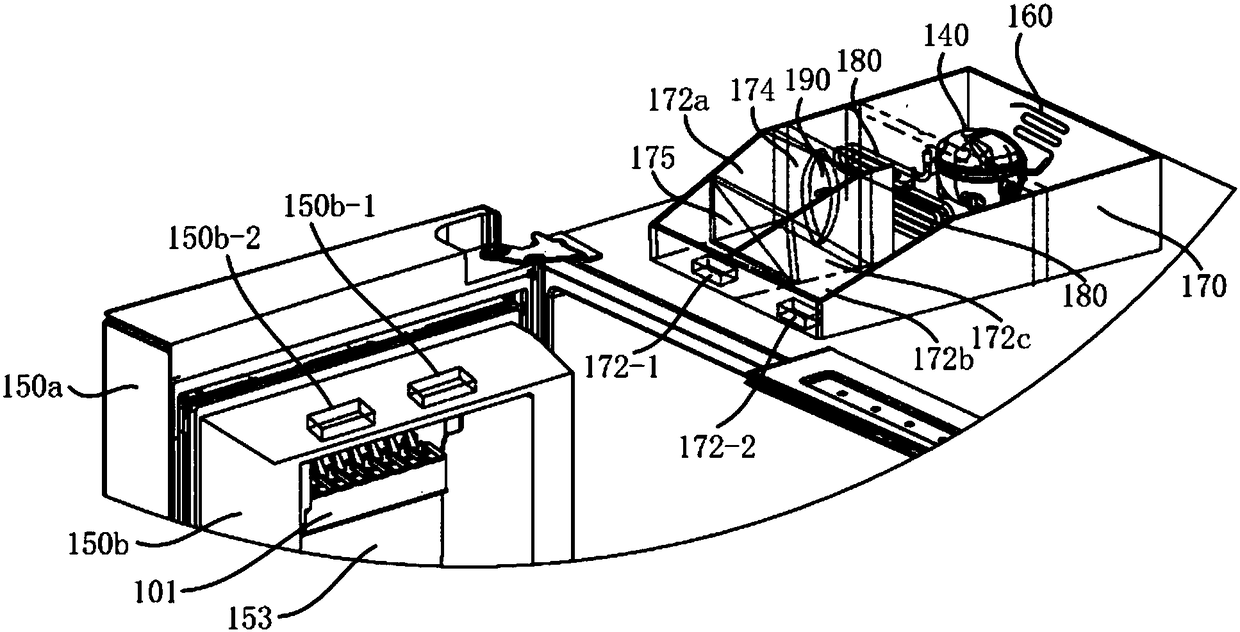

Refrigerator

ActiveCN106885420AGood eating experienceReduce path lengthLighting and heating apparatusDomestic refrigeratorsEngineeringCold store

The invention discloses a refrigerator comprising a refrigerator body, door bodies, an ice-making compartment, a cooling system and an ice-making air channel system. The refrigerator body is provided with a refrigerating room and a freezing room in a limiting mode. The door bodies are movably connected to the refrigerator body and comprise the refrigerating door body for opening and closing the refrigerating room and the freezing door body for opening and closing the freezing room. The ice-making compartment is limited to the refrigerating door body, and ice blocks can be formed in the ice-making compartment. The cooling system comprises a freezing evaporator for providing cooling capacity for the freezing room, a refrigerating evaporator for providing cooling capacity for the refrigerating room and an ice-making evaporator for providing cooling capacity for the ice-making compartment. The ice-making air channel system comprises an ice-making evaporator compartment, an ice-making air conveying channel and an ice-making air returning channel, wherein the ice-making evaporator compartment is arranged on the back wall of a liner of the refrigerating room and accommodates the ice-making evaporator; and the ice-making air conveying channel and the ice-making air returning channel are arranged on the side wall of the liner of the refrigerating room and communicate with an ice-making evaporator compartment and the ice-making compartment. Compared with the prior art, the ice-making efficiency is high, and serious frosting of the freezing evaporator and the peculiar smell of the ice blocks are avoided.

Owner:HAIER SMART HOME CO LTD

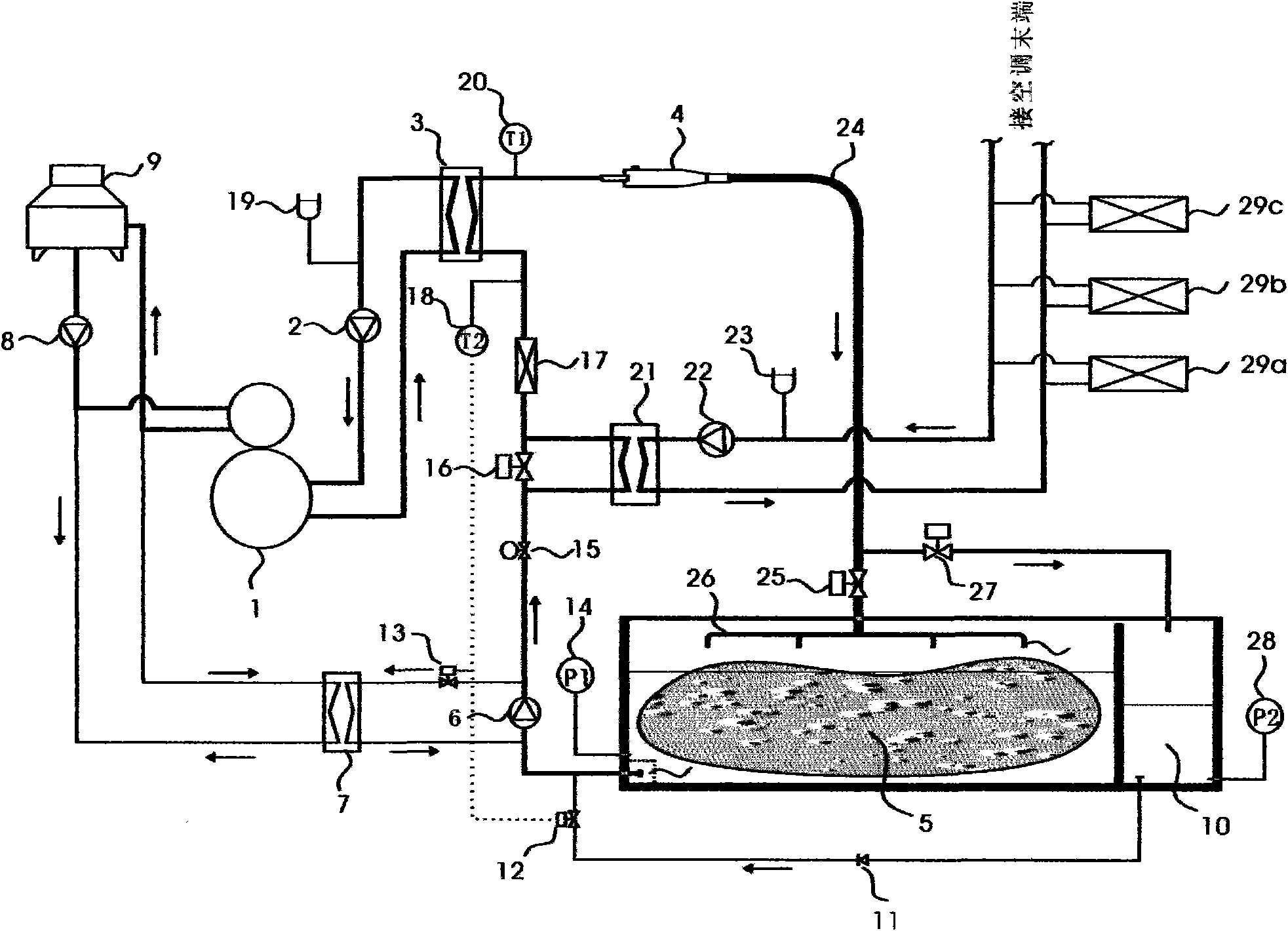

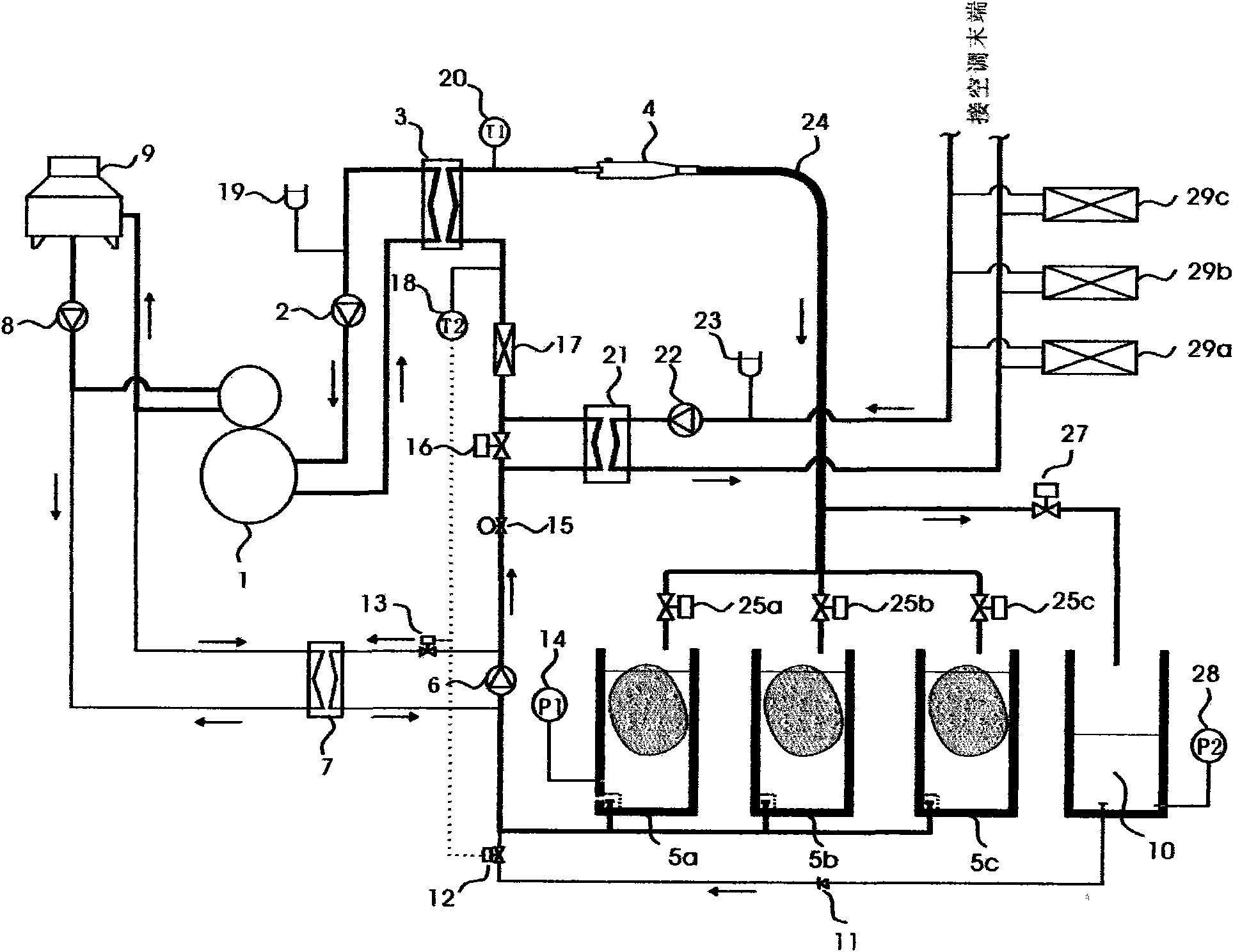

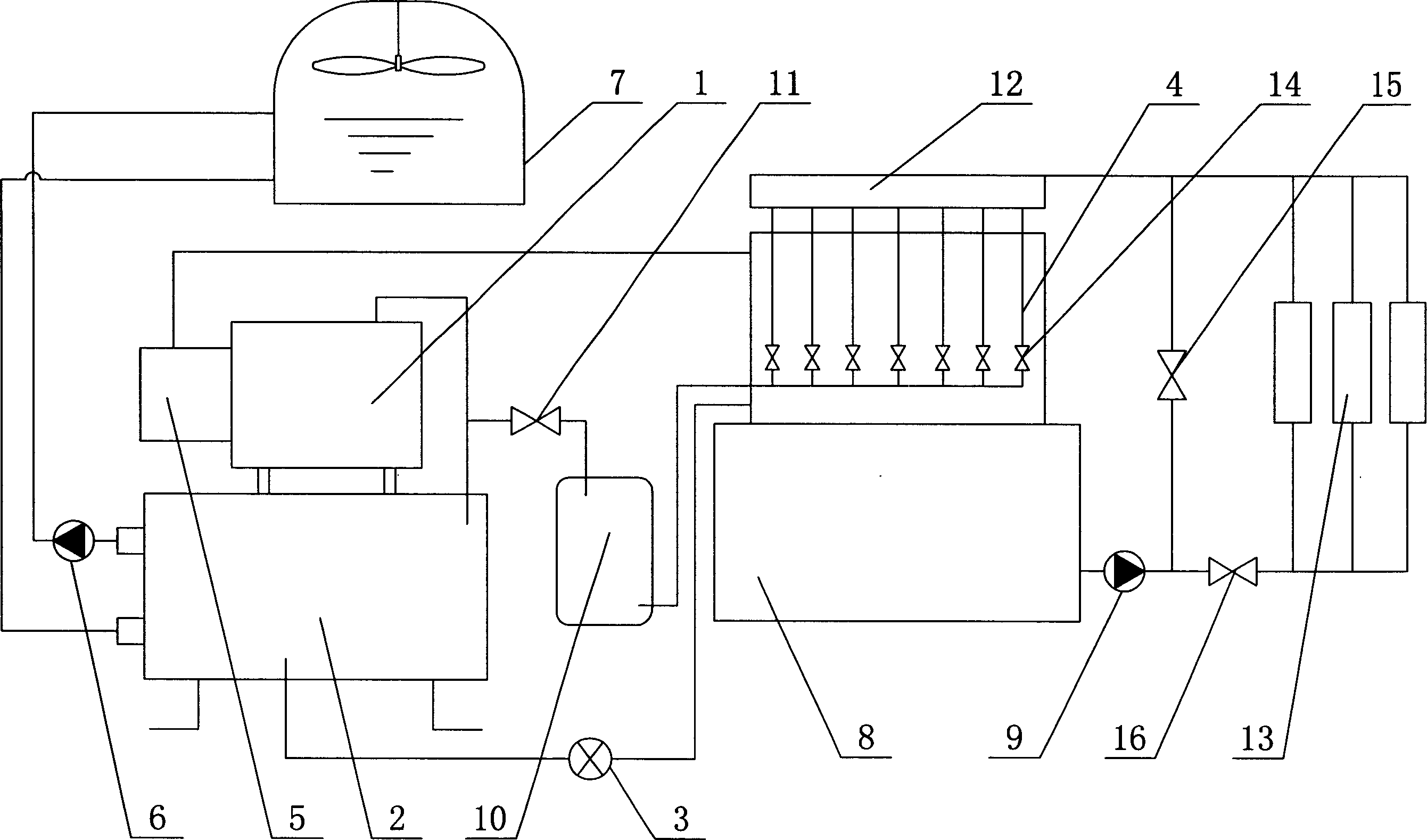

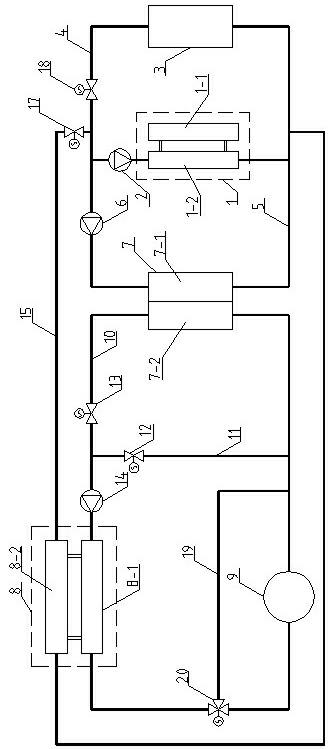

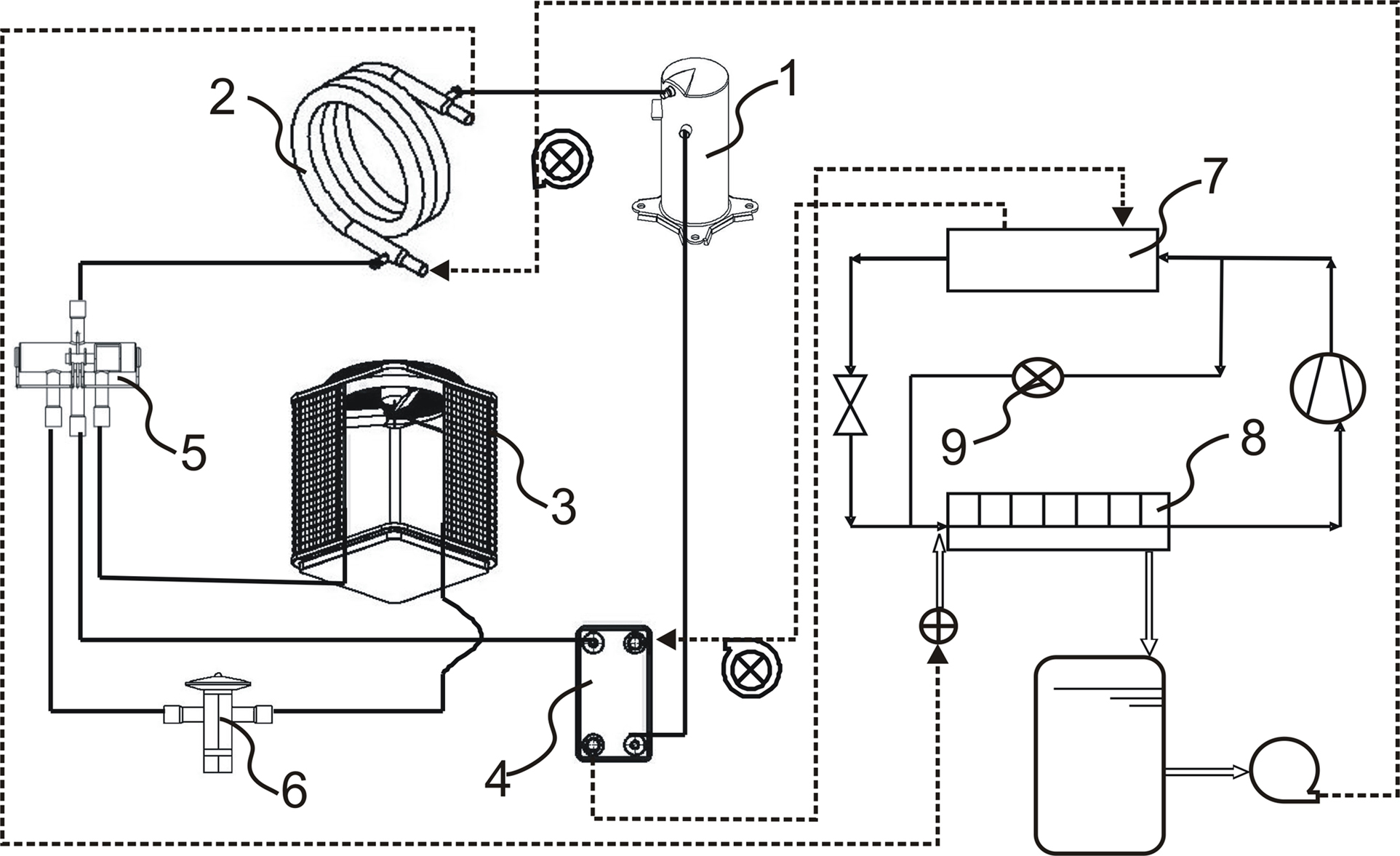

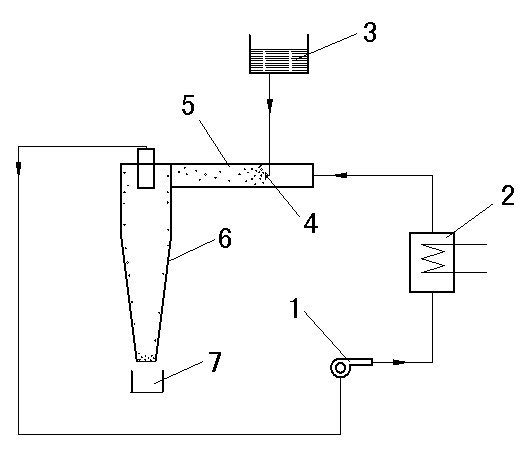

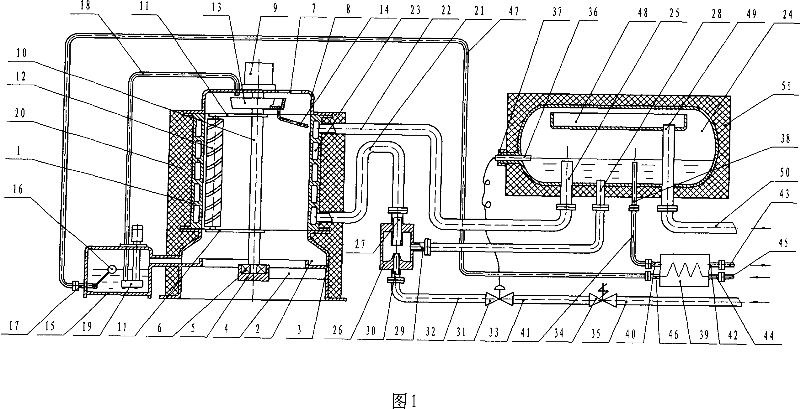

Dynamic ice-storage energy saving unit

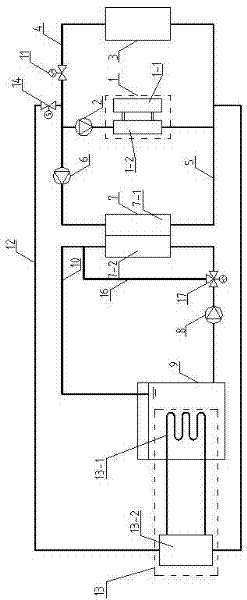

InactiveCN1840973ALess investmentLow running costDomestic cooling apparatusLighting and heating apparatusCooling towerIce storage

The invention discloses a dynamic ice-reserving energy-saving set in the air-conditioner power-saving domain, which comprises the following parts: compressor (1), condenser (2), choke valve (3), evaporator (4), reservoir (5), cooling pump (6), cooling tower (7), ice-reserving groove (8), circulating pump (9), indoor heat exchanger (13), gas-reserving cylinder (10) and water-locator (12), wherein the evaporator (4) is board-typed exchanger, which lies on the ice-reserving groove (8); the inlet of gas-reserving cylinder (10) connects the refrigerating working pipe between compressor (1) and condenser (2), whose outlet parallels several IV electromagnetic valves (14) in the inlet of board-typed exchanger working side.

Owner:广东惠生能源技术有限公司

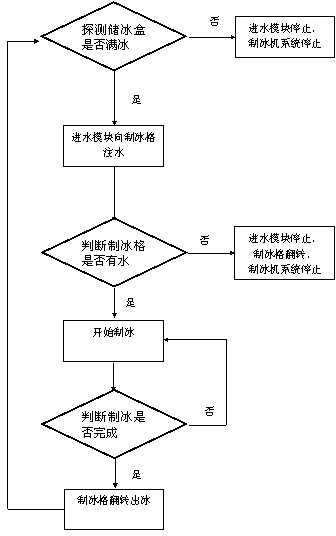

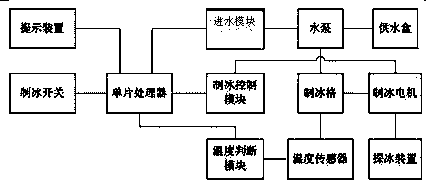

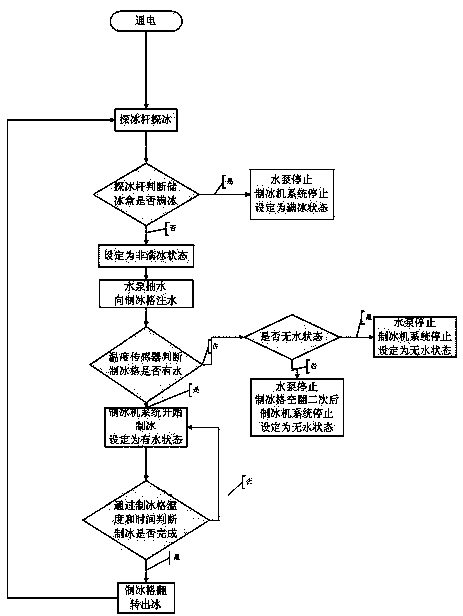

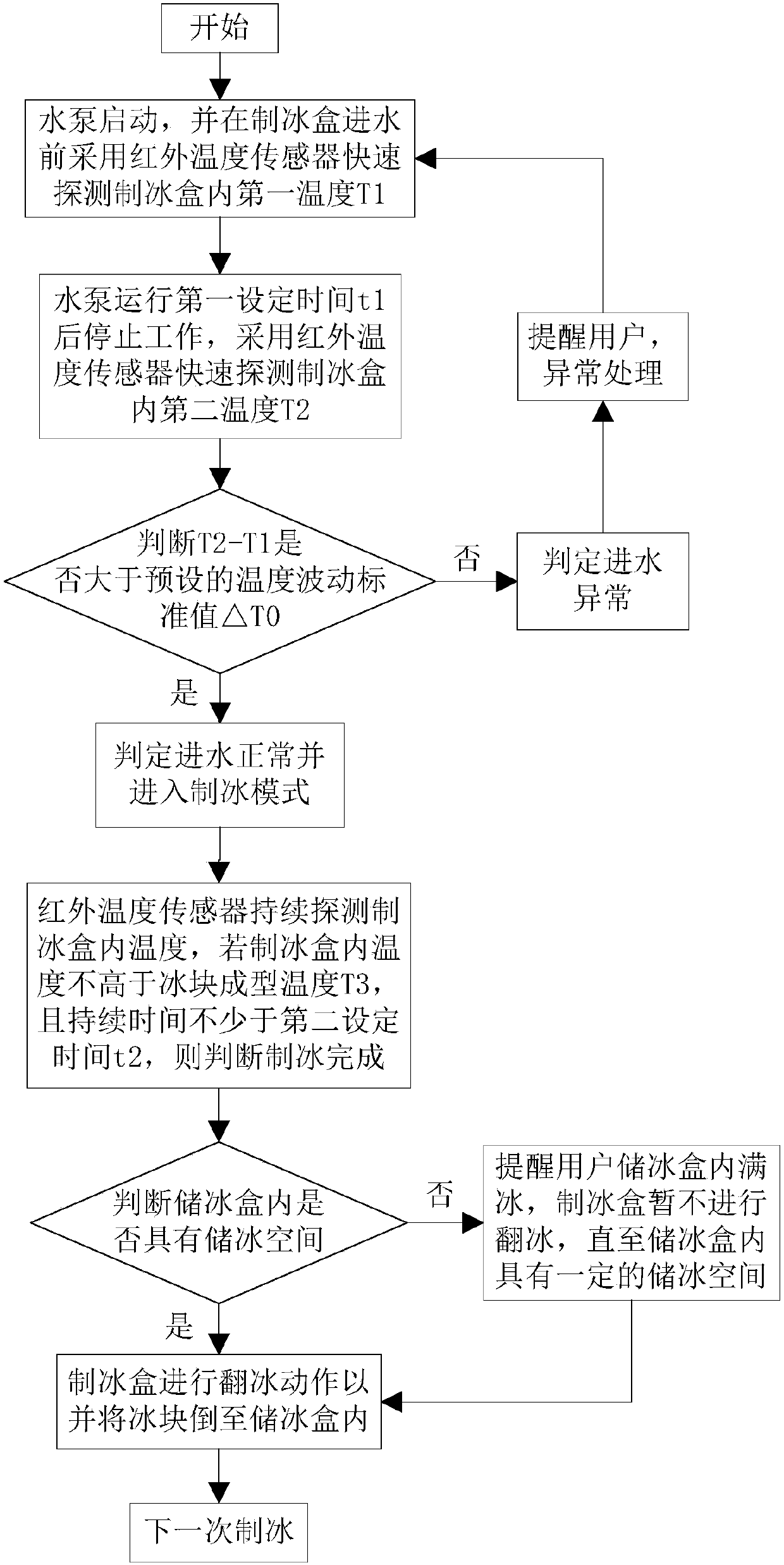

Control method of automatic ice maker system of refrigerator

ActiveCN103851877AImprove ice production efficiencyDomestic cooling apparatusLighting and heating apparatusStopped workIce storage

The invention relates to a control method of an automatic ice maker system of a refrigerator. The control method comprises the following steps of S1, detecting whether an ice storage box is full of ice, if so, causing a water inlet module to stop water supply and an ice maker to stop working, if not, entering S2; S2, injecting water to an ice cube tray through the water inlet module; S3, judging whether the ice cube tray has water, if so, causing a processor to control the ice maker to make ice and executing S4, if not, causing the processor to control the water inlet module to stop water supply and control the ice cube tray to turn at least once, and stopping the ice maker; S4, judging whether ice making is completed by the processor so as to control the ice cube tray to turn to discharge the ice, and returning to S1 after the ice is discharged. According to the method, the water is added into the ice maker timely or the ice making is stopped timely, idling of a motor and the ice maker is avoided, the working efficiency of the ice maker is improved, and meanwhile, the working condition of the ice maker is fed back timely so as to be more user-friendly.

Owner:HISENSE RONSHEN GUANGDONG REFRIGERATOR

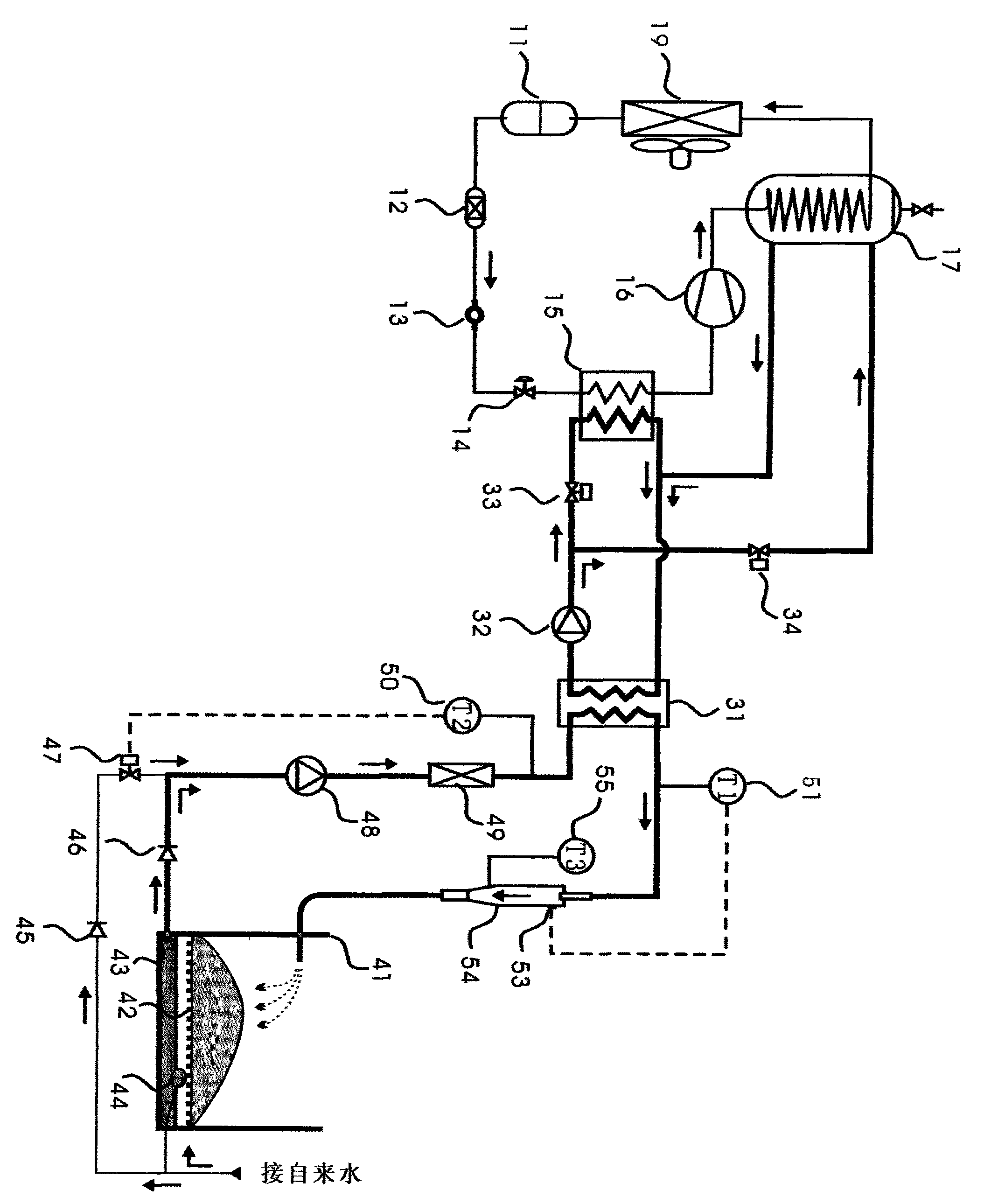

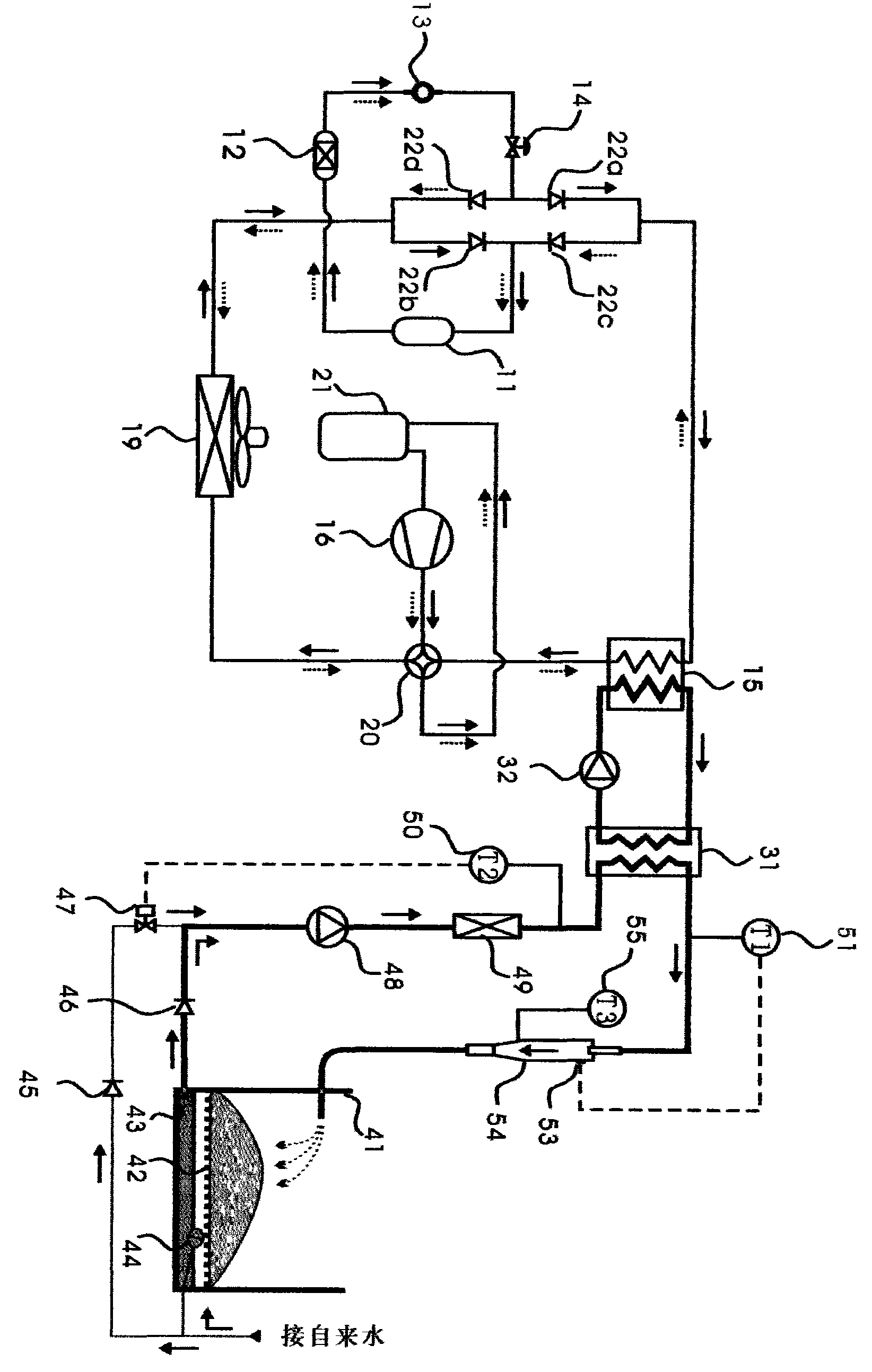

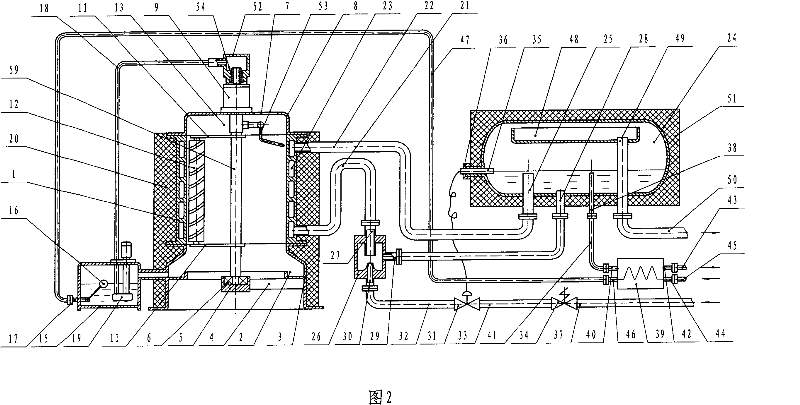

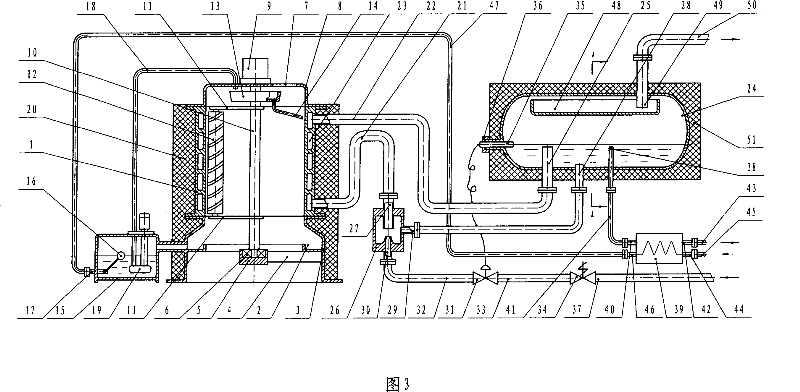

Novel method and device for producing ice

InactiveCN101603752ARefrigeration evaporation temperature is highImprove ice production efficiencyIce productionEnergy industryDry iceShrimp

The invention belongs to a method and a device for producing ice crystals by water, and particularly discloses a method and a device for producing snowflake ice crystals by normal-temperature tap water or purified water. The device comprises a refrigerating system, a cold carrying system, a waterway system, a control system, and the like. Compared with the prior ice producing mechanism, the method and the device have the characteristics of high ice producing efficiency, power utilization economy and small ice particles; the produced ice can be ice water mixture or ice slurry or water-filtered dry ice; and the method and the device are mainly used for processing factories, transportation industry and supermarkets to refrigerating and cooling vegetables, fruits, meat, fishes and shrimps, and have the advantages of large contact surface, quick temperature reduction, low fresh-keeping temperature, no damage, and the like.

Owner:深圳力合节能技术有限公司 +2

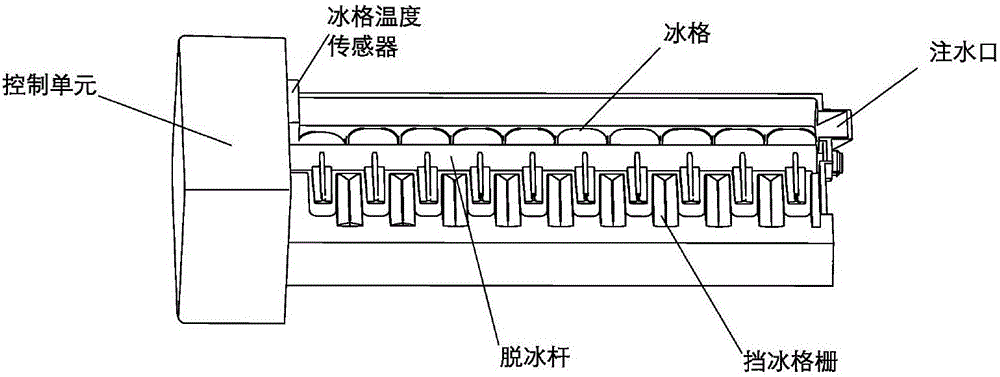

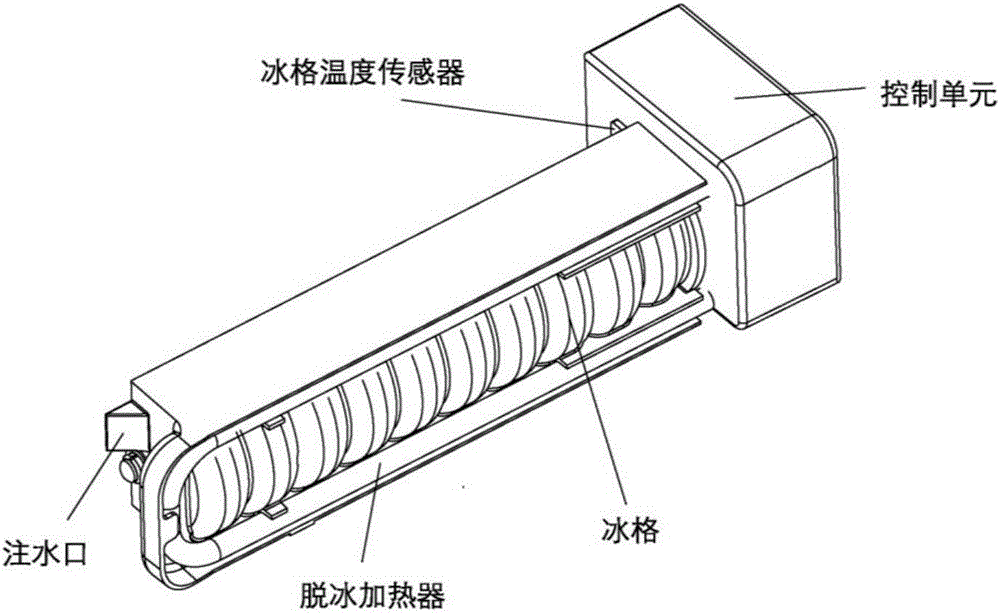

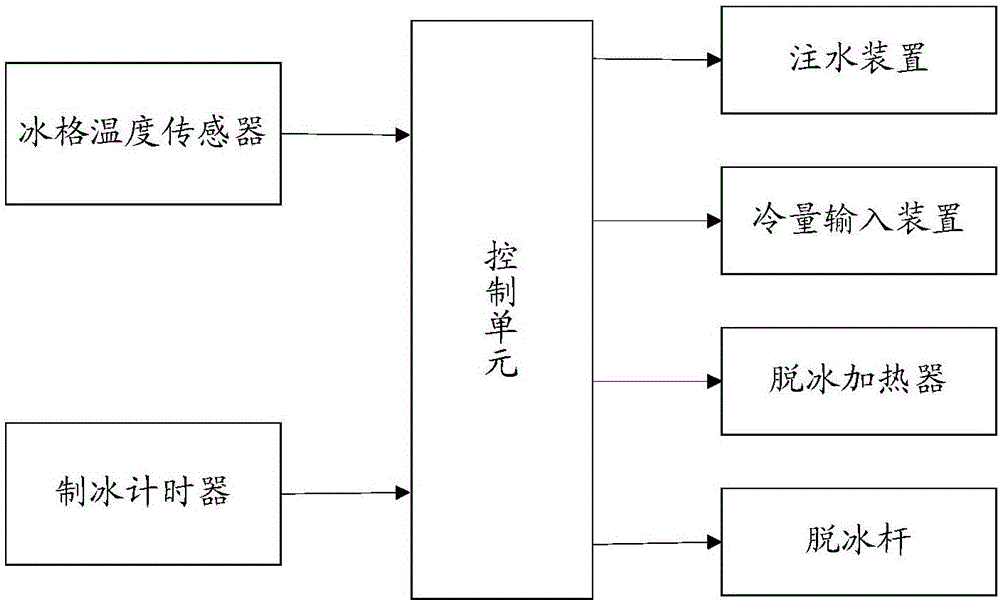

Ice unloading control method and device as well as ice maker

ActiveCN106766454AGuaranteed ice production reliabilityShorten the timeLighting and heating apparatusIce productionIce waterMinimum time

The embodiment of the invention provides an ice unloading control method and device as well as an ice maker, and relates to the field of household appliances. The ice unloading control method is used for solving the problem that cold energy waste and low ice-making efficiency are caused as an existing ice unloading temperature is set to be too low. The method comprises the following steps of: obtaining the temperature of a current ice cube tray and current ice-making cumulative time of the ice maker; and then, judging whether the ice marker performs ice unloading operation or not according to a first difference value between current ice-making cumulative time of the ice maker and a first preset threshold value as well as a second difference value between the temperature of the current ice tube tray and a second preset threshold value, wherein the current ice-making cumulative time is cumulative time from time of starting to injecting water into the ice cube tray to current time of the ice maker, the first preset threshold value is greater than or equal to minimum time when a liquid-state water phase is changed into an ice-water mixture, and the second preset threshold value is smaller than or equal to the highest temperature of solid ice in the ice tube tray of the ice maker.

Owner:HISENSE RONSHEN GUANGDONG REFRIGERATOR

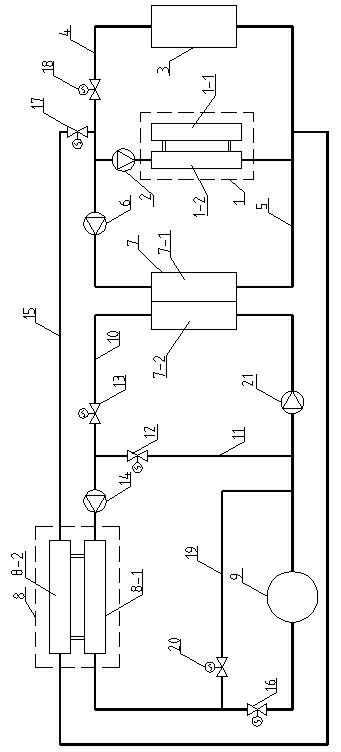

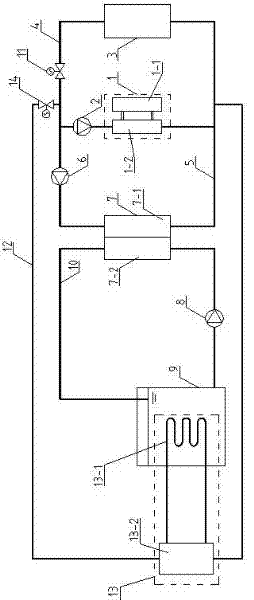

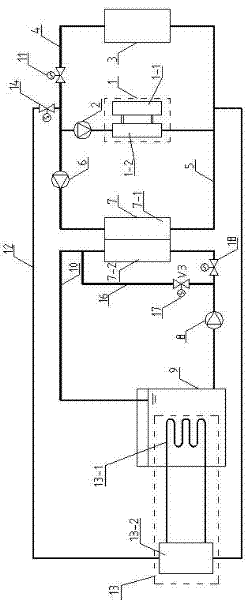

Ice storage refrigeration system and refrigeration method thereof

InactiveCN102313331AOvercoming the large compression ratioOvercome costsLighting and heating apparatusSpace heating and ventilation detailsIce storageEngineering

The invention discloses an ice storage refrigeration system and a refrigeration method thereof, which relate to the technical field of refrigeration air conditioners. The ice storage refrigeration system comprises a refrigeration unit, a tail end device, an ice making unit, a heat exchange device and an ice storage device, wherein an evaporator of the ice making unit, the ice storage device and acold fluid flow passage in the heat exchange device are connected by a pipeline loop; a hot fluid flow passage in the heat exchange device is connected with the loop of the tail end device via a pipeline; a loop between the condenser of the ice making unit and the evaporator of the refrigeration unit is provided with a pipeline; and the cooling water of the condenser of the ice making unit is supplied after being precooled to 2-20 DEG C by the refrigeration unit. According to the ice storage refrigeration system, the problems that the traditional refrigeration unit can not work under the ice making working condition and a refrigeration unit of double working conditions has big compression ratio, high cost and the like and is complex to control under the ice making working condition are solved, the cost of the refrigeration system can be lowered, and ice making efficiency and operation stability are improved.

Owner:江苏新七彩节能有限公司

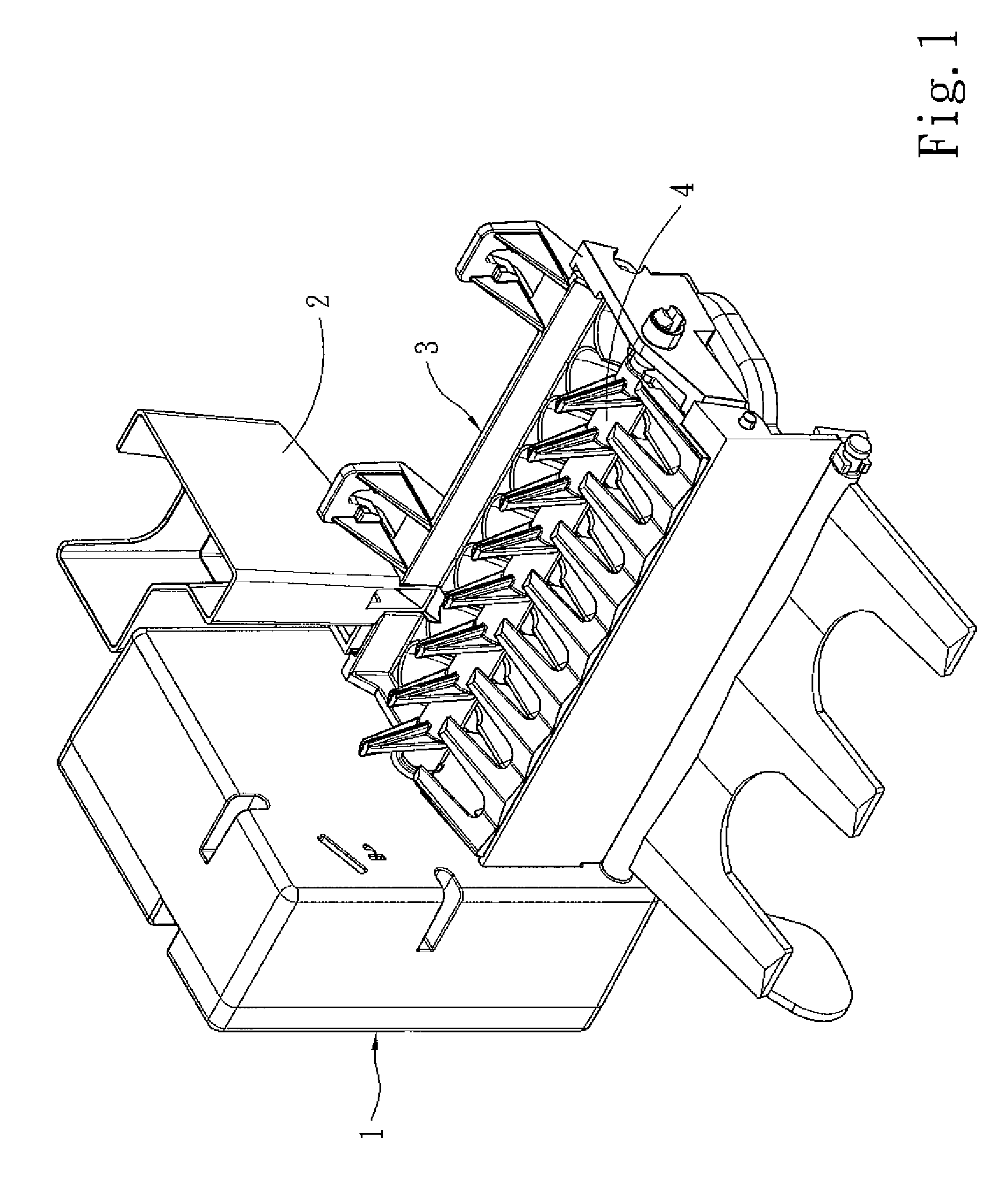

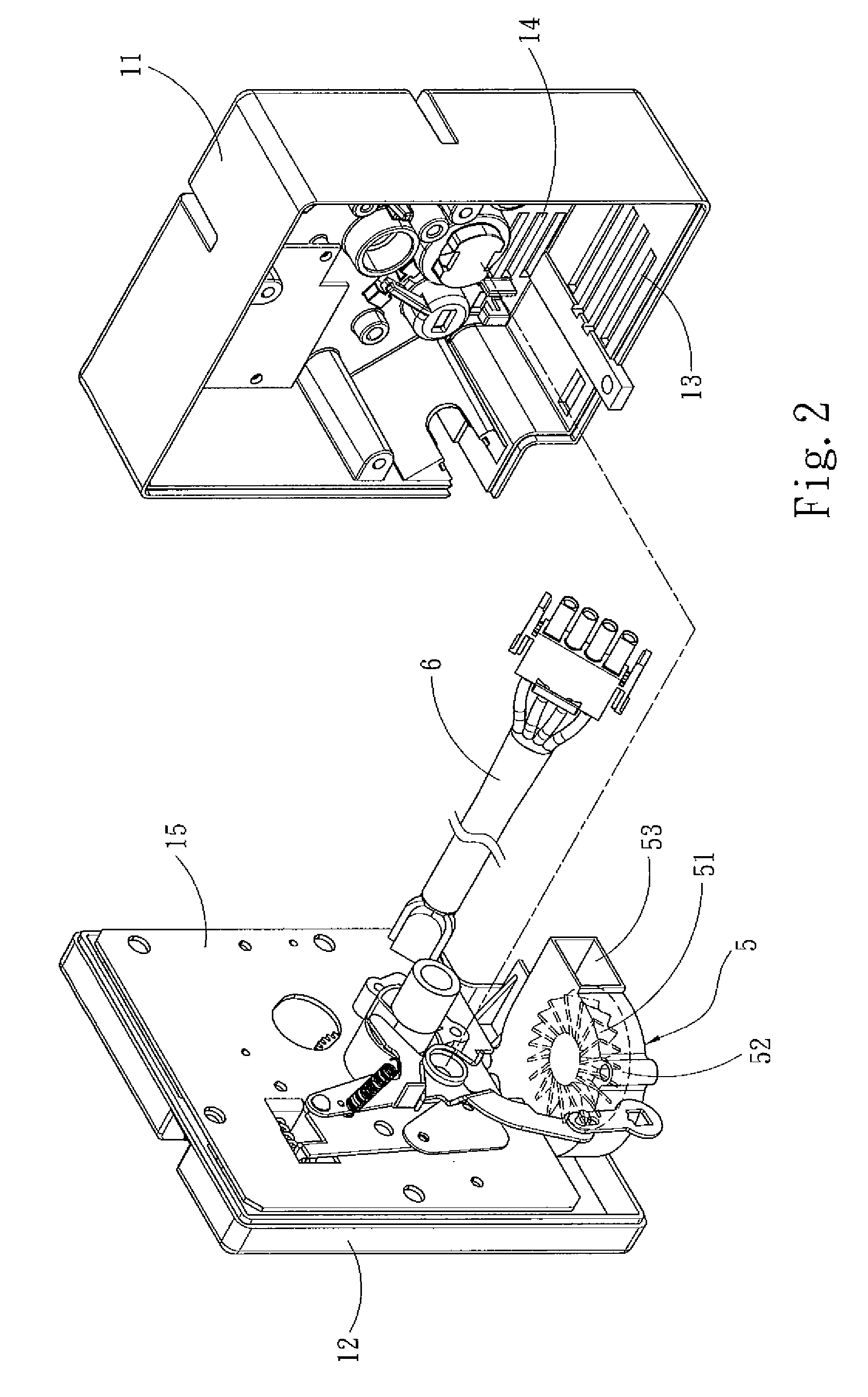

Ice maker equipped with a convection fan

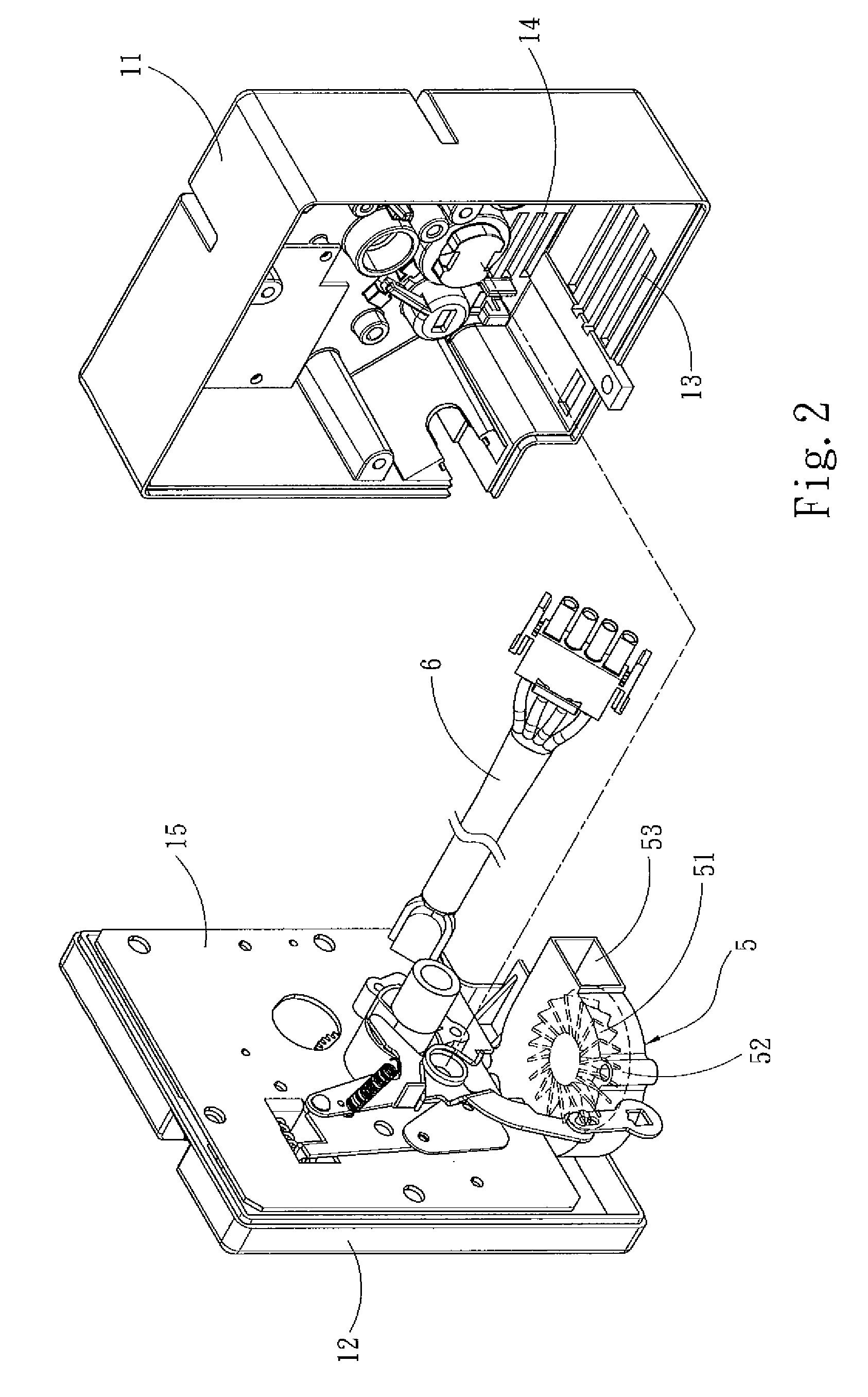

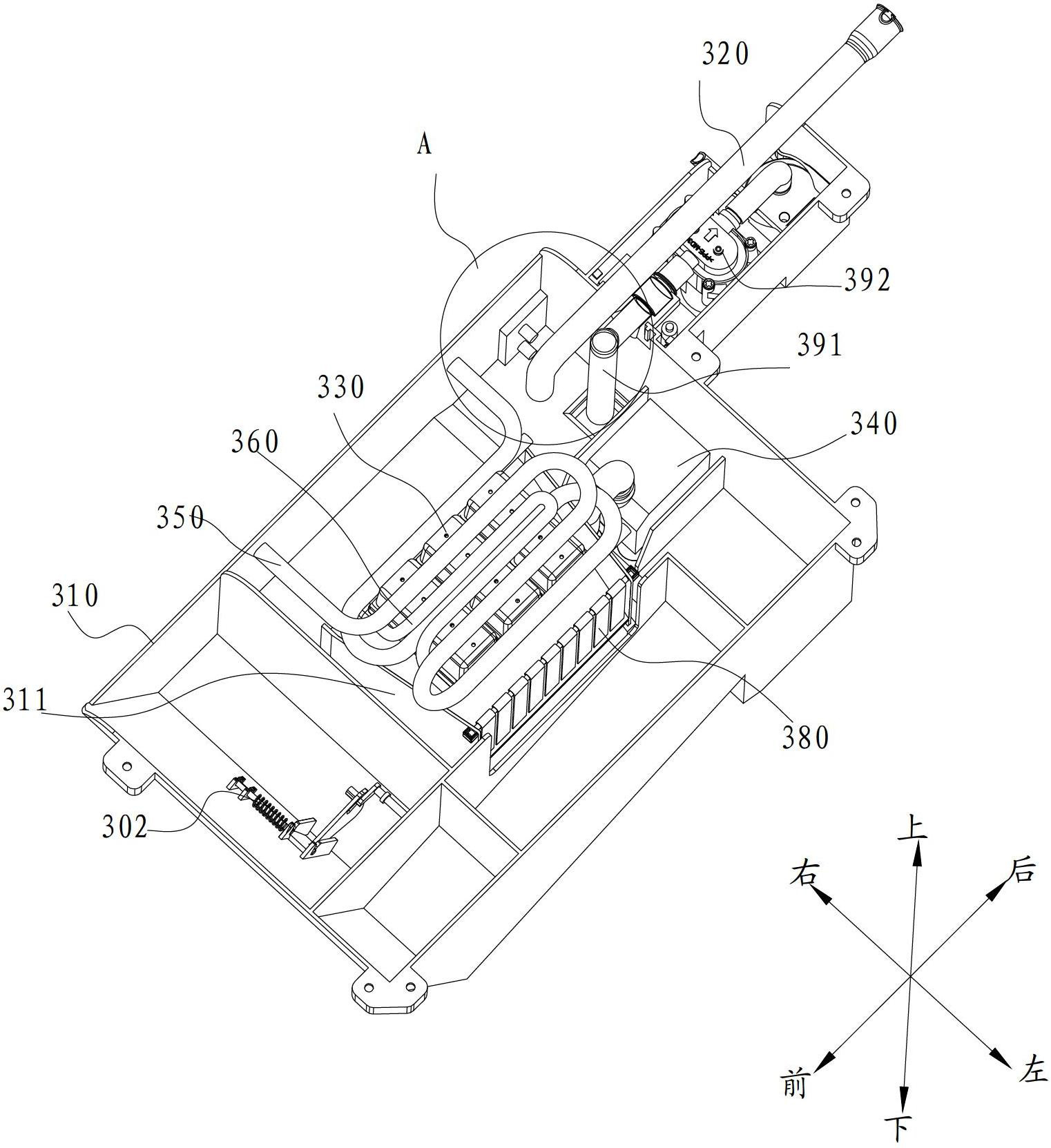

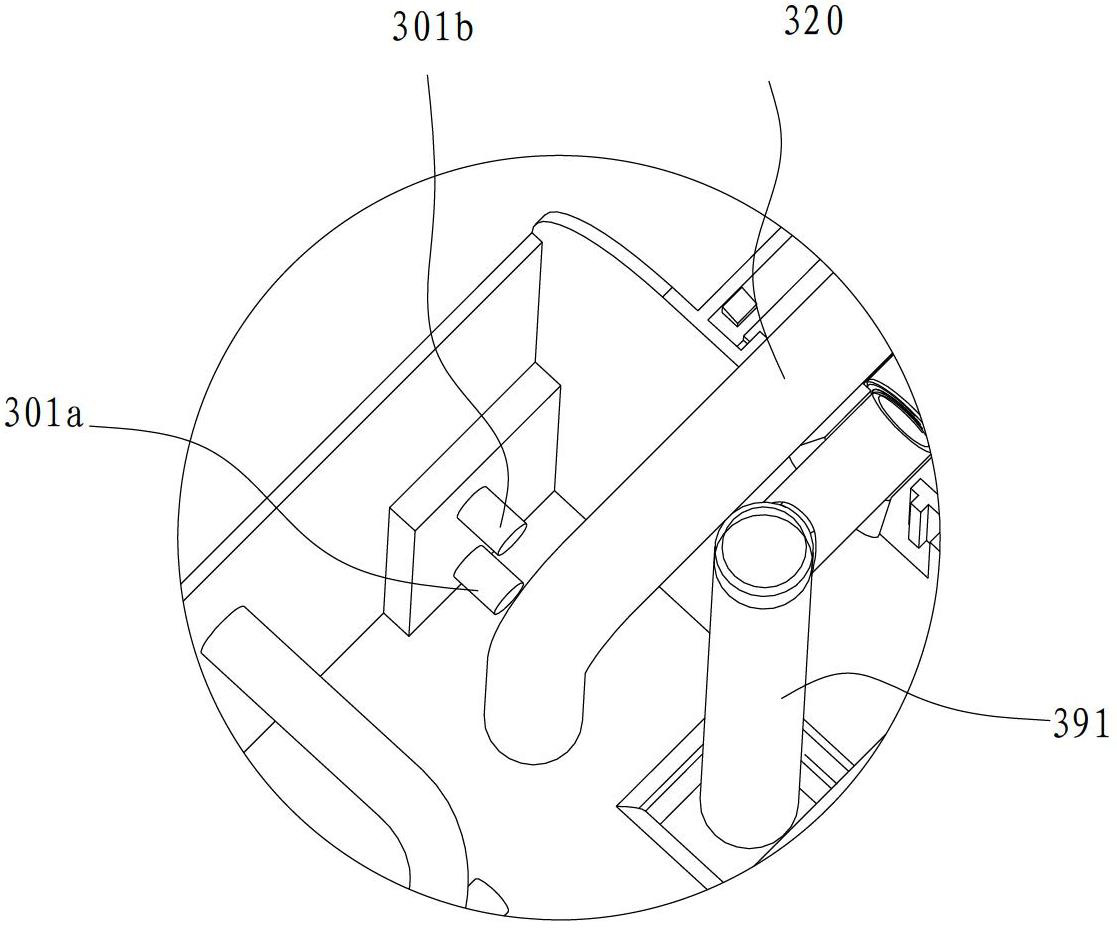

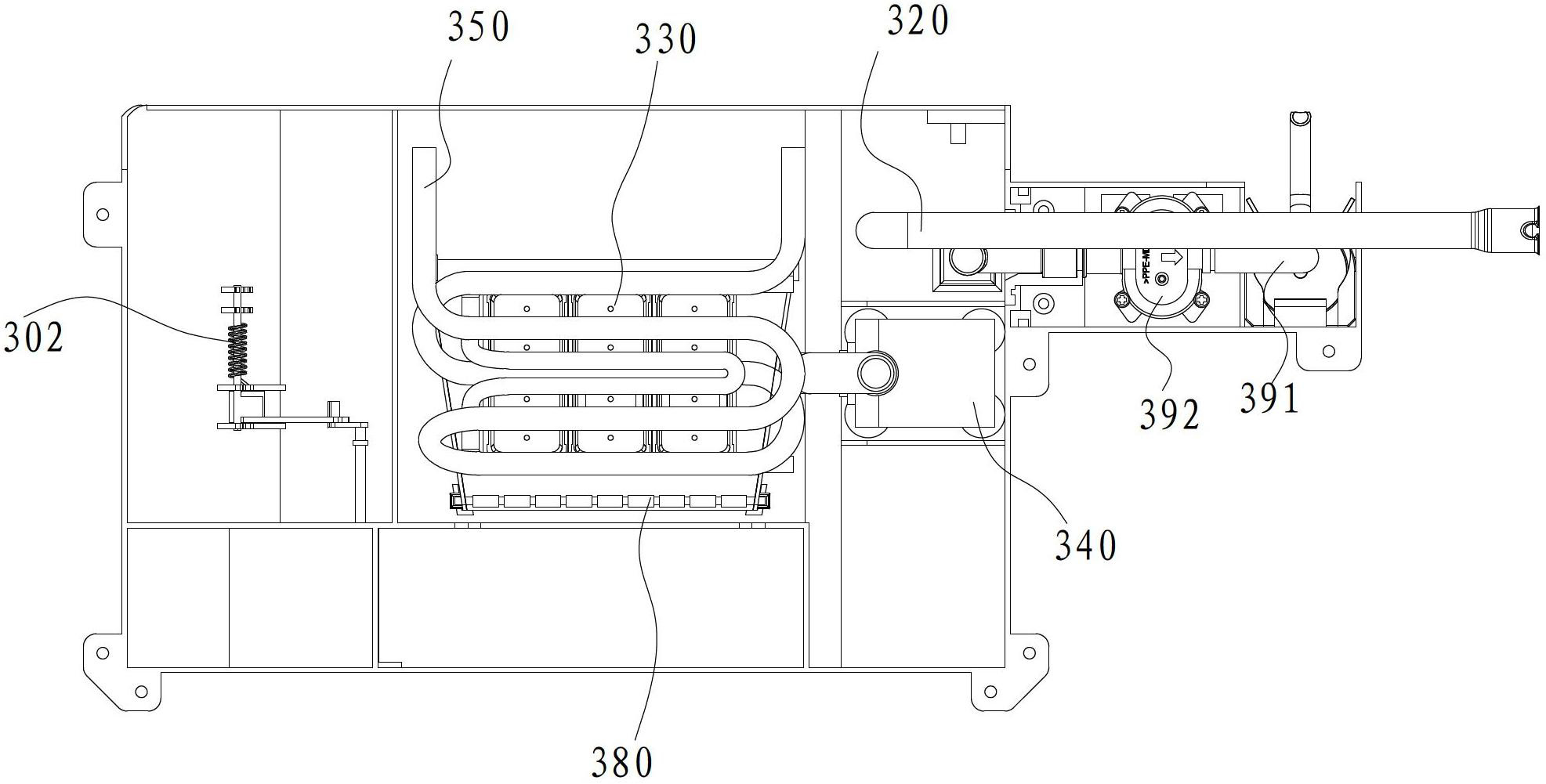

InactiveUS7870755B2Utilize powerUtilize spaceLighting and heating apparatusIce productionEngineeringWater intake

An ice maker equipped with a convection fan includes a control box, an ice making tray, a water intake unit and an ice sweeping shaft. The control box holds at least one convection fan and has at least one air inlet and one air outlet to allow the convection fan to generate cooling air convection to accelerate cooling speed and improve ice making efficiency.

Owner:ZIPPY TECH

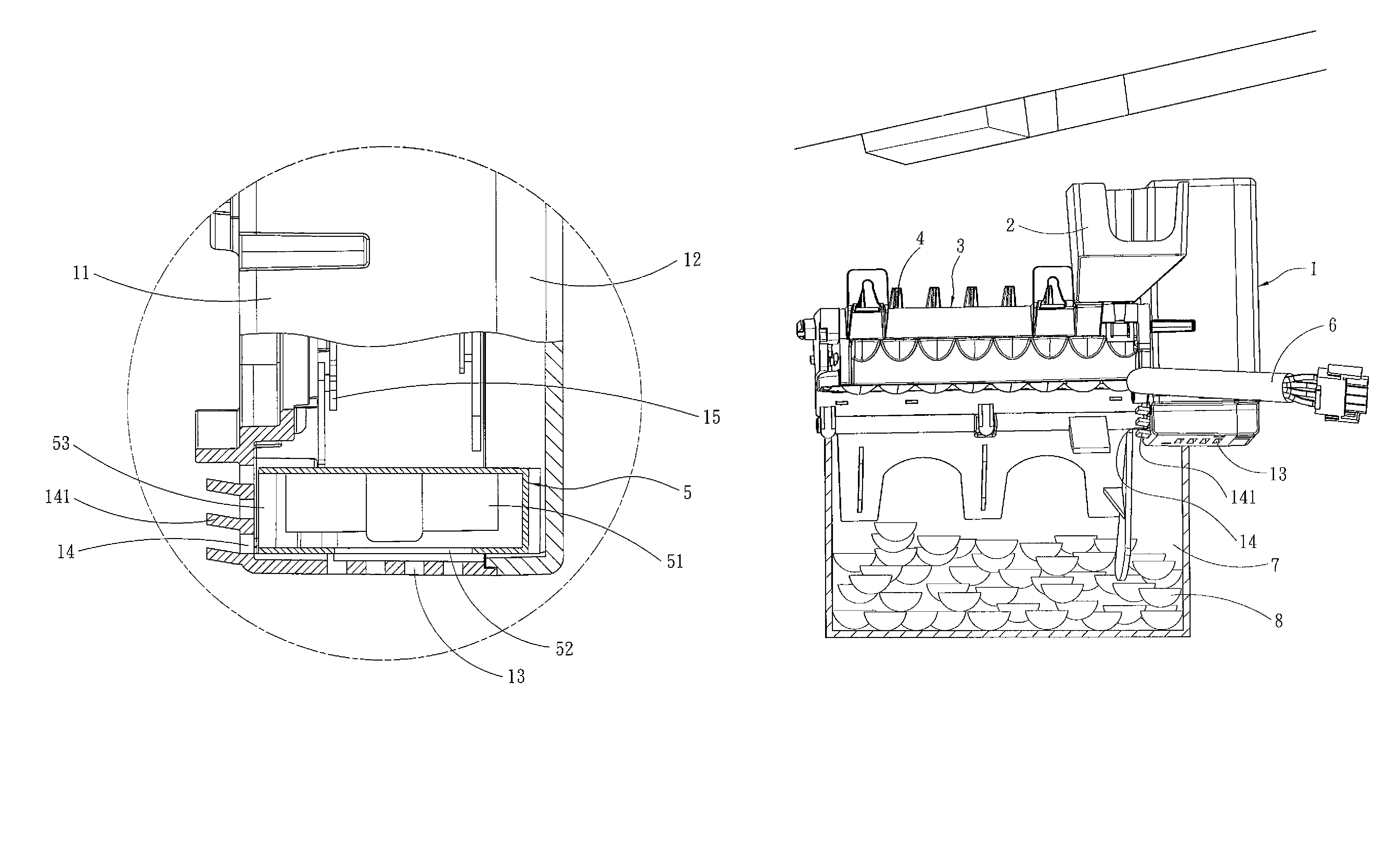

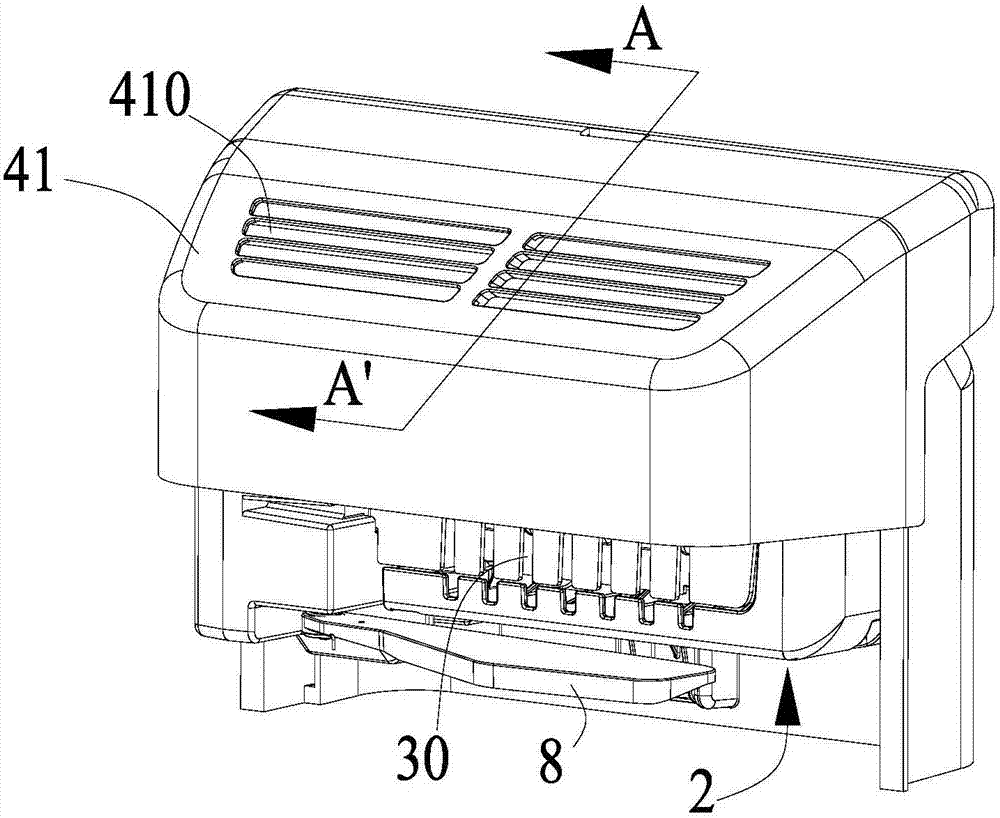

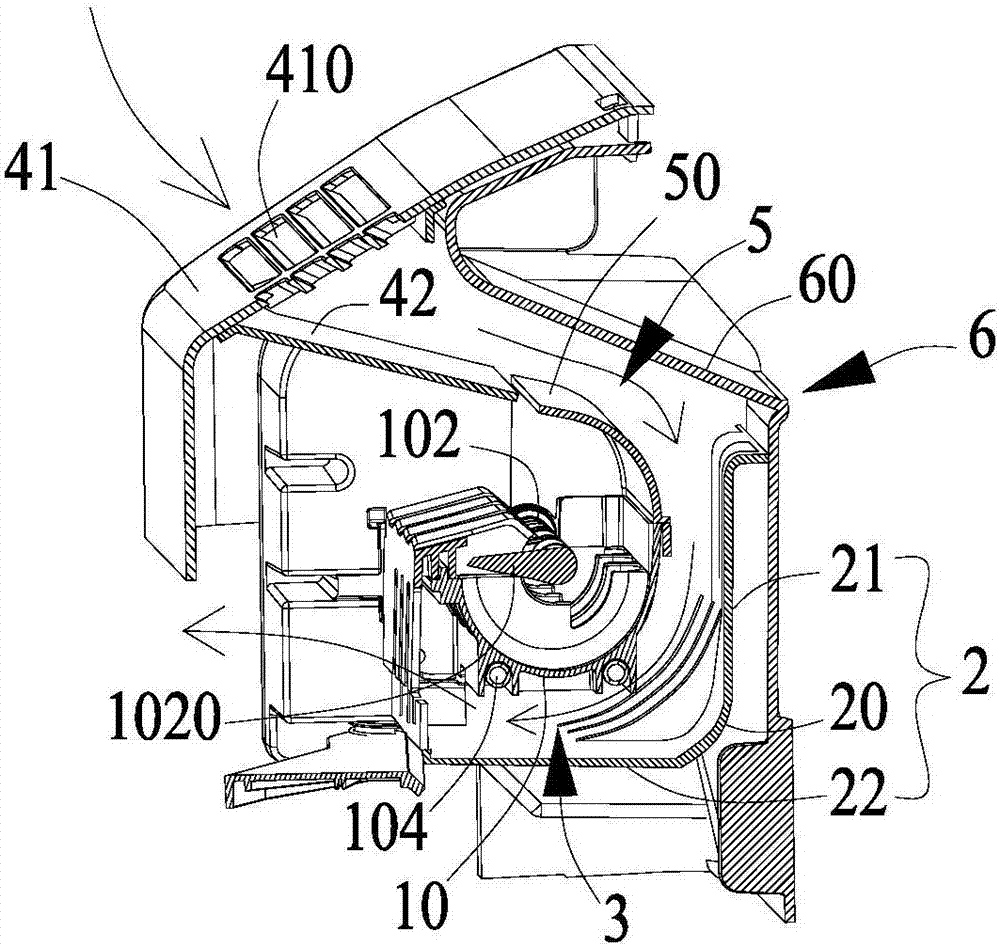

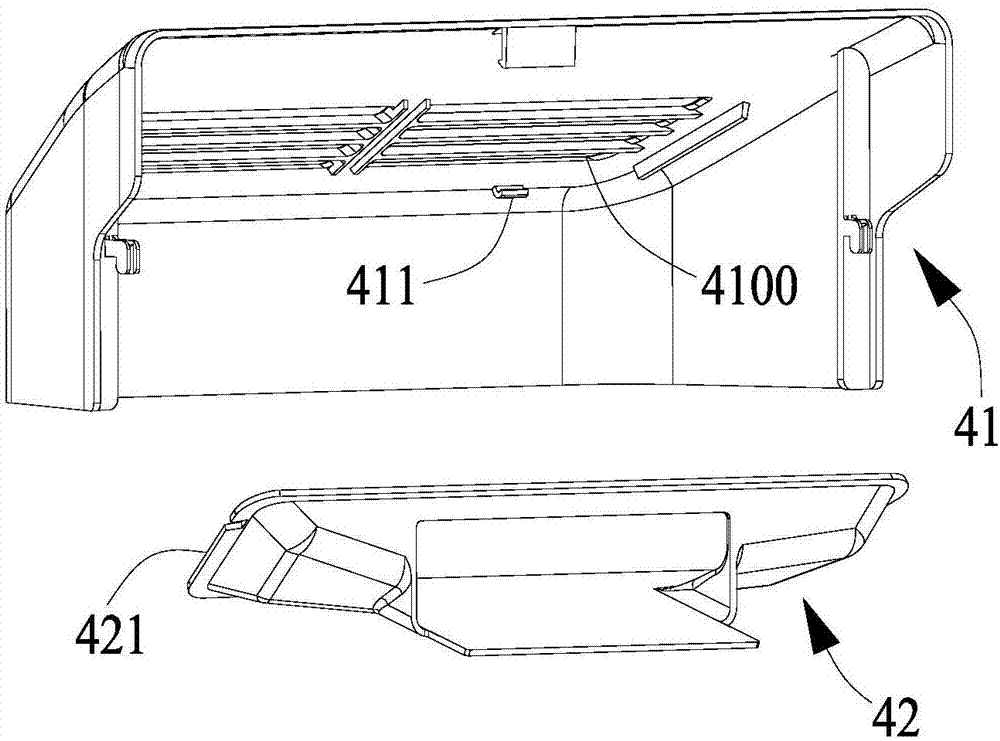

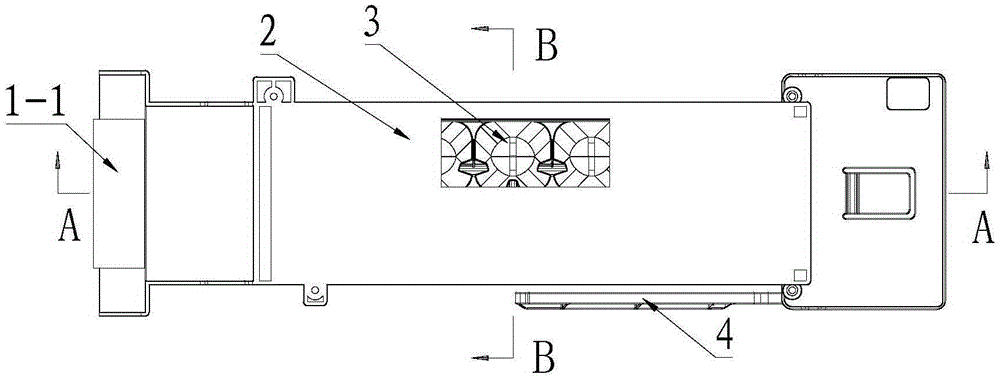

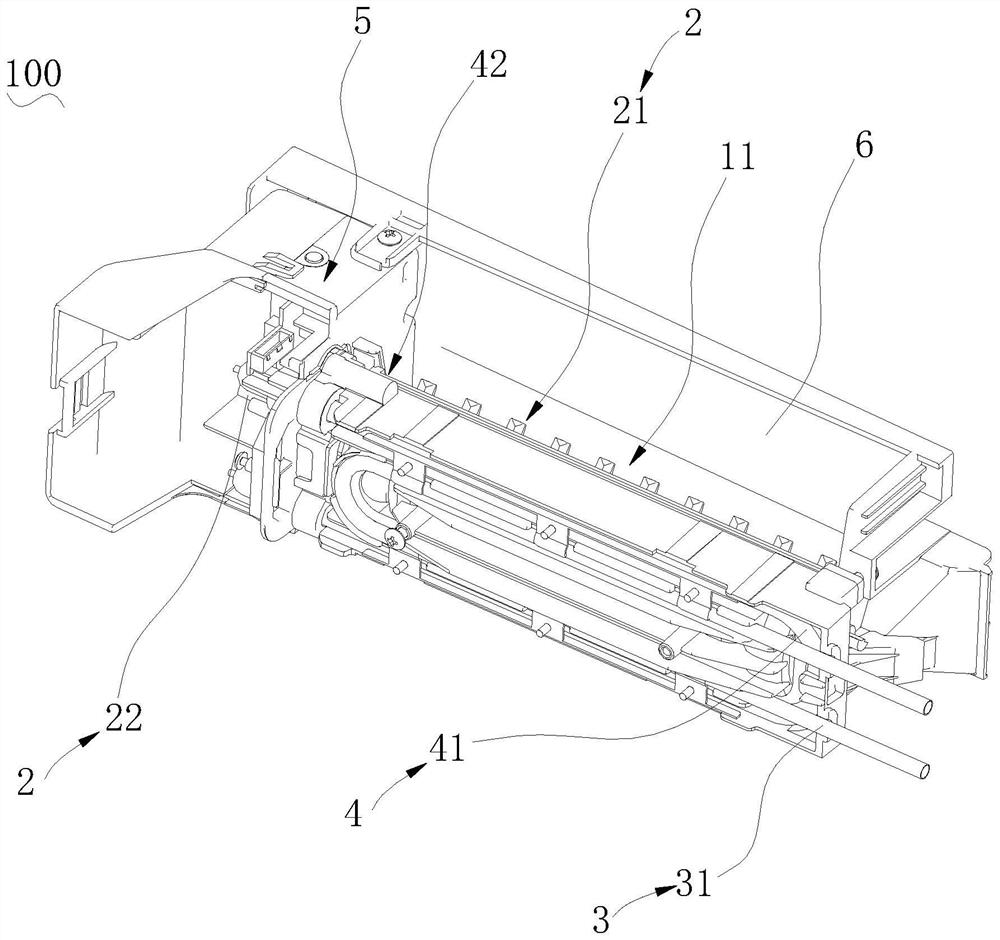

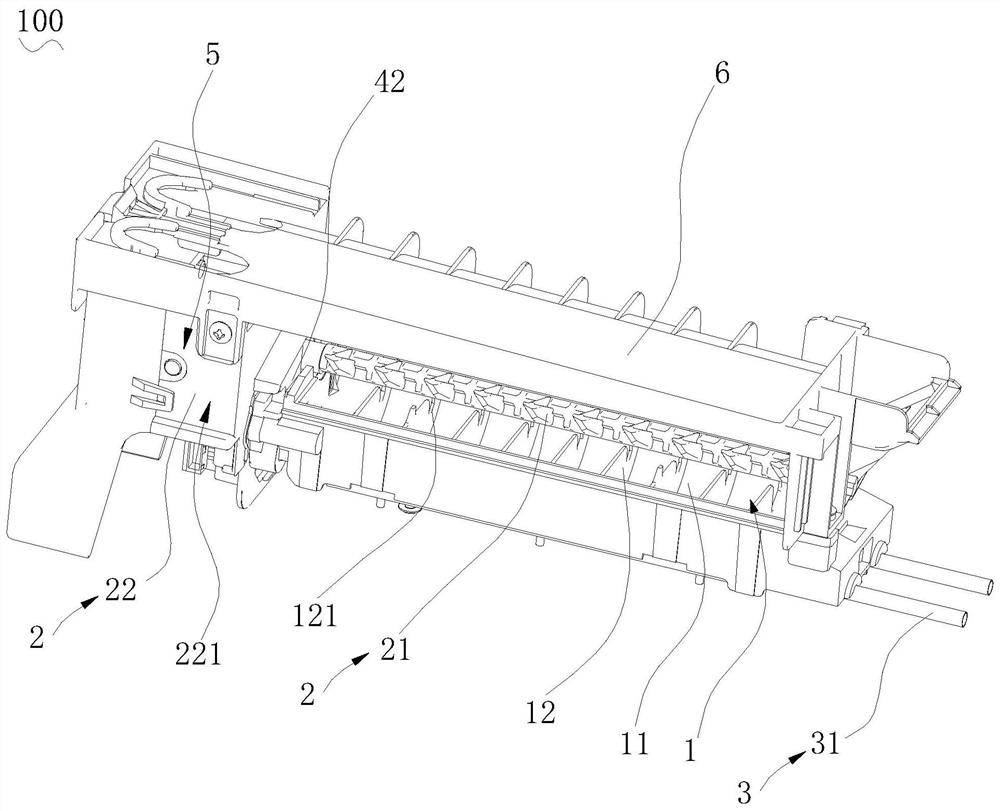

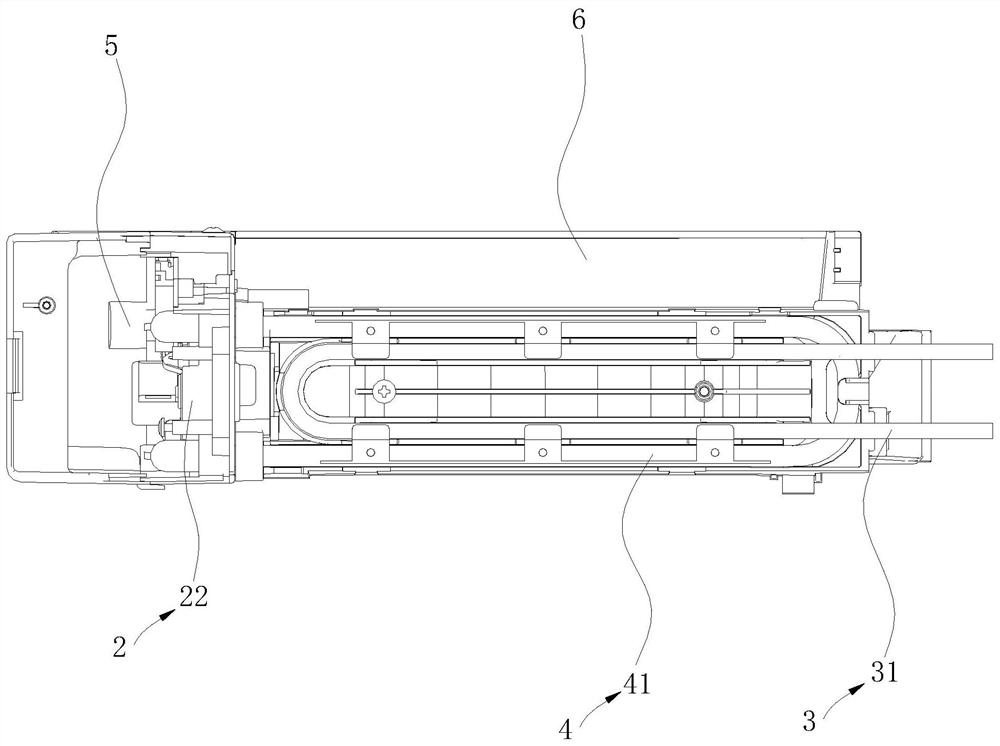

Ice machine and refrigerator

InactiveCN102679657AImprove ice production efficiencyHigh degree of automationDomestic cooling apparatusLighting and heating apparatusWater storageIcebox

The invention discloses an ice machine and a refrigerator with the ice machine. The ice machine comprises a box, a water inlet pipe, an ice making box, a water supply pump, an evaporation tube and an ice removing part, wherein an ice making space, a water storage space and an ice discharging channel are arranged in the box; a water separator is arranged between the ice making space and the water storage space; a water-retaining part which allows ice blocks to pass through but prohibits water to pass through is arranged between the ice making space and the ice discharging channel; the water inlet pipe is used for supplying water to the water storage space; the ice making box is provided with a plurality of ice lattices; the ice making box is arranged on an ice making frame and the ice lattices downward face to the water separator; and the water supply pump is arranged in the water storage space and is connected with the water separator so as to inject water in the water storage space into the ice lattices through the water separator. According to the ice machine provided by the embodiment of the invention, the ice-making speed and the ice-making efficiency are high, the ice blocks are transparent, the ice is easily removed, and the ice is made in the refrigerating chamber of the refrigerator.

Owner:HUBEI MIDEA REFRIGERATOR CO LTD +1

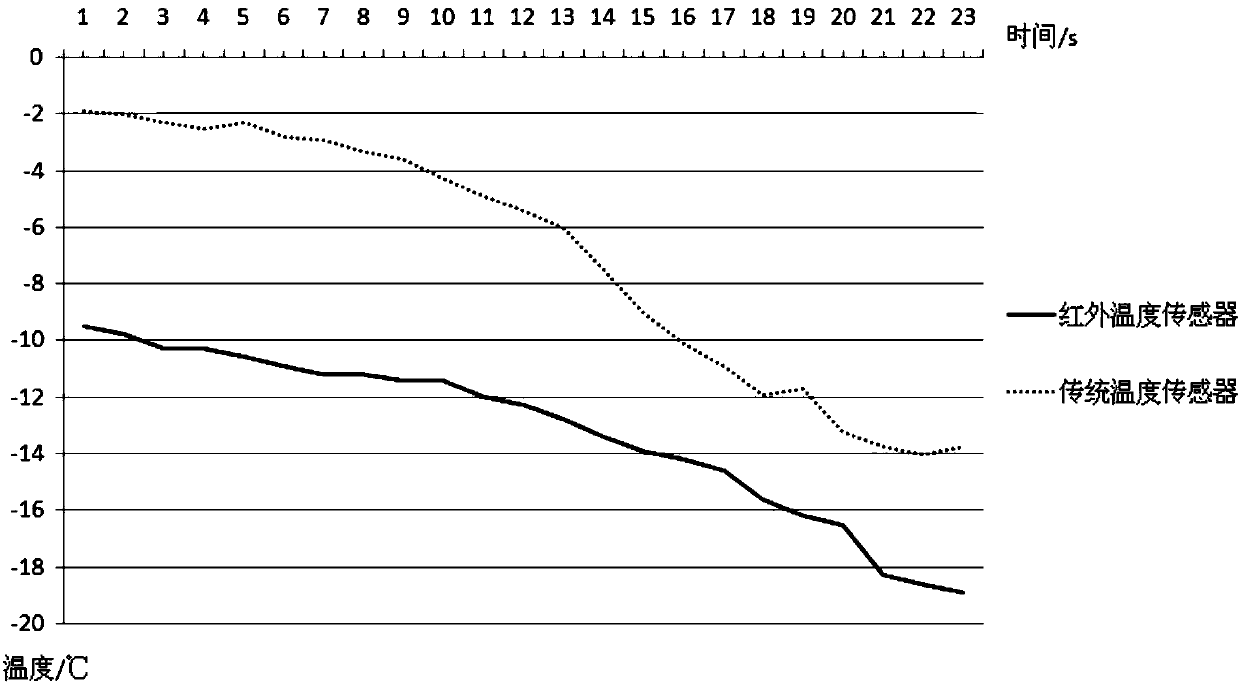

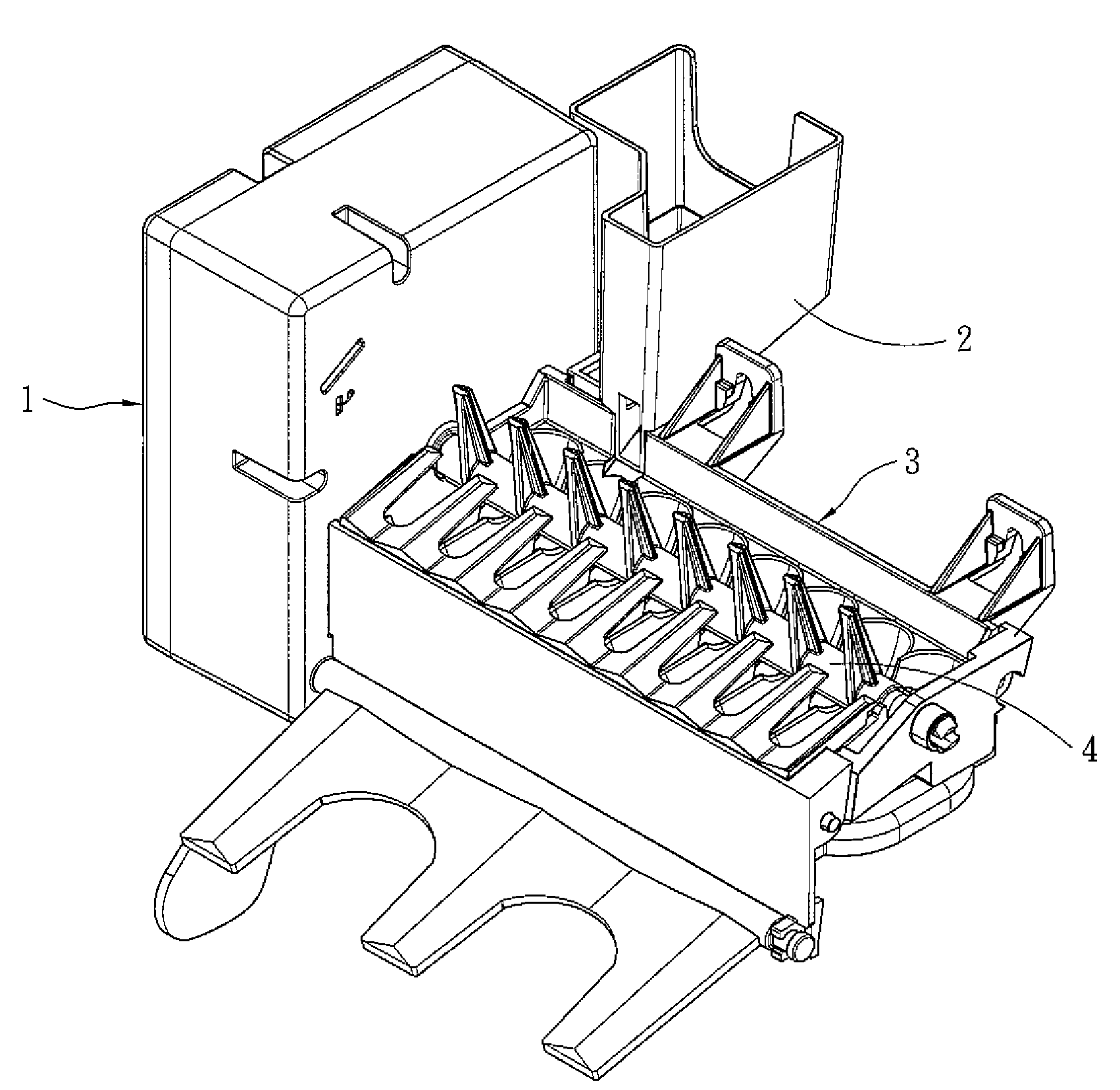

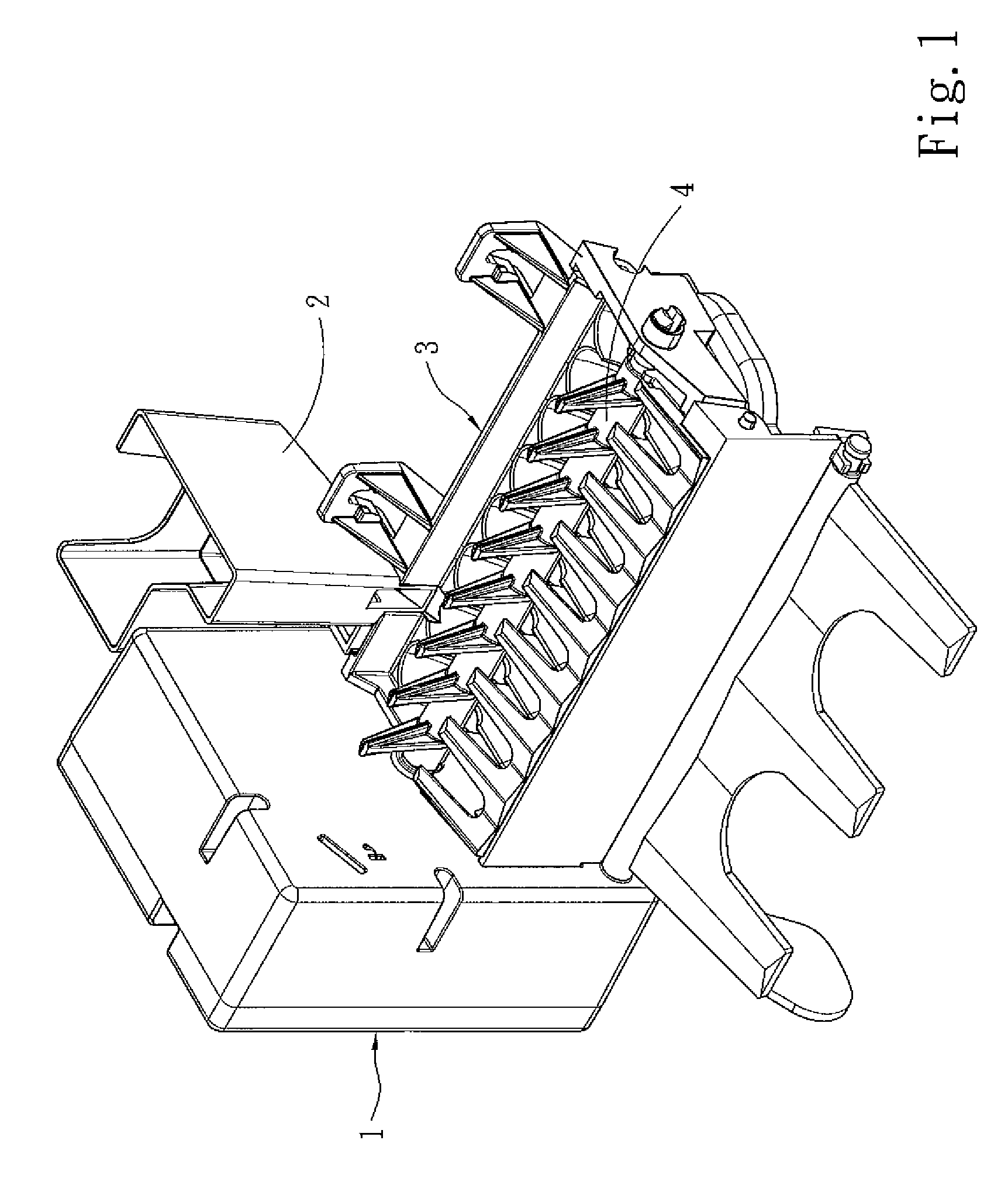

Control method for making rice in refrigerator

InactiveCN107763914AHigh control reliabilityImprove ice production efficiencyLighting and heating apparatusIce productionEngineeringRefrigerated temperature

The invention discloses a control method for making ice in a refrigerator. The specific method is characterized in that the temperature in an ice making box is detected by adopting an infrared temperature sensor; and the ice making process in the ice making box is controlled by the detected temperature signal. Due to high response speed of the infrared temperature sensor, current actual temperature in the ice making box in the ice making process can be detected in time; the ice making process of the ice making box is controlled by adopting the current actual temperature in the ice making box;and the control method has higher reliability, and further the ice making efficiency can be effectively improved, and the ice making effect is ensured.

Owner:HAIER SMART HOME CO LTD

Ice maker equipped with a convection fan

InactiveUS20080223069A1Accelerate ice making speedImprove cooling effectLighting and heating apparatusIce productionEngineeringWater intake

An ice maker equipped with a convection fan includes a control box, an ice making tray, a water intake unit and an ice sweeping shaft. The control box holds at least one convection fan and has at least one air inlet and one air outlet to allow the convection fan to generate cooling air convection to accelerate cooling speed and improve ice making efficiency.

Owner:ZIPPY TECH

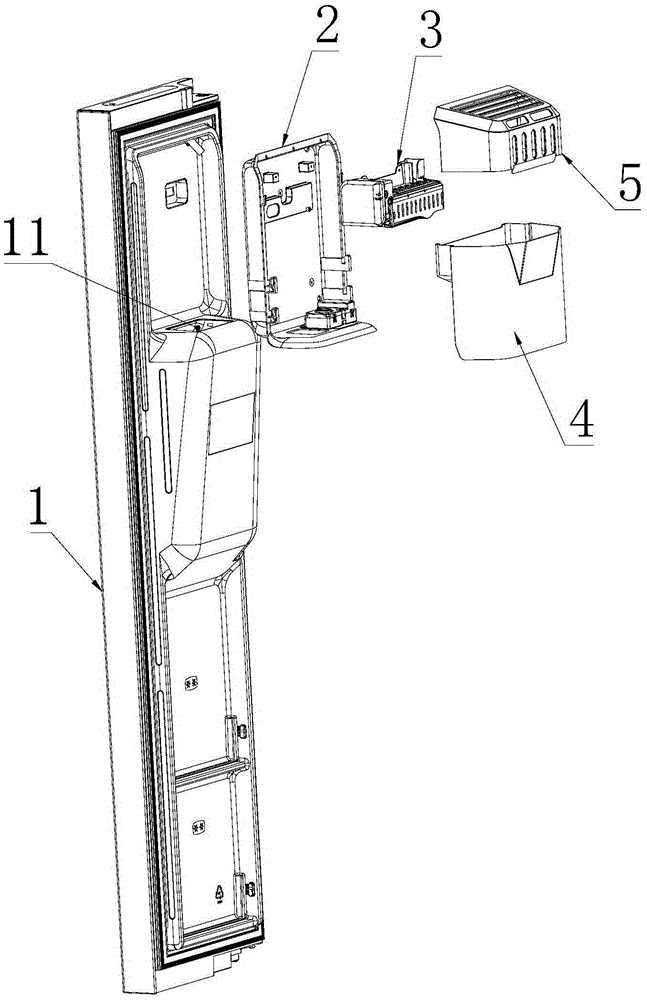

Door ice making system for making transparent ice and refrigerator

ActiveCN105758100AGuaranteed supplyHigh transparencyDomestic cooling apparatusLighting and heating apparatusClosed loopEngineering

The invention belongs to the technical field of door ice making and discloses a door ice making system for making transparent ice and a refrigerator. The door ice making system comprises an ice making unit arranged on a door body, an ice making cavity and a water filling nozzle. The ice making unit is formed by connecting a compressor, an evaporator and a condenser in a closed loop mode. The evaporator stretches into the ice making cavity, the water filling nozzle is communicated with the ice making cavity, and the water filling nozzle is used for enabling injected water to flow along the surface of the evaporator. Due to the fact that the independent refrigerating unit is arranged in the door body to make ice directly on the surface of the evaporator, the independent ice making unit can guarantee supplying of cooling capacity in the ice making process, and the ice making efficiency is high. Ice is made on the surface of the evaporator of the ice making unit, the cooling capacity is directly transmitted to water, and therefore the evaporator with the same heat exchanging efficiency can make more ice. An ice block condenses outwards gradually from the surface of the evaporator, bubbles can be discharged through water on the surface of the ice block, no bubble exists in the ice block, and the ice block with high transparency can be made.

Owner:HEFEI HUALING CO LTD +1

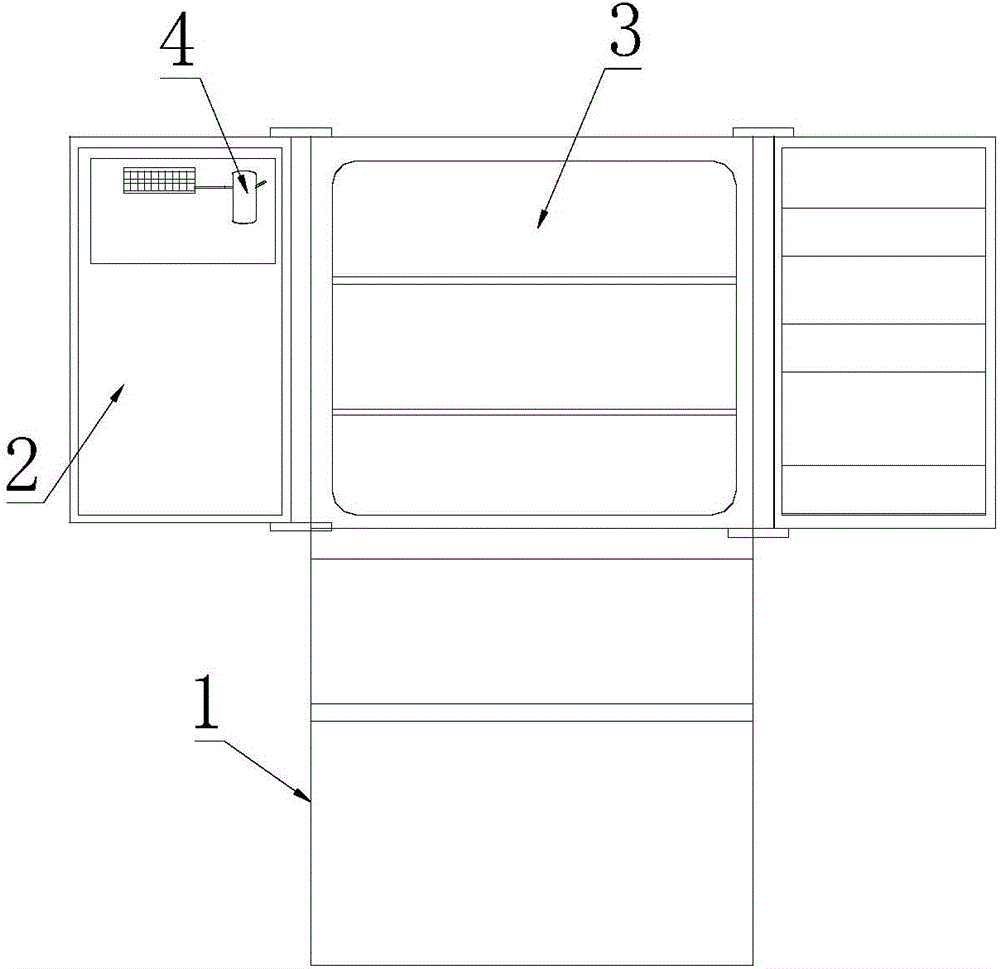

Manual ice maker and refrigerator

InactiveCN102494449AEasy to add waterImprove ice production efficiencyDomestic cooling apparatusLighting and heating apparatusIce storageEngineering

The invention discloses a manual ice maker which comprises an ice maker support, a first ice making box, a second ice making box, an ice removing component, a water supply box and an ice storage box, wherein the first ice making box and the second ice making box are matched on the ice maker support, and each of the first ice making box and the second ice making box is provided with a plurality of ice making trays along the left-and-right direction; the ice removing component is respectively connected with the first ice making box and the second ice making box; and the water supply box is detachably arranged on the top of the ice maker support in a left-and-right moving manner so as to supply water for the first ice making box and the second ice making box. According to the manual ice maker disclosed by the embodiment of the invention, because the water supply box is added, when water is poured, the water supply box is taken down, after water is supplied and filled in the water supply box fully, the water supply box is pulled horizontally into the ice maker support, water fills into the ice making trays automatically, thus time and labor are saved; and a structure of two ice making boxes is adopted, thus the ice making efficiency of the ice maker is improved.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

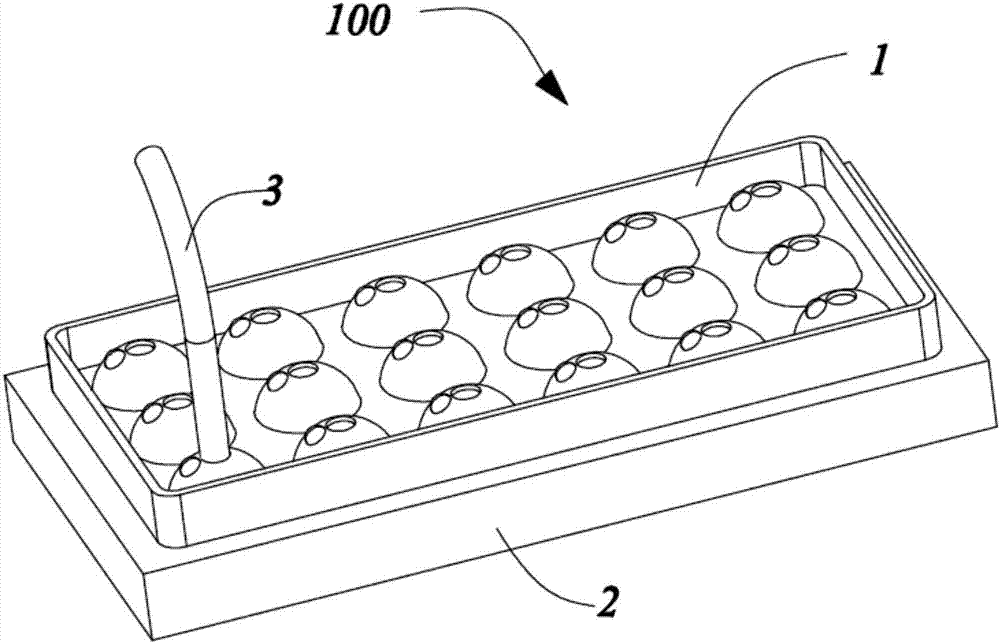

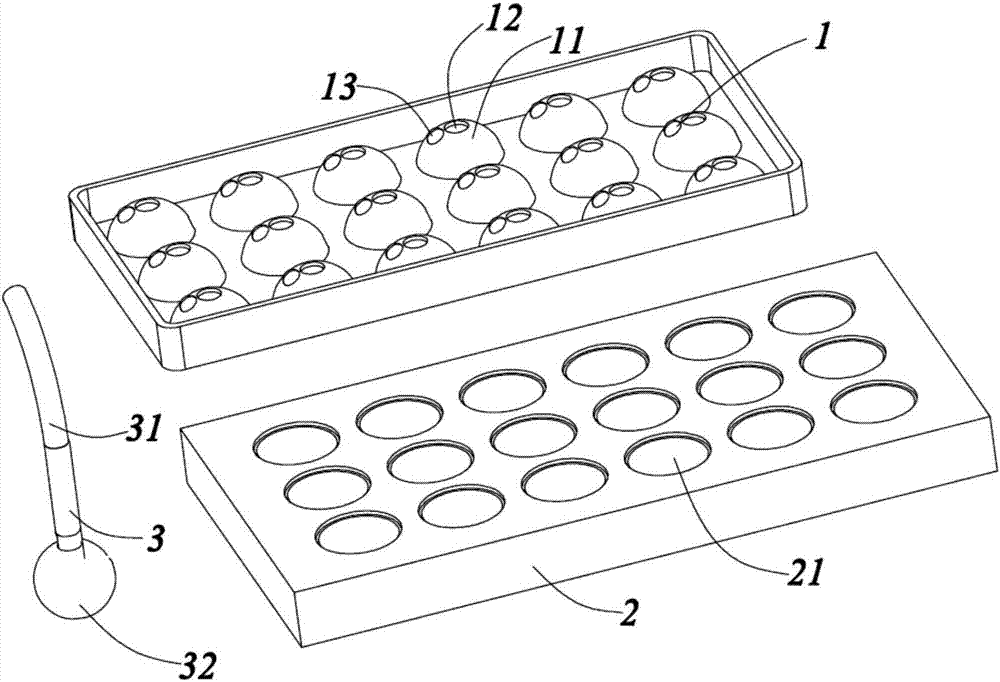

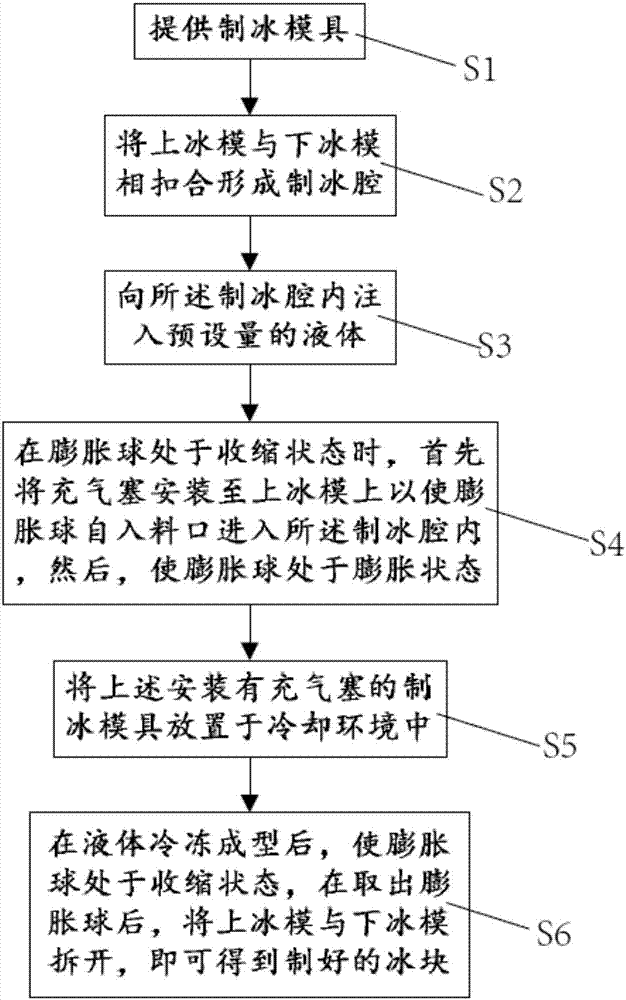

Ice making mold and ice making method thereof

ActiveCN107144065AThe overall thickness is thinImprove ice production efficiencyLighting and heating apparatusIce productionEngineeringGas-filled tube

The invention provides an ice making mold and an ice making method thereof. The ice making mold comprises an upper ice mold body, a lower ice mold body and an air inflation plug; at least one first ice making grid is arranged on the upper ice mold body, and feed ports penetrating through the first ice making grids are formed in the first ice making grids; second ice making grids are arranged on the lower ice mold, wherein ice making cavities can be defined by the second ice making grids and the first ice making grids; the air inflation plug comprises an air inflation tube and an expansion ball, wherein the shape of the air inflation tube is matched the shapes of the feed ports, the expansion ball is connected to one end of the air inflation tube and can be switched between an expansion state and a contraction state, and when the expansion ball is in the contraction state, the expansion ball can enter / exit the ice making cavities from the feed ports; and the air inflation plug 3 is arranged on the upper ice mold body 1, the expansion ball 32 located in one ice making cavities is in the expansion state, liquid in the ice making cavities fills between the expansion ball 32 and the ice making cavities, and therefore the liquid can be frozen to form hollow ice cubes, and meanwhile, some meaningful things such as a font and a fluorescent substance can be placed in the ice making cavities according to requirements.

Owner:HAIER SMART HOME CO LTD

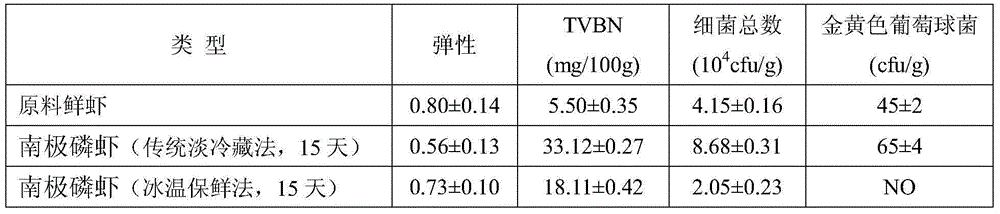

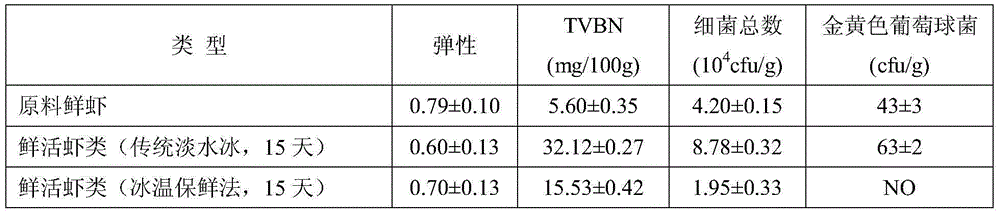

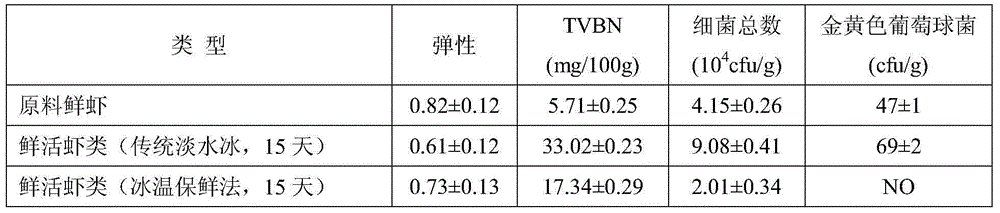

Euphausia superba ice temperature preservation method

InactiveCN105010498AImprove ice production efficiencyAvoid surface damageMeat/fish preservation by freezing/coolingMeat/fish preservation using chemicalsPathogenSpoilage microorganisms

The present invention relates to an euphausia superba ice temperature preservation method which comprises the following steps: (1) pre-treatment; (2) preservative agent A treatment; (3) preservative agent B treatment; and (4) low temperature storage. The preservative agent A is a fluidized ice solid-liquid mixture which consists of a fluidized ice solid and aqueous solution; and wherein the mass concentration of the fluidized ice solid is 30-40%, and concentrations of each components of the aqueous solution are as follows: 6-10 g / L smoked plum extract, 8-12 g / L honeysuckle extract, 3-5 g / L citric acids, 1-2 g / L phytic acids, and 0.05-0.3 g / L magnesium salt. The preservative agent B is also a fluidized ice solid-liquid mixture, wherein the mass concentration of the fluidized ice solid is 50-80%, and concentrations of each components of the aqueous solution are as follows: 7-10 g / L smoked plum extract, 10-14 g / L honeysuckle extract, 2-3 g / L citric acids, and 0.8-1 g / L phytic acid. The ice temperature preservation method can effectively suppress the large reproduction of pathogens and spoilage organisms, effectively prevent shrimp body melanosis, and ensure shrimp meat quality and freshness.

Owner:ZHEJIANG OCEAN UNIV

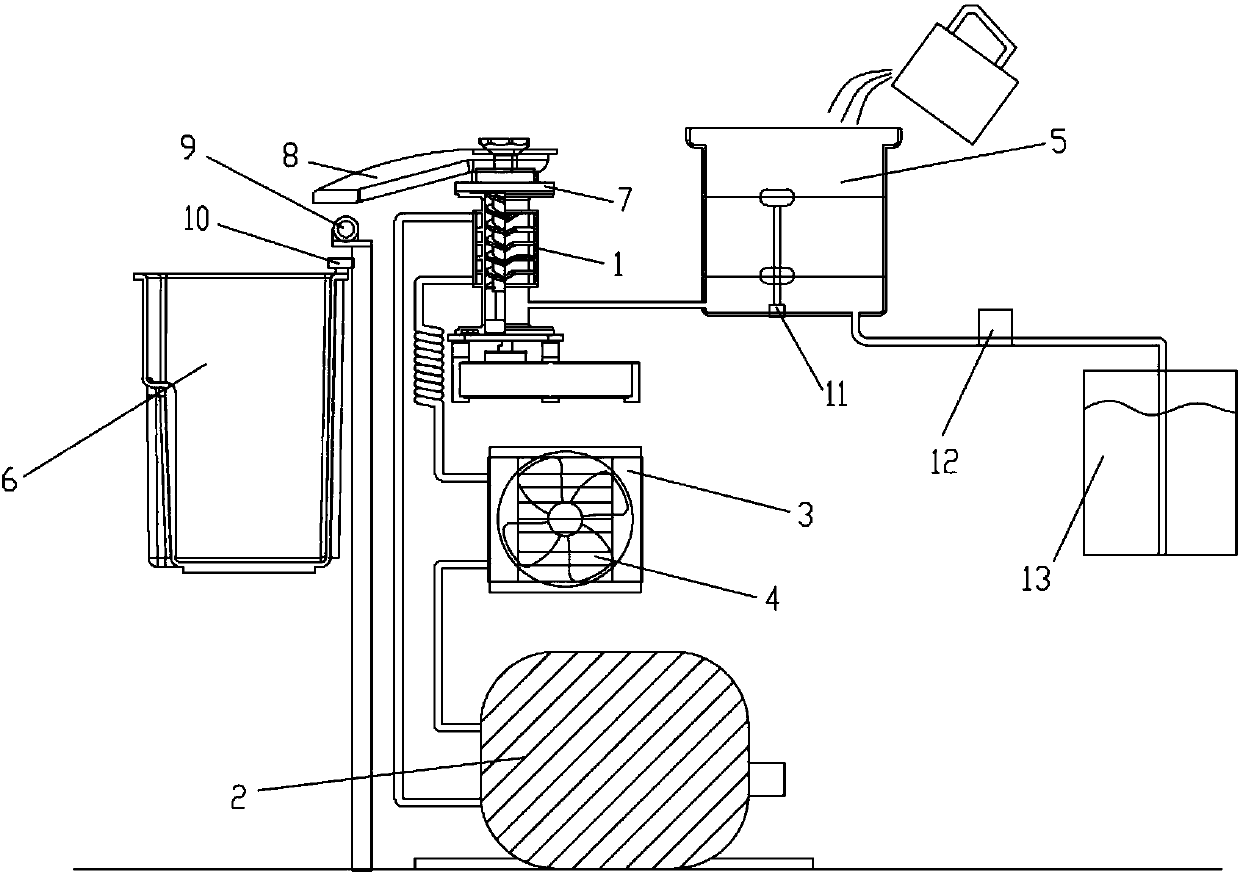

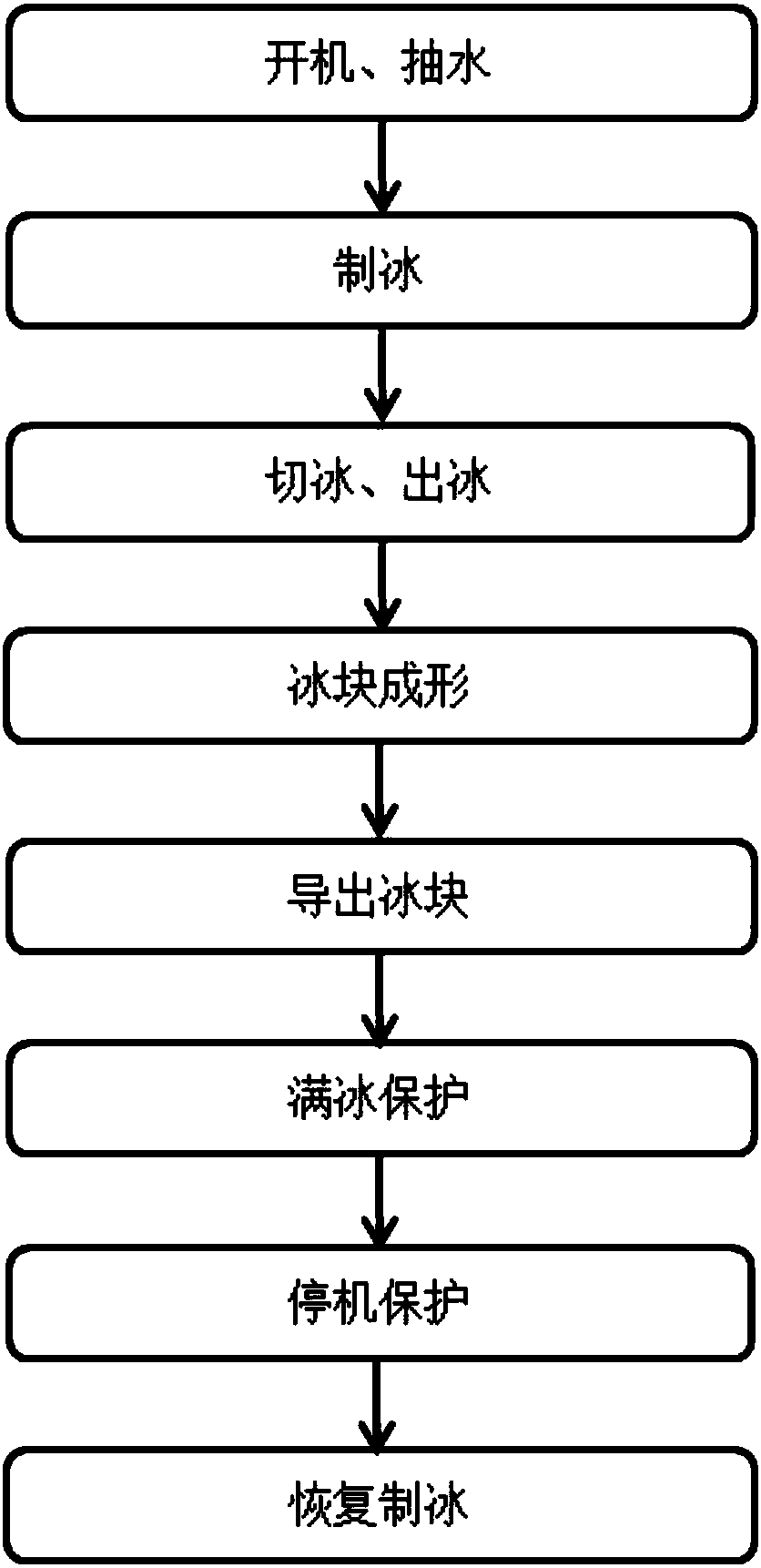

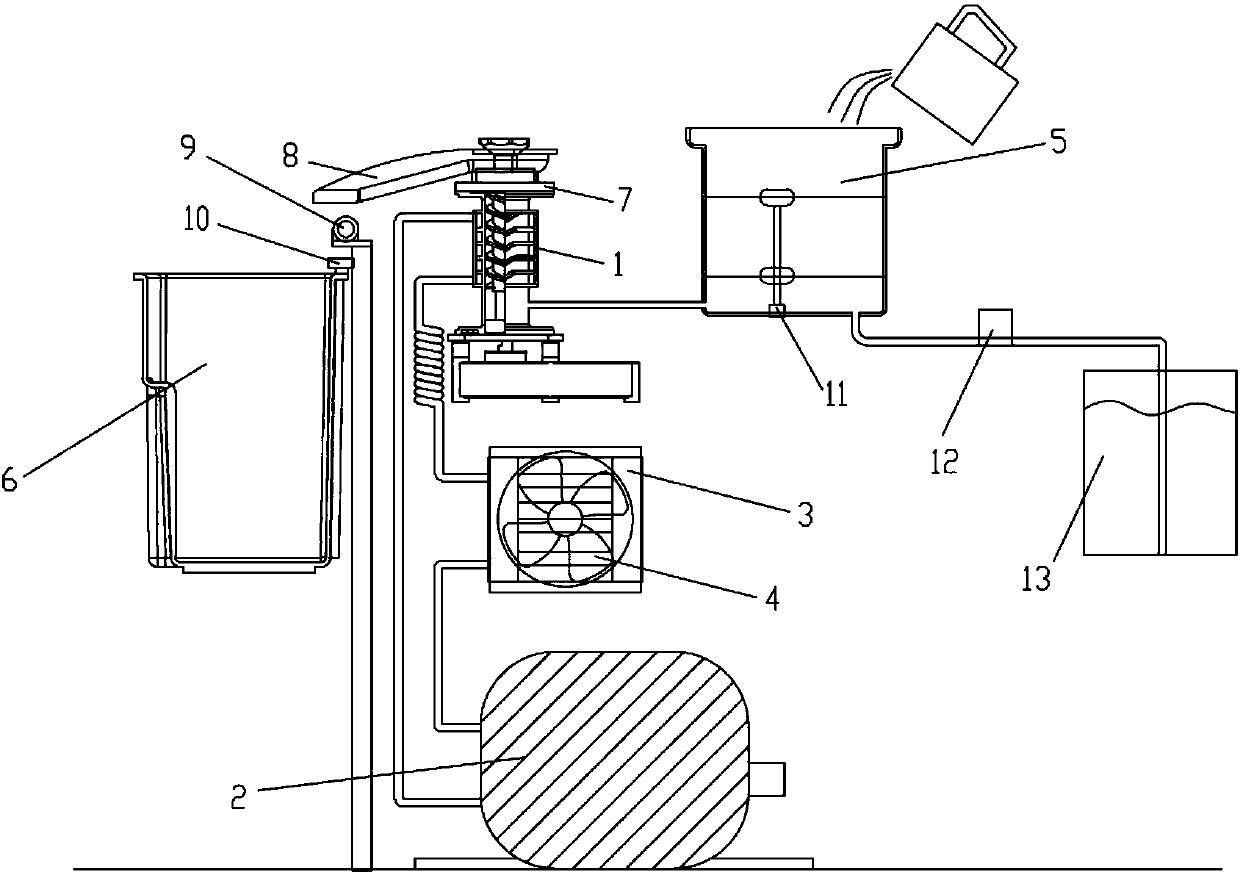

Ice maker system and ice-making method thereof

PendingCN110006198ARealize automatic water fillingGet ice in timeLighting and heating apparatusIce productionIce storageWater storage tank

The invention provides an ice maker system and an ice-making method thereof. The ice maker system comprise an evaporator, a condenser, a radiating fan, a compressor, a water storage tank and an ice storage box, wherein an ice making device is composed of the evaporator, the condenser, the radiating fan and the compressor; an ice outlet of the evaporator is connected with a shaper; an outlet end ofthe shaper is connected with an ice guider; a magnetic switch and an infrared detector are sequentially arranged above the ice storage box; and a water level sensor is arranged inside the water storage tank. According to the ice maker system and the ice-making method thereof, the capacity conditions of the water storage tank and the ice storage box are sensed and detected in real time, and various ice maker protection mechanisms are adopted, so that automatic water injection and timely ice taking of the ice maker are achieved, and the ice making efficiency is obviously improved; and moreover,the uniformity of the extruded ice blocks is consistent, and the user experience is improved.

Owner:冰加优享科技(东莞)有限公司

Refrigerator

InactiveCN108286855ASmall impact on structureAffect heat transfer performanceLighting and heating apparatusIce productionCooling chamberRefrigerated temperature

The invention provides a refrigerator, which comprises a box body defining a refrigerating chamber inside and a refrigerating chamber door body composed of a door body, a door liner and a foaming layer. A containing box with an ice making and cooling chamber is arranged at the top of the box body, an ice making evaporator and a fan are arranged in the ice making and cooling chamber, and a heatingpart is arranged on the ice making evaporator to heat and defrost the ice making evaporator; an ice making chamber with an ice maker is formed in the door liner; a top air supply chamber is formed inthe containing box, a top air inlet chamber and a top air return chamber are formed in the top air supply chamber, the bottom of the top air inlet chamber is respectively provided with a top air outlet and a top air return inlet penetrating through the top of the box body, and the upper part of the door liner is provided with an ice making chamber air inlet and an ice making chamber air return inlet penetrating through the ice making chamber. When the refrigerating chamber door body is closed, the ice making chamber air inlet communicates with the top air outlet, the ice making chamber air return inlet communicates with the top air return inlet, so that the amount of cooling supplied to the ice maker is increased and the ice making efficiency of the ice maker is improved.

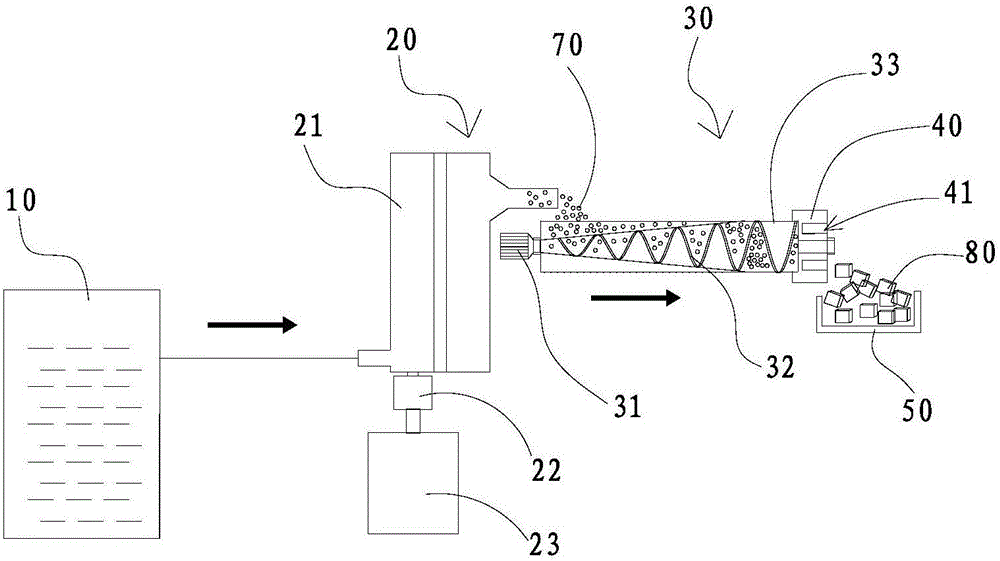

Ice making device

PendingCN106642860ADeicingImprove ice production efficiencyLighting and heating apparatusIce productionSuper coolingEngineering

The invention relates to an ice making device. The ice making device comprises a super-cooled water supplying mechanism, an ice grain transforming mechanism, a squeezing and conveying mechanism and an ice block forming mold. An input end of the ice grain transforming mechanism is communicated with an output end of the super-cooled water supplying mechanism; the ice grain transforming mechanism is used for transforming super-cooled water into ice grains. The ice block forming mold is provided with one or more separation channels. The input end of the squeezing and conveying mechanism is used for receiving the ice grains output by the output end of the ice grain transforming mechanism; the output end of the squeezing and conveying mechanism is communicated with the separation channel; the squeezing and conveying mechanism is used for squeezing and pushing the crystal grains into the separation channel. By adopting the ice making device provided by the invention, the ice block forming mold does not need to be heated and deiced, and the ice grains are directly conveyed into the separation channel in the ice block forming mold to form ice blocks; the ice blocks are pushed out of the ice block forming mold through the follow-up fed ice grains, so that the effect of continuously making ice can be realized and the ice making efficiency is greatly improved.

Owner:南京野崎制冷科技有限公司

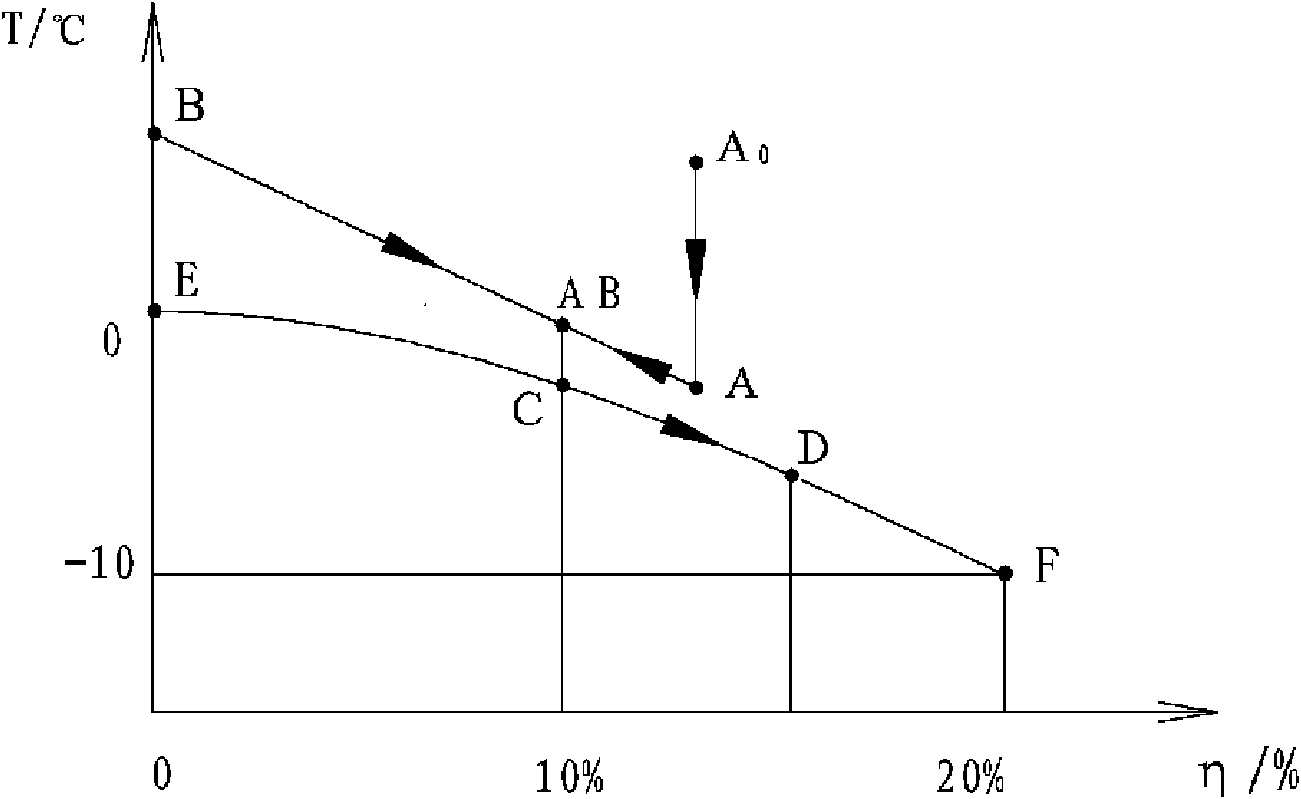

Fluid ice preparation method, preparation equipment and fluidization crystallizer

InactiveCN101660853AReduce concentrationIncrease profitIce productionCompression machines with several evaporatorsDiluentCooling capacity

The invention relates to a fluid ice preparation method, a preparation equipment and a fluidization crystallizer; the preparation method is as follows: firstly, carrying out a first-stage cooling on ice making solution, cooling below 0 DEG C and above minus 15 DEG C; and then injecting diluent into ice making solution to obtain ice making solution with reduced concentration; and finally carrying out a second-stage cooling on reduced ice making solution and continuously cooling to produce fluid ice. A fluid ice crystallization passage of the fluidization crystallizer of the preparation equipment of fluid ice is divided into a first refrigeration section and a second refrigeration section in the flow direction; a first stage evaporator and a second evaporate are respectively and correspondingly arranged at outer sides of the two refrigeration sections; one end of the fluid ice crystallization passage close to the first refrigeration section is provided with an ice making solution inlet and the other end is provided with a fluid ice outlet; a diluent inlet is arranged between the two refrigeration sections. The invention carries out two-stage cooling on ice making solution and reducesthe concentration of ice making solution in the ice making process, thus increasing the utilization rate of cooling capacity and refrigeration efficiency of a refrigeration system.

Owner:HENAN UNIV OF SCI & TECH

Ice making machine

ActiveCN107044751AIncrease the heat exchange areaImprove ice production efficiencyLighting and heating apparatusIce productionSolid-stateEngineering

The invention discloses an ice making machine. The ice making machine comprises an accommodating tank for accommodating water, and a cold air refrigerating module for providing cold to the accommodating tank for changing the water to ice, and also comprises an air guide cover arranged at the periphery of the accommodating tank; a heat exchange air duct for enabling cold air to pass through is sandwiched between the air guide cover and the outer wall of the accommodating tank; and when the ice making machine makes the ice, the cold air passing through the heat exchange air duct transfers the cold from the outer wall of the accommodating tank into the accommodating tank for cooling the water. The accommodating tank directly exchanges heat with the cold air in the heat exchange air duct through the outer wall, so that the heat exchange area between the water in the accommodating tank and the cold air can be effectively increased, and the ice making efficiency is improved; and as the cold air does not make direct contact with liquid-state water or solid-state ice in the accommodating tank, the made ice has no peculiar smell, and is clean and sanitary.

Owner:QINGDAO HAIER REFRIGERATOR CO LTD +1

Ice maker

InactiveCN101929773AIncrease exhaust pressureImprove efficiencyHeat pumpsIce productionEngineeringThermal water

The invention discloses an ice maker. The ice maker comprises a condenser, an evaporator and a multisource load self-balancing heat pump, wherein a refrigerant circularly flows in a pipeline between the condenser and the evaporator; the multisource load self-balancing heat pump is used for supplying stable circulating hot water and circulating cold water for a system; the cold water of the multisource load self-balancing heat pump is communicated with the condenser of the ice maker; and the hot water of the multisource load self-balancing heat pump is communicated with the evaporator of the ice maker. Circulating low-temperature water is used for the condensation side and ice-collecting can be guaranteed without limiting water quantity, so the ice maker has the advantages of stable working condition, stable ice yield in all the year round, shortened ice-collecting time, capacities of optimizing the design of a compressor and optimizing the efficiency of the system, reduction in liquid-returning probability and great improvement on reliability.

Owner:李洲

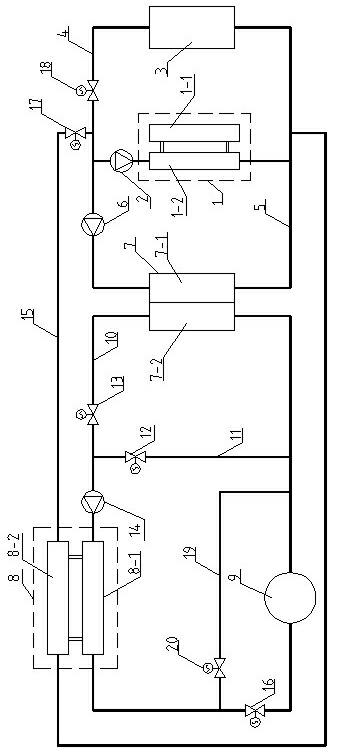

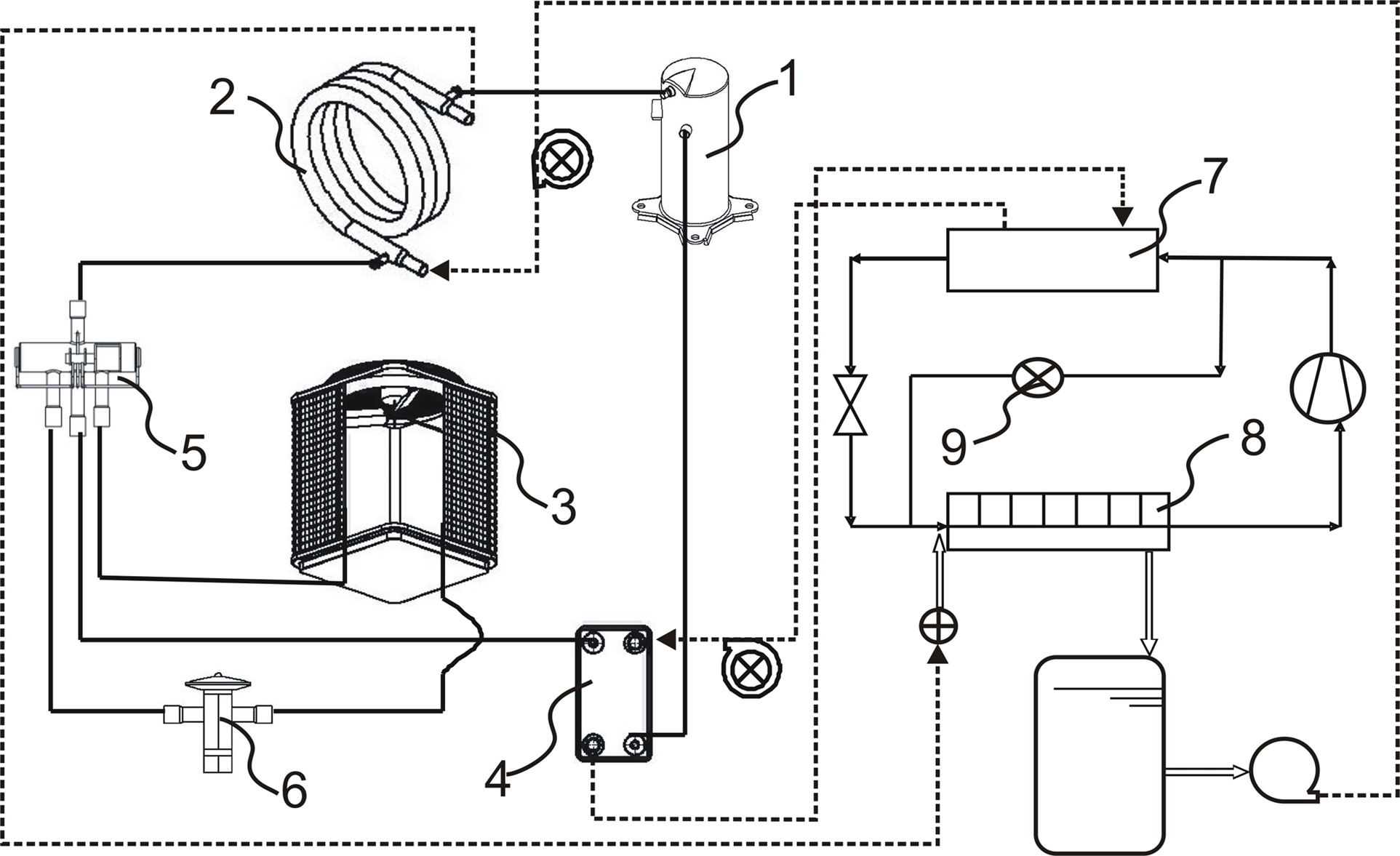

Direct-evaporating type ice cold accumulation refrigerating system and refrigerating method thereof

InactiveCN102506473ALow costImprove ice production efficiencyFluid circulation arrangementAir conditioning systemsProcess engineeringEngineering

The invention provides a direct-evaporating type ice cold accumulation refrigerating system and a refrigerating method thereof, relating to the technical field of refrigerating air conditioners. The refrigerating system comprises a refrigerating unit, an end device, an ice making unit, a heat exchanging device and an ice accumulation tank, wherein an evaporator of the ice making unit is arranged in the ice accumulation tank, the ice accumulation tank is connected with a clod fluid channel of the heat exchanging device, a hot fluid channel of the heat exchanging device is connected with the end device, a pipeline is arranged on a loop between a condenser of the ice making unit and the evaporator of the refrigerating unit and a corresponding circulating pump and control valve are arranged on the pipeline. Cooling water of the condenser of the ice making unit is supplied after being precooled to 2-20 DEG C by the refrigerating unit. The problem that the conventional refrigerating unit cannot work on an ice making operation condition and the problem that an air-cooling ice maker has a large compression ratio, is high in cost and is complicated to control can be overcome, the cost of a refrigerating system can be reduced and ice making efficiency and operational stability can be improved.

Owner:JIANGSU QICAI TECH

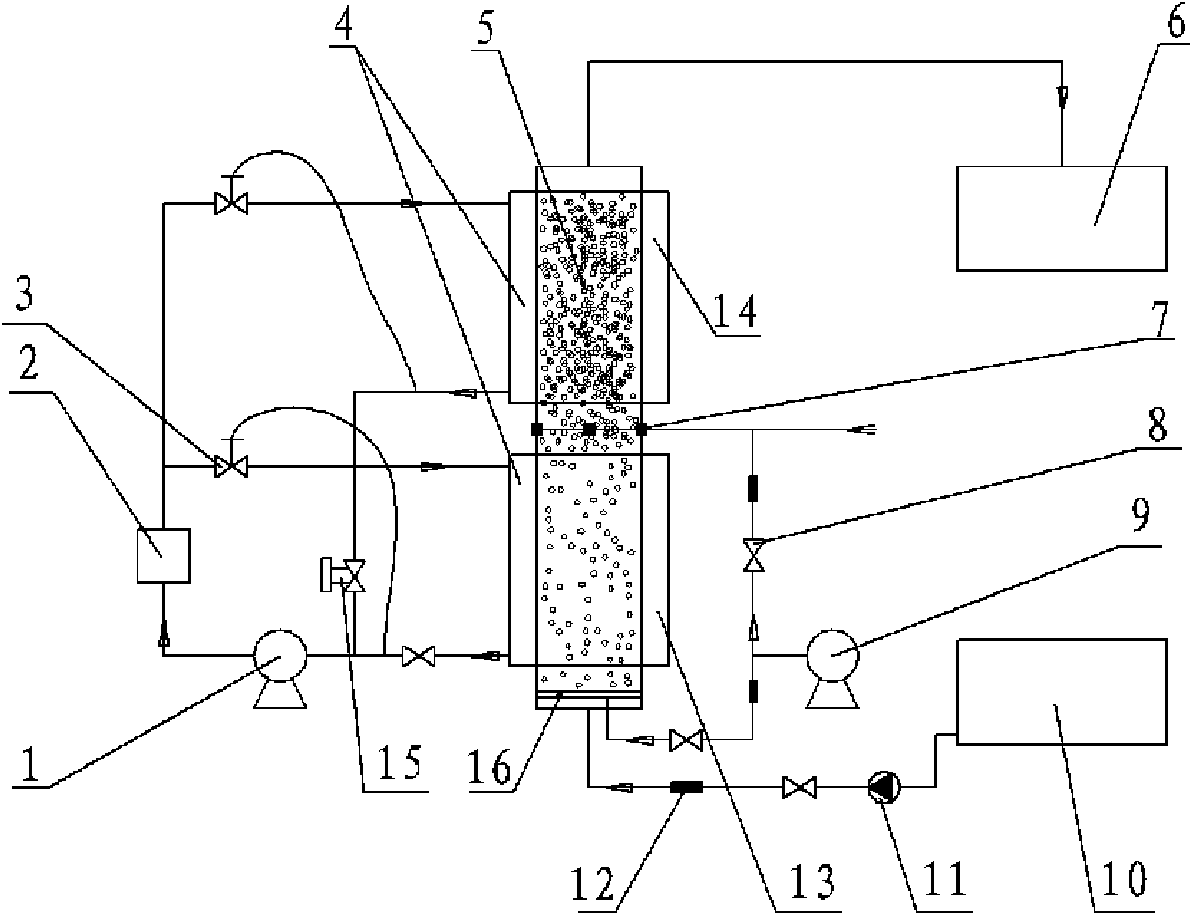

Rapid dynamic ice making method of ice making system

InactiveCN104729175AIncrease the level of upscalingGuaranteed uptimeLighting and heating apparatusIce productionIce waterHeat resistance

The invention discloses a rapid dynamic ice making method of an ice making system. The ice making system comprises a cooler, a supercooling elimination device and an ice storage tank. Water is pumped out from the ice storage container, the temperature of the water is larger than or equal to zero DEG C at the moment, and the water becomes supercooled water with the temperature lower than zero DEG C after heat exchange with a refrigerant in the cooler. The supercooled water becomes an ice water mixture after passing the supercooling elimination device and enters the ice storage container, and ice and water are separated from each other in the ice storage container. The ice separated out of the ice water mixture is stored in the ice storage container, and the water separated out of the ice water mixture continues to circulate in the ice making system. When the rapid dynamic ice making method is used for ice making, ice layers are not generated on the surface of heat exchange equipment, heat resistance of heat exchange between an ice making solution and the refrigerant is not increased or changed along with ice making, the system works stably in the whole ice making process, and accordingly, ice making efficiency of the system is improved; ice making speed is high, stable operation is achieved, maximum ice making quantity per unit can reach 1.5t / day, and scale expanding level of ice making equipment is improved.

Owner:安徽绿能技术研究院有限公司

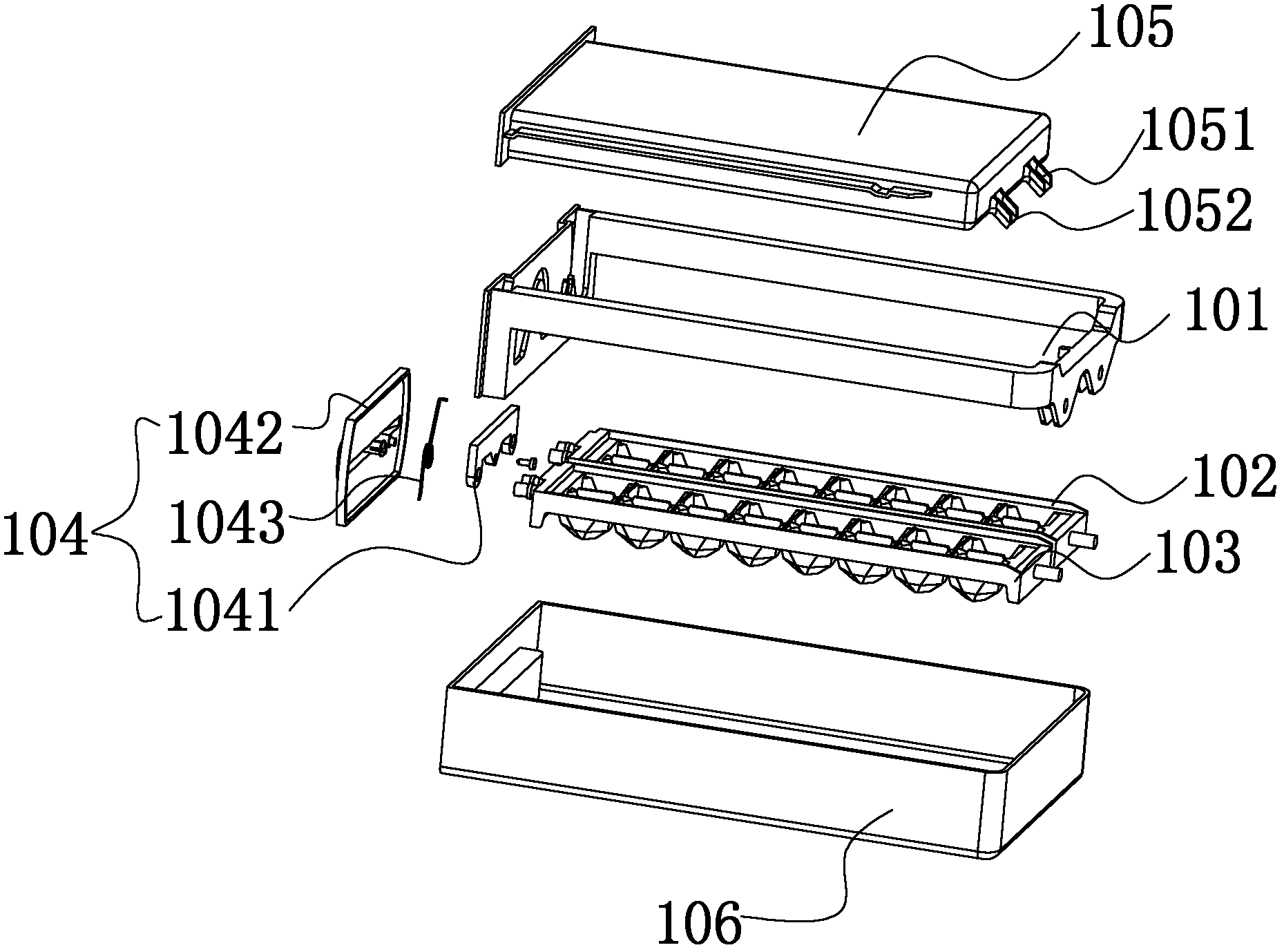

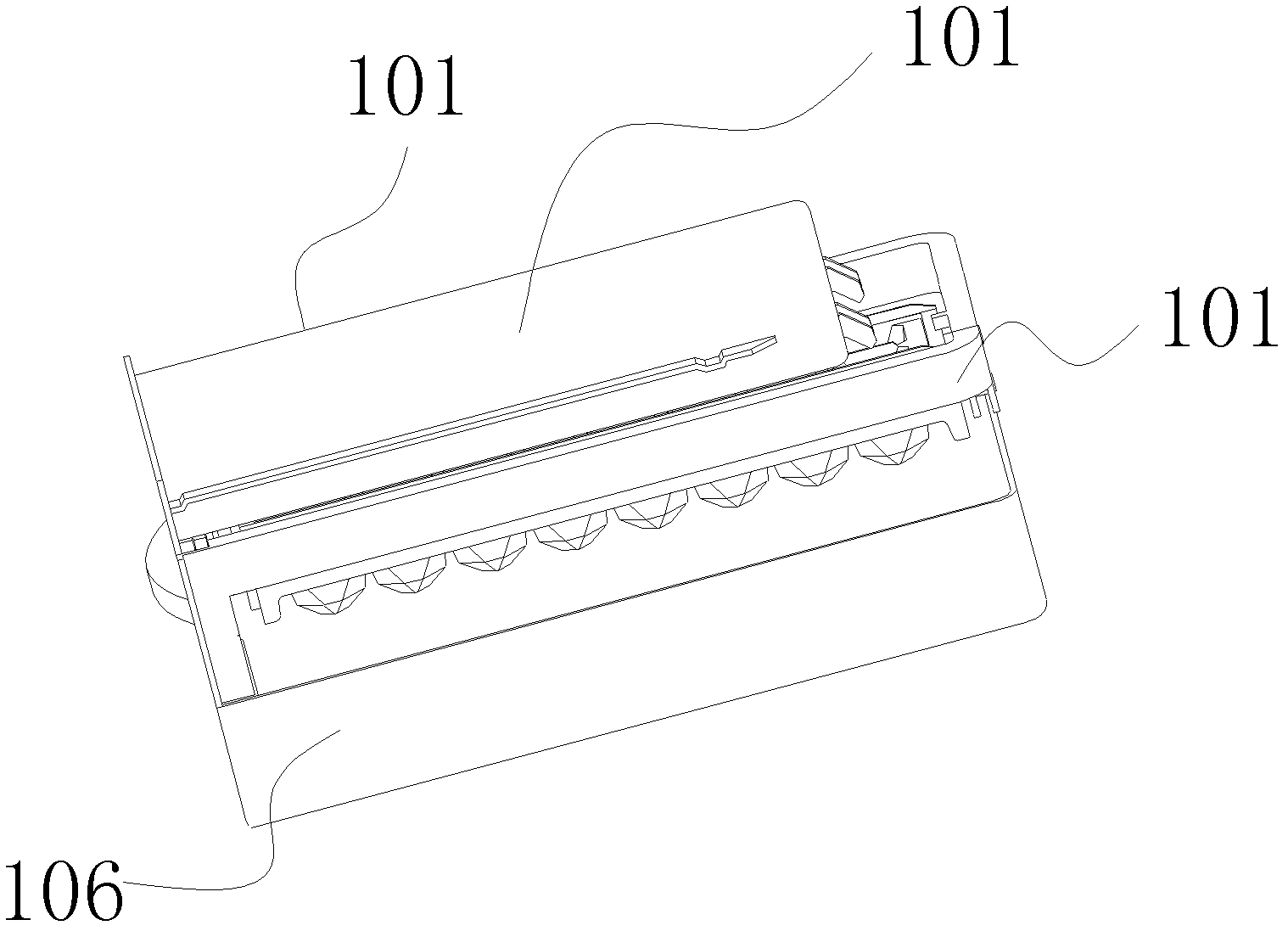

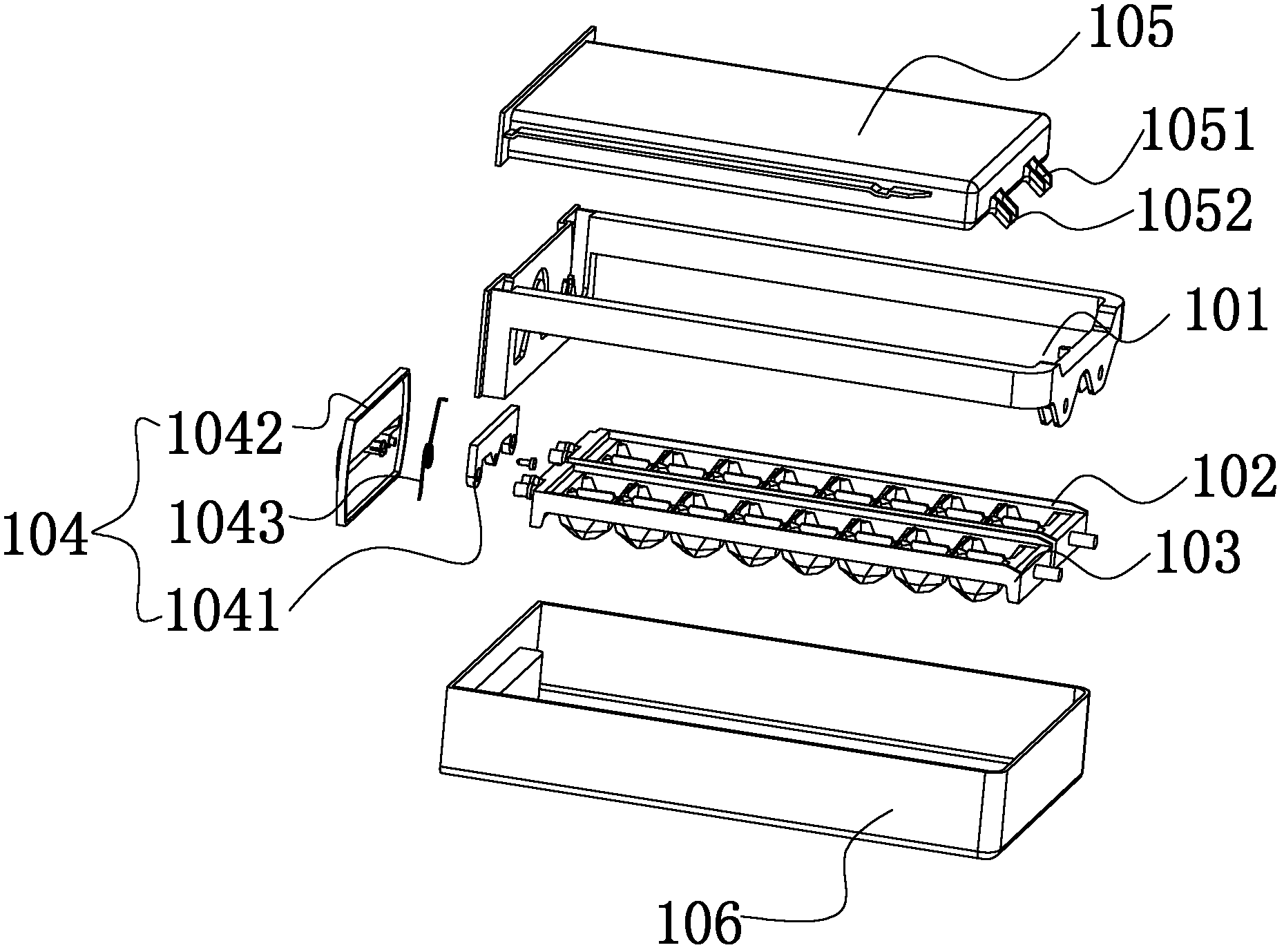

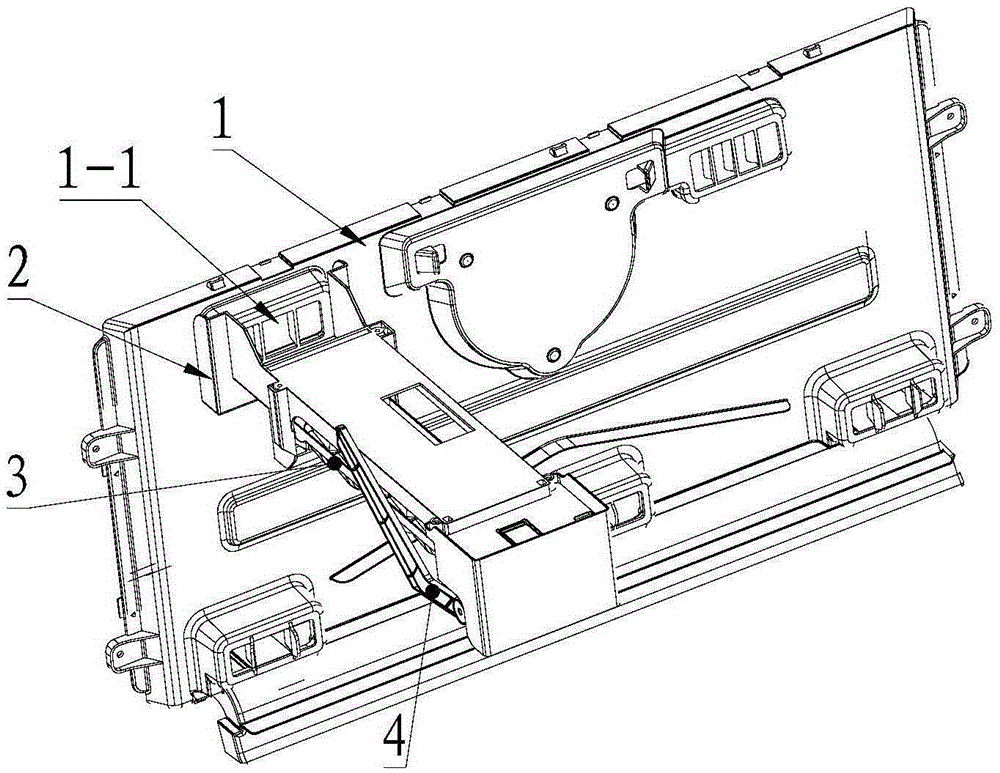

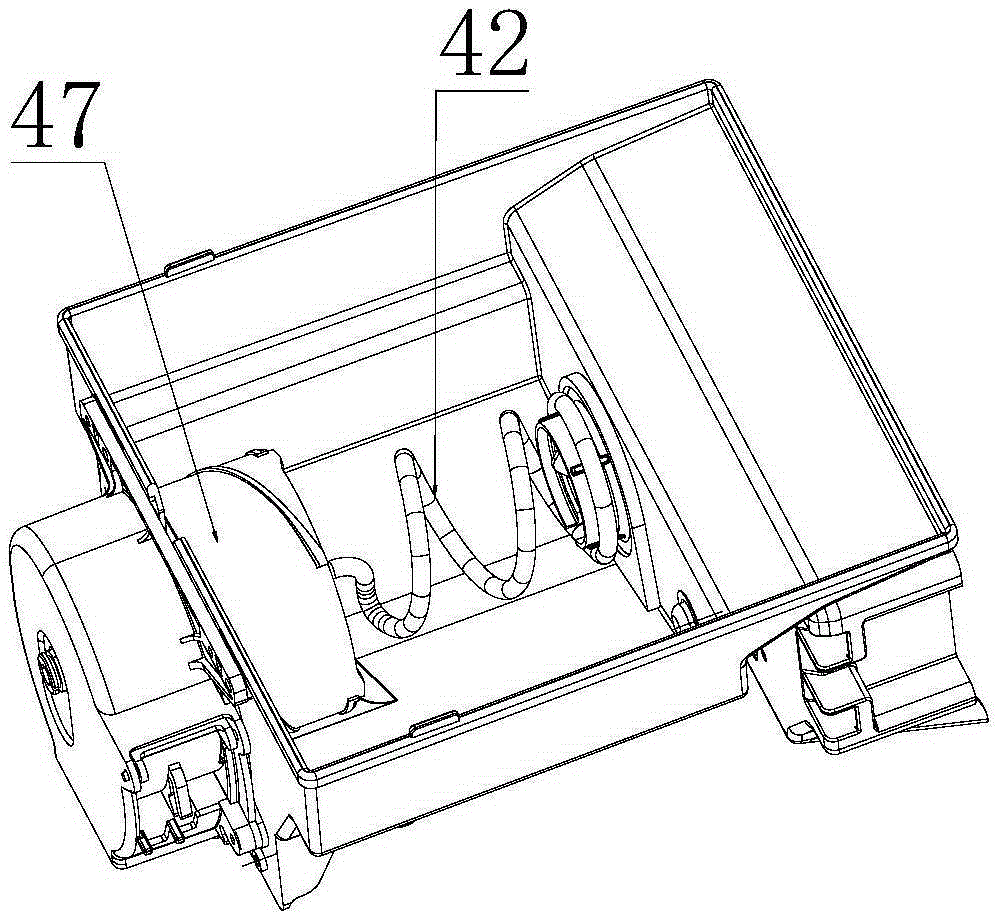

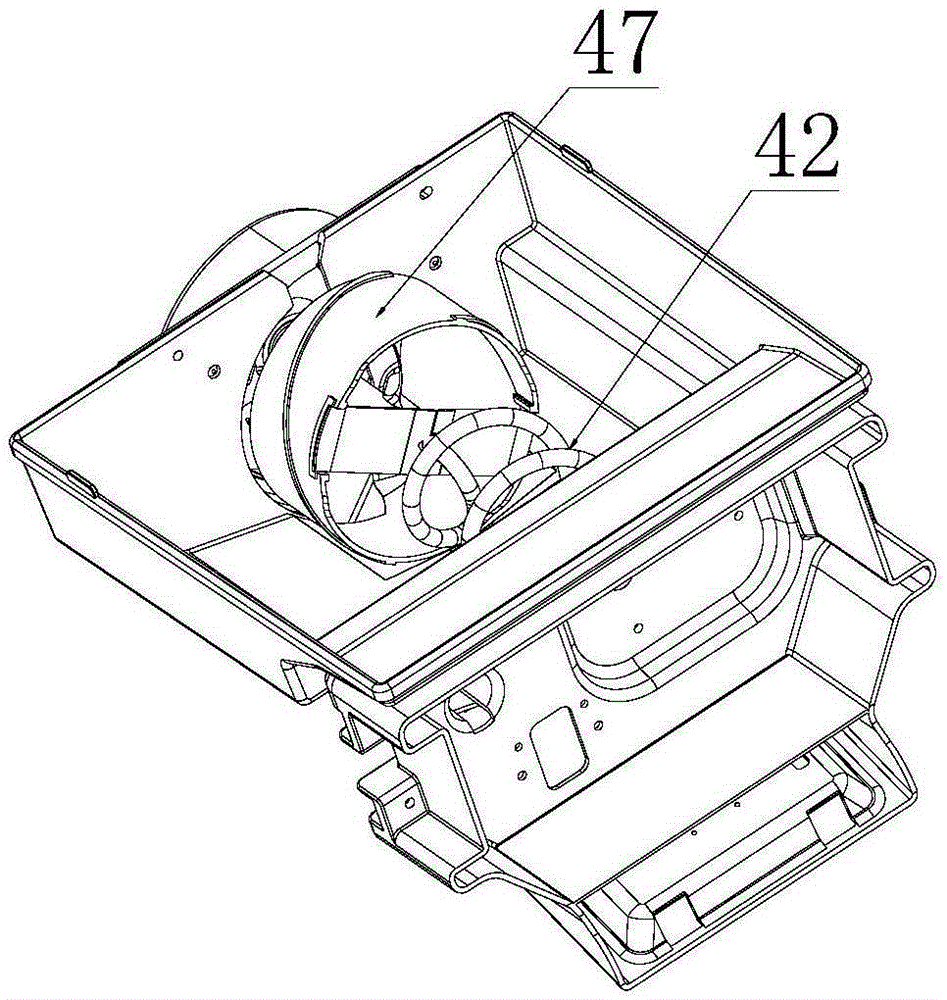

Ice making machine and refrigerator

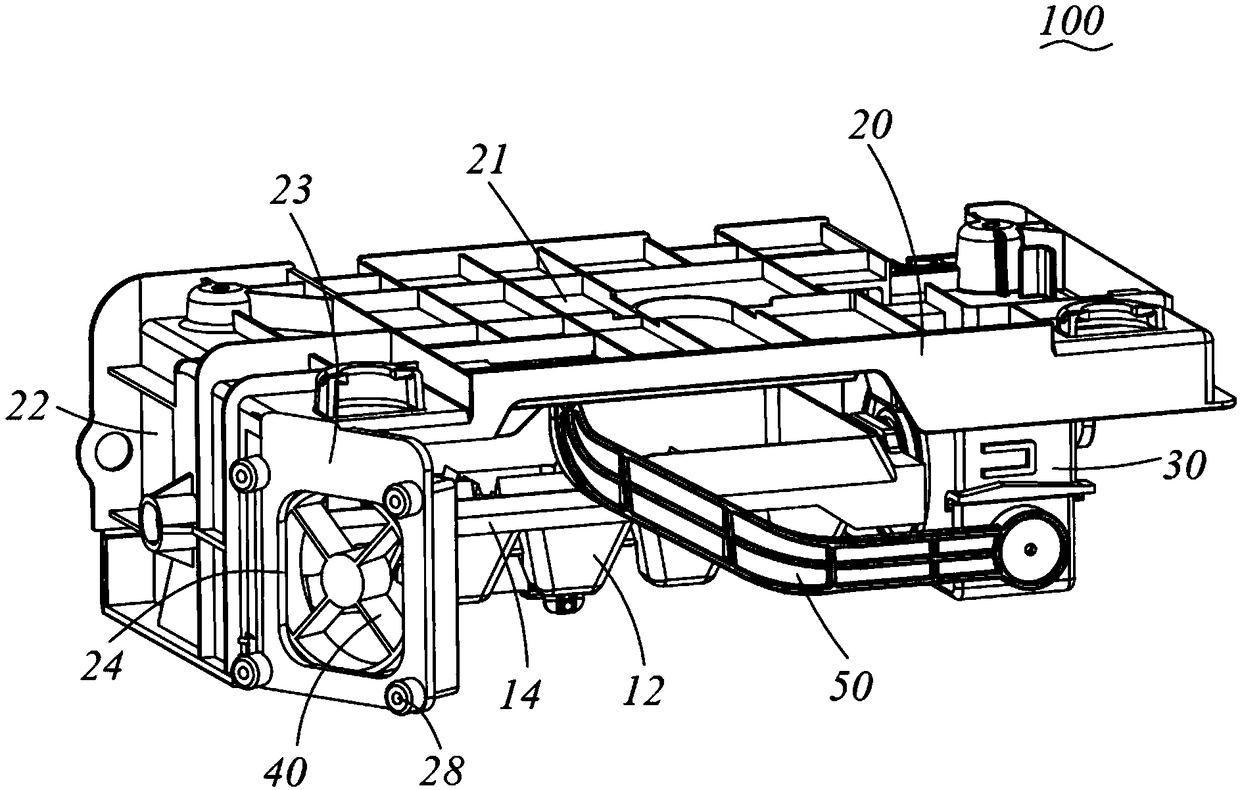

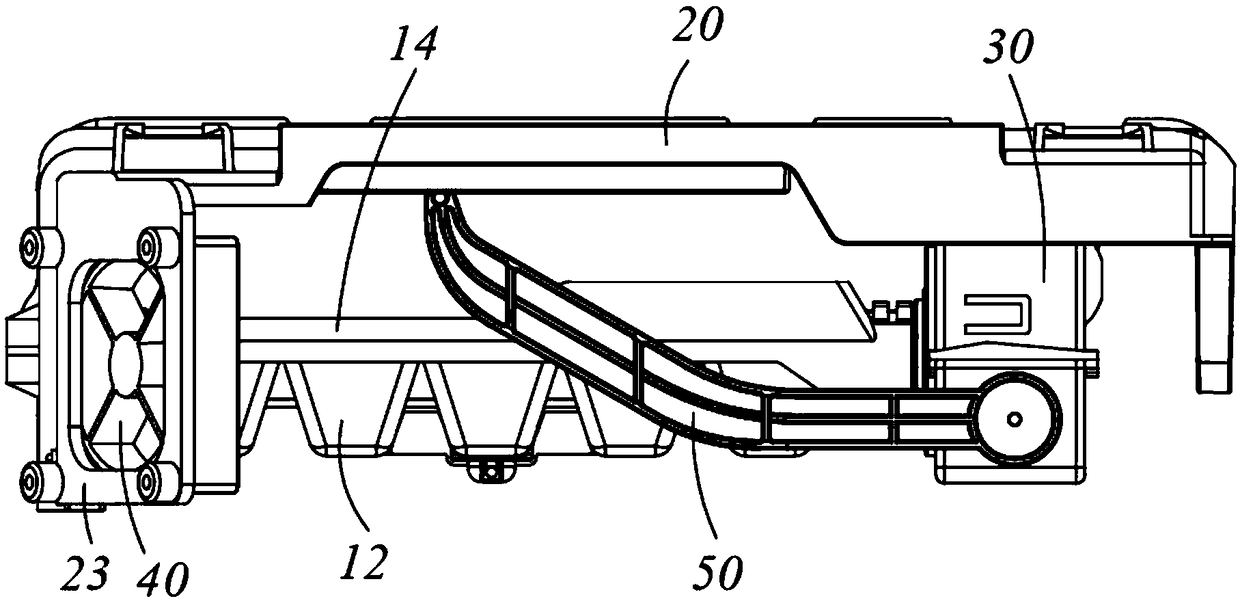

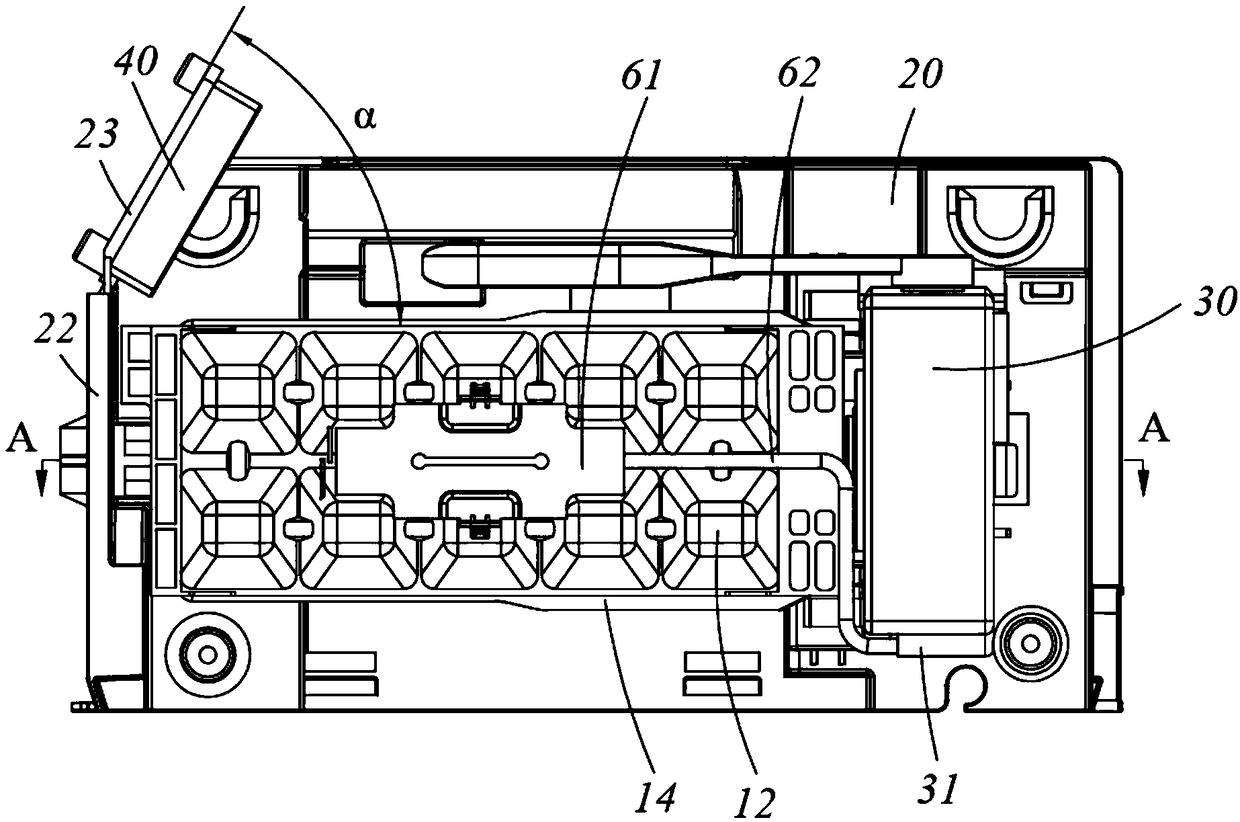

ActiveCN108895740AHigh efficiency of forced convectionImprove ice production efficiencyLighting and heating apparatusIce productionEngineeringMechanical engineering

The invention discloses an ice making machine and a refrigerator. The ice making machine is provided with an ice making box with a plurality of ice making grids, a motor assembly driving the ice making box and a bracket. Each ice making grid is provided with an opening. The motor assembly is connected to the bracket. One end of the ice making box is rotatably supported by the bracket. The other end of the ice making box is connected to the motor assembly and is driven to rotate by the motor assembly. The ice making machine also includes a fan mounted on the bracket. The bracket includes a topplate located on the upper parts of the openings and a side plate located on one side of the top plate. One end of the ice making box is supported by the side plate. The side plate extends out of a support plate relative to the side edge of the ice making box. The fan is connected to the support plate and the air inducing direction of the fan is toward the ice making box. The ice making machine and the refrigerator provided by the invention have high ice making efficiency.

Owner:HAIER SMART HOME CO LTD

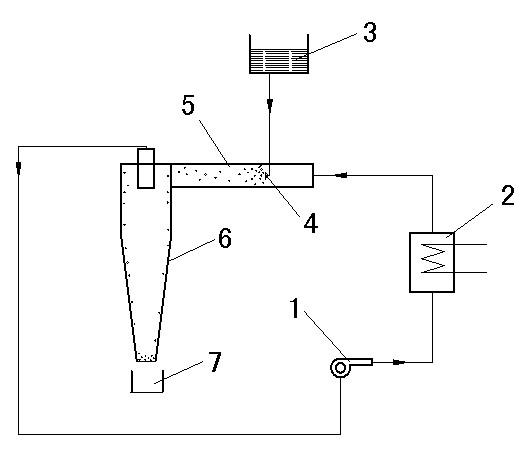

Method and device for preparing granular ice by freezing atomized water drops in cold carrying airflow

InactiveCN102128531AIncrease contact heat exchange areaLow energy consumption for ice makingLighting and heating apparatusIce productionThermodynamicsAtomizer nozzle

The invention discloses a method and a device for preparing granular ice by freezing atomized water drops in cold carrying airflow. The method mainly comprises the following steps of: delivering the cold carrying airflow to a refrigerating device through a circulating booster fan to cool the airflow; delivering the low-temperature airflow to a granular ice freezing passage, meanwhile, spraying the atomized water drops into the granular ice freezing passage through an atomizing nozzle, and cooling the atomized water drops by the low-temperature airflow to form granular ice; and discharging the cold carrying airflow and the granular ice into a cyclone separator together, wherein the granular ice slides down along the inner wall of the cyclone separator and is discharged from the lower part of the cyclone separator and collected. The device for preparing the granular ice according to the method comprises the circulating booster fan, the refrigerating device, a water supply tank, the atomizing nozzle, the granular ice freezing passage and the cyclone separator. By using the method and the device for preparing the granular ice, the thermal resistance problem of an ice layer produced on a solid heat transfer surface can be avoided, and the heat efficiency of the ice making process is improved; and the method and the method are suitable for large-scale industrial ice making.

Owner:SOUTHEAST UNIV

Ice maker and refrigerator

ActiveCN105423689AHigh speedSmall speed differenceDomestic cooling apparatusLighting and heating apparatusCold airThermodynamics

The invention belongs to the technical field of refrigerator ice making, and discloses an ice maker and a refrigerator. The ice maker comprises a bracket, ice making cells and an ice discharge motor; the ice discharge motor is mounted on the bracket; the ice making cells are in drive connection with the ice discharge motor; a cavity is formed in the bracket; the ice making cells are positioned in the cavity; an air inlet and at least one air outlet are formed in the side wall of the bracket; and the air inlet is used for leading cold air to pass through the upper surfaces of the ice making cells. Compared with the prior art, the ice maker has the following prominent improvements: (1) more ice blocks can be made under the same conditions, so that the ice making quantity in unit time is large; (2) the frost blockage condition cannot be generated under the same conditions; and (3) the ice making cost is lower under the same ice making technical scheme conditions.

Owner:HEFEI HUALING CO LTD +1

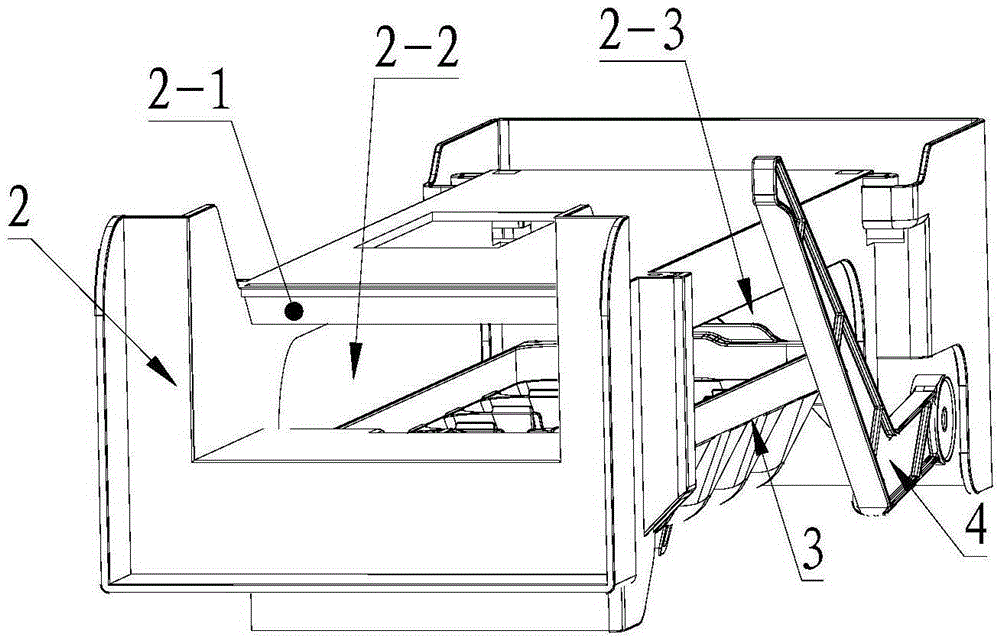

Ice making system on refrigerator door

ActiveCN105402970AAvoid stickingNo stagnant waterDomestic cooling apparatusLighting and heating apparatusRefrigerator carEngineering

The invention belongs to the technical field of refrigerator ice making and discloses an ice making system on a refrigerator door. The structure that an ice stirring rod is arranged above a separation board, an ice selection barrel is arranged in an ice discharging channel, and ice is discharged through the side wall or the joint of the side wall and the bottom wall of the ice selection barrel is adopted, the ice stirring rod is vertically arranged, and ice stirring resistance is small. Ice discharging efficiency is high by the adoption of the structure that the ice is discharged from the side wall and the bottom wall at the same time. The ice stirring rod is arranged so that ice blocks can be prevented from being bonded and it can be guaranteed that the ice blocks can be conveyed out. The ice blocks gradually enter the ice selection barrel through an ice inlet and the ice blocking phenomenon is not likely to happen in the ice selection barrel. When the ice blocks are moved to the side wall communicated with an ice falling channel or the joint of the side wall and the bottom wall along with the ice selection barrel, the ice blocks can automatically fall into the ice falling channel, the resistance in the ice discharging process is small, and the ice is not likely to be stuck. The bottom wall is obliquely arranged, so that it is guaranteed that water cannot be accumulated in the ice discharging channel.

Owner:HEFEI HUALING CO LTD +1

Control method of ice maker, ice maker and refrigerator

ActiveCN112212554AImprove ice production efficiencySpeed up meltingLighting and heating apparatusIce productionThermodynamicsIcebox

The invention discloses a control method of an ice maker, the ice maker and a refrigerator. The ice maker comprises an ice cube tray, a deicing module, a refrigerating module and a heating module. Thecontrol method comprises the steps that the refrigerating module is controlled to refrigerate stored water in the ice cube tray till the ice making ending condition is met; the heating module is controlled to heat the ice cube tray and monitoring the heating state of the heating module when the ice making ending condition is met; when the heating state of the heating module meets a deicing starting condition, the deicing module is controlled to carry out deicing treatment on the ice cube tray; and the heating module is controlled to continue heating so as to defrost the refrigerating module till the heating state of the heating module meets a defrosting ending condition. According to the control method of the ice maker, the ice maker and the refrigerator, the heating module is controlledto continue heating so as to defrost the refrigerating module while the deicing module is controlled to carry out deicing treatment on the ice cube tray, and therefore the ice making efficiency and the deicing efficiency of the ice maker can be improved.

Owner:HISENSE RONSHEN GUANGDONG REFRIGERATOR

Ejector pump liquid feeding vertical cylinder type ice-making machine

ActiveCN101042273AImprove ice production efficiencyReduce energy consumptionLighting and heating apparatusIce productionPipingRefrigerant

It relates to a cylindrical ice making machine that comprises the vertical cylindrical clamping cooling steam icing barrel, cylindrical base with ring shape water accumulation slot, center of the cylindrical base having bearing base and bearing, end cover on the icing barrel, electric decelerator on the end cover, center of the icing barrel having electric decelerating drive main return shaft that have ice scraper and showering pipe, water tank connected to the ring water accumulation slot, water level controller on the water tank, inlet pipe and water pump, icing barrel having cooling agent inlet pipe and outlet pipe, icing barrel connecting with horizontal low pressure circulating barrel, ejection pump, horizontal low pressure circulating barrel and water tank connected with the heat exchanger respectively, and the insulation protective layer outside the icing barrel and horizontal low pressure circulating barrel. It has strong icing ability, with economical and reliable running.

Owner:SIFANG TECH GRP CO LTD

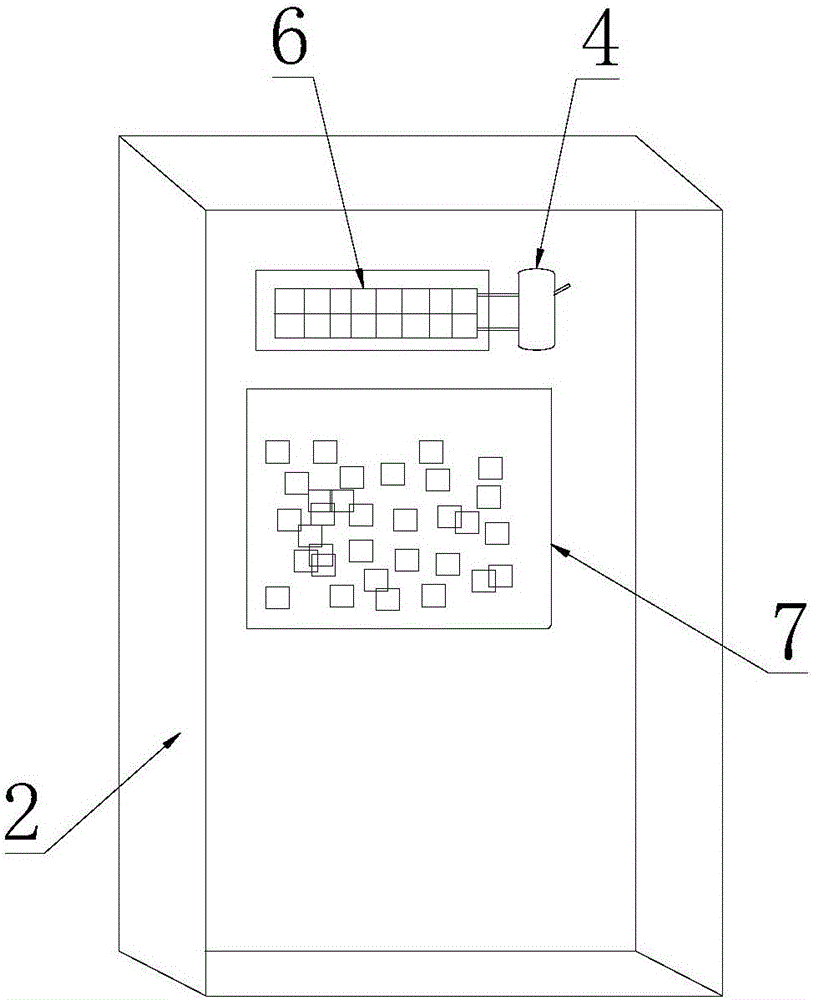

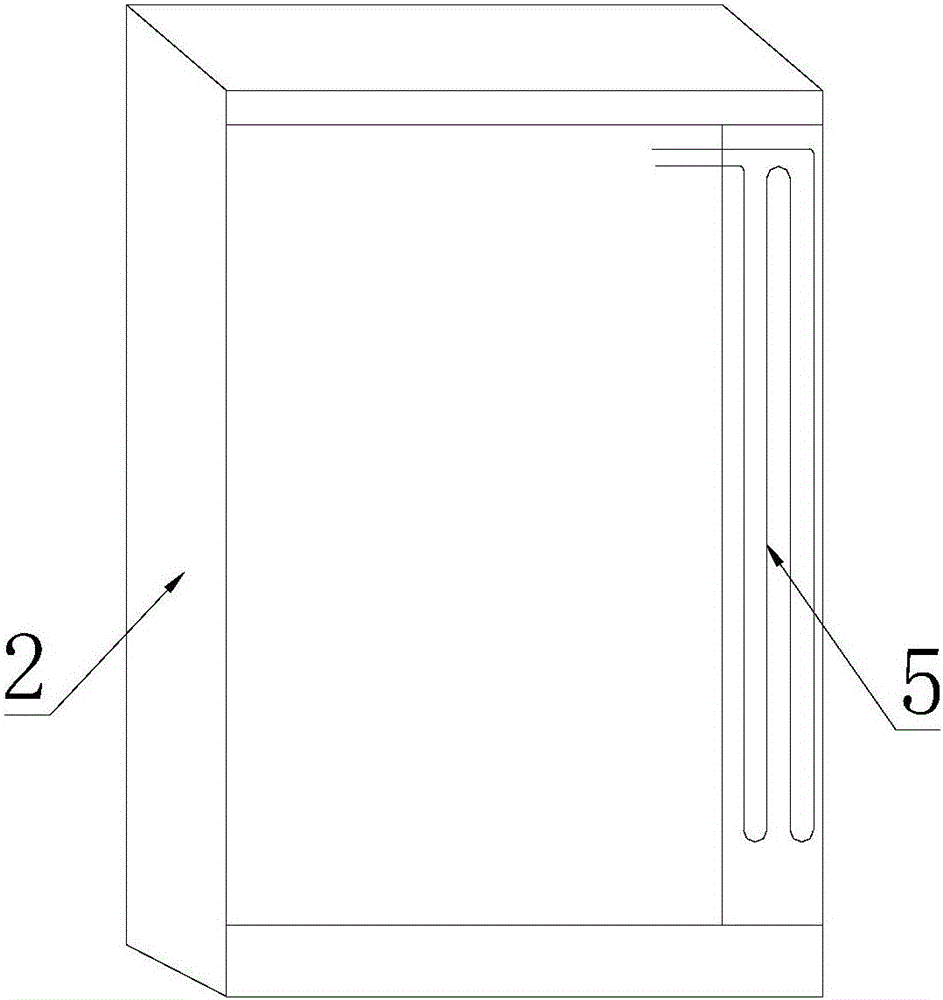

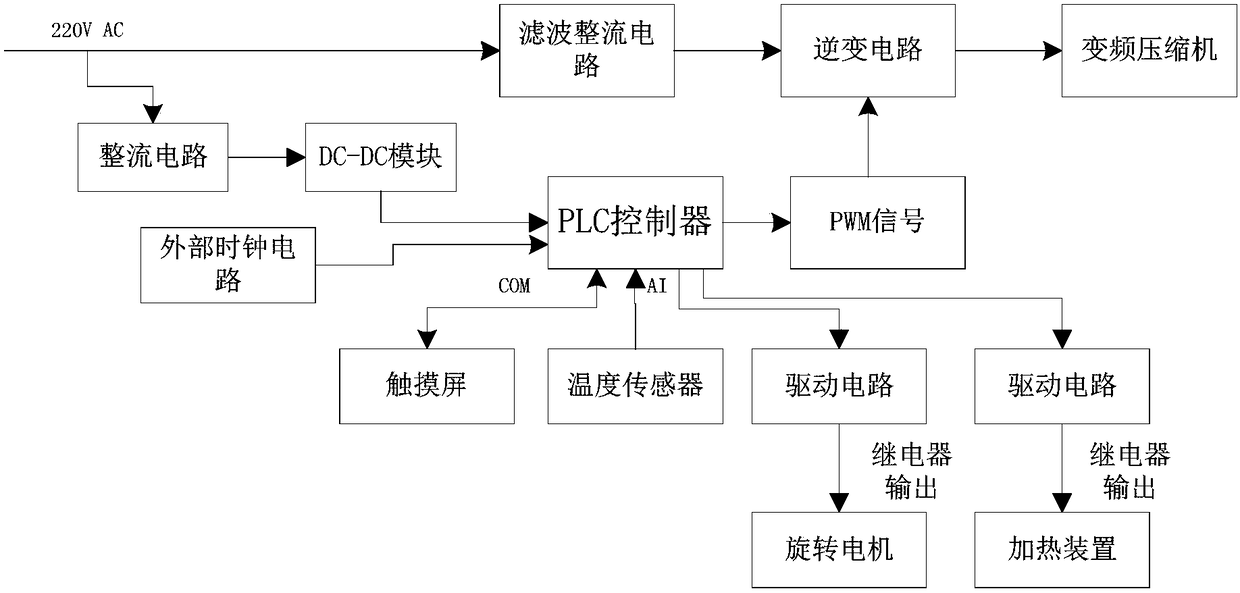

Intelligent control system for ice maker

InactiveCN108131874AImprove ice production efficiencyLighting and heating apparatusIce productionElectricitySite monitoring

The invention provides an intelligent control system for an ice maker. The intelligent control system for the ice maker realizes intelligent ice making without manual on-site monitoring, the control system is capable of performing intelligent cooling and heating according to the set time condition, and the ice making efficiency is improved effectively. The intelligent control system comprises a PLC, a touch screen and a temperature sensor, wherein the touch screen and the temperature sensor are connected with the PLC. The PLC is arranged in a box body at the side face of a body. The touch screen is connected with the PLC through a COM interface. The temperature sensor is arranged in a cavity structure in the ice maker. The temperature sensor is used for feeding the temperature in the cavity structure of the ice maker back to the PLC. The PLC also controls a compressor through a control circuit. Mains supply sequentially passes a rectifying circuit and a DC-DC module and supplies powerto the PLC. By the adoption of the intelligent control system for the ice maker, intelligent ice making is achieved without manual on-site monitoring, the control system is capable of performing intelligent cooling and heating according to the set time condition, and the ice making efficiency is improved effectively.

Owner:新昌县新崎制冷设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com