Patents

Literature

53results about How to "Good viscosity controllability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of high temperature resistant single-component solventless epoxy adhesive

InactiveCN101649174AConvenient sourceSimple preparation processEpoxy resin adhesivesSolventThermoplastic polyimide

The invention relates to a preparation method of high temperature resistant single-component solventless epoxy adhesive. The method comprises the following steps: adding aromatic binary primary amine and strongly polar non-proton organic solvent in a reaction tank, stirring at room temperature to dissolve, adding aromatic binary acid anhydride to perform refluxing and water-segregating reaction at 120-150 DEG C for 6-12h, cooling, adding the reaction solution in a stamp tank with precipitant to precipitate solid powder, namely white thermoplastic polyimide powder, adding white thermoplastic polyimide powder and tertiary amine compound or imidazole compound in epoxy resin to react for 1-2h, adding active diluent and latent curing agent to stir evenly and obtaining the product. The production process is easy and the cost is low so as to realize industrialized production; the tensile shear intensions of the epoxy adhesive at room temperature and 120 DEG C are respectively up to 28Mpa and26Mpa and the epoxy adhesive has broad application prospect in fields such as electronics and microelectronics, electrical motors, aviation and aerospace and the like.

Owner:DONGHUA UNIV

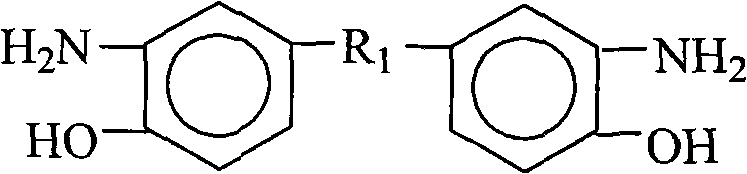

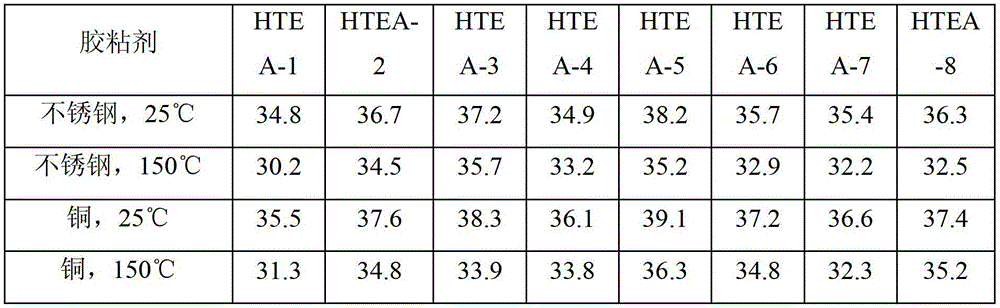

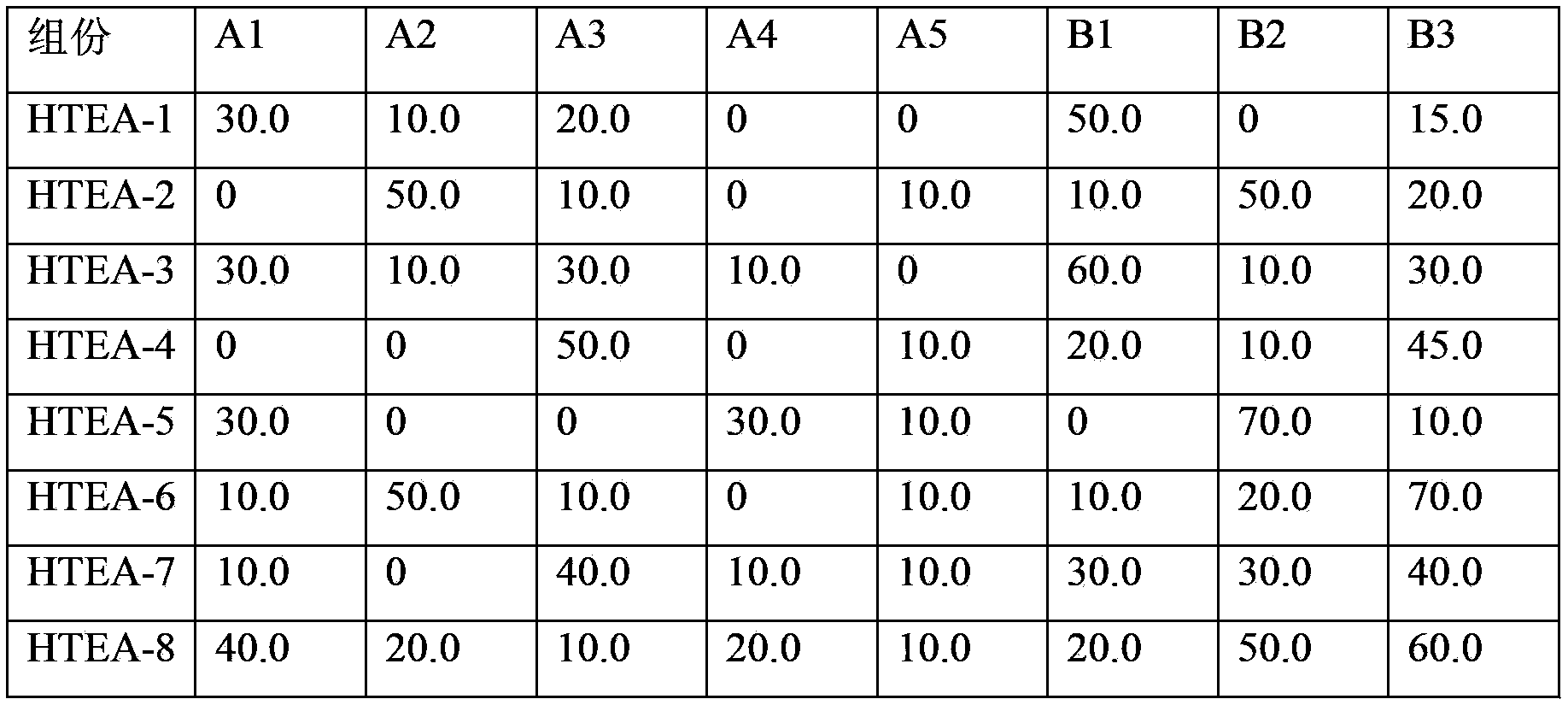

4,4'-bis(2,4-diamidophenoxy)biphenyl high-temperature-resistant epoxy adhesive and preparation method thereof

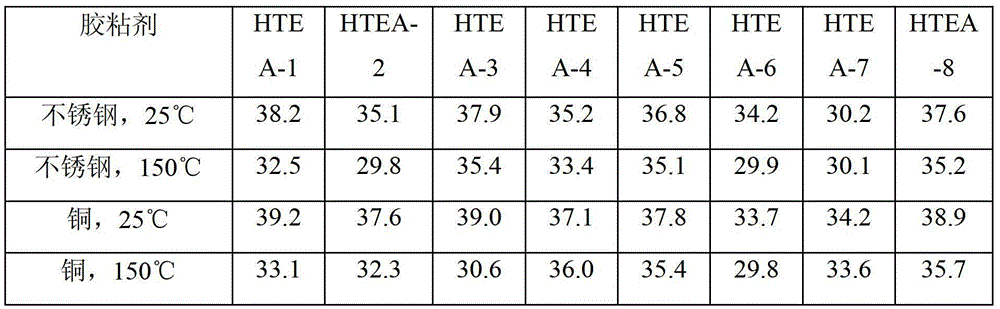

InactiveCN103146331AGood adhesionGood viscosity controllabilityMacromolecular adhesive additivesEpoxynovolac adhesivesTolueneDibasic acid

The invention relates to a 4,4'-bis[4-(2,4-diamidophenoxy)phenyl]biphenyl high-temperature-resistant epoxy adhesive and a preparation method thereof. The 4,4'-bis(2,4-diamidophenoxy)biphenyl high-temperature-resistant epoxy adhesive is composed of a component A and a component B, wherein the component A is a copolymer prepared by reacting 4,4'-bis(2,4-diamidophenoxy)biphenyl and epoxy resin; and the component B is a homogeneous transparent solution with the solid content of 15-30%, which is prepared by reacting 4,4'-bis(2,4-diamidophenoxy)biphenyl and aromatic dibasic acid anhydride in a strong-polarity non-proton organic solvent and toluene. The preparation method comprises the following step: evenly mixing the component A and the component B in a mass ratio of 1:(1-2) at room temperature. The preparation technique is simple; and the adhesive has excellent comprehensive properties, can be widely used for bonding steel, copper, aluminum or any other metal with ceramic, glass, resin-base composite material or any other substrate, and has favorable industrialization prospects.

Owner:DONGHUA UNIV +1

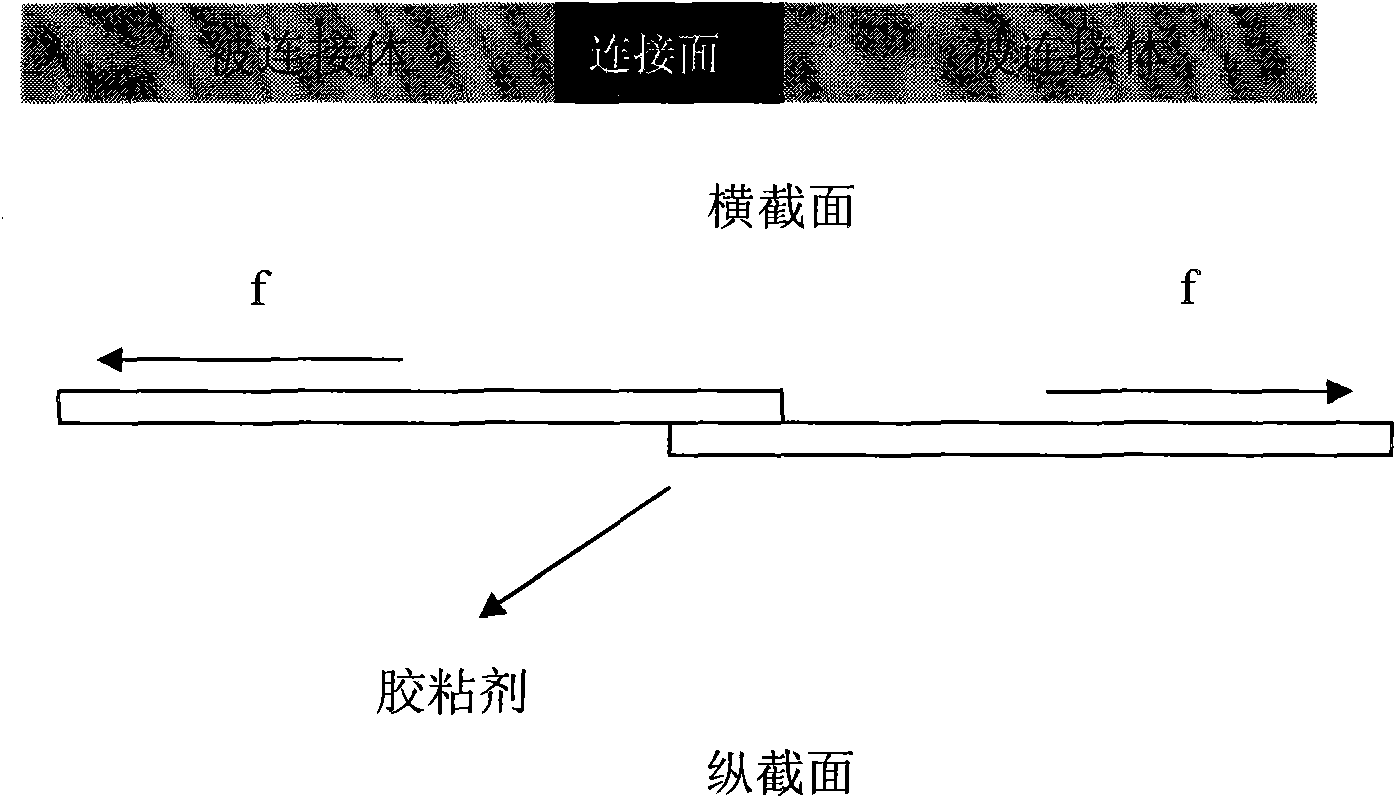

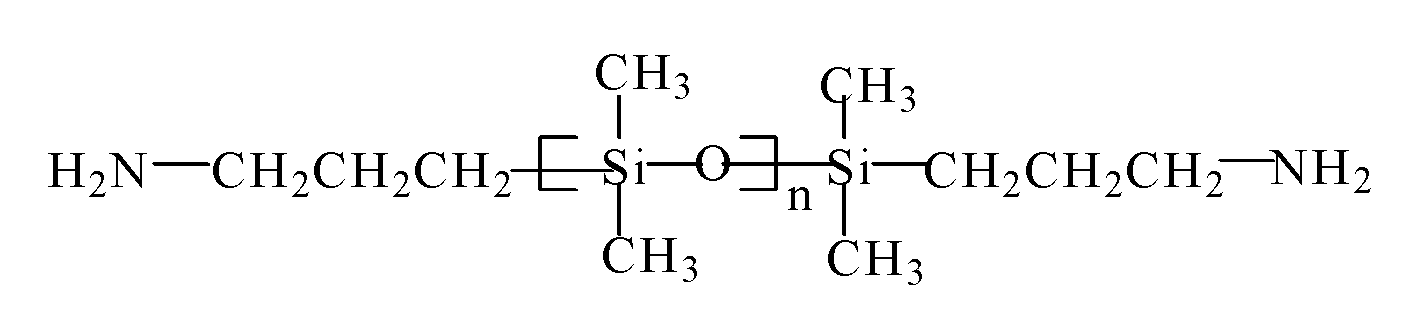

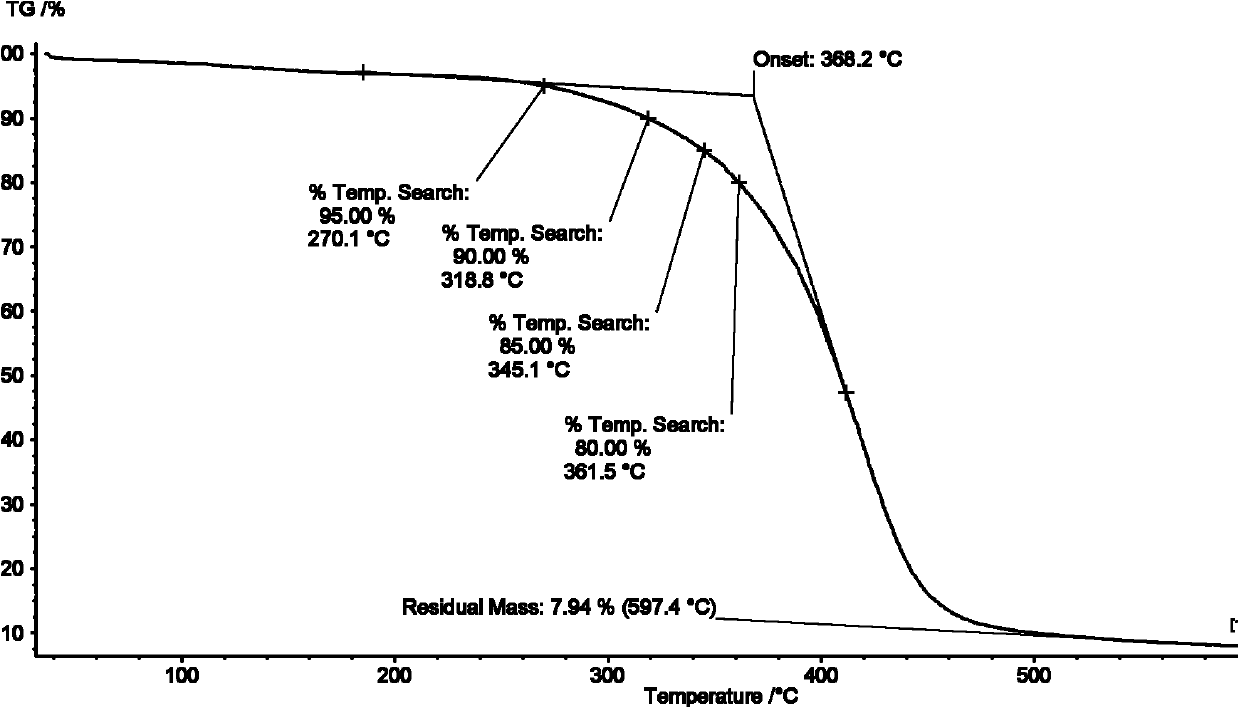

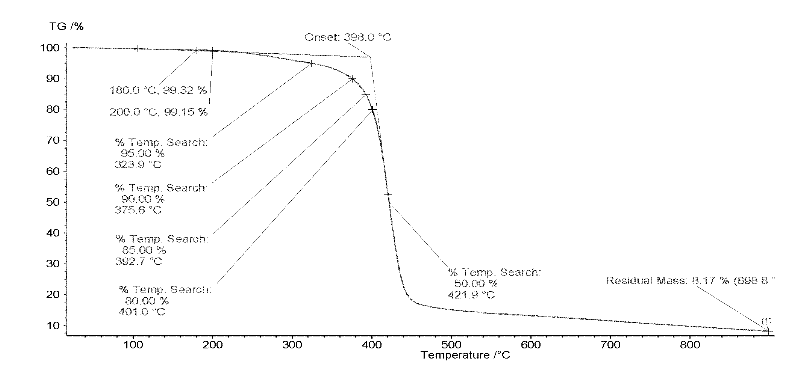

High-performance conducting resin and preparation method thereof

InactiveCN101781540AConvenient sourceSimple preparation processNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyRoom temperature

The invention relates to a high-performance conducting resin, comprising the following components: epoxy, latent curing agent, active toughener and conducting particles. The preparation method comprises the following steps: adding the epoxy and the active toughener in a reaction bulb to react, then adding the latent curing agent, uniformly stirring, adding the surface-treated conducting particles, uniformly stirring, and defoaming in vacuum to obtain the high-performance conducting resin. The conducting resin in characterized in that the bonding strength reaches up to 24.1 MPa; the volume resistivity is 4.30*10<-5>-2.12*10<-4> ohm.cm; the Tonset thermal decomposition temperature reaches up to 398.7 DEG C; the water absorption is only 0.2%; and storage life at the room-temperature is as long as more than 3 months. The invention has the advantages of simple preparation process, low cost, convenient operation and convenient reaction material source, can complete the preparation process in universal devices, is beneficial to realizing industrial production, and has wide application prospects in the fields of electronic components, resonators, relays, electronic capacitors and the like.

Owner:DONGHUA UNIV +1

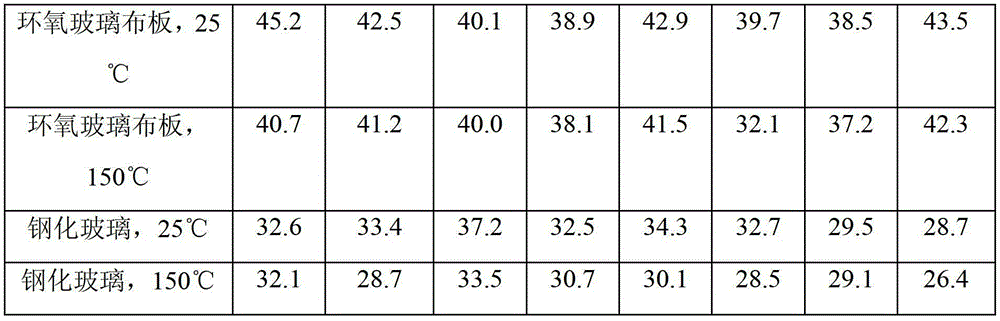

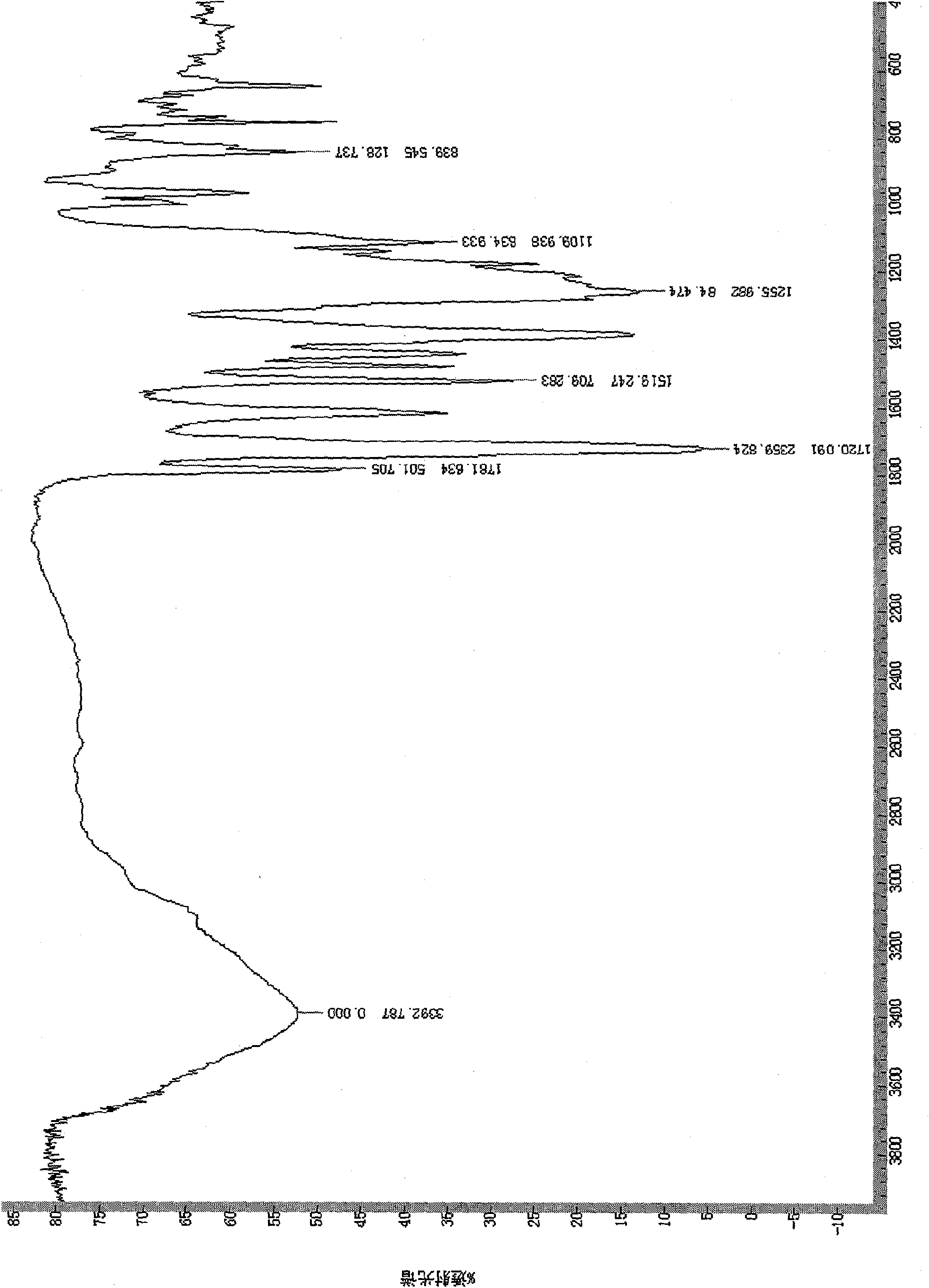

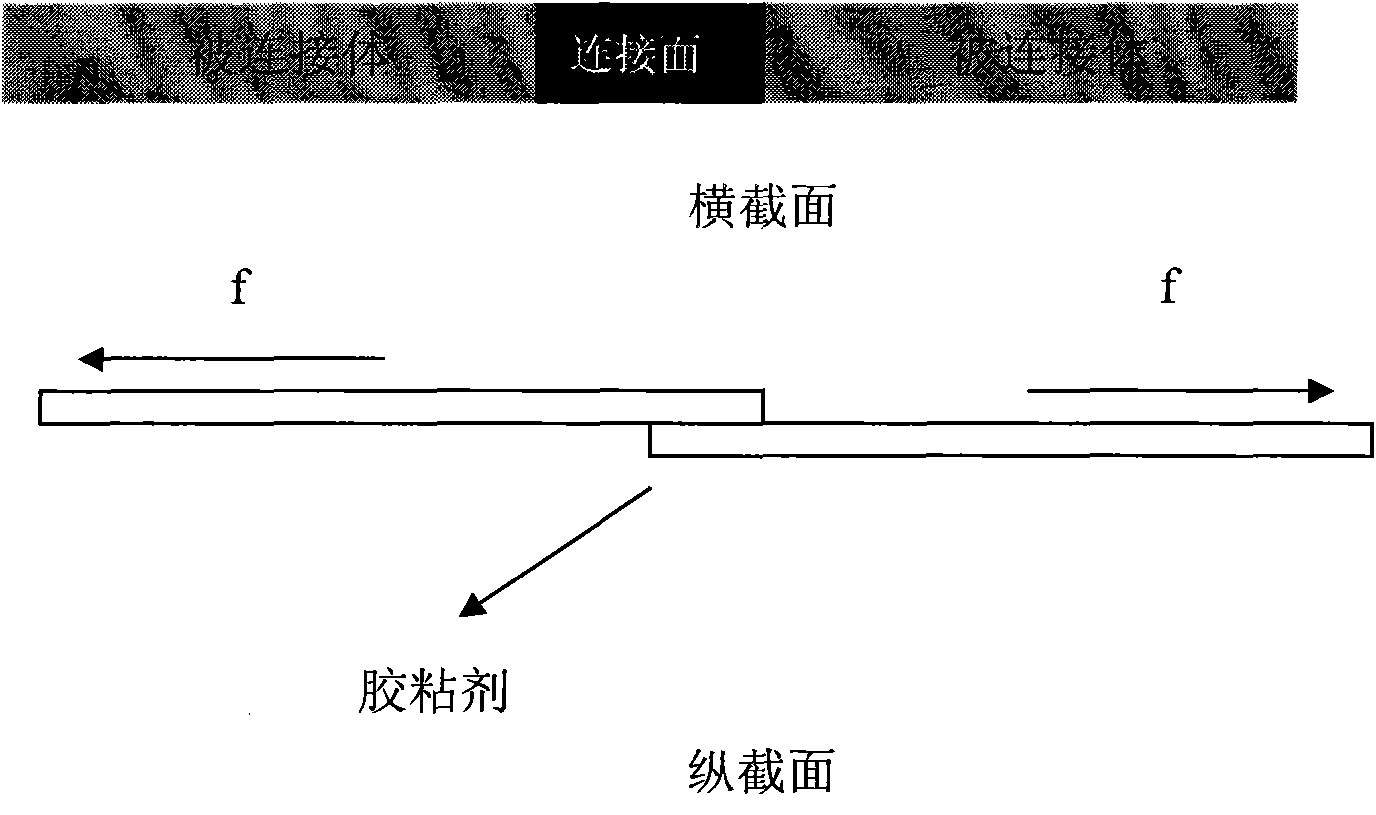

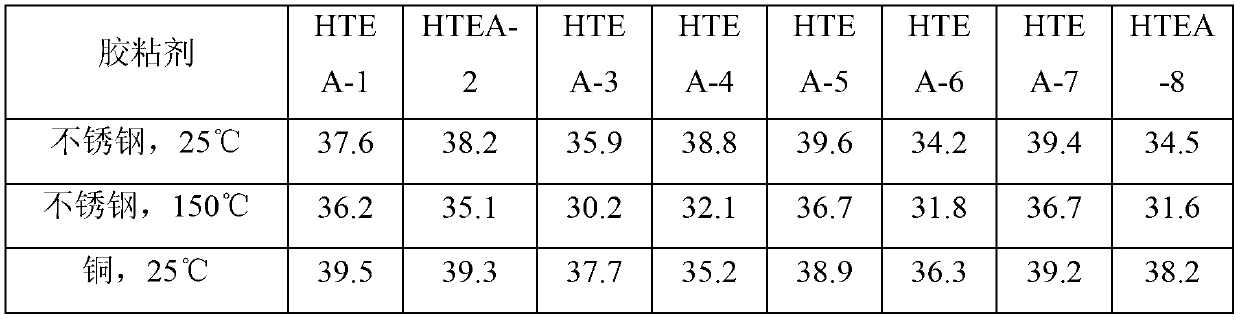

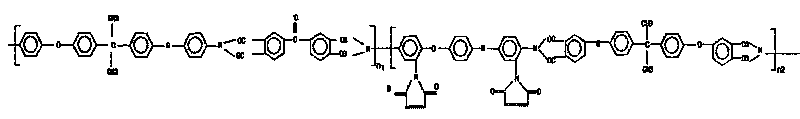

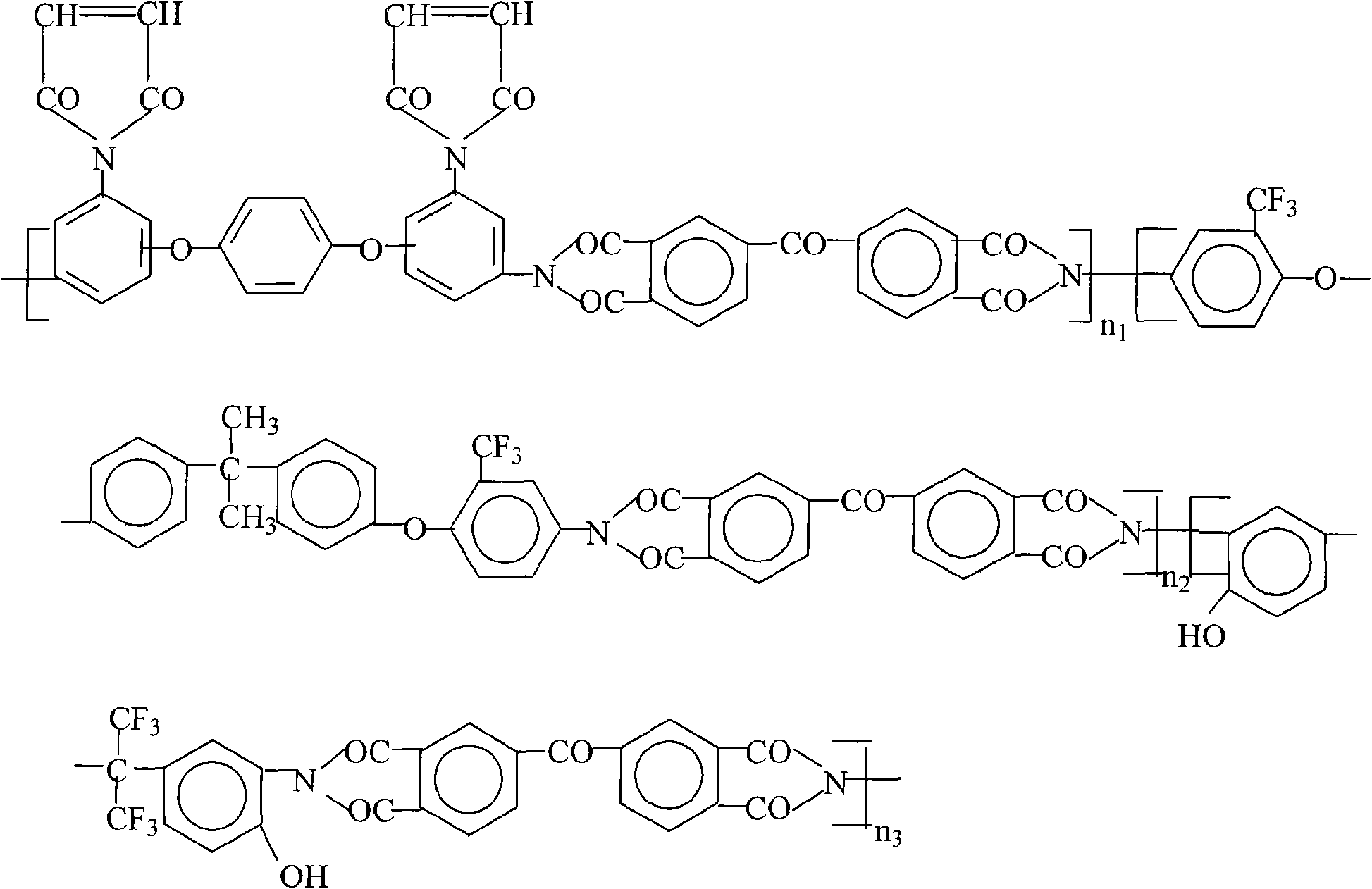

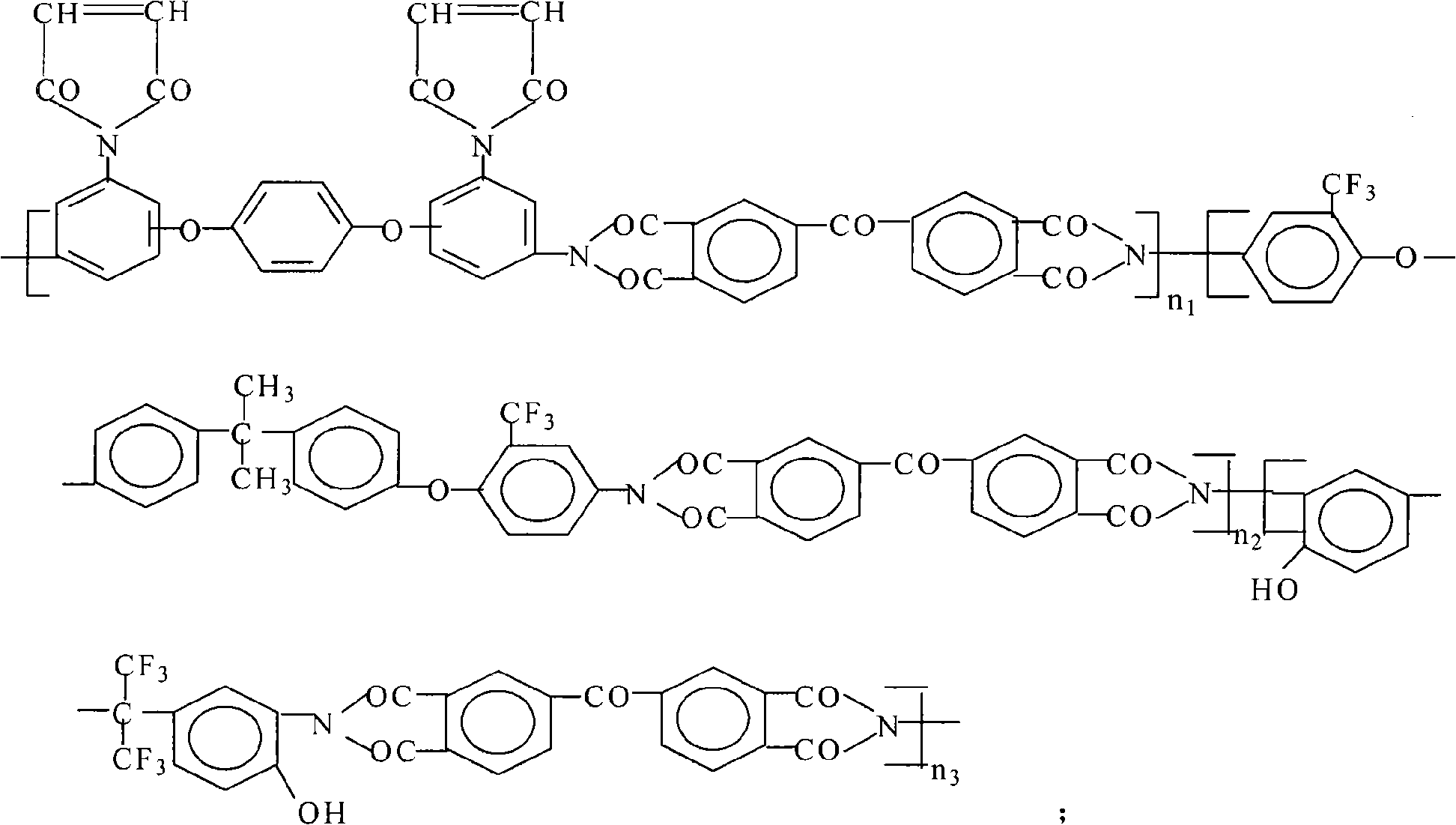

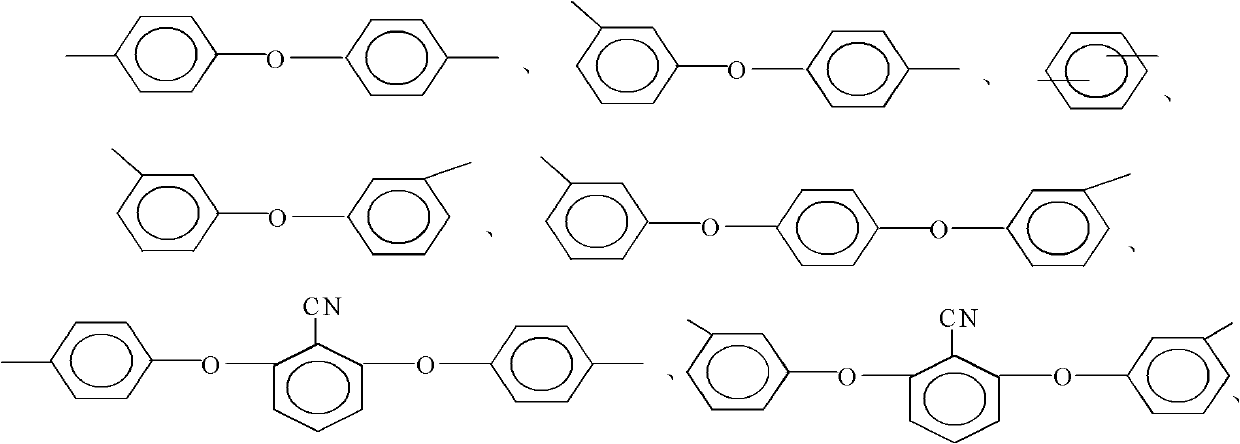

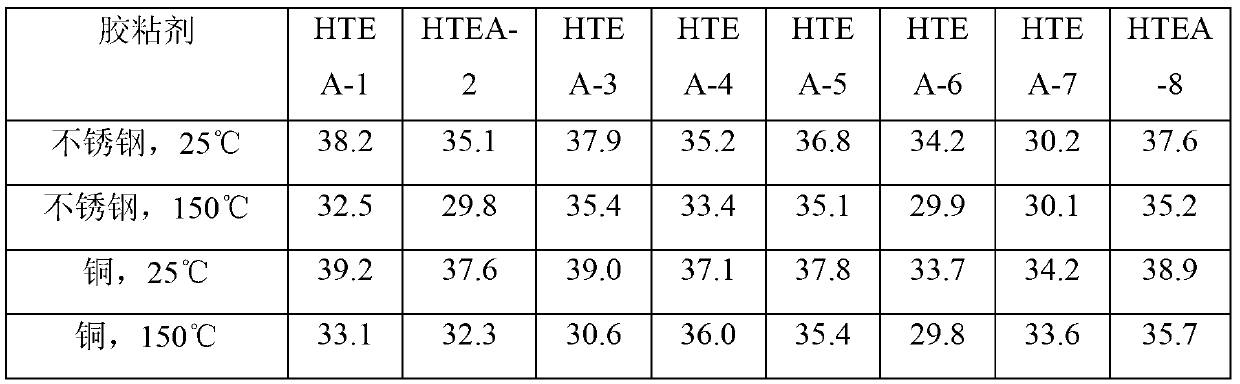

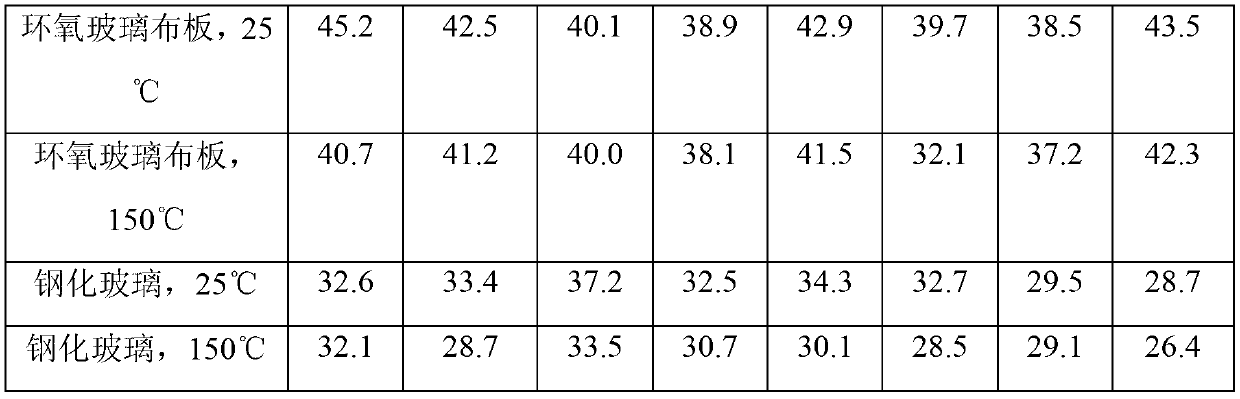

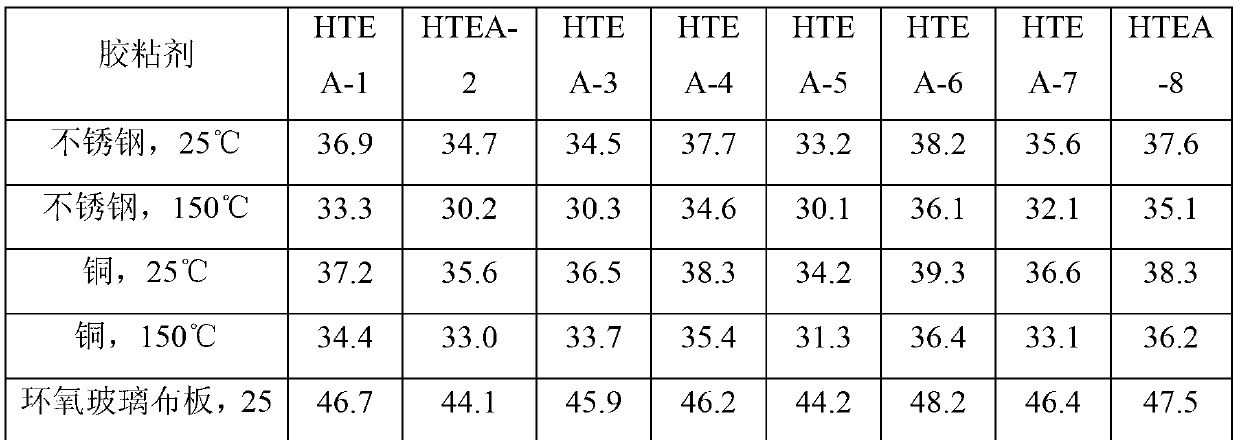

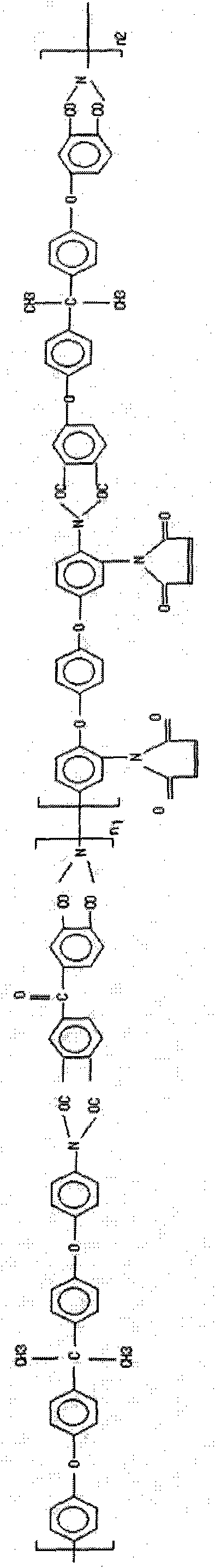

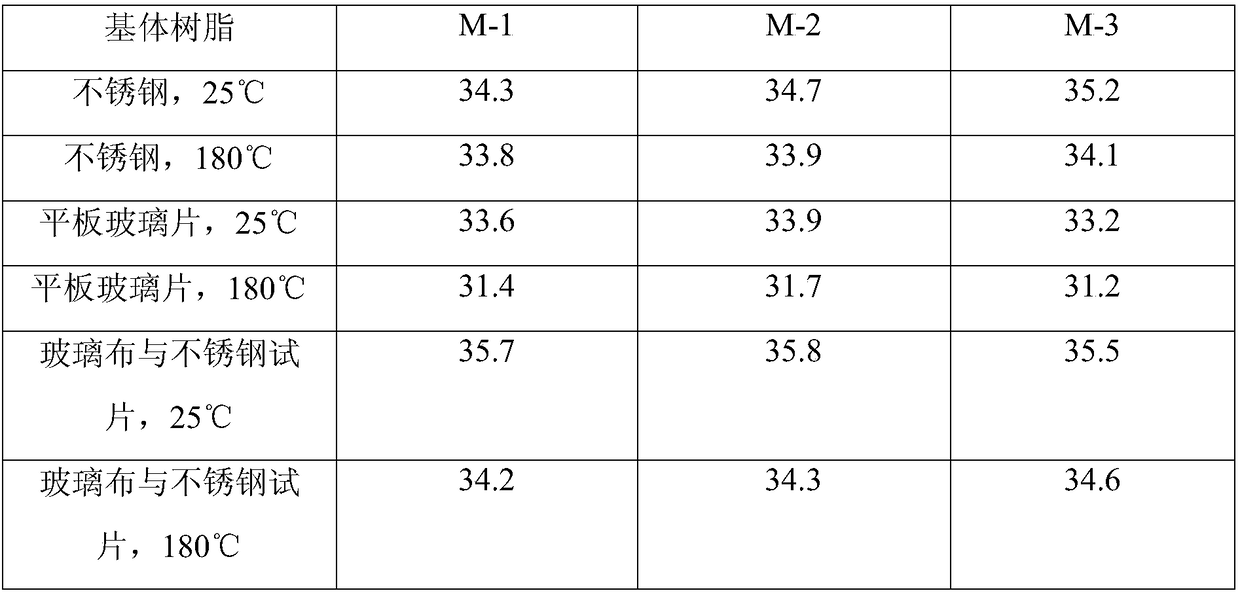

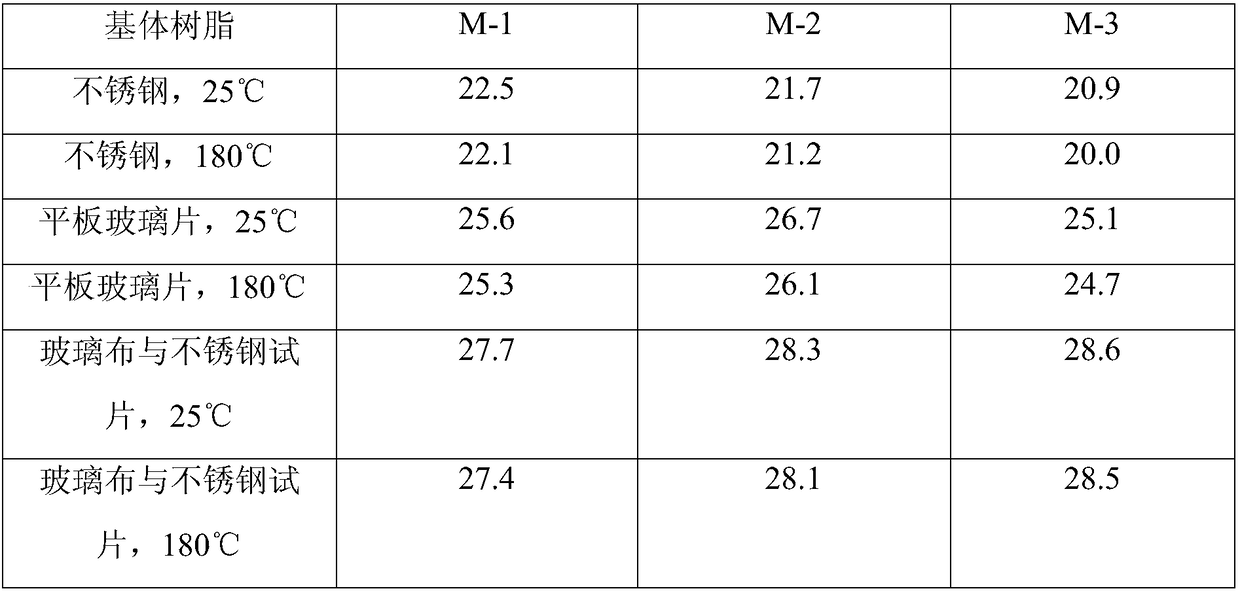

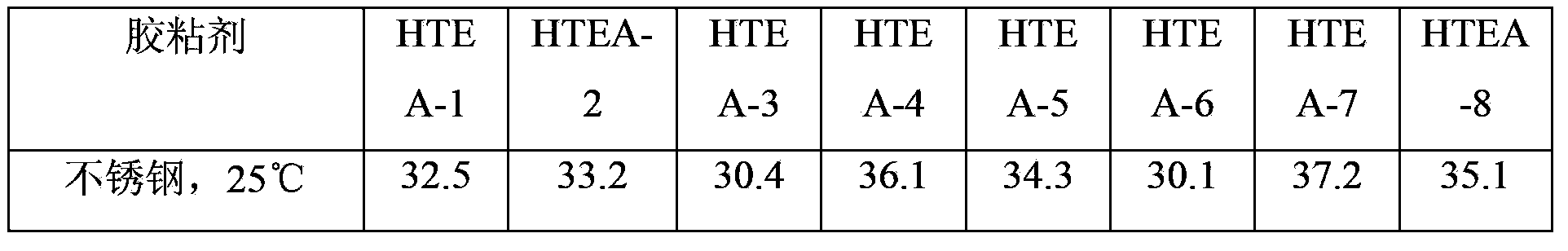

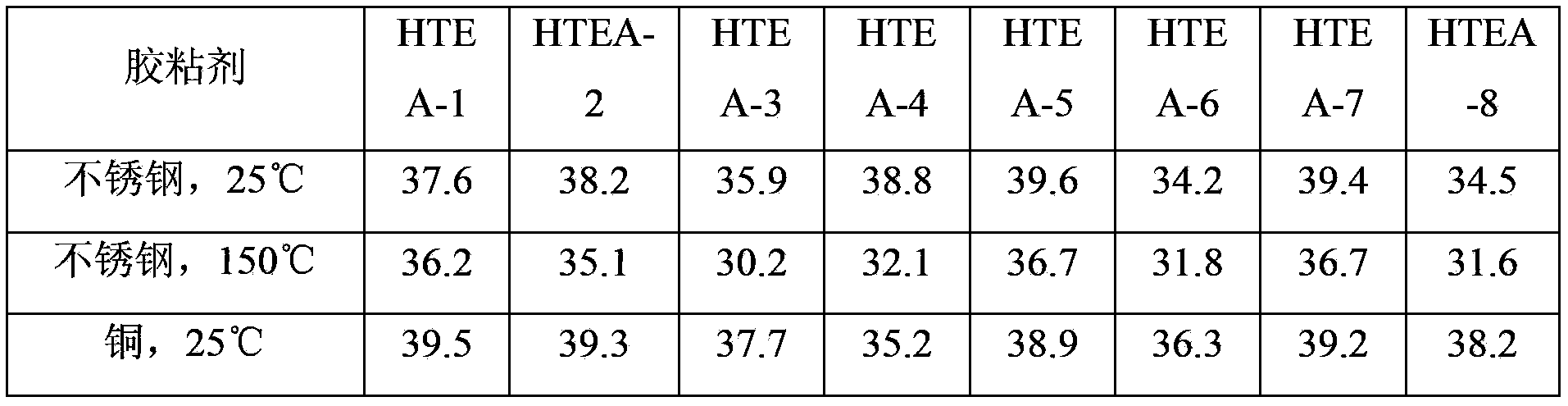

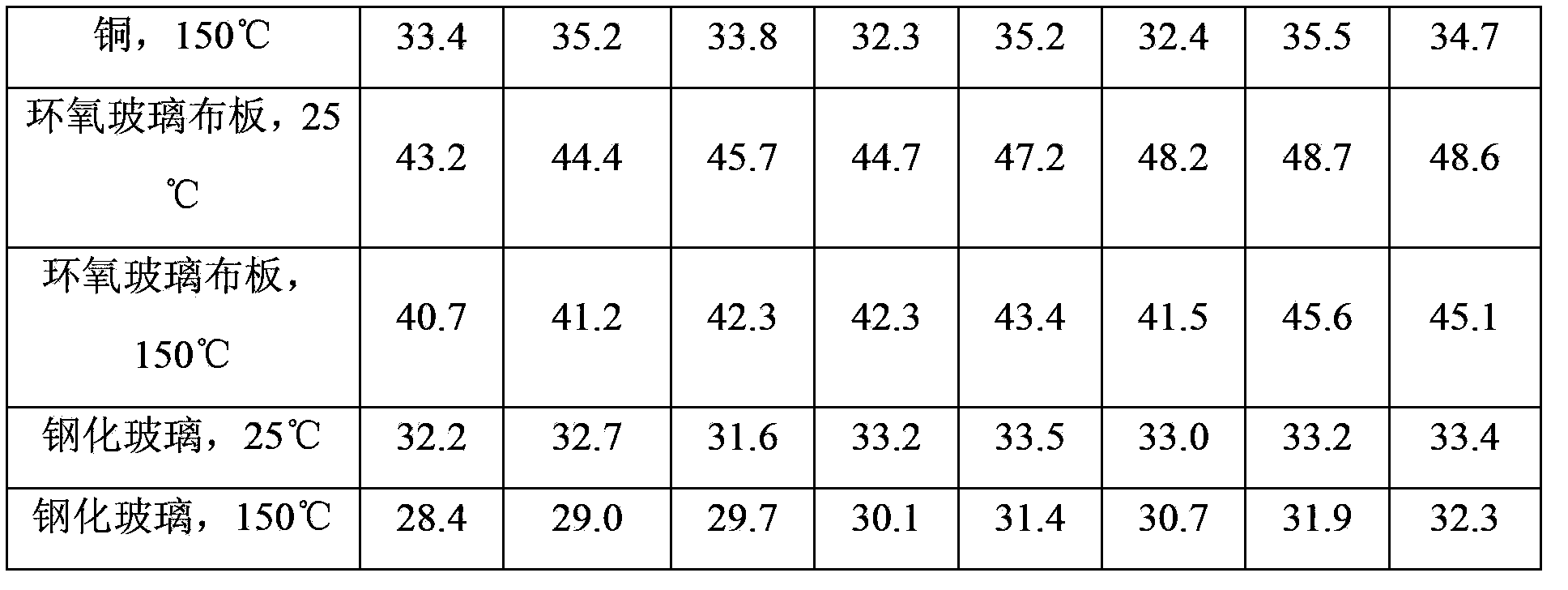

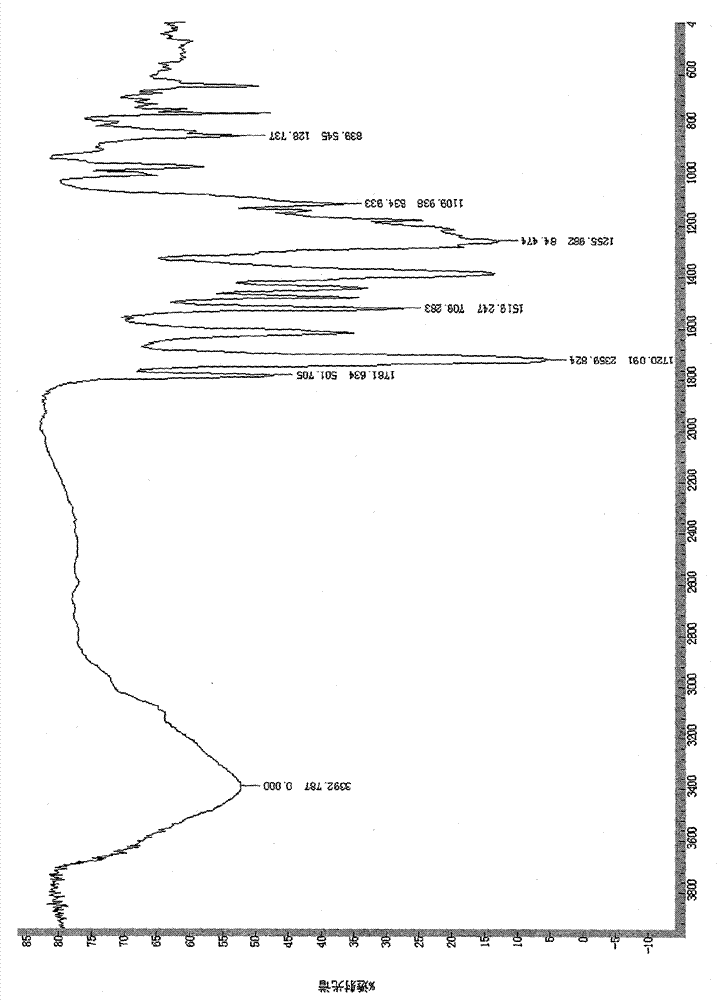

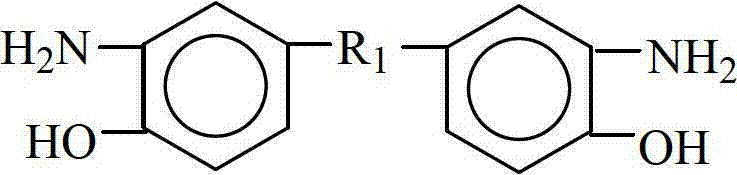

2,2-bis[4-(2,4-diamidophenoxy)phenyl]hexafluoropropane high-temperature-resistant epoxy adhesive and preparation method thereof

InactiveCN103146330AGood adhesionGood viscosity controllabilityMacromolecular adhesive additivesEpoxynovolac adhesivesResin-Based CompositePhenyl group

The invention relates to a 2,2-bis[4-(2,4-diamidophenoxy)phenyl]hexafluoropropane high-temperature-resistant epoxy adhesive and a preparation method thereof. The 2,2-bis[4-(2,4-diamidophenoxy)phenyl]hexafluoropropane high-temperature-resistant epoxy adhesive is composed of a component A and a component B, wherein the component A is a copolymer prepared by reacting 2,2-bis[4-(2,4-diamidophenoxy)phenyl]hexafluoropropane and epoxy resin; and the component B is a homogeneous transparent solution with the solid content of 15-30%, which is prepared by reacting 2,2-bis[4-(2,4-diamidophenoxy)phenyl]hexafluoropropane and aromatic dibasic acid anhydride in a strong-polarity non-proton organic solvent and toluene. The preparation method comprises the following step: evenly mixing the component A and the component B in a mass ratio of 1:(1-2) at room temperature. The preparation technique is simple; and the adhesive has excellent comprehensive properties, can be widely used for bonding steel, copper, aluminum or any other metal with ceramic, glass, resin-base composite material or any other substrate, and has favorable industrialization prospects.

Owner:DONGHUA UNIV +1

4,4'-bis(2,4-diamidophenoxy)diphenylsulphone high-temperature-resistant epoxy adhesive and preparation method thereof

InactiveCN103131369AGood adhesionGood viscosity controllabilityMacromolecular adhesive additivesEpoxynovolac adhesivesOrganic solventRoom temperature

The invention relates to a 4,4'-bis(2,4-diamidophenoxy)diphenylsulphone high-temperature-resistant epoxy adhesive and a preparation method thereof. The 4,4'-bis(2,4-diamidophenoxy)diphenylsulphone high-temperature-resistant epoxy adhesive is composed of a component A and a component B in a mass ratio of 1:(1-2), wherein the component A is a copolymer prepared by reacting 4,4'-bis(2,4-diamido phenoxy)diphenylsulphone and epoxy resin; and the component B is a homogeneous-phase transparent solution with the solid content of 15-30%, which is prepared by reacting 4,4'-bis(2,4-diamidophenoxy)diphenylsulphone and aromatic dibasic acid anhydride in a strong-polarity non-proton organic solvent and diphenylsulphone. The preparation method comprises the following step: evenly mixing the component A and the component B in a mass ratio of 1:(1-2) at room temperature. The preparation technique is simple; and the adhesive has excellent comprehensive properties, can be widely used for bonding steel, copper, aluminum or any other metal with ceramic, glass, resin-base composite material or any other substrate, and has favorable industrialization prospects.

Owner:DONGHUA UNIV +1

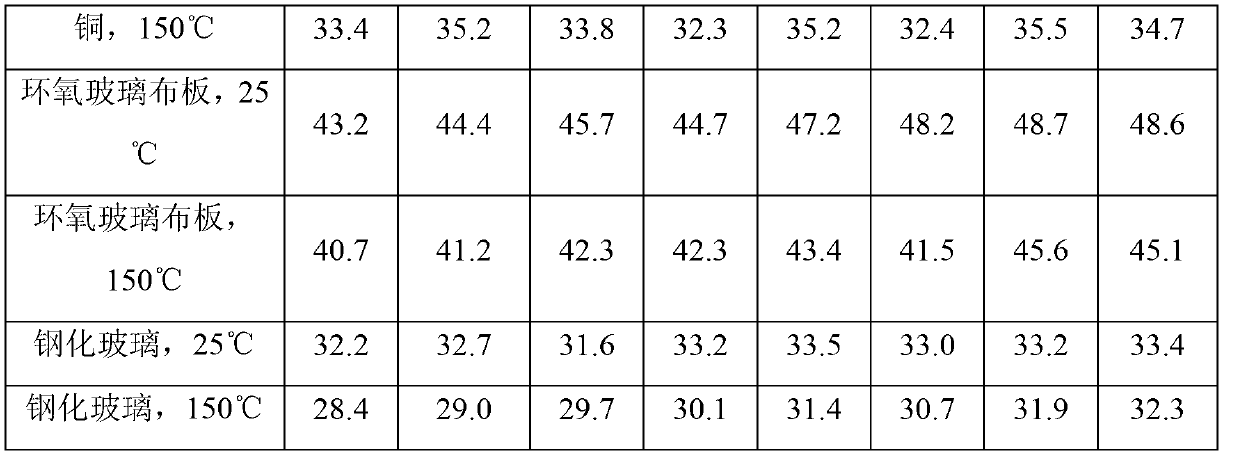

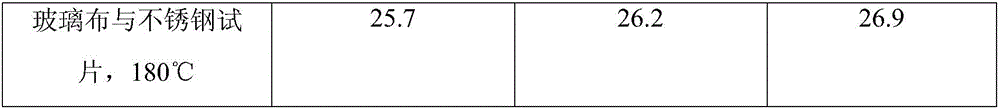

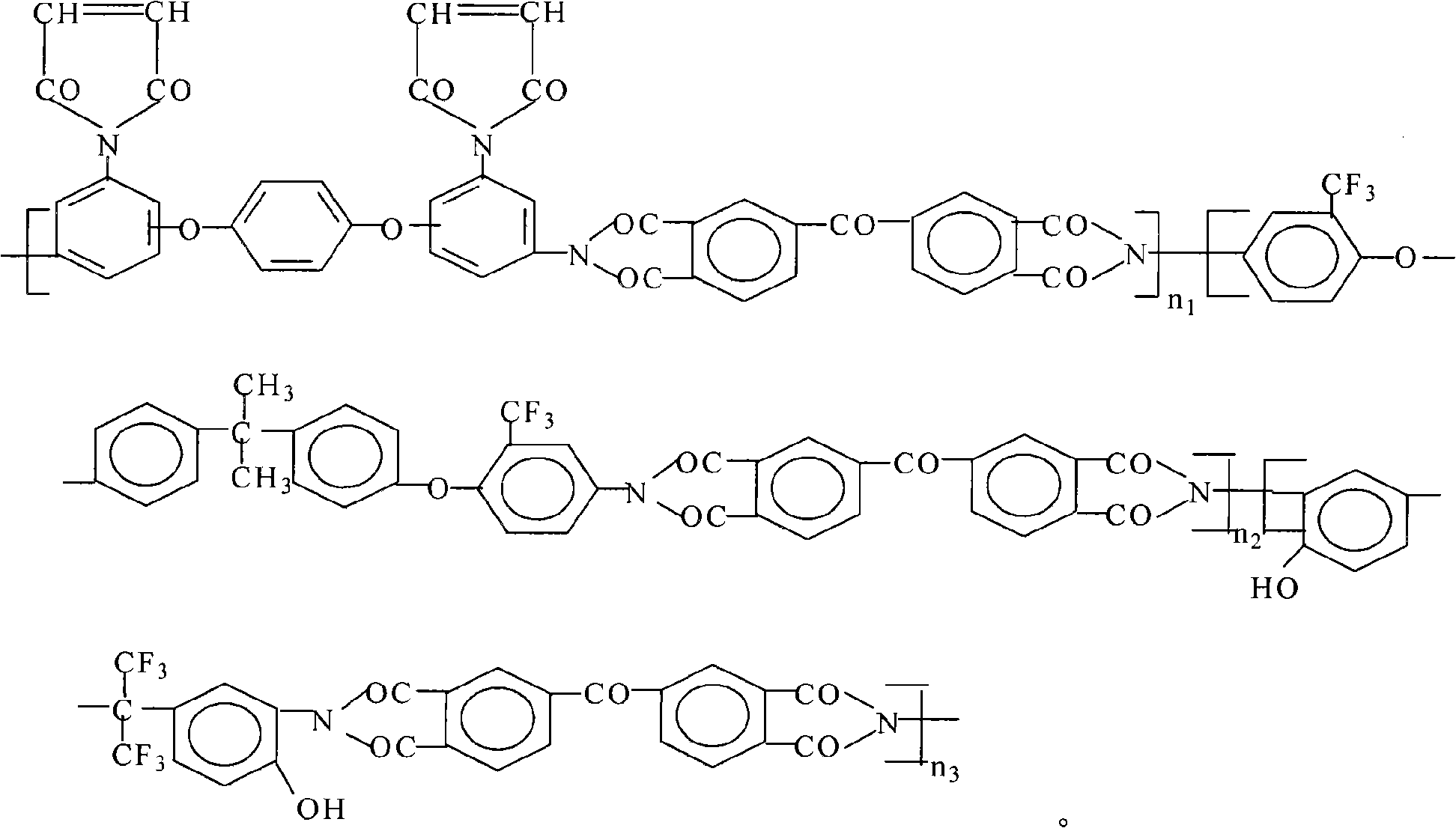

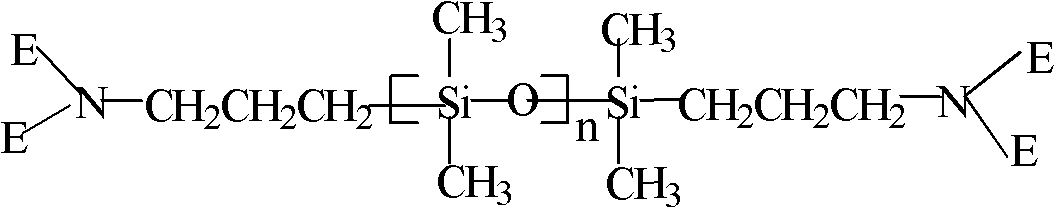

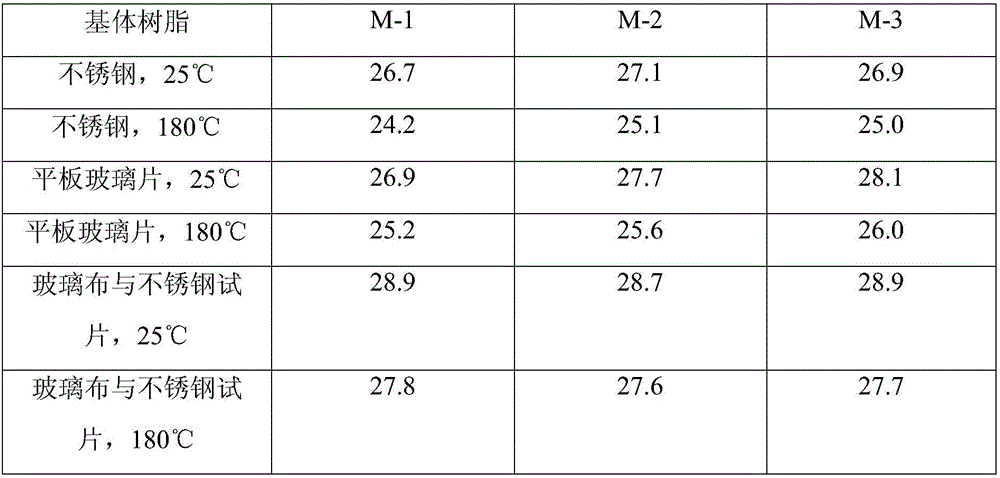

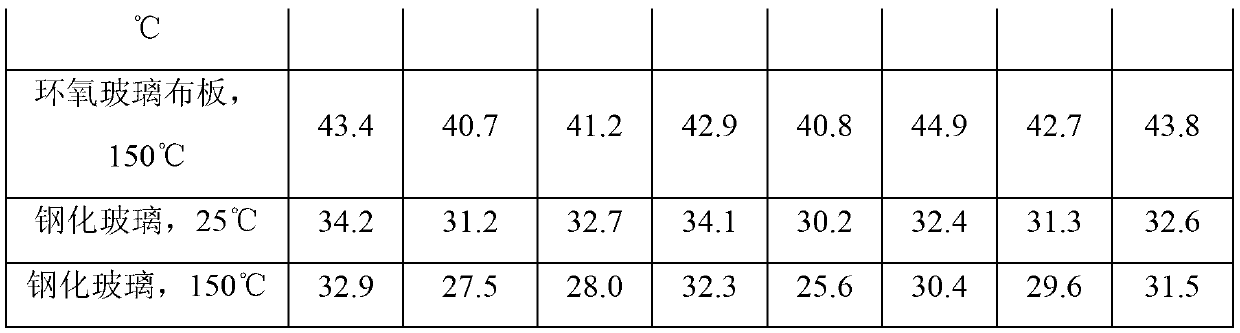

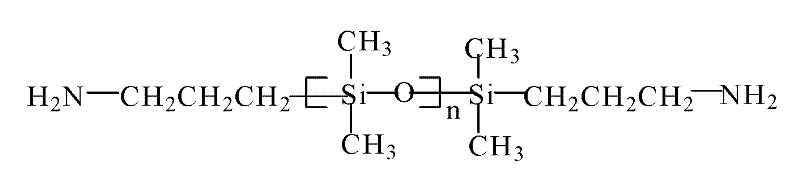

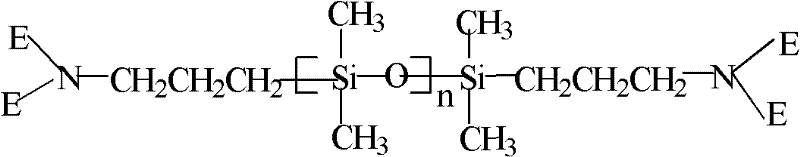

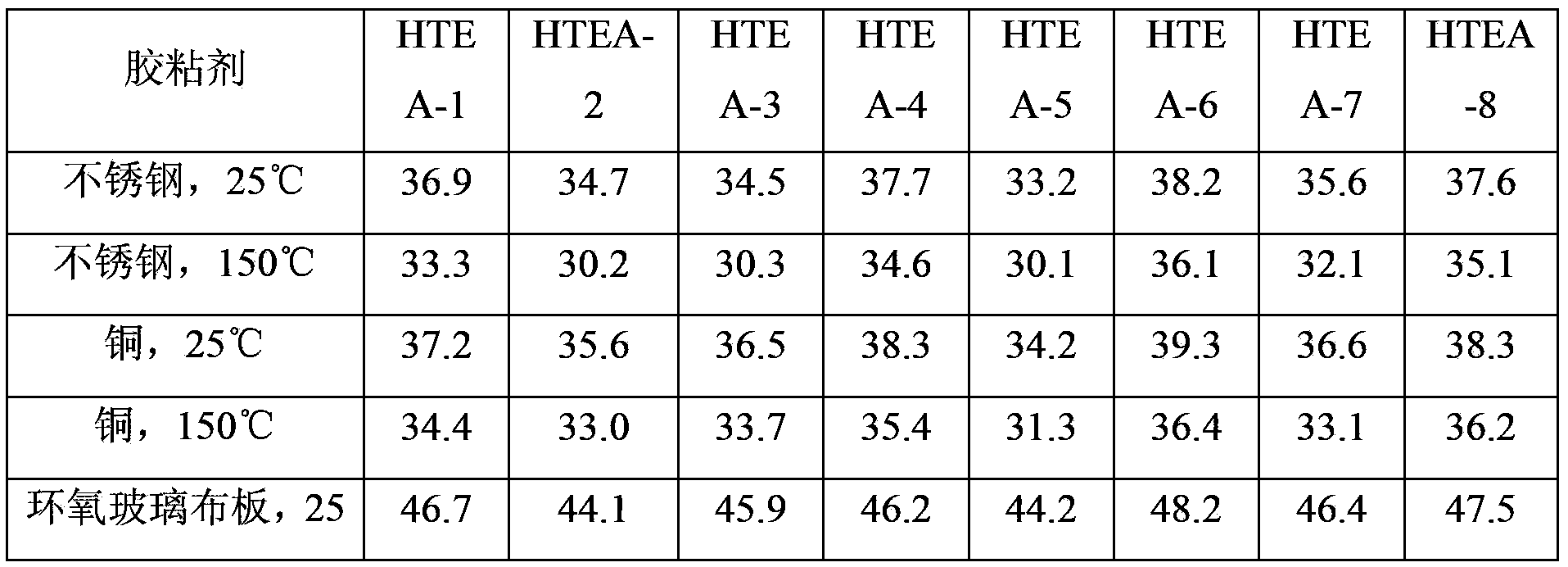

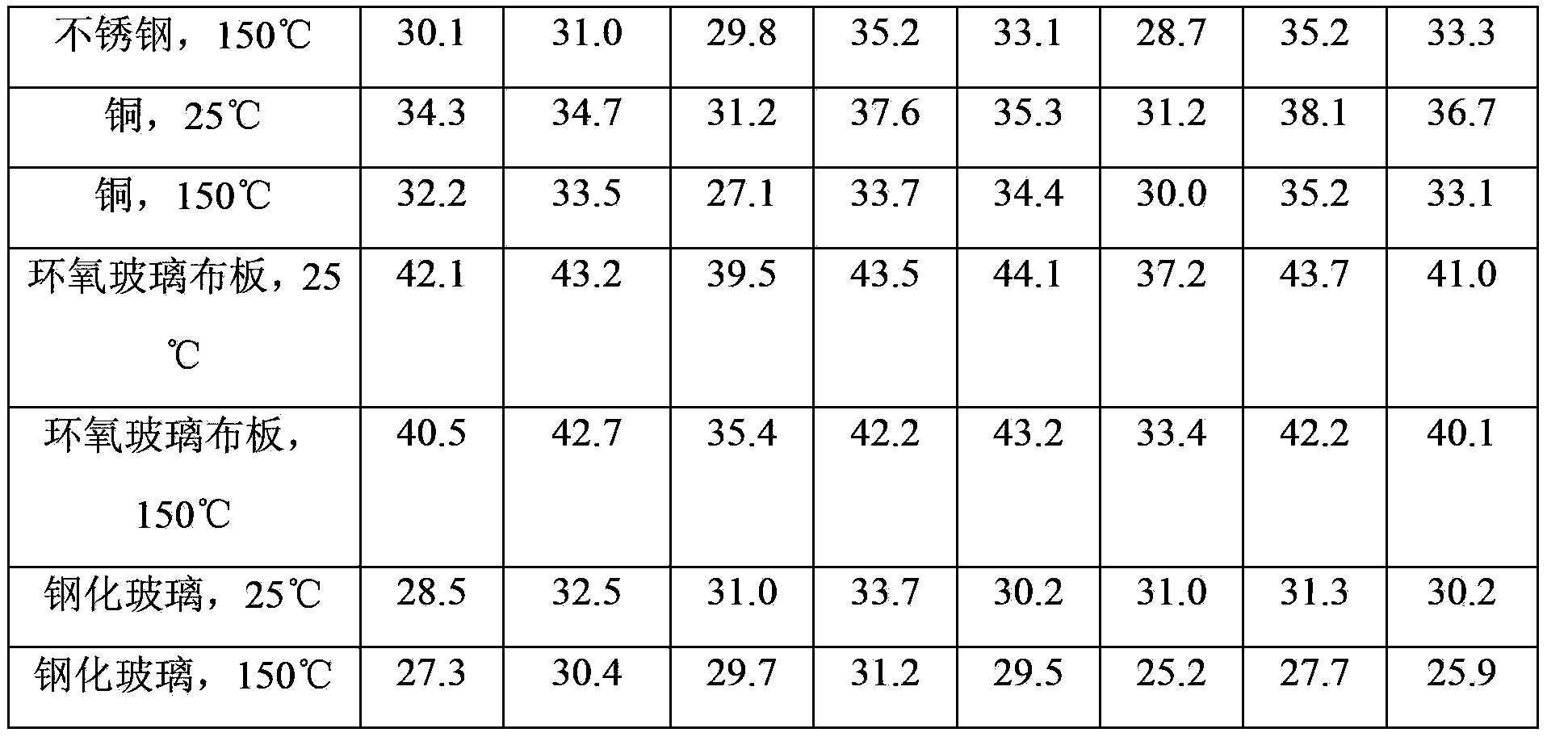

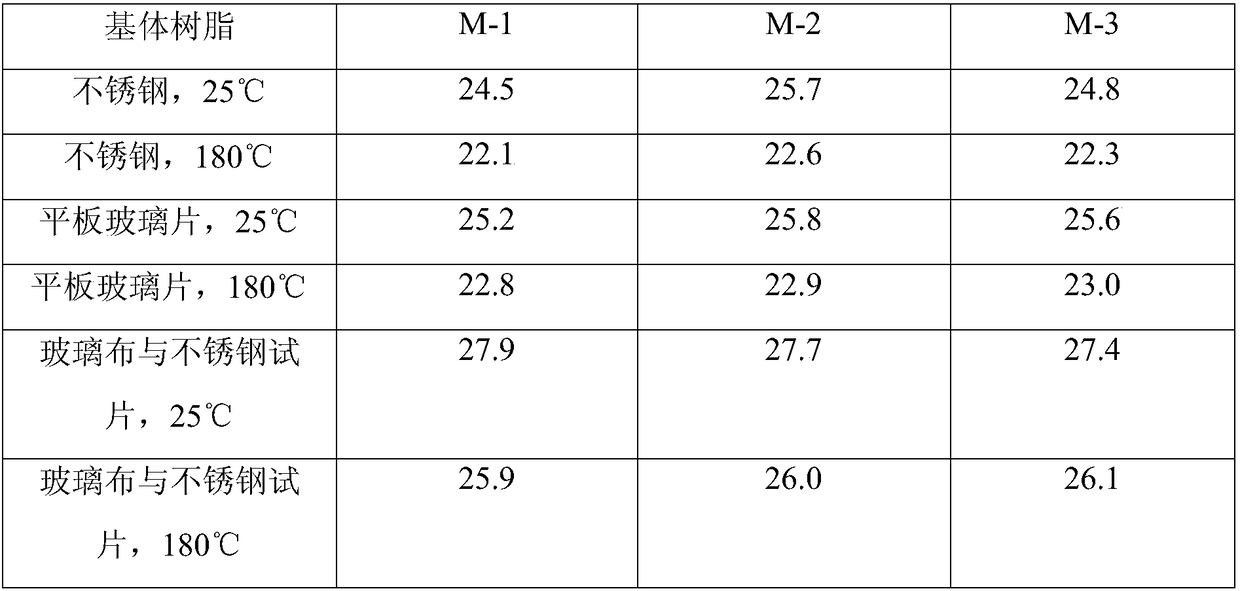

YASI (bis(gamma-aminopropyl) polydimethyl siloxane) siliceous epoxy imide matrix resin and preparation method thereof

The invention relates to a YASI (bis(gamma-aminopropyl) polydimethyl siloxane) siliceous epoxy imide matrix resin and a preparation method thereof. The matrix resin is composed of YASI, an epoxy resin, 3-aminopropyl trialkoxysilane, an imide oligomer and a curing agent. The preparation method comprises the following steps: (1) preparing the imide oligomer; and (2) adding the YASI and epoxy resin into a reaction kettle, stirring and mixing to react, adding the imide oligomer, continuing stirring to react, adding the 3-aminopropyl trialkoxysilane, stirring to react, adding the curing agent, and uniformly stirring and mixing. The resin can be widely used for bonding metals (such as steel, copper, aluminum and the like) and substrates (ceramic, glass, resin-base composite materials and the like), and preparing glass fibers, aramid fibers and carbon-fiber-reinforced polymer composite materials, and thus, has favorable industrialization prospects.

Owner:DONGHUA UNIV +1

Alpha-cyanogroup-beta-ethyl ethoxyacrylate modified epoxy resin adhesive and preparation method thereof

InactiveCN103013414AGood adhesionGood viscosity controllabilityModified epoxy resin adhesivesSolventChemistry

The invention relates to an alpha-cyanogroup-beta-ethyl ethoxyacrylate modified epoxy resin adhesive and a preparation method thereof. The adhesive comprises the following components: epoxy resin, epoxy ester resin, activity flexibilizer, alpha-cyanogroup-beta-ethyl ethoxyacrylate and a curing agent at a mass ratio of 100:(100-50): (60-30): (5-20): (30-80). The preparation method comprises the following steps that the epoxy resin and the activity flexibilizer are mixed, react at 60-80 DEG C for 15-20min, then are added with the epoxy ester resin and alpha-cyanogroup-beta-ethyl 3-ethoxyacrylate, and stirred and mixed uniformly, and a component A is obtained; the curing agent is a component B; and in a using process, the component A and the component B are mixed uniformly, and the adhesive is obtained. The adhesive is high in bonding strength, excellent in combination property, solvent-free and environment-friendly, can be used for bonding base materials such as metal, glass and ceramic, and has a good application prospect.

Owner:DONGHUA UNIV +2

High-temperature resistant copper foil glue and preparation and application thereof

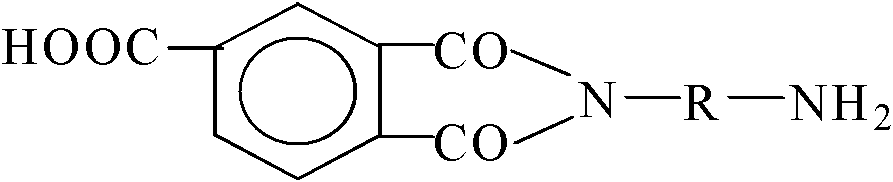

InactiveCN101717613AGood viscosity controllabilityGood workmanshipInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentOrganic solventPolyetherimide

The invention relates to high-temperature resistant copper foil glue containing the following components: 5-15wt percent of trifluoromethyl-contained maleimide resin, 10-30wt percent of polyfunctional ethoxyline resin, 10-40wt percent of bisphenol A epoxy resin, 5-15wt percent of ethylene-contained polyetherimide, 5-10wt percent of curing agent and 25-45wt percent of organic solvent; the preparation comprises the following steps of: adding the trifluoromethyl-contained maleimide resin and the ethylene-contained polyetherimide to the mixture of the polyfunctional ethoxyline resin and the bisphenol A epoxy resin, stirring while heating for reacting, and then cooling to 30-50 DEG C; adding the organic solvent and the curing agent; evenly stirring to obtain the high-temperature resistant copper foil glue the homogeneous phase of which is transparent and clear. The high-temperature resistant copper foil glue has Tonset temperature reaching up to 415 DEG C and excellent comprehensive performance, can be applied to the high-tech fields of electronics and microelectronics, automobiles, electrical machines, aerospace and the like; moreover, the invention has simple preparation process, low cost, convenient operation and available reaction raw materials, thereby being beneficial to realizing industrial production.

Owner:DONGHUA UNIV

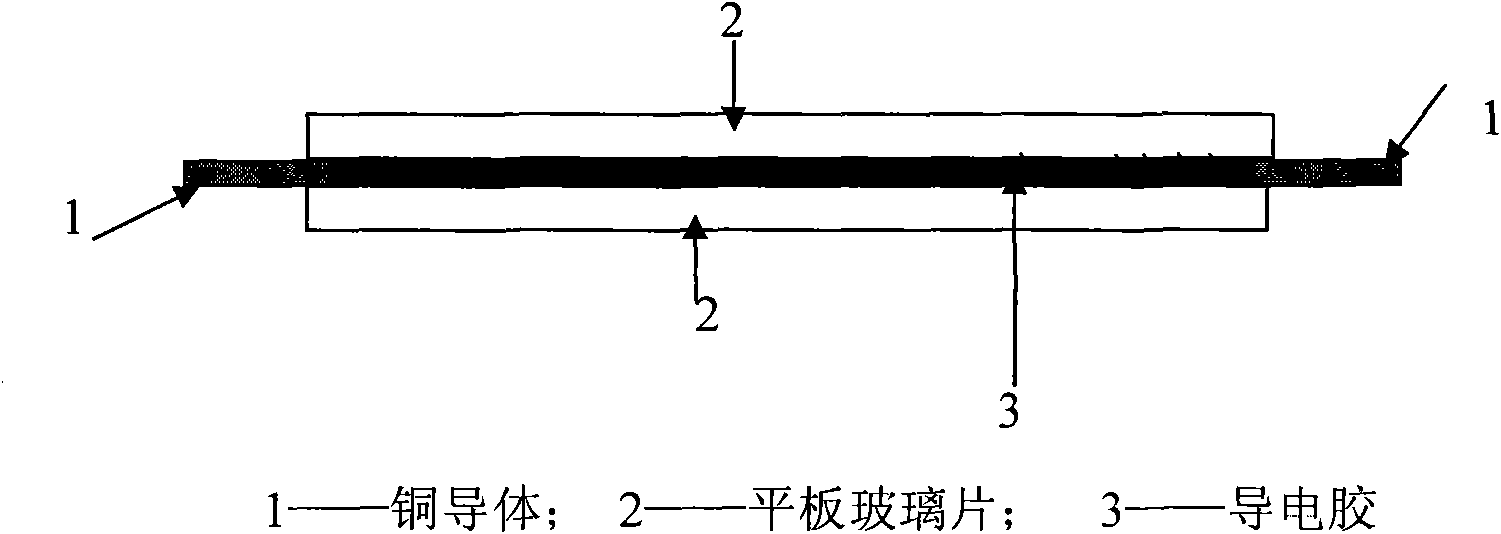

Polyimide-epoxy resin adhesive and preparation method and application thereof

InactiveCN101629062ASimple preparation processLow costEpoxy resin adhesivesMicroelectronicsChemistry

The invention relates to a polyimide-epoxy resin adhesive and a preparation method and an application thereof; the adhesive comprises the following components: maleimidopolyimide, polyfunctional epoxy resin, curing agent, promoter and organic solvent; the preparation method comprises the following steps: adding maleimidopolyimide powder and polyfunctional epoxy resin in a reaction rank to react for 1-2h, cooling, adding organic solvent, stirring the solution for dissolving, obtaining component A; mixing curing agent, promoter and organic solvent, stirring the solution for dissolving, obtaining component B; mixing the component A and component B, stirring evenly and obtaining the finished product. The adhesive has good adhesive property, the tensile shear strength is up to 30MPa; the preparation process is simple, the cost is low, the operation is simple, the reaction raw materials are accessible so that the method is applicable to industrialized production; and the adhesive can be used in high-tech fields such as electronics and microelectronics, flexible clad-copper laminates, flexible printed wiring boards, hard clad-copper laminates, automobiles, motors, aviation and aerospace and the like, and has broad application prospect.

Owner:DONGHUA UNIV

Heat-resistant solvent-free immersion paint and preparation method thereof

InactiveCN101921529AConvenient sourceSimple preparation processEpoxy resin coatingsHeat resistanceElectric machine

The invention relates to a heat-resistant solvent-free immersion paint which comprises the following components in percentage by weight: 10%-15% of organosilicon polyfunctional epoxy resin, 15%-35% of silicon-free polyfunctional epoxy resin, 5%-10% of curing agent and 45%-65% of reactive diluent. The preparation method thereof comprises the following steps: adding the organosilicon polyfunctional epoxy resin, the reactive diluent and the silicon-free polyfunctional epoxy resin into a kettle, reacting for 0.5h at the temperature of 100 DEG C, cooling, adding the curing agent, and evenly stirring at room temperature, thus obtaining sticky liquid, i.e. the heat-resistant solvent-free immersion paint. The preparation process is simple, the cost is low, and the industrialized production can be easily realized; the room-temperature longitudinal shear strength of the heat-resistant solvent-free immersion paint is high; and the heat-resistant solvent-free immersion paint has excellent heat resistance, strong hydrophobic property and wide application prospects in the fields of high-power traction electric machines, high-power generators, drilling motors, mining motors and the like.

Owner:DONGHUA UNIV +1

DAHTM type silicon-containing epoxy imide matrix resin and preparing method thereof

InactiveCN106146841AGood viscosity controllabilitySimple preparation processChemistryCarbon fiber reinforced composite

The invention relates to DAHTM type silicon-containing epoxy imide matrix resin and a preparing method thereof. The matrix resin is prepared from 4,4'-diamido-4''-hydroxy triphenylmethane (DAHTM), epoxy resin, 3-aminopropyl trialkoxysilane, an imide oligomer and a curing agent. The preparing method includes the following steps that 1, the imide oligomer is prepared; 2, DAHTM and epoxy resin are put into a reaction kettle, stirred and mixed for reaction, then the imide oligomer is added, the mixture continues to be stirred for reaction, then 3-aminopropyl trialkoxysilane is added and stirred for reaction, the curing agent is added and stirred to be mixed uniformly to obtain the matrix resin. The matrix resin can be widely applied to adhesion between metal such as steel, copper and aluminum and a base material such as ceramic, glass and a resin-based composite material and used for preparing glass fiber, aramid fiber and carbon fiber reinforced composite and has good industrial prospects.

Owner:DONGHUA UNIV +1

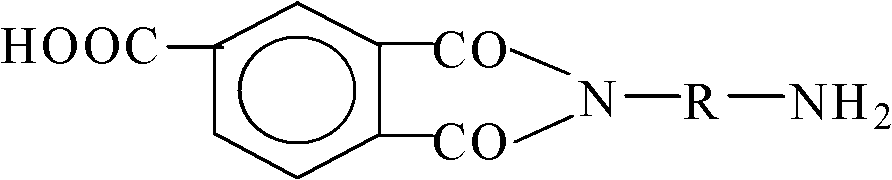

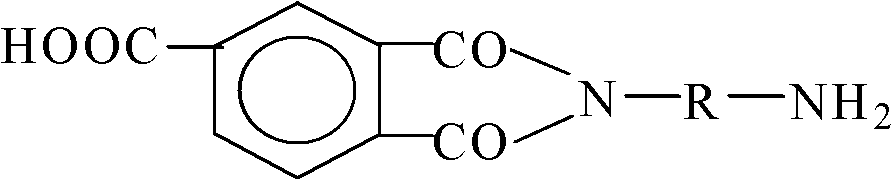

Active phthalimide epoxy solvent-free dripping impregnating varnish and preparation method thereof

InactiveCN101921531AConvenient sourceSimple preparation processEpoxy resin coatingsEpoxyHeat resistance

The invention relates to an active phthalimide epoxy solvent-free dripping impregnating varnish and a preparation method thereof. The varnish has the following components: 10wt%-15wt% of active phthalimide, 35wt%-45wt% of epoxy resin, 5wt%-10wt% of active toughening agent, 5wt%-10wt% of curing agent, 20wt%-45wt% of active diluent. The preparation method comprises the preparation of the active phthalimide and the solvent-free dripping impregnating varnish. The preparation features simple process and low cost and contributes to the realization of industrialized production; in addition, the solvent-free dripping impregnating varnish enjoys excellent comprehensive property, fine manufacturability and cohesiveness, excellent heat resistance and hydrophobicity, thus enjoying bright application prospect in fields such as motors of electric tools, small electric machine and the like.

Owner:DONGHUA UNIV +1

1,3-bis(2,4-diamidophenoxy)benzene high-temperature-resistant epoxy adhesive and preparation method thereof

InactiveCN103131370AGood adhesionGood viscosity controllabilityMacromolecular adhesive additivesEpoxynovolac adhesivesBenzeneOrganic solvent

The invention relates to a 1,3-bis(2,4-diamidophenoxy)benzene high-temperature-resistant epoxy adhesive and a preparation method thereof. The 1,3-bis(2,4-diamidophenoxy)benzene high-temperature-resistant epoxy adhesive is composed of a component A and a component B in a mass ratio of 1:(1-2), wherein the component A is a copolymer prepared by reacting 1,3-bis(2,4-diamido phenoxy)benzene and epoxy resin; and the component B is a homogeneous-phase transparent solution with the solid content of 15-30%, which is prepared by reacting 1,3-bis(2,4-diamidophenoxy)benzene and aromatic dibasic acid anhydride in a strong-polarity non-proton organic solvent and toluene. The preparation method comprises the following step: evenly mixing the component A and the component B in a mass ratio of 1:(1-2) at room temperature. The preparation technique is simple; and the adhesive has excellent comprehensive properties, can be widely used for bonding steel, copper, aluminum or any other metal with ceramic, glass, resin-base composite material or any other substrate, and has favorable industrialization prospects.

Owner:DONGHUA UNIV +1

4,4'-bis(2,4-diamidophenoxy)diphenylmethane high-temperature-resistant epoxy adhesive and preparation method thereof

InactiveCN103131371AGood adhesionGood viscosity controllabilityMacromolecular adhesive additivesEpoxynovolac adhesivesDiphenylmethaneResin-Based Composite

The invention relates to a 4,4'-bis(2,4-diamidophenoxy)diphenylmethane high-temperature-resistant epoxy adhesive and a preparation method thereof. The 4,4'-bis(2,4-diamidophenoxy)diphenylmethane high-temperature-resistant epoxy adhesive is composed of a component A and a component B in a mass ratio of 1:(1-2), wherein the component A is a copolymer prepared by reacting 4,4'-bis(2,4-diamido phenoxy)diphenylmethane and epoxy resin; and the component B is a homogeneous-phase transparent solution with the solid content of 15-30%, which is prepared by reacting 4,4'-bis(2,4-diamidophenoxy)diphenylmethane and aromatic dibasic acid anhydride in a strong-polarity non-proton organic solvent and diphenylmethane. The preparation method comprises the following step: evenly mixing the component A and the component B in a mass ratio of 1:(1-2) at room temperature. The preparation technique is simple; and the adhesive has excellent comprehensive properties, can be widely used for bonding steel, copper, aluminum or any other metal with ceramic, glass, resin-base composite material or any other substrate, and has favorable industrialization prospects.

Owner:DONGHUA UNIV +1

BDAPP type silicon-containing epoxy imide matrix resin and preparation method thereof

The invention relates to BDAPP type silicon-containing epoxy imide matrix resin and a preparation method thereof. The matrix resin comprises 2, 2-bis[4-(2, 4-diaminobenzene oxygroup) phenyl] propane (BDAPP), epoxy resin, 3-aminopropyl trialkoxy silane, imide oligomer and curing agent. The preparation method includes the steps of firstly, preparing the imide oligomer; secondly, placing the 2, 2-bis[4-(2, 4-diaminobenzene oxygroup) phenyl] propane (BDAPP) and the epoxy resin into a reaction kettle, stirring and mixing for reaction, adding the imide oligomer, continuing stirring for reaction, adding the 3-aminopropyl trialkoxy silane, stirring for reaction, adding the curing agent, and evenly stirring and mixing to obtain the BDAPP type silicon-containing epoxy imide matrix resin. The BDAPP type silicon-containing epoxy imide matrix resin is widely applicable to the bonding of metals such steel, copper and aluminum and base materials such as ceramics, glass and resin-based composite materials and the preparation of glass-fiber-enhanced, aramid-fiber-enhanced and carbon-fiber-enhanced composite materials and is promising in industrialization prospect.

Owner:DONGHUA UNIV +1

High-temperature resistant copper foil glue and preparation and application thereof

InactiveCN101717613BGood viscosity controllabilityGood workmanshipInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentPolyetherimideOrganic solvent

Owner:DONGHUA UNIV

Heat-resistant solvent-free immersion paint and preparation method thereof

InactiveCN101921529BConvenient sourceSimple preparation processEpoxy resin coatingsElectric machineHeat resistance

The invention relates to a heat-resistant solvent-free immersion paint which comprises the following components in percentage by weight: 10%-15% of organosilicon polyfunctional epoxy resin, 15%-35% of silicon-free polyfunctional epoxy resin, 5%-10% of curing agent and 45%-65% of reactive diluent. The preparation method thereof comprises the following steps: adding the organosilicon polyfunctionalepoxy resin, the reactive diluent and the silicon-free polyfunctional epoxy resin into a kettle, reacting for 0.5h at the temperature of 100 DEG C, cooling, adding the curing agent, and evenly stirring at room temperature, thus obtaining sticky liquid, i.e. the heat-resistant solvent-free immersion paint. The preparation process is simple, the cost is low, and the industrialized production can beeasily realized; the room-temperature longitudinal shear strength of the heat-resistant solvent-free immersion paint is high; and the heat-resistant solvent-free immersion paint has excellent heat resistance, strong hydrophobic property and wide application prospects in the fields of high-power traction electric machines, high-power generators, drilling motors, mining motors and the like.

Owner:DONGHUA UNIV +1

A kind of bdapfp type silicon-containing epoxy imide matrix resin and preparation method thereof

The invention relates to BDAPFP type silicon-containing epoxy imide matrix resin and a preparation method thereof. The matrix resin comprises 2, 2-bis[4-(2, 4-diaminobenzene oxygroup) phenyl] hexafluoropropane (BDAPFP), epoxy resin, 3-aminopropyl trialkoxy silane, imide oligomer and curing agent. The preparation method includes the steps of firstly, preparing the imide oligomer; secondly, placing the 2, 2-bis[4-(2, 4-diaminobenzene oxygroup) phenyl] hexafluoropropane (BDAPFP) and the epoxy resin into a reaction kettle, stirring and mixing for reaction, adding the imide oligomer, continuing stirring for reaction, adding the 3-aminopropyl trialkoxy silane, stirring for reaction, adding the curing agent, and evenly stirring and mixing to obtain the BDAPFP type silicon-containing epoxy imide matrix resin. The BDAPFP type silicon-containing epoxy imide matrix resin is widely applicable to the bonding of metals such steel, copper and aluminum and base materials such as ceramics, glass and resin-based composite materials and the preparation of glass-fiber-enhanced, aramid-fiber-enhanced and carbon-fiber-enhanced composite materials and is promising in industrialization prospect.

Owner:DONGHUA UNIV +1

A kind of dahtm type silicon-containing epoxy imide matrix resin and preparation method thereof

Owner:DONGHUA UNIV +1

A kind of bdabp type silicon-containing epoxy imide matrix resin and preparation method thereof

InactiveCN106220852BGood viscosity controllabilitySimple preparation processEpoxyResin-Based Composite

Owner:DONGHUA UNIV +1

4,4'-bis(2,4-diamidophenoxy)diphenylmethane high-temperature-resistant epoxy adhesive and preparation method thereof

InactiveCN103131371BGood adhesionGood viscosity controllabilityMacromolecular adhesive additivesEpoxynovolac adhesivesDiphenylmethaneResin-Based Composite

The invention relates to a 4,4'-bis(2,4-diamidophenoxy)diphenylmethane high-temperature-resistant epoxy adhesive and a preparation method thereof. The 4,4'-bis(2,4-diamidophenoxy)diphenylmethane high-temperature-resistant epoxy adhesive is composed of a component A and a component B in a mass ratio of 1:(1-2), wherein the component A is a copolymer prepared by reacting 4,4'-bis(2,4-diamido phenoxy)diphenylmethane and epoxy resin; and the component B is a homogeneous-phase transparent solution with the solid content of 15-30%, which is prepared by reacting 4,4'-bis(2,4-diamidophenoxy)diphenylmethane and aromatic dibasic acid anhydride in a strong-polarity non-proton organic solvent and diphenylmethane. The preparation method comprises the following step: evenly mixing the component A and the component B in a mass ratio of 1:(1-2) at room temperature. The preparation technique is simple; and the adhesive has excellent comprehensive properties, can be widely used for bonding steel, copper, aluminum or any other metal with ceramic, glass, resin-base composite material or any other substrate, and has favorable industrialization prospects.

Owner:DONGHUA UNIV +1

1,4-di(2,4-diamino phenoxy) benzenoid form high-temperature epoxy adhesive and preparation method thereof

InactiveCN103122231BGood adhesionGood viscosity controllabilityEpoxynovolac adhesivesBenzeneOrganic solvent

The invention relates to 1,4-di(2,4-diamino phenoxy) benzenoid form high-temperature epoxy adhesive and a preparation method thereof. The adhesive consists of a component A and a component B in a mass ratio of 1:1-2, wherein the component A is a co-polymer formed by the reaction between 1,4-di(2,4-diamino phenoxy) benzene and epoxy resin; and the component B is a homogeneous transparent solution which has the solid content being 15-30 percent and is formed by the reaction between 1,4-di(2,4-diamino phenoxy) benzene and binary acid anhydride in strong polar aprotic organic solvent and toluene. The preparation method comprises the following steps of stirring and uniformly mixing the component A and the component B at room temperature in a mass ratio of 1:1-2. The preparation process is simple, and the adhesive is excellent in comprehensive performance, so that the adhesive can be widely applied to adhesion among steel, copper, aluminum and other metals, as well as ceramic, glass, resin-based composite materials and other base materials, and has an excellent industrial prospect.

Owner:DONGHUA UNIV +1

A kind of dadhbp type silicon-containing epoxy imide matrix resin and preparation method thereof

InactiveCN106220850BGood viscosity controllabilitySimple preparation processResin matrixResin-Based Composite

The invention relates DADHBP (dihydroxybiphenyl) type silicon-containing imide epoxy matrix resin and a preparation method thereof. The matrix resin is composed of 3,3'-diamido-4,4'-dihydroxybiphenyl (DADHBP), epoxy resin, 3-aminopropyl trialkoxysilane, imide oligomer and a curing agent. The preparation method includes the steps of 1), preparing the imide oligomer; 2), putting the 3,3'-diamido-4,4'-dihydroxybiphenyl (DADHBP) and the epoxy resin into a reaction kettle, after mixing reaction, adding the imide oligomer for continuous mixing reaction, then adding the 3-aminopropyl trialkoxysilane for mixing action, and then adding the curing agent for even mixing to obtain the matrix resin. The DADHBP (dihydroxybiphenyl) type silicon-containing imide epoxy matrix resin and the preparation method thereof can be widely used in adhesion between metals of steel, copper, aluminum and the like and base materials of ceramics, glass, resin matrix composites and the like as well as preparation of glass fiber, aramid fiber and carbon fiber reinforced composites, and good industrialization prospect is achieved.

Owner:DONGHUA UNIV +1

A kind of 14bdapb type silicon-containing epoxy imide matrix resin and preparation method thereof

The invention relates to 14BDAPB type silicon-containing epoxy imide matrix resin and a preparation method thereof. The matrix resin is prepared from 1,4-bis(2,4-diaminophenoxy)benzene 14BDAPB, epoxy resin, 3-aminopropyl trialkoxy silane, an imide oligomer and a curing agent. The preparation method comprises the following steps: (1) preparing the imide oligomer; (2) putting the 1,4-bis(2,4-diaminophenoxy)benzene and the epoxy resin into a reaction kettle, stirring and mixing for reacting; after that, adding the imide oligomer and continuously stirring for reacting; then adding the 3-aminopropyl trialkoxy silane and stirring for reacting; and adding the curing agent and stirring and mixing uniformly to obtain the 14BDAPB type silicon-containing epoxy imide matrix resin. The 14BDAPB type silicon-containing epoxy imide matrix resin provided by the invention can be widely applied to the bonding of metals such as steel, cooper and aluminum and base materials such as ceramic, glass and resin-based composites and the preparation of glass fiber, aramid fiber and carbon fiber reinforced composites, and has good industrialization prospect.

Owner:DONGHUA UNIV +1

4,4'-bis(2,4-diamidophenoxy)diphenylsulphone high-temperature-resistant epoxy adhesive and preparation method thereof

InactiveCN103131369BGood adhesionGood viscosity controllabilityMacromolecular adhesive additivesEpoxynovolac adhesivesOrganic solventRoom temperature

The invention relates to a 4,4'-bis(2,4-diamidophenoxy)diphenylsulphone high-temperature-resistant epoxy adhesive and a preparation method thereof. The 4,4'-bis(2,4-diamidophenoxy)diphenylsulphone high-temperature-resistant epoxy adhesive is composed of a component A and a component B in a mass ratio of 1:(1-2), wherein the component A is a copolymer prepared by reacting 4,4'-bis(2,4-diamido phenoxy)diphenylsulphone and epoxy resin; and the component B is a homogeneous-phase transparent solution with the solid content of 15-30%, which is prepared by reacting 4,4'-bis(2,4-diamidophenoxy)diphenylsulphone and aromatic dibasic acid anhydride in a strong-polarity non-proton organic solvent and diphenylsulphone. The preparation method comprises the following step: evenly mixing the component A and the component B in a mass ratio of 1:(1-2) at room temperature. The preparation technique is simple; and the adhesive has excellent comprehensive properties, can be widely used for bonding steel, copper, aluminum or any other metal with ceramic, glass, resin-base composite material or any other substrate, and has favorable industrialization prospects.

Owner:DONGHUA UNIV +1

Preparation method of high temperature resistant single-component solventless epoxy adhesive

The invention relates to a preparation method of high temperature resistant single-component solventless epoxy adhesive. The method comprises the following steps: adding aromatic binary primary amine and strongly polar non-proton organic solvent in a reaction tank, stirring at room temperature to dissolve, adding aromatic binary acid anhydride to perform refluxing and water-segregating reaction at 120-150 DEG C for 6-12h, cooling, adding the reaction solution in a stamp tank with precipitant to precipitate solid powder, namely white thermoplastic polyimide powder, adding white thermoplastic polyimide powder and tertiary amine compound or imidazole compound in epoxy resin to react for 1-2h, adding active diluent and latent curing agent to stir evenly and obtaining the product. The production process is easy and the cost is low so as to realize industrialized production; the tensile shear intensions of the epoxy adhesive at room temperature and 120 DEG C are respectively up to 28Mpa and26Mpa and the epoxy adhesive has broad application prospect in fields such as electronics and microelectronics, electrical motors, aviation and aerospace and the like.

Owner:DONGHUA UNIV

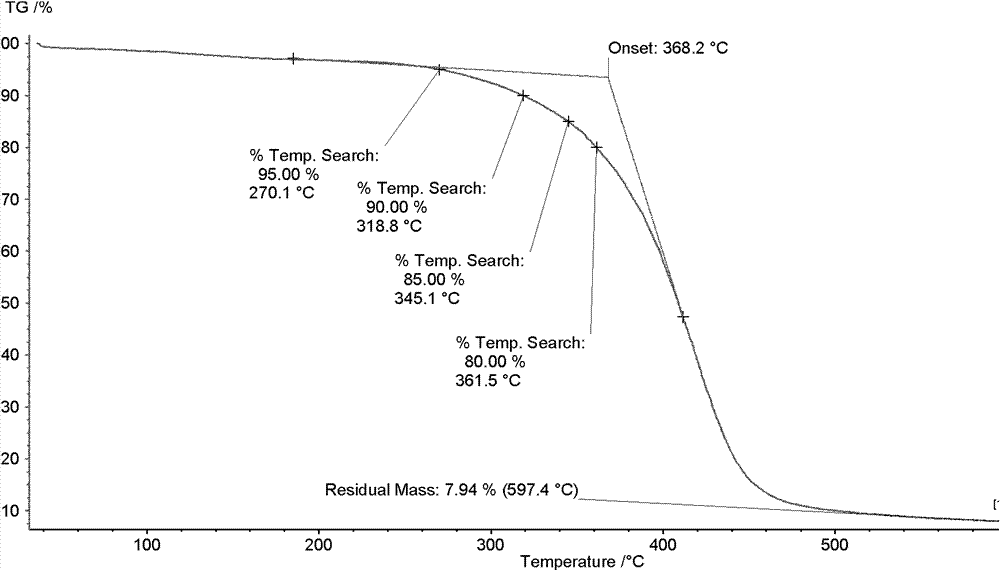

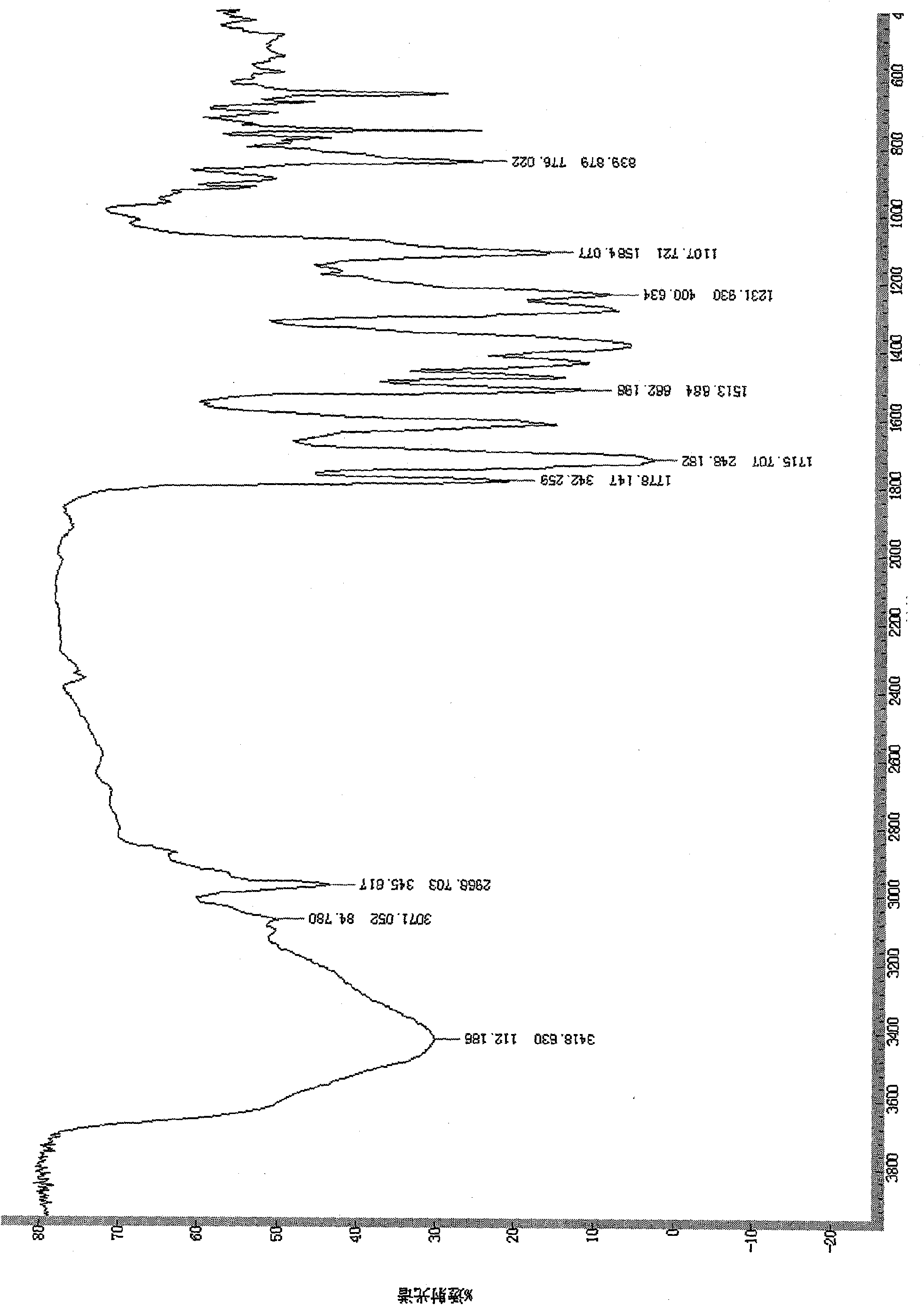

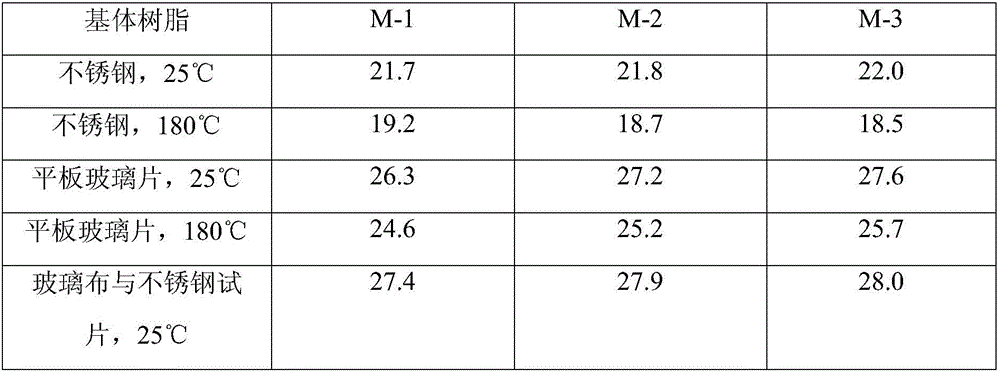

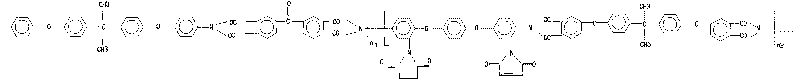

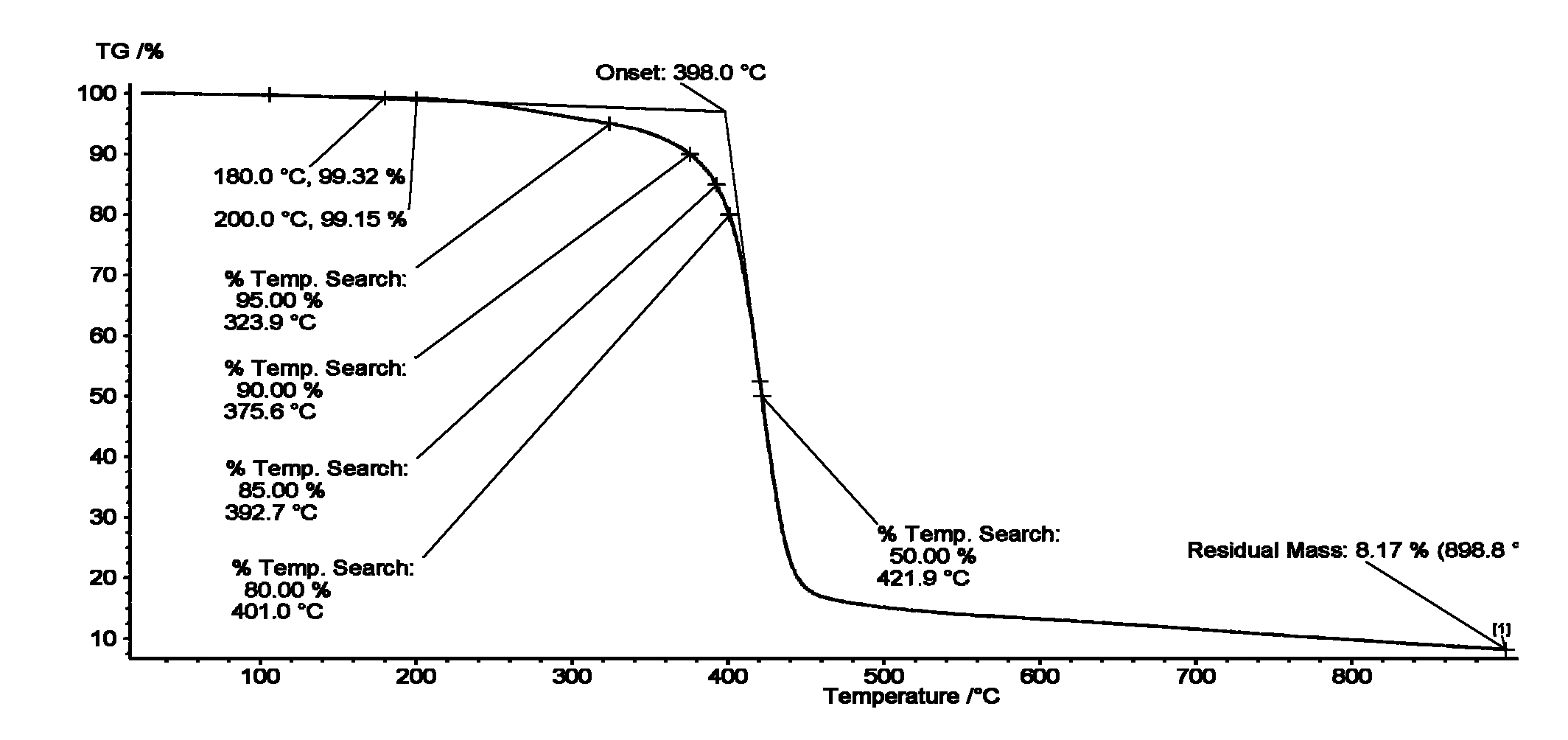

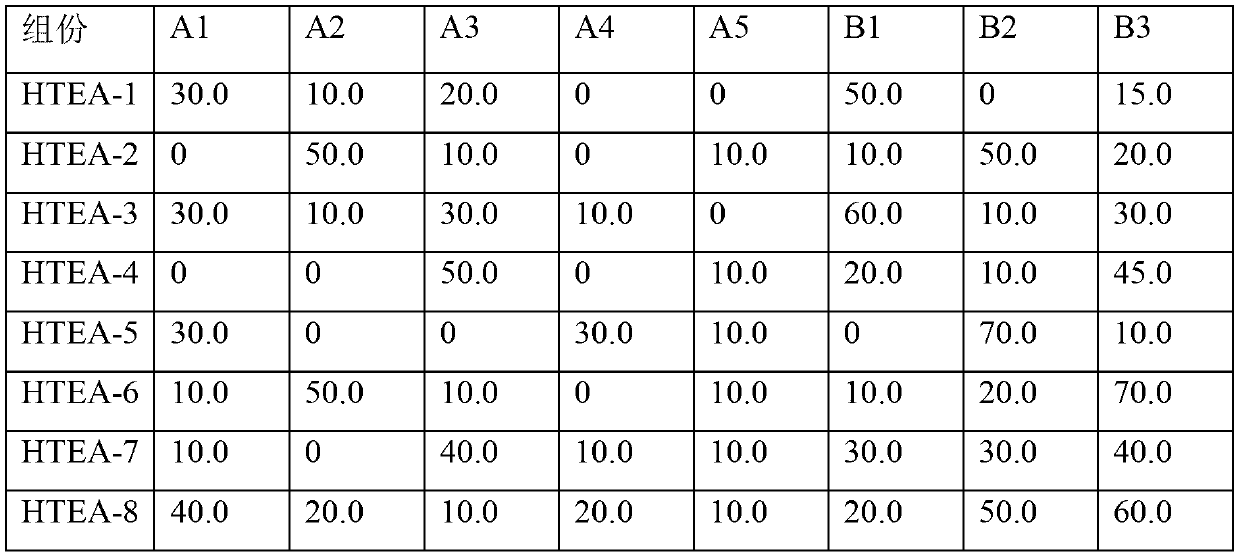

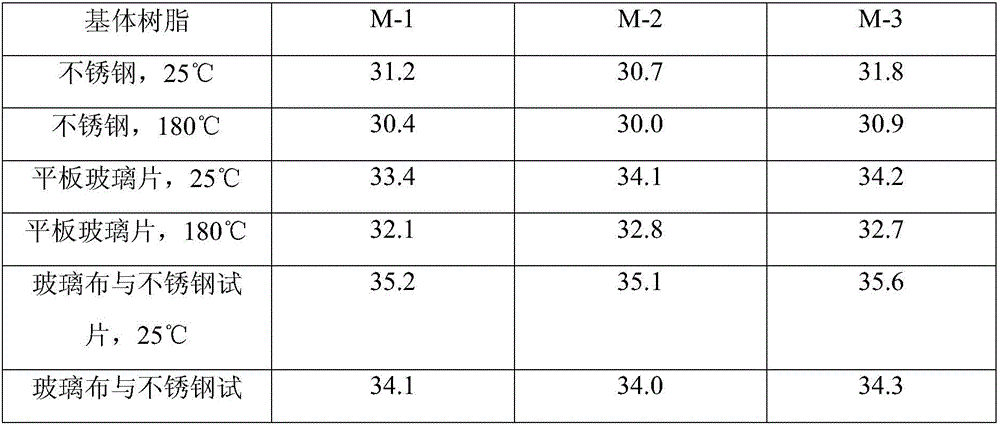

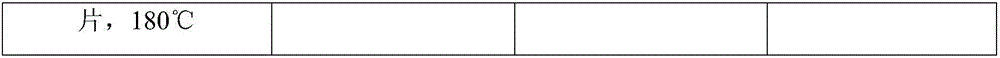

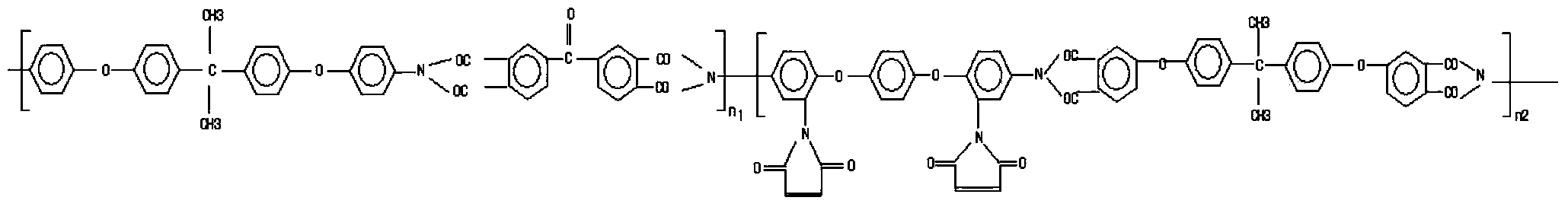

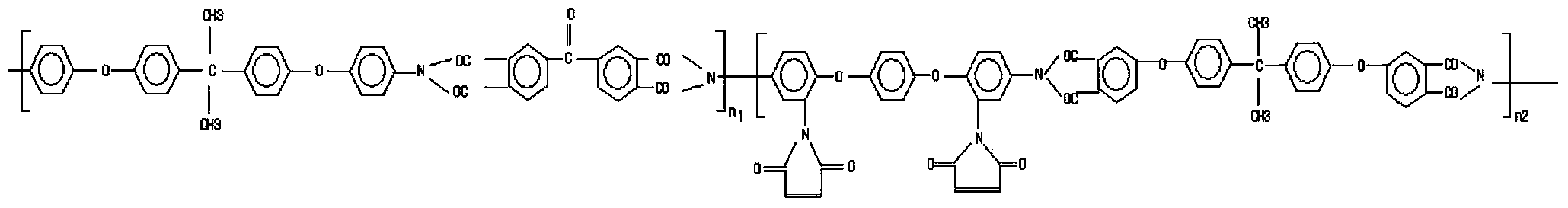

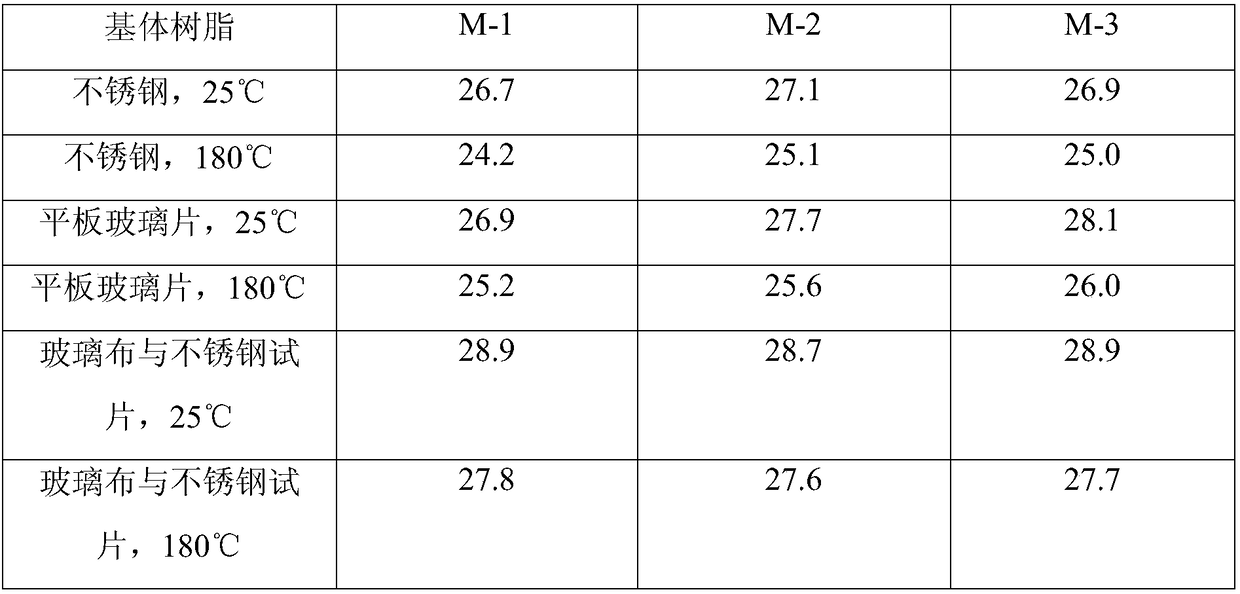

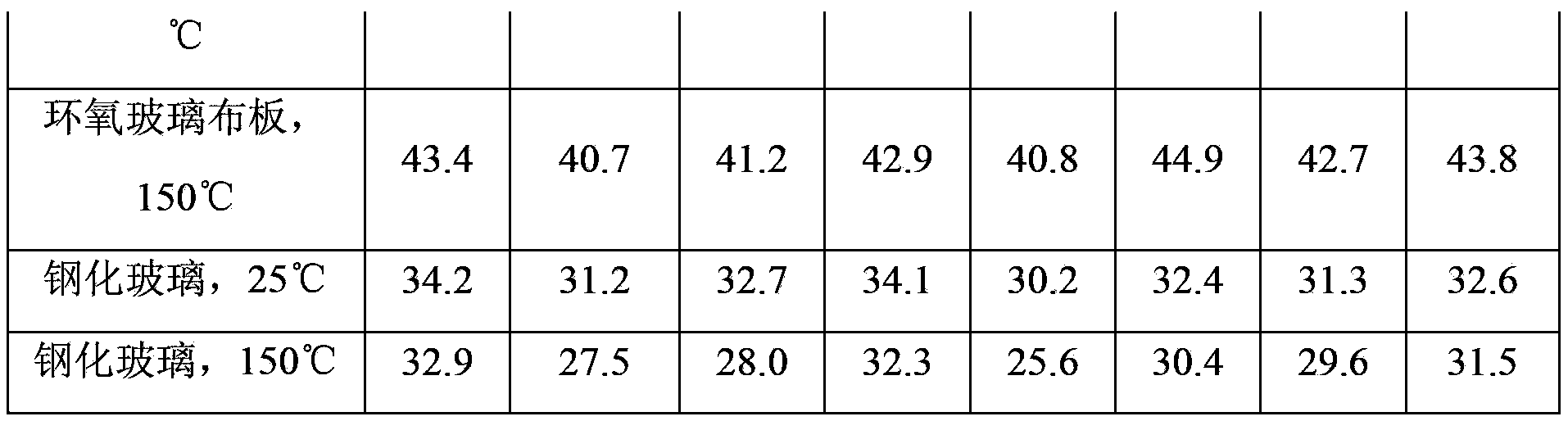

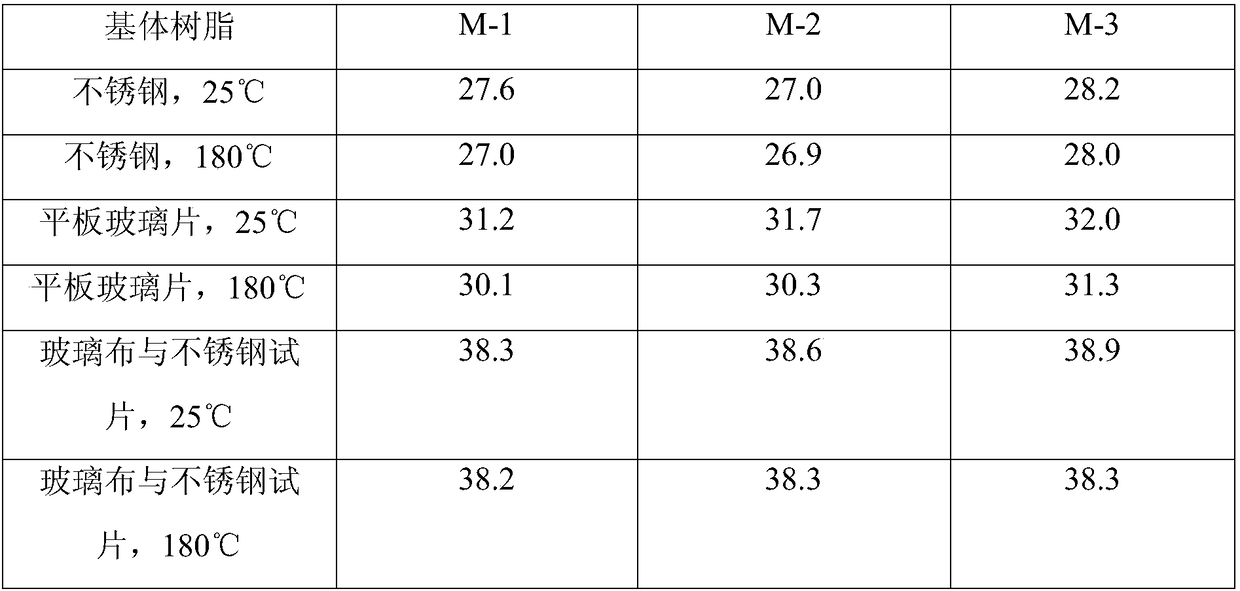

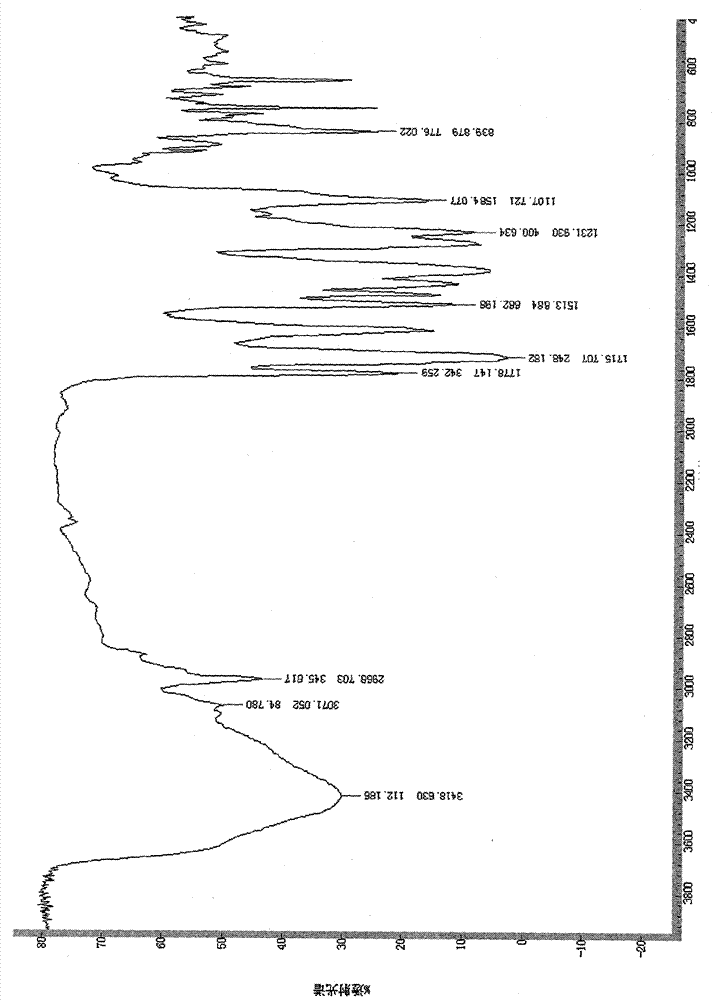

2,2-di[4-(2,4-diamino phenoxy) phenyl] propane form high-temperature epoxy adhesive and preparation method thereof

InactiveCN103122232BGood adhesionGood viscosity controllabilityEpoxynovolac adhesivesOrganic solventRoom temperature

The invention relates to 2,2-di[4-(2,4-diamino phenoxy) phenyl] propane form high-temperature epoxy adhesive and a preparation method thereof. The adhesive consists of a component A and a component B in a mass ratio of 1:1-2, wherein the component A is a co-polymer formed by the reaction between 2,2-di[4-(2,4-diamino phenoxy) phenyl] propane and epoxy resin; and the component B is a homogeneous transparent solution which has the solid content being 15-30 percent and formed by the reaction between 2,2-di[4-(2,4-diamino phenoxy) phenyl] propane and binary acid anhydride in strong polar aprotic organic solvent and toluene. The preparation method comprises the following steps of stirring and uniformly mixing the component A and the component B at room temperature in a mass ratio of 1:1-2. The preparation process is simple, and the adhesive is excellent in comprehensive performance, so that the adhesive can be widely applied to adhesion among steel, copper, aluminum and other metals, as well as ceramic, glass, resin-based composite materials and other base materials, and has an excellent industrial prospect.

Owner:DONGHUA UNIV +1

1,3-bis(2,4-diaminophenoxy)benzene type high temperature resistant epoxy adhesive and preparation method thereof

InactiveCN103131370BGood adhesionGood viscosity controllabilityMacromolecular adhesive additivesEpoxynovolac adhesivesBenzeneOrganic solvent

The invention relates to a 1,3-bis(2,4-diamidophenoxy)benzene high-temperature-resistant epoxy adhesive and a preparation method thereof. The 1,3-bis(2,4-diamidophenoxy)benzene high-temperature-resistant epoxy adhesive is composed of a component A and a component B in a mass ratio of 1:(1-2), wherein the component A is a copolymer prepared by reacting 1,3-bis(2,4-diamido phenoxy)benzene and epoxy resin; and the component B is a homogeneous-phase transparent solution with the solid content of 15-30%, which is prepared by reacting 1,3-bis(2,4-diamidophenoxy)benzene and aromatic dibasic acid anhydride in a strong-polarity non-proton organic solvent and toluene. The preparation method comprises the following step: evenly mixing the component A and the component B in a mass ratio of 1:(1-2) at room temperature. The preparation technique is simple; and the adhesive has excellent comprehensive properties, can be widely used for bonding steel, copper, aluminum or any other metal with ceramic, glass, resin-base composite material or any other substrate, and has favorable industrialization prospects.

Owner:DONGHUA UNIV +1

Active phthalimide epoxy solvent-free dripping impregnating varnish and preparation method thereof

InactiveCN101921531BConvenient sourceSimple preparation processEpoxy resin coatingsImidePolymer science

The invention relates to an active phthalimide epoxy solvent-free dripping impregnating varnish and a preparation method thereof. The varnish has the following components: 10wt%-15wt% of active phthalimide, 35wt%-45wt% of epoxy resin, 5wt%-10wt% of active toughening agent, 5wt%-10wt% of curing agent, 20wt%-45wt% of active diluent. The preparation method comprises the preparation of the active phthalimide and the solvent-free dripping impregnating varnish. The preparation features simple process and low cost and contributes to the realization of industrialized production; in addition, the solvent-free dripping impregnating varnish enjoys excellent comprehensive property, fine manufacturability and cohesiveness, excellent heat resistance and hydrophobicity, thus enjoying bright application prospect in fields such as motors of electric tools, small electric machine and the like.

Owner:DONGHUA UNIV +1

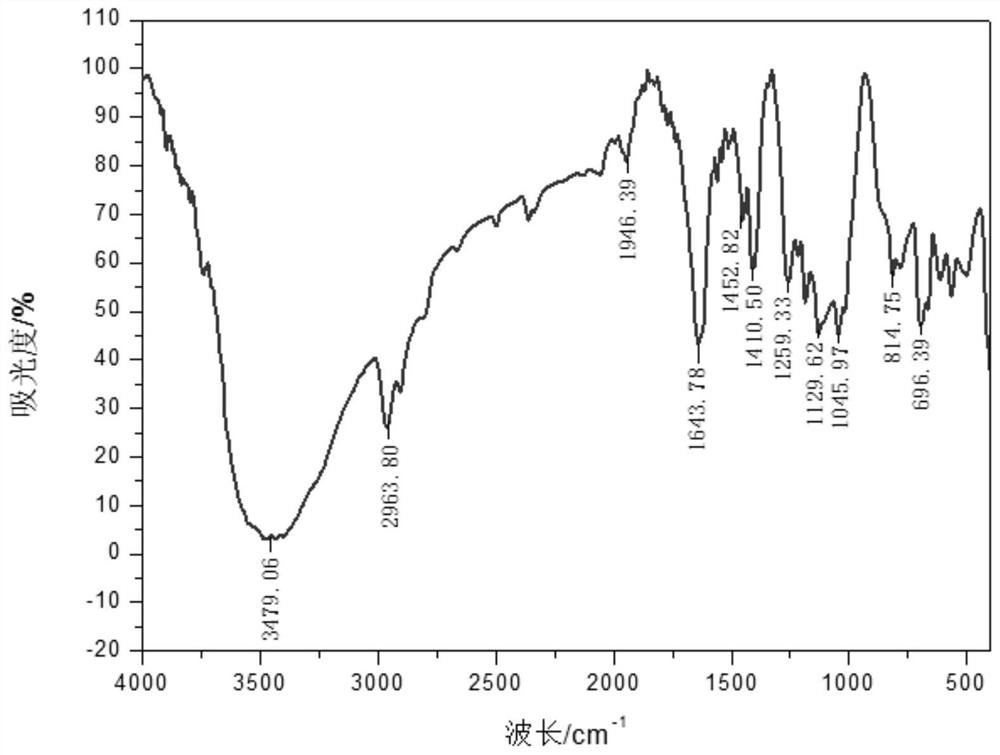

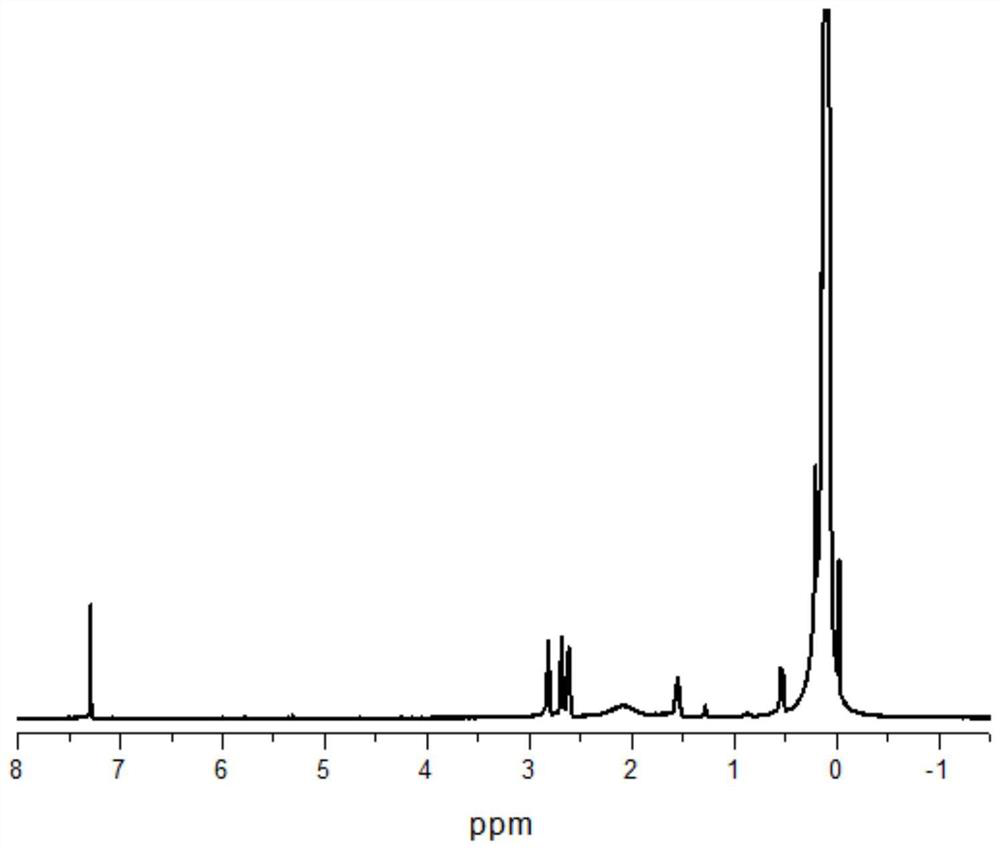

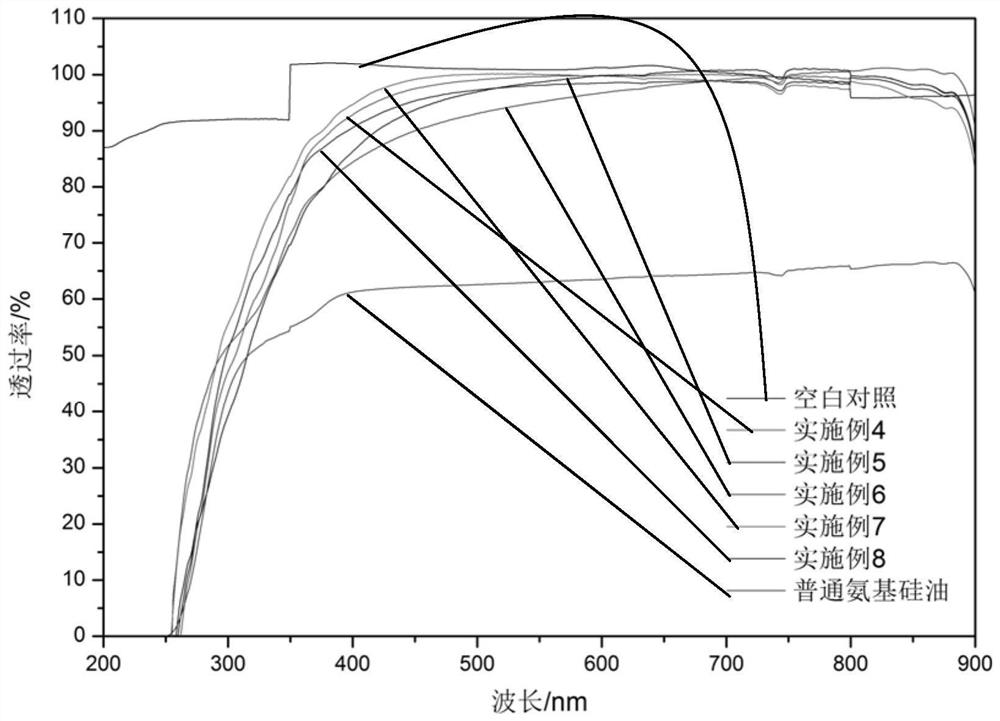

A kind of preparation method of high permeability amino silicone oil

ActiveCN108912333BImprove transmittanceViscosity is easy to controlAnimal fibresPtru catalystEngineering

The invention provides a preparation method of high permeability amino silicone oil, which comprises a step of preparing coupling agent hydrolyzate; a step of preparing amino silicone oil, dehydrating octamethylcyclotetrasiloxane; , add the catalyst to dissolve; then add the coupling agent hydrolyzate under reduced pressure to mix; then add the end-capping agent under reduced pressure to react and then heat up to deactivate the catalyst; then heat up to remove low molecular compounds; stand for cooling to obtain high permeability Amino silicone oil. The amino silicone oil prepared by the invention has high transmittance, controllable viscosity, is easily emulsified into a transparent microemulsion and has excellent stability, is suitable for applications such as fabric treatment, additives in personal care products and the like, and has good application effect .

Owner:SHANGHAI RESIN FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![2,2-bis[4-(2,4-diamidophenoxy)phenyl]hexafluoropropane high-temperature-resistant epoxy adhesive and preparation method thereof 2,2-bis[4-(2,4-diamidophenoxy)phenyl]hexafluoropropane high-temperature-resistant epoxy adhesive and preparation method thereof](https://images-eureka.patsnap.com/patent_img/c3dc5c5a-1b77-468c-bc0c-b8ed519f1fb6/BDA00002903323100091.PNG)

![2,2-di[4-(2,4-diamino phenoxy) phenyl] propane form high-temperature epoxy adhesive and preparation method thereof 2,2-di[4-(2,4-diamino phenoxy) phenyl] propane form high-temperature epoxy adhesive and preparation method thereof](https://images-eureka.patsnap.com/patent_img/5f9b883b-a80d-4f2d-a1bd-b2fd38f87a50/BDA00002903342300091.PNG)