Core-pulling and demoulding combination device

A combined device and demoulding technology, applied in the field of plastic molds, can solve the problems of difficult extraction of lateral cores, and achieve the effects of low cost, good demoulding effect and good process performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

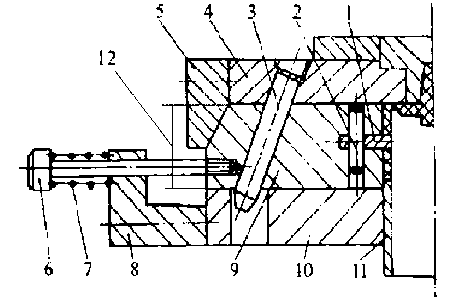

[0019] Such as figure 1 As shown, the present embodiment includes a fixed template 4 and a movable template 10. The fixed template 4 and the movable template 10 form a cavity, and the cavity is provided with a slider 9, an inclined guide post 3, a lateral core 1 and The ejector rod 11, the lateral core 1 is hinged with the slider 9, and the ejector rod 11 and the inclined guide post 3 are fixed in the cavity. The inclined guide column 3 is fixed on the fixed template 4, and the lateral core 1 is hinged with the slider 9 through the pin 2. When the mold is opened, the fixed template 4 moves up so that the inclined guide column 3 forces the slider 9 to slide on the movable template 10. Move to the left in the groove to complete the core-pulling action; in order to ensure that the inclined guide post 3 can accurately enter the inclined hole of the slider 9 when the mold is closed, so as to reset the slider 9, a positioning mechanism is provided on the mechanism, relying on the sc...

Embodiment 2

[0021] Such as figure 1 As shown, on the basis of Embodiment 1, this embodiment further includes a spring disposed at the bottom of the push rod 11, and the spring is a coil spring. The use of scroll springs can provide strong power for the rotation of the ejector rod 11, so that it can quickly complete the core-pulling action and improve the production efficiency of the injection mold; The rod 11 is subjected to an impact force, and the spring can buffer the impact force generated, thereby better protecting the equipment components and improving the service life of the equipment.

Embodiment 3

[0023] Such as figure 1 As shown, this embodiment is based on Embodiment 1. As a preference, the inclination angle of the inclined guide column 3 is 20°. If the inclination angle is too large, the space layout in the mold will be increased; if the inclination angle is too small, the slider 9 will move. The distance becomes smaller, and the effect of complete demoulding cannot be achieved. Therefore, the inclination angle is 20°, which not only satisfies a reasonable space layout, but also achieves a good demoulding effect;

[0024] Preferably, the core-pulling distance 12 is less than 80mm. If the core-pulling distance 12 is too long, the compression spring 7 or the length of the lateral core 1 will increase, thereby increasing the mold specification; if the core-pulling distance 12 is too short, the lateral core 1 cannot be completely pulled out from the plastic part. Limited to the internal structure layout of the injection molding machine, the core-pulling distance is lim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com