Methyl methoxyacetate (MMAC) synthesis method

A technology of methyl methoxyacetate, chemical synthesis, applied in the direction of carbon monoxide or formate reaction preparation, chemical instruments and methods, molecular sieve catalysts, etc., can solve problems such as high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

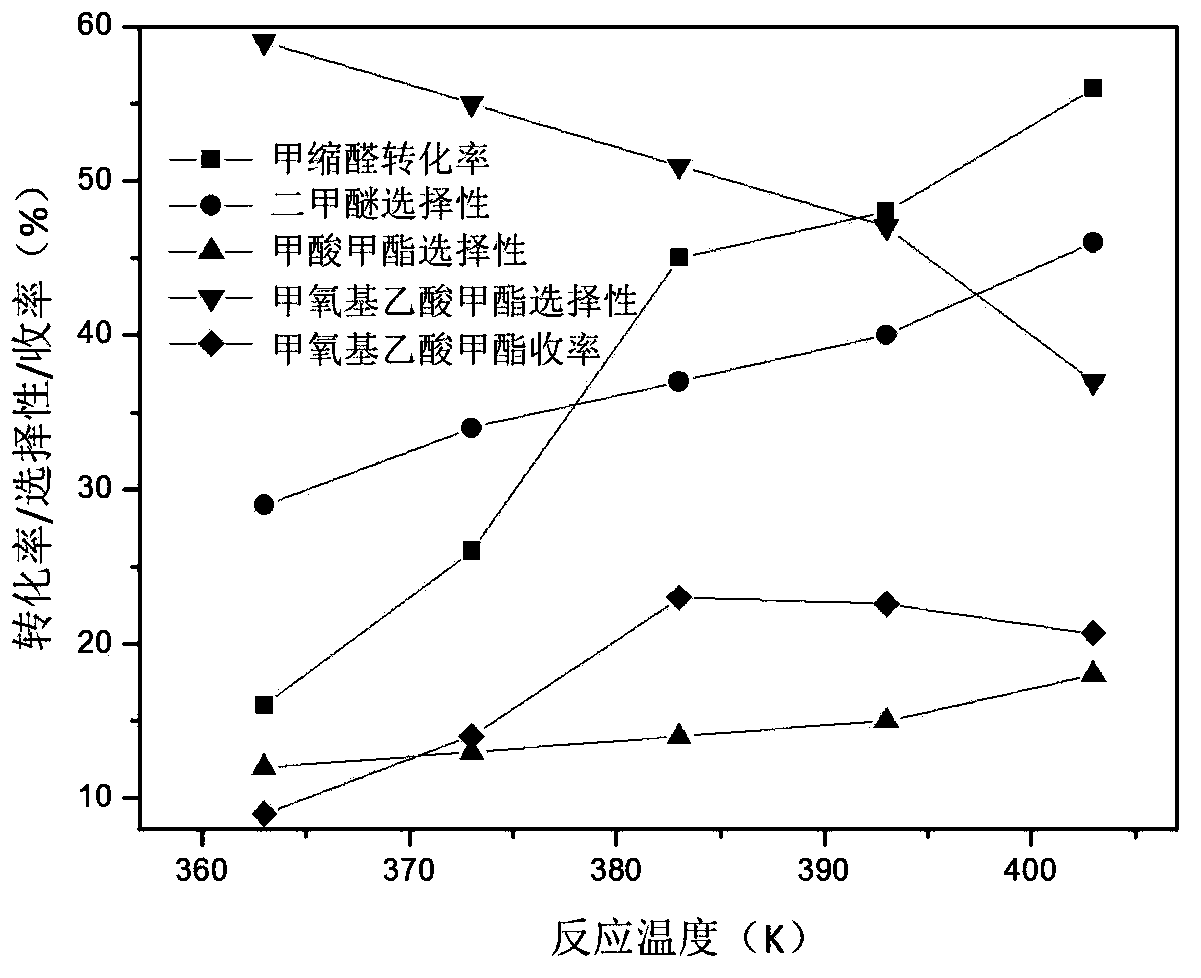

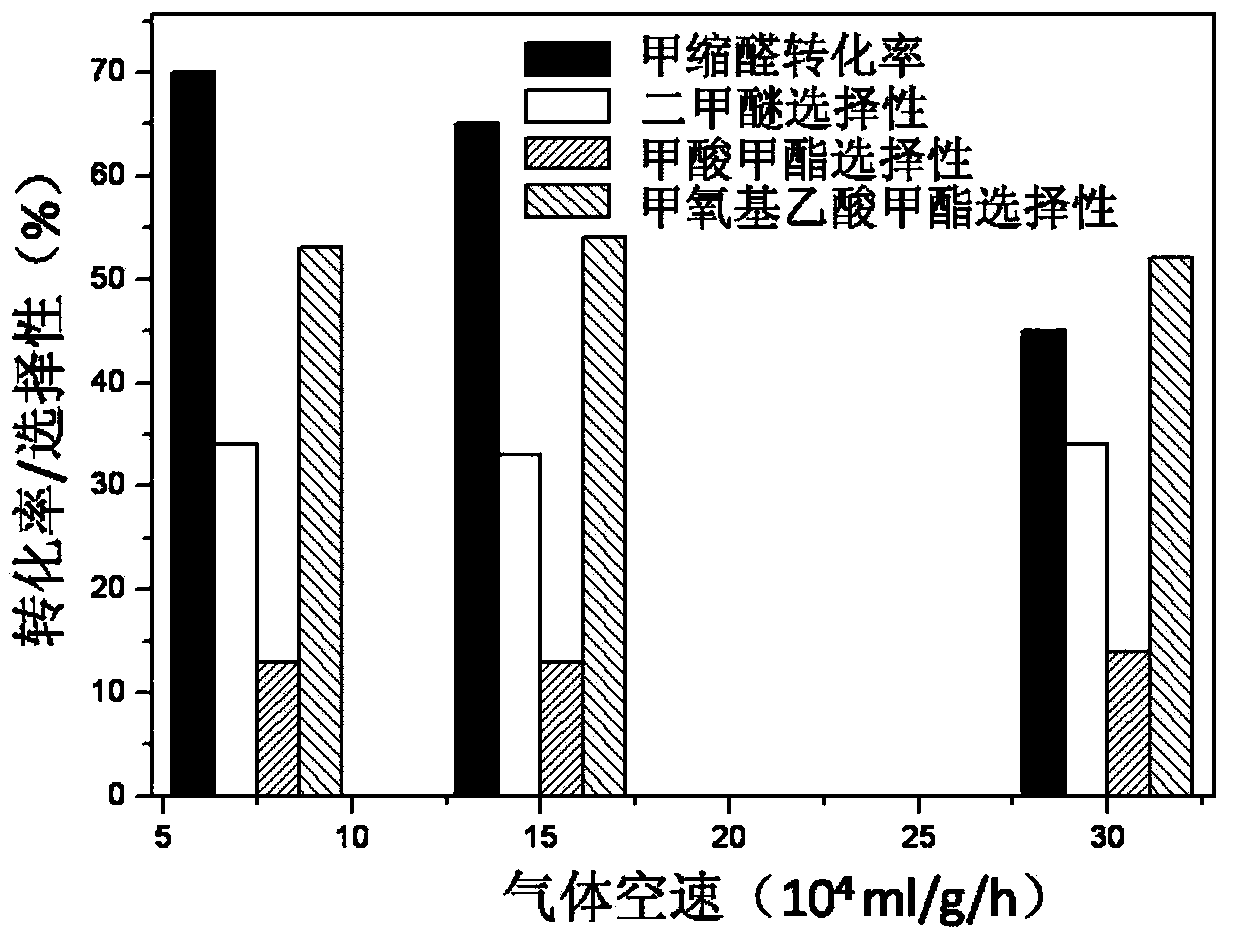

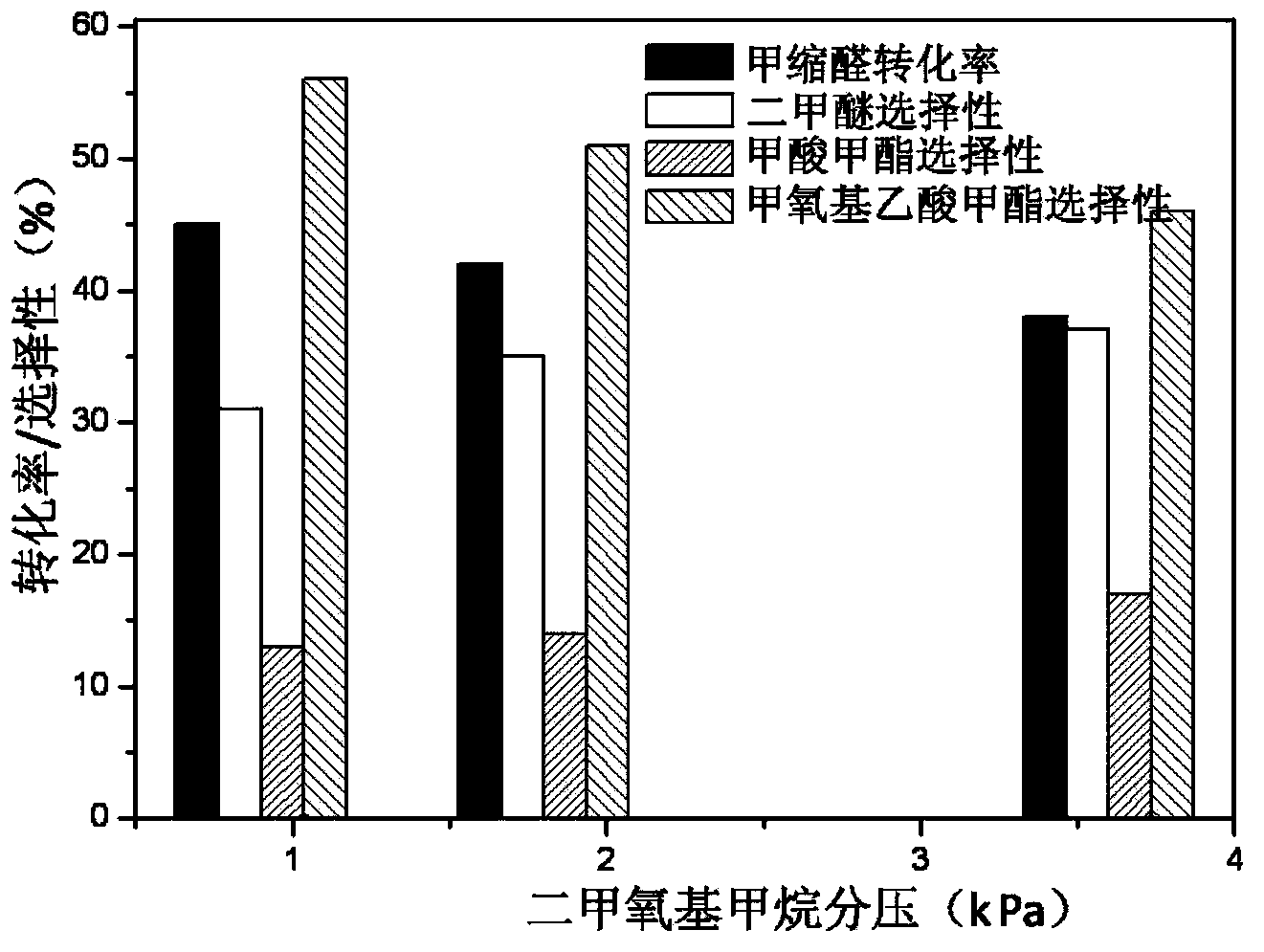

[0035] Embodiment 1: Hydrogen type MCM-22 molecular sieve (SiO 2 / Al 2 o 3Ratio 45) 50 mg, placed in a tubular stainless steel fixed-bed reactor, heated from room temperature to 500 °C at 5 °C / min in 50 ml / min He, cooled to 90 °C after 500 °C treatment for 1 hour, and introduced CO and DMM mixed gas, DMM partial pressure is 1.8kPa, CO partial pressure is 398.2kPa, and the space velocity under normal pressure is 300L·g -1 h -1 . The reaction tail gas was detected online by gas chromatography. The above process was repeated, and the reaction temperature was changed at 100°C, 110°C, 120°C, 130°C and 140°C, respectively.

Embodiment 2

[0036] Embodiment 2: Hydrogen type MCM-49 molecular sieve (SiO 2 / Al 2 o 3 Ratio 25) 50 mg, placed in a tubular stainless steel fixed-bed reactor, heated from room temperature to 500 °C at 5 °C / min in 50 ml / min He, cooled to 110 °C after 500 °C treatment for 1 hour, and introduced CO and DMM mixed gas, DMM partial pressure is 1.8kPa, CO partial pressure is 398.2kPa, and the space velocity under normal pressure is 300L·g -1 h -1 . The reaction tail gas was detected online by gas chromatography.

Embodiment 3

[0037] Embodiment 3: Hydrogen type Beta molecular sieve (SiO 2 / Al 2 o 3 Ratio 25) 50mg reaction performance test, the operation is the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com