A kind of dadhbp type silicon-containing epoxy imide matrix resin and preparation method thereof

A technology of silicon epoxy imide matrix and epoxy resin, which is applied in the field of DADHBP type silicon-containing epoxy imide matrix resin and its preparation, can solve problems such as unsatisfactory heat resistance, and achieve good industrialization prospects, Simple preparation process and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 73.2 grams (0.2 moles) of 2,2-bis(3-amino-4-hydroxyphenyl) hexafluoropropane (BAHPFP, 366 g / mol), 735.0 grams of o-cresol, 52.0 grams (0.1 moles) of 2,2- Bis[4-(3,4-dicarboxyphenoxy)phenyl]propanedianhydride (BPADA, 520g / mol) and 19.6 grams (0.2mol) of maleic anhydride (MA, 98g / mol) were placed in the reactor , feed nitrogen, stir, heat up to 80°C, add 3.8 grams of isoquinoline dropwise, heat to 100°C, stir and react for 5 hours, then cool to 60°C, pour the reactant into a precipitate containing 1500 grams of methanol Stir in the kettle at high speed to precipitate solid matter, filter, and vacuum-dry at 80°C for 10 hours to obtain 308.3 g of imide oligomer (theoretical yield: 314.0 g), with a yield of 98.2%, which is designated as BBMO-1.

Embodiment 2

[0045] 73.2 g (0.2 mol) of 2,2-bis(3-amino-4-hydroxyphenyl) hexafluoropropane (BAHPFP, 366 g / mol), 1460 g of o-cresol, 52.0 g (0.1 mol) of 2,2- Bis[4-(3,4-dicarboxyphenoxy)phenyl]propanedianhydride (BPADA, 520g / mol) and 19.6 grams (0.2mol) of maleic anhydride (MA, 98g / mol) were placed in the reactor , feed nitrogen, stir, heat up to 80°C, add 14.0 grams of isoquinoline dropwise, heat to 110°C, stir and react for 12 hours, cool to 60°C, pour the reactant into 2000 grams of ethanol and 920 grams of In the settling tank of ethylene glycol monomethyl ether, high-speed stirring, the solid matter was precipitated, filtered, and vacuum-dried at 80°C for 10 hours to obtain 313.4 grams of imide oligomers (theoretical yield: 314.0 grams), with a yield of 99.8%. Denoted as BBMO-2.

Embodiment 3

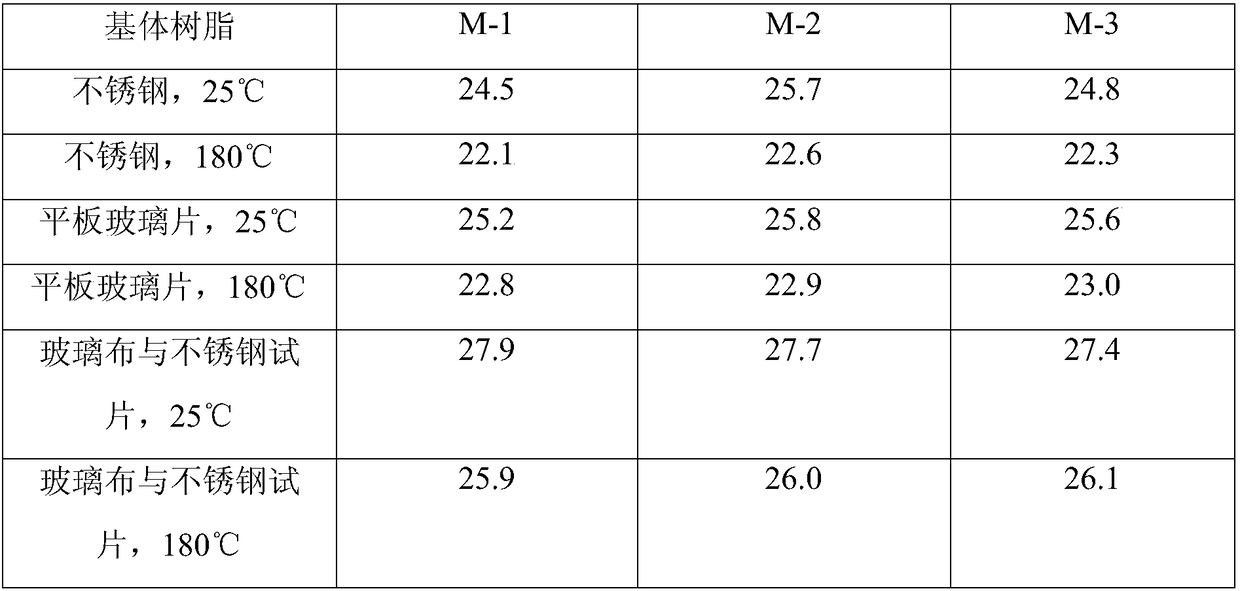

[0047]1.0 g of 3,3'-diamino-4,4'-dihydroxybiphenyl (DADHBP), 20.0 g of diglycidyl isophthalate epoxy resin, 30.0 g of 4,5-epoxycyclohexane- Diglycidyl 1,2-dicarboxylate epoxy resin, 25.0 g CE793 epoxy resin, and 25.0 g N,N,N',N'-tetraglycidyl-2,2-bis[4-(4-amino Phenoxy) phenyl] propane epoxy resin was put into the reaction kettle, after stirring and mixing reaction at 100 ℃ for 0.5 hour, add 2.0 grams of BBMO-1 imide oligomers and continue to stir and react for 1 hour, then add 3.0 grams of 3 - Aminopropyltrimethoxysilane stirred for 5 minutes, cooled to room temperature, then added 30.0 grams of 1,8-diaza-bicyclo[5.4.0]undecene-7 and 20.0 grams of tung oilic anhydride, stirred and mixed evenly, 156.0 g of DADHBP type silicon-containing epoxyimide matrix resin was obtained, denoted as M-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com