Patents

Literature

401 results about "Gas conditioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

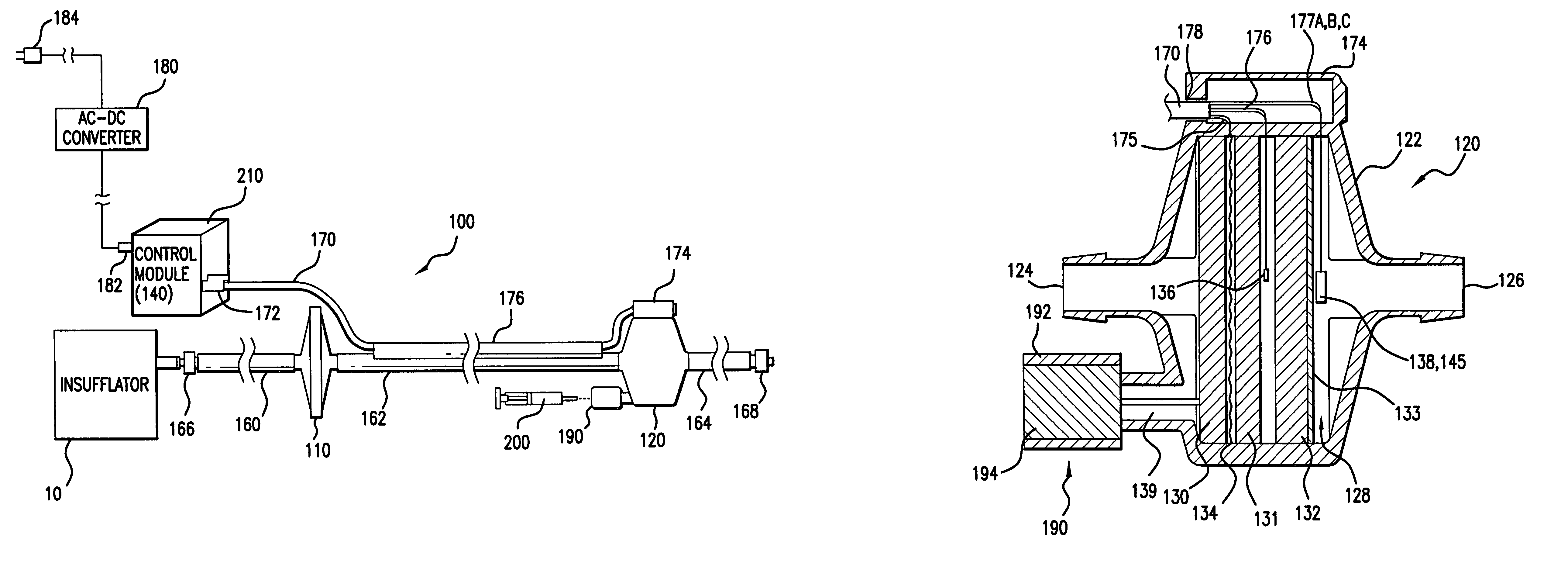

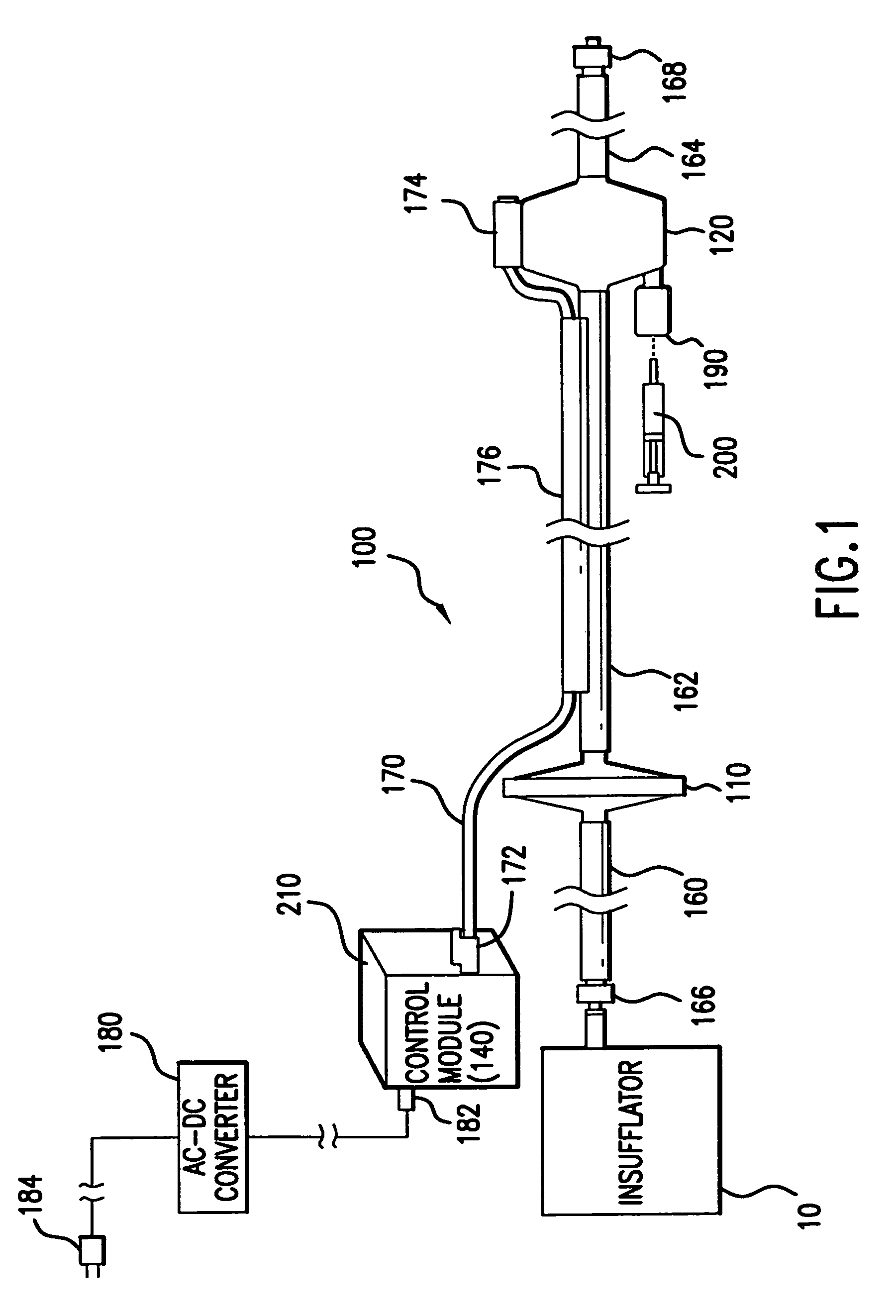

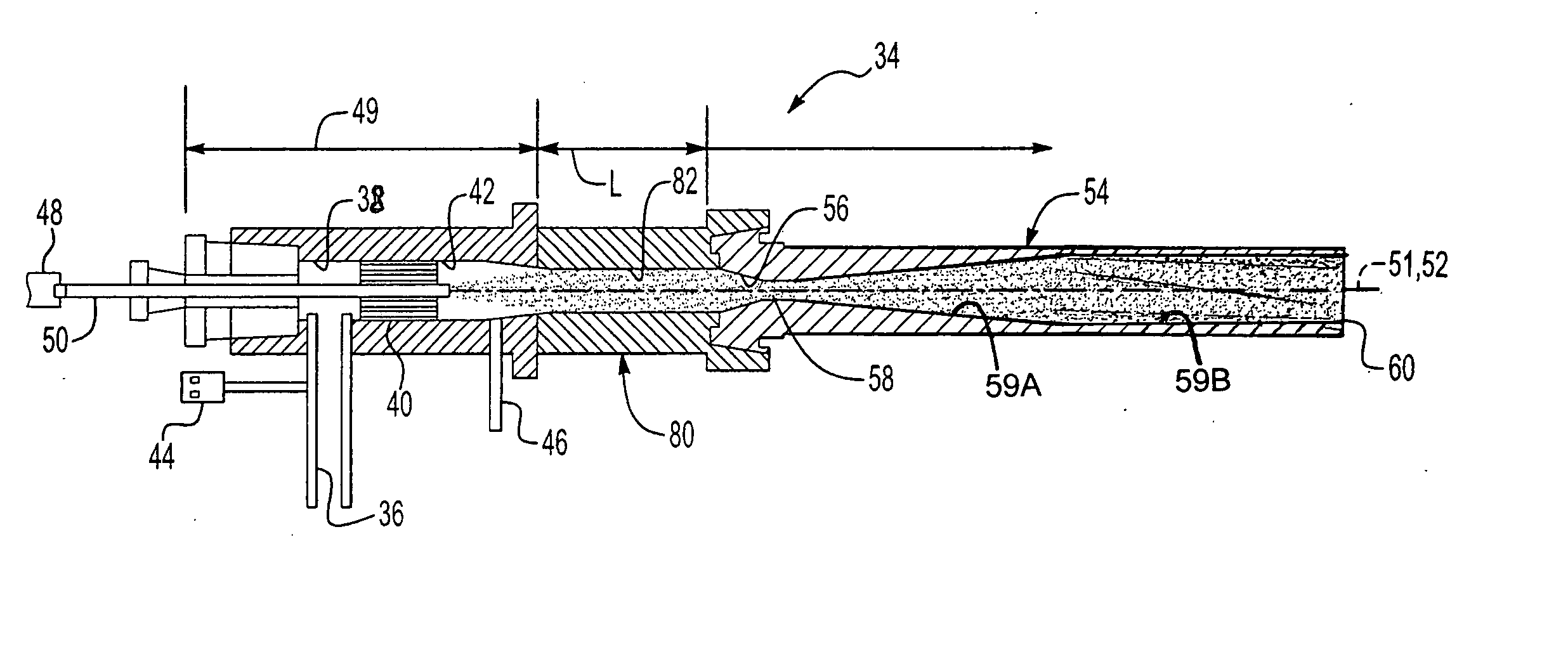

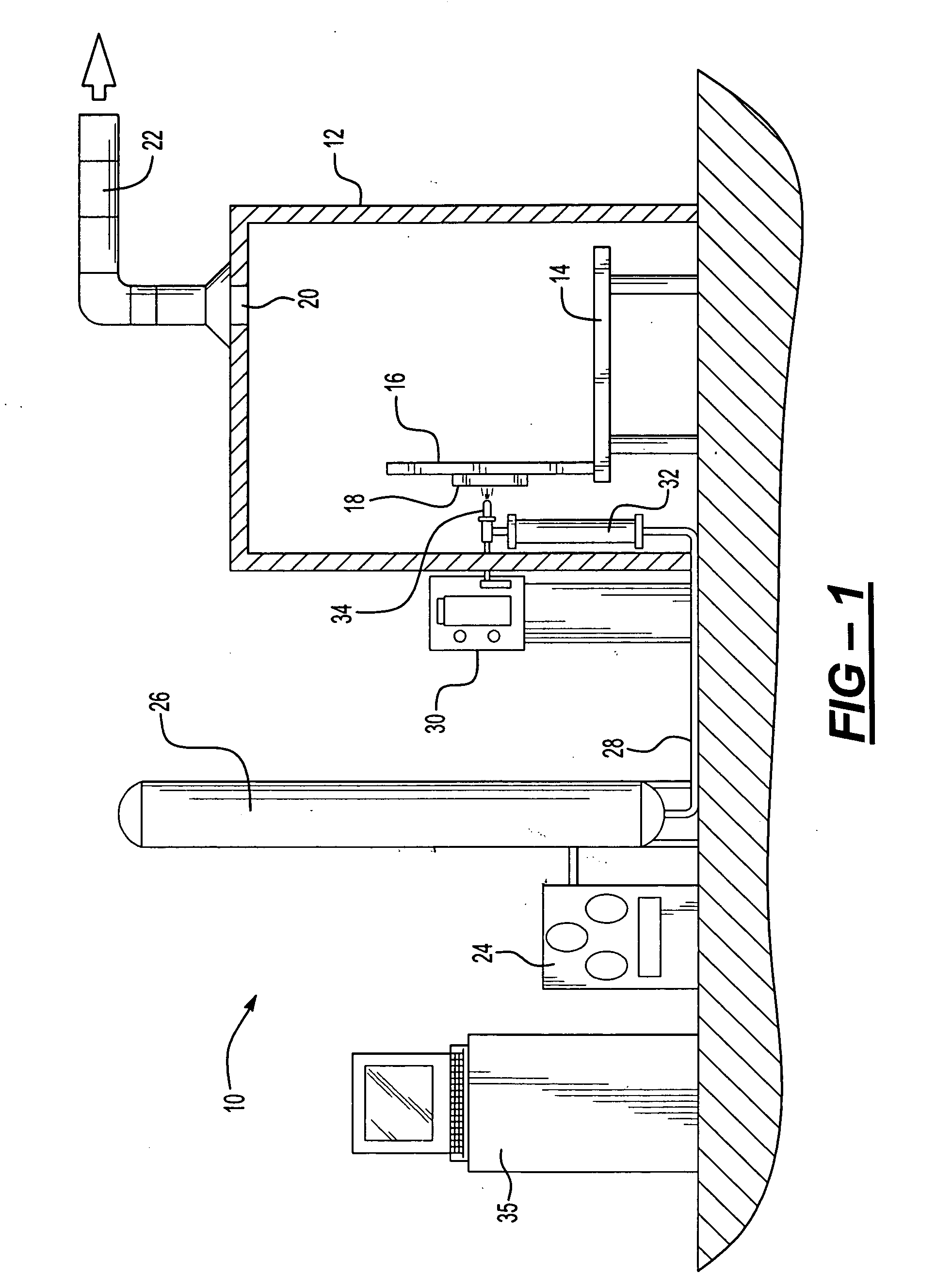

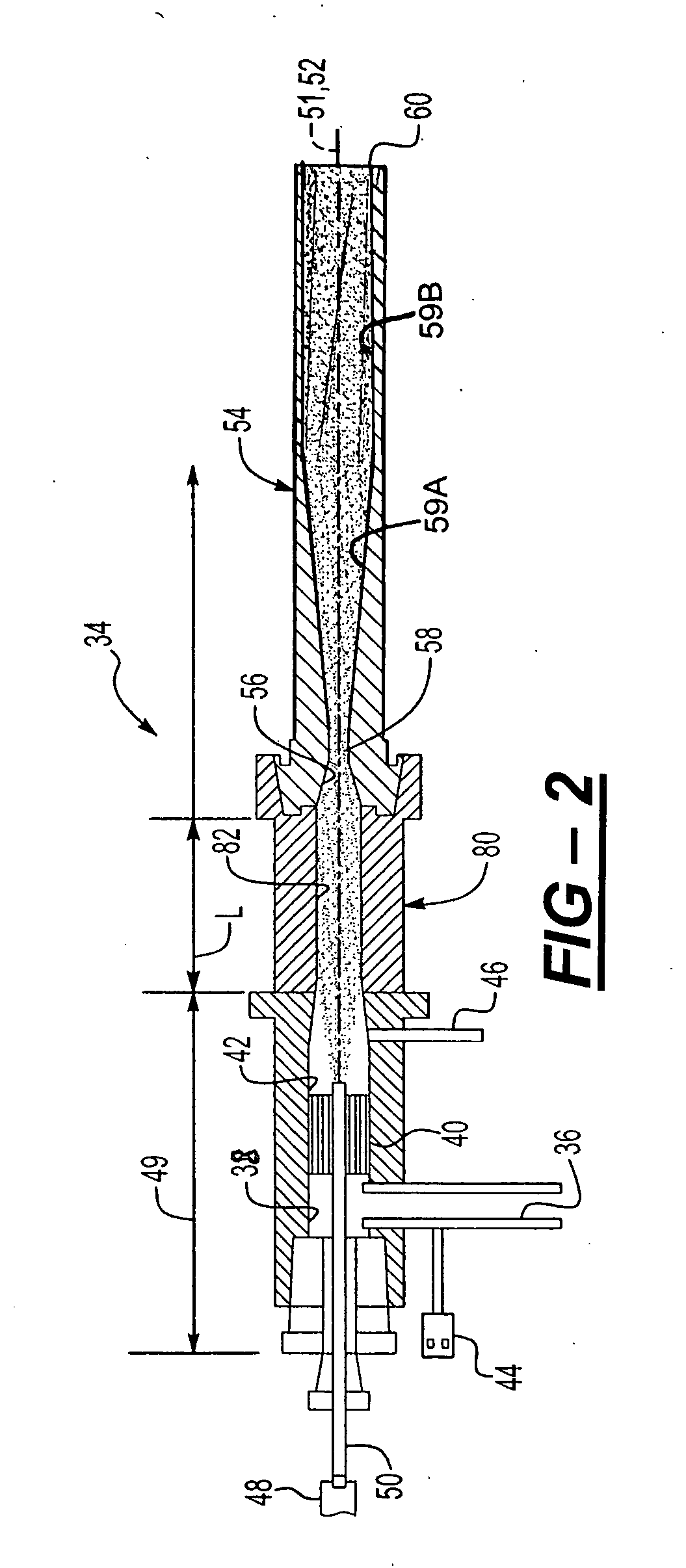

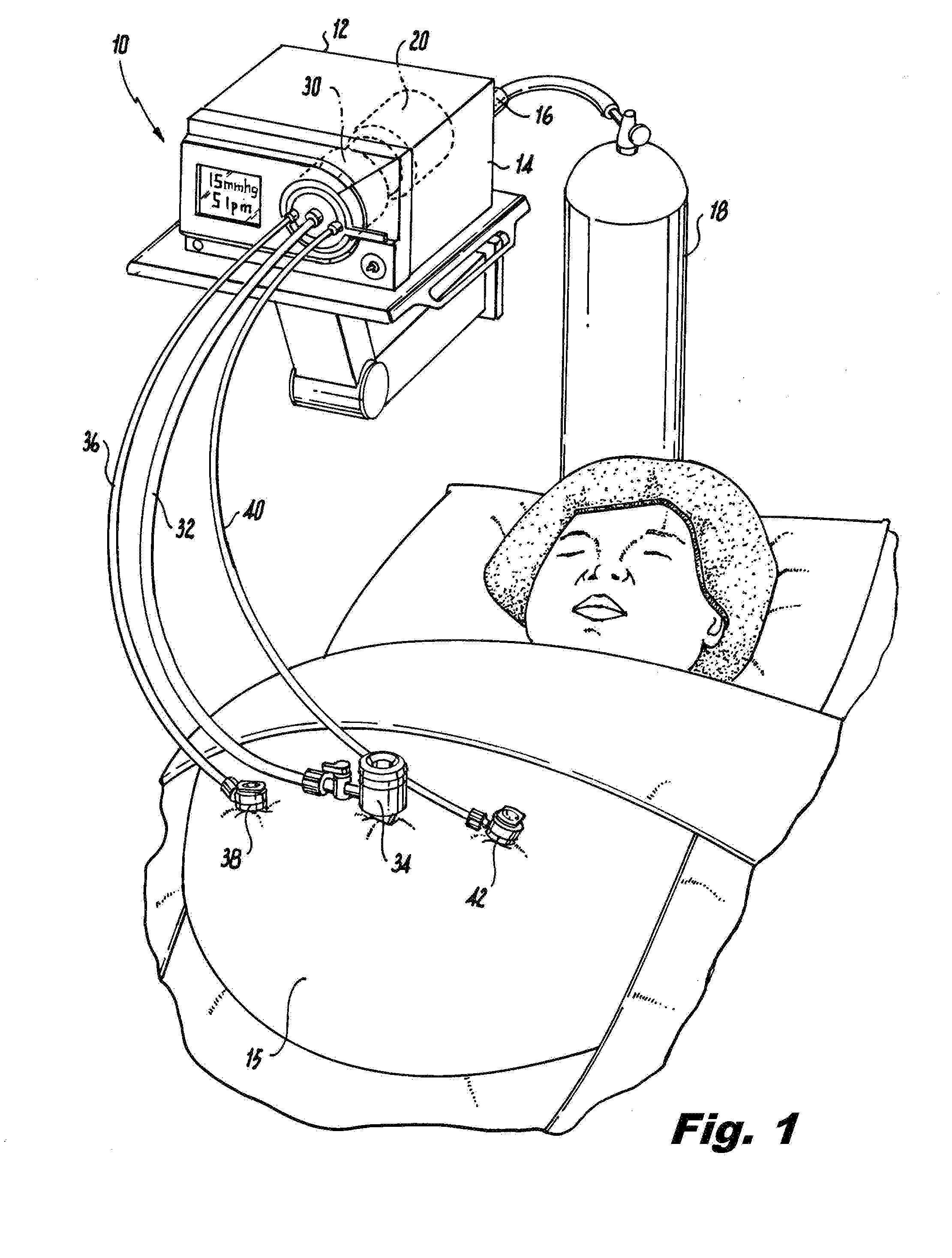

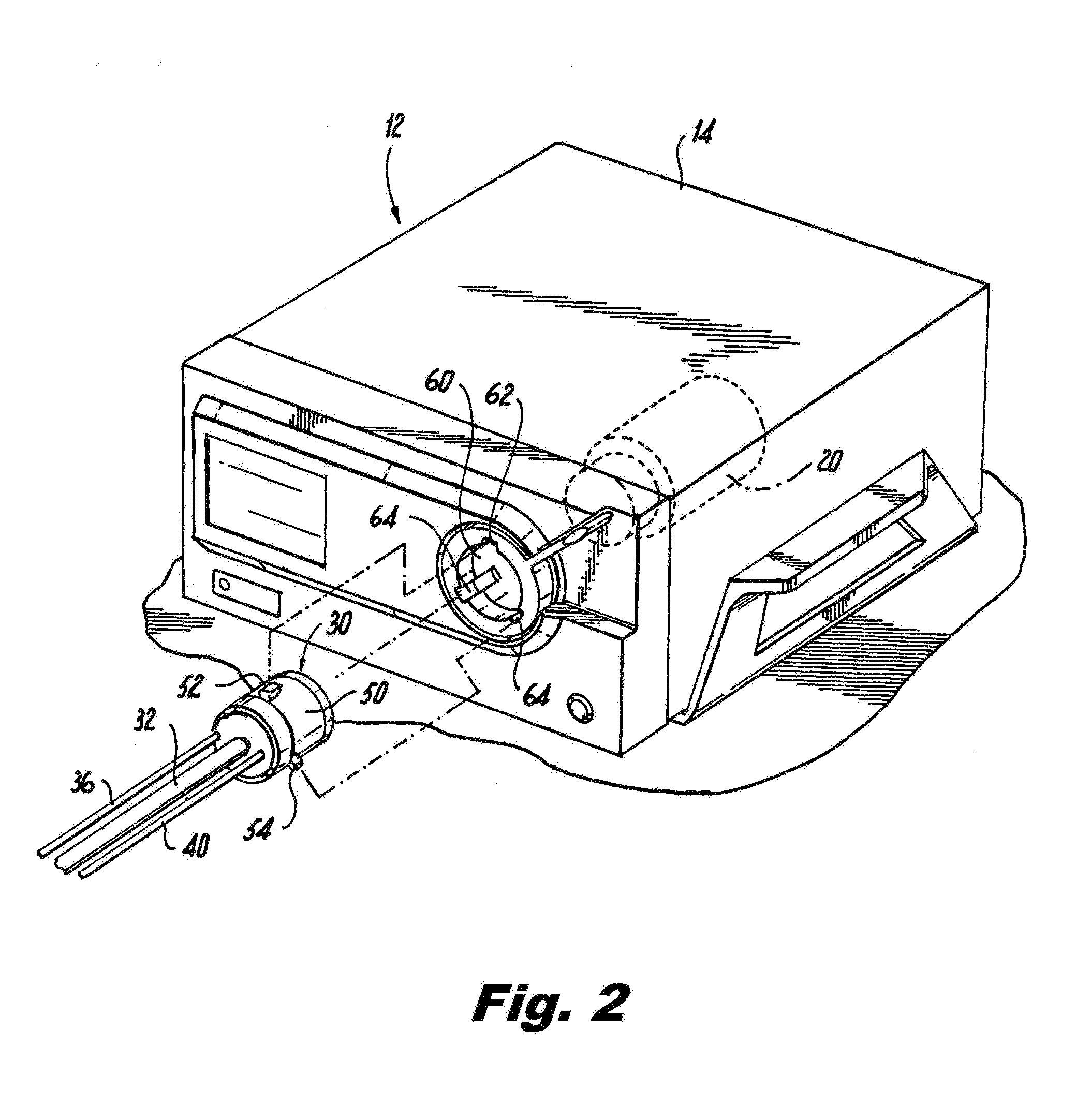

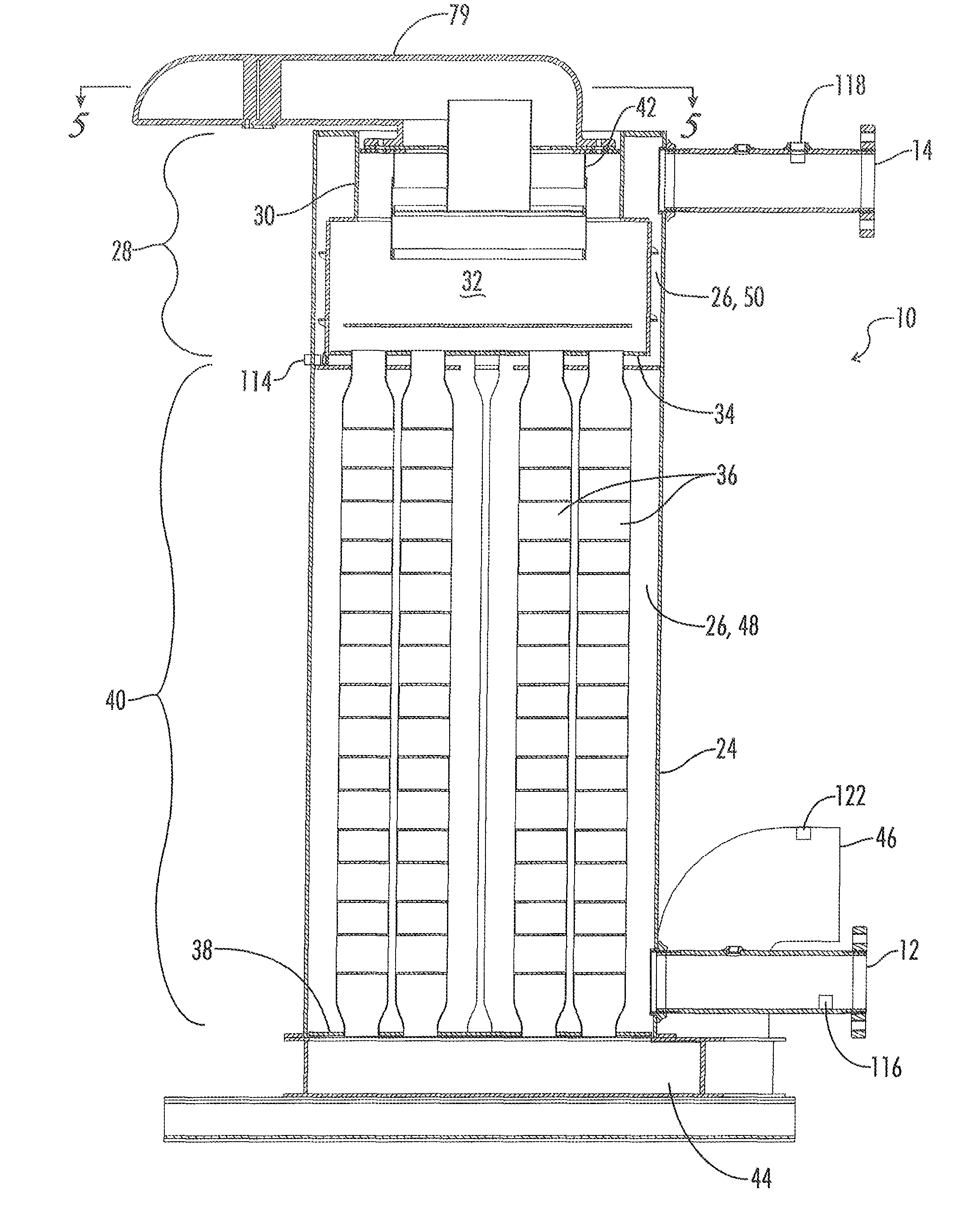

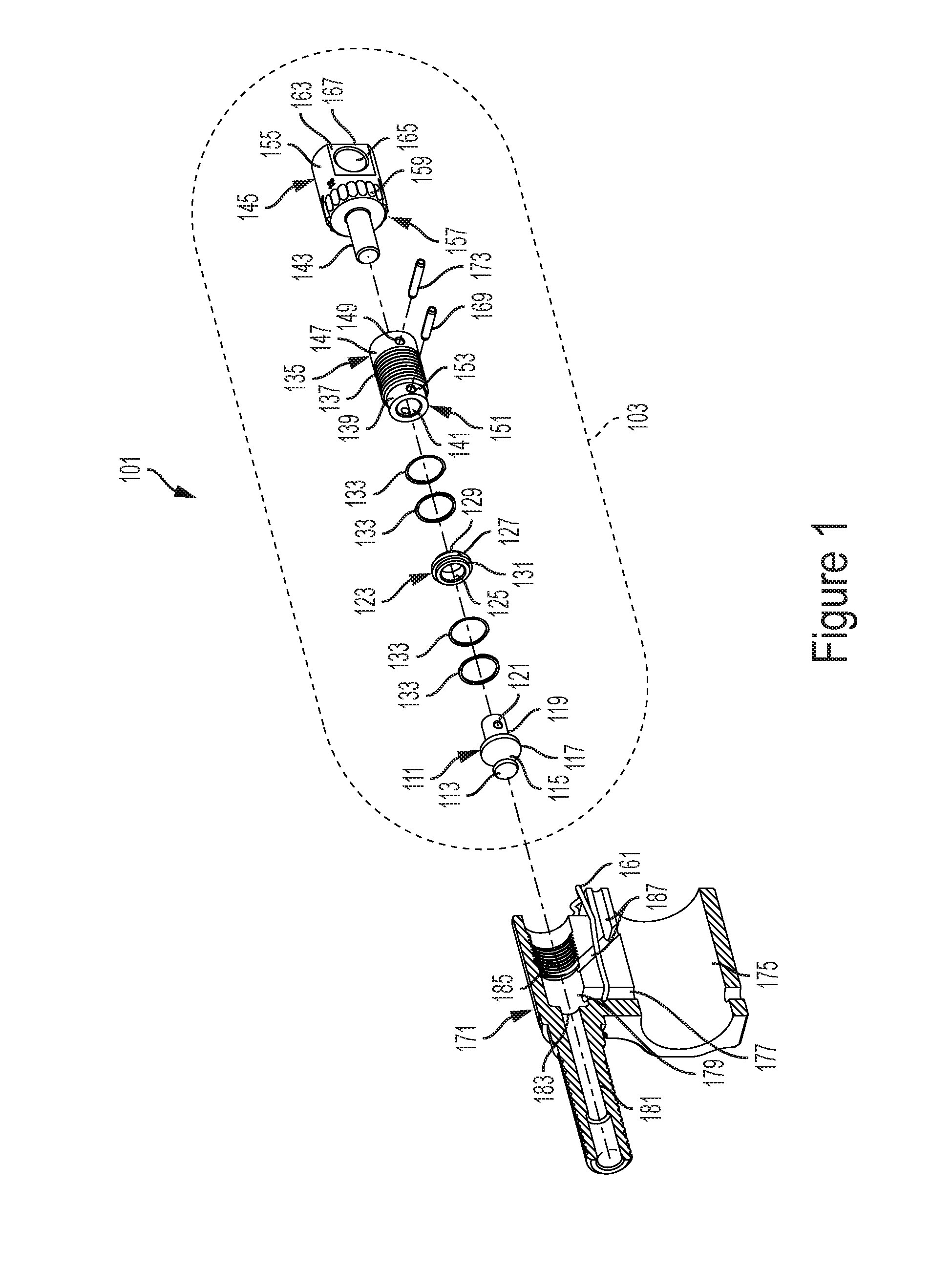

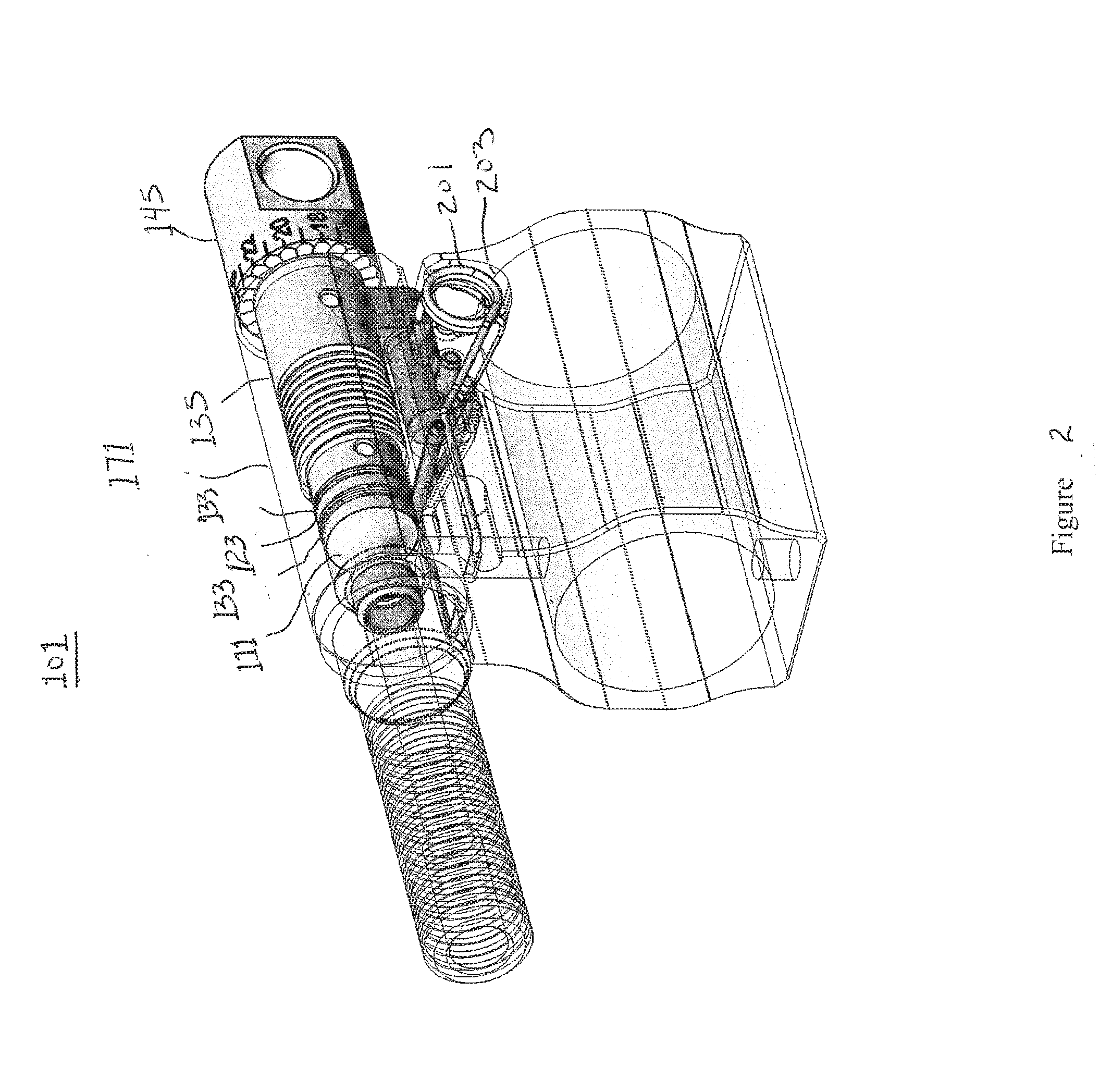

Filter cartridge with internal gaseous seal for multimodal surgical gas delivery system having a smoke evacuation mode

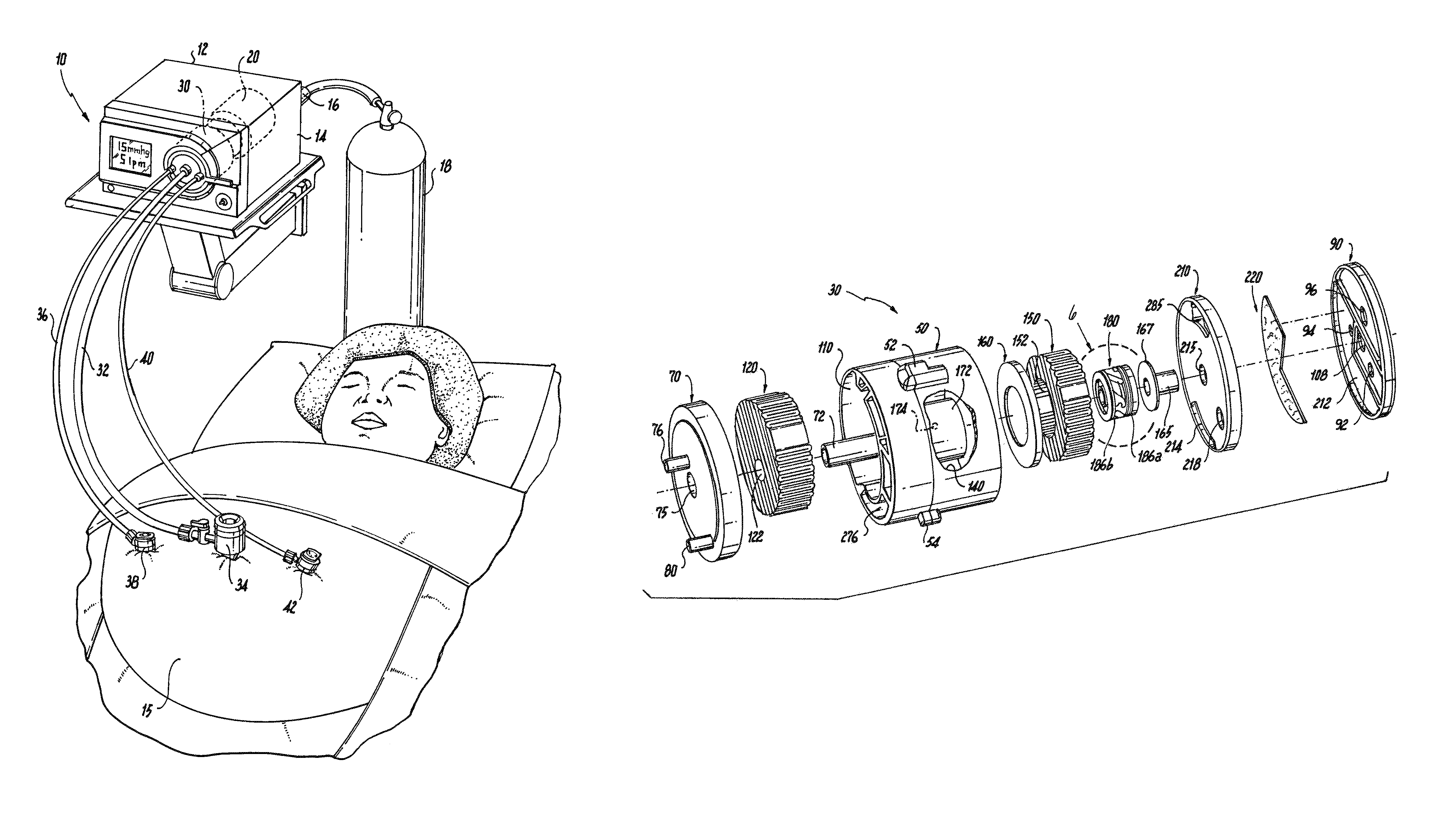

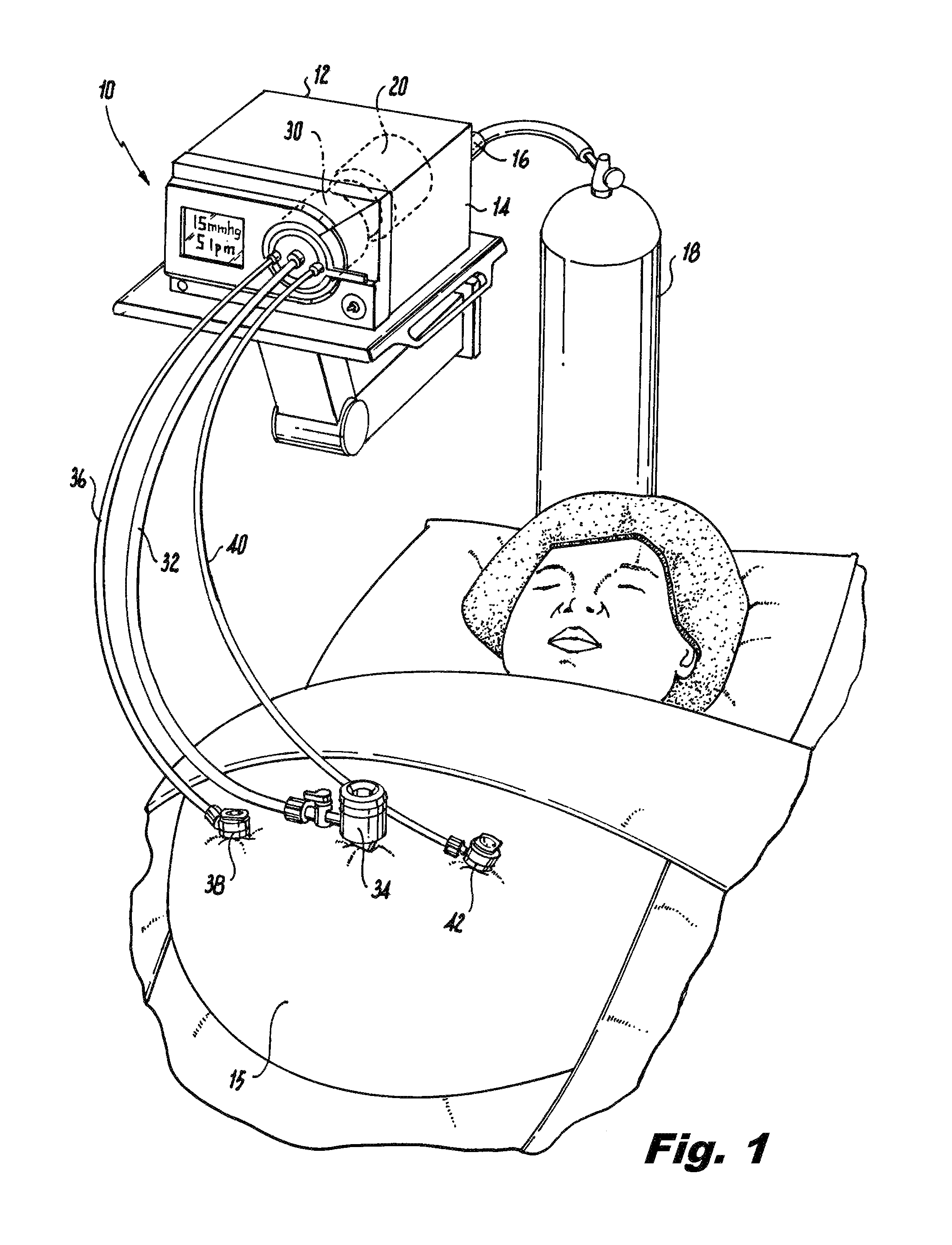

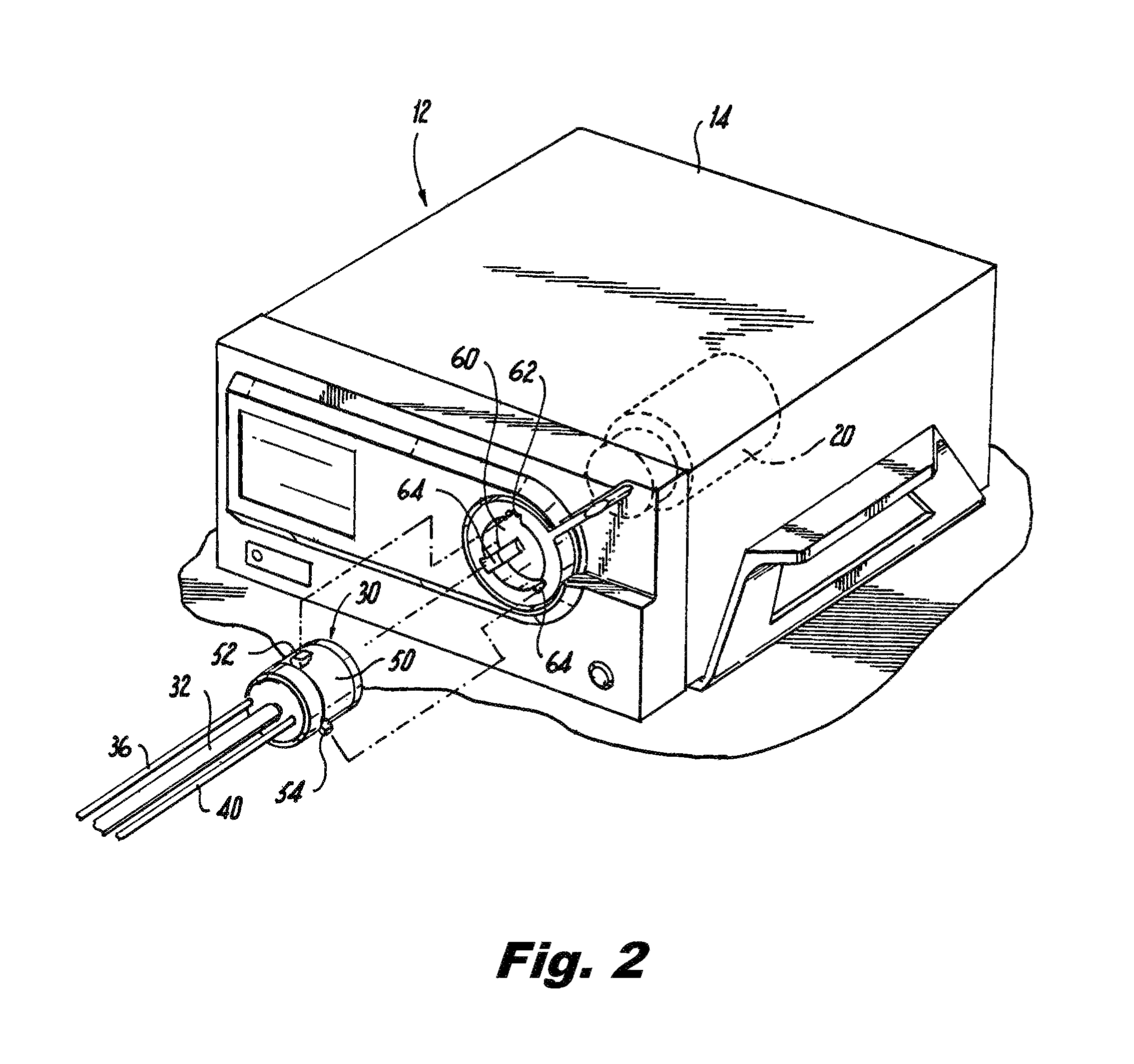

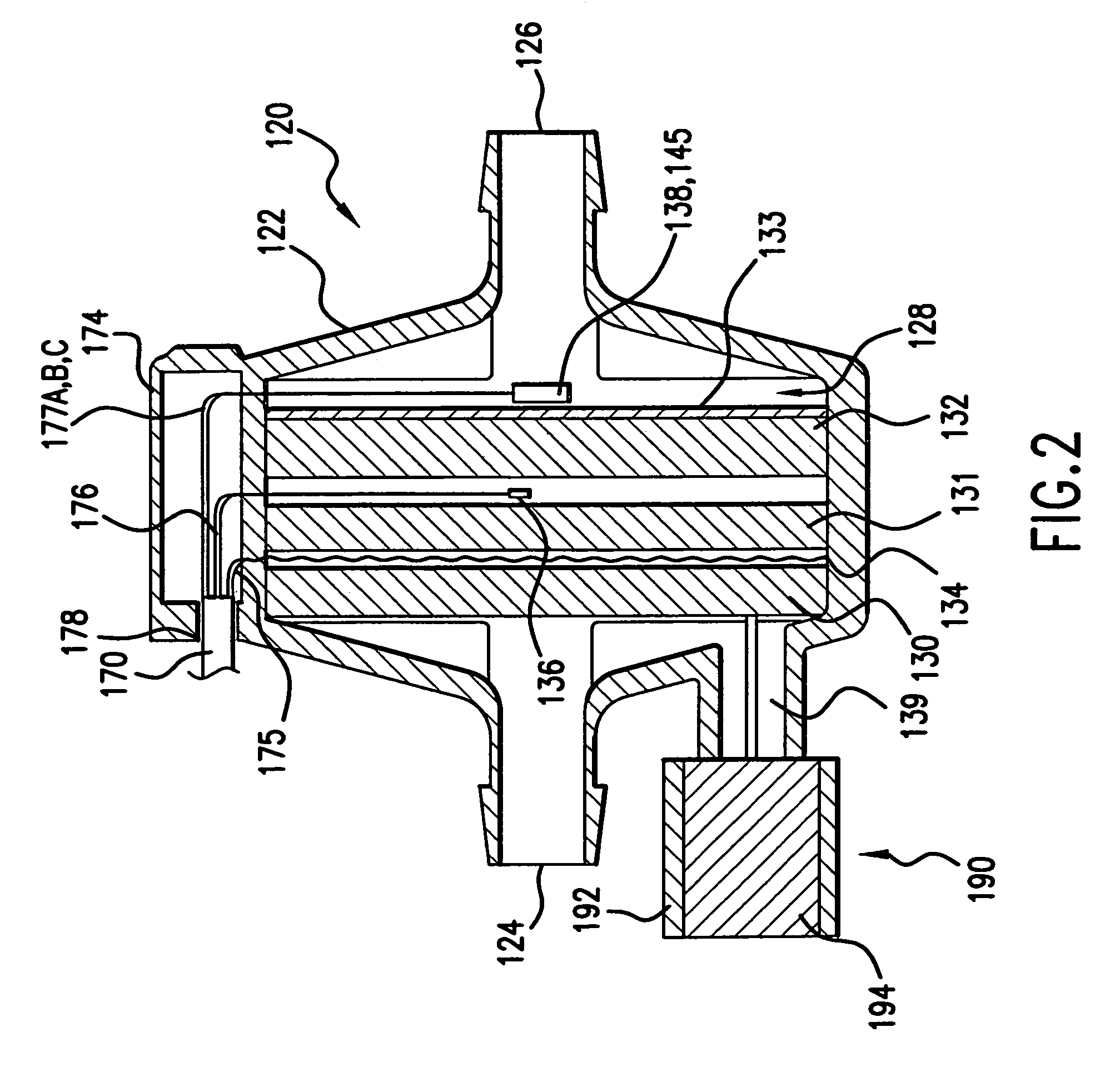

A system is disclosed for delivering gas during a laparoscopic surgical procedure performed within a patient's abdominal cavity requiring smoke evacuation which includes a gas delivery device having a housing with a port for receiving pressurized insufflating gas from a gas source, a pump assembly for circulating gas throughout the system, and a disposable gas conditioning unit or filter cartridge configured for operative association with the gas delivery device.

Owner:SURGIQUEST

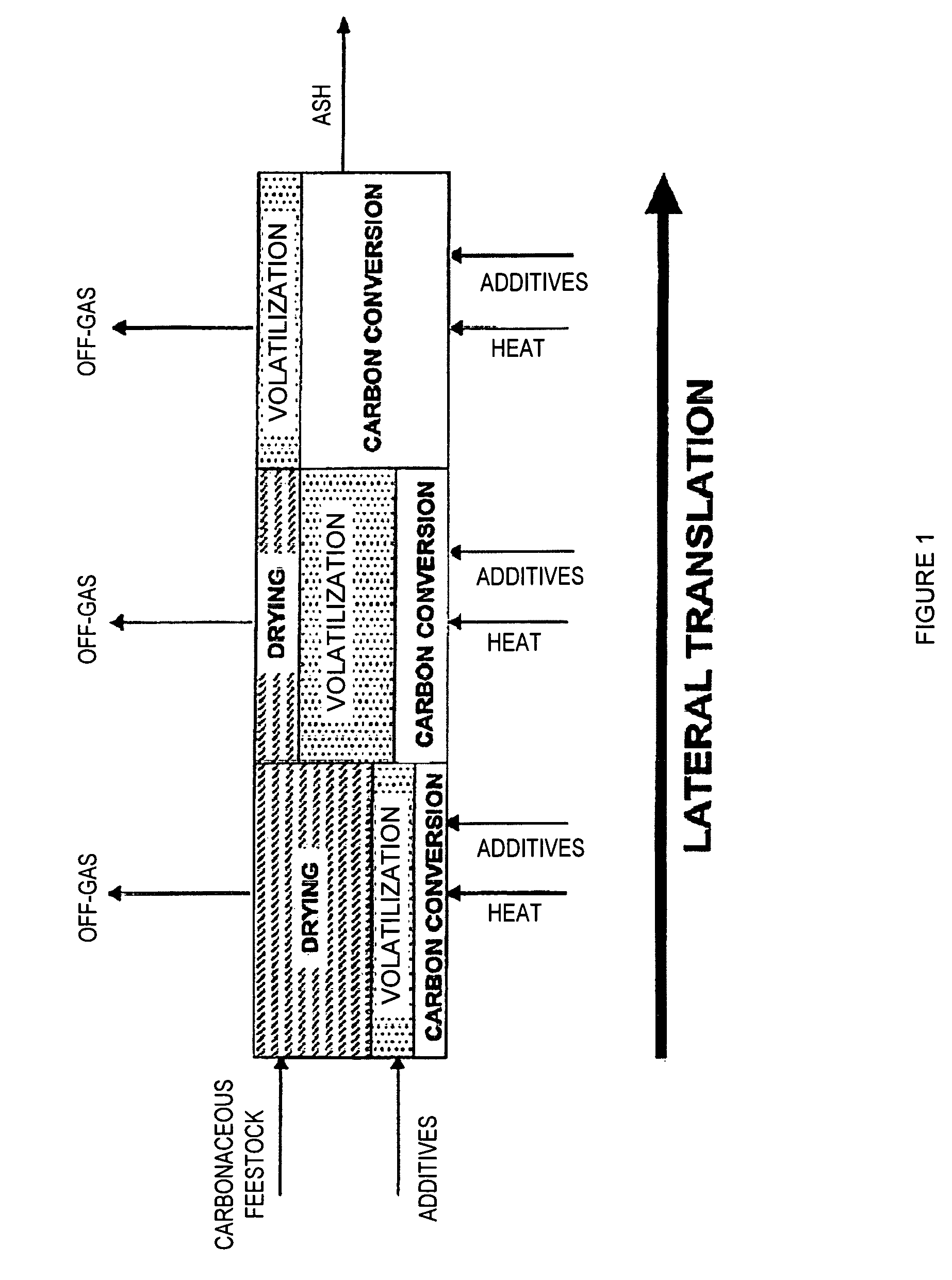

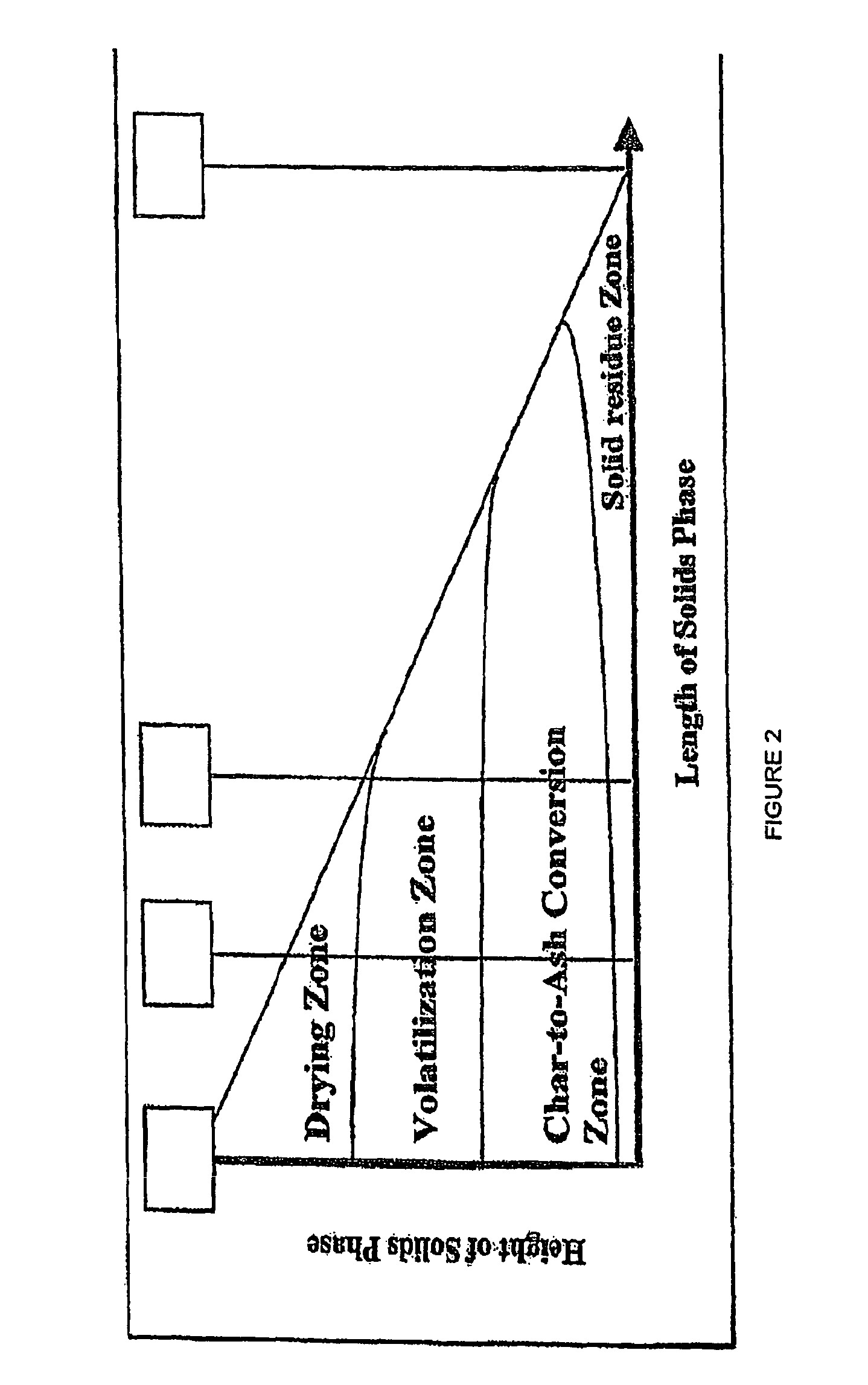

Low Temperature Gasification Facility with a Horizontally Oriented Gasifier

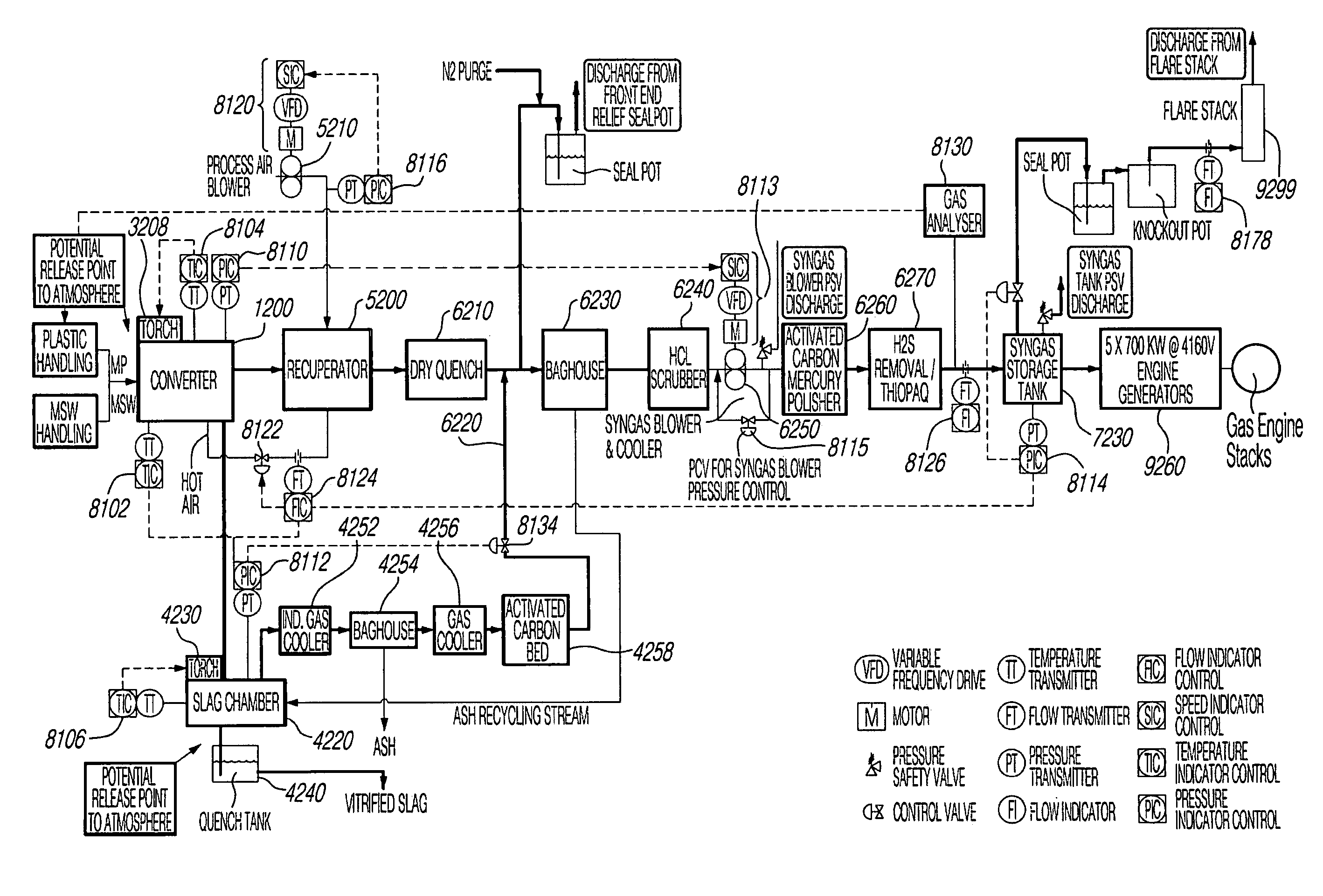

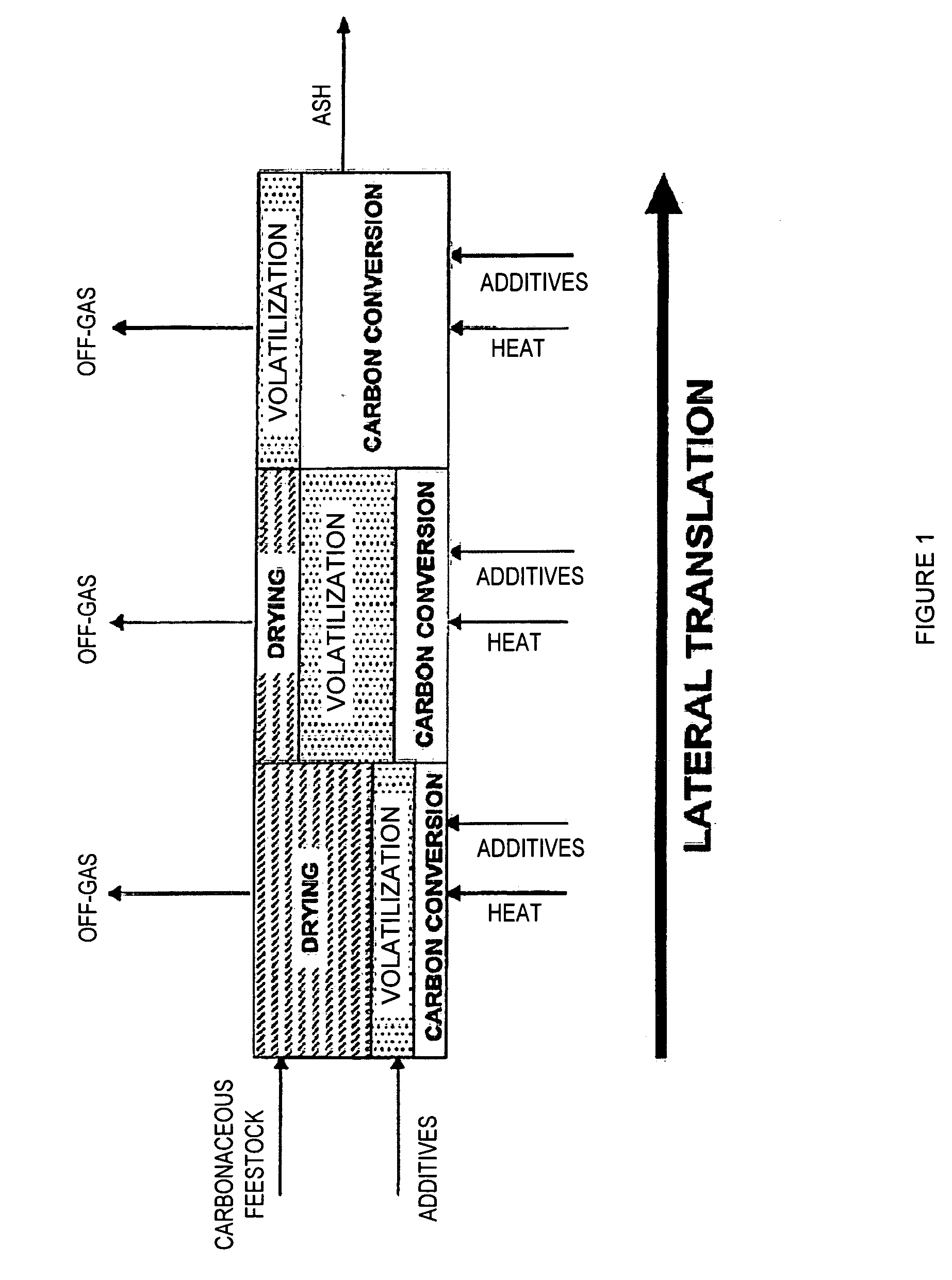

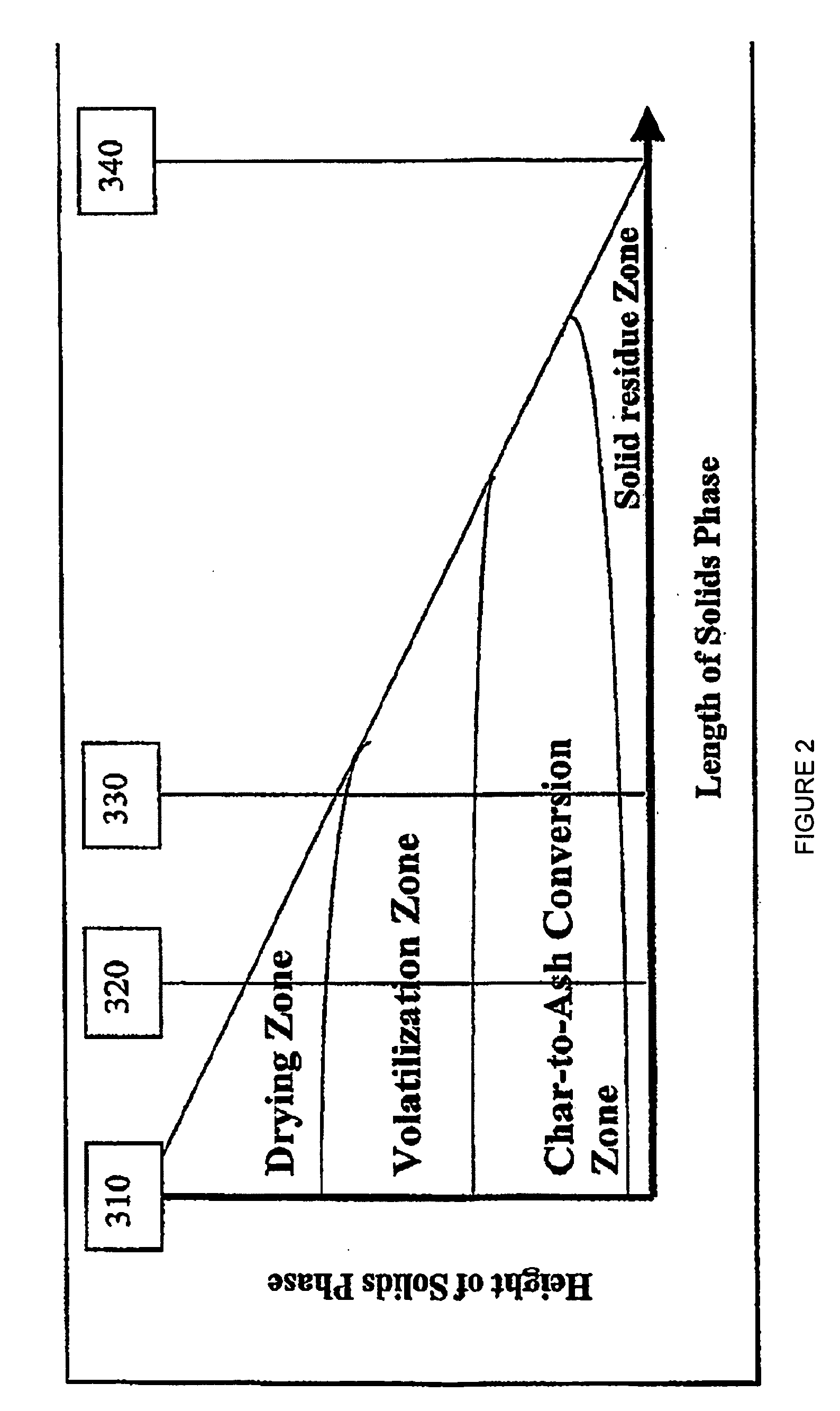

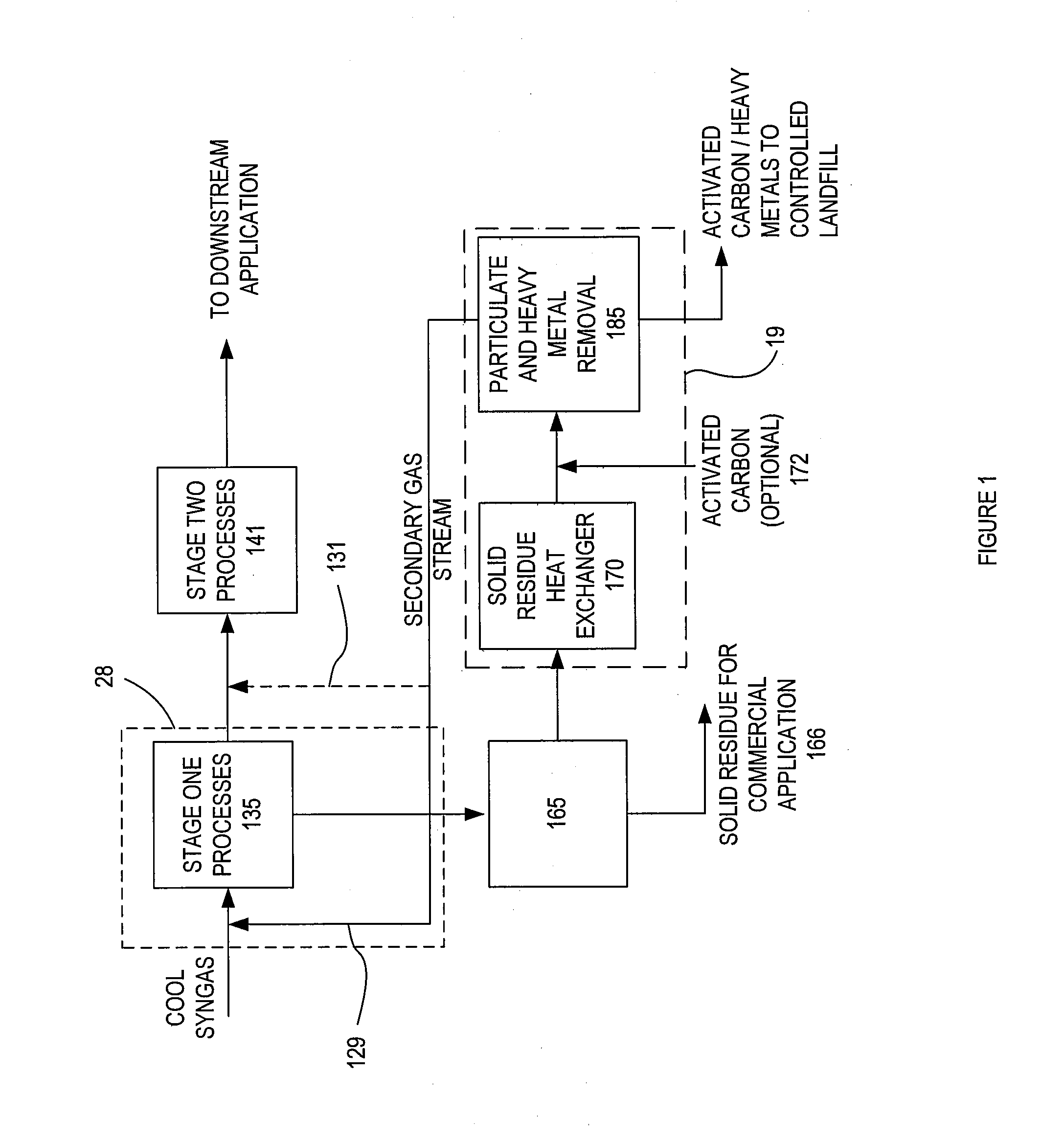

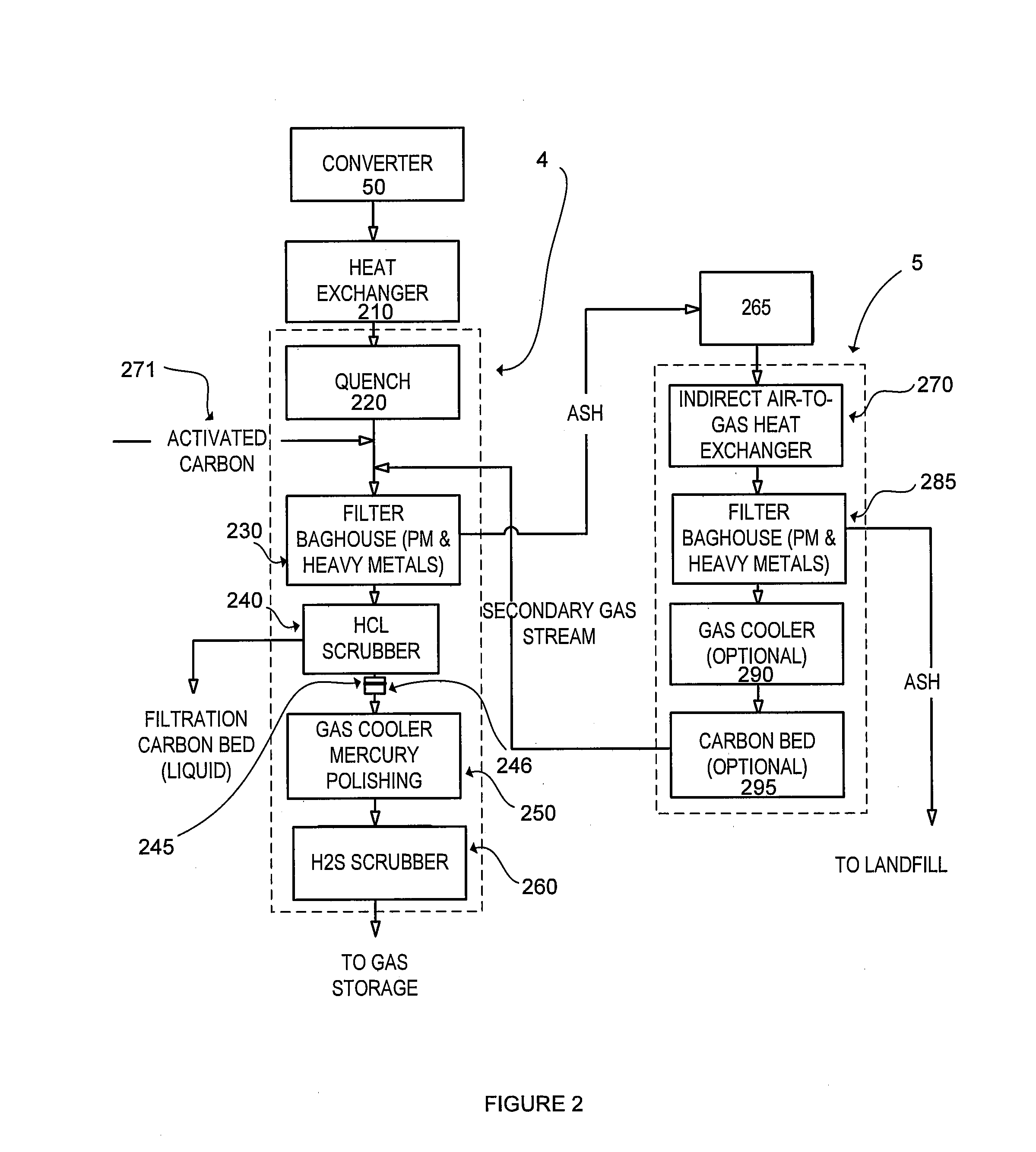

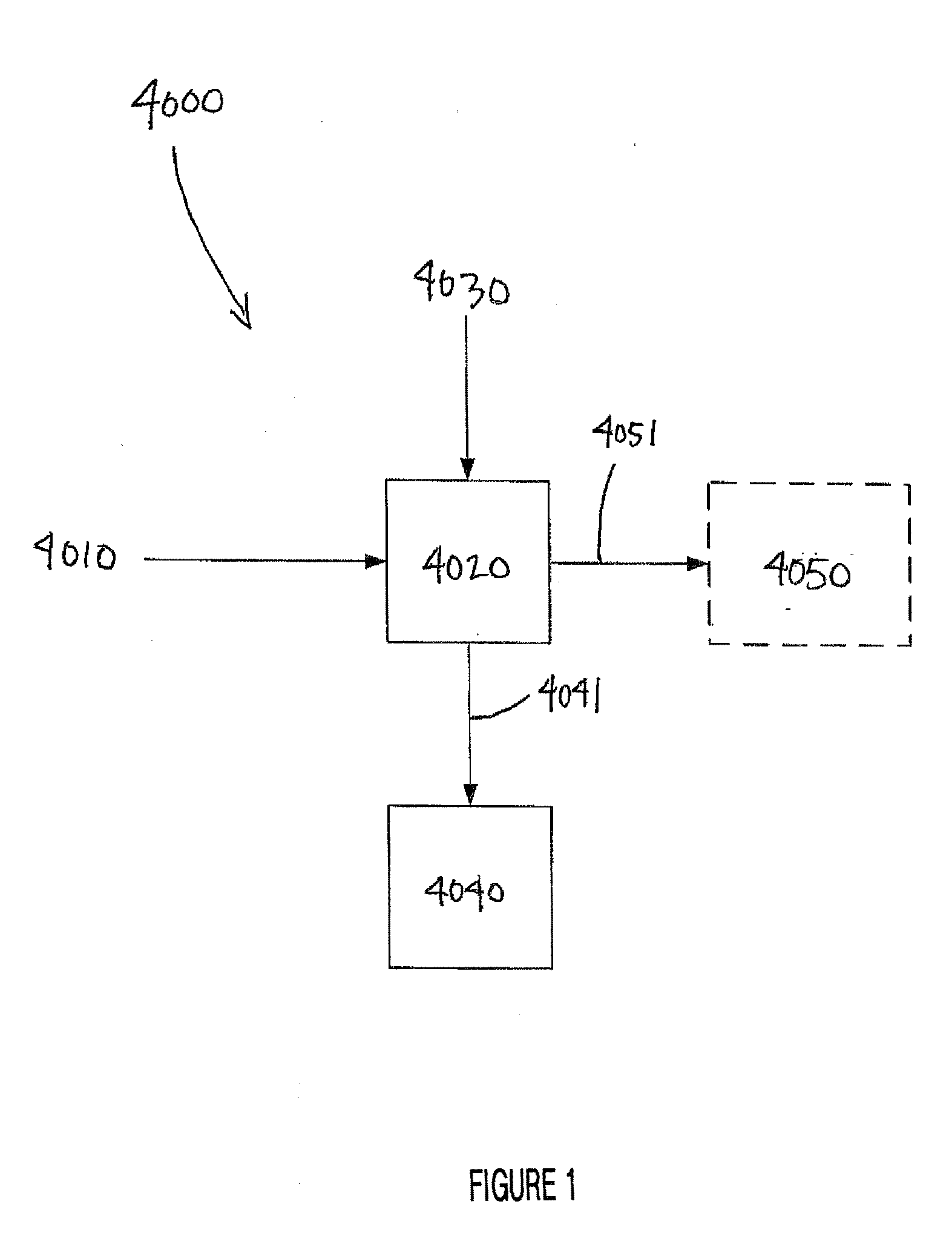

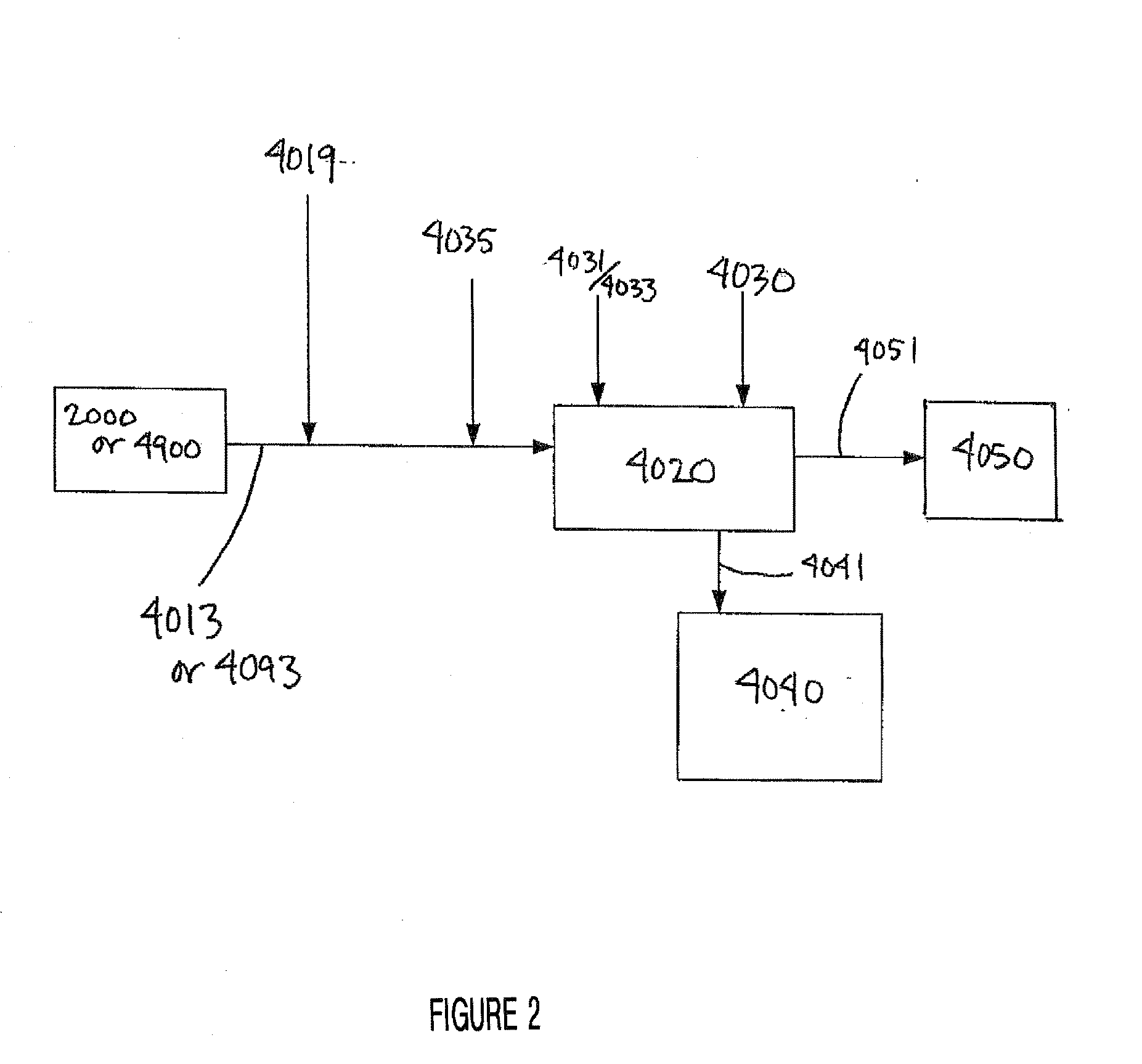

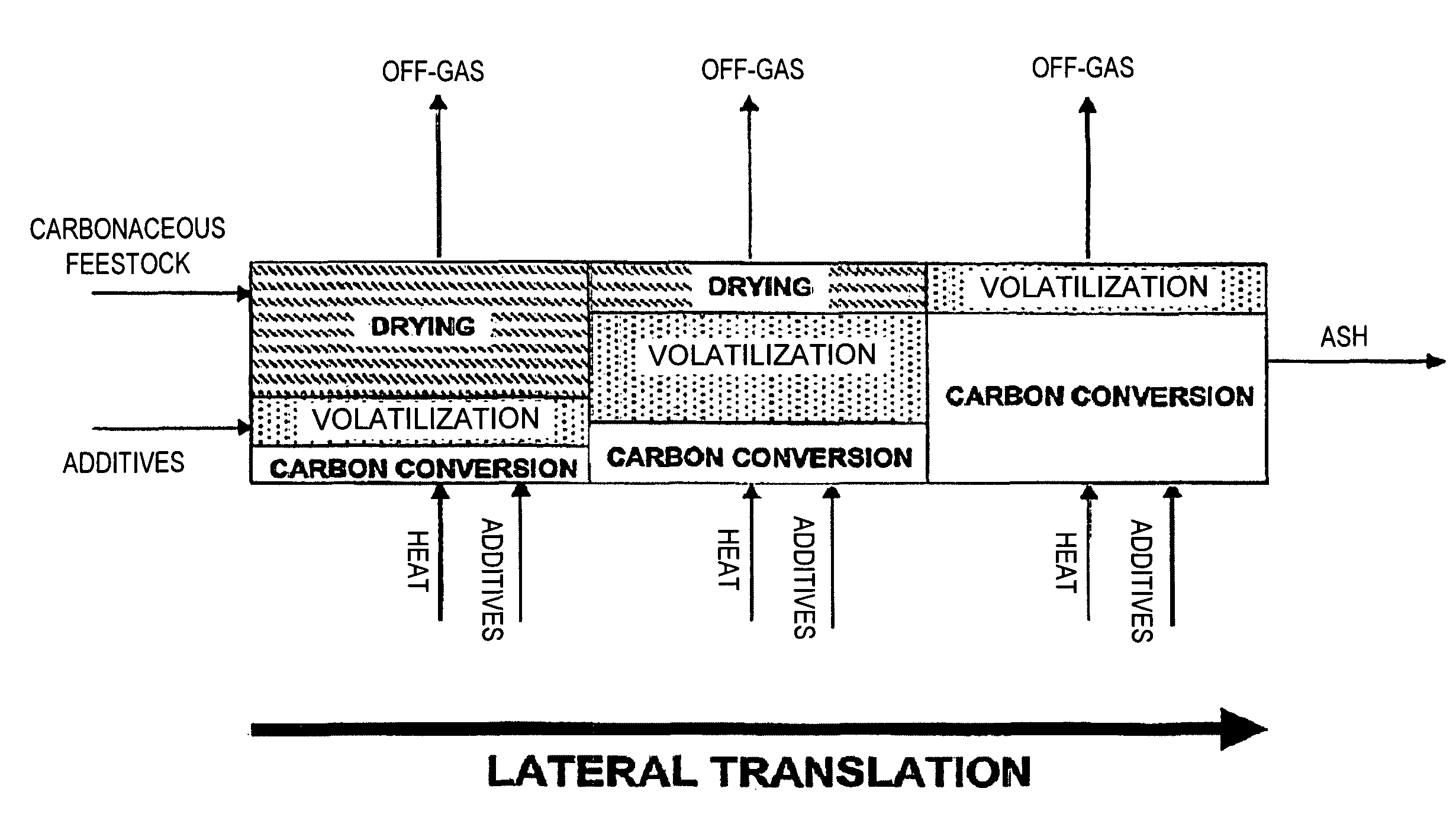

A low-temperature gasification system comprising a horizontally oriented gasifier is provided that optimizes the extraction of gaseous molecules from carbonaceous feedstock while minimizing waste heat. The system comprises a plurality of integrated subsystems that work together to convert municipal solid waste (MSW) into electricity. The subsystems comprised by the low-temperature gasification system are: a Municipal Solid Waste Handling System; a Plastics Handling System; a Horizontally Oriented Gasifier with Lateral Transfer Units System; a Gas Reformulating System; a Heat Recycling System; a Gas Conditioning System; a Residue Conditioning System; a Gas Homogenization System and a Control System.

Owner:PLASCO CONVERSION TECH INC

Gas conditioning system

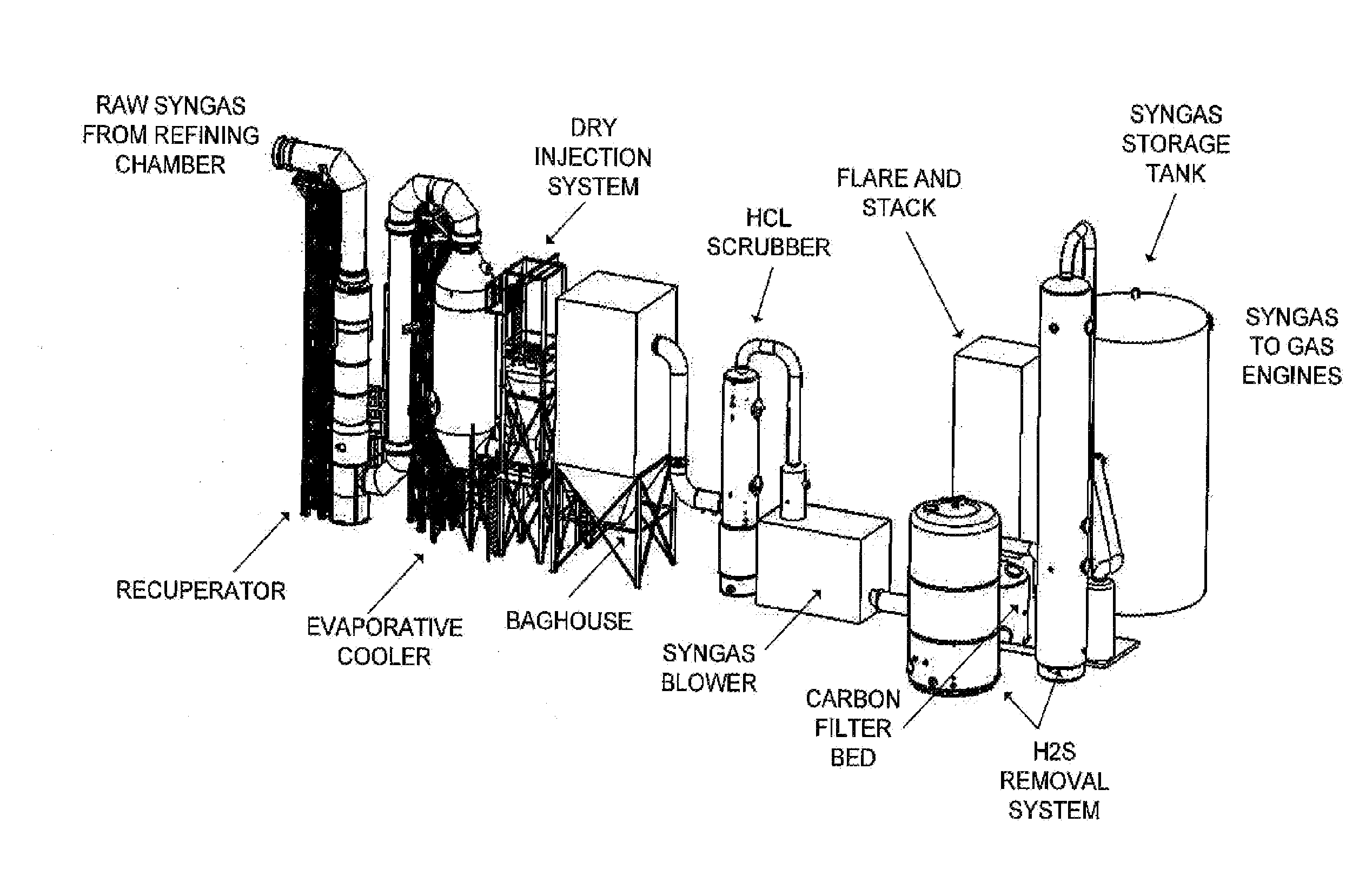

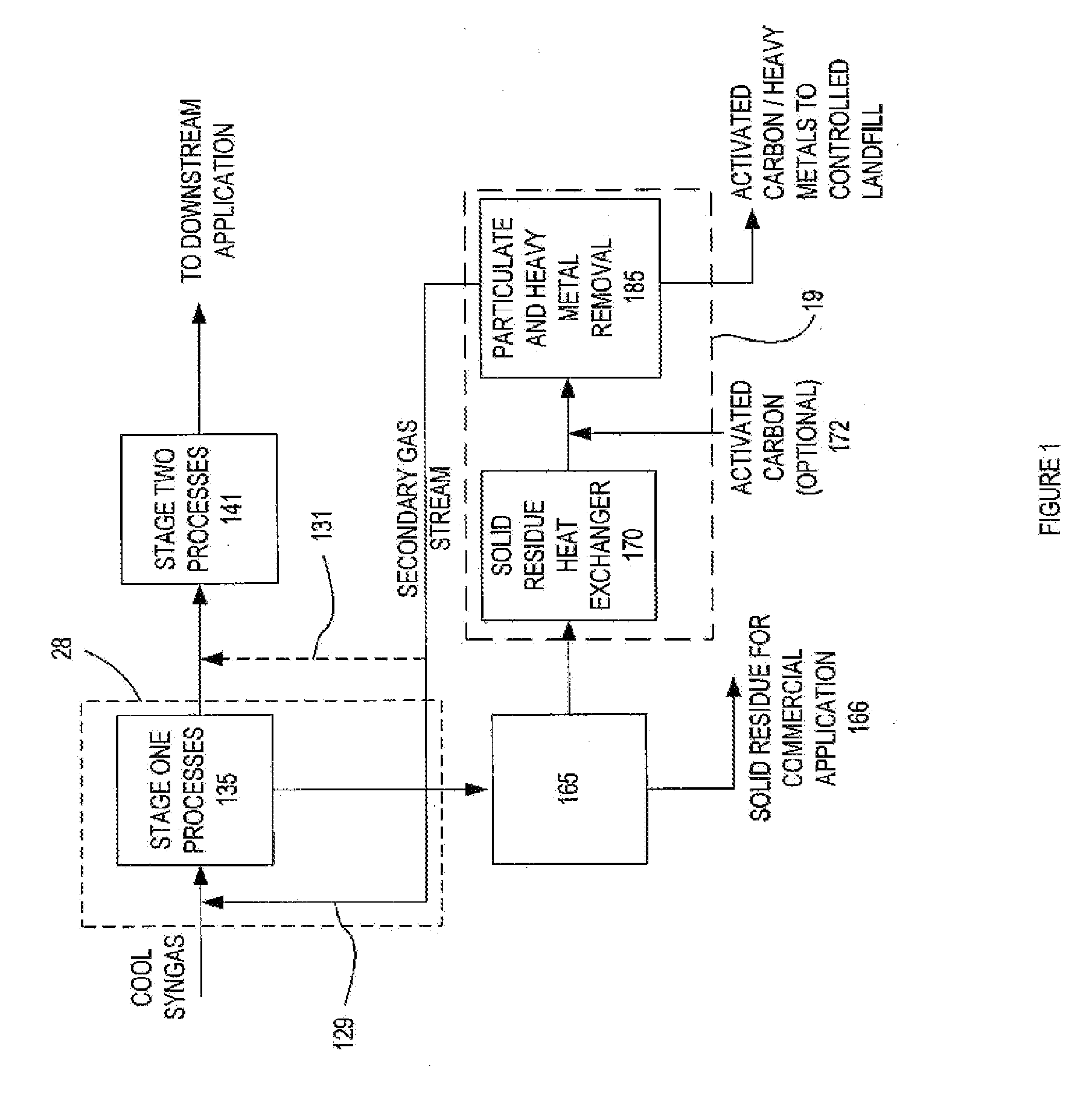

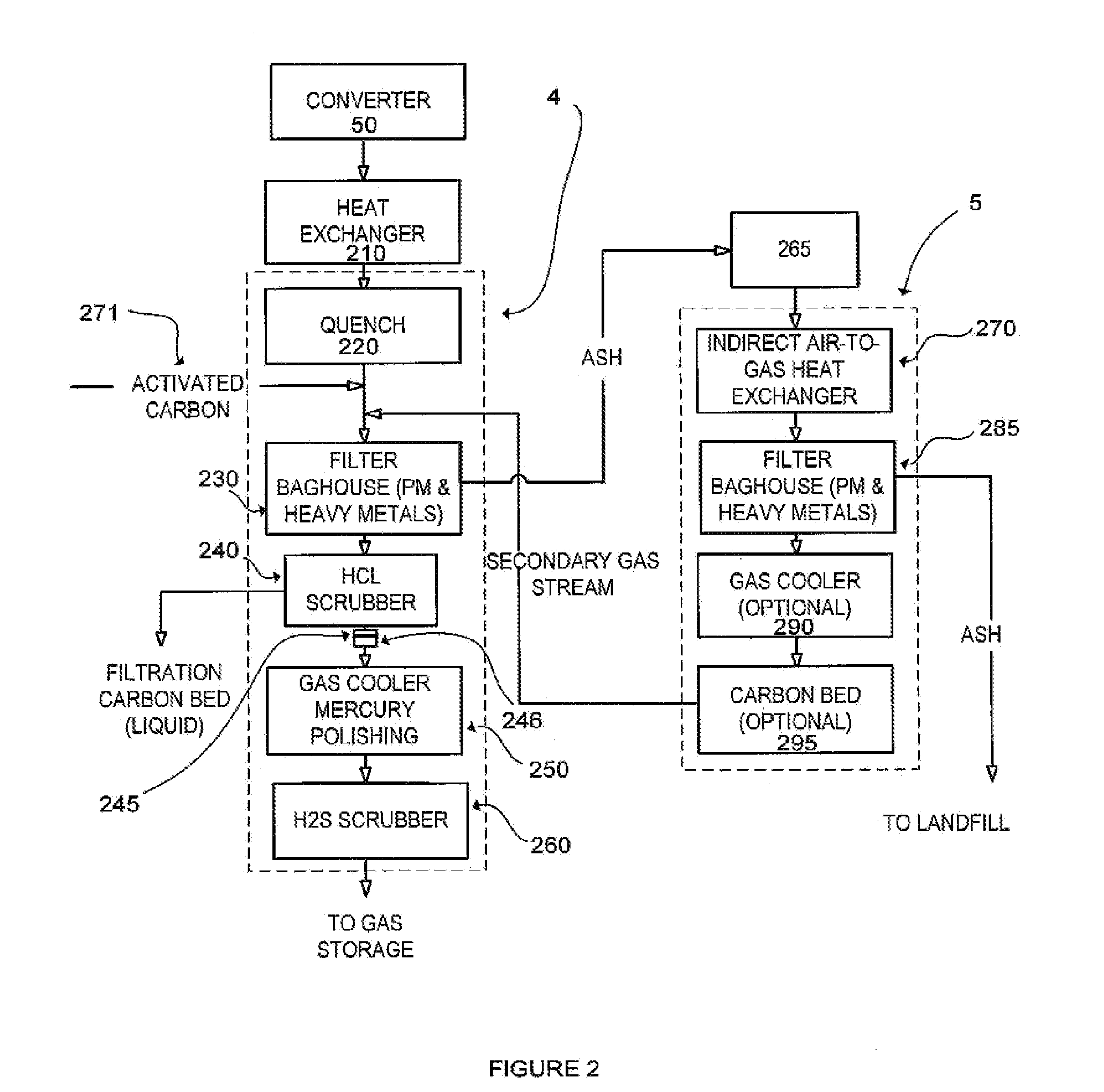

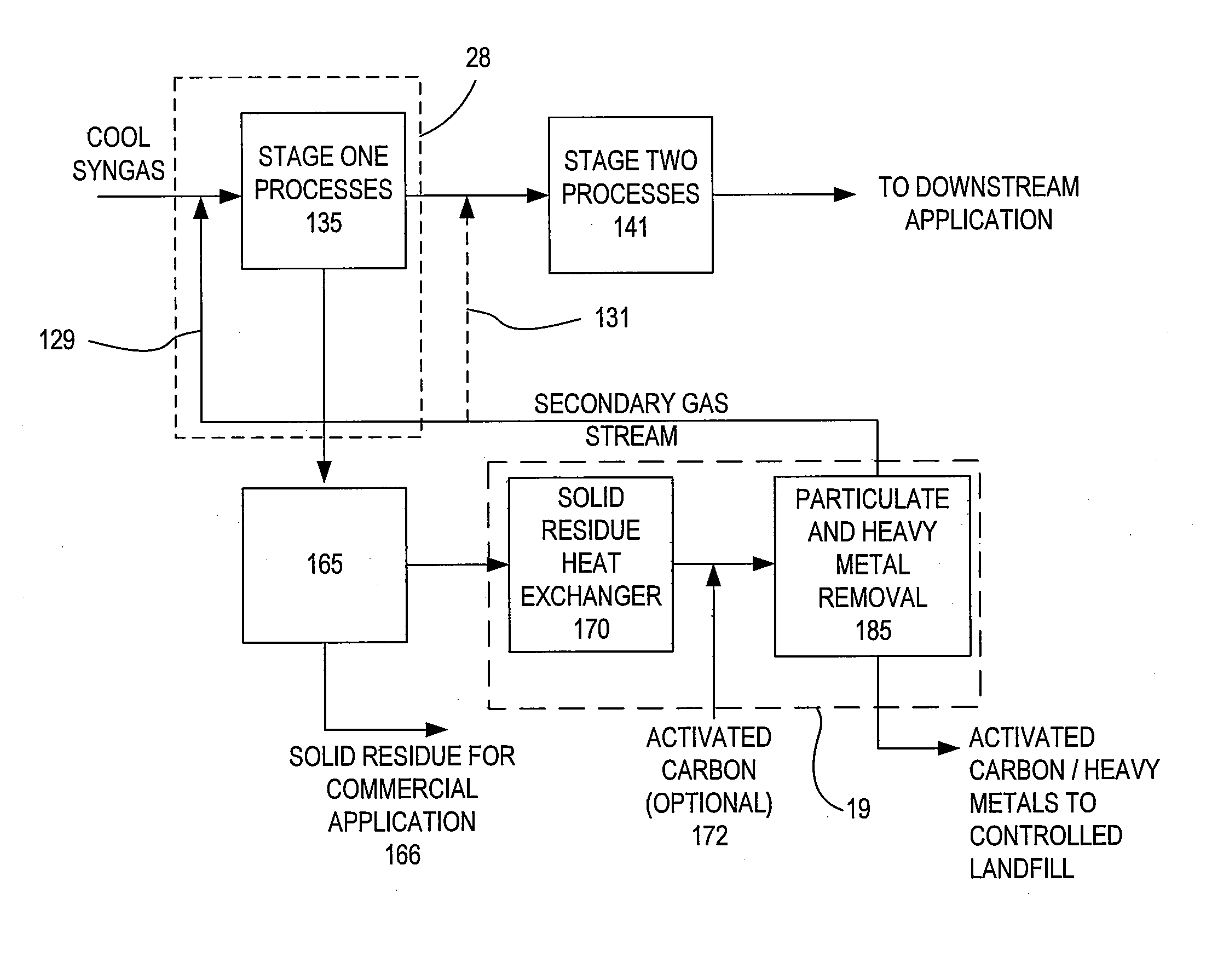

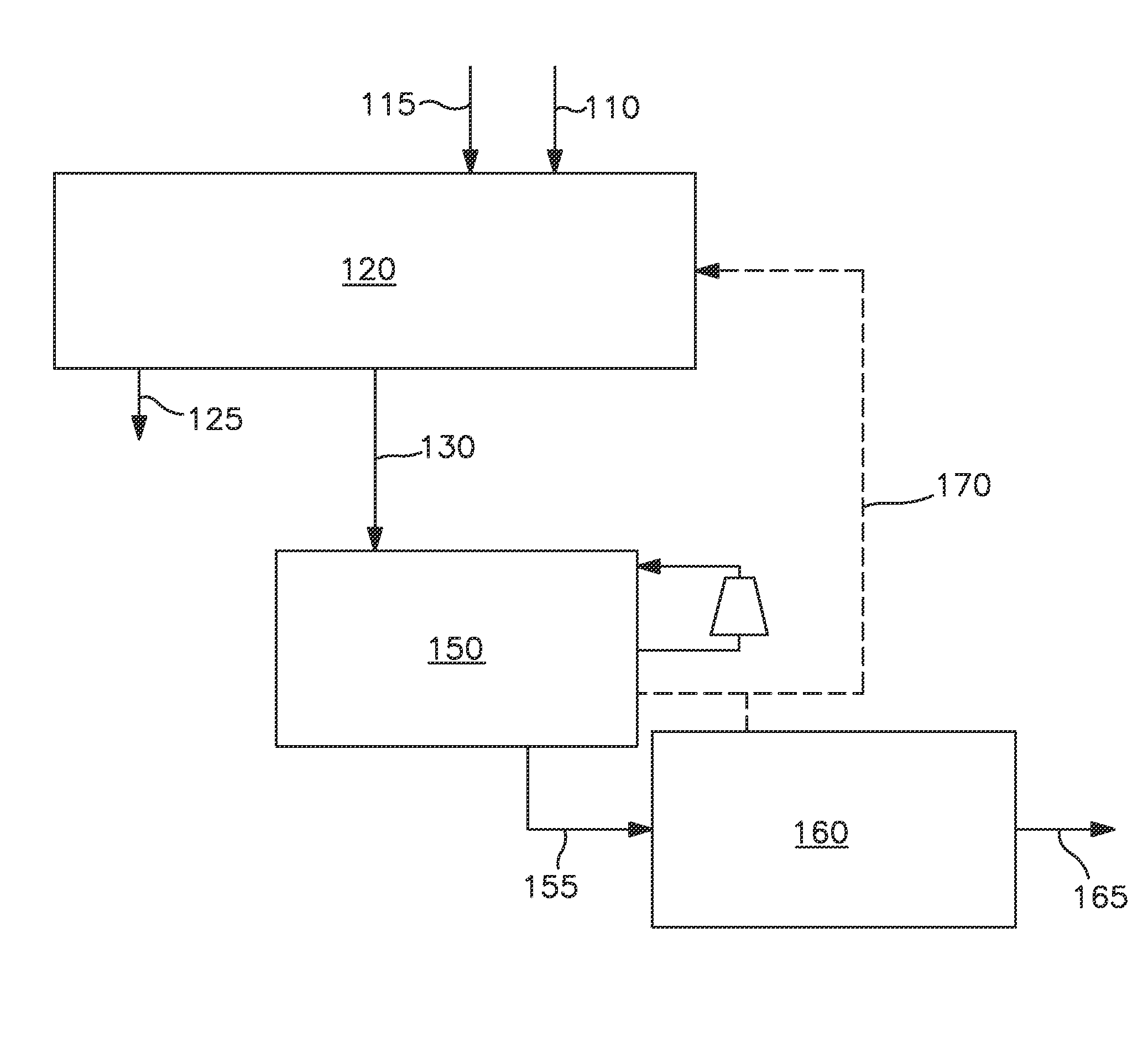

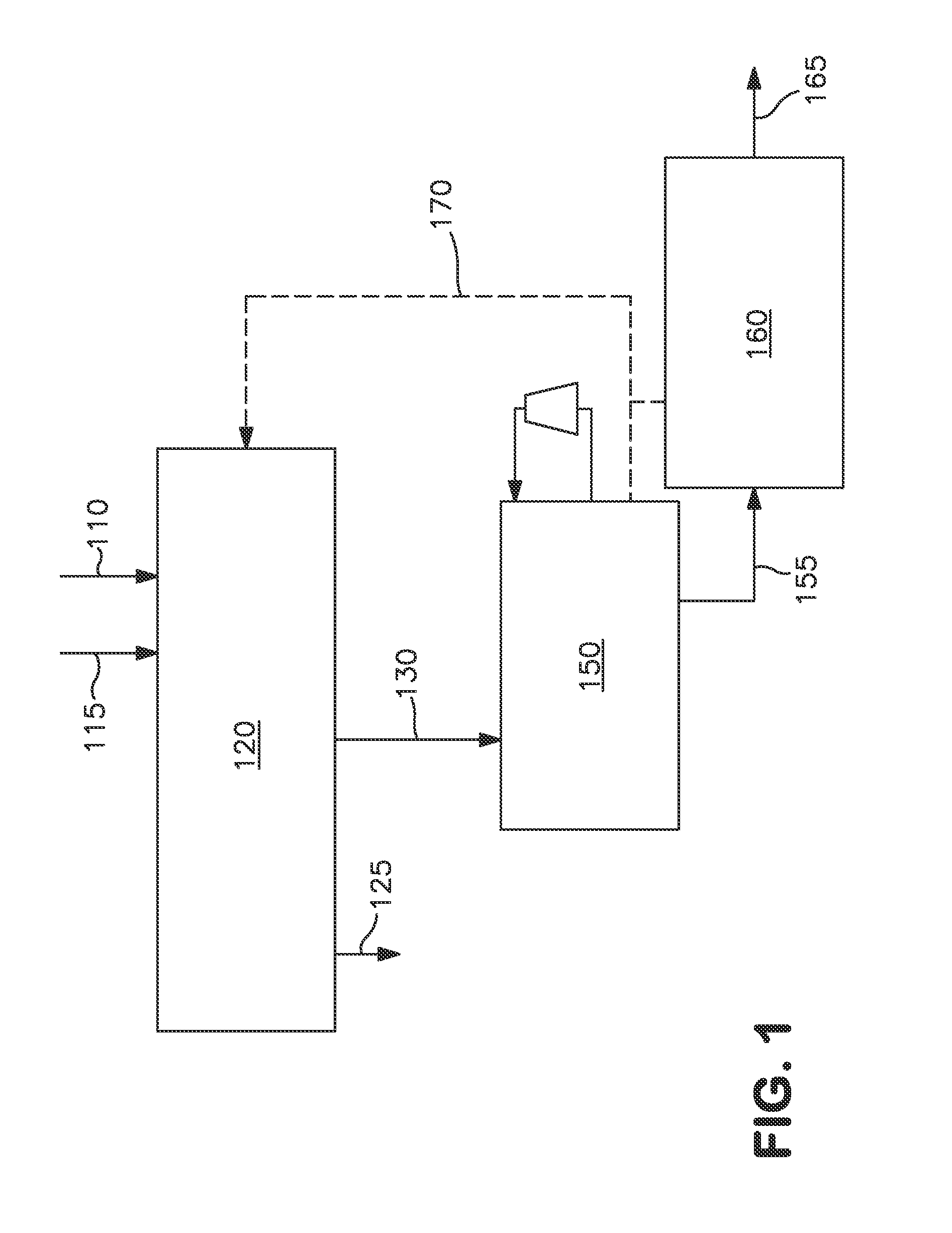

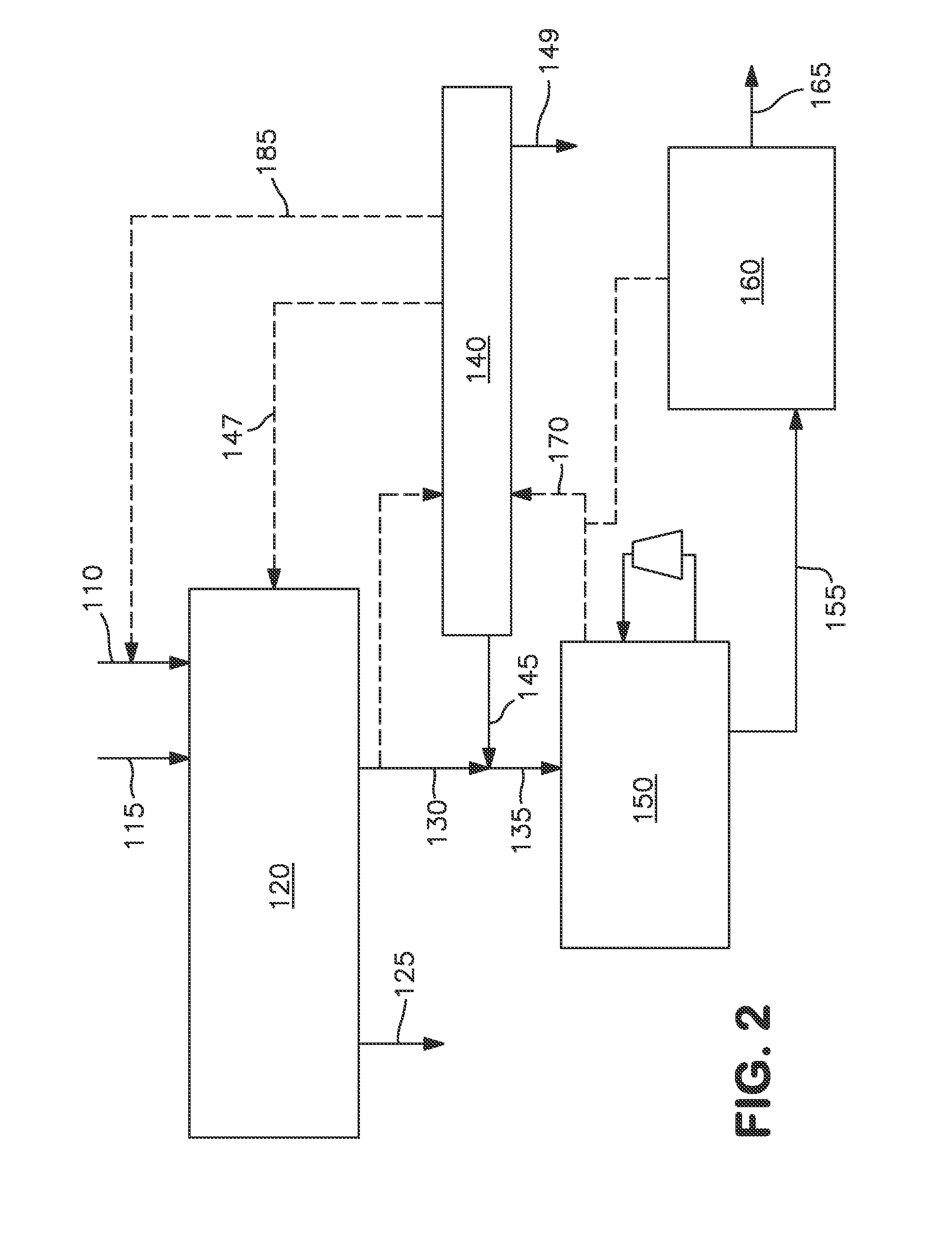

The present invention provides a gas conditioning system for processing an input gas from a low temperature gasification system to an output gas of desired characteristics. The system comprises a two-stage process, the first stage separating heavy metals and particulate matter in a dry phase, and the second stage including further processing steps of removing acid gases, and / or other contaminants. Optional processes include adjusting the humidity and temperature of the input gas as it passes through the gas conditioning system. The presence and sequence of processing steps is determined by the composition of the input gas, the desired composition of output gas for downstream applications, and by efficiency and waste minimization.

Owner:PLASCO ENERGY GROUP INC

Gas Conditioning System

The present invention provides a gas conditioning system for processing an input gas from a low temperature gasification system to an output gas of desired characteristics. The system comprises a two-stage process, the first stage separating heavy metals and particulate matter in a dry phase, and the second stage including further processing steps of removing acid gases, and / or other contaminants. Optional processes include adjusting the humidity and temperature of the input gas as it passes through the gas conditioning system. The presence and sequence of processing steps is determined by the composition of the input gas, the desired composition of output gas for downstream applications, and by efficiency and waste minimization.

Owner:PLASCO ENERGY GROUP INC

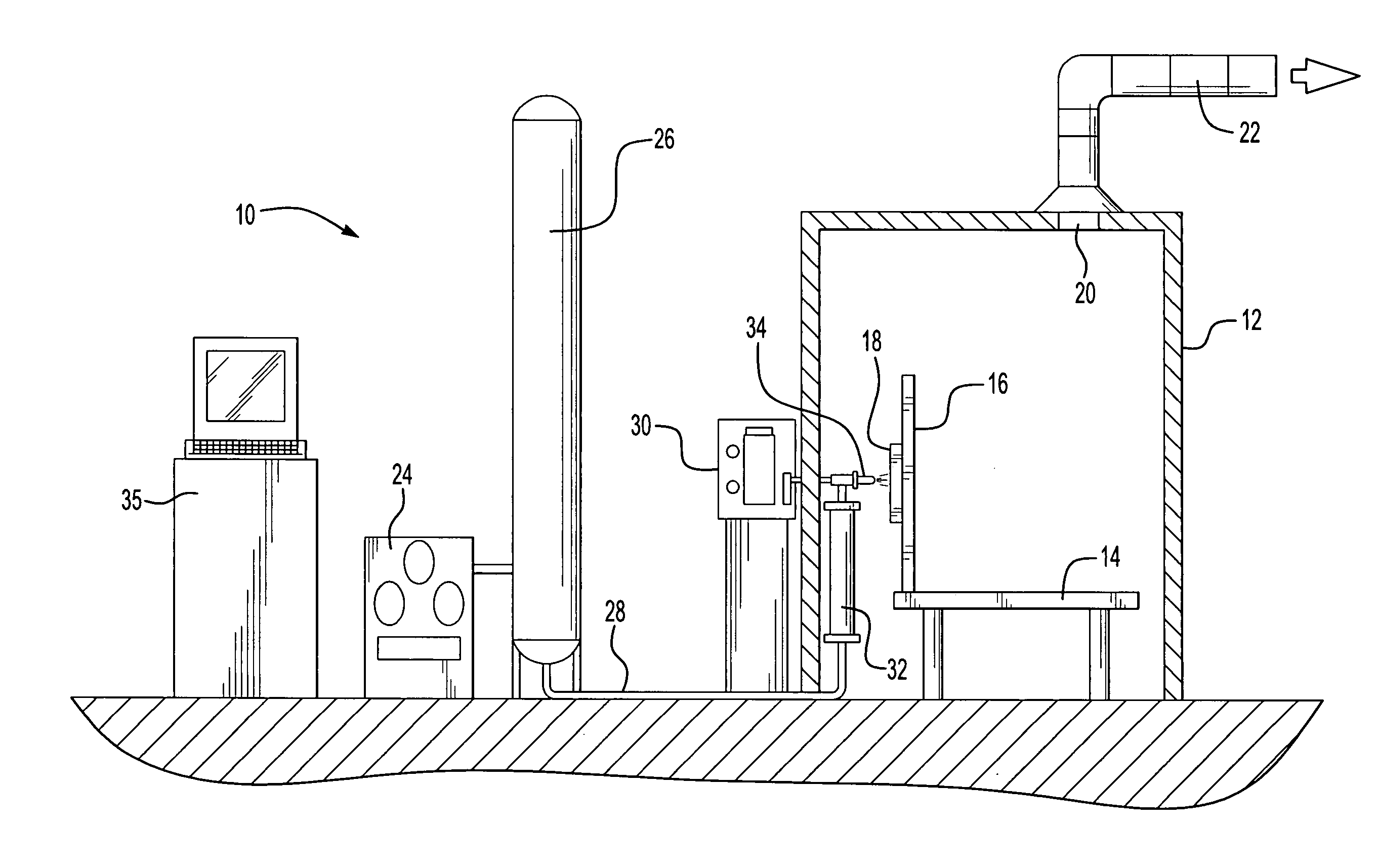

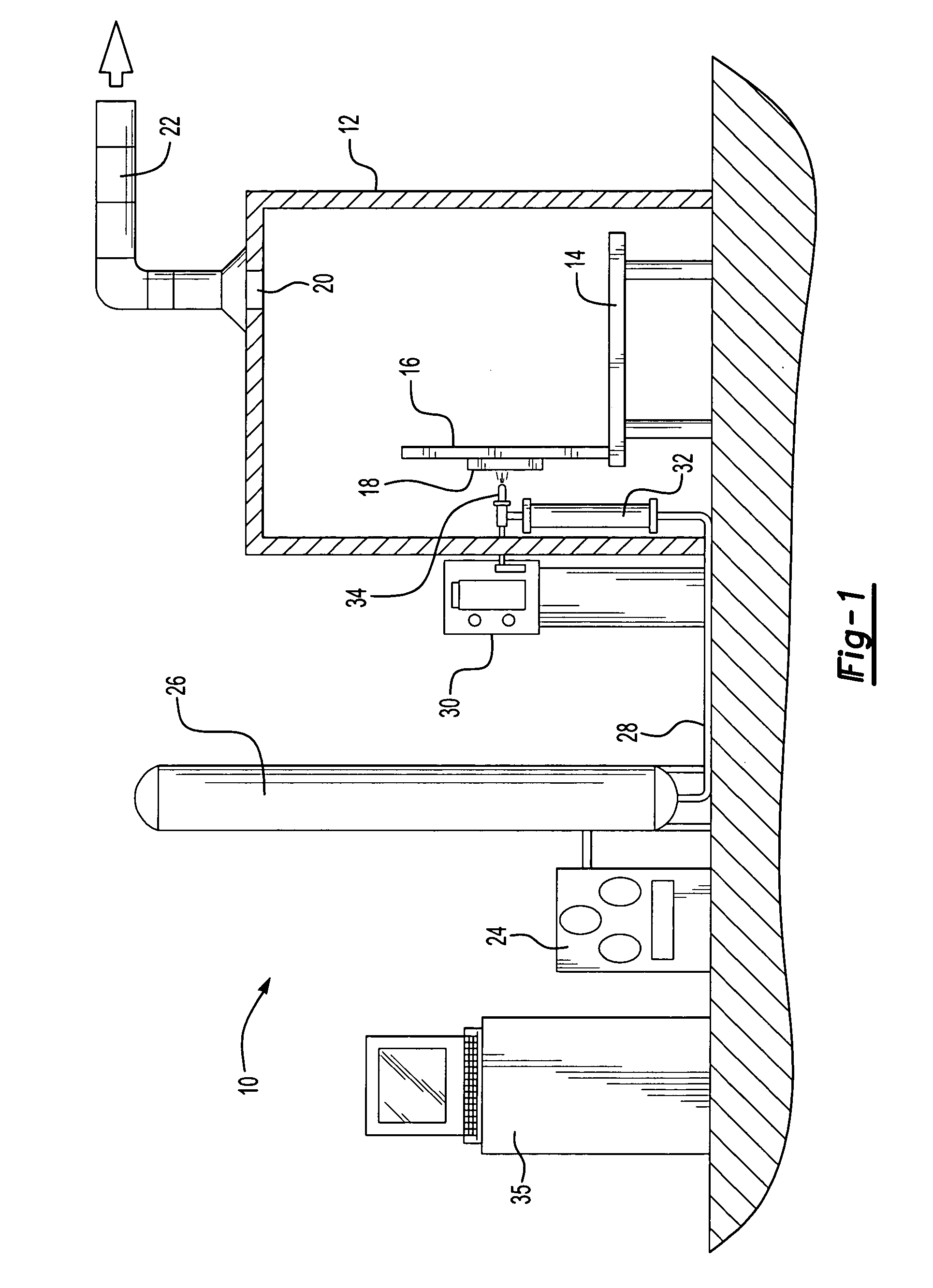

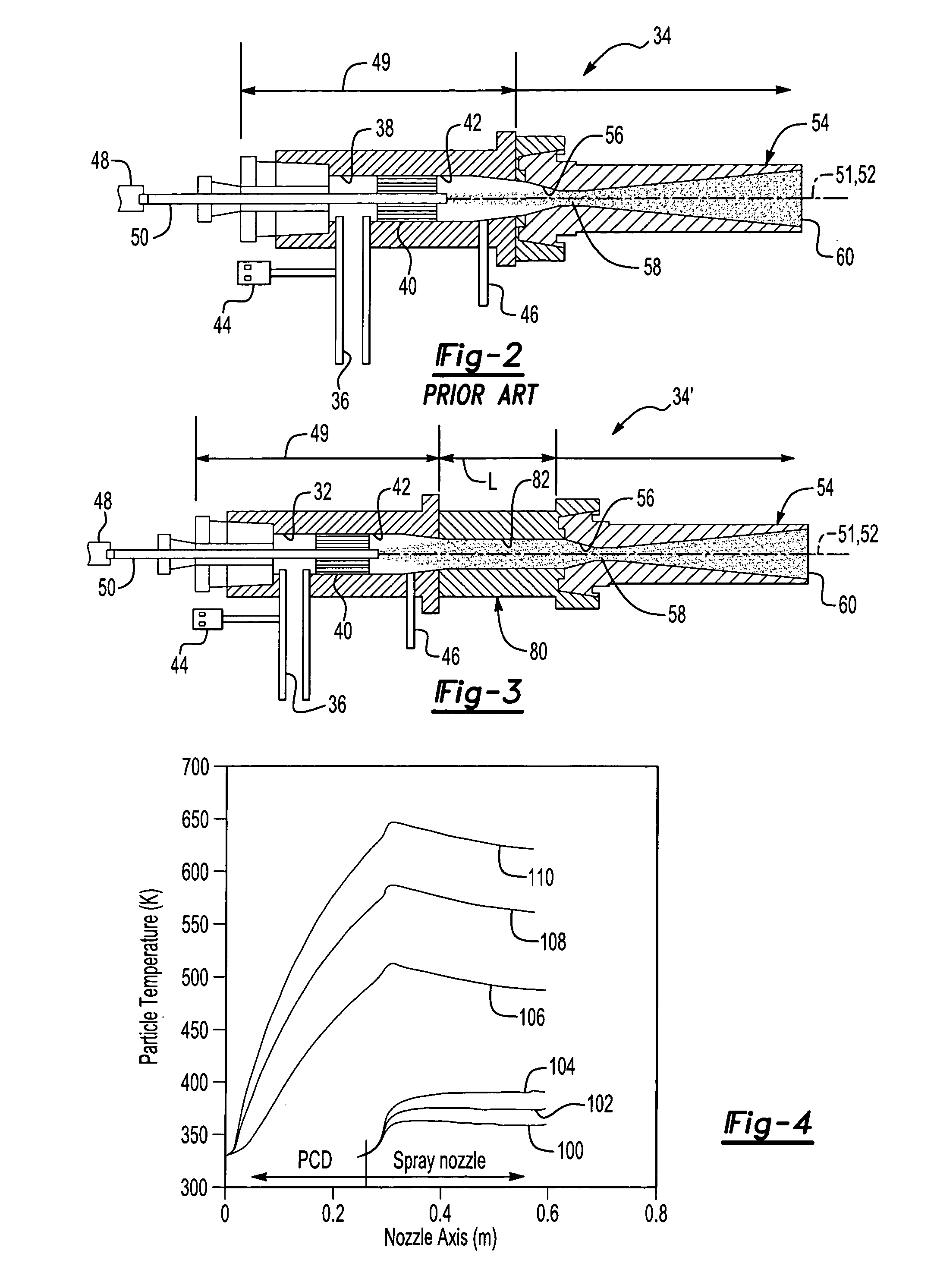

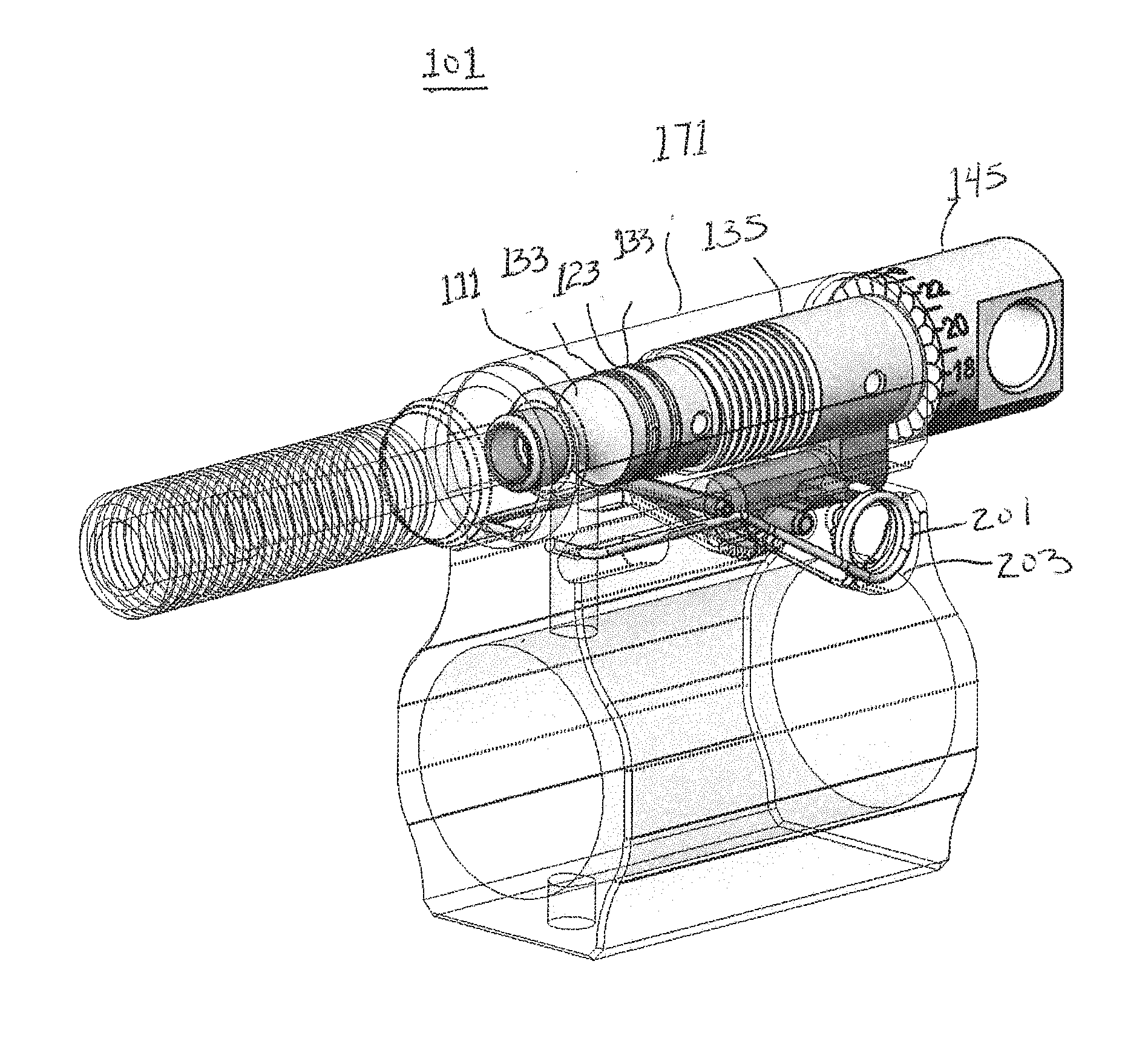

Kinetic spray nozzle system design

InactiveUS20050214474A1Molten spray coatingLiquid/solution decomposition chemical coatingSystems designSpray nozzle

An improved kinetic spray nozzle system is disclosed in addition to improved methods for injection particle powders into a nozzle. Utilization of the nozzle enables one to dramatically increase the deposition efficiency of a variety of particles using a kinetic process. The improved nozzle includes a powder / gas conditioning chamber that increases the particle residence time within the nozzle enabling one to achieve higher particle temperatures prior to their acceleration in the supersonic portion of the kinetic spray nozzle.

Owner:DELPHI TECH INC

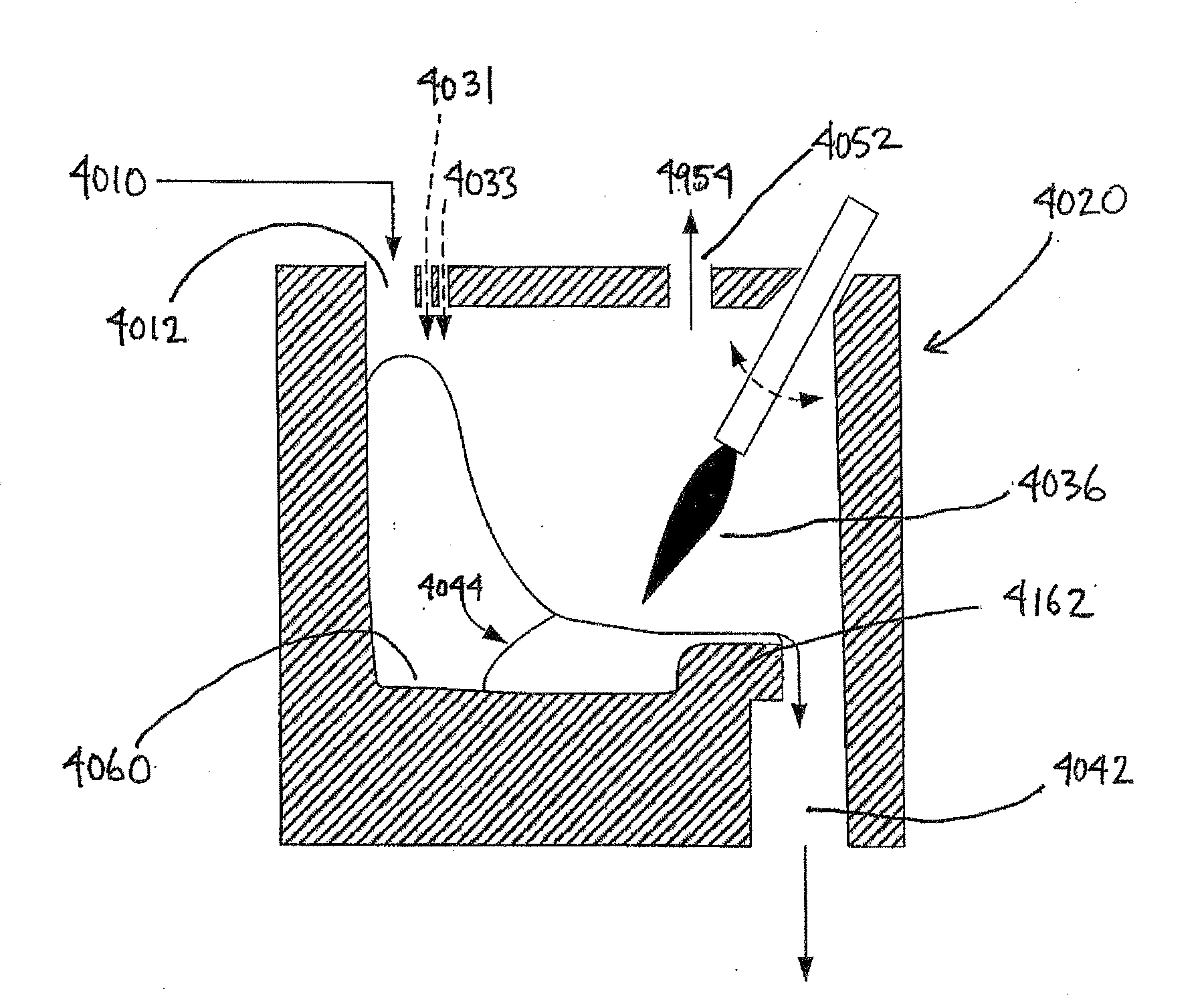

Residue conditioning system

The present invention provides a system for converting the residue of a carbonaceous feedstock gasification or incineration process into an inert slag and a gas having a heating value. The residue is converted by plasma heating in a refractory-lined residue conditioning chamber. The gas produced is optionally passed through a gas conditioning system for cooling and cleaning to provide a product gas that is suitable for use in downstream applications. The system also comprises a control subsystem for optimizing the conversion reaction

Owner:PLASCO ENERGY GROUP INC

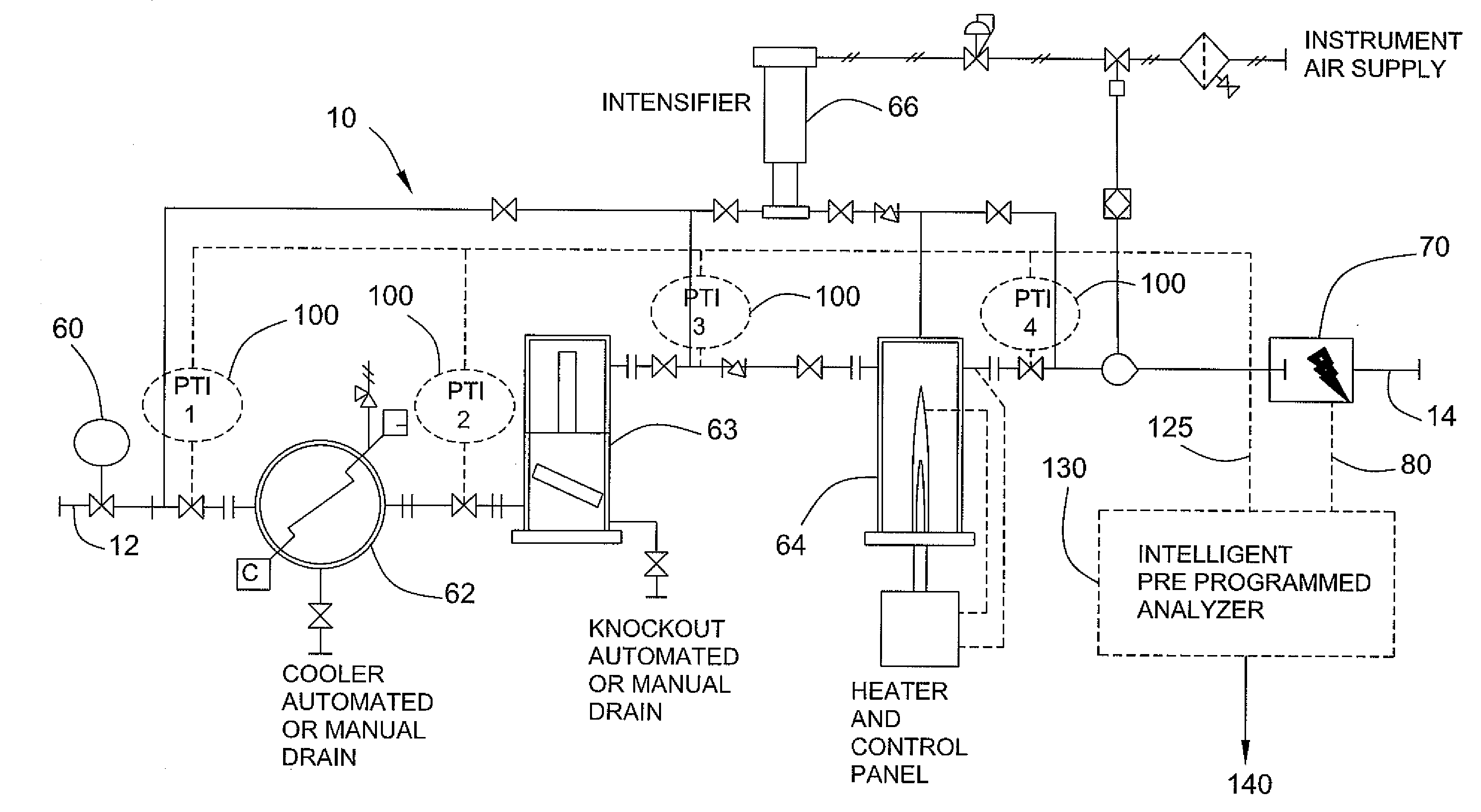

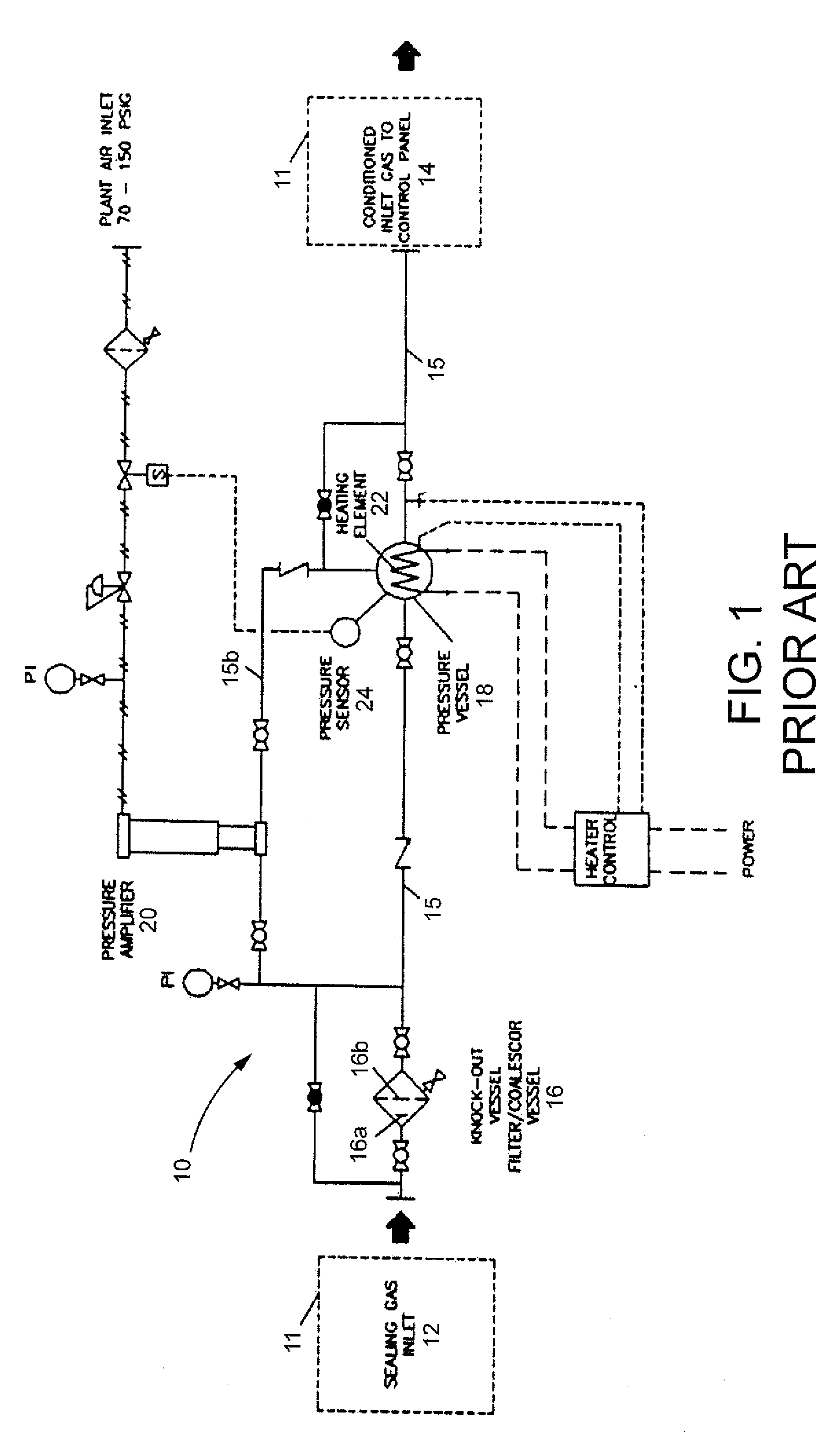

Seal gas monitoring and control system

ActiveUS20130031960A1Ensure sealing performanceAvoid causingDetection of fluid at leakage pointEngine sealsBaseline dataProgrammable logic device

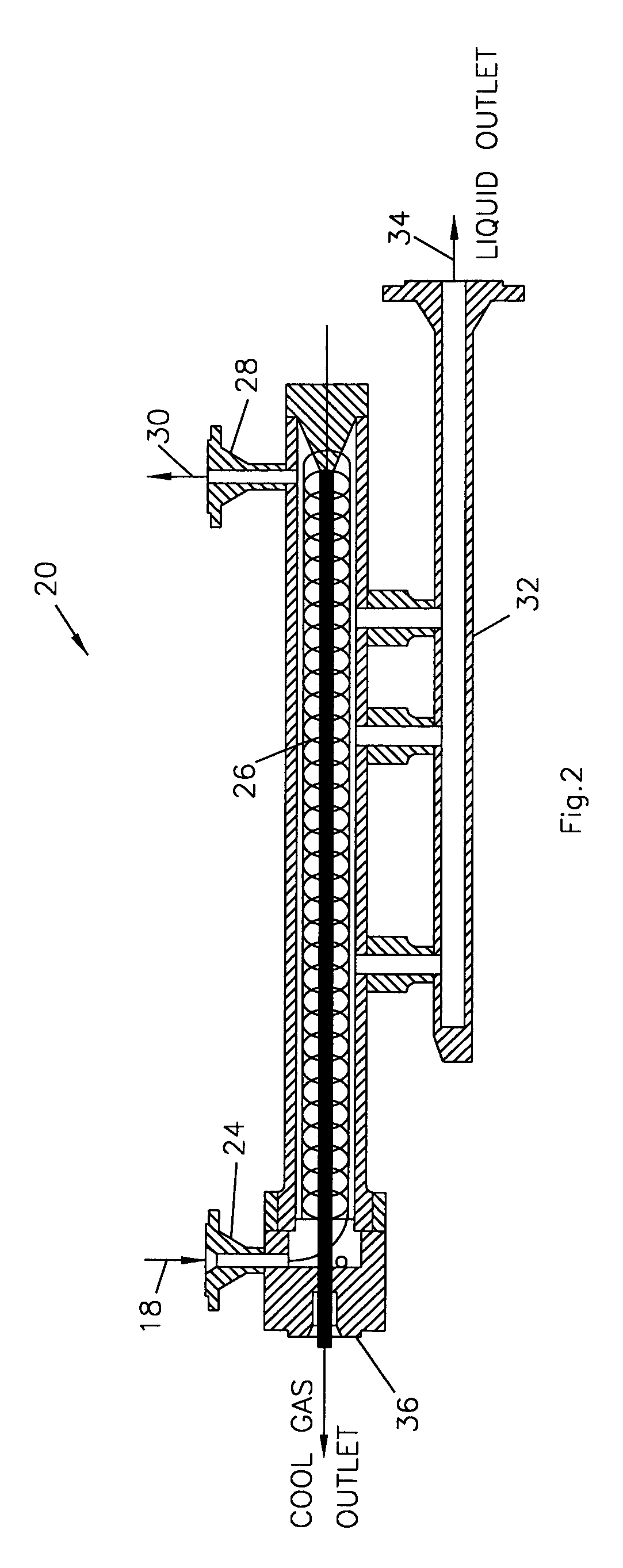

A monitoring and control system for a seal gas supply system for a non-contacting gas seal. The supply includes several gas conditioning elements or units. The monitoring and control system includes an evanescent wave sensor to sense the presence of liquid in the seal gas. Multiple sensors to sense the temperature and pressure of the treated seal gas are disposed at the outlet of the conditioning elements. A programmable logic device is provided with information regarding the phase of the gas at various pressures and temperatures and compares the sensed data to the baseline data. Recognition of liquid concentrate results in an output signal.

Owner:JOHN CRANE INC

Method and system for producing methanol using an integrated oxygen transport membrane based reforming system

A method and system for producing methanol that employs an integrated oxygen transport membrane based reforming system is disclosed. The integrated oxygen transport membrane based reforming system carries out a primary reforming process, a secondary reforming process, and synthesis gas conditioning to produce synthesis gas having a desired module of between about 2.0 and 2.2 for a methanol production process thereby optimizing the efficiency and productivity of the methanol plant.

Owner:PRAXAIR TECH INC

Residue Conditioning System

The present invention provides a system for converting the residue of a carbonaceous feedstock gasification or incineration process into an inert slag and a gas having a heating value. The residue is converted by plasma heating in a refractory-lined residue conditioning chamber. The gas produced is optionally passed through a gas conditioning system for cooling and cleaning to provide a product gas that is suitable for use in downstream applications. The system also comprises a control subsystem for optimizing the conversion reaction

Owner:PLASCO ENERGY GROUP INC

Low temperature gasification facility with a horizontally oriented gasifier

A low-temperature gasification system comprising a horizontally oriented gasifier is provided that optimizes the extraction of gaseous molecules from carbonaceous feedstock while minimizing waste heat. The system comprises a plurality of integrated subsystems that work together to convert municipal solid waste (MSW) into electricity. The subsystems comprised by the low-temperature gasification system are: a Municipal Solid Waste Handling System; a Plastics Handling System; a Horizontally Oriented Gasifier with Lateral Transfer Units System; a Gas Reformulating System; a Heat Recycling System; a Gas Conditioning System; a Residue Conditioning System; a Gas Homogenization System and a Control System.

Owner:PLASCO CONVERSION TECH INC

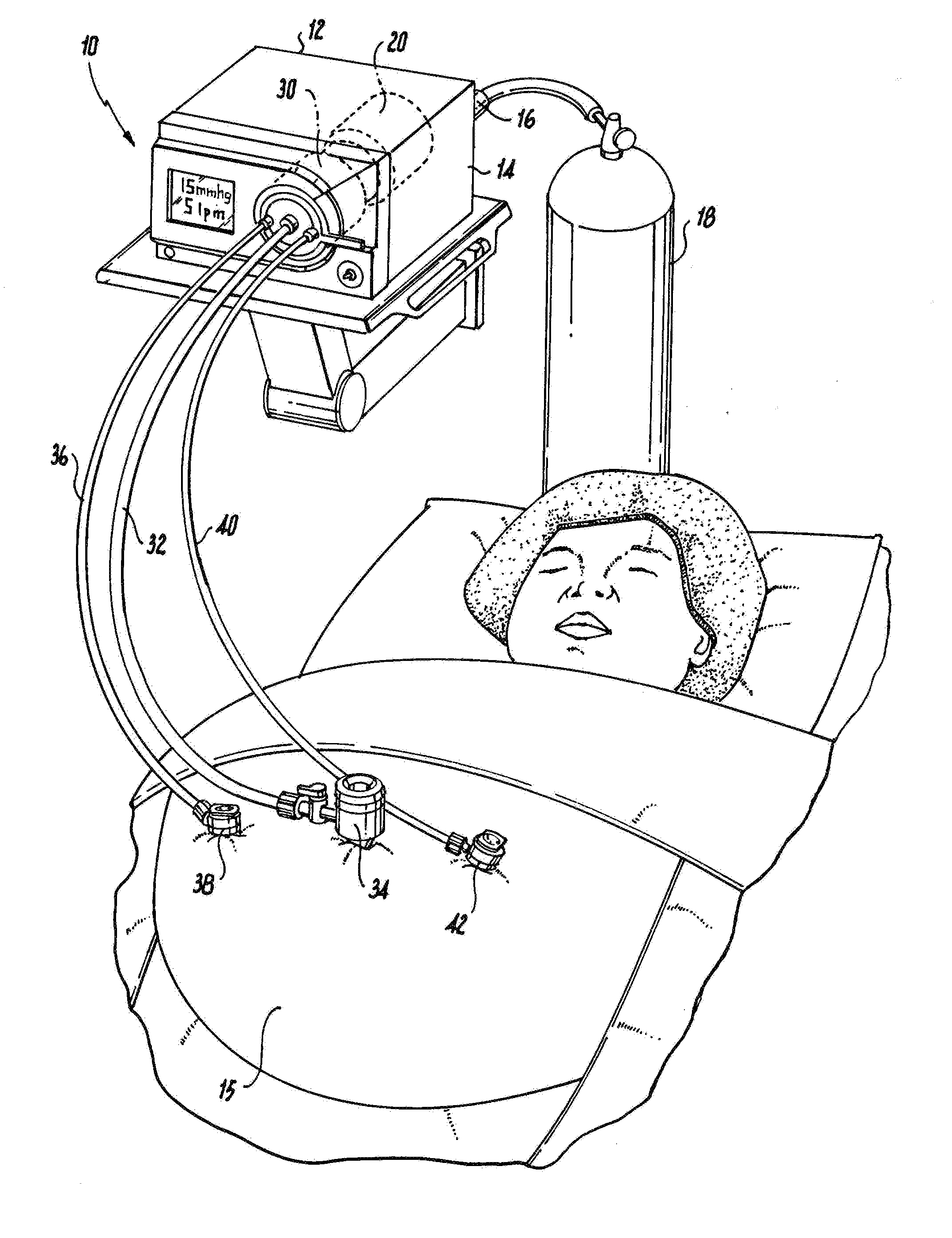

Method and apparatus for conditioning gas for medical procedures having humidity monitoring and recharge alert

InactiveUS7066902B1Heat loss in transfer of the gas is minimizedReduce heat lossRespiratorsSurgical needlesGas passingProduct gas

An apparatus for conditioning gas for use in a medical procedure, such as endoscopy, the gas being received into the apparatus from a gas source. The apparatus comprises a housing defining a chamber having an entry port and an exit port. A humidification means comprising at least one water-retainer layer is disposed within the chamber in the path of travel of the gas for humidifying the gas as it passes through the chamber. A humidity sensor is disposed within the chamber that senses the humidity of the gas exiting the chamber. A monitoring circuit is connected to the humidity sensor that detects when the chamber requires a recharge of liquid based on the humidity of the gas in the chamber, and generates a recharge signal indicative thereof. A charging port on the housing provides access into the chamber to recharge the chamber with water. A heating element and temperature sensor are also disposed within the chamber. A control circuit further regulates the temperature of the gas exiting the chamber.

Owner:OTT FAMILY THE

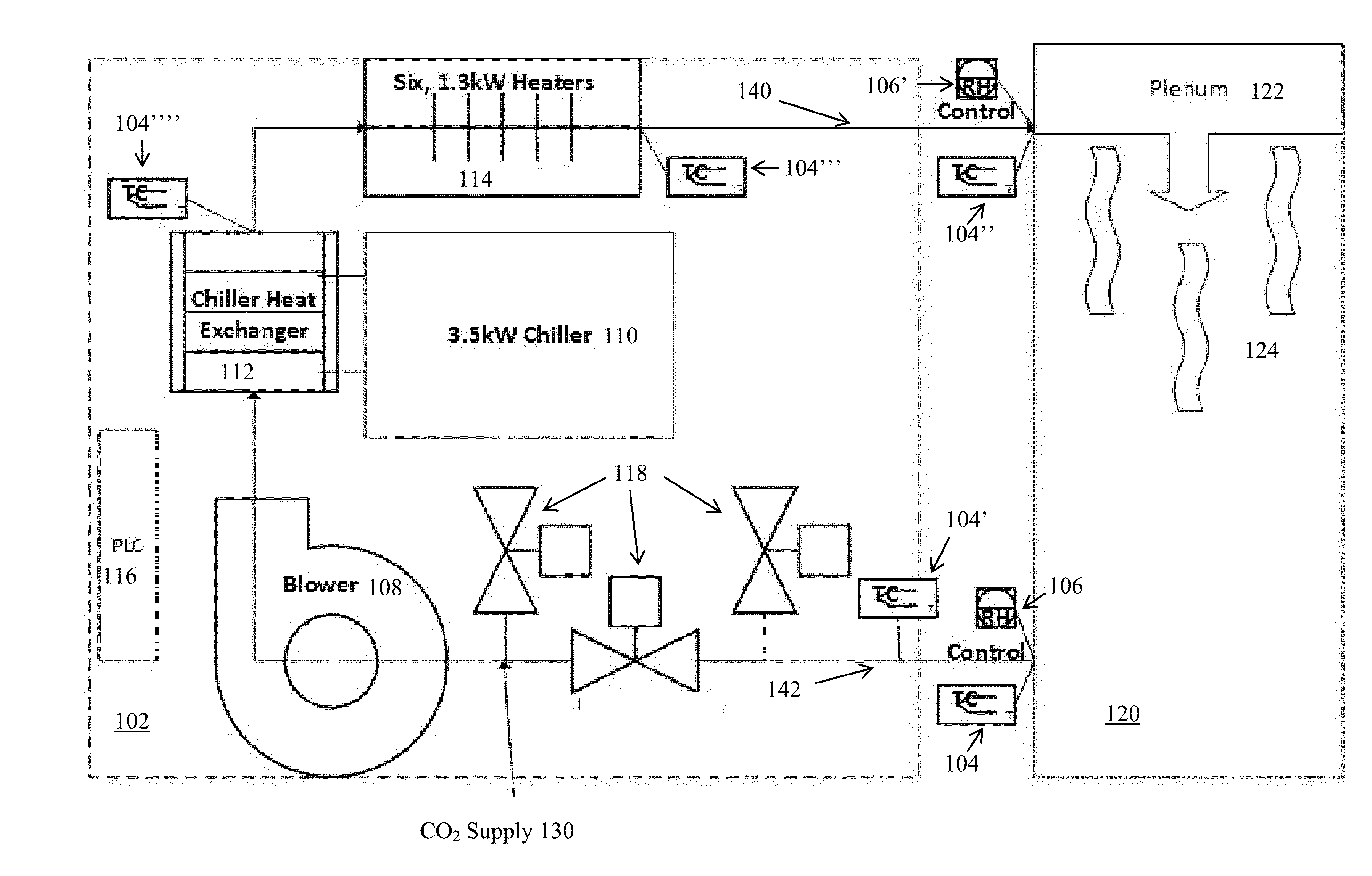

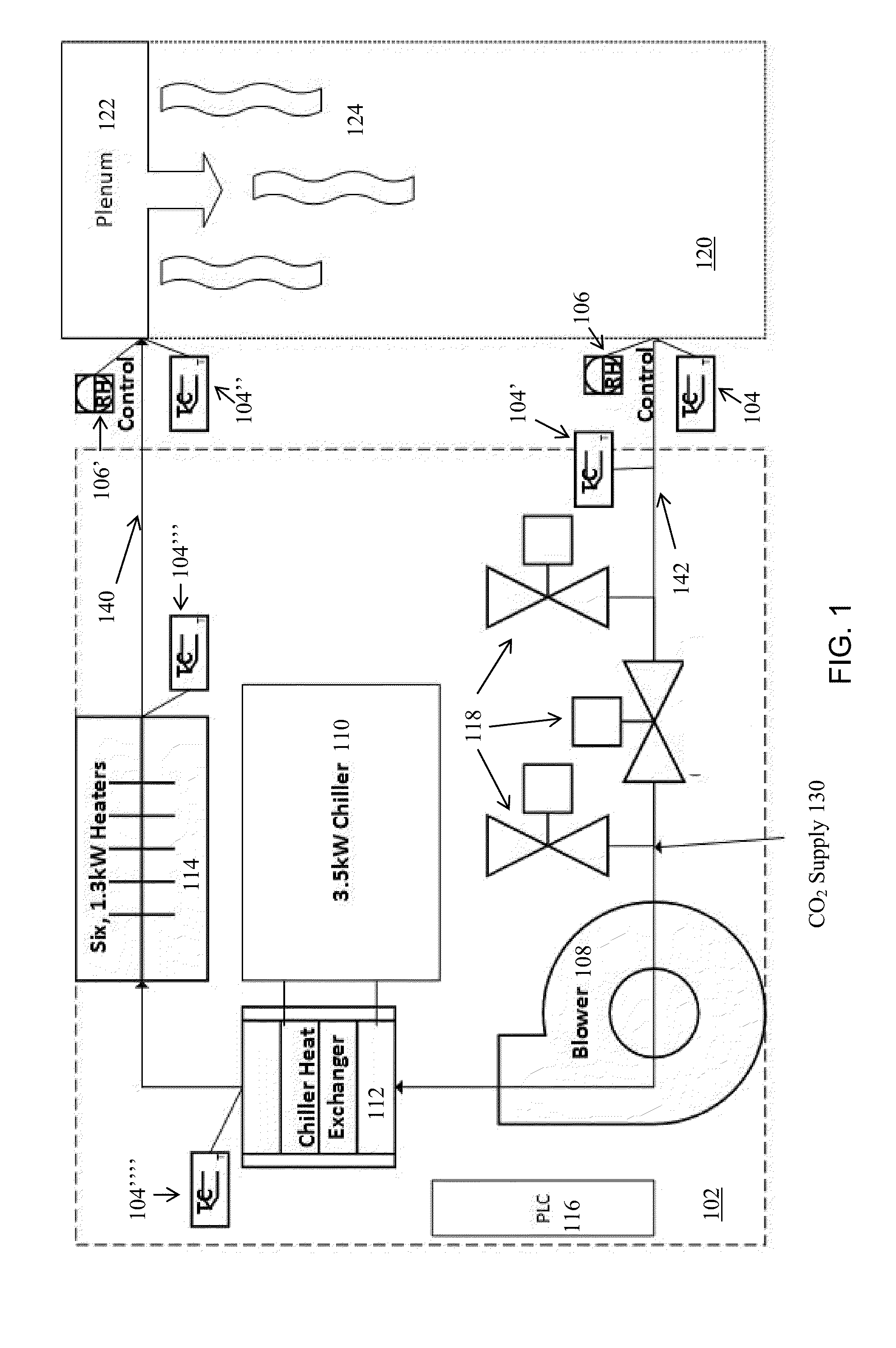

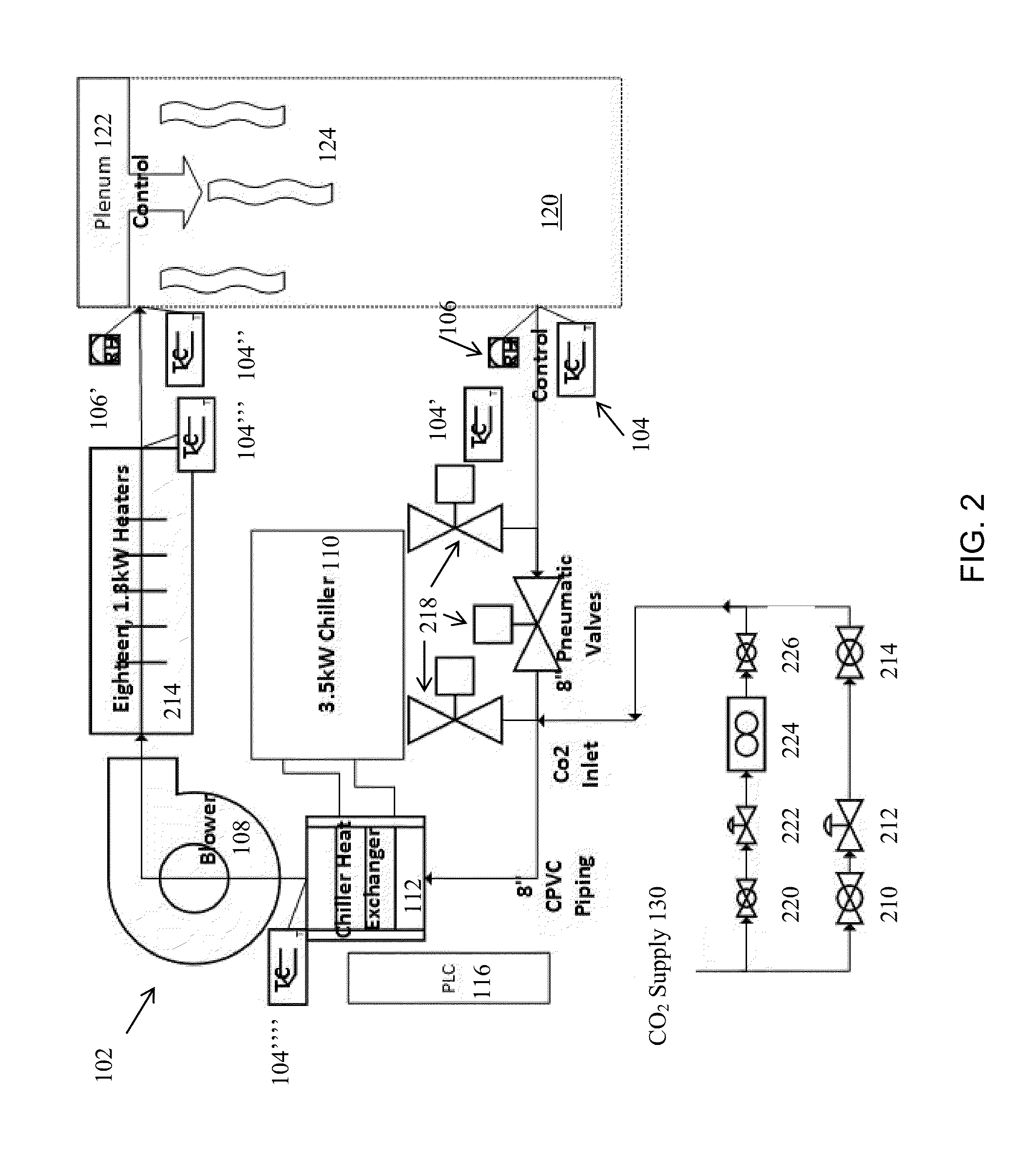

Method and apparatus for the curing of composite material by control over rate limiting steps in water removal

ActiveUS20150336852A1Long period of timeProcess control/regulationGaseous chemical processesRate limitingControl system

The invention encompasses equipment used to condition a recirculating gas stream in order to cure a CO2 Composite Material (CCM) and processes that use such equipment to cure the CCM. The gas conditioning equipment allows for a process that controls, reduces or eliminates the rate-limiting steps associated with water removal during the curing of a composite material. The equipment may include, but will not be limited to, control over the temperature, relative humidity, flow rate, pressure, and carbon dioxide concentration within the system; which includes the conditioning equipment, any vessel containing the CCM, and the material itself. Flow rate control can be used as a means to achieve uniformity in both gas velocity and composition.

Owner:SOLIDIA TECH

Continuous in-line manufacturing process for high speed coating deposition via a kinetic spray process

InactiveUS20060040048A1Constant cross-sectional areaMolten spray coatingPretreated surfacesSpray coatingEngineering

An improved kinetic spray system and a method for using the same in a high speed manufacturing environment are disclosed. The improved kinetic spray nozzle system comprises: a gas / powder exchange chamber connected to a first end of a powder / gas conditioning chamber having a length along a longitudinal axis of equal to or greater than 20 millimeters; a converging diverging supersonic nozzle, the supersonic nozzle having a converging section separated from a diverging section by a throat, the diverging section comprising a first portion and a second portion, with the first portion having a cross-sectional area that increases along a length of the first portion and with the second portion having a substantially constant cross-sectional area along a length of the second portion; and the converging section connected to a second end of the powder / gas conditioning chamber opposite the first end. The method includes: use of the disclosed nozzle system with the addition of hard particles that permit maximum enhancement of particle temperature while not permitting clogging of the nozzle; use of controlled particle feed rates to match the desired very high traverse speeds; and use of pre-heating of the substrate to clean it an to enhance particle bonding. With the disclosed nozzle system coupled with the disclosed methods one can apply kinetic spray coatings at traverse speeds of over 200 centimeters per second with a deposition efficiency of over 80 percent.

Owner:F W GARTNER THERMAL SPRAYING

Filter cartridge with internal gaseous seal for multimodal surgical gas delivery system having a smoke evacuation mode

ActiveUS20160220768A1Auxillary pretreatmentDispersed particle filtrationAbdominal cavityPERITONEOSCOPE

A system is disclosed for delivering gas during a laparoscopic surgical procedure performed within a patient's abdominal cavity requiring smoke evacuation which includes a gas delivery device having a housing with a port for receiving pressurized insufflating gas from a gas source, a pump assembly for circulating gas throughout the system, and a disposable gas conditioning unit or filter cartridge configured for operative association with the gas delivery device.

Owner:SURGIQUEST

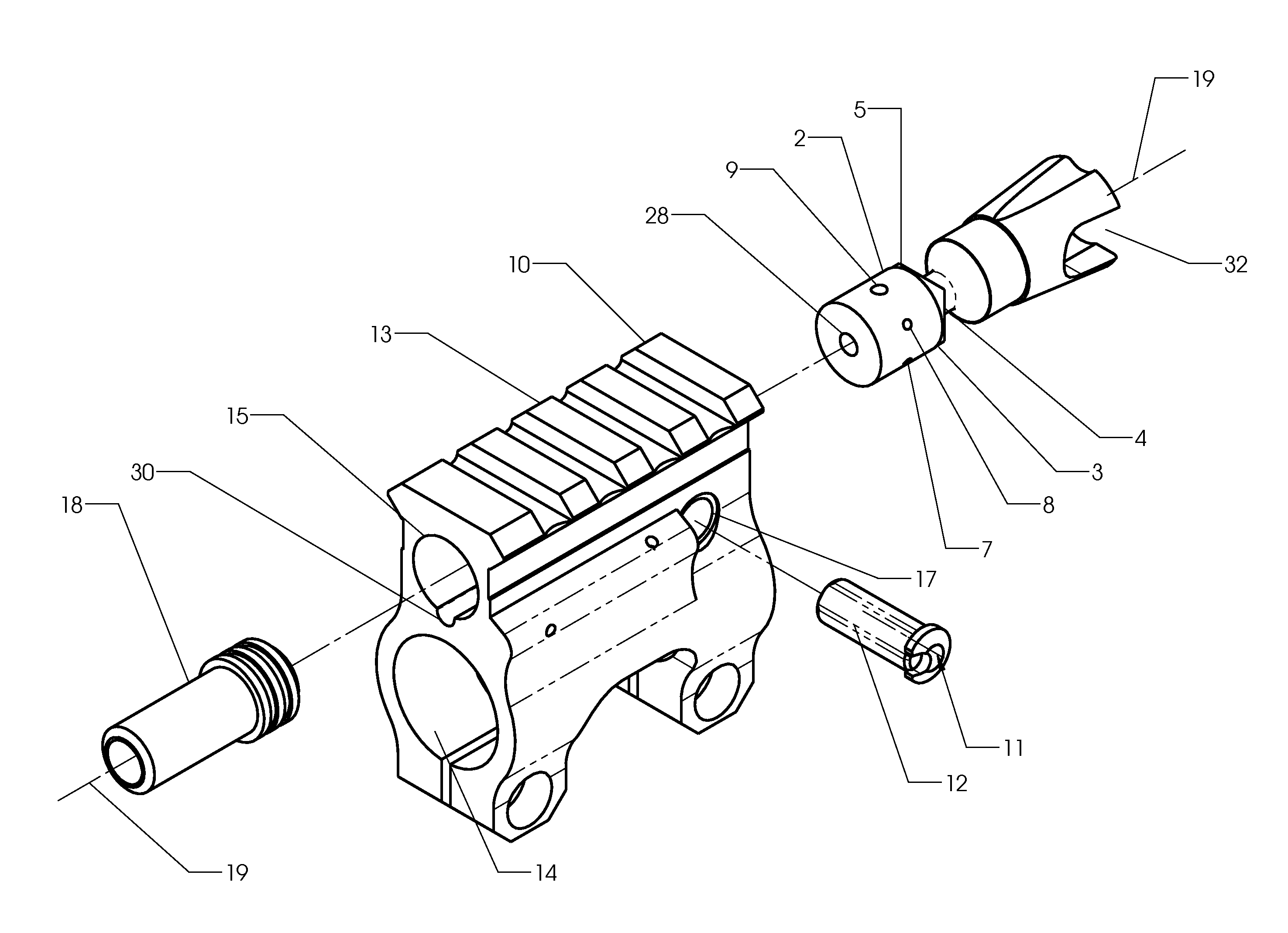

Multi-block gas regulator

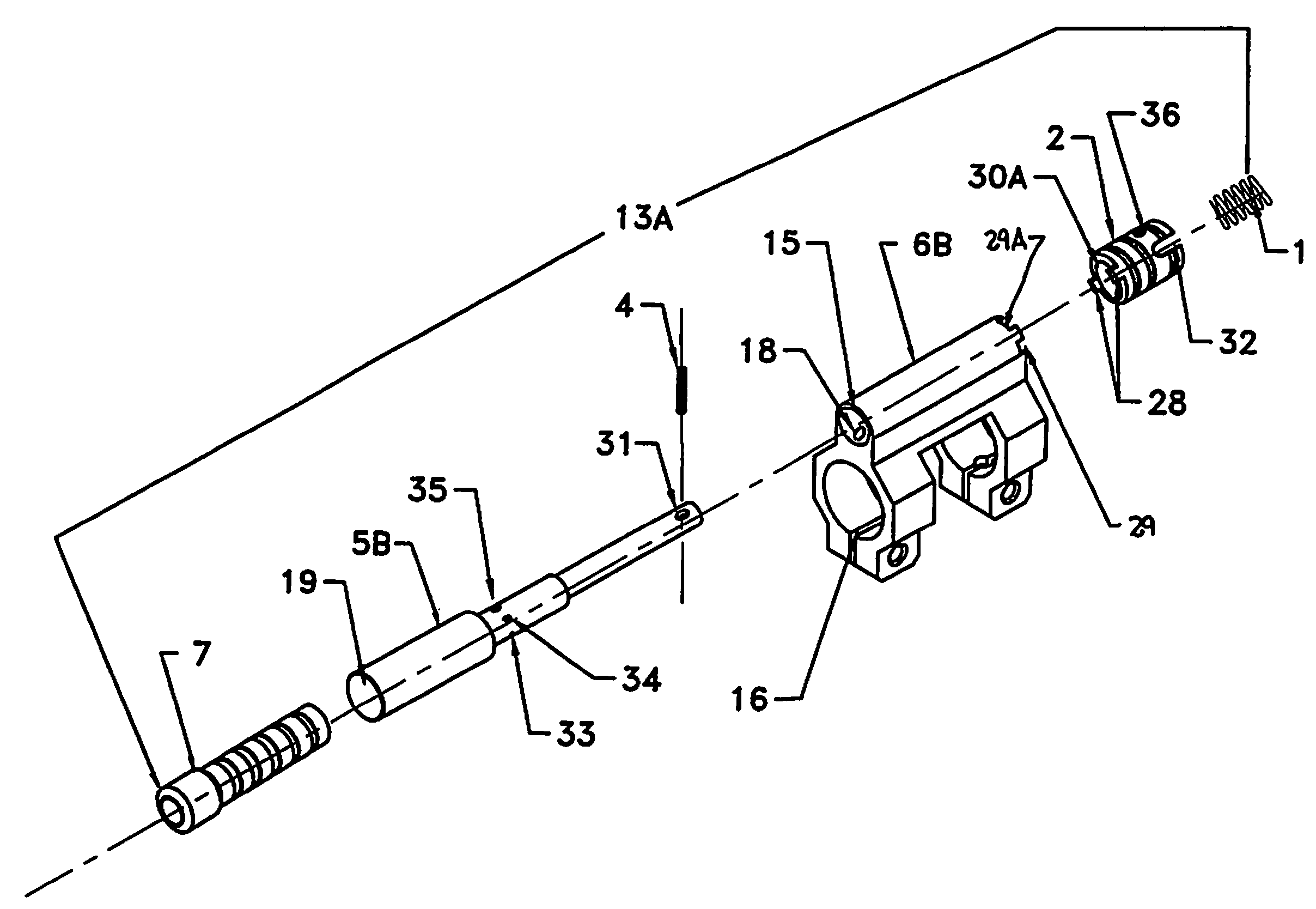

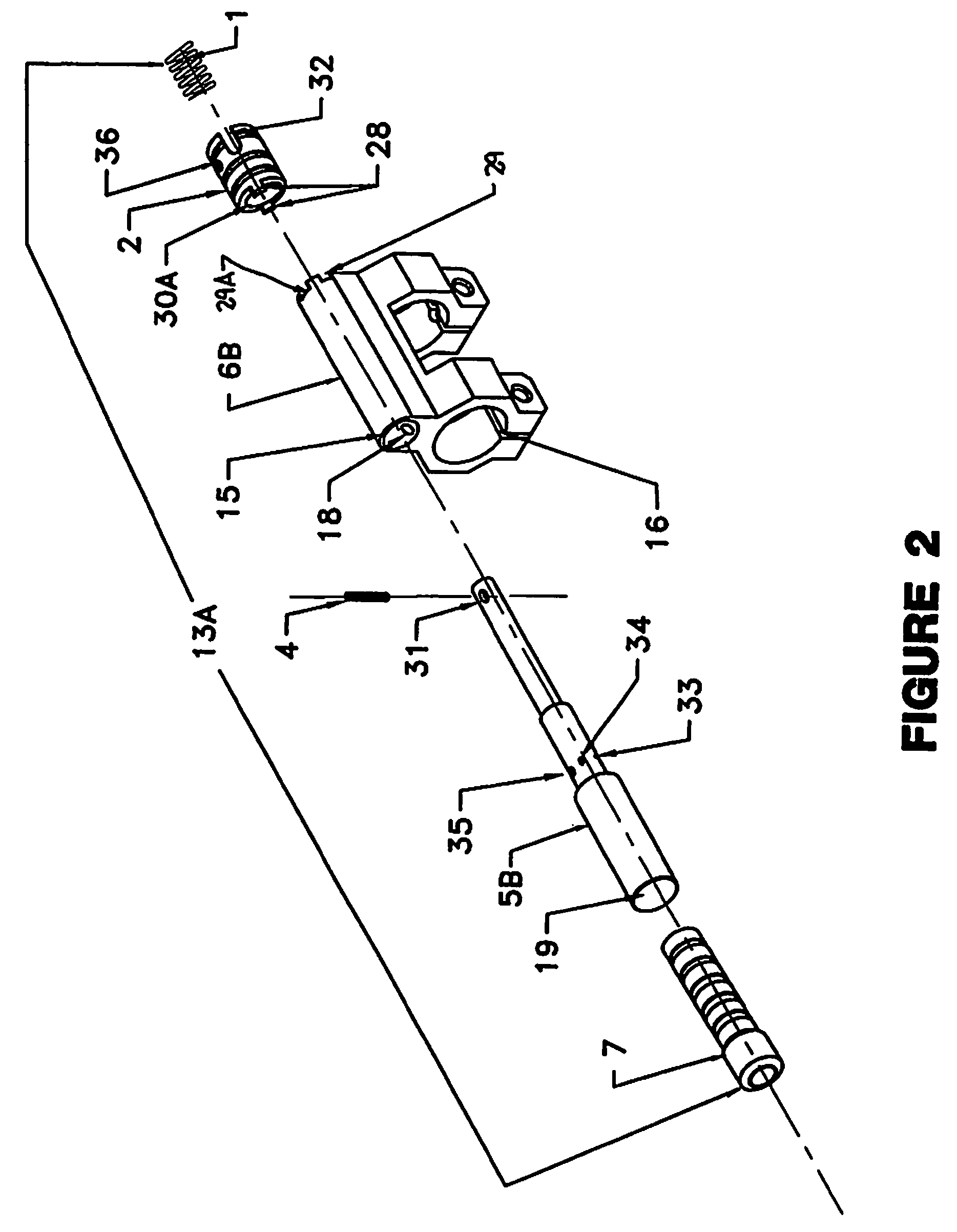

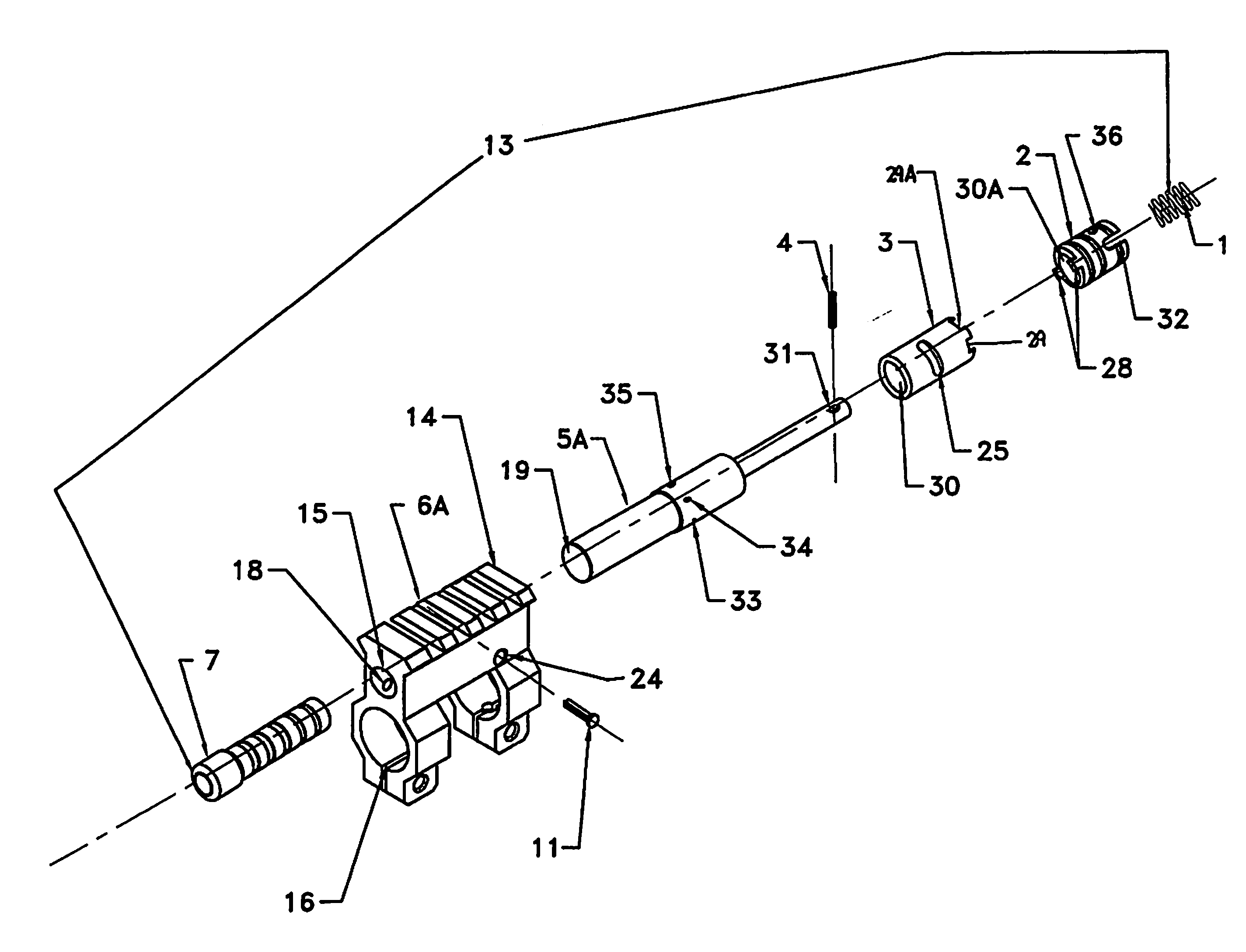

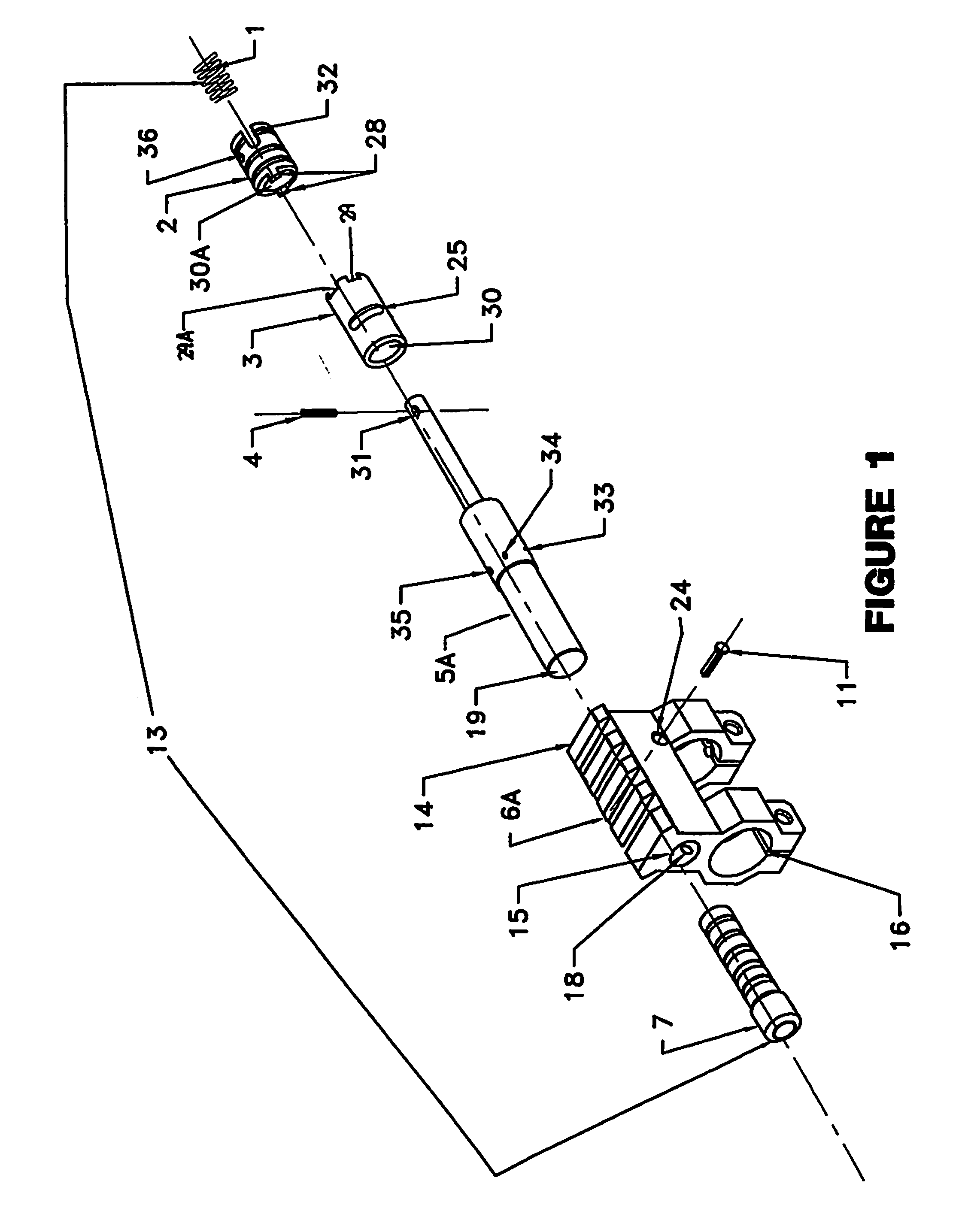

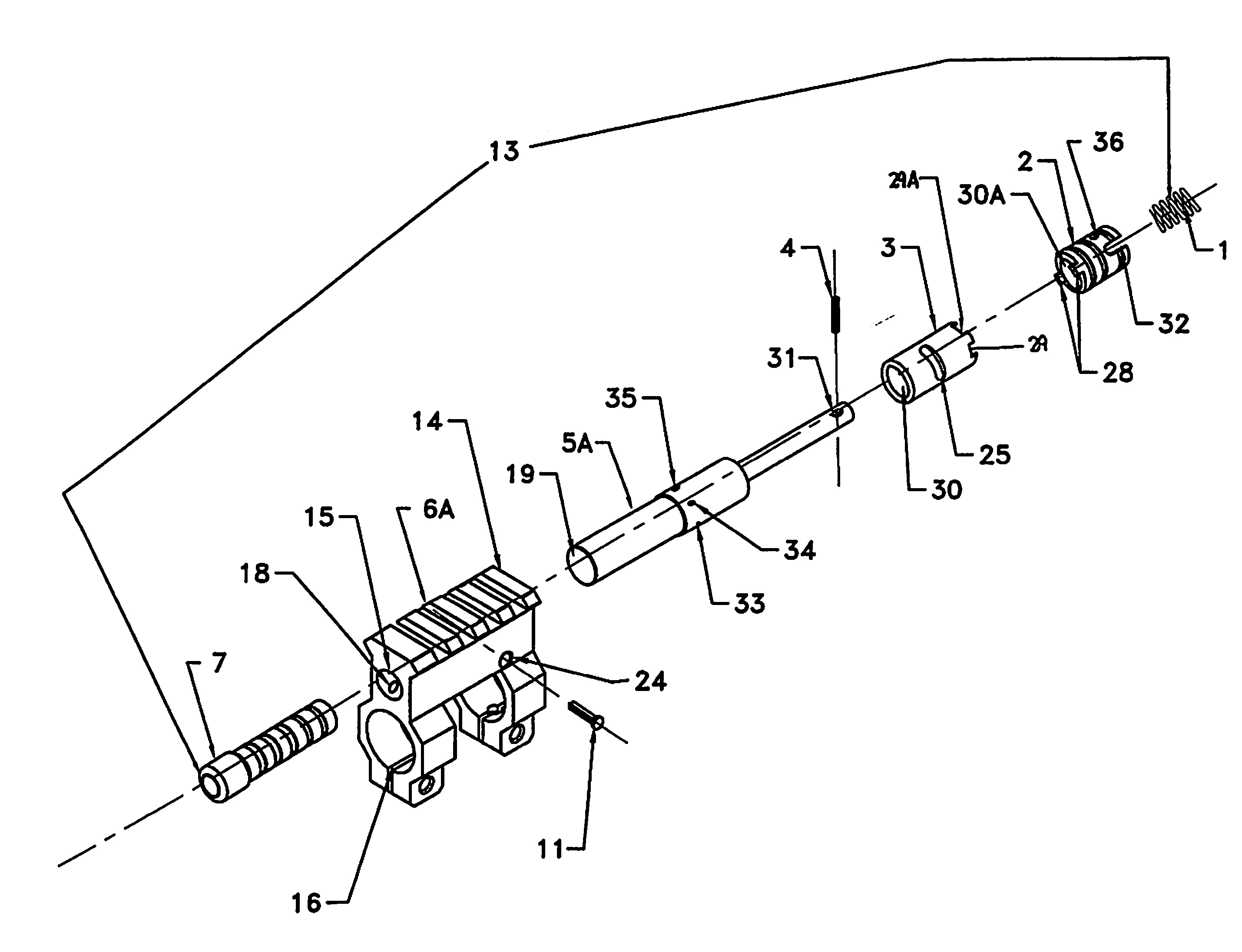

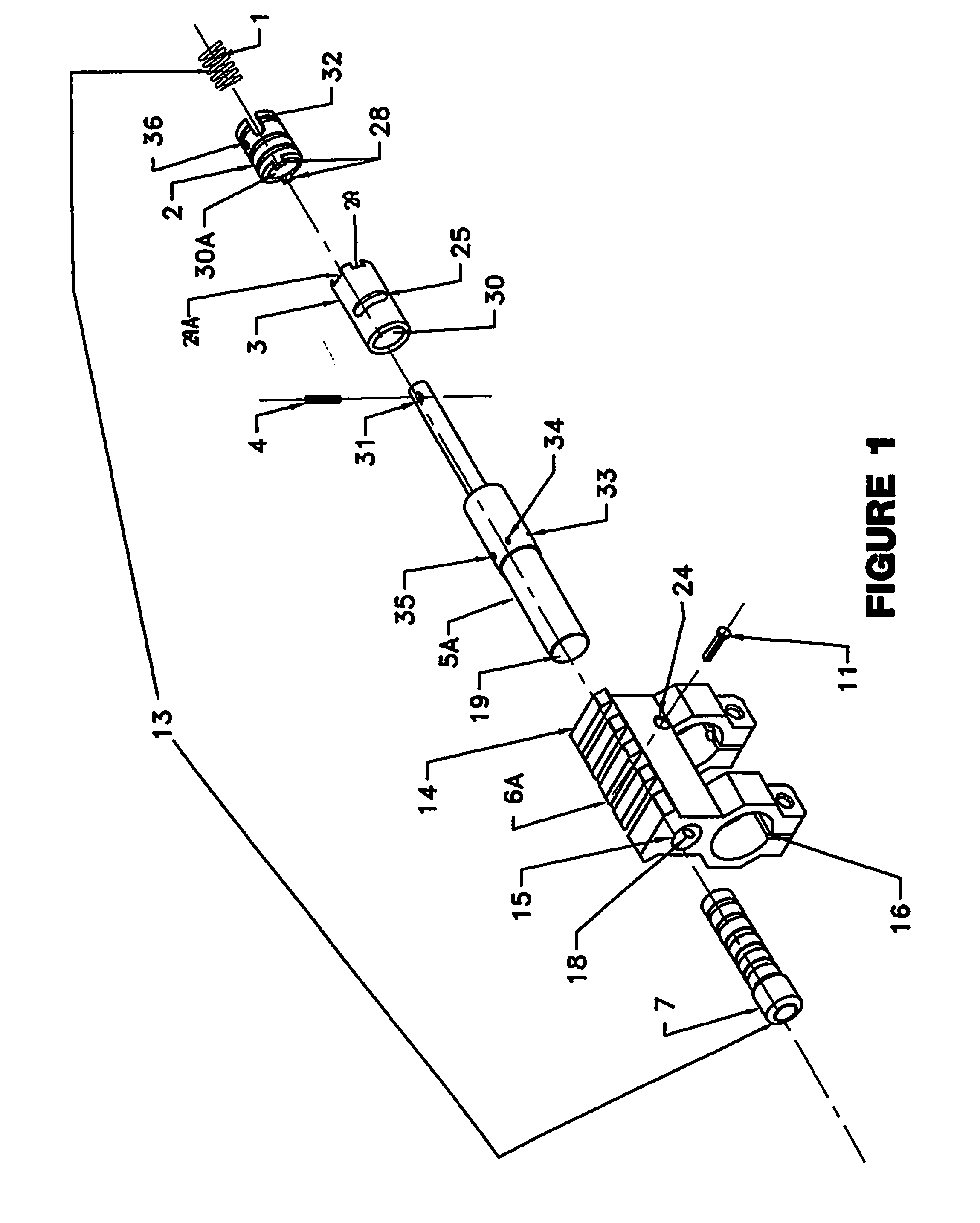

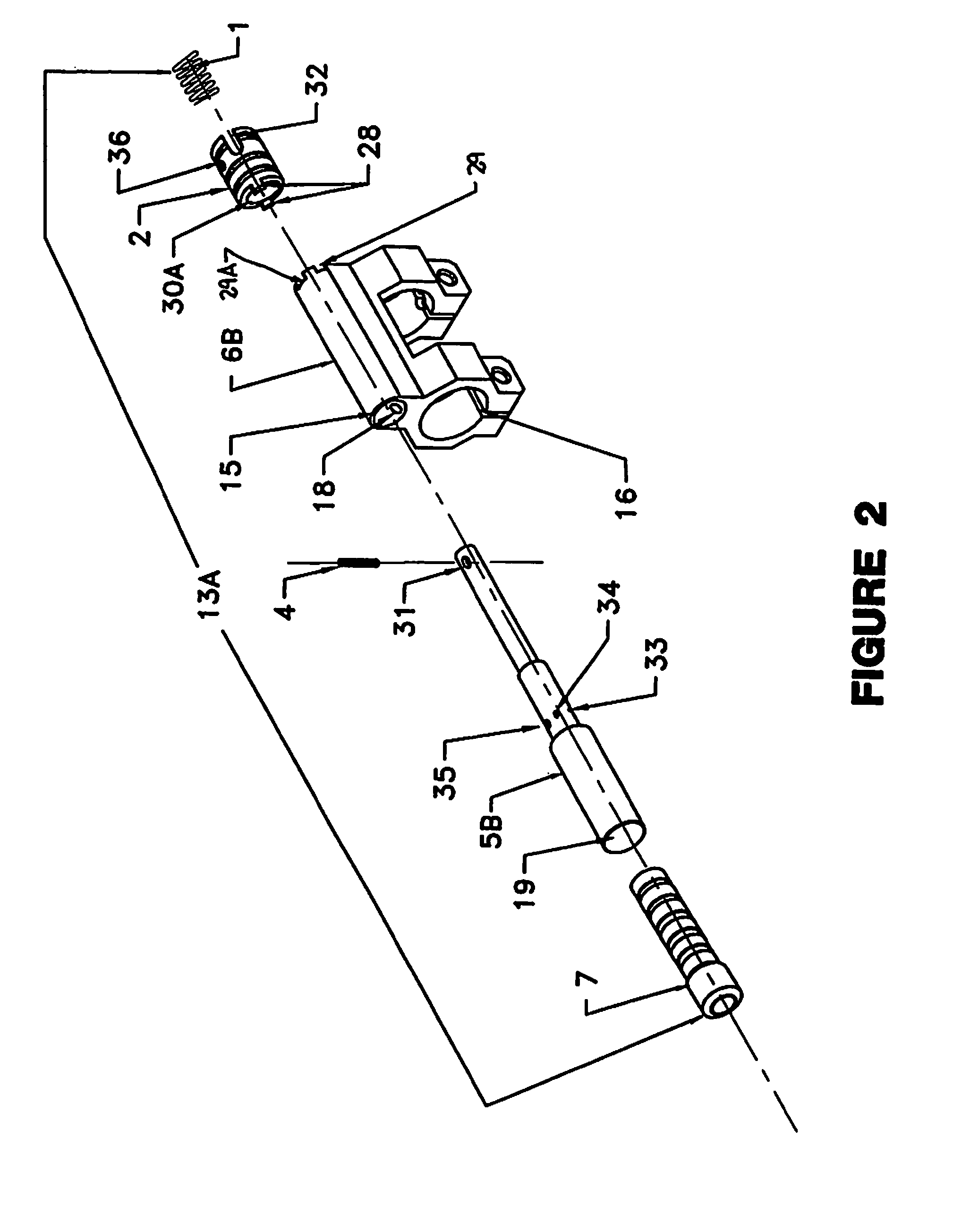

A multi use retro fit capable adjustable gas block designed to interface with an autoloading gas operated firearm is provided to replace existing gas blocks. The adjustable gas block optimizes gas flow into the host firearms operating system. The adjustable gas block has a spring loaded adjustment knob that releases when pulled forward allowing it to rotate. By rotating the adjustment knob the gas flow is increased or decreased based on one of four provided gas settings. Setting one is optimal for using a silencer, setting two is optimal for normal operations, setting three is optimal for adverse conditions, and setting four either turns the gas flow off optimizing sound reduction and providing for manual operation, or provides an extra high gas setting for the host firearm. The system works by precisely metering gas entering the operating system and not by exhausting excess gas into the atmosphere. The adjustable gas regulator may be configured with a piston operating system or a direct gas impingement operating system, e.g. gas tube, as is the case with the standard AR-15 / AR-10 family of firearms.

Owner:CASSELS CHARLES B

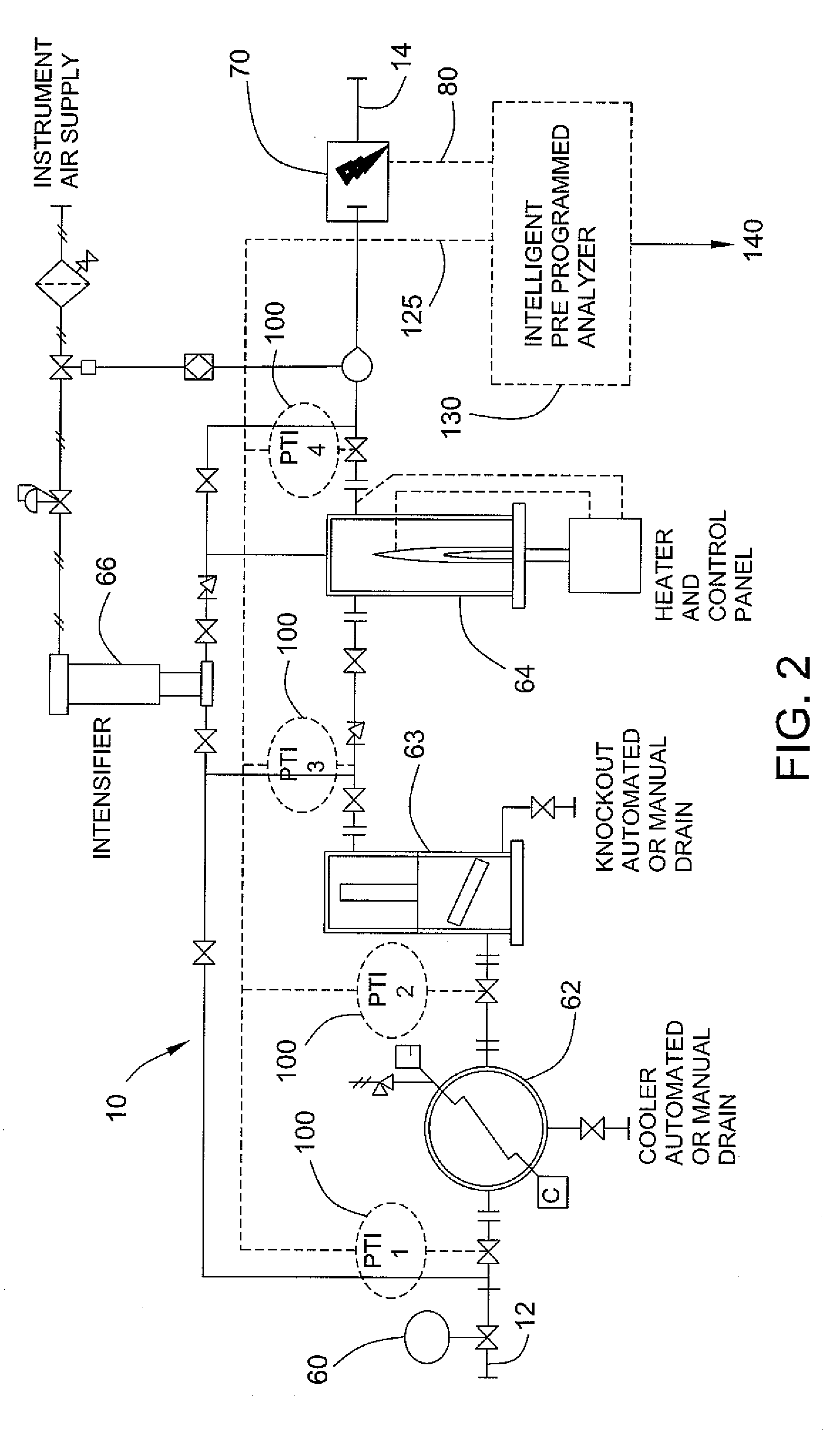

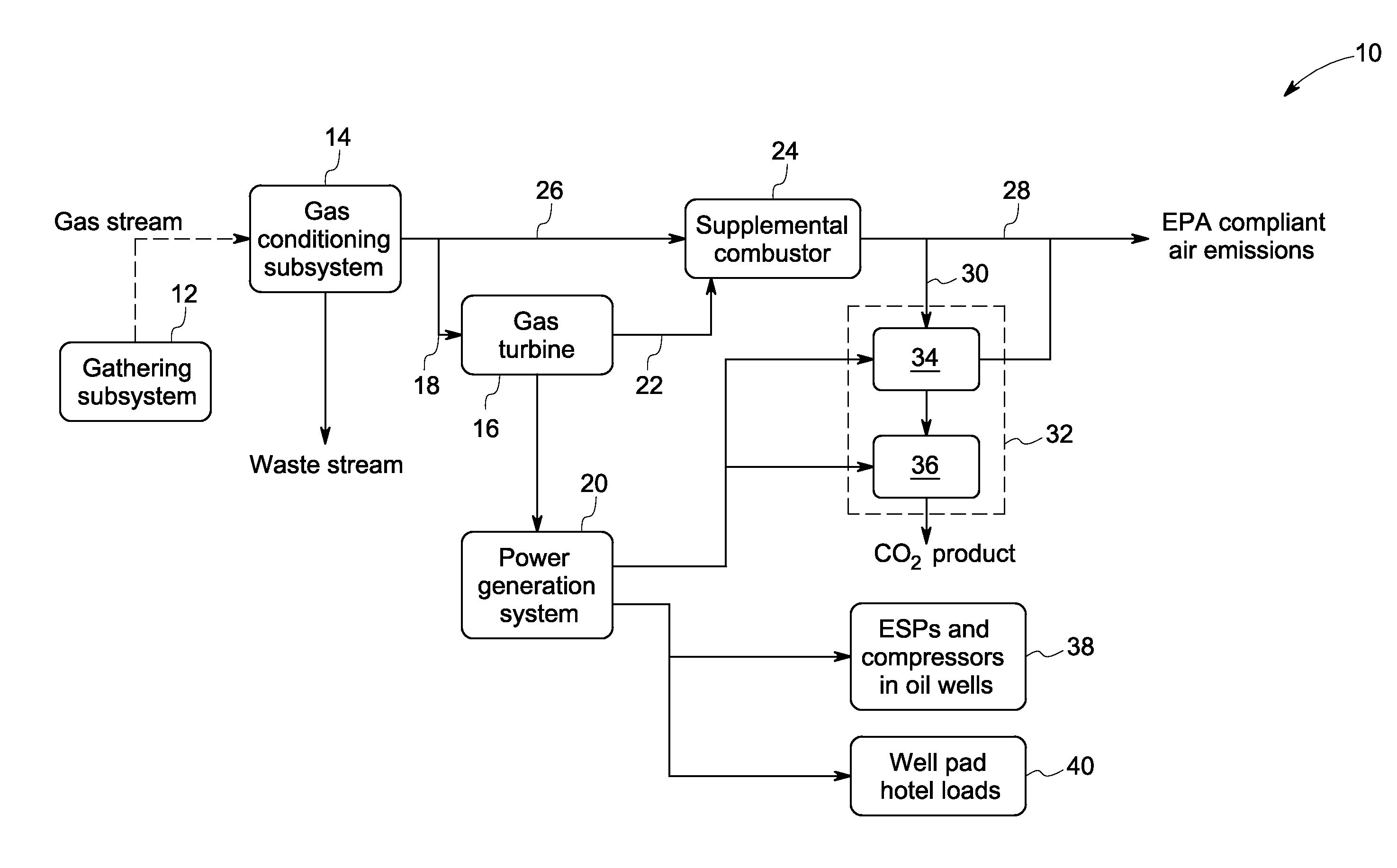

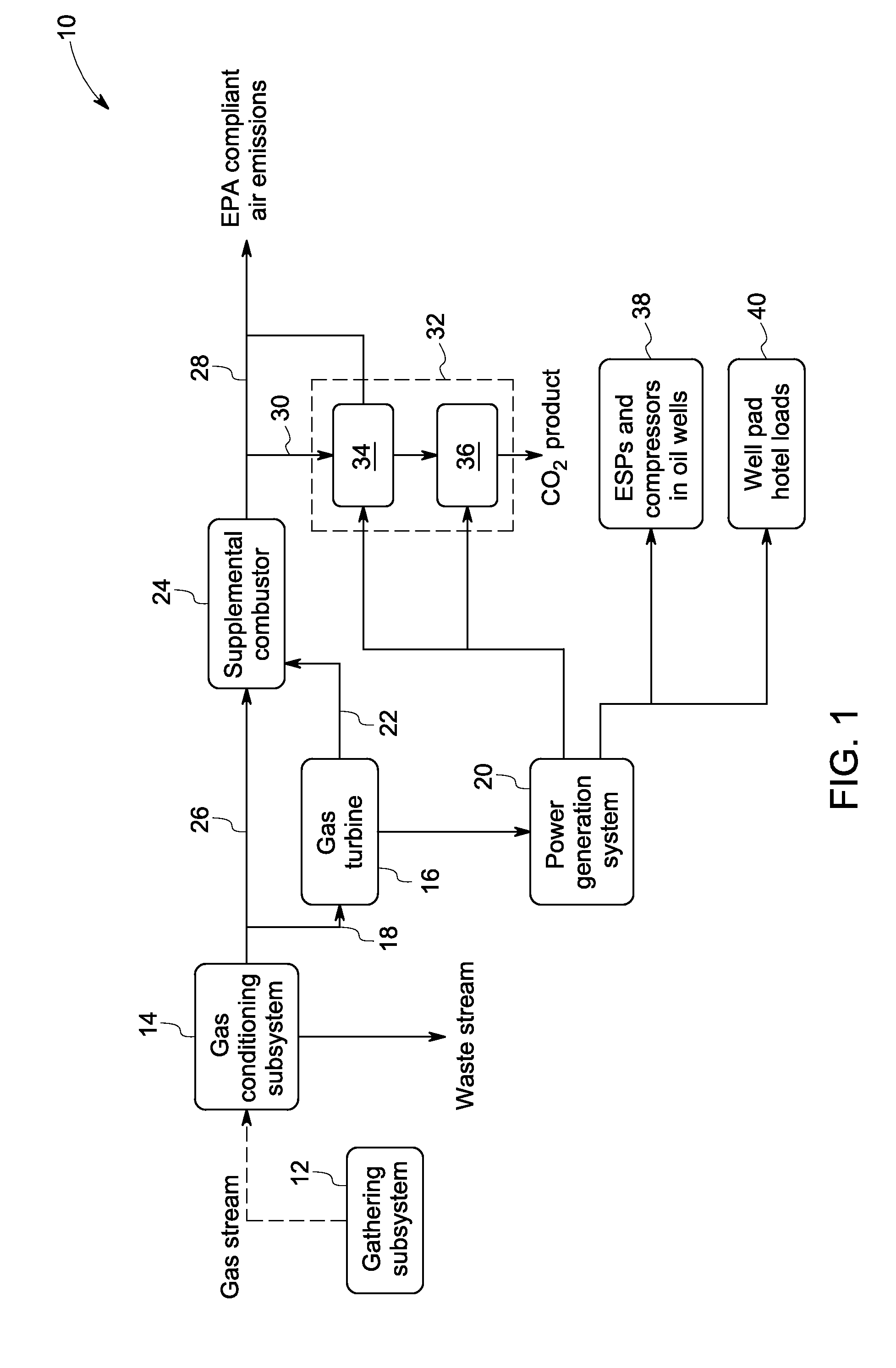

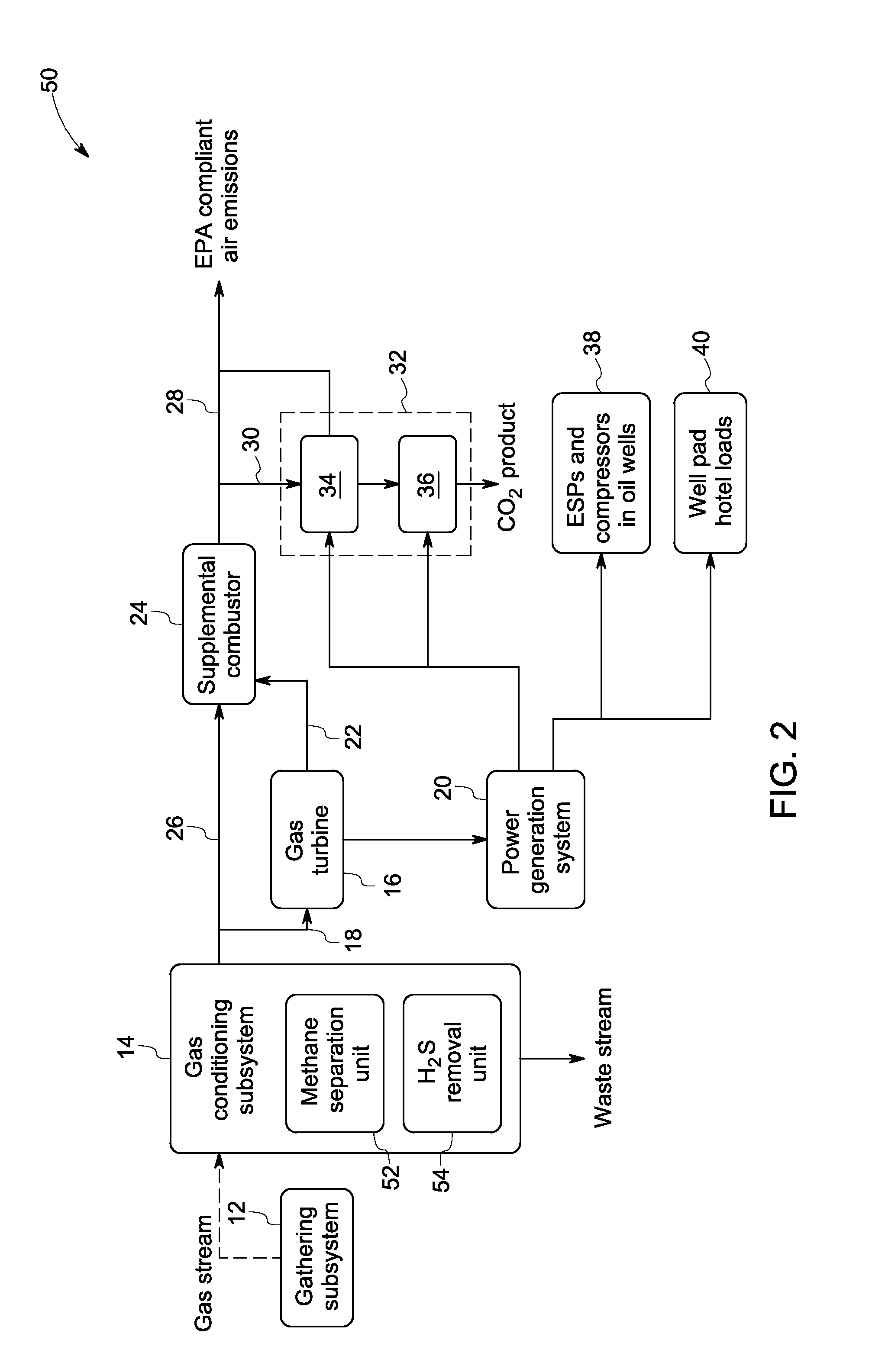

System and method for processing gas streams

A system for processing a gas stream includes a gathering subsystem configured to collect the gas stream from a well-head and a gas conditioning subsystem for receiving the gas stream from the gathering subsystem and providing physical conditioning of the gas stream. The system includes one or more gas turbines configured to receive and combust a first flow of the conditioned gas stream from the gas conditioning subsystem and coupled with an electrical generator. The system includes one supplemental combustor configured to receive heated exhaust gases from the one or more gas turbines and a second flow of the conditioned gas stream from the gas conditioning subsystem, wherein the at least one supplemental combustor is configured to combust the second flow of the conditioned gas stream and the heated exhaust gases such that an exhaust gas stream flow from the at least one supplemental combustor meets emission regulation requirements.

Owner:GENERAL ELECTRIC CO

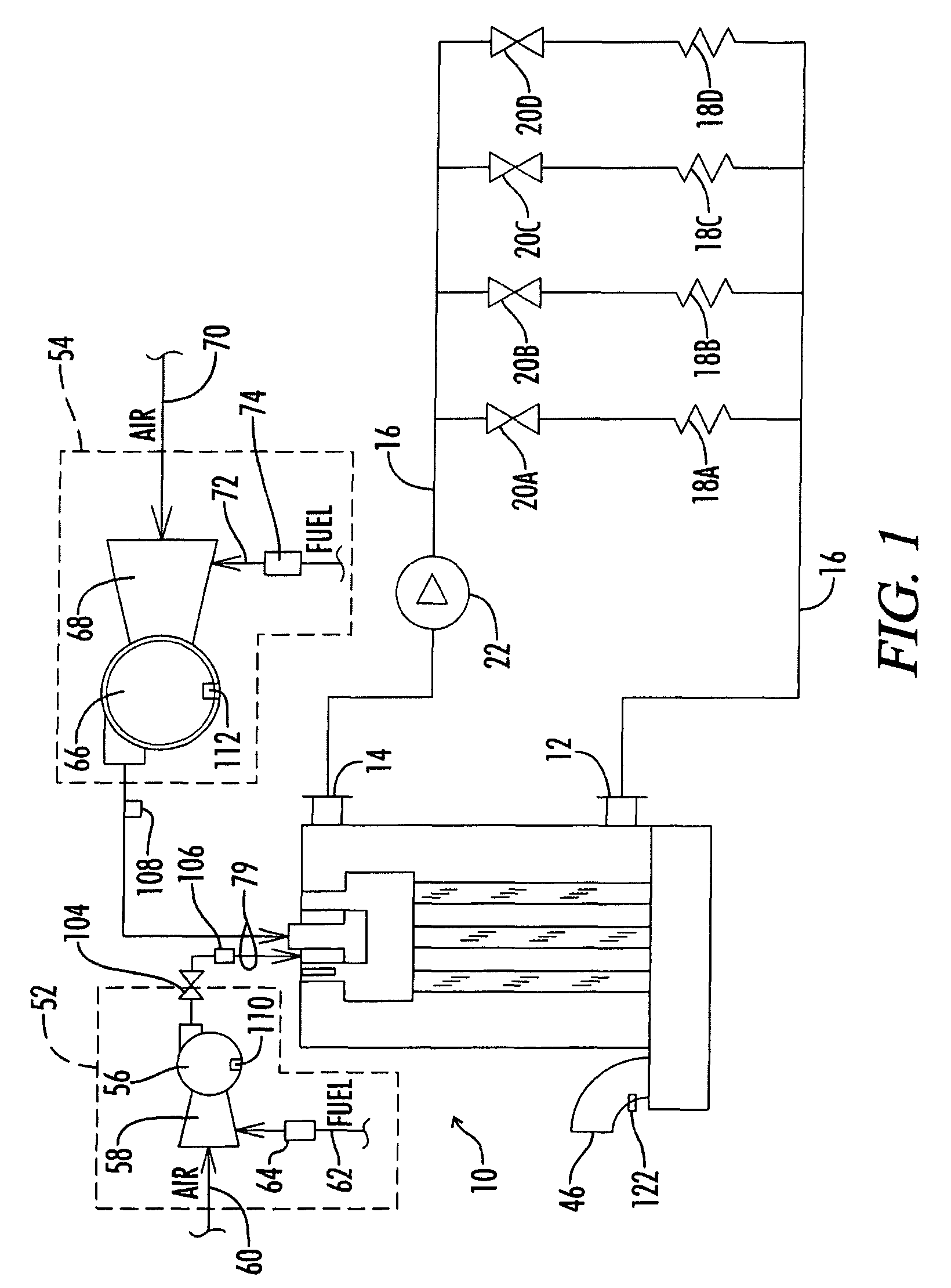

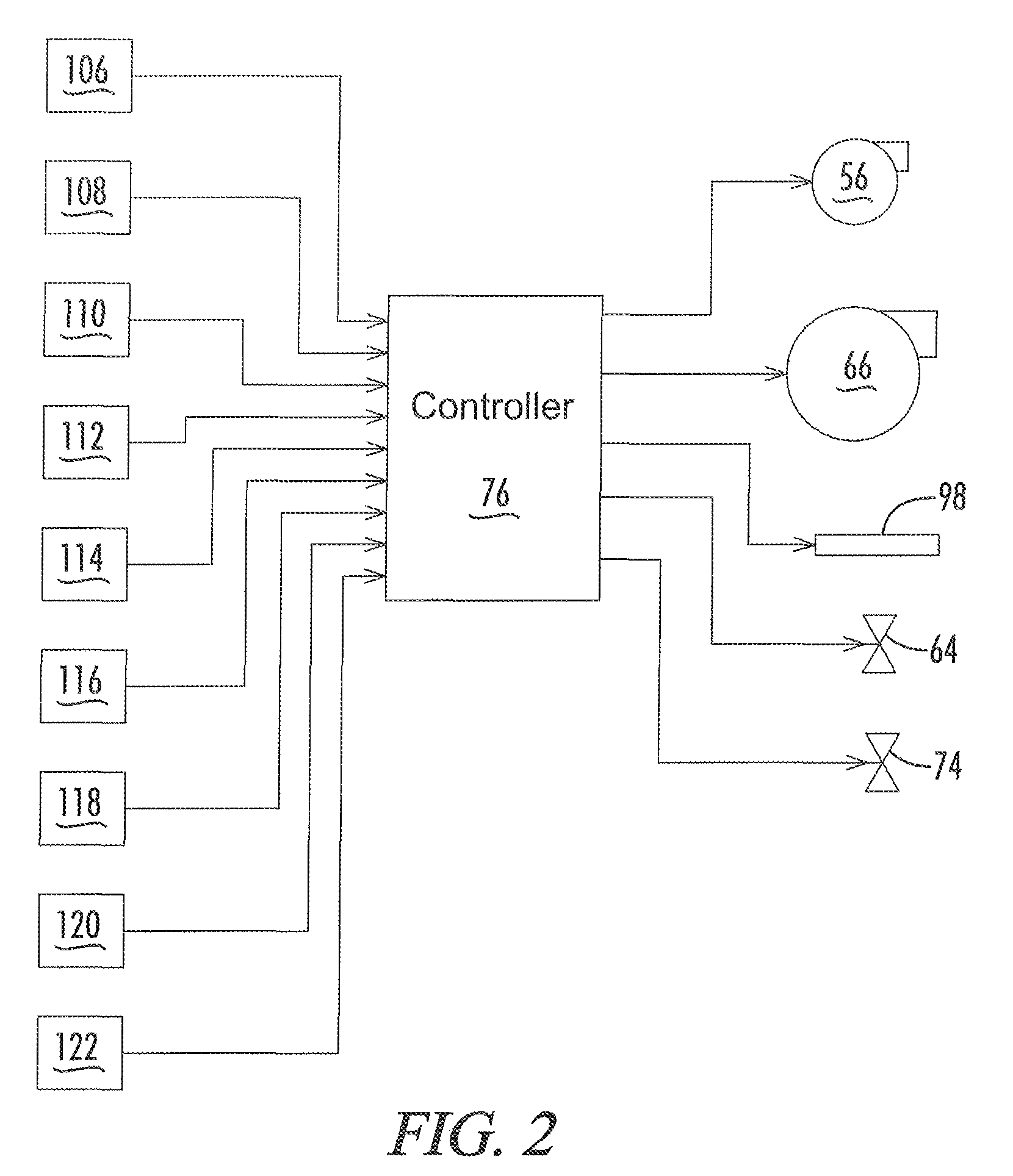

Gas fired modulating water heating appliance with dual combustion air premix blowers

ActiveUS8286594B2Avoid condensationIncrease the turndown ratioWater circulationEnergy efficient heating/coolingCombustorEngineering

A water heating apparatus uses a low range blower assembly and a high range blower assembly, each providing a variable flow of premixed fuel and air to a burner assembly. Appropriate choice of the operating ranges of the blower assemblies can provide a high turndown ratio approximately equal to the product of the turndown ratios of each of the individual blower assemblies. Turndown ratios as high as 25:1 are achievable.

Owner:LOCHINVAR

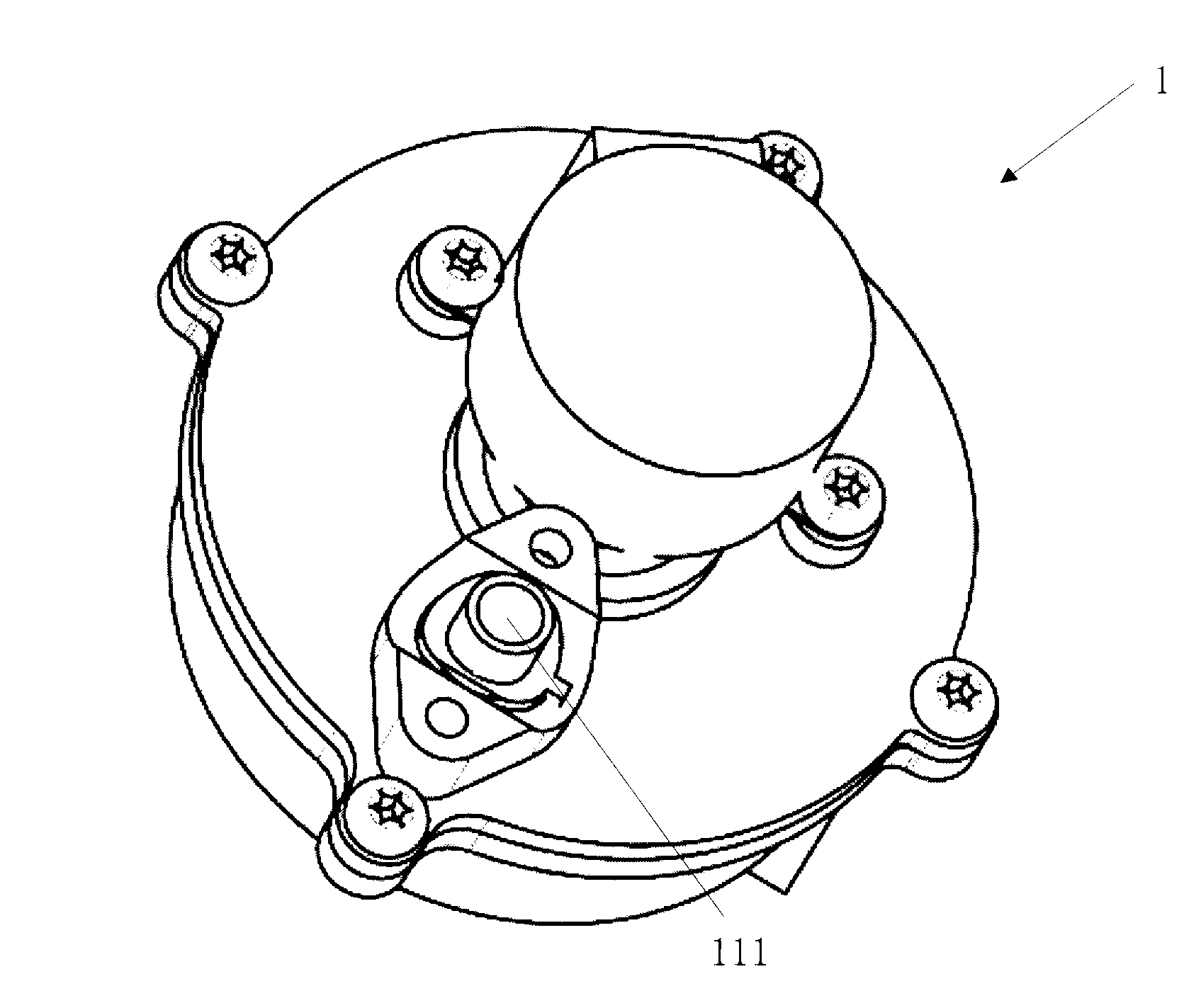

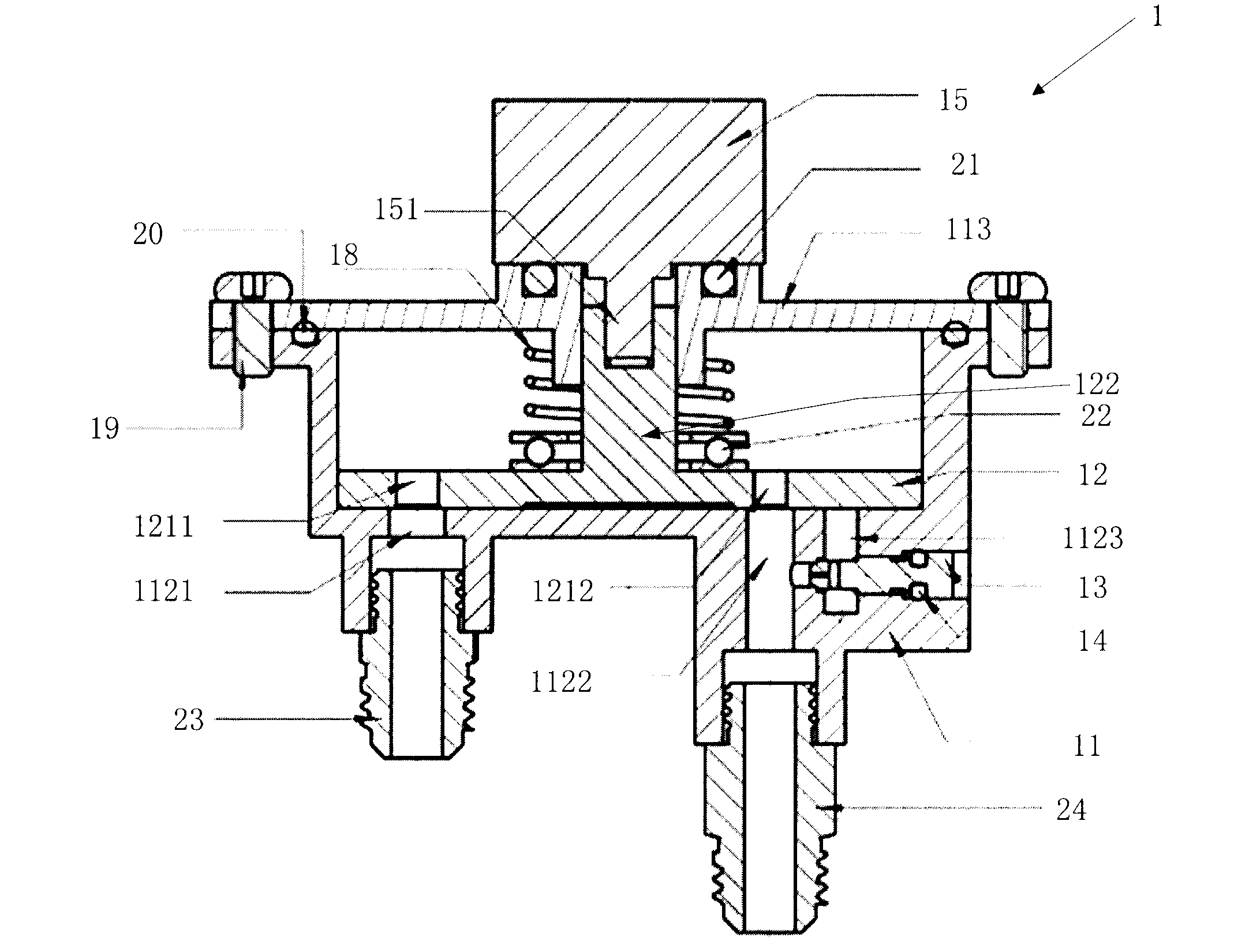

Gas adjusting valve and electric control gas adjusting valve used for gas stove and gas stove

ActiveCN103133718ARealize segment controlEasy to controlFuel supply regulationGaseous fuel feeder/distributionEngineeringElectric control

A gas adjusting valve used for a gas stove comprises a valve body and a rotary disc which contacts the plane of the inner cavity surface of the valve body and rotates relative to the inner cavity surface of the valve body, wherein a gas inlet and a gas outlet are formed in the valve body. The valve body matches with the contact face of the rotary disc in a sealed mode. The rotary disc is provided with a connecting passage, and the connecting passage can selectively enable the gas outlet which is formed in the valve body to be connected or disconnected with the inner cavity of the valve body or change a connecting degree. The invention further provides an electric control gas adjusting valve used for the gas stove and the gas stove with the gas adjusting valve or the electric control gas adjusting valve. Due to the technical scheme, the problems that the existing gas stove adopts a plug valve which is inconvenient to manufacture and is high in cost can be avoided.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU

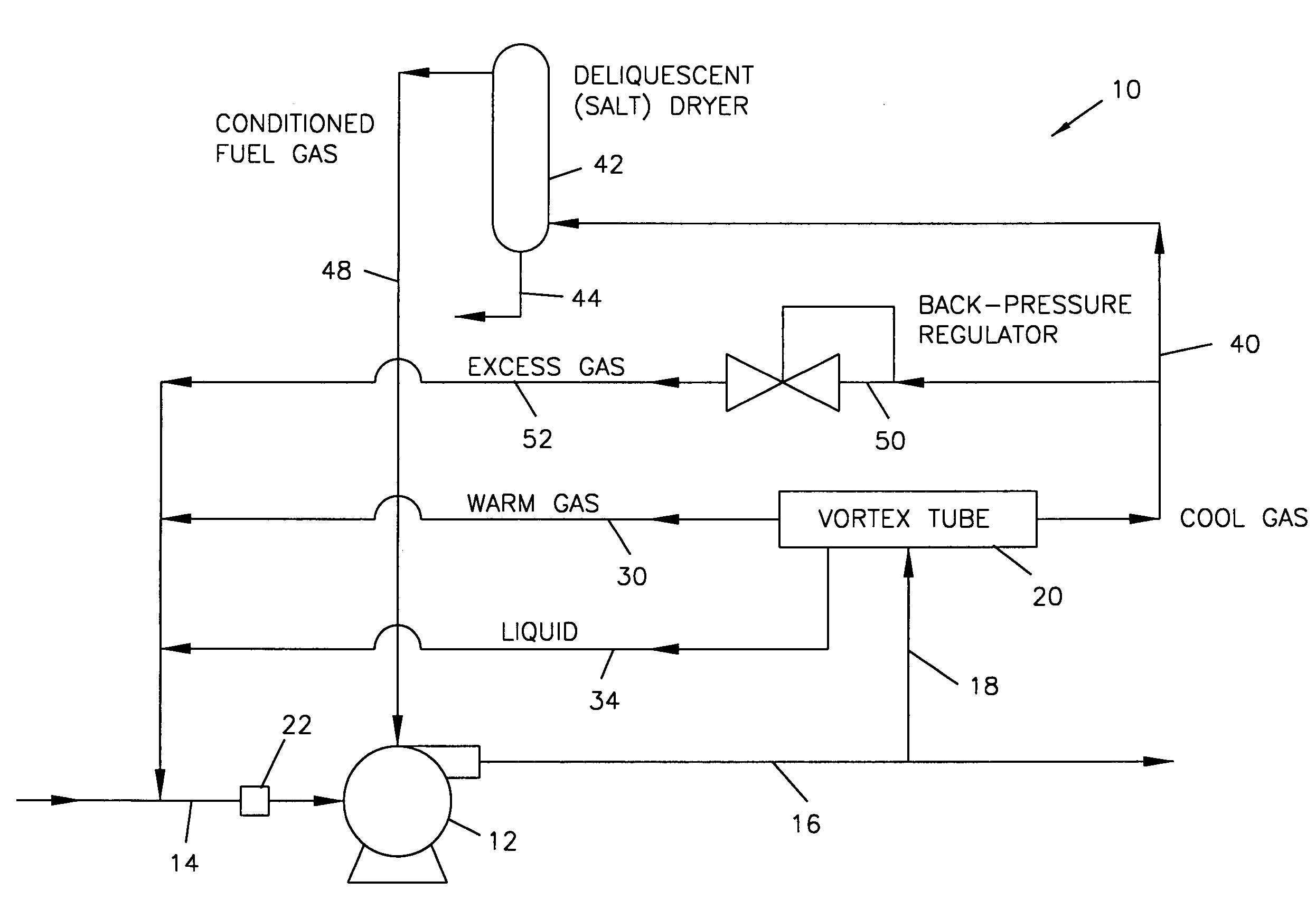

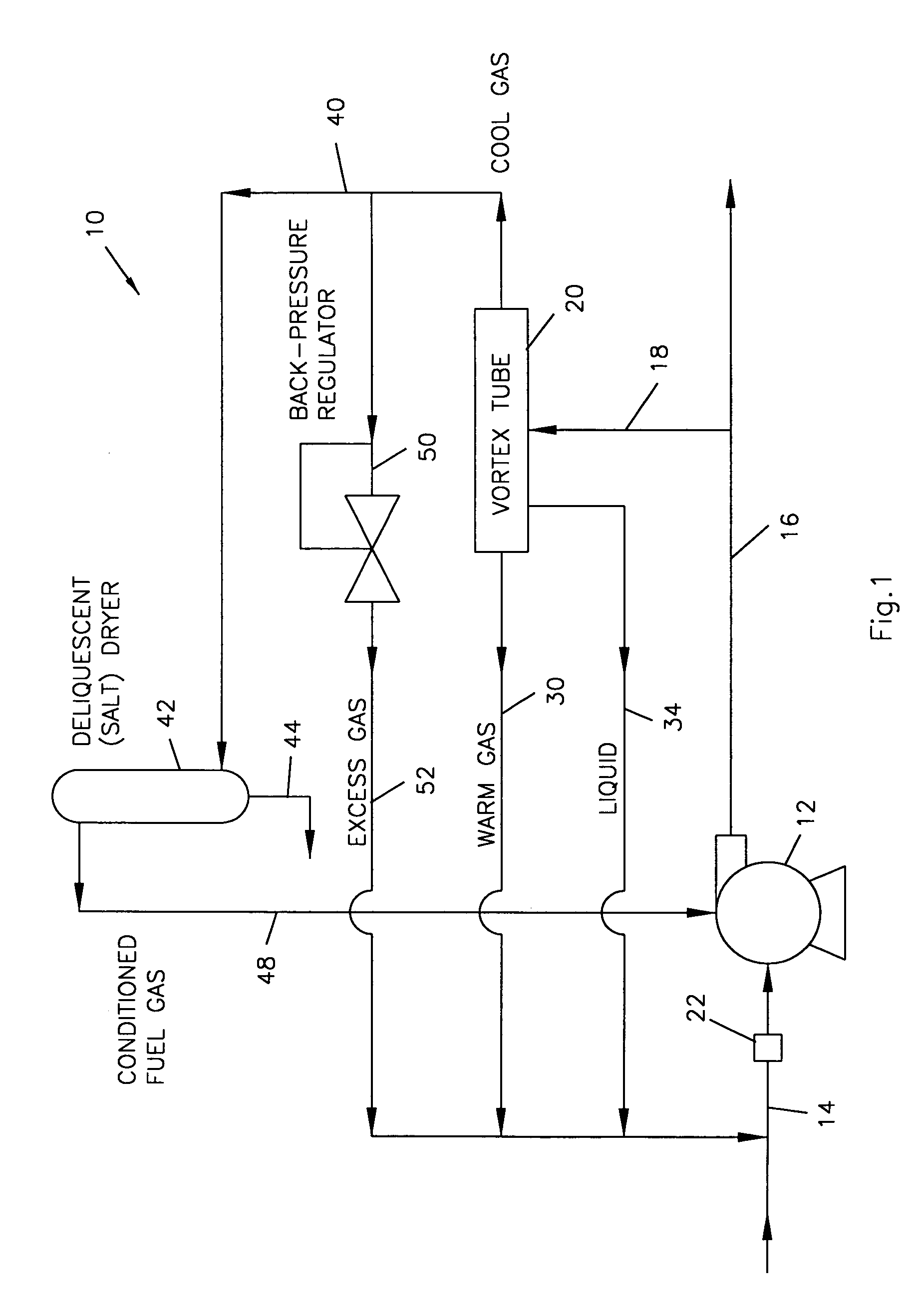

Compressor fuel gas conditioner

ActiveUS7219500B1Positive displacement pump componentsCompression machinesCompressed natural gasProcess engineering

A compressor fuel gas conditioner for a natural gas well having a compressor which utilizes natural gas from the well as a fuel. The conditioner includes a vortex tube having an inlet to receive compressed natural gas from the compressor, a warm gas outlet for gas which has been heated by circular motion in the vortex tube, and a cool gas outlet for cool gas exiting the vortex tube after passing through the tube wherein the warm gas is returned to an inlet side of the compressor. A salt dryer includes a dryer inlet to receive the cool gas exiting the cool gas outlet of the vortex tube and a dryer outlet to deliver gas from the salt dryer as fuel gas to the compressor.

Owner:PROCESS EQUIP & SERVICE

Multi-block gas regulator

A multi use retro fit capable adjustable gas block designed to interface with an autoloading gas operated firearm is provided to replace existing gas blocks. The adjustable gas block optimizes gas flow into the host firearms operating system. The adjustable gas block has a spring loaded adjustment knob that releases when pulled forward allowing it to rotate. By rotating the adjustment knob the gas flow is increased or decreased based on one of four provided gas settings. Setting one is optimal for using a silencer, setting two is optimal for normal operations, setting three is optimal for adverse conditions, and setting four either turns the gas flow off optimizing sound reduction and providing for manual operation, or provides an extra high gas setting for the host firearm. The system works by precisely metering gas entering the operating system and not by exhausting excess gas into the atmosphere. The adjustable gas regulator may be configured with a piston operating system or a direct gas impingement operating system, e.g. gas tube, as is the case with the standard AR-15 / AR-10 family of firearms.

Owner:CASSELS CHARLES B

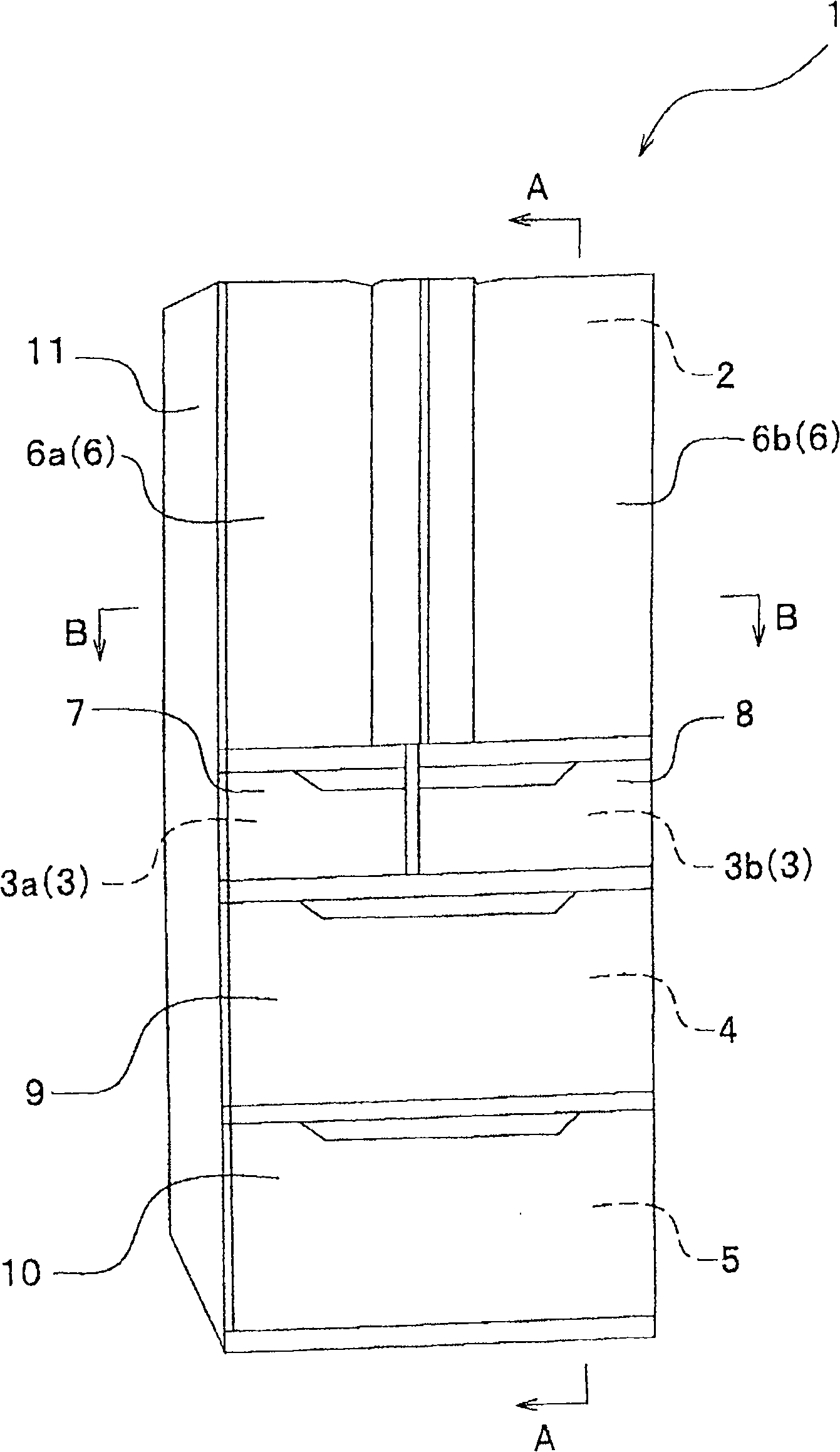

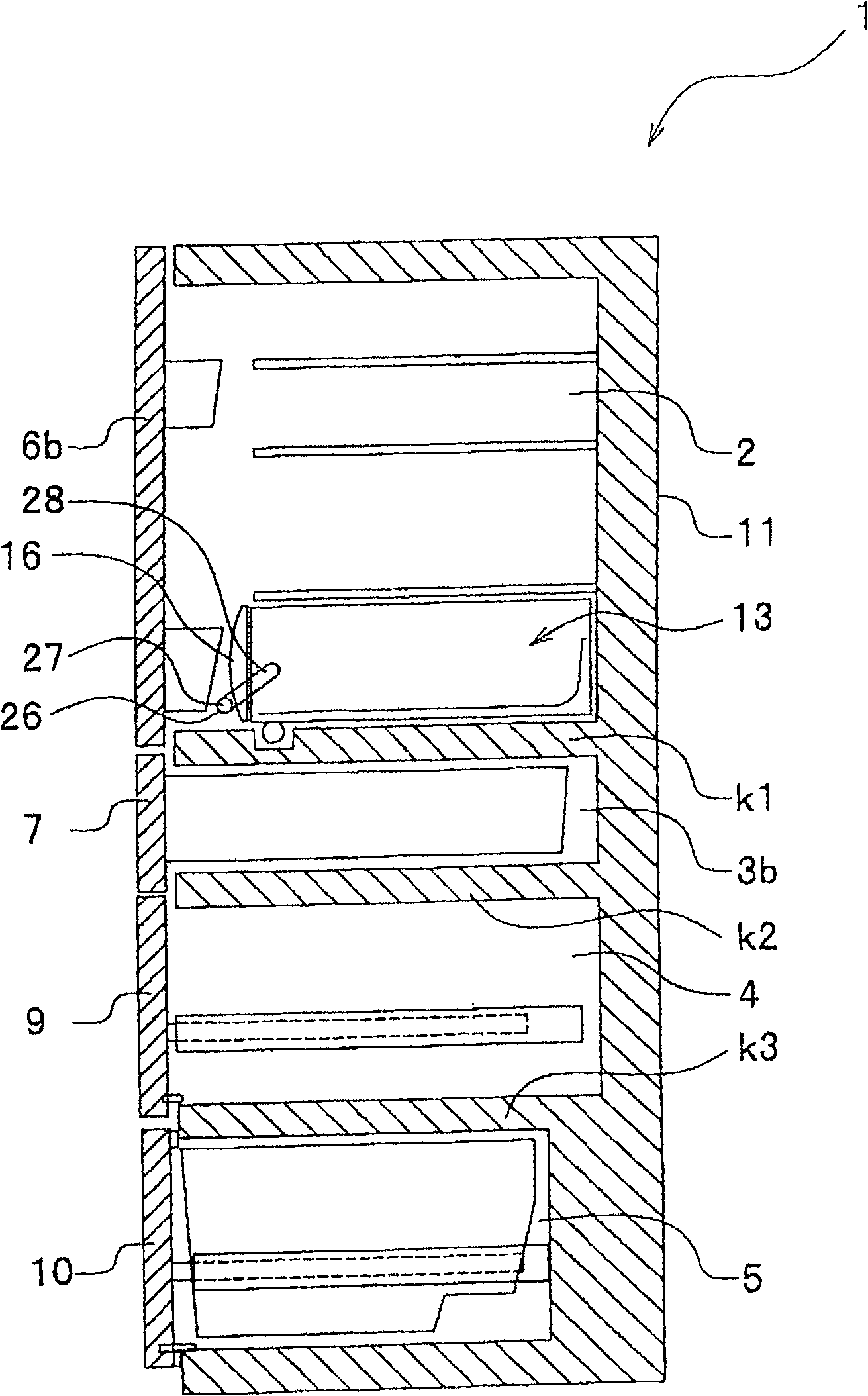

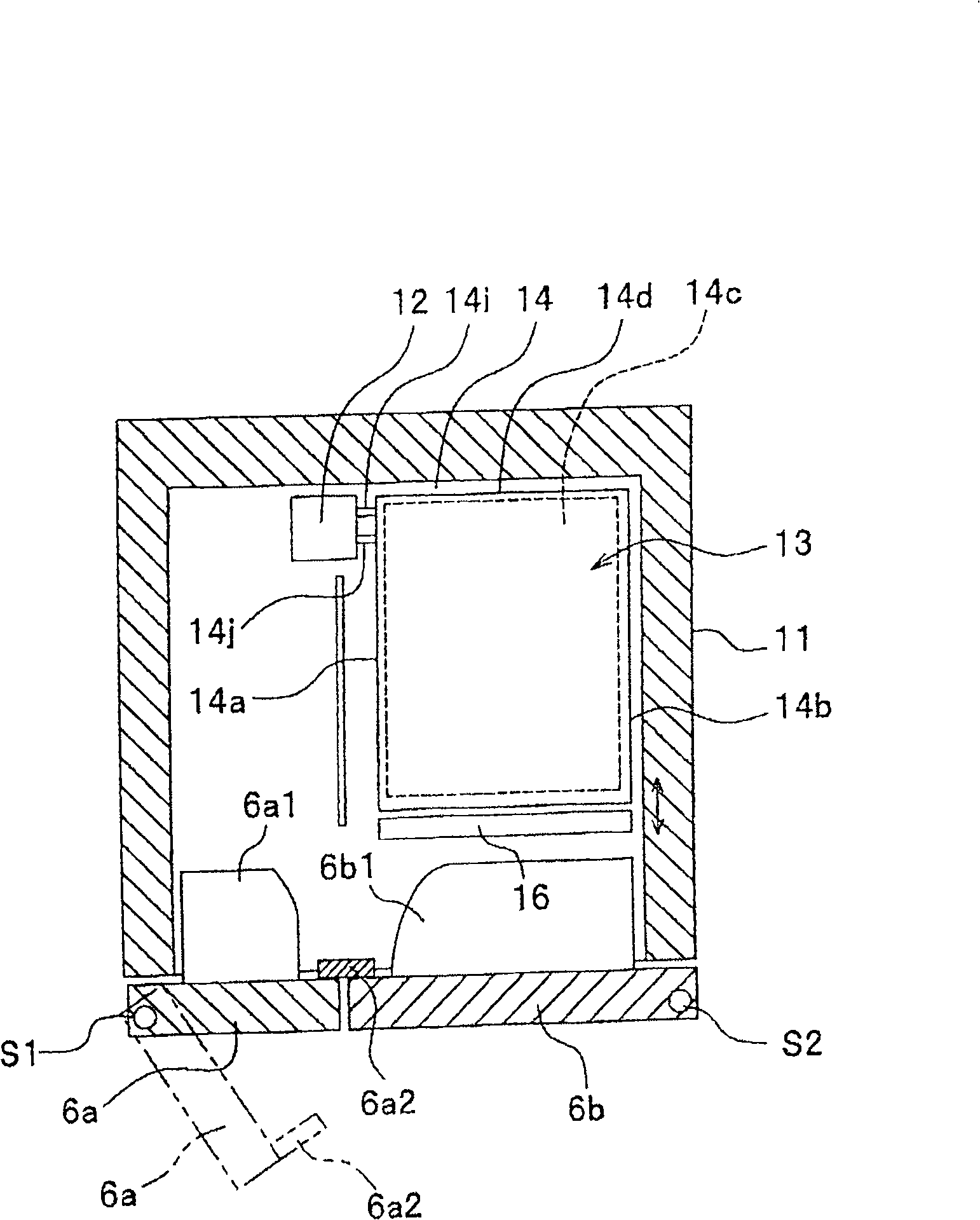

Refrigerator

ActiveCN101358794AEasy to operateOff stableLighting and heating apparatusDomestic refrigeratorsEngineeringPressure reduction

The invention provides an electric refrigerator that is convenient to operate open and close of cover of a storage chamber of a pressure reduction chamber, for example, a gas conditioning chamber. The electric refrigerator having a refrigerating chamber and a freezing chamber comprises a gas conditioning chamber in a shape of box for changing the state of gas in the refrigerating chamber, wherein said gas conditioning chamber comprise an opening part that opens in the front, a cover component that closes the opening part, a guiding component that is mounted in the left and right of the cover component and makes the cover component move fore and aft, and a synchronizing unit (gear, rack and so on) that synchronizes the movement of the guiding component.

Owner:HITACHI APPLIANCES INC

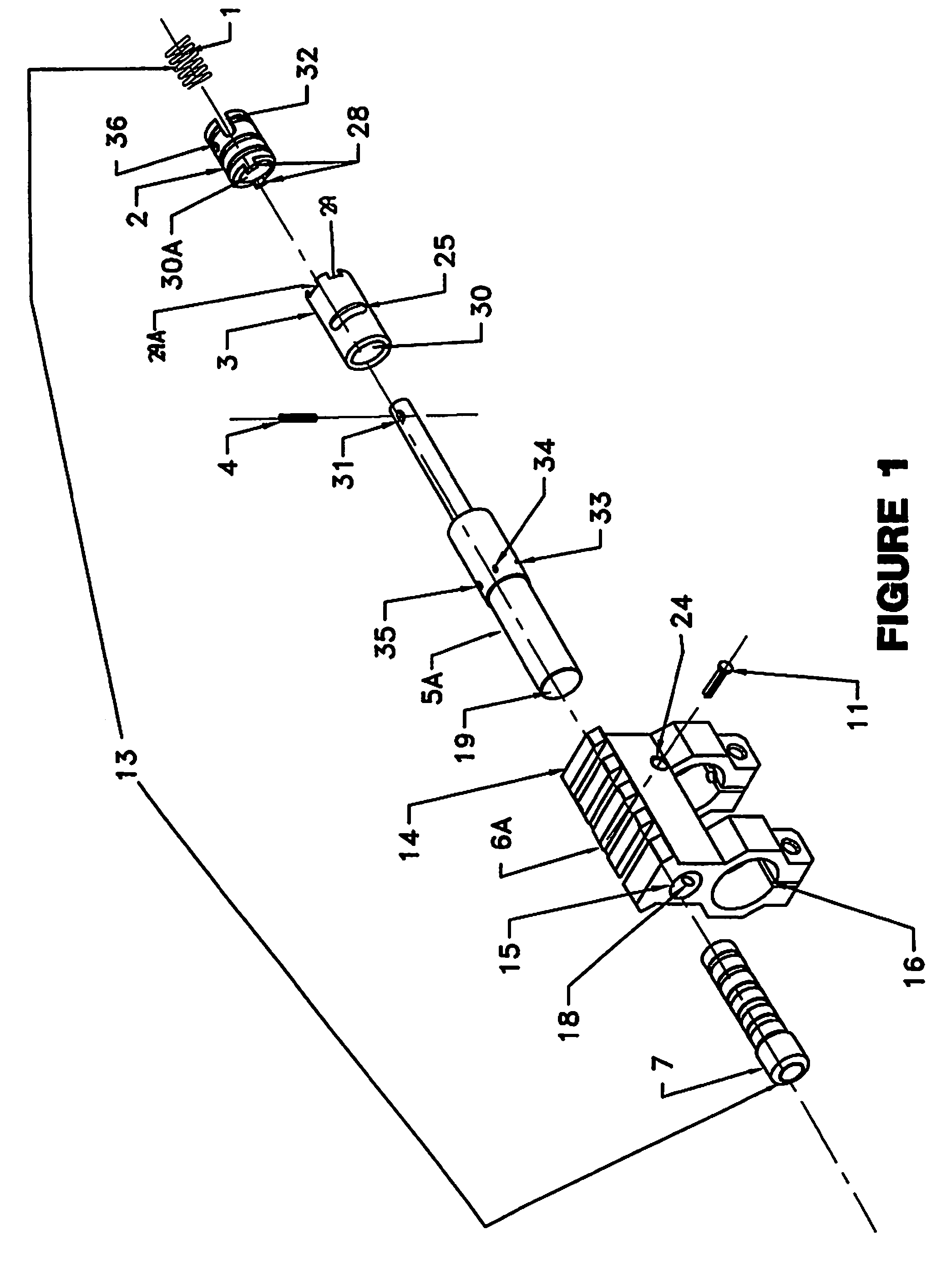

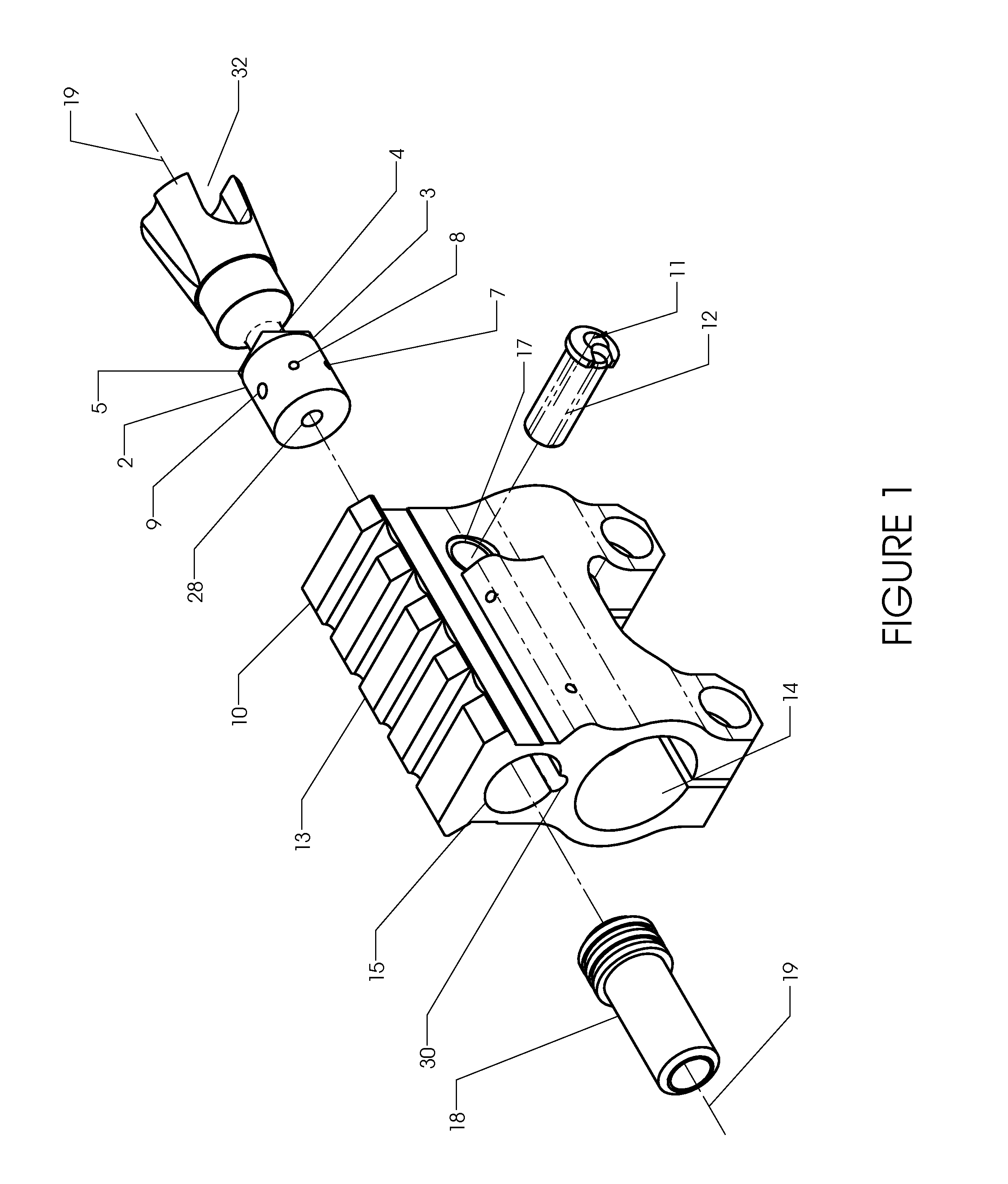

Adjustable gas block

Systems and methods for an adjustable gas block are described. Systems may include an adjustment subassembly. The adjustment subassembly may include a valve stem end with a front-most portion larger in diameter than the rear-most portion and a boss extending from the forward portion of the valve stem end; a valve ring surrounding the boss of the valve stem end; a valve threaded portion for receiving the boss of the valve stem end and having a threaded portion; and a valve rotator coupled to the valve threaded portion for adjusting the flow of gas. Systems may include a gas block assembly. The gas block assembly may include a gas block through hole; a first duct to direct pressurized gas from a barrel to a plenum; a second duct to direct a regulated volume of gas to a gas operating system; a seat valve to control the regulated volume of gas to the gas operating system; and a gas block threaded portion for coupling to the valve threaded portion. The adjustment subassembly may be coupled to the gas block assembly.

Owner:LWRC INTERNATIONAL

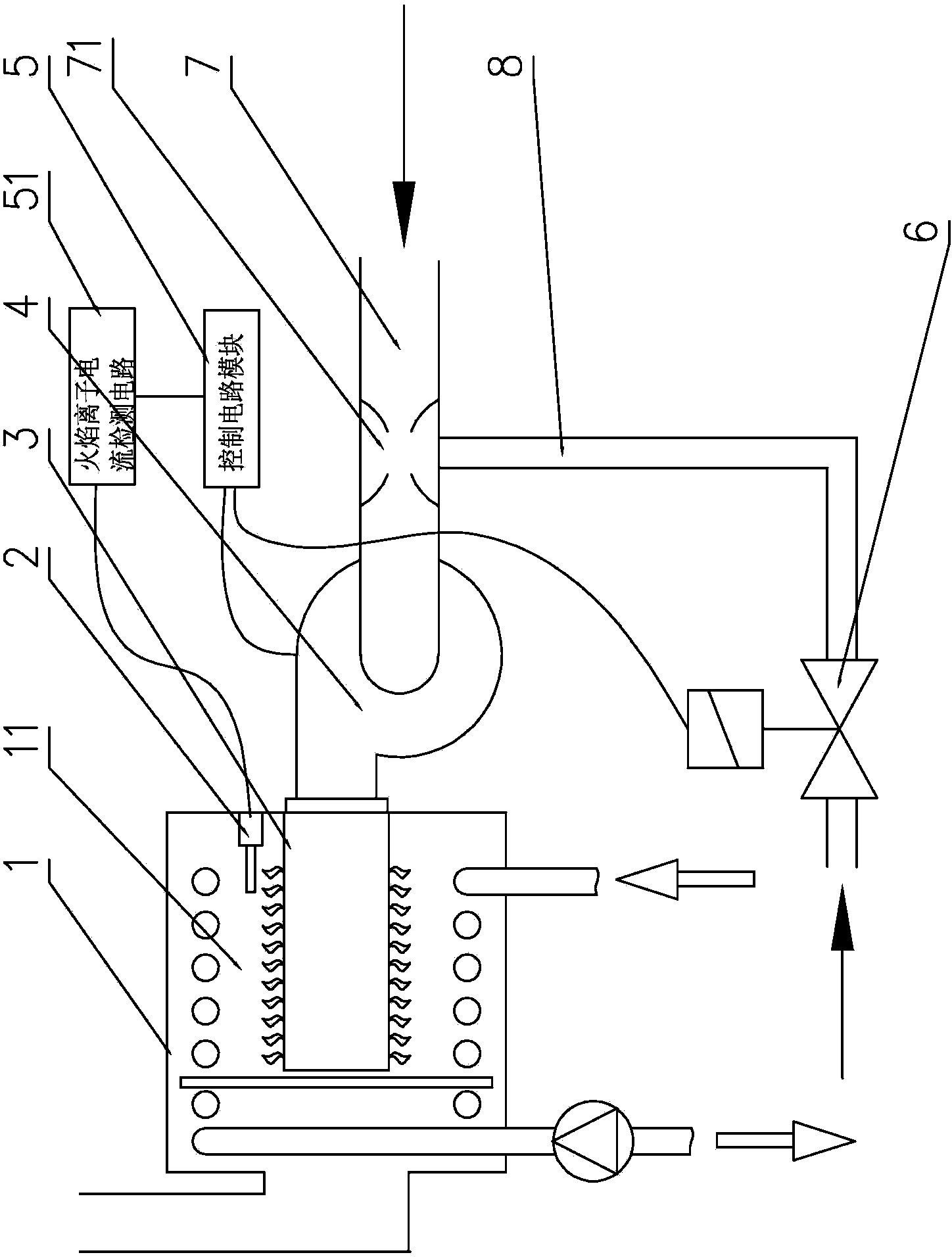

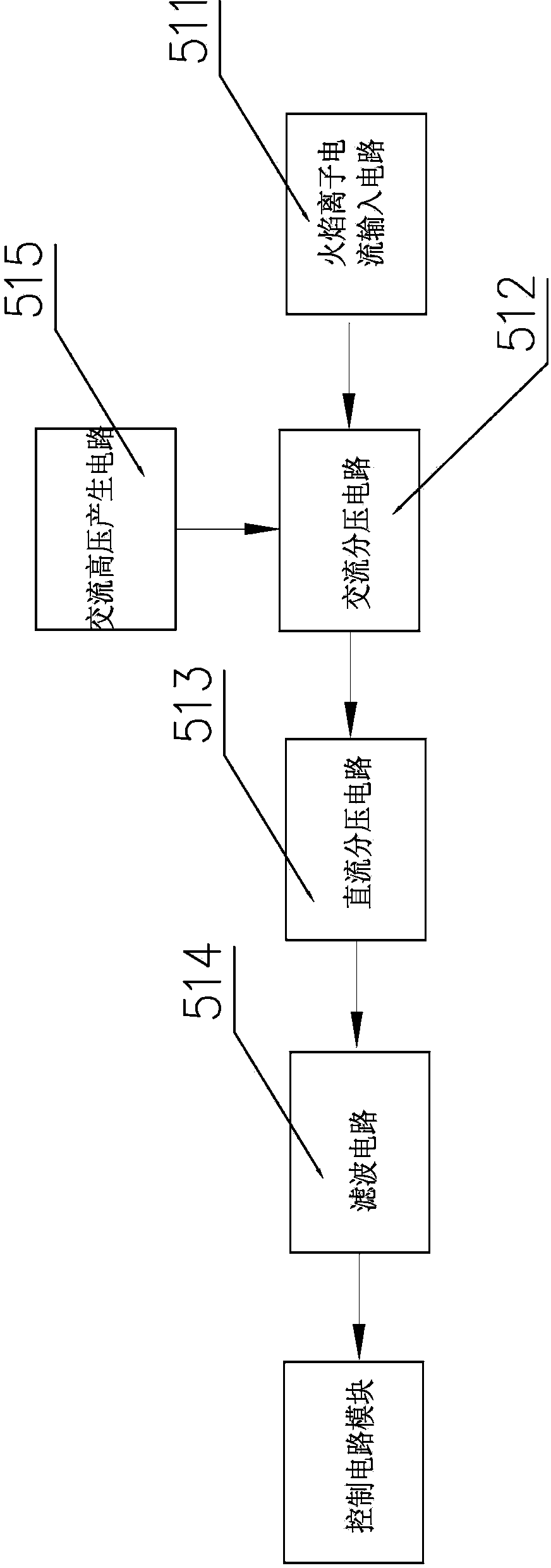

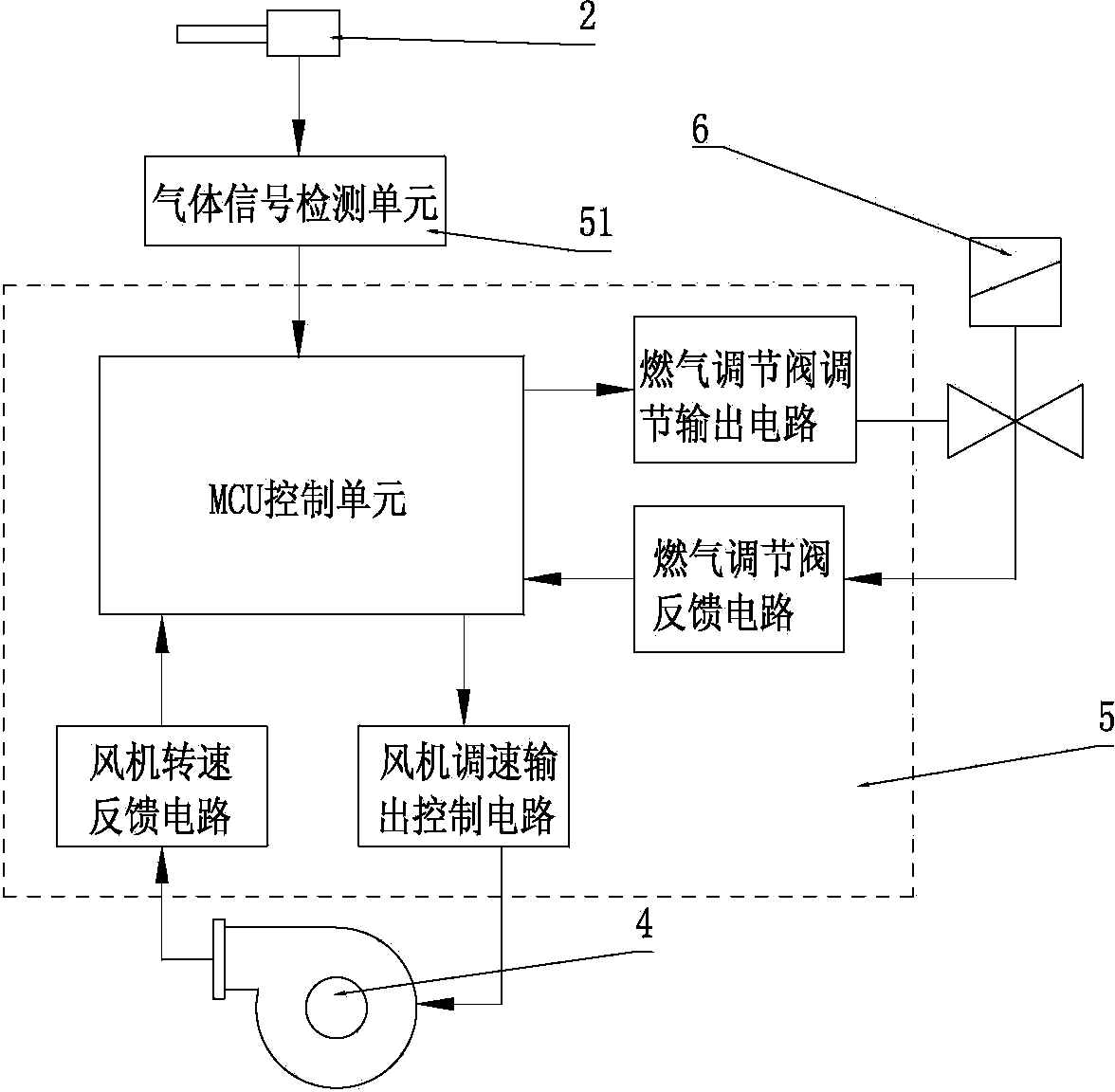

Fully premixed combustion gas heating water heater

InactiveCN103615798ABurn completelyBest burning stateWater heatersGaseous fuel burnerCombustion chamberEngineering

A fully premixed combustion gas heating water heater comprises a heat exchanger, a combustor, a fan, a gas regulating valve, a gas pipe and an air pipe. A closed combustion chamber is formed in an inner cavity of the heat exchanger, the combustor is arranged in the closed combustion chamber, an air outlet of the fan is communicated with an air inlet of the combustor, the gas pipe and the air pipe are communicated with an air inlet of the fan, the gas regulating valve is connected to the gas pipe in series, and the gas regulating valve and the fan are electrically connected with a control circuit module. The fully premixed combustion gas heating water heater further comprises an ionic current feedback pin and a flame ionic current detecting unit. The ionic current feedback pin is installed inside the closed combustion chamber, and the flame ionic current detecting unit is electrically connected with the ionic current feedback pin and the control circuit module. When gas component changes, the fully premixed combustion gas heating water heater enables the proportion of gas and air to be adjusted to a new air-fuel ratio, and therefore the purpose of enabling gas to be combusted fully is achieved.

Owner:GUANGDONG VANWARD NEW ELECTRIC CO LTD

Multi-block gas regulator

A multi use retro fit capable adjustable gas block designed to interface with an autoloading gas operated firearm is provided to replace existing gas blocks. The adjustable gas block optimizes gas flow into the host firearms operating system. The adjustable gas block has a spring loaded adjustment knob that releases when pulled forward allowing it to rotate. By rotating the adjustment knob the gas flow is increased or decreased based on one of four provided gas settings. Setting one is optimal for using a silencer, setting two is optimal for normal operations, setting three is optimal for adverse conditions, and setting four either turns the gas flow off optimizing sound reduction and providing for manual operation, or provides an extra high gas setting for the host firearm. The system works by precisely metering gas entering the operating system and not by exhausting excess gas into the atmosphere. The adjustable gas regulator may be configured with a piston operating system or a direct gas impingement operating system, e.g. gas tube, as is the case with the standard AR-15 / AR-10 family of firearms.

Owner:CASSELS CHARLES B

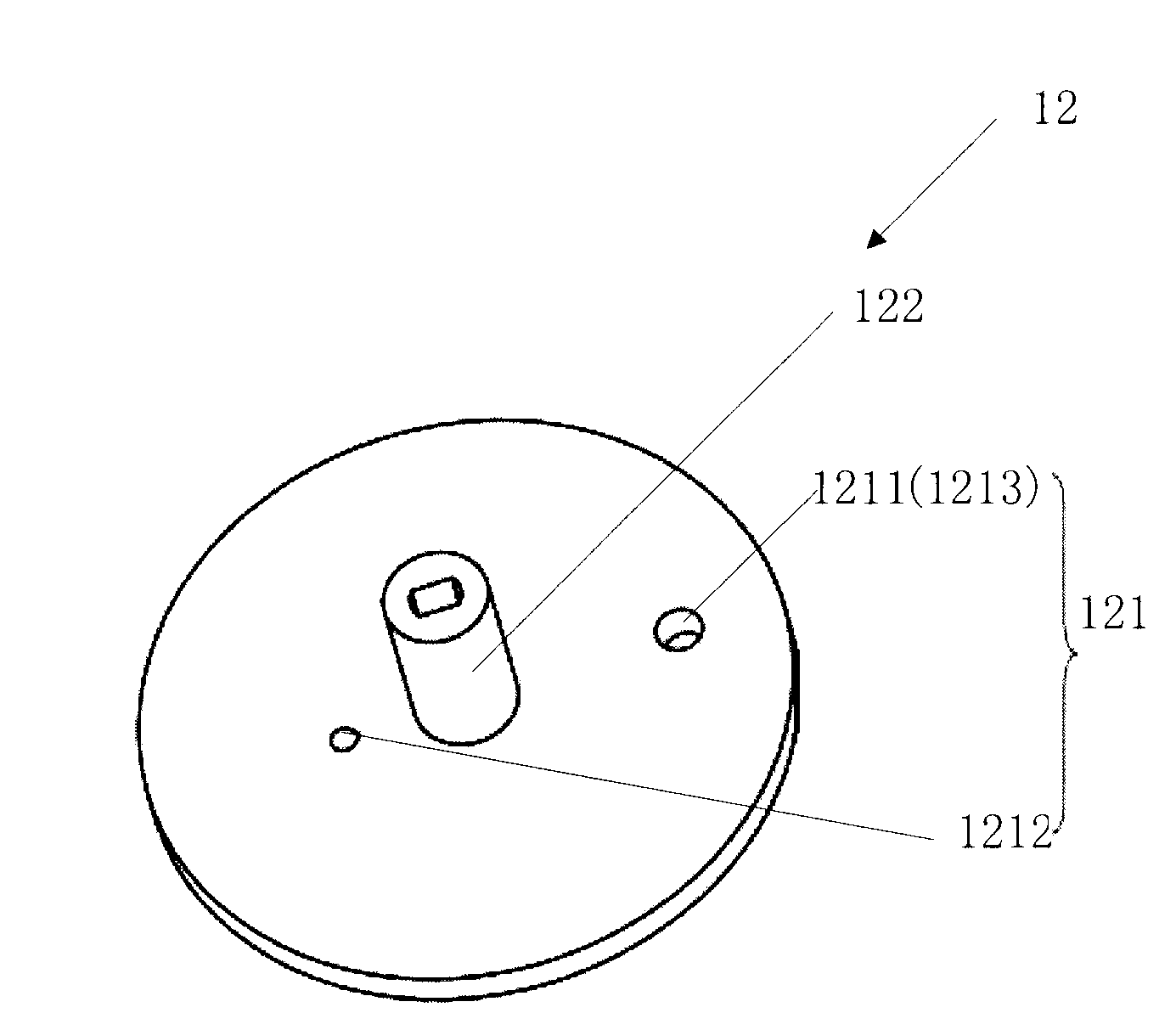

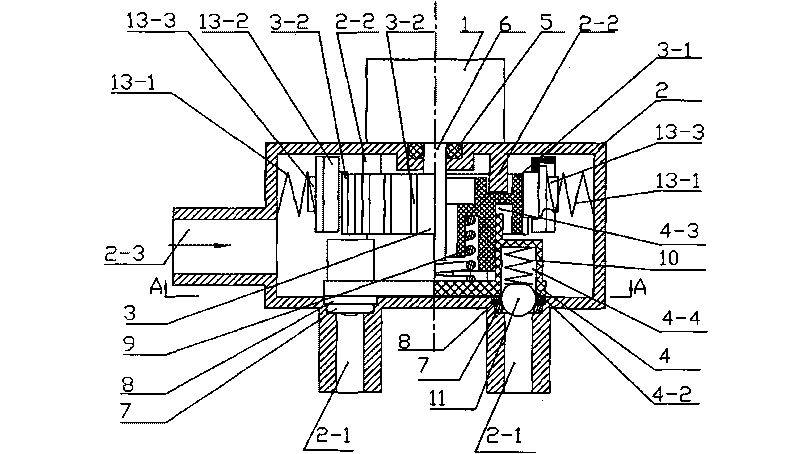

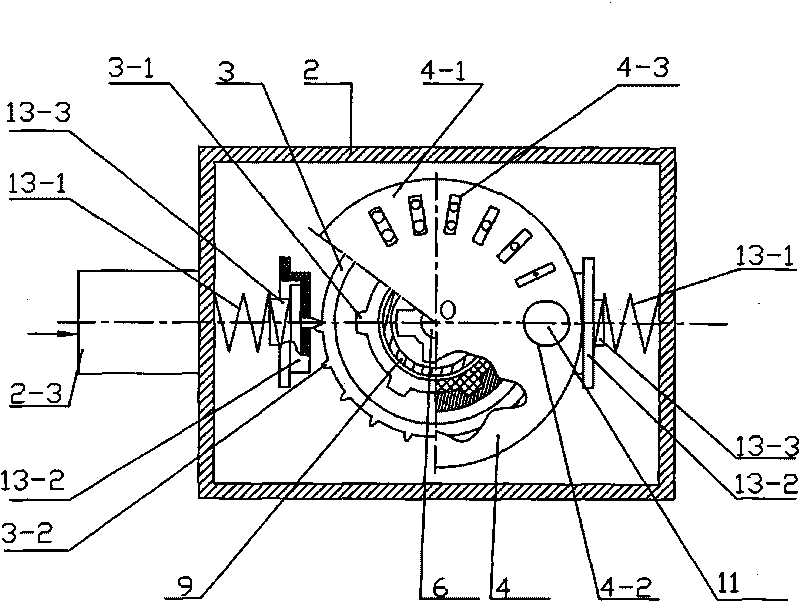

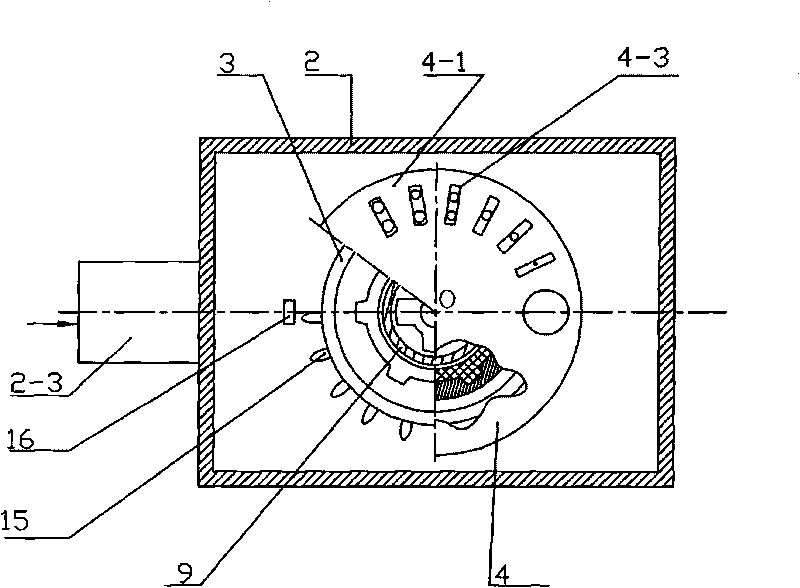

Multi-channel stepped electric gas control valve

InactiveCN101696742AAccurate closed-loop adjustmentNo power consumptionFuel supply regulationOperating means/releasing devices for valvesCircular discDrive shaft

The invention discloses a multi-channel stepped electric gas control valve which mainly comprises a valve shell, a speed reducing motor, a locator, an airflow distributor and a circular disk thereof and a locator rotational angle detection mechanism, wherein one side surface of the valve shell provided with a plurality of gas outlets is vertical to the driving shaft of the motor; the center lines of the driving shaft, the locator and the airflow distributor and the circular disk thereof are superposed; the circular disk is provided with starting holes and a plurality of groups of airflow distribution hole slots the number of which is the same as that of the gas outlets, wherein each hole slot is provided with through holes with different cross-section areas; the circular disk is closely clung to a rigid hollow washer arranged at the inner end opening of each gas outlet; locating joints which correspond to each group of hole slots with the same serial number are arranged on the outer periphery of the locator, and a locating end is arranged in the corresponding valve shell. The gas control valve is controlled exactly by action position feedback signals and a control circuit, multi-level stepped gas flow control can be carried out on a plurality of paths of gas channels, and the plurality of paths of gas channels can be shut off separately.

Owner:FOSHAN CHANCHENG HENGDELI ELECTRIC APPLIANCE FACTORY

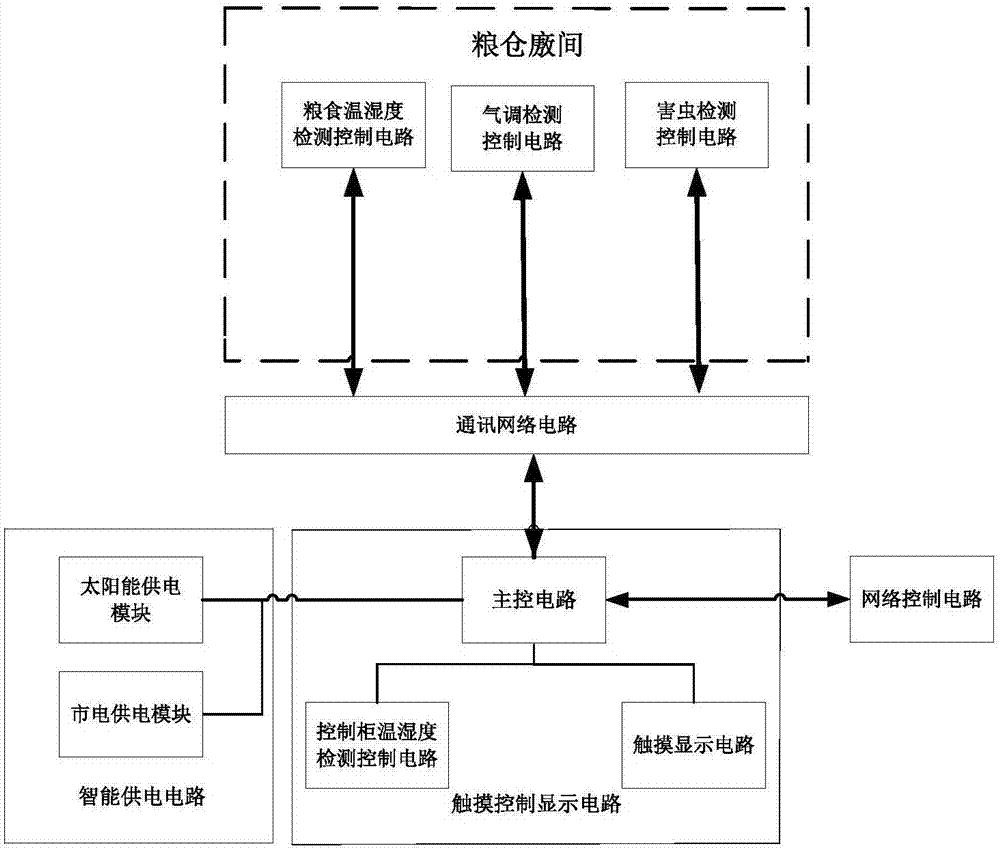

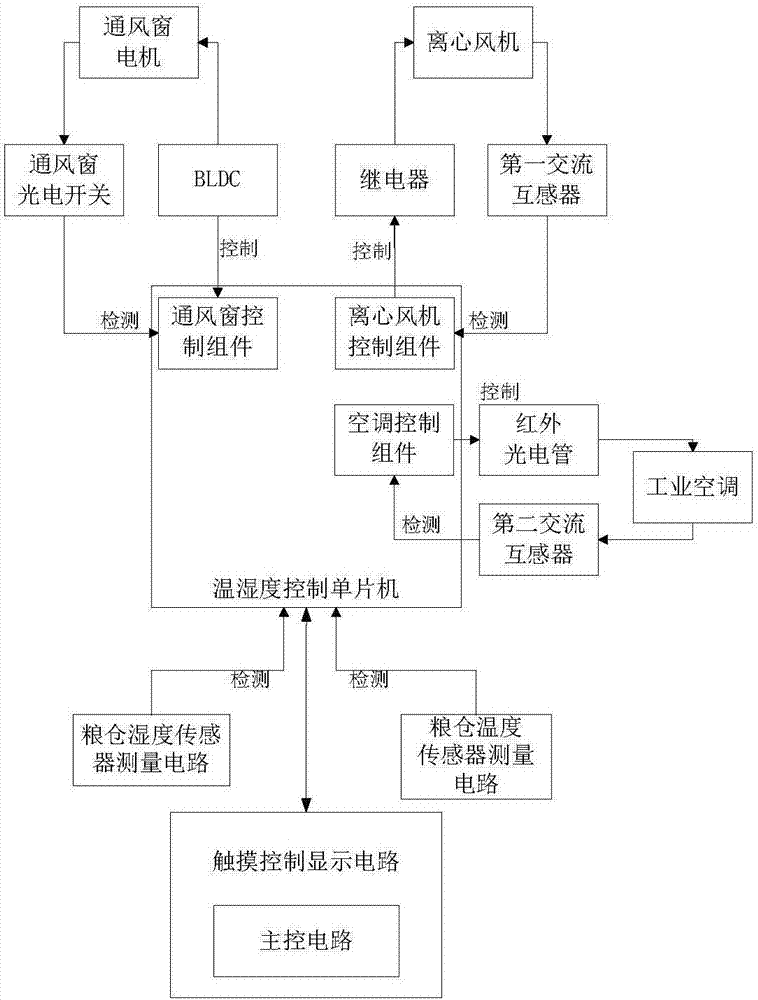

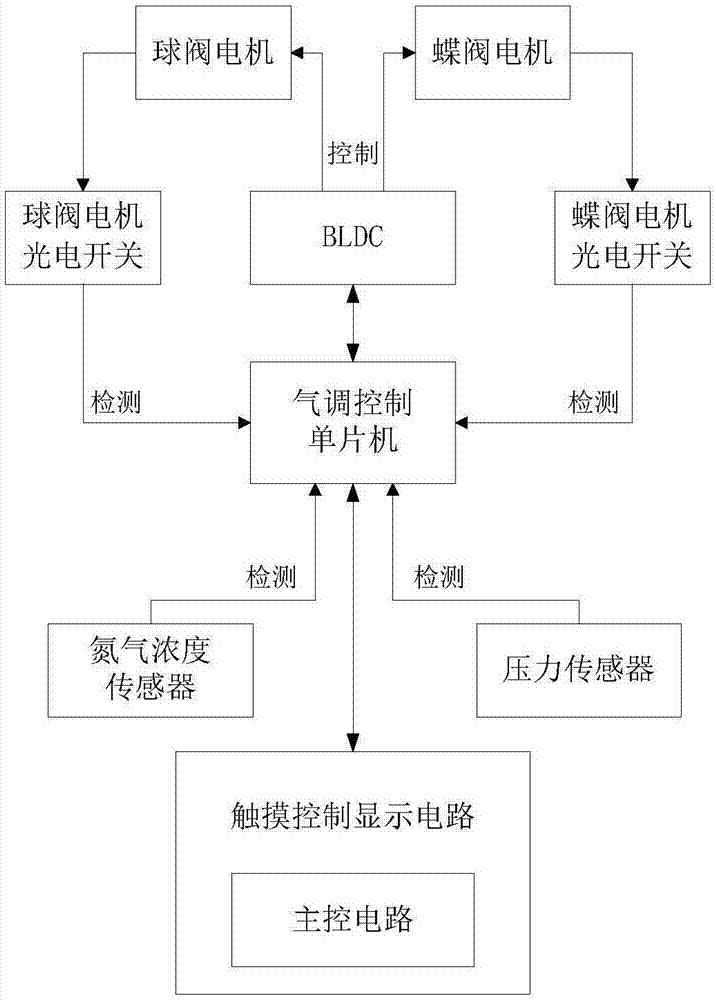

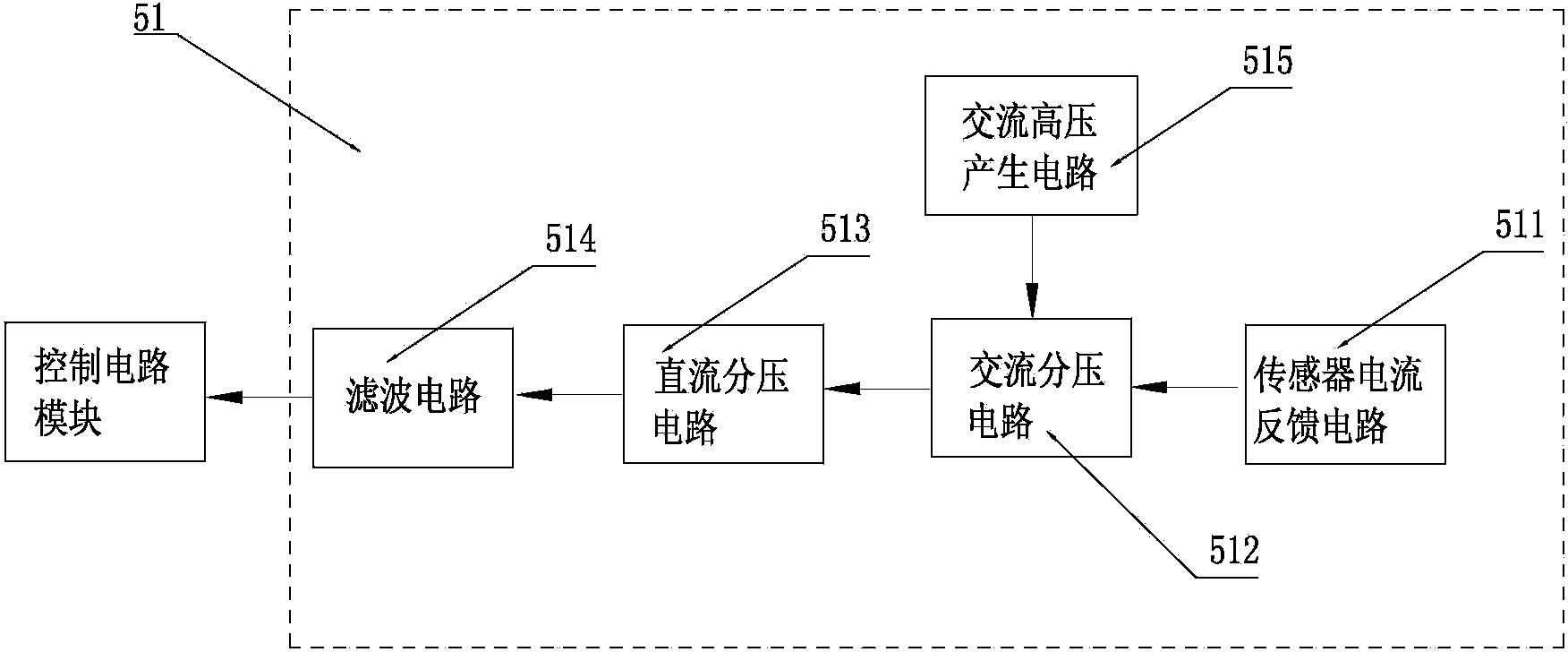

Control circuit of intelligent and integrated display control system of granary

ActiveCN107168273AImprove detection accuracyHigh degree of detection automationTotal factory controlSimultaneous control of multiple variablesAnalog circuit designControl system

The invention discloses a control circuit of an intelligent and integrated display control system of a granary. The control circuit comprises a grain temperature and humidity detection control circuit, a gas conditioning detection control circuit, a pest detection control circuit, an intelligent power supply circuit, a communication network circuit, a touch control display circuit and a network control circuit, wherein the intelligent power supply circuit is connected with the touch control display circuit, the touch control display circuit is connected with the grain temperature and humidity detection control circuit, the gas conditioning detection control circuit and the pest detection control circuit by means of the communication network circuit, and the touch control display circuit comprises a main control circuit, a touch display circuit connected with the main control circuit and a control cabinet temperature and humidity detection control circuit, thus the corresponding control system can be adjusted in one or more ways of a local intelligent mode, a local manual mode, a network intelligent mode and a network manual mode. The control circuit adopts a modular and analog circuit design, and creates an ideal grain storage environment.

Owner:ANHUI BOWEI CHANGAN ELECTRONICS

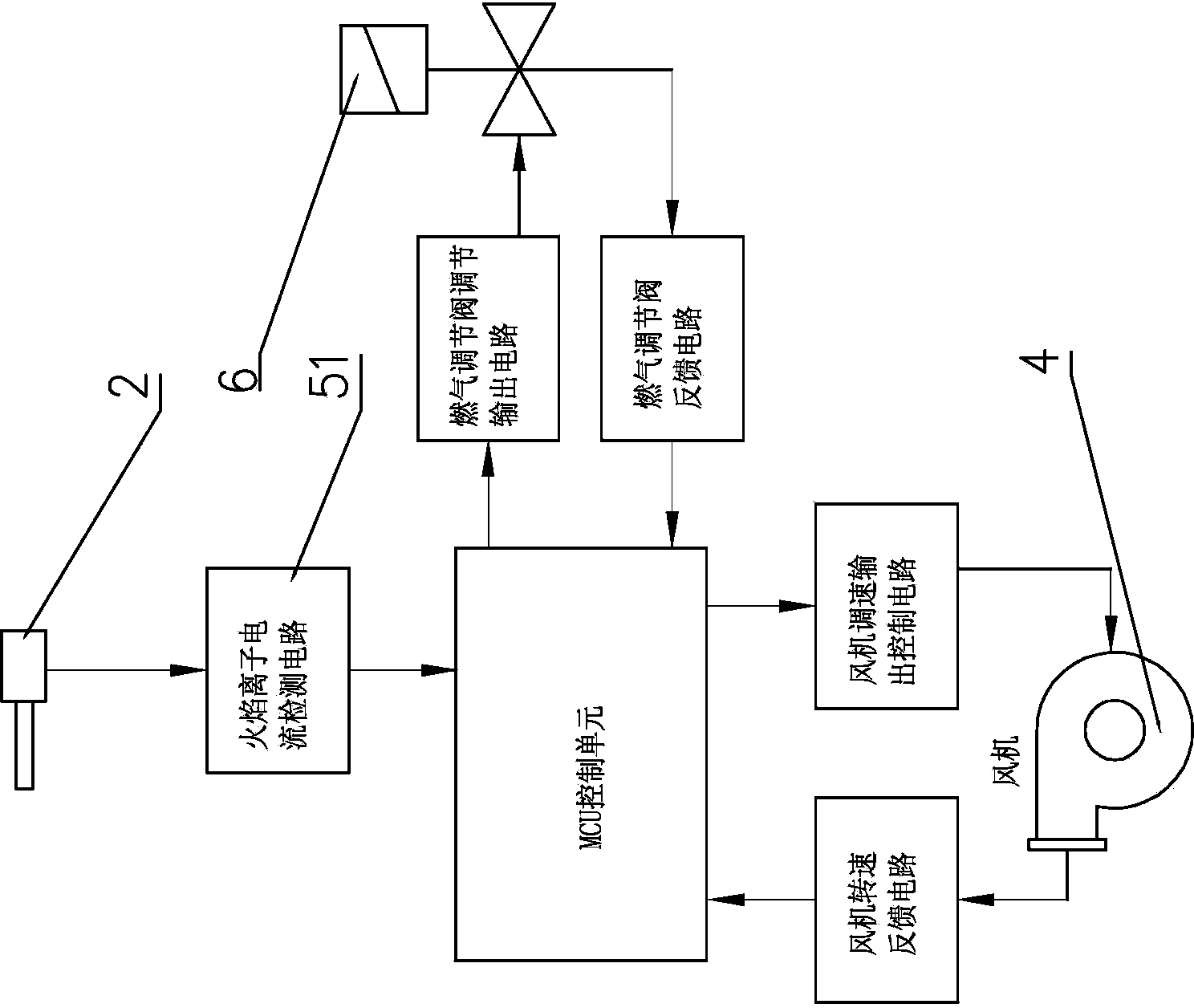

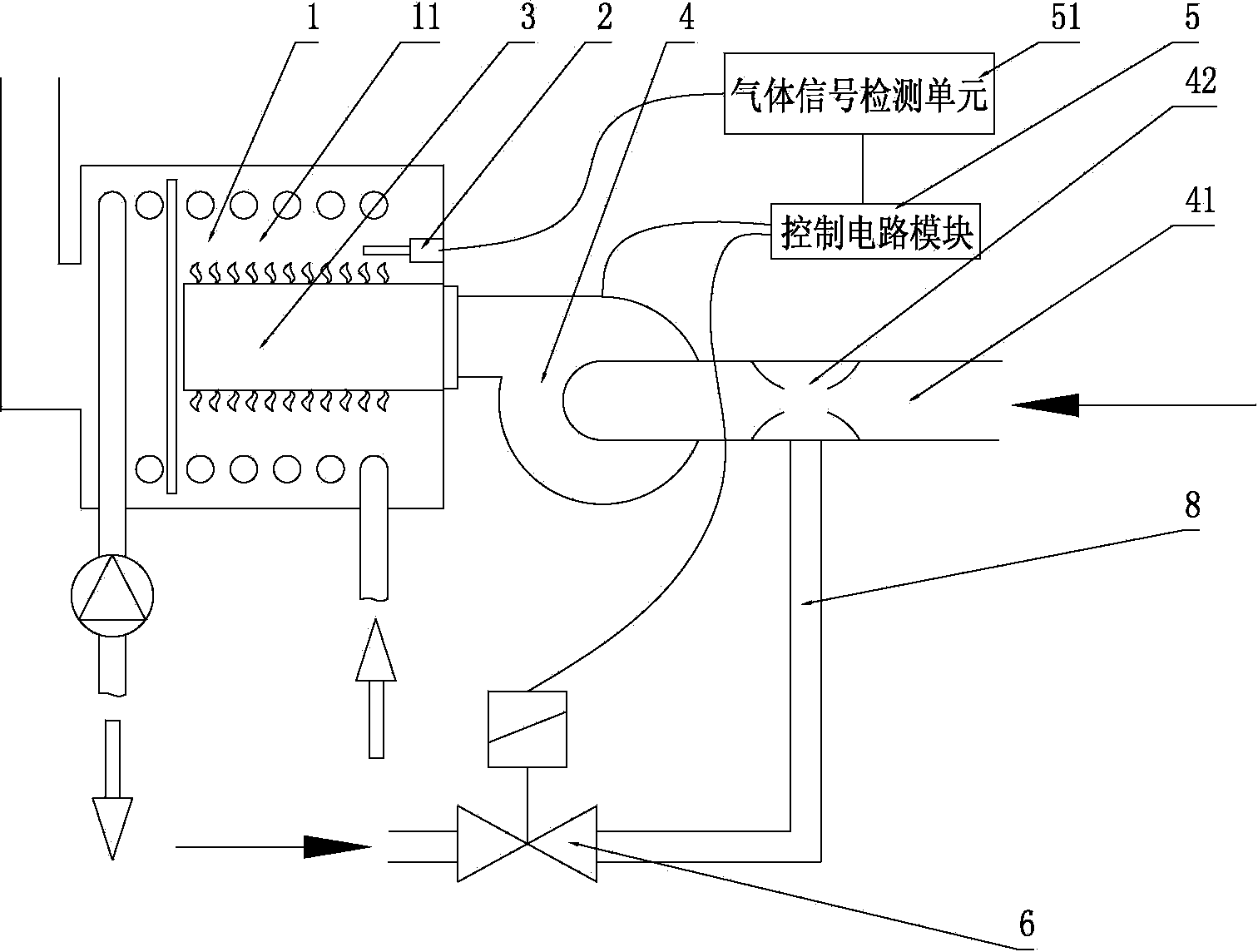

Gas water heating device capable of realizing self-adaptive fully-premixed combustion

ActiveCN104296392AAchieve complete combustionBest burning stateFluid heatersCombustion chamberGas composition

A gas water heating device capable of realizing self-adaptive fully-premixed combustion comprises a heat exchanger, a combustor, a fan, a gas adjusting valve, a gas pipe, a gas sensor, a gas signal detection unit and a control circuit module. An inner cavity of the heat exchanger forms a closed combustion chamber, the combustor and the gas sensor are arranged in the closed combustion chamber, the fan and the gas pipe are communicated with the combustor respectively, the gas adjusting valve is serially connected on the gas pipe, and the gas adjusting valve, the fan, the gas signal detection unit and the gas sensor are electrically connected with the control circuit module respectively. The gas sensor is adopted to detect content of specific gas in smoke after gas combustion, so that a ratio between gas and air can be effectively adjusted to be a new air-gas ratio when gas composition changes to achieve the object of complete combustion of gas.

Owner:GUANGDONG VANWARD NEW ELECTRIC CO LTD

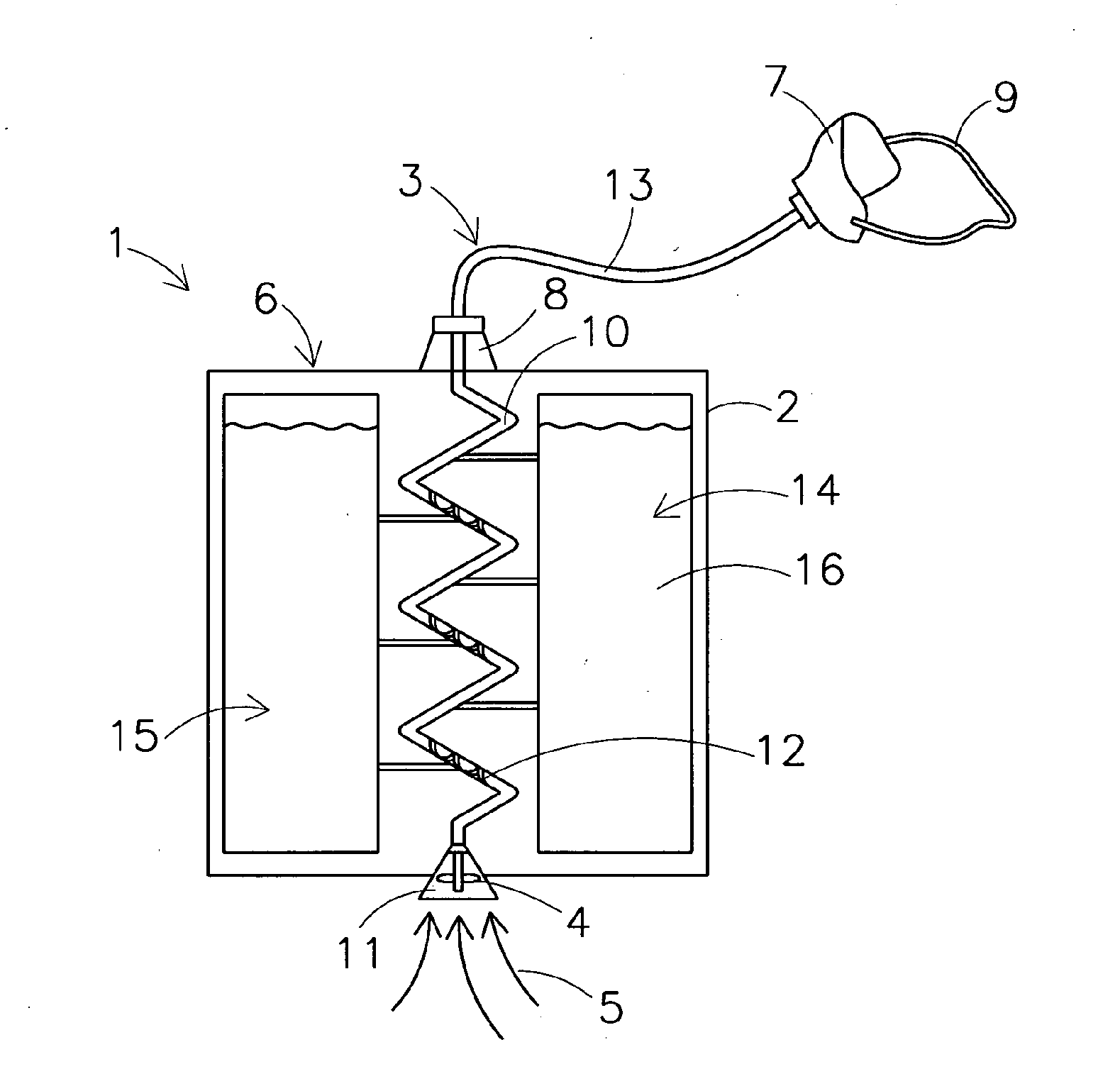

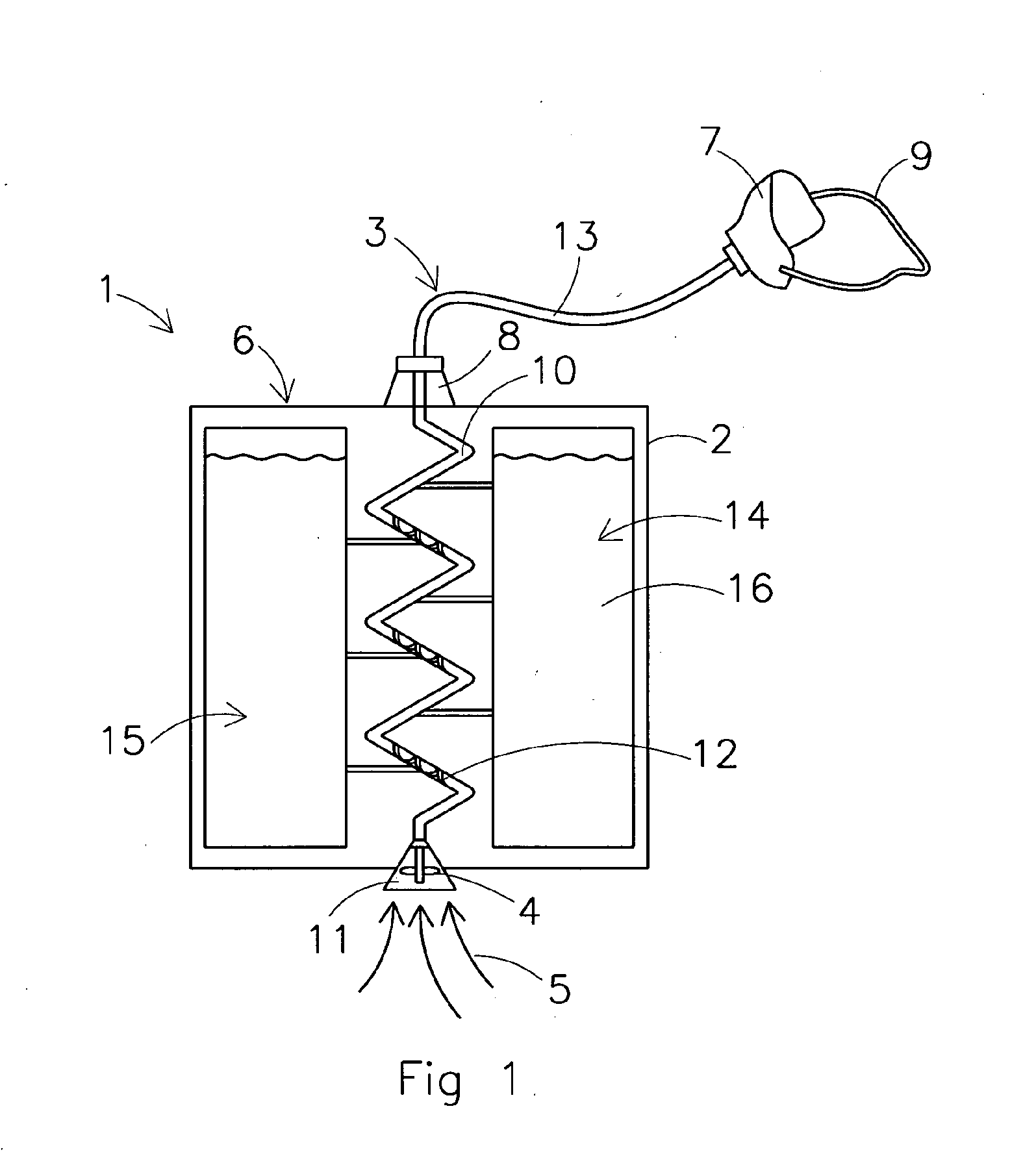

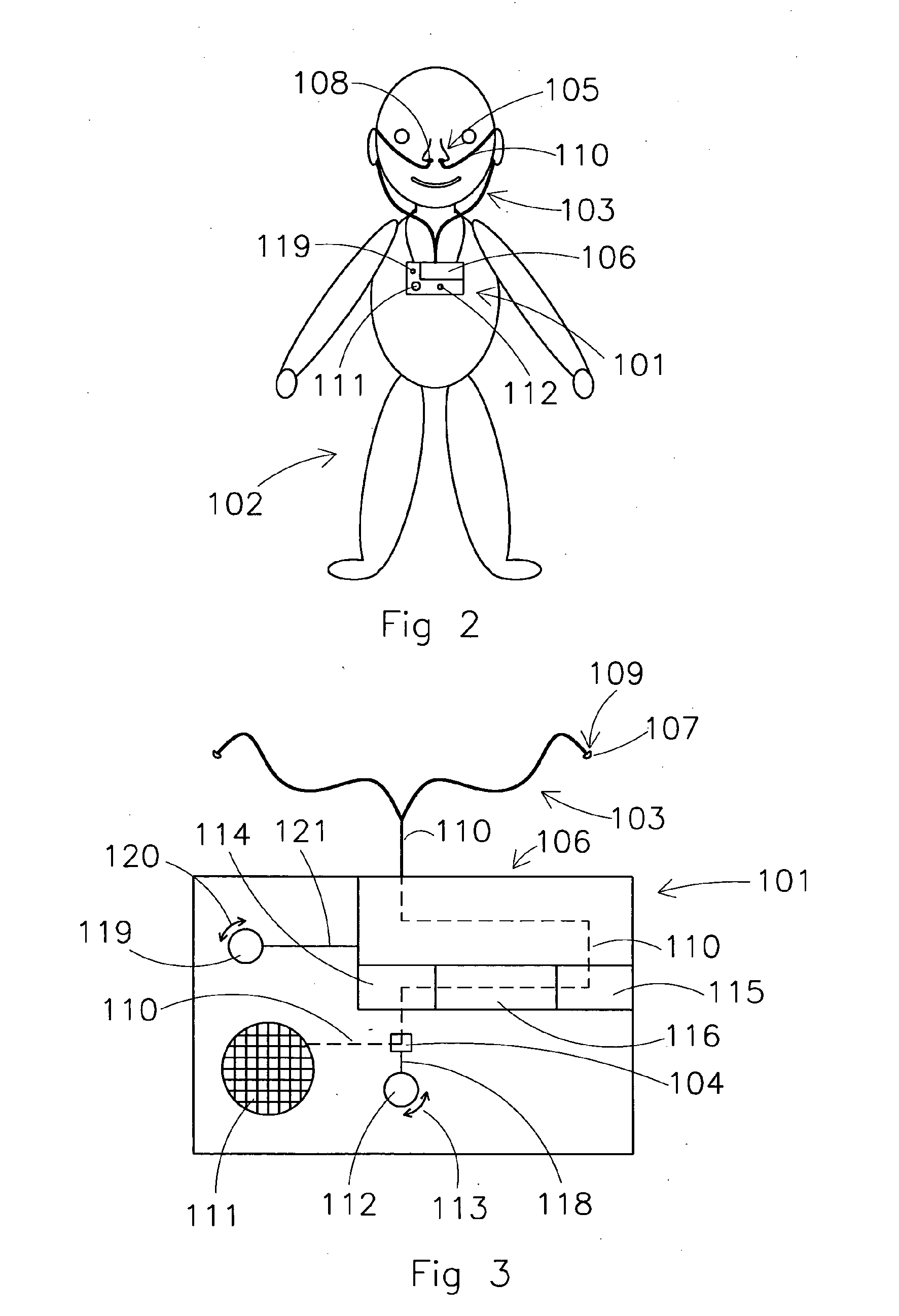

Device for providing a breathing gas

InactiveUS20110005522A1Improve energy consumptionTo promote metabolismRespiratorsMedical devicesBiological bodyMedicine

The invention relates to a device for providing a breathing gas, in particular to a device for conditioning a breathing gas for stimulating weight reduction of a breathing creature. The invention provides a device for providing a breathing gas, comprising gas supply means and gas conditioning means. The device provides a breathing creature with a breathing gas which is conditioned by adding particles comprising a frozen fluid to the breathing gas. When the breathing creature inhales the breathing gas, his body comes into contact with the gas and the particles comprising the frozen fluid. The breathing gas and the particles will be warmed by the body of the creature, preferably to a temperature at which the frozen fluid starts to melt. The warming of the particles and the breathing gas by the body of the breathing creature requires energy, and therefore stimulates the metabolism of a breathing creature, promoting fat burning and inducing weight reduction.

Owner:INST ON MY WAY

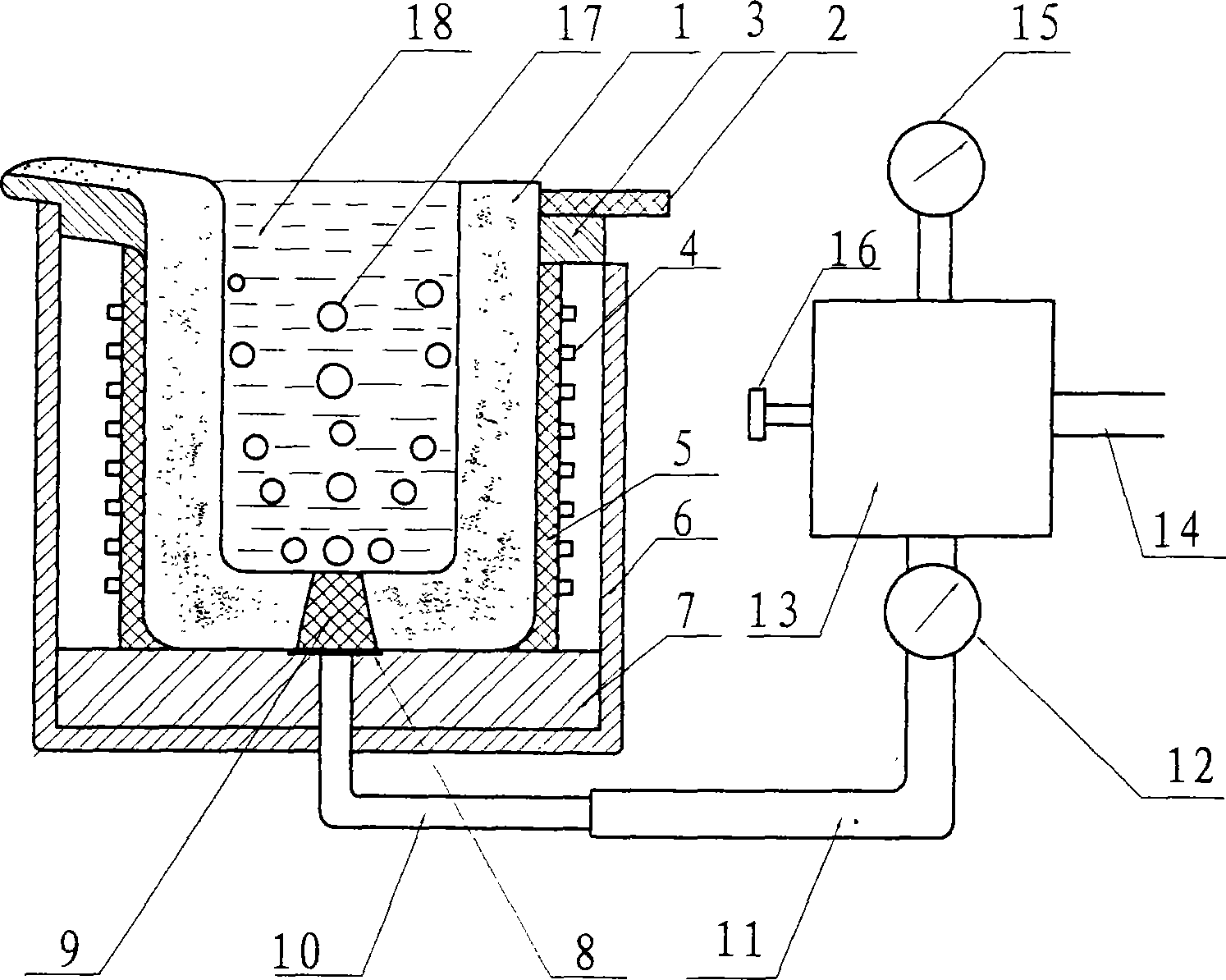

Bottom-blowing medium-frequency smelting furnace and in-furnace auxiliary refining method

The present invention discloses one kind of bottom blown MF smelting furnace, which has a furnace body comprising furnace lining, porous brick, cover plate, induction coil, shell and other parts; and a gas supply system comprising pipe, gas regulator, flowmeter, pressure meter, regulating valve and other parts. The gas supply system is connected to the furnace body through corrugated metal pipe and union. The present invention also discloses the auxiliary refining process in the bottom blown MF smelting furnace, and the process includes introducing inert gas after all the charges inside the furnace are molten to the porous brick in the pressure of 0.1-1.0 MPa and flow rate of 100-700 1 / s, and auxiliary refining for 3-5 min. The present invention is especially suitable for use in MF smelting furnace of capacity less than 250 kg, and has simple furnace structure, good permeating property, good auxiliary refining effect and other advantages.

Owner:TAIZHOU JINDING PRECISION CASTING +1

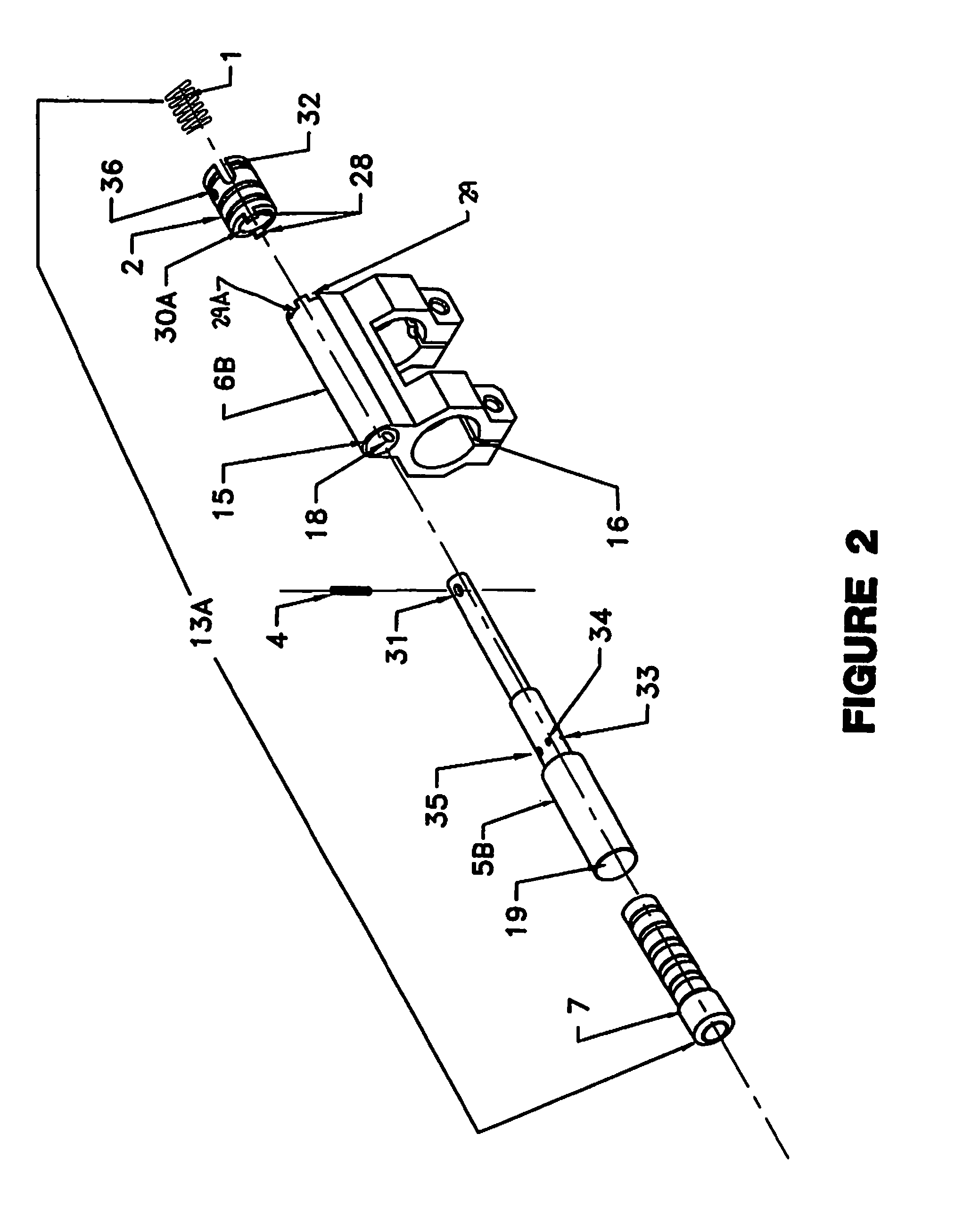

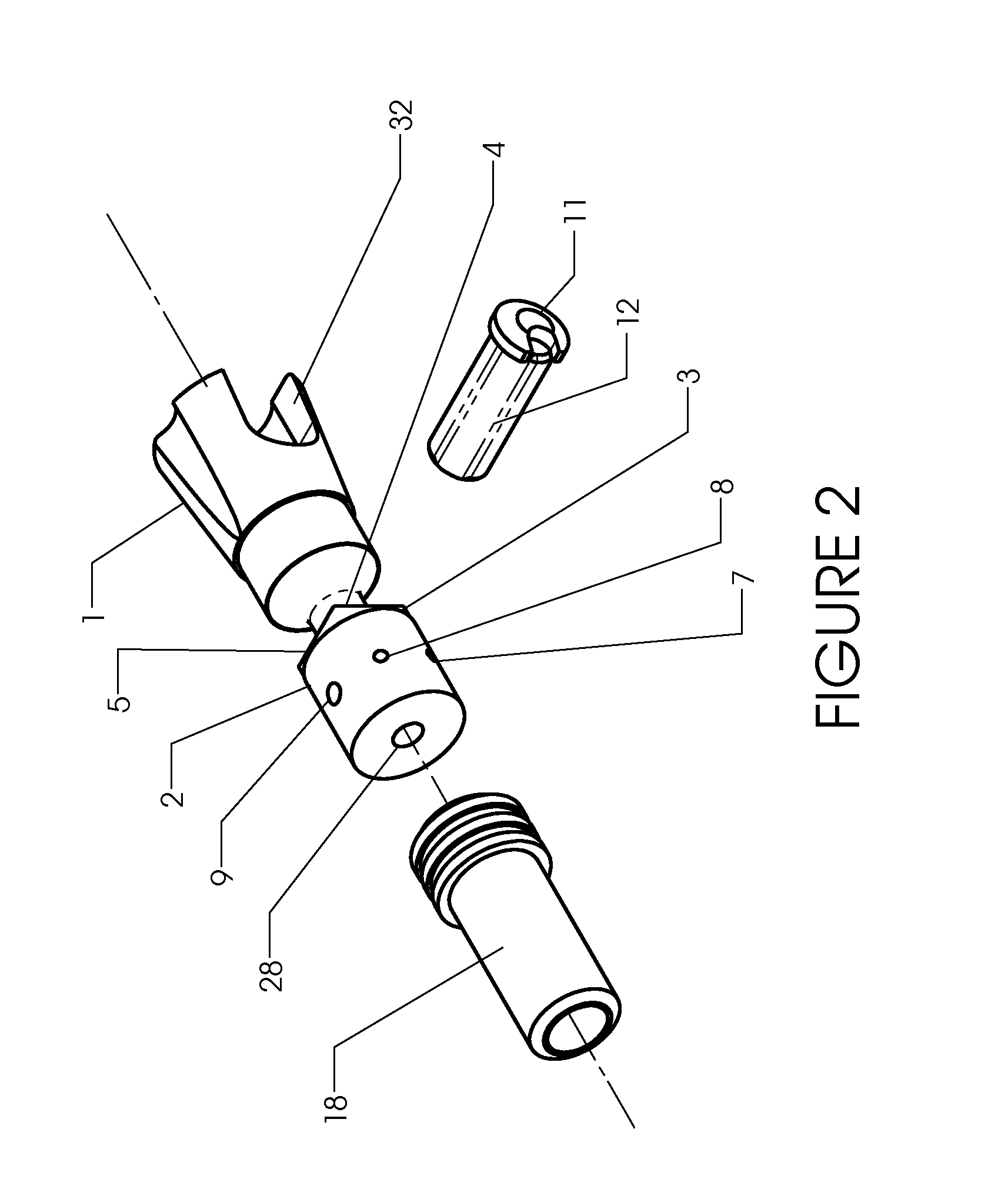

Super & subsonic gas regulator assembly

A retro fit capable super & subsonic gas regulator assembly designed to interface with an auto-loading gas operated host firearm is provided to replace existing gas systems. The gas regulator assembly optimizes gas flow into the host firearm's operating system. The gas regulator has a spring actuated gas regulator and cross-pin including a flat that disengages with the gas regulator when the gas regulator is rotated to allow the gas flow to be set to one of a plurality of gas settings e.g., four. In embodiments, setting one is optimal for using supersonic ammunition with a silencer, setting two is optimal for using supersonic ammunition without a silencer, setting three is optimal for subsonic ammunition, and setting four turns the gas flow off optimizing sound reduction and providing for manual operation of the host firearm. The system works by precisely metering gas entering the operating system and not by exhausting excess gas into the atmosphere. The super & subsonic gas regulator assembly provides optimal performance with both subsonic and supersonic ammunition in a single firearm allowing the operator full advantage.

Owner:CASSELS CHARLES B

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com