Patents

Literature

17622results about "Waste based fuel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

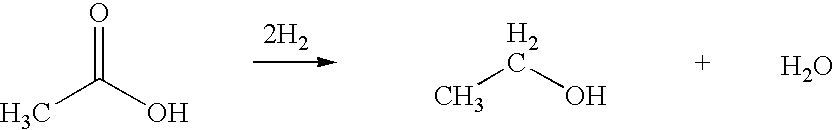

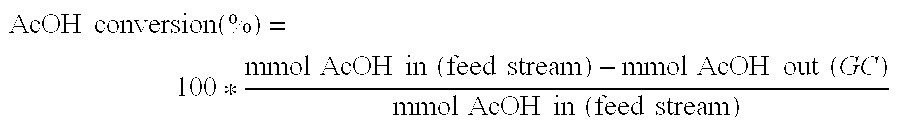

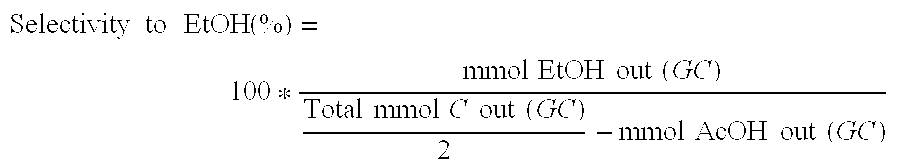

Ethanol production from acetic acid utilizing a cobalt catalyst

InactiveUS7608744B1High selectivityHigh yieldOrganic compound preparationOxygen compounds preparation by reductionAcetic acidPlatinum

A process for the selective production of ethanol by vapor phase reaction of acetic acid over a hydrogenating catalyst composition to form ethanol is disclosed and claimed. In an embodiment of this invention reaction of acetic acid and hydrogen over either cobalt and palladium supported on graphite or cobalt and platinum supported on silica selectively produces ethanol in a vapor phase at a temperature of about 250° C.

Owner:CELANESE INT CORP

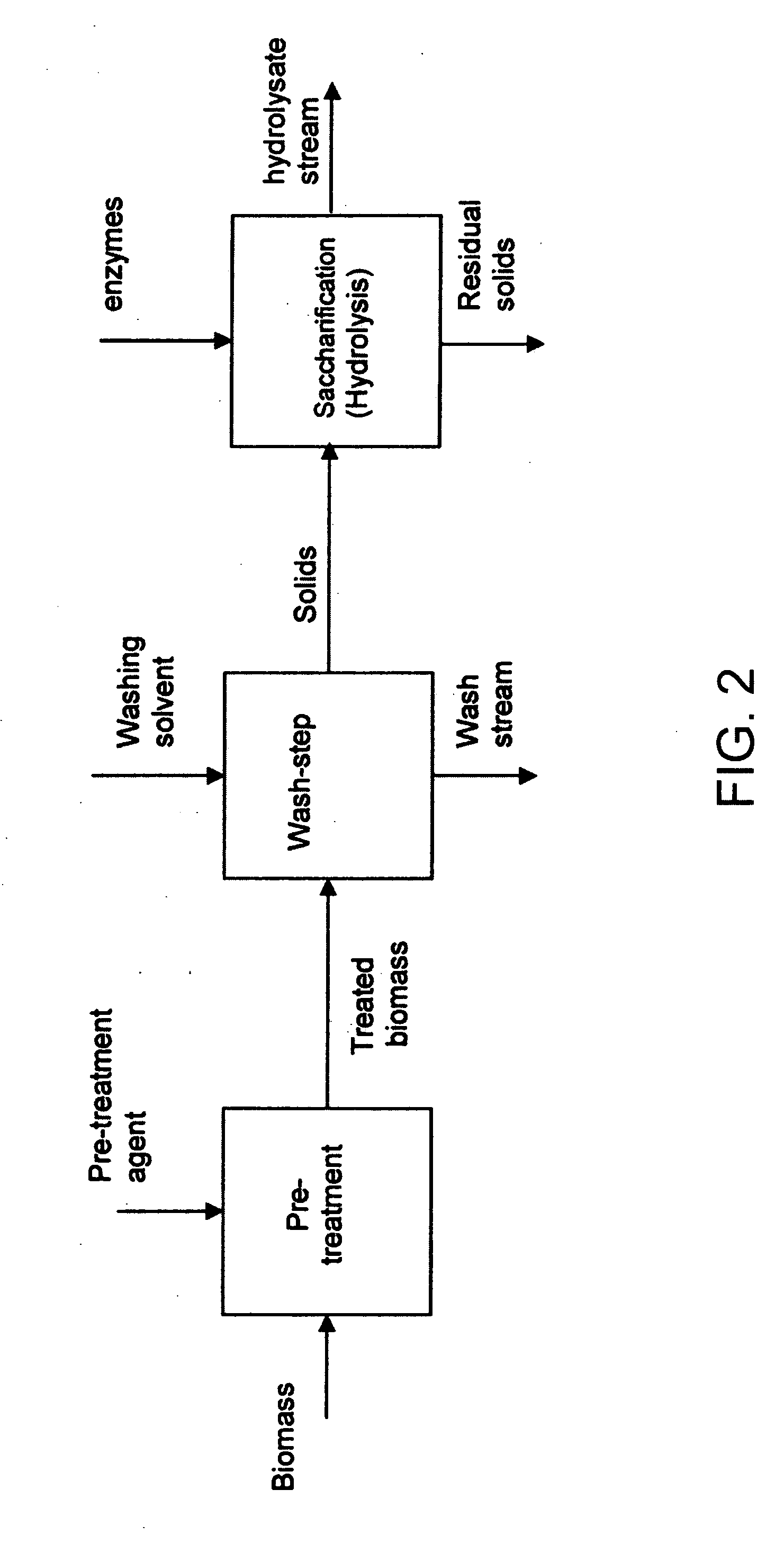

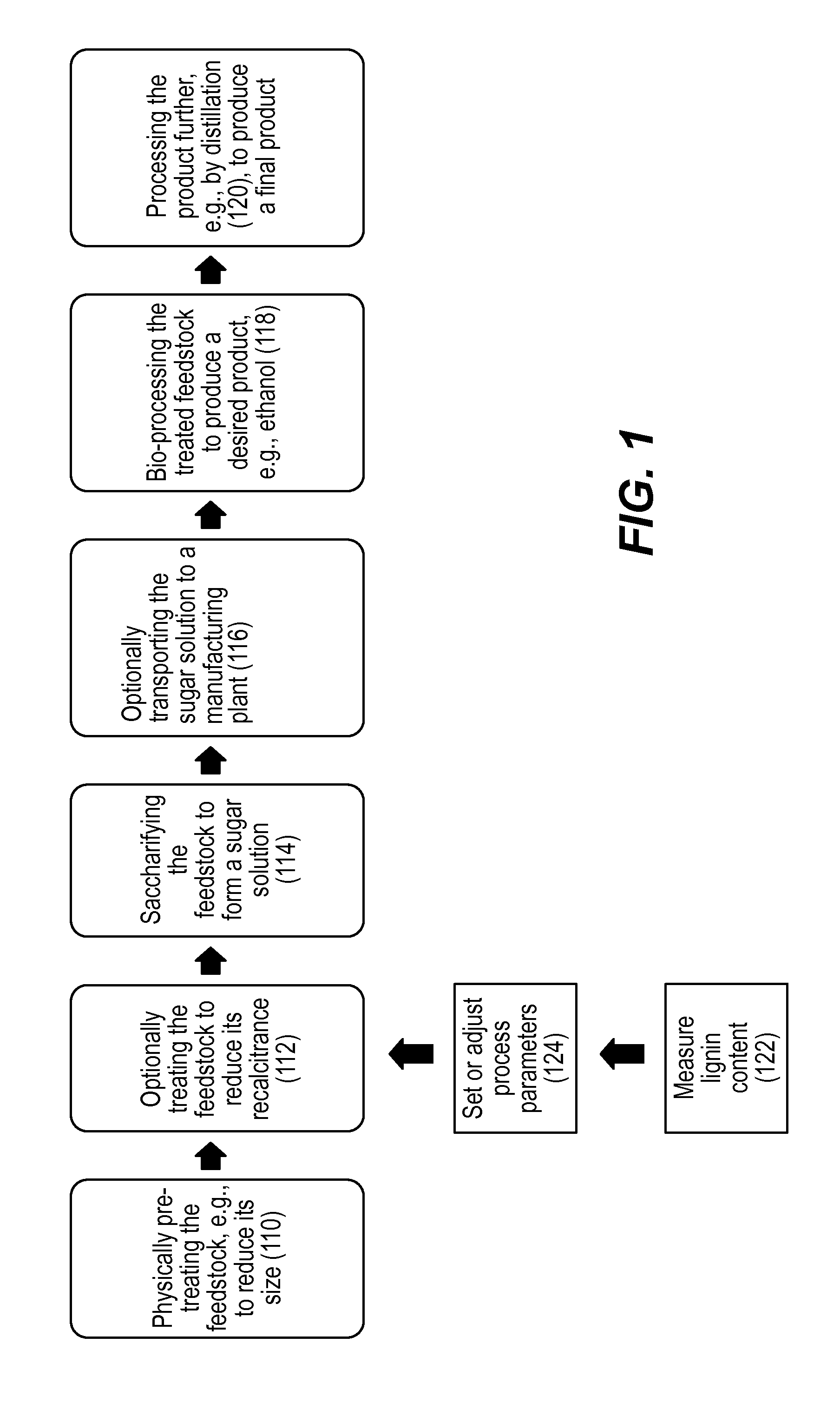

Treatment of biomass to obtain fermentable sugars

InactiveUS20070031918A1Toxic reductionReduce needBiological substance pretreatmentsByproduct vaporizationFermentable sugarCompound (substance)

Biomass is pretreated using a low concentration of aqueous ammonia at high biomass concentration. Pretreated biomass is further hydrolyzed with a saccharification enzyme consortium. Fermentable sugars released by saccharification may be utilized for the production of target chemicals by fermentation.

Owner:ALLIANCE FOR SUSTAINABLE ENERGY +1

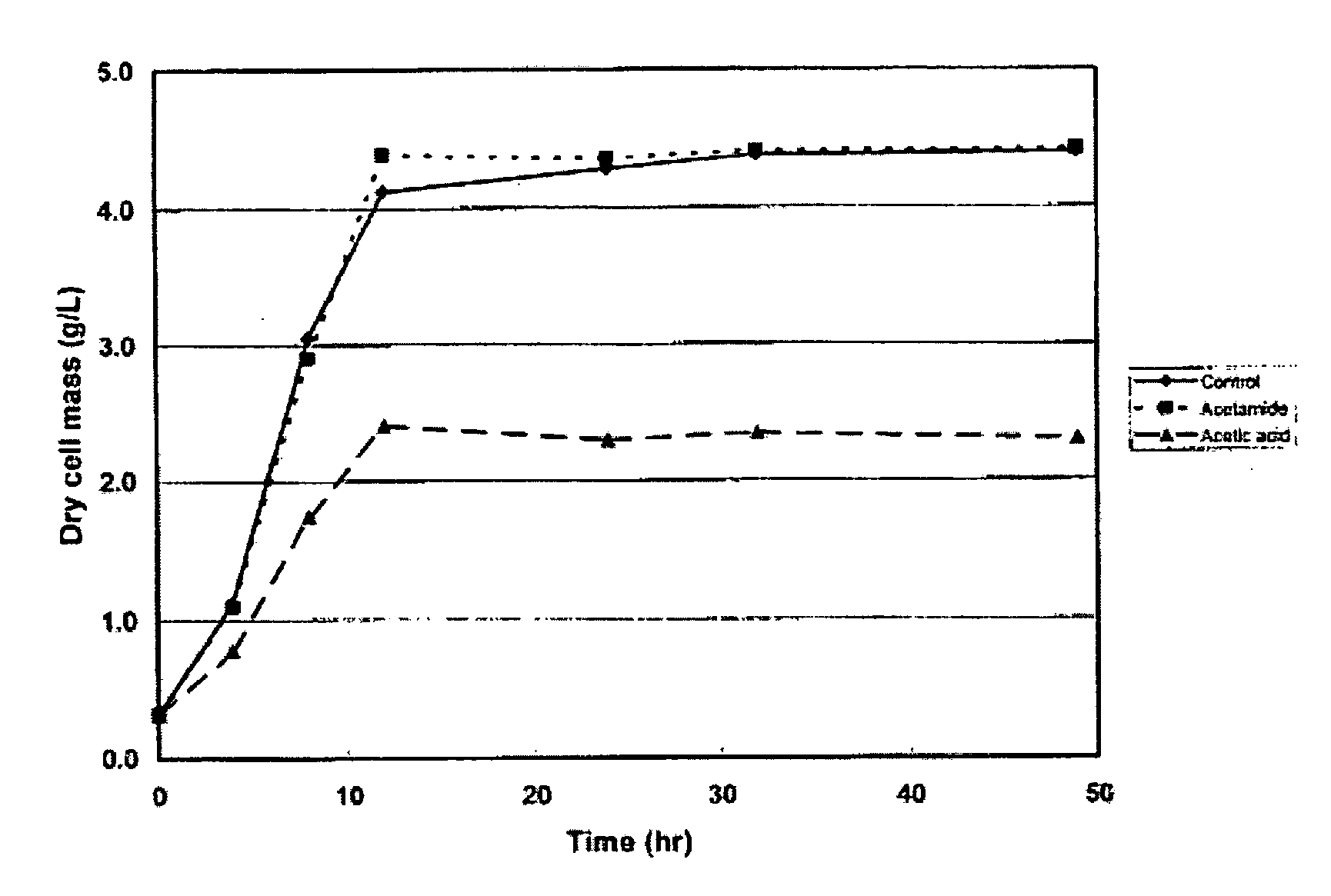

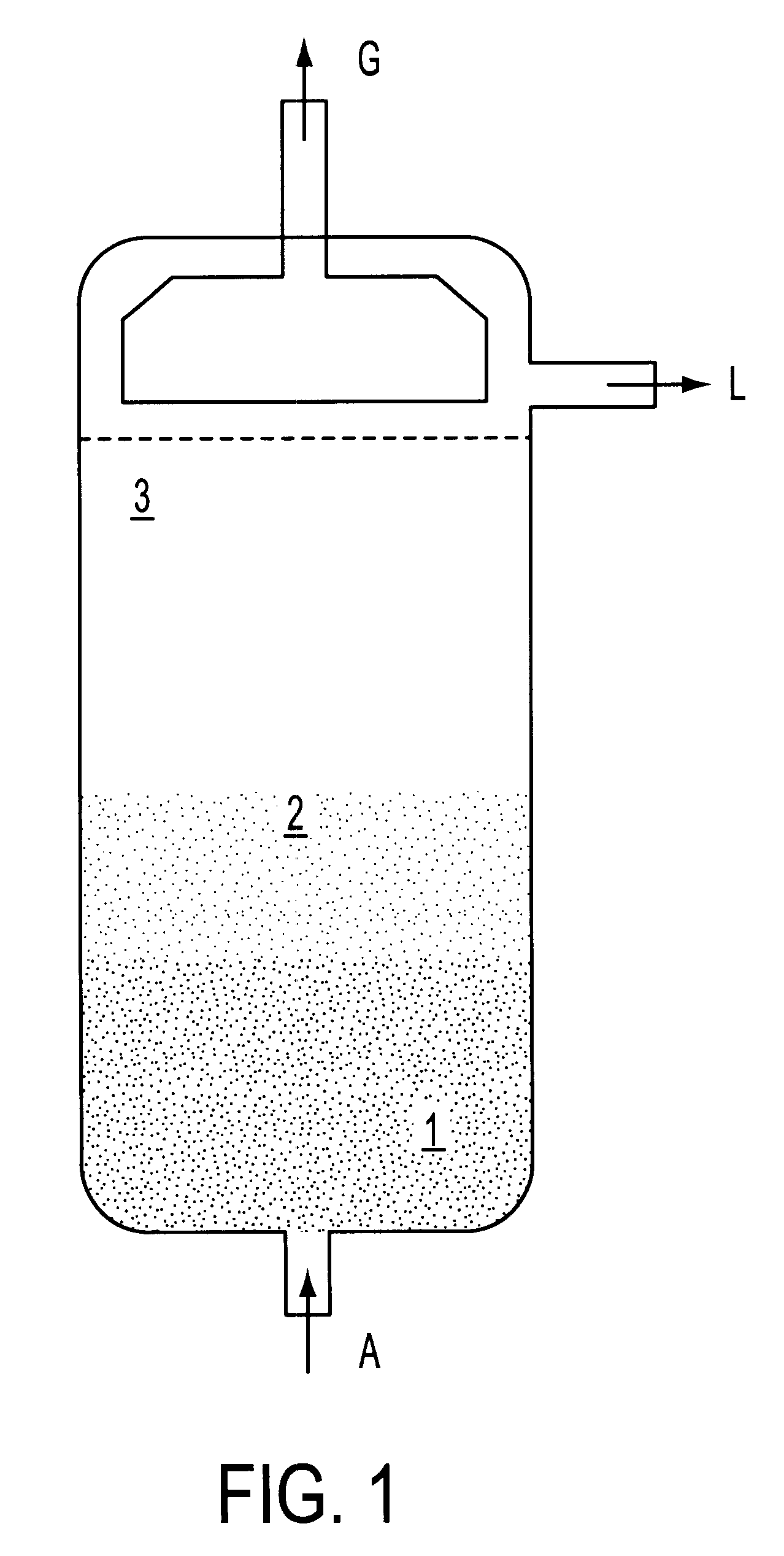

Methods for increasing the production of ethanol from microbial fermentation

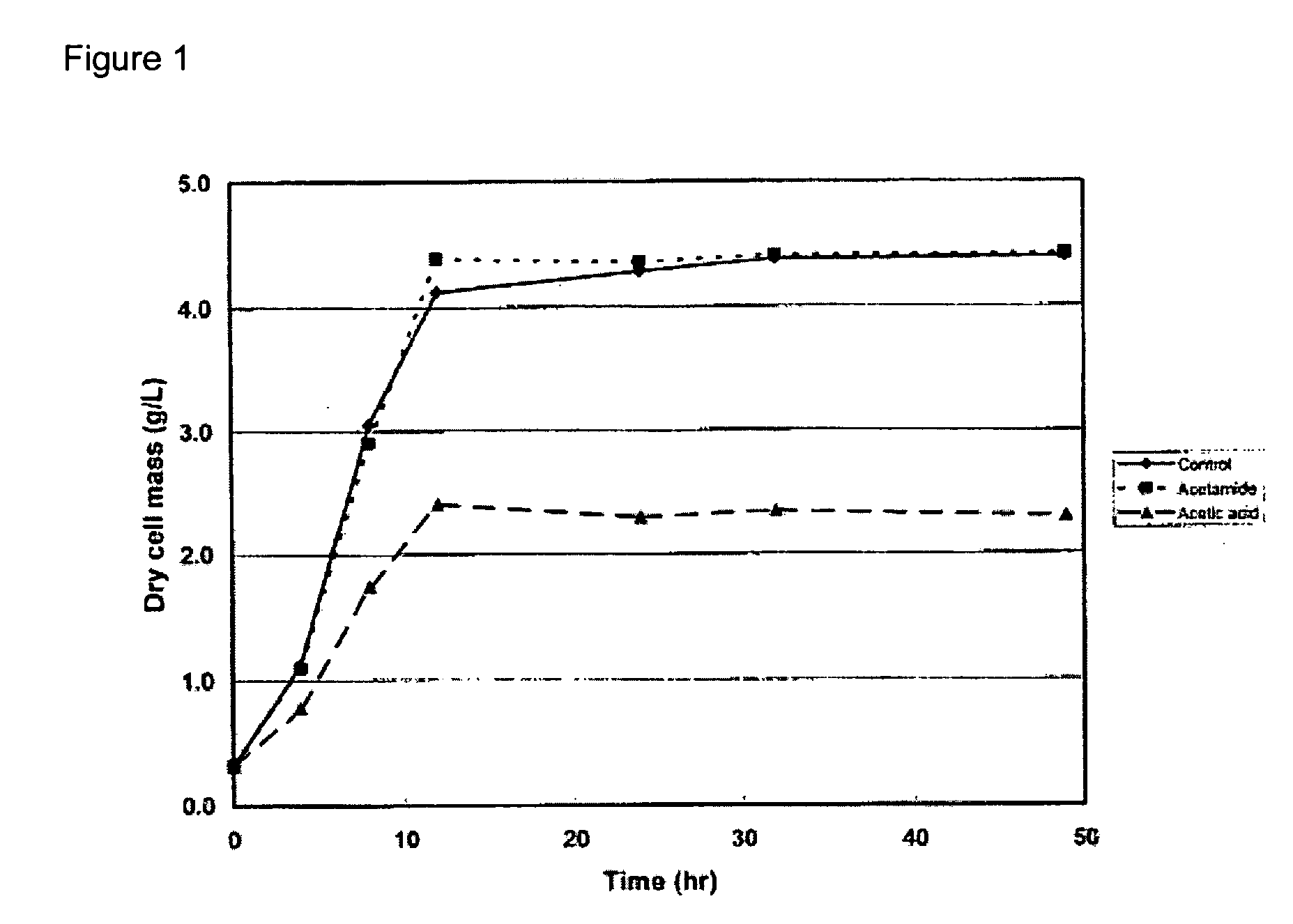

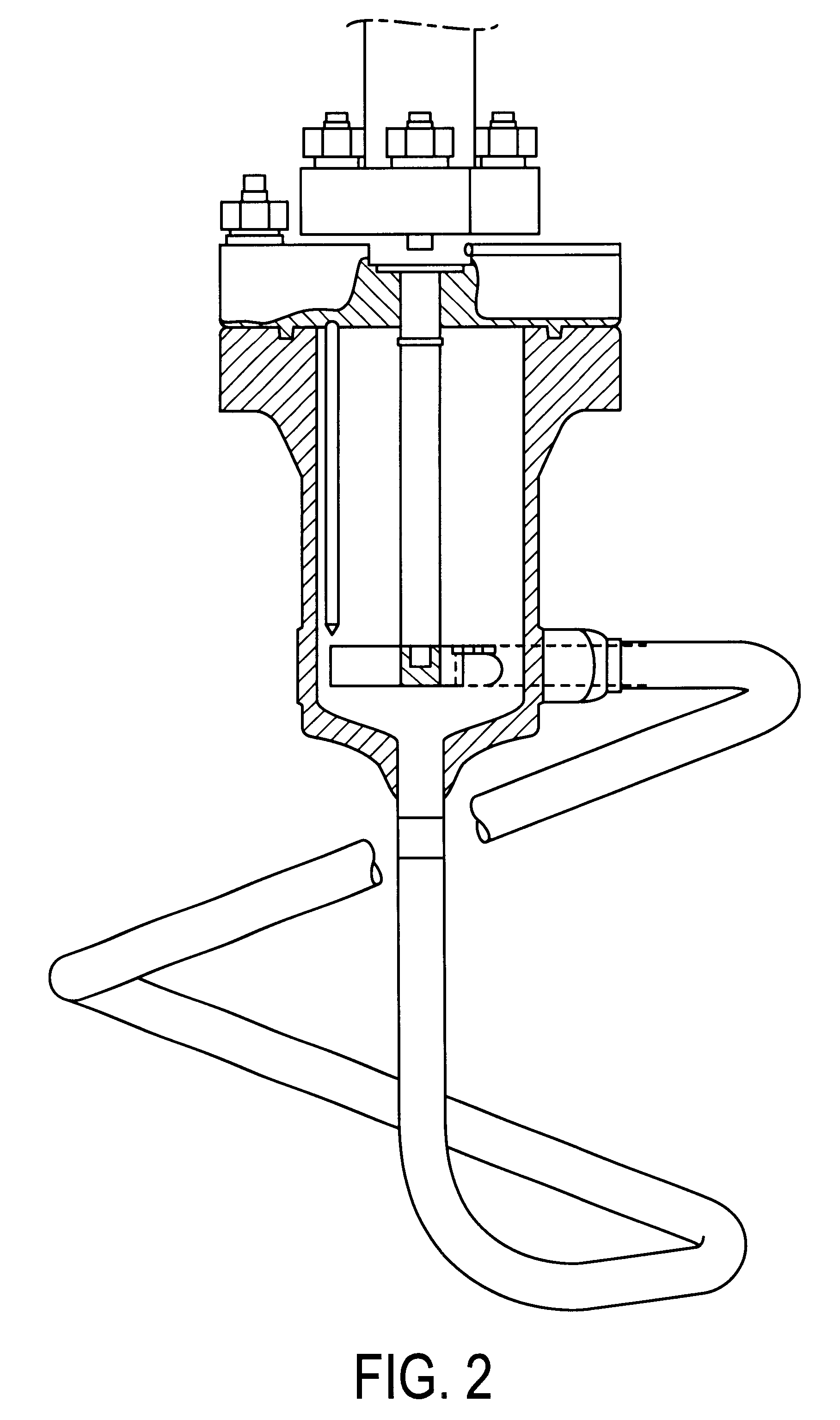

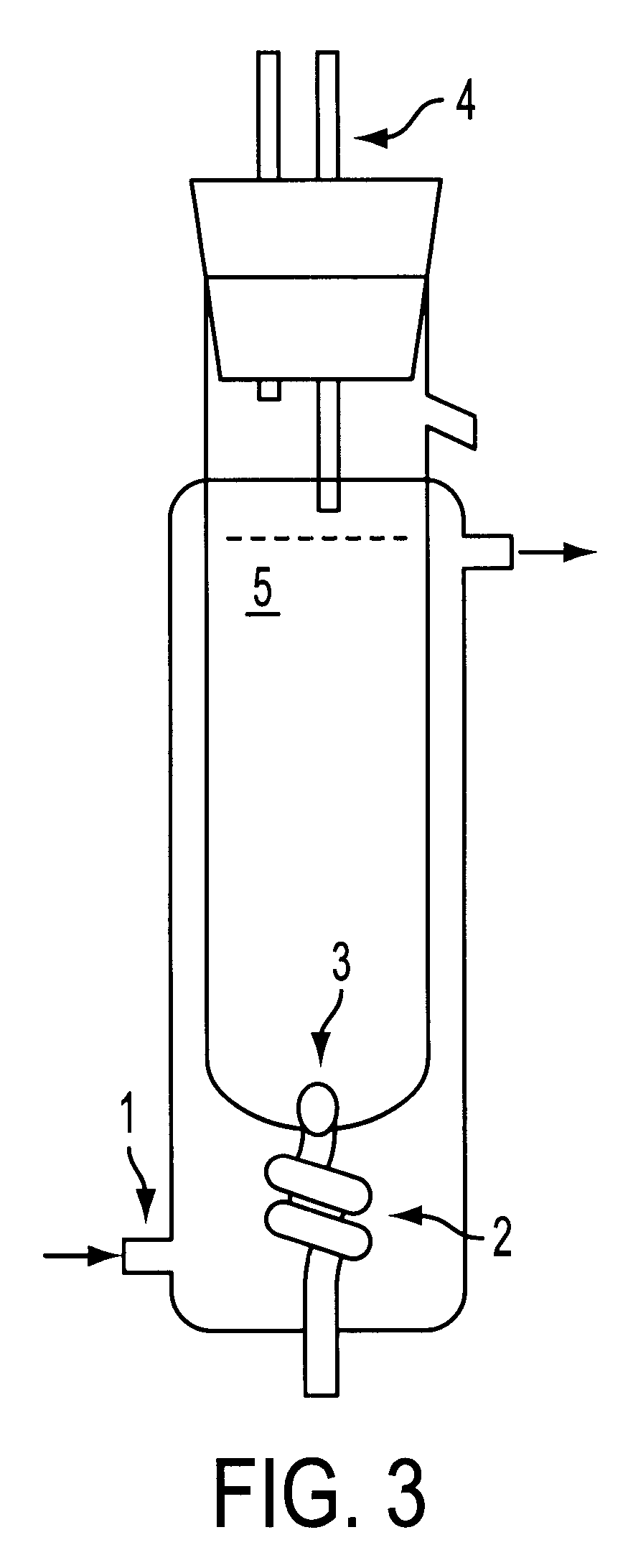

InactiveUS7285402B2Good culture stabilityPermit growthBioreactor/fermenter combinationsSolid waste disposalBioreactorNutrient

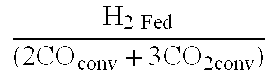

A stable continuous method for producing ethanol from the anaerobic bacterial fermentation of a gaseous substrate containing at least one reducing gas involves culturing a fermentation bioreactor anaerobic, acetogenic bacteria in a liquid nutrient medium; supplying the gaseous substrate to the bioreactor; and manipulating the bacteria in the bioreactor by reducing the redox potential, or increasing the NAD(P)H TO NAD(P) ratio, in the fermentation broth after the bacteria achieves a steady state and stable cell concentration in the bioreactor. The free acetic acid concentration in the bioreactor is maintained at less than 5 g / L free acid. This method allows ethanol to be produced in the fermentation broth in the bioreactor at a productivity greater than 10 g / L per day. Both ethanol and acetate are produced in a ratio of ethanol to acetate ranging from 1:1 to 20:1.

Owner:JUPENG BIO HK LTD

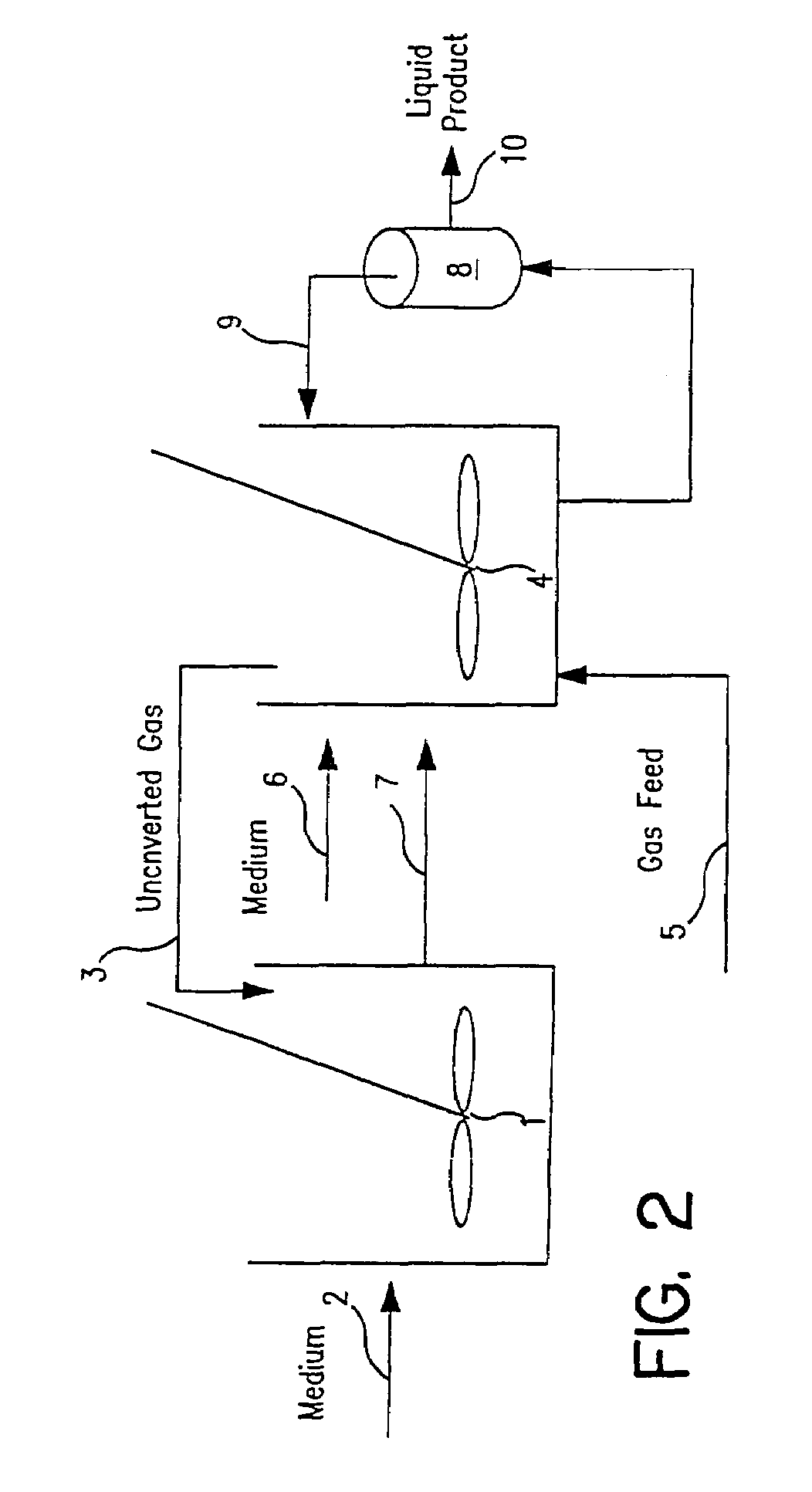

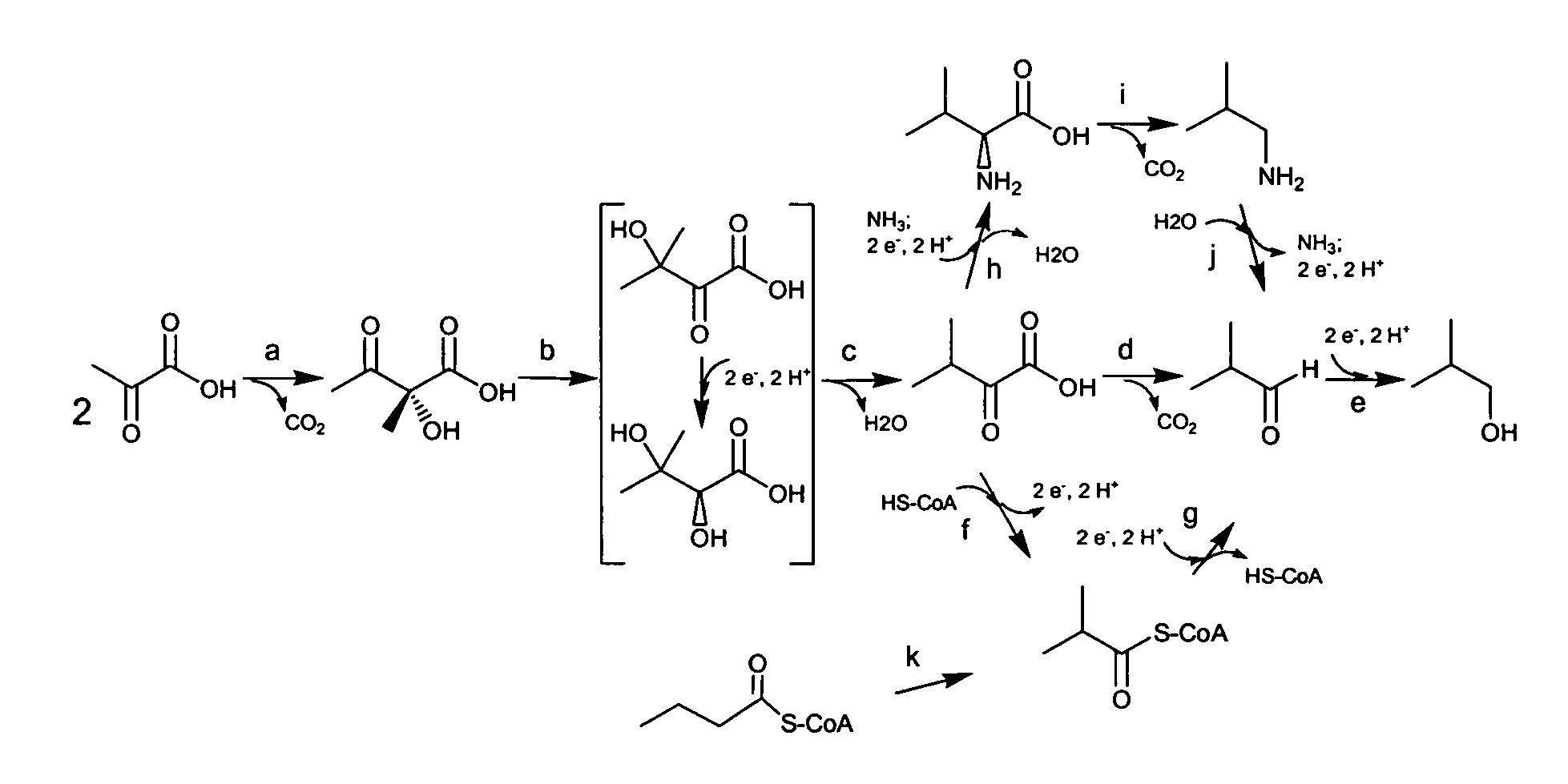

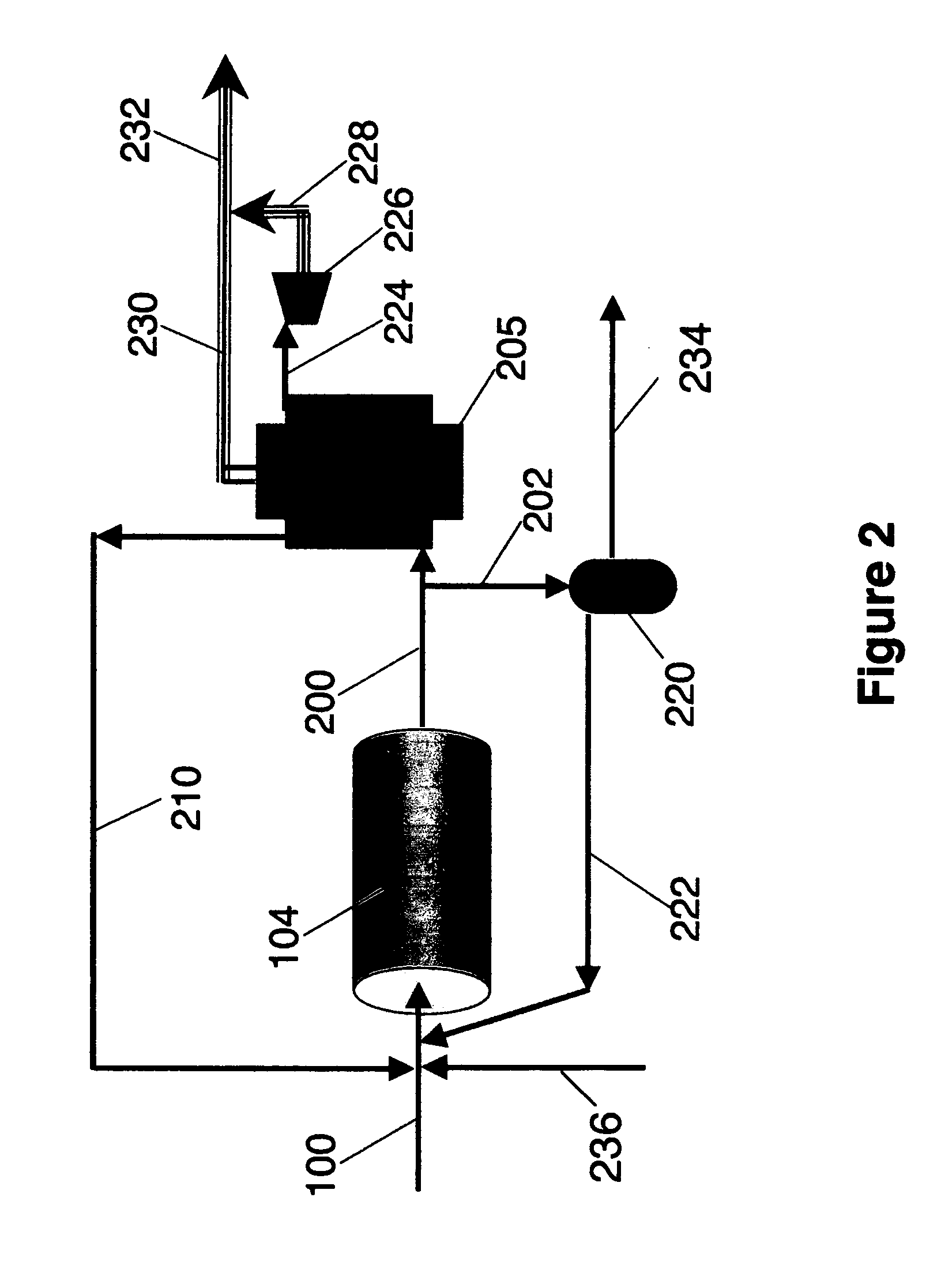

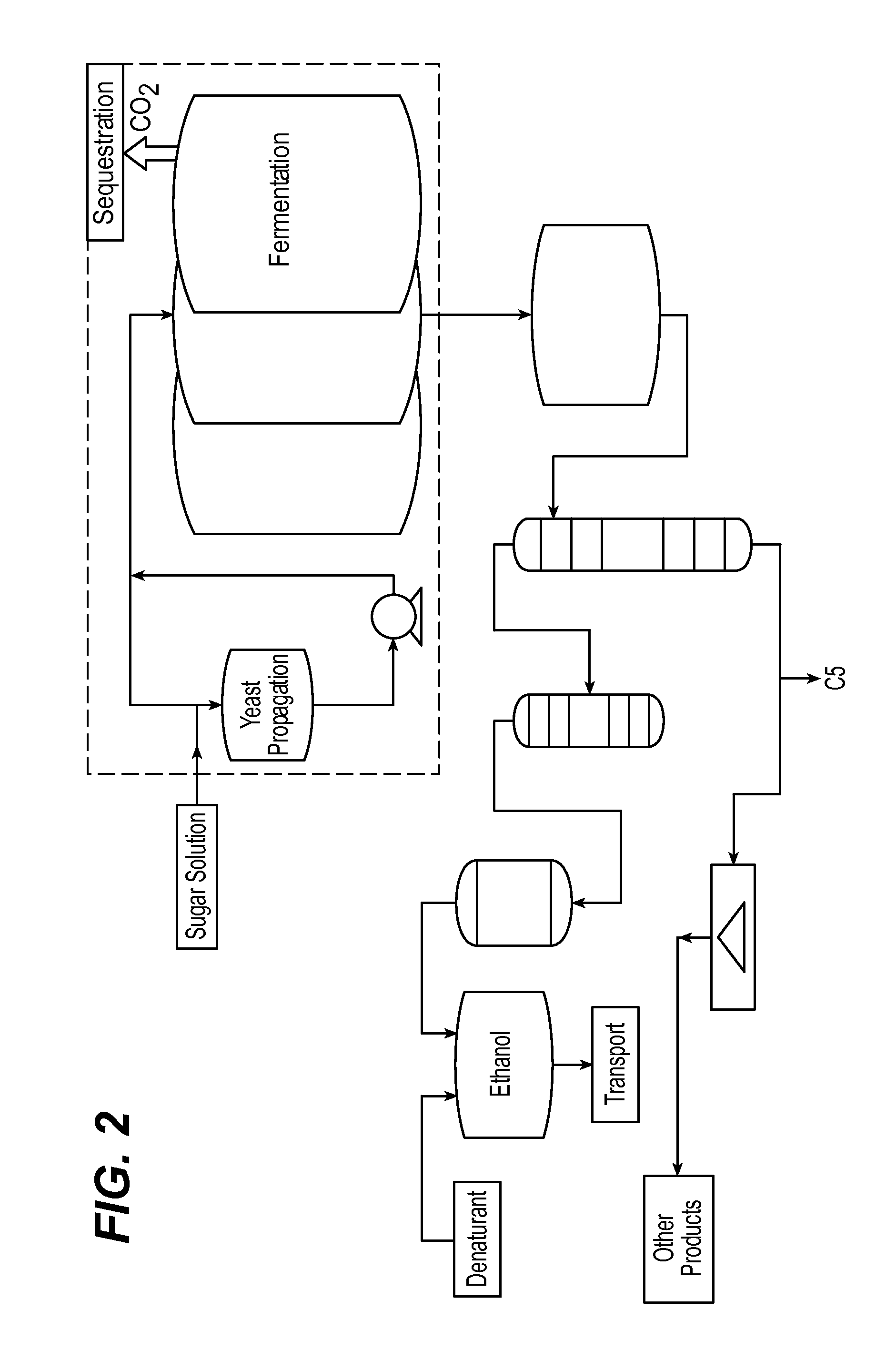

Energy Efficient Methods to Produce Products

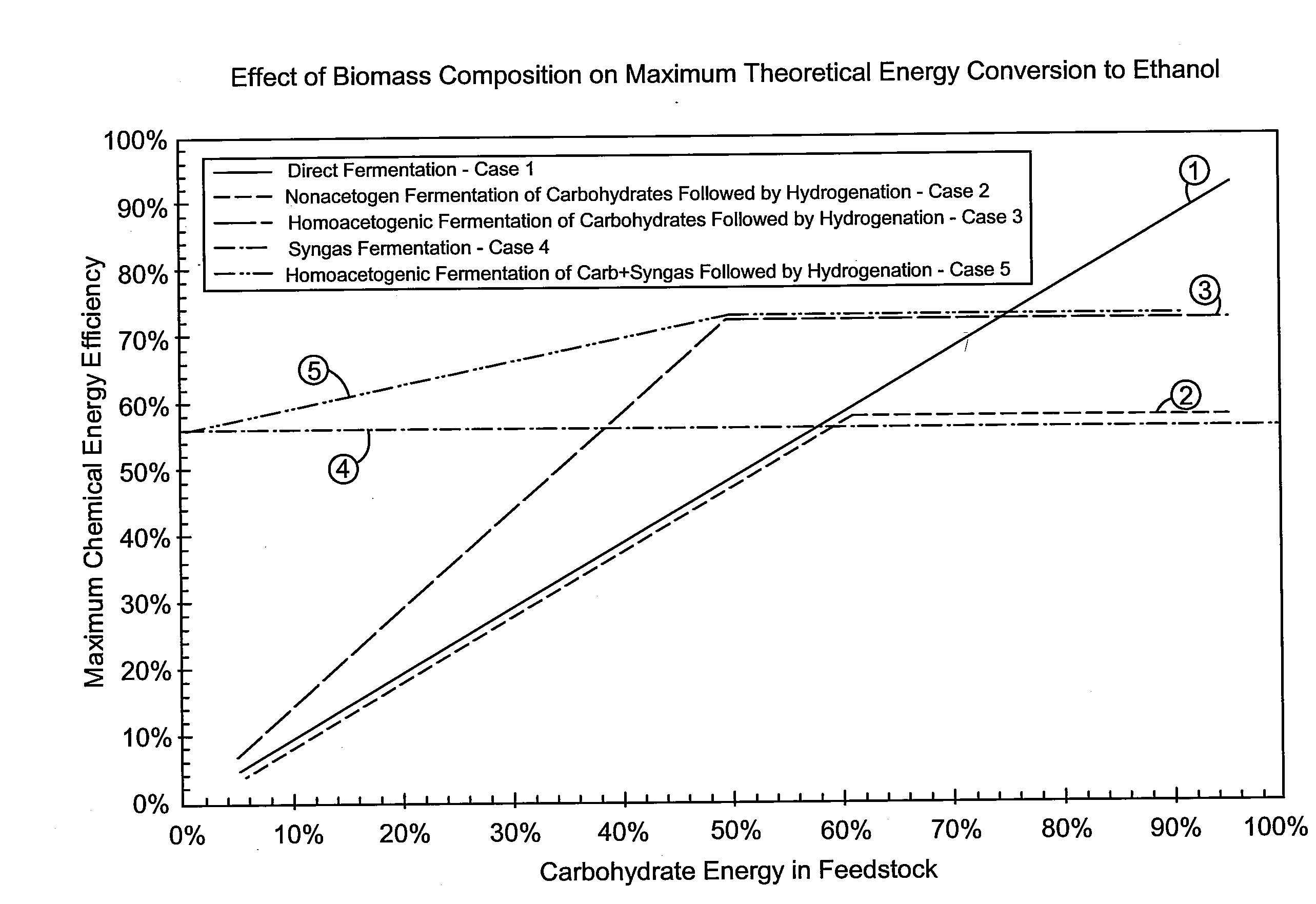

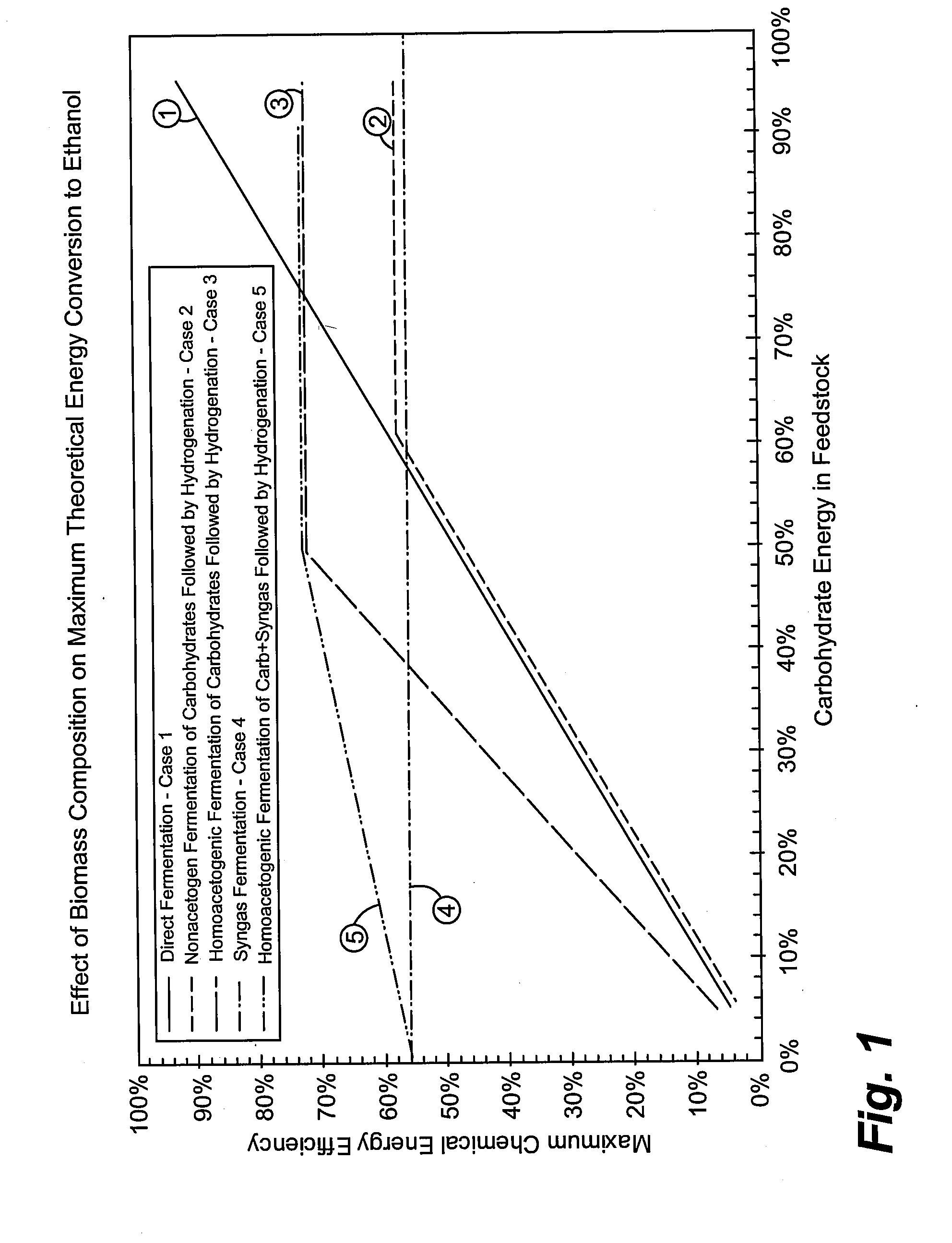

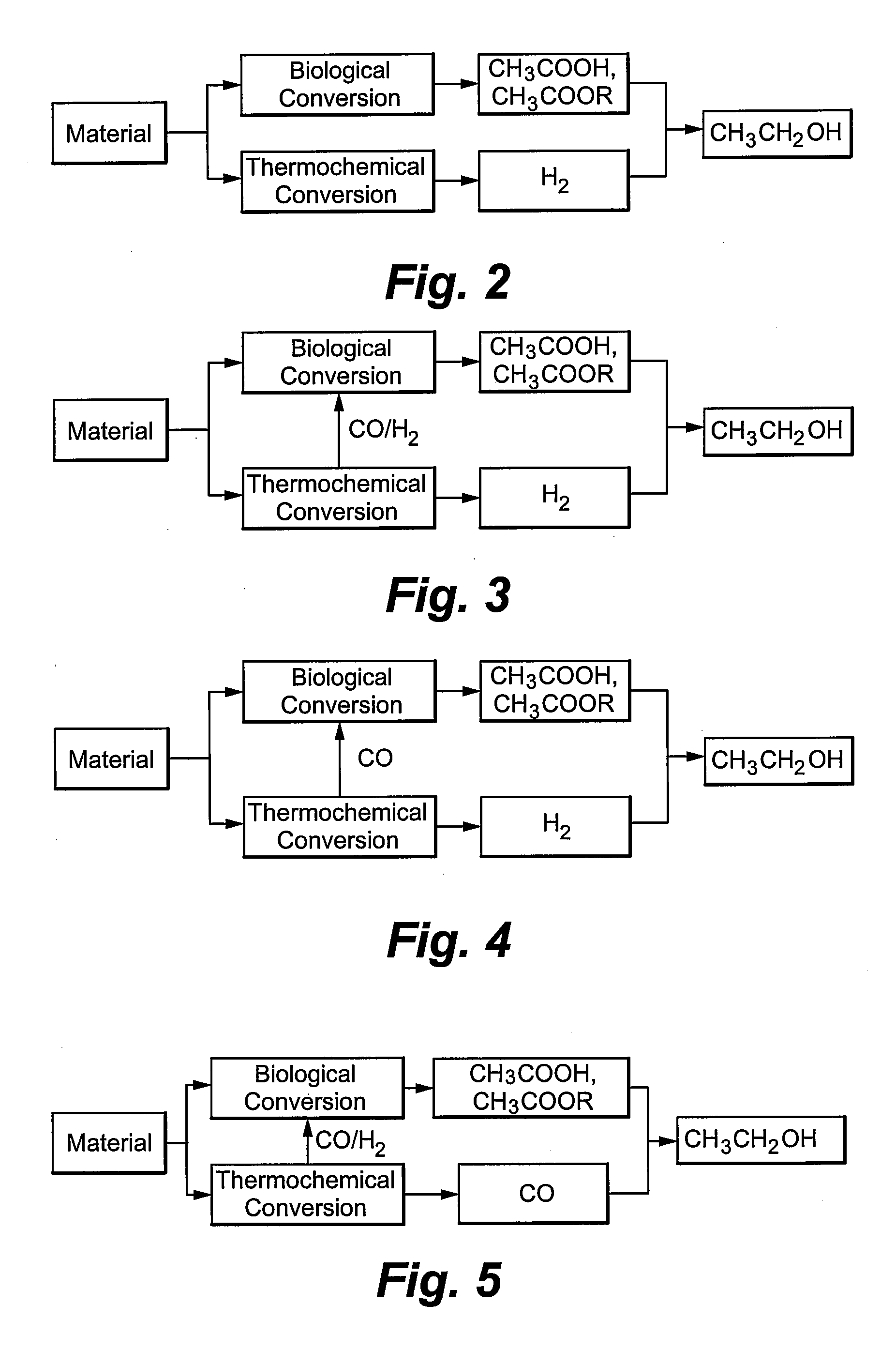

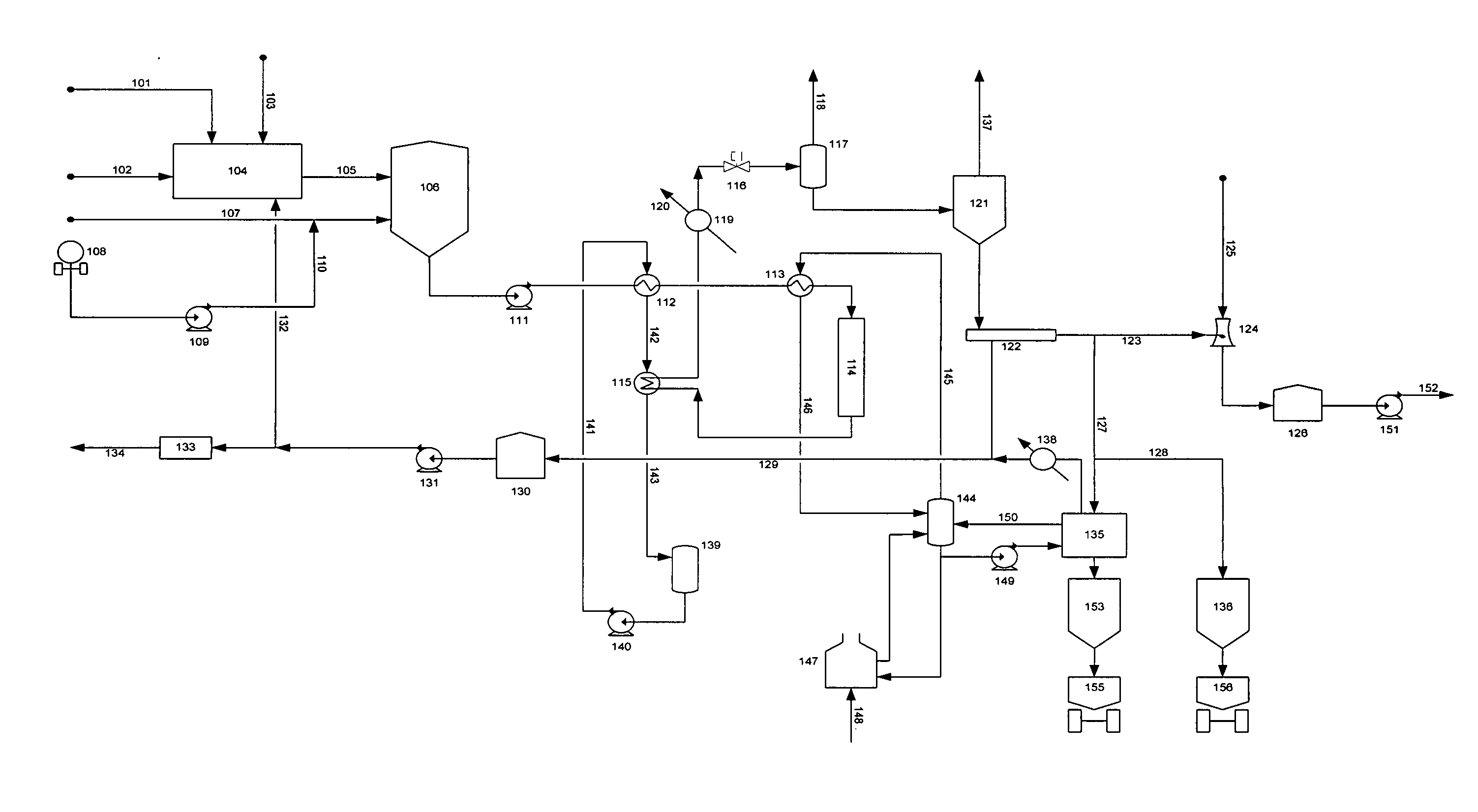

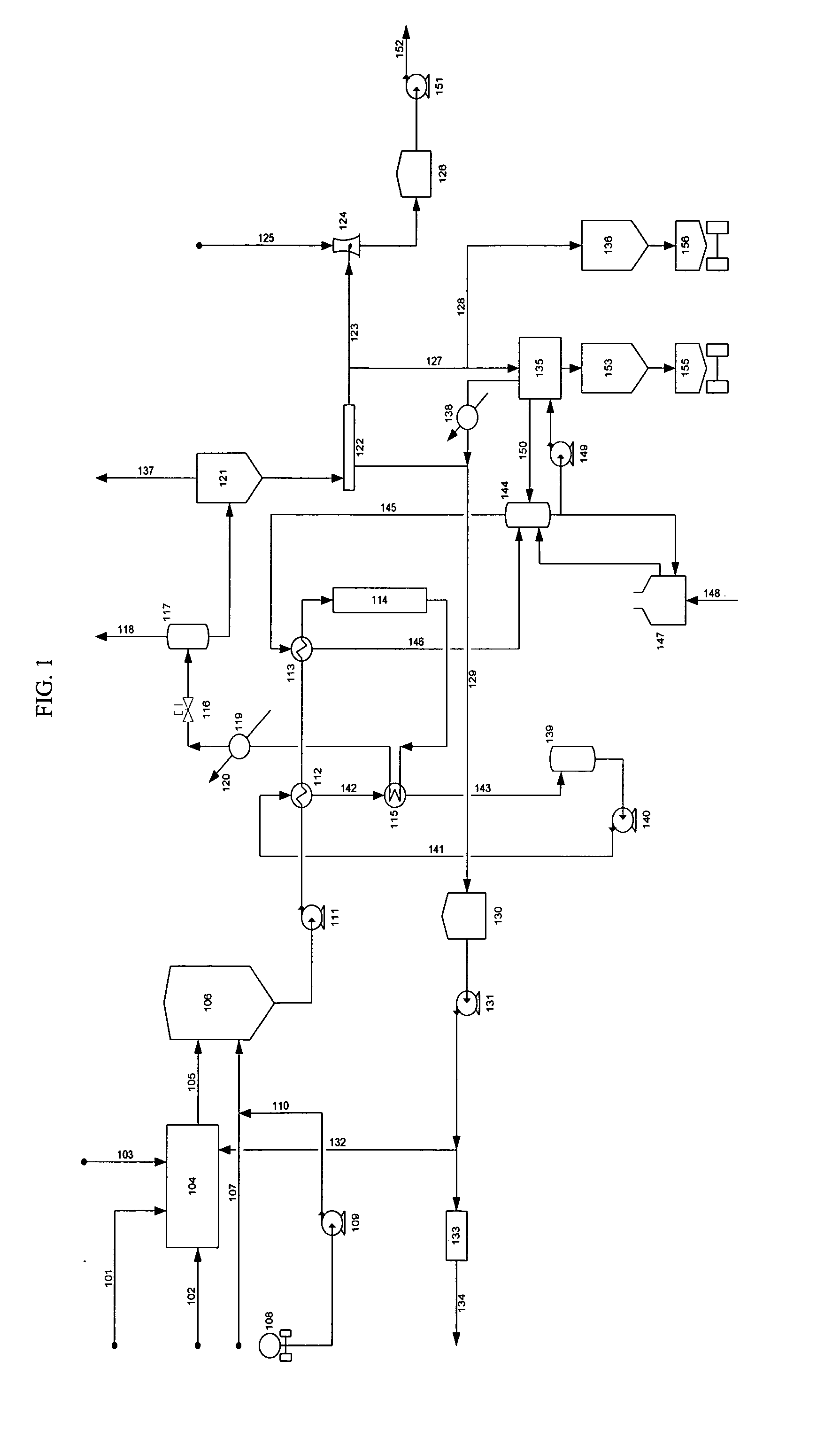

InactiveUS20080193989A1Improve energy efficiencyEnergy efficiencyBiofuelsWaste based fuelBiomassChemistry

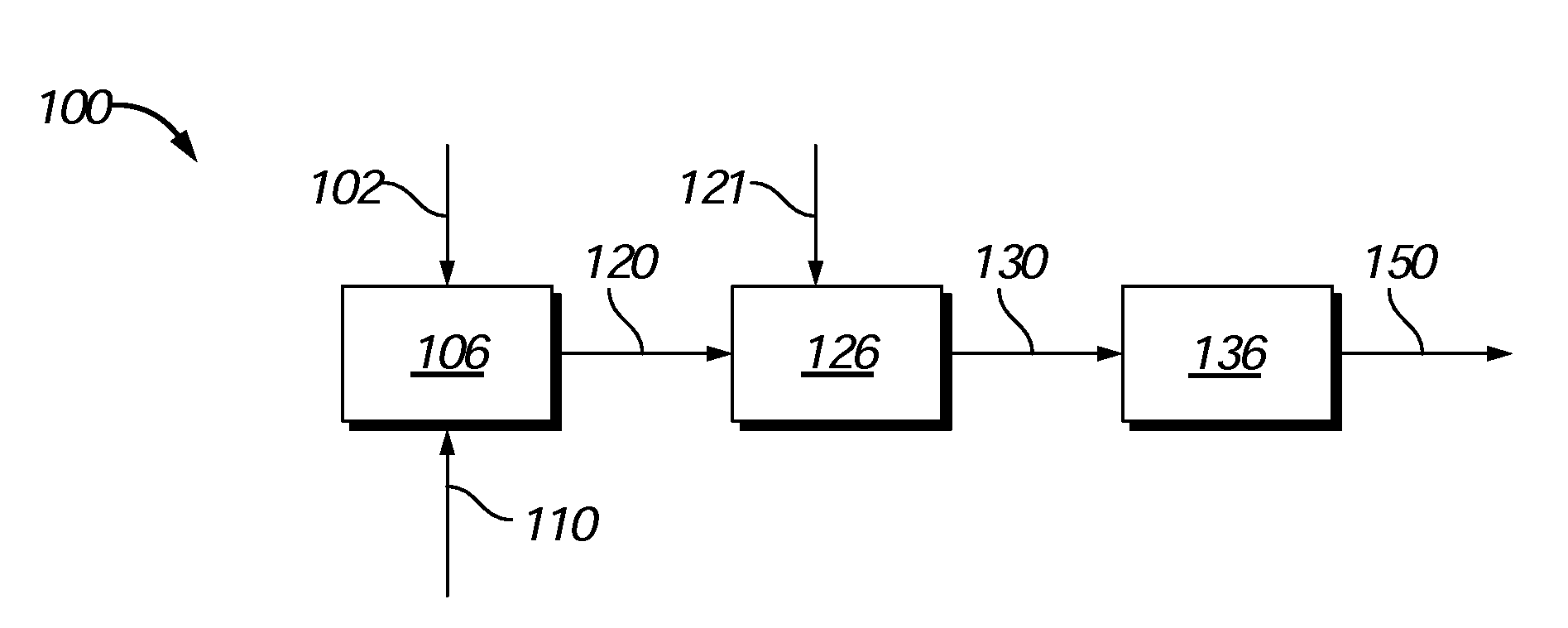

The invention relates to processes that efficiently convert carbon-containing materials, such as biomass, into products in such a manner that the energy, carbon, and mass content of the materials are efficiently transferred into such products. Such methods include converting the materials into at least one intermediate by a biological conversion process and at least one intermediate by a thermochemical conversion process and reacting the intermediates to form the product. Such methods have a chemical energy efficiency to produce the product that is greater than the chemical energy efficiency of a solely biological conversion process to produce the product and that is greater than the chemical energy efficiency of a process in which all of the material is initially subjected to a thermochemical conversion step as part of the process to produce the product.

Owner:ZEACHEM

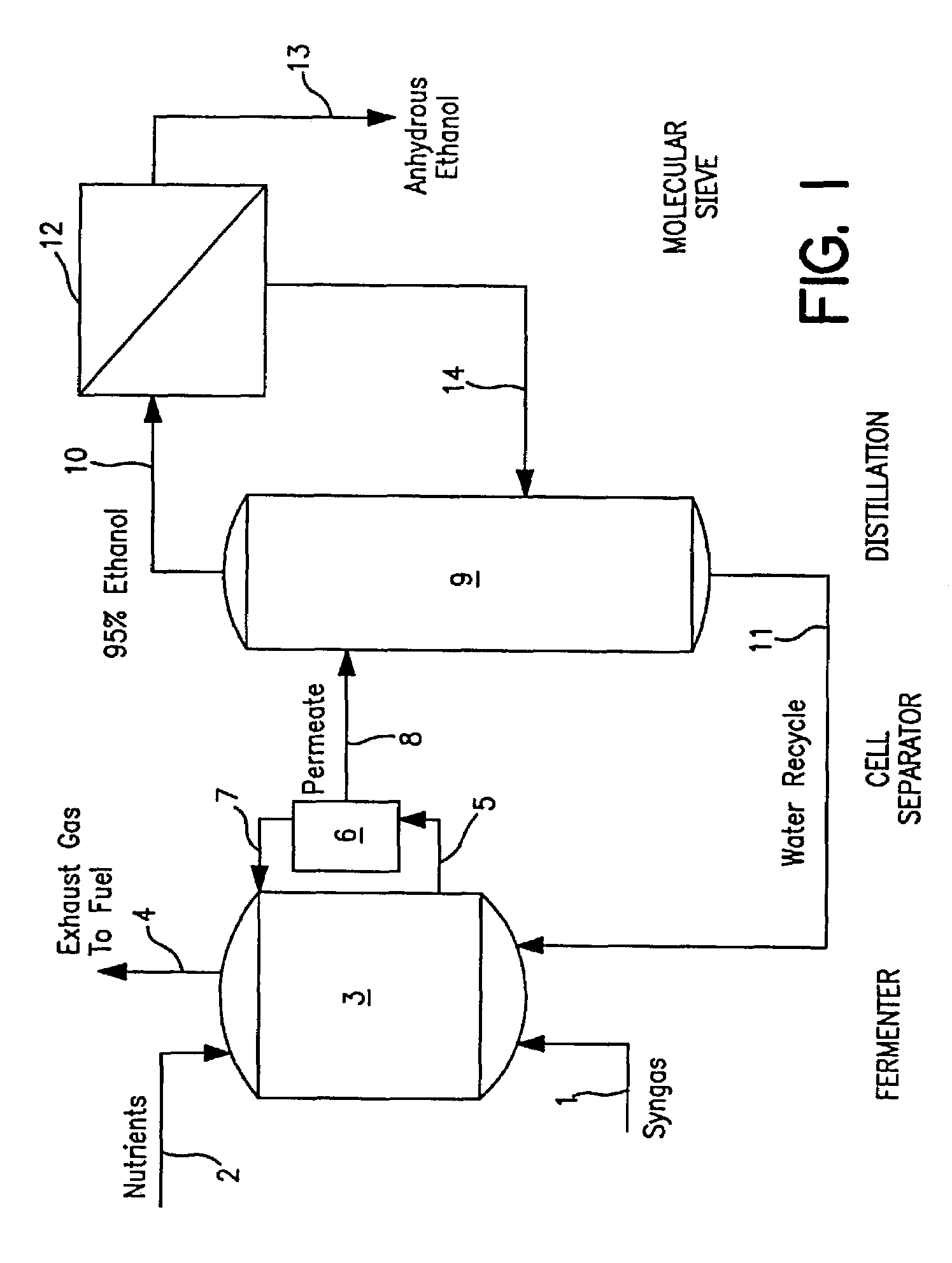

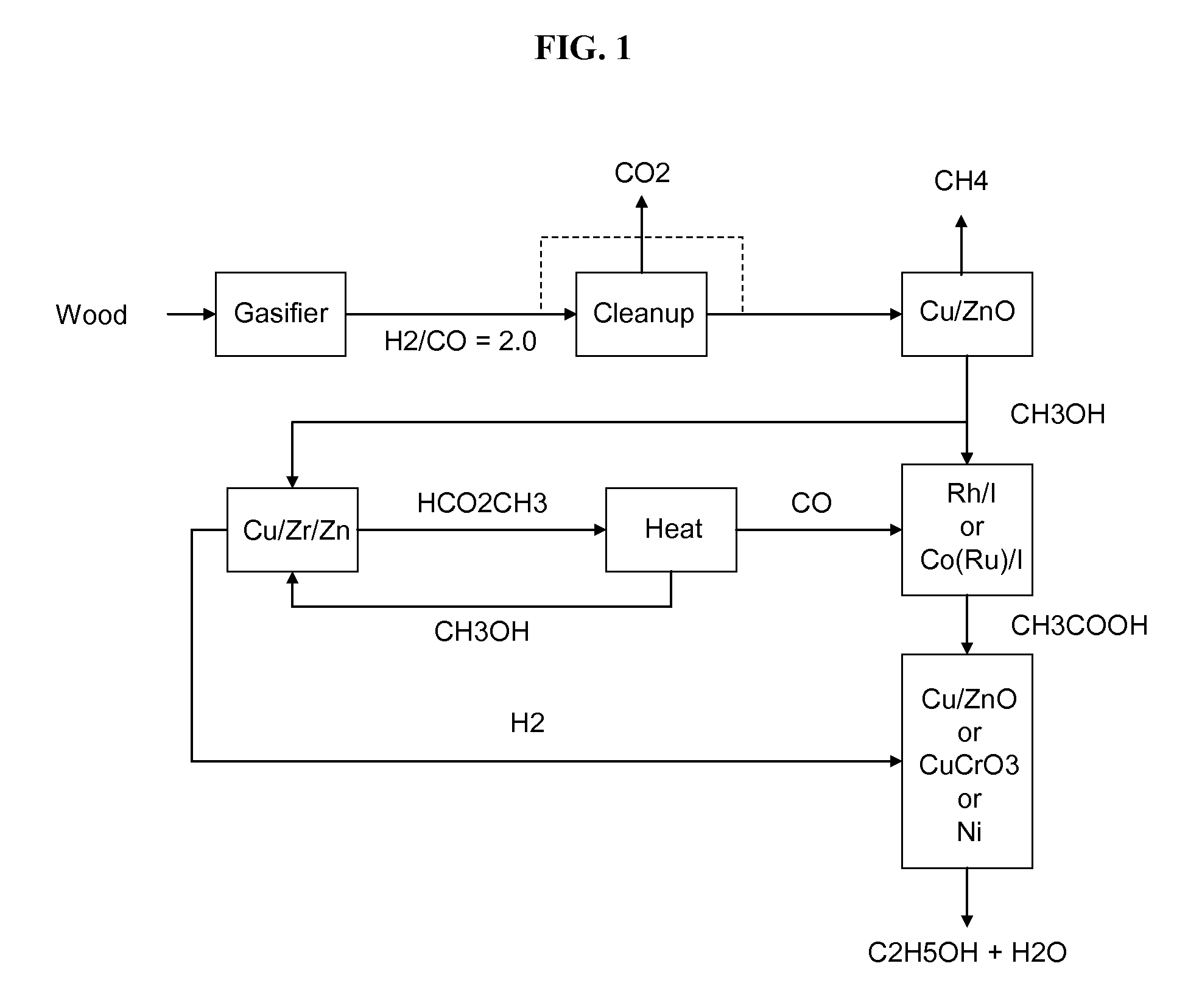

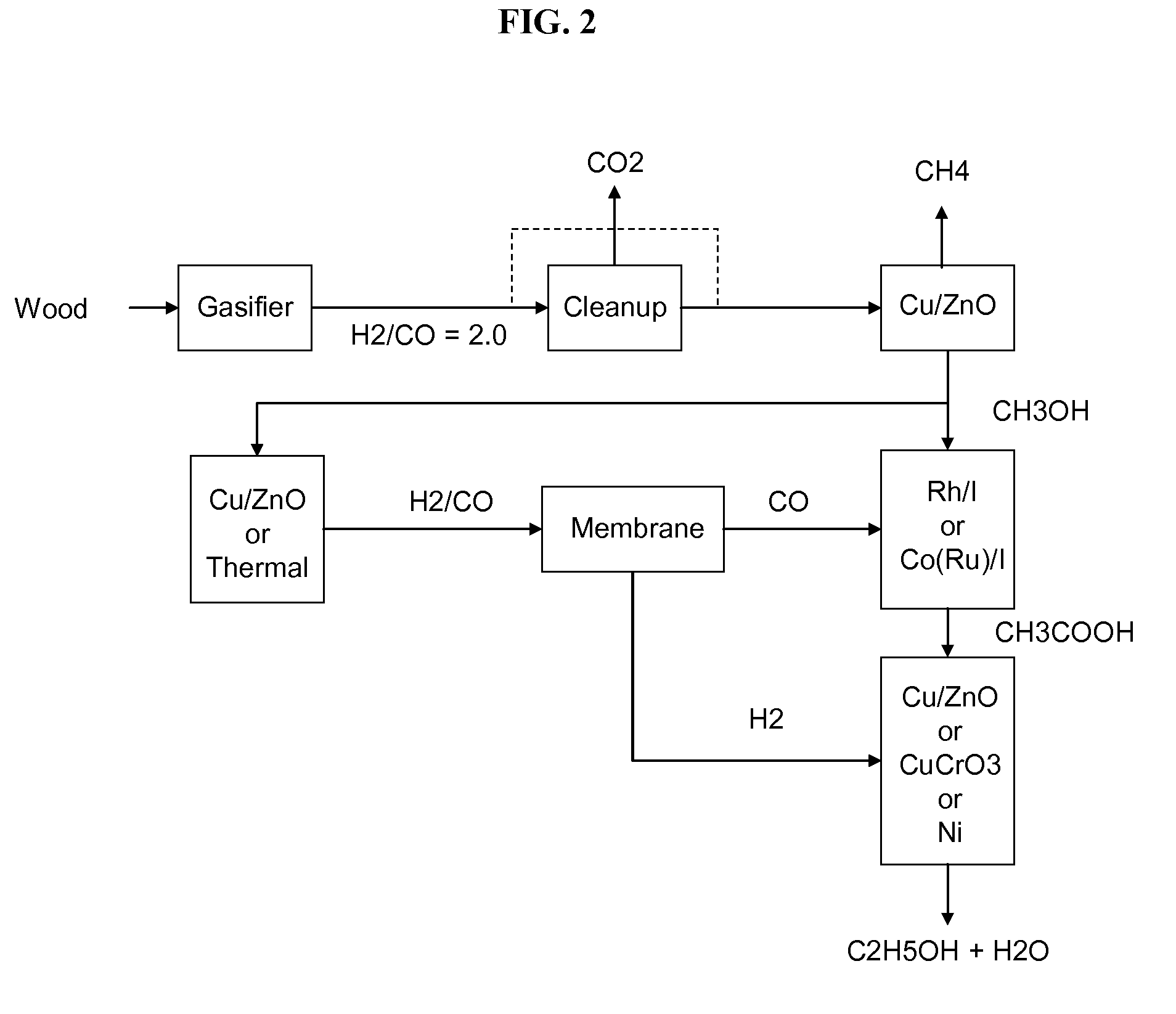

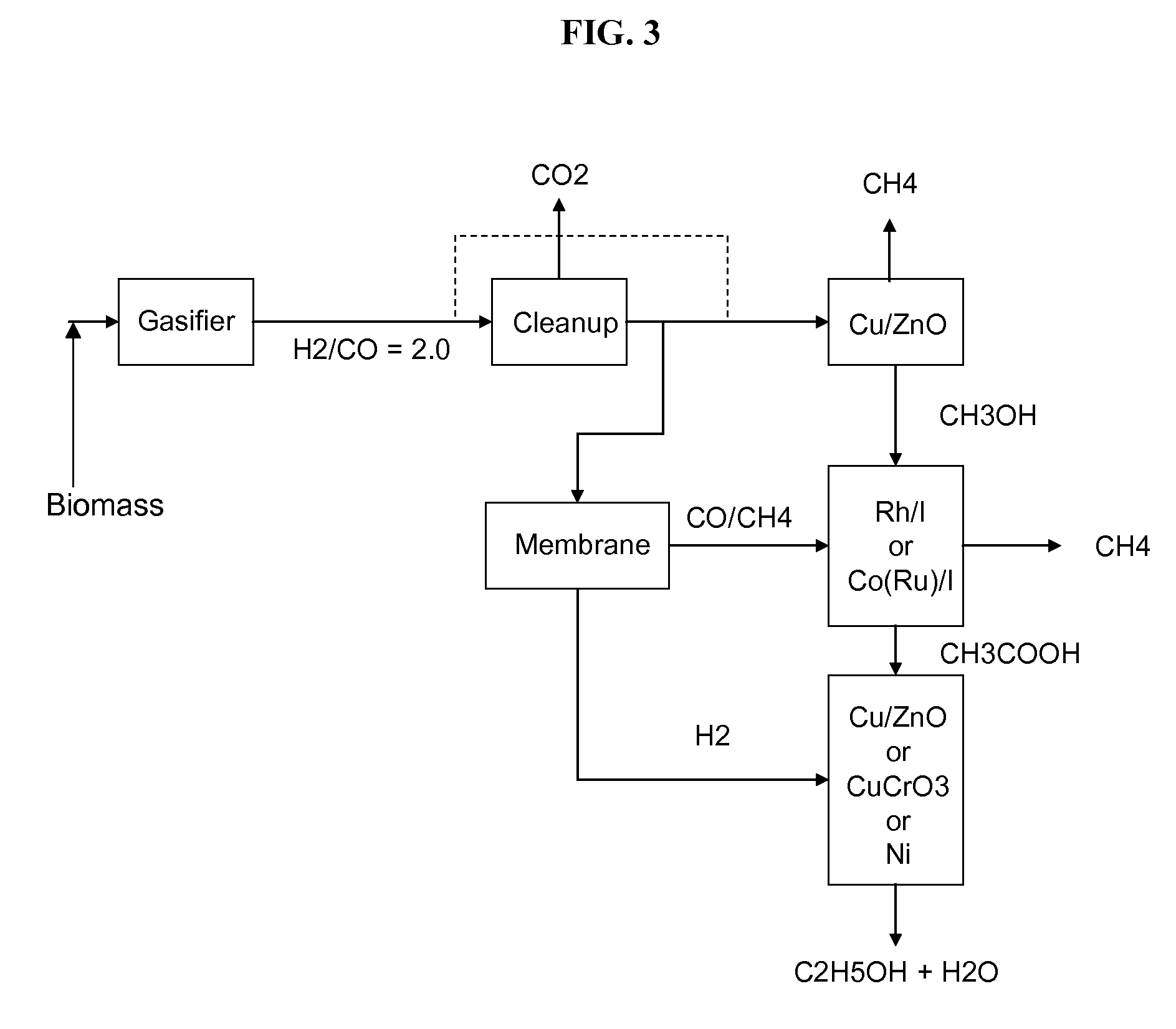

Methods and apparatus for selectively producing ethanol from synthesis gas

The invention provides methods and apparatus for selectively producing ethanol from syngas. As disclosed herein, syngas derived from cellulosic biomass (or other sources) can be catalytically converted into methanol, which in turn can be catalytically converted into acetic acid or acetates. Finally, the acetic acid or acetates can be reduced to ethanol according to several variations. In some embodiments, yields of ethanol from biomass can exceed 100 gallons per dry ton of biomass.

Owner:CELANESE INT CORP

Fermentive production of four carbon alcohols

Owner:GEVO INC

Method for processing lignocellulosic material

InactiveUS6555350B2High degreeReduce water consumptionSludge treatment by oxidationBiofuelsCelluloseWater flow

A method wherein lignocellulosic biomass materials are converted into combustible fuel products. In particular, the method is a continuous process, involving wet oxidation or steam explosion, for fermentatively converting such biomass materials into ethanol using a process design that permits all or part of the process water from the ethanol fermentation process to be recycled to reduce the consumption of process water. The effluent from the ethanol fermentation step may be subjected to an anaerobic fermentation step generating methane and a water effluent in which the amount of potentially inhibitory substances is at a sub-inhibitory level, which in turn permits all or part of the effluent water from the anaerobic fermentation step to be recycled into the process.

Owner:POET RES INC

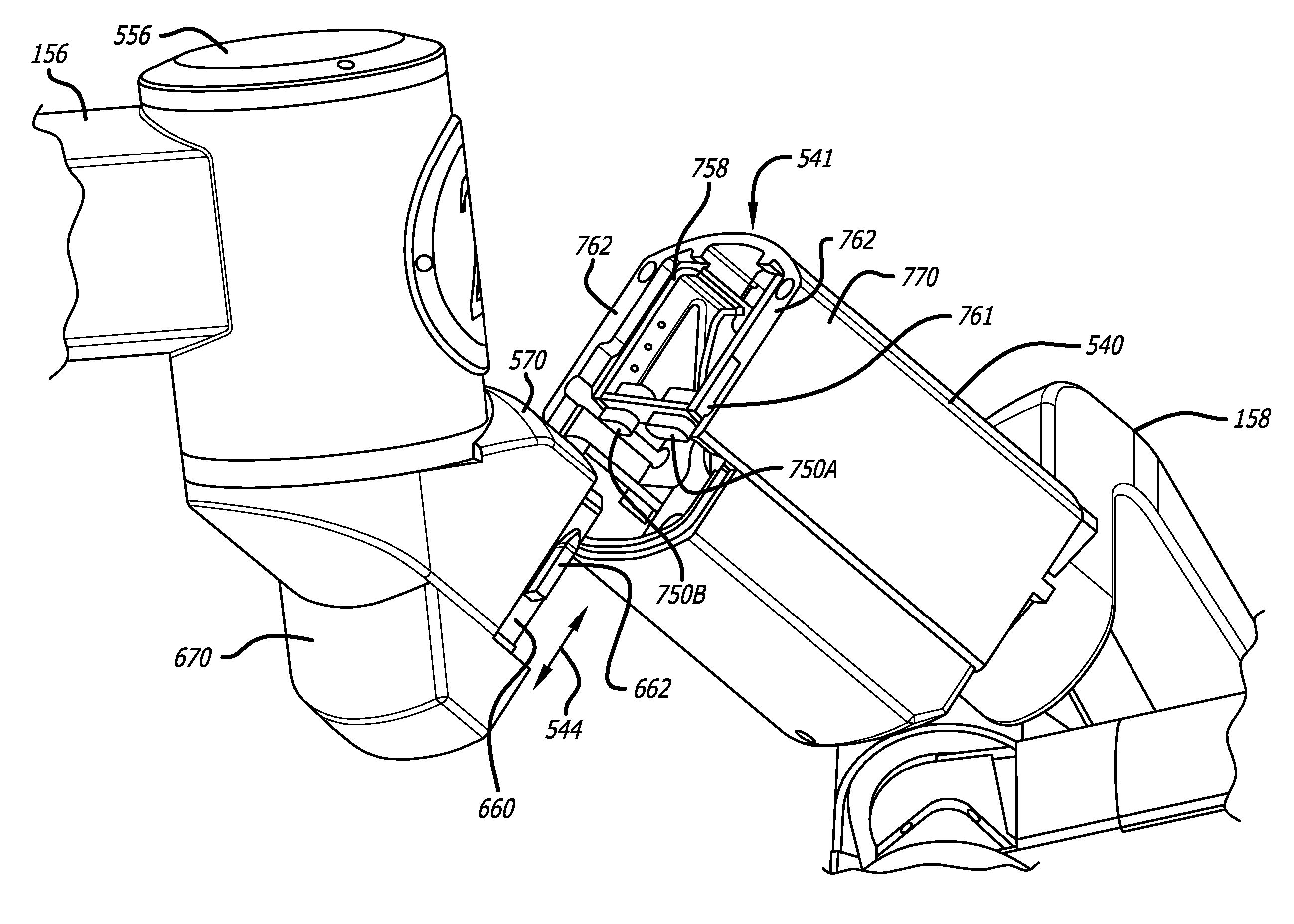

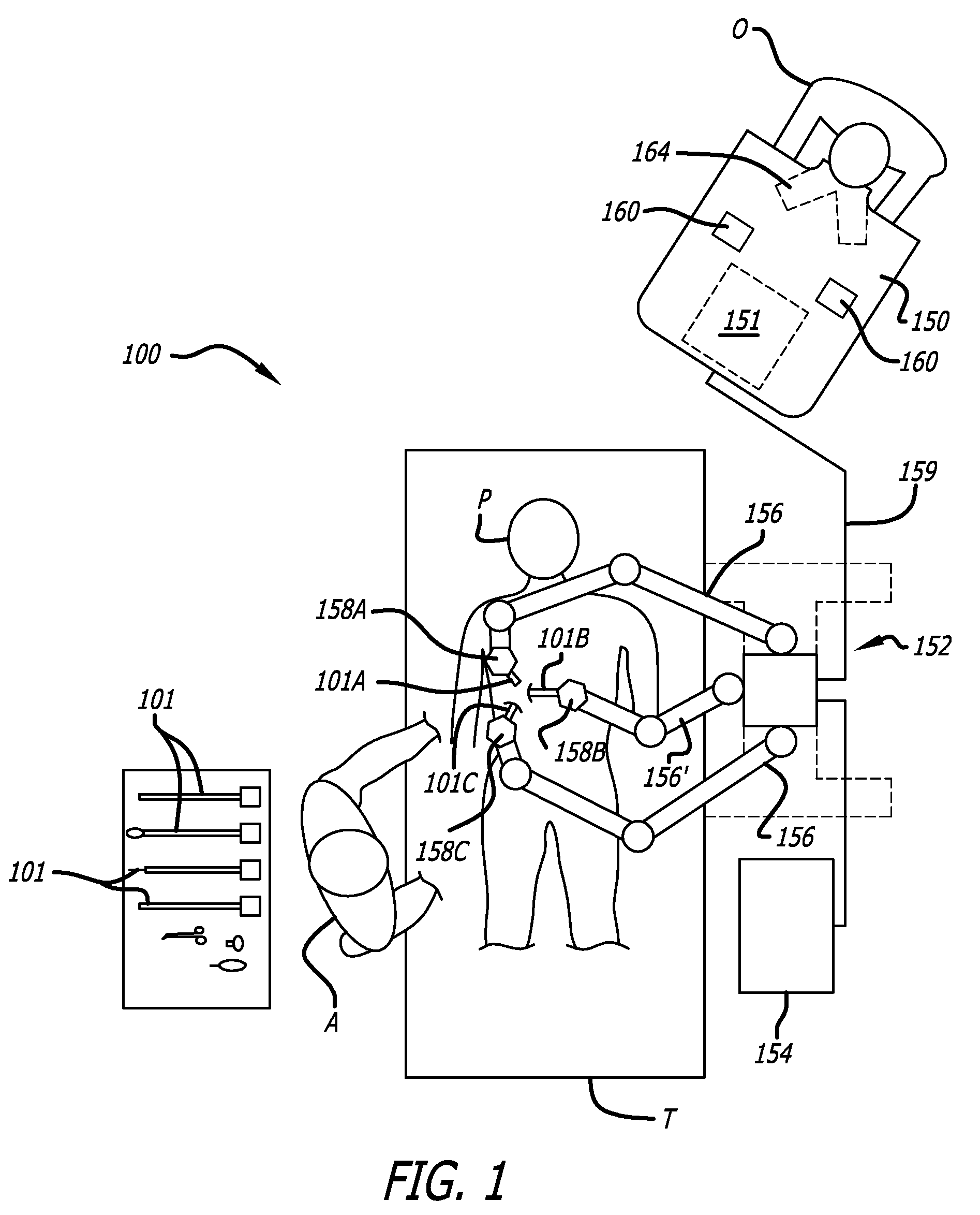

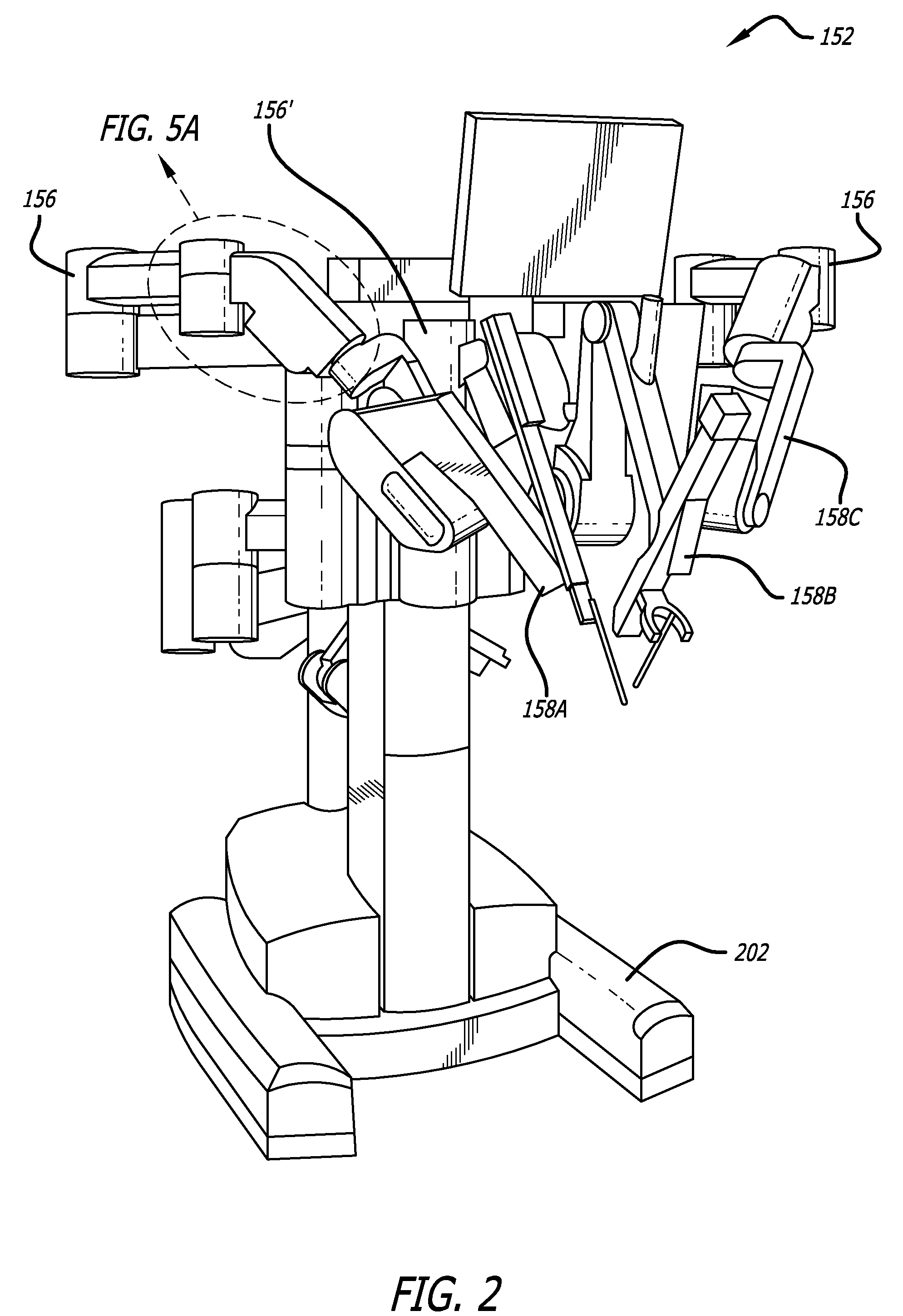

Electro-mechanical interfaces to mount robotic surgical arms

In one embodiment of the invention, a method of mounting a surgical robotic arm to a set-up arm of a robotic surgical system is provided that includes sliding a pair of guide slots of the surgical robotic arm over a pair of guide tabs in the set-up arm; aligning electrical connectors in the set-up arm to electrical connectors of the surgical robotic arm; and coincidentally mating male electrical connectors to female electrical connectors while finally mating the guide tabs in the set-up arm to flanges of a housing of the surgical robotic arm.

Owner:INTUITIVE SURGICAL OPERATIONS INC

Biomass Char Compositions for Catalytic Gasification

InactiveUS20090217575A1Efficient utilization of carbonEfficient comprehensive utilizationProductsReagentsParticulatesHydrogen

Particulate compositions are described comprising an intimate mixture of a biomass char producedfrom the combustion of a biomass, such as switchgrass or hybrid poplar, with at least a second carbonaceous material, such as petroleum coke or coal, and, optionally a gasification catalyst, for gasification in the presence of steam to yield a plurality of gases including methane and at least one or more of hydrogen, carbon monoxide, and other higher hydrocarbons are formed. Processes are also provided for the preparation of the particulate compositions and converting the particulate composition into a plurality of gaseous products.

Owner:SURE CHAMPION INVESTMENT LTD

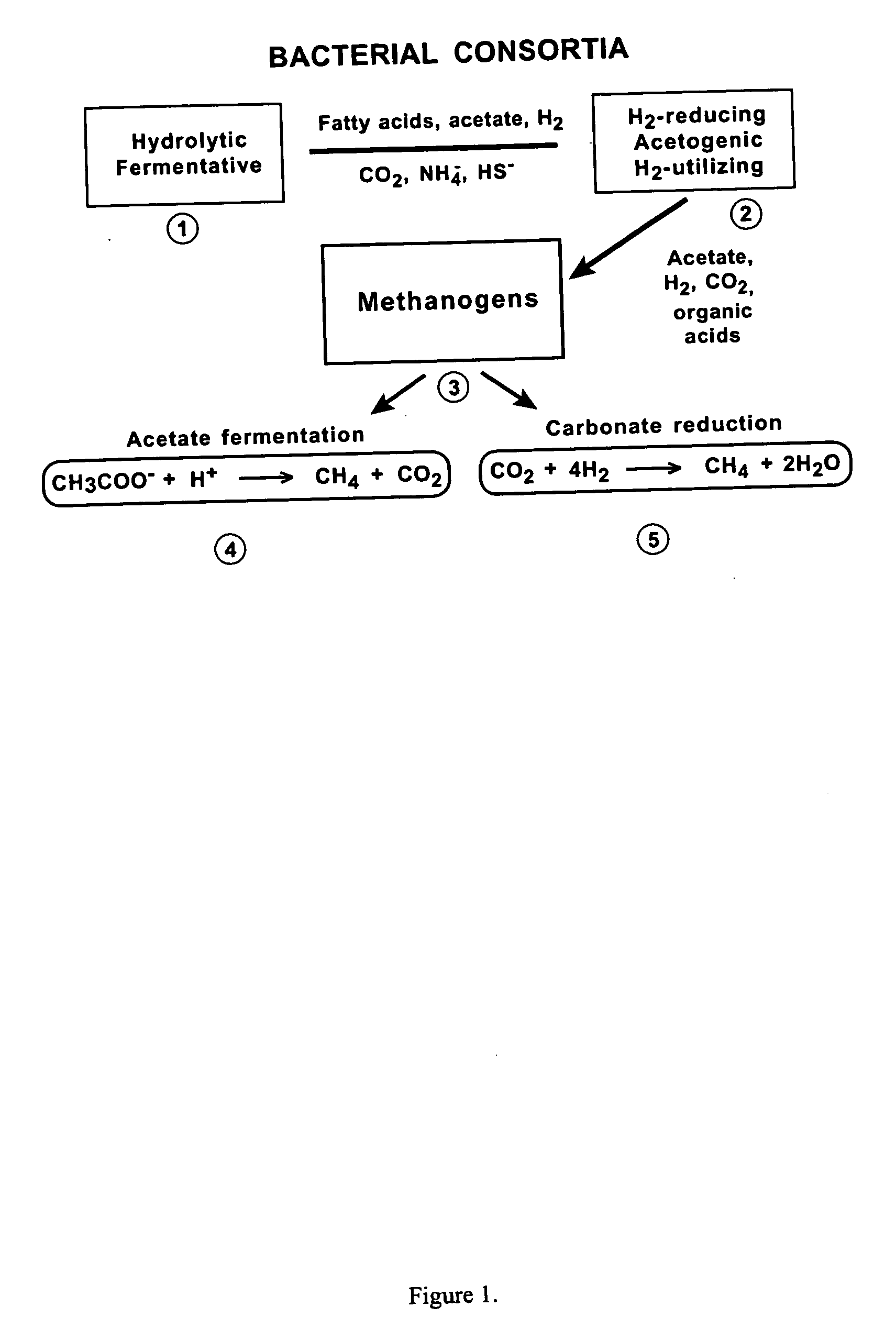

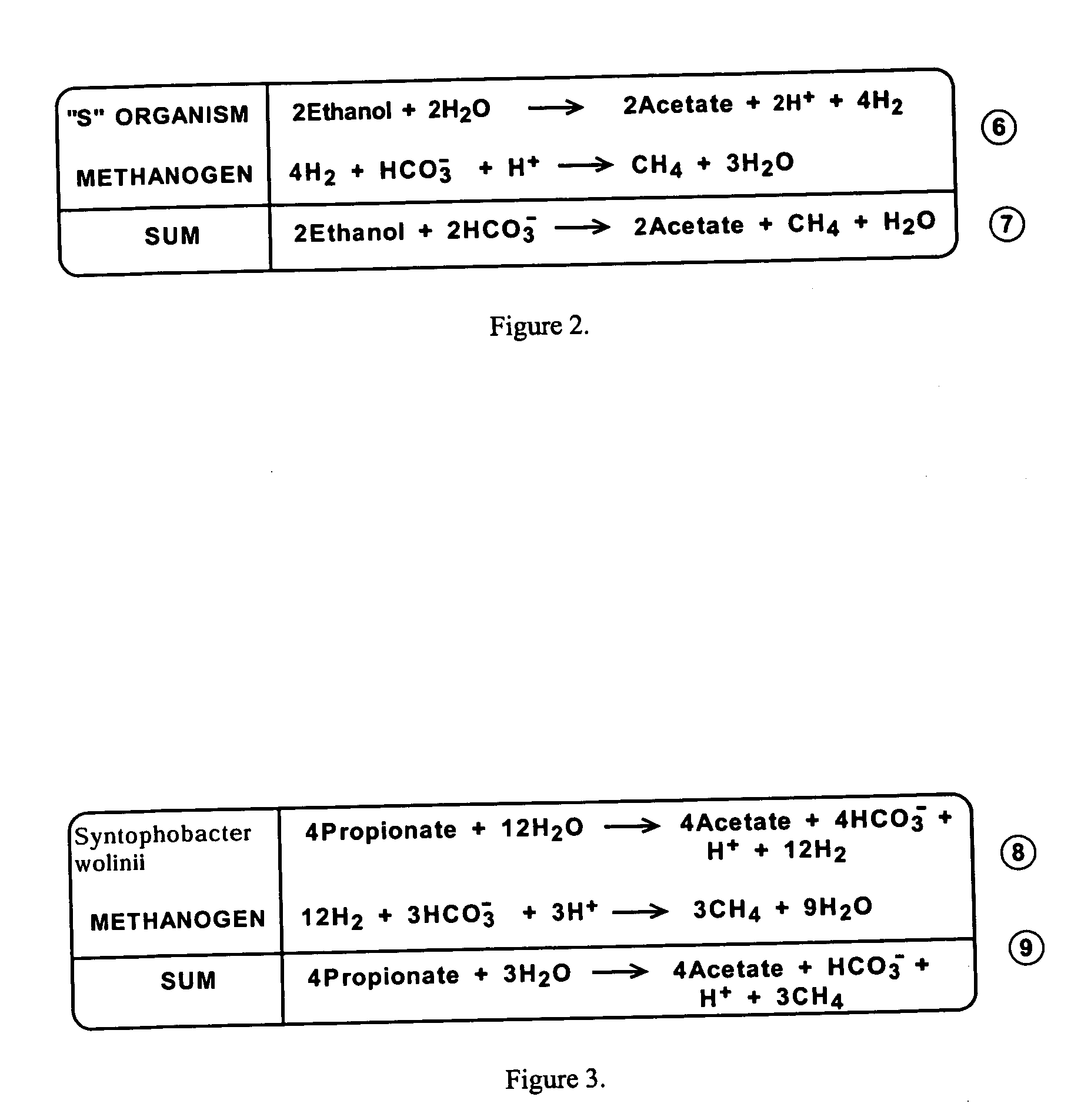

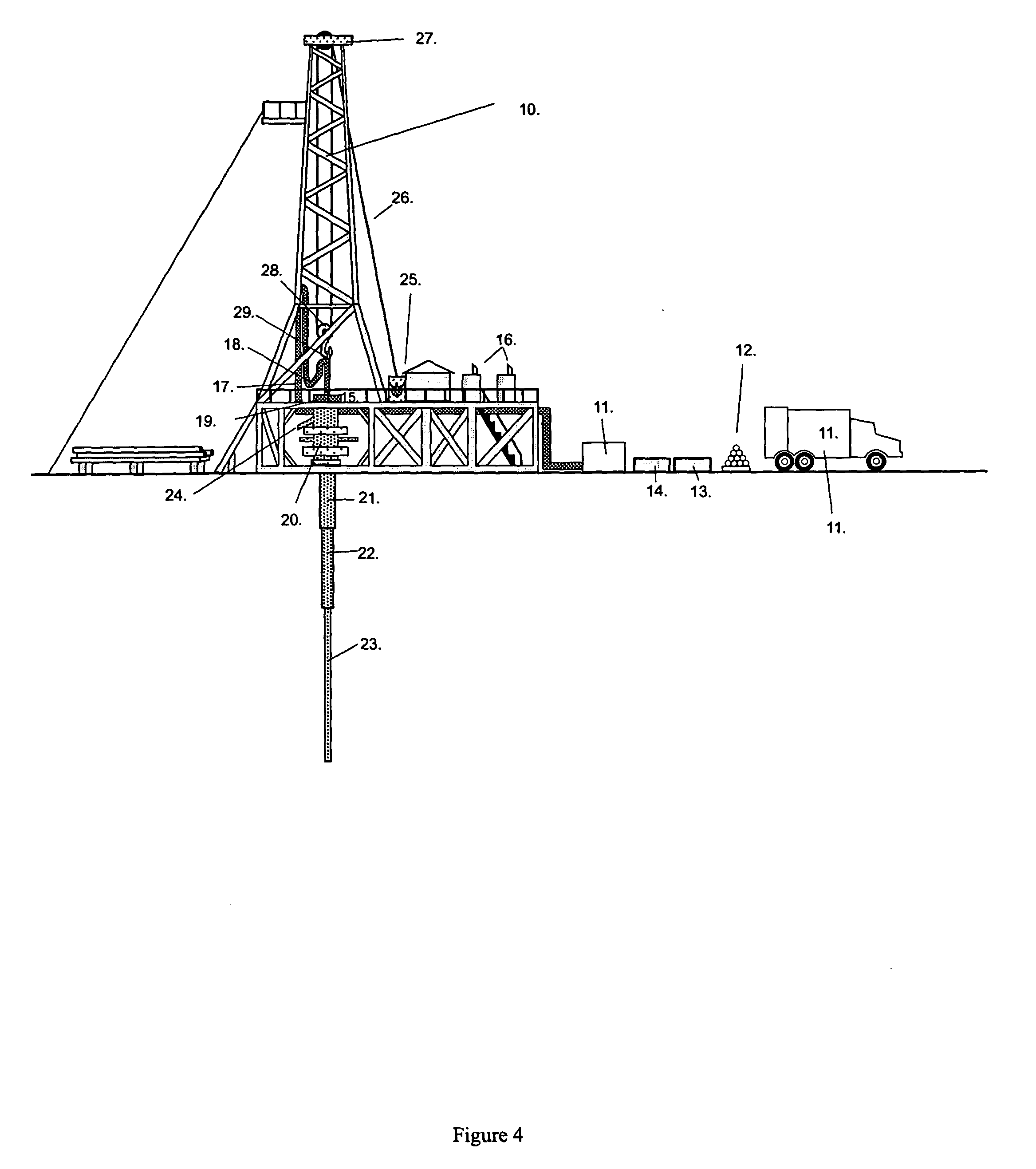

Method of generating and recovering gas from subsurface formations of coal, carbonaceous shale and organic-rich shales

InactiveUS20040033557A1Maximizes bacterial degradationStable and economically favorable and environmentally cleanMicrobiological testing/measurementGas production bioreactorsOrganic compoundCoal

A method of generating and recovering gas from naturally existing subsurface formations Of coal, carbonaceous shale or organic-rich shales comprising the steps Of: injecting into fracture of the subsurface formation, under substantially anaerobic conditions, a consortia of selected anaerobic, biological microorganisms for in situ conversion of organic compounds in said formation into methane and other compounds; and producing methane through at least one well extending from said subsurface formation to the surfaces.

Owner:SCOTT ANDREW R +1

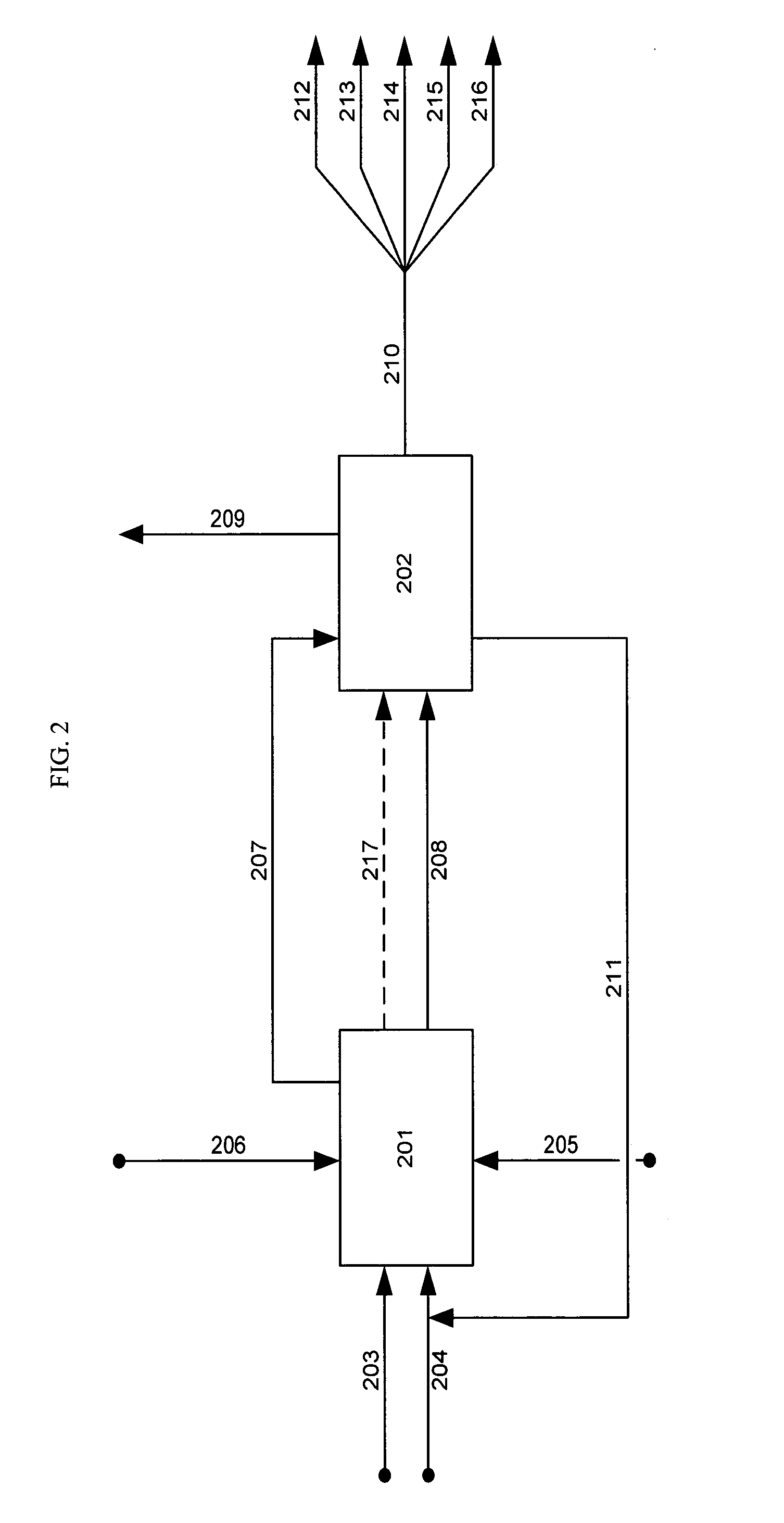

System and method for converting biomass to ethanol via syngas

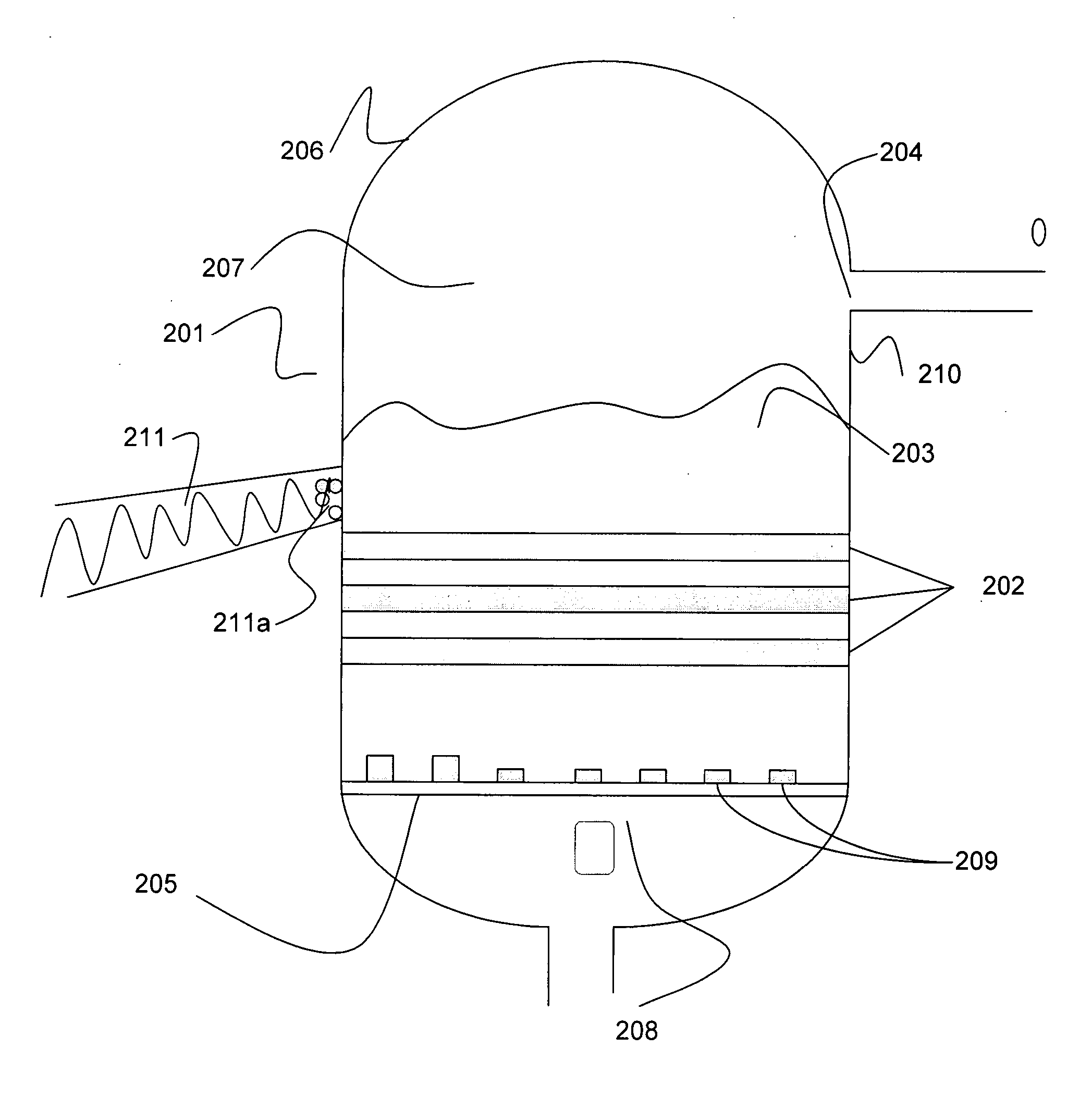

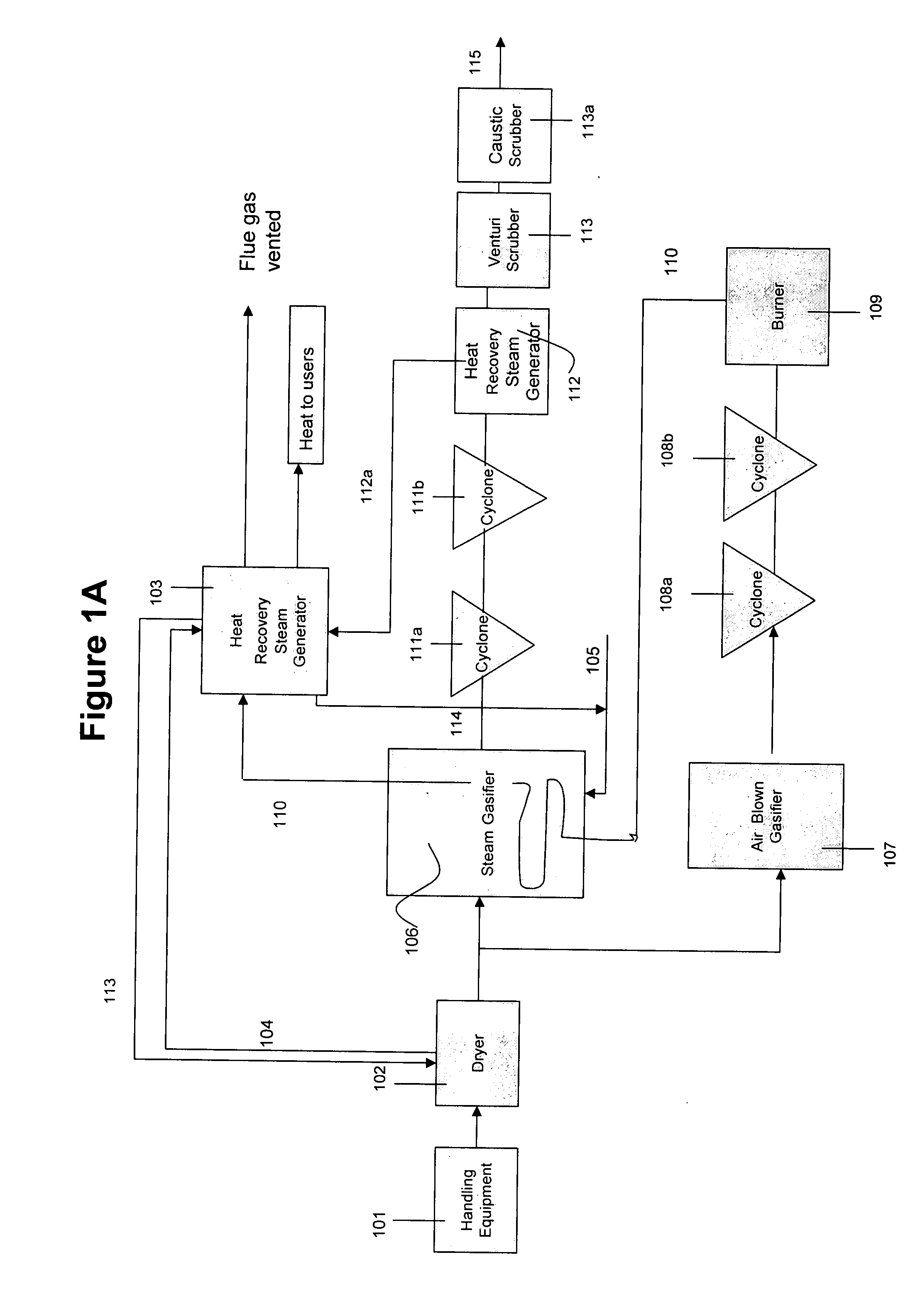

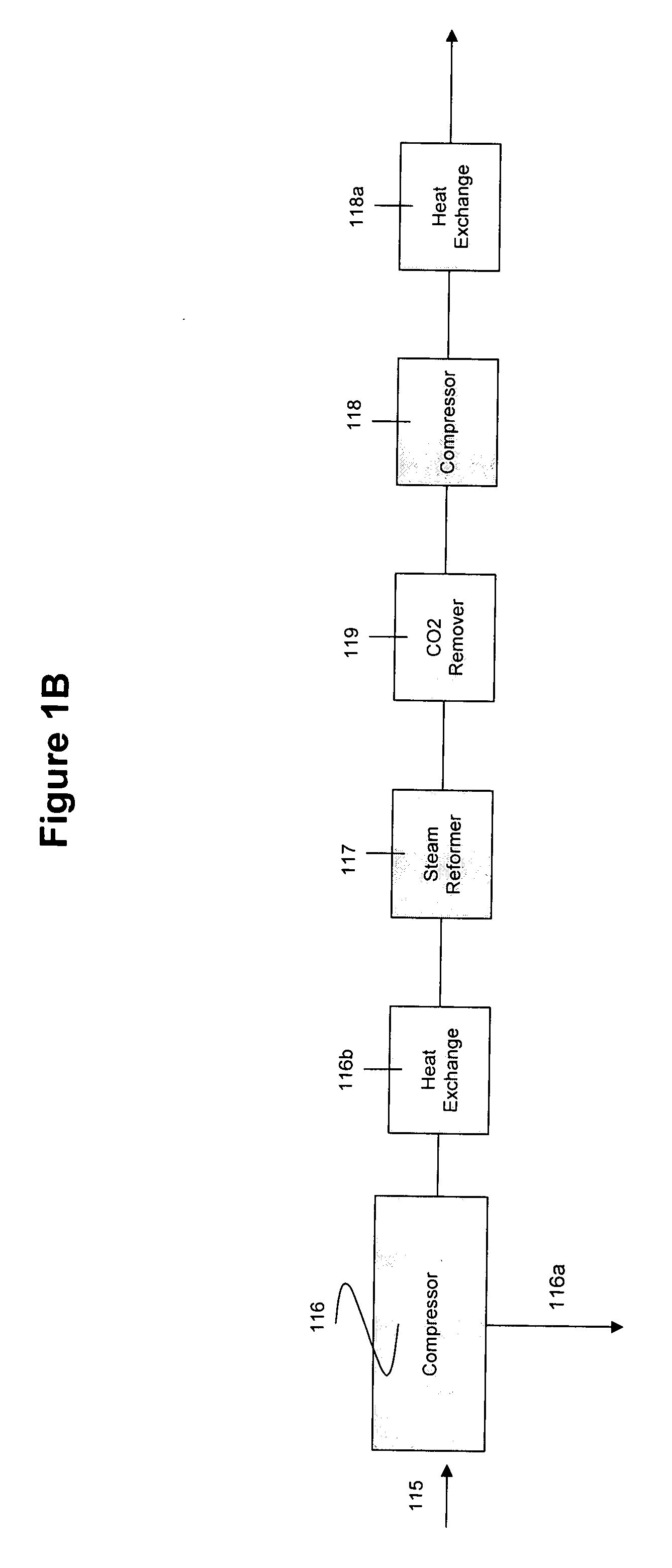

A method and apparatus for synthesizing ethanol using synthetic routes via synthesis gas are disclosed. A method and apparatus for gasifying biomass, such as biomass, in a steam gasifier that employs a fluidized bed and heating using hot flue gases from the combustion of synthesis gas is described. Methods and apparatus for converting synthesis gas into ethanol are also disclosed, using stepwise catalytic reactions to convert the carbon monoxide and hydrogen into ethanol using catalysts including iridium acetate.

Owner:WOODLAND BIOFUELS

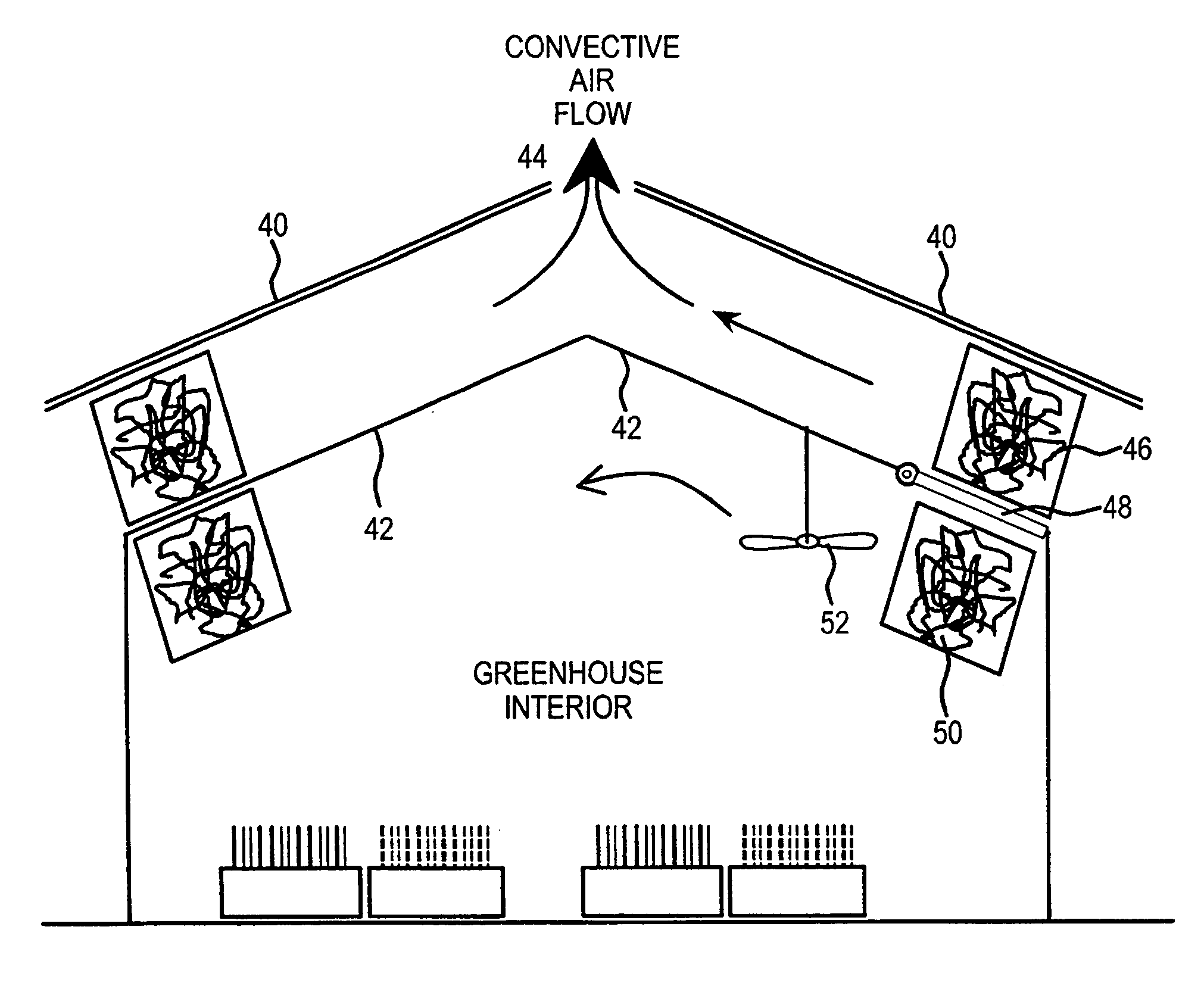

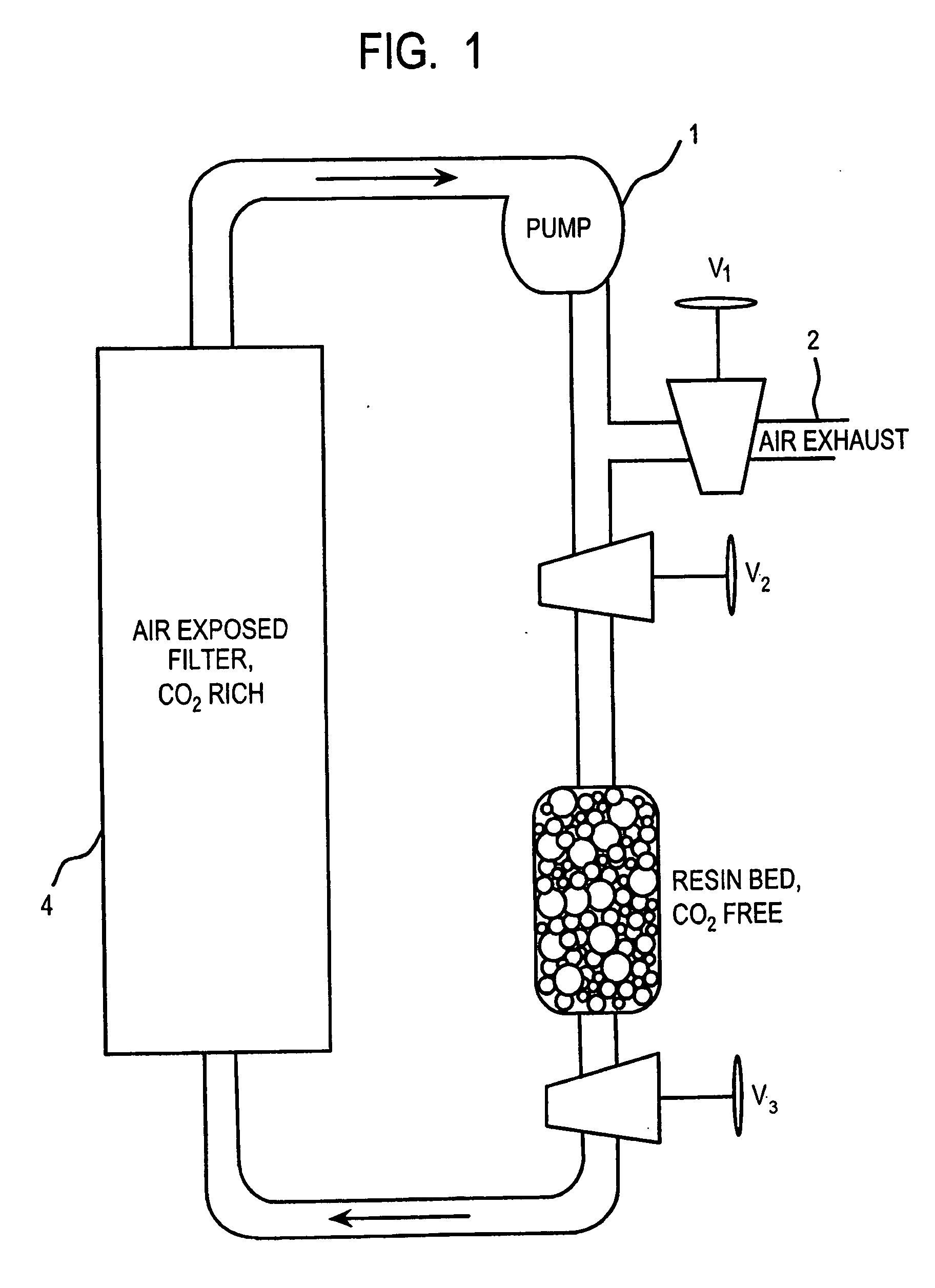

Method and apparatus for extracting carbon dioxide from air

A method and apparatus for extracting CO2 from air comprising an anion exchange material formed in a matrix exposed to a flow of the air, and for delivering that extracted CO2 to controlled environments. The present invention contemplates the extraction of CO2 from air using conventional extraction methods or by using one of the extraction methods disclosed; e.g., humidity swing or electro dialysis. The present invention also provides delivery of the CO2 to greenhouses where increased levels of CO2 will improve conditions for growth. Alternatively, the CO2 is fed to an algae culture.

Owner:CARBON SINK

Use of Cellulosic Materials for Cultivation of Microorganisms

Owner:CORBION BIOTECH INC

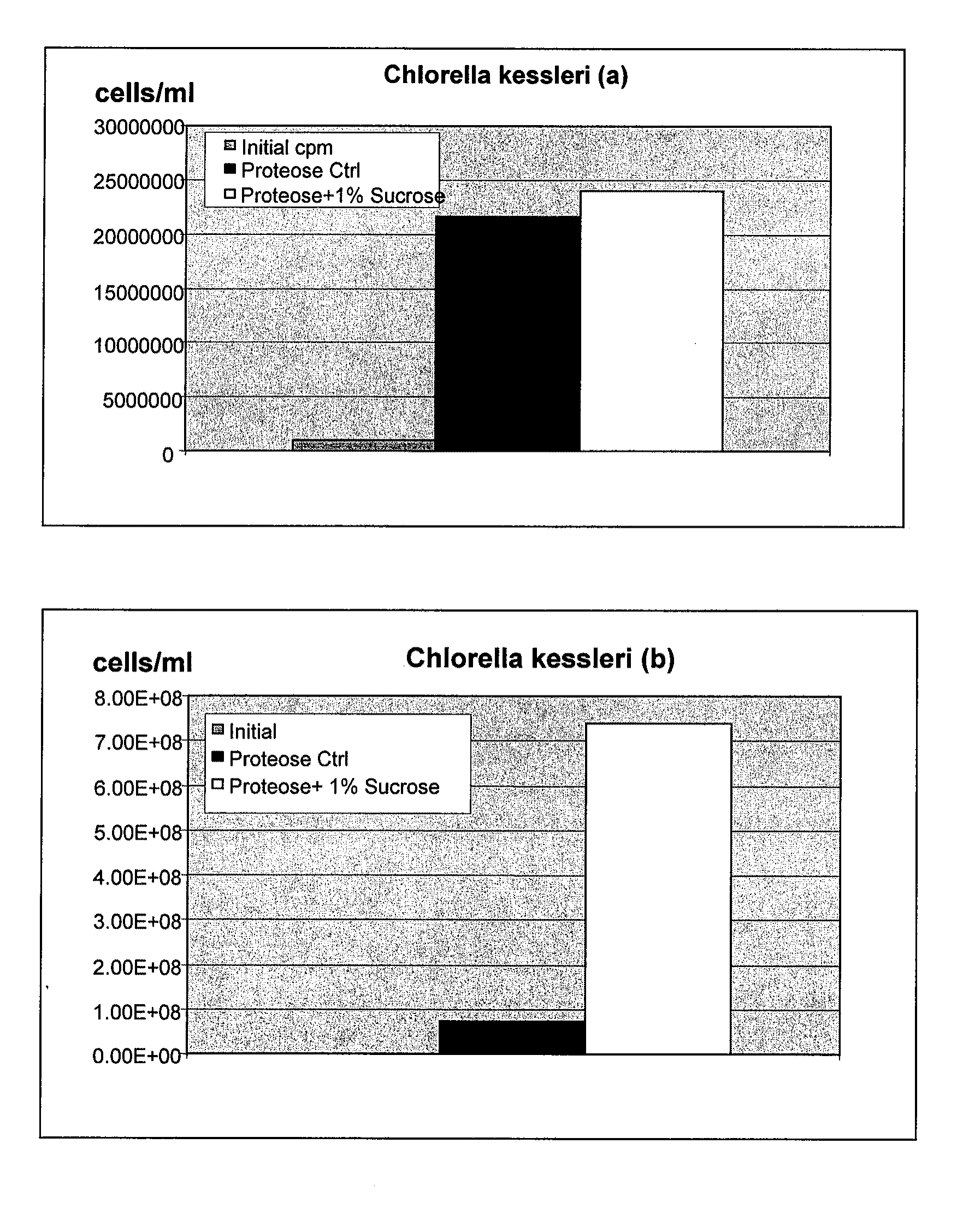

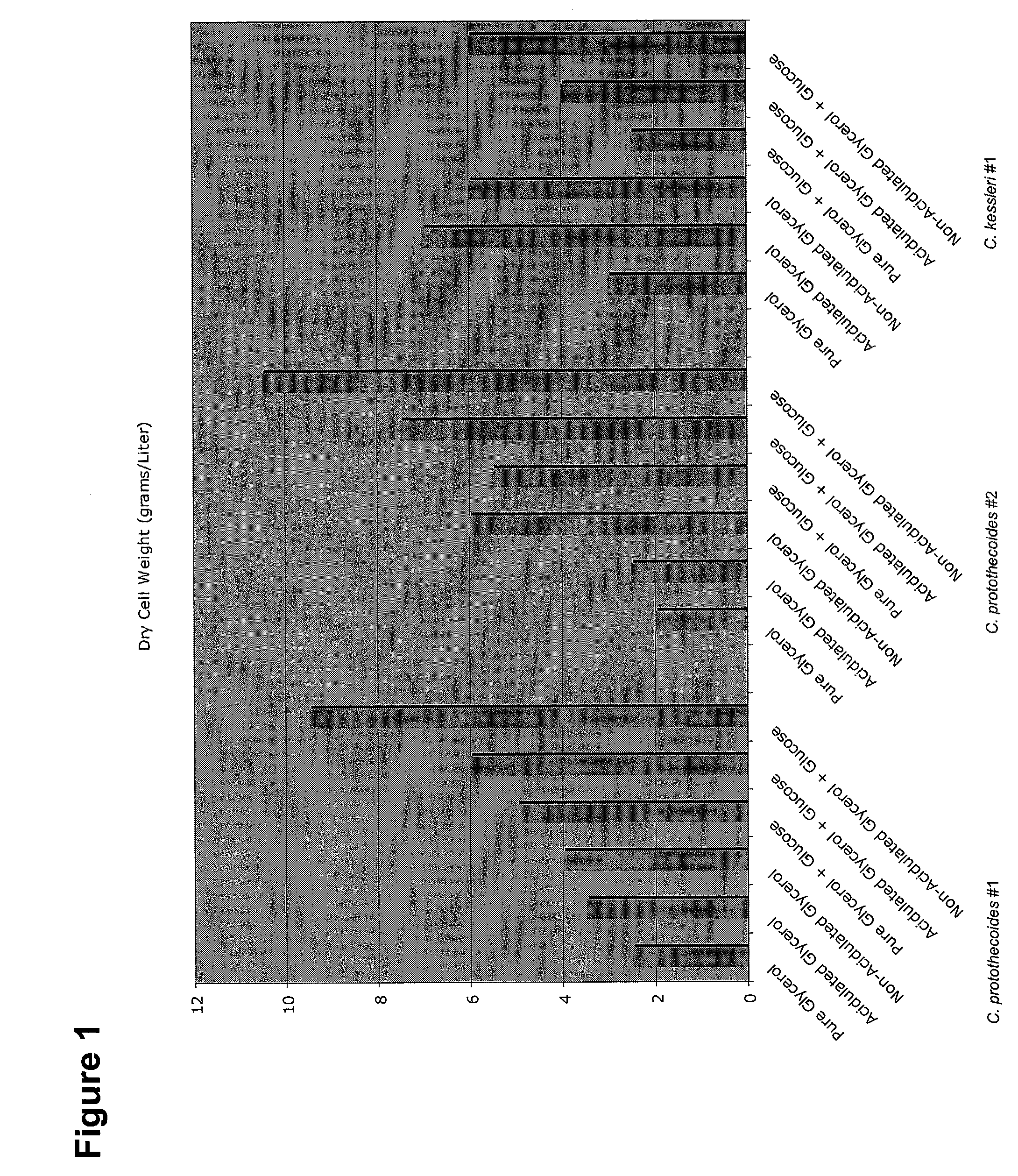

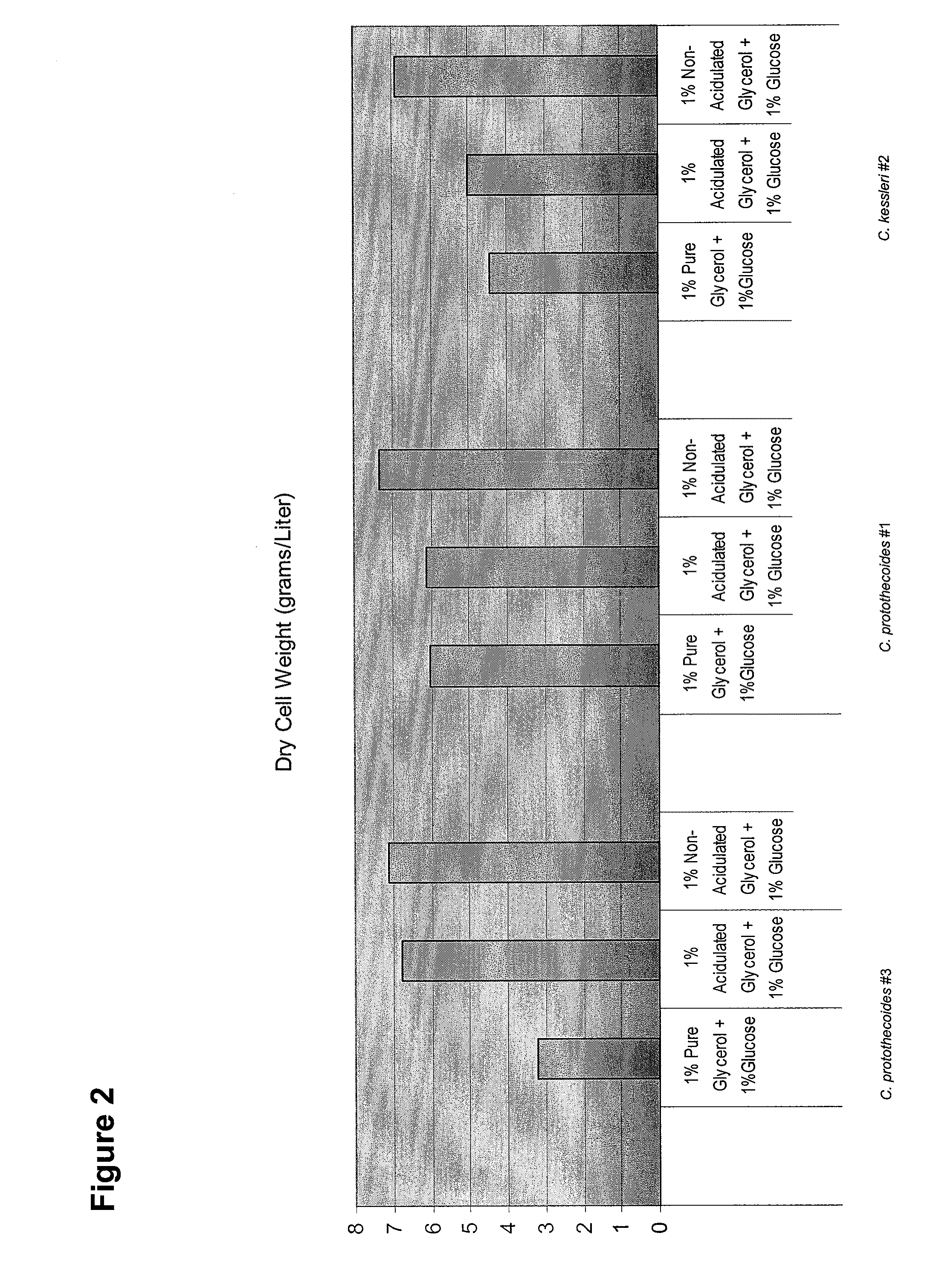

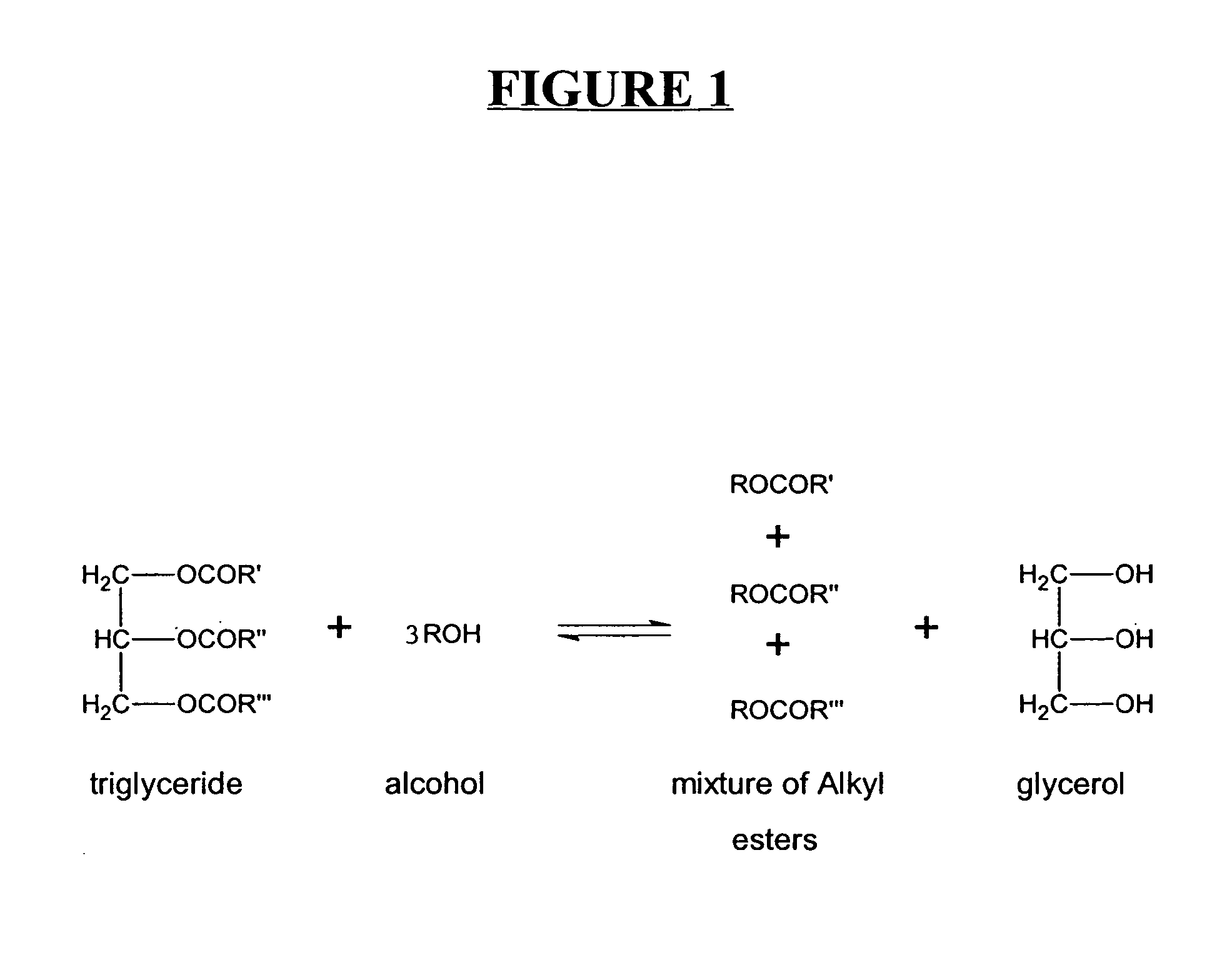

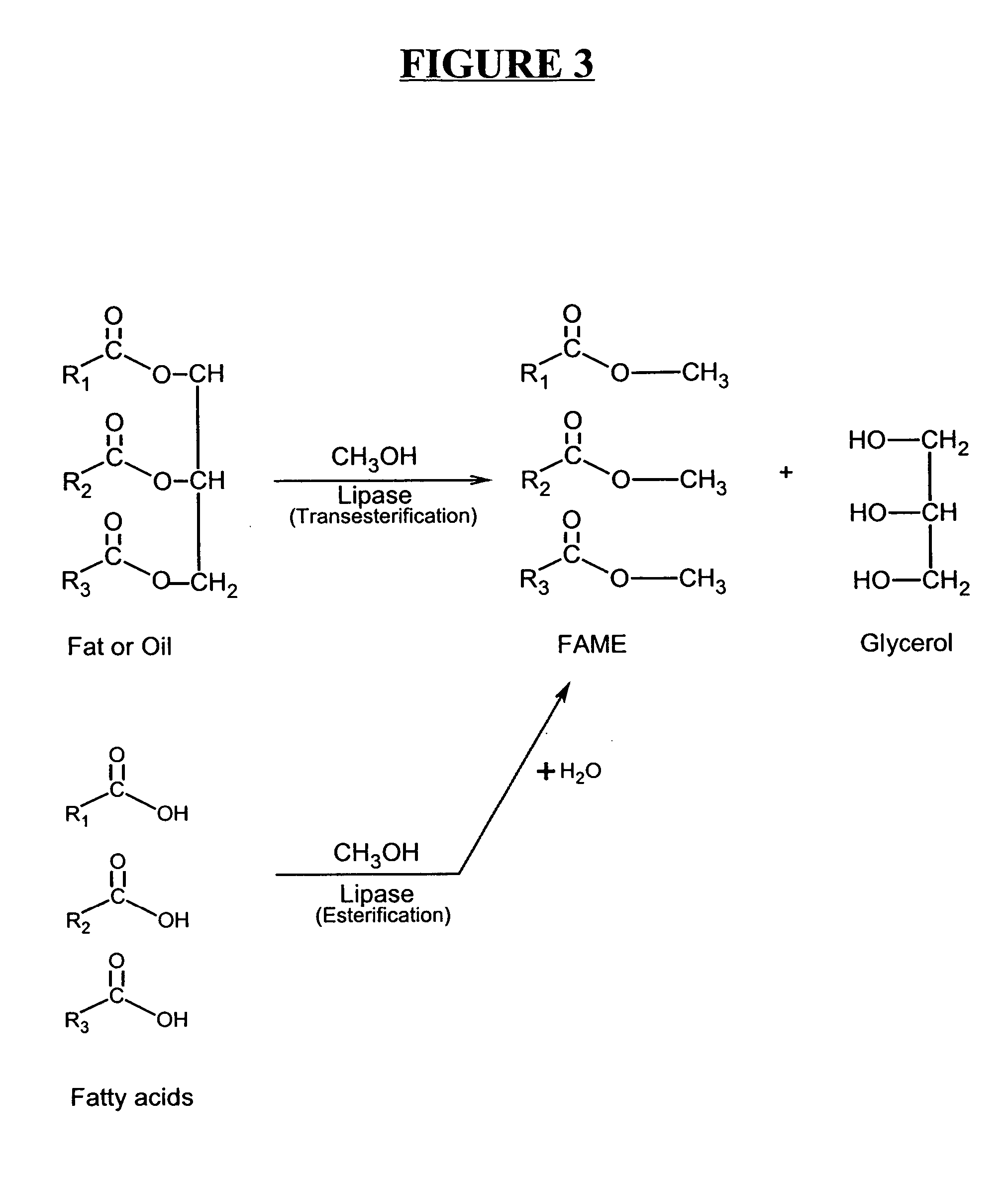

Glycerol Feedstock Utilization for Oil-Based Fuel Manufacturing

InactiveUS20090004715A1Bioreactor/fermenter combinationsFatty acid chemical modificationMicroorganismTransesterification

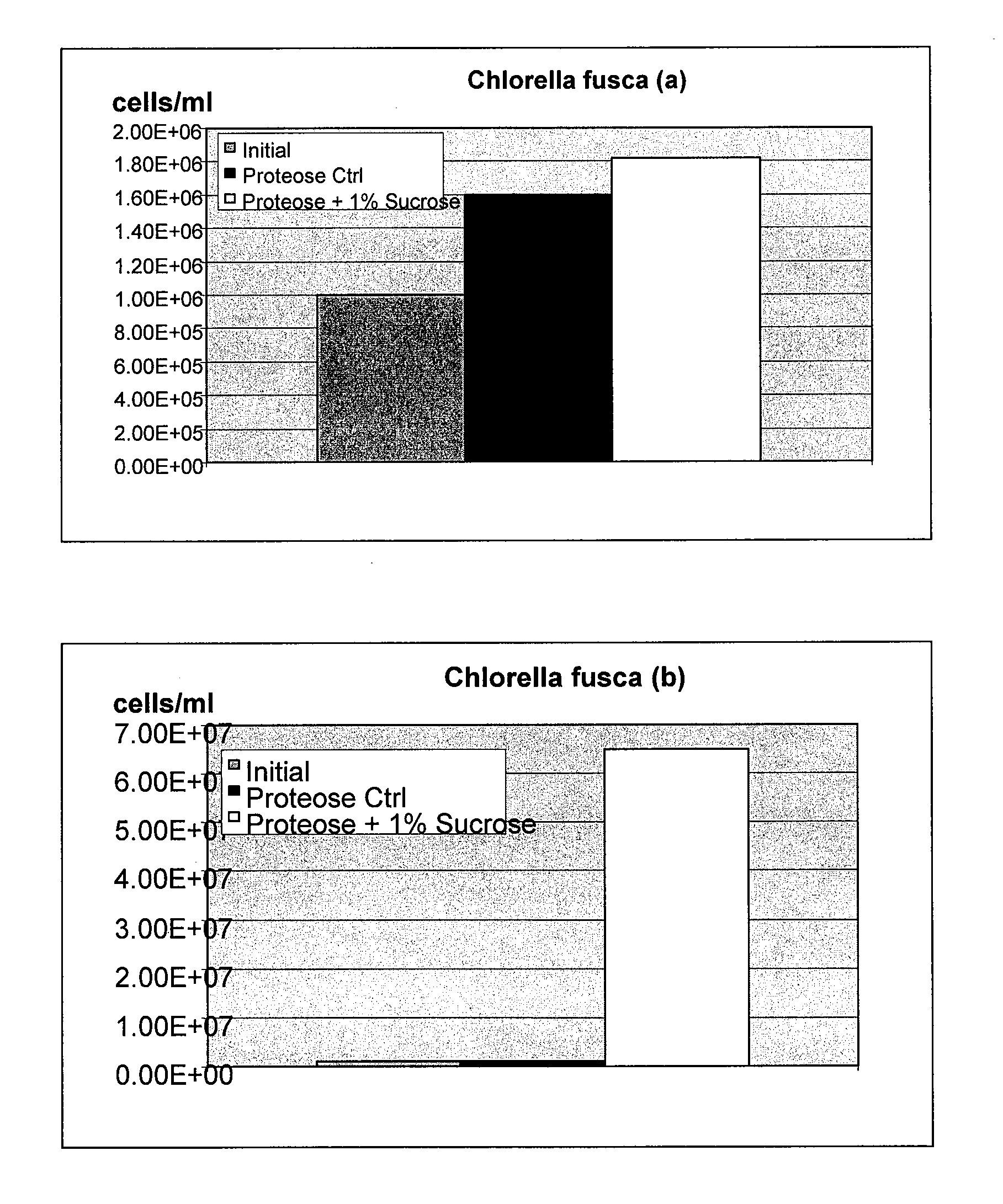

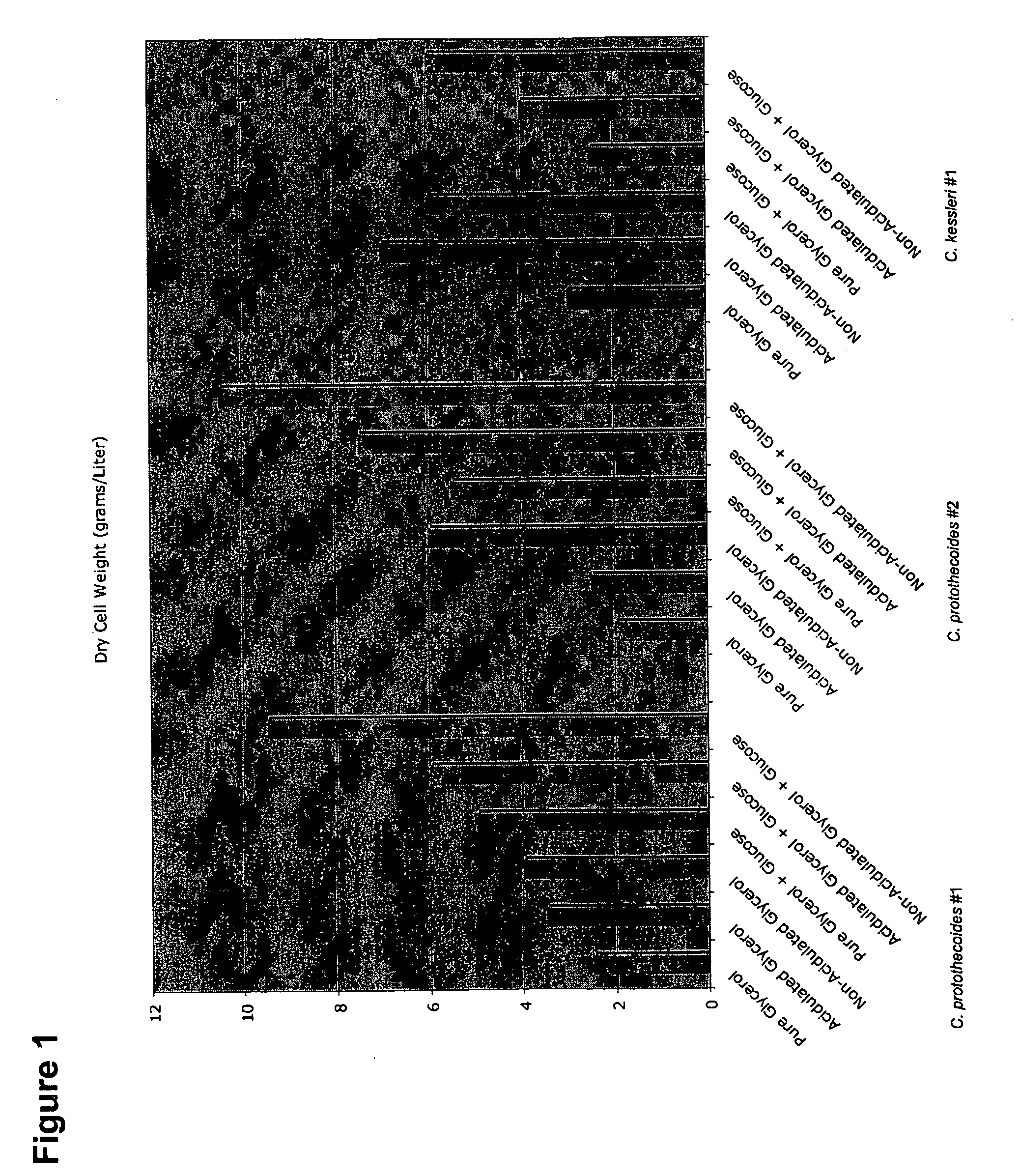

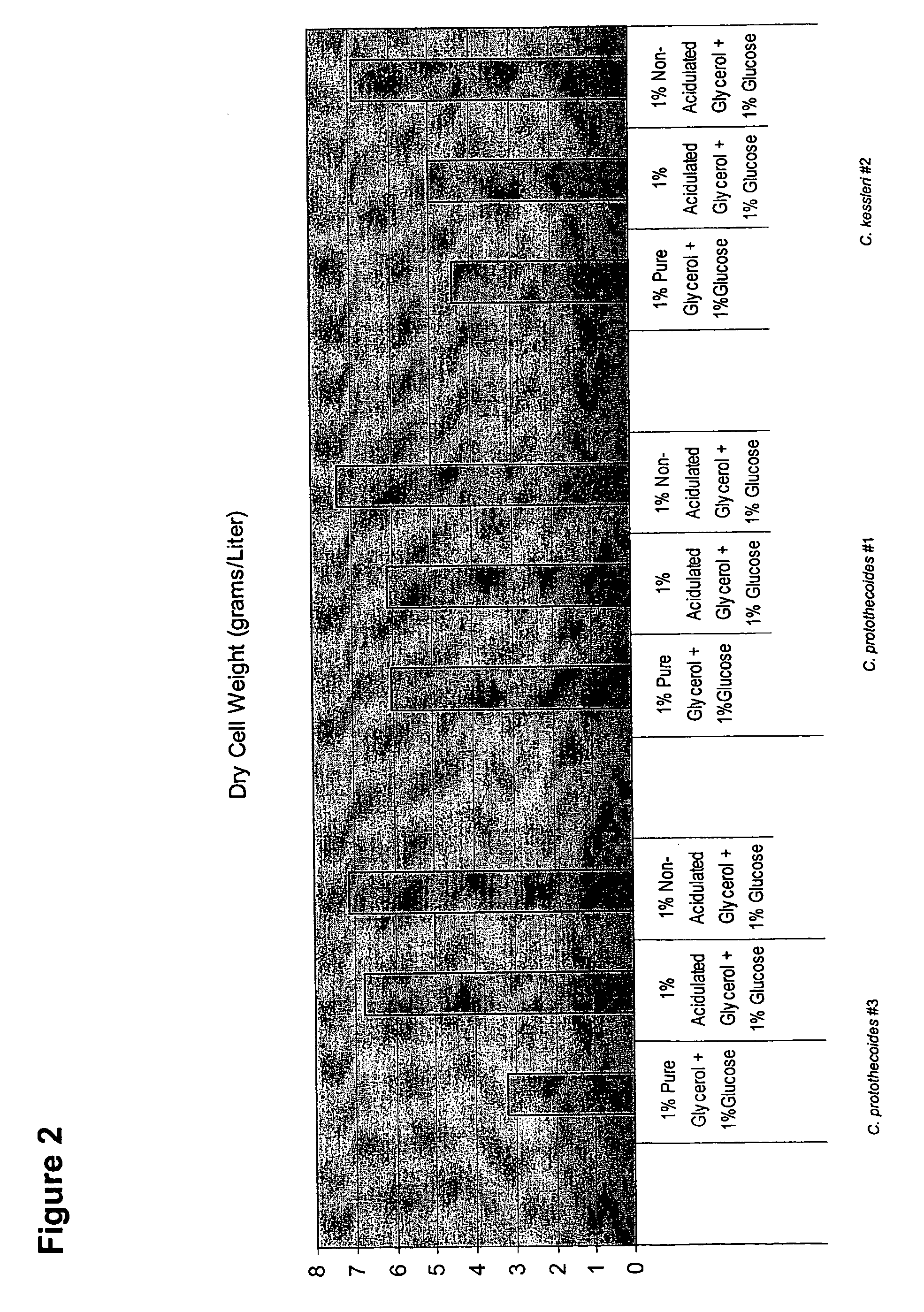

The invention provides methods of manufacturing biodiesel and other oil-based compounds using glycerol and combinations of glycerol and other feedstocks as an energy source in fermentation of oil-bearing microorganisms. Methods disclosed herein include processes for manufacturing high nutrition edible oils from non-food feedstock materials such as waste products from industrial waste transesterification processes. Also included are methods of increasing oil yields by temporally separating glycerol and other feedstocks during cultivation processes. Also provided herein are oil-bearing microbes containing exogenous oil production genes and methods of cultivating such microbes on glycerol and other feedstocks.

Owner:TERRAVIA HLDG INC

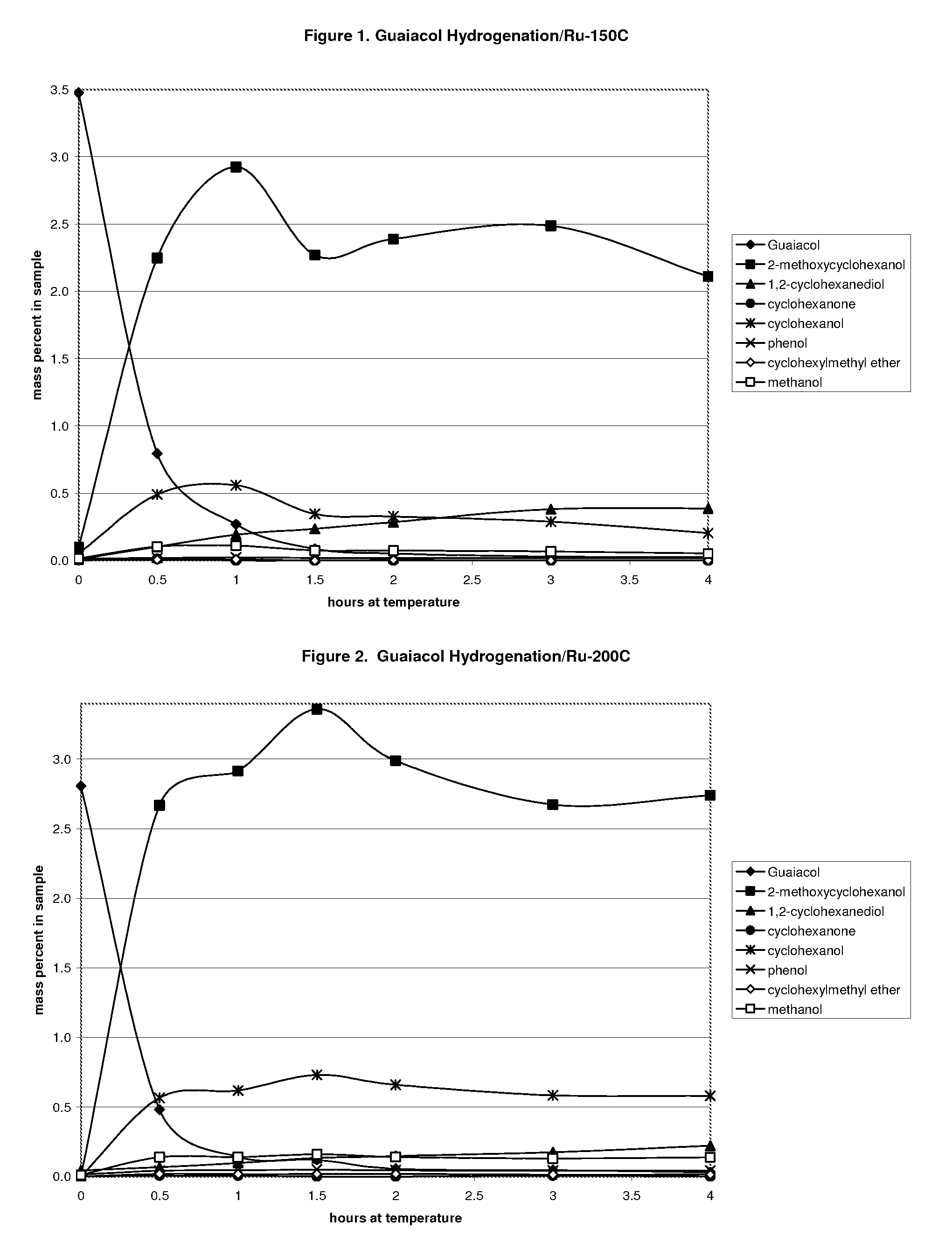

Process to produce biofuels from biomass

Biofuels can be produced by: (i) providing a biomass containing celluloses, hemicelluloses, lignin, nitrogen compounds and sulfur compounds; (ii) contacting the biomass with a digestive solvent to form a pretreated biomass containing carbohydrates; (iii) contacting the pretreated biomass with hydrogen in the presence of a supported hydrogenolysis catalyst containing (a) sulfur, (b) Mo or W, and (c) Co and / or Ni incorporated into a suitable support to form a plurality of oxygenated intermediates, and (vi) processing at least a portion of the oxygenated intermediates to form a liquid fuel.

Owner:SHELL OIL CO

Slurry dewatering and conversion of biosolids to a renewable fuel

ActiveUS20060096163A1Readily removed mechanicallyLow oxygenBio-organic fraction processingBiofuelsEmission standardSlurry

In the processes for treating municipal sewage and storm water containing biosolids to discharge standards, biosolids, even after dewatering, contain typically about 80% water bound in the dead cells of the biosolids, which gives biosolids a negative heating value. It can be incinerated only at the expense of purchased fuel. Biosolids are heated to a temperature at which their cell structure is destroyed and, preferably, at which carbon dioxide is split off to lower the oxygen content of the biosolids. The resulting char is not hydrophilic, and it can be efficiently dewatered and / or dried and is a viable renewable fuel. This renewable fuel can be supplemented by also charging conventional biomass (yard and crop waste, etc.) in the same or in parallel facilities. Similarly, non-renewable hydrophilic fuels can be so processed in conjunction with the processing of biosolids to further augment the energy supply.

Owner:SGC ADVISORS

Process and system for converting carbonaceous feedstocks into energy without greenhouse gas emissions

ActiveUS20070099038A1High hydrogen contentFuel cells groupingHydrogen separation using solid contactPetroleum cokePetroleum

The process of the invention converts carbonaceous feedstock such as coal, hydrocarbon oil, natural gas, petroleum coke, oil shale, carbonaceous-containing waste oil, carbonaceous-containing medical waste, carbonaceous-containing military waste, carbonaceous-containing industrial waste, carbonaceous-containing medical waste, carbonaceous-containing sewage sludge and municipal solid waste, carbonaceous-containing agricultural waste, carbonaceous-containing biomass, biological and biochemical waste, and mixtures thereof into electrical energy without the production of unwanted greenhouse emissions. The process uses a steam / CO2 reformer operating in the exit range of at least 700° to about 1600° C. (1300-2900°0 F.) to convert the carbonaceous feedstock and a greenhouse gas stream into a synthesis gas comprising mostly carbon monoxide and hydrogen that contains poisons and the compounds that poison fuel cells. The syngas is sent to an interface zone to remove these poisons and other fouling compounds that are electrochemically oxidized in an electricity-producing fuel cell into an exit gas comprising carbon dioxide and water.

Owner:RAVEN SR INC

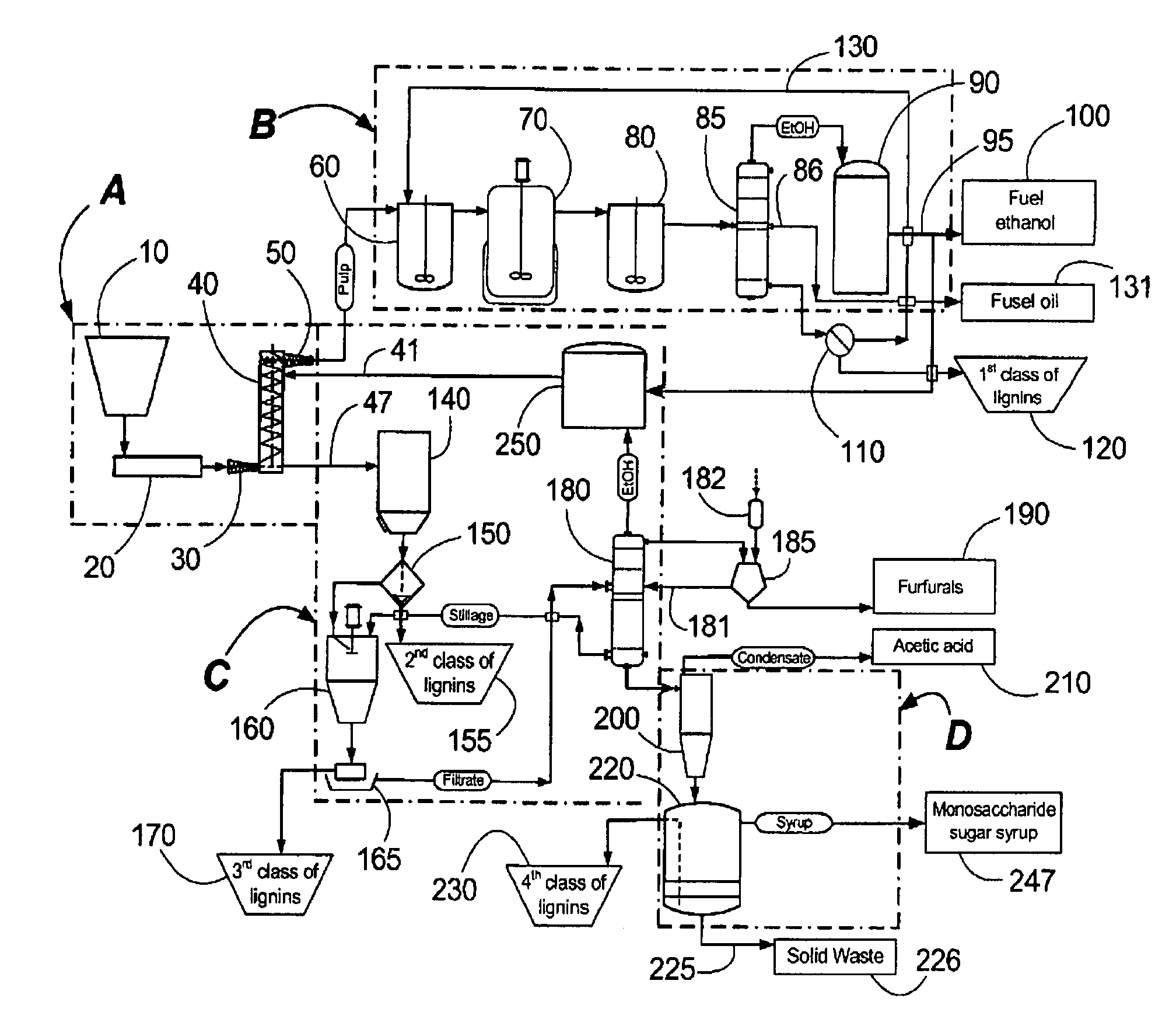

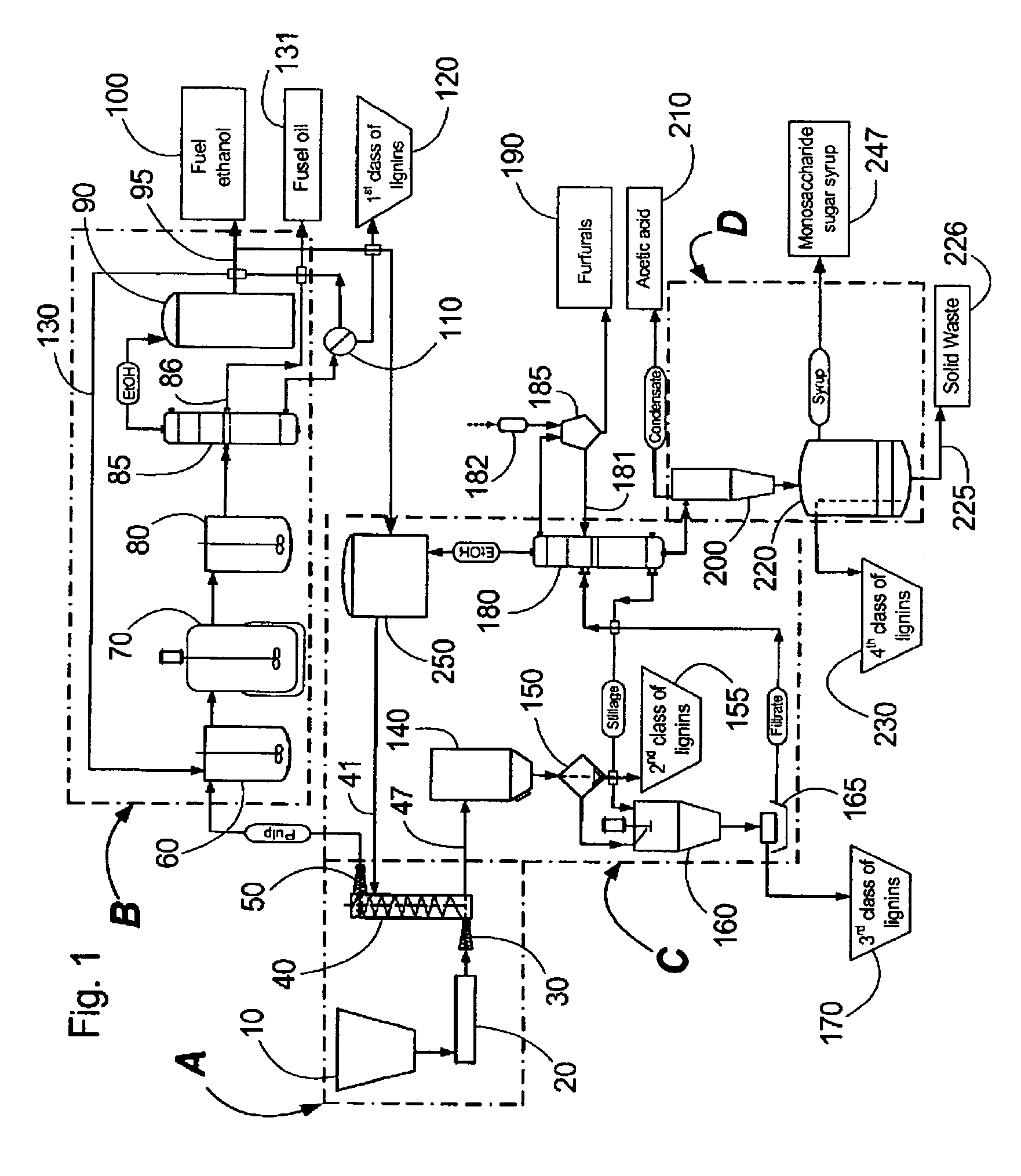

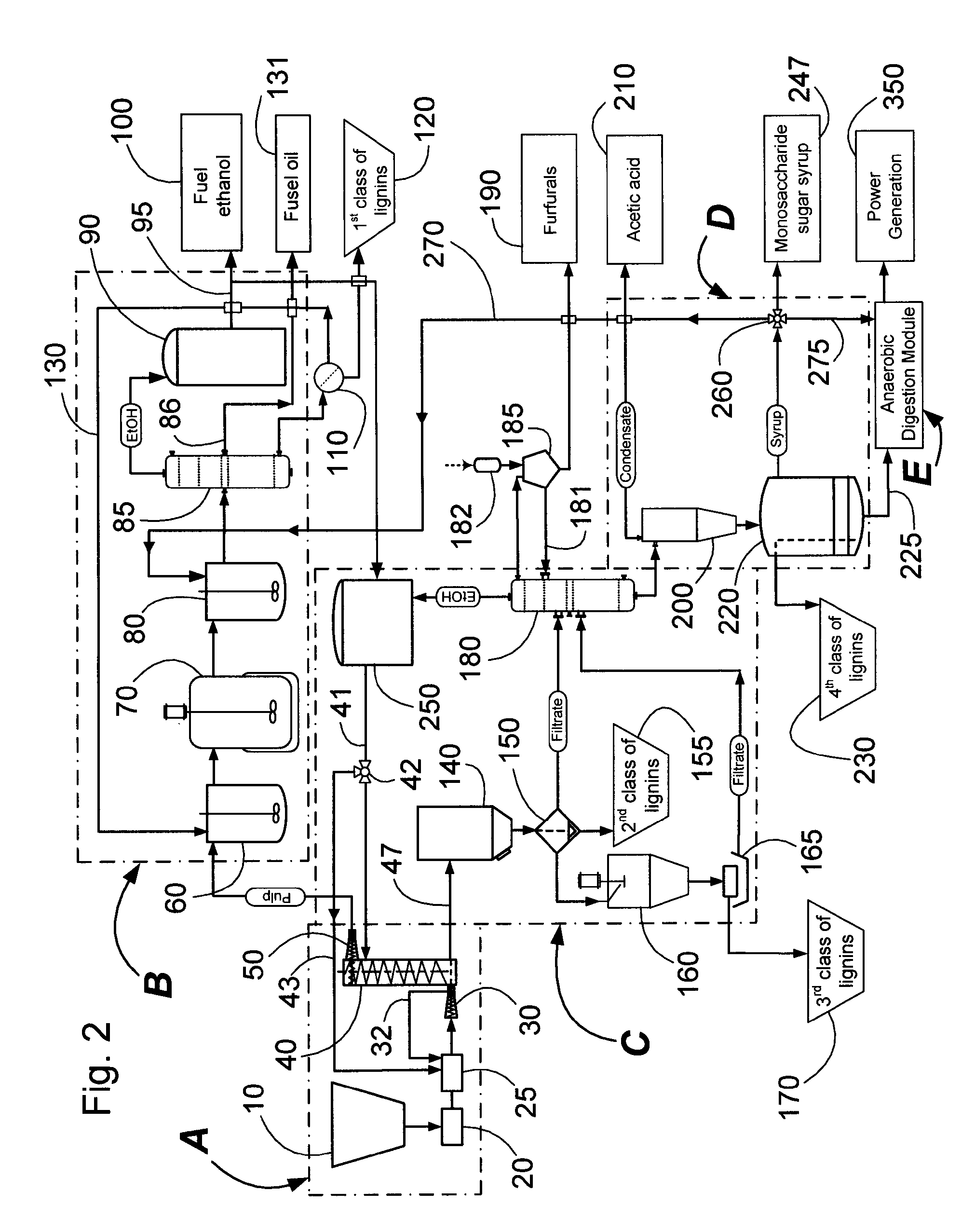

Continuous counter-current organosolv processing of lignocellulosic feedstocks

InactiveUS7465791B1Low viscosityNon-fibrous pulp additionBiological substance pretreatmentsFractionationOrganosolv

A modular process for organosolv fractionation of lignocellulosic feedstocks into component parts and further processing of said component parts into at least fuel-grade ethanol and four classes of lignin derivatives. The modular process comprises a first processing module configured for physico-chemically digesting lignocellulosic feedstocks with an organic solvent thereby producing a cellulosic solids fraction and a liquid fraction, a second processing module configured for producing at least a fuel-grade ethanol and a first class of novel lignin derivatives from the cellulosic solids fraction, a third processing module configured for separating a second class and a third class of lignin derivatives from the liquid fraction and further processing the liquid fraction to produce a distillate and a stillage, a fourth processing module configured for separating a fourth class of lignin derivatives from the stillage and further processing the stillage to produce a sugar syrup.

Owner:SUZANO CANADA INC

Coal Compositions for Catalytic Gasification

Particulate compositions are described comprising an intimate mixture of a coal and a gasification catalyst. The particulate compositions are gasified in the presence of steam to yield a plurality of gases including methane and at least one or more of hydrogen, carbon monoxide, carbon dioxide, hydrogen sulfide, ammonia and other higher hydrocarbons. Processes are also provided for the preparation of the particulate compositions and converting the particulate composition into a plurality of gaseous products.

Owner:SURE CHAMPION INVESTMENT LTD

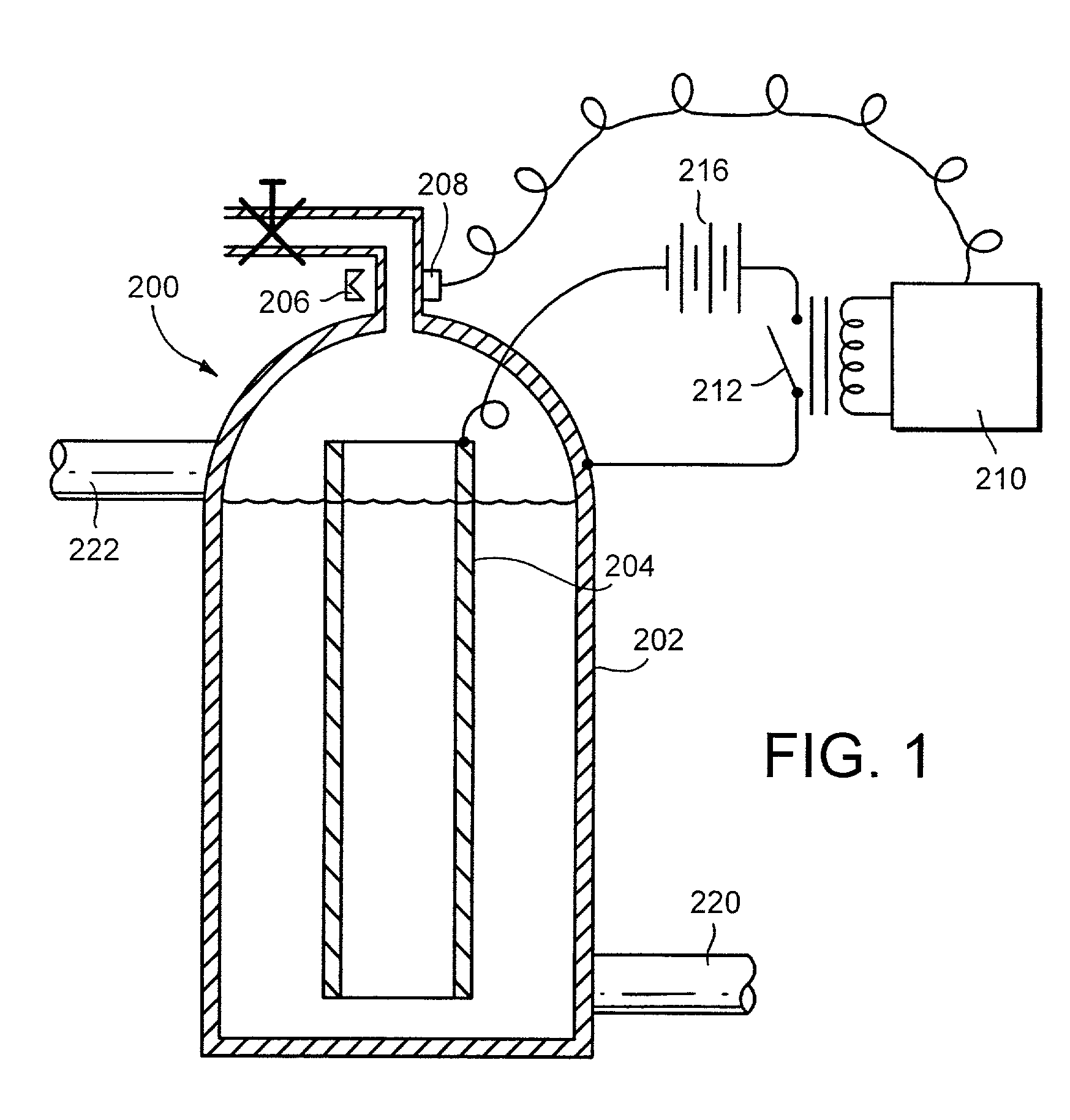

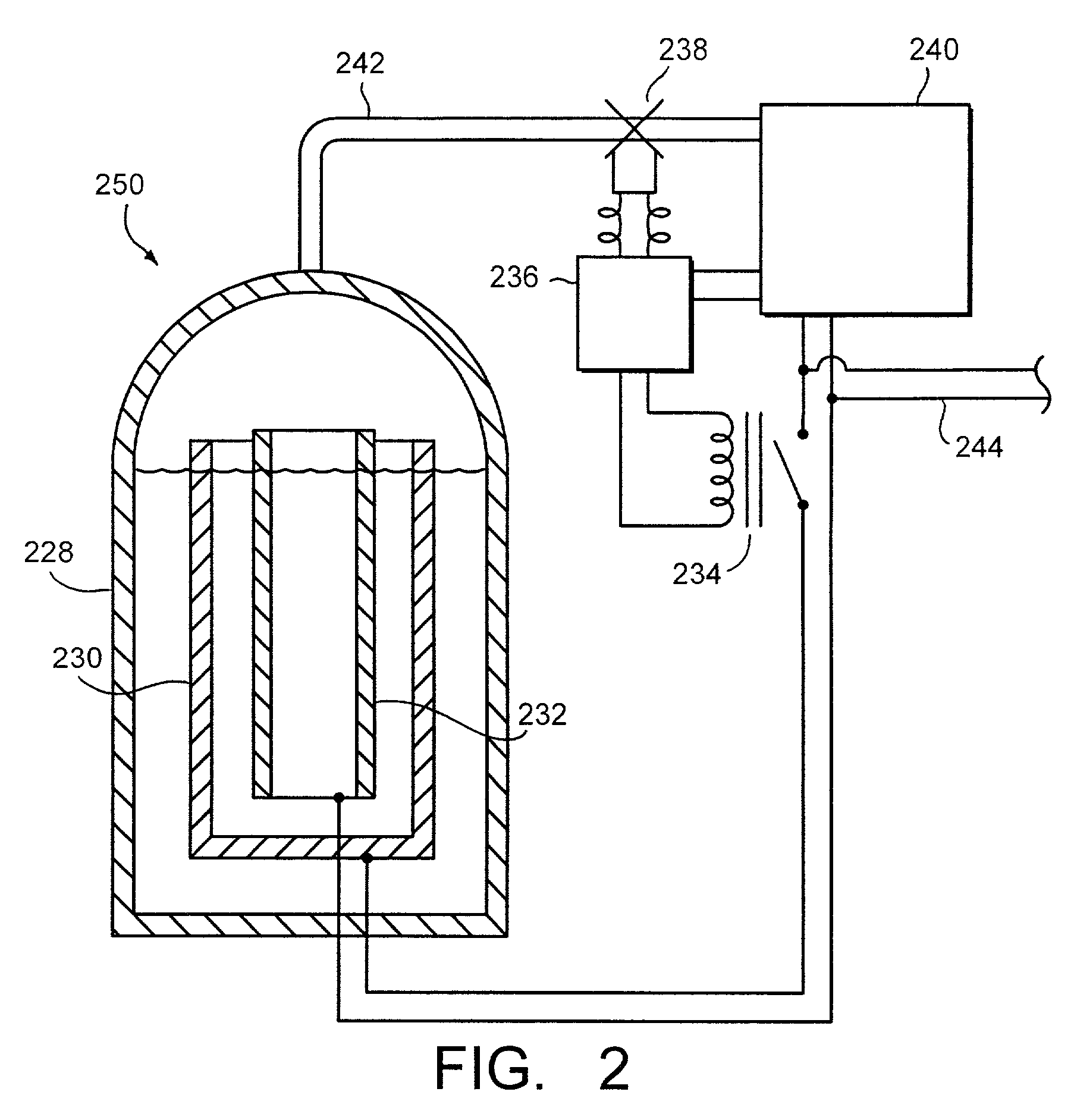

Method and apparatus for sustainable energy and materials

A process for the production of hydrogen from anaerobically decomposed organic materials by applying an electric potential to the anaerobically decomposed organic materials, including landfill materials and sewage, to form hydrogen, and for decreasing the time required to treat these anaerobically decomposed organic materials. The organic materials decompose to volatile acids such as acetic acid, which may be hydrolyzed by electric current to form hydrogen. The process may be continuously run in sewage digestion tanks with the continuous feed of sewage, at landfill sites, or at any site having a supply of anaerobically decomposed or decomposable organic materials.

Owner:MCALISTER TECH LLC +1

Biomass Compositions for Catalytic Gasification

Particulate compositions are described comprising an intimate mixture of a biomass, such as switchgrass or hybrid poplar, a non-biomass carbonaceous material, such as petroleum coke or coal, and a gasification catalyst, where the gasification catalyst is loaded onto at least one of the biomass or non-biomass for gasification in the presence of steam to yield a plurality of gases including methane and at least one or more of hydrogen, carbon monoxide, and other higher hydrocarbons are formed. Processes are also provided for the preparation of the particulate compositions and converting the particulate composition into a plurality of gaseous products.

Owner:SURE CHAMPION INVESTMENT LTD

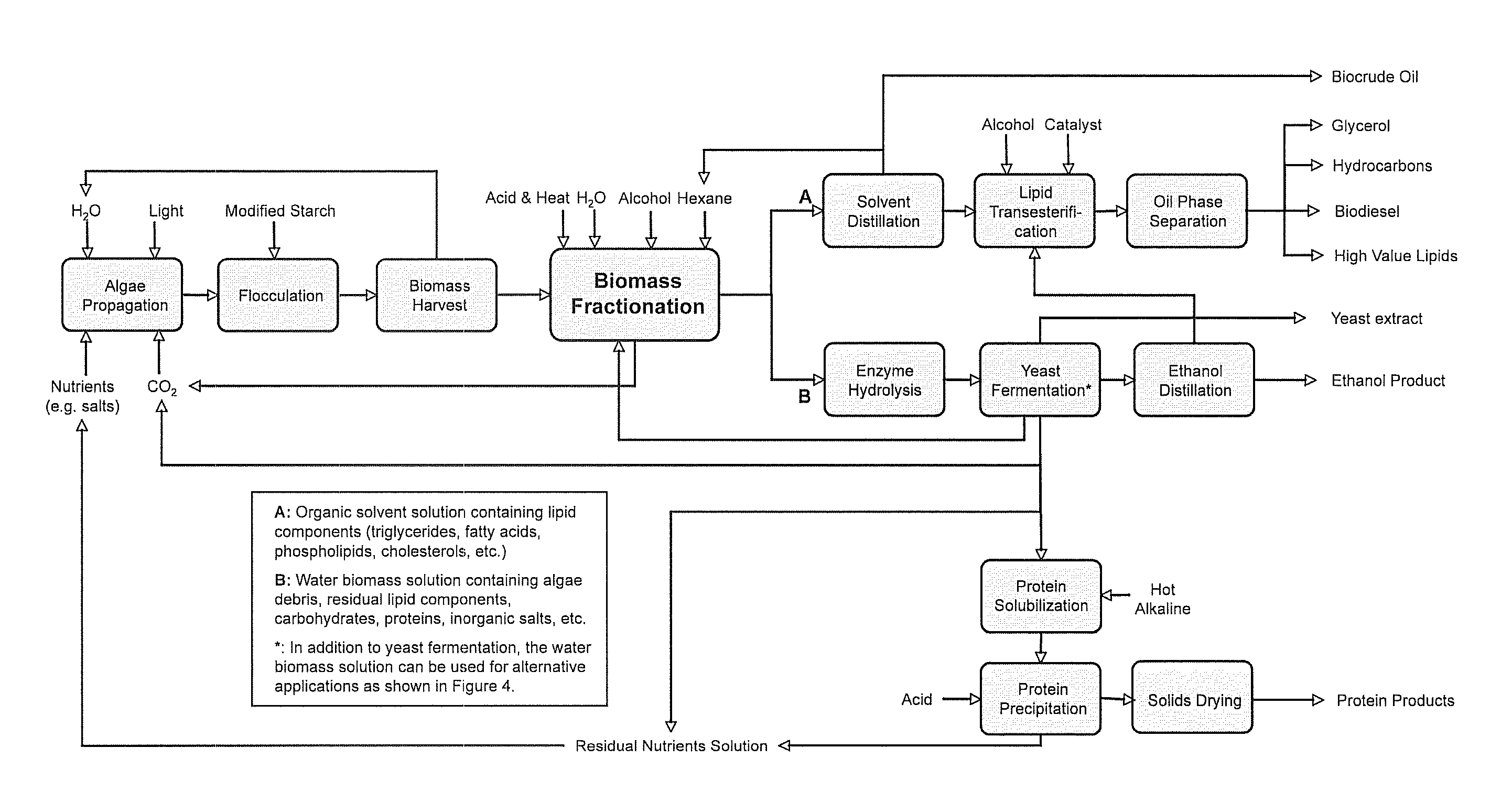

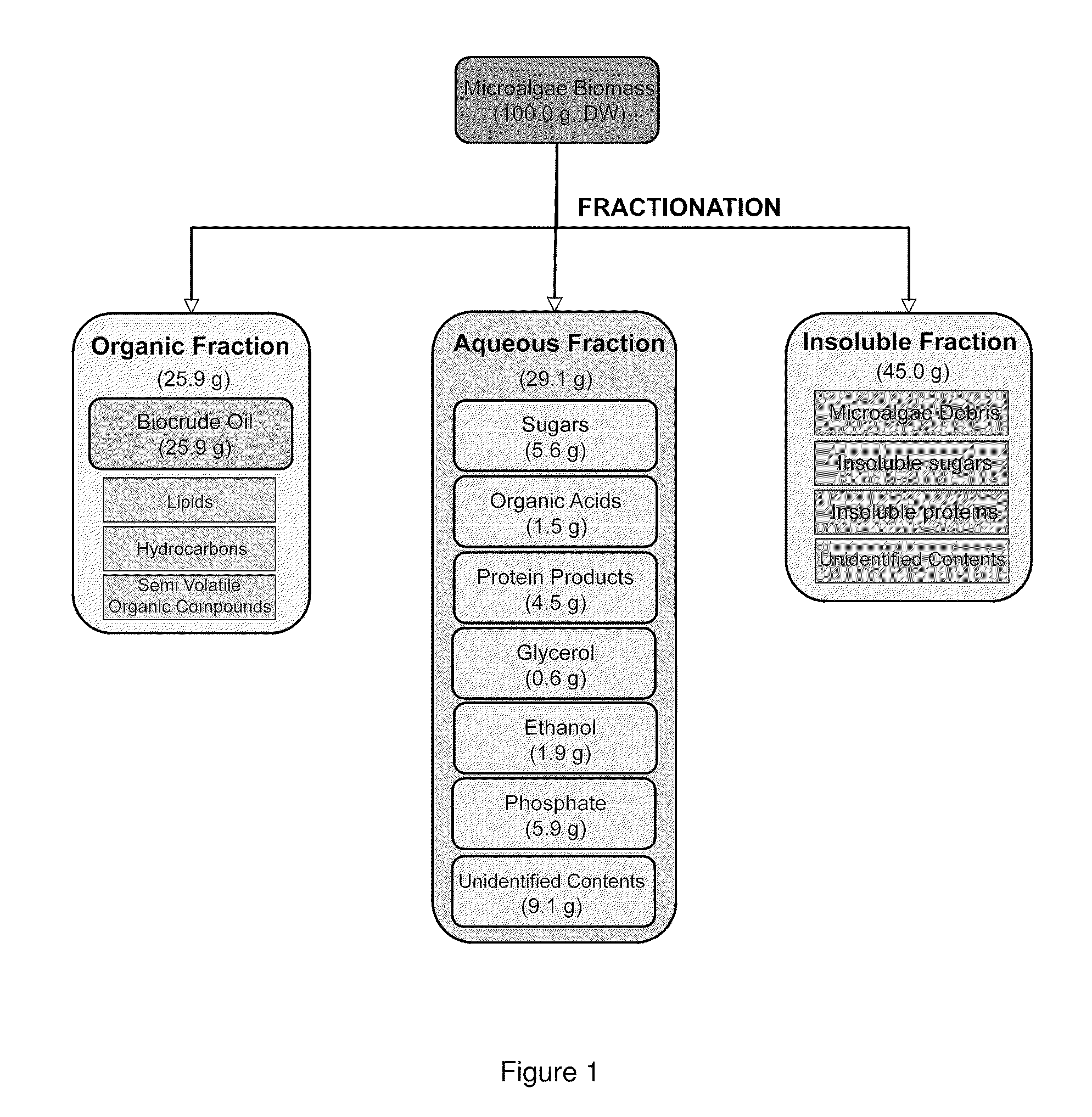

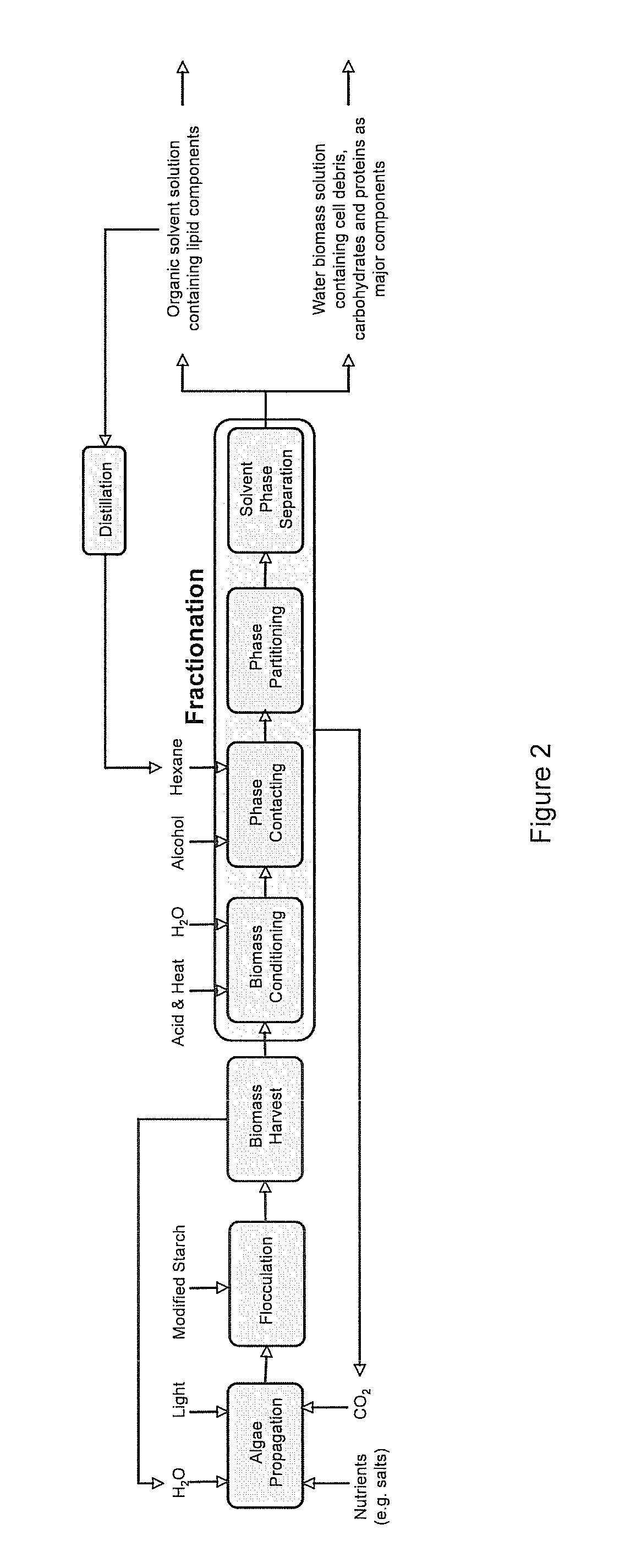

Algae biomass fractionation

A method of fractionating biomass, by permeability conditioning biomass suspended in a pH adjusted solution of at least one water-based polar solvent to form a conditioned biomass, intimately contacting the pH adjusted solution with at least one non-polar solvent, partitioning to obtain an non-polar solvent solution and a polar biomass solution, and recovering cell and cell derived products from the non-polar solvent solution and polar biomass solution. Products recovered from the above method. A method of operating a renewable and sustainable plant for growing and processing algae.

Owner:VALICOR

Catalytic Gasification Particulate Compositions

ActiveUS20090229182A1Efficient use ofBiofuelsGas modification by gas mixingPtru catalystPetroleum coke

Particulate compositions are described comprising a carbonaceous material, such as petroleum coke and / or coal, treated or otherwise associated with a gasification catalyst, where the catalyst is at least in part derived from a leachate from a biomass char, for gasification in the presence of steam to yield a plurality of gases including methane and at least one or more of hydrogen, carbon monoxide, and other higher hydrocarbons are formed. Processes are also provided for the preparation of the particulate compositions and converting the particulate composition into a plurality of gaseous products.

Owner:SURE CHAMPION INVESTMENT LTD

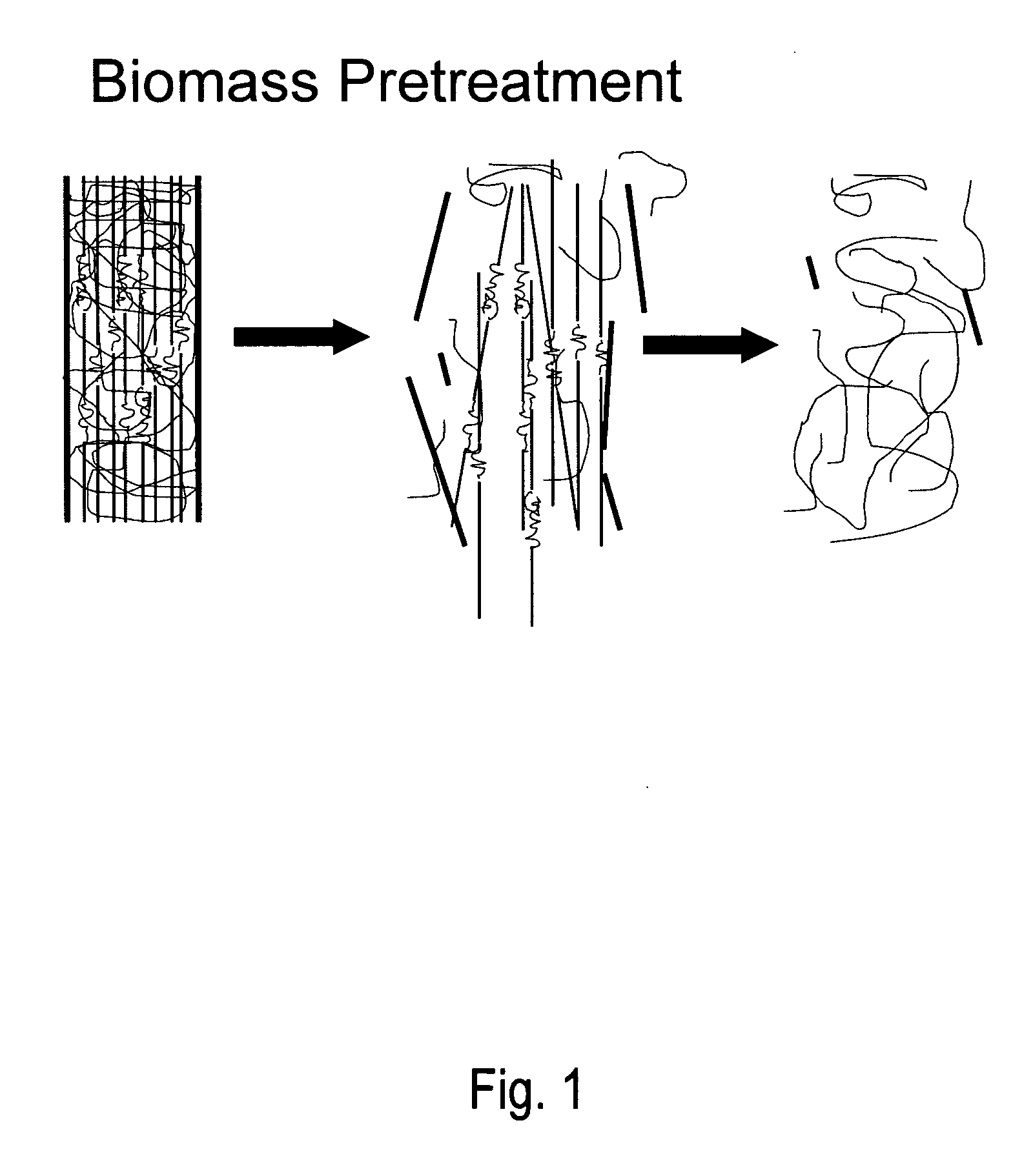

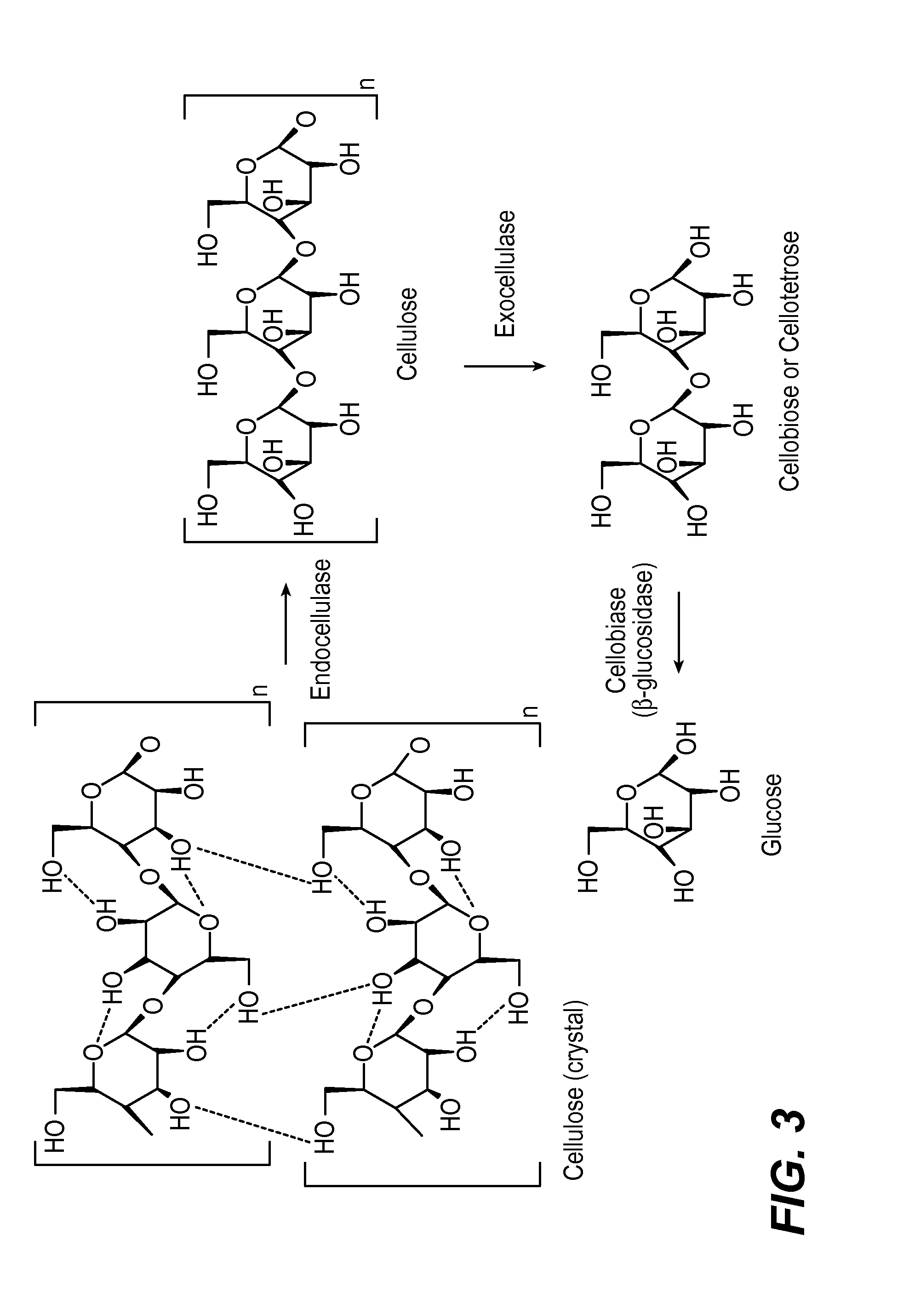

Biomass pretreatment

A method for lignocellulose conversion to sugar with improvements in yield and rate of sugar production has been developed by using ionic liquid pretreatment. This new pretreatment strategy substantially improves the efficiency (in terms of yield and reaction rates) of saccharification of lignocellulosic biomass. Cellulose and hemicellulose, when hydrolyzed into their sugars, can be converted into ethanol fuel through well established fermentation technologies. These sugars also form the feedstocks for production of variety of chemicals and polymers. The complex structure of biomass requires proper pretreatment to enable efficient saccharification of cellulose and hemicellulose components to their constituent sugars. Current pretreatment approaches suffer from slow reaction rates of cellulose hydrolysis (by using the enzyme cellulase) and low yields.

Owner:UNIVERSITY OF TOLEDO +1

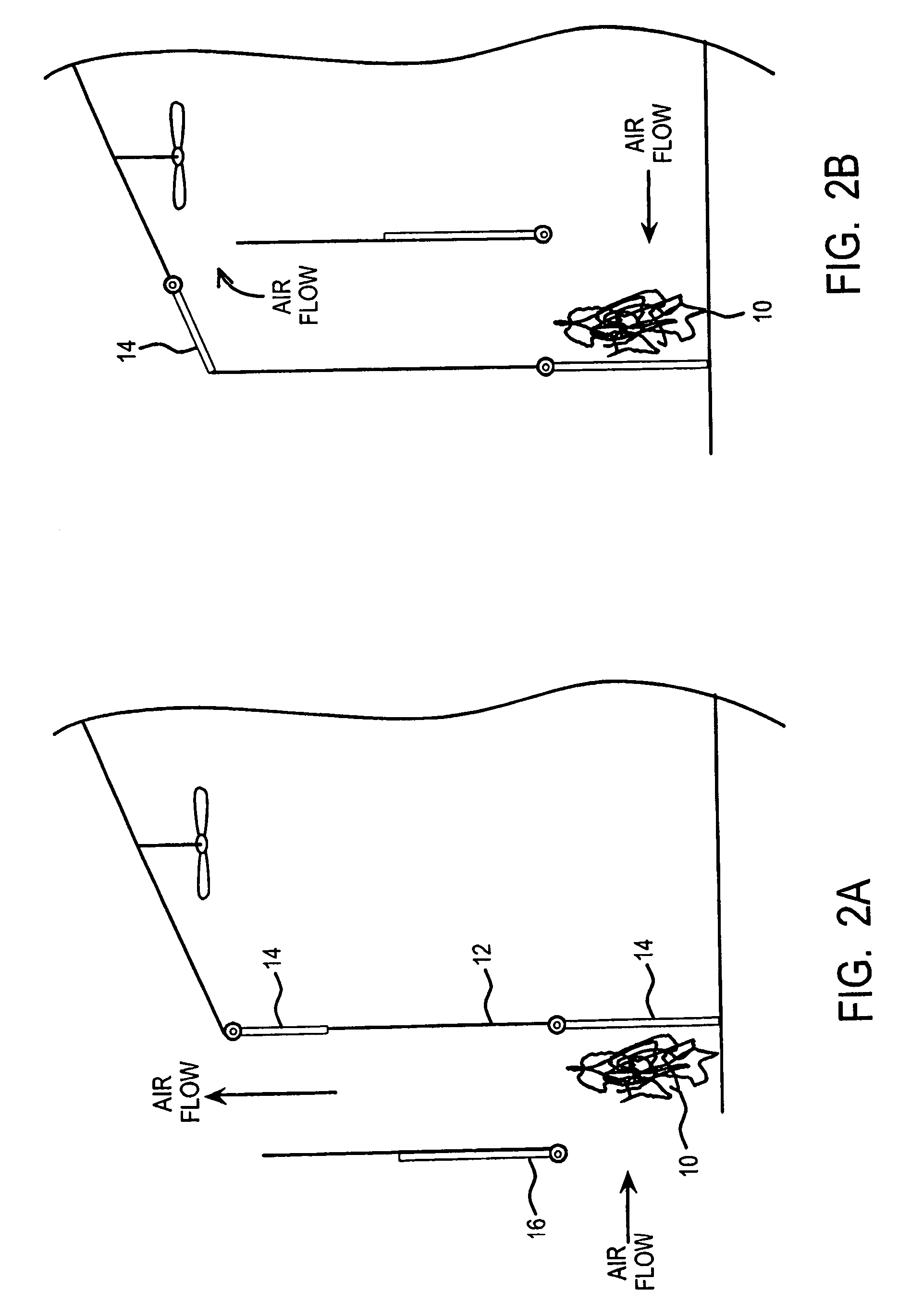

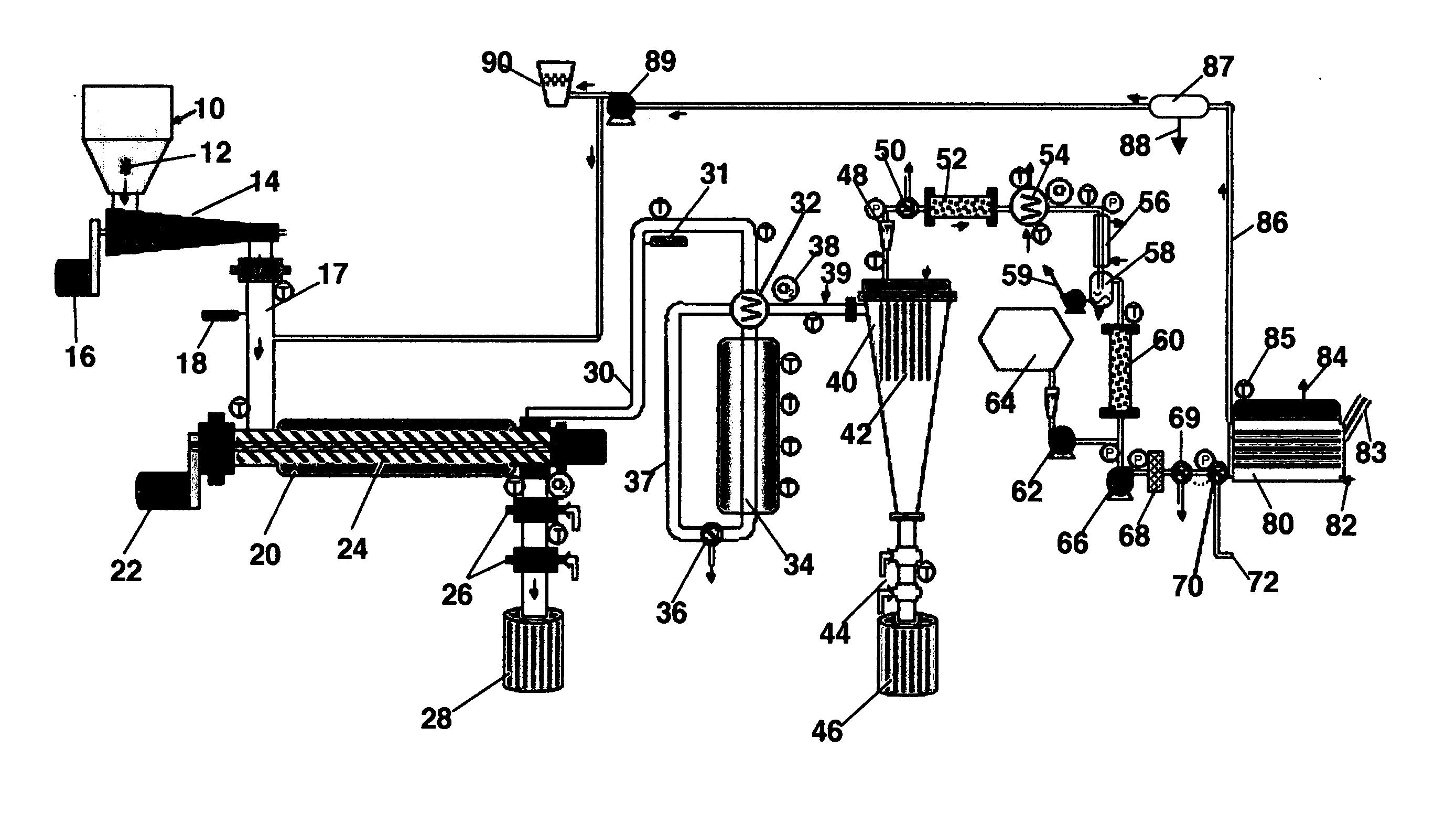

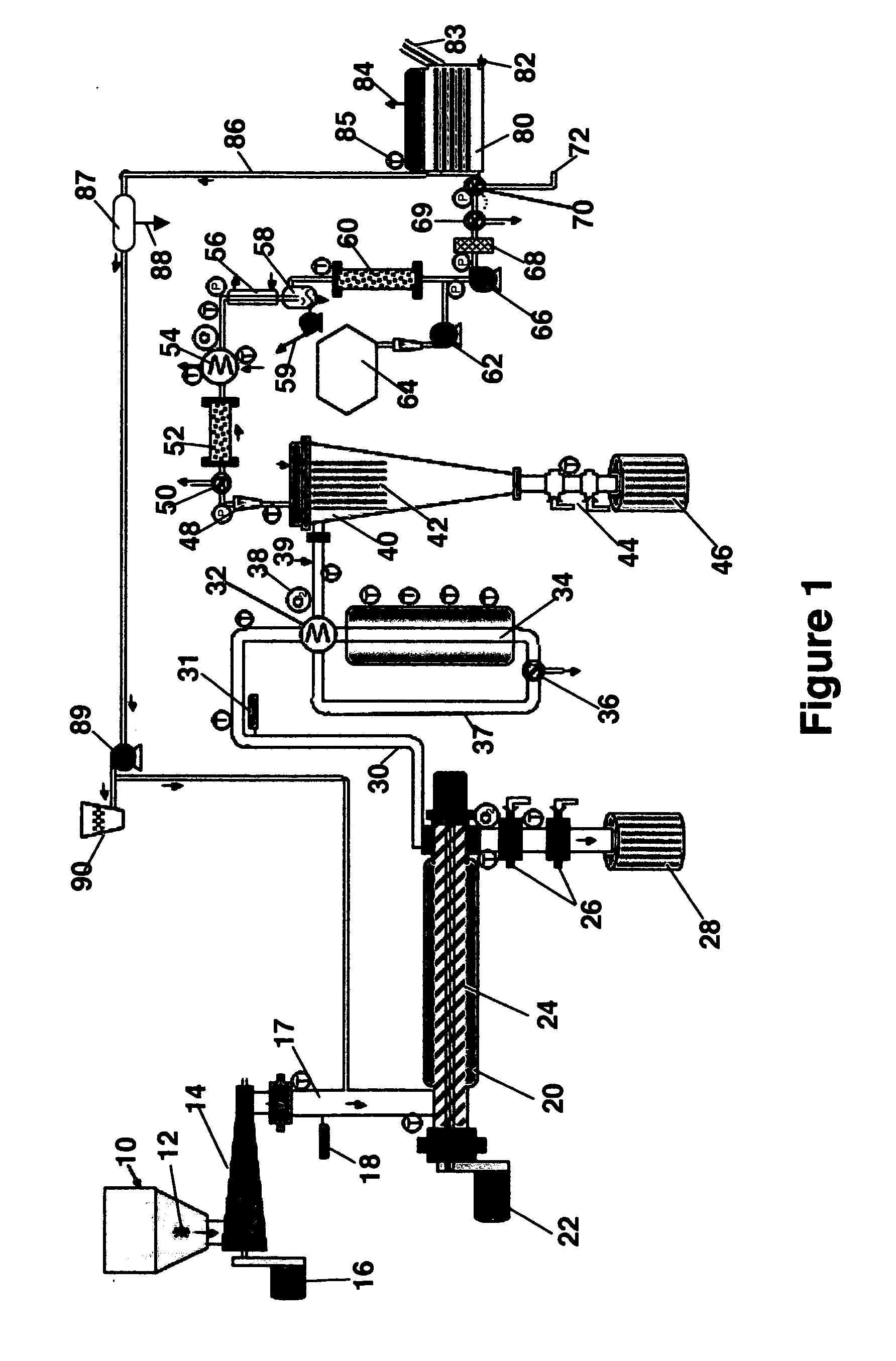

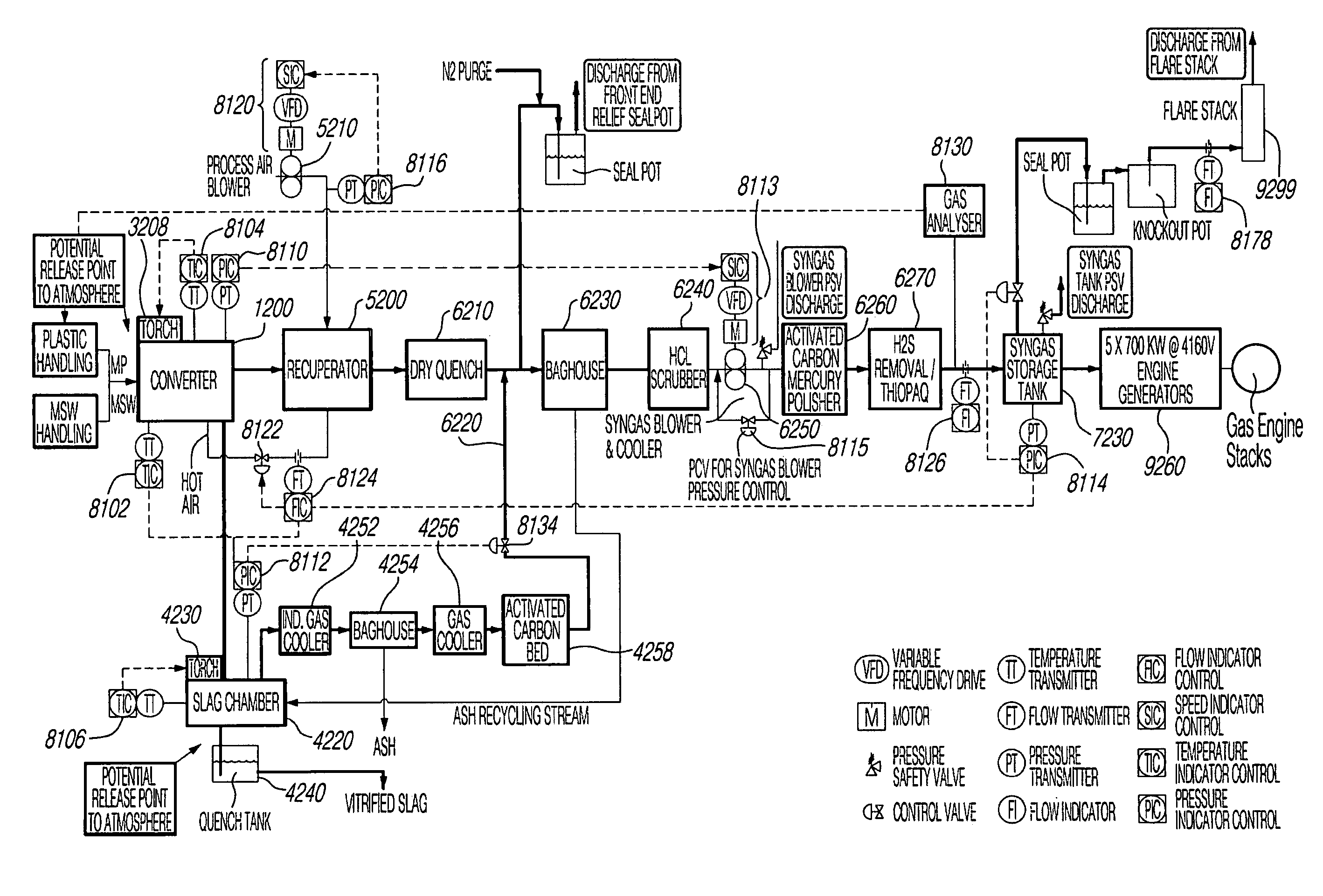

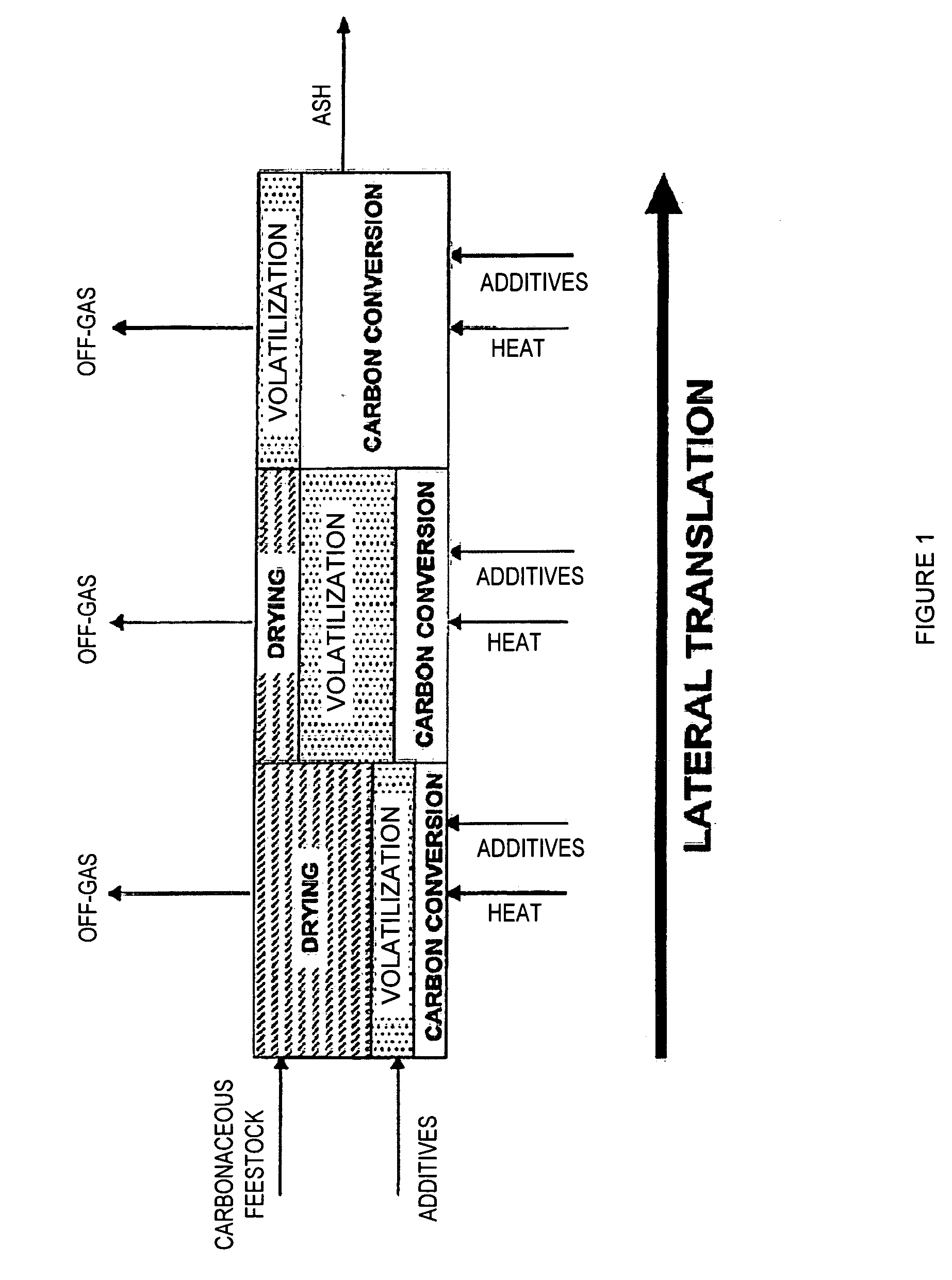

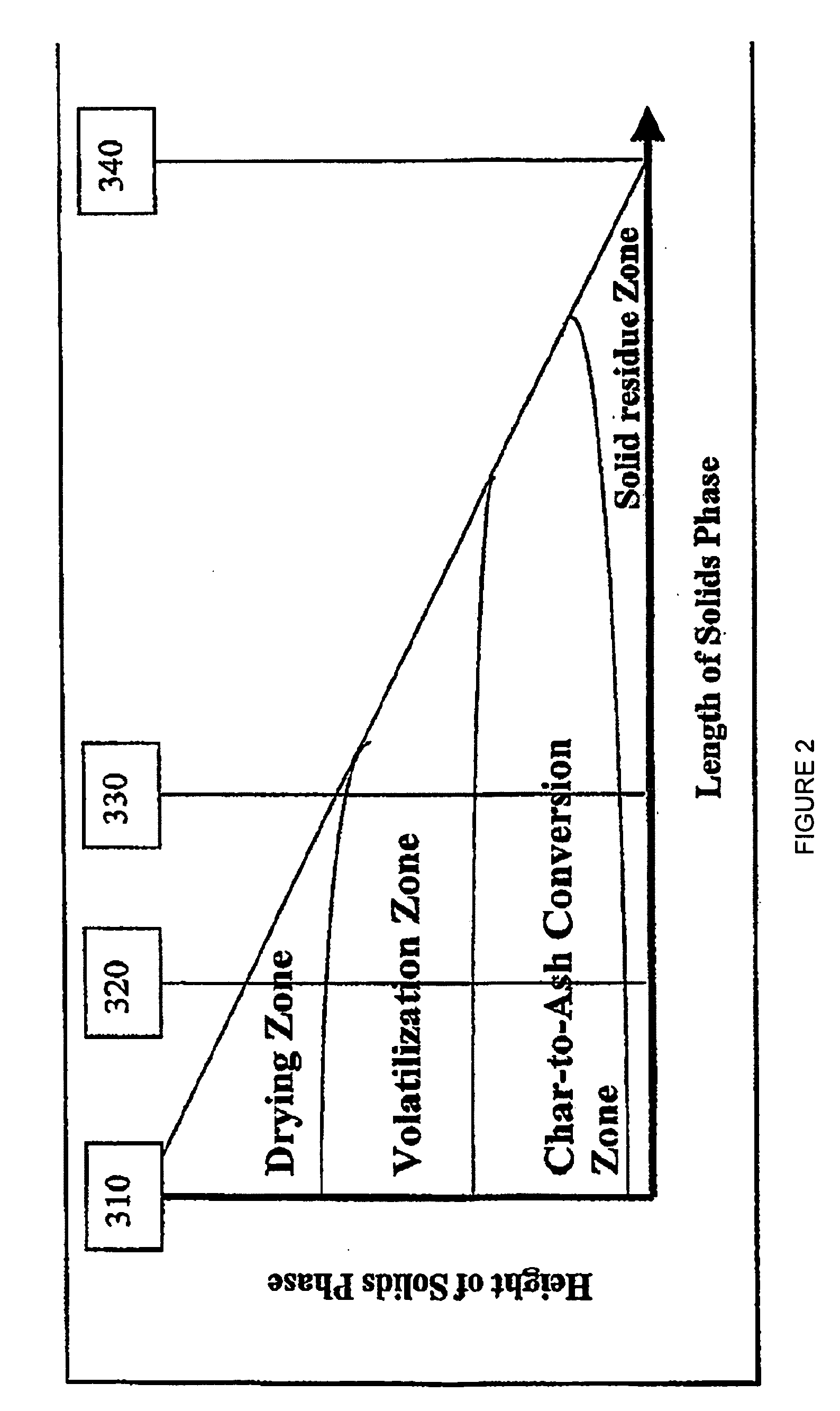

Low Temperature Gasification Facility with a Horizontally Oriented Gasifier

A low-temperature gasification system comprising a horizontally oriented gasifier is provided that optimizes the extraction of gaseous molecules from carbonaceous feedstock while minimizing waste heat. The system comprises a plurality of integrated subsystems that work together to convert municipal solid waste (MSW) into electricity. The subsystems comprised by the low-temperature gasification system are: a Municipal Solid Waste Handling System; a Plastics Handling System; a Horizontally Oriented Gasifier with Lateral Transfer Units System; a Gas Reformulating System; a Heat Recycling System; a Gas Conditioning System; a Residue Conditioning System; a Gas Homogenization System and a Control System.

Owner:PLASCO CONVERSION TECH INC

Processing biomass

Biomass (e.g., plant biomass, animal biomass, and municipal waste biomass) is processed to produce useful intermediates and products, such as energy, fuels, foods or materials. For example, methods are described that can use feedstock materials, such as cellulosic and / or lignocellulosic materials, to produce an intermediate or product, e.g., by fermentation.

Owner:XYLECO INC

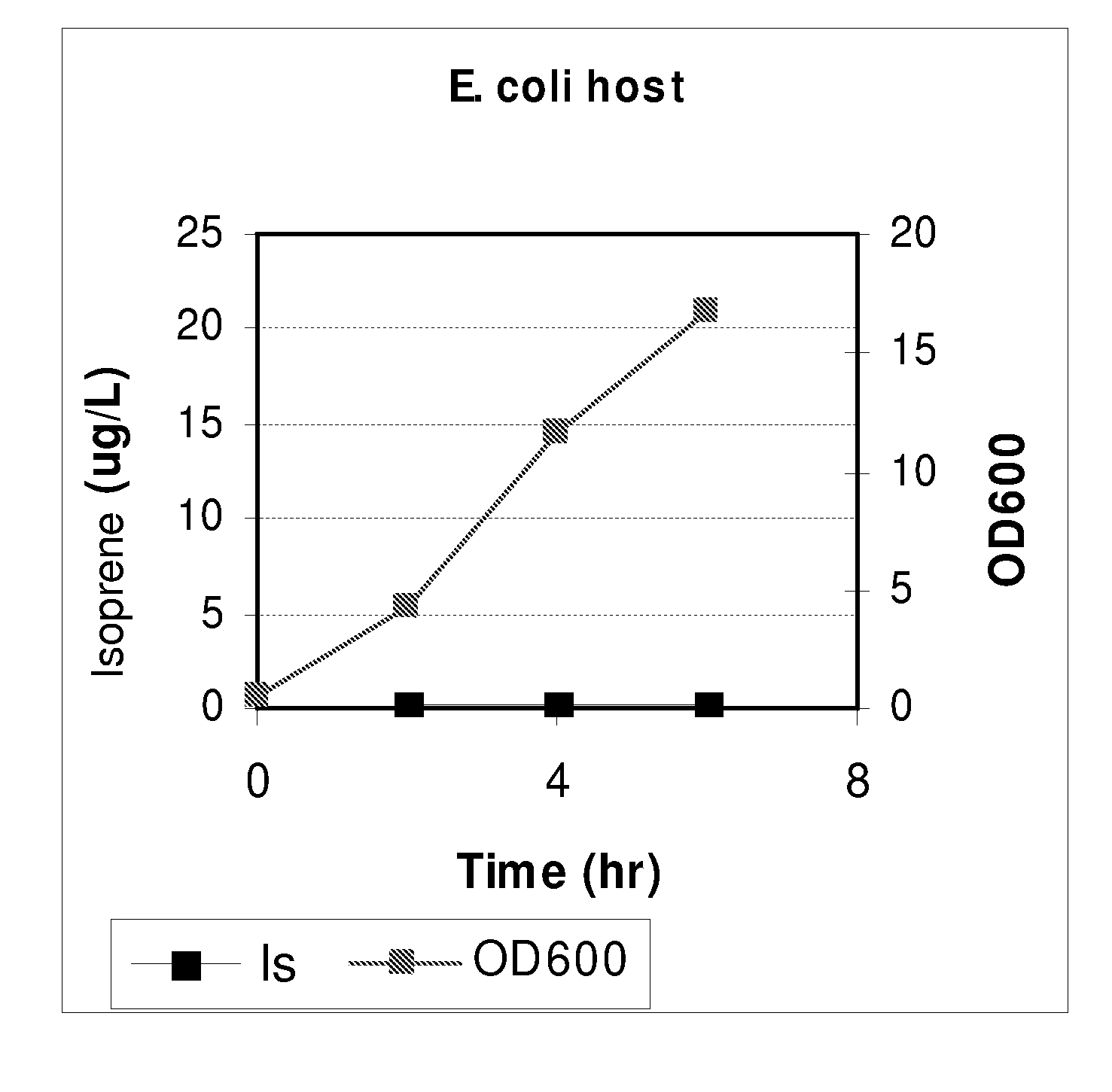

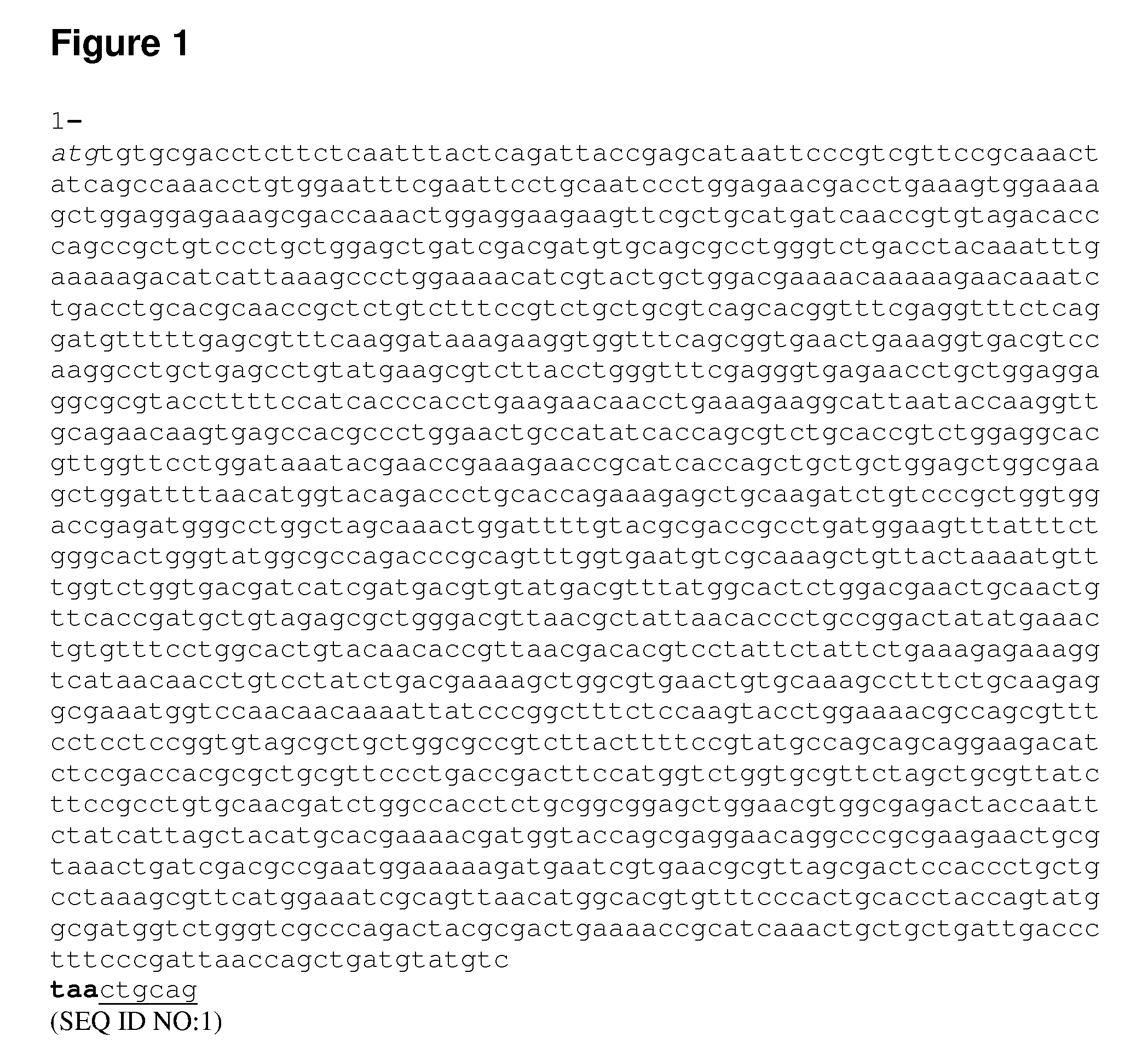

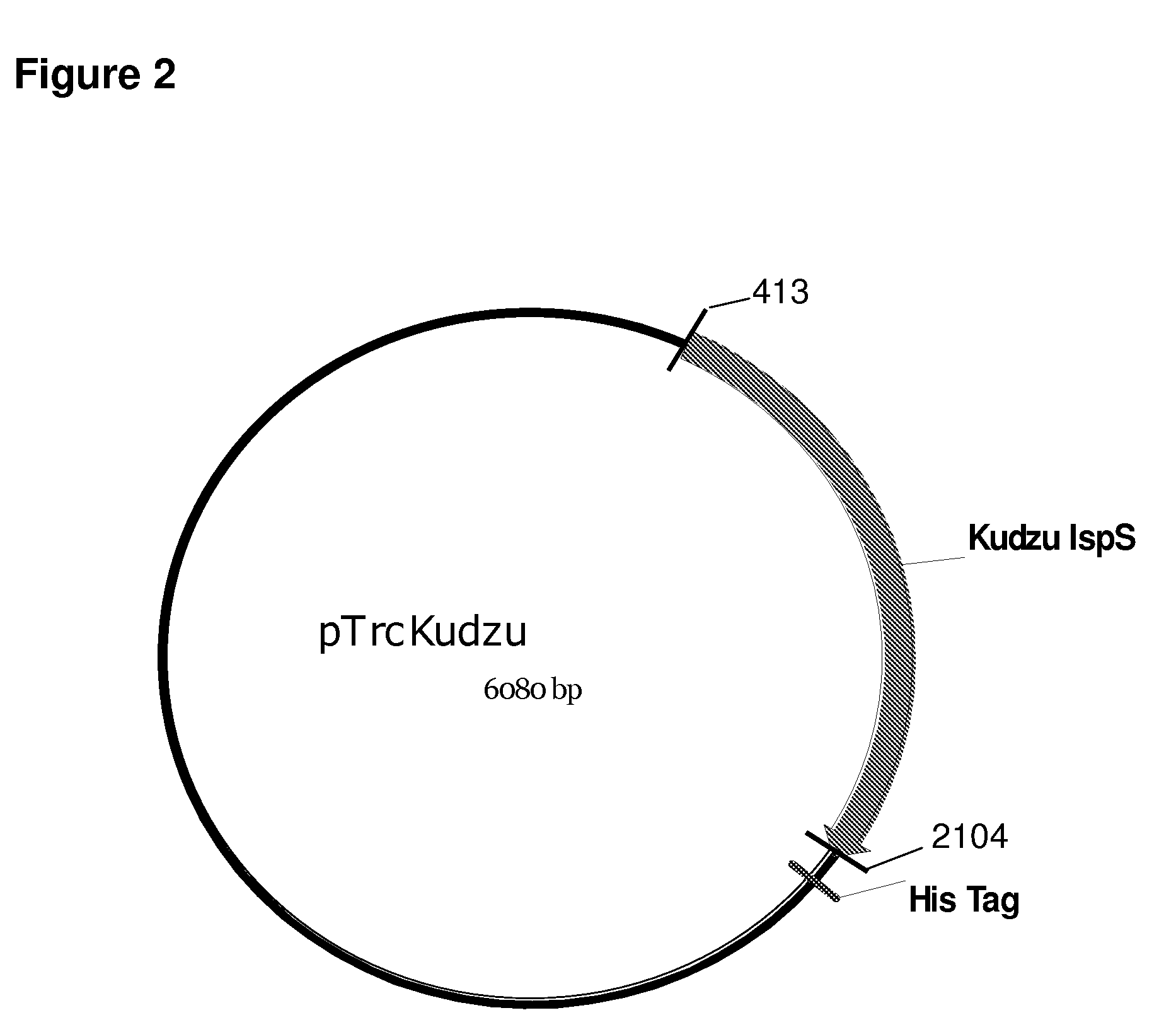

Compositions and methods for producing isoprene free of c5 hydrocarbons under decoupling conditions and/or safe operating ranges

The invention features methods for producing isoprene from cultured cells wherein the cells in the stationary phase. The invention also provides compositions that include these cultured cells and / or increased amount of isoprene. The invention also provides for systems that include a non-flammable concentration of isoprene in the gas phase. Additionally, the invention provides isoprene compositions, such as compositions with increased amount of isoprene or increased purity.

Owner:DANISCO US INC +1

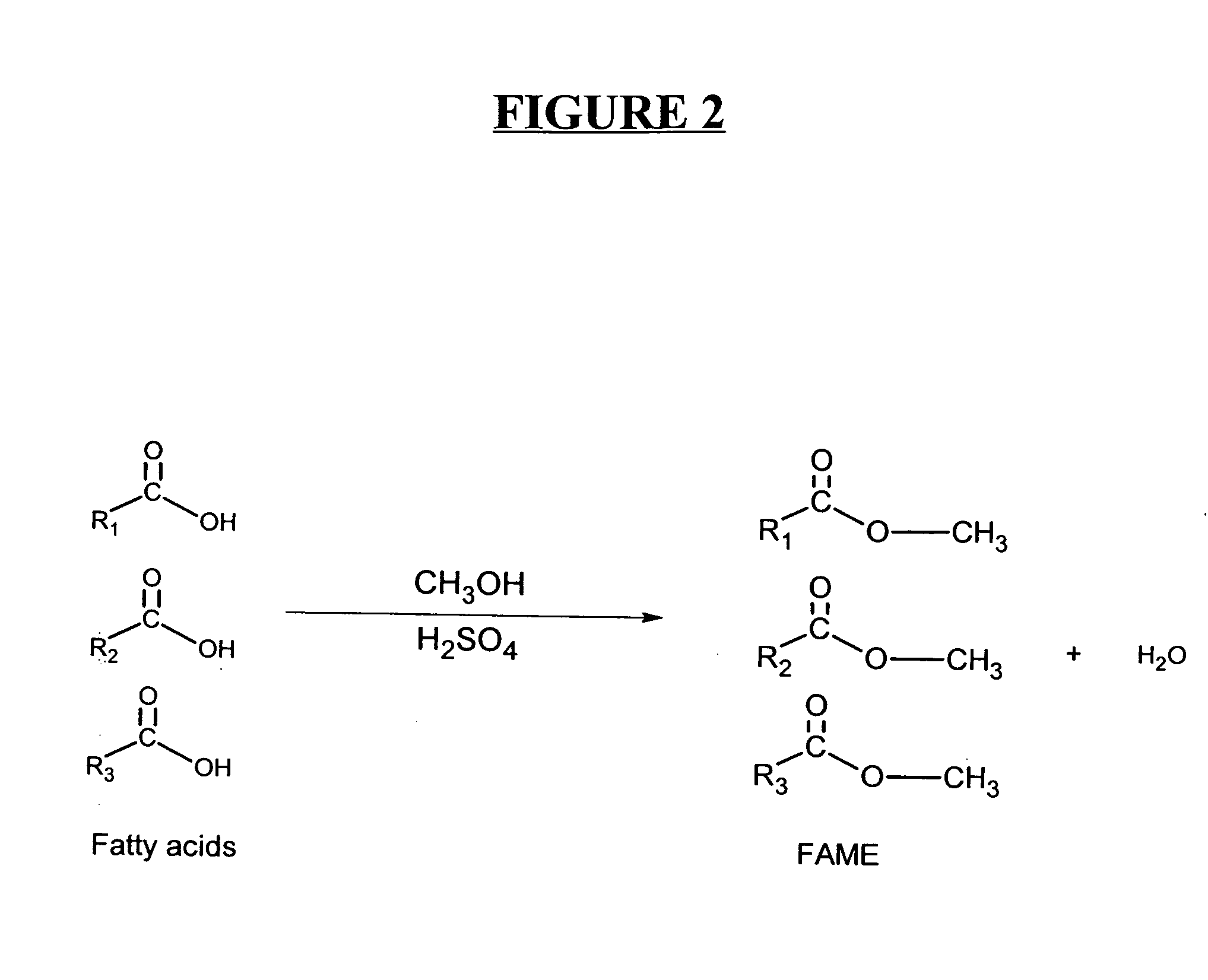

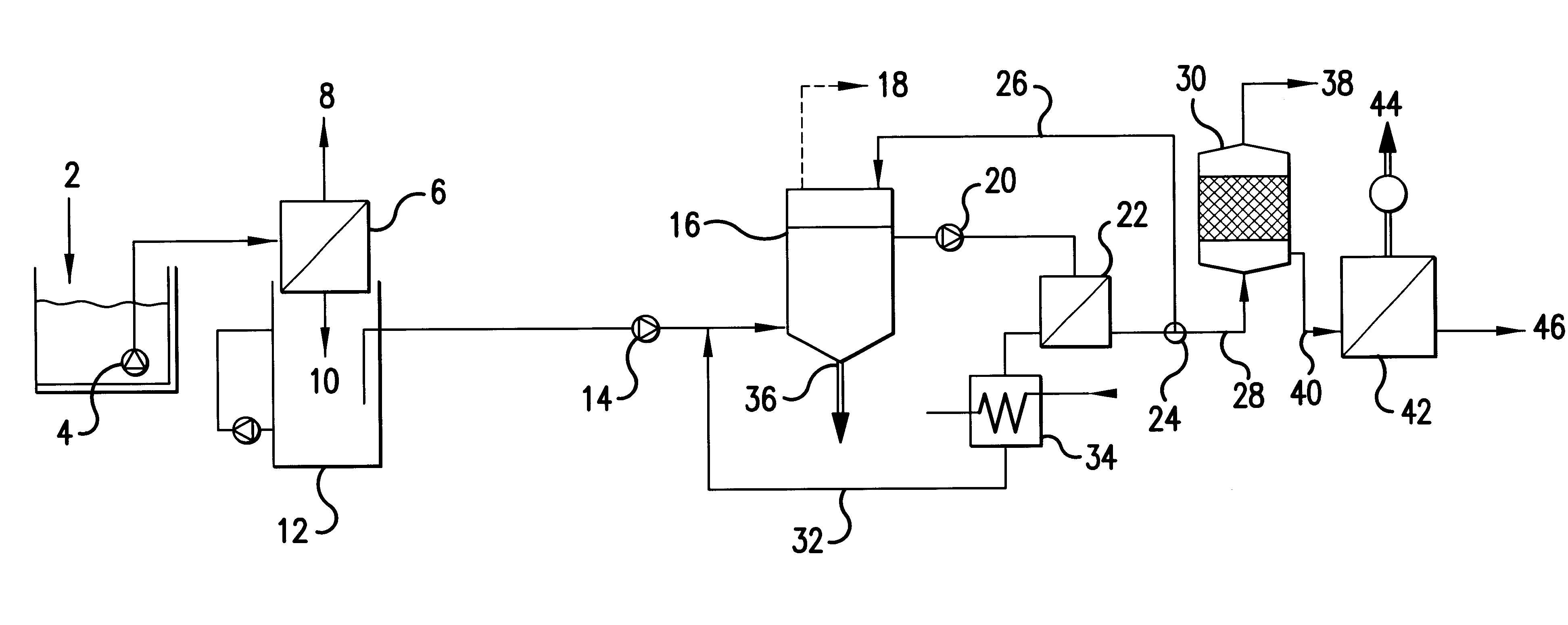

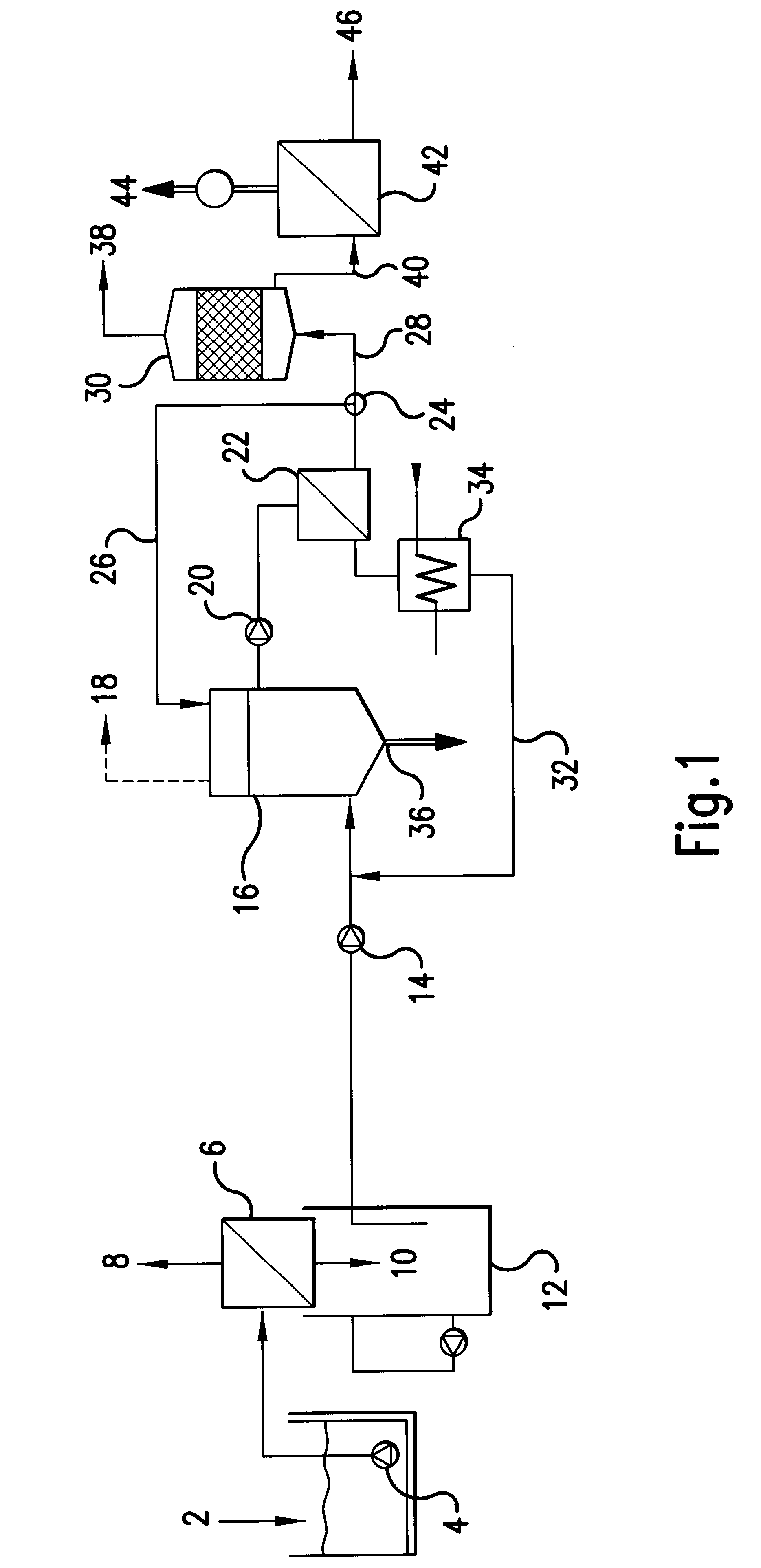

Production of biodiesel and other valuable chemicals from wastewater treatment plant sludges

ActiveUS20050112735A1Reduce the environmentPromote digestionBio-organic fraction processingByproduct vaporizationLipid formationSludge

A process for producing biodiesel has been invented by first extracting lipids from the sludges generated during primary and / or biological treatment of municipal, agricultural, and industrial wastewaters using primary, secondary, and tertiary treatments followed by the transesterification of the extracted lipids using transesterification conversion into alcohol-based esters. The resulting products from this process include biodiesel, glycerol, lipid-free proteins, various other useful chemicals and an aqueous-based substrate well suited for optimized digestion within subsequent biological digestion (either aerobic or anaerobic). The lipids extracted from the sludges containing high levels of microorganisms are phospholipids which can also be directly used as lecithin. The extraction of the lipids from the sludges will be performed using chemical extraction techniques with the transesterification of the extracted lipids accomplished using basic, acidic, and / or a combination of the two transesterification techniques.

Owner:MISSISSPPI STATE UNIV RES & TECH

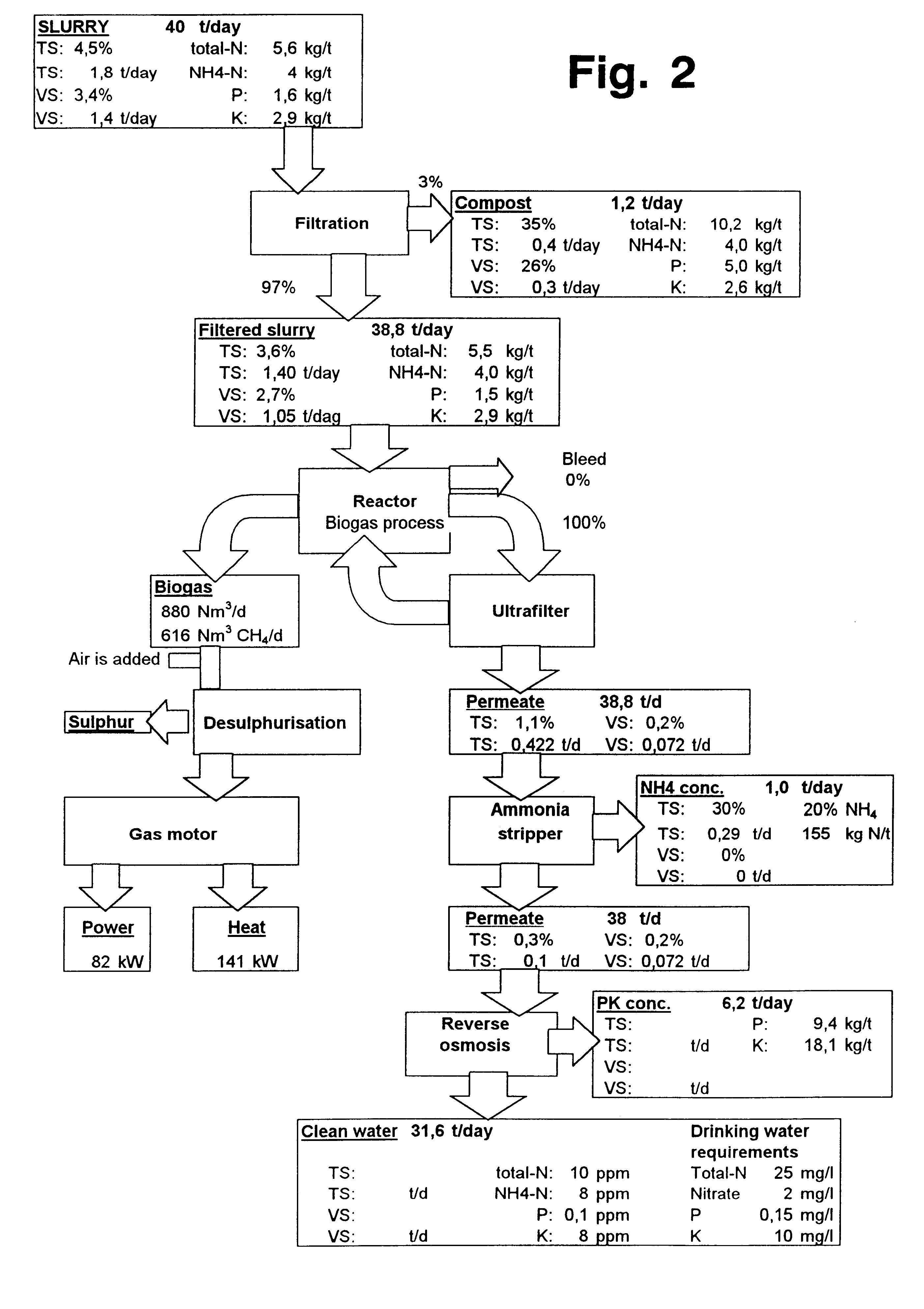

Method and plant for the treatment of liquid organic waste

InactiveUS6368849B1Increase profitReduce environmental impactBioreactor/fermenter combinationsBio-organic fraction processingFiberUltrafiltration

A method and plant for the treatment of an organic waste material in liquid form, e.g. liquid manure from livestock, the method comprising filtering fibres and particles from the liquid, subjecting the liquid to anaerobic fermentation in a biogas reactor, separating a substantially sterile and particle-free permeate stream from the biogas reactor, e.g. using ultrafiltration, subjecting the permeate stream to treatment with an ammonia stripper at an elevated temperature and preferably at reduced pressure to remove substantially all ammonia and carbon dioxide and to result in an ammonia fraction and a nutrient salt fraction, and separating the nutrient salt fraction into a fertiliser concentrate fraction and a water fraction, e.g. using reverse osmosis. The end products of the method are clean water, ammonia concentrate, fertiliser concentrate containing salts of P and K, compost and high-quality biogas with a high methane content.

Owner:GR BIOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com