Patents

Literature

1782 results about "Vertical cylinder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

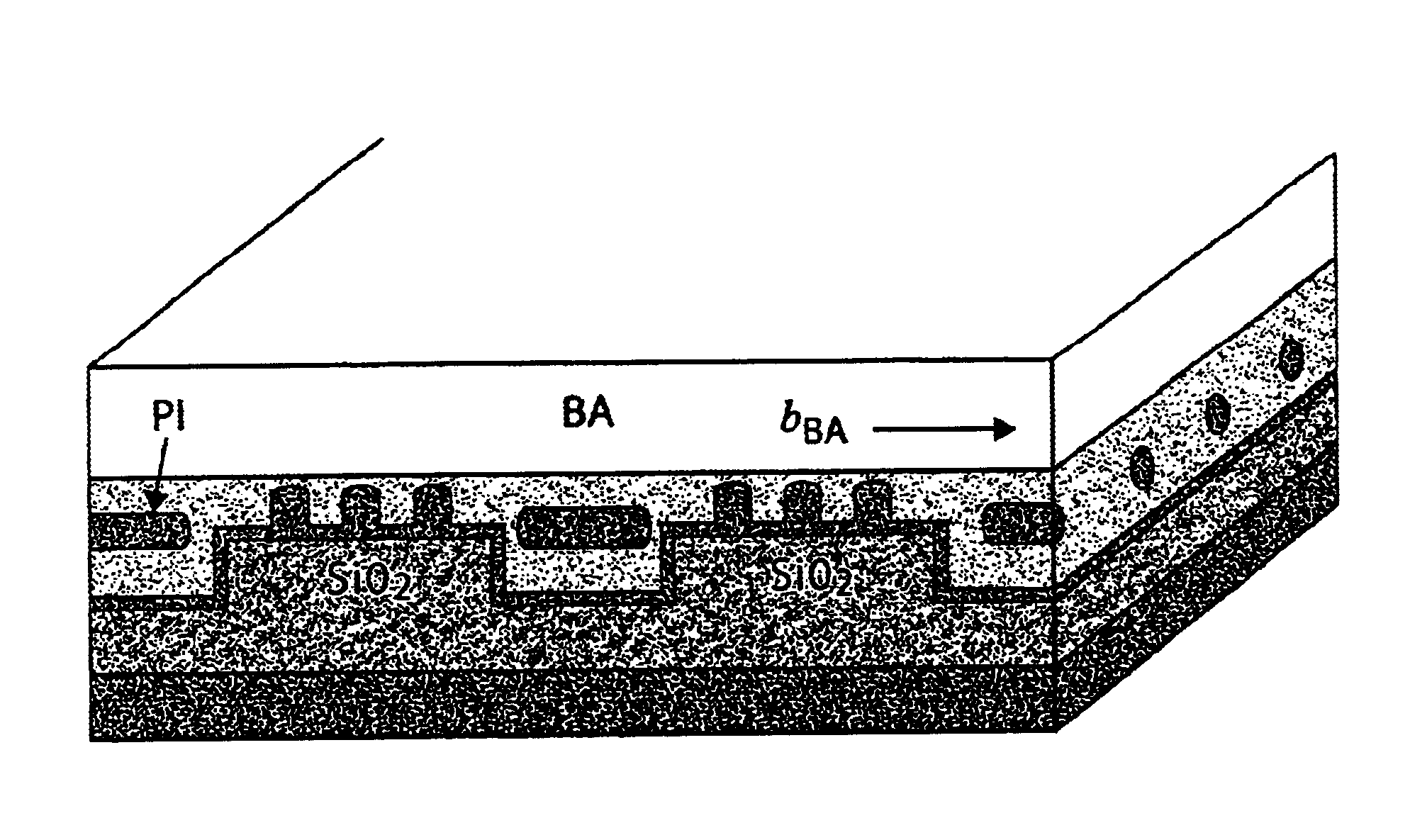

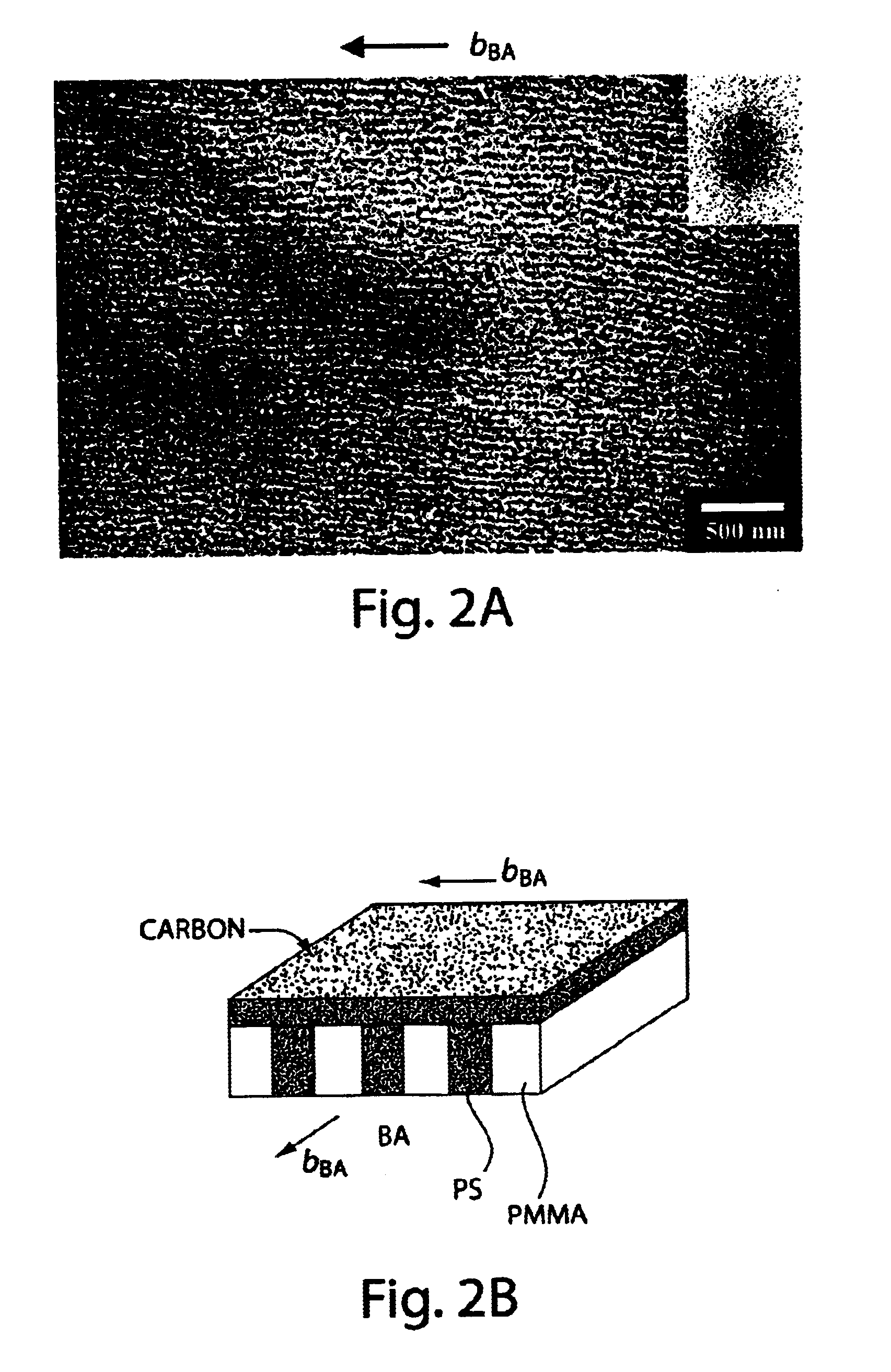

Large area orientation of block copolymer microdomains in thin films

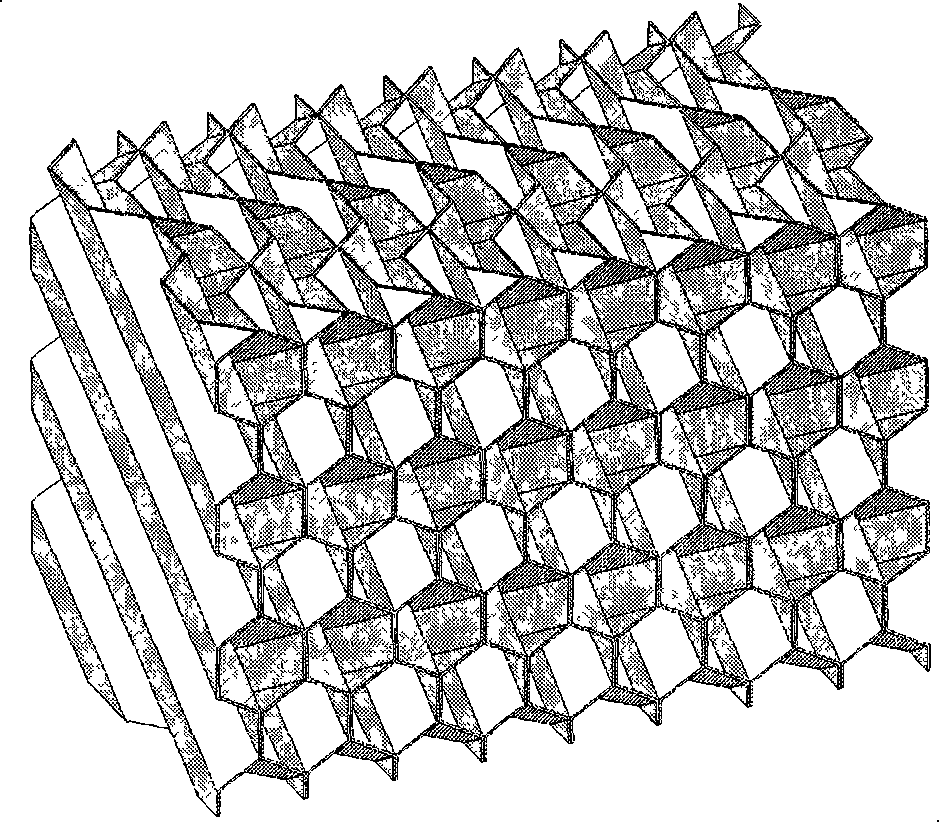

InactiveUS6893705B2Free from defectIndividual molecule manipulationPhotomechanical apparatusIn planeDirectional solidification

A method and apparatus for orientation of block copolymer microdomains via rapid solidification. Rapid solidification from a solvent may include directional solidification and / or epitaxy to form patterns of microdomains in a film of block copolymer. Microdomains may include various structures formed by components of a block copolymer, such as vertical lamellae, in-plane cylinders, and vertical cylinders, and may depend on film thickness. Orientation of structures in microdomains may be controlled to be approximately uniform, and spatial arrangement of microdomains may be controlled.

Owner:MASSACHUSETTS INST OF TECH

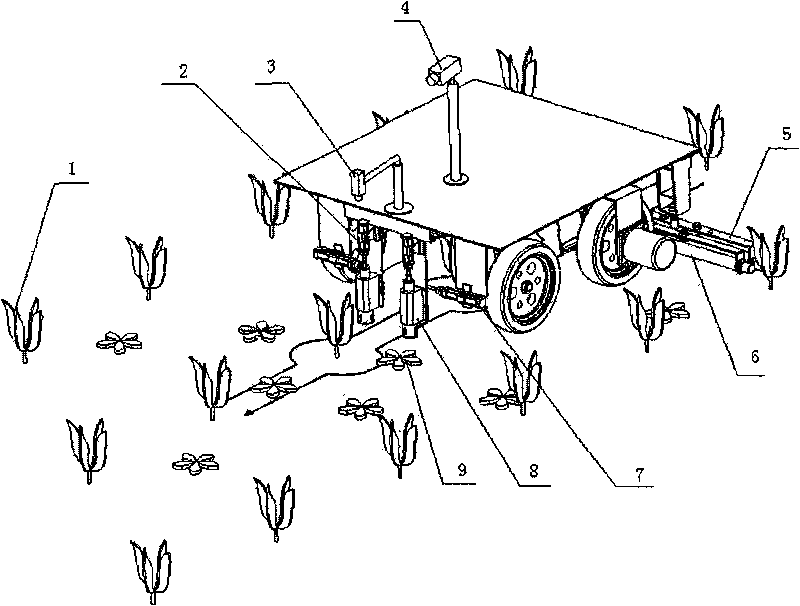

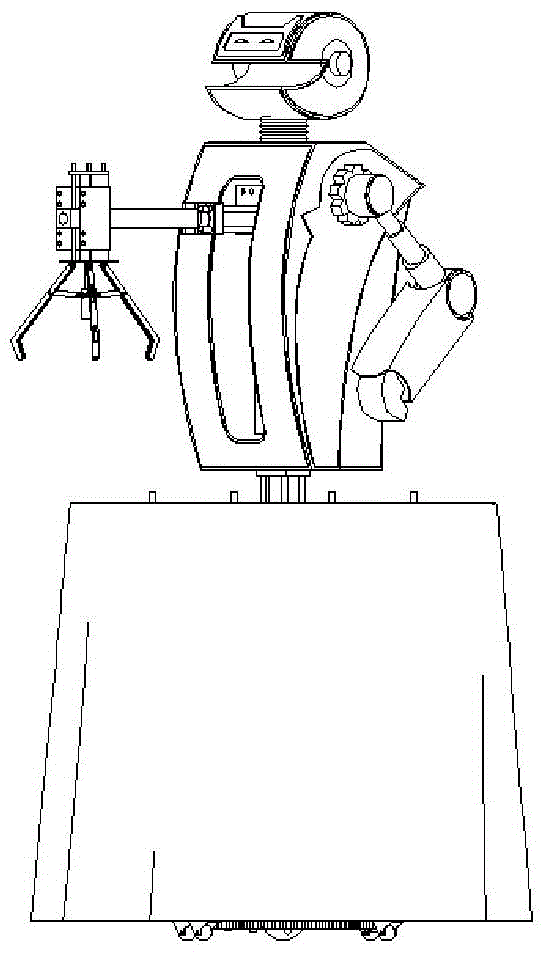

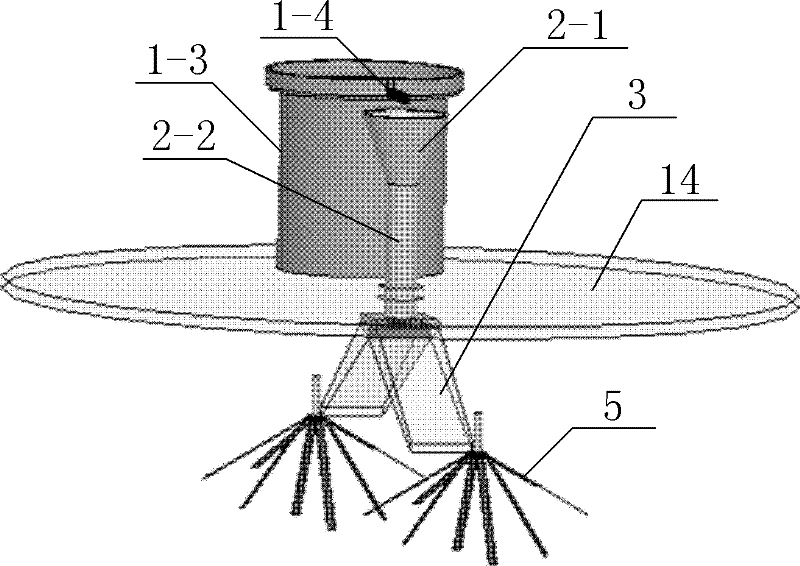

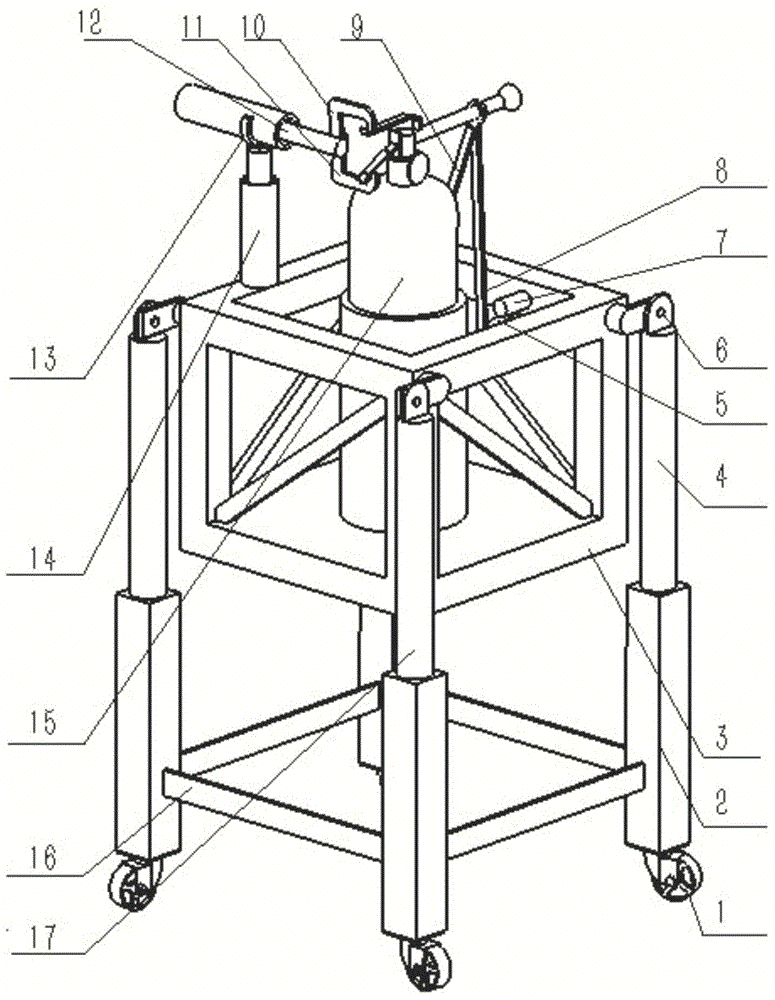

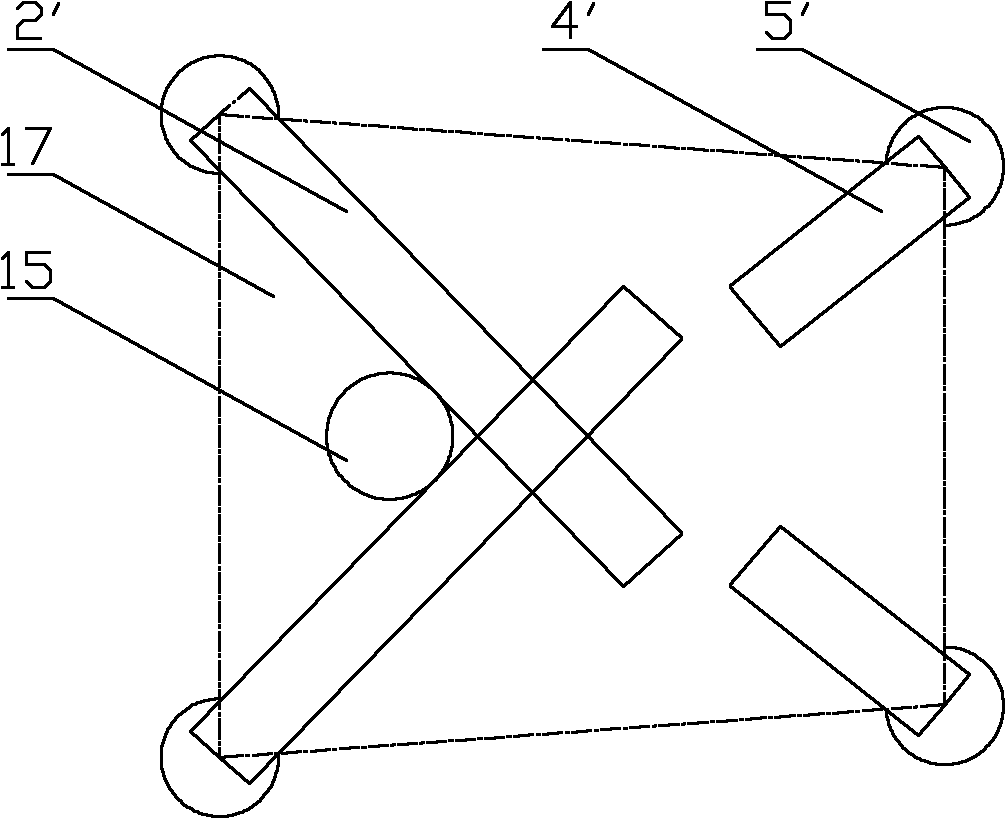

High-efficiency weeding robot

InactiveCN101707992AAchieve clearingSolve Clearing PuzzlesSoil-working equipmentsGuiding agricultural machinesCircular discControl system

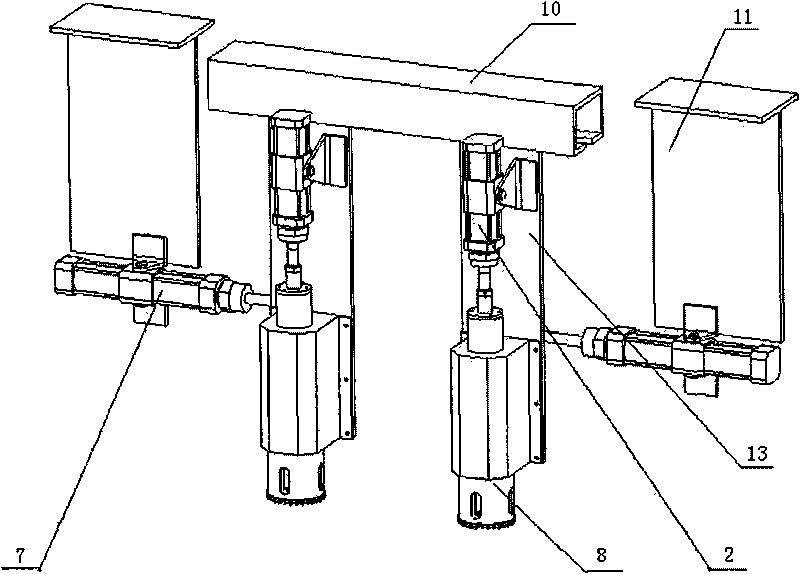

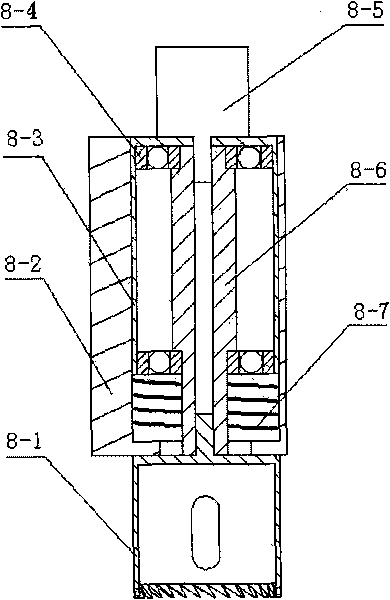

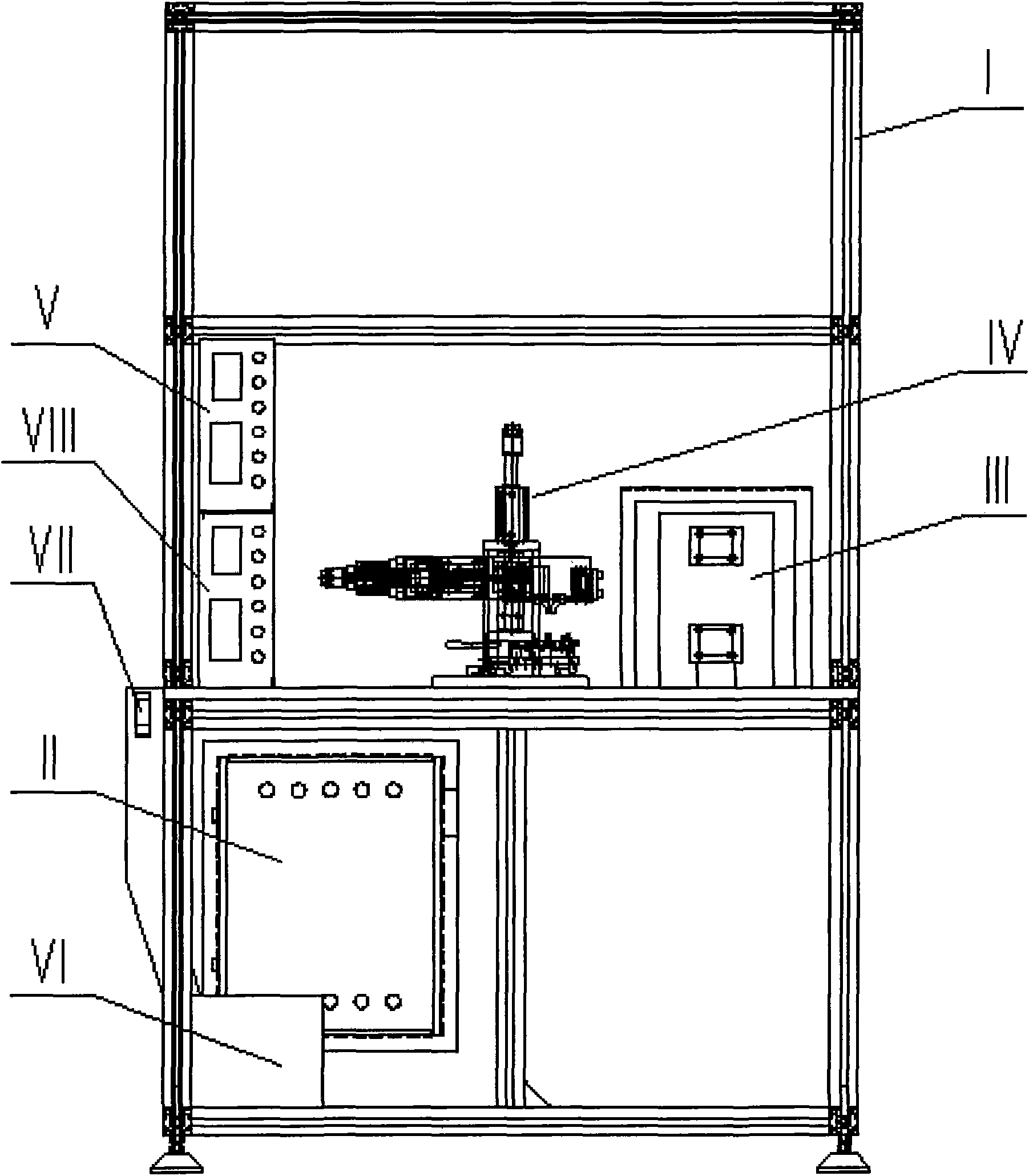

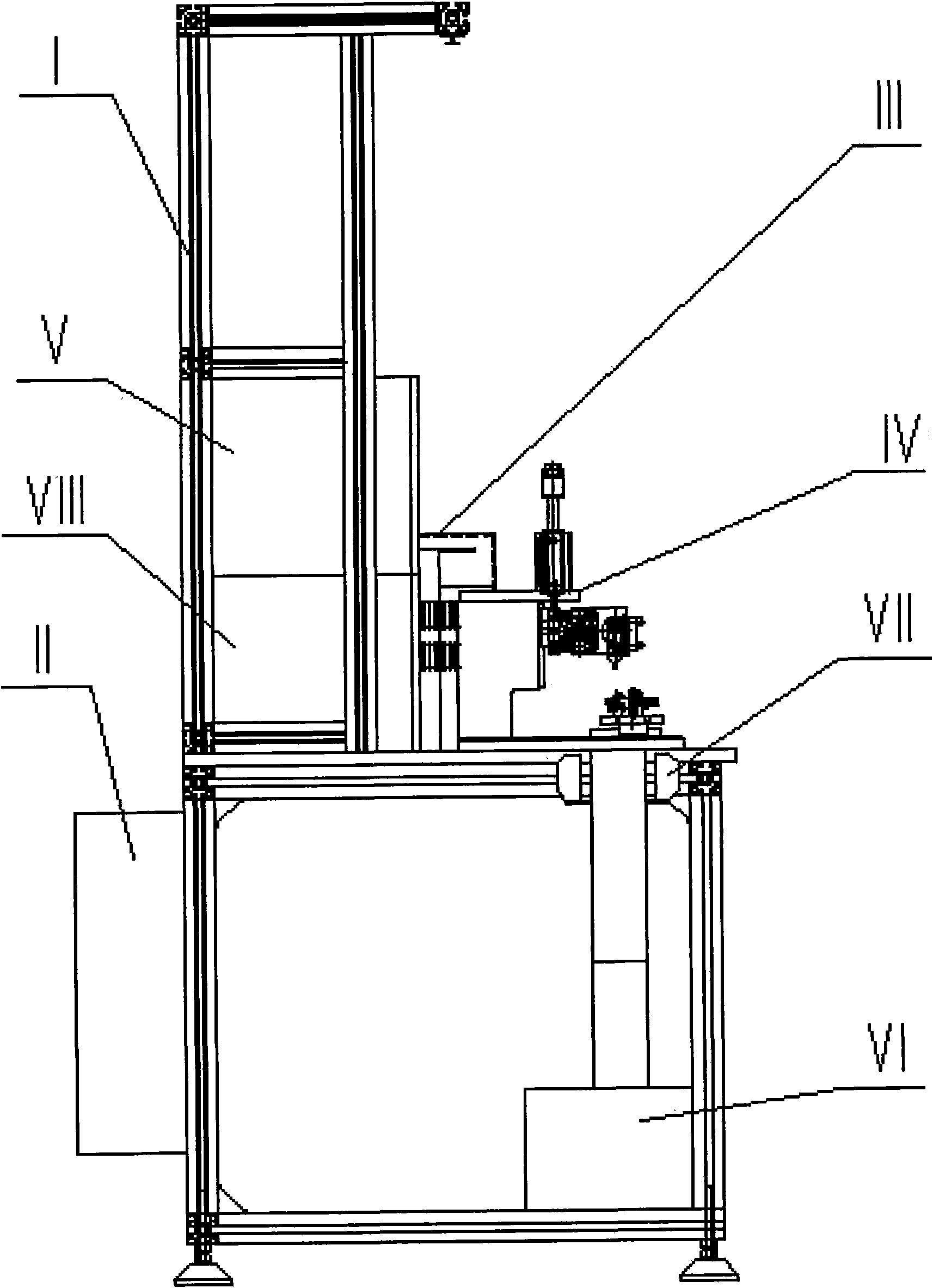

The invention relates to a high-efficiency weeding robot which belongs to the technical field of agricultural machinery application. The robot comprises an automatic navigation and weed identification camera head and a control system, wherein a weeding device comprises an interline cutting and smearing weeding mechanism arranged below a trolley, and an inline weeding mechanism; the cylinder bodies of a left horizontal cylinder and a right horizontal cylinder of the inline weeding mechanism are respectively arranged at the bottom of the trolley; horizontal piston rods of the left horizontal cylinder and the right horizontal cylinder are respectively and fixedly connected with installment frames of a left vertical cylinder and a right vertical cylinder; the upper ends of the installment frames of the left vertical cylinder and the right vertical cylinder are installed in horizontal rails on the trolley to form a moving pair; the cylinders of the left vertical cylinder and the right vertical cylinder are respectively installed on the installment frames of the left vertical cylinder and the right vertical cylinder; and the lower ends of vertical pistons of the left vertical cylinder and the right vertical cylinder are respectively connected with a left end effector and a right end effector the bottoms of which are provided with electric circular saws. The invention can remove weeds in lines and among lines with high working speed and high weeding efficiency, thereby radically solving the difficulty of removing weeds in lines.

Owner:NANJING FORESTRY UNIV

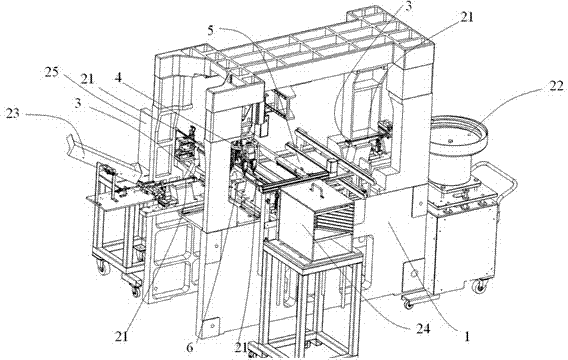

Resistance welding equipment and welding control method

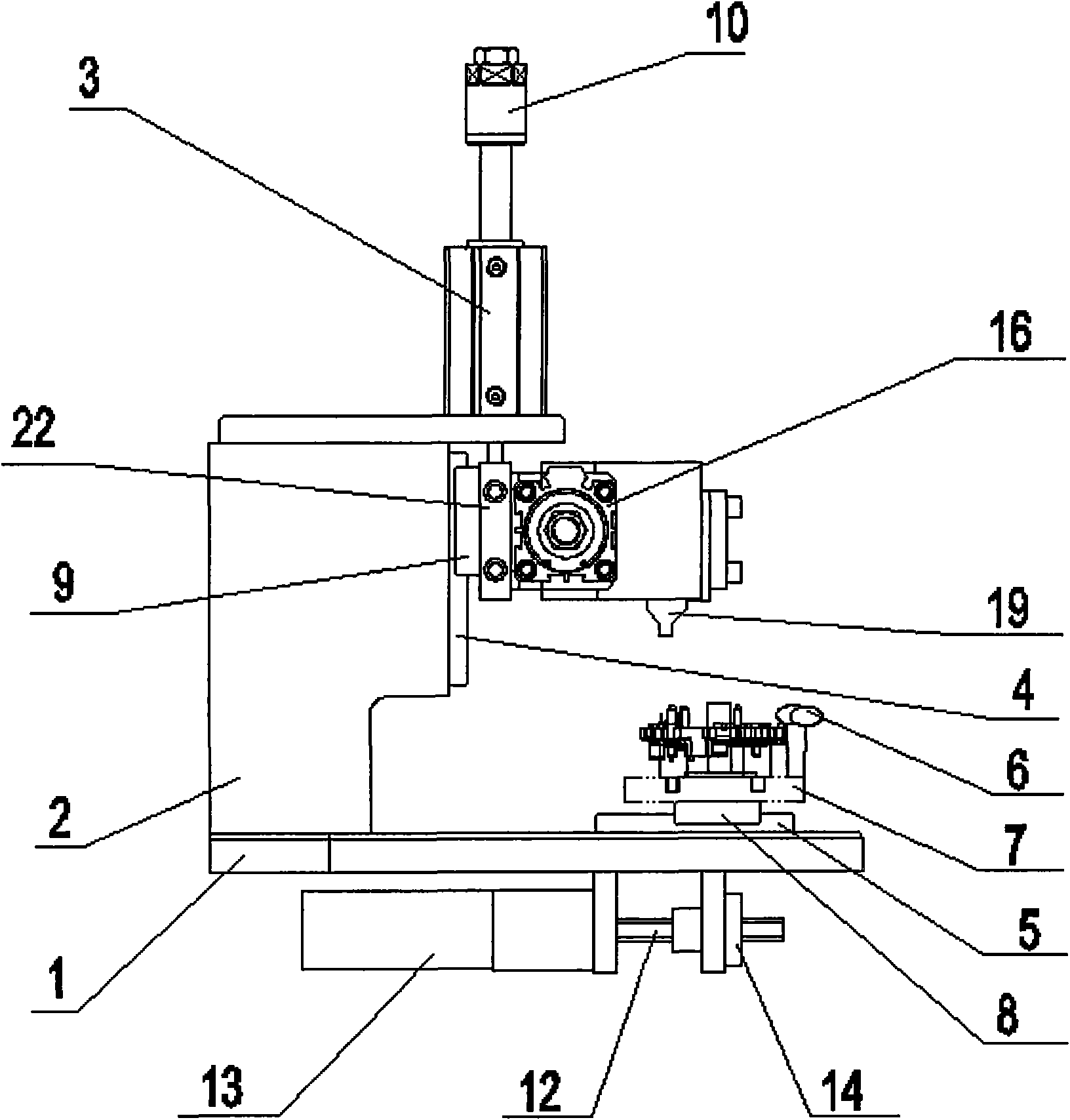

ActiveCN101590562AHigh degree of automationIncrease visibilityWelding monitoring devicesElectrical resistance and conductanceTransformer

The invention provides resistance welding equipment and a welding control method. The resistance welding equipment consists of a frame, an electric cabinet and a PLC system, a welding transformer, an action mechanism, a welder controller, a waste box, an optical fiber sensor and a sensor controller, wherein the action mechanism consists of a baseplate, a main frame, a vertical cylinder, a main linear guide rail, a linear guide rail, a positioning manual press claw, a positioning fixture, a linear bearing, a main linear bearing, a positioning nut, an adjusting pressure spring, a screw mandrel, a servomotor, a coupler, a displacement sensor, a clamping cylinder, a pressure sensor, a left electrode, a right electrode, left and right linear guide rails, left and right linear bearings, an auxiliary frame, a connecting rod and a clamping pressing plate. The pressure sensor and a tracking system are adopted to collect pressure signals, the displacement sensor and the tracking system are adopted to collect displacement signals, and a PLC operational program is adopted for control, so that the welding of metal workpieces adopts dynamic on-line control to comprehensively monitor various welding control points in the whole process, and the welding deformation is controlled between 0.01 and 0.45mm to ensure welding quality.

Owner:镇江泛沃新能汽车技术股份有限公司

Symbology for representing aircraft position

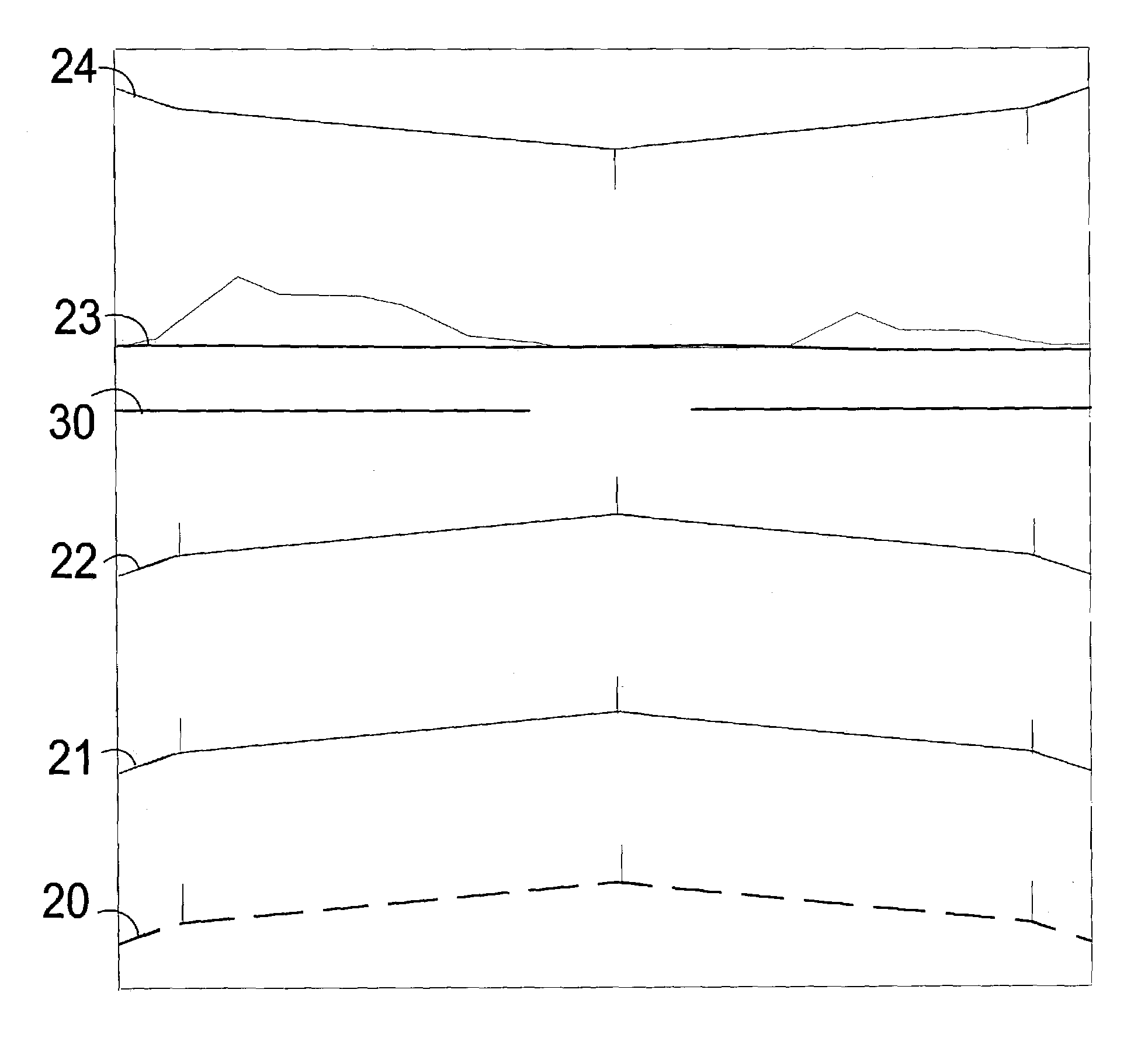

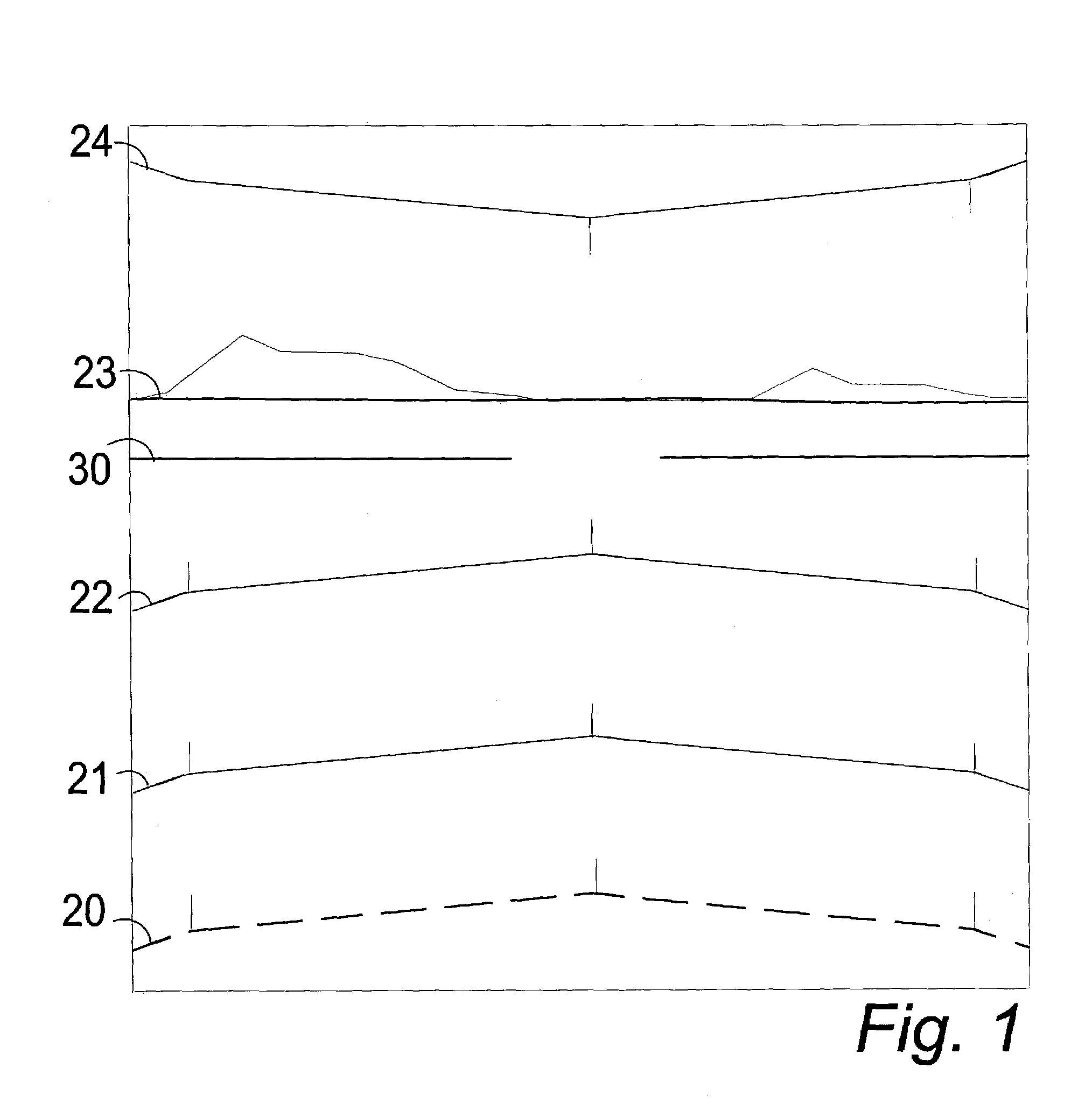

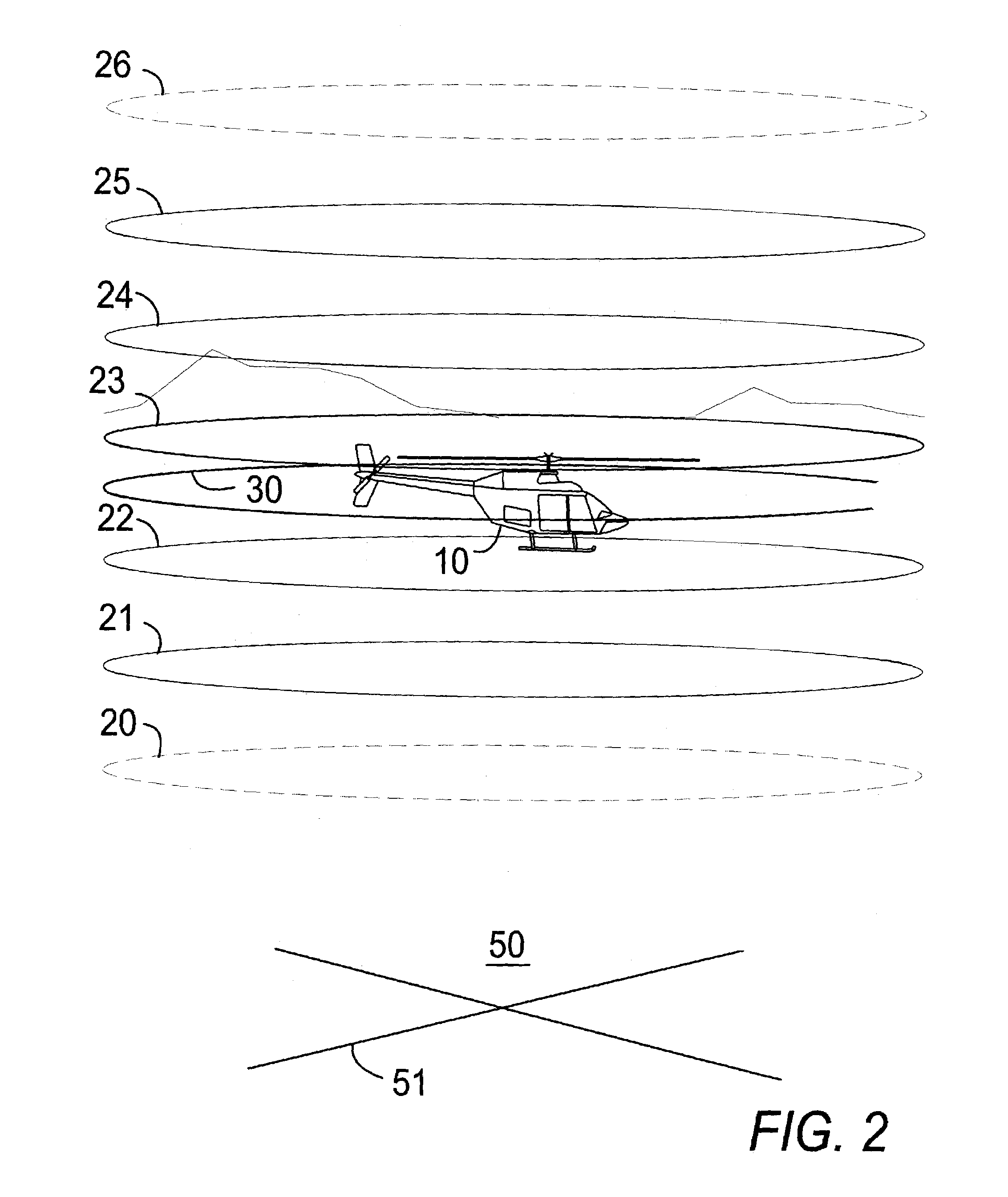

InactiveUS6992597B2Significant to useAircraft componentsRoad vehicles traffic controlTerrainSymbolic Systems

A symbology system uses programmable software in a computerized system interacting with the altitude, attitude, air speed, and other flight indicators of an aircraft to create symbology in the pilot's display seen in the field of view of the pilot. The symbology represents a virtual geometric solid form, such as a vertical cylinder, always appearing perpendicular to the horizon and moving across the terrain with the aircraft in the center of the form. The pilot sees a front portion of a virtual series of horizontal circles or other shapes, spaced by a programmable distance, symbolizing the geometric solid form appearing to surround the aircraft. The geometric form references the world as-ground for use in recognizing the attitude of the aircraft-as-figure. On landing, the form appears to stop at the ground and the aircraft appears to descend within it. A virtual bank indicator line changes orientation to the geometric solid corresponding to the attitude change of the aircraft relative to the horizon.

Owner:ROGERS STEVEN P +1

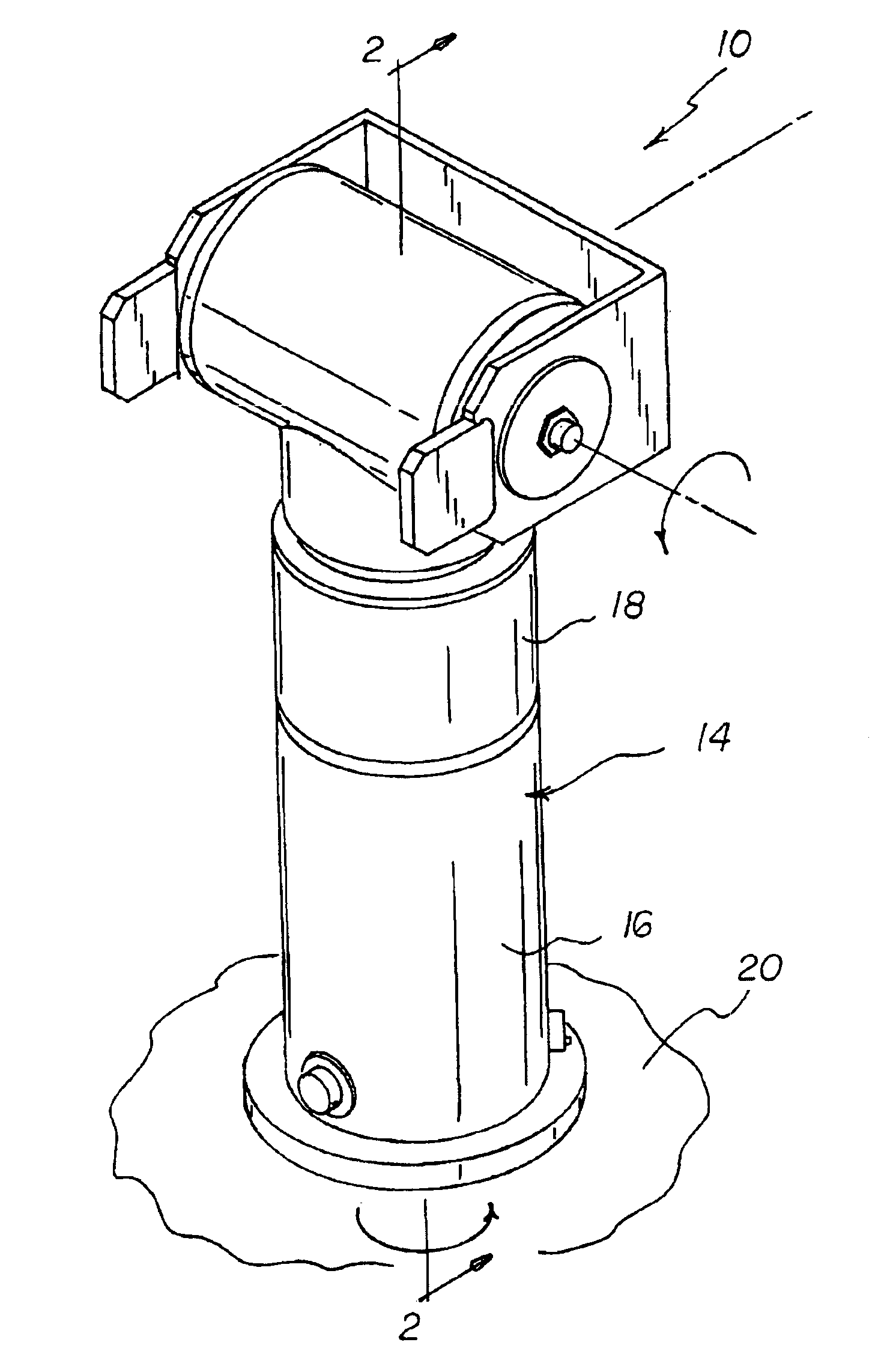

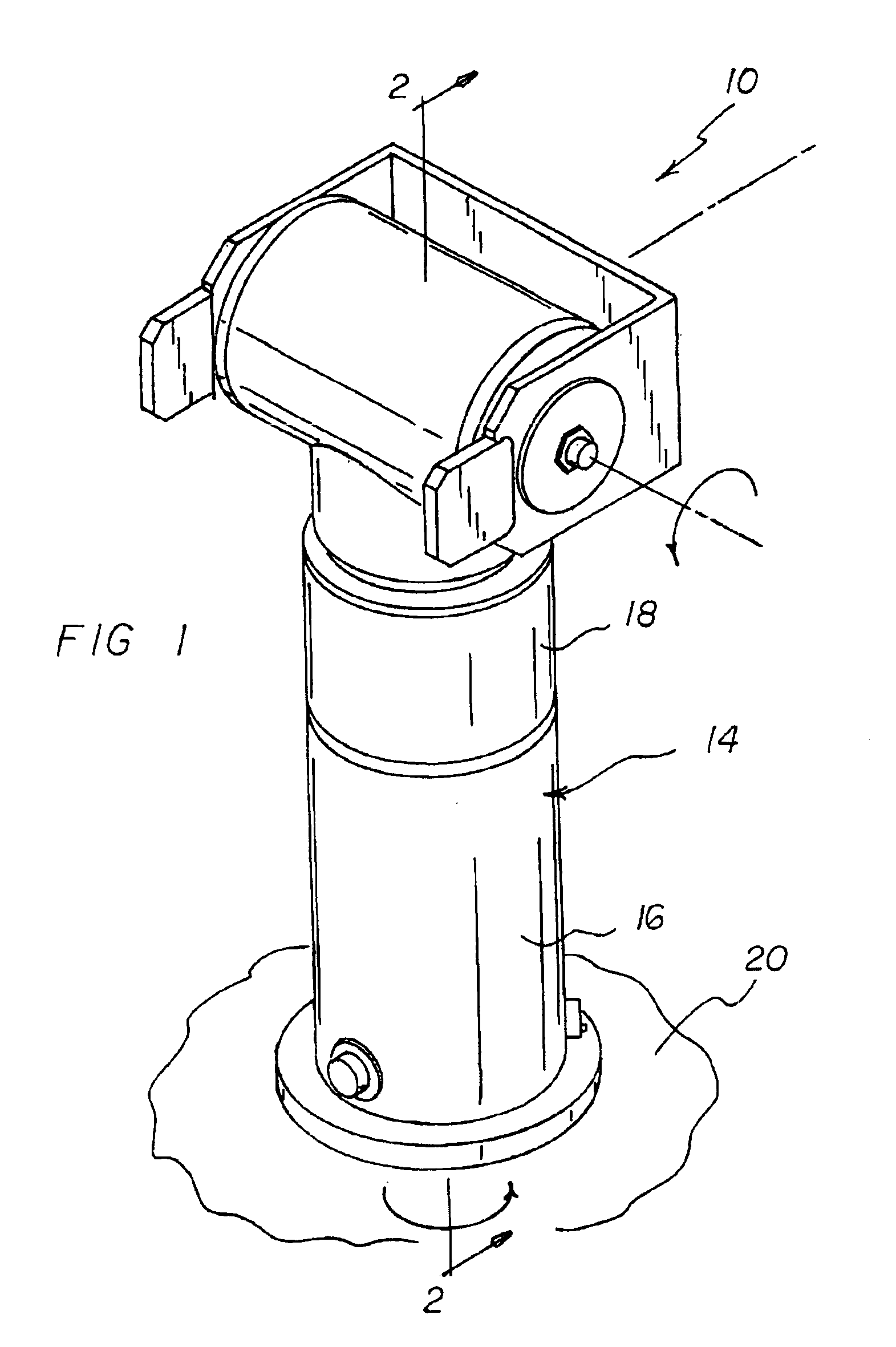

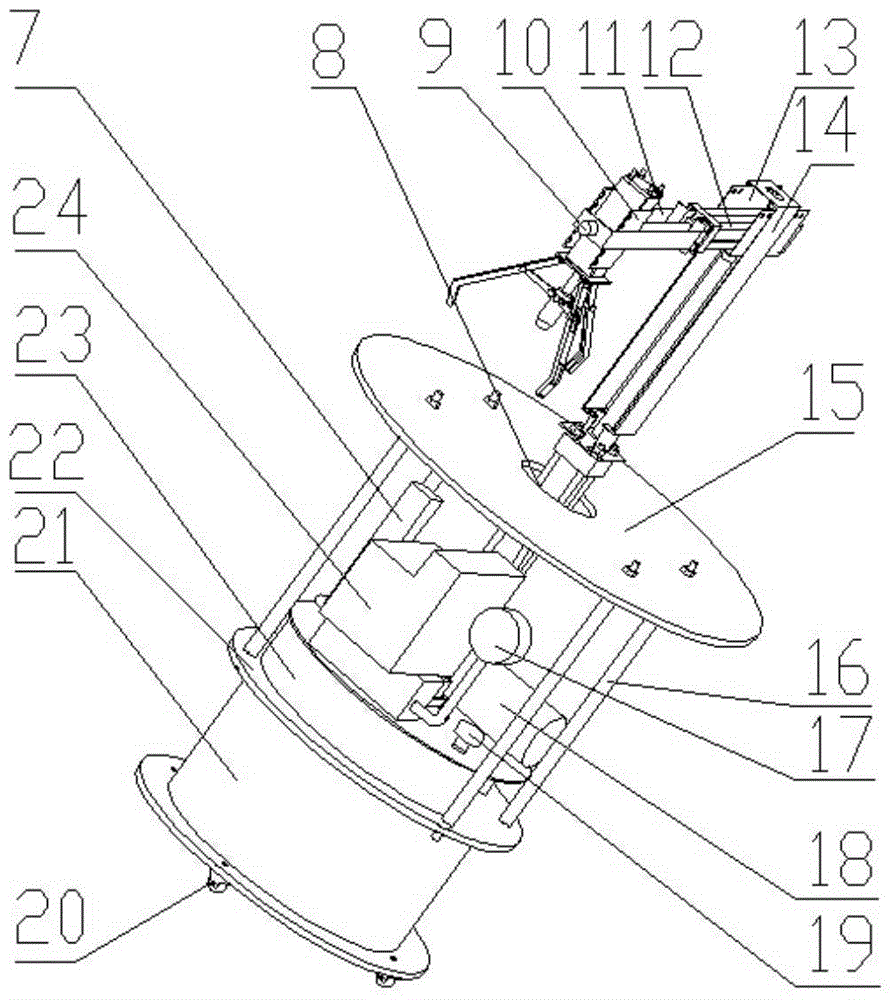

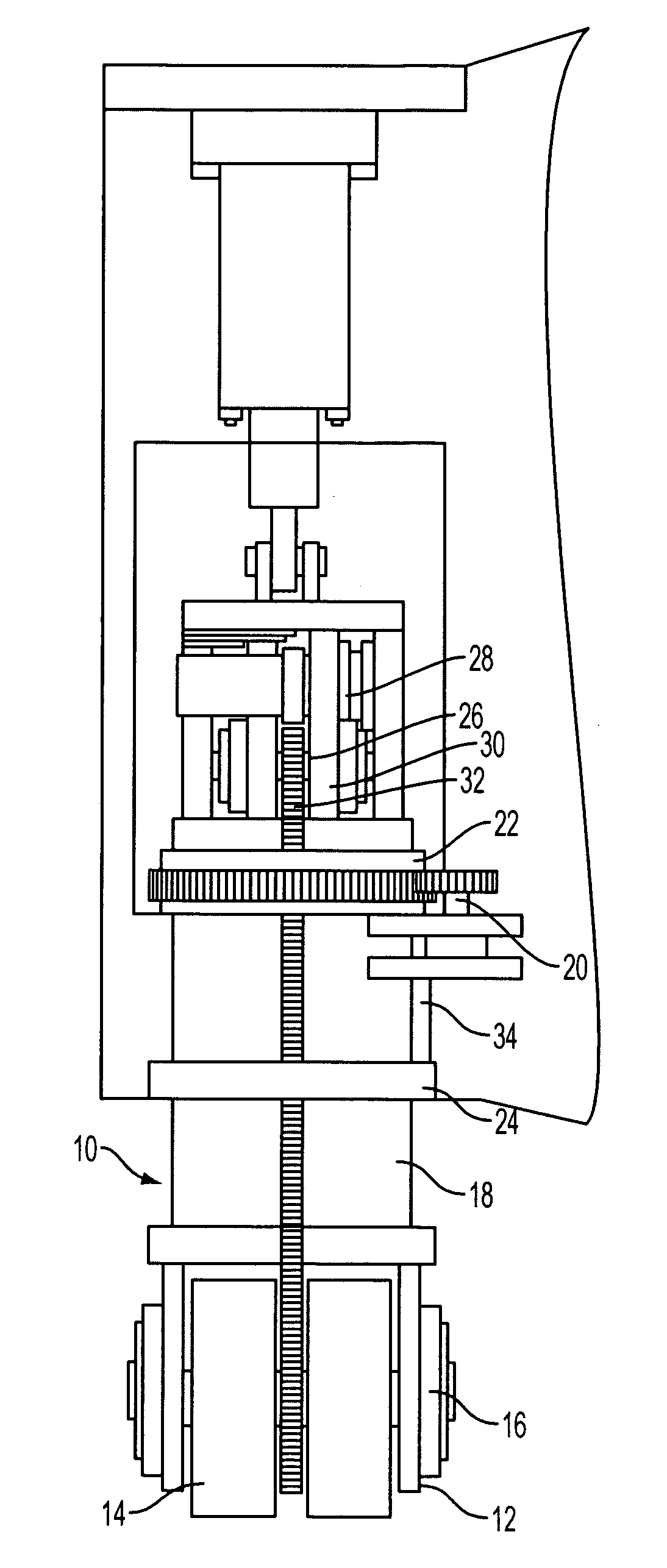

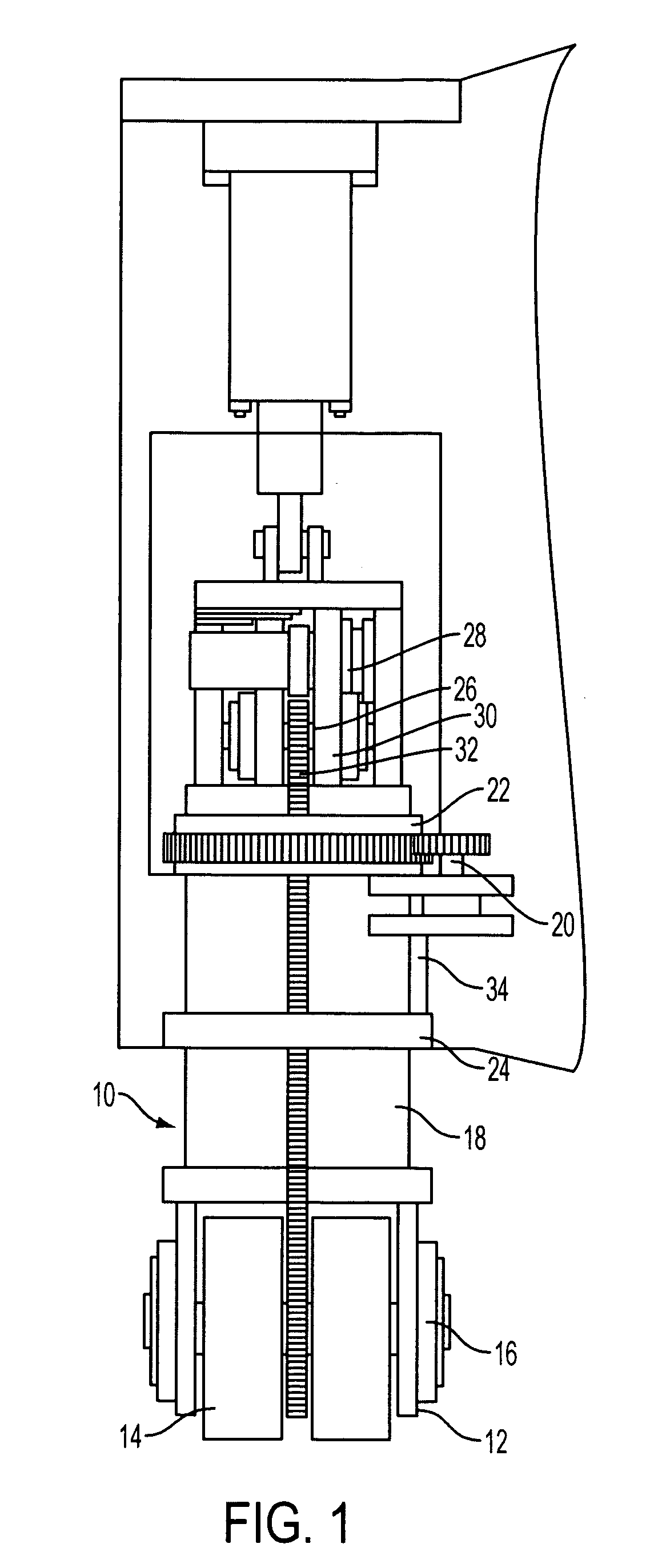

Pedestal system and method of controlling rotational and bearing stiffness

InactiveUS6914578B1Easy and efficient to manufactureDurable and reliable constructionAntenna supports/mountingsLower upperControl theory

A pedestal system comprises a base having a lower cylinder and an upper rotatably supported with respect to the lower vertical cylinder. A lower motor is coupled between the lower and upper cylinders to selectively cause rotational motion between the cylinders. Also provided is a top-most horizontal cylinder with a rotating shaft. The shaft has a bearing coupling the top-most horizontal shaft with respect to the upper vertical cylinder. Finally, an upper motor is provided. The upper motor is coupled between the top-most horizontal shaft and upper cylinder to selectively cause a rotational motion between the top-most horizontal shaft and the upper vertical cylinders.

Owner:MENAHEM ISRAEL

A Dynamic Compensation Control Method Based on Multi-stage Oil Cylinder Erection System

InactiveCN102269191ASolve the accuracy problemFix stability issuesServomotorsProportional controlAngular degrees

The invention discloses a dynamic compensation control method based on a multi-stage oil cylinder erecting system. Firstly, a multi-stage oil cylinder erecting system is built; After the valgus point, the one-way balance valve establishes back pressure in the rod cavity of the erecting cylinder to balance the valgus moment of the launching cylinder; after the multi-stage cylinder is erected to 89 degrees, the upper computer performs differential calculation on the feedback angle of the inclination sensor, If the vertical angular velocity is less than 2' / s, the upper computer increases the output current of the proportional valve amplifying board, and if the vertical angular velocity is greater than 6' / s, the upper computer reduces the output current of the proportional valve amplifying board. When the erecting angle reaches 90 degrees, stop erecting. The method improves the control precision, stabilizes the erection time, and can meet the application requirements of high-precision and rapid erection systems of other launching vehicles.

Owner:BEIJING MECHANICAL EQUIP INST

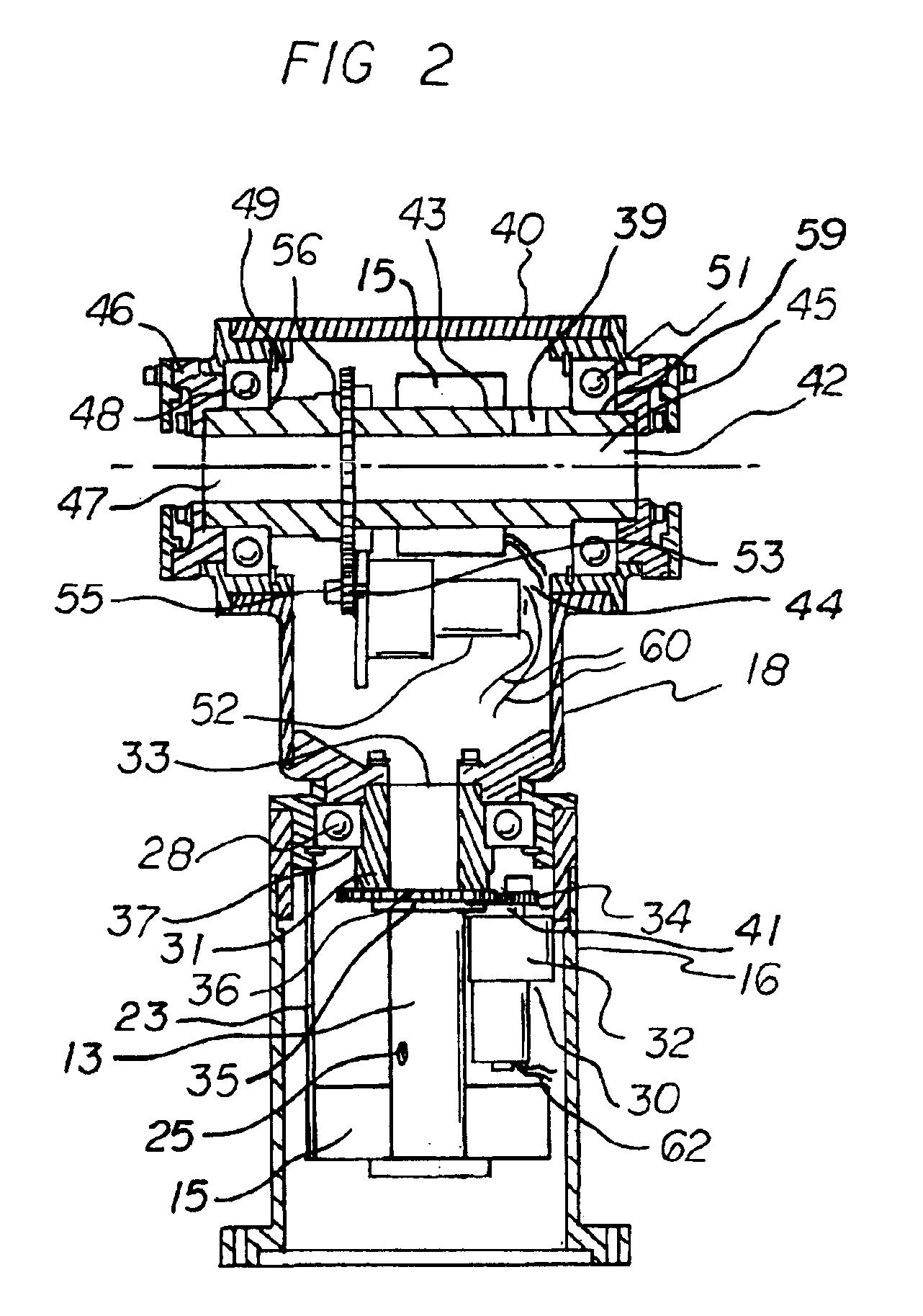

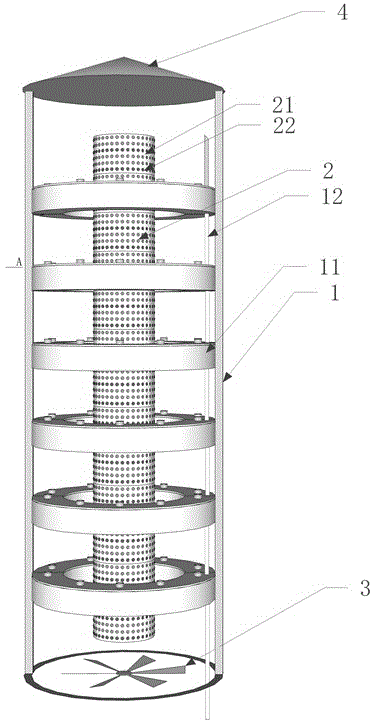

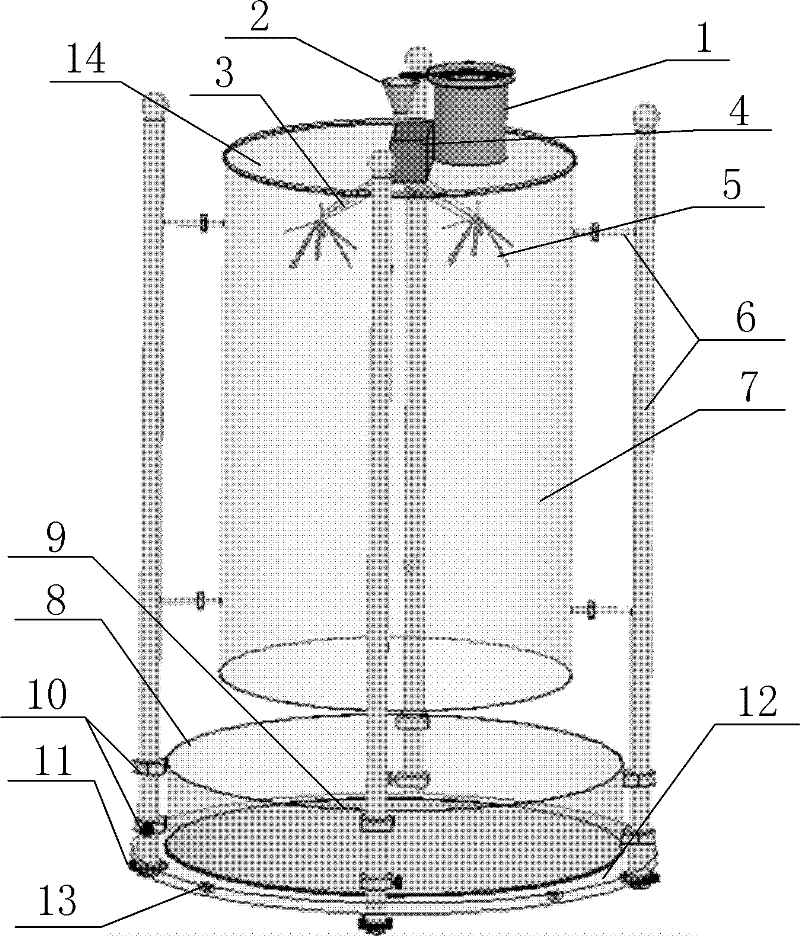

Plant cultivation device

InactiveCN104904584AHigh light source space efficiencyReduce spacingAgriculture gas emission reductionCultivating equipmentsPlant cultivationVertical cylinder

The invention belongs to the field of plant cultivation and particularly relates to a plant cultivation device. The plant cultivation device is based on a central radiation mode. The plant cultivation device comprises a vertical cylinder-shaped plant cultivation frame, the plant cultivation frame is provided with multiple layers of cultivation grooves and a cylinder-shaped light source, and the light source is vertically arranged at the center of the plant cultivation frame. The plant cultivation device has the advantages that high light source space efficiency is achieved, natural lighting can be used, and light source heat is easy to manage.

Owner:周晚来

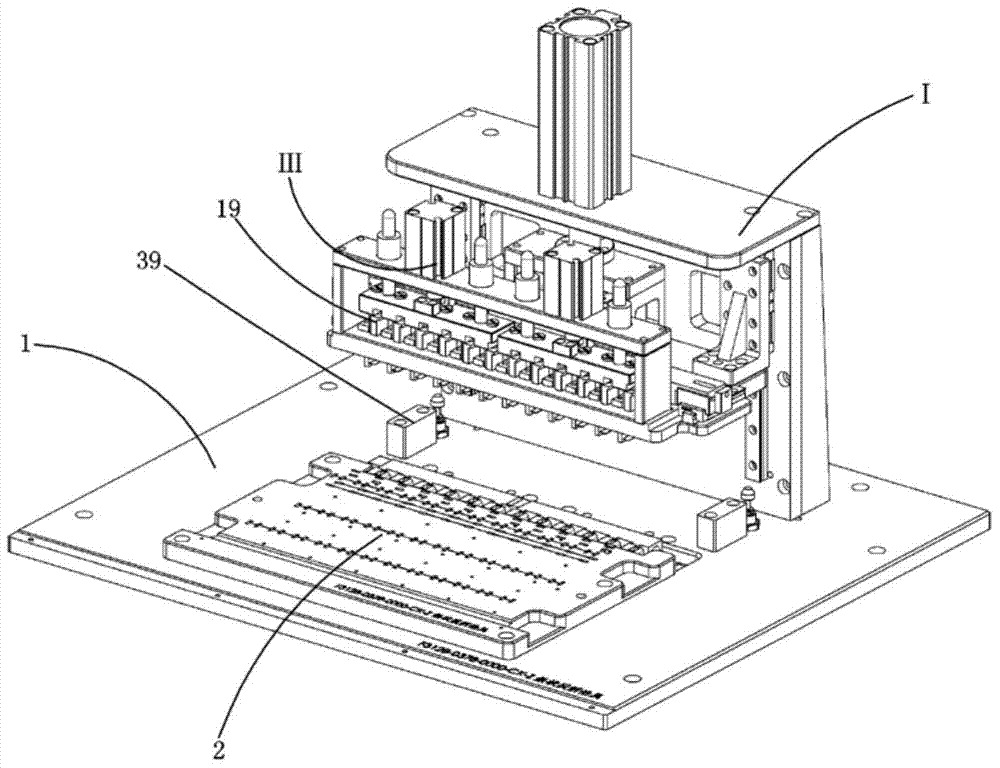

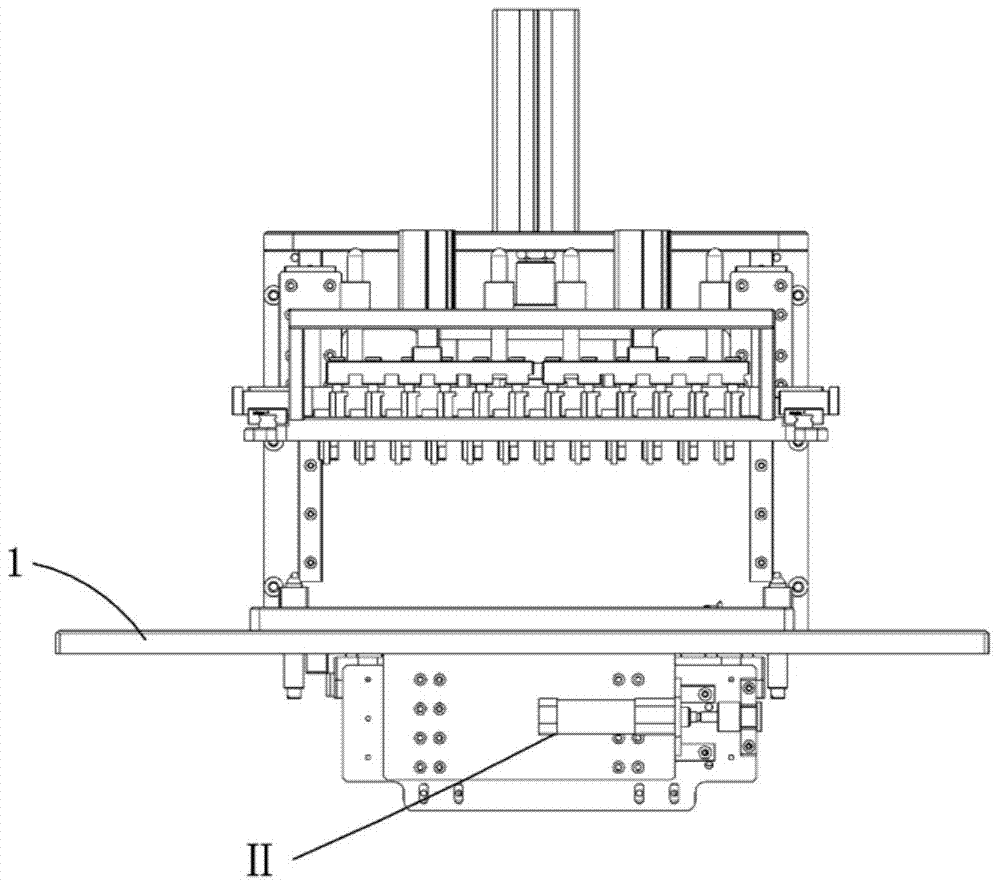

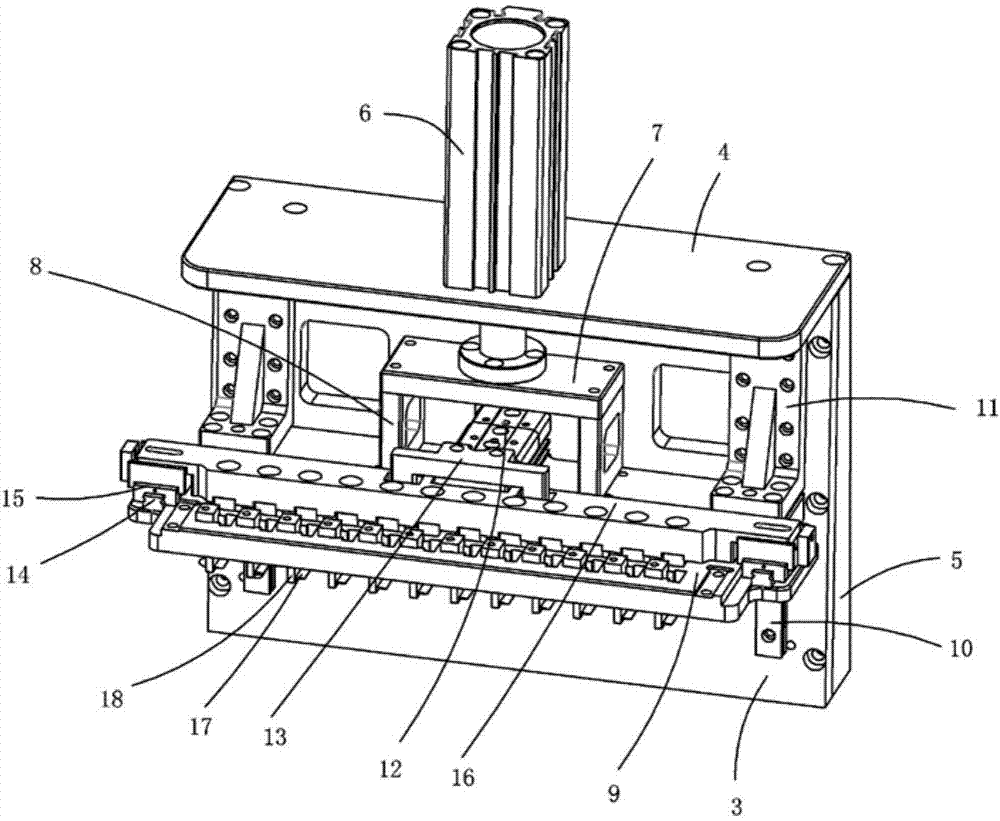

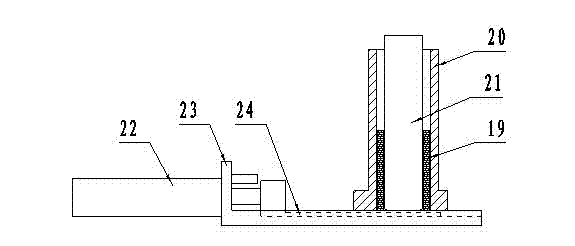

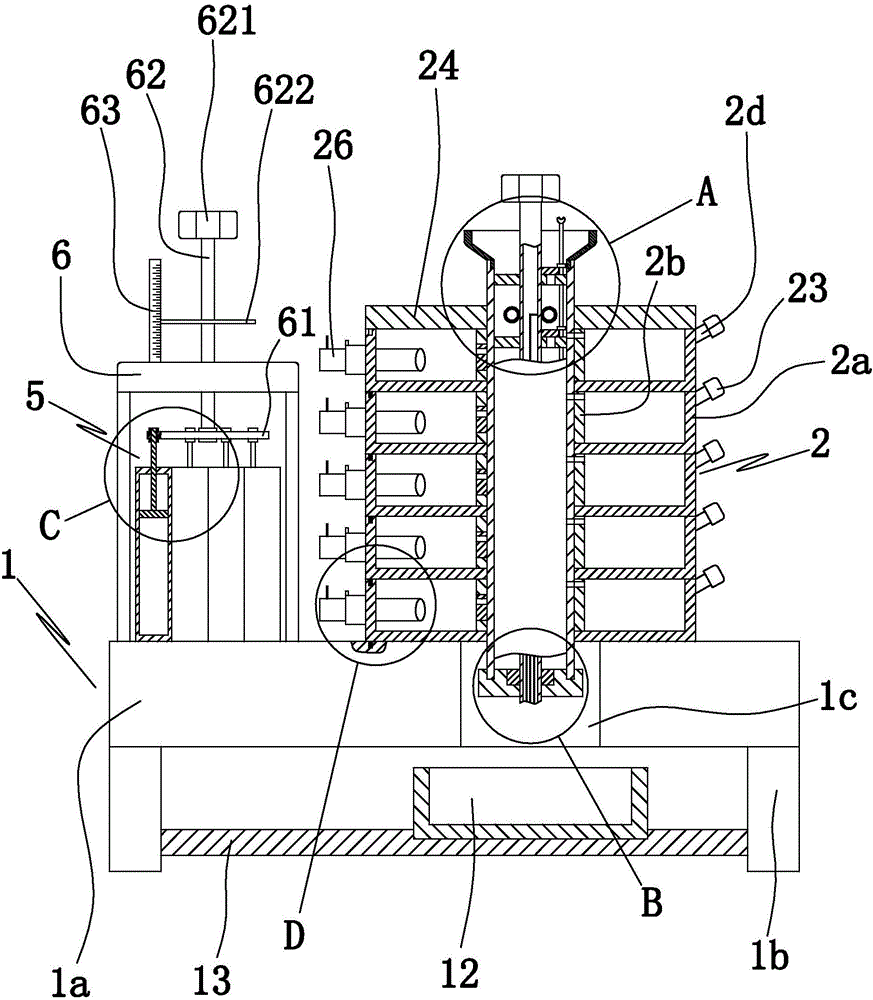

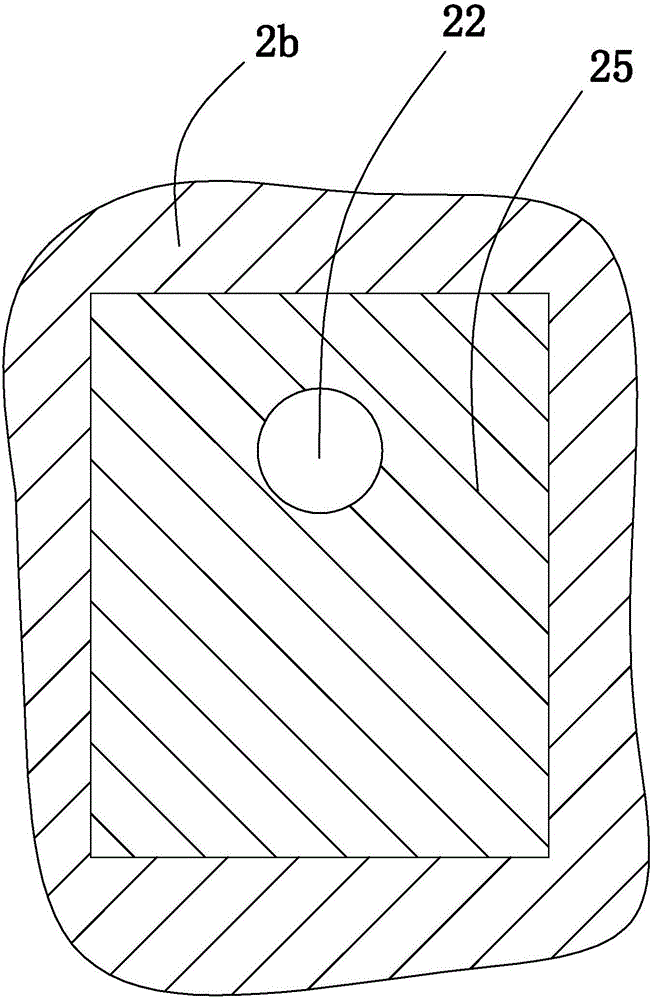

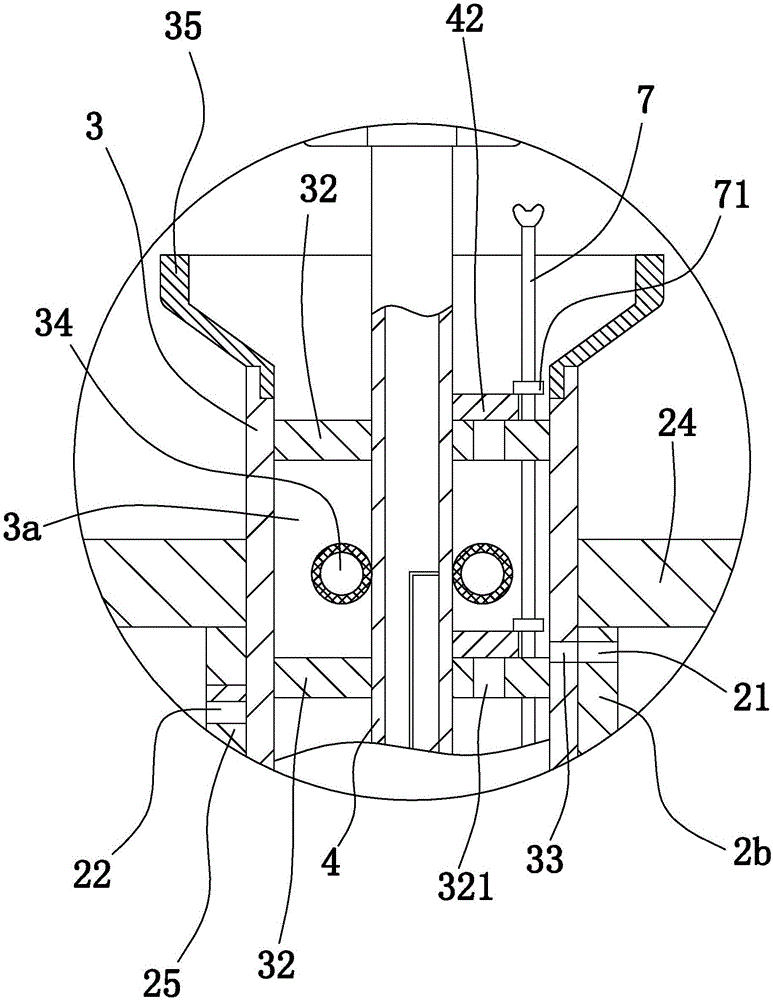

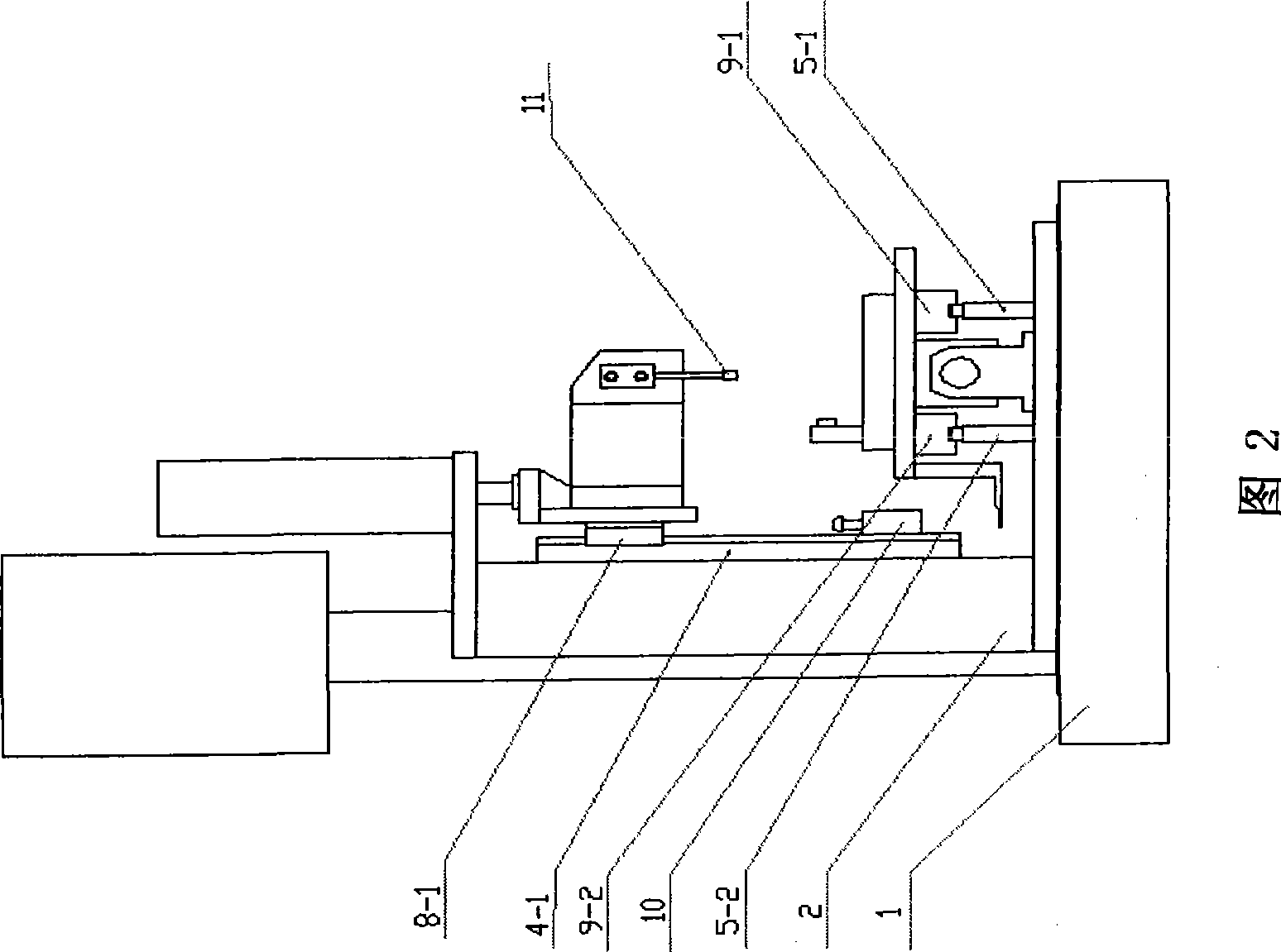

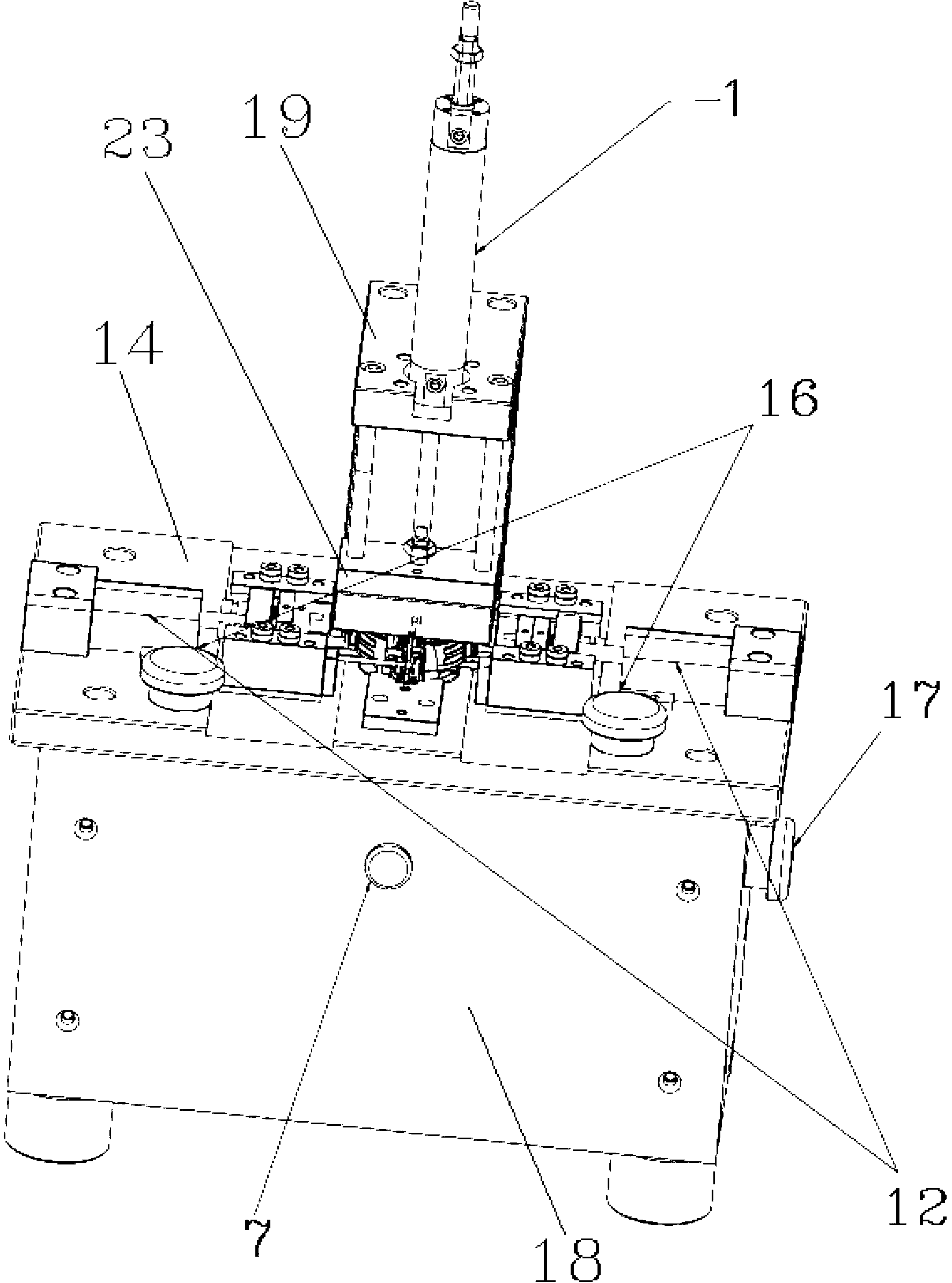

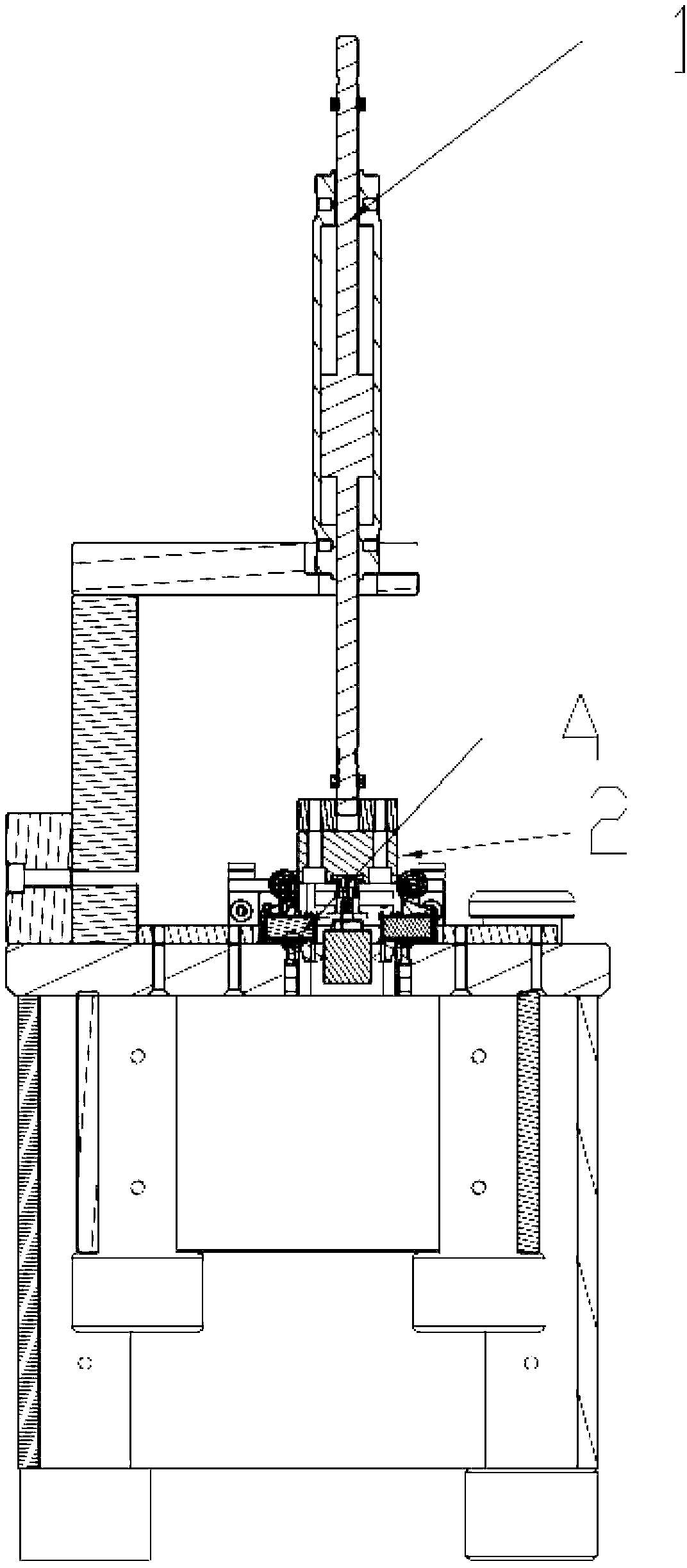

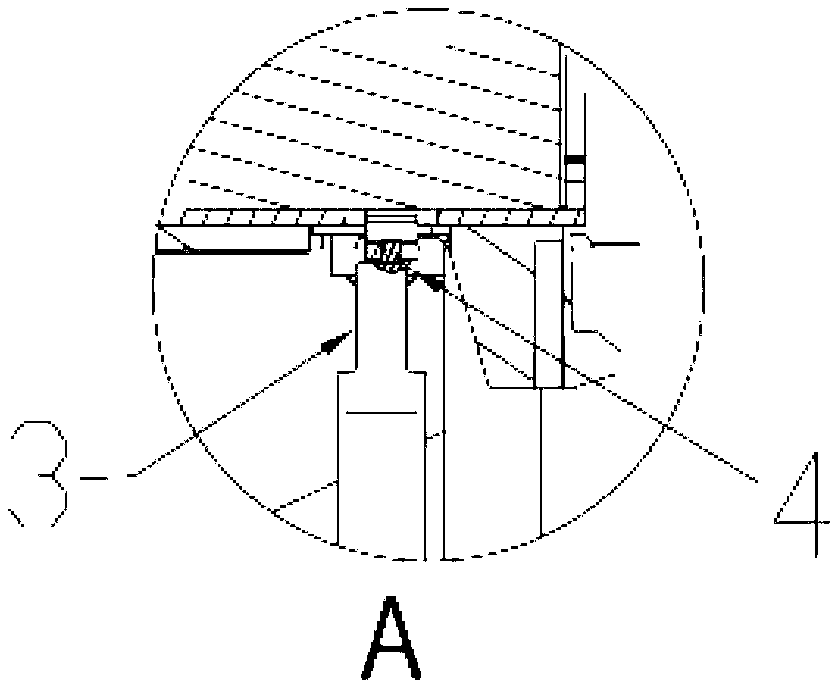

Flexible flat cable bending mechanism

ActiveCN104242019AEasy to moveWith anti-bounce functionLine/current collector detailsEngineeringVertical cylinder

The invention relates to the field of bending equipment, in particular to a flexible flat cable bending mechanism. The flexible flat cable bending mechanism comprises a panel, a carrier plate, an upper mold device and a lower mold device, wherein the carrier plate is arranged on the panel; a product is positioned on the carrier plate; the upper mold device is arranged on the upper portion of the panel; the lower mold device is arranged on the lower portion of the panel; the upper mold device is driven by a vertical cylinder and a transverse cylinder so that a pre-pressing block and a bending stopping block can reach standard operation positions, and preparations are made for bending of flexible flat cables; the upper mold device is also provided with a bending stopping block micro-adjusting mechanism; bending positions can be slightly adjusted by the bending stopping block micro-adjusting mechanism so that the bending precision of the flexible flat cables is high; a horizontal pushing block which is driven by a horizontal cylinder of the lower mold device drives a connecting plate to move along a horizontal sliding track in the left-right direction, and a bending mold is driven to move in the left-right direction; and under the driving effect of a lifting cylinder, a fixing seat can be pushed to move along a lifting sliding track in the up-down direction, and the bending mold is driven to move in the up-down direction. By the flexible flat cable bending mechanism, the flexible flat cables of a plurality of groups of connecting plates can be bent. The bending mechanism is stable and reliable and is high in bending precision, so that the production efficiency and the yield are improved, and the production cost is reduced.

Owner:BOZHON PRECISION IND TECH CO LTD

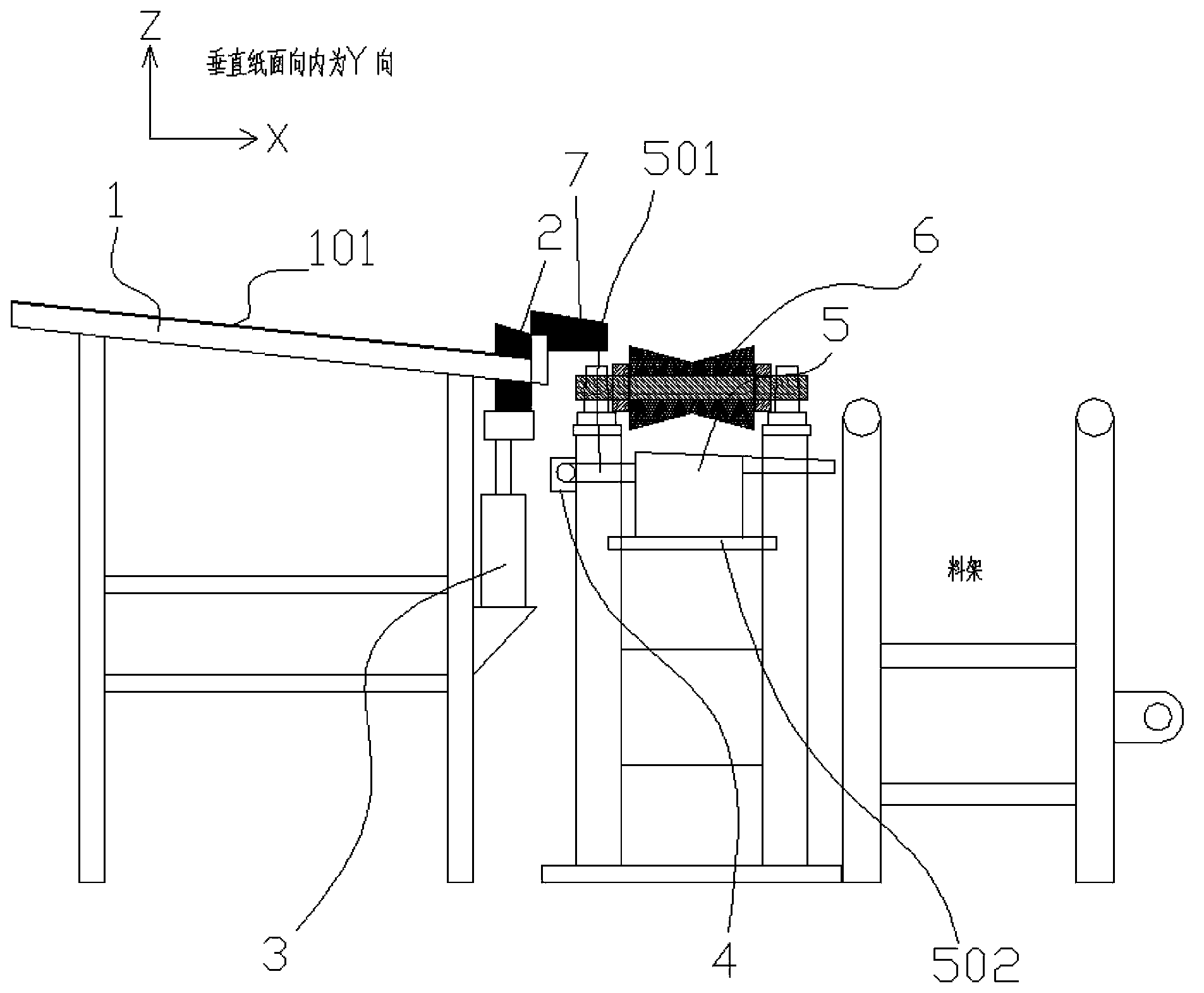

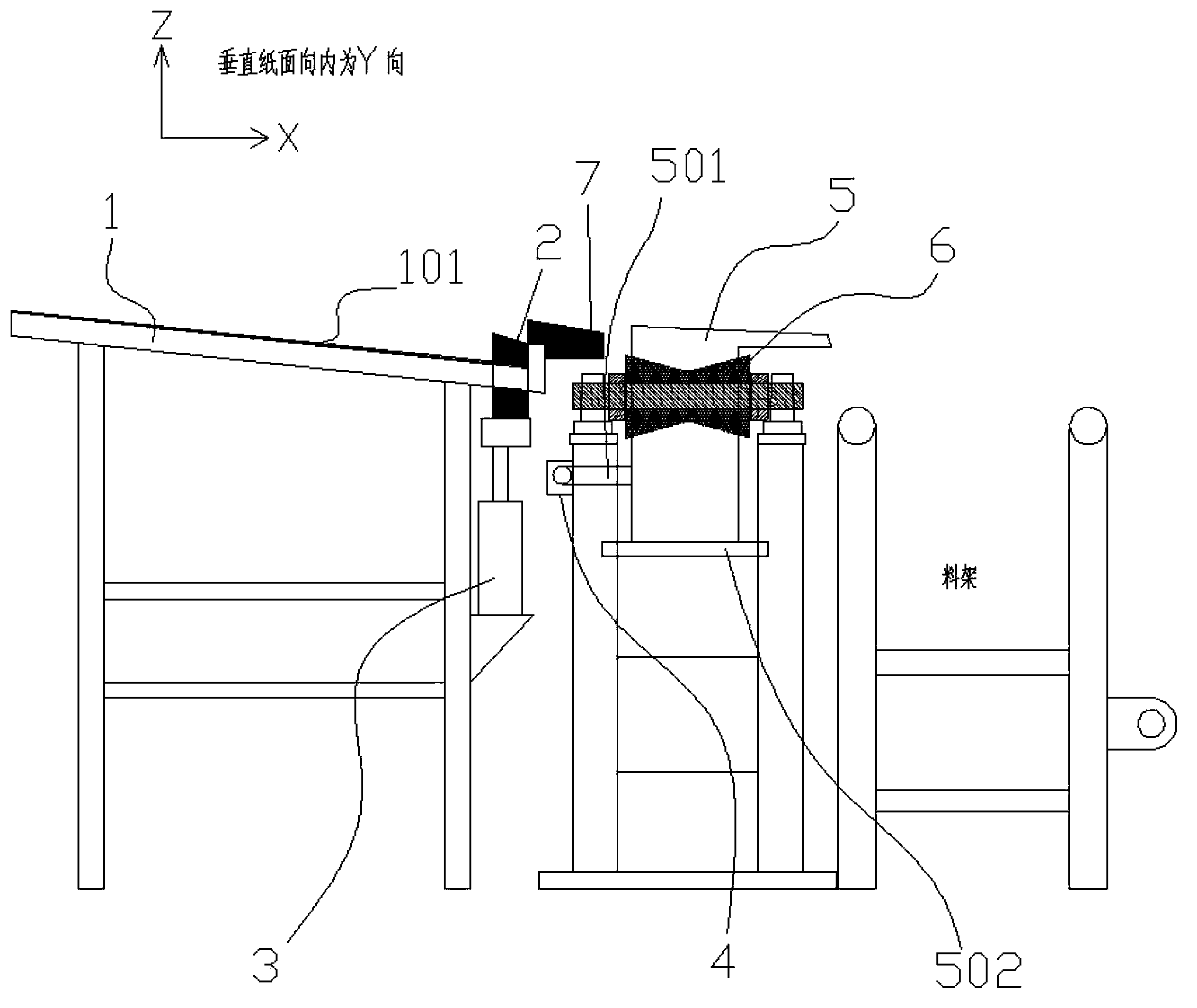

Device for conveying steel pipe transversely falling step by step

InactiveCN103407760ARealize root-by-root mobile conveyingSimple structureConveyor partsLong axisVertical cylinder

The invention relates to a device for conveying a steel pipe transversely falling step by step. The device comprises rolling supporting rods which are obliquely placed downwards in the X direction, wherein vertical cylinders are arranged in the positions corresponding to the lower ends of the rolling supporting rods, and are connected with pushing blocks; the height of each pushing block is lower than that of the lower end of each rolling supporting rod, and the upper end surfaces of the pushing blocks are tilted downwards in the X direction; the lower ends of the rolling supporting rods are further connected with guide blocks; the guide blocks are positioned in front of the pushing blocks in the X direction, and the upper end surfaces of the guide blocks are tilted downwards in the X direction; ejector rods of the vertical cylinders are used for lifting up upwards; the front side of the upper end surface of each pushing block in the X direction and the rear side of the upper end surface of each guide block in the X direction are positioned in the positions at the same height; carrier roller support frames are arranged in front of the guide blocks in the X direction; rotating plates are arranged below carrier rollers, and the upper side edges of the carrier rollers are tilted downwards in the X direction; a horizontal cylinder is fixedly arranged on the carrier roller support frame at the rearmost end in the Y direction, and an ejector rod of the horizontal cylinder is connected with a long shaft; the long shaft is fixedly connected with the rotating plates, and the ejector rod of the horizontal cylinder contracts to drive the rotating plates to rotate around rotating shafts thereof, so as to lift up a steel pipe together and enable the steel pipe to roll down along the upper side edges of the rotating plates.

Owner:嘉兴永励精密钢管有限公司

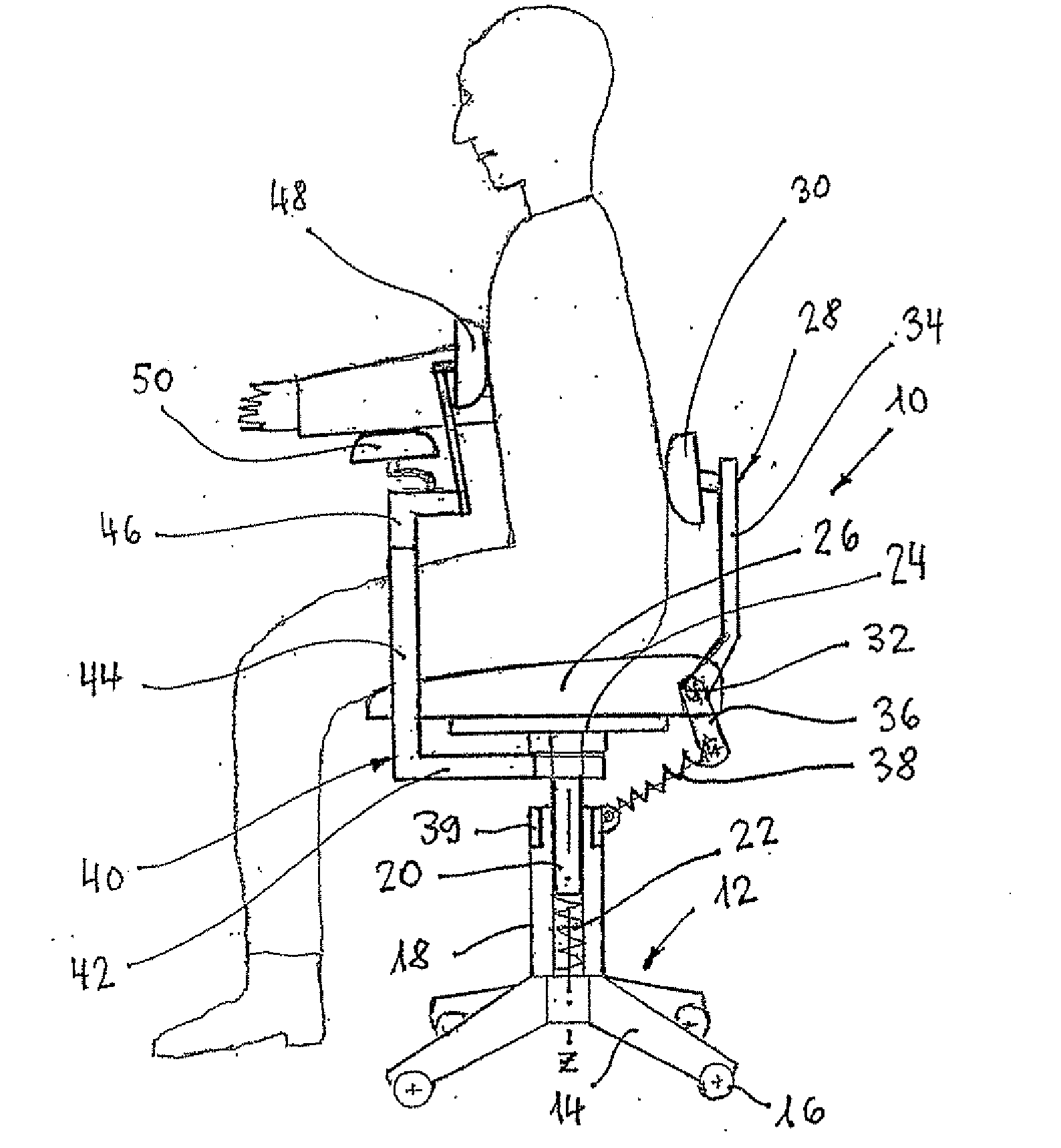

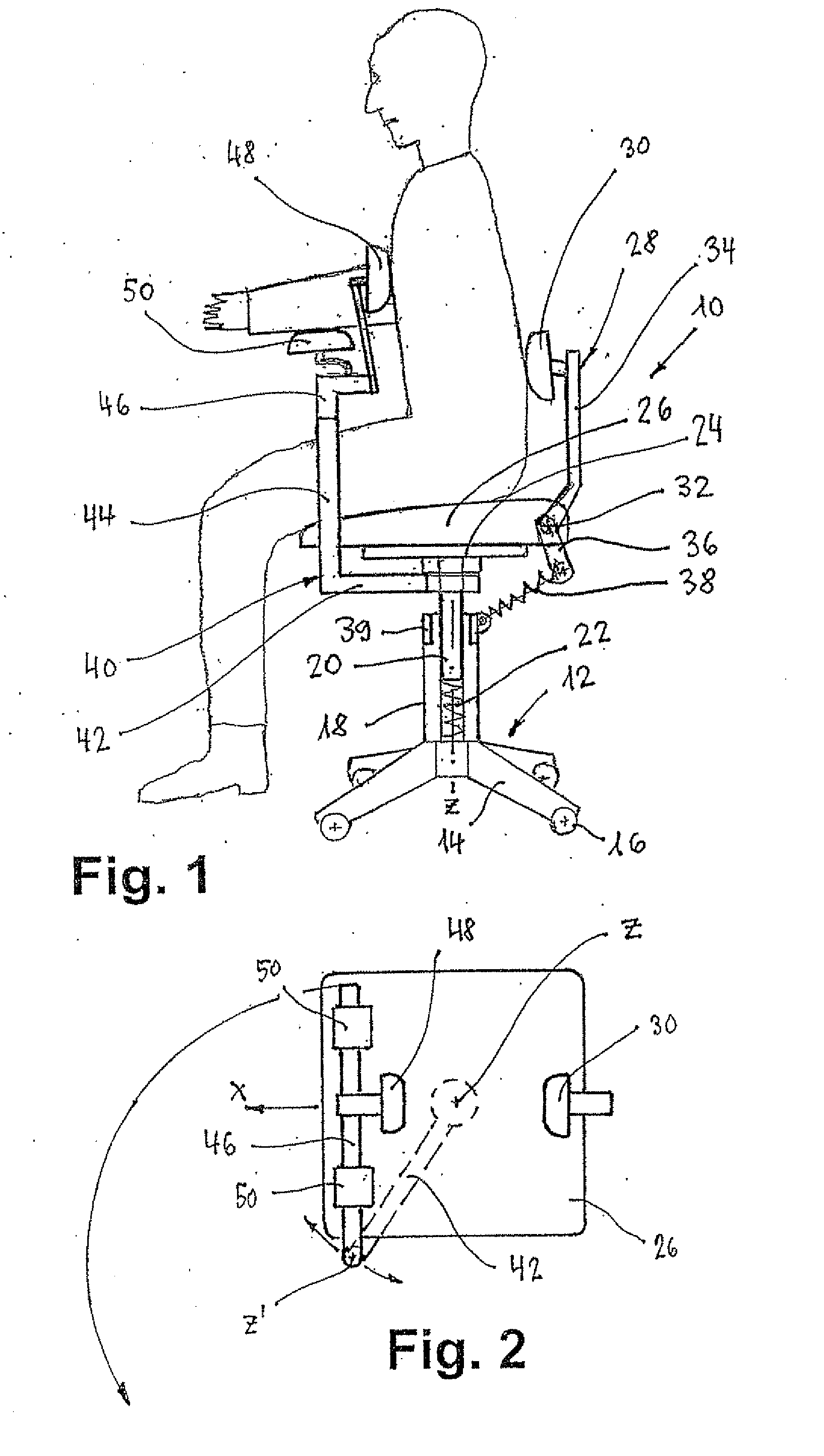

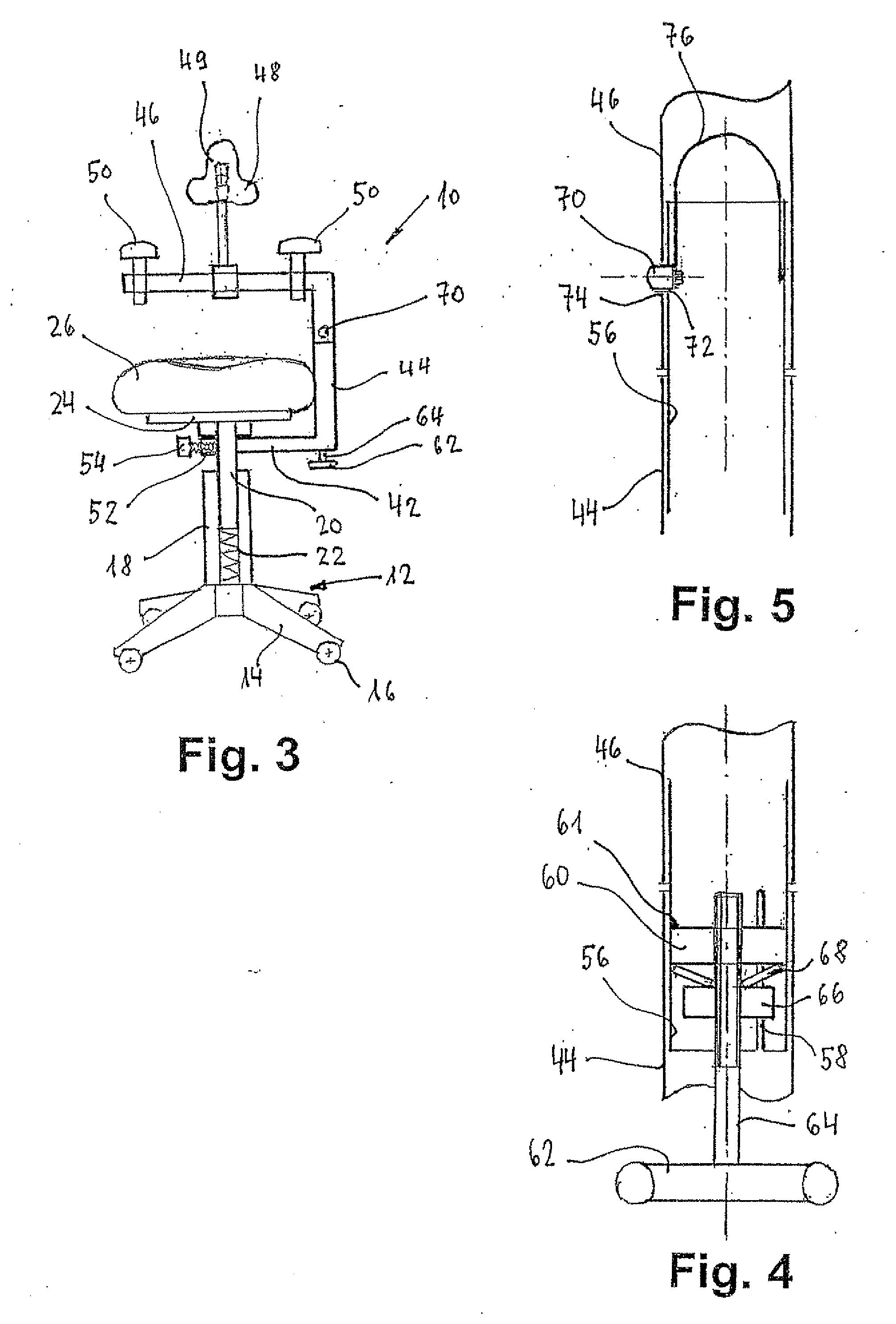

Work Chair

An ergonomic work chair for activities requiring a bent-forward posture has the following features: a supporting cylinder which protrudes from a star base, a supporting column, which is mounted in the supporting cylinder such that it can be displaced in a vertical cylinder axis, for a base plate with a seat which is fixed on the base plate, a base arm which is fitted to the supporting column or to the base plate, and a pivoting arm, which is mounted on the base arm such that it can be rotated out of the seat region about a vertical axis, having a chest rest and side arm rests, and a support which has a star rest and is hinge-connected to the base plate via a lever mechanism which has fulcrums such that pressing down on the seat causes the star rest to move in the direction of the chest rest.

Owner:ULRICH HANS JURGEN

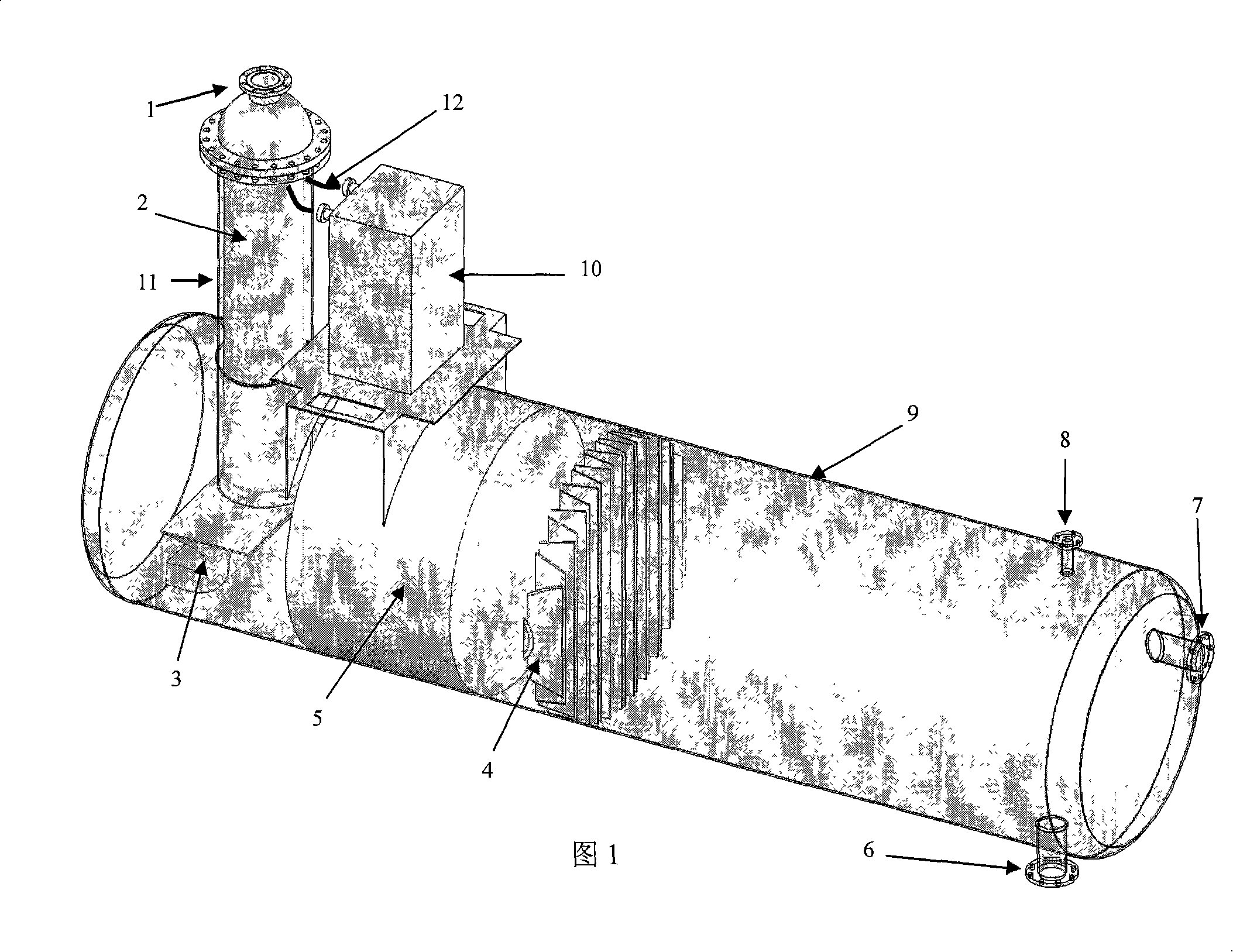

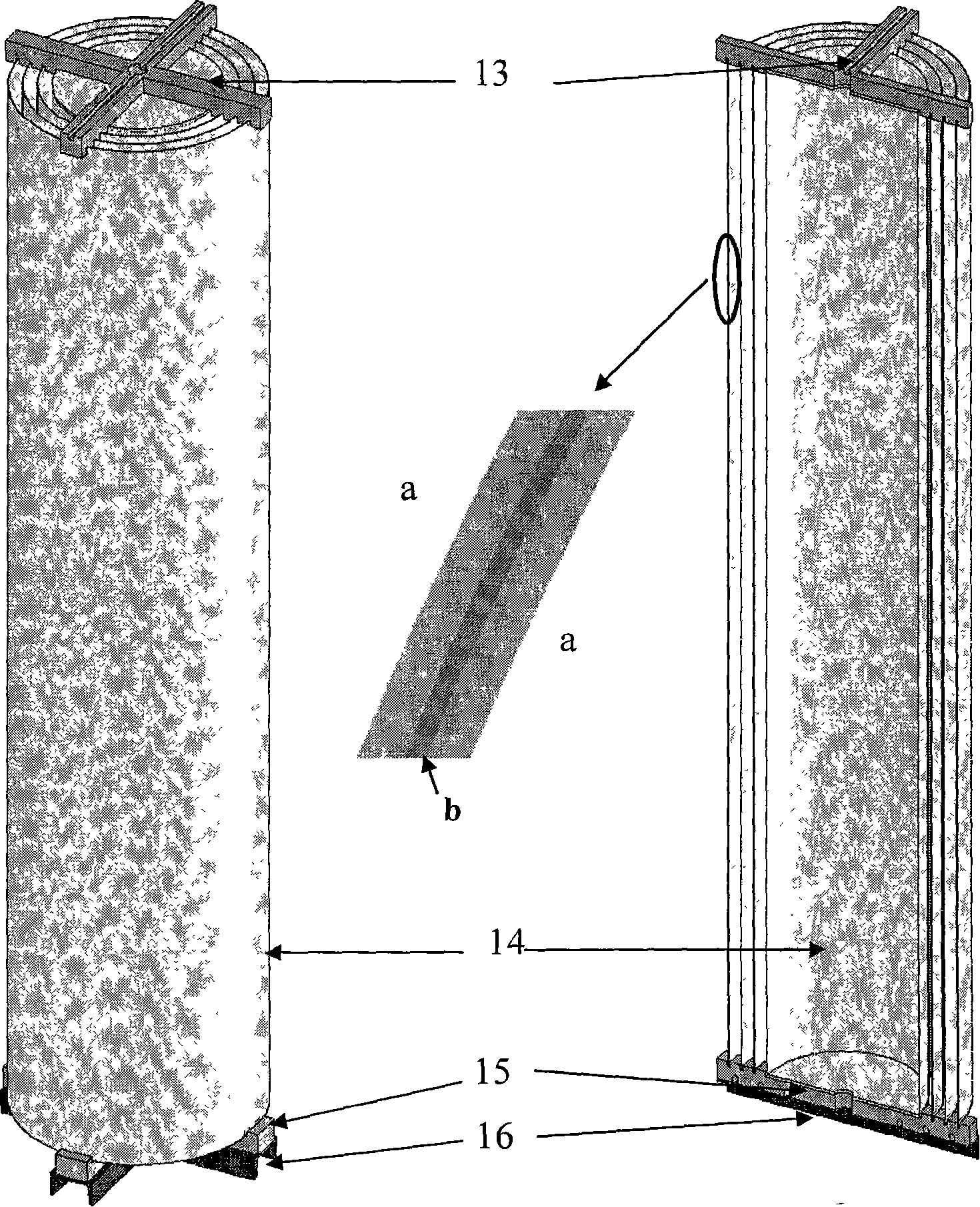

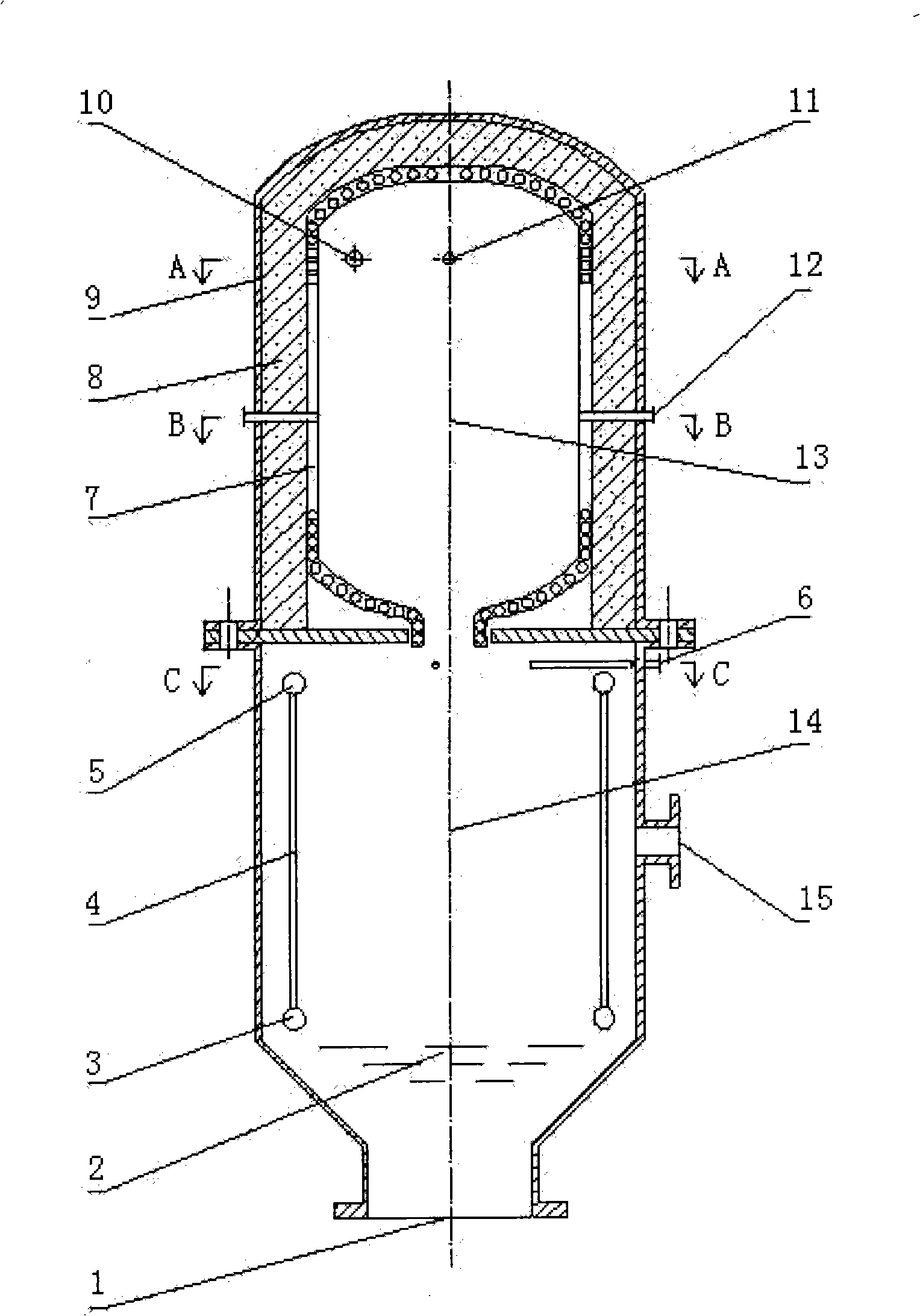

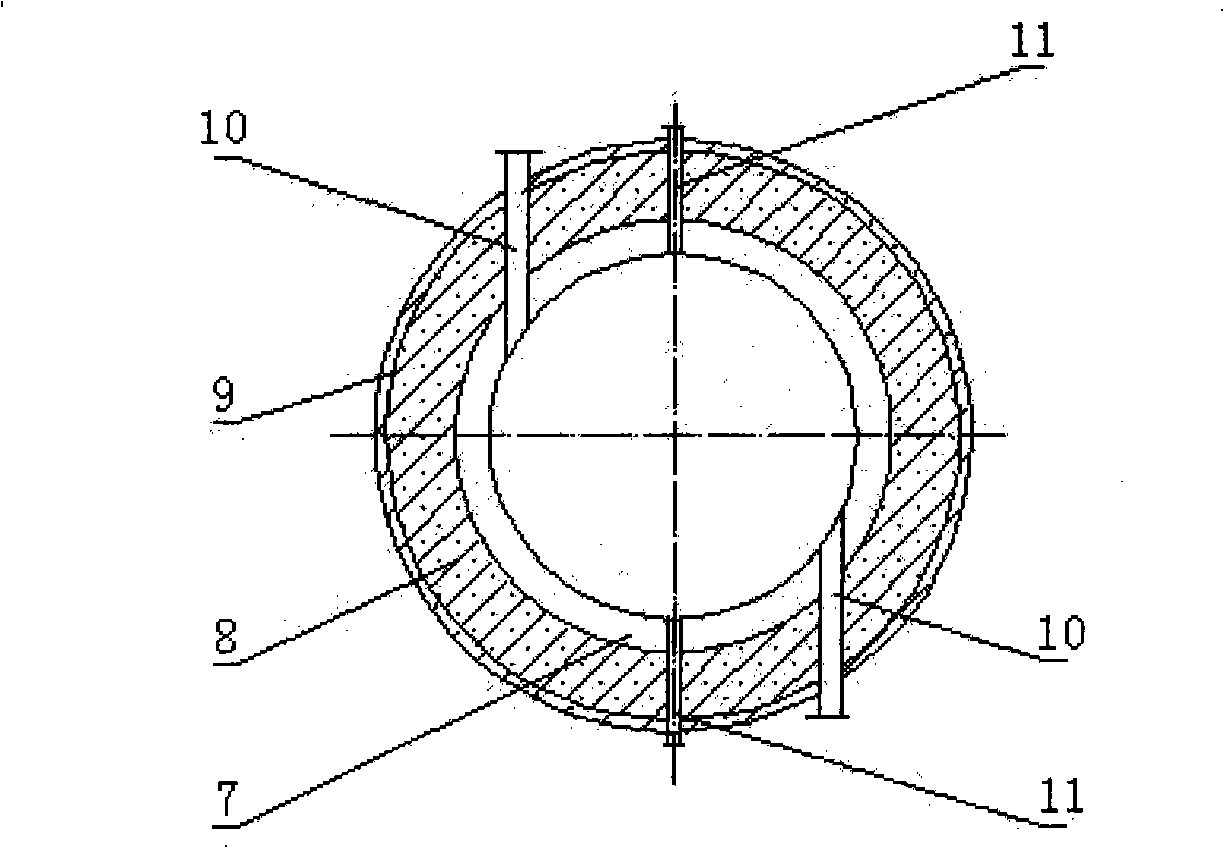

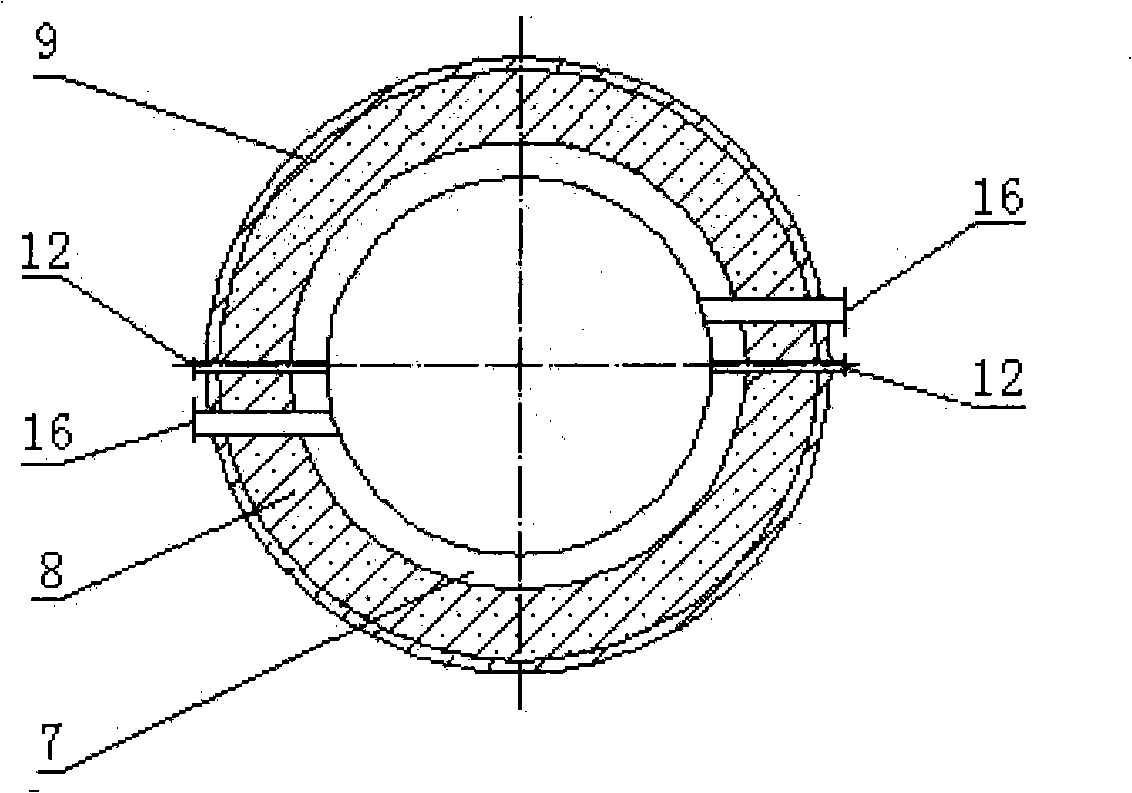

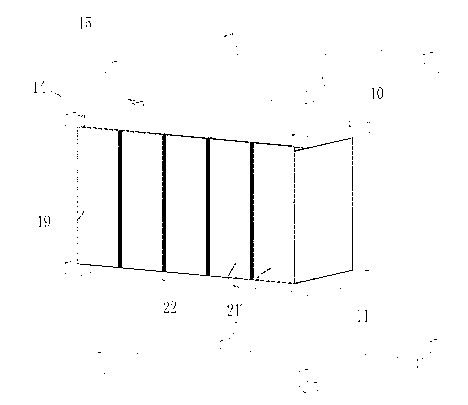

Novel crude oil emulsion electrostatic dehydrator

InactiveCN101173182ACompact structureSmall footprintDewatering/demulsification with electric/magnetic meansInsulation layerEngineering

The invention relates to an electrostatic coalescer with high efficiency, which is a piece of compact equipment for the electrostatic dehydration of crude oil emulsion with high efficiency, and is applied for the crude oil dehydration in the production process of oil fields. The invention is characterized in that: the invention comprises a housing, which comprises a coalescence part arranged vertically and a sedimentation and separation part arranged horizontally; the coalescence part is a vertical cylinder shaped structure with a cylinder shaped electrode assembly arranged inside; the sedimentation and separation part is a horizontal tank structure arranged below a dehydrator, with an emulsion distribution device, a spoiler and a staggered corrugated coalescing plate arranged inside. A high voltage transformer is arranged on the sedimentation and separation part and is connected with the cylinder shaped electrodes by a high voltage insulated cable. The cylinder shaped electrodes are covered by a compact insulation layer which can reduce leakage current and prevent the short circuit among the electrodes. The distance among the cylinder shaped electrodes is small, so a narrow runner is formed, and high strength electric field is formed in the narrow runner. The invention has the advantages that: the crude oil emulsion successively experiences the effects of electrostatic coalescence, staggered corrugated coalescing plate coalescence and the eddy current coalescence of the spoiler; the contained water drops grow bigger; the settling velocity is accelerated, and the rapid separation between crude oil and water is realized.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

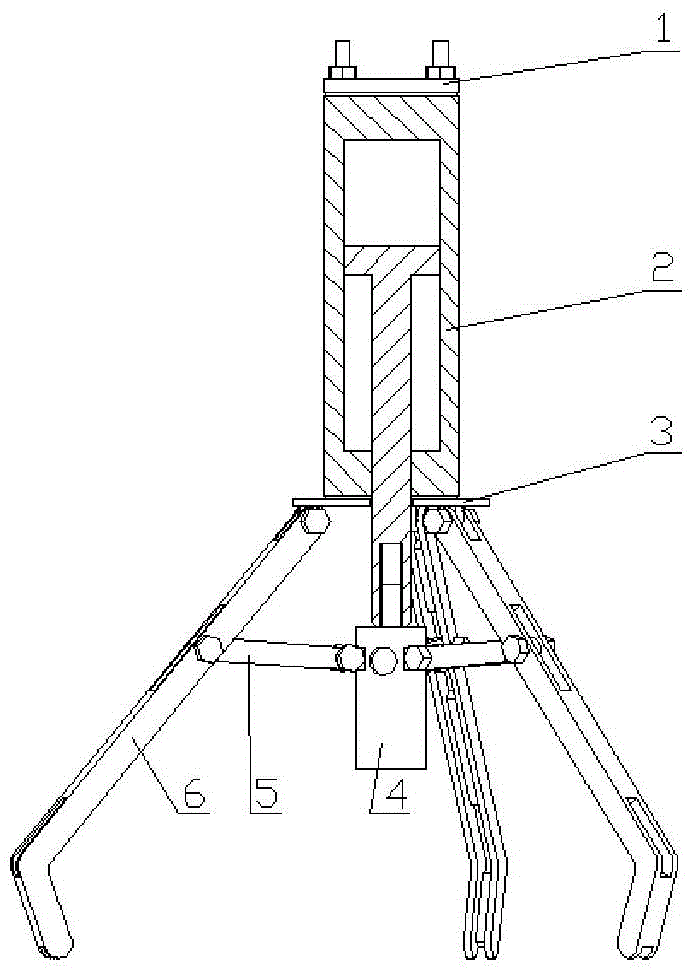

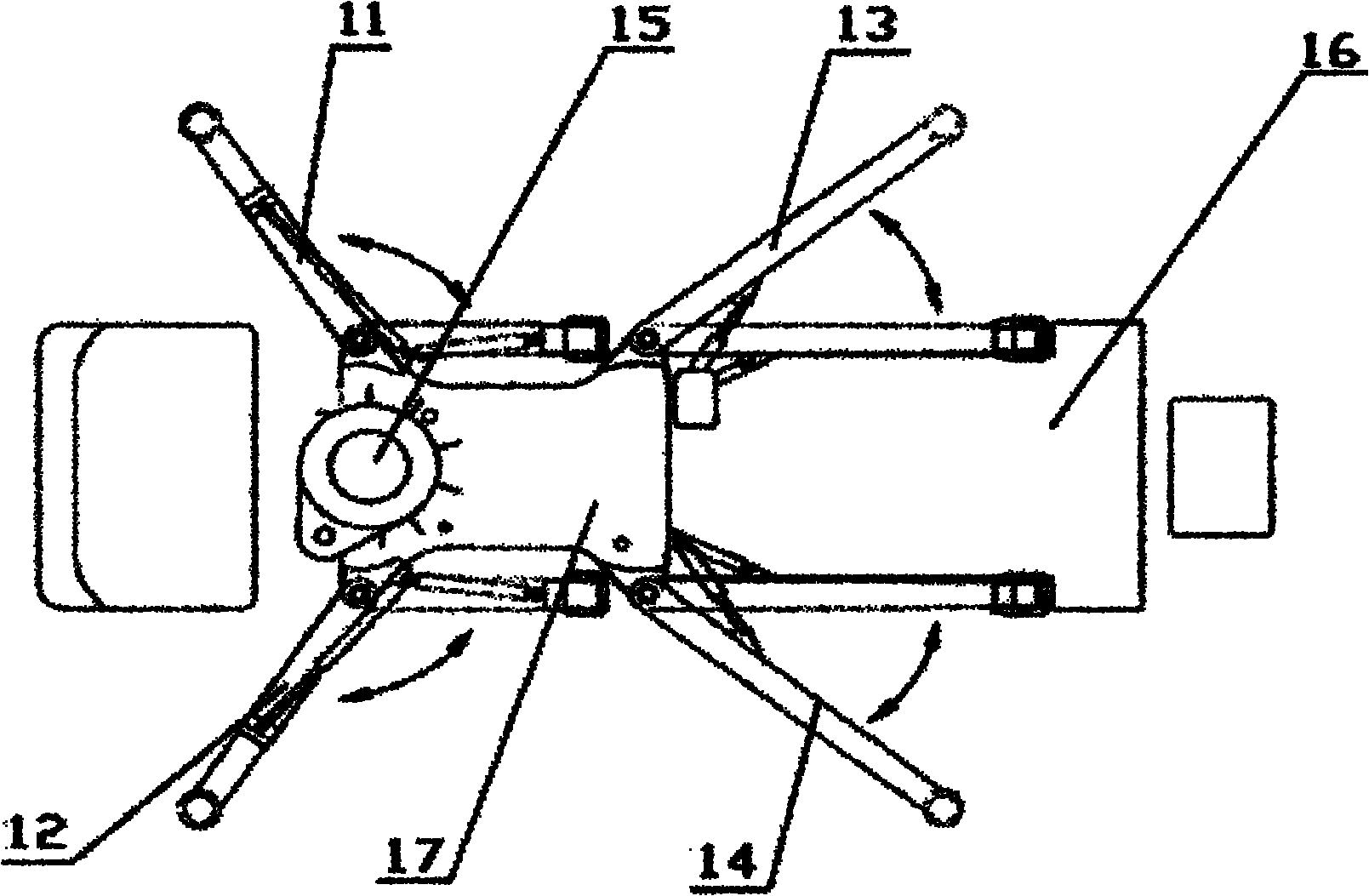

Tracking meal delivering robot

The invention discloses a tracking meal delivering robot which is a mechanical, electrical and hydraulic combinational integrated product. The tracking meal delivering robot is composed of a mechanical system, a hydraulic system and a control system; the mechanical system comprises a driving wheel, a direct-current walking motor, a step-by-step steering motor and a sensor; the robot achieves the functions such as walking and turning through the mechanical system; the hydraulic system comprises an oil tank, a gear pump, a direct-current motor, a vertical cylinder, a horizontal cylinder and a grabbing cylinder; the functions of looking for plates, grabbing the plates and sending the plates to a guest dinner table are achieved through the hydraulic system; the analysis and detection on the movement track in the robot walking process and positioning on the plates in the robot dish serving process are achieved through the control system, and the control system has the advantages that the feedback precision is high and the system operation is stable. The tracking meal delivering robot is simple in structure, steady in system operation and low in manufacturing cost, and capable of saving labor force for foodservice industry and solving the problem of human resource shortage.

Owner:郅伦臣

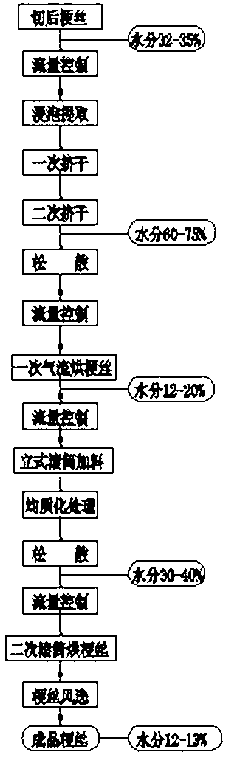

Recombination processing method for tobacco stem shreds

InactiveCN102697164AAchieve quality transformationImprove use valueTobacco treatmentCombustionChemical composition

The invention provides a recombination processing method for tobacco stem shreds, for performing recombination processing on chemical components of the stem shreds after the tobacco is cut into shreds. The recombination processing method comprises the following steps: soaking and extracting; separating solid from liquid; flexibly loosening; pneumatically drying; charging into a vertical cylinder and homogenizing; loosening; drying a heat-transferring oil cylinder; and winnowing the stem shreds. The stem shreds processed according to the recombination processing method provided by the invention have higher filling property, fragrance quality and purity; the combustion state of the tobacco is improved; the smoke quality of the tobacco is not influenced and even is promoted; and an effective way for applying the stem shreds to high-class cigarette is developed.

Owner:ZHISI HLDG GRP

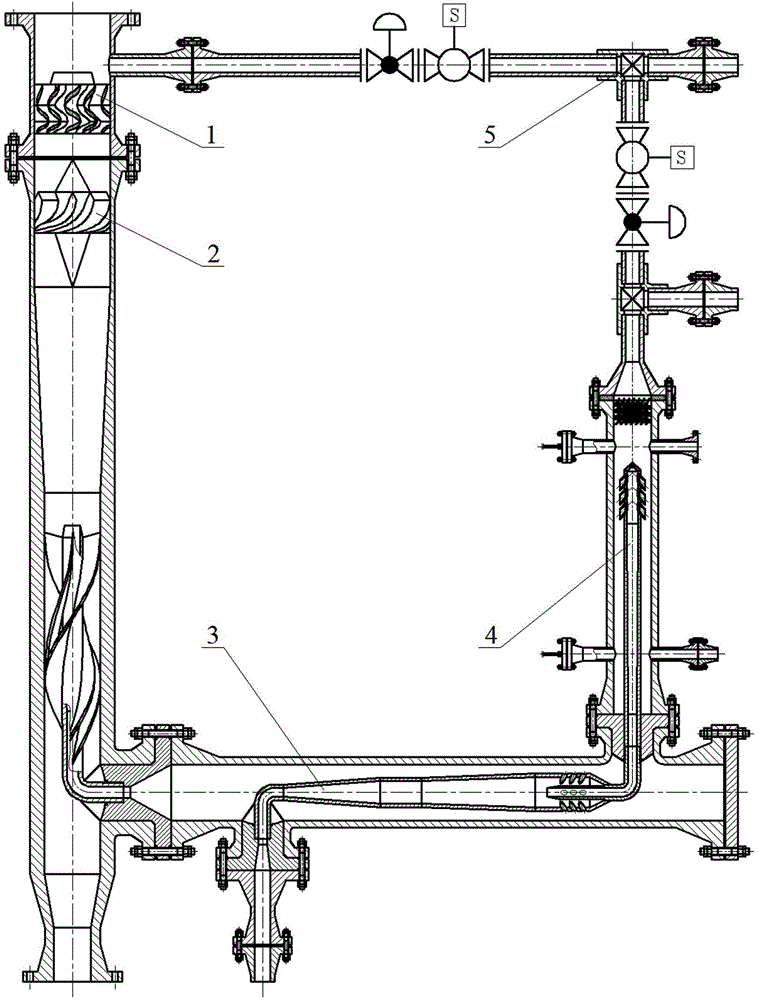

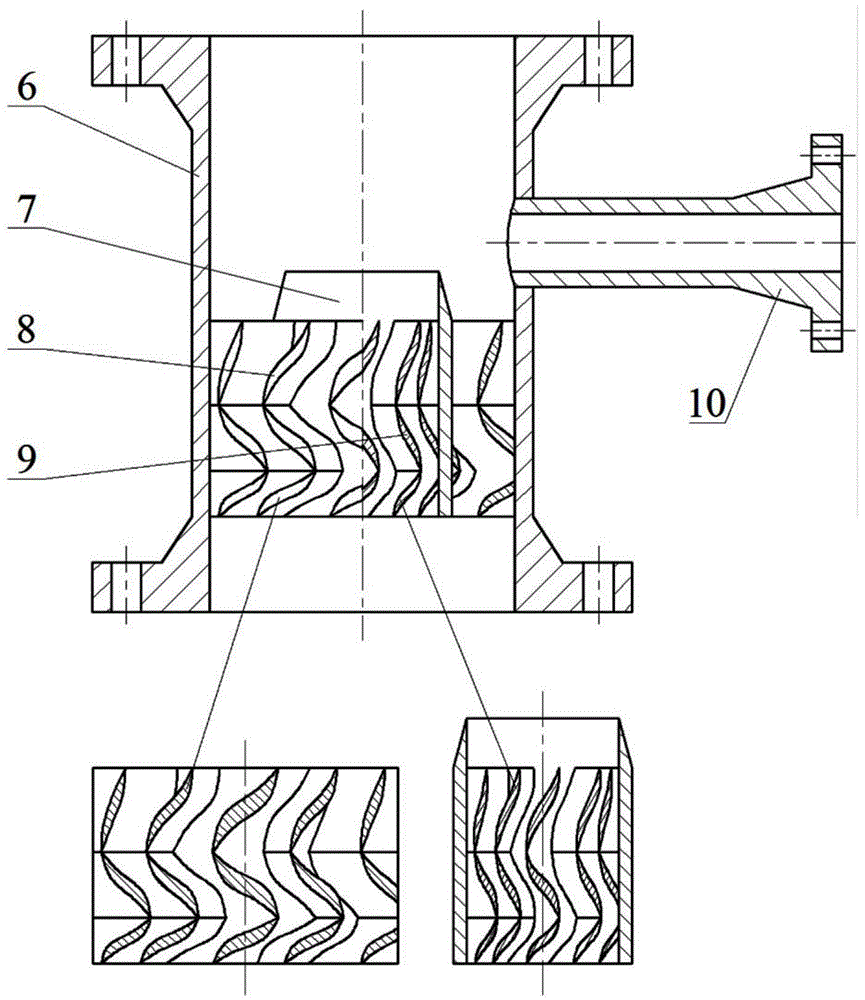

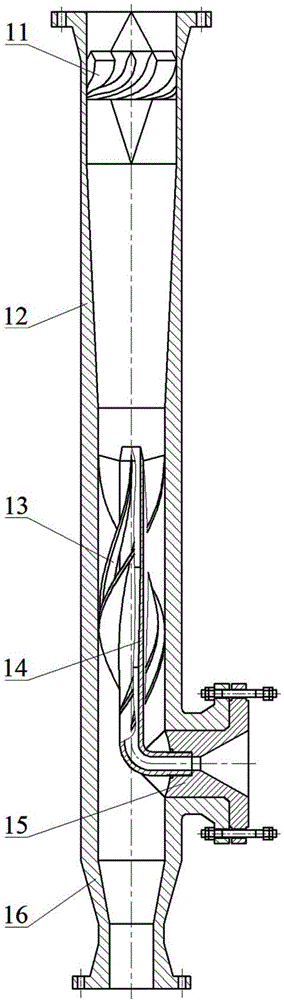

Two-stage axial-flow type online gas-liquid separation device for underwater pipeline

ActiveCN104801071ASimplify the gathering and transportation processRealize self-cleaningCombination devicesLiquid degasificationOcean bottomPressure stabilization

The invention provides an online gas-liquid separation device for an underwater pipeline, and applies to efficient gas separation of well flow of an underwater production system. The gas-liquid separation device realizes online installation and operation of the pipeline and has the characteristics of simplifying of oil and gas gathering and transferring processes, reduction of gathering and transferring energy consumption and compact structure; a uniform gas-liquid mixing device adopts layered screw blades in opposite rotating directions to crush big bubbles to form uniform gas-liquid mixing flow, so that the gas-liquid ratio adaption range of the device is broad; a first-stage axial flow device adopts a single vertical cylinder to implement first-stage vertical high-speed swirling flow gas-liquid separation to remove most liquid phase, a second-stage axial flow device adopts double horizontal cylinders to implement second-stage horizontal layered rotating flow gas-liquid separation to remove the residual liquid flow, and efficient separation of the two-phase well flow is realized; a scrubbing balancer adopts double vertical cylinders to realize buffer pressure stabilization and complete separation of the gas-phase well flow, and a cleaning pipe performs cleaning operation automatically; a gas-liquid separation control system implements remote automatic control so as to control the well flow of the submarine pipeline and realize dynamic balance of pressure of the scrubbing balancer.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

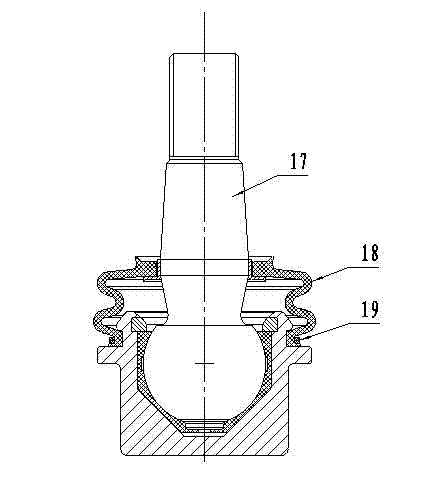

Device for automatically installing snap spring

InactiveCN102248515AImplement automatic installationReduce labor intensityMetal-working hand toolsEngineeringVertical cylinder

The invention discloses a device for automatically installing a snap spring. The device is composed of a frame, a vertical cylinder, a pressing sleeve, a follower lever and a cone cylinder; the vertical cylinder is fixed at the top part of the frame, the pressing sleeve is coaxially fixed at a lower end of a hollow piston rod of the vertical cylinder, and a plurality of mandrils along the snap spring is arranged on the periphery of the lower end of the pressing sleeve; an upper end of the follower lever is thicker and positioned in the piston rod of the vertical cylinder and a lower end of the follower lever is fixed with a driving magnet, and a buffer spring is arranged in the piston rod of the vertical cylinder; the cone cylinder is positioned under the vertical cylinder, a diaphragm plate in the cone cylinder is fixed with a driven magnet which has a thick lower end and is positioned in a through hole on a horizontal baffle in the middle of the frame, a cone cylinder top block is arranged in a side wall of the through hole, and a compression spring is arranged between the cone cylinder top block and the horizontal baffle. The device for automatically installing the snap spring can well realize the automatic installation of a dustproof sleeve snap spring of ball pin products, the product quality is improved, the labor intensity of the worker is reduced, and the working efficiency is improved.

Owner:BAODING GREAT MACHINERY CO LTD

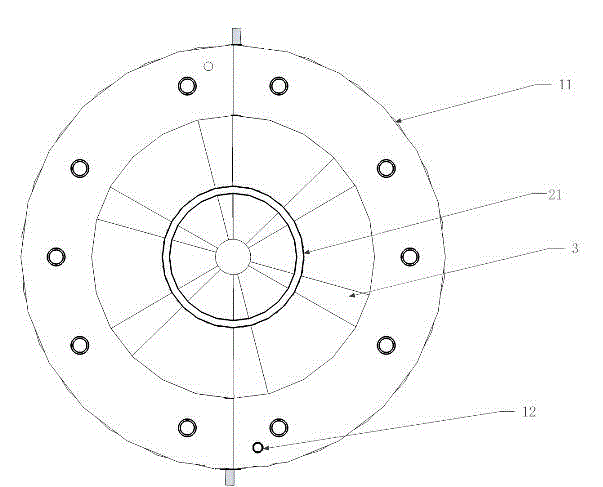

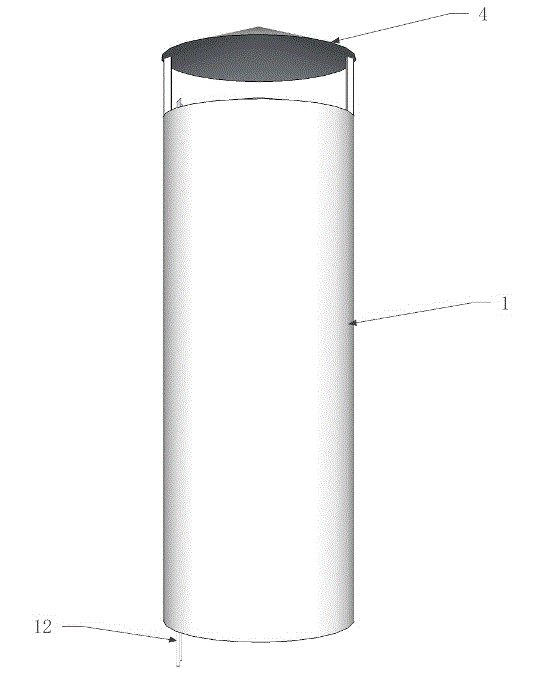

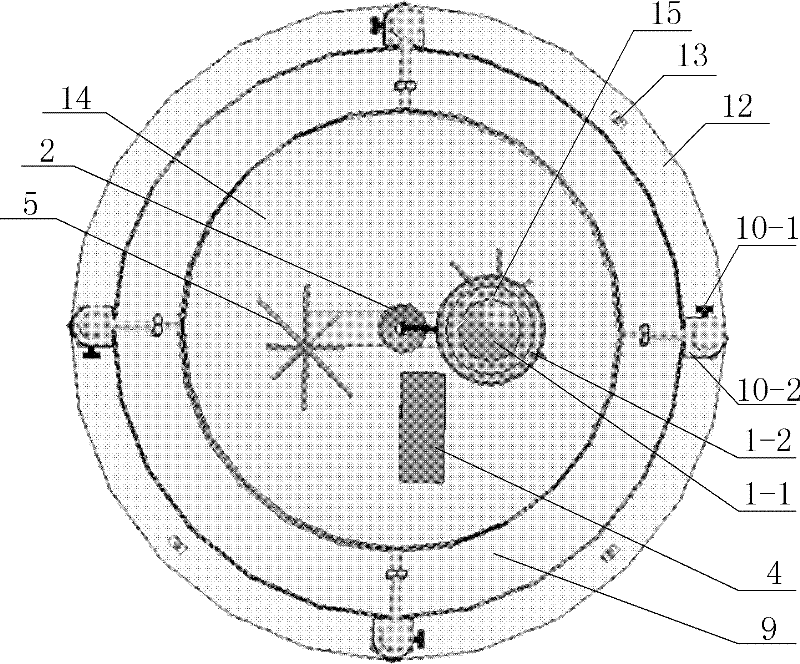

Demonstration instrument for Buffon probability experiment

InactiveCN102522031AIntuitive and visual teachingEasy to understandEducational modelsAbstract conceptDiameter ratio

The invention discloses a demonstration instrument for a Buffon probability experiment, and mainly aims to solve the problem of influence of personal habits on an experimental result and effectively simulate Buffon probability experiment conditions by a machine instead of manual labor. The demonstration instrument comprises a bracket structure (6), a circular bottom plate (12) and a vertical cylinder (7). An electromagnetic vibration disk (1) is positioned on a hollow top plate (14) above the vertical cylinder (7). A needle scattering shaft (2) penetrates through the center of the top plate. Rotating arms (3) are arranged at the lower end of the needle scattering shaft. A rotating claw (5) is connected to the lower end of each rotating arm. The needle scattering shaft, the rotating arms, the rotating claws and the vertical cylinder form an experimental small needle running channel. A horizontal needle receiving disk (9) is arranged on the circular bottom plate (12). Small needles are scattered from the electromagnetic vibration disk, pass through the small needle running channel and fall on the horizontal needle receiving disk. The number of the small needles and the number of intersection points of the small needles with three groups of parallel lines are counted to obtain a circumference-to-diameter ratio. By the demonstration instrument, an abstract concept is embodied, andthe teaching of a probability theory is vivid and convenient to comprehend.

Owner:XIDIAN UNIV

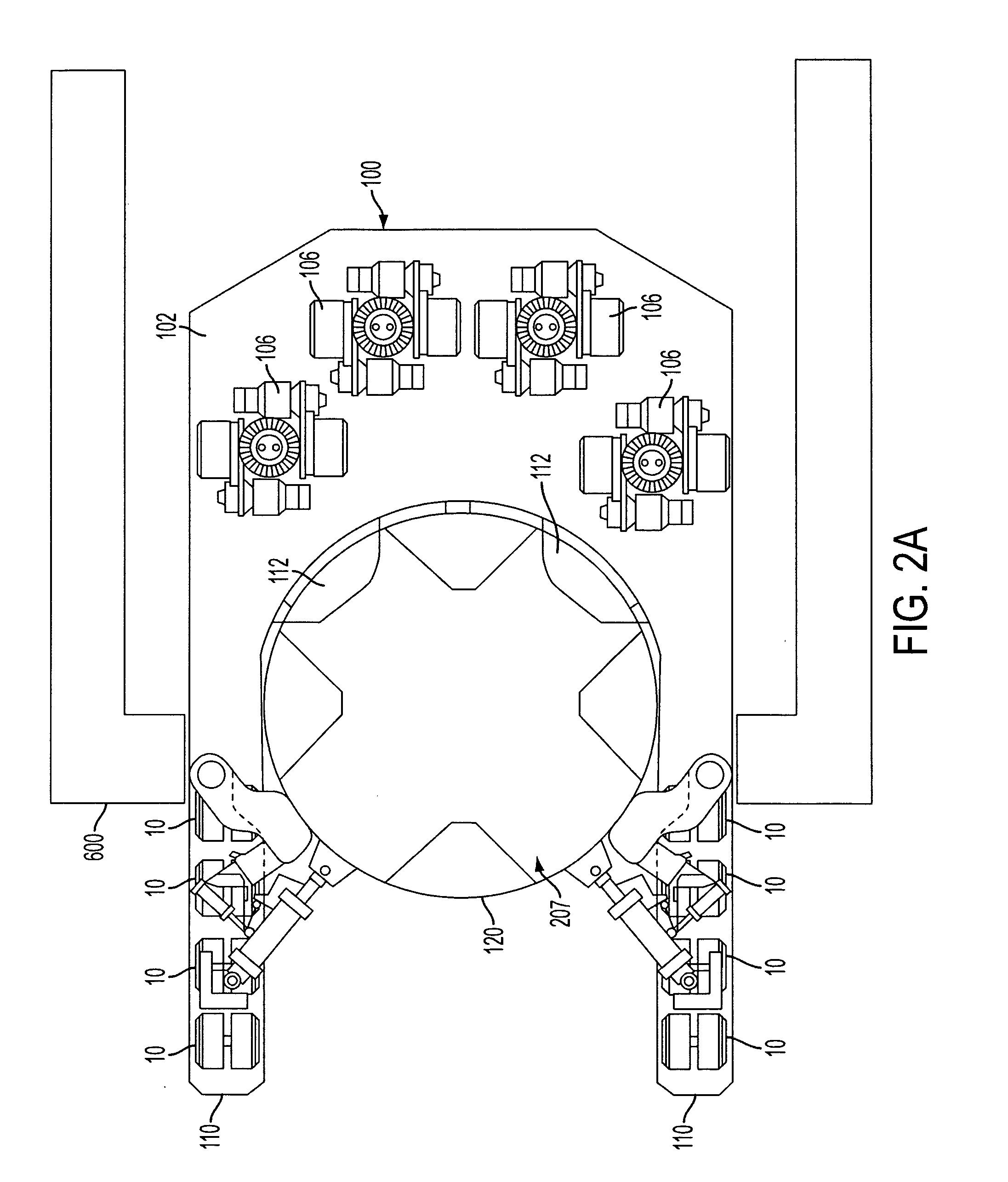

Stack axle assembly and transporters having the same

InactiveUS20110094815A1Provide supportReduce effortPortable shielded containersMotor depositionDrive wheelDrive motor

A stack axle assembly as used in a cask transporter or an horizontal storage module (HSM) gantry transporter. The stack axle assemblies include a slew gear; an upper bearing; a lower bearing; a vertical cylinder retained by the slew gear, upper bearing and lower bearing; an independent driver wheel and idler wheel revolving on a common shaft / trunnion assembly attached to the bottom of the vertical cylinder; a frame assembly formed on top of the vertical cylinder, the frame assembly including one or more drive motors connecting an upper drive assembly downwardly to a driven assembly mounted between the idler wheel and driver wheel; and a slew driver motor to drive the slew gear.

Owner:INTELLIPORT CORP

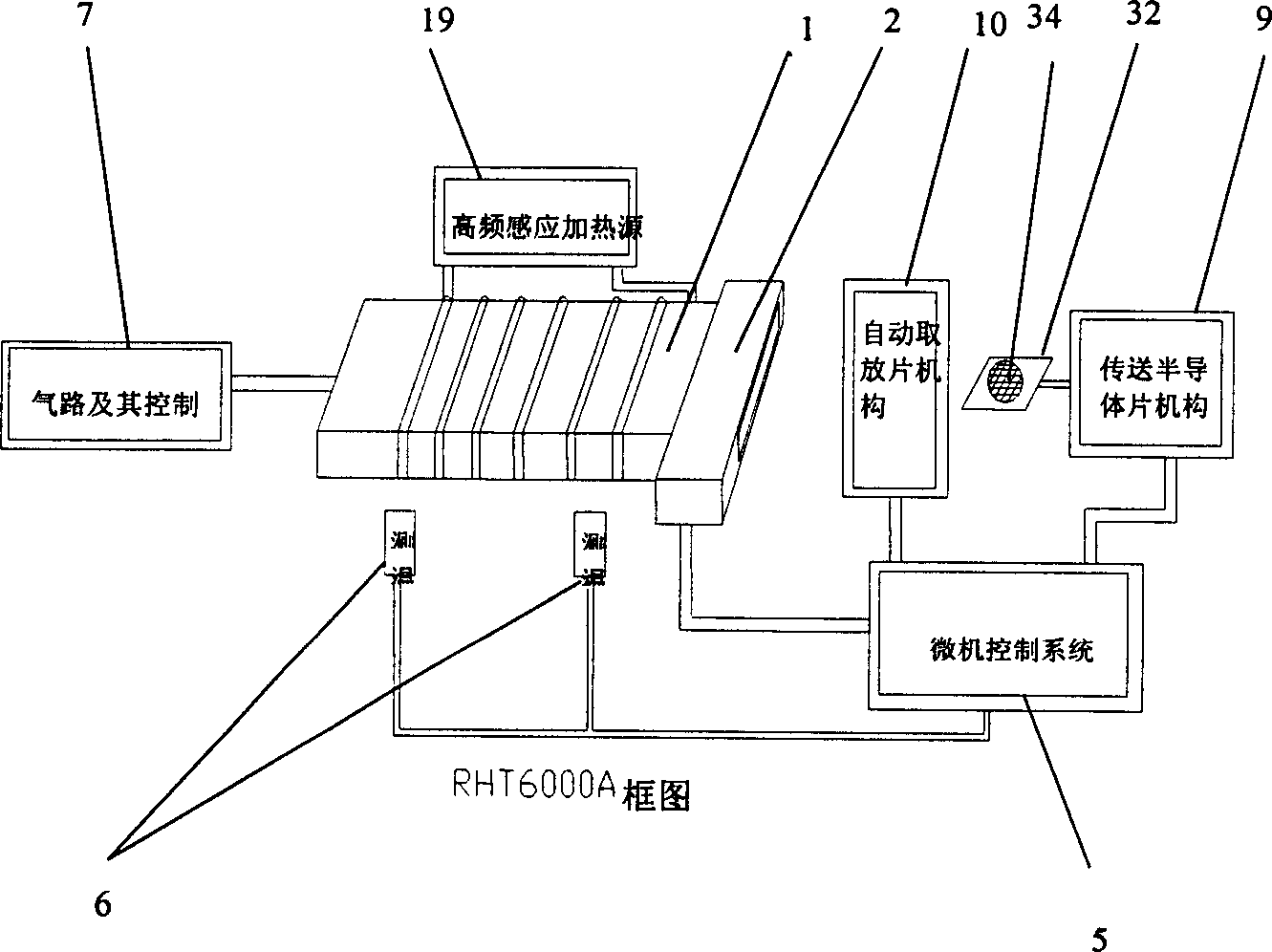

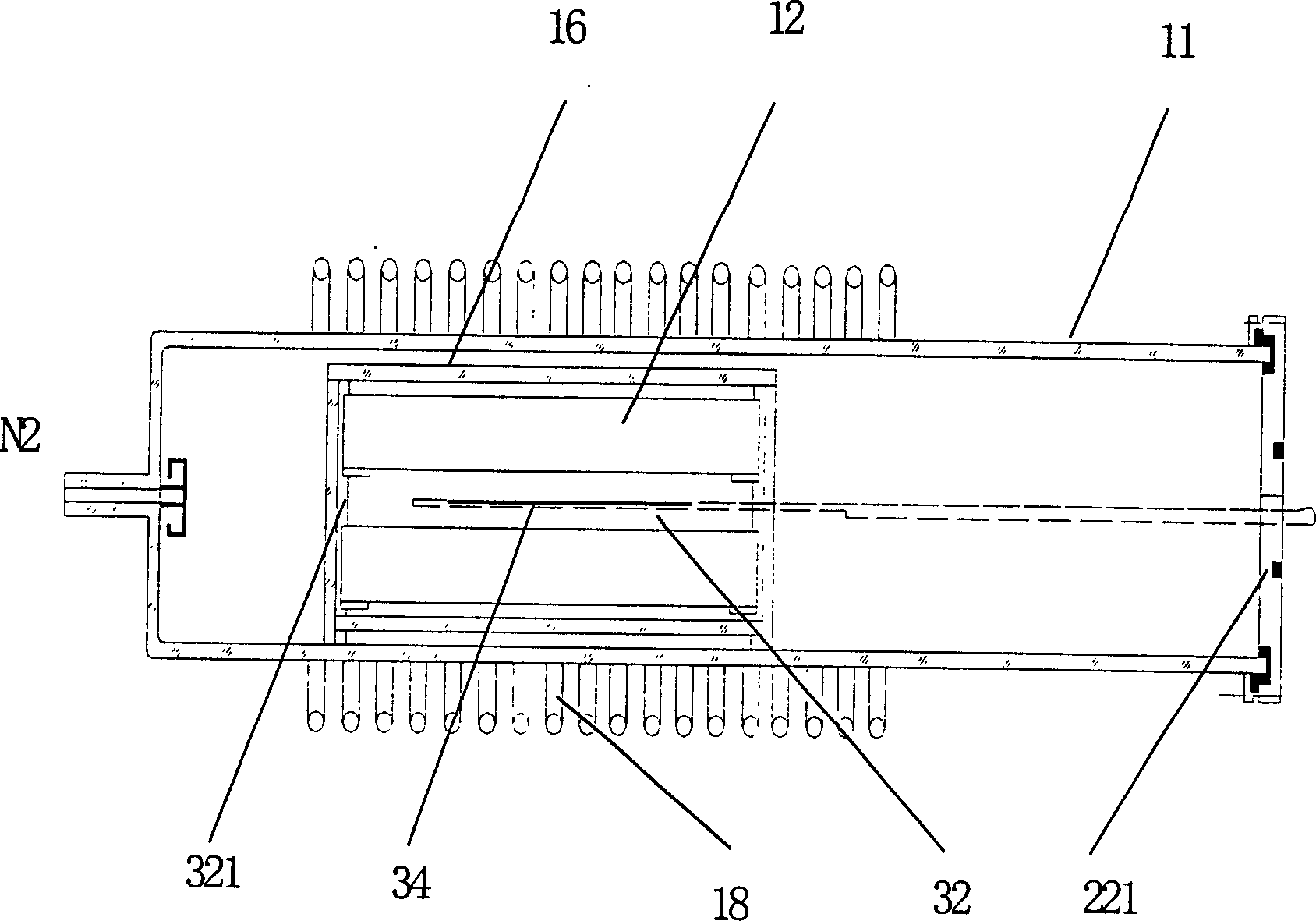

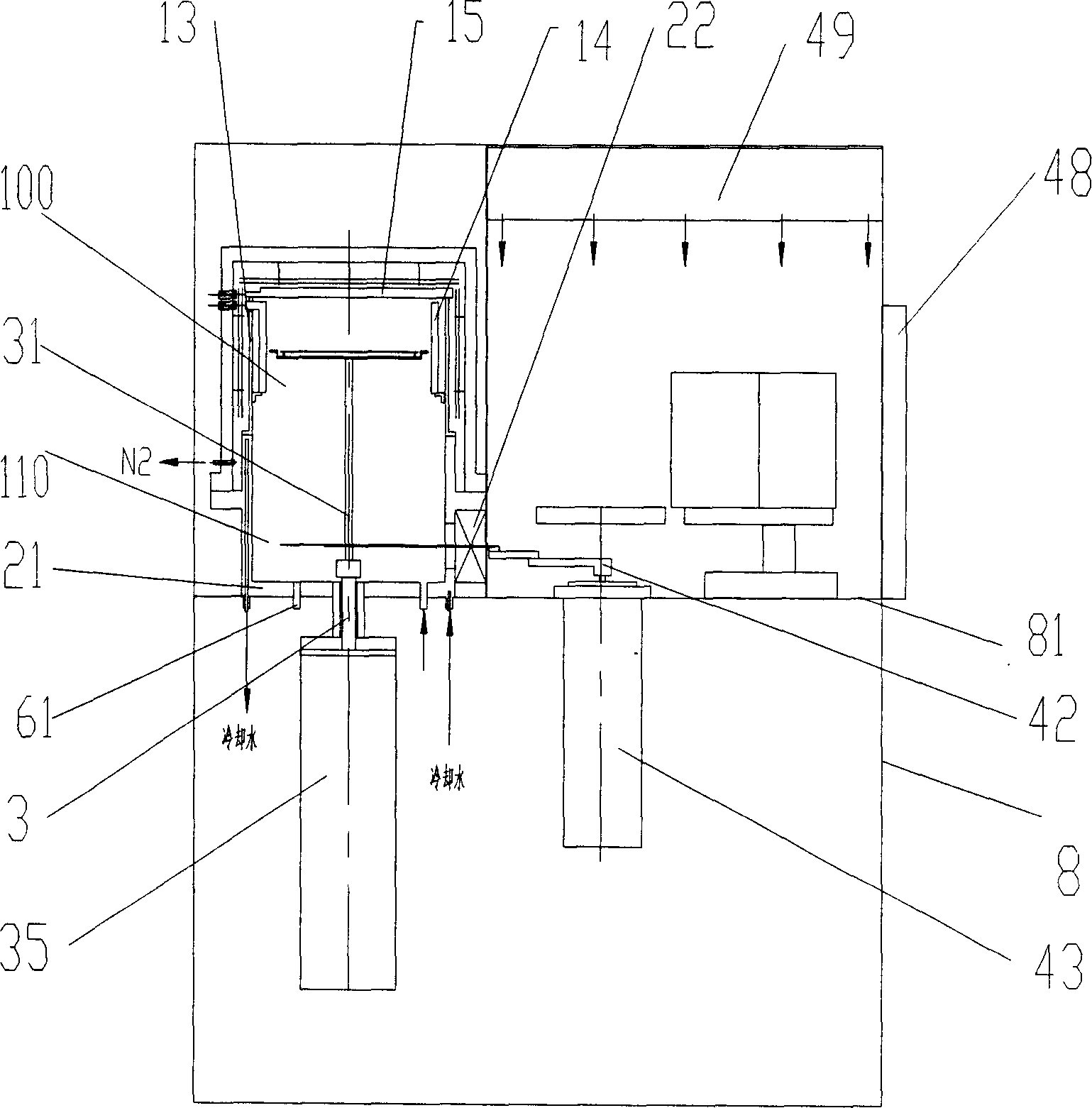

Fast semiconductor heat-treating facility with vertical heat treating chamber

InactiveCN1635608AControl heating and cooling rateRapid thermal nitridingSemiconductor/solid-state device manufacturingVery large scale integrated circuitsTemperature control

This invention relates to semiconductor rapid thermal process device with vertical process chamber, which belongs to large-scale integration circuit technique field. It is characterized by the following: it comprises the vertical process chamber, loading chamber, semiconductor transistor lifting structure and also mechanic hand sub-system by case to case, micro machine control sub-system, temperature control sub-system, gas device and heating power. The thermal process chamber comprises vertical cylinder quartz heating chamber, top plate graphite heating device in chamber, and side cylinder graphite heating device.

Owner:TSINGHUA UNIV

Dry coal powder airflow bed gasification furnace

InactiveCN101328434AAvoid problemsImprove protectionGranular/pulverulent flues gasificationFurnace temperatureLiquid state

A dry coal dust entrained flow gasification furnace comprises the structure that: an outer wall is a vertical cylinder and the inner structure consists of an upper main gasification chamber and a lower chilling chamber; the main gasification chamber is horizontally provided with a coal dust-gasification agent nozzle, while the chilling chamber is provided with a chilling water atomization nozzle, a slag notch and a synthetic gas outlet. The dry coal dust entrained flow gasification furnace is characterized in that: the upper part of the main gasification chamber is provided with two first-stage coal dust nozzles of central opposite spray type and two first-stage gasification agent nozzles parallel to the first-stage coal dust nozzles and deflecting a certain distance opposite to each other; meanwhile, the middle part of the main gasification chamber is provided with two second-stage coal dust nozzles and two second-stage gasification agent nozzles in an identical mode; moreover, the first-stage coal dust nozzles are perpendicular to the central lines of the second-stage coal dust nozzles, and the rotation directions of gasification agents sprayed out by the first-stage gasification agent nozzles and the second-stage gasification agent nozzles are identical. The dry coal dust entrained flow gasification furnace realizes spatial gasification reaction and more even in-furnace temperature field, and in-furnace average temperature is 50 DEG C higher than ash fusion point; therefore, clinker can be smoothly discharged in liquid state, and safe and efficient gasification of coal dust is realized.

Owner:UNIV OF SCI & TECH OF CHINA

Laminating device and laminating method for iron cores of reactors

ActiveCN103280308AEnsure consistencyReduce air gap errorInductances/transformers/magnets manufactureEngineeringVertical cylinder

Owner:襄阳中车电机技术有限公司

Culture carrier structure for test

ActiveCN106244457AReasonable space layoutStable structureBioreactor/fermenter combinationsBiological substance pretreatmentsFiltrationEngineering

The invention discloses a culture carrier structure for a test. The culture carrier structure comprises a base and a plurality of culture dishes, wherein various culture dishes are stacked, the culture dish comprises a dish body, a vertical cylinder, a projecting block and a liquid injecting pipe, the end surface on the top portion of the dish body is provided with a dish top groove, the top portion of the base is provided with a base top groove, the projecting block on the bottom culture dish is positioned inside the base top groove, a rotation pipe penetrates through all vertical cylinders and can rotate relative to the vertical cylinders, the outer side wall of the rotation pipe and the inner side wall of the vertical cylinders form sealed contact, the outer side wall of the rotation pipe is provided with a liquid discharge groove, the vertical cylinder is provided with a liquid homogenizing hole communicated to the internal of the dish body, a cell filtration screen and a liquid homogenizing one-way valve are arranged inside the liquid homogenizing hole, the lower end of the liquid injecting pipe is communicated to the internal of the dish body, and the projecting block of the culture dish on the upper portion is positioned inside the dish top groove of the culture dish on the lower portion. According to the present invention, the culture carrier structure is suitable for cell culture and determination and comparison, and has beneficial effects of rational spatial arrangement, stable structure, convenient operation process, and good adjustment consistency and high accuracy during the test.

Owner:凤阳县一星农业发展有限公司

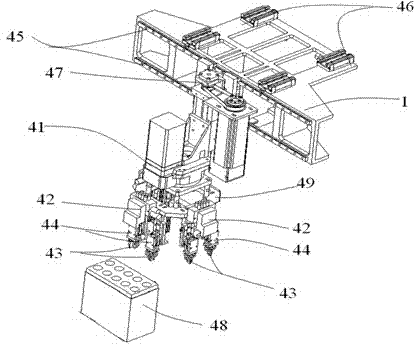

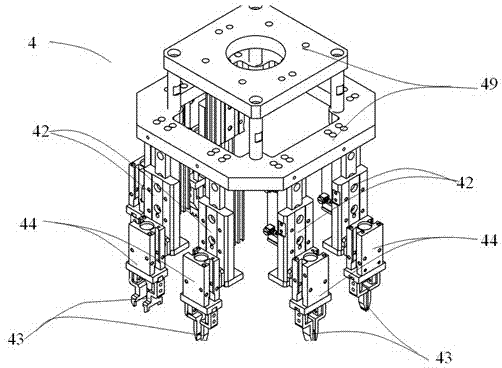

Component taking and inserting device and fully-automatic inserting machine

InactiveCN104768361AEasy to grabEasy to insertPrinted circuit assemblingElectrical componentsRobot handMachine

The invention relates to the field of mechanical arms and discloses a component taking and inserting device (4) and a fully-automatic inserting machine. A Z-axis module (47) is fixed to an X-axis module (45), the X-axis module (45) is fixed to a Y-axis module (46), one end of a rotary head (41) is fixed to the Z-axis module (47), the other end of the rotary head (41) is fixed to the top of a machine frame (49), a vertical cylinder (42) is fixed to the bottom of the machine frame (49), a clamping jaw fixing cylinder (44) is fixed to the vertical cylinder (42), and a clamping jaw (43) is fixed to the clamping jaw fixing cylinder (44). The rotary head of the component taking and inserting device can move vertically and horizontally and rotate in all directions so as to drive the clamping jaw fixed to the machine frame to grab and insert components more conveniently. The component taking and inserting device is applied to the inserting machine, the inserting machine can grab multiple components at a time and then insert the components into a PCB into which components are to be inserted, and working efficiency is improved greatly.

Owner:广东华技达精密机械有限公司

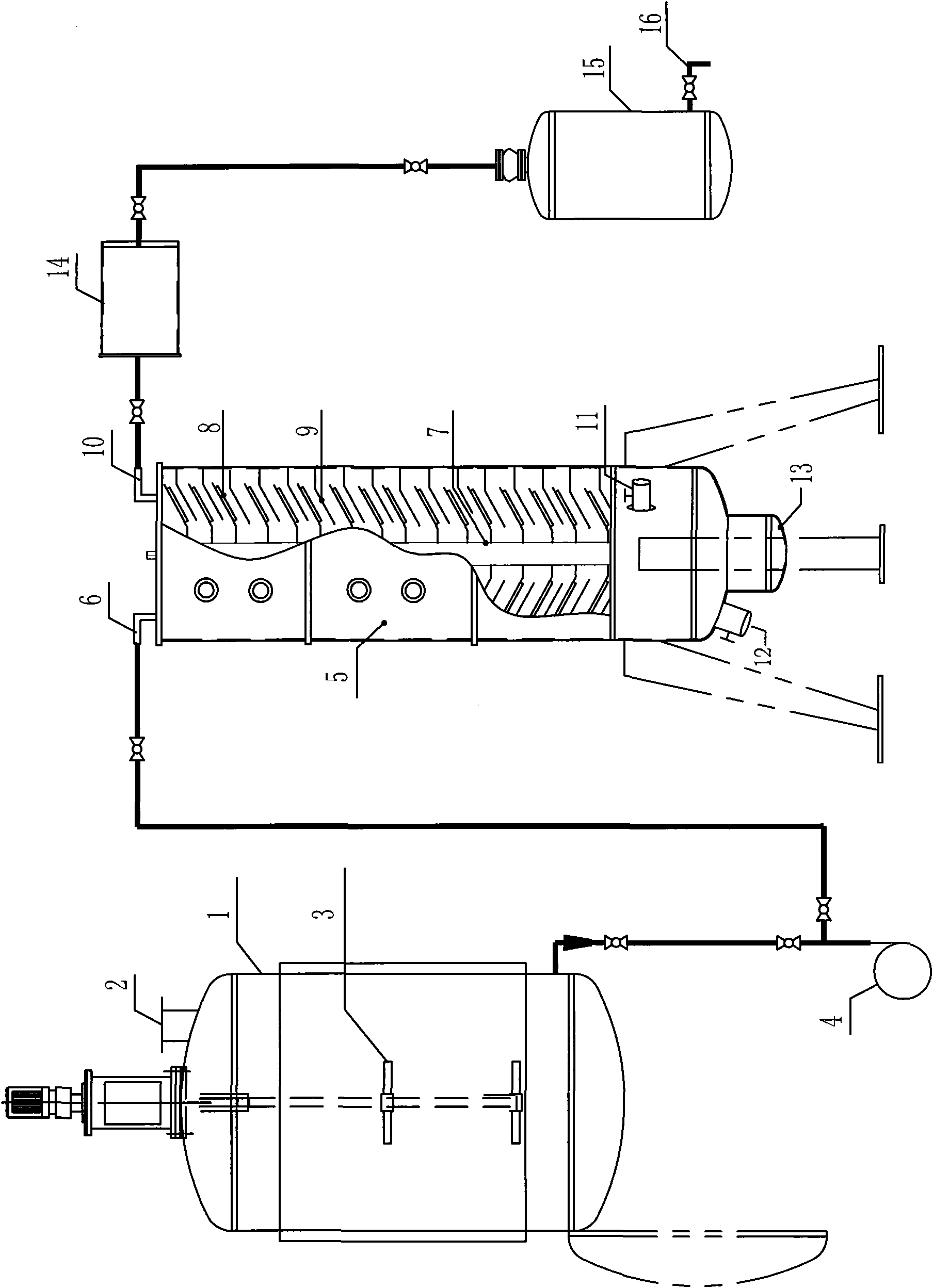

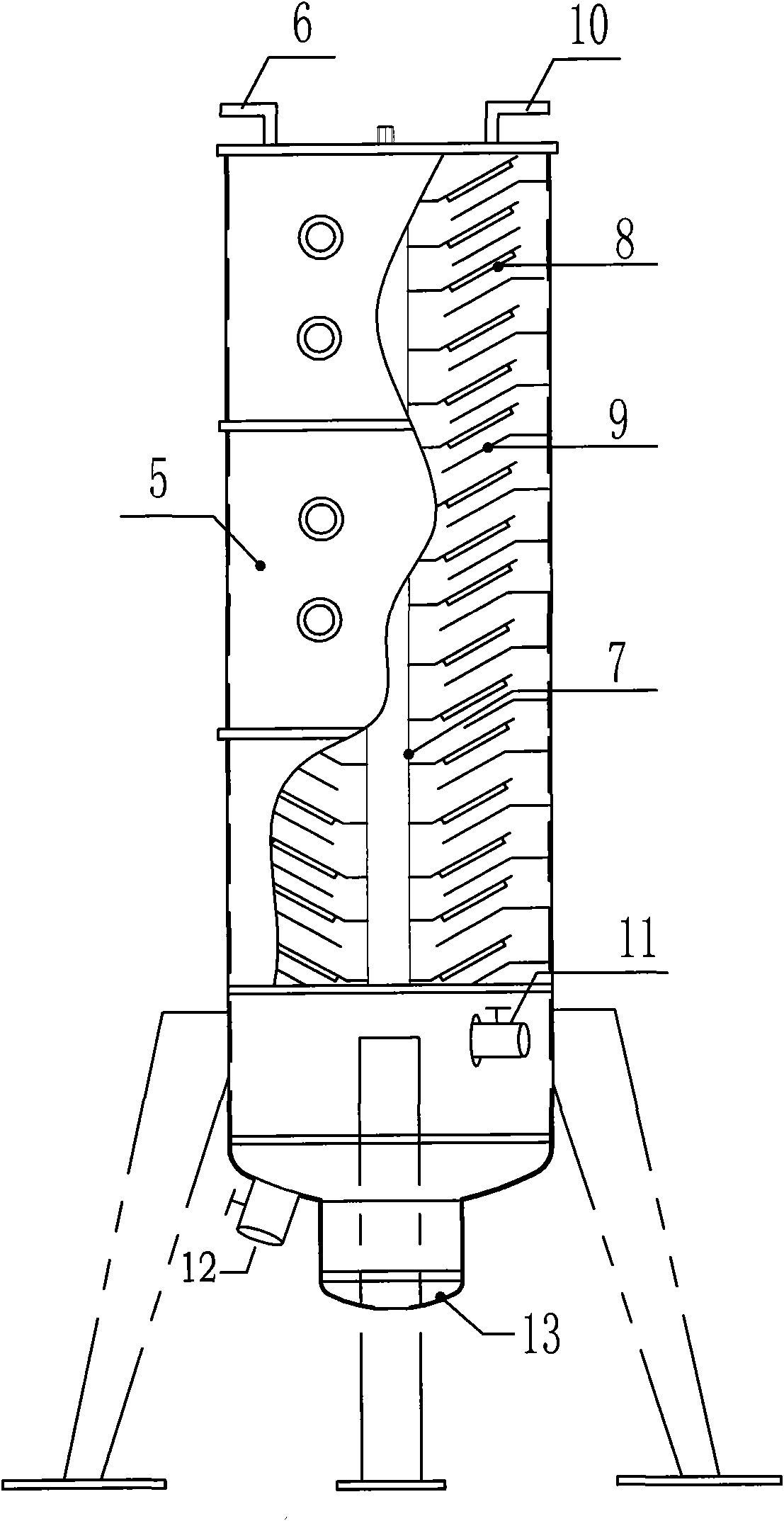

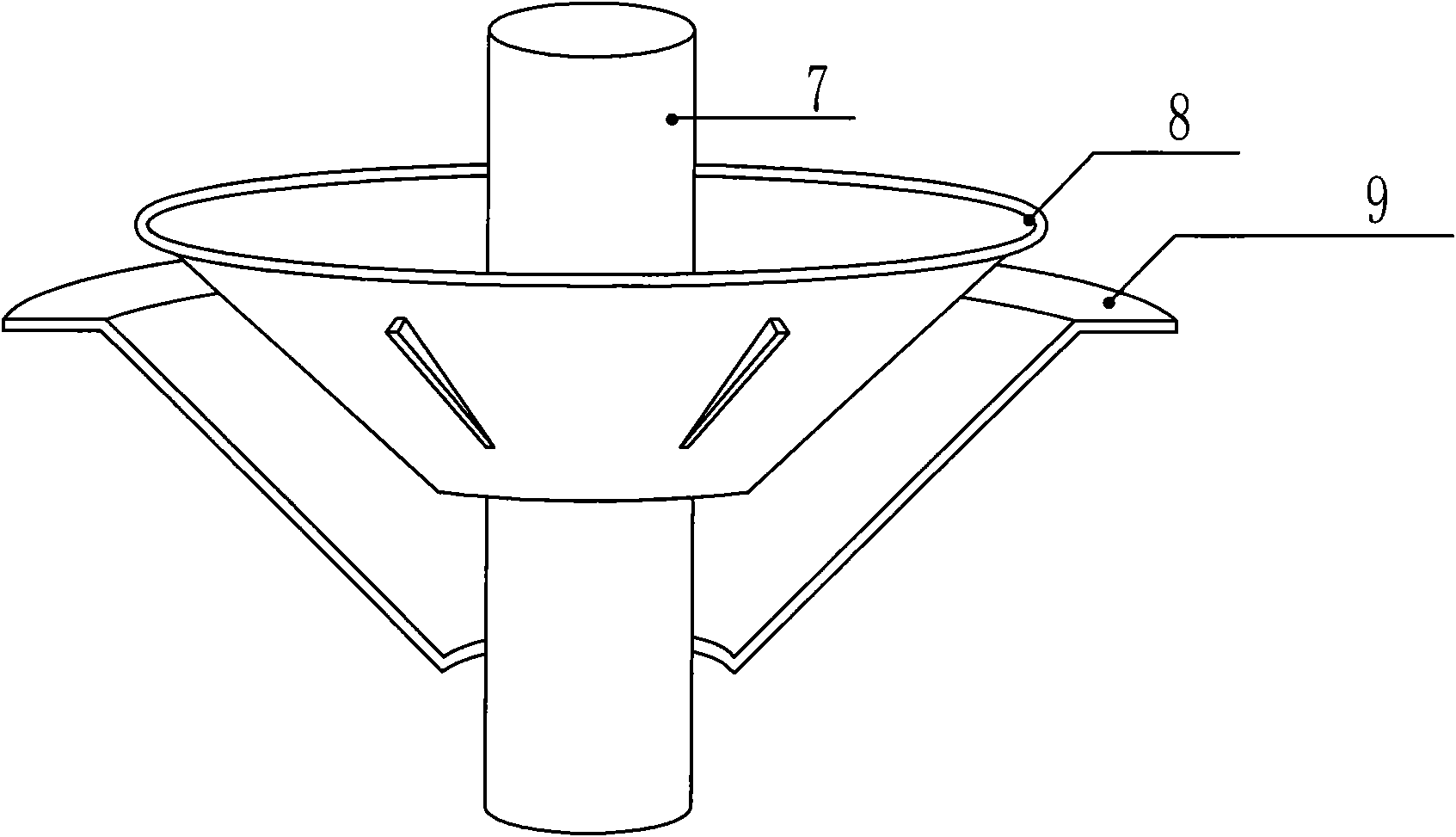

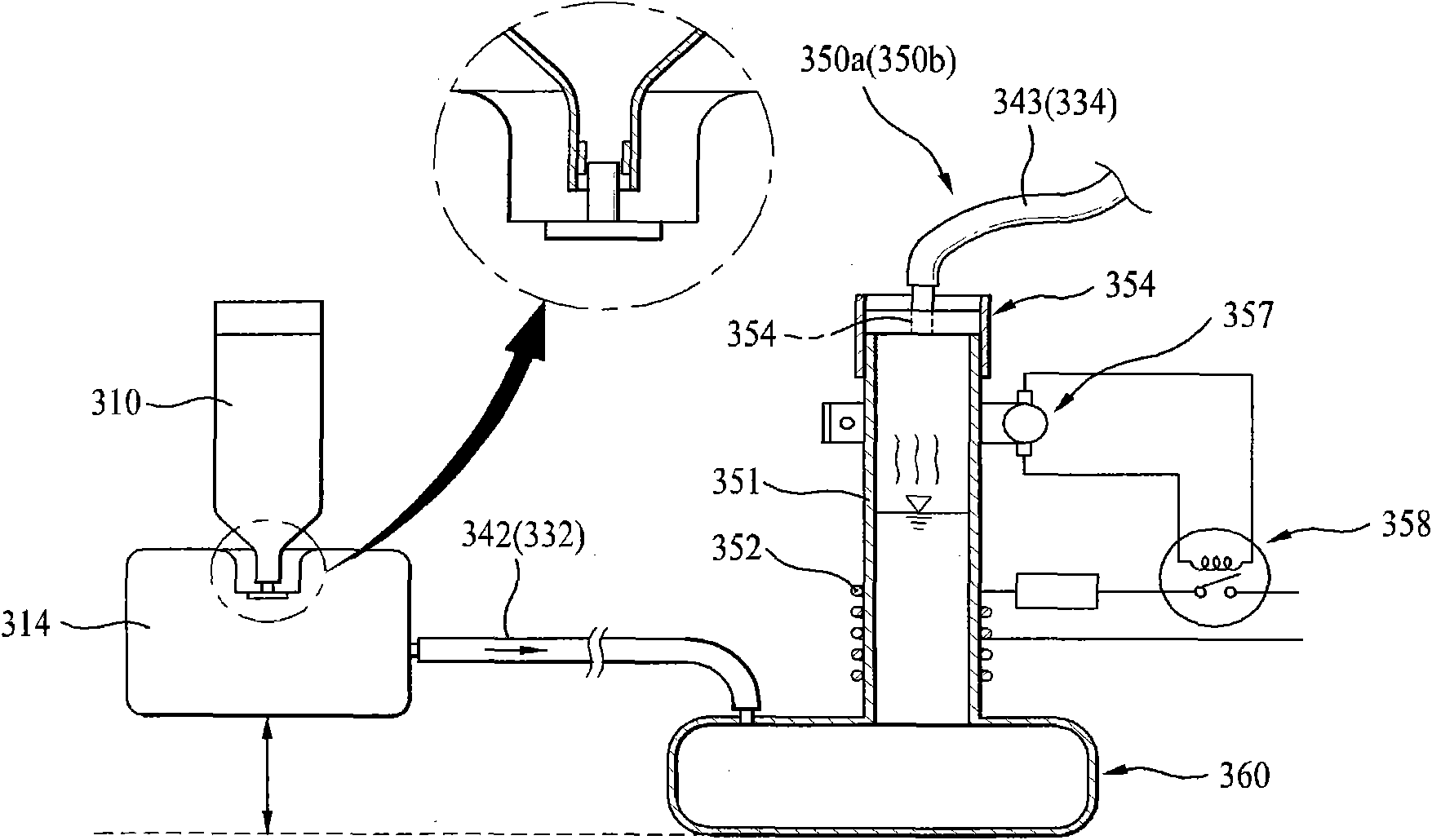

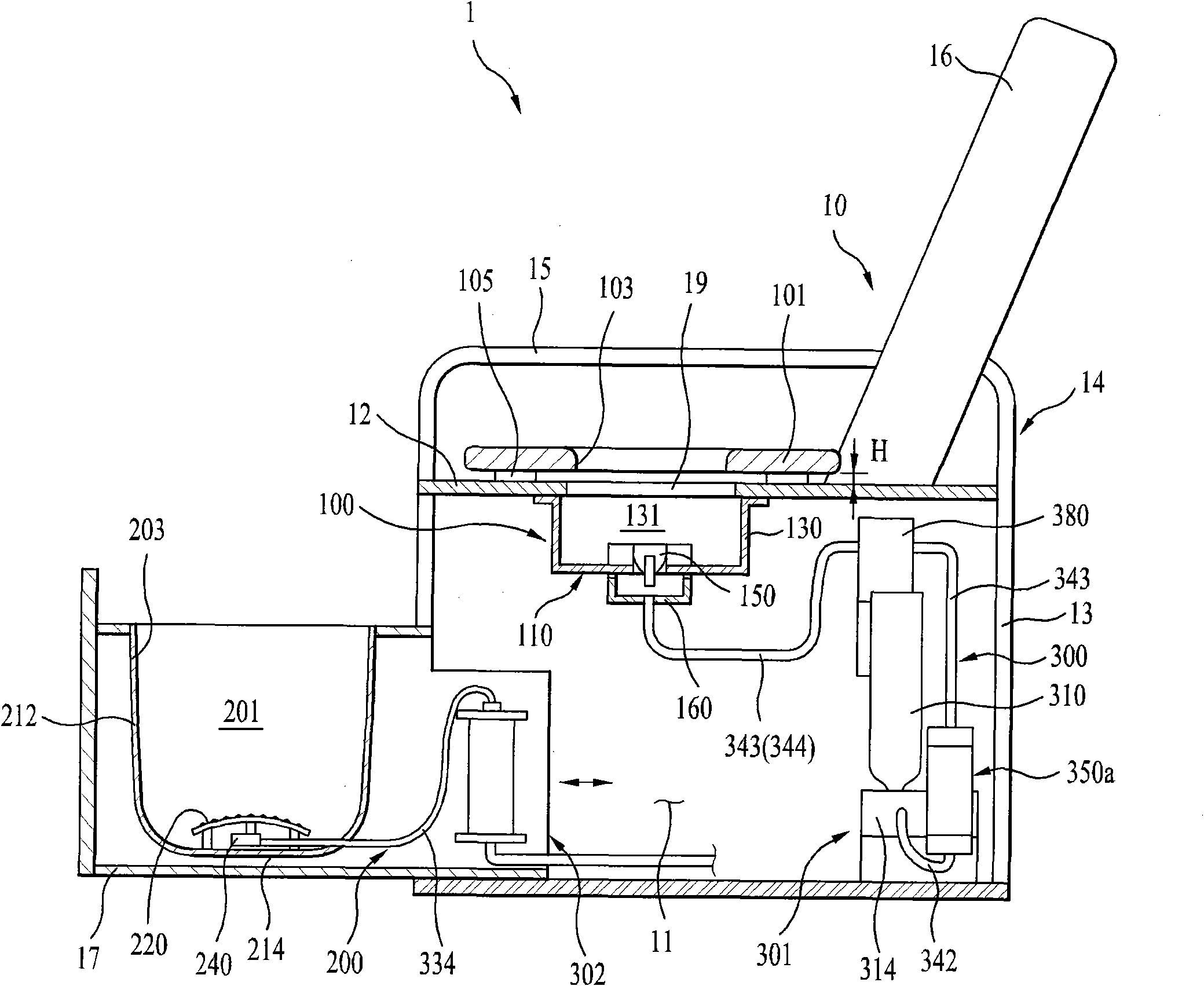

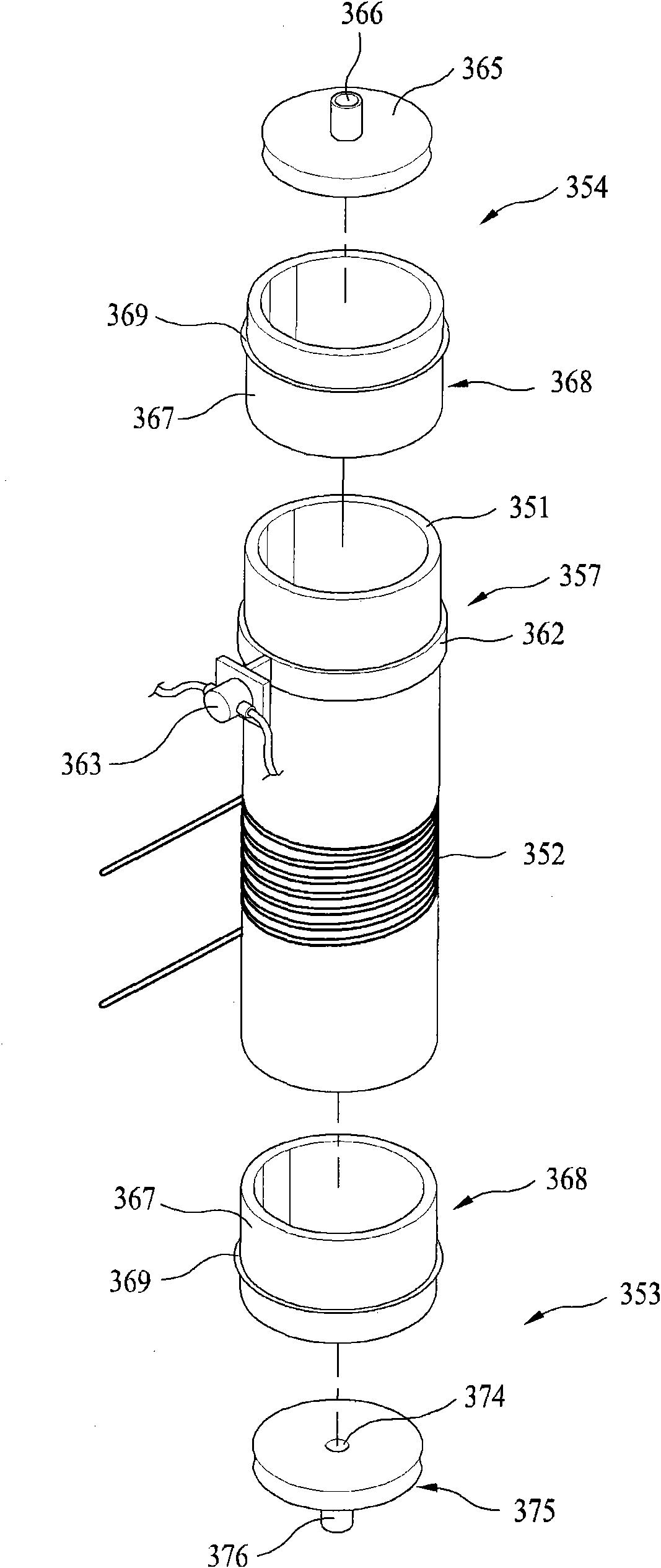

Rotary steam distillation equipment

InactiveCN101612486AAchieve continuous supplyIncrease productivitySteam distillationWater vaporSteam distillation

The invention discloses rotary steam distillation equipment and belongs to the technical field of steam distillation equipment. The rotary steam distillation equipment is a vertical cylinder body, wherein the center of the shell is provided with a vertical rotary plunger; the rotary plunger is provided with a plurality of layers of funnel-form conical shells; and funnel-form conical shells connected with the shell are inserted between the funnel-form conical shells. The number of the layers of the funnel-form conical shells is 7 to 35. The rotating speed of a motor is 0 to 10,000 r / min. The included angle between the funnel-form conical shells and the rotary plunger is 30 to 75 degrees. The plurality of funnel-form conical shells are parallel. The funnel-form conical shells connected with the rotary plunger are parallel to the funnel-form conical shells connected with the shell. The rotary steam distillation equipment has the advantages that: the continuous feed of raw materials is realized, so the production efficiency is improved; the efficiency is high; the natural flavor of the materials is retained, so high-quality of fragrance is obtained; the loss of the components of the fragrance is less; and the selection range of the fragrant materials is wide.

Owner:HUBEI CHINA TOBACCO IND

A simple fire-fighting robot

ActiveCN104147729AEasy to replaceRealize the function of automatic fire extinguishingFire rescueRubber ringStructural engineering

A simple fire-fighting robot comprises universal wheels, cylinder barrels, a stock, piston rods, a crank, cylindrical pins, a motor, a connecting bar, a rocking bar, an upper jaw, a lower jaw, a horizontal cylinder, a rotary strut, a vertical cylinder, a fire extinguisher, a lateral support, and a guide rod. The motor is connected with the crank through a stand, and arranged at the front end inside the stock. The universal wheels are arranged at the lower parts of the cylinder barrels. Two cylinder rods that are in a diagonal line are arranged inside the cylinder barrels. The stock is connected with the cylinder rods through cylindrical pins. The upper end of the part of the rocking bar articulated with the connecting bar is provided with an elastic rubber ring that sleeves the nozzle of the fire extinguisher. The upper jaw and the lower jaw are fixedly arranged on the horizontal cylinder. The rotary strut is arranged at the upper part of the piston rod of the vertical cylinder. The horizontal cylinder sleeves the rotary strut. The simple fire-fighting robot can quickly put out fire at the place that is inaccessible to human, and the robot has a simple and compact structure, labor can be saved, and the replacement of the fire extinguisher is convenient.

Owner:广东省机安消防维保检测有限公司

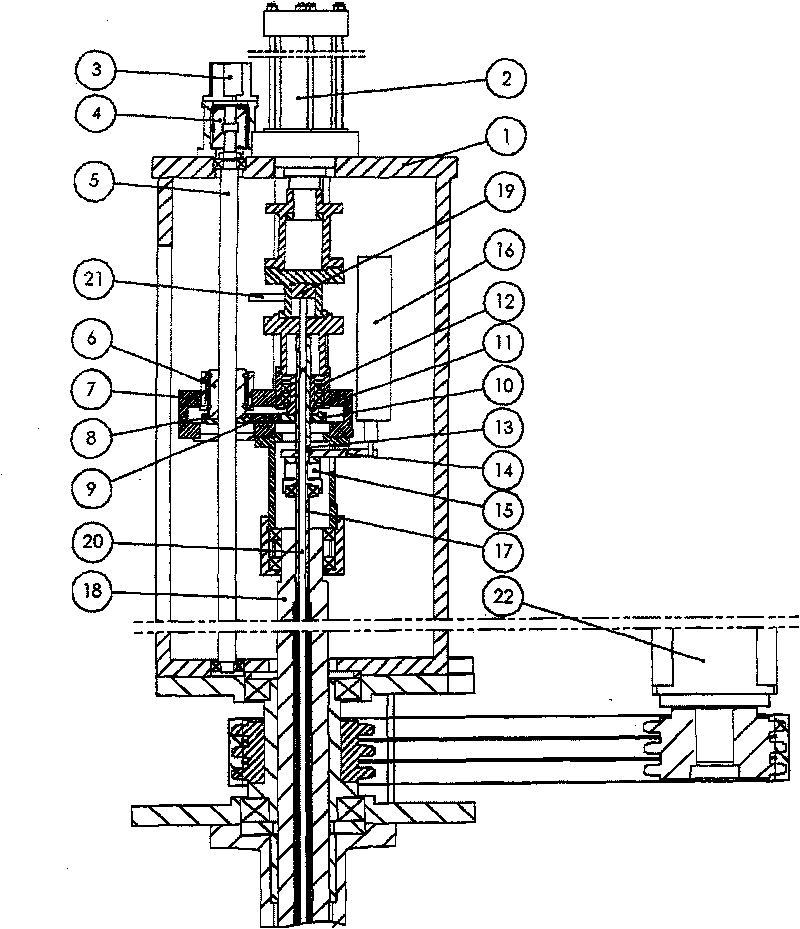

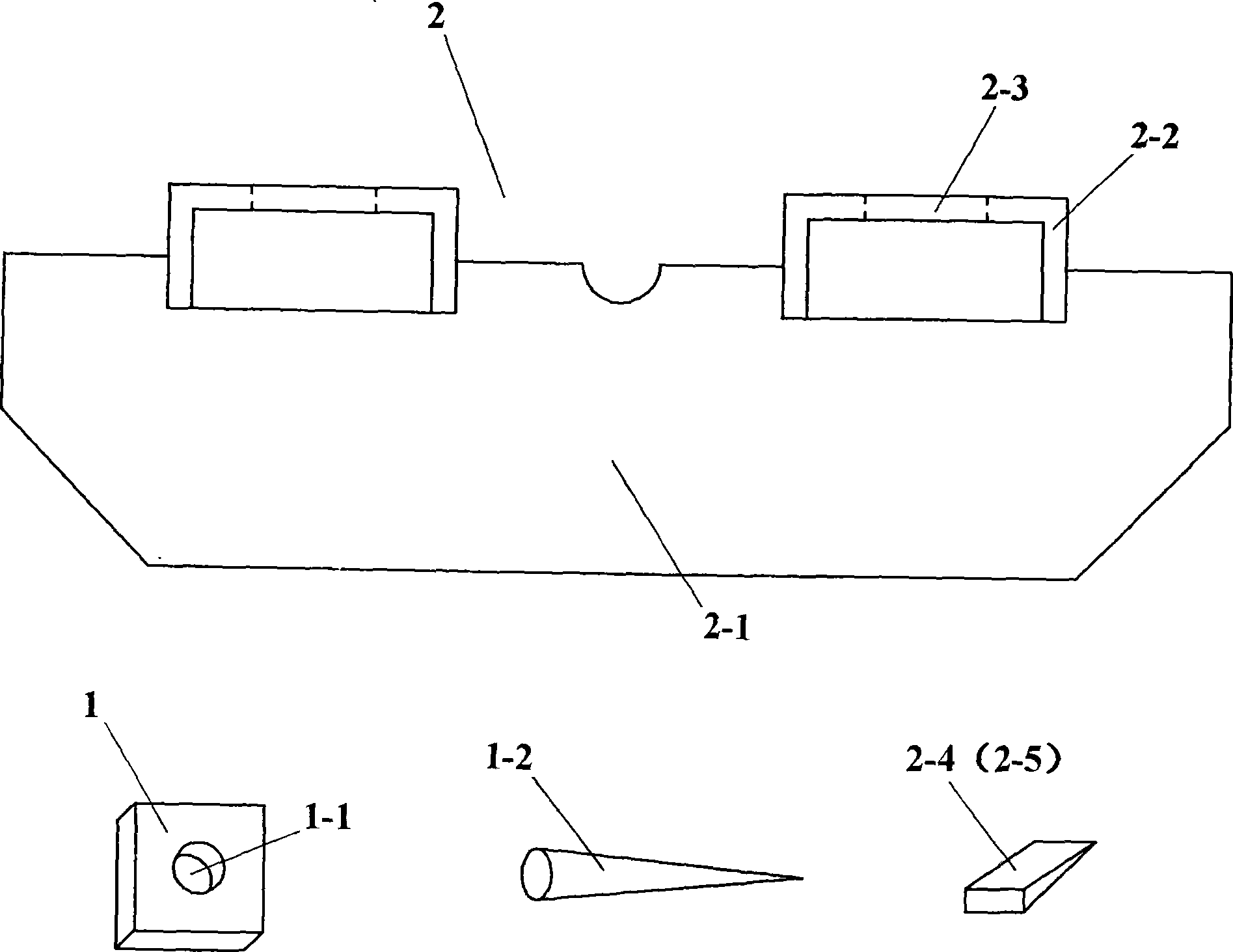

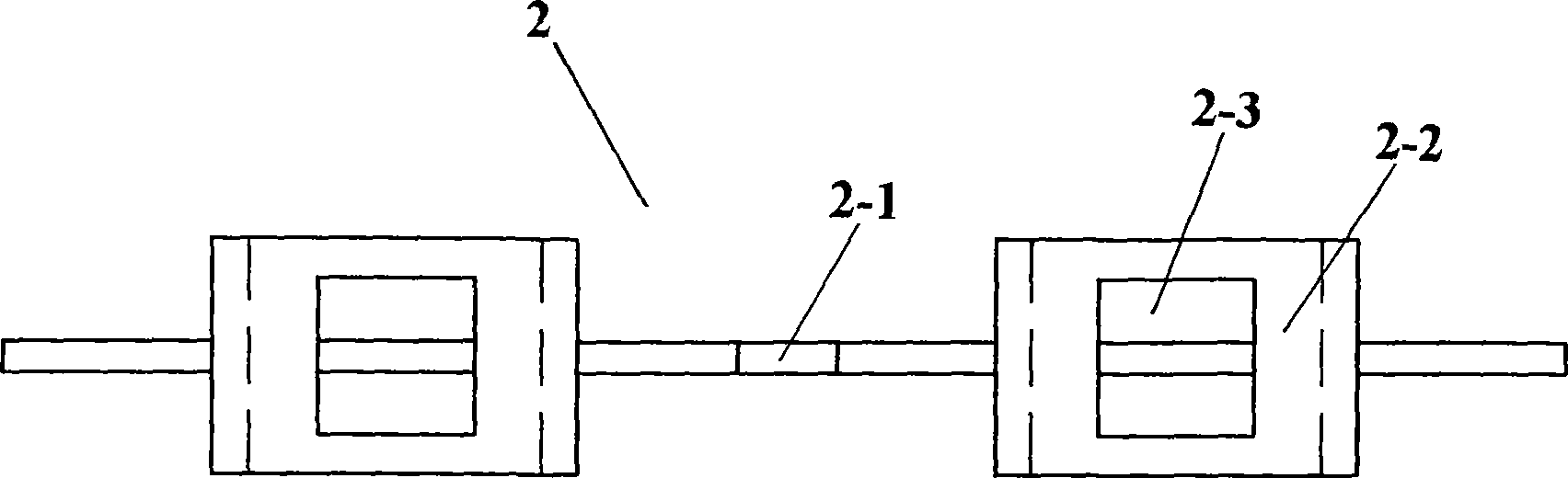

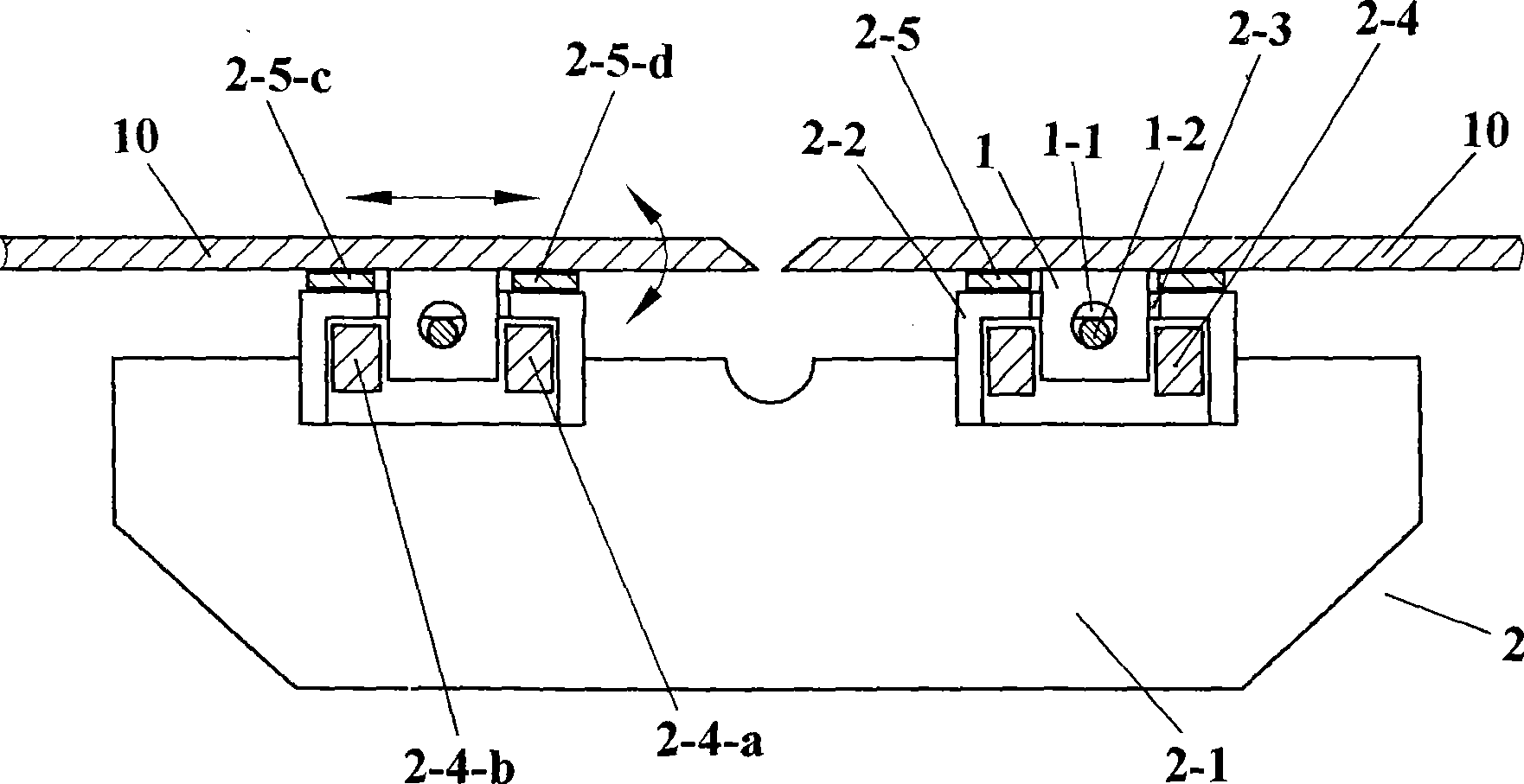

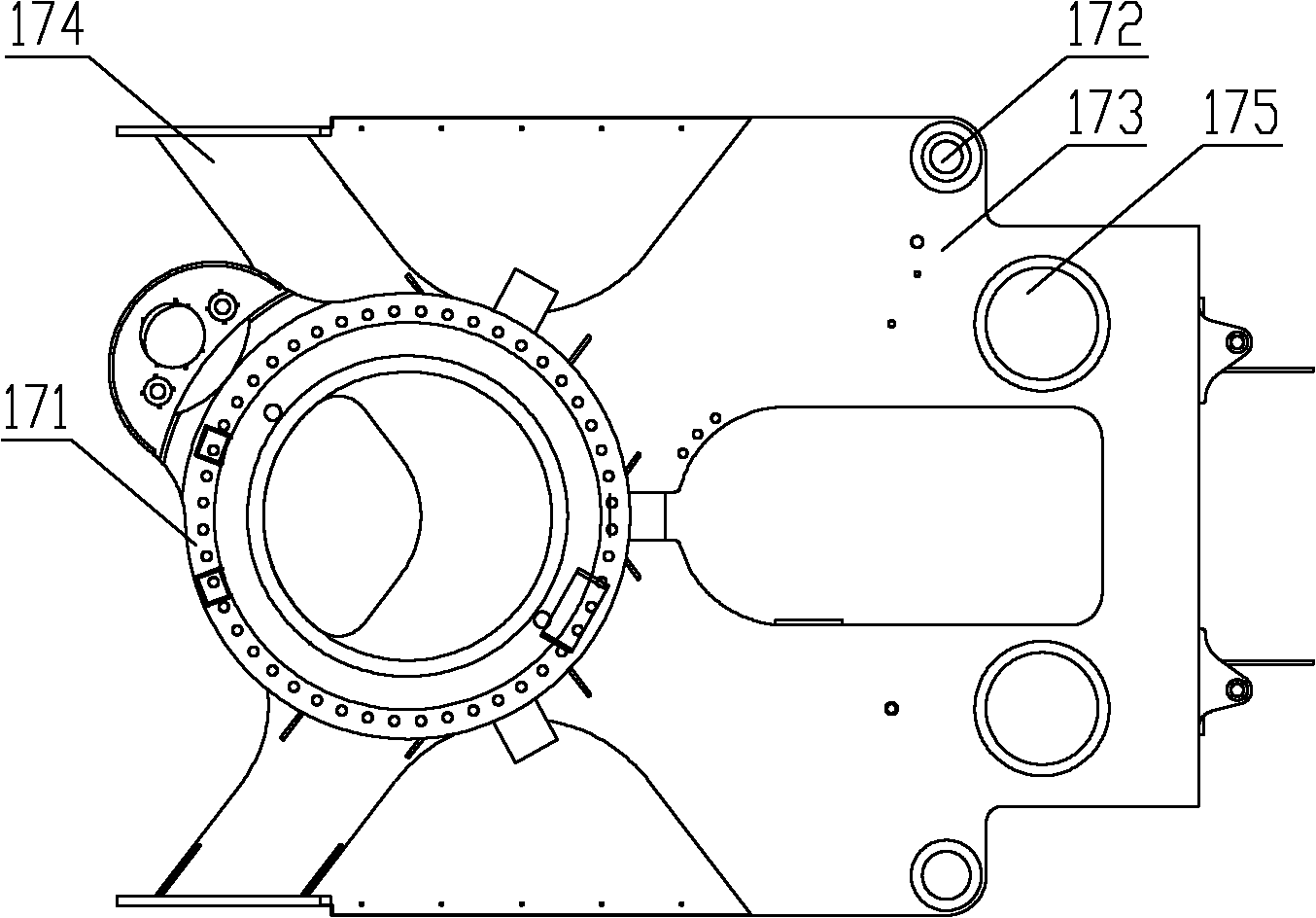

Servo-hydraulic double-feeding mechanism for numerical control vertical cylinder sleeve honing machine

ActiveCN101722466APrecise micro controlHigh precisionGrinding drivesHoning machinesNumerical controlLoop control

The invention discloses a servo-hydraulic double-feeding mechanism for a numerical control vertical cylinder sleeve honing machine, which comprises an inner push rod and an outer push rod positioned at the middle part of a hollow stroke main shaft, wherein the inner push rod is positioned in the outer push rod; the outer push rod is driven by a servo feeding closed-loop control mechanism to move up and down; the inner push rod is driven by a hydraulic feeding closed-loop control mechanism to move up and down; and a programmable digital control system is connected with sensors in the a servo feeding closed-loop control mechanism and the hydraulic feeding closed-loop control mechanism to realize straight line-driven closed-loop feedback and hydraulically-driven closed-loop feedback, and is arranged outside an integrated safety protector of a machine tool. The servo-hydraulic double-feeding mechanism has the advantages of simple structure, rational layout, excellent working stability and reliability, high machining precision, a visual operating interface and the capacity of realizing the high-quality machining of a flat reticulate pattern for a cylinder (sleeve) internal hole of an internal combustion engine.

Owner:宝鸡忠诚机床股份有限公司

Non-rolling construction method for vertical cylinder storage tank and fixture thereof

InactiveCN101440669ASimplify the assembly processShorten the construction periodWelding/cutting auxillary devicesAuxillary welding devicesClassical mechanicsVertical cylinder

The invention relates to a plate-rolling-free construction method for a vertical cylindrical storage tank and a clamp thereof. The method comprises the following steps: during construction, not using a plate roller to roll a wall plate of the storage tank, correspondingly welding at least one vertical welding line positioning plate at two edges inside the wall plate, welding at least one wall plate positioning frame at the upper edge and the lower edge, regulating radians of most wall plates by adopting the elasticity of the most wall plates for direct installation, and regulating the width of the vertical welding lines at the joint of each wall plate, the radians of the wall plates, the vertical positioning of each wall plate, and the like by using a special vertical welding line adjusting clamp and other normal clamps, to achieve assembly installation of the wall plates at the cylindrical part of the tank. The method has the advantages of simple and easily-mastered installation construction process, simple structure and low cost of the required clamps, fewer constructors and auxiliary facilities, low intensity of labor, short construction period, low cost, good installation quality, wide application range, and the like. Compared with the plate rolling construction method, the method can save labor by more than 5 percent, can reduce the construction period and the construction cost by more than 10 percent, and has great popularization value.

Owner:CHINA GASOLINEEUM JILIN CHEM ENG & CONSTR

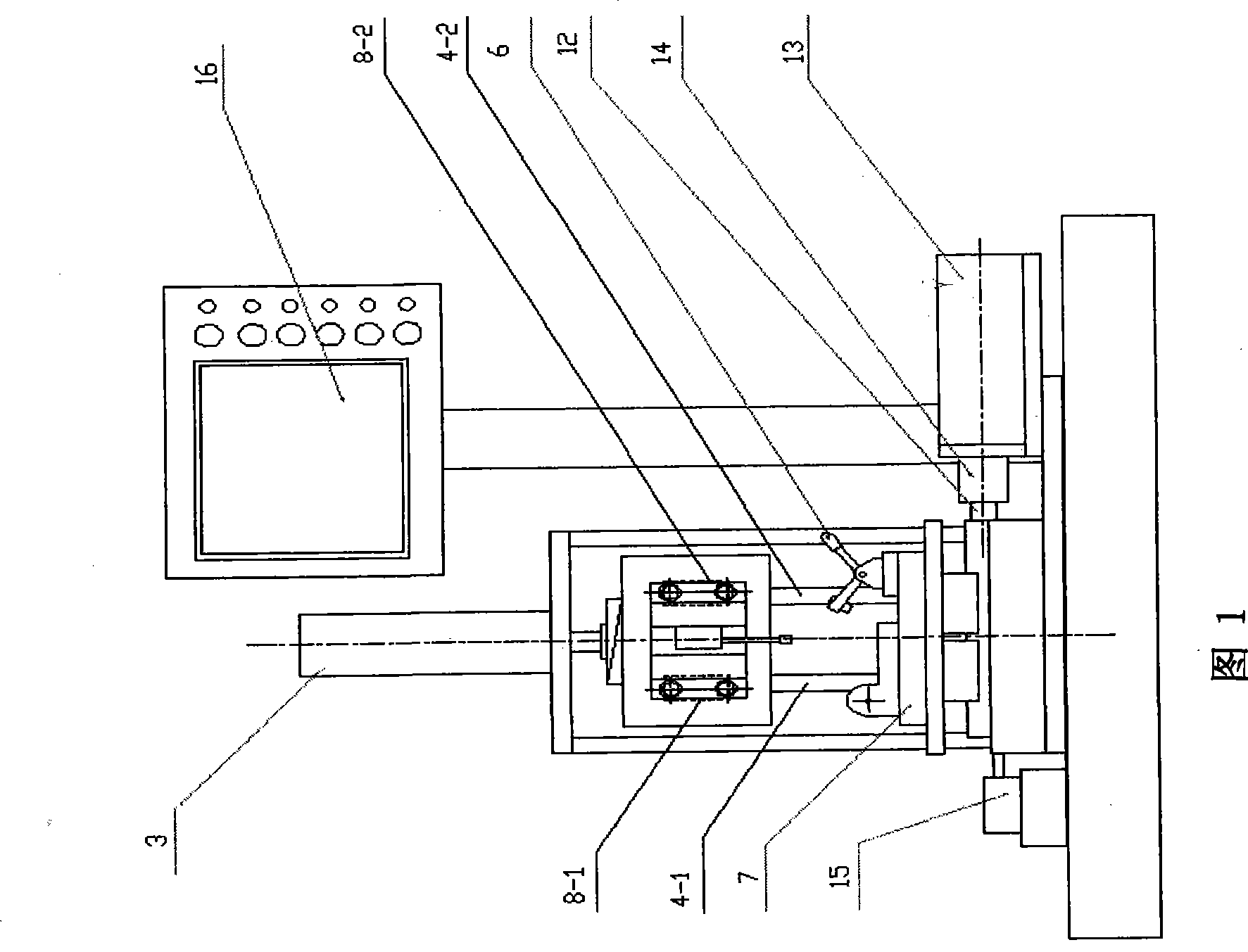

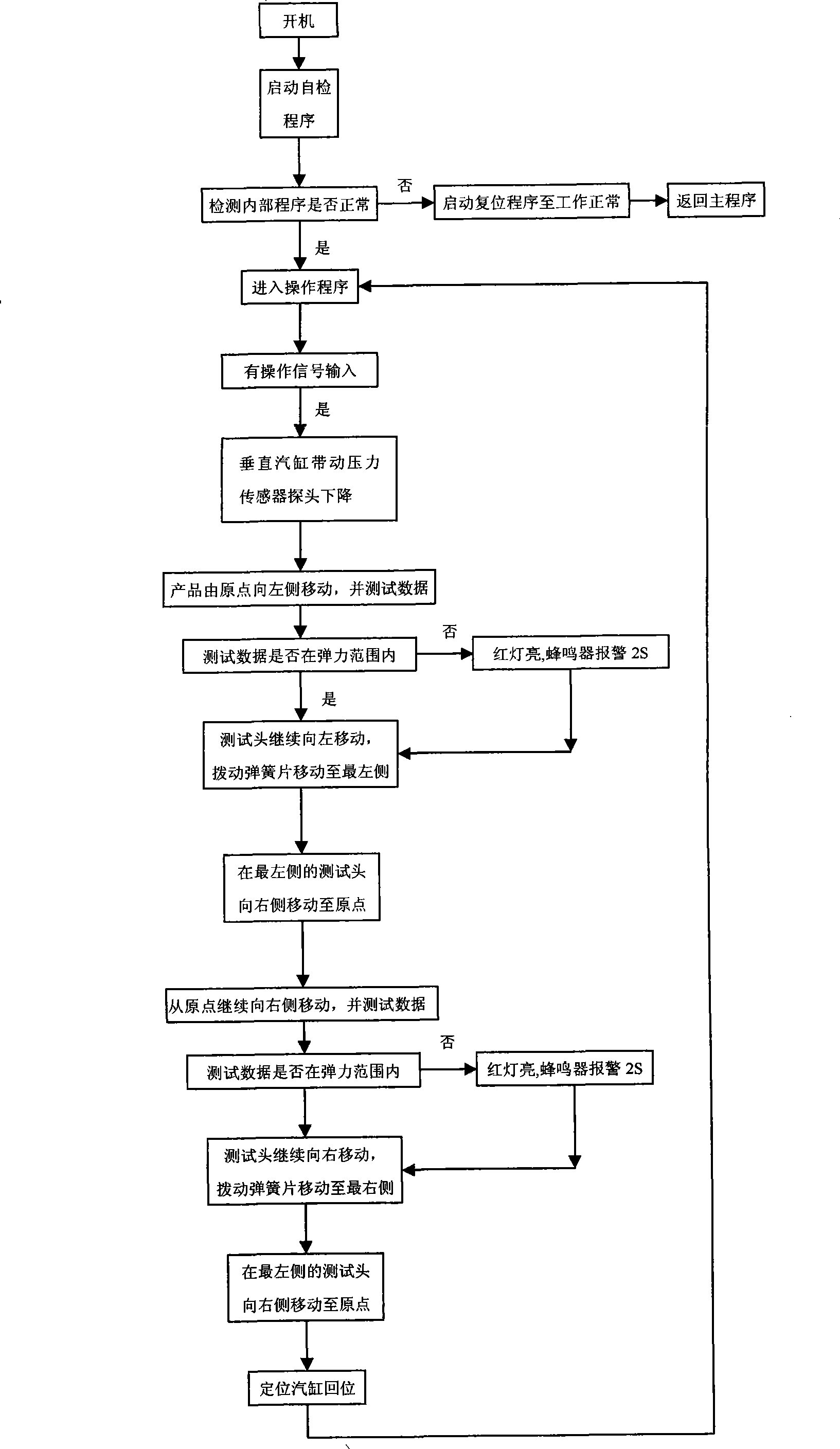

Motor brush rocker and carbon brush elastic force dynamic test device and test method

ActiveCN101458151AAvoid the hassle of detectionQuality improvementForce measurementElasticity measurementCouplingElectric machine

The invention provides a device for testing the elasticity of the carbon brush of a motor brush rocker dynamically and a testing method thereof. The device for testing the elasticity of the carbon brush of a motor brush rocker dynamically consists of a bottom plate, a stander, a vertical cylinder, left and right linear guide rails, front and back linear guide rails, a positioning and fixing pressure gripper, a positioning tooling, left and right linear bearings, front and back linear bearings, a damping curb pin, a pressure sensor, a screw mandrel, a servo motor, a shaft coupling, a displacement sensor and a programmable network digital monitor. The test device can test the change of the elasticity curvilinear of a tested work-piece.

Owner:镇江泛沃新能汽车技术股份有限公司

Engineering machinery

ActiveCN102108789AReduce the difficulty of layoutReduce volumeBase supporting structuresBraking devices for hoisting equipmentsPower componentVertical cylinder

The invention discloses engineering machinery, which comprises ground jacks and a fixed turret; the fixed turret comprises a turret base provided with a ground jack base, and a chassis connected with the engineering machinery; the turret base comprises a vertical cylinder and a rotary table connection board located over the vertical cylinder, an underframe is integrated with the turret base and located under the turret base; a lower end of the vertical cylinder of the turret base extends to a lower end surface of the underframe, a ground jack arm of the ground jack is a support jack, a cylinder barrel of the support jack is hinged with the ground jack base through a hinge shaft, and an axis of the hinge shaft is parallel to the chassis; one end of a power component is unfolded to be connected with the cylinder barrel while the other end of the power component is connected with the body of the engineering machinery. The engineering machinery provided by the invention has simpler structures of the ground jacks and the fixed turret, so that difficulty in the distribution of the ground jacks and limitation of site on unfolding the ground jacks are both reduced, and volume and weight of the fixed turret are also reduced.

Owner:SANY GRP

Device for automatically detecting whether components are left out of installation

InactiveCN103257373AAvoid missingImprove detection efficiencyGeological measurementsEngineeringVertical cylinder

The invention relates to a device for automatically detecting whether components are left out of installation. The device comprises cylinders, an elastic top, a microswitch, a buzzer, a detecting assembly block, elastic ejector pins and an insulating plate, wherein a vertical cylinder and a horizontal cylinder are installed on a tooling table, and the elastic ejector pins are matched, so detection for assemblies of products is carried out one by one through a conductive mode or a mechanical mode. When installation missing or installation leakage occurs, signals are transmitted to a PLC, and alarming is carried out through the buzzer. According to the device, comprehensive detection is carried out on the components through a mode of matching of energizing detection and mechanical detection, the phenomena of the installation missing and the installation leakage can be effectively avoided, meanwhile efficiency of detection is improved to a great degree, and detection quality is guaranteed.

Owner:NINGBO TIANLONG ELECTRONICS

High efficiency steam generator and method for controlling water level thereof

InactiveCN101799153AReduce consumptionAvoid burn hazardSteam generation heating methodsWater feed controlElectricityWater source

The invention relates to a steam generator and a method for controlling water level thereof, in particular a method for controlling the water level of a high efficiency steam generator, wherein the high efficiency steam generator is provided with a thin and long vertical cylinder; a water source is supplied from the bottom of the vertical cylinder so that the interior of the vertical cylinder form a certain water level; a power supply is connected on a heater wound outside the vertical cylinder; the vertical cylinder is heated so that the water level inside the vertical cylinder generates steam, and the steam is sprayed outwards through a steam discharge device at the top of the vertical cylinder; and the water source is periodically supplied into the thin and long vertical cylinder, and the steam can be continuously generated. The high efficiency steam generator not only can save water and electricity consumption, but also can adjust the water level in the vertical cylinder by using a temperature measurement instrument, a water supply pump and a timer.

Owner:姜豪奎 +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com