Ejector pump liquid feeding vertical cylinder type ice-making machine

A technology of ejector pump and ice maker, which is applied to ice making, ice making, lighting and heating equipment, etc., can solve the problems of low ice making capacity, high operating cost, low evaporative heat transfer efficiency of ice cylinder, etc. The effect of improving ice-making capacity, reducing energy consumption and improving ice-making efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

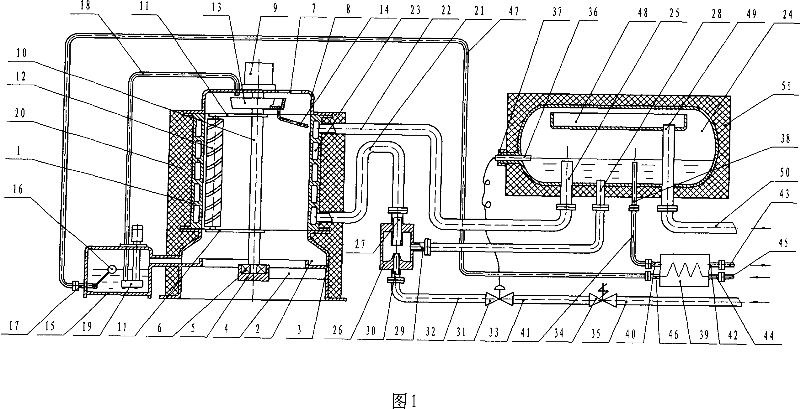

Embodiment 1

[0020] Ejector pump liquid supply vertical cylinder ice machine (see Figure 1), including a vertical cylindrical jacket type refrigeration evaporation icing cylinder 1, below the icing cylinder 1 there is a cylindrical base 3 with an annular water collection tank 2, In the center of the cylindrical base 3, there is a bearing seat 5 connected with the support rod 4 and the cylindrical base 3. There is a bearing 6 in the bearing seat 5. There is an end cover 8 with an observation window 7 on the icing cylinder 1, and the observation window may not be provided. , the end cover 8 is equipped with an electric reducer 9, and the center of the icing cylinder 1 has a rotary main shaft 10 whose lower end is supported by a bearing 6 and whose upper end is connected to the output shaft of the electric reducer 9. There is a cantilever 11 on the rotary main shaft 10, and a cantilever 11 is installed at one end. The ice scraper 12, the water spray pipe 14 for spraying freezing water to the i...

Embodiment 2

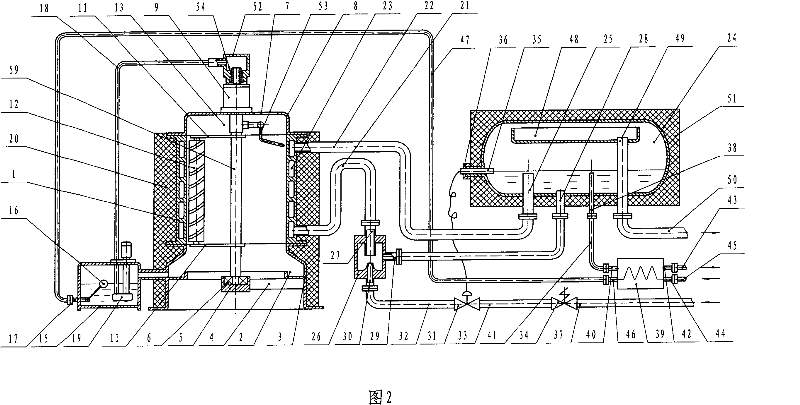

[0030] The difference from Embodiment 1 is: the water pump 19 is connected with the sealing joint 52 on the upper end of the rotary main shaft 59 with the water injection pipe 18 (see Figure 2), the sealing joint 52 is sealed with the rotary main shaft 59, and the joint between the rotary main shaft 59 and the water spray pipe 53 is The upward part is a hollow structure, 54 is a dynamic sealing ring, and the upper end of the rotary main shaft 59 can rotate in the sealing ring 54 .

Embodiment 3

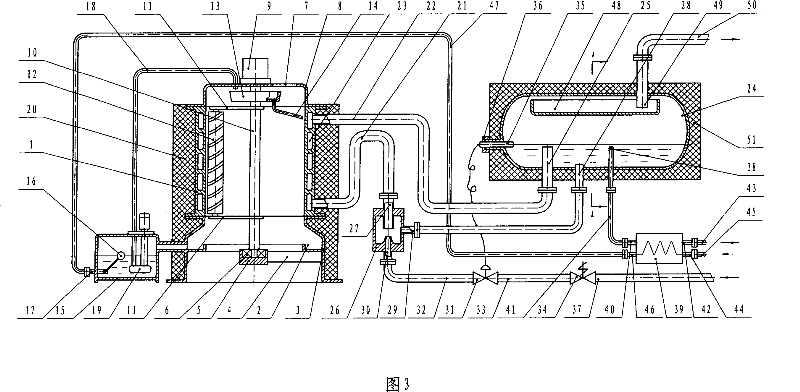

[0032] The difference from Embodiment 1 or 2 is: the air inlet of the horizontal low-pressure circulation barrel 24 back air outlet pipe 49 extends from the barrel wall of the horizontal low-pressure circulation barrel 24 on the upper part of the gas collection long disk 48 into the gas collection long disk 48 Inside, the air outlet of the horizontal low-pressure circulation barrel 24 return air outlet pipe 49 passes through the barrel wall on the top of the low-pressure circulation barrel 24 and links to each other with the suction pipe 50 of the refrigeration compressor unit (seeing Fig. 3, 4).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com