Patents

Literature

408 results about "Dimethoxymethane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

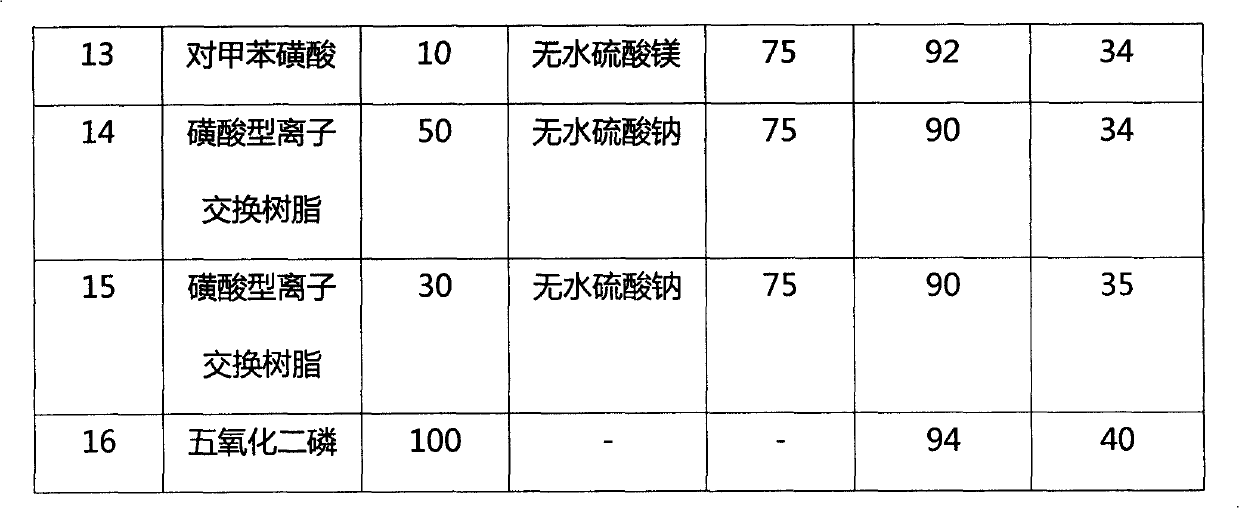

Application Year

Inventor

Dimethoxymethane, also called methylal, is a colorless flammable liquid with a low boiling point, low viscosity and excellent dissolving power. It has a chloroform-like odor and a pungent taste. It is the dimethyl acetal of formaldehyde. Dimethoxymethane is soluble in three parts water and miscible with most common organic solvents.

Method for continuous production of polyformaldehyde dimethyl ether

InactiveCN102786397ARealize industrial productionImprove stabilityOrganic chemistryOrganic compound preparationPtru catalystDistillation

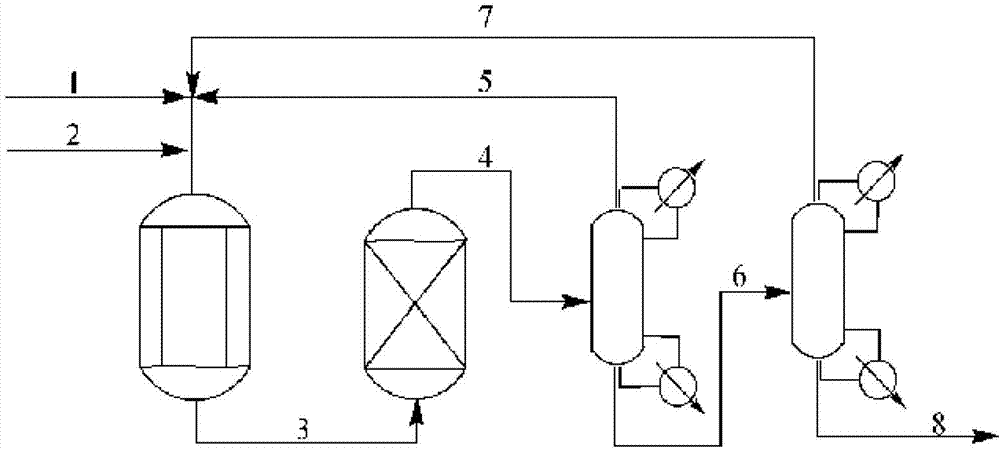

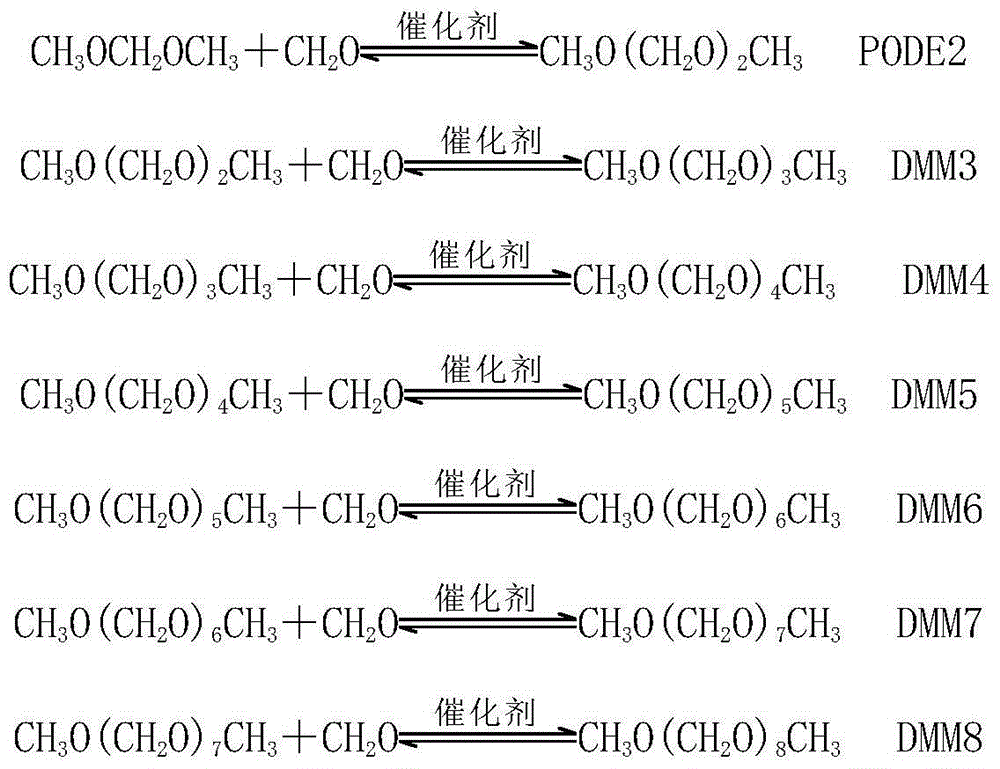

The invention provides a method for continuous production of polyformaldehyde dimethyl ether. The method is characterized by comprising the following steps: a) feeding dimethoxymethane and hot-melted paraformaldehyde into a fixed bed reactor and adopting an acidic resin catalyst, so as to prepare polyformaldehyde dimethyl ether (DMM3-8), wherein the reaction temperature is 120-180 DEG C and the pressure is 0.1-10 MPa; b) cooling the reaction product, and then performing adsorptive separation through a dehydrating tower, so as to obtain polyformaldehyde dimethyl ether of which most water, cytidine glycol and hemiacetal are desorbed; c) feeding the polyformaldehyde dimethyl ether subjected to desorption into a distillation tower for separation, wherein most of a low-boiling component (dimethoxymethane (DMM)), poly-di-formaldehyde dimethyl ether (DMM2), a by-product (methanol) and triformol are extracted first, and then the materials in a tower kettle are fed into a rectifying tower in the next step, so as to extract the rest of the DMM2 and the triformol; and d) returning the low-boiling component (dimethoxymethane (DMM)), the methanol, the DMM2 and the triformol, which are evaporated out by the distillation tower and the rectifying tower in the last step, into the fixed bed reactor to continue to react to prepare polyformaldehyde dimethyl ether.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Porous polymer material and preparation method thereof

ActiveCN102093539AThe synthesis method is simpleMild reaction conditionsSemi-permeable membranesCatalyst carriersDimethoxymethaneStorage material

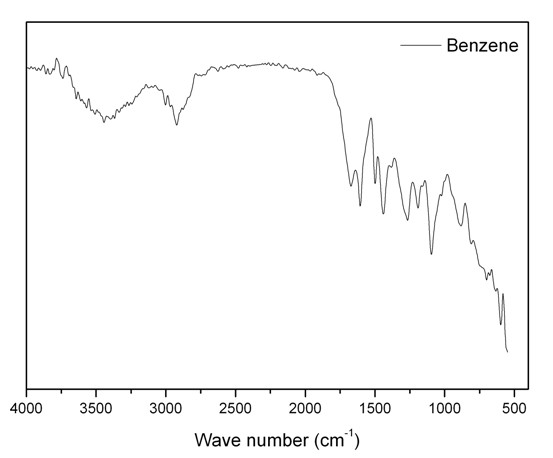

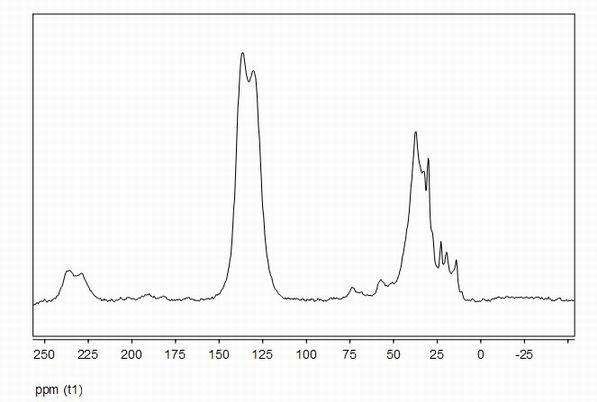

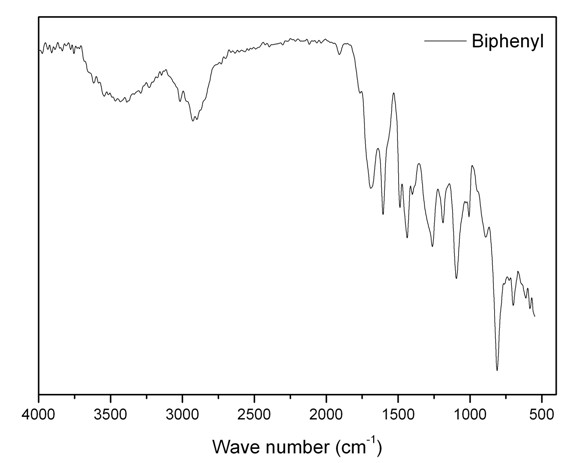

The invention provides a porous polymer material and a preparation method thereof. The porous polymer provided by the invention is prepared by crosslinking aromatic compounds with a crosslinking agent; the specific area of the porous polymer material is up to 2000 m<2>g<-1>, and the controllable range of the pore size is 0.3-100nm; and the porous polymer material can be used as a catalyst carrier, separation membrane, gas storage material and ion adsorbent. The preparation method comprises the following step: by using dimethoxymethane or chloromethyl methyl ether as the crosslinking agent andusing Lewis acid as the catalyst, crosslinking various aromatic compounds to obtain the porous polymer material by a one step method. The method has the characteristics of cheap and accessible raw materials and simple preparation technology, and the varieties of the aromatic compounds can be flexibly selected according to different application demands.

Owner:武汉华科中英纳米科技有限公司

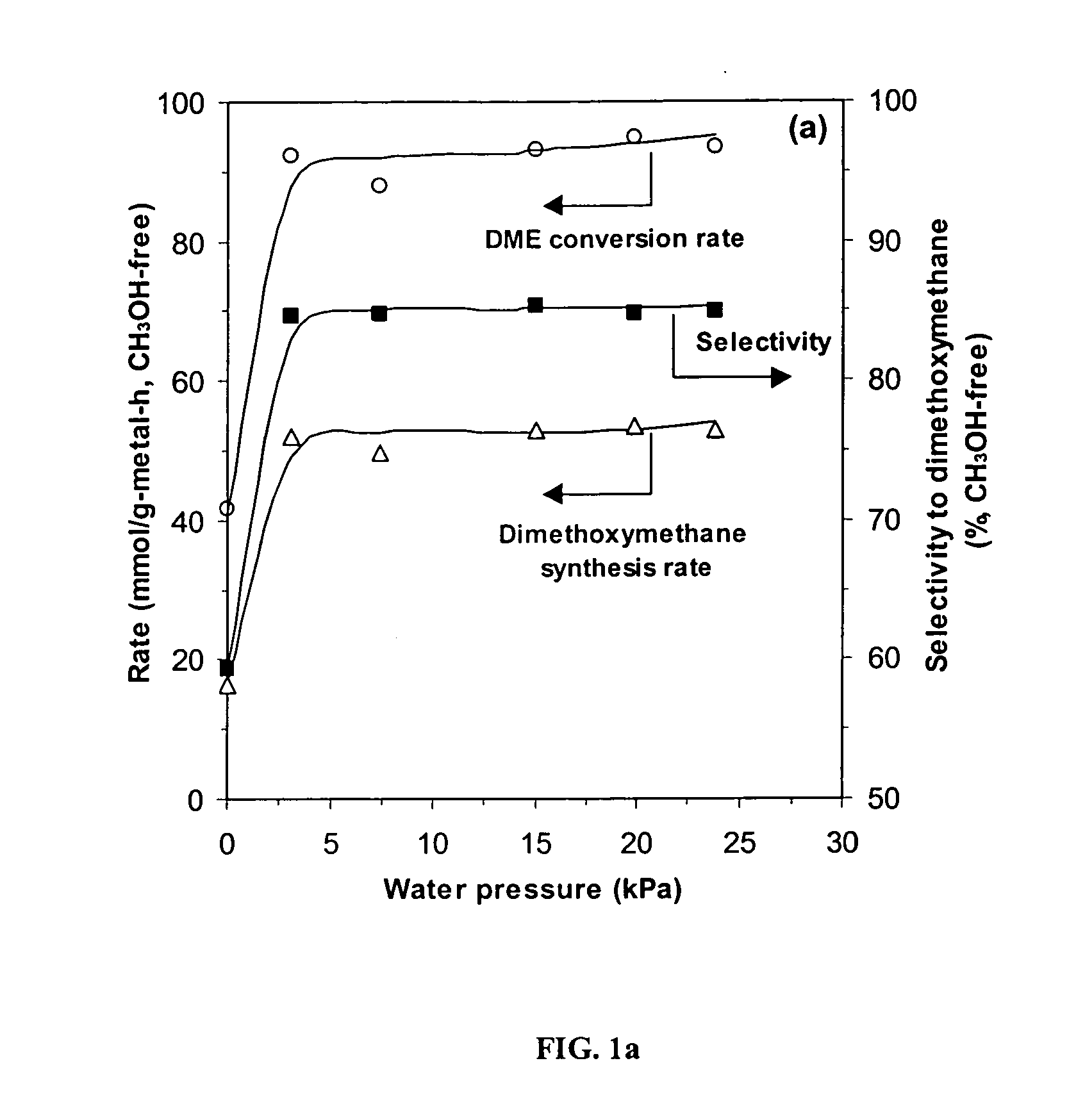

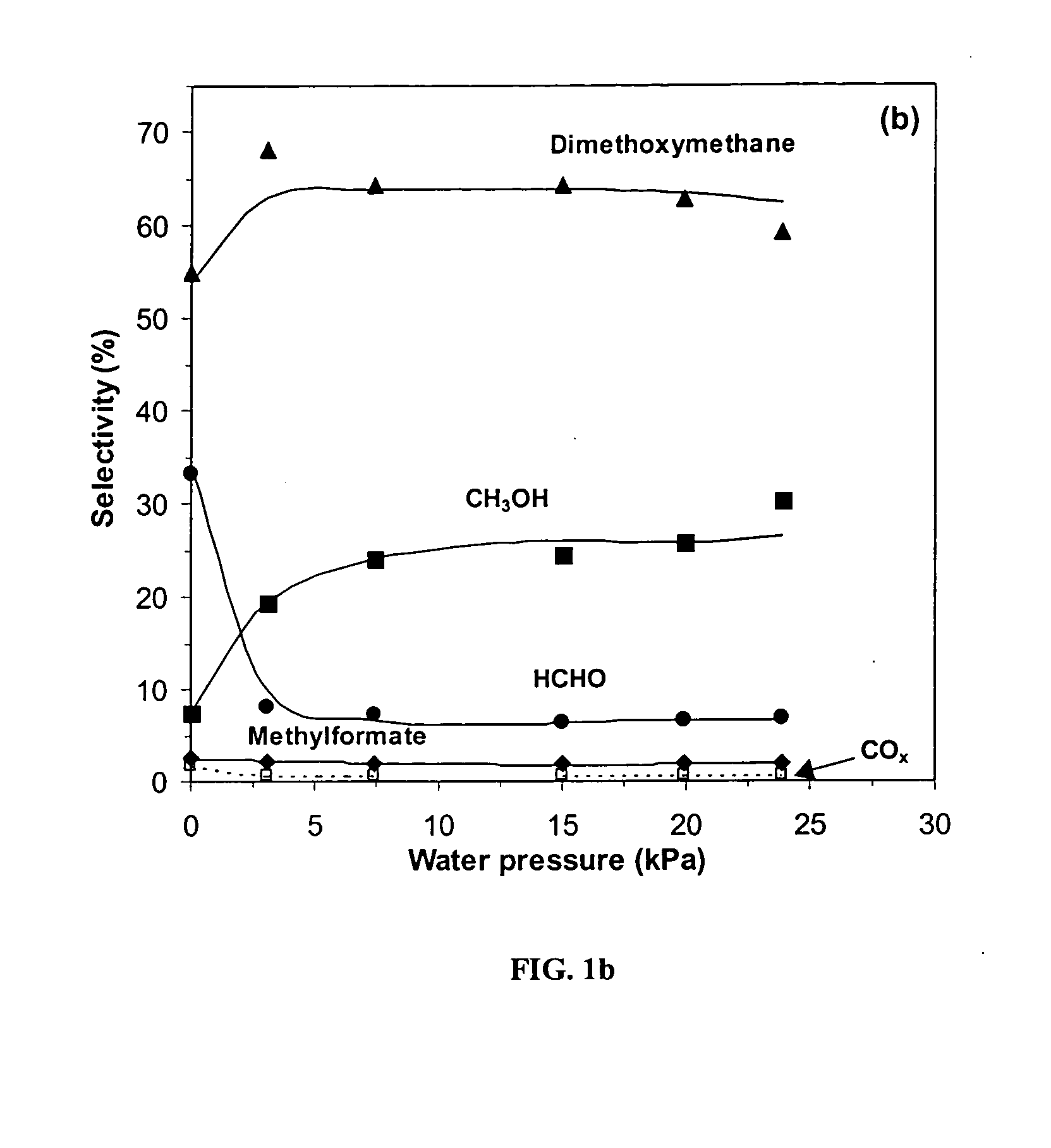

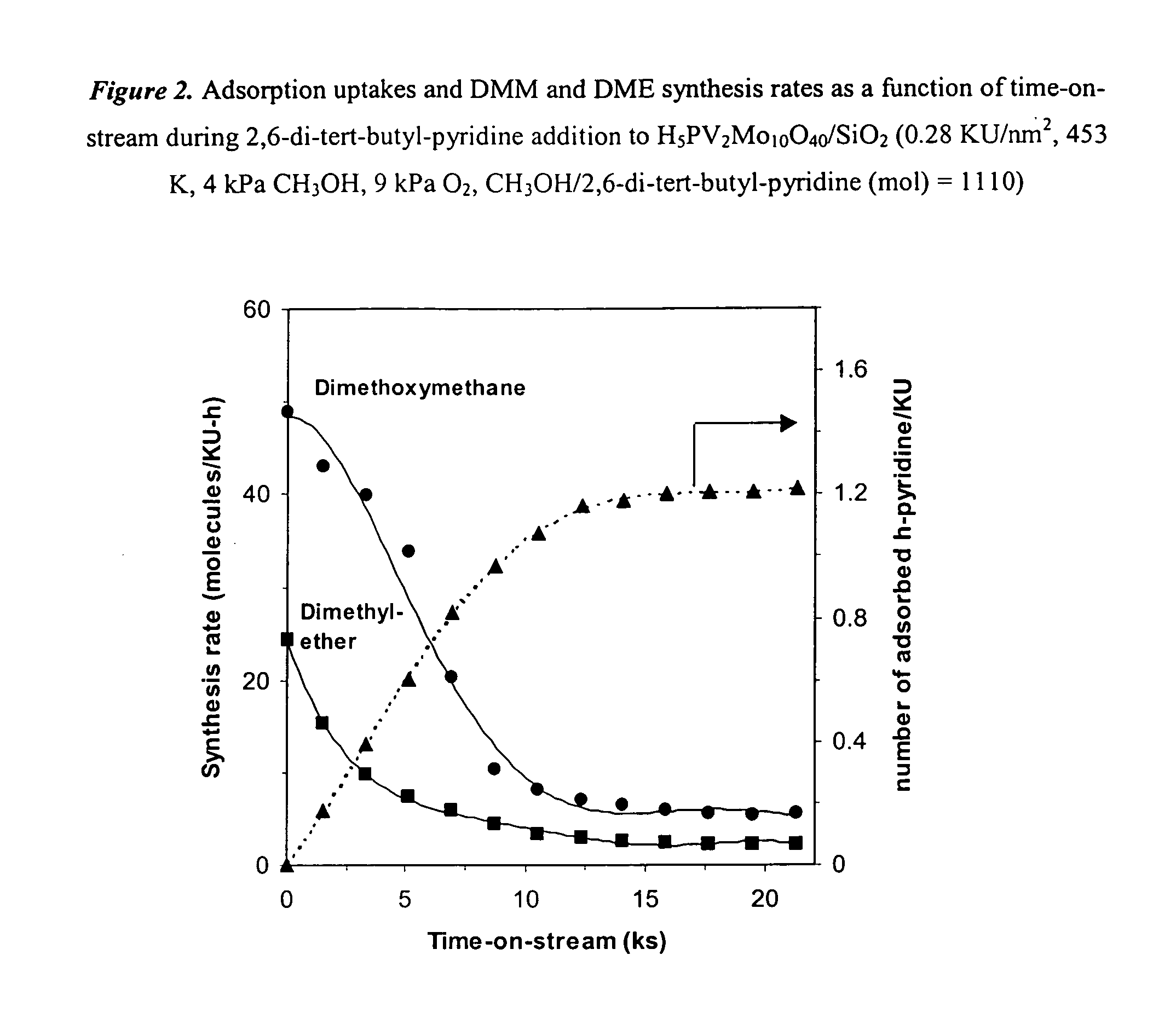

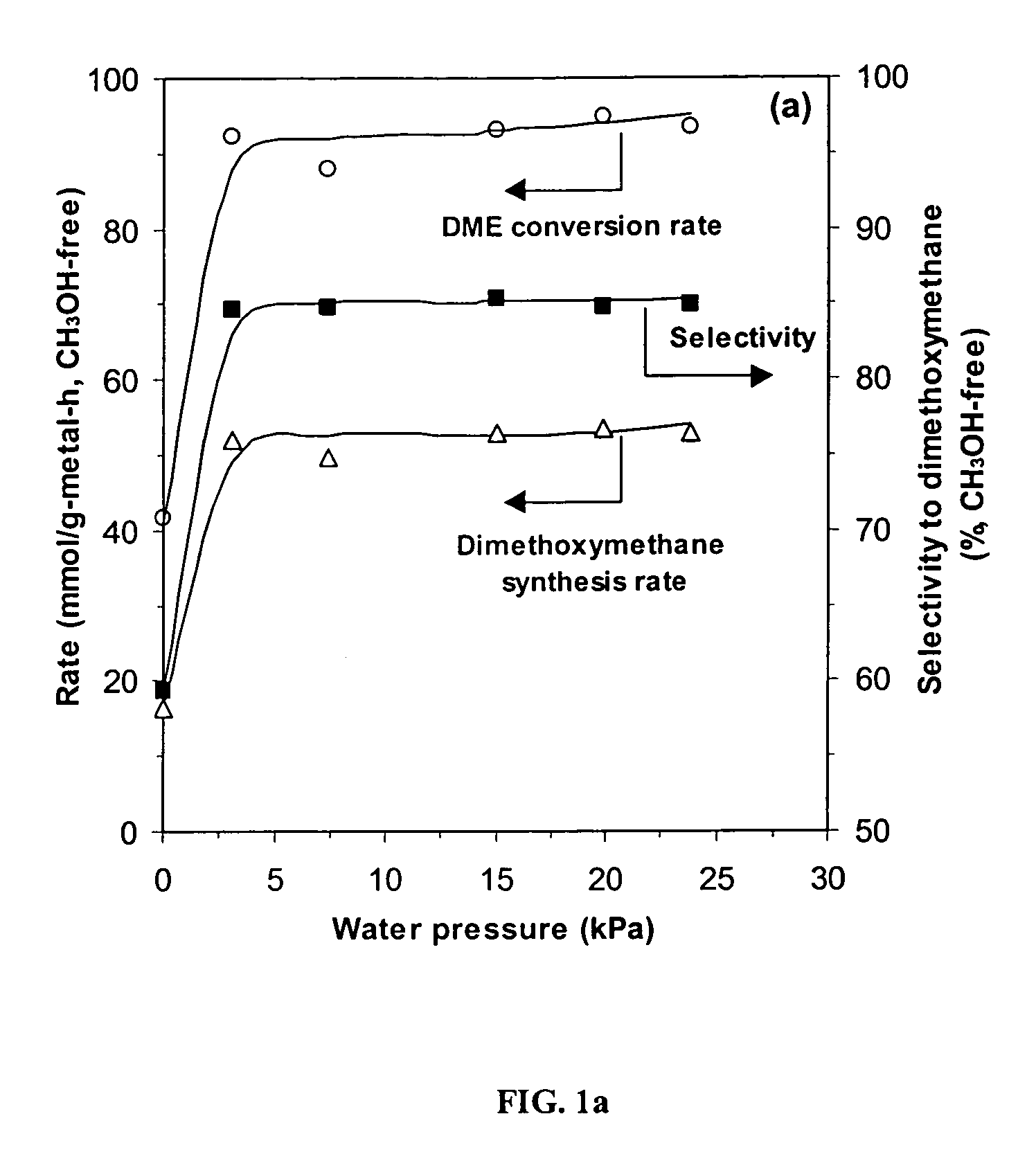

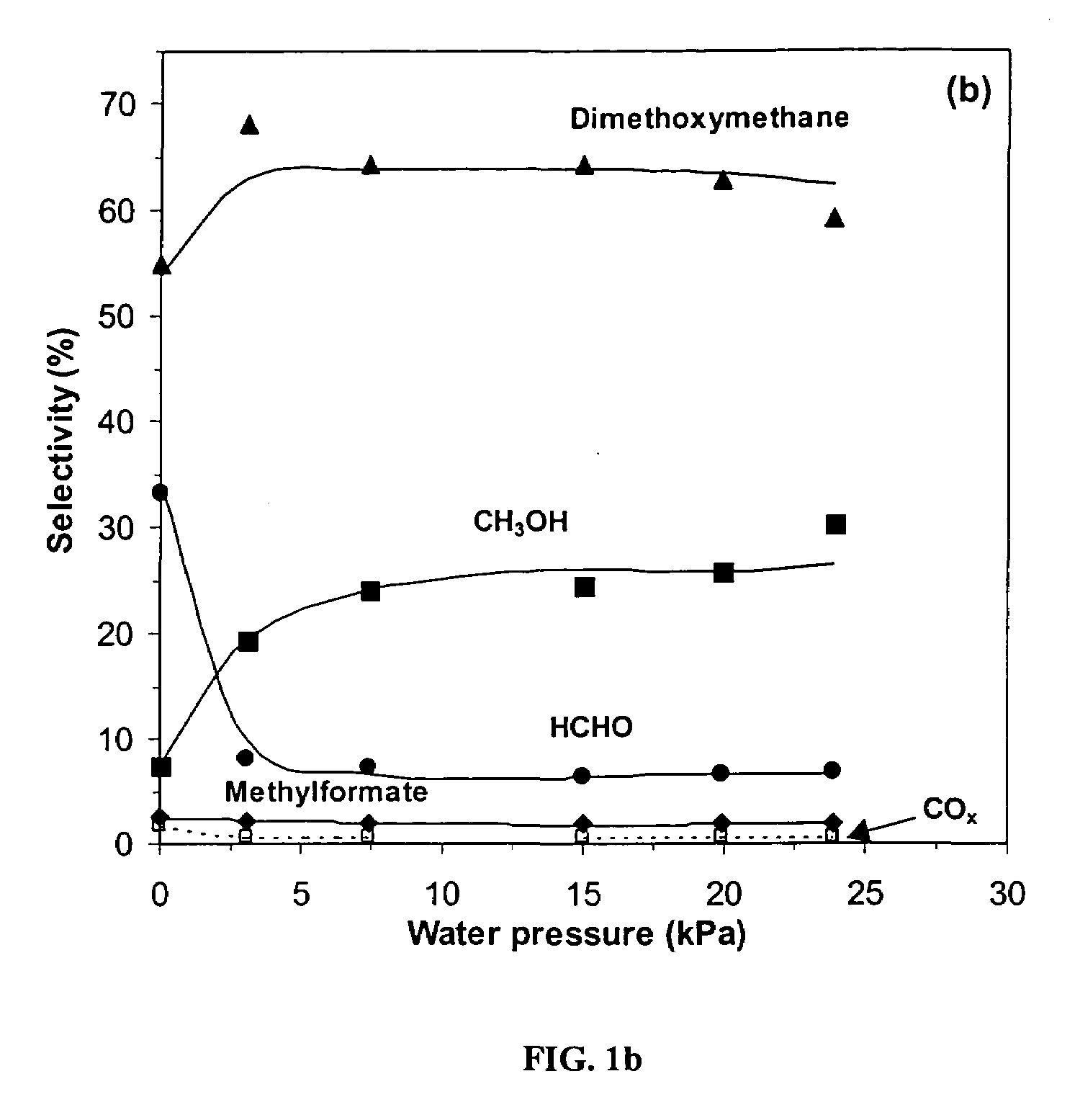

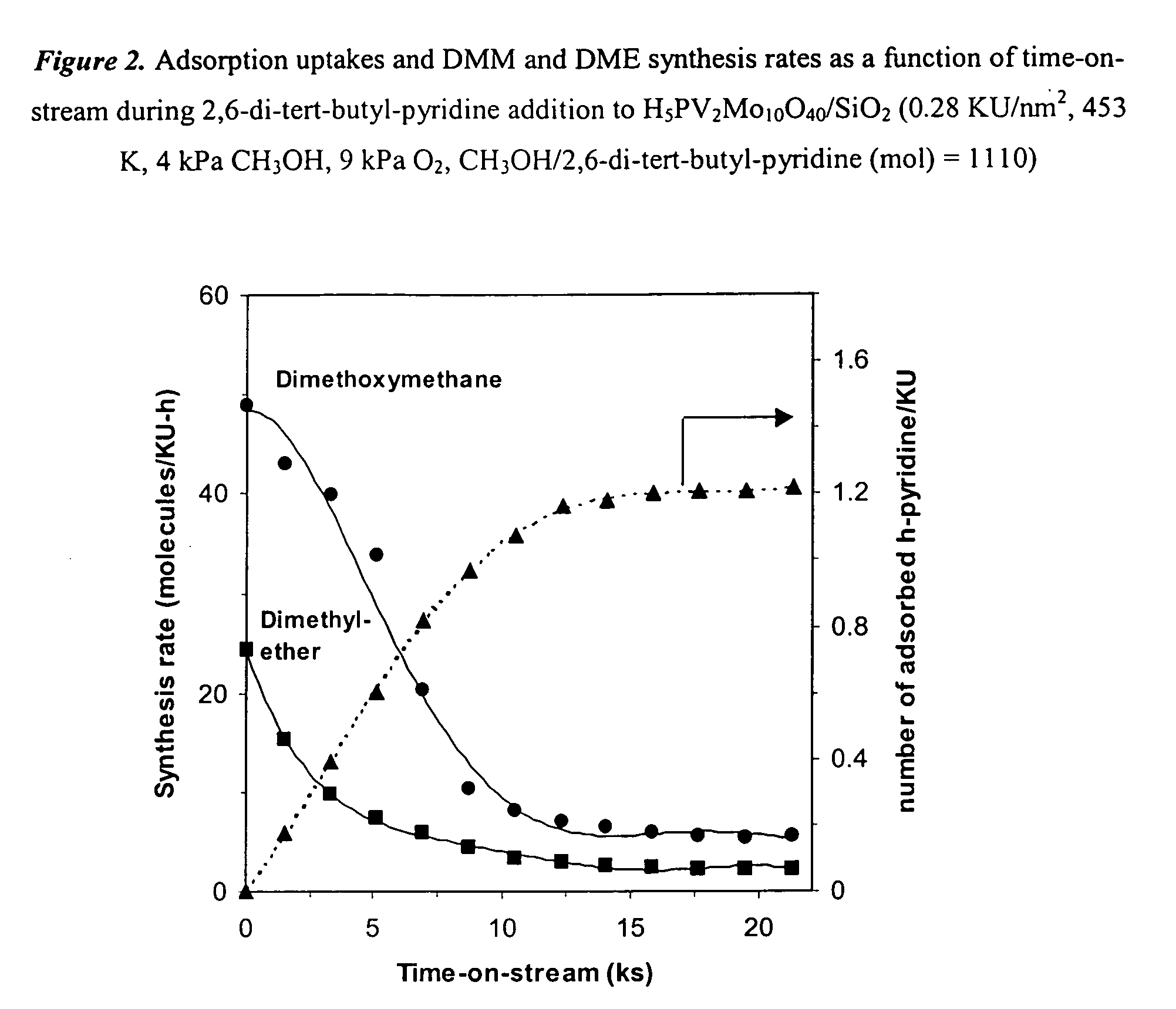

Oxidation of methanol and/or dimethyl ether using supported molybdenum-containing heteropolyacid catalysts

InactiveUS20050154226A1Reduce productionPromote conversionOrganic compound preparationPreparation by carbon monoxide or formate reactionOxygenDimethoxymethane

Feeds comprising methanol, dimethyl ether or a mixture of the two are oxidized by contacting the feed with an oxygen-containing gas and a supported heteropolyacid catalyst containing molybdenum or molybdenum and vanadium. The primary products are methylal (dimethoxymethane) and methyl formate. Production of dimethyl ether from methanol can be inhibited by partial deactivation of acid sites on the Keggin catalyst.

Owner:REGENTS OF CALIFORNIA UNIV OF THE +1

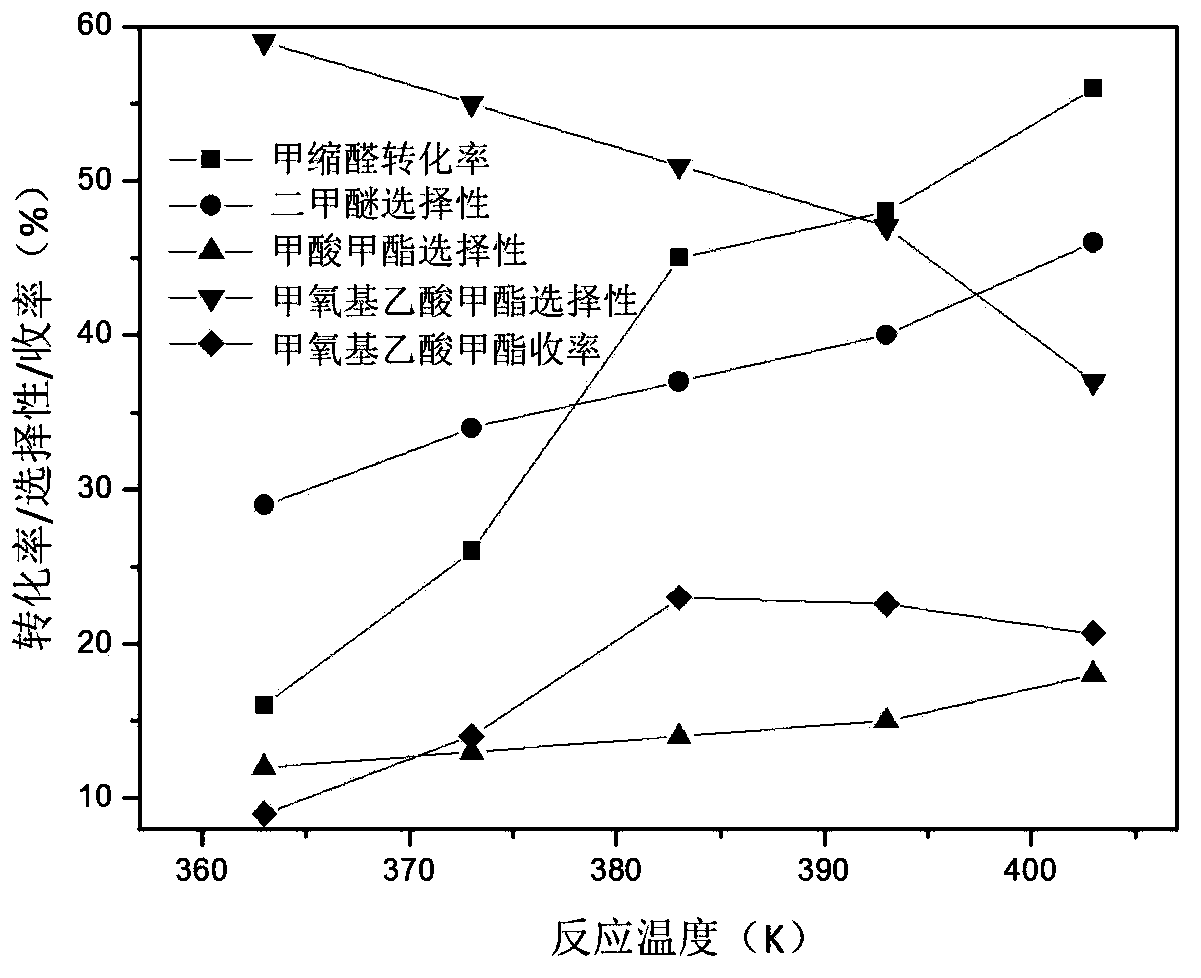

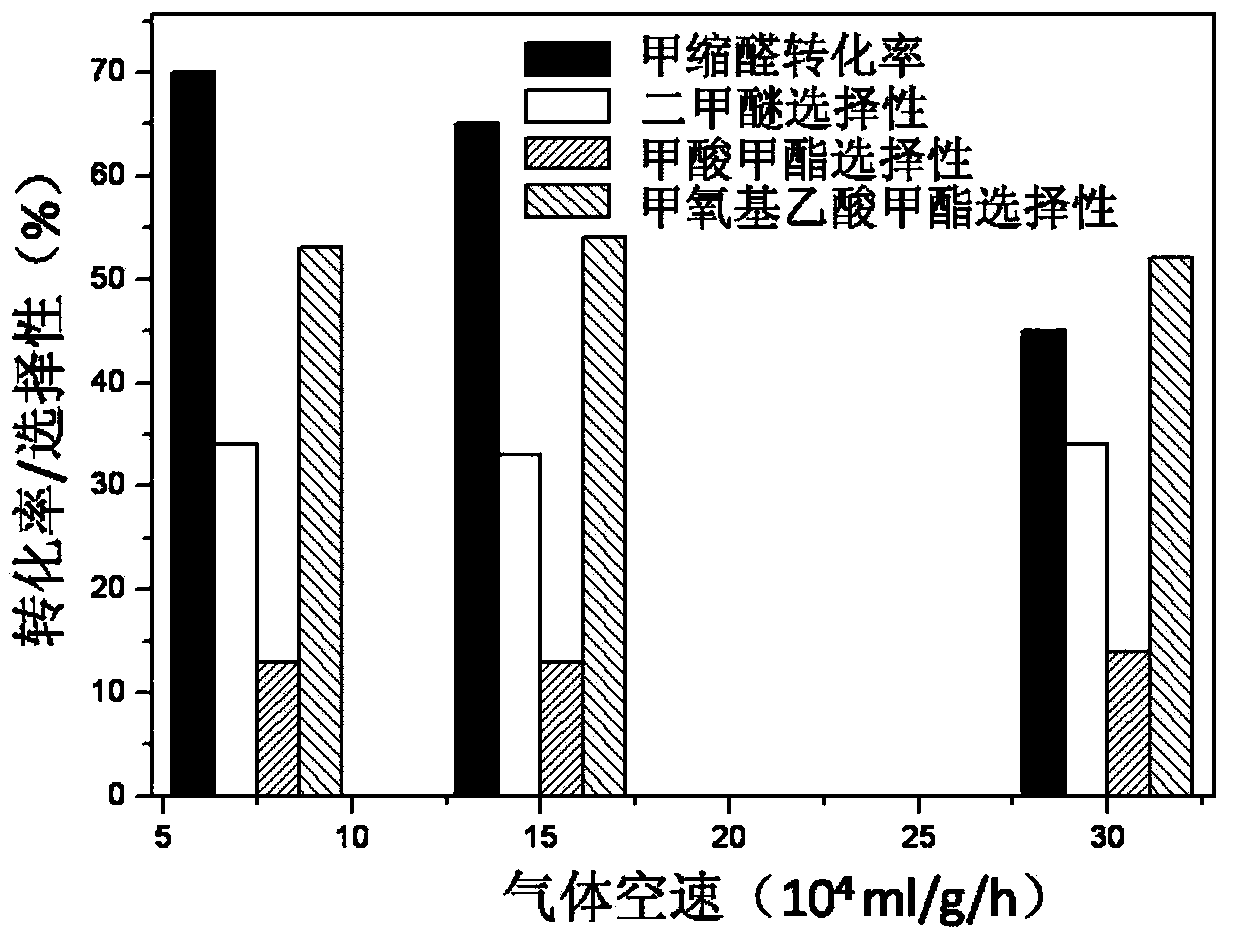

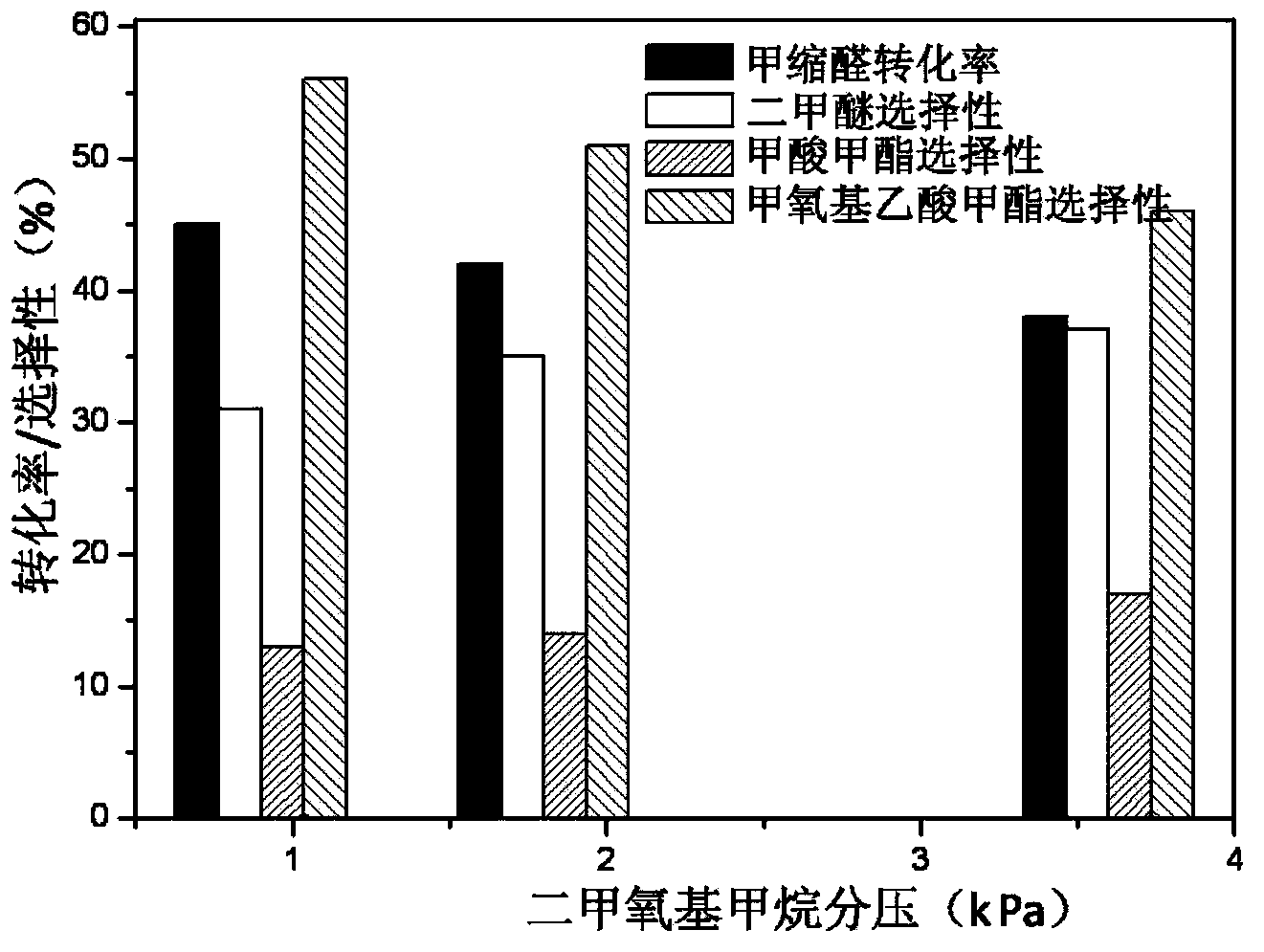

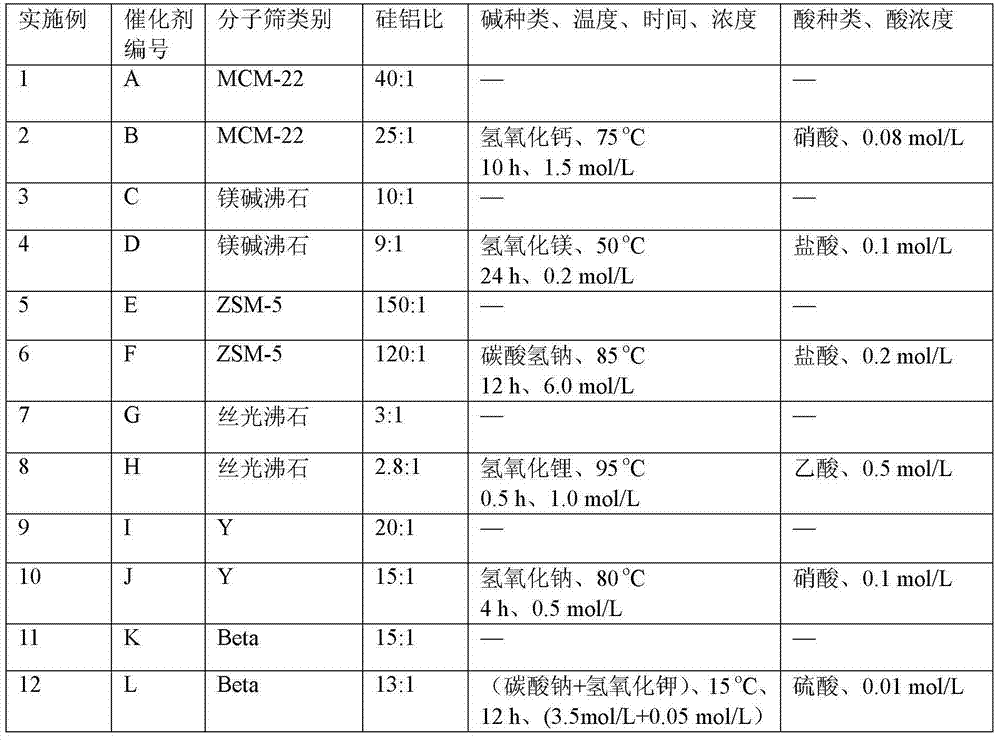

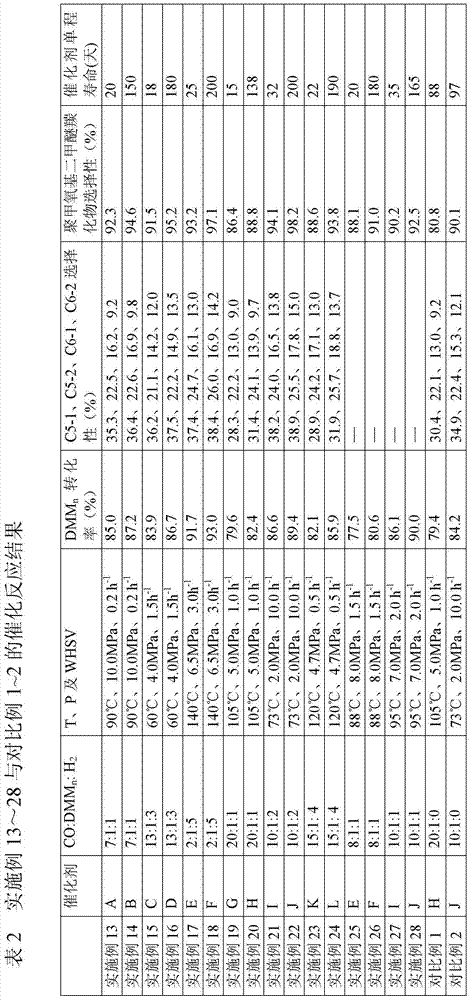

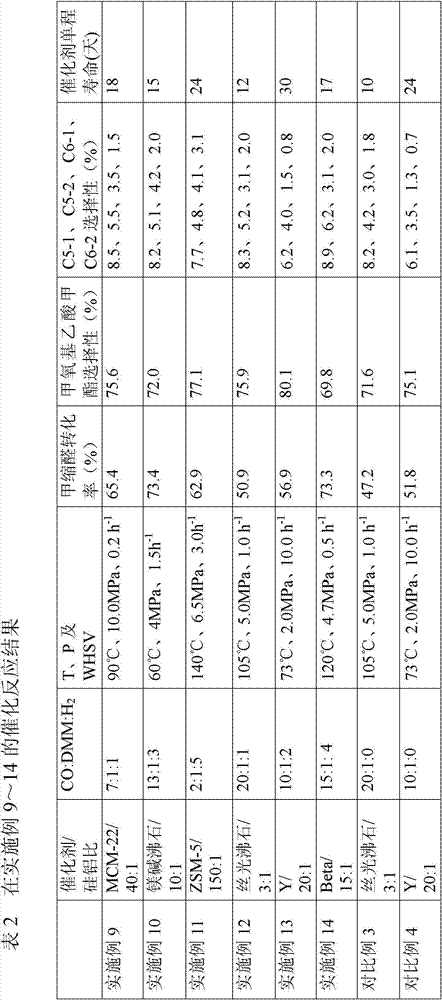

Methyl methoxyacetate (MMAC) synthesis method

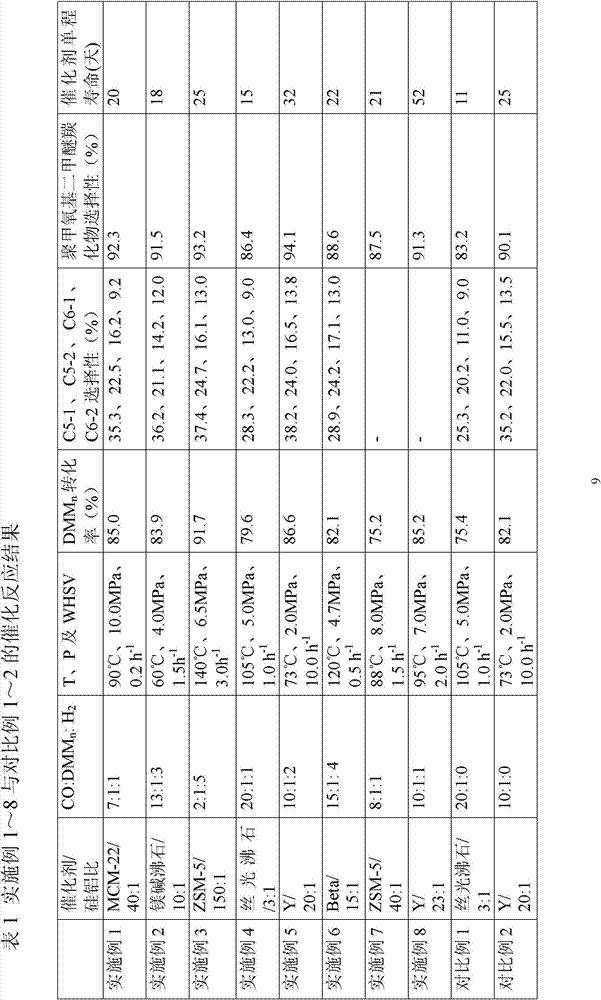

InactiveCN104119228AEfficient synthesisMolecular sieve catalystsPreparation by carbon monoxide or formate reactionMolecular sieveHydrogen

The invention discloses a catalyst for synthesis of methyl methoxyacetate (MMAC) by use of dimethoxymethane (DMM) and CO as raw materials, the catalyst is a molecular sieve with twelve membered ring cavity, ten membered ring channel and supercage structures, the International Zeolite Association (IZA) defines the topological structure of the catalyst as MWW type such as MCM-22 and MCM-49, the molecular formula is SixAlyOz, and the molecular sieve is hydrogen type. The molecular sieve SiO2 / Al2O3 ratio is 10-200. Carbonylation reaction is performed in a gas-solid phase fixed bed reactor, the reaction pressure is 1-50*105Pa, a reaction raw material gas comprises the dimethoxymethane with the partial pressure of 1-50kPa and balance of CO (1-49*105Pa) or CO / He (1-49* 105Pa), the reaction temperature is 60-180 DEG C, and the space velocity is 20-500L .g<-1>.h<-1>. Compared with a MFI type molecular sieve (HZSM-5) only having a crossed ten membered ring structure and a BEA type molecular sieve (Hbeta) only having a twelve membered ring structure, the MWW type molecular sieve has higher methyl methoxyacetate selectivity.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

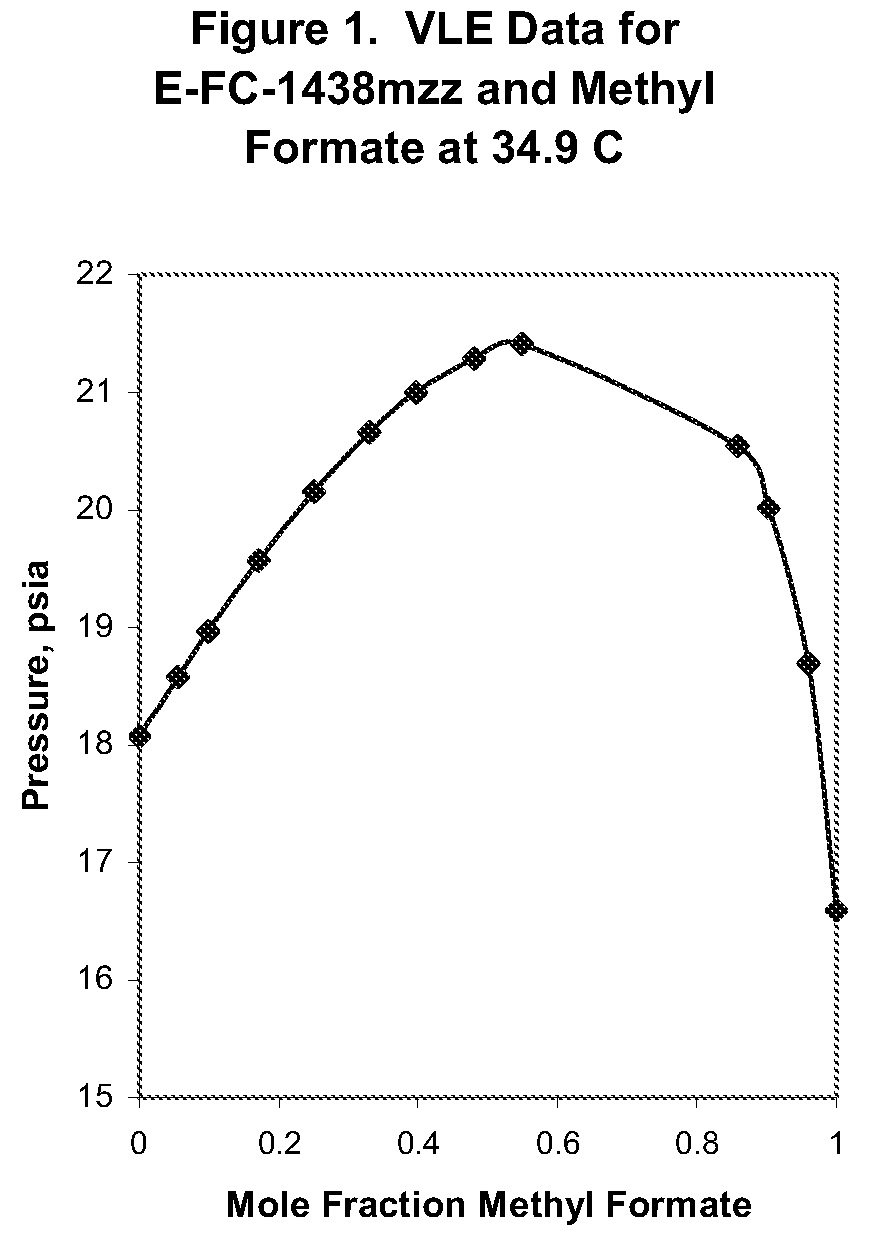

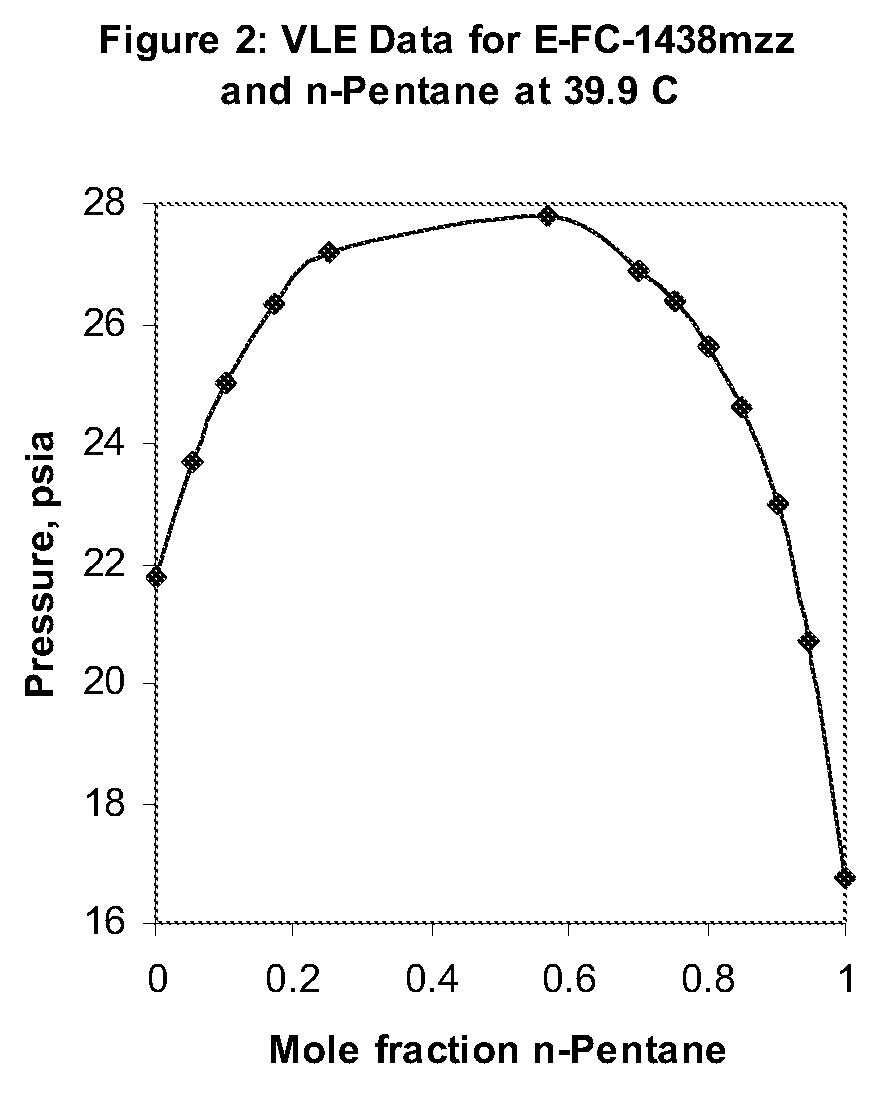

Azeotropic and azeotrope-like compositions of e-1,1,1,4,4,5,5,5-octafluoro-2-pentene

InactiveUS20100243943A1Organic compounds purification/separation/stabilisationOther chemical processesDielectricThermoplastic

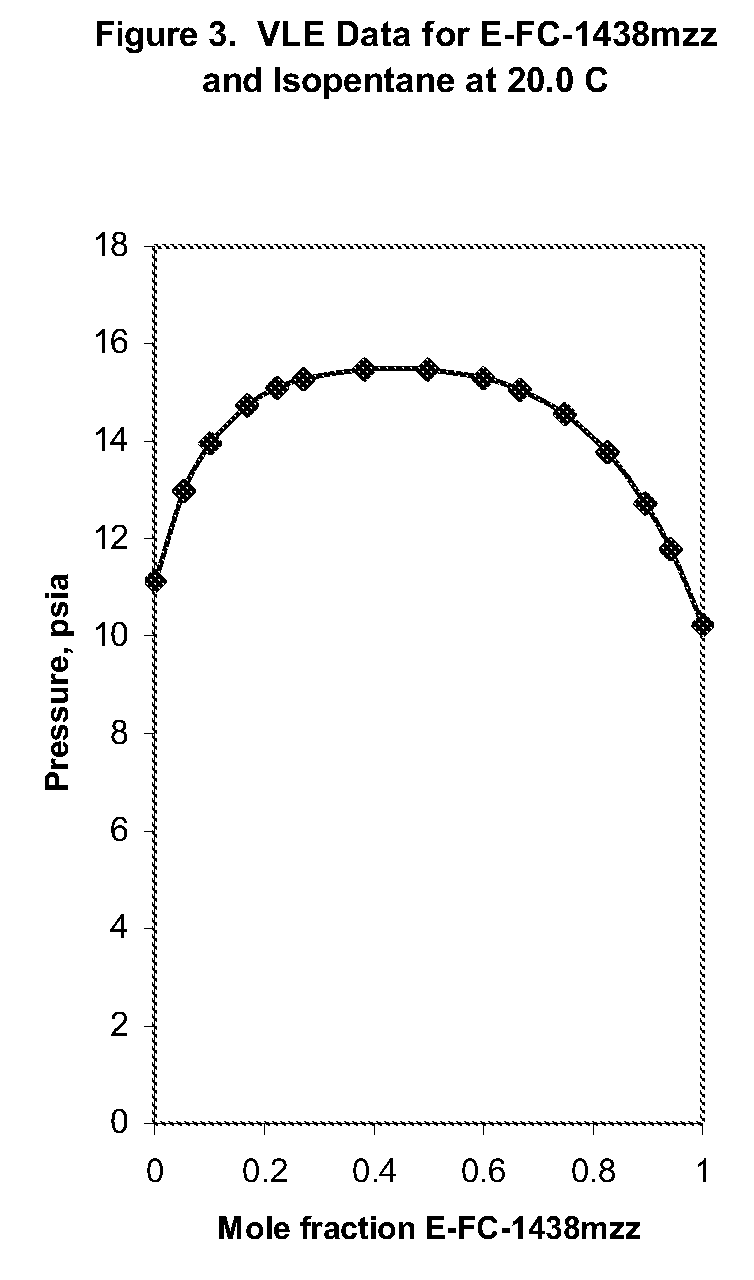

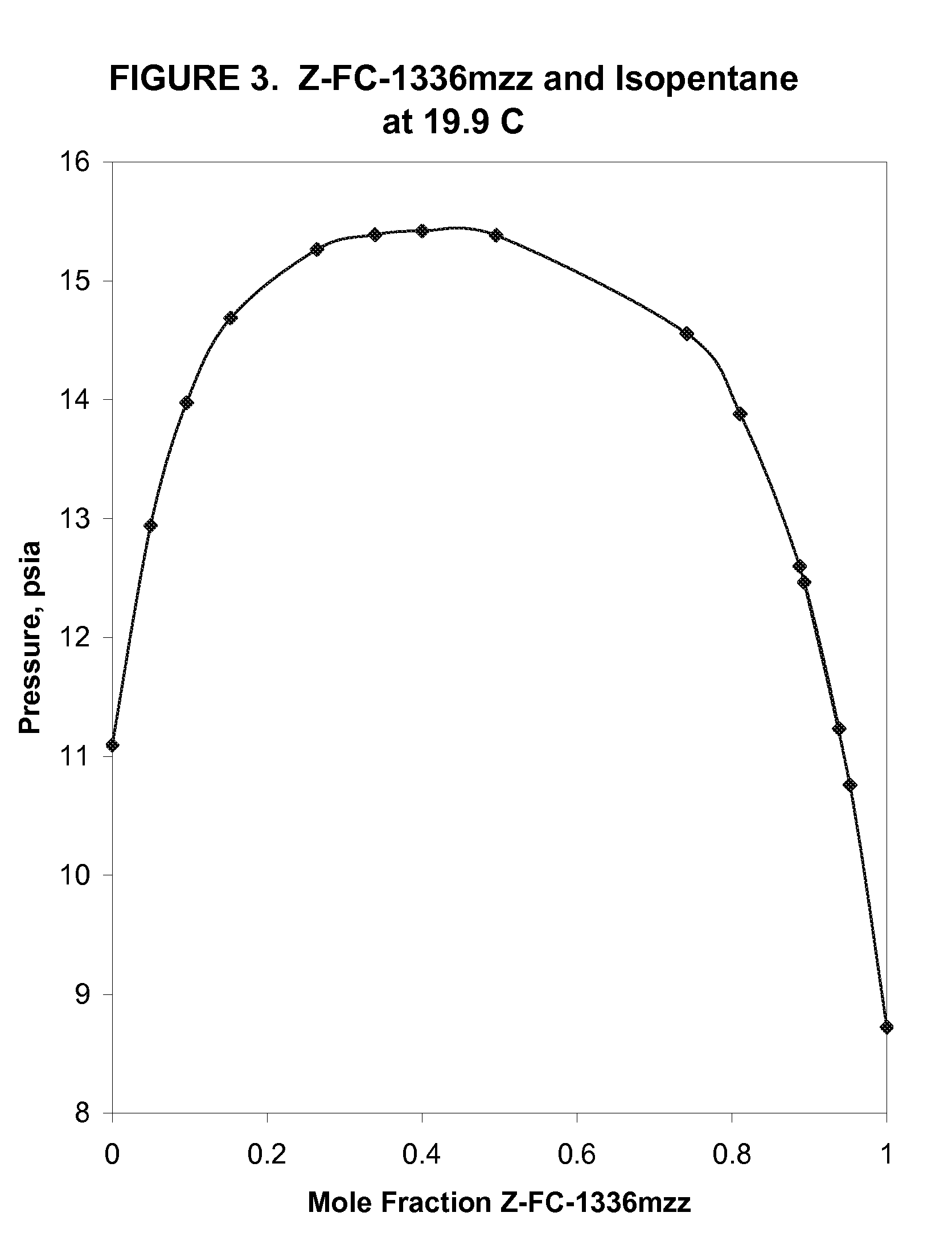

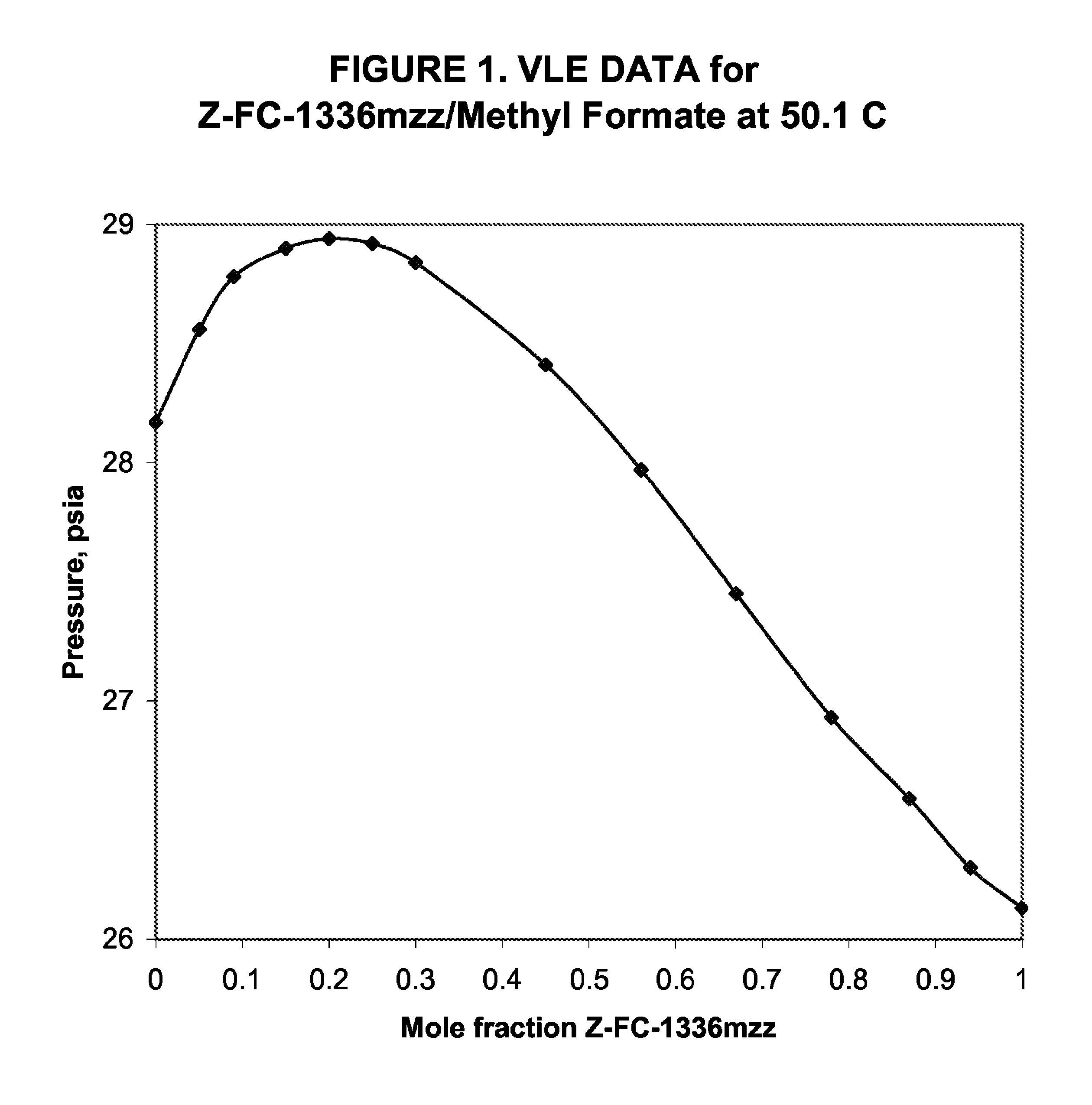

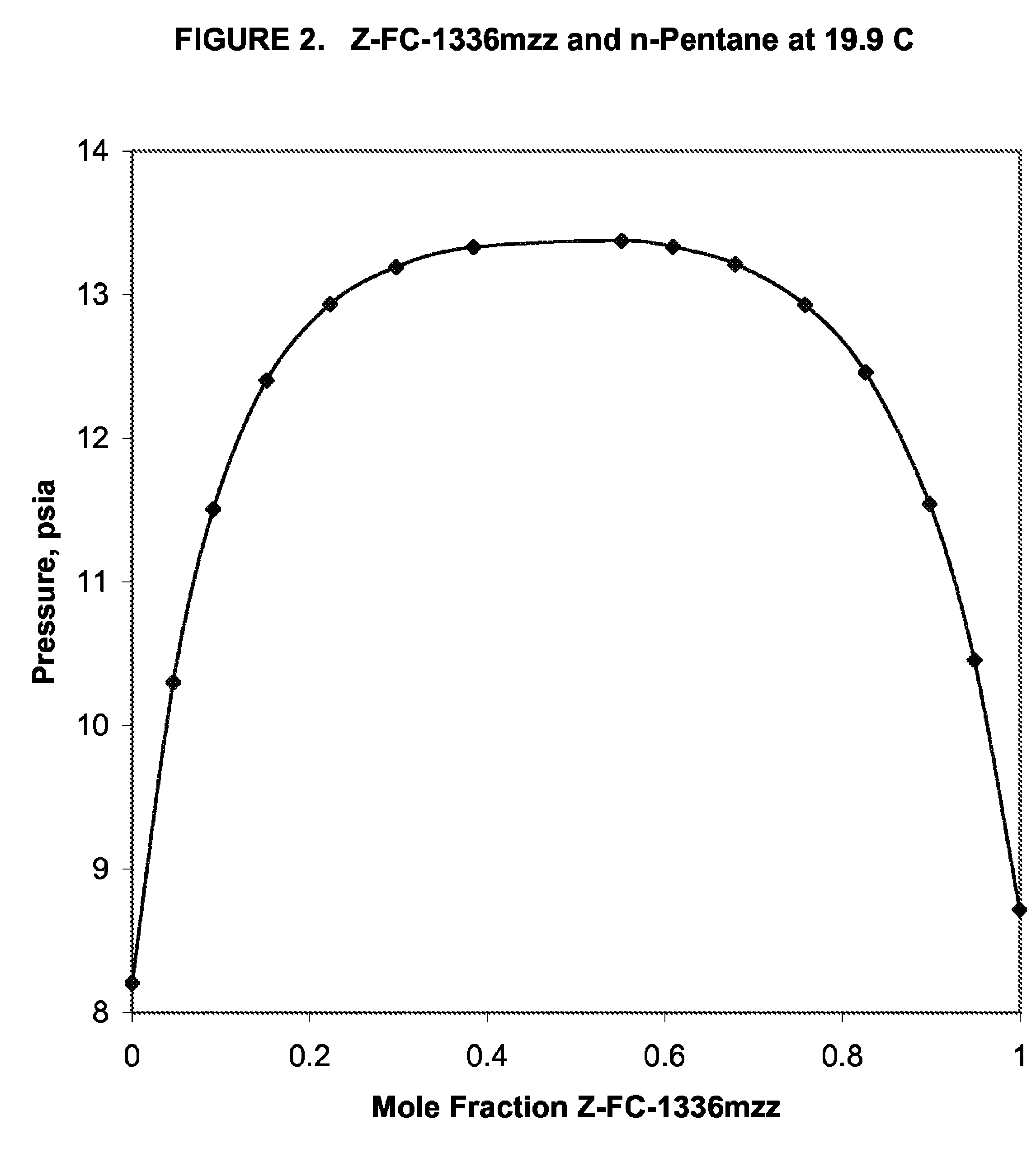

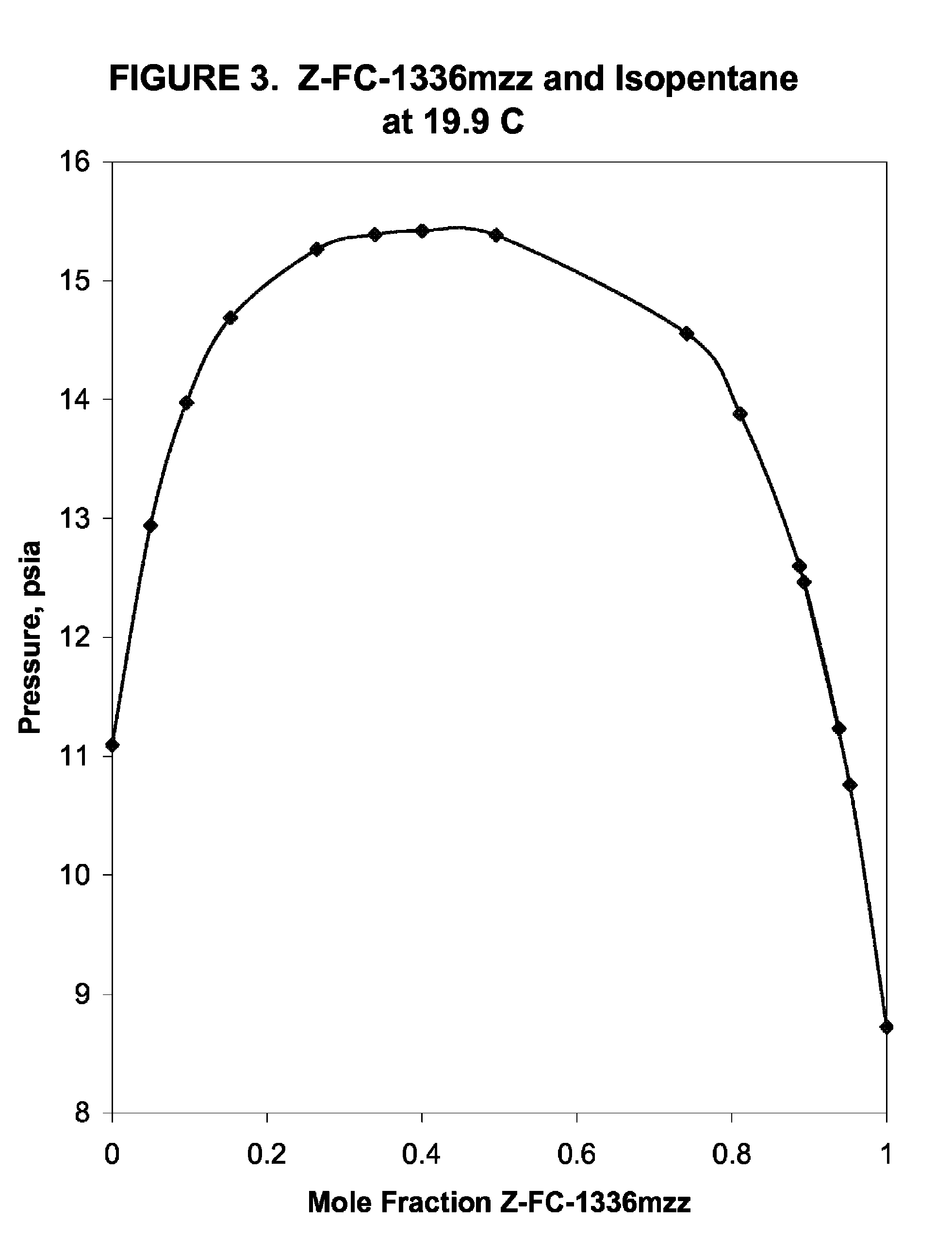

Azeotropic or azeotrope-like compositions are disclosed. The azeotropic or azeotrope-like compositions are mixtures of E-1,1,1,4,4,5,5,5-Octafluoro-2-pentene with methyl formate, n-pentane, 2-methylbutane, 1,1,1,3,3-pentafluorobutane, trans-1,2-dichloroethylene, 1,1,1,3,3-pentafluoropropane, dimethoxymethane, cyclopentane or Z-1,1,1,4,4,4-hexafluoro-2-butene. Also disclosed is a process of preparing a thermoplastic or thermoset foam by using such azeotropic or azeotrope-like compositions as blowing agents. Also disclosed is a process of producing refrigeration by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as solvents. Also disclosed is a process of producing an aerosol product by using such azeotropic or azeotrope-like compositions as propellants. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as heat transfer media. Also disclosed is a process of extinguishing or suppressing a fire by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as dielectrics. Also disclosed is a process for the separation of a chemical compound from a mixture of two or more chemical compounds using such azeotropic or azeotrope-like compositions.

Owner:THE CHEMOURS CO FC LLC

Combined process for preparing poly methoxy-dimethyl ether

InactiveCN103360224AEasy to separateEasy to use equipmentOrganic chemistryOrganic compound preparationSolid acidDimethoxymethane

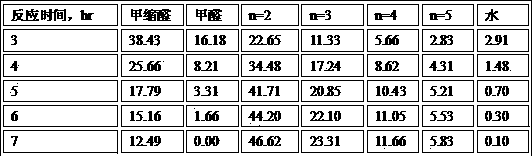

The invention relates to a combined process for preparing poly methoxy-dimethyl ether. According to the method, methylal and paraformaldehyde are used as reactants and a solid acid is used as a catalyst. The combined process comprises the following steps of feeding raw materials: adding the solid acid catalyst and solid paraformaldehyde in a reactor, then adding methylal in the reactor and stirring the above materials uniformly; meting and reacting: heating the reactor slowly and reacting for 2-6 hours by keeping a temperature within 100-200 DEG C and a pressure between 0.1 MPa and 2 MPa; dehydrating the reaction liquid: pumping the reaction liquid into a film separation and dehydration device at a flow velocity of 5-15 L / hr so as to remove water in a reaction mixture and send the water to the reactor; and circulating the reaction materials: circulating the reaction materials between the reactor and the film separation and dehydration device, dehydrating while reacting, and taking a sample for analysis every one hour until methylal is completely reacted. By the combined process, water generated during the reaction process is removed continuously, thereby allowing paraformaldehyde to be reacted completely and benefiting the separation of reaction products. The process is simple in use of apparatuses, reasonable in process flow and suitable for large-scale popularization.

Owner:DONGYING RUNCHENG CARBON MATERIAL TECH +1

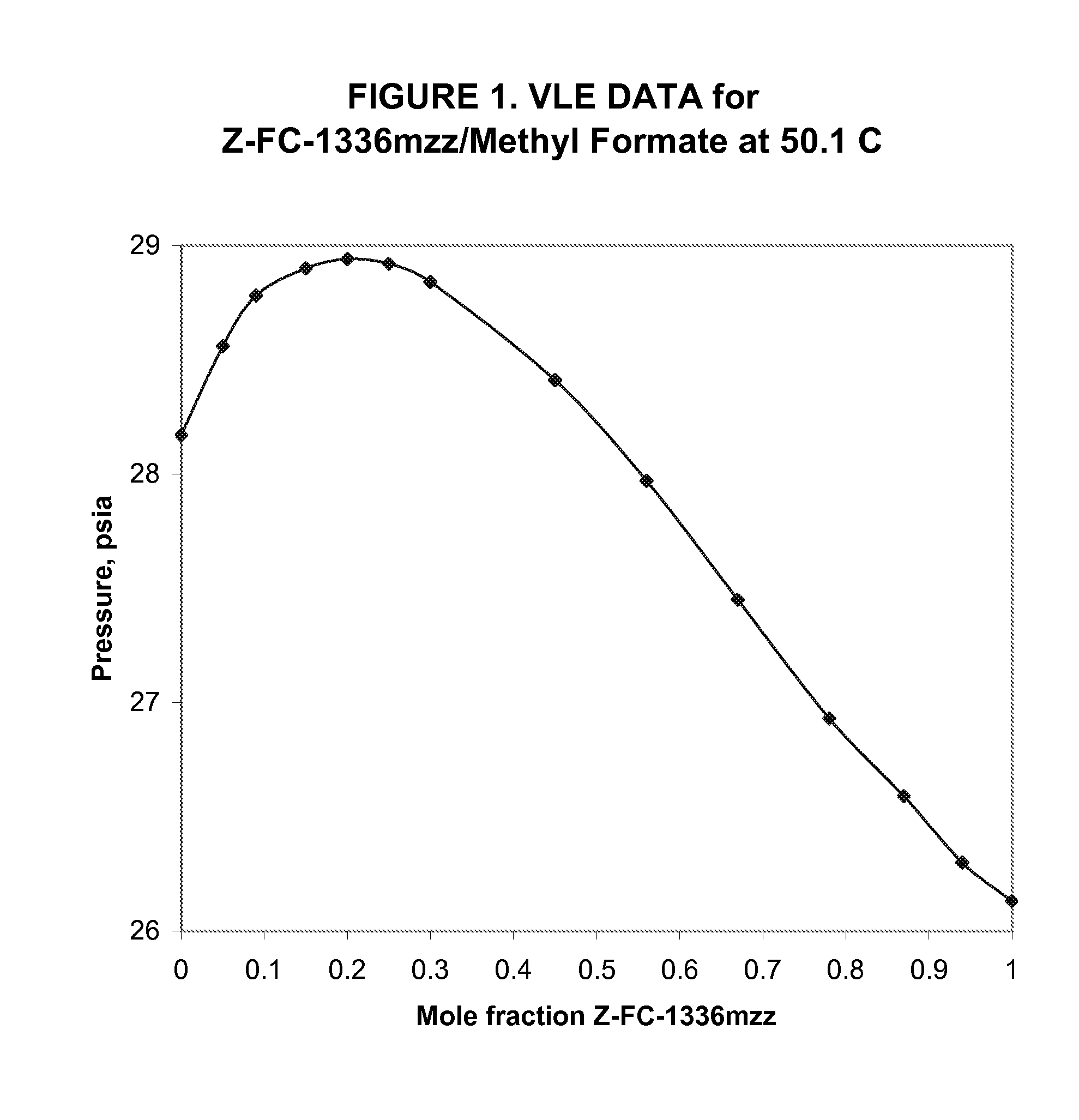

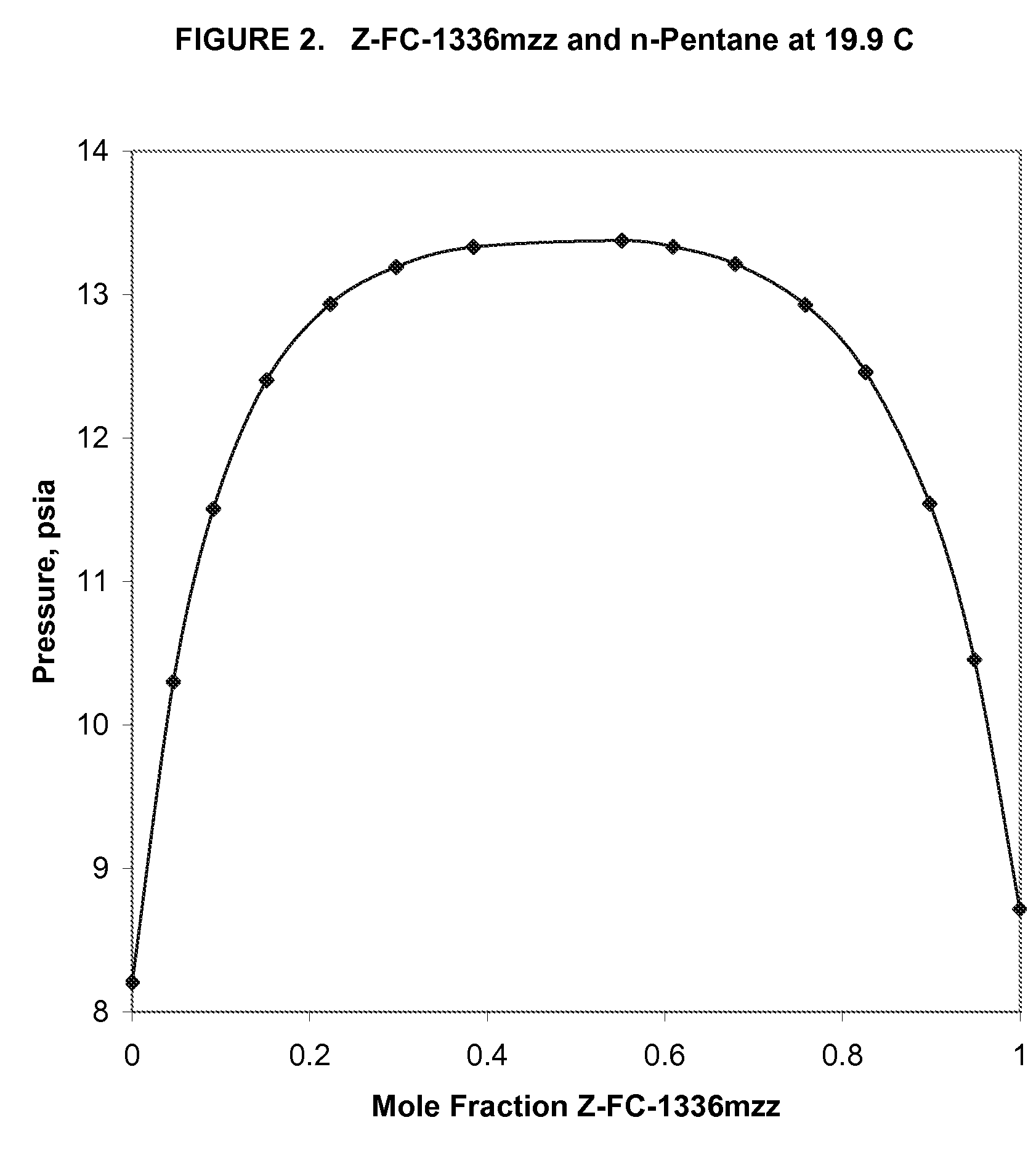

Azeotropic and azeotrope-like compositions of z-1,1,1,4,4,4-hexafluoro-2-butene

Azeotropic or azeotrope-like compositions are disclosed. The azeotropic or azeotrope-like compositions are mixtures of Z-1,1,1,4,4,4-hexafluoro-2-butene with methyl formate, pentane, 2-methylbutane, 1,1,1,3,3-pentafluorobutane, trans-1,2-dichloroethylene, 1,1,1,3,3-pentafluoropropane, dimethoxymethane, or cyclopentane. Also disclosed is a process of preparing a thermoplastic or thermoset foam by using such azeotropic or azeotrope-like compositions as blowing agents. Also disclosed is a process of producing refrigeration by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as solvents. Also disclosed is a process of producing an aerosol product by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as heat transfer media. Also disclosed is a process of extinguishing or suppressing a fire by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as dielectrics.

Owner:THE CHEMOURS CO FC LLC

Method for synthesizing PODE (polyformaldehyde dimethyl ether)

ActiveCN102040488AHigh yieldIncrease profitOrganic chemistryOrganic compound preparationMolecular sieveReaction temperature

The invention relates to a method for synthesizing PODE (polyformaldehyde dimethyl ether), which mainly solves the problems of high content of methylal and low yield coefficient of poly products in the traditional process of synthesizing the PODE with carbinol and trioxymethylene as raw materials. The method adopts the carbinol, the methylal and the trioxymethylene as the raw materials, and the raw materials contact a catalyst under conditions that reaction temperature is 50-200 DEG and reaction pressure is 0.1-10 MPa so as to react to generate the PODE, wherein the catalyst is at least one of Beta zeolum, ZSM-5 molecular sieve and MCM-22 or MCM-56 zeolum molecular sieve. The method preferably solves the problems and can be used for the industrial production of the PODE.

Owner:CHINA PETROLEUM & CHEM CORP +1

Azeotropic and azeotrope-like compositions of Z-1,1,1,4,4,4-hexafluoro-2-butene

Azeotropic or azeotrope-like compositions are disclosed. The azeotropic or azeotrope-like compositions are mixtures of Z-1,1,1,4,4,4-hexafluoro-2-butene with methyl formate, pentane, 2-methylbutane, 1,1,1,3,3-pentafluorobutane, trans-1,2-dichloroethylene, 1,1,1,3,3-pentafluoropropane, dimethoxymethane, or cyclopentane. Also disclosed is a process of preparing a thermoplastic or thermoset foam by using such azeotropic or azeotrope-like compositions as blowing agents. Also disclosed is a process of producing refrigeration by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as solvents. Also disclosed is a process of producing an aerosol product by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as heat transfer media. Also disclosed is a process of extinguishing or suppressing a fire by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as dielectrics.

Owner:THE CHEMOURS CO FC LLC

Fuel cell system for low pressure operation

Owner:HYENERGY SYST

Foam-forming compositions containing azeotropic or azeotrope-like mixtures containing z-1,1,1,4,4,4-hexafluoro-2-butene and their uses in the preparation of polyisocyanate-based foams

Foam-forming compositions containing azeotropic or azeotrope-like mixtures containing cis-1,1,1,4,4,4-hexafluoro-2-butene are disclosed. The foam-forming composition contains (a) an azeotropic or azeotrope-like mixture of cis-1,1,1,4,4,4-hexafluoro-2-butene with methyl formate, 1,1,1,3,3-pentafluorobutane, trans-1,2-dichloroethylene, pentane, isopentane, cyclopentane, HFC-245fa, or dimethoxymethane; and (b) an active hydrogen-containing compound having two or more active hydrogens. Also disclosed is a closed-cell polyurethane or polyisocyanurate polymer foam prepared from reaction of an effective amount of the foam-forming composition with a suitable polyisocyanate. Also disclosed is a process for producing a closed-cell polyurethane or polyisocyanurate polymer foam by reacting an effective amount of the foam-forming composition with a suitable polyisocyanate.

Owner:THE CHEMOURS CO FC LLC

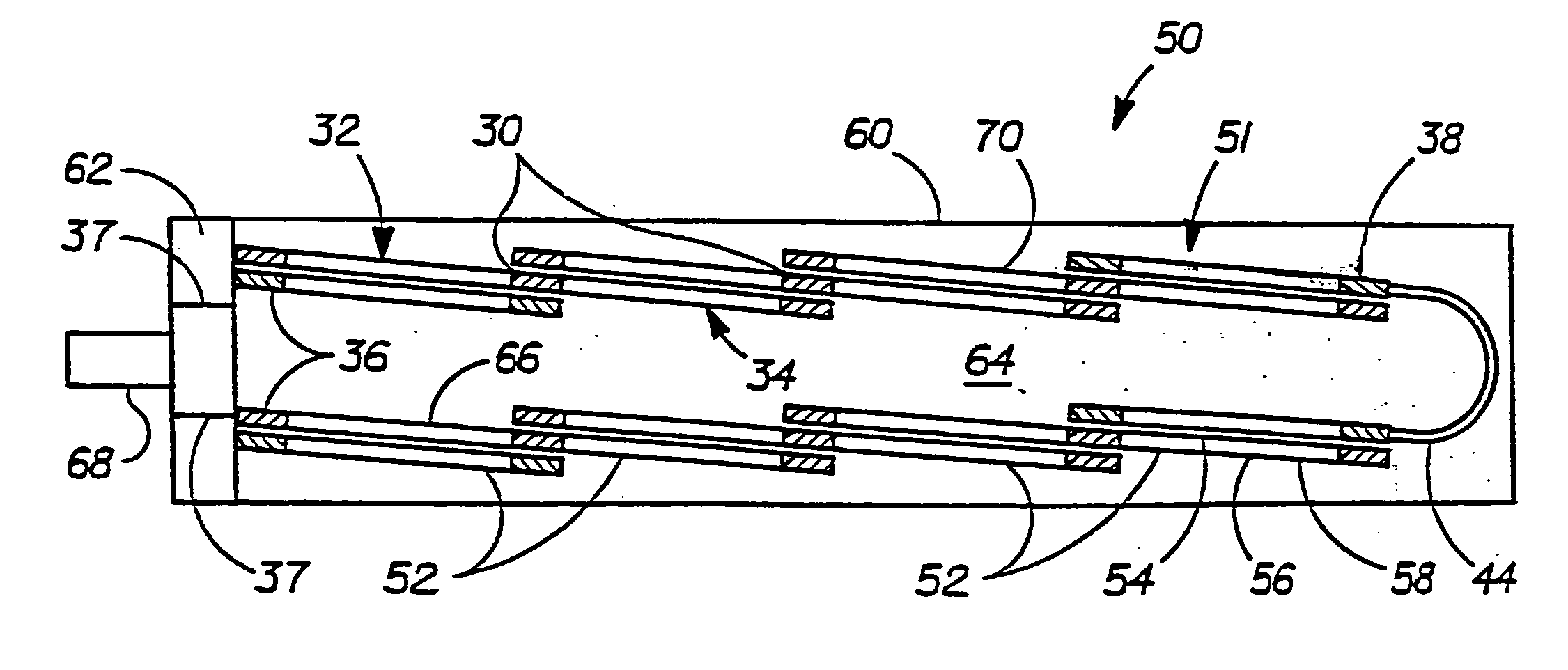

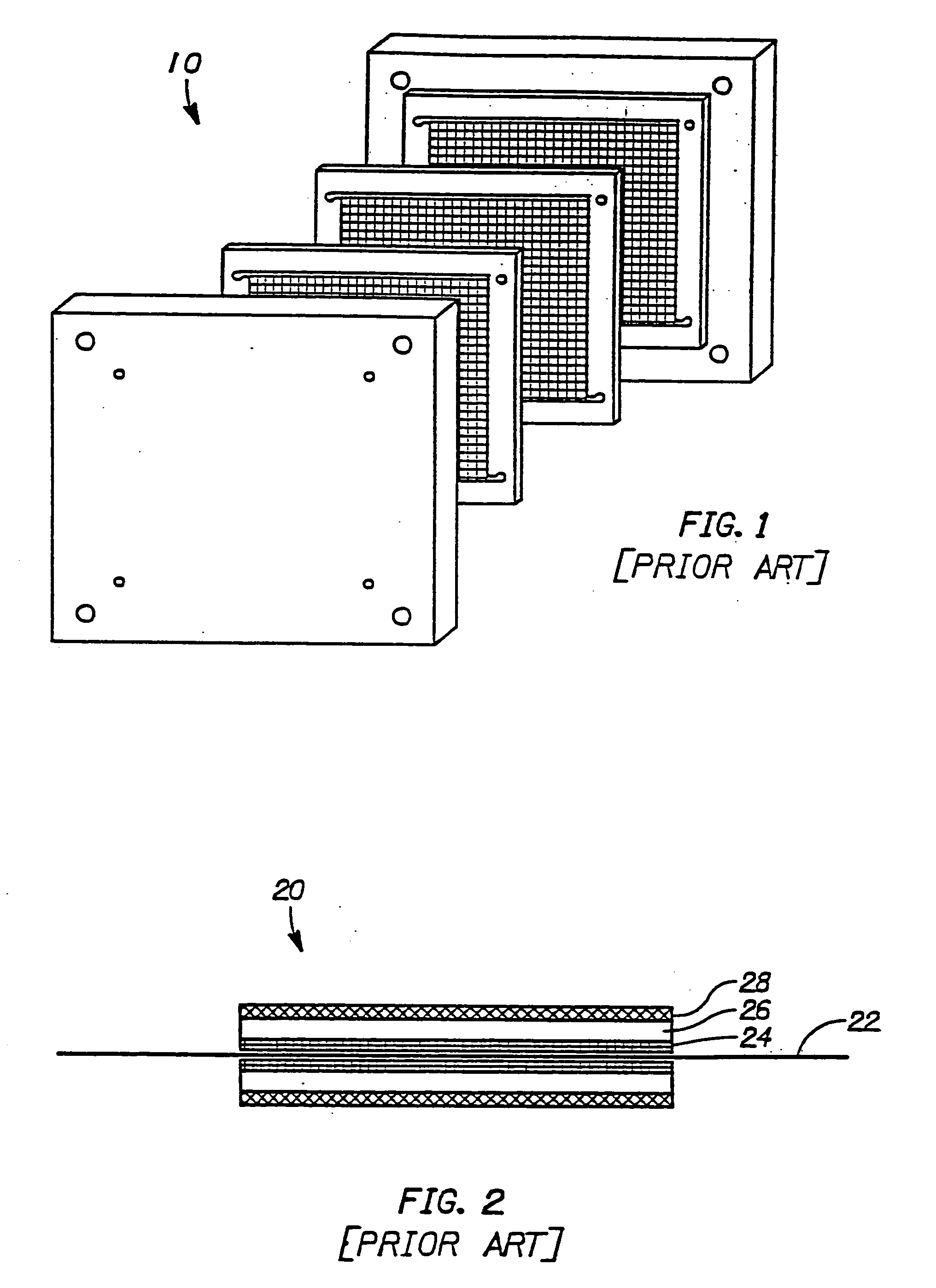

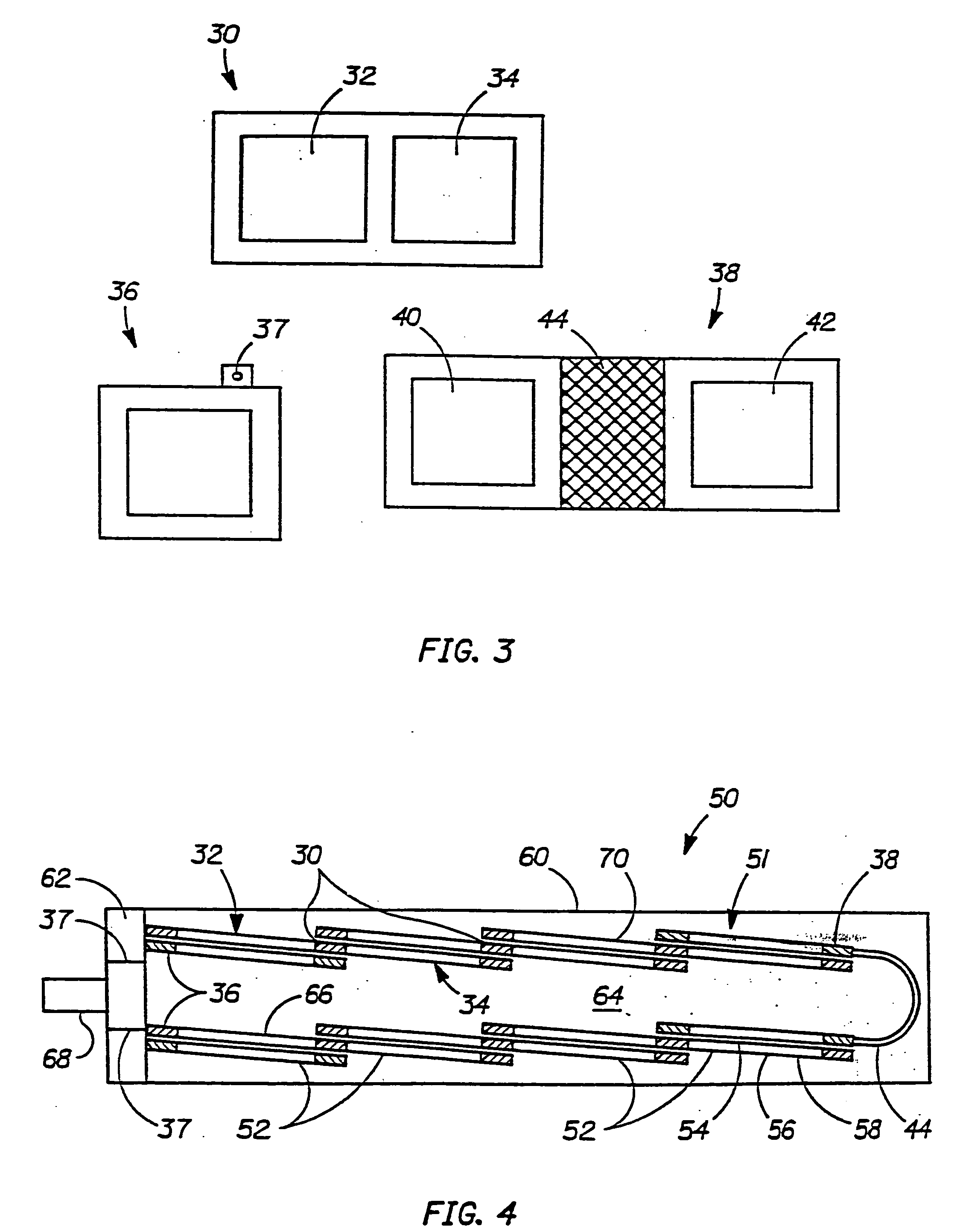

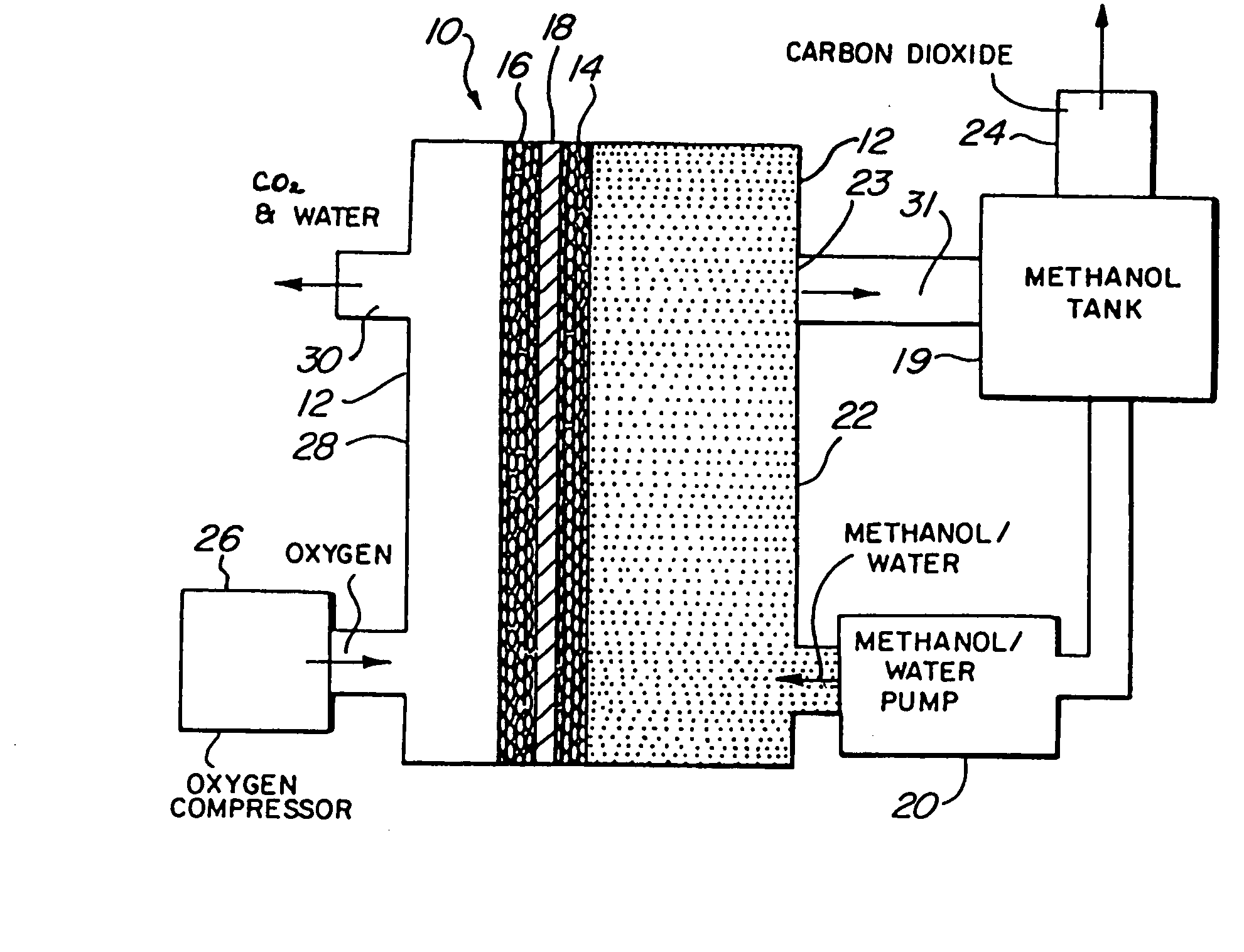

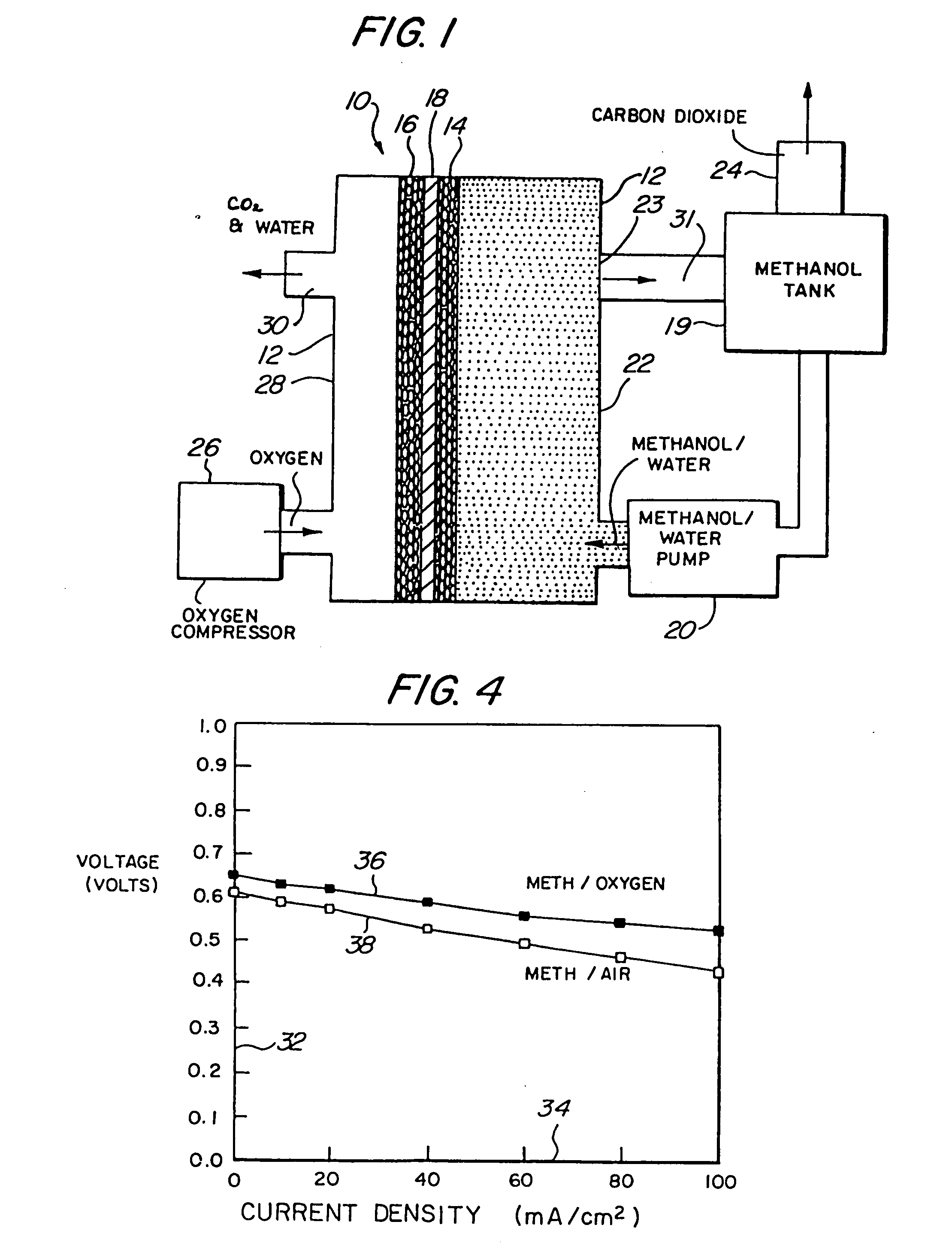

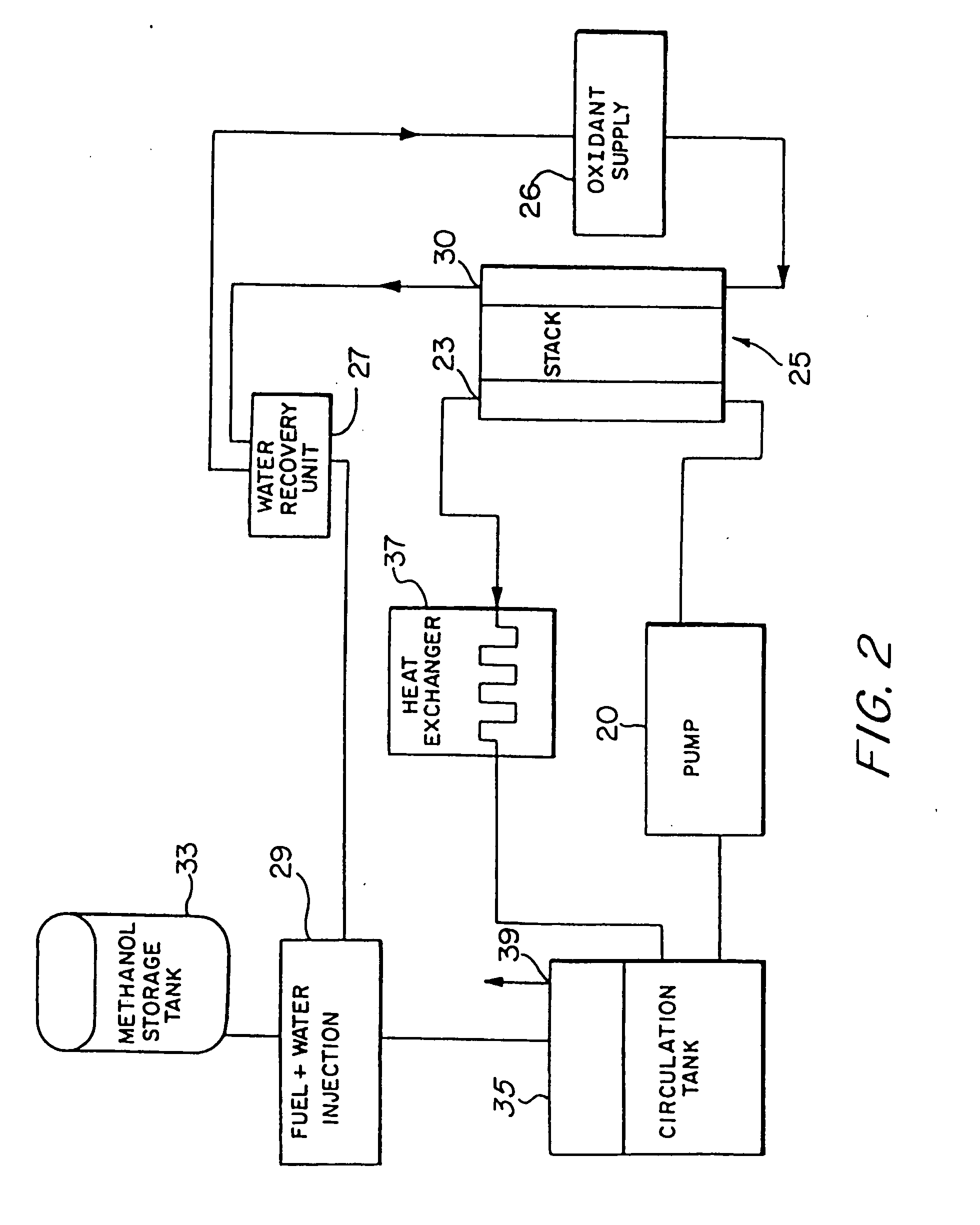

Organic fuel cell methods and apparatus

InactiveUS20060204810A1Poor fuel wetting propertyImprove wettabilitySolid electrolytesFuel cells groupingElectrical batteryOrganic fuel

A liquid organic, fuel cell is provided which employs a solid electrolyte membrane. An organic fuel, such as a methanol / water mixture, is circulated past an anode of a cell while oxygen or air is circulated past a cathode of the cell. The cell solid electrolyte membrane is preferably fabricated from Nafion™. Additionally, a method for improving the performance of carbon electrode structures for use in organic fuel cells is provided wherein a high surface-area carbon particle / Teflon™-binder structure is immersed within a Nafion™ / methanol bath to impregnate the electrode with Nafion™. A method for fabricating an anode for use in a organic fuel cell is described wherein metal alloys are deposited onto the electrode in an electro-deposition solution containing perfluorooctanesulfonic acid. A fuel additive containing perfluorooctanesulfonic acid for use with fuel cells employing a sulfuric acid electrolyte is also disclosed. New organic fuels, namely, trimethoxymethane, dimethoxymethane, and trioxane are also described for use with either conventional or improved fuel cells.

Owner:CALIFORNIA INST OF TECH +1

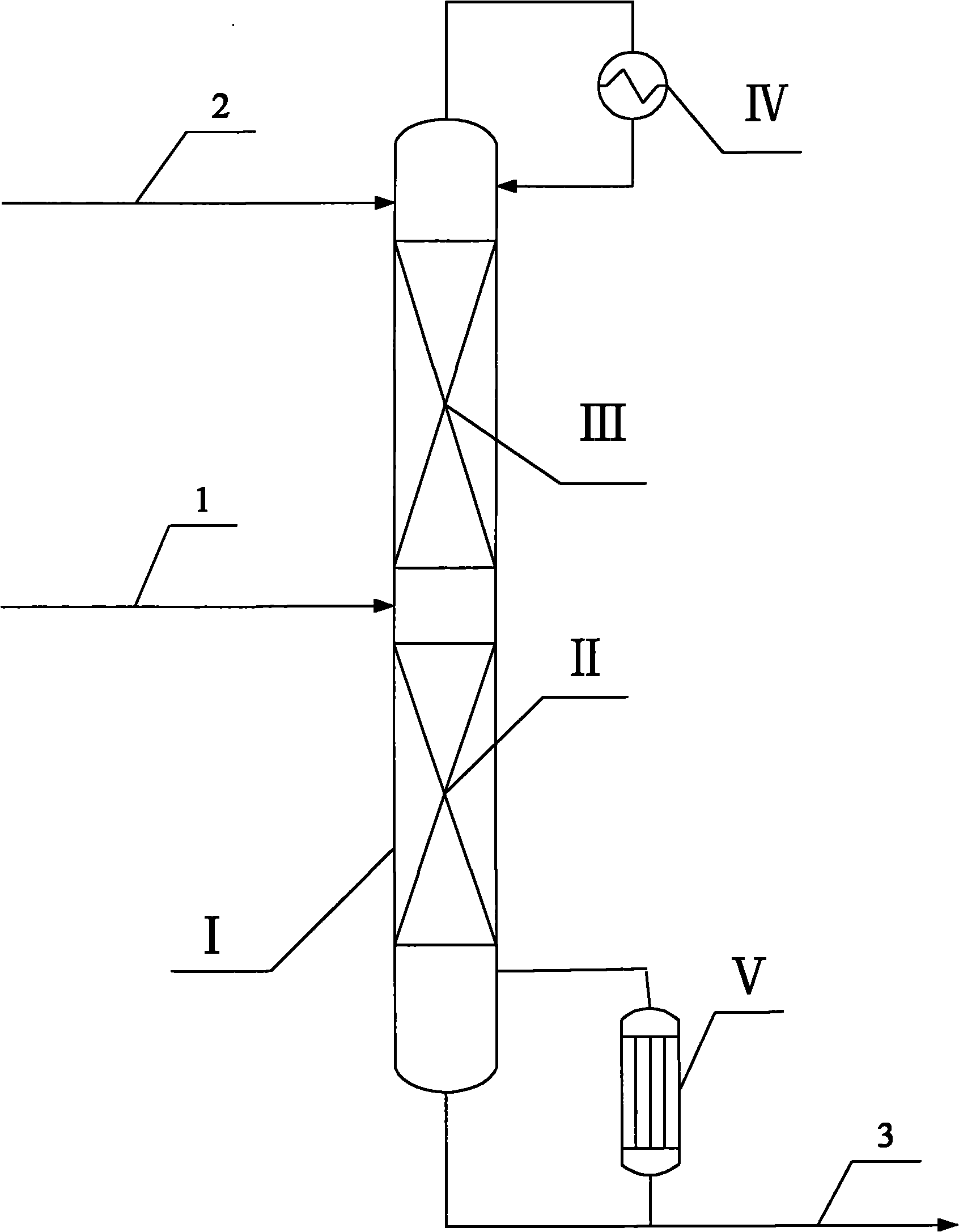

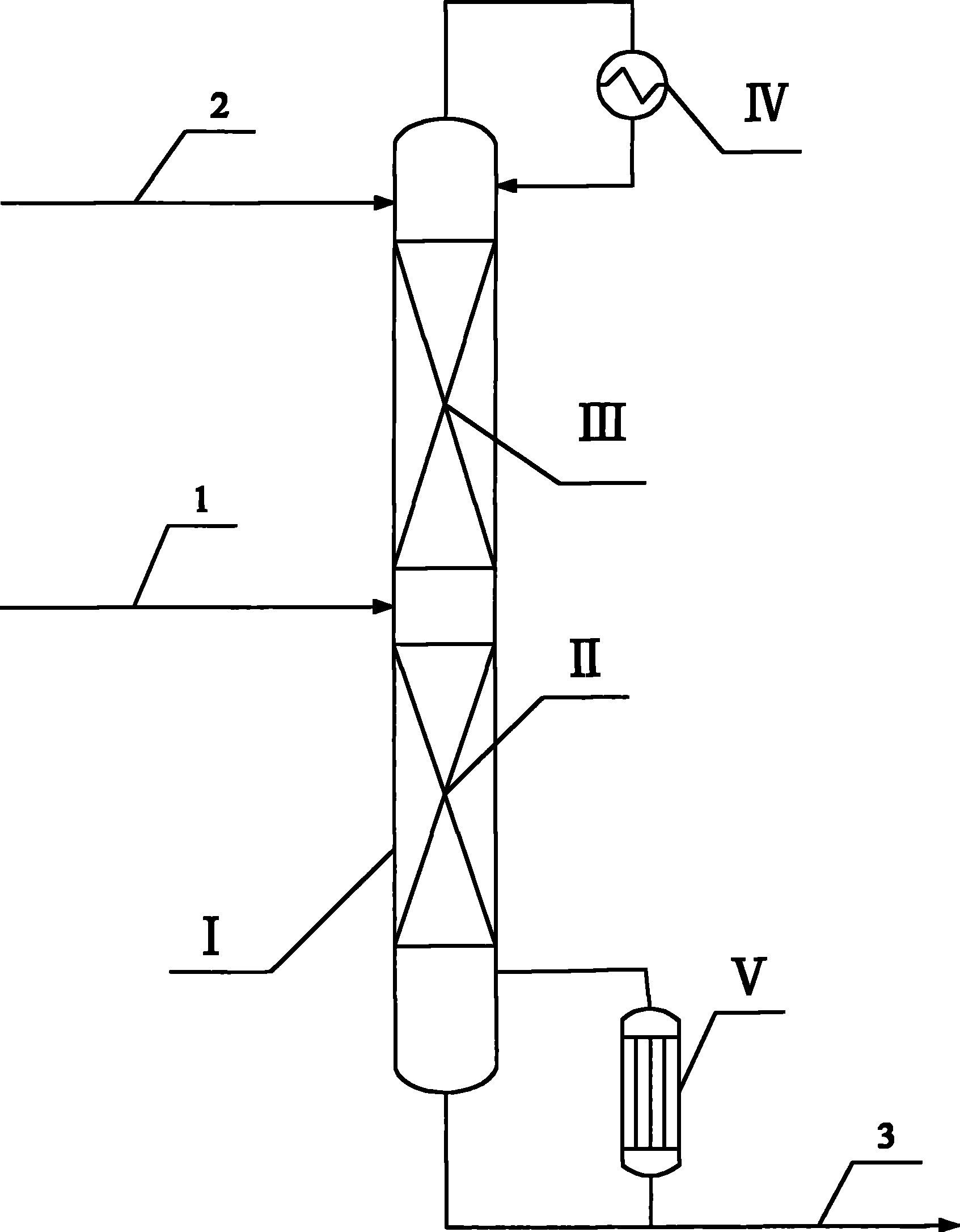

Method for preparing polyoxymethylene dimethyl ether

ActiveCN102372611AImprove conversion rateHigh selectivityOrganic chemistryOrganic compound preparationReboilerCatalytic distillation

The invention relates to a method for preparing polyoxymethylene dimethyl ether, which mainly solves the problems of low conversion rate of trioxymethylene and low selectivity of DMM 3-8 in current polyoxymethylene dimethyl ether production. According to the invention, under the effective reaction condition, methylal and trioxymethylene are reacted in a catalytic distillation tower, a components separation is performed simultaneously, steam at the top of the tower is condensed and then reflowed, a first part of the materials at the bottom of the tower is vaporized by a reboiler and returned back to the catalytic distillation tower, a second part of the materials is taken as produced liquid, the mass ratio of the first part to the second part is 1-10:1, wherein the trioxymethylene enters from the top of the tower, methylal can enter from any position from a stripping section to the tower top. The technical scheme of catalyst capable of being a heterogeneous phase acidic catalyst can effectively solve the problem, and the catalyst can be used for industrial production of polyoxymethylene dimethyl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

Methanol gasoline additive and process for producing methanol gasoline

The invention relates to a preparation method for a methanol oil additive and the methanol oil thereof. The compound additive consists of the components of the following weight percentages; 30 to 50 percent of isopropanol, 10 to 20 percent of tertiary butyl alcohol, 1 to 5 percent of butyl acetate, 1 to 5 percent of methyl ethyl ketone peroxide, 1 to 5 percent of peroxide, 1 to 5 percent of sherwood oil, 5 to 10 percent of dimethylbenzene, 1 to 4 percent of octane enhancing additive, 1 to 5 percent of dimethoxymethane, 0.1 to 0.5 percent of antioxidizing and antigum agent, 0.1 to 0.5 percent of antiseptic, 1 to 8 percent of antiwear agent, 3 to 6 percent of waterproofing agent, 1 to 5 percent of dispersant, 1 to 3 percent of fatty acid amine, 10 to 30 percent of 120# solvent oil as well as 5 to 10 percent of ethanol. The methanol oil consists of the components of the following weight percentages: 10 to 80 percent of methanol, 0 to 85 percent of diesel oil as well as 5 to 20 percent of methanol oil additive. The methanol oil has the advantages of low cost, excellent performance, good environment protection effect, remarkable economic benefit and convenient popularization.

Owner:王宇

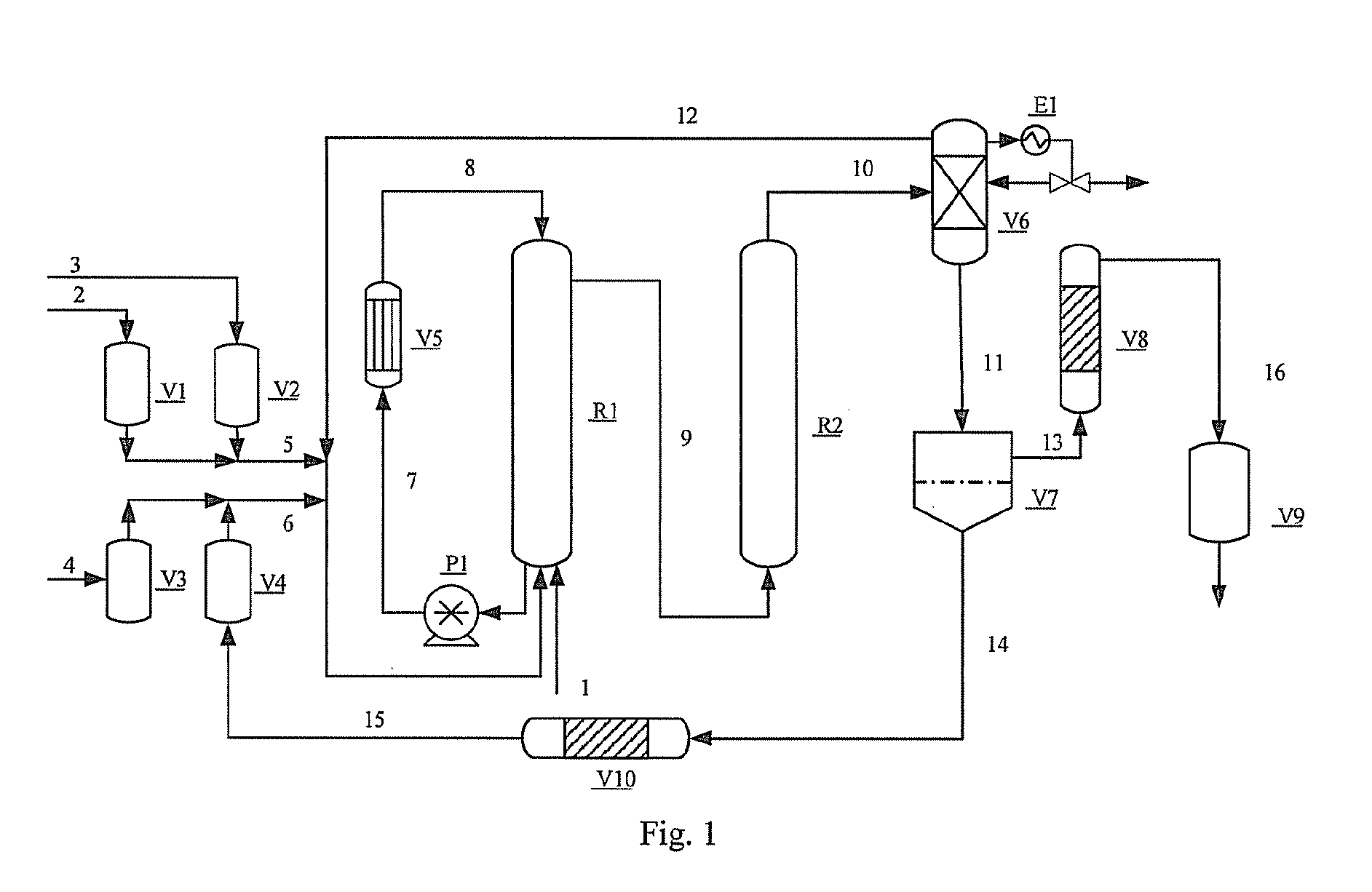

Process for preparing polyoxymethylene dimethyl ether

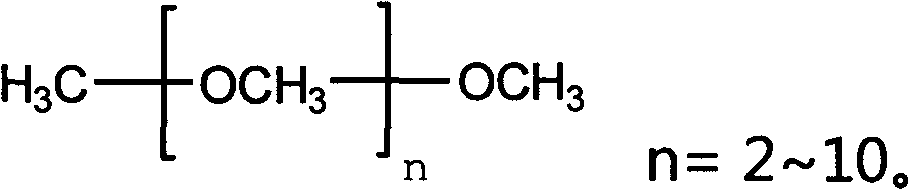

ActiveCN102617305AMild reaction conditionsReduce energy consumptionOrganic chemistryOrganic compound preparationDimethoxymethaneMedicinal chemistry

The invention provides a process for preparing polyoxymethylene dimethyl ether represented by general formula (1). The process for preparing the polyoxymethylene dimethyl ether is characterized by subjecting methanol, methylal and / or dimethyl ether and formaldehyde and / or paraformaldehyde to reaction under the action of an acid catalyst and a water absorbing agent. The general formula (1) is as follows.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

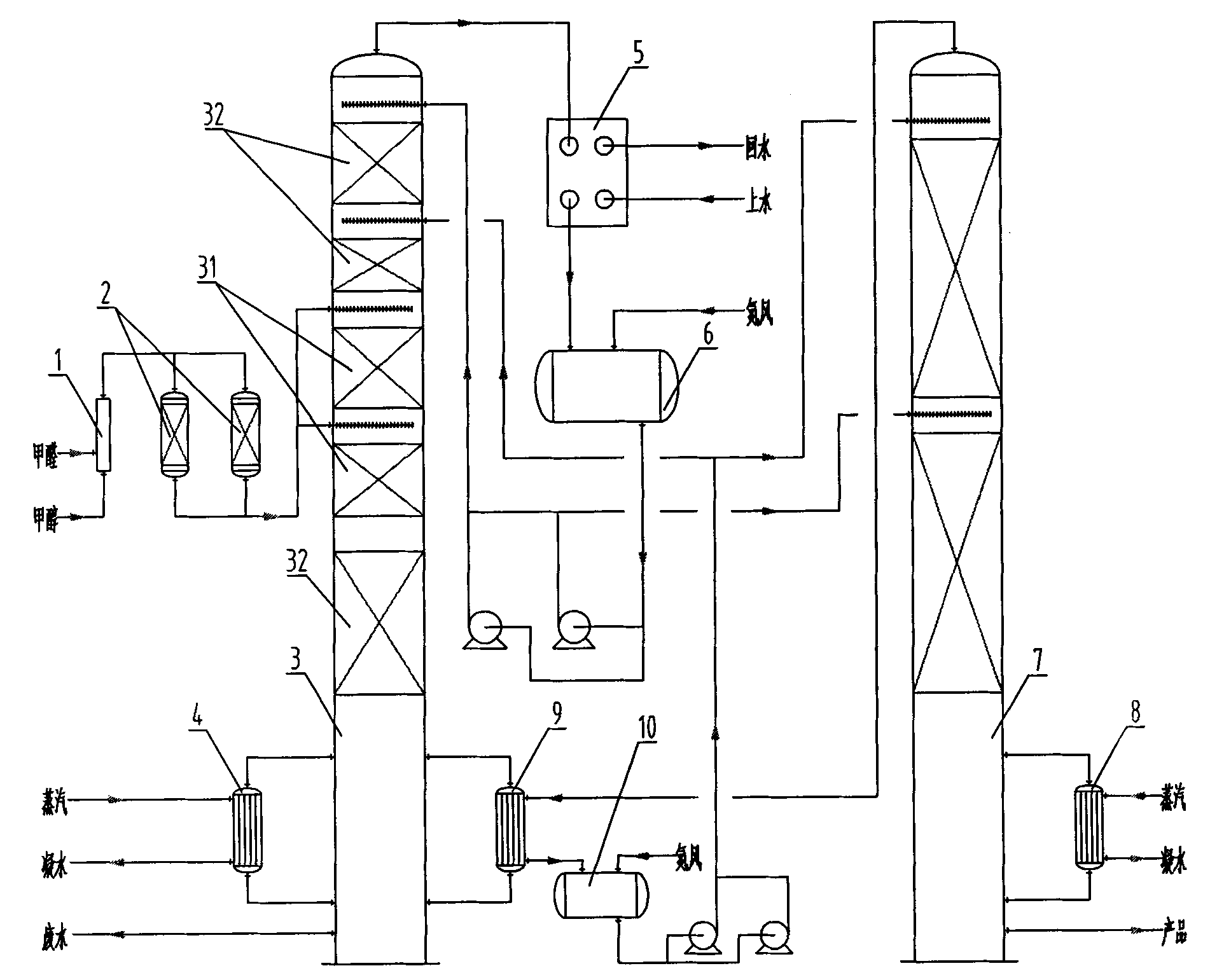

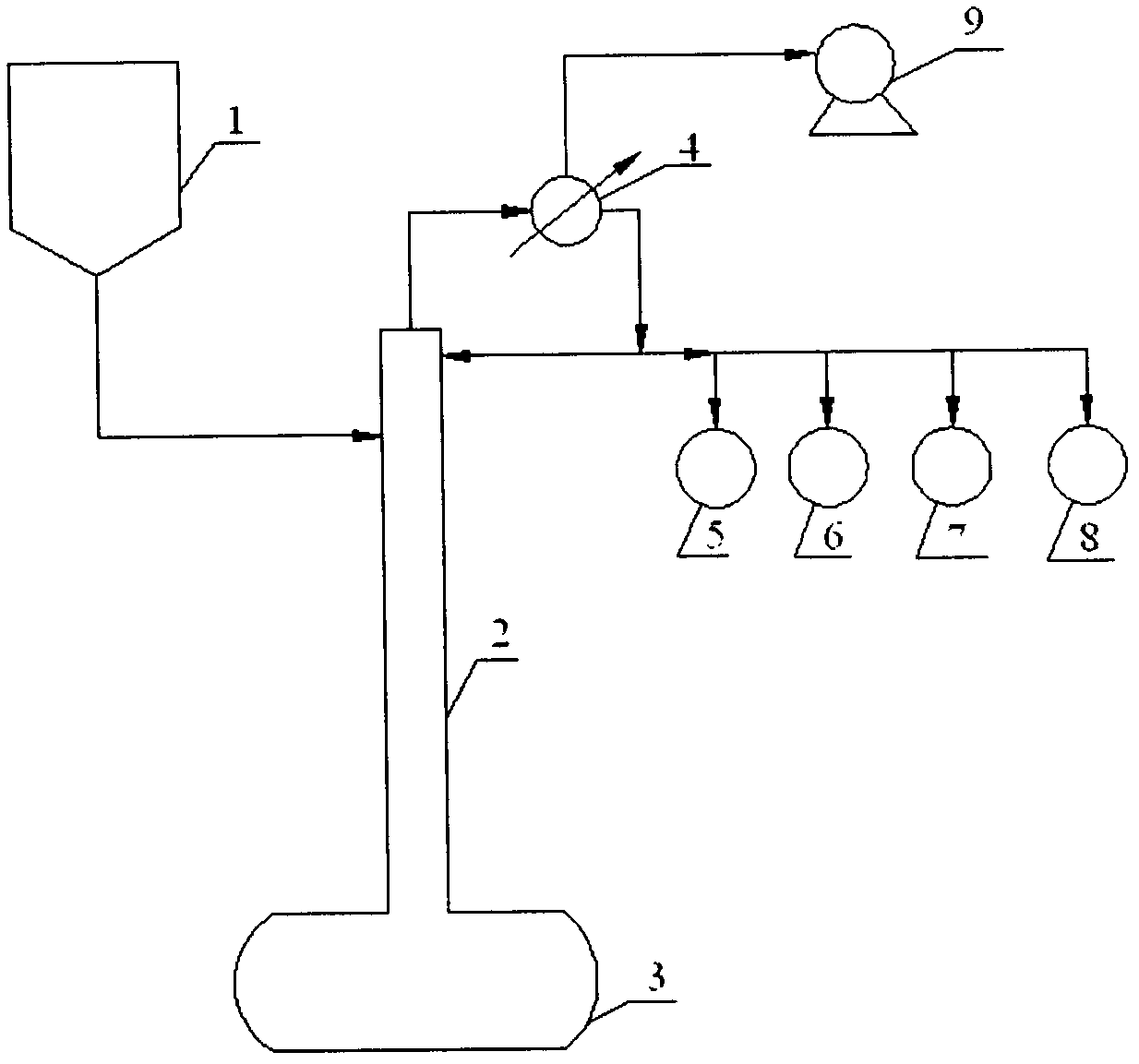

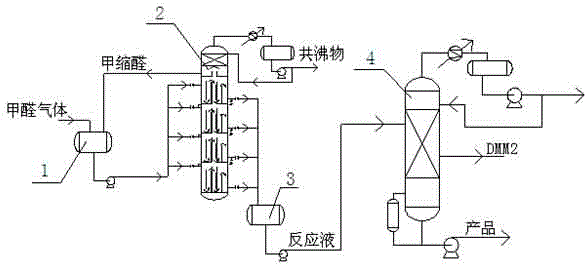

Process device special for preparing polyoxymethylene dimethyl ethers through formaldehyde gas

InactiveCN105693479AReduce participation in aggregationImprove heat transfer effectOrganic chemistryOrganic compound preparationFluidized bedReaction zone

The invention discloses a special process device for preparing polyoxymethylene dimethyl ether from gaseous formaldehyde. The raw materials for synthesizing polyoxymethylene dimethyl ether are formaldehyde gas and methylal solution. The special process device includes sequentially connecting A fluidized bed reactor, an extraction and recovery unit and a refining unit, the fluidized bed reactor includes at least two layers of reaction sections from bottom to top, each layer of reaction section is filled with catalyst, and the bottom of each layer of reaction section is equipped with gas The distributor is directly connected to the reaction section, and each layer of the reaction section is also provided with a downcomer to connect the adjacent reaction sections, and the top of the downcomer is also provided with a wire mesh; the bottom of the fluidized bed reactor is provided with a There is an inlet for formaldehyde gas, and an inlet for methylal solution is set on the top of the fluidized bed reactor. The invention reduces the cost, improves the synthesis conversion rate and the yield is low, and the invention has a good heat transfer effect, can efficiently promote the reaction, and realizes controllability of the conversion degree.

Owner:江苏道尔顿石化科技有限公司

Method for synthesizing methyl acrylate by means of filling catalysts in sections

InactiveCN101575290AImprove reaction efficiencyImprove conversion rateComponent separationOrganic compound preparationFurnace temperatureMethyl acetate

The invention provides a method for synthesizing methyl acrylate by means of filling catalysts in sections; the method comprises the steps: methyl acetate and methylal are taken as raw materials for synthesizing methyl acrylate; the mole ratio of the methyl acetate to the methylal is 1:1 to 3:1; charging space velocity is 1 to 5h; the furnace temperature is fixed to be 350 DEG C to 420 DEG C; a reaction tube is divided into 9 sections; when two catalysts, i.e. phosphovanadate and Cs-Sb2O5 / SiO2, are filled in different sections from top to bottom, the phosphovanadate can be filled in the second section to the sixth section and the cesium or alkali metal catalyst can be filled in the second section to the ninth section; the conversion per pass of methylal is 30 percent to 50 percent; the selectivity of the methyl acrylate is 60 percent to 91 percent; and the yield per pass of the methyl acrylate is 40 percent to 50 percent. With the method for synthesizing the methyl acrylate by means of filling catalysts in sections, the reaction between the methyl acetate and the methylal can be further improved, the conversion rate of the methylal can be raised, and the yield of the target product, namely, the methyl acrylate, can be increased.

Owner:HARBIN INST OF TECH +1

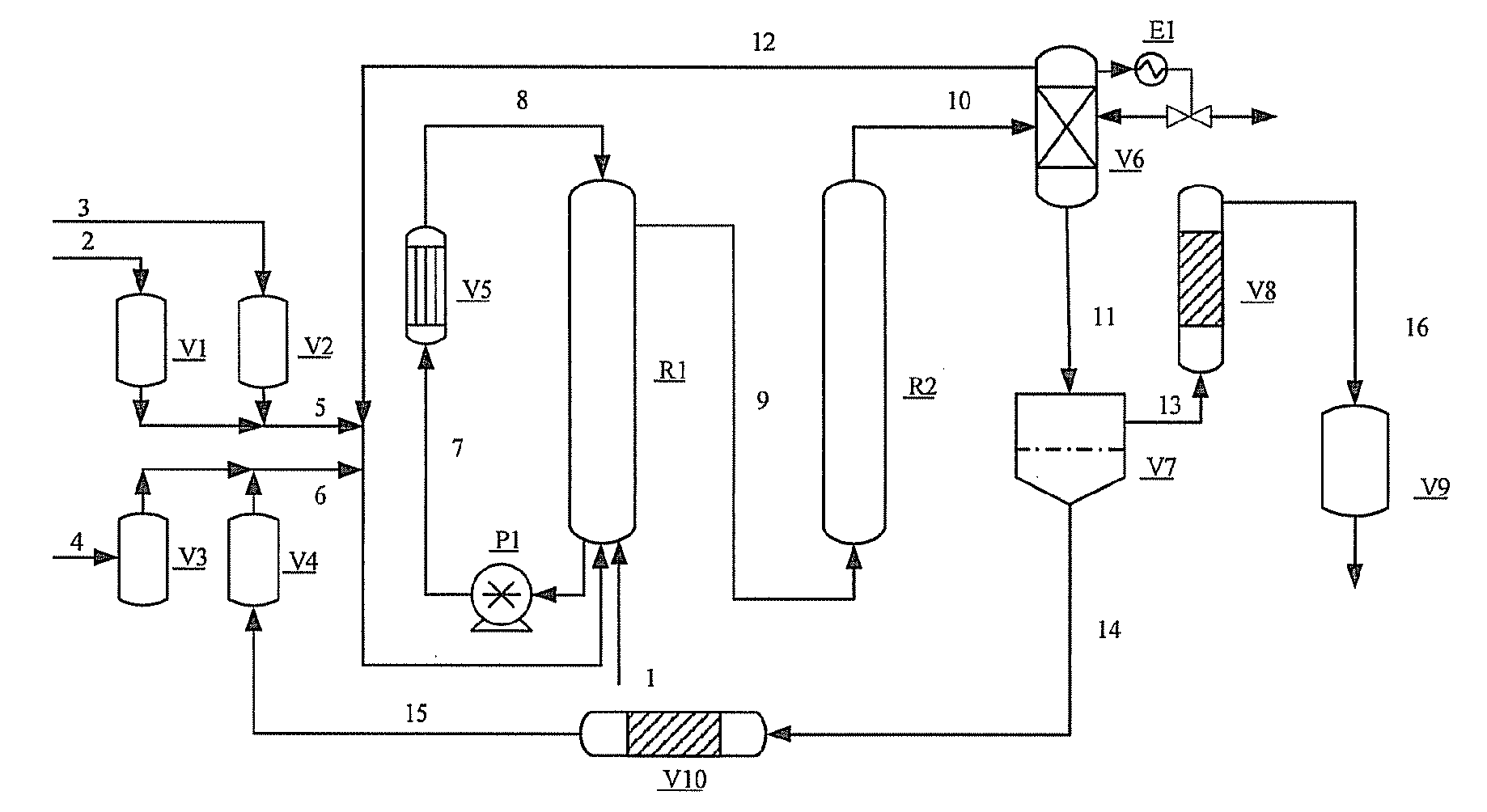

Method for synthesizing polyoxymethylene dimethyl ethers catalyzed by an ionic liquid

InactiveUS20110288343A1Increase conversionsHigh selectivityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsReaction zoneDimethoxymethane

It is related to a method for preparing polyoxymethylene dimethyl ethers by a continuous acetalation reaction of trioxymethylene and methanol or methylal catalyzed by an ionic liquid. The processing apparatus used in the method includes a reaction zone, a separation zone, a catalyst regeneration zone and a product dehydration zone. A manner of circulating tubular reaction is used, resulting in a high external heat exchange efficiency, a simple structure of design and a low investment. A film evaporator is used, realizing a rapid separation and recycling of the light component, with a high separation efficiency. The separation of the catalyst solution from the crude product is simple, thereby realizing the regeneration and recycling of the catalyst.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

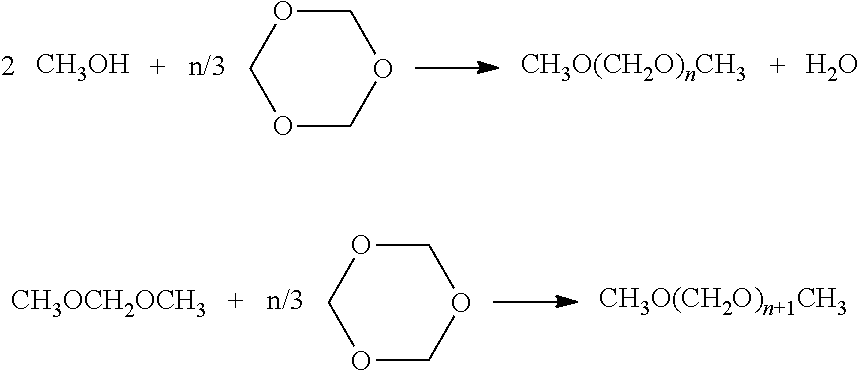

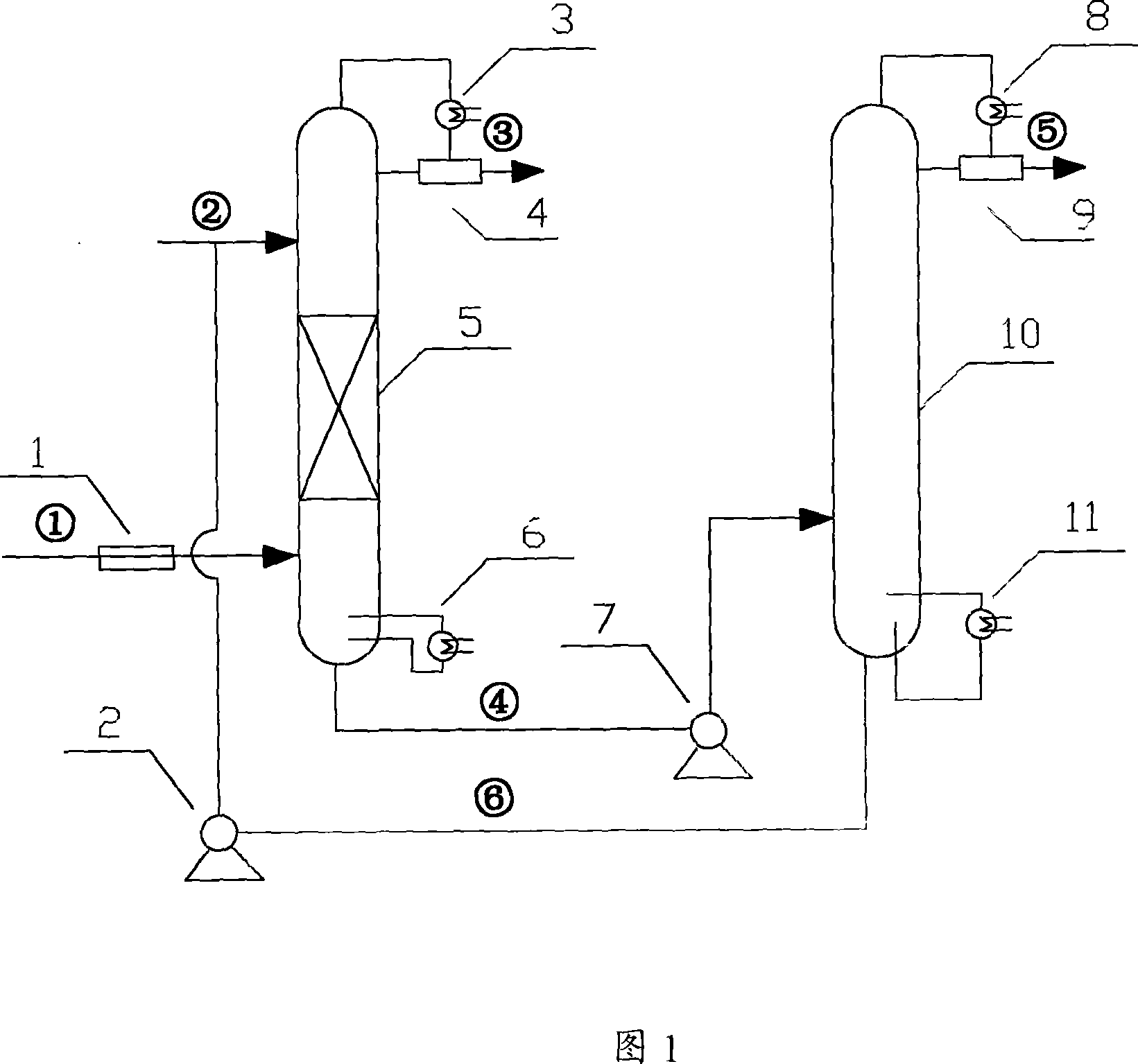

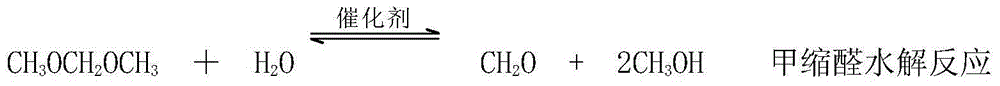

High concentration methylal pressure distillation process and preparation device thereof

ActiveCN102371079AOrganic chemistryOrganic compound preparationHigh concentrationDifferential pressure

The present invention relates to the technical field of methylal production, especially to a high concentration methylal pressure distillation process and a preparation device thereof. According to the present invention, a formaldehyde solution and a methanol solution are mixed in a mixer, and enter a pre-reactor to carry out a liquid phase reaction to generate a mixed solution containing the methylal; the mixed solution enters a reaction distillation tower to carry out a methylal treatment, such that an azeotrope containing the methylal and the methanol is generated on the top of the tower; the azeotrope enters a pressurization tower to carry out differential pressure distillation to separate the methylal and the methanol so as to obtain the high concentration methylal.

Owner:JIANGSU KAIMAO PETROCHEM TECH

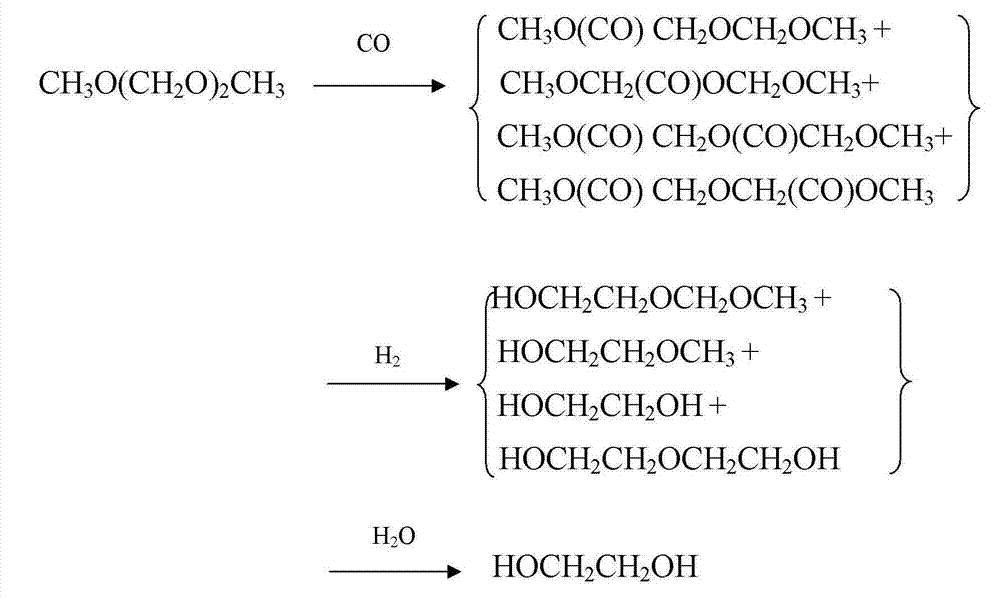

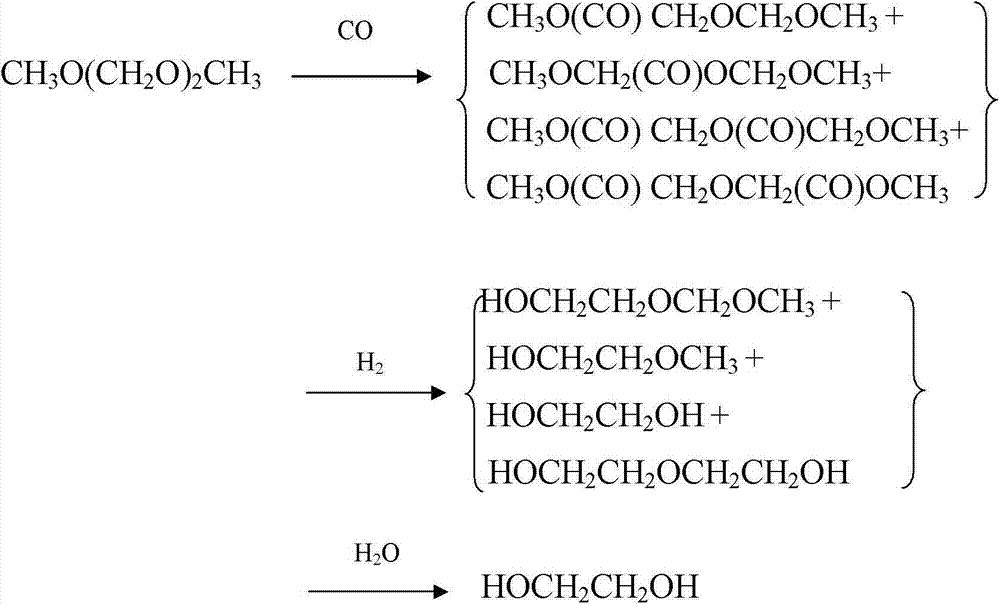

Method for preparing polyoxymethylene dimethyl ether carboxylate and methyl methoxy acetate

ActiveCN104725230AImprove conversion rateHigh selectivityMolecular sieve catalystsPreparation by carbon monoxide or formate reactionMethyl methoxyacetateSolvent

The invention provides a method for preparing polyoxymethylene dimethyl ether carboxylate and / or methyl methoxy acetate which serves as an intermediate for producing ethylene glycol. The method comprises the step of enabling a raw material, namely polyoxymethylene dimethyl ether or methylal, together with carbon monoxide and hydrogen gas to react in a desiliconisation modified acidic molecular sieve catalyst loaded reactor under appropriate reaction conditions without adding other solvents, so as to prepare corresponding products, wherein a reaction process is of gas-liquid-solid three-phase reaction. According to the method provided by the invention, the conversion ratio of the raw material polyoxymethylene dimethyl ether or methylal is high, the selectivity of each product is high, the service life of a catalyst is long, external solvents are not required to be used, reaction conditions are relatively mild, and continuous production can be carried out, so that the method has industrial application potential. Furthermore, the obtained products can be used for producing ethylene glycol through hydrolyzing after hydrogenating or hydrogenating after hydrolyzing.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

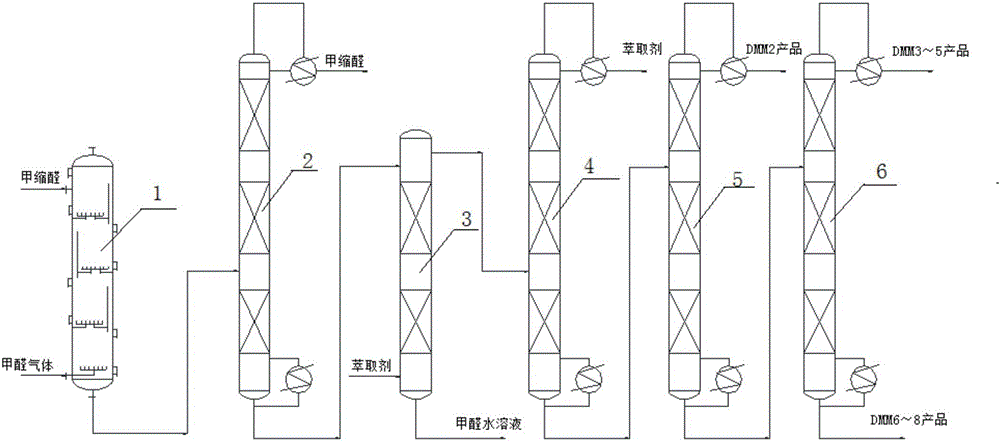

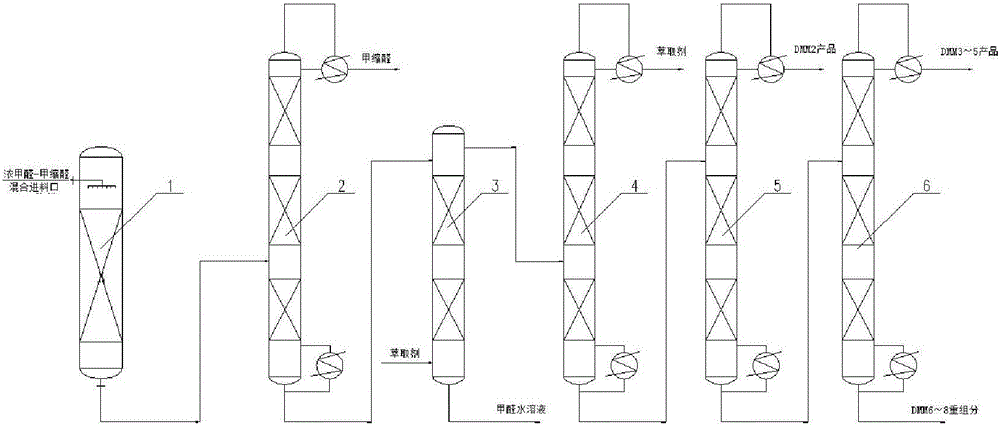

Technical method and device for preparing polymethoxydimethyl ether by concentrated formaldehyde

InactiveCN106146266ASolve the costSolve the conversion rateOrganic chemistryOrganic compound preparationDistillationDehydrogenation

The invention discloses a process method and a device for preparing polyoxymethylene dimethyl ether from concentrated formaldehyde. It uses methylal and a formaldehyde solution with a concentration of 50% to 88% as raw materials, and reacts to obtain polyoxymethylene dimethyl ether containing polyoxymethylene dimethyl ether. The reaction solution of methyl ether, unreacted formaldehyde aqueous solution and methylal; the reaction solution is sent to the extraction tower from the upper part of the tower after dehydrogenation, and carries out countercurrent contact reaction with the extractant entering from the bottom of the tower, and the reaction solution in the reaction solution Polyoxymethylene dimethyl ether is dissolved in the extractant to obtain an organic phase, and the formaldehyde aqueous solution and the organic phase are separated, and the organic phase is taken out and sent to the extractant recovery tower; the organic phase is sent to the extractant recovery tower for extraction. Atmospheric pressure distillation and separation, recovery of the extraction agent at the top of the tower and polyoxymethylene dimethyl ether with a polymerization degree of 2-8 extracted from the tower bottom. The invention reduces the cost, improves the synthesis conversion rate and the yield is low, and the invention has a good heat transfer effect, can efficiently promote the reaction, and realizes controllability of the conversion degree.

Owner:江苏道尔顿石化科技有限公司

Method for preparing methylal by combining reaction rectification and extraction

InactiveCN101092337AHigh purityHigh yieldOrganic chemistryOrganic compound preparationCombined methodSolvent

This invention relates to a method for preparing dimethoxymethane by combination of rectification and extraction. The method comprises: adding raw materials, extractant and catalyst at a certain ratio into a rectification column from different parts at a weight flow rate of 15 mL / min, reacting to obtain high-purity dimethoxymethane at the overhead and mixed liquids at the bottom, sending the mixed liquids to a solvent recovery column, recovering the extracting solvent, and recycling. The weight ratio of methanol to 37-40% formaldehyde solution (raw materials) is 0.9:1. The weight ratio of extractant ethylene glycol to raw materials is 1.2:1. The addition amount of catalyst is 5% of raw materials. The method adopts only one column to finish the preparation of dimethoxymethane. The concentration of dimethoxymethane is up to 99.5%, and the yield is up to 85% or higher. The method has such advantages as simple process, high product purity and yield, and low energy consumption (saved by 50% compared with combined method of reaction rectification and extraction rectification).

Owner:NANJING NORMAL UNIVERSITY

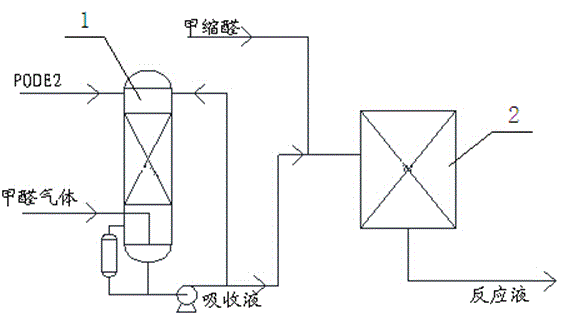

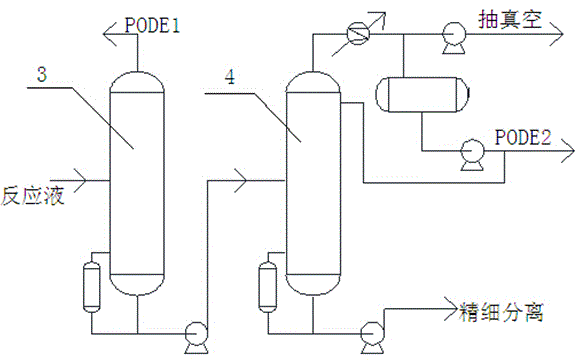

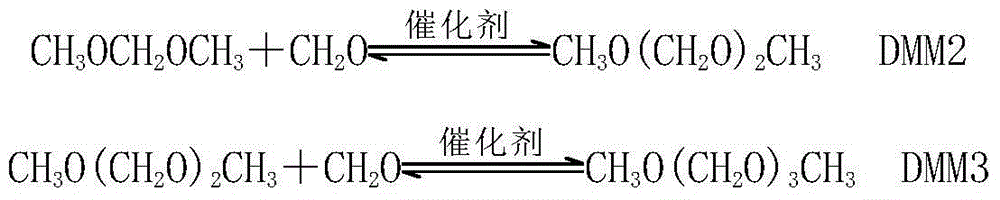

Process unit and method for absorbing formaldehyde in polymethoxy dimethyl ether synthesis

ActiveCN104817440APrevent self-aggregationAvoid reactionOrganic chemistryOrganic compound preparationBoiling pointDimethoxymethane

The invention discloses a process unit and method for absorbing formaldehyde in polymethoxy dimethyl ether synthesis. According to the process, higher-boiling-point intermediate component dimer PODE2 of polymethoxy dimethyl ether is adopted, the formaldehyde dissolved amount is much higher than the methylal dissolved amount, and a PODE2 solution of formaldehyde is obtained, so that the operating pressure and temperature for the subsequent reaction are on the lower level, thereby avoiding the self-polymerization and disproportionation reaction of the formaldehyde, further avoiding the pipeline blockage, lowering the acid content in the polymethoxy dimethyl ether product, and finally enhancing the product yield.

Owner:JIANGSU KAIMAO PETROCHEM TECH

Batch extractive distillation separation method of methylal-methanol azeotropic mixture

InactiveCN102627536AReduce energy consumptionFlexible operationOrganic compound preparationHydroxy compound preparationSeparation technologyExtractive distillation

Belonging to separation technologies of methylal-methanol azeotropic mixtures, the invention discloses a batch extractive distillation separation method of a methylal-methanol azeotropic mixture. The method takes propanol, isopropanol, butanol, tert-butyl alcohol, 1, 3-propylene glycol or dimethyl sulfoxide as the extracting agent. An extractive distillation tower are operated according to the operation conditions that, under normal pressure or reduced pressure, the extracting agent and an overhead product are in a mass ratio of 0.5:1-10:1, the feed temperature of the extracting agent is 20-40DEG C, and the extractive distillation tower top is controlled at different temperatures and reflux ratios, so that a methylal product, a methylal-methanol transition section I, a methanol product and a methanol-extracting agent transition section II can be obtained from the extractive distillation tower top respectively. When composition of the extracting agent of a heating kettle meets requirements, the extracting agent is pumped into a high storage tank, and feeding is conducted for next batch of extractive distillation separation. The method of the invention has the advantages of low cost of single-tower equipment, flexible operation, adoption of an extracting agent to destroy a methylal-methanol azeotropic system, and can obtain high purity methanol and methylal products.

Owner:UNIV OF JINAN

Method for preparing dimethoxymethane by adopting supported niobium oxide catalyst

InactiveCN102000559AEasy to prepareReduce loadOrganic chemistryOrganic compound preparationBoiling pointReaction temperature

The invention discloses a method for preparing polyformaldehyde dimethyl ether by adopting a supported niobium oxide catalyst, which is characterized by comprising the following steps of: a) performing catalytic reaction to prepare the polyformaldehyde dimethyl ether, wherein a molar ratio of the dimethoxymethane to trioxymethylene is 0.5 to 5; supported niobium oxide is taken as a catalyst and accounts for 0.1 to 5 percent based on the total mass of reactants; the reaction temperature is between 100 and 200 DEG C; the time is between 10 minutes and 48 hours; and the reaction pressure is between 0.1 and 10MPa; b) performing rectification separation, namely separating a low-boiling point component dimethoxymethane DMM, polydiformaldehyde dimethyl ether DMM2 and the unreacted trioxymethylene, and separating polyformaldehyde diformaldehyde DMM3-8, wherein a kettle bottom is provided with high-polymerization degree polyformaldehyde dimethyl ether DMMn, and n is more than 8; and c) adding a small amount of fresh trioxymethylene into the dimethoxymethane, the diformaldehyde dimethyl ether DMM2 and the unreacted trioxymethylene which are separated in the step b and continuously reacting to prepare the polyformaldehyde diformaldehyde DMM3-8, which is suitable to be used as a diesel fuel-blended component so as to improve the utilization rate of the raw materials.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Method for preparing polyoxymethylene dimethyl ether carboxylate and methyl methoxy acetate

ActiveCN104725224AImprove conversion rateHigh selectivityPreparation by carbon monoxide or formate reactionMethyl methoxyacetateCarboxylic salt

The invention provides a method for preparing polyoxymethylene dimethyl ether carboxylate and / or methyl methoxy acetate which serves as an intermediate for producing ethylene glycol. The method comprises the step of enabling a raw material, namely polyoxymethylene dimethyl ether or methylal, together with carbon monoxide and hydrogen gas to react in an acidic molecular sieve catalyst loaded reactor under appropriate reaction conditions without adding other solvents, so as to prepare corresponding products, wherein a reaction process is of gas-liquid-solid three-phase reaction. According to the method provided by the invention, the conversion ratio of the raw material polyoxymethylene dimethyl ether or methylal is high, the selectivity of each product is high, the service life of a catalyst is long, external solvents are not required to be used, reaction conditions are relatively mild, and continuous production can be carried out, so that the method has industrial application potential. Furthermore, the obtained products can be used for producing ethylene glycol through hydrolyzing after hydrogenating or hydrogenating after hydrolyzing.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Adjustable fuel power booster component composition

InactiveUS20070204506A1Reduce gas emissionsBiofuelsLiquid carbonaceous fuelsMethyl carbonateInternal combustion engine

An adjustable fuel power booster component composition having three components: (A) an ignition accelerator which is preferably normal propyl nitrate and / or diterbutyl peroxide; (B) propylene glycol monoalkyl ether and / or butylene glycol monoalkyl ether; and (C) methyl carbonate and / or ethyl carbonate and / or propyl carbonate and / or butyl carbonate, which may be used mixed in any proportion with methylal (dimethoxymethane) or ethylal (diethoxymethane). The adjustable fuel power booster component composition of the present invention can be used by itself or in mixture with gasoline, diesel or burning oils in combustion engines without the need for modification thereof. The adjustable fuel power booster component composition enables low energy content alcohol based fuels to substitute conventional fuels, such as gasoline or diesel, in conventional non-modified internal combustion engines, thereby generating lower amounts of toxic gas emission all the while proving more power.

Owner:BRENES MARIO ARAYA

The method for synthesizing polyoxymethylene dimethyl ether

ActiveCN102295734AImprove utilization efficiencyLow selectivityOrganic chemistryOrganic compound preparationMolecular sieveMass ratio

The invention relates to a method for synthesizing polyoxymethylene dimethyl ether, which mainly solves the problems of low reaction efficiency of a solid superacid catalyst, high cost of raw material trioxymethylene and more byproducts after reaction during synthesis of polyoxymethylene dimethyl ether existing in the prior art. In the method, dimethoxymethane and paraformaldehyde are used as rawmaterials, wherein the mass ratio of the dimethoxymethane to the paraformaldehyde is 0.5-10:1; the raw materials are in contact with the catalyst to generate catalytic reaction to prepare the polyoxymethylene dimethyl ether under the conditions of reaction temperature of 70-200 DEG C and reaction pressure of 0.2-6MPa; the amount of the used catalyst is 0.1-5.0 percent; and the used catalyst comprises the following components in percentage by weight: (a) 30-80 parts of molecular sieve carrier; and (b) 20-70 parts of solid superacid. Due to the technical scheme, the problems are solved well; and the method can be used for industrial production of the polyoxymethylene dimethyl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

Dehydration technique and dehydration device for synthesizing poly-methoxy-dimethyl ether

InactiveCN104817437AReduce bring inRelieve pressureOrganic chemistryOrganic compound preparationHigh concentrationAcid catalysis

The invention discloses a dehydration technique and a dehydration device for synthesizing poly-methoxy-dimethyl ether. The dehydration technique comprises the following steps: selecting a formaldehyde gas of which the moisture content is within 0.1% and high-concentration dimethoxymethane to form a methylal solution of formaldehyde as a reactant; obtaining a poly-methoxy-dimethyl ether product under the acid catalysis condition; further carrying out hydrolysis reaction on high-concentration dimethoxymethane, and further consuming moisture, so as to control the reaction system in an anhydrous state. Therefore, the poly-methoxy-dimethyl ether yield is improved; furthermore, the reaction condition of the reaction system is also reduced; and the reaction energy consumption is reduced.

Owner:无锡智归科技有限公司

Oxidation of methanol and/or dimethyl ether using supported molybdenum-containing heteropolyacid catalysts

InactiveUS6956134B2Reduce productionPromote conversionOrganic compound preparationPreparation by carbon monoxide or formate reactionOxygenDimethoxymethane

Feeds comprising methanol, dimethyl ether or a mixture of the two are oxidized by contacting the feed with an oxygen-containing gas and a supported heteropolyacid catalyst containing molybdenum or molybdenum and vanadium. The primary products are methylal (dimethoxymethane) and methyl formate. Production of dimethyl ether from methanol can be inhibited by partial deactivation of acid sites on the Keggin catalyst.

Owner:REGENTS OF CALIFORNIA UNIV OF THE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com