Patents

Literature

4309results about How to "Realize industrial production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

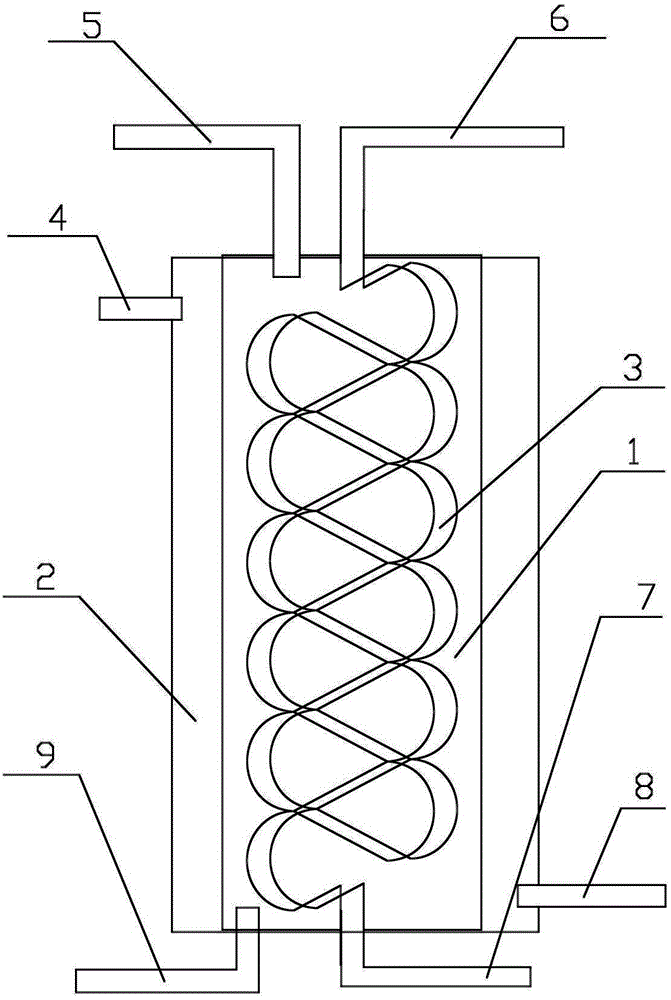

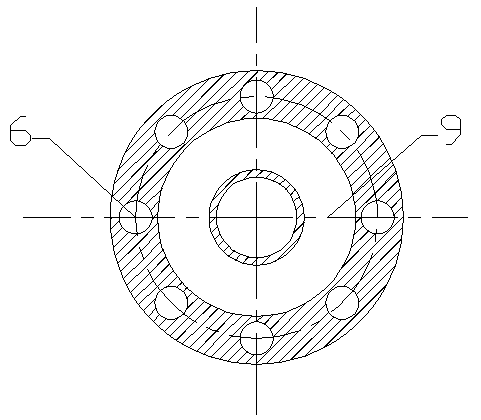

Efficient paraffin sweatbox

InactiveCN102977917AHeating evenlyMeet production requirementsPetroleum wax recoveryParaffin waxParaffin oils

The invention discloses an efficient paraffin sweatbox. The sweatbox comprises an inner cavity, a heating layer, a heating tube, an outer water inlet tube, a feeding tube, an inner water inlet tube, an inner water outlet tube, an outer water outlet tube and a discharging tube, wherein a heating tube which is arranged in a rotating mode is arranged inside the inner cavity; the feeding tube is arranged on the upper part of the inner cavity; the discharging tube is arranged on the lower part of the inner cavity; the heating layer is arranged outside the inner cavity; the external water inlet tube is arranged on the upper part of the heating layer; the outer water outlet tube is arranged on the lower part of the heating layer; the inner water inlet tube connected to the outer side of the inner cavity is arranged on the upper part of the heating tube; and the inner water outlet tube connected to the outer side of the inner cavity is arranged at the lower side of the heating tube. The heating tube which is extended like a spring in a rotating mode is arranged inside the effective paraffin sweatbox, so that the paraffin is heated uniformly; and the efficient paraffin sweatbox is used in the industry.

Owner:DALIAN LONSIN NEW MATERIALS

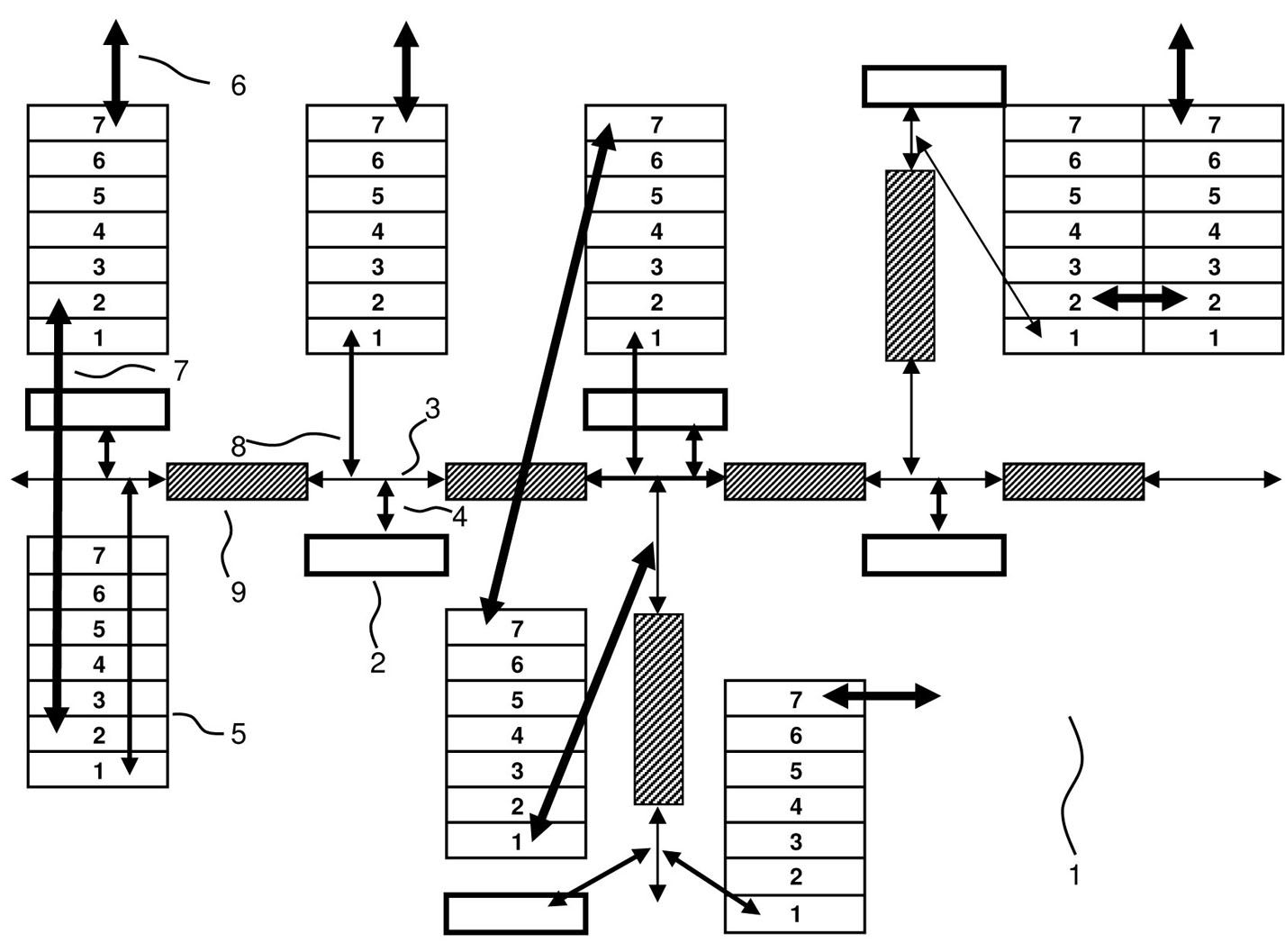

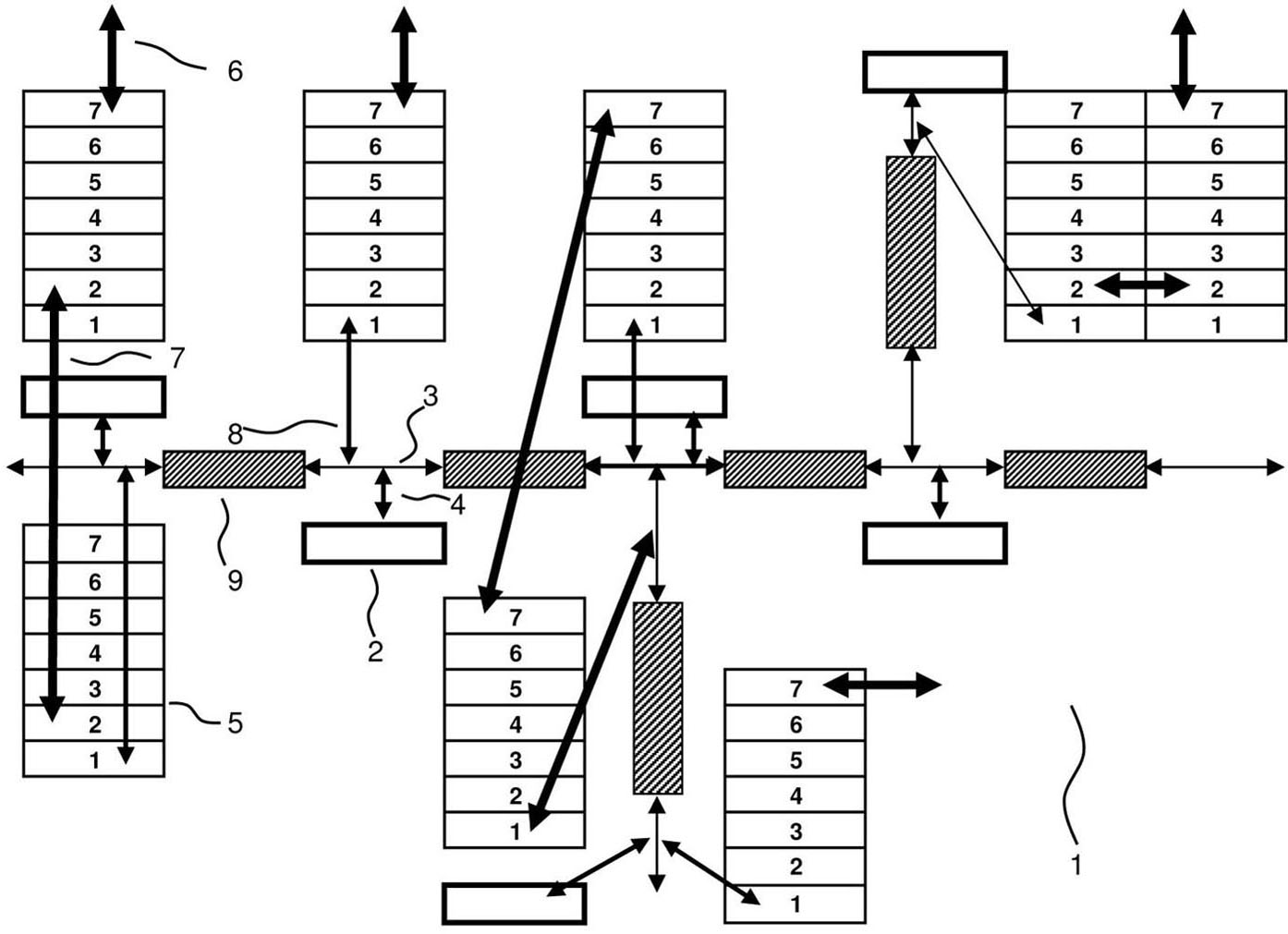

Signal repeater system arrangement for stable data communication

InactiveCN101978613AGuaranteed communication qualityGuaranteed Bit Error RateSystems using filtering and bypassingPower distribution line transmissionPower gridEngineering

Signal repeater system of the general type that facilitates using various standards and various modulation types to improve properties with various infrastructure, in particular power grid systems.

Owner:盖尔.蒙森.瓦维克

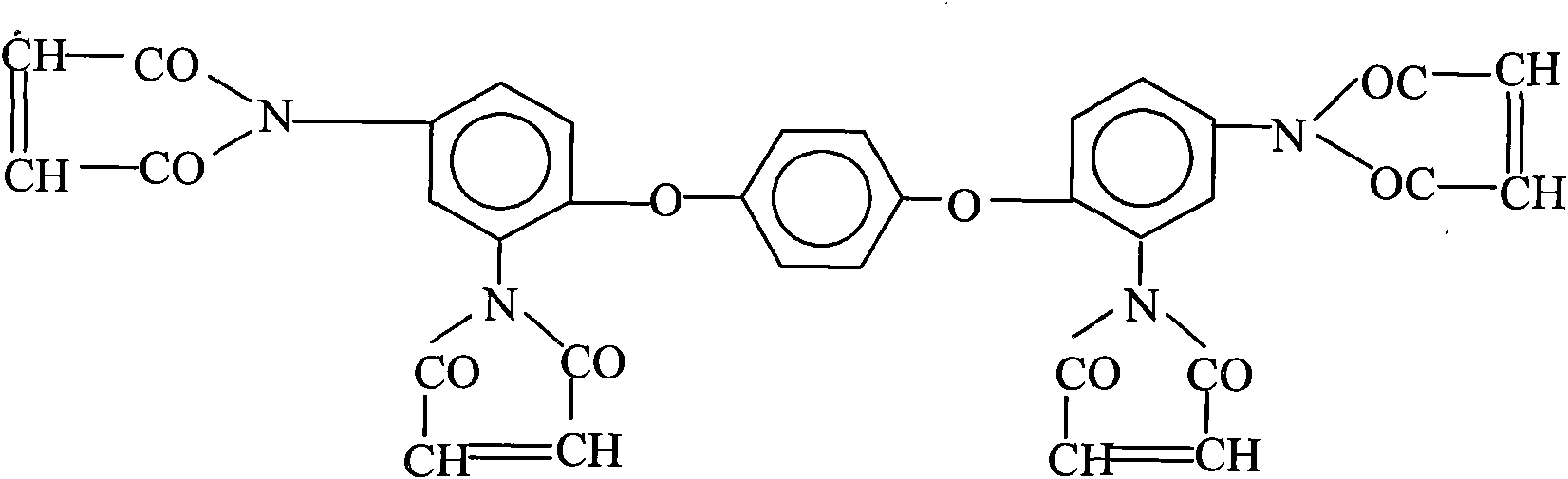

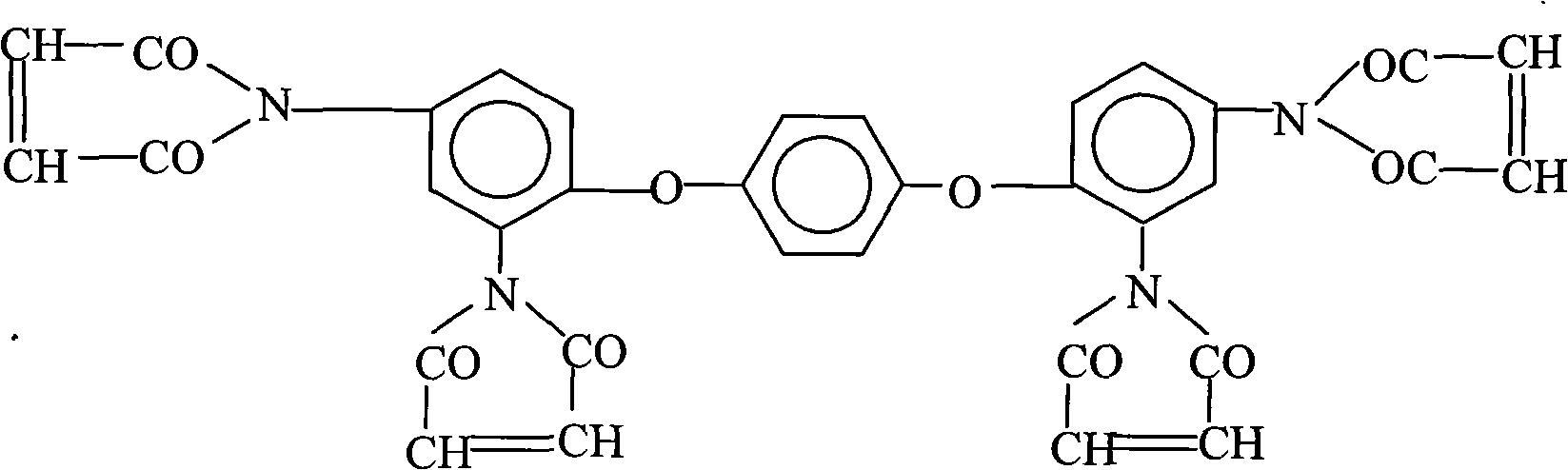

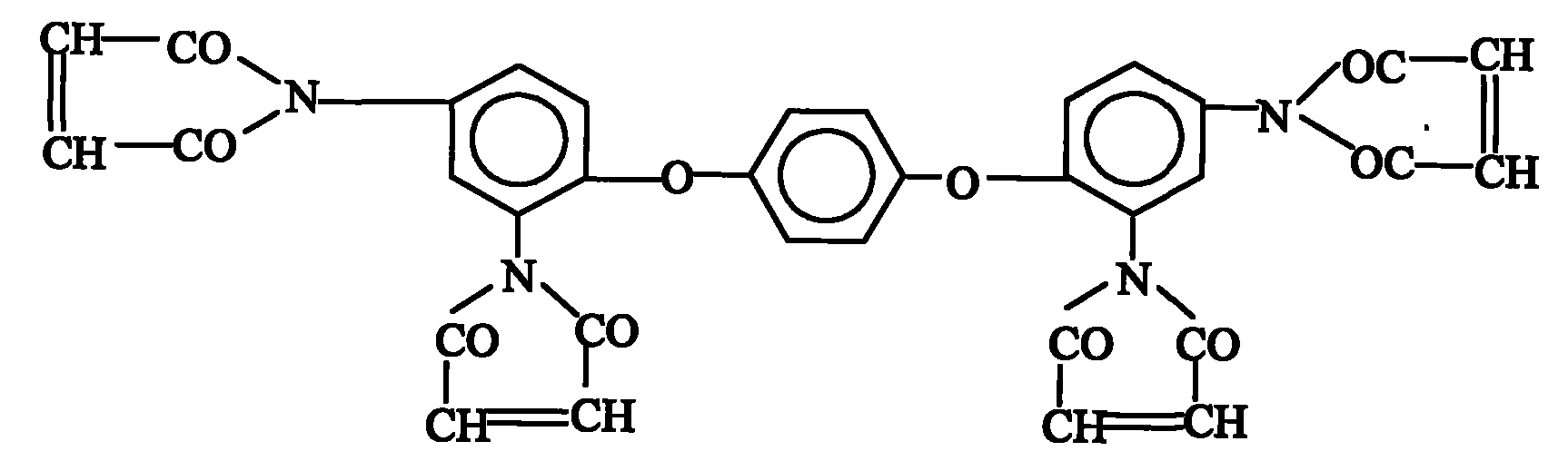

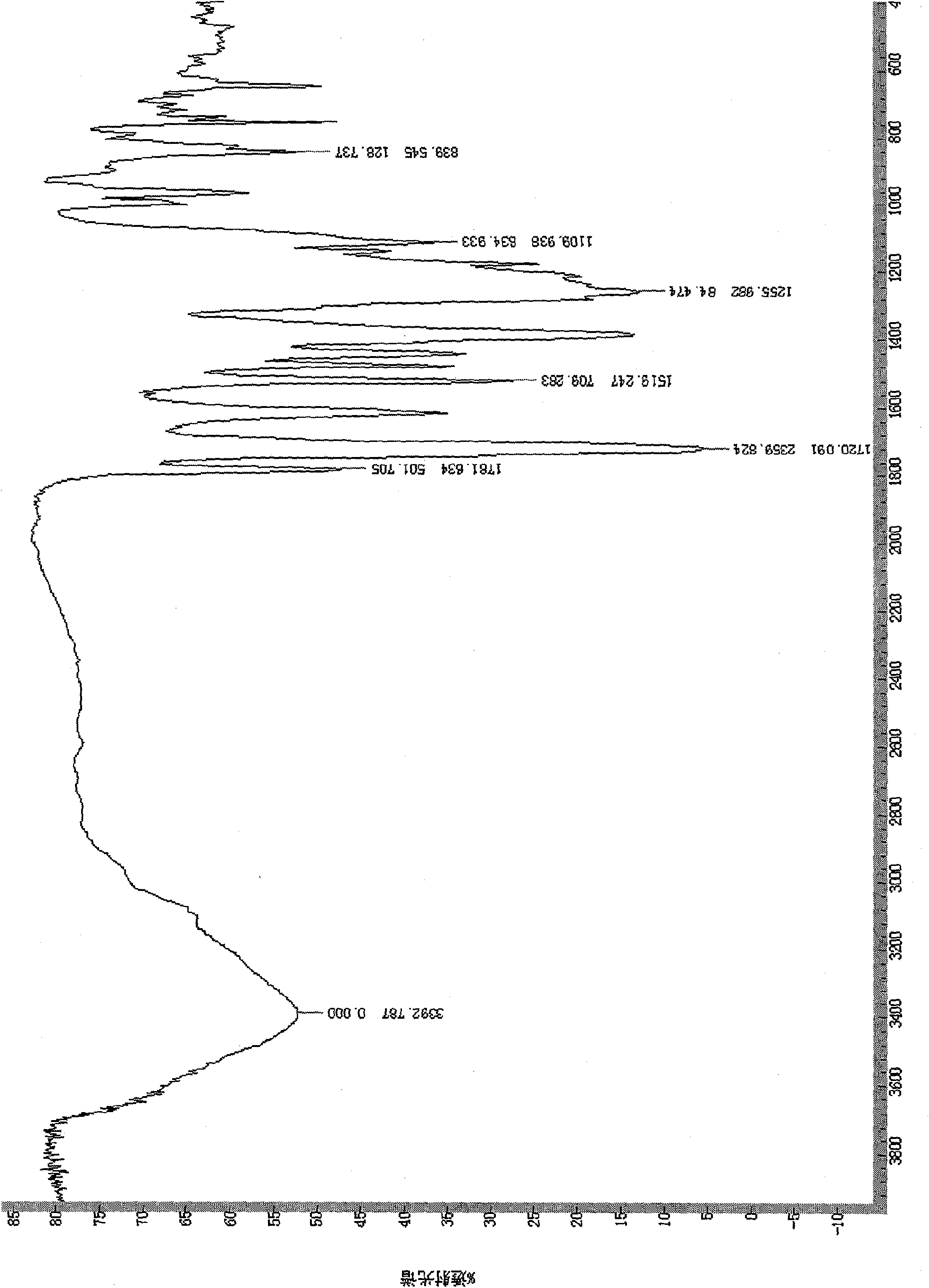

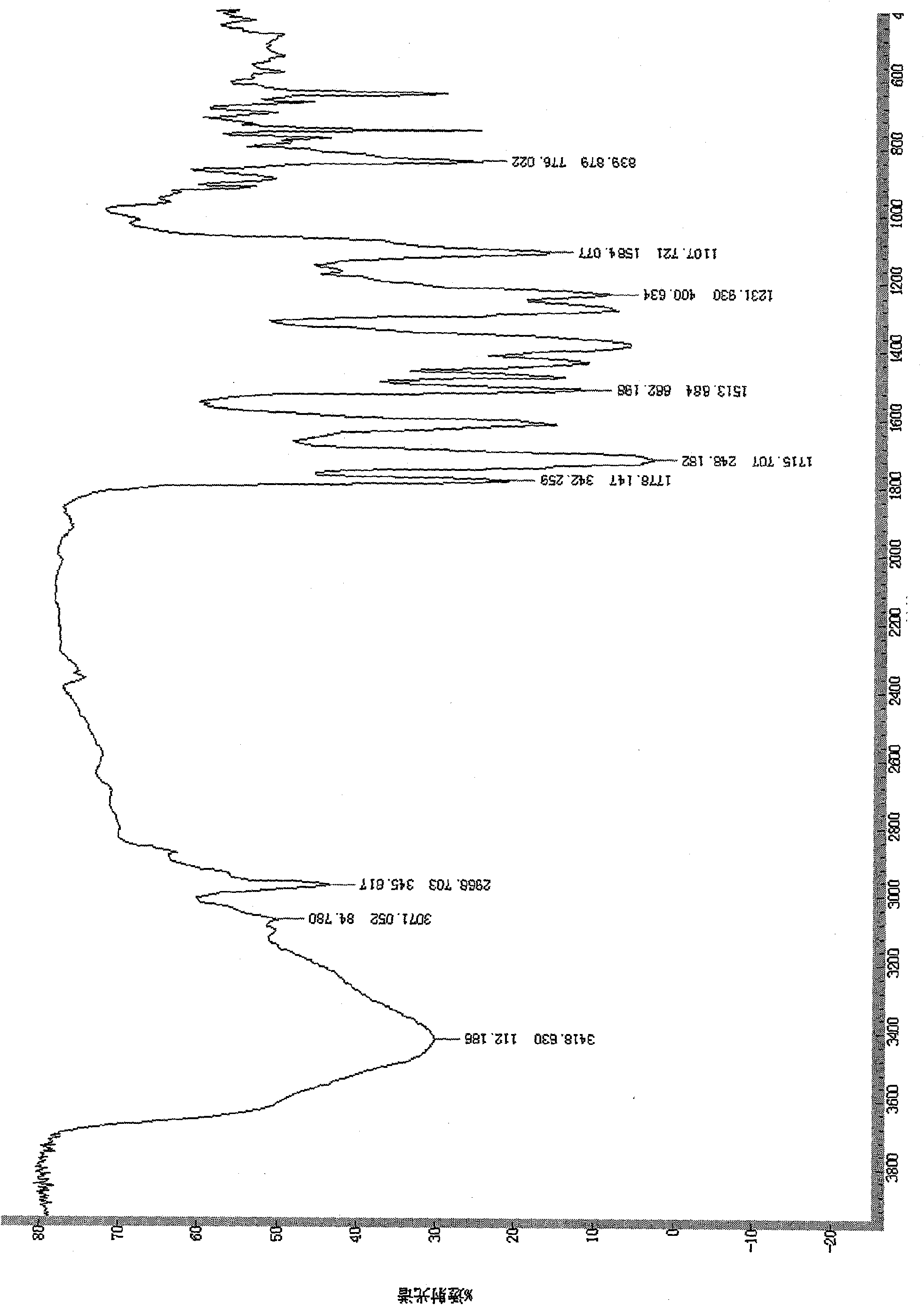

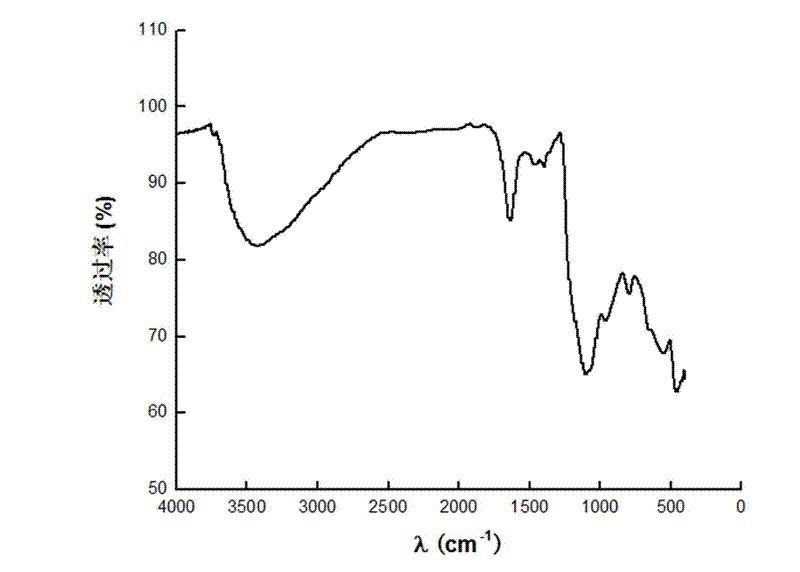

High-temperature-resistant modified polyfunctional epoxy matrix resin for advanced composite material and preparation thereof

The invention relates to high-temperature-resistant modified polyfunctional epoxy matrix resin for an advanced composite material. The resin comprises tetramaleimide resin, carboxy terminated nitrile rubber, polyfunctional epoxy resin, a curing agent and an organic solvent. A preparation method comprises the following steps of: adding the tetramaleimide resin, the carboxy terminated nitrile rubber and the polyfunctional epoxy resin into a reaction kettle and reacting at the temperature of 110 DEG C for one hour; adding the organic solvent and dissolving under stirring to obtain a component A;mixing the curing agent and the organic solvent and dissolving under stirring to obtain a component B; and mixing the component A and the component B and uniformly stirring during use. The high-temperature-resistant modified polyfunctional epoxy matrix resin provided by the invention has the advantages of high room temperature tensile shear strength, high heat resistance, wide application prospect in the fields such as electronics, micro-electronics, printed circuit boards (PCB), motors, aerospace and the like, simple preparation process, low cost and contribution to realizing industrial production.

Owner:DONGHUA UNIV +1

Preparation method of high temperature resistant single-component solventless epoxy adhesive

InactiveCN101649174AConvenient sourceSimple preparation processEpoxy resin adhesivesSolventThermoplastic polyimide

The invention relates to a preparation method of high temperature resistant single-component solventless epoxy adhesive. The method comprises the following steps: adding aromatic binary primary amine and strongly polar non-proton organic solvent in a reaction tank, stirring at room temperature to dissolve, adding aromatic binary acid anhydride to perform refluxing and water-segregating reaction at 120-150 DEG C for 6-12h, cooling, adding the reaction solution in a stamp tank with precipitant to precipitate solid powder, namely white thermoplastic polyimide powder, adding white thermoplastic polyimide powder and tertiary amine compound or imidazole compound in epoxy resin to react for 1-2h, adding active diluent and latent curing agent to stir evenly and obtaining the product. The production process is easy and the cost is low so as to realize industrialized production; the tensile shear intensions of the epoxy adhesive at room temperature and 120 DEG C are respectively up to 28Mpa and26Mpa and the epoxy adhesive has broad application prospect in fields such as electronics and microelectronics, electrical motors, aviation and aerospace and the like.

Owner:DONGHUA UNIV

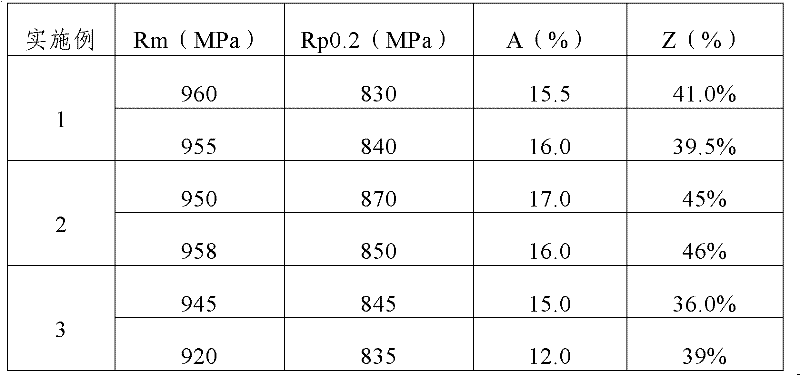

Processing method for TC4 titanium alloy large-sized bar

The invention discloses a processing method for a TC4 titanium alloy large-sized bar. The method comprises the following steps of: cogging and forging TC4 titanium alloy ingots for 2 to 3 heating times to obtain forging billets; 2, upsetting the forging billets repeatedly and performing drawing-out forging for 2 to 3 heating times; 3, upsetting the forging billets subjected to forging repeatedly and performing drawing-out forging for 3 to 5 heating times; and 4, performing chamfering round forging on the forging billets subjected to forging for 2 heating times to obtain the TC4 titanium alloy large-sized bar with the diameter of 200 to 400 mm and length of not less than 2,500 mm. The TC4 titanium alloy bar processed by the method has uniform and fine grains, few internal defects and high safety and accords with the domestic advanced level of the like products. In the processed TC4 titanium alloy bar, the room-temperature tensile strength is 920 to 960 MPa; the yield strength is 830 to 870 MPa; the elongation percentage is not less than 12 percent; the contraction ratio of the cross section is not less than 36 percent; flaw detection clutter reflects small signals; and the flaw detection level is high.

Owner:WESTERN TITANIUM TECH

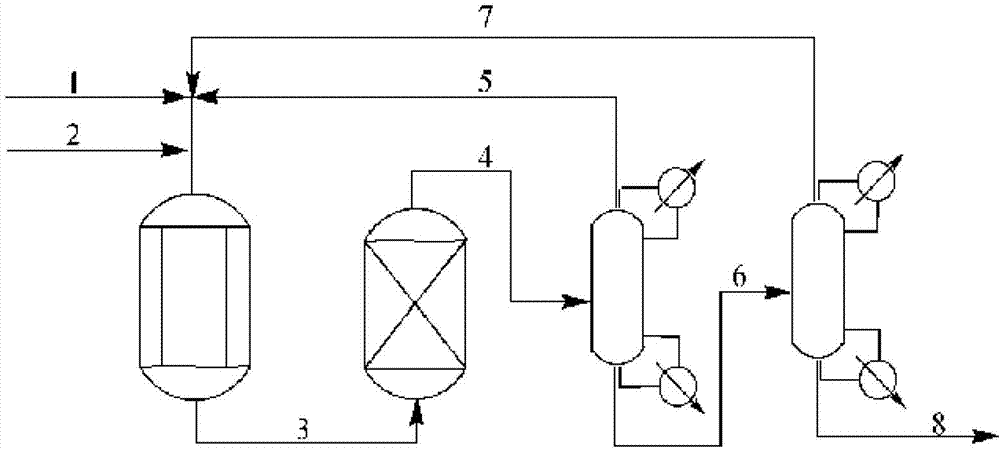

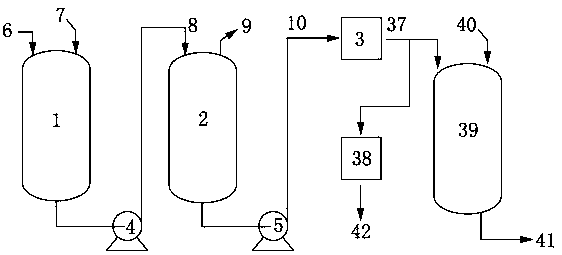

Method for continuous production of polyformaldehyde dimethyl ether

InactiveCN102786397ARealize industrial productionImprove stabilityOrganic chemistryOrganic compound preparationPtru catalystDistillation

The invention provides a method for continuous production of polyformaldehyde dimethyl ether. The method is characterized by comprising the following steps: a) feeding dimethoxymethane and hot-melted paraformaldehyde into a fixed bed reactor and adopting an acidic resin catalyst, so as to prepare polyformaldehyde dimethyl ether (DMM3-8), wherein the reaction temperature is 120-180 DEG C and the pressure is 0.1-10 MPa; b) cooling the reaction product, and then performing adsorptive separation through a dehydrating tower, so as to obtain polyformaldehyde dimethyl ether of which most water, cytidine glycol and hemiacetal are desorbed; c) feeding the polyformaldehyde dimethyl ether subjected to desorption into a distillation tower for separation, wherein most of a low-boiling component (dimethoxymethane (DMM)), poly-di-formaldehyde dimethyl ether (DMM2), a by-product (methanol) and triformol are extracted first, and then the materials in a tower kettle are fed into a rectifying tower in the next step, so as to extract the rest of the DMM2 and the triformol; and d) returning the low-boiling component (dimethoxymethane (DMM)), the methanol, the DMM2 and the triformol, which are evaporated out by the distillation tower and the rectifying tower in the last step, into the fixed bed reactor to continue to react to prepare polyformaldehyde dimethyl ether.

Owner:CHINA NAT OFFSHORE OIL CORP +1

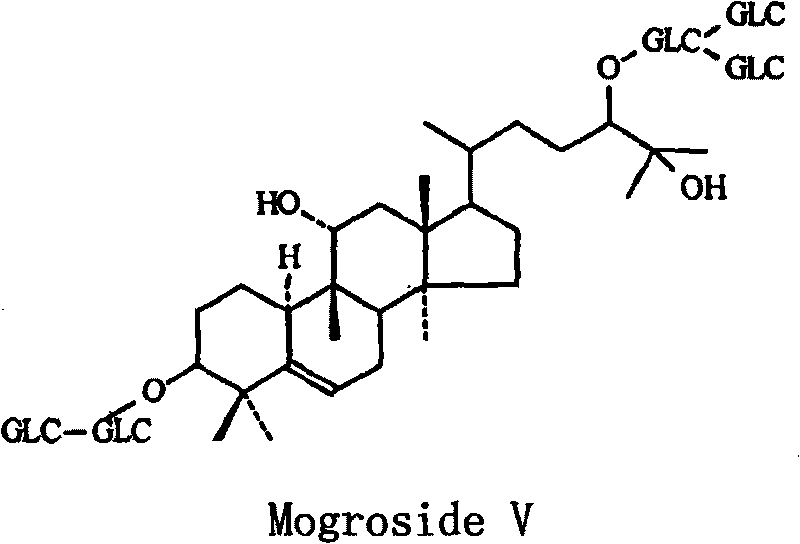

Production method of fructus monordicae extract with over 60% of mogroside V content

ActiveCN101690573APromote leachingEasy to separateCosmetic preparationsToilet preparationsSucroseAdditive ingredient

The invention provides a production method of fructus monordicae extract with over 60% of mogroside V content. In the method, the fresh momordica grosvenori is subjected to the following technique processes: smashing, saccharification, extraction by water, concentration, sedimentation and centrifugation, ion exchange resin refining, macroporous resin refining, concentration, aluminum oxide refining, concentration, spray drying and finishing product. The method can produce high-quality fructus monordicae extract products, reduce material loss, shorten period of production, increase product yield, lower production cost, and is suitable for industrial production. The mogroside V content in the fructus monordicae extract produced by the method is more than or equal to 60%; the fructus monordicae extract has high product purity, single composition, pure white color, good color and taste, fresh and cool sweet taste like that of sugar, simultaneously overcomes the technical problem for industrial production of the high-content and high-quality fructus monordicae extract, and successfully realizes large-scale production.

Owner:YONGZHOU YIDONG BIOTECH

Method for separating and extracting stem cells from placenta, umbilical cord or adipose tissue

ActiveCN101693884AEasy accessSpecification acquisitionSkeletal/connective tissue cellsArtificially induced pluripotent cellsFicollDisease

The invention relates to a method for separating and extracting stem cells from a placenta, umbilical cord or adipose tissue, which comprises the following process steps: firstly mixing the placenta, umbilical cord or adipose tissue and a cell maintenance fluid according to the proportion by weight of 2.5-4:1, putting the mixture into a tissue crushing barrel, adding collagenase after crushing, uniformly mixing, hatching at the temperature of 37 DEG C, filtering, adding a precipitator, sucking a supernatant fluid after settling, centrifuging, removing the supernatant fluid, adding concentrated cells into a liquid of diatrizoate sodium-ficoll 400#, then centrifuging, collecting 10-15 ml of intermediate cell layer, washing with the cell maintenance fluid, counting the collected cells, and providing the cells for clinical use when the cell survival ratio is more than or equal to 95 percent. The invention not only realizes the separation and the extraction of all stem cells from the placenta, umbilical cord or adipose tissue, but also realizes industrialized production, and enables doctors to conveniently, safely and canonically obtain the adult stem cells in clinic and use the adult stem cells for treating the diseases of patients as using medicaments, thereby solving the bottleneck problem of difficult obtainment of adult stem cells in clinic and popularizing a cell treatment technology.

Owner:NINGXIA ZHONGLIANDA BIOPHYSICS

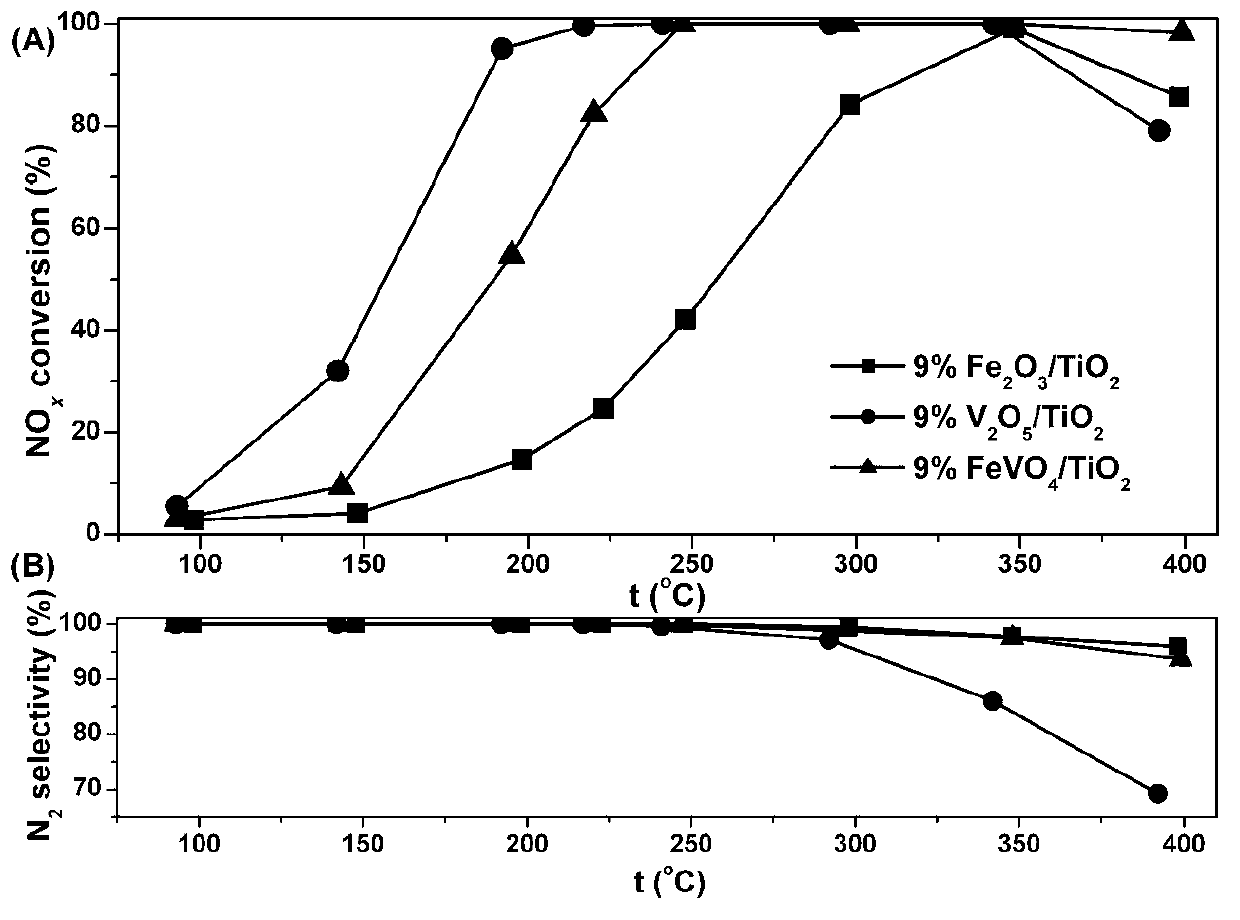

Titanium oxide supported ferric vanadate catalyst, as well as preparation method and use thereof

ActiveCN102989467AEvenly dispersedReduce manufacturing costDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsNitrogen oxideNitric oxide

The invention relates to a titanium oxide supported ferric vanadate catalyst. The catalyst is composed of a TiO2 carrier, and a FeVO4 active constituent supported on the TiO2 carrier. In term of the mass of the catalyst as 100wt%, FeVO4 is 1.5-15 wt%, preferably 2.5-13.5 wt%, further preferably 8-10 wt%, and most preferably 9 wt%. According to the invention, the TiO2 supported FeVO4 catalyst is used for purifying fixed-source and movable-source nitric oxides in NH3-SCR (selective catalytic reduction) reaction for the first time; and moreover, the preparation method for the catalyst is simple and practicable, and easily realizes industrialized production. The FeVO4 / TiO2 catalyst disclosed by the invention is extremely excellent in anti-H2O-poisoning and anti-SO2-poisoning performances in the NH3-SCR reaction, and very suitable for practical application.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

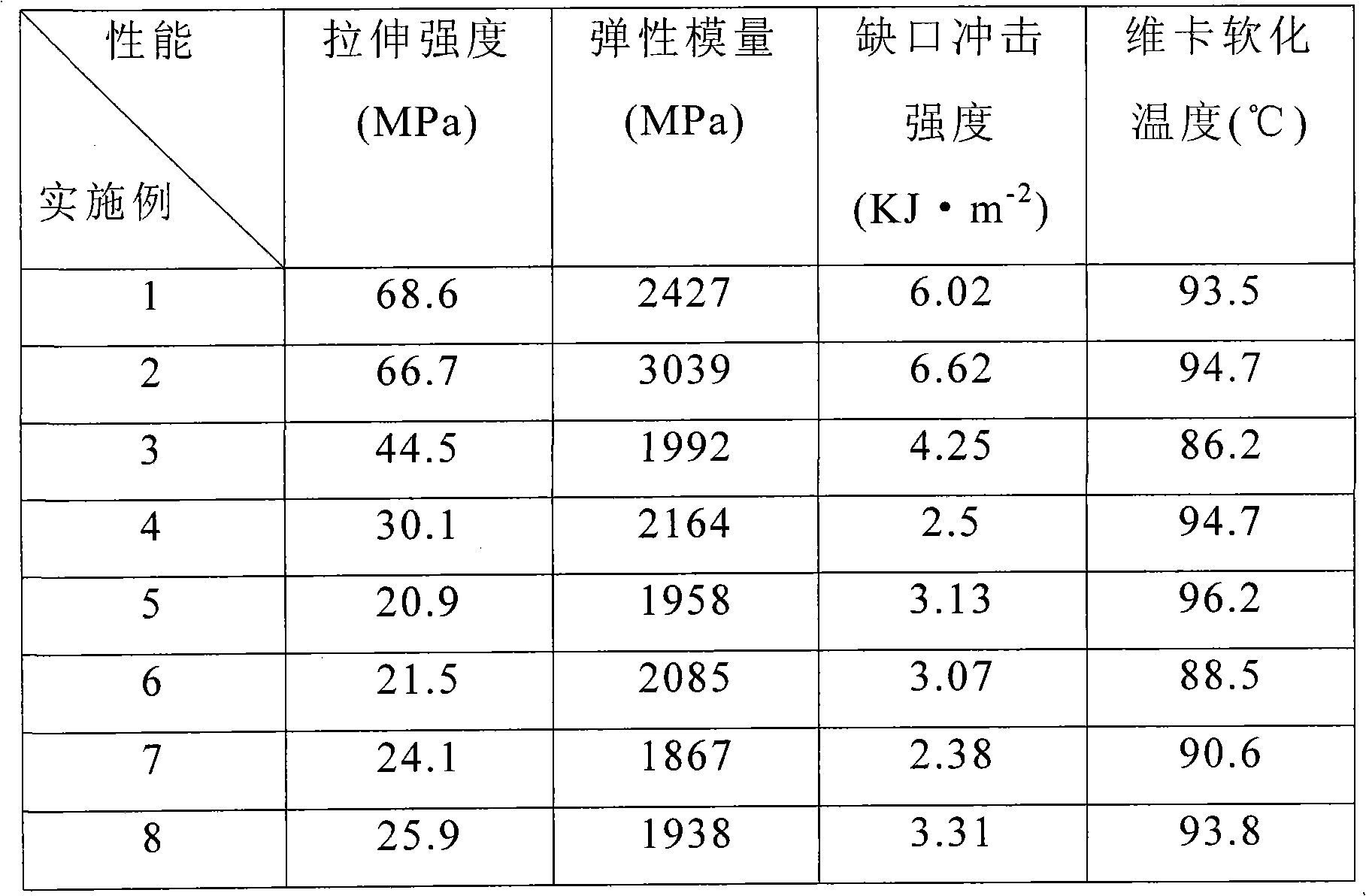

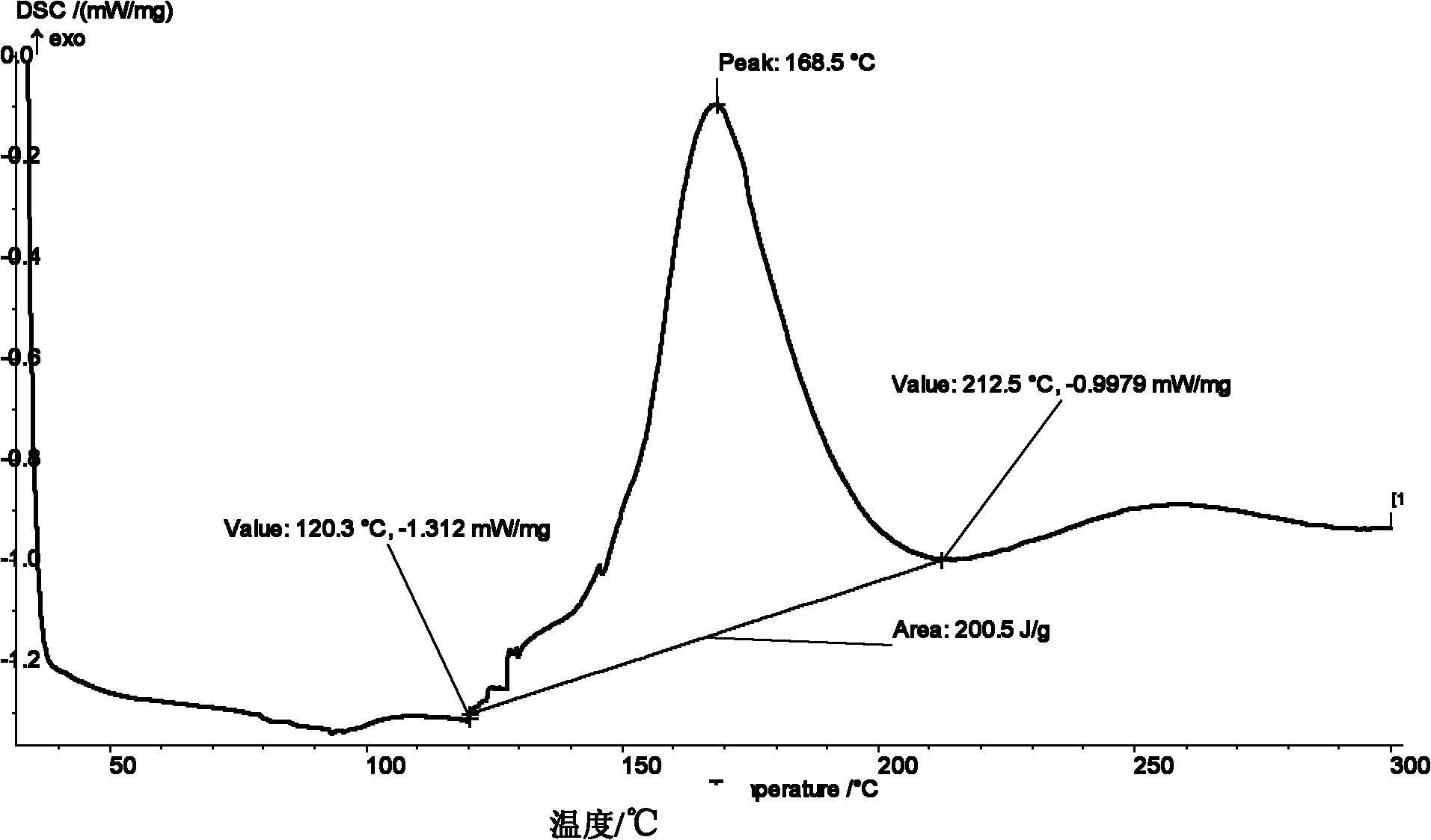

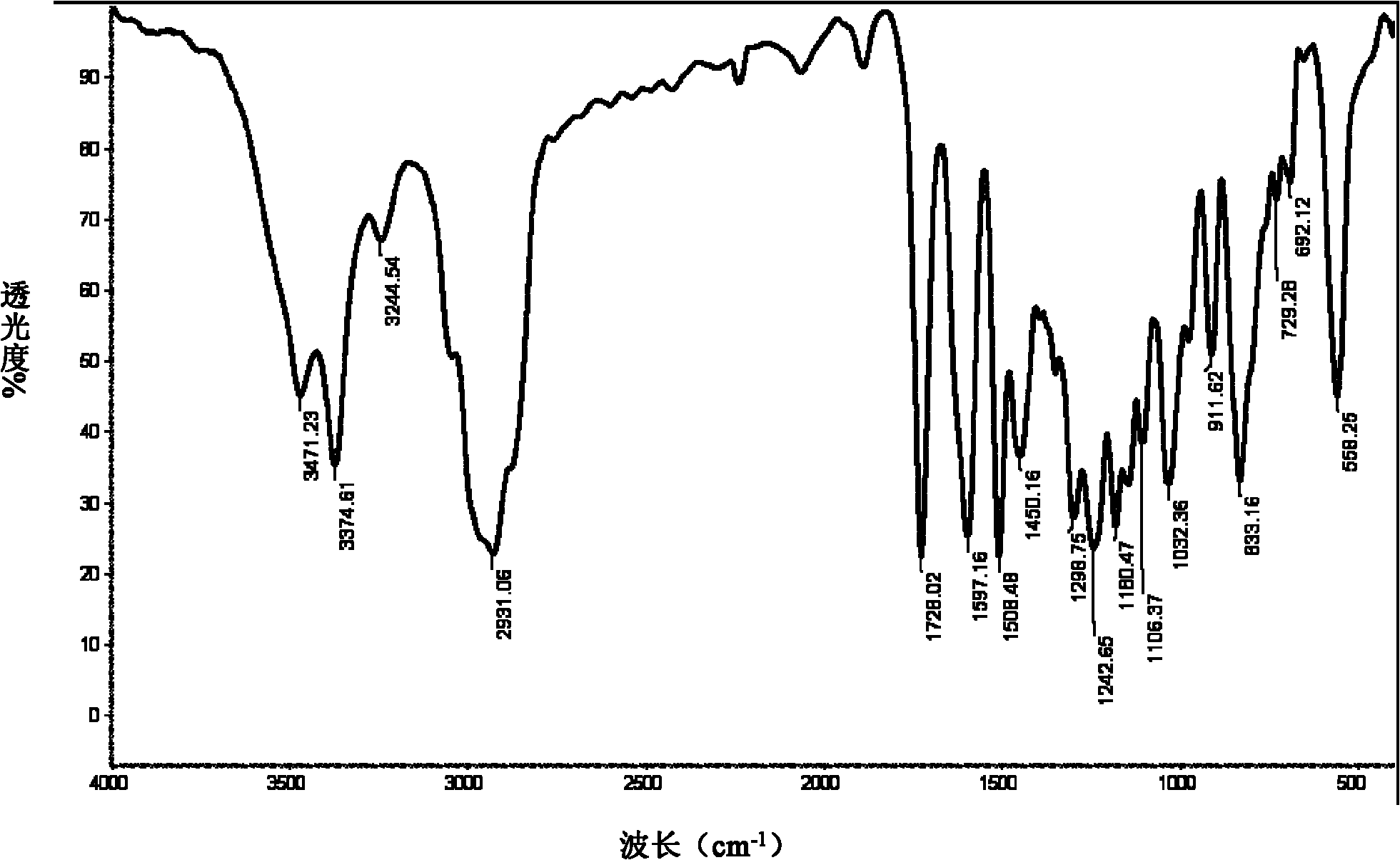

Heat-resistant polylactic acid composite material and preparation method thereof

The invention provides a heat-resistant polylactic acid composite material and a preparation method thereof, which belong to the technical field of polymer materials. The preparation method solves the technical problems of low product biodegradability, high cost, poor mechanical performance and the like of the prior method for preparing polylactic acid crosslinking materials and polymer crosslinking materials. The heat-resistant polylactic acid composite material comprises the following components in portion by weight: 50 to 99 portions of polylactic acid resin with an oligomerization-D lactic acid content, 0.1 to 15 portions of nucleating agent and 1 to 50 portions of starch or modified starch, wherein the content of a poly-D lactic acid in the poly-lactic acid resin with the oligomerization-D lactic acid content is less than 5 weight percent. The preparation method for the composite material comprises the following steps: a, mixing and pelleting; b, injection molding; and c, heat treatment. The composite material has the advantages of high mechanical and heat-resistant performance. The preparation method for the composite material is simple in technical process, high in processability and low in cost and can realize large-scale industrial production.

Owner:ZHEJIANG HISUN BIOMATERIALS

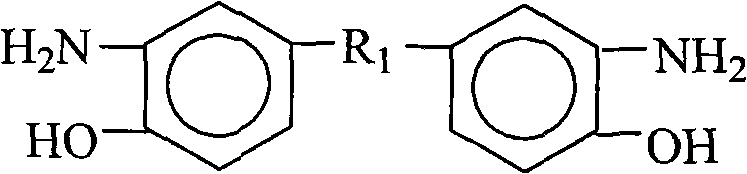

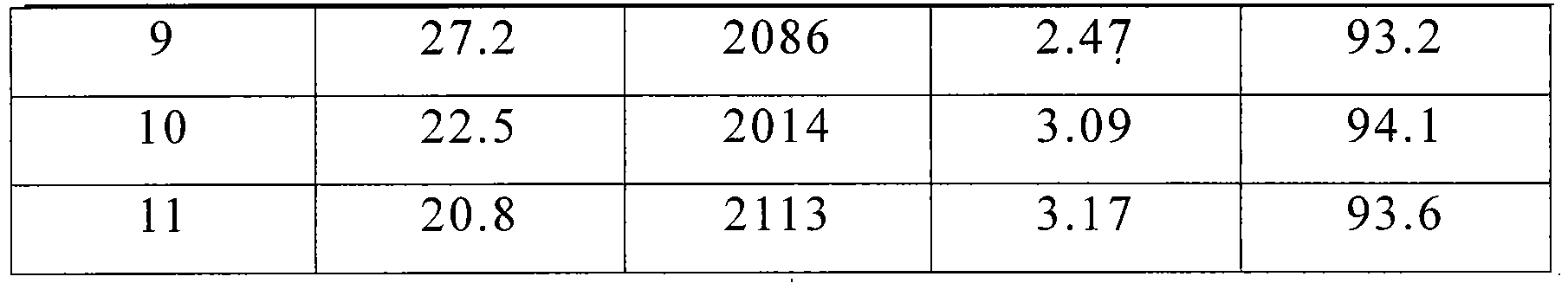

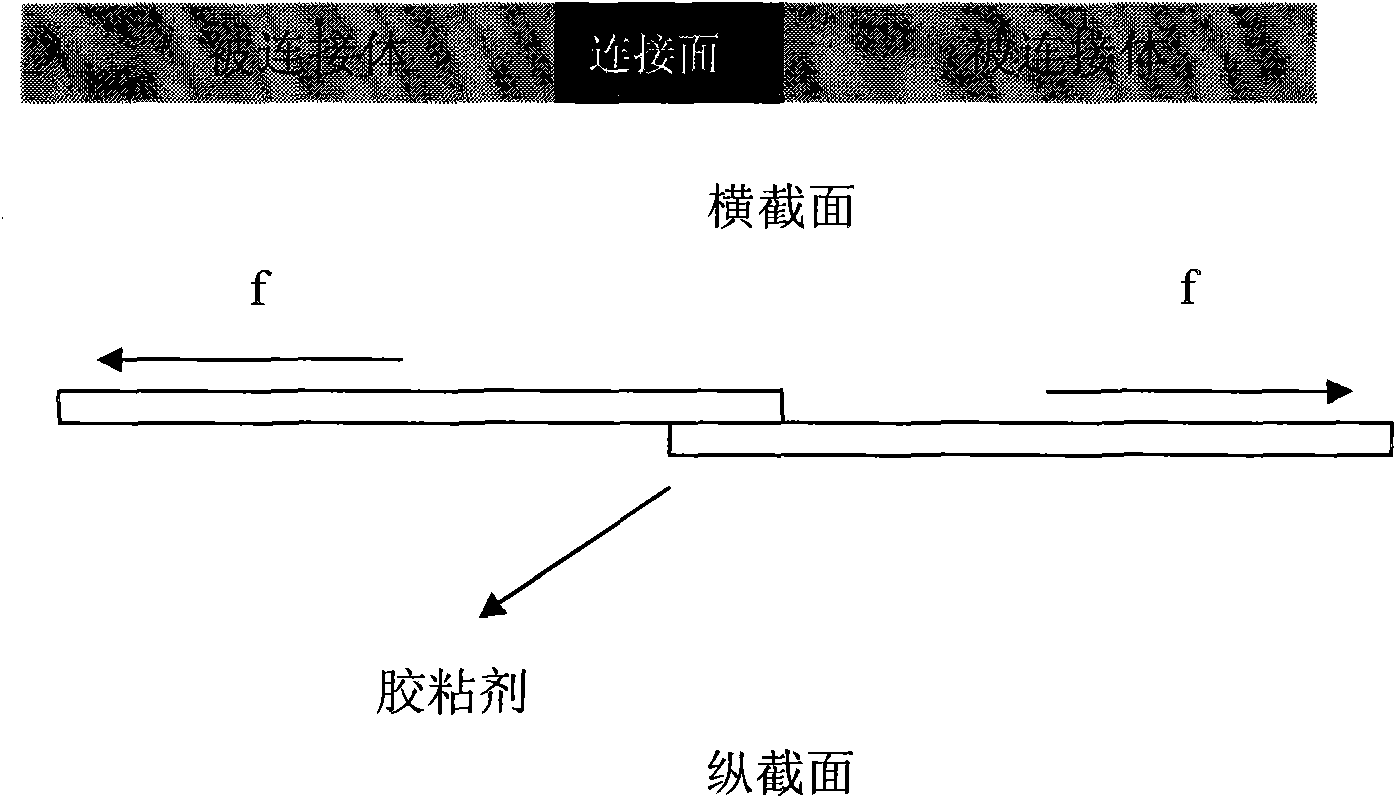

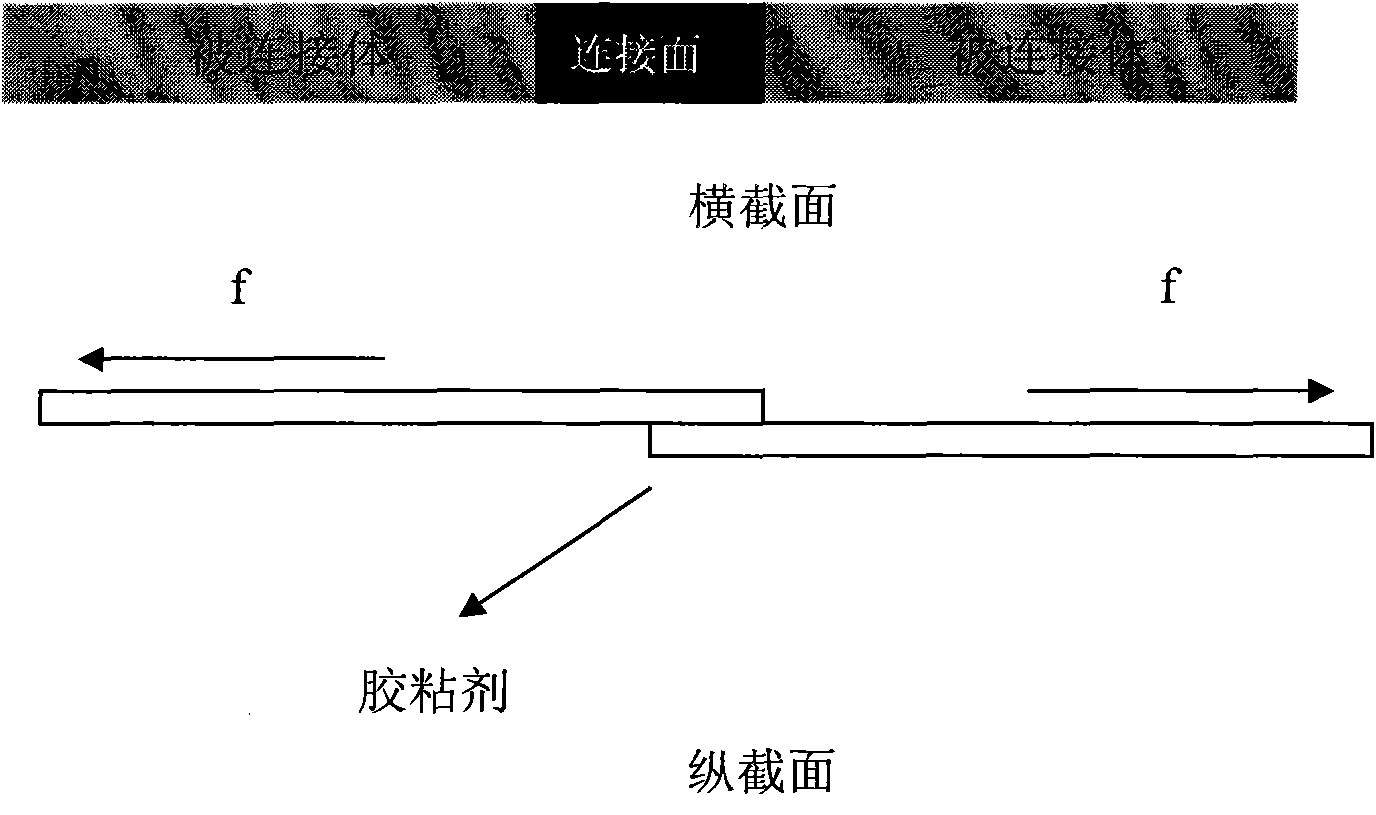

Benzimidazole diamine curing type epoxy adhesive and preparation method thereof

InactiveCN102031082AHigh tensile and shear strength at room temperatureConvenient sourceNon-macromolecular adhesive additivesCarboxyl rubber adhesivesViscous liquidElectronics

The invention relates to a benzimidazole diamine curing type epoxy adhesive and a preparation method thereof. The adhesive is prepared from the following raw materials: a component A, namely a benzimidazole diamine curing agent and a component B, wherein the component B is prepared from terminal carboxyl group butadiene-nitrile rubber, epoxy resin and a reactive diluent. The preparation method comprises the following steps of: (1) adding the terminal carboxyl group butadiene-nitrile rubber and the epoxy resin into a reaction kettle, reacting at the temperature of 90 DEG C with stirring, cooling to the temperature of 50 DEG C, adding the reactive diluent, and stirring at the temperature of 80 DEG C to obtain homogeneous and transparent viscous liquid, namely the component B; and (2) mixingthe components A and B, and stirring uniformly to obtain the adhesive. The tensile shear strength of the adhesive is 33.5MPa at the room temperature, and the adhesive has wide application prospect infields of electronics and microelectronics, rigid copper-clad laminates, motors, aerospace and the like; and the preparation process is simple, is low in cost and is convenient to operate, the resources of reaction raw materials are wide, and the adhesive can be conveniently industrially produced.

Owner:DONGHUA UNIV +1

Diamond wire saw production method of surface modified diamond

InactiveCN101812710AAchieve electroplating depositionEasy to operateElectrophoretic coatingsElectrophoresisDiamond wire saw

The invention relates to a diamond wire saw production method of a surface modified diamond, which comprises the following steps: 1. removing surface grease and surface metal oxides on the surface of the diamond; 2. placing diamond micropowder into a cationic surfactant solution, applying positive potential and forming a layer of positive charge film on the surface of the diamond under the electrophoretic action by action of a cationic surfactant; and 3. carrying out composite electroplating of a diamond wire saw. In the invention, conductive processing is carried out on the diamond, so that diamond grains can orderly move in a plating solution under the action of an electric field to realize the electroplating deposition on the surface of a metal wire without the influence of the size of the diamond grains; the surfactant is adsorbed on the surface of the diamond, so that a plating layer and the diamond present an infiltrative type interface, and a Ni plating layer has strong holding capability on the diamond; and the diamond micropowder has high utilization ratio. The invention has simple process method and convenient operation, the diamond grains have rapid deposition speed, good deposition uniformity and high deposition density on the metal wire, an electroplating layer has high holding force on the diamond grains, and the diamond micropowder has high utilization ratio. The invention can realize industrialized production and provides a method for efficiently and rapidly producing the diamond wire saw.

Owner:CHANGSHA DIAT NEW MATERIAL SCI & TECH

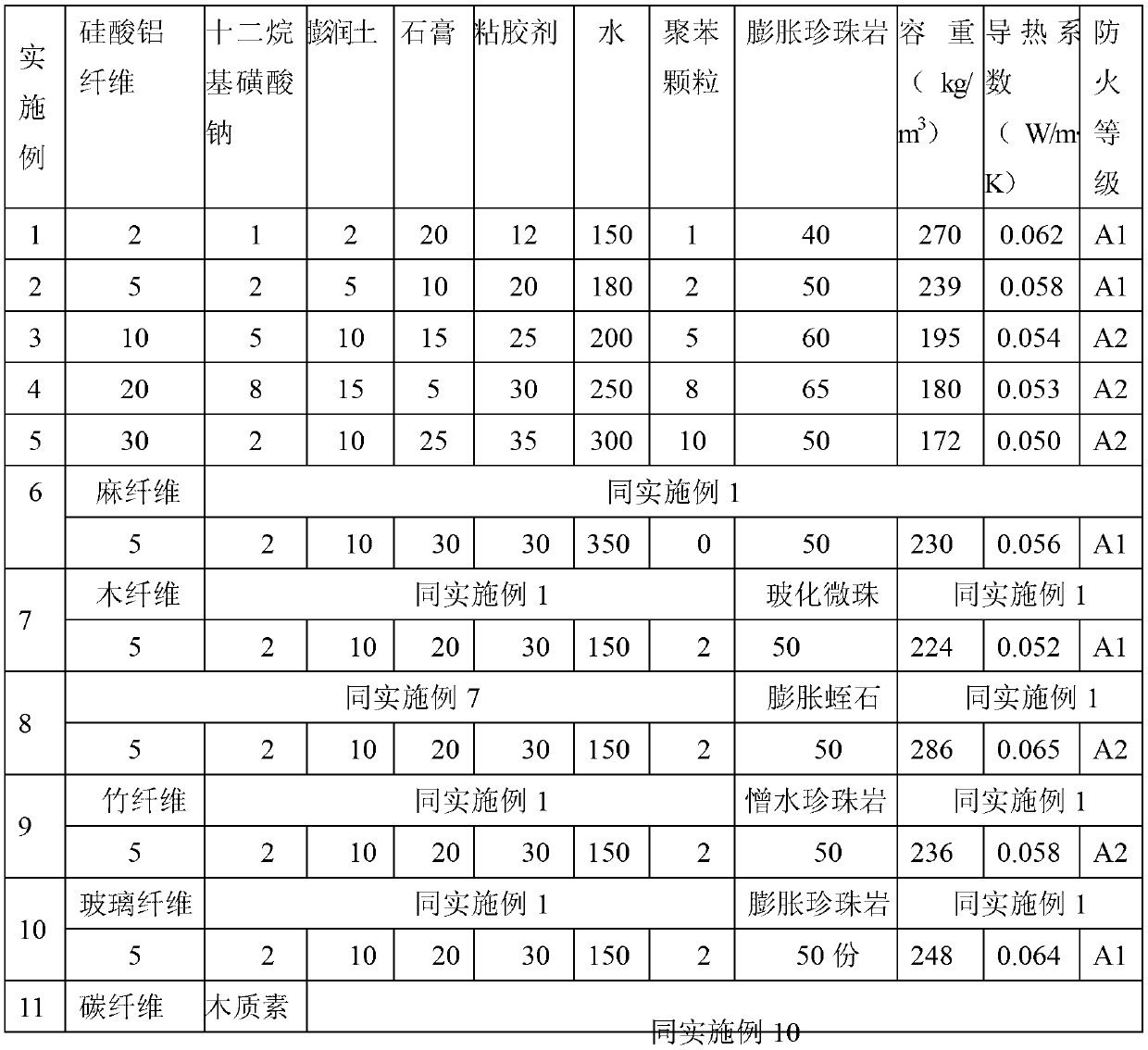

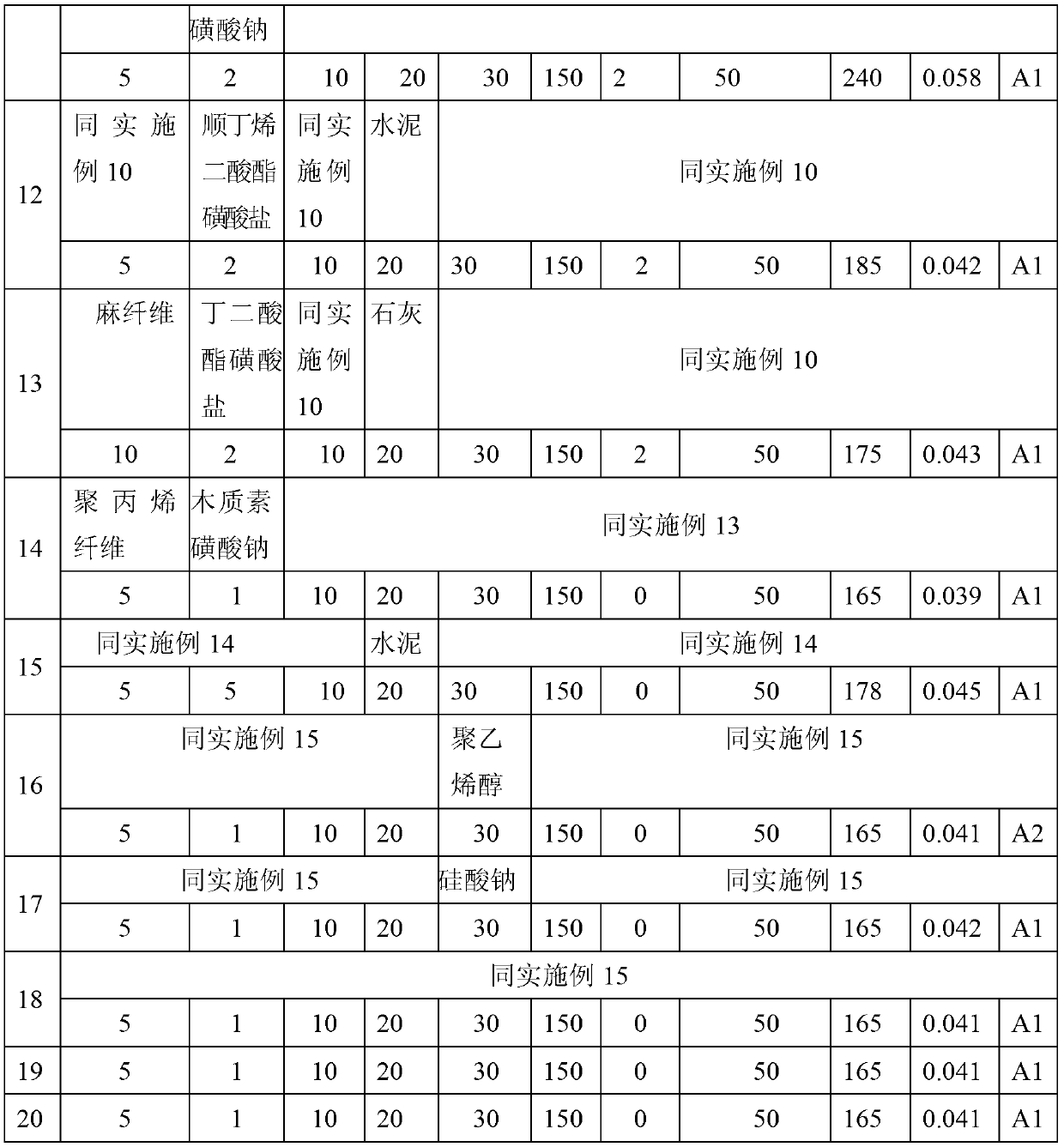

Inorganic fireproof heat-insulating material and preparation method thereof

The invention discloses an inorganic fireproof heat-insulating material, which comprises the following components by weight: 0.5-30 parts of reinforced fibers; 40-65 parts of lightweight aggregate; 2-15 parts of bentonite; 12-35 parts of an adhesive; 5-20 parts of an inorganic gel material; 2-10 parts of an interface agent; 0-10 parts of expanded polyphenyl particles; and 200-260 parts of water. Specifically, the expanded polyphenyl particles play a buffering role in a stirring process, so that the lightweight aggregate can avoid breakage. The interface agent can enhance the compatibility of various raw materials and has a foaming effect. The adhesive and the inorganic gel material retain the produced foam. The reinforced fibers endow the material with certain elasticity and good mechanical strength. The preparation method of the material provided in the invention is simple and convenient, and is easy to operate and to realize industrial production. The material disclosed in the invention has the characteristics of high temperature resistance, good heat insulation performance, and small unit weight, not only can be used as a heat insulation sheet material and a heat insulation slurry, and also can be used as a fireproof door core, a fireproof plugging material and other inorganic refractory materials.

Owner:应急管理部天津消防研究所

Lubricity coatings preparation method on the medical catheter polymers surface

InactiveCN101455861AImprove surface physicochemical propertiesChange adsorption stateCatheterCoatingsPolymer scienceGraft reaction

The invention discloses a method for preparing a lubricant coating on the surface of polymer materials of a medical catheter, which comprises the following steps: (A), pretreating the surface of the polymer materials of the medical catheter, so as to obtain hydrophilic adsorption active sites; (B), soaking the pretreated polymer materials of the medical catheter in step (A) into a prepared precursor solution of the lubricant coating for adsorption; and (C), performing grafting reaction on the soaked polymer materials of the medical catheter in step (B), and washing and drying the polymer materials of the medical catheter. The method can be widely used for preparing medical polymer materials and coating materials on the surface of a medical apparatus.

Owner:SOUTHEAST UNIV

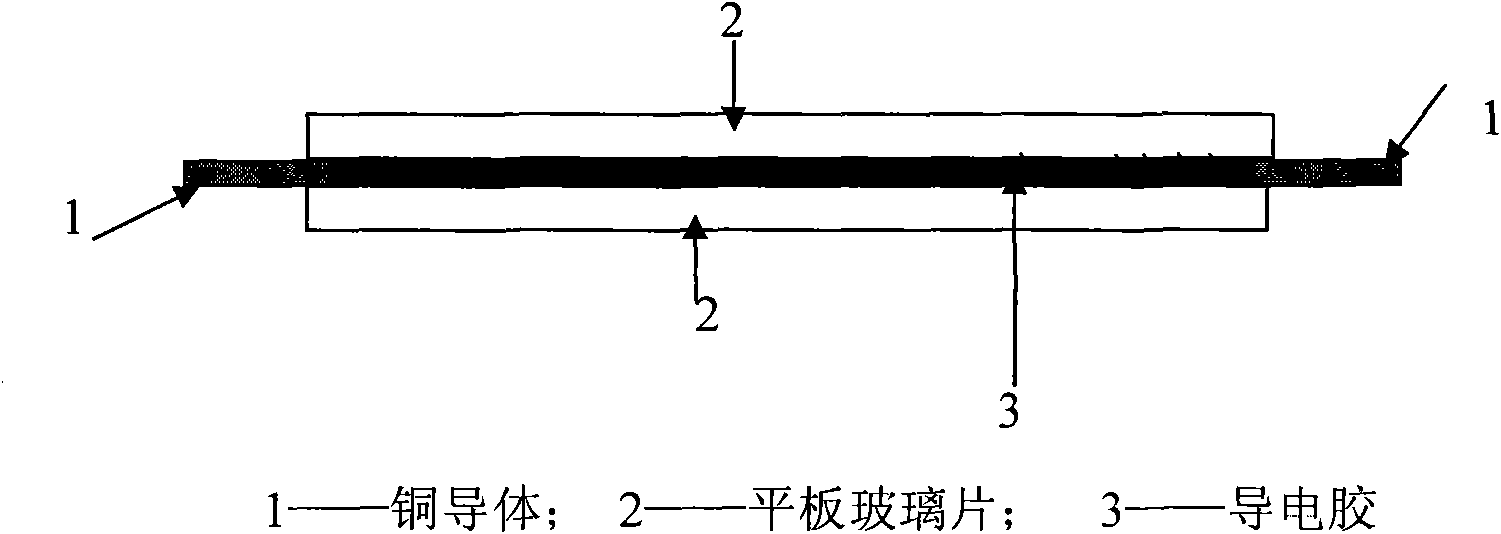

High-performance conducting resin and preparation method thereof

InactiveCN101781540AConvenient sourceSimple preparation processNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyRoom temperature

The invention relates to a high-performance conducting resin, comprising the following components: epoxy, latent curing agent, active toughener and conducting particles. The preparation method comprises the following steps: adding the epoxy and the active toughener in a reaction bulb to react, then adding the latent curing agent, uniformly stirring, adding the surface-treated conducting particles, uniformly stirring, and defoaming in vacuum to obtain the high-performance conducting resin. The conducting resin in characterized in that the bonding strength reaches up to 24.1 MPa; the volume resistivity is 4.30*10<-5>-2.12*10<-4> ohm.cm; the Tonset thermal decomposition temperature reaches up to 398.7 DEG C; the water absorption is only 0.2%; and storage life at the room-temperature is as long as more than 3 months. The invention has the advantages of simple preparation process, low cost, convenient operation and convenient reaction material source, can complete the preparation process in universal devices, is beneficial to realizing industrial production, and has wide application prospects in the fields of electronic components, resonators, relays, electronic capacitors and the like.

Owner:DONGHUA UNIV +1

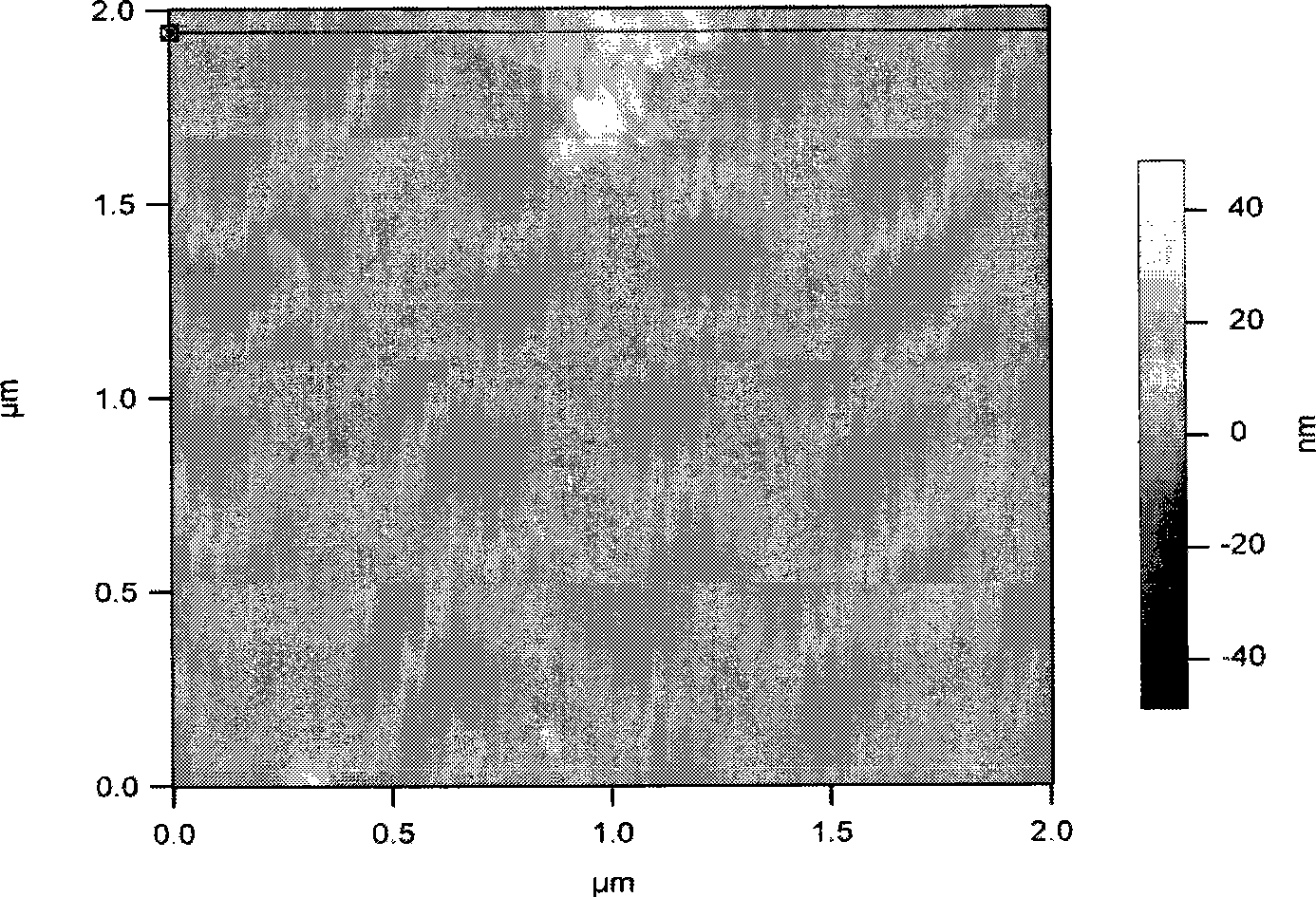

Preparation method and use of hydrophilic automatically-cleaning coating with photocatalytic activity

The invention provides a preparation method of a hydrophilic automatically-cleaning coating with photocatalytic activity, and belongs to the technical field of chemical engineering. The preparation method is characterized in that butyl titanate and ethyl orthosilicate are utilized as precursors; nanoscale TiO2 / SiO2 sol is formed through a sol-gel method; and the nanoscale TiO2 / SiO2 sol is coated on the surface of an object and is naturally dried at normal temperature to form an anatase nanoscale TiO2 / SiO2 composite film with photocatalytic activity. When the anatase nanoscale TiO2 / SiO2 composite film with photocatalytic activity is coated on a solar photovoltaic panel, a vehicle window glass plate or a building glass plate at a normal temperature, the anatase nanoscale TiO2 / SiO2 composite film with photocatalytic activity can fast form a hydrophilic coating. Under natural light irradiation, the hydrophilic coating can decompose greasy dirt adhered to the hydrophilic coating into inorganic pollutants, and through rainwater flushing or artificial washing, the inorganic pollutants are removed so that the solar photovoltaic panel or the vehicle window glass plate or the building glass plate is kept as clean as a new one for a long time. The preparation method provided by the invention reduces a production management cost and improves solar photovoltaic panel generating efficiency.

Owner:NORTH WEST YONGXIN GROUP

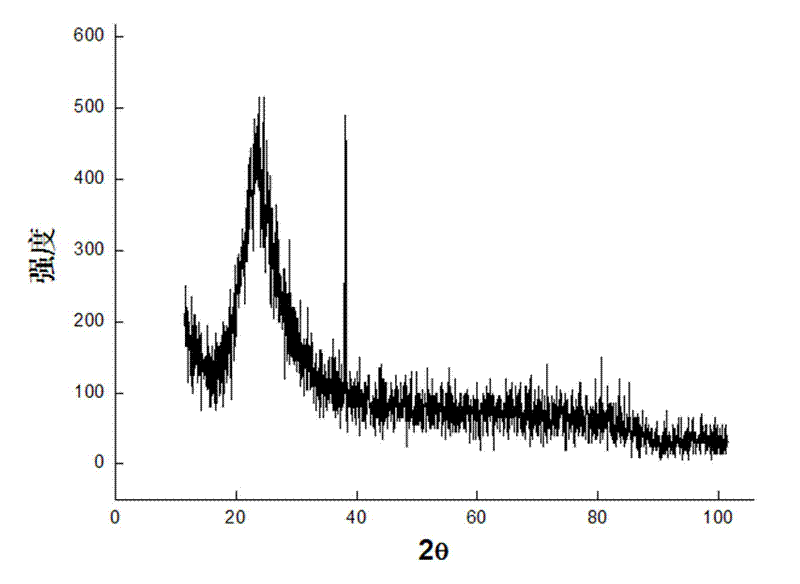

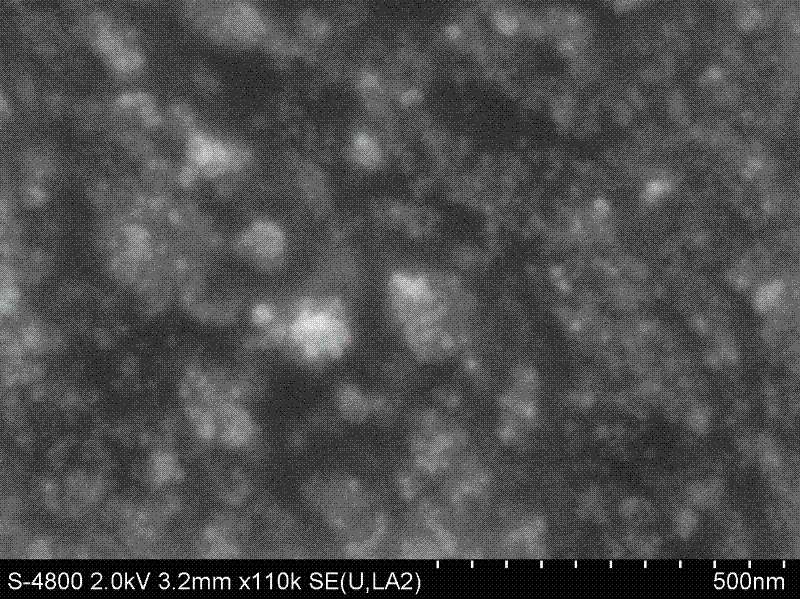

Negative pole material for lithium ionic cell and preparation process thereof

InactiveCN101478043AImprove cycle performanceSimple methodElectrode manufacturing processesTin dioxideLithium

The invention discloses a negative electrode material of a Li-ion battery and a preparation method thereof. The negative electrode material is a load-type negative electrode material, i.e. tin dioxide loaded with grapheme nanometer sheet. The negative electrode material has the advantages of higher electron and ion conductivity, large reaction area, large free expansion space, adaptability to various environments with large charge / discharge rate, and can endow the battery with high cycle performance, high specific capacity and quick charge / discharge capability; and the reversible specific capacity of the battery can be kept at a value larger than 600 mAh.g during charge / discharge with a current of 300 mAh.g. The preparation method of the negative electrode material is simple and feasible and suits industrial production.

Owner:SHANGHAI JIAO TONG UNIV

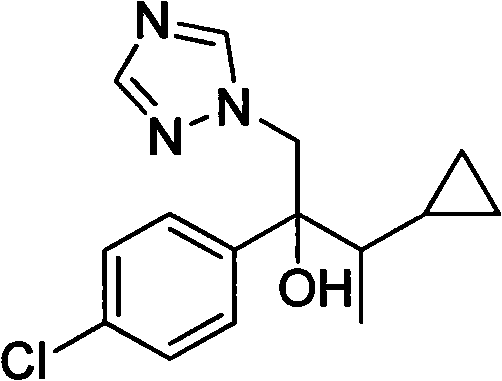

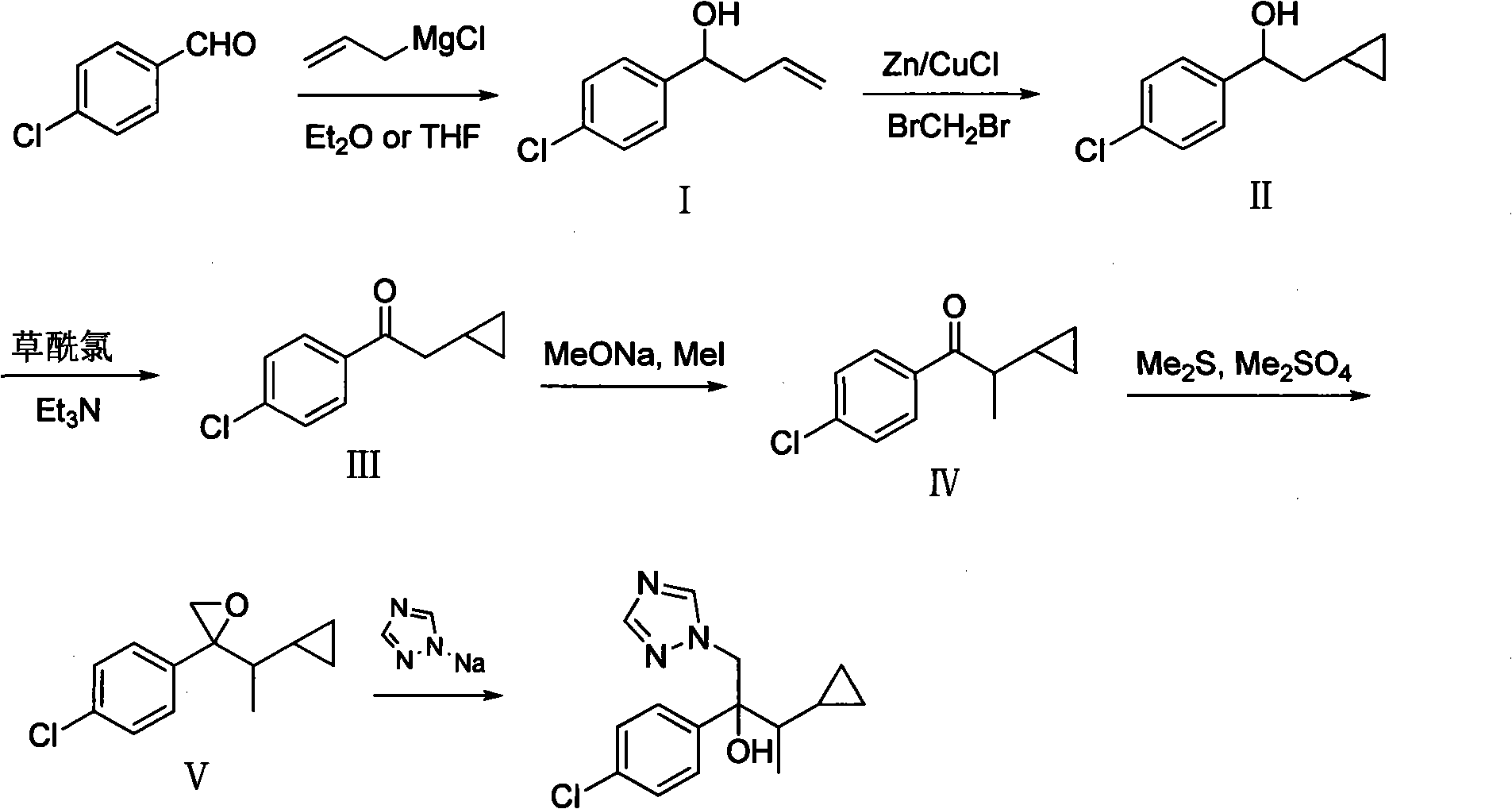

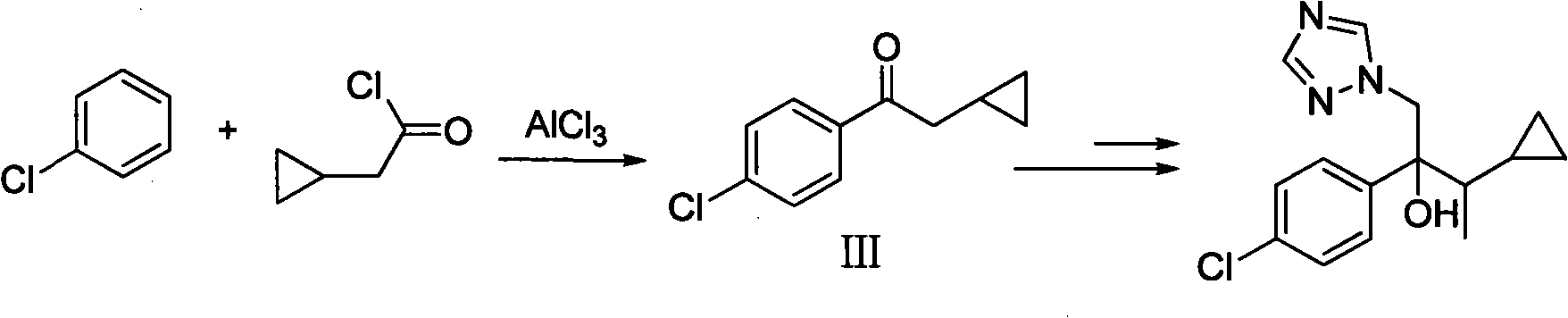

Simple method for preparing cyproconazole by cyclopropyl methyl ketone

The invention relates to a simple method for synthesizing cyproconazole through cyclopropyl methyl ketone. P-chlorobenzyl choride VI is taken as a starting raw material to prepare into a Grignard reagent which performs nucleophile substitution reaction with the cyclopropyl methyl ketone to generate alcohol VII; the alcohol VII is dehydrated in the presence of ortho-position benzene ring and oxygen phosphorus chloride to form conjugated alkene VIII; hydroxyl is introduced at benzyl position through hydroboration oxidation reaction to obtain alcohol IX; Dess-Martin oxidation is carried out on the obtained alcohol to obtain ketone IV; Darzens condensation is performed on the ketone IV and sulfonium iodide at alkalescence condition to further obtain cyproconazole through ring opening of triazole. The invention is a cyproconazole synthesizing method with simple operation, good safety, environmentally friendliness and high yield, can realize industrialized production, and satisfy heavy demands of agricultural production to cyproconazole.

Owner:SHANGHAI INST OF ORGANIC CHEMISTRY - CHINESE ACAD OF SCI

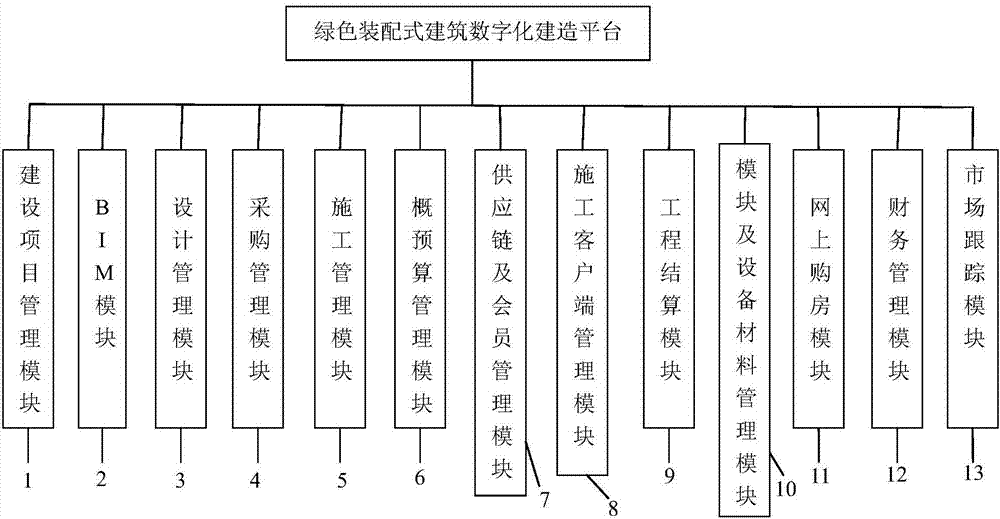

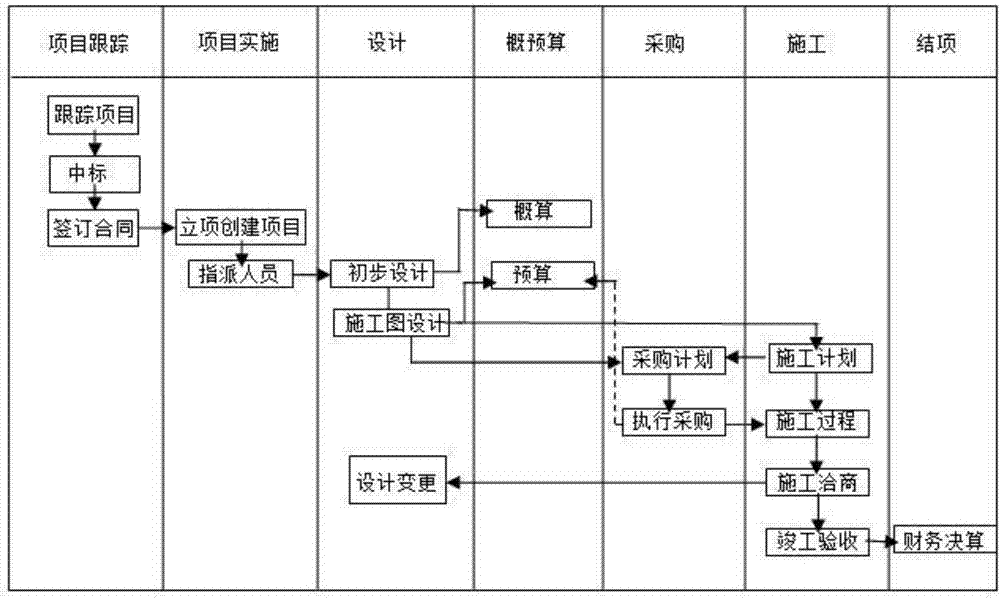

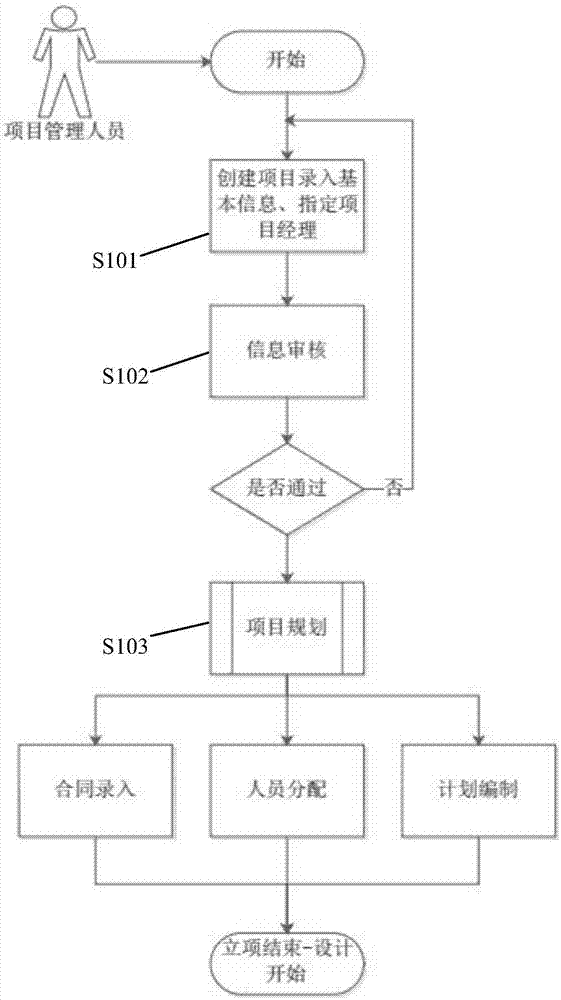

Green assembly type digital construction platform and working method thereof

InactiveCN107958328ALive UpdateDigitization hasGeometric CADResourcesInformation sharingModular design

The invention discloses a green assembly type digital construction platform and a working method thereof and belong to the assembly building field. The platform includes a construction project management module, a BIM module, a design management module, a procurement management module and a construction management module; the information data of each module are stored in an BIM (digital information model); and with the digital information model adopted as the basis of each construction project, relevant work is carried out, information can be updated in real time, and information sharing can be realized. According to the green assembly type digital construction platform of the invention, construction projects are planed and designed in a unified manner; building components and general equipment materials manufactured in factories are transported to construction sites on time according to constructional engineering requirements; and the whole process of the construction of more than a dozen of construction sites can be simultaneously monitored, controlled and managed remotely; and modular design, industrial production, assembly-based construction, and intelligent management are completely realized.

Owner:北京善筑科技股份有限公司

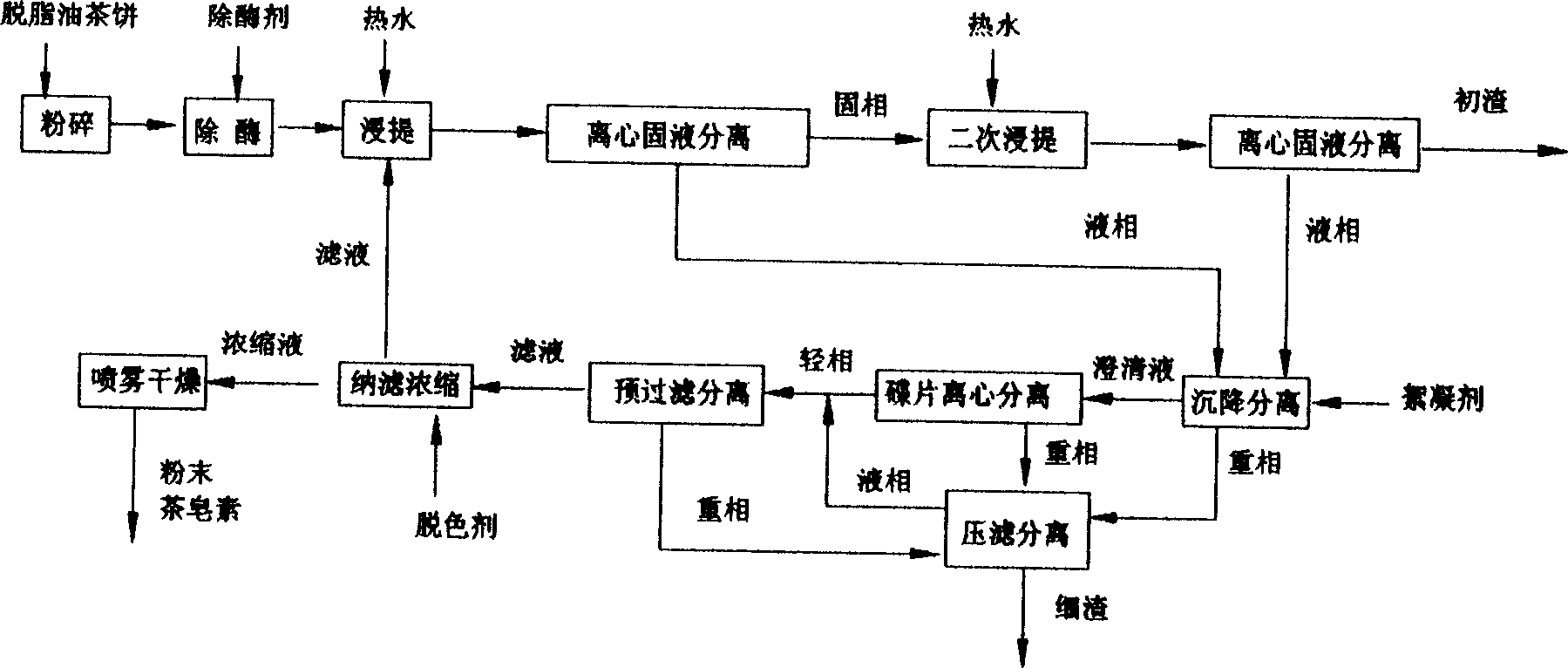

Production process for extracting tea saponin from tea-oil tree cake by using water as dissoluent

InactiveCN1754883AAvoid hydrolysisEfficient removalSugar derivativesGlycosidesChemical treatmentCamellia oleifera

The preparation method to extract tea saponin from oil meal, which comprises smashing, removing enzyme, leaching with hot mixing to boost infiltration capacity, centrifugal solid-liquid separating to add flocculant, deposition separating, disc centrifugal separating for cleaning solution, prefiltration separating for flocculation deposition, nano-membrane concentrating, and spray drying. Wherein, using chemical treatment to inhibit and eliminate hydrolase activity before leaching. This invention is simple and low cost with yield more than 70% and 80% purity.

Owner:NANHUA UNIV

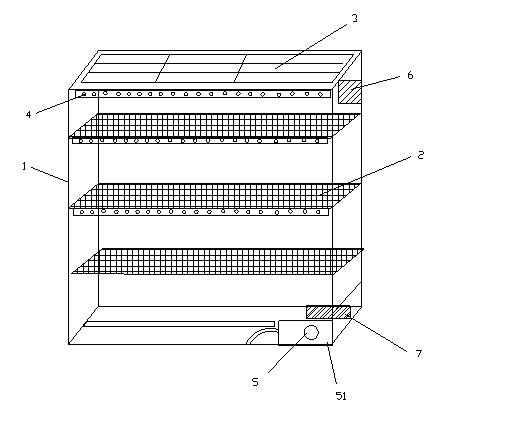

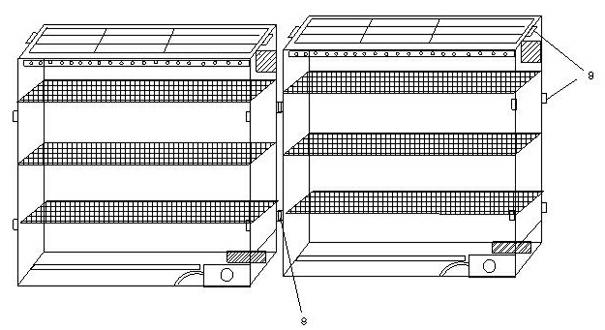

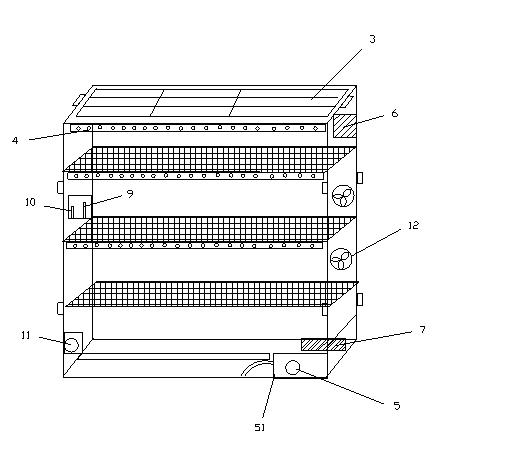

Intelligent integrated control planting device

InactiveCN102084789APromote growthIncrease productionClimate change adaptationGreenhouse cultivationControl dataEngineering

The invention discloses an intelligent integrated control planting device which comprises a planting frame and a planting disk arranged on the planting frame, also comprises a power supply, an LED lighting lamp connected with the power supply, a low-pressure water pump and central control equipment; the LED lighting lamp is arranged the upper end of the planting frame or above the planting disk, the low-pressure water pump is arranged in a water supply system at the bottom of the planting frame and used for conveying water to the planting disk through a water pipe; and the central control equipment reads a correspondingly stored control data command according to different economic planting plants and centrally controls lighting frequency and time, temperature variation and watering quantity. By combining with accurate test planting parameters and through three-dimensionally planting plants in an intelligent integrated control and scientific efficient manner, the device disclosed by the invention greatly increases the output and meets the requirement for environmental protection.

Owner:梁雄

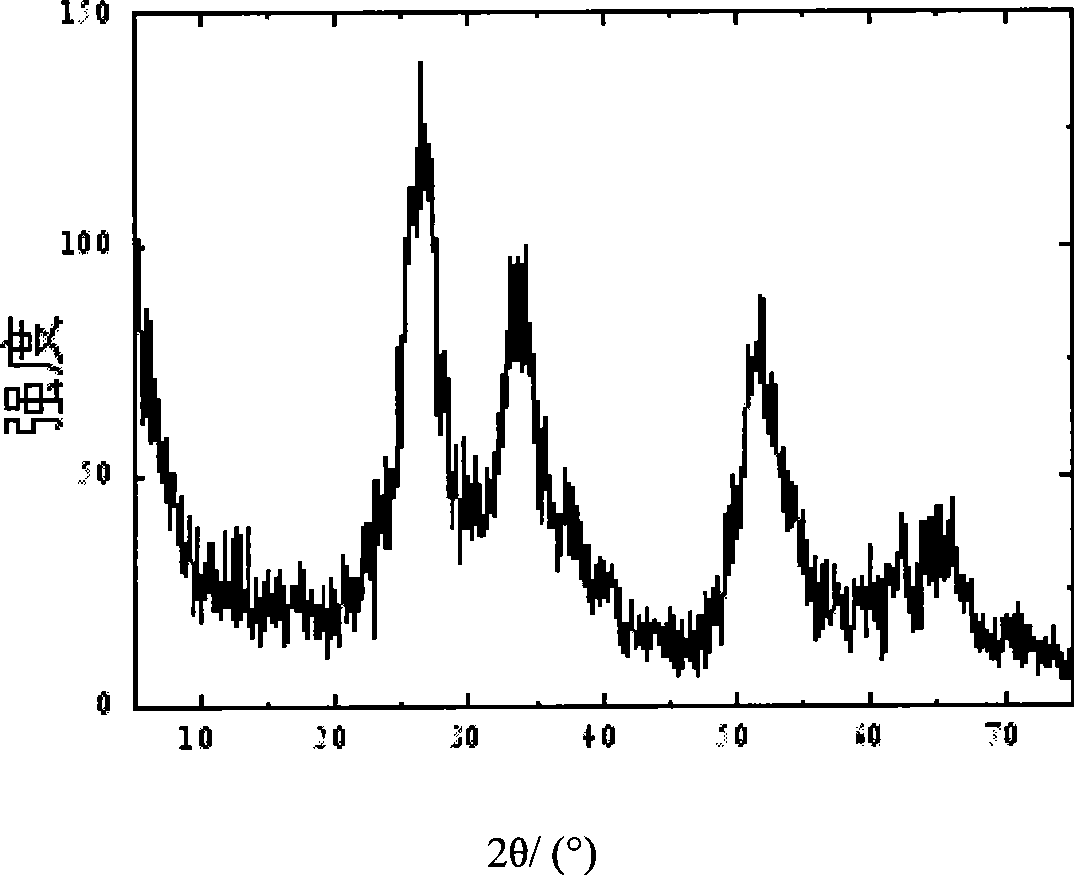

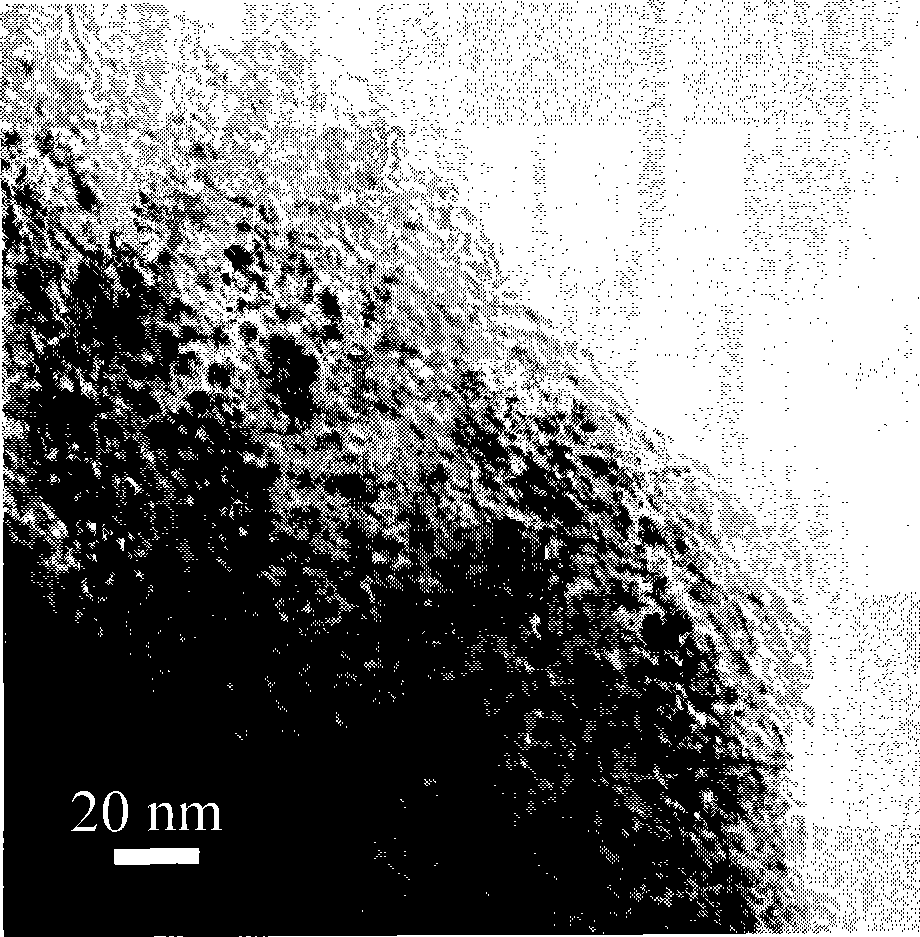

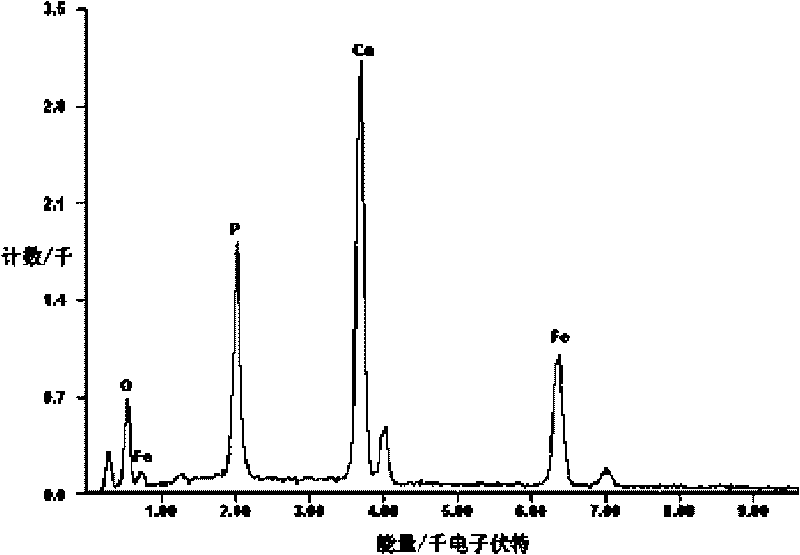

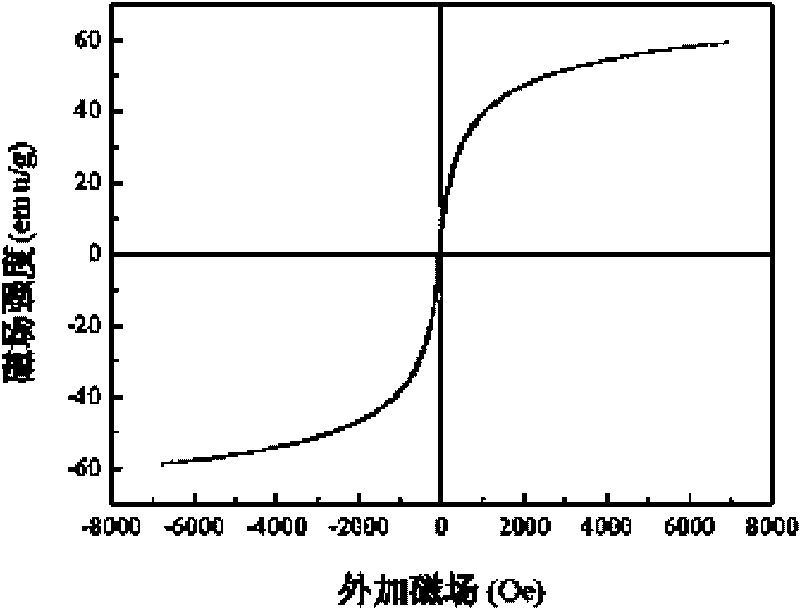

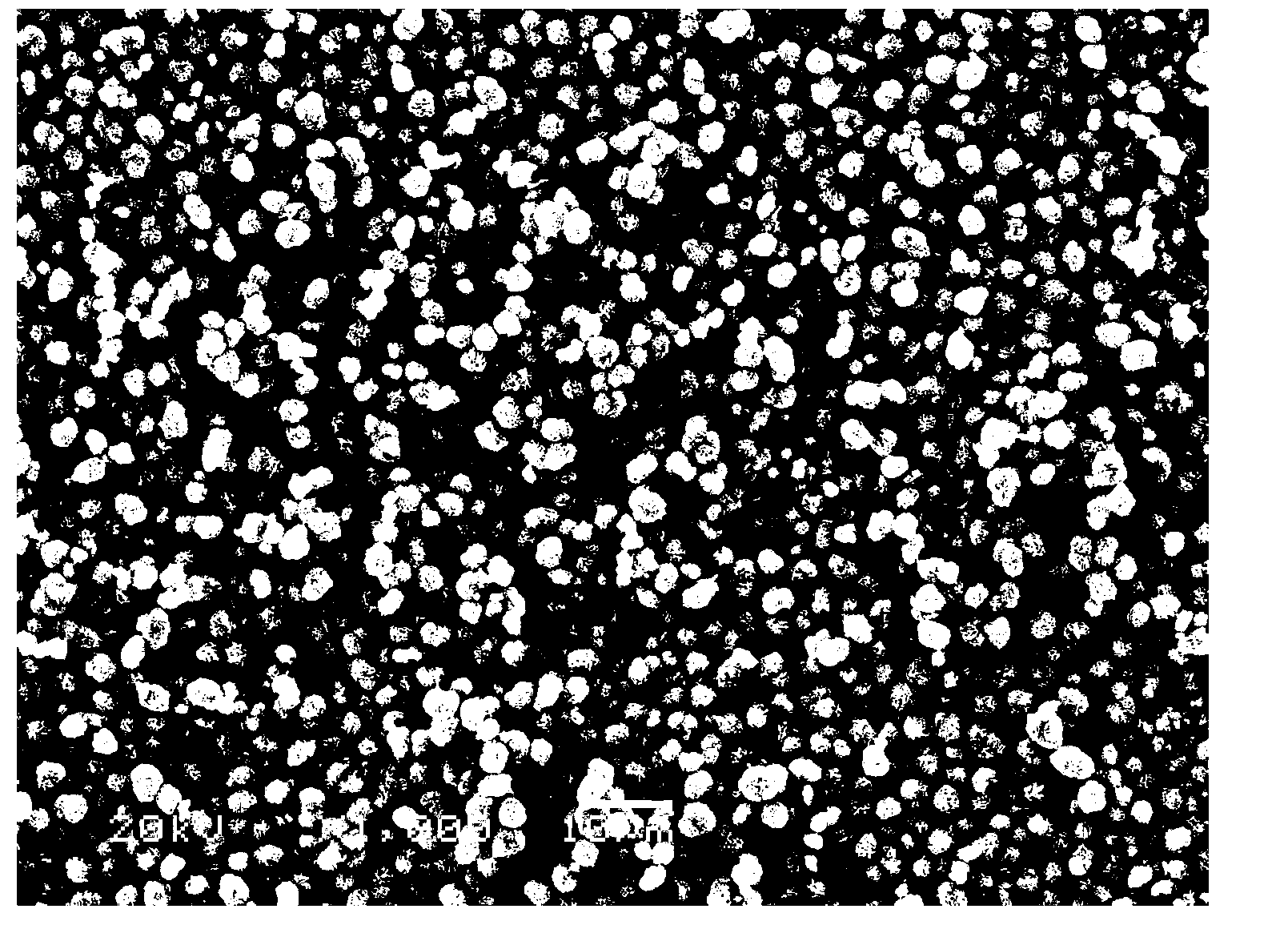

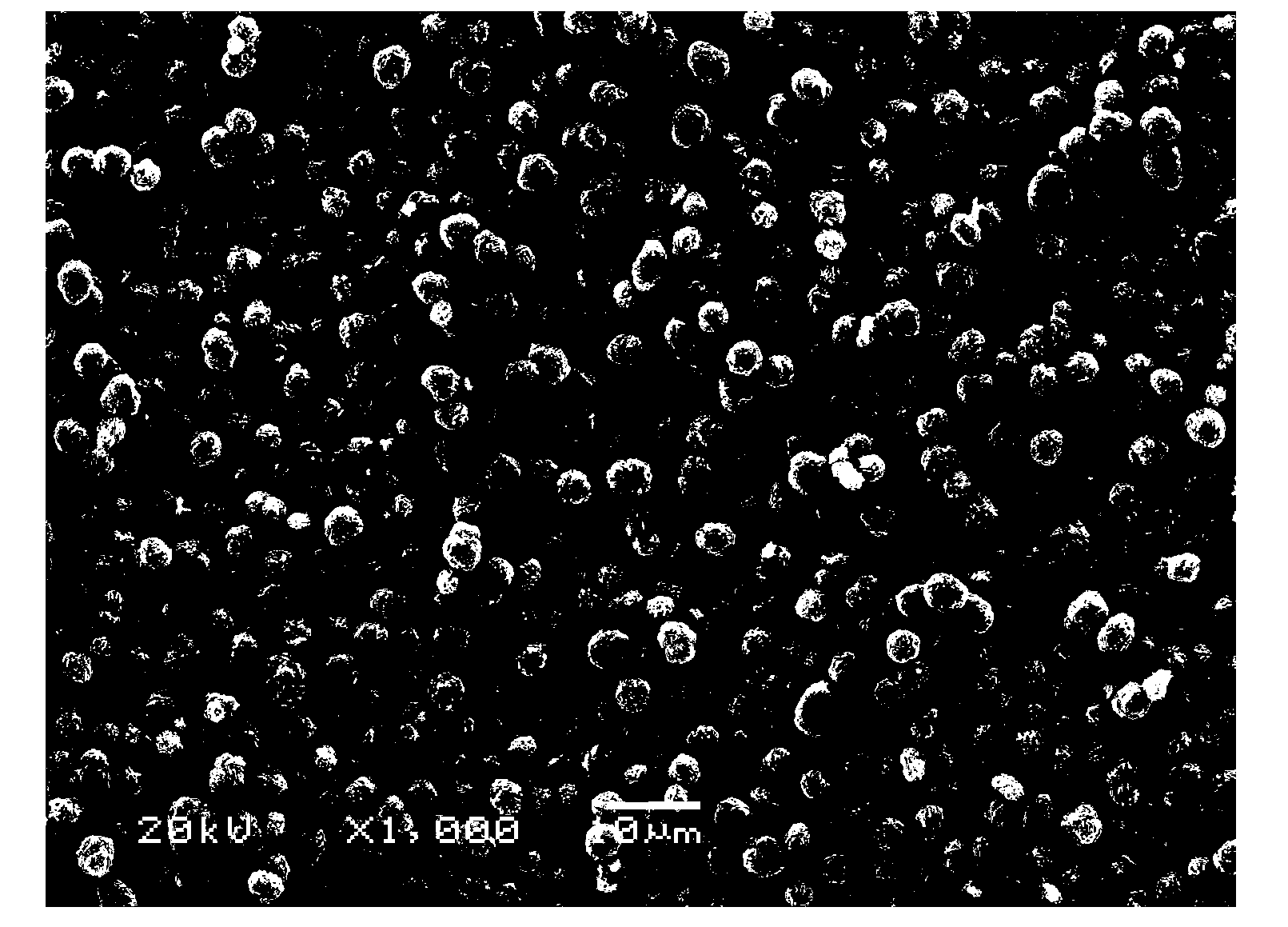

Magnetic nano hydroxyapatite adsorbent, preparation and application thereof

InactiveCN101703917AImprove adsorption efficiencyEasy to makeOther chemical processesWater contaminantsApatiteSorbent

The invention discloses a magnetic nano hydroxyapatite adsorbent, preparation and application thereof. Nano hydroxyapatite Ca10(PO4)6(OH)2 is used as a matrix of the adsorbent, and magnetic powder Fe3O3 is uniformly dispersed in the matrix, wherein the mass ratio of the nano hydroxyapatite to the magnetic powder Fe3O3 is (1.5-1):1. The preparation method comprises the following steps of: dissolving FeCl2 and FeCl3 with a mass ratio of (0.75-0.85):1 in deoxidized water; then adding an ammonia solution and uniformly stirring; simultaneously adding a Ca(NO3)2 solution and a (NH4)2HPO4 solution and uniformly stirring to obtain liliquoid; heating the liliquoid at the temperature of 90-100 DEG C; and then obtaining the magnetic nano hydroxyapatite adsorbent through cooling, separating, washing, drying and grinding. The magnetic nano hydroxyapatite adsorbent has large specific surface area, high adsorption efficiency, low cost and easy separation and can effectively remove heavy metal ions in waste water.

Owner:HUNAN UNIV

Method for preparing small-size nickel-cobalt lithium manganate precursor

ActiveCN103253717ARealize industrial productionConcentrated particle size distributionManganese oxides/hydroxidesNickel oxides/hydroxidesManganateManganese

The invention relates to a method for preparing a small-size nickel-cobalt lithium manganate precursor. The method is characterized by comprising the following steps of: (1) preparing a solution from soluble salts of nickel, cobalt and manganese as materials, adopting a sodium hydroxide water solution as a precipitator, and adopting ammonia water or ammonium salt as a complexing agent; (2) merging and adding the obtained three solutions into a reaction kettle which contains bottom water and includes stirring and temperature control devices; leading in nitrogen to protect in a reaction process, and continuously carrying out reaction; and (3) stirring and aging for 4-6 hours after a temporary kettle is full, putting the aged material into washing and press filtering equipment to wash; removing moisture in a filter pressing manner; and then mixing and sieving by a 200mesh screen after baking and crushing. By adopting the method disclosed by the invention, industrialized production of the small-size nickel-cobalt lithium manganate precursor can be conveniently achieved; and the method is stable to control the particle size, and convenient to achieve requirements of the materials and equipment.

Owner:宁夏中色金辉新能源有限公司

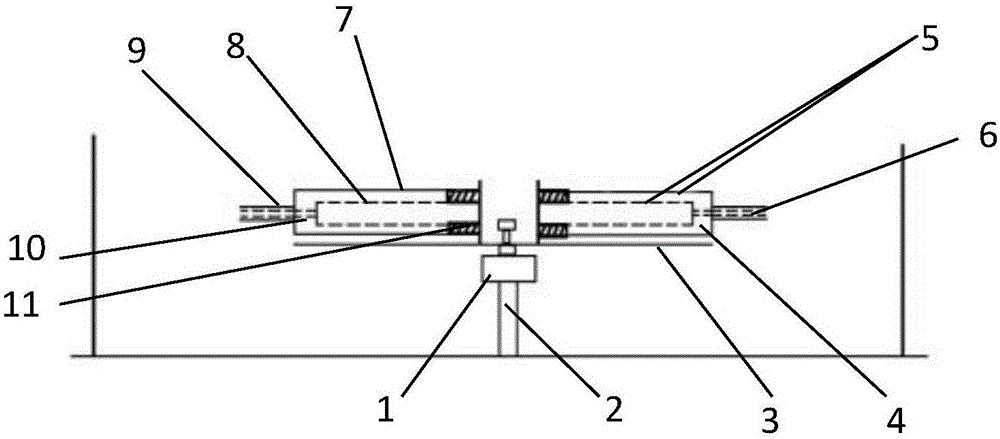

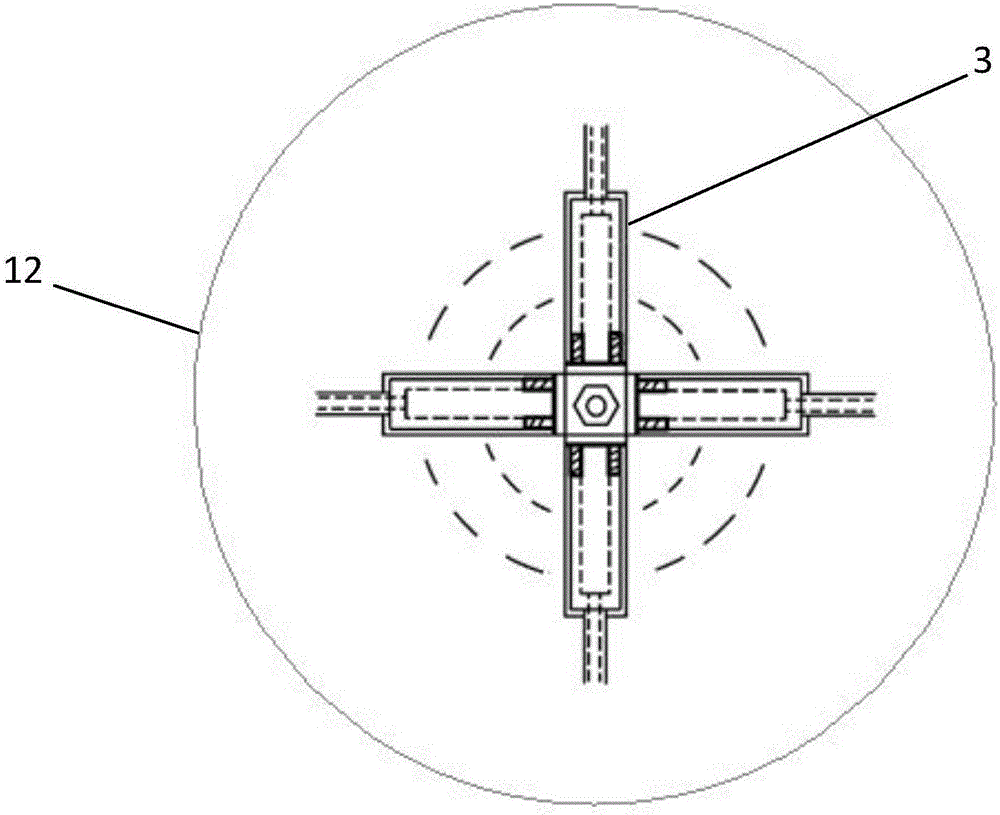

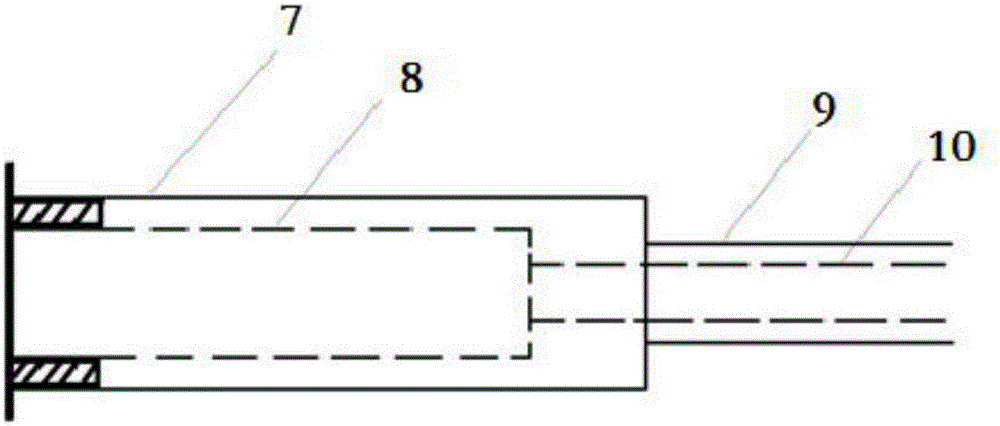

Coaxial centrifugal spinning device and method

InactiveCN106222767AStable productionGuaranteed suitabilityArtificial thread manufacturing machinesFilament/thread formingEngineeringSpin speed

The invention discloses a coaxial centrifugal spinning device and method. The device comprises a direct-current motor, a supporting device, a spinning support, coaxial centrifuge tubes, spinning needle heads and a receiving device, wherein the direct-current motor is fixed to the supporting device, the spinning support is directly and fixedly connected with an output shaft of the direct-current motor, the coaxial centrifuge tubes are fixed to the spinning support, and under the action of the direct-current motor, the spinning support drives the coaxial centrifuge tubes to rotate at high speed; each coaxial centrifuge tube comprises an outer layer centrifuge tube and an inner layer centrifuge tube, each spinning needle head comprises an outer layer needle head and an inner layer needle head, during spinning, a spinning solution or melt in the outer layer centrifuge tubes and the inner layer centrifuge tubes is tossed out under the action of centrifuge force, an outer layer solution wraps an inner layer solution, and superfine fiber of a skin-core structure is formed due to centrifuge force drafting, solvent volatilization and phase separation. The coaxial centrifugal spinning device is simple, high in spinning speed and production efficiency and capable of producing coaxial superfine fiber on a large scale.

Owner:TIANJIN POLYTECHNIC UNIV

Fire retardant for wood, and preparation method and treatment process thereof

ActiveCN102069519ASimple processRealize industrial productionPressure impregnationWood impregnation detailsEnvironmental resistanceSilicon dioxide

The invention discloses a fire retardant for wood, and a preparation method and a treatment process thereof. The fire retardant for wood is prepared from the following raw materials in percentage by weight: 40 to 60 percent of silica sol, 5 to 20 percent of sodium octaborate tetrahydrate, 1 to 20 percent of ammonium polyphosphate, 1 to 20 percent of carbonate and 0 to 53 percent of water. The preparation method comprises steps of: putting the substances into a stirrer, and uniformly mixing fully to obtain the flame retardant. During use, wood is put into a treatment tank, and is vacuumized, the flame retardant is injected at normal temperature, the treatment tank is vacuumized and the vacuum is eliminated so as to obtain the flame-retardant wood. By utilizing advantages of nontoxicity, environmental friendliness, high flame-retardant efficiency, low price, wide sources and easy preparation of the materials such as the sodium octaborate tetrahydrate and the silica sol, after the materials are compounded, the flame retardant with good anti-loss performance is obtained and can be used for flame-retardant protection of interior and exterior decorative wood and wood structures of buildings.

Owner:ZHEJIANG UNIV

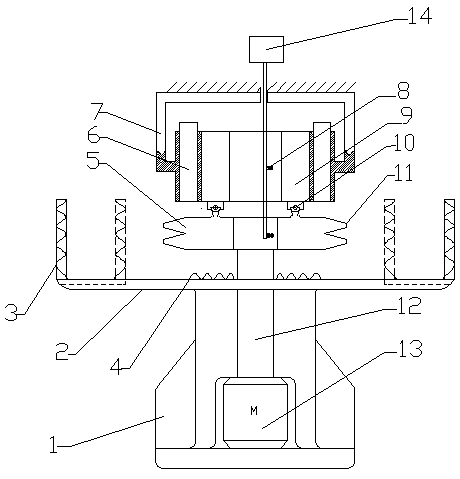

Novel centrifugal melt electrostatic spinning device

ActiveCN103215666ARealize continuous spinningRealize industrial productionFilament/thread formingFiberCollection system

The invention discloses a novel centrifugal melt electrostatic spinning device and belongs to the field of electrostatic spinning. The whole set of the device comprises a supporting and power system, a material supplying and temperature controlling system, a spinning sprayer and a collection system. The novel centrifugal melt electrostatic spinning device utilizes the common effect of high-voltage electric field force and high-speed centrifugal force, so that a nano superfine fiber is spun by using a macromolecular melt; materoals can be discontinuously added into a charging room to realize continuous spinning of the whole device; and a plurality of layers of shower nozzles not only can greatly improve the spinning efficiency, but also can obtain a fiber membrane with the certain width, being good for realizing industrial production.

Owner:BEIJING UNIV OF CHEM TECH

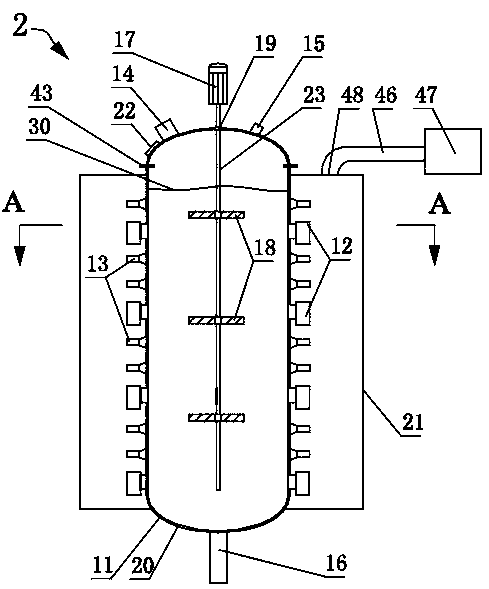

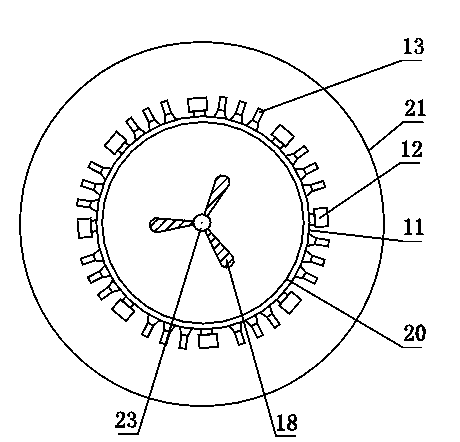

Industrial microwave ultrasonic reaction kettle

InactiveCN103418323ASave operating timeImprove work efficiencyChemical/physical/physico-chemical stationary reactorsEnergy based chemical/physical/physico-chemical processesMicrowaveEngineering

Disclosed is an industrial microwave ultrasonic reactor. The inner wall of the reactor is provided with a liner; a microwave generation device is composed of microwave units distributed over the outer sidewall of the reactor in a spaced manner, or of a microwave pipe provided outside the reactor and microwave units distributed over the microwave pipe in a spaced manner. One end of the microwave pipe is in communication with the bottom of the reactor via a connecting pipe I and the other end is in communication with the top of the reactor via a return pipe. A shield is provided outside the microwave generation device to space the microwave units apart from the outer space, with a heat removal device being provided outside the shield. The microwave generation device is composed of ultrasonic pulse units provided along the outer sidewall of the reactor in a spaced manner; there are 10 - 30 sets of ultrasonic pulse units provided from top to bottom, each set having 10 - 50 members and being distributed along the circumferential direction of the reactor, and a stirring shaft of a stirring device is fixed below a stirring motor and extends into the reactor. The present reactor can shorten the time for chemical leaching, improve the purity of a product extracted and increase operation efficiency.

Owner:SONGXIAN EXPLOITER MOLYBDENUM

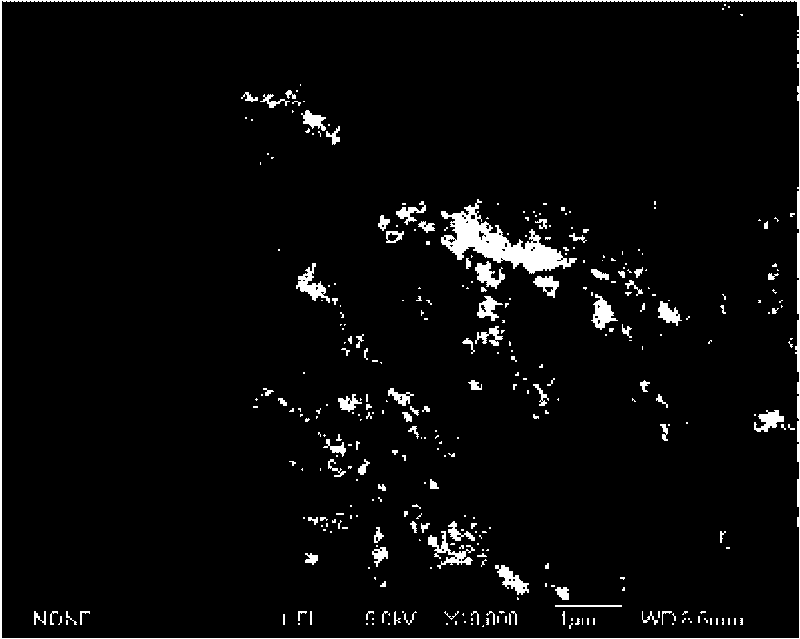

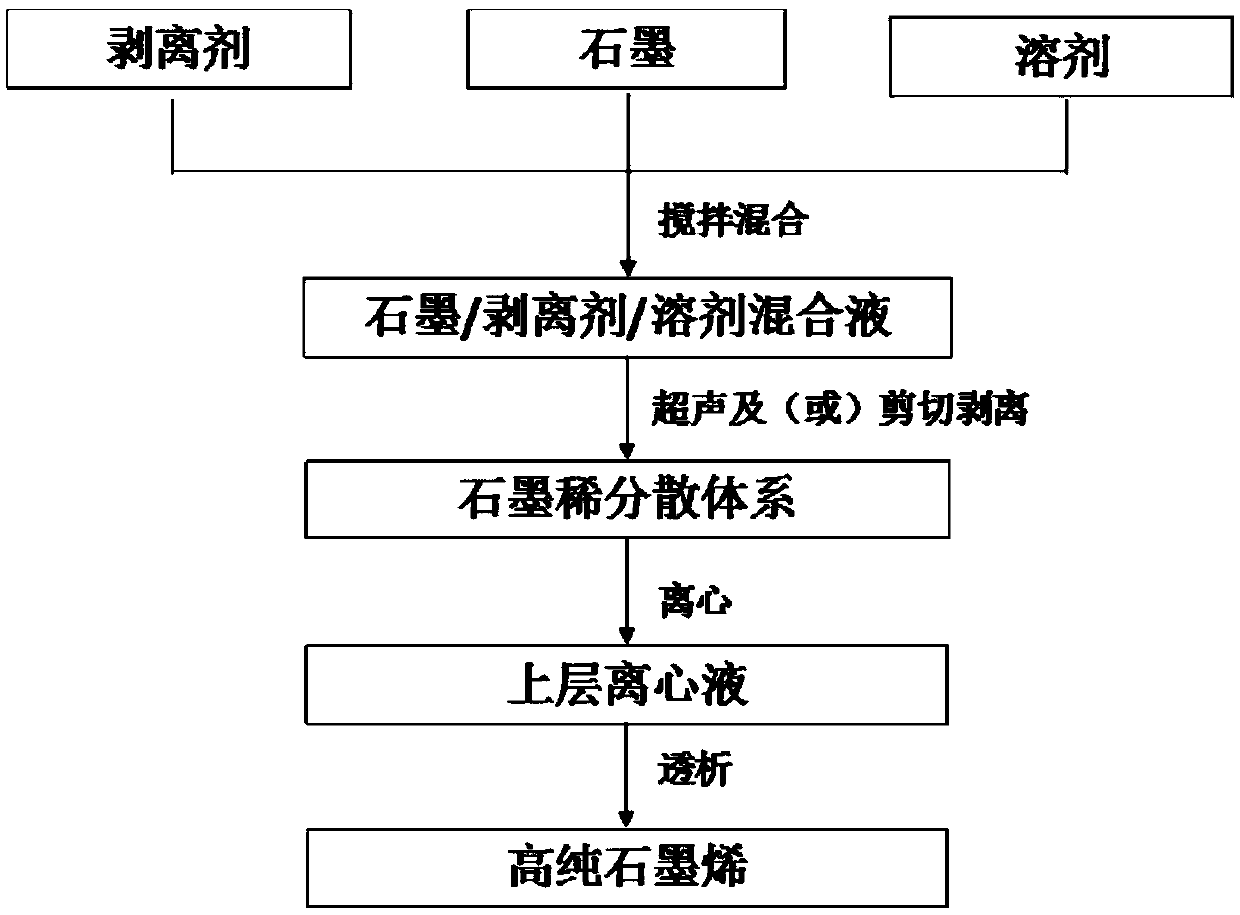

Liquid-phase stripping preparation method of graphene

ActiveCN105502371AReduce the number of layersHigh monolayer ratioSingle layer grapheneGraphiteCvd graphene

The invention provides a liquid-phase stripping preparation method of graphene. The liquid-phase stripping preparation method comprises the steps that first, an aromatic compound is used as a stripping agent to prepare a stripping agent solution, graphite powder is added, and graphite pre-stripping dispersion liquid is obtained after sufficient stirring; second, the graphite pre-stripping dispersion liquid obtained in the first step is subjected to stripping dispersion through ultrasonic and / or mechanical shear to obtain a graphene mixed dispersion system; third, the graphene mixed dispersion system obtained in the second step is centrifuged, the upper-layer solution can be taken for dialysis, and impurities are remove to obtain a pure graphene product. The liquid-phase stripping preparation method can effectively separate graphite flake layers, a large amount of graphene is obtained within a short period of time, and the prepared graphene is single-layer or double-layer graphene and is good in conductive / thermal performance and excellent in comprehensive performances. The liquid-phase stripping preparation method has the advantages of being simple in operation, high in efficiency and green, being environmentally-friendly and the like, and achievement of industrialized graphene preparation is hopeful.

Owner:SHANGHAI HIWAVE COMPOSITE MATERIALS CO LTD

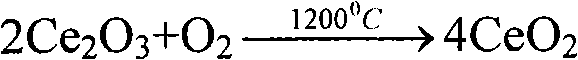

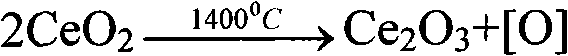

Ultra-white glass

The invention relates to ultra-white glass, belonging to the preparation field of glass. The preparation method of the ultra-white glass is as follows: La2(CO3)3, Ce2(CO3)3, Nd2(CO3)3, MnO2, CoO and CuSO4 are added in common float glass to perform compound clarification and decoloring, wherein under the combined action of chemical decoloring and physical decoloring, the thickness of the molten glass is 4mm, the visible light transmittance is more than 94.5% under the wavelength of 380-780nm, the whiteness is less than 0.082, the flexural strength is more than 380MPa and the microhardness is more than 8320MPa. The ultra-white glass has the advantages of higher visible light transmittance, low whiteness, high flexural strength and higher microhardness; and the quality of the white float glass can be obviously increased. The ultra-white glass can be widely used in the fields such as building glass, photovoltaic technology, experimental apparatus and the like.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

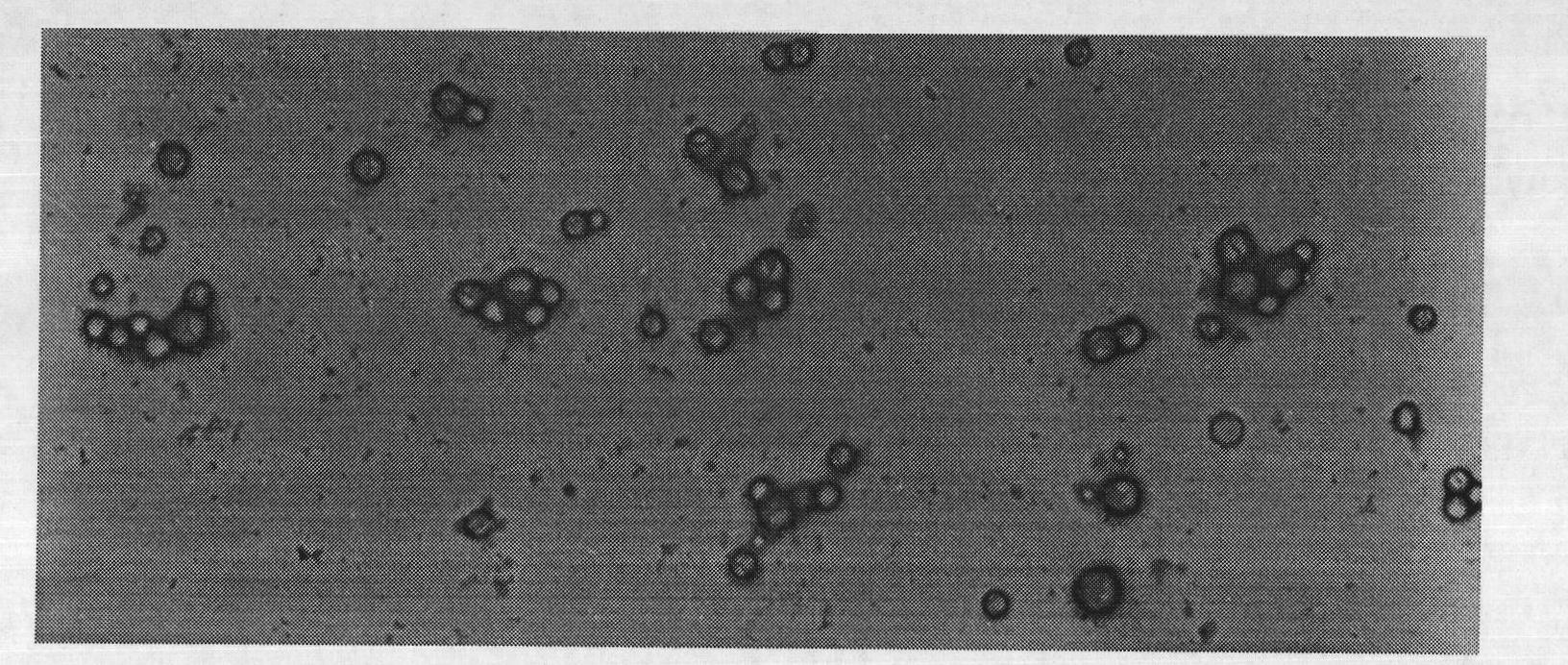

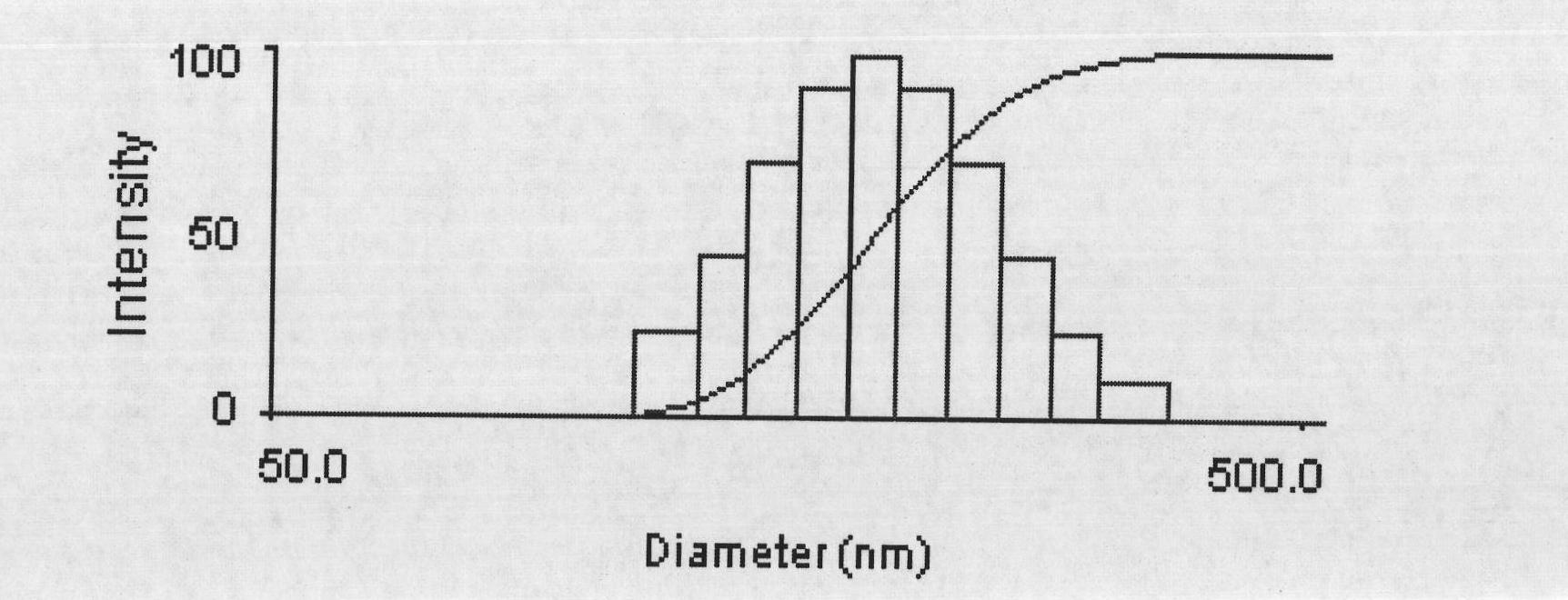

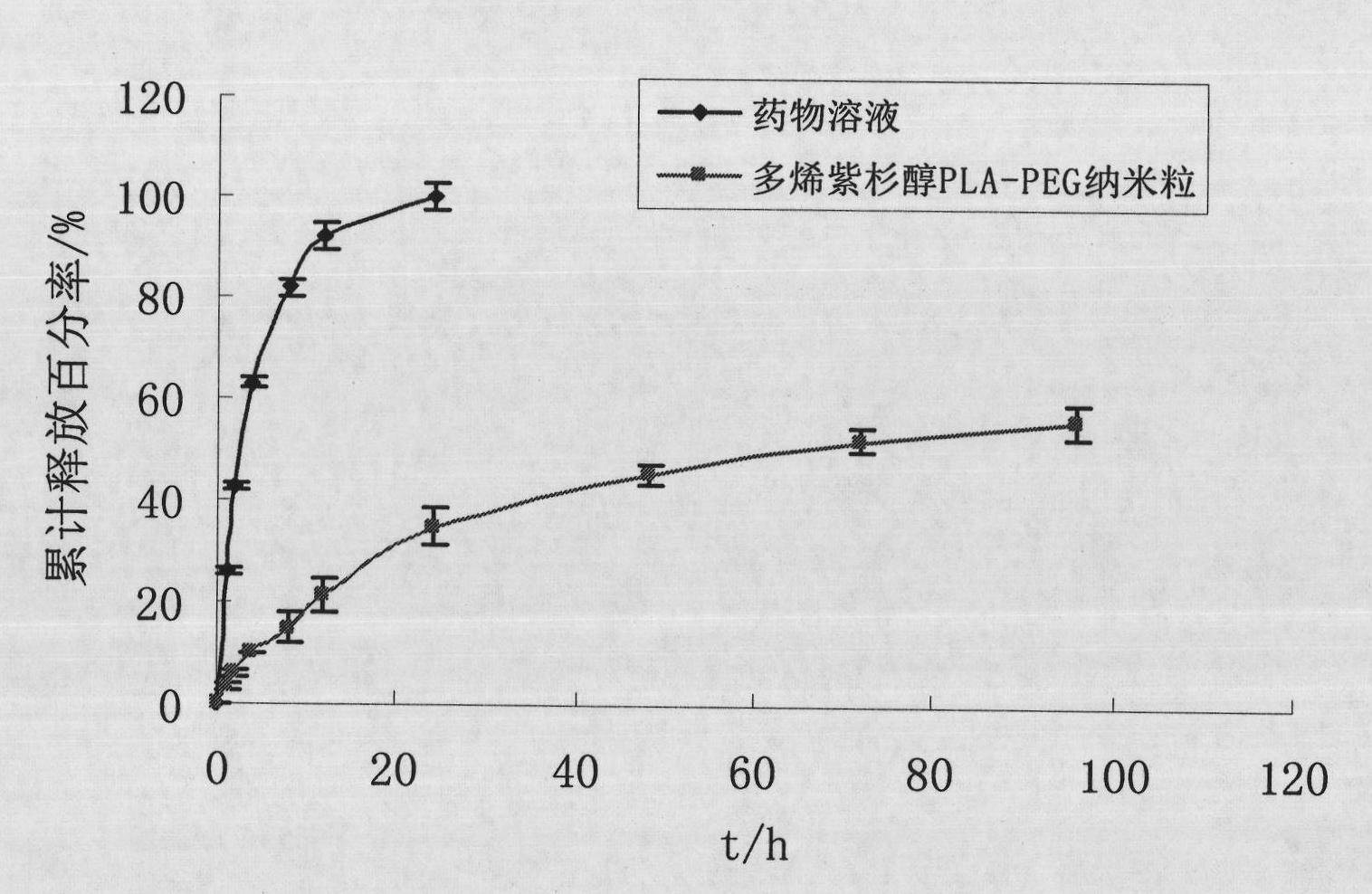

Preparation method of polyene-containing taxol nanoparticle mixed micelle preparation and freeze-drying agent

InactiveCN101804021AImprove solubilityHigh metabolic stabilityOrganic active ingredientsPowder deliveryMixed micelleFreeze-drying

The invention discloses a preparation method of a polyene-containing taxol nanoparticle mixed micelle preparation and a freeze-drying agent, which prepares docetaxel PLA-PEG nanoparticles or micelle or nanoparticle mixed micelle through a modified solvent evaporation method, takes PLA-PEG copolymer as a carrier, and wraps docetaxel in a PLA hydrophobic core. When in use, the docetaxel PLA-PEG containing long cycle freeze-dried preparation only needs to be added with water and is dissolved, and uniform nanoparticle suspension, micellar solution or mixed micellar nanoparticle suspension can be prepared. The preparation method does not need tween-80 and ethanol solubilization, only takes the biodegradable PLA-PEG as the carrier, and does not contain any surfactant; and compared with the docetaxel injection on sale, the preparation can reduce the toxicity and the adverse reactions of the medicine, and improve the clinical application safety of the medicine.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com