Patents

Literature

316results about How to "Reasonable space layout" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

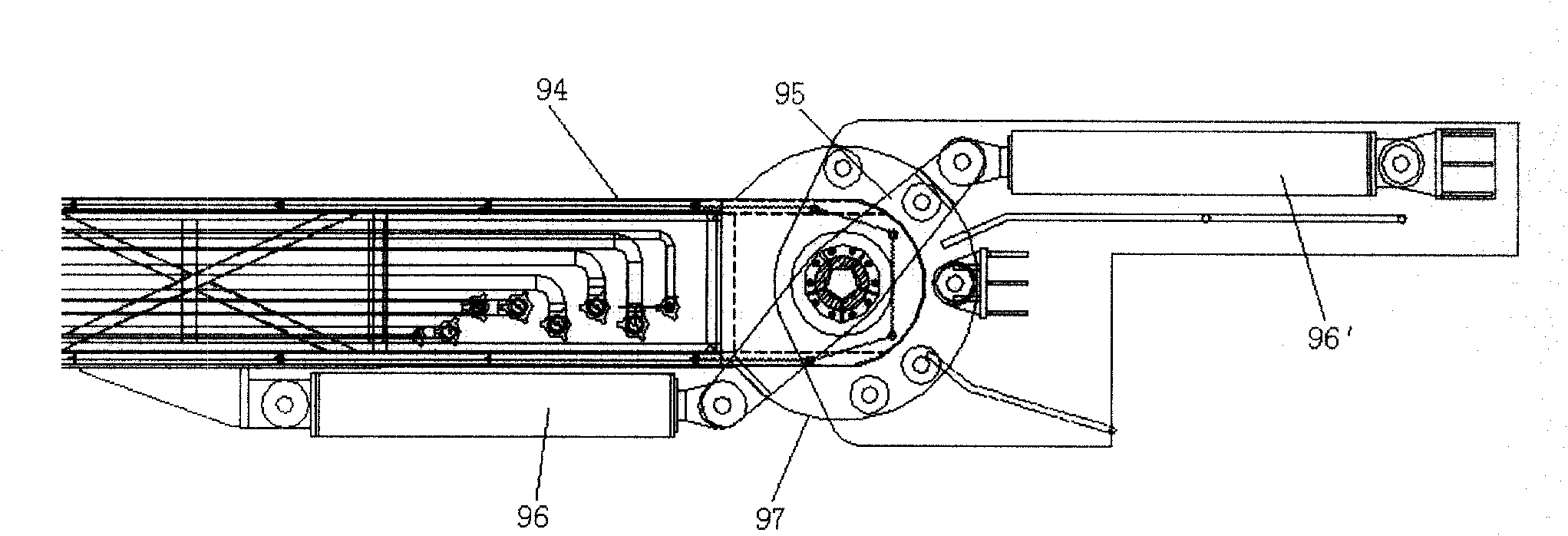

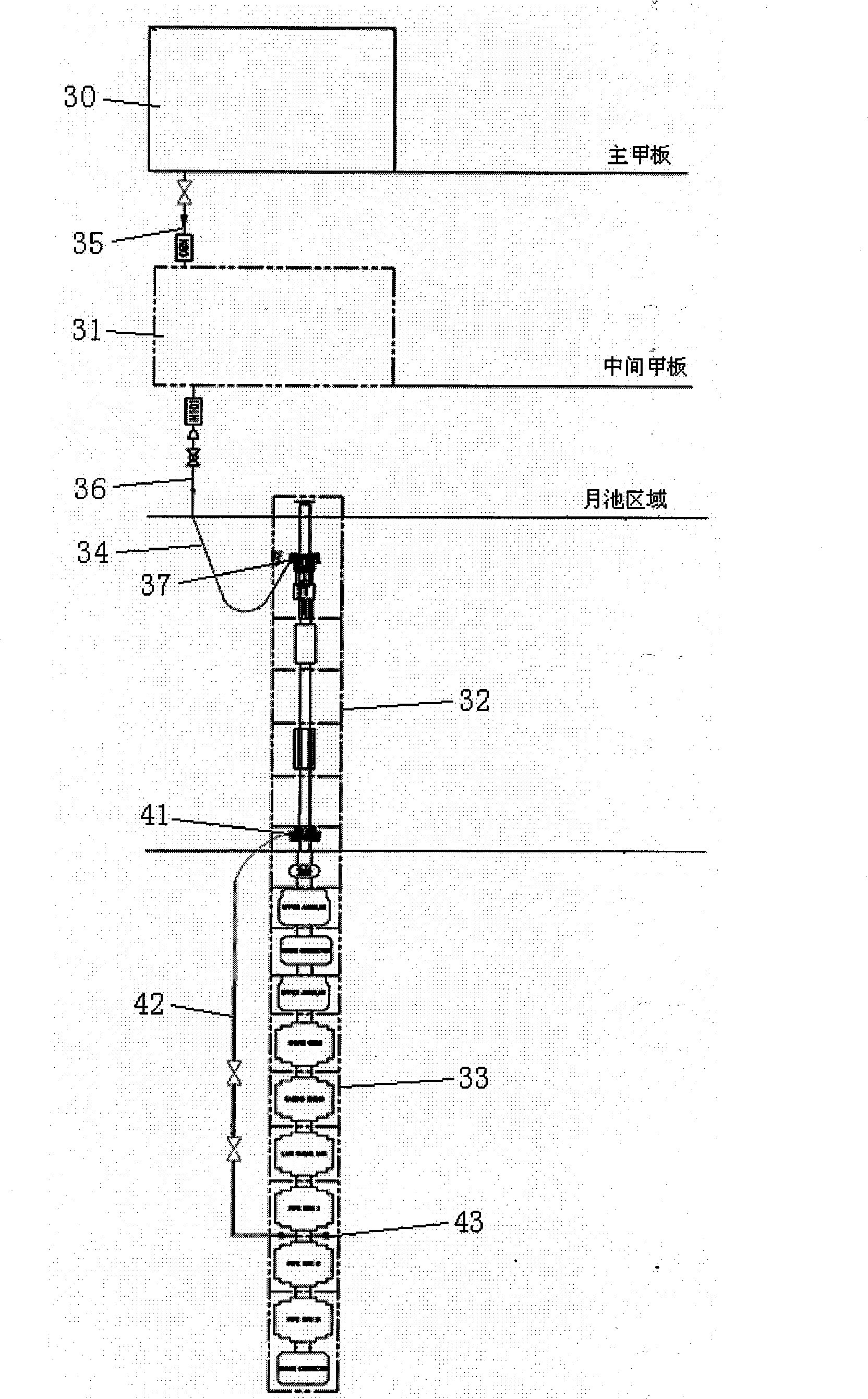

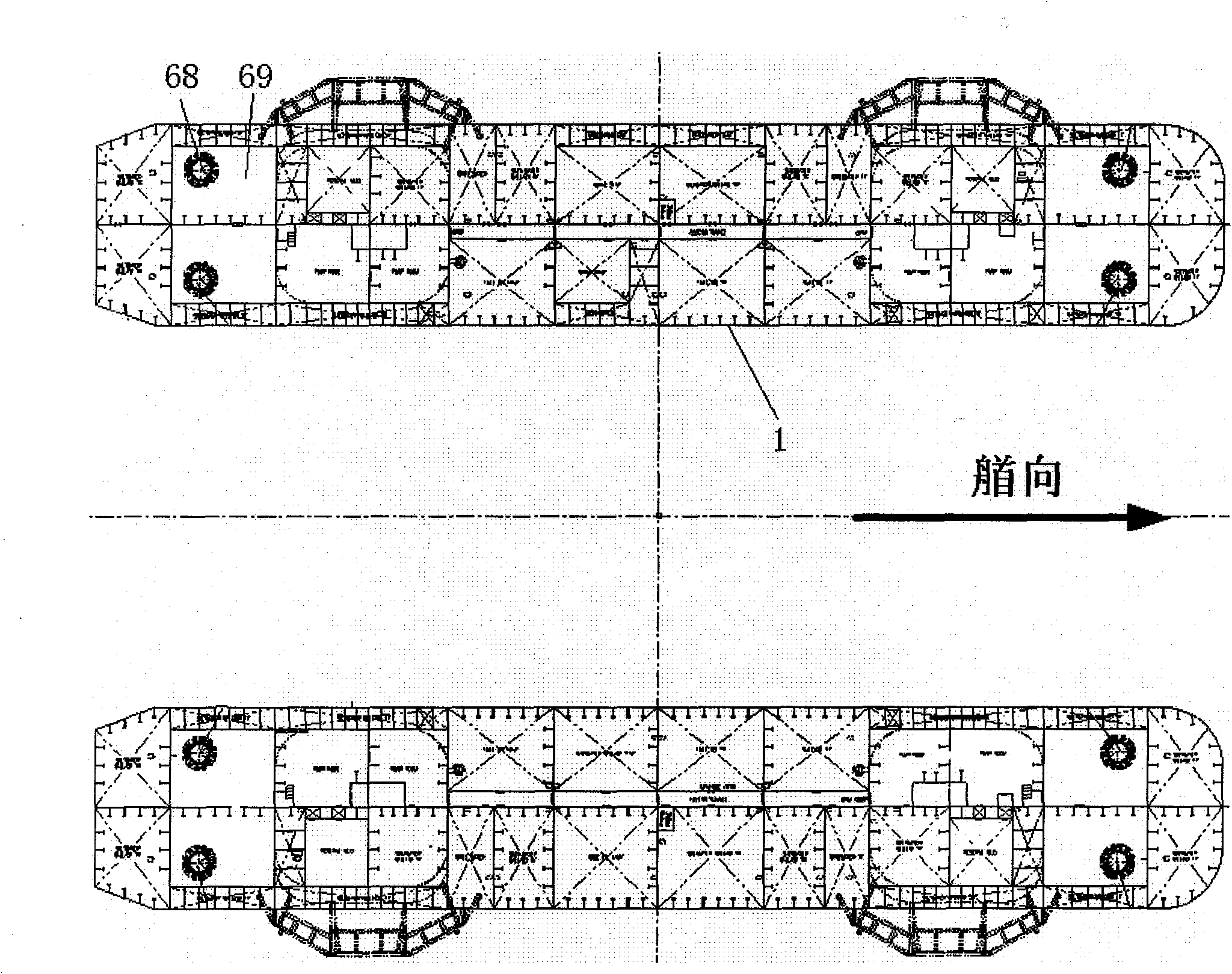

Deepwater semi-submerged drilling platform

ActiveCN101954959ASmall footprintConvenient pre-connection workFloating buildingsEngineeringDrilling riser

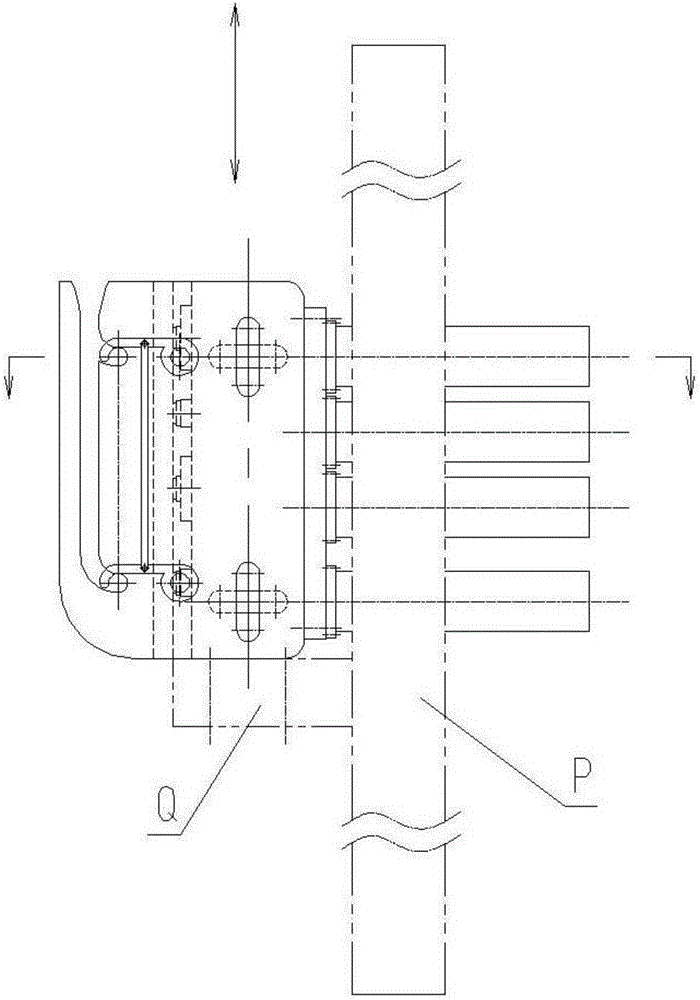

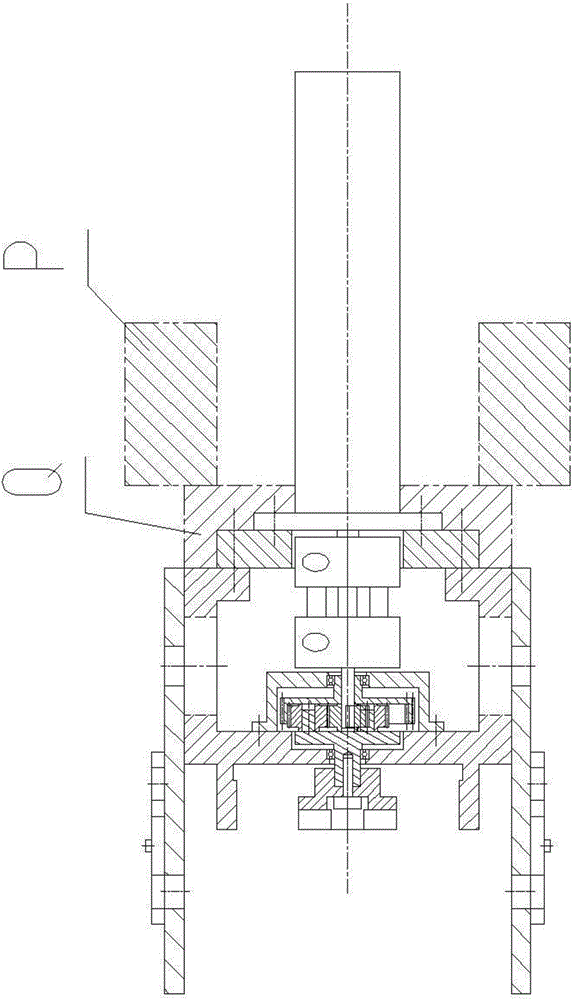

The invention relates to a deepwater semi-submerged drilling platform, which comprises floating tanks, an upright post, a transverse supporting rod and a main deck, wherein a drilling block is arranged above a moon pool in the middle of the main deck; and a derrick is arranged on the drilling block. The deepwater semi-submerged drilling platform is characterized in that: a half derrick space for pre-connecting a drilling tool is reserved on one side of the derrick; a water isolating pipe, a drilling stem, a blowout preventer and a production tree are arranged on the main deck around the moon pool respectively; and an anchor moored positioning and dynamic positioning combined position system which consists of front and back four groups of anchor gears distributed on the left and right sides of the main deck is adopted, each group of anchor gears are provided with 3 anchor chains, a dynamic positioning system consists of 8 dynamic thrusters capable of rotating 360 degrees at the front and back four corners of the bottom of the two floating tanks. In the deepwater semi-submerged drilling platform, the maximum operation water depth is up to 3,000 meters, the maximum drilling depth is up to 12,000 meters, and the maximum variable load is up to 9,000 tons. The deepwater semi-submerged drilling platform can operate in the South China Sea, Southeast Asian sea area and West Africa sea area with severe sea conditions efficiently and safely.

Owner:CHINA NAT OFFSHORE OIL CORP +1

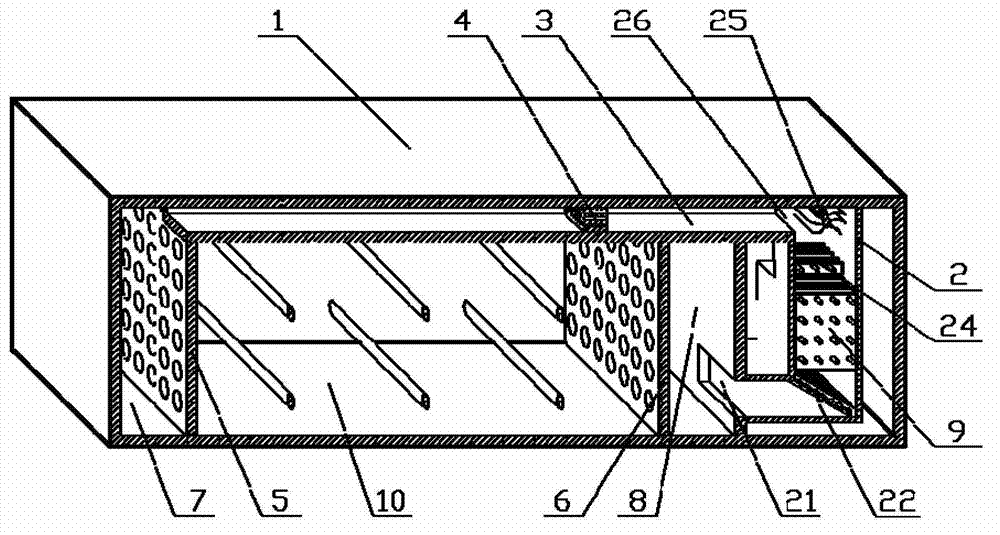

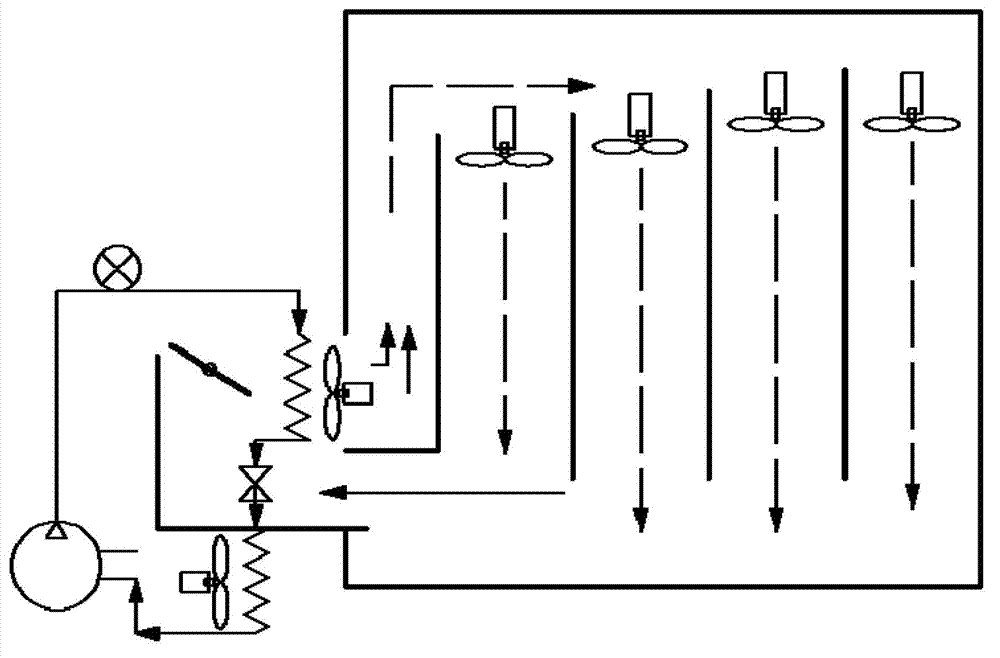

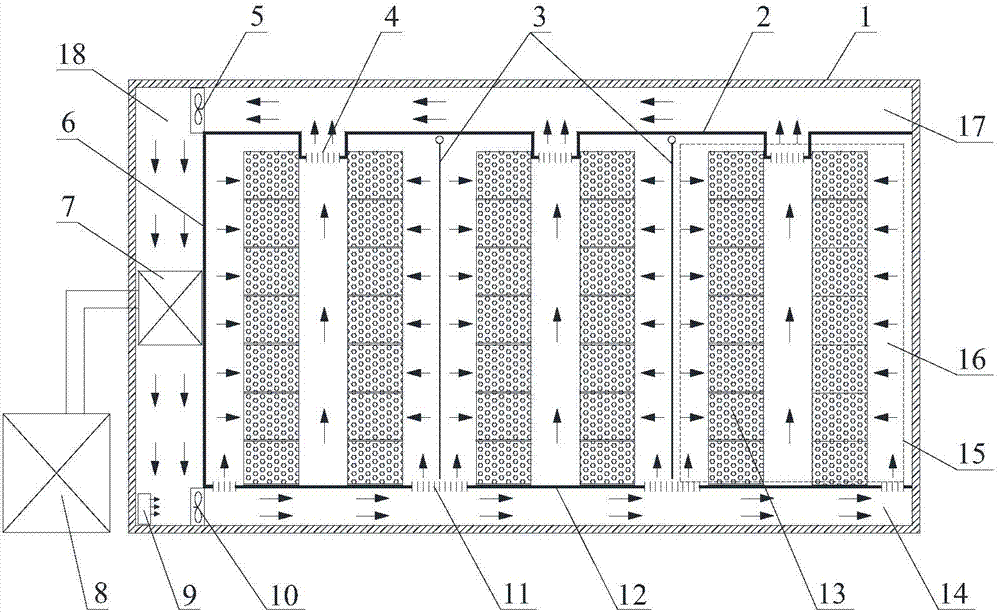

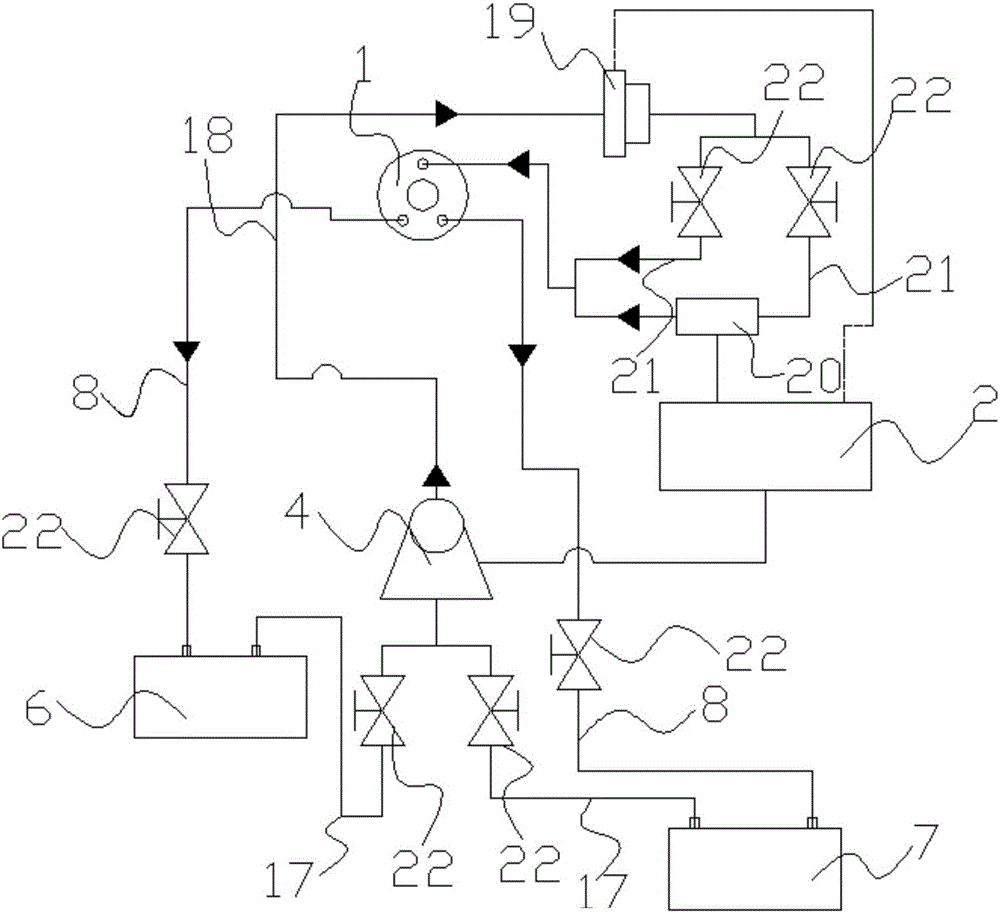

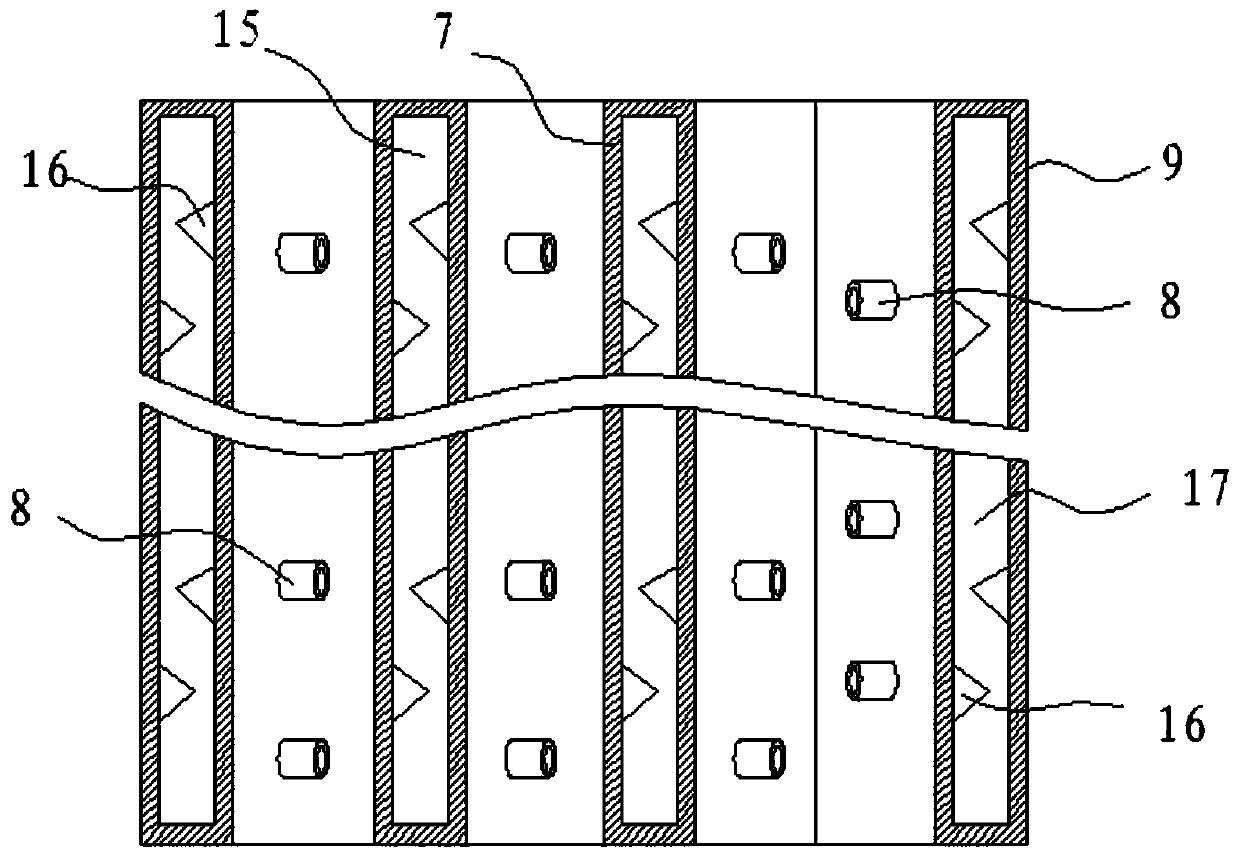

Edible fungus dried air circulation treatment device

ActiveCN103202520ASuitable for dry conditionsWell organized airflowFood processingFood treatmentRefrigerant distributionThermodynamics

The invention discloses an edible fungus dried air circulation treatment device which comprises a baking chamber, an air treatment unit, an air supply header pipe, an air mixing device, and an air supply pore plate and an air return pore plate which are arranged in the baking chamber in parallel, wherein the baking chamber is segmented into an air supply static pressure space, an air return static pressure space and a baking workshop; the air treatment unit consists of an air inlet, a solid adsorption and dehumidification device, a heat pump loop, a fan, an auxiliary electric heater and an air outlet; the heat pump loop consists of a condenser and three groups of compressors and an evaporator assembly which are arranged in parallel; and the compressors and the evaporator assembly comprise an expansion valve, an evaporator and compressors which are sequentially connected. By employing the parallel air supply mode and the general-branch-general-branch refrigerant distribution mode, the air distribution is improved, and the uniformity and stability of the air flow and temperature field in the baking chamber during operation are guaranteed, so that the consistency of the baking effect is guaranteed, and the energy consumption in the process of operating the baking chamber at a low load is reduced.

Owner:NANJING NORMAL UNIVERSITY +1

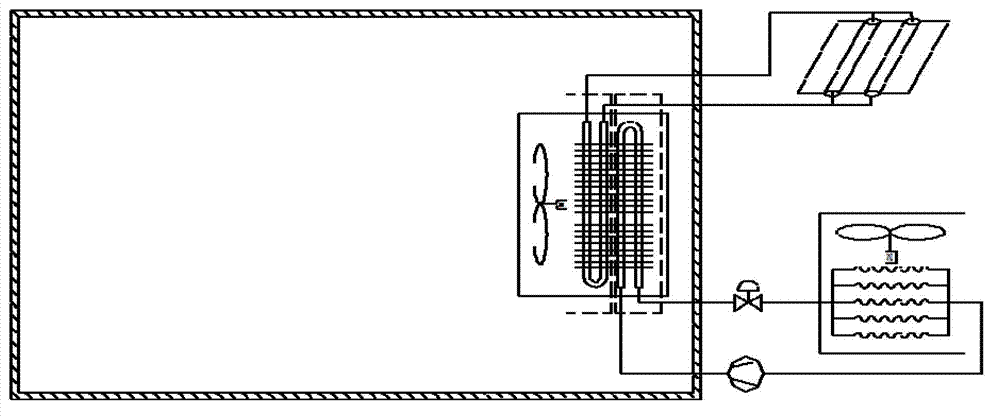

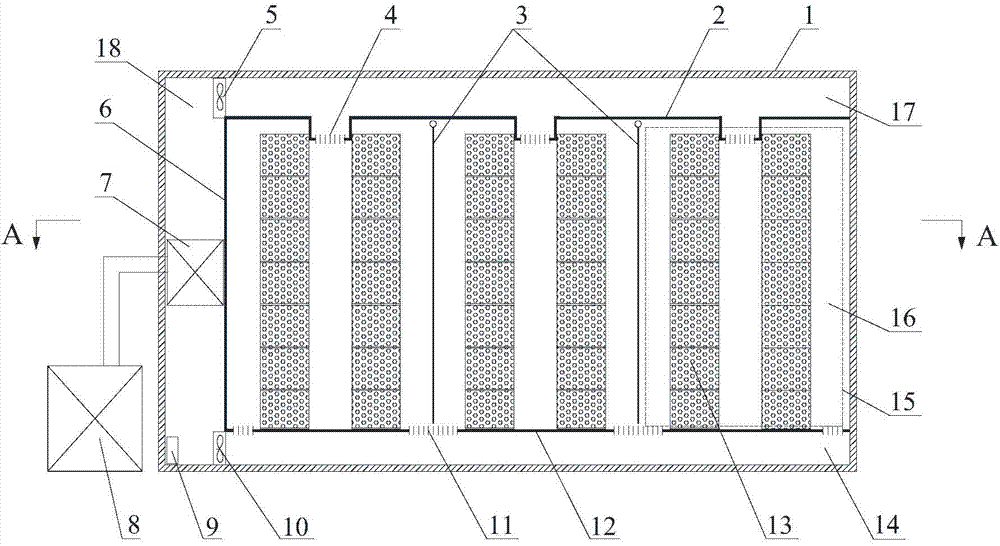

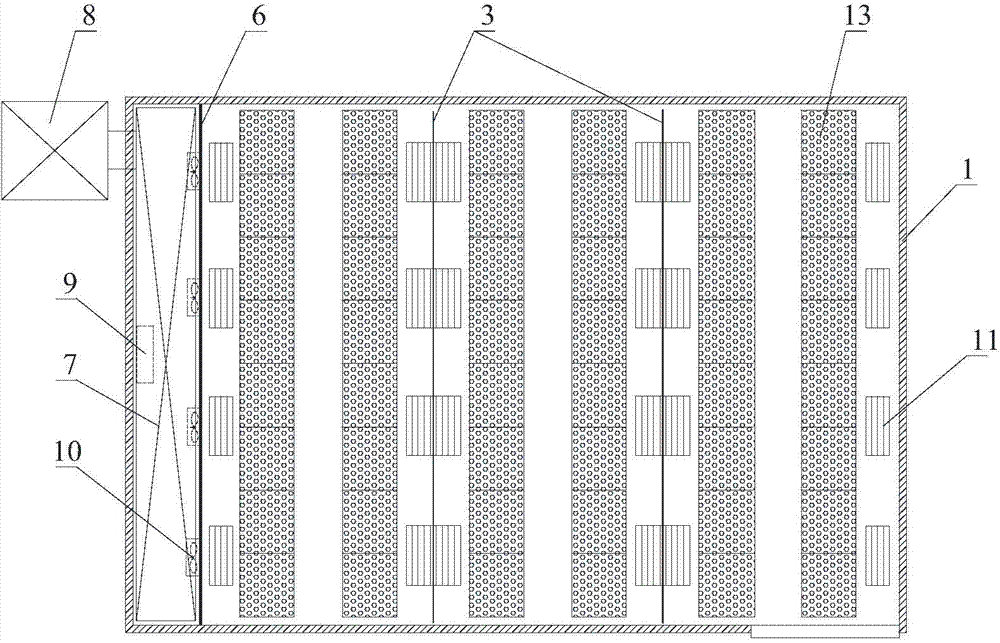

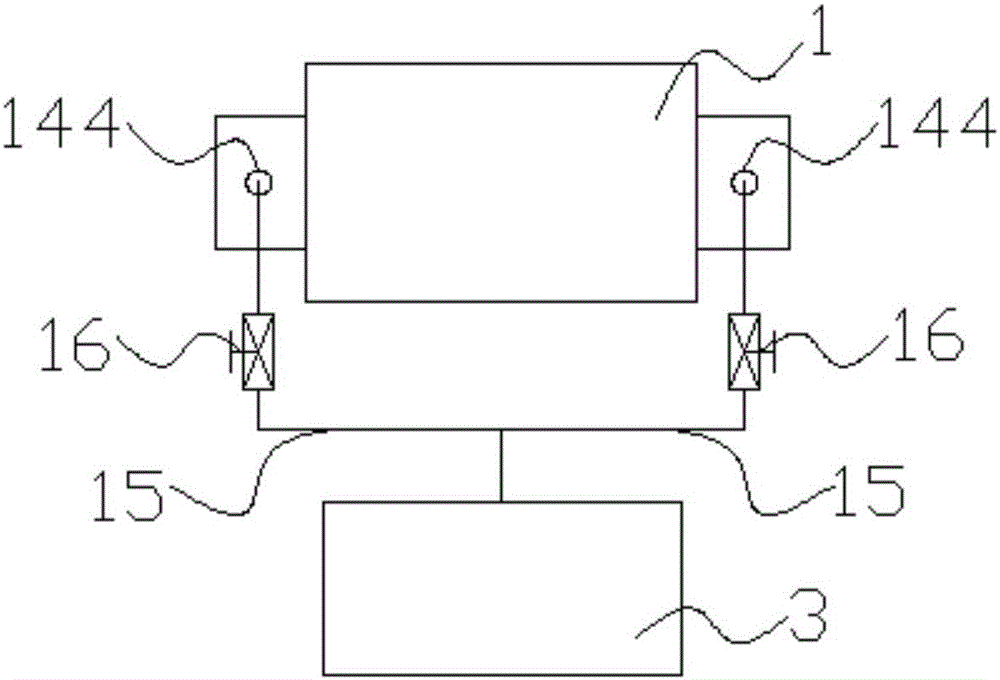

Energy-saving differential pressure type fruit and vegetable precooling warehouse

InactiveCN104839317AAvoid cooling lossUniform pre-cooling effectLighting and heating apparatusFood processingEvaporatorCold air

The invention relates to an energy-saving differential pressure type fruit and vegetable precooling warehouse, comprising a warehouse body, a refrigeration system, a humidifier, a blower, a return fan and fruit and vegetable boxes; the warehouse body is formed by an air treatment chamber, an air return static pressure box, an air supply static pressure box and a precooling room; the precooling room is divided into multiple precooling room compartments by flexible roller shutters; an air return hole of a return air top plate and an air supply hole of an air supply floor are staggered left and right; an evaporator and the humidifier are arranged in the air treatment chamber, the blower is embedded in the inlet position of the air supply static pressure box, and the return fan is embedded in the outlet position of the air return static pressure box, and air holes are formed in side walls of the fruit and vegetable boxes. The energy-saving differential pressure type fruit and vegetable precooling warehouse has the beneficial effects that an operation mode of separating hot and cold air ducts before and after precooling and combining air supply and air return is adopted, and the humidifier for precooling is provided, so the characteristics that loss of refrigeration capacity for precooling is less, the precooling is uniform, the precooling speed is fast, water loss of fruits and vegetables is less, the precooling capacity is adjustable, energy is saved, the efficiency is high, and the like are achieved.

Owner:TIANJIN AOLV AGRI & SIDELINE PROD GRP

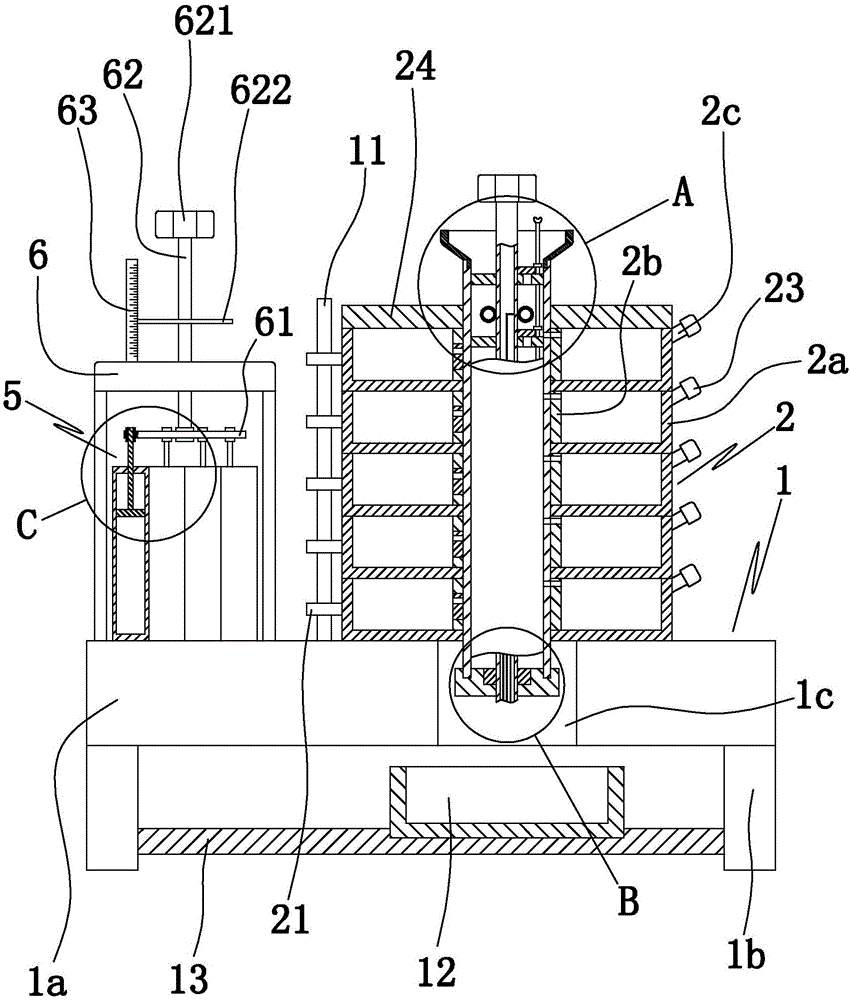

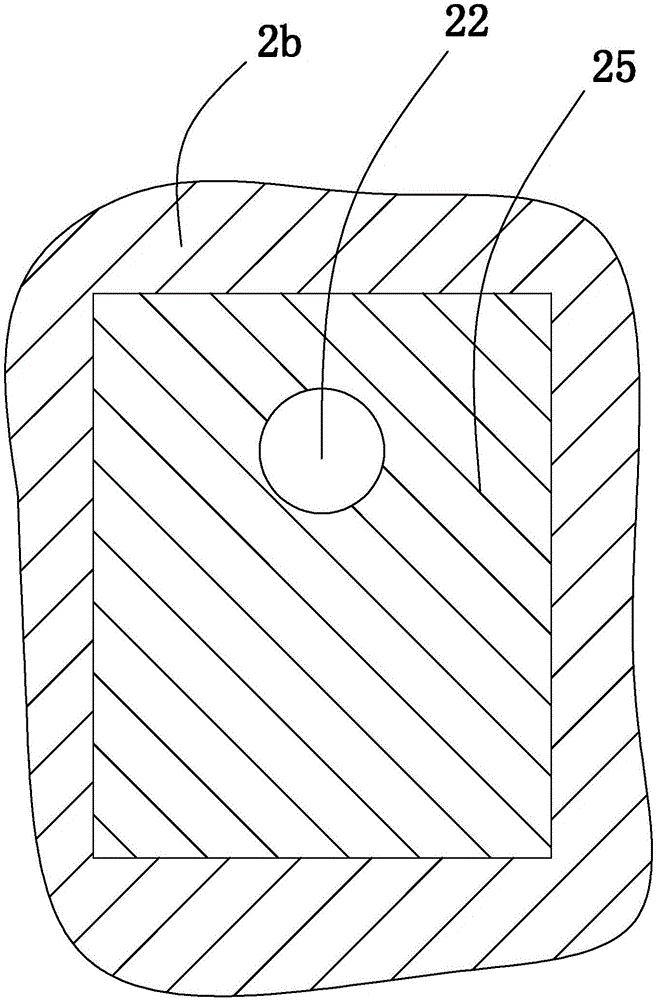

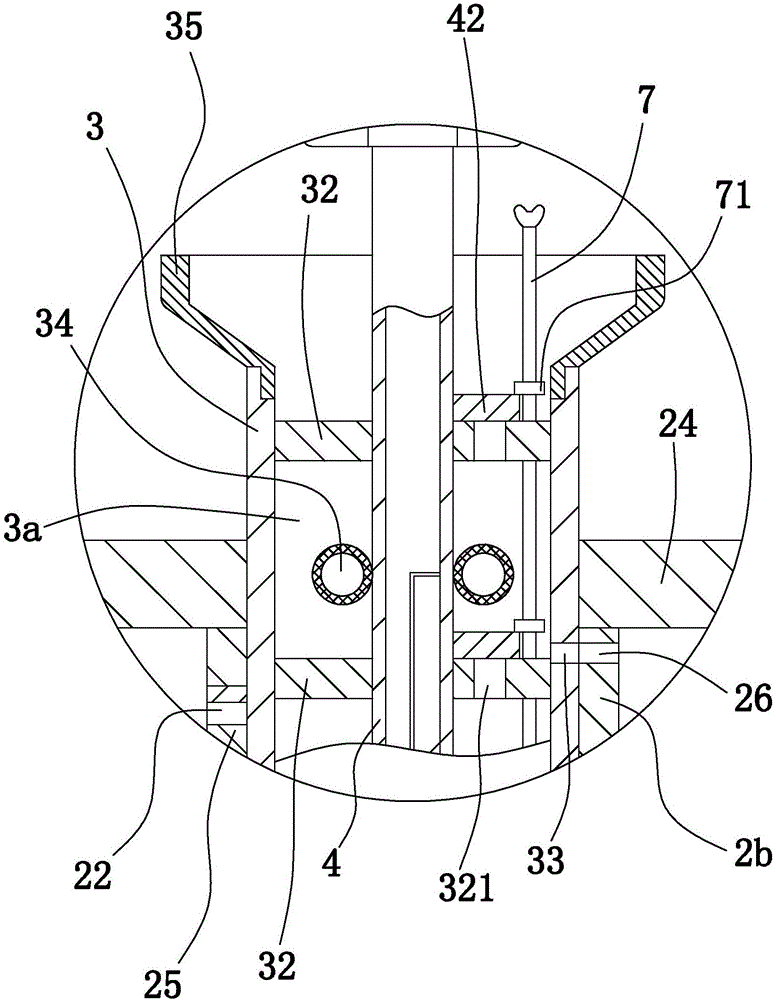

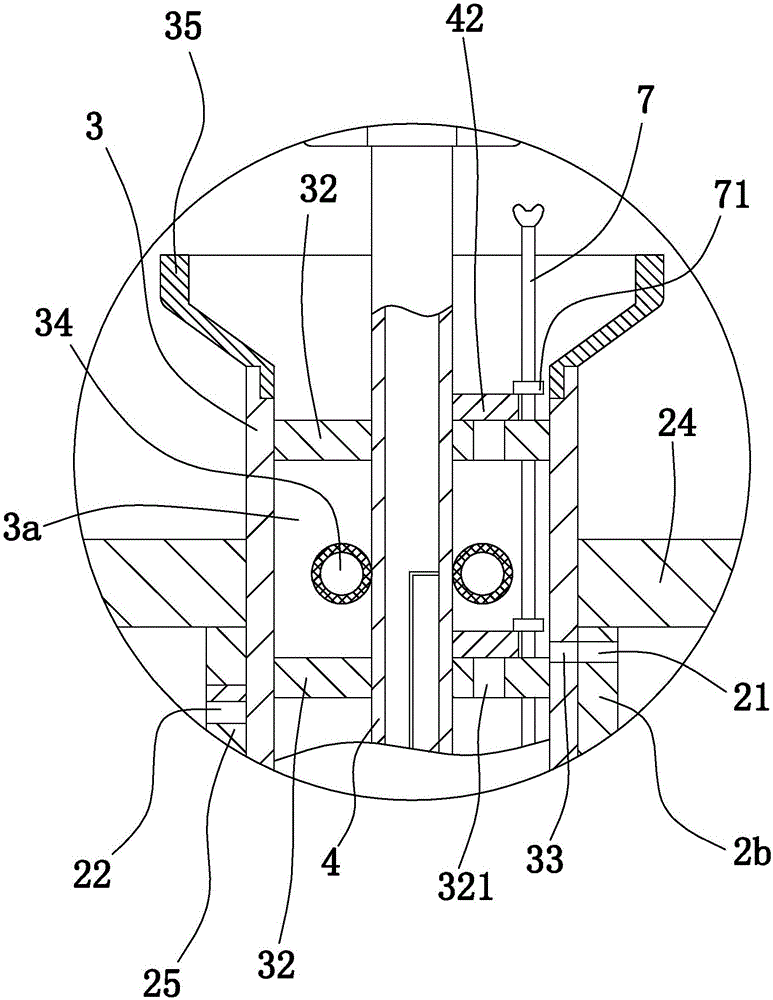

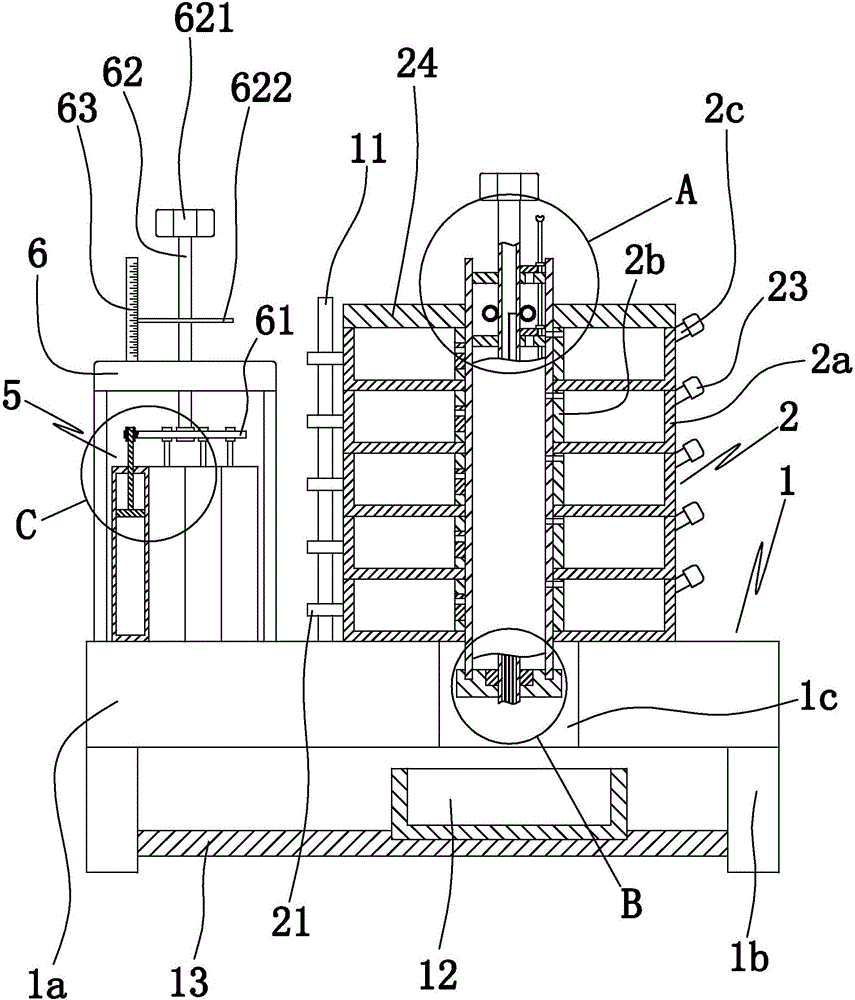

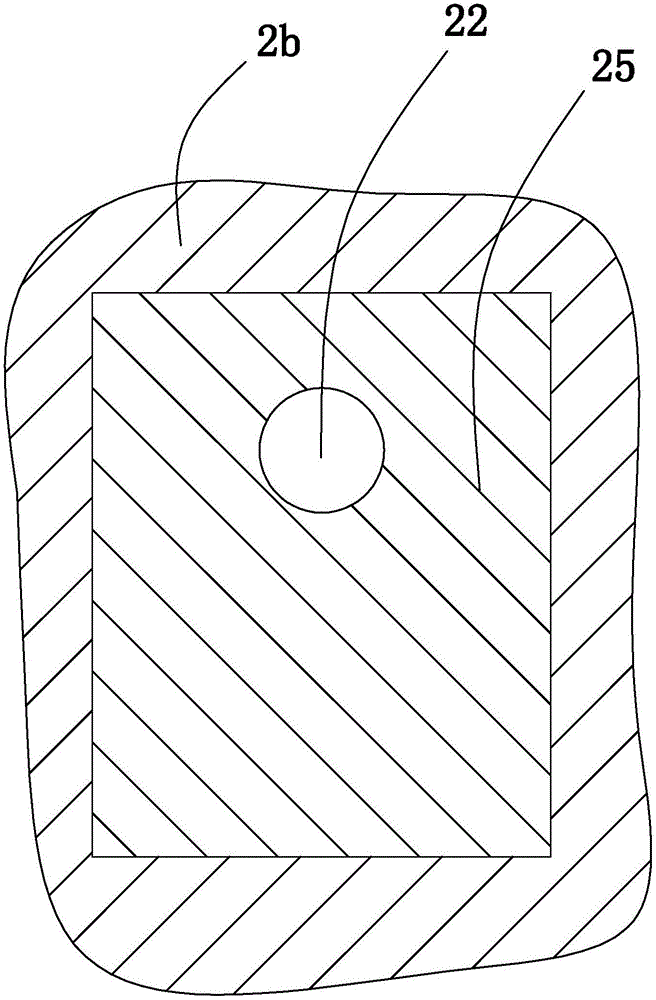

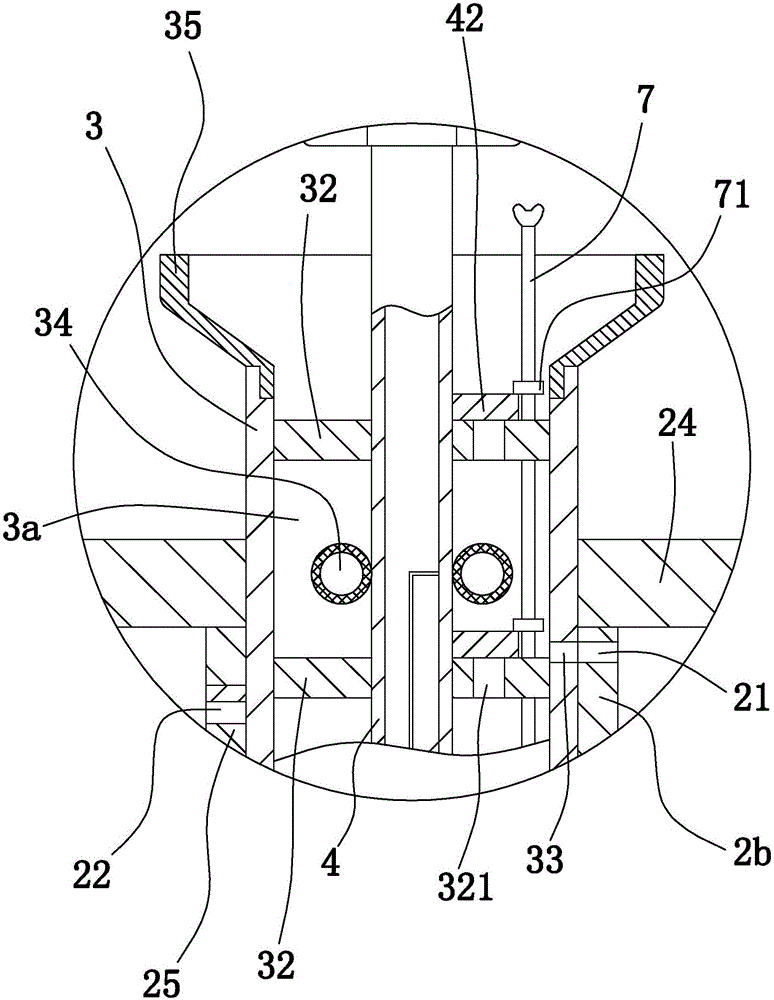

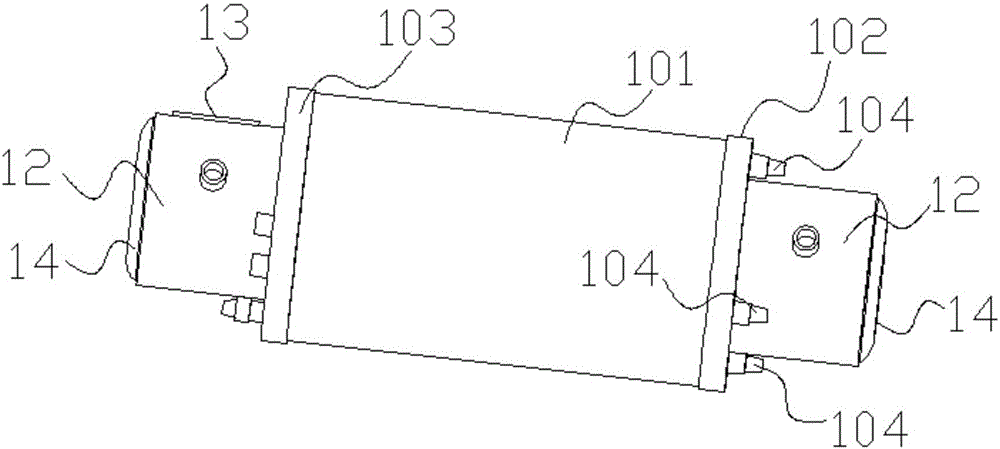

Cell culture device applicable to comparison tests

ActiveCN106190839AReasonable space layoutStable structureBioreactor/fermenter combinationsBiological substance pretreatmentsCulture vesselEngineering

The invention discloses a cell culture device applicable to comparison tests. The cell culture device comprises a pedestal and a plurality of culture vessels, wherein the culture vessels are sequentially stacked; each culture vessel comprises a vessel body, a vertical column and a liquid injection tube, and the upper and lower ends of the vertical column are respectively opened; a rotary tube penetrates through all the vertical columns, and can rotate relative to the vertical columns; the rotary tube and each vertical column form a sealing contact; and the outer side wall of the rotary tube is provided with a drainage groove. In one culture vessel, the vertical column is provided with a liquid balancing hole which communicates with the inside of the vessel body, a cell filter screen and a liquid balancing one-way valve are arranged in the liquid balancing hole, the liquid balancing one-way valve is positioned between the cell filter screen and the rotary tube, the passable direction of the liquid balancing one-way valve is from the inside to the outside of the vessel body, and the lower end of the liquid injection tube communicates with the inside of the vessel body. The cell culture device is suitable for cell culture, determination and comparison, has the advantages of reasonable spatial arrangement and stable structure, is convenient in the operational process, and has high adjusting consistency and accuracy in the test process.

Owner:杭州荣泽生物科技集团有限公司

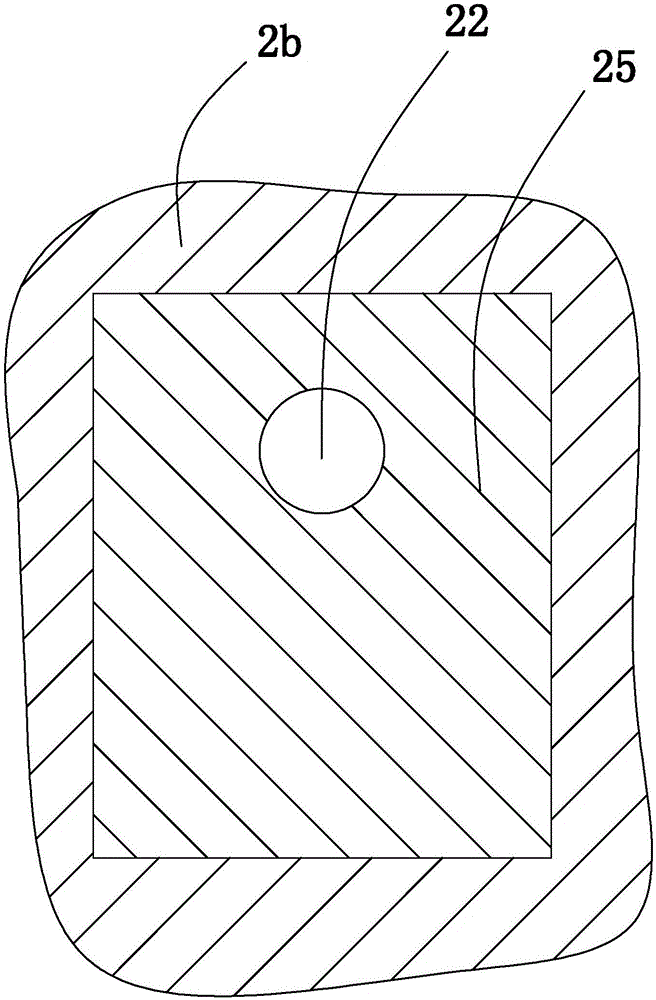

Sample culture carrier

ActiveCN106222087AReasonable space layoutStable structureBioreactor/fermenter combinationsBiological substance pretreatmentsCulture vesselMarine engineering

The invention discloses a sample culture carrier. The sample culture carrier comprises a base and multiple culture vessels, all the culture vessels are stacked, each culture vessel comprises a vessel body, a vertical cylinder, a bump and an injection tube, the end face of the top of each vessel body is provided with a vessel top groove, the top of the base is provided with a base top groove, and the bump of the lowest culture vessel is located in the base top groove; a rotating tube penetrates through all the vertical cylinders, the rotating tube and the vertical cylinders can rotate relatively, the outer side wall of the rotating tube makes close contact with the inner side walls of the vertical cylinders, and a drain groove is formed in the outer side wall of the rotating tube; each vertical cylinder is provided with a liquid equalizing hole communicated with the interior of the corresponding vessel body, each liquid equalizing hole is provided with a cell filtering net and a liquid equalizing one-way valve, and the lower end of each injection tube is communicated with the interior of the corresponding vessel body; the bump of the upper culture vessel is located in the vessel top groove of the corresponding lower culture vessel. The sample culture carrier has the advantages of being suitable for cell culture, determination and comparison, reasonable in spatial arrangement, stable in structure, convenient and rapid to operate, good in consistency of adjustment in the experimental process and high in accuracy.

Owner:南京乐诊生物技术有限公司

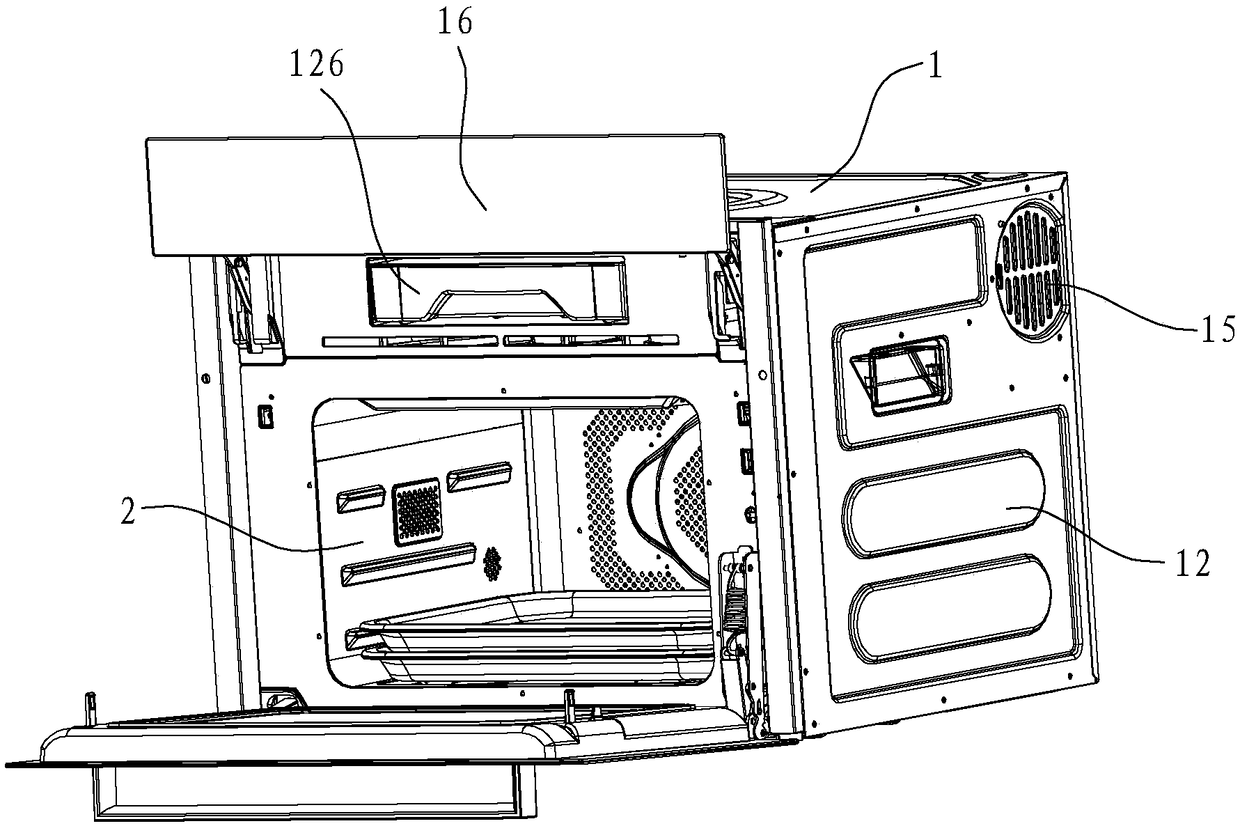

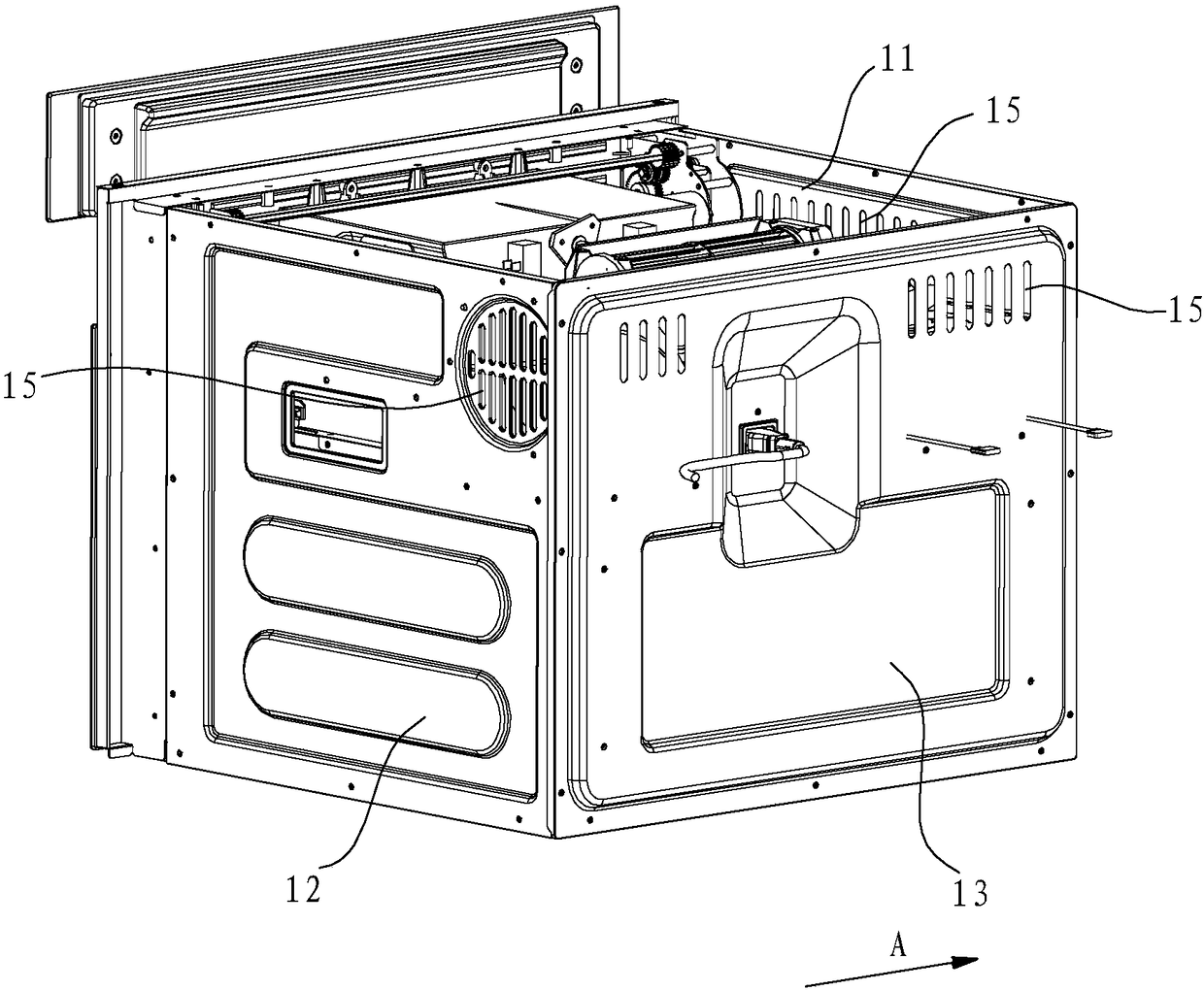

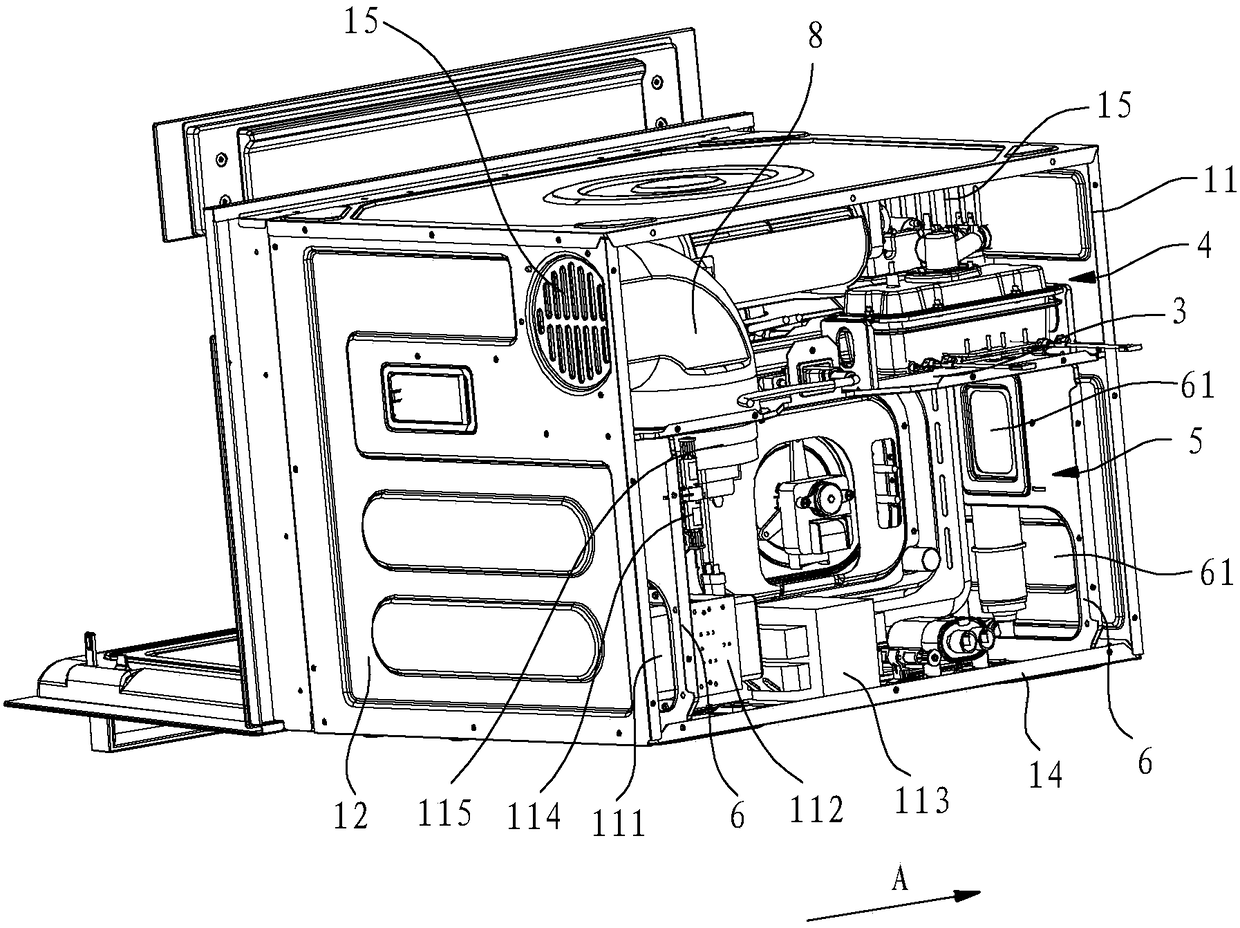

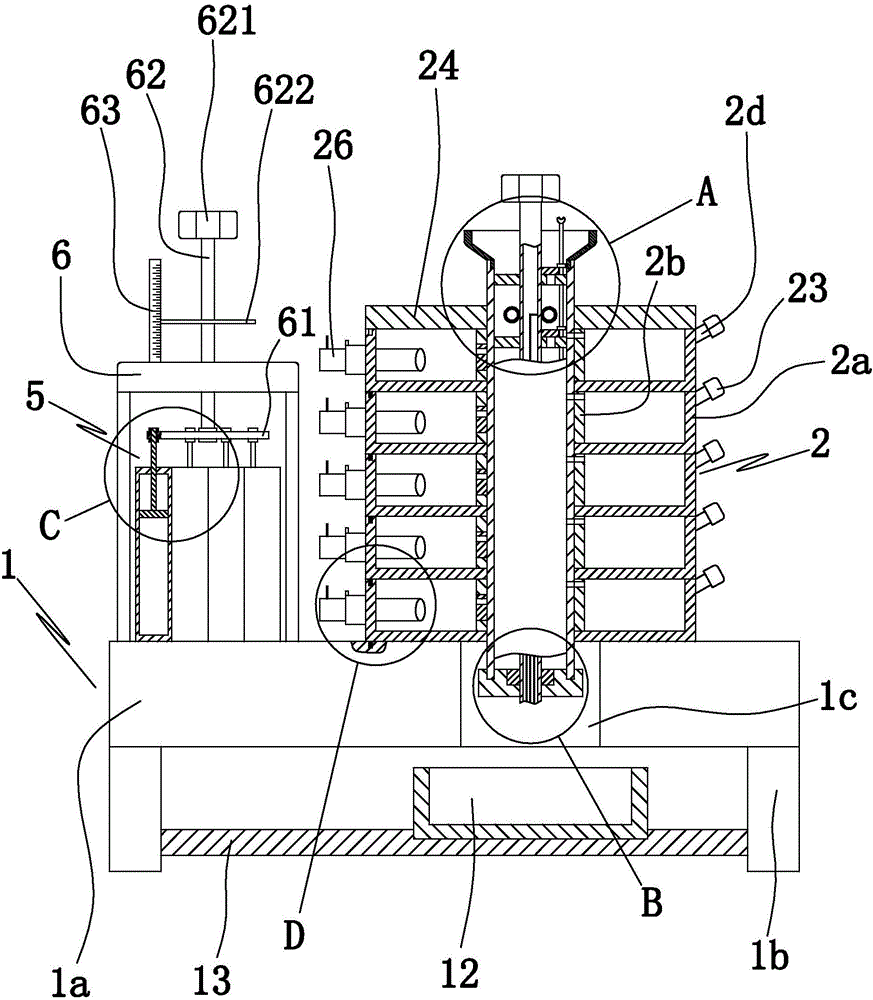

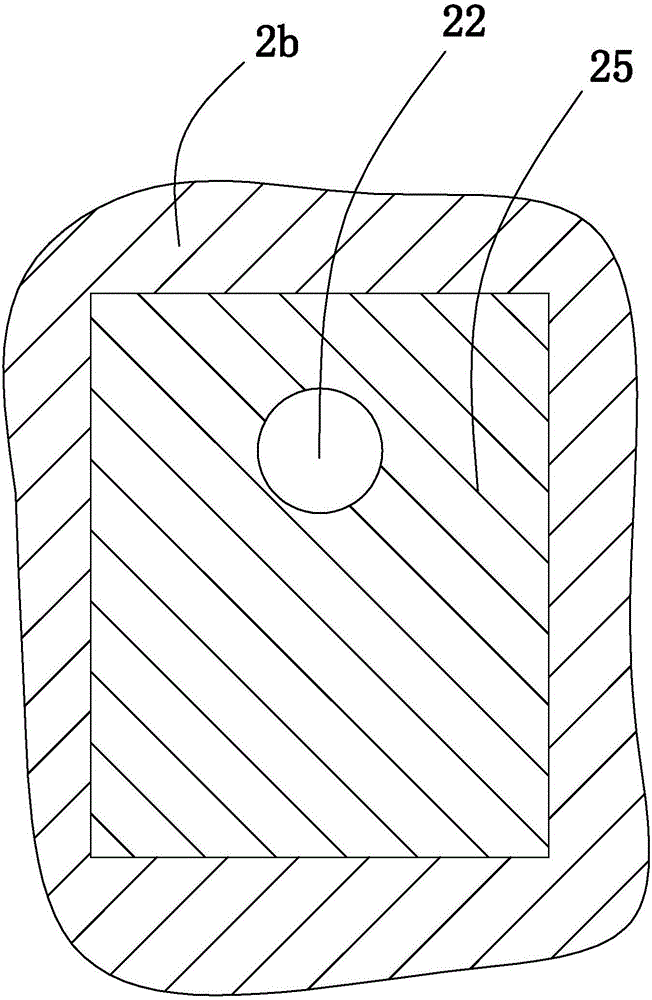

All-in-one machine integrating steam box, oven and microwave oven

PendingCN108236354AExtended service lifeImprove the safety of useDomestic stoves or rangesLighting and heating apparatusMicrowave ovenEngineering

The invention relates to an all-in-one machine integrating a steam box, an oven and a microwave oven. The all-in-one machine comprises a box body and a cooking room furnace chamber located in the boxbody; a steam generating device, a microwave generating device and a barbecue generating device are installed inside the box body and outside the cooking room furnace chamber; the back space of the cooking room furnace chamber is divided into upper layer space and lower layer space by a partition board; the steam generating device is arranged in the upper layer space, and the microwave generatingdevice is arranged in the lower layer space; ventilation openings are formed in the side board of the box body, and the upper and lower layer spaces are communicated to each other and the ventilationopenings are communicated to the outside of the box body. According to the all-in-one machine integrating the steam box, the oven and the microwave oven, the steam generating device is arranged in theupper layer space and the microwave generating device is arranged in the lower layer space, so that the all-in-one machine has a reasonable spatial layout and solves the problems of air circulation in upper and lower layer spaces by designing with unique double air ducts of the upper and lower layer spaces; and the all-in-one machine can perform heat dissipation and cooling on electronic components in a timely manner quickly and effectively, thereby facilitating to extend the service life of the all-in-one machine and improving safety in use.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

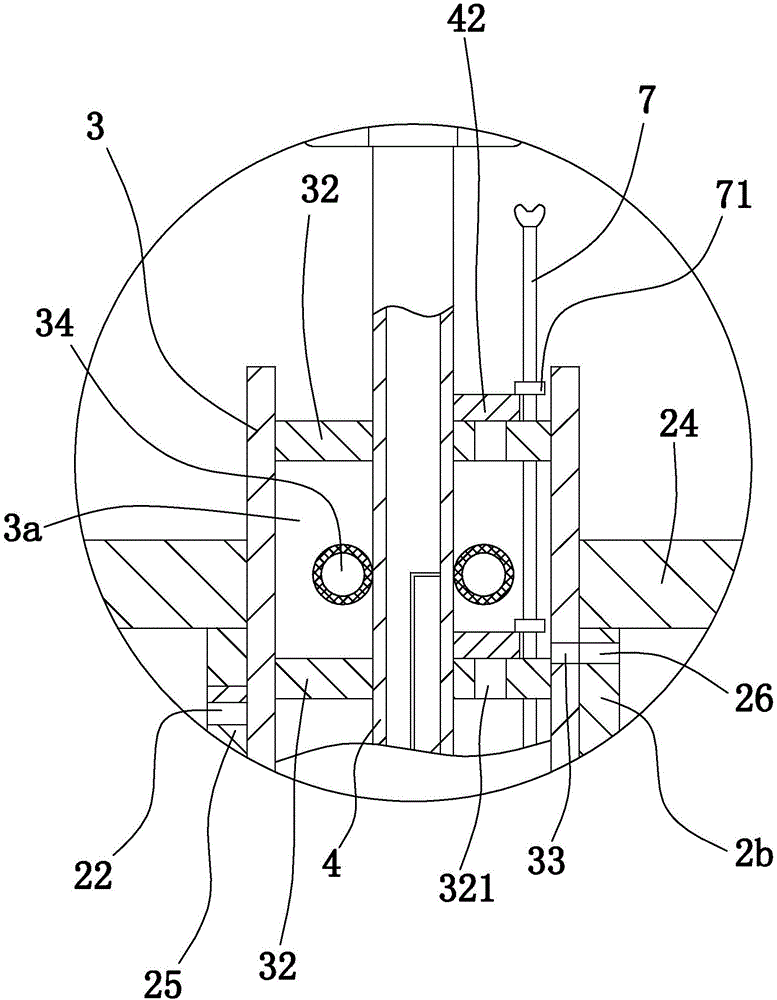

Multi-sample culture device

InactiveCN106190843AReasonable space layoutStable structureTissue/virus culture apparatusBiological material testing proceduresCulture vesselEngineering

The invention discloses a multi-sample culture device which comprises a base and a plurality of culture vessels. All the culture vessels are stacked, each culture vessel comprises a vessel body, a vertical barrel, a protruding block and a liquid injection pipe, a vessel top groove is formed in the top end face of each vessel body, a base top groove is formed in the top of the base, and the protruding block of the bottommost culture vessel is located in the base top groove. A rotary pipe penetrates through all the vertical barrels, the rotary pipe and the vertical barrels can relatively rotate, the outer side wall of the rotary pipe and the inner side walls of the vertical barrels are in sealed contact, and a liquid drainage groove is formed in the outer side wall of the rotary pipe. A liquid balancing hole communicated with the inside of the corresponding vessel body is formed in each vertical barrel, a cell filter screen and a liquid balancing one-way valve are arranged in each liquid balancing hole, and the lower end of each liquid injection pipe is communicated with the inside of the corresponding vessel body. The protruding blocks of the upper culture vessels are located in the vessel top grooves of the lower culture vessels. The multi-sample culture device has the advantages of being suitable for cell culture, testing and comparing, reasonable in spatial arrangement, stable in structure, convenient to operate, good in adjusting consistence in the experiment process and high in accuracy.

Owner:刘力伟

Cell cultivating device for cultivating, determining and analyzing

ActiveCN106244453AReasonable space layoutStable structureBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringLiquid injection

The invention discloses a cell cultivating device for cultivating, determining and analyzing. The cell cultivating device for cultivating, determining and analyzing comprises a base and a plurality of cultivating utensils. All the cultivating utensils are sequentially stacked, and comprise utensil bodies, vertical drums and liquid injection pipes; the upper ends and the lower ends of the vertical drums are opened, a rotating pipe penetrates through all the vertical drums, the rotating pipes and the vertical drums can oppositely rotate, the rotating pipes are in contact with the vertical drums in a sealed mode, and liquid discharging grooves are formed in the outer side alls of the rotating pipes; in one cultivating utensil, a liquid distribution hole internally communicated with the utensil body is formed in the vertical drum, a cell filtering net and a liquid-distribution one-way valve are arranged in the liquid distribution hole, the liquid-distribution one-way valve is located between the cell filtering net and the rotating pipe and can be from the inside of the utensil body to the outside of the utensil body in the direction, and the lower end of the liquid injection pipe is internally communicated with the utensil body. The cell cultivating device has the advantages that the cell cultivating device is suitable for cell cultivating, determining and comparing, spatial arrangement is reasonable, the structure is stable, the operating process is convenient and fast, and in the test process, the adjusting consistency is high, and the accuracy is high.

Owner:杭州荣泽生物科技集团有限公司

Integrated sample culture device

ActiveCN106282017AReasonable space layoutStable structureBioreactor/fermenter combinationsBiological substance pretreatmentsCulture vesselMarine engineering

The invention discloses an integrated sample culture device. The integrated sample culture device comprises a base and a plurality of culture vessels which are stacked. Each culture vessel comprises a vessel body, a vertical cylinder, a protruding block and a liquid injection pipe, wherein a vessel top groove is formed in the top end face of the vessel body. A base top groove is formed in the top of the base, the protruding block of the lowermost culture vessel is located in the base top groove, a rotating pipe penetrates through all the vertical cylinders, the rotating pipe and the vertical cylinders can rotate relatively, the outer side wall of the rotating pipe and the inner side walls of the vertical cylinders are in sealed contact, and a liquid discharging groove is formed in the outer side wall of the rotating pipe. Liquid unifying holes communicated with the interiors of the vessel bodies are formed in the vertical cylinders, cell filter screens and liquid unifying one-way valves are arranged in the liquid unifying holes, and the lower ends of the liquid injection pipes are communicated with the interiors of the vessel bodies. The protruding blocks of the culture vessel bodies on the upper portion are located in the vessel top grooves of the culture vessel bodies on the lower portion. The integrated sample culture device has the advantages of being suitable for cell culture, measuring and comparing, reasonable in space layout, stable in structure, capable of achieving convenience and fastness in the operation process and high in adjusting consistency and accuracy in the experiment process.

Owner:SHENZHEN XBIOME BIOTECH CO LTD

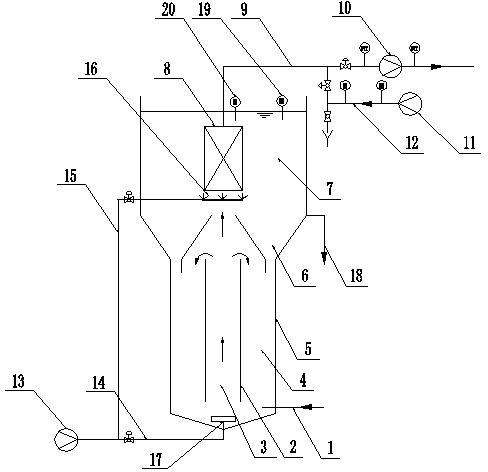

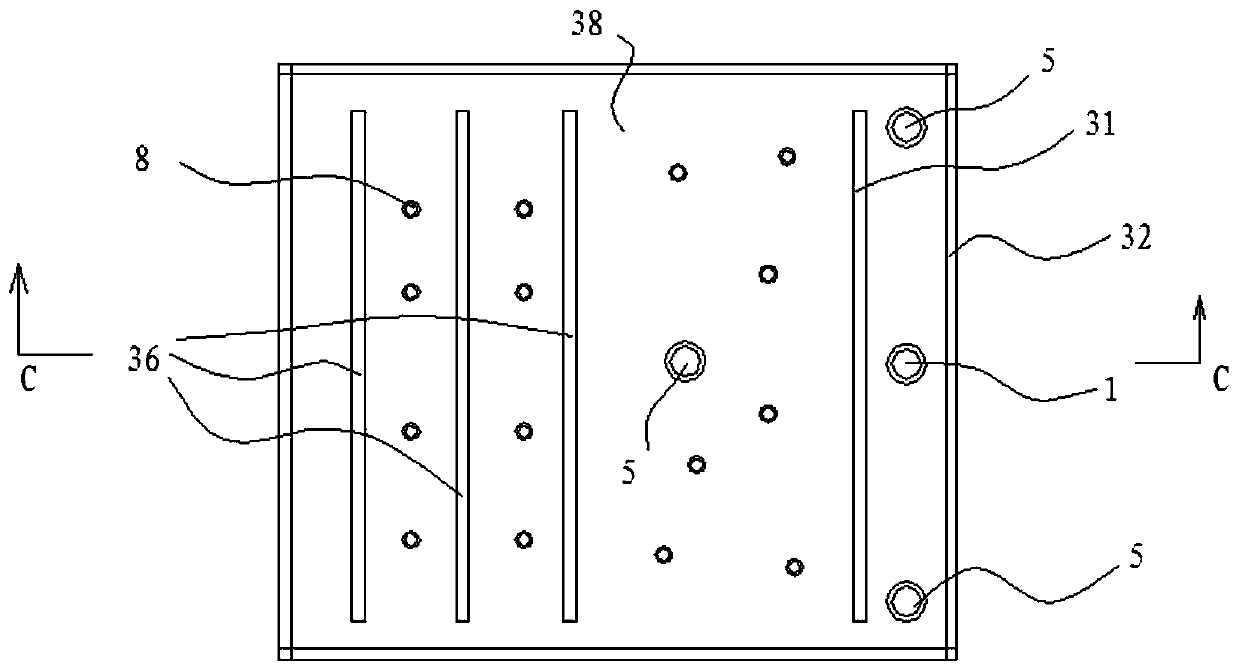

Inner-loop three-phase biological fluidized bed type membrane bioreactor (MBR)

ActiveCN104045148AIncrease water productionEffective combinationTreatment using aerobic processesSustainable biological treatmentInner loopThree-phase

The invention discloses an inner-loop three-phase biological fluidized bed type membrane bioreactor (MBR). The reactor comprises an inner-loop fluidization region and an MBR membrane bioreaction region, wherein the bottom of the inner-loop fluidization region is communicated with a water inlet pipe; the inner-loop fluidization region comprises an internal cylinder and an external cylinder sleeving the internal cylinder; a gap serving as a downstream area is formed between the internal cylinder and the external cylinder; the internal cylinder is provided with a channel serving as an upstream area; an air-blast system for driving water to rise along the upstream area is arranged inside or at the bottom of the internal cylinder; a packing is arranged in or at the bottom of the internal cylinder; an MBR membrane component is mounted in the MBR membrane bioreaction region; an aerator pipe is arranged at the bottom of the MBR membrane component; the water outlet of the MBR membrane component is communicated with a water producing pipe. The inner-loop three-phase biological fluidized bed is combined with the MBR to form the inner-loop three-phase biological fluidized bed type MBR which is reasonable in spatial arrangement, and therefore, the energy consumption can be further reduced; in addition to treating domestic sewage, the inner-loop three-phase biological fluidized bed type MBR is further capable of treating industrial wastewater in the fields of printing and dyeing process, oils and fats, food, leather and the like.

Owner:POWERCHINA ZHONGNAN ENG +1

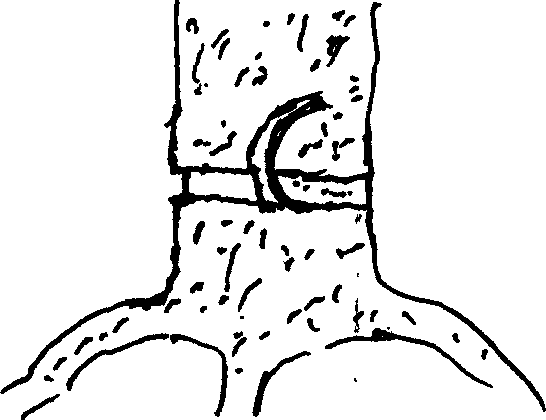

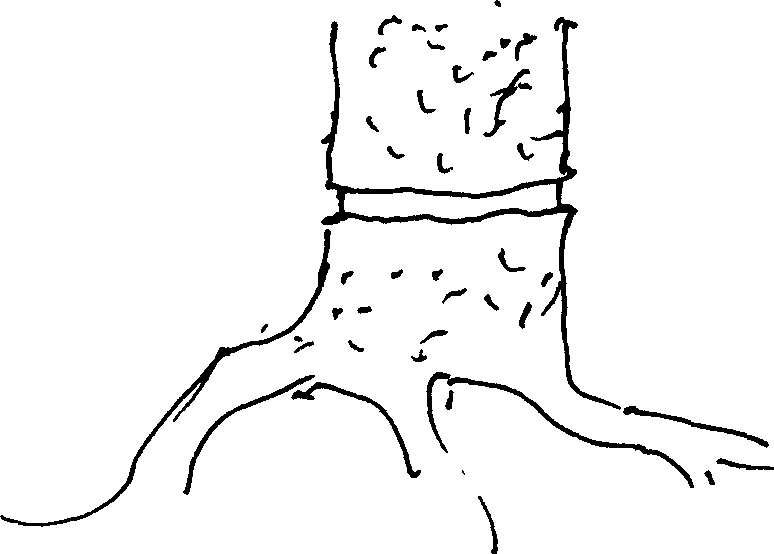

Method for cultivating natural dendriform Chinese rose

A cultivation method for natural style tree-shaped Chinese rose, wherein the hedge rose stake wood is selected from cold-resistant varieties with good growing state, the graft is also selected from fine varieties, the method also comprises stake wood culture, tree shape selection for obtaining stake wood with strong roots, thick stems and multi-branches, carrying out circumferential stripping to the root portion of the grafting sprout within 1-2 months before grafting.

Owner:陈家瑞

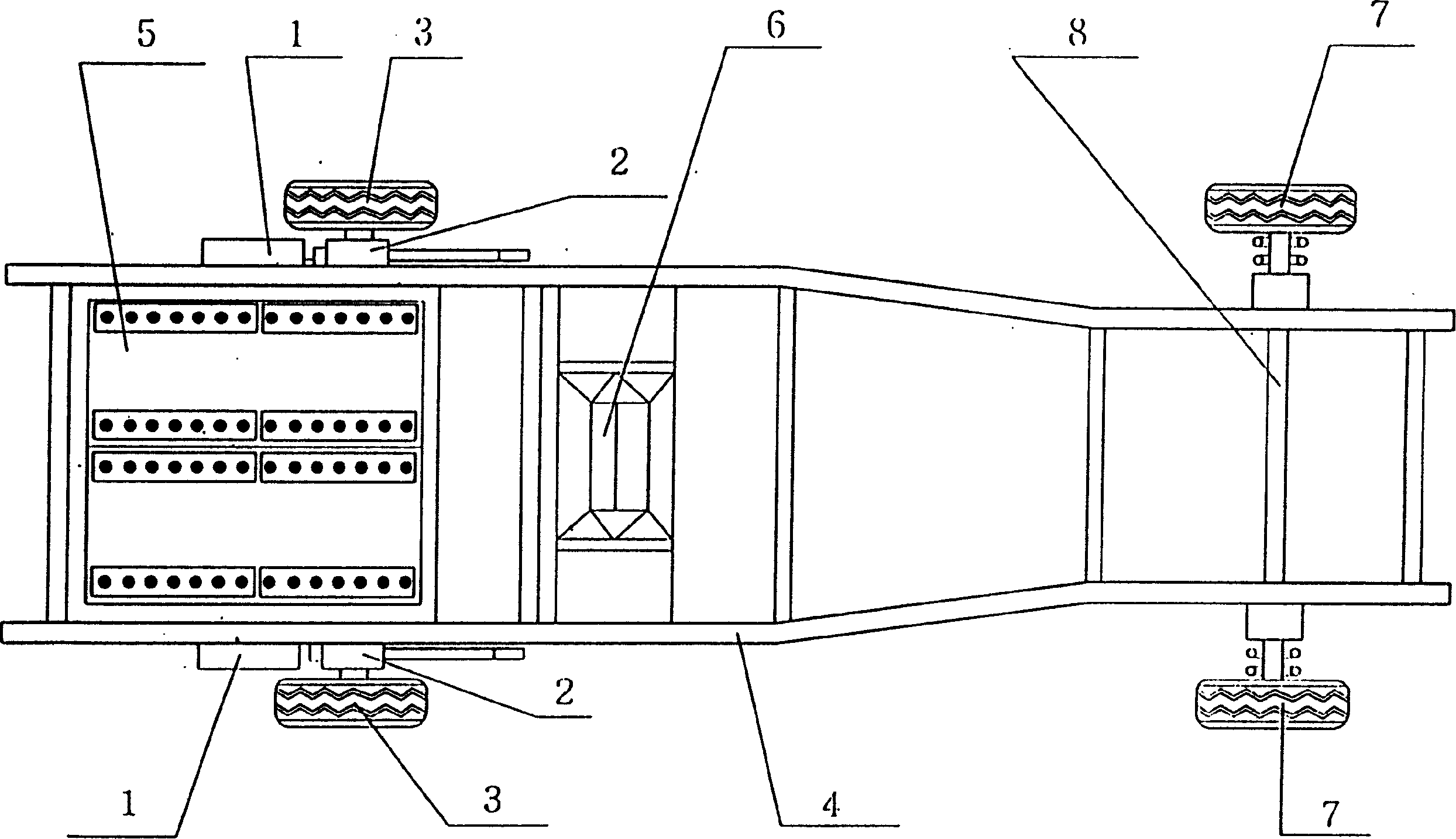

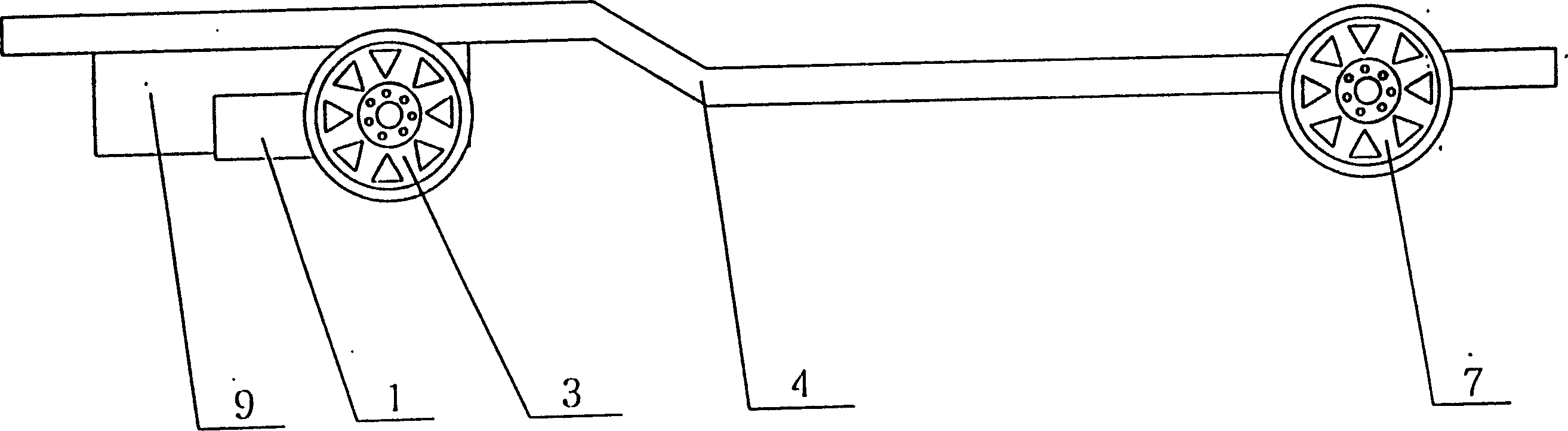

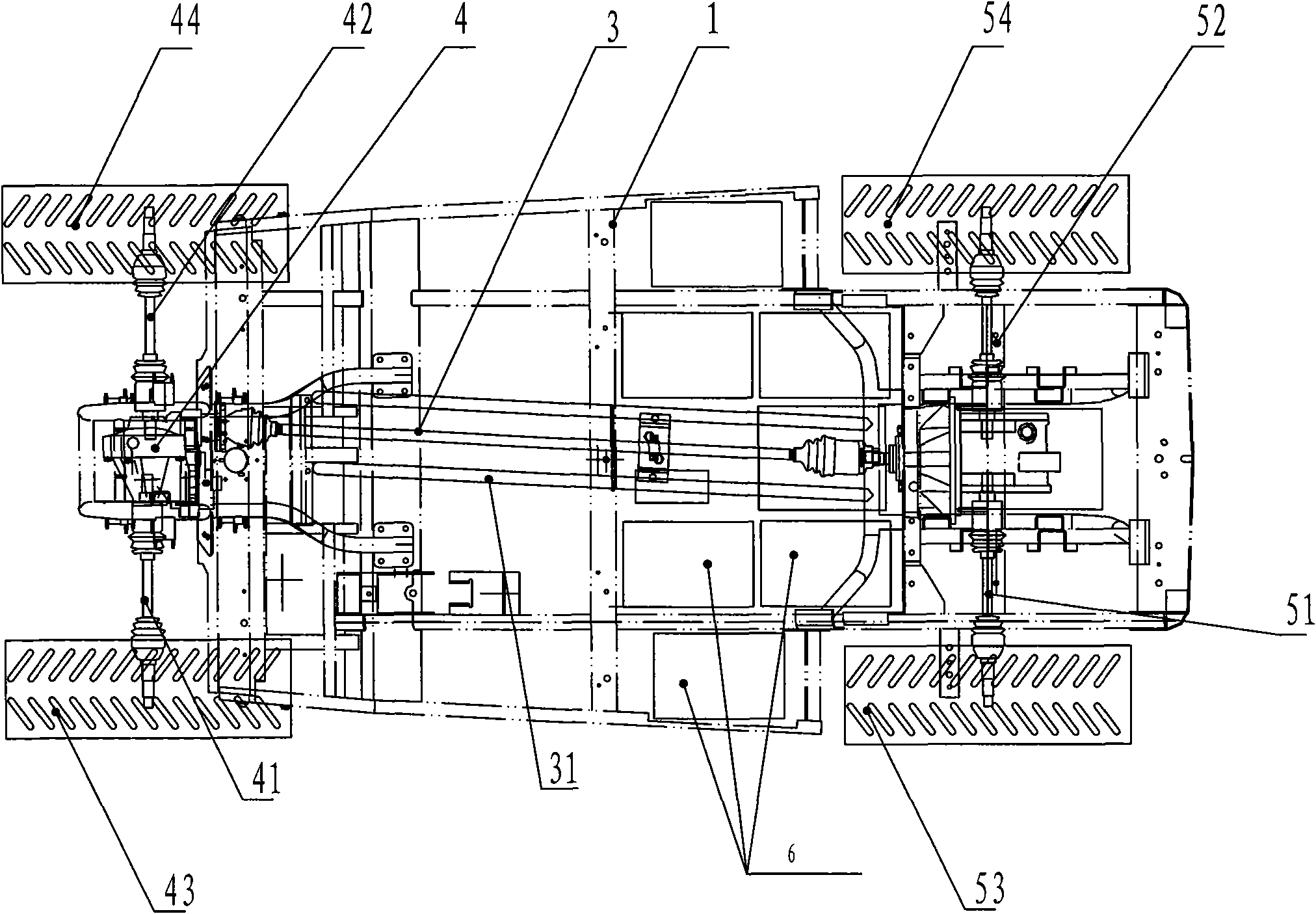

Independently driven Electric automobile chassis with independently suspended rear tyres

InactiveCN1631690AReasonable space layoutSpatial layout is practicalMotor depositionDrive wheelVehicle frame

The invention discloses a kind of trailing wheel independently-hanging-and-driving electromotion car chassis which consist of the frame and the driving devices. The driving devices include the independently-hanging trailing wheel, controller, decelerater, battery suit. The two trailing wheel each installed with a driving electromotor and each independently hanged at the side of the frame so to form a loading room between the two trailing wheels. The so constructed electromotion car chassis changes the room the existing cars used to setting up back bridge for a loading room to place the battery suit without taking any space upwards. This makes the room arrangement of the cab more reasonable, practical and regardable. It is provided with some merits suck as simple, perfectly functional, novelty and easy to control.

Owner:郭义

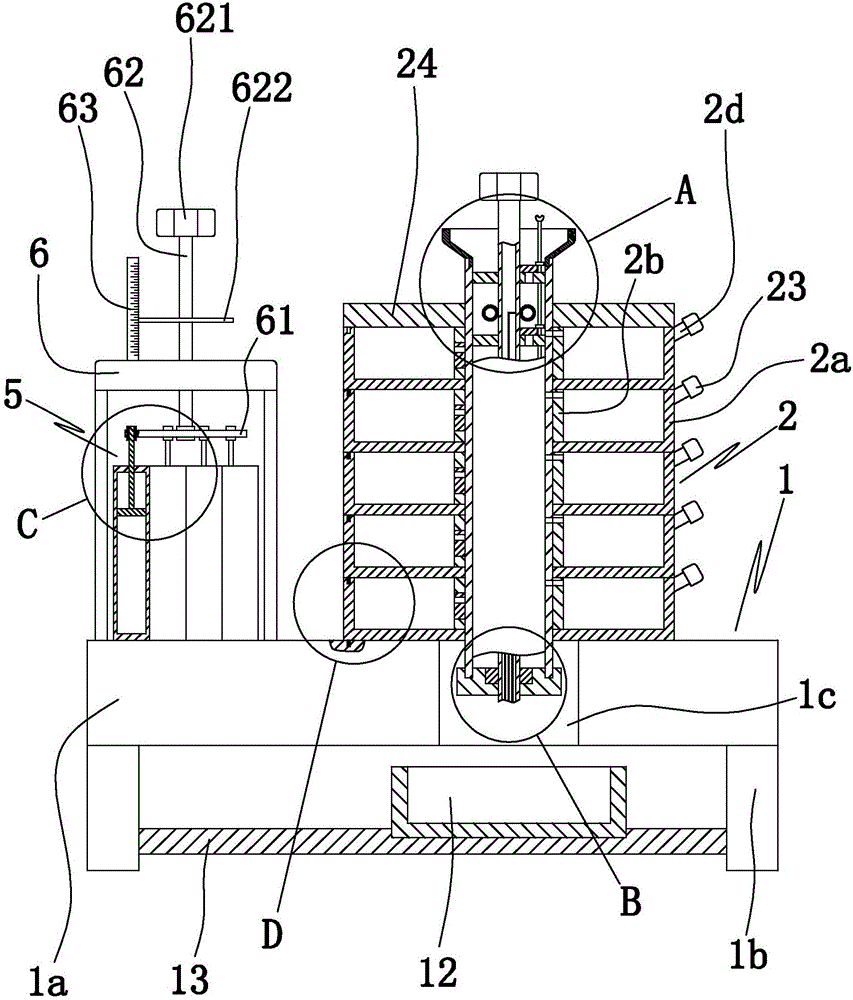

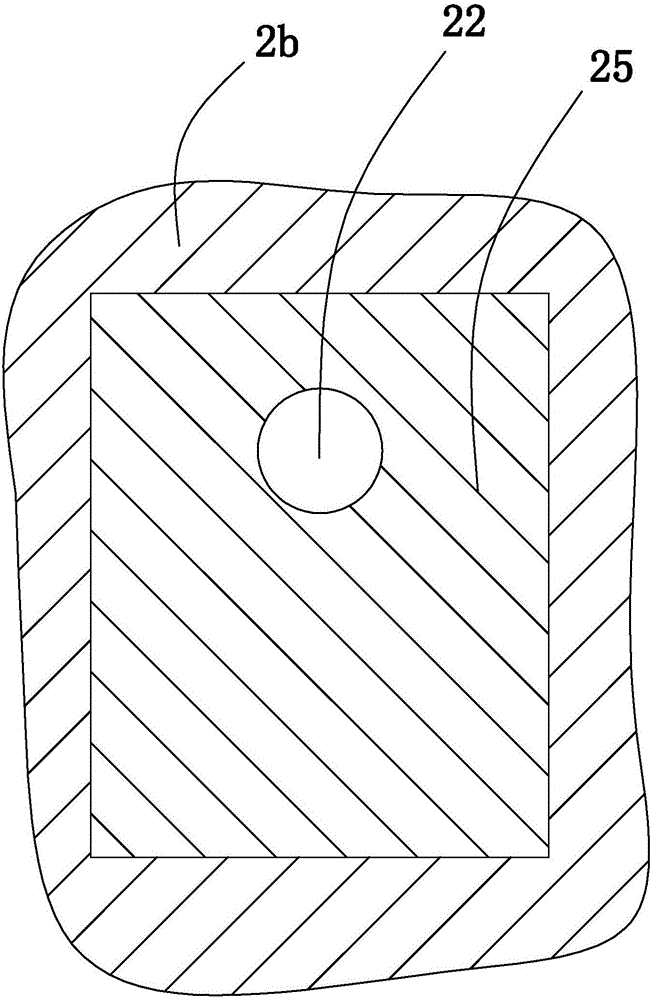

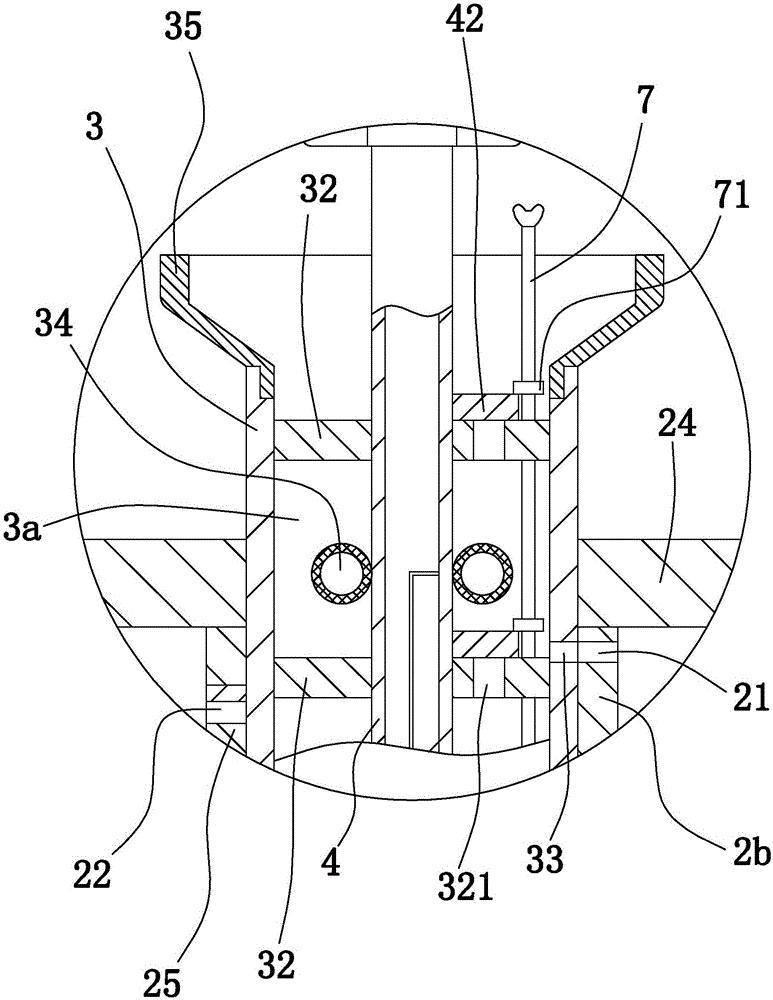

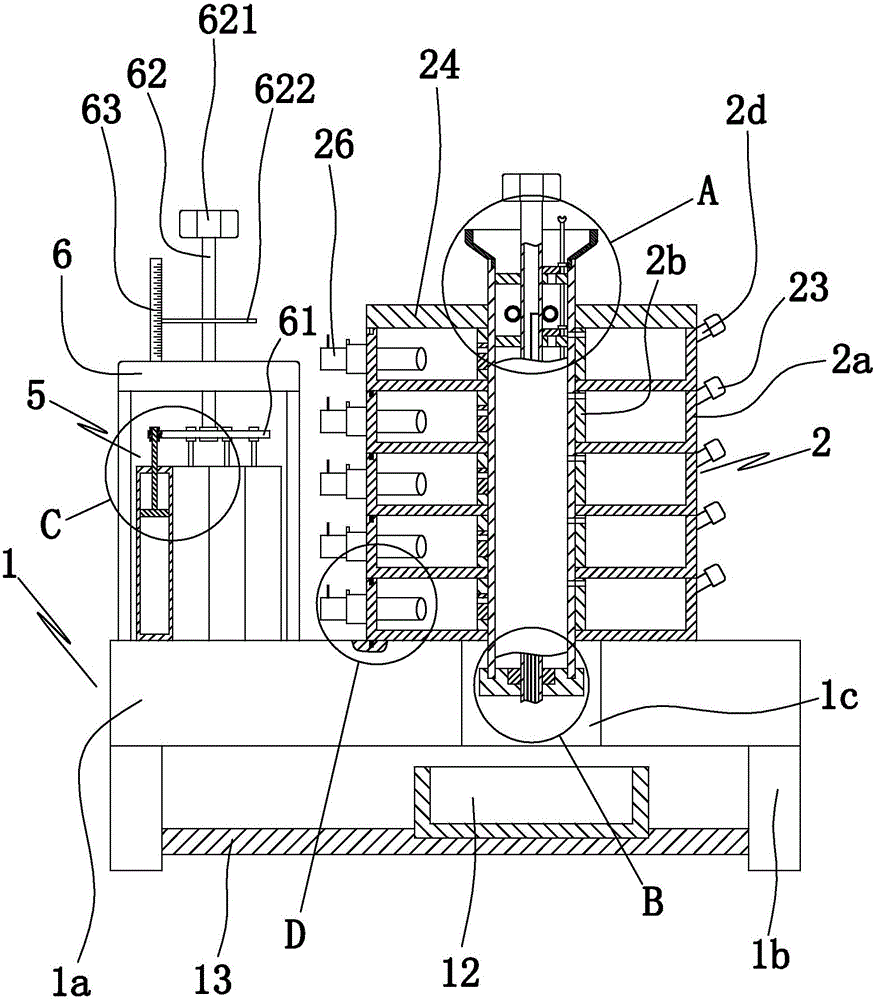

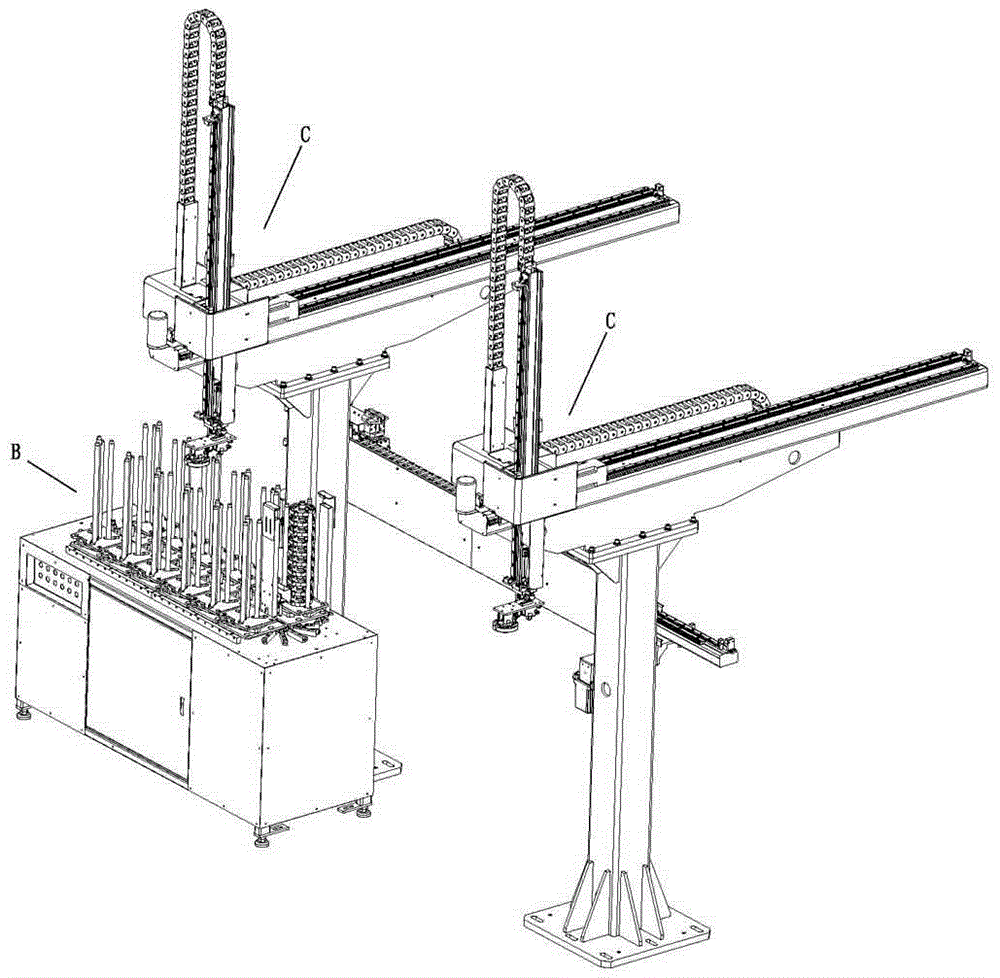

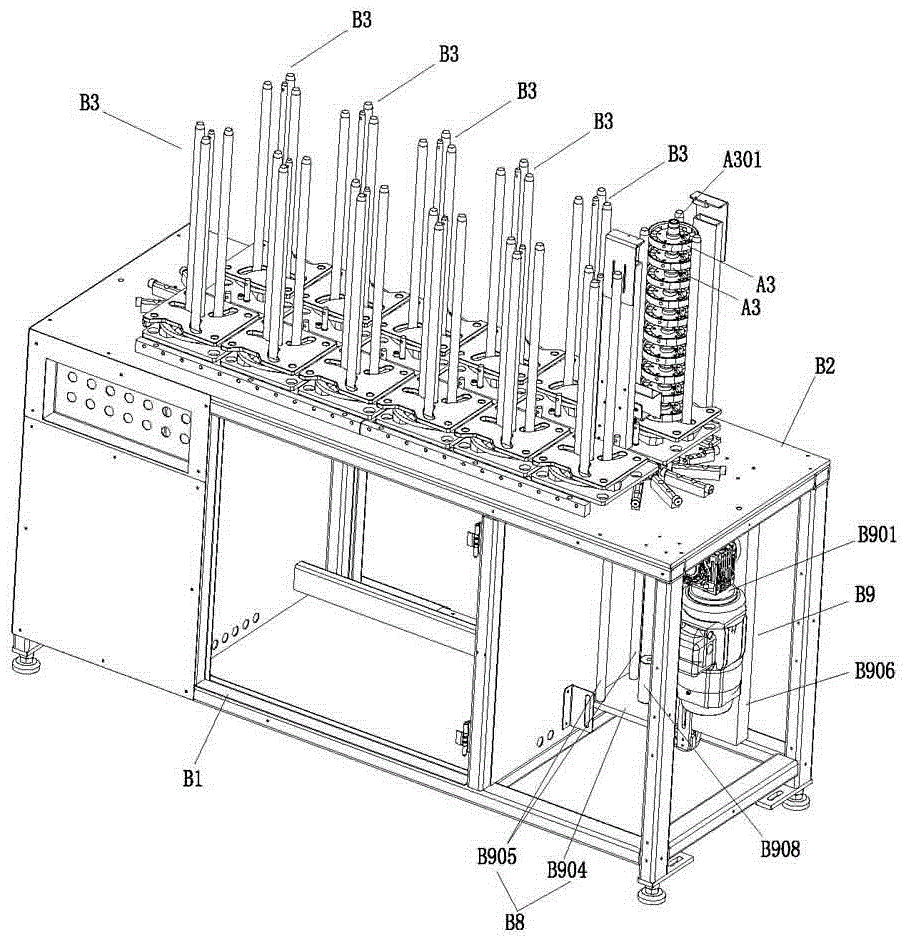

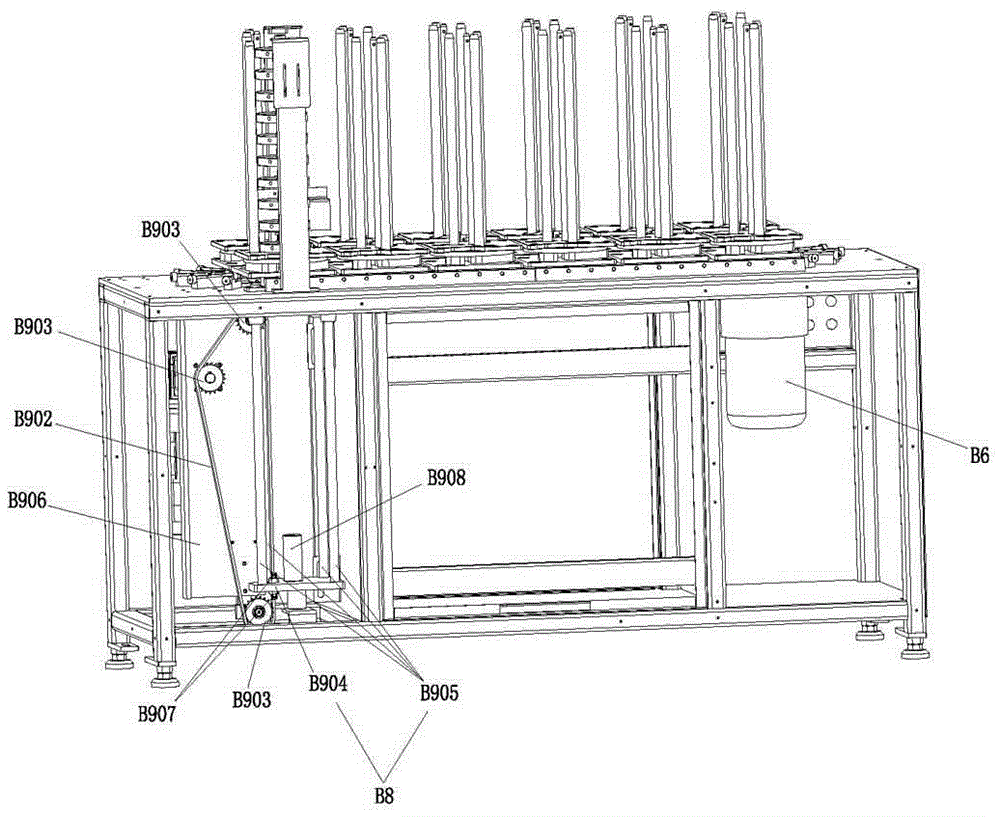

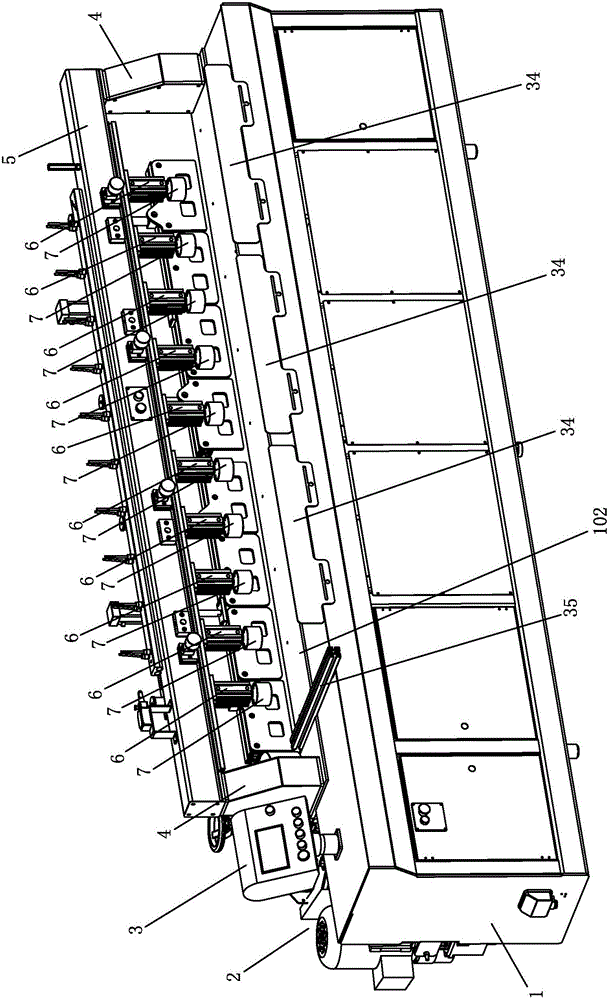

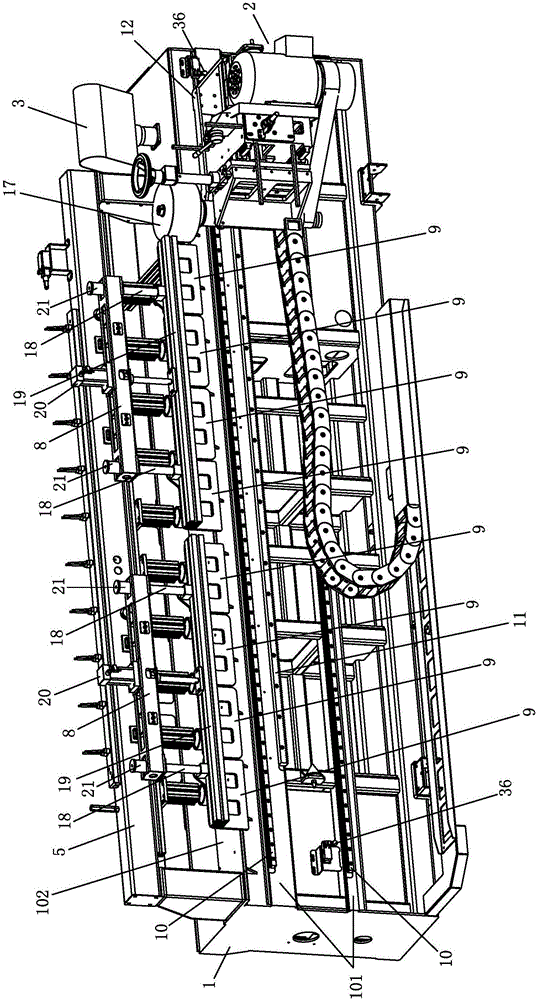

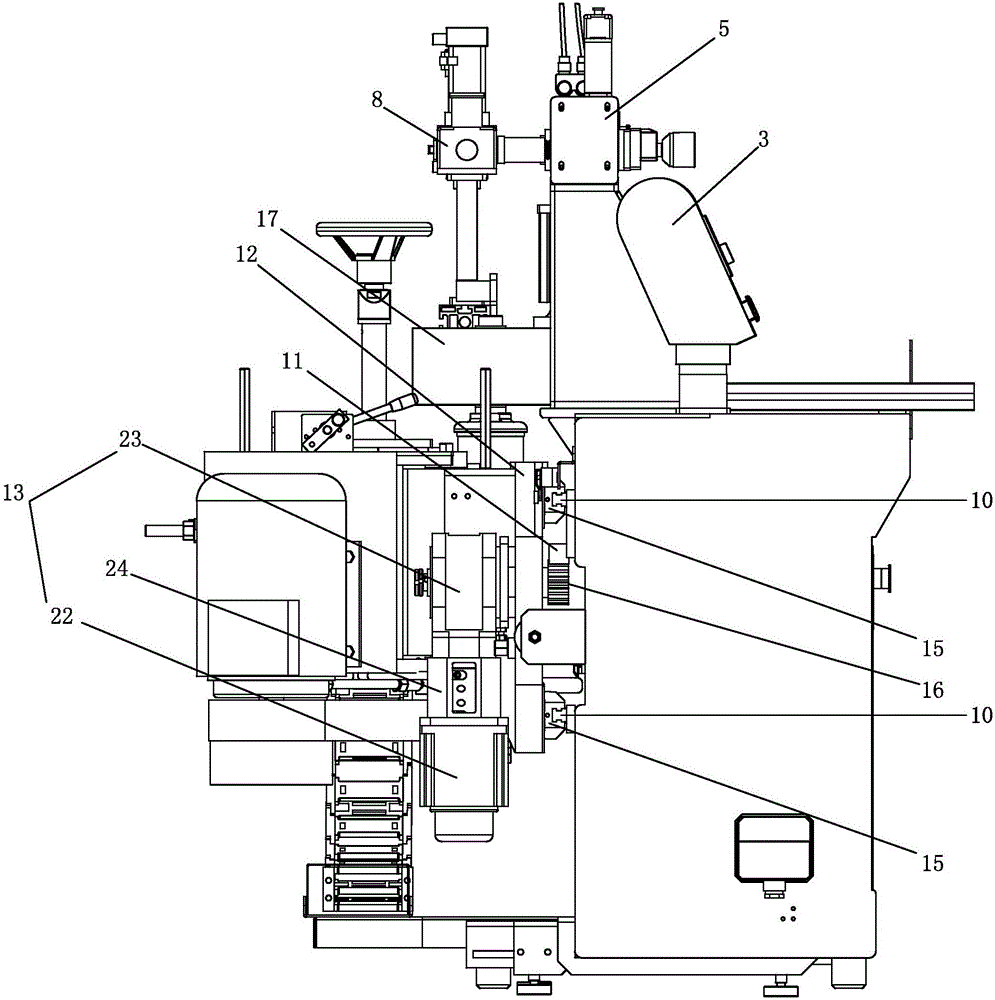

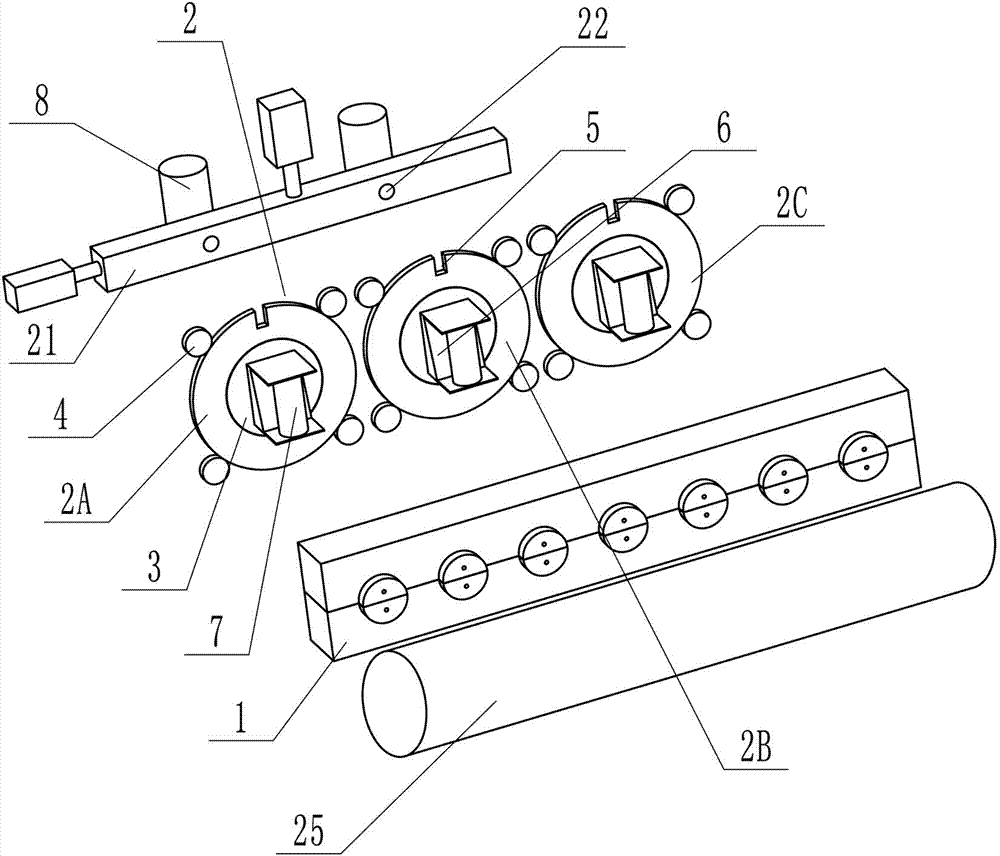

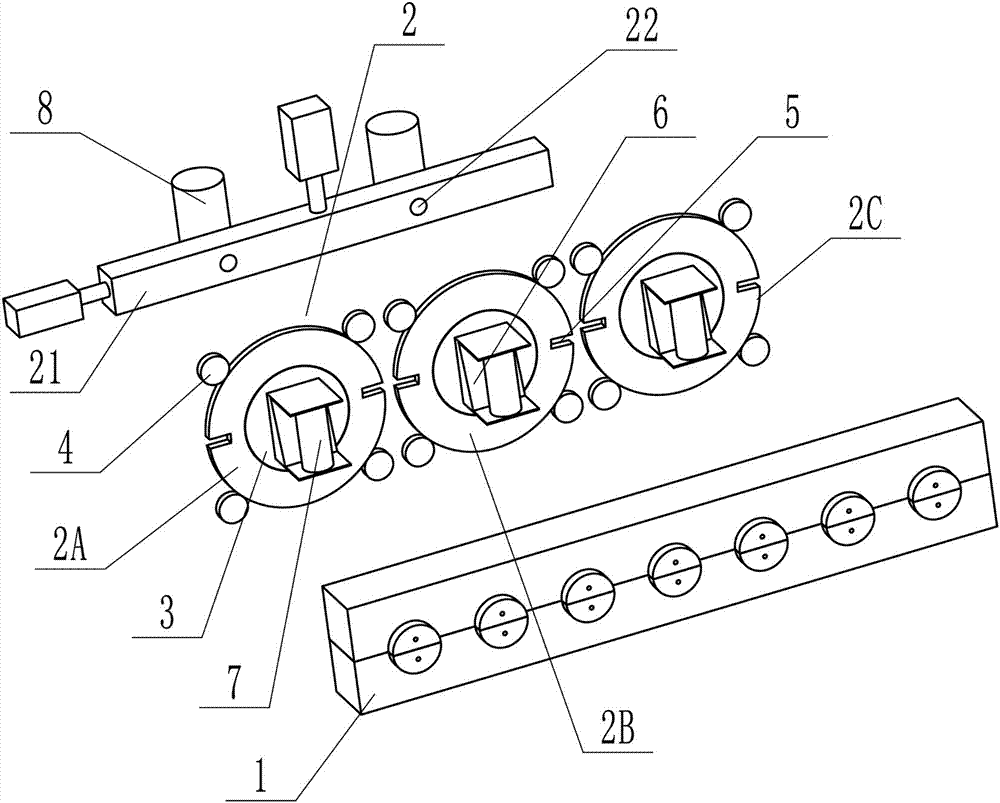

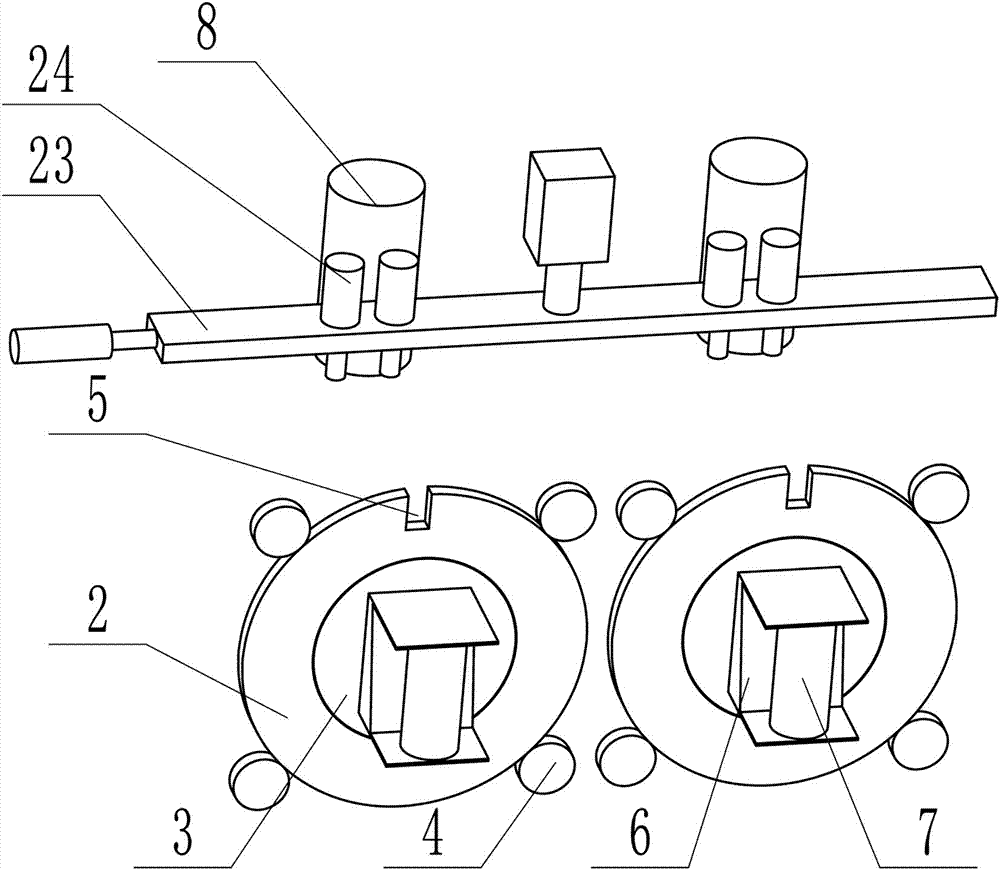

Automatic feeding and taking equipment with u-turning device

The invention relates to automatic feeding and taking equipment with a u-turning device. The automatic feeding and taking equipment comprises a rotary type material bin and two two-shaft mechanical arms and a u-turning transferring device; the rotary type material bin comprises a material bin base, a working table is arranged at the top of the material bin base, a plurality of material storage frames are installed on the working table, and a plurality of workpieces are stacked on each material storage frame; two transmission chain wheels are arranged on the two sides of the working table correspondingly, the two transmission chain wheels are connected through a transmission chain, and one of the transmission chain wheels is driven by a transmission chain wheel motor; the multiple material storage frames are arranged in the layout extending direction of the transmission chain, each material storage frame is in connected fit with the transmission chain through a connecting assembly, and each material storage frame achieves movement along with transmission of the transmission chain; a lifting frame is installed in the material bin base and is driven by a lifting assembly, so that the lifting frame penetrates the working table to upwards lift the workpieces; and the multiple material storage frames are all arranged to be capable of moving along with the transmission chain, rotary workpiece conveying is formed, the storage capacity of the workpieces is effectively increased, and the machining efficiency is effectively improved.

Owner:广东圣特斯数控设备有限公司

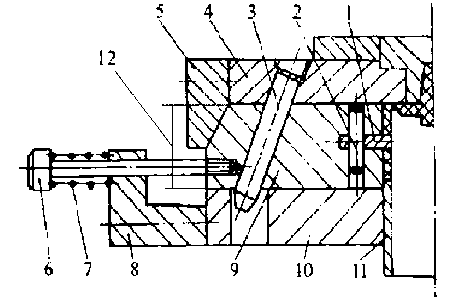

Core-pulling and demoulding combination device

The invention declares a core-pulling and demoulding combination device, which comprises a fixed template and a movable template forming a cavity, wherein a slide block, an inclined guide post, a lateral mold core, a positioning mechanism and an ejector rod are arranged in the cavity; the lateral mold core is hinged to the slide block; the ejector rod and the inclined guide post are fixed in the cavity; the positioning mechanism comprises a compression spring and a bolt; the inclined guide post is fixed on the fixed template; the lateral mold core is hinged to the slide block through a pin; during mold opening, the fixed template move upwards, the inclined guide post drives the slide block to move to the left in a guide sliding chute in the movable template, so as to complete the core-pulling action; in order to guarantee that during mold closing, the inclined guide post can accurately enter into an inclined hole in the slide block to facilitate reset of the slide block, a positioning device is arranged on the mechanism; and with the bolt and the compression spring, the slide block is propped against a spacing stop block for positioning when withdrawn. During the whole process, the demoulding and core-pulling are good in processing property, the cost is low, and therefore, the device provided by the invention is suitable for medium and small sized injection moulded pieces.

Owner:AIMBON (CHENGDU) ELECTRIC APPLICANCE CO LTD

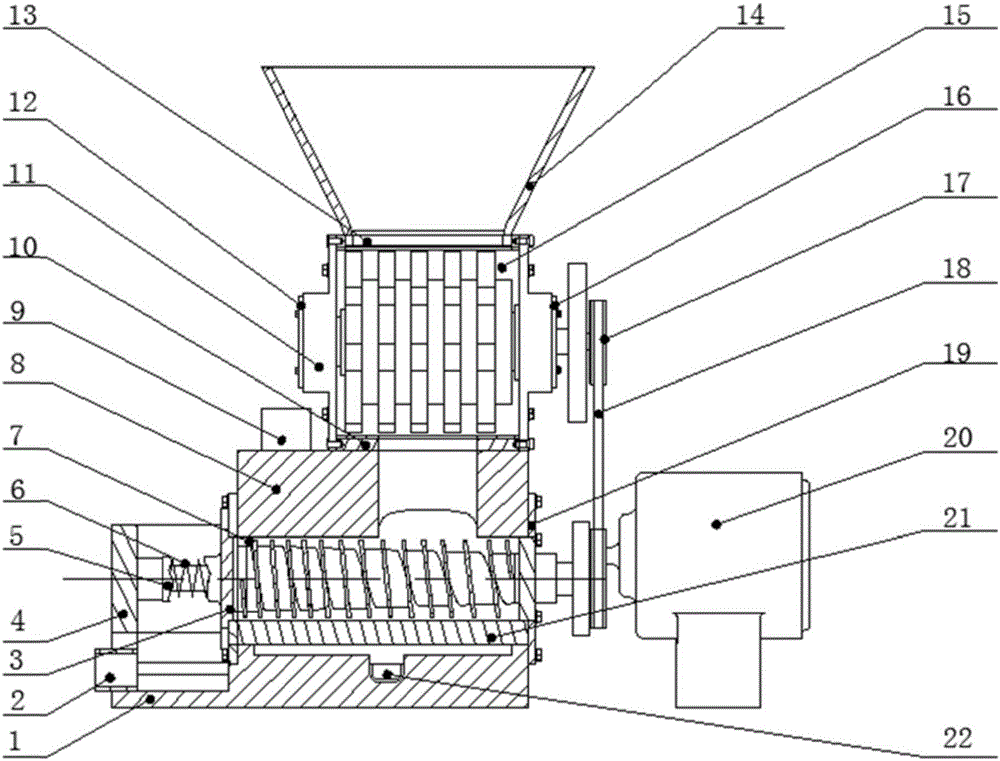

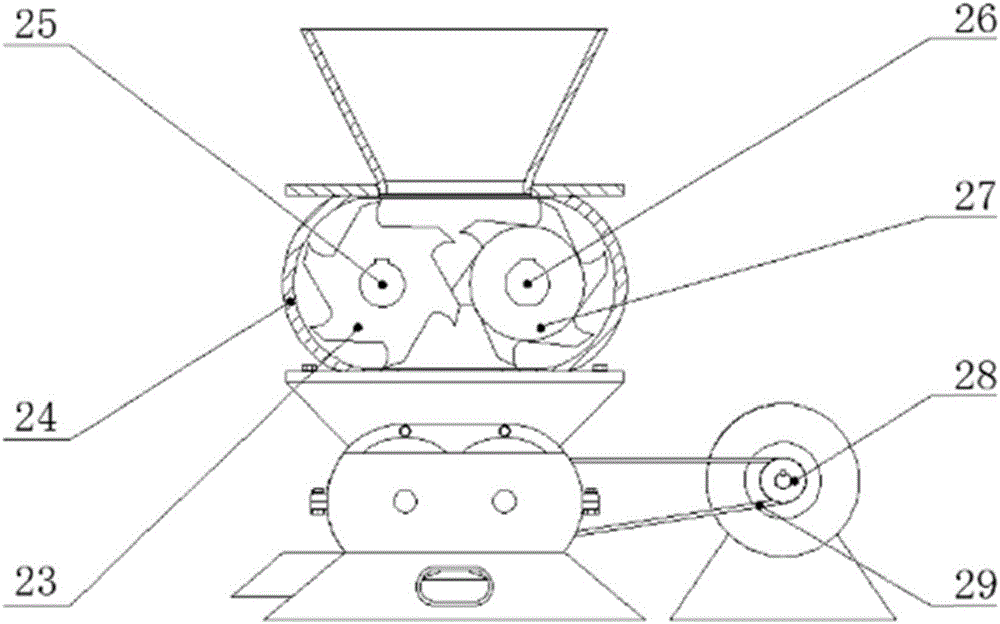

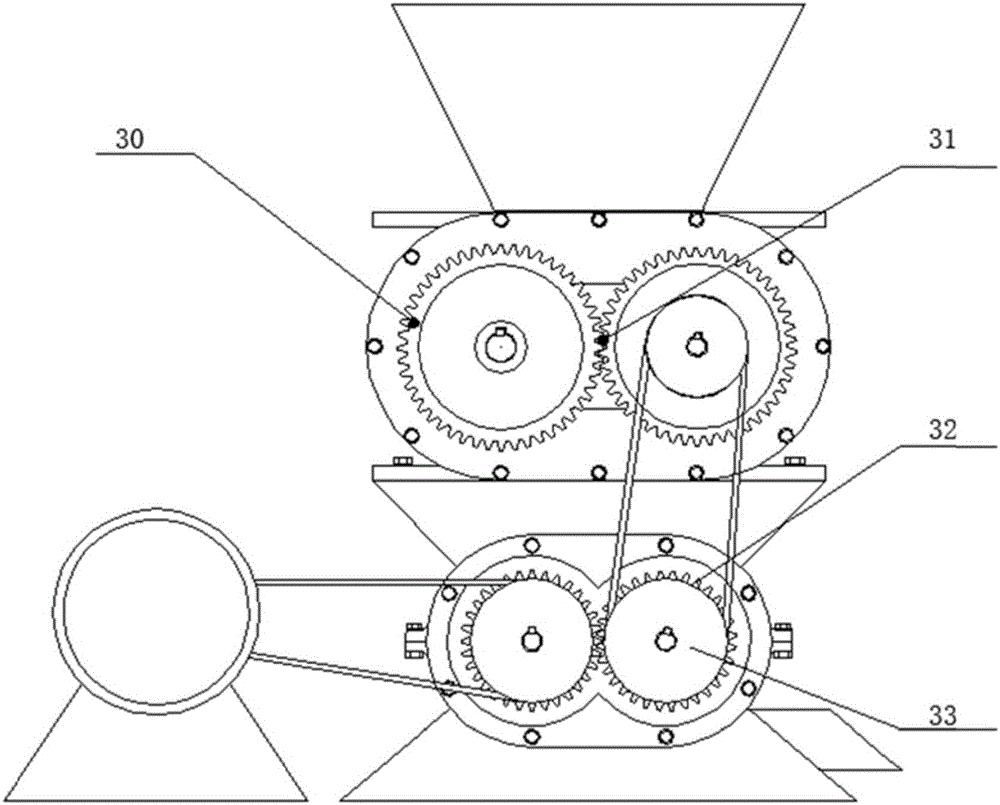

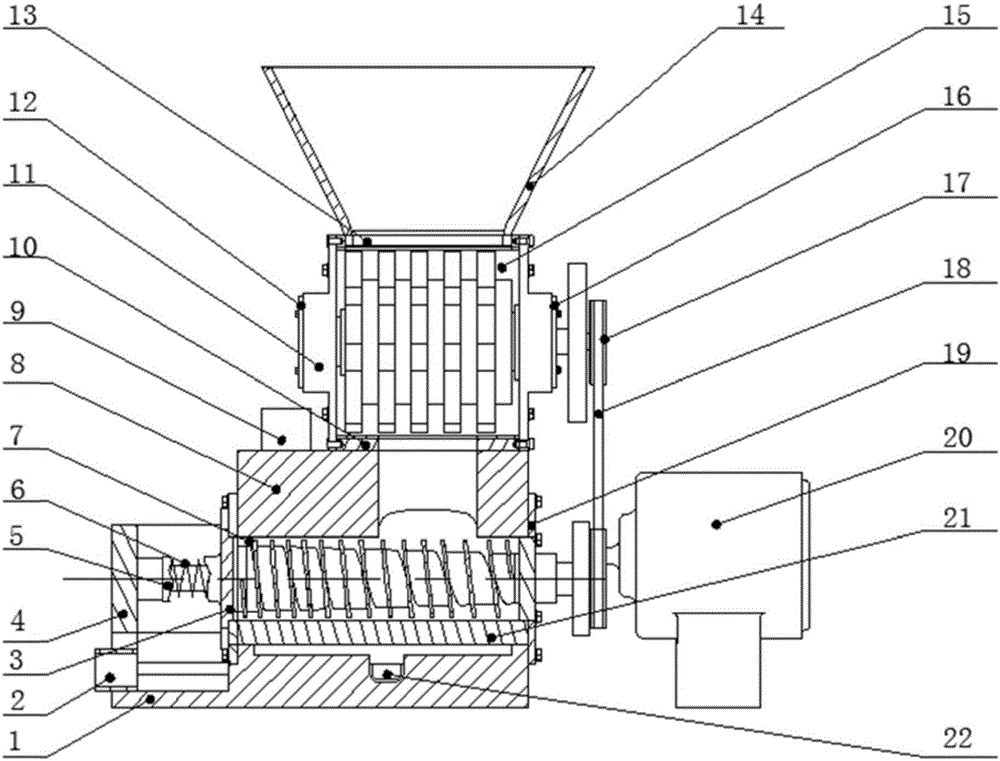

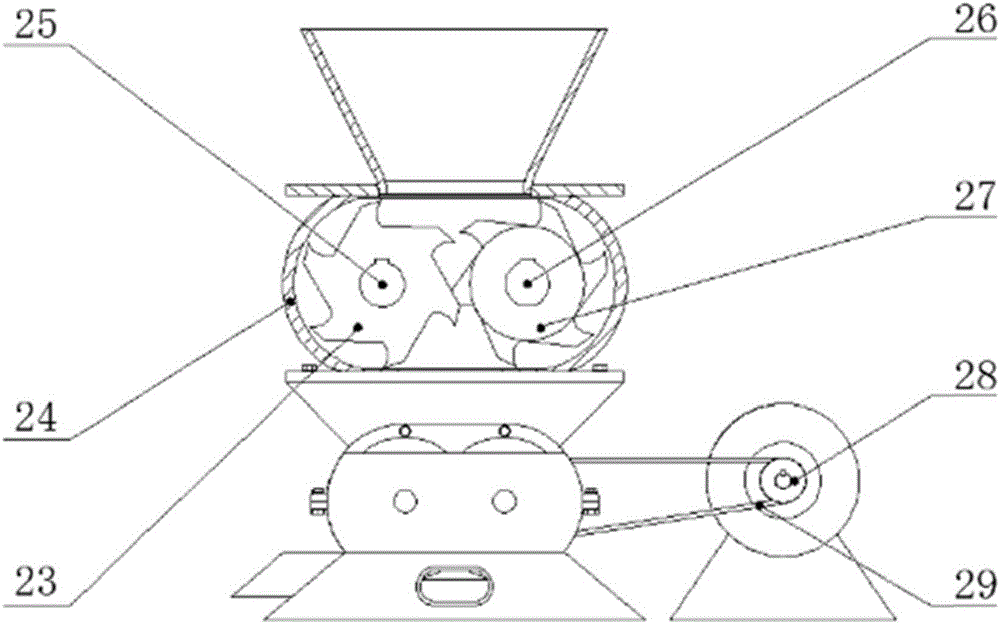

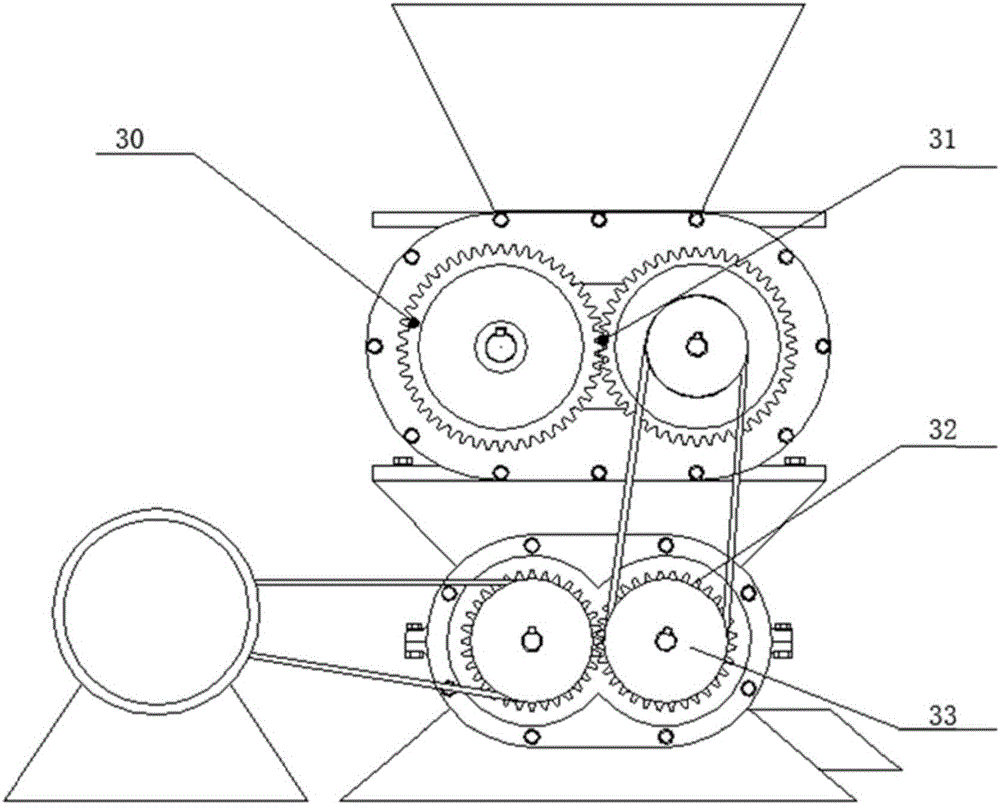

Garbage disposal machine

InactiveCN106000576AReasonable space layoutSimple designGrain treatmentsPressesAutomatic controlMotor drive

The invention discloses a garbage processing machine, which comprises a machine base, an extrusion mechanism, a crushing mechanism, a control unit, and a transmission mechanism; the upper end of the crushing mechanism is connected with a material inlet, and the crushing mechanism is used for crushing the garbage materials introduced from the material inlet processing; the extrusion mechanism and the crushing mechanism each include a box body, the extrusion box body is connected with the crushing box body, and the two boxes are fixed, and the extrusion mechanism is used to squeeze and dehydrate the crushed garbage materials; one end of the extrusion mechanism is The discharge port is equipped with a spring platen mechanism for controlling the extrusion discharge speed; the transmission mechanism includes a motor, a pulley and a transmission gear, and the motor operates through a pulley variable speed transmission and a gear meshing transmission drive device; the control The unit is used to realize automatic control of the working state of the garbage disposal device. The device solves the problem of secondary pollution to the environment caused by inefficient and improper garbage disposal, and relieves the pressure on the disposal of kitchen garbage in daily life.

Owner:范志杰

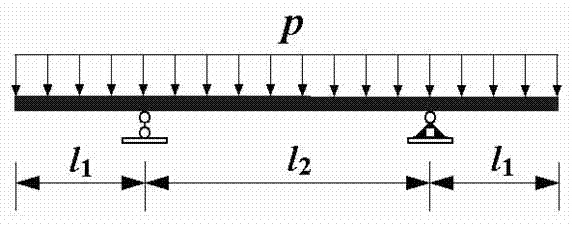

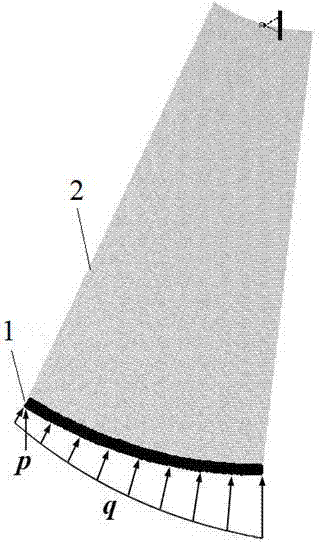

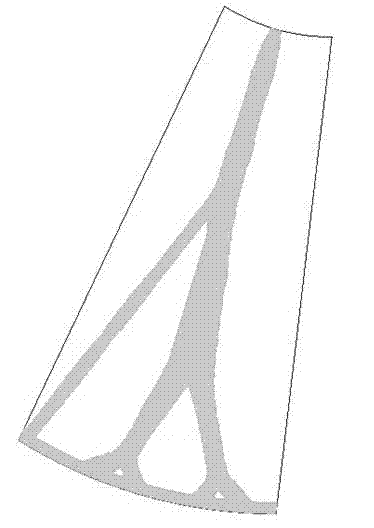

Topology optimization design method for novel down-the-hole arc-shaped hydraulic steel gate

InactiveCN102968518AReduce dosageReasonable space layoutSpecial data processing applicationsTopology optimizationMaterial consumption

The invention discloses a design method based on topology optimization for a novel down-the-hole arc-shaped hydraulic steel gate. The design method comprises the steps of: design of support arms: determining the position of the center of the main support arm relative to vertical symmetric surfaces of a water retaining surfacedeck; topology optimization: to obtain the layout of vertical ribs in a support framework; determination of a new design area and topology optimization to obtain the layout of horizontal ribs in the support framework; construction of the overall structure of the down-the-hole steel gate, and dimensional optimization; and safety check of the structure under other conditions. On the premises of satisfying force-bearing requirements and reducing the dead weight of the structure, the optimal topology of the structural layout can be realized. Large-size two / three-dimensional design of the structure can be performed while actual engineering conditions are satisfied, and the spatial layout is reasonable. Compared with the traditional design, the designed novel gate has the advantages of low material consumption and light dead weight.

Owner:蔡坤

Woodworking straight line edge trimming machine

InactiveCN106378830ASmooth slidingImprove machining accuracyProfiling/shaping machinesEngineeringWoodworking

The invention discloses a woodworking straight line edge trimming machine. The woodworking straight line edge trimming machine comprises a machine base, a main shaft device installed on the rear end face of the machine base and a control device. A worktable is arranged on the machine base. Two material pressing seats are fixed to the positions, close to the rear end face of the machine base, of the two sides of the worktable. A material pressing cross beam is connected between the two material pressing seats. Multiple material pressing air cylinders are perpendicularly installed on the bottom face of the material pressing cross beam. The tail ends of telescopic rods of the material pressing air cylinders are connected with material pressing heads. The rear end face of the material pressing cross beam is connected with at least one positioning seat, and positioning backup plates capable of being adjusted to ascend and descend are connected below the positioning seats. Two guide rails are arranged on the part, below the positioning backup plates, of the rear end face of the machine base, wherein the two guide rails are arranged in an up-and-down manner and extend in the transverse direction of the machine base, and a rack is further fixed to the rear end face of the part, between the two guide rails, of the machine base. The woodworking straight line edge trimming machine is simple and reasonable in structure, multiple wood blocks or wood bars can be machined at the same time, the machining efficiency is effectively improved, the machining precision of the machine is high, and consistency of flatness of end faces obtained after edge trimming is relatively high.

Owner:NEW MAS WOODWORKING MACHINERY & EQUIP

Treatment device for kitchen waste

InactiveCN105817306AReasonable space layoutSimple designGrain treatmentsPressesAutomatic controlWaste treatment

The invention discloses a treatment device for kitchen waste, and belongs to the field of waste treatment. The treatment device for kitchen waste comprises a machine seat, a squeezing mechanism, a crushing mechanism, a control unit and a transmission mechanism, wherein the upper end of the crushing mechanism is connected with a feeding opening; the crushing mechanism is used for crushing waste introduced from the feeding opening; the squeezing mechanism and the crushing mechanism each comprise a box body, and the squeezing box body communicates with the crushing box body and is fixed to the crushing box body; the squeezing mechanism is used for dehydrating the crushed waste in a squeezing mode; one end of the squeezing mechanism is provided with a discharging opening, and a spring pressing plate mechanism used for controlling the squeezing and discharging speed is arranged at the discharging opening; the transmission mechanism comprises a motor, a belt wheel and a transmission gear, and the motor drives the device to operate through variable transmission of the belt wheel and engagement transmission of the gear; the control unit is used for realizing automatic control over the work state of the treatment device for kitchen waste. By means of the treatment device for kitchen waste, the problem of secondary environment pollution caused by low-efficiency and inappropriate waste treatment is solved, and pressure on kitchen waste treatment in the life is relieved.

Owner:CHAOHU UNIV

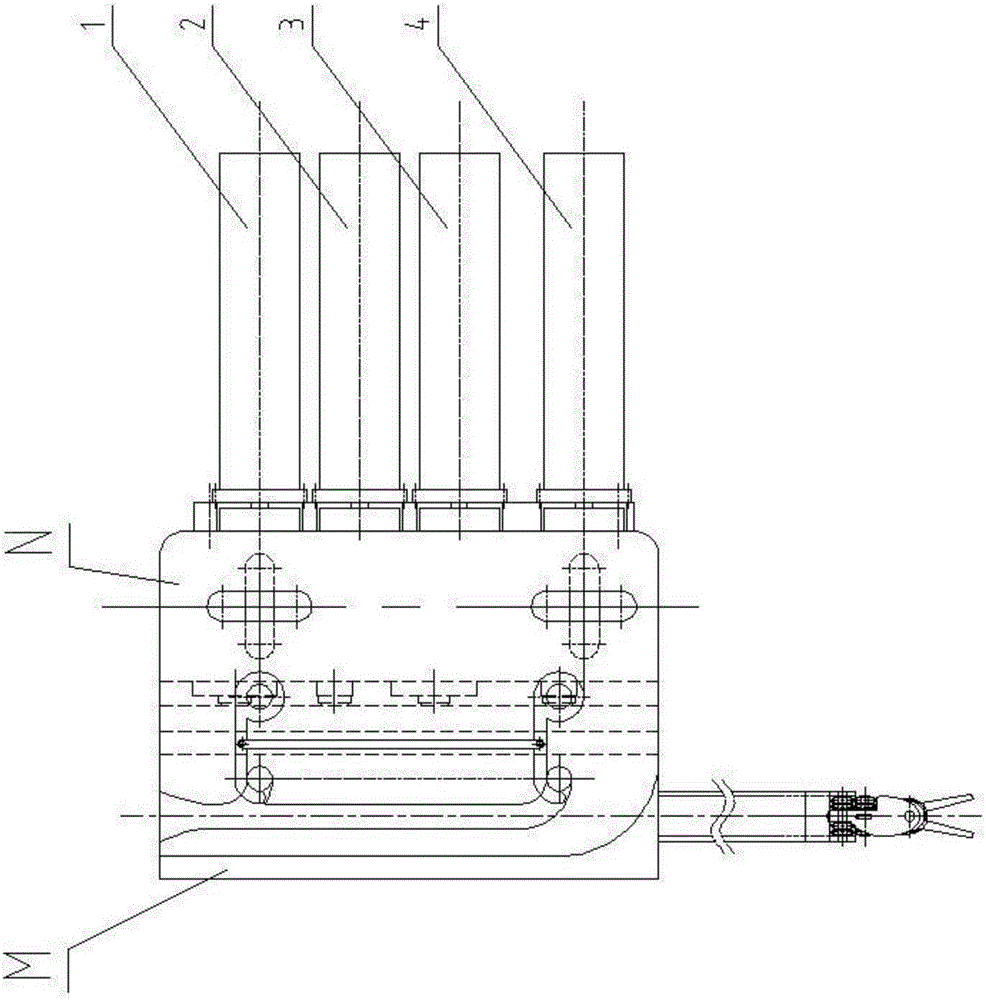

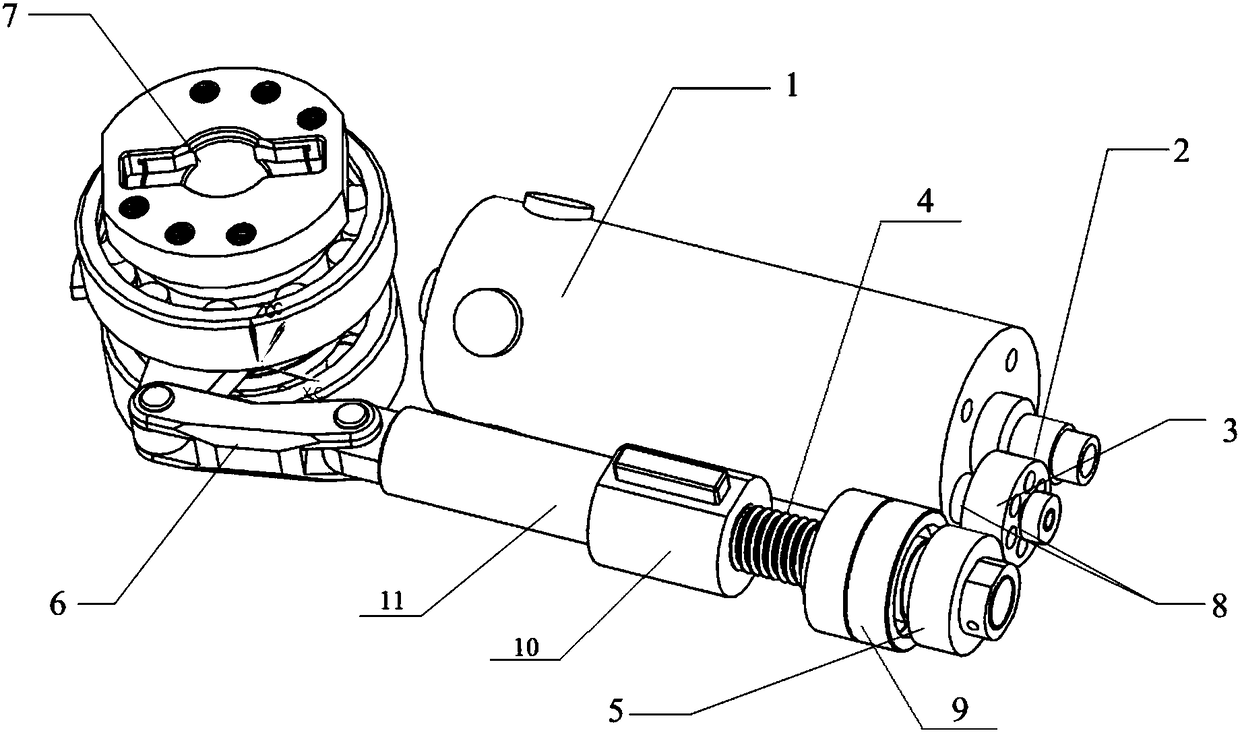

Quick changing mechanism of operation robot for minimally invasive surgery

PendingCN106725650AEasy to assemble and disassembleEasy to adjustSuture equipmentsInternal osteosythesisLocking mechanismLeft fingers

The invention discloses a quick changing mechanism of an operation robot for minimally invasive surgery, comprising a left finger driving mechanism, a wrist joint driving mechanism, a right finger driving mechanism, an operation pipe driving mechanism and a base shell, a base cover, a connector and a locking mechanism. Through long bolt holes on the base cover and the base shell, relative installing position between the base cover and the base shell is adjusted; through a guide chute on a cutter base cover, relative installing position of an operation apparatus executing mechanism and an interface base is accurately positioned; a parallelogram hanging hook locking mechanism can exactly and conveniently lock and unlock the operation apparatus executing mechanism a decoupling mechanism is installed on the interface base, so as to simplify the structural design of the operation apparatus executing mechanism, and benefit the massive production of the operation apparatus executing mechanism. The quick changing mechanism of the operation robot for minimally invasive surgery is convenient to mount and dismount, easy to adjust, accurate in location, big in rigidity, reasonable in layout, miniaturization and light weight.

Owner:SHANDONG UNIV QILU HOSPITAL

High-load compact electric steering engine transmission mechanism

InactiveCN108657419AReasonable space layoutCompact structureWithout power ampliicationBall screwActuator

The invention belongs to the technical field of electro-mechanical actuators and in particular relates to a high-load compact electric steering engine transmission mechanism. The high-load compact electric steering engine transmission mechanism comprises a shell, a servo motor, a motor gear, an idle wheel, a ball screw, a lead-screw gear, a connecting rod, an output shaft, an idle wheel bearing, alead-screw bearing, a lead-screw nut and a nut sleeve. According to the high-load compact electric steering engine transmission mechanism, the technical problem that a high-speed small-sized aircraftdimension requirement and a loading capacity requirement cannot be both taken into consideration in the existing electric steering engine transmission mechanism is solved; and as the ball screw is used as a main transmission part of a steering engine, the layout of the spatial position of each part is reasonably, the structure is compact, the volume and dimension are smaller, and the higher loading capacity is realized.

Owner:BEIJING AUTOMATION CONTROL EQUIP INST

Mesh weaving structure of hexagonal wire mesh weaving machine

InactiveCN107138656APrevent falling outSmall structureWire networkBraidEngineeringMechanical engineering

The invention relates to a mesh weaving structure of a hexagonal wire mesh weaving machine. The mesh weaving structure comprises a wire twisting device, first wire feeding devices, rotating devices, a wire poking device and second wire feeding devices; the first wire feeding devices are arranged behind the wire twisting device and used for feeding wires to the wire twisting device, the rotating devices are arranged between the first wire feeding devices and the wire twisting device and used for enabling the mesh wires to rotate, the wire poking device is arranged between the rotating devices and the first wire feeding devices and used for poking the mesh wires from one gear disc to a gear disc located at the adjacent position of the gear disc, and the second wire feeding devices are used for feeding the wires to the wire twisting device. According to the mesh weaving structure of the hexagonal wire mesh weaving machine, the gear discs used for enabling the mesh wires to rotate are arranged behind the wire twisting device, therefore, the condition that the mesh wires located behind the wire twisting device are woven when weaving is conducted can be effectively prevented, it is guaranteed that the weaving work is smoothly conducted, a spring-shaped mesh wire structure is omitted, and the labor intensity of workers is greatly reduced; meanwhile, the using time of the first wire feeding devices is long, therefore, frequent replacement is not needed, and the working efficiency is improved.

Owner:定州市精锐机械科技有限公司

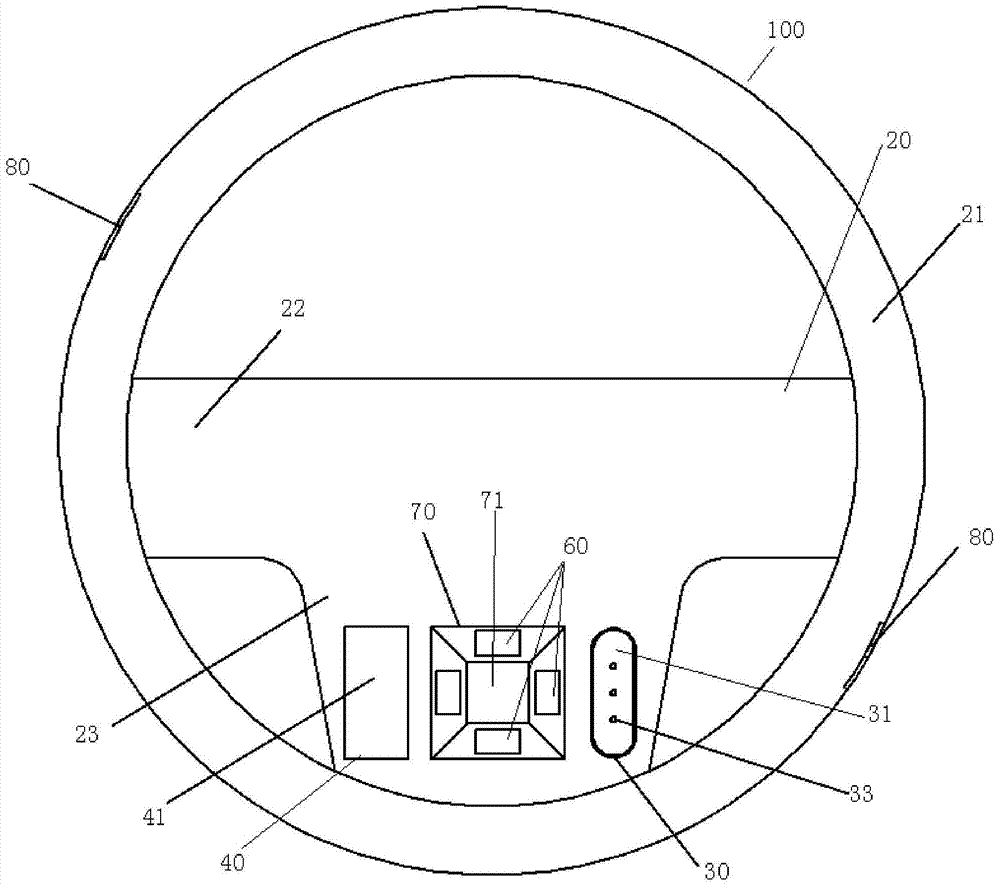

Control system of vehicle

InactiveCN107031697AReduce in quantityReasonable space layoutDashboard fitting arrangementsHand wheelsVibration controlSteering wheel

The invention discloses a control system of a vehicle. The control system comprises a multimedia entertainment unit, a steering wheel and a main control unit; a vibration control unit and a touch control unit are arranged on the steering wheel; the vibration control unit is used for perceiving the knocking action of a driver and sending a vibration signal; the touch control unit is used for perceiving the touch control action of the driver and sending a touch control signal; and the main control unit communicates with the multimedia entertainment unit, the vibration control unit and the touch control unit and is used for receiving the vibration signal and the touch control signal and controlling the multimedia entertainment unit to enter corresponding functions based on the received signals. The driver can realize the corresponding functions of the multimedia entertainment unit through the vibration control unit and the touch control unit, so that the number of keys arranged on the steering wheel is reduced, and the space utilization on the steering wheel is improved.

Owner:BAIC MOTOR CORP LTD

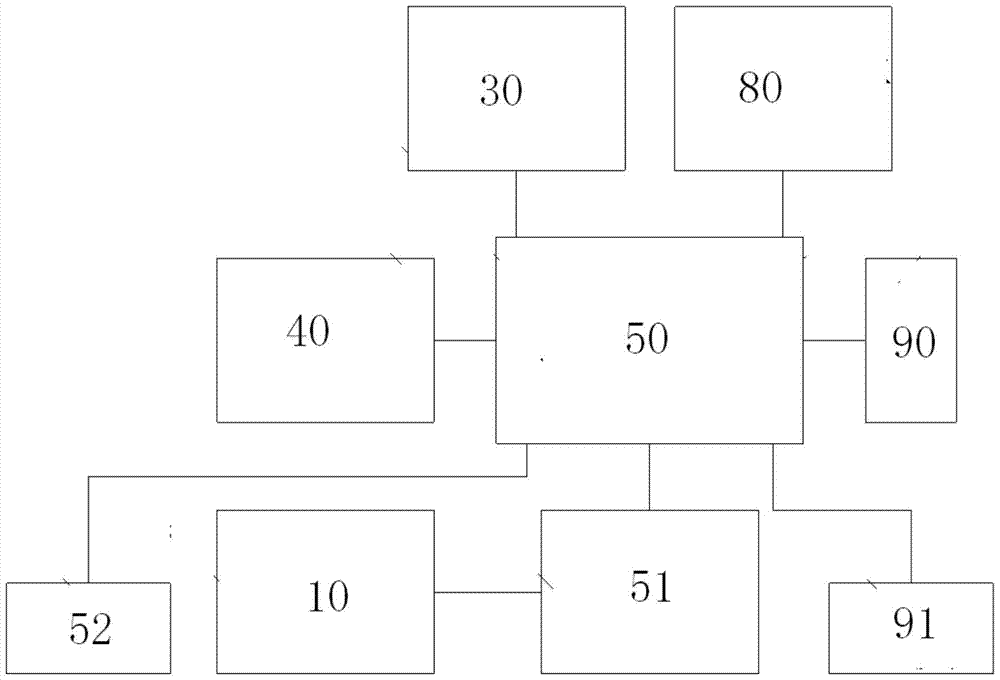

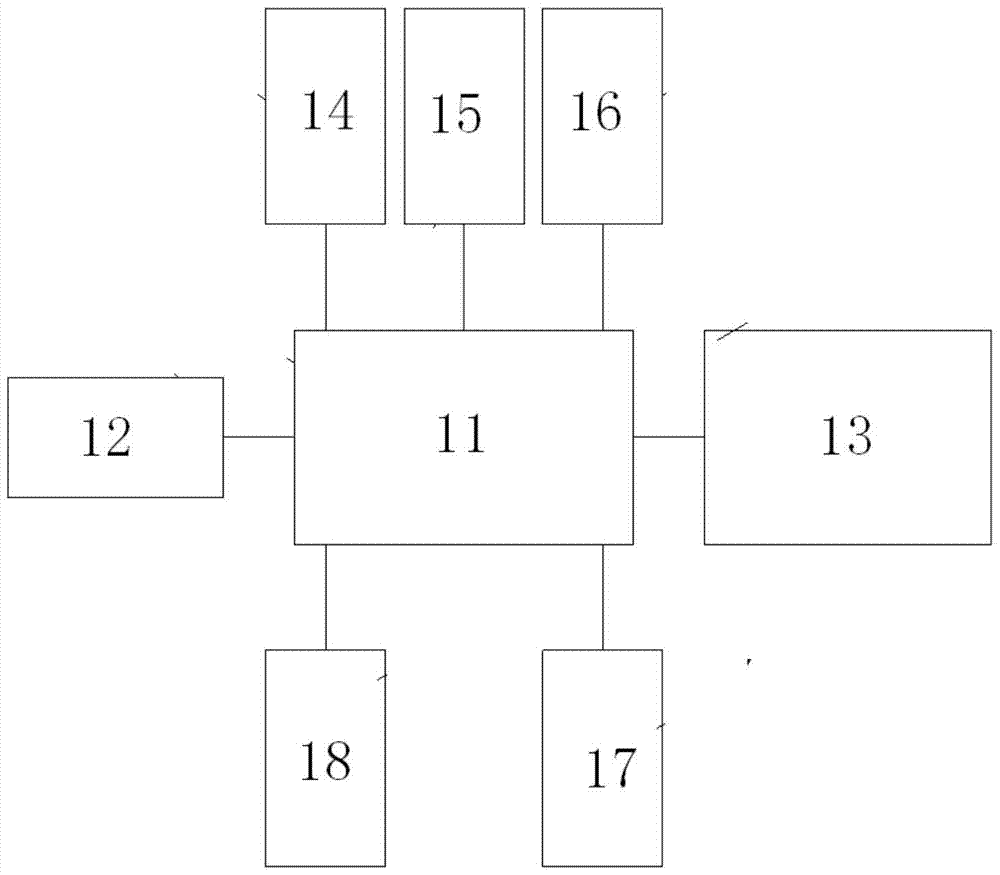

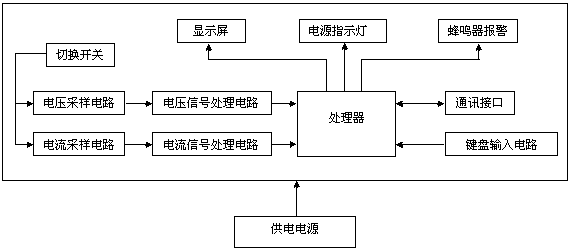

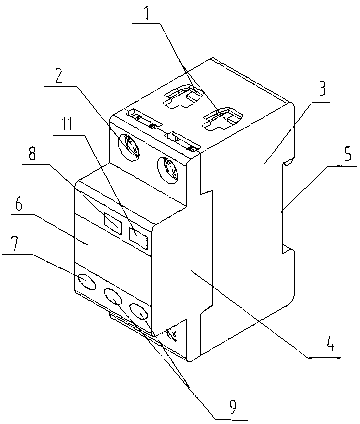

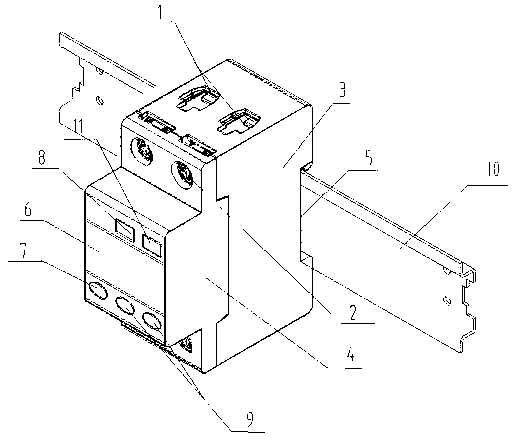

Household electric energy quality monitoring and control device

InactiveCN103063960APlay a protective effectAvoid damagePower network operation systems integrationCircuit arrangementsPower qualityProcess engineering

The invention relates to a household electric energy quality monitoring and control device. A shell body is arranged on a monitoring and control unit, a fixed part which is matched with a guide rail inside a PZ 30 distribution box is arranged on a base bottom of the shell body, so that the aim that the fixed part is conveniently arranged inside the PZ 30 distribution box is achieved. The household electric energy quality monitoring and control device is suitable for distribution box standard of existing household users, and users of the PZ 30 distribution box achieve combination of the distribution box and electric monitoring and control equipment just by low cost. Due to the fact that the monitoring and control unit is wholly arranged in the shell body, the shell body plays a role of protecting for the monitoring and control unit, and misoperation or display screen damaging can be effectively prevented.

Owner:RENMIN ELECTRIC APPLIANCES GROUP

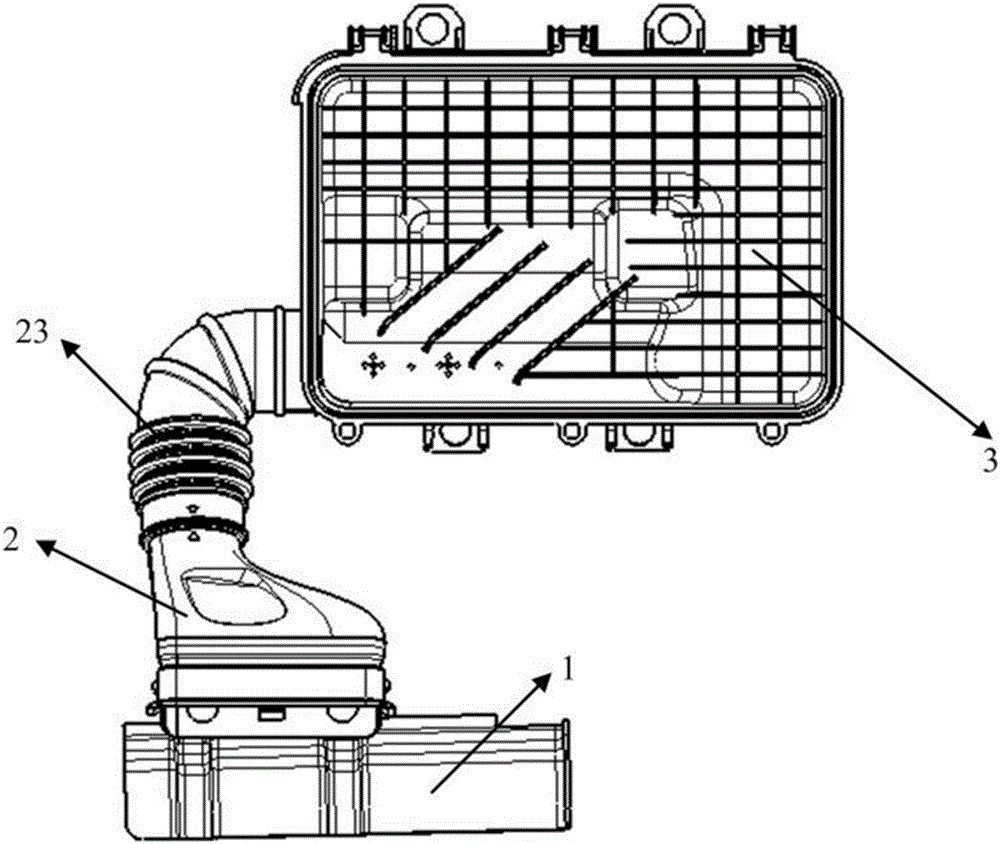

Air inflow guiding device

ActiveCN106481439AEfficient dischargeRealize the function of waterproof and snowproofInternal combustion piston enginesCombustion-air/fuel-air treatmentAir filterEngineering

The invention discloses an air inflow guiding device which comprises a snow blocking plate, an air inflow pipe, an air inlet formed in a lower end of an air filter, and a blocking piece. The snow blocking plate is located below the air inflow pipe and comprises a fixed plate, a connection plate, a snow containing plate and a side face baffle, wherein the fixed plate is fixedly connected with a radiator assembly of an automobile, the fixed plate, the connection plate and the snow containing plate jointly form a structure with the cross section in a right-angle-n shape, and the side face baffle is located at one end of the snow containing plate. The air inflow pipe is made communicated with the air inlet. The blocking piece is fixed to the inner side wall of the lower cover of the air filter. According to the air inflow guiding device, due to the arrangement of the structure of the snow blocking plate, the fixed plate, the connection plate and the snow containing plate jointly form the structure with the cross section in the right-angle-n shape, and the function of preventing water and snow is effectively achieved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Drawing method of multi-display-level map

ActiveCN108563793AReduce time complexityReduce space complexityMaps/plans/chartsSpecial data processing applicationsThinningCode conversion

The invention discloses a drawing method of a multi-display level map. The method includes the steps of weight table processing, wherein by making an interest point criteria classification code tableand setting weight values for classification categories, a weight table is formed; data weight conversion, wherein a classification code conversion comparison table is made, and existing geographic information data is converted and then assigned with values according to the weight table; data thinning, wherein the final weight values of to-be-thinned geographic information data within the thinningradius of each display level are calculated, and the data with the maximum weight value is the thinning result under the display level; illustration drawing, wherein the thinned geographic information data is imported into map engineering for drawing. In the method, the geographic information data is classified according to interest points, the weight values are calculated, and then data thinningis completed level by level according to the map display levels, so that the data thinning result with the most reasonable data layout and the most comprehensive data importance expression is obtained.

Owner:成都瀚涛天图科技有限公司

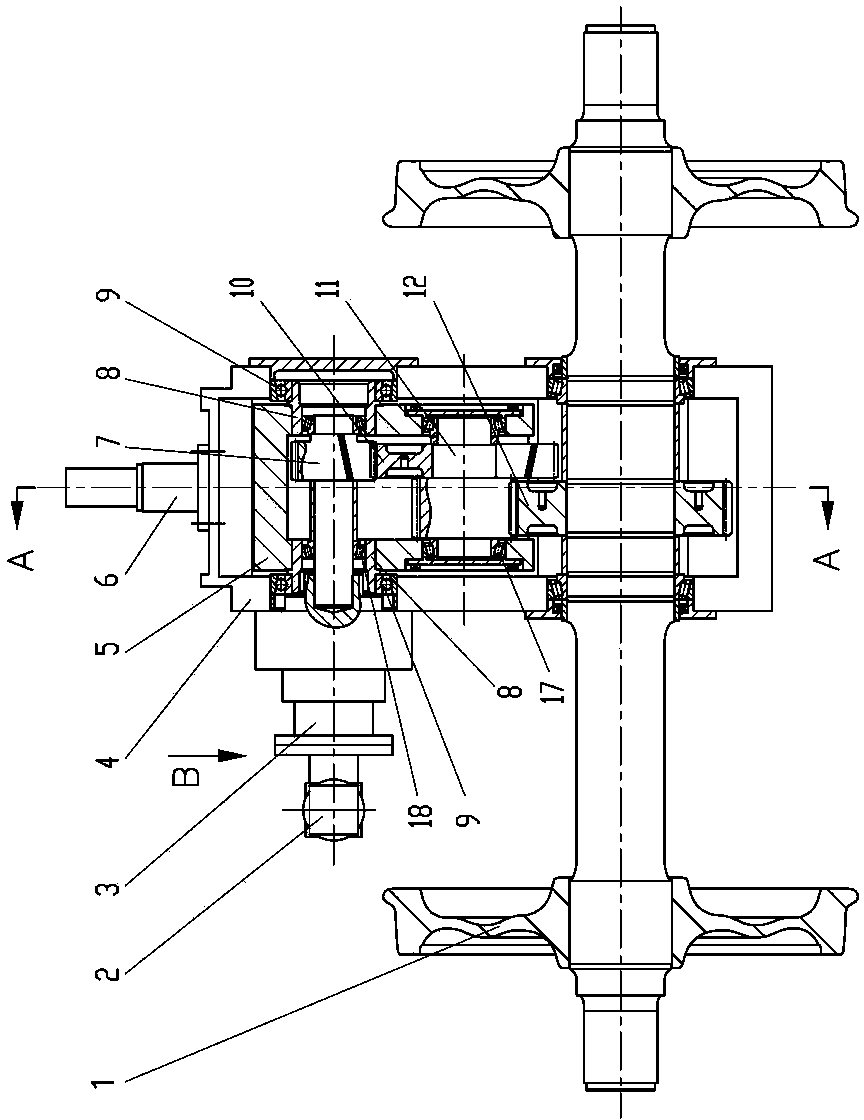

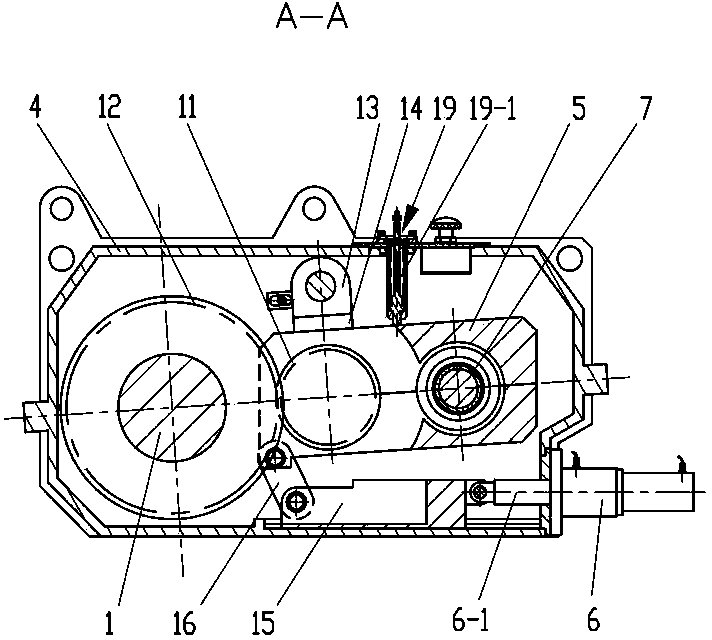

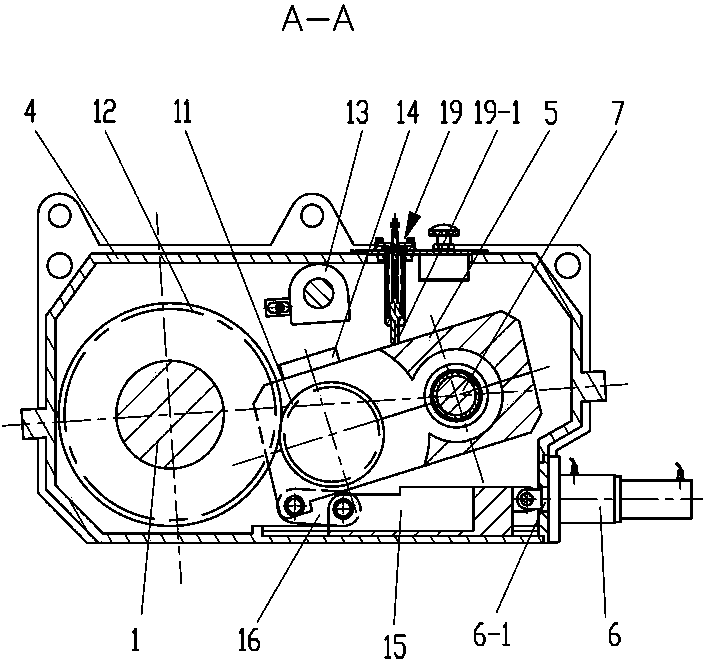

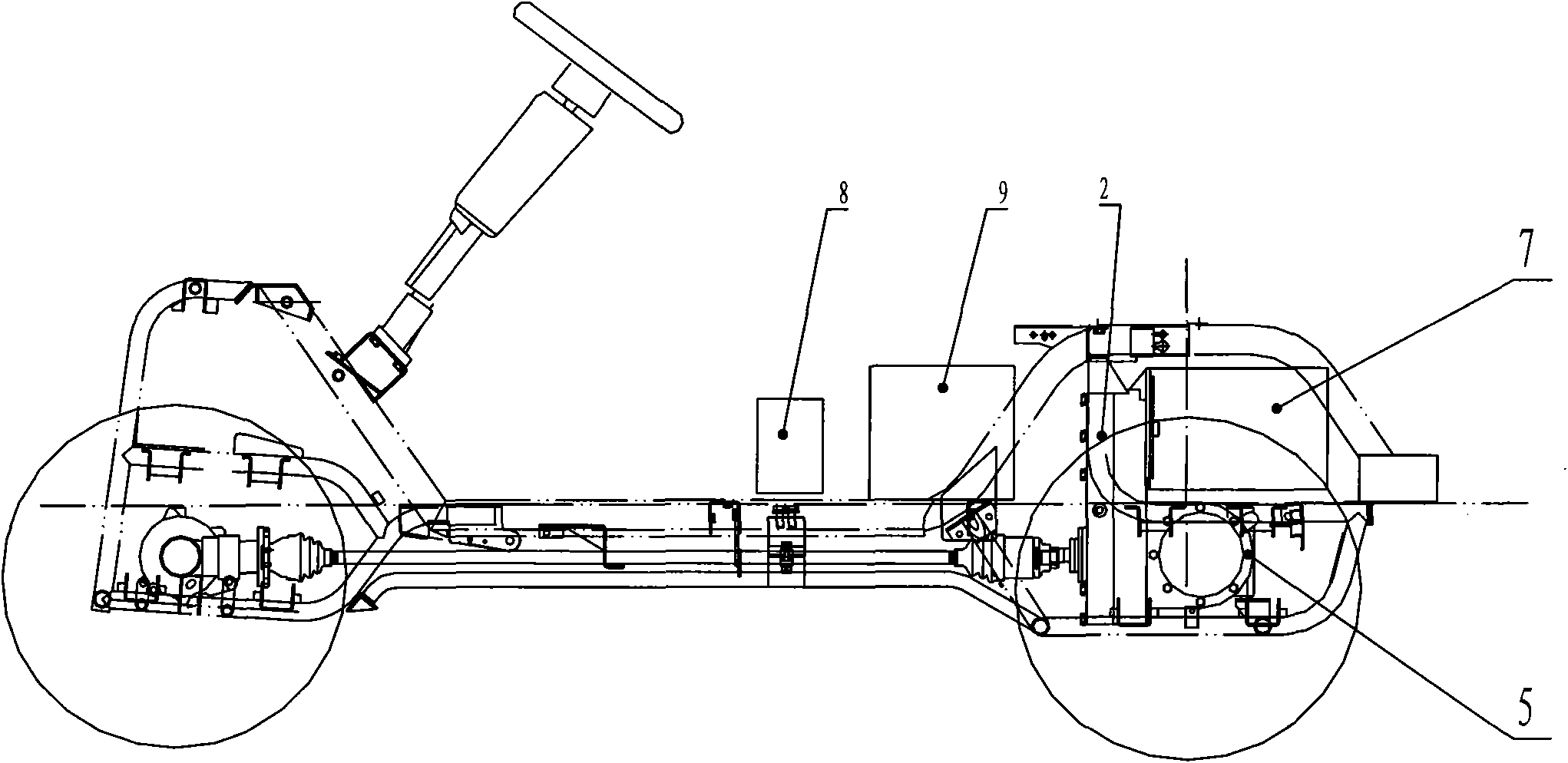

Operating gearbox

ActiveCN104235303AAchieve zero backlash transmissionSave space for horizontal installationToothed gearingsGearing controlHydraulic motorLocking mechanism

The invention discloses an operating gearbox of a large railway maintenance machine, and particularly relates to an operating gearbox. The operating gearbox comprises a hydraulic motor, a box body, a driving gear shaft, a driven gear, an intermediate gear shaft, an axle gear, a wheel set, a shifting mechanism and a locking mechanism, wherein the box body is provided with a planetary reduction mechanism; the planetary reduction mechanism is connected with the driving gear shaft; the input end of the planetary reduction mechanism is transmitted by a bevel gear pair; the hydraulic motor is vertically connected with the planetary reduction mechanism by the bevel gear pair; the box body is also provided with a shifting display mechanism which comprises a mounting plate, a sleeve, a display shaft, a spring and a platen. The operating gearbox has the advantages of big speed ratio, high transmission precision, stable shifting process, safety and convenience in operation, reasonable structure and easiness in manufacture.

Owner:CHANGZHOU RUITAI ENG MASCH CO LTD +1

Four-drive electric car

InactiveCN101648526AThe overall structure is simple and reliableCompact structureOff-road vehiclesPropulsion by batteries/cellsLeft halfDc dc converter

The invention discloses a four-drive electric car comprising a car body, a chassis and a power device, wherein the power device comprises an accumulator battery, a motor, a DC-DC converter and a motorcontroller; the chassis comprises a car frame, a speed-change torque divider, a transmission shaft, a front axle assembly and a rear axle assembly, wherein the speed-change torque divider, the frontaxle assembly and the rear axle assembly are arranged on the car frame, and the transmission shaft is connected between an output shaft of the speed-change torque divider and the front axle assembly;the accumulator battery, the motor, the DC-DC converter and the motor controller are electrically connected, the accumulator battery provides electric power to enable the motor to rotate and transmitpower to the speed-change torque divider, the speed-change torque divider transmits a part of the power to the front axle assembly and finally transmits the power to a left front wheel and a right front wheel through a front axle left half shaft and a front axle right half shaft; the output shaft of the speed-change torque divider is connected with the rear axle assembly, and the other part of thepower is transmitted to a rear axle rear half shaft and a rear axle right half shaft through the output shaft by the rear axle assembly and then transmitted to a left rear wheel and a right rear wheel.

Owner:GREENWHEEL ELECTRIC VEHICLE

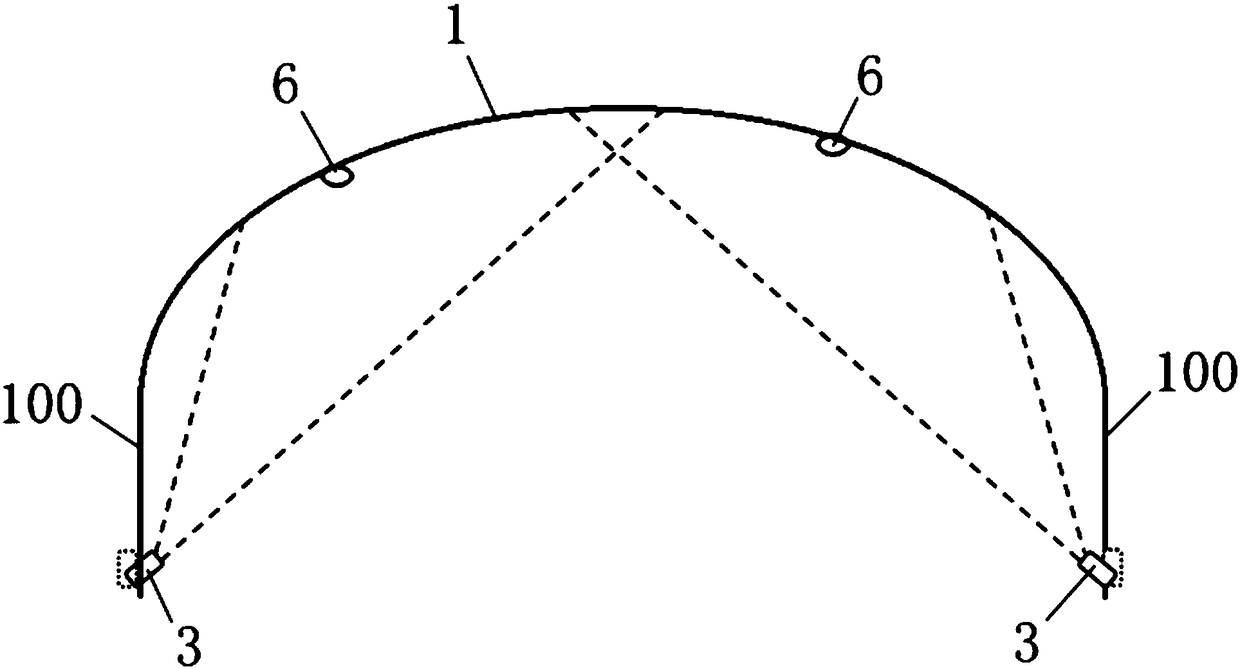

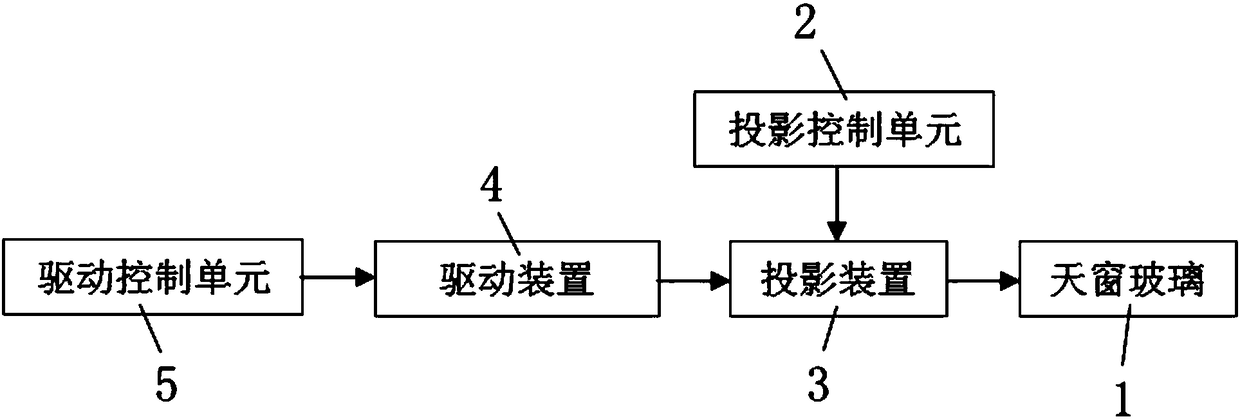

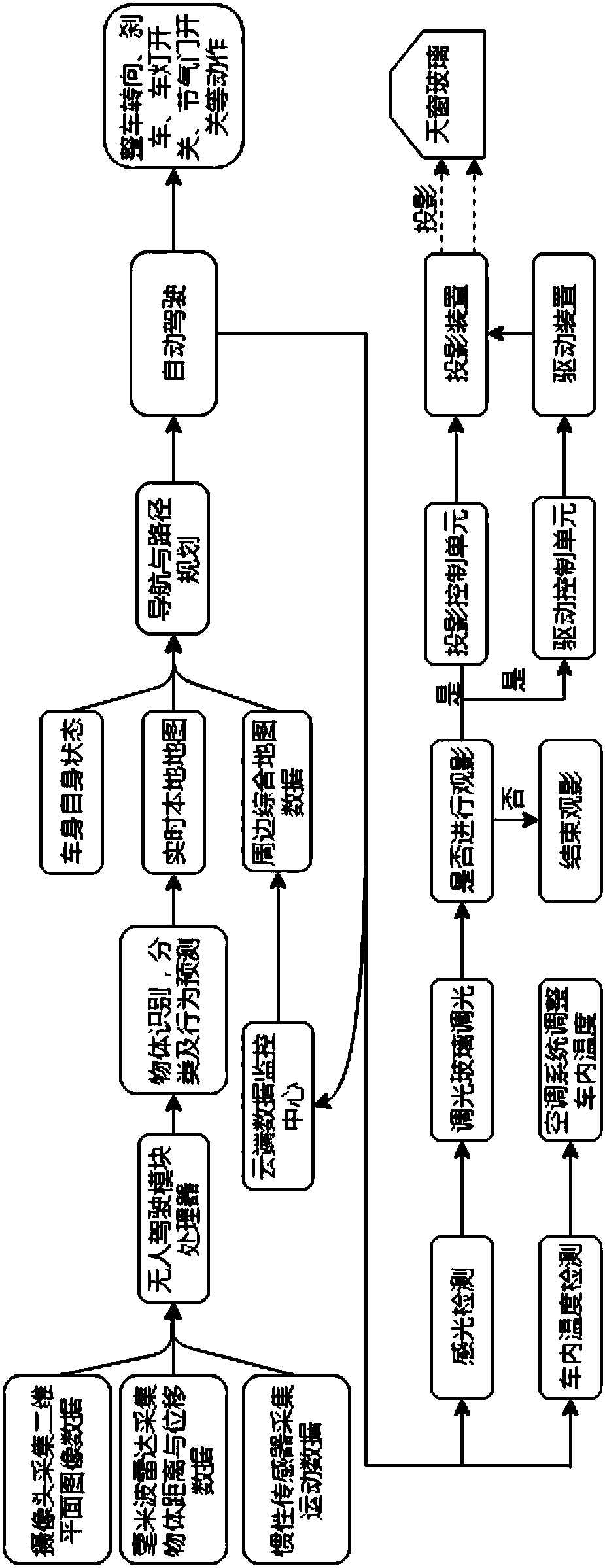

Automobile with arc-shaped display cinema and film watching method

ActiveCN108312975AThe interior space is arrangedAvoid harmWindowsWindscreensShape displayTransmittance

The invention provides the field of vehicles and relates to an automobile which is provided with a display screen and can play multimedia resources, in particular to an automobile with an arc-shaped display cinema and a film watching method in an unmanned state. The automobile comprises sunroof glass, a projection control unit and two projection devices. The two projection devices are embedded intwo automobile columns B, and the projection control unit is connected with the two projection devices and controls the two projection devices to carry out projection on the sunroof glass. The sunroofglass is privacy glass, and when the two projection devices carry out projection on the sunroof glass, the sunroof glass can be converted into the state with the visible light transmittance smaller than or equal to 8% from the state with the visible light transmittance larger than or equal to 70%. The arc-shaped display cinema with a good actual film watching effect can be conveniently formed intime, reasonable intra-automobile space arrangement and a good display and playing effect can be guaranteed, people can watch the film in the unmanned state, and therefore all the people in the automobile can enjoy the driving and riding pleasure.

Owner:FUYAO GLASS IND GROUP CO LTD

Closed type fumigating and washing instrument for elbow joint segments

InactiveCN105943356APrevent up and down movementPromote recoveryBathing devicesWater storage tankDisplay device

The invention relates to a closed type fumigating and washing instrument for elbow joint segments. The closed type fumigating and washing instrument for elbow joint segments comprises a fumigating and washing sleeve, a control cabinet, an air pump, a liquid supply pump, a heating device, a liquid storage tank and a water storage tank. The fumigating and washing sleeve is correspondingly connected with the liquid storage tank and the water storage tank through two liquid return pipes respectively. The liquid supply pump is connected with the liquid storage tank and the water storage tank through first liquid supply pipelines, and is connected with the fumigating and washing sleeve through a second liquid supply pipeline. An air pressure sensor, a temperature sensor, a differential valve, two fixing pipes and a display device are arranged on the fumigating and washing sleeve, and inflation and deflation contraction sets are arranged on the inner walls of the two fixing pipes. The closed type fumigating and washing instrument for elbow joint segments has the advantages that the fumigating and washing instrument is wide in application range, applicable to users with different arm thicknesses and good in leakproofness; a user can know the current specific fumigating and washing condition conveniently, and data measurement is accurate; closed fumigating and washing of partial elbow joint segments can be achieved, the requirement for scientific and standard treatment can be met, and the temperature and the fumigating and washing pressure can be accurately controlled or set.

Owner:THE AFFILIATED HOSPITAL OF TRADITIONAL CHINESE MEDICAL TO SOUTHWEST MEDICAL UNIV

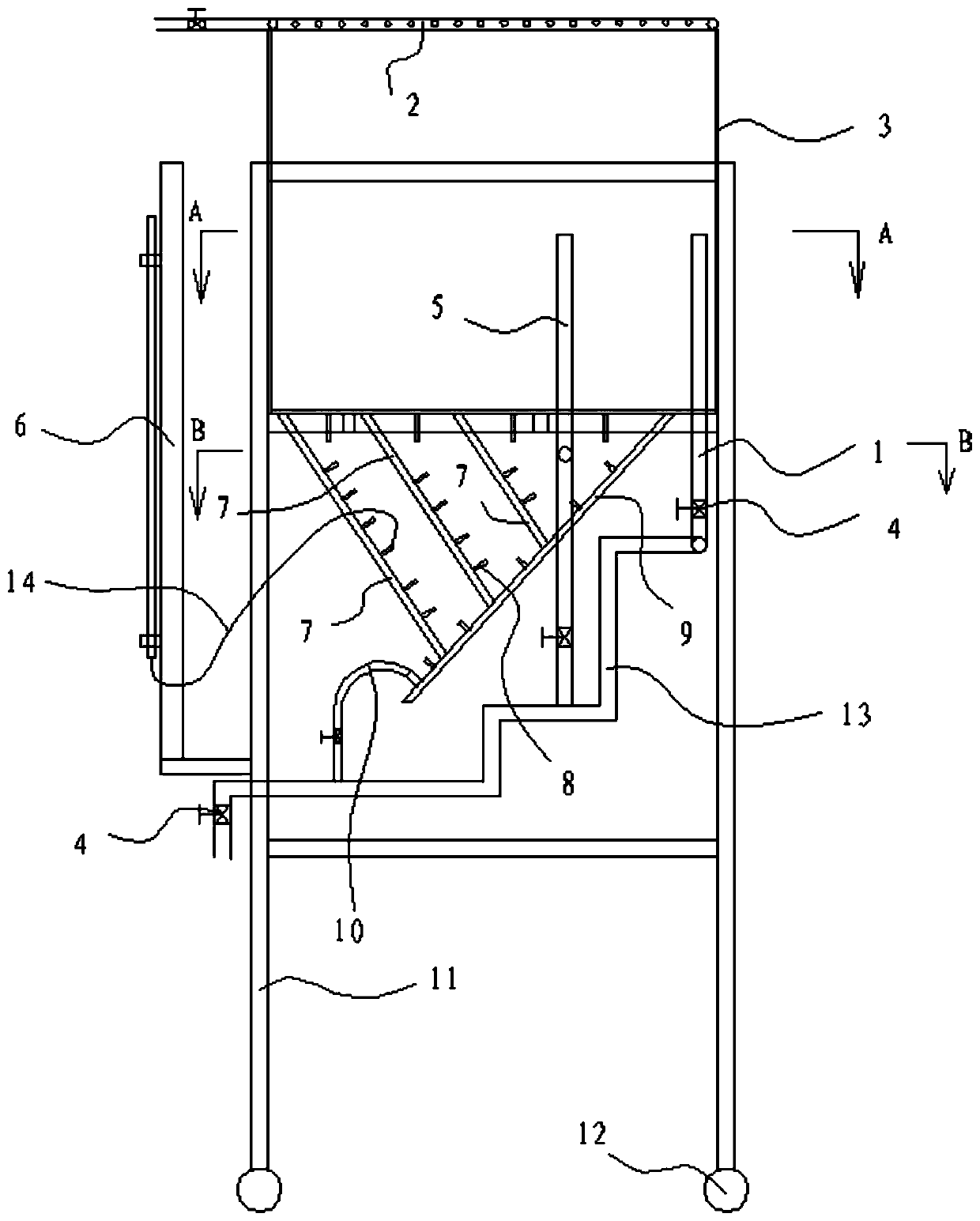

Test device for simulating karst fissure-pipeline water and solute migration rule

The invention discloses a test device for simulating karst fissure-pipeline water and solute migration rule, which comprises a rack, wherein the upper part of the rack is provided with a surface karstzone infiltration tank, and the side of the rack is provided with a pressure monitoring device; the top of the surface karst zone infiltration tank is of an open structure and is provided with a rainfall simulator; one side of the bottom of the surface karst zone infiltration tank is connected with a large fracture plate, and the other side of the bottom of the surface karst zone infiltration tank is connected with three small fracture plates; the bottom ends of the small fracture plates are connected with the side of the large fracture plate and are of a V-shaped structure; the large fracture plate and the small fracture plates are internally provided with a large crack and small cracks; a plurality of pressure measuring pipe joints are arranged on the sides of the large fracture plate and the small fracture plates and at the bottom of the surface karst zone infiltration tank, and are communicated with the pressure monitoring device through hoses. The device has the advantages of complete structure, reasonable spatial layout, high similarity with the characteristics of actual water-containing structure, high operability and controllable influence factors, and is suitable for exploring the karst fissure-pipeline water and solute migration rule.

Owner:GUIZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com